Comprehensive recovering method of waste lithium iron phosphate battery

A lithium iron phosphate battery, waste technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problem of inappropriate use of waste lithium iron phosphate battery, etc., to achieve high product added value, simple and reasonable process, raw materials low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

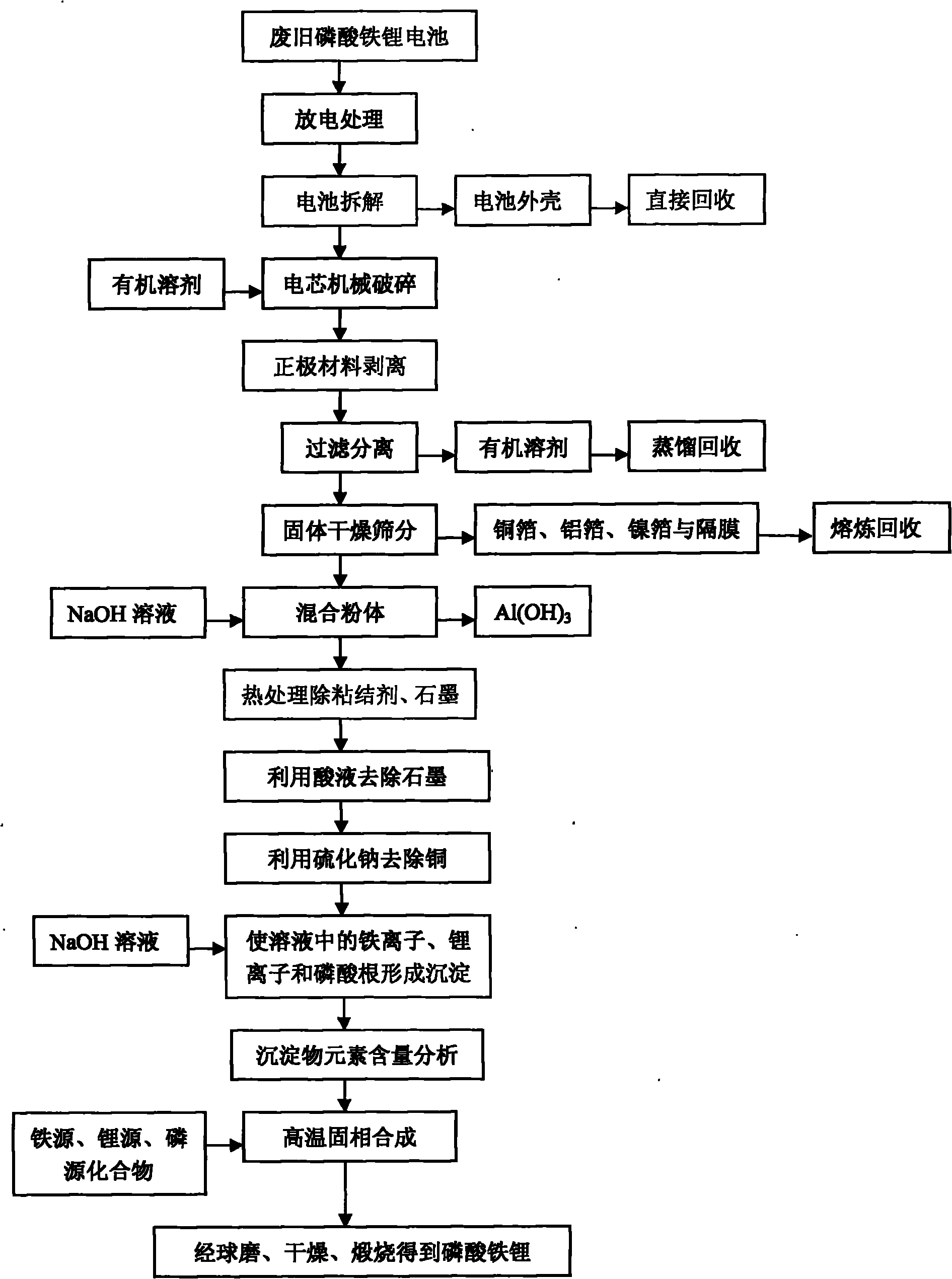

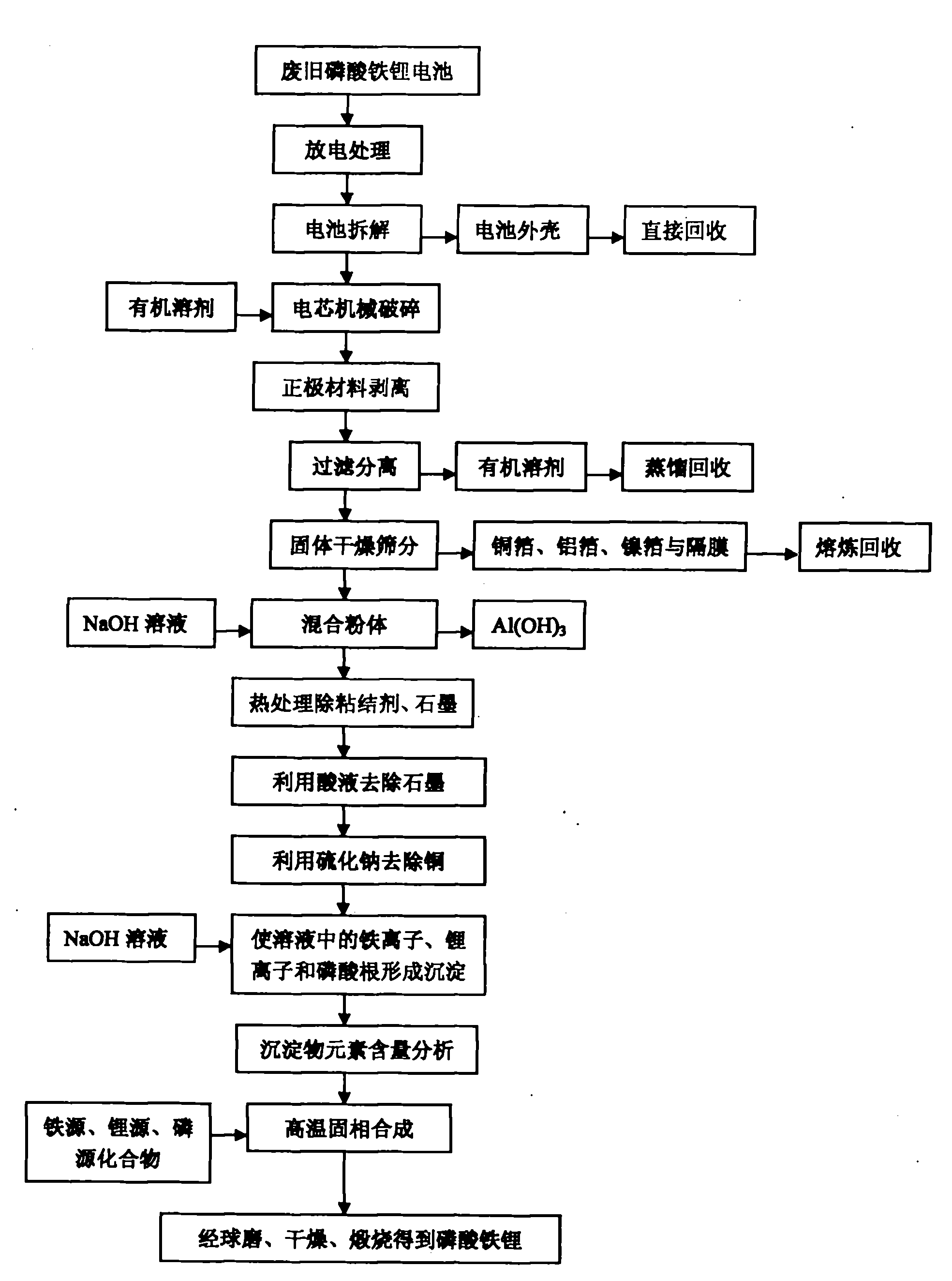

[0031] Such as figure 1 As shown, the method for the comprehensive recovery of waste lithium iron phosphate batteries in this embodiment includes the following steps:

[0032] A: First discharge the waste lithium iron phosphate battery with special discharge equipment, remove the outer packaging and shell of the battery with the help of a shearing machine or cutting machine, take out the battery cell, and directly recycle the outer packaging and shell;

[0033] B: Use a pulverizer to crush the batteries of the waste lithium iron phosphate battery to 0.5-5cm 2 The size of the fragments, and soak the cell fragments in N, N-dimethylformamide organic solvent, the solid-liquid ratio of the cell fragments to the solvent is 0.05 ~ 1kg / L, and carry out mechanical stirring and intermittent ultrasonic oscillation treatment at the same time, soak Time 5 hours, temperature 25°C;

[0034] C: After the soaked cell fragments are separated from the solvent by filtration, the filter residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com