Recovery method for electrolyte of waste lithium ion battery

A lithium-ion battery and electrolyte recycling technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of low recovery rate, complicated recycling process, and low safety, so as to avoid secondary pollution , The process is simple and efficient, and the effect of safety is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

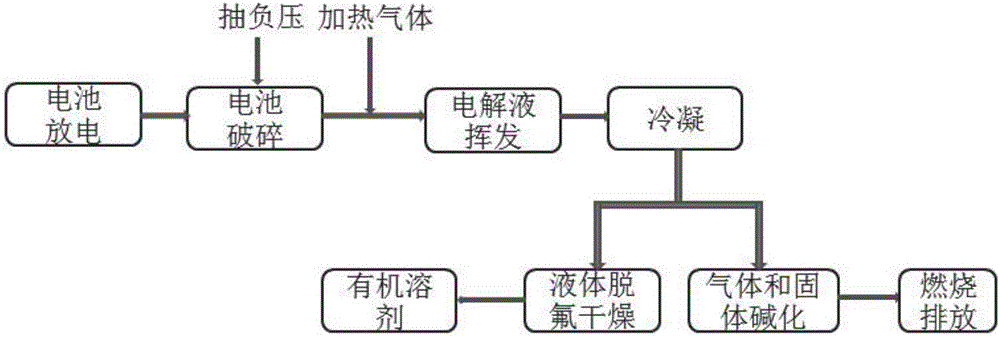

Method used

Image

Examples

Embodiment 1

[0063] (1) Short-circuit discharge the collected 10 18650 waste lithium-ion batteries to 0V, then put them into a negative pressure (90kPa) space, and use a pulverizer to crush the batteries vigorously;

[0064] (2) Mix nitrogen and water vapor heated to 150°C and blow it to the broken battery at a speed of 1.5m / s, so that the organic solvent and lithium salt (LiPF 6 Decomposition) volatilization, with trace solids;

[0065] (3) Condensing the volatile matter (purged air flow) obtained in step (2) to obtain a solid-liquid mixture and gas (purged tail gas);

[0066] (4) filtering the solid-liquid mixture obtained in step (3) through a 1000 mesh screen to separate solid and liquid;

[0067] (5) Ca(OH) that the gas of step (3) gained and the solid of step (4) are passed into pH 10 2 Solution, the calcium fluoride precipitate is recovered to be 0.38g, and then combusted and discharged;

[0068] (6) Pass the liquid obtained in step (5) through anhydrous alumina to remove moistur...

Embodiment 2

[0070] Compared with Example 1, the difference is that the gas flow temperature in (2) is 180°C, the calcium fluoride precipitate is reclaimed in step (4) and increased to 0.53g, and the organic DEC and DMC are reclaimed in step (6) and increased to 10.1 g.

Embodiment 3

[0072] Compared with Example 1, the difference is that the gas flow temperature in (2) is 240°C, and the calcium fluoride precipitate is reclaimed in step (4) to 0.98g, and organic EC, DEC and DMC are reclaimed in step (6). to 18.2g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com