Patents

Literature

5727results about "Waste accumulators reclaiming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

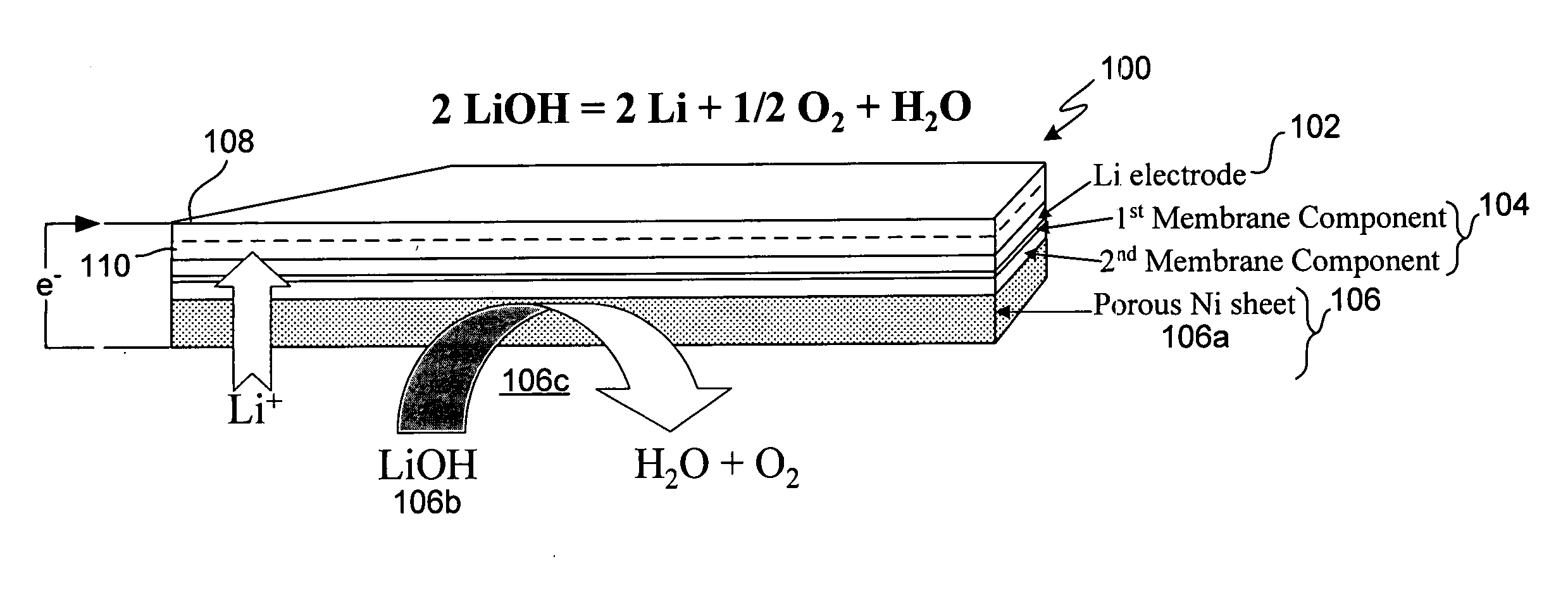

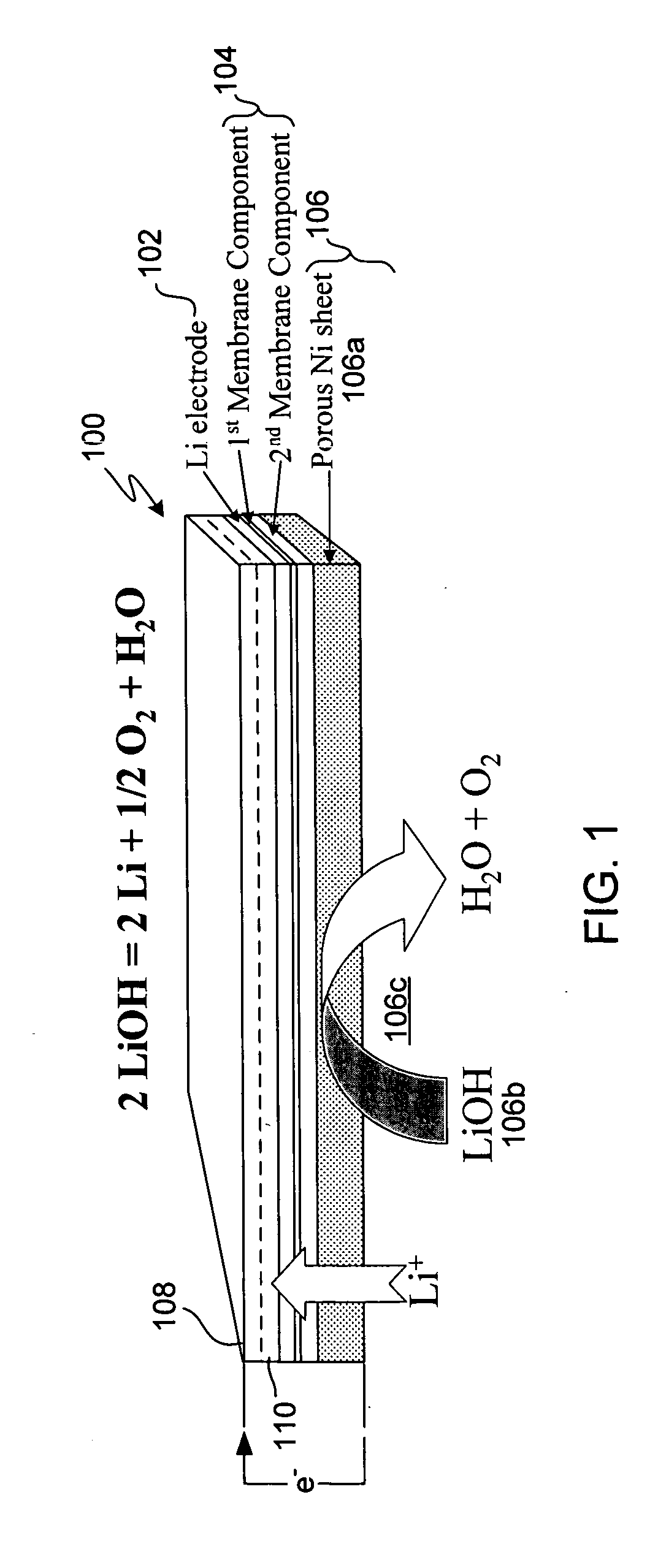

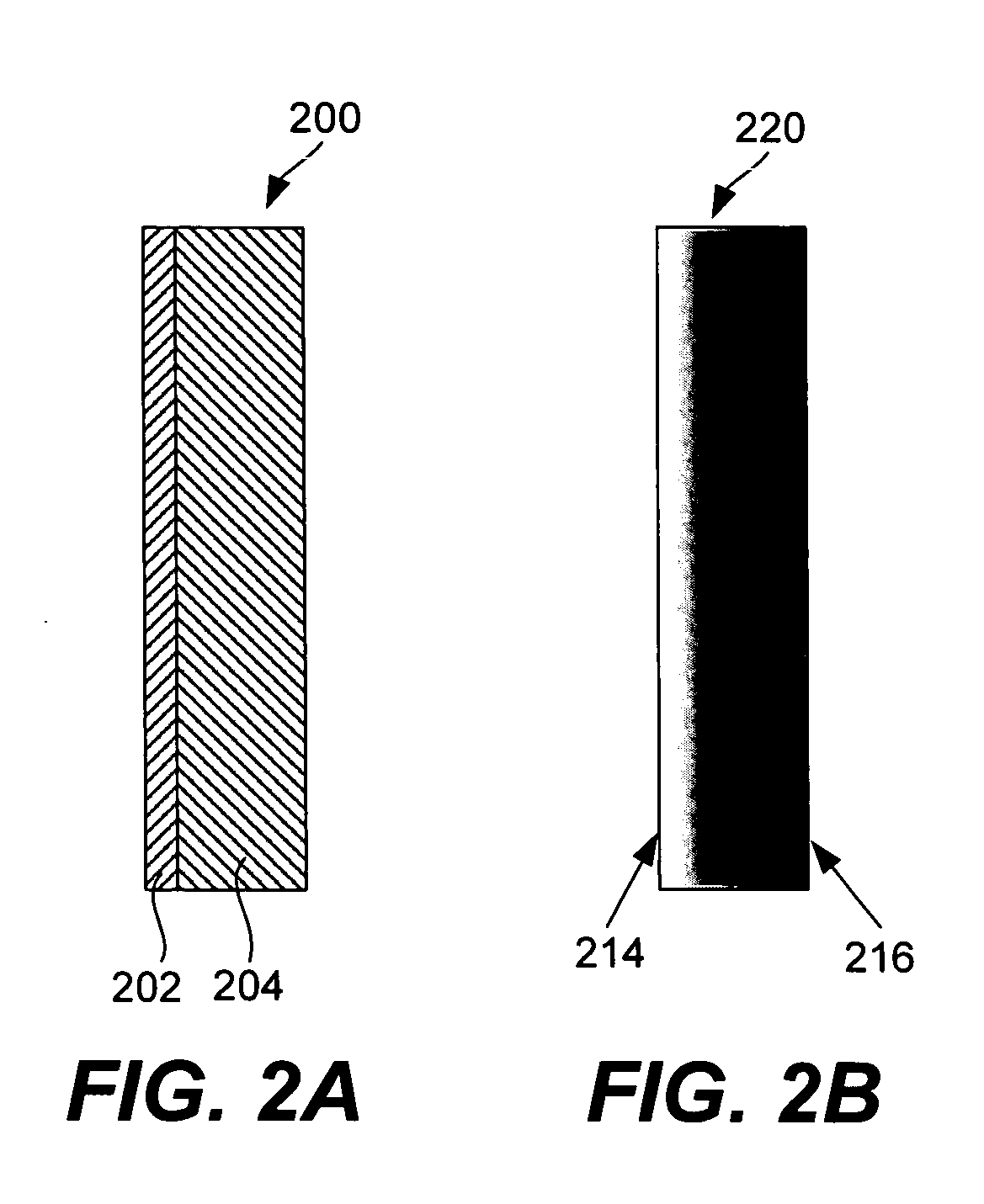

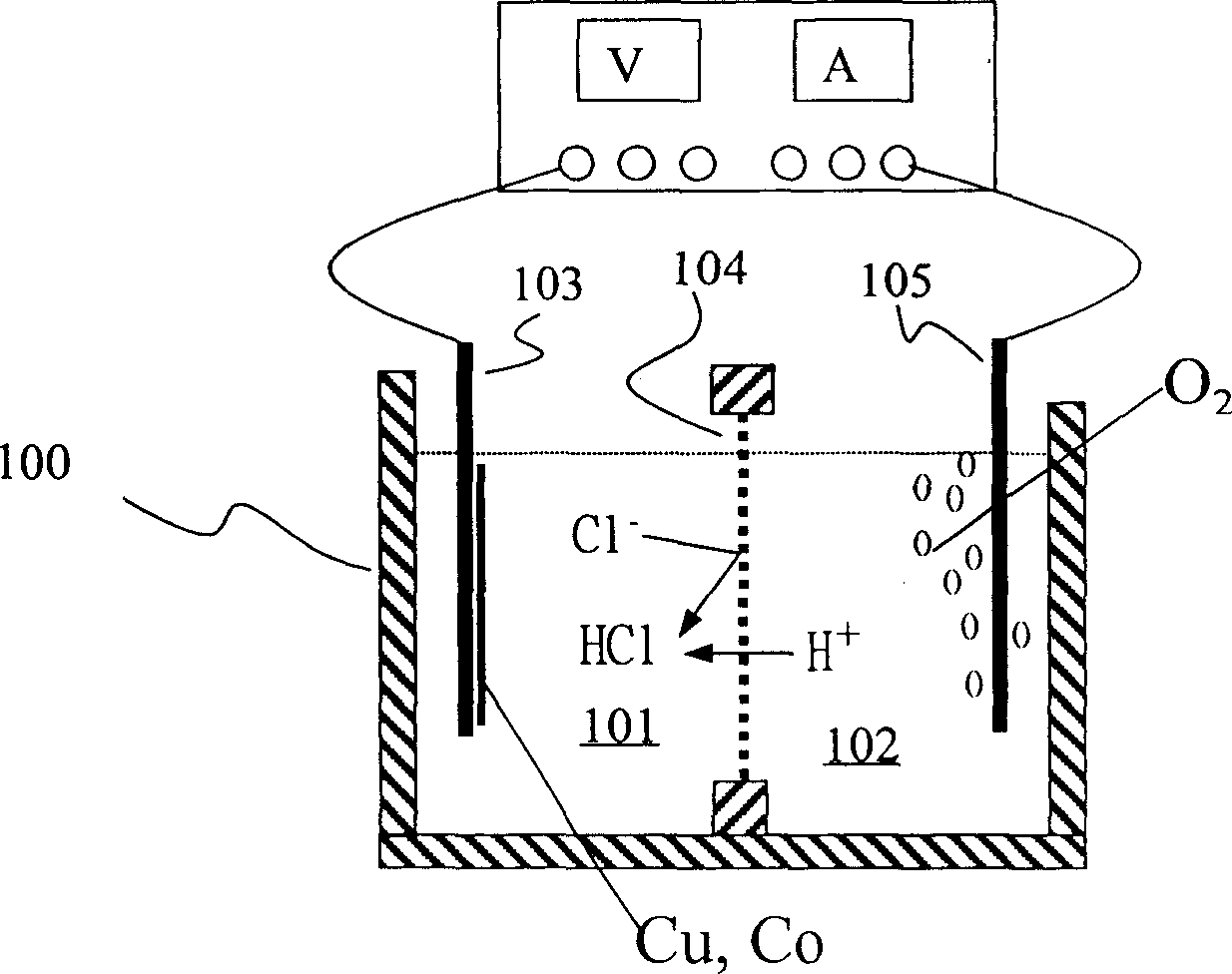

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

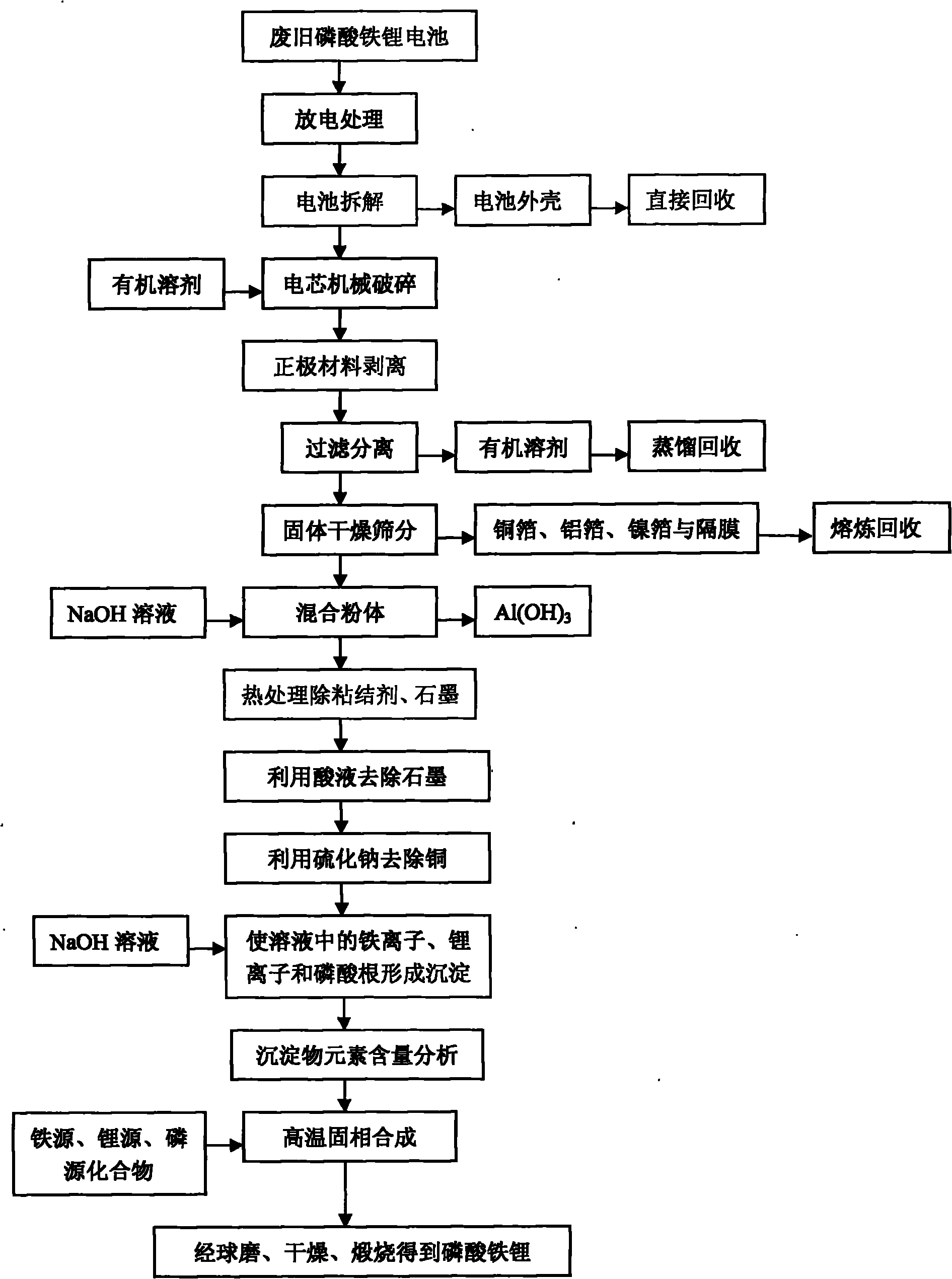

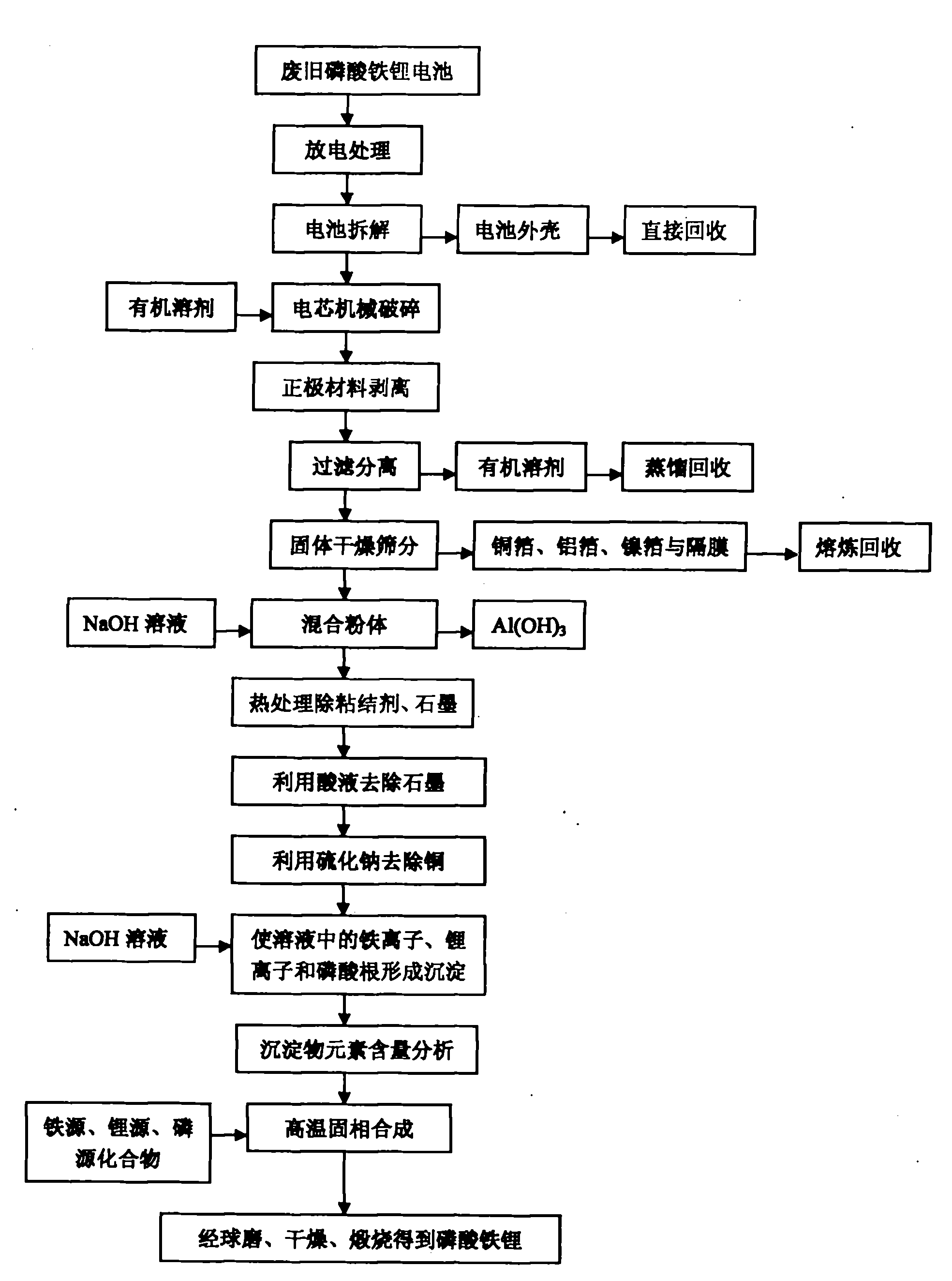

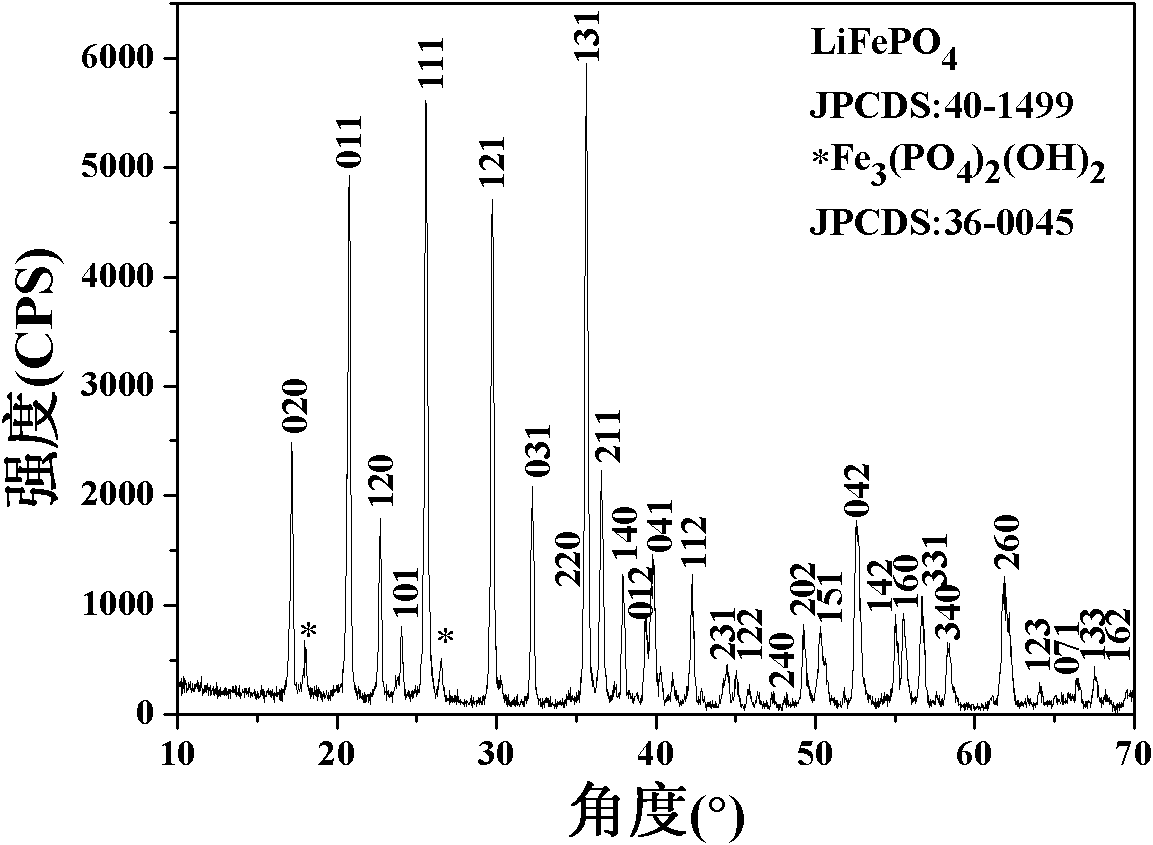

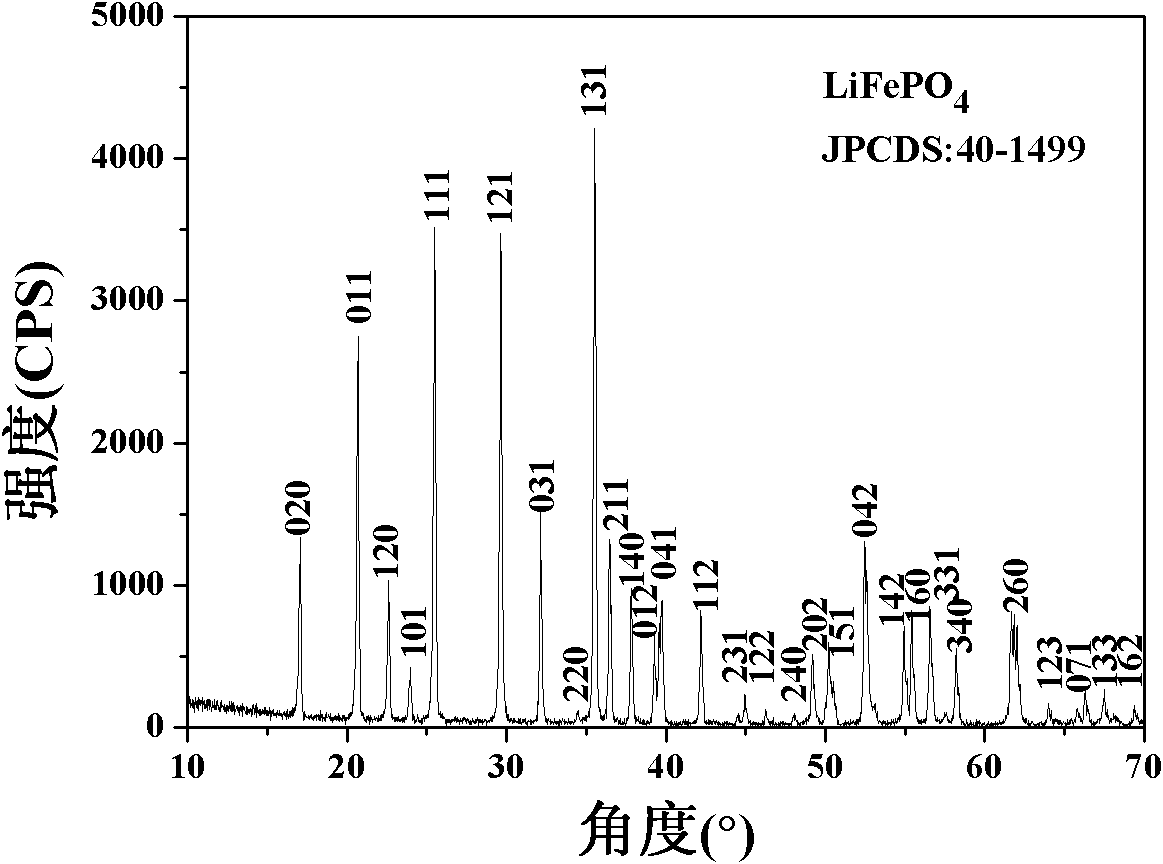

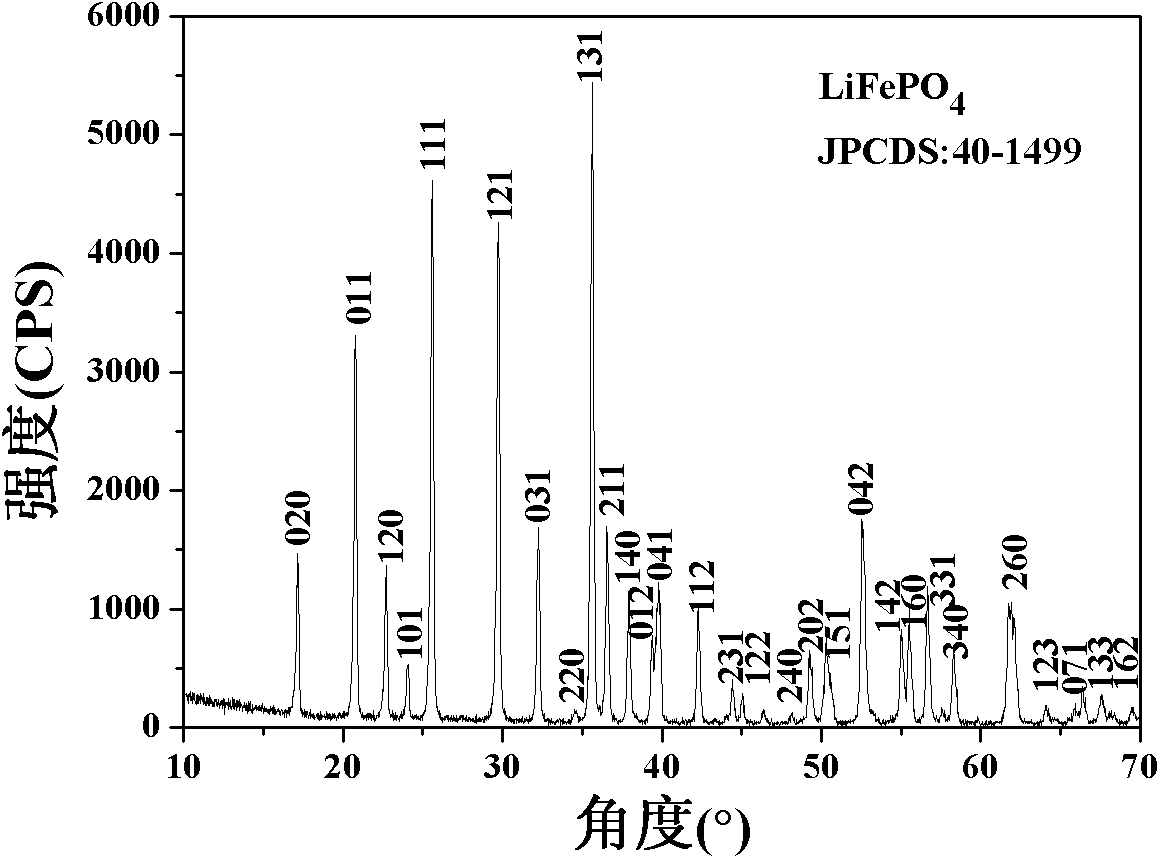

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

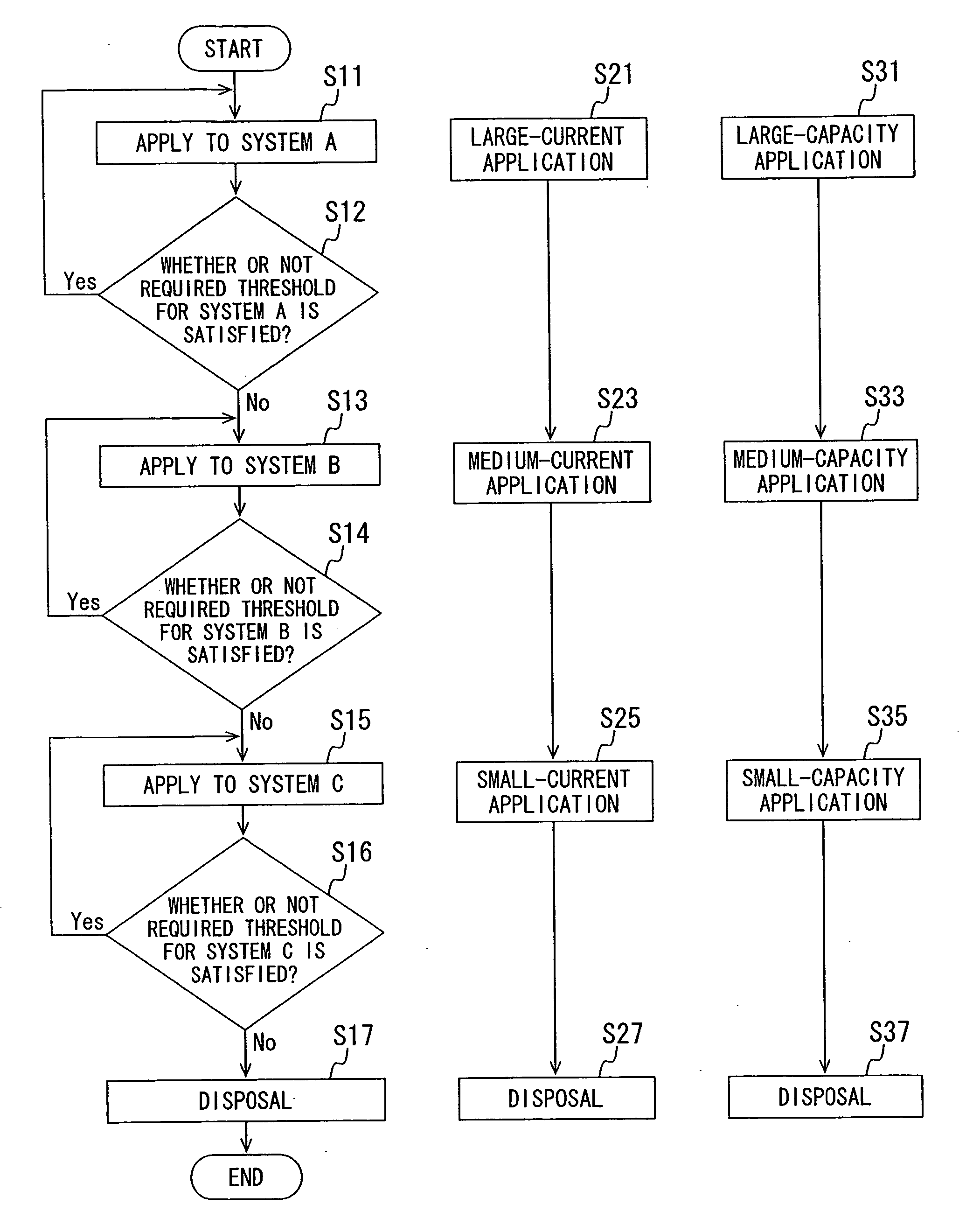

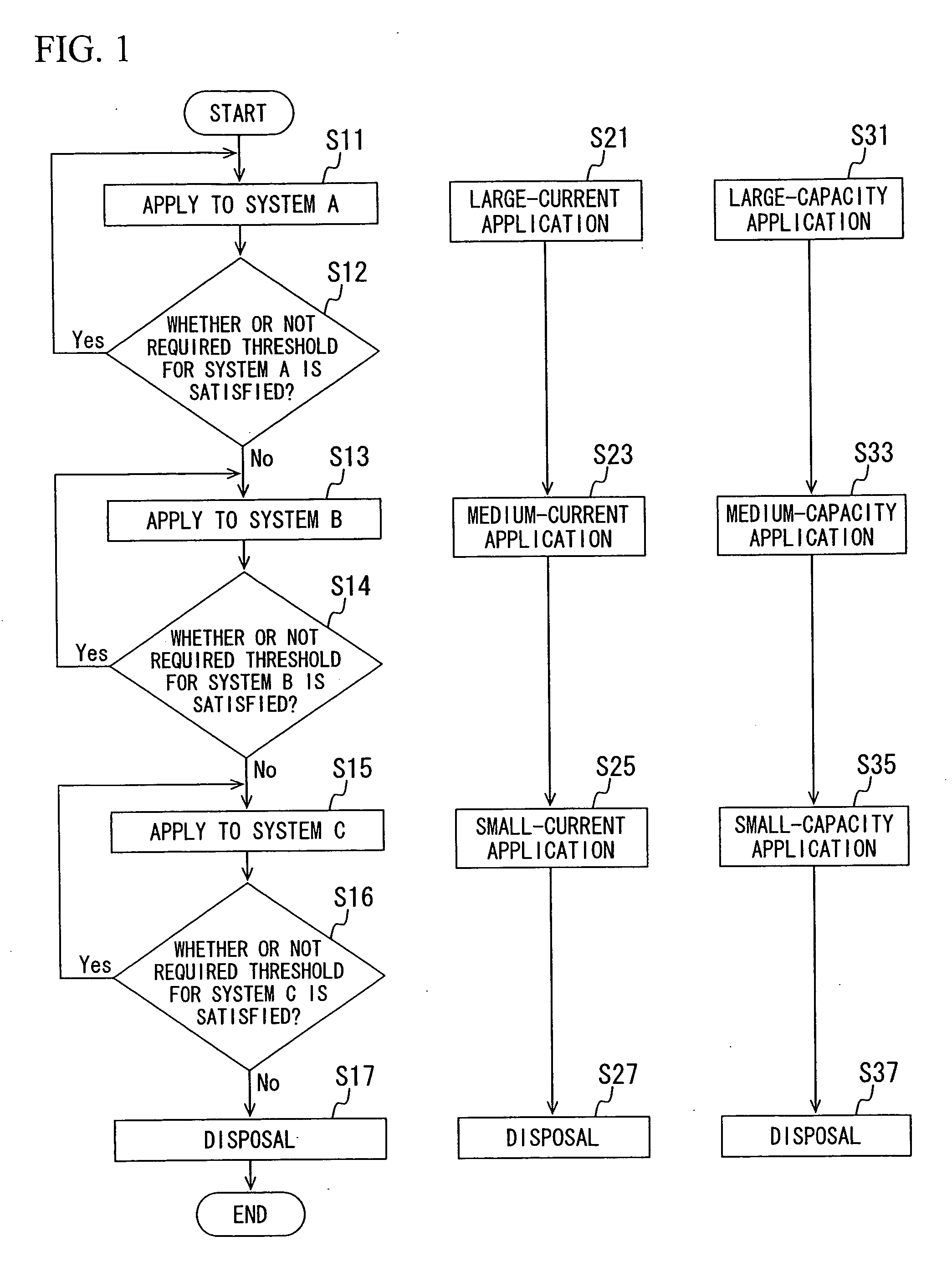

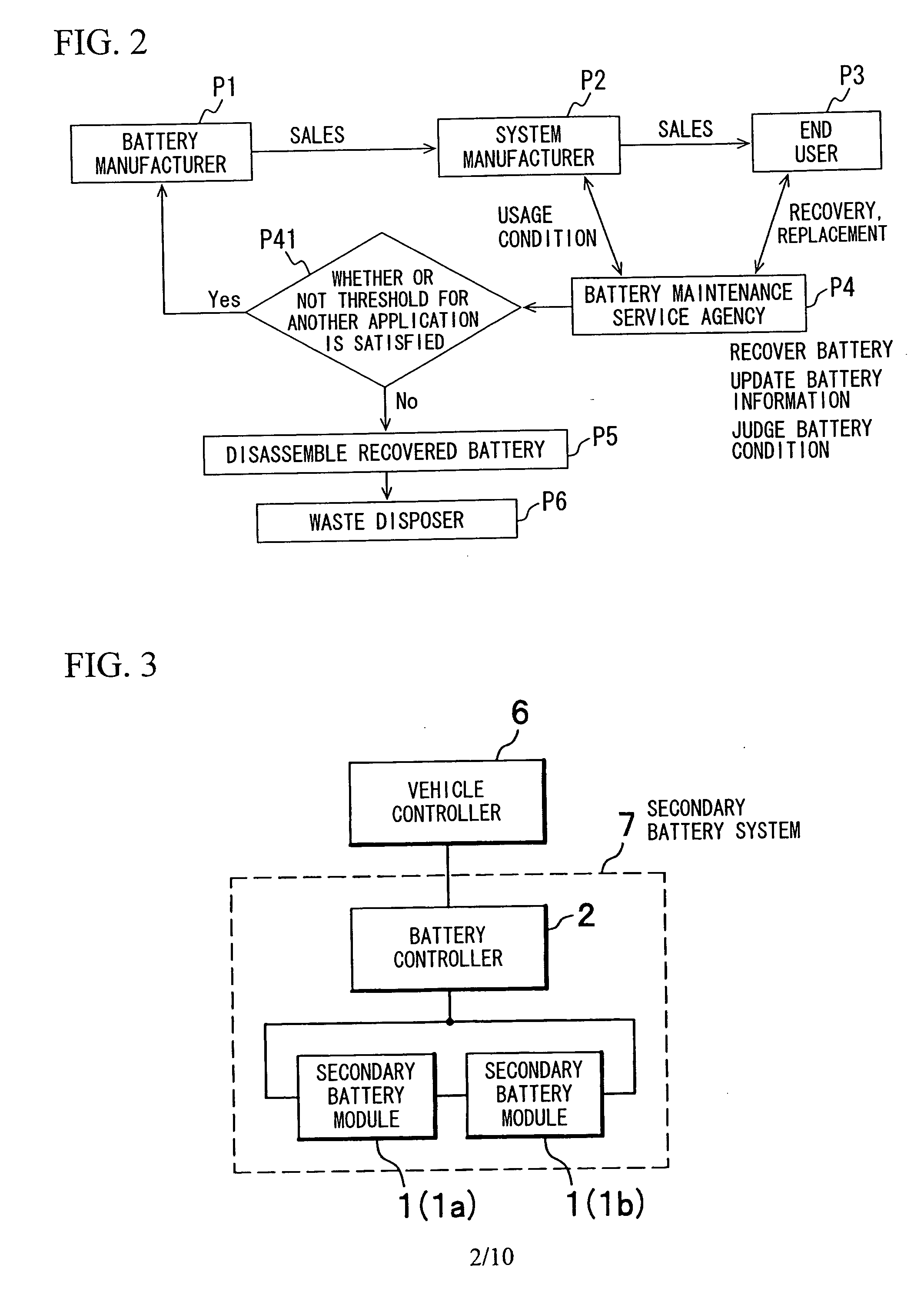

Secondary battery module, battery information management device, battery information management system, secondary battery reuse system, secondary battery recovery and sales system, secondary battery reuse method, and secondary battery recovery and sales method

ActiveUS20070108946A1Reduce processingAddress rising pricesBatteries circuit arrangementsReclaiming serviceable partsElectricityTerminal equipment

A secondary battery module includes a battery information storage unit for storing electric characteristic information and usage history information of the secondary battery module. A battery information management device and a terminal device respectively include interfaces to be connected to the secondary battery module. The battery information management device is provided with a battery information database. The battery information management device is connected to the terminal device through a communications network. In this way, battery information stored in the battery information storage unit, which is acquired by the battery information management device and the terminal device, is accumulated in the battery information database. Moreover, the battery information management device grades the secondary battery module for reuse based on the battery information and a predetermined threshold.

Owner:HITACHI ASTEMO LTD

Method for comprehensively recovering valuable metals from waste lithium-ion battery material

