Patents

Literature

83results about How to "Avoid axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

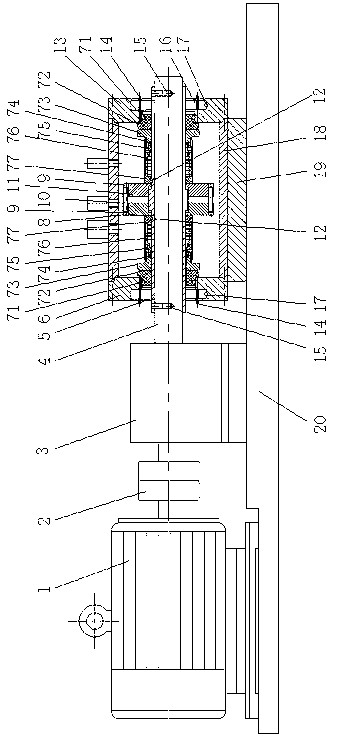

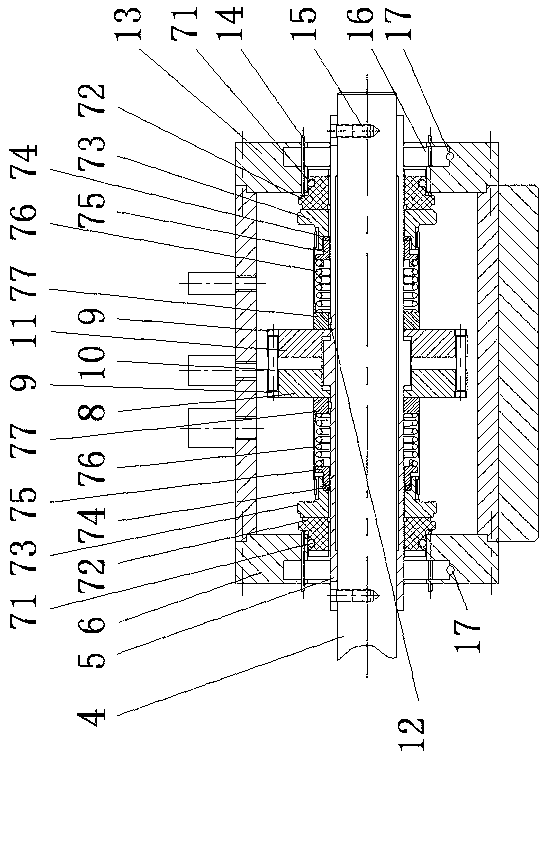

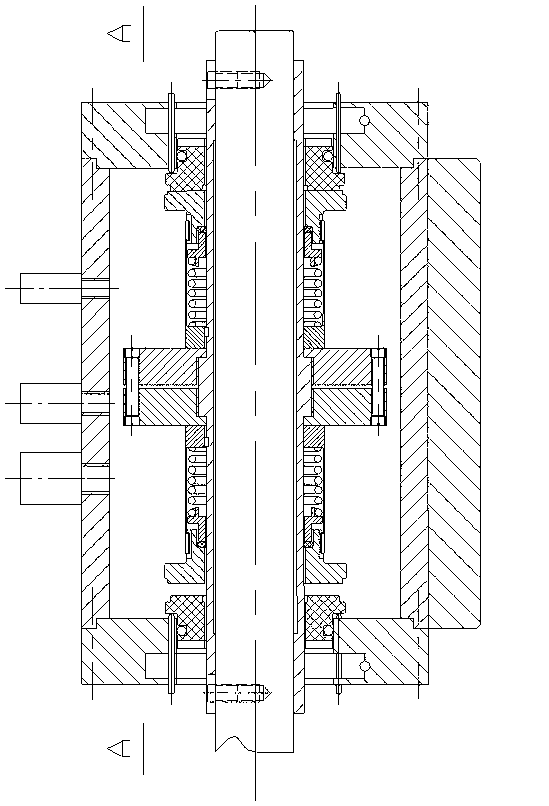

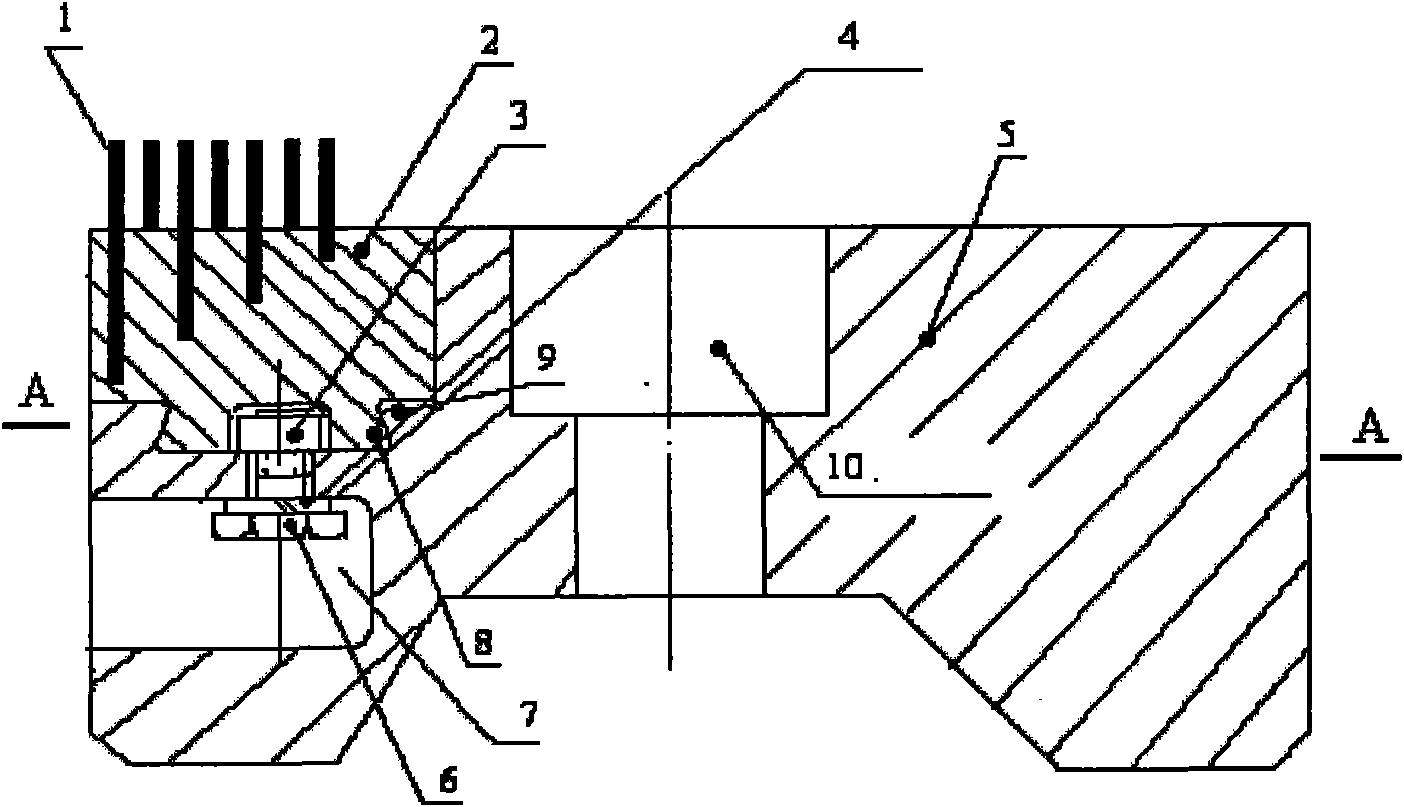

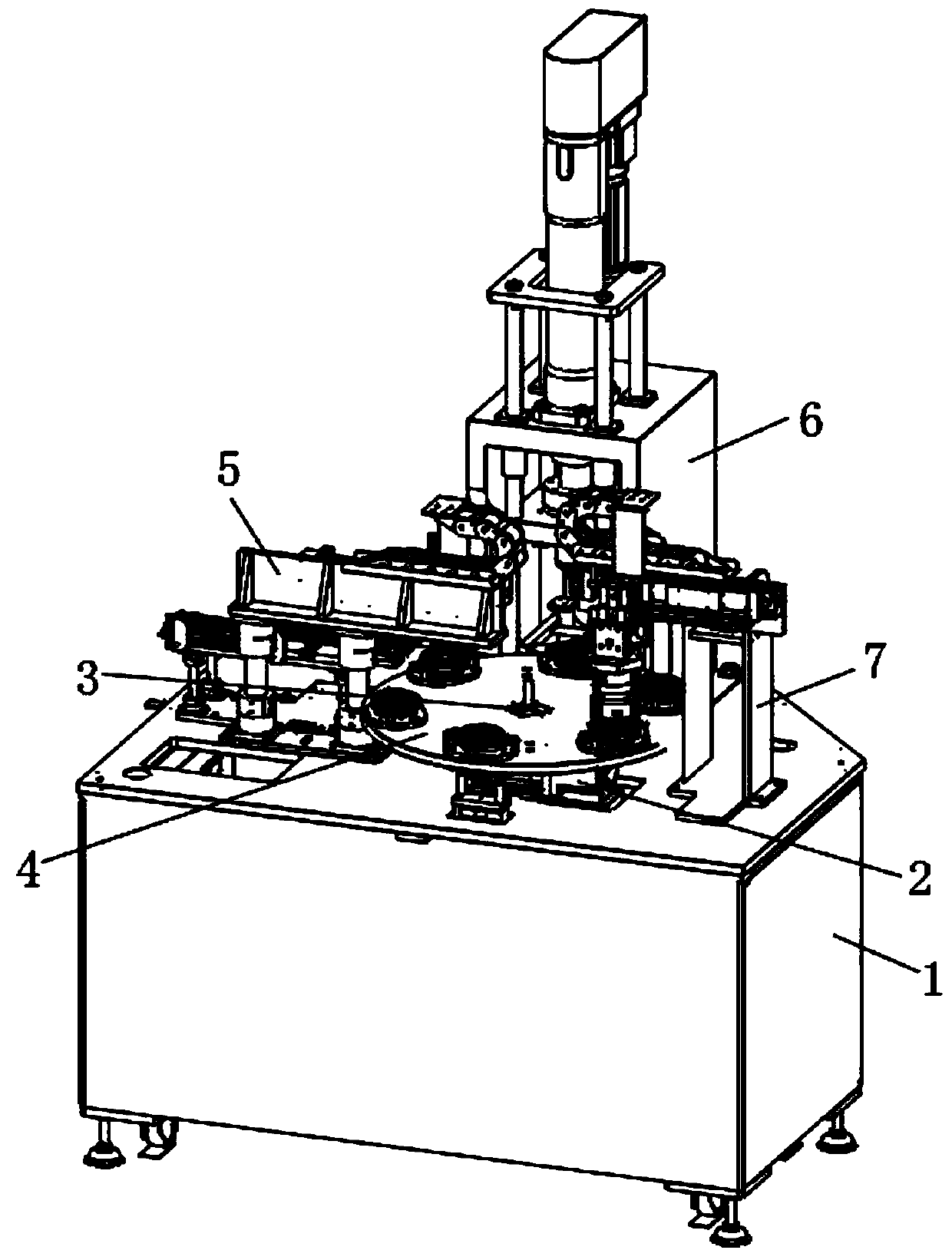

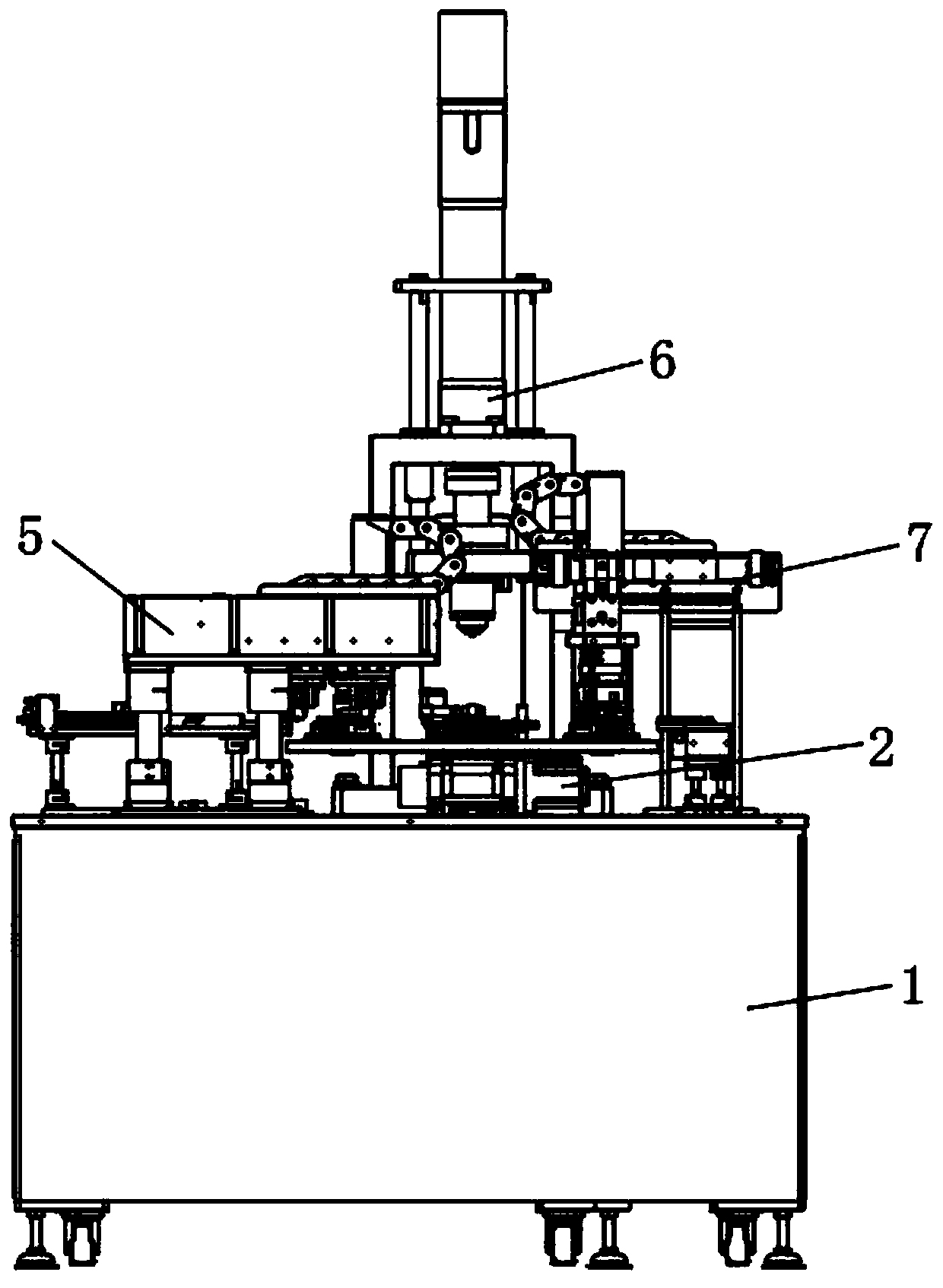

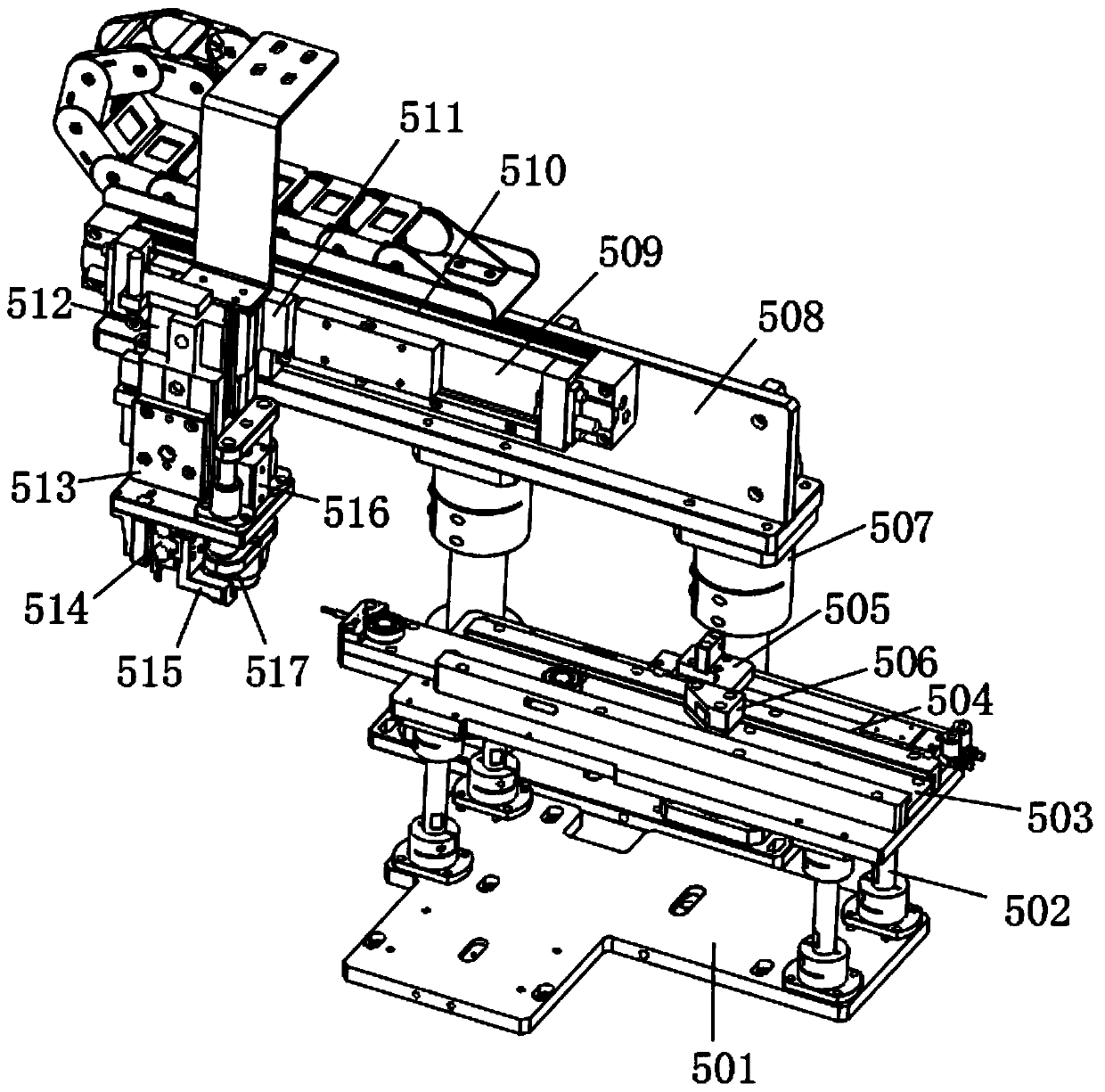

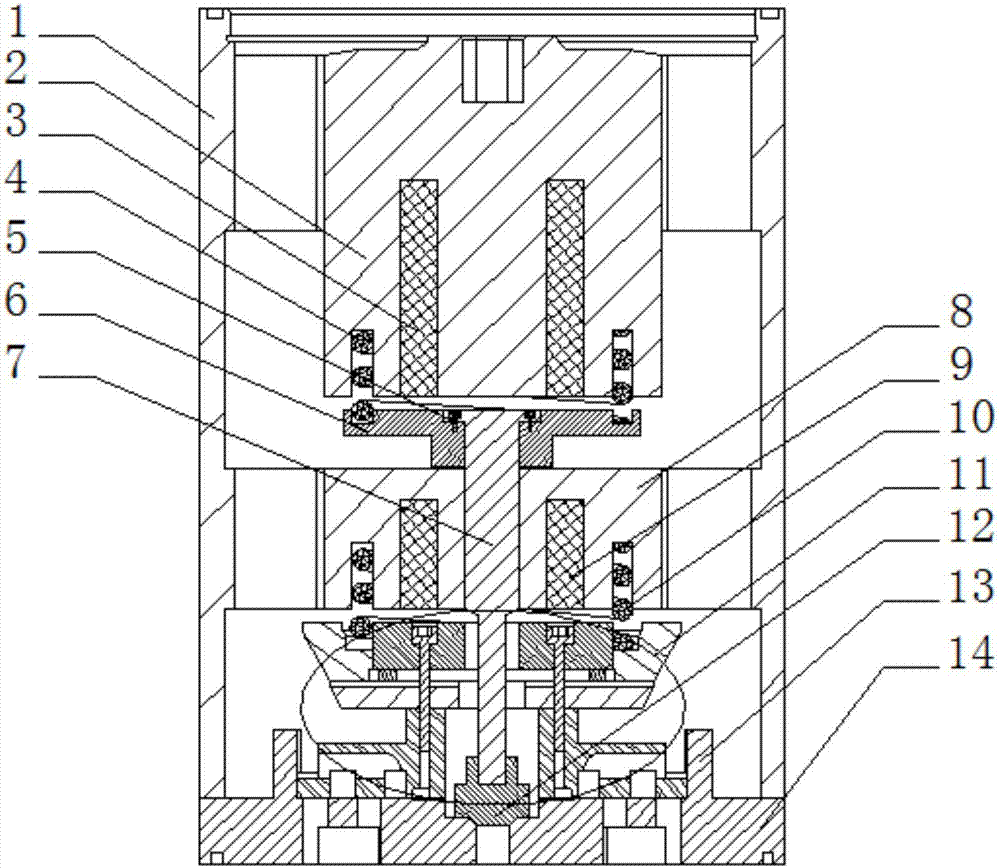

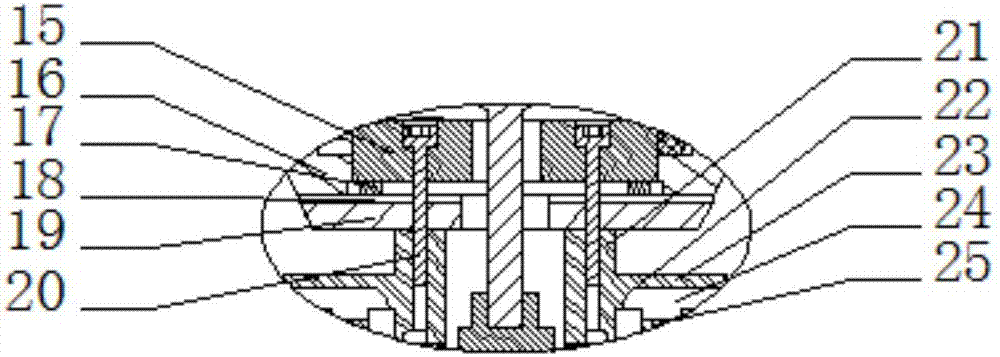

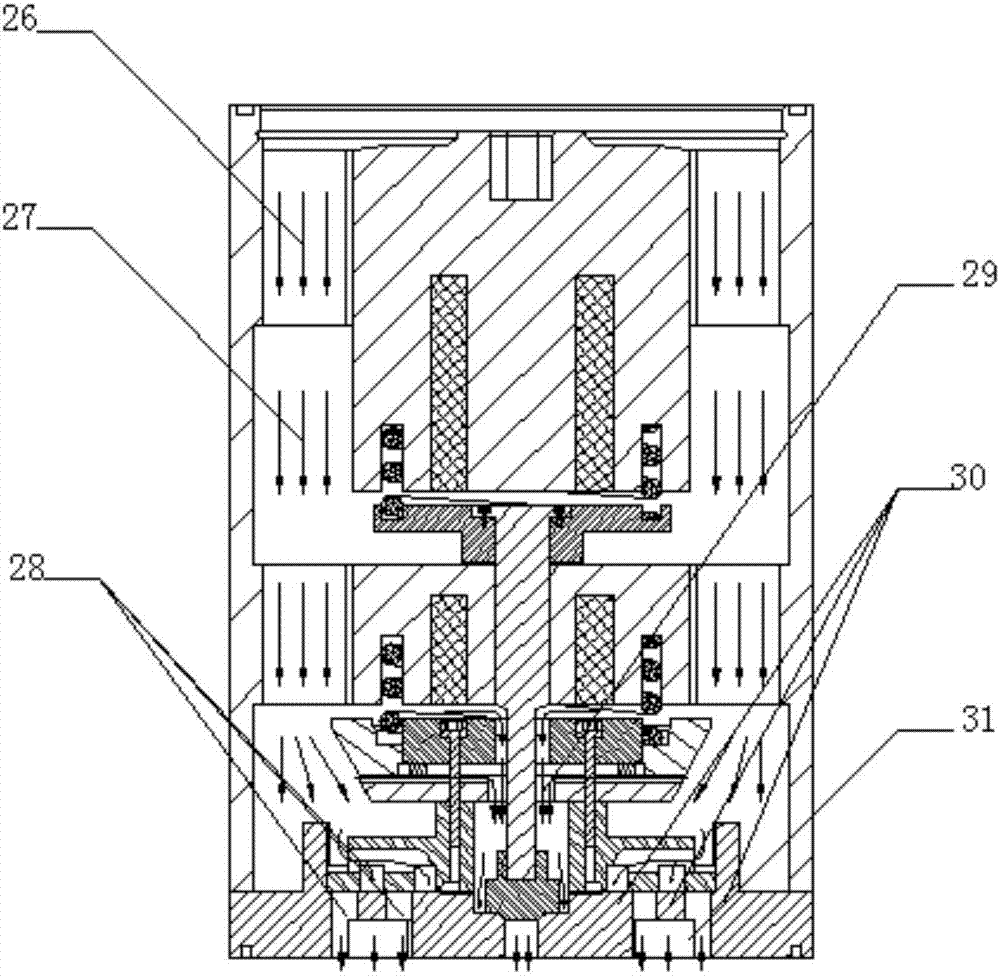

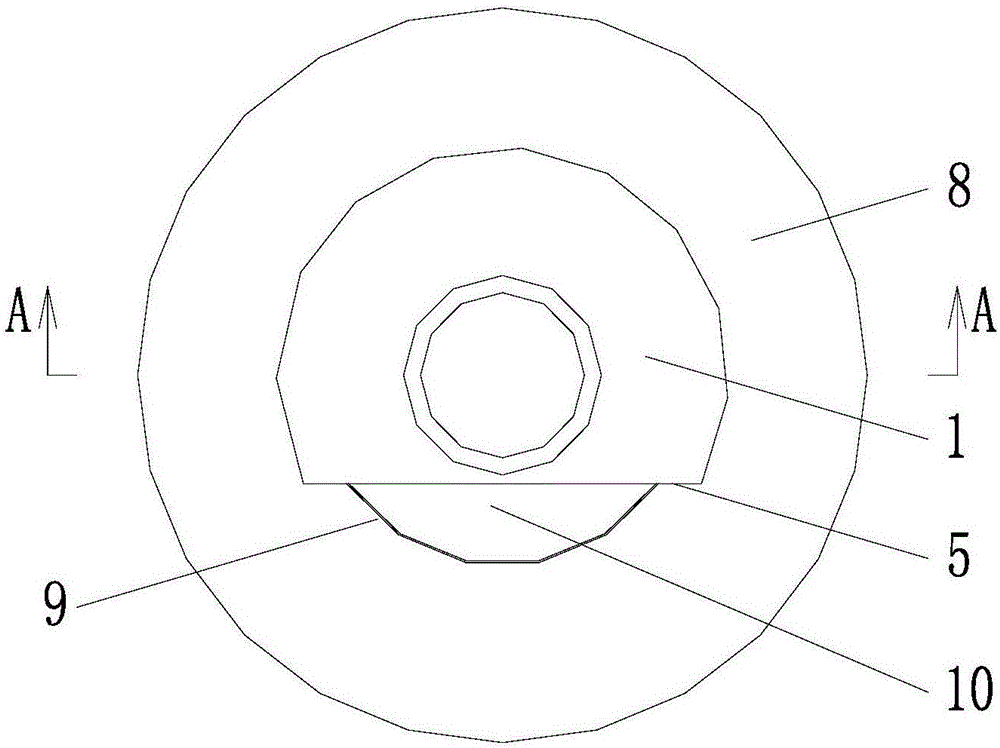

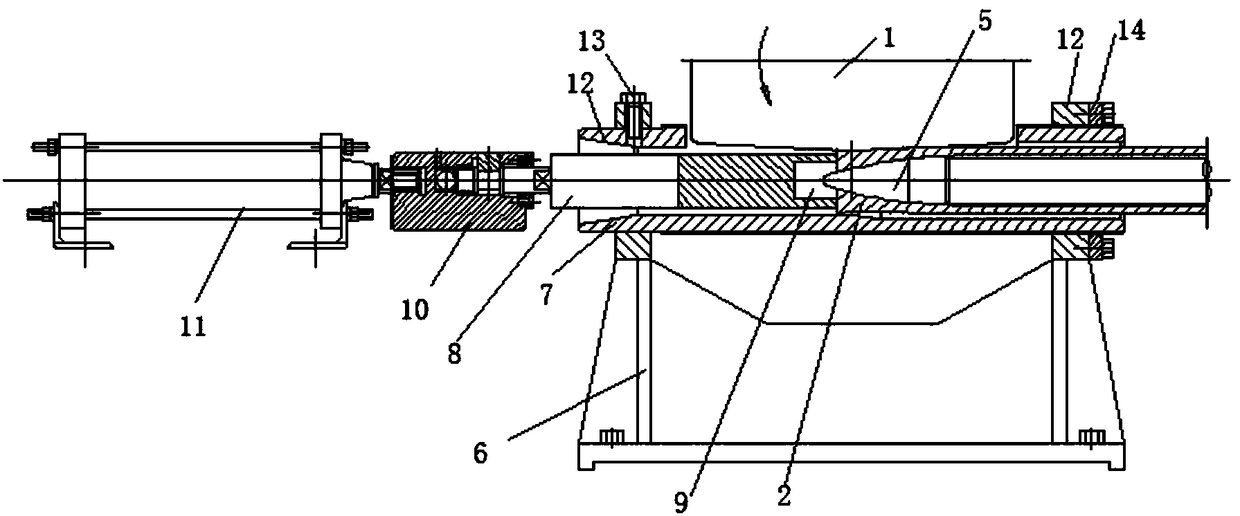

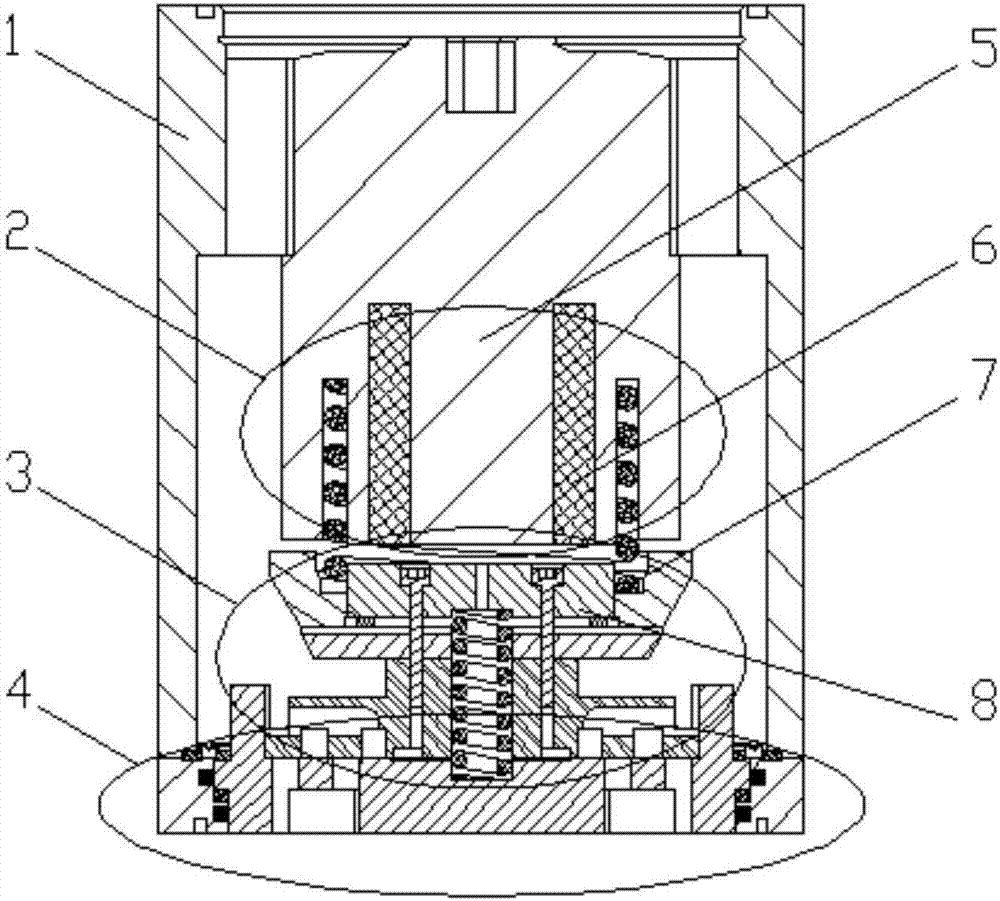

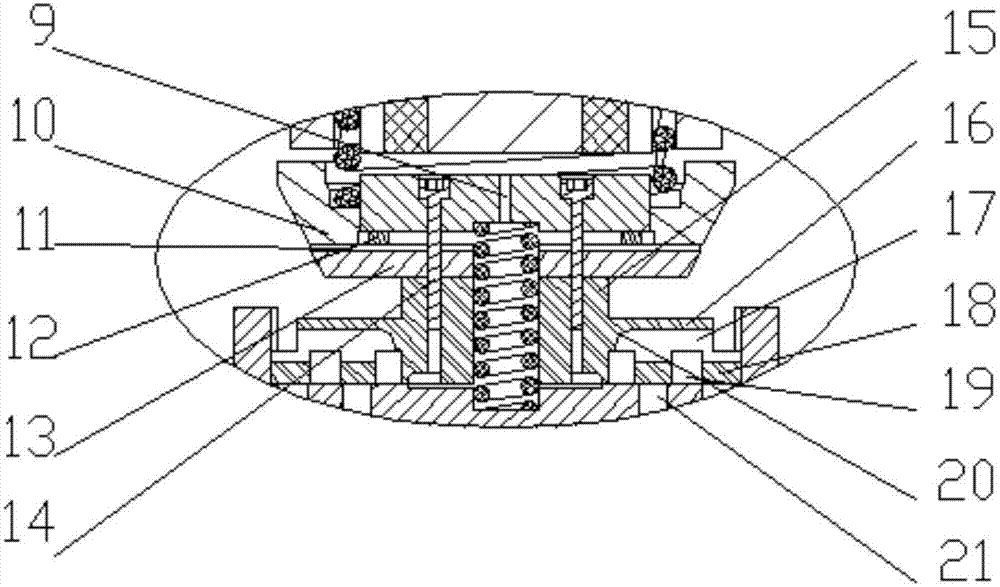

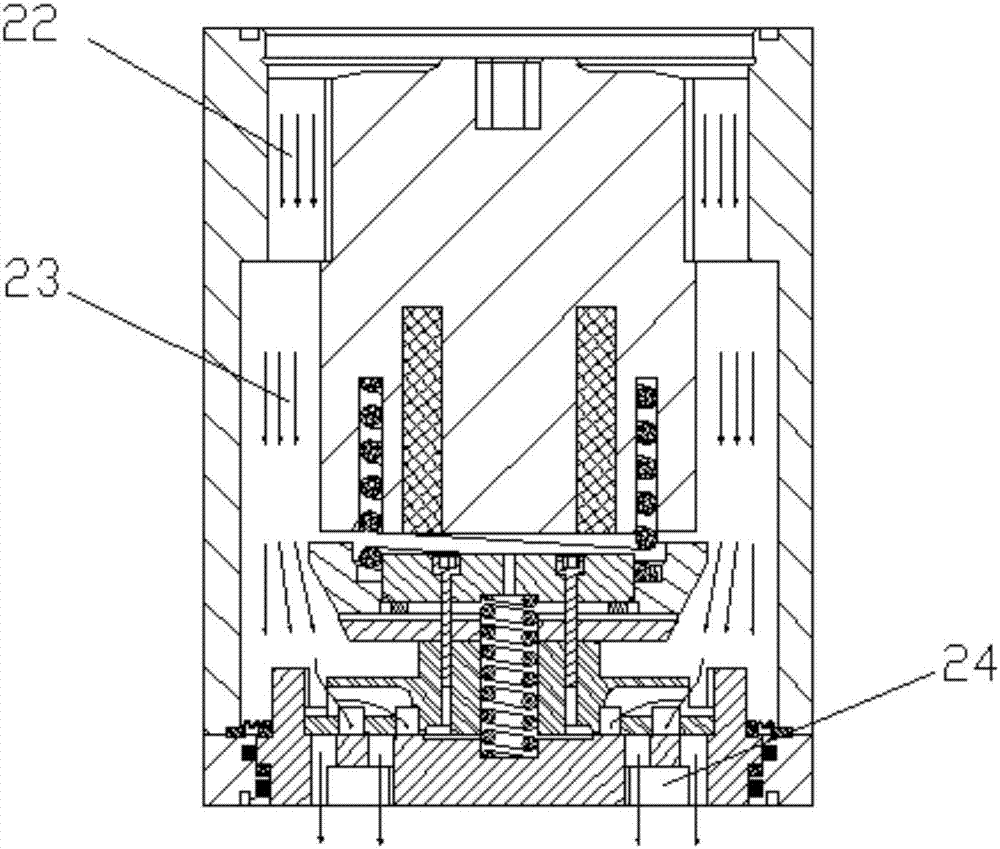

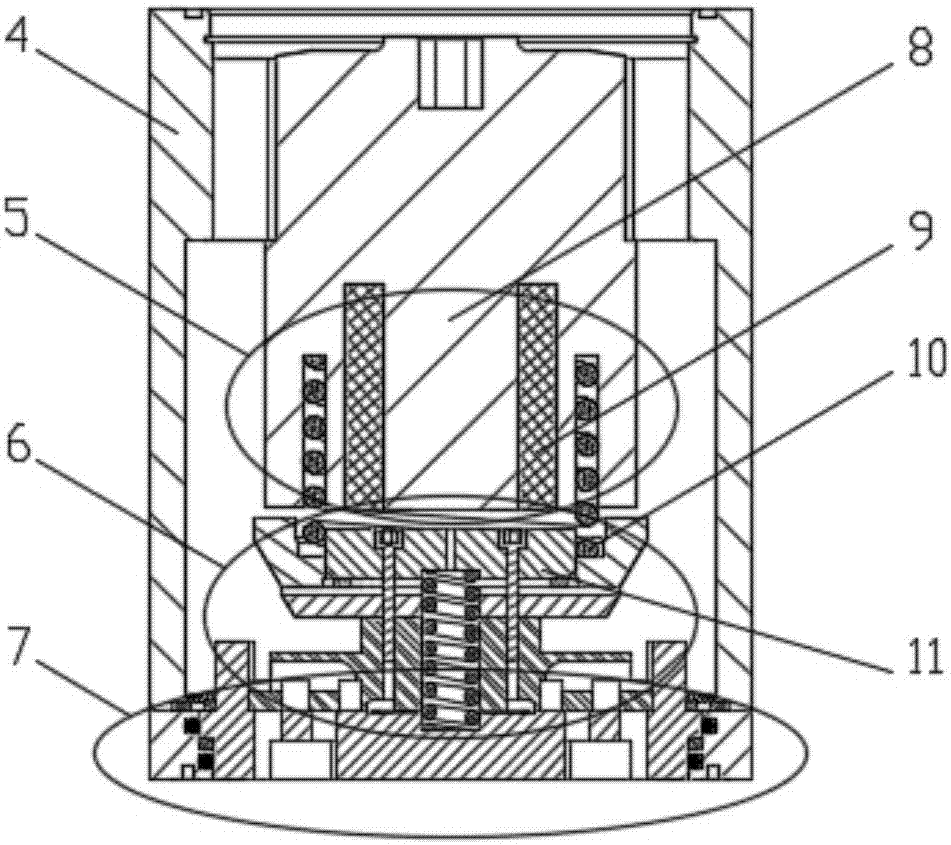

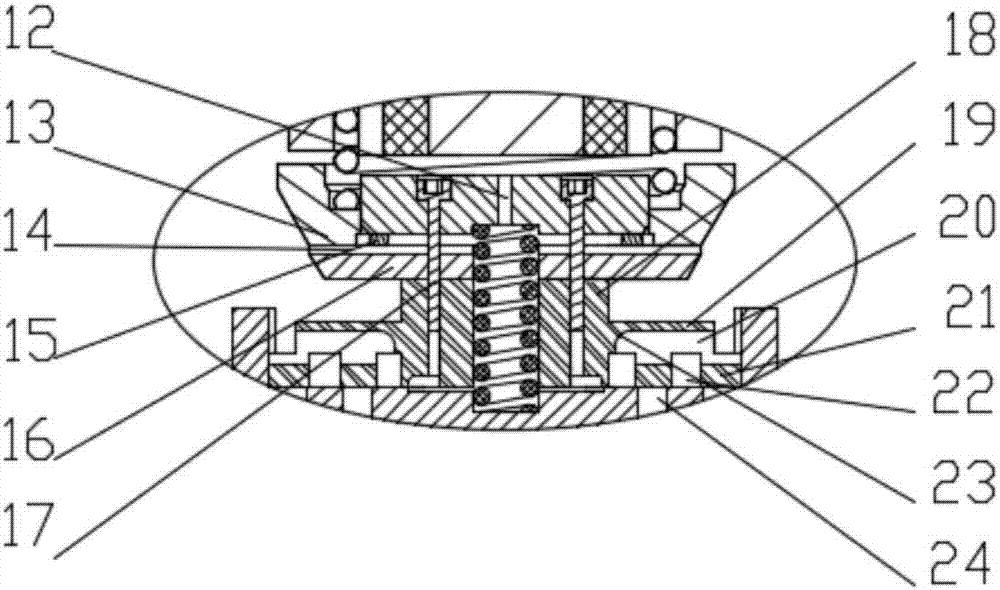

Mechanical seal performance testing device

ActiveCN103267613AAvoid axial forceRealize automatic adjustmentMeasurement of fluid loss/gain rateWork measurementFriction torqueAxial force

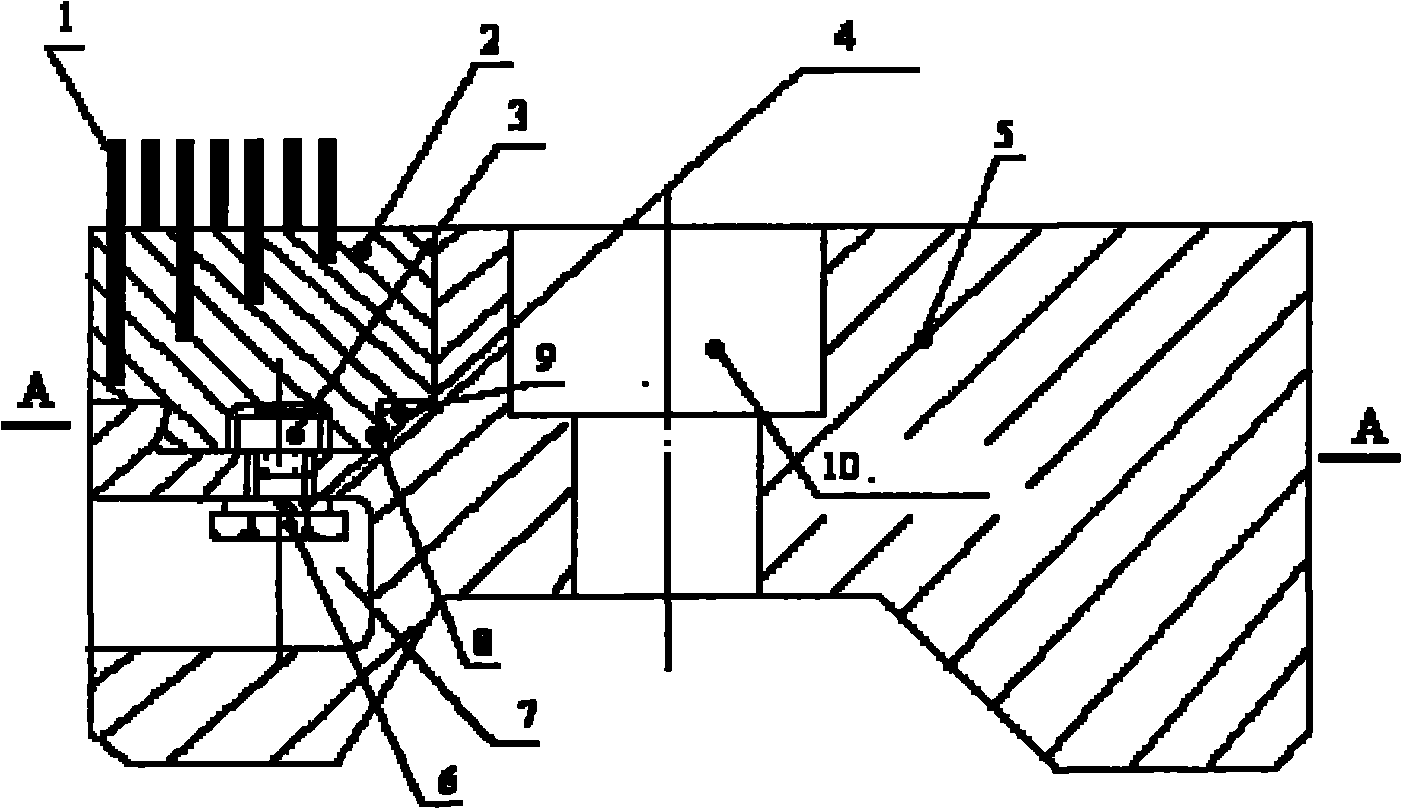

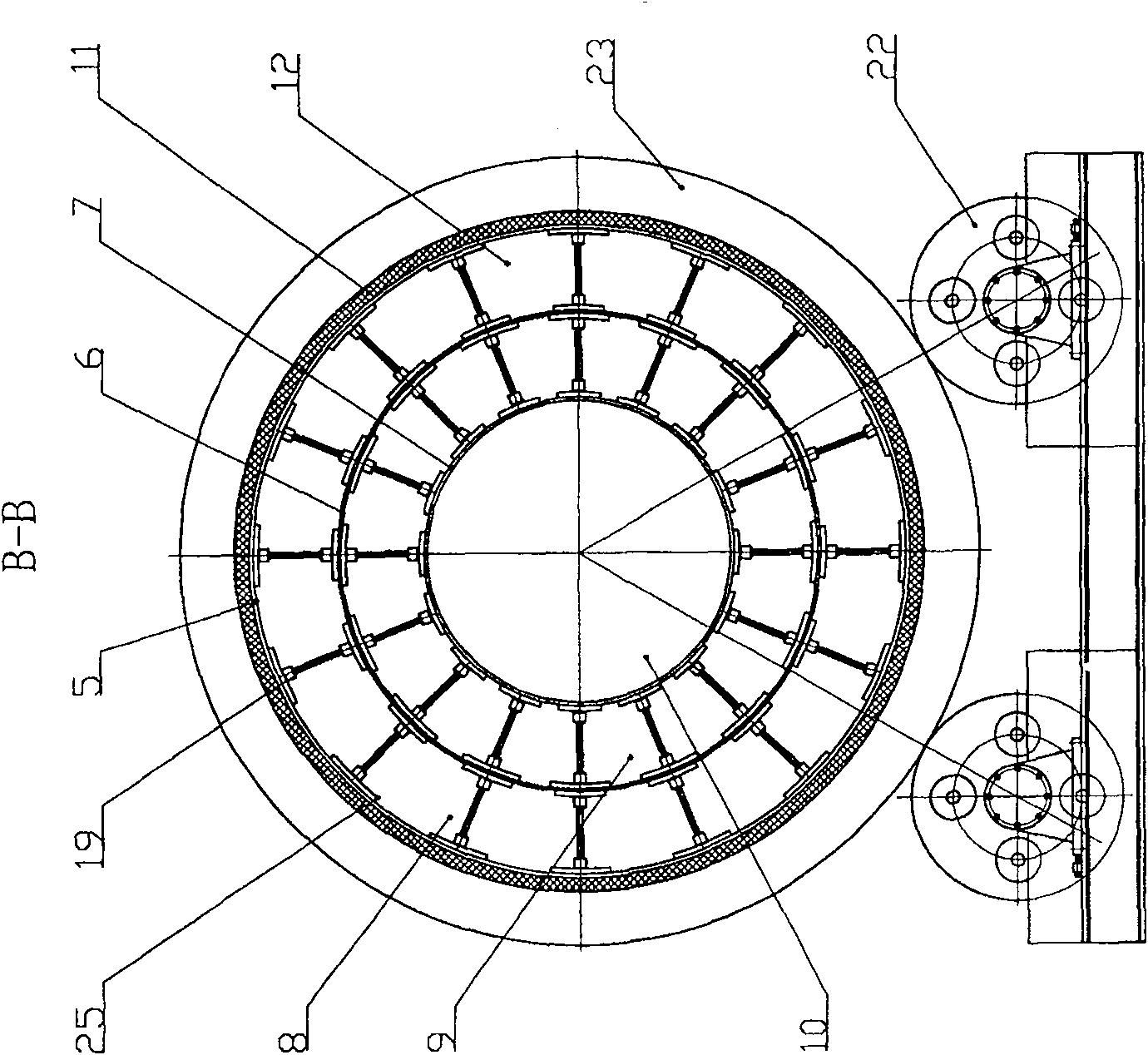

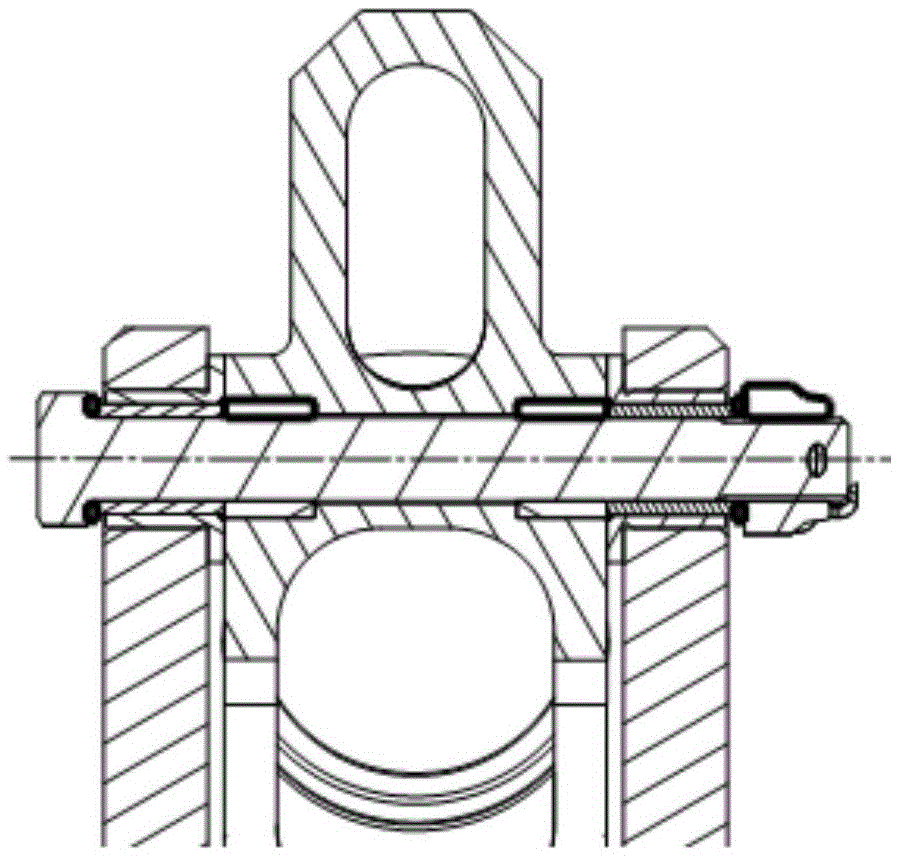

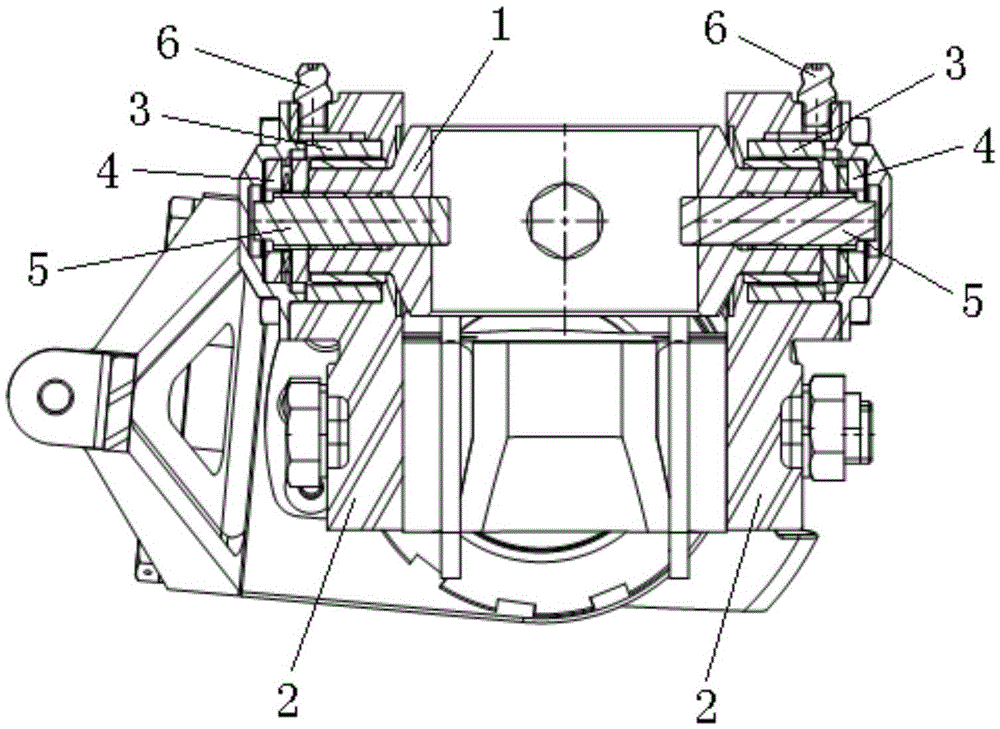

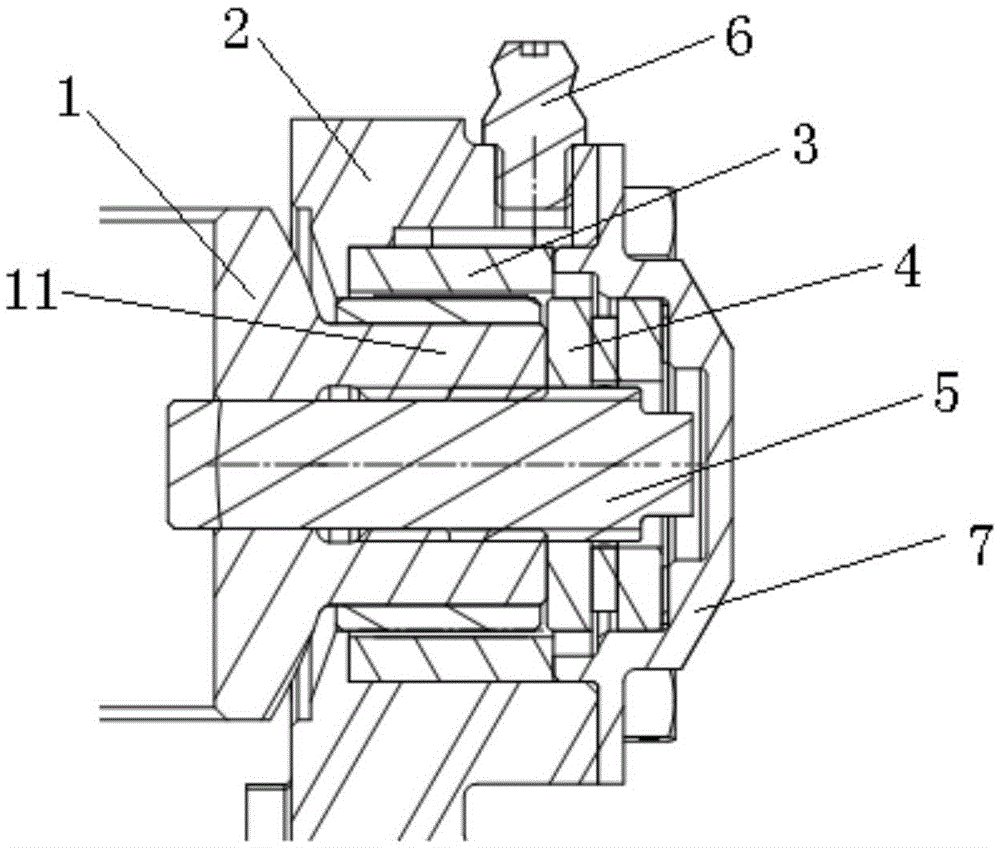

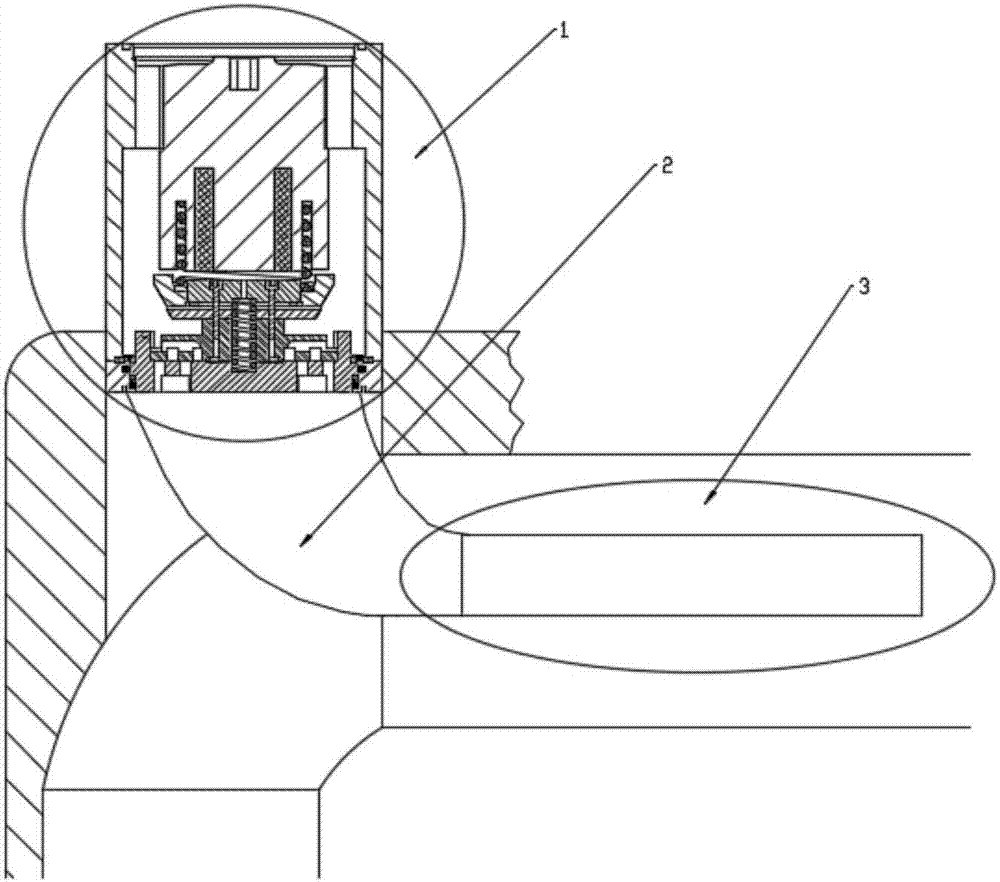

Provided is a mechanical seal performance testing device. The mechanical seal performance testing device comprises a main shaft, a working cavity with end caps at two ends, and two sets of mechanical seals to be tested. A shaft sleeve and the main shaft are in clearance fit and penetrate through the end caps at the two ends of the working cavity together. U-shaped openings on the same generatrix are arranged in two ends, extending out of the end caps, of the shaft sleeve, and a transmission pin is arranged on a portion, corresponding to the U-shaped openings, of the main shaft; two sections of threads which are equal in thread pitch and opposite in screwing direction are arranged in the middle of the shaft sleeve, and movable ring bases in the two mechanical seals to be tested are arranged on the back sides of two nuts screwed on the threads respectively; the movable ring bases and the shaft sleeve slide in the axial direction and are located and connected in the circumferential direction; a radial force sensor used for measuring end face friction torque indirectly is arranged on the transmission pin, and an axial force sensor used for measuring end face specific pressure is arranged between the back side of a static ring and the end cap of the working cavity; the end cap is provided with an annular ring which is concentric with a center hole, and therefore a leakage cavity used for collecting leakage amount is formed. The mechanical seal performance testing device is suitable for mechanical seal performance tests of various pressure working conditions and various size series, including performance tests of high-pressure and large-diameter mechanical sealing.

Owner:NANJING FORESTRY UNIV

Method for manufacturing outer ring of tapered roller bearing

