Patents

Literature

92results about How to "Avoid stress deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

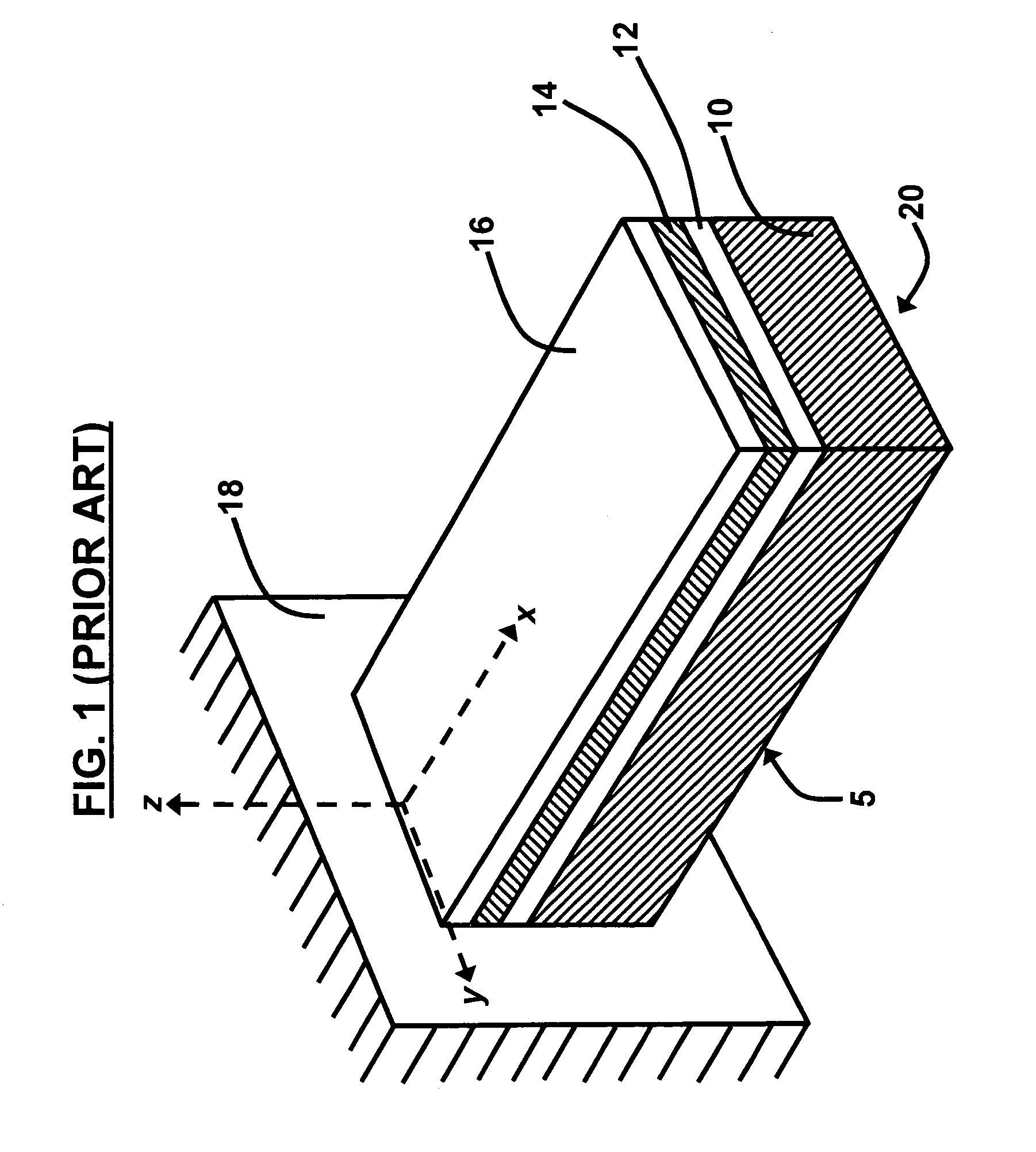

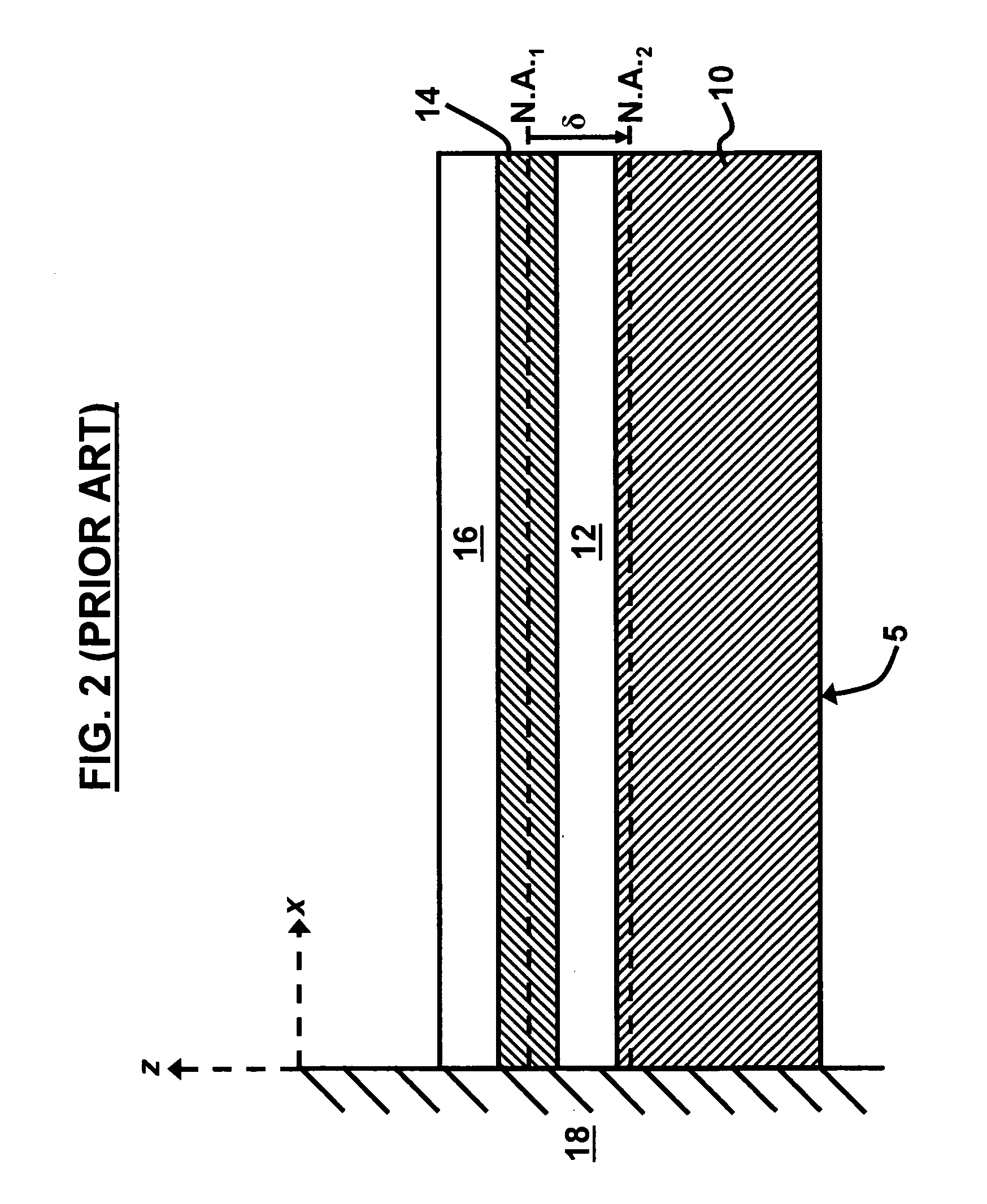

Lateral piezoelectric microelectromechanical system (MEMS) actuation and sensing device

InactiveUS7420318B1High sensitivityEfficiently actuatedImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringMicroelectromechanical systems

A microelectromechanical system (MEMS) device comprises a substrate; an anchored end connected to the substrate; a free end comprising an end effector opposite to the anchored end; a spring attached to the end effector; multiple actuation beams; multiple connection beams adapted to connect the multiple actuation beams to one another; and an actuator / sensor comprising a first electrode; a piezoelectric layer over the first electrode; and a set of second electrodes over the piezoelectric layer, wherein the set of second electrodes being defined by a transverse gap therebetween. Each of the multiple actuation beams comprises two sets of the second electrodes. The set of second electrodes comprise an extensional electrode and a contraction electrode. One of the sets of second electrodes is actuated asymmetrically with respect to a first plane resulting in a piezoelectrically induced bending moment arm in a lateral direction that lies in a second plane.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

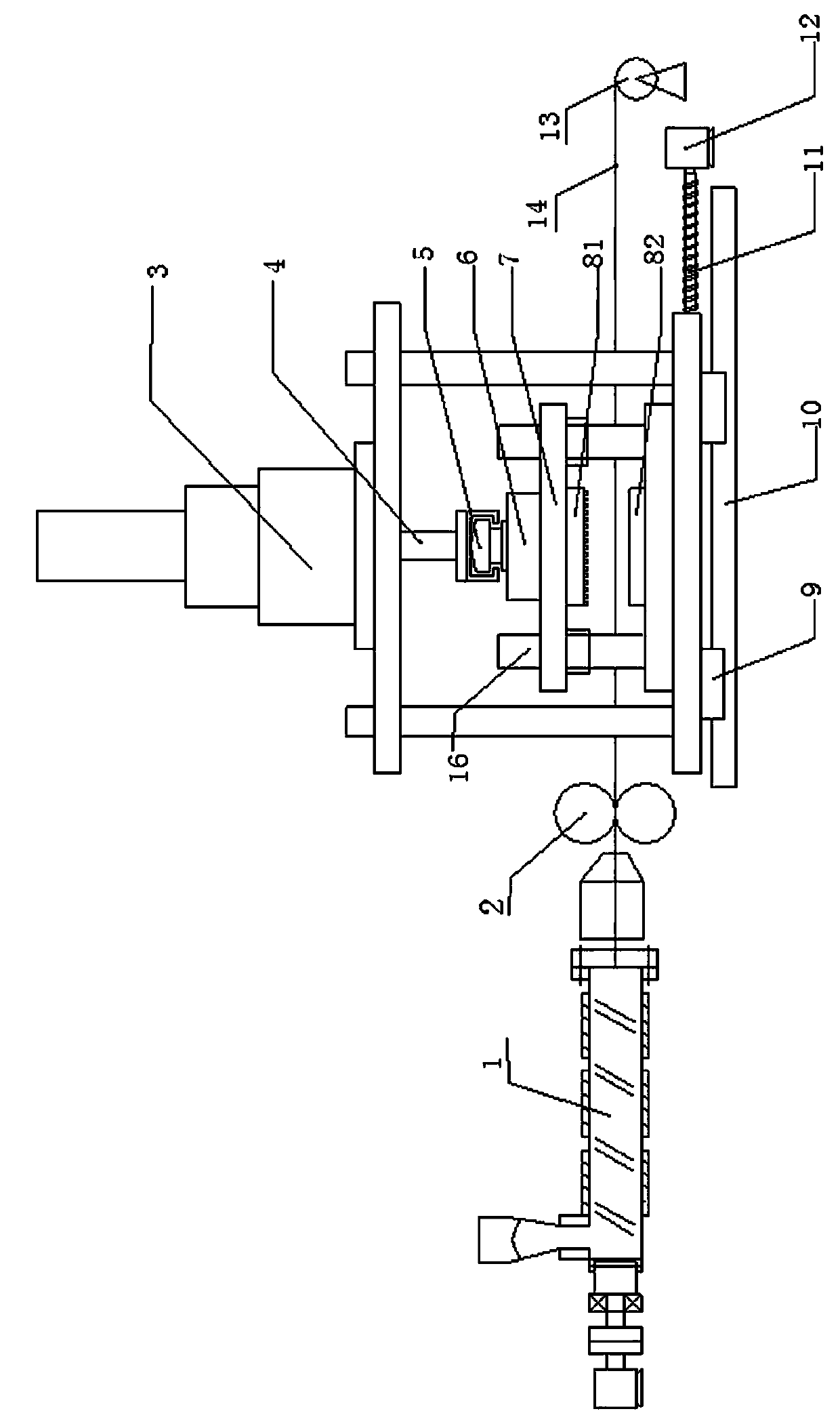

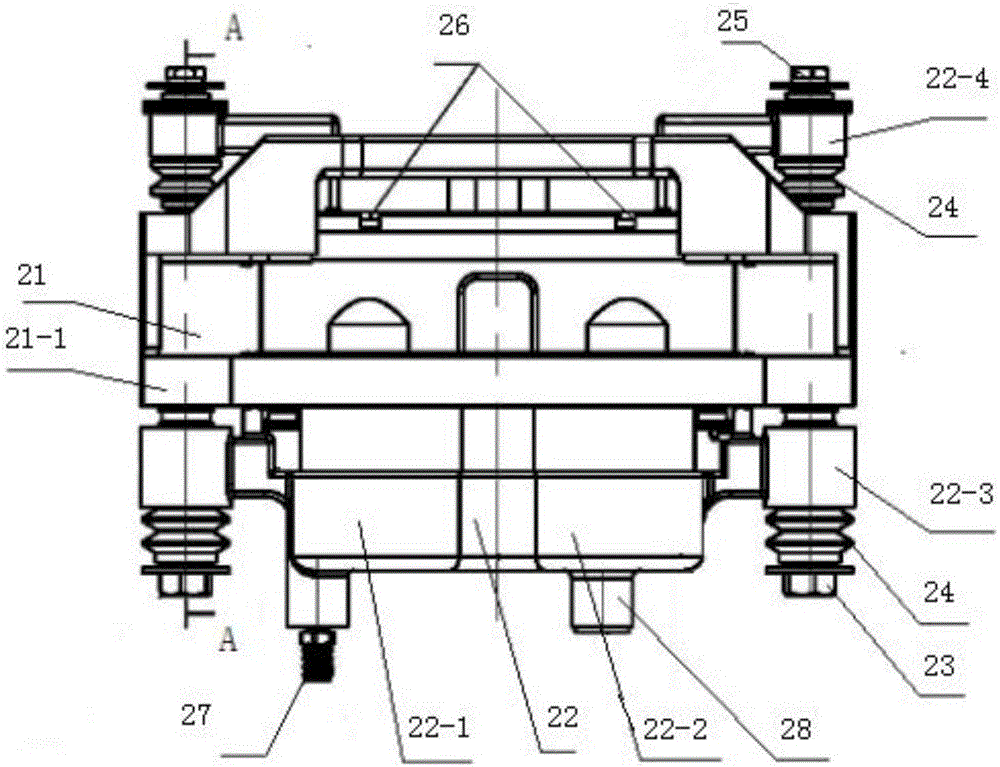

Pressing device and method of polymer microstructure

ActiveCN103624992AAvoid stress deformationGuaranteed flatness and heat uniformityPolymeric surfacePolymer substrate

The invention discloses a pressing device and a pressing method of a polymer microstructure. The pressing device comprises a sheet extrusion machine, a compression roller device capable of leveling and regulating thickness, and a mold press. The pressing method comprises the steps of directly entering slab pressing equipment after a polymer substrate is extruded from the extrusion machine; flattening the polymer substrate through rolling of two rollers and shaping preliminarily, carrying out rapid heating treatment on the surface of the polymer, and enabling the polymer substrate to enter a slab pressing mold when the temperature of the surface of the polymer substrate is higher than a glassy state or a melting point to press the microstructure. According to the pressing device and the pressing method, the microstructure slab pressing equipment is connected with the extrusion machine in series, so that abundant energy is saved, and the production efficiency is improved, meanwhile, with the slab pressing technology for preparing the polymer microstructure, enough pressure-maintaining cooling and shaping time, accurate cooling temperature and high geometric replication rate can be ensured and continuous large-scale high-efficiency industrial production for slab pressing can be realized.