ActiveCN106129511AEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementManganeseAmmonia

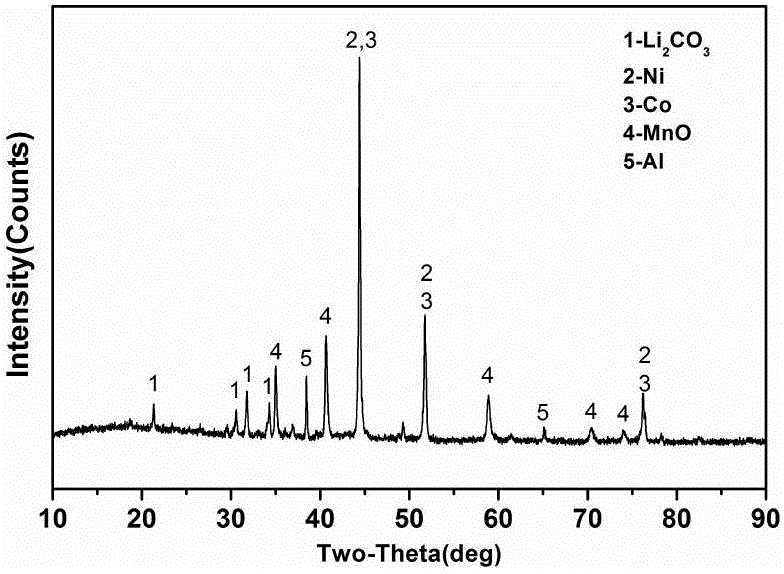

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

Recycling treatment method of waste and old lithium iron phosphate battery anode materials

InactiveCN102208706ANo pollution in the processEasy to operateSolid waste disposalWaste accumulators reclaimingLithium iron phosphateHigh energy

The invention discloses a recycling treatment method of waste and old lithium iron phosphate battery anode materials, which comprises the following steps of: firstly, scattering waste and old lithium iron phosphate batteries and stripping and collecting anode materials in the waste batteries; heating the collected anode materials at high temperature and removing carbon and an adhesion agent to obtain solid powder; adding a lithium source compound and a carbon source into the solid mixture; ball-milling the mixture through a high-energy wet method; and finally, charging the ball-milled powder into a non-oxide atmosphere and roasting at high temperature to obtain the qualified lithium iron phosphate anode materials. The recycling method disclosed by the invention has the advantages of simple process, convenience for operation and high recovery rate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for recycling nickel-cobalt-manganese ternary anode material

ActiveCN103199320AAchieve recyclingPromote sustainable developmentWaste accumulators reclaimingNickel compoundsManganeseCobalt

The invention relates to a method for recycling a nickel-cobalt-manganese ternary anode material, belongs to the technical field of recovery of waste cells, and solves the technical problem that a method for recycling the nickel-cobalt-manganese ternary anode material is provided. The method for recycling the nickel-cobalt-manganese ternary anode material comprises a step of removing a binder from the positiveplate of the nickel-cobalt-manganese ternary material by thermal treatment, and the method for removing the binder in the positive plate of the nickel-cobalt-manganese ternary material is thermal treatment of the positive plate of the nickel-cobalt-manganese ternary anode material at 400-1000 DEG C for 0.5-5 hours.

