Patents

Literature

306 results about "Kingpin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The kingpin, also king-pin and king pin, is the main pivot in the steering mechanism of a car or other vehicle. The term is also used to refer to part of a fifth wheel coupling apparatus.

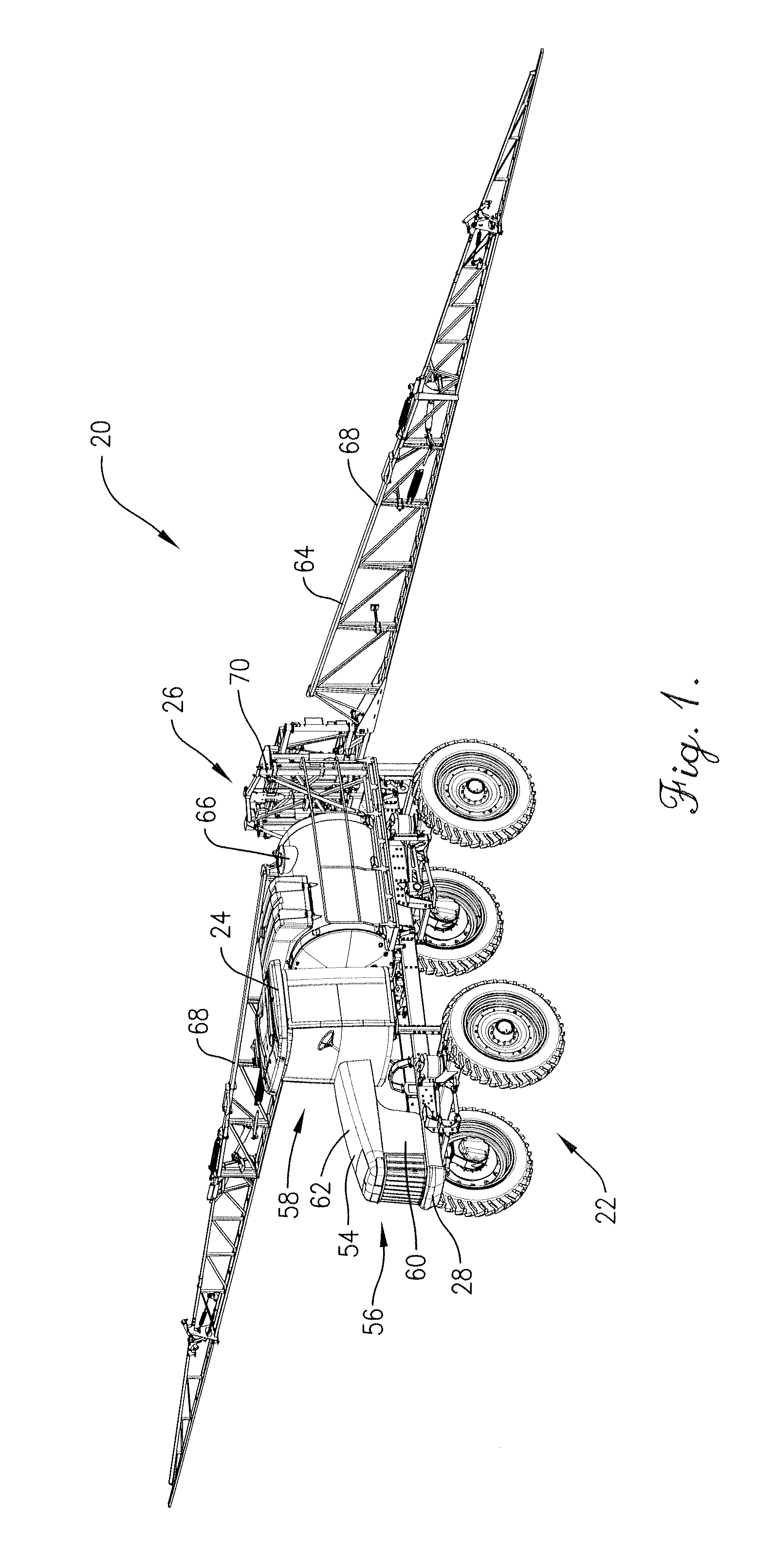

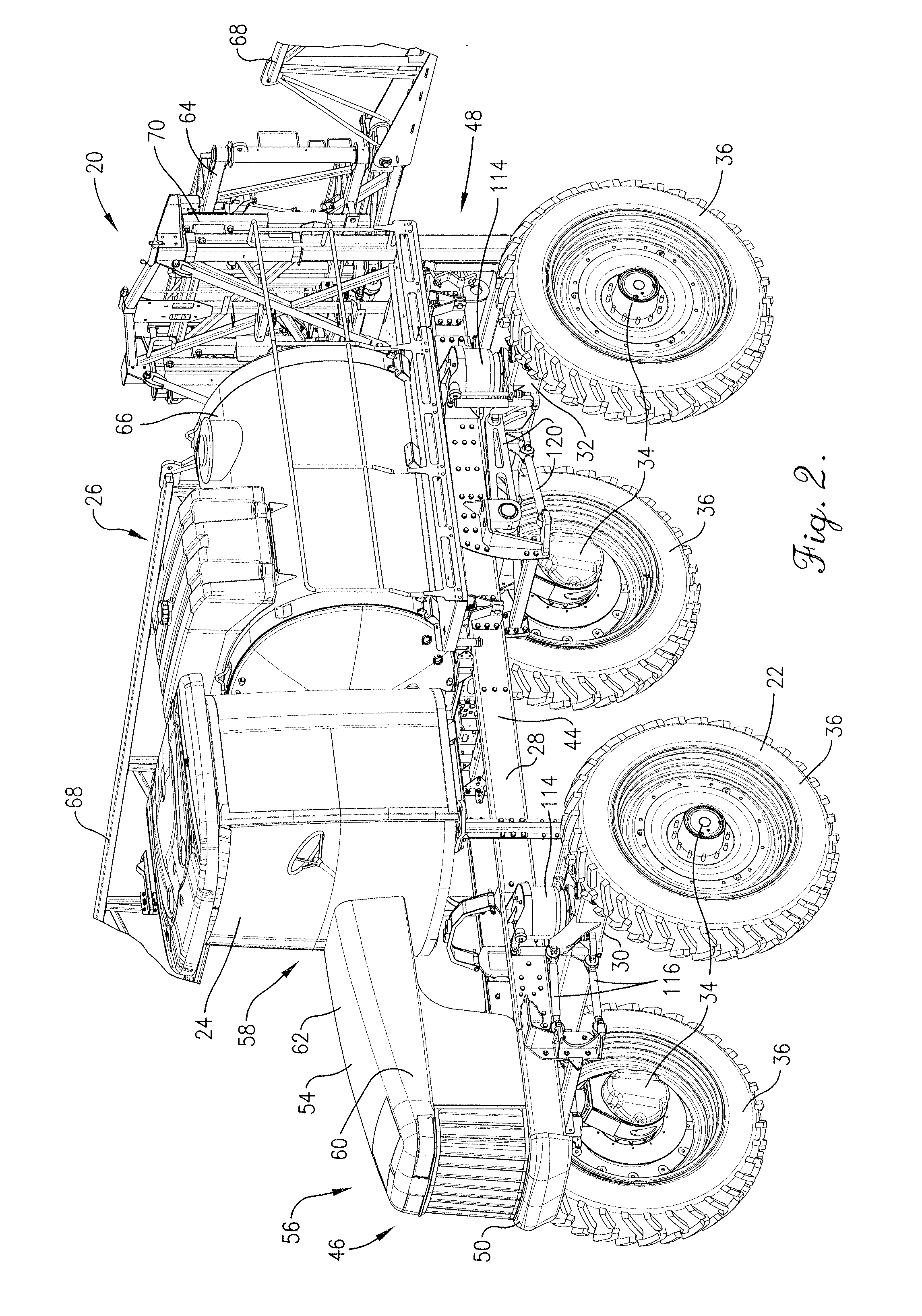

Adjustable height device for high clearance vehicle

Owner:AGCO CORP

Adjustable height device for high clearance vehicle

ActiveUS20110148053A1Increase the gapAgricultural vehiclesVehicle body stabilisationDrive wheelHeight device

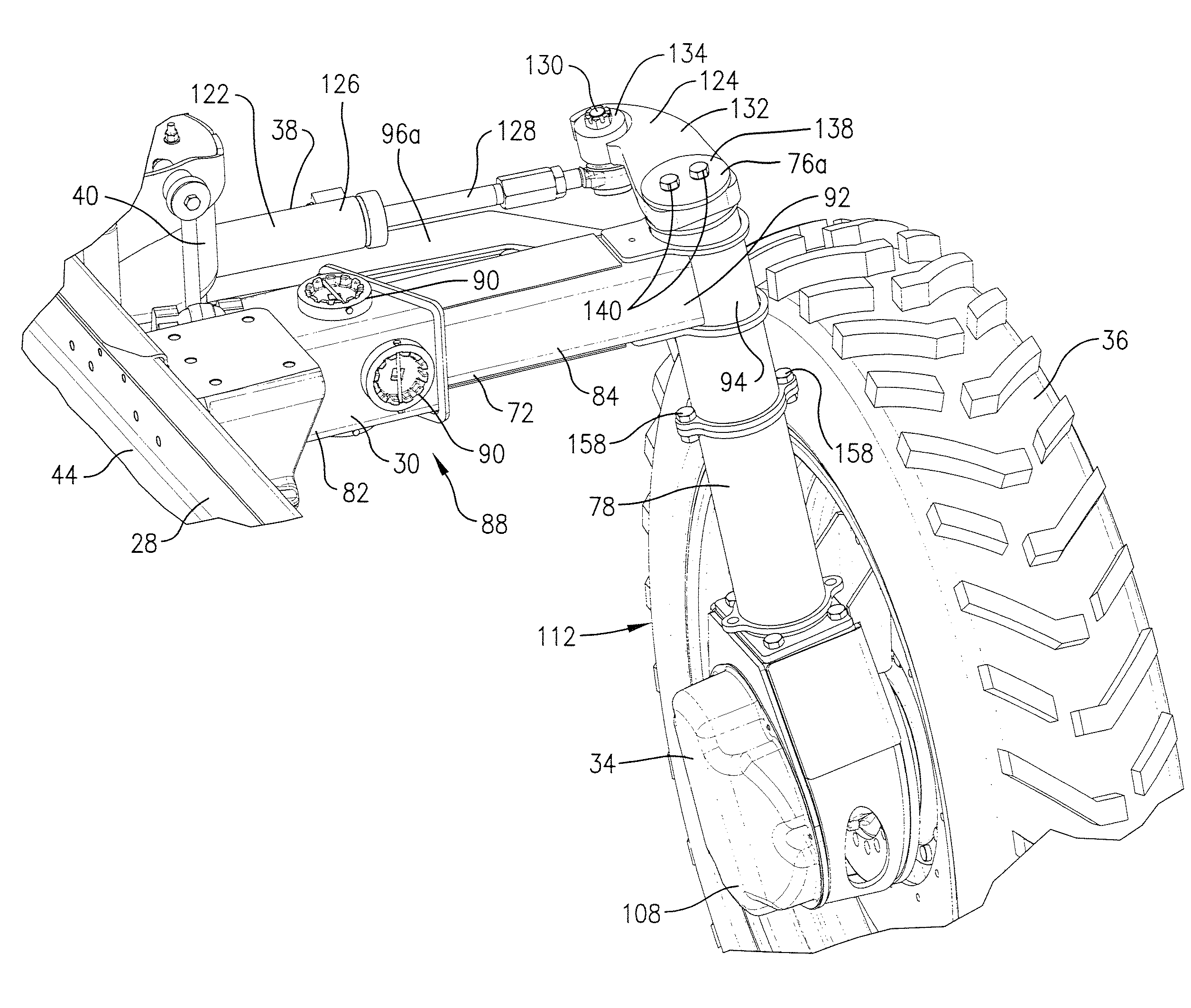

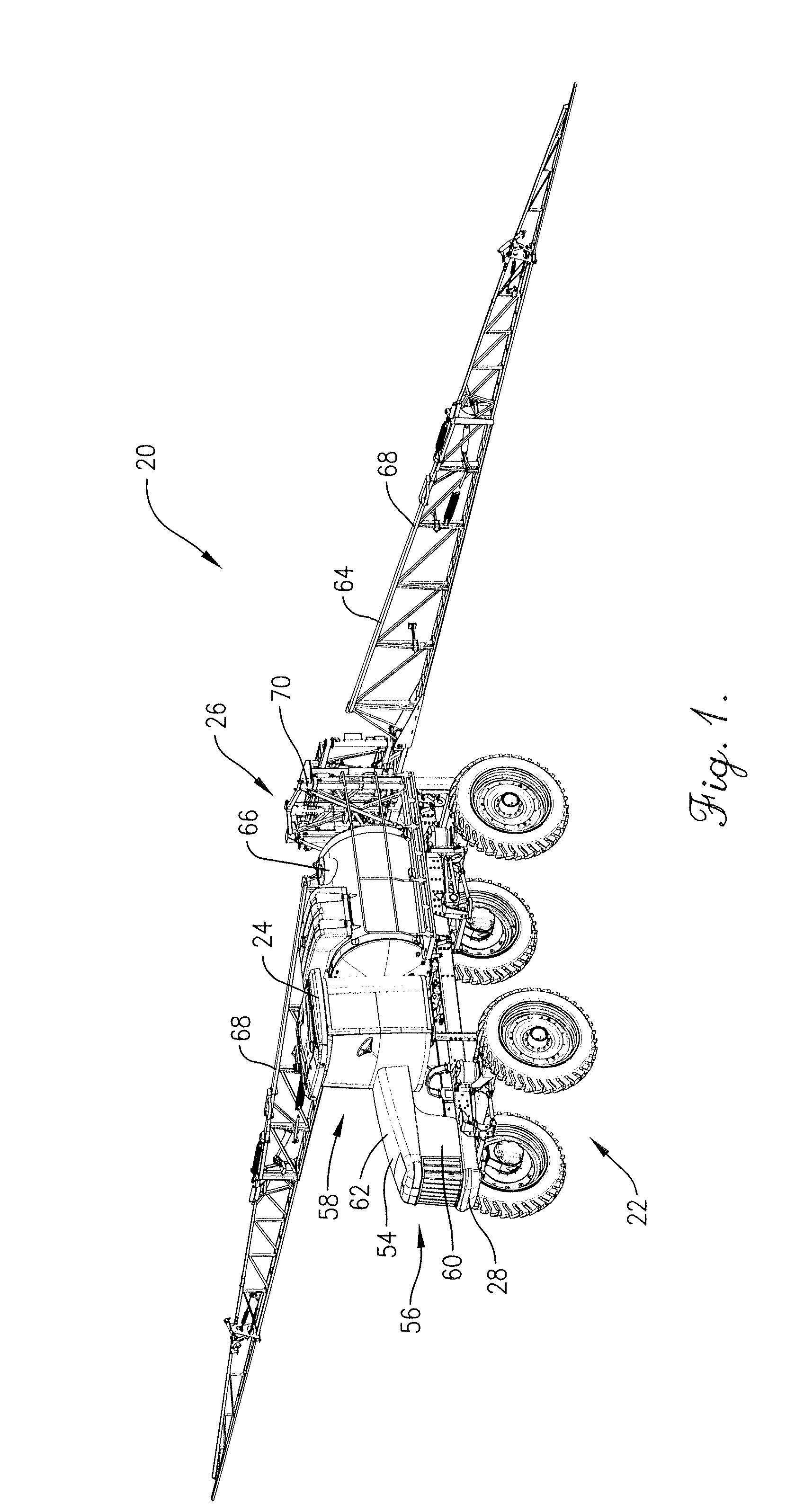

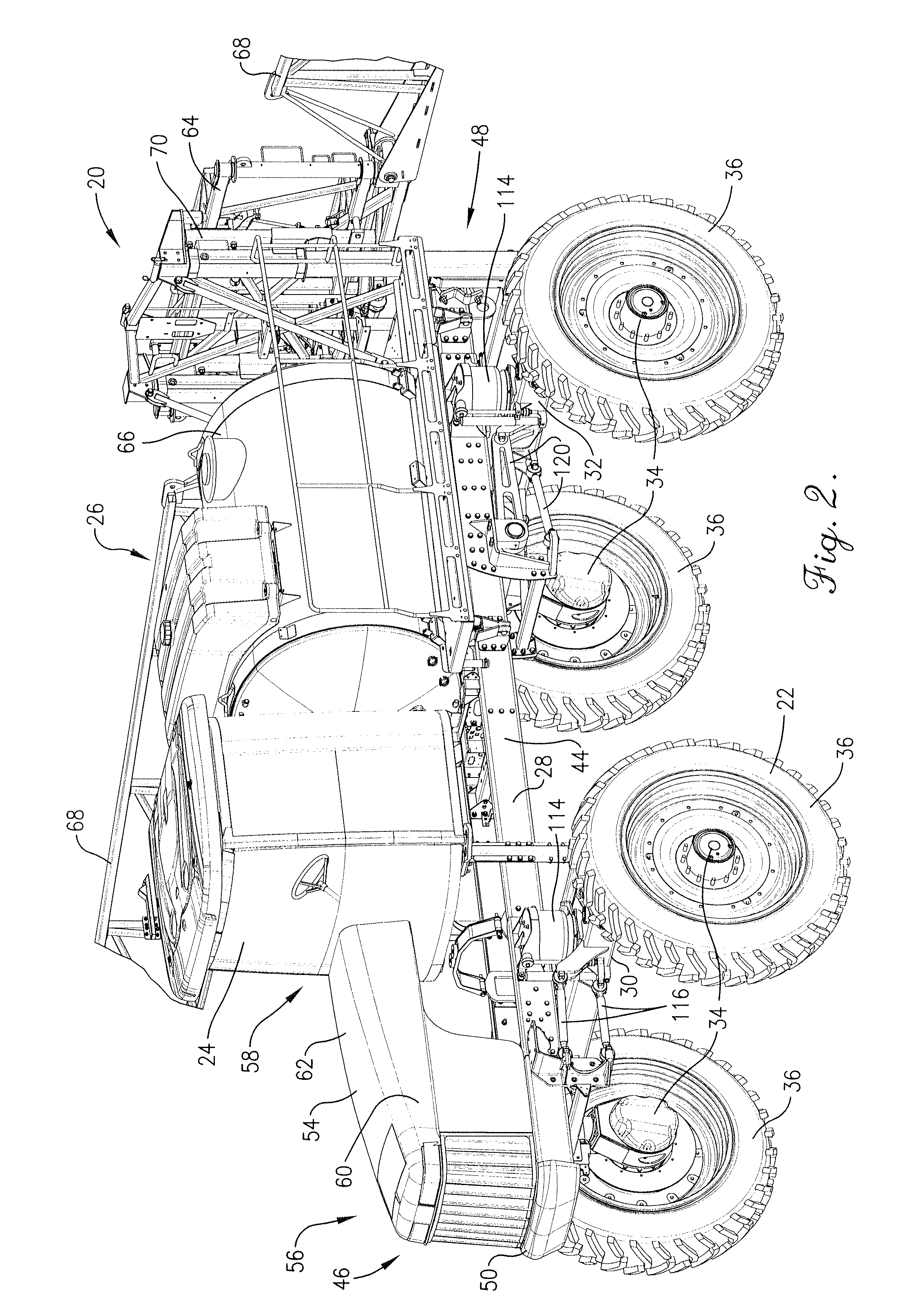

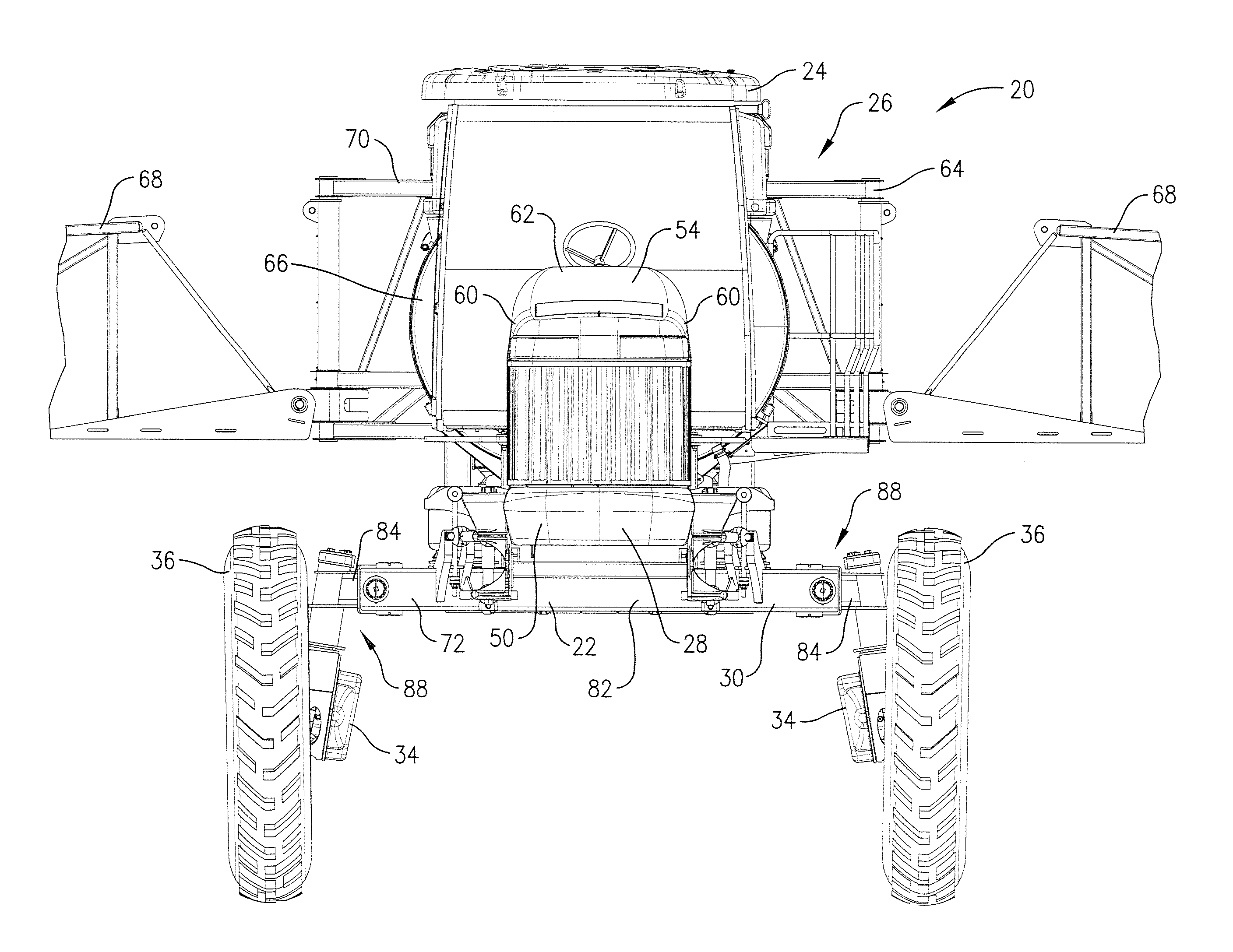

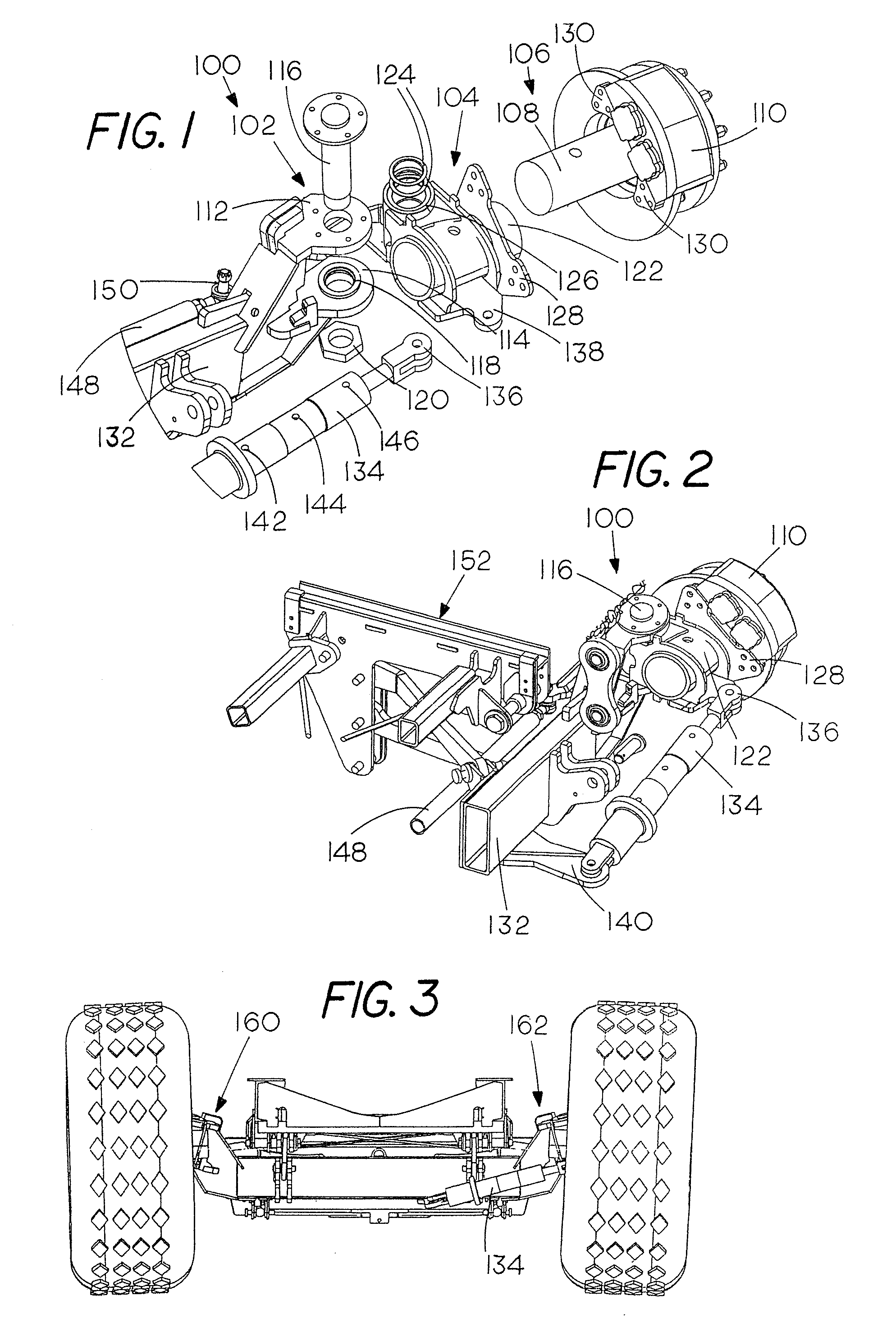

A self-propelled, dirigible agricultural vehicle includes a height-adjustable chassis with an axle and a driven wheel hub. The axle is shiftable between a normal clearance position above the wheel hub and a relatively higher elevated clearance position. The chassis further includes a kingpin and a spacer section that is removably connectable to the kingpin. The axle is in the normal clearance position when the spacer is removed from the kingpin and is in the elevated clearance position when the spacer is connected to the kingpin.

Owner:AGCO CORP

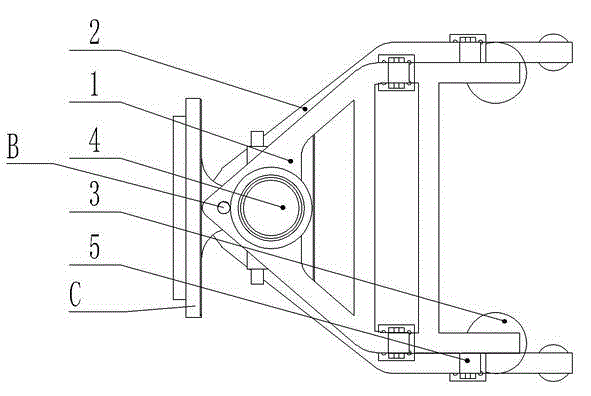

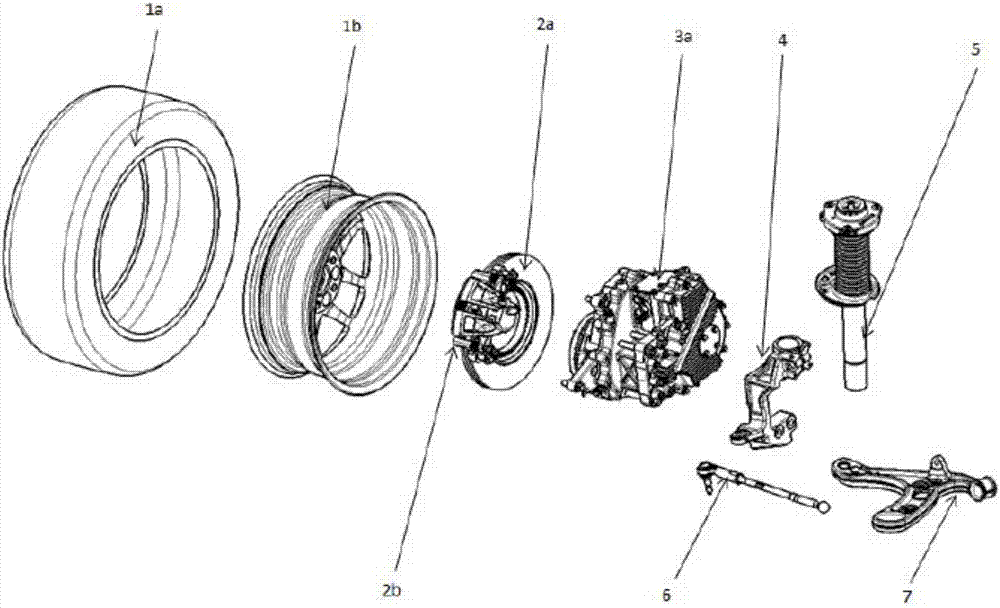

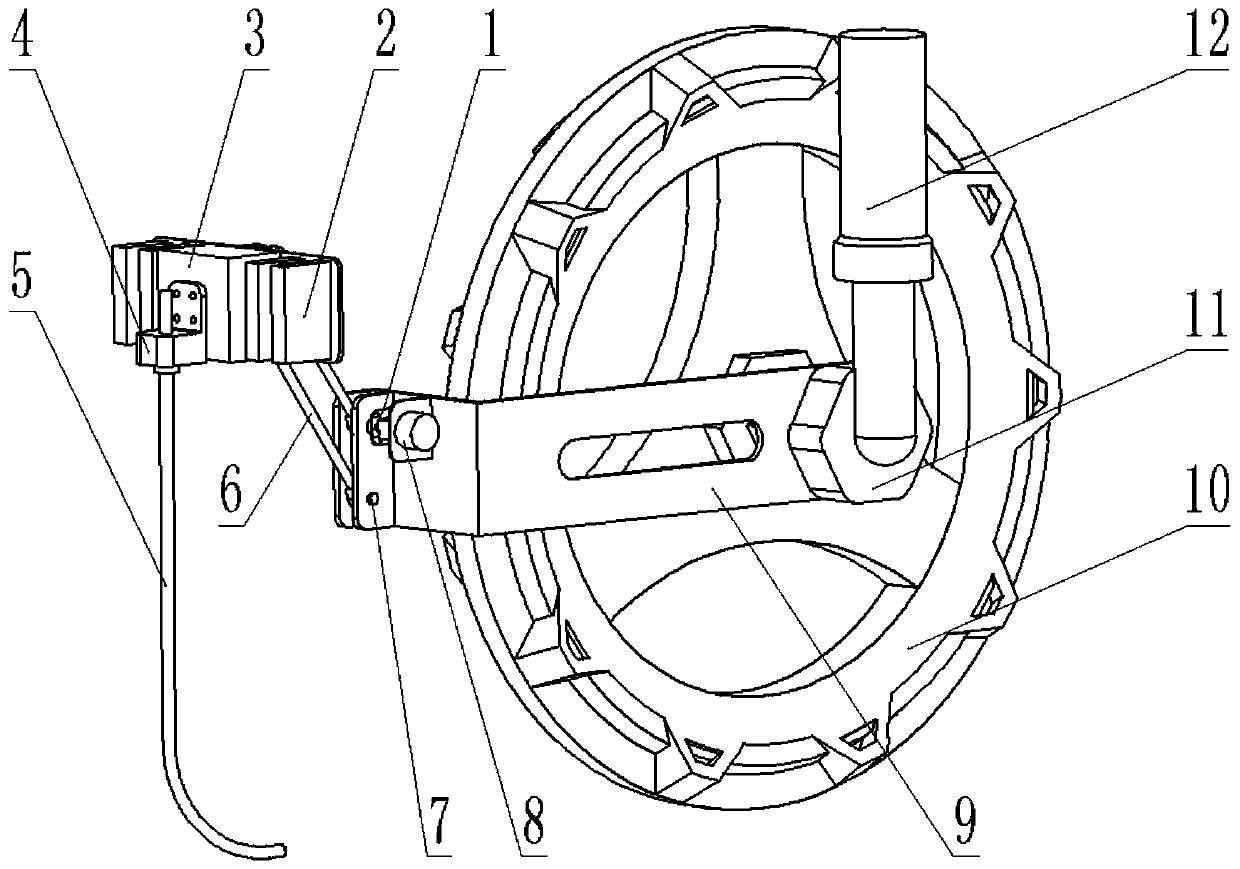

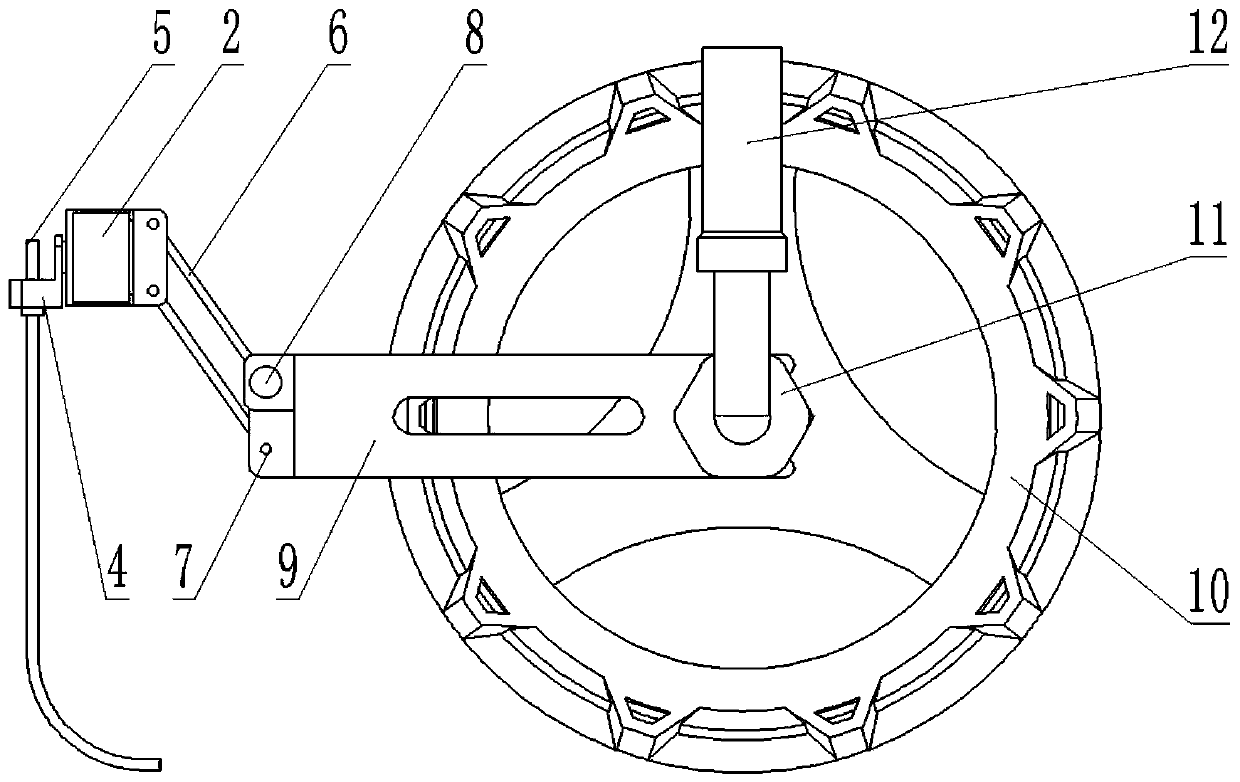

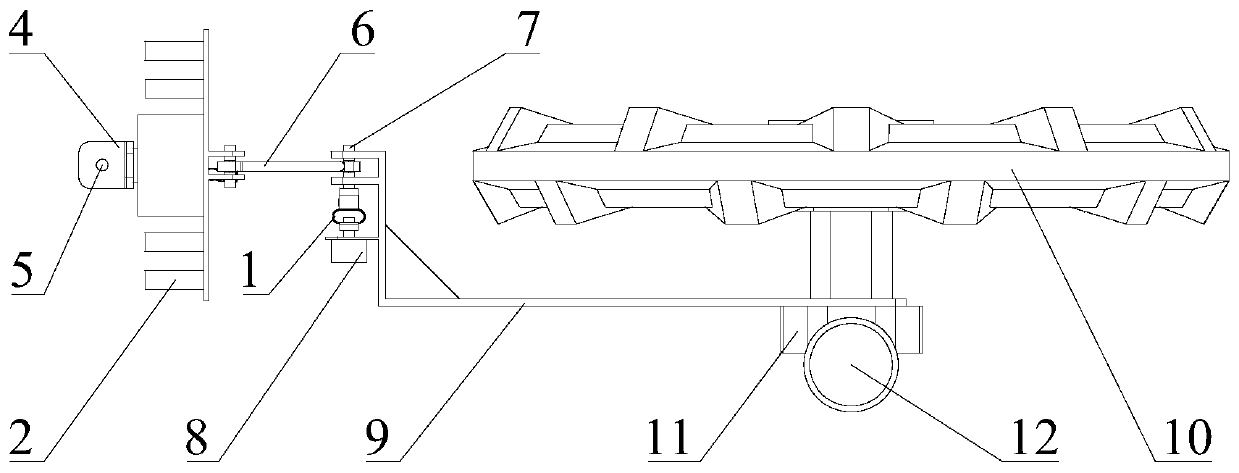

Wire controlled wheel independent steering execution mechanism and wheel assembly