Owner:BEIJING UNIV OF CHEM TECH

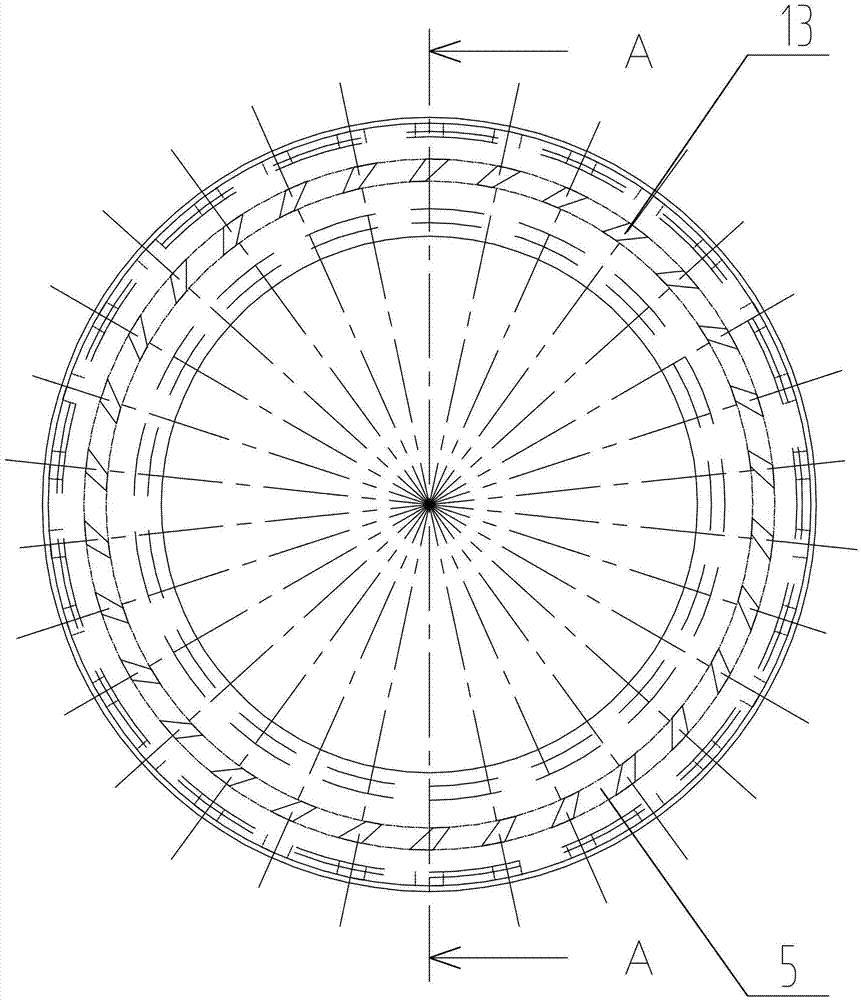

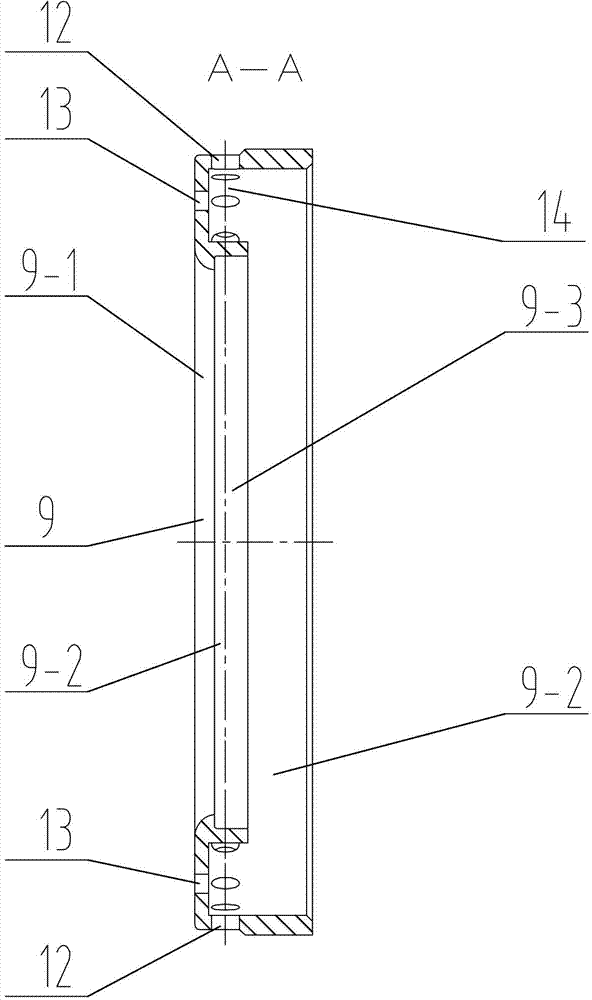

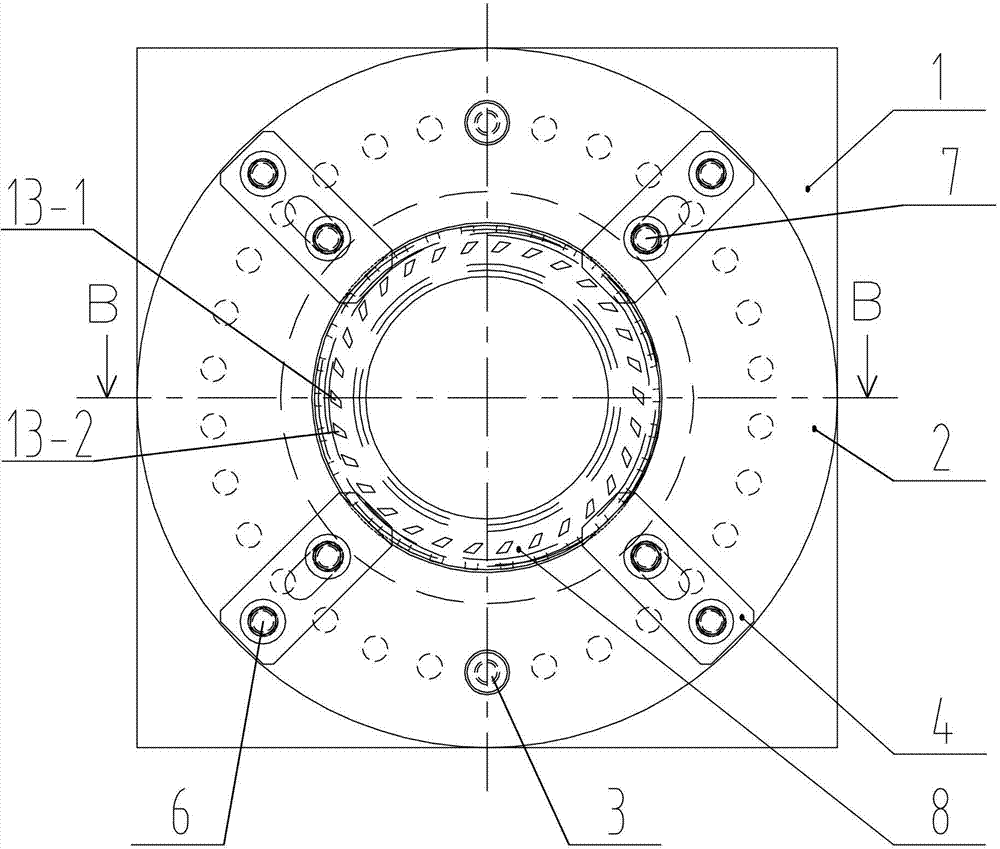

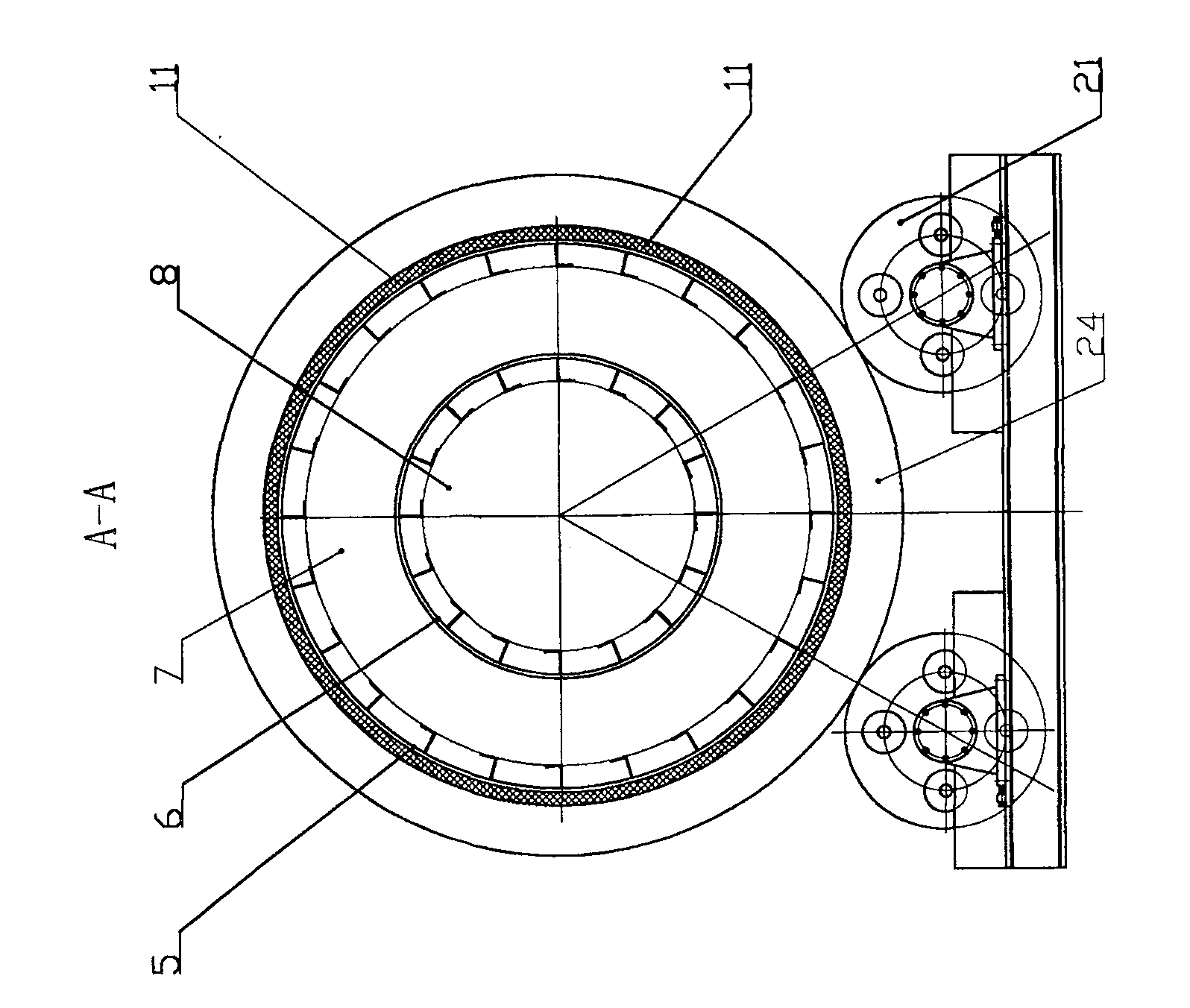

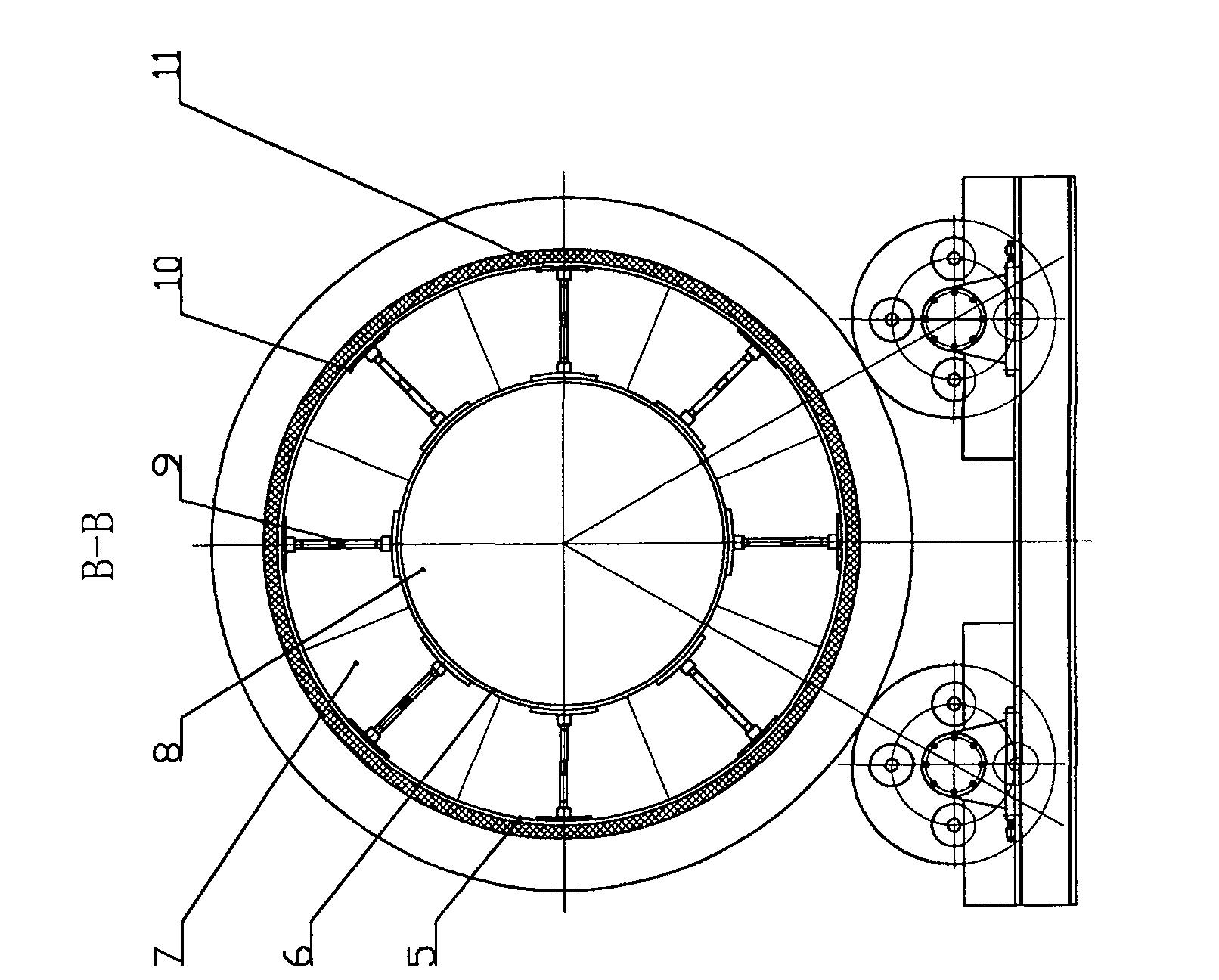

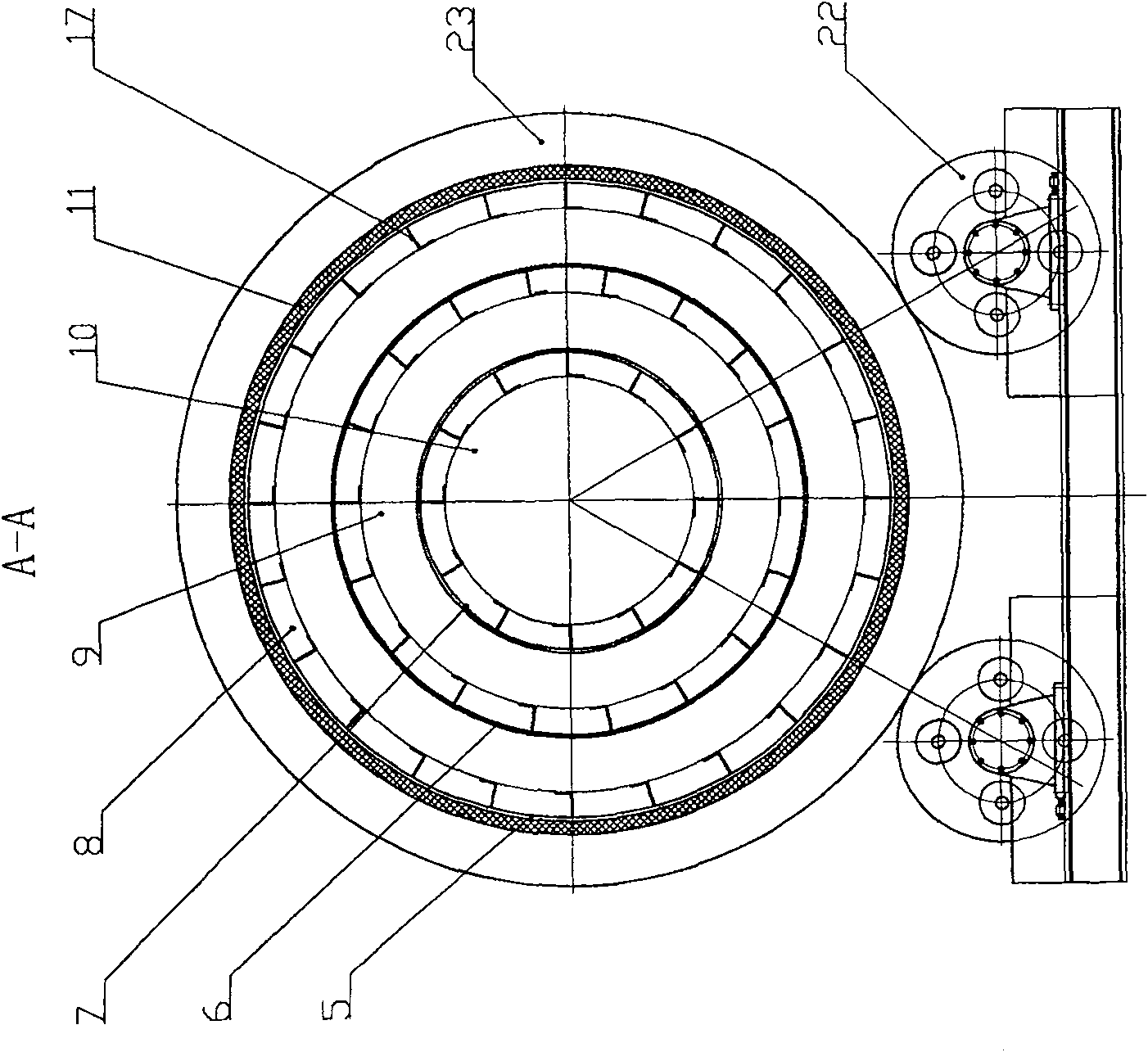

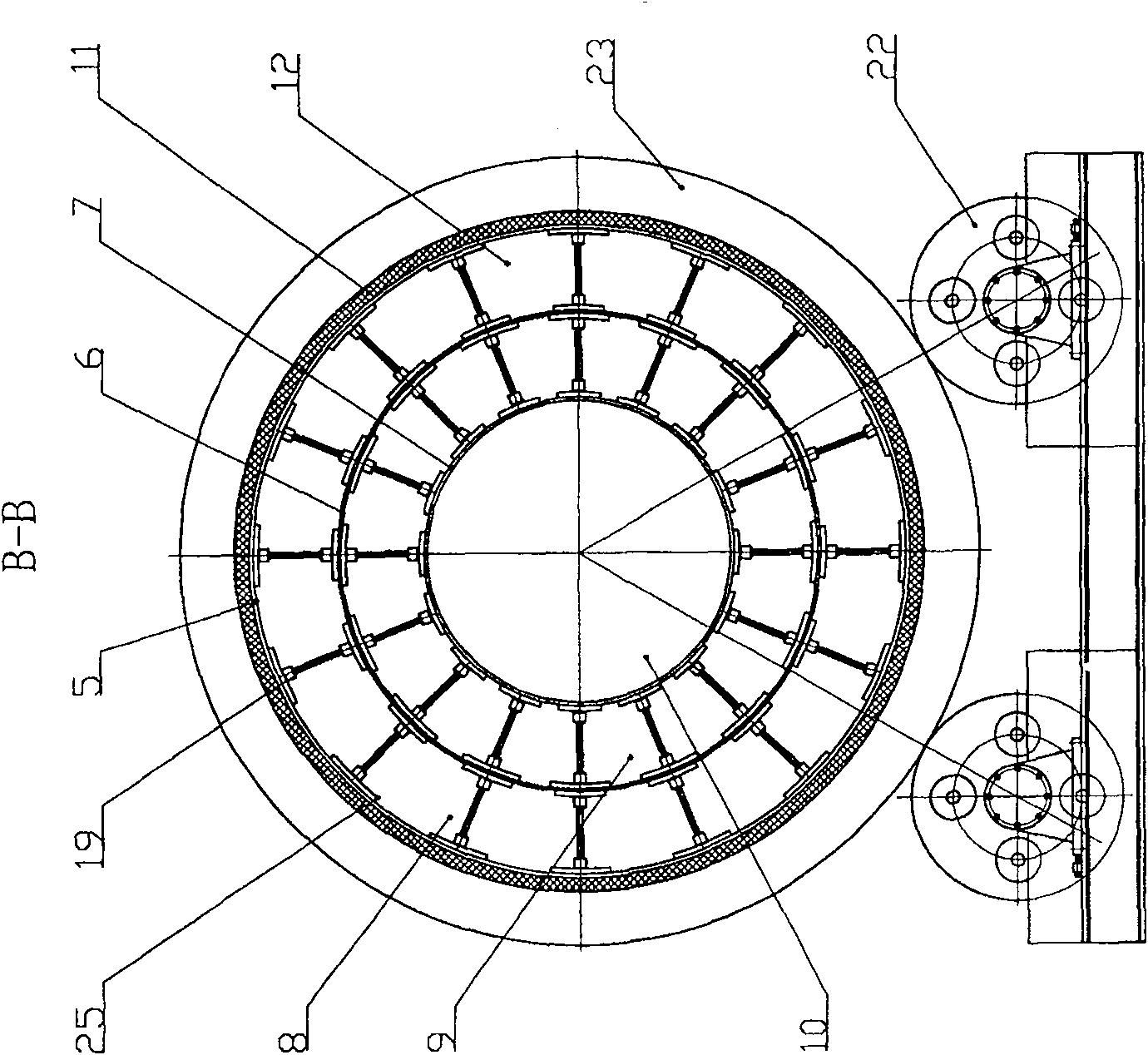

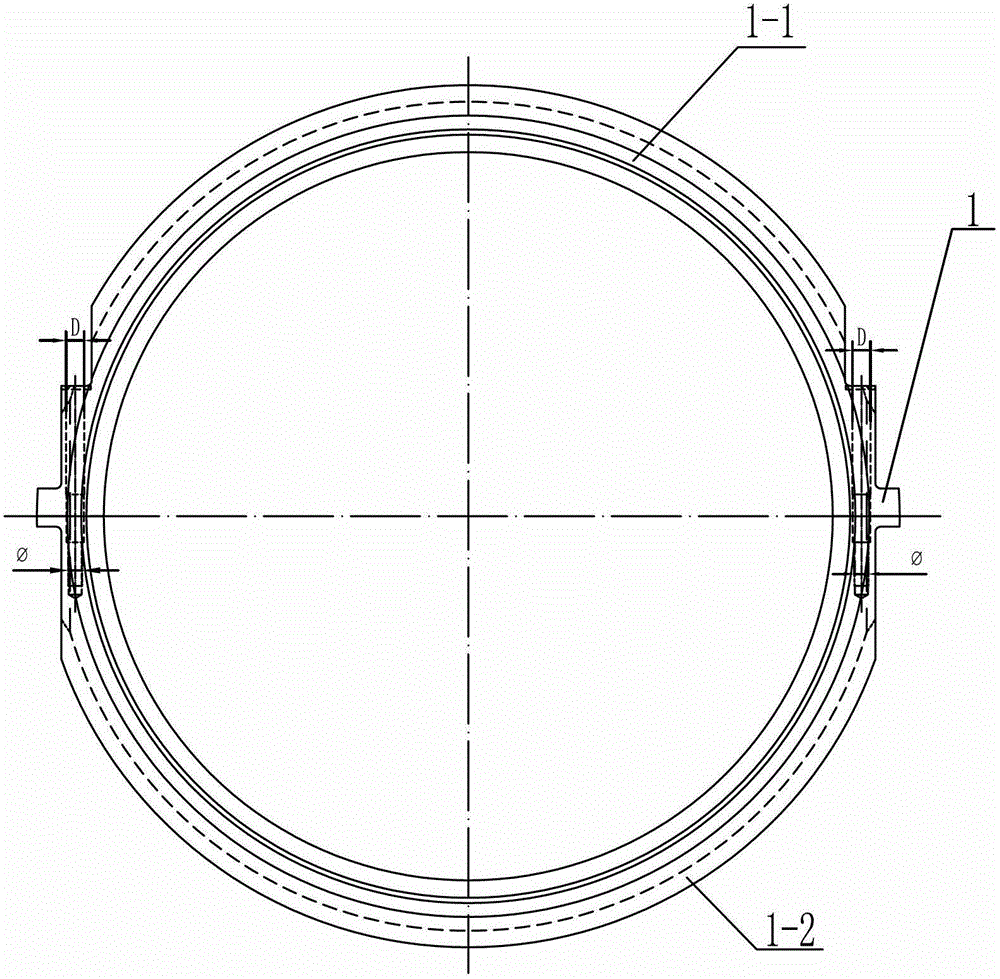

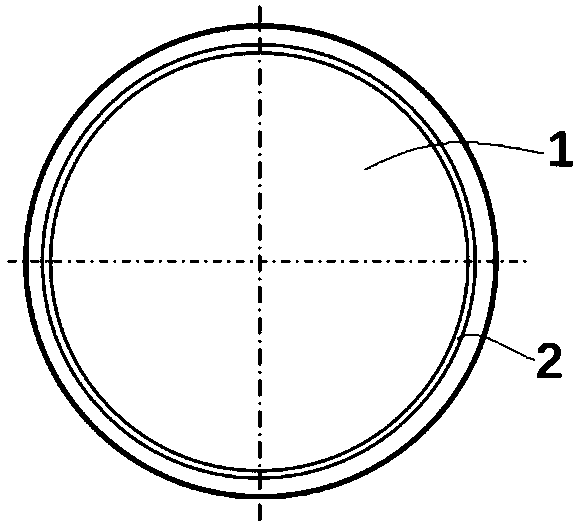

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

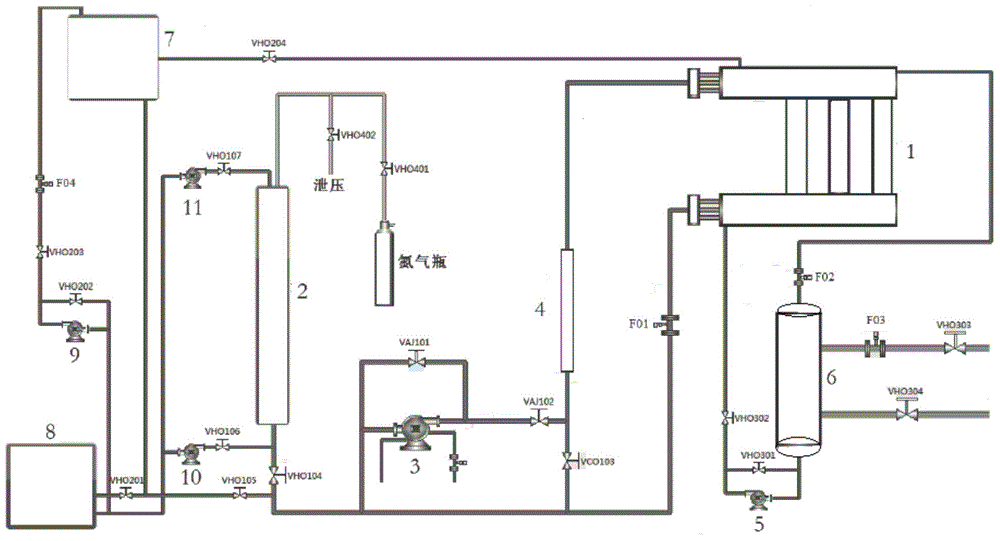

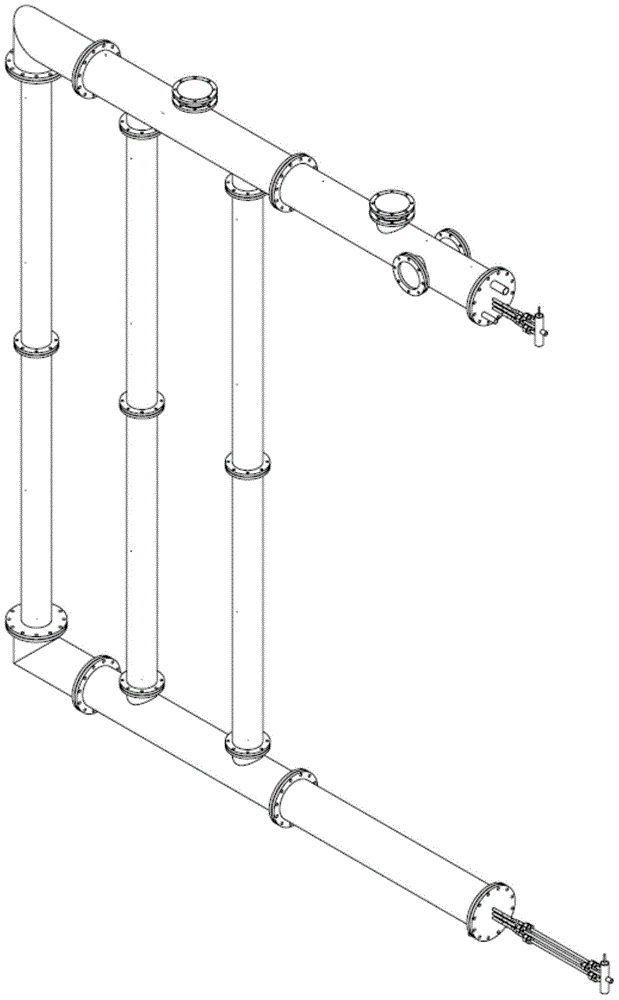

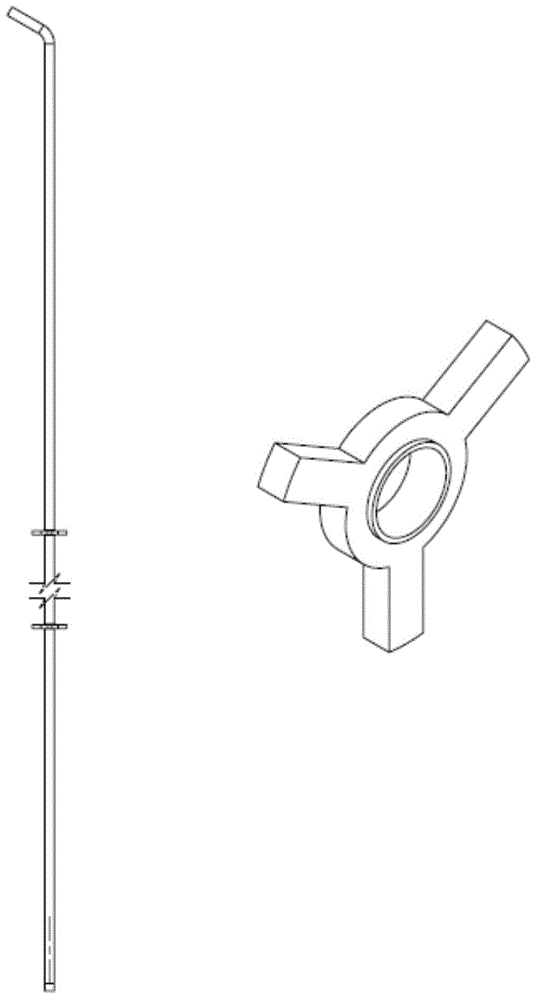

Passive residual heat removal heat exchanger testing device

ActiveCN104952497AReduce water consumptionAvoid stress deformationNuclear energy generationNuclear monitoringWater useEngineering

The invention relates to a passive residual heat removal heat exchanger testing device which comprises a heat transfer testing section, a voltage stabilizer, a shield pump, a heater, a circulation pump, a heat exchanger, a high-level water tank, a low-level water tank, a lifting pump, a water supplying pump and a spraying pump, wherein the heat transfer testing section, the voltage stabilizer, the shield pump, and the heater form a main loop system of the testing device; the heat transfer testing section comprises 3 C-shaped heat transfer pipes and a cooling water tank; the voltage stabilizer is connected with an outlet pipeline of the heat transfer testing section and an inlet pipeline of the shield pump; the shield pump is connected with the outlet pipeline of the heat transfer testing section; the flowing amount of a main loop is adjusted by adjusting a valve and a bypass valve in front of the shield pump; the heater is arranged between the shield pump and the heat transfer testing section. According to the device, the forms, sizes and materials of the heat transfer pipes are designed reasonably, so that the stress deformation problem can be reasonably avoided, the water use amount can also be greatly reduced, the heat transfer process can be simulated relatively accurately, and relatively accurate heat transfer data can be obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

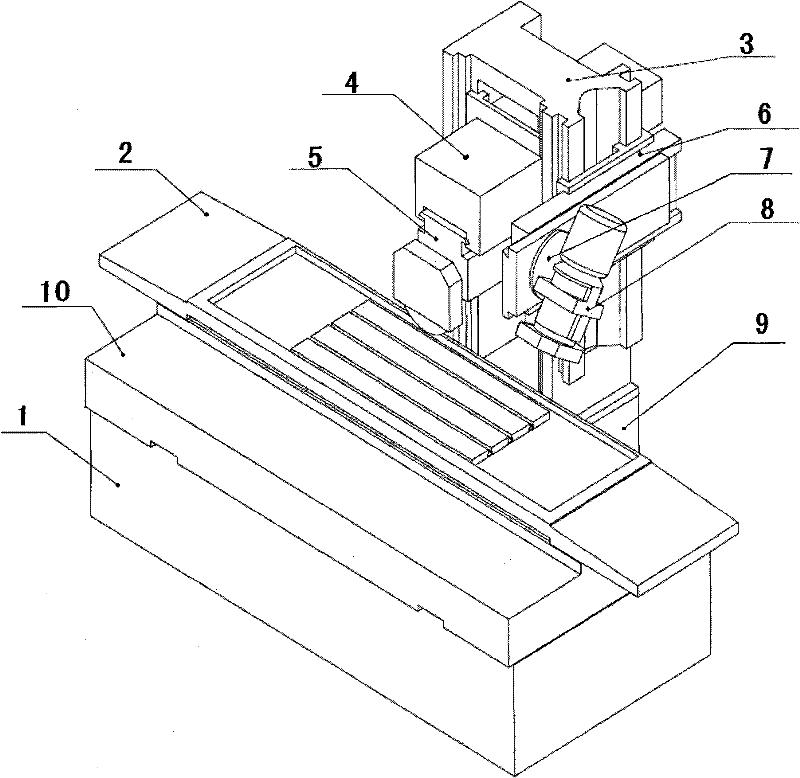

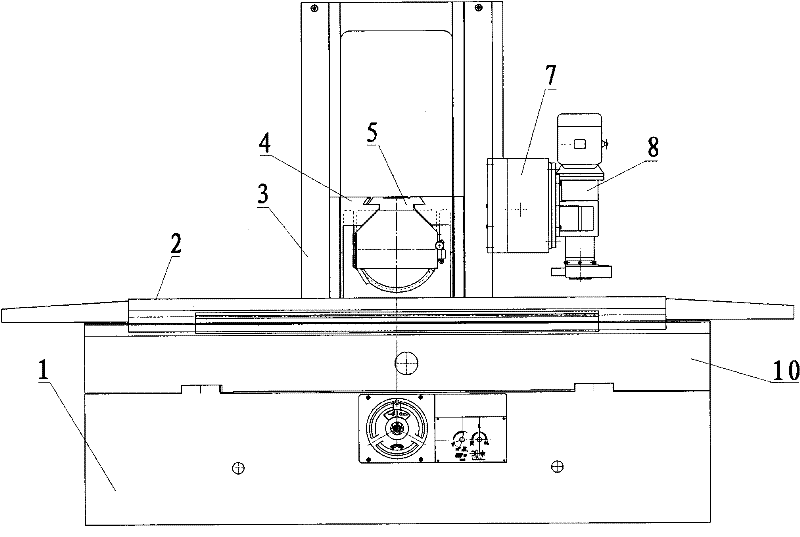

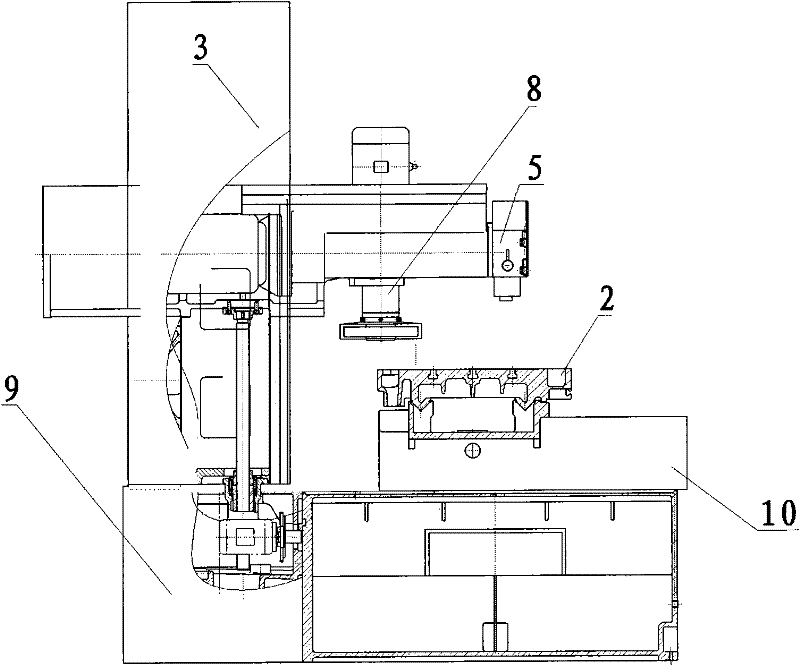

Grinding Center

InactiveCN102259282ACompact structureImprove transmission efficiencyRevolution surface grinding machinesControl systemEngineering

A grinding processing center, in order to solve the problem of single function of the existing grinding machine, it includes a bed, a large carriage, a workbench, a column, a horizontal grinding head assembly and a vertical grinding head assembly, a lubrication system, and a control system. The control system includes The computer numerical control system and servo system mainly adopt the vertical and horizontal double grinding head structure with external memory, which can realize six-axis linkage, compact structure and high transmission efficiency, which can meet various grinding processing needs.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