Owner:天齐锂业(江苏)有限公司 +2

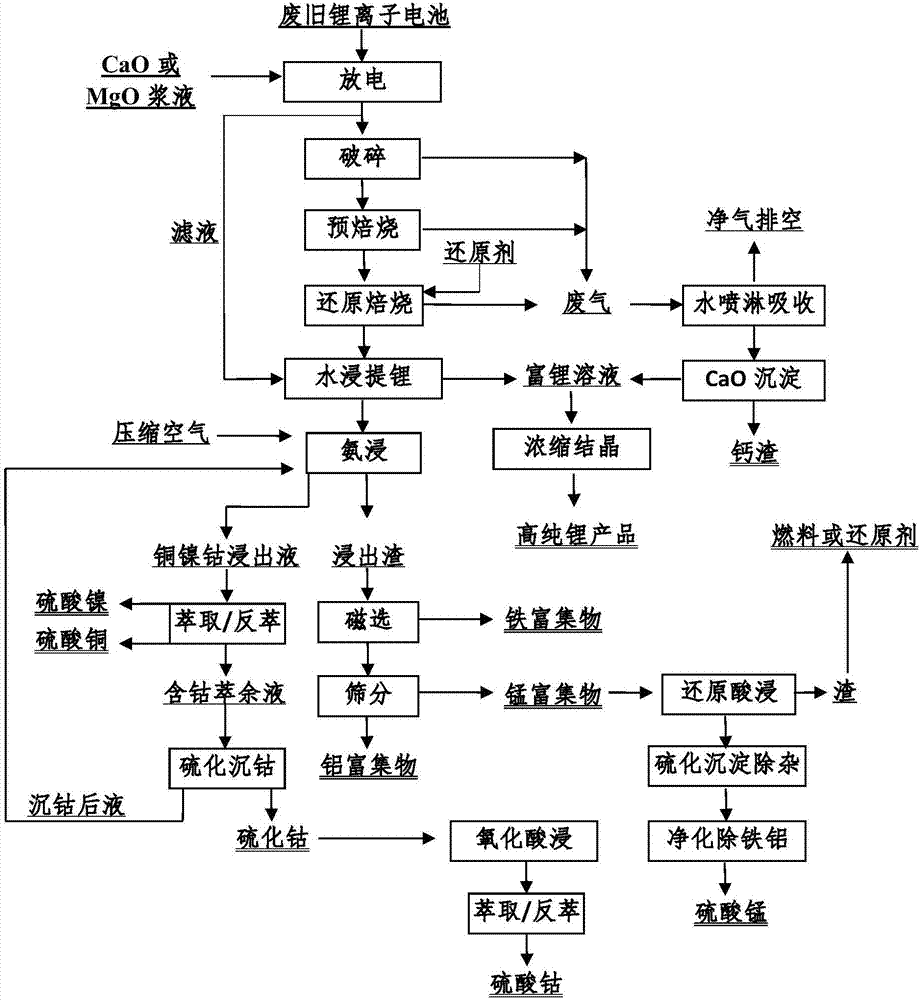

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

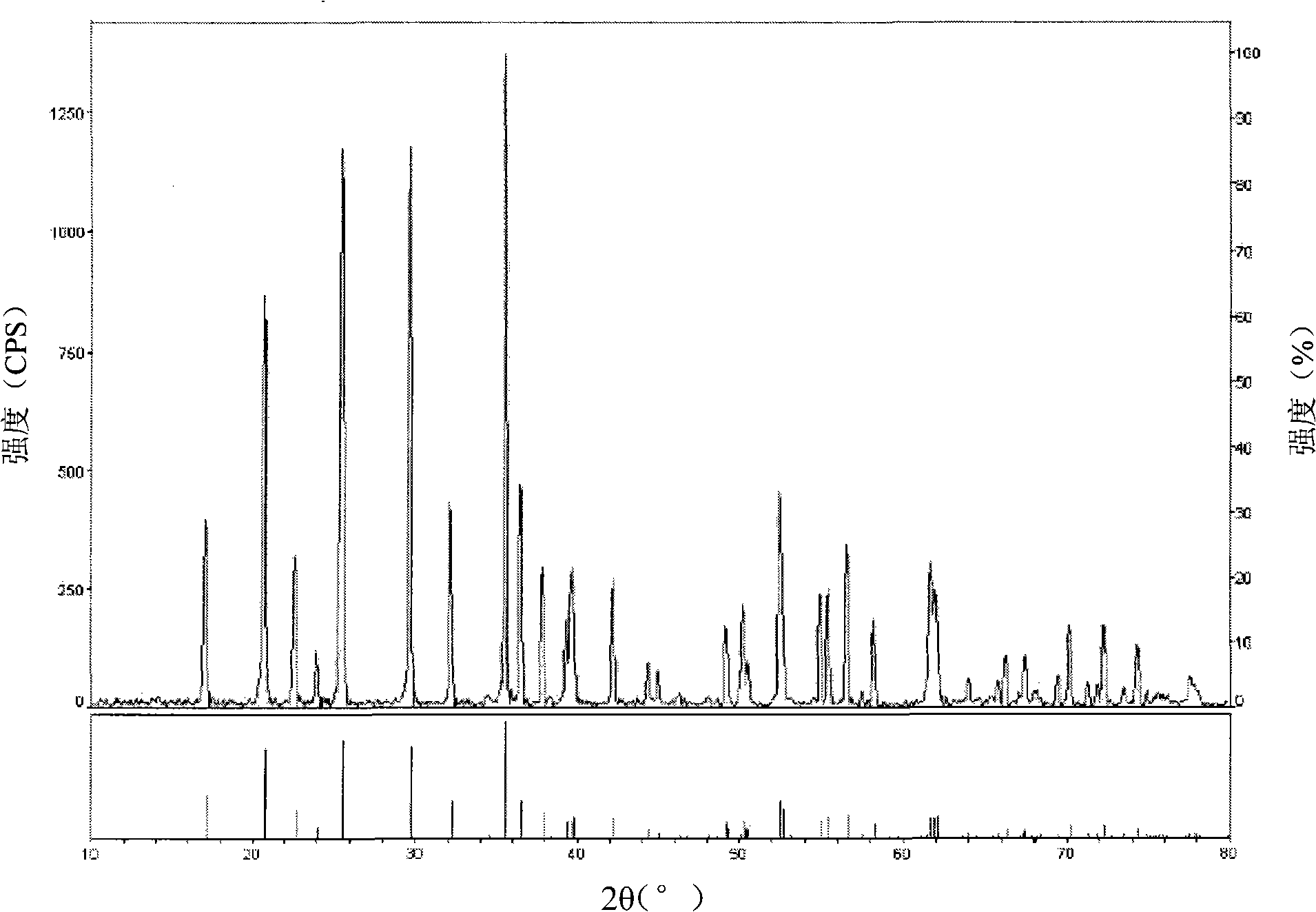

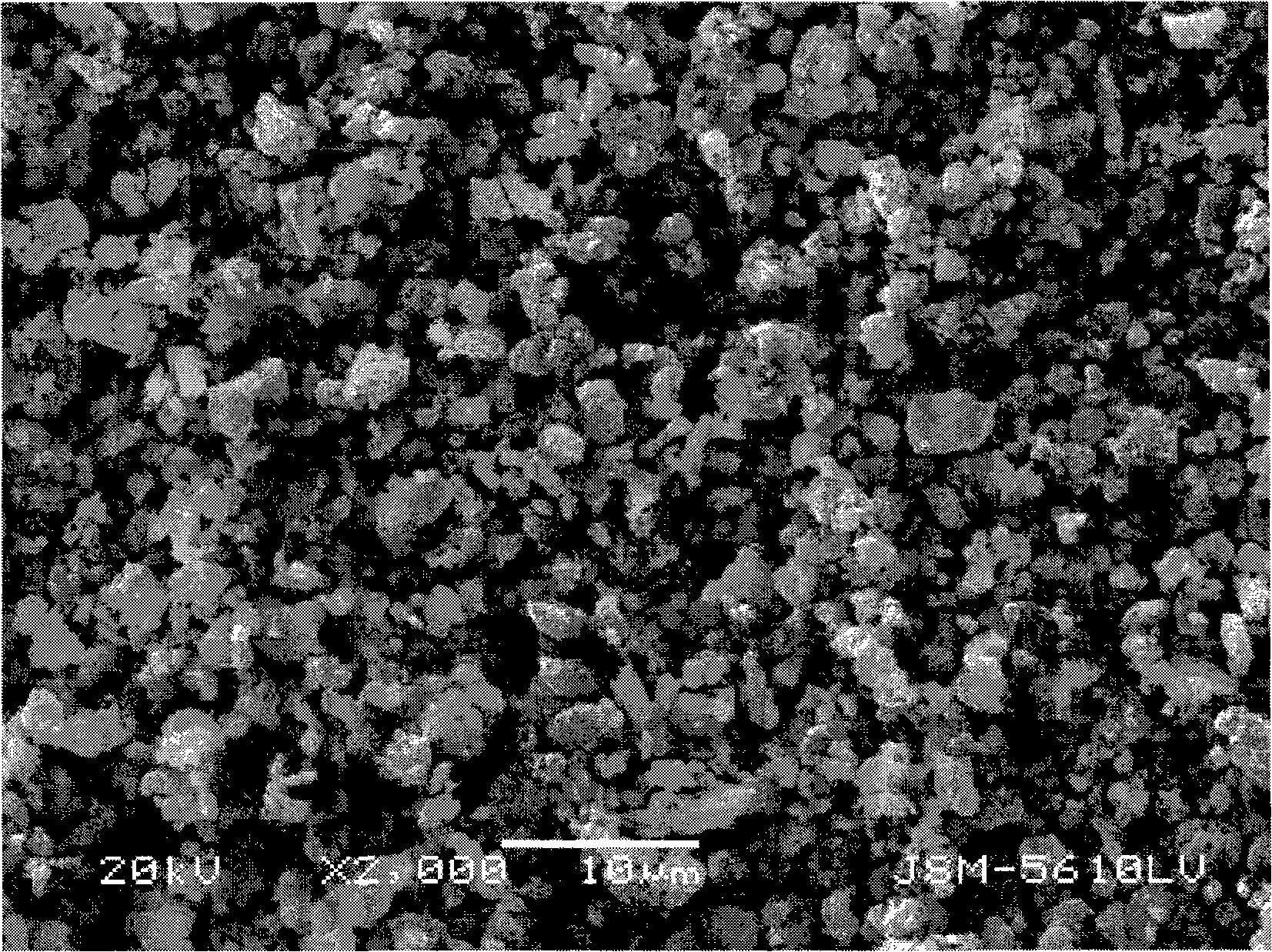

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

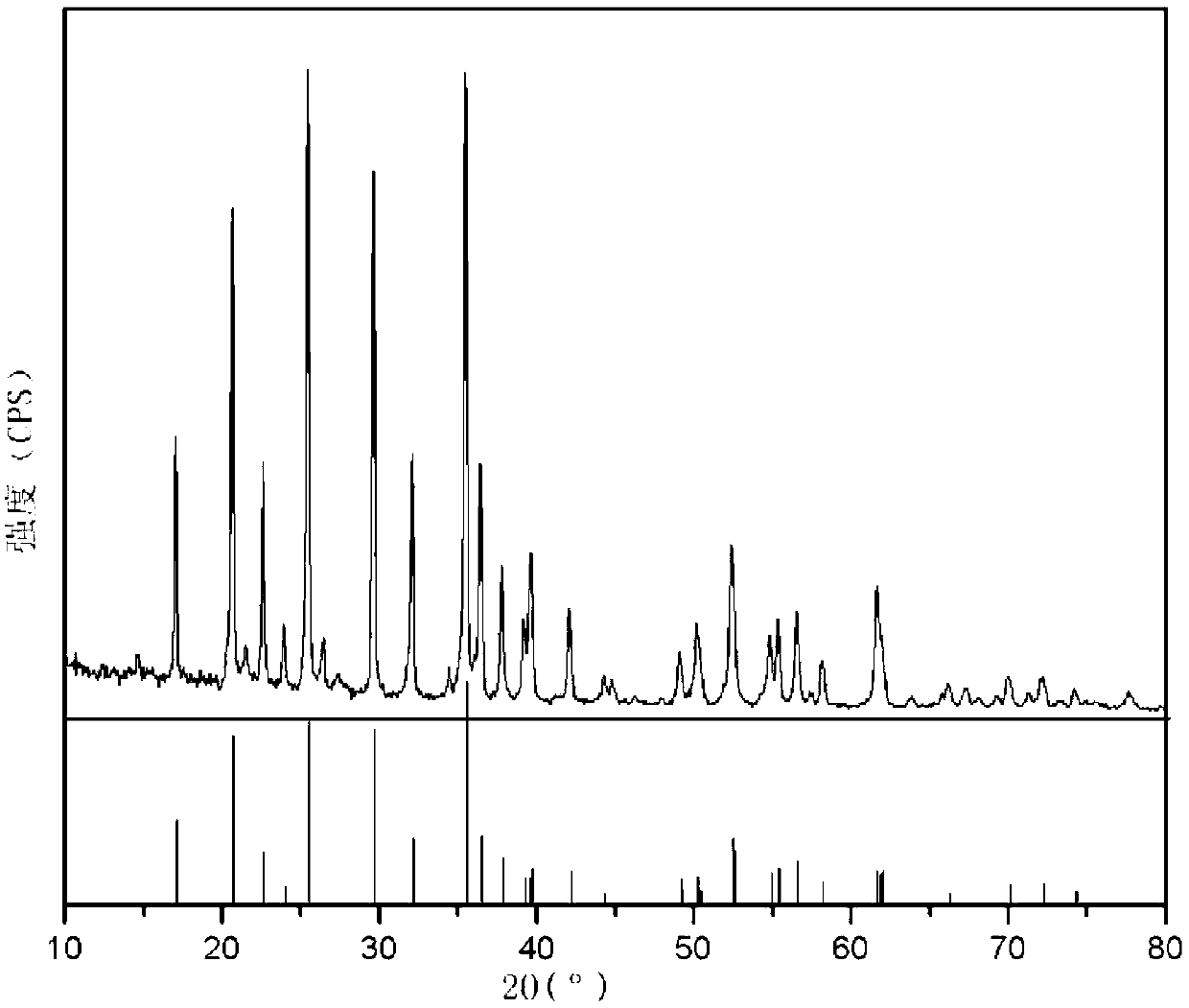

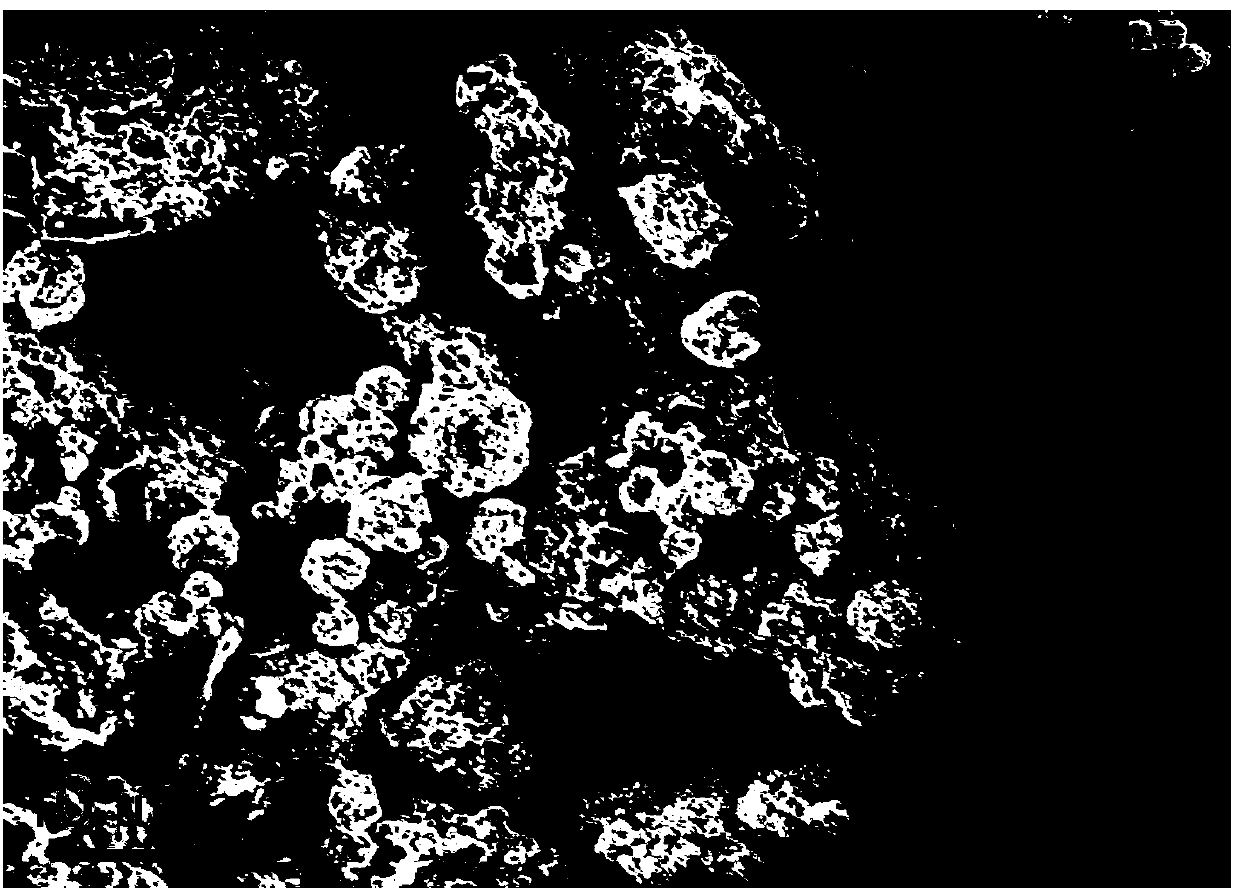

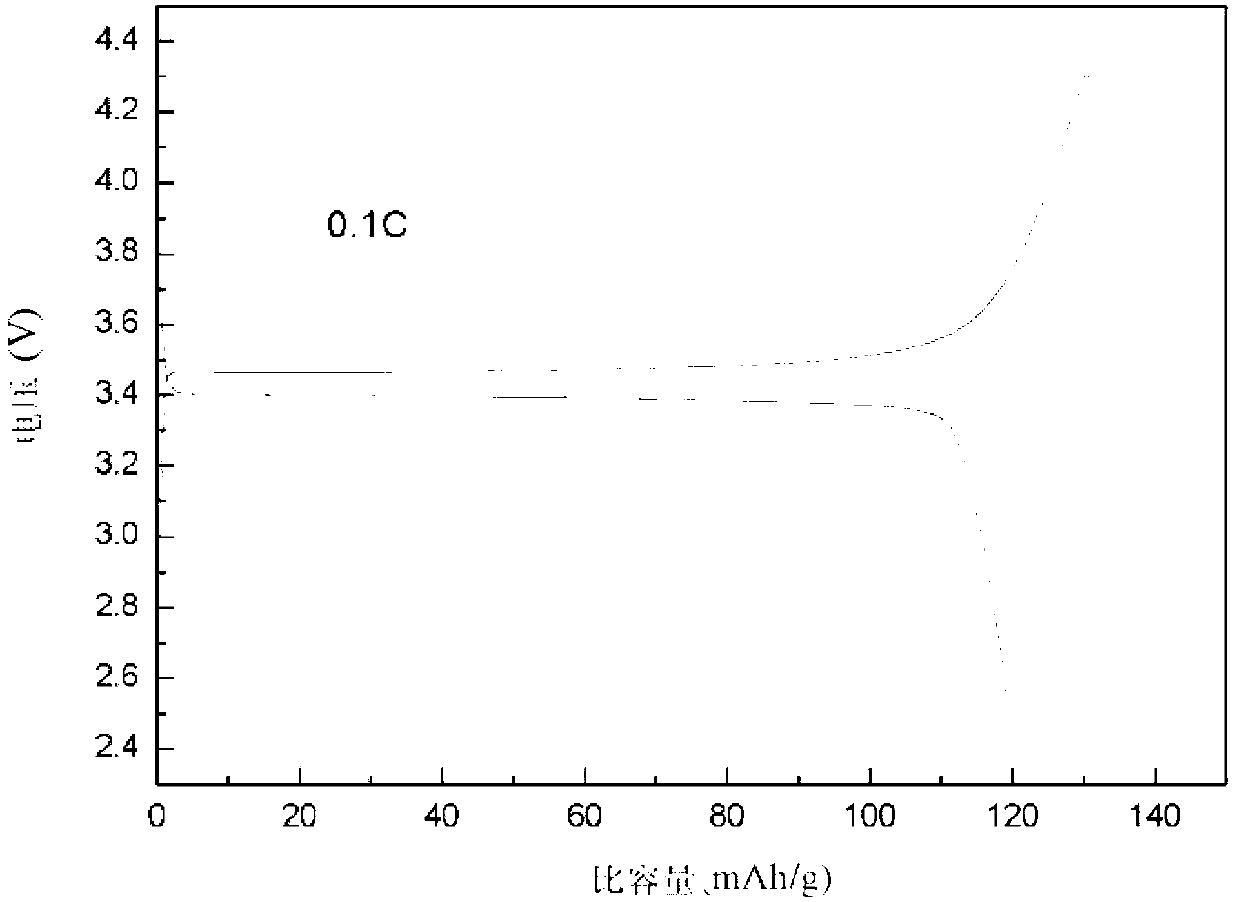

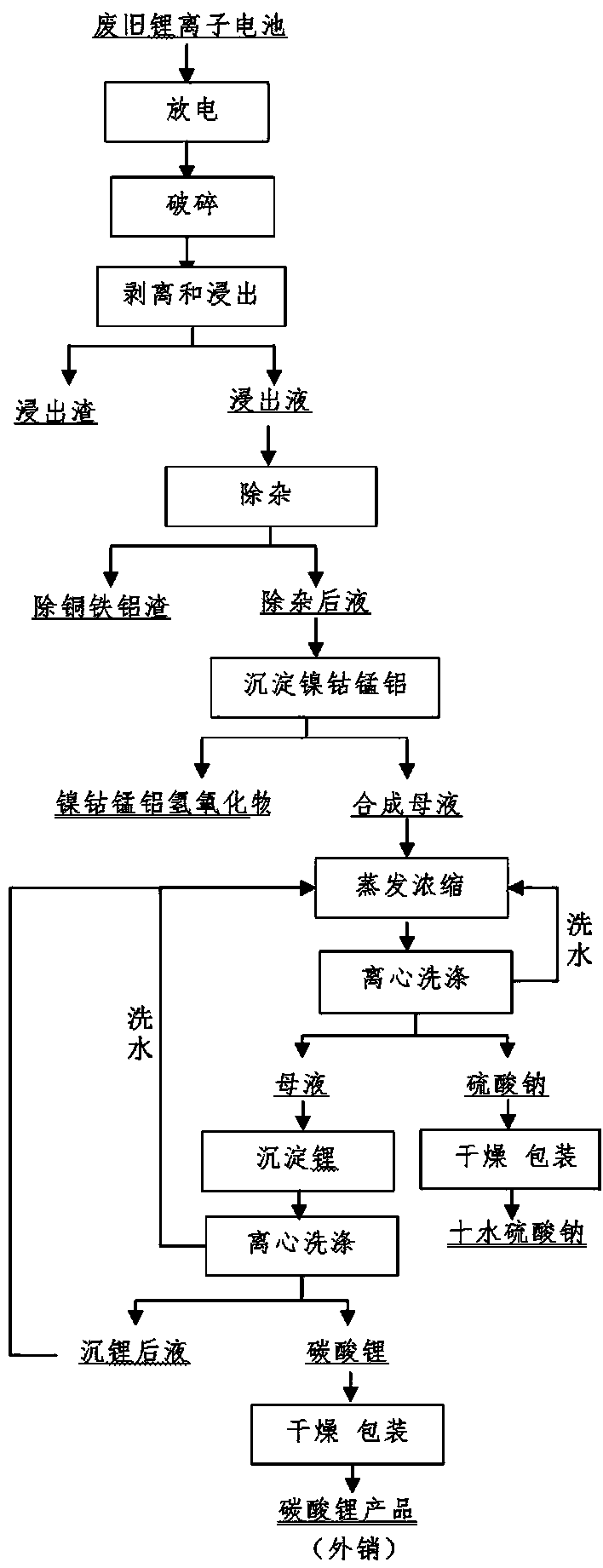

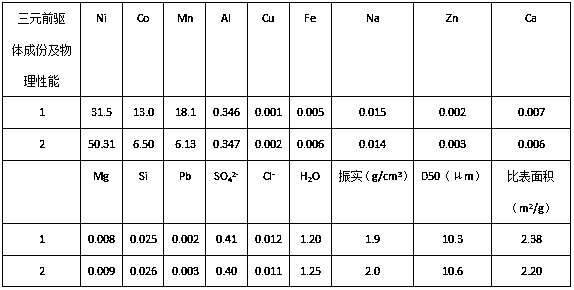

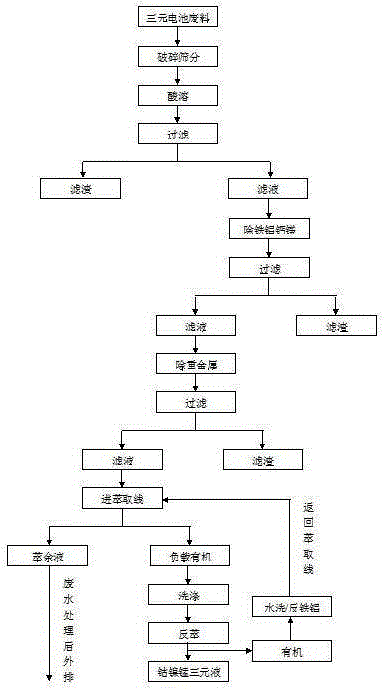

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

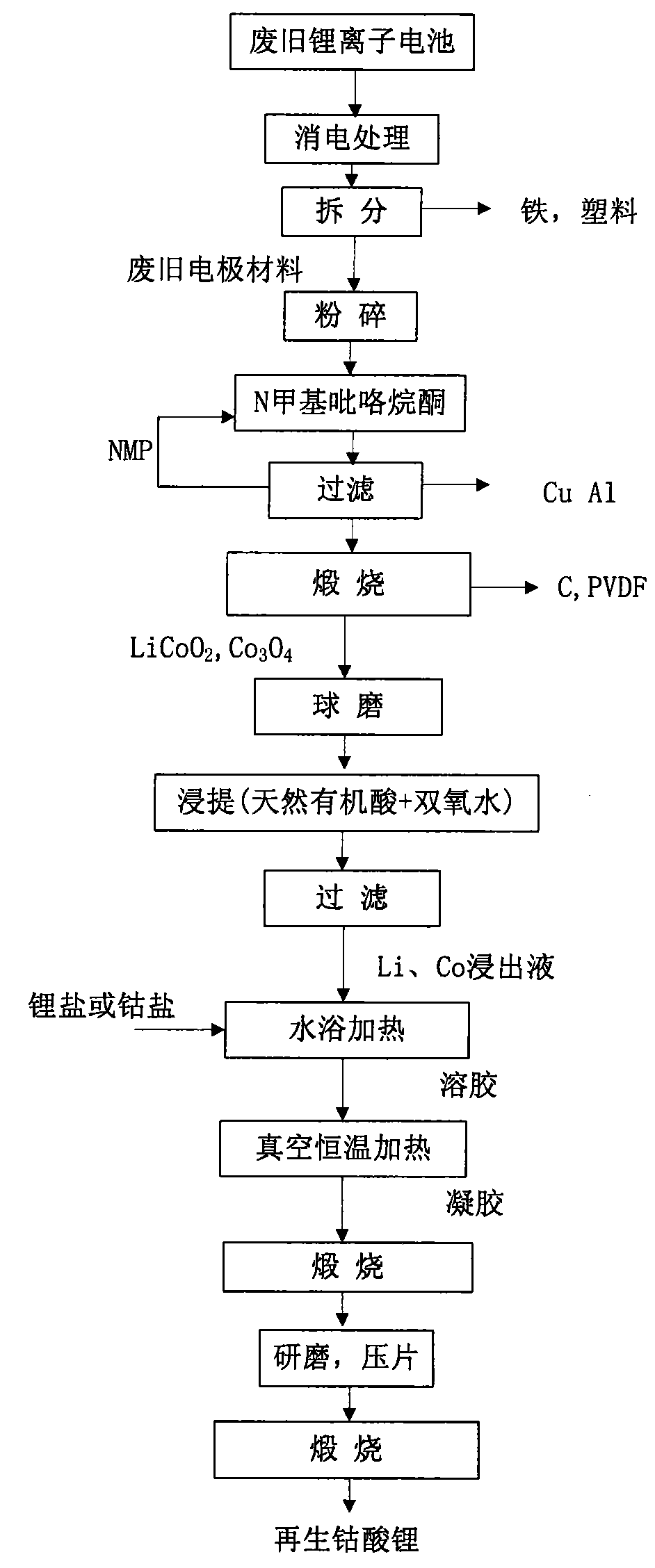

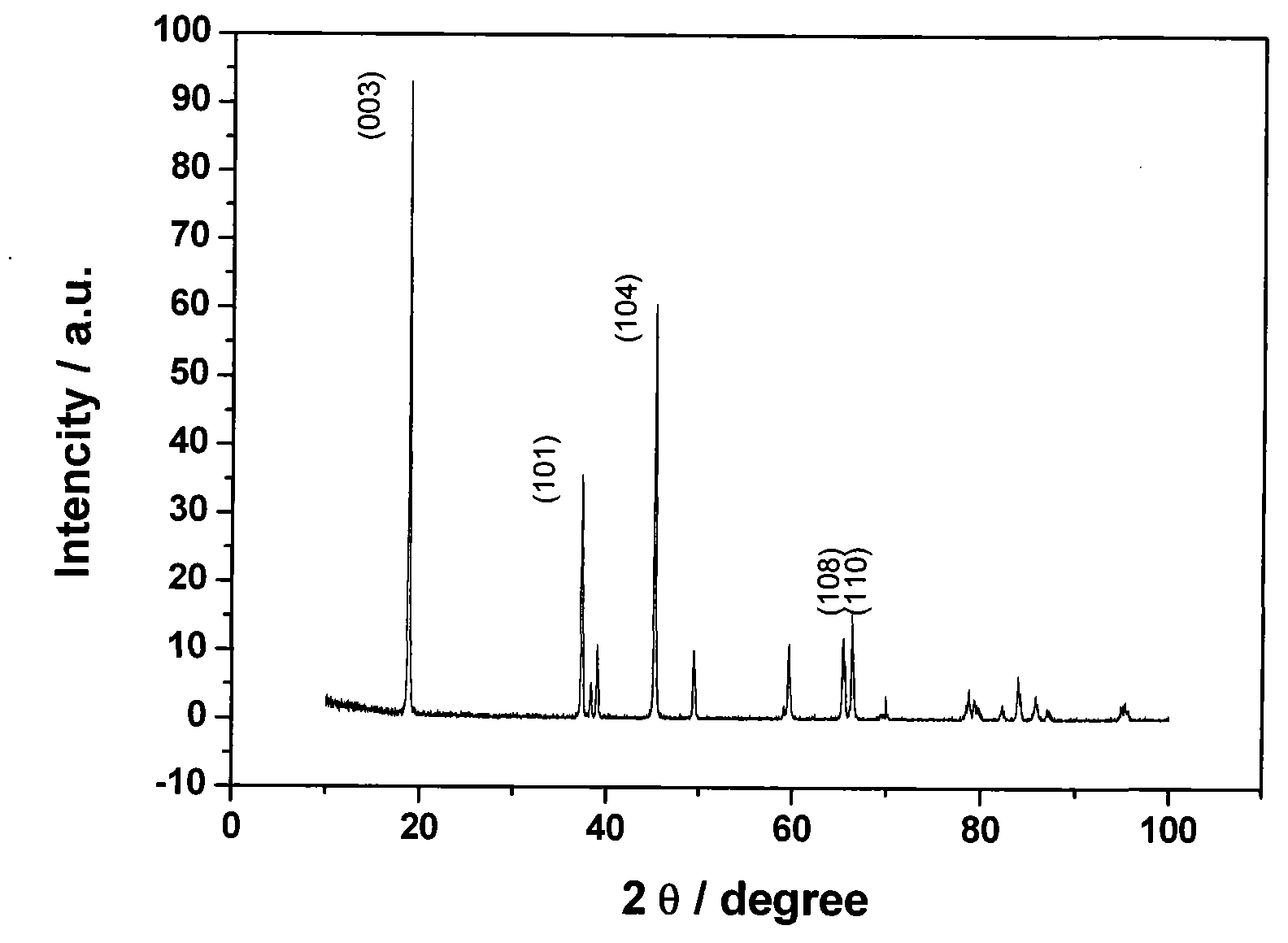

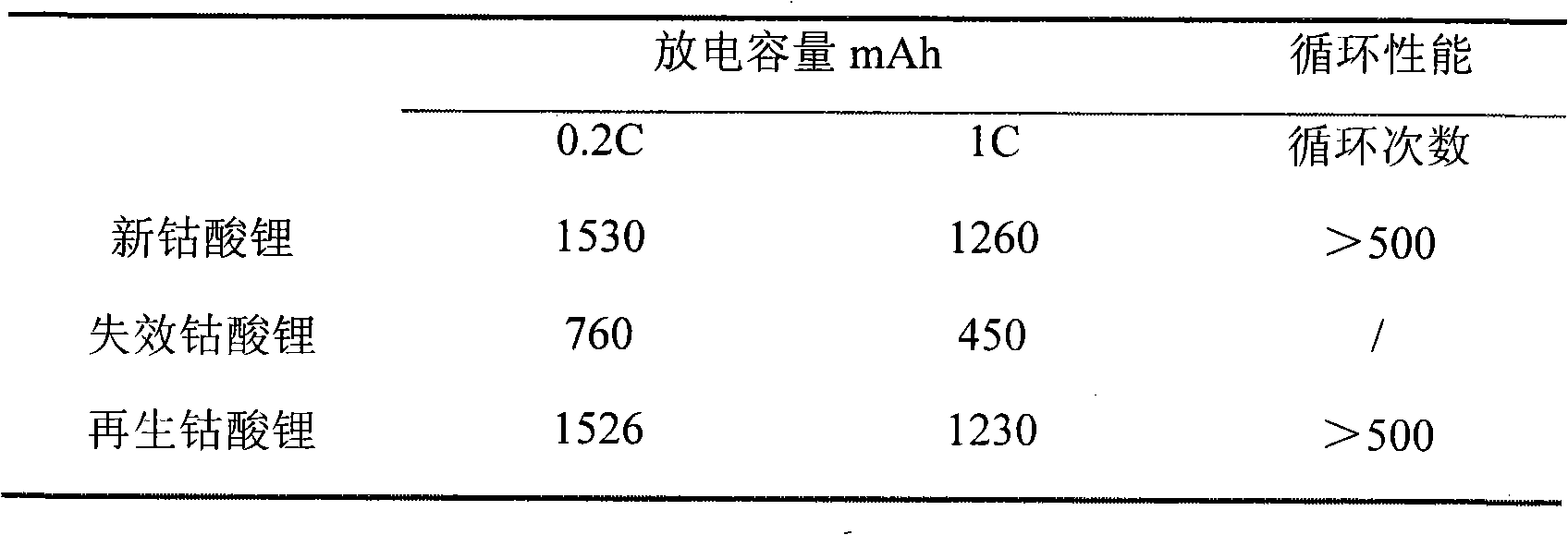

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

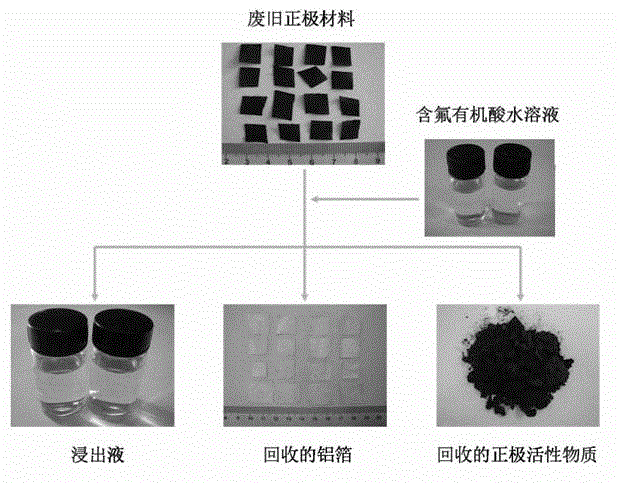

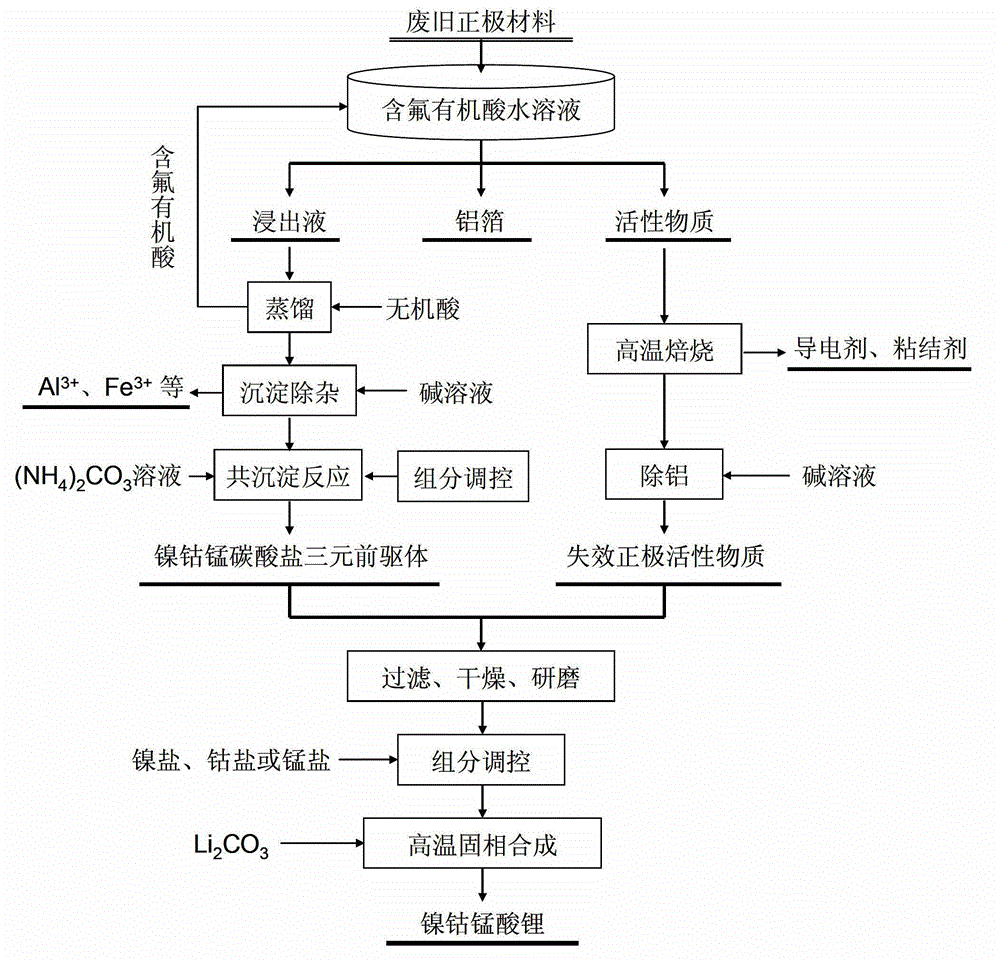

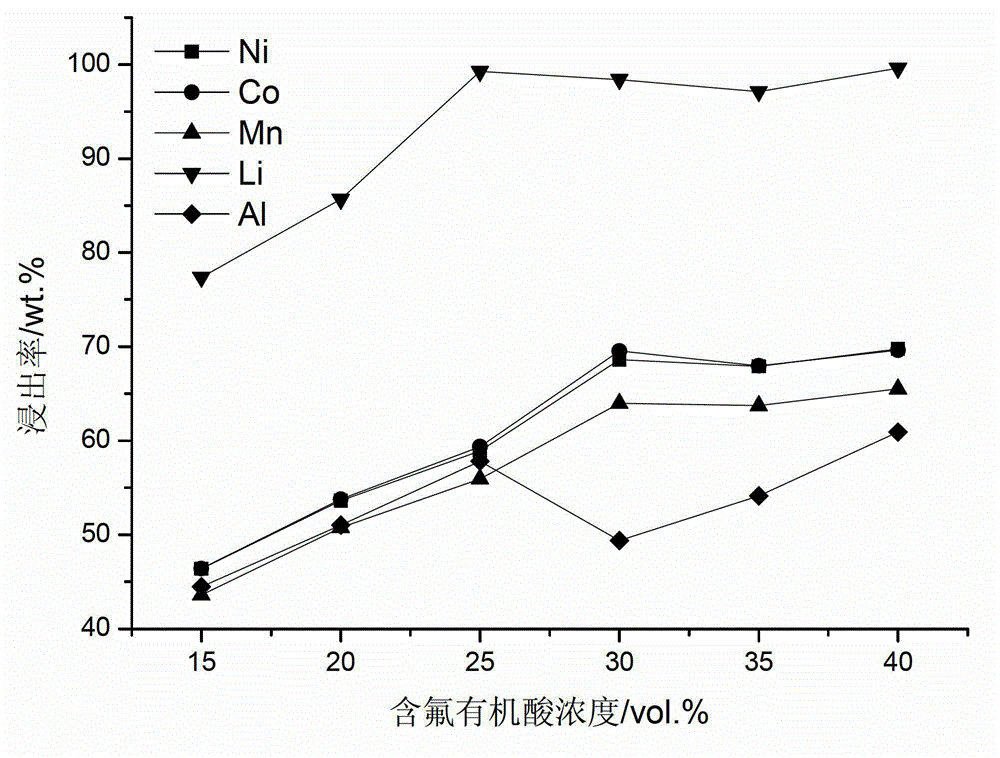

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

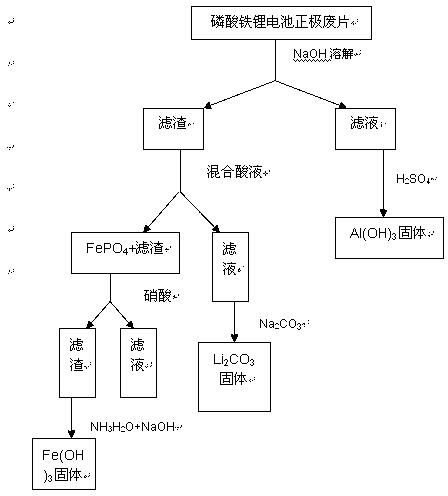

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

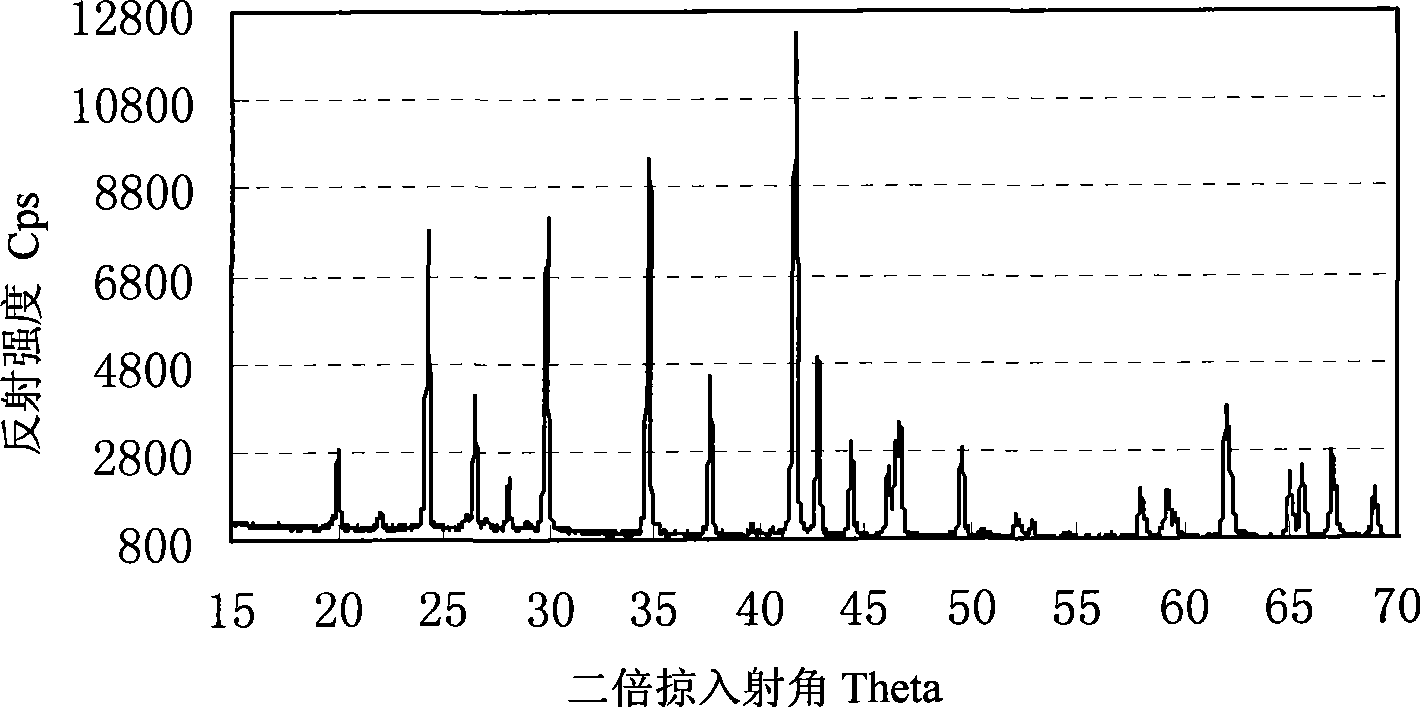

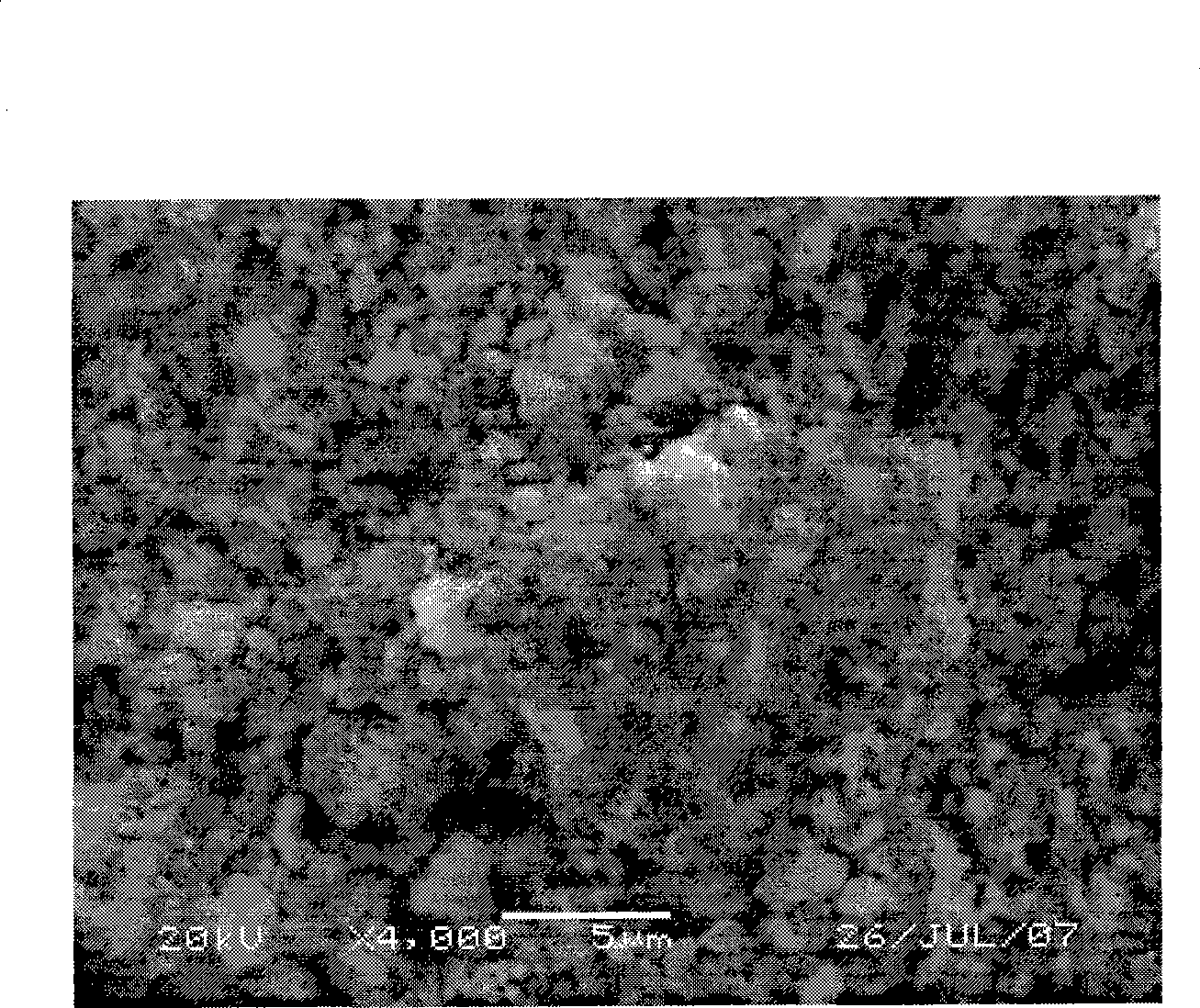

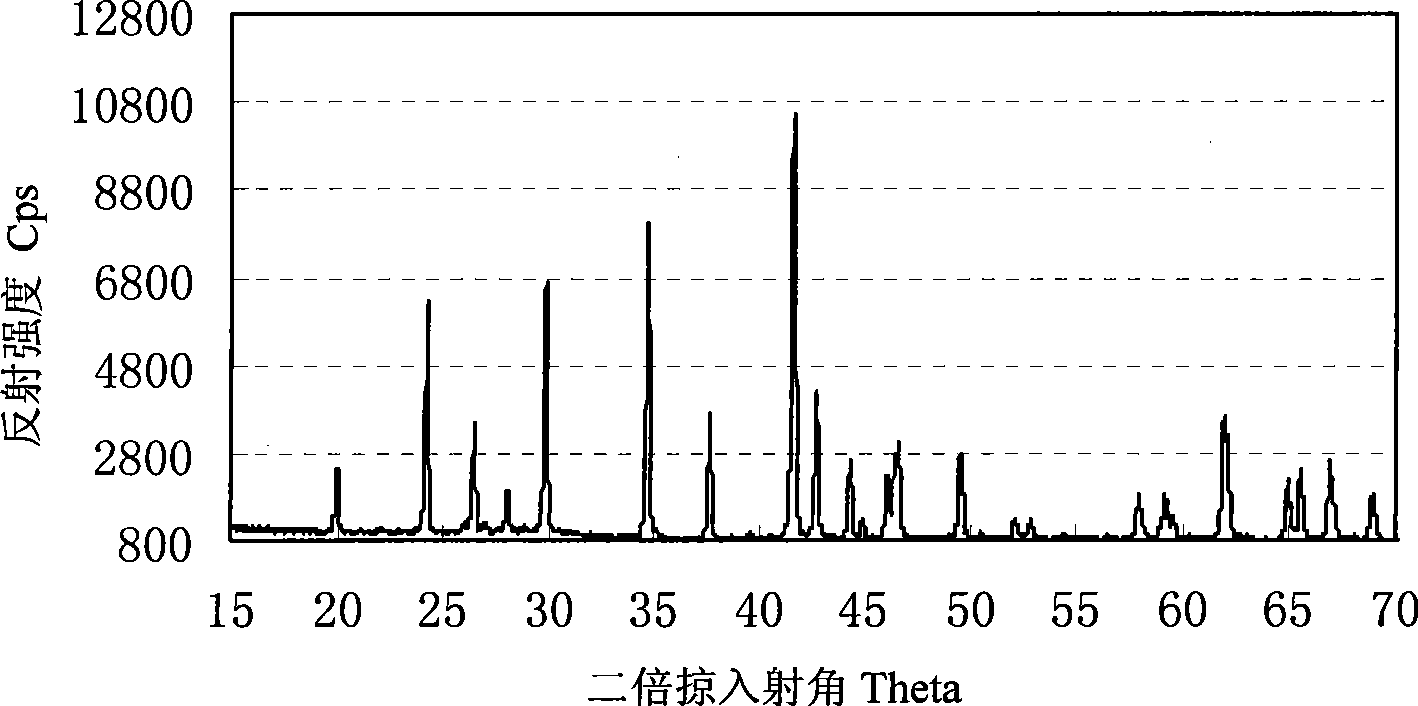

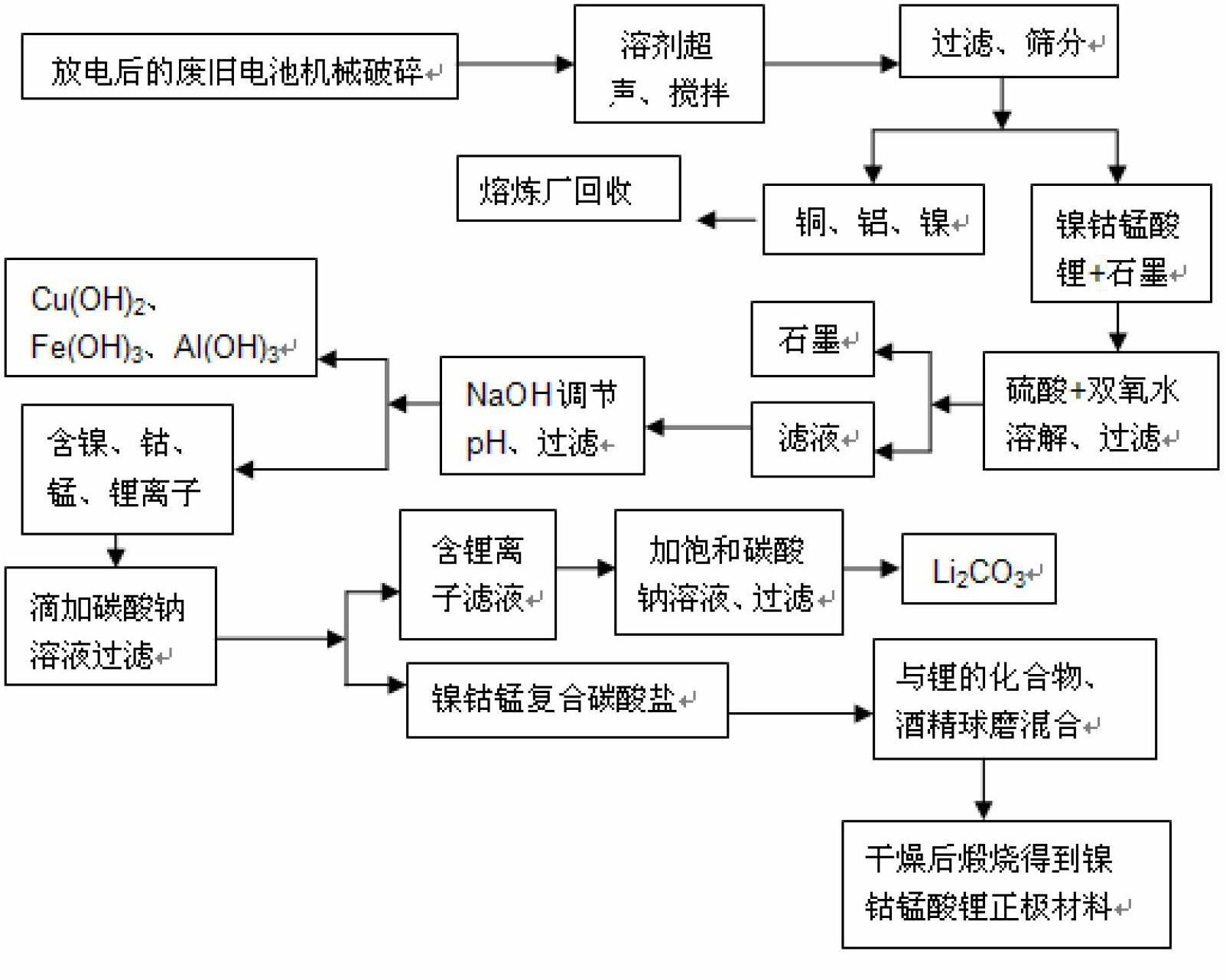

Method for recovering valuable metal from nickel cobalt lithium manganate batteries and positive pole materials

ActiveCN102676827ASimple processHigh recovery rateCell electrodesWaste accumulators reclaimingRecovery methodPower battery

The invention provides a method for recovering valuable metal from waste nickel cobalt lithium manganate batteries and positive pole materials made of the valuable metal and belongs to the technical field of waste power battery recovery. The method can solve the problems in the existing recovery method that proportions of nickel, cobalt and manganese in the waste nickel cobalt lithium manganate batteries are different and corresponding metal is required to be added in recovery steps so as to adjust content of nickel, cobalt and manganese to reach required proportions. In the recovering method, by screening the positive pole materials of all nickel cobalt lithium manganate batteries from the waste nickel cobalt lithium manganate batteries and using the positive pole materials as recovery raw materials of the waste nickel cobalt lithium manganate batteries with the same positive pole materials, nickel cobalt manganate composite carbonate capable of being applied to preparation of the positive pole materials of lithium ion batteries directly without adjusting the proportion of nickel, cobalt and manganese is obtain.

Owner:CHERY AUTOMOBILE CO LTD

Method for recycling lithium iron phosphate anode material from lithium ionic cell waste

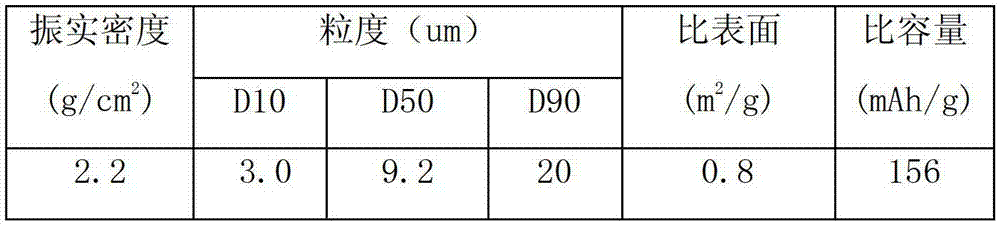

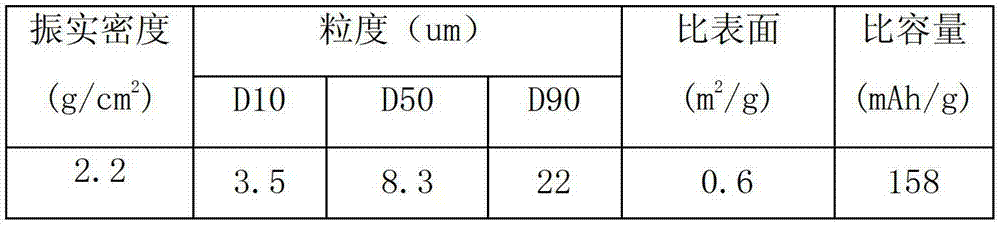

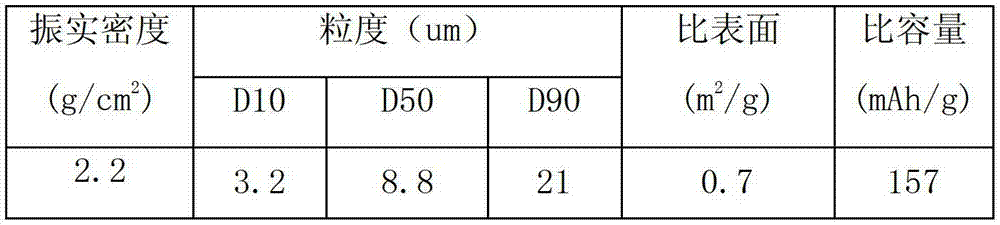

ActiveCN101359756AHigh tap densityIncrease capacityWaste accumulators reclaimingBattery recyclingRecovery methodLithium iron phosphate