The invention discloses a method for manufacturing an outer ring of a tapered roller bearing, comprising the following steps of: a: taking a material: setting the quality of the finished product outer ring as M, setting the outer diameter as D, taking a bearing steel pipe with the outer diameter of D1 as the raw material, taking the bearing steel pipe with the quality of M1 and meeting the condition that one half of D is less than or equal to D1 which is less than D, and M1 is equal to 2M plus M2 plus 2M3, wherein M2 is the margin of quality by cutting, and M3 is the margin of quality of single outer ring by grinding process; b: cold rolling: rolling on the bearing steel pipe taken in the step a for obtaining a combined blank of the outer ring; c. cutting: cutting the combined blank at the connecting ring for obtaining a single blank of the two outer rings; d: thermal processing; and e: finish machining: grinding the single blank of the outer ring. The proposal leads the outer ring of the tapered roller bearing to realize the cold rolling for shaping, has the advantages of small material loss, saved energy consumption, simple process, high production efficiency and the like, and simultaneously ensures the product quality.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

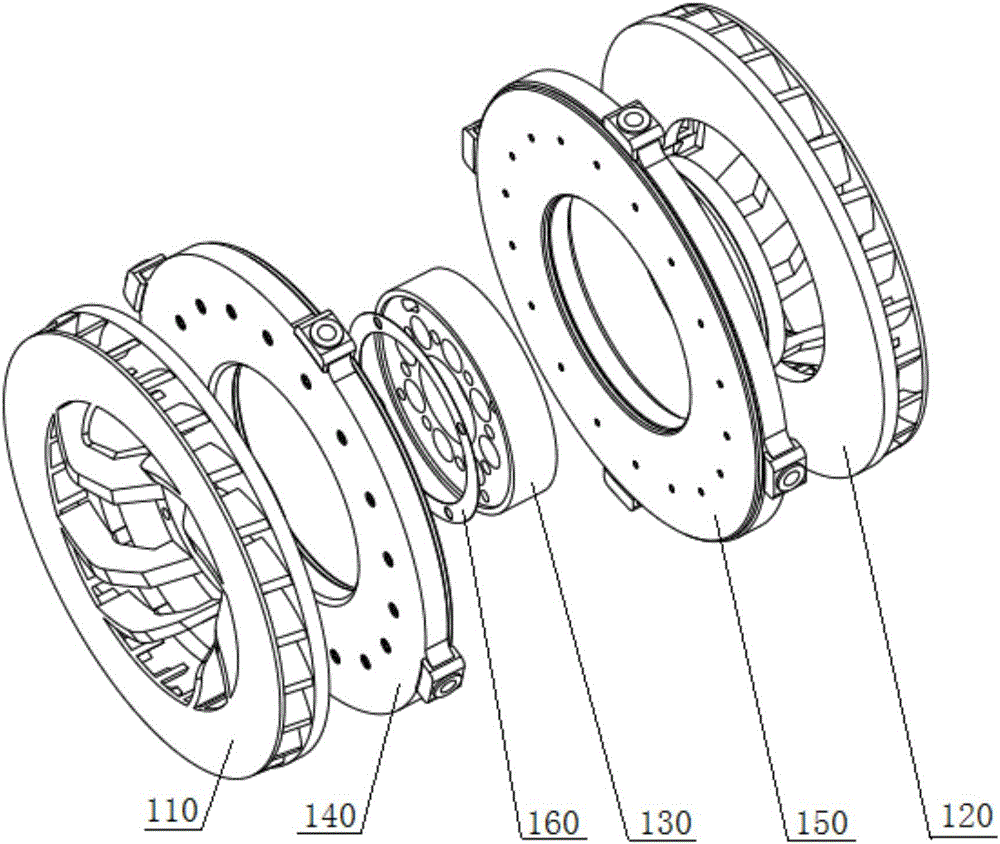

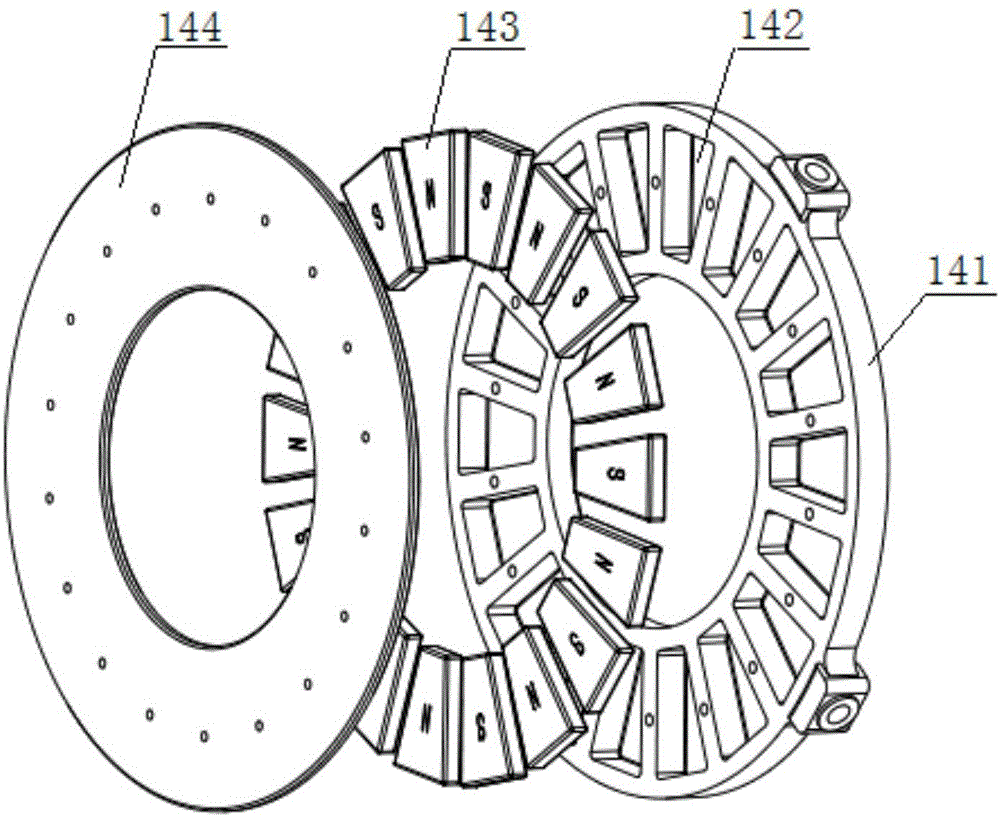

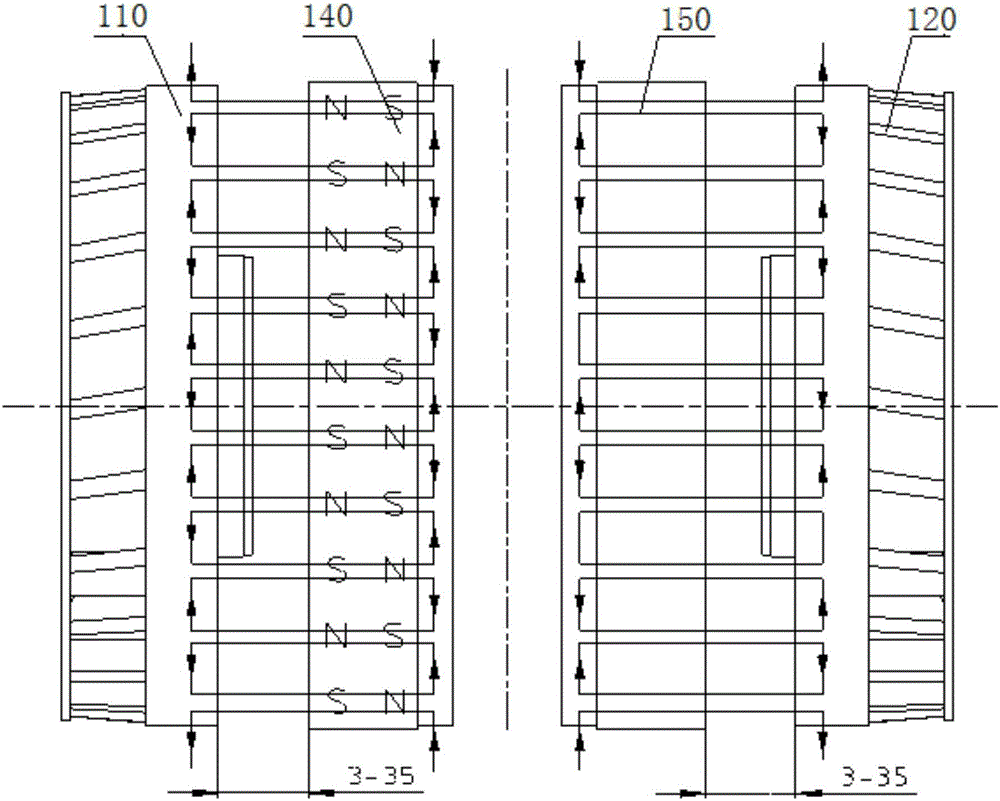

Vehicular disk-type permanent magnet eddy current retarder

PendingCN106712417AOvercome the disadvantage of high power consumptionSave electricityElectrodynamic brake systemsElectric machinesVehicle frameAxial force

The invention discloses a vehicular disk-type permanent magnet eddy current retarder, comprising a first rotor, a second rotor, a first stator, a second stator, a support frame, a connecting rod and an execution mechanism, wherein the first rotor and the second rotor are coaxially arranged at interval; the first stator and the second stator are coaxially arranged between the first rotor and the second rotor; the support frame is fixedly connected with a vehicle gearbox shell or a frame; the middle part of the connecting rod is connected with the extension end of the support frame by adopting a cylindrical pair, and two ends of the connecting rod respectively form spherical hinges with the peripheral edges of the first stator and the second stator; and the execution mechanism is articulated with the other extension end of the connecting rod. A high-performance neodymium iron boron permanent magnet provides a magnetic field, so that power supply is not needed, and the defect of power consumption of an electric eddy current retarder is overcome; two disks are articulated together by the connecting rod via a joint bearing to avoid axial force caused by non-uniform air gaps on two sides, and simultaneously, the maximum axial resistance is skillfully converted into circumferential rotation and axial motion to reduce the driving force.

