Patents

Literature

71 results about "Process flow diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

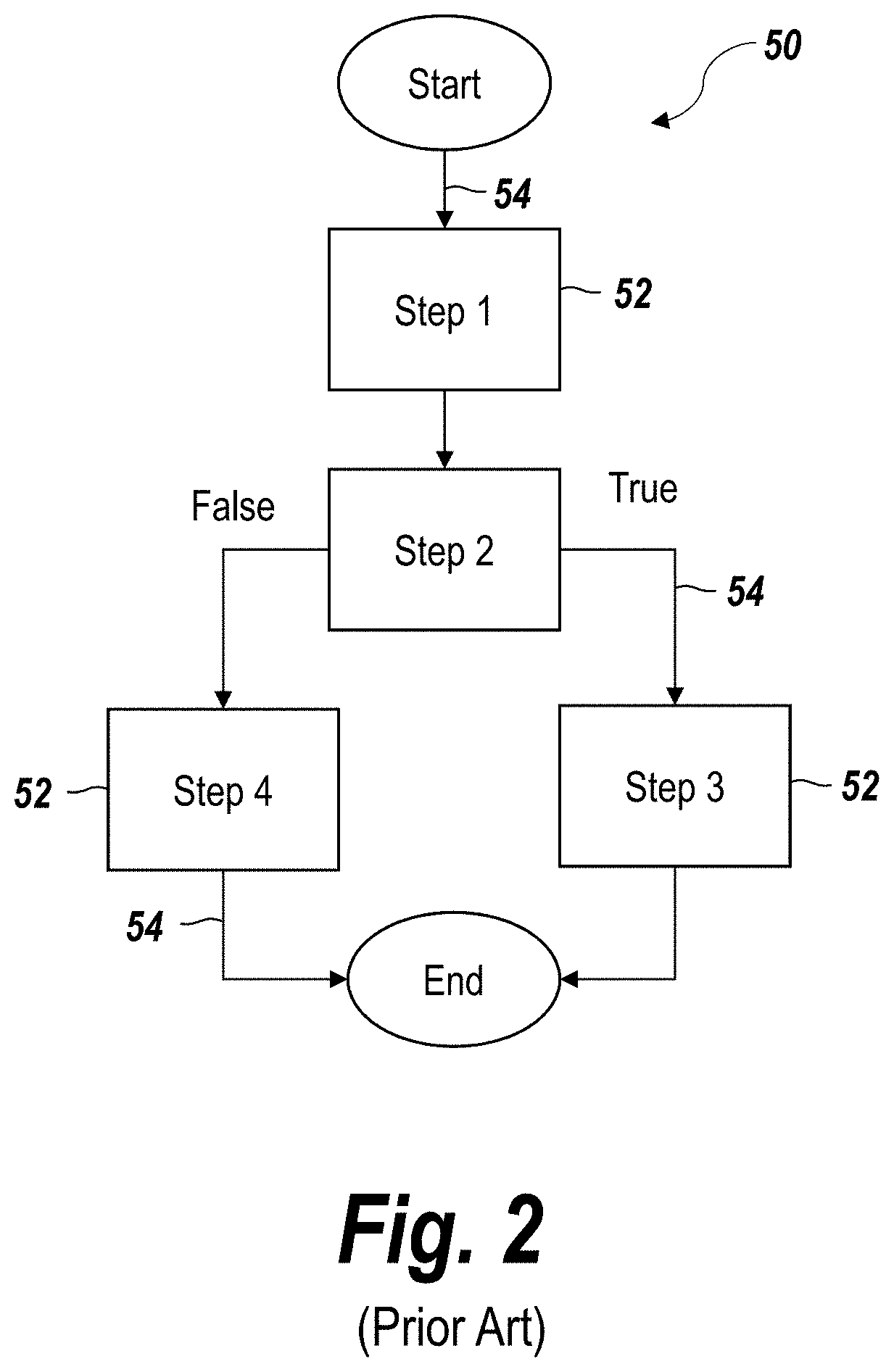

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is a flowsheet.