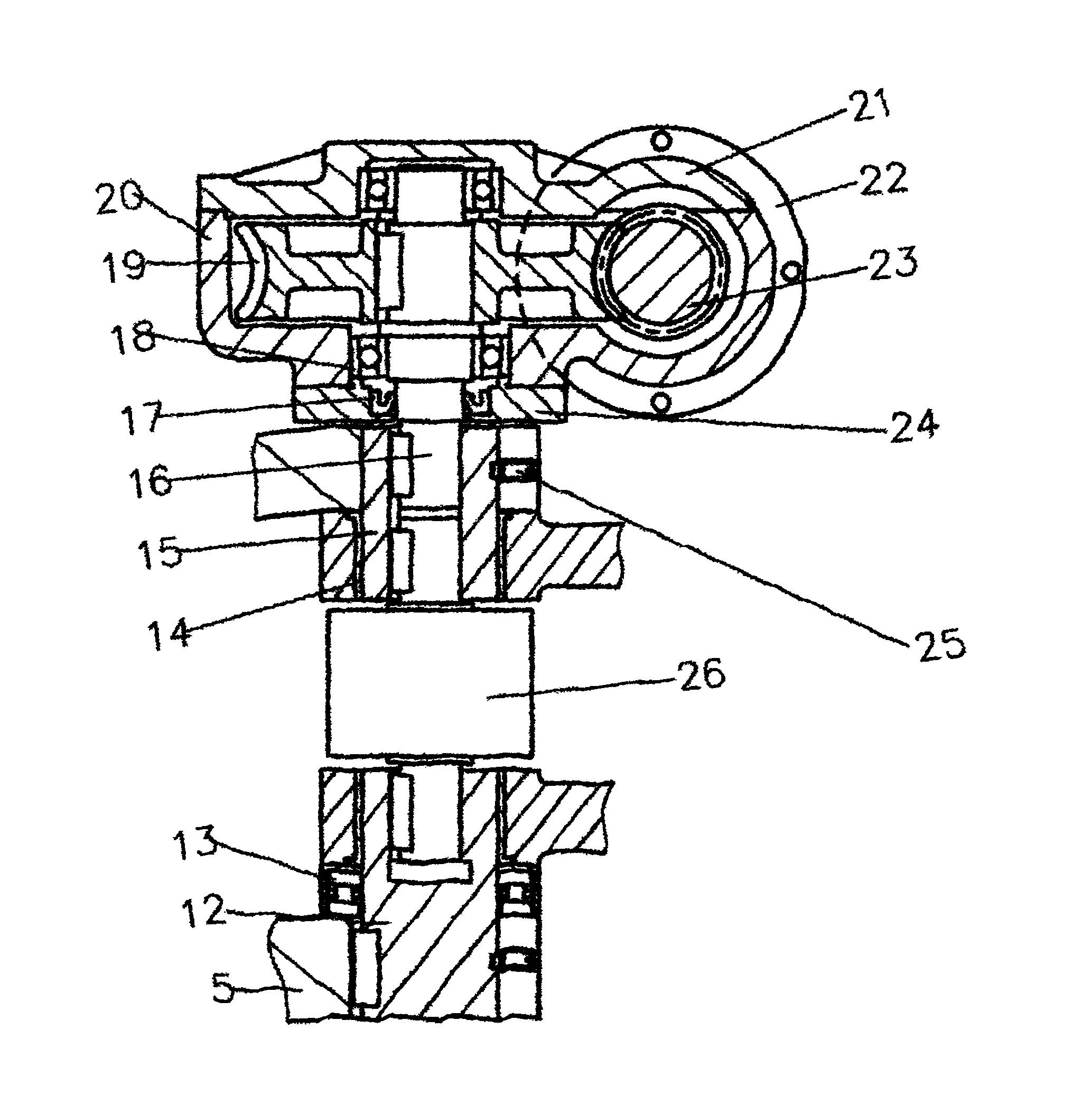

InactiveCN102069843ASimple structureOptimize layoutSteering linkagesMechanical steering gearsCouplingThrust bearing

The invention discloses a wire controlled wheel independent steering execution mechanism and a wheel assembly. The wire controlled wheel independent steering execution mechanism comprises a steering gear, a lower master pin, a master pin thrust bearing, two master pin sliding bearings with the same structure, an upper master pin, a steering motor and photoelectric encoder combined unit, and a torque sensor. The output shaft of the steering motor is connected with the input shaft of the steering gear by a coupler, the output shaft of the steering gear is in key connection with one end of the torque sensor through the upper master pin, the other end of the torque sensor is in key connection with the other end of the torque sensor, the lower end of the upper master pin is sleeved with the master pin sliding bearing and is in dynamic fit with the master pin sliding bearing, and the lower master pin is sleeved with the master pin sliding bearing and the master pin thrust bearing, which have the same structure, in turn from top down, and is in dynamic fit with the master pin sliding bearing and the master thrust bearing. The wheel assembly comprises a tire, a hub, an annual hub motor, a brake, an annular brake disc and the line controlled wheel independent steering executing mechanism. The annular hub motor consists of an annular hub motor outer rotor, a large-diameter cone roller bearing, a steering joint and a motor inner stator component.

Owner:JILIN UNIV

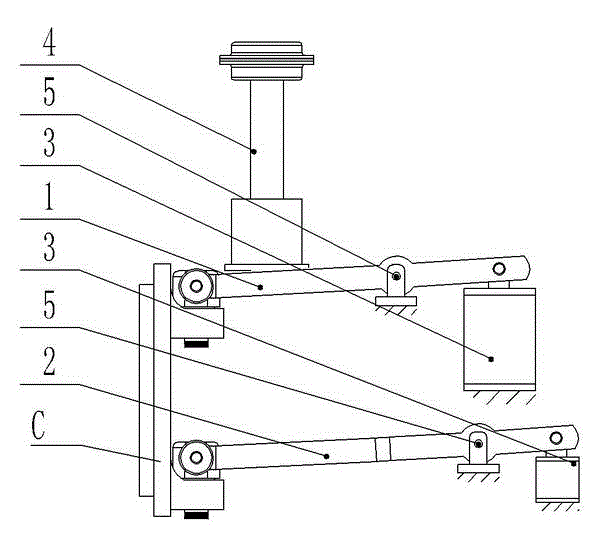

Self compensation floating swing arm independent suspension system

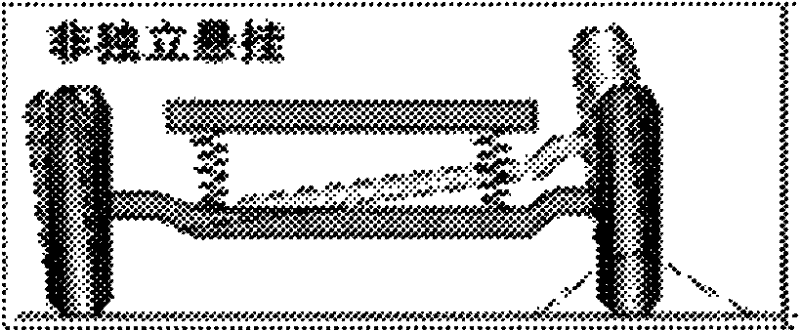

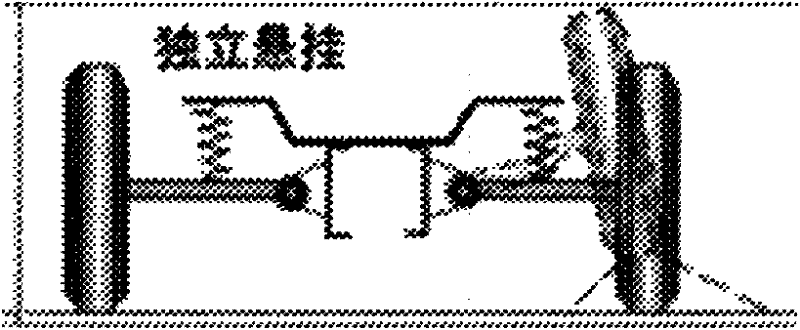

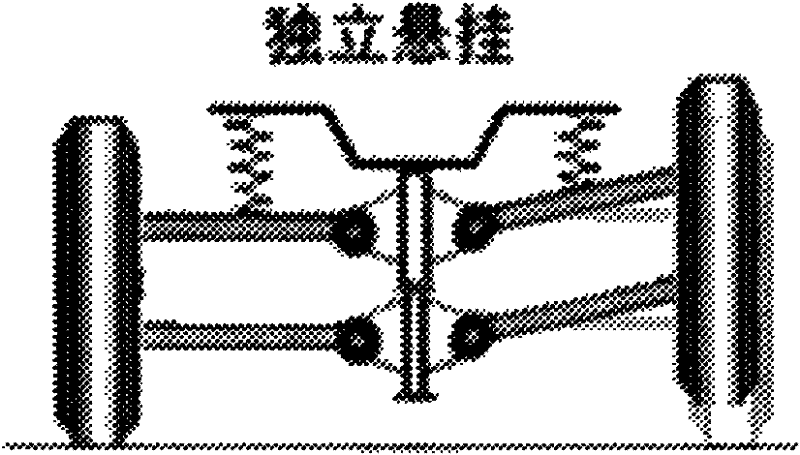

ActiveCN102363408AIdeal handlingIdealized securityInterconnection systemsResilient suspensionsAnti-roll barCamber angle

The invention provides a self compensation floating swing arm independent suspension system, comprising a self compensation floating swing arm independent suspension device and a centrifugal force control scissors-type anti-roll bar device. The two mechanisms can be used in combination or independently and are applicable to both front wheels and rear wheels. The self compensation floating swing arm independent suspension system guarantees that wheels perform line bounce along a vertical direction of a car body on various kinds of road surfaces when a car runs at a low speed or at a high speed or makes turns and guarantees maximum contact area between the wheels and the road surfaces, with the parameters of king pin angle, toe-in angle, camber angle, wheel track, and axle base being maintained the same as original parameters; and, when the car makes turns, the centrifugal force control scissors-type anti-roll bar device works automatically, offsets a roll force with a force equal to the roll force in magnitude and opposite to the roll force in direction, and enables the car body to lower automatically, thereby improving anti-roll capacity and realizing idealization of controllability, safety, stability and comfort of the car. The self compensation floating swing arm independent suspension system has a simple structure, excellent performance, and low cost, and is easy to realize.

Owner:侯贺

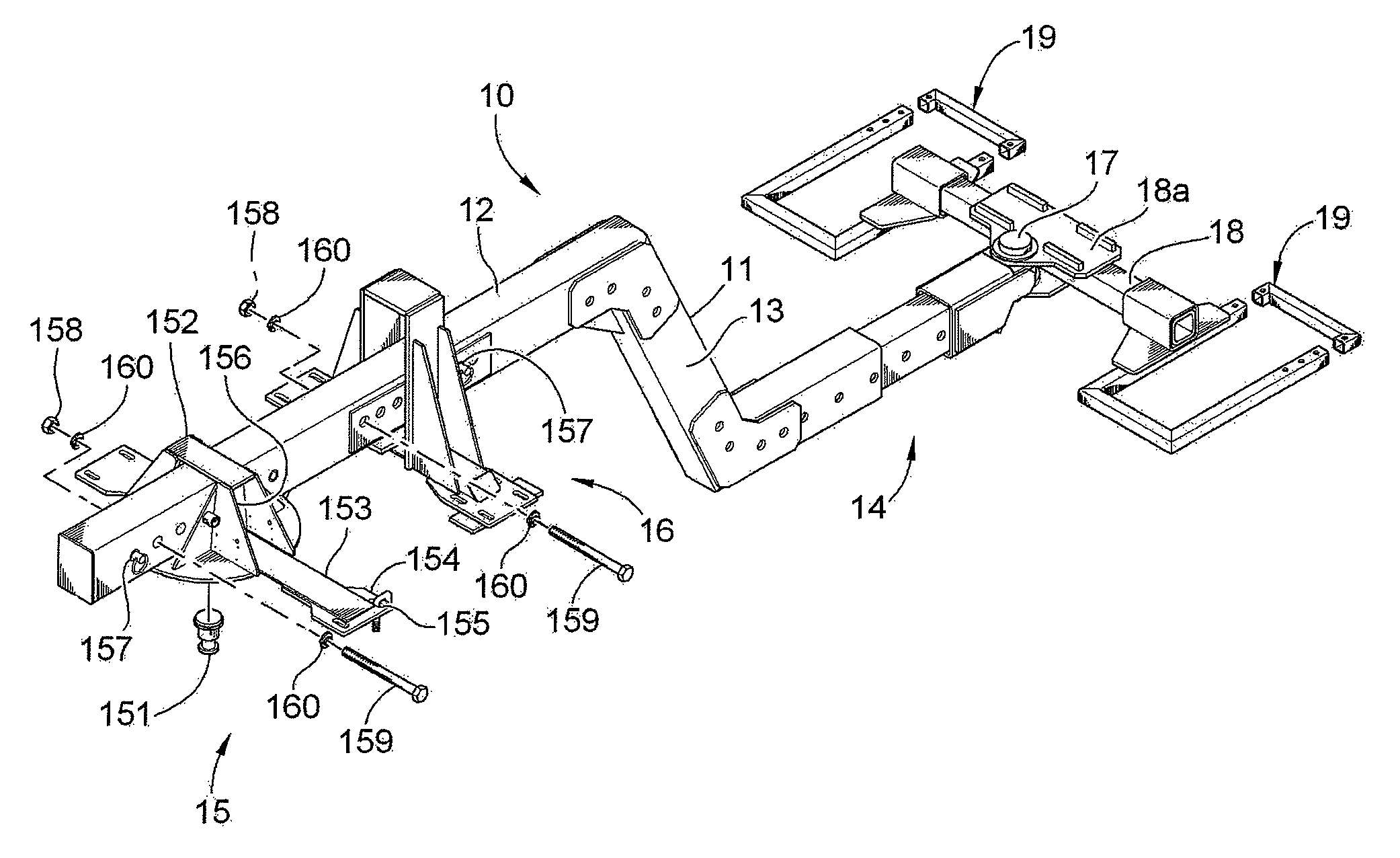

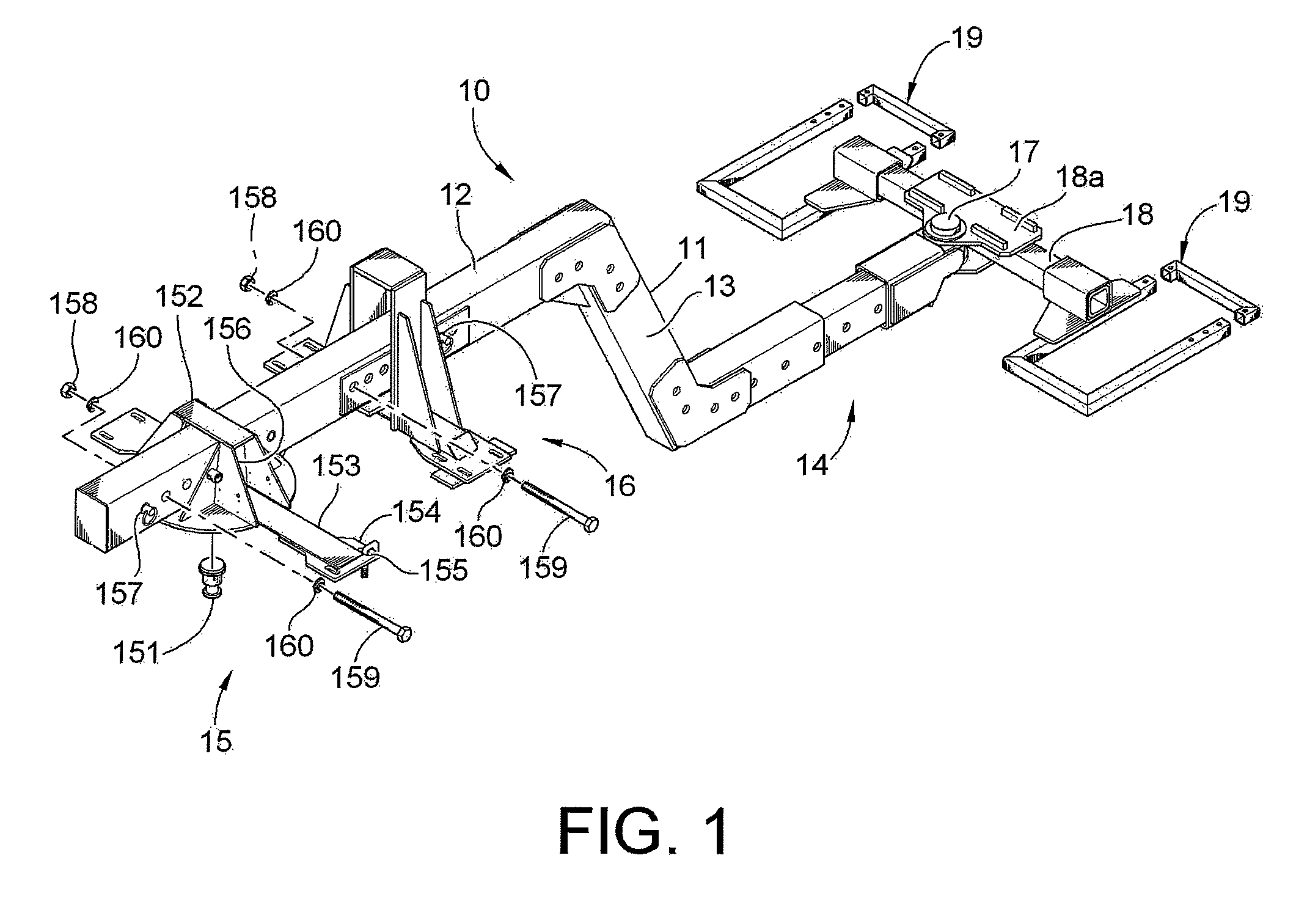

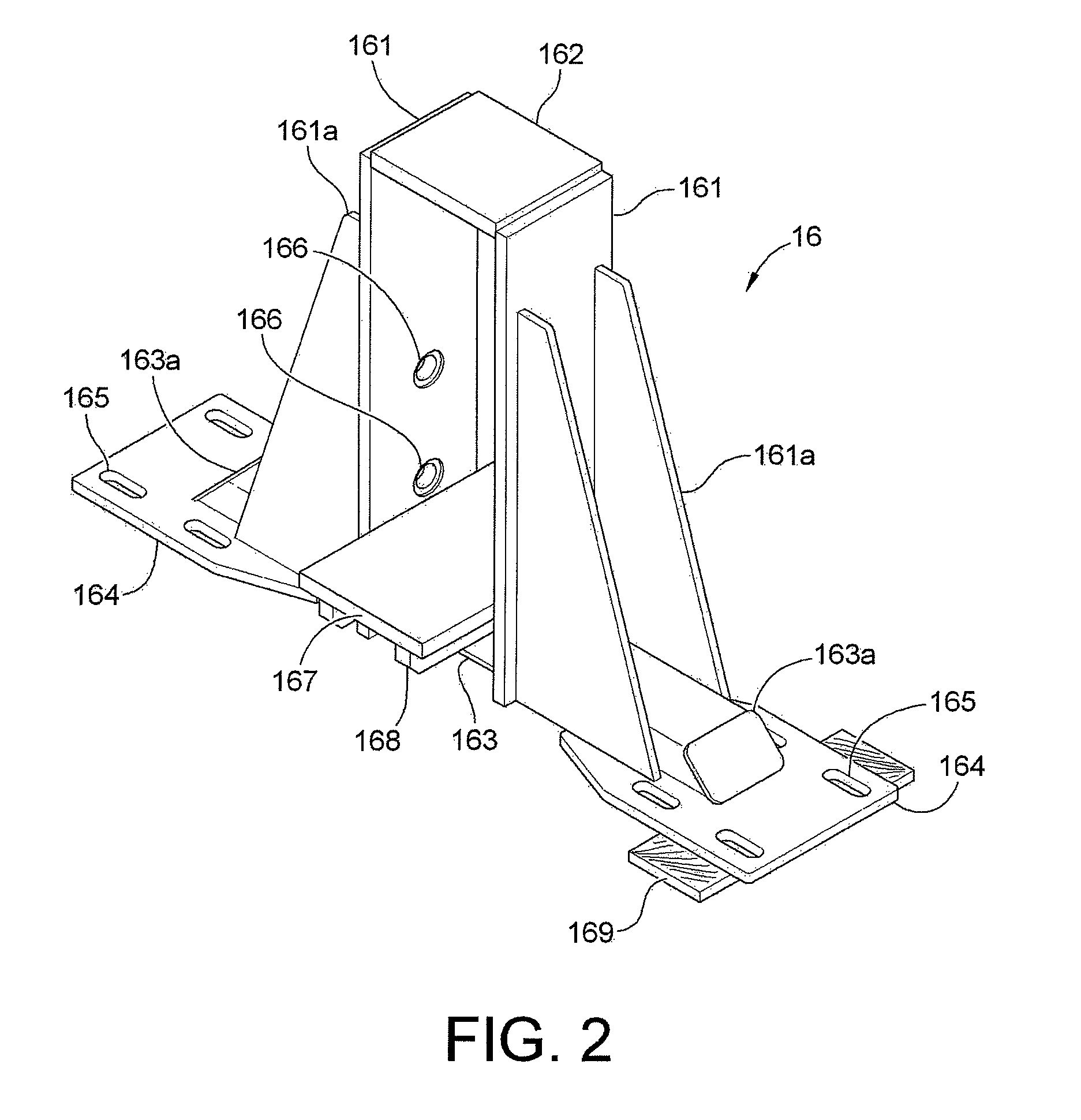

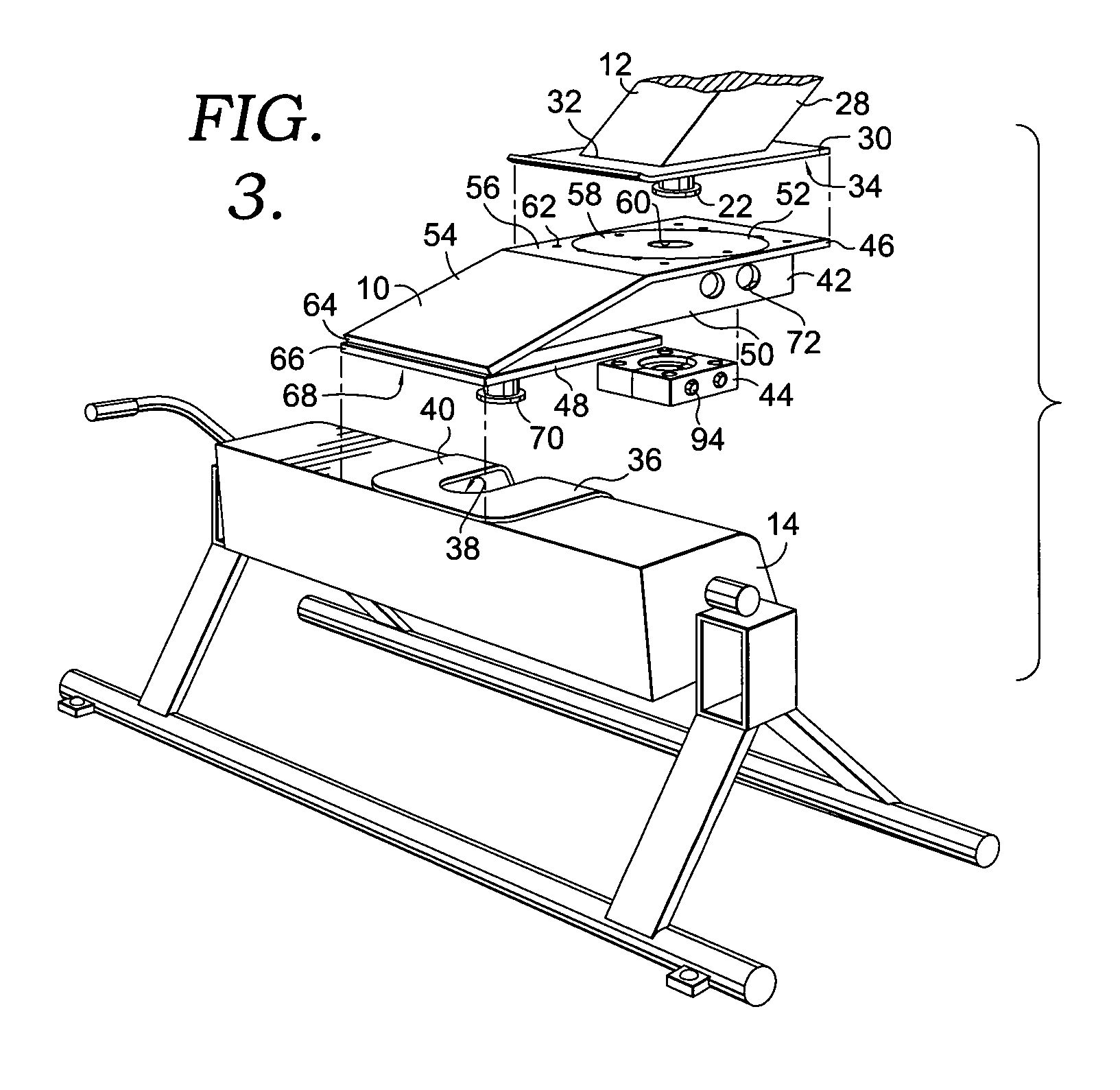

Extended forward tow saddlemount—single rail

An extended forward tow, single rail saddlemount or tow bar is disclosed. The tow bar allows a first towing truck to mount a second truck, facing forward, behind the first truck, in order to tow the second truck. The tow bar allows the towed truck to face forward during transport, thus allowing for normal loads and stresses of movement on the towed truck, rather than the much higher high wind loads and unusual stresses imposed by a rear-ward facing tow. The saddlemount is also designed to minimize the required vertical rise on the towed truck, which also avoids additional stresses during loading and unloading onto the towing truck. Lower stress is achieved by using a pivot pin nearer the towed truck rather than the usual pivot pin or king pin on the towing truck.

