Patents

Literature

1714 results about "Neck parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

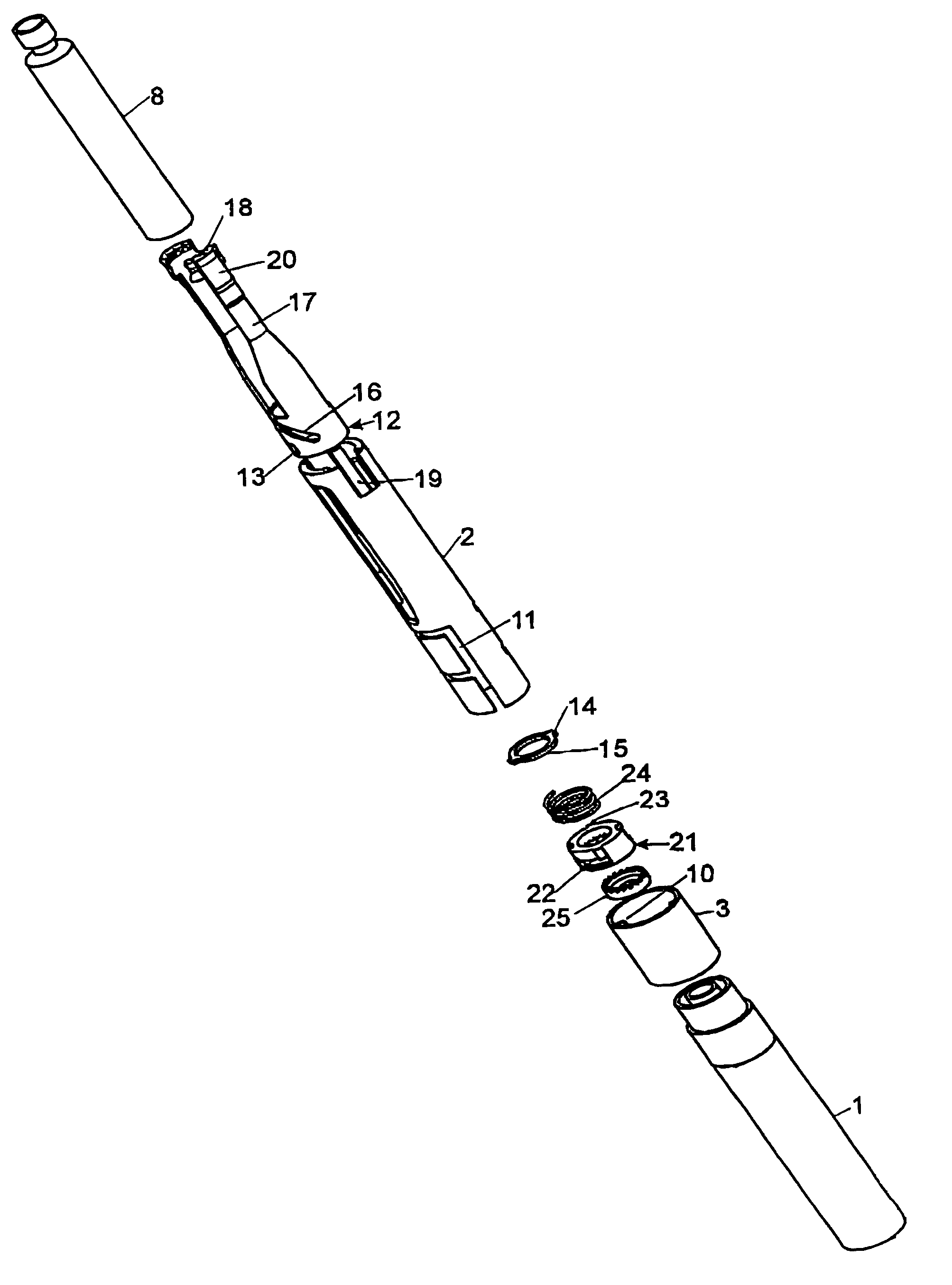

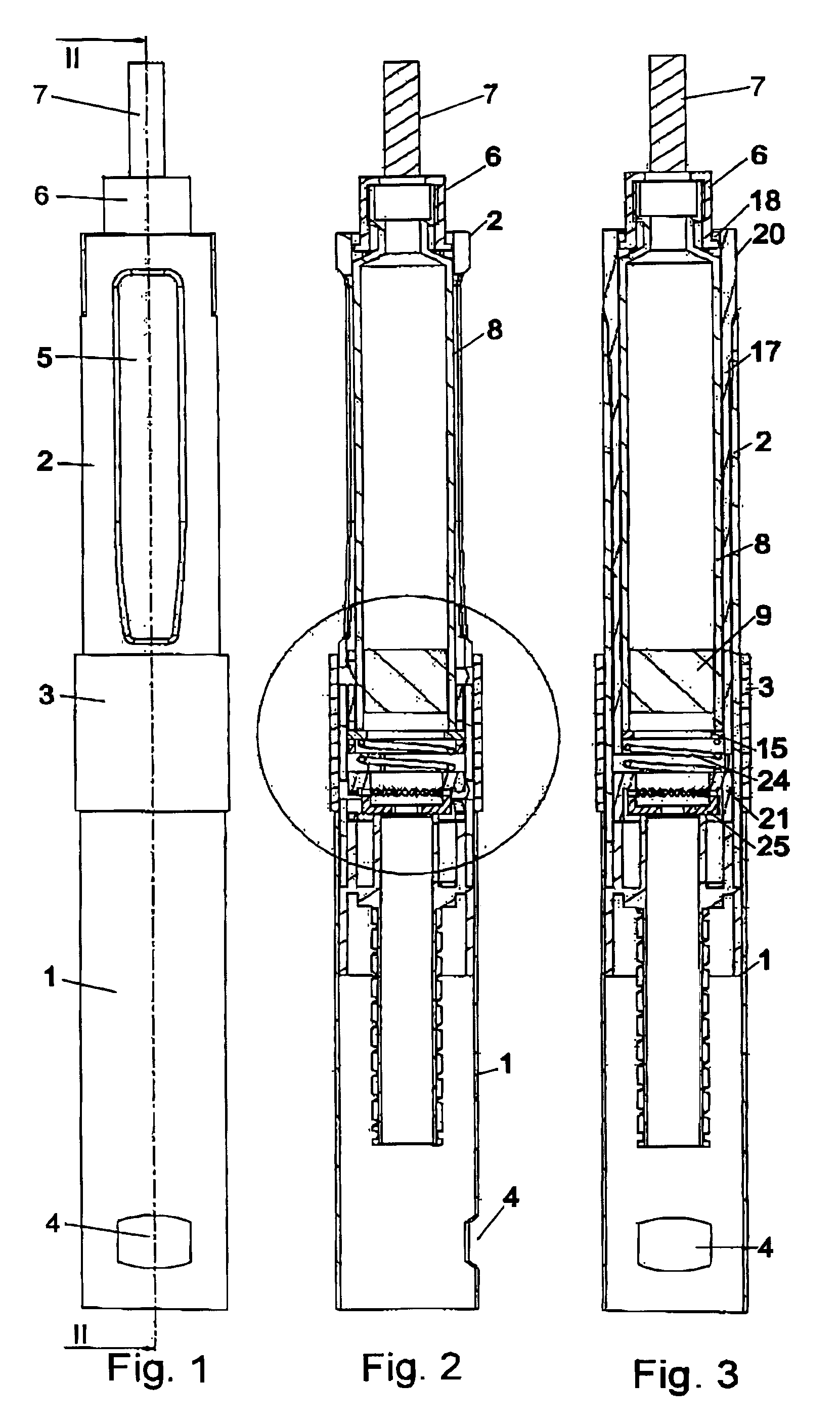

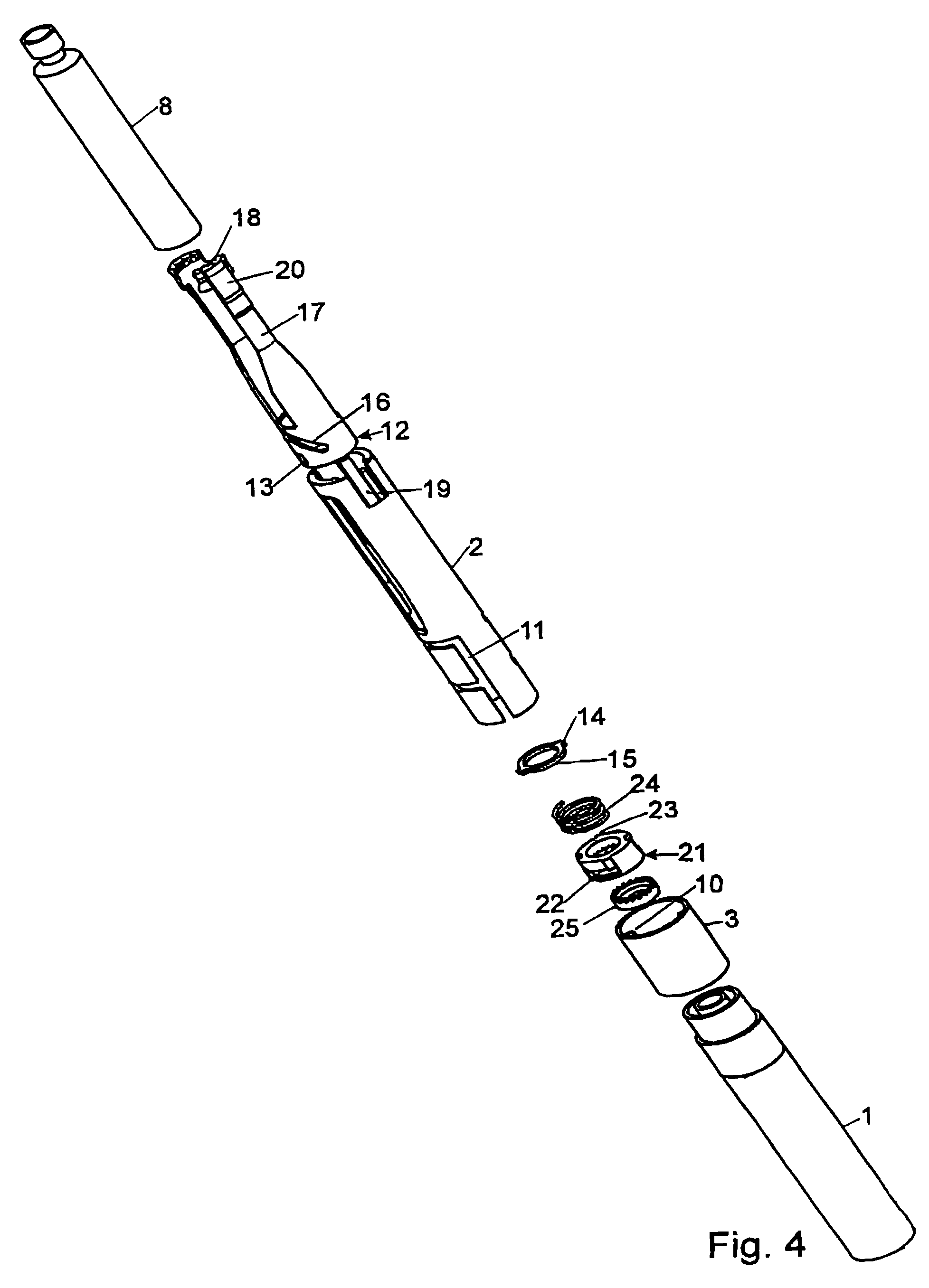

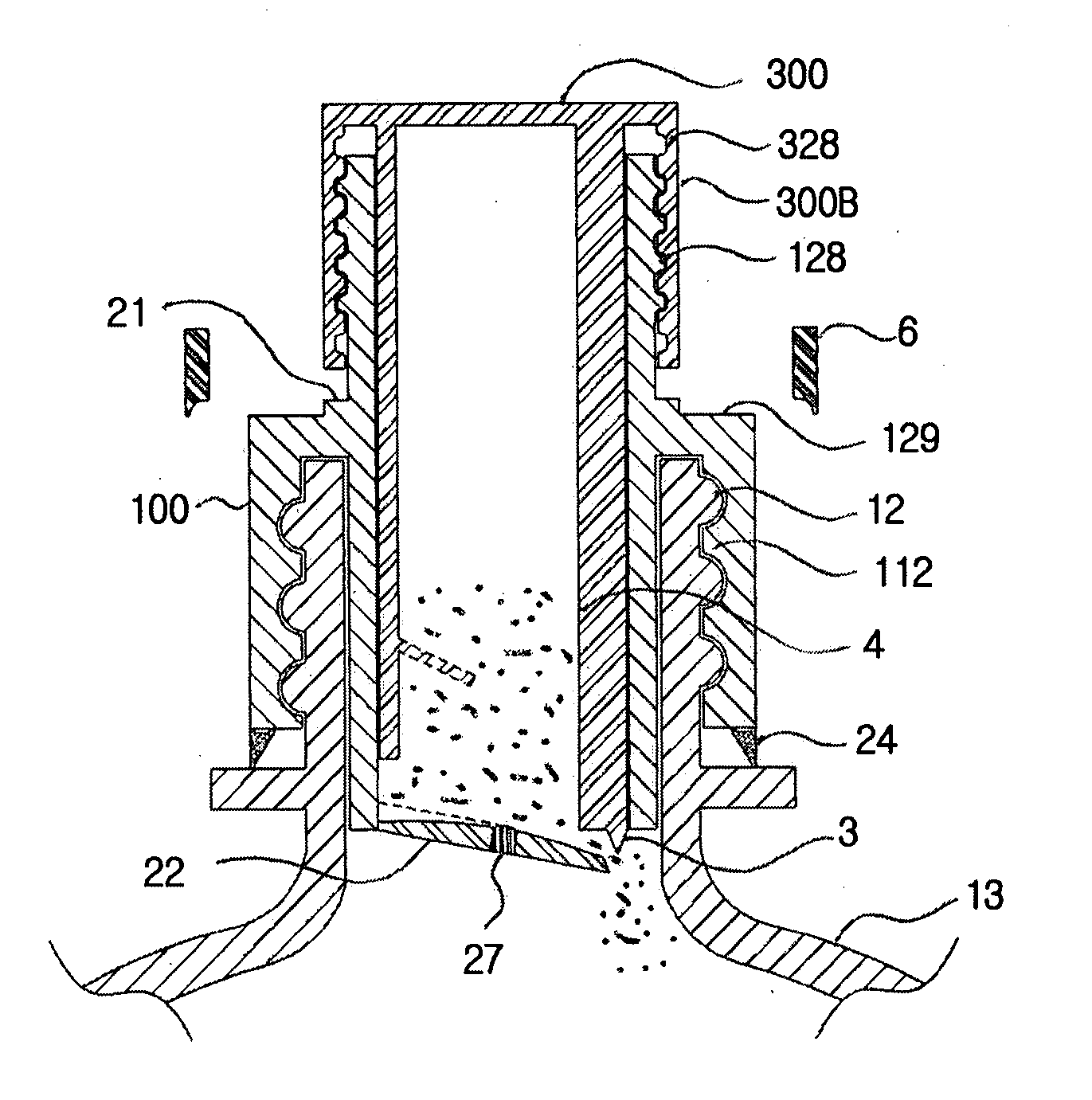

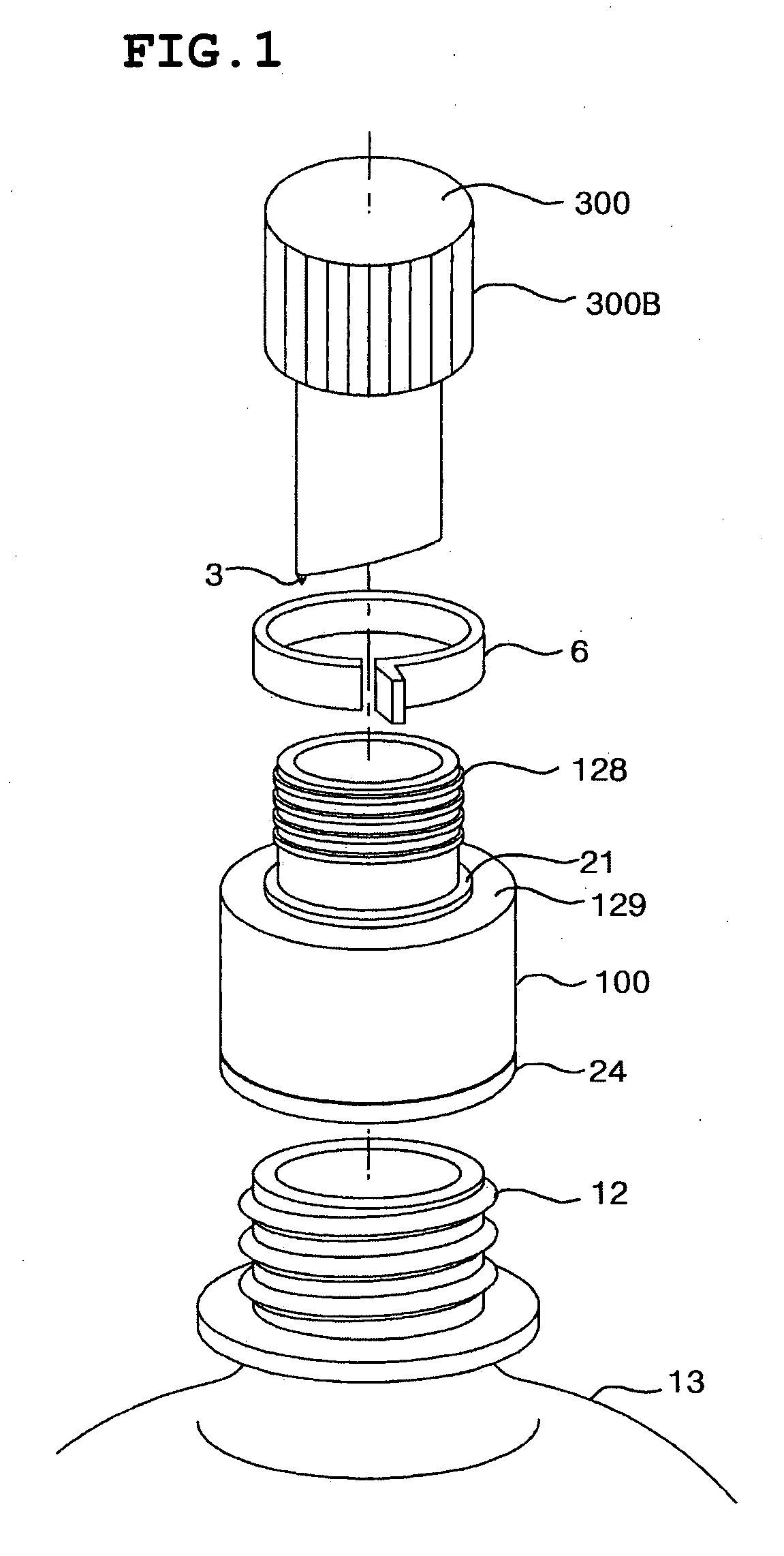

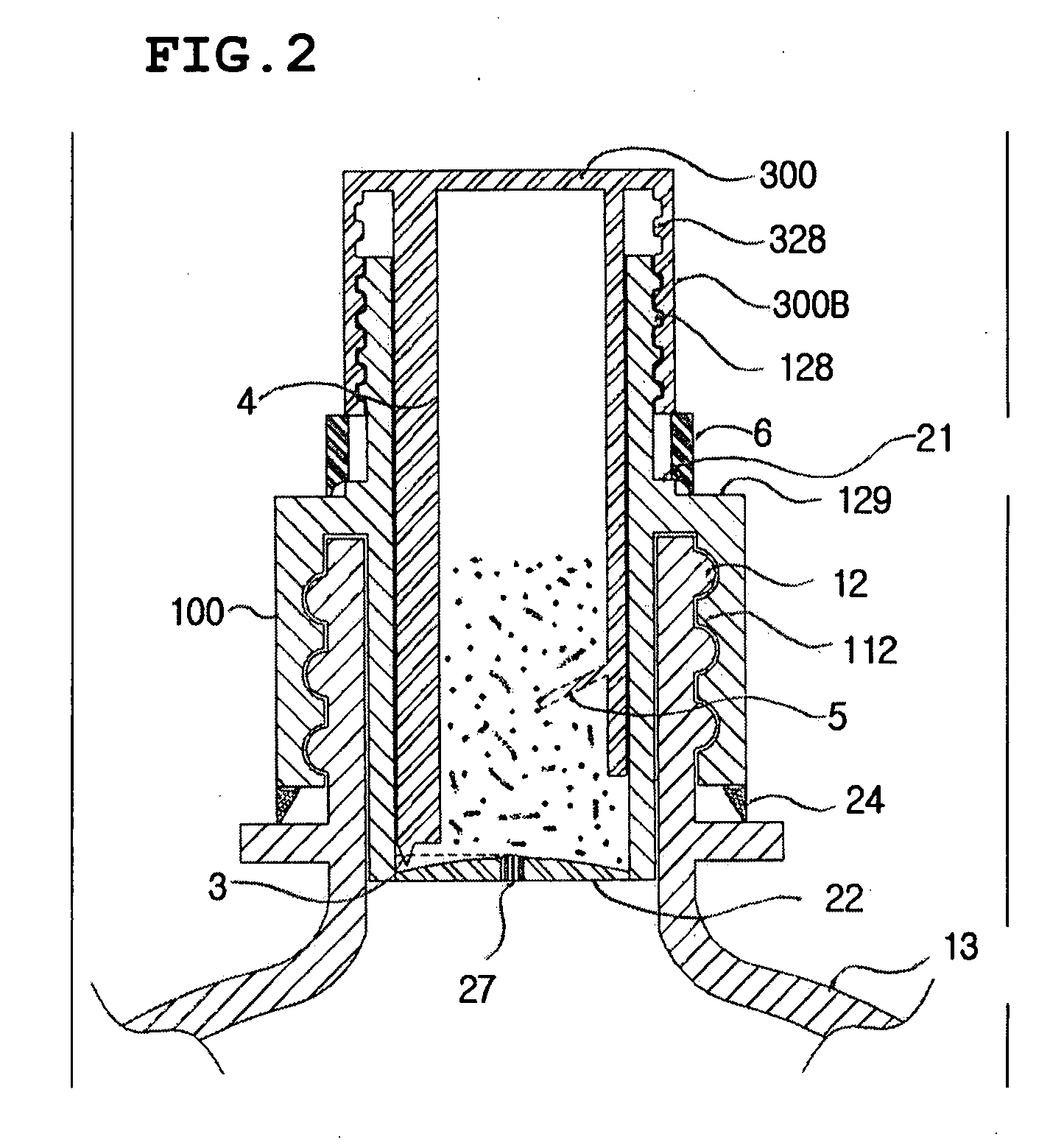

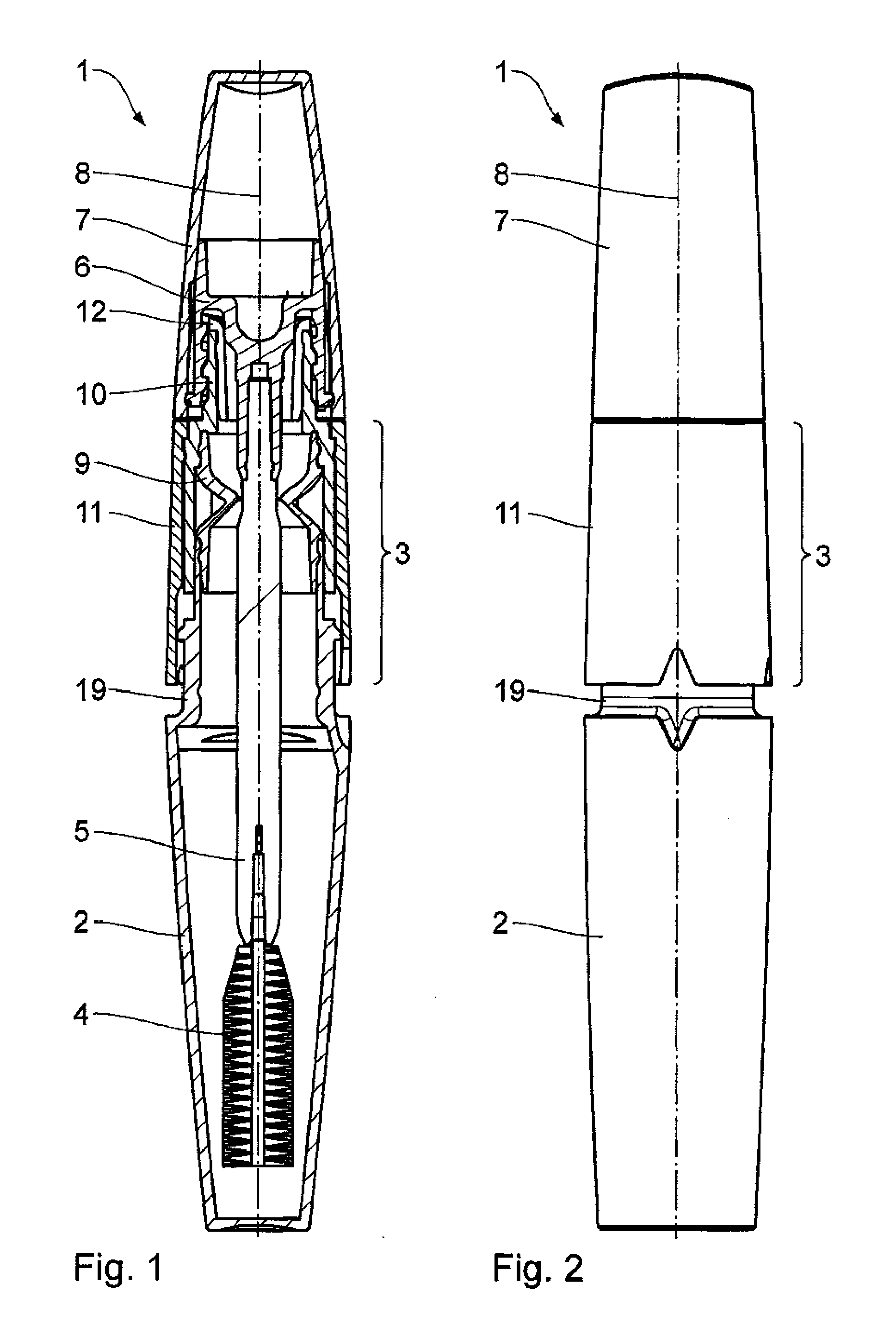

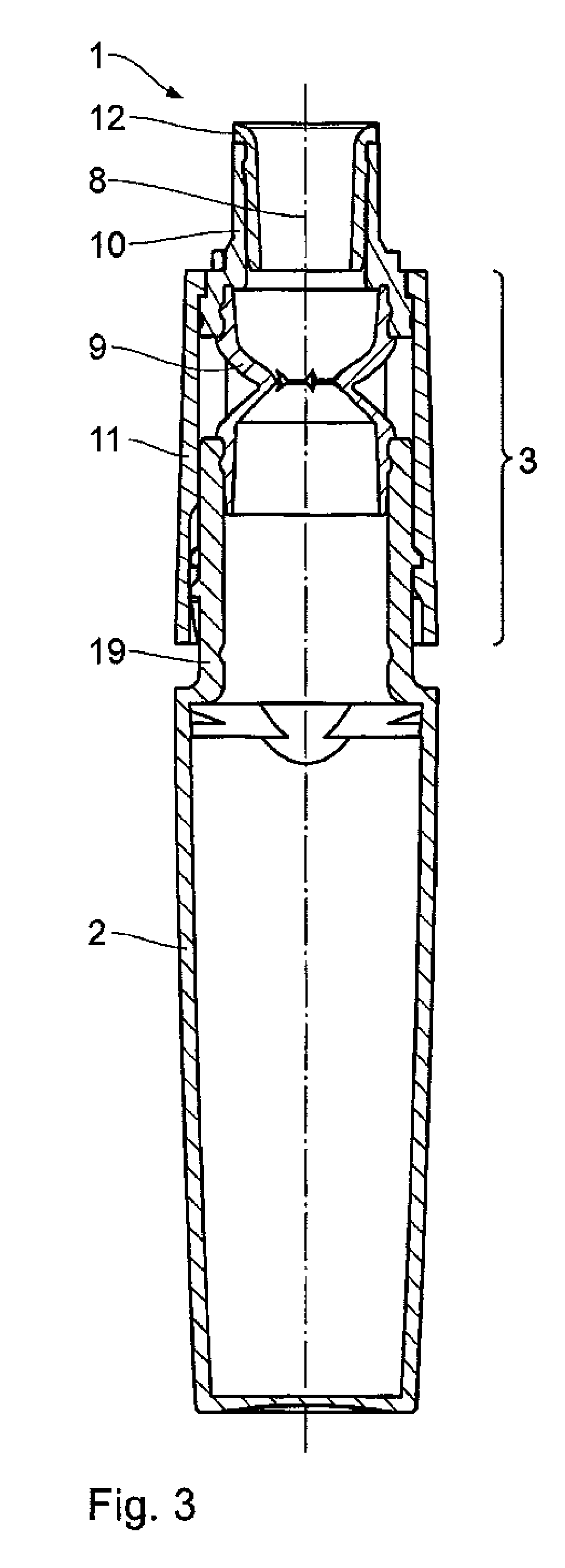

Frontloaded injection device

A frontloaded injection device that includes a cartridge holder into which a replaceable cartridge containing a fluid is inserted. The cartridge holder includes a closing element such as a pair of claws which are displaceable in a radial direction. The closing element is provided at the front of the injection device and locks the cartridge by gripping at the neck part of the cartridge after the cartridge has been loaded into the cartridge holder from the front of the injection device. The closing element is preferably biased in an outwardly radial direction when the locking element is moved axially out of the cartridge holder.

Owner:NOVO NORDISK AS

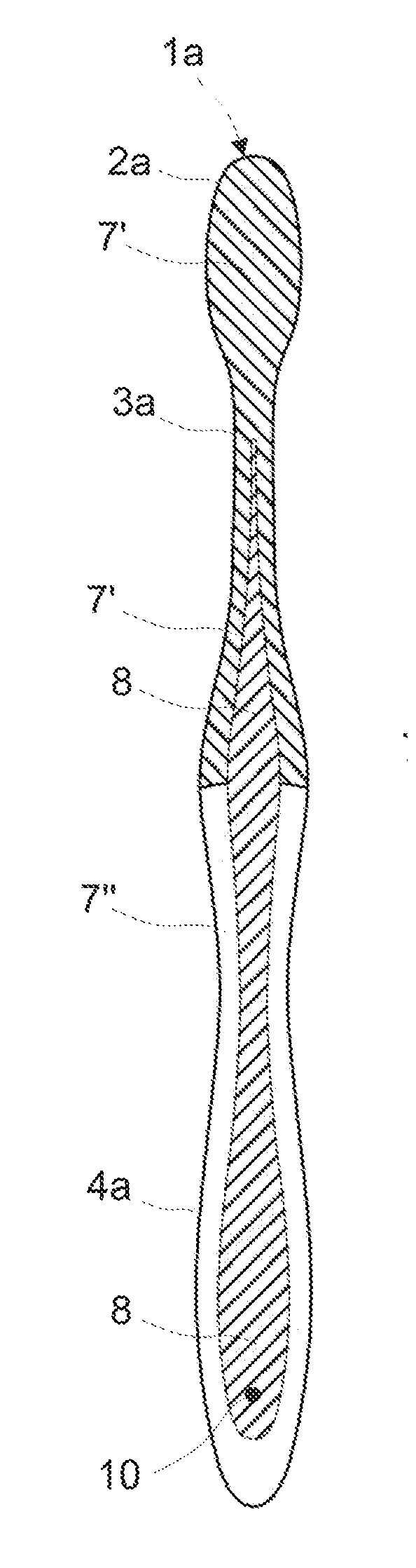

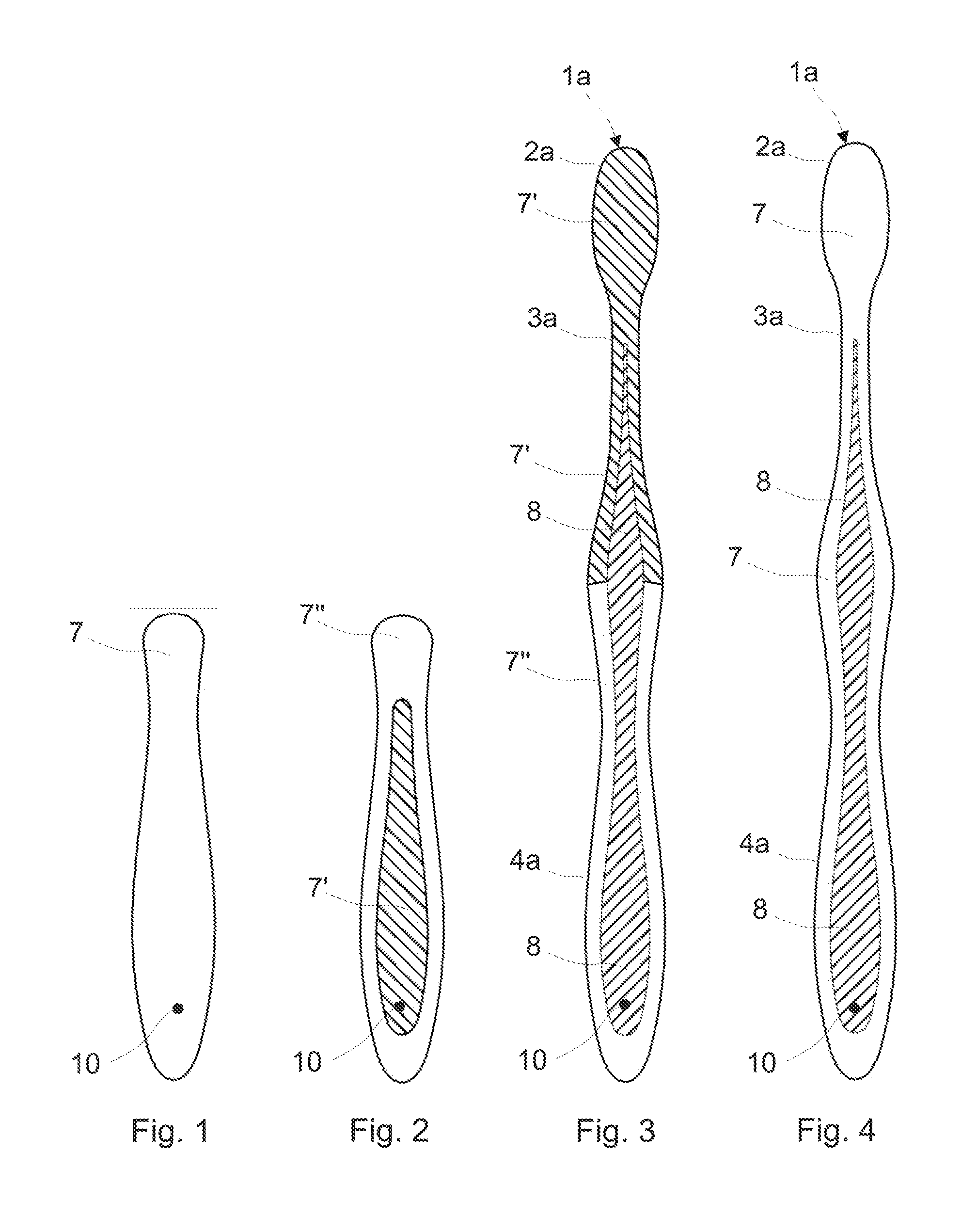

Method for producing a toothbrush, and toothbrush

InactiveUS20140173853A1High degreeFew method stepTravelling carriersHoldersThermoplasticInjection point

A grip body of a body care article, such as toothbrush, includes a grip part, a neck part and a head part. The grip body includes a first and a second material component of a thermoplastic plastic. The first and the second material component have a common injection point that is arranged outside a mould partition line formed by the mould partition.