Owner:MAGNA MAGNETOMOTIVE CO LTD

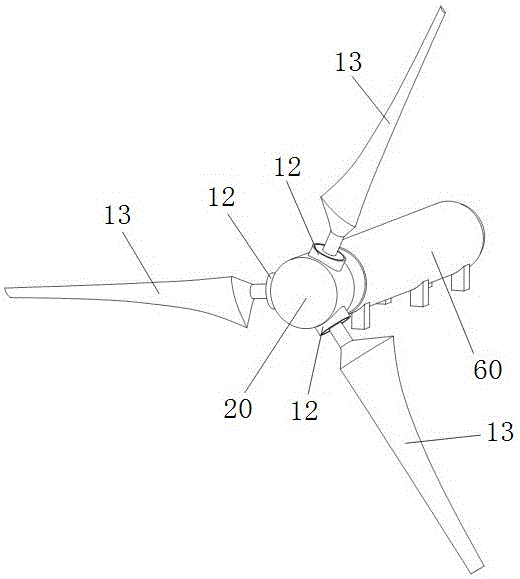

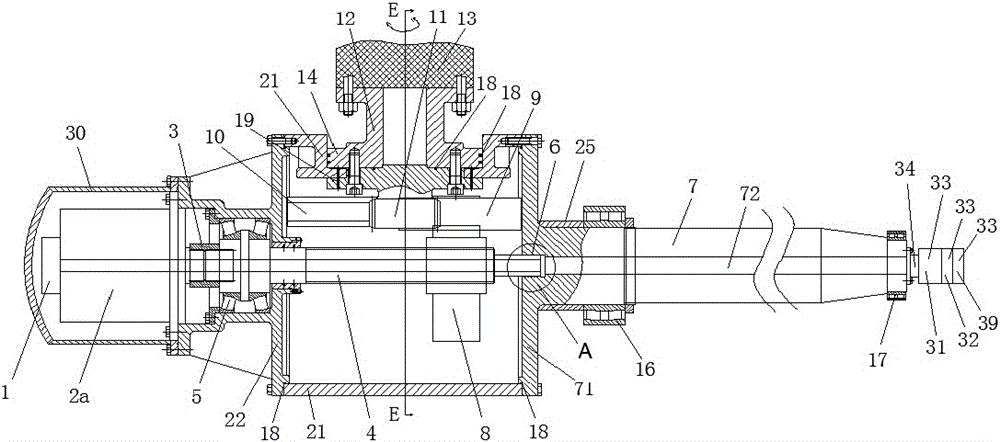

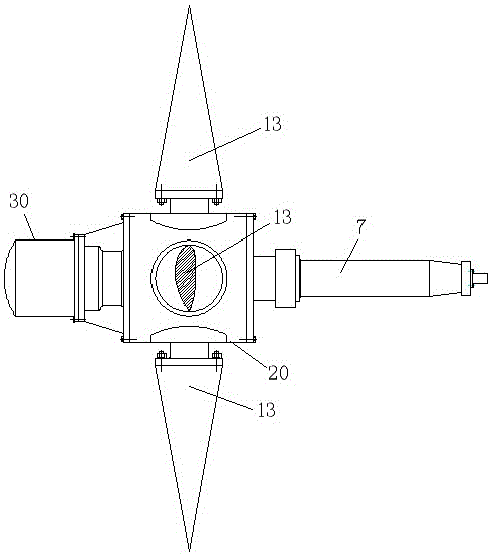

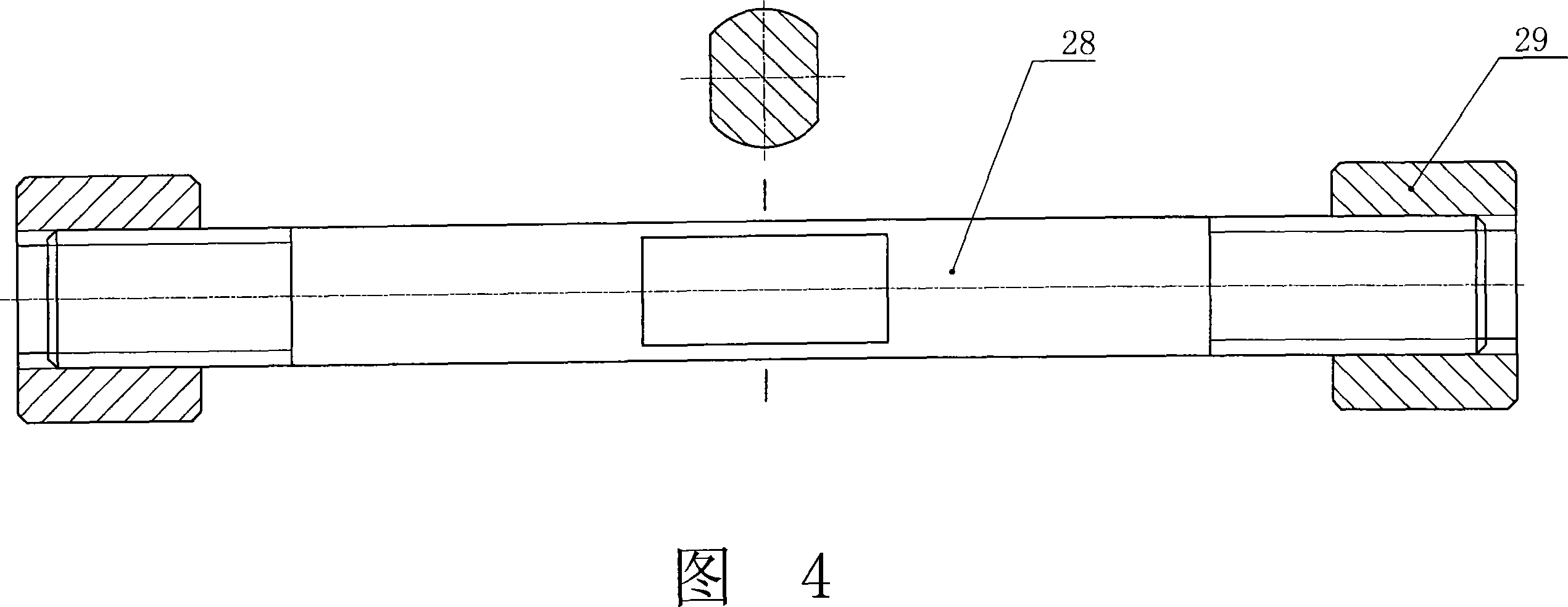

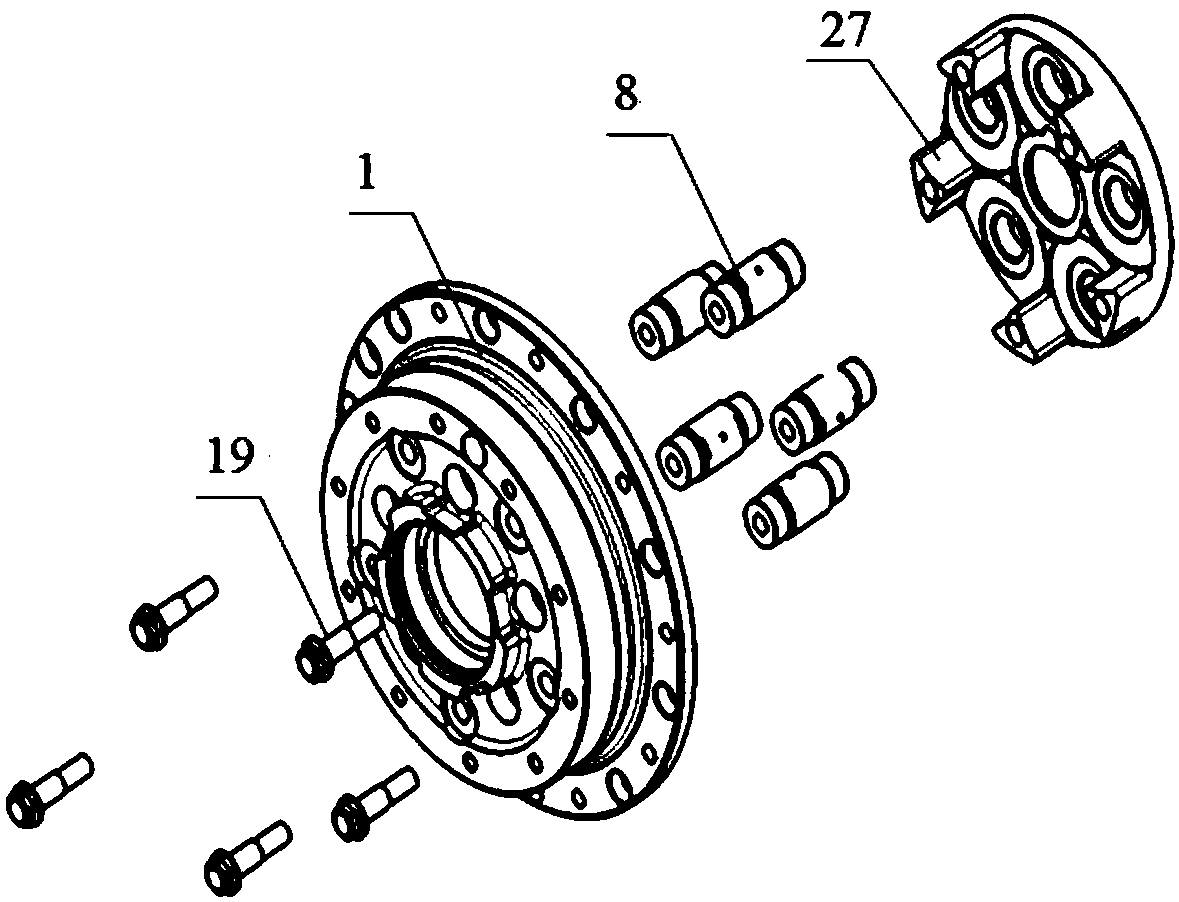

Horizontal axis ocean current energy electric generator variable-pitch device and horizontal axis ocean current energy electric generator

ActiveCN105840411AEasy to captureHigh transmission powerHydro energy generationReaction enginesGear wheelHorizontal axis

The invention discloses a horizontal axis ocean current energy electric generator variable-pitch device and a horizontal axis ocean current energy electric generator. The variable-pitch device comprises a driving part which is a motor or a hydraulic motor, a screw rod which is fixedly connected with an output shaft of the driving part through a coupler and a push plate which is arranged on the screw rod in a sleeving mode and is in threaded connection with the screw rod. The left end of the screw rod is supported through a pair of centripetal thrust bearings. The right end of the screw rod extends into the left end of a central hole of a spindle flange and a spindle. A first sliding bearing is formed between the screw rod and the left end of the central hole of the spindle flange and the spindle. Electric slip rings or a hydraulic slip ring are / is mounted at the right end of the spindle. One gear rack is fixed to each side surface of the push plate, each gear rack is engaged with a gear wheel, all the gear wheels are fixedly connected with the roots of corresponding blades through variable-pitch flanges, and second sliding bearings are formed between the variable-pitch flanges and the wheel hub wall. An angle transducer is installed at the left end of the driving part. By means of the horizontal axis ocean current energy electric generator variable-pitch device and the horizontal axis ocean current energy electric generator, the variable-pitch angle larger than 180 degrees can be achieved, therefore, double-way electricity generation is achieved, unified pitch variation can be achieved, and operation is stable.

