Patents

Literature

2028 results about "Iron phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron phosphate may refer to: Iron phosphate Iron phosphate

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

Composite-coated lithium iron phosphate and preparation method therefor, and lithium ion battery

ActiveUS20180097228A1Improve conductivityHigh activityMaterial nanotechnologyElectrode thermal treatmentNanonetworkConductive polymer

A composite-coated lithium iron phosphate in a three-dimensional nanonetwork layered structure and a preparation method therefor, and a lithium ion battery, wherein a composite is prepared by compounding a conducting polymer, graphene and a carbon nano tube. The preparation method for the coated lithium iron phosphate comprises the following steps: doping the composite and anhydrous ferric phosphate in situ in the process of preparing the anhydrous ferric phosphate, serving as a lithium iron phosphate precursor, then mixing the composite in-situ doped anhydrous ferric phosphate, a lithium source, a traditional carbon material and a solvent to obtain slurry, spray drying the slurry, and calcining to obtain the composite-coated lithium iron phosphate in a three-dimensional nanonetwork layered structure. The preparation method is simple and has a wide raw material source, low cost and very broad practical application prospect. Serving as an anode material of the lithium ion battery, the coated lithium iron phosphate has higher electrical conductivity and cycling stability, and more excellent comprehensive electrochemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Method for recovering waste lithium iron phosphate battery positive pieces

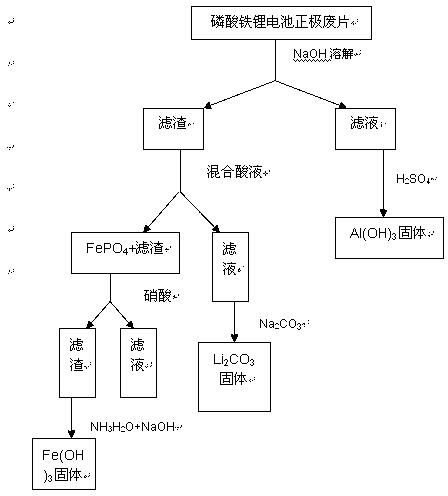

ActiveCN103280610AReduce pollutionWaste accumulators reclaimingProcess efficiency improvementPhosphoric acidImpurity

The invention discloses a method for recovering Al, Fe and Li in waste lithium iron phosphate battery positive pieces through an acid-alkali leaching process. The method comprises the following steps: dismounting the lithium iron phosphate battery positive pieces, dissolving the positive pieces by using an alkali, filtering, and dissolving obtained filter residues by a mixed acid solution for making Fe exist in an iron phosphate precipitate form and be separated from impurities comprising carbon black and the like and a lithium-containing solution; adding the lithium-containing solution to a 95DEG C saturated sodium carbonate solution for precipitation to obtain lithium carbonate; and adding an acid to obtain an iron-containing precipitate for leaching iron ions, and adding an alkaline solution to obtain Fe(OH)3. Al, Fe and Li in the waste lithium iron phosphate battery positive pieces are simply and effectively recovered through using low-concentration acids and alkalis and routine chemicals, and raw materials having economic benefits are recovered through using simple and effective equipment and the method.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

Method for selectively recycling lithium from lithium iron phosphate waste

ActiveCN106910959AEfficient leachingLow costWaste accumulators reclaimingProcess efficiency improvementHypochloriteSelective leaching

The invention discloses a method for selectively recycling lithium from lithium iron phosphate waste through a direct oxidization method. The method is characterized by comprising the steps that the lithium iron phosphate waste is added into a water solution, meanwhile, an oxidizing agent is added, stirring is carried out, lithium iron phosphate and the oxidizing agent react to generate iron phosphate, lithium ions enter the solution, and therefore a pure lithium-containing solution and iron phosphate solids are obtained. The adopted oxidizing agent comprises one or a mixture of persulfate, ozone, oxygen, pypocholoride and hydrogen peroxide. The molar weight of the oxidizing agent is 0.6-20 times that of lithium iron phosphate. The lithium-containing solution can be directly used for preparing a high-purity lithium product. According to the method, efficient and selective leaching of lithium can be achieved simply by adding a certain amount of oxidizing agent, and the method is mild in reaction condition, short in process and simple in equipment.

Owner:GUANGDONG GUANGHUA SCI TECH

Anode material made of doped lithium-iron phosphate active material and carbon and method for producing the same

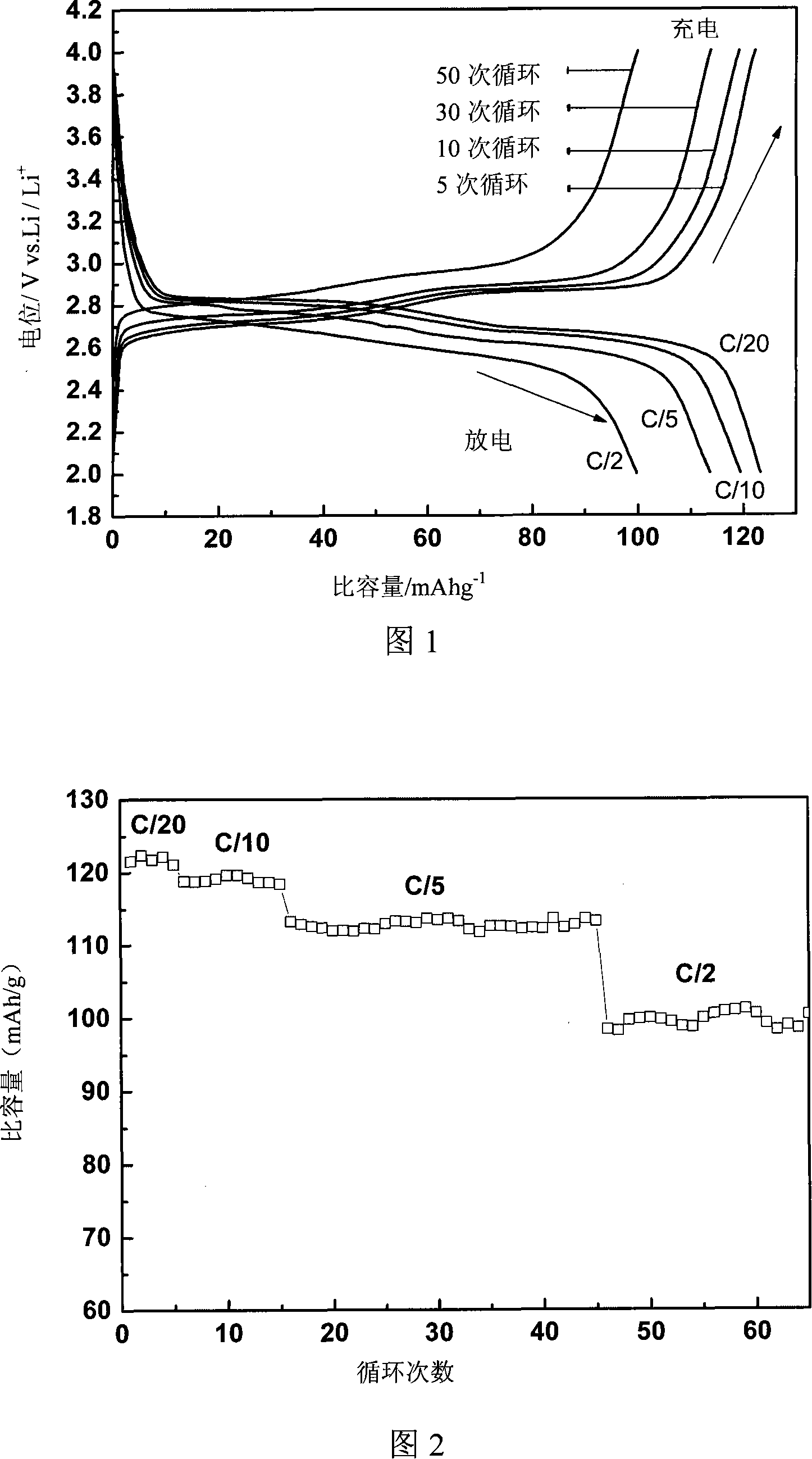

ActiveCN101212049ALow priceImprove securityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateSolid reaction

The invention relates to an anode material composed by doping phosphate iron and lithium active substance and carbon and used for the secondary lithium battery and a manufacturing method thereof. The invention is characterized in that the general expression of the active substance is Li<3+Y>Fe<2-X>Mex(PO4)3(Me = Ti, Sc, Ge, Al, Zr, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, and Pb, etc.); the characteristic in preparation is that the raw material is synthesized into the crystal state of Li<3+Y>Fe<2-X>Mex(PO4)3 through a solid reaction, an hydrothermal method and a sol-gel method in a proper proportion. Then the prepared powder and the carbon is grinded and mixed through a planetary ball mill to obtain the anode material Li<3+Y>Fe<2-X>Mex(PO4)3 / C The specific capacity of the anode material can be up to 122mAhg<-1> (charging and discharging at the rate of C / 20) and 100mAhg<-1> (charging and discharging at the rate of C / 2); furthermore, the material has a good circulation performance and retentivity of specific capacity, thus providing a favorable anode material for the practicality of the secondary lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

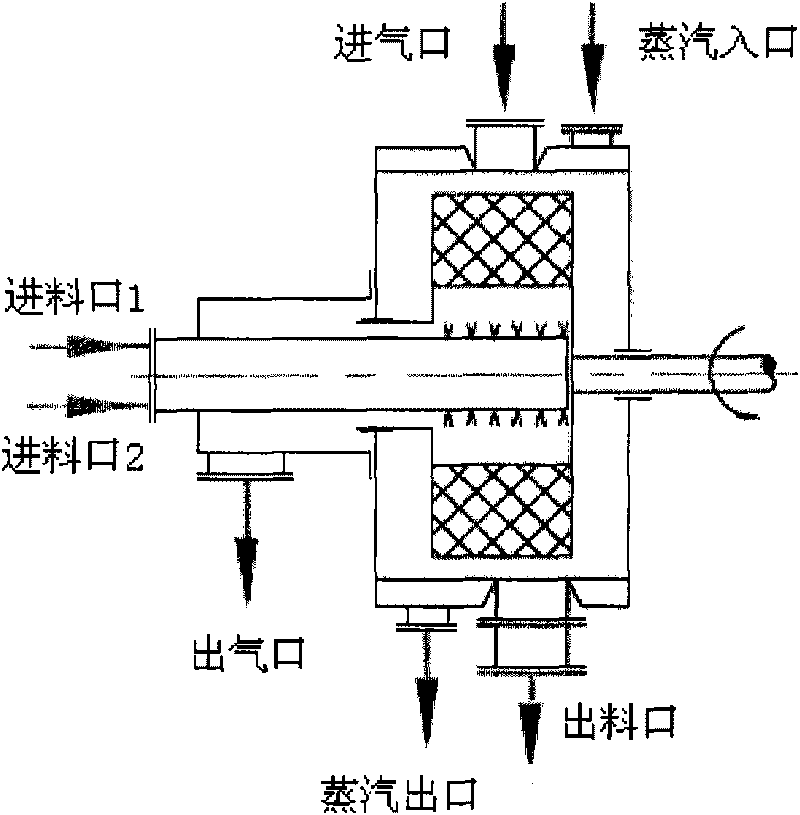

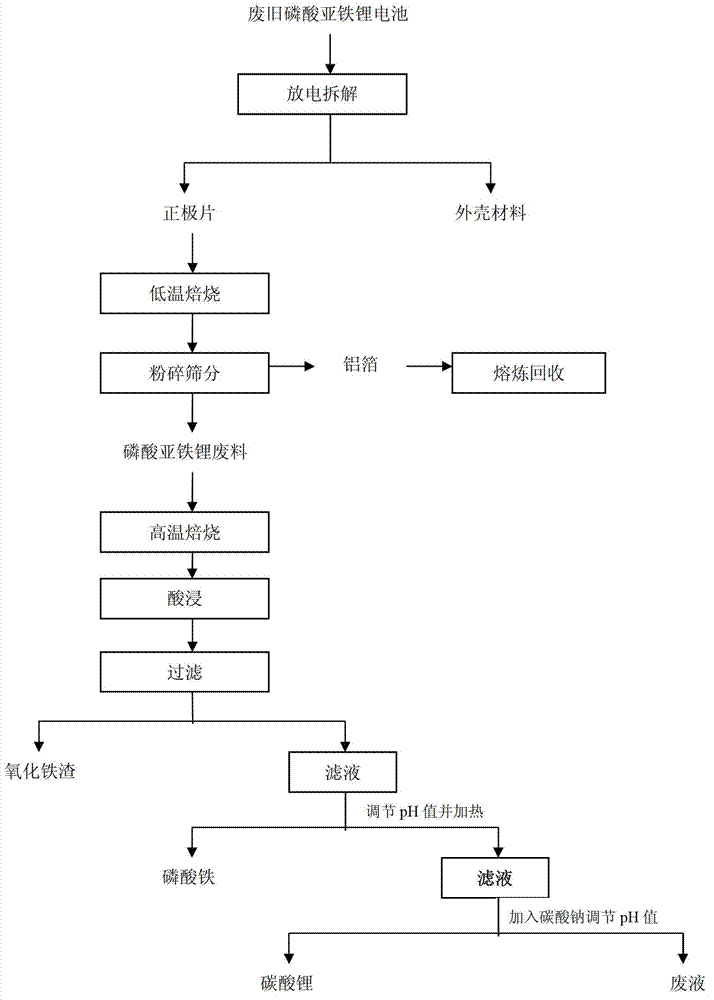

Method for recycling battery-grade iron phosphate in lithium iron phosphate battery and preparing lithium iron phosphate positive material by utilizing waste lithium ion phosphate battery

ActiveCN104953200AAchieve synthesisRealize the recovery of added valueWaste accumulators reclaimingBattery recyclingPhosphatePhosphoric acid

The invention relates to a method for recycling battery-grade iron phosphate in a lithium iron phosphate battery and preparing a lithium iron phosphate positive material by utilizing a waste lithium ion phosphate battery, and relates to a method for recycling a battery and preparing the battery positive material by utilizing the waste battery recycled material, solving the problems of the traditional method for recycling the LiFePO4 lithium ion battery positive electrode that the purity of the obtained element or substances is low and the obtained element or substances cannot be used for preparing the LiFePO4 lithium ion battery positive electrode. The method comprises the steps: I, crushing a positive pole piece, and carrying out heat treatment; II, dissolving the crushed positive pole piece in an acid solution; III, charging a surface active agent; IV, charging an alkaline solution, thereby obtaining a battery-grade iron phosphate; V, charging sodium carbonate to obtain a lithium carbonate; VI, mixing iron phosphate, lithium carbonate and a carbon source reduction agent; and VII, calcining. In the process for recycling the battery-grade iron phosphate in the lithium iron phosphate battery and preparing the lithium iron phosphate positive material by utilizing the waste lithium iron phosphate battery, no secondary pollution is produced, and the comprehensive and high-added-value recycling of the waste lithium iron phosphate battery can be realized.

Owner:HARBIN INST OF TECH

Mixed positive electrode material, positive plate using the same, and lithium ion battery

ActiveCN104300123AIncrease energy densityStable thermal decompositionCell electrodesSecondary cellsHigh energyManganese

The invention discloses a mixed positive electrode material, a positive plate using the same, and a lithium ion battery. The mixed positive electrode material comprises the following component by weight: 50-90 parts of a nickel-cobalt-manganese ternary material and 10-50 parts of lithium-manganese-iron phosphate. The mixed positive electrode material provided by the invention combines the nickel-cobalt-manganese ternary material with high energy density and lithium-manganese-iron phosphate with high safety performance, and plays complementary advantages of nickel-cobalt-manganese and lithium-manganese-iron phosphate, so that comprehensive performances of the positive electrode active material are improved. The positive plate prepared by using the mixed positive electrode material increases the safety performance and cycle performance of the lithium ion battery, increases average voltage of the lithium ion battery, and keeps relatively high energy density; and the lithium ion battery using the positive plate has excellent electrochemical performances, high energy density and high safety performances and long cycle life, and is suitable for popularization and application.

Owner:中创新航科技(江苏)有限公司

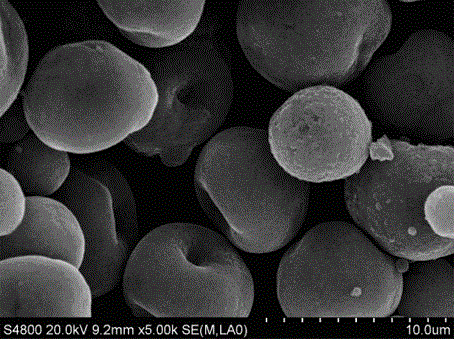

Method for preparing spherical ferric lithium phosphate by oxidation control crystal-carbon thermal reduction method

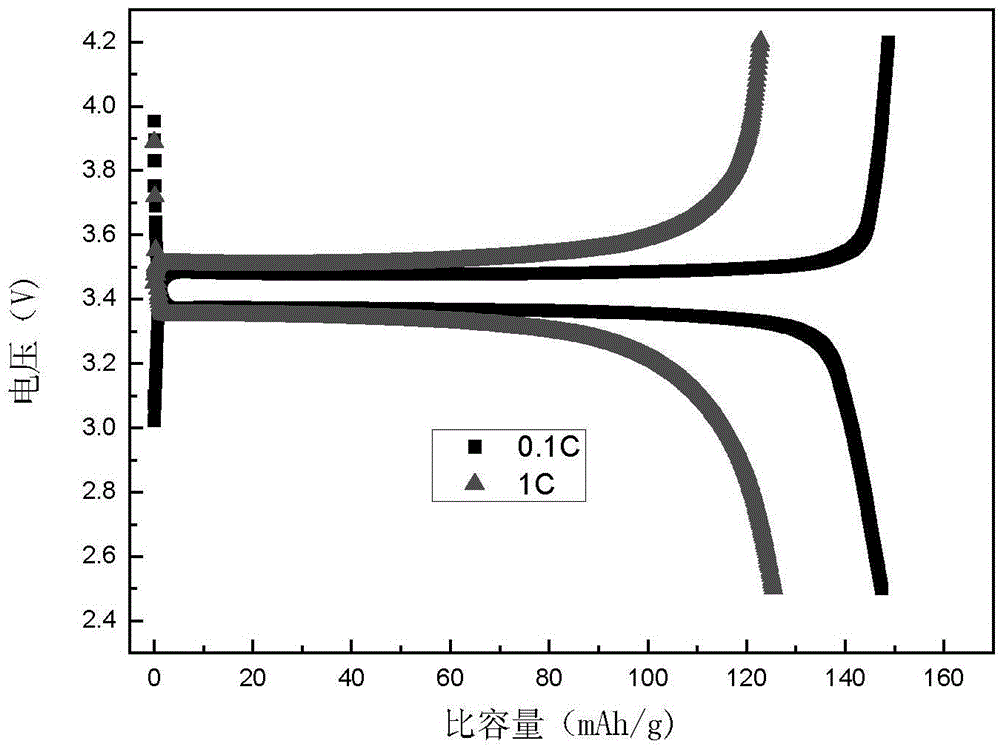

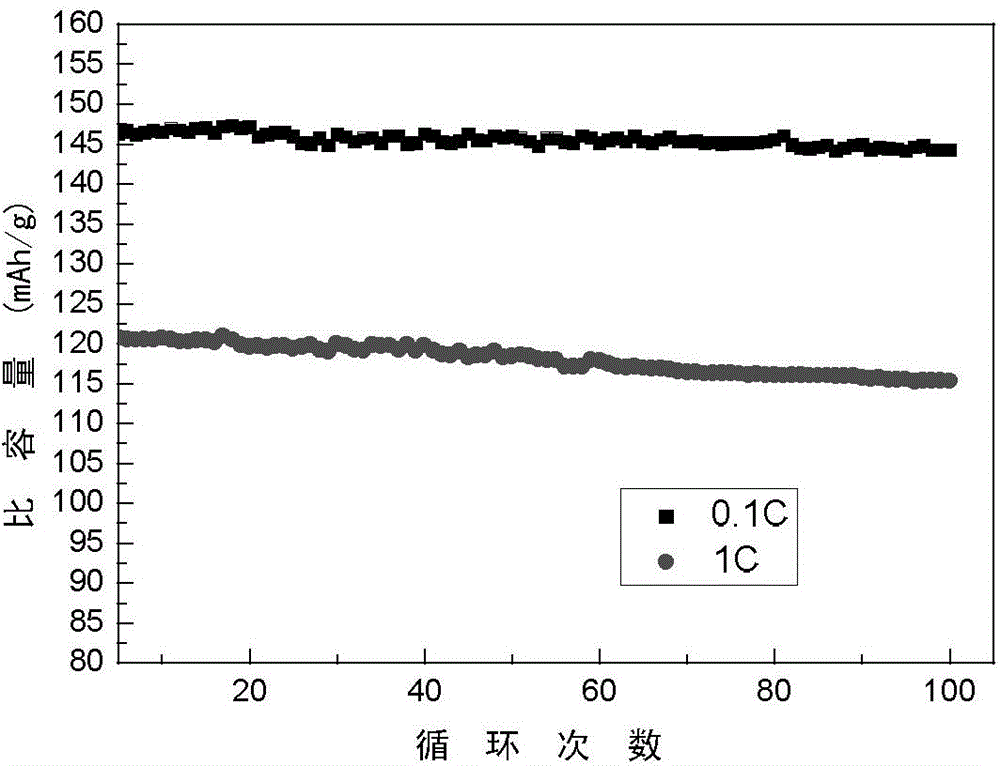

InactiveCN101337666AWide variety of sourcesLow costCell electrodesPhosphorus compoundsElectric dischargePhosphoric acid