Owner:TRISA HLDG AG

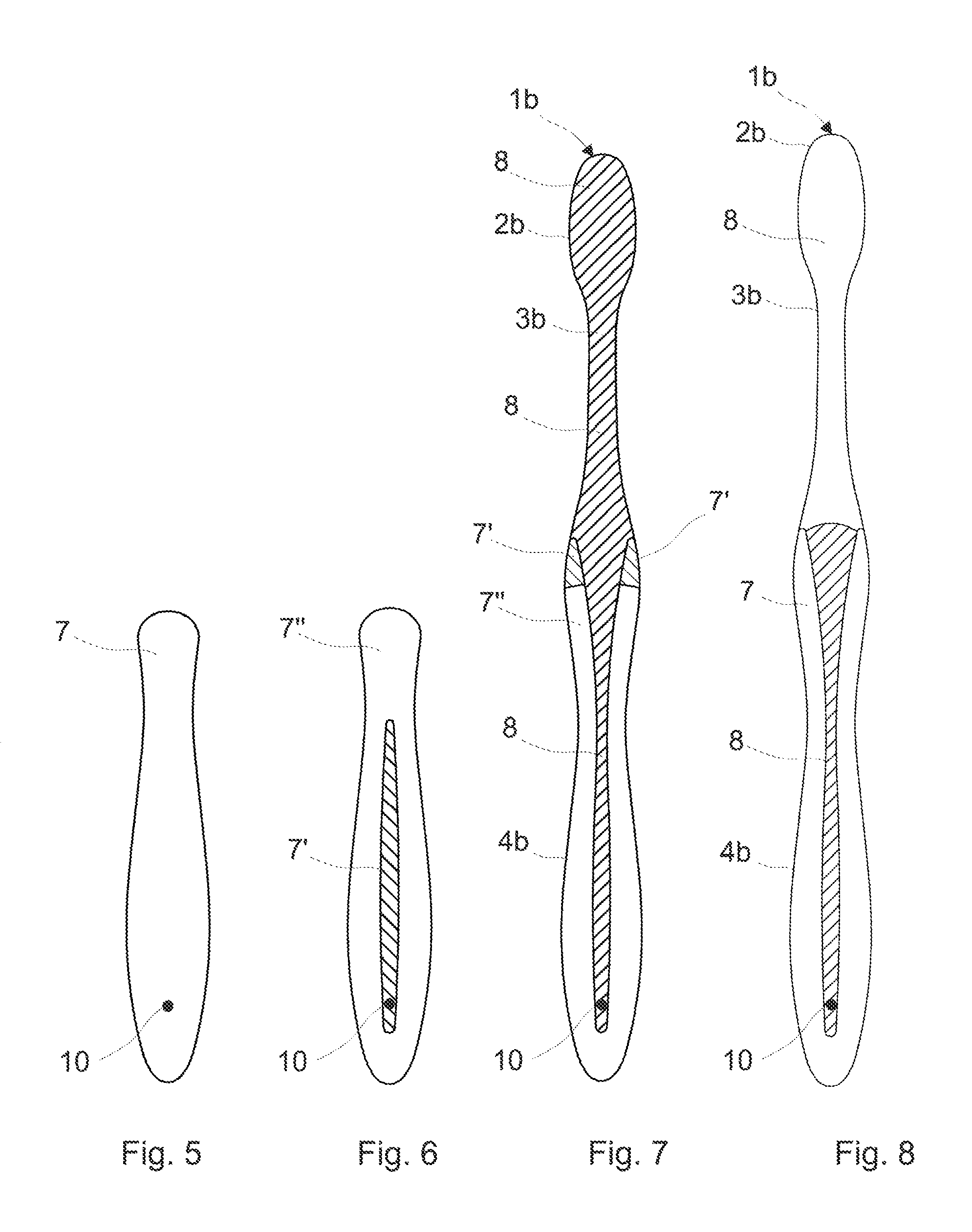

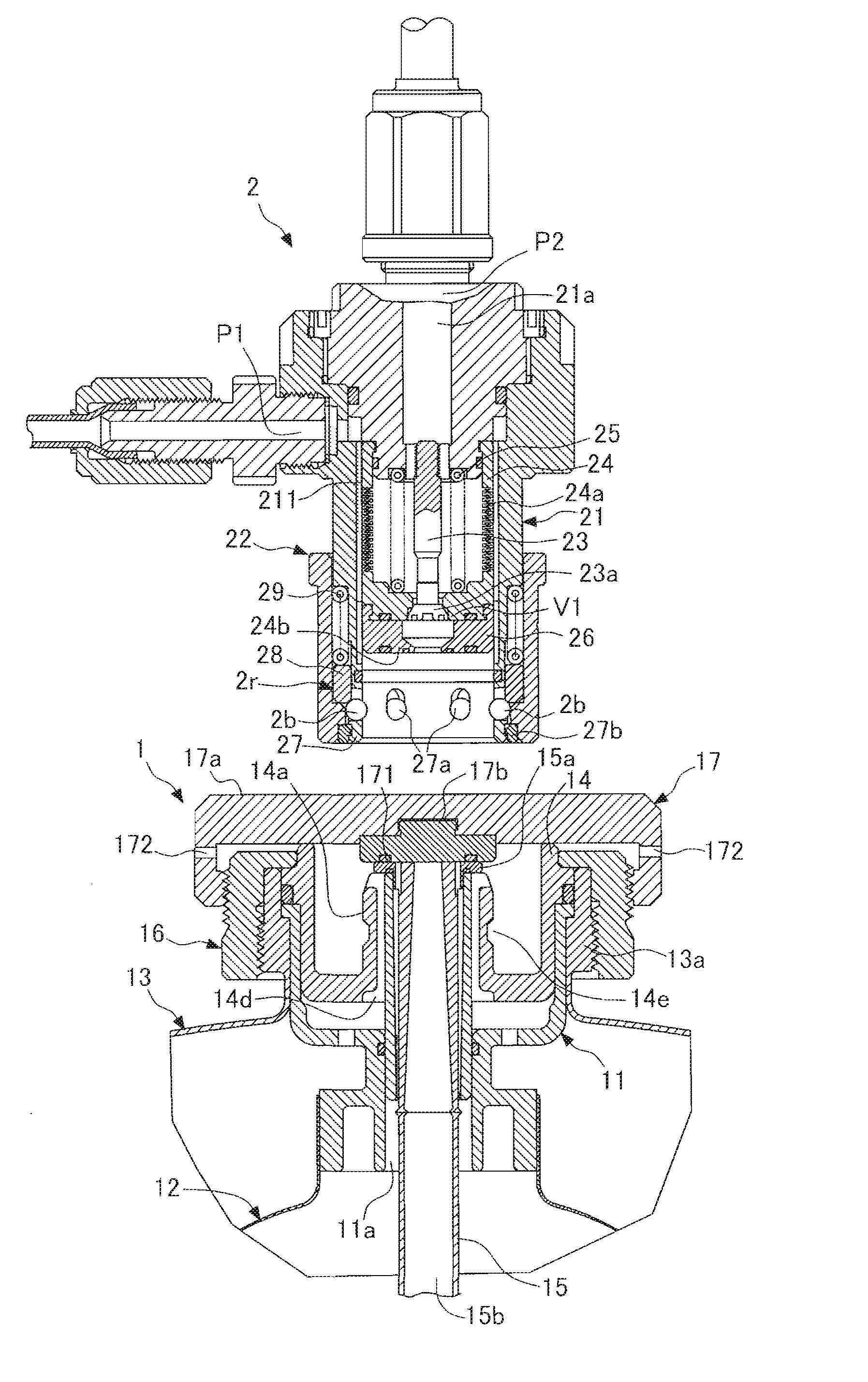

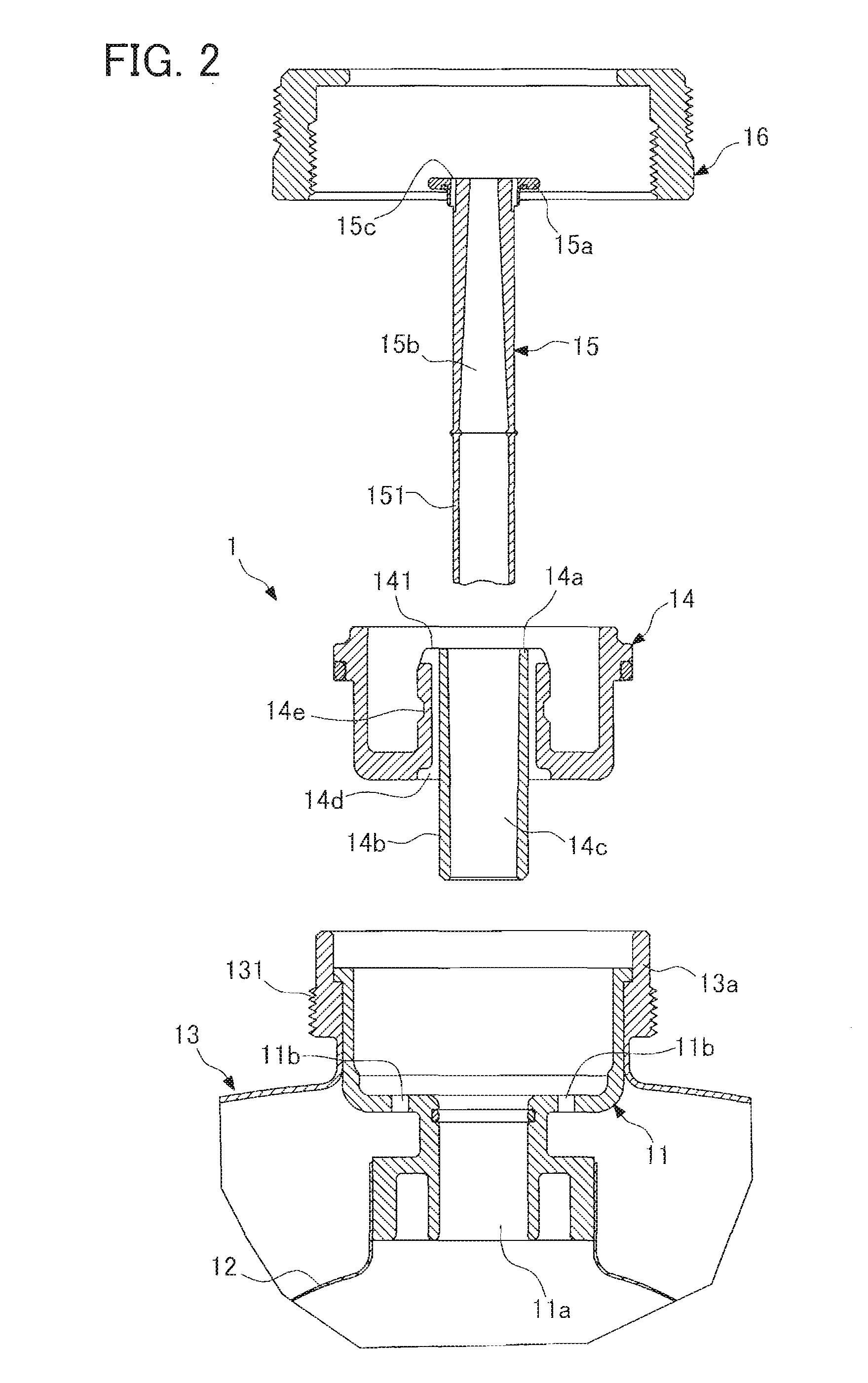

Joint for fluid container

ActiveUS20090020176A1Good adhesionFirmly connectedValve arrangementsPressure pumpsNeck partsEngineering

A joint for duplex storage type fluid container that can attain secure fitting of a liquid discharge tube and can attain easy, secure connection of a passage for fluid emission disposed in a dispenser to the liquid discharge tube. There is provided a joint for fluid container comprising flexible bag (12) furnished with neck part (11) openable for permitting injection of liquid and comprising outside container (13) formed so as to support the neck part (11) by mouth part (13a) and accommodate the bag (12), which joint is so structured that liquid discharge tube (15) with collar part (15a) can be fitted through plug (14) to the mouth part (13a) of the outside container (13), and further so structured that flow channel (21a) fitted to dispenser (2) can be linked directly to fluid passage (15b) of the liquid discharge tube (15).

Owner:TOKYO OHKA KOGYO CO LTD +1

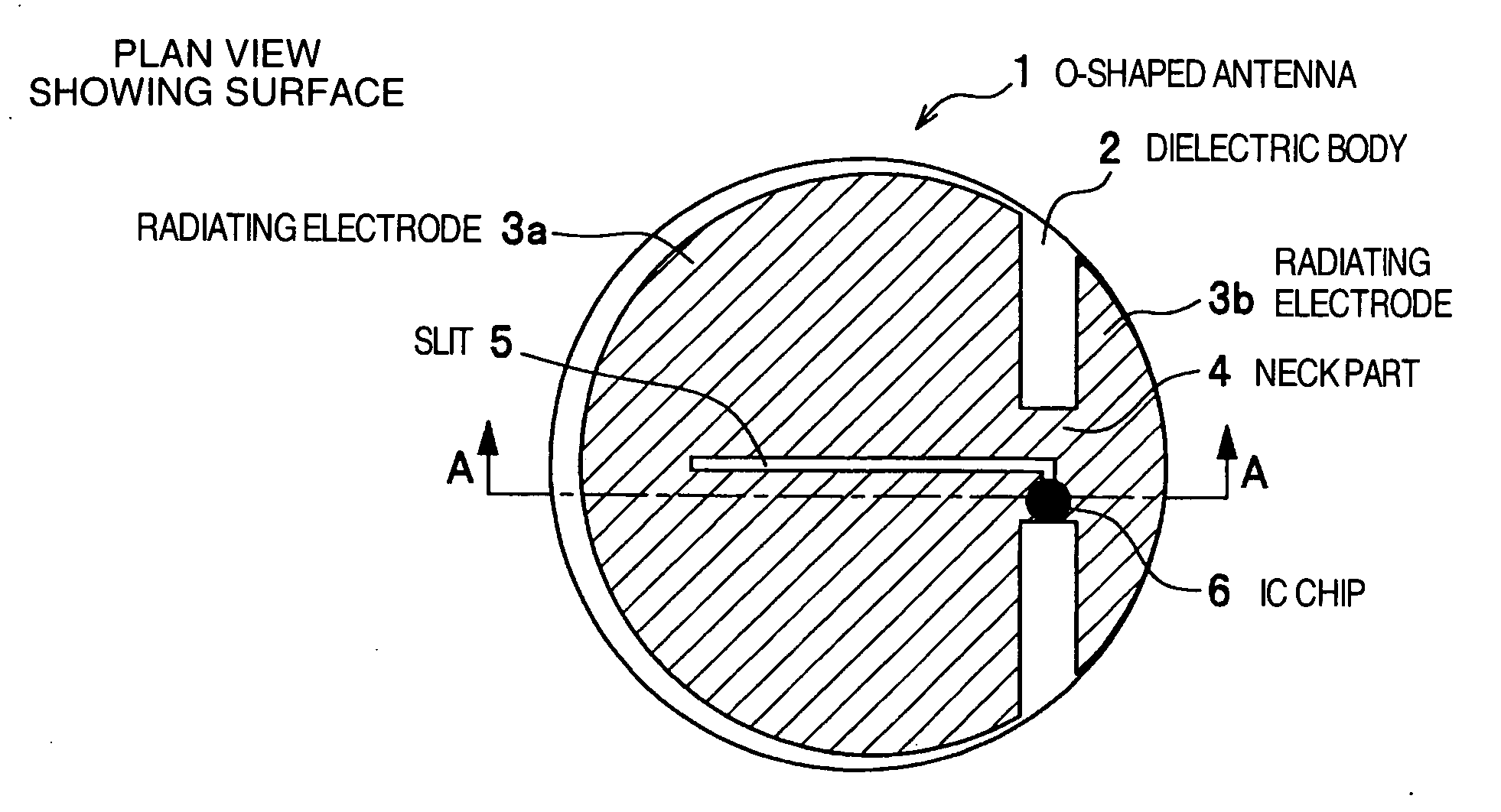

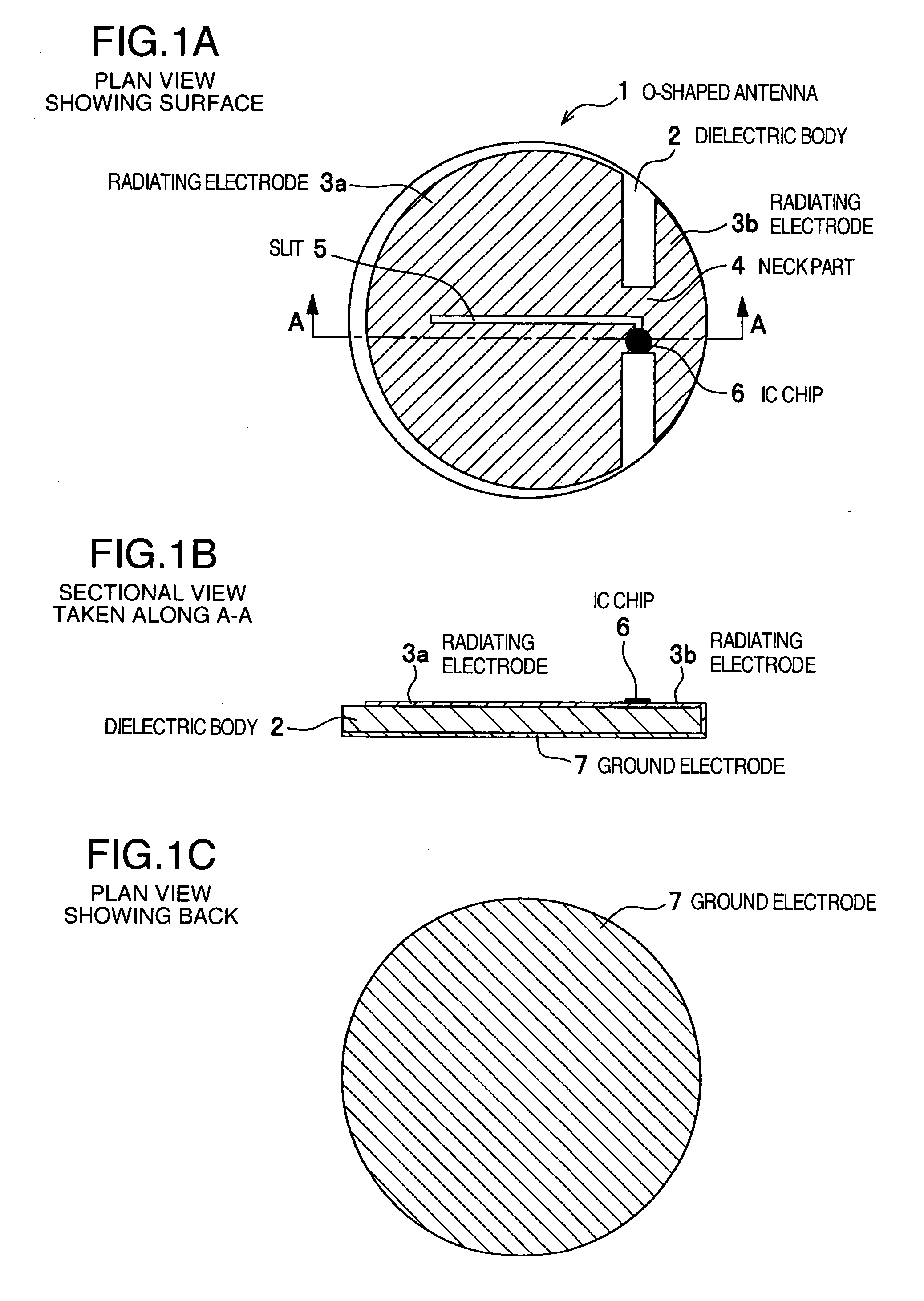

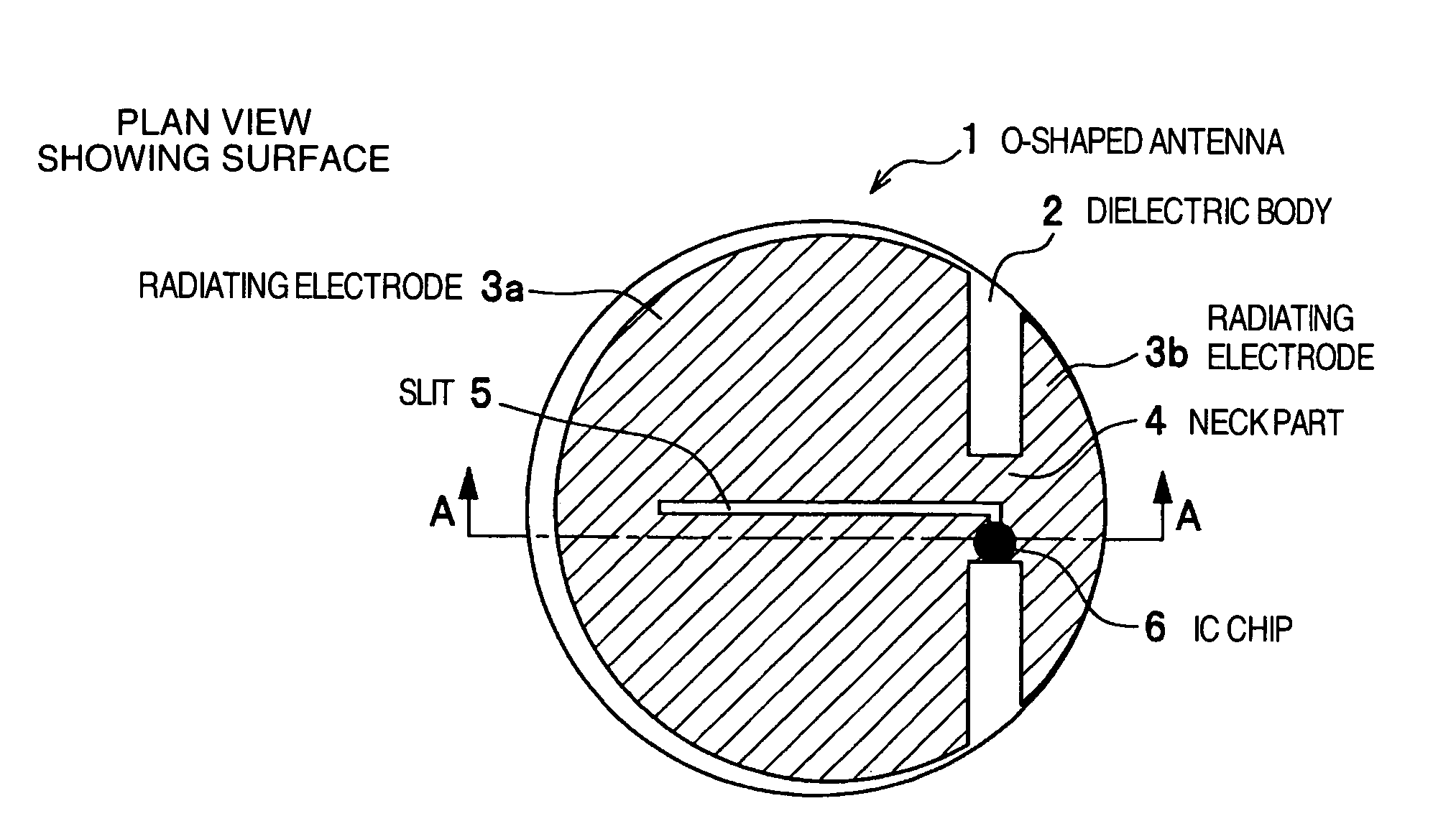

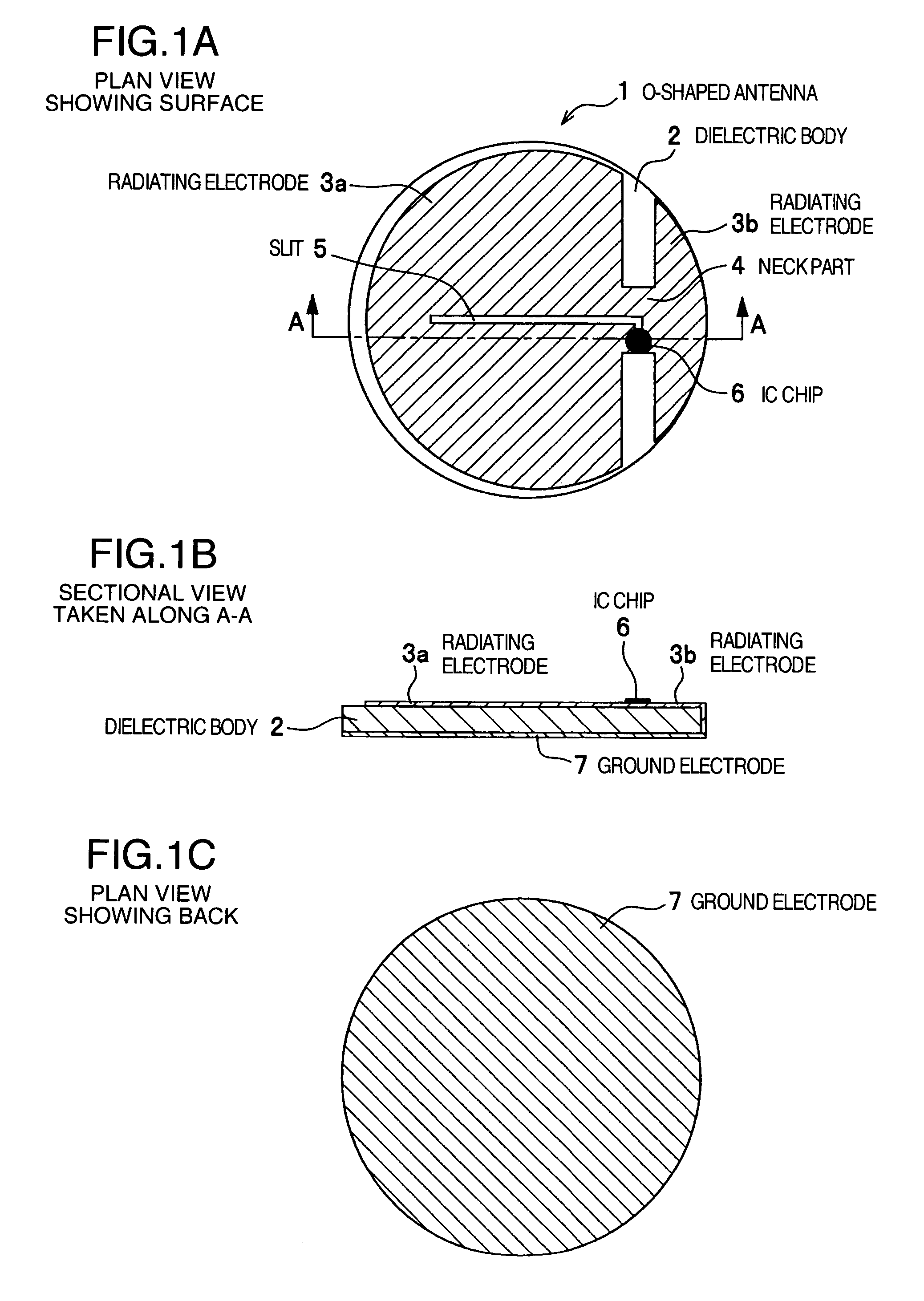

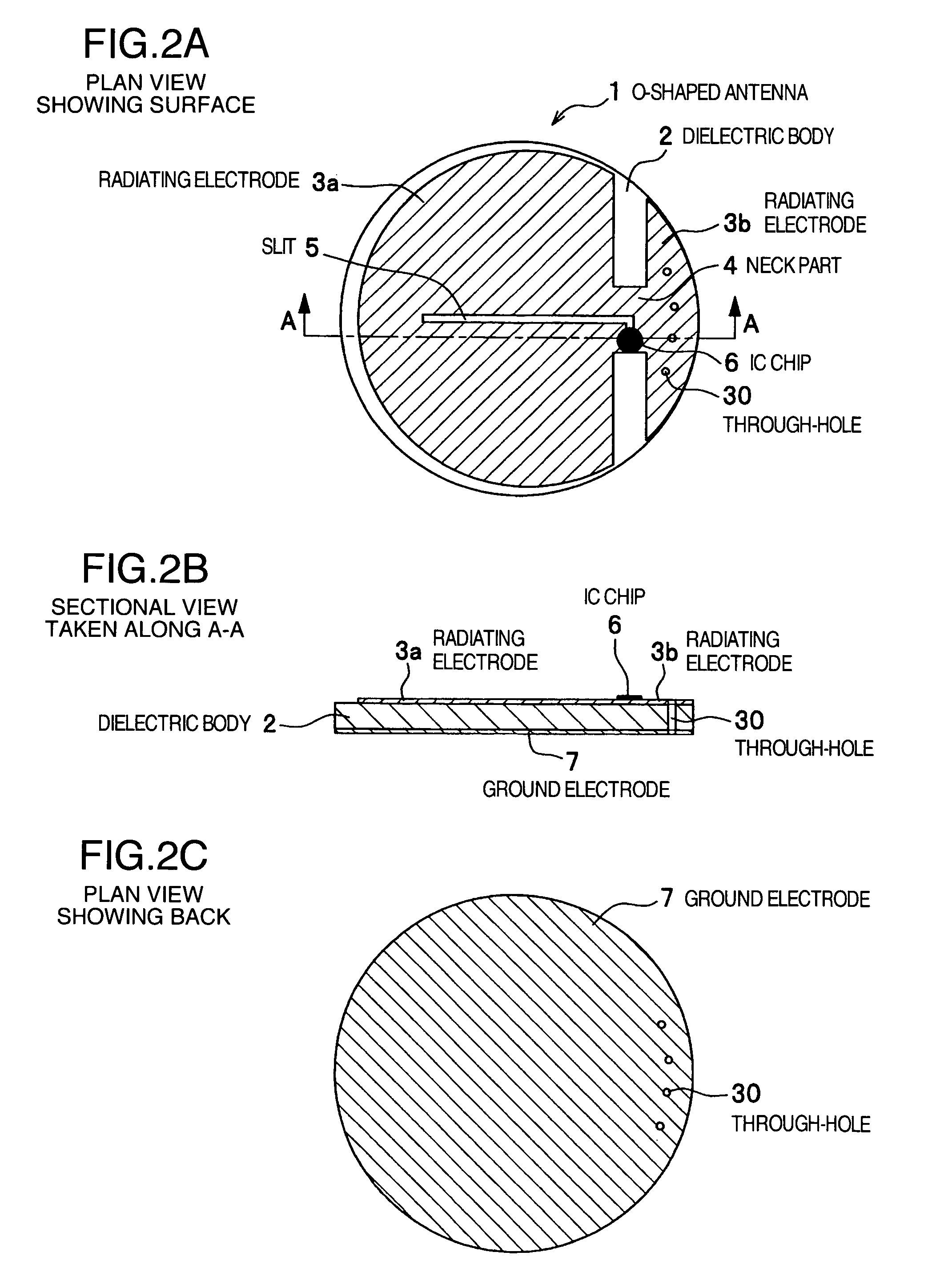

Radio frequency IC tag and method for manufacturing same

InactiveUS20060267843A1Reduces efficiency of antennaHigh sensitivitySimultaneous aerial operationsAntenna supports/mountingsNeck partsRadio frequency

A small radio frequency IC tag which can obtain sufficiently long communication distance with radio wave in the microwave band even if an antenna is made small and the radio frequency IC tag is embedded in metal material. An O-shaped antenna is formed to narrow the width of a neck part in which an IC chip is mounted and widen the width of radiating electrodes constituting radiating part of radio wave. The radiating electrodes are formed into offset structure on right and left sides of the feeding point so that areas of right and left radiating parts of the feeding point in which the IC chip is mounted are unsymmetrical. Further, a ground electrode is provided so that a dielectric body is held between the radiating electrodes and the ground electrode and the radiating electrode is connected to the ground electrode at the side of the dielectric body.

Owner:HITACHI LTD

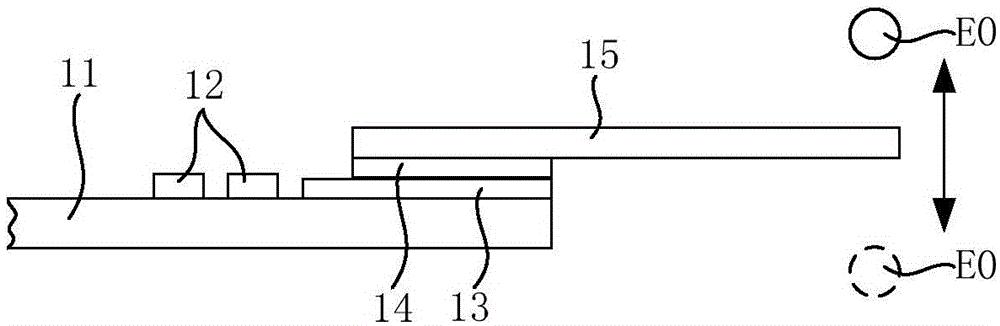

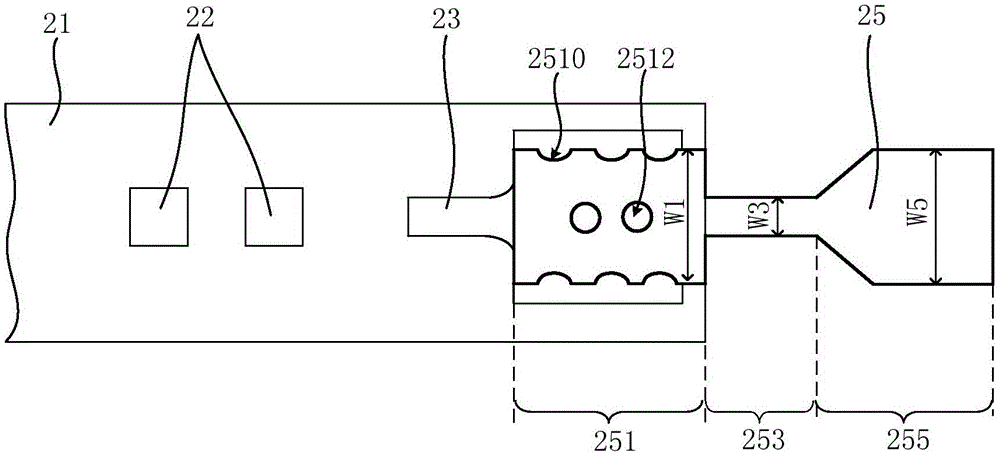

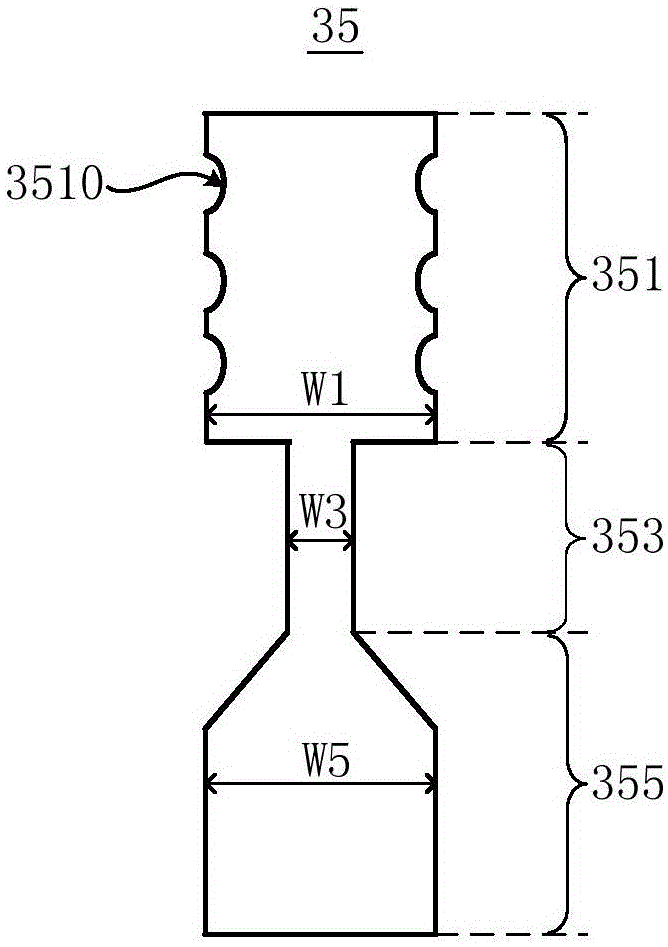

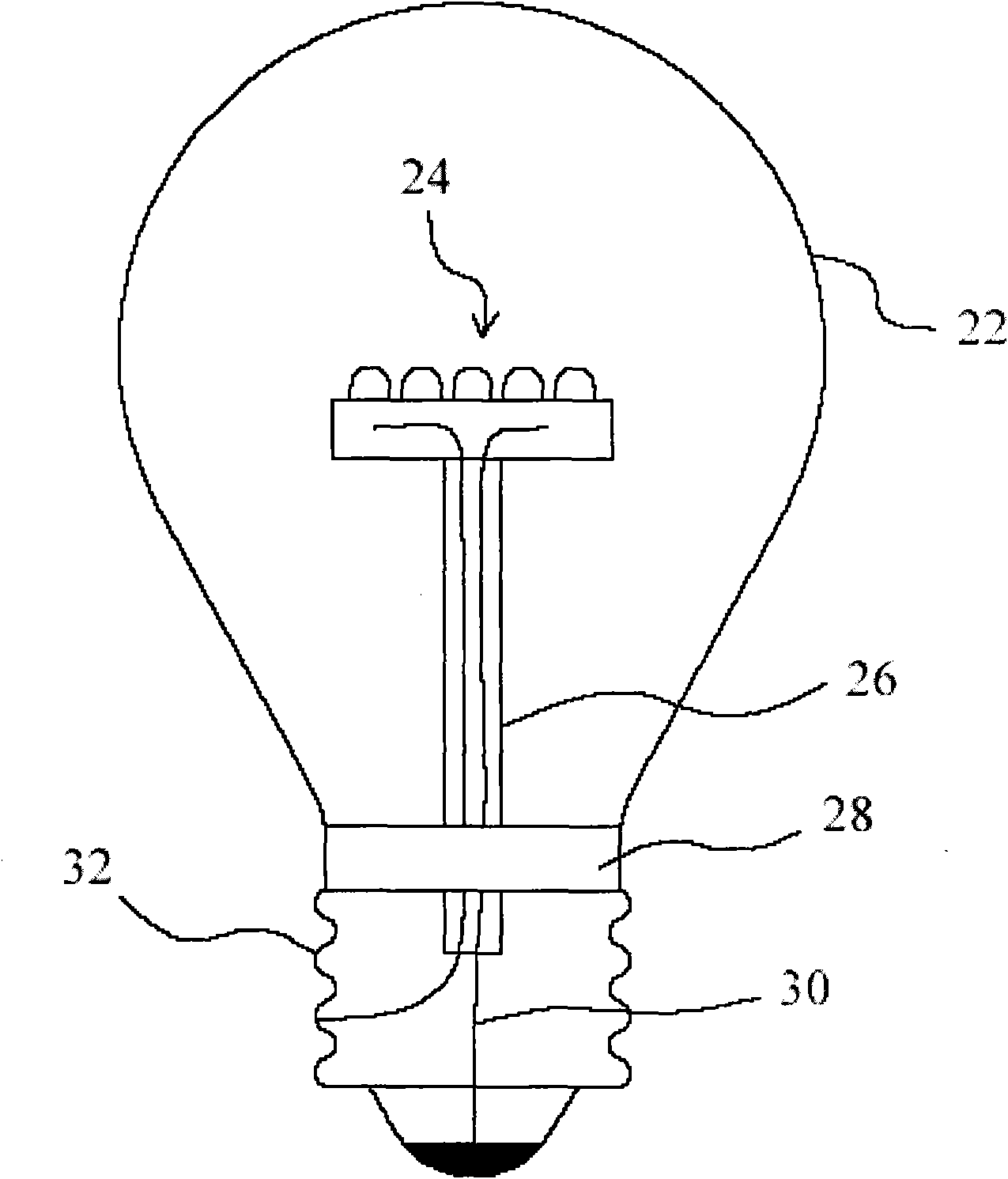

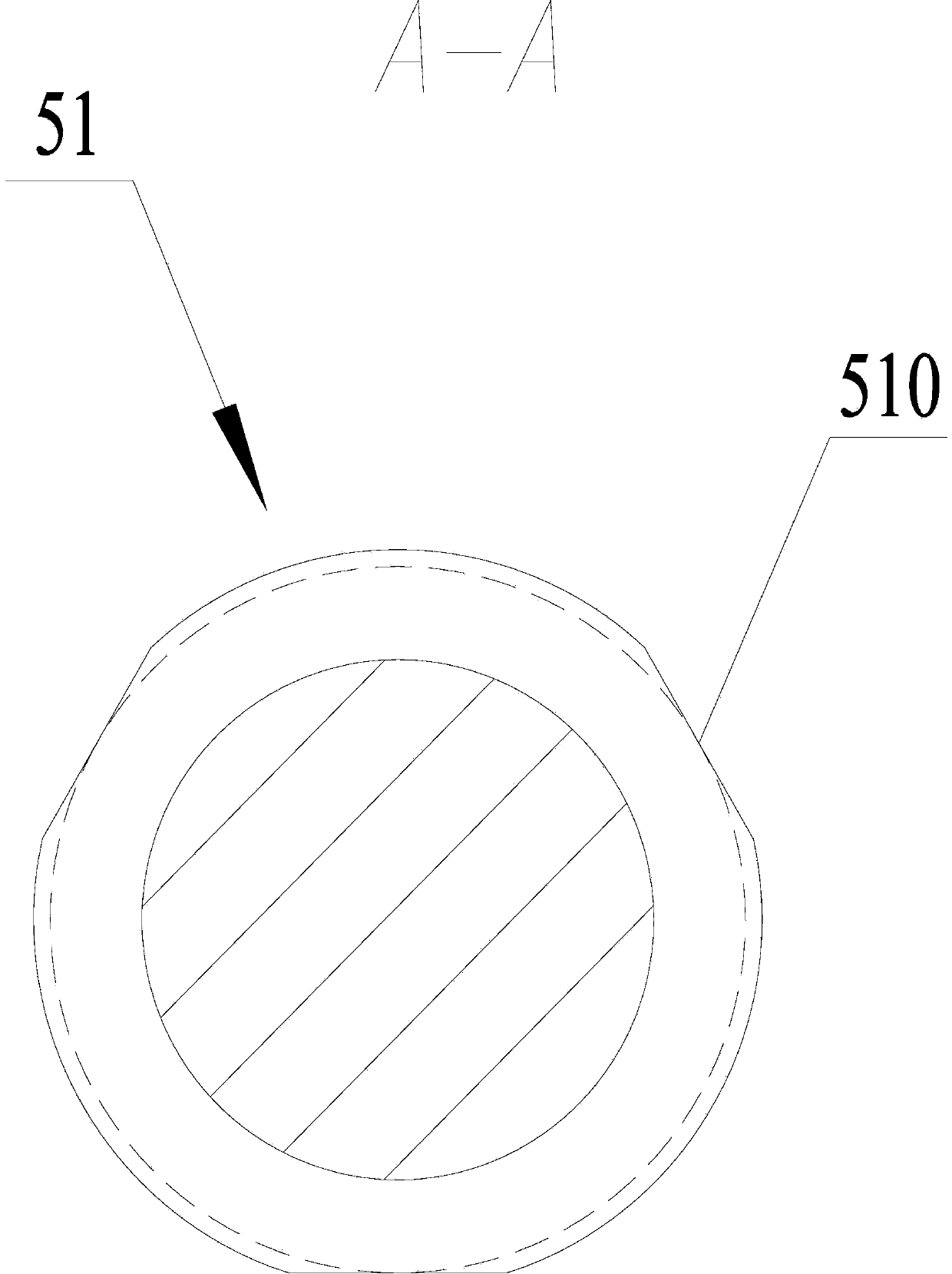

LED filament and filament type LED bulb

ActiveCN105090782AHigh bonding strengthIncrease joint areaPoint-like light sourceElectric circuit arrangementsNeck partsEngineering

The invention relates to an LED filament and a filament type LED bulb using the LED filament. The LED filament comprises a carrier, LED chips arranged on the carrier, and an electric conduction pin fixedly connected with the carrier. The electric conduction pin is electrically connected with the LED chips. The electric conduction pin comprises a pin head part, a pin tail part and a pin neck part used connected with the pin head part and the pin tail part. The entity width of the pin neck part is smaller than the maximum entity width of the pin head part. The pin neck part with the reduced entity width is obtained through the mode of internally reducing the width of the pin head part relative to the pin neck part or opening a through hole in the pin neck part or other modes, the pin neck part becomes a weak point of the electric conduction pin; and in this way, when stress is generated, the pin neck part acts firstly, and the joint of the pin head part and the carrier or the carrier itself can be protected.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

Container cap

InactiveUS20080093326A1Easy to cutImprove sealingCapsClosure using stoppersNeck partsBiomedical engineering

Disclosed herein is a container cap allowing the addition of an adjunct. The container cap includes a base cap member, which is a lower cap body coupled to a neck part of a container, an operational cap member, which is an upper cap body coupled to the upper end of the base cap member, and an openable sheet, which is provided on the lower end of one selected from the base cap member and the operational cap member. The openable sheet is able to be cut to discharge the adjunct. The container cap further includes a cutting means for cutting the openable sheet. The cutting means is provided in a remaining one selected from the base cap member and the operational cap member at a position corresponding to the openable sheet. The openable sheet includes a weight member, which has a diameter less than a diameter of an arc part of the openable sheet to be cut. A connection rib is connected between the weight member and a lower edge of an adjunct receiving part of the base cap member. The openable sheet further includes an openable sealing film, which seals both the lower edge of the adjunct receiving part and the weight member.