The invention relates to a method for recovering a lithium iron phosphate anode material in lithium ion battery scraps, comprising: roasting the scraps in the atmosphere of inert gases at a temperature of between 450 and 600 DEG C for 2 to 5 hours, wherein, the method also includes: adding the powdered products into an ethanol solution of soluble ferric salt for mixing, drying the mixture, then roasting the mixture in the atmosphere of inert gases at a temperature of between 300 and 500 DEG C for 2 to 5 hours, and obtaining the lithium iron phosphate anode material through recovery. The recovery method can be used to obtain the lithium iron phosphate anode material with rather high tap density, so the lithium ion secondary battery made by adopting the anode material has rather high capacity.

Owner:贵州中伟资源循环产业发展有限公司

Method for recovering waste lithium iron phosphate battery positive pieces

ActiveCN103280610AReduce pollutionWaste accumulators reclaimingProcess efficiency improvementPhosphoric acidImpurity

The invention discloses a method for recovering Al, Fe and Li in waste lithium iron phosphate battery positive pieces through an acid-alkali leaching process. The method comprises the following steps: dismounting the lithium iron phosphate battery positive pieces, dissolving the positive pieces by using an alkali, filtering, and dissolving obtained filter residues by a mixed acid solution for making Fe exist in an iron phosphate precipitate form and be separated from impurities comprising carbon black and the like and a lithium-containing solution; adding the lithium-containing solution to a 95DEG C saturated sodium carbonate solution for precipitation to obtain lithium carbonate; and adding an acid to obtain an iron-containing precipitate for leaching iron ions, and adding an alkaline solution to obtain Fe(OH)3. Al, Fe and Li in the waste lithium iron phosphate battery positive pieces are simply and effectively recovered through using low-concentration acids and alkalis and routine chemicals, and raw materials having economic benefits are recovered through using simple and effective equipment and the method.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

Treatment method for waste LiMn1-x-yNixCoyO2 ternary battery cathode material

ActiveCN105206889ASimple processImplement directional loopWaste accumulators reclaimingProcess efficiency improvementManganesePre treatment

The invention relates to a treatment method for a waste LiMn1-x-yNixCoyO2 ternary battery cathode material and belongs to the field of waste battery treatment. The method comprises the following steps: (1), pretreatment; (2), chemical dissolution; (3), chemical impurity removal; (4), extraction, deep impurity removal and enrichment of cobalt, nickel and manganese. By adopting the treatment method for the waste LiMn1-x-yNixCoyO2 ternary battery cathode material, the full utilization and directional circulation of nickel, cobalt and manganese in the waste LiMn1-x-yNixCoyO2 ternary battery cathode material can be realized, the comprehensive recovery rate of nickel, cobalt and manganese is high and the treatment cost is low.