The invention discloses a method for preparing spherical lithium iron phosphate by adopting oxidation control crystallization-carbon thermal reduction. The preparation method comprises the steps of conducting reaction among a mixed water solution of bivalence malysite and phosphoric acid, an aqueous solution of ammonia and an oxidant; synthesizing a spherical precursor of a spherical hydration iron phosphate through the process of oxidation control crystallization; washing; drying; pre-burning for dewatering; mixing with lithium carbonate and a carbon source; and obtaining the lithium iron phosphate through high temperature carbon thermal reduction under the protection of inertial or reducing atmosphere. By using the preparation method, the spherical lithium iron phosphate, an anode material of a lithium ion battery, is prepared, and has high bulk density and high volume specific capacity. The average grain size of the spherical lithium iron phosphate is between 6 and 8 mum, the electric discharge specific capacity thereof for the first time can reach up to 145-150mAh / g at the room temperature of 0.5C.

Owner:TSINGHUA UNIV

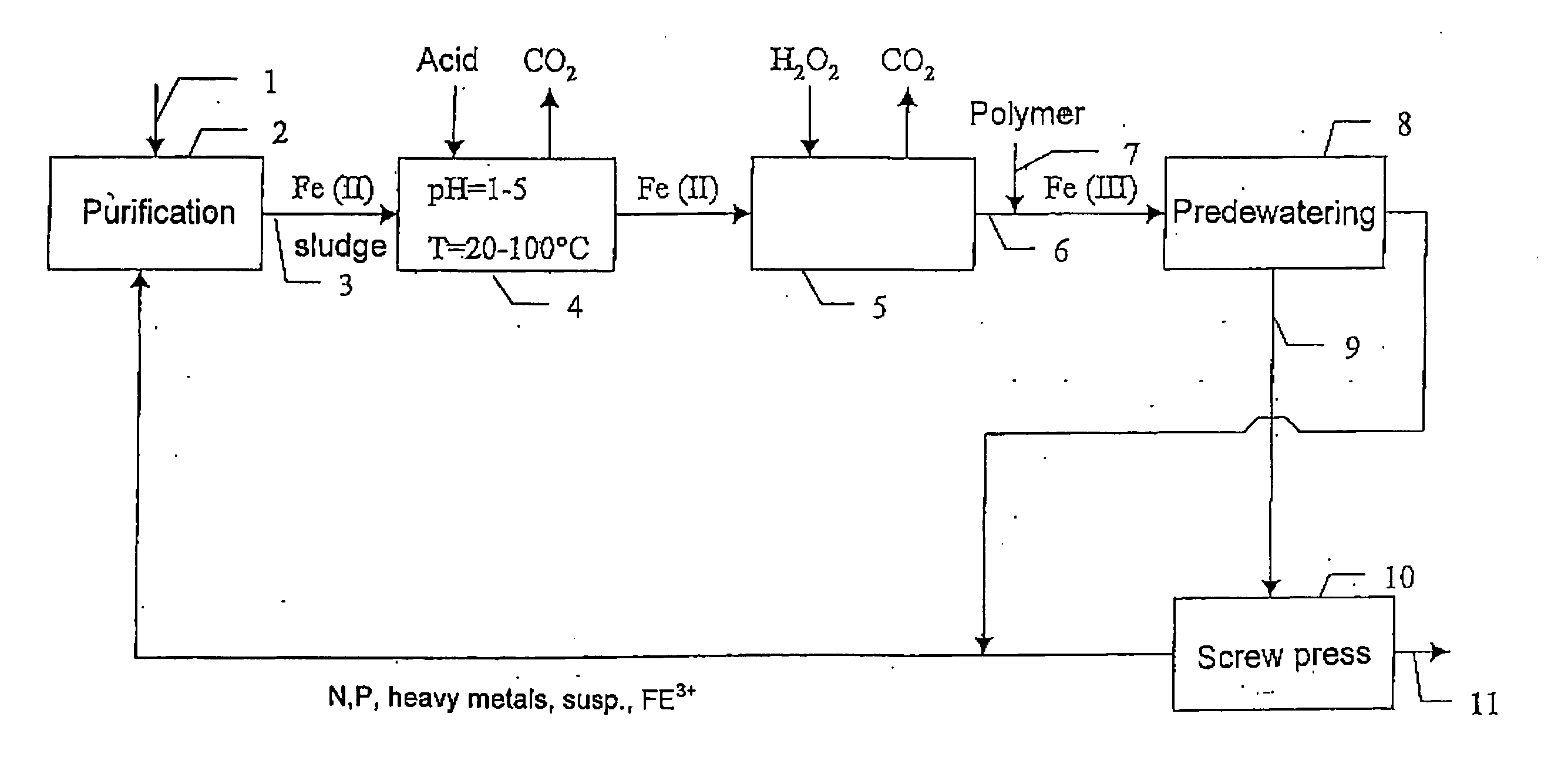

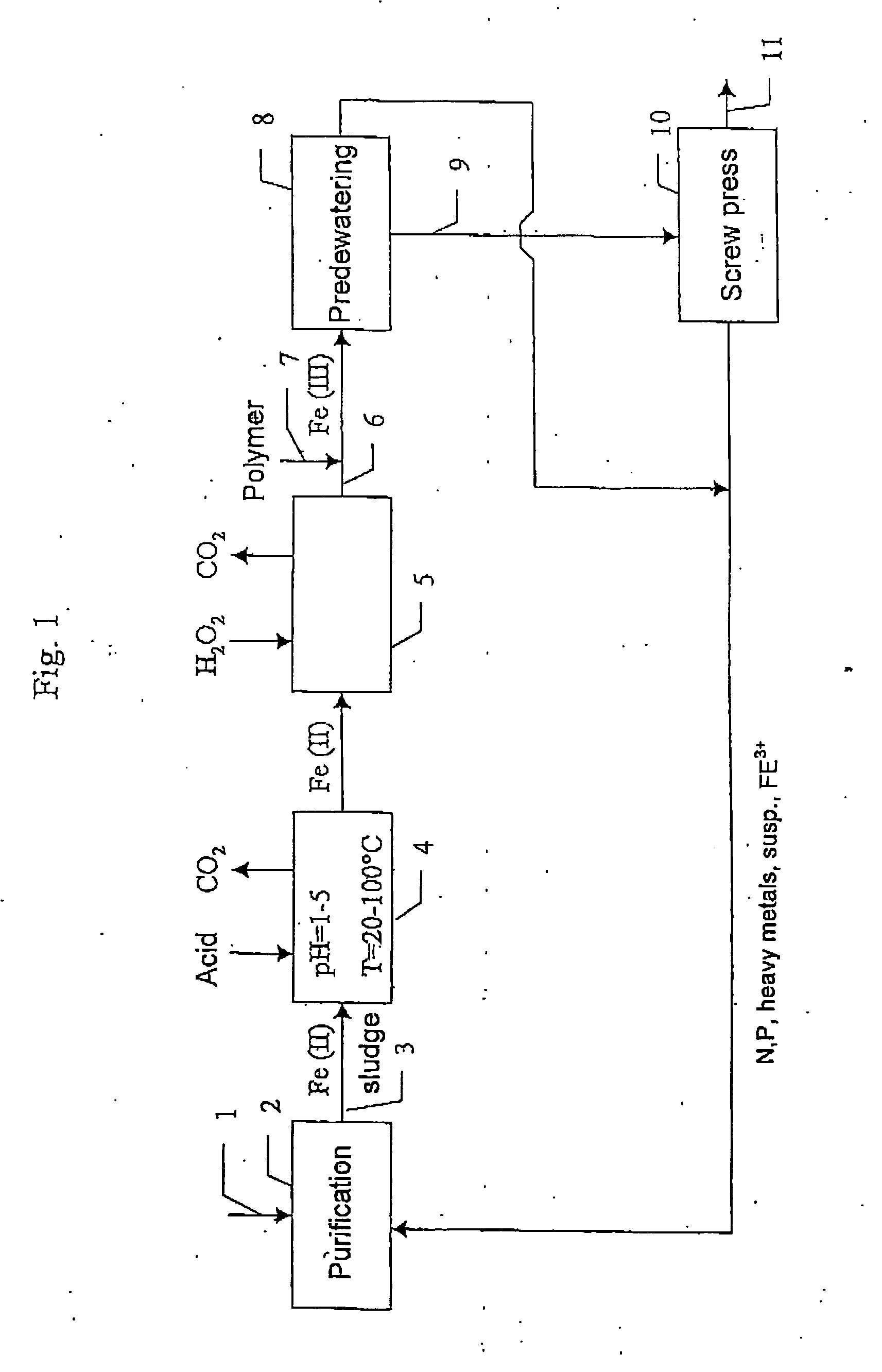

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

Process for producing iron phosphate for producing iron lithium phosphate material

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

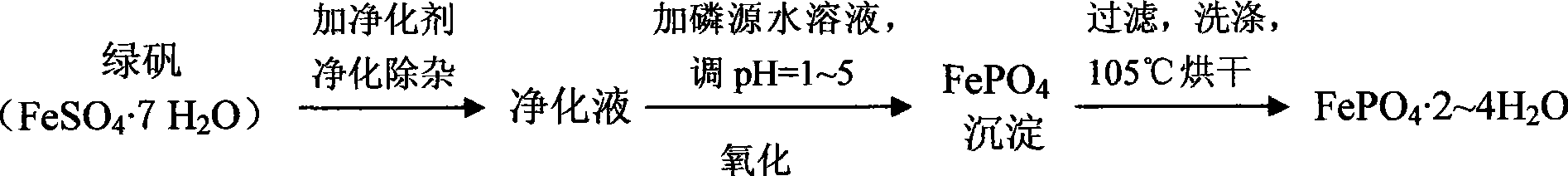

Method for preparing high purity ferric phosphate using ferrous sulfate as by-product of white titanium pigment

InactiveCN101531355AEasy to oxidizeSolve the use problemPhosphorus compoundsLithium iron phosphateGlaze

The invention relates to a preparation method of pure ferric phosphate, characterized in that: iron vitriol, phosphorus source as by-product of white titanium pigment are used as reactant and purificant and oxidant are added into the reactant and the reaction temperature is controlled at 25-100 DEG C and the reaction time is 0.5-10 hours, thus white ferric phosphate powder (FePO[4]2-4H[2]O) with 2-4 crystal water is obtained. The technological process has features of simple process, low production cost, high product purity, increased added value of ferrous sulfate as by-product of white titanium pigment and the product can be used as ceramic metal glaze-color glaze material and raw material for producing lithium iron phosphate as lithium ionization cell anode material.

Owner:GUANGXI UNIV +1

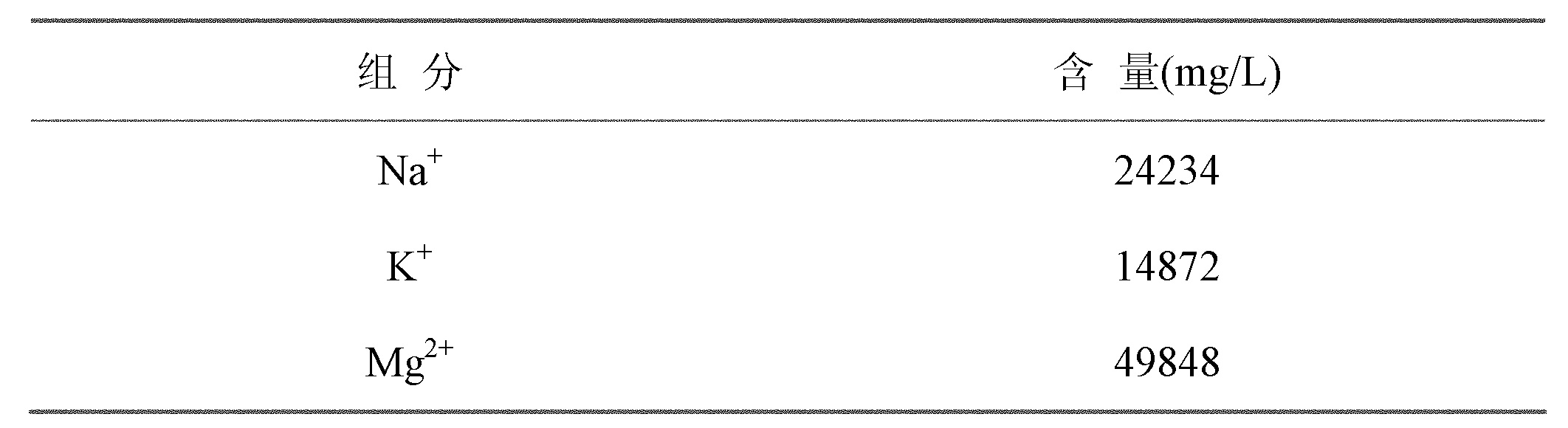

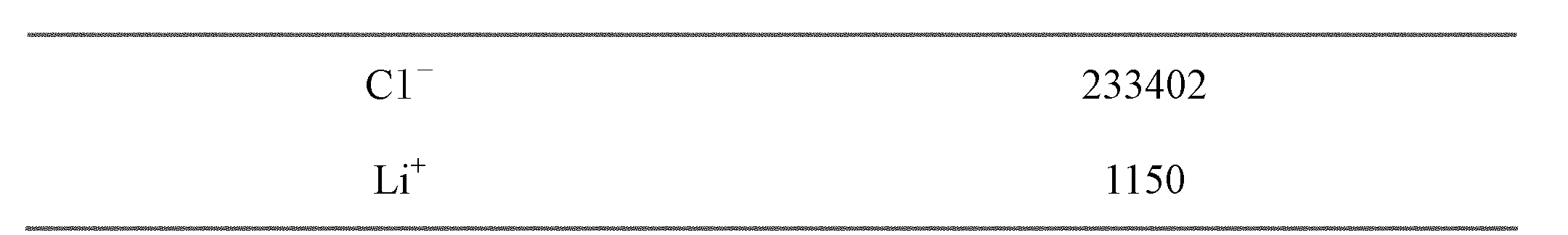

Iron phosphate ion sieve for selectively extracting Li and application thereof

The invention relates to an iron phosphate ion sieve for selectively extracting Li and an application thereof. The iron phosphate ion sieve is one or a mixture of FePO4 and MexFeyPO4; Me is one of Mg, Al, Ti, Ni, Co, Mn, Mo and Nb or a mixture of several of Mg, Al, Ti, Ni, Co, Mn, Mo and Nb; and x is higher than 0 and lower than 1, and y is higher than 0 and lower than 1. The iron phosphate ion sieve is particularly suitable for the separation of Mg and Li in brine with a high Mg / Li ratio and has good Li<+> embedding and disembedding performances. Materials for preparing the iron phosphate ion sieve described by the invention are cheap, and easy to obtain, and the iron phosphate ion sieve has high selectivity and higher adsorption capacity for Li<+>, and can be used for more than 2000 times; and when being used for the separation between Mg and Li and the extraction of Li, the iron phosphate ion sieve has short process flow and low production cost, and is simple in operation and convenient for industrial application.