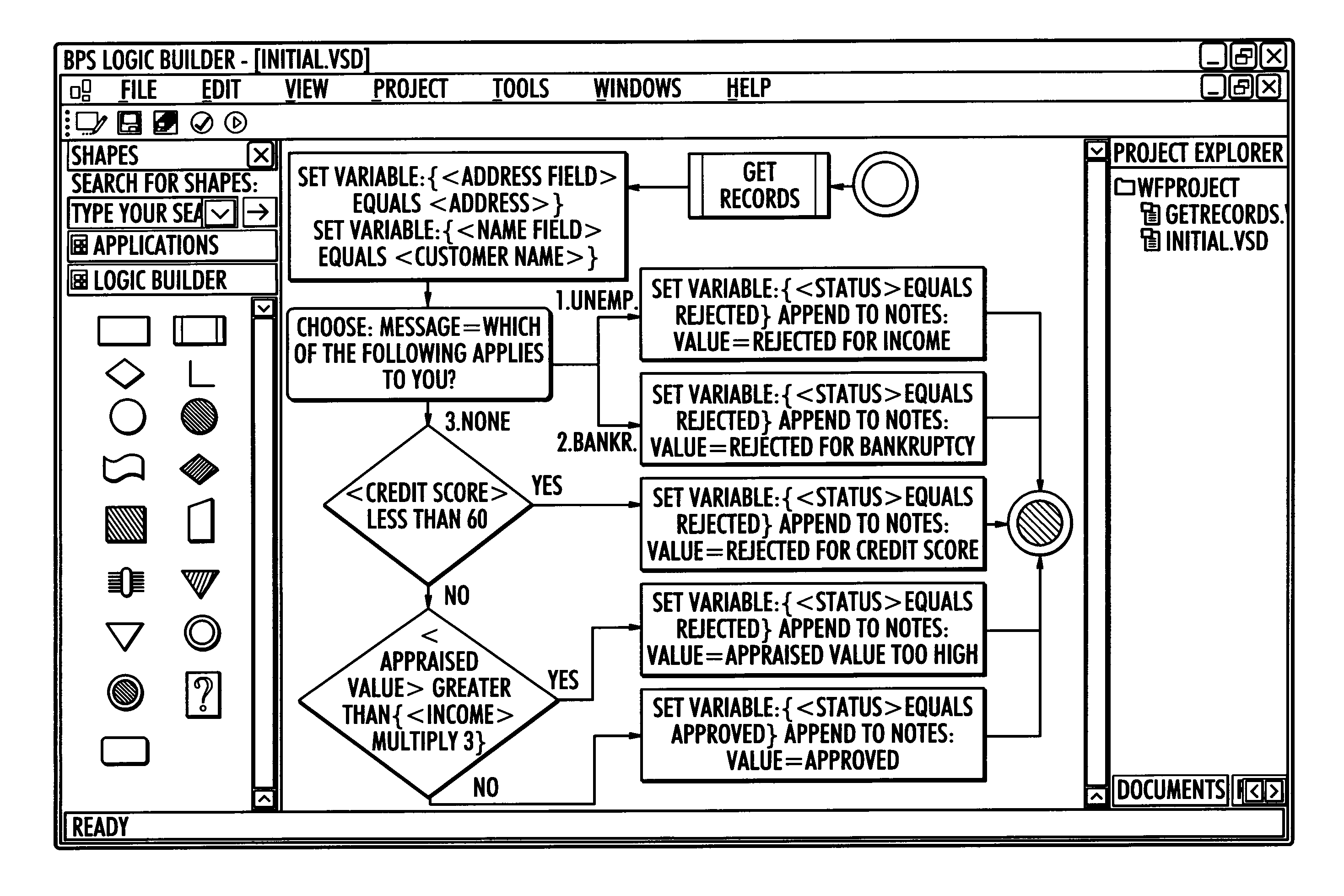

