Patents

Literature

116results about How to "Reduce crushing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

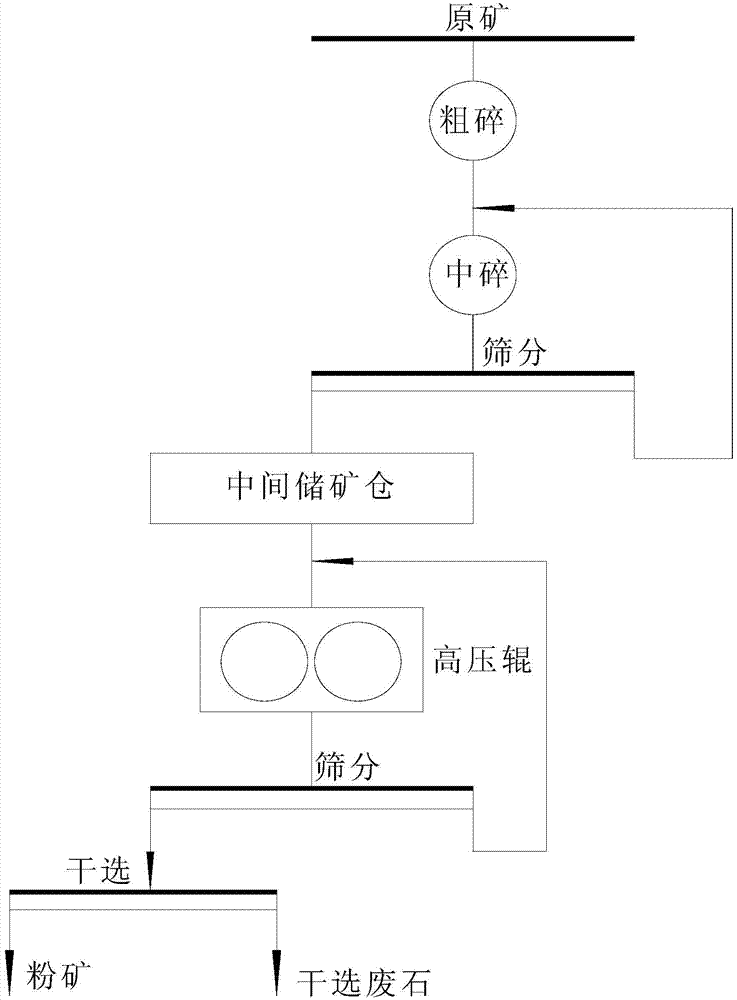

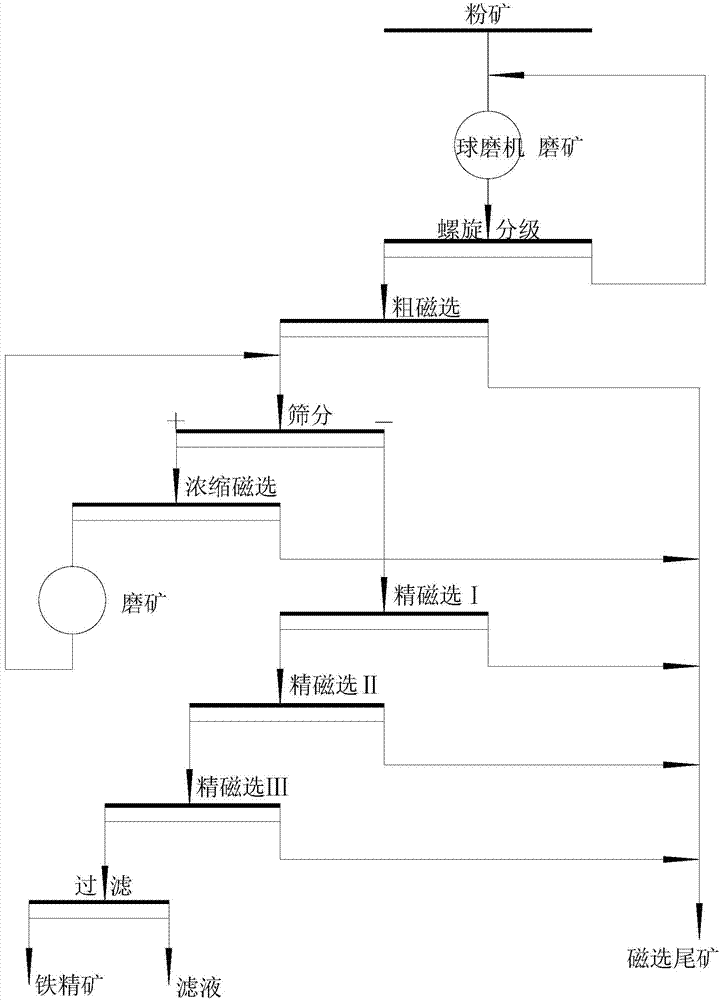

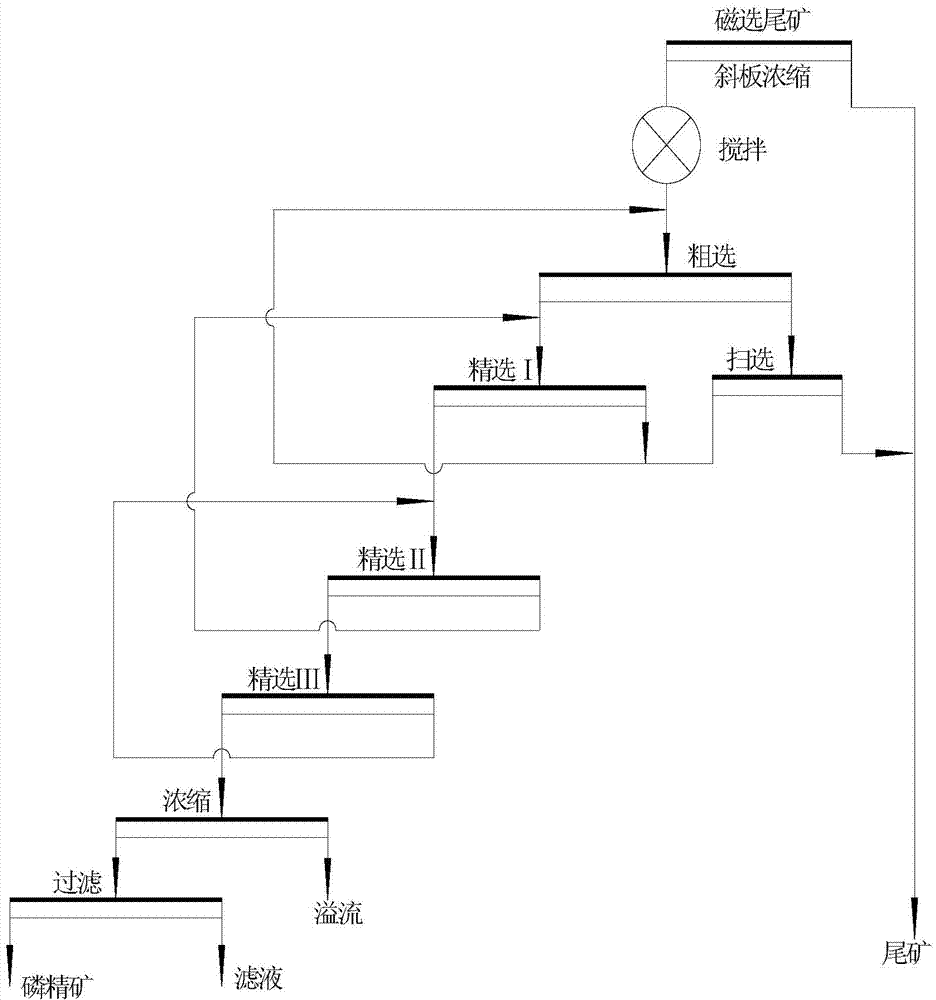

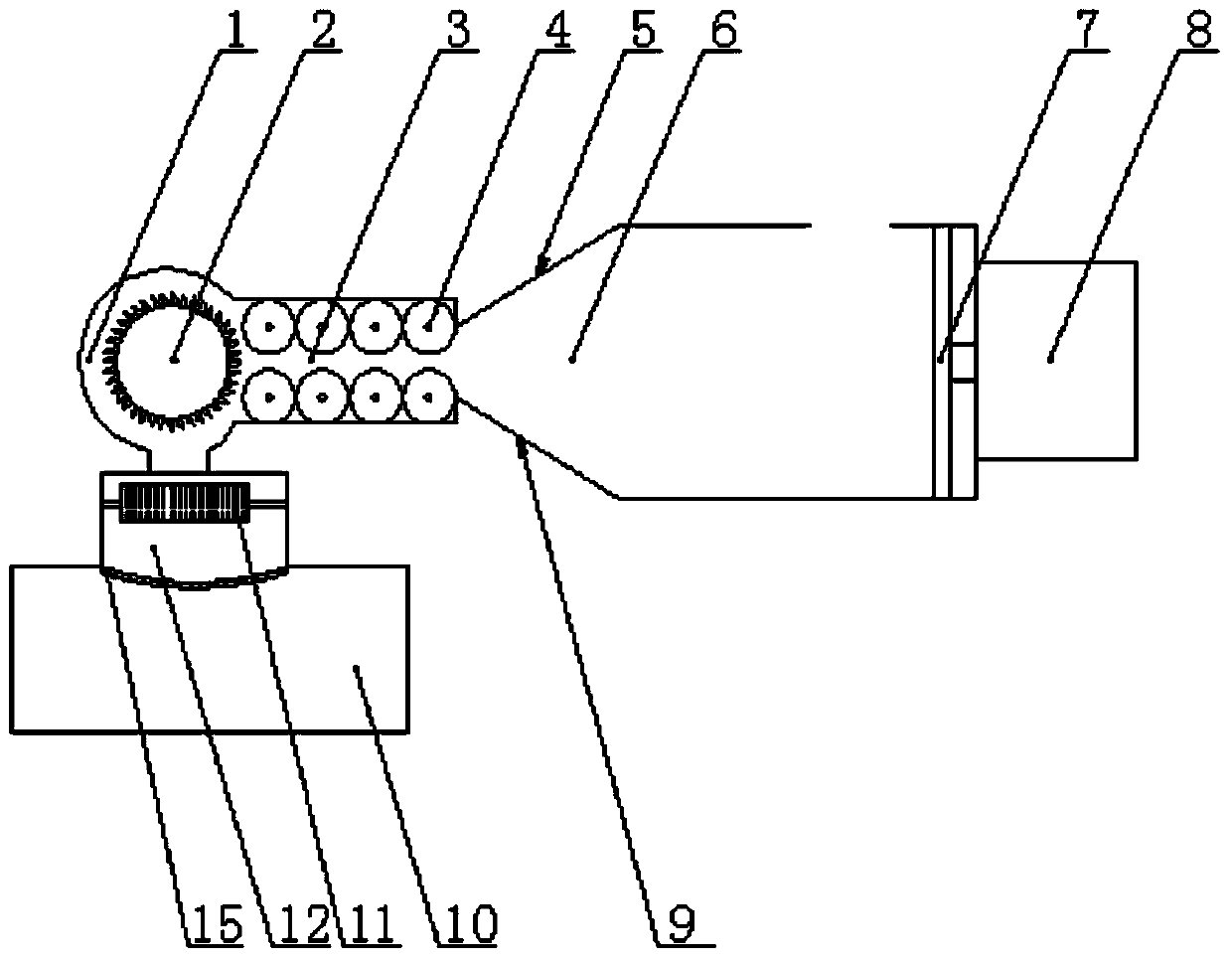

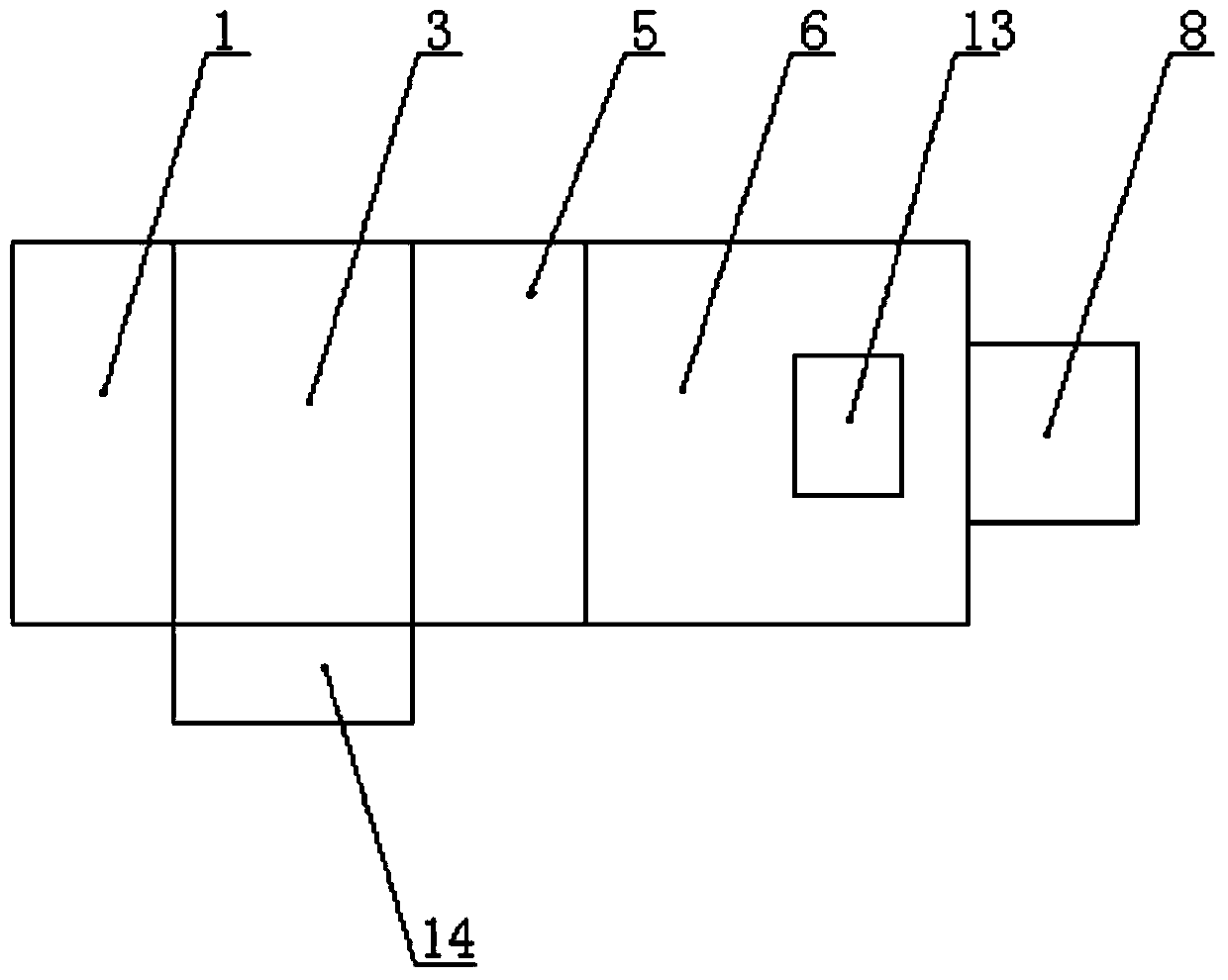

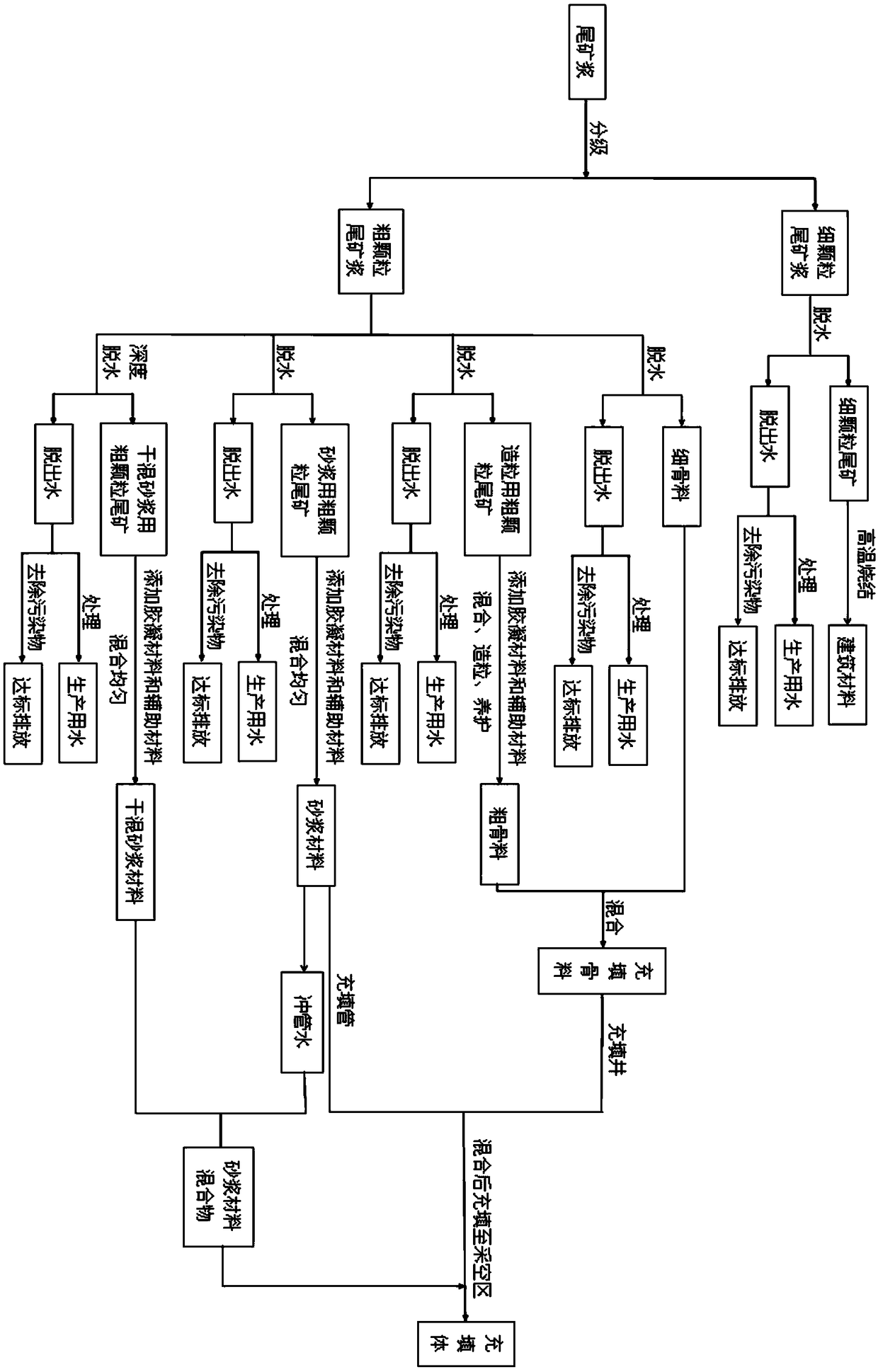

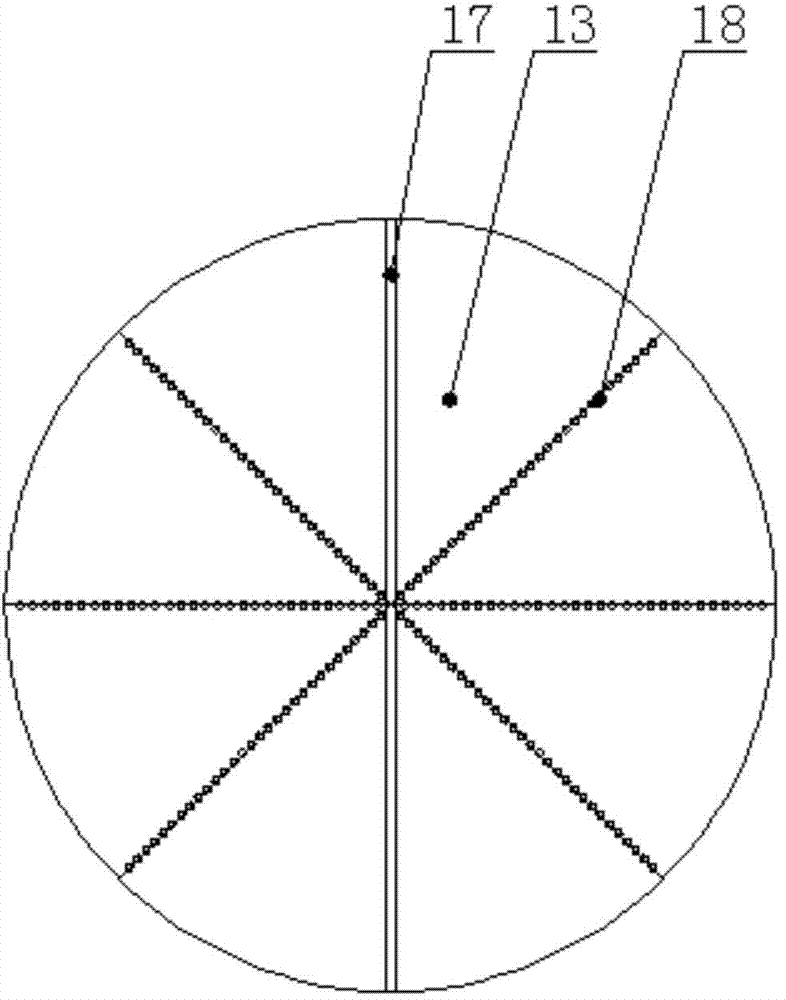

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

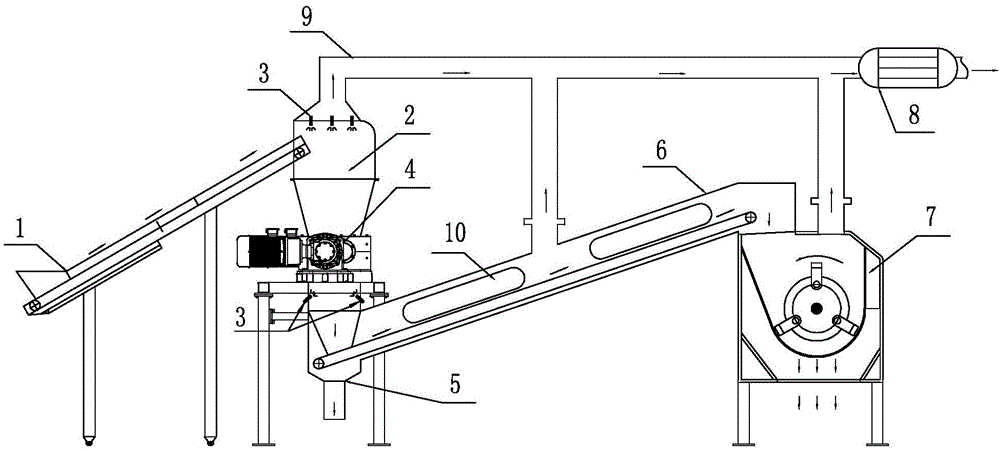

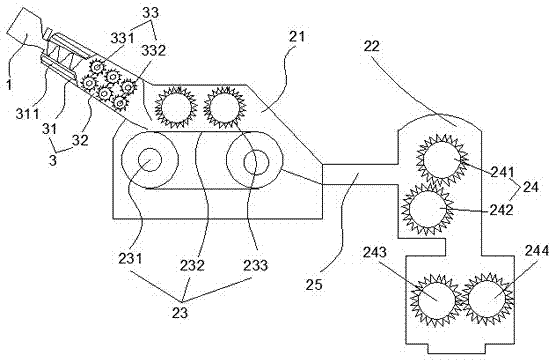

Charged crushing assembly device of scrapped lithium-ion power lithium battery

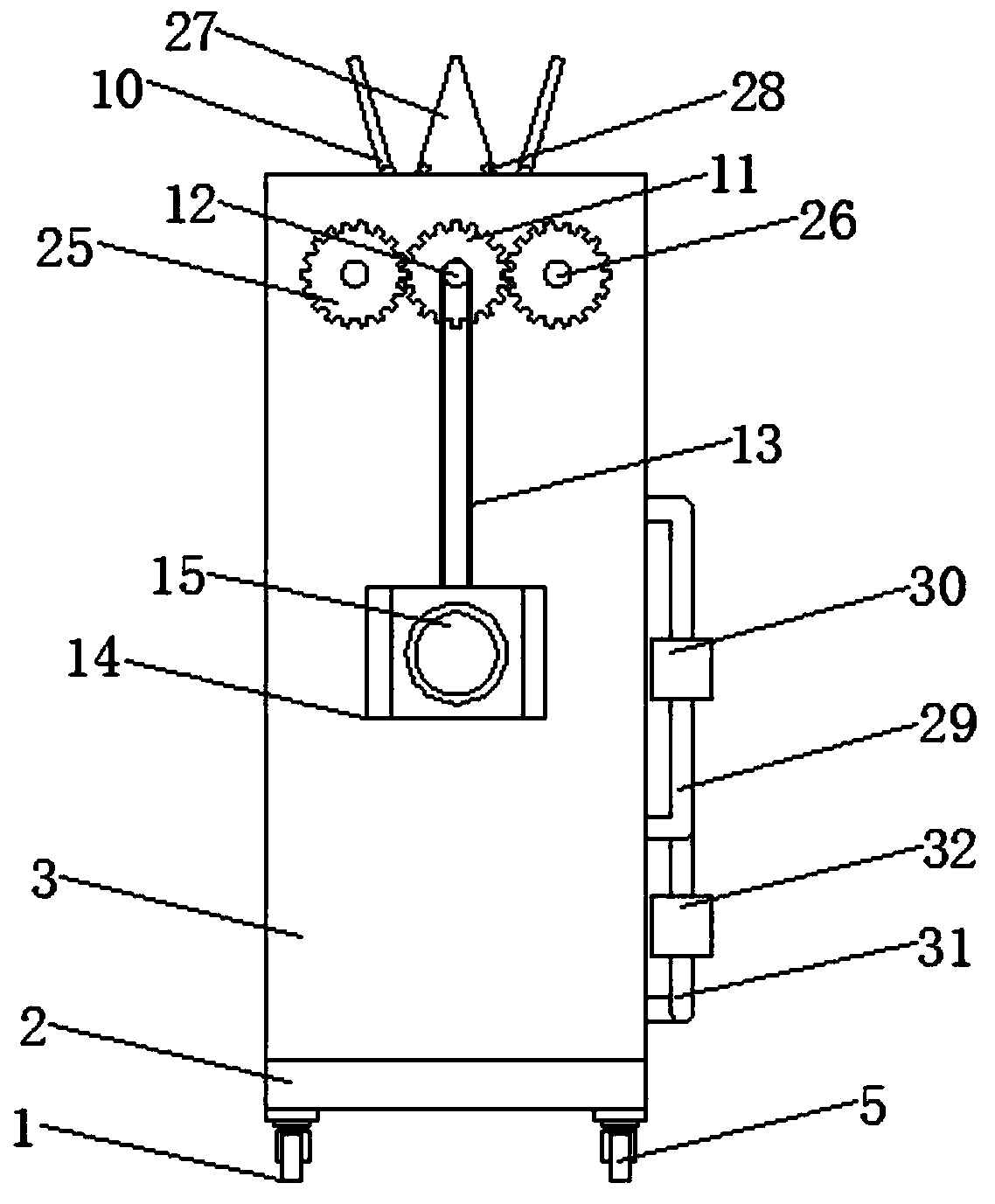

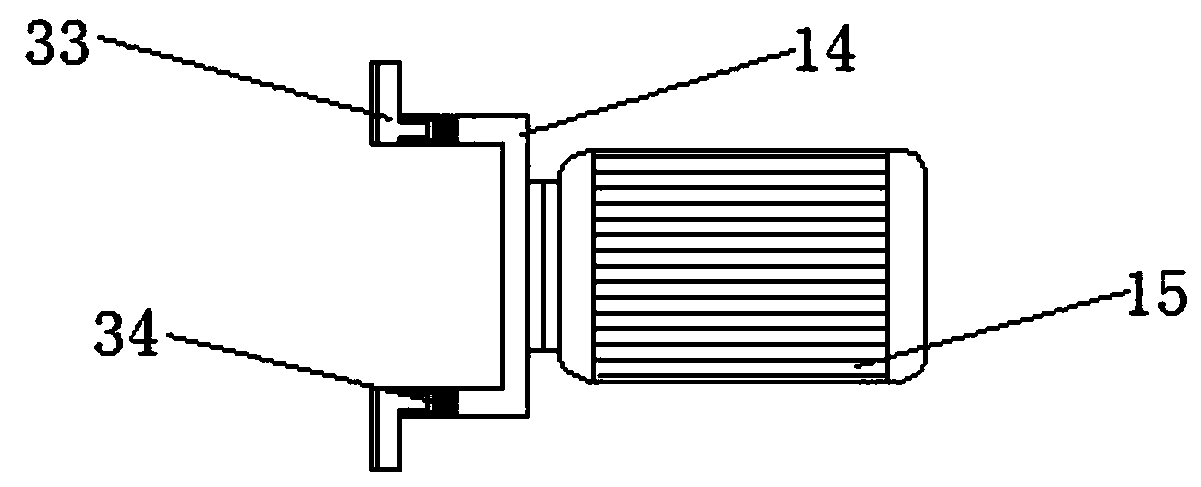

The invention discloses a charged crushing assembly device of a scrapped lithium-ion power lithium battery, and belongs to the field of waste battery crushing. The charged crushing assembly device solves the problems that an existing battery crushing technology easily generates combustion and easily generates explosion. A battery double-shaft shredding machine is arranged above a waste battery; a feeding hopper is arranged above the battery double-shaft shredding machine; a spray head is arranged inside shredding equipment to prevent combustion explosion; the upper end of an open type loader is arranged on the side wall of the feeding hopper; the lower end of a sealed type loader extends into a waste water tank; the upper end of the sealed type loader is connected with a feeding hole of a hammer type crusher; the upper end of the feeding hopper, the sealed type loader and a gas outlet of the hammer type crusher are connected with an inlet end of a suction ventilator through an air suction pipeline; and an outlet end of the suction ventilator is connected with a waste gas treater. The charged crushing assembly device adopts a direct charged crushing mode and does not need to discharge a battery, so that the period of crushing the battery is shortened, universal performances are strengthened, personnel operation is convenient, performances are reliable and the charged crushing assembly device is safer.

Owner:哈尔滨巴特瑞资源再生科技有限公司

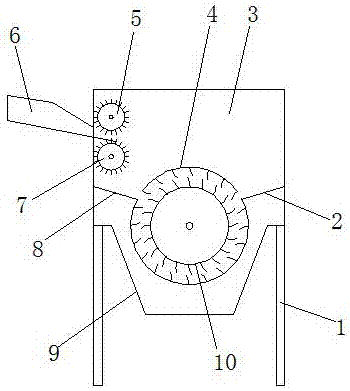

Paper shredder achieving cyclic utilization

InactiveCN109772541AReduce crushing costsImprove practicalityRotary stirring mixersGrain treatmentsCartonHand held

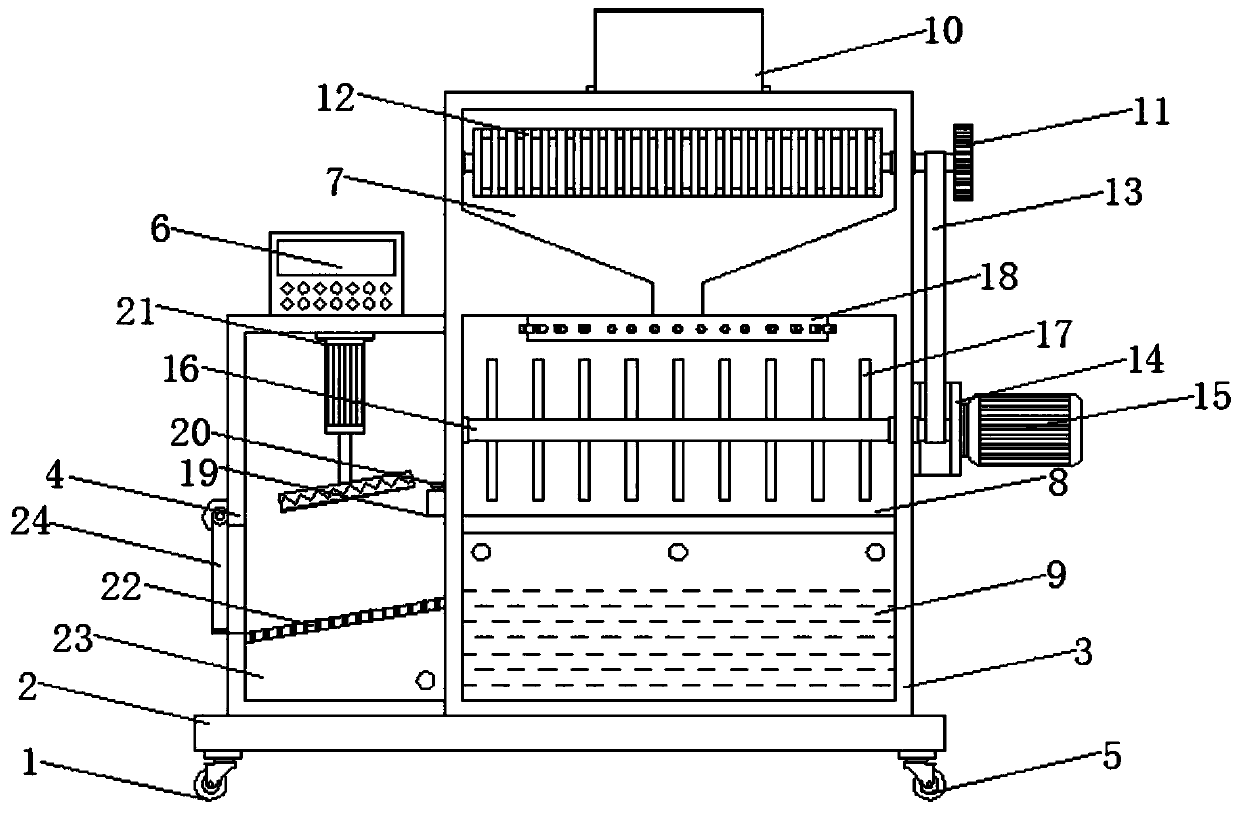