Owner:江苏中南锂业有限公司

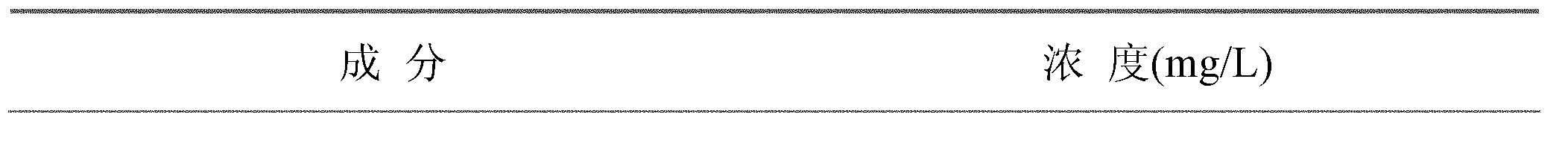

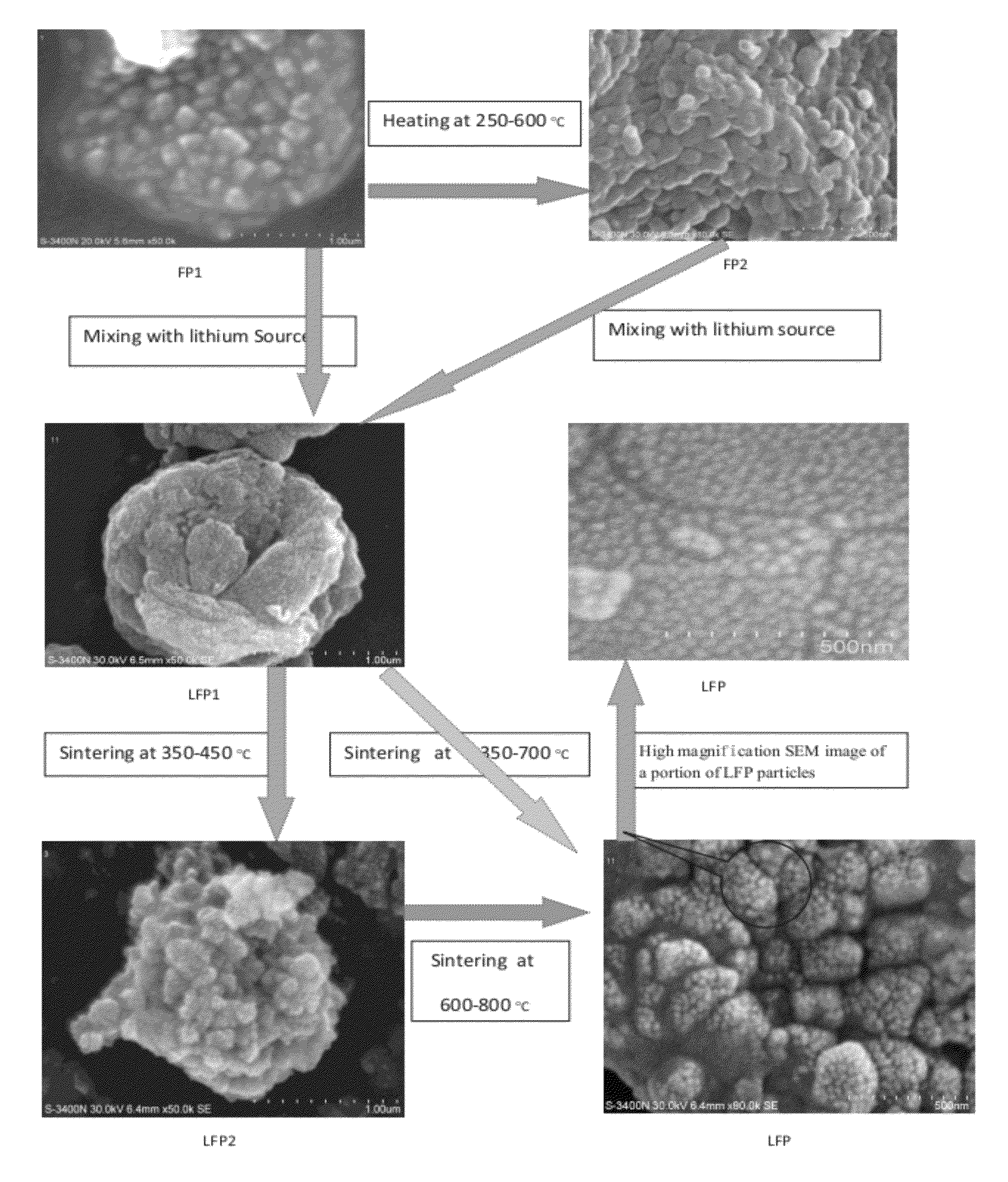

HIGH PERFORMANCE CATHODE MATERIAL LiFePO4, ITS PRECURSORS AND METHODS OF MAKING THEREOF

ActiveUS20120058039A1High discharge rateQuality improvementMaterial nanotechnologyPhosphatesLithium iron phosphateIron phosphate

In one aspect of the invention, methods of synthesizing iron phosphate precursors and lithium iron phosphate active material usable for a lithium secondary battery include the steps of first forming fine particle iron phosphate precursors hydrated and anhydrous, then forming electrode active material lithium iron phosphate with said iron phosphate precursors. The unique methods are generally efficient and cost effective, as well as stable and scalable for a high performance electrode active material with high capacity, good discharge profile, high electronic conductivity, as well as long cycle life.

Owner:HUANG GUIQING

Recovery method for cathode material of waste lithium iron phosphate battery

InactiveCN107739830AEasy to separate naturallyLow costWaste accumulators reclaimingProcess efficiency improvementRecovery methodPhosphate

Owner:FUZHOU UNIV

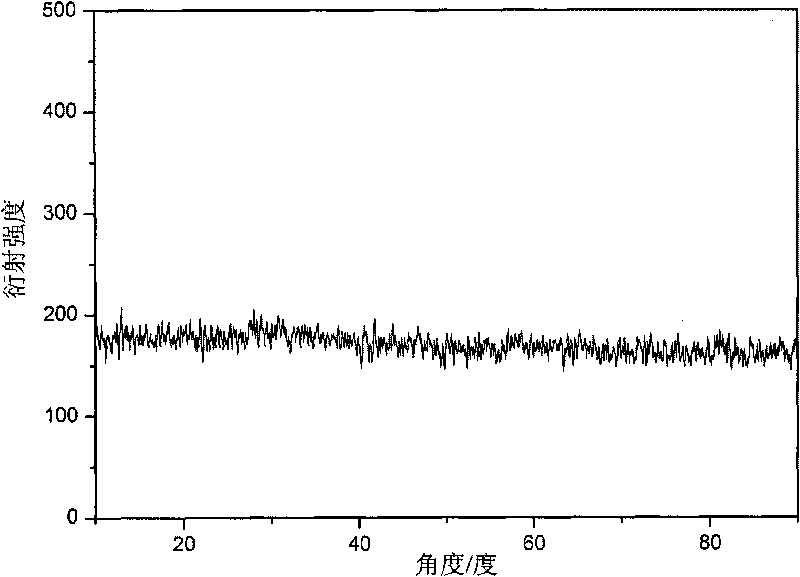

Method for preparing nano iron phosphate

InactiveCN101693531AReduce volumeReduce energy consumptionNanostructure manufacturePhosphorus compoundsPhosphateFerrous salts

The invention relates to a method for preparing nano iron phosphate, belonging to the technical field of the preparation of lithium ion battery cathode materials. The method is characterized by comprising the following steps: inputting an alkaline aqueous solution and a mixed solution formed by one of phosphoric acid or a soluble phosphate solution, one of a water-soluble ferrous salt solution and an oxidant or a ferric salt solution and a water-soluble dispersing agent into a rotating packed bed layer by a metering pump at a certain feeding speed; regulating the rotating speed of the rotating packed bed and controlling the pH value of the reaction system by an alkaline solution; discharging nano iron phosphate particles generated by reaction crystallization from a discharge hole of the rotating packed bed along with the mixed solution; and filtering, washing and drying the nano iron phosphate particles to obtain nano iron phosphate (FePO4.2H2O) powder. The method is simple and has easy operation and high efficiency, and the prepared iron phosphate reaches the nano grade, has uniform particle size and narrow distribution range and is suitable for industrialized production. The nano iron phosphate is a good precursor material for preparing lithium iron phosphate which is used as a cathode material of high-power type lithium ion batteries.

Owner:TSINGHUA UNIV

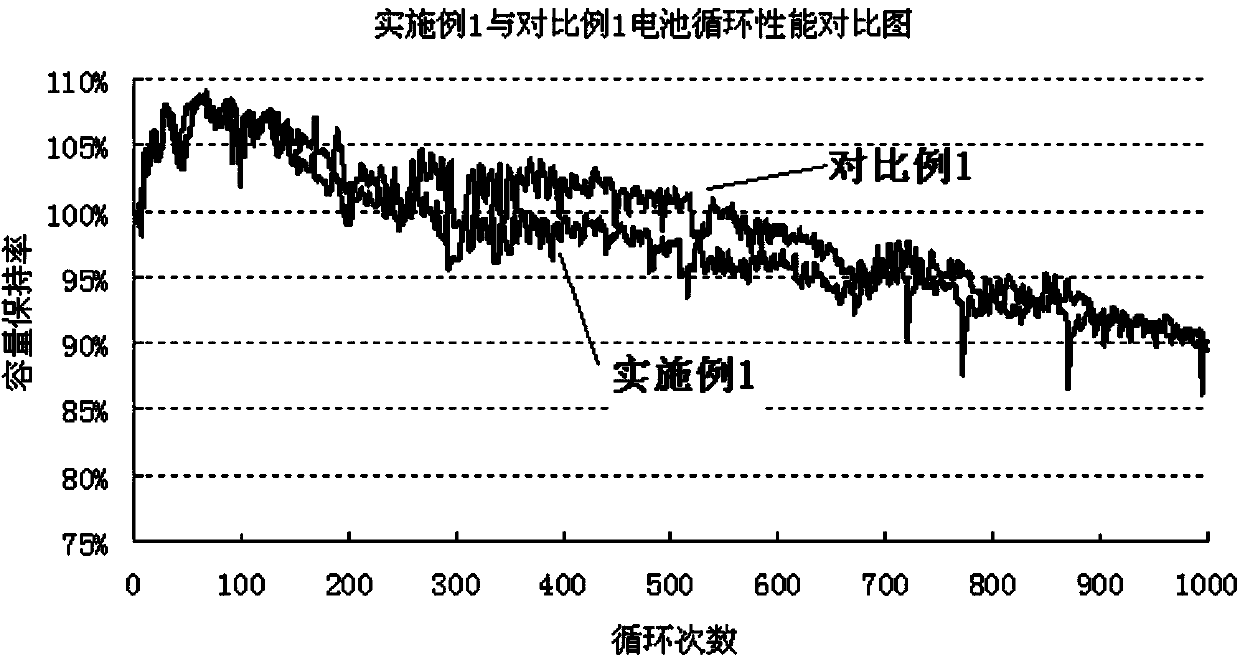

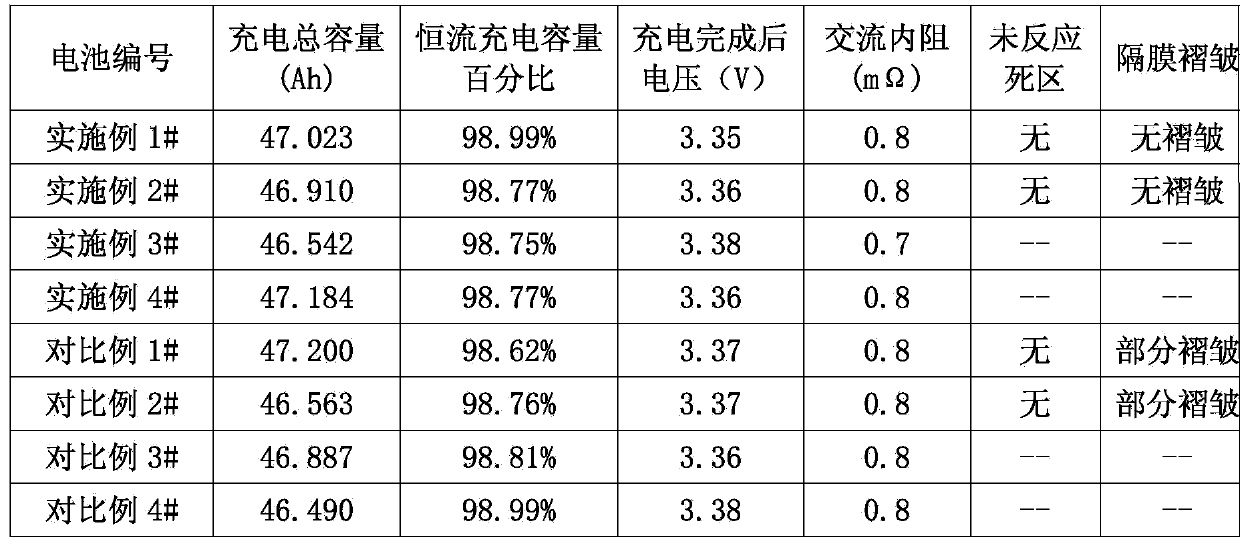

Rapid forming process of iron phosphate lithium battery

InactiveCN104037456AImpact capacityFast and full wettingFinal product manufactureElectrolyte accumulators manufactureLithium iron phosphateThermostat

The invention discloses a rapid forming process of an iron phosphate lithium battery. The rapid forming process comprises the following steps: vacuumizing after the battery is assembled, and injecting electrolyte by several times, and sealing the battery; putting the battery into a thermostat, standing for 8-12 hours at 45-50 DEGC, turning or rotating the battery in a standing process so as to putting each face of the battery downwards for a certain time; after the standing, carrying out ultrasonic treatment on the battery for 10-20 minutes; putting the battery on a cabinet, and carrying out low-current step type charging excitation and intermittent pulse discharge on the battery; after the charging is finished, carrying out deflation and one time of vacuumizing on the battery in a glove box, and carrying out sealing, ageing and capacity grading. According to the rapid forming process, firstly a diaphragm, an anode piece and a cathode piece of the battery are adequately infiltrated by virtue of the electrolyte, and then the battery is simultaneously subjected to high-current step type charging and intermittent pulse discharge, so that the time of the forming procedure is substantially shortened, the equipment loss is reduced, the performance of the formed battery is excellent, and the formed battery has no difference from a battery formed by virtue of a traditional forming process.

Owner:LVCHI AUTO TECH SHANGHAI CO LTD

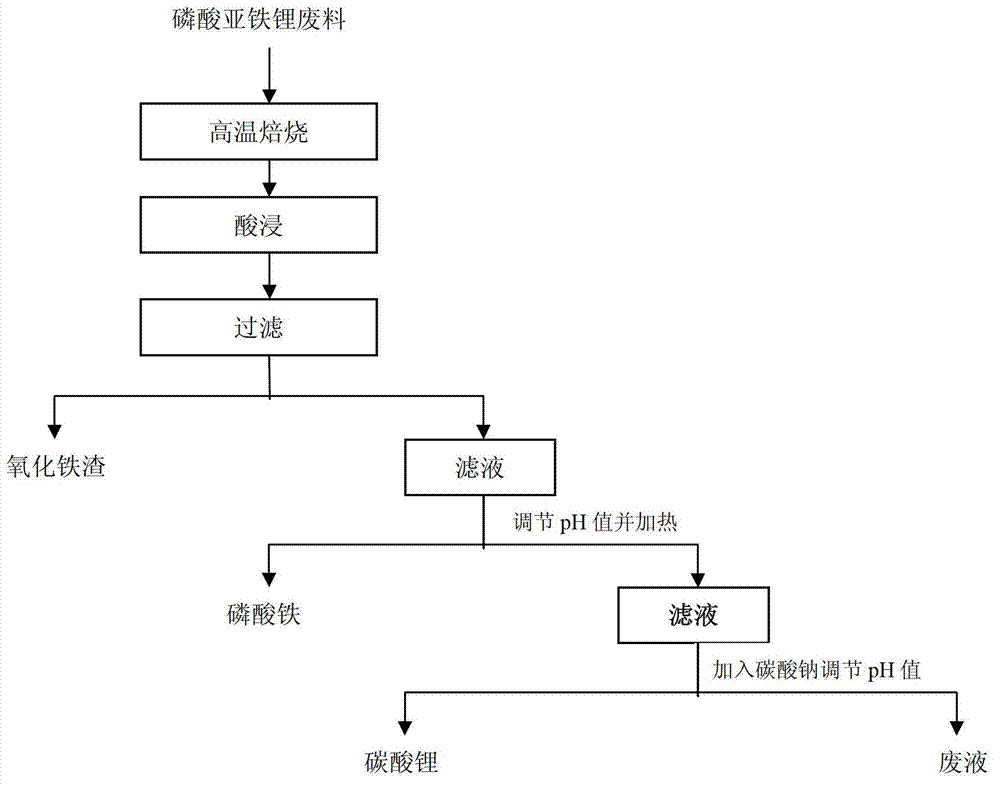

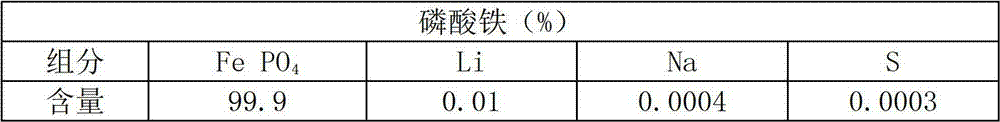

Method for recycling lithium carbonate from lithium iron phosphate waste material

ActiveCN102903985ASolve the problem of resource recyclingSolve your worriesWaste accumulators reclaimingBattery recyclingIron sulfateWaste material

The invention relates to a method for recycling lithium carbonate from a lithium iron phosphate waste material, and belongs to the technical field of waste lithium oil battery recycling. The technical problem to be solved by the invention is that a method for recycling lithium carbonate from the lithium iron phosphate waste material is provided. The method provided by the invention comprises the following steps of: roasting the lithium iron phosphate waste material at 500-800 DEG C for 1-4 hours; adding sulfur into the roasted waste material and leaching, and filtering so as to obtain a mixed solution of lithium phosphate, iron phosphate and ferric sulfate; heating the mixed solution to 80-100 DEG C, and adjusting the pH value to 2-2.5, reacting for 1-4 hours, filtering, washing, and drying to obtain iron phosphate; adjusting the pH value of a filtrate obtained by filtering to be 6-7, adding calcium chloride and dephosphorizing, and filtering; and adjusting the pH value of the filtrate obtained by filtering to be 10-12 by sodium carbonate, reacting for 0.5-2 hours, filtering, washing, and drying so as to obtain battery grade lithium carbonate.

Owner:天齐锂业(江苏)有限公司 +2

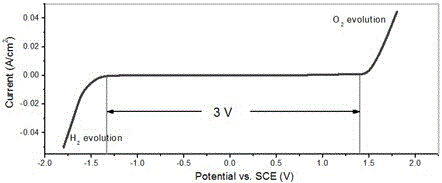

Water system high-voltage mixed ion secondary battery based on zinc-lithium ferric manganese phosphate

InactiveCN105826520AIncrease capacityExcellent rate performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention relates to a water system high-voltage mixed ion secondary battery. A positive pole material of the battery is a high-voltage battery positive pole material, namely zinc-lithium ferric manganese phosphate (LiFe1-xMnxPO4), the element zinc serves as the majority of a negative pole material, and electrolyte is a liquid-state or gel-state material which is formed by lithium bis(trifluoromethane sulfonimide) (LiTFSI) and soluble zinc salt as solute and water as solvent and has ionic conductivity. The battery is based on the energy storage mechanisms of a dissolution-out / deposition reaction of zinc ions (Zn2+) on a negative pole and a reversible embedding / ejection reaction of the zinc ions (Zn2+) on a positive pole, meanwhile, through the water-in-salt electrolyte formed by high-concentration LiTFSI, the electrochemical water decomposition process is inhibited, a potential window of the water system electrolyte is remarkably broadened, the zinc-lithium mixed ion secondary battery has the advantages of being high in capacity, long in cycling life, safe, environmentally friendly, low in cost and the like, and the battery can be applied to the fields such as consumer electronic equipment, electromobiles and large-scale energy storage.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Wafer-like ferric phosphate, preparation method and application thereof

ActiveCN101708834AUniform sizeShort reaction timeCell electrodesPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a method for preparing wafer-like ferric phosphate, which comprises the following steps of: adding deionized water of which the pH value is pre-adjusted to 1 by nitric acid into a reactor with stirring, then adding an iron source into the reactor, completely dissolving the iron source with the stirring, then adding a certain amount of phosphoric acid or phosphate, urea and surfactant into the reactor respectively, adjusting the pH value of reaction solution by using the nitric acid or sodium hydroxide, heating the solution in the reactor to be between 80 and 100 DEG C, performing reaction for 1.5 to 3 hours within the temperature range to obtain a white suspension, cooling and filtering the suspension, washing a filter cake by using the deionized water, and drying the filter cake for 3 to 6 hours in a baking oven at the temperature of between 102 and 120 DEG C to obtain ferric phosphate powder. The product has good whiteness, is of wafer shapes and has more uniform particle sizes; the average particle size is between 0.3 and 0.5 microns; and the tap density is more than or equal to 0.95g / cm3. The discharge capacity of lithium ferric phosphate, which is further synthesized by using the ferric phosphate prepared by the method as a raw material and is taken as an anode material of a lithium ion battery, can reach more than 140mAh / g under the condition of 0.5C. The method has the advantages of short reaction time, simple process, high product purity, and more regular morphology, and is easy to realize industrialization.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +1