Owner:CHO YOUNG KOOK

Securing means for a device for detecting the pressure and temperature in the intake tube of an internal combustion engine

A device for detecting the pressure and the temperature in the intake tube of an internal combustion engine, including a temperature sensor, a pressure sensor and a substrate each of which are secured in a housing with as little stress as possible with the pressure sensor secured on a substrate together with an evaluation circuit. The temperature sensor measures precise temperature measurement. In order to introduce a fluid medium that is under pressure, a neck part is secured to the housing and an adapter is joined both to the substrate and to the neck part via adhesive seals that decouple mechanical stress from the pressure and temperature detectors.

Owner:ROBERT BOSCH GMBH

Sock having part for preventing slipping-down phenomenon of sock

InactiveUS20060260024A1Preventing a slipping-down phenomenon of a sockInsolesPanty-hoseNeck partsEngineering

A sock includes a slipping-down prevention part which is provided at an inner side surface of a neck part of a sock and is made of a smooth material such as a silicon resin or a rubber resin known as a non-harmful material to a human body. The slipping-down prevention part is formed of a coating part or a slim band, which are provided at an inner side surface of the neck part of the sock, with the coating part being formed of a smooth material, and with the slim band being formed of stripe patterns.

Owner:DOOCHANG

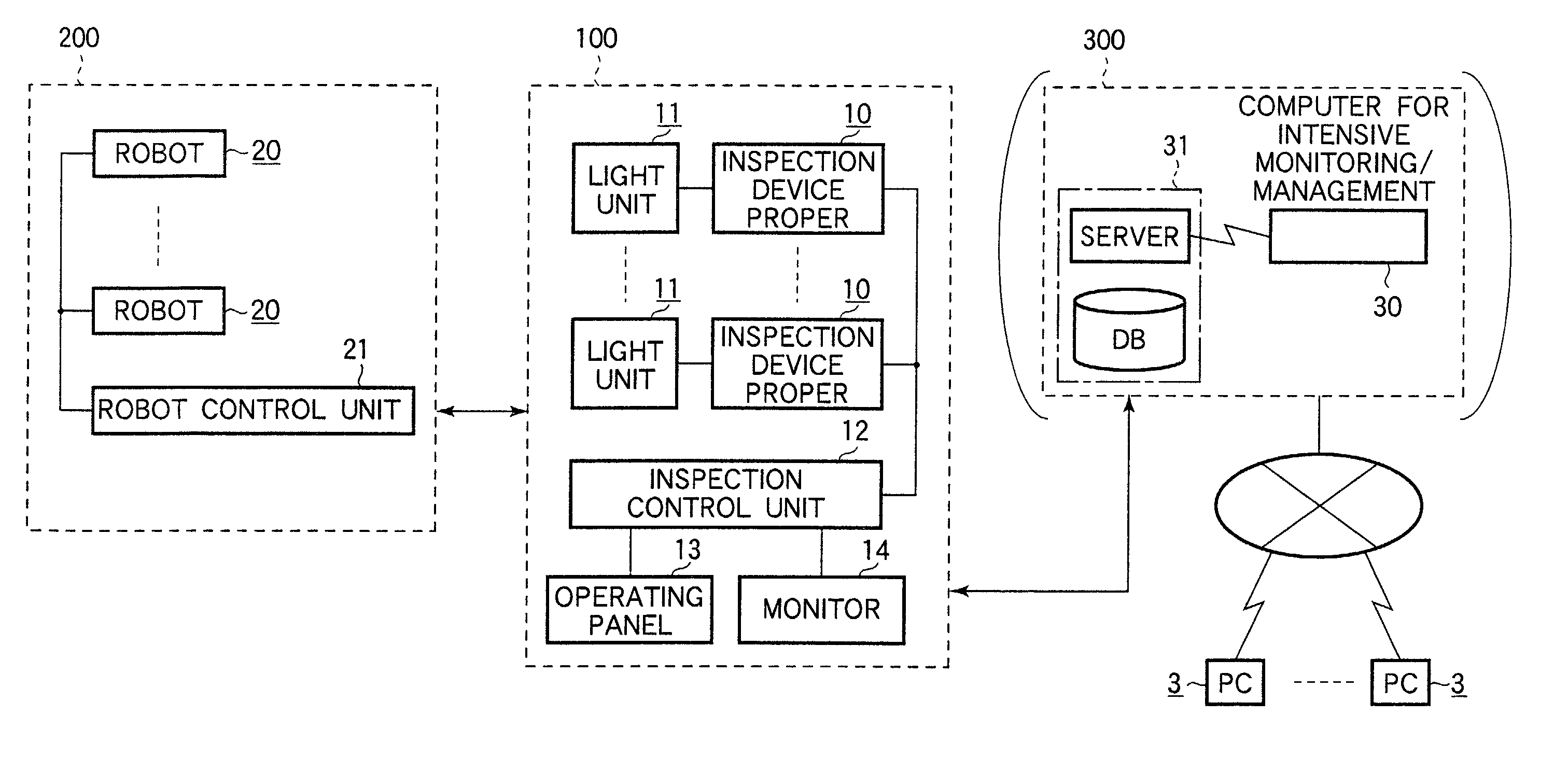

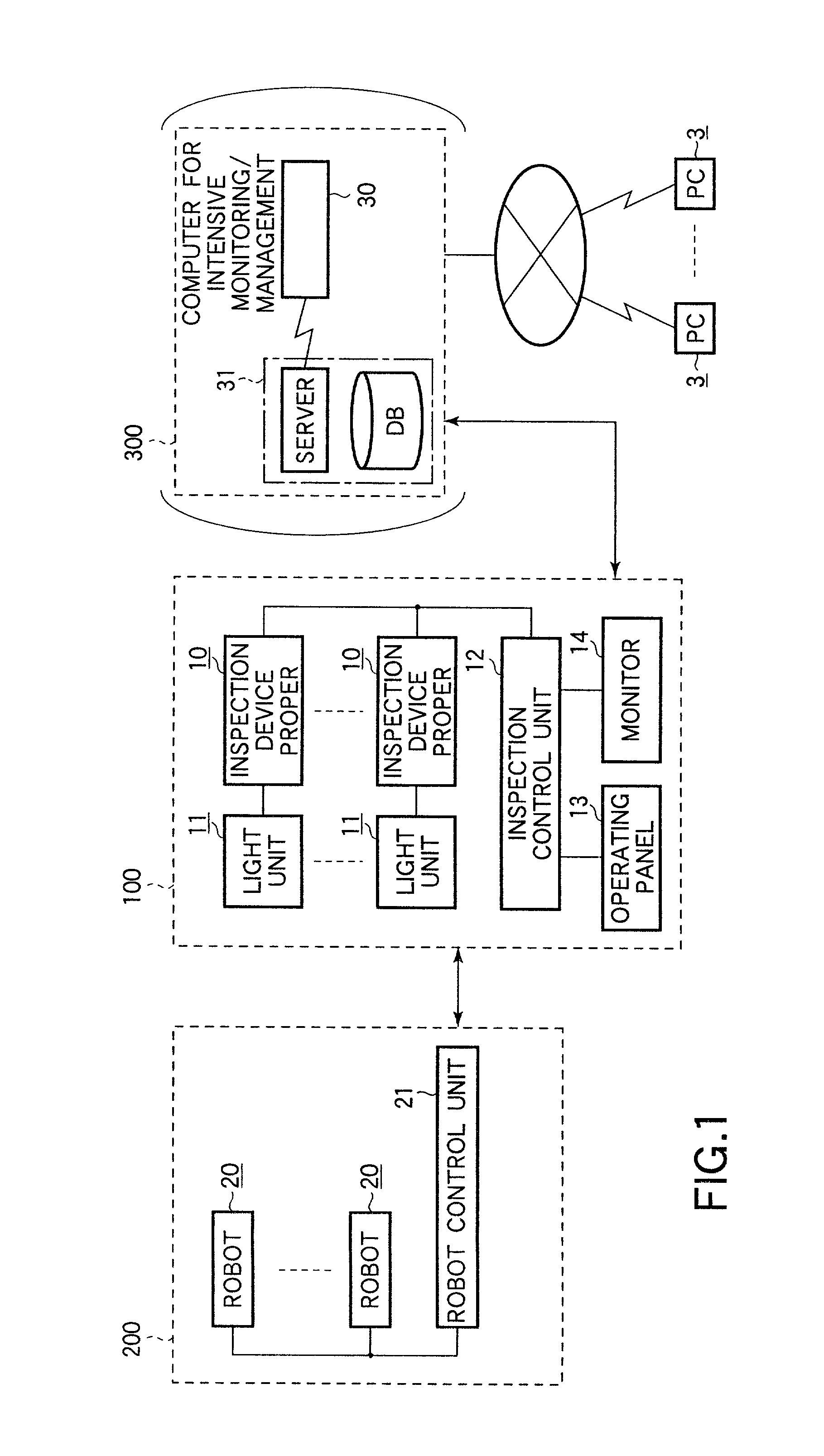

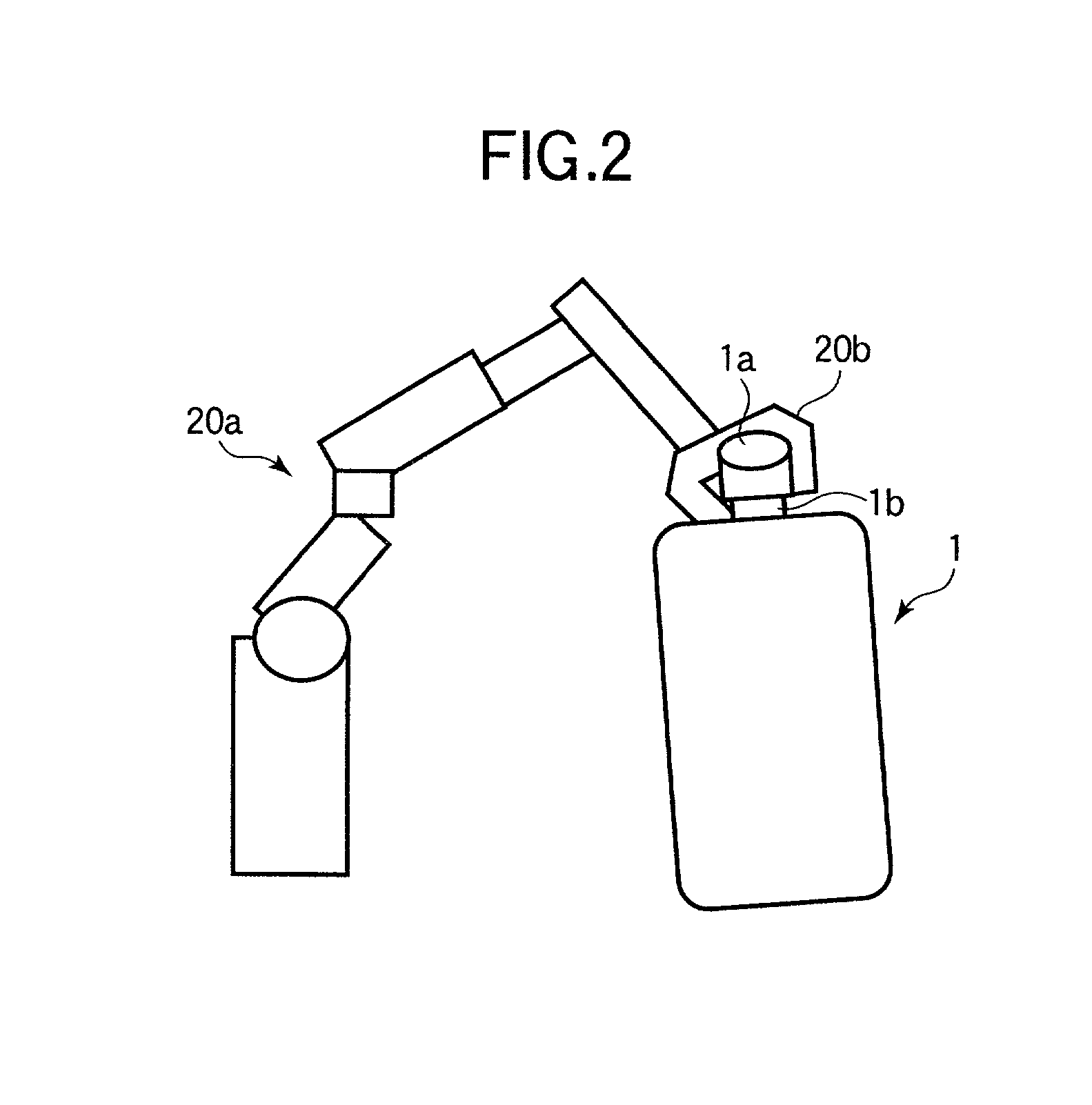

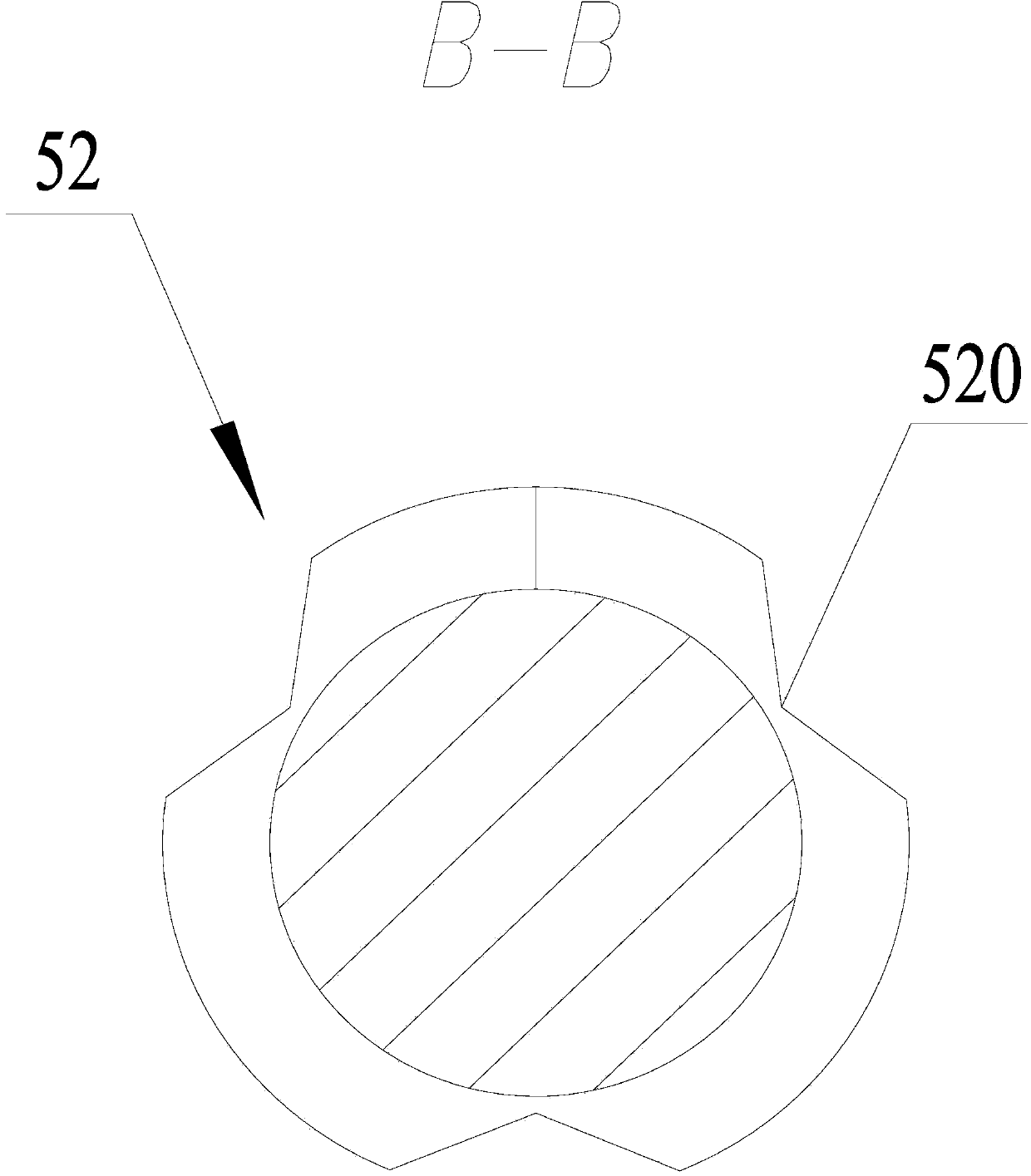

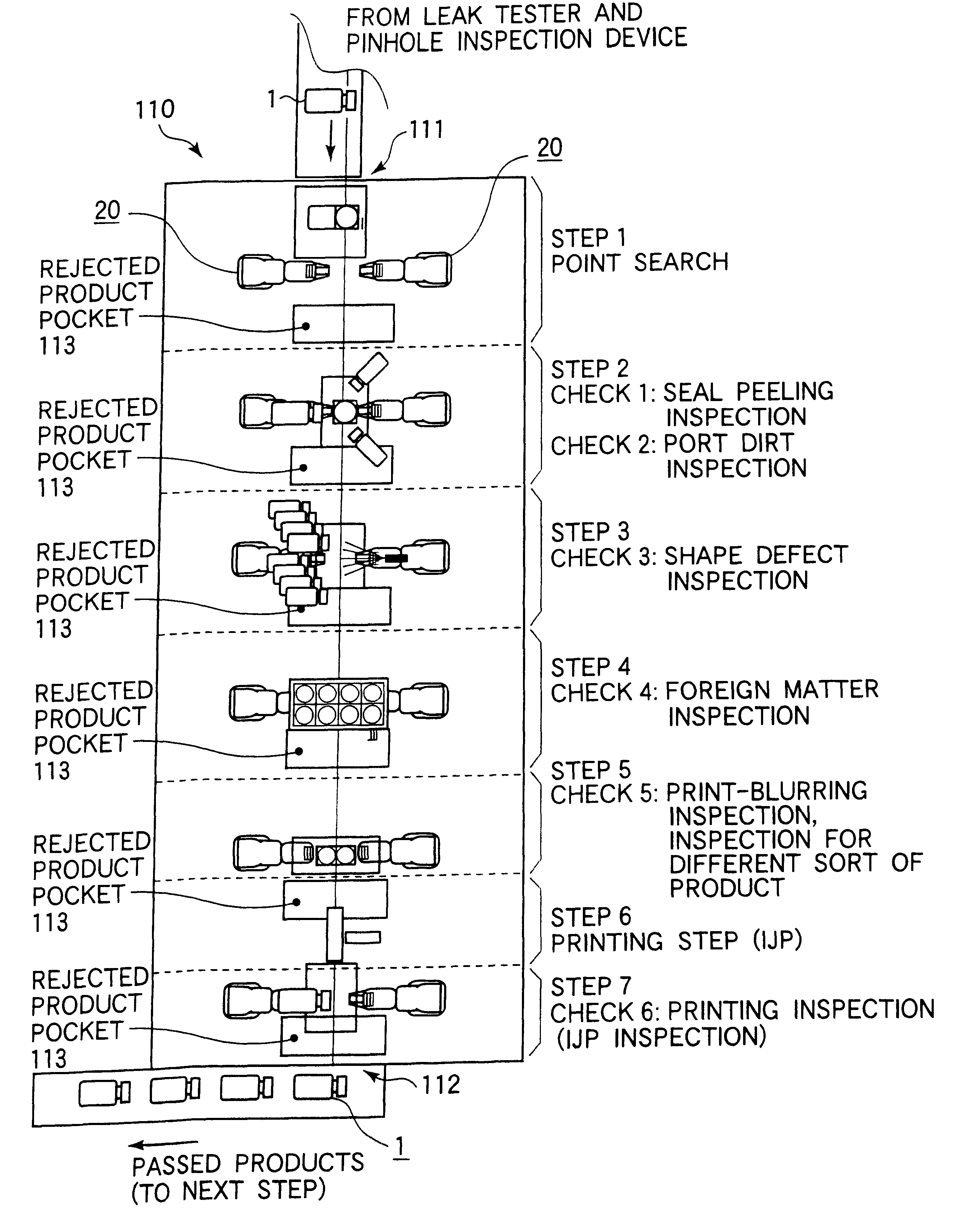

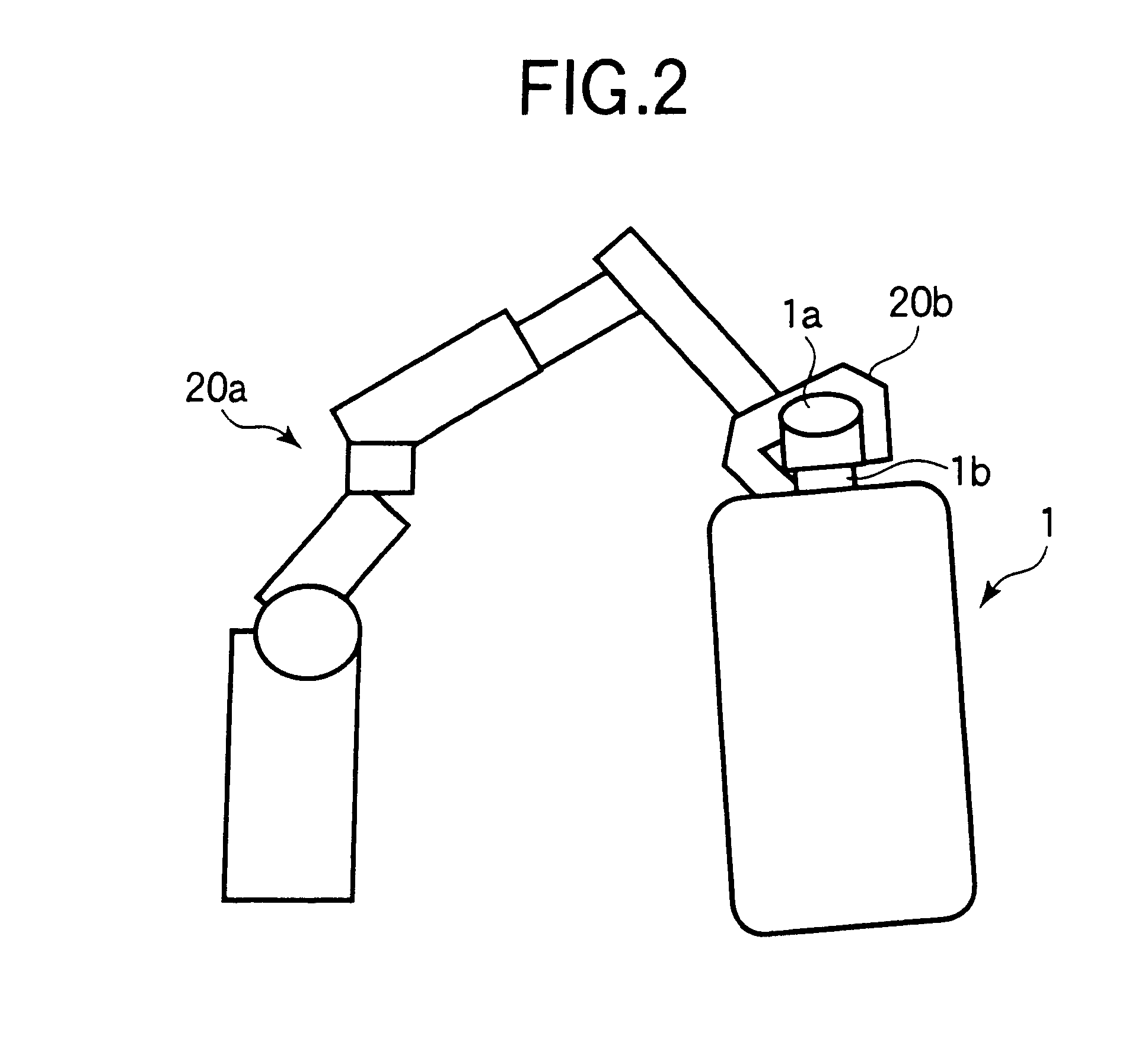

Integrated soft bag inspection system

InactiveUS20020039183A1Scattering properties measurementsParticle suspension analysisLocation detectionProduction line

An integrated soft bag inspection system overcomes the difficulty of inspection associated with the unstable shape peculiar to soft bags (for example soft bags for intravenous feed use) and makes it possible to carry out inspection of soft bags automatically and with high precision. The system uses a robot having at least a robot hand and has image pickup means for picking up an image of a soft bag and grip position detecting means for detecting a position on a neck part of the soft bag to be gripped by the robot hand on the basis of image information from the image pickup means. A carrying system may be made using a plurality of such robots and carrying control means provided for controlling the robots so that the robot hand of each robot grips the neck part of the soft bag and carries the soft bag to a predetermined inspection position and soft bags arriving from a production line are continuously transferred between adjacent robots and various inspections are carried out on the soft bags successively.

Owner:SCANTECH

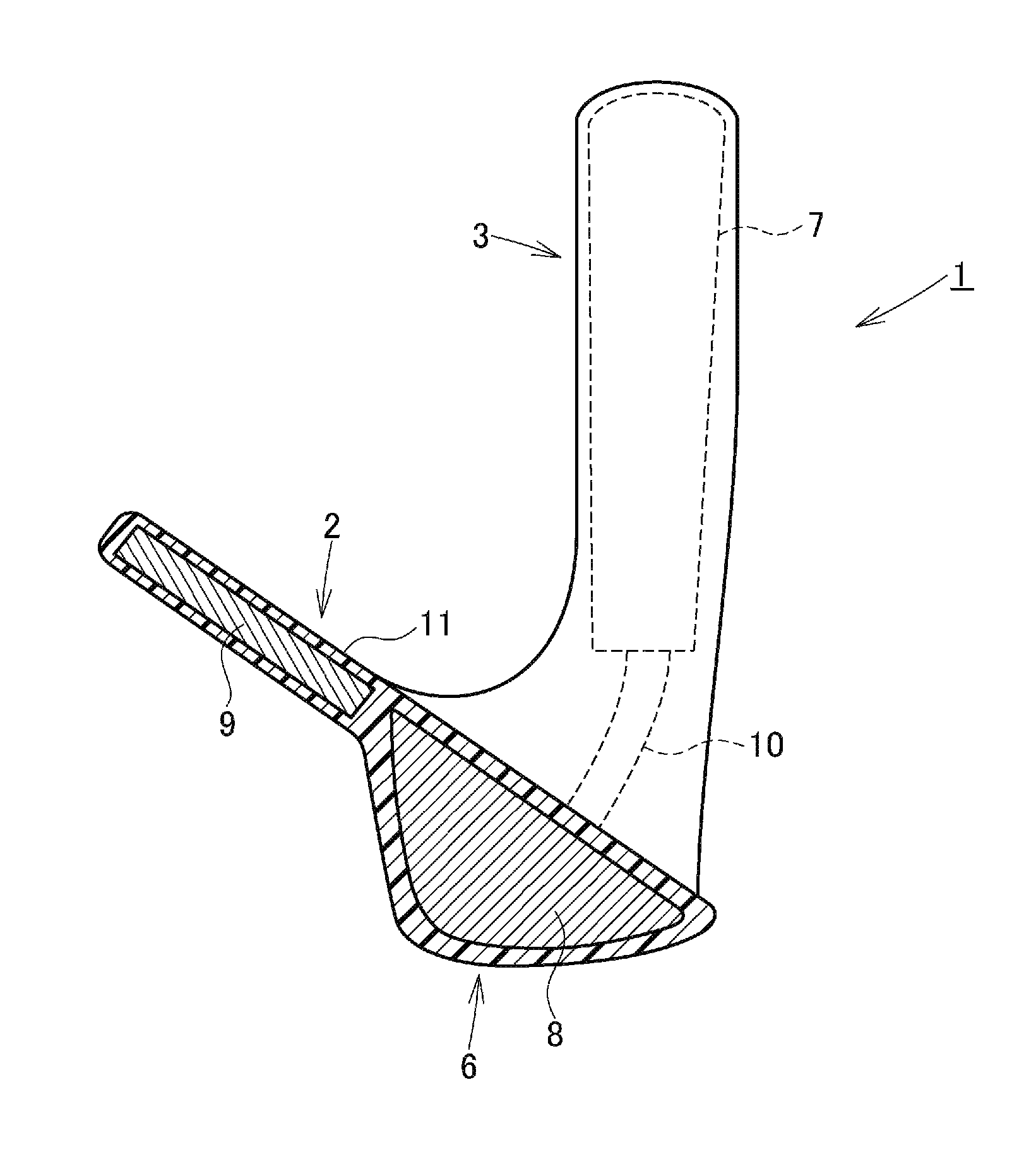

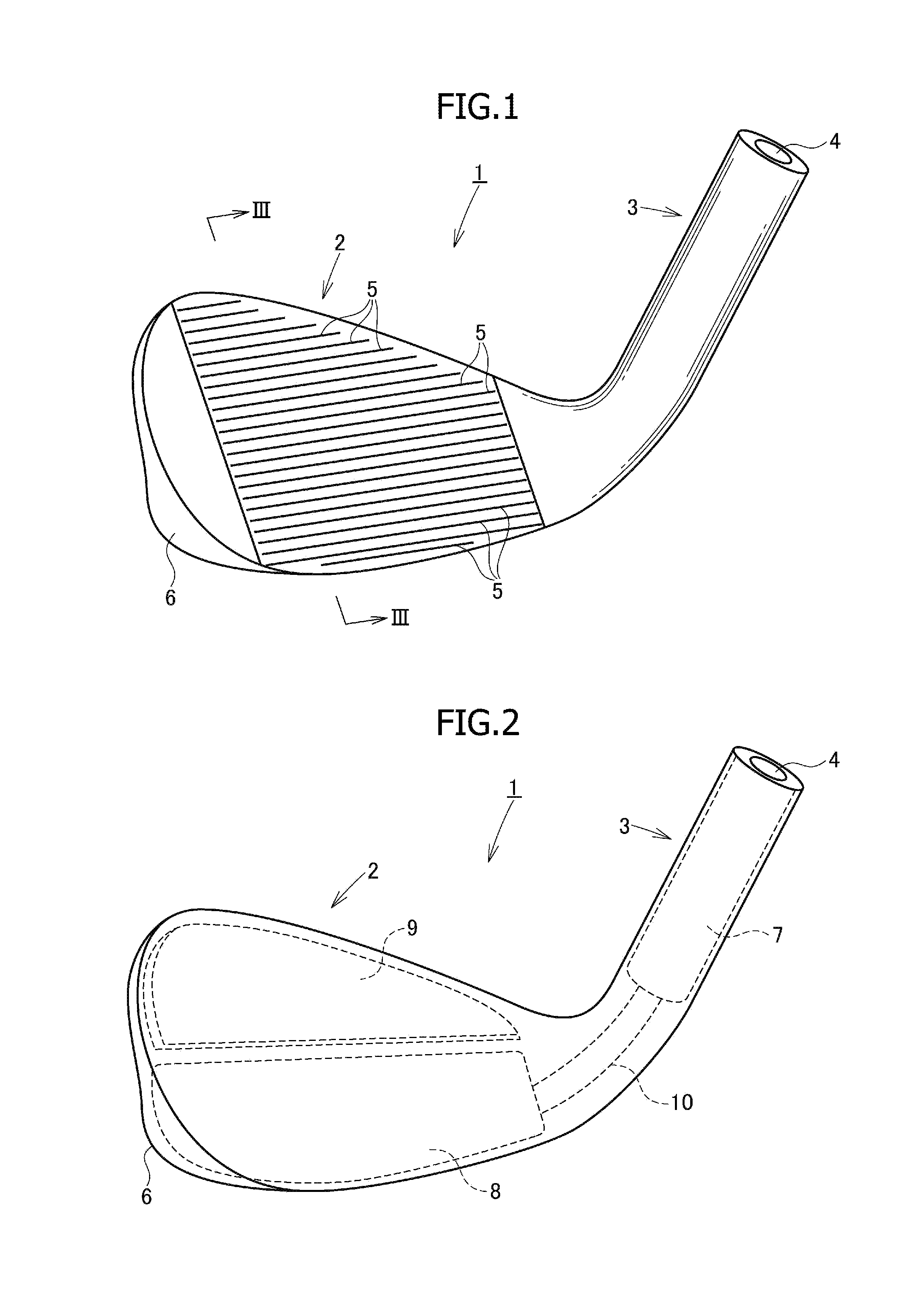

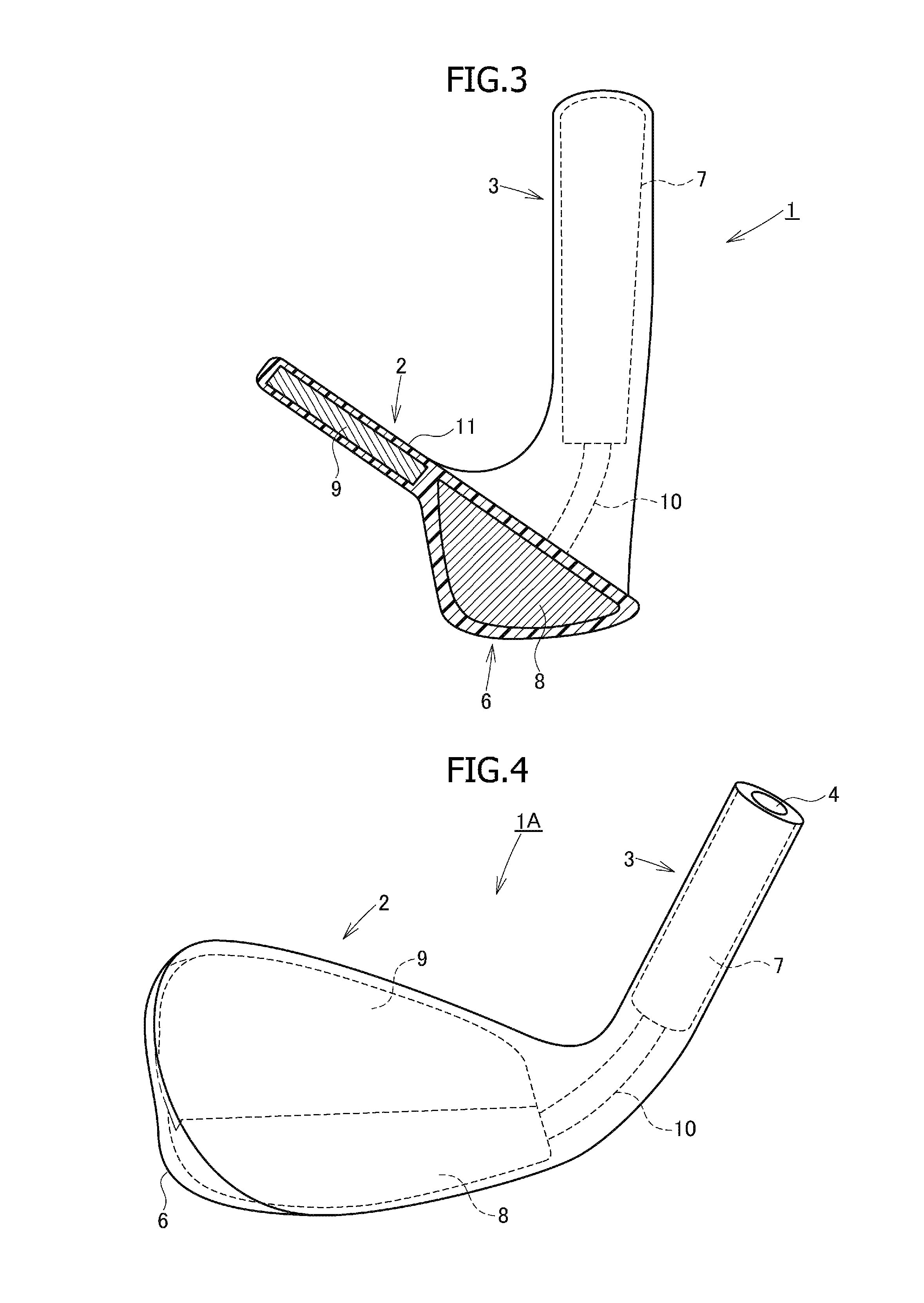

Iron golf club head

Owner:BRIDGESTONE SPORTS

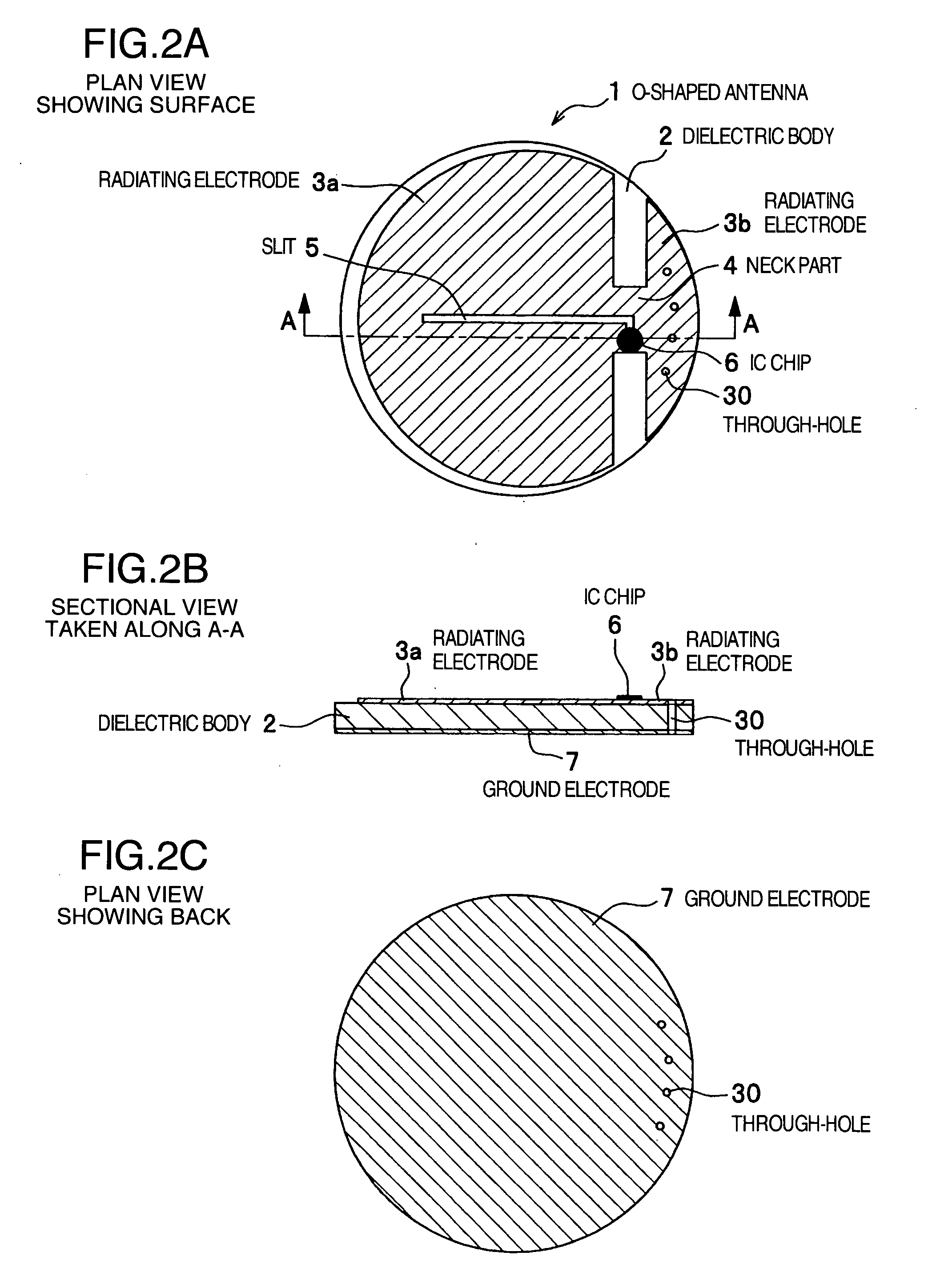

Radio frequency IC tag and method for manufacturing same

InactiveUS7365686B2Simple structureImprove featuresSimultaneous aerial operationsAntenna supports/mountingsNeck partsEngineering