Owner:ZHEJIANG UNIV

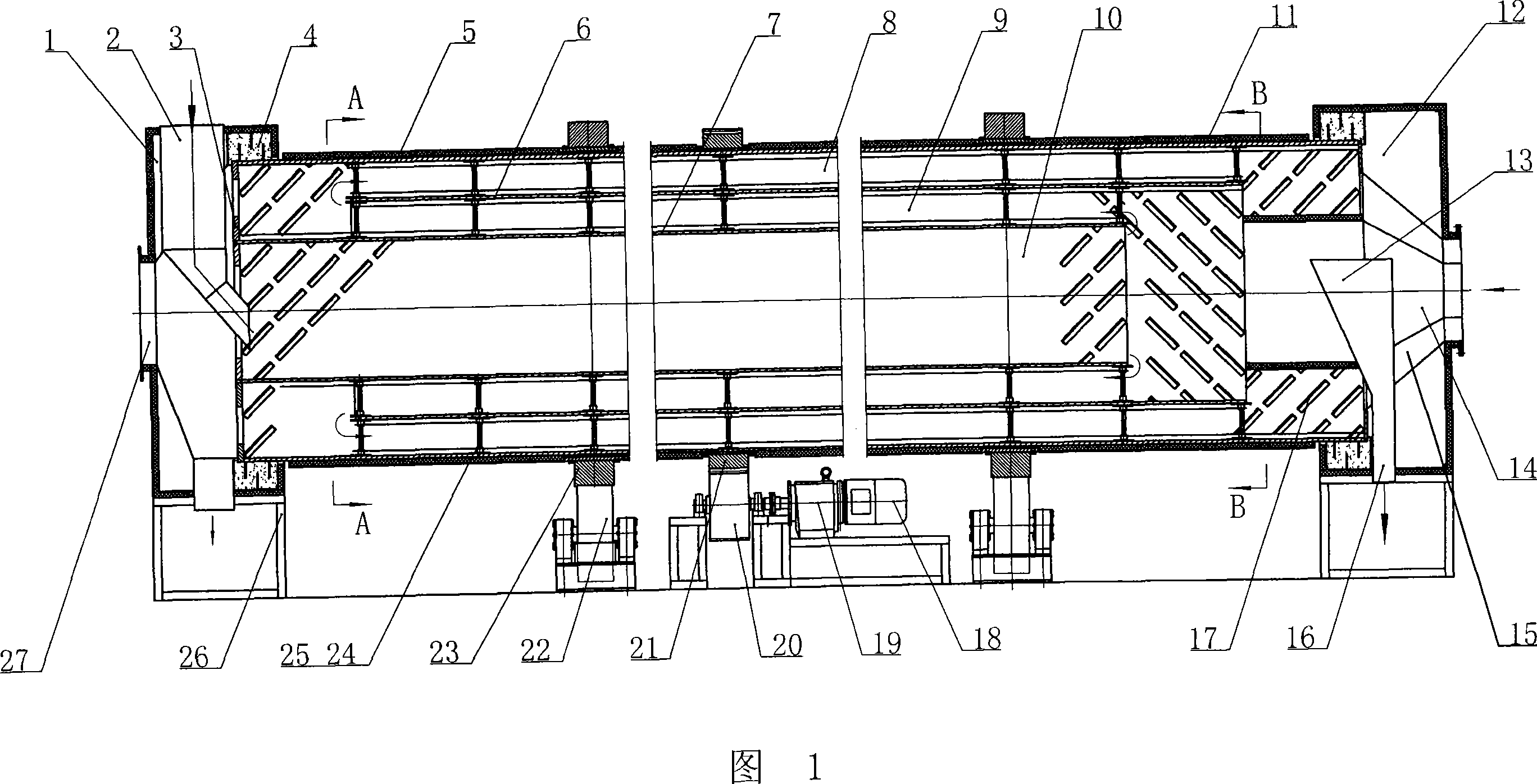

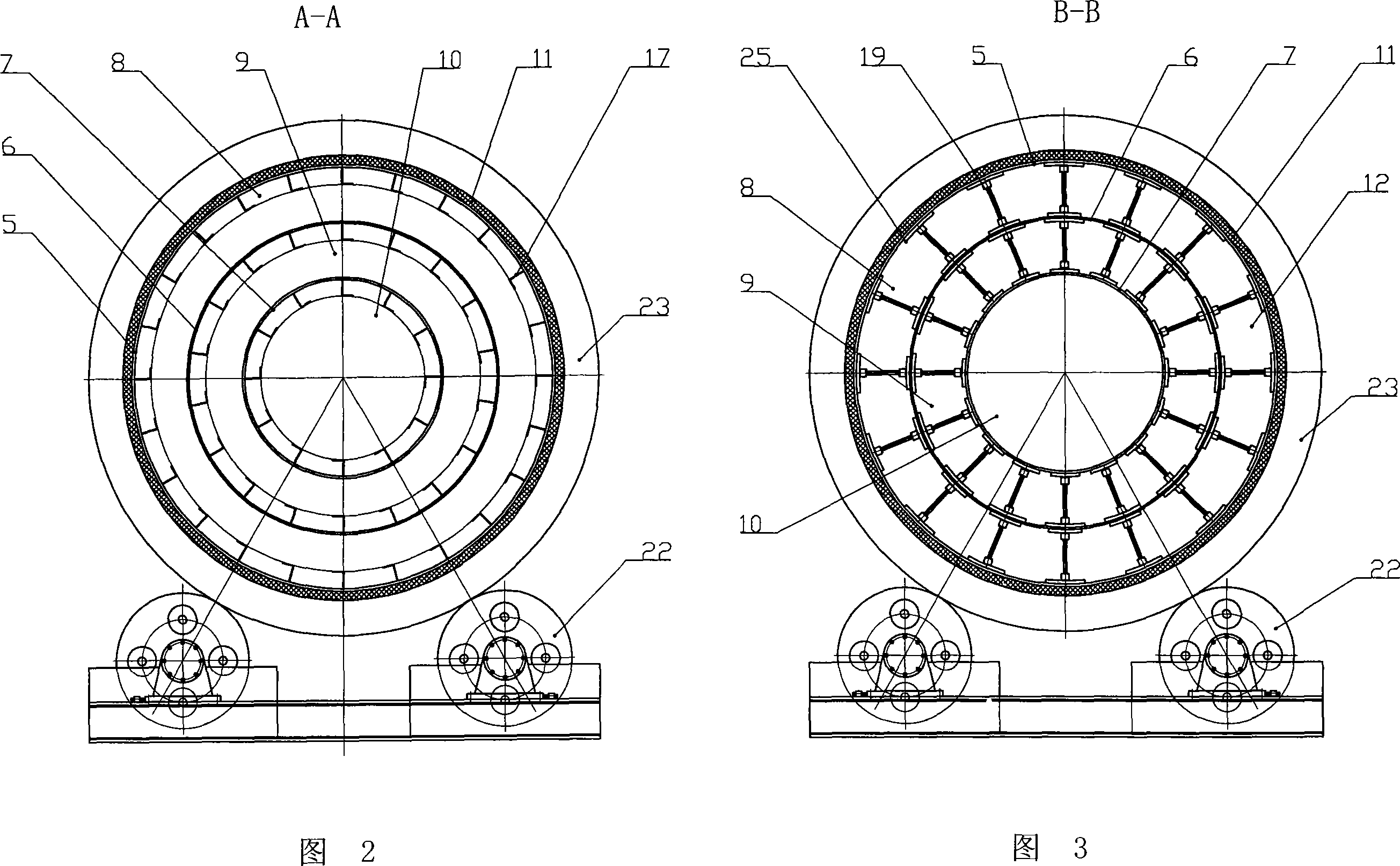

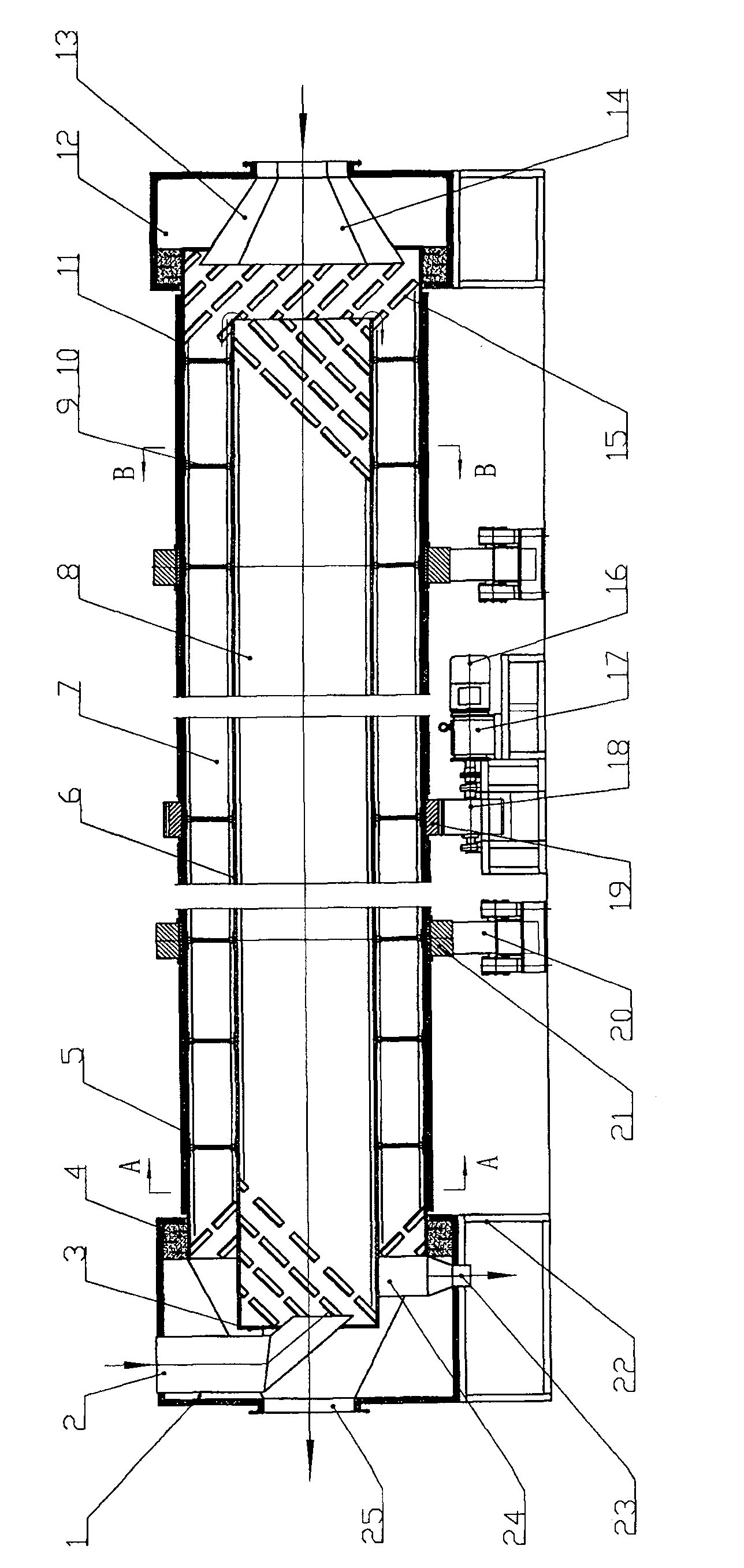

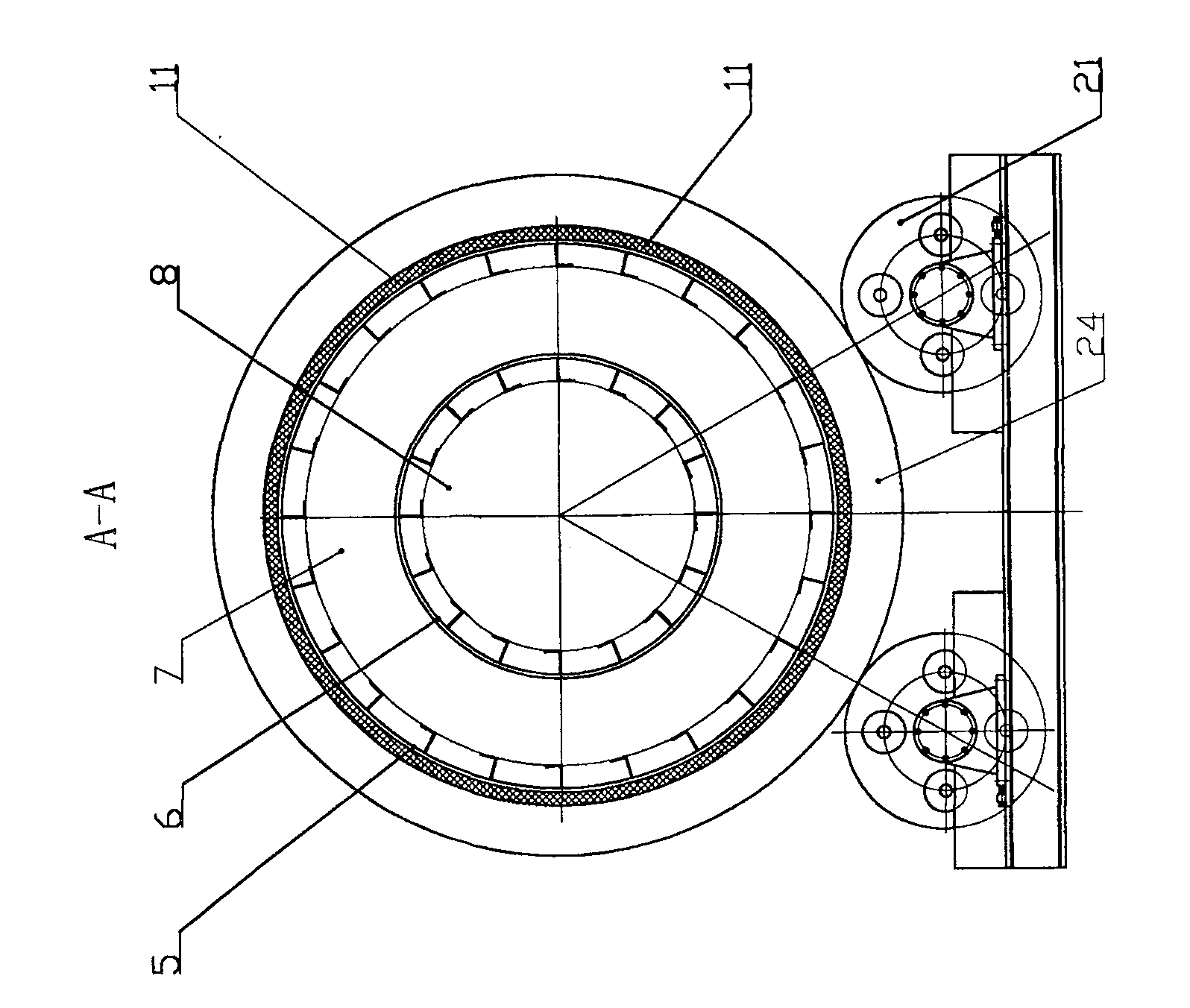

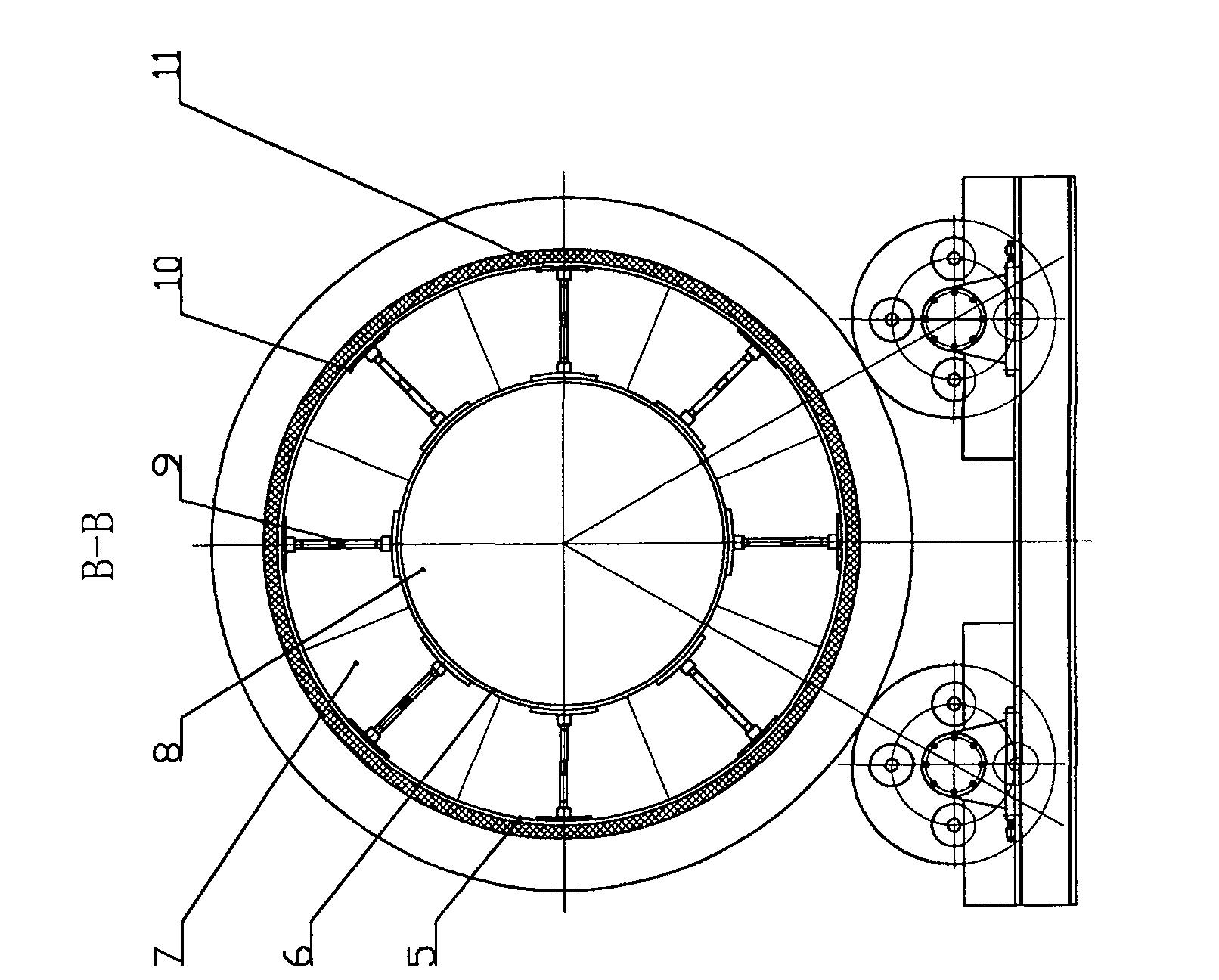

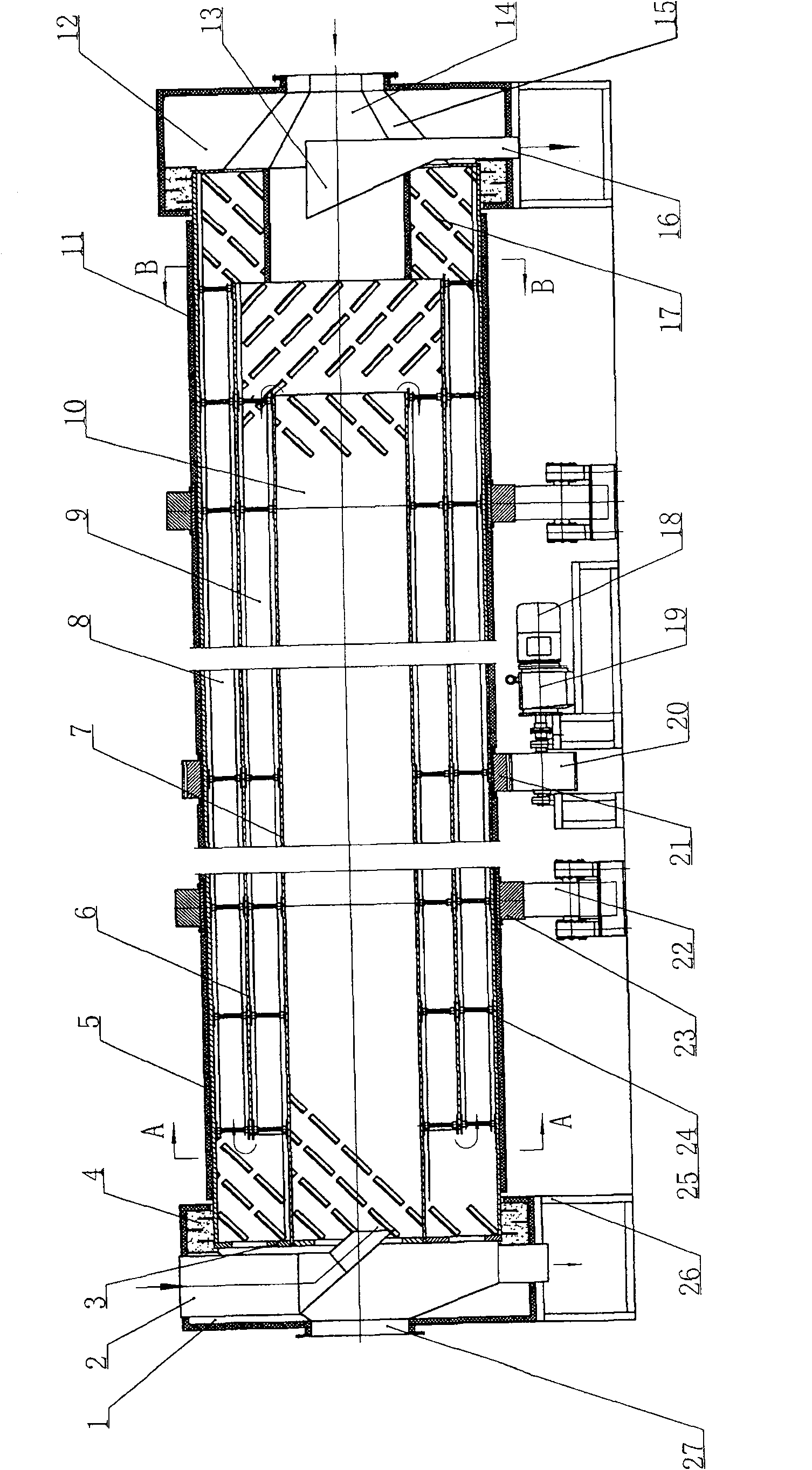

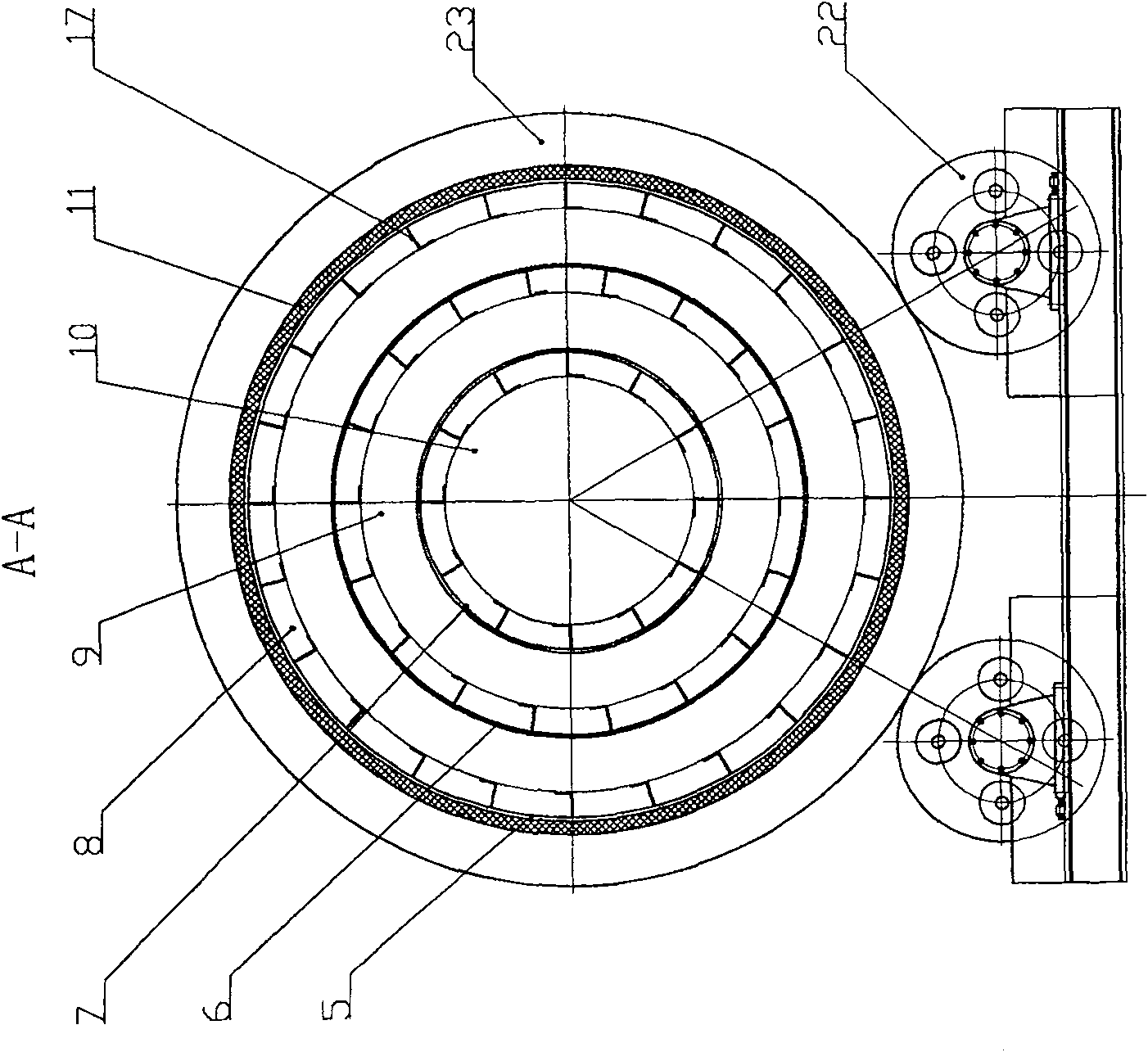

Three return journey barrel type drying machines

InactiveCN101216241AAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineEngineering

An improved three-pass cylinder drying machine comprises a machine body composed of a bracket, a sealed tank and a cylinder body, and a driving device, a supporting device and a controller, wherein the axial line of the cylinder body of the machine body is parallel to the horizontal surface, an inner cylinder and an outer cylinder that are concentrically arranged are assembled together in a staggered way to form the cylinder body, the formed cavities are used as three drying and precipitation units, the adjacent wallboards of the inner, middle and outer cylinders are connected and positioned via regulating and supporting plates and reinforced buffer plates, a heat insulating cover is disposed at the outer periphery of the wallboard of the outer cylinder, three material homogenizing and spreading machines are respectively disposed at the inner surfaces of the inner, middle and outer wallboards in a screw propulsion way and has reversed helical lines, and gears at the outer periphery of the machine body are aligned with the center of gravity of the cylinder. The inventive three-pass cylinder drying machine effectively solves the shortcomings of the conventional cylinder drying machine, including high deformation and misplacement liability and high axial dislocation liability; and has the advantages of reasonable structural design, stable performance, large precipitation range for one time, high thermal efficiency, saved energy consumptionand wide application range.

Owner:沈阳清井环保机械工程有限公司

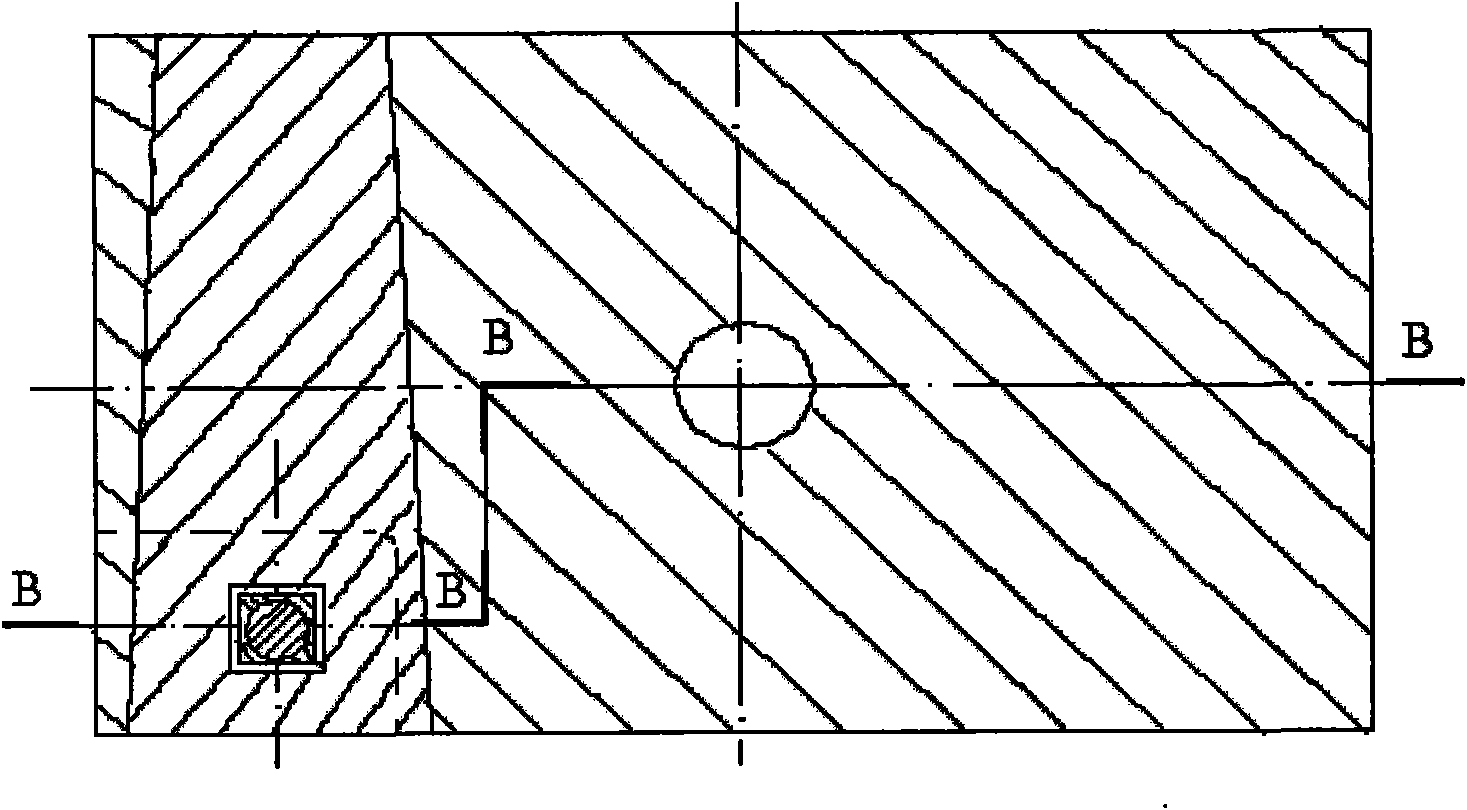

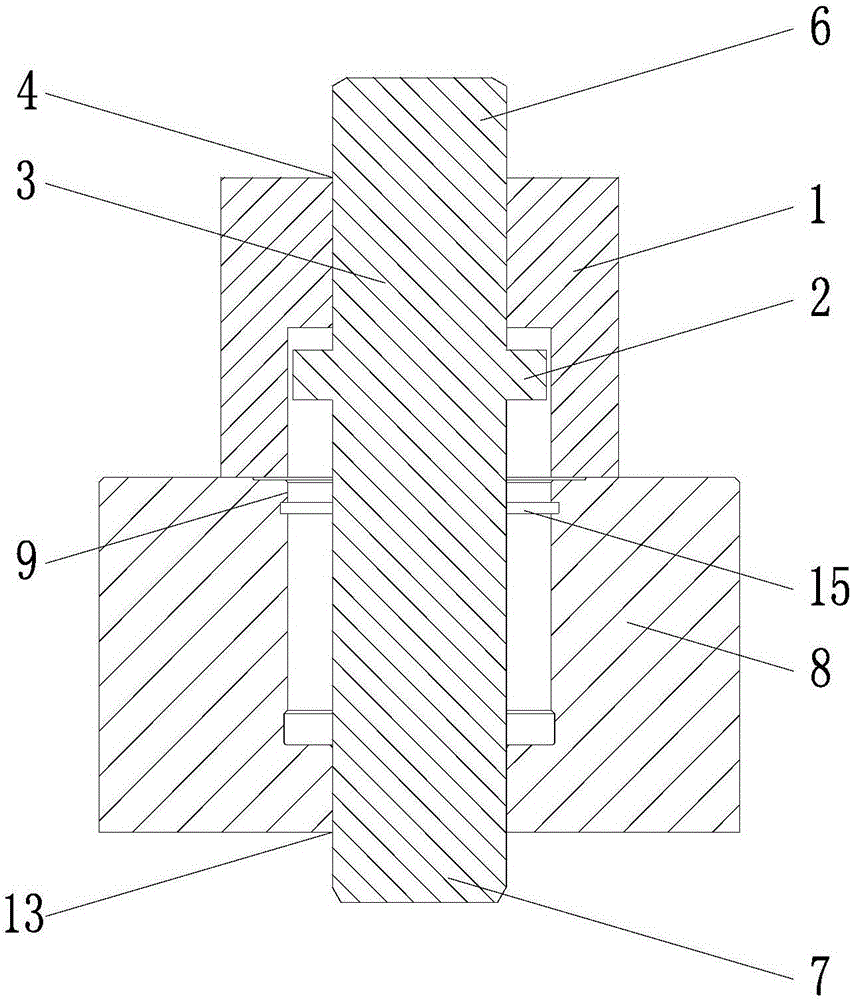

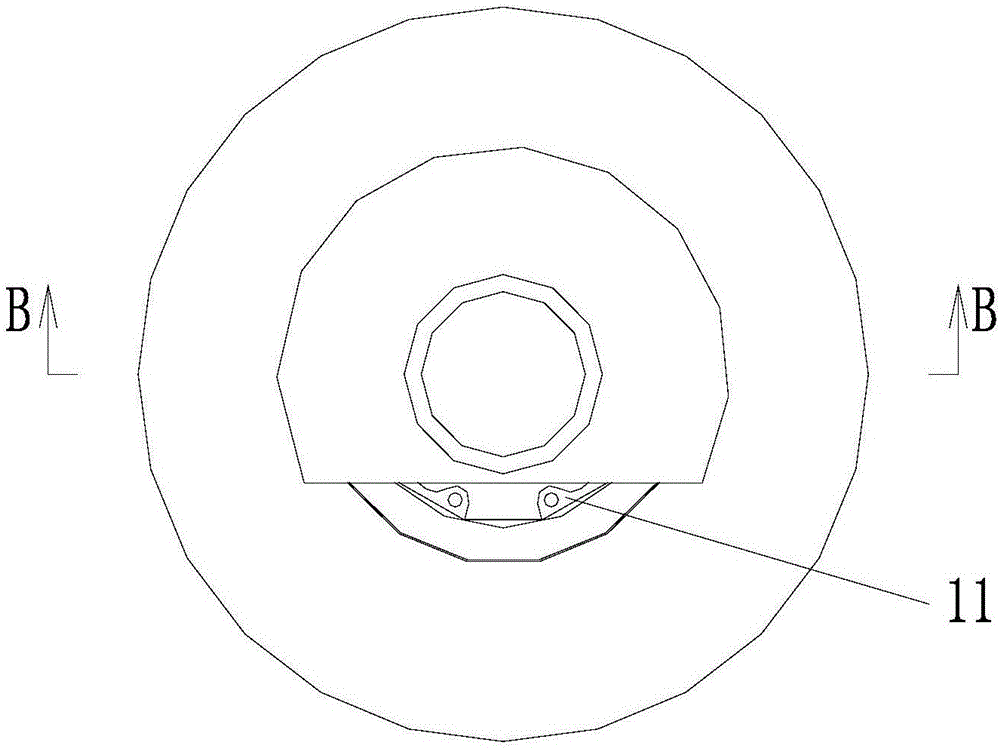

Combined position board hammer of reaction crusher capable of rapidly changing wear position and manufacturing method thereof

InactiveCN101850285AWear resistanceSave materialFoundry moulding apparatusGrain treatmentsCrusherLost-foam casting

The invention discloses a composition board hammer of a reaction crusher capable of rapidly changing wear positions and a manufacturing method thereof. The board hammer consists of a combined wearing strip (2) and a board hammer body (5), wherein the board hammer body (5) and the combined wearing strip (2) are produced by using high chromium cast iron through lost foam casting; the central position at the lower end of the combined wearing strip (2) is provided with a tenon (8); the center of the board hammer body (5) is provided with mounting holes (10); the position for installing the combined wearing strip (2) on the board hammer (5) is provided with a mortise (9) matching with the tenon (8) of the combined wearing strip (2); the board hammer body (5) and the combined wearing strip (2) are connected through the mortise (9) and the tenon(8) to form the whole board hammer; and the assembled wearing strip is positioned at the wearing position on the board hammer. The invention has the advantages that the combined wearing strip of the combined board hammer can be rapidly changed after being wore and the board hammer body is not changed or less changed, thereby improving production efficiency, saving metal materials and being suitable for manufacturing a T-shaped board hammer of the reaction crusher.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