Owner:浙江三晟化工有限公司

Method for preparing iron lithium phosphate by recovering water-system waste lithium-ion power battery

ActiveCN101916889AReduce manufacturing costSolving Recycling ProblemsWaste accumulators reclaimingBattery recyclingPower batteryIron salts

The invention discloses a method for preparing iron lithium phosphate by recovering water-system waste lithium-ion power batteries, comprising the following steps: 1) cutting and brushing a water-system waste lithium-ion power battery, processing by deionized water, sieving and drying to recover the mixture of an electrode material and a conductive agent; 2) adding inorganic acid to the dried mixture of the electrode material and the conductive agent to process, filtering to obtain acid solution containing Li+, Fe2+ and PO43-; 3) adding lithium salt or iron salt to the acid solution containing Li+, Fe2+ and PO43-, adding ascorbic acid and stirring, controlling the pH value to equal to 3-7, and filtering to obtain precipitation; and 4) adding the crude product LiFePO4 obtained in step 3) to a water solution of cane sugar for ball milling, drying and calcining to obtain a regenerative LiFePO4 material. The method has low cost, simple operation and no secondary pollution.

Owner:长春劲能科技集团有限公司

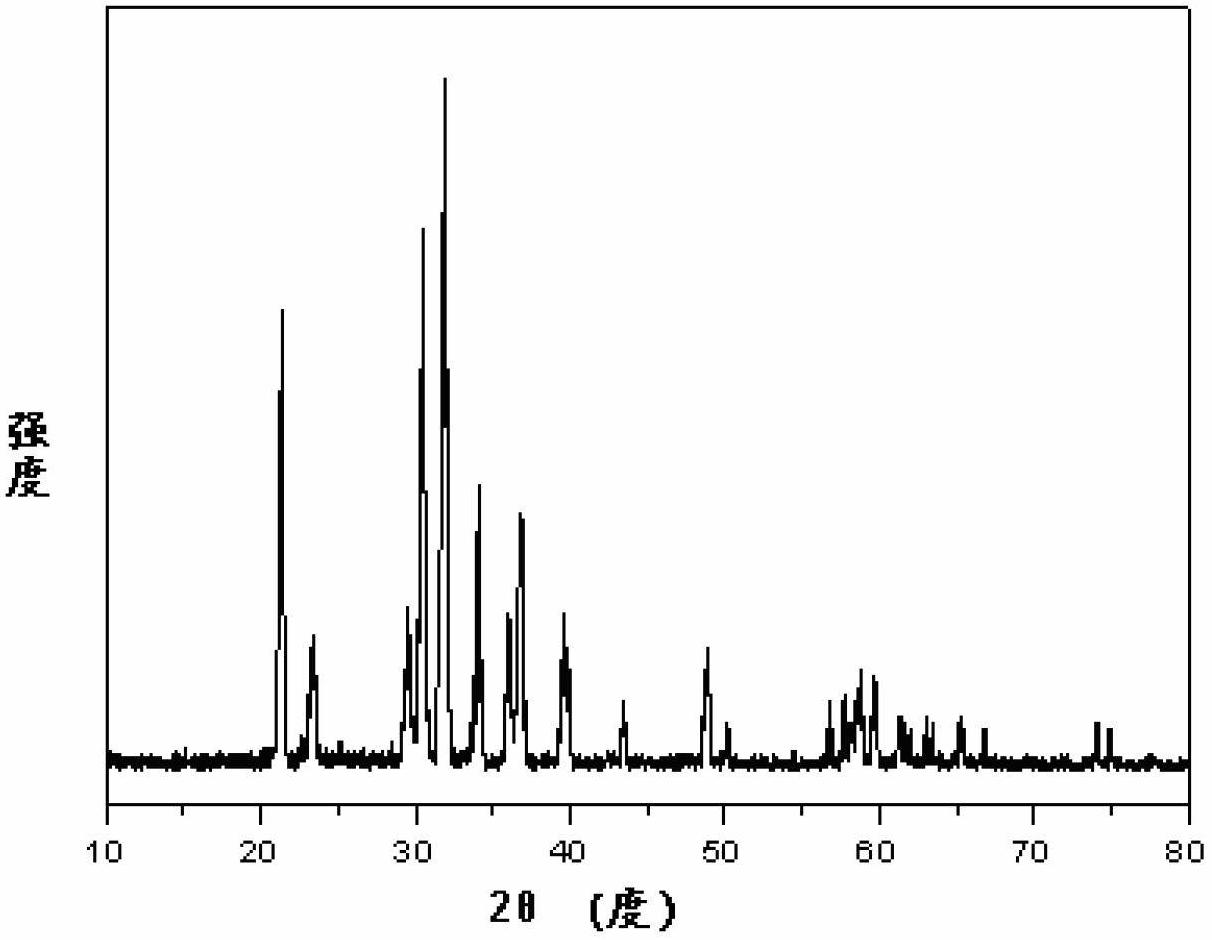

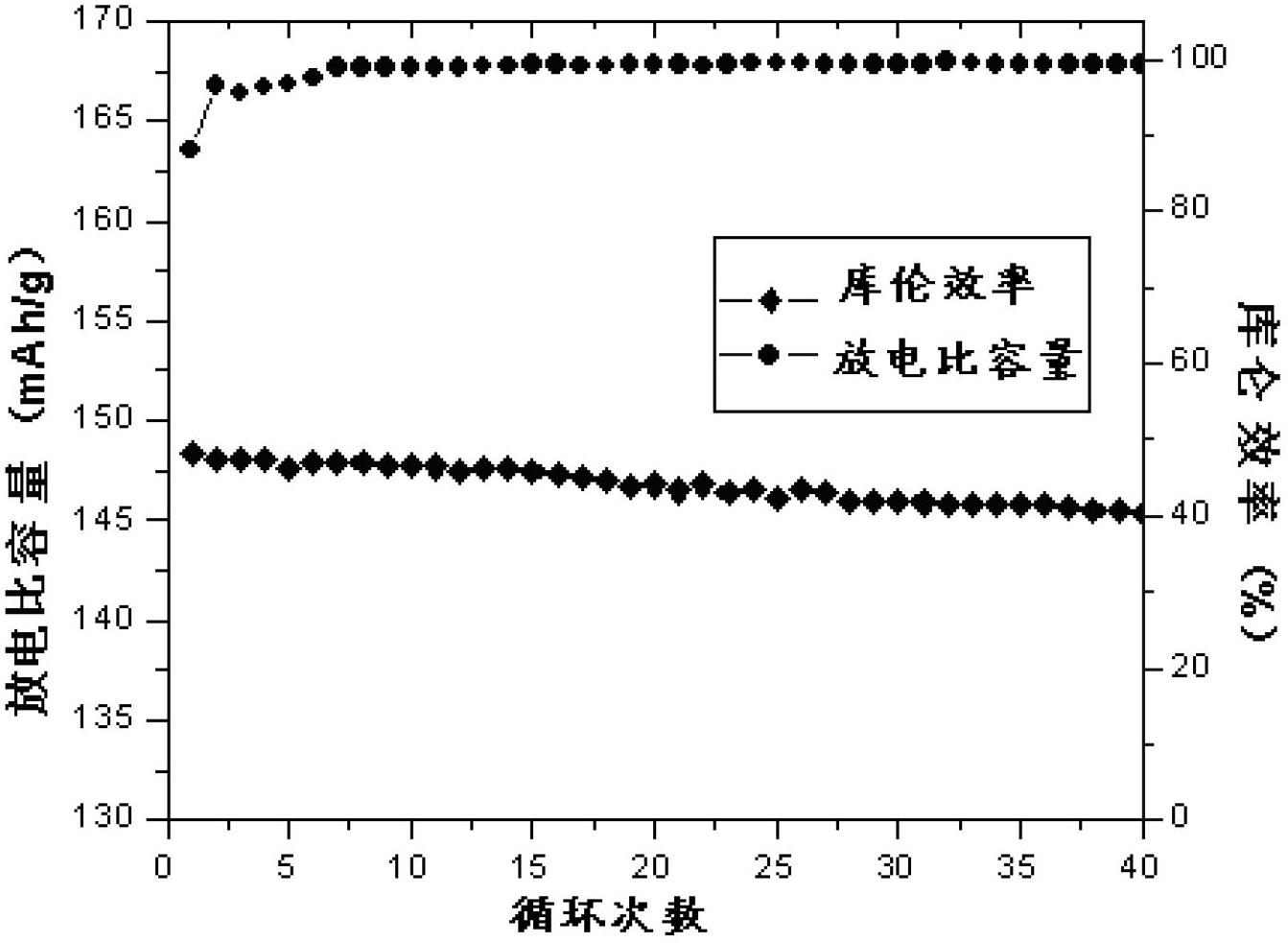

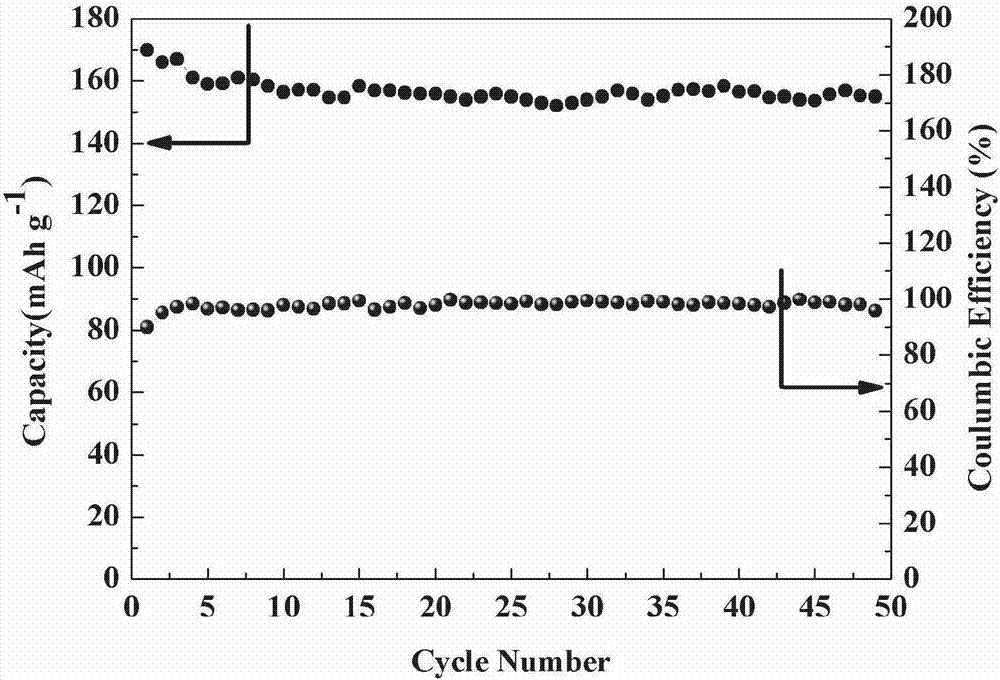

Method for repair and regeneration of waste lithium iron phosphate battery cathode material

ActiveCN102208707AReduce pollutionSave resourcesSolid waste disposalWaste accumulators reclaimingLithium iron phosphateEngineering

The invention discloses a method for repair and regeneration of waste lithium iron phosphate battery cathode materials, which allows a lithium-source solution or a suspension to react with a recovered waste lithium iron phosphate battery material by a hydrothermal reaction or a solvent-thermal reaction, or allows the recovered waste lithium iron phosphate battery material to be processed by solid-phase ball-milling and calcination with the lithium source, performs liquid-phase or solid-phase direct lithium-supplementing repair of delithiated waste lithium iron phosphate, and then performs pertinent repair and regeneration by coating conductive agents or coating conductive agents and doping metal ions. The invention adopts a direct repair and regeneration method; the repaired waste lithium iron phosphate battery cathode material has excellent performance, and the specific capacity can reach above 90% of the specific capacity before discard; the method not only can effectively reduce environmental pollution of waste batteries, but also can make full use of waste resources and changes waste into valuables.