Owner:HITACHI LTD

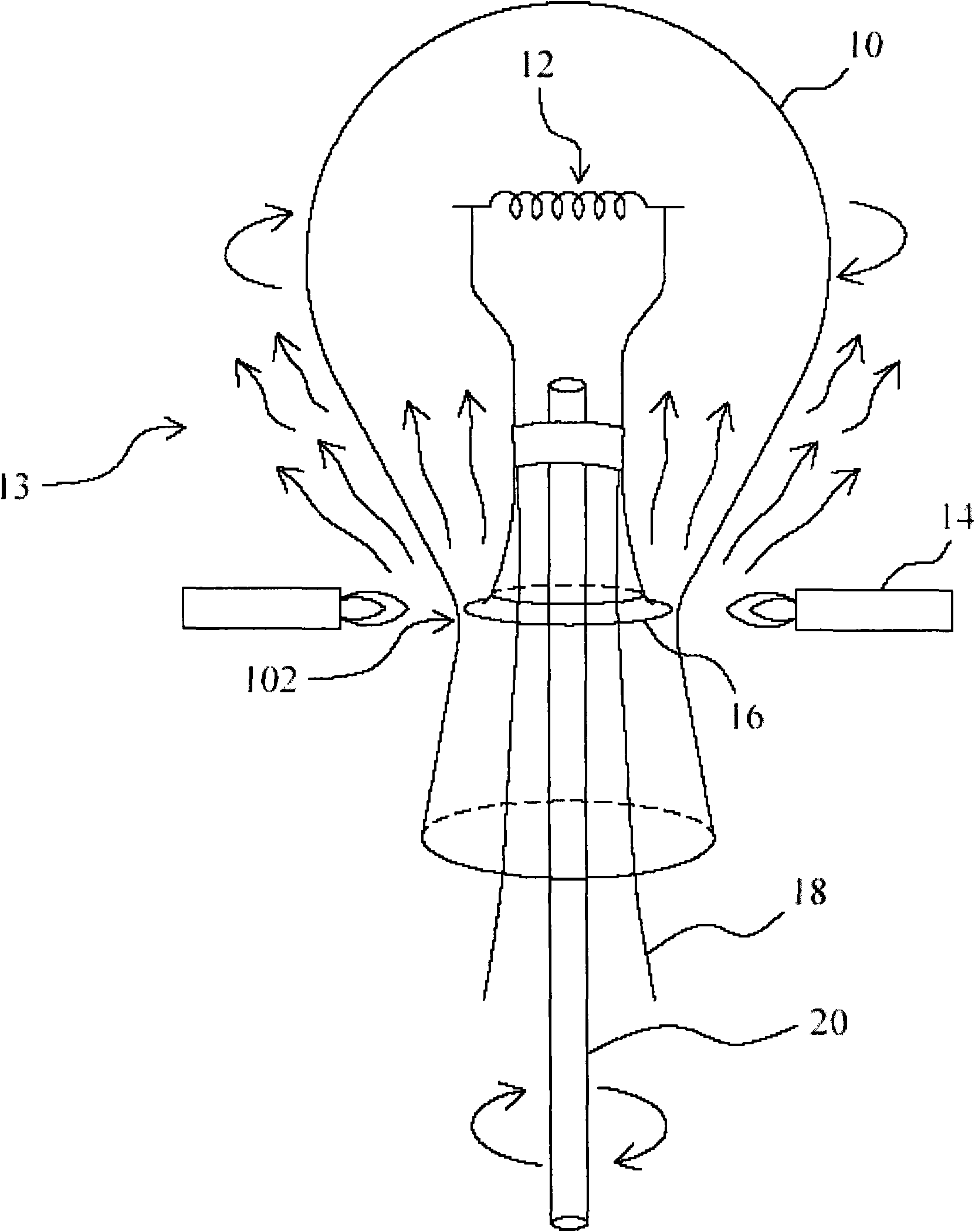

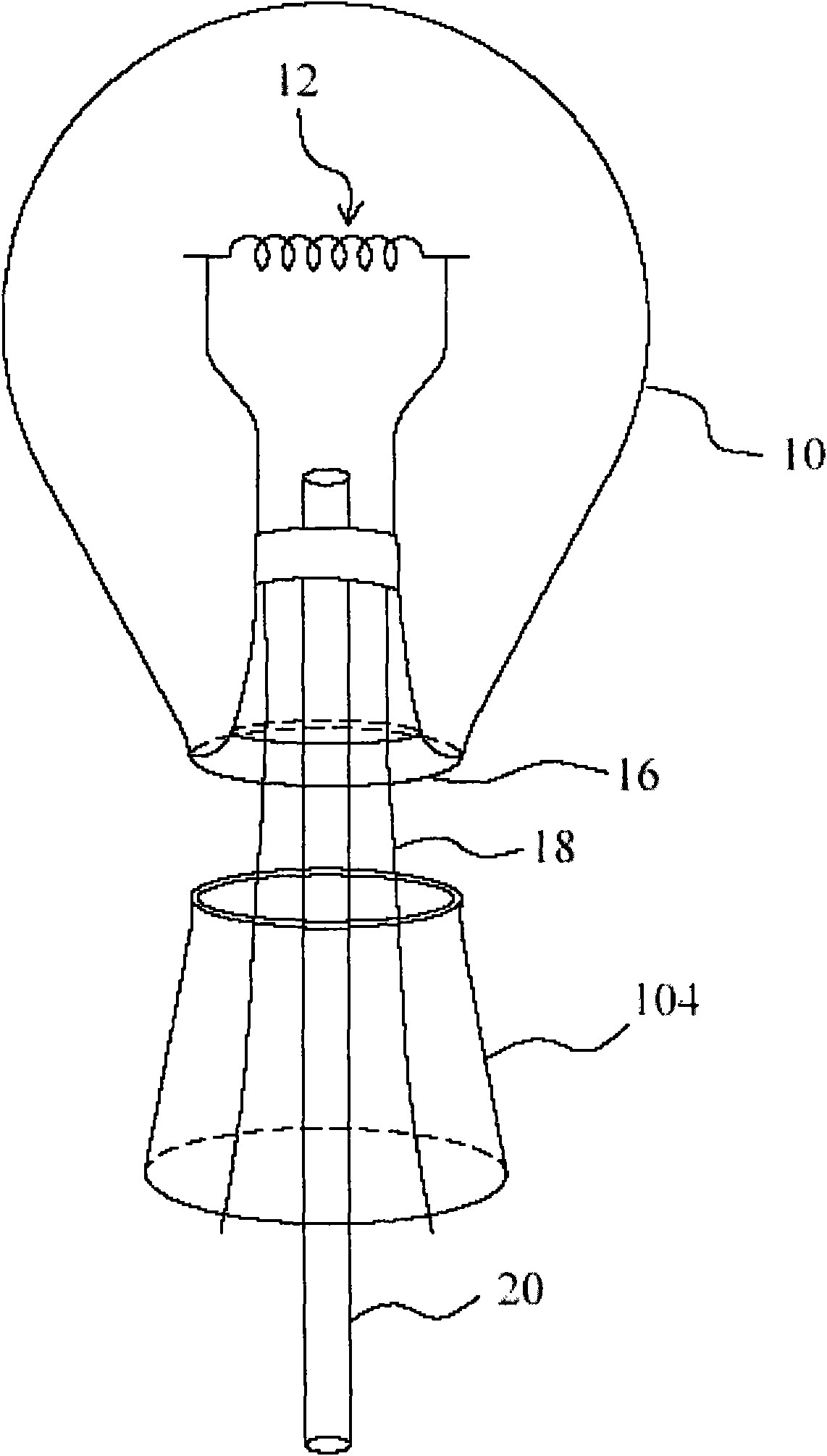

Glass packaging LED bulb and manufacturing method thereof

InactiveCN101561121AStrong resistanceLong-term reliable sealing effectPoint-like light sourceProtective devices for lightingNeck partsEngineering

The invention relates to a glass packaging LED bulb comprising a flared glass tube, a strutting piece, an LED wick, a stem assembly and a glass bulb case, wherein the flared glass tube is coated with a power lead, and one end of the power lead reversely extends to pass through the flared glass tube; the strutting piece and an exhaust tube are fixed on the flared glass tube; the LED wick is installed on the strutting piece; the stem assembly is assembled with the flared glass tube, the strutting piece and the LED wick; and the glass bulb case is provided with a neck part which is melted and connected with the flared glass tube of the stem assembly to form a chamber, the LED wick is arranged in the chamber, light-permeable liquid is injected into the chamber, and the LED wick is soaked in the light-permeable liquid. The glass packaging LED bulb has the long-term and reliable sealing effect of glass package, provides the resistance capability of serious environment, such as moisture, dust, corrosive gas, and the like, improves the manufacturing quality and speed of the LED bulb and reduces the production cost of the LED bulb.

Owner:LIQUIDLEDS LIGHTING

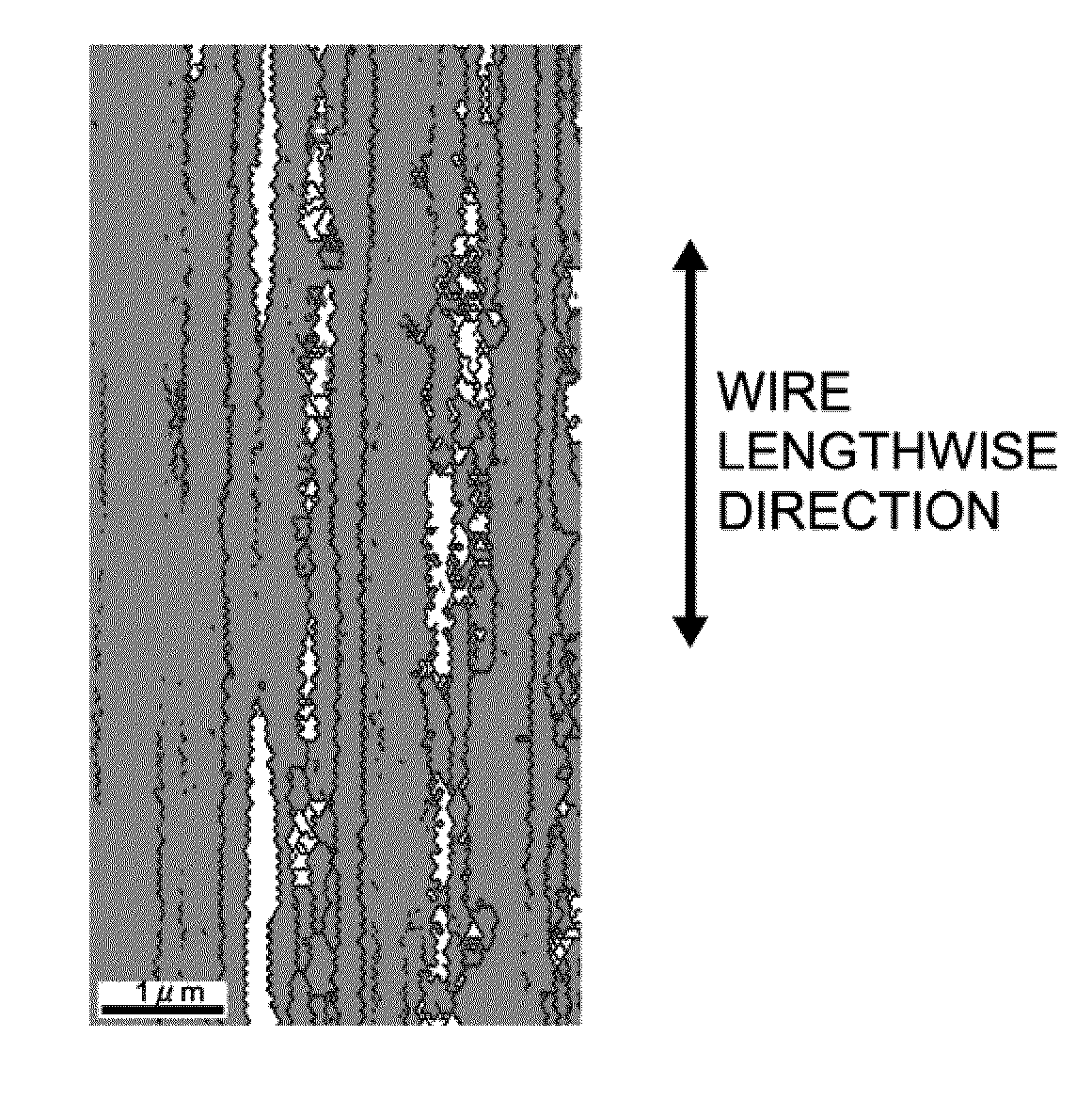

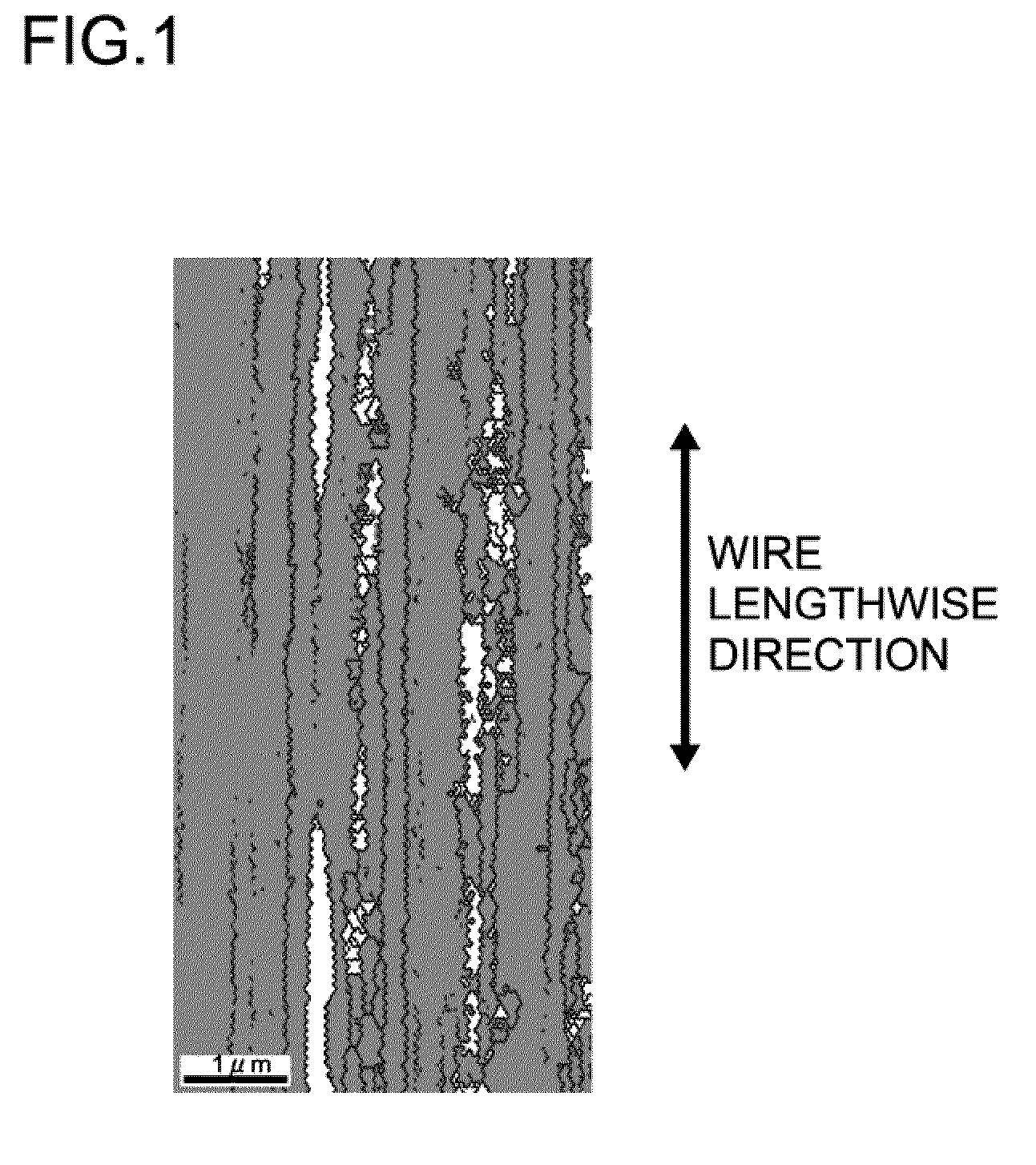

Bonding wire for semiconductor devices

ActiveUS20110011619A1Reduce harmImprove linearityNon-insulated conductorsSolid-state devicesDevice materialNeck parts

It is an object of the present invention to provide a highly-functional bonding wire which can reduce damages at a neck part, has good linearity of loops, stability of loop heights, and stability of bonded shape of a bonding wire, and can cope with semiconductor packaging techniques, such as low looping, thinning, achievement of a fine pitch, and three-dimensional packaging. A semiconductor-device bonding wire comprises a core member formed of an electrically-conductive metal, and a skin layer mainly composed of a face-centered cubic metal different from the core member and formed thereon. The percentage of <100> orientations in crystalline orientations in the lengthwise direction in the surface of the skin layer is greater than or equal to 50%.

Owner:NIPPON MICROMETAL CO LTD +1

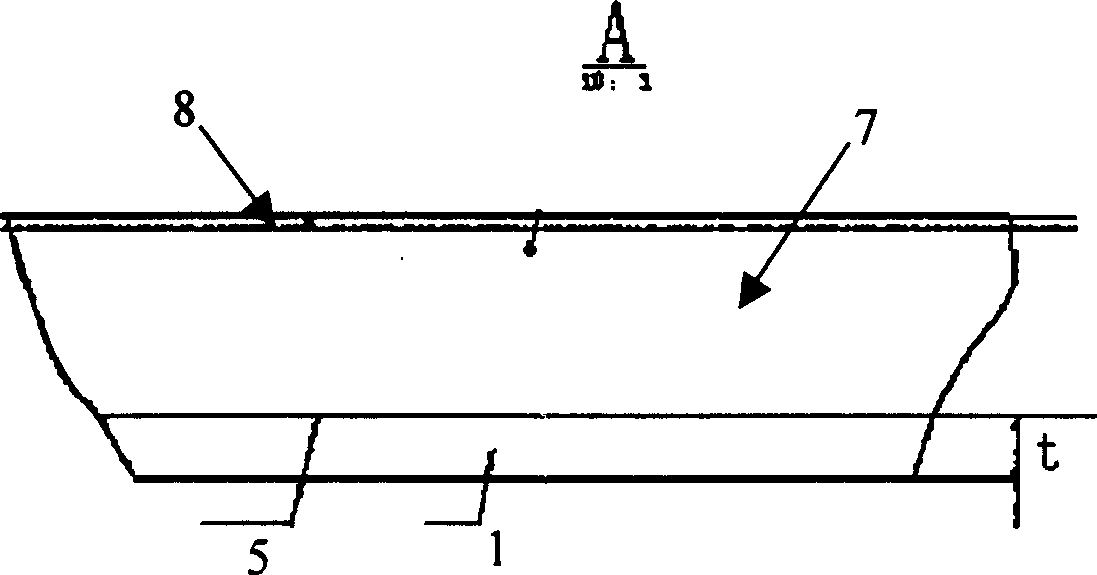

6.8 liter aluminium inner lining carbon fiber full winding composite gas cylinder

The invention is a kind of 6.8L aluminum inner lining carbon fiber total winding compound air collector, which uses the aluminum inner lining made up of elliptical crank tail end, cylinder part, elliptical crank neck part and inner-screwed cock as the core model, the aluminum inner lining surface are winded with carbon fiber layer according to the designed laying order, the outer surface is winded with a glass fiber impact resisting protection layer, and process with 'self tightening' technology in manufacturing process, the aluminum inner lining barrel is winded with fiber layer alternately, spirally and roundly, the elliptically crank tail part and elliptical crank neck carbon fiber layer are variable angle lengthwise fiber layer, there uses ring thick winding on the two ends of the barrel where connecting the elliptical crank tail part and the elliptical crank neck part. The compound air collector satisfies the stress field distribution, it has excellent air tight performance and safety performance.

Owner:SHANGHAI JIAO TONG UNIV

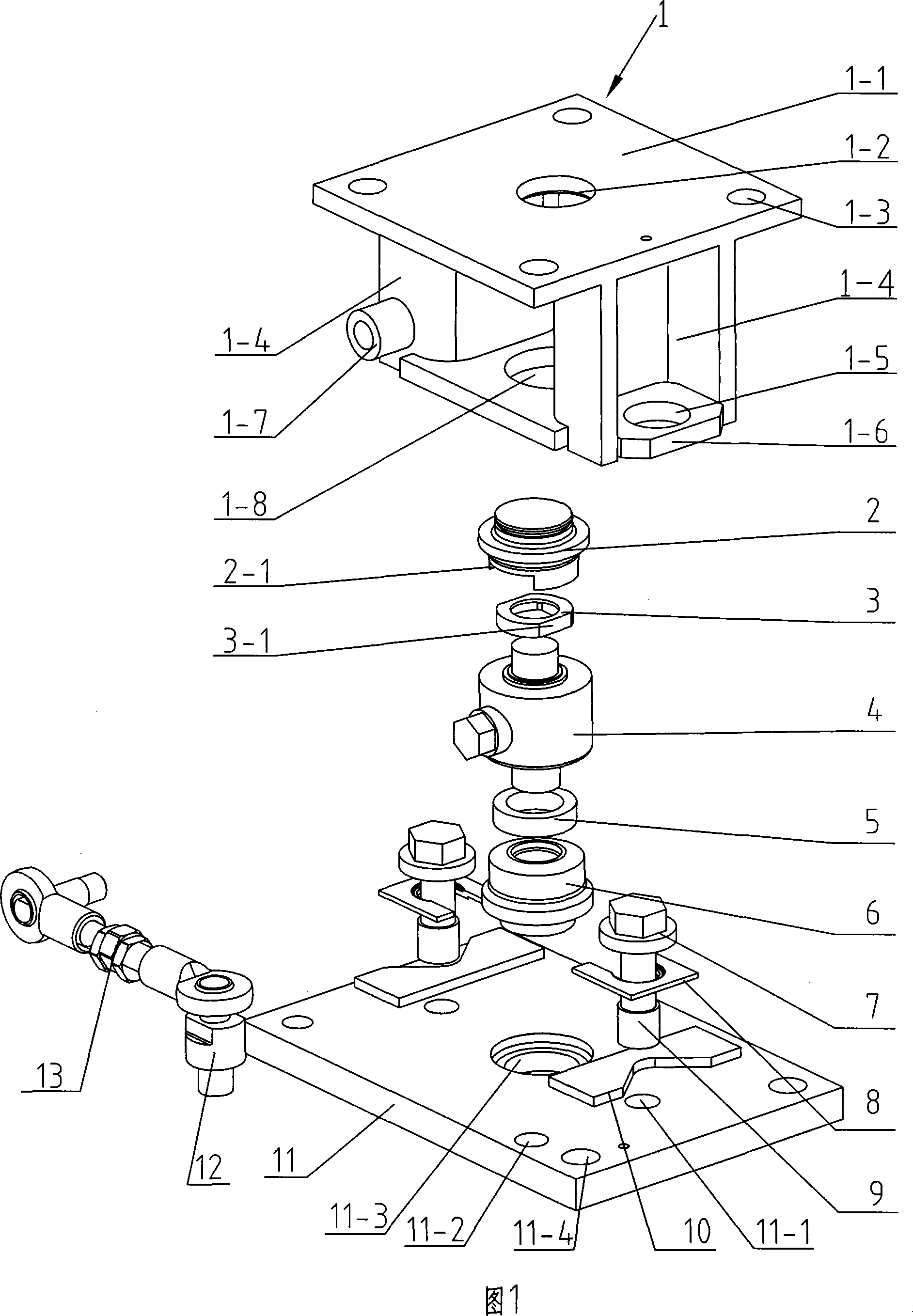

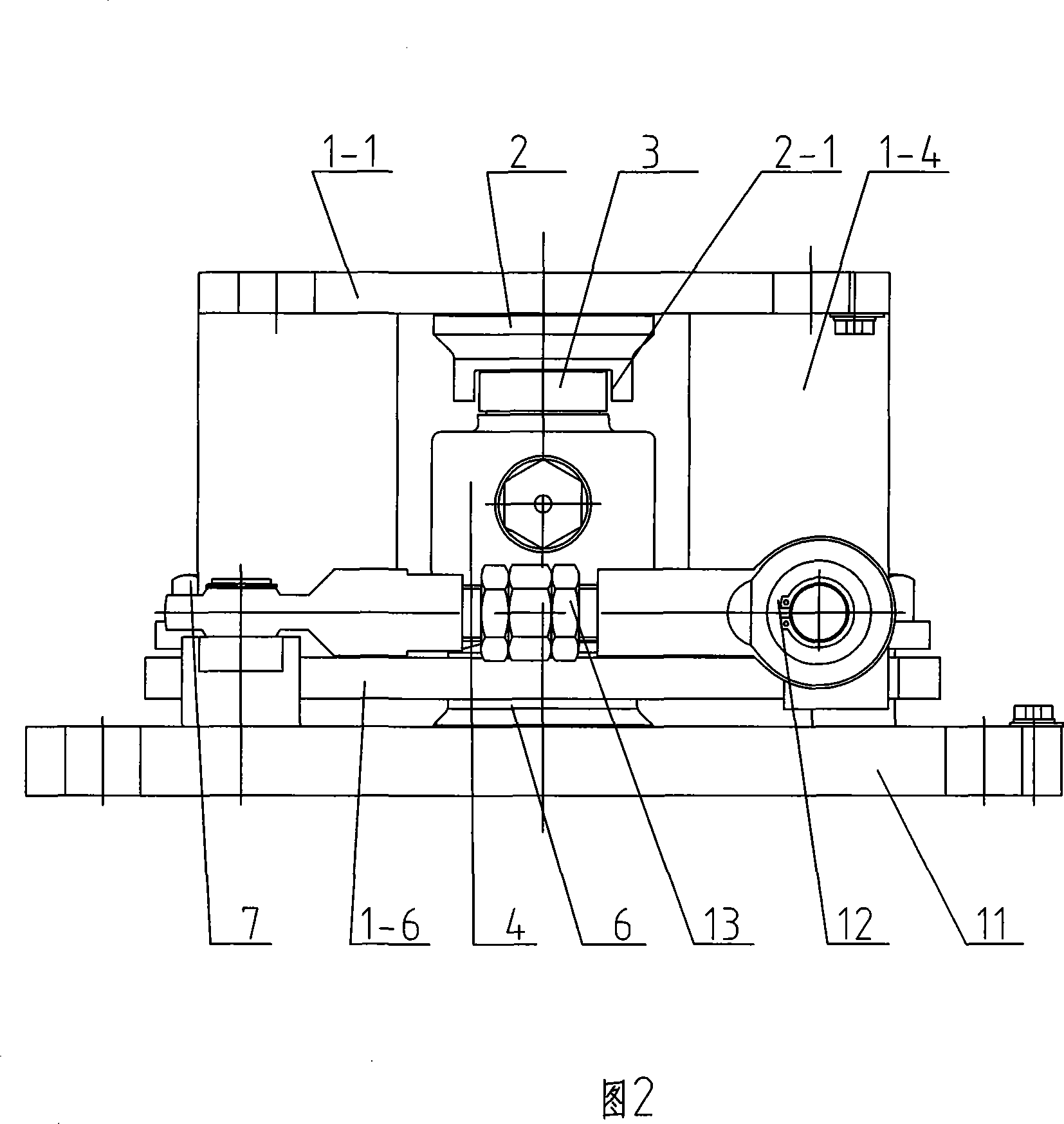

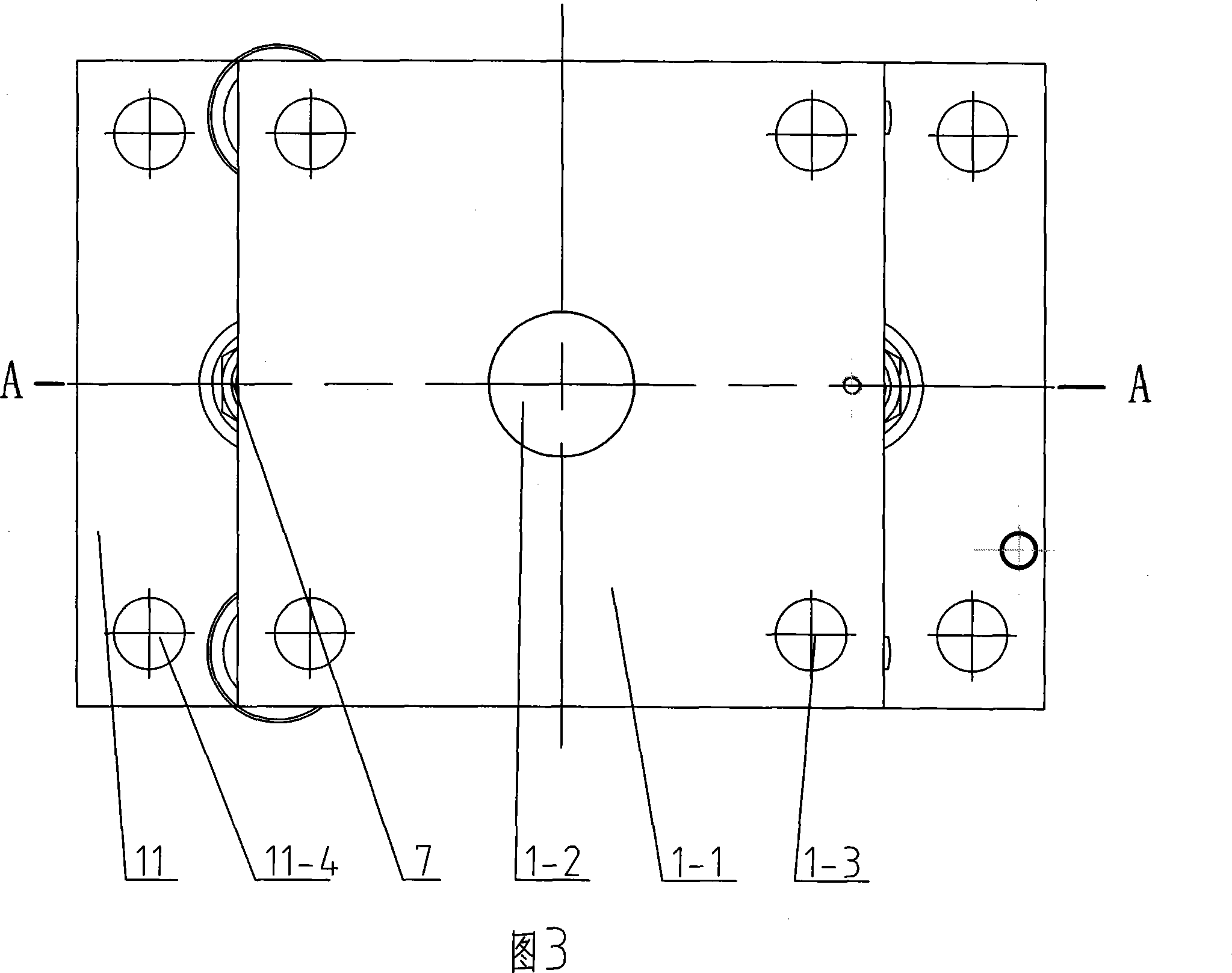

Weighing module

ActiveCN101078649ADoes not affect accuracyHigh precisionWeighing apparatus detailsAgricultural engineeringNeck parts

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

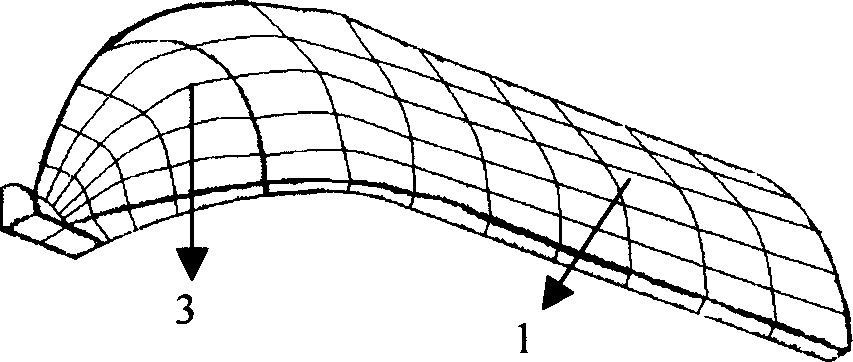

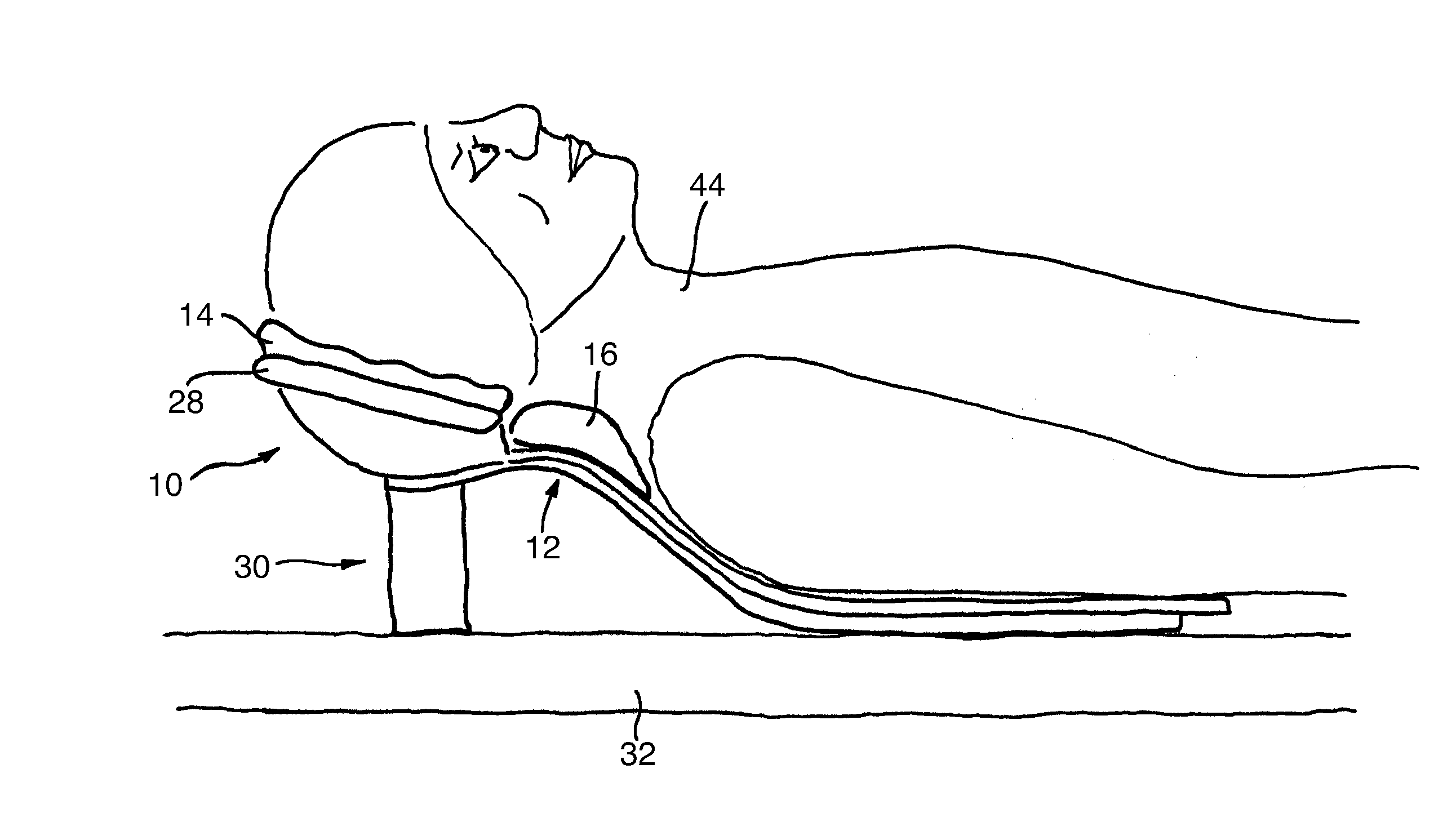

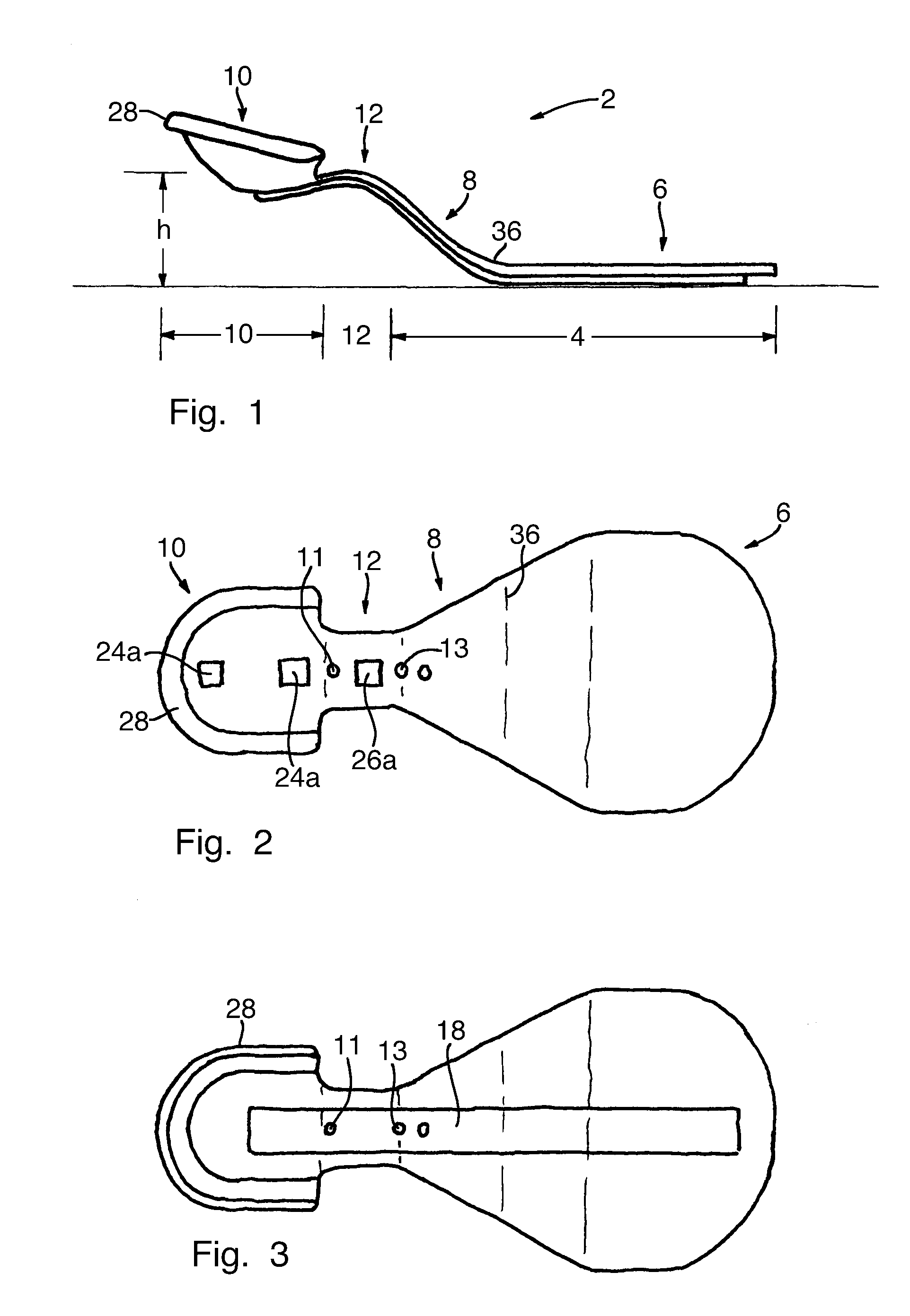

Support for supporting a patient

InactiveUS20100147313A1Improve stabilitySimple handlingOperating chairsOperating tablesNeck partsShoulder region

In order to improve a support (2) for supporting a patient, particularly for surgical procedures in the shoulder region, said support comprising a substantially flat body part (4) and a bowl-shaped head part, said body part (4) comprising a back part (6) and a thorax part (8) tapered in relation thereto, the head part (10) being disposed on said thorax part by means of a transitional region, with the thorax part (8) and the transitional region sloping upwards such that the head part (10) is higher than the back part (6), and with said head part being adapted to the human profile and comprising a removable, inflatable support for adapting the position of the patient to the current positional or treatment requirements, the invention proposes that the transitional region be designed as neck part (12) and also be adapted to the human profile, comprising a removable, inflatable support for adapting the position of the patient to the current positional or treatment requirements.