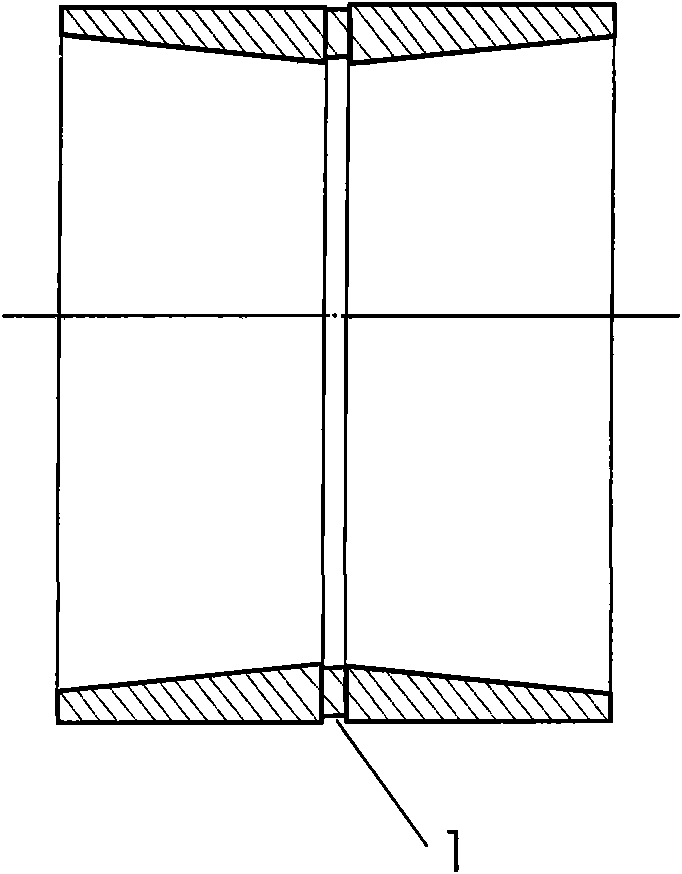

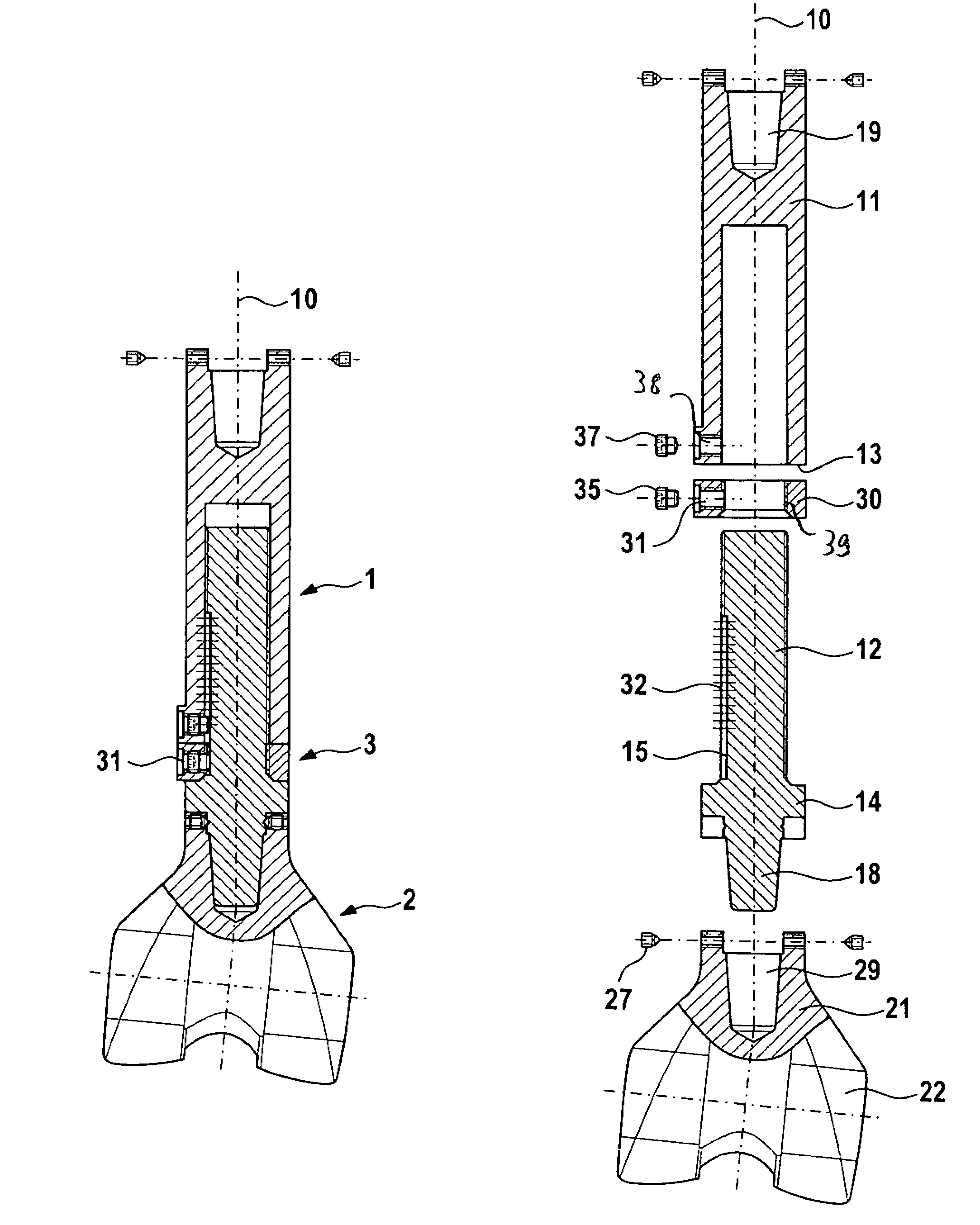

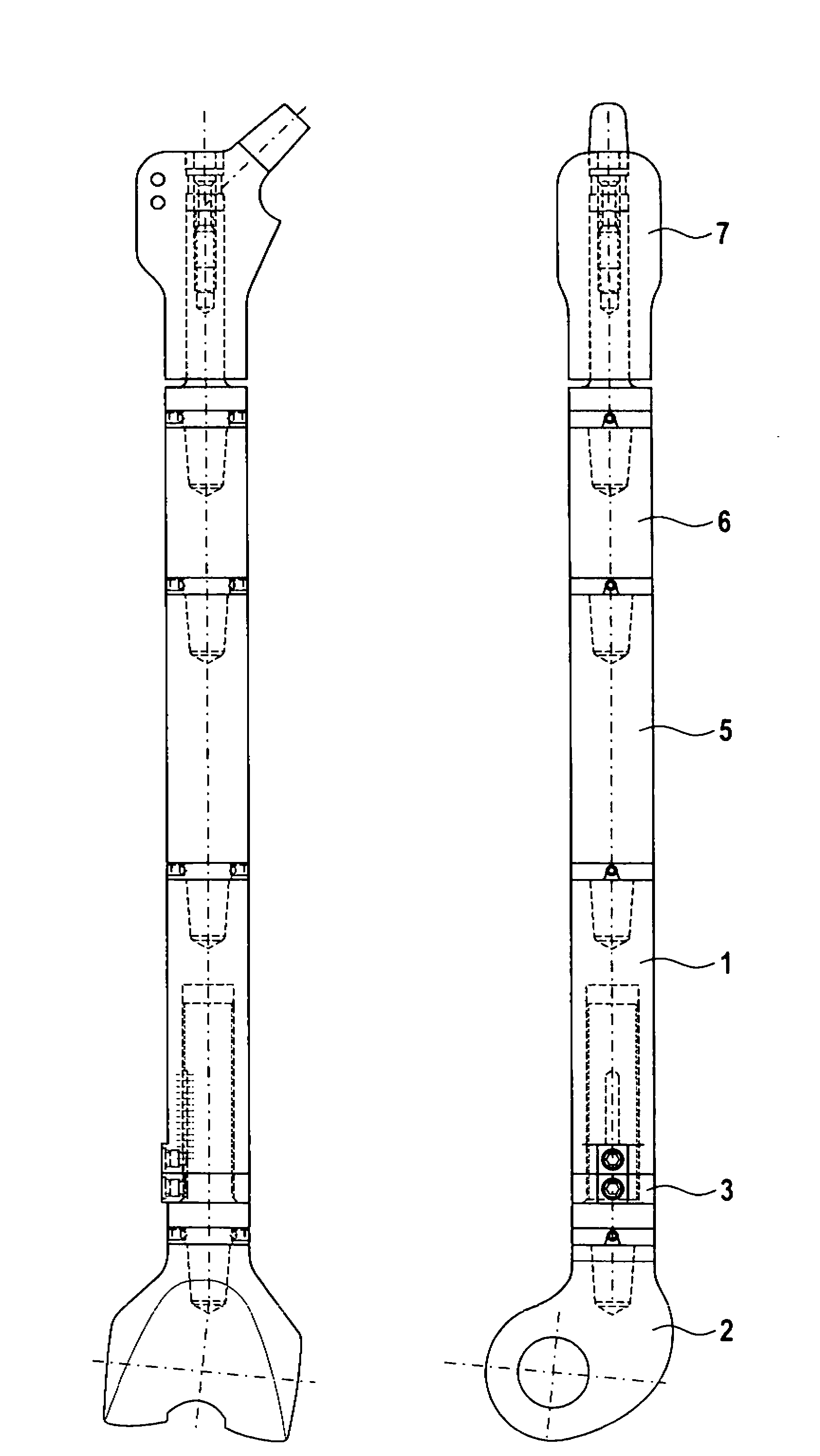

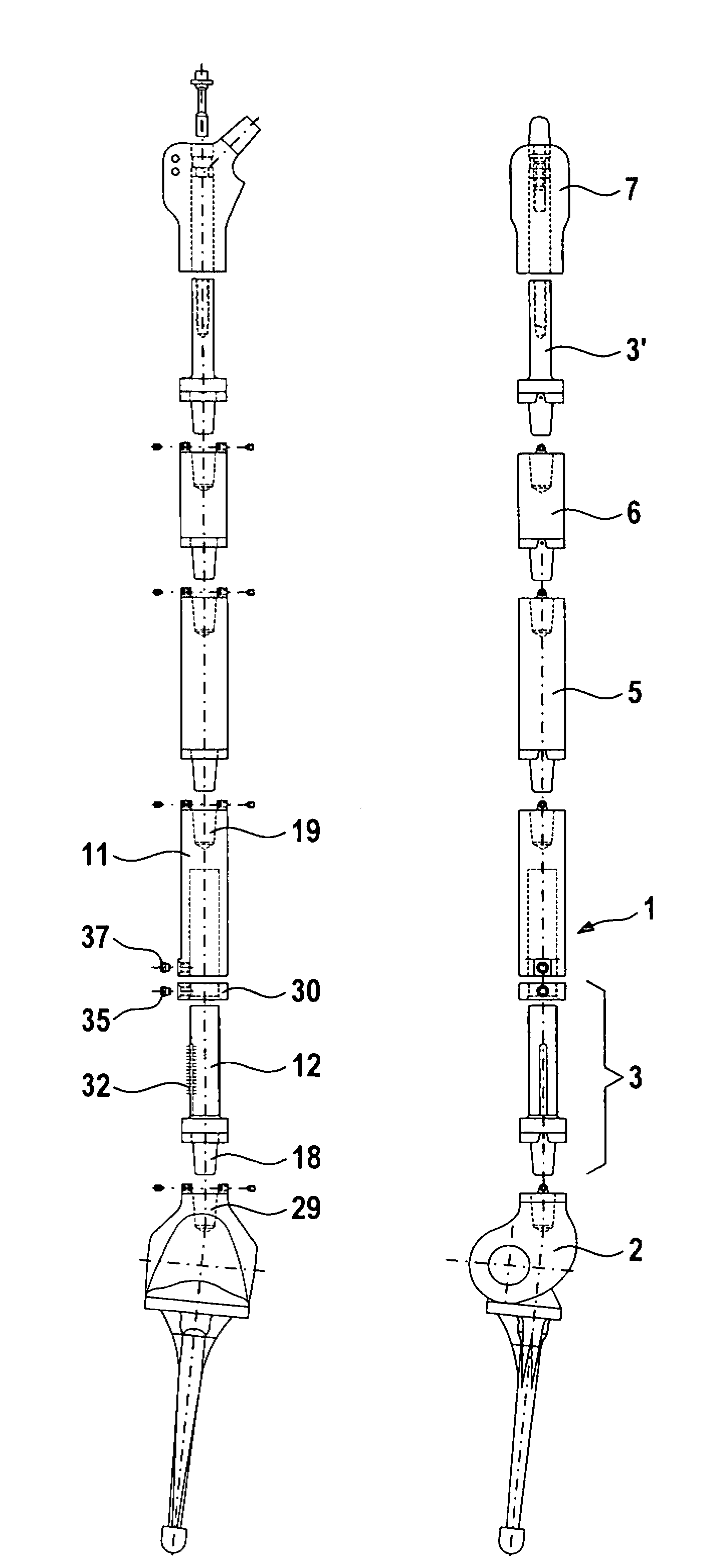

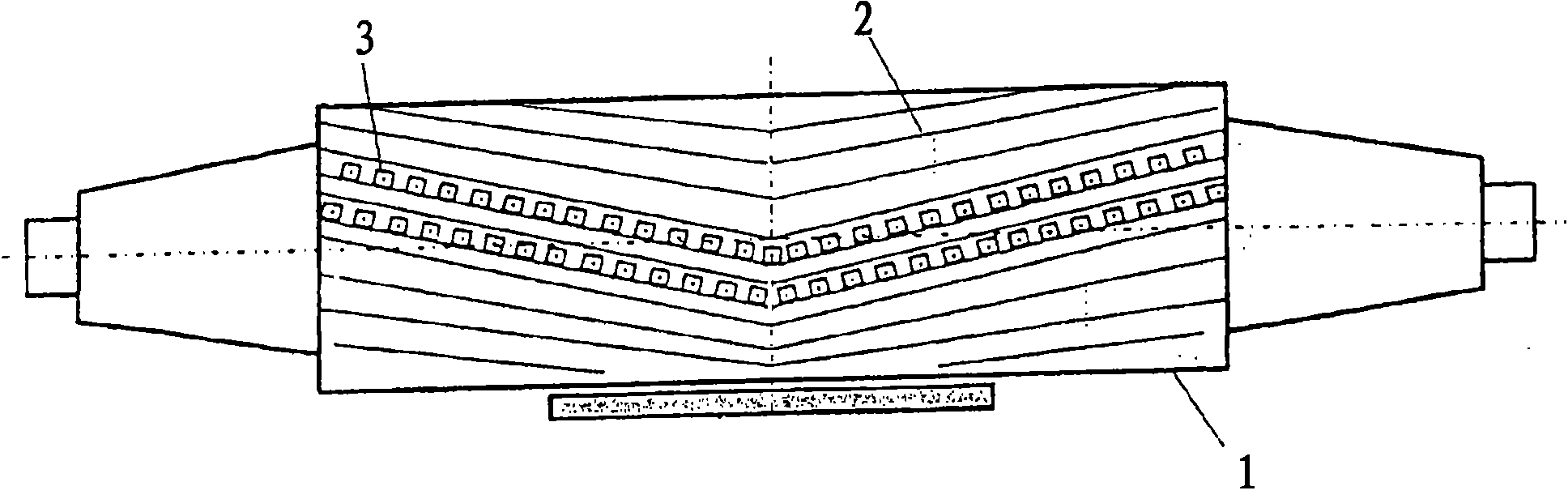

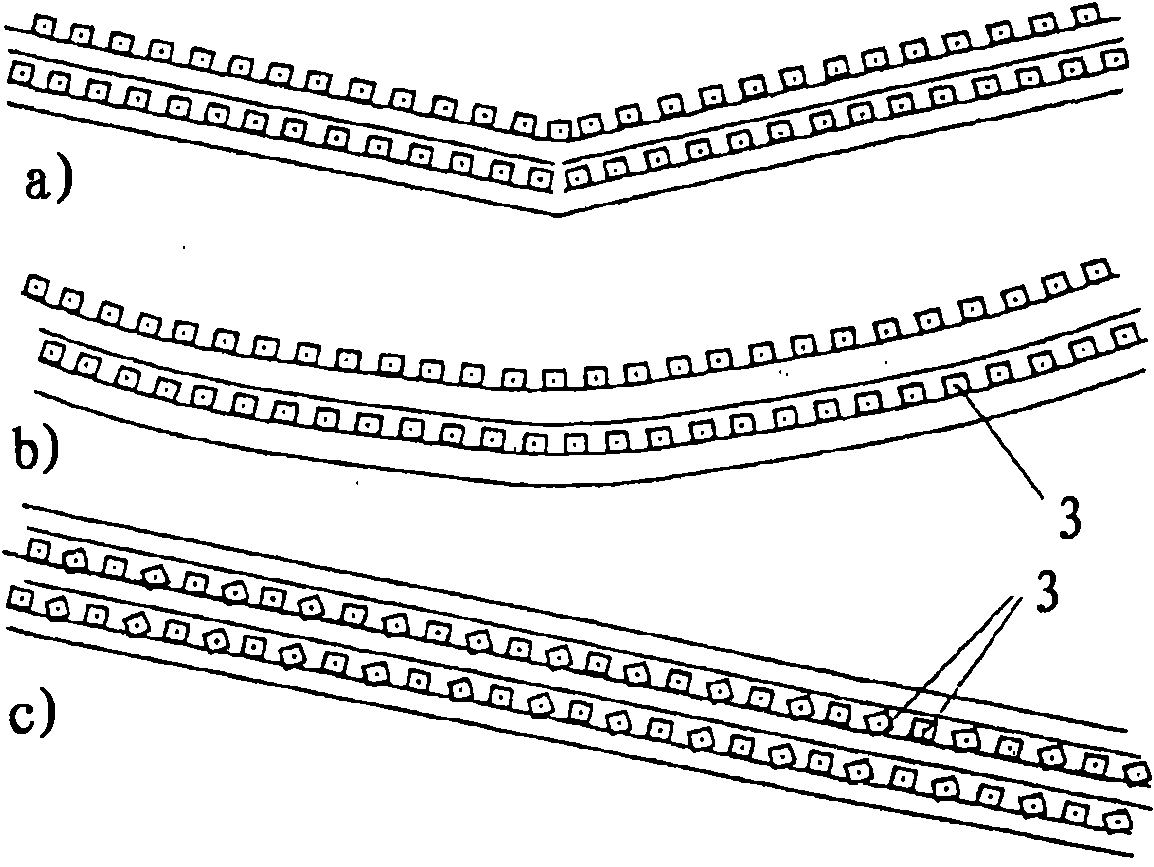

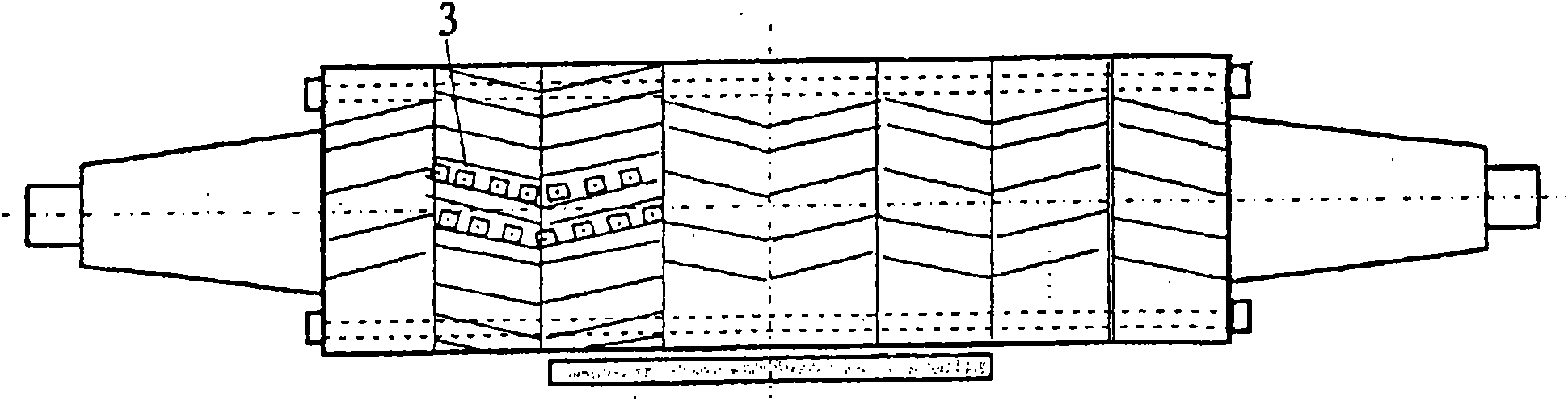

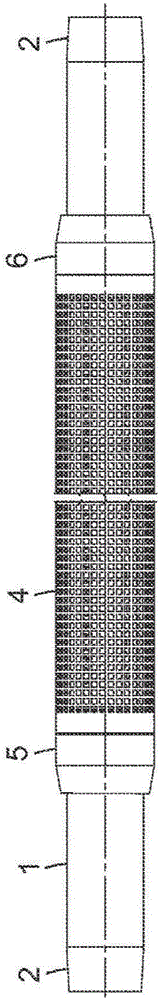

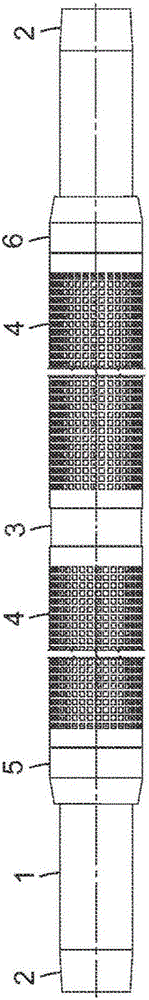

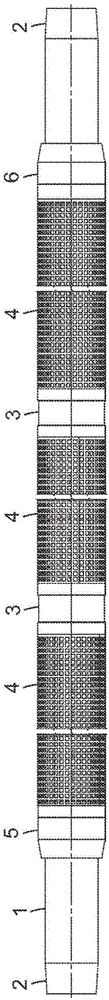

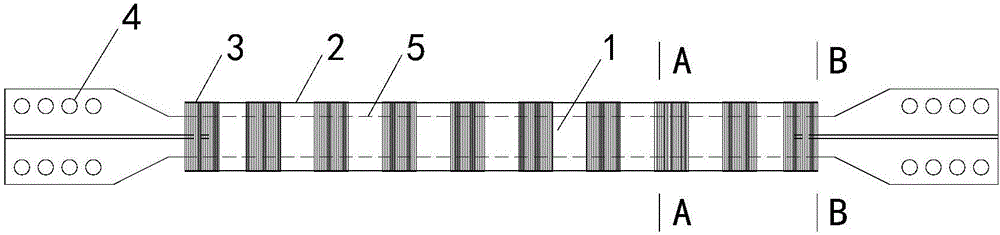

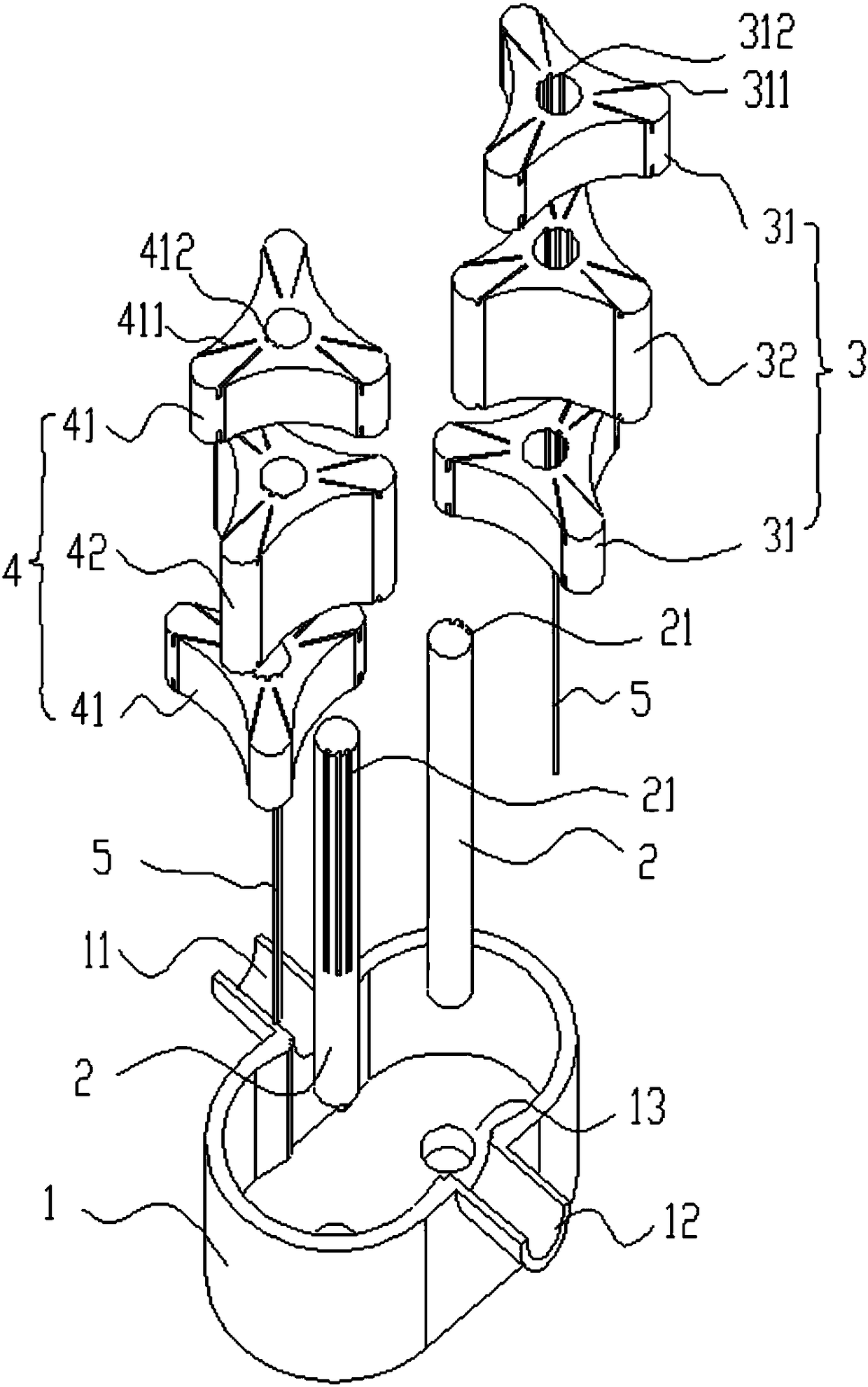

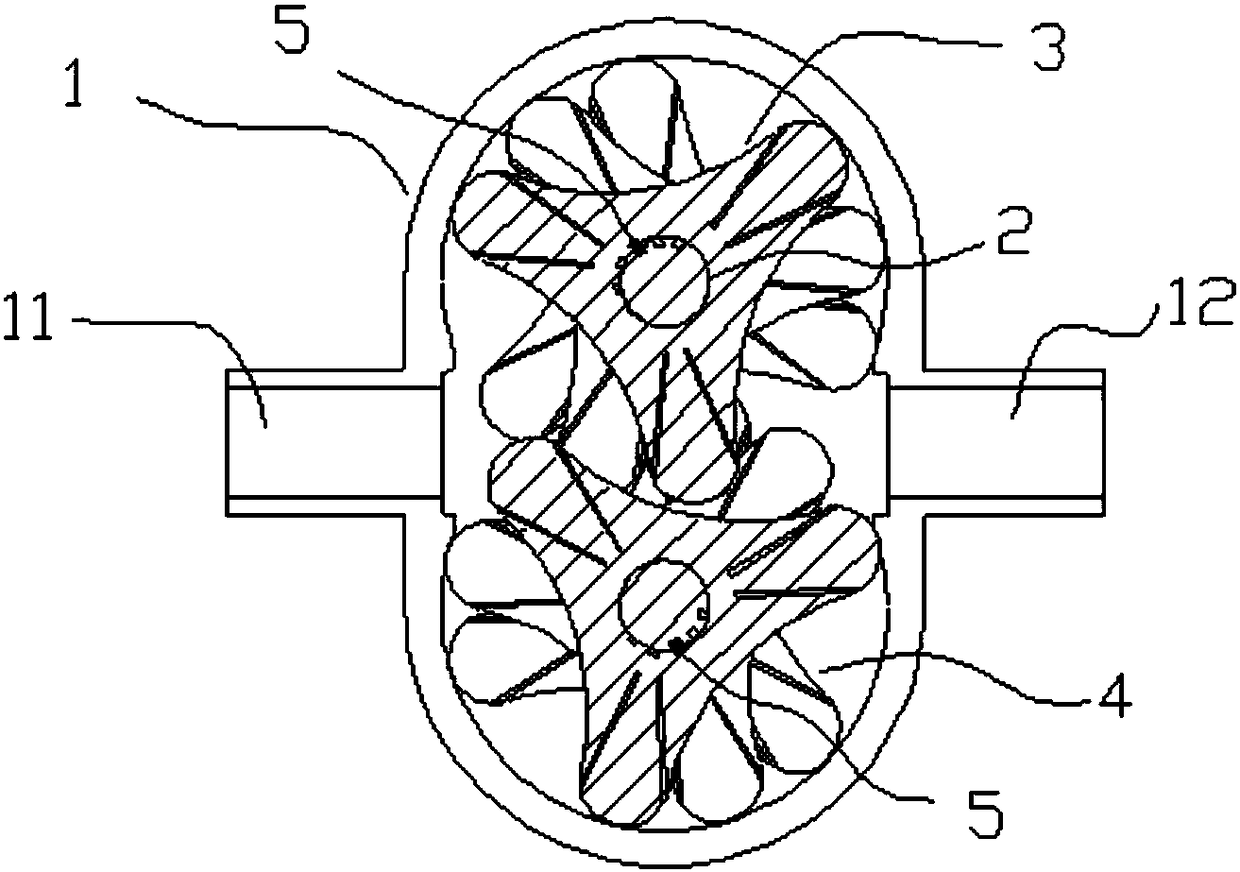

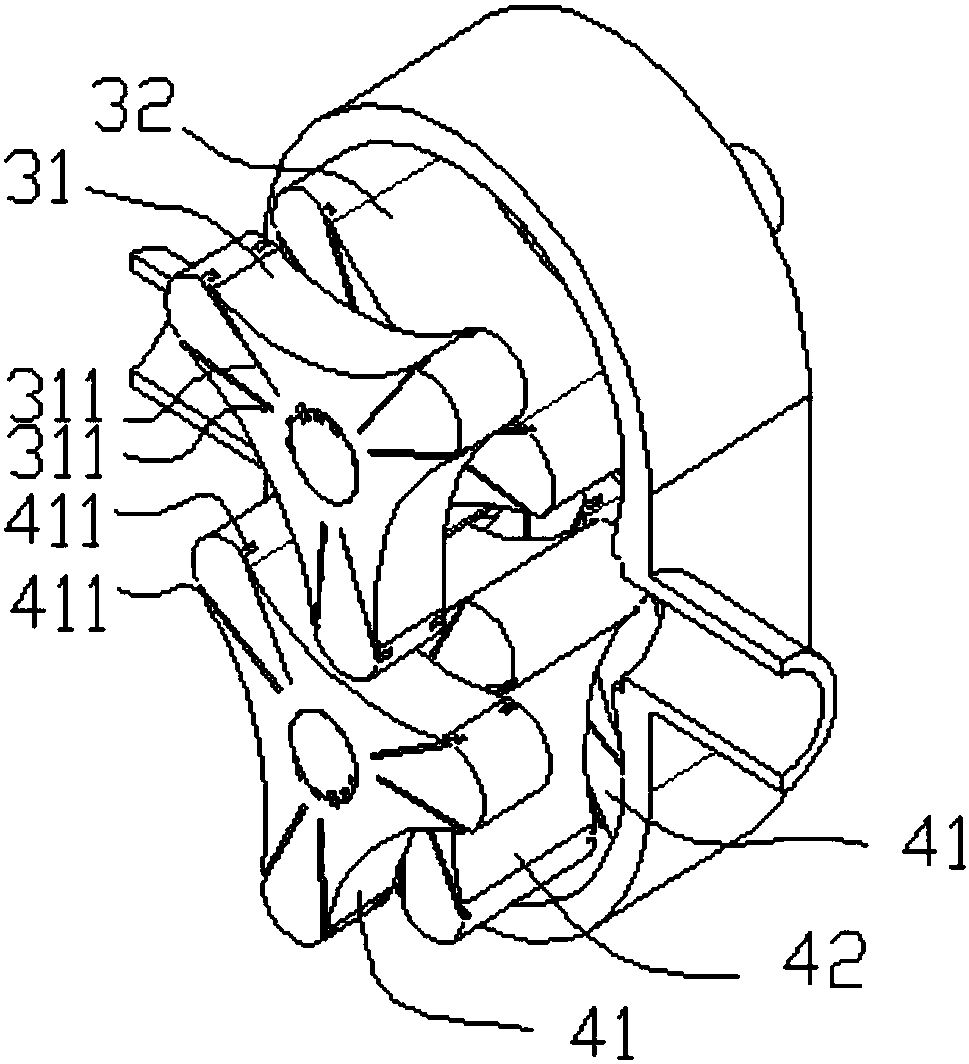

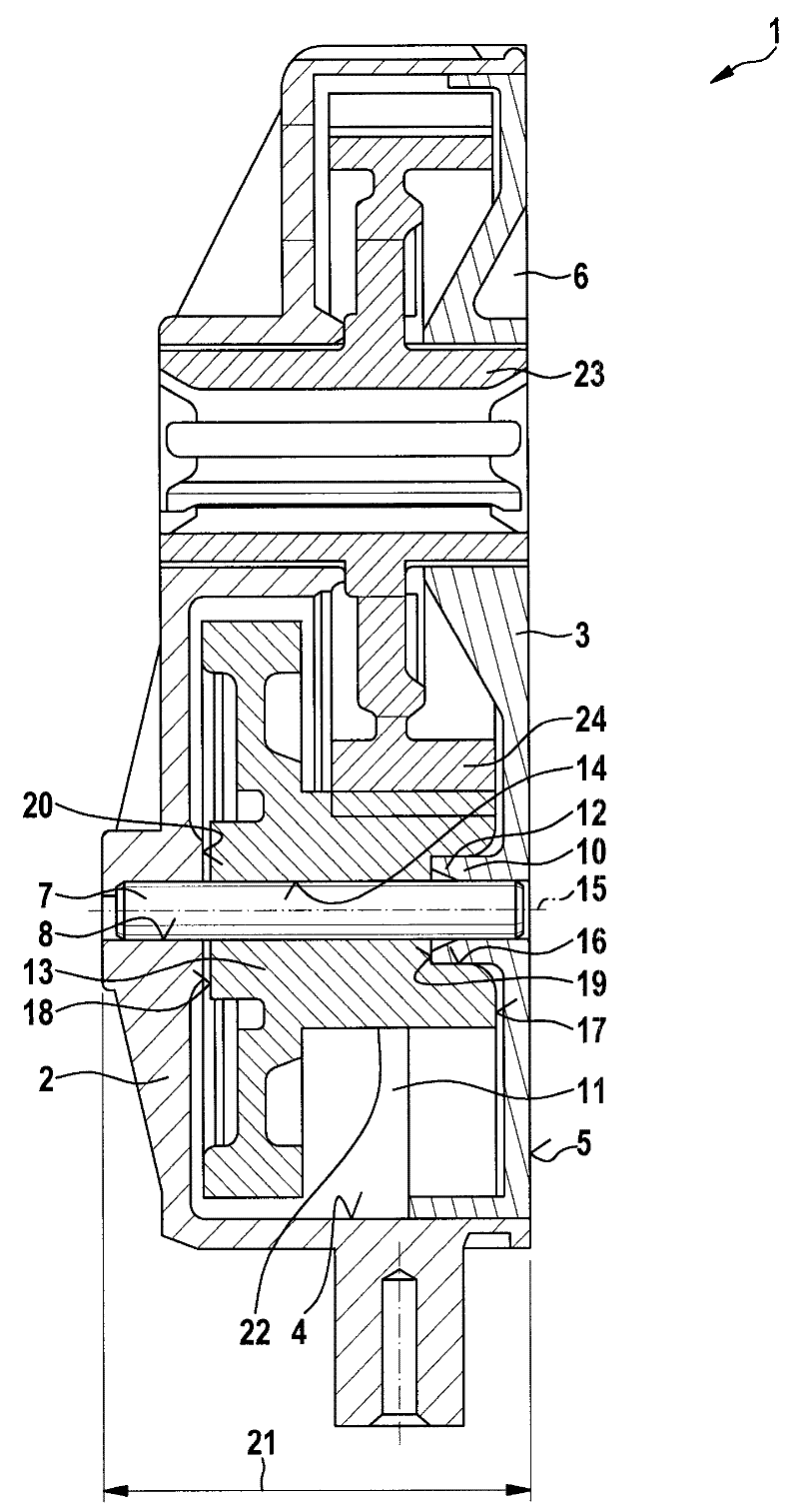

Prosthesis for partial replacement of a tubular bone

The invention relates to a prosthesis for at least partial replacement of a tubular bone and of an adjacent joint, comprising an elongate shaft (1) with a first end and a second end, and a joint mechanism (2) arranged at the second end of the shaft (1), wherein a length-adjusting mechanism (3) is provided which actuates the shaft (1) along the axis (10) thereof in the manner of a telescope.

Owner:WALDEMAR LINK GMBH & CO

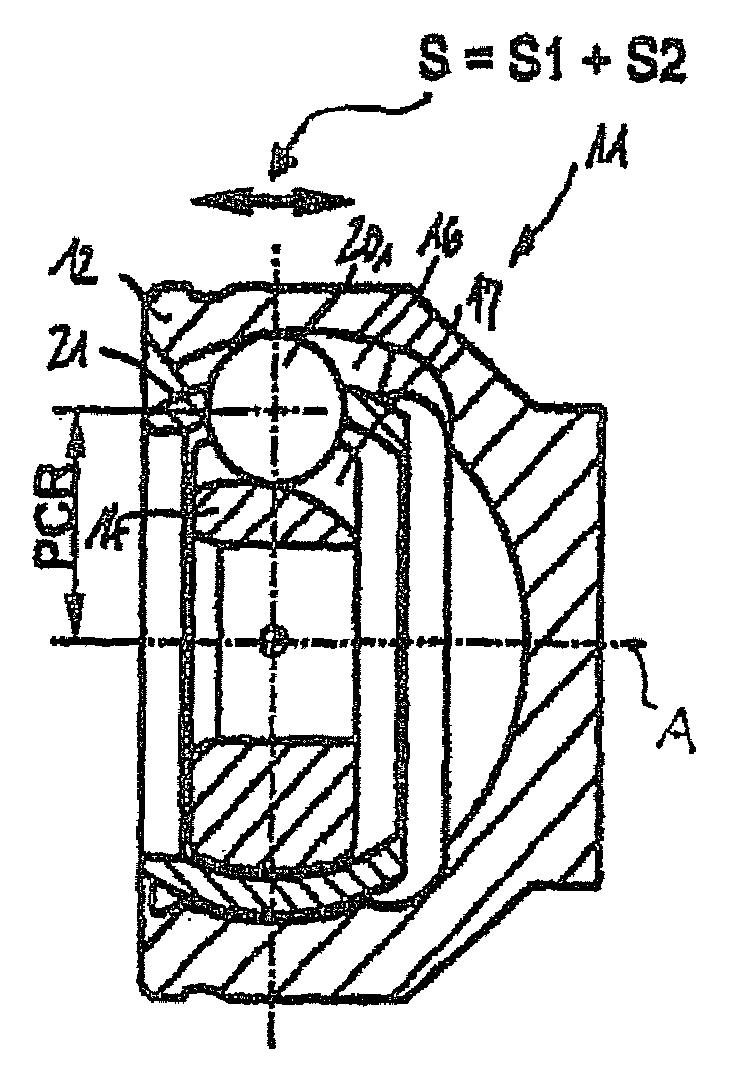

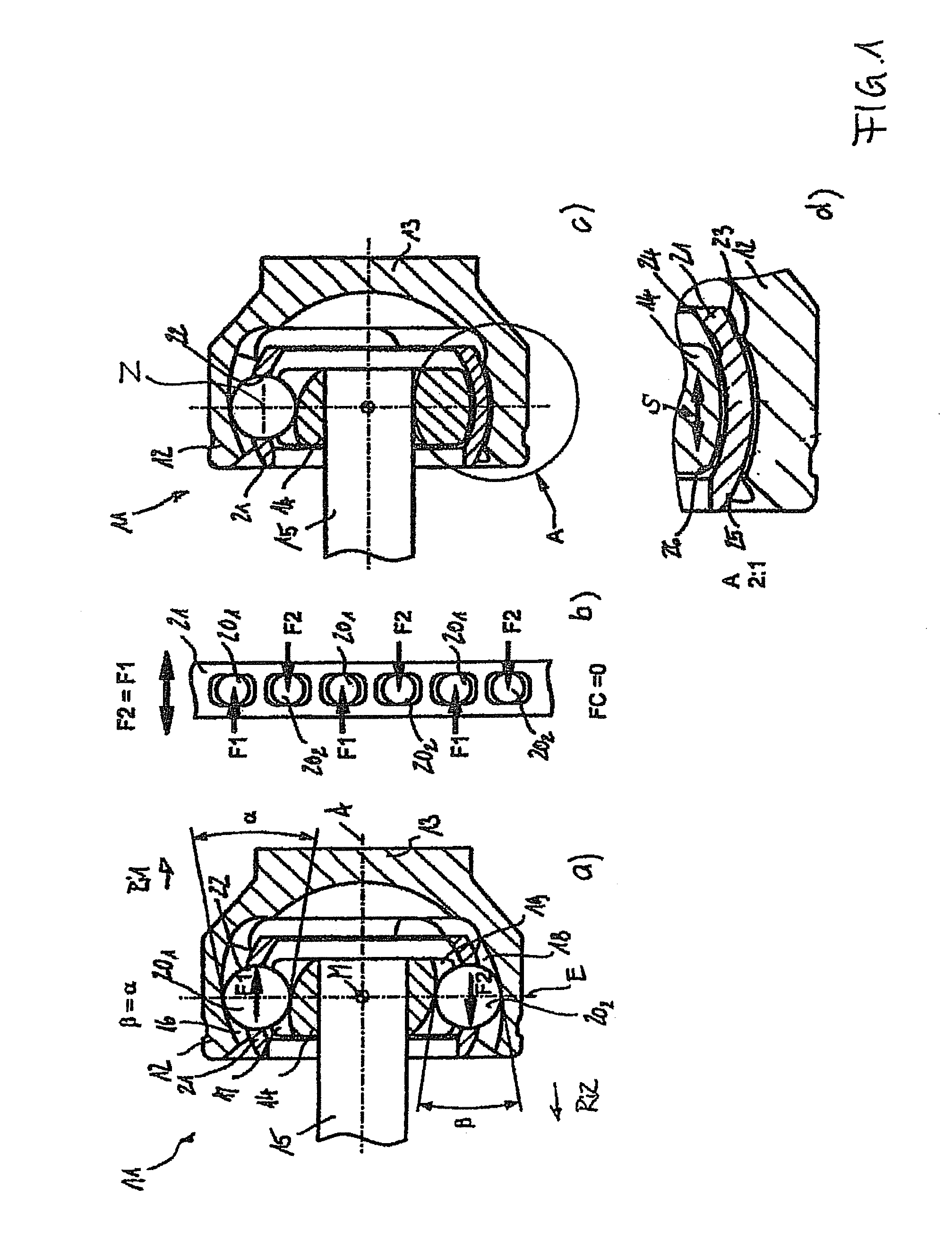

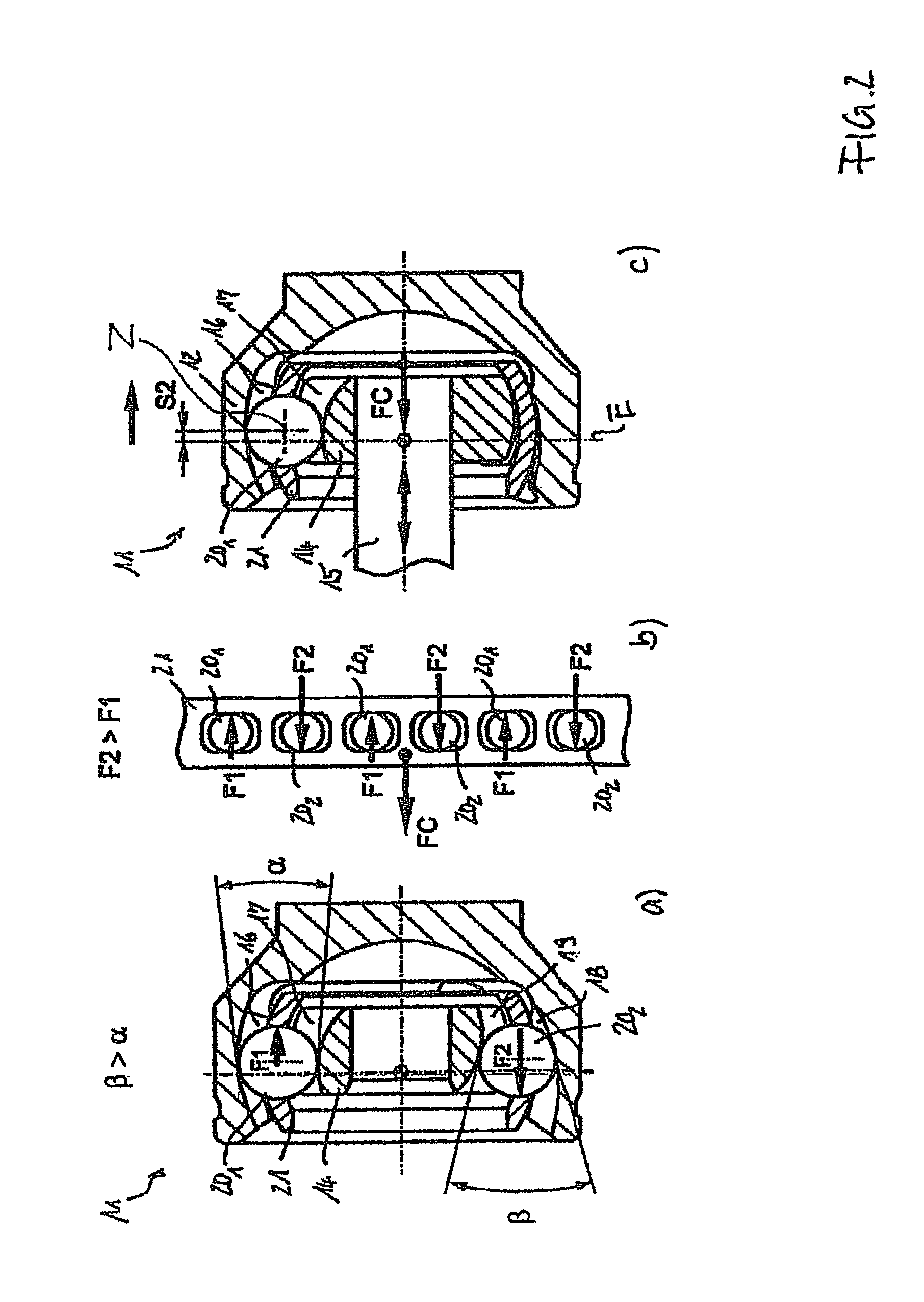

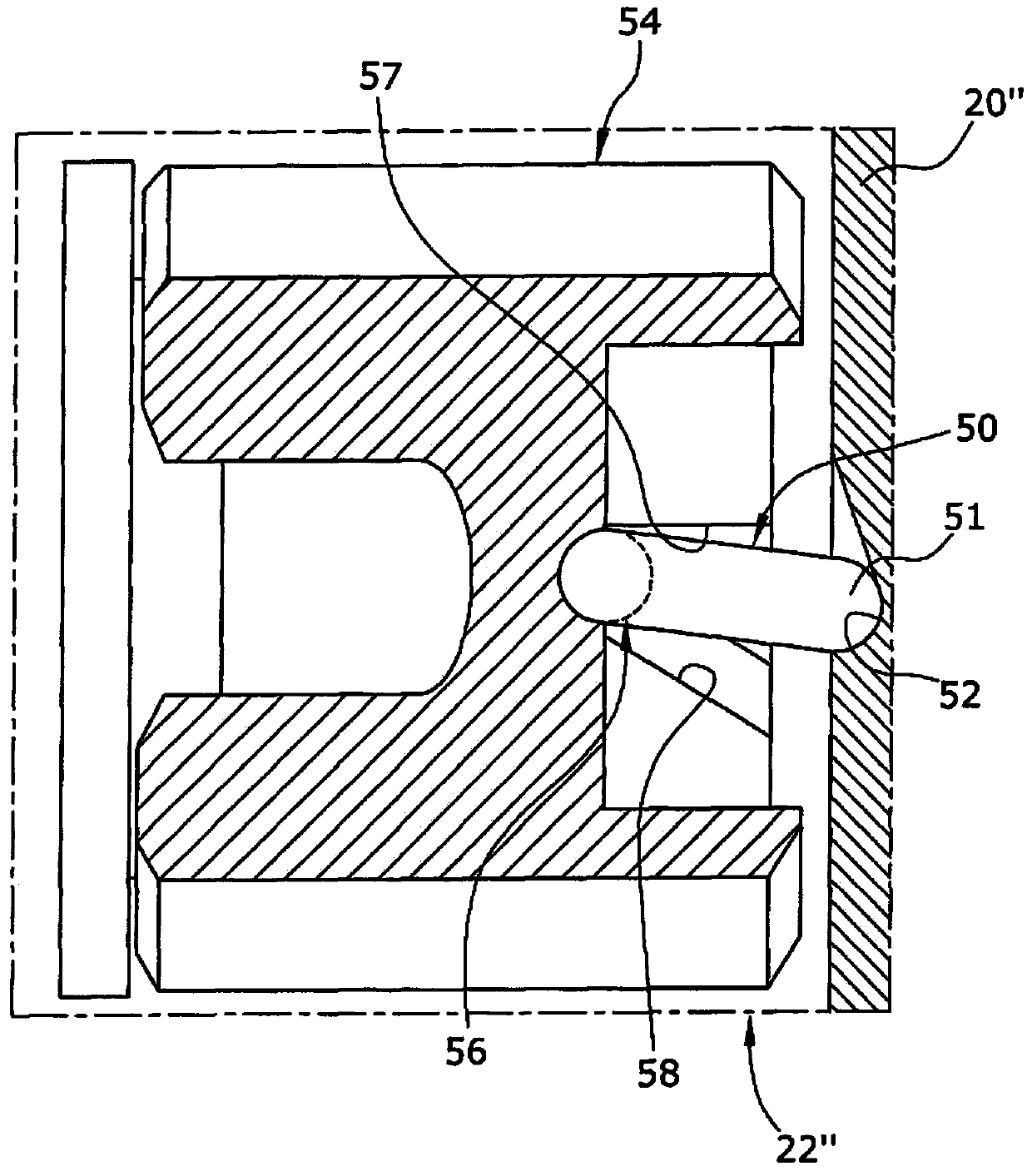

Driveshaft comprising a counter track joint featuring a delimited axial displacement path