Owner:ATC TRANSPORTATION

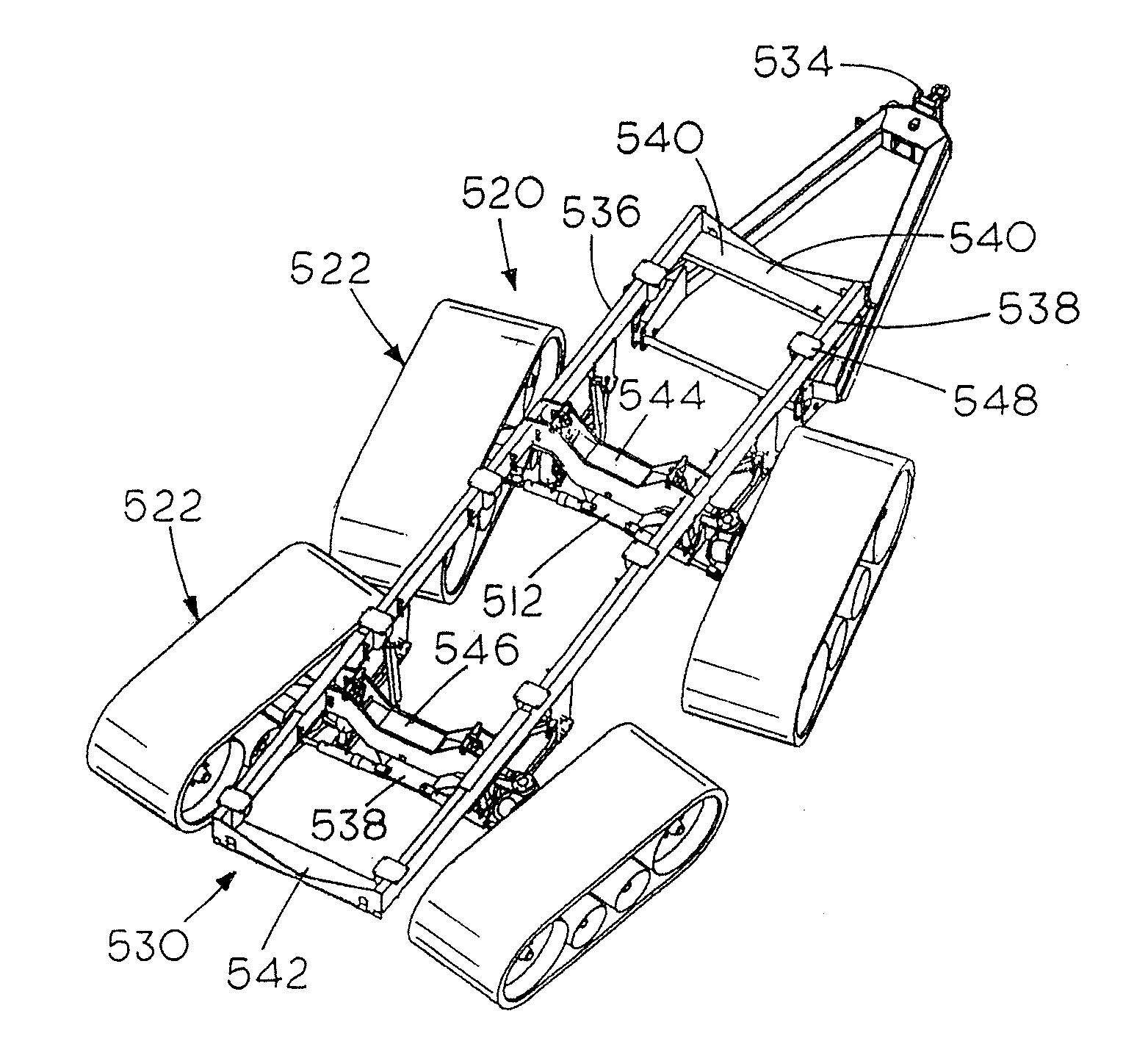

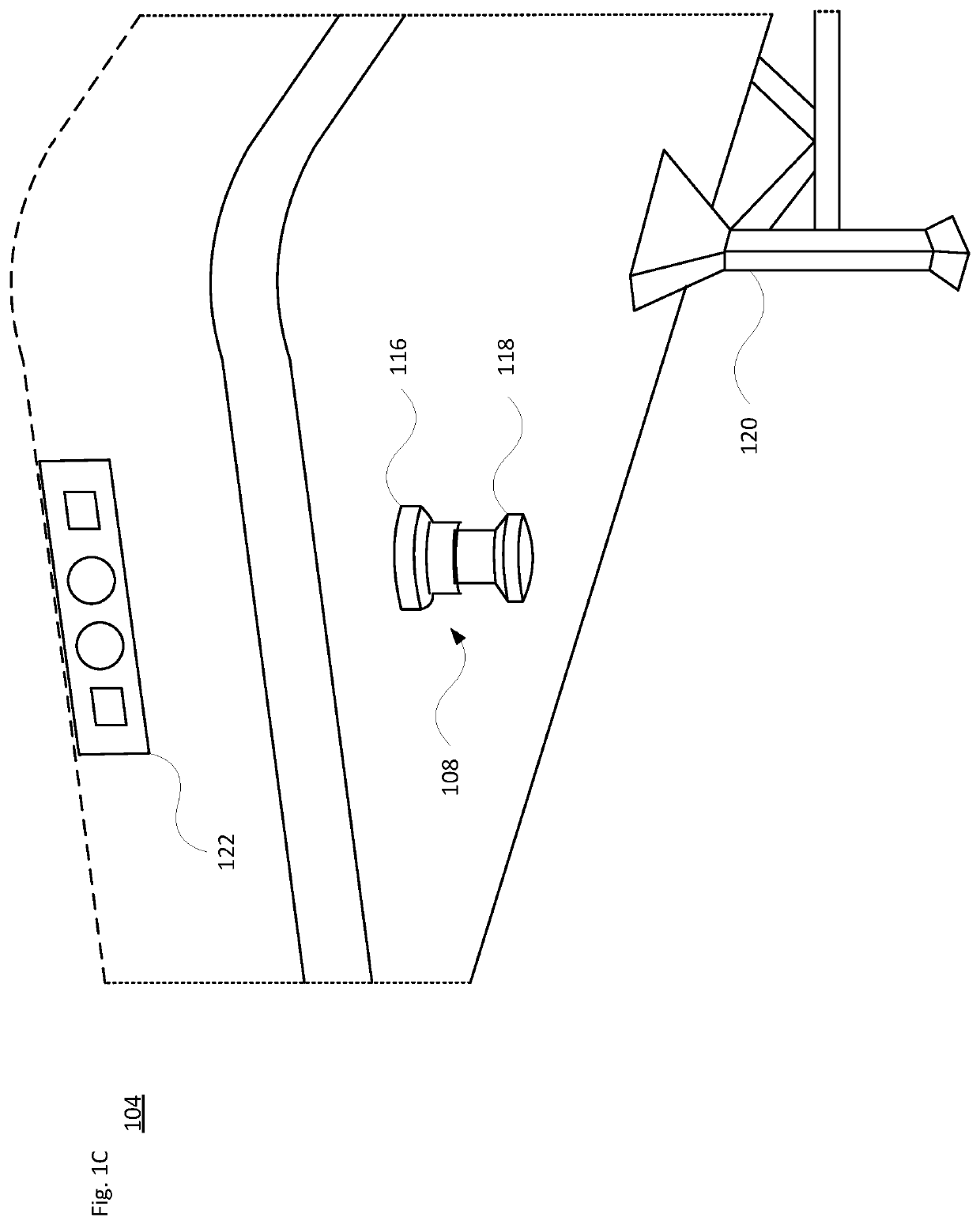

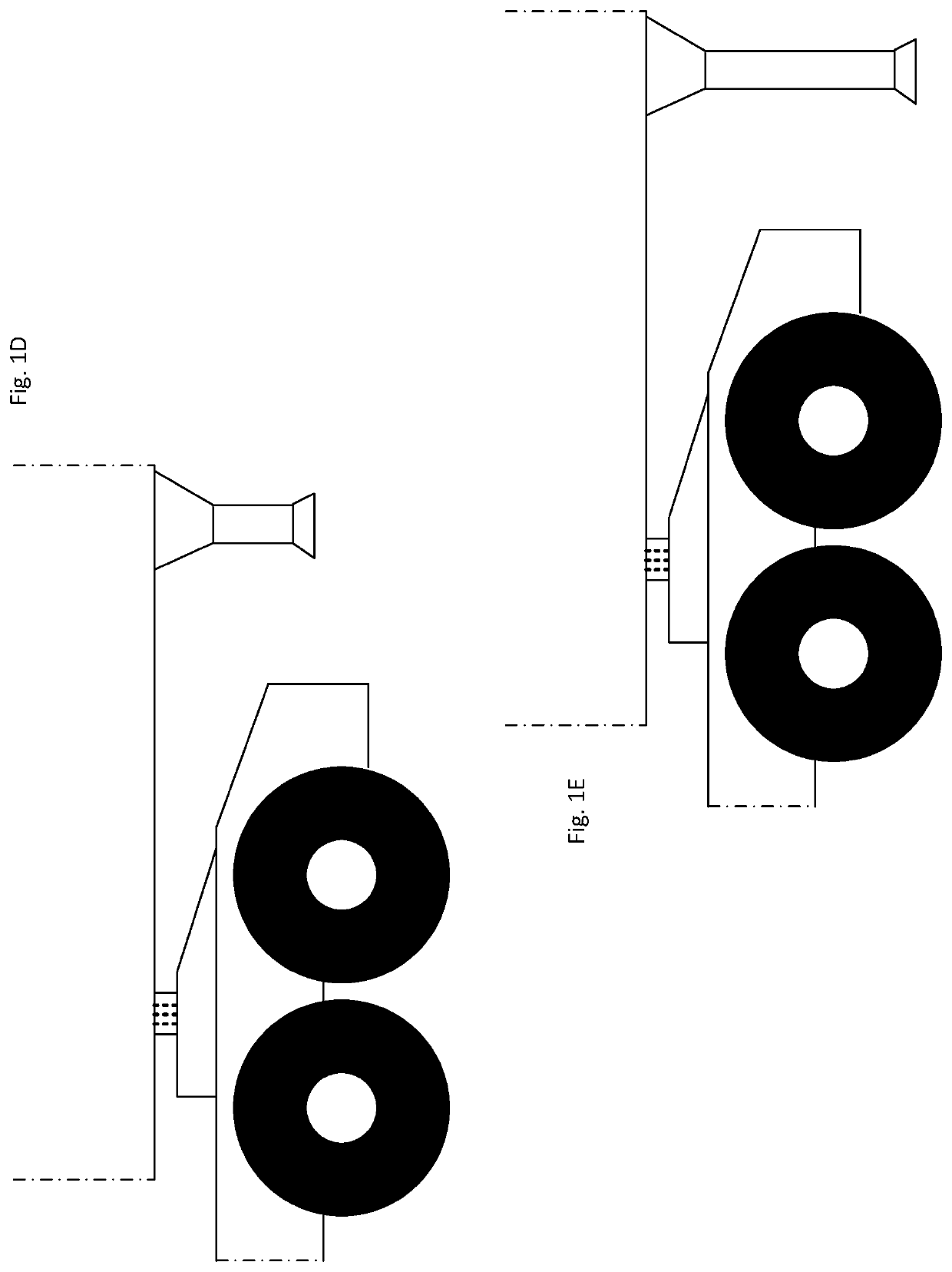

Self-steering agriculture grain carts and manure tanks

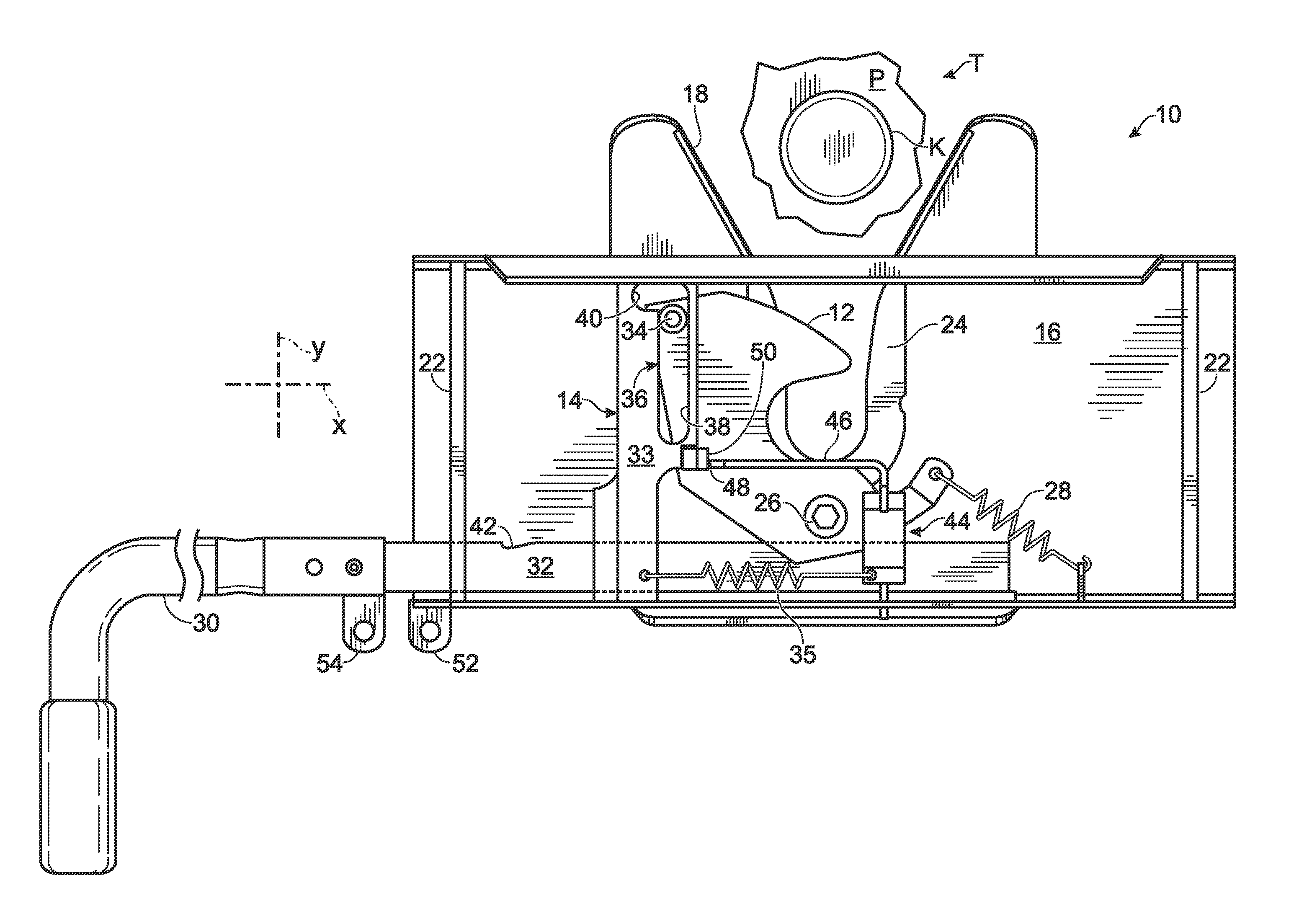

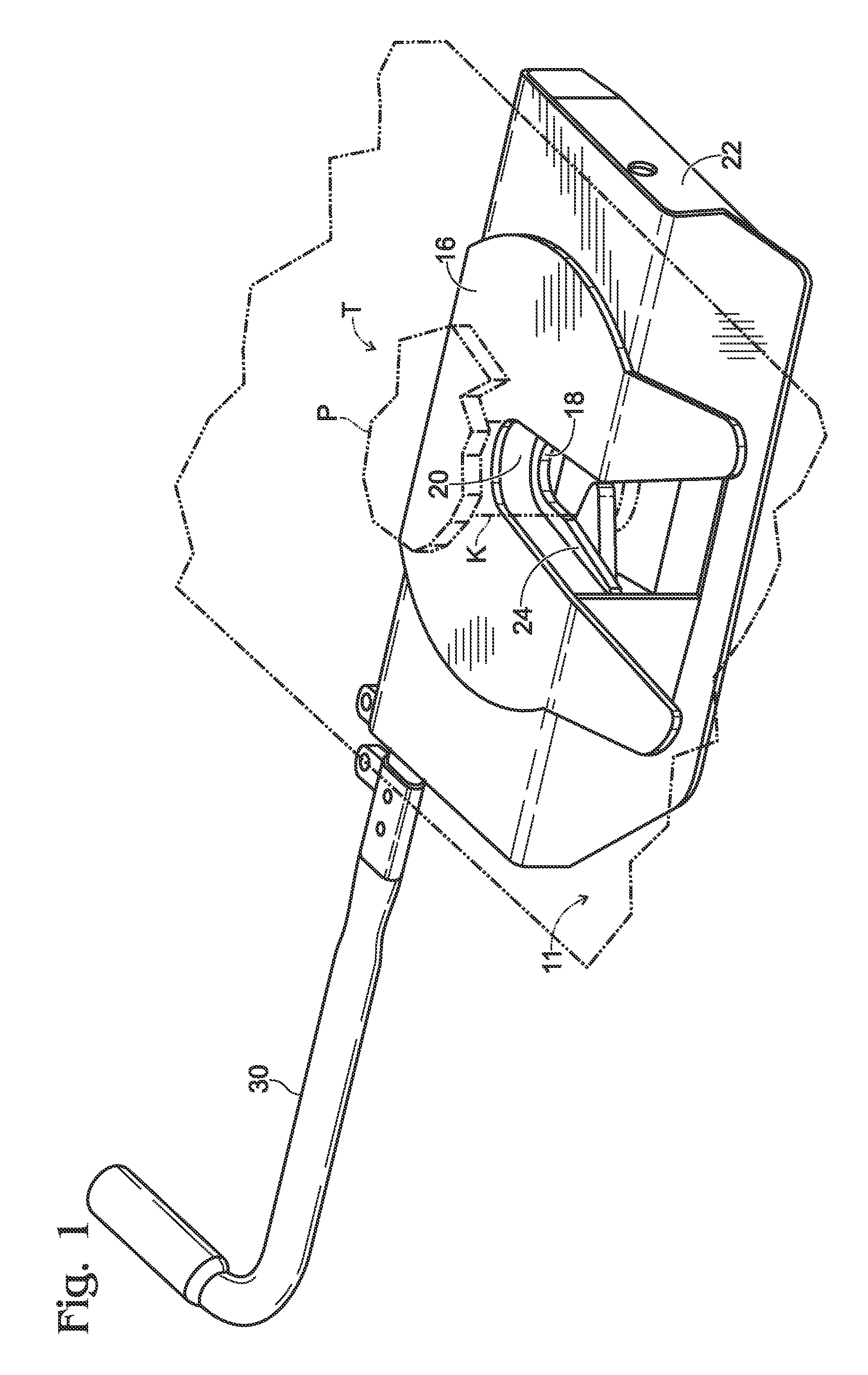

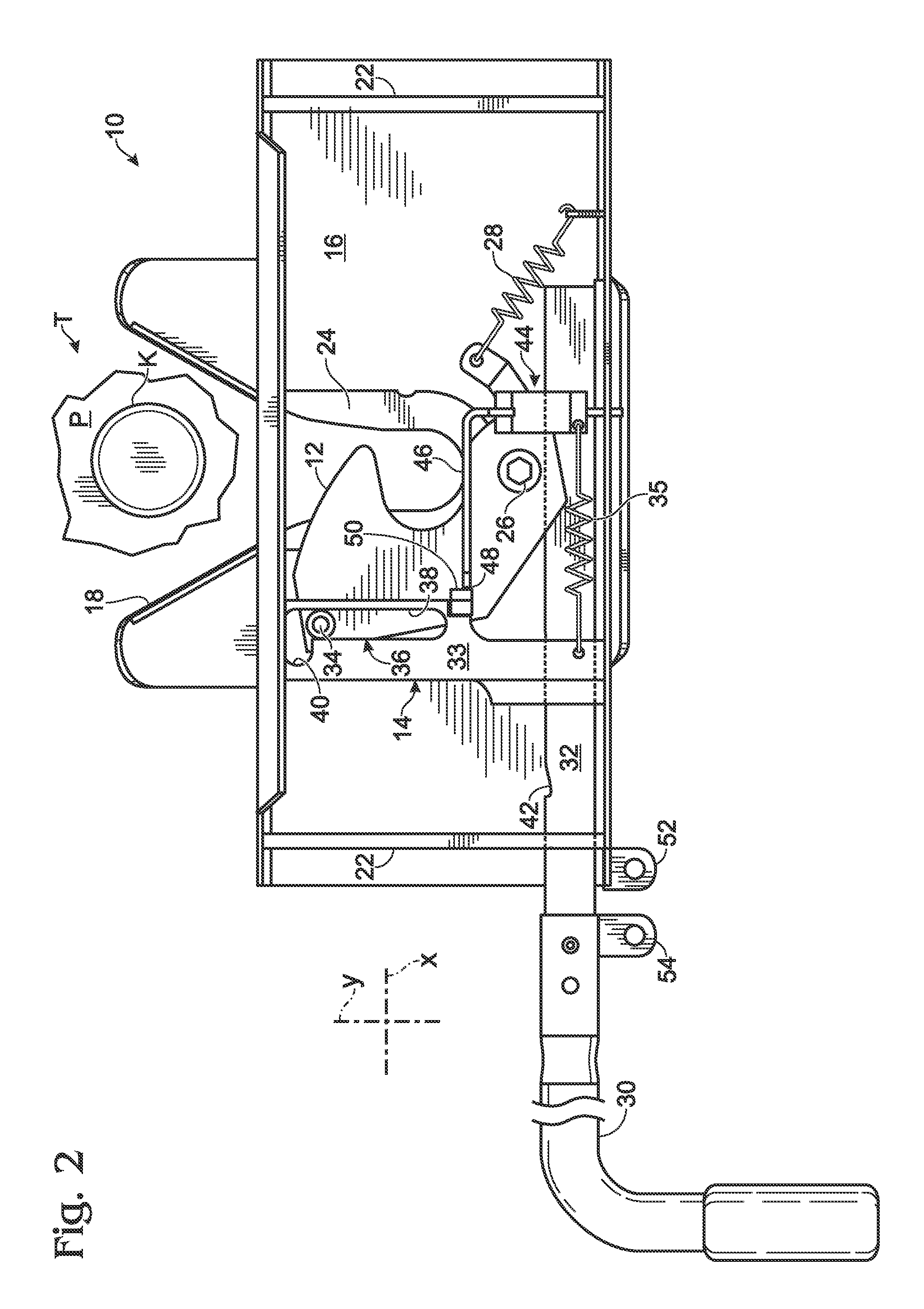

InactiveUS20130181431A1Convenient guidanceImprove safety and maneuverabilityTank vehiclesUnderstructuresAutomatic steeringEngineering

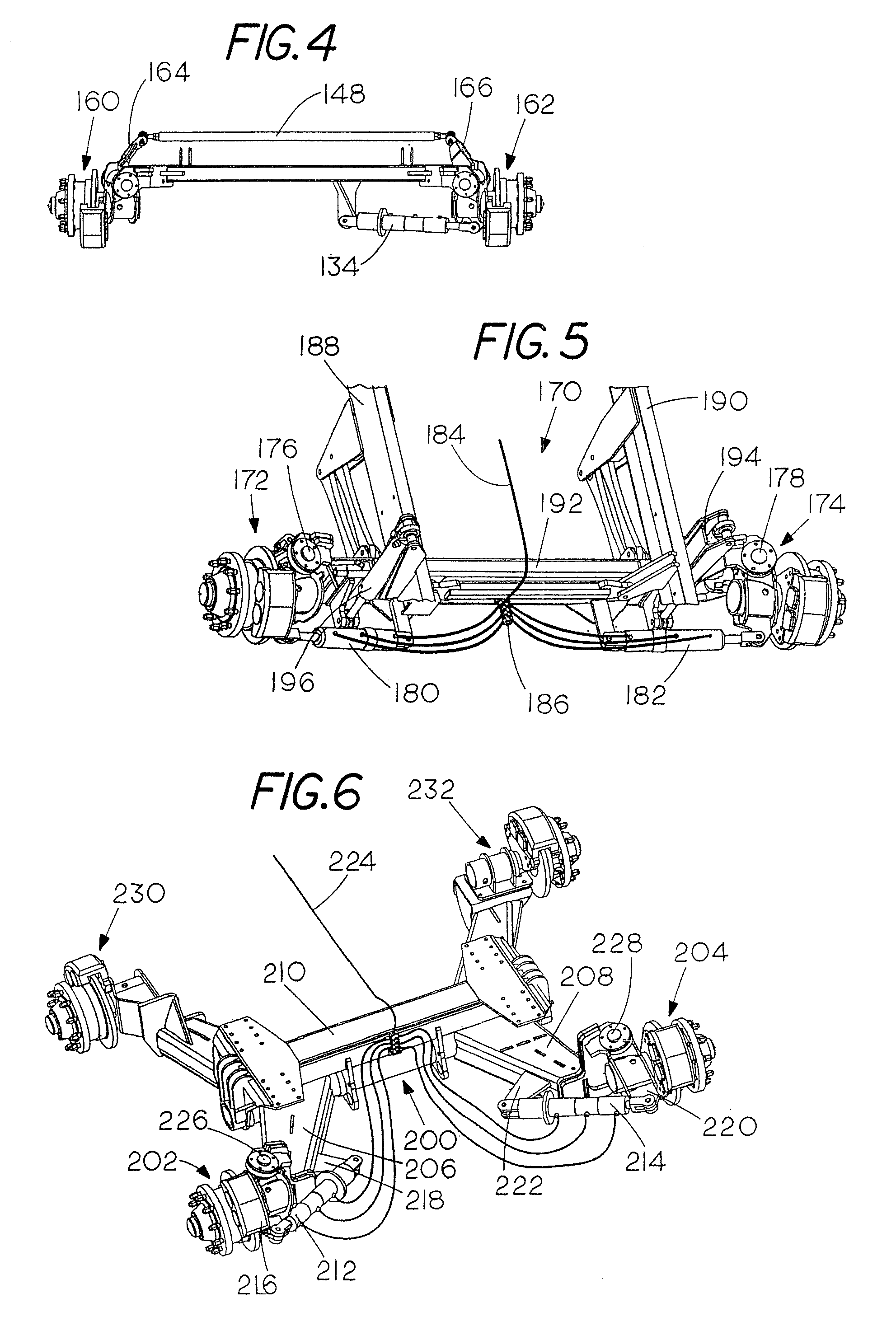

A frame and undercarriage track mounted assembly for a grain cart or manure tank unit designed to be pulled in a forward direction over and agricultural field by a farm tractor is disclosed. The invention involves a steering axle assembly that is adapted to turn dual spaced track assemblies. The steering axle is easily guided to improve the maneuverability and safety of the unit and reduce field compaction. The steering system design features compound angled kingpins that transfer some of the unit weight to assist in turns. Thus, the steering system reduces the resistance of the unit steering system to turning and the large footprint of the track assemblies minimizes ground compaction during turns.

Owner:BALZER

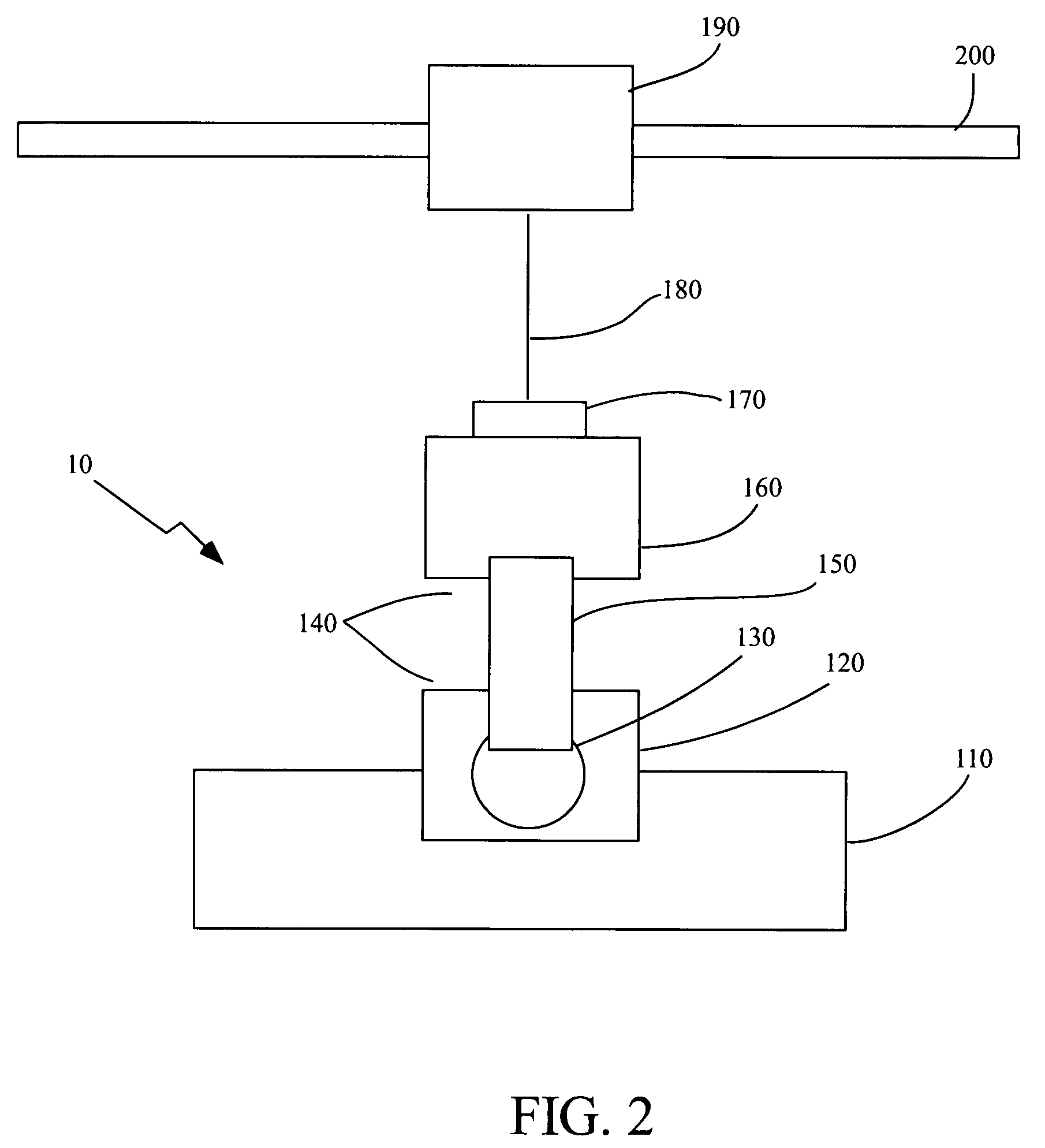

Offset coupler for kingpin trailer

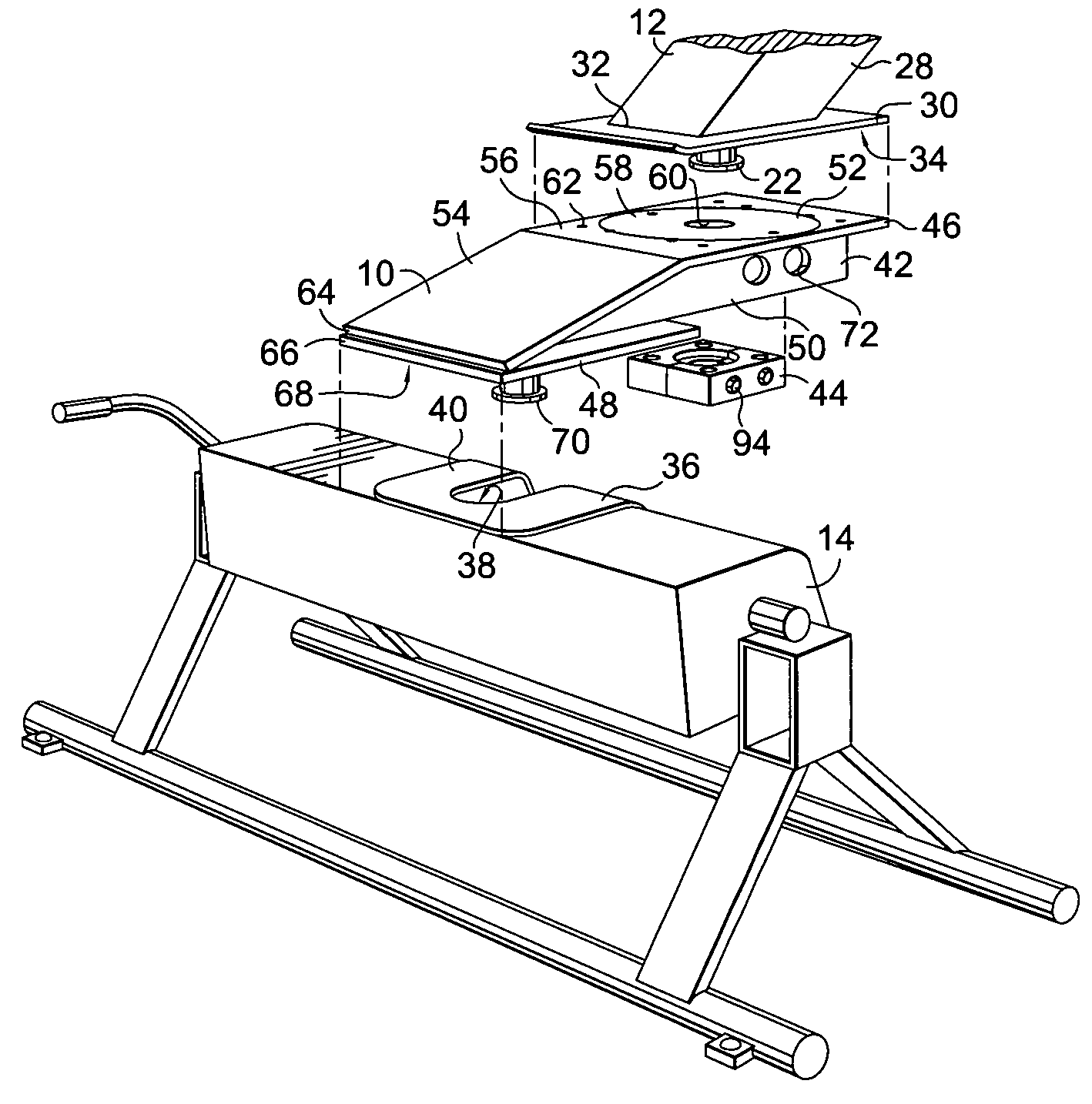

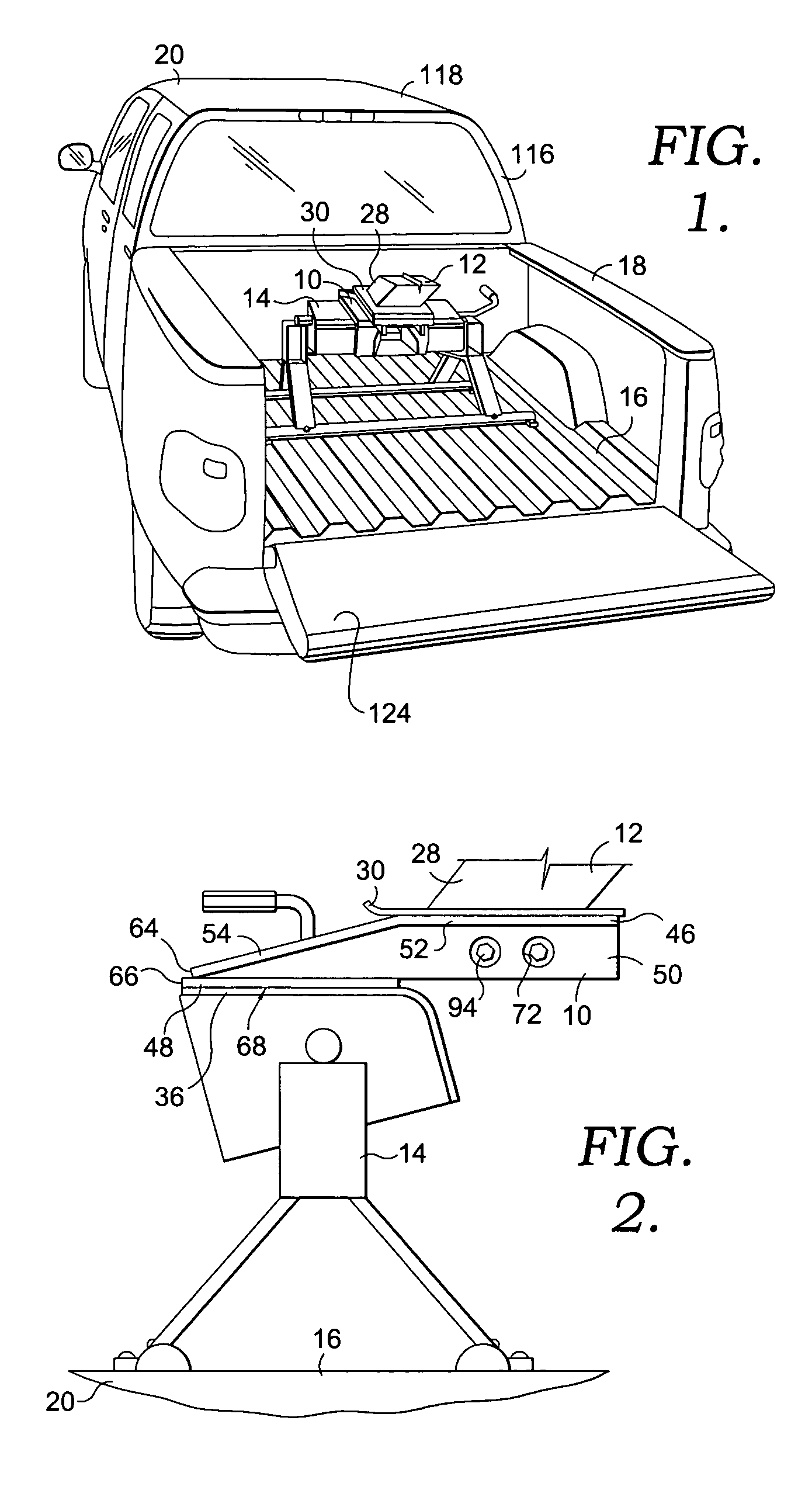

An offset coupler device for increasing the relative distance between a tow vehicle having a fifth wheel hitch and a trailer having a kingpin during use is provided. The offset coupler has an upper plate member with an opening therein for receiving the kingpin of the trailer. A clamp member is clamped on the kingpin of the trailer and includes a means for pressing the upper plate member into abutting engagement with a skid plate of the trailer. A lower plate member of the offset coupler has a kingpin depending downwardly from a lower surface thereof. The kingpin of the offset coupler is spaced apart laterally from the opening to provide an offset. Once the offset coupler is coupled with the trailer, the trailer is coupled with the tow vehicle by receiving the kingpin of the offset coupler in the fifth wheel hitch.