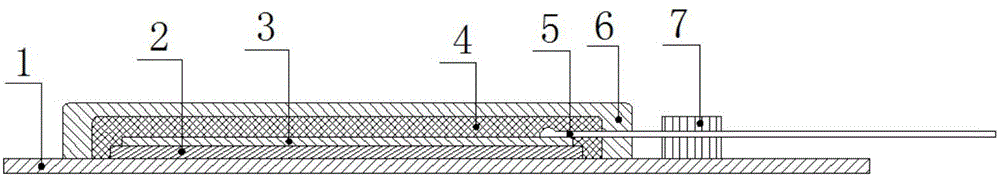

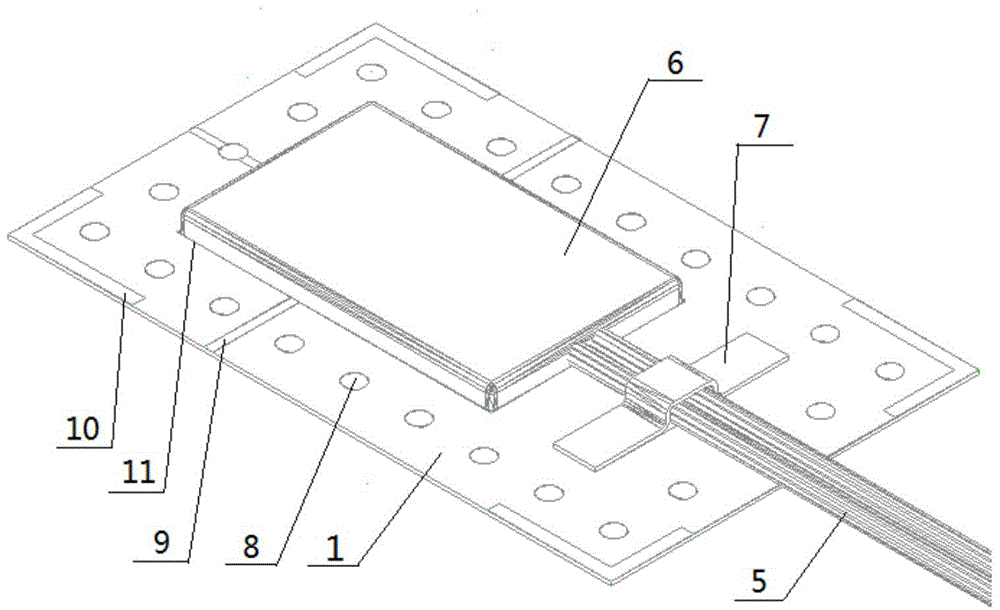

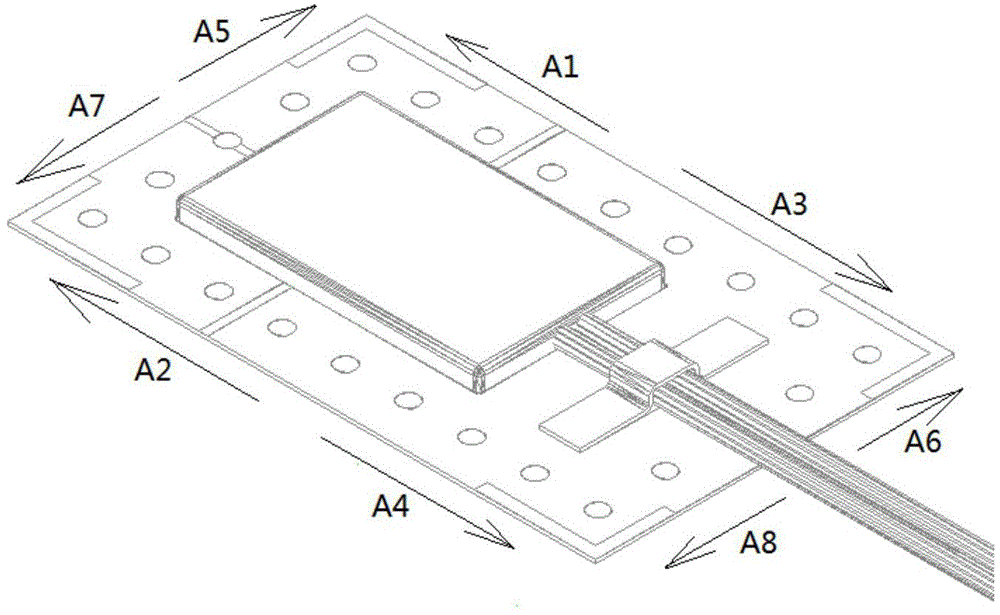

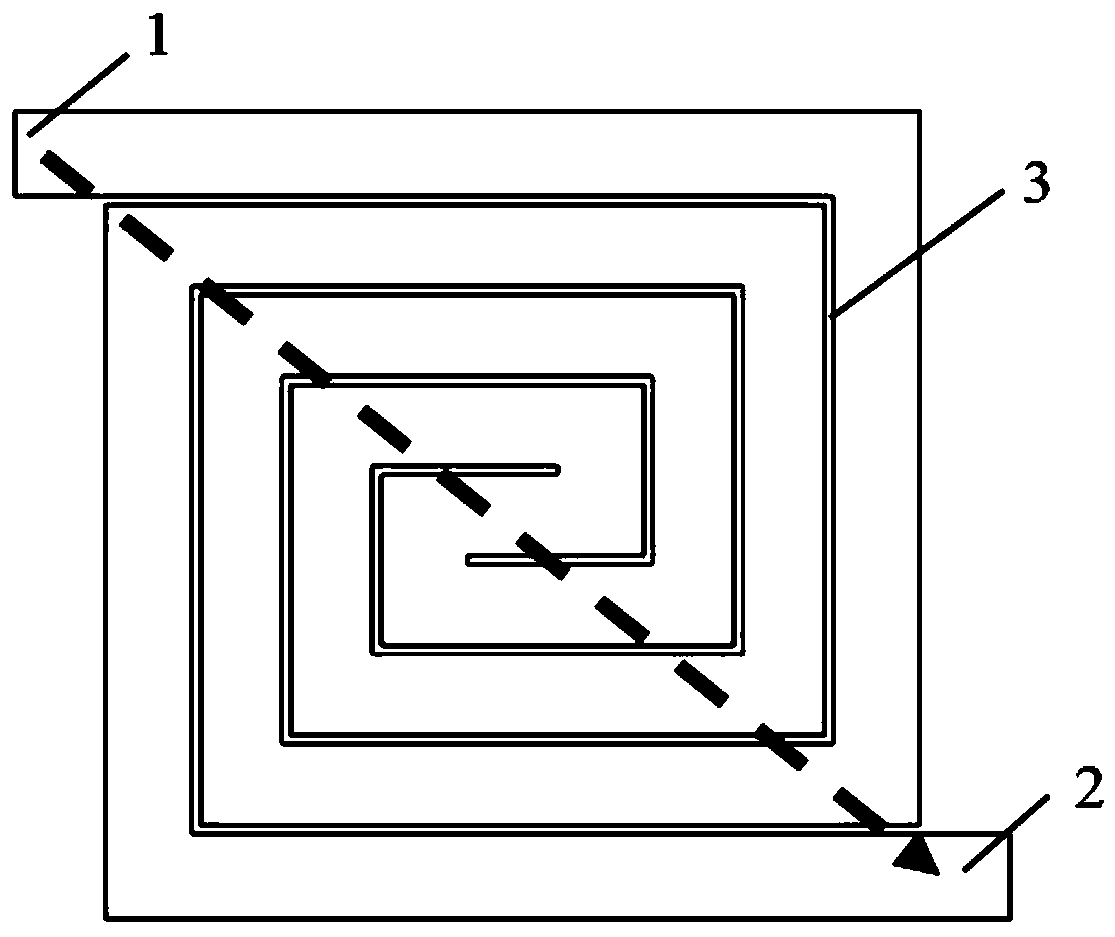

Strain gauge and methods for manufacturing and mounting strain gauge

ActiveCN104359393AExcellent heat and humidity resistanceFirmly connectedElectrical/magnetic solid deformation measurementAdhesiveEngineering

The invention provides a strain gauge which is quick to mount, high in test accuracy, high in resistance to heat and humidity, high in stability and suitable for stress strain test of medium-sized and large-sized metal components, and methods for manufacturing and mounting the strain gauge. The strain gauge comprises a metal base body, an adhesive layer, a resistance strain gauge, a moisture-proof layer, a signal lead and a protective layer, wherein the resistance strain gauge is fixedly mounted on the metal base body by virtue of the adhesive layer; the signal lead is electrically connected with a bonding pad of the resistance strain gauge and is led out; the moisture-proof layer coats the surface of the resistance strain gauge; the protective layer coats the surface of the moisture-proof layer. The manufacturing method comprises the following steps: (a) adhering the resistance strain gauge to the metal base body by virtue of an adhesive; (b) leading the signal lead out of the bonding pad of the resistance strain gauge; (c) forming the moisture-proof layer on the surface of the resistance strain gauge by virtue of a moisture-proof adhesive, wherein the coverage area of the moisture-proof layer is greater than that of the resistance strain gauge; (d) forming the protective layer on the surface of the moisture-proof layer by virtue of a protective adhesive, wherein the coverage area of the protective layer is greater than that of the moisture-proof layer. During mounting, the strain gauge is fused and welded on a measured metal component by virtue of spot welding equipment.

Owner:中航电测仪器(西安)有限公司

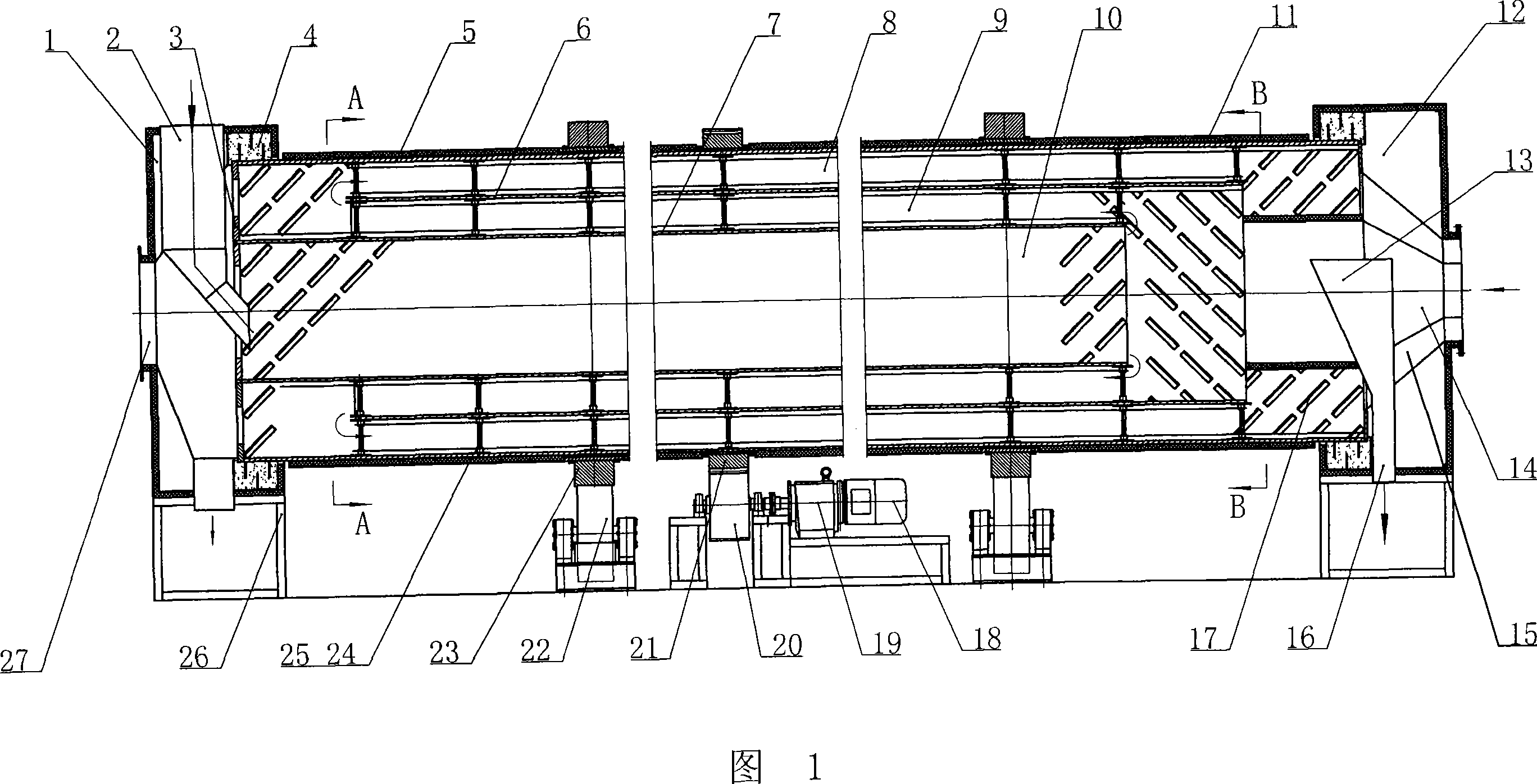

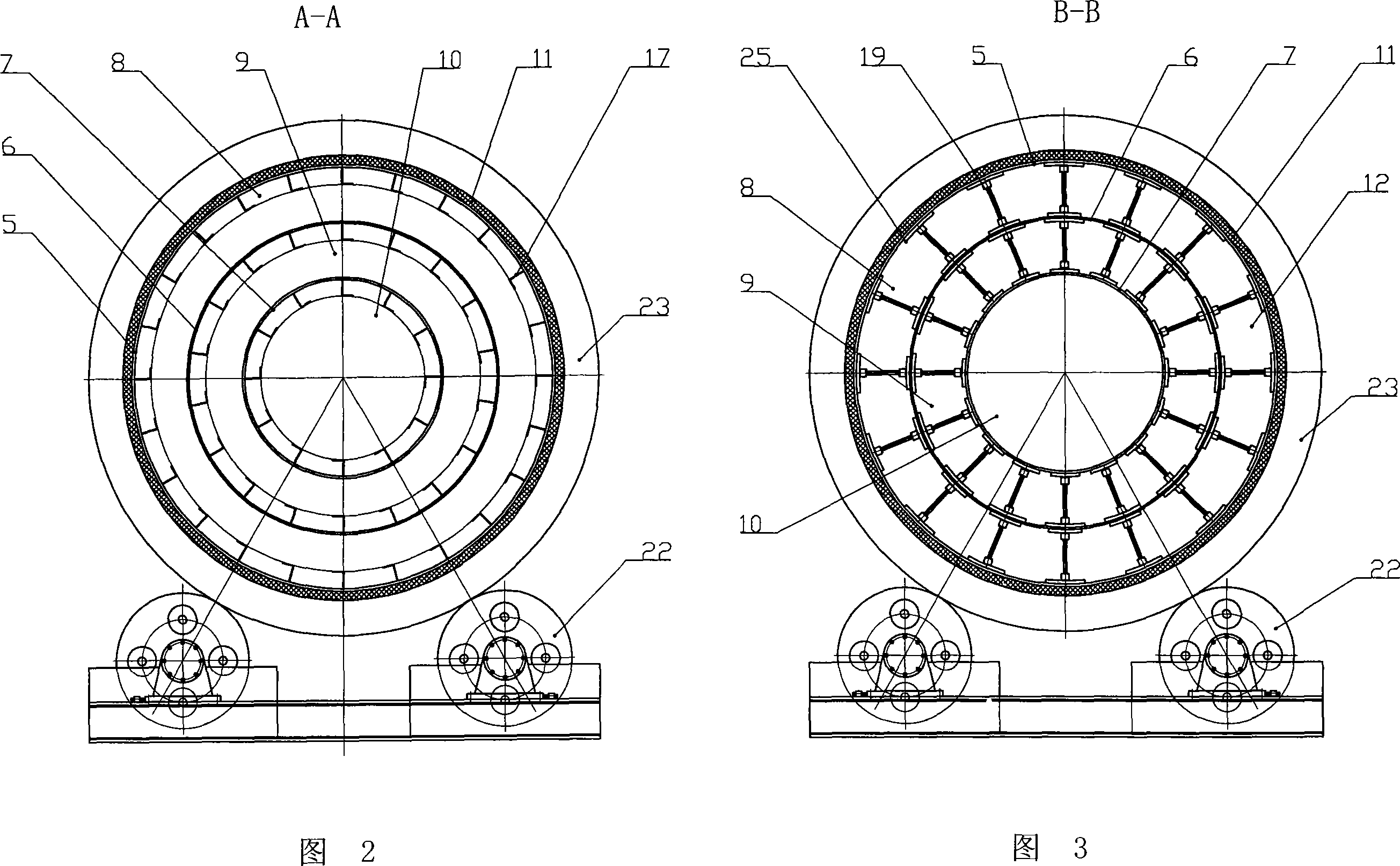

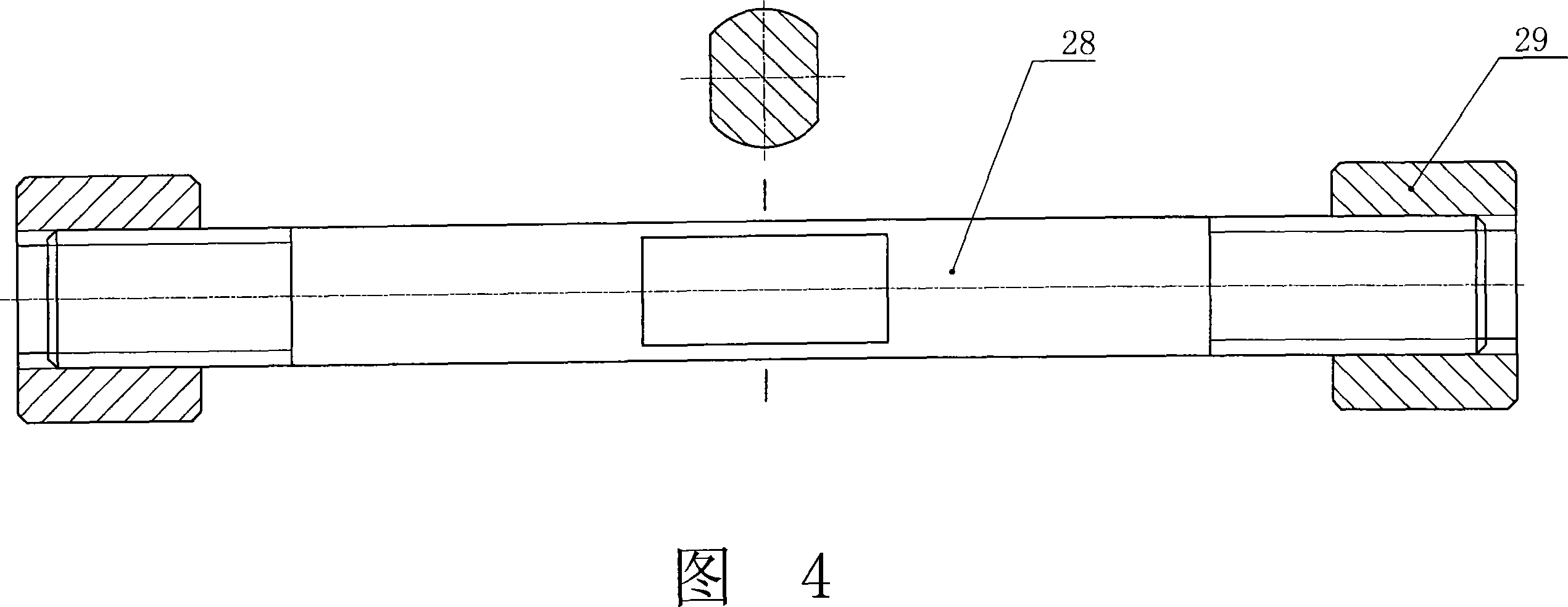

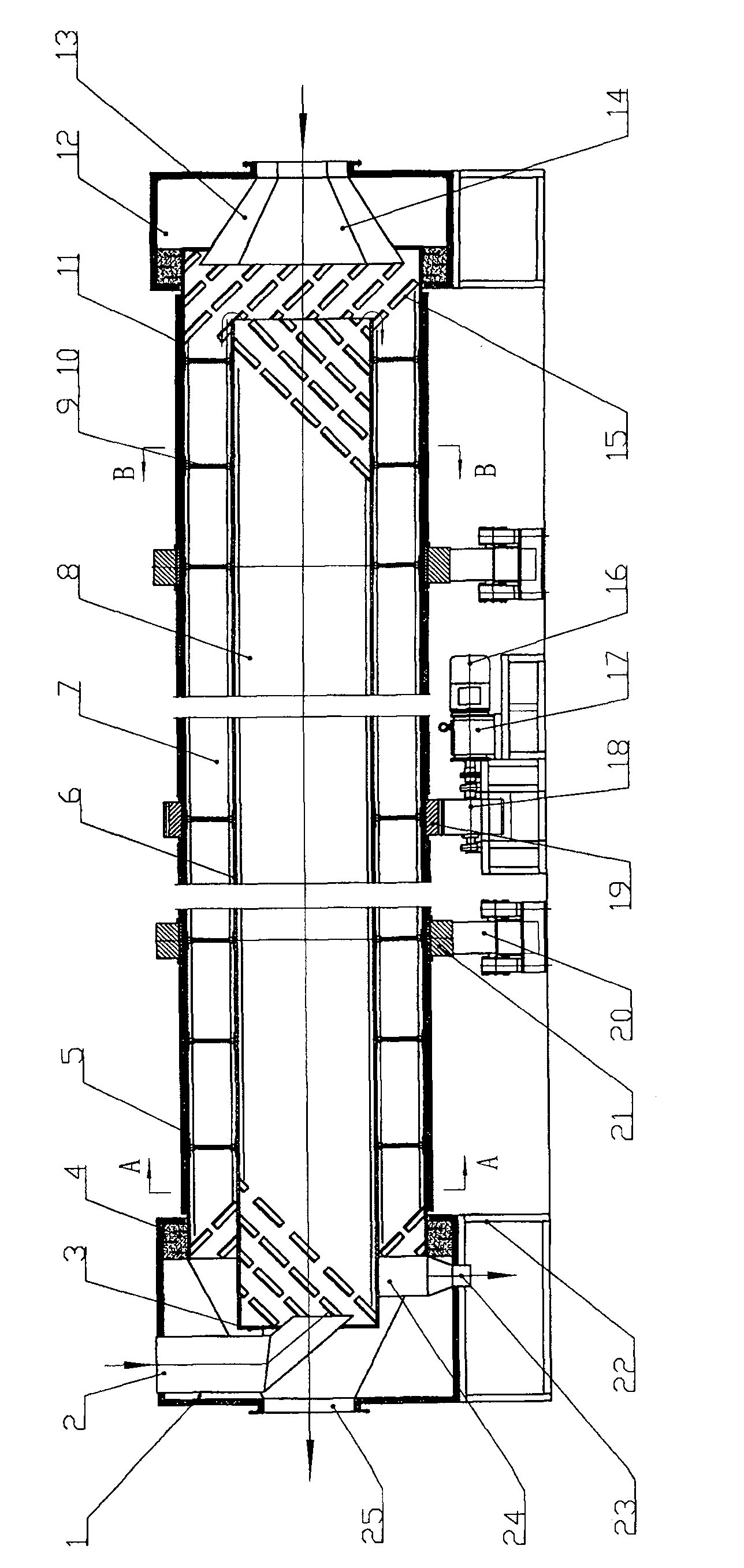

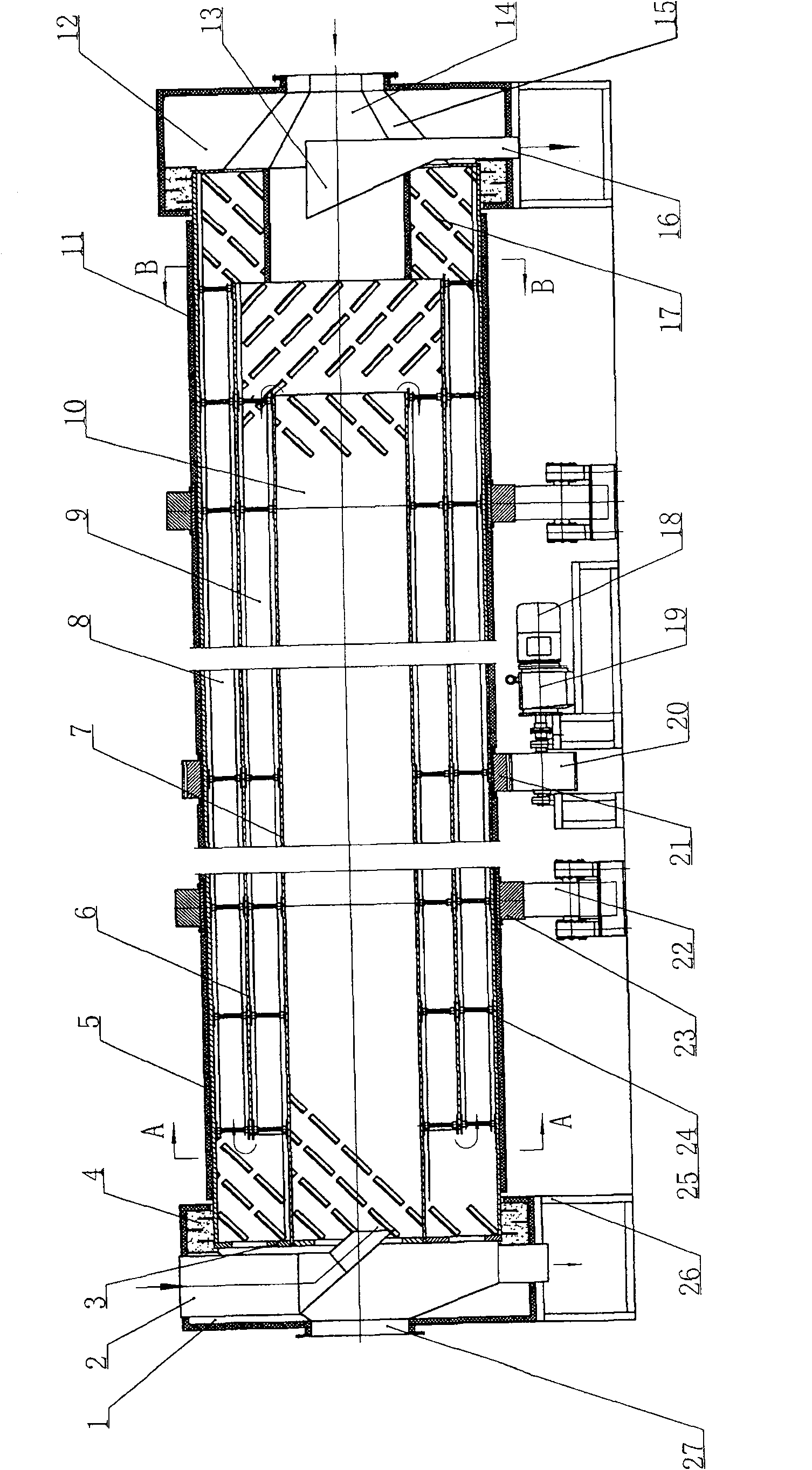

Three return journey barrel type drying machines

InactiveCN101216241AAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineEngineering

An improved three-pass cylinder drying machine comprises a machine body composed of a bracket, a sealed tank and a cylinder body, and a driving device, a supporting device and a controller, wherein the axial line of the cylinder body of the machine body is parallel to the horizontal surface, an inner cylinder and an outer cylinder that are concentrically arranged are assembled together in a staggered way to form the cylinder body, the formed cavities are used as three drying and precipitation units, the adjacent wallboards of the inner, middle and outer cylinders are connected and positioned via regulating and supporting plates and reinforced buffer plates, a heat insulating cover is disposed at the outer periphery of the wallboard of the outer cylinder, three material homogenizing and spreading machines are respectively disposed at the inner surfaces of the inner, middle and outer wallboards in a screw propulsion way and has reversed helical lines, and gears at the outer periphery of the machine body are aligned with the center of gravity of the cylinder. The inventive three-pass cylinder drying machine effectively solves the shortcomings of the conventional cylinder drying machine, including high deformation and misplacement liability and high axial dislocation liability; and has the advantages of reasonable structural design, stable performance, large precipitation range for one time, high thermal efficiency, saved energy consumptionand wide application range.