The invention discloses a paper shredder achieving cyclic utilization. A base is arranged at the bottom of a paper shredder body. A paper shredding box is mounted at the top of the base. A crushing chamber is arranged at the top end in the paper shredding box. A soaking chamber is arranged at the bottom of the crushing chamber. A water box is arranged at the bottom of the soaking chamber. An extrusion box is mounted on the left side of the paper shredding box. An extruder is mounted at the top end in the extrusion box. An electric push rod is arranged at the top end of the extruder. A press plate is mounted at the bottom end of the electric push rod. An electric heating wire is mounted in the press plate. A water collection trough is arranged at the bottom of a filter plate. Trundles are mounted at the bottom of the base. According to the paper shredder, baffles are hinged to the two sides of a check block, the baffles and the check block are used in cooperation, a certain guide function can be achieved on waste paper, and the situation that hands hold paper all the time is avoided; the work intensity is reduced, and meanwhile smoothness of paper discharging is also guaranteed; andthrough the baffles in hinged design, the inclination degree can be adjusted at any time according to needs, and containing and storage are also facilitated.

Owner:WENZHOU SHENGMIAO IND DESIGN CO LTD

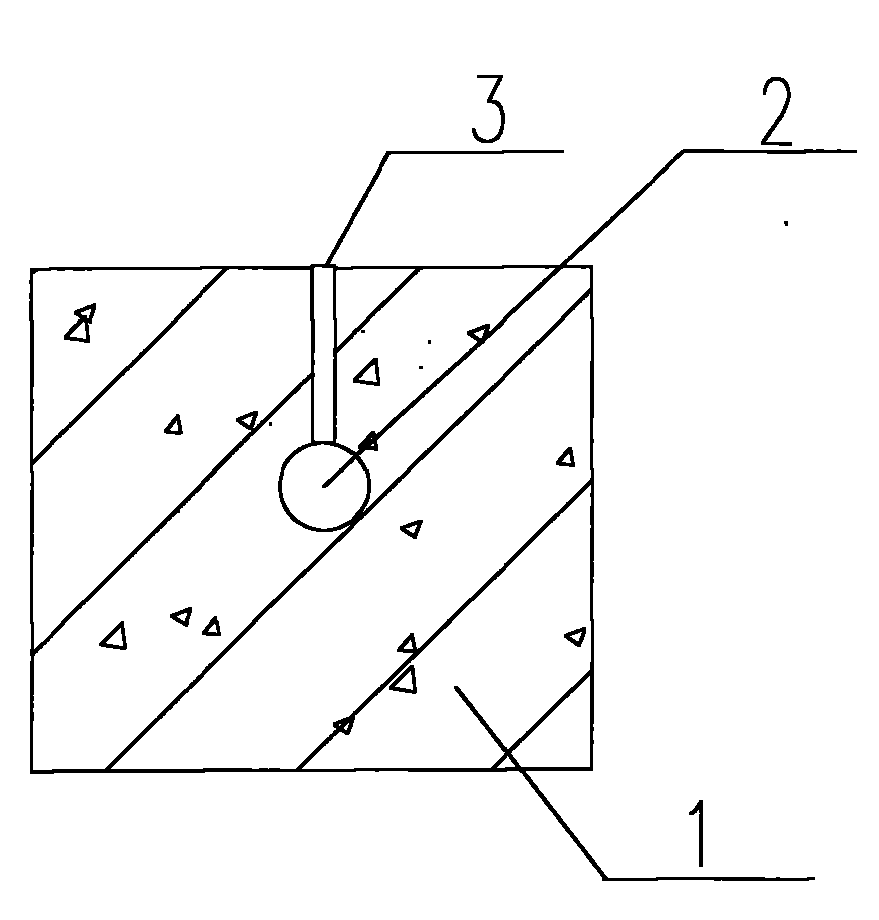

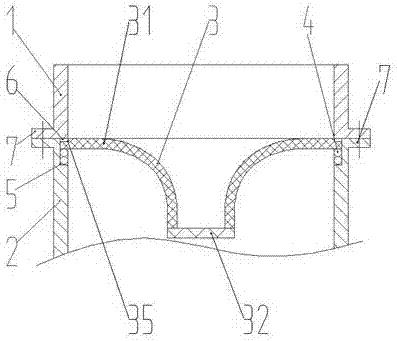

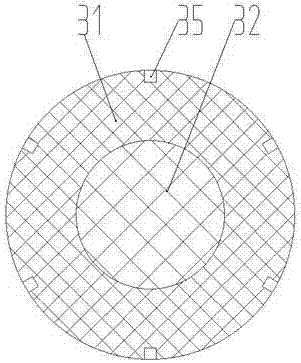

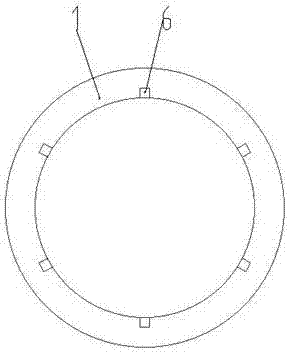

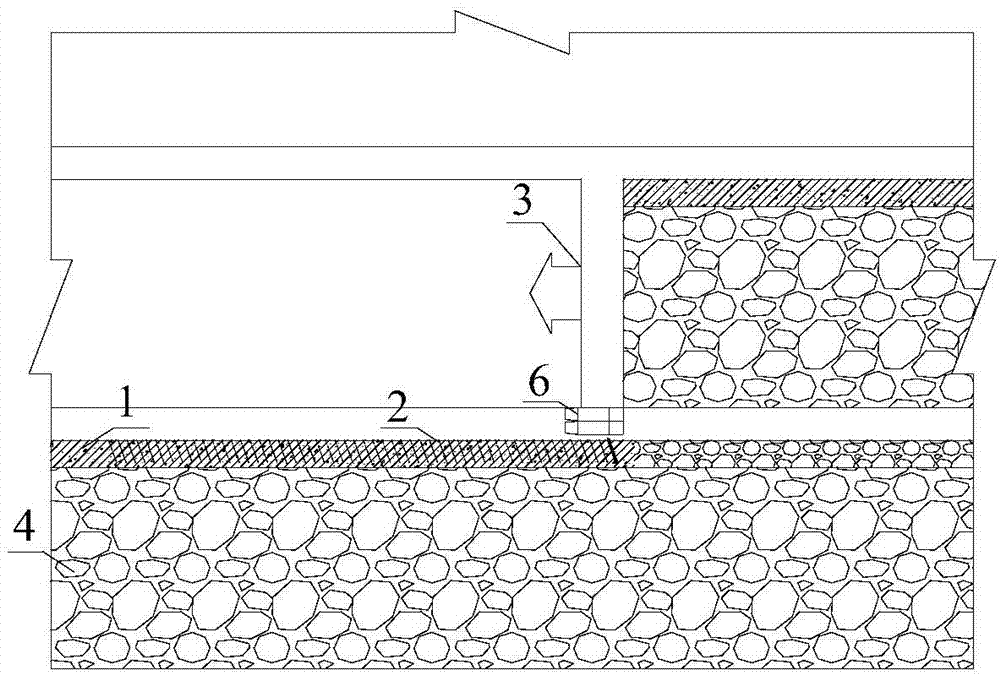

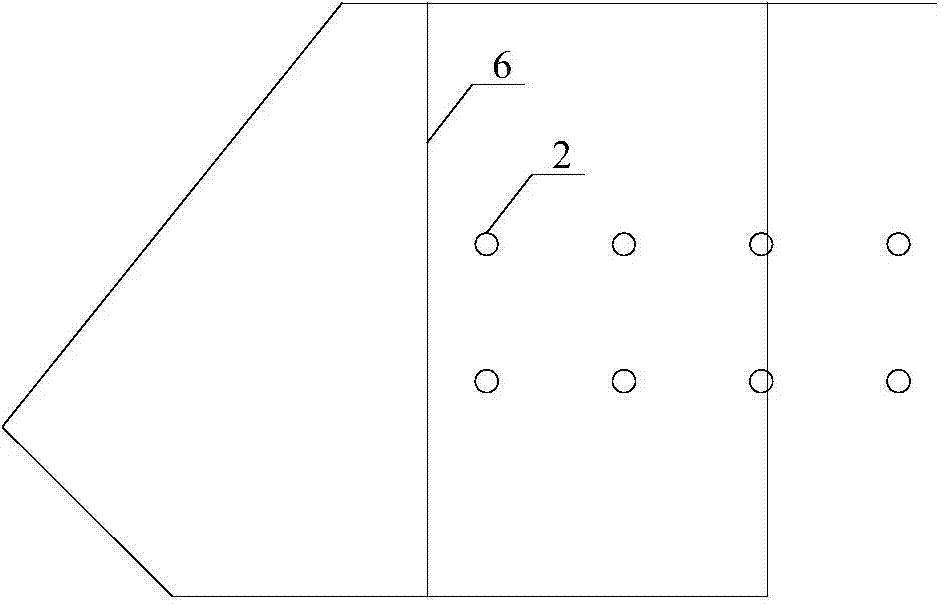

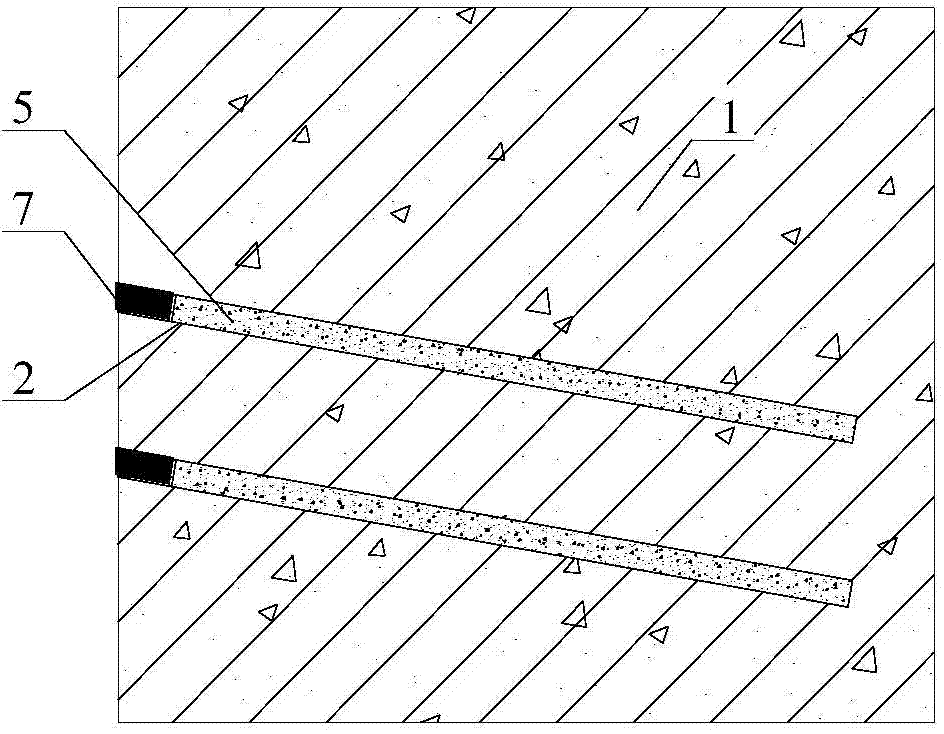

Concrete beforehand pore-forming static breaking technology

InactiveCN102127975AFlexible placementIncrease inner diameterBuilding repairsChemical reactionWorking capacity

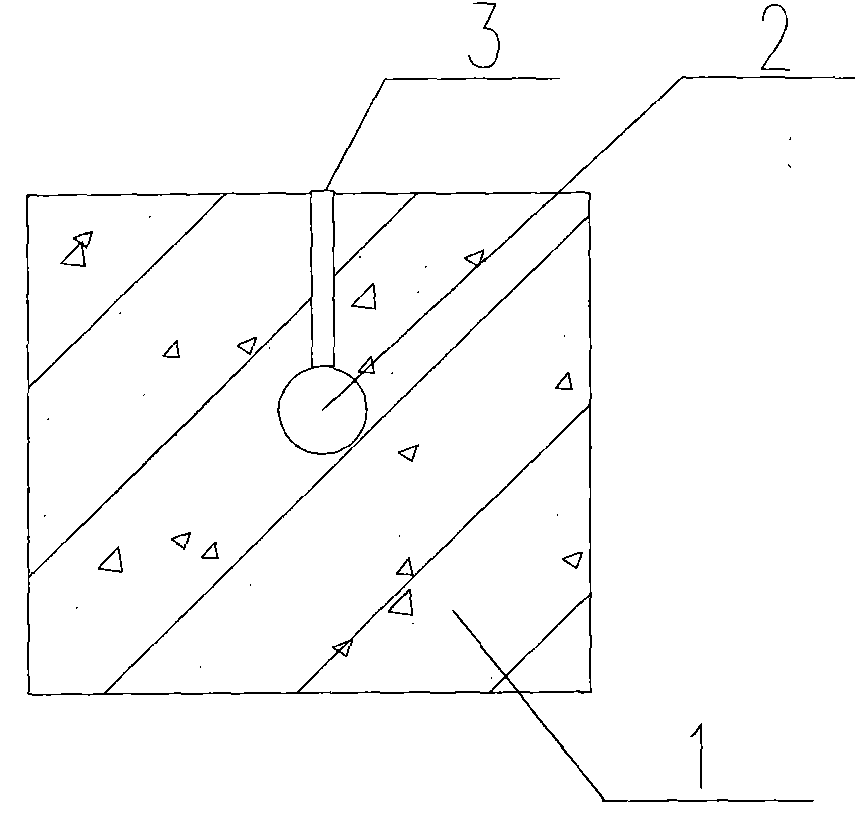

The invention provides a concrete beforehand pore-forming static breaking technology. A plurality of containers with a certain sizes, shapes and amounts are embedded in a concrete member before the concrete is cast, a plurality of orifices are arranged above the containers, the inner diameters of the orifices are less than the inner diameters of the containers, and the orifices are extended to the edge of the concrete member. When the concrete member needs to be disassembled, the expanding agent is filled into the containers along with the orifices, the expanding agent is chemically reacted in the containers to generate the expansibility, the concrete member is expanded to be broken, and the whole process is free of noise, vibration and slungshots. Compared with the normal pore-forming type static breaking technology, the expansibility is larger, the expanding agent can be effectively avoided to be sprayed out of the orifices, and the construction is safe and environment-friendly; and the drilling working capacity is eliminated, so that the cost can be reduced, and the disassembly construction period can be shortened, therefore, the technology is suitable for the static breaking of engineering temporary facilities.