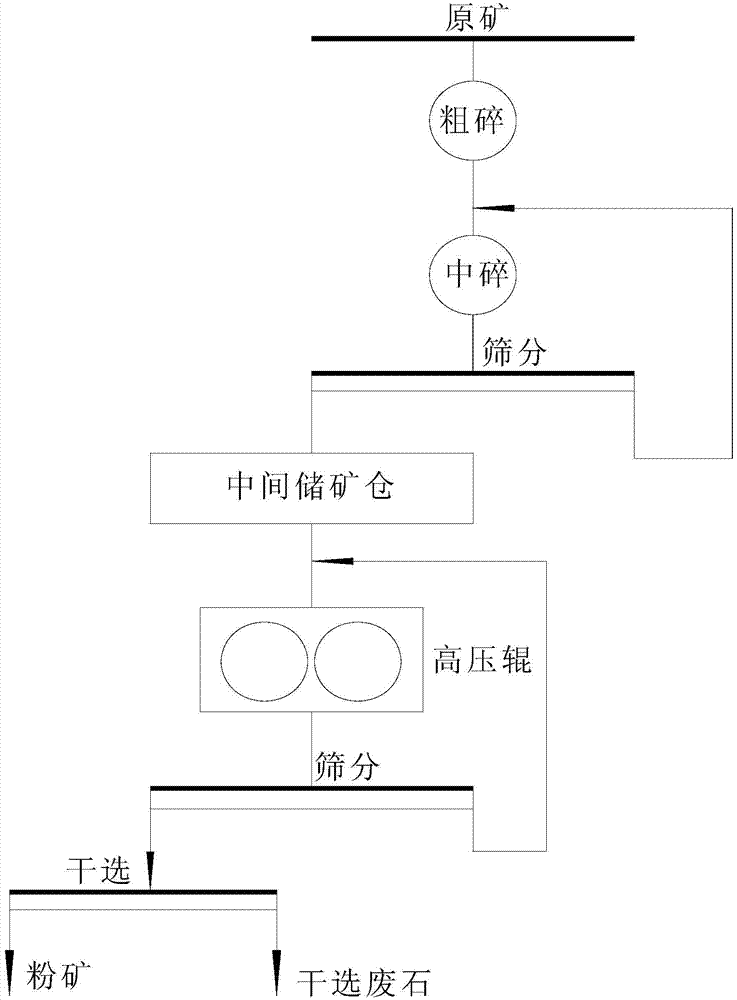

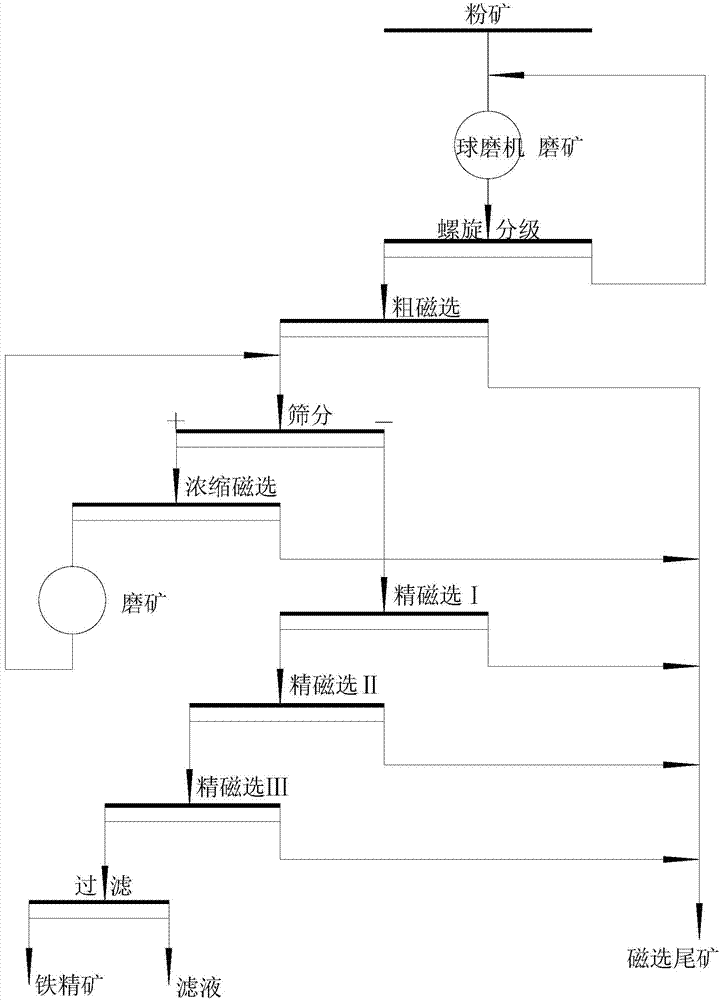

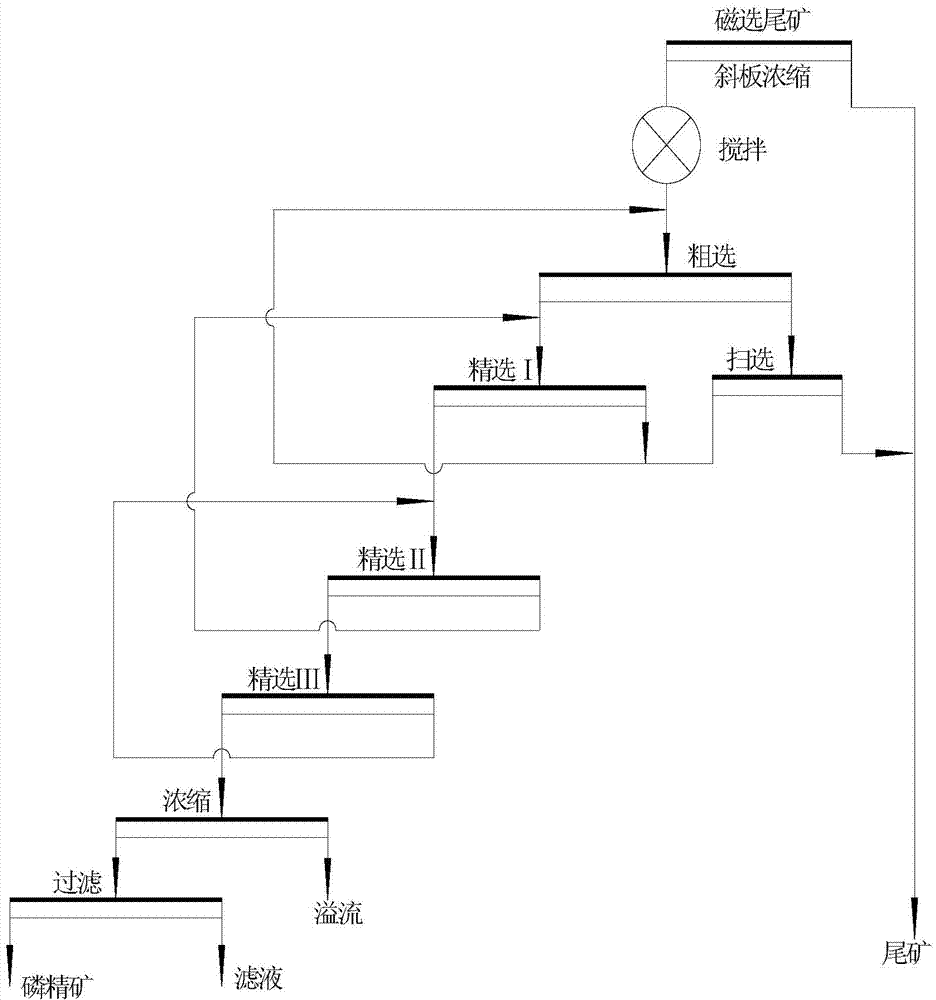

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

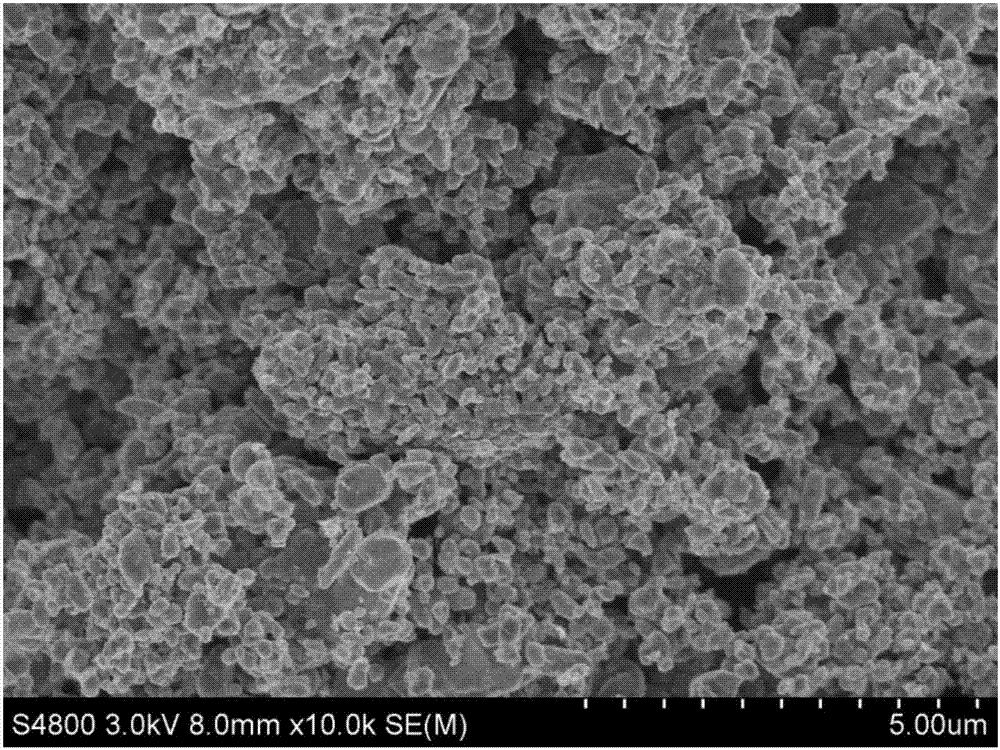

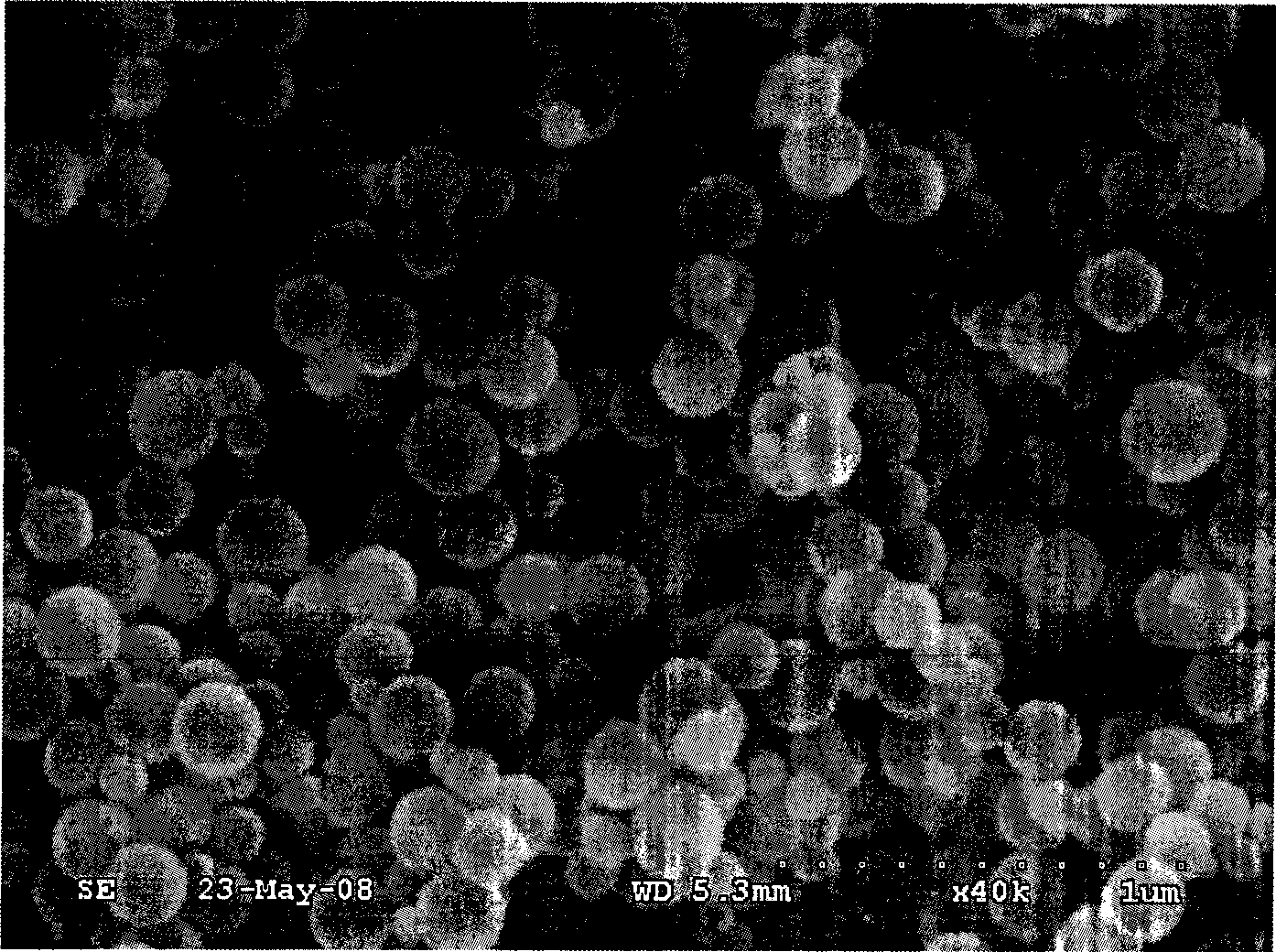

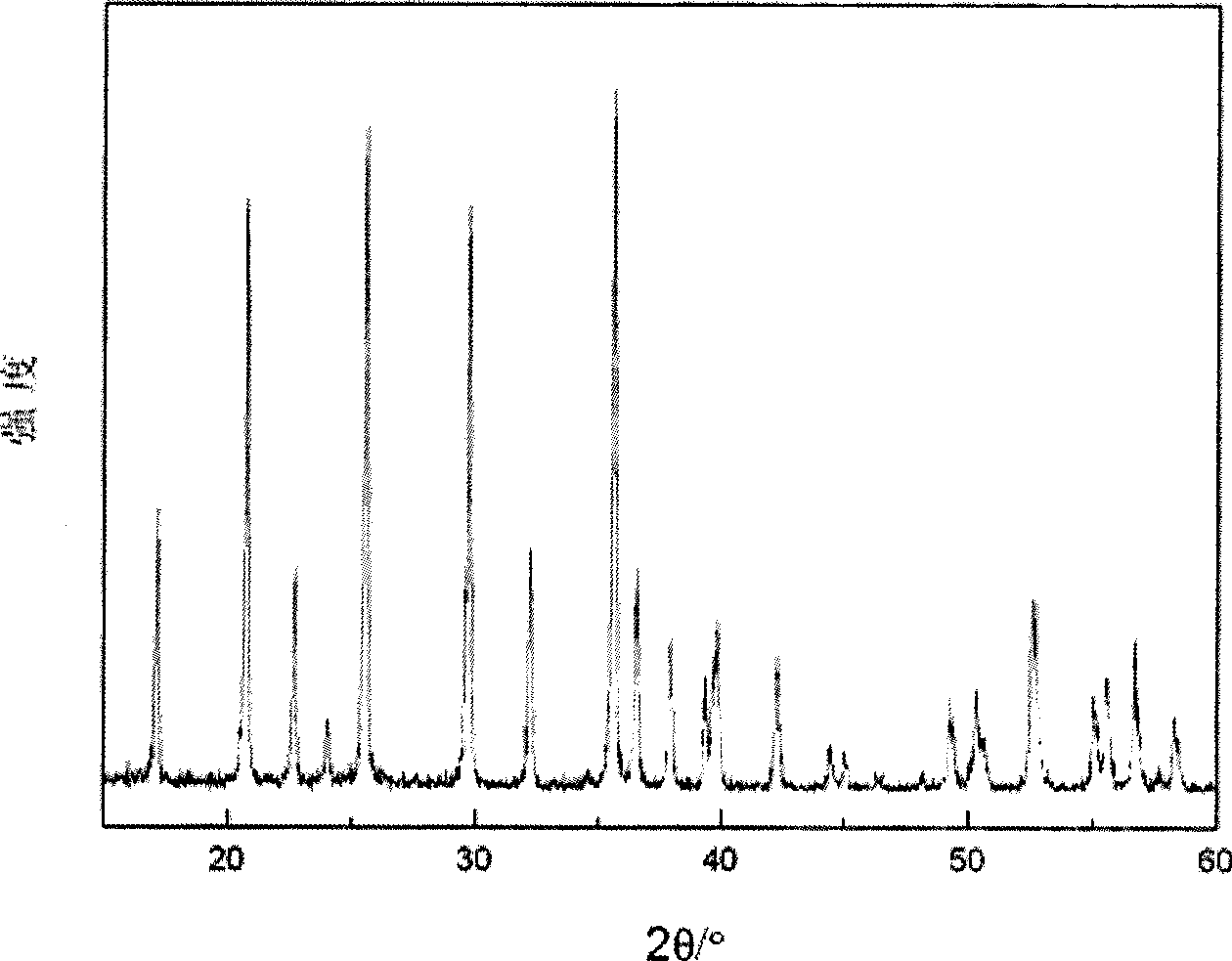

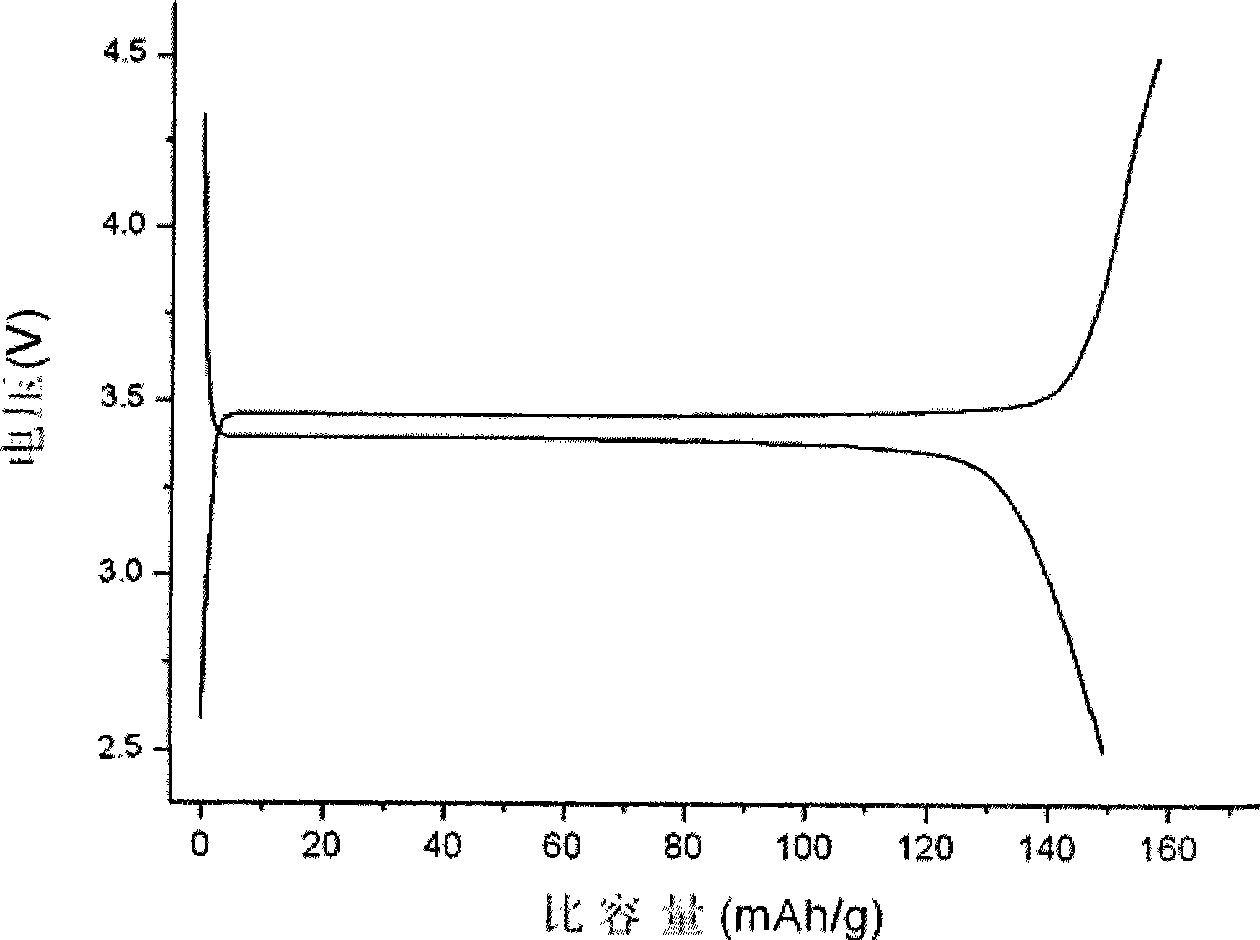

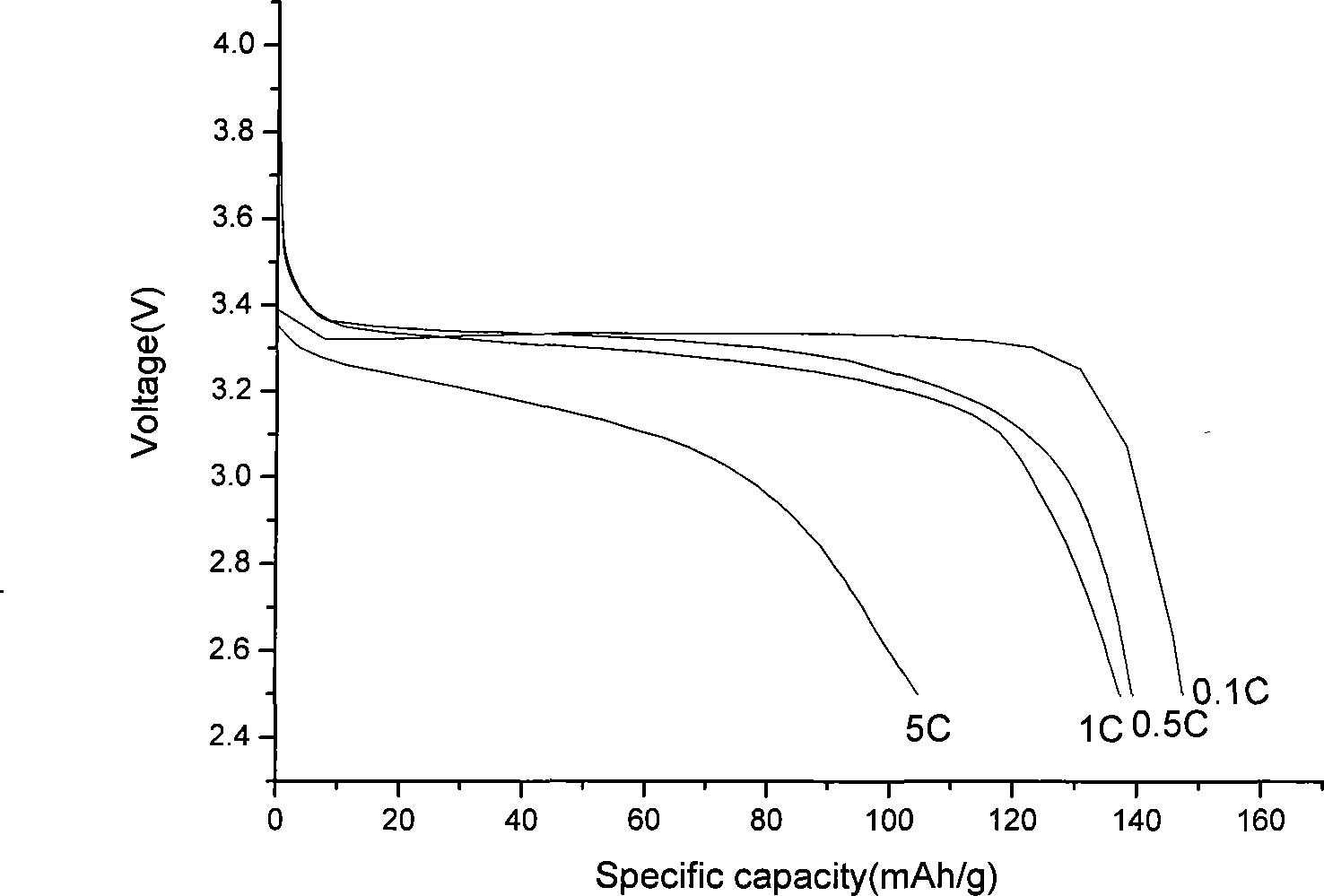

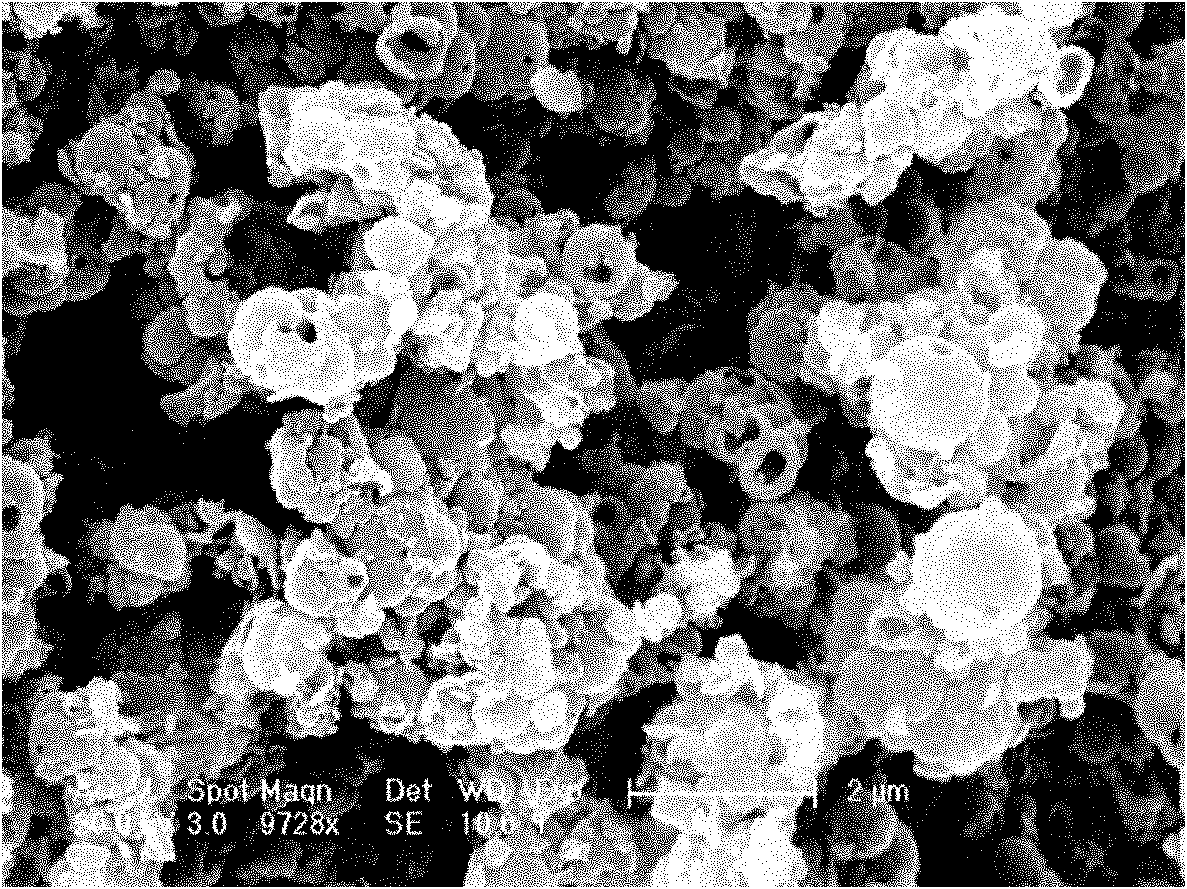

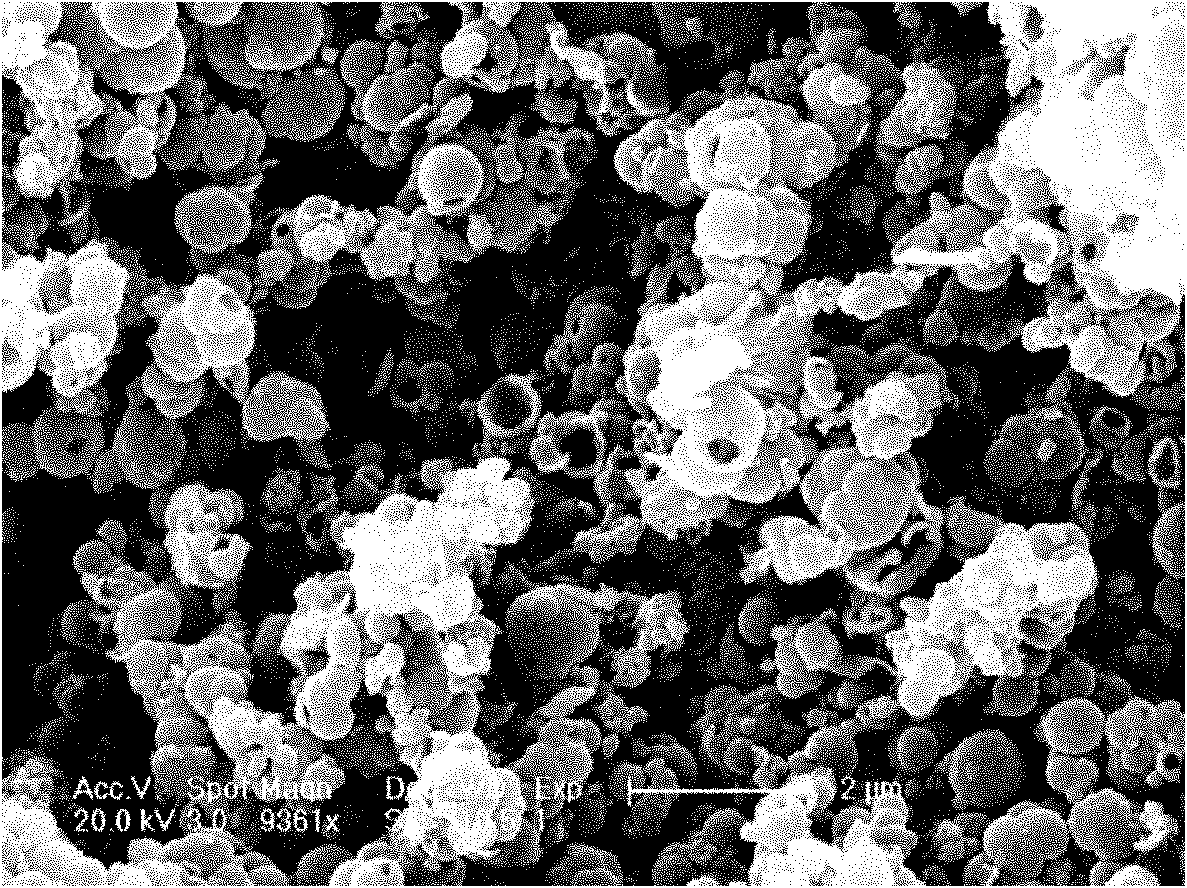

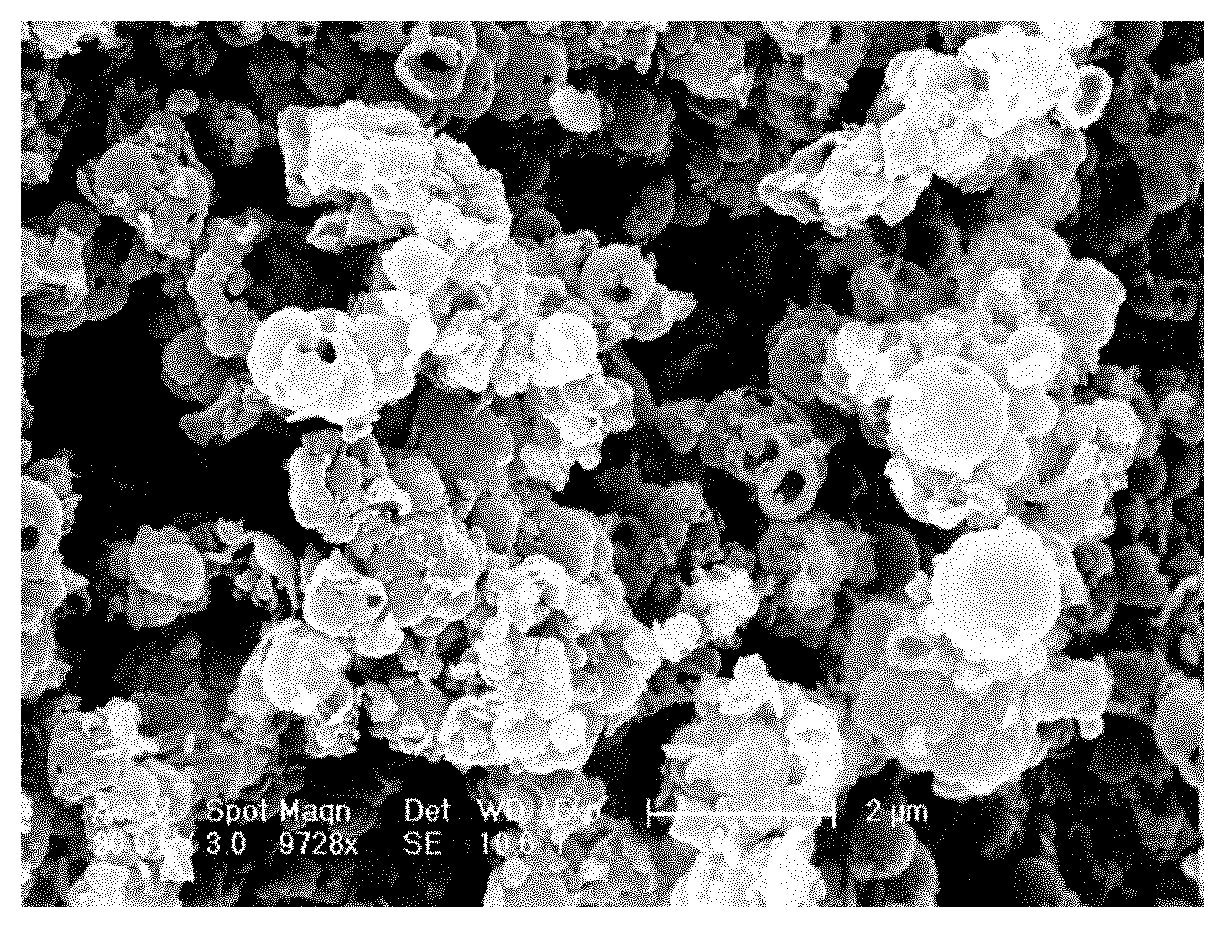

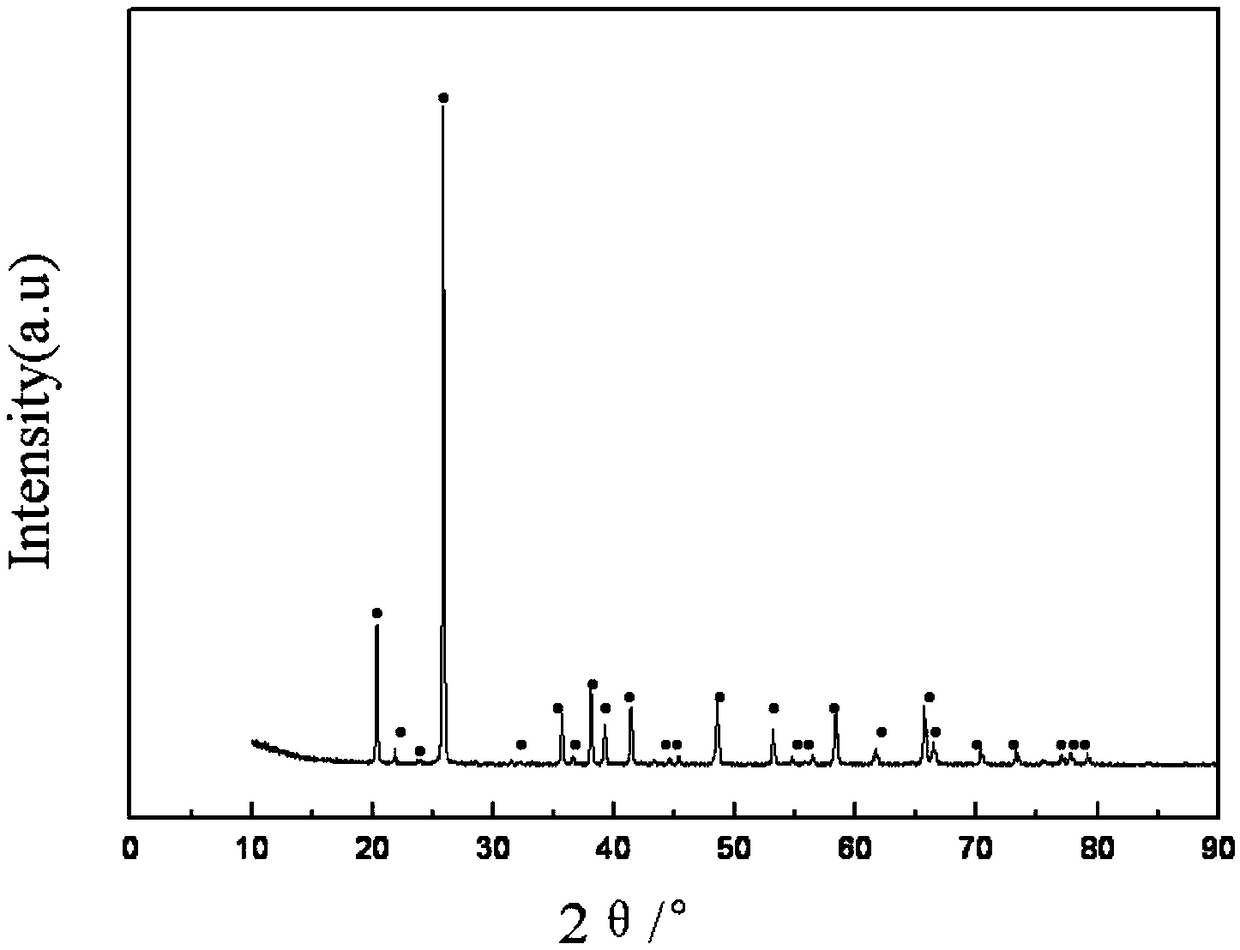

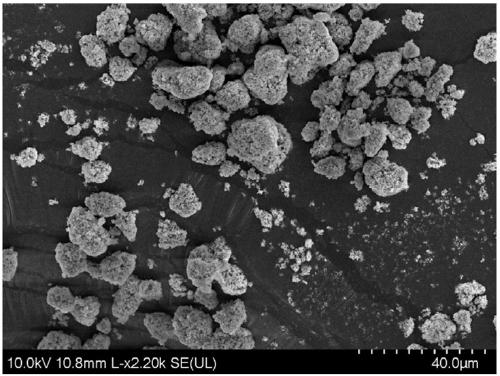

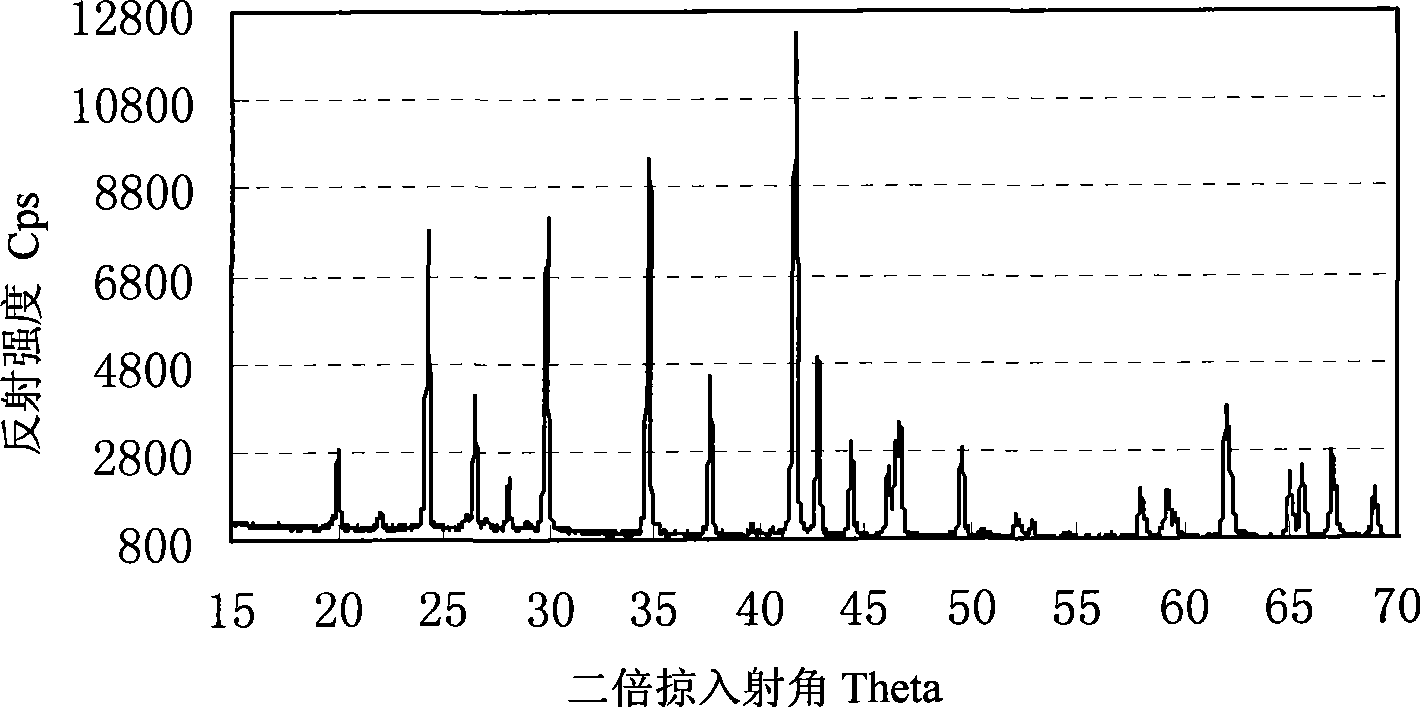

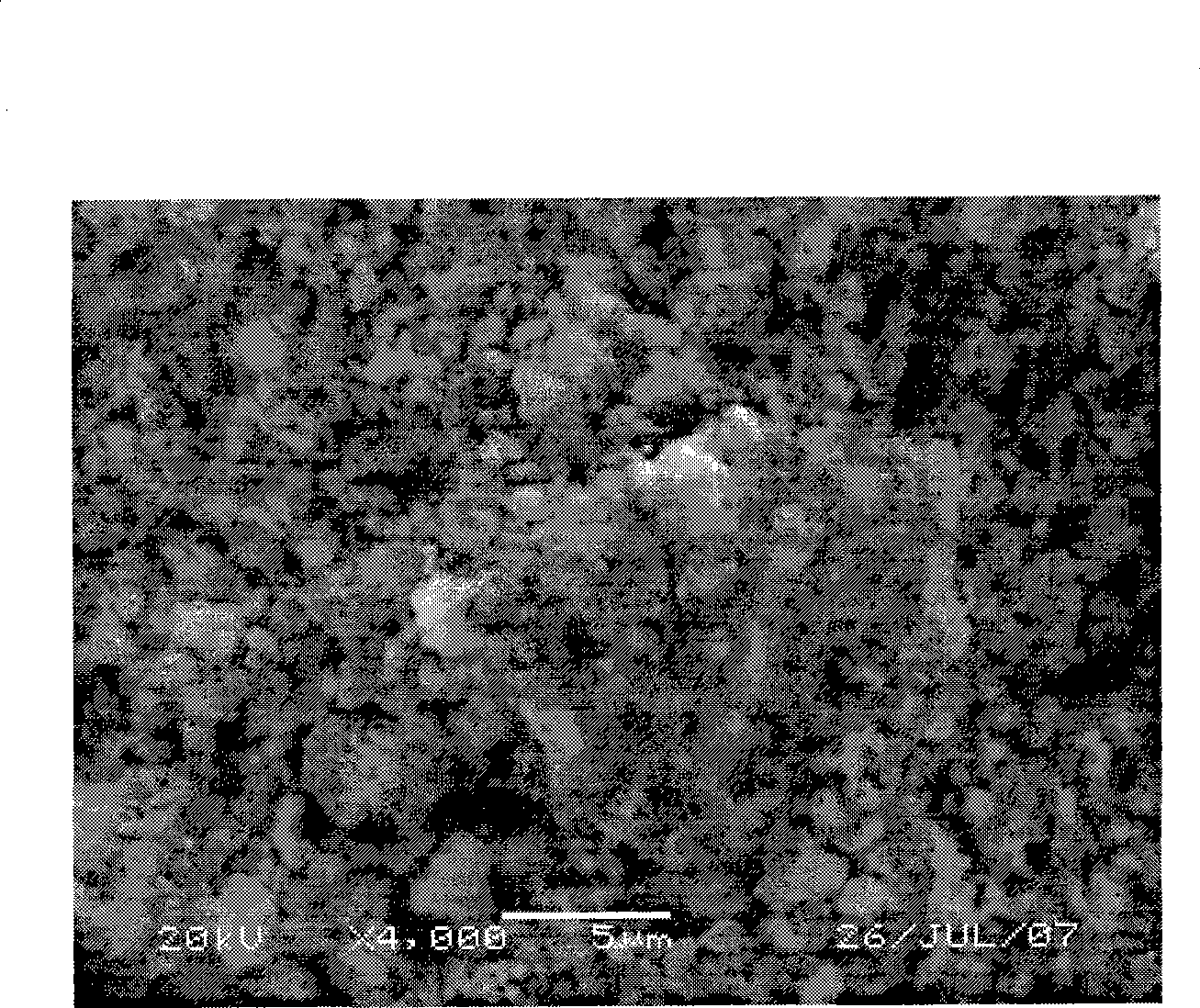

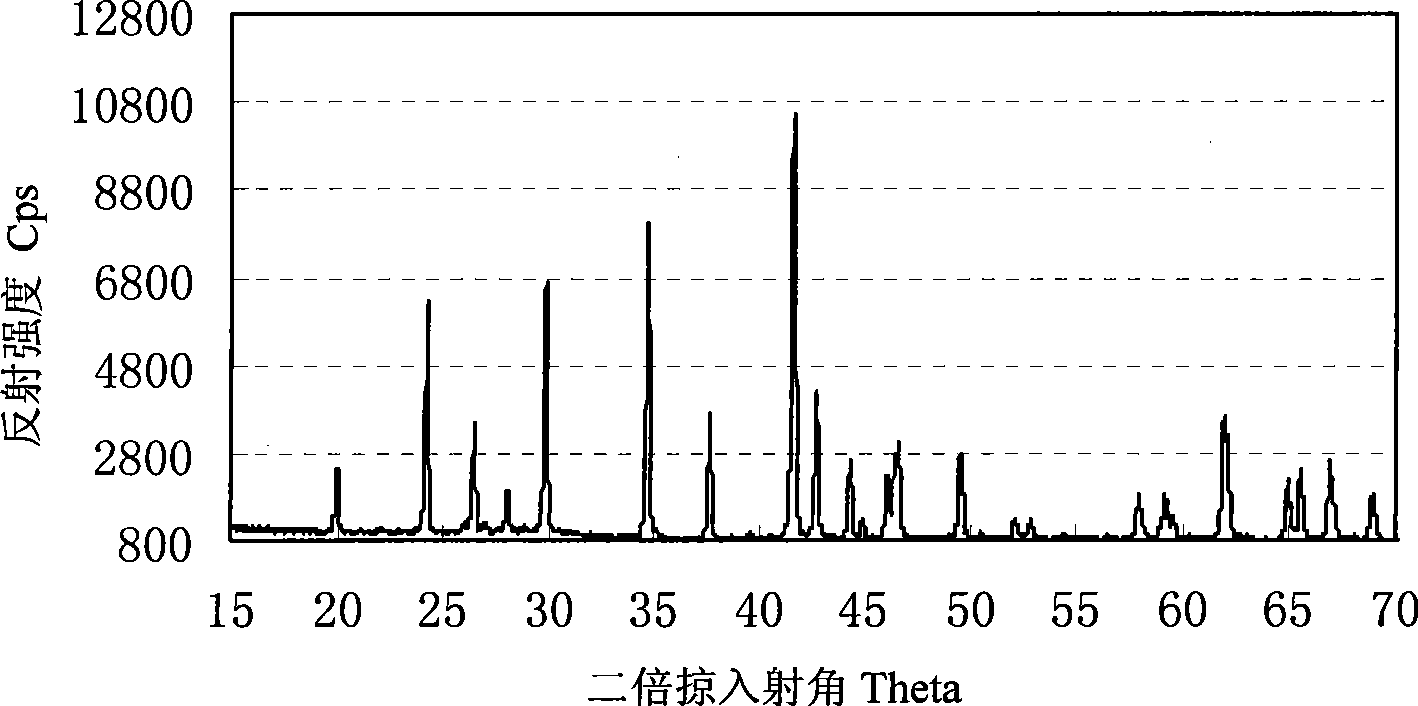

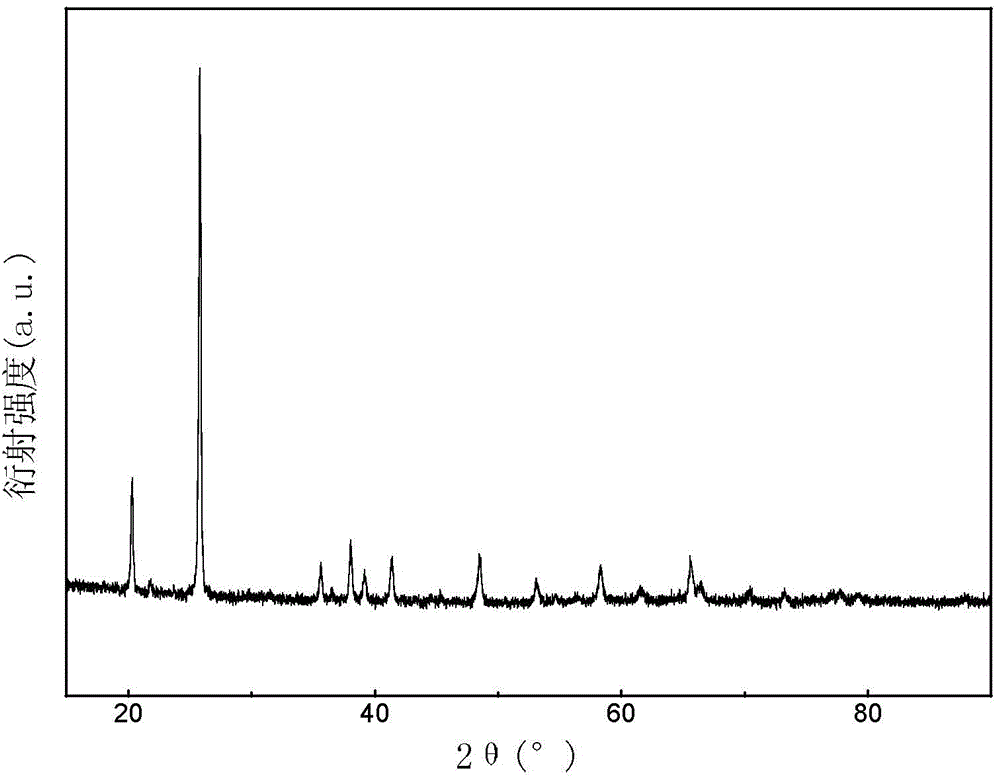