Owner:YOUNGS PRODS

Method for forming hollow front shaft

The invention relates to a method for forming a hollow front shaft, which is characterized in that the specific process is as follows: (1) firstly blanking a pipe section, adopting a band sawing machine and the like to cut a circular pipe material into a fixed-scale pipe blank in a required size, (2) utilizing a medium frequency induction heating furnace to heat pipe ends and a transition region of the cut pipe blank; (3) utilizing a special diameter-reducing machine to perform extrusion and diameter reduction or utilizing a rotary forging device to perform diameter reduction forming on the pipe ends and the transition region through a rotary extrusion and diameter reduction process; (4) carrying out upset forging and forming on the pipe ends; (5) heating the whole; (5) forming the whole; and (7) machining main pin holes at two ends of a pipe. The method for manufacturing a hollow front shaft through the forming process of a pipe blank is simple in manufacturing process, easy to realize the standardization of a mold, fast to remodel, few in production steps, light in weight of a front beam, low in remodeling cost, short in production preparation time and low in cost.

Owner:FAW GROUP

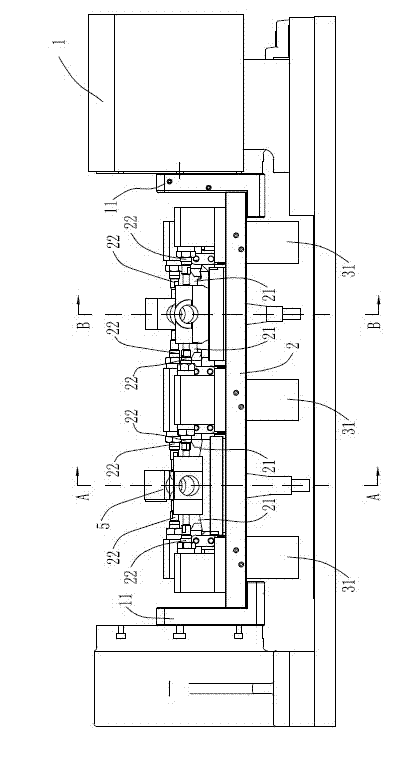

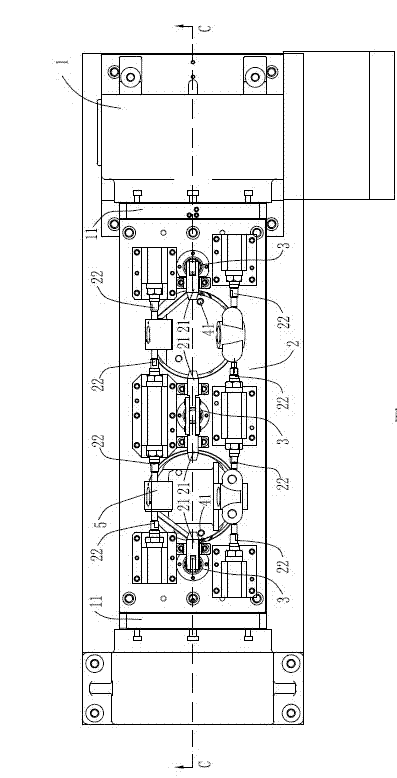

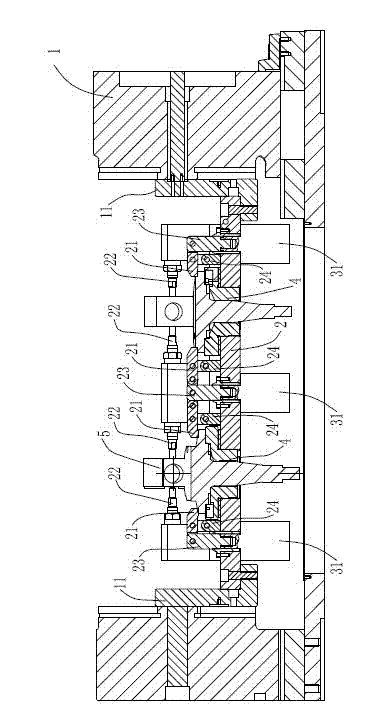

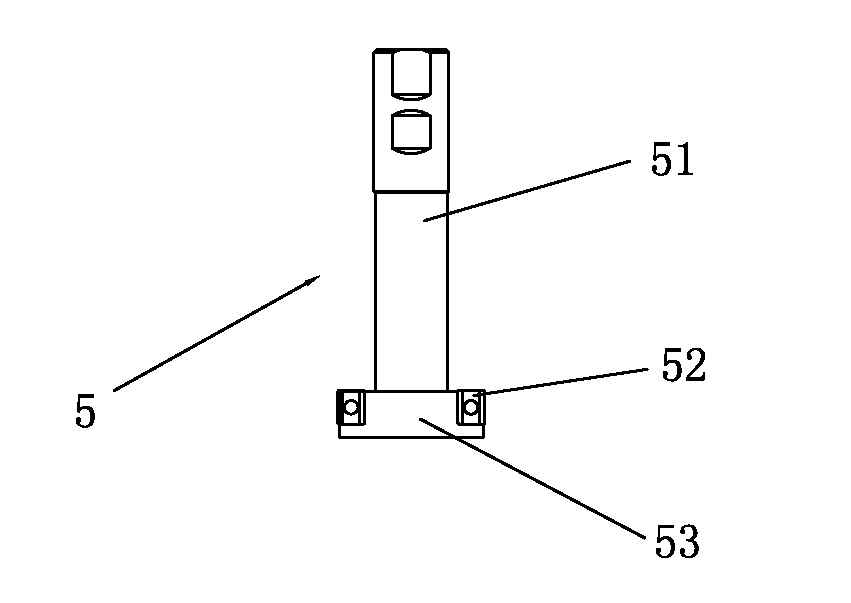

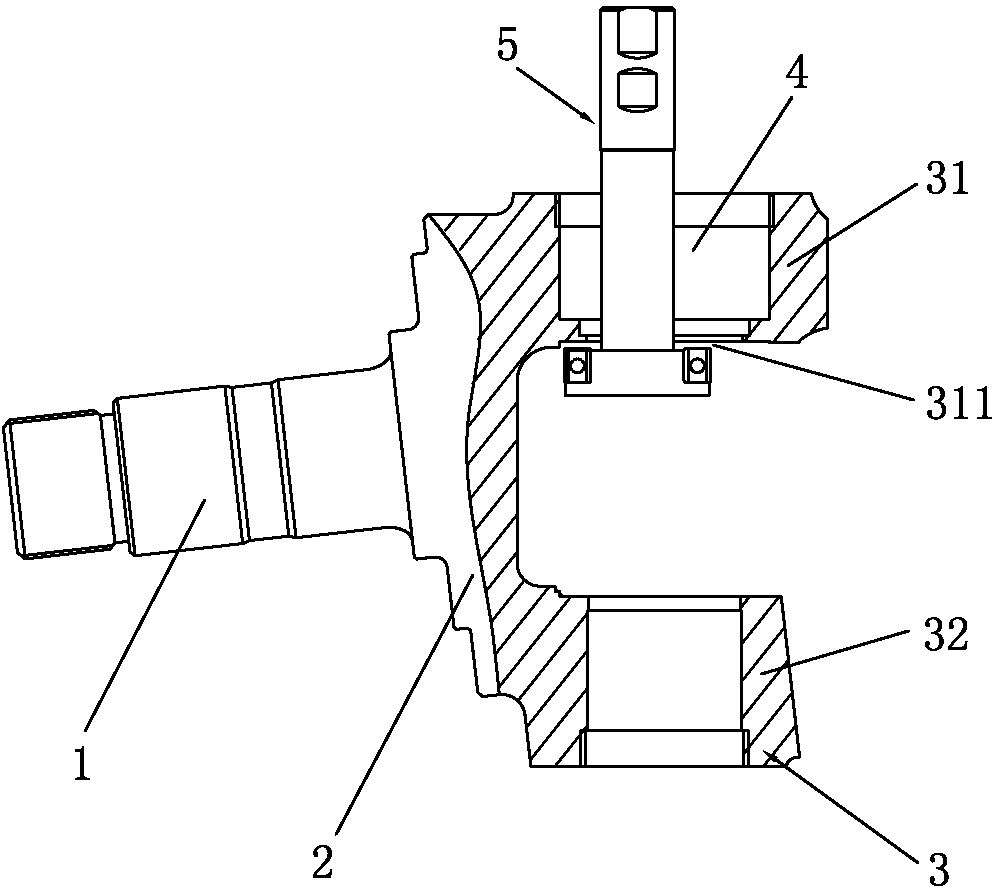

Fourth shaft rotary processing device of processing center special for steering knuckle

InactiveCN103028950AReduce processing timeGuaranteed machining accuracyLarge fixed membersPositioning apparatusStructural engineeringKingpin

The invention discloses a fourth shaft rotary processing device of a processing center special for a steering knuckle. The device comprises a bridge plate which takes the fourth shaft as a center to rotate; at least one steering knuckle placing hole for containing steering knuckle shaft necks to pass through is arranged on the bridge plate; a clamping device and a pressing device for fixing the steering knuckle on the bridge plate are arranged on the bridge plate; and a steering positioning device is arranged on the bridge plate. Through once clamping, the coarse and fine boring of a main pin hole of the steering knuckle, the finish milling treatment of the fork ear external surface of the steering knuckle and the ABS (acrylonitrile-butadiene-styrene) hole processing can be carried out; the processing precision can be guaranteed, the processing total time of the steering knuckle is reduced, and the production efficiency is improved.

Owner:日照市七星汽车部件股份有限公司

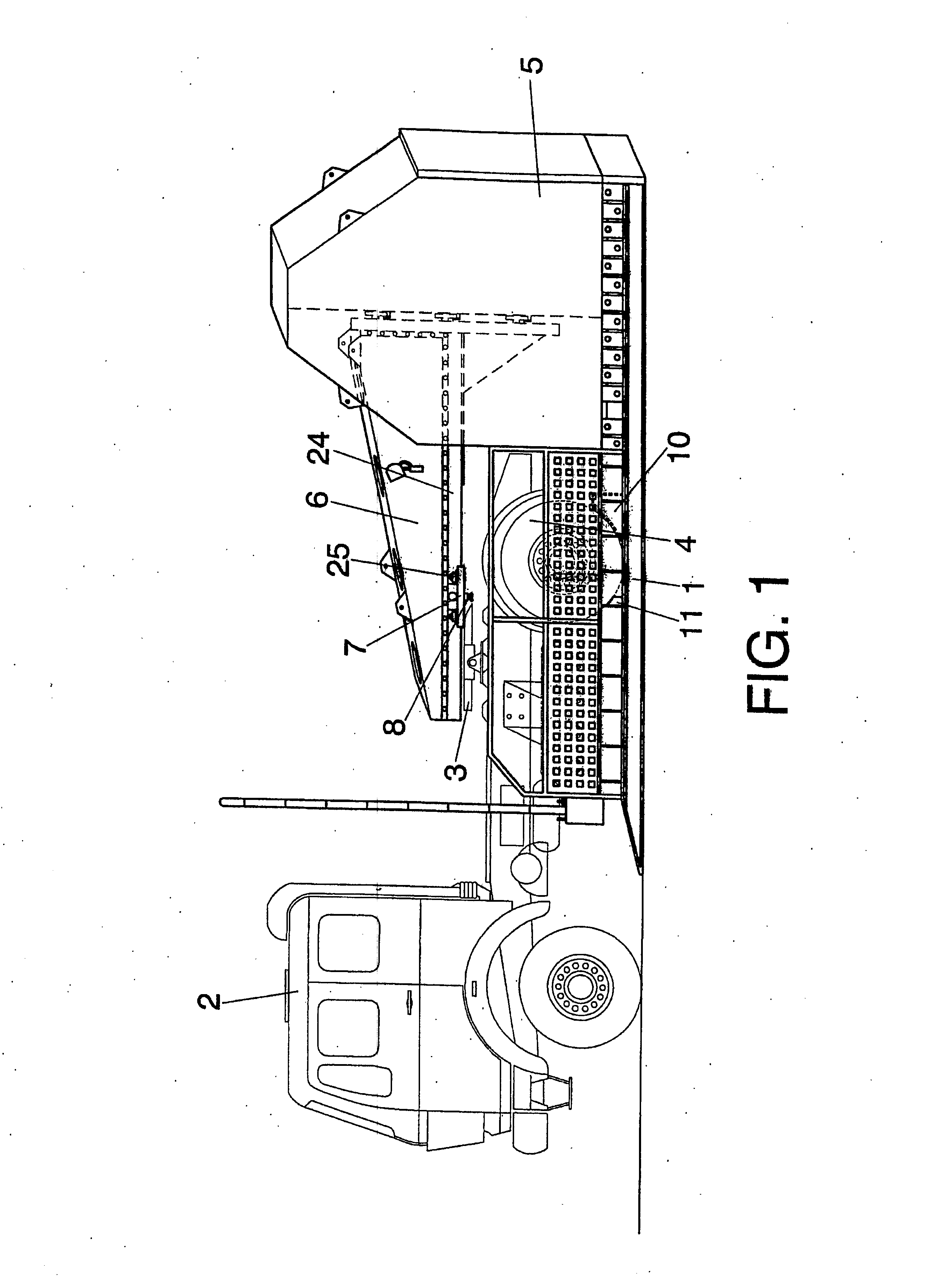

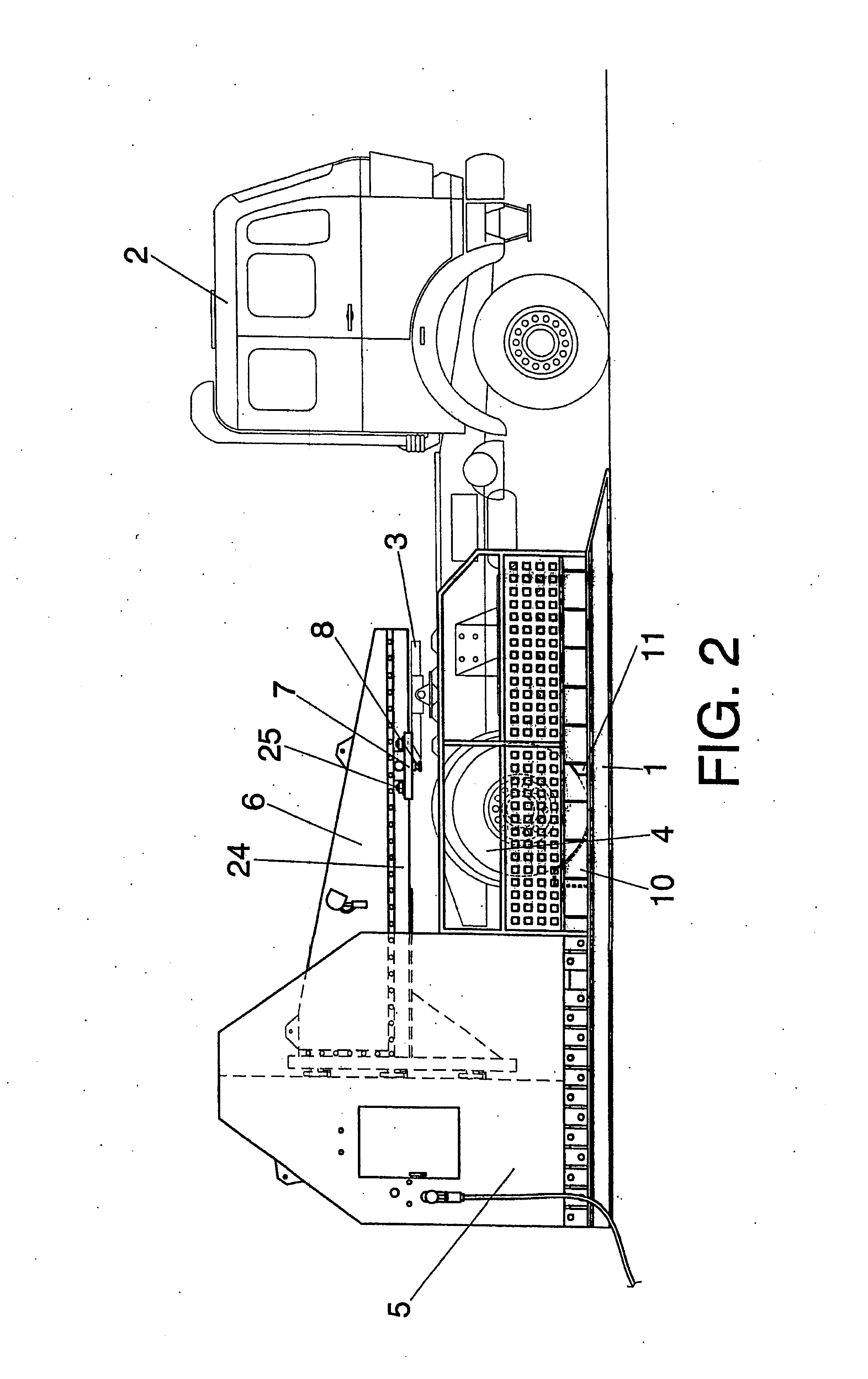

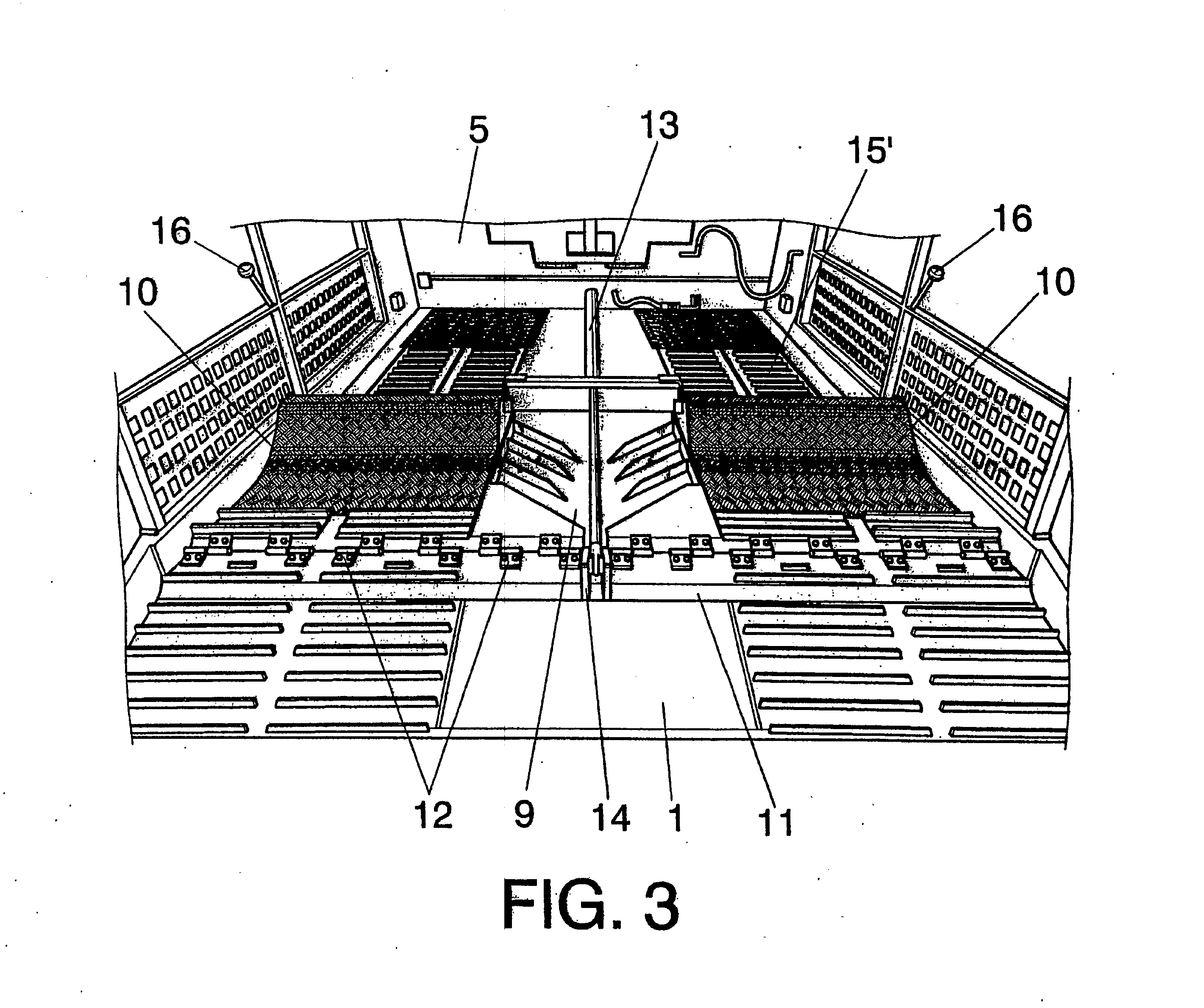

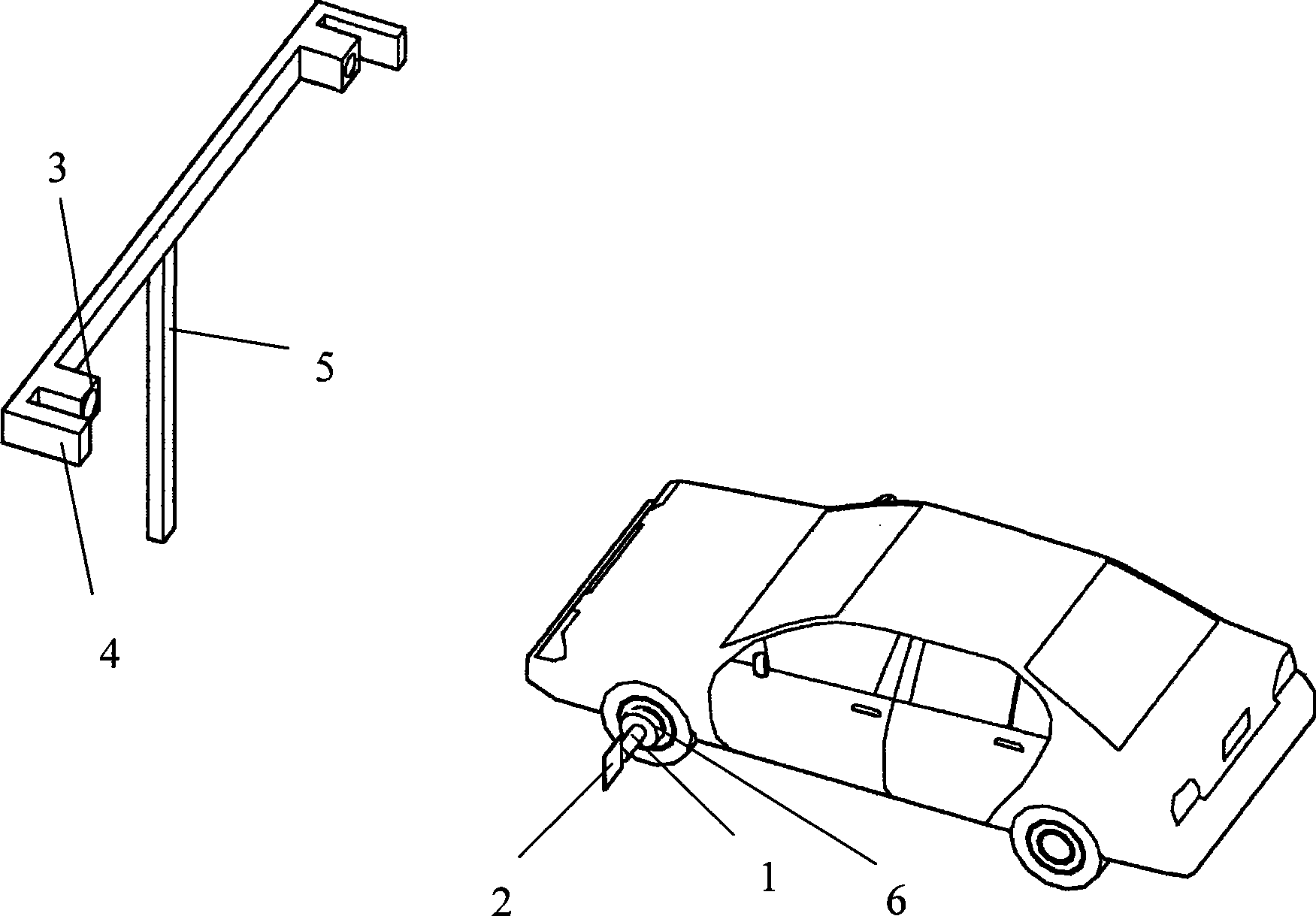

Machine for Inspecting the Coupling System Used to Hitch a Semi-Trailer to a Towing Vehicle

It comprises a base platform (1), on which is mounted a sliding platform (9) that receives the rear wheels (4) of the tractor vehicle (5) provided with the hitch or fifth wheel (3), securing it with the assistance of chocks (10,11) which immobilize said rear wheels (4), said platform being capped at its rear end with a structure (5) that supports an upper bridge (6), parallel to the base platform (1), adjustable for position both vertically and transversely, carrying a moving lower plate (7) on which a king-pin (8) similar to that of a semi-trailer is established, such that a mobilization of the lower platform (9) and of the bridge (6) enables the king-pin (8) to be aligned with the fifth wheel (3), and a subsequent movement of the plate (7) determines the final hitch between both, stresses then being applied to the king-pin (8), so that by means of a telemetry system the relative movements between the king-pin (8) and the fifth wheel (3) may be monitored and thereby the current state of the hitch.

Owner:BETANCOR BETHENCOURT FRANCISCO

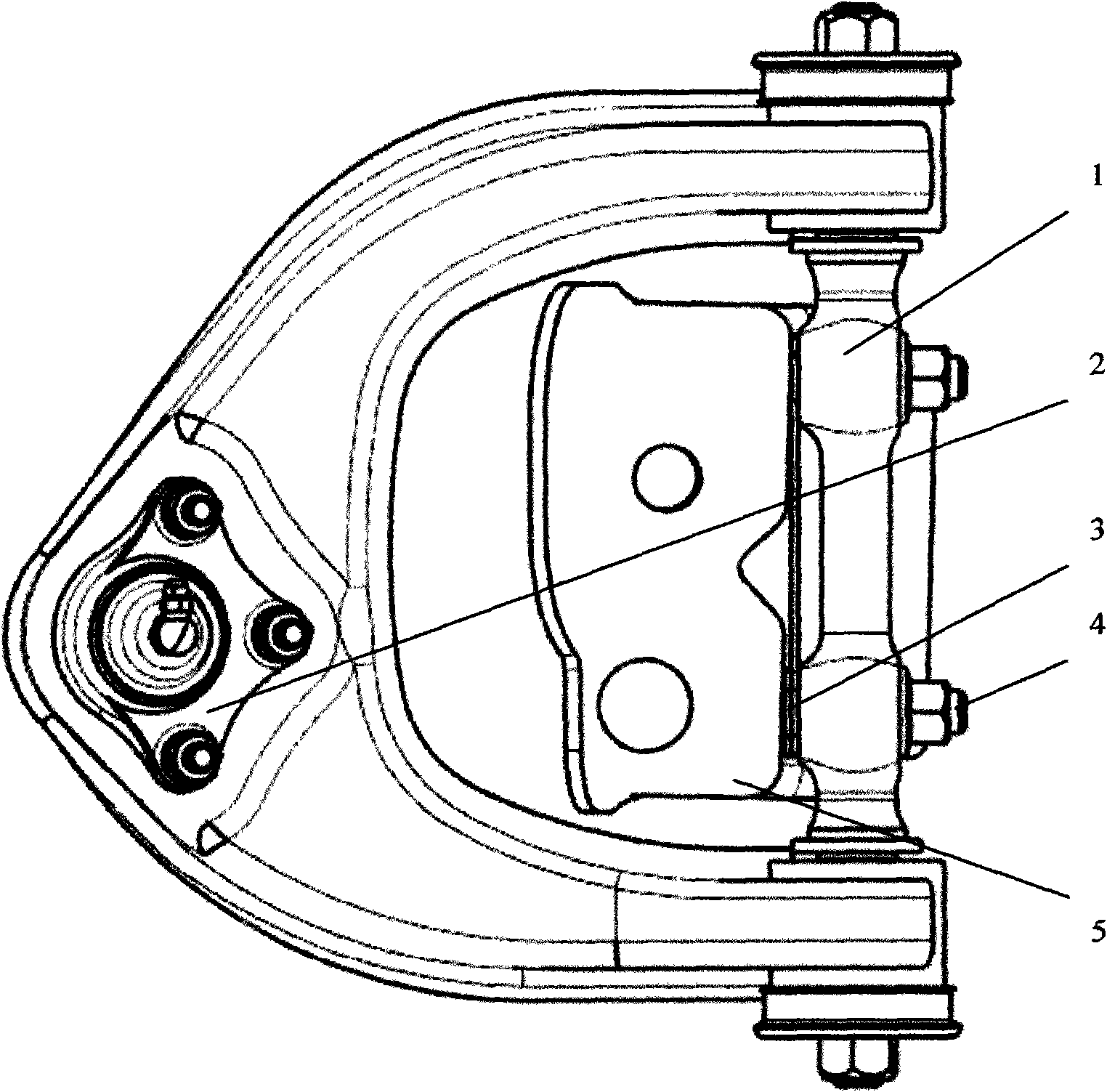

Adjusting device and adjusting method for kingpin caster angle of double wish-bone arm type front suspension system

InactiveCN101624066AMake up for the error of processing technologySteering partsSteering wheelVehicle frame

The invention relates to an adjusting device of a kingpin caster angle of a double wish-bone arm type front suspension system, which comprises at least one adjusting inserting piece (3) which is inserted and fixed between attaching surfaces wherein an upper swinging arm shaft is connected a fixed bracket (5) of a frame. Connecting points comprises front connecting points and rear connecting pints; when the inserting piece (3) is inserted into the front connecting points, the kingpin caster angle is reduced, and when the inserting piece (3) is inserted into the rear connecting points, the kingpin caster angle is increased. By setting the inserting piece, the kingpin caster angle is adjusted within the design requirements, thereby the errors of processing technique is made up, and vehicles retain the capability of linear running or quick restoration of a steering wheel after steering in the process of running.

Owner:CHERY AUTOMOBILE CO LTD

Capacitive sensors for monitoring loads

ActiveUS20120043417A1Improve accuracyImprove reliabilityForce measurementUsing electrical meansRelative displacementCapacitive sensing

A sensor for monitoring loads in a landing gear torque linkage includes a main pin having an axial interior bore defined therein. The main pin is configured and adapted to engage a torque link to a strut lug of a landing gear strut. A core pin is mounted axially within an interior bore of the main pin and is spaced radially inwardly from the interior bore for relative displacement with respect to the main pin. A capacitor is included having an inner capacitor plate mounted to the core pin. An outer capacitor plate is mounted to the main pin. Relative displacement of the core pin and the main pin due to loads acting on the torque link and strut lug results in relative displacement of the inner and outer capacitor plates. Signals can thereby be produced indicative of the loads acting on the torque link.

Owner:THE BF GOODRICH CO

Method and device for detecting vehicle front wheel angle

InactiveCN101469983AAccurately reflect deviationsSimple structureVehicle testingUsing optical meansCamber angleEngineering

An automobile front wheel angle test method comprises: respectively fixing a connecting rod on the outer end faces of two front wheels of an automobile; respectively and fixedly connecting a flat plate with the outer end of each connecting rod; connecting the connecting rods with the flat plates axially; respectively arranging a camera at the front of two front wheels and on the flat plates; respectively arranging a laser indicator at the front of the two front wheels, while the laser beams of the laser indicators have cross-type sections; projecting the laser beams on the flat plates; driving the vehicle forward; using cameras to record the projection positions of the laser beams on the flat plates; according to the projection positions of the laser beams on the flat plates, using mathematical method to respectively calculate main pin trim angle, main pin leaning angle, front wheel lateral obliquity angle and front wheel front beam of the two front wheels. The invention further provides a device for realizing the method. The invention can accurately reflect grounding deviation of wheels, having simple structure and operation.

Owner:SHANGHAI TONGYUN AUTOMOBILE TECH

Output type multi-bearing-point independent suspension

InactiveCN104589943ADoes not affect layoutDoes not affect functionResilient suspensionsPivoted suspension armsVehicle frameEngineering

The invention discloses an output type multi-bearing-point independent suspension, which comprises an upper fork arm, a lower fork arm, elastic elements, a shock absorber and fork arm-positioning pivots; the upper fork arm and the lower fork arm are A-shaped structural parts, the front ends of the upper fork arm and the lower fork arm are respectively connected with the upper suspension point and lower suspension point of a wheel through main pins, the shock absorber is mounted on the top of the front end of the upper fork arm, and the rear ends of the upper fork arm and the lower fork arm are connected with a chassis through the elastic elements. A corresponding available space is expanded around the upper fork arm and the lower fork arm, reasonable bearing pivot points and transfer parts of the chassis are structured, the lever principle, the torsion bar principle and the principle of moments are utilized, so that double-fork arm pivotal suspension point motion can absorb bearing elastic force by means of returning force and the arms of force or direction change, the conventional one-point supporting elastic element is changed into the multiple multi-point supporting elastic elements, consequently, the force applied on the wheel is decomposed by multiple points, and thereby average running speed is increased. The increase in the number of the elastic elements and the reasonable arrangement of the elastic elements can reduce the height of a vehicle, optimize space utilization and improve the stability and running smoothness of the vehicle.

Owner:石宇 +1

Machining technology for inner end surfaces of lugs of automobile steering knuckle

ActiveCN104028816AGuaranteed verticalityGuaranteed distanceMilling equipment detailsNumerical controlMilling cutter

The invention relates to the technical field of automobile steering knuckles, and in particular relates to a machining technology for the inner end surfaces of lugs of an automobile steering knuckle. The machining technology comprises the following steps: fixing the steering knuckle on a numerically-controlled machine tool through a clamp, machining a rod part, and rotating the clamp so as to rotate the steering knuckle for a certain angle, wherein the rotated angle is an included angle between the central lines of the steering knuckle rod part and each master pin hole; and roughly milling the inner end surfaces of an upper lug and a lower lug along a direction vertical to the central line of each master pin hole by using a rough milling cutter, and reversely finish-milling the inner end surface of the upper lug through a finish-milling cutter after penetrating through the master pin hole in the upper lug. According to the machining technology disclosed by the invention, when the inner end surfaces of the lugs are machined, the finish-milling cutter is used for finish-milling the inner end surfaces of the lugs after penetrating through the master pin holes so as to well guarantee the perpendicularity of the master pin holes and the inner end surfaces and the distance between the inner end surface of the upper lug and the inner end surface of the lower lug, and the yield of the product is improved.