Owner:葛培中

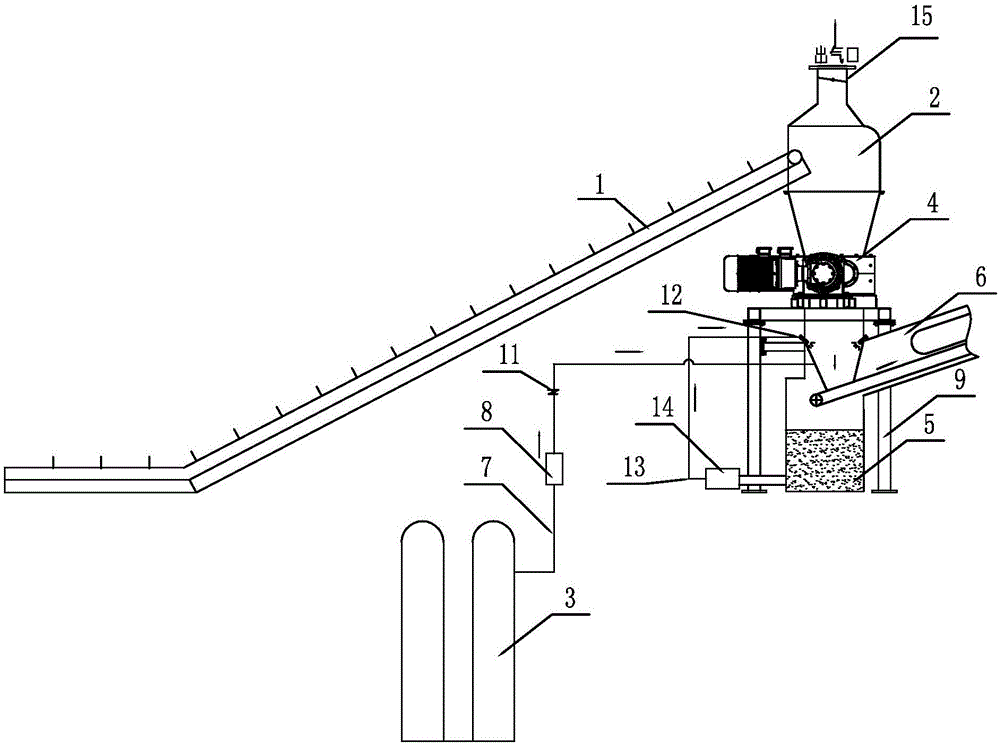

Scraped power lithium battery nitrogen-protection crushing equipment

ActiveCN106424100APlay a cooling roleAvoid enteringSolid waste disposalDirt cleaningCombustionSolenoid valve

The invention discloses scraped power lithium battery nitrogen-protection crushing equipment, and belongs to the technical field of waste battery disposal. The scraped power lithium battery nitrogen-protection crushing equipment solves the problem that safety of operators is threatened due to the fact that combustion is easily generated and explosion easily happens in the existing battery crushing technology. An outlet of a shredding machine of the scraped power lithium battery nitrogen-protection crushing equipment corresponds to an inlet of a water tank; a feeding hopper is arranged above the shredding machine; a gas outlet is formed in the top cover of the feeding hopper; the upper end of an insulating conveyor is arranged on the side wall of the feeding hopper; the lower end of a crushing conveyor extends into the water tank; the outlet of a discharge hopper of the shredding machine is opposite to the crushing conveyor; a nitrogen making machine communicates with the inner part of a discharge hopper of the shredding machine through a gas conveying pipeline; and a nitrogen gas refrigerator and a solenoid valve are arranged on the gas conveying pipeline. The scraped power lithium battery nitrogen-protection crushing equipment adopts a direct powered crushing mode without discharging batteries, so that period of crushing batteries is shortened, universal performance is strengthened, staff operation is convenient, performances are reliable, and the scraped power lithium battery nitrogen-protection crushing equipment is safer.

Owner:哈尔滨巴特瑞资源再生科技有限公司

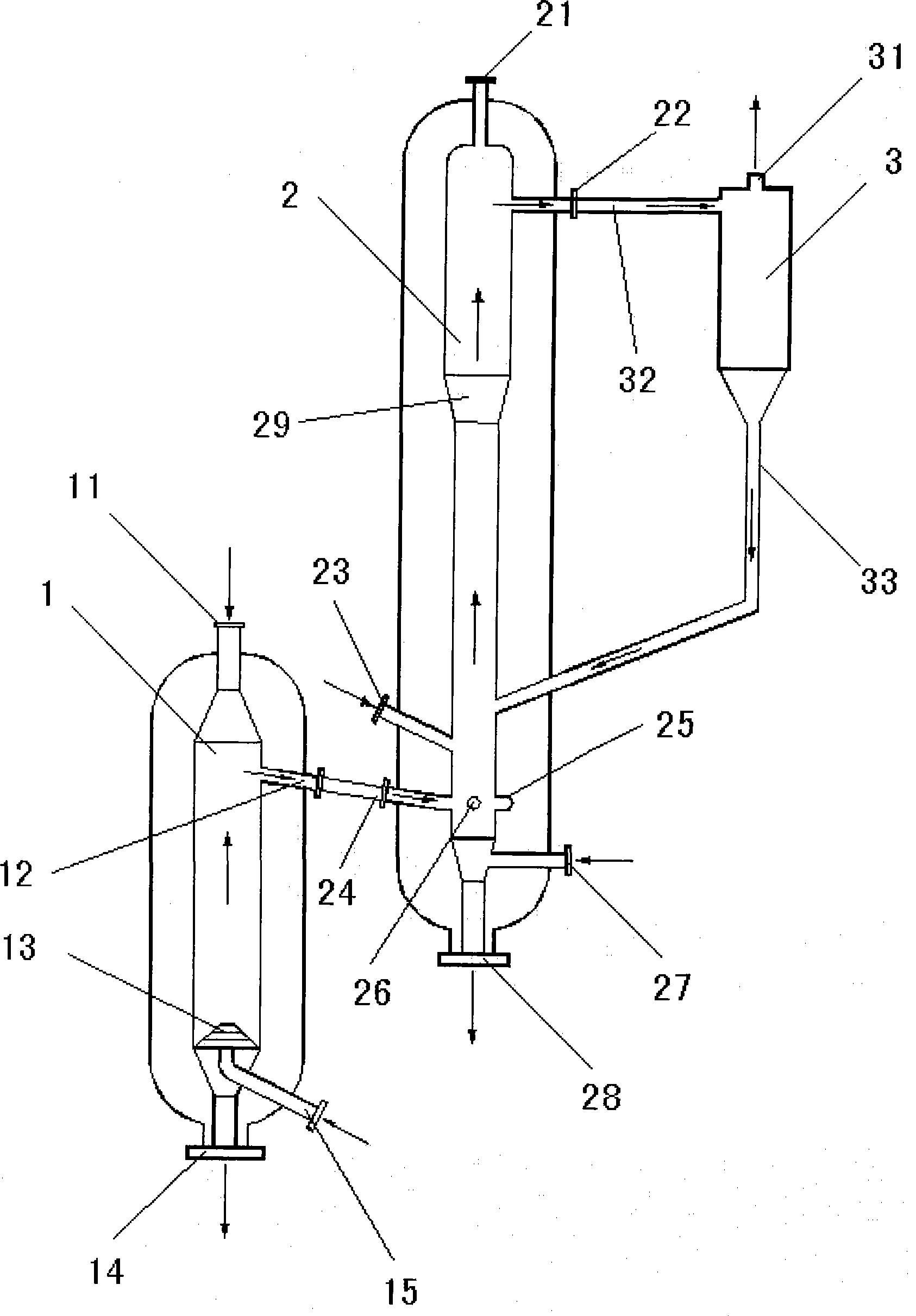

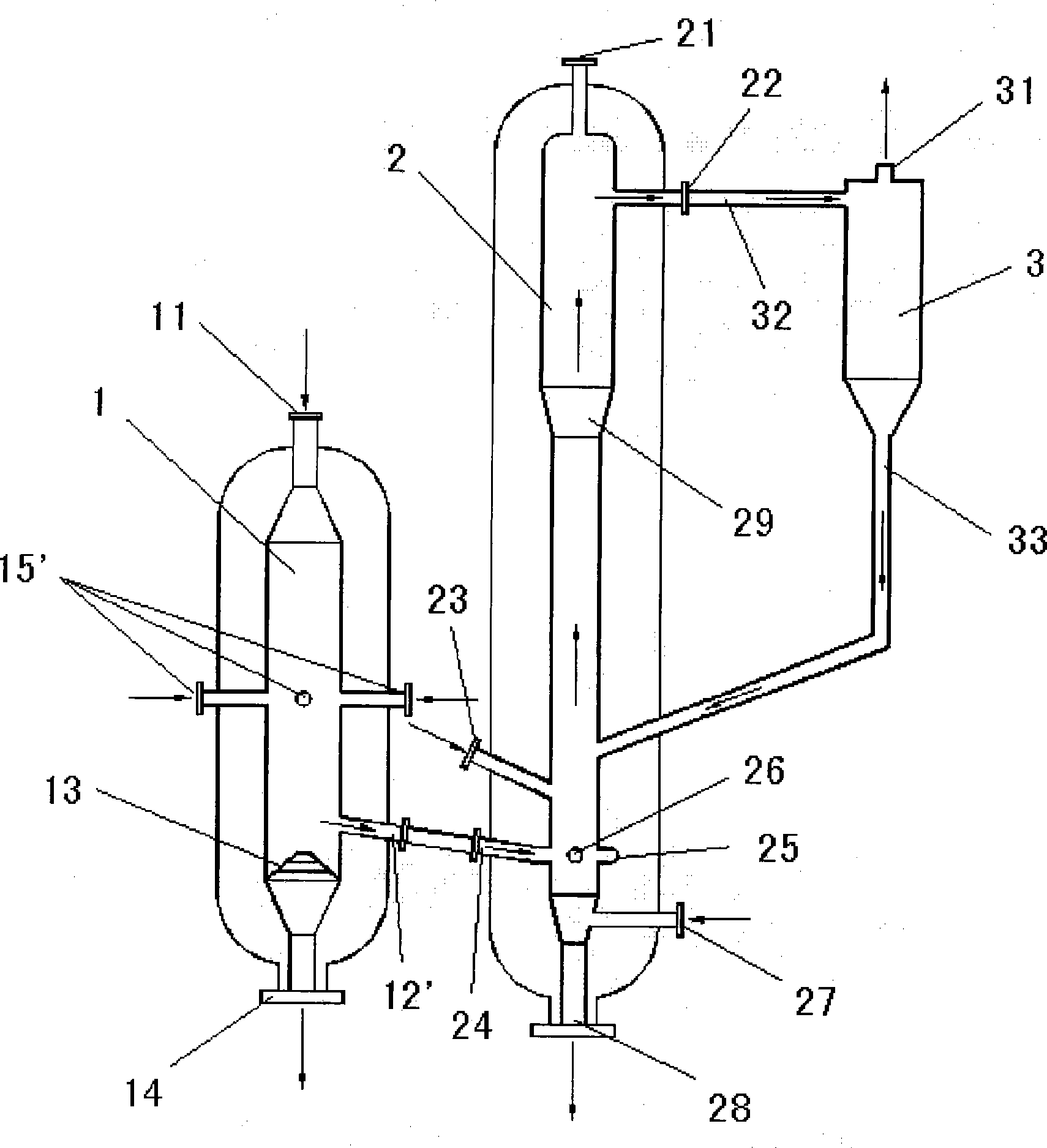

Fixed bed-fluidized bed serially connected gasification method and apparatus

ActiveCN101440308AReduce tar contentEmission reductionCombined combustion mitigationCombustible gas productionFluidized bed gasifierFluidized bed

The invention relates to a method and a device for gasification, in particular to the method and the device for serial gasification of a fixed bed and a fluidized bed, wherein the method comprises the following steps: 1) feeding a gasification raw material with the particle size of between 13 and 50 millimeters and a gasification agent to a fixed bed gasifier to perform gasification reaction so as to generate coal gas and ash content, discharging the ash content from an ash discharging opening of the fixed bed, and introducing the coal gas to the lower part of a dense phase zone of a fluidized bed gasifier; 2) feeding a thin particle shapeed coal gasification raw material with the particle size of between 0.5 and 8 millimeters and the gasification agent into a fluidized bed gasifier to perform gasification reaction with the vertically raising coal gas so as to generate the coal and the ash content, discharging the ash content from the ash discharging opening of the fluidized bed, and introducing the coal gas into a cyclone separator; and 3) performing gas-solid separation on the coal gas in the cyclone separator, outputting the coal gas from a coal gas outlet of the cyclone separator, and sending back solid particles carried by the coal gas to the fluidized bed gasifier through a dipleg of the cyclone separator to perform the gasification reaction continuously. The method and the device have quite important significance on improving the economic benefit and reducing the sewage treatment cost for the medium and small-sized coal chemical enterprises in China.

Owner:CCTEG CHINA COAL RES INST

Waste plastic crushing device

InactiveCN103737748AReduce work intensitySpeed up decompositionPlastic recyclingMechanical material recoveryReciprocating motionEngineering

The invention provides a waste plastic crushing device. The waste plastic crushing device comprises a compressing chamber, a heating chamber, a crushing chamber and a discharging chamber which are connected sequentially, wherein a feed port is formed in the top of the compressing chamber; a briquette which can reciprocate towards the opposite side is arranged on one side in the compressing chamber; a plurality of pressing rollers are arranged on the upper and lower parts in the heating chamber respectively; serrated knifes are distributed on each pressing roller; the crushing chamber is composed of a transverse crushing chamber and a vertical crushing chamber; one side of the transverse crushing chamber is communicated with the heating chamber; and the bottom part of the transverse crushing chamber is communicated with the vertical crushing chamber; due to the adoption of the waste plastic crushing device, the problems that the crushing is incomplete, the noise is high, the wearing of a tool bit is serious and splashing materials are likely to cause a safety hidden in a crushing process of a traditional plastic crushing device are solved; the waste plastics are compressed, heated, crushed and degraded, the degrading speed of the waste plastics is significantly improved, on the premise that the complete crushing is guaranteed, the working strength of the tool bit is lowered, the working efficiency is improved, and the crushing cost is reduced.

Owner:TIANJIN HUAQING BAISHENG PLASTIC INDAL

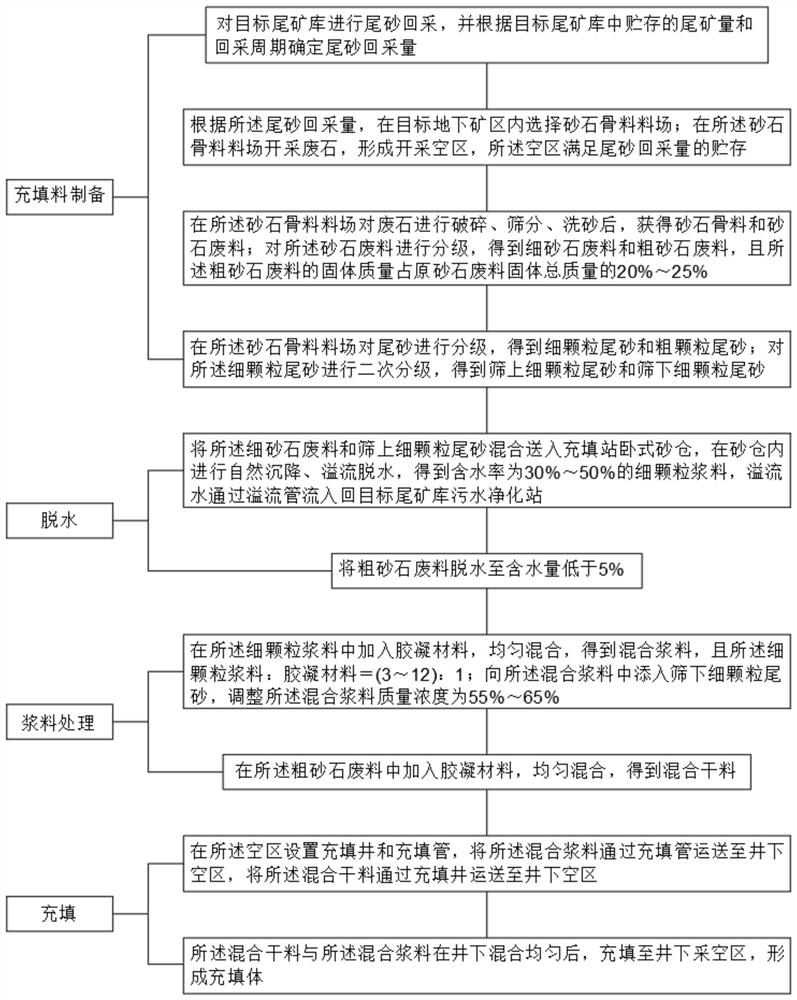

Tailings disposing and filling method

The invention discloses a tailings disposing and filling method and belongs to the field of tailings utilization and disposal. The method includes: grading tailing pulp to obtain fine-particle tailings pulp and coarse-particle tailings; dewatering the fine-particle tailings pulp and the coarse-particle tailings pulp respectively according to application to obtain fine-particle tailings and fine aggregate and coarse-particle tailings for granulation, mortar and dry-mixed mortar; sintering the fine-particle tailings at high temperature, and adding a binding material into the coarse-particle tailings for granulation, mortar and dry-mixed mortar to obtain coarse aggregate, a mortar material and a dry-mixed mortar material; mixing the coarse aggregate and the fine aggregate, conveying the samedown into a well through a filling well, conveying the mortar material down into the well through a filling pipe, mixing, and then filling; conveying the dry-mixed mortar material down into the well to be mixed with pipe flushing water to prepare a dry-mixed mortar material mixture, mixing the mixture with the aggregate, and filling. By the method, treating and hardening time of the filling material can be shortened, strength of a filled body can be enhanced, downhole operation conditions can be improved, and pollution of underground environment can be reduced.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Ultralow-density ceramisite sand proppant and preparation method thereof

InactiveCN104592970ASmall bulk densityLow densityFluid removalDrilling compositionSurface finishExpanded clay aggregate

The invention discloses an ultralow-density ceramisite sand proppant and a preparation method thereof. The ultralow-density ceramisite sand proppant is prepared from the following raw materials in percentage by weight: 15-20% of purple clay, 10-15% of silica and 65-75% of raw aluminum ores. The preparation method comprises the following steps: crushing the required raw materials at first, then performing blending and grinding, and putting obtained fine powder into a granulator for granulation; and screening obtained raw granules after granulation, then calcining in a rotary kiln, cooling, and finally screening again to obtain a product. The ceramisite sand proppant prepared by the method disclosed by the invention has the advantages of ultralow volume density, relatively low apparent density, relatively high crushing resistance and good surface finish quality. By using the ultralow-density ceramisite sand proppant disclosed by the invention, the exploitation cost of an oil field can be reduced, and the yield of the oil field can be increased.

Owner:ZHENGZHOU JUYING CERAMSITE SAND

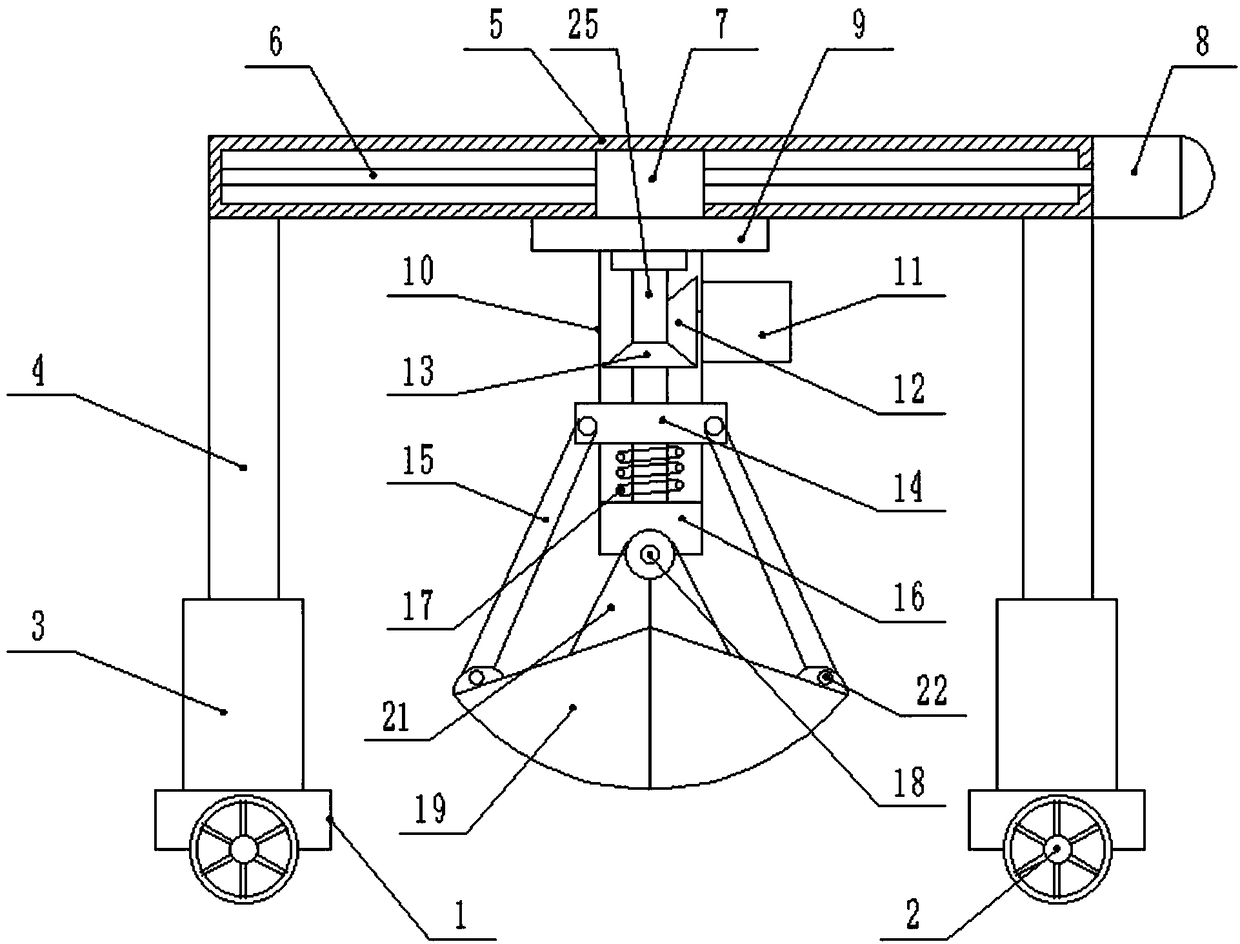

Grab bucket type feeding and transporting device for garbage crushing treatment

ActiveCN108273648AEasy to movePrevent movementProgramme-controlled manipulatorGrain treatmentsArchitectural engineeringScrew thread

The invention discloses a grab bucket type feeding and transporting device for garbage crushing treatment. The grab bucket type feeding and transporting device comprises moving seats, lifting cylinders are installed at the upper ends of the moving seats, and lifting frames are mounted at the upper ends of the lifting cylinders. A guide sleeve is mounted on the upper ends of the lifting frames, anda moving block is installed inside the guide sleeve. A first screw rod is installed on the middle portion of the moving block, and a fixing plate is installed at the lower end of the moving block. Afixed tube is installed at the lower end of the fixing plate, and a second screw rod is installed inside the fixing tube. A driven gear is mounted on the middle portion of the upper end of the secondscrew rod, and a driving gear is arranged at the right end of the driven gear in a meshing mode. A lifting disk is installed on the middle portion of the lower end of the second screw rod through a threaded hole, and hinged bars are fixed to both ends of the lifting disk. Pull rods are hinged to the middle portions of the hinged bars, and hinged blocks are hinged to the tail ends of the pull rods.A limiting block is installed at the bottom end of the fixed tube, a rotating pin is installed on the middle portion of the lower end of the limiting block, and pulling plates are installed on both sides of the lower end of the rotating pin. According to the grab bucket type feeding and transporting device for the garbage crushing treatment, the grabbing of garbage is realized, and manual feedingand transportation are avoided, time and labor are saved, and the crushing cost is greatly reduced.