Owner:HEFEI UNIV OF TECH

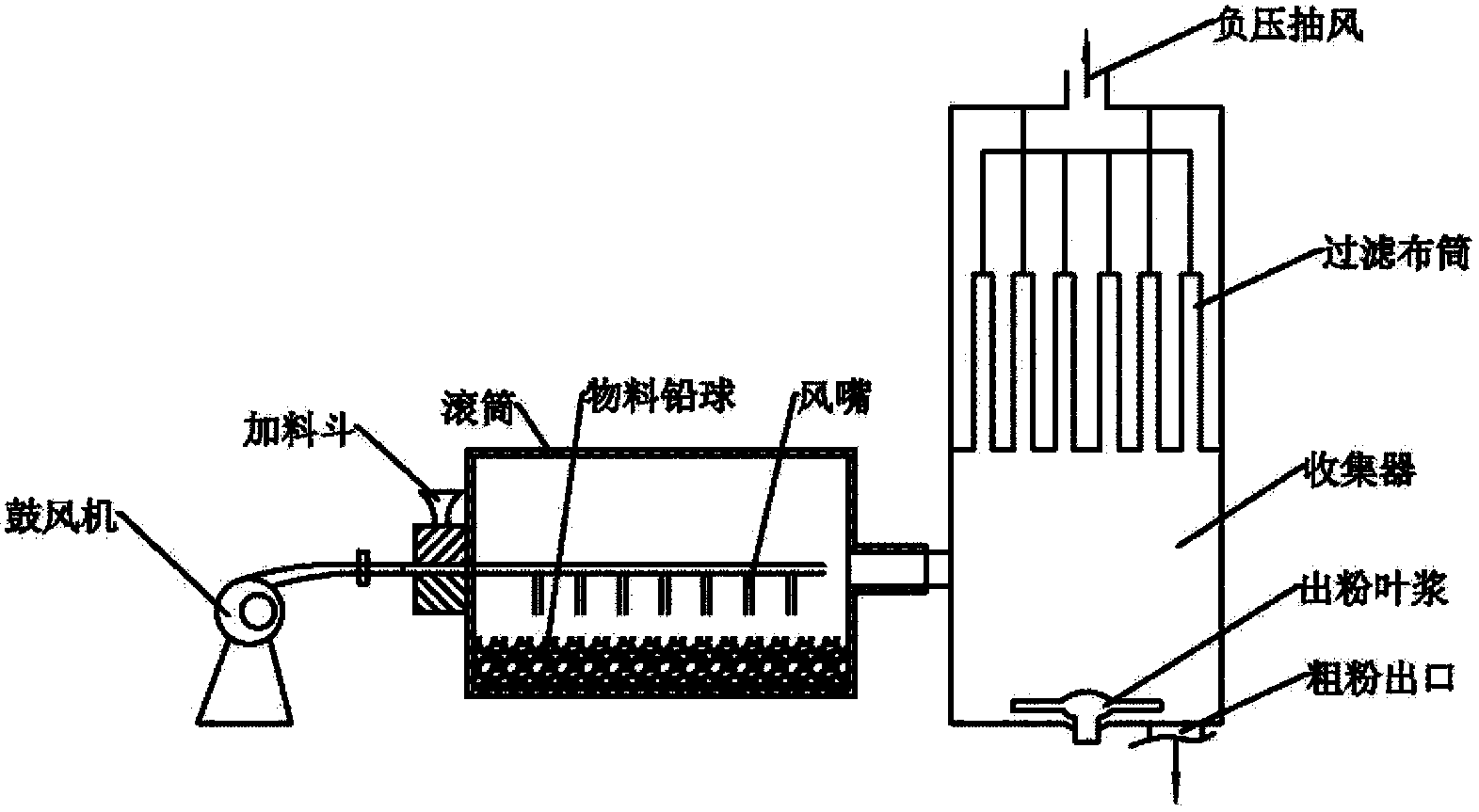

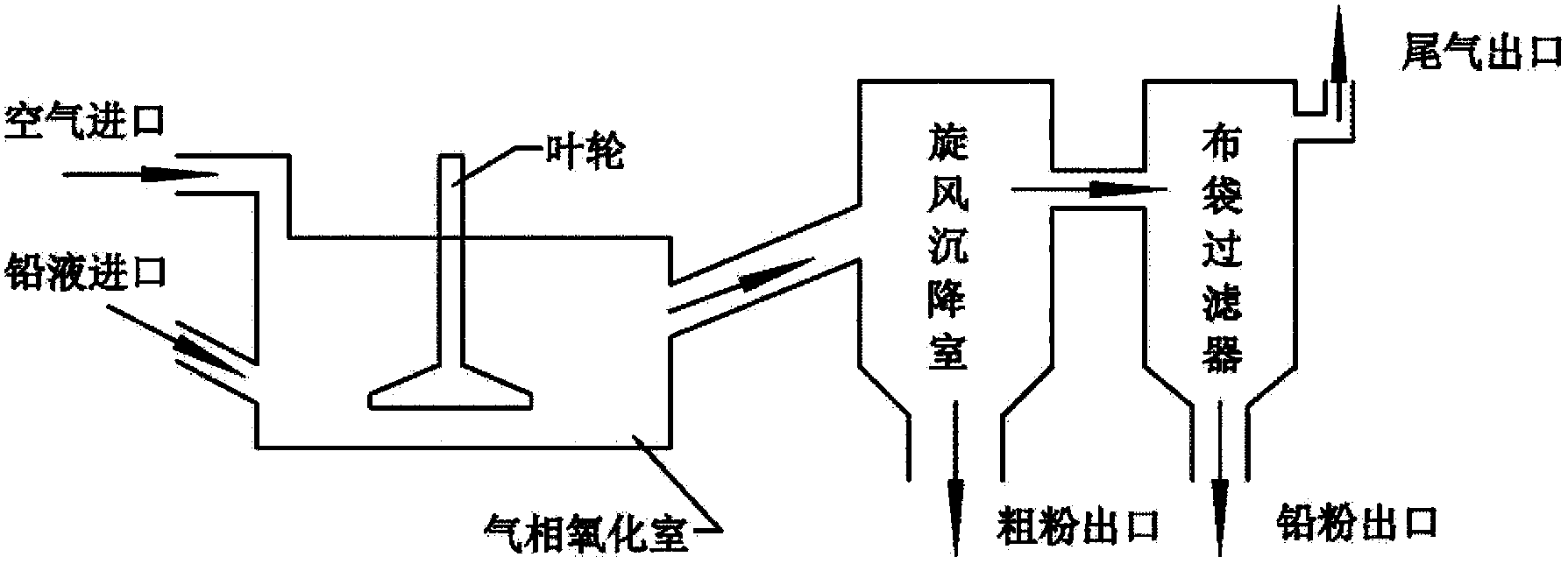

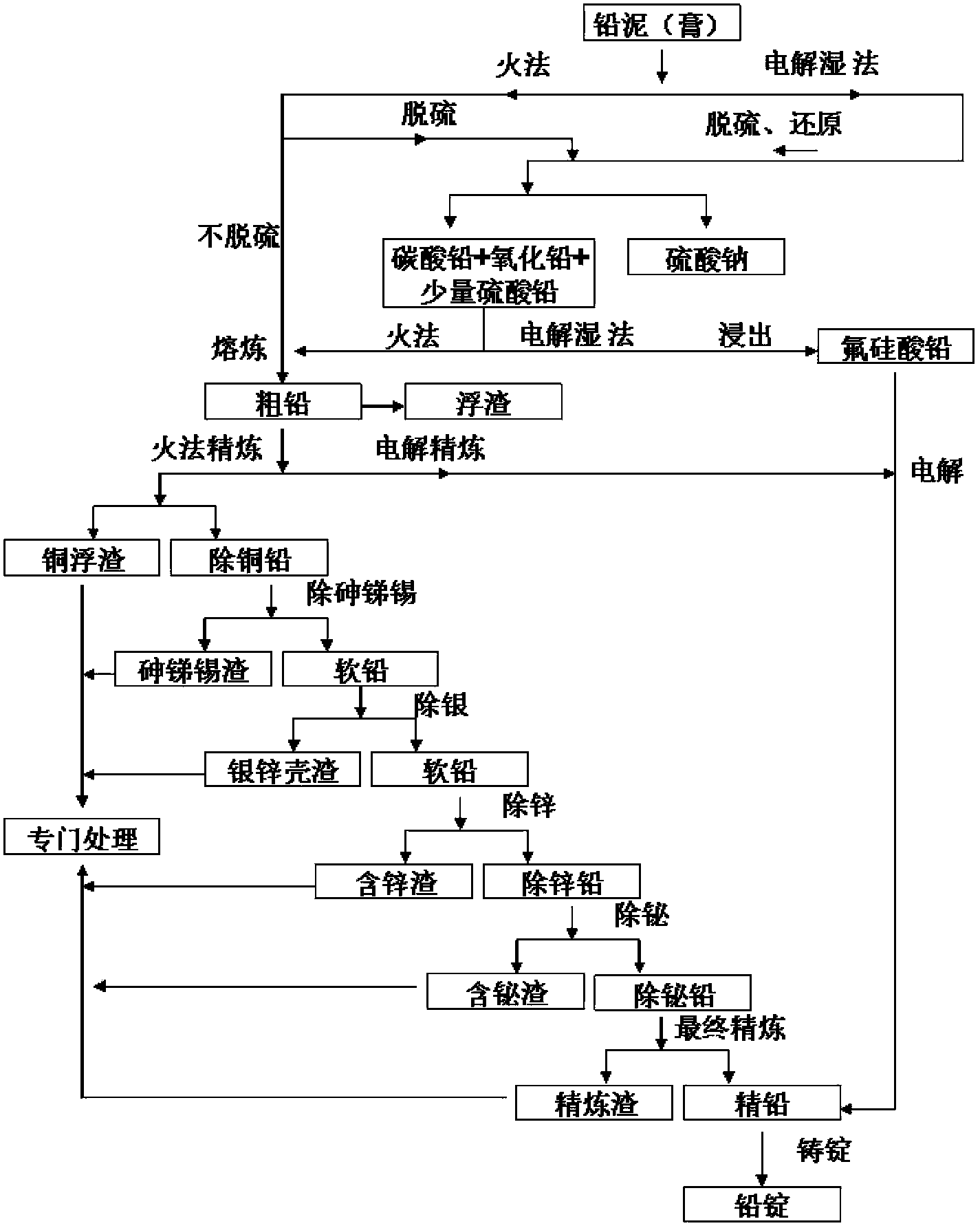

Methods and equipment for recovering waste diachylon by wet method and manufacturing electrode active material of high performance lead acid battery by wet method

ActiveCN103509949AIncrease profitLarge particle sizeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryEngineering

The invention discloses methods and equipment for recovering waste diachylon by a wet method and manufacturing an electrode active substance material of a high performance lead acid battery by the wet method. The equipment comprises device required for a technology process by a chemical method, a chemical machinery method or an electrochemical machinery method. The active substance material provided by the invention can substantially raises an utilization rate of the active substance of the lead acid battery, specific energy of the battery and charging capability of the battery, simultaneously avoids generation and discharge of harmful substances such as lead gas, lead smoke, lead dust and SO2, raises a lead utilization rate in a production process, is beneficial for treating and recycling lead compounds and lead-containing liquid generated in a lead gas recovering process in a plate casting or welding technology, and reduces cost.

Owner:杨春晓

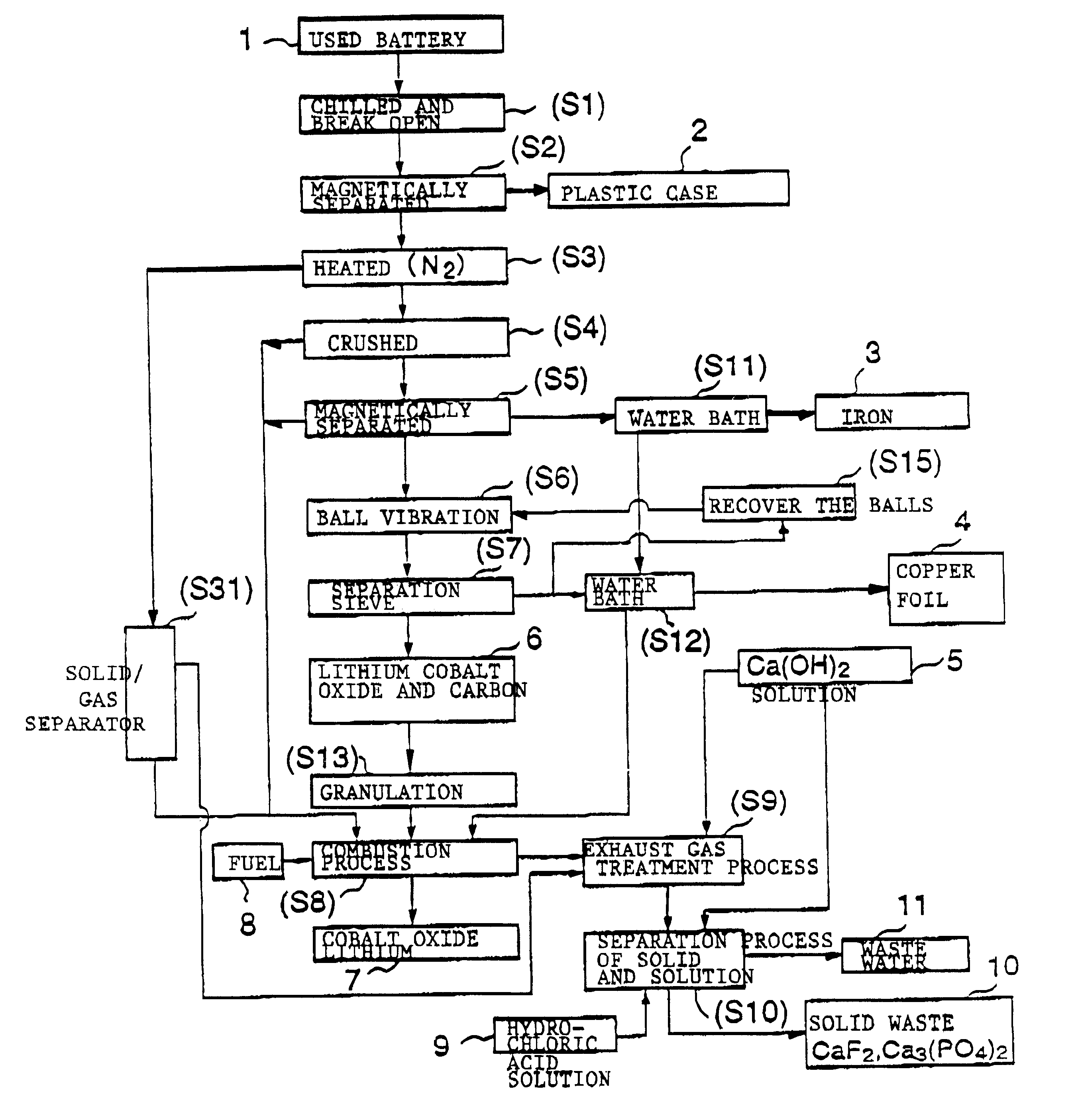

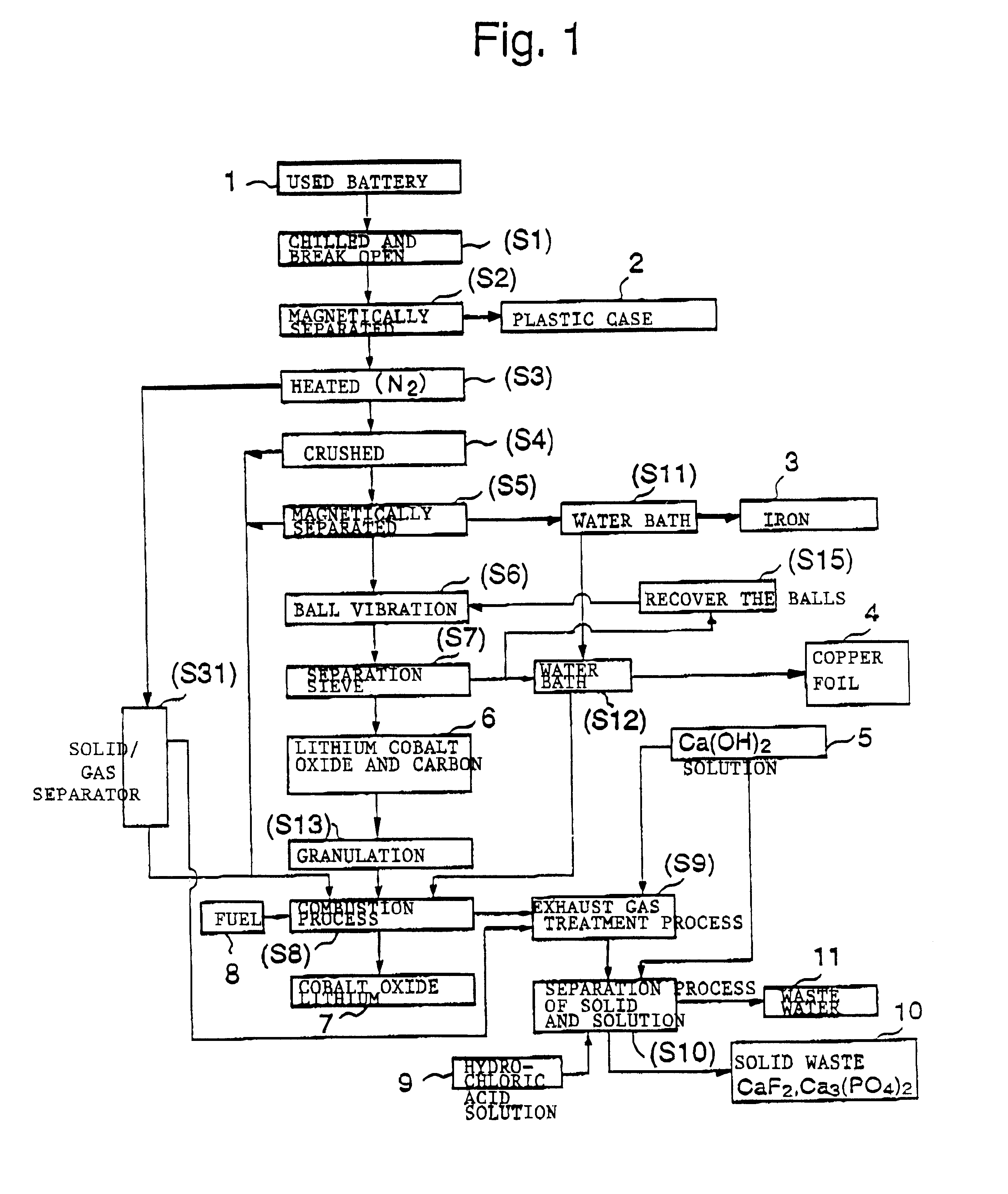

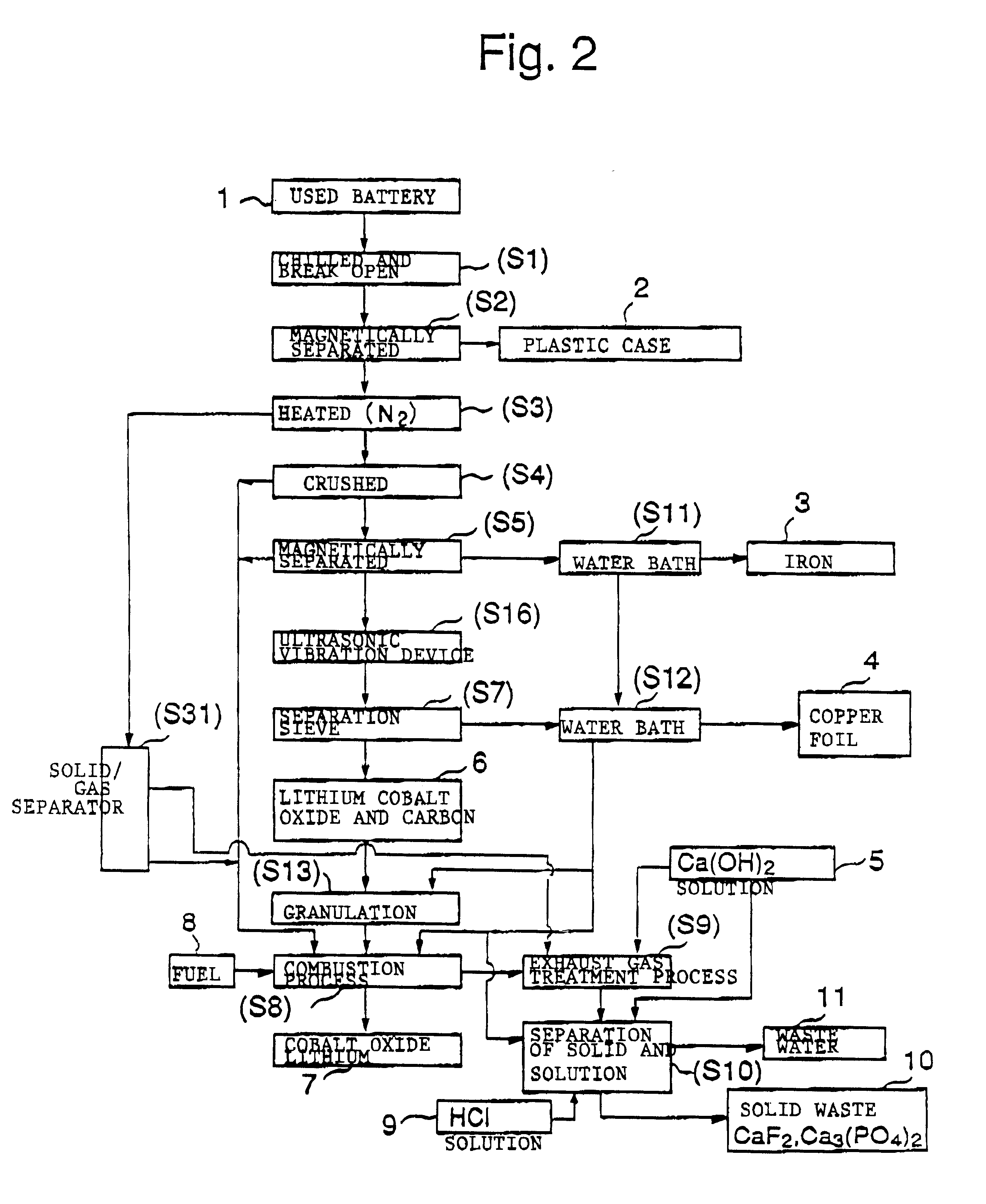

Method for crushing cell

InactiveUS6524737B1Non-aqueous electrolyte accumulatorsPrimary cell maintainance/servicingEngineeringCopper

This invention provides a safe and efficient method of dismantling used lithium ion batteries. More specifically, the plastic cases which protect sealed battery cells are removed from the system in a stable and reliable fashion. Valuable materials such as lithium cobalt oxide, an oxide of a lithium-transition metal compound, aluminum and copper must be separated and recovered. The invention is distinguished by the fact that it entails the following processes. In the crushing process, the batteries are chilled to a temperature of -50° C. or lower. In this state they are repeatedly subjected to vibration and pressure by a number of objects whose rigidity and specific gravity are greater than those of the plastic. In this way the batteries are separated into sealed battery cells and plastic cases. In the heating process, the sealed battery cells separated in the process are heated to a temperature of at least 200° C. in a non-oxidizing atmosphere to separate mainly the organic materials. Finally, in one or more separation processes, the useless materials are removed and the targeted valuable materials are separated in a sequential fashion from the crushed fragments produced in the crushing process.