Owner:沈阳清井环保机械工程有限公司

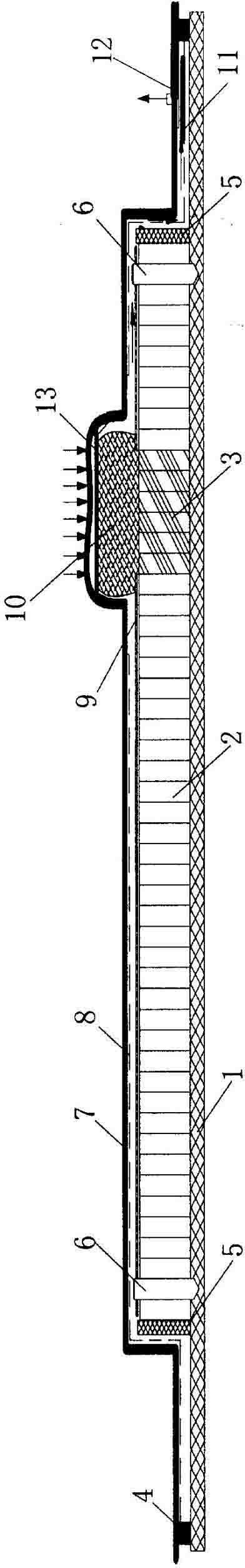

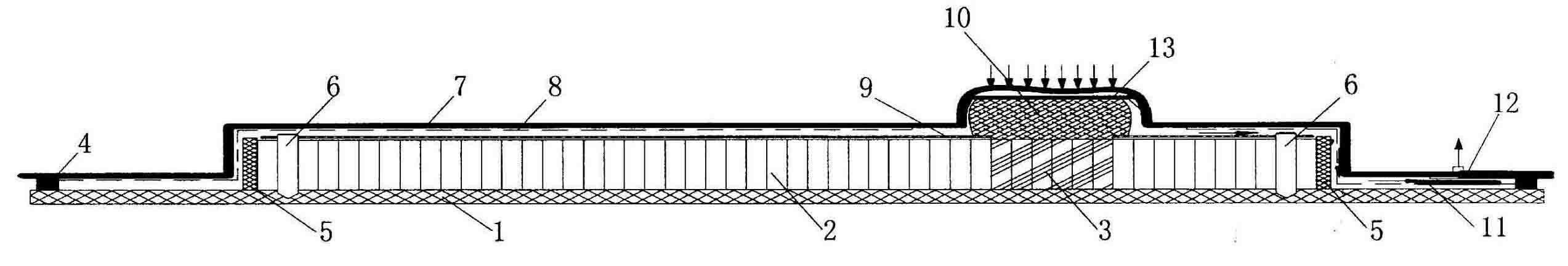

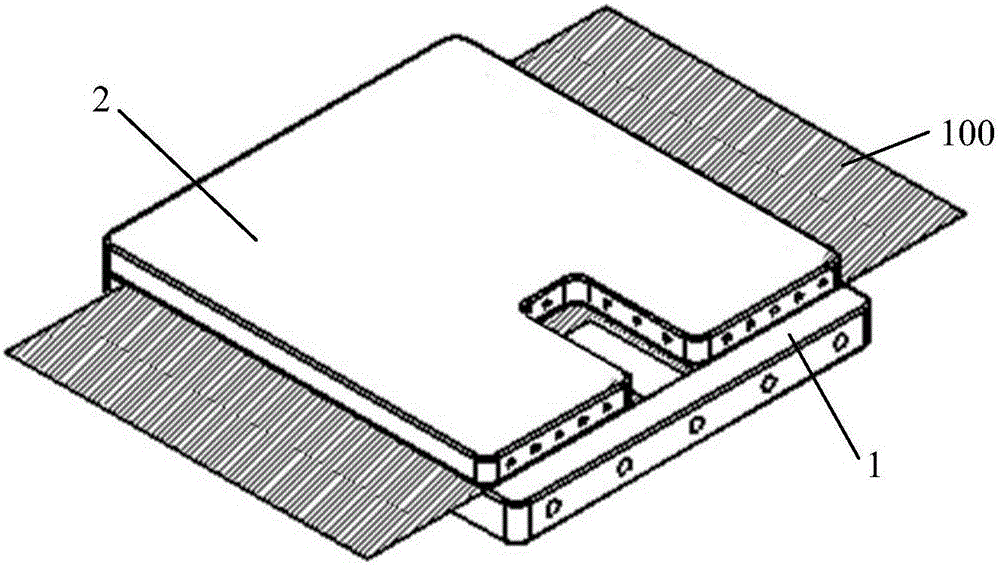

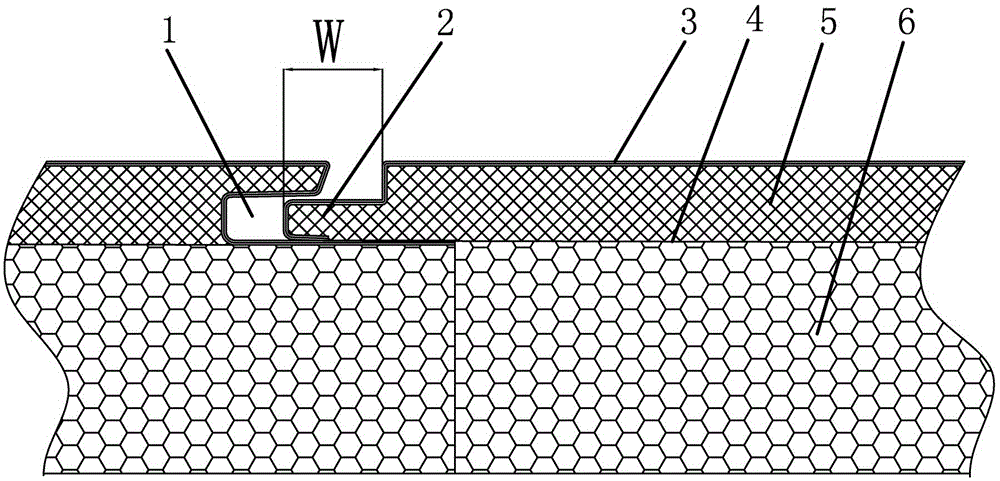

Honeycomb Sandwich Part Pre-filling and Forming Tooling and Its Process Method

InactiveCN102275342AEven by forceAvoid stress deformationLamination ancillary operationsLaminationHoneycombNozzle

The invention relates to a honeycomb sandwich piece pre-encapsulation molding tool, which comprises a honeycomb core and an encapsulation material, wherein a mold is arranged below the honeycomb core and is connected with the honeycomb core through positioning pins; baffle strips are arranged at the periphery of the honeycomb core; an encapsulation sample plate is arranged on the upper part of a honeycomb core encapsulation area and is connected in a positioning way through the positioning pins; a notch for accommodating the encapsulation material is reserved in the encapsulation sample plate; the encapsulation material is arranged in the notch; a pressure plate is arranged on the encapsulation material; an insulation membrane is arranged on the upper surface of an integral structure; a vacuum bag is arranged on the upper surface of the insulation membrane; the periphery of the vacuum bag passes through a sealing rubber strip; a venting felt is arranged on the lower surface at one endof the vacuum bag and in the sealing rubber strip; and a vacuum nozzle is arranged on the upper side corresponding to the venting felt. By the process method, encapsulation positions are accurate; simultaneously, vacuum is used for auxiliary pressurization, so that uniform downward pressure is applied onto all the encapsulation positions, and the phenomenon of stress deformation of a cured honeycomb core caused by non-uniform honeycomb stress is prevented.

Owner:SHENYANG AIRCRAFT CORP

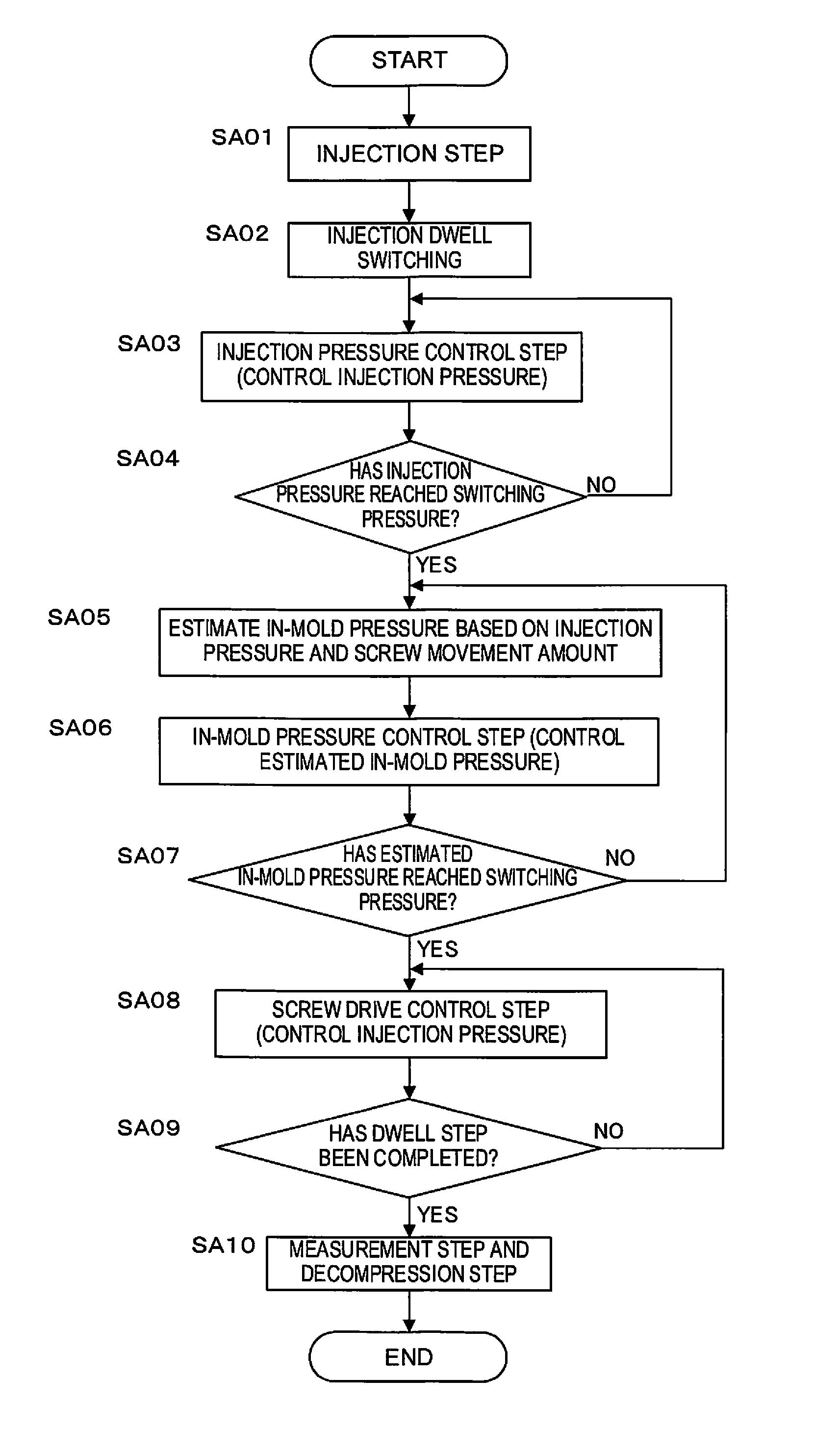

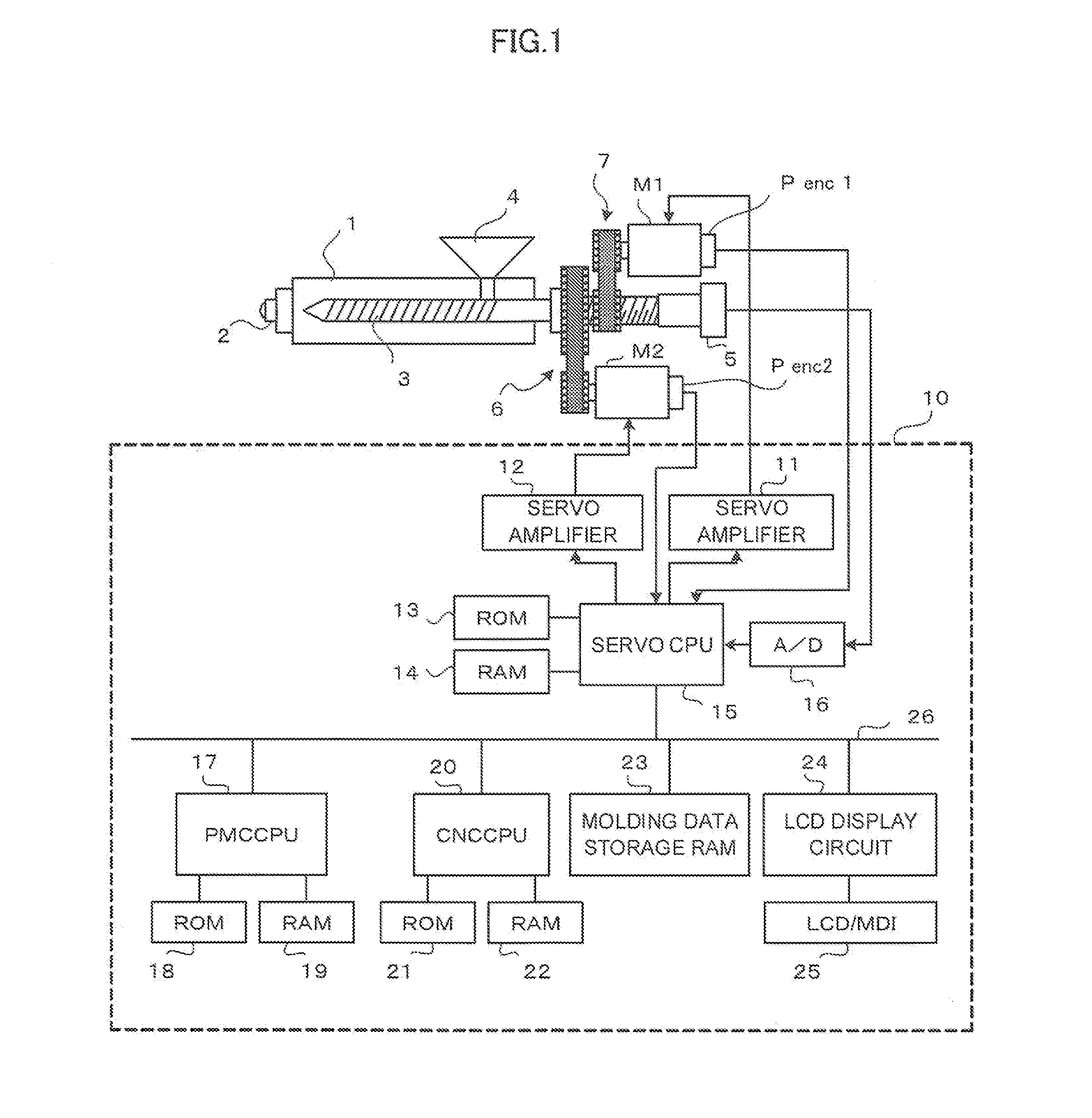

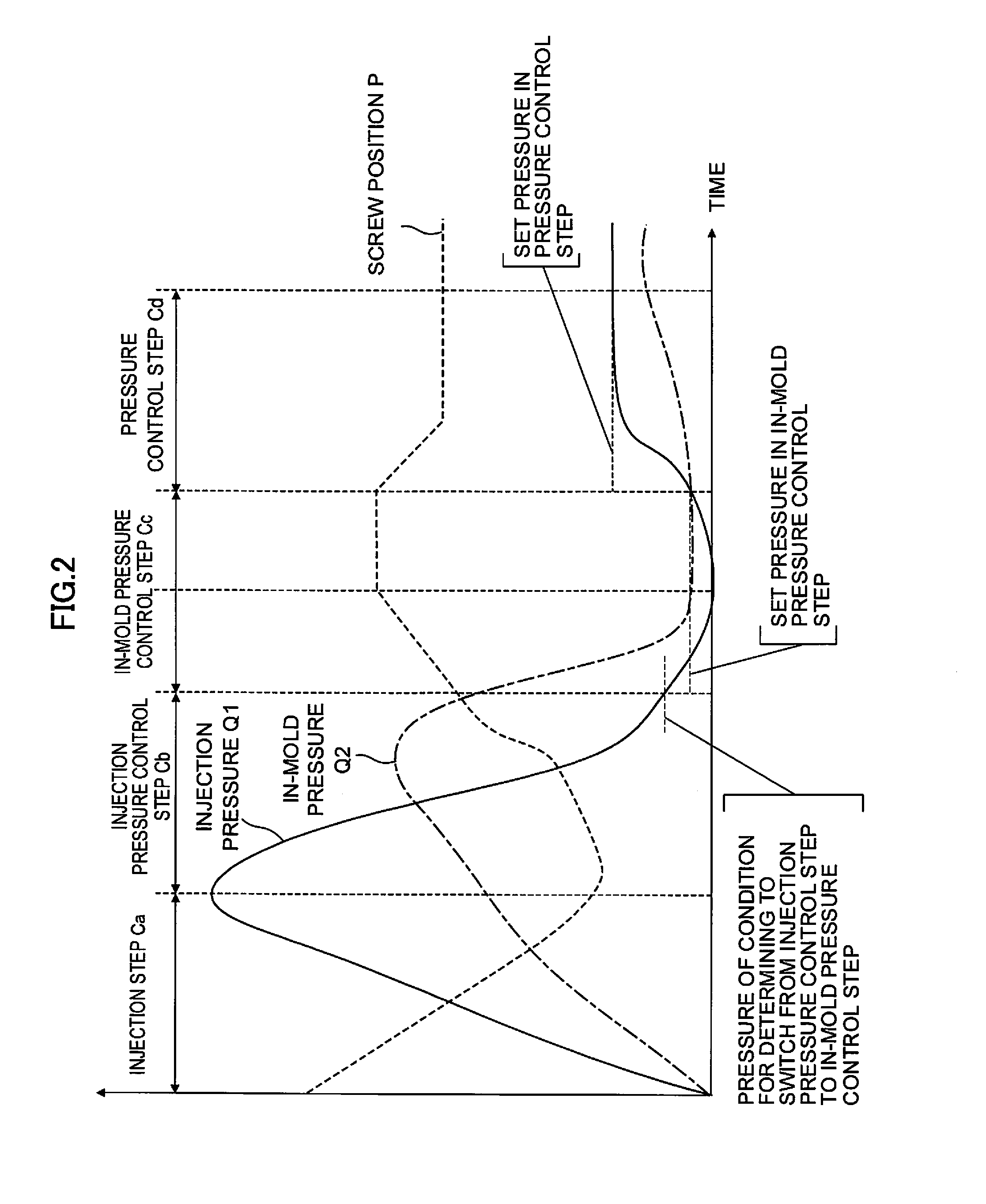

Pressure controller for injection molding machine

ActiveUS20160257047A1Reduce pressure changesQuality improvementCoatingsInjection pressureInjection molding machine

A pressure controller for an injection molding machine capable of reducing variations of pressure in a mold in molding cycles and providing molded articles of stable quality is provided. The pressure controller includes an in-mold pressure estimation unit for estimating a pressure in the mold based on an injection pressure detected with an injection pressure detection unit, and an amount of movement of a screw detected with a screw movement amount detection unit, and an in-mold pressure control unit for controlling such that the estimated in-mold pressure becomes a set in-mold pressure after the pressure control is performed in a dwell step with an injection pressure control unit.

Owner:FANUC LTD

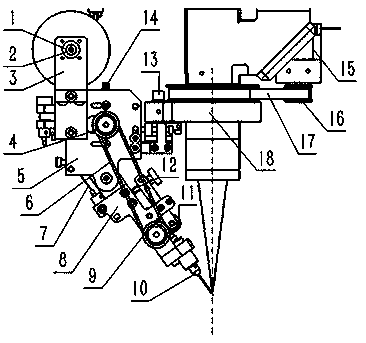

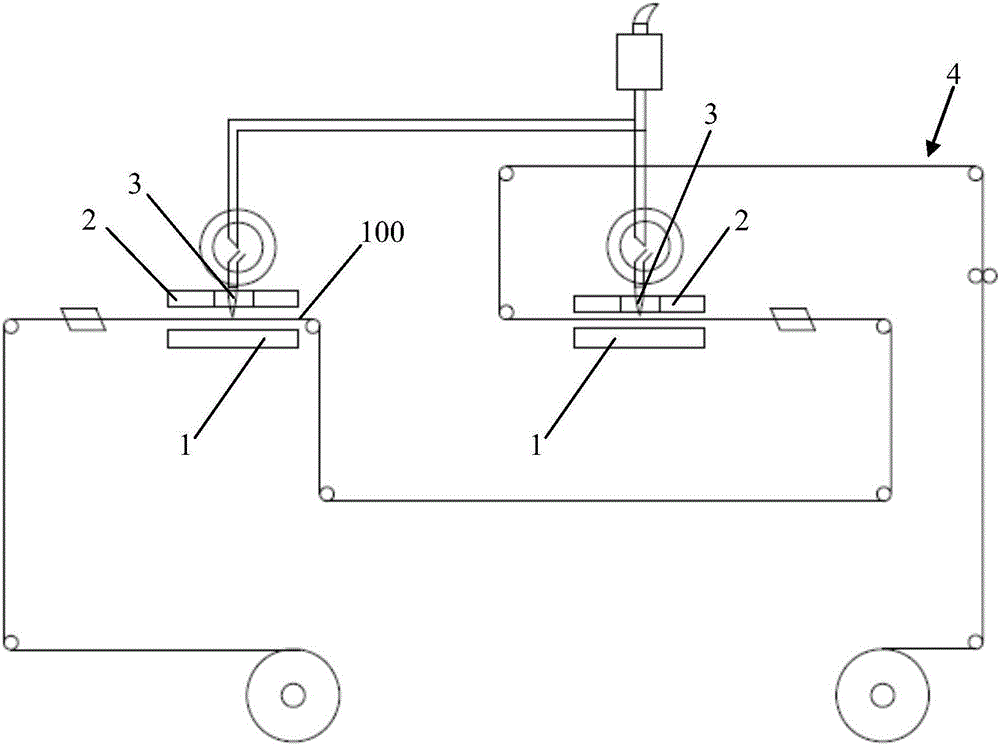

Automatic tin wire feeding device for laser welding

PendingCN109365936ASolve stress deformationSolve the cloggingSolder feeding devicesEngineeringArc welding

The invention discloses an automatic tin wire feeding device for laser welding. The automatic tin wire feeding device comprises a wire feeding mechanism and a welding rotating mechanism, wherein the wire feeding mechanism is formed by connecting a tin wire fixing device, a tin wire transmission device, a tin wire guide device, and a tin wire pressing regulating device; the welding rotating mechanism is fixedly connected with the wire feeding mechanism through a lifting mechanism; after the welding head centre line of the welding rotating mechanism is superposed with the centre line of a seconddriven wheel, the welding rotating mechanism and a wire feeding nozzle outlet are positioned on the same welding position. In this way, when the wire feeding mechanism has an angle of deflection, thewire outlet position is ensured to be kept consistent with a laser welding spot all the time; and moreover, wire feeding resistance can be prevented from being too great, stress deformation generatedby a tin wire during wire feeding is avoided, and a wire blocking phenomenon further can be prevented.

Owner:威克锐光电科技(苏州)有限公司

Double return journey barrel type drying machines

InactiveCN100573003CAvoid axial forceAvoid stress deformationDrying solid materials with heatDrying chambers/containersHelical lineHorizontal axis

An improved double-return cylinder dryer, including a body composed of a bracket, a sealed box and a cylinder, and its driving device, supporting device and controller, wherein the axis of the cylinder of the body is parallel to the horizontal plane, and the cylinder is arranged concentrically. The inner and outer cylinders are misplaced and fitted together, and the volume cavities formed constitute two drying and precipitation units respectively. The outer periphery of the cylinder wall board is provided with a heat insulation cover, and the inner peripheral surface of the inner and outer cylinder wall boards is respectively provided with a spiral propulsion type distribution device, and the direction of the helix is reversed. The center of gravity of the ring gear and the barrel is assembled. It effectively solves the defects of easy deformation and displacement and axial displacement of traditional drum dryers. It has reasonable structural design, stable performance, smooth process flow, large precipitation at one time, high thermal efficiency, energy saving and consumption reduction, and a wide range of applications. .

Owner:沈阳清井环保机械工程有限公司

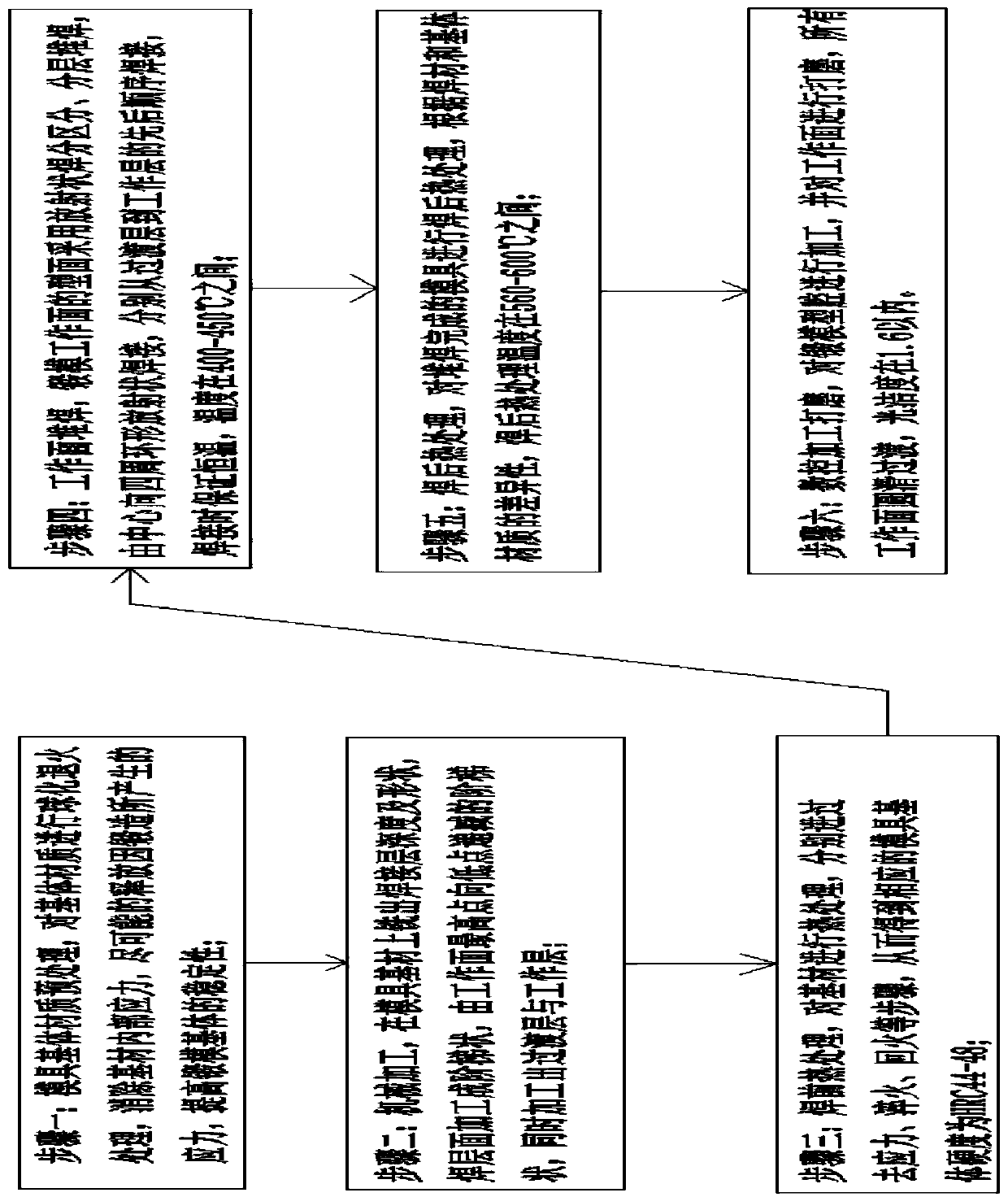

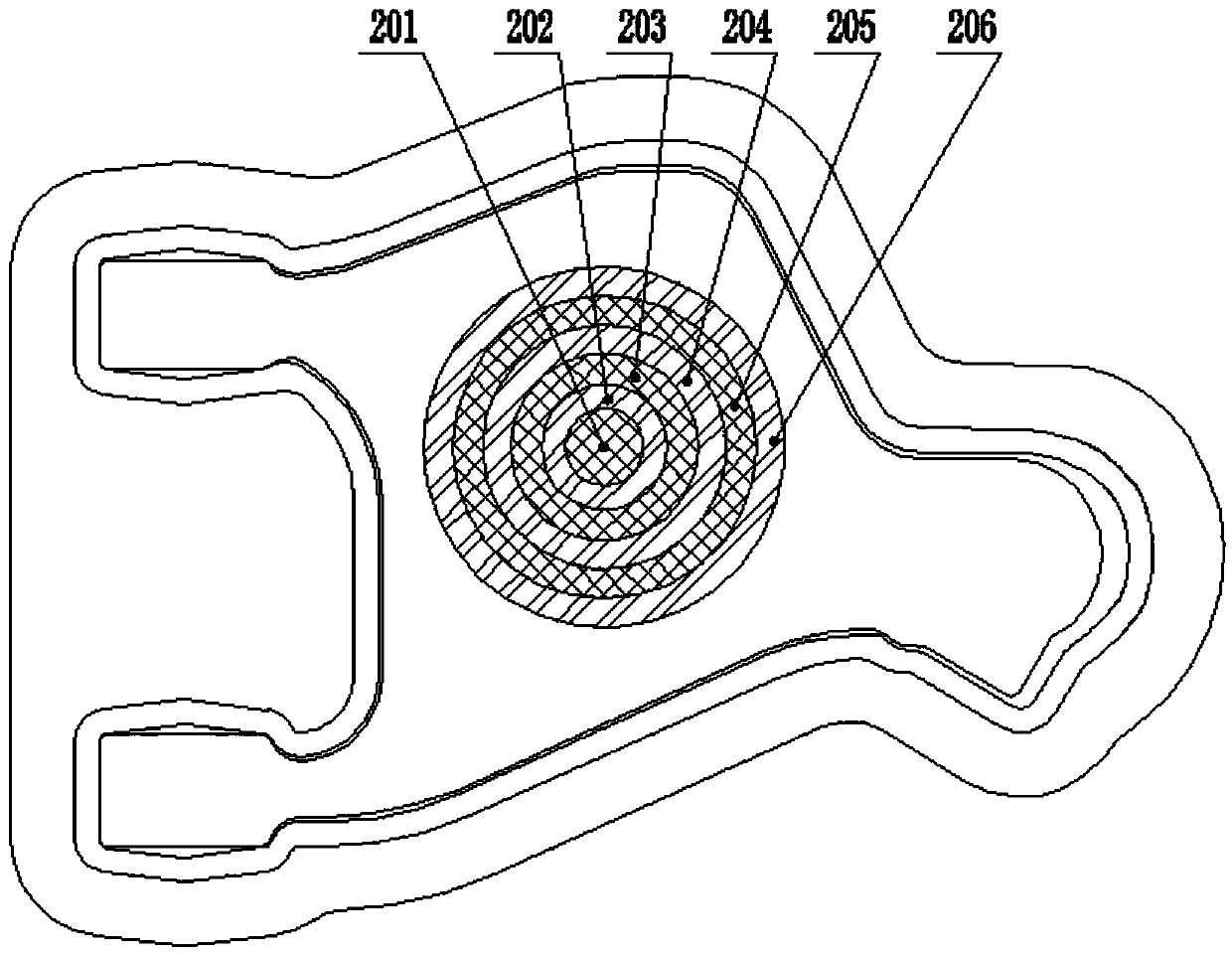

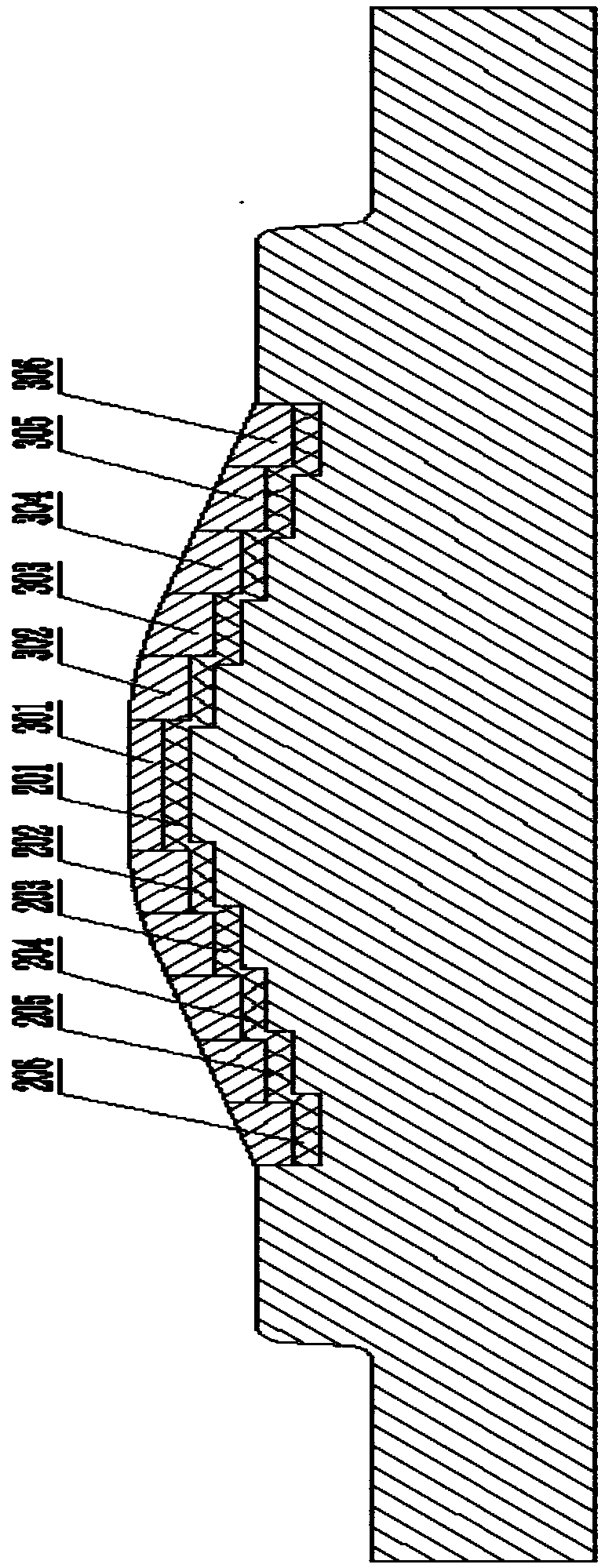

Processing technology of molded surface of high-strength wear-resistant titanium alloy forging mold

The invention discloses a processing technology of a molded surface of a high-strength wear-resistant titanium alloy forging mold, and belongs to the field of high alloy material forging mold processing. The processing technology comprises the following step of: step 1. pretreating a mold base material; step 2. machining, to be specific, milling the depth and shape of a welding layer on the mold base material, and processing a welding layer surface into a stepped shape decreasing from the highest point of a working face to a low point; step 3. carrying out pre-weld heat treatment, to be specific, carrying out heat treatment on the base material; step 4. carrying out build-up welding on the working face, carrying out subdivision build-up welding on the molded surface of the forging mold working face by adopting a radial welding unit, annularly and radially welding from the center to the periphery; step 5. carrying out post-weld heat treatment, to be specific, carrying out post-weld heattreatment on the mold subjected to build-up welding; and step 6. carrying out numerical control machining and polishing, machining a cavity of the forging mold, and grinding the working face. The processing technology improves the performance of the forging mold, and prolongs the service life of the forging mold. According to the particularity of a forged product, the radial welding process is adopted to improve the stability of the working face and reduce the abrasion of the forging mold.