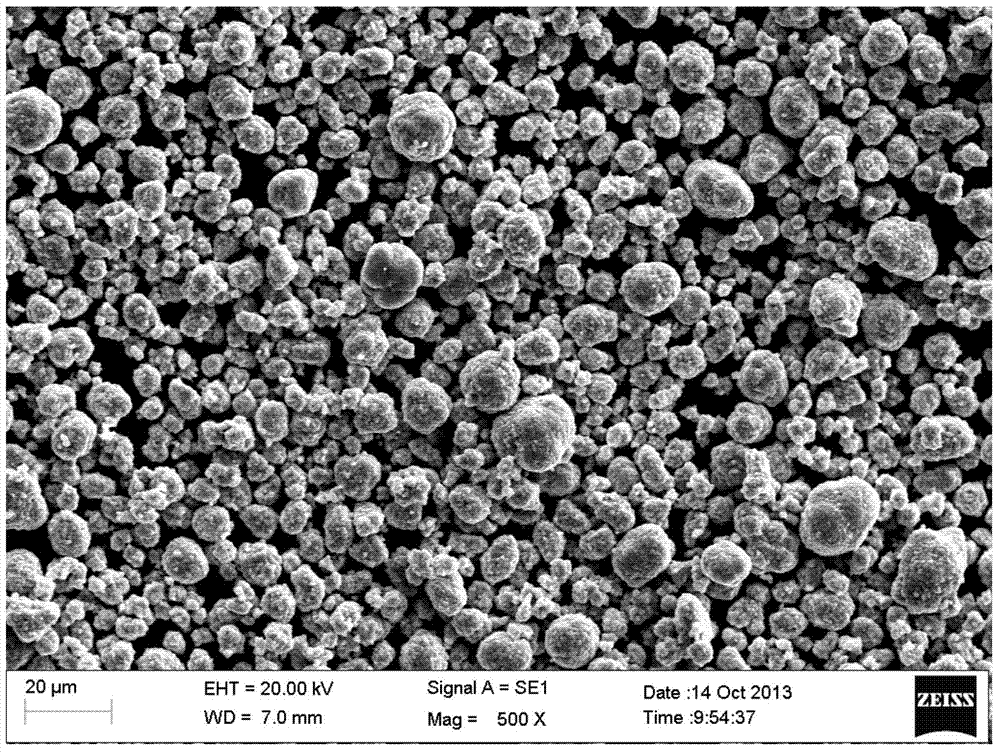

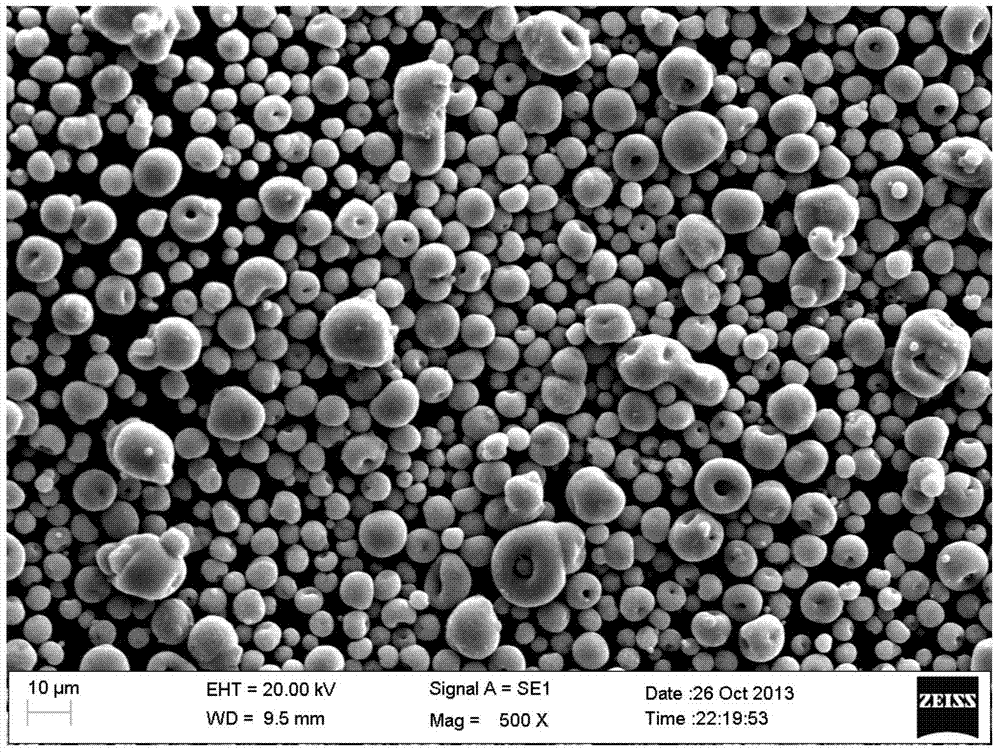

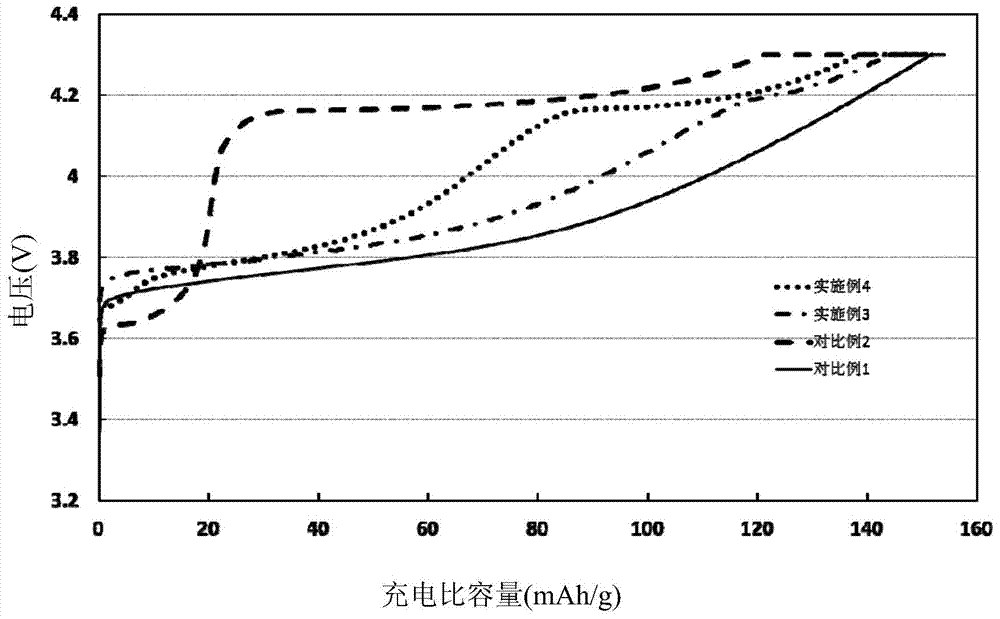

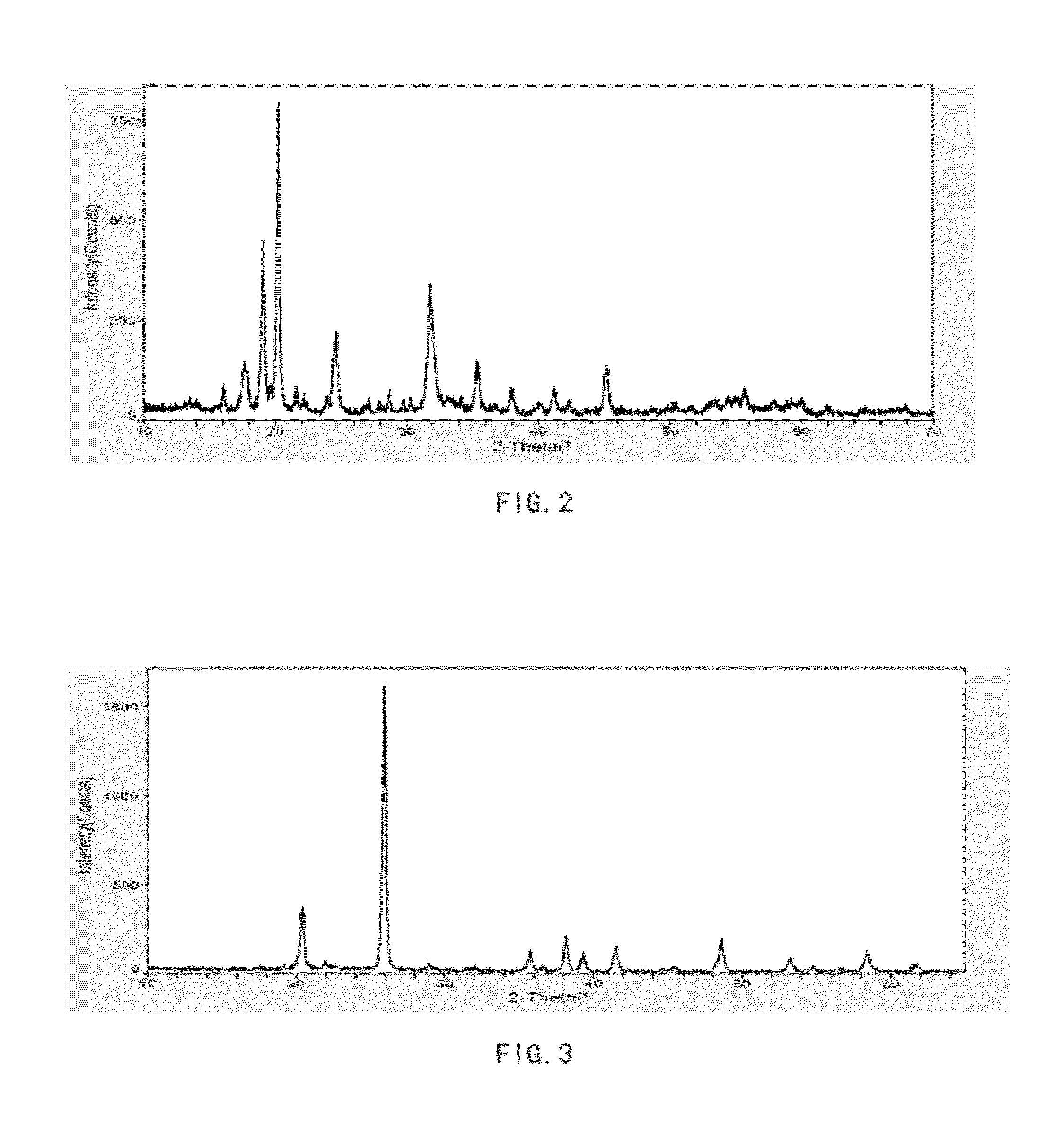

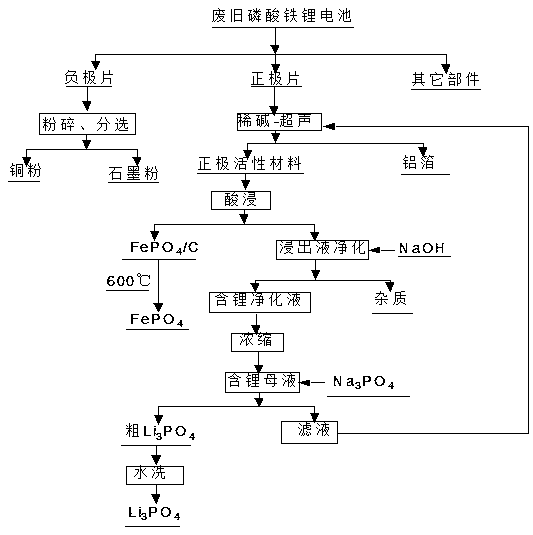

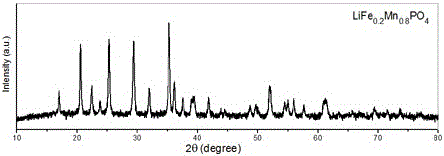

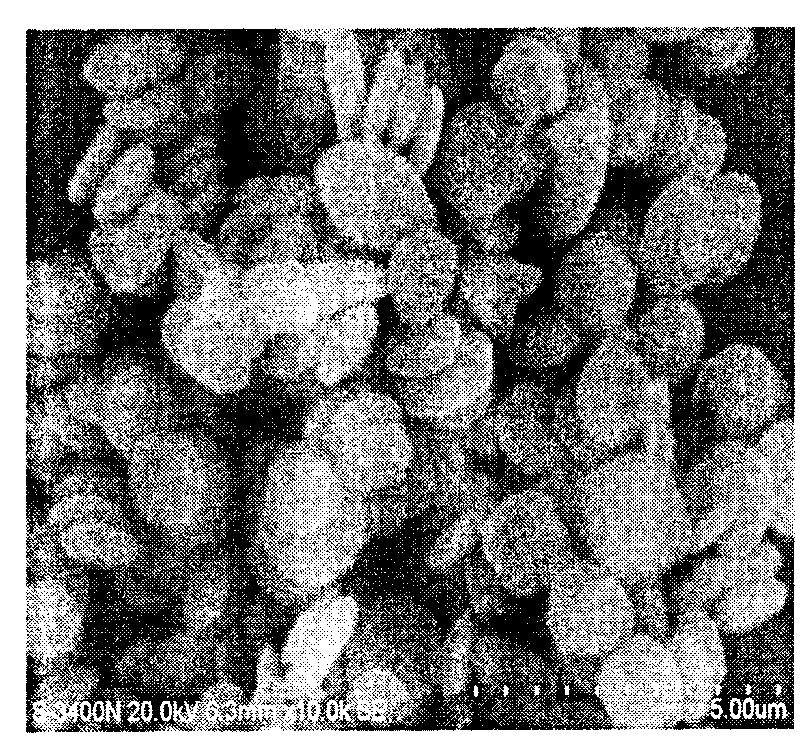

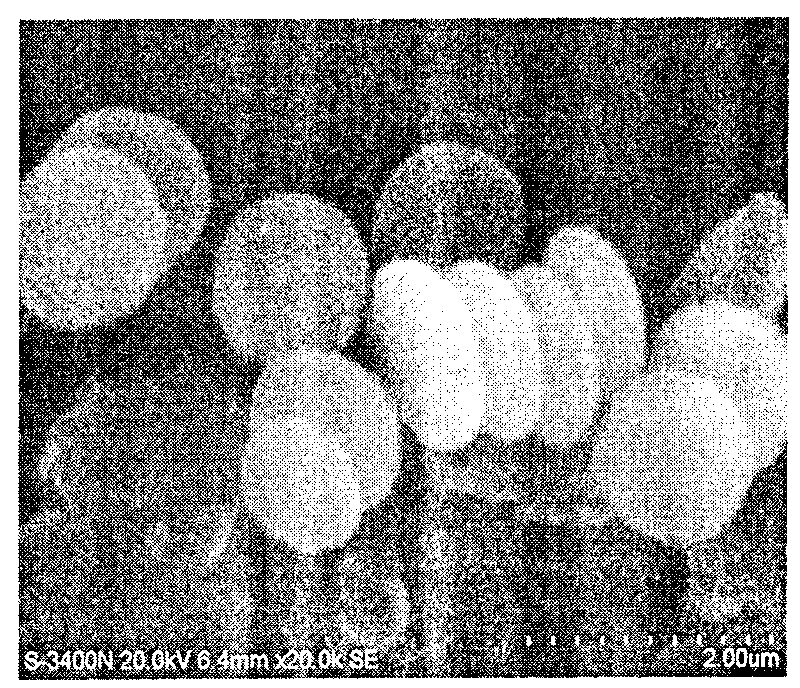

Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material

InactiveCN102013475AEasy to processImprove performanceCell electrodesNanotechnologyLithium iron phosphatePhosphor

The invention discloses a method for preparing a porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y] / 3) / C material, comprising the specific steps of: dissolving a lithium-containing compound, an iron-containing compound, a phosphor-containing compound and a element-doped compound