Owner:HUBEI XINXINLAN ENVIRONMENTAL PROTECTION TECH CO LTD

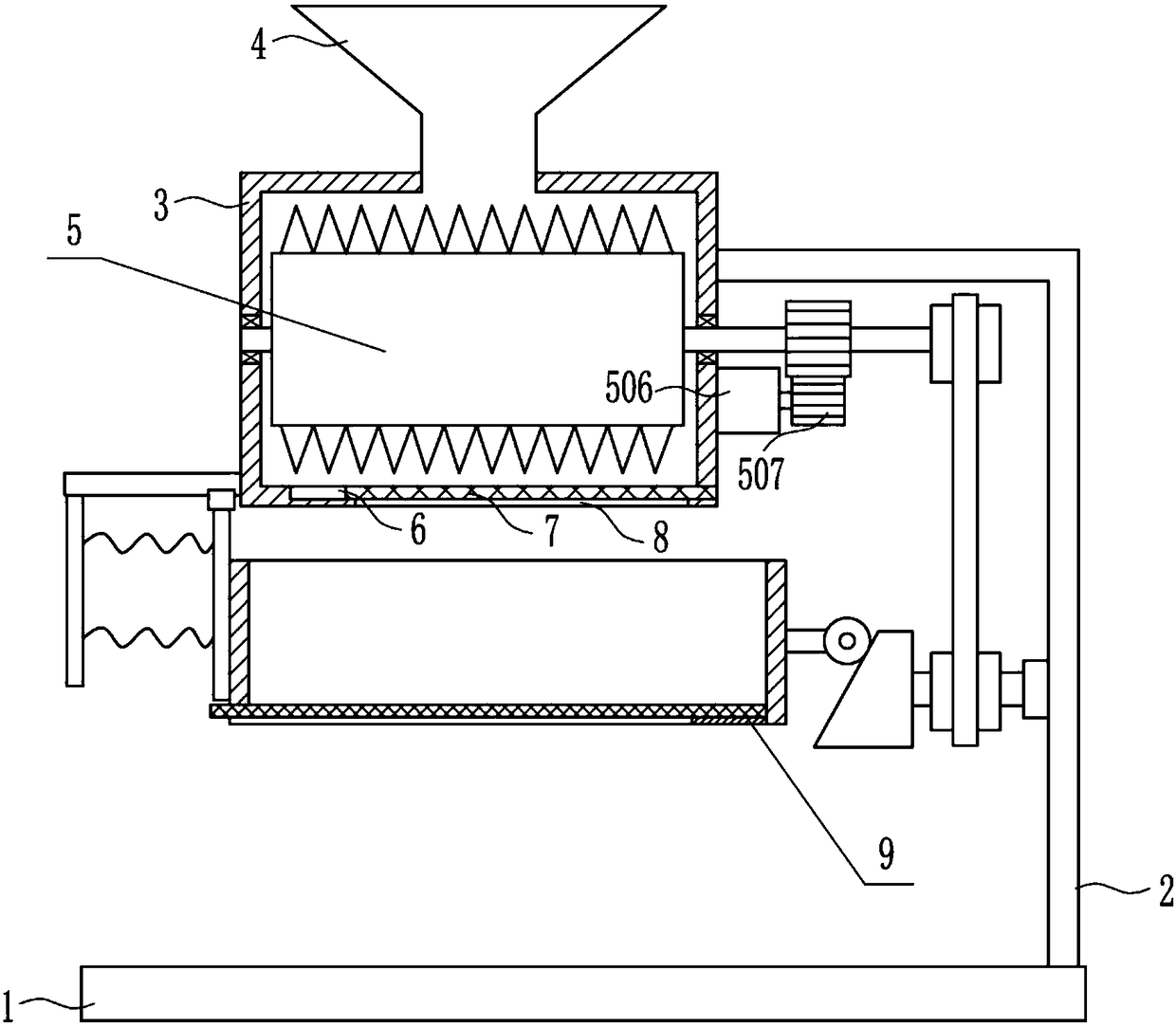

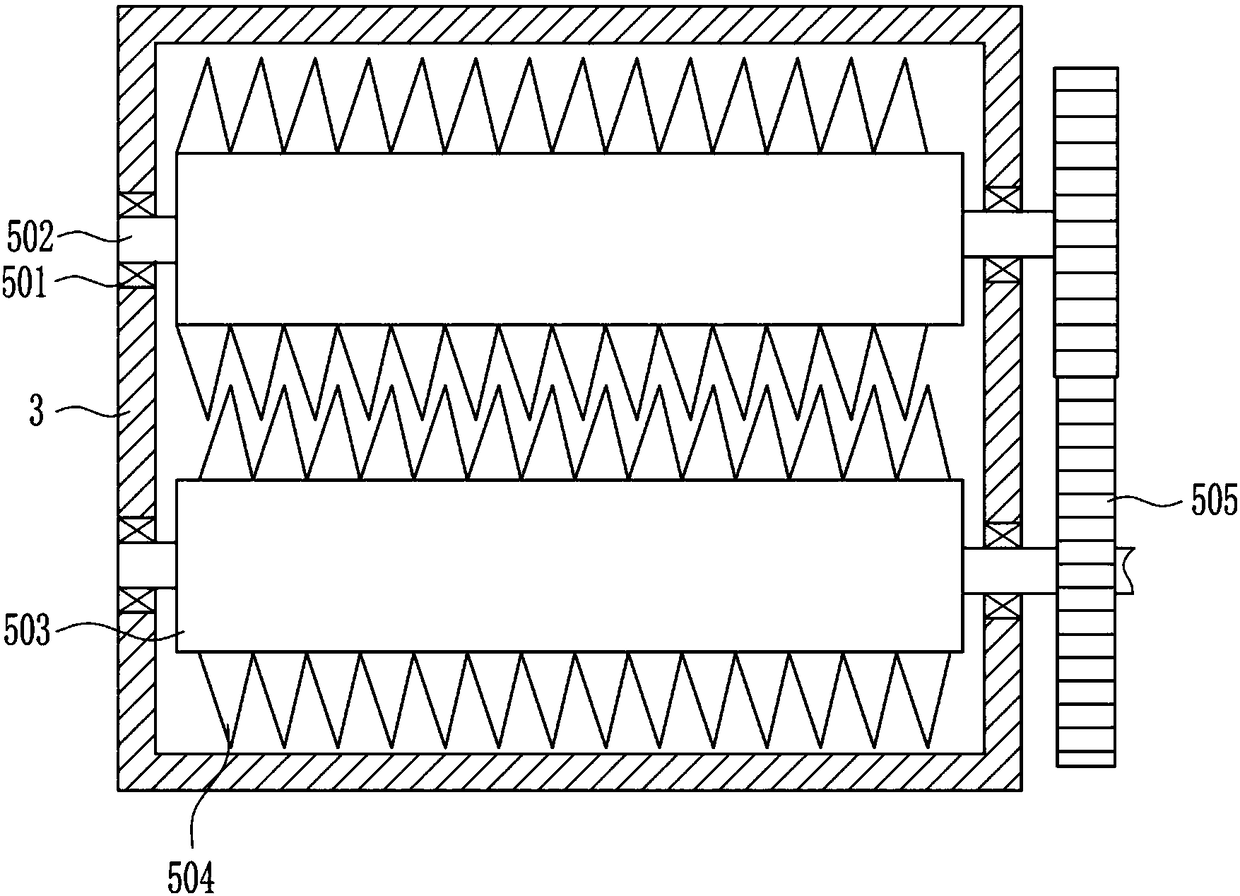

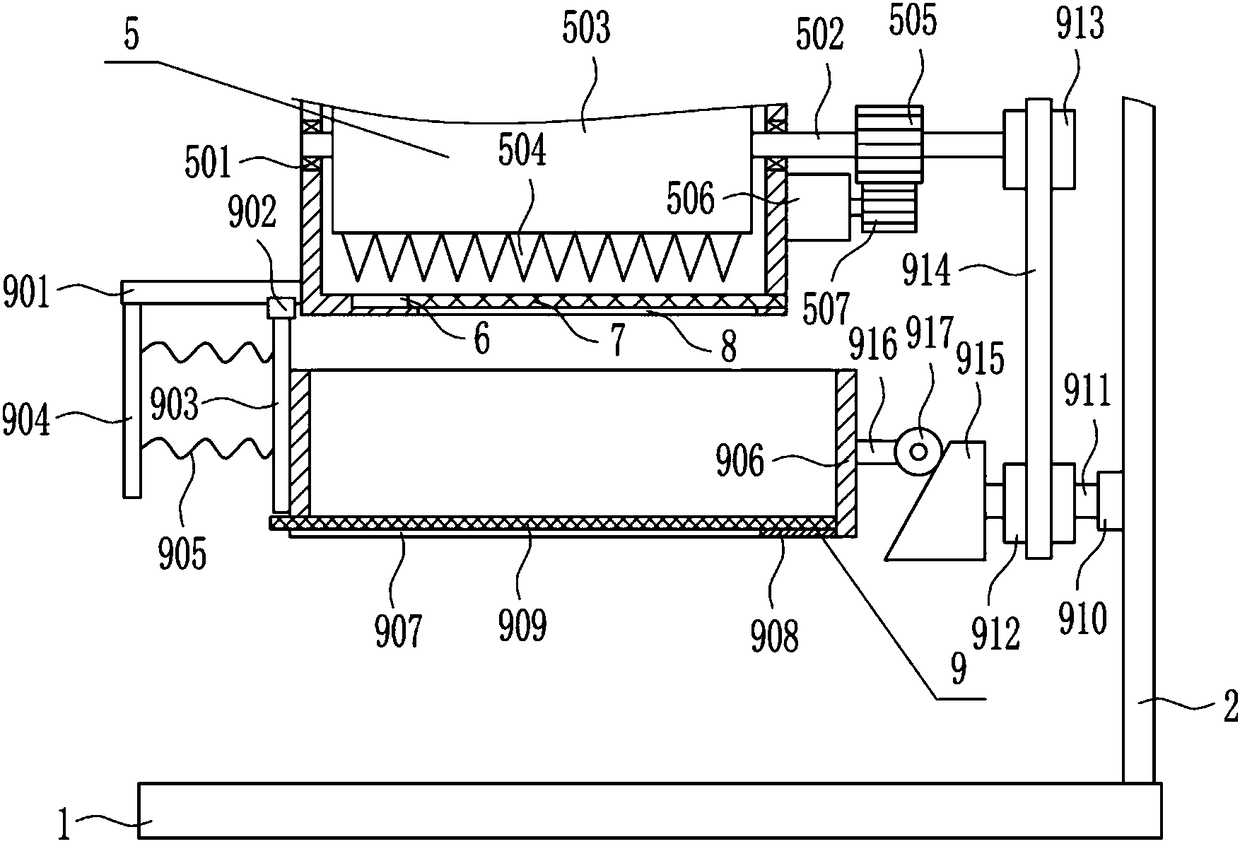

Building waste smashing device with smashing rollers with extrusion rollers

InactiveCN108097360AReduce distanceFacilitate subsequent crushing and refinementNon-rotating vibration suppressionGrain treatmentsArchitectural engineeringExtrusion

The invention discloses a building waste smashing device with smashing rollers with extrusion rollers. The building waste smashing device comprises a shell, a base, a support plate and a feed hopper.A plurality of support springs and a damping block are fixedly connected between the support plate and the base. Two horizontally side-by-side pre-smashing rollers are arranged in a corresponding pre-smashing cavity under the feed hopper. The parts, corresponding to the lower portions of two movable plates, of a fixed seat are each provided with a downwards-concave smashing groove. The smashing rollers coaxial with the smashing grooves are arranged in the smashing grooves. A plurality of grooves which are concave toward the centers of the smashing rollers are evenly distributed on the side walls of the smashing rollers. The extrusion rollers of a cylindrical structure are installed in the grooves. According to the building waste smashing device, extrusion and smashing are conducted throughthe two pre-smashing rollers which go close to each other, and waste is pretreated. Building waste located between the smashing rollers and the smashing grooves are extruded by the extrusion rollerson the smashing rollers, the distance between the extrusion rollers and the smashing grooves is small, the smashing effect is ensured, the small effect of the smashed waste is ensured, and the numberof times of repeated smashing is reduced.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Pig blood composition and pig blood chewable tablet made therefrom

InactiveCN101829158AEasy dischargePromote peristalsisOrganic active ingredientsMetabolism disorderWater bathsVitamin C

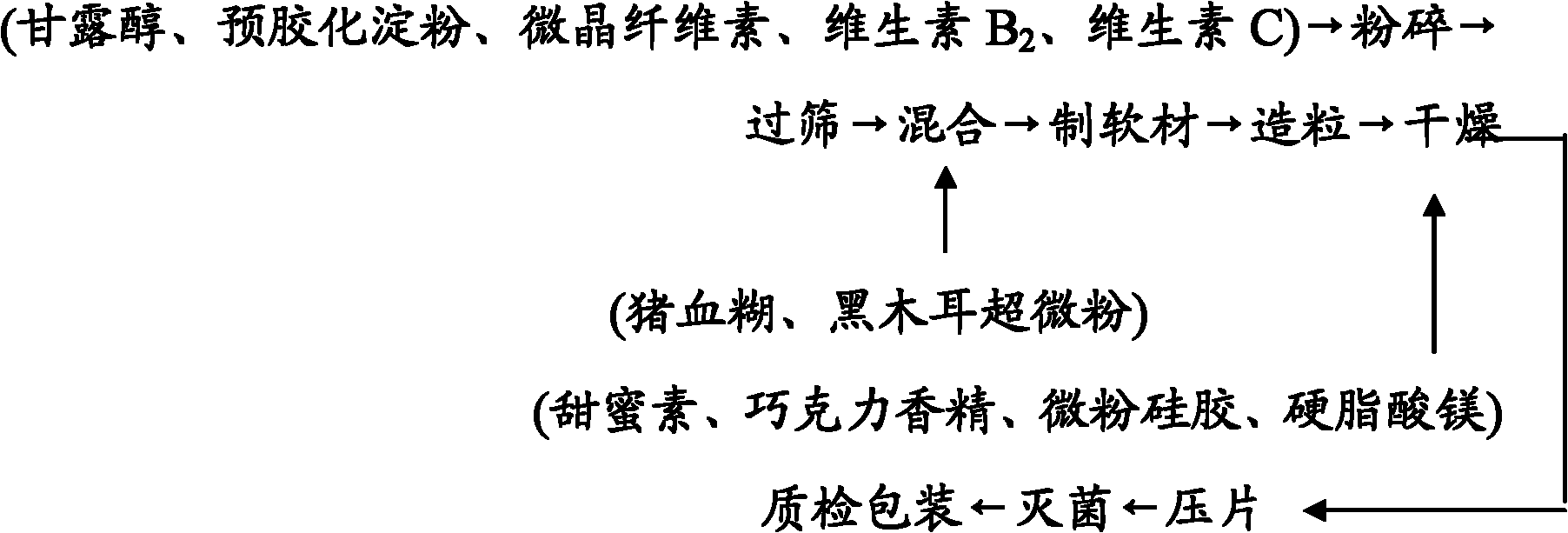

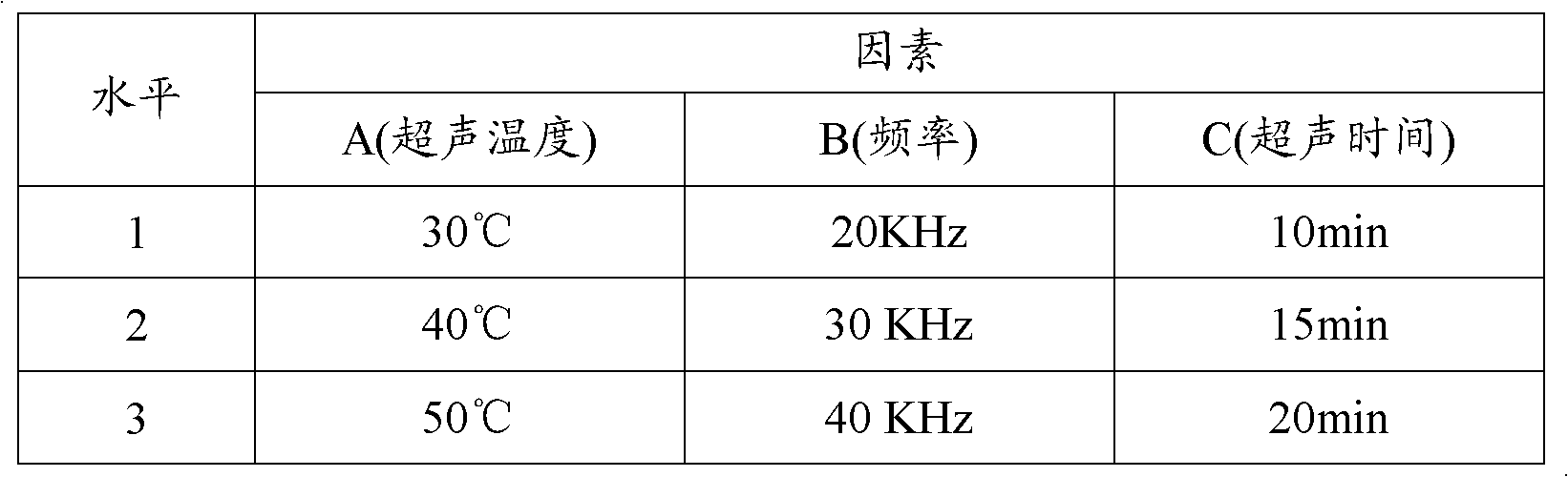

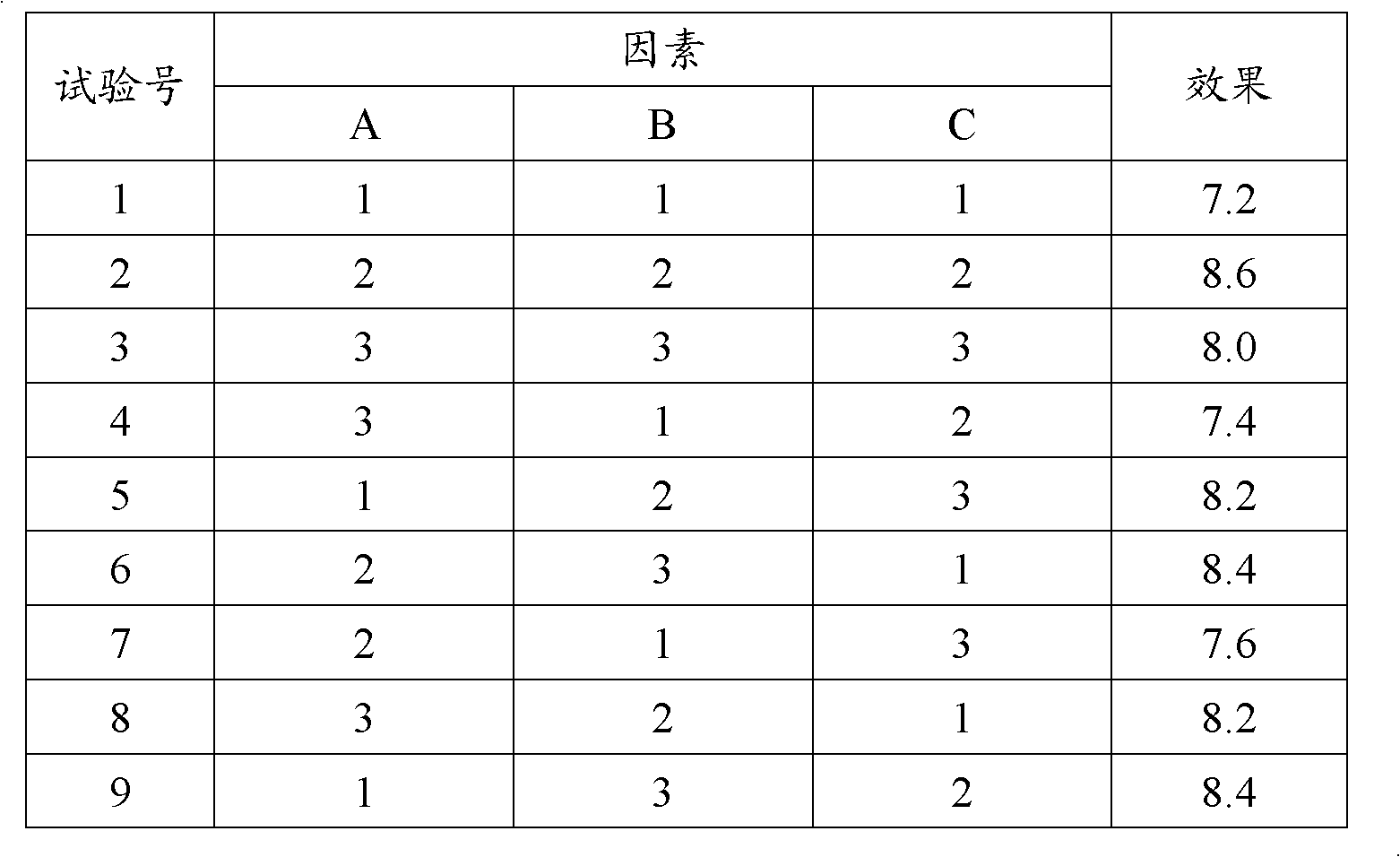

The invention discloses a pig blood composition, mainly comprising the following components: 20-40 parts of pig blood, 10-20 parts of ultrafine black fungus powder, 0.5-2 parts of vitamin B2 and 3-12 parts of vitamin C. The pig blood is made into pig blood paste by embedding pig blood solution added with sodium citrate b for anticoagulation using hydroxypropyl beta-cyclodextrin, ; or boiling the pig blood solution added with sodium citrate for anticoagulation in a boiling water bath into a coagulated block and then filtering, taking the coagulated block and crushing into paste, then adding hydroxypropyl beta-cyclodextrin into the coagulated block (the mass of the added hydroxypropyl beta-cyclodextrin is 1 / 2 the mass of the coagulated block), and processing by ultrasonic of 20-40KHz for 10-20min. The ultrafine black fungus powder has a fineness higher than 300 meshes. The invention also discloses a pig blood chewable tablet made from the pig blood composition. The hydroxypropyl beta-cyclodextrin is taken as the wall material, and an embedding technique is combined with an ultrasonics technique so that an offensive smell of pig blood can be effectively hidden.

Owner:CHINA JILIANG UNIV

Chemical pigment crushing device

The invention relates to a crushing device, in particular to a chemical pigment crushing device. In order to solve the technical problems, the invention provides the chemical pigment crushing device which has a filter function, can reduce crushing cost, is convenient to use, and is simple to operate. The chemical pigment crushing device comprises a base and the like, wherein the right side on thebase is connected with a 7-shaped plate; the left side surface of the 7-shaped plate is connected with a crushing box; the top of the crushing box is equipped with an unloading hopper; a crushing device is arranged in the crushing box; a slide slot is horizontally formed in the bottom in the crushing box; a screen is arranged in the slide slot; a discharge hole is horizontally formed in the bottomof the crushing box; the discharge hole communicates with the slide slot; and a filter device is arranged at the lower side of the crushing box. The chemical pigment crushing device can be used for crushing chemical pigments by crushing, and the filter device can filter the crushed chemical pigments, so that the effects of having a filter function, being capable of reducing crushing cost, being convenient to use and being simple to operate are achieved.