Owner:MAANSHAN CITY ZHONGYE MACHINERY

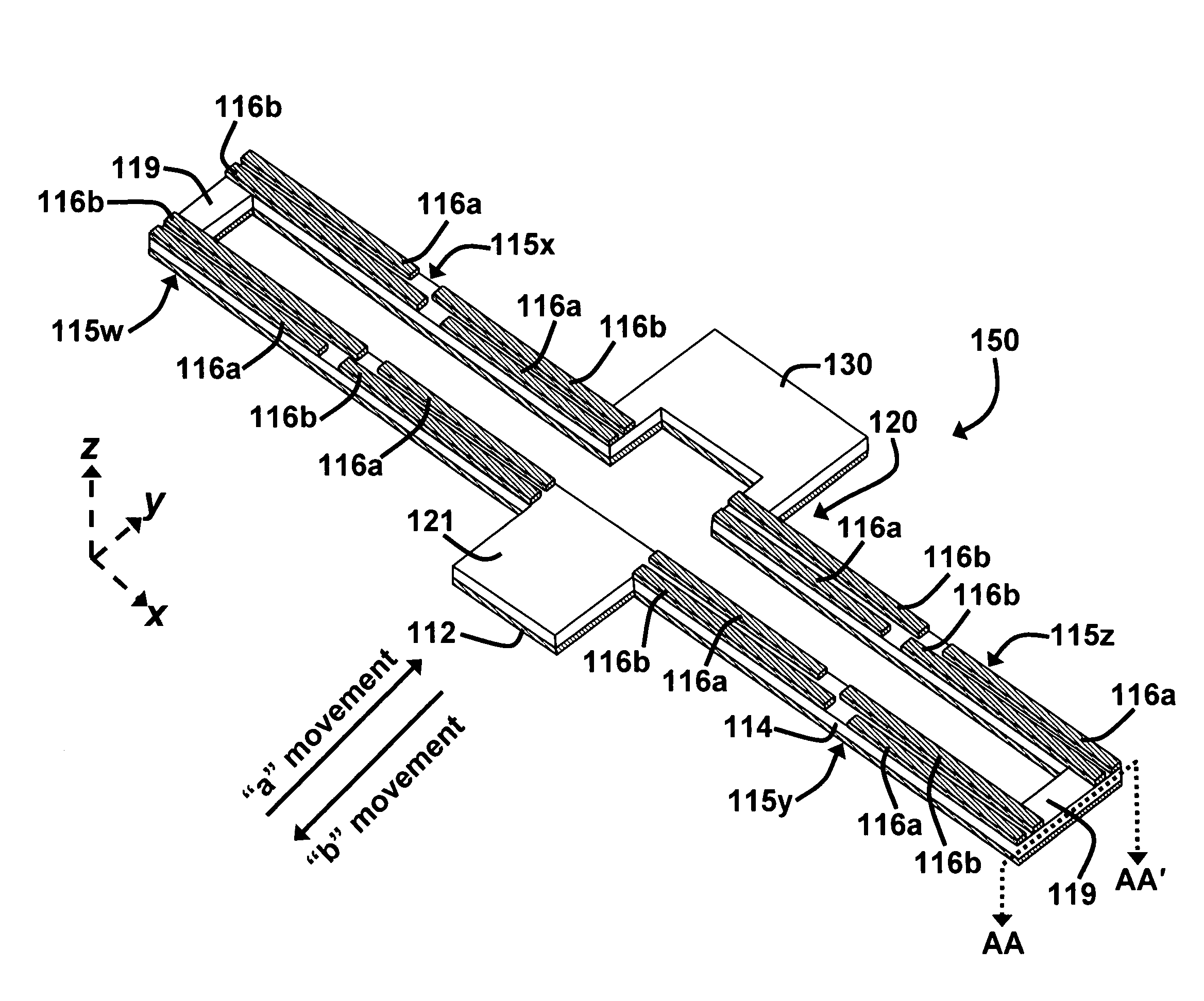

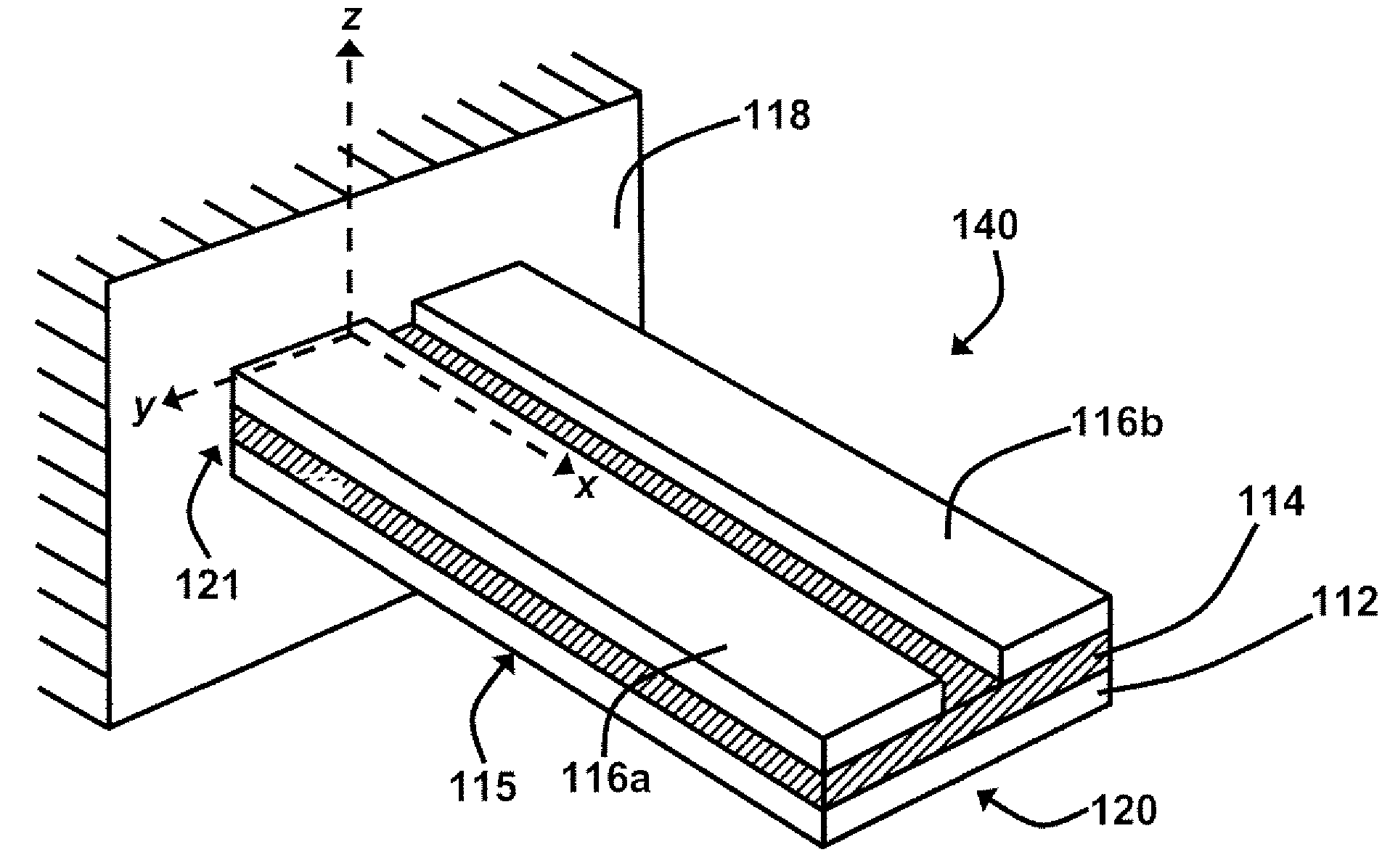

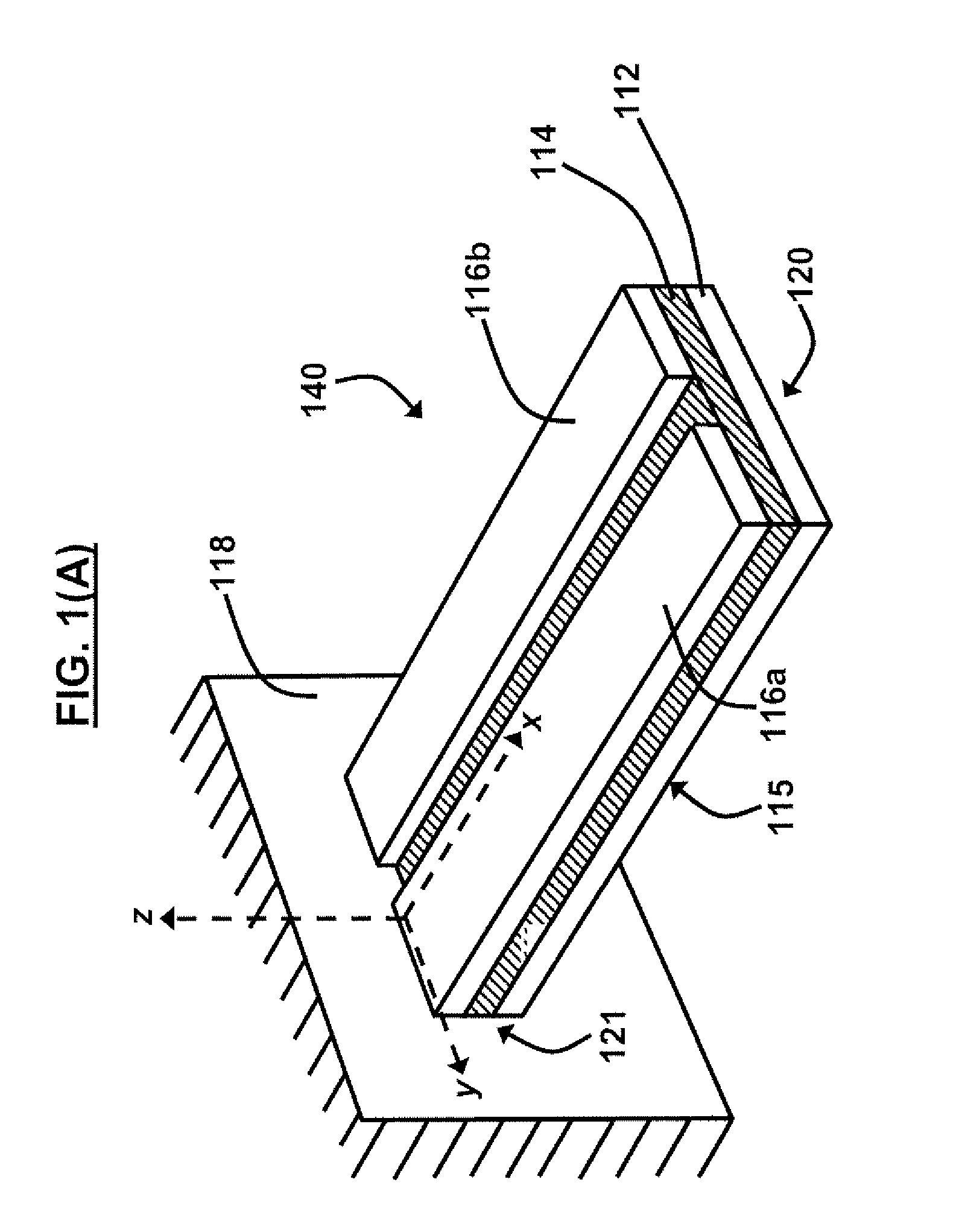

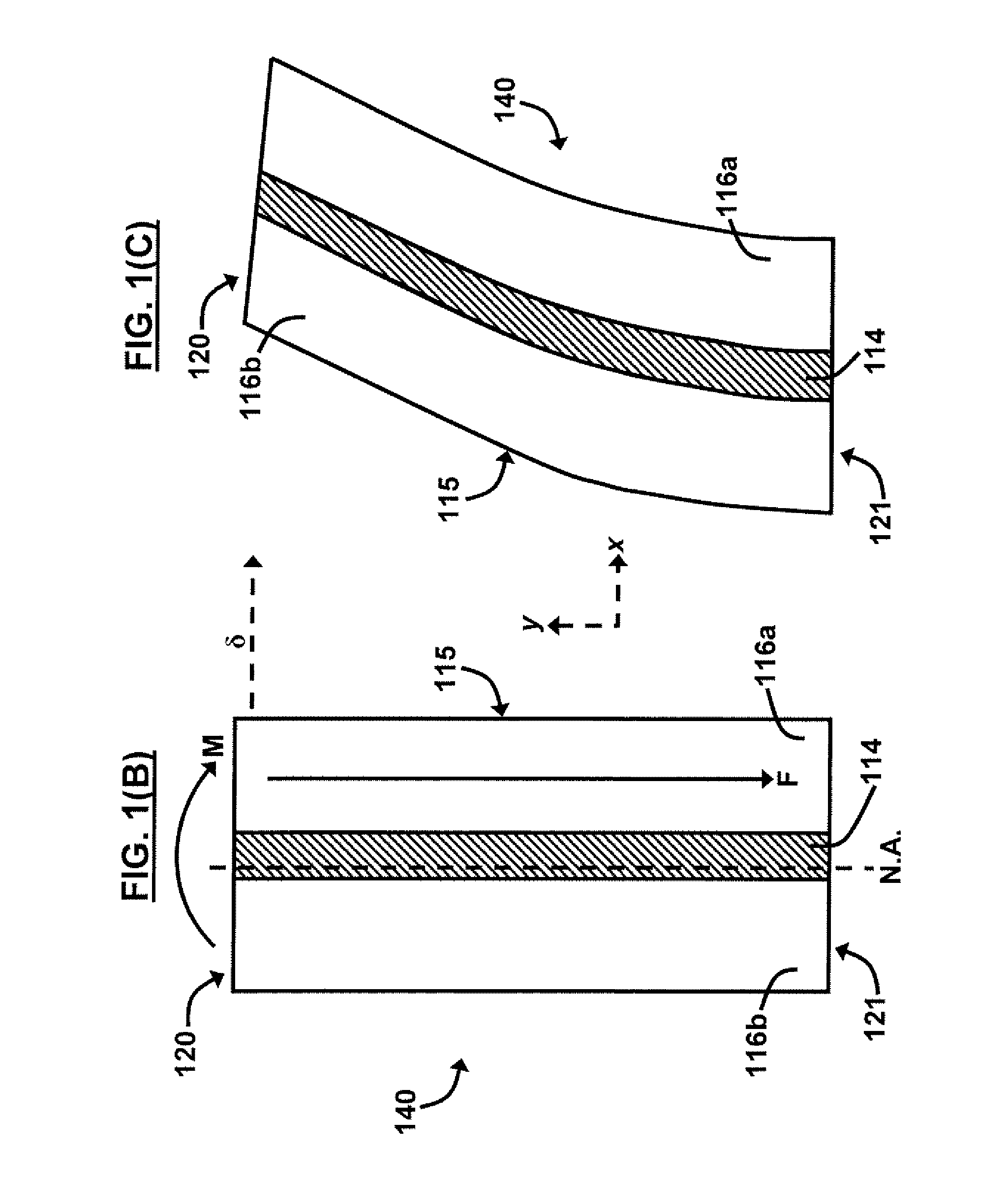

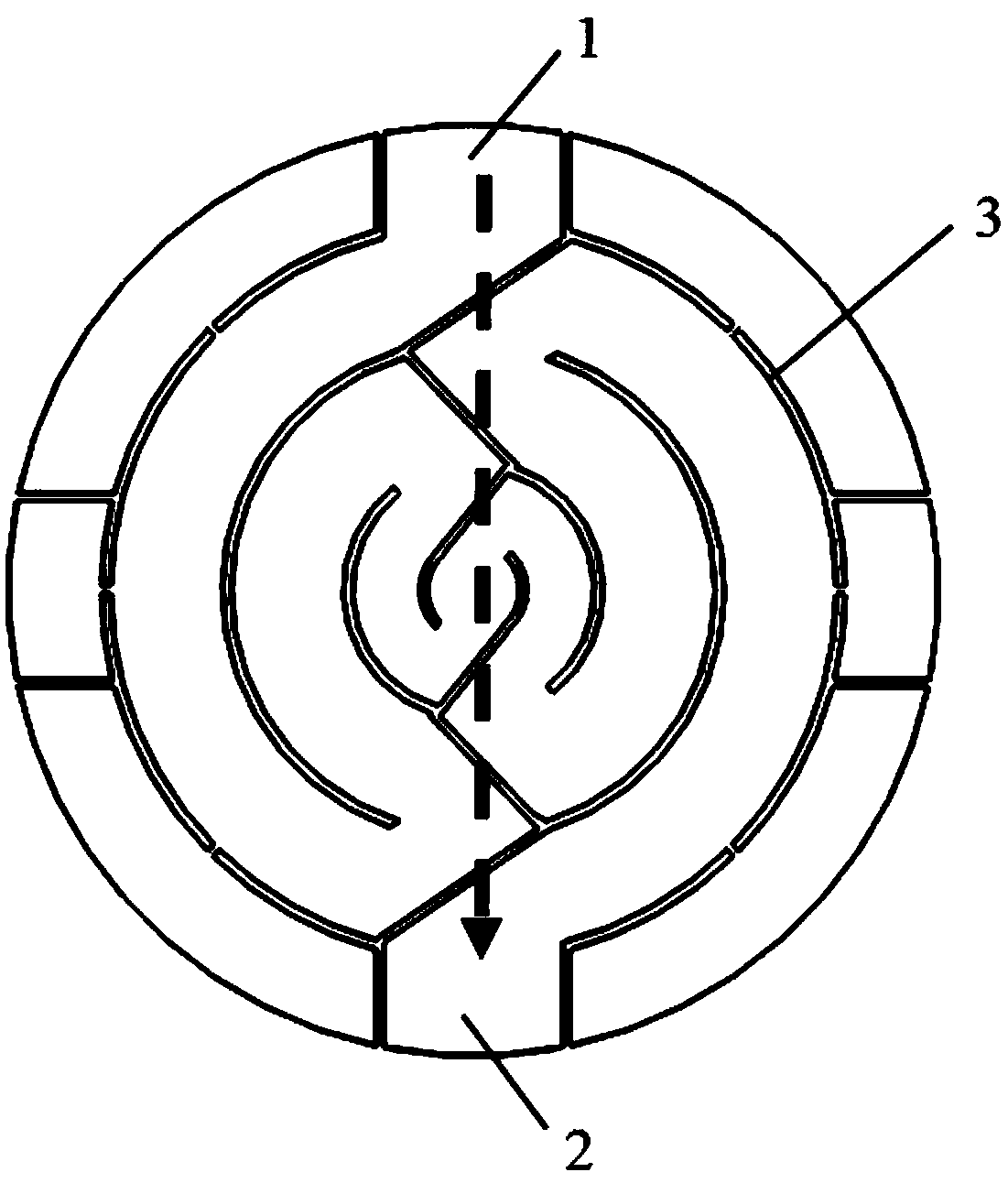

Lateral piezoelectric driven highly tunable micro-electromechanical system (MEMS) inductor

InactiveUS7486002B2Avoid stress deformationLimit translational motionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringInductor

A MEMS device comprising a substrate; an anchored end connected to the substrate; and an actuator comprising a first electrode; a piezoelectric layer over the first electrode; and multiple sets of second electrodes over the piezoelectric layer, wherein each of the sets of second electrodes being defined by a transverse gap there between, and wherein one of the sets of second electrodes are actuated asymmetrically with respect to a first plane resulting in a piezoelectrically induced bending moment arm in a lateral direction that lies in a second plane. The device further comprises an end effector opposite to the anchored end and connected to the actuator; a ferromagnetic core support structure connected to the end effector; a movable ferromagnetic inductor core on top of the ferromagnetic core support structure; and a MEMS inductor coiled around the ferromagnetic core support structure and the movable ferromagnetic inductor core.