Owner:SAMARIT MEDIZINTECHN

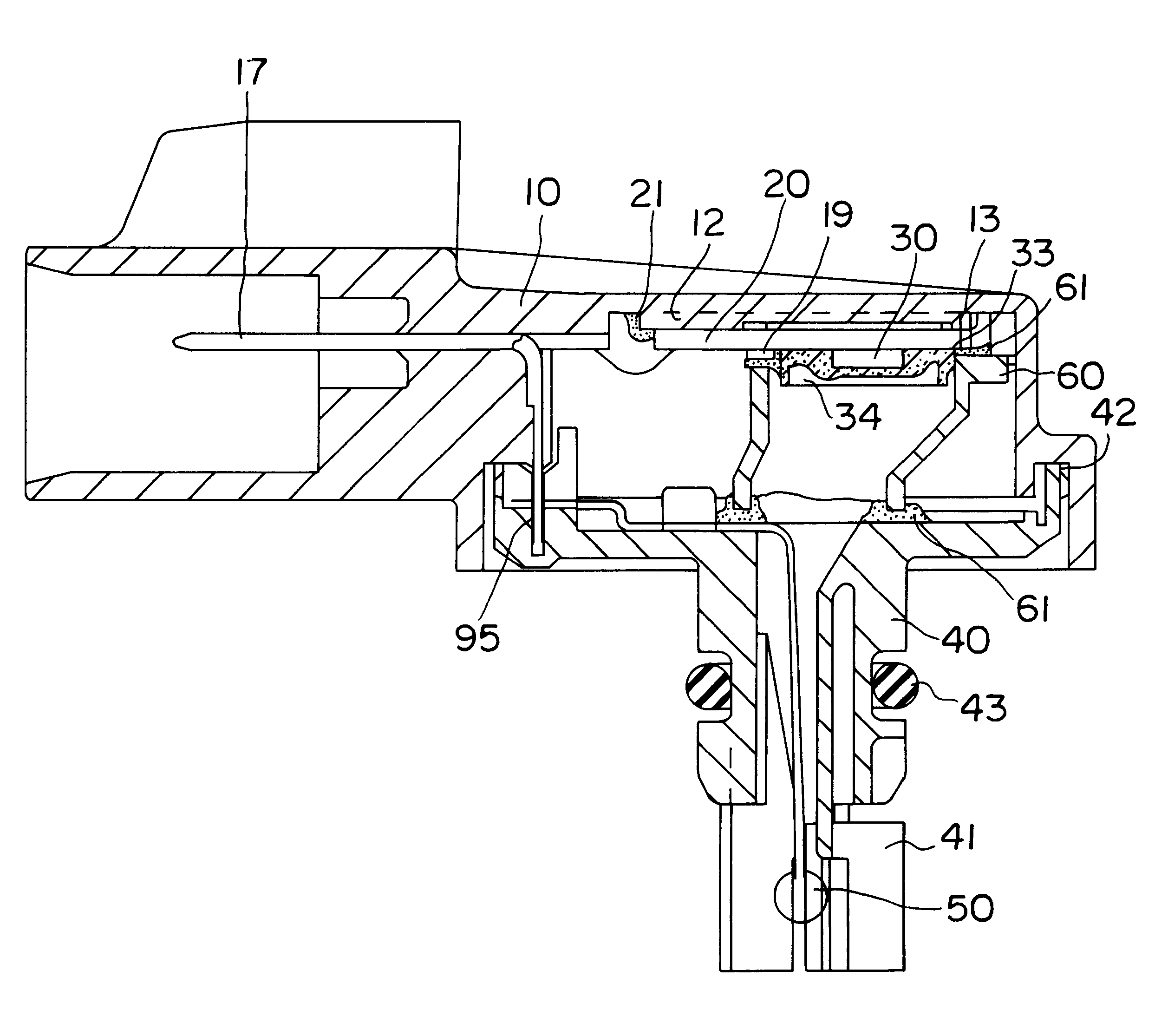

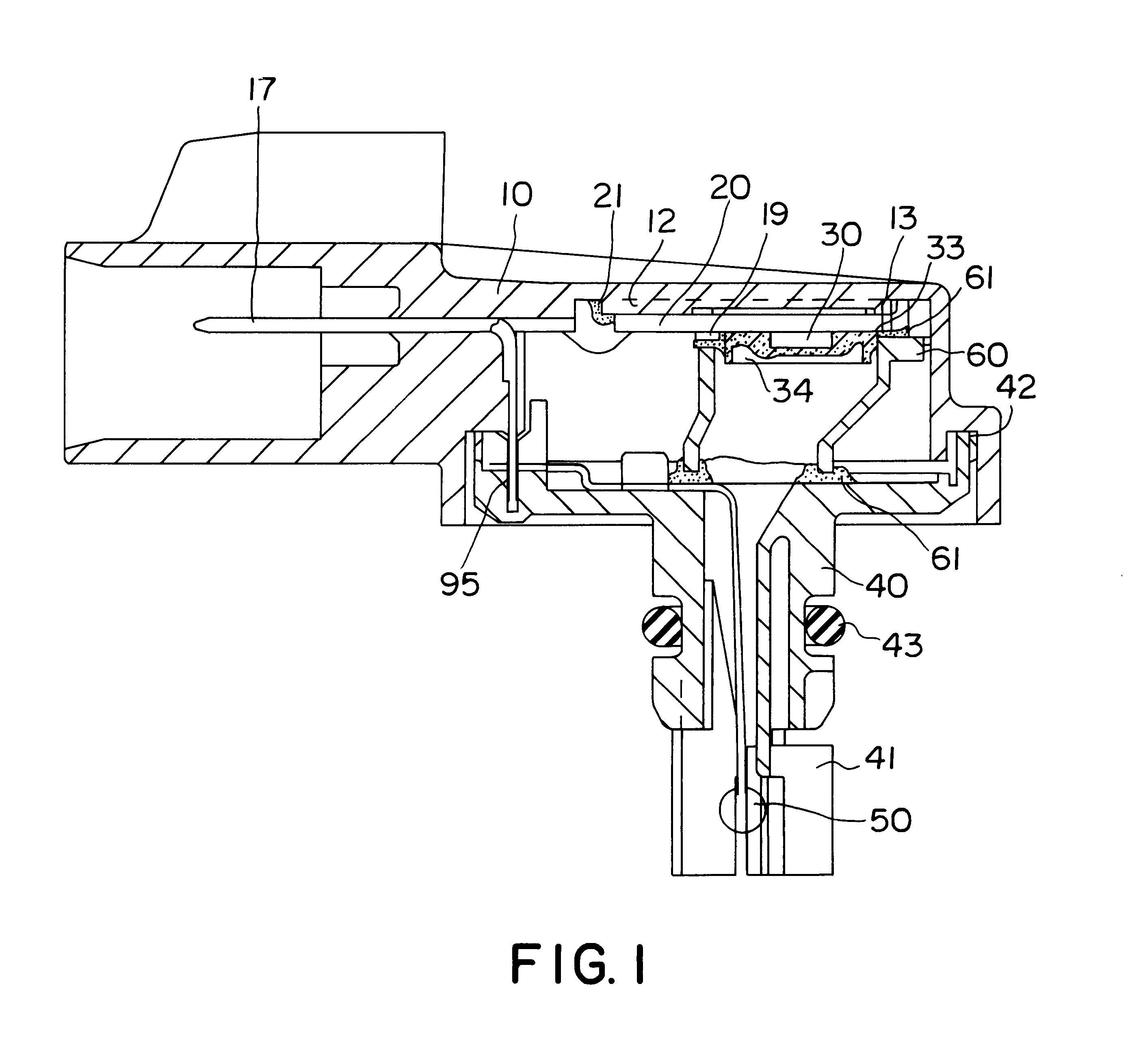

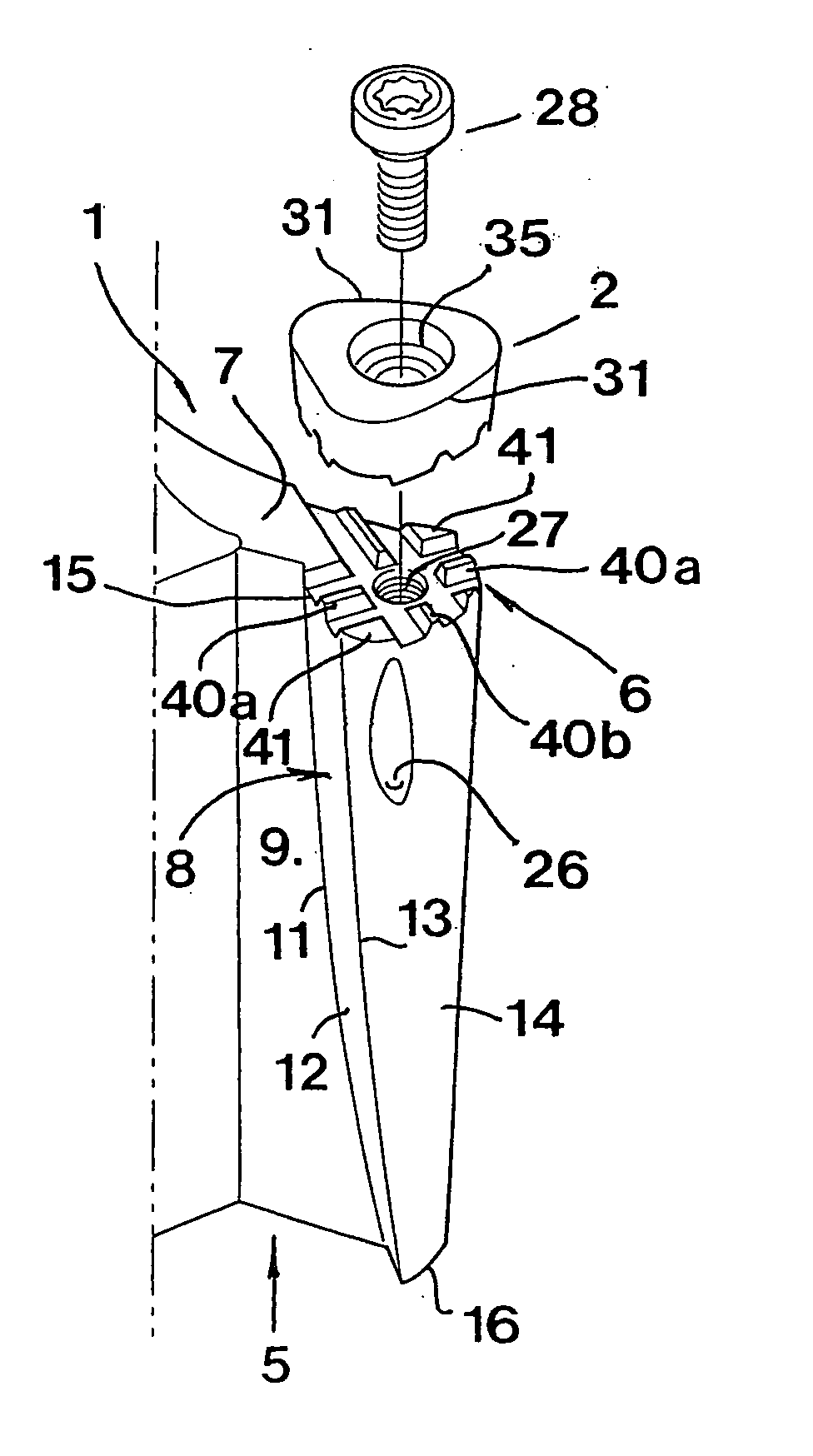

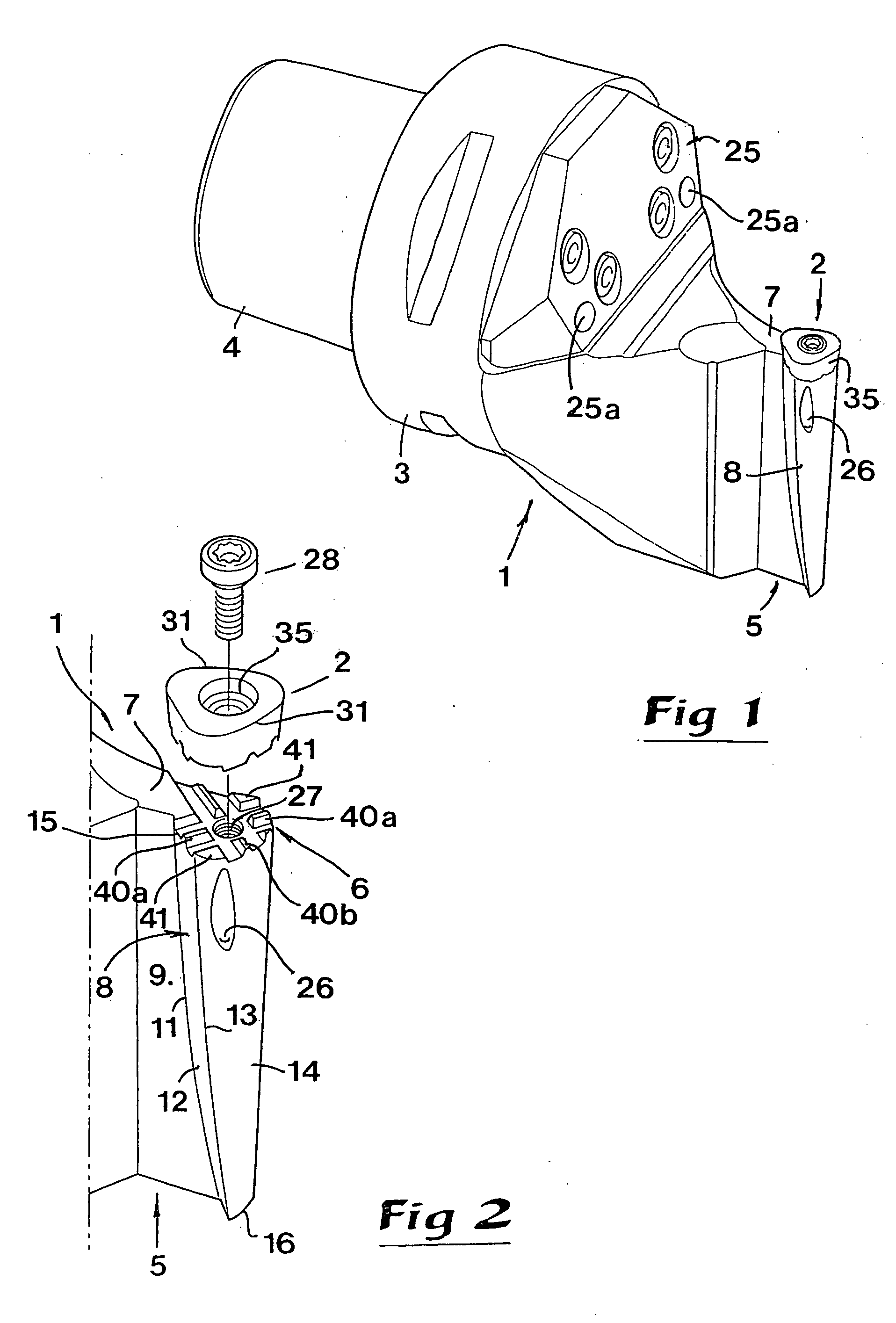

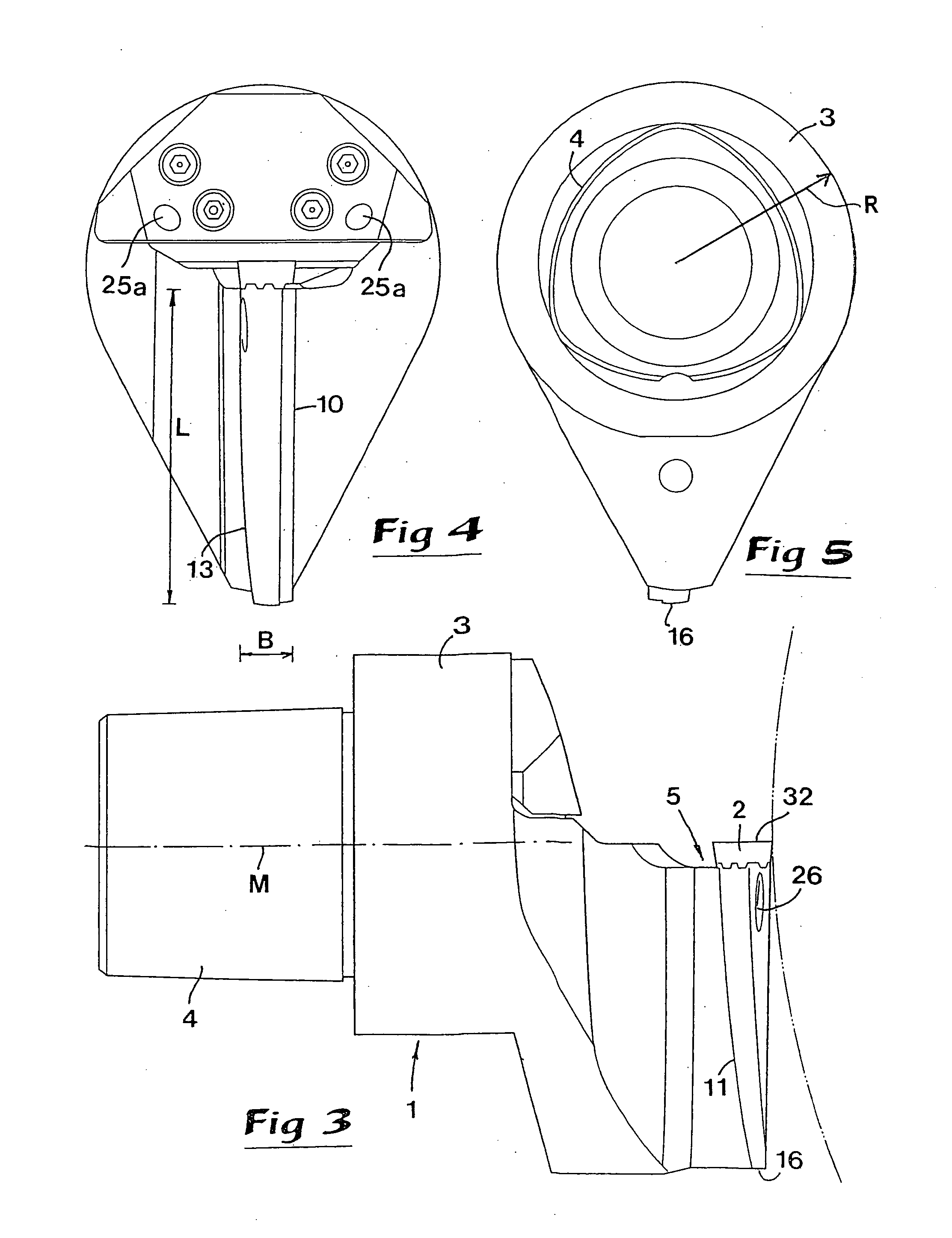

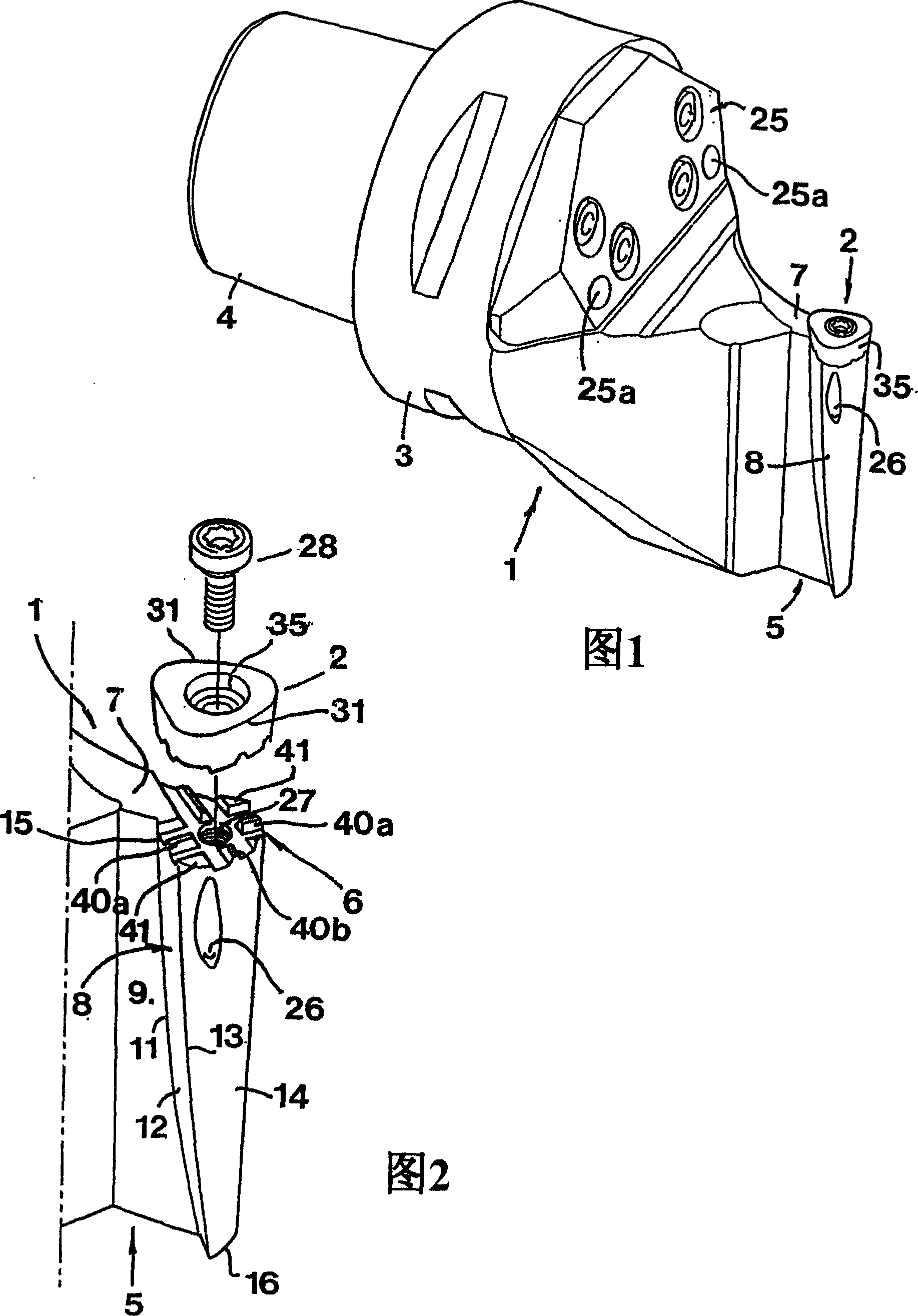

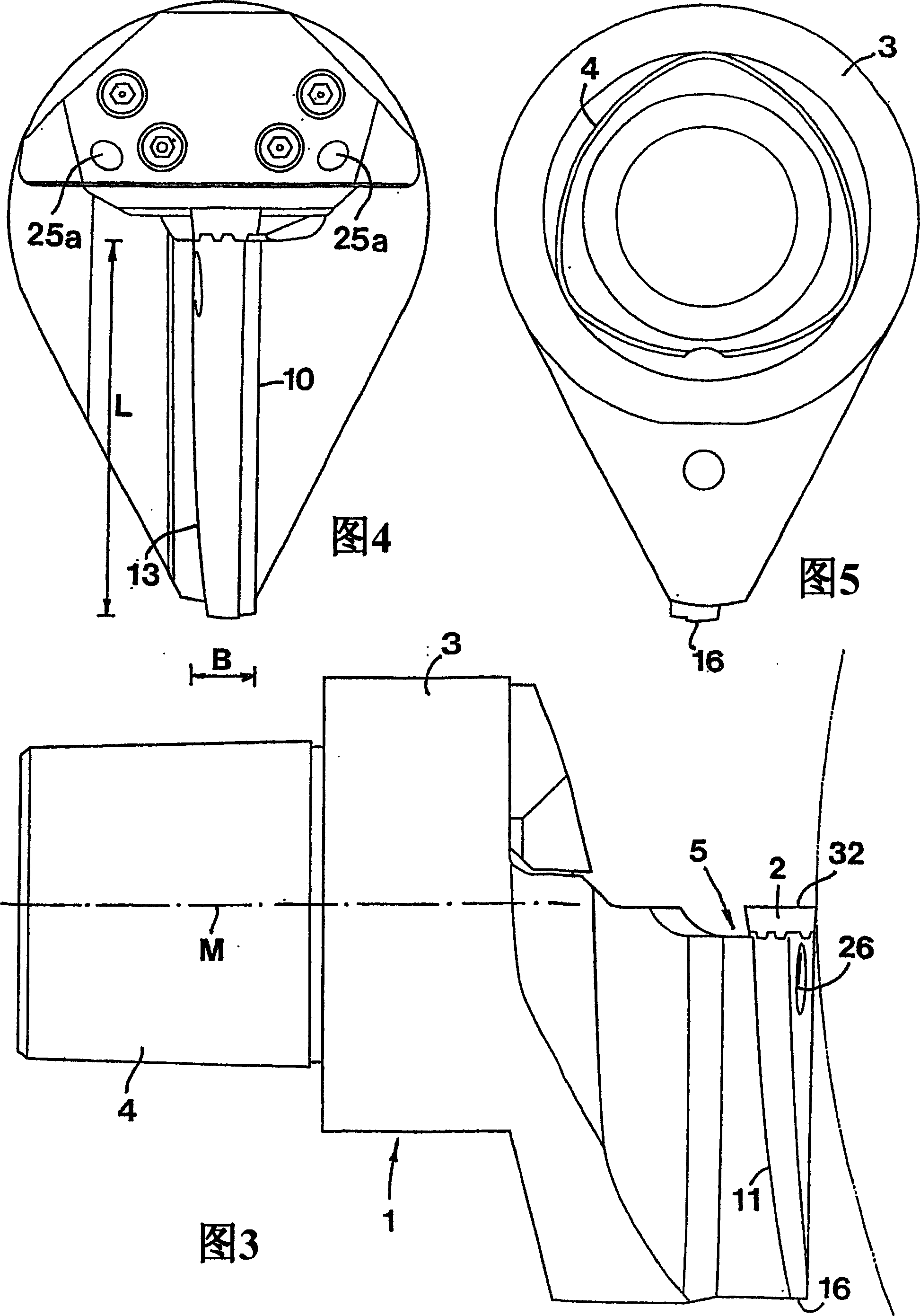

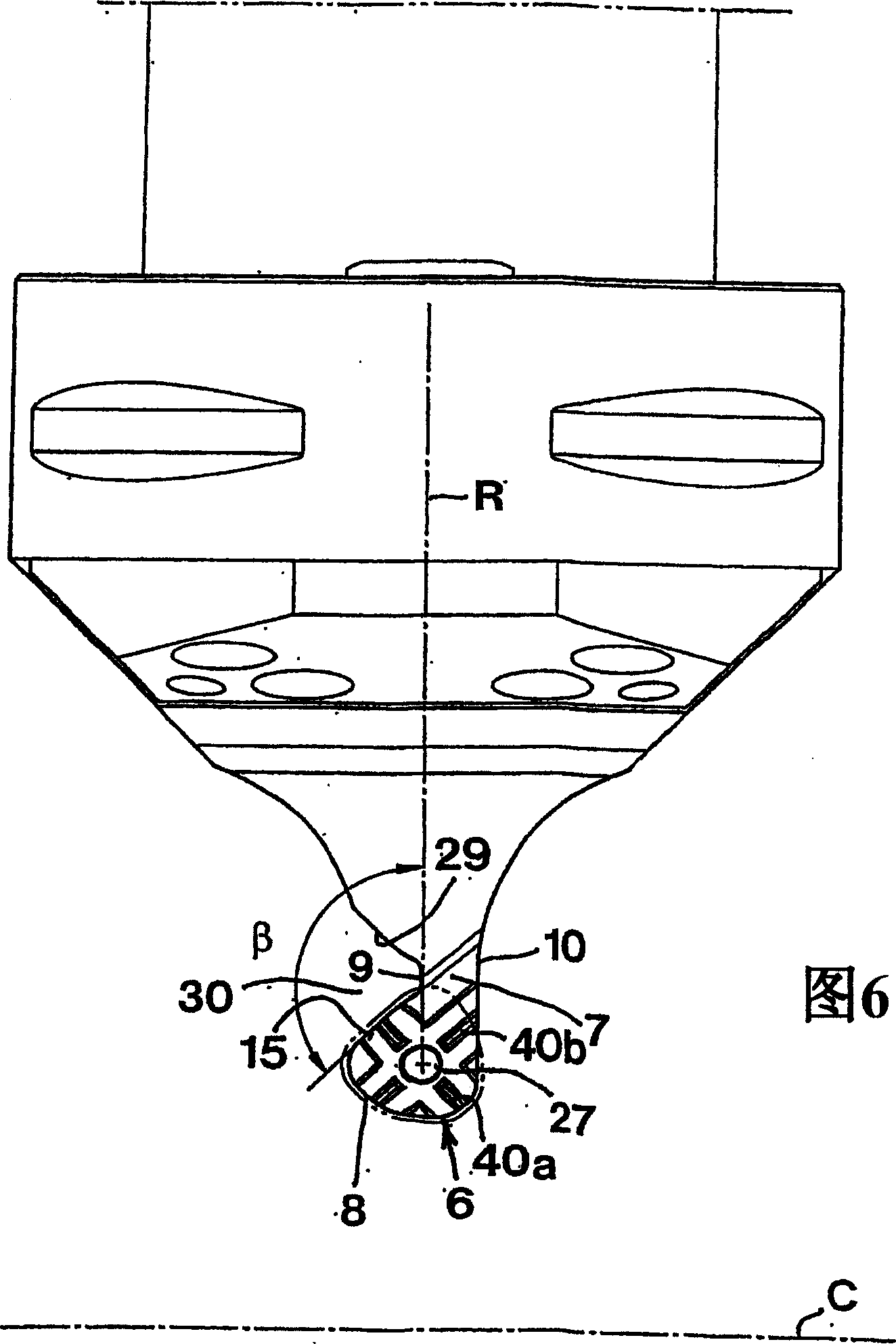

Tool and cutting insert for the fine turning of grooves in workpieces

A tool for the fine-turning of grooves in workpieces including a basic body having a rearwardly extending mounting part, and a forwardly projecting bracket. The bracket includes a narrow neck part and an enlarged support part disposed at an end of the neck part. The support part, which forms an insert seat, extends laterally from the neck part wherein the seat is arranged asymmetrically with respect to an imaginary center line of the basic body. A cutting insert includes a bottom side supported on the insert seat. The insert includes two spaced apart convexly arched side cutting edges arranged so that the imaginary center line passes therebetween. A hole is provided through the insert for receiving a fastening screw. The bottom side and the insert seat include mutually engaging stabilizing structures preventing angular displacement of the insert about an axis of the hole.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