Owner:江苏彩瑞实业有限公司

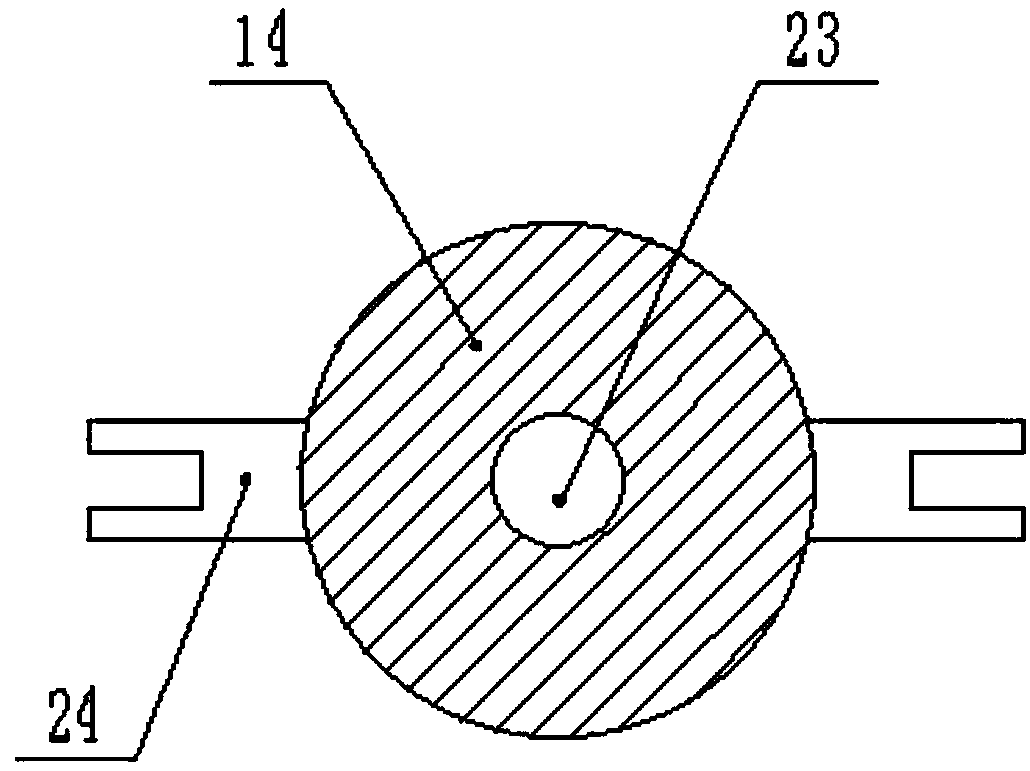

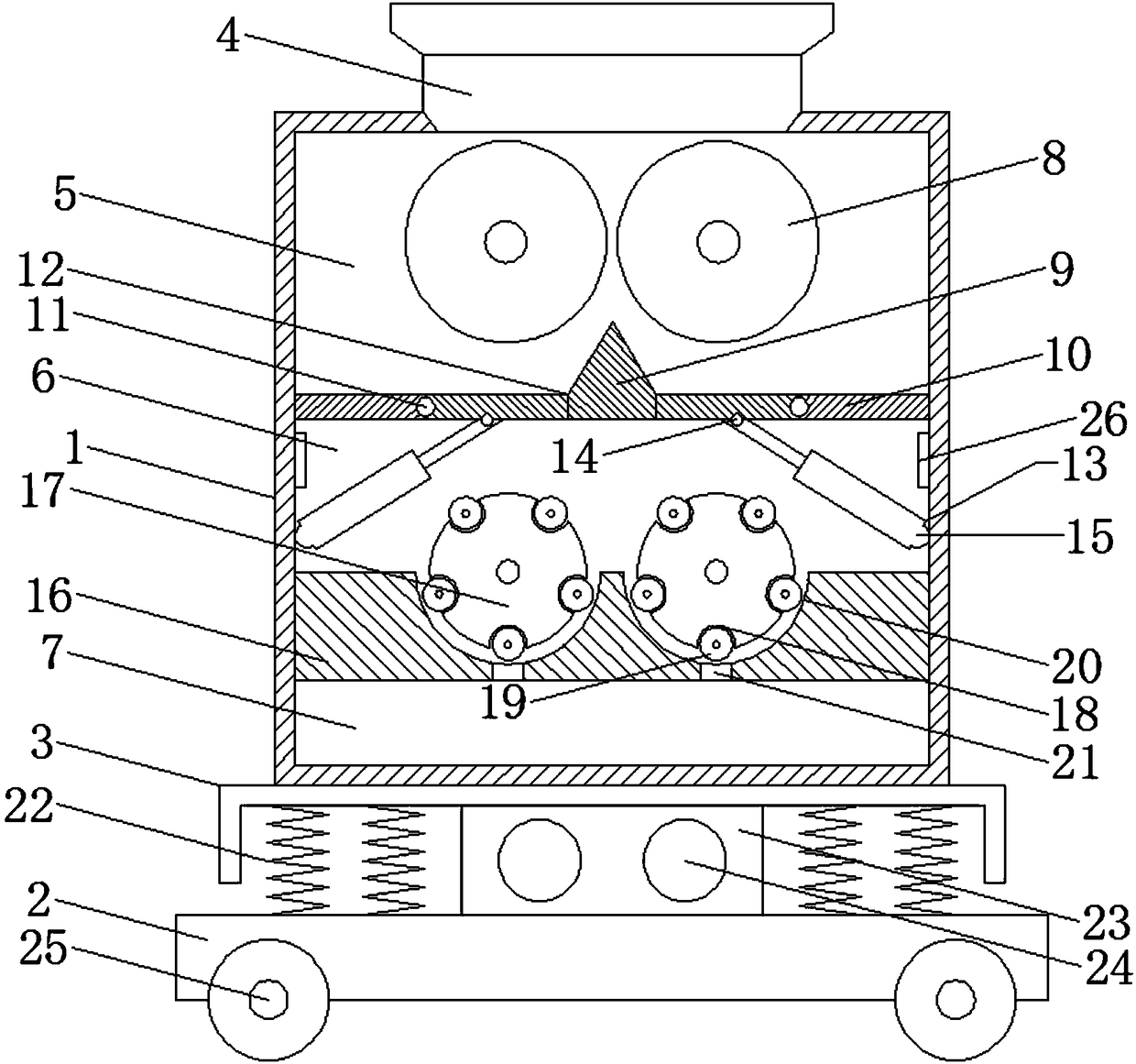

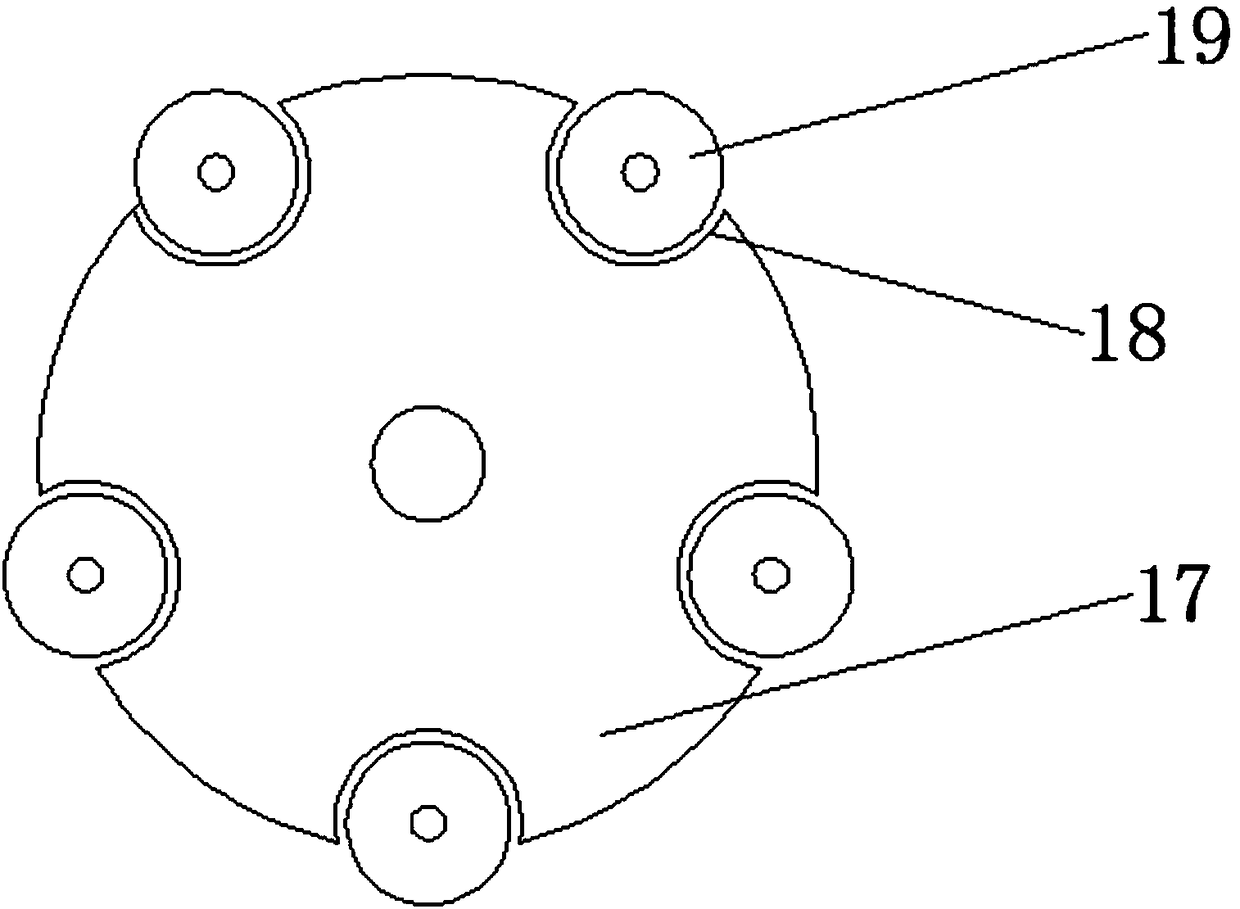

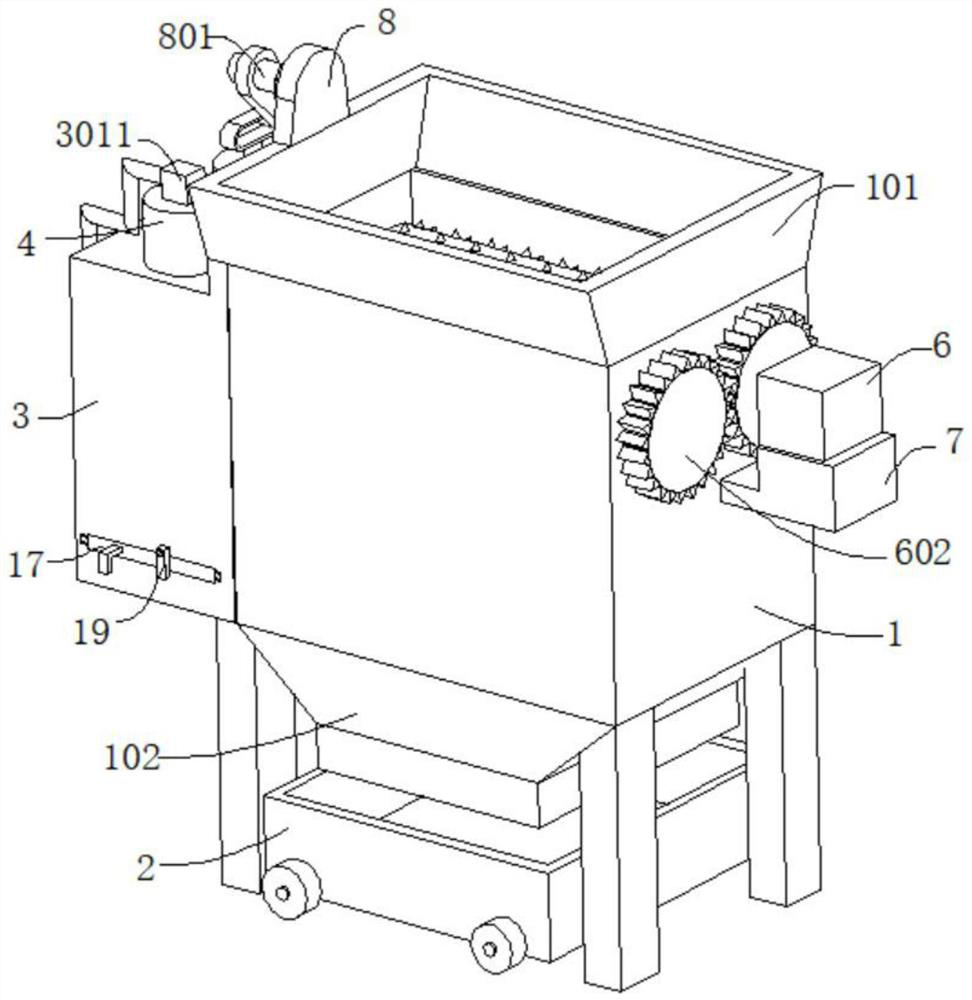

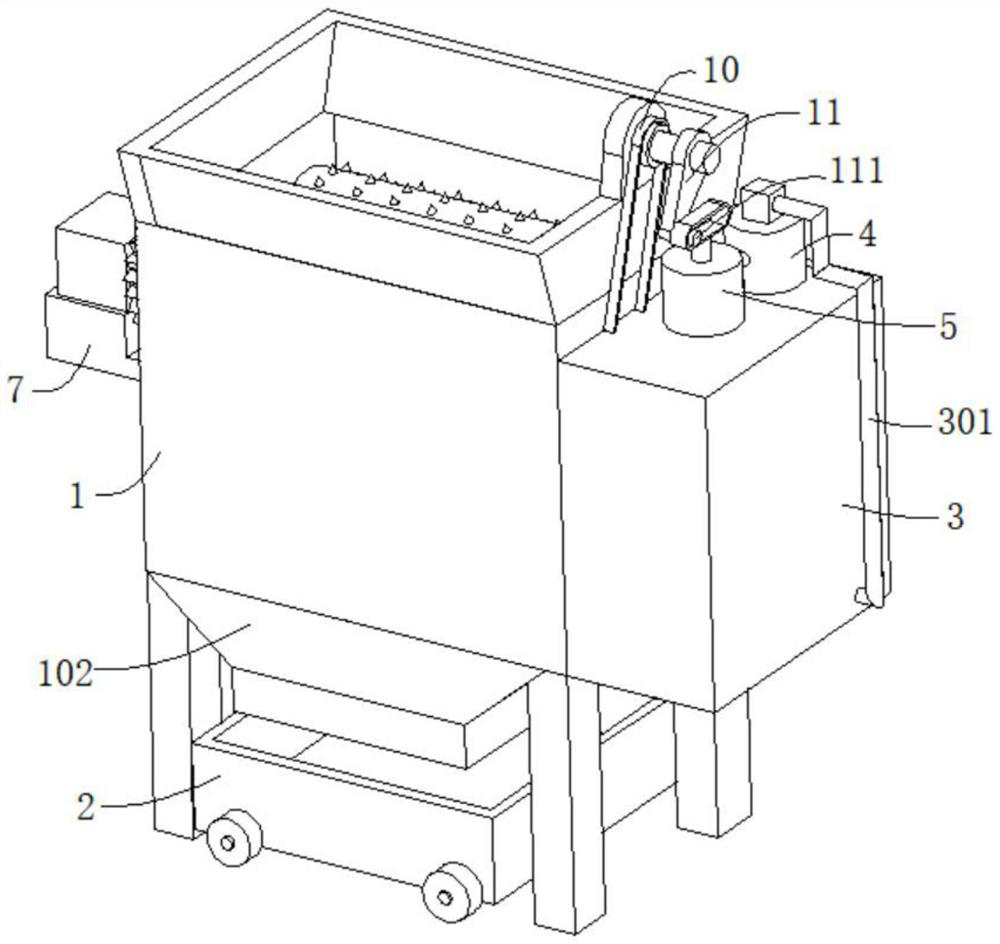

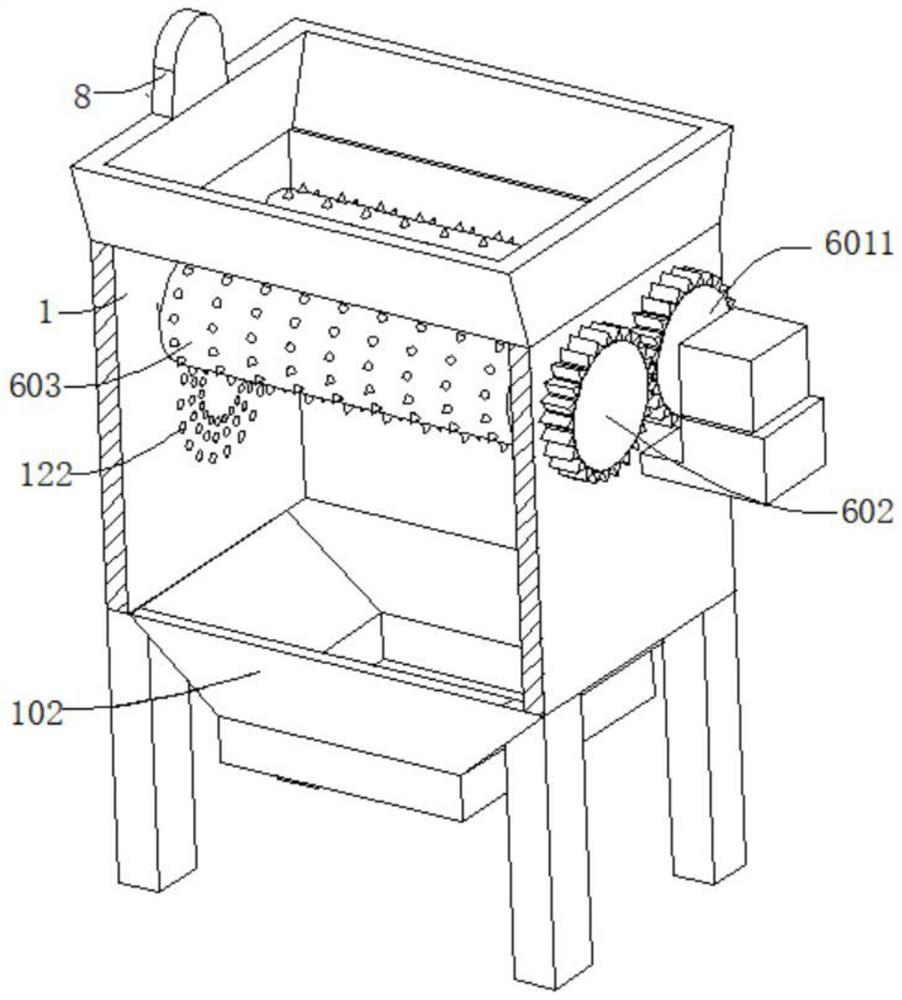

Construction waste crushing device for constructional engineering and using method thereof

ActiveCN111686866AReduce crushing costsEasy to reuseUsing liquid separation agentTreatment involving filtrationRefuse collectionWater resources

The invention discloses a construction waste crushing device for constructional engineering and a using method thereof, and belongs to the technical field of the constructional engineering. The construction waste crushing device for the constructional engineering comprises a crushing box and a waste collecting vehicle, wherein the waste collecting vehicle is arranged at the bottom of the crushingbox, a feeding opening and a discharging opening are formed at the upper side and the lower side of the crushing box, a crushing mechanism is connected to the interior of the crushing box, a dust falling box is connected to the outer wall of the crushing box, a water supplementing box and a water sprinkling box are connected to the interior of the dust falling box, a first pipeline and a second pipeline are connected between the water supplementing box and the water sprinkling box, a water conveying pipe is connected to the bottom of the dust falling box, the end, away from the dust falling box, of the water conveying pipe is connected to the top of the water supplementing box, a water pump is connected to the outer wall of the water conveying pipe, and the water pump is connected to the outer wall of the water supplementing box. According to the construction waste crushing device, water resources for dust fall are reused favorably, the water resources are saved favorably, and the crushing cost of construction waste is reduced.

Owner:徽仁(宁夏)环保科技有限公司

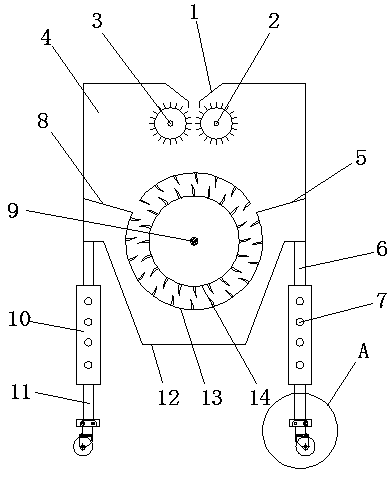

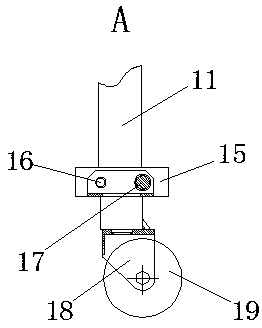

Movable lifting type plastic garbage crushing device

InactiveCN107599239ANovel structureWorking principle is clearPlastic recyclingGrain treatmentsMechanical engineeringPollution

The invention discloses a movable lifting type plastic garbage crushing device, and belongs to the technical field of garbage recycling equipment. The device comprises fixed supporting legs and a machine cover, wherein a sleeve is arranged on each fixed supporting leg in a sleeving mode; a movable supporting leg is arranged below each sleeve; a supporting block is arranged below each movable supporting leg; a wheel plate frame with a rolling wheel is arranged on each supporting block; a rotary drum cutter is arranged in the middle position of the interior of the machine cover; a fixed drum cutter is arranged on the outer side of the rotary drum cutter; left and right partition plates are arranged on the shell of the fixed drum cutter; left and right hobs are arranged above the fixed drum cutter; a feeding port is arranged above the left hob and the right hob; and a material collecting cylinder is arranged at the outer bottom end of the fixed drum cutter. The movable lifting type plastic garbage crushing device is novel in structure and clear in working principle, and compared with traditional waste plastic equipment, height adjustment can be carried out and mobile operation can becarried out, thus the crushing efficiency is improved, the development of the waste plastic recycling industry is promoted, prevention of the problem that the white pollution is intensified is facilitated, and the device has important significance on the environment protection.