Owner:ARMY US SEC THE

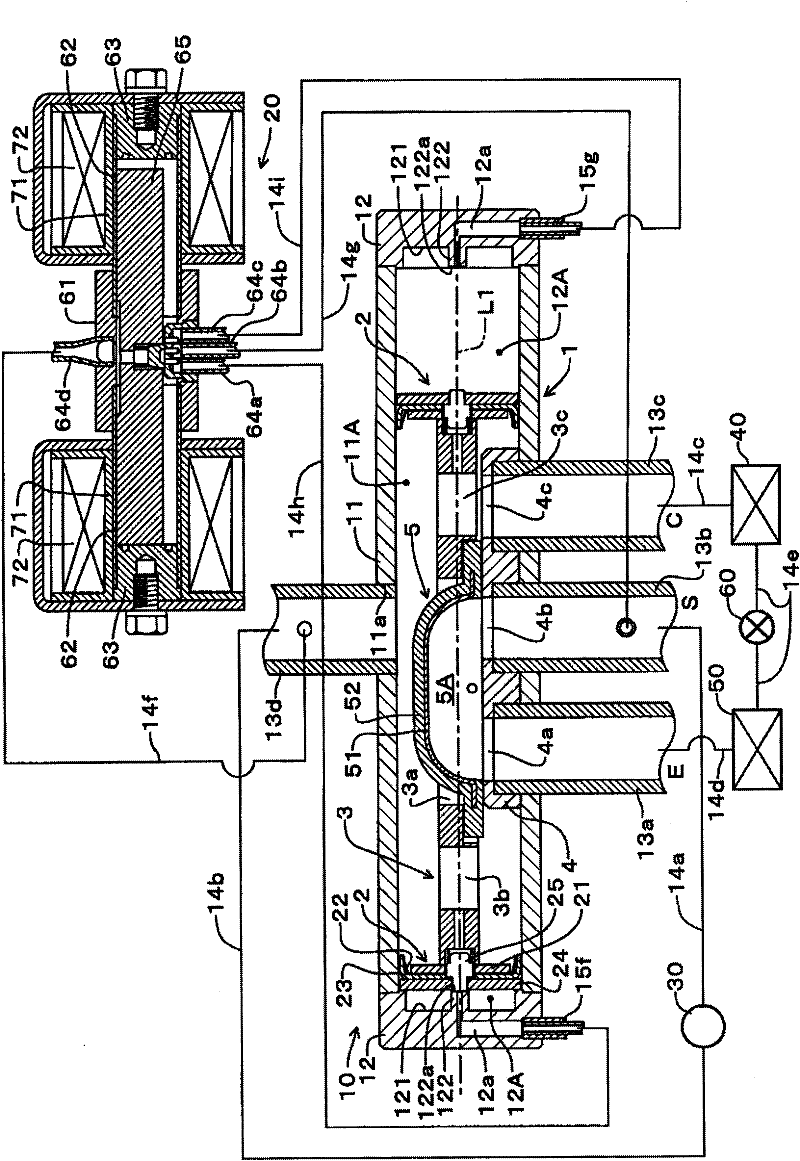

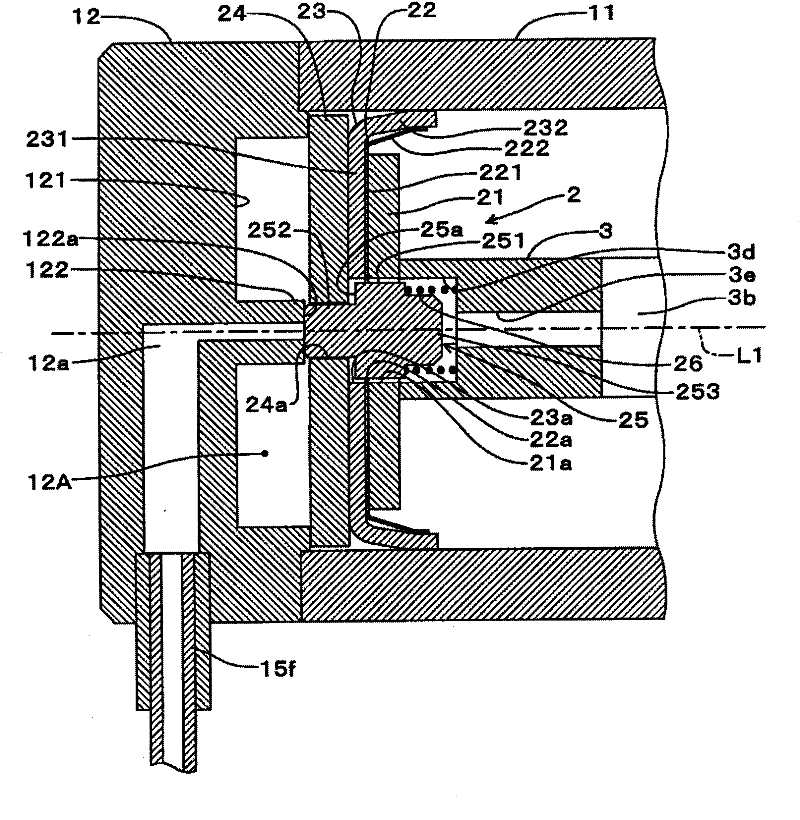

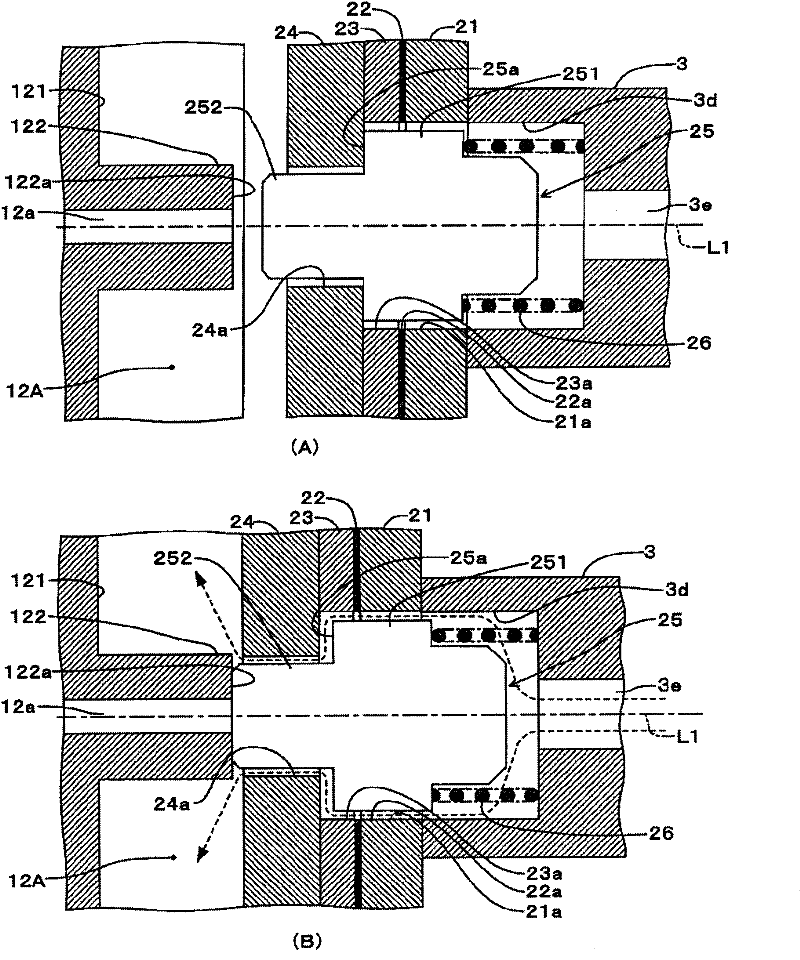

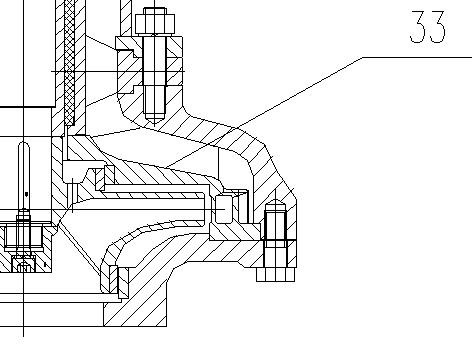

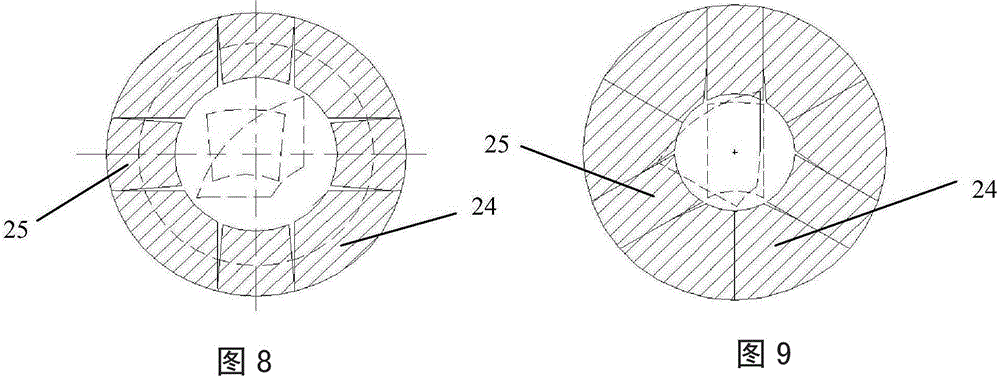

Flow path switching valve

ActiveCN102252114APrevent creep deformationAvoid stress deformationOperating means/releasing devices for valvesMultiple way valvesEngineeringPath switching

The invention relates to a flow path switching valve. The flow path switching valve 10 uses two pistons 2, 2 to divide a valve shell 1 into a primary valve chamber 11A and the secondary valve chambers 12A, 12A on two sides. One secondary valve chamber 12A on one side is decompressed and a pressure difference between this secondary valve chamber and a refrigerant pressure in the primary valve chamber 11A is used to drive the piston 2 and a primary valve core 5 to move, convert the flow path of the refrigerant in circulation and guarantee the service durability of the piston 2. A pressure equalizing path is provided in the center of the piston 2, and a secondary valve 25 is disposed in the pressure equalizing path. When the piston 2 is moved toward a cap 12, the secondary valve 25 closes anopening of an exhaust path 12a at a secondary valve seat, and opens the pressure equalizing path.

Owner:SAGINOMIYA SEISAKUSHO INC

Method for removing pole piece coating and pole piece coating cleaning device

PendingCN106410113AAvoid stress deformationAvoid dentsElectrode thermal treatmentPole pieceCooling fluid

The invention discloses a method for removing a pole piece coating and a pole piece coating cleaning device. When the pole piece coating is removed, a pole piece is placed on a cleaning platform, and a circular cooling pipeline for circulating cooling fluid is arranged in the cleaning platform; the pole piece is pressed on the cleaning platform by a pressing block, a through groove is arranged on the pressing block; the through groove exposes a to-be-cleaned zone on the pole piece; a vacuum nozzle is arranged on the side wall of the through groove, and the vacuum nozzle is interconnected with a vacuum pipeline arranged in the pressing block; the pole piece zone exposed at the through groove of the pressing block is fired by laser, so as to remove the coating of the zone; when the laser cleans the pole piece coating, the cooling fluid in the platform is cleaned so as to cool the pole piece; the vacuum nozzle on the pressing block can collect the powder grain, and a foil material is shown after the coating is cleaned by laser, thus the cleaning is completed. The invention can guarantee that the pole piece cleaning zone is constantly under a low temperature state, thus preventing an empty foil of the cleaning zone from oxidization, preventing the pole piece of the cleaning zone from deformation and guaranteeing the cleaning degree of the pole piece after cleaning.

Owner:ZHUHAI COSMX BATTERY CO LTD

Three return journey barrel type drying machines

InactiveCN100570253CAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineThermal insulation

An improved three-pass cylinder dryer, including a body composed of a bracket, a sealed box and a cylinder, and its driving device, supporting device and controller, wherein the axis of the cylinder of the body is parallel to the horizontal plane, and the cylinder is arranged concentrically. The inner, middle and outer cylinders are misplaced and fitted together, and the volume cavities formed constitute three drying and dewatering units respectively. The adjacent wall panels of the inner, middle and outer cylinders are adjusted by supporting and reinforcing buffer pads. Connection and positioning, the outer circumference of the outer cylinder wall board is provided with a heat insulation cover, and the inner peripheral surface of the inner, middle and outer cylinder wall boards is respectively provided with a spiral propulsion spreader, and the rotation of the helix On the contrary, the ring gear on the outer periphery of the machine body is assembled with the center of gravity of the barrel. It effectively solves the defects of easy deformation and displacement and axial displacement of traditional drum dryers. It has reasonable structural design, stable performance, smooth process flow, large precipitation at one time, high thermal efficiency, energy saving and consumption reduction, and a wide range of applications. .

Owner:沈阳清井环保机械工程有限公司

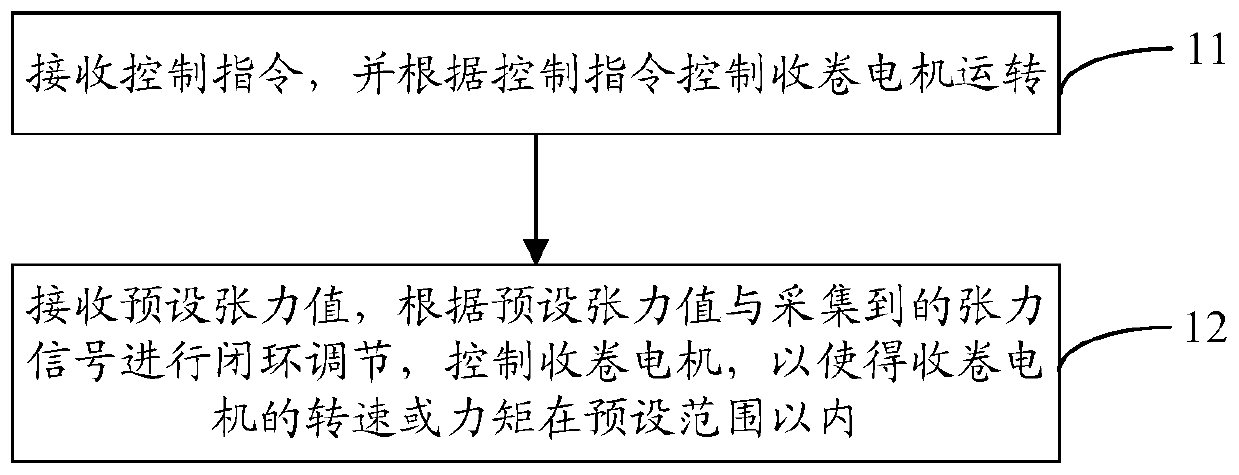

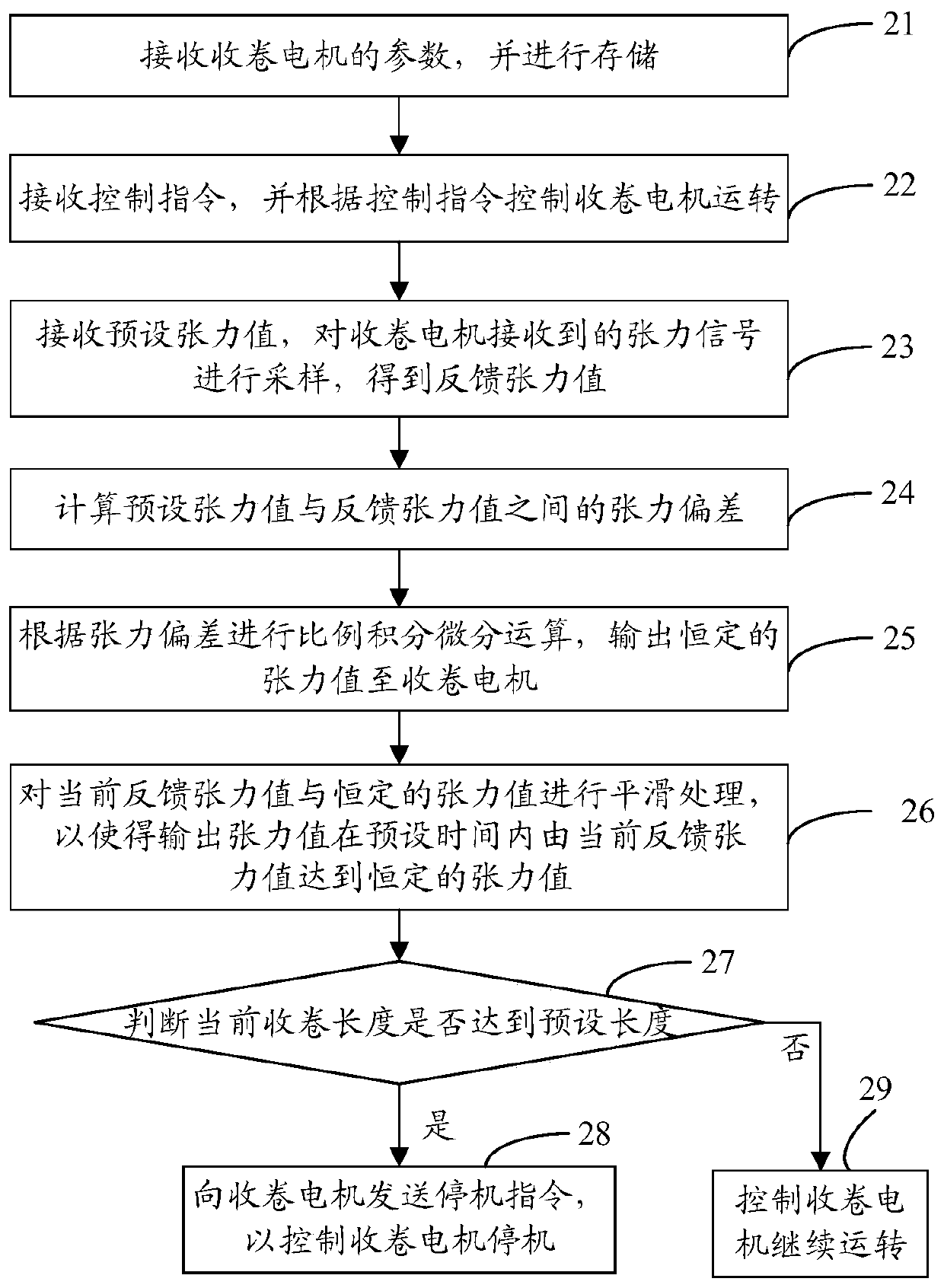

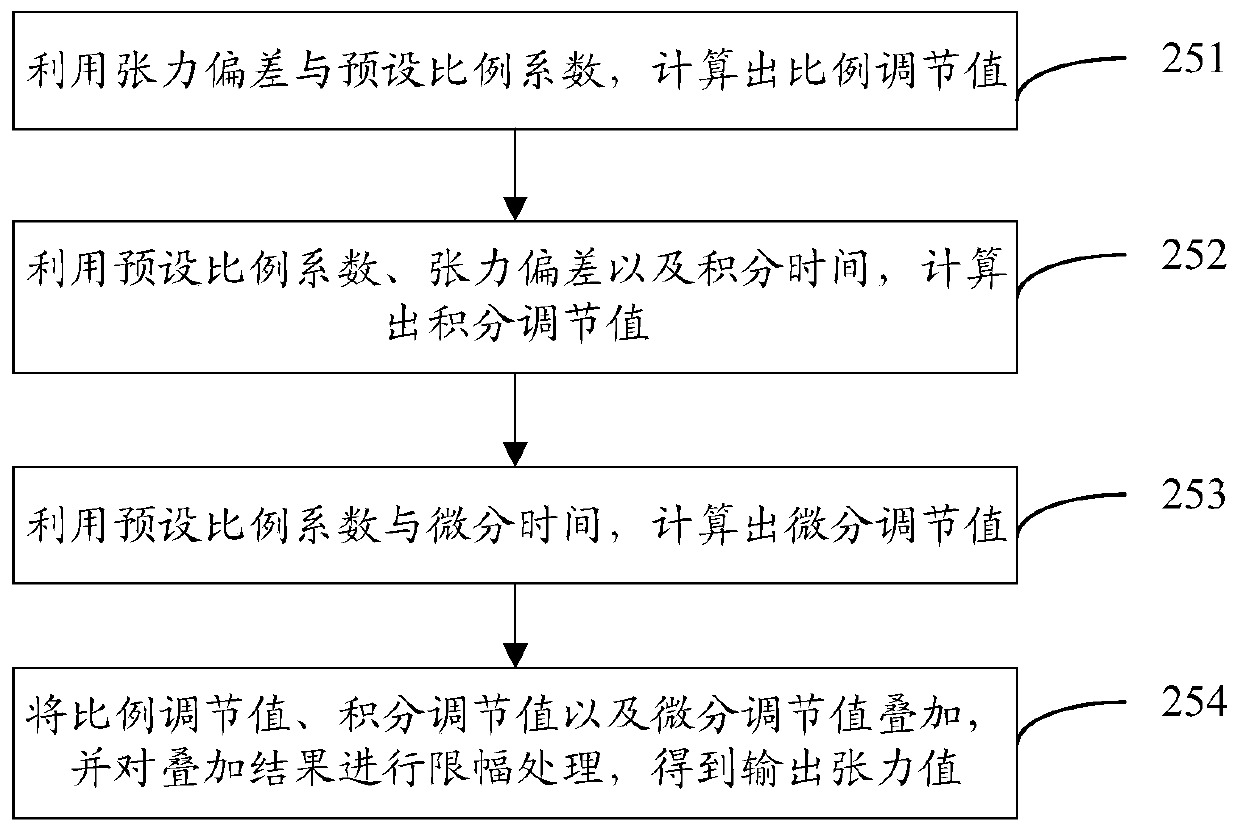

Winding control method, device and system and computer storage medium

The invention discloses a winding control method, device and system and a computer storage medium. The winding control method is applied to the winding system, and the winding system involves a winding motor; and the method comprises the following steps of receiving a control instruction and controlling the winding motor to operate according to the control instruction; and receiving a preset tension value, carrying out closed-loop adjustment according to the collected tension signal and the preset tension value, and controlling the winding motor, so that the rotating speed or moment of the winding motor is within a preset range. According to the winding control method, device and system, the tension control precision can be improved, and the winding quality is guaranteed.

Owner:苏州安驰控制系统有限公司

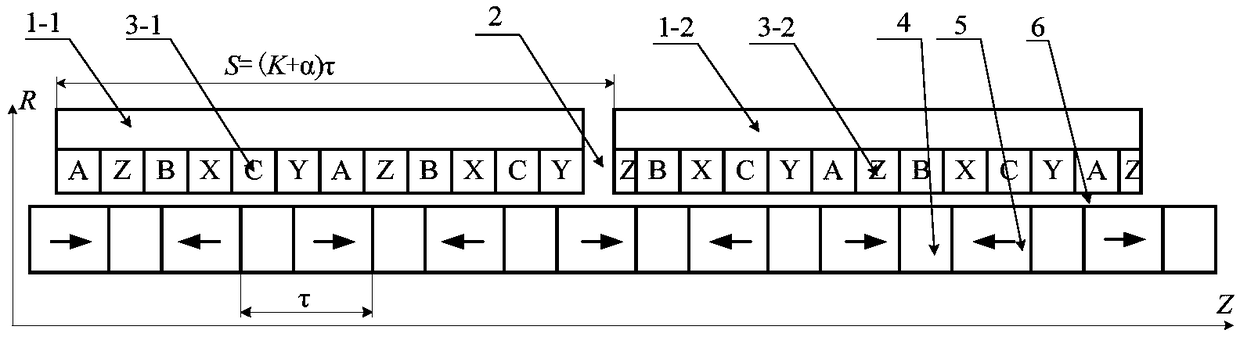

Two-stage slot less cylindrical permanent magnet linear motor

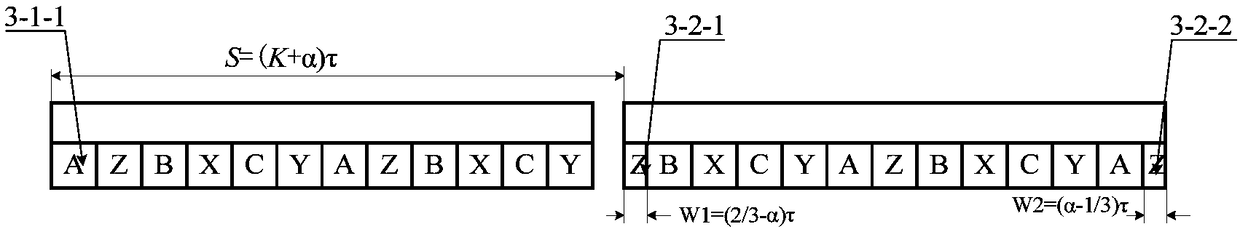

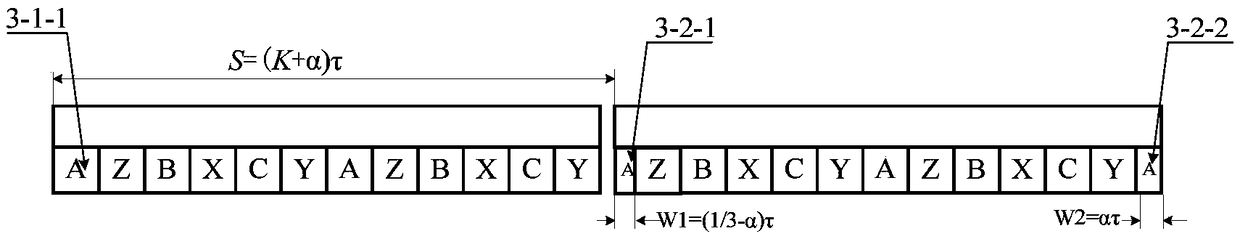

ActiveCN108880183ASmall space volumeReduce thrust fluctuationPropulsion systemsWindings conductor shape/form/constructionPermanent magnet linear motorMagnetic isolation

The invention discloses a two-stage slot less cylindrical permanent magnet linear motor. A first stage primary component comprises a first stage primary iron core and a first stage armature winding, asecond stage primary component comprises a second stage primary iron core and a second stage armature winding, the first stage armature winding and the second stage primary components are adopt slotless structure; the first stage armature winding and the second stage armature winding are respectively fixed in a first stage primary iron core and a second stage primary iron core; The secondary assembly is consist of a secondary core and a permanent magnet; Air gaps are formed between the first stage primary component, a magnetic isolation bridge is arranged between the two stage of primary components, sum of length of the first stage primary iron core and the magnetic isolation bridge is (K+[alpha])*[tau], K is a positive integer, [tau] is pole pitch of the motor, [alpha] is width coefficient of the magnetic isolation bridge, and 0<[alpha]<=0.5; the beginning and end of the second stage armature winding adopt different winding coil according to different [alpha] values, and the windingphase needs to be adjusted according to the value of [alpha]. The motor structure is benefits reducing the locating force and thrust ripple caused by the edge effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

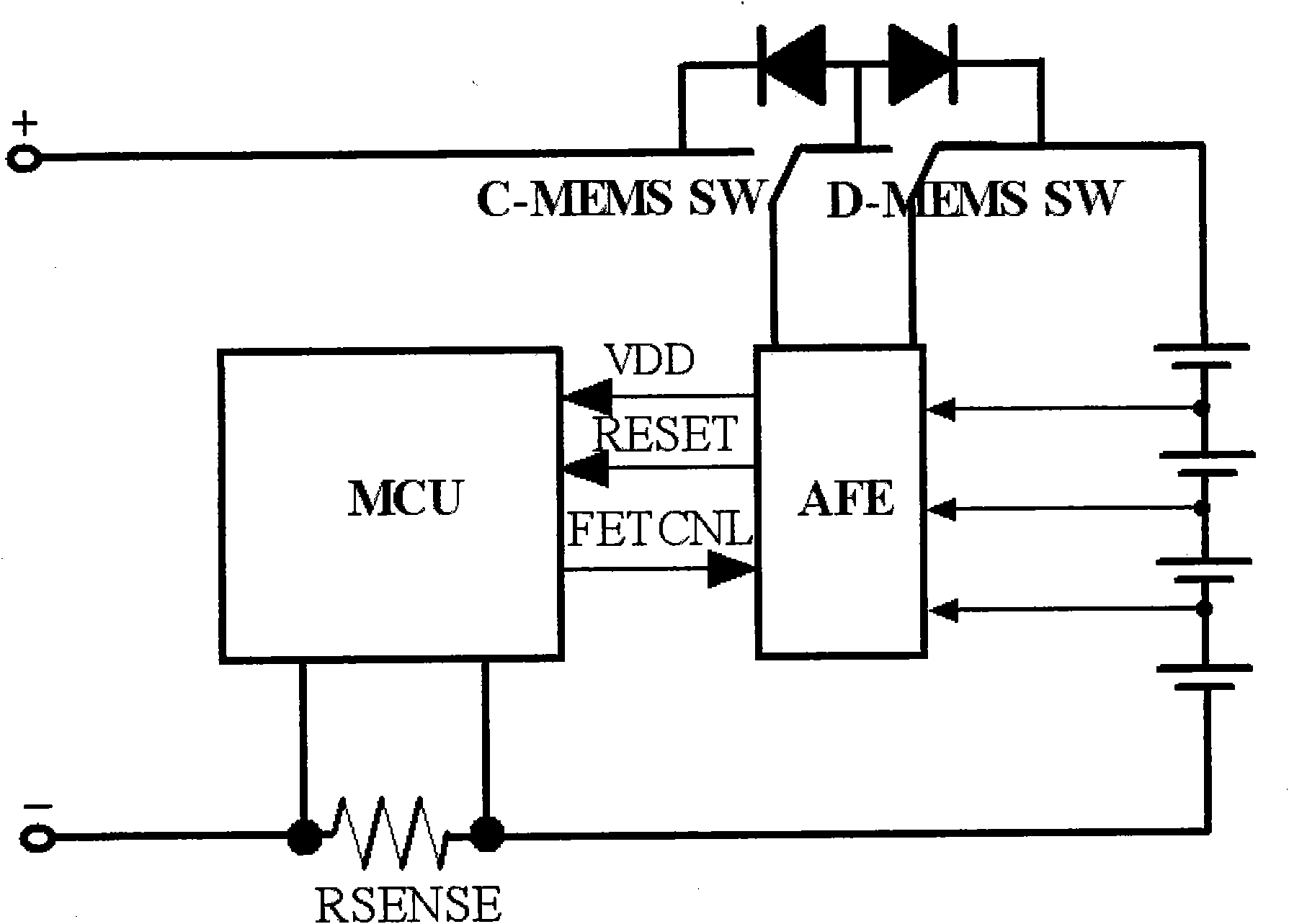

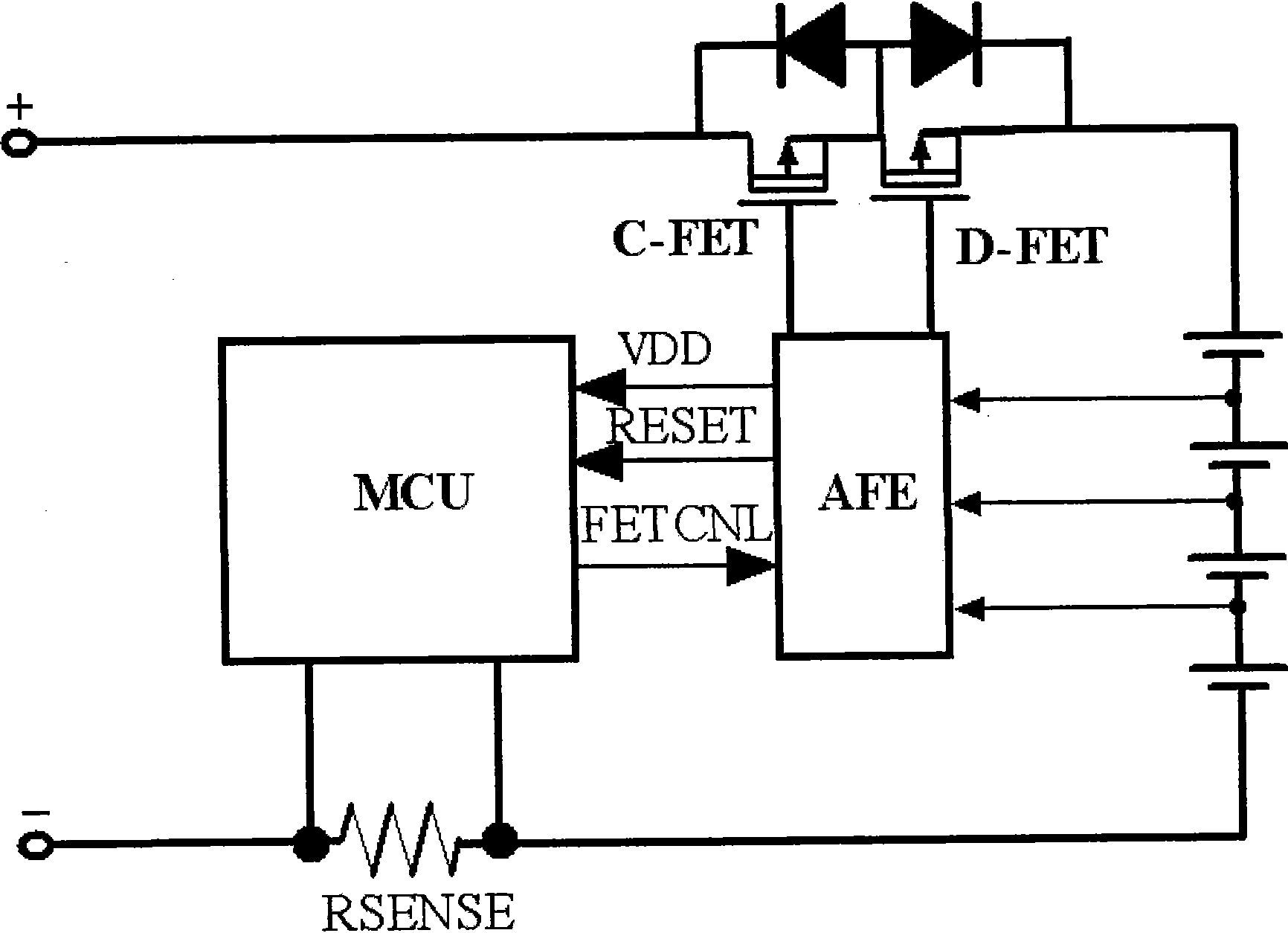

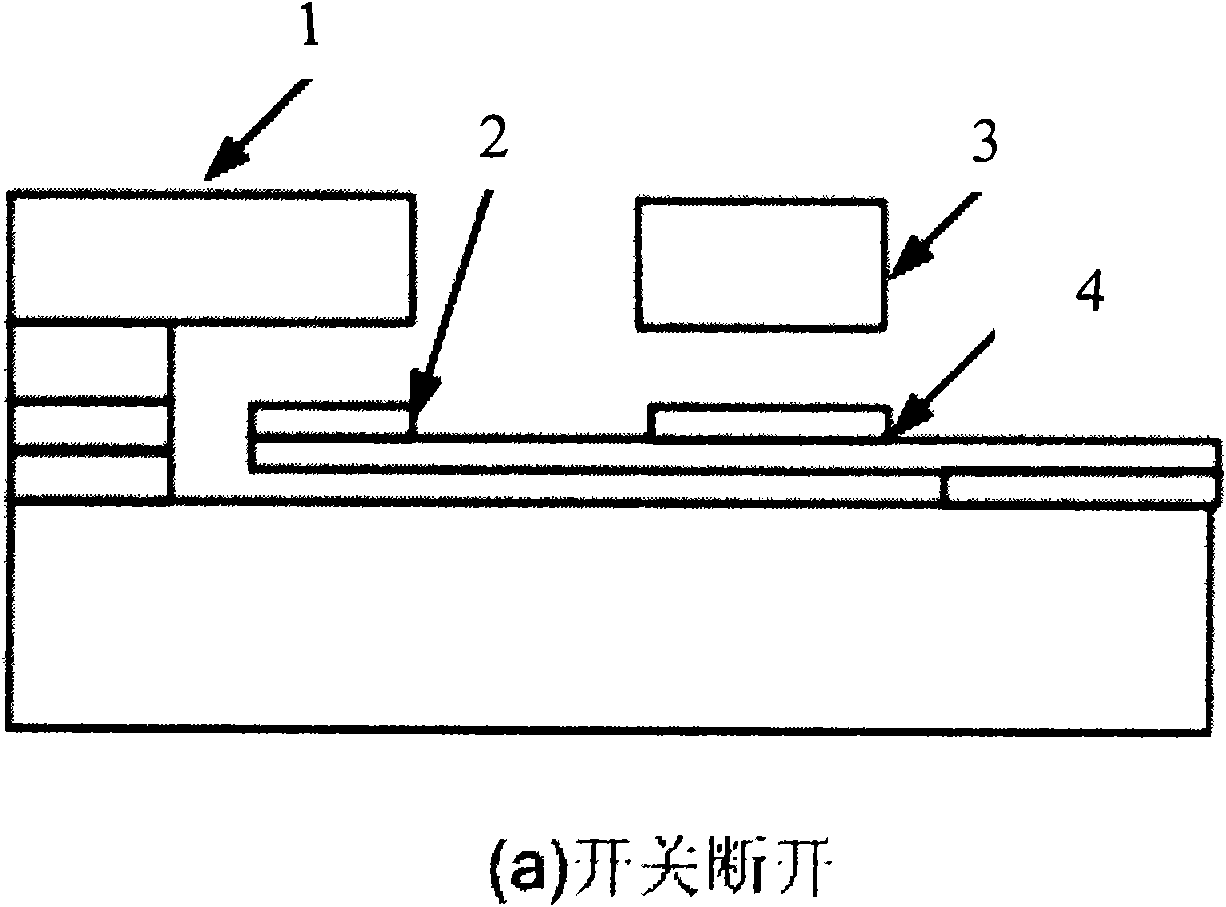

Battery pack protective circuit applying micro-electromechanical system (MEMS) switch