additive in a dispersing agent to form a sizing agent; dispersing a mixture of a pore-forming agent, a cladding agent and a stabilizer in a dispersing agent through ultrasound, then adding into the sizing agent and mixing to form a new sizing agent; carrying out a physical method or a chemical method on the new sizing agent to obtain a sizing agent with the primary particles in nano grade; carrying out spraying drying and granulating on the obtained sizing agent with the primary particles in nano scale to obtain a dry mixed material with secondary particles with spherical appearances; then carrying out a sintering process on the dry mixed material to obtain the product of the invention. The method has the advantages that besides that the primary particles reach the nano scale, the particle diameters are more uniform in distribution and more regular in appearance, an iron phosphate product synthesized from the material has the particle diameters with uniform distribution, and the material has favorable processability, good electric conductivity, excellent power multiplication performance and higher actual capacity.

Owner:秦波

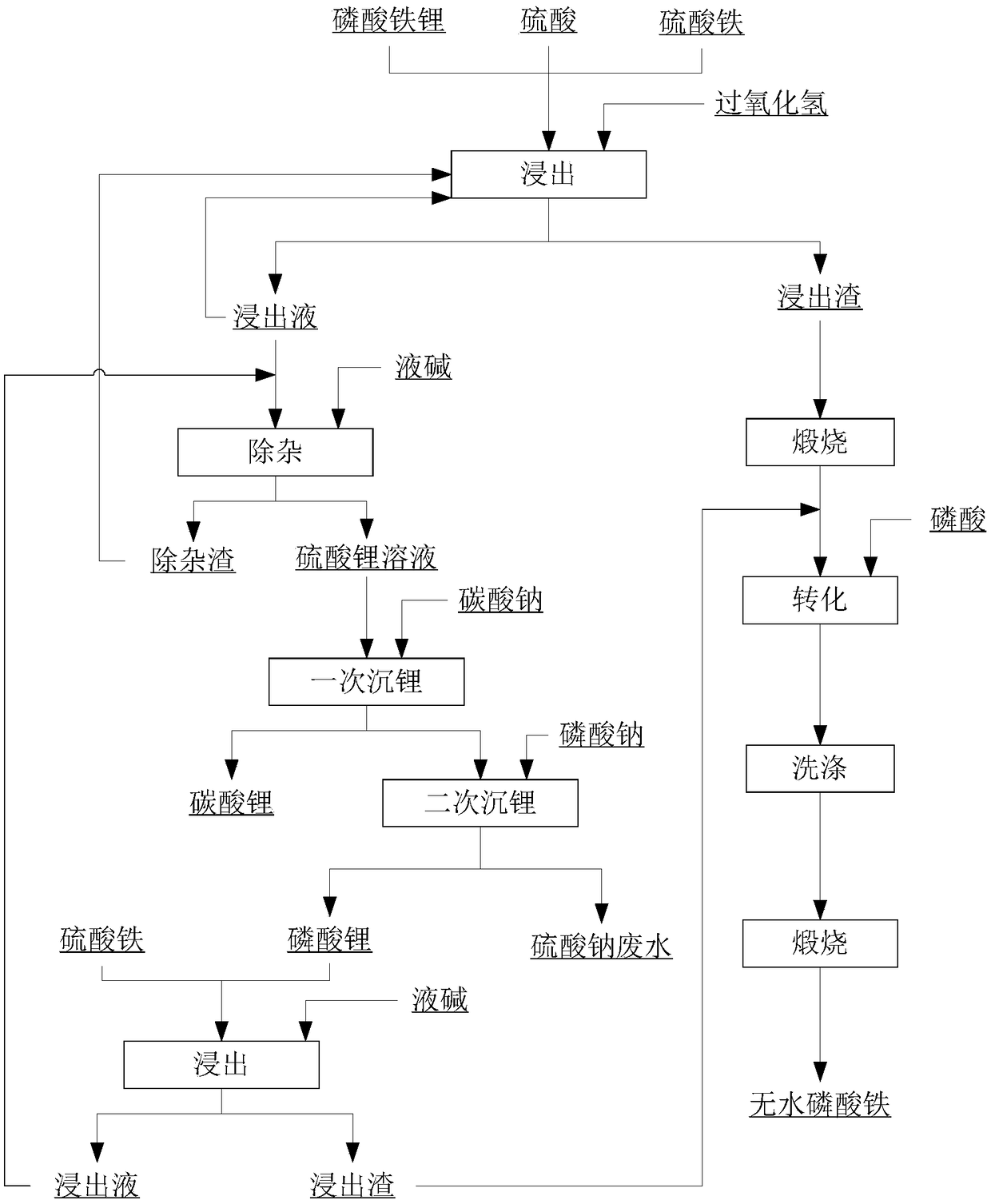

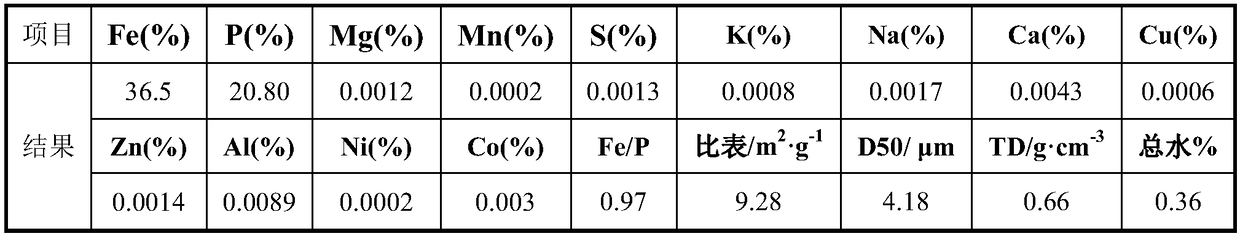

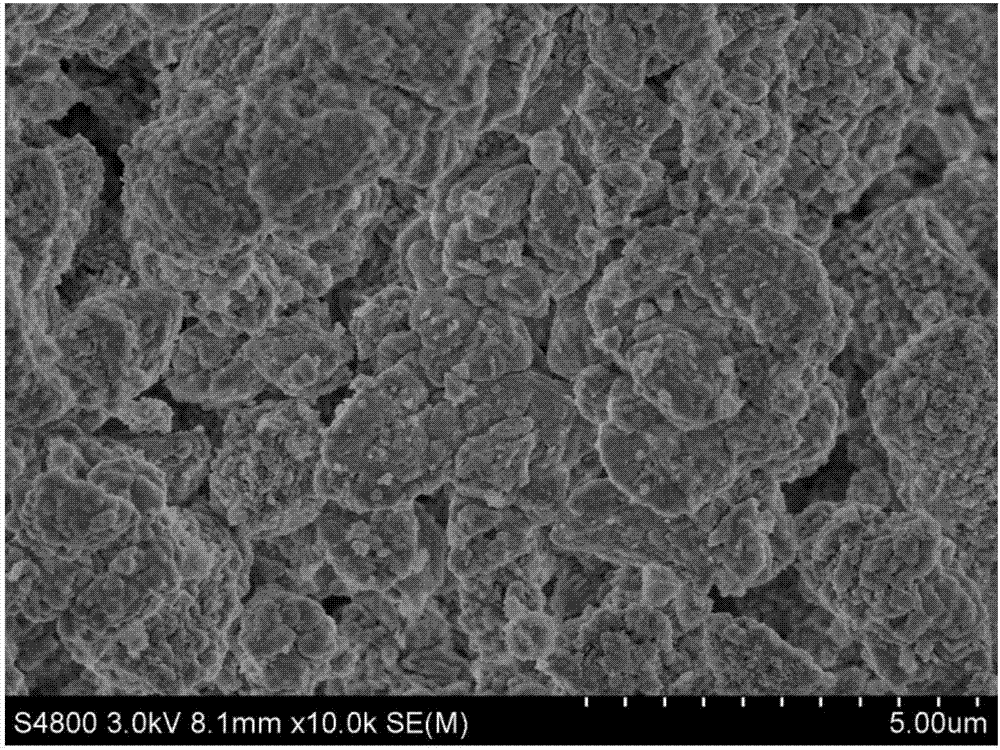

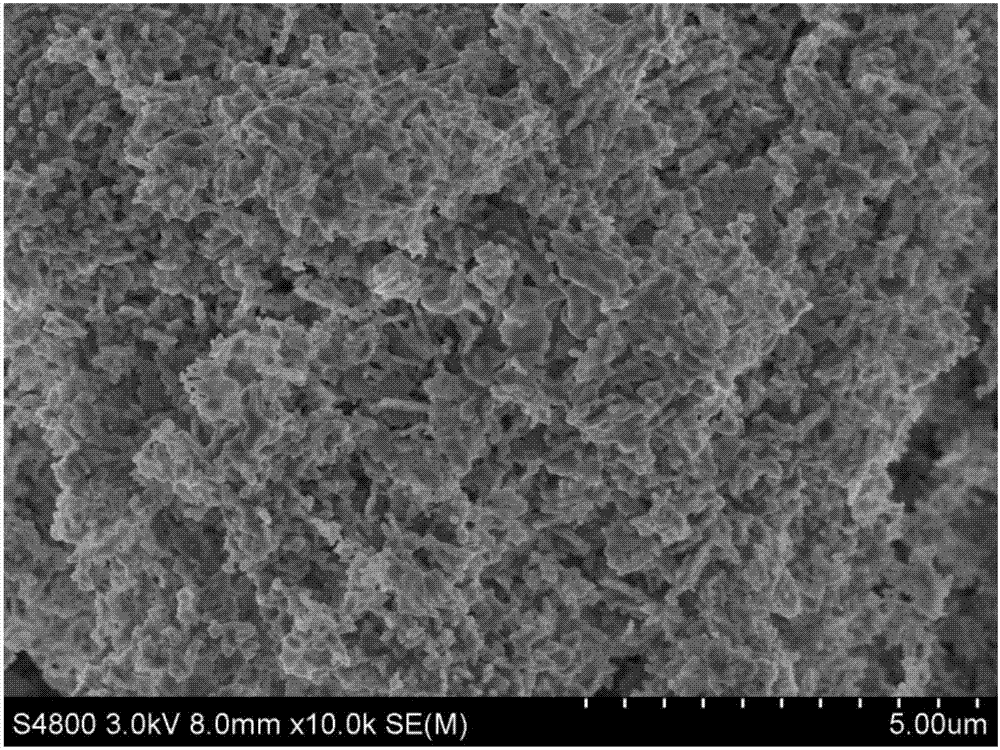

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

High-compaction-density lithium iron phosphate and preparation method thereof

InactiveCN107256968AIncrease compaction densityHigh specific capacityCell electrodesLithium iron phosphatePhosphoric acid