Owner:HUBEI TRI RING FORGING

Method and device for detecting movement track of automotive tire

InactiveCN101469980AAccurately reflect deviationsSimple structureVehicle testingUsing optical meansRectangular coordinatesProjection screen

The invention relates to an automobile tire motion track test method, comprising fixedly connecting three laser indicators vertical and crossed with each other to the outer end face of a tire; projecting laser beams to three projection screens vertical to each other; driving the vehicle forward; using cameras to record the positions of the laser beams on the projection screens vertical to each other; according to the positions of the three laser beams on the projection screens, calculating main pin trim angle, main pin leaning angle, front wheel lateral obliquity angle and front wheel front beam. A device realizing the method is composed of a connecting base, three cameras and three projection plates, wherein the three projection plates are respectively arranged on the laser projection directions of the three laser indicators and are vertical and crossed with each other, the three cameras are respectively arranged at the front of the projection plates. The invention utilizes three laser indictors and three projection plates to display the motion state of automobile tires in space rectangular coordinates, to accurately reflect the grounding deviation of tires, having simple structure and operation.

Owner:SHANGHAI TONGYUN AUTOMOBILE TECH

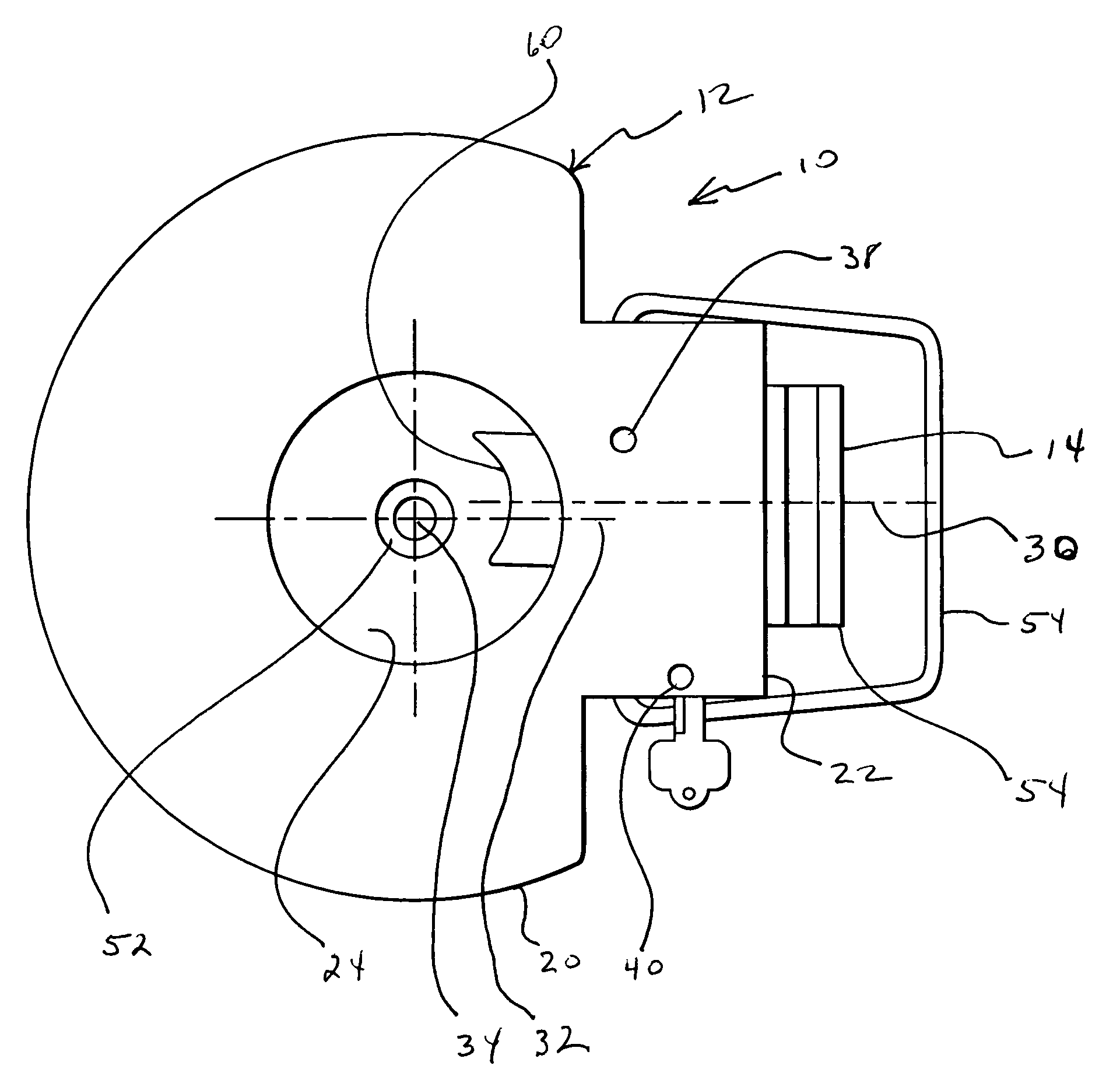

Fifth wheel hitch

A fifth wheel hitch assembly is provided for use with a kingpin, the hitch assembly including a hitch frame including a throat for receiving the kingpin therein, a jaw member pivotally coupled to the hitch frame and moveable between an open orientation and a closed orientation, and a locking arm having a cooperative relationship with the jaw member. One of the jaw member and locking arm defines a guide surface and another of the jaw member and locking arm includes a follower configured to traverse the guide surface, traverse of the follower along a guide segment of the guide surface directing rotation of the jaw member between the open orientation and the closed orientation, and traverse of the follower along a lock segment directing releasable locking of the jaw member in the closed orientation.

Owner:THE COAST DISTRIBUTION SYSTEM INC

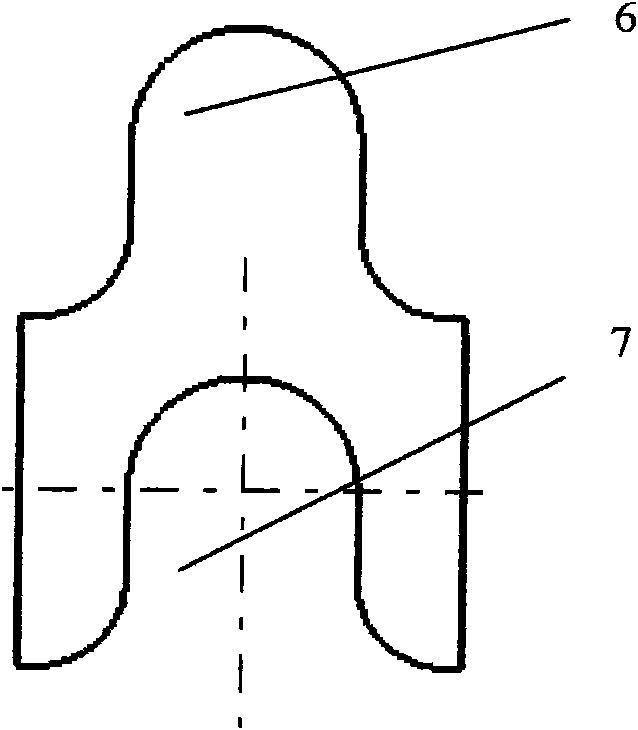

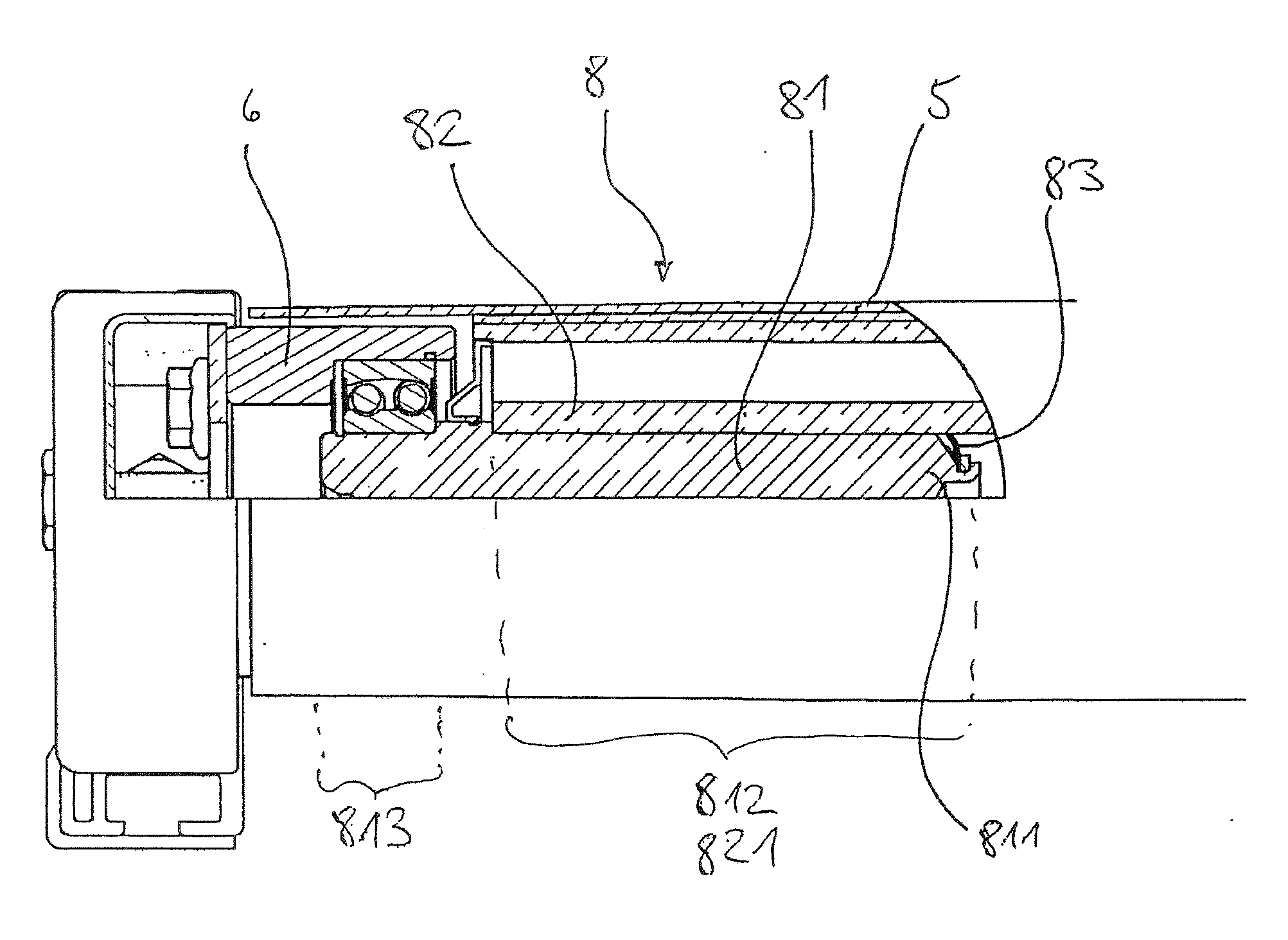

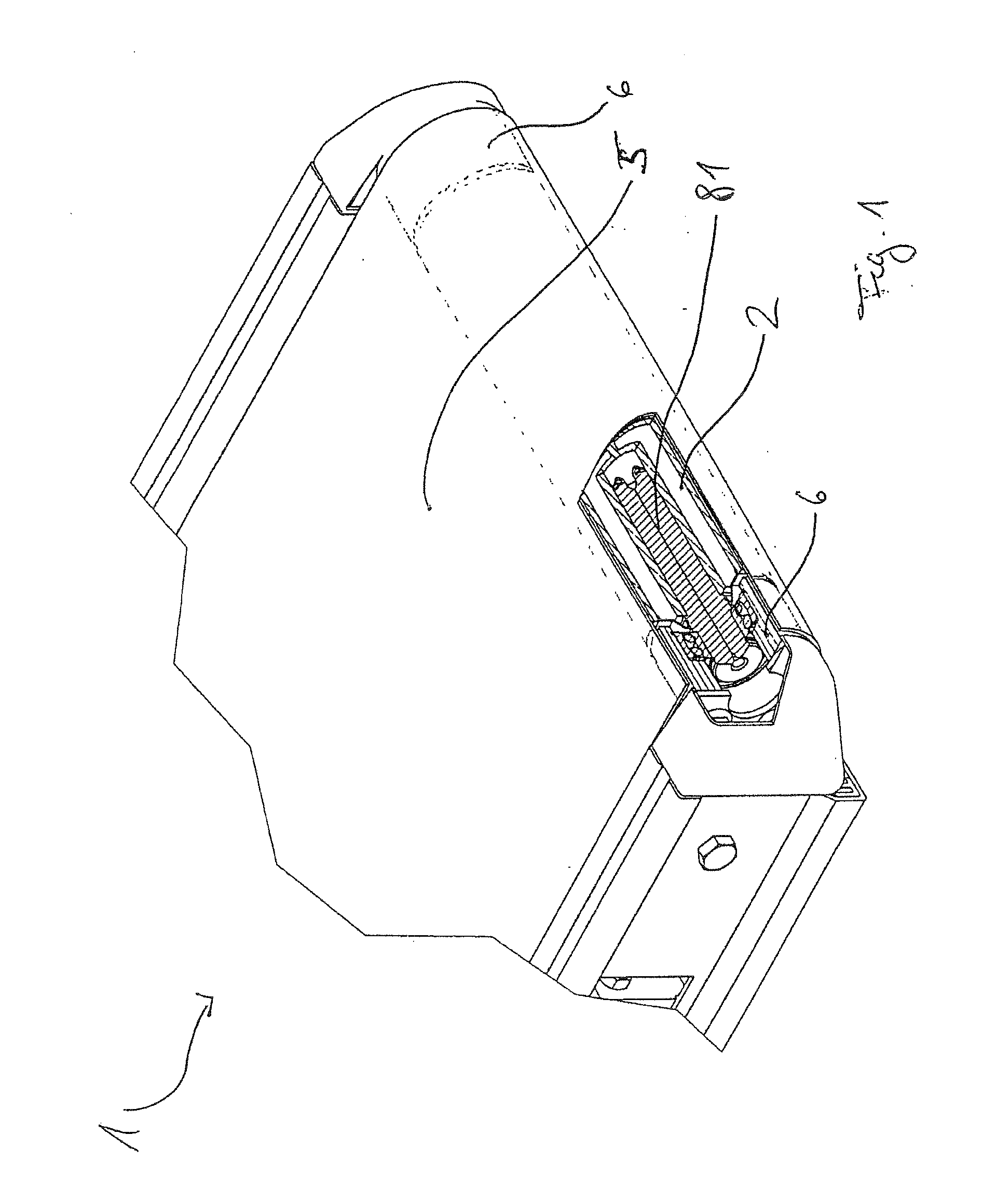

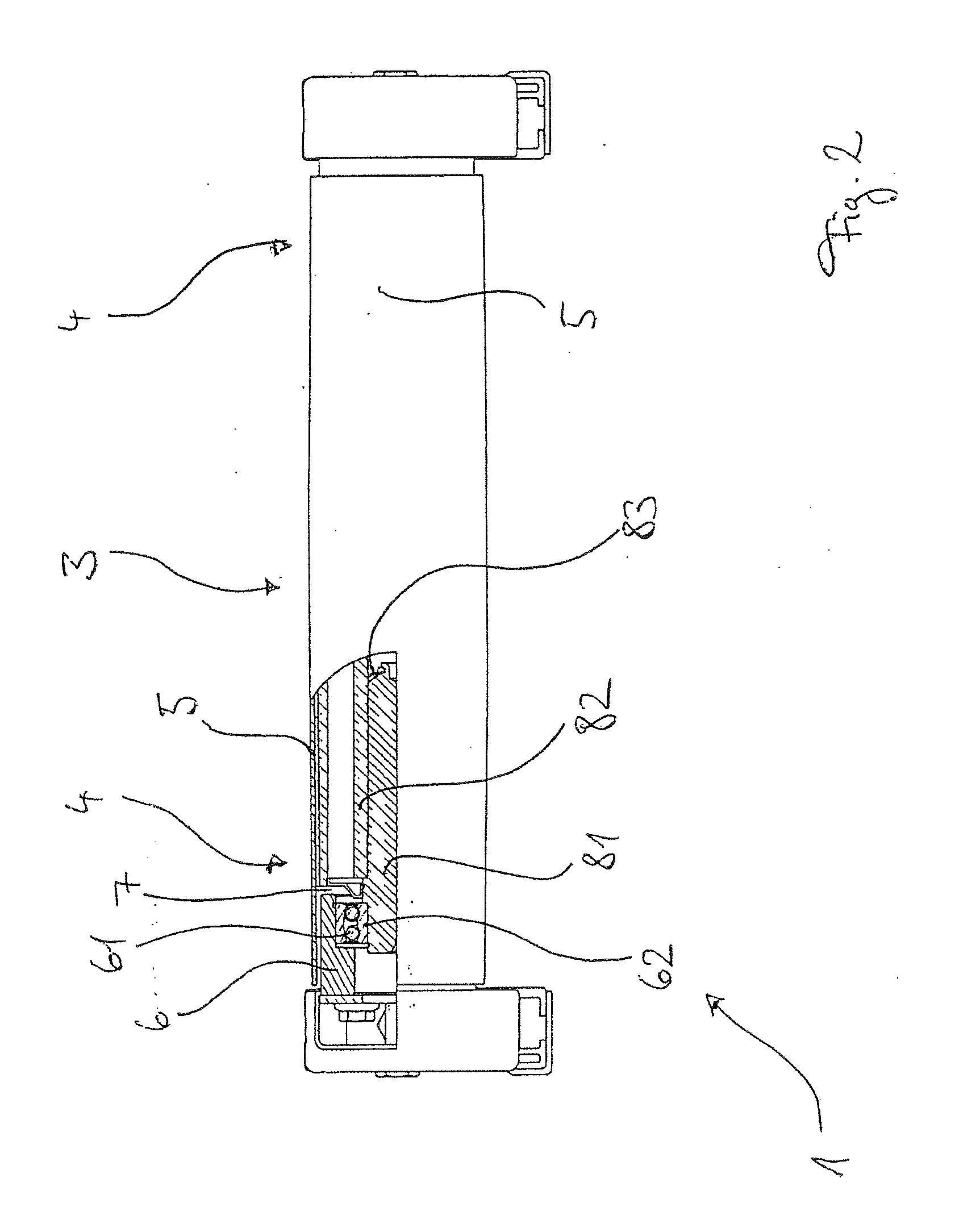

Shaft-hub assembly with expansion element

InactiveUS20100230250A1Improve scalabilitySolving the Insufficiency of ElasticityConveyorsCouplings for rigid shaftsAxial displacementEngineering

A conveying system has a roller and a shaft-hub assembly with a kingpin (81), an expansion element (83) and a hub (82). The kingpin has a cross-section corresponding to a cross-section of the hub so that the kingpin is fixed radially to the hub. The kingpin (81) is fixed rotationally to the hub (82). The expansion element in a relaxed state, has an external diameter that exceeds the internal diameter of the hub. The expansion element also is deformed elastically when the kingpin is disposed in the hub so that the external peripheral region (831) of the expansion element shifts from the relaxed position. Axial displacement of the external peripheral region of the expansion element is coupled with a reduction in the external diameter so that the reduced external diameter of the expansion element corresponds to the internal diameter of the corresponding internal peripheral region of the hub.

Owner:INTERROLL HLDG

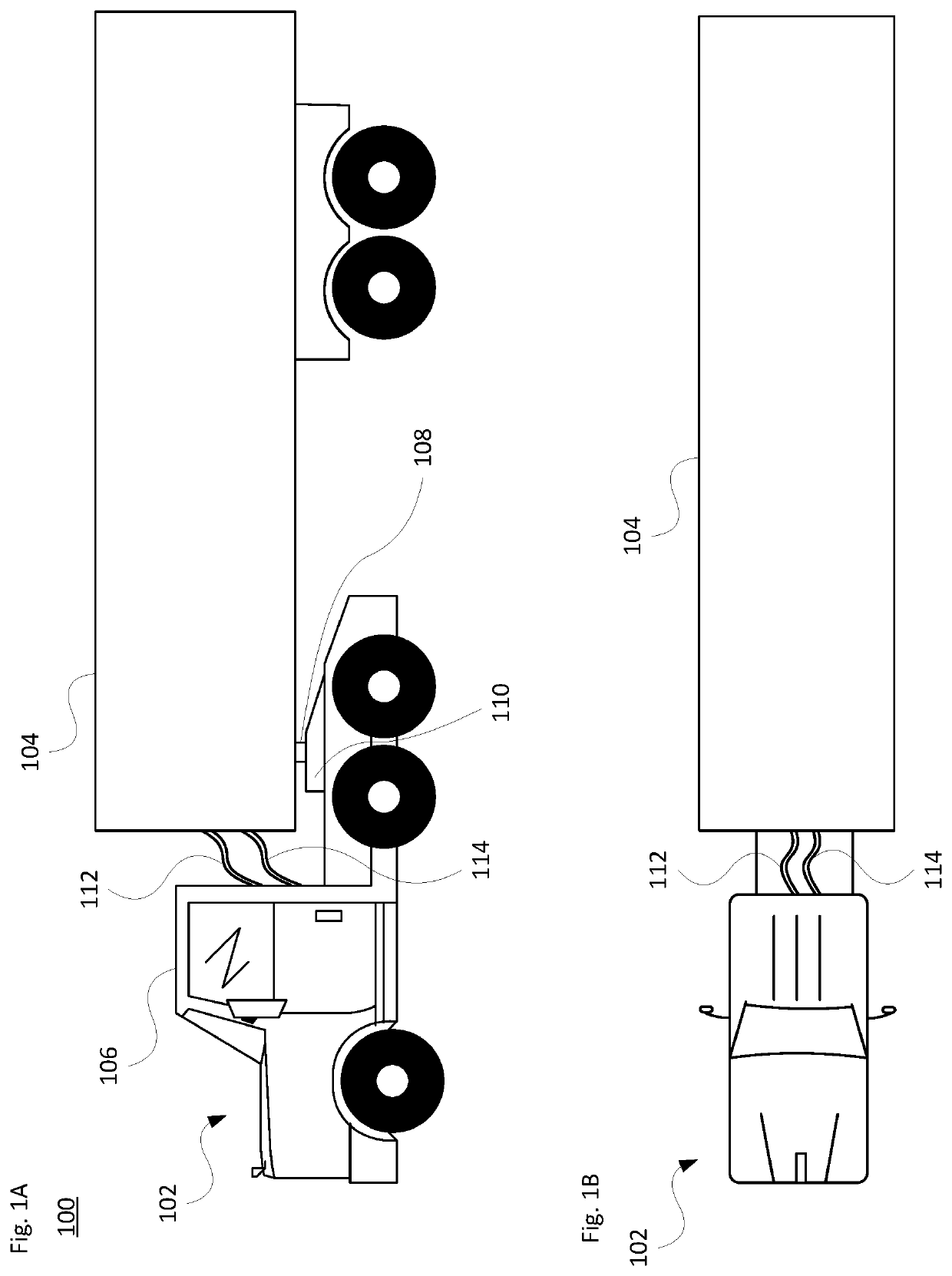

Systems and methods for automatic air and electrical connections on autonomous cargo vehicles

ActiveUS20190367105A1Prevent air leakageTractor-trailer combinationsElectromagnetic wave reradiationElectrical connectionControl theory

The technology relates to autonomous vehicles having hitched or towed trailers for transporting cargo and other items between locations. Aspects of the technology provide a smart hitch connection between the fifth-wheel of a tractor unit and the kingpin of a trailer. This avoids requiring a person to make physical pneumatic and electrical connections between the fifth-wheel and kingpin using external hoses and cables. Instead, the necessary connections are made internally, autonomously. For instance, the fifth-wheel may provide air pressure via one or more slots arranged on a connection surface, and the trailer is configured to receive the air pressure through one or more openings on a contact surface of the kingpin. An electrical connection section of the fifth-wheel may also provide electrical signals and / or power to an electrical contact interface of the kingpin. Rotational information about relative alignment of the trailer to the tractor unit may also be provided.