Owner:江都区众扬物资经营部

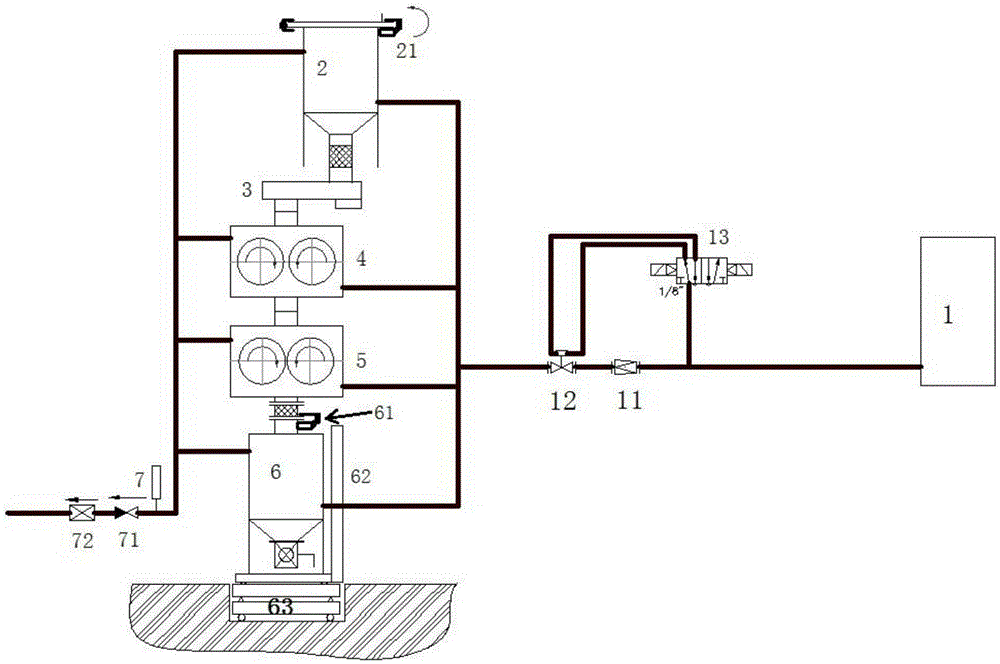

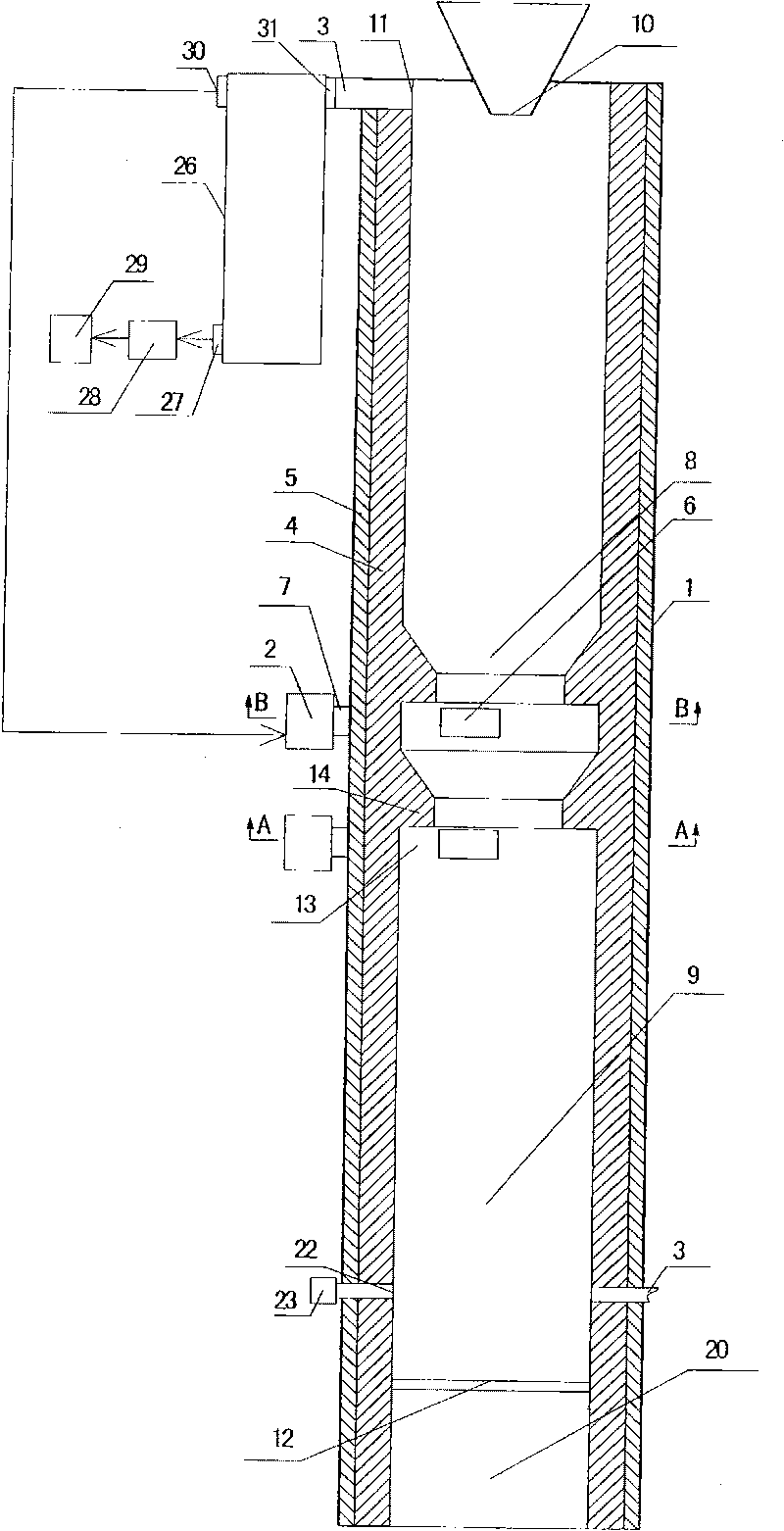

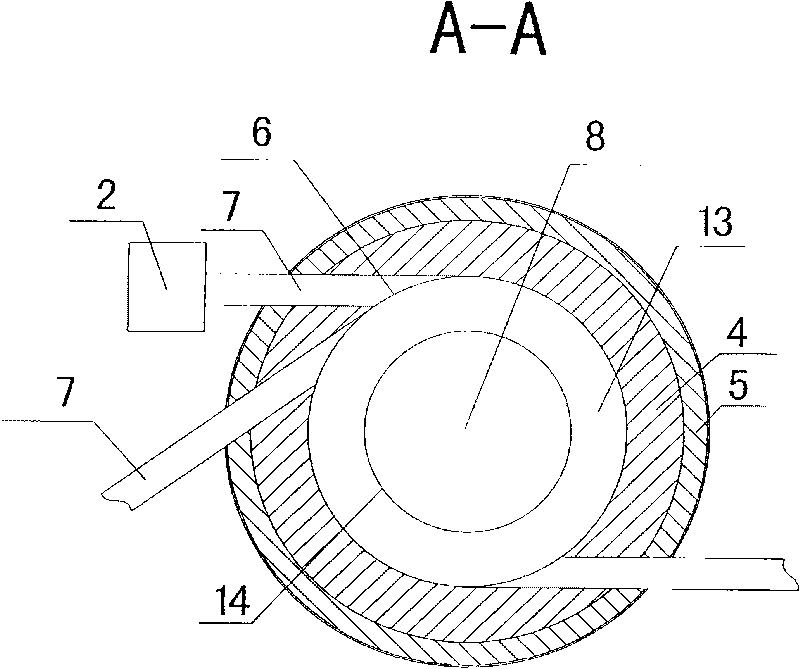

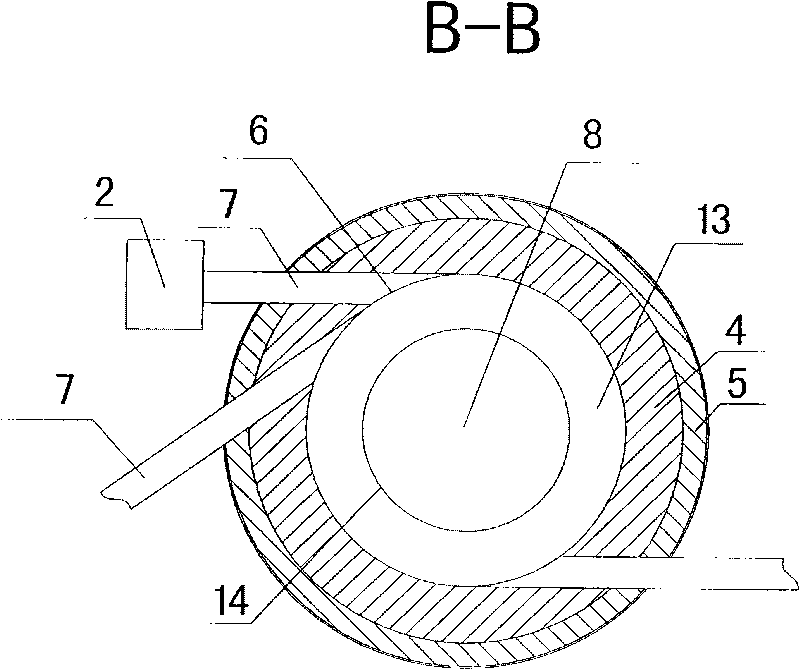

Magnesium alloy crushing system and method

The invention discloses a magnesium alloy crushing system and a magnesium alloy crushing method. The magnesium alloy crushing system comprises a gas source, an upper hopper, an electromagnetic vibration feeder, an upper-section double-roller crusher, a lower-section double-roller crusher, a lower hopper and an oxygen gas detector, wherein the upper hopper, the electromagnetic vibration feeder, the upper-section double-roller crusher, the lower-section double-roller crusher and the lower hopper are sequentially connected from top to bottom; the upper hopper, the upper-section double-roller crusher, the lower-section double-roller crusher and the lower hopper comprise a gas inlet close to the bottom and a gas outlet close to the top; the gas source is connected with the gas inlet through a pipeline; the gas outlet is connected with a gas exhaust tube; the gas exhaust tube is provided with the oxygen gas detector; two pipelines are connected with the gas source, one pipeline is connected with the gas inlet through a pressure reducing valve and a pneumatic ball valve, and the other pipeline is connected with an electromagnetic directional valve. According to the magnesium alloy crushing system, the working environment is safe, a little of gas-source gas is used, the device structure is simple, and the operation is convenient. And requirements on an environment are low, the crushing cost is low and the recycling efficiency is high.

Owner:南京中锗科技有限责任公司

Shaft kiln

The invention discloses a shaft kiln, which comprises a fuel supply device, an ignition device, a discharge device, a kiln chamber, a refractory material, an insulating material, a fan and a pipeline. The side wall of the kiln chamber is provided with at least one air inlet which is at least connected with an air inlet passage. The fan is arranged on the air inlet passage. The kiln chamber is provided with a heating chamber and a cooling chamber, wherein the lower part of the heating chamber is communicated with the cooling chamber; the upper part of the heating chamber is provided with a feed inlet and an air outlet for the heating chamber; and the lower part of the cooling chamber is provided with a discharge outlet. The discharge outlet is provided with the discharge device; and at least one flame path is arranged on the side wall of the kiln chamber between the heating chamber and the cooling chamber, and is communicated with the air inlet. Due to the use of heat convection and vortexes for combustion, the shaft kiln is more energy-saving and environment-friendly. The vortexes are formed in the kiln chamber by using forced air, so that the material is uniformly heated. The movement of hot air around the material replaces a heating mode of rolling the material, and the material naturally moves to a preheating zone, a heating zone, and a cooling zone by using natural sedimentation. The shaft kiln can be applied to burning cement, lime, alumina and other blocked materials.

Owner:陈久斌

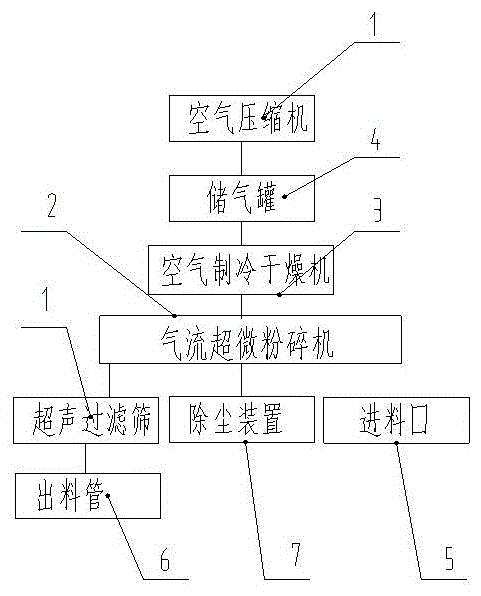

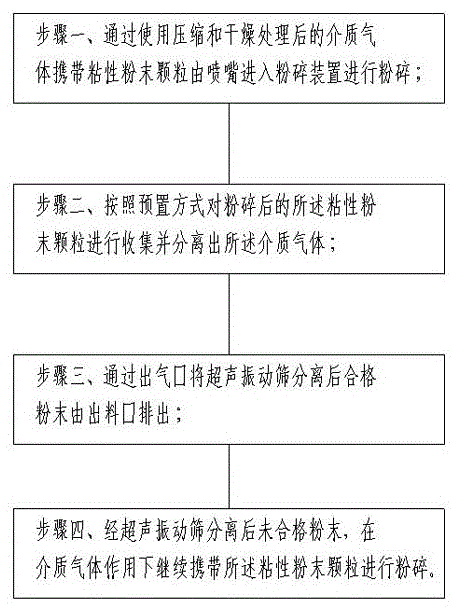

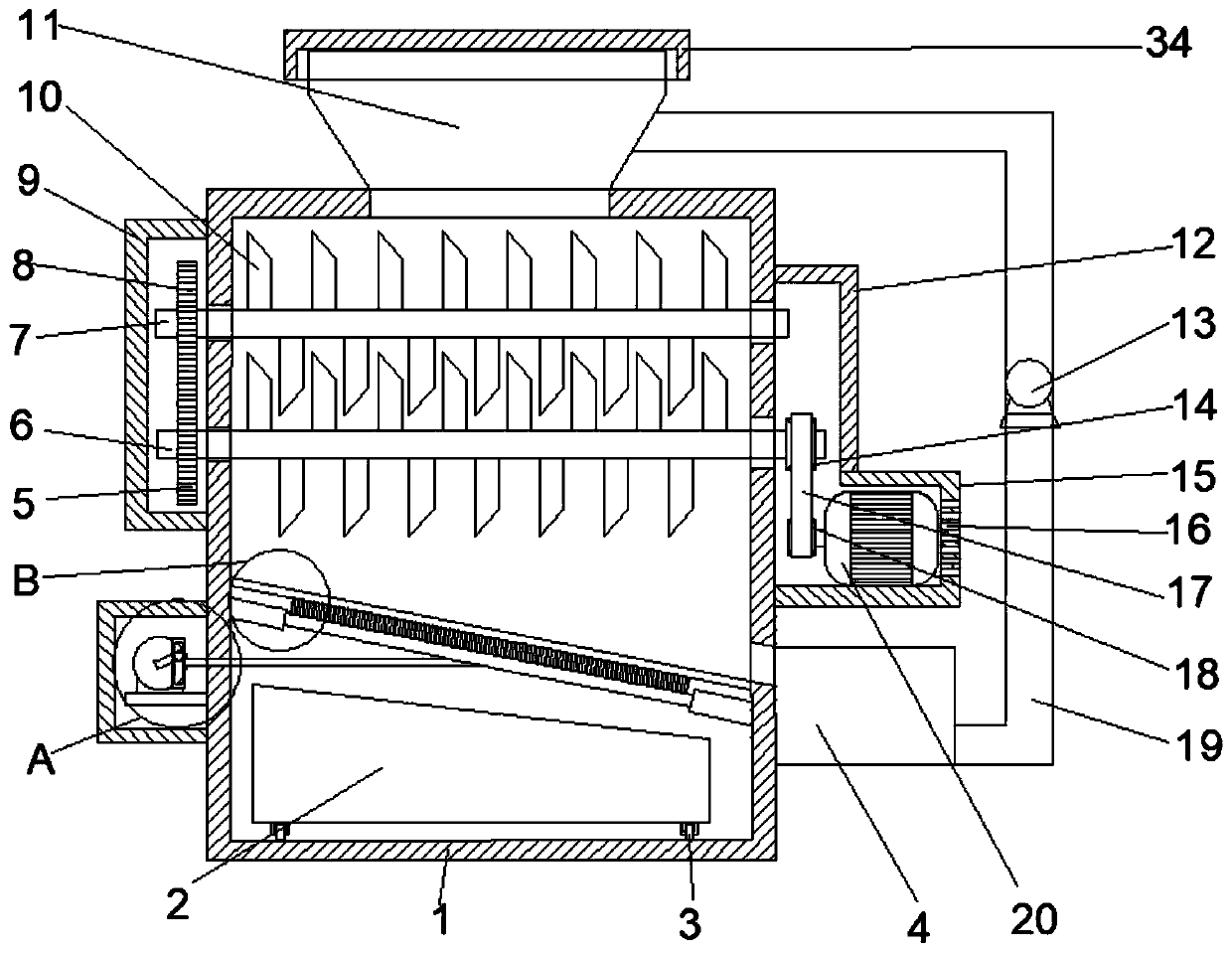

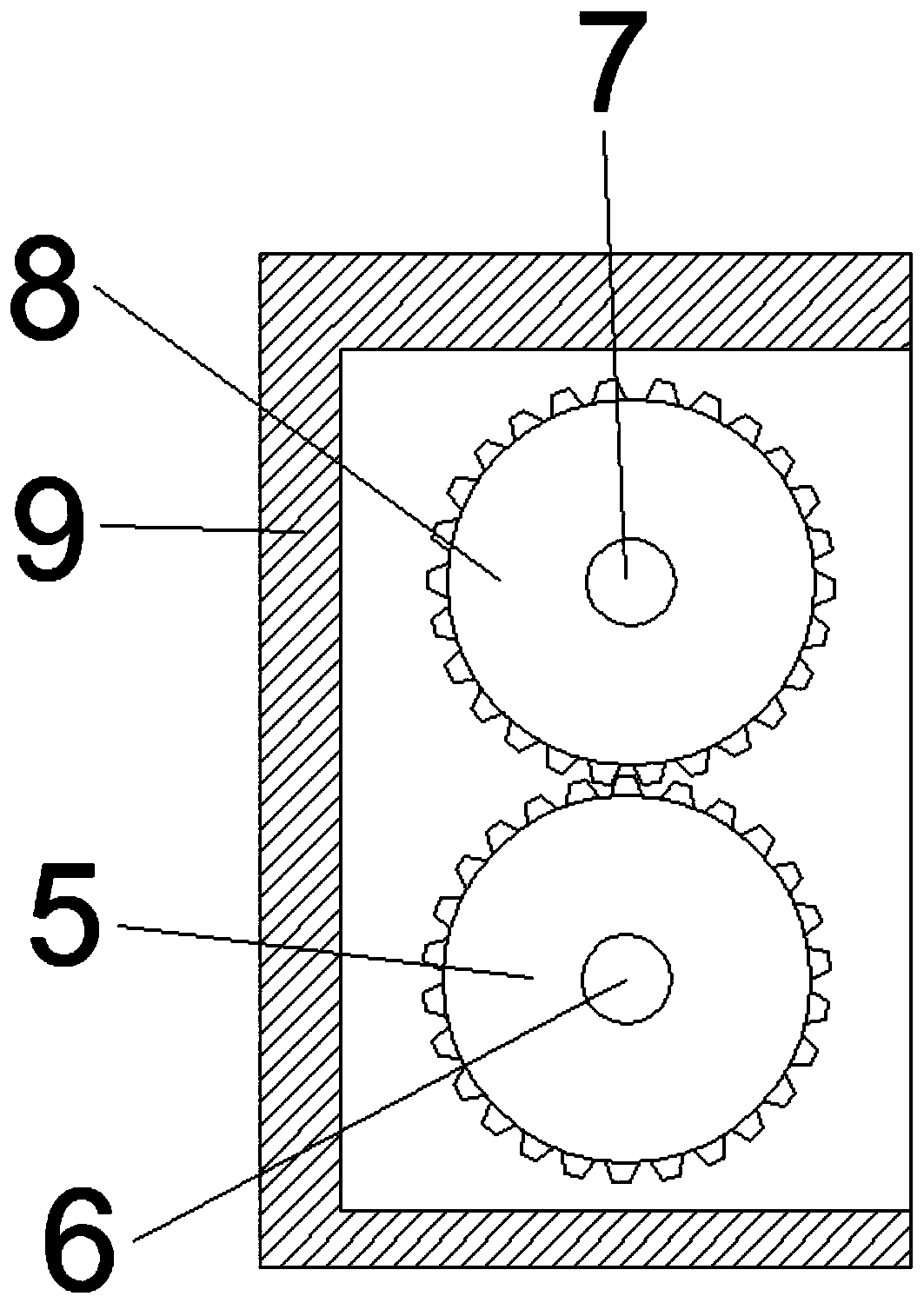

Airflow powder grinding system and powder treatment process

InactiveCN105080687AReduce the temperatureGuarantee that the efficacy of the ingredients remains unchangedGrain treatmentsGas compressorEngineering

The invention discloses an airflow powder grinding system and a powder treatment process. The airflow powder grinding system comprises an air compressor and an airflow ultrafine grinder which are sequentially connected. An air refrigerator is connected between the air compressor and the airflow ultrafine grinder. An air inlet of the air refrigerator is connected the air compressor, and an air outlet of the air refrigerator is connected with the airflow ultrafine grinder. An air storage tank is connected between the air compressor and the air refrigerator, and the airflow ultrafine grinder is connected with a dust removal device. By means of an airflow ultrafine grinding system, the temperature of compressed air can be lowered, and it is guaranteed that the components and effect of powder are not changed. An ultrasonic vibration screen is adopted, so that adhesion, friction, flat reducing, wedging in and other screen blocking factors can be restrained through ultrasonic vibration waves attached to the screen, screening efficiency and screen cleaning efficiency are improved, grinding precision is improved, and grinding cost is reduced.

Owner:四川省有色冶金研究院有限公司

Method for cultivating edible fungi with cotton stalk column block type nutrition matrix

InactiveCN102422774AStrong growthDense fruiting bodyHorticultureFertilizer mixturesBiotechnologyNutrition

The invention discloses a cultivating method of edible fungi, which comprises the step of taking 12 cm-18 cm cotton stalk as a main material and doping an auxiliary material to form column block type nutrition matrix for cultivating edible fungi; the edible fungi have one of following proportioning by weight: in the first formulation, the main material is 80-84 parts of cotton stalks, the auxiliary materials are 4-8 parts of soybean meal, 2-6 parts of wheat bran, 3-5 parts of lime, 1-3 parts of superphosphate, 1-3 parts of plant ash, and 0.08-0.12 parts of partricin; in the second formulation, the main material is 60-64 parts of cotton stalks, the auxiliary materials are 19-23 parts of cotton seed hulls, 4-8 parts of soybean meal, 2-6 parts of wheat bran, 2-4 parts of lime, 1-3 parts of superphosphate, 1-3 parts of plant ash, and 0.08-0.12 parts of partricin. The nutrition matrix is prepared by the following method: crushing the main material, softening the mixed materials, setting up fungi growing column blocks, and growing the fungi. According to the method provided by the invention, 12 cm-18 cm cotton stalks cut into sections are adopted as the main material, the expensive cotton seed hulls are not used or used in less quantity, so that the cost for crushing the cotton stalks is reduced 40%, the total cost is reduced, the production efficiency is improved, and meanwhile, then a new route for changing and utilizing the cotton stalks is found.

Owner:河北省农业环境保护监测站

Urban solid waste crushing device

The invention discloses an urban solid waste crushing device. The urban solid waste crushing device comprises a box, a fine material storage box, wheels, a coarse material storage box, a first gear, afirst rotary shaft, a second rotary shaft, a second gear, a first protective box, cutters, a feed port, a fixed box, a material pump, a first belt pulley, a supporting box, heat dissipation holes, abelt, a second belt pulley, a feed pipe, a first motor, a supporting plate, a second motor, a rotary rod, a second protective box, a moving plate, a moving rod, a fixed block, a groove, a supporting block, a telescopic rod, a mesh screen, a brush, an inclined rod and a cover. The bottom end of the side face of the box is provided with a discharge port. The discharge port is consistent with the fine material storage box in size. The bottom end of one side of the outer portion of the box is fixedly connected with one end of the second protective box through bolts. The urban solid waste crushingdevice is simple in structure and convenient to use, avoids manual moving of coarse materials, conducts secondary crushing on coarse materials, reduces the labor force and facilitates screening on crushed materials through the mesh screen.

Owner:FUZHOU JIN XIANG FOOD MACHINERY & EQUIP TECH

A combined charged crushing device for scrapped lithium-ion power lithium batteries

The invention discloses a charged crushing assembly device of a scrapped lithium-ion power lithium battery, and belongs to the field of waste battery crushing. The charged crushing assembly device solves the problems that an existing battery crushing technology easily generates combustion and easily generates explosion. A battery double-shaft shredding machine is arranged above a waste battery; a feeding hopper is arranged above the battery double-shaft shredding machine; a spray head is arranged inside shredding equipment to prevent combustion explosion; the upper end of an open type loader is arranged on the side wall of the feeding hopper; the lower end of a sealed type loader extends into a waste water tank; the upper end of the sealed type loader is connected with a feeding hole of a hammer type crusher; the upper end of the feeding hopper, the sealed type loader and a gas outlet of the hammer type crusher are connected with an inlet end of a suction ventilator through an air suction pipeline; and an outlet end of the suction ventilator is connected with a waste gas treater. The charged crushing assembly device adopts a direct charged crushing mode and does not need to discharge a battery, so that the period of crushing the battery is shortened, universal performances are strengthened, personnel operation is convenient, performances are reliable and the charged crushing assembly device is safer.