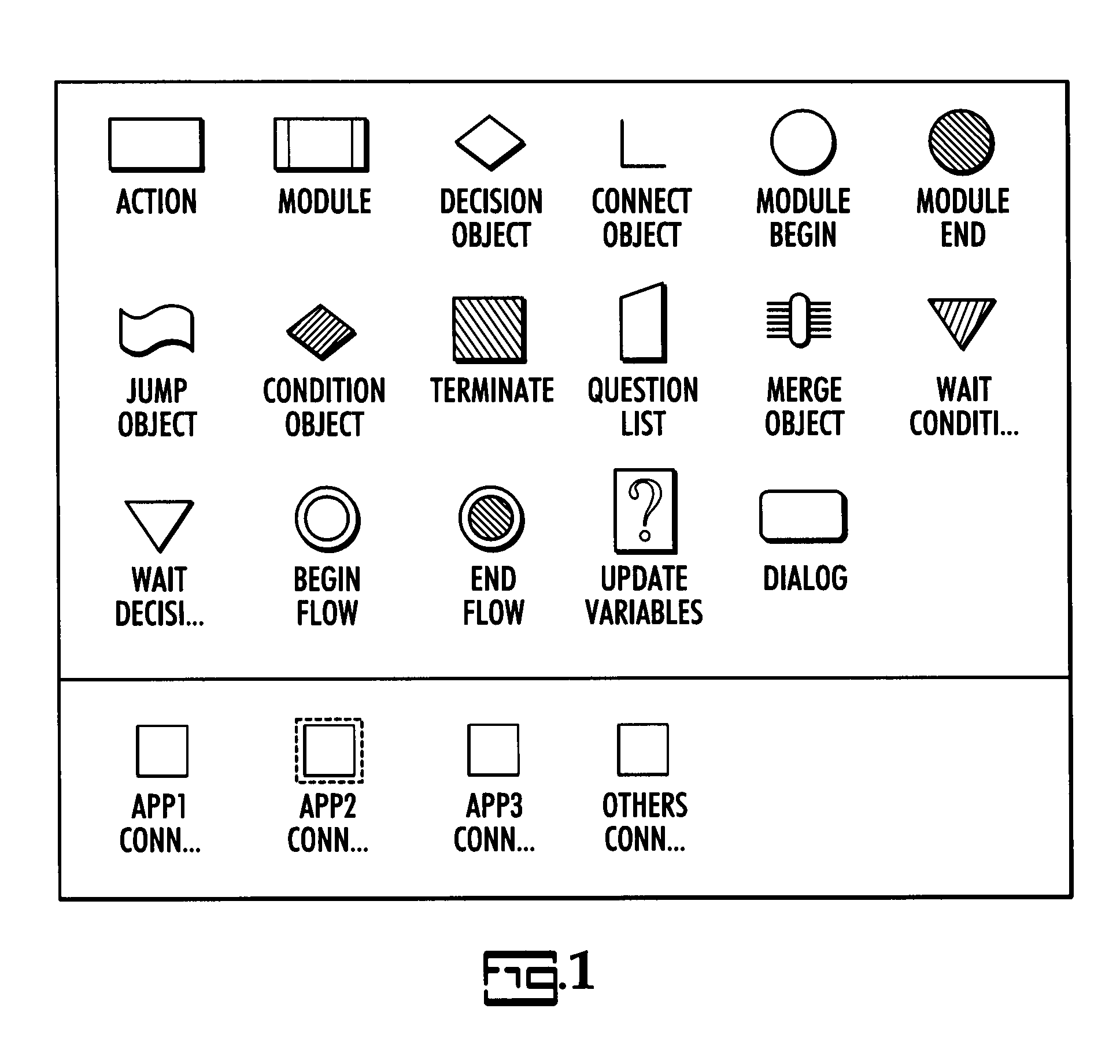