Owner:WAYMO LLC

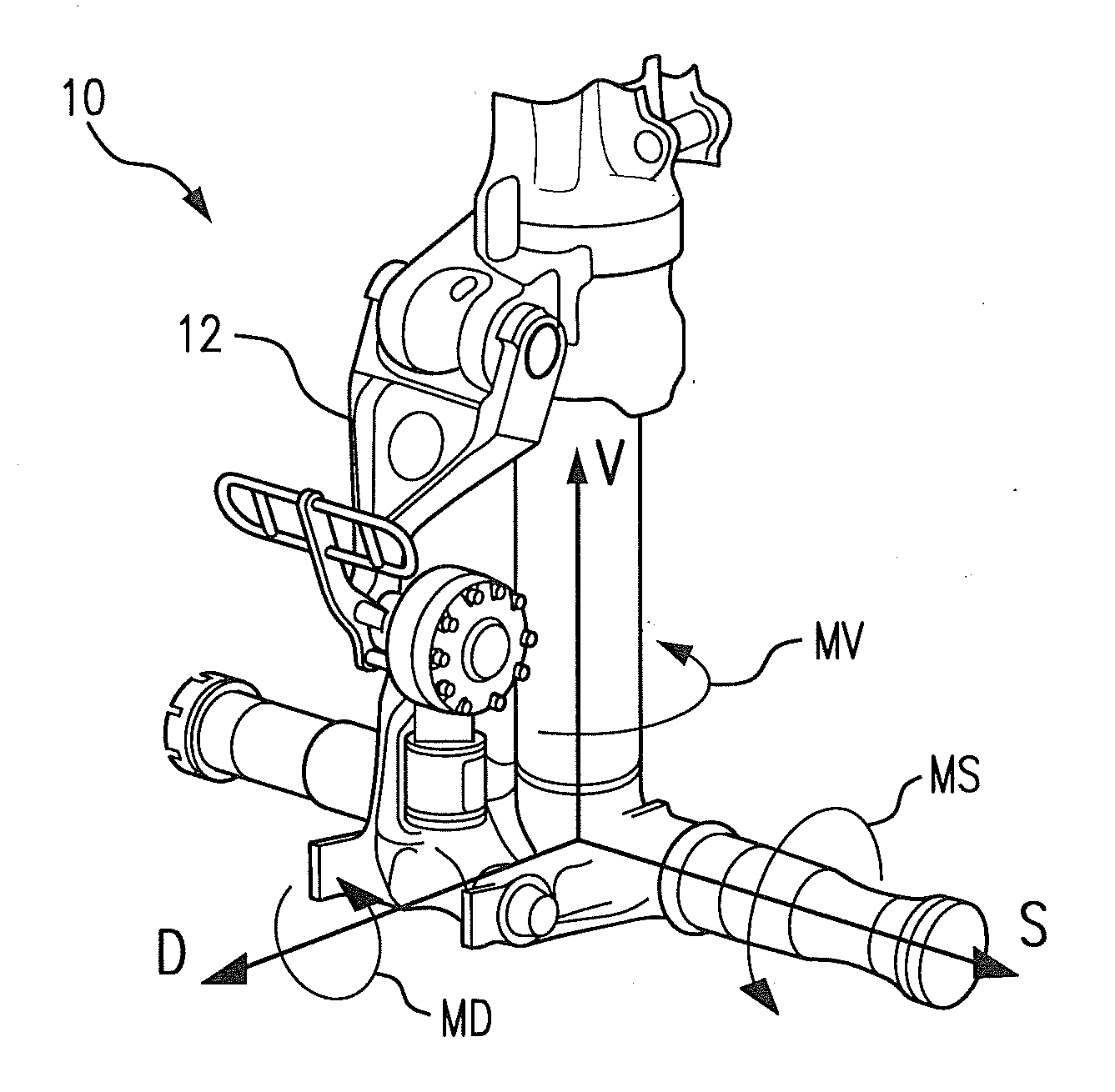

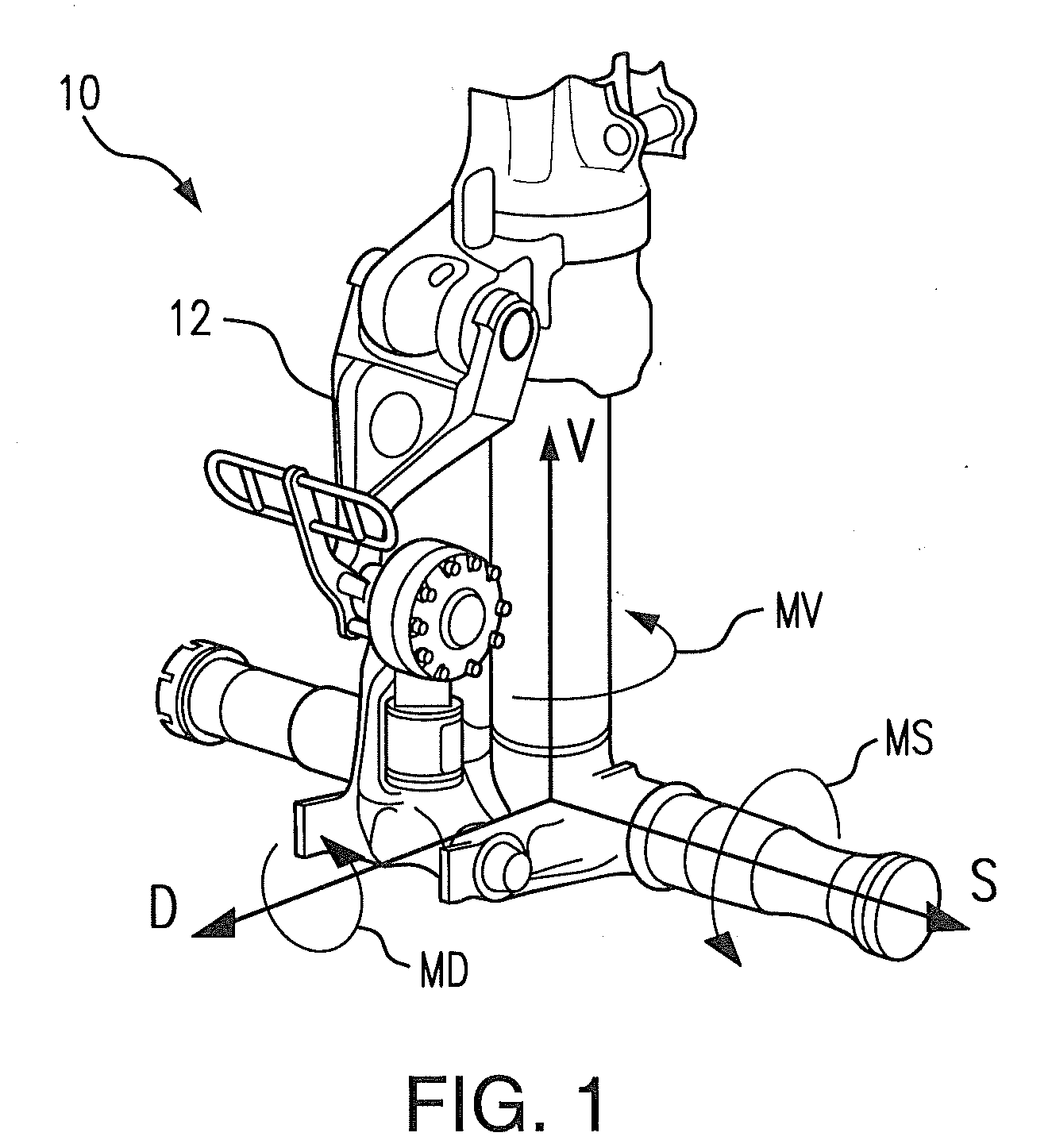

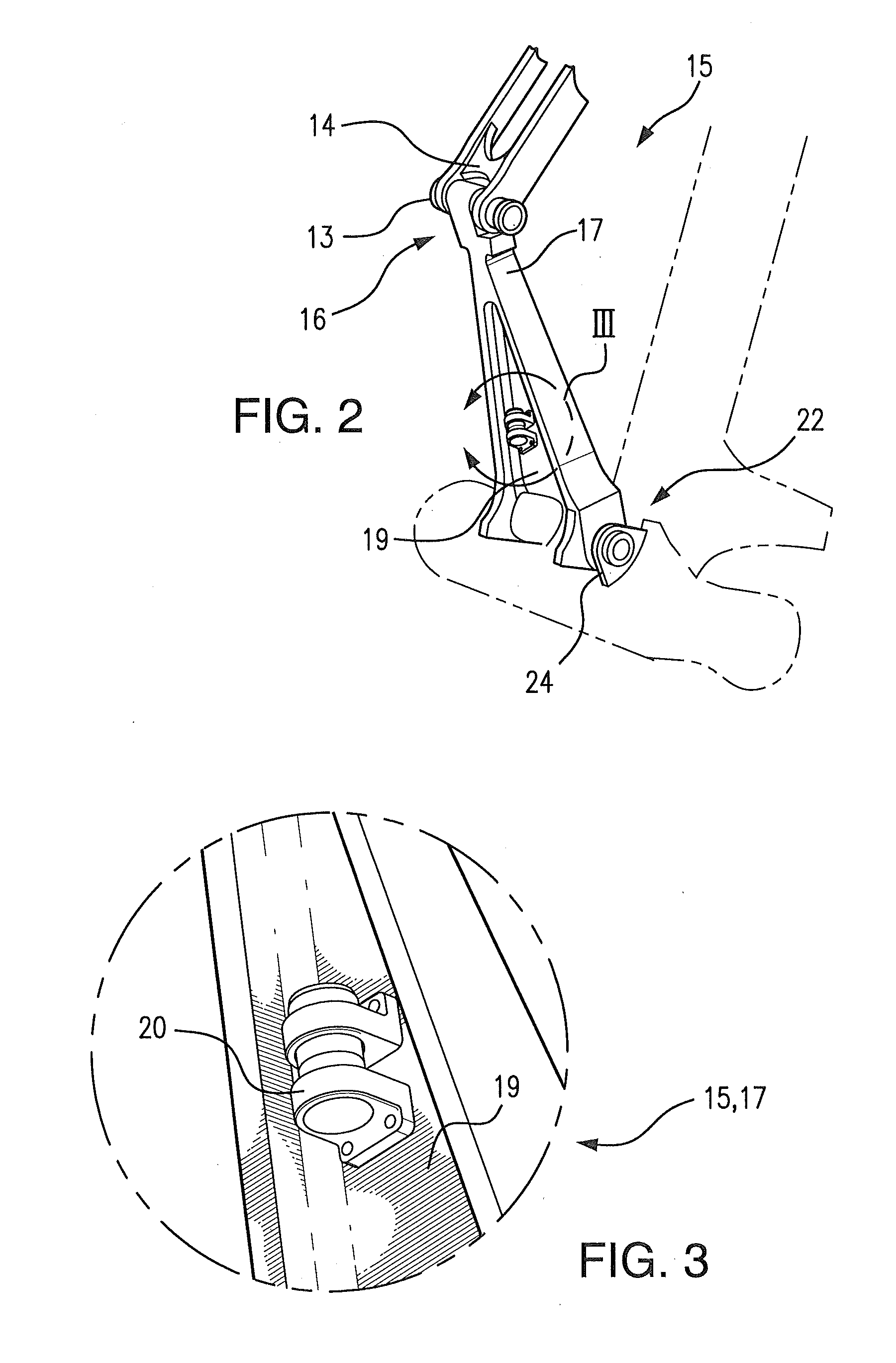

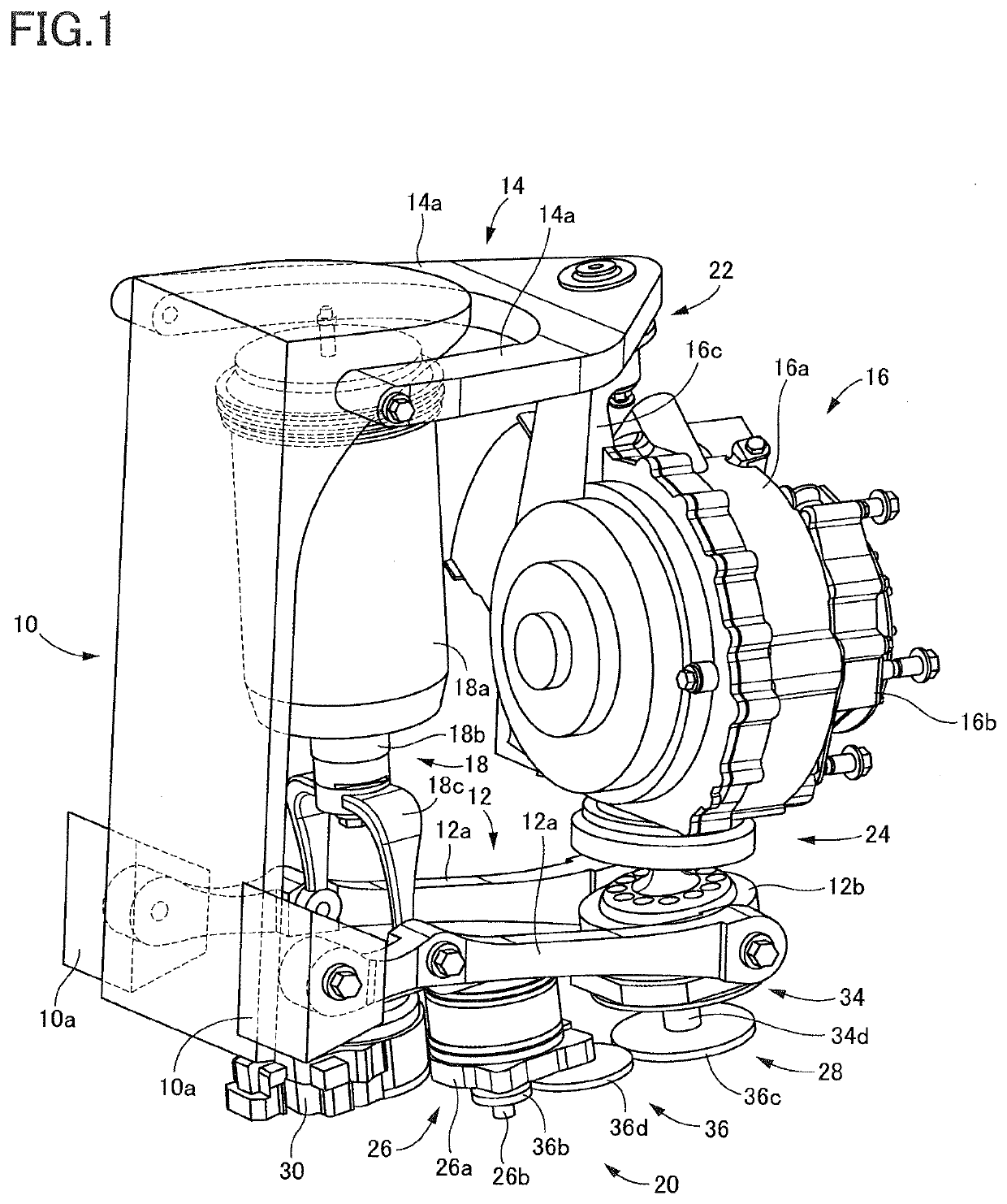

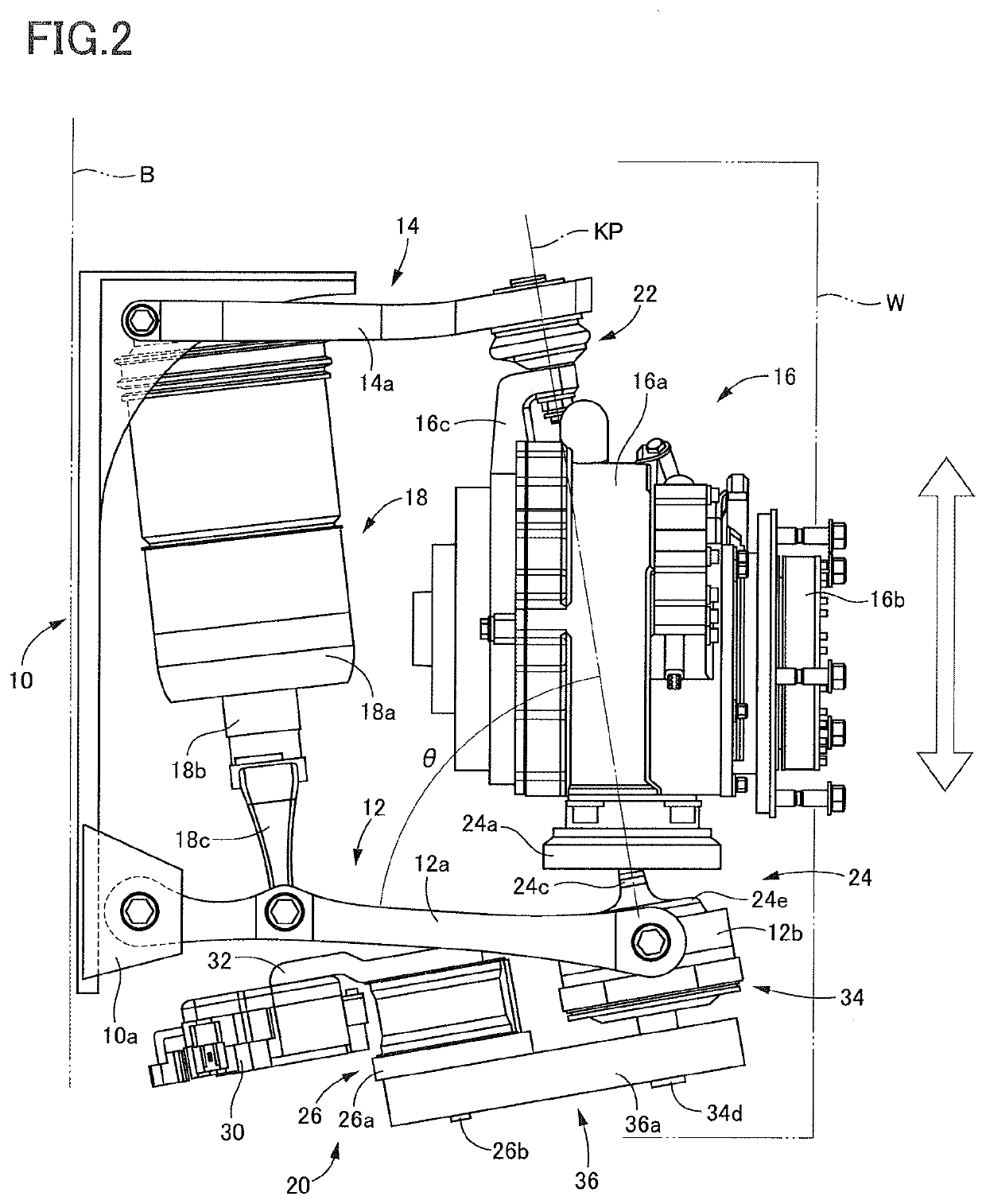

Steering device and vehicle wheel mounting module including the same

ActiveUS20200207405A1Increase in sizeIncrease profitSteering linkagesElectrical steeringReduction driveSuspension (vehicle)

A steering device, including: a steering knuckle rotatably holding a wheel; an electric motor and a speed reducer configured to decelerate rotation of the electric motor, the electric motor and the speed reducer being fixed to a suspension arm; and a joint through which the steering knuckle is supported by the suspension arm in a state in which a kingpin axis is allowed to incline with respect to the suspension arm, the joint coupling the steering knuckle and an output shaft of the speed reducer such that the steering knuckle pivots about the kingpin axis by an operation of the electric motor.

Owner:TOYOTA JIDOSHA KK

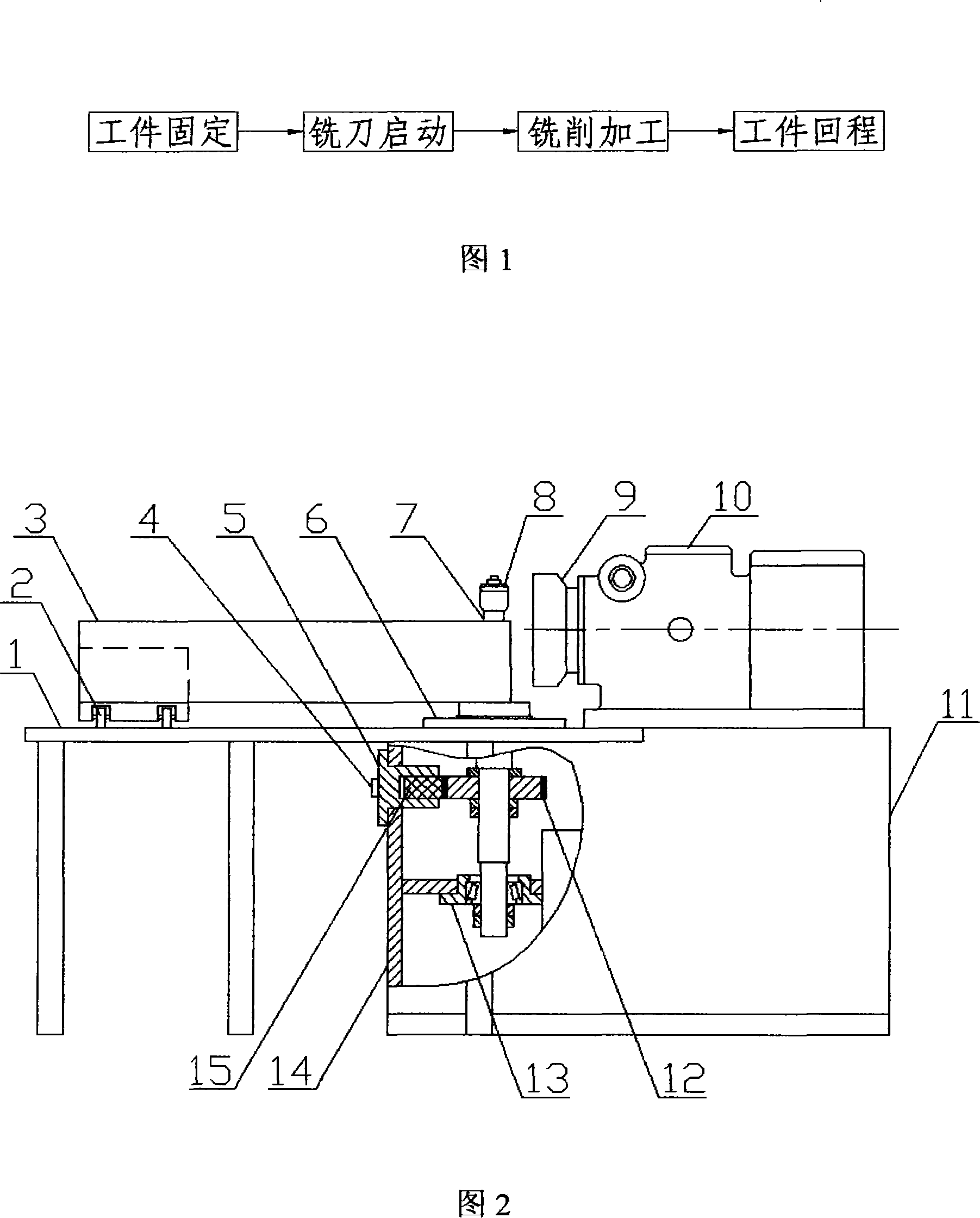

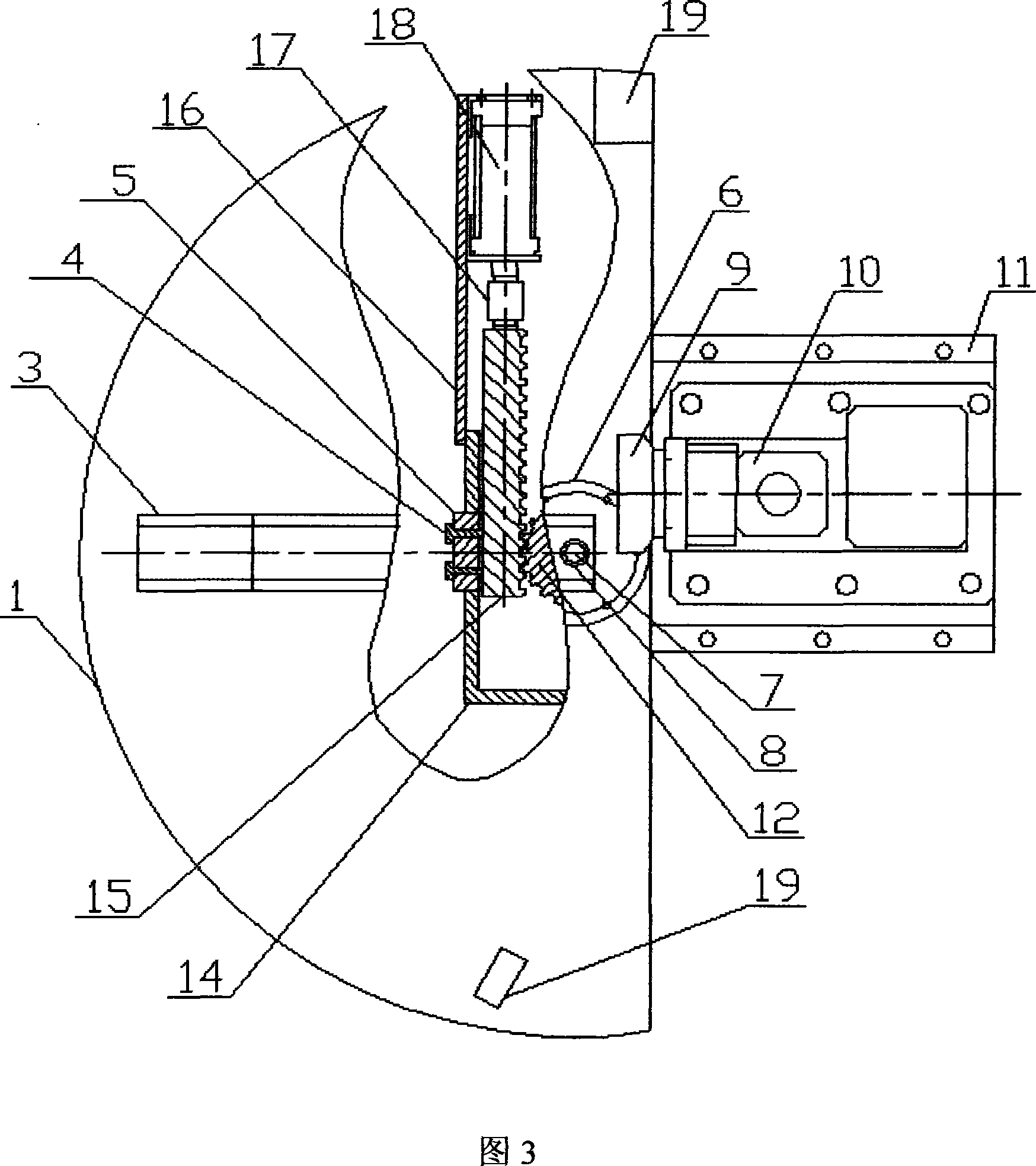

Method and equipment for milling processing cambered surface of vehicle fist section

ActiveCN101234437AShorten the production cycleImprove processing efficiencyLarge fixed membersMilling equipment detailsFistCounter rotation

The invention relates to a method of milling and processing of a cambered surface of a fist-shaped part of a forward shaft of a vehicle, and equipment of milling and processing of a cambered surface of a fist-shaped part of a forward shaft of a vehicle is also disclosed. The technical scheme is: (1) the forward shaft of a vehicle waiting to be processed is placed to a workpiece rotary bracket arranged over a work table; an upper end of a rotating shaft fixed and connected with the workpiece rotary bracket is inserted in a pin hole of the fist-shaped part of the forward shaft of a vehicle waiting to be processed and the workpiece is fixed; (2) a milling cutter is working and rotating around an axis of the milling cutter; (3) a power system works in a positive direction and drive a rotating shaft to rotate through a transmission mechanism, thus driving the vehicle forward shaft fixed on the rotating shaft to rotate around an axis of the rotating shaft on the work table to realize the milling and processing of the milling cutter to the cambered surface of the fist-shaped part of the forward shaft of the vehicle; (4) the power system works in an opposite direction and drive the rotating shaft to rotate reversely through the transmission mechanism, thus driving the workpiece to return. The method of milling and processing of a cambered surface of a fist-shaped part of a forward shaft of a vehicle has the outstanding advantages that the production cycle is shortened; the processing efficiency is improved and the production cost is lowered.

Owner:青岛海通车桥有限公司

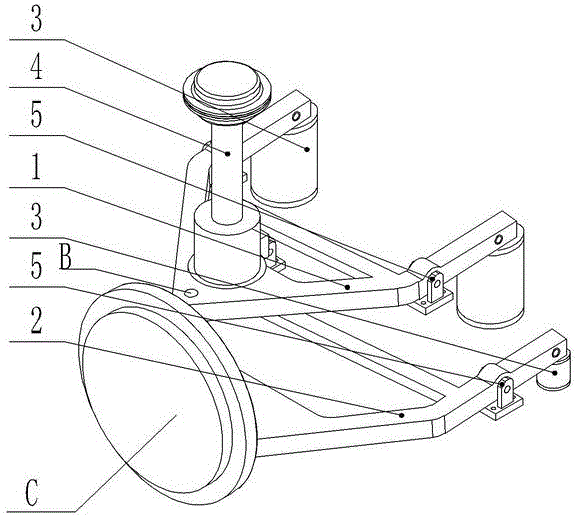

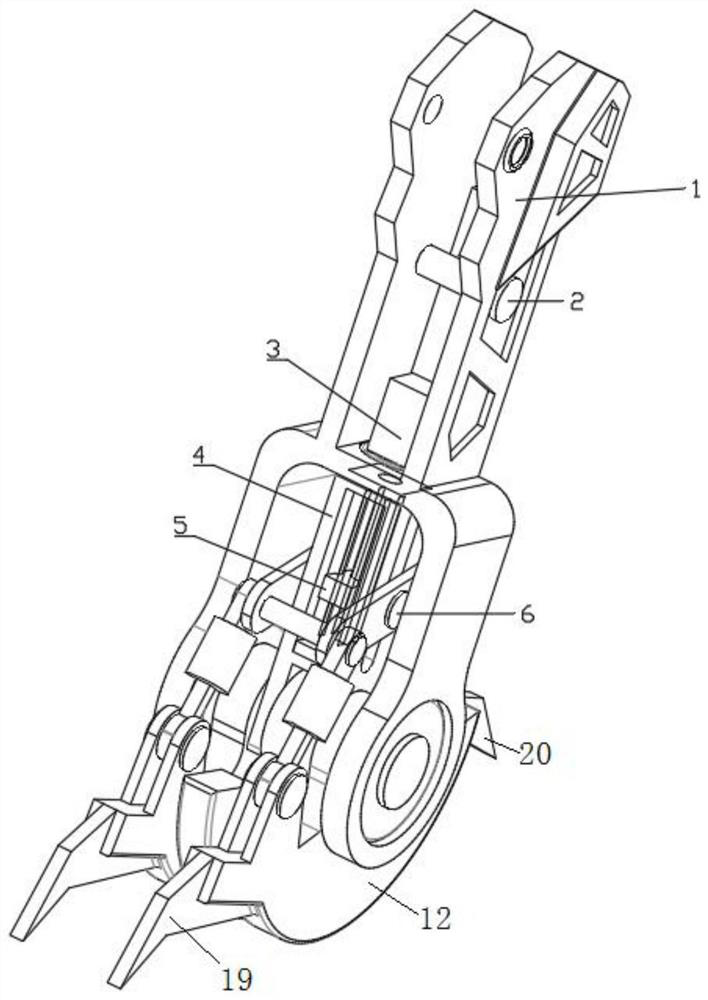

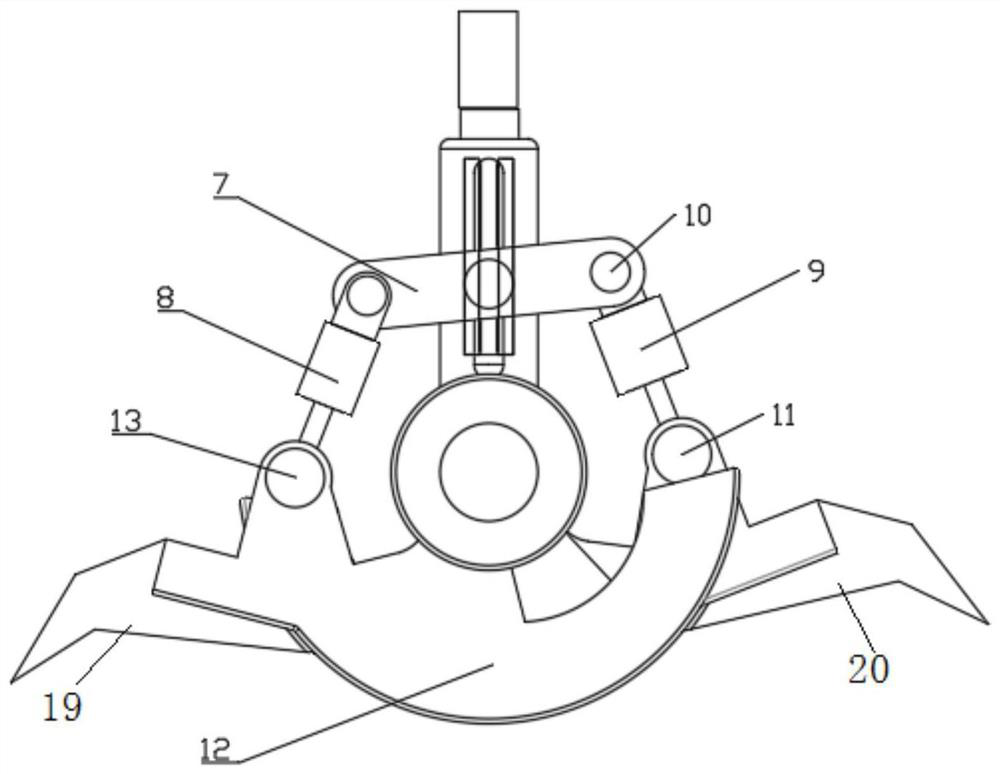

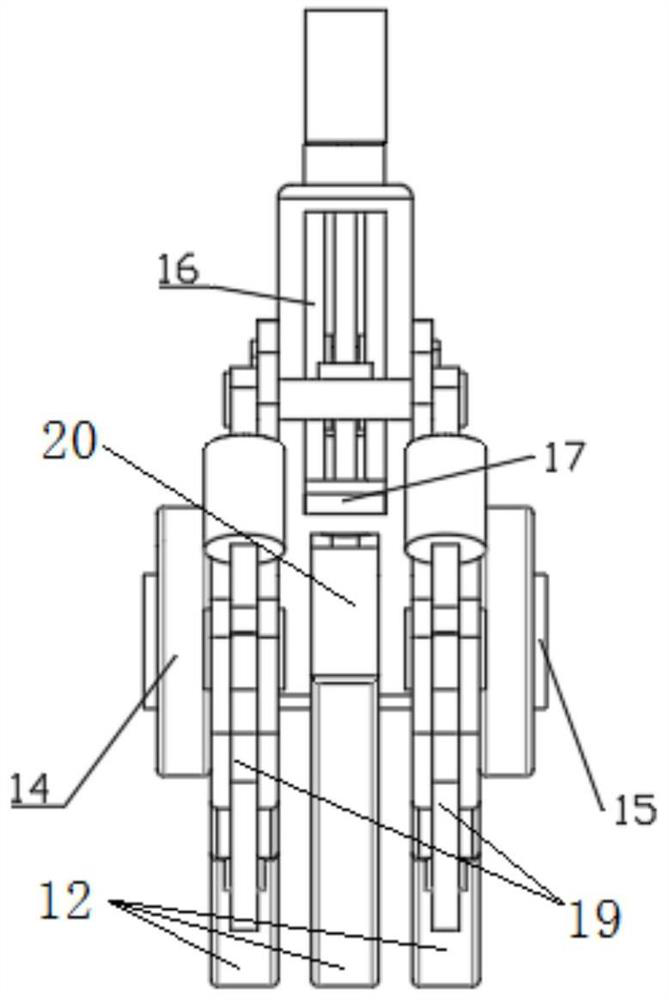

Wheel walking type robot foot end mechanism suitable for all-terrain road conditions

The invention discloses a wheel walking type robot foot end mechanism suitable for all-terrain road conditions. The mechanism comprises a foot body shell, a wheel step conversion mechanism and a solepaw. The wheel step conversion mechanism is arranged on the foot body shell; the sole paw comprises a paw and a wheel body, the wheel body is connected at the lower end of the foot body shell througha main pin shaft, the wheel body is connected with one end of the paw, the other end of the paw is connected with the wheel step conversion mechanism, and the wheel step conversion mechanism drives the paw and the wheel body to rotate around the main pin shaft. The wheel walking type robot with the all-terrain road conditions can stably advance on the complex terrain.

Owner:WUHAN UNIV OF TECH

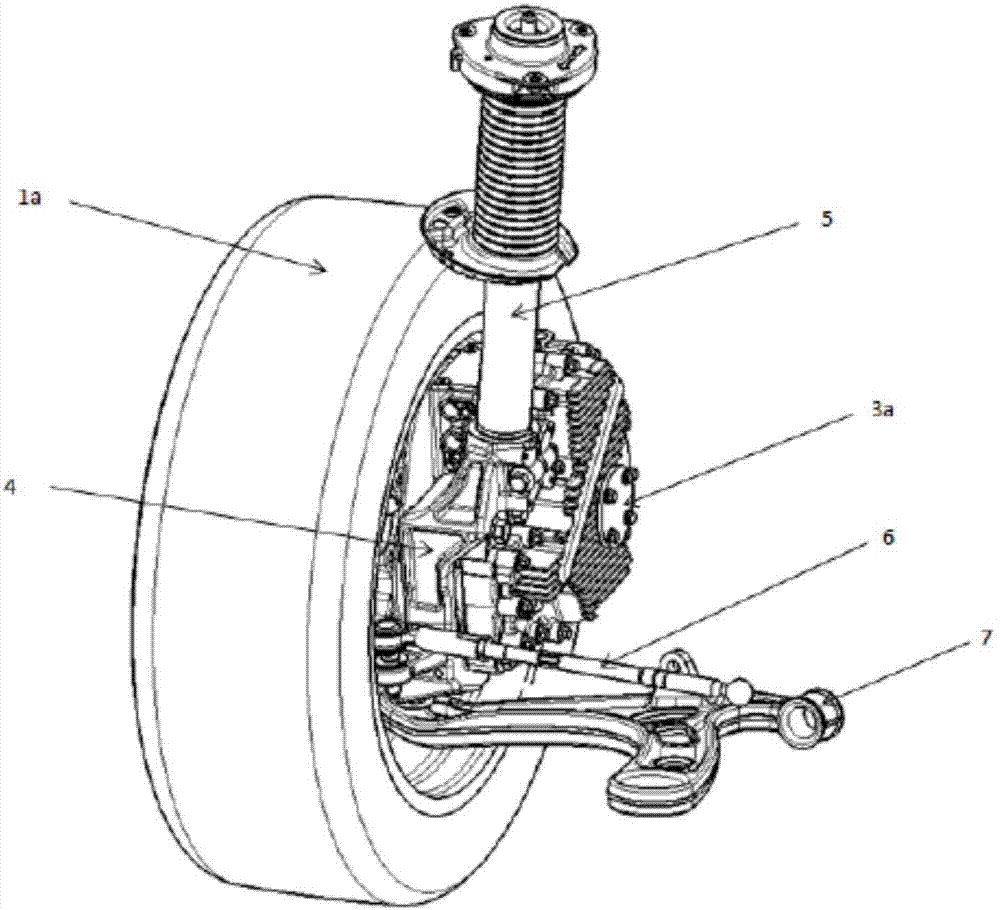

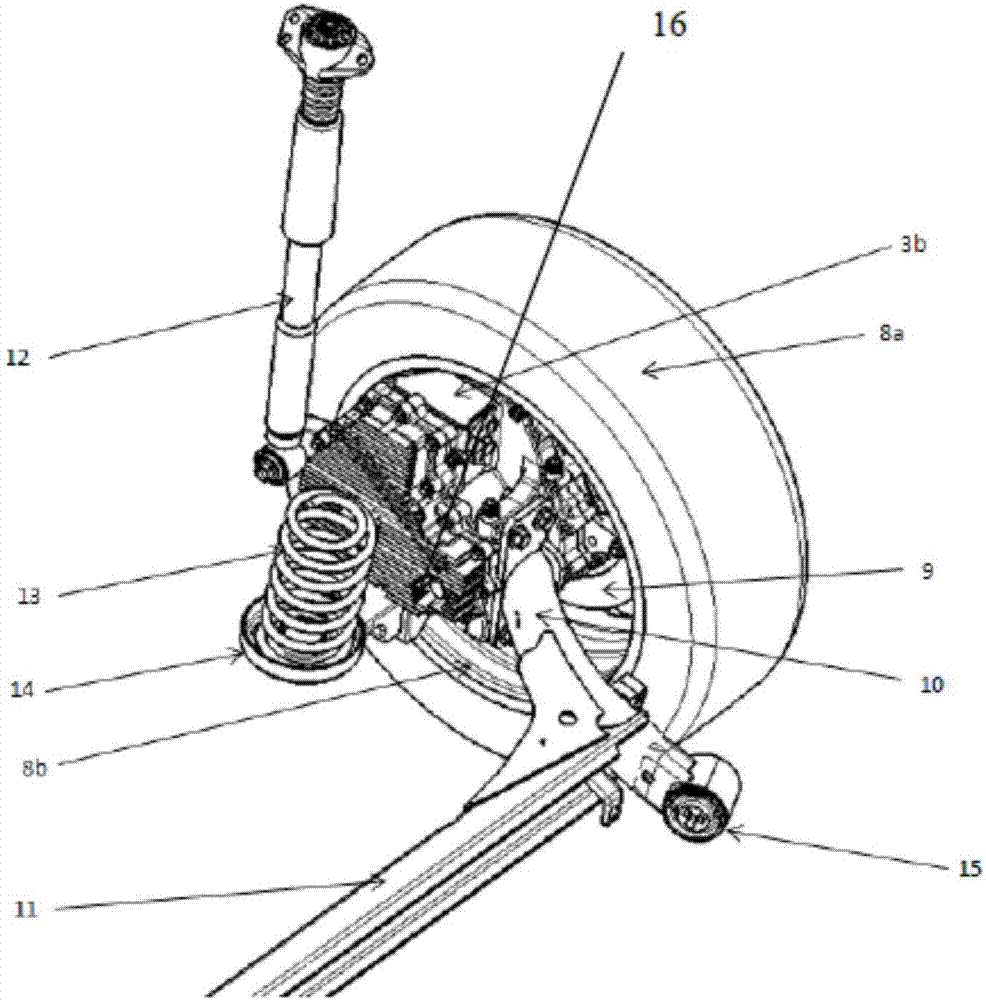

Automobile chassis integrated with hub motor drive device

PendingCN107415675AGuaranteed design statusSuppress pitch characteristicsMotor depositionResilient suspensionsReduction driveElectric machinery

The invention discloses an automobile chassis integrated with a hub motor drive device. The automobile chassis comprises a front wheel drive assembly and a rear wheel drive assembly, wherein the front wheel drive assembly consists of a hub motor with a parallel-axis type speed reducer, a MacPherson type front suspension, a brake system, a steering system and the like; and the rear wheel drive assembly consists of a hub motor with a parallel-axis type speed reducer, a torsion beam type non-independent rear suspension, a brake system, a steering system and the like. According to the automobile chassis disclosed by the invention, the parallel-axis type hub motor is integrated with the MacPherson type front suspension, a motor of an eccentric-axis structure can avoid the optimal arrangement position of each hard point of the chassis, especially can guarantee a design state that offset distance of a front wheel main pin is 0, so that chassis performances when a vehicle drives, brakes and steers are improved. A rear wheel adopts the hub motor which is the same as that of the front wheel, and can carry the torsion beam suspension, so that pitching characteristics when the vehicle starts and brakes can be inhibited; and meanwhile, a motor control function is combined, and side inclining when the vehicle steers further can be inhibited.