Owner:哈尔滨巴特瑞资源再生科技有限公司

Palm sheet drying and crushing machine

InactiveCN104494193AOvercome technical difficulties of incomplete decompositionReduce work intensityCocoaDrying solid materialsFiberReciprocating motion

The invention discloses a palm sheet drying and crushing machine. The palm sheet drying and crushing machine consists of a compression chamber, a heating chamber, a crushing chamber and a discharge storehouse, which are successively communicated, wherein a feed opening is formed in the top of the compression chamber, the compression chamber is communicated with the heating chamber through an upper pressing plate and a lower pressing plate, and a pressing block capable of doing reciprocating movement to the opposite side is mounted on one side in the compression chamber; a plurality of material pressing rolls capable of heating and drying a palm sheet are mounted at an upper position and a lower position in the heating chamber, and toothed cutters are respectively arranged on all the material pressing rolls; the crushing chamber consists of a lateral crushing storehouse and a longitudinal crushing storehouse, wherein the bottom of the longitudinal crushing storehouse is communicated with the discharge storehouse. The palm sheet drying and crushing machine disclosed by the invention solves the technological difficult problem that because the fiber entanglement of the palm sheet is tighter, the fiber decomposition of the palm sheet is incomplete, a form of cutting after the heating and the drying is adopted to cooperate with a manner of lateral and longitudinal crushing, at the premise that the complete crushing is sufficiently ensured, the work intensity of a cutter head is reduced, the work efficiency is improved, and the crushing cost is reduced.

Owner:TIANJIN CITY SHANGDE WIRE MACHINERY

Waste organic glass cutting and crushing device

InactiveCN105437410AEfficient crushingReduce noisePlastic recyclingGrain treatmentsNeck partsDrive motor

The invention relates to the recycling field of organic glass, in particular to a waste organic glass cutting and crushing device which comprises a feeding structure and a crushing structure, wherein the crushing structure comprises a primary crushing cavity, a secondary crushing cavity, a primary crushing part arranged in the primary crushing cavity and a secondary crushing part arranged in the secondary crushing cavity; the primary crushing cavity and the secondary crushing cavity are connected by virtue of a neck part; the primary crushing part comprises two drive rolls driven by a drive motor, a conveyor belt arranged on the outer rings of the two drive rolls, and a cutting roll arranged above the conveyor belt; a cutting blade is arranged on the cutting roll; a cutting point of the cutting blade is within the surface of the conveyor belt; and the drive rolls drive the conveyor belt to move. The waste organic glass cutting and crushing device can be used for efficiently crushing the waste organic glass, and is small in noise, so that the working efficiency is improved and the crushing cost is reduced on the premise of guaranteeing complete crushing.

Owner:SHANDONG HEISHAN GLASS GROUP

Plastic waste smashing device

InactiveCN107457942AReduce volumeConvenient granulation and reusePlastic recyclingGrain treatmentsPlastic wastePlastic recycling

The invention discloses a plastic waste smashing device, and belongs to the technical field of waste recycling equipment. The device comprises a supporting frame and a machine cover arranged on the supporting frame, a feeding platform is arranged on the side face above the machine cover, a driving hob and a driven hob which are engaged for cutting are arranged above the interior of the machine cover, the feeding platform is connected to the position between the driving hob and the driven hob, an outer cutting column and an inner cutting column which are concentric are arranged at the central position of the interior of the machine cover, cutting teeth are arranged on the inner wall of the outer cutting column, cutting teeth are arranged on the outer surface of the inner cutting column, a gap is arranged between the outer cutting column and the inner cutting column, gaps are formed in the left side and the right side above the outer cutting column, a left partition and a right partition are arranged on the gaps fixedly, and a blanking cylinder is arranged at the bottom of the machine cover. Compared with a traditional waste plastic device, the smashing device has the beneficial effects that smashing cost is saved, smashing efficiency is improved, the waste plastic can be subject to further granulation and recycling conveniently, development of the waste plastic recycling industry is promoted, white pollution is prevented from being intensified, and the device has the important significance in environment protection.

Owner:江都区众扬物资经营部

Multifunctional feeding device for vertical sieving and vibrating sand making machine

PendingCN107282276AAvoid easy cloggingBroken evenly and fullySievingScreeningBreaking strengthEffective solution

The invention discloses a multifunctional feeding device for a vertical screen vibrating sand making machine, which comprises a feeding box body, a material distribution plate and elastic parts; the upper end of the feeding box body is an incompletely closed feeding The lower end surface is a fully-opened discharge port; in the feed box, a distribution plate is arranged transversely relative to its axis; an elastic member is axially arranged between the distribution plate and the feed box; The feed box is located on the square of the impeller of the sand making machine, and the material distribution plate, the impeller, the feed pipe of the sand making machine, and the vibrating mechanism of the sand making machine are arranged correspondingly on the same axis from top to bottom; The material distributing mechanism and the vibrating mechanism on the vertical vibrating vibrating machine work together to make the material make full use of the collision force, and the crushing strength is greater. The above structure can effectively solve the problem of unsmooth discharge of materials in the vibrating vibrating vertical vibrating mechanism and sand making. The problem of low crushing efficiency and insufficient crushing of materials has greatly improved the crushing efficiency and quality of materials, and reduced the energy consumption of crushing.

Owner:尹国祥

Method for fracturing retained filled wall of adjacent coal face

ActiveCN104847406AEliminate the effects of stress concentrationAvoid safety hazardsMaterial fill-upStress concentrationEngineering

Disclosed is a method for fracturing a retained filled wall of an adjacent coal face. The method is applicable to continuous pressure relief mining of deep coal seam groups. The method comprises the steps that the arrangement mode and parameters of drilled holes and the explosive load are designed according to the size, the construction mode and the earlier-stage breakage state of the filled wall; one to three rows of downwards-inclined reused drilled holes for construction of the filled wall are retained by a leading coal face for the adjacent coal face in a roadway; one to two columns of drilled holes which are formed in the rear portion of the interior of an end hydraulic support are filled with slurry and explosives and are sealed; and the drilled holes which are formed in the rear portion of the interior of the end hydraulic support and filled with the explosives enter the position behind the coal face along with propulsion of the coal face, fracturing of the filled wall is enhanced through microcracks generated by the earlier-stage mine pressure of the filled wall, and finally the retained filled wall is fractured through the combination between the microcracks and the lagged mining-induced stress influence. According to the invention, the filled wall retained by the adjacent coal face in goaf can be fractured, and therefore the influence of the filled wall on stress concentration in an upper adjacent coal seam and a lower adjacent coal seam is effectively eliminated, the purpose of continuous pressure relief is achieved, and the potential safety hazard of adjacent coal seam mining is eliminated.

Owner:CHINA UNIV OF MINING & TECH

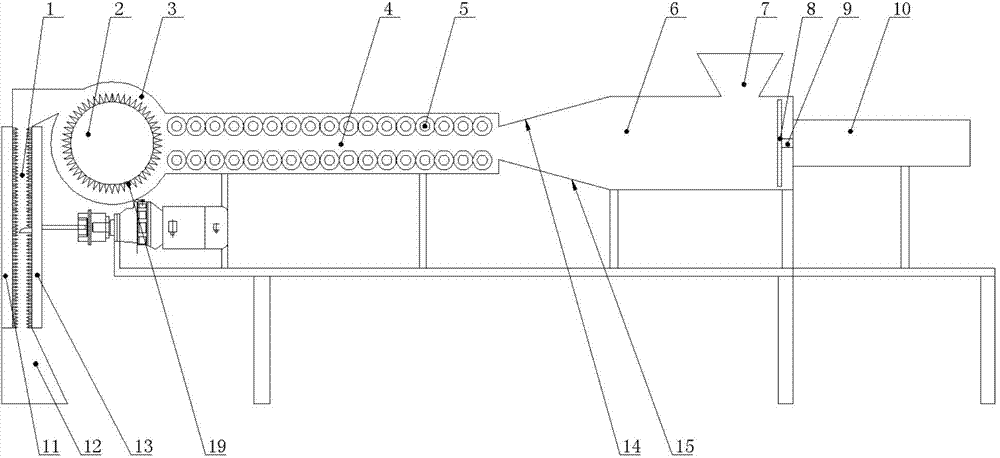

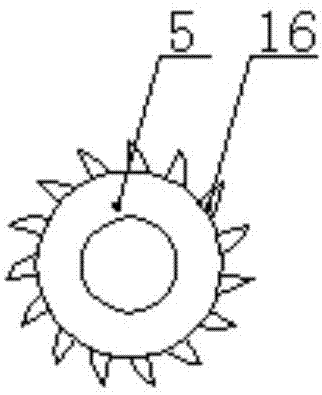

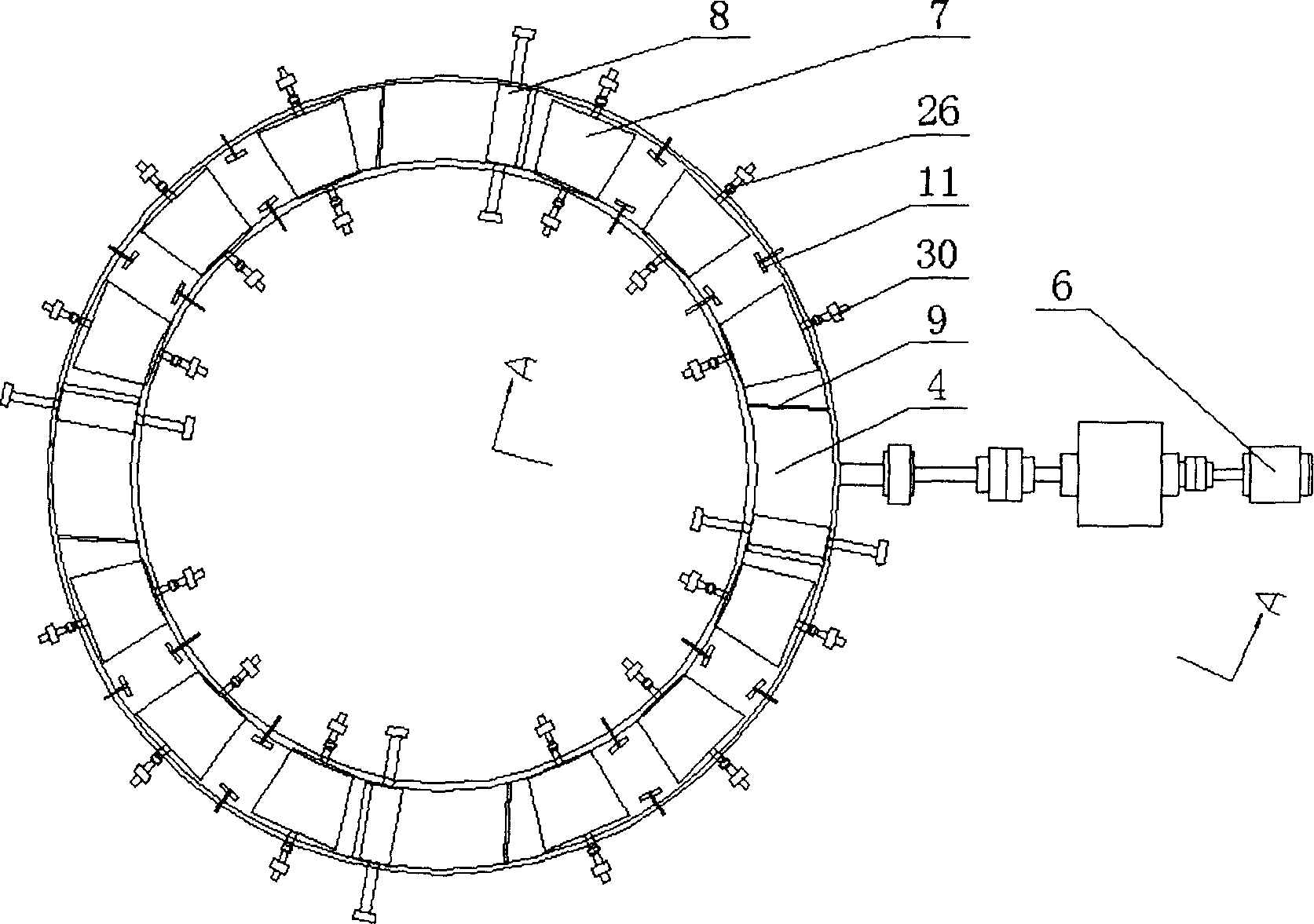

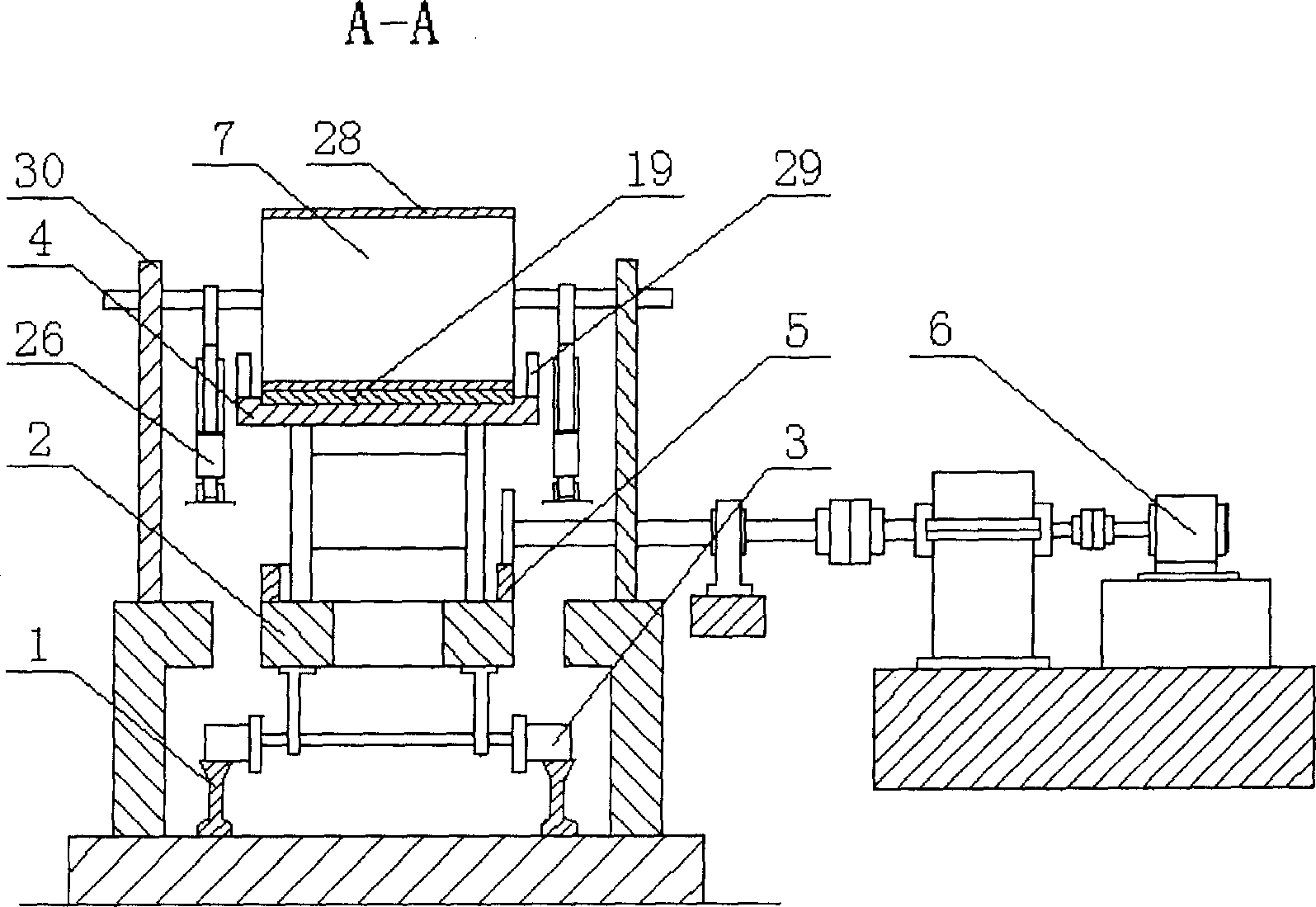

Unit roll-disk breaker

InactiveCN1712136AIncreased crush strengthEfficient crushingGrain treatmentsHydraulic cylinderGear wheel

A unit-type roller-disk pulverizer is composed of an annular grinding disk made up by embedding a flat lining plate on the annular flat bed car on an annular track, an annular machine frame, a toothed ring linked via gear to power mechanism, and 2-10 grinding units on said annular grinding disk. Said grinding unit consists of 2-6 grinding rollers with hydraulic cylinder at its both ends, pulverized material layer controller, unloader, plate cleaner for grinding roller, and material collecting small scraper.

Owner:吴碧碧

Tailing pond selling method

PendingCN112412531AImprove structural strengthEnsure filling safetySolid waste managementMaterial fill-upMining engineeringSlurry

The invention belongs to the technical field of tailing pond treatment, and discloses a tailing pond selling method. The method comprises the following steps of step 1, preparing a filling material byutilizing mining waste rocks and mining tailings in a grading manner; step 2, dewatering the graded filling material; step 3, conducting slurry treatment of the graded filling material; step 4, filling. According to the method, replacement between waste rock mining and the tailing pond mining tailings is formed, specifically, the mining waste rocks are made into sandstone aggregates, and the mining tailings are used for filling a goaf formed by waste rock mining, so that benefit maximization of tailing pond selling treatment is achieved. Specifically, the mining tailings of the tailing pond are subjected to grading treatment, and coarse particle tailings are used as the sandstone aggregates to be sold after pollutants are deeply removed or innocent treatment is conducted. Oversize fine particle tailings are mixed with sandstone waste, and the goaf formed by mining the waste rocks is filled. Undersize fine particle tailings adjust the concentration of filling slurry, and can also be used as a preparation raw material of a novel cementing agent.

