Method and equipment for milling processing cambered surface of vehicle fist section

An automobile front axle and milling technology, applied in the field of automobile parts processing, can solve the problems of unguaranteed processing quality, unable to meet the needs of production, low productivity and precision, etc., to achieve convenient operation, shortened production cycle, processing Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

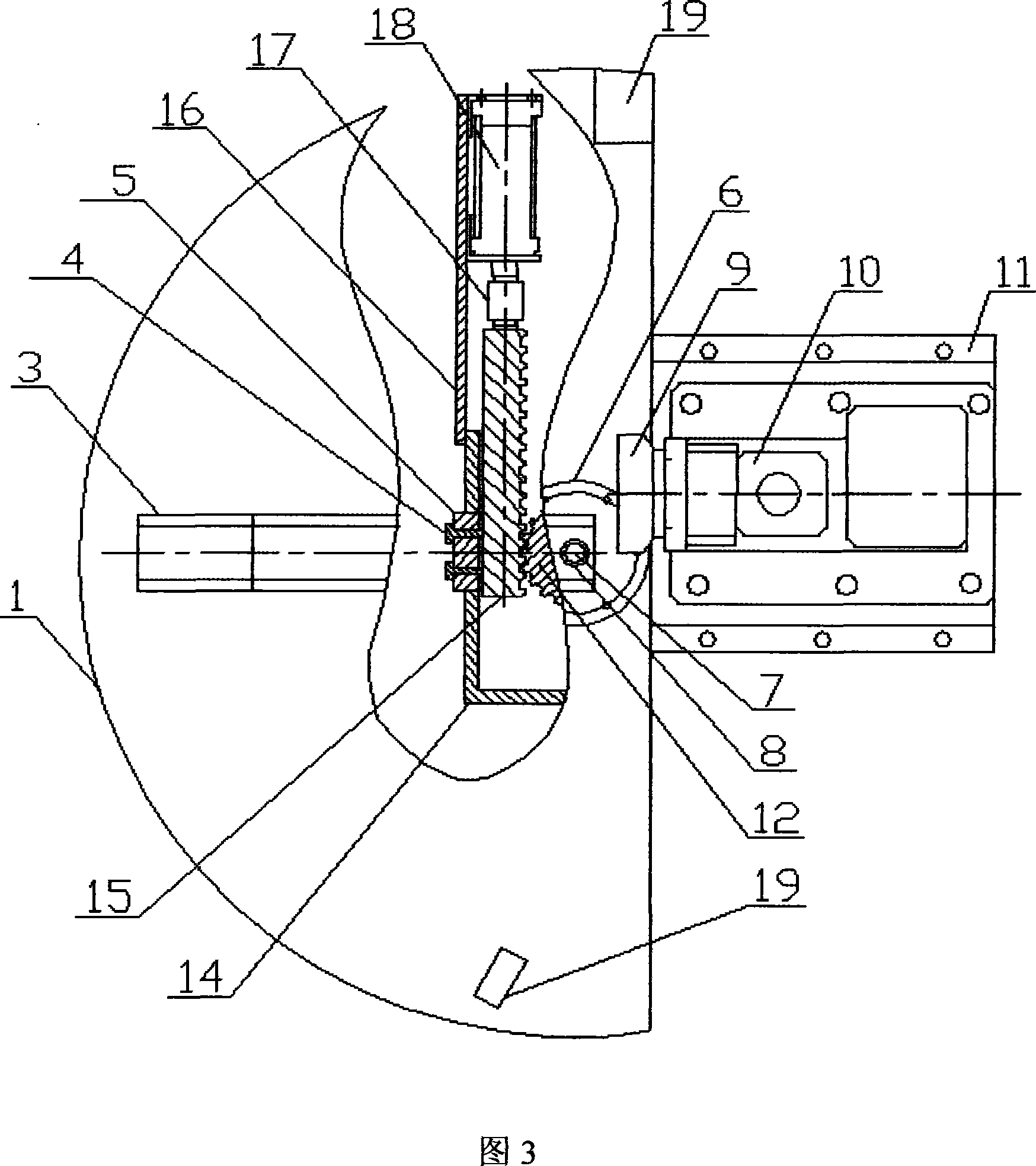

[0022] As shown in Figure 1, it is a process flow diagram of the present invention, that is, the method for milling the curved surface of the fist part of the automobile front axle of the present invention includes the following steps: (1) placing the automobile front axle to be processed on the top of the workbench On the rotating bracket of the workpiece, the upper end of the rotating shaft fixedly connected with the rotating bracket of the workpiece is inserted into the king pin hole of the fist part of the front axle of the automobile to be processed to fix the workpiece; (2) the milling cutter works and rotates around its own axis; (3) The power system works in the forward direction, and the transmission mechanism drives the rotating shaft to rotate, thereby driving the front axle of the car fixed on the rotating shaft to rotate and move around the axis of the rotating shaft on the worktable, so as to realize the milling of the arc surface of the fist part of the car front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com