Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

A beneficiation method and mineral technology, which is applied in the field of combined beneficiation method and system for comprehensive recovery of associated iron and phosphorus minerals, can solve problems such as inability to throw out gangue minerals, large heating boiler volume, and large investment in heating systems. Achieve the effect of reducing the grinding operation cost, occupying a small area, and investing in a small site and infrastructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

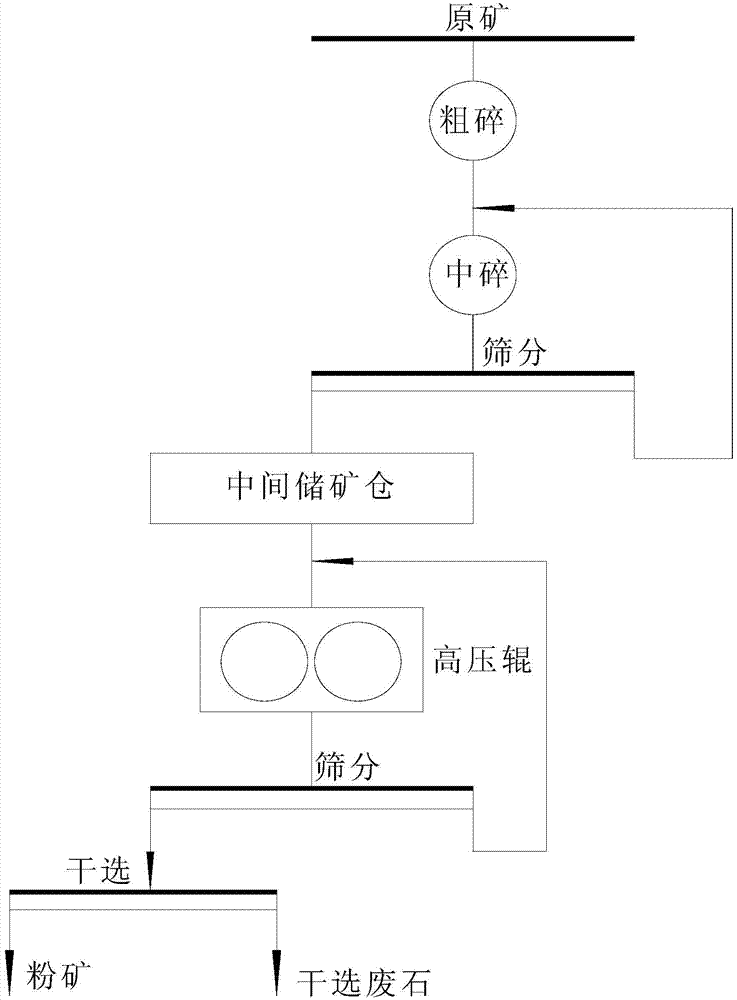

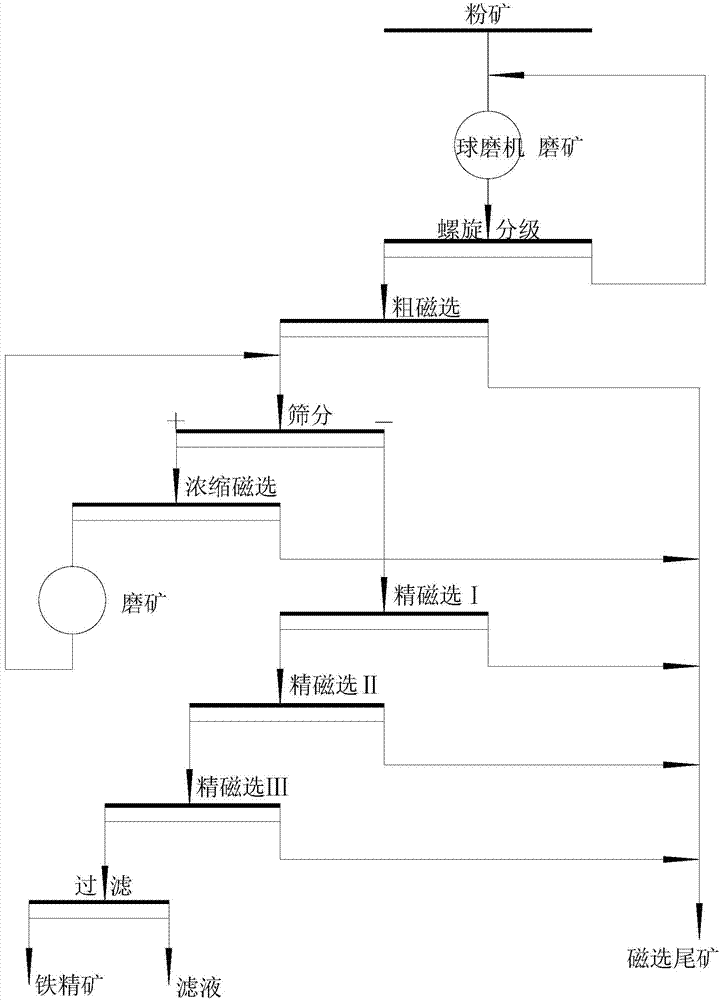

[0089] Step 1, the raw ore goes through three stages, two closed circuits, crushing, and screening processes, and the fine ore is dry-selected;