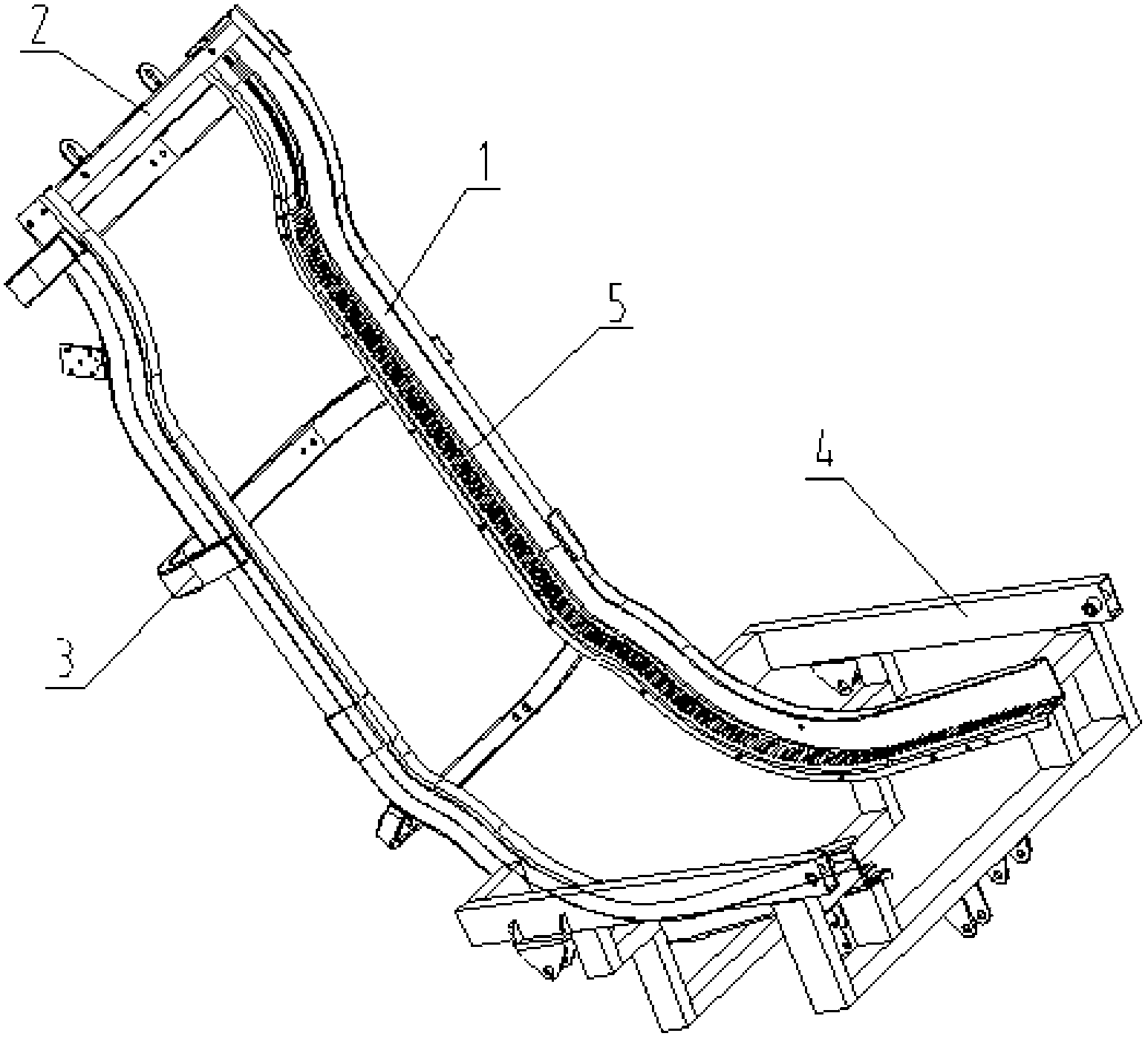

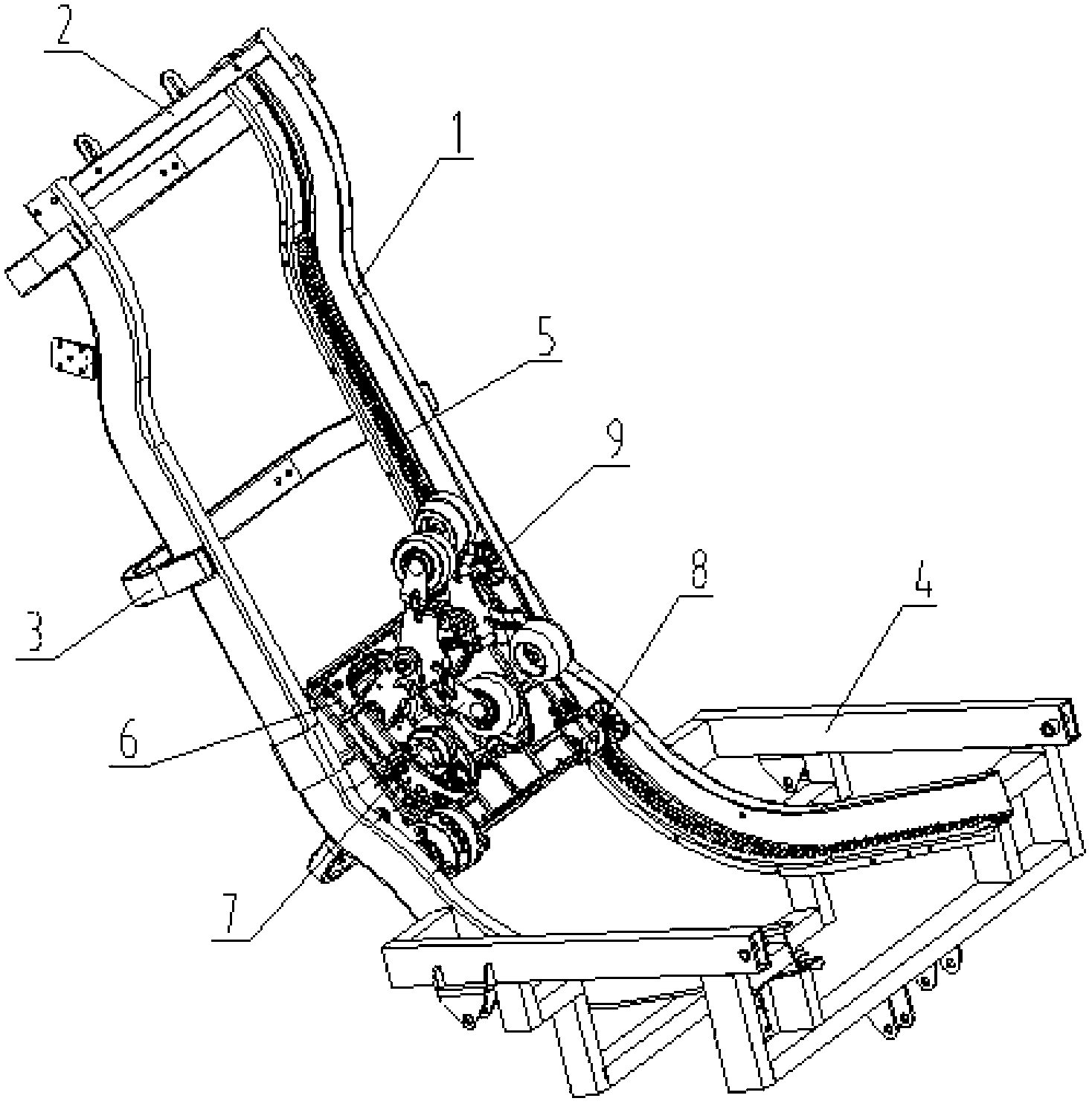

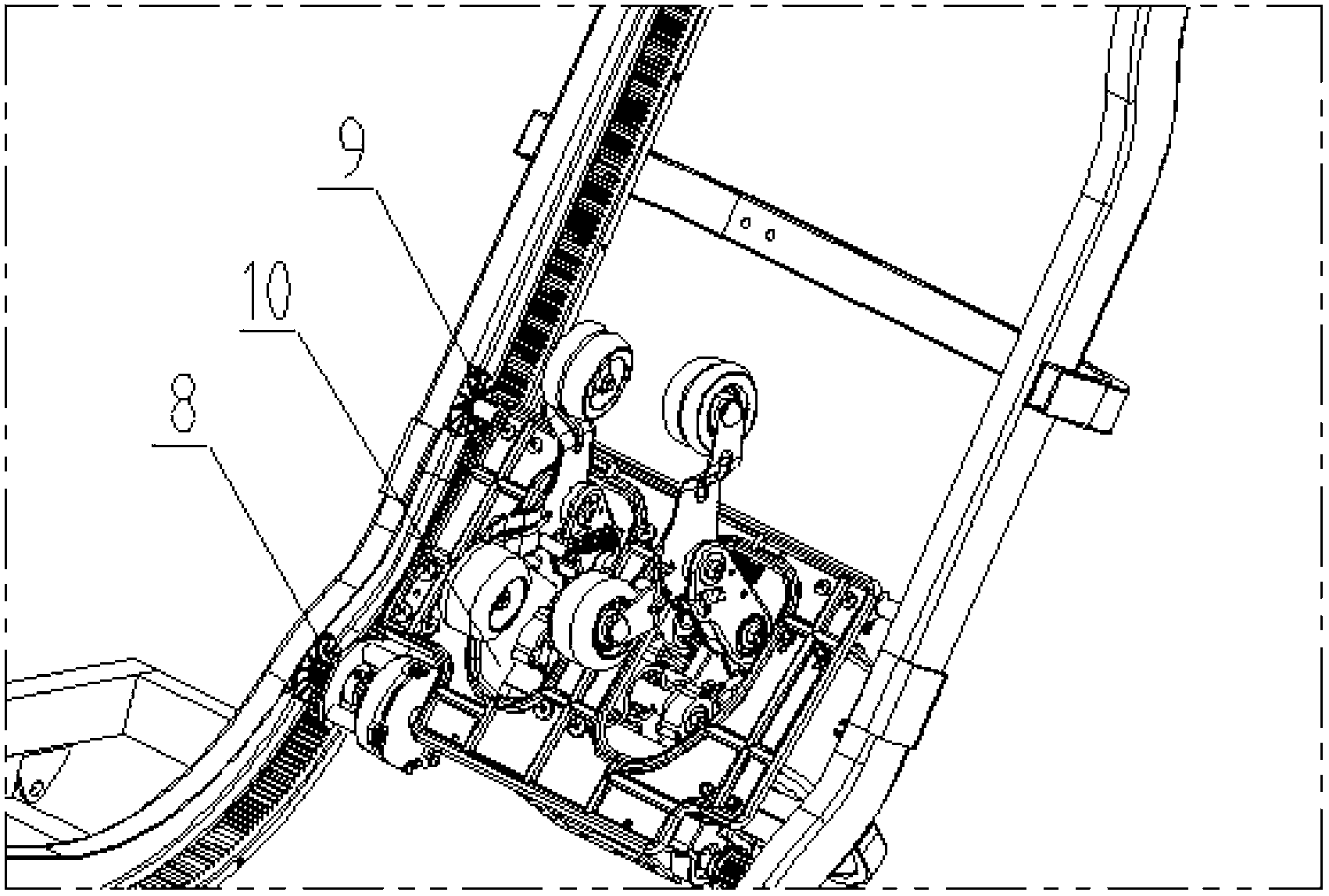

Special back frame structure for massage chair

InactiveCN102697626AImprove comfortRealize personal massageDevices for pressing relfex pointsVibration massageNeck partsMassage

The invention belongs to the technical field of health-care massage chairs, and particularly relates to a special back frame structure for a massage chair. The back frame structure comprises an L-shaped whole curve guide rail and a manipulator massage machine core, wherein the L-shaped whole curve guide rail is installed and welded by a left channel steel type curve guide rail and a right channel steel type curve guide rail which are parallel mutually through a plurality of back frame bending pipes; the lower end of the L-shaped whole curve guide rail is fixedly arranged on a base of the massage chair; the channel steel type curve guide rails are integrally forged and formed by a back frame curve section and a seat frame curve section, wherein the back frame curve section simulates the structures of the head part, the neck part and the back part of a human body, and the seat frame curve section simulates the structures of the caudal vertebra, the hip part and the huckle part; and when in message, the manipulator massage machine core can extend from the head part and the back part to the caudal vertebra till the hip part and the huckle part. The special back frame structure has the advantages that the manipulator massage machine core can reach the caudal vertebra, the hip part and the huckle part for carrying out multi-manipulation massage such as kneading, finger-pressing and knocking, so that the comfort of massage is thoroughly and effectively improved.

Owner:SHANGHAI RONGTAI FITNESS TECH DEV CO LTD

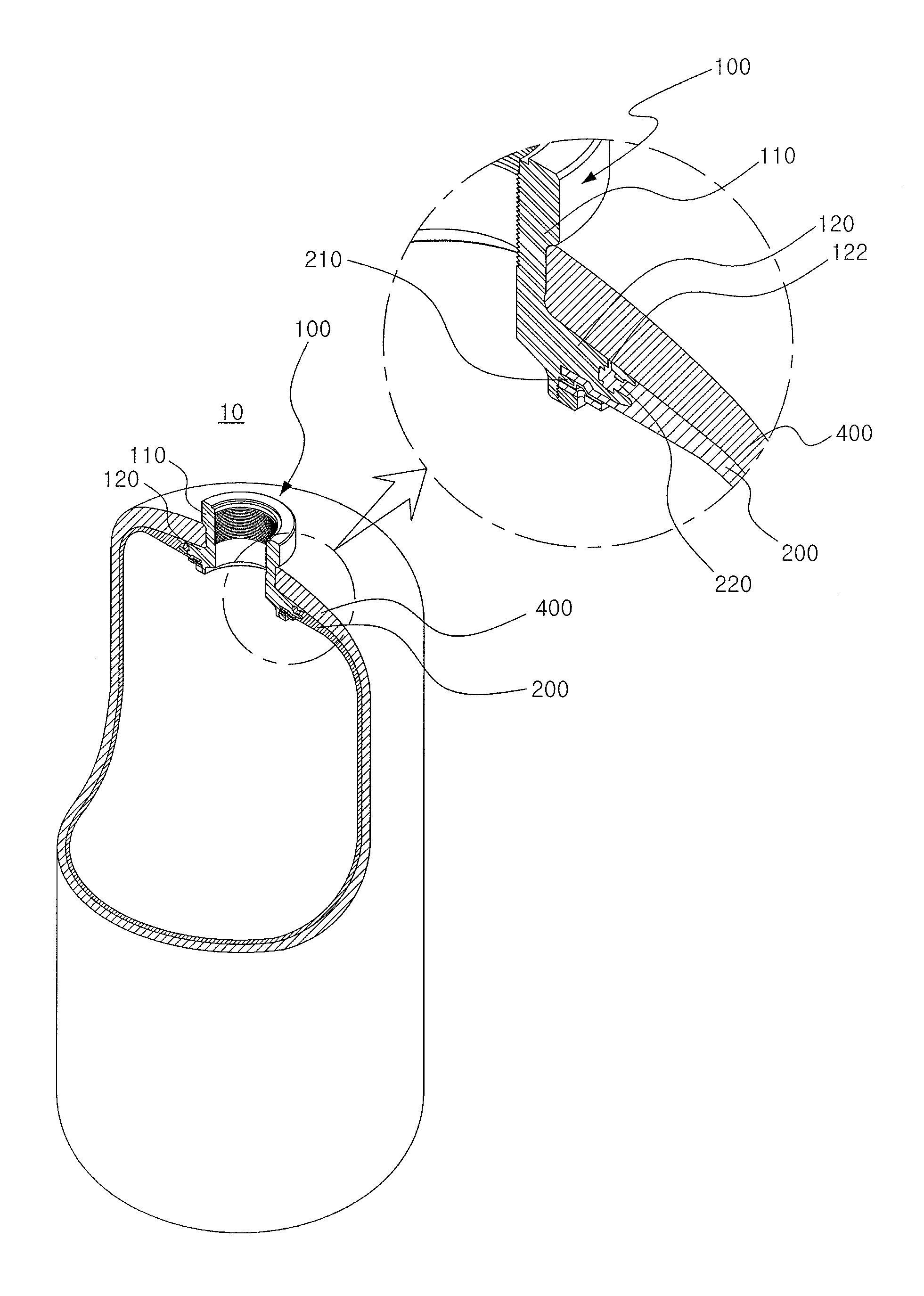

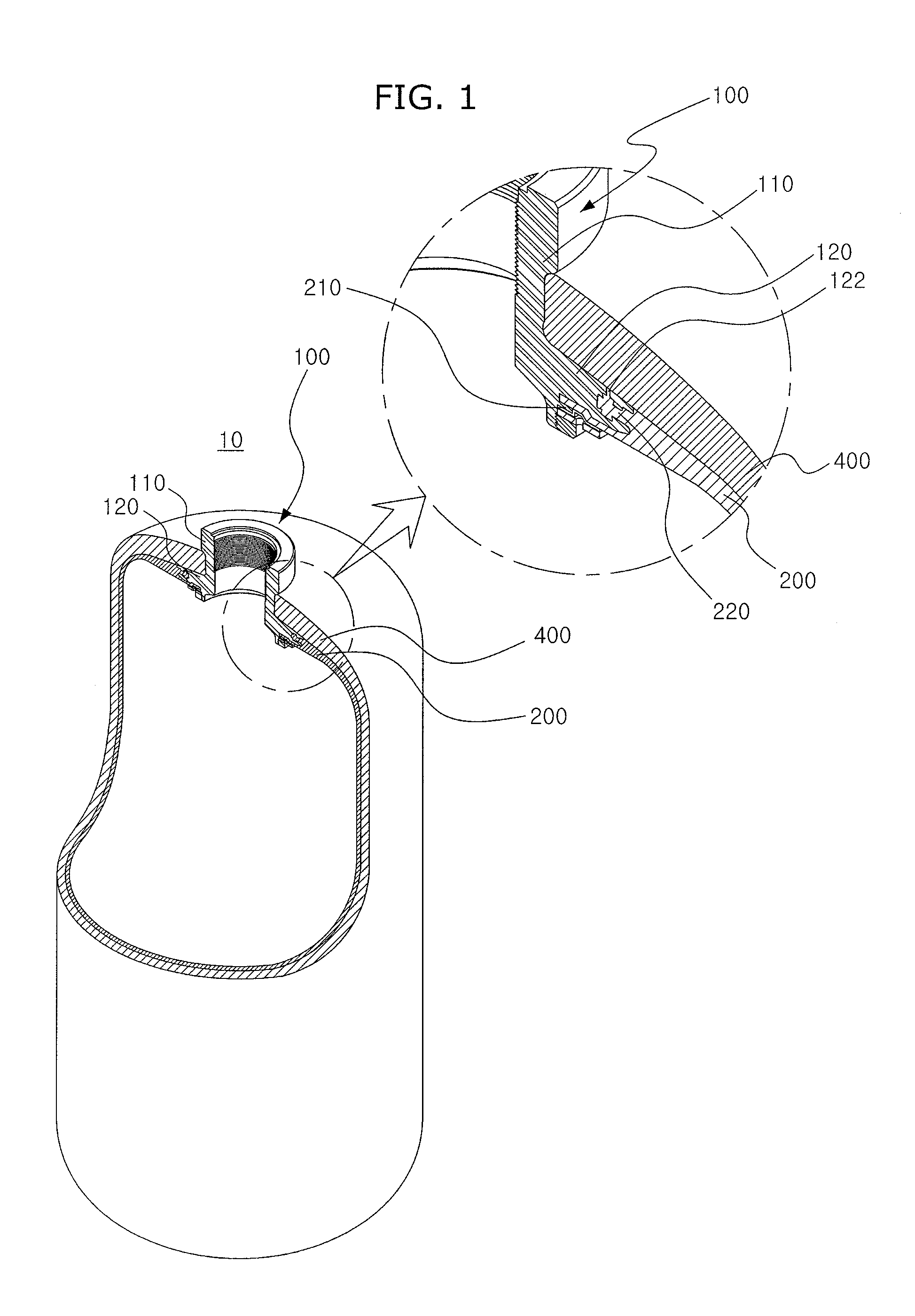

Pressure vessel

ActiveUS20140144866A1Enhanced couplingPrevent liquid leakageVessel mounting detailsCapsNeck partsEngineering

There is provided a pressure vessel. The pressure vessel may include a nozzle-boss comprising a neck part including a hollow portion and a flange part extended outward from the neck part, a liner coupled with the nozzle-boss to provide a space filled with a fluid therein, and a sealing part inserted into a lower end of the neck part to prevent a spillage of the fluid via a boundary between the nozzle-boss and the liner by preventing a direct contact between the fluid and the boundary.