Owner:MITSUBISHI HEAVY IND LTD

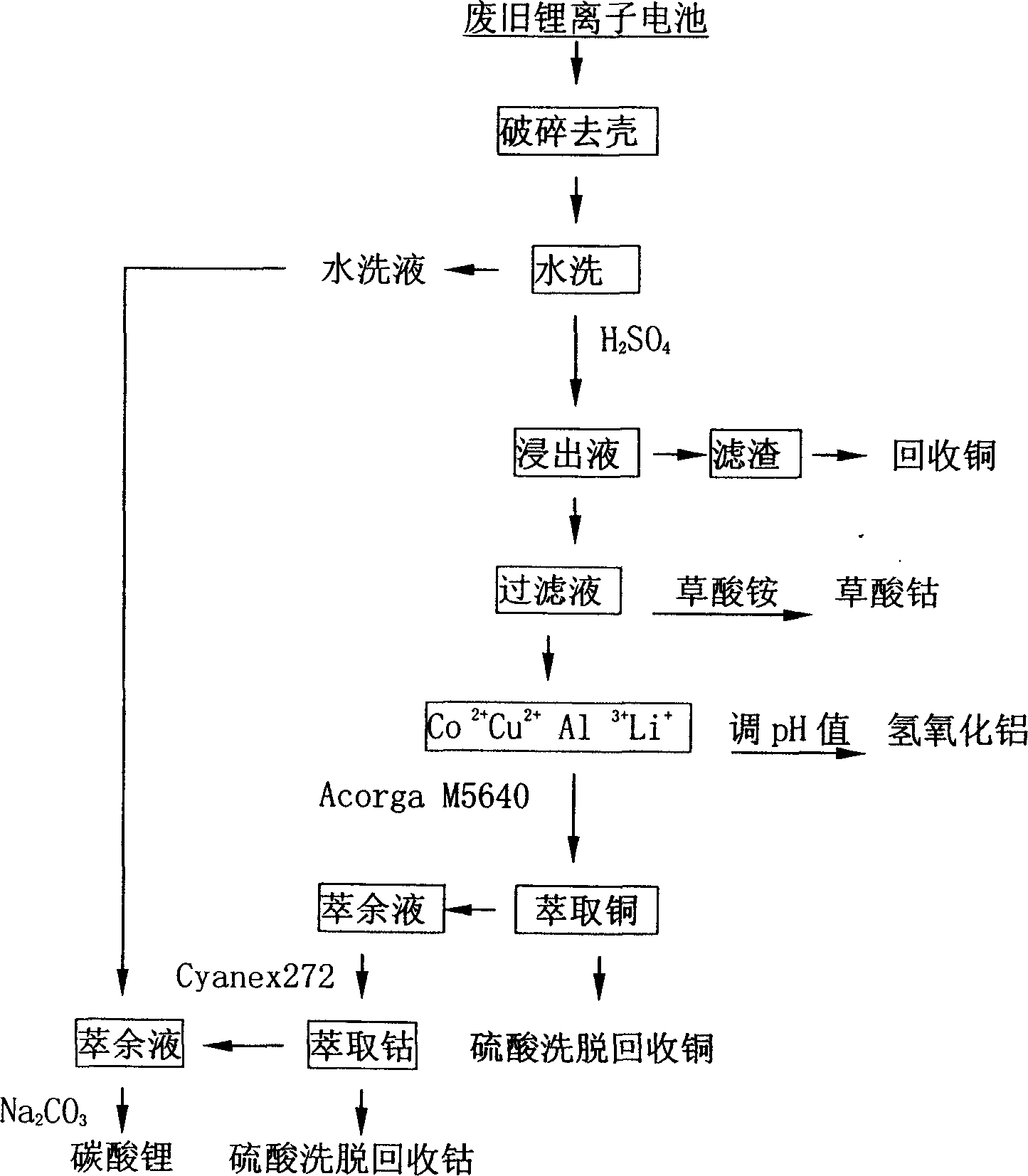

Recovery and treatment method for waster lithium ion cell

InactiveCN1601805AAvoid it happening againEasy to recycleSolid waste disposalWaste accumulators reclaimingSolventCobalt

The method for recycling and processing worn-out lithium ion battery includes steps: (1) taking out pack of worn-out battery; (2) using crushing facilities to open up case of battery, and segregation through magnetic method; (3) dissolving wastes of pole core of battery by using acid, and separating out most of cobalt through ammonium oxalate depositing method; (4) cobalt and copper deposited in residual liquid is extracted through solvent extraction method. Adding sodium carbonate generates deposition to retrieve lithium. Advantages are: simple technique, on solving pollution of worn-out batteries, and reclaining resources at same time.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for separating and recovering cobalt from waste lithium ion cell

InactiveCN1688065AHigh purityHigh recovery rateReclaiming serviceable partsWaste accumulators reclaimingLithiumOrganic solvent

This invention relates to a method for separating and recovering Co from the positive material lithium cobaltate of waste Li ionic batteries discharging of the battery to get a positive material containing lithium cobaltate to be annealed or dipped by an organic solvent to strip Al plates of the positive material to get a black solid material containing lithium cobaltate to be put under an acid condition and take H2O2 or Na2S2O3 as the reducer to be heated and dissolved to get a solution with Co2+ and Li+, then take NaOH solution as the precipitant to transfer the iron Co2+ to Co(OH)2 to be deposited and filtered after settlement.

Owner:WUHAN UNIV OF TECH

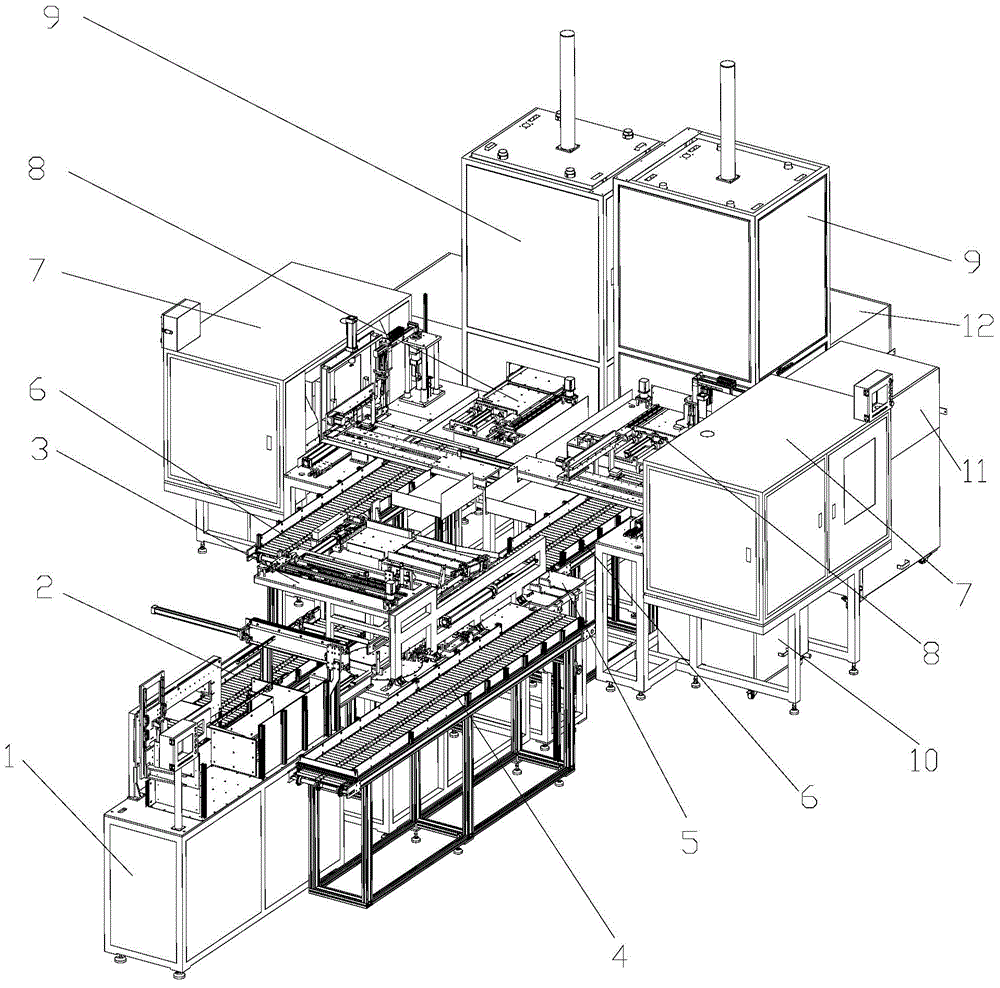

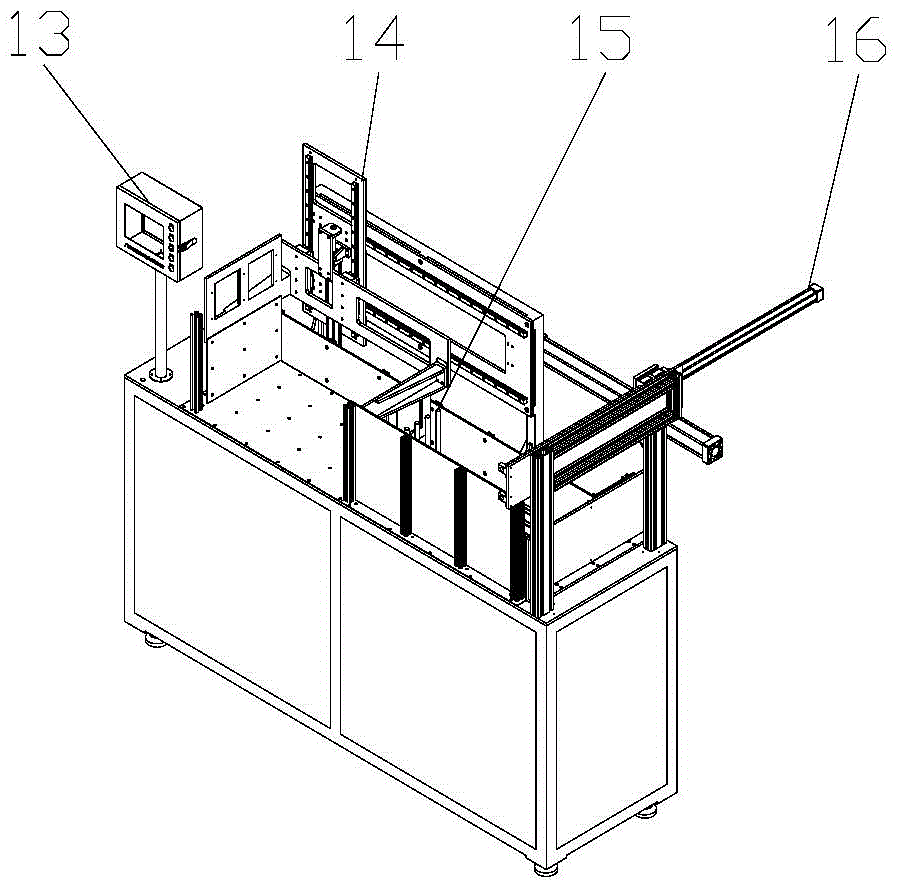

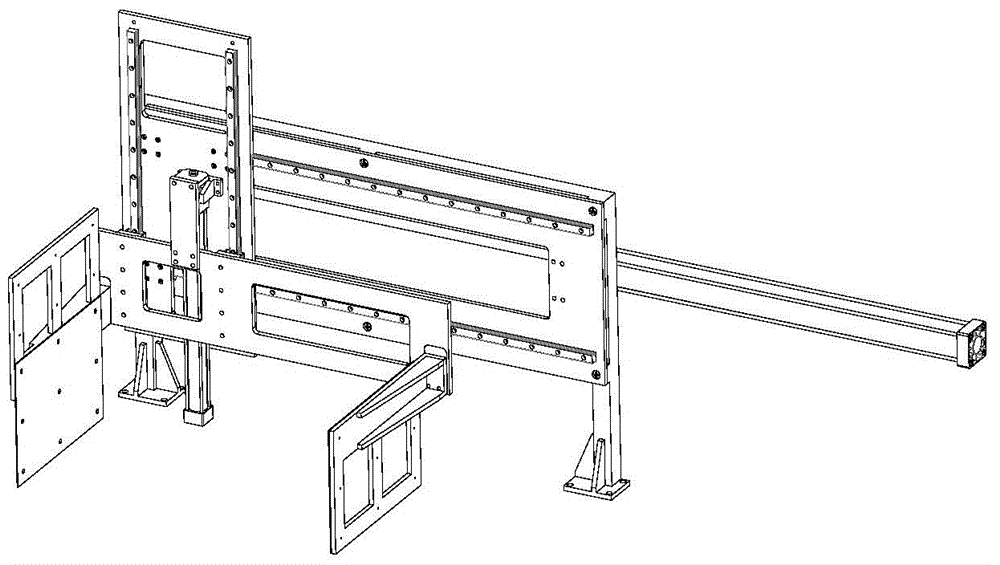

Novel waste power battery full-automatic dismantling device and method

ActiveCN104157927AReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryMaterial distribution

The invention relates to a novel waste power battery full-automatic dismantling device including: 1, a loading mechanism, 2, a loading conveyer, 3, a four-station material poking mechanism, 4, material distribution conveyers, 5, cutting devices, 6, separation feeding mechanisms, 7, separators, 8, outer shell storage boxes, and 9, electric core storage boxes. Along the power battery heading direction, the loading mechanism, the loading conveyer, the four-station material poking mechanism, the material distribution conveyers, the cutting devices, the separation feeding mechanisms and the separators are successively arranged; the outer shell storage boxes and the electric core storage boxes are respectively connected with the separators. The invention also relates to a novel waste power battery full-automatic dismantling method. The device has the advantages of simple structure and high dismantling efficiency, adopts a battery mechanical dismantling way integrating electrode head end one-time cutting and electric core clipping-out, and belongs to the power battery recycling processing field.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

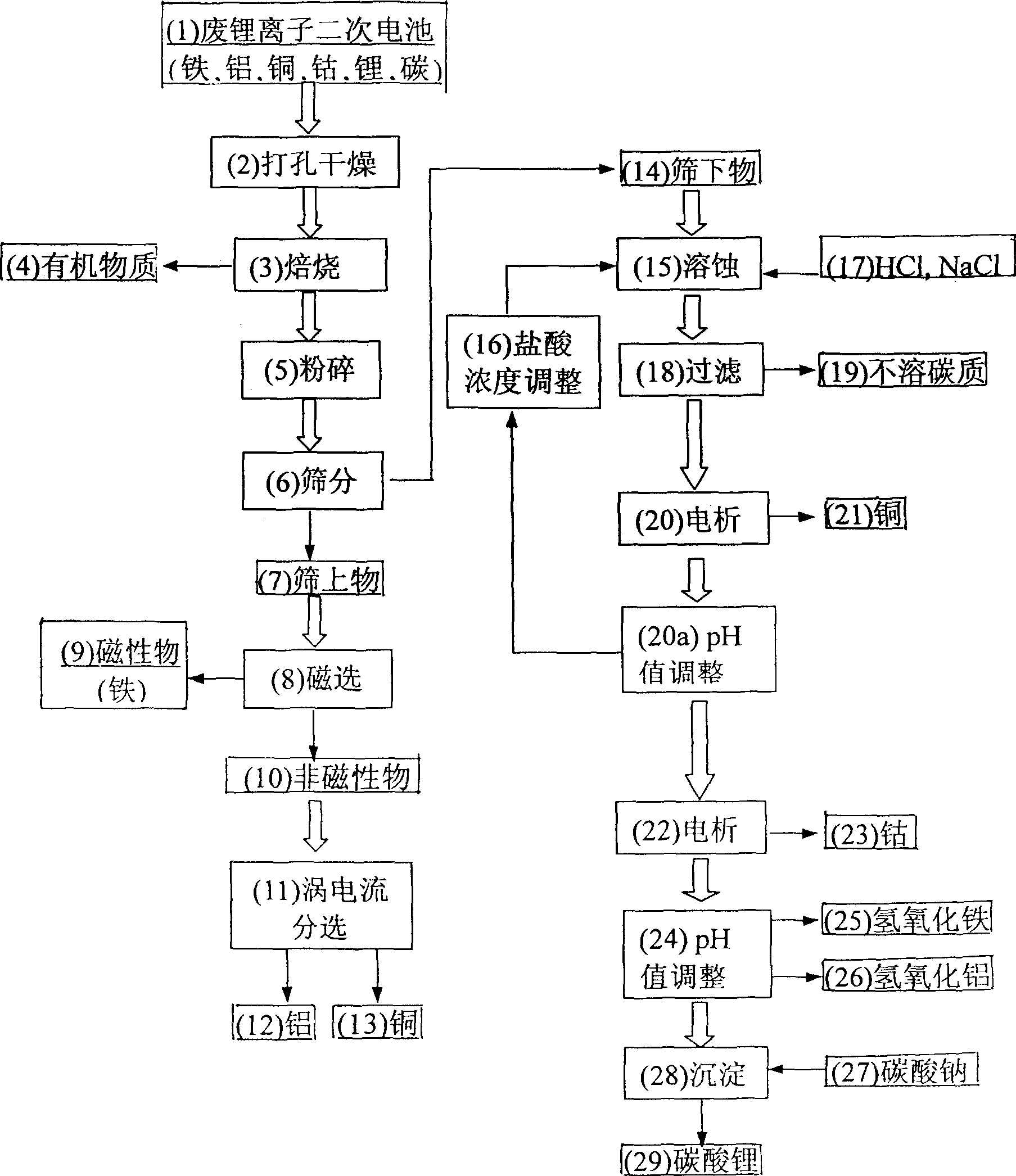

Method for recovering metal from used Li ion cell

InactiveCN1402376ATo achieve the purpose of separationReduce lossWaste accumulators reclaimingBattery recyclingDielectricCopper foil

The invented method includes the physical separation method combining with the preparation procedure of the cleaning wet recycle, providing the features of simple and high purity of the recovered metal. The invention includes following steps. With the disused lithium ion cells being burned in the high-temperature furnace, the organic dielectric is removed. After the smashing and sieving treatment, the oversize material is processed through the magnetic separation and the eddy current sorting so as to obtain the iron case, copper foil and aluminium foil etc. The undersize is processed through the steps of corrosion, filtering and electrolysis so as to obtain copper and cobalt. With carbonic acid radical being added to the solution richen in lithium ion, the high purity carbonate of lithiumis formed so as to recovery lithium.