Owner:金建工程设计有限公司

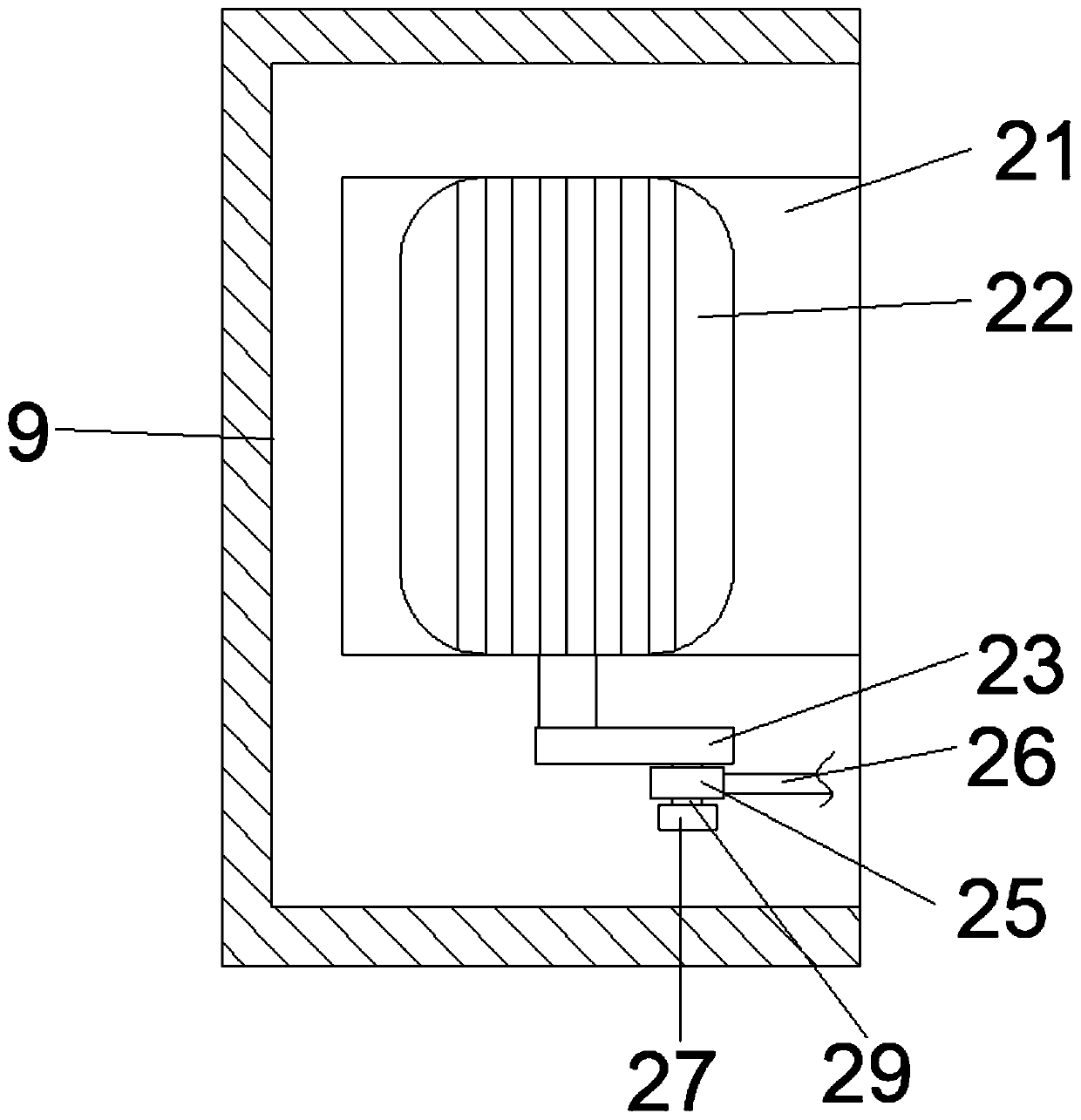

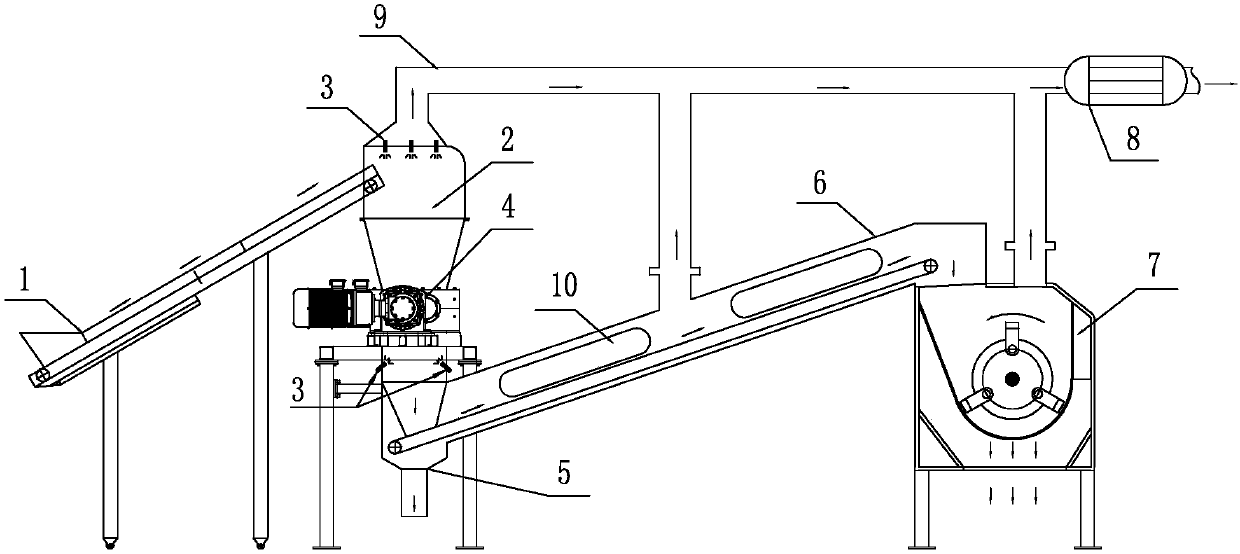

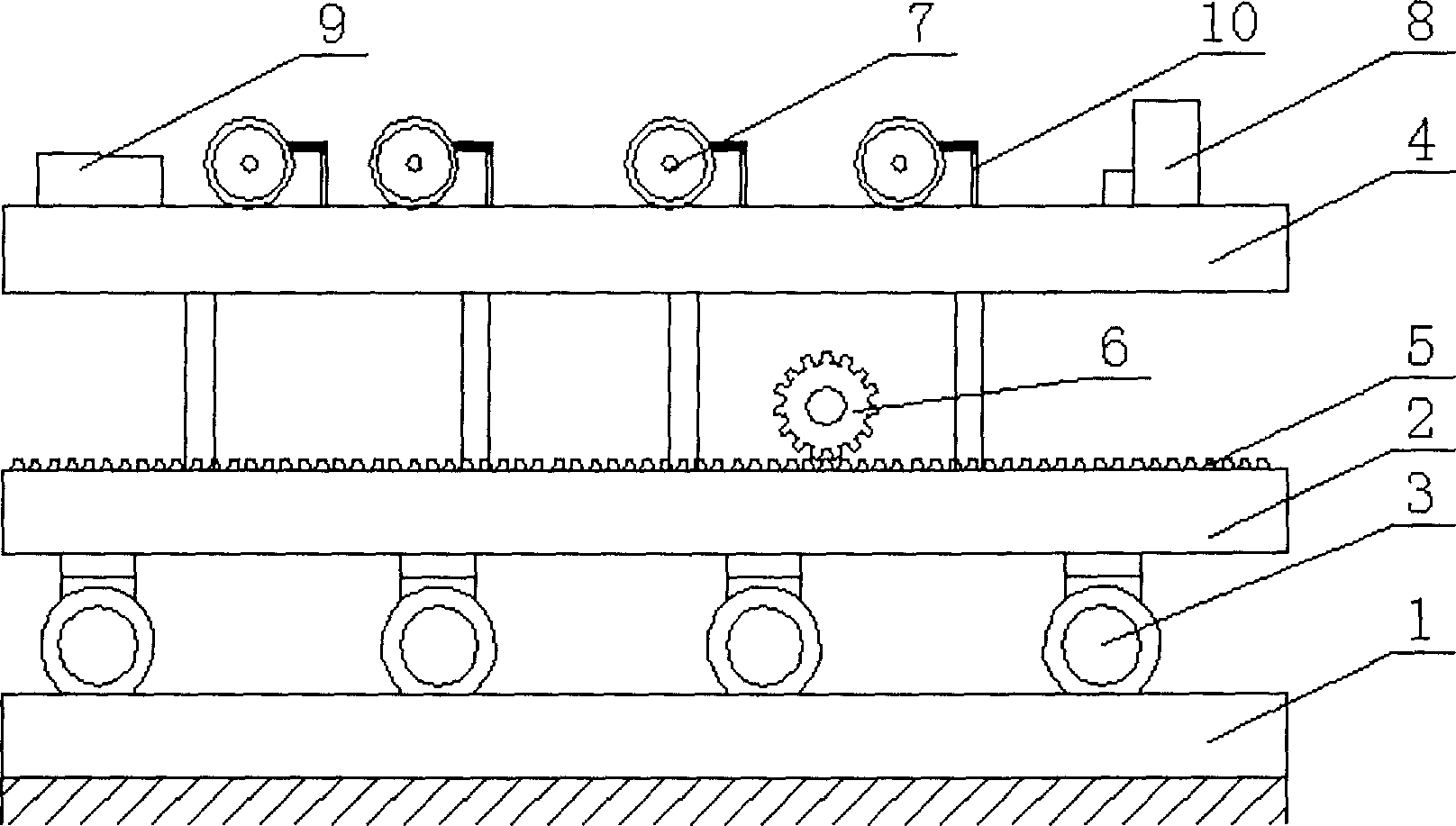

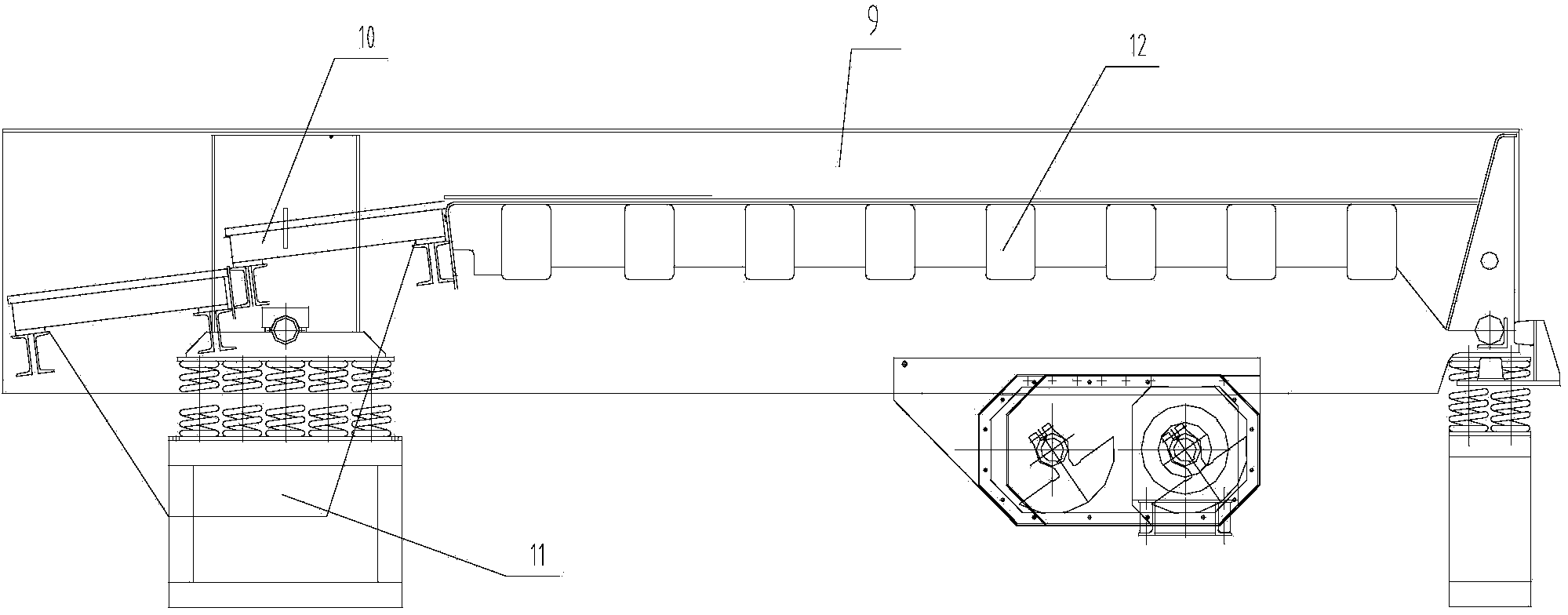

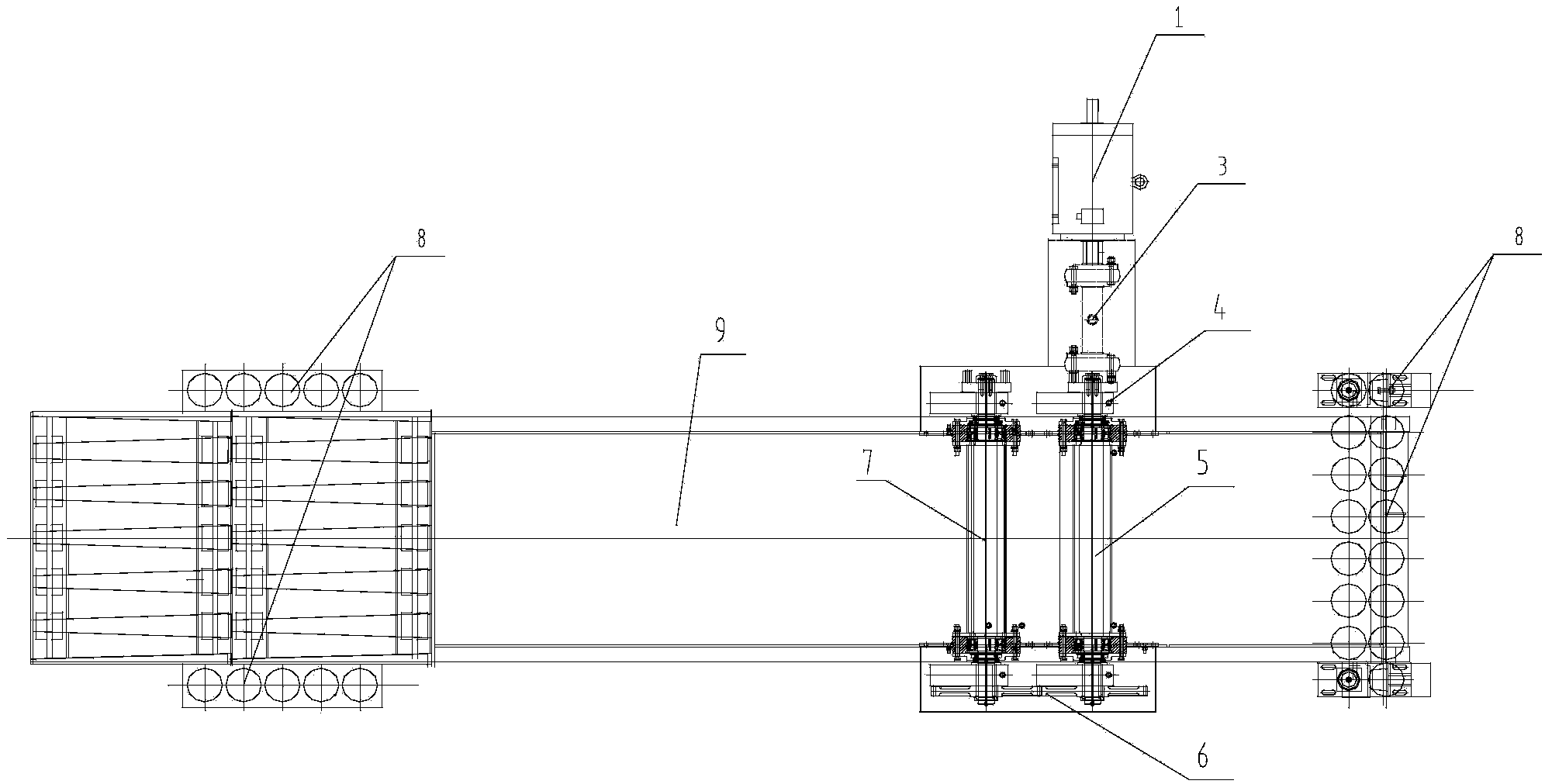

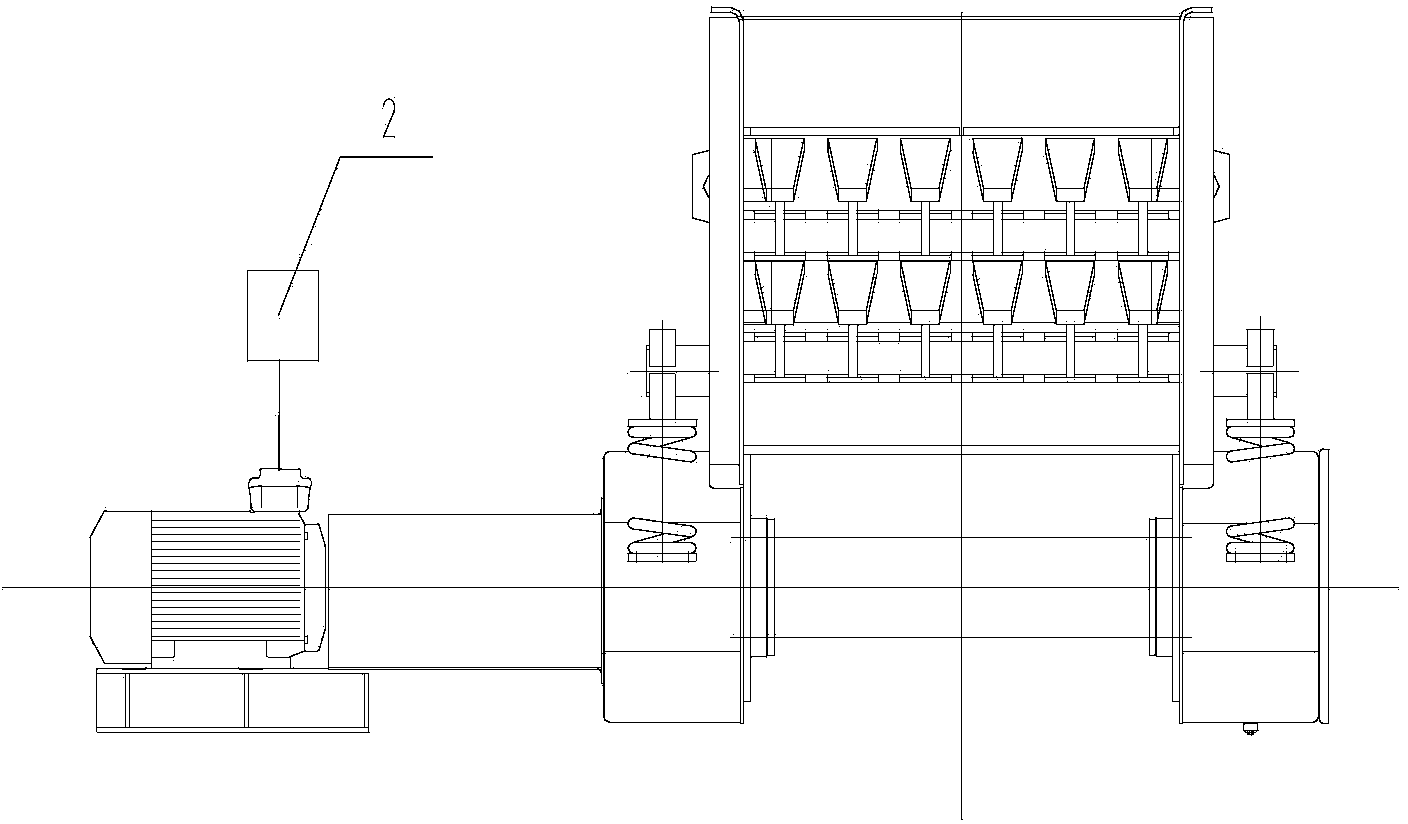

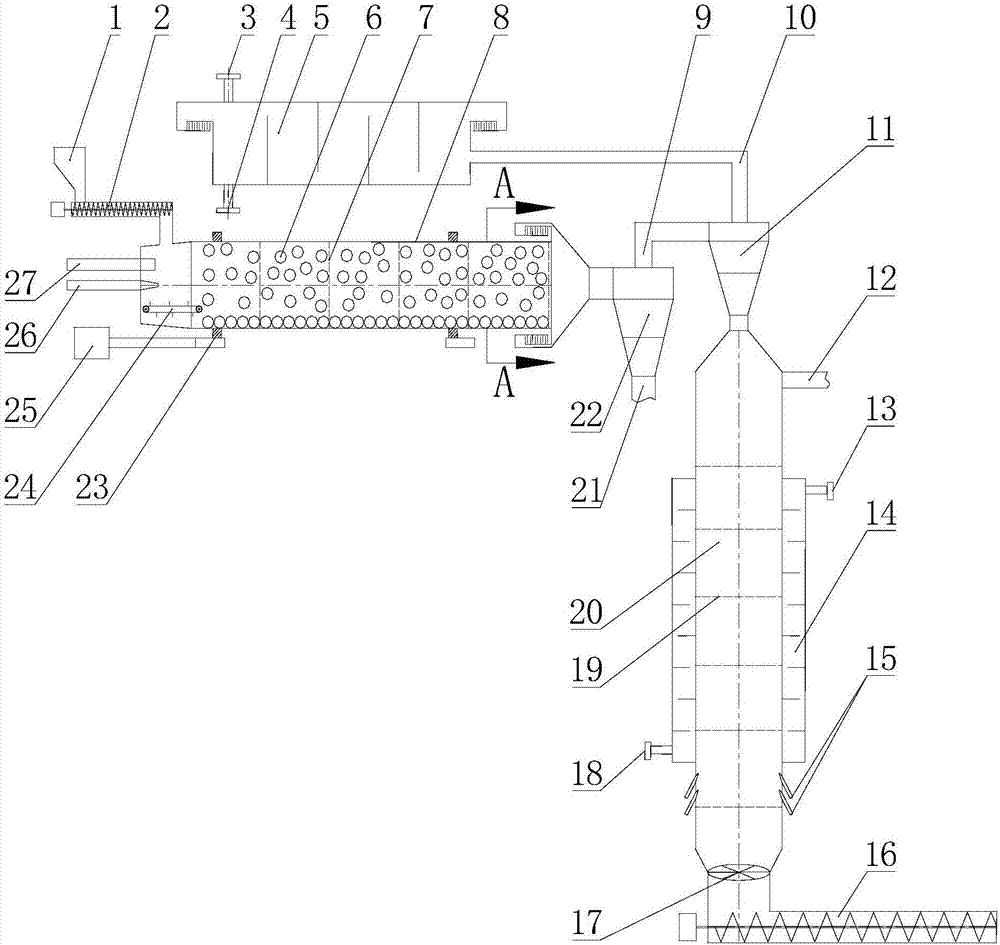

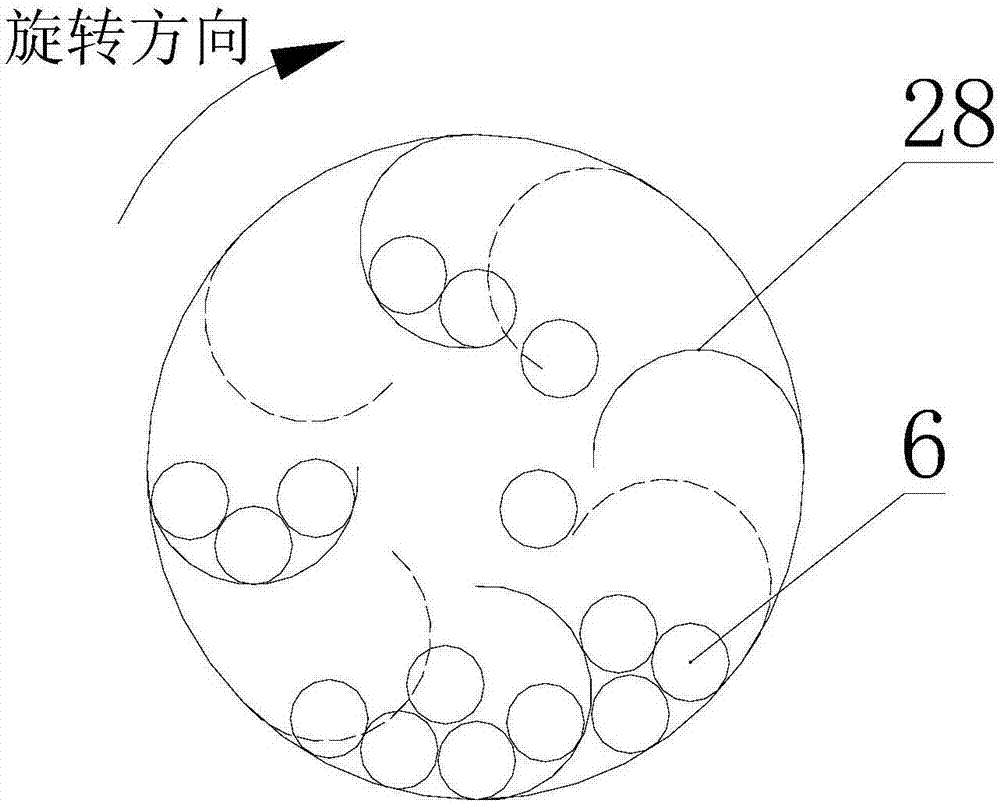

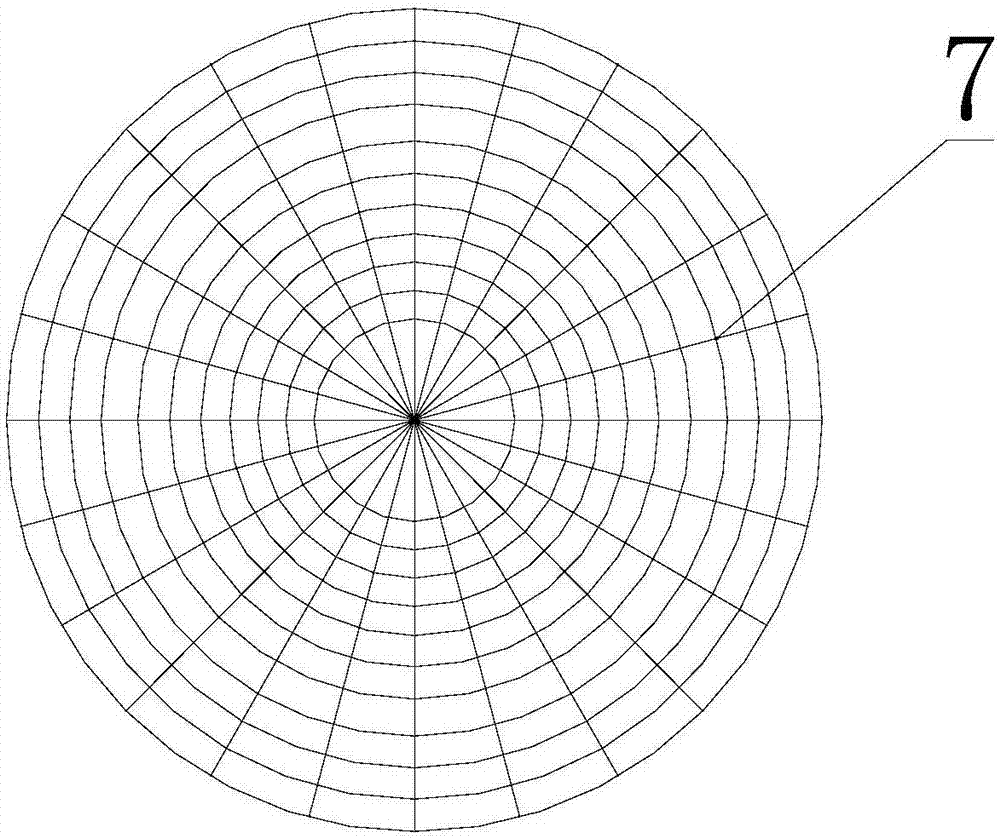

Rod screening and feeding machine

InactiveCN104070007AGreat exciting forceEasy to handleSievingScreeningElectric machineControl system

The invention discloses a rod screening and feeding machine which comprises a feeding machine tank composed of a feeding tank (9), a bar section (10) and a fine screen (11). The feeding machine tank is provided with an excitation system. The excitation system is a double-shaft excitation device. The excitation system is arranged on the lower portion of the feeding machine tank. According to the structure of the double-shaft excitation device, a control system of a motor (1) is connected with a frequency converter (2), a main shaft of the motor (1) is connected with a main eccentric shaft (5) through a flexible coupler (3), and the main eccentric shaft (5) is connected with an auxiliary eccentric shaft (7) through a gear (6) in a transmission mode. The rod screening and feeding machine is large in excitation force and high in processing ability, and the feeding quantity can be convenient to adjust.

Owner:HUNAN ZHAOSHENG MINING MACHINERY

Device for co-producing phenol-enriching liquid and iron-doped carbon electrode material

ActiveCN106995711AAchieve conversionCrushed fullyHybrid capacitor electrodesCarbon preparation/purificationLiquid productBiological activation

The invention discloses a device for co-producing a phenol-enriching liquid and iron-doped carbon electrode material. The device comprises a wood tar catalytic thermal decomposition rotary reactor and an iron-doped carbon activation furnace, wherein the wood tar catalytic thermal decomposition rotary reactor comprises a feeding packing auger, a wood tar spraying nozzle, crushing iron balls, a screen mesh, a rough and fine grain separator and a gas-solid separator; an iron ore catalyst is sufficiently crushed and sieved and is in sufficient contact with wood tar, so that the wood tar is subjected to sufficient catalytic thermal decomposition reaction to generate high-quality phenol-enriching liquid and iron-doped carbon product; the iron-doped carbon activation furnace comprises an activated gas spraying nozzle, rotary fan blades and a high-temperature flue gas flue; high-temperature activated gas forms intensive disturbance under the action of the rotary fan blades and the high-temperature activated gas and iron-doped carbon, which moves downward layer by layer, are subjected to deep activation reaction to prepare a super-capacitor iron-doped carbon electrode material. According to the device disclosed by the invention, two grades of wood tar catalytic thermal decomposition and iron-doped carbon activation reaction are utilized and high-quality phenol-enriching liquid products and super-capacitor iron-doped carbon electrode materials can be prepared; efficient and high-value utilization of the wood tar can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com