The invention discloses high-compaction-density lithium iron phosphate and a preparation method thereof. The preparation method includes that an iron phosphate material mixed with large particles and small particles is mixed with a lithium source, a lithium iron phosphate precursor with iron phosphate as a skeleton is obtained by further grinding, and the high-compaction-density lithium iron phosphate can be obtained through calcination. The maximum available compaction density of a pole piece produced from the obtained lithium iron phosphate is between 2.3g / cm<3> and 2.45g / cm<3>; a battery prepared by taking the high-compaction-density lithium iron phosphate as a cathode active material is high in specific capacity and good in cycle performance, 1C discharge is above 140mAh / g, and the cycle of the average value of cycling to less than 80% of the capacity of the first three cycles is above 3895; in addition, the preparation method is simple in process and high in operability, requirements of current industry fields on the compaction density of the cathode material can be met, and good cost advantage can be provided.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

Process for producing homodisperse spherical iron lithium phosphate

InactiveCN101508431ALow costSimple process controlCell electrodesPhosphorus compoundsLithium iron phosphateRoom temperature

The invention relates to a method for preparing uniformly dispersed spherical lithium iron phosphate-an anode material for a lithium ion battery, and belongs to the field of green energy materials. The method comprises the following steps: firstly, preparing a spherical iron phosphate precursor through liquid-phase homogeneous precipitation; secondly, performing predecomposition on the spherical iron phosphate precursor at a temperature of between 350 and 450 DEG C for 2 to 8 hours under the protection of inert gas; and thirdly, performing reaction at the temperature of between 550 and 800 DEG C for 2 to 24 hours to obtain the uniformly dispersed spherical lithium iron phosphate. The particle diameter of the product is between 100 and 200 nanometers, the tap density is between 1.6 and 2.0 g / cm, and the specific capacity of initial discharge at the room temperature reaches 140 to 160 mAh / g. The method utilizes a liquid-phase spheroidization process to prepare the uniformly dispersed spherical lithium iron phosphate, has simple process, and is easy to realize industrialized production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High capacity lithium iron phosphate power cell and production technique thereof

InactiveCN101183729AFinal product manufactureElectrode carriers/collectorsCooking & bakingCopper foil

The invention relates to a high-capacity iron phosphate lithium power battery, which is characterized in that the anode material uses the iron phosphate lithium; an anode current collector uses the aluminum foil; a conductive agent uses the superconducting carbon black and the conductive graphite; the anode material binder uses the polyvinylidene fluorine; the cathode material uses the natural graphite or the artificial graphite; the cathode current collector uses copper foil; the conductive agent uses the superconducting carbon black and the conductive graphite; and the cathode material binder uses the polyvinylidene fluorine or the sodium carboxymethylcellulose and the styrene butadiene rubber. The invention also discloses a processing technology of the high capacity iron phosphate lithium power battery, comprising the following step: matching ingredients, coating, baking, rolling, processing slice, baking, staking, assembling upper cover , baking, liquid injection, formation and partial volume. The invention adopts a stacking type, and has simple processing technology, compact battery structure and stable performance; thus, the battery capacity is greatly improved. The invention has an advantage of providing the lithium ion secondary battery of a driving energy source to the small and medium sized electric tools, such as the household electric appliance, the electric bicycle, the electric motorcycle and the electric automobile.

Owner:山东海霸电池有限公司

Method for making ferrous lithium phosphate/carbon compound material of high active disorderly ferric phosphate

InactiveCN101237043AHigh activitySmall particle sizeElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

The present invention belongs to energy material, and in particular relates to a method of using high-activity disordered iron phosphate to prepare ferrous phosphate lithium / carbon composite material. A ferrous iron source is mixed with phosphorus source solution according to stoichiometric ratio, has hydrogen peroxide added in, has pH value controlled and is stirred so as to prepare high-activity disordered iron phosphate. iron phosphate, a lithium source and a carbon source are mixed pro rata, ball-milled uniformly, spray-dried and treated via high temperature under protective atmosphere, so as to obtain high specific capacity ferrous phosphate lithium / carbon composite material of which the average particle diameter is 200-500nm, 0.25C rate specific discharge capacity reaches 145-150mAh / g, 1C rate specific discharge capacity reaches 130-140mAh / g, and 5C rate specific discharge capacity reaches 105-110mAh / g. The method is low in cost and simple in process. Prepared material is good in electrochemical performance and especially excellent in rate performance, which is applicable to battery anode material of electric vehicles and other large-scale mobile devices.

Owner:NORTHEAST NORMAL UNIVERSITY

Method for preparing hollow polyaniline microspheres

InactiveCN102153747AAvoid conversionLow costMicroballoon preparationMicrocapsule preparationMicrosphereAniline

The embodiment of the invention discloses a method for preparing hollow polyaniline microspheres, comprising the following steps: mixing aniline and an oxidant at the molar ratio of 1:(1.5-15) in a solvent for reaction, wherein the aniline can be potassium ferricyanide, sodium ferricyanide, iron phosphate or copper sulfate; and drying the products of reaction to obtain the hollow polyaniline microspheres. In the process of preparing the hollow polyaniline microspheres, spherical micelles are formed by the aniline in the solvent, and the cores of the spherical micelles are filled with aniline droplets. Because the oxidant adopted by the method has low oxidation-reduction potential, the oxidant can not generate acidic materials in the aniline polymerization process, the spherical micelle structure can be prevented from being changed to be in linear or sheet shape, and the hollow polyaniline microspheres can be finally obtained. The method does not require a dopant, is simple, ensures lower cost and can be used for preparing the hollow polyaniline microspheres.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

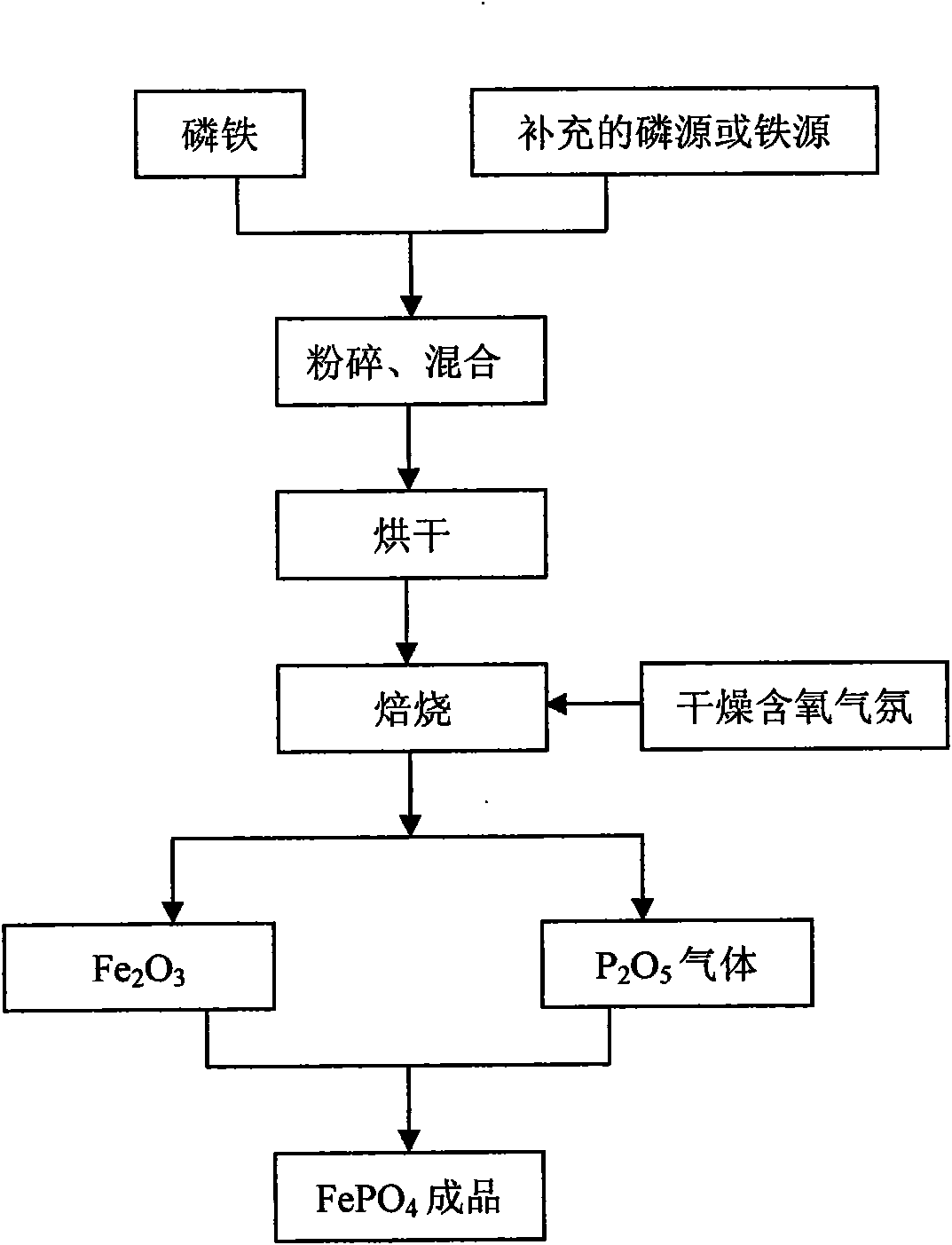

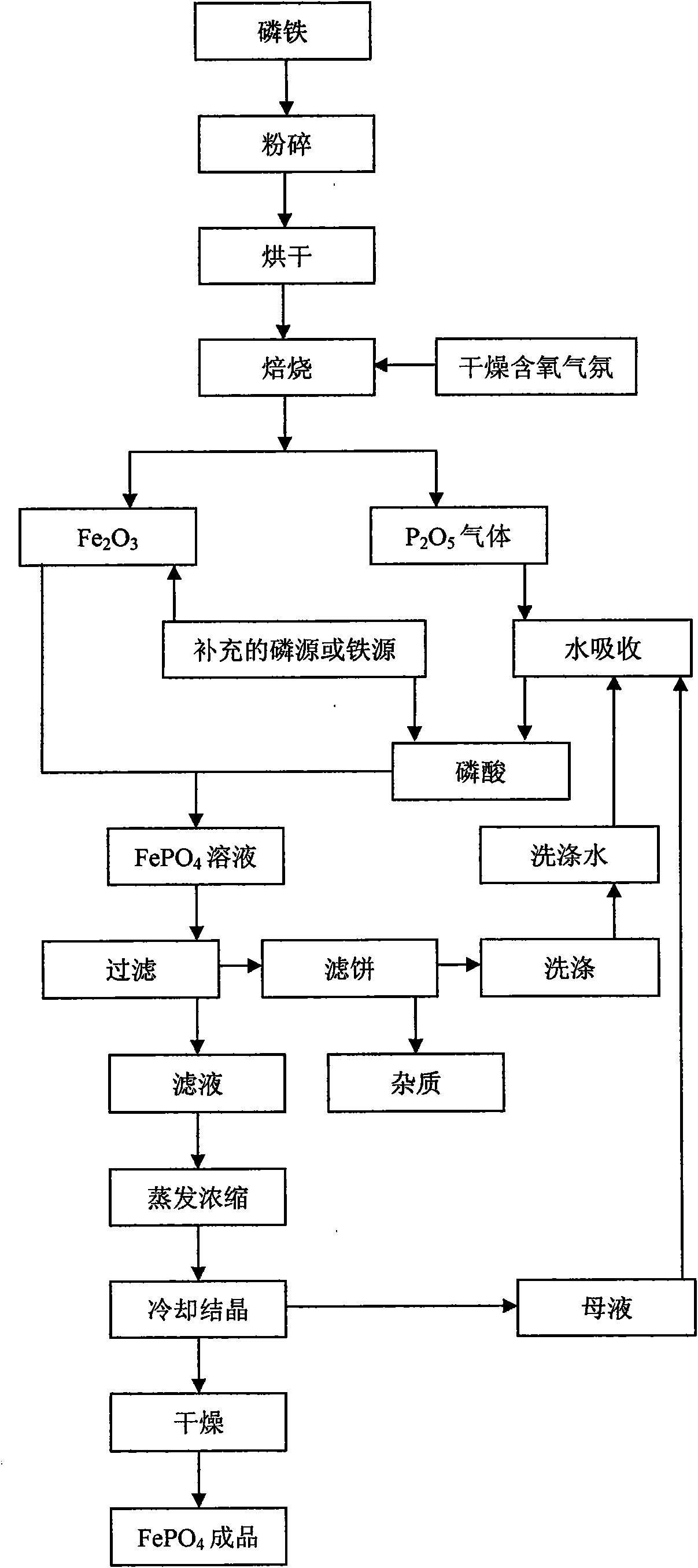

Method for preparing iron phosphate from ferrophosphorus

InactiveCN101659406AOvercome the problem of difficult ratioWide variety of sourcesPhosphorus compoundsLow demandResource utilization

The invention relates to a method for preparing iron phosphate from ferrophosphorus. The ferrophosphorus is used as a part or the whole of a phosphorus source and an iron source for preparing the ironphosphate. The phosphorus source or the iron source is supplemented according to a mol ratio of (0.8-1.2):1.0 between total phosphorus elements and total iron elements. The ferrophosphorus is roastedin a dry and oxygen-containing atmosphere. The iron phosphate product is obtained by means of dry or wet oxidation product reaction. The method adopts the ferrophosphorus as the raw material for preparing the iron phosphate, makes full use of elements in the ferrophosphorus and creates a novel preparing process of iron phosphate. In addition, as the reaction process can be used for weakening or eliminating the influence of impurity elements in the ferrophosphorus on the iron phosphate product, the method indirectly purifies the ferrophosphorus and eliminates the influence of the impurities inthe ferrophosphorus and the problem of severe corrosion caused by the existence of water during the roasting of ferrophosphorus. The reaction process has relatively low demand on apparatuses. The preparing method has simple process, short production flow and low production cost, is clean and environment-friendly, realizes high resource utilization rate, low investment and good benefit and is suitable for large-scale, industrial, low-cost and clean preparation of iron phosphate.

Owner:SICHUAN UNIV

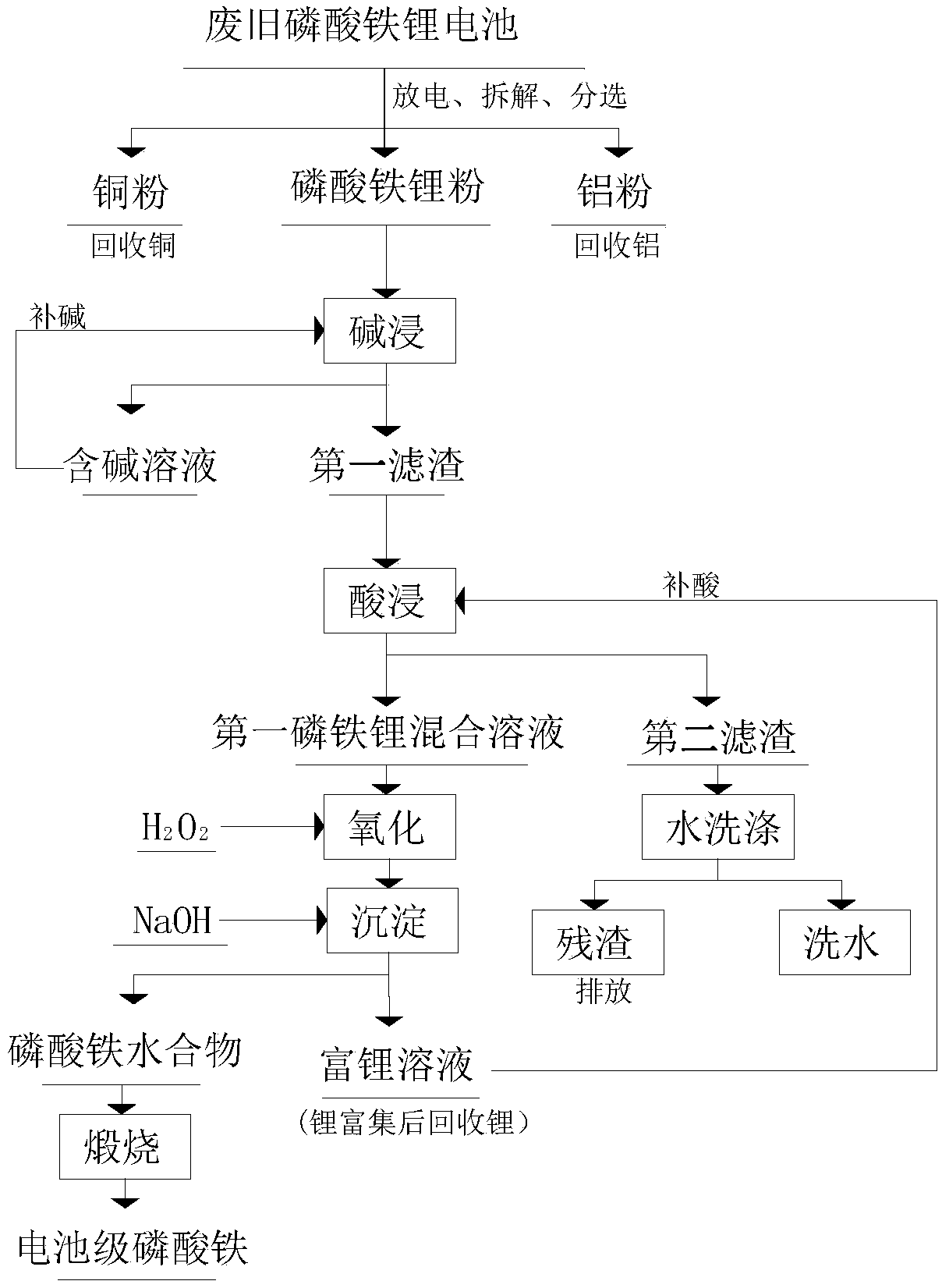

Method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries

ActiveCN109179358AEfficient removalHigh purityPhosphorus compoundsLithium iron phosphatePhosphoric acid

The invention discloses a method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries and relates to the technical field of battery recovery. The method can prepare anhydrous battery grade iron phosphate by battery disassembly and separation, alkali leaching, acid leaching, oxidation, precipitation and calcination. Through alkali leaching and then acid leaching and precipitation, impurities such as aluminum in lithium iron phosphate can be removed and the purity of iron phosphate can be improved. The alkali leaching solution and the lithium-rich solution can be reused so that a recovery cost is reduced. After repeated acid supply, the lithium-rich solution immerses novel filter wastes so that the concentration of lithium in the solution and the recovery rate of lithium can be increased and the recovery cost of lithium can be reduced. pH at the precipitation end point is low in a range of 1.0-2.5 so that the formation trend of iron hydroxide isreduced. The aging process after the precipitation reaction can improve the purity of iron phosphate and the produced iron phosphate meets the industry standards. The whole process is carried out at alow temperature so that the corrosion of the solution to the equipment is delayed and the energy consumption and recycling cost are reduced.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000011.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000012.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000013.PNG)