Owner:IND TECH RES INST

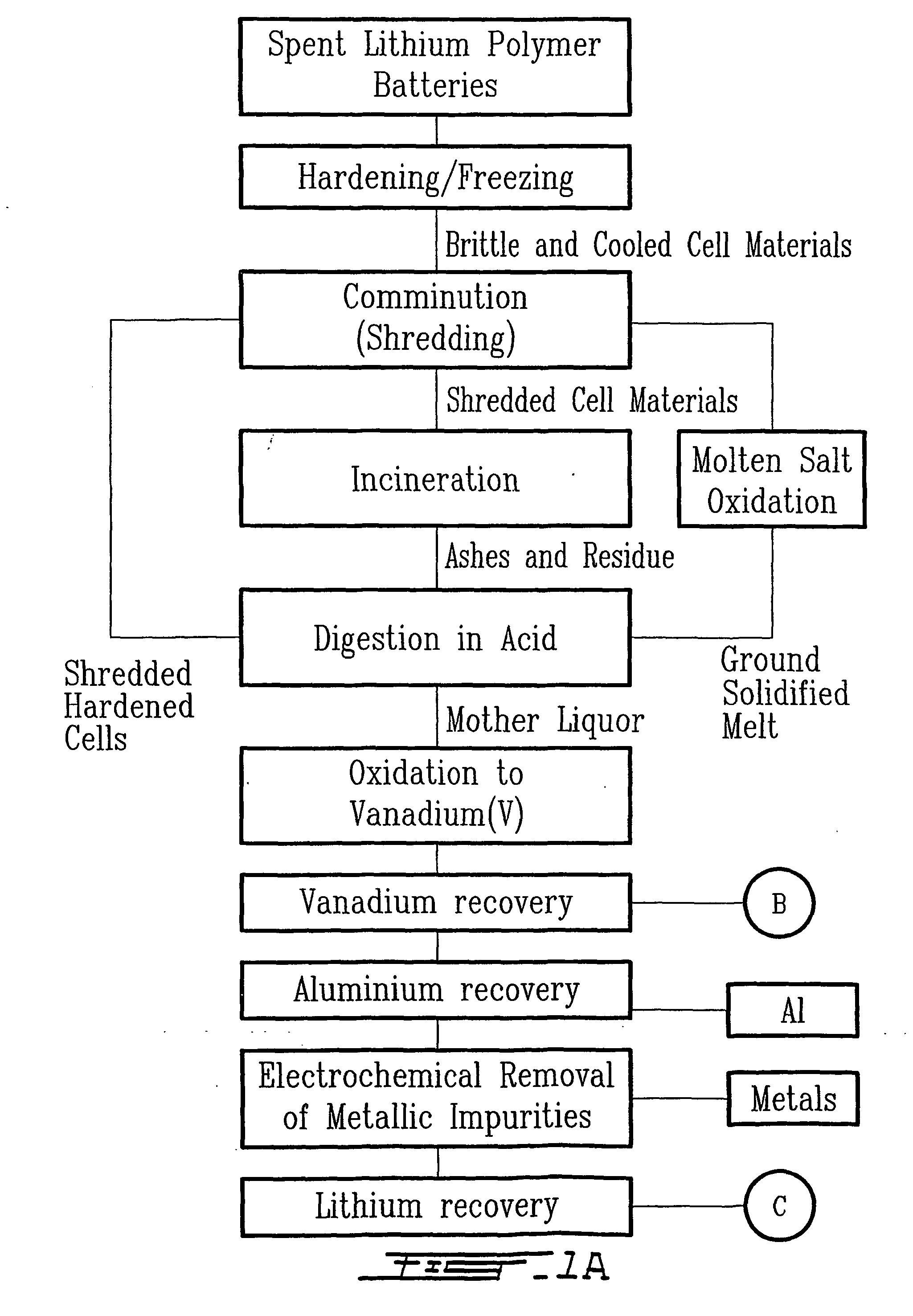

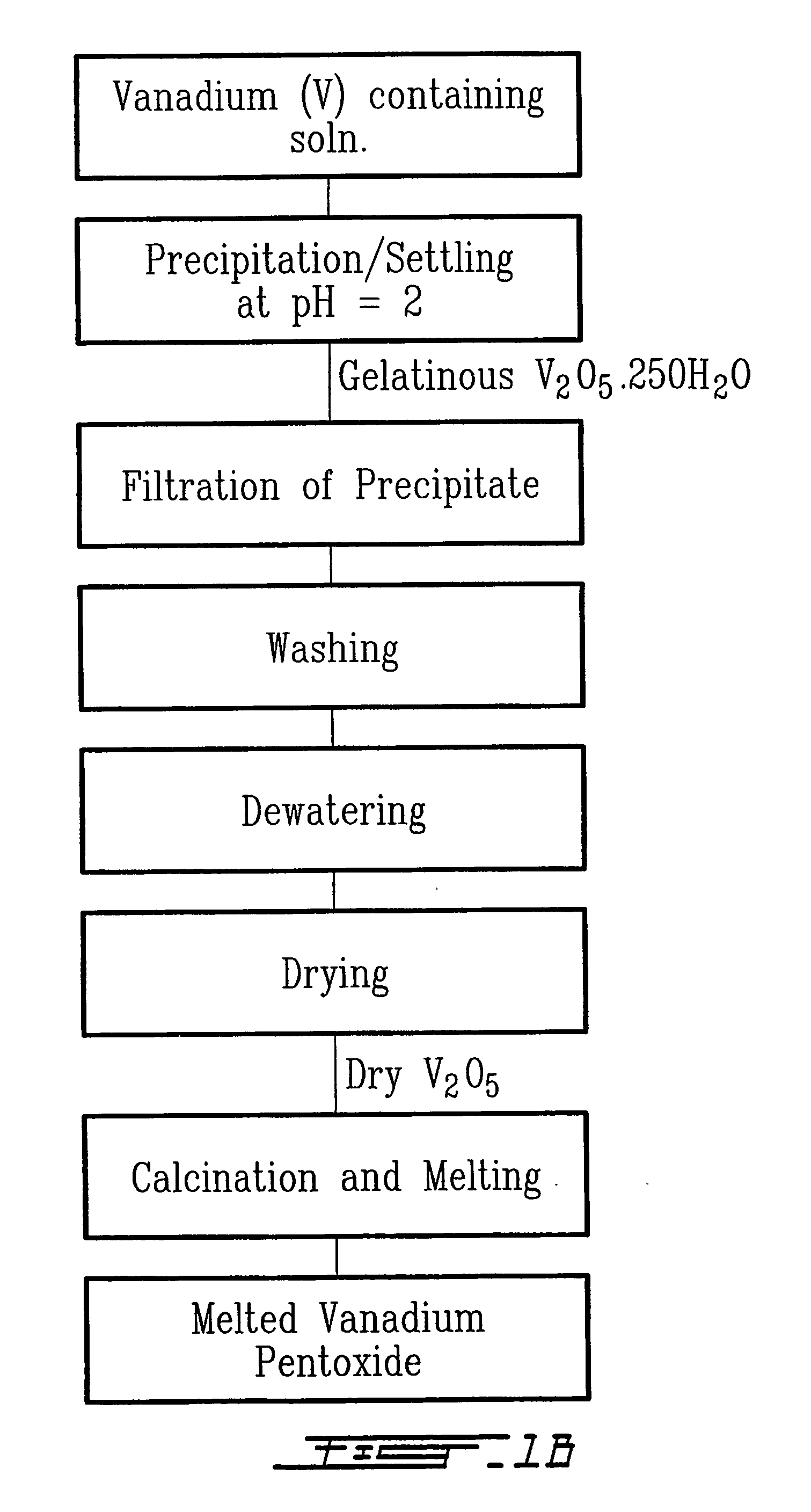

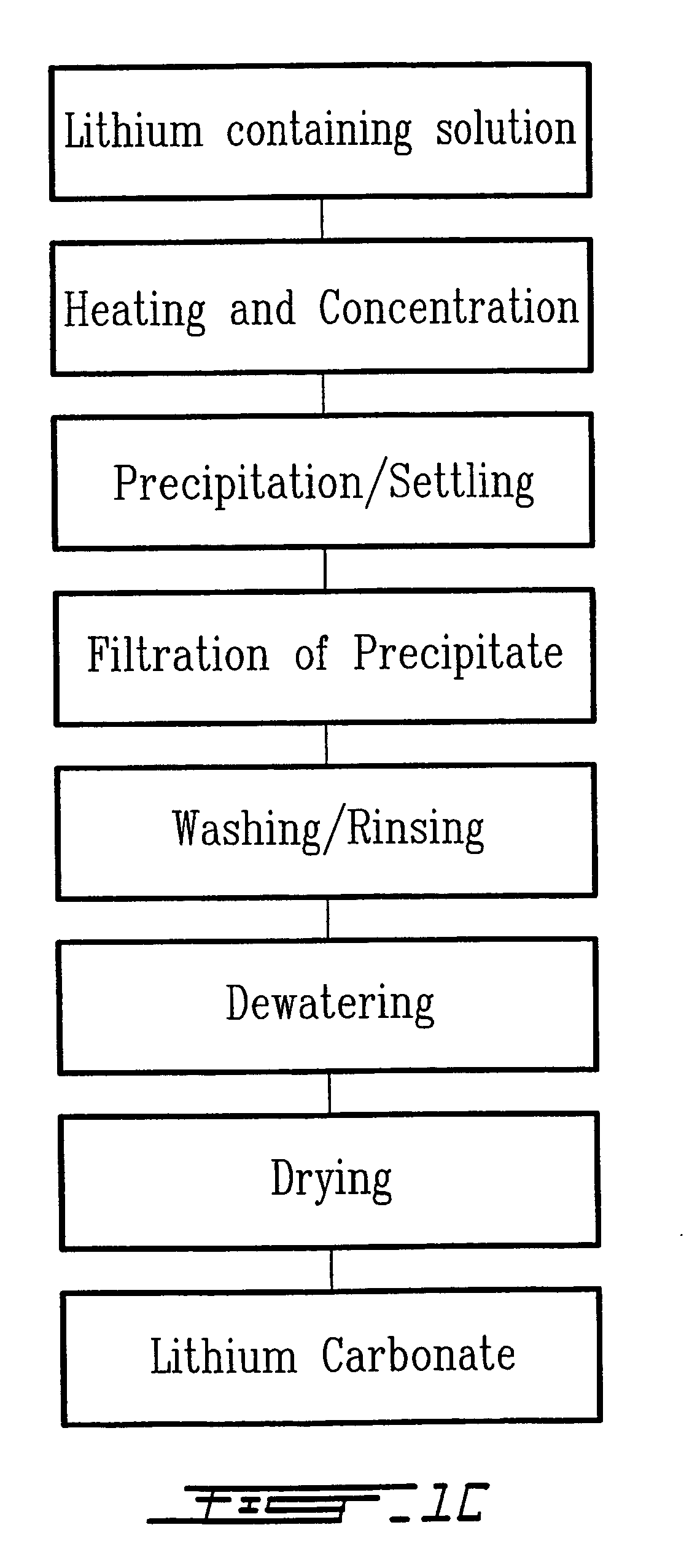

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

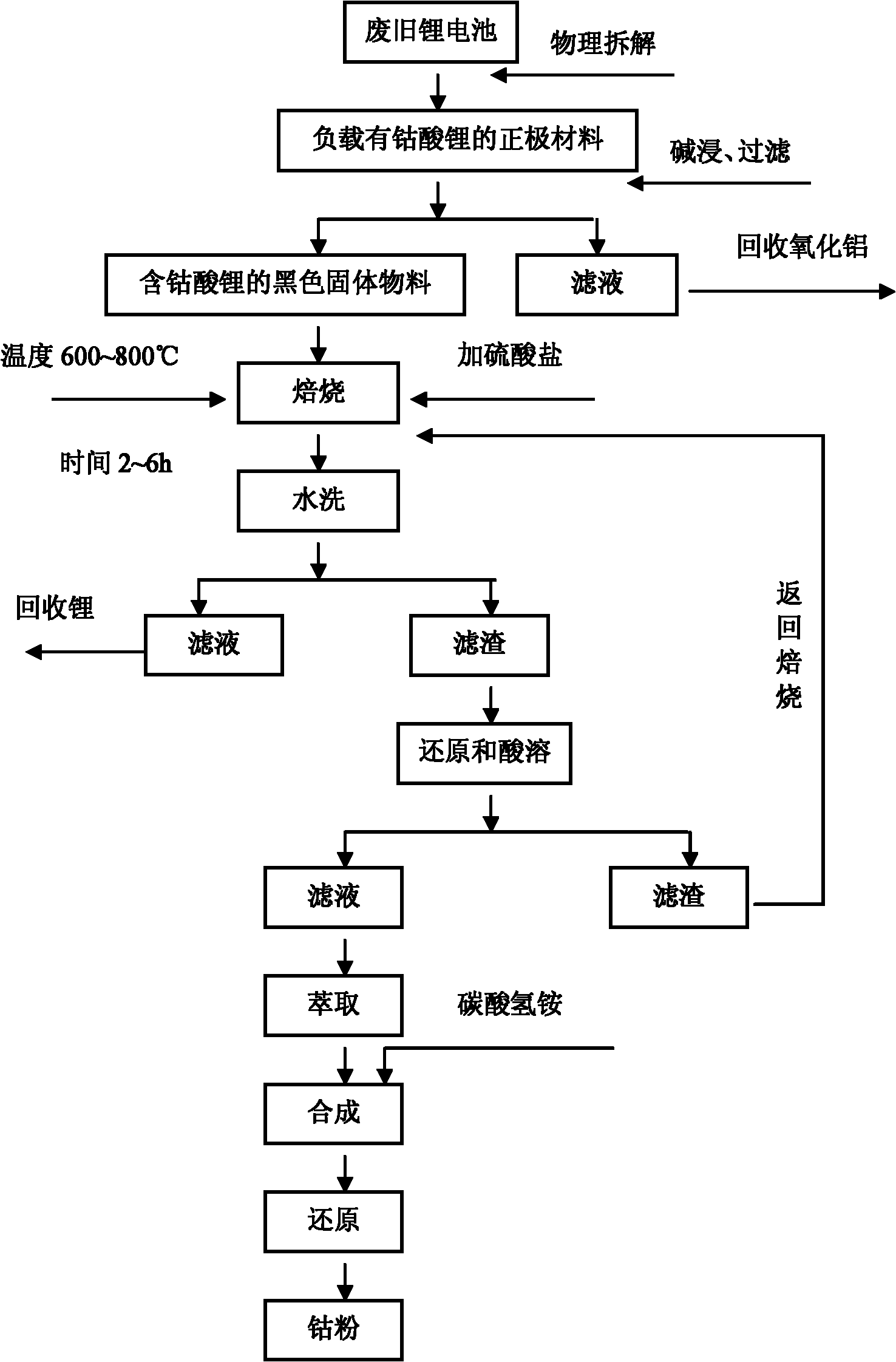

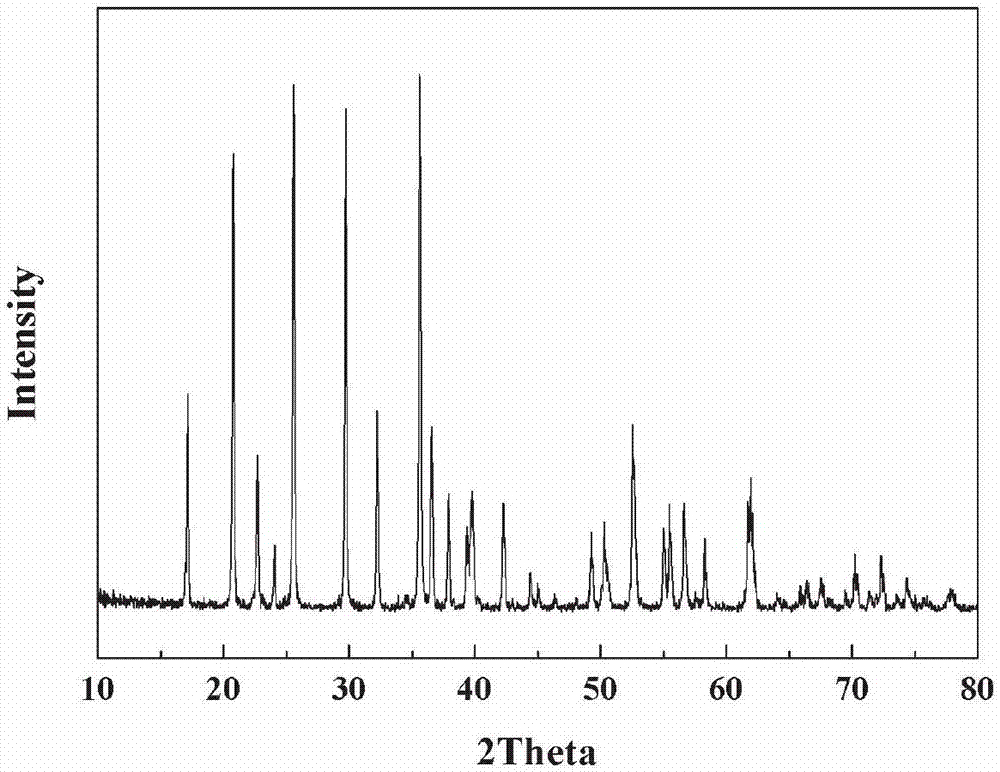

Method for separating and recovering lithium and cobalt from positive electrode material of lithium battery

ActiveCN102163760AAchieve recyclingReduce or eliminate adverse effectsWaste accumulators reclaimingProcess efficiency improvementLithiumSocial benefits

The invention provides a method for separating and recovering lithium and cobalt from a positive electrode material of a lithium battery. The method comprises the following: (1) a step of physical disassembly and alkaline leaching; (2) a step of roasting and washing, namely adding sulfate into a black solid material containing lithium cobalt oxide obtained in the step (1) in the weight ratio of the black solid material to the sulfate being 1:(0.8-1.2), mixing, roasting for 2 to 6 hours at a temperature of between 600 and 800 DEG C, cooling, adding a cleaning solution in terms of the ratio of solid to liquid being 1:(3-5) to wash, agitating for 1 to 2 hours at a temperature of between 60 and 80 DEG C and filtering to obtain Li<+>-containing filtrate and filter residue containing lithium and a small amount of cobalt; (3) a step of reducing and acid saluting; and (4) a step of extracting the cobalt to obtain pure Co2<+> solution. By the method, high recovery ratios of the metal lithium and the metal cobalt are achieved, the recovery ratio of the lithium is over 90 percent, the obtained lithium and the obtained cobalt have high purity, the content of the lithium mixed in the cobalt isgreatly reduced, and the purity of the cobalt can reach over 99.5 percent. Therefore, the method has higher economic benefits and social benefits.

Owner:JINGMEN GEM NEW MATERIAL +1

Method for selectively recycling lithium from lithium iron phosphate waste

ActiveCN106910959AEfficient leachingLow costWaste accumulators reclaimingProcess efficiency improvementHypochloriteSelective leaching

The invention discloses a method for selectively recycling lithium from lithium iron phosphate waste through a direct oxidization method. The method is characterized by comprising the steps that the lithium iron phosphate waste is added into a water solution, meanwhile, an oxidizing agent is added, stirring is carried out, lithium iron phosphate and the oxidizing agent react to generate iron phosphate, lithium ions enter the solution, and therefore a pure lithium-containing solution and iron phosphate solids are obtained. The adopted oxidizing agent comprises one or a mixture of persulfate, ozone, oxygen, pypocholoride and hydrogen peroxide. The molar weight of the oxidizing agent is 0.6-20 times that of lithium iron phosphate. The lithium-containing solution can be directly used for preparing a high-purity lithium product. According to the method, efficient and selective leaching of lithium can be achieved simply by adding a certain amount of oxidizing agent, and the method is mild in reaction condition, short in process and simple in equipment.

Owner:GUANGDONG GUANGHUA SCI TECH

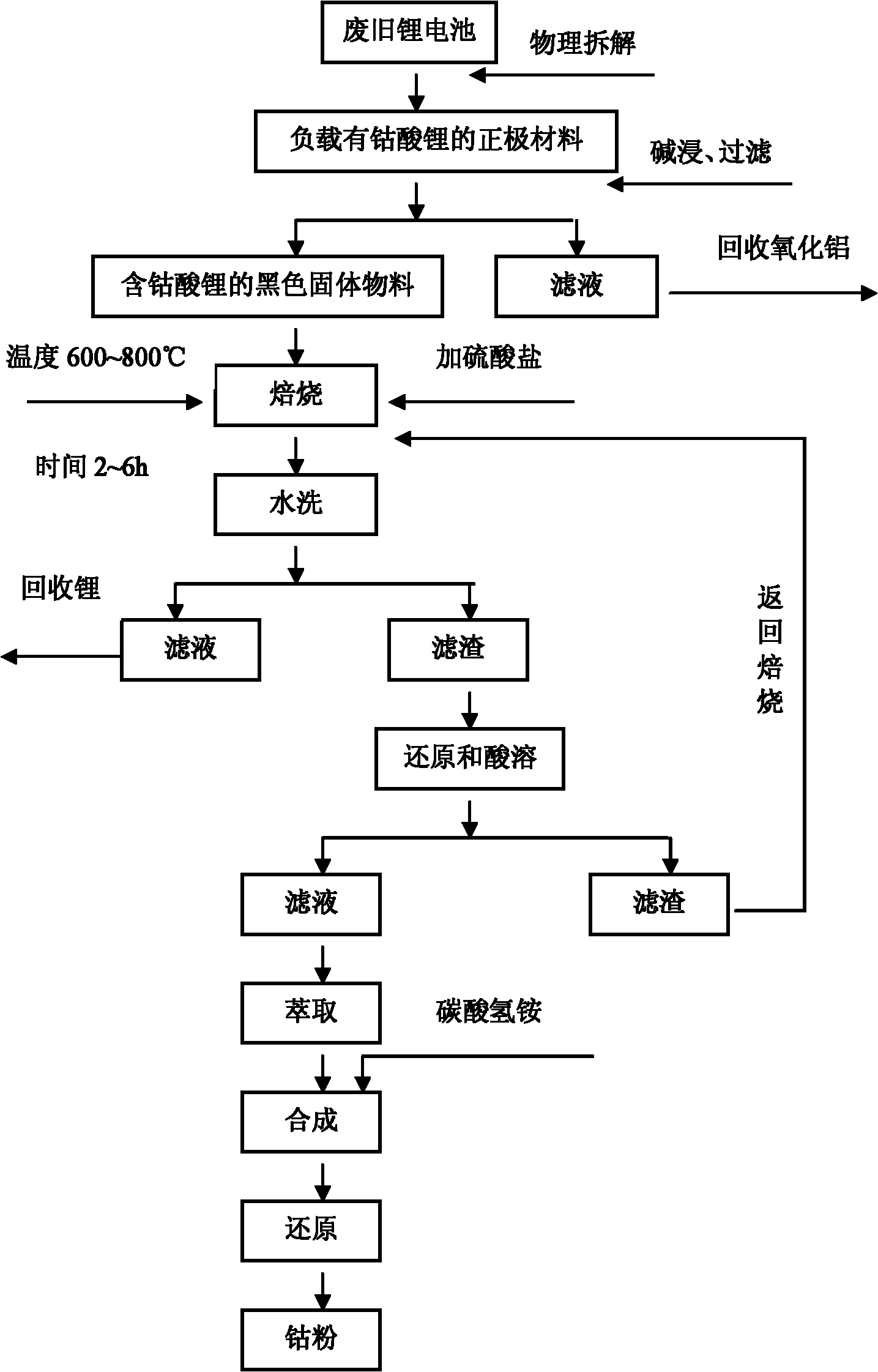

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

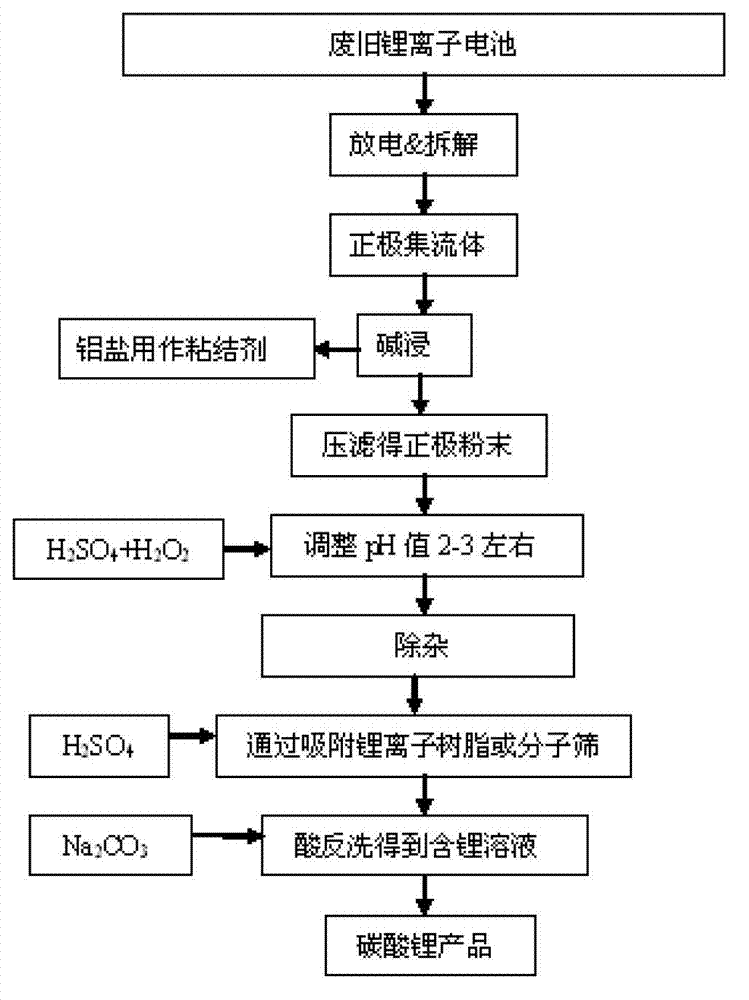

Method for separating and recovering lithium from waste lithium ion battery

ActiveCN103035977AEasy to recycleHigh purityWaste accumulators reclaimingBattery recyclingRecovery methodPhysical chemistry

The invention discloses a method for separating and recovering lithium from a waste lithium ion battery. The method comprises the following steps: dismounting after discharging the waste lithium ion battery, and removing a battery case; crashing a battery cell; leaching and filtering the crushed battery cell with inorganic acid and oxidant to obtain a filter liquor; regulating the pH of the filter liquor to be more than or equal to 8, then filtering to remove impurities and sediment to obtain a recovery liquor containing lithium ions; adsorbing the lithium ions in the recovery liquor through resin; and desorbing the resin to obtain the separated and recovered lithium salt. The recovery method provided by the invention is simple and efficient, has high purity of lithium and brings no pollution.

Owner:深圳市泰力废旧电池回收技术有限公司

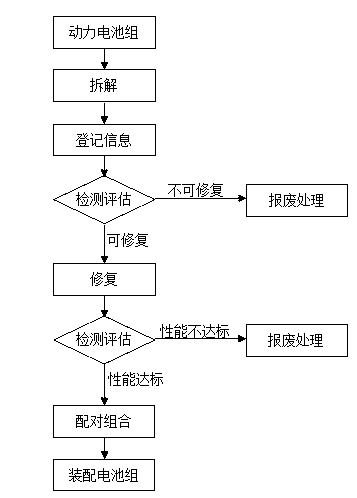

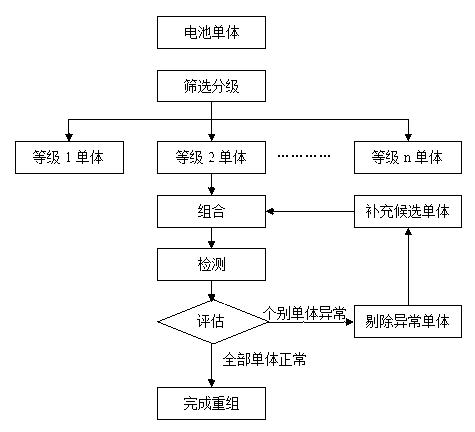

Waste energy echelon utilization method of power battery for electric vehicle

ActiveCN103138019AGood performance consistencyEasy to operateWaste accumulators reclaimingSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses a waste energy echelon utilization method of a power battery for an electric vehicle. The waste energy echelon utilization method of the power battery for the electric vehicle comprises the following steps: firstly, a waste power battery set is disassembled; secondly, performance detection is conducted on battery monomers without damaged appearance to screen out battery monomers capable of being directly used and ensure that a fifth step is accessed, the battery monomers capable of being repaired and reused are screened out, and processed in a third step, and unrepairable battery monomers are processed in a discarded mode; thirdly, the battery monomers capable of being repaired and reused are repaired; fourthly, performance detection is conducted on repaired battery monomers to screen out battery monomers with the difference of nominal voltage and virtual voltage not larger than 0.02V and the virtual capacity not lower than 70% of nominal capacity, the battery monomers with the difference of the nominal voltage and the virtual voltage not larger than 0.02V and the virtual capacity not lower than 70% of the nominal capacity are processed according to the next step, and the repaired battery monomers not capable of reaching the standards are processed in a discarded mode; and fifthly, a new power battery set is assembled. Because waste capacity of a monomer battery of the power battery is reasonably utilized, and is recombined to a new power battery applied to different occasions, the waste energy echelon utilization method of the power battery for the electric vehicle not only satisfies requirements of using occasions, but also utilizes performance of the power batteries.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com