Owner:ILJIN COMPOSITES CO LTD

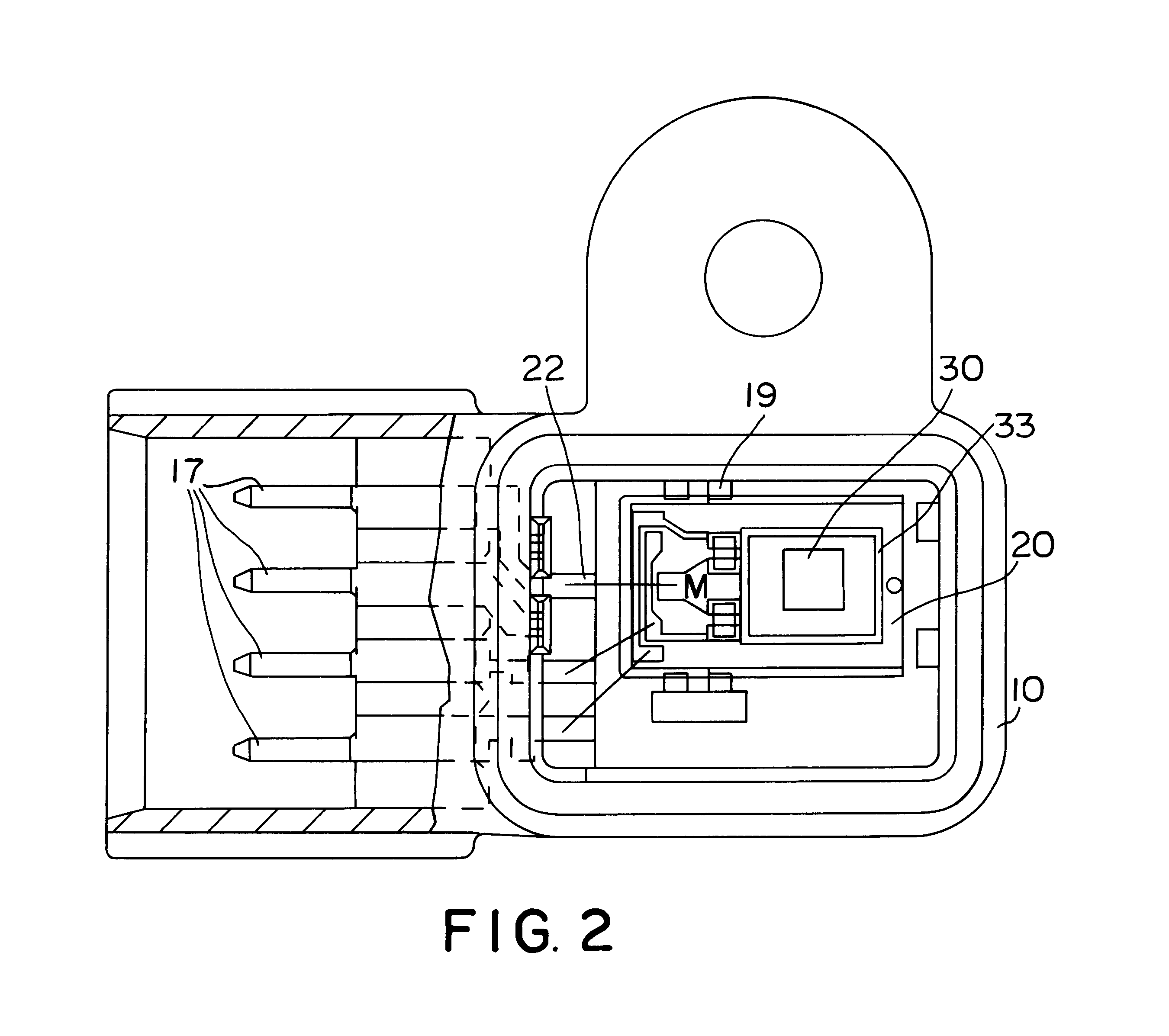

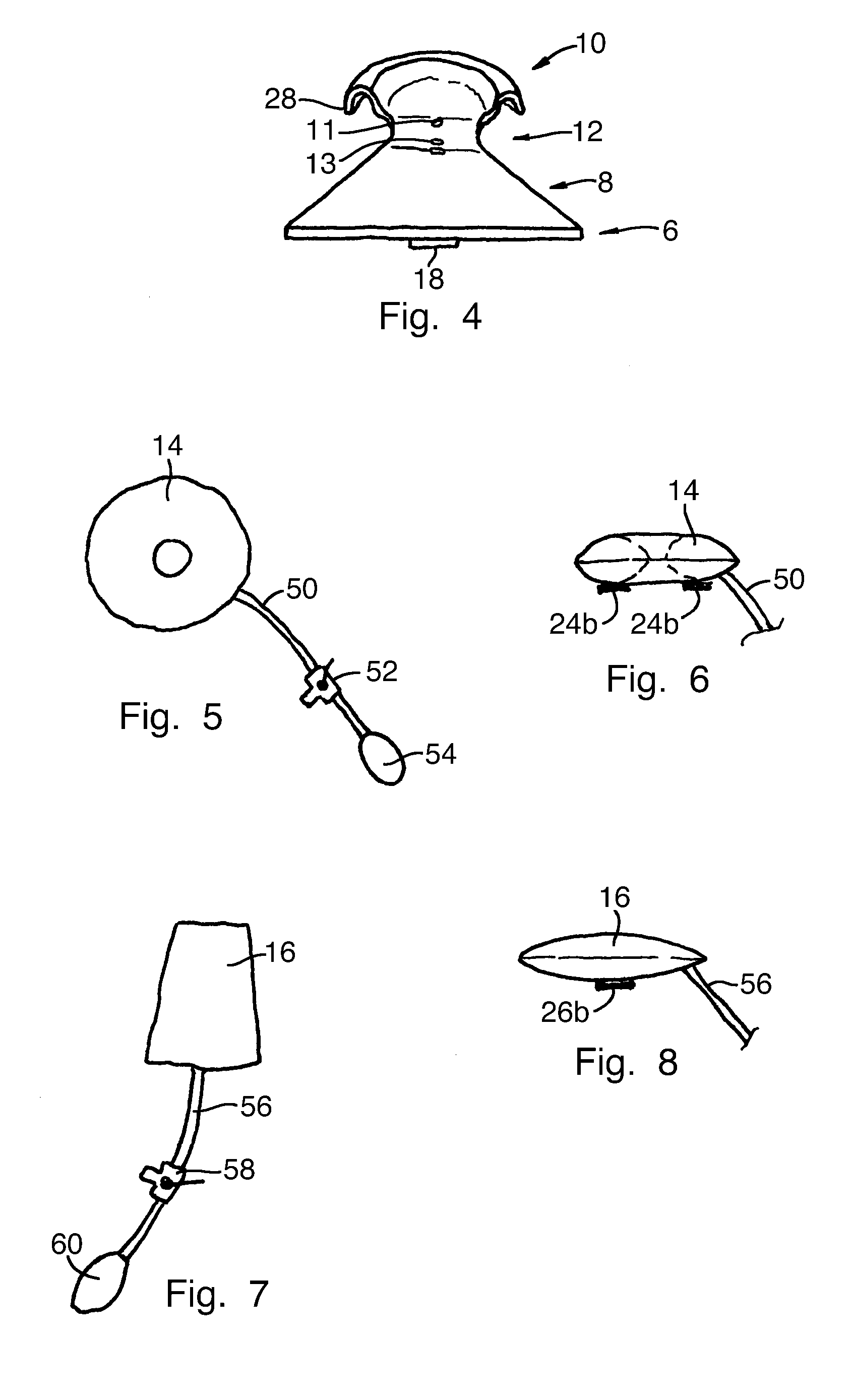

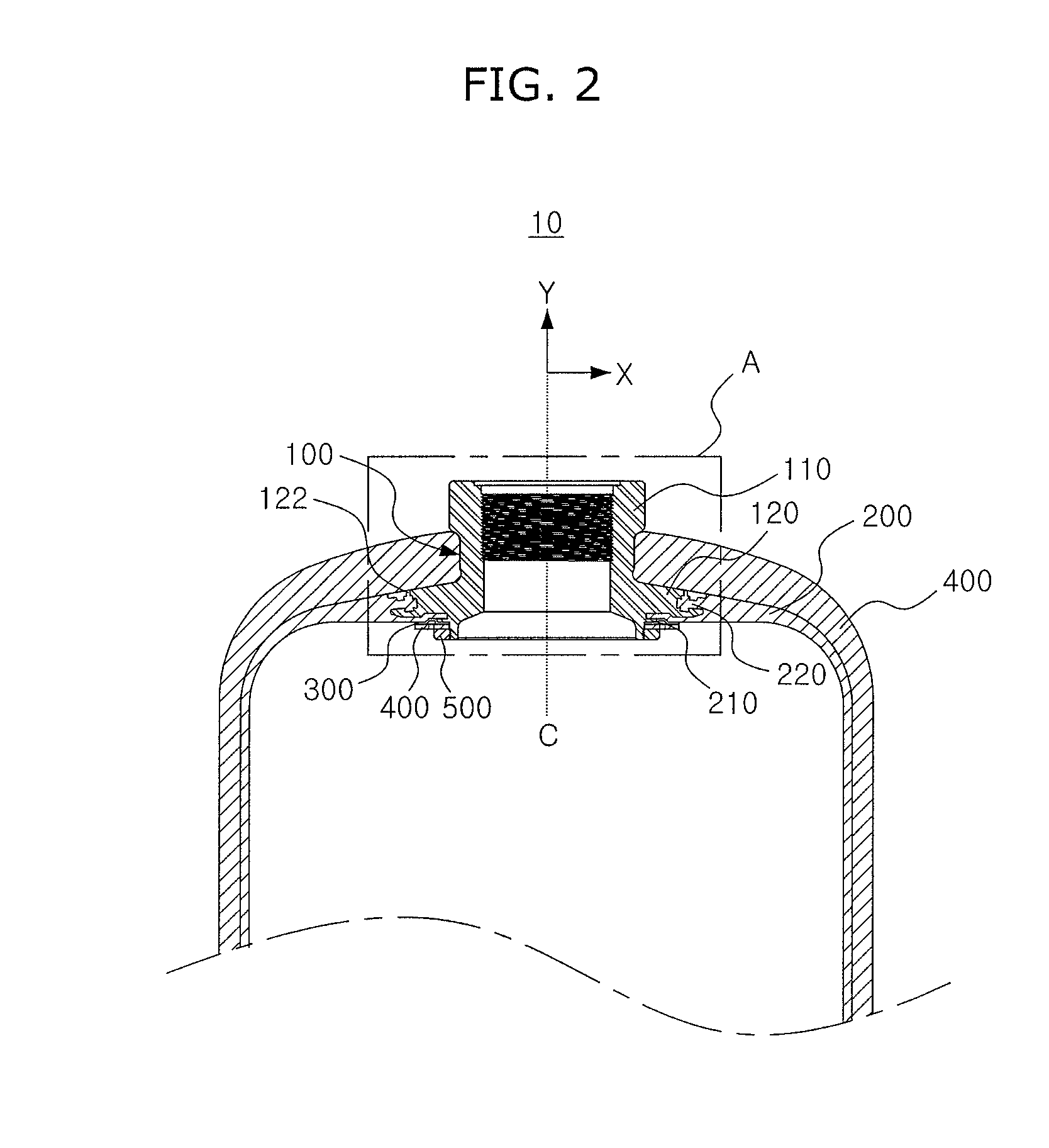

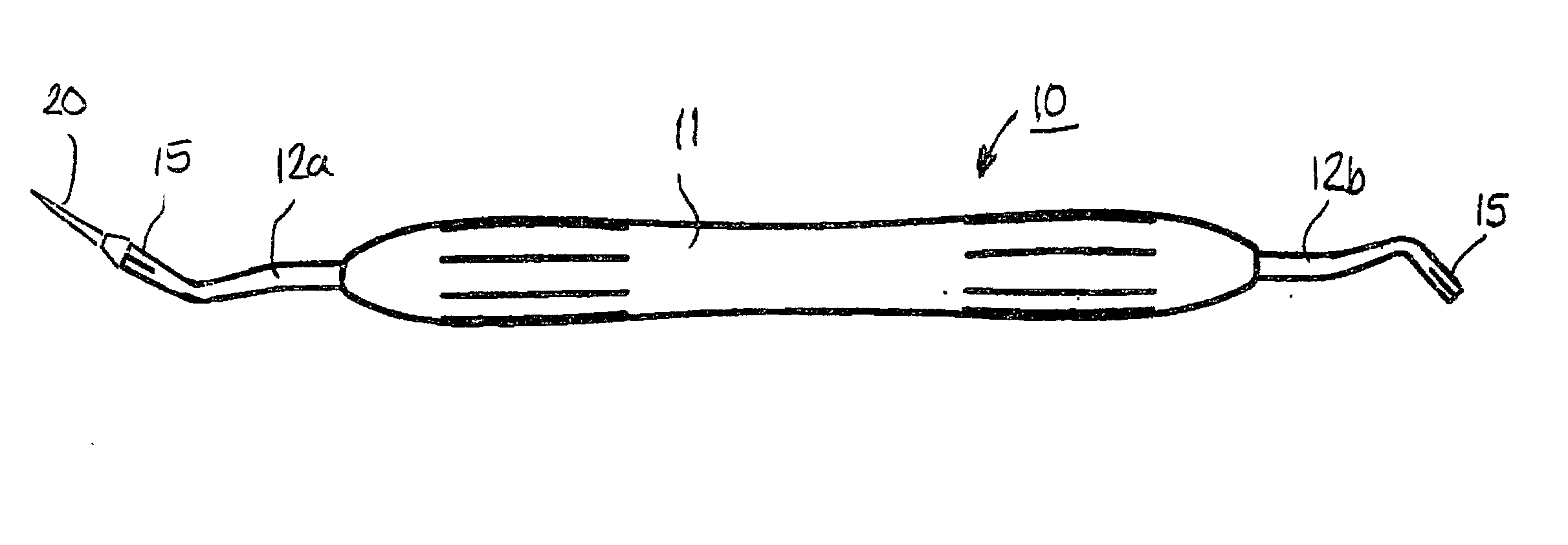

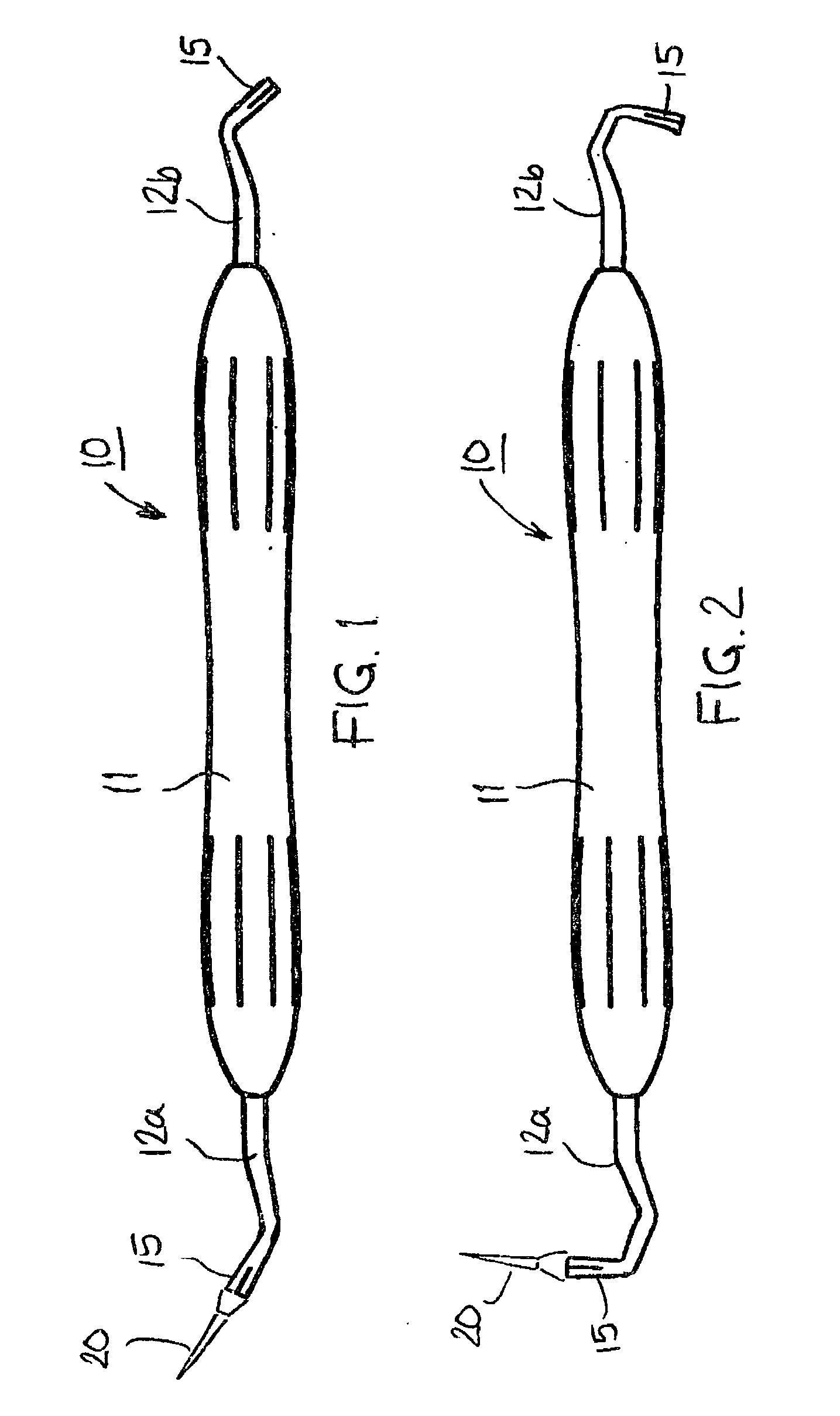

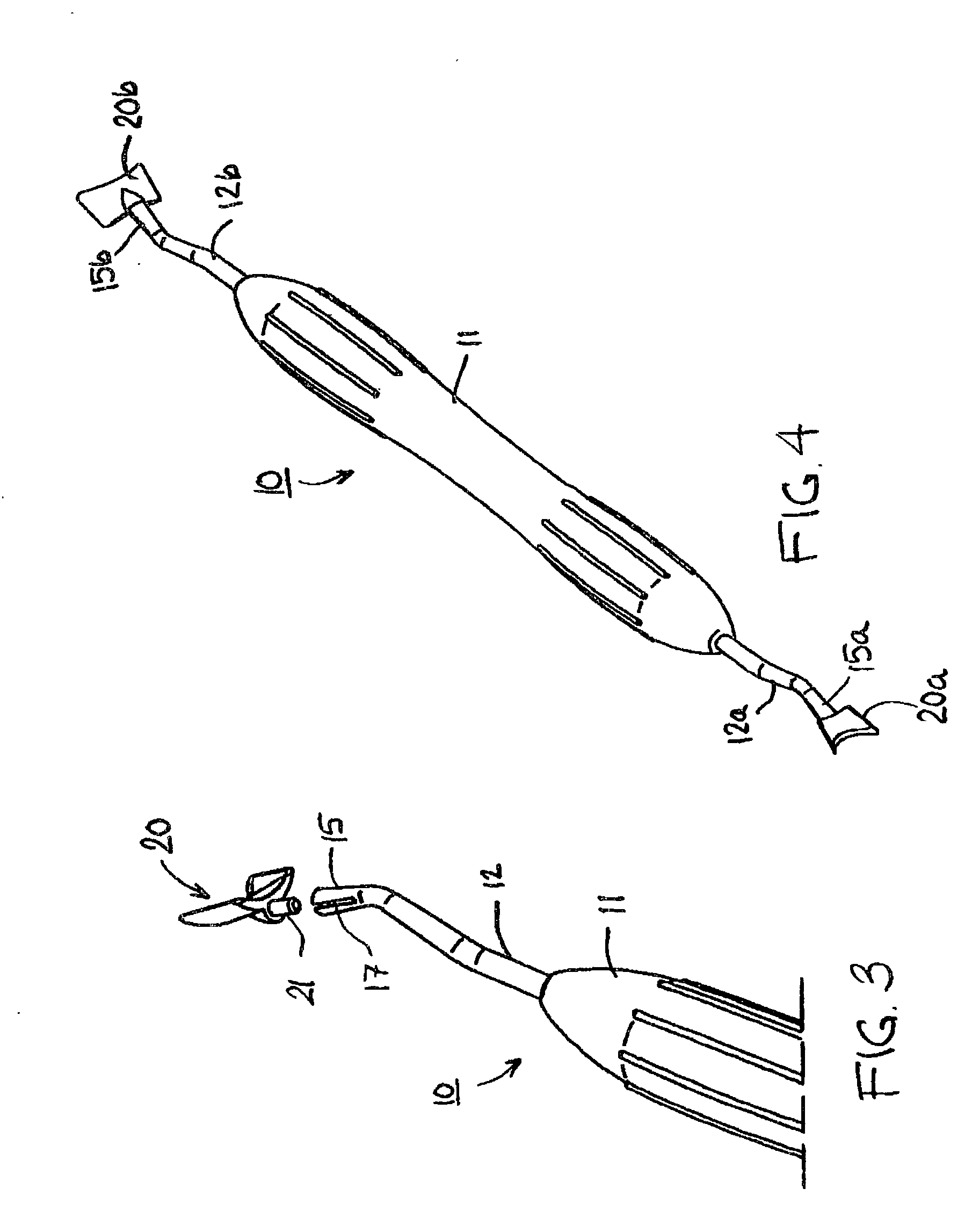

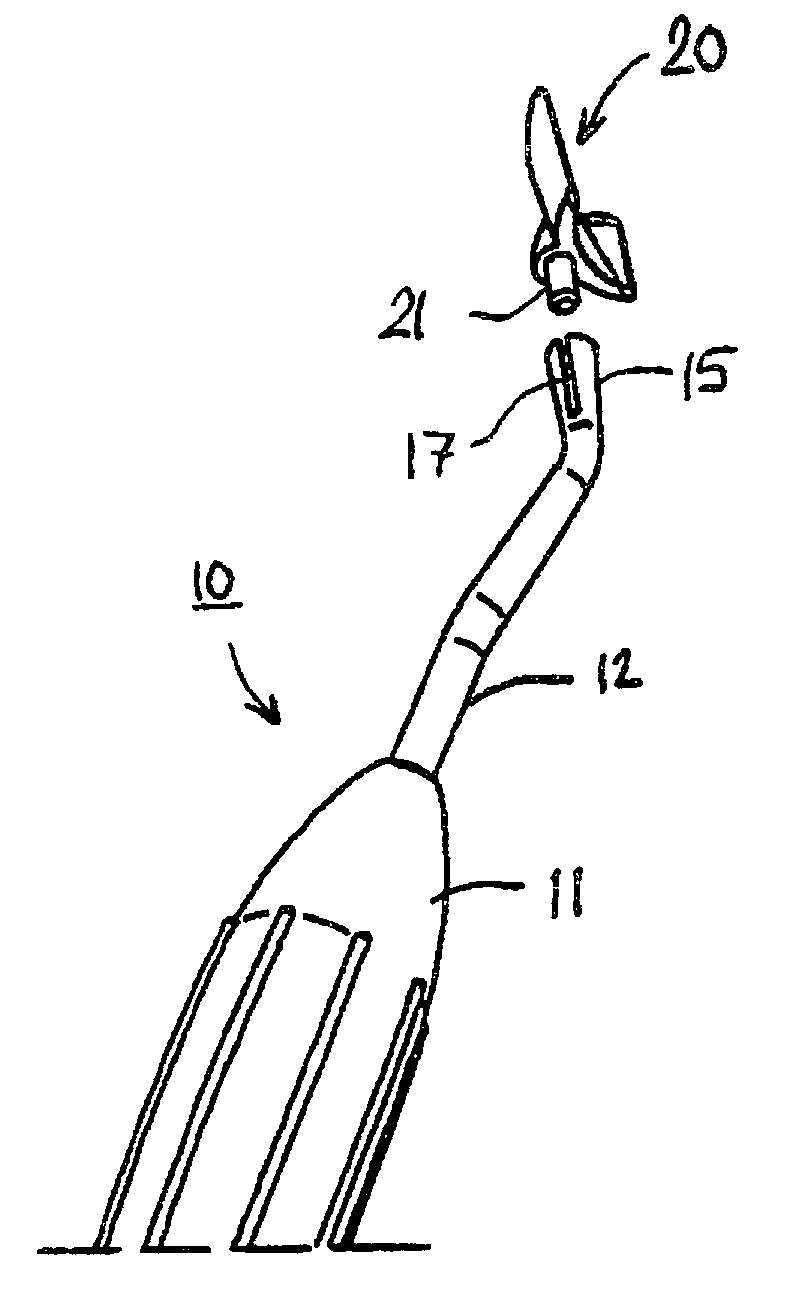

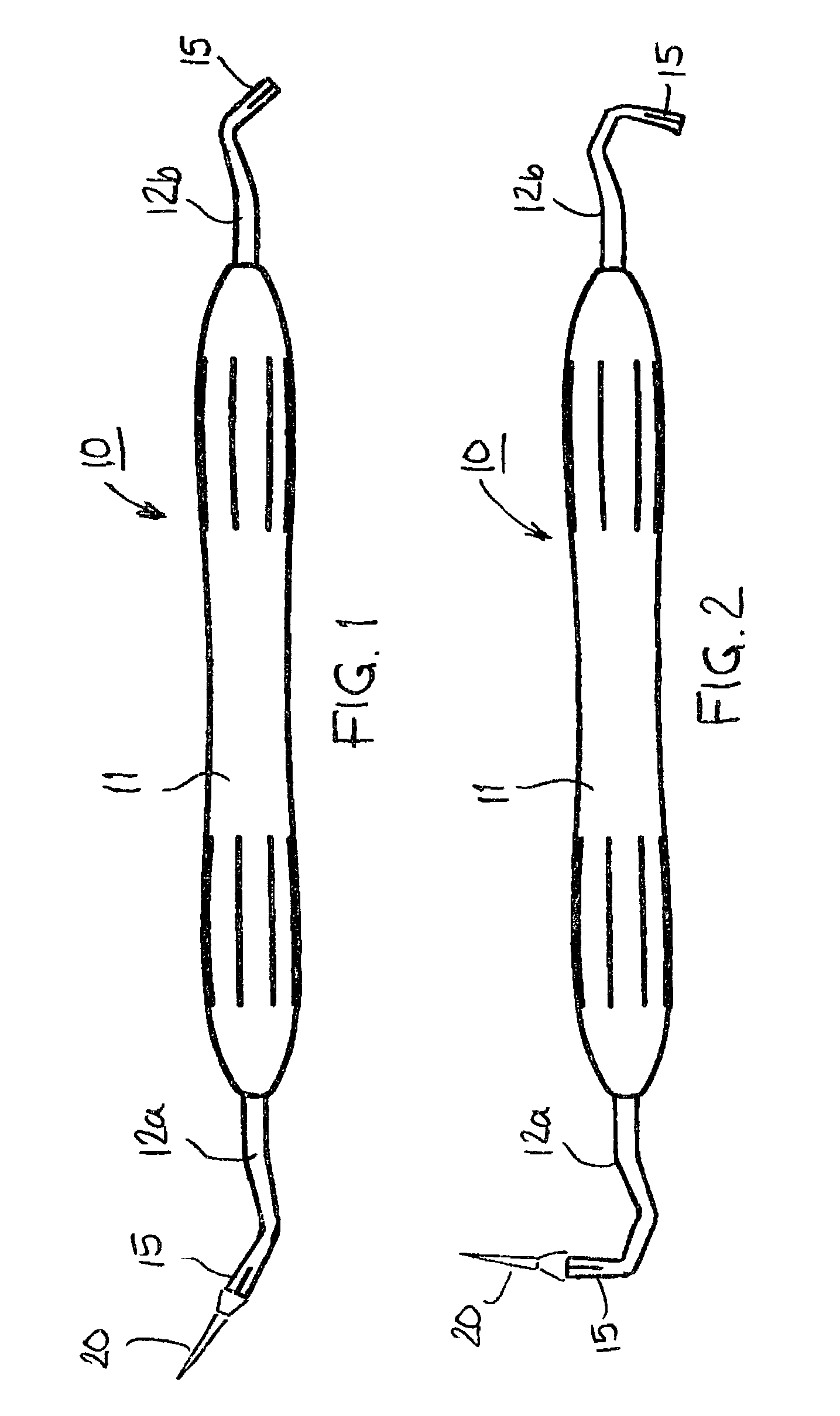

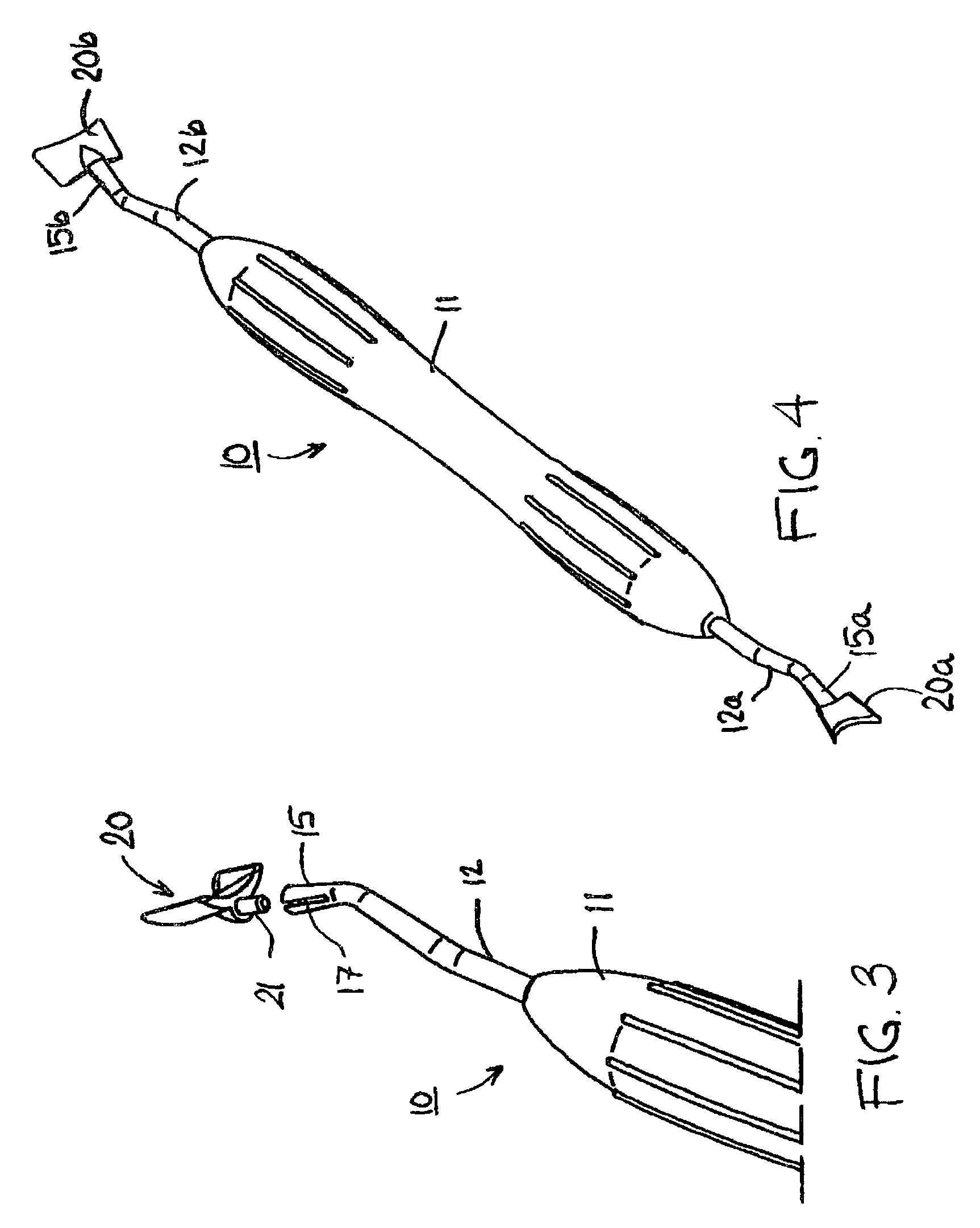

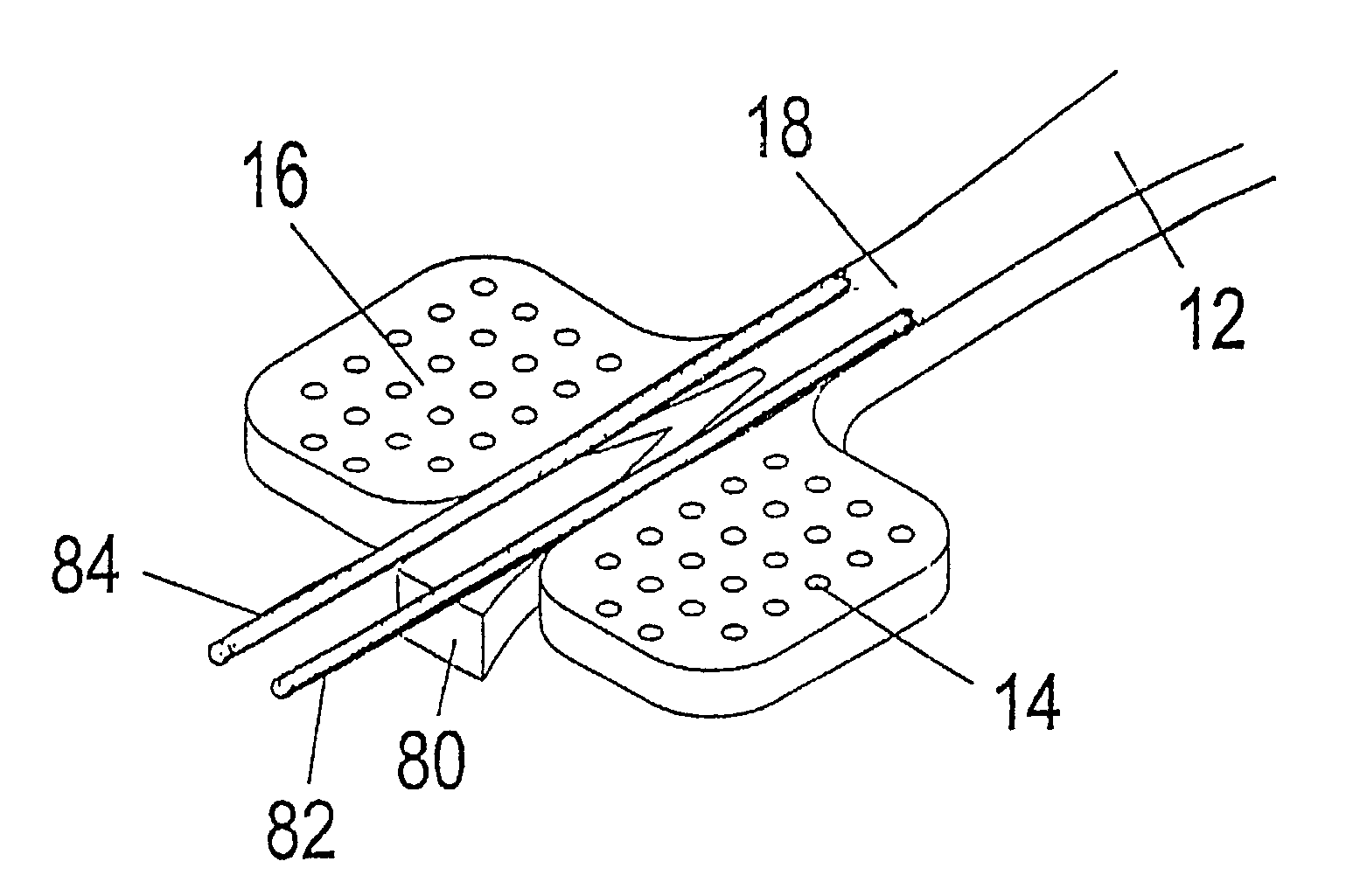

Dental hand instrument and tip of the instrument

A dental hand instrument (10), comprising a handle (11) with parts (12a, 12b) at its ends. The end of each neck part is provided with a coupling element (15) designed for the connection of replaceable tips (20) and oriented in the same direction with the neck part. The coupling element is a socket or pin (19) extending in the same direction with the neck part and allowing a corresponding concentric pin (21) or socket (26) of the tip to be fitted into / onto it. The socket of the coupling element may be provided with slots (17), and the inner surface of the socket has a circular or cornered cross-sectional form. The neck part and coupling element of the hand instrument are preferably made of stainless steel and the tip is made of steel, aluminun, plastic-coated aluminum, steel or titanium.

Owner:LM INSTRUMENTS OY

Dental hand instrument and tip of the instrument

A dental hand instrument (10), comprising a handle (11) with parts (12a, 12b) at its ends. The end of each neck part is provided with a coupling element (15) designed for the connection of replaceable tips (20) and oriented in the same direction with the neck part. The coupling element is a socket or pin (19) extending in the same direction with the neck part and allowing a corresponding concentric pin (21) or socket (26) of the tip to be fitted into / onto it. The socket of the coupling element may be provided with slots (17), and the inner surface of the socket has a circular or cornered cross-sectional form. The neck part and coupling element of the hand instrument are preferably made of stainless steel and the tip is made of steel, aluminum, plastic-coated aluminum, steel or titanium.

Owner:LM INSTRUMENTS OY

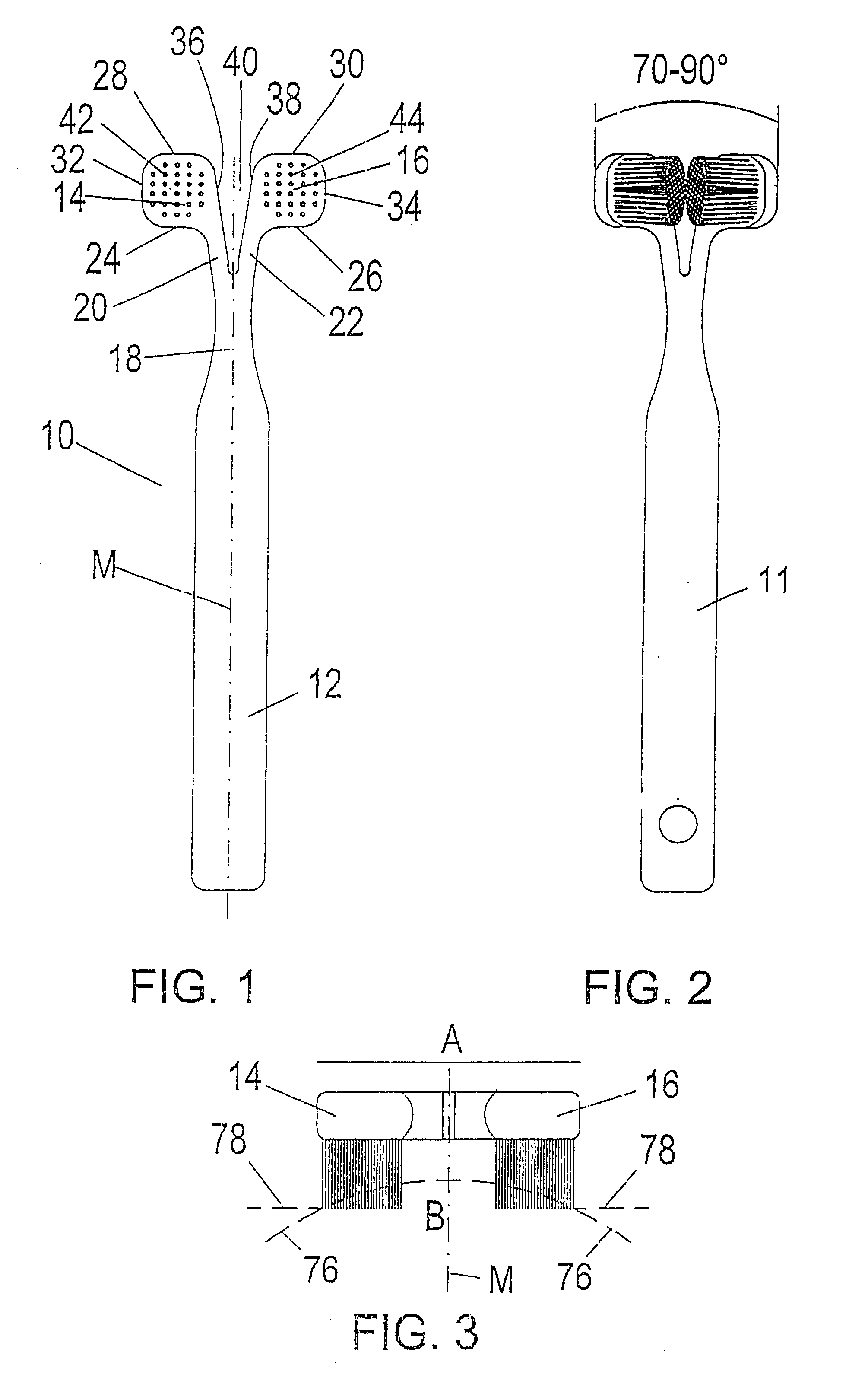

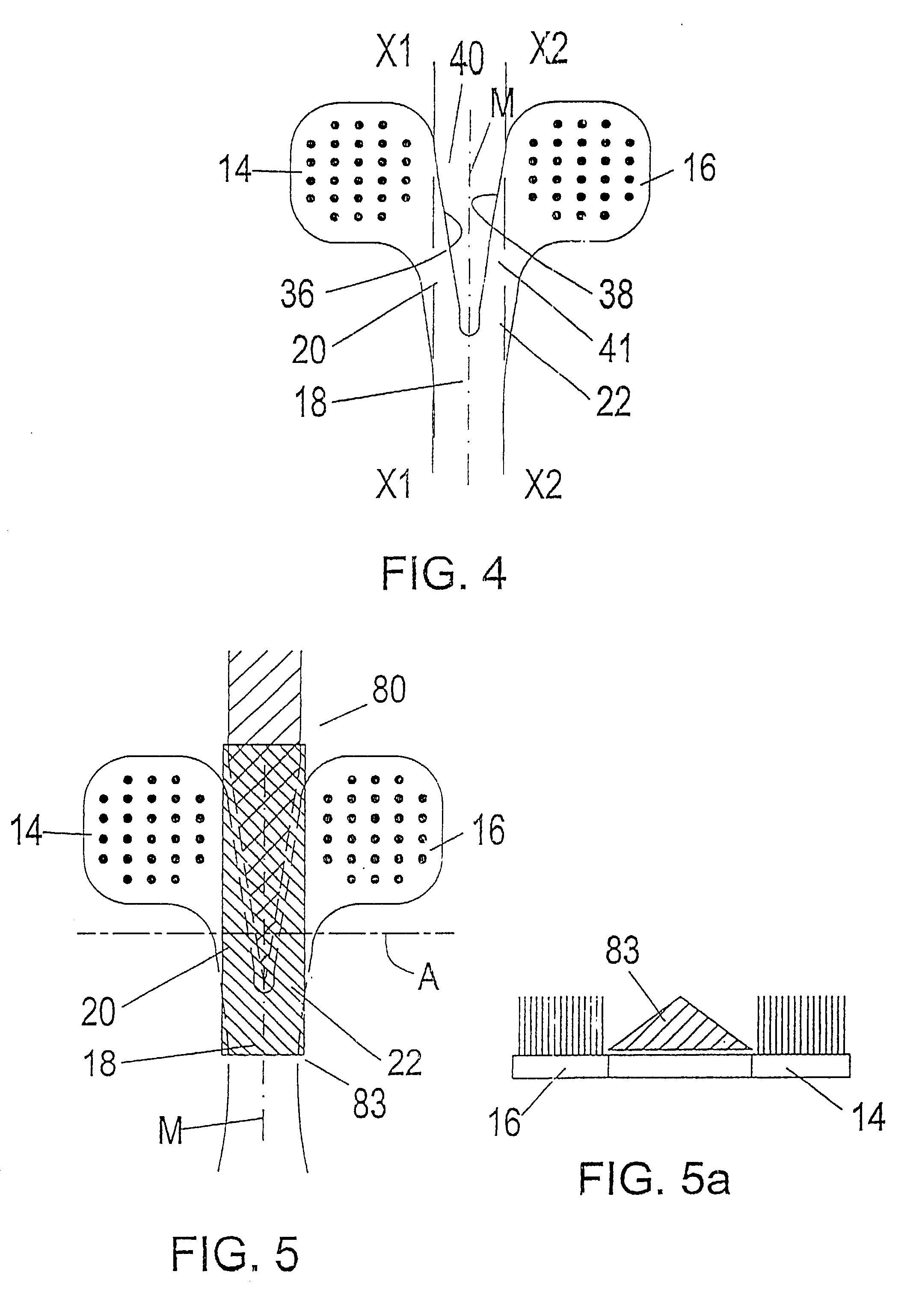

Process and arrangements for producing a toothbrush, the toothbrush, and also the use of the toothbrush

A method and a device are described for manufacturing of a toothbrush from a starting-material which comprises a handle that runs into a neck part which divides into two equal and diverging arms / head parts, in which the bristle-carrying surface (bottom surfaces) of the head parts is approximately in a plane which runs parallel to the main axis of the toothbrush and head, and in which bristle which extend approximately vertically out from the surface is inserted and is of approximately equal of different lengths. According to the invention the starting-material is arranged in a shaping appliance in which the neck and head part adjacent to the respective associated arms, is supported with its underside on a support body, and the two head parts are bent, in particular by twisting / deformation, to the desired angle position by torsion-twisting of the two arms / heads along the respective axes approximately parallel to the center-line axis of the handle, approximately at the same height as the underside of the neck part, so that the edges of the head parts and the upper sides of the arms in the V-shaped opening form a head part with decreasing height towards the foremost part of the head part. The manufactured toothbrush is particularly suited to animals, in particular domestic animals, pets and especially intended for dogs and cats but can also be used by humans.

Owner:ATOFINA

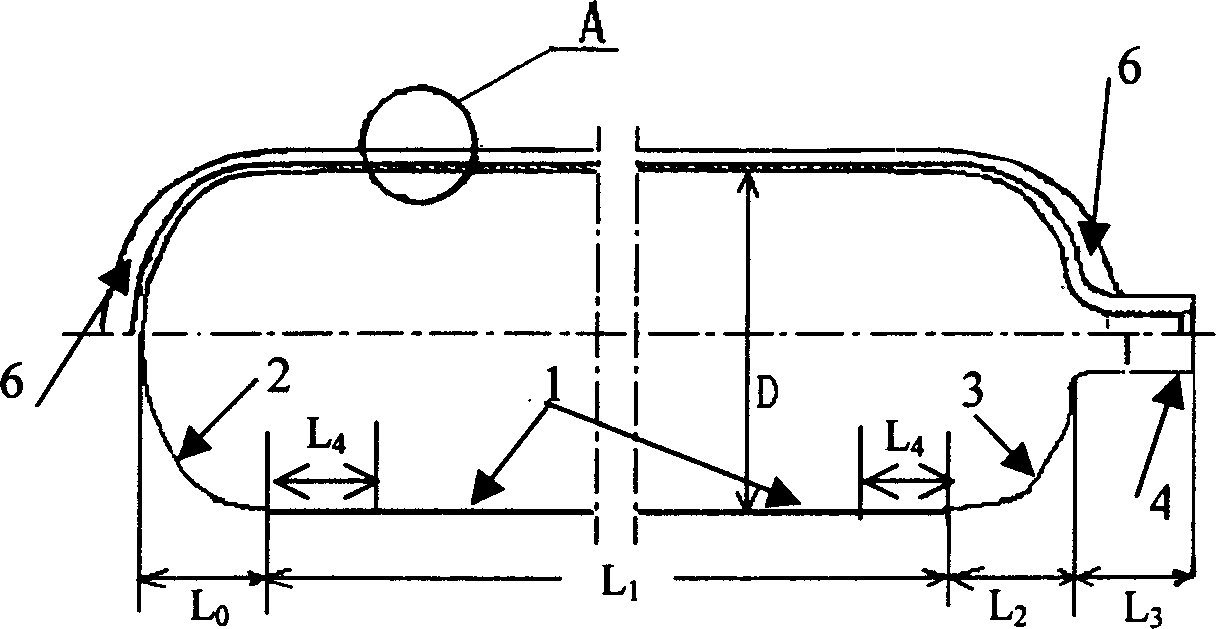

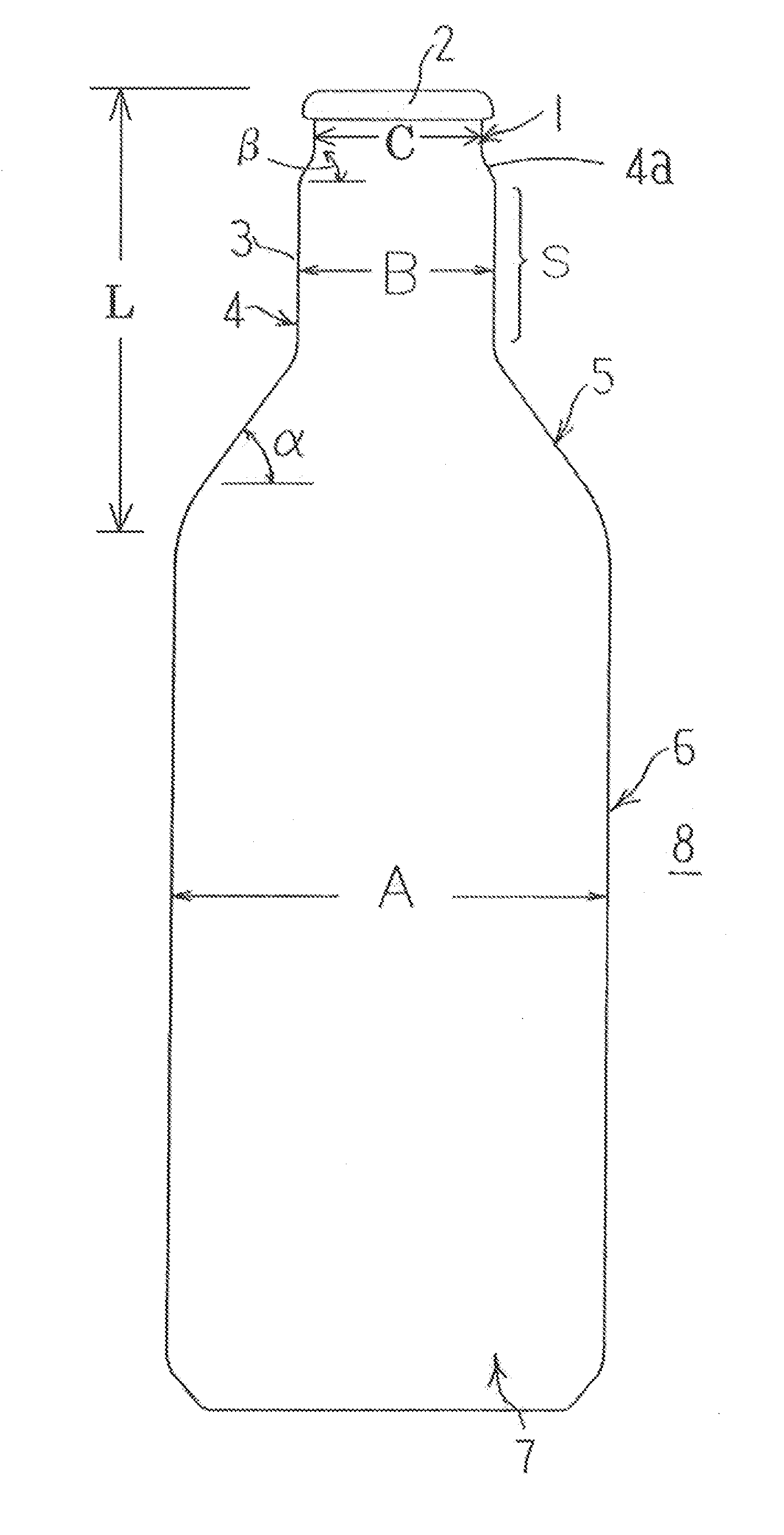

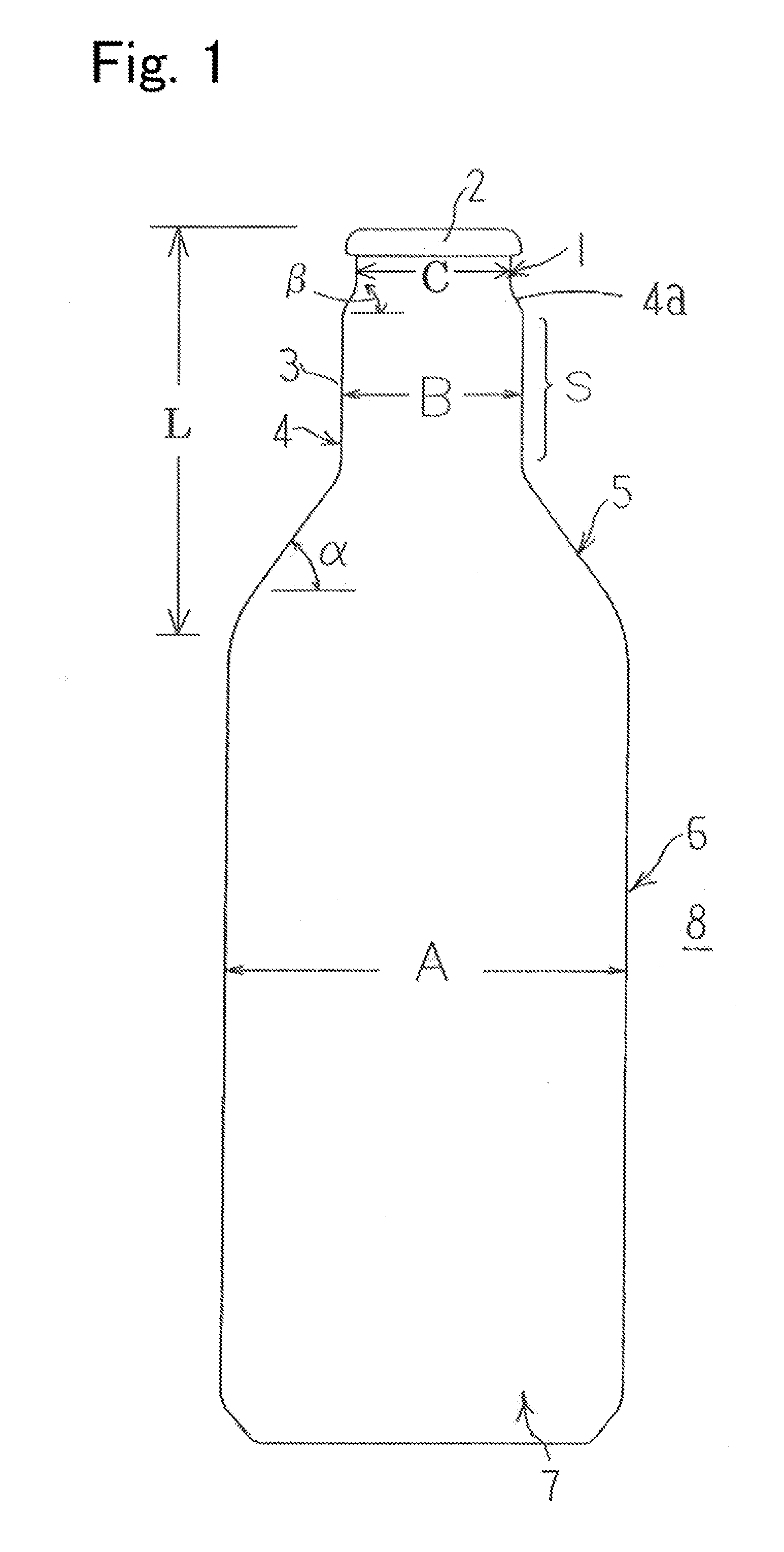

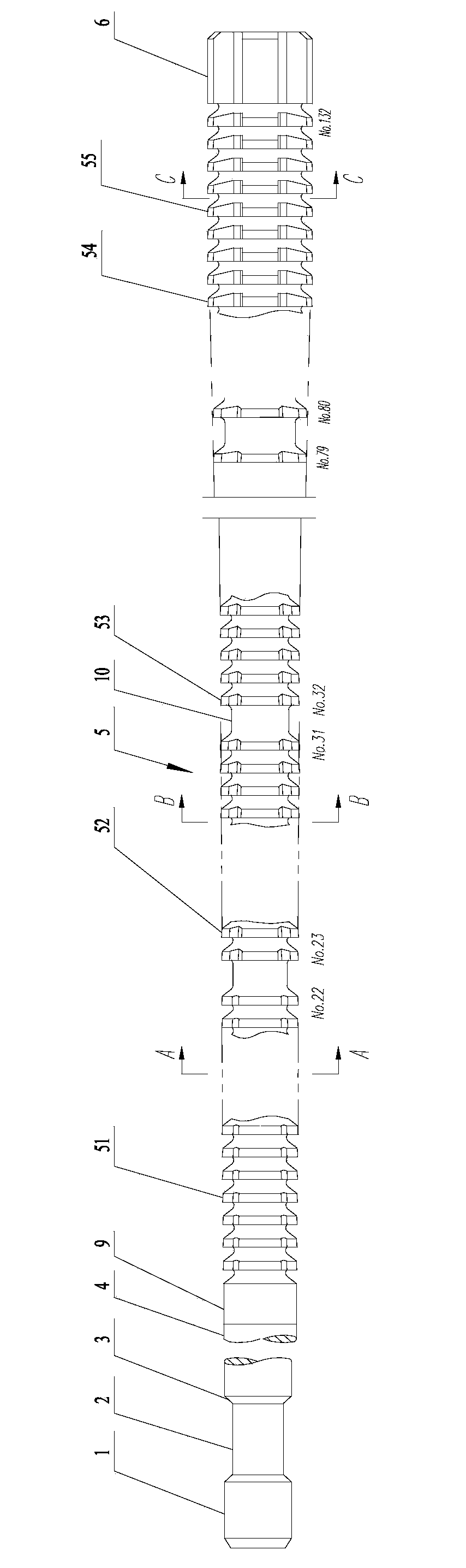

Metal bottle can

A metal bottle can comprises a mouth part having a curl portion at the end, a neck part having a straight part in parallel to the can axis, a taper-shaped shoulder part, a barrel part, and a bottom part. The metal bottle can is integrally formed from a primitive plate of the thickness (wall thickness T) of 0.48 mm to 0.30 mm by drawing-processed. The metal bottle can has the barrel part with the diameter A of 40 mm to 70 mm, the neck part with the diameter B of 20 mm to 35 mm, the straight portion of the neck part with the length S of 10 mm to 40 mm, the shoulder part with the angle a of 40 degrees to 70 degrees, the mouth part with the wall thickness X of 0.46 mm to 0.33 mm, and straight portion of the neck part with the wall thickness Y of 0.43 mm to 0.30 mm.