InactiveCN101567554AReduce static power consumptionHighly integratedEmergency protective circuit arrangementsElectrical batteryAnalog front-end

The invention relates to a battery pack protective circuit applying a micro-electromechanical system (MEMS) switch, which can be ued for a rechargeable battery or a battery pack, for example a lithium battery pack used for a notebook computer and a rechargeable protective circuit of an electric bicycle or an electric car. The charge and discharge protective circuit comprises a battery, an analog front end (AFE) circuit of a charge and discharge control circuit of a battery pack, a micro-control unit (MCU) and one or more micro-electromechanical system (MEMS) switches. The invention can reduce static power consumption of the batter or the battery pack in a process of charging and discharging, provides higher degree of isolation in a disconnection process and improves the density of integration of a charge and discharge circuit.

Owner:TIANJIN VAST TECH

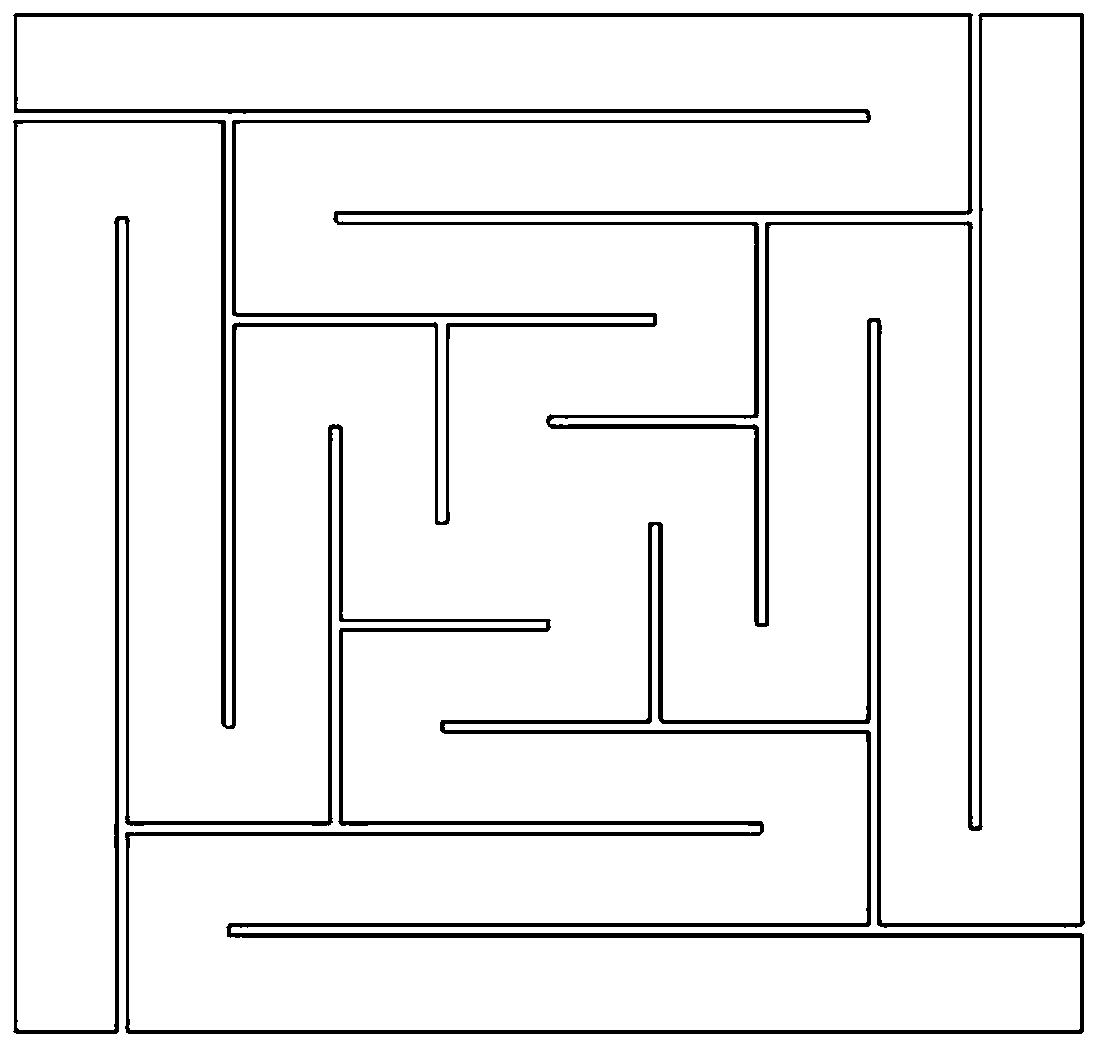

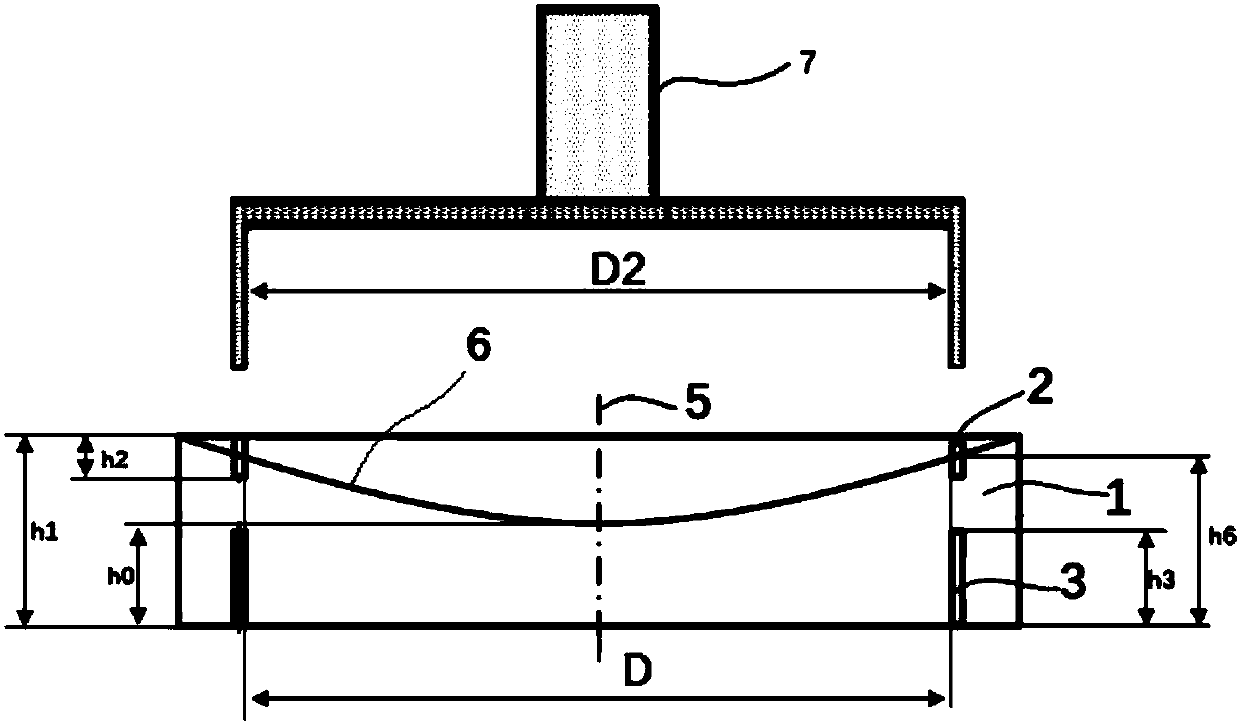

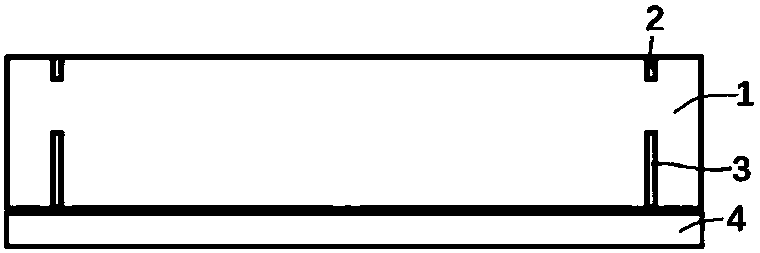

A flat filament for an X-ray CT tube

PendingCN109065430AAvoid stress deformationExtended service lifeX-ray tube electrodesX-ray tube cathode assemblyX-rayCentrifugal force

The invention discloses a flat-plate filament for an X-ray CT tube, belonging to the technical field of medical instruments. The flat filament for an X-ray CT tube includes a flat plate and an emitting structure formed on the flat plate. The emission structure is a four-pin square or circular structure formed by a plurality of through grooves, and the stability of the structure is improved throughthe four-pin structure, and the filament stress deformation caused by the strong centrifugal force generated by the high-speed rotation of the CT machine is avoided. The plate filament prolongs the service life of the filament by optimizing the groove structure and reducing the ignition caused by the pressure difference between the grooves. By reasonably directing the electric current, the influence of the self-generated magnetic field of the flat filament on the electron beam focusing is weakened, and the focal spot quality is ensured.

Owner:麦默真空技术无锡有限公司

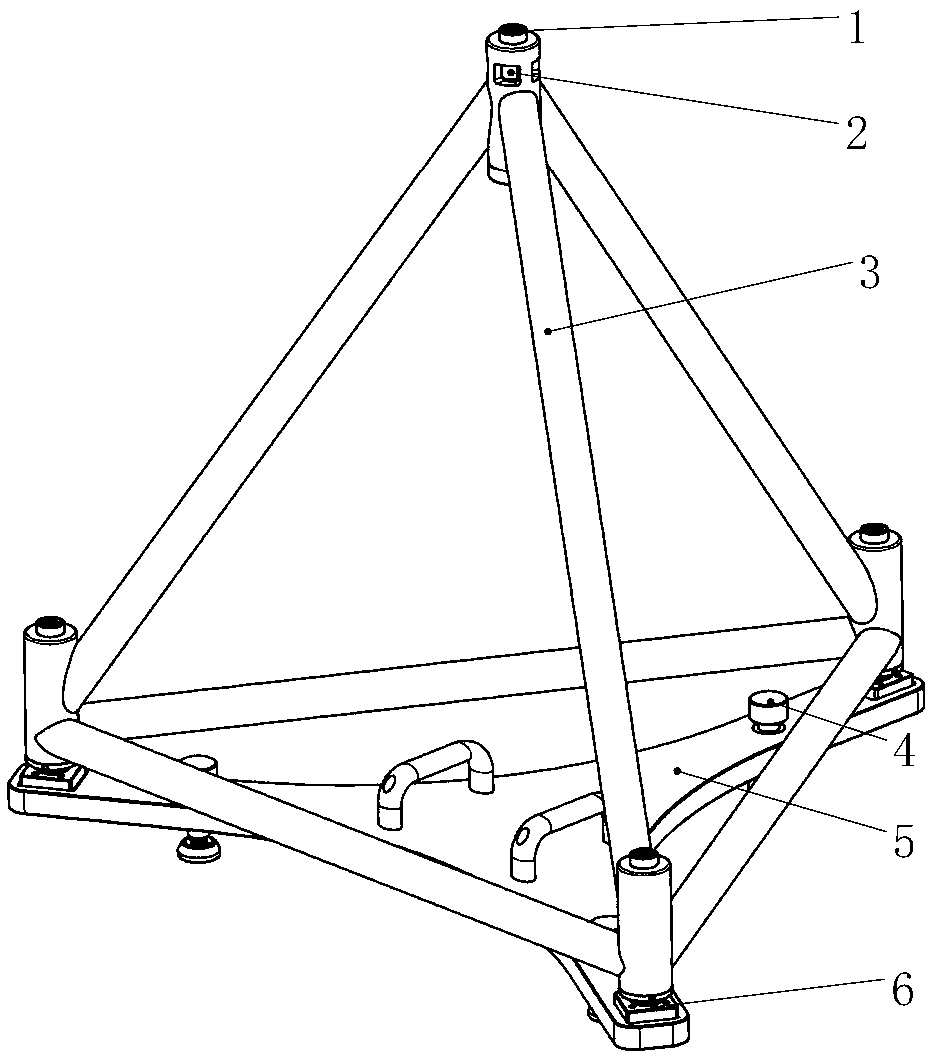

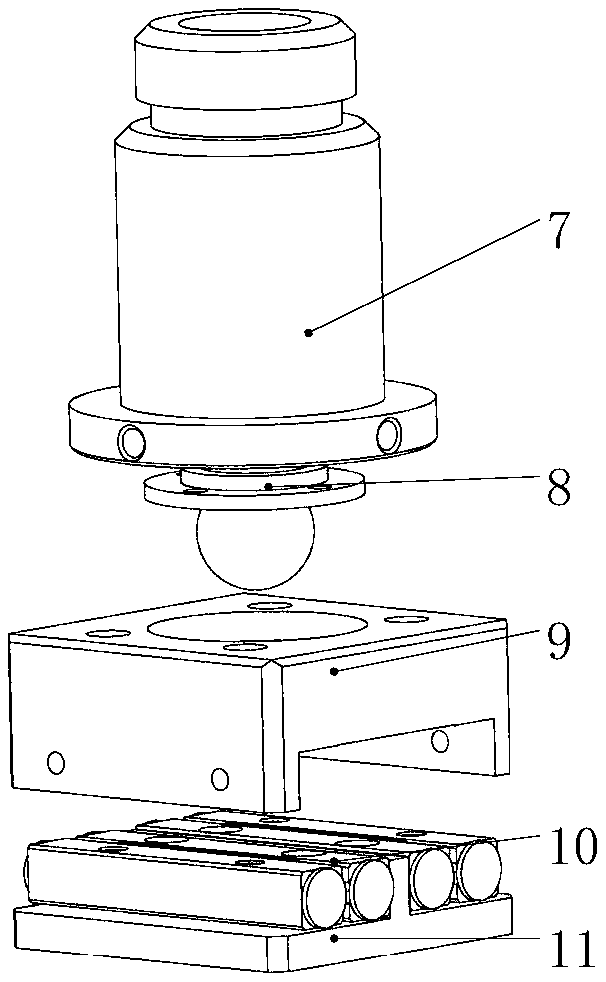

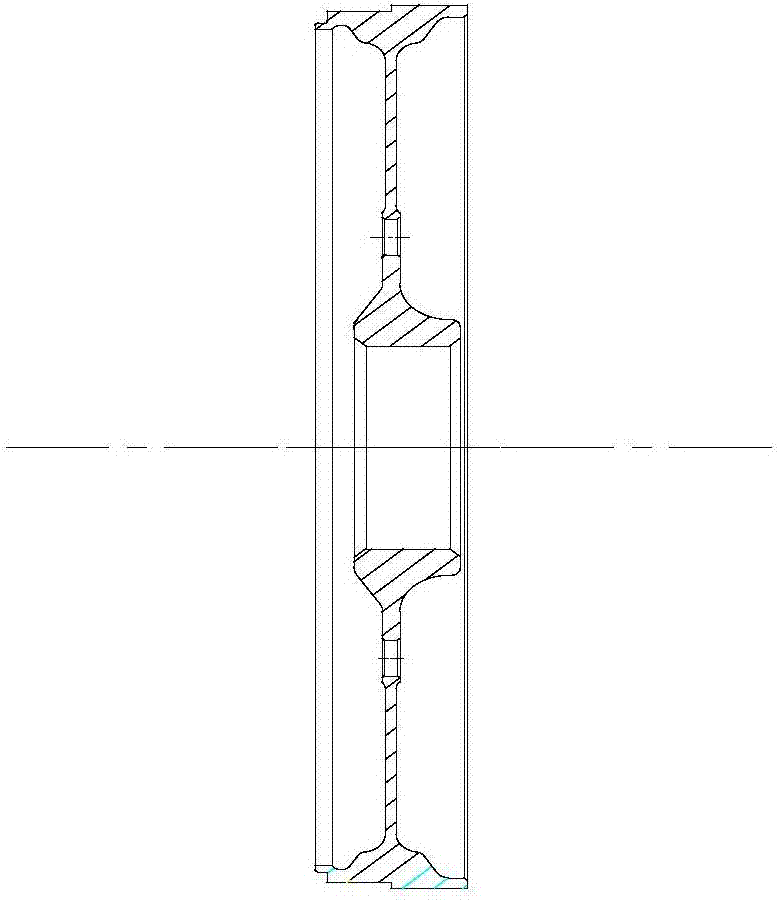

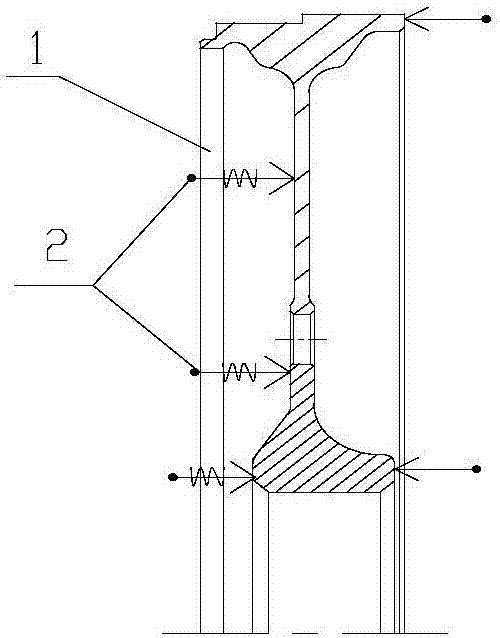

Stereo standard device for multi-system coordinated measurement calibration

A stereo standard device for multi-system coordinated measurement calibration belongs to the field of geometric quantity. The stereo standard device is mainly composed of two parts, wherein one part is a tetrahedral coordinate frame for placing a measurement target, and the other part is a base with a heat expansion release function. The tetrahedral coordinate frame for placing a measurement target is composed of a fixed frame, target seats, a reference cube mirror and a reference cube mirror seat. The base with a heat expansion release function is composed of a heat expansion release component, a bottom plate and rotary adjustment foot pads. The stereo standard device is applied to coordinate system unification and field calibration during coordinated measurement by large-size measuring equipment in order to improve the field evaluation efficiency. The data stability of the stereo standard device for multi-system coordinated measurement calibration in a wide range of temperature changes can be ensured, the rapid field calibration requirement of coordinated measurement by various kinds of measuring equipment can be satisfied, and an effect of field use can be achieved. The large-size measuring equipment includes a laser tracker, laser radar, a theodolite coordinate collimator, a photogrammetry device, an articulated arm and other measuring systems.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Machining method for compressor disc

InactiveCN107214477AAchieve stress deformationAvoid stress deformationAircraft componentsStress relievingEngineering

The invention relates to a machining method for a compressor disc. By adding the stress relieving process after rough machining and before finish machining, the cutting depth and the blade angle of finish machining are limited, a self-made clamp is adopted to conduct axial supporting and compressing, and thus a part is machined. By setting the process steps, designing the clamping mode and selecting machining parameters, finally the deformation amount of the moulding surface and an stop opening of the compressor disc is reduced to be less than 0.005 mm, and the size tolerance and the geometrical tolerance both meet the drawing requirements.

Owner:HARBIN DONGAN ENGINE GRP

Brake disc and manufacturing method thereof

InactiveUS20210207670A1Low densityReduce weightBraking discsFriction liningMetal matrix compositeMechanical engineering

A brake disc used for brake systems of motor vehicles, rail vehicles and aircrafts and the brake disc includes a brake disc body, wherein the brake disc body is an aluminum alloy brake disc body, the two working surfaces of the aluminum alloy brake disc body are respectively attached with a wear-resistant layer, the wear-resistant layers are wear-resistant layers made of ceramic high-temperature resistant metal matrix composite (MMC) reinforced materials, and the wear-resistant layers made of ceramic high-temperature resistant MMC reinforced materials metallurgically bond with the aluminum alloy brake disc body through a squeeze casting technique.

Owner:NINGBO HIGHRISE NEW MATERIAL CO LTD

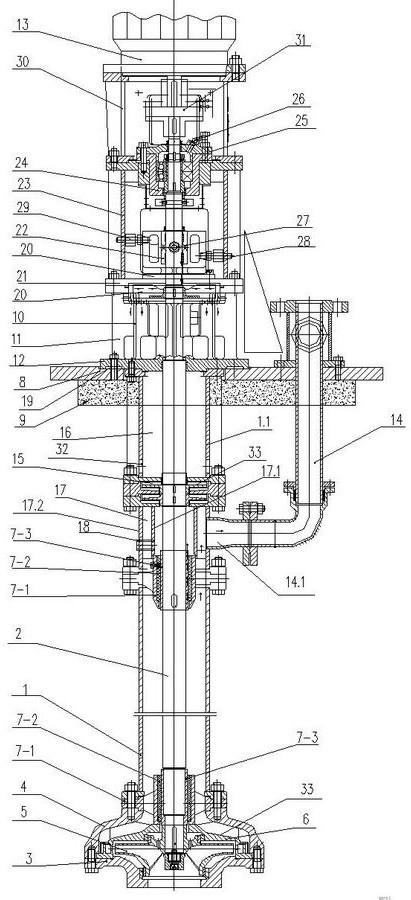

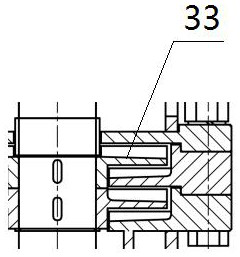

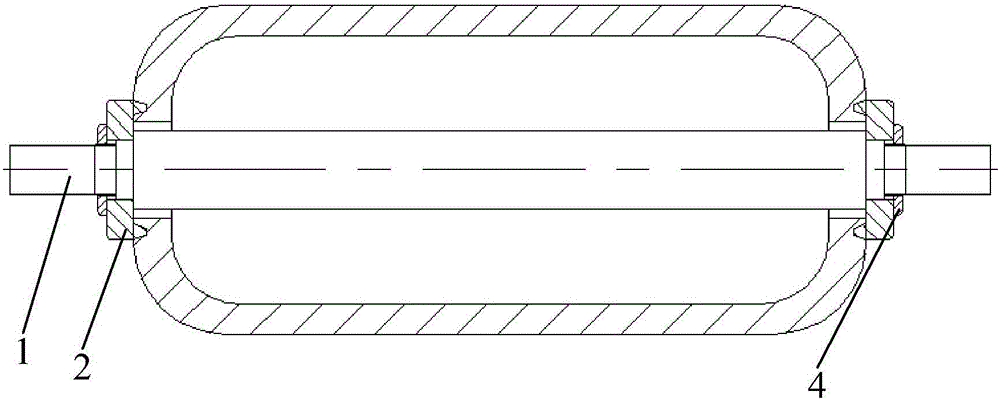

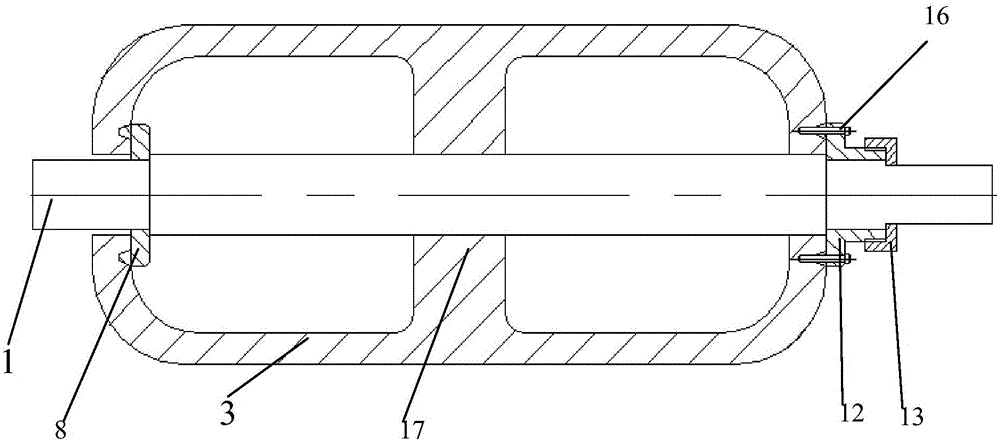

High-temperature molten salt pump

PendingCN112096615AReduce heat transferGuaranteed uptimeSpecific fluid pumpsPump componentsImpellerCylindrical tube

The invention relates to a high-temperature molten salt pump. A main shaft is arranged in the pump from top to bottom in a penetrating manner, a suction cover is arranged at the bottom of the pump, adischarging body is arranged at the upper portion of the suction cover, an impeller is arranged in the center of the suction cover, guide vanes are arranged on the outer circle and the upper end of the impeller, the bottom end of the discharging body is connected with the suction cover through bolts, and the top end of the discharging body is connected to a cylindrical pipe through bolts; and theouter circles of the guide vanes are connected with the suction cover and an inner spigot of the discharging body in a matched manner, and a sliding bearing body is arranged above the discharging bodyand connected with the discharging body and the cylindrical pipe through flanges. According to the high-temperature molten salt pump, the manner of a liquid outlet pipe is improved, a power seal is arranged above the liquid outlet pipe, gas is arranged between the power seal and a bottom plate, thermal isolation of a high-temperature medium is achieved, and heat is directly conducted to the bottom plate and a support of the pump without high-temperature molten salt; and the temperature of the shaft is guaranteed to have a reasonable temperature drop gradient from the high-temperature end of the bottom plate to the bearing installation position, and stress deformation of the shaft due to sudden drop of the shaft temperature in a traditional cooling manner is avoided.