InactiveUS7621816B2Avoid axial forceConducive to simplificationYielding couplingShaftsAxial displacementEngineering

A constant velocity universal ball joint 11 having first and second outer ball tracks 16, 18, and first and second inner ball tracks 17, 19, forming first pairs of tracks 16, 17 which widen in a first axial direction Ri1 (alpha), and forming second pairs of tracks 18, 19 which widen in a second axial direction Ri2 (beta). Balls 20 are guided in the pairs of tracks and have centers Z positioned on a pitch circle radius PCR around a joint centre M. A ball cage 21 holds the balls 20 in a common central plane E on to the angle-bisecting plane when the joint is articulated. There is provided an axial clearance permitting a relative axial displacement S wherein, when in the aligned condition, the ratio between the axial clearance S and the pitch circle radius PCR ranges between 0.01 and 0.09 (0.01<S / PCR<0.09).

Owner:GKN DRIVELINE INT GMBH

Double return journey barrel type drying machines

InactiveCN100573003CAvoid axial forceAvoid stress deformationDrying solid materials with heatDrying chambers/containersHelical lineHorizontal axis

An improved double-return cylinder dryer, including a body composed of a bracket, a sealed box and a cylinder, and its driving device, supporting device and controller, wherein the axis of the cylinder of the body is parallel to the horizontal plane, and the cylinder is arranged concentrically. The inner and outer cylinders are misplaced and fitted together, and the volume cavities formed constitute two drying and precipitation units respectively. The outer periphery of the cylinder wall board is provided with a heat insulation cover, and the inner peripheral surface of the inner and outer cylinder wall boards is respectively provided with a spiral propulsion type distribution device, and the direction of the helix is reversed. The center of gravity of the ring gear and the barrel is assembled. It effectively solves the defects of easy deformation and displacement and axial displacement of traditional drum dryers. It has reasonable structural design, stable performance, smooth process flow, large precipitation at one time, high thermal efficiency, energy saving and consumption reduction, and a wide range of applications. .

Owner:沈阳清井环保机械工程有限公司

Three return journey barrel type drying machines

InactiveCN100570253CAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineThermal insulation

An improved three-pass cylinder dryer, including a body composed of a bracket, a sealed box and a cylinder, and its driving device, supporting device and controller, wherein the axis of the cylinder of the body is parallel to the horizontal plane, and the cylinder is arranged concentrically. The inner, middle and outer cylinders are misplaced and fitted together, and the volume cavities formed constitute three drying and dewatering units respectively. The adjacent wall panels of the inner, middle and outer cylinders are adjusted by supporting and reinforcing buffer pads. Connection and positioning, the outer circumference of the outer cylinder wall board is provided with a heat insulation cover, and the inner peripheral surface of the inner, middle and outer cylinder wall boards is respectively provided with a spiral propulsion spreader, and the rotation of the helix On the contrary, the ring gear on the outer periphery of the machine body is assembled with the center of gravity of the barrel. It effectively solves the defects of easy deformation and displacement and axial displacement of traditional drum dryers. It has reasonable structural design, stable performance, smooth process flow, large precipitation at one time, high thermal efficiency, energy saving and consumption reduction, and a wide range of applications. .

Owner:沈阳清井环保机械工程有限公司

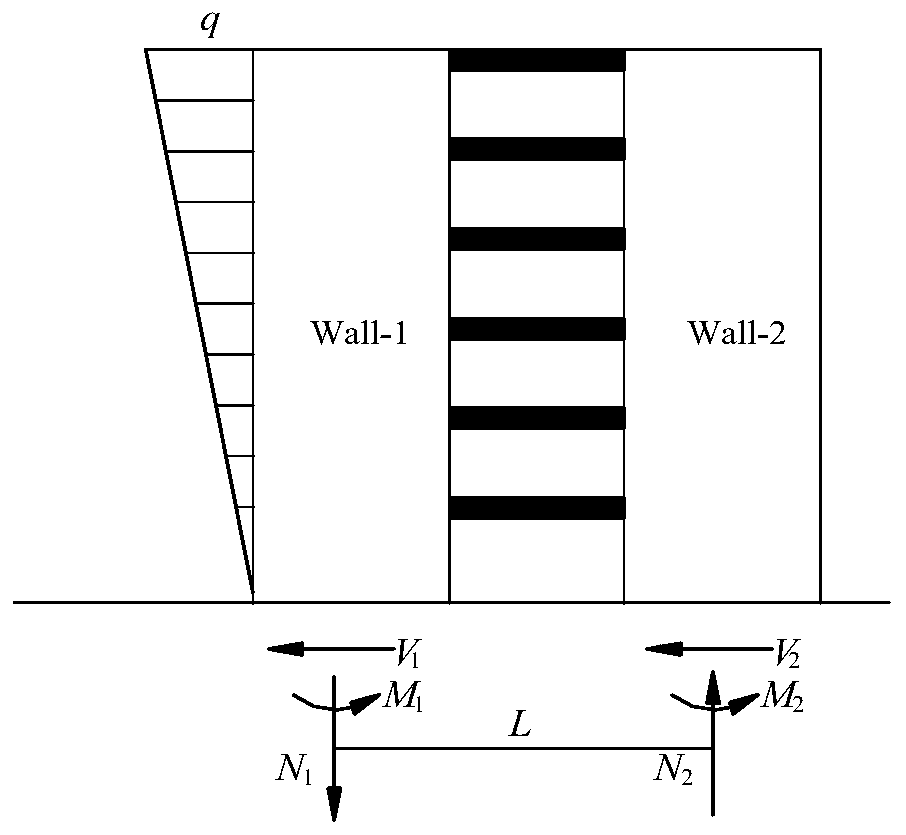

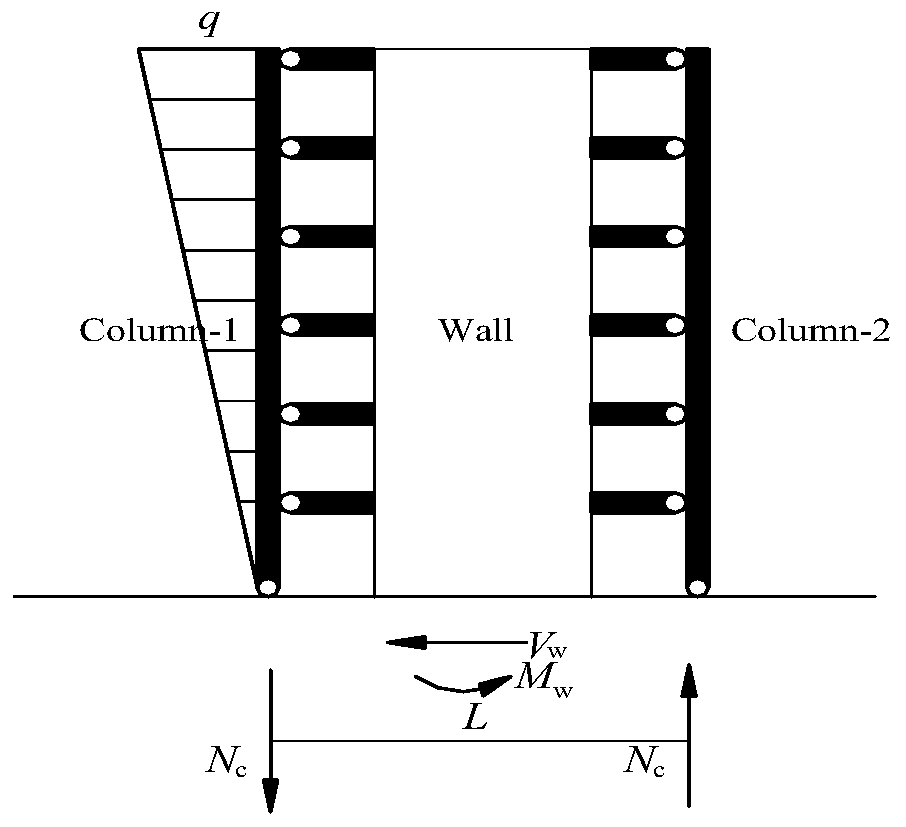

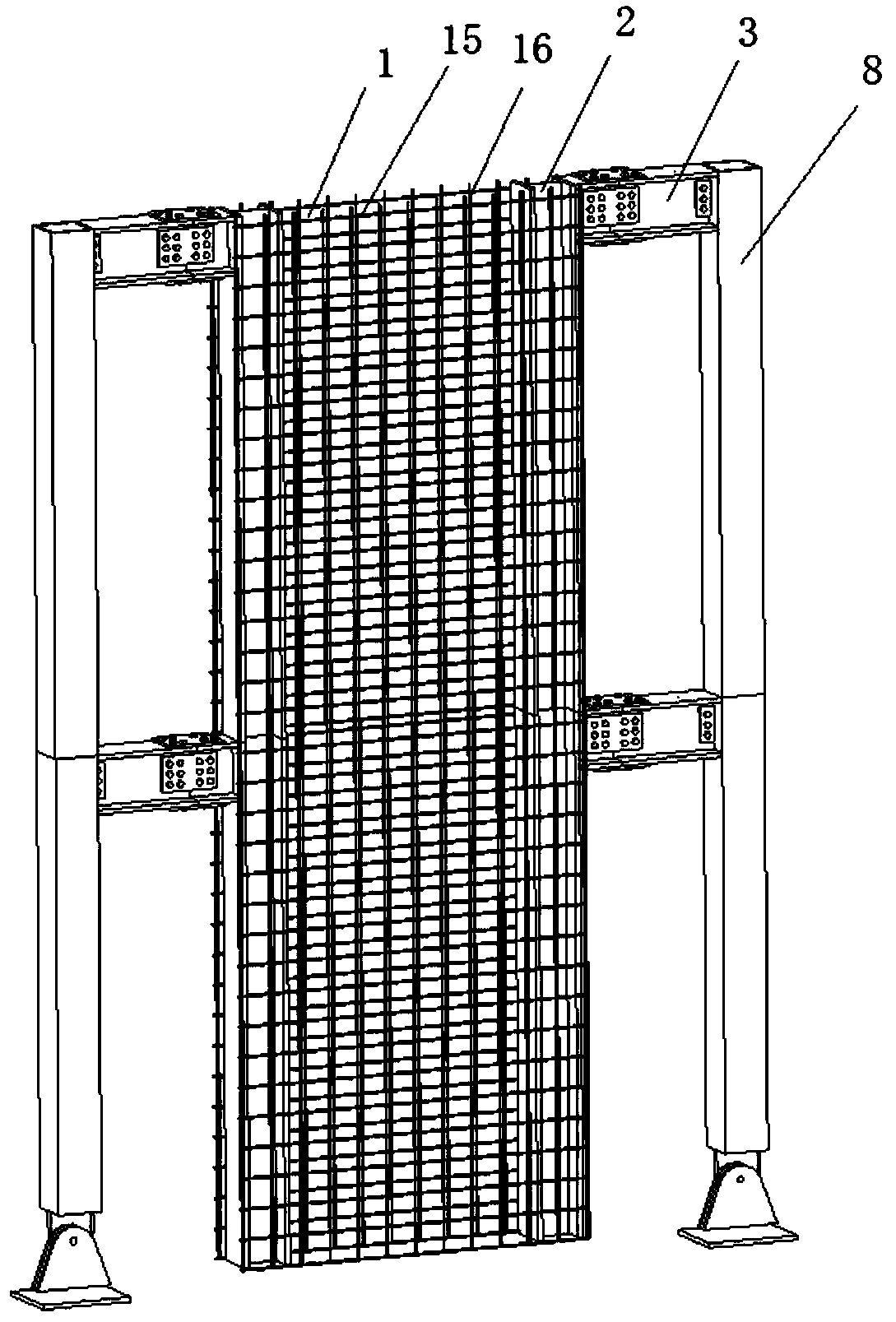

Swing column-hybrid limb-connected wall structure capable of restoring after being damaged in earthquake and assembly method

InactiveCN111236488ADamage is easy to controlDamage controlWallsProtective buildings/sheltersAxial forceCoupling beam

The invention discloses a swing column-hybrid limb-connected wall structure capable of restoring after being damaged in an earthquake and an assembly method. According to the swing column-hybrid limb-connected wall structure capable of restoring after being damaged in the earthquake and the assembly method, a reinforced concrete wall only generates a bending moment and shear force, axial force generated at the bottoms of wall limbs under the coupling effect is avoided, the energy dissipation requirement for a reinforcing region at the bottom of a shear wall is effectively lowered, damage to the wall limbs can be controlled more easily, the original axial force of the wall limbs is transferred to swing columns on the two sides, brittle shear damage to the wall limbs of the reinforced concrete wall under tension can be effectively avoided as long as the stability of the swing columns can be guaranteed under stress, and force transmission is simple and reliable. According to the swing column-hybrid limb-connected wall structure used as a first defense line for earthquake fortification, a steel coupling beam is good in ductility and high in energy dissipation capacity; a joint connection manner beneficial to replacement is adopted, so that disassembly is easy, and operation is simple; all fixing parts are of a detachable structure and can be re-spliced and re-connected after the energy-dissipation coupling beam is replaced, so that construction and post-earthquake consolidation are made very convenient.

Owner:XI'AN PETROLEUM UNIVERSITY

Cylindrical cutter

The invention relates to a cylindrical cutter, the roller body of which comprises grooves provided along the length thereof at a distance from one another and at an angle to the longitudinal axis. Indexable inserts, particularly coated hard metal inserts, are disposed in the grooves. In order to largely prevent axial forces from acting on the milling cutter or on the material to be worked, either the grooves and thus the cutting edges of the indexable inserts are aligned sectionally at different angles, said angles being selected such that the axial forces generated in the one section during the milling process are neutralized or are reduced to a defined degree by the axial forces generated in the neighboring section, or the indexable inserts are disposed or aligned alternately in the grooves such that the axial force generated by one indexable insert during the milling process is neutralized by the axial force generated by the neighboring indexable insert.

Owner:SMS DEMAG AG

Assembling tool for assembling pump valve bearing and working method thereof

InactiveCN110883526AImprove assembly efficiencyImprove securityMetal working apparatusHydraulic cylinderAxial force

The invention discloses an assembling tool for assembling a pump valve bearing and a working method thereof. A pressing ring is fixedly arranged at the bottom end of a piston rod, when a clamping mechanism clamps the bearing to be assembled on a pump valve fixed on a support table, a hydraulic cylinder pushes the piston rod to move downwards, so that the piston rod drives a movable plate to move downwards, the pressing ring presses the bearing to be assembled downwards into the pump valve, and the bearing is clamped to the upper end of the pump valve before being assembled. Furthermore, in theprocess of pressing the bearing into the pump valve by the pressing ring, no extra clamp is arranged on the bearing, so that the bearing to be assembled cannot generate axial force with the pump valve in the downwards pressing process of the pressing ring, after the bearing is pushed into the pump valve by the pressing ring to complete assembly, the bearing cannot have staggered force with the pump valve, the assembly efficiency of the pump valve is greatly improved, the operation safety of the bearing after assembly is improved, and the service life of the pump valve is prolonged.

Owner:合肥华升泵阀股份有限公司

Coaxial dual-electromagnetic fuel gas injection valve with flowing sectional area adjustable

ActiveCN107091362AAvoid axial forceQuick responseOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure balance

The invention aims at providing a coaxial dual-electromagnetic fuel gas injection valve with the flowing sectional area adjustable. The adjustable gas injection flow is achieved through a dual-valve-element dual-electromagnet control structure. The air inflowing and flow guiding process is achieved through a bypass structure and a flow guiding cavity structure; valve element control and gas way control are achieved through actuator control, and a gas injection function is achieved; through cooperation of an external guiding structure, an internal flow guiding cavity and a pressure balancing groove, the perpendicularity of a valve element is guaranteed, stable and reliable work of gas flow is achieved, and the high responding speed is achieved; through a mixed gas inflowing mode of combining direct gas inflowing of an axial main gas groove and gas inflowing of circumferential gas supplementing holes, high flow is achieved, the gas supplying efficiency of an engine is effectively improved, and meanwhile gas flow interference can be avoided, so that gas way stability is achieved; face sealing and high reliability of the fuel gas injection valve are achieved through multiple annular strip structures between the valve element and a valve base.

Owner:HARBIN ENG UNIV

Assembly tool and assembly method of circlip for hole

The invention discloses an assembly tool and assembly method of a circlip for a hole. The tool comprises a guide column and a press fitting rod, the longitudinal section of the guide column is in a U type, the press fitting rod is provided with an annular boss, a through hole is formed in the center of the guide column, the guide column is inverted so that the U-type opening can be downward, the press fitting rod is sleeved with the guide column, the annular boss is in butt joint of the inner bottom wall of the guide column, the diameter of the annular boss is slightly smaller than the diameter of a workpiece hole of the to-be-installed circlip for the hole, and the diameter of the lower end of the press fitting rod is smaller than the aperture of the to-be-installed circlip for the hole. The invention further discloses an assembly method using the assembly tool. The assembly tool has the advantages that a guide sleeve serves as a limiting device, the circlip is pushed by the press fitting rod to overcome axial force to be assembled in a workpiece, the circlip is stable to move, the assembly tool is simple in structure and can be automatically controlled, a special circlip installation machine is not needed, cost is reduced, use is convenient, the assembly process is convenient and easy, and remodeling is quick.

Owner:DANFOSS POWER SOLUTIONS (JIANGSU) CO LTD

Separating device for removing solid particles from liquid and gas flows for high differential pressures

ActiveCN106574494AAvoid axial forceGuaranteed filtering effectFluid removalFiberDifferential pressure

Owner:3M INNOVATIVE PROPERTIES CO

Novel buckling energy consumption support

InactiveCN106593060ALight weightAdditional load is smallProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention discloses a steel and wood buckling energy consumption support and belongs to the technical field of structural engineering. The buckling energy consumption support comprises a core force bearing steel plate, a periphery constraint part and a no-bonding layer, wherein the main body part of inner core force bearing steel plate is in a linear shape. Connecting sections and transition sections at the two ends of the inner core force bearing steel plate are welded to an auxiliary connecting plate to form a cross-shaped cross section. The periphery constraint part is composed of a wood block wrapped with a steel plate and a CFRP material wrapped transversely in the length direction of a member together. The no-bonding layer is arranged between the core steel plate and the constraint wood block. The invention belongs to the technical field of civil engineering structural damping. Hysteretic energy performance of the steel support member under the effect of a strong earthquake is obviously improved. Compared with the prior art, the process of twining the CFRP outside is adopted in the steel and wood buckling energy consumption support, the structure is compact, the economical and practical effects are achieved. A constraint unit is made of light weight timber, so that the shortcoming that the self weight of a traditional buckling preventing energy consumption support is large is overcome. The steel and wood buckling energy consumption support is easy to machine, is convenient and flexible to use, and has wide market popularizing prospects.

Owner:TONGJI UNIV

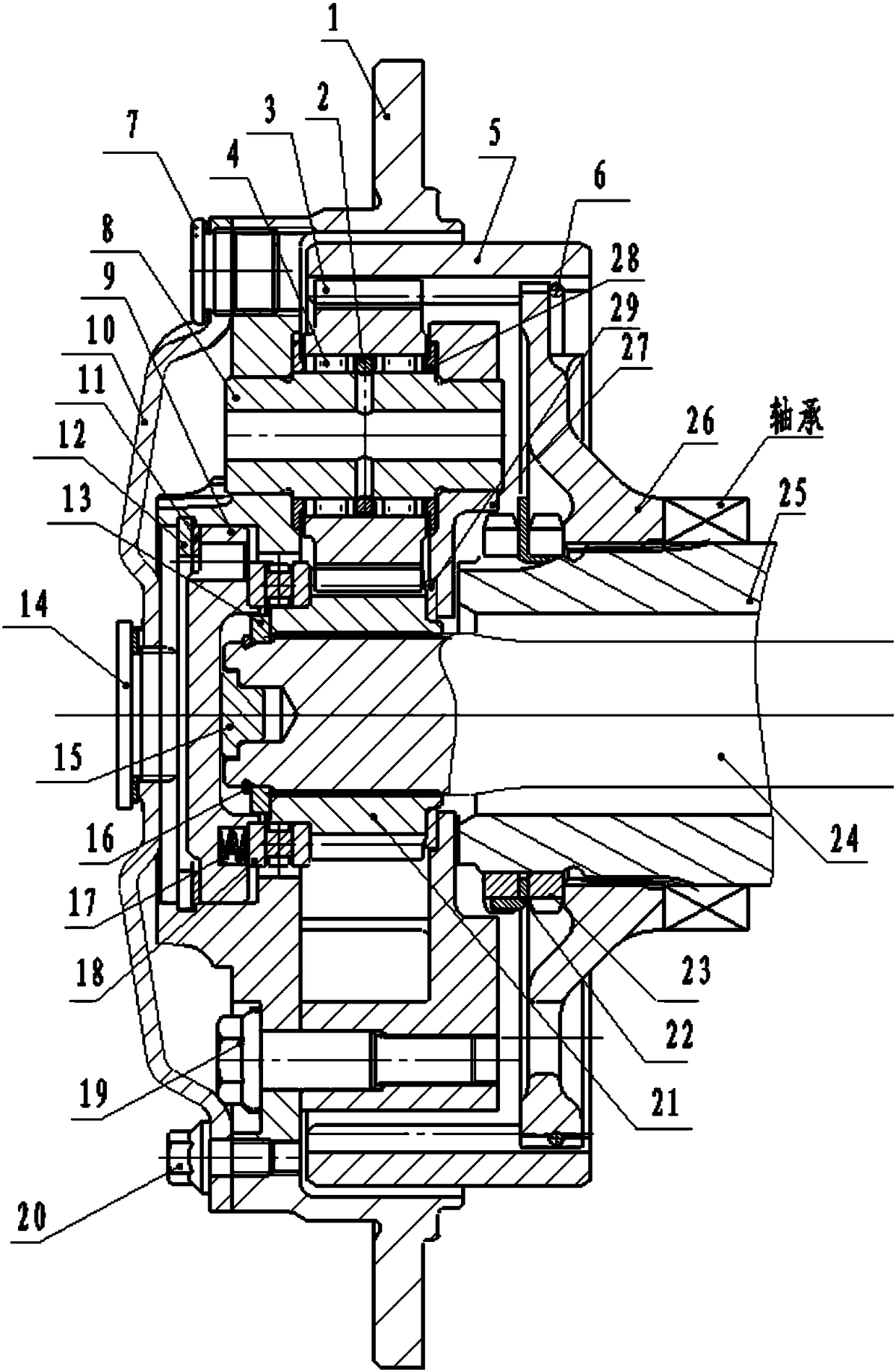

Planetary reducing structure of bevel wheel of steering drive axle

InactiveCN108167395AHigh coincidenceImprove bearing capacityToothed gearingsRolling resistanceGear wheel

The invention discloses a planetary reducing structure of a bevel wheel of a steering drive axle. The structure comprises a thrust bearing(18), a spring (17), a bell-shaped hub (1), a planetary bracket (27), a thrust washer (28), a helical tooth gear ring bracket (26), a kingpin (4), a space ring (2), a fixed steel wire ring spring (6), an adjusting pad (11), a retainer ring (13), a helical toothsun wheel (21), a helical planetary gear (3), a helical internal tooth gear ring (5) and a helical tooth gear ring bracket (26). A straight tooth planetary reducing mechanism is optimized, and meanwhile, a steering function is added to the helical tooth planetary reducing mechanism, so that the axial fore is overcome effectively. Meanwhile, the axial force is converted into a force of rolling friction effectively, so that the power loss is reduced, and furthermore, the helical planetary reducing mechanism of the drive axle with the steering function is additionally arranged.

Owner:BEIBEN TRUCKS GRP

Totally closed guide device for oblique rolling three-roll piecing mill for pipes

PendingCN108555035APass smoothlyAvoid axial forceGuiding/positioning/aligning arrangementsMechanical engineeringHollow cylinder

The invention discloses a totally closed guide device for an oblique rolling three-roll piecing mill for pipes. The totally closed guide device comprises a framework. A closed guide device is mountedon the framework and comprises a hollow cylinder, three grooves which are matched with the side walls of three rolls of the oblique rolling three-roll piecing mill are formed in the side walls of thecylinder, and pipe blanks can be arranged in the cylinder. The totally closed guide device for the oblique rolling three-roll piecing mill for the pipes has the advantages that tail triangles can be prevented when the pipe blanks are machined, pipe walls have uniform thicknesses, and the totally closed guide device is simple in equipment structure.

Owner:SHANXI CHUANGQI IND

Rotor pump

InactiveCN108591050AReduce axial loadExtended service lifeRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention discloses a rotor pump. The rotor pump comprises a pump body, a drive rotor, a driven rotor, connecting shafts and dowel pins, wherein the pump body is equipped with a liquid inlet and aliquid outlet; the liquid inlet and the liquid outlet are at the same height, and are isolated by the drive rotor and the driven rotor; the two connecting shafts are separately mounted in two rotaryshaft through holes of the pump body, and are separately fixed with the drive rotor and the driven rotor through the dowel pins; and the drive rotor or the driven rotor is formed by alternatively assembling a plurality of linear rotors. According to the rotor pump disclosed by the invention, the linear rotors are alternatively assembled, and rotor blade grooves are alternatively designed, so thatthe defect that a conventional rotor pump is limited in application and is high in using and maintaining cost is solved, and therefore, using and maintain cost is reduced, the pump body structure is not replaced and changed, and labor power and equipment expenditure are saved.