Owner:TAKEUCHI PRESS IND CO LTD

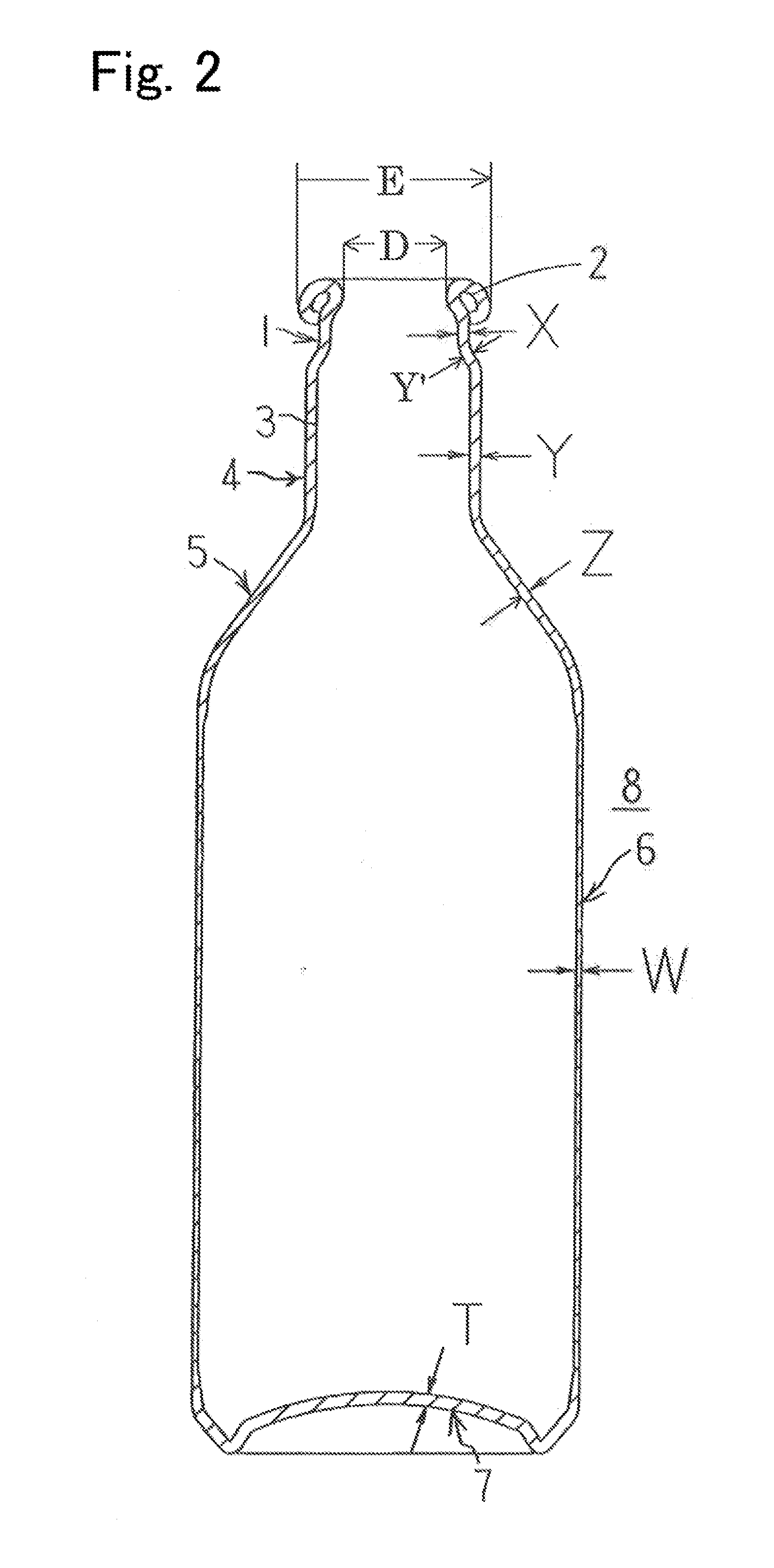

Special-shaped hole broach and machining process method thereof

InactiveCN104191036AGood technical effectAvoid stress deformationBroaching toolsNeck partsEngineering

The invention relates to a broach and discloses a special-shaped hole broach which comprises a handle part, a neck part, a transition conical part, a front guide part, cutting parts and a tail part. The handle part, the neck part, the transition conical part, the front guide part, the cutting parts and the tail part are sequentially connected into a whole from the cutting-in end to the cutting-out end. A scrap containing groove is formed between every two adjacent cutting teeth. The total length from the front end of the handle part to the tail end of the tail part is not smaller than 1200 mm, and the outer diameters from the front guide part to the tail part in sequence are sequentially increased; the cutting parts comprise round hole teeth, circular arc teeth, cutting teeth, transition teeth and calibration teeth, wherein the round hole teeth, the circular arc teeth, the cutting teeth, the transition teeth and the calibration teeth are sequentially arranged from front to back and connected into a whole. The number of the teeth of the cutting parts is from 130 to 150. The invention further discloses a machining process method for the special-shaped hole broach. The broach is large in total length and high in slenderness ratio; the multiple cutting parts different in tooth shape are used for broaching a special-shaped hole, based on the high-precision ultra-slenderness machining and thermal treating process, a method for carrying out segmentation gradual grinding through a locating sleeve and a supporting point is adopted, it is ensured that jump of the solid broach is from 0.01 mm to 0.02 mm, stress deformation caused by cutter relieving and drooping can be effectively avoided, and therefore the stability of machining and forming is good.

Owner:金华市红太阳工具厂

Integrated soft bag inspection system

InactiveUS6504606B2Scattering properties measurementsParticle suspension analysisLocation detectionProduction line

An integrated soft bag inspection system overcomes the difficulty of inspection associated with the unstable shape peculiar to soft bags (for example soft bags for intravenous feed use) and makes it possible to carry out inspection of soft bags automatically and with high precision. The system uses a robot having at least a robot hand and has image pickup means for picking up an image of a soft bag and grip position detecting means for detecting a position on a neck part of the soft bag to be gripped by the robot hand on the basis of image information from the image pickup means. A carrying system may be made using a plurality of such robots and carrying control means provided for controlling the robots so that the robot hand of each robot grips the neck part of the soft bag and carries the soft bag to a predetermined inspection position and soft bags arriving from a production line are continuously transferred between adjacent robots and various inspections are carried out on the soft bags successively.

Owner:SCANTECH

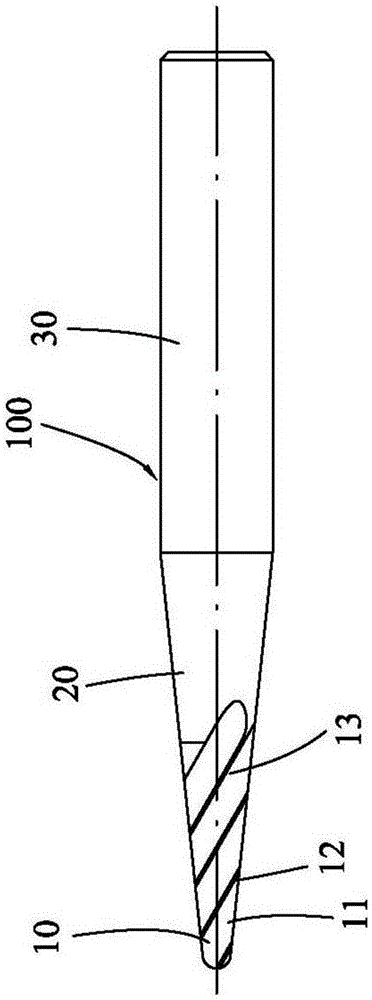

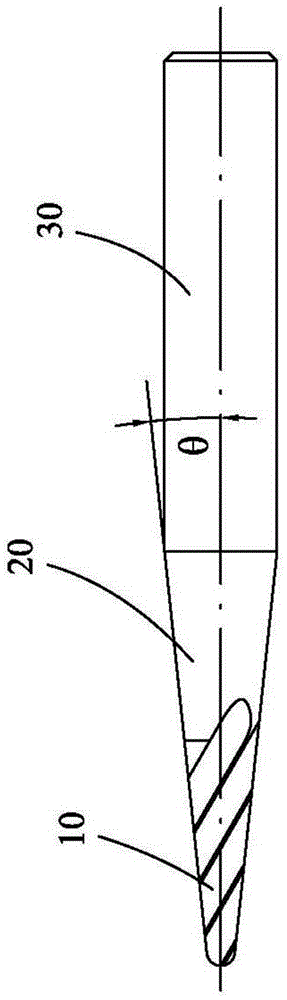

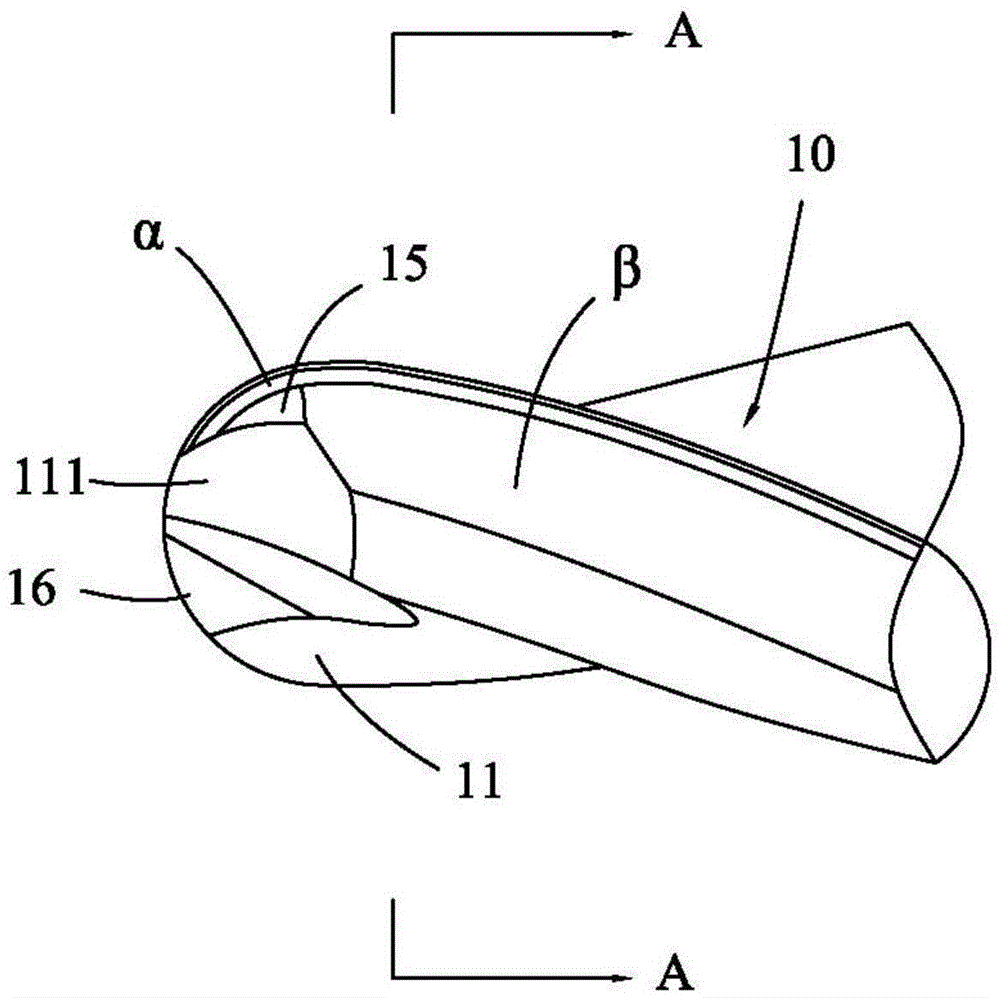

Taper and ball-end milling cutter

InactiveCN105642986AIncrease sharpnessGuaranteed StrengthMilling cuttersMilling cutting insertsMilling cutterNeck parts

The invention provides a taper and ball-end milling cutter. The milling cutter comprises a head part, a neck part connected with the head part, and a handle part connected with the neck part, wherein the head part is provided with a chip removal slot, an entity part used for forming the chip removal slot, and a cutting edge formed at an intersection line between the chip removal slot and the entity part, wherein the cutting edge is provided with a front cutter face and a rear cutter face, the front cutter surface and the rear cutter surface are contacted and form a front angle, and the rear cutter face of the cutting edge and a machining piece are contacted and form two rear angles, including the first rear angle and the second rear angle respectively. According to the taper and ball-end cutter provided by the invention, the front angle and the rear angles are reasonably designed, so that the rigidity of the milling cutter is guaranteed, the sharp degree of the milling cutter is guaranteed at the same time, and the probability of burr generation in a milling process is effectively reduced; the taper and ball-end milling cutter has a long service life and can keep good surface roughness when machining an aluminum alloy pressure wheel.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

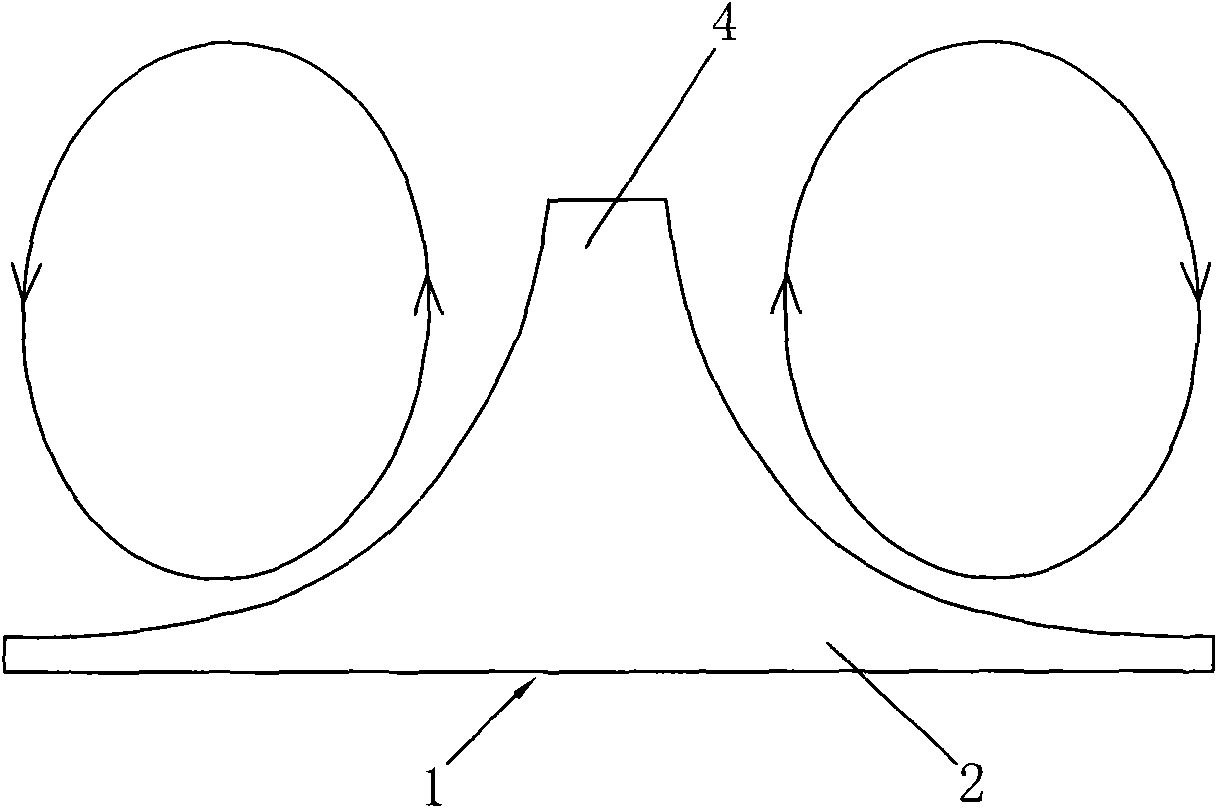

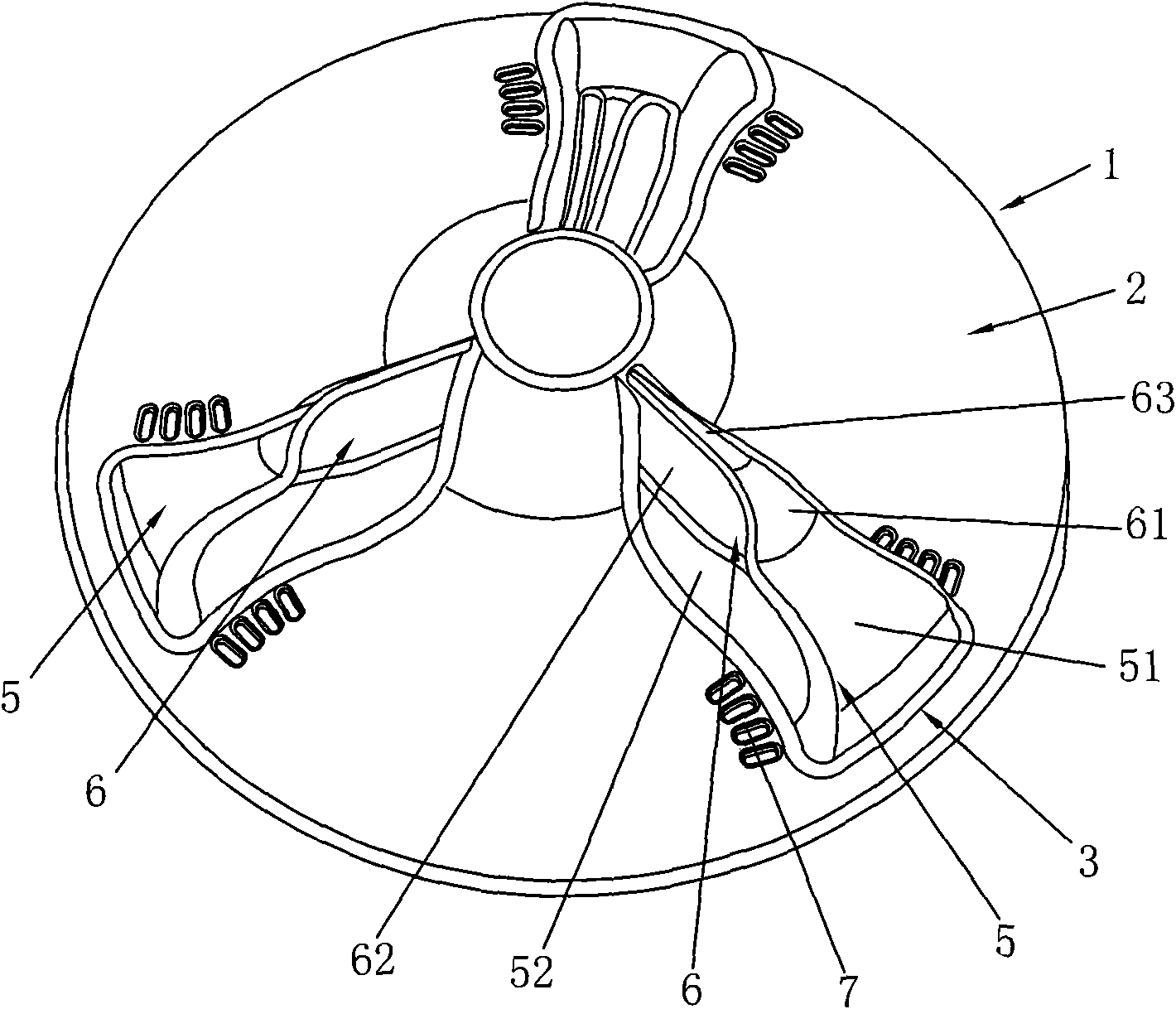

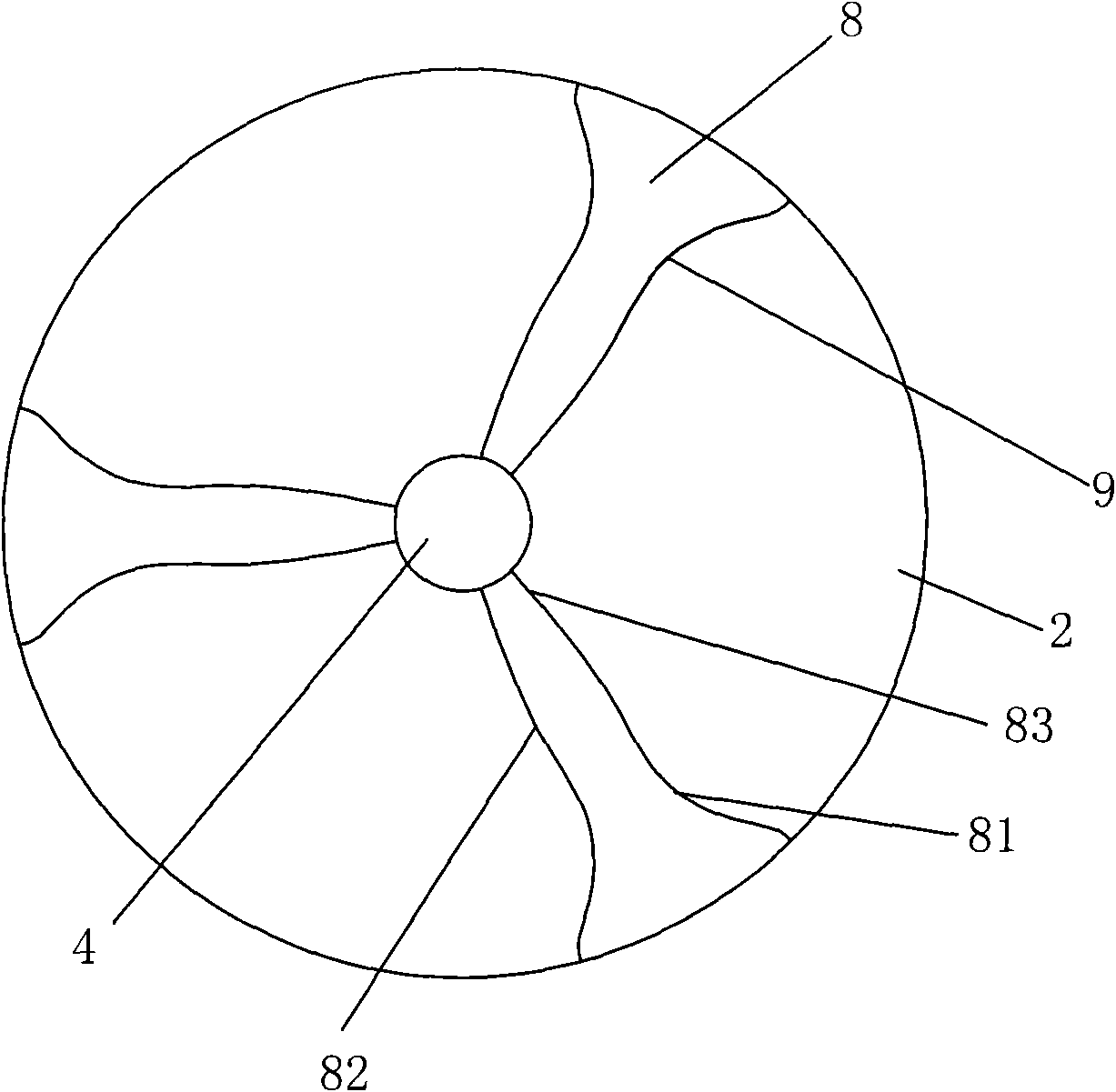

Direct-driven fully automatic impeller type washing machine and washing method thereof

ActiveCN101886317AIncrease heightImprove cleanlinessOther washing machinesControl devices for washing apparatusImpellerNeck parts

The invention discloses a direct-driven fully automatic impeller type washing machine and a washing method thereof. The washing is performed by directly driving an impeller through a direct-driven motor; when the washing machine is started to a washing state, the initial speed of a motor is less than a constant speed of a running process; during the constant speed running, the flow in a corresponding washing tube is circulated and turned over by adopting a circulating variable-speed circulating water-flow driving mode; and the motor first performs long-term strong water flow driving to turn over clothes, then performs short-time balanced water flow driving to automatically correct the offset of the clothes in the washing tube and circulates the processes in turn. The clothes do spiral ascending motion around blades of the impeller while revolving around the center of the impeller in the washing tube, and are turned over from the centre of the impeller to the periphery when moving to the space behind a neck part of the impeller in the centre of the impeller and then fall down to the periphery of the bottom of the tube along the wall of the washing tube; then the clothes at the bottom of the tube are turned over upwards from the periphery to the centre of the impeller; and the clothes in the upper space are turned over downwards from the centre to the periphery. Through the washing machine and the washing method, the load can be automatically balanced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Tool and cutting insert for the fine turning of grooves in workpieces

InactiveCN1758974AEliminate risk of cloggingEliminate or reduce the need for post-processingCutting insertsTurning toolsNeck partsKnife blades

The invention relates to a tool for the fine turning of rotationally symmetrical grooves in workpieces. The tool comprises a basic body (1) and a cutting insert (2), which is possible to fix in a cutting seat (6) on a bracket (5) included in the basic body, which bracket includes a narrow neck part (7) and a support part (8) protruding laterally from the same with the purpose of supporting a portion of the cutting insert (2) protruding laterally in relation to the neck part with the purpose of enabling, in a workpiece, the turning of internal shoulder surfaces of a hollow space countersunk inside a gap of the groove and having a greater width than the gap. According to the invention, the cutting insert (2) is indexable by including two spaced-apart, convexly arched and alternately applicable cutting edges (31), and has a hole (35) for a screw (28) by means of which the same can be clamped and fixed in the cutting seat (6) on the bracket. The cutting seat (6) has means (40a, 40b) that in co-operation with analogous means on the bottom side of the cutting insert prevent angular displacement of the cutting insert in relation to the cutting seat.

Owner:SANDVIK INTPROP AB +1

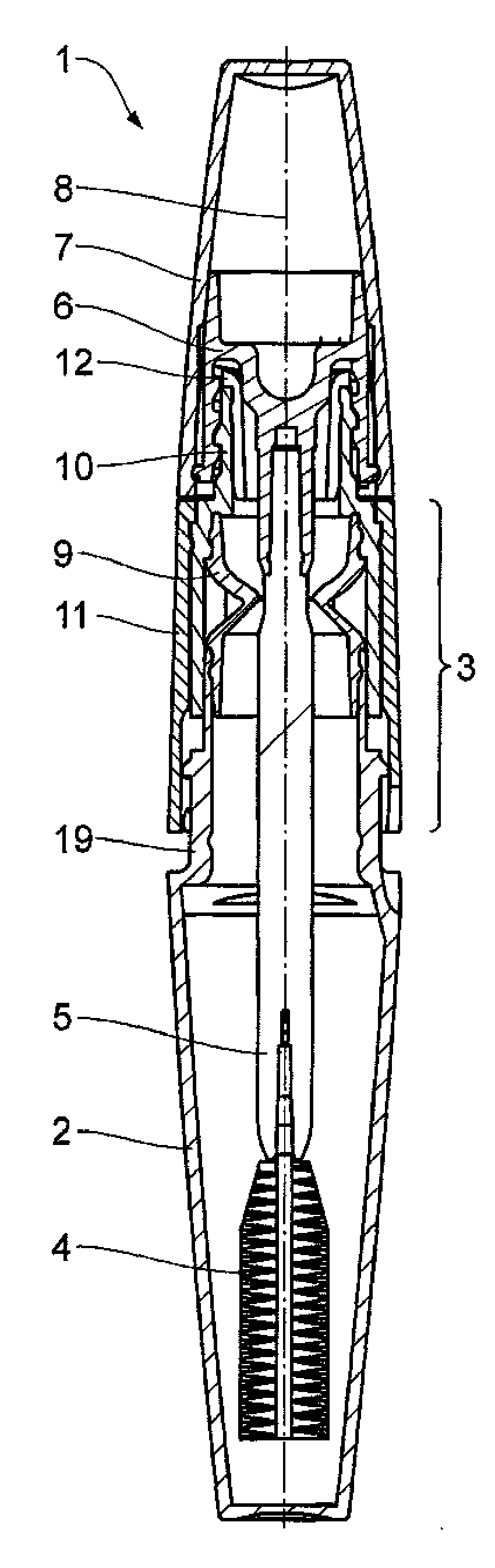

Cosmetics unit with adjustable wiper

The cosmetics unit (1) comprises a storage container (2) for receiving a cosmetic substance therein, an applicator (4) that can be immersed into the cosmetic substance, and an adjustable wiper part unit (3) disposed on a container opening (19a) of the storage container (2), for wiping off cosmetic substance from the applicator (4). The wiper part unit (3) comprises, as respectively separate components, a deformable wiper (9), a neck part (10), and an adjustment sleeve (11) accessible from the outside. The wiper (9) is disposed between the container opening (19a) and the neck part (10), wherein a lower axial peripheral zone (17) of the wiper (9) is firmly connected with the storage container (2), and an upper axial peripheral zone (14) of the wiper (9) is firmly connected with the neck part (10). The adjustment sleeve (11) encloses the container opening (19a), the wiper (9) and, partially, the neck part (10). The adjustment sleeve (11) is rotatably mounted on the neck part (10) as well as on the storage container (2), so that an axial distance between the container opening (19a) and the neck part (10), an axial dimension of the wiper (9), and a surface area of a wiper opening of the wiper (9), which area extends perpendicularly relative to the axial direction, can be altered by means of a rotational movement of the adjustment sleeve (11).

Owner:GEKA

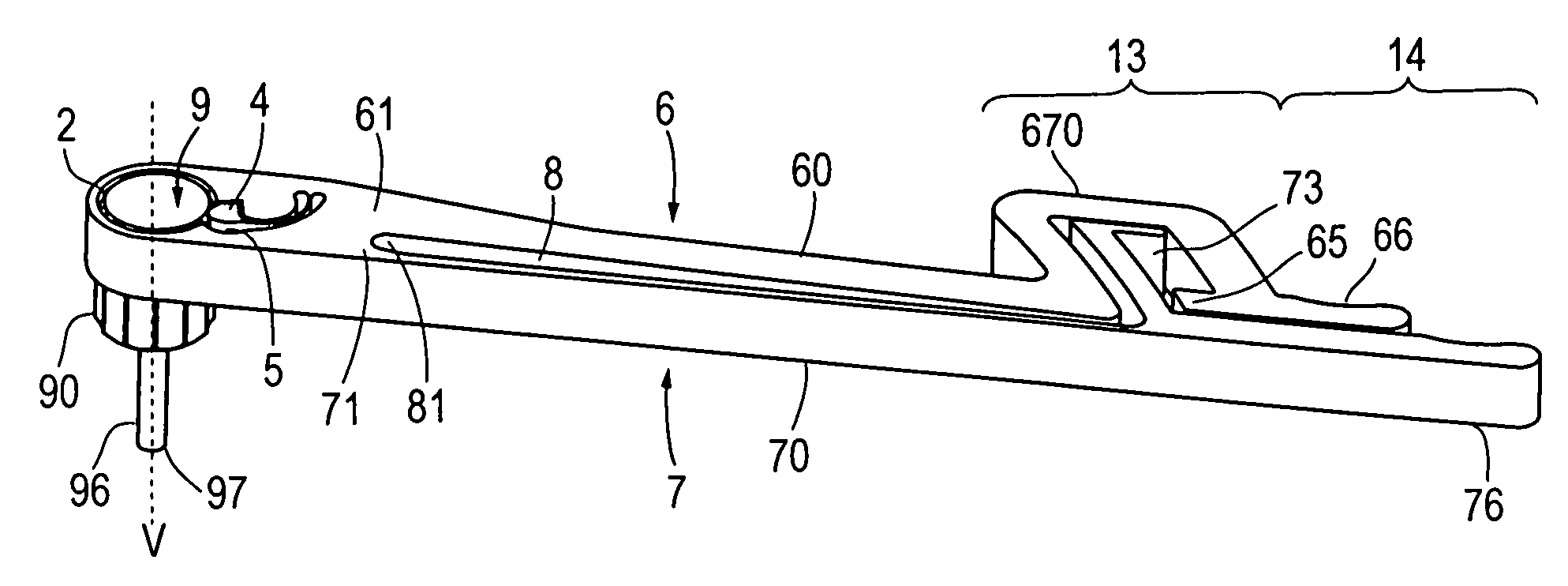

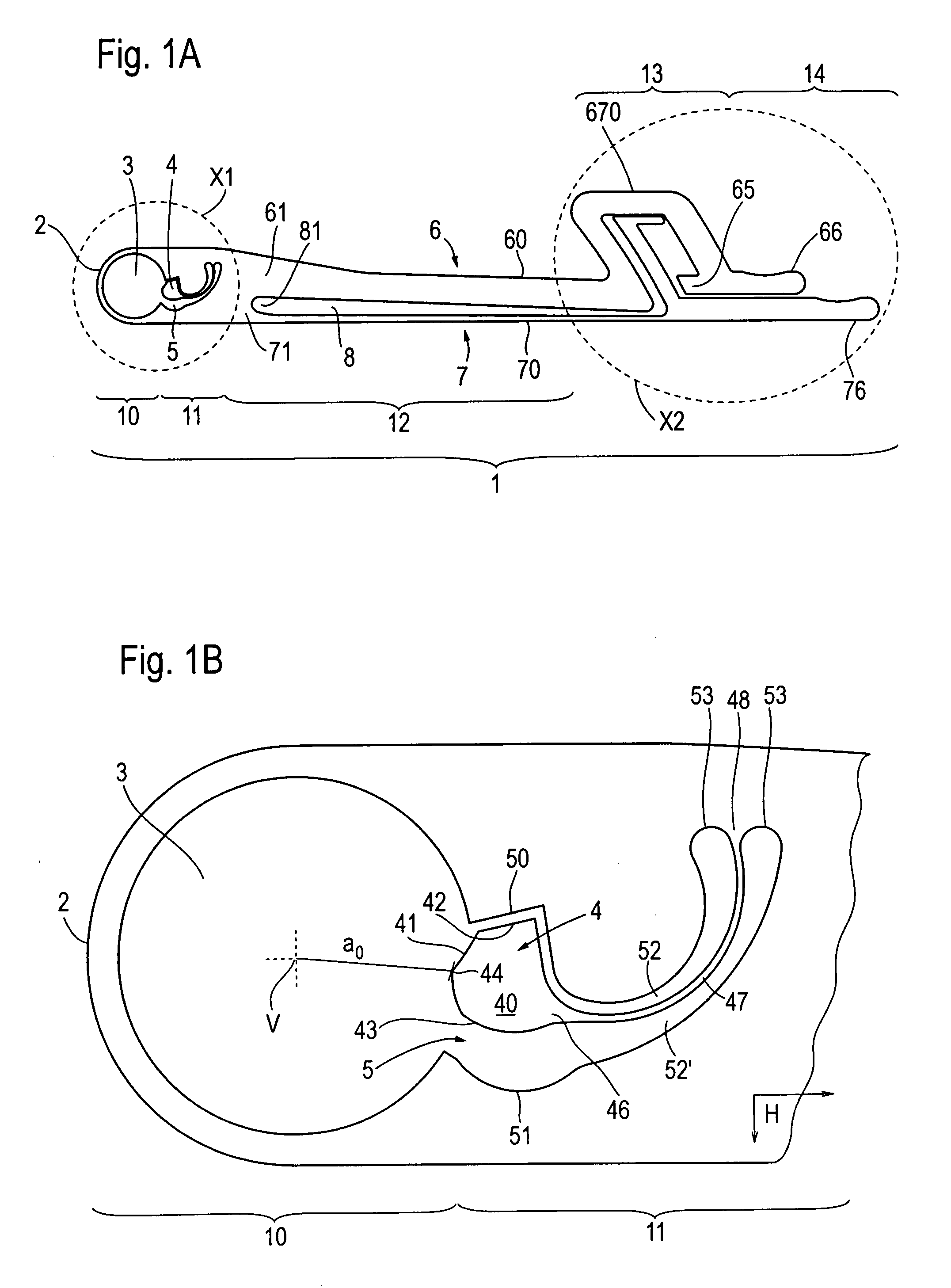

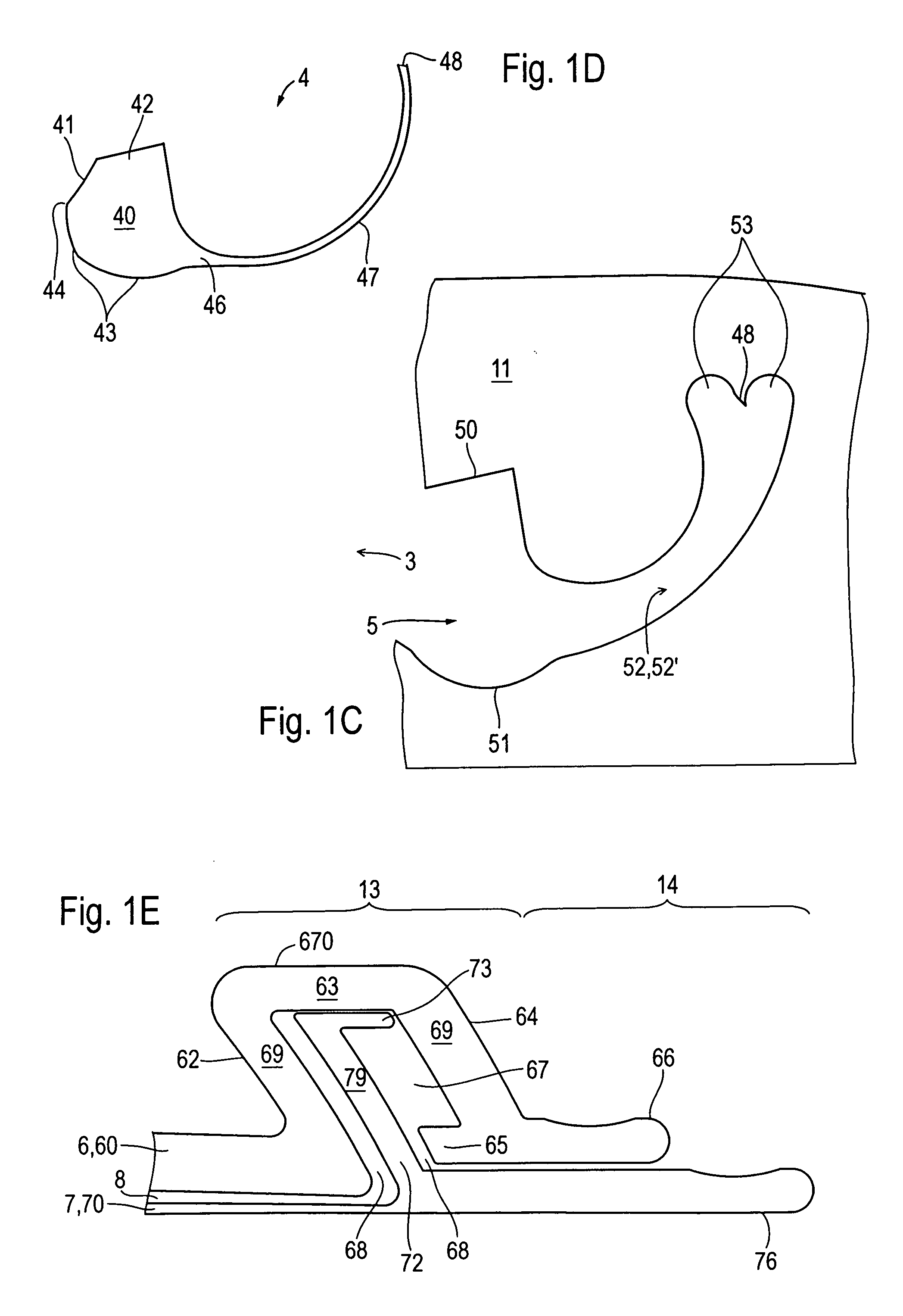

Torque Wrench As A Ratchet Instrument For The Medical Field

The invention relates to a torque wrench (1) which is embodied as a ratchet instrument in the medical field. A catch segment (40) which can be displaced in a defined manner is arranged on the periphery of the receiving opening, and the front part thereof is oriented towards the receiving opening. When the torque wrench (1) is actuated in a forward direction, the torque which is to be generated is applied by means of a forward force (F) exerted by means of a user, by a deflectable, preferably linear-elastic flexible arm (7). A catch spring extends from the catch segment into the neck area. The catch segment and the catch spring form a single-pieced or several part catch (4). The catch segment and the catch spring are arranged in a channel-shaped space (5) which enables said two elements to be deviated on the plane counter to the force of the catch spring. The catch (4) is a single-piece with the neck part or is fixed thereto as a separate component.

Owner:THOMMEN MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com