Owner:CHINA FIRST AUTOMOBILE

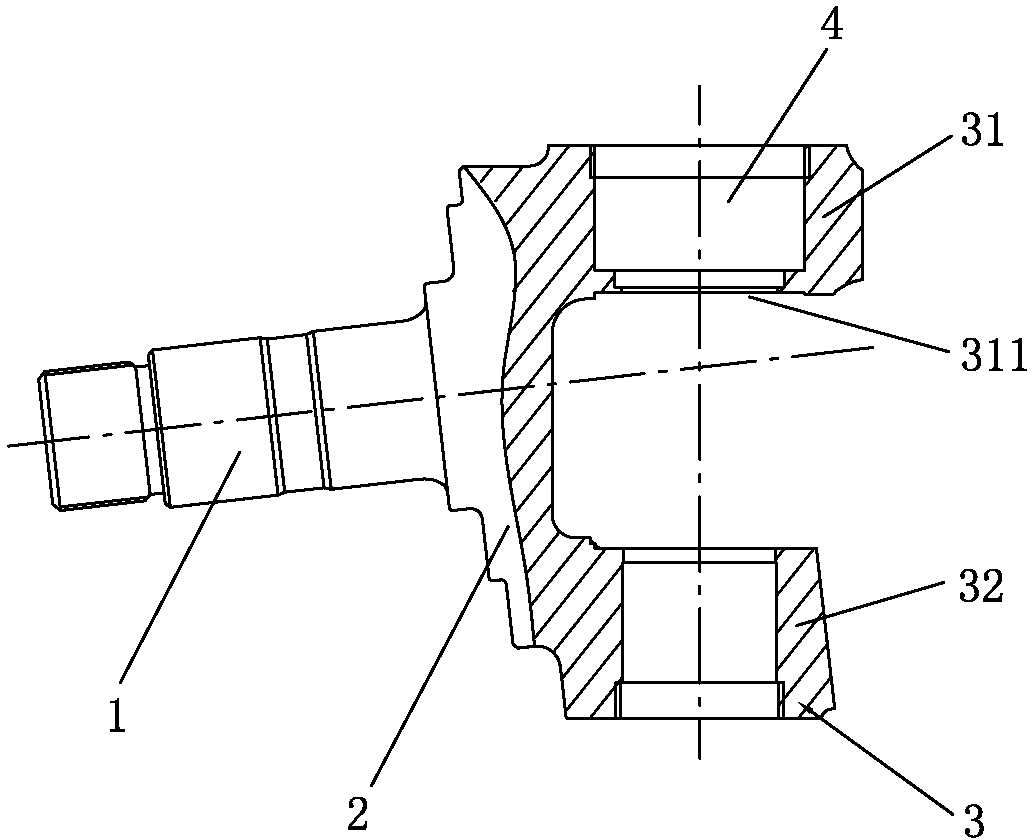

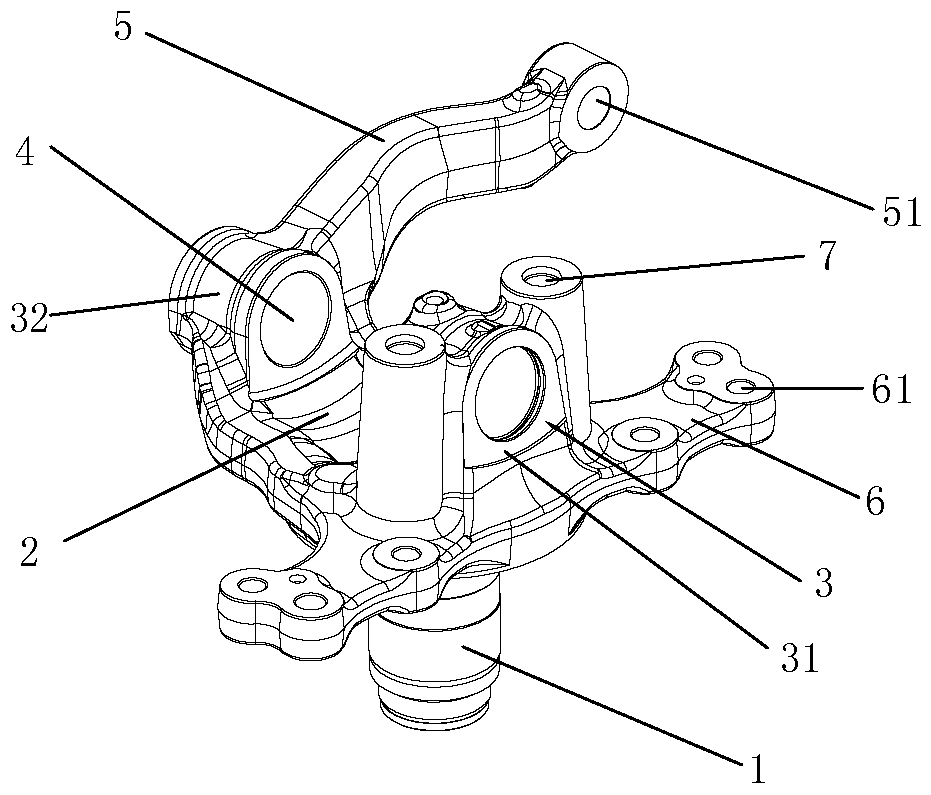

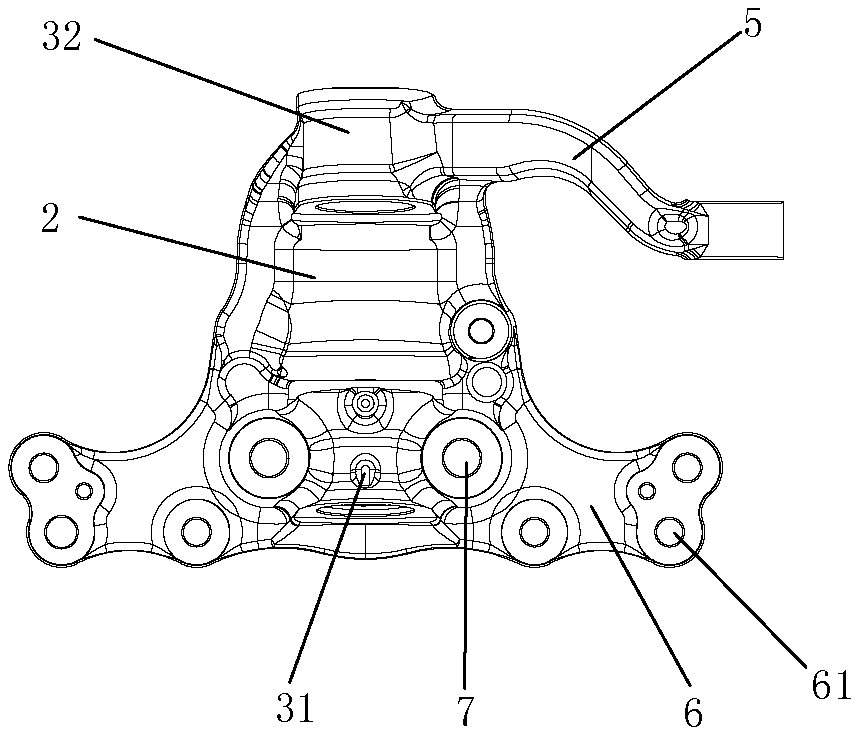

Automotive disc-type steering joint integrated with steering arm and processing technology of steering joint

InactiveCN107813872AStructural scienceSimple structureSteering linkagesRailway componentsCalipersSteering system

The invention relates to the technical field of steering joints, in particular to an automotive disc-type steering joint integrated with a steering arm and a processing technology of the steering joint. The steering joint includes a rod part, a disc part and a lug part, the lug part includes a long lug and a short lug, the long lug and the short lug are provided with main pin holes respectively, and the steering arm, used for being connected with a steering transverse pulling rod, of the front end of the short lug stretches out from a plane perpendicular to the corresponding main pin hole to the lateral surface; the disc-type steering join is integrally forged and formed, and connecting arms, connected with brake calipers, of the long lug horizontally and separately stretch out from the plane where the disc part is located to the two sides, and form a T shape with the corresponding main pin hole. The automotive disc-type steering joint is scientific in structure; by directly integrating the steering arm with the disc-type steering joint, connecting devices are reduced; by extending the steering arm to be connected with other components, the structure of an automotive steering system is simplified, the novel disc-type steering joint of a lightweight structure is obtained, and more convenience is provided for achieving the lightweight automatic disc-type steering joint on the premise of ensuring the mechanical performance of a product.

Owner:HUBEI TRI RING FORGING

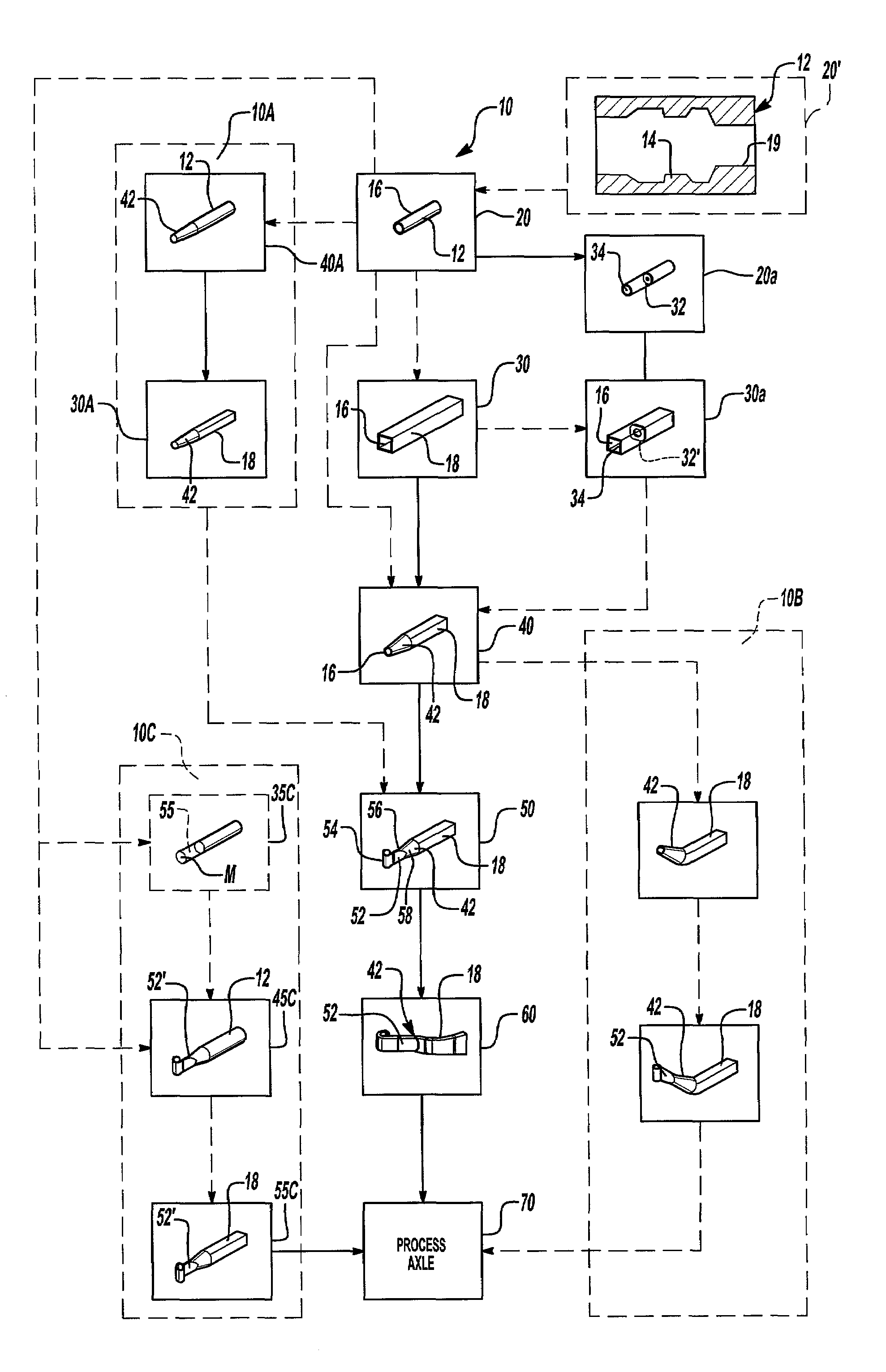

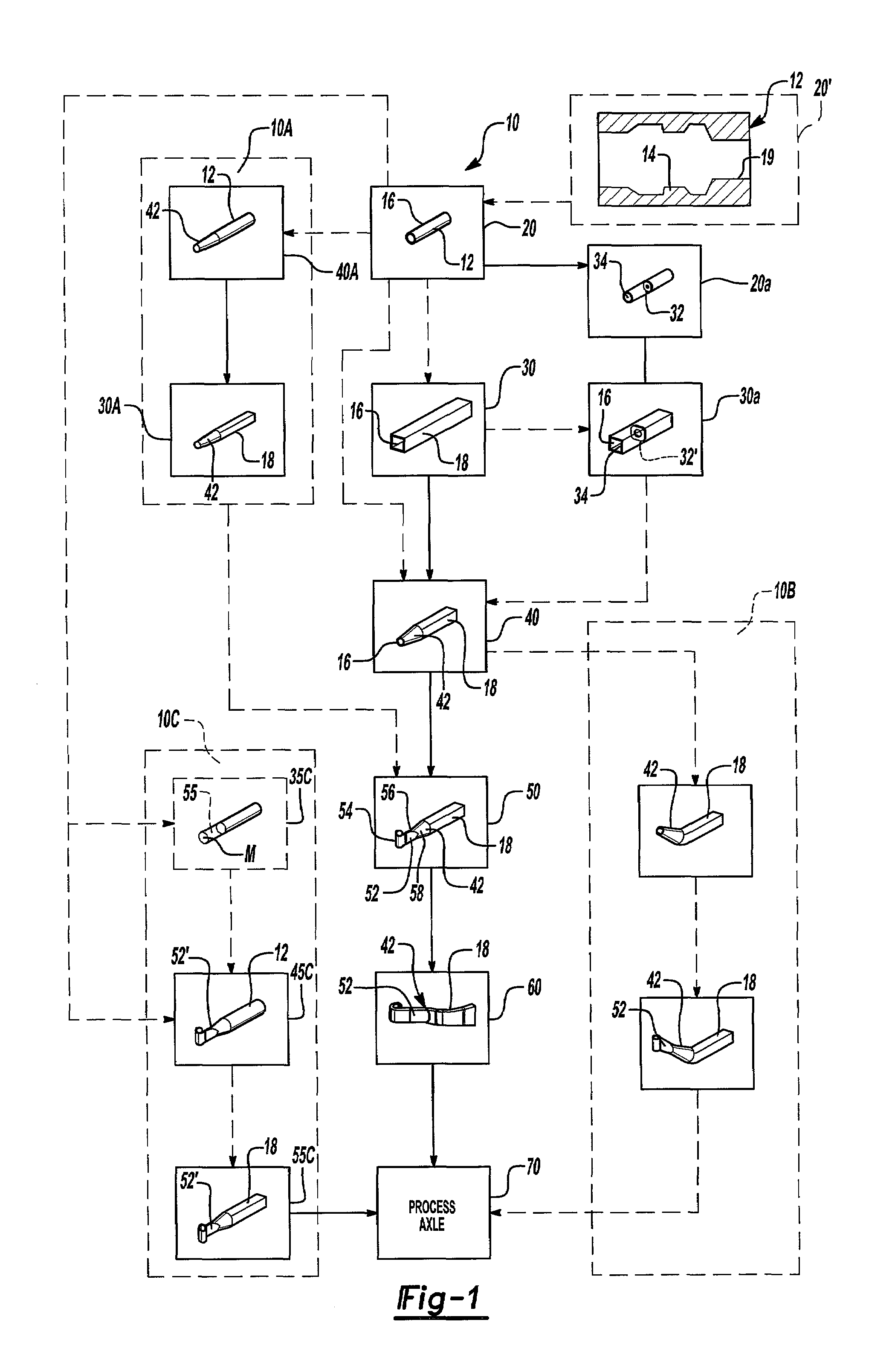

Method of forming a tubular axle

ActiveUS7568286B2Maximum manufacturing versatilityDesirable bendingSteering linkagesPivoted suspension armsMechanical engineeringConoid

A method of forming an axle assembly having a hollow member. A hollow member such as a cylindrical tube is formed into a polygonal cross-section having an end portion. Bulkheads maybe located into the hollow member prior or after the polygonal forming step to improve proximate strength and transfer suspension bending moments. The end portions are formed to receive a preformed king pin boss having an end portion of approximately the same size as the frustoconical end. The members are welding together and the king pin and hollow member are bent to a desired axle shape. In another method sequence, the kingpin boss is directly formed into the end of the hollow member.

Owner:MERITOR LIGHT VEHICLE TECH LLC

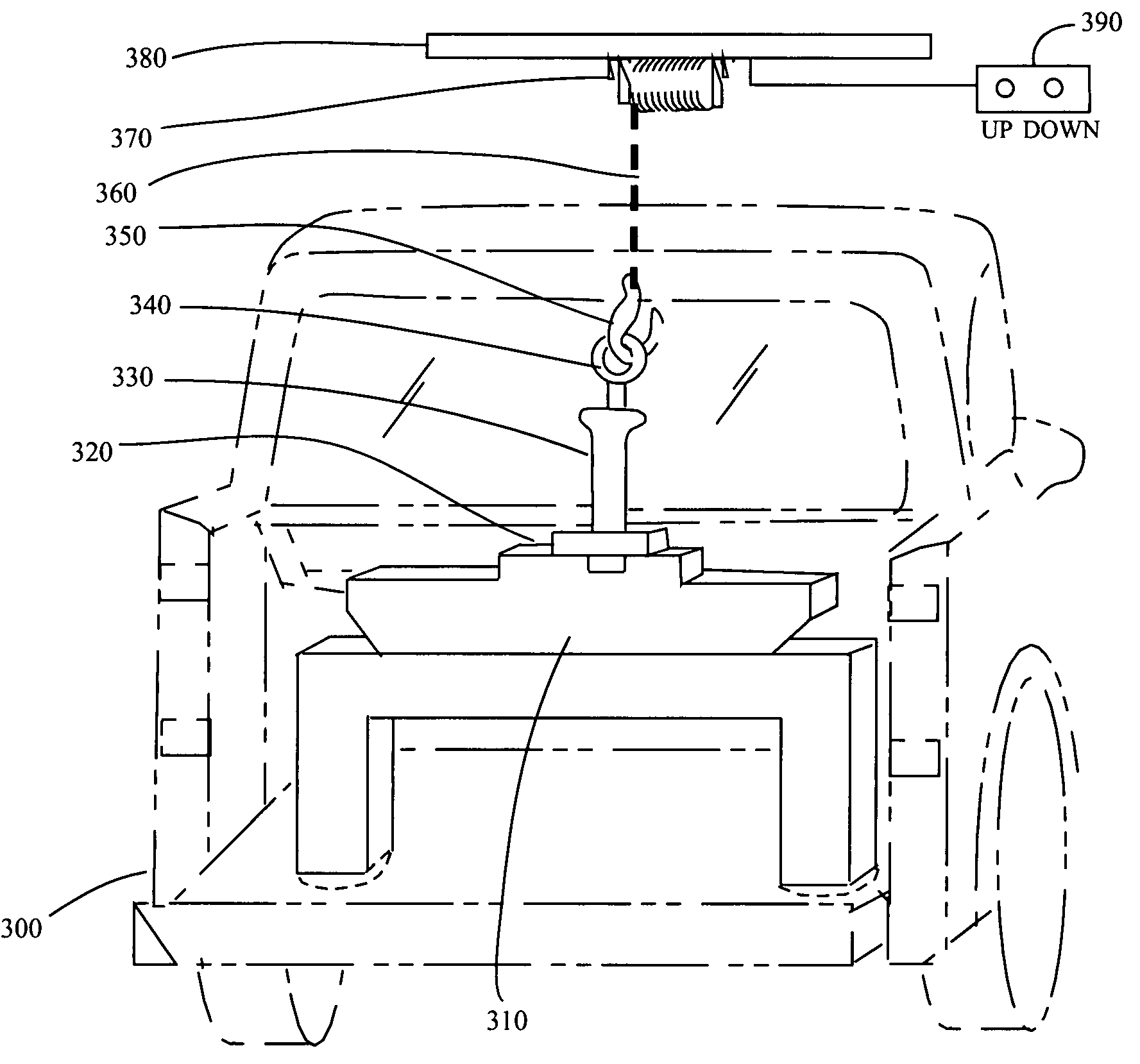

Hitch lift device

Owner:MATURINO STEVE

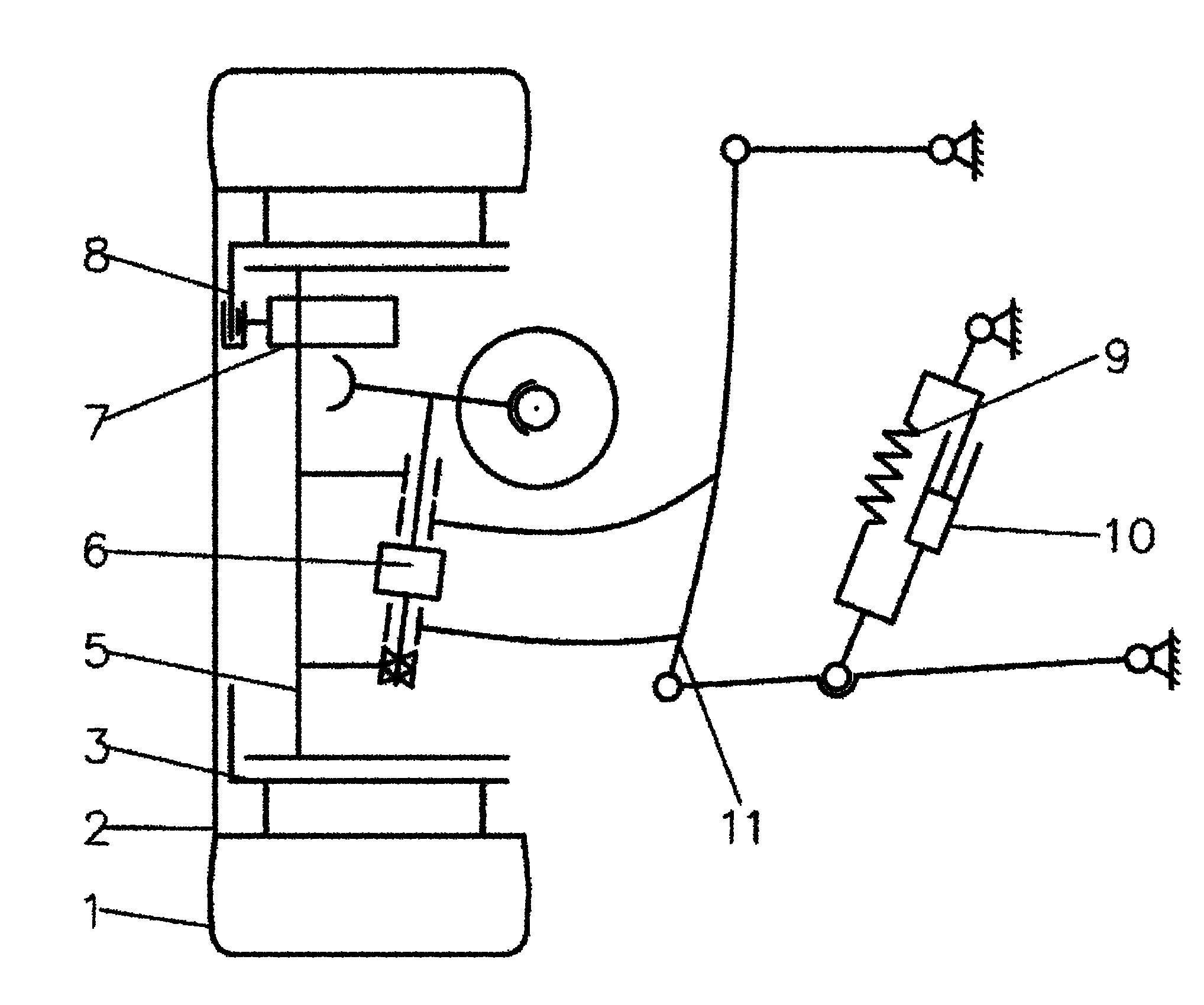

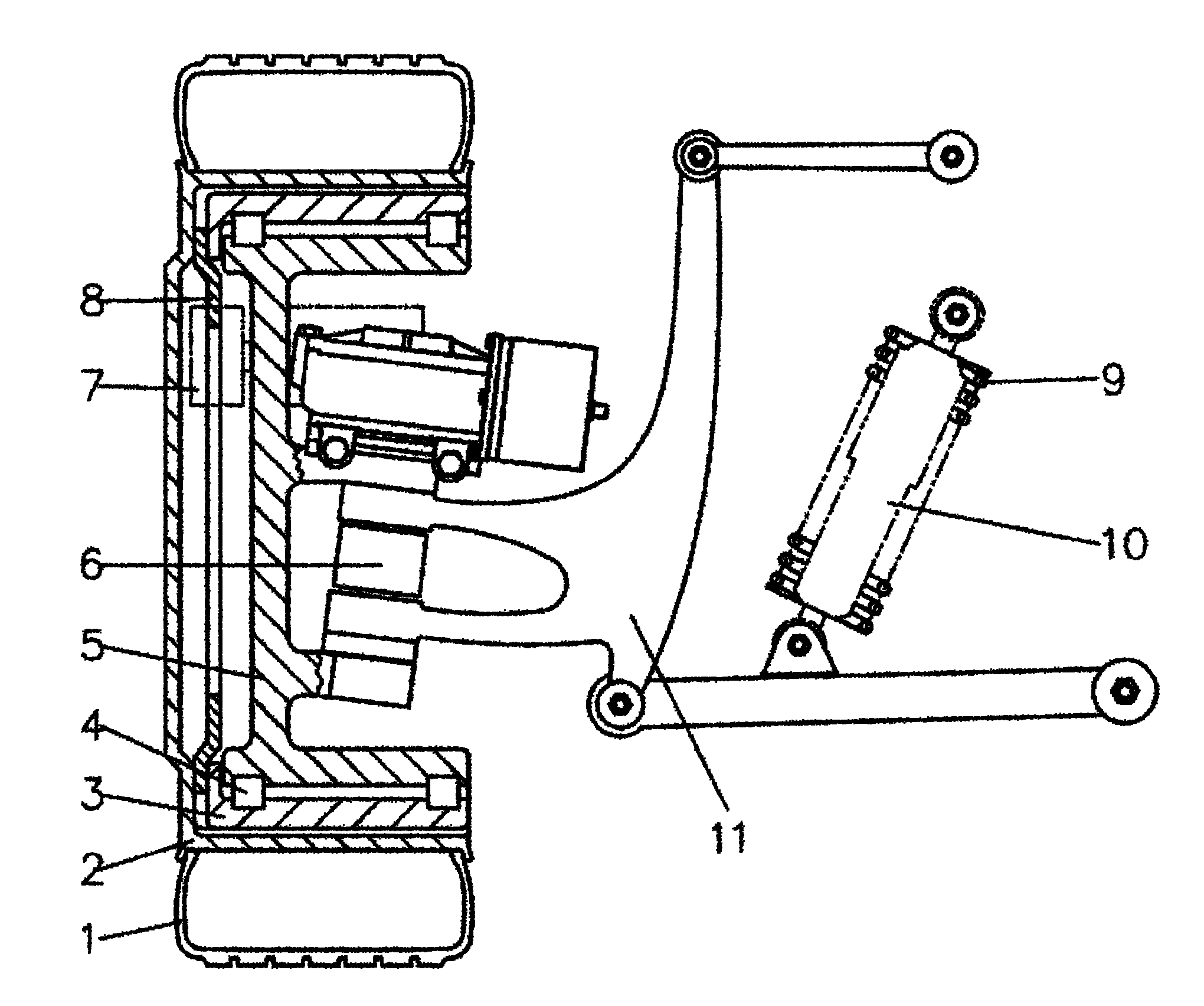

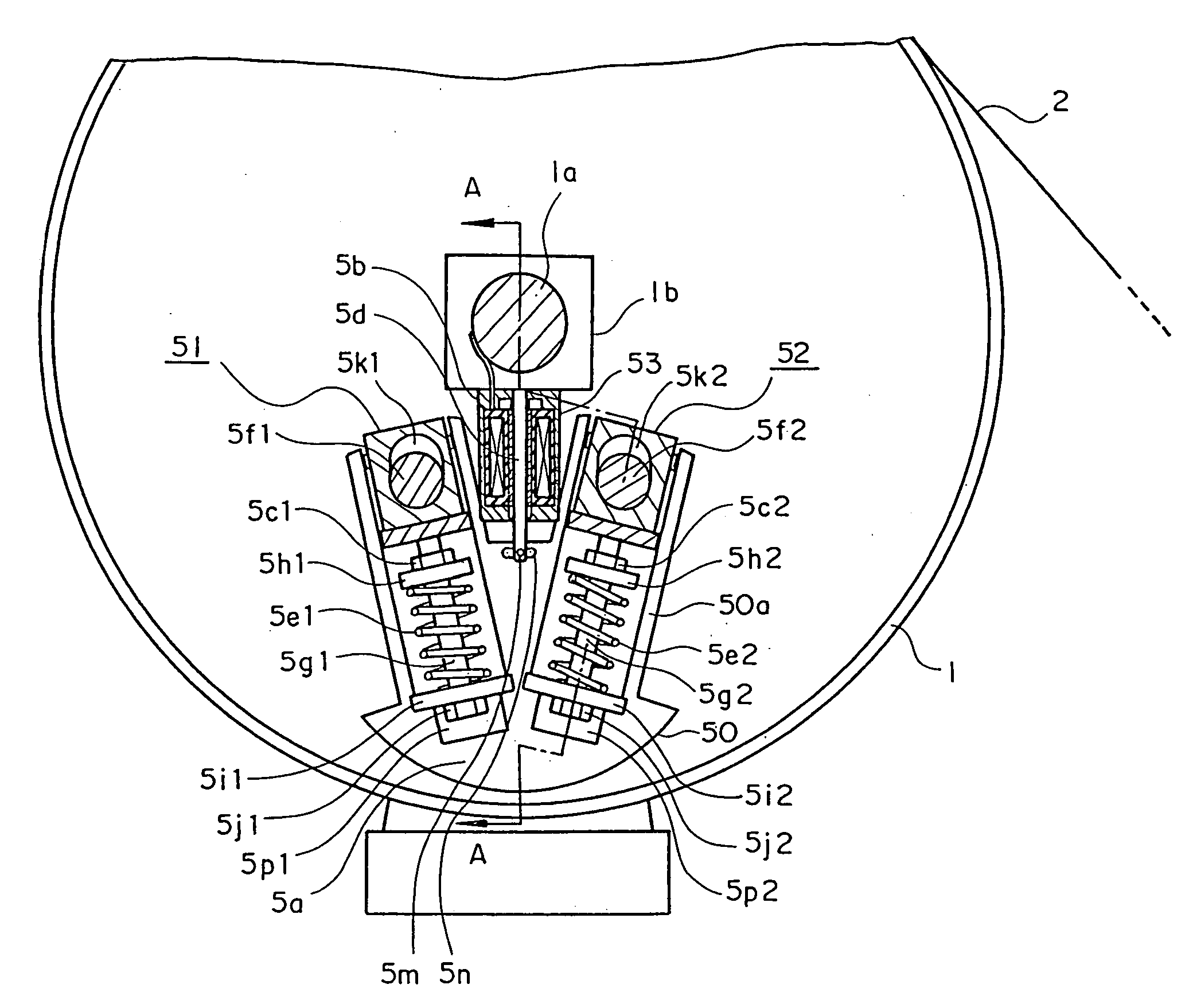

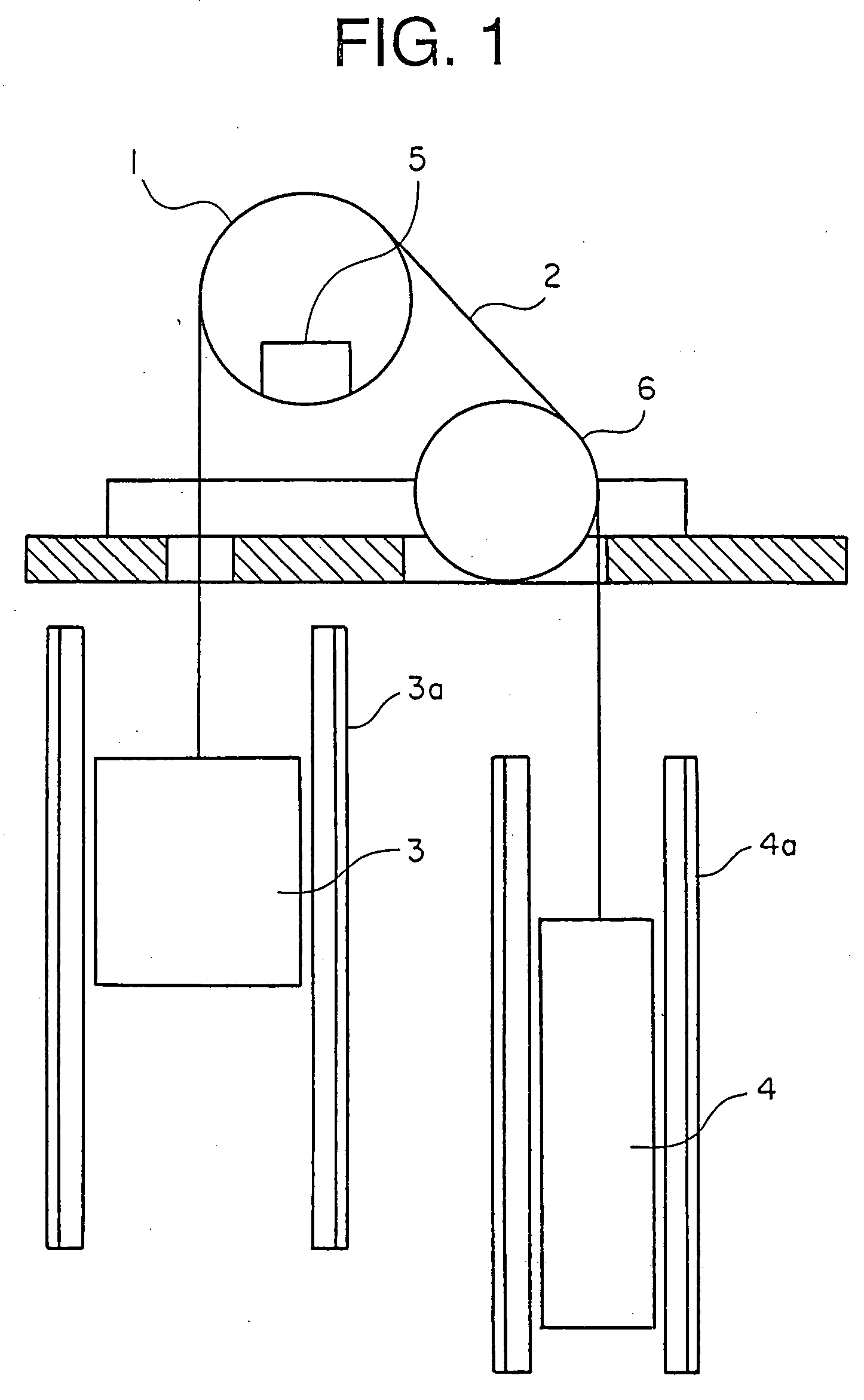

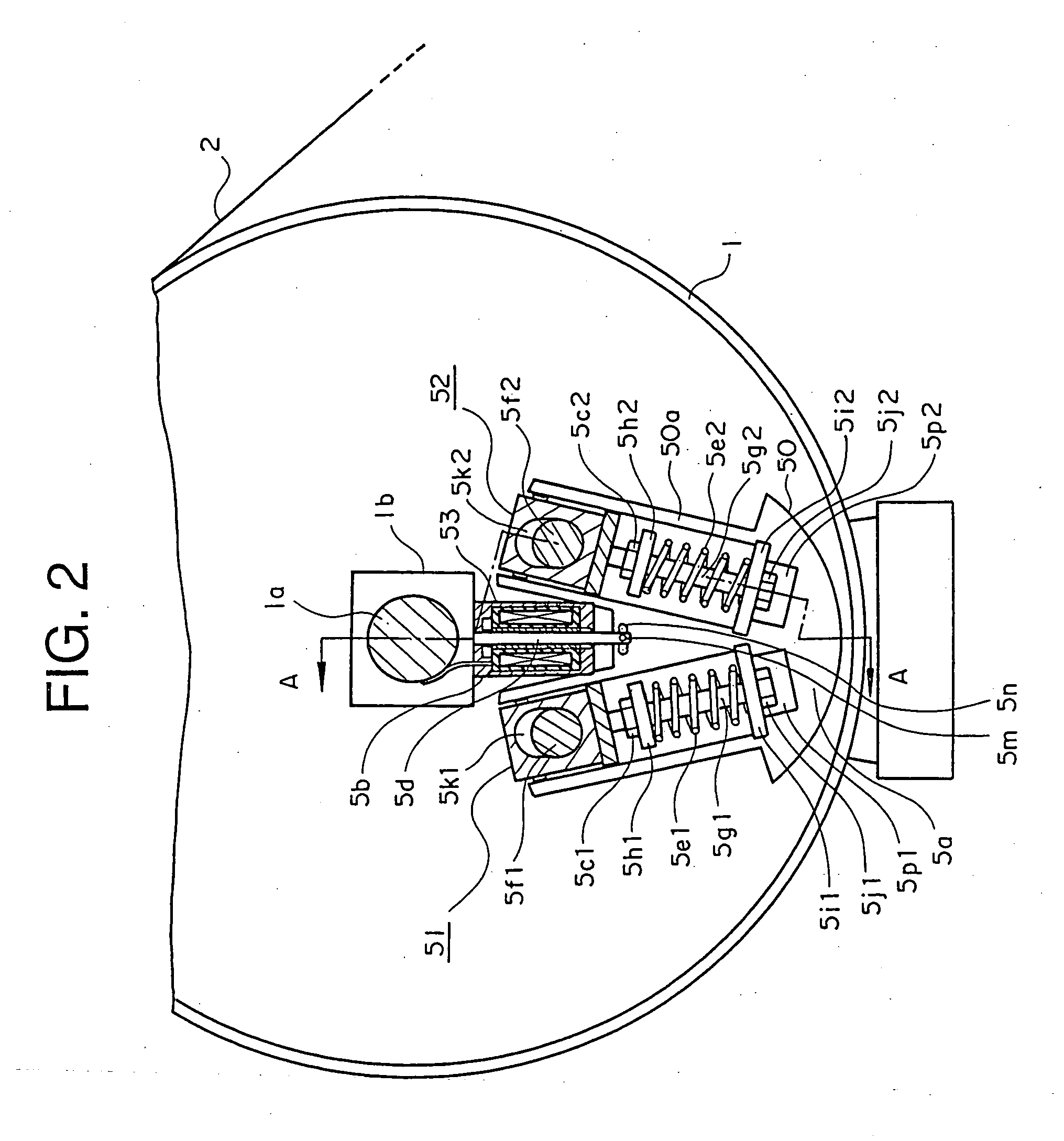

Emergency brake device for elevator

InactiveUS20070089937A1Simple structureFacilitated releaseBraking action transmissionElevatorsRotational axisControl theory