Owner:大连海特泵业有限公司

Winding forming die for small-opening composite material container

ActiveCN106515050AReduce weightHigh dimensional accuracyDomestic articlesSized smallHigh dimensional

The invention belongs to the technical field of forming of composite material products. Stress deformation generated in a die assembling process while the positioning of a clack die is realized by adopting traction positioning; and by means of a positioning mode combined with supporting positioning, the aims of reducing the weight of the die and guaranteeing the precision of a product at the same time are achieved. A winding forming die for a small-opening composite material container, disclosed by the invention, consists of a clack die, a mandrel and a clack die positioning mechanism; and the clack die is positioned by adopting a traction mode, a reference positioning end is internal positioning and a locking positioning end is external positioning. The winding and forming die has the advantages of light weight, high dimensional precision, good stability, convenience in use and capabilities of being repeatedly assembled and used. The winding and forming die is suitable for winding forming of a small-opening container and is particularly suitable for winding forming of a large-sized small-opening container with a great slenderness ratio.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

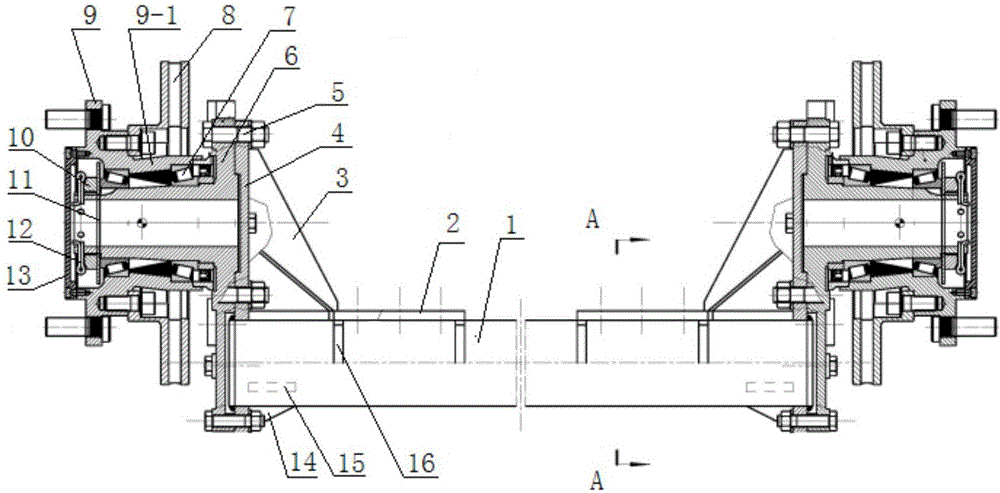

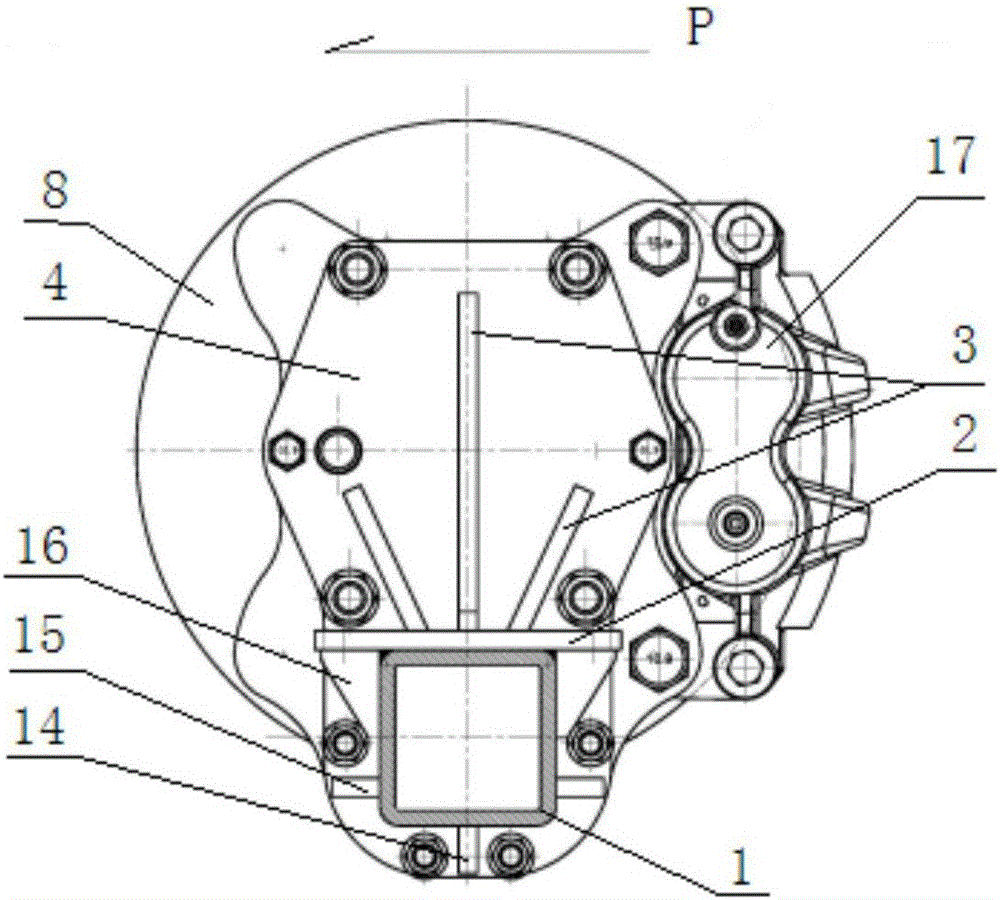

Independent suspension type front drive rear axle assembly

InactiveCN106183632ABig spaceImprove battery lifeBraking element arrangementsAxle unitsGravity centerEngineering

The invention discloses an independent suspension type front drive rear axle assembly. The two ends of a rear axle cross beam are welded and fixed to the lower portions of the inner sides of flange discs respectively. Rear shaft heads are fastened on the outer sides of the upper portions of the flange plates through bolts respectively. The distance between the center of each rear shaft head and the axis of the rear axle cross beam ranges from 130 mm to 160 mm. The rear shaft heads support rear wheel hubs, the rear wheel hubs are provided with shaft sleeves corresponding to the rear shaft heads, and paired single-row tapered roller bearings for bearing positive and reverse axial force are arranged between the shaft sleeves and the rear shaft heads. Locknuts in threaded connection with the rear shaft heads and gaskets of the locknuts are arranged at the ends of the rear shaft heads, the gaskets are jointed with the inner rings of the single-row tapered roller bearings on the outer sides, and stop cotter pins are arranged at the ends of the locknuts and the ends of the rear shaft head. The rear axle cross beam is a square steel pipe, brake discs are fixed to the inner sides of the rear wheel hubs, brake assemblies in friction joint with the brake discs are symmetrically arranged at the transverse front and back positions of the brake discs, and brakes are hydraulic drive brakes. The gravity center of a finished automobile is lowered, and the driving stability can be improved. The independent suspension type front drive rear axle assembly is more beneficial for the arrangement of electrical apparatus elements such as battery packs of purely electric large and medium buses and buses, and therefore the higher speed per hour and the larger endurance mileage can be achieved.

Owner:通天汽车桥(天津)有限公司

Method for producing metal decorating surface heat-insulating plate with anti-thermal deformation structure

InactiveCN106149908AAvoid stress deformationGuaranteed flatnessCovering/liningsLaminationAluminium foilElectric heating

The invention discloses a method for producing a metal decorating surface heat-insulating plate with an anti-thermal deformation structure. The method comprises the following steps: (1) feeding an aluminium alloy plate or a zinc plated or aluminium and zinc plated steel plate which forms a metal decorating surface layer into a pressing moulding machine through a screen open-type unwinding machine for performing pressing moulding treatment; (2) uniformly mixing isocyanate and premixed polyether polyol according to the ratio of 1:1 in a polyurethane pouring machine, coating the metal decorating surface layer with a mixture to form a polyurethane heat-insulating layer, then, covering the polyurethane heat-insulating layer with an aluminium foil, a glass fibre fabric, a cement base fabric, an embossed steel plate or an embossed aluminium foil which forms an interlayer, and sizing through a laminating machine; (3) feeding a cured and moulded plate into an electric heating treatment box through a conveying belt for performing heat treatment, wherein the heating temperature in the heat treatment box is at least 50 DEC G, and the heat treatment time is at least one minute; (4) uniformly pouring phenolic foam resin on the bottom surface of the plate which is produced in the step (3) through a pouring metering pump to form a base layer, feeding the base layer in a laminating conveying machine, and cutting the moulded plate into required sizes through a cutting machine.

Owner:URUMQI QIXIN NUOLANGDA ENERGY SAVING TECH CO LTD

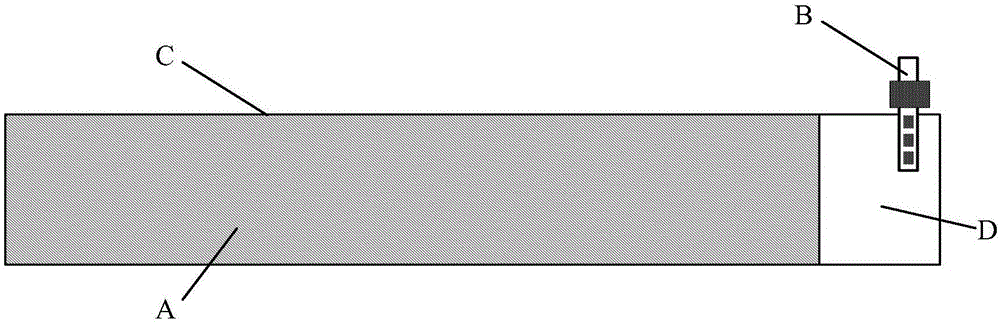

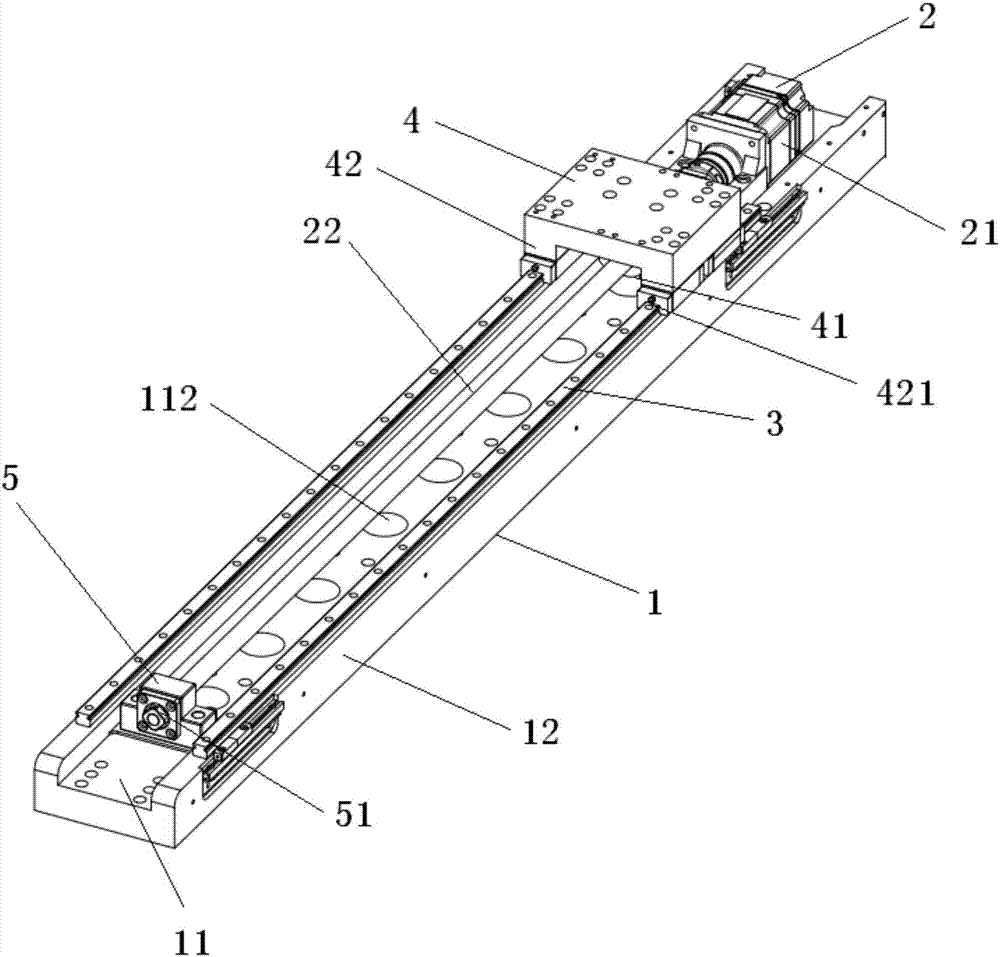

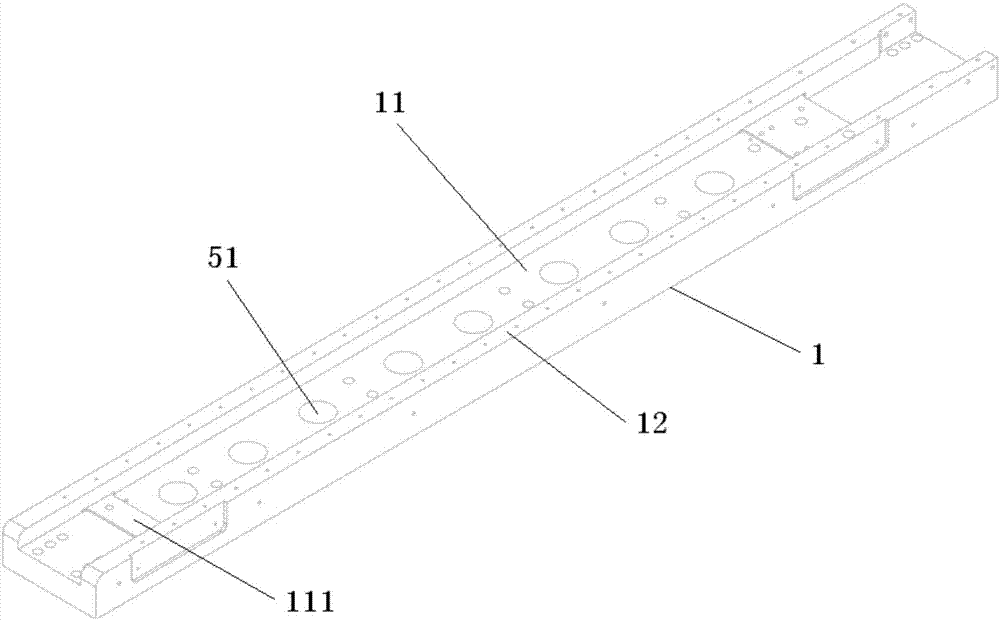

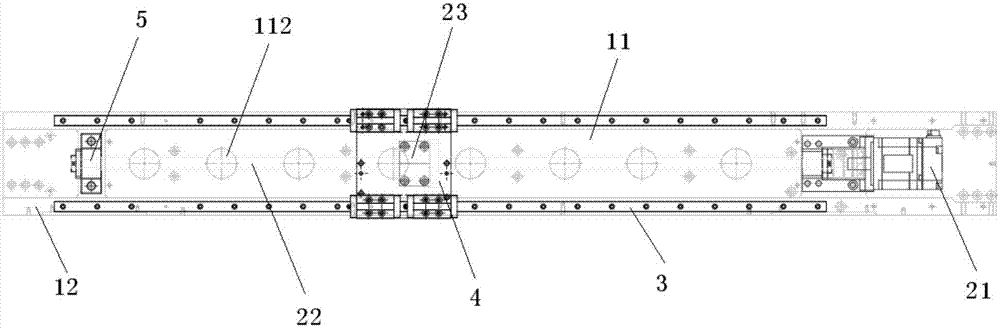

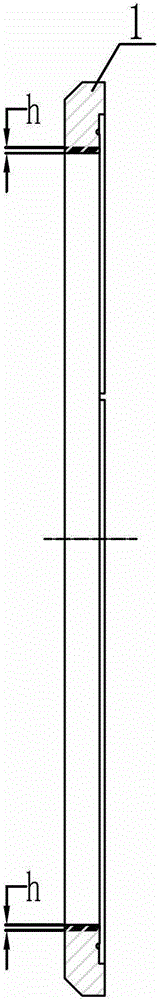

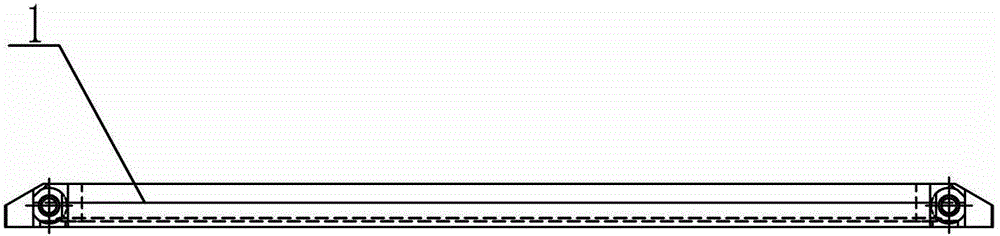

PCB impedance automatic test machine, and integrated structure of linear module and mounting pedestal of the same

PendingCN107390028AImprove bending abilityAvoid stress deformationResistance/reactance/impedenceMechanical energy handlingEngineering

The invention relates to the technical field of a test machine, and specifically relates to an integrated structure of a linear module and a mounting pedestal. The integrated structure of a linear module and a mounting pedestal includes a U-shaped mounting pedestal (1) and a linear module, wherein the U-shaped mounting pedestal (1) includes a base plate (11) and two side plates (12) which are arranged along two edges of the length direction of the base plate (11); the linear module includes a driving structure (2) and two slide rails (3); the driving structure (2) and the two slide rails (3) are directly arranged on the U-shaped mounting pedestal (1); the two slide rails (3) are arranged at the top surface of the two side plates (12); and linear module also includes a slide piece (4) which makes a reciprocating linear movement on the slide rails (3). The invention provides an integrated structure of a linear module and a mounting pedestal, having the advantages of being simple in structure, being easy for processing, being low in cost, being small in the precise processing area of the base plate, and being able to reduce stress deformation caused by cutting heating to the greatest extent. The invention also provides a PCB impedance automatic test machine.

Owner:JOINT STARS TECH

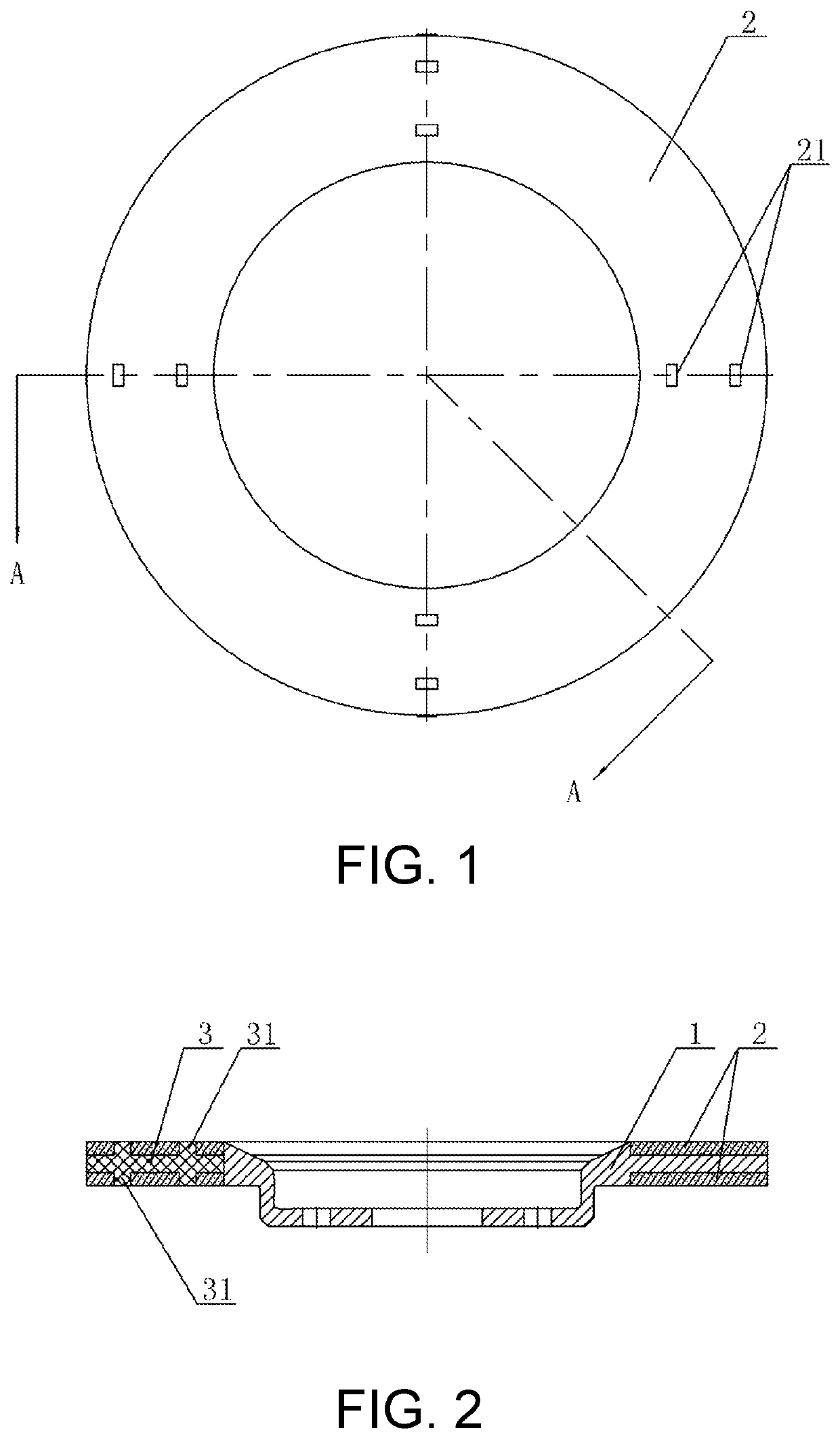

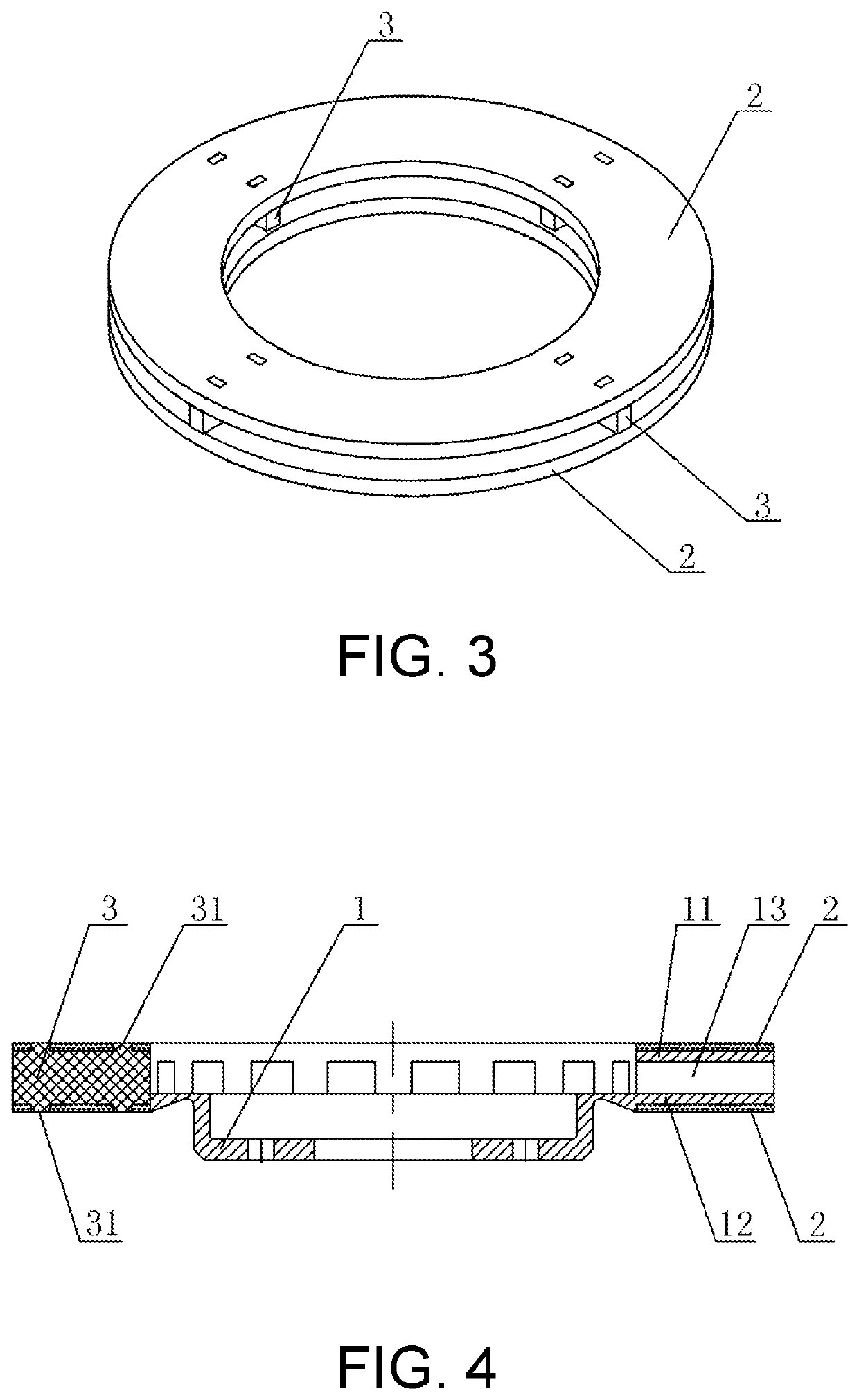

Sealing pad machining method

The invention discloses a sealing pad machining method, relating to a machining method of a sealing piece, particularly relating to a machining method of a sealing pad for a steam turbine rotor, and aiming at solving the problem that the sealing pad is lower in machining precision in the conventional machining method of a sealing pad of a steam turbine rotor; the machining method comprises the following main steps of: step 1, milling a split plane of an upper half sealing pad and a split plane of a lower half sealing pad; step 2, roughly milling inner arcs, outer arcs and two planes of the upper half sealing pad and the lower sealing pad; steps 3, carrying out a distressing process on the upper half sealing pad and the lower sealing pad respectively; step 4, semi-finely milling the inner arcs, the outer arcs and the two planes of the upper half sealing pad and the lower sealing pad; steps 5, boring each stair of the upper half sealing pad and each stair of the lower half sealing pad; step 6, connecting the upper half sealing pad and the lower sealing pad integrally; and step 7, finely milling inner holes, outer circles and concave stair standards of the sealing pads. The method is used for machining the sealing pads for the steam turbine rotor.

Owner:HARBIN TURBINE

Aspherical mirror embryo eliminating edge effect

ActiveCN108051882AAvoid warpingAvoid stress deformationMirrorsOptical surface grinding machinesEdge effectsClassical mechanics

The invention discloses an aspherical mirror embryo eliminating edge effect. The aspherical mirror embryo eliminating edge effect is characterized in that the aspherical mirror embryo is made of a cylindrical mirror embryo being greater than the aspherical caliber; the cylindrical mirror embryo includes a first end surface, a second end surface, and a cylindrical surface sidewall; an aspherical structure is located at the first end surface of the cylindrical mirror embryo; a first circular groove is also formed in the aspherical structure; the revolving axis of the first circular groove and the revolving axis of the aspherical surface are coincided; the internal diameter of the first circular groove is greater than the caliber of the aspherical surface; and when the mirror is used to process the aspherical surface, the range in which the edge effect occurs is controlled in the annular area outside the first circular groove on the aspherical surface, and the annular area outside the caliber of the aspherical surface is removed and then the residual part is a reflector having no edge effect. The technical scheme of the aspherical mirror embryo eliminating edge effect effectively solves the edge effect problem and the stress deformation problem, and is not easy to generate breakage edge and breakage opening at the edge of the aspherical surface.

Owner:SUZHOU BANGTIKE INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com