Owner:奥戈恩(广州)泵业有限公司

Transmission mechanism

ActiveCN102529753AImprove carrying capacityReduce manufacturing costsGearing controlMovable seatsMechanical engineering

Owner:ROBERT BOSCH GMBH

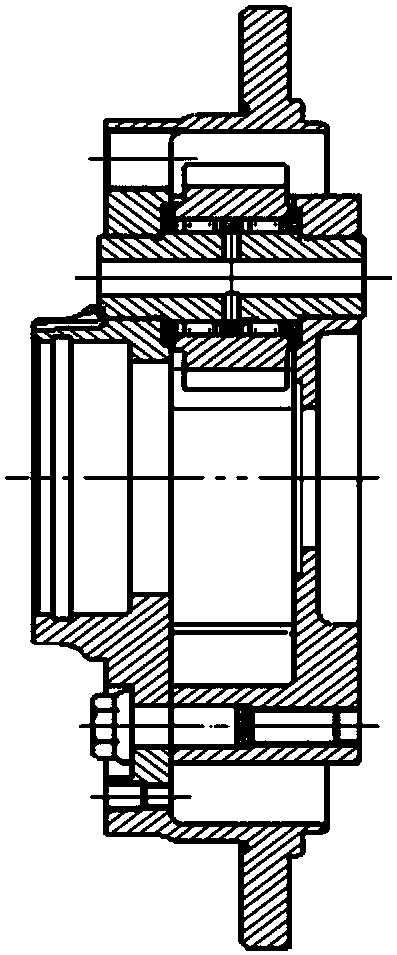

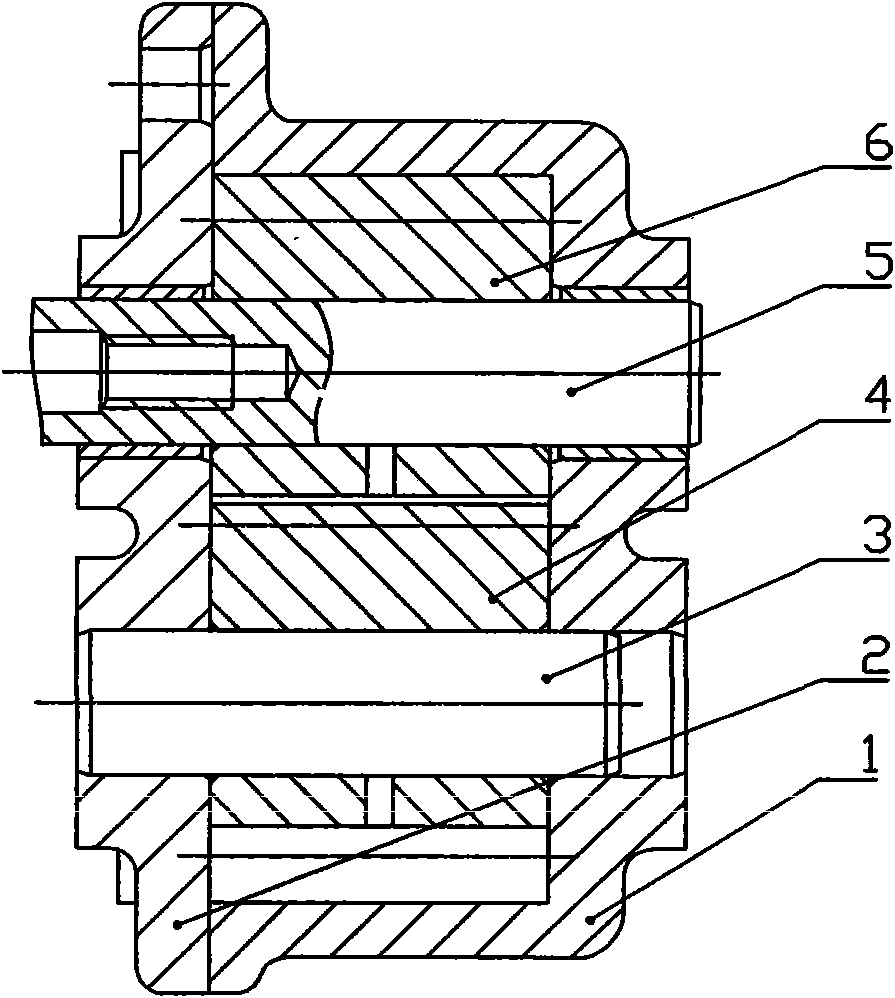

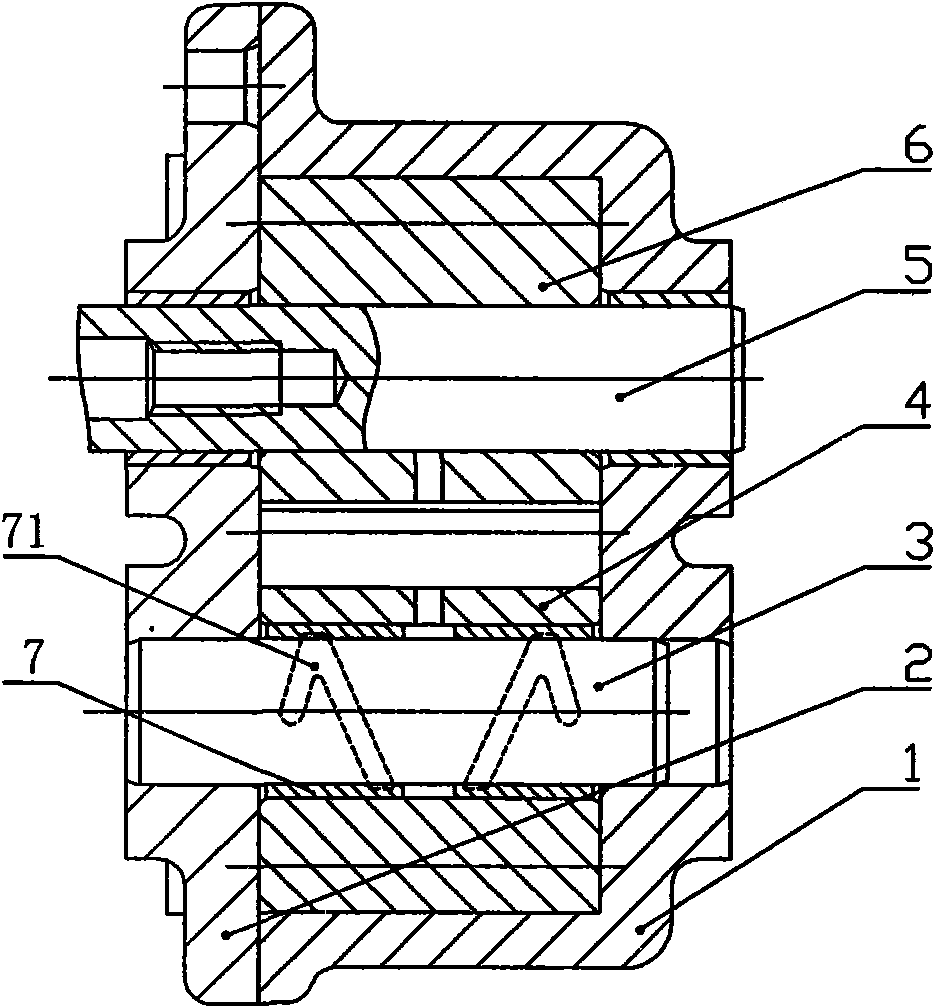

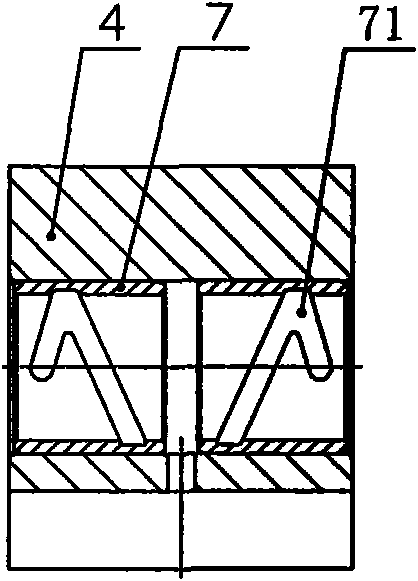

Double steel back lining lubricating pump

InactiveCN101539139AIncrease surface tensionAvoid axial forceRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention provides a double steel back lining lubricating pump. The pump comprises a pump body 1, a pump cover 2, a driven shaft 3, a driven gear 4, a driving shaft 5, a driving gear 6 and steel back linings 7, wherein the driving shaft 5 is arranged in shaft holes of the pump body 1 and the pump cover 2, and the middle part of the driving shaft 5 is in interference connection with the driving gear 6; the outer end of the driven shaft 3 is in interference connection with the pump cover 2, and the inner end of the driven shaft 3 is arranged in the shaft hole of the pump body 1; the driven gear 4 is sleeved on the middle part of the driven shaft 3 by the two steel back linings 7; and balance grooves 71 arranged on the inner surfaces of the two steel back linings 7 are opposite in direction. Because the driven gear 4 is sleeved on the driven shaft 3 by the two steel back linings 7, and the balance grooves 71 arranged on the inner surfaces of the two steel back linings 7 are opposite in direction, the steel back linings 7 can generate inward thrust while rotating, and the inward thrust and the outward thrust which is generated due to the pressure in a middle oil storage groove are kept balanced, so the scratch on the surface of the pump cover and abrasion of the shaft hole ends is avoided and the safety, reliability and service life of the lubricating pump are improved.

Owner:HUNAN OIL PUMP

Straight-through type outer guide gas injection valve with float valve seat

ActiveCN107143438AIn case of reverse leakageGuaranteed reliabilityInternal combustion piston enginesFuel supply apparatusEngineeringPressure balance

The invention aims to provide a straight-through type outer guide gas injection valve with a float valve seat. Through the float valve seat structure, the function of avoiding reverse leakage caused by unbalanced pressures inside and outside the gas injection valve is achieved, and the operation reliability of the gas injection valve is ensured; the gas inlet and flow guiding processes are achieved through a straight-through structure and a flow guiding cavity structure; control over a valve element and a gas path is achieved through control of an actuator, and the gas injection function is achieved; through cooperation of an outer guide structure, a pressure balance hole and a pressure balance groove, the verticality of the valve element is ensured, stable operation and reliable operation of gas flow are achieved, and the high response speed is achieved; through a mixed gas inlet mode of axial main gas groove direct gas inlet and circumferential supplementation hole gas inlet, high flow is achieved, the gas supply efficiency of an engine is effectively improved, meanwhile, gas flow interference can be avoided, and gas path stability is achieved; and through a plurality of annulus structures between the valve element and the valve seat, face seal of the gas injection valve is achieved, and the high reliability is also achieved.

Owner:HARBIN ENG UNIV

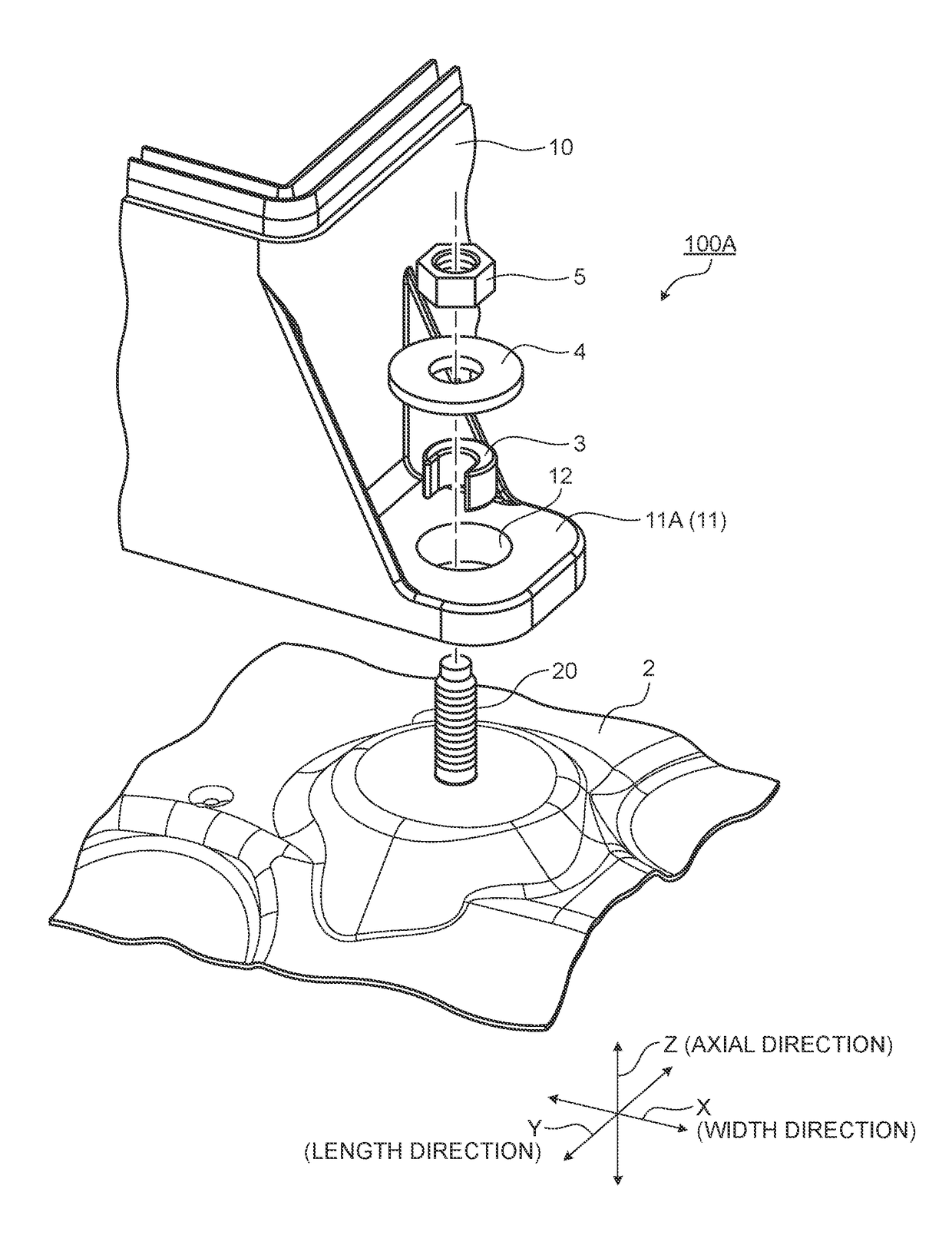

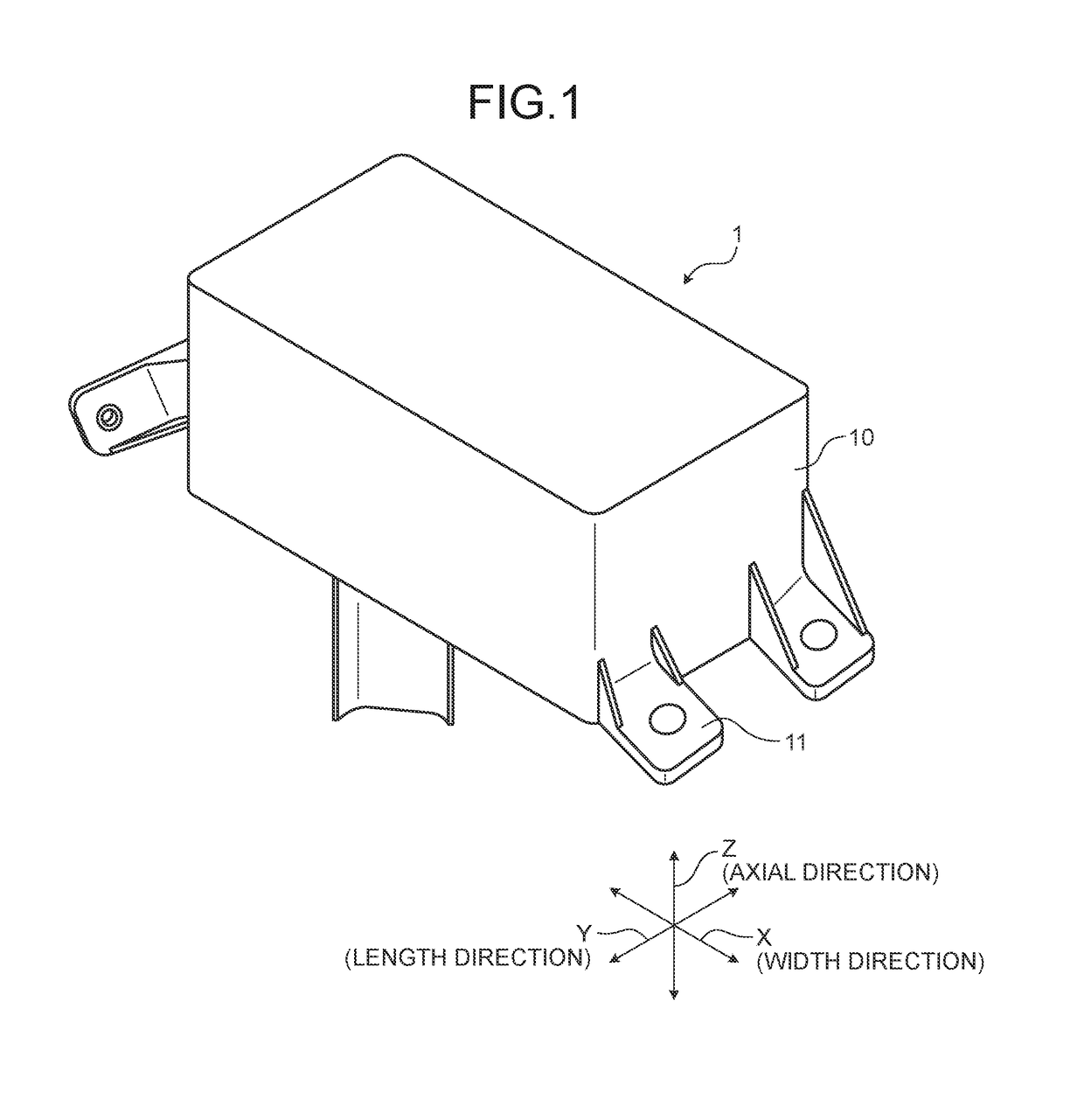

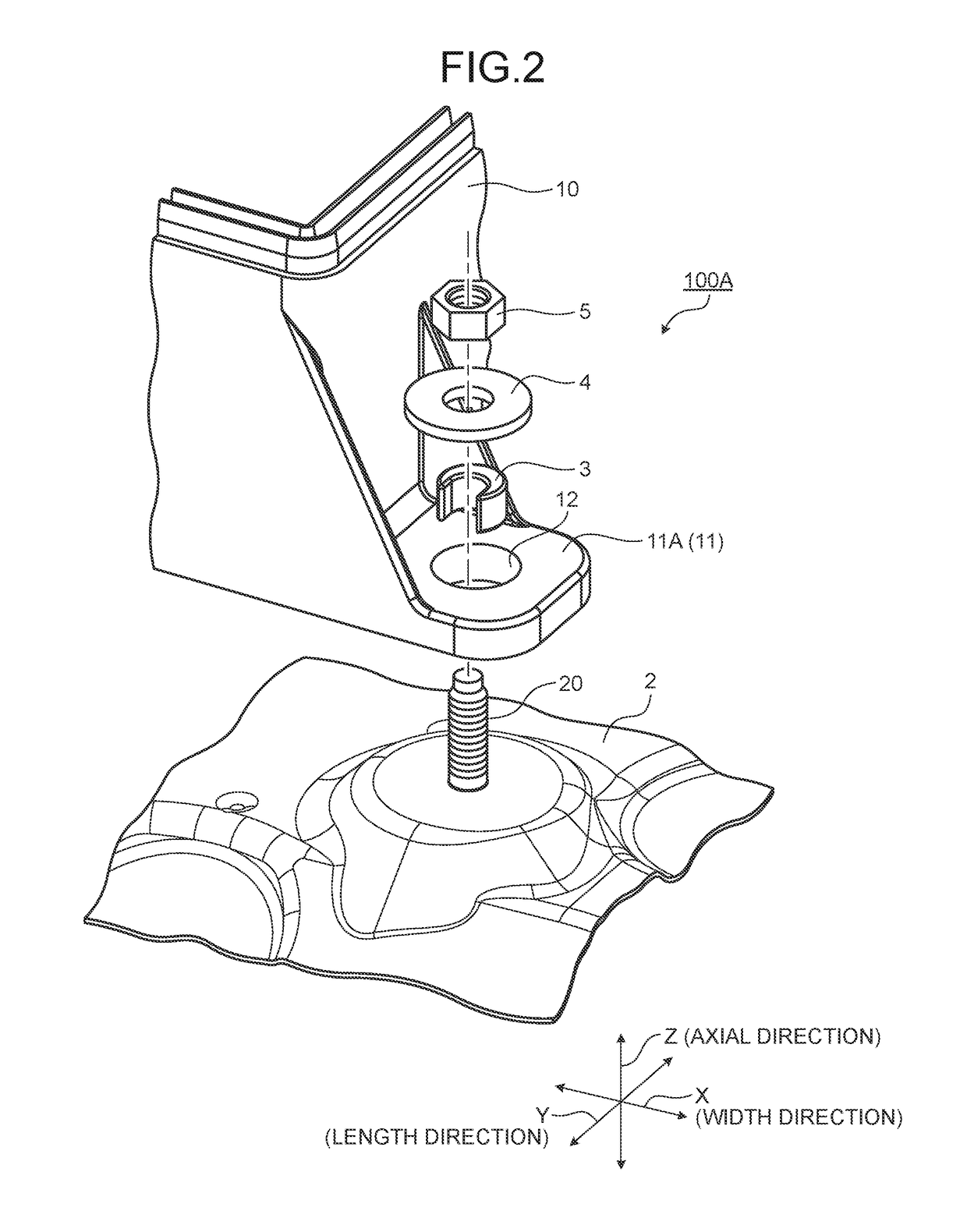

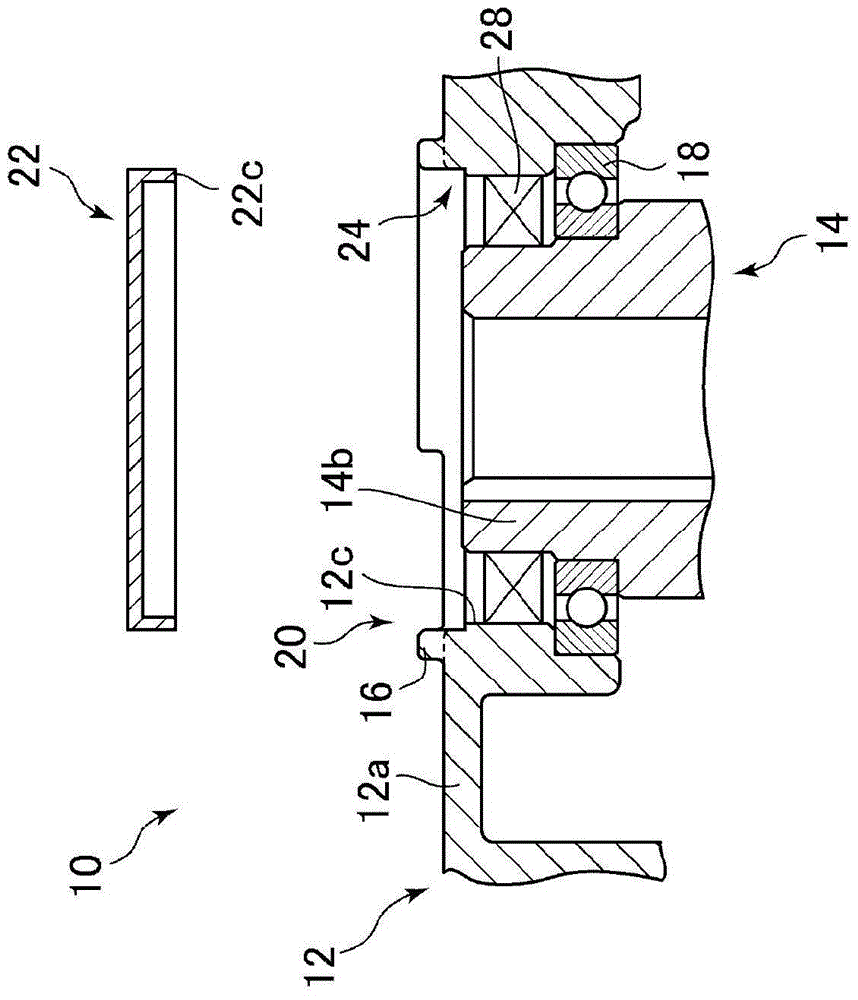

Fixing structure and electrical connection box

ActiveUS20180102635A1Avoid axial forceElectrical apparatusElectric/fluid circuitElectrical connectionEngineering

A fixing structure includes an attaching portion, a nut, and a spacer. The attaching portion has an attaching hole through which an attaching bolt provided to a vehicle body is inserted. The nut fixes the attaching portion to the vehicle body by being tightened to the attaching bolt with a washer interposed between the nut and the attaching portion. The spacer is disposed between an inner circumferential surface of the attaching hole and an outer circumferential surface of the attaching bolt, and is in contact with the vehicle body and the washer in an axial direction of the attaching bolt in a state where the attaching bolt and the nut are tightened. The spacer has an opening on a cylindrical side surface thereof and is capable of rotating around the axial direction of the attaching bolt in a state where the attaching bolt is inserted into the opening.

Owner:YAZAKI CORP +1

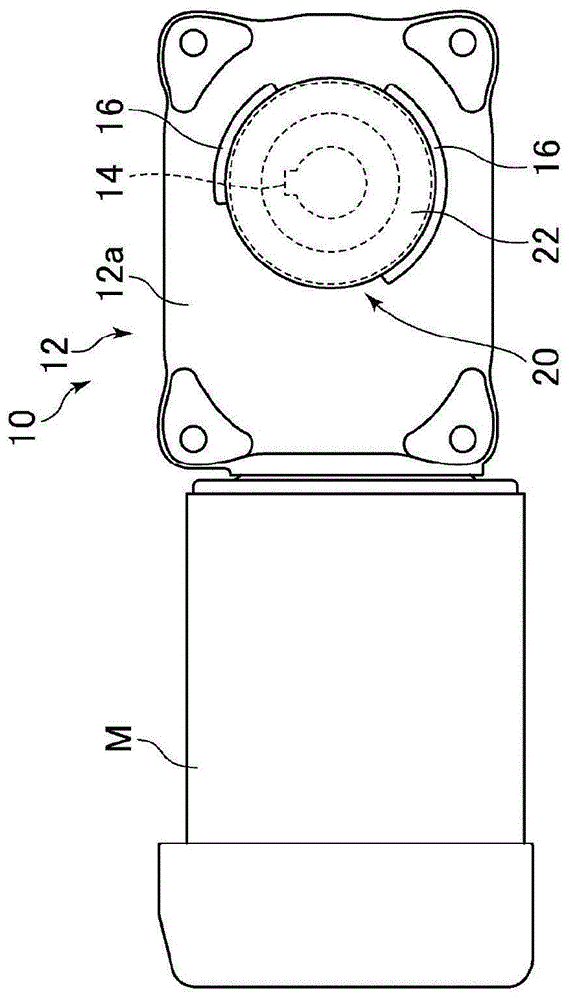

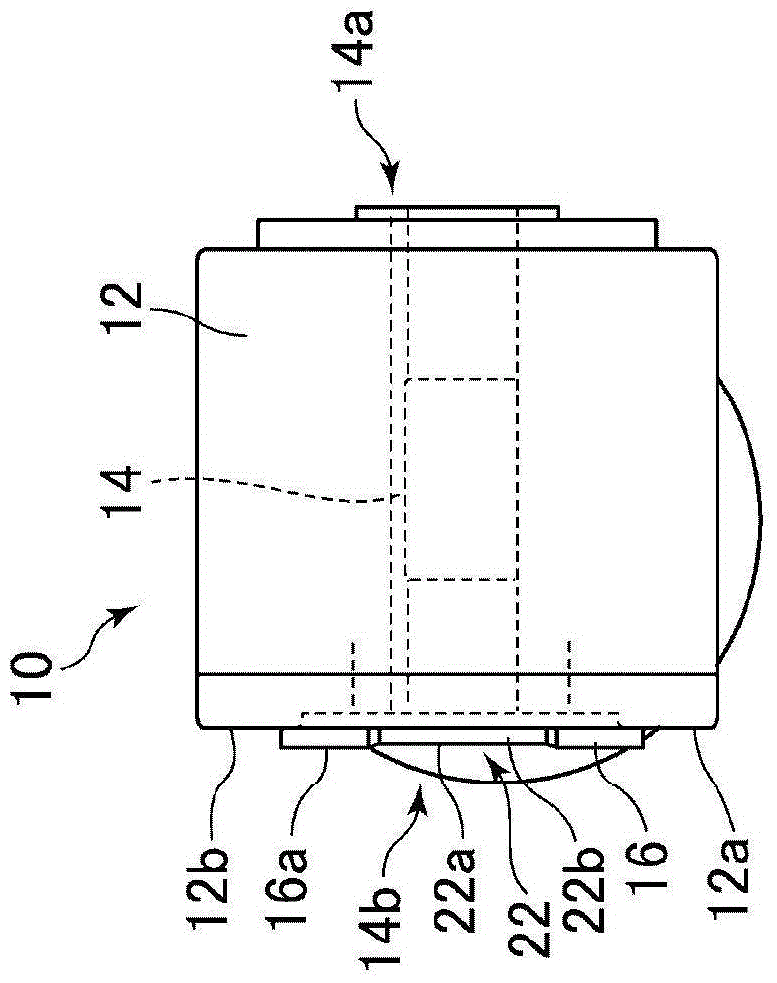

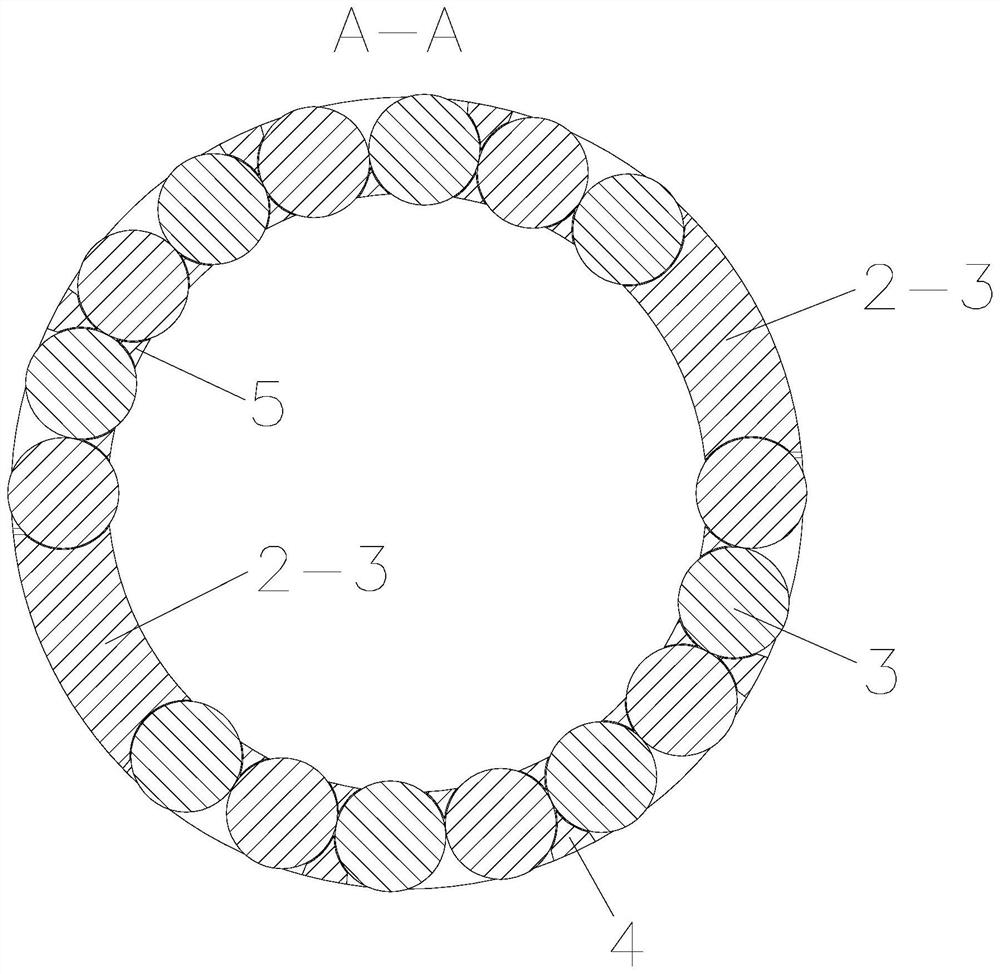

Speed reducer

The invention provides a speed reducer which can simply assemble and unassemble a shaft end cover, in which the shaft end cover can not accidently fall off, and the manufacture cost is relative low. The speed reducer (10) is provided with a round opening part (20) coaxial with a hollow output shaft (14) and having a radial direction size more than an external diameter of an oil seal (28) at a wall part (12a) of the exposure side of the end (14b) of the hollow output shaft (14) of a housing (12). Non-continuous projection strip parts (16) projecting from an external wall surface (12b) of the wall part (12a) are arranged in the peripheral direction at the edge of the opening part (20). A shaft end cover (22) is embedded in the opening part (20). The surface (22a) of the shaft end cover (22) is arranged between end faces (16a) of the projection strip parts (16) and external wall faces (12b) of the wall part (12a), thus the shaft end cover (22) can be simply assembled and unassembled, the shaft end cover (22) won't accidently fall off, and the manufacture cost is relative low.