[0090] The ore mined in the stope is transported by car to the receiving bin of the PXZ-1200 / 160 gyratory crusher, and then coarsely crushed by the PXZ-1200 / 160 gyratory crusher; the coarsely crushed ore is transported to the intermediate crushing buffer bin by the belt conveyor, Then it is conveyed to HP500 standard cone crusher by belt conveyor for intermediate crushing; the intermediate crushed product is conveyed by belt conveyor to the distribution bin before the stage of screening, and then sent to 2YAH2460 heavy-duty double-layer circular vibrating screen for stage of screening; the product on the stage of sieve It is transported to the intermediate crushing buffer bin by the belt conveyor, and forms a closed circuit with the intermediate crushing; the under-screen product is transferred through the No. 1 transfer station, tran...

experiment example 1

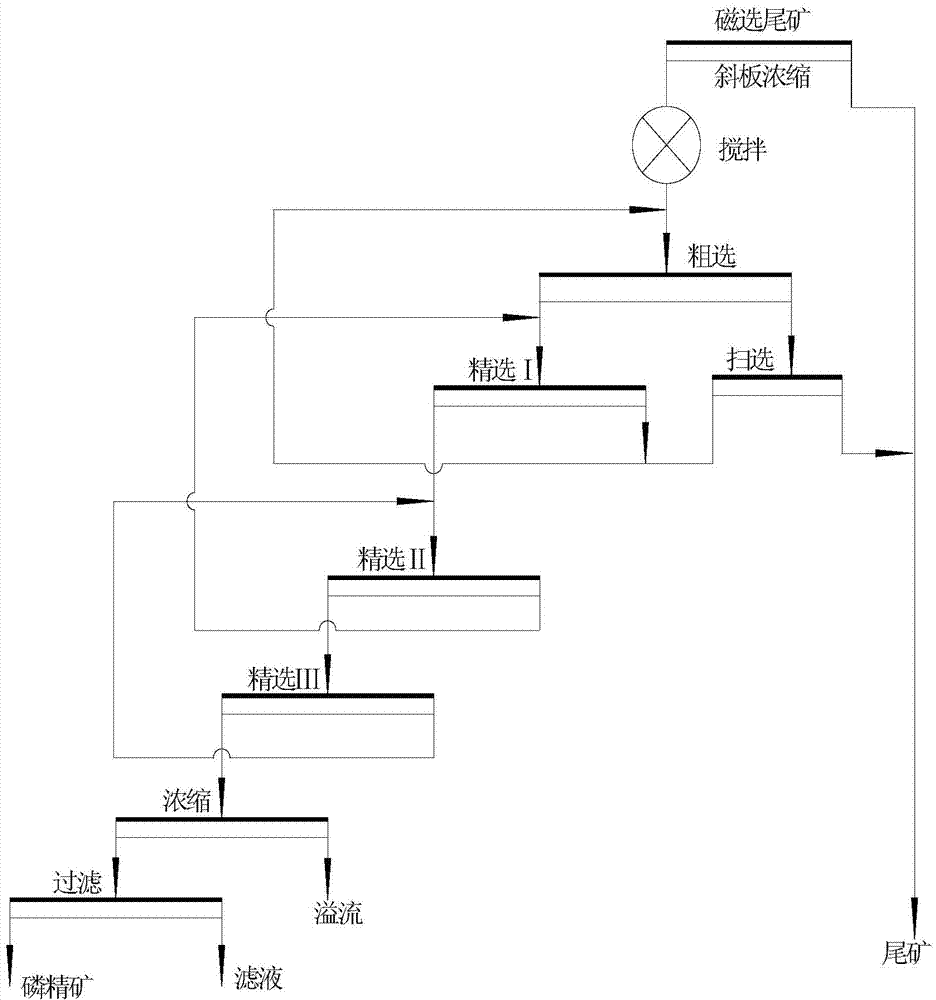

[0095] Experimental Example 1: Table 1 is the use of composite reagents composed of oxidized paraffin wax soap, fatty acid and MES as a collector, using the flotation method provided in Example 1 of the present invention at different temperatures of the flotation test results:

[0096]

[0097]

[0098] According to the test results, as the flotation temperature decreases, the concentrate yield and recovery rate gradually decrease, and the concentrate grade increases gradually with the decrease of temperature when the flotation temperature is higher than 11°C; when it is lower than 11°C, the concentrate grade begin descending. When the flotation temperature is 15°C, the grade of rough-selected phosphorus concentrate is 14.18%, and the recovery rate is 91.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com