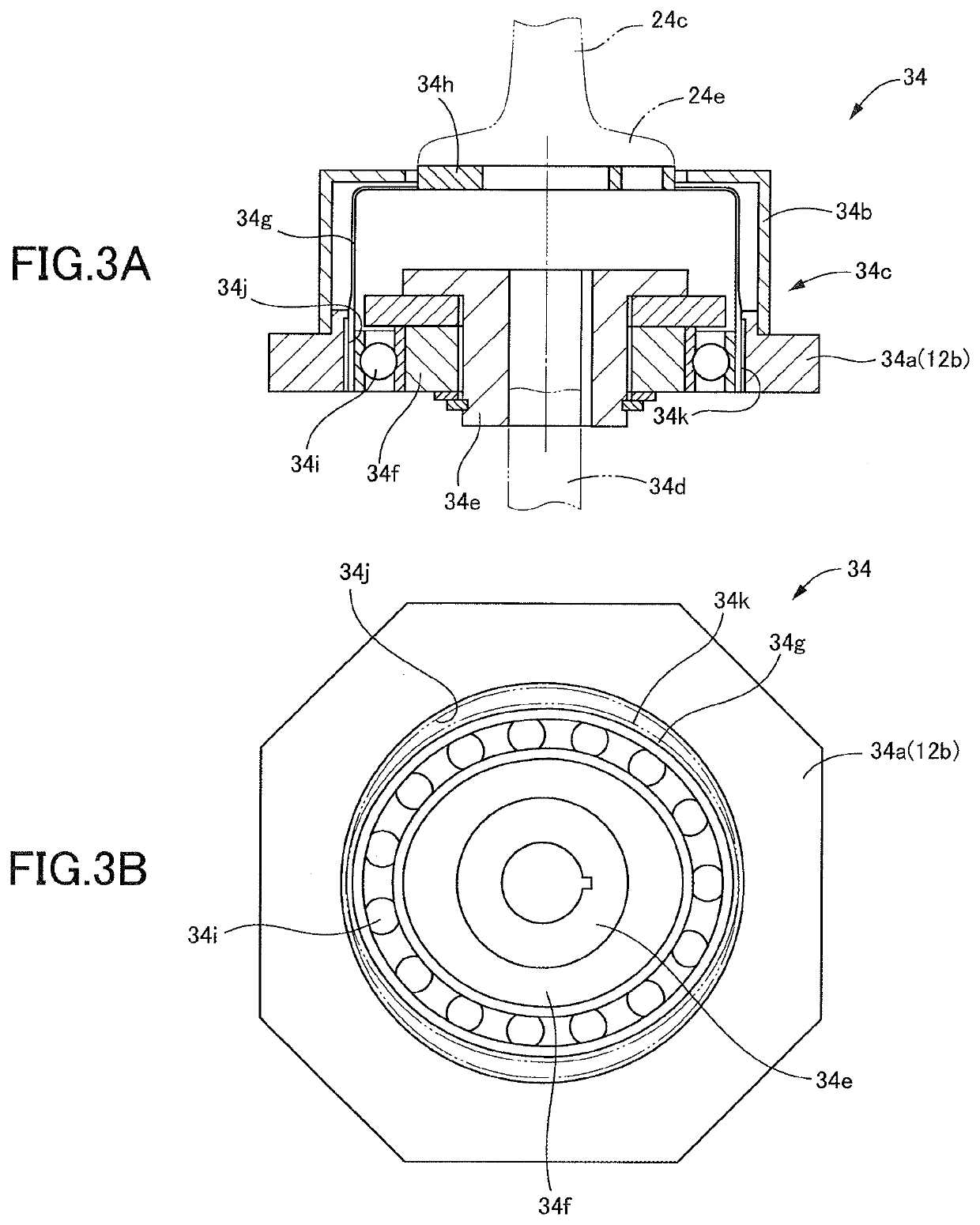

An emergency brake device for an elevator includes a brake shoe portion provided inside a sheave 1 or deflector sheave of an elevator and having a brake shoe 5a at a lower end of the brake shoe portion, the brake shoe generating a braking force due to friction upon abutting an inner wall of an outer peripheral frame of the sheave or deflector sheave at a time of braking, the brake shoe portion having built therein spring mechanisms 51, 52 provided between the brake shoe and king pins 5f1, 5f2, which are offset in a rotation direction of the sheave or deflector sheave with respect to a centerline passing through a rotation shaft of the sheave or deflector sheave and are fixed on a bearing 1b side of the rotation shaft, the spring mechanisms each absorbing a force generated between the brake shoe and the king pin due to the braking force and being connected to the king pin at one end.

Owner:MITSUBISHI ELECTRIC CORP

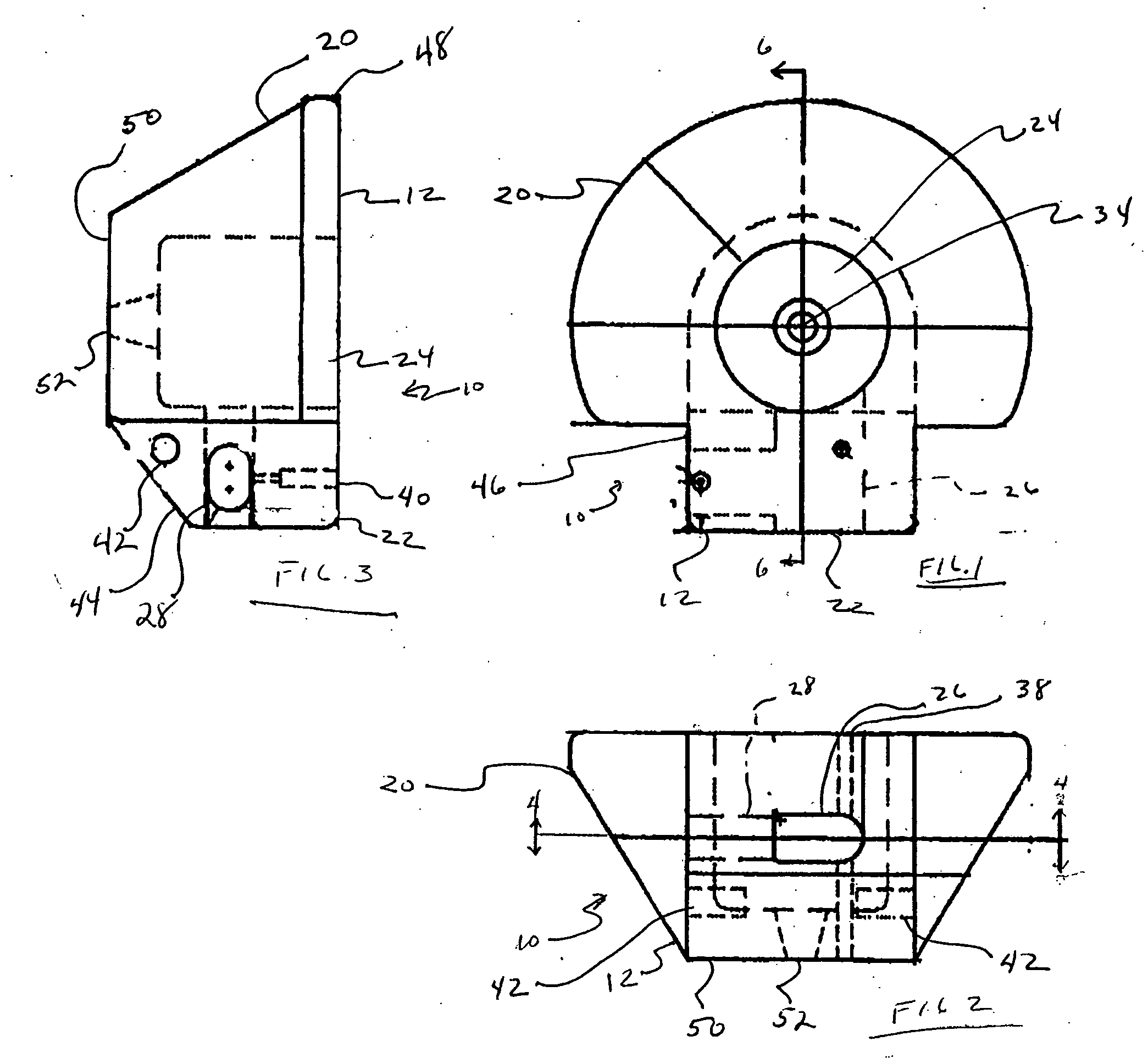

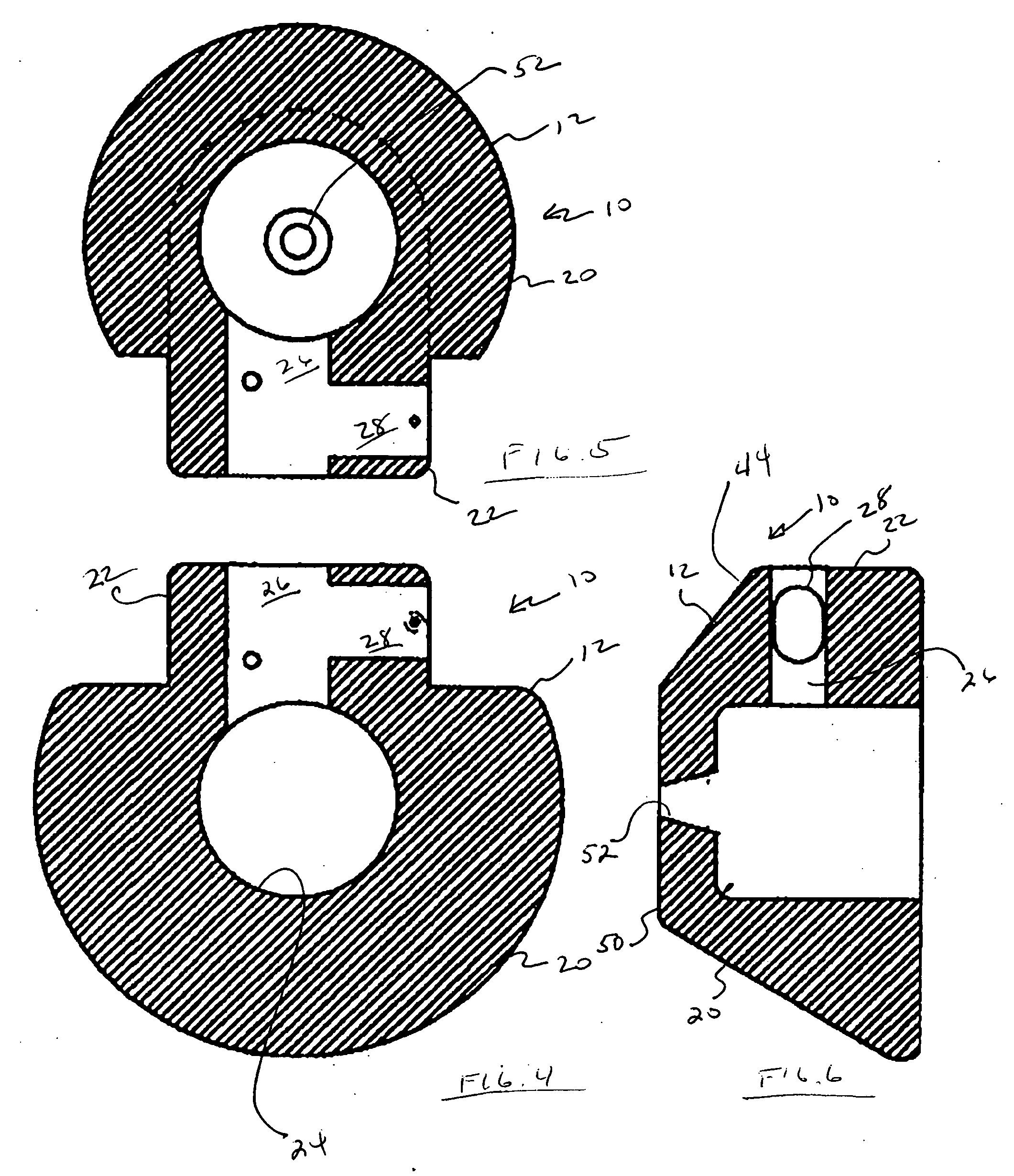

Kingpin lock

A kingpin lock including a body having a substantially frustoconical portion and a kingpin cavity having a central axis, a slide channel having a central axis and a sleeve channel having a central axis. The slide channel intersects the kingpin cavity such that its central axis is substantially offset from a radius that extends outwardly from the central axis of the kingpin cavity. The sleeve channel intersects the slide channel. A slide member is shiftable between an engaged position extending partially into the kingpin cavity and a disengaged position where the slide member does not engage the kingpin. A locking member is shiftable between an engaged position and a disengaged position such that the locking member engages an indentation in the slide member so that the slide member is secured in the engaged position and the kingpin lock is secured to the kingpin.

Owner:CARGO PROTECTORS

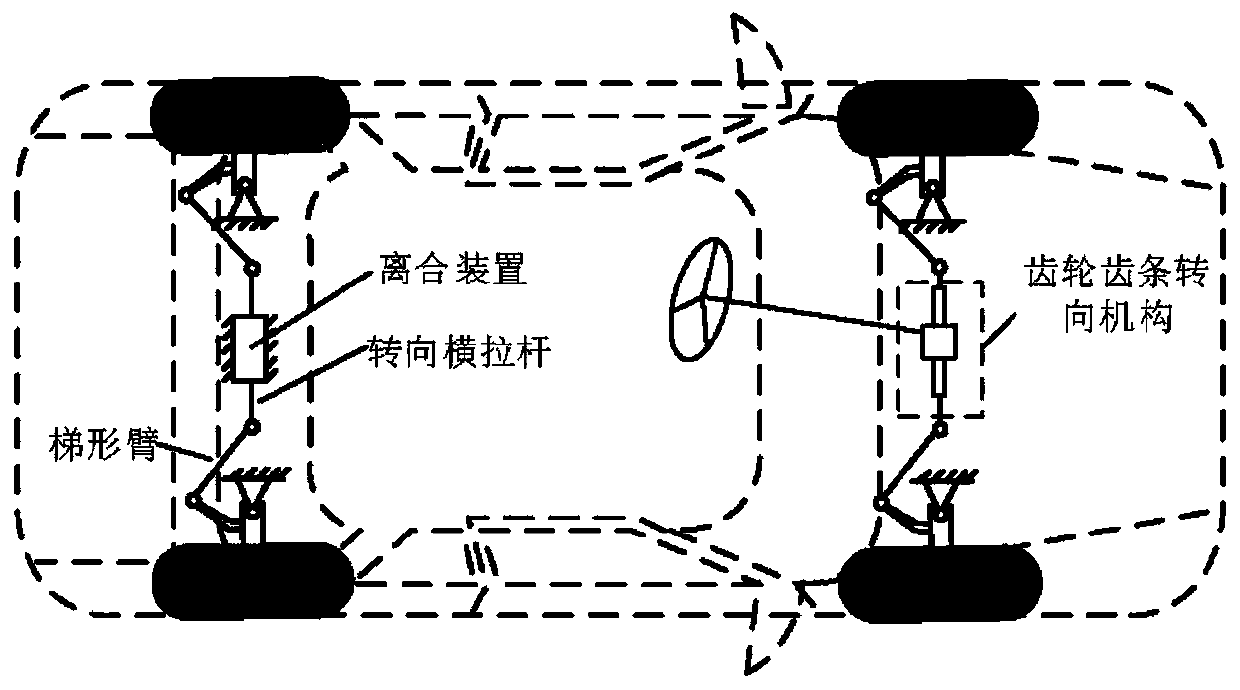

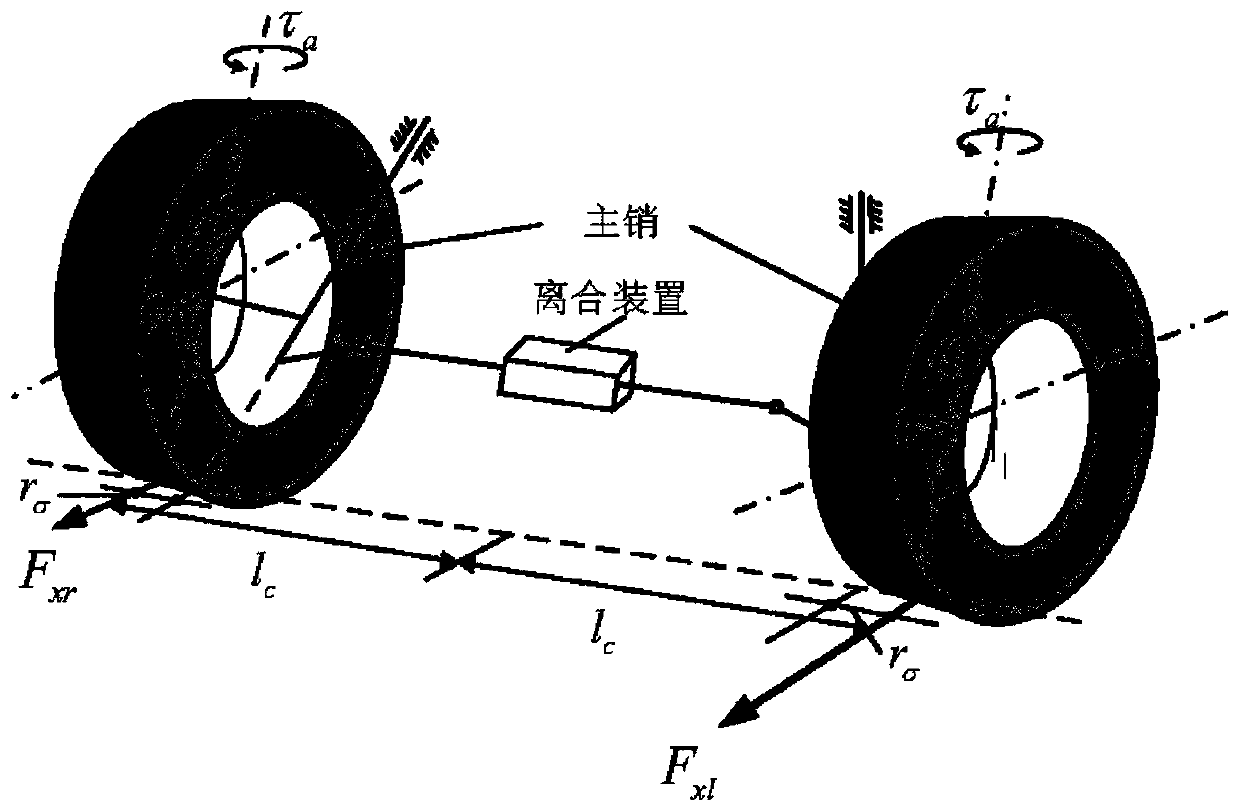

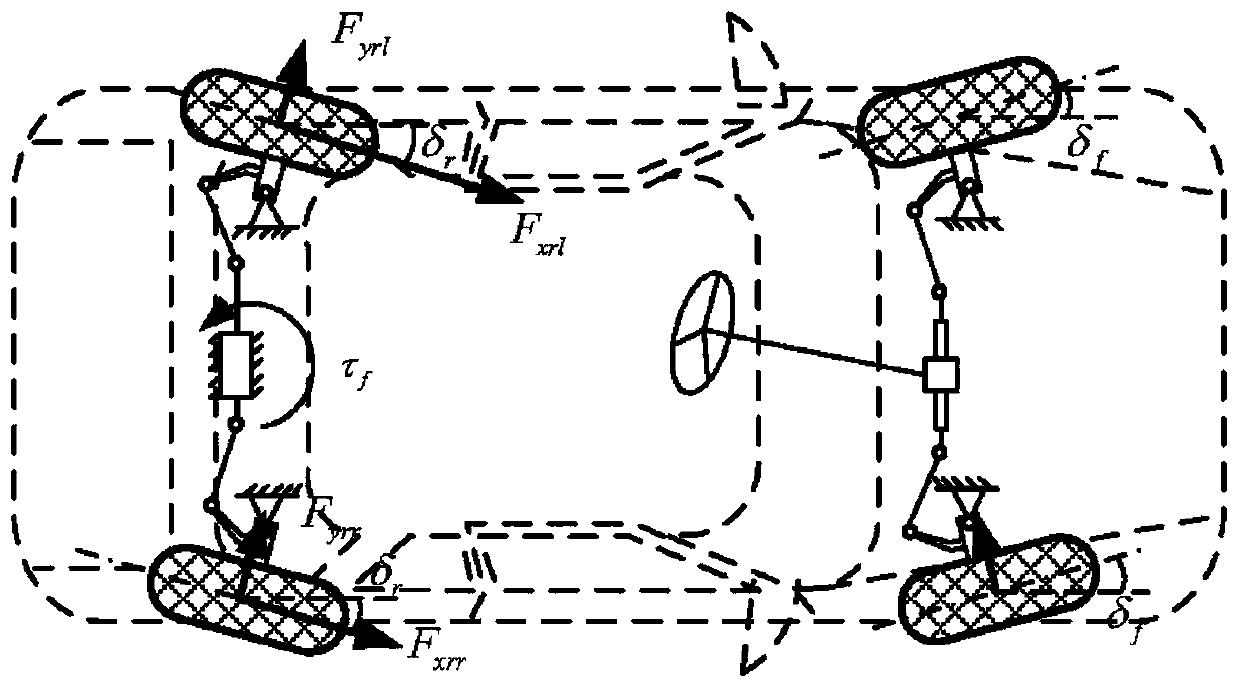

Four-wheel steering mode for four-wheel independent drive electric automobile

ActiveCN111232052AImprove space utilizationSimplify complexitySpeed controllerSteering linkagesAuto regulationSteering angle

The invention discloses a novel four-wheel steering mode for a four-wheel independent drive electric automobile. The steering mode combines a traditional front wheel steering system and a rear wheel differential steering system. The differential steering mode of the rear wheels is that the driving force difference is generated by controlling the different driving forces of the driving motors of the left and right wheels, so that the wheels are driven to rotate around the main pins to generate rear wheel steering angles, and the advantage of four-wheel steering is reflected. The four-wheel steering system can greatly improve the operation stability and the low-speed steering maneuverability of the vehicle during high-speed steering. A complex steering mechanism can be canceled by adopting rear wheel steering, the structure is simple, and the space utilization of the vehicle is improved. For the limit working condition, due to the fact that the aligning torque of the wheels is very small, the extremely small driving torque difference can generate the extremely large steering angle. The clutch device is installed at the steering tie rod of the rear wheel, the combination pressing degree can be automatically adjusted to generate friction torque for overcoming excessive driving torque difference, and therefore an expected rear wheel steering angle is obtained.

Owner:SOUTHEAST UNIV

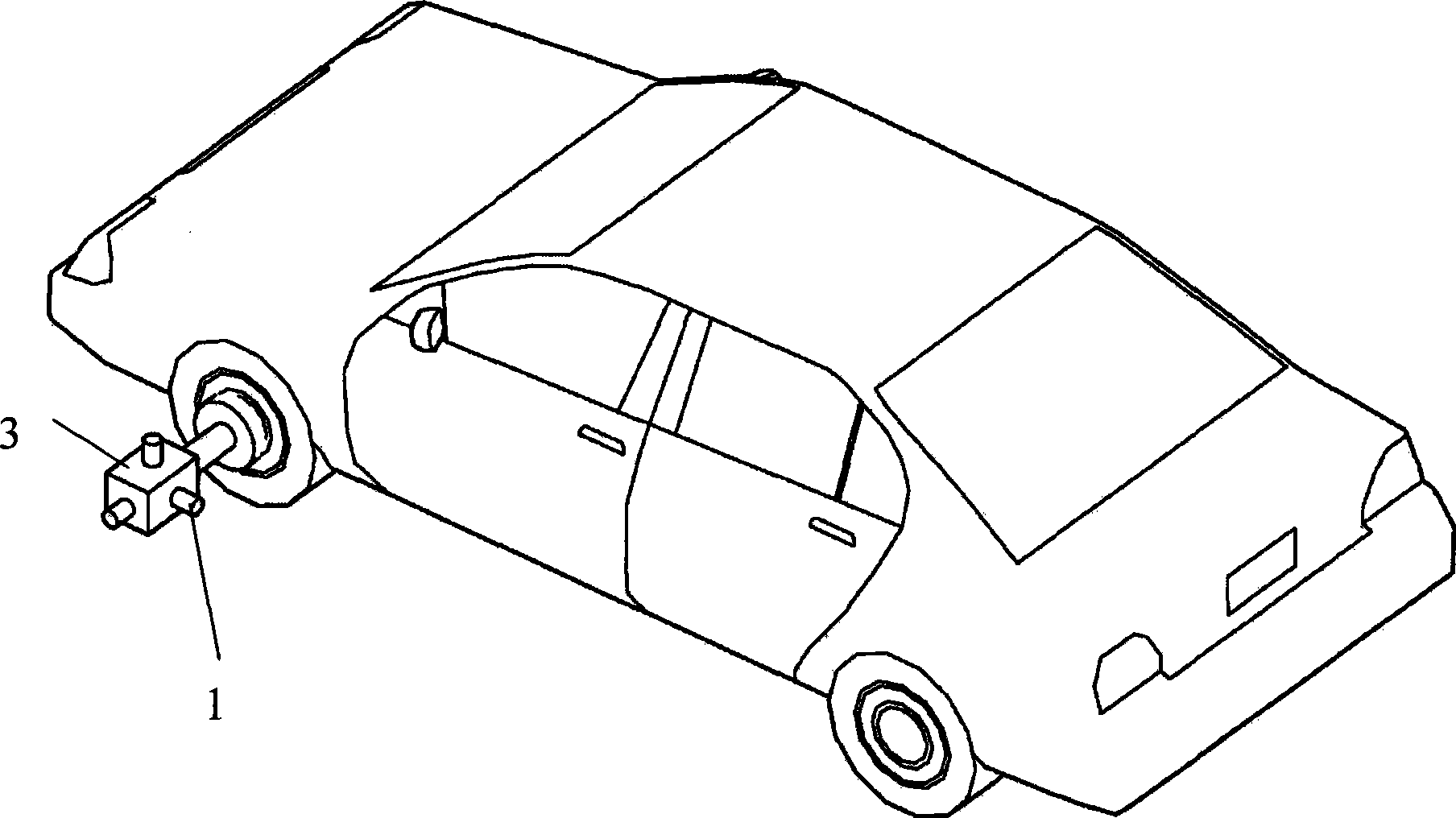

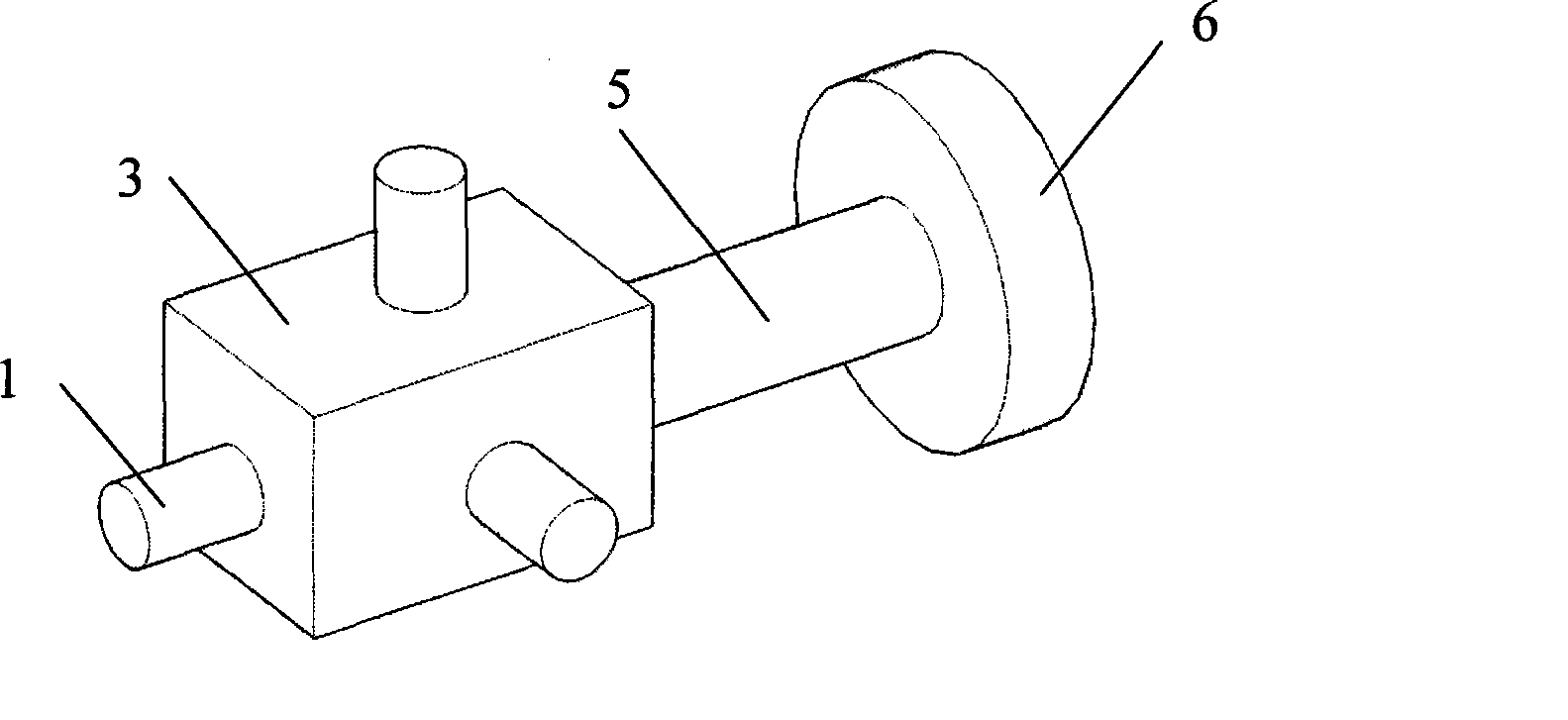

Paddy field plow pan information continuous sensing device and method

PendingCN111077284ASimple structureSimple and fast operationForce measurementEarth material testingAgricultural engineeringData acquisition

The invention relates to a paddy field plow pan information continuous sensing device which comprises an attitude sensor, two sets of feeler lever sensing devices and a data acquisition device. The attitude sensor is installed on a tractor body, and the two sets of feeler lever sensing devices are installed on left and right front wheel main pins of a tractor respectively; the feeler lever sensingdevice comprises a supporting frame, a parallelogram mechanism, a force sensor, an angular displacement sensor, a feeler lever and a constant-pressure mechanism; the supporting frame is relatively fixed to the main pins, the feeler lever, the constant-pressure mechanism and the force sensor ascend and descend relative to the supporting frame through the parallelogram mechanism, and the angular displacement sensor is installed on the parallelogram mechanism. The invention further relates to a paddy field plow pan information continuous sensing method. Plow pan depth information and plow pan depth soil resistance on a running path of the paddy field tractor can be continuously sensed at the same time, measurement means of a paddy field terrain and a soil bearing capacity are enriched, and the device and the method belong to the technical field of soil information sensing.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com