Owner:TSUBAKIMOTO CHAIN CO

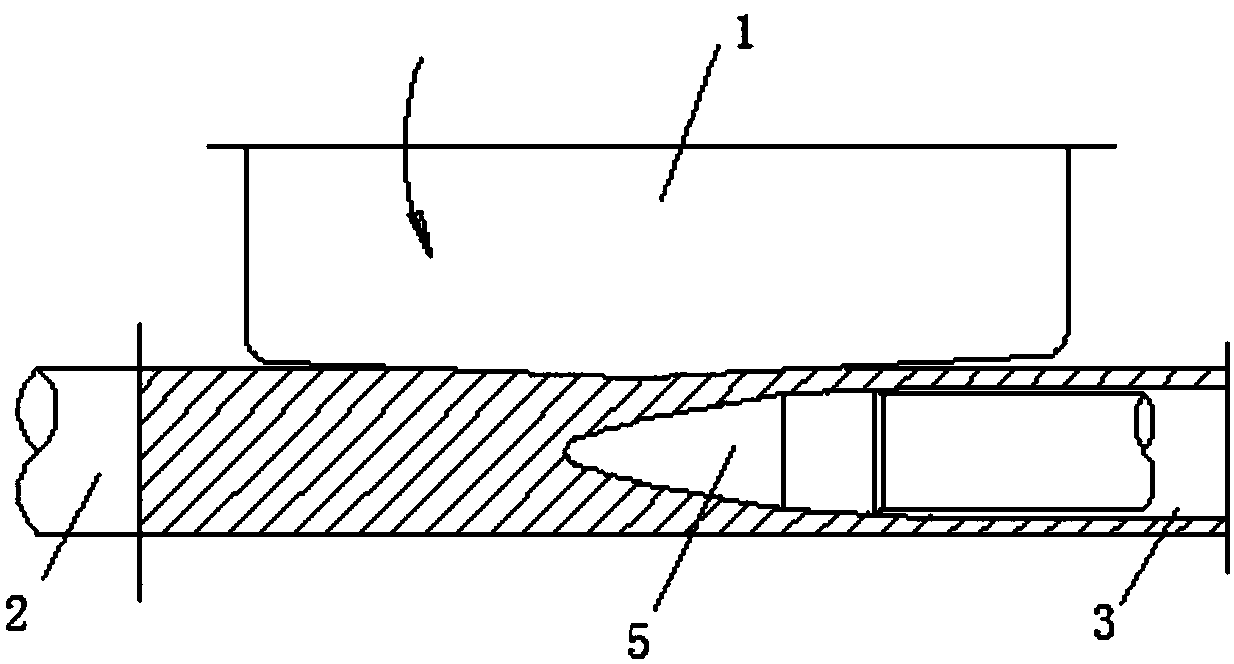

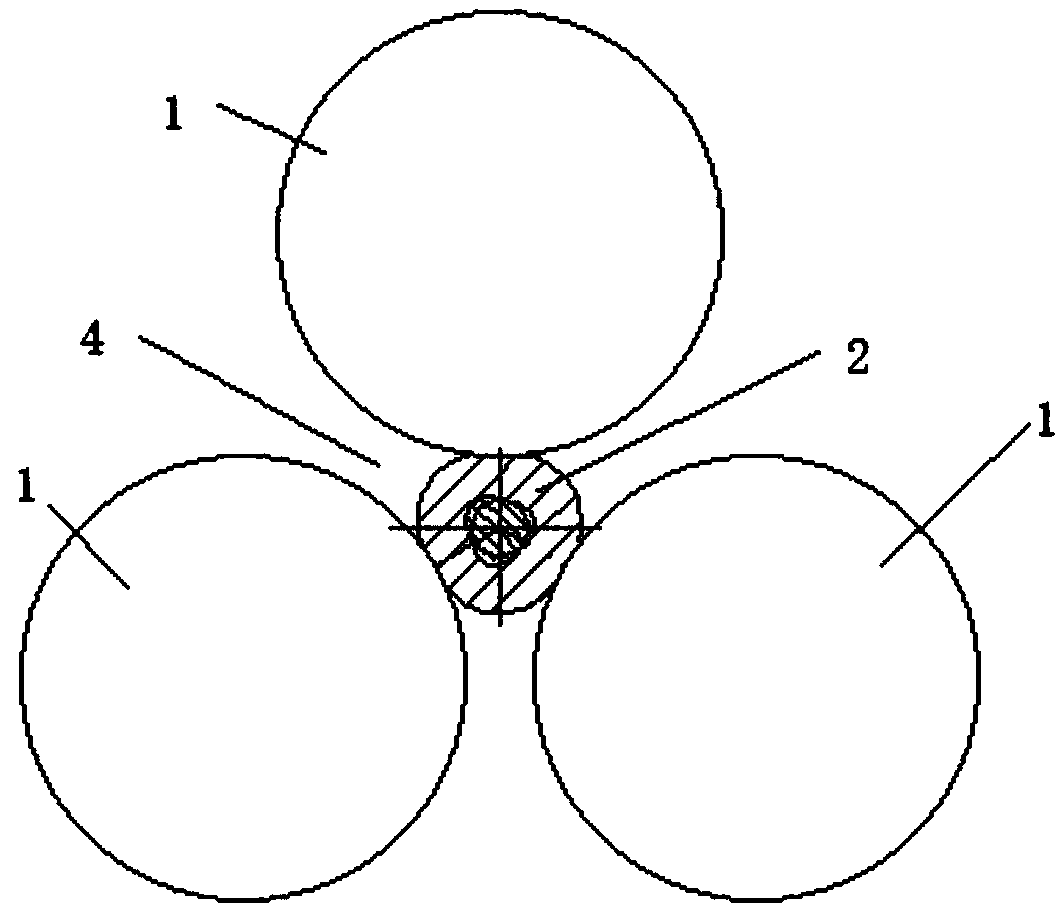

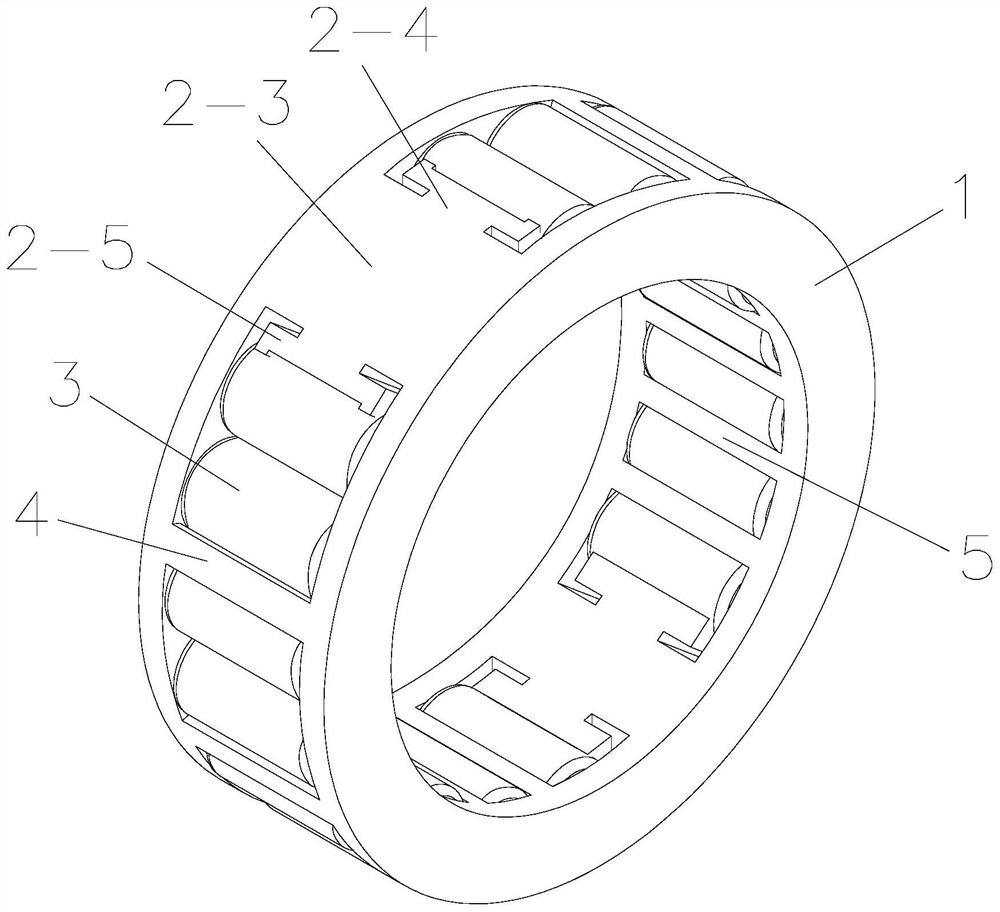

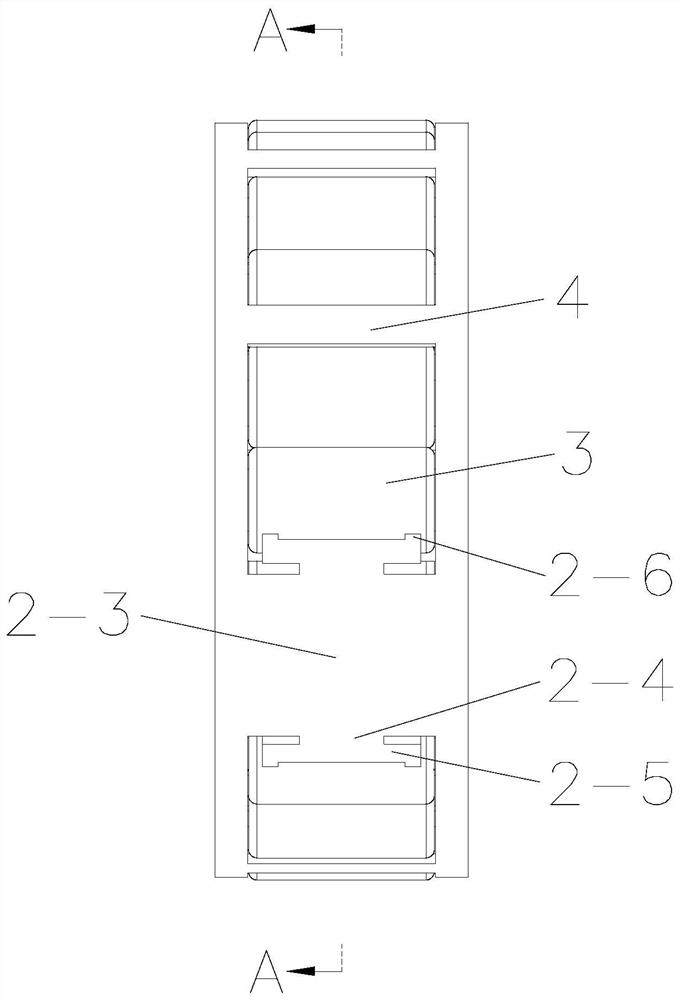

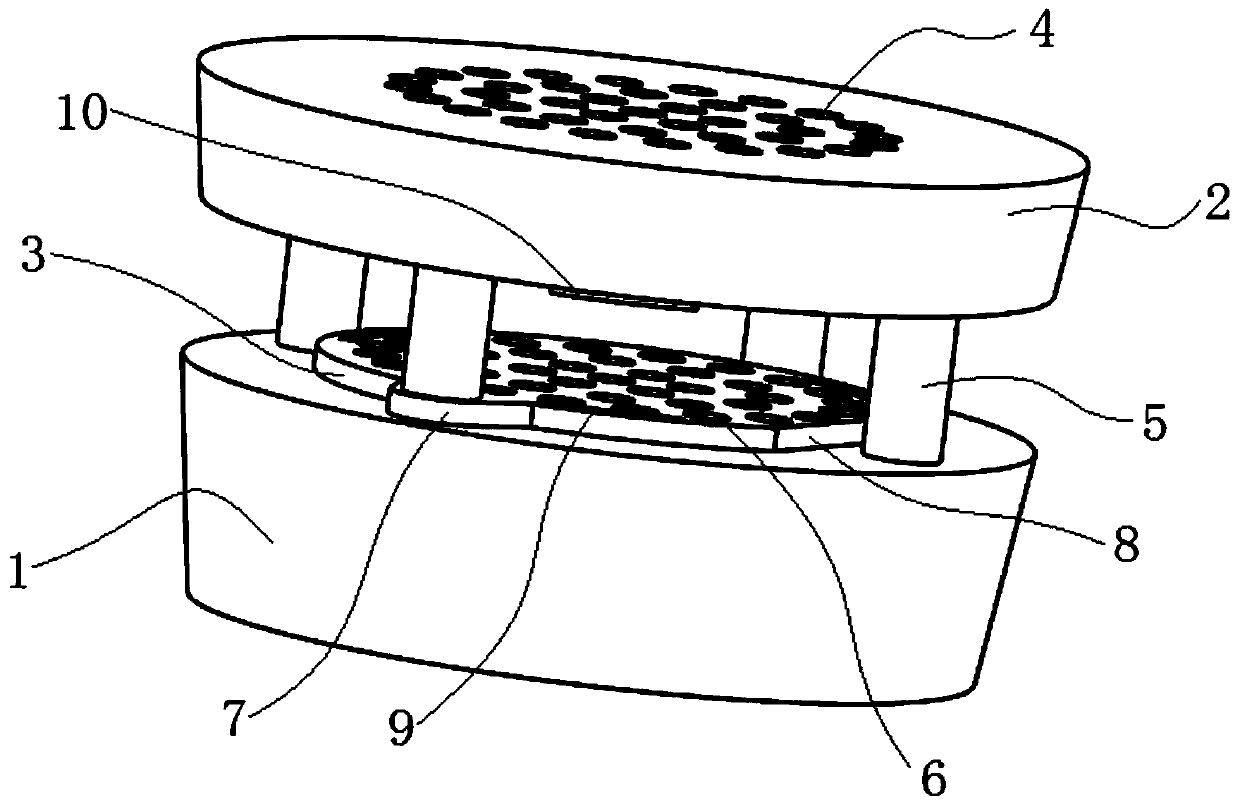

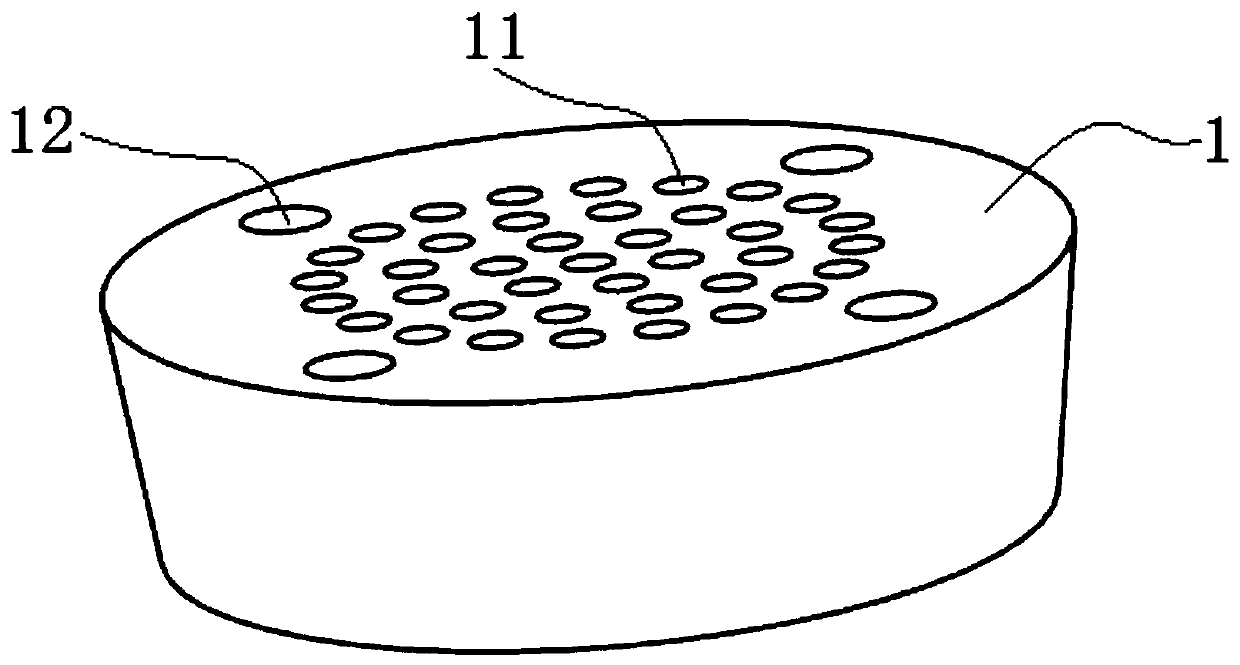

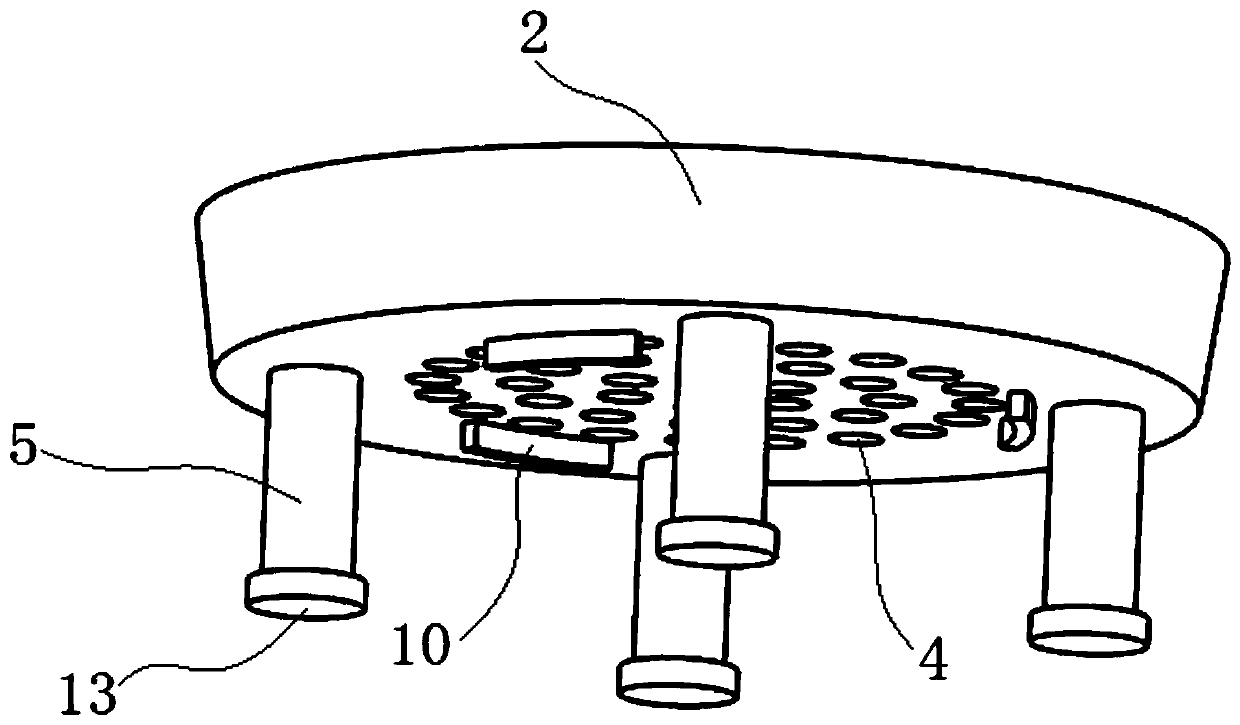

Elastic self-locking full roller bearing and robot reduction gear thereof

The invention relates to an elastic self-locking full roller bearing and a robot reduction gear thereof. A roller is axially fixed by two baffles, so that axial force in running of the bearing is reduced; an elastic main beam is connected between the two baffles, a first elastomer and a second elastomer are fixedly installed on two ends of the elastic main beam respectively, rollers are mounted ina full type between the first elastomer and the second elastomer, circumferential clearance of the rollers is adjusted and limited by the elastic main beam, the two adjacent rollers are disposed in acontact manner, skewing of the rollers caused when the clearance between the two rollers is too large can be prevented, and stability of the bearing is high. The rollers mounted in a full type between the first elastomer and the second elastomer are standard rollers, an inner ring and an outer ring of the bearing are also standard parts, the size of the elastic main bear can be adjusted to fit the circumferential clearance of the rollers, only a holding frame needs to be processed separately, separate processing of the inner ring, the outer ring and the rollers is not needed, processing procedures are simple, and processing cost is low.

Owner:JIANG SU NAN FANG BEARING CO LTD

Helicopter rotor flapping hinge

The invention discloses a helicopter rotor flapping hinge and relates to the technical field of helicopters. The helicopter rotor flapping hinge is installed on a rotor shaft (9) and comprises a lantern ring (1), two clamp plates (2) and two antifriction bearings (3), wherein the rotor shaft (9) is sleeved with the lantern ring (1) which rotates along with the rotor shaft (9), and bearing installation sections (11) are arranged on the circumferential outer side of the lantern ring (1) at a 180-degree interval; the two clamp plates (1) are arranged on the bearing installation sections (11) through the antifriction bearings (3), the axis of the antifriction bearings (3) is perpendicular to the axis of the rotor shaft (9), and the two clamp plates (1) are fixedly connected through a connector. The helicopter rotor flapping hinge has the advantages that the two clamp plates are arranged on the bearing installation sections through the antifriction bearings and are fixedly connected through the connector, the clamp plates swing around the lantern ring through the antifriction bearings, abrasion of the lantern ring and the clamp plates does not occur easily, and the service life of the flapping hinge is longer.

Owner:CHINA HELICOPTER RES & DEV INST

Anti-reversed integrated cross circular-groove gas fuel spraying and mixing device

ActiveCN107084075AEnhanced open responsivenessAvoid axial forceInternal combustion piston enginesFuel supply apparatusWork performanceProduct gas

The purpose of the invention is to provide an anti-reversed integrated cross circular-groove gas fuel spraying and mixing device. Gas fuel is conveyed to the system through a pipeline, firstly a fuel spraying valve is passed, and an actuator controls the opening and the closing of a valve by controlling a valve element; mass flow is achieved through a mixed air-incoming mode of axial main air drain direct air-incoming and circumferential air-supplying hole air-incoming, and the air-supplying efficiency of an engine is effectively improved; surface sealing of a fuel gas spraying valve is achieved through a multichannel zone structure between the valve element and a valve seat, and the high reliability is achieved; through a floating valve seat structure, the function that reverse leakage caused by imbalance of internal and external pressure of the fuel gas spraying valve is avoided is achieved, and the working reliability of the fuel gas spraying valve is ensured; through a fuel diffusing pipe cavity structure, the fuel can be distributed in the whole system, and the continuity and the responsiveness of air-supplying of an air-supplying system are achieved; and through a circular groove structure, the improvement of the mixing degree of the fuel and air is promoted, the circular groove structure is beneficial to combustion, and the working performance of the system is improved.

Owner:HARBIN ENG UNIV

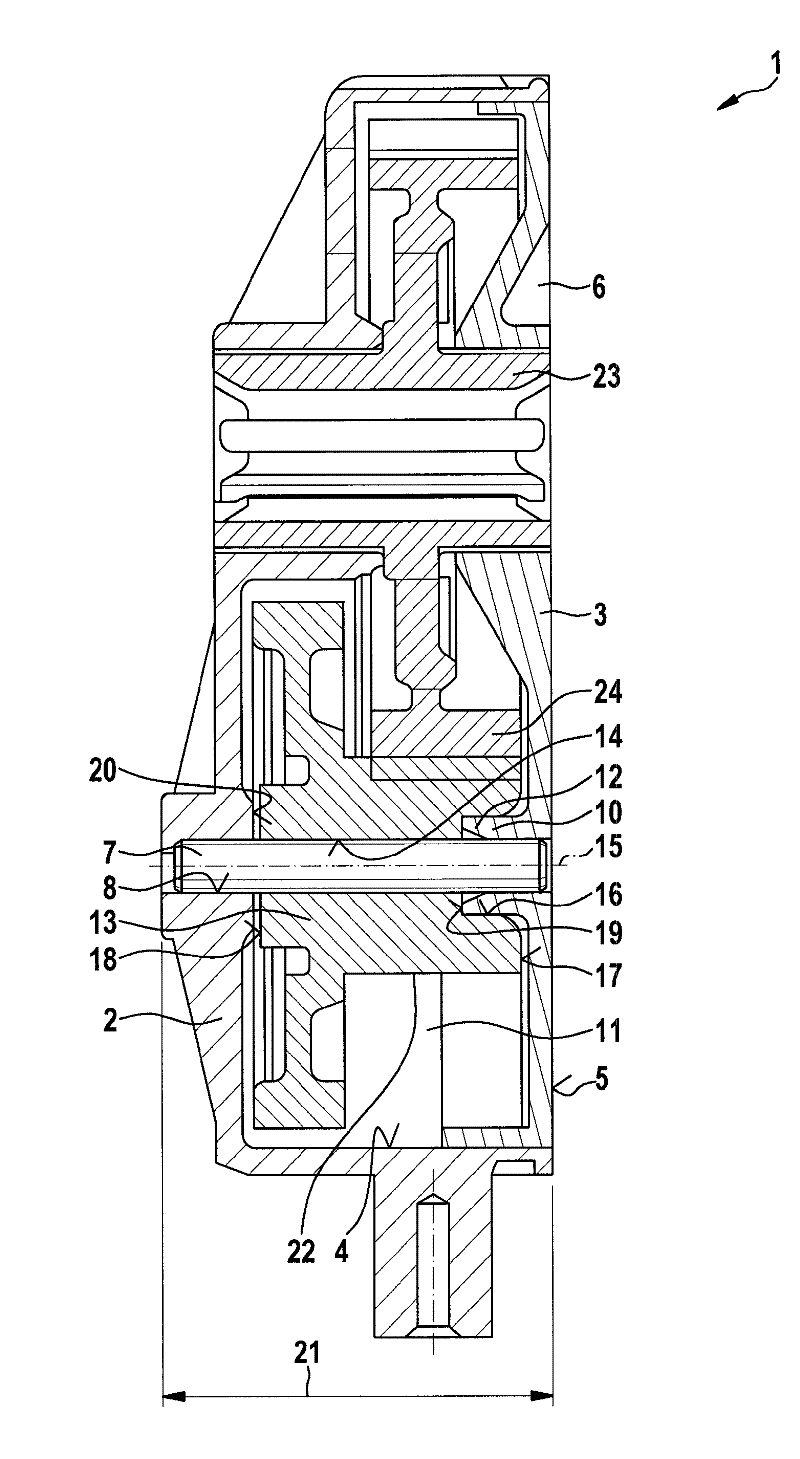

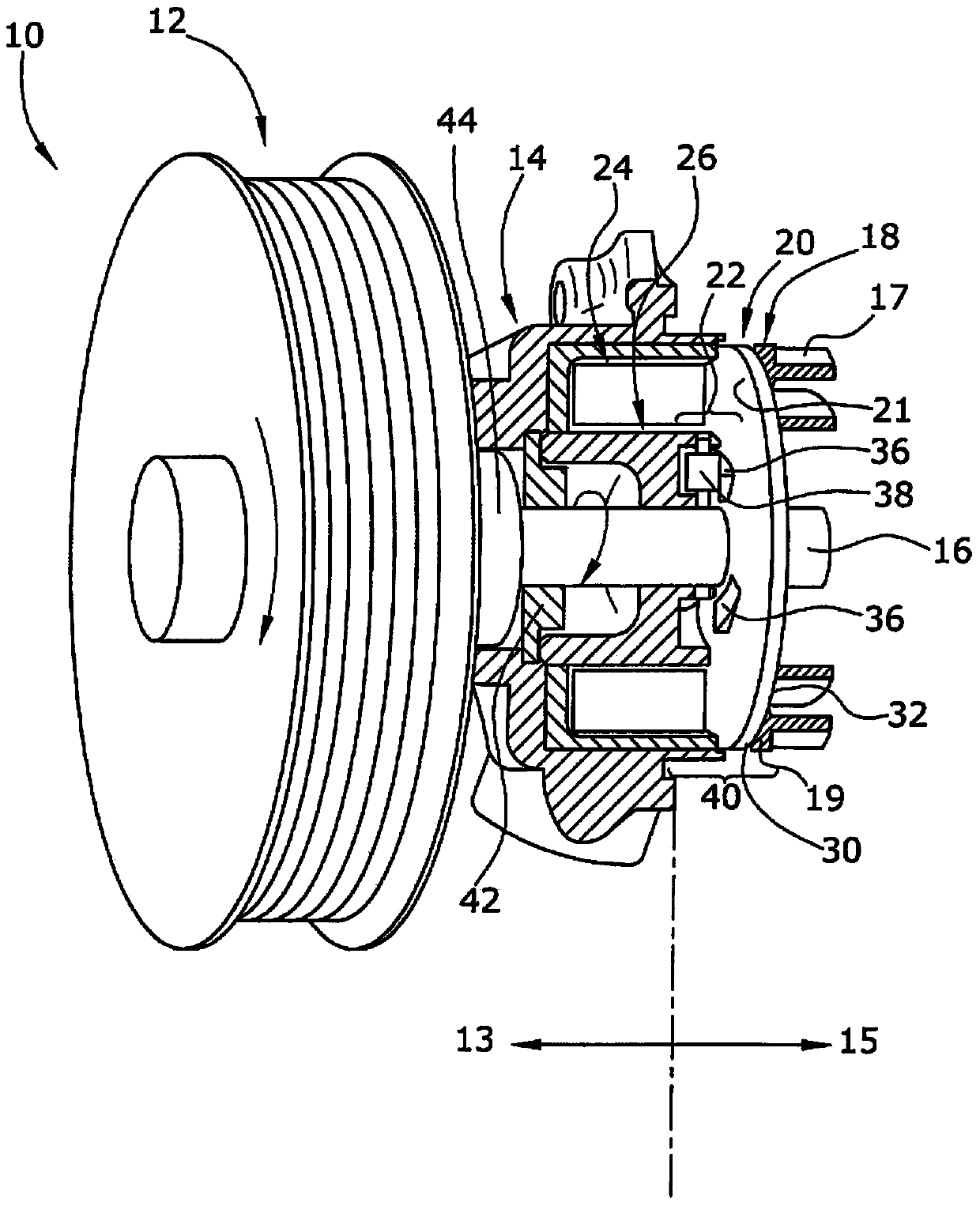

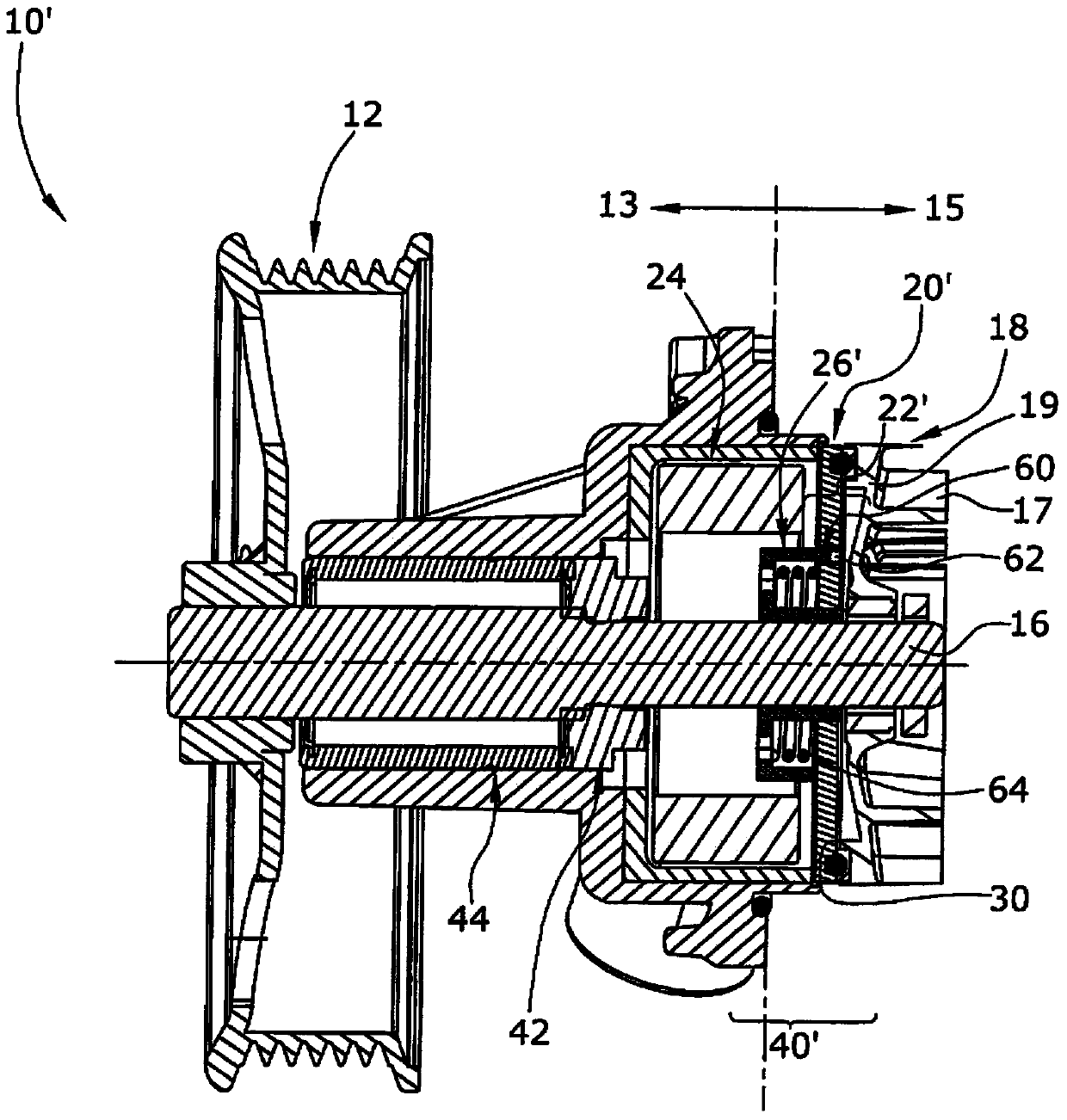

Switchable mechanical coolant pump

InactiveCN103827502AIncrease fluid resistanceLarge axial thrustMechanical actuated clutchesMagnetically actuated clutchesCombustionEngineering

The invention refers to a switchable mechanical coolant pump (10) comprising a pulley wheel (12) co-rotating with and supported by a rotatable rotor shaft (16), the pulley wheel (12) being directly drivable by a combustion engine, a pump wheel (18) rotatably supported at the rotor shaft (16), an electrically switched wedge-coupled wet friction clutch (40) with a clutch support (26) being fixed to the rotor shaft (16), a clutch ring (30) at the proximal side of the pump wheel (18), and a separate clutch disk (20) rotatably and shiftably supported by the rotor shaft (16), the clutch disk (20) comprising a ferromagnetic element (21) and being arranged axially between the clutch support (26) and the clutch ring (30), a static electromagnet (24) axially pulling the clutch disk (20) to the clutch support (26) into a disengaged position when energized, and a wedge coupling mechanism (22); defined at the proximal side of the clutch disk (20) and the distal side of the clutch support (26), the wedge coupling mechanism (22) comprising: a wedge element (36) and a counter-wedge element (38).

Owner:PIERBURG PUMP TECH

Centrifugal machine adapter

The invention discloses a centrifugal machine adapter comprising a lower adapter part, an upper adapter part and an isolation plate. The lower adapter part is provided with lower test tube holes and guiding holes; the upper adapter part is provided with upper test tube holes, and each upper test tube hole is aligned at the corresponding lower test tube hole; an opening in the upper end of each upper test tube hole is larger than the outer diameter of a test tube and smaller than a step at the upper end of the test tube; the upper adapter part is further provided with guide posts, and each guide post is sleeved with one guiding hole; the isolation plate can be arranged at the upper end of the lower adapter part in a manner of being capable of swinging, and middle test tube holes are formedin the isolation plate; the upper adapter part can rise until the lower end of the test tube is higher than the middle test tube holes; the isolation plate can swing until each middle test tube hole aligns at the corresponding lower test tube hole, and the isolation plate can swing until each middle test tube hole deviates from the corresponding lower test tube hole. According to the centrifugal machine adapter, after centrifugation is completed, the upper part of the test tube can be exposed out by lifting of the adapter and swinging of the isolation plate, the test tube is conveniently takenout, and the risk that the test tube falls off from the test tube is greatly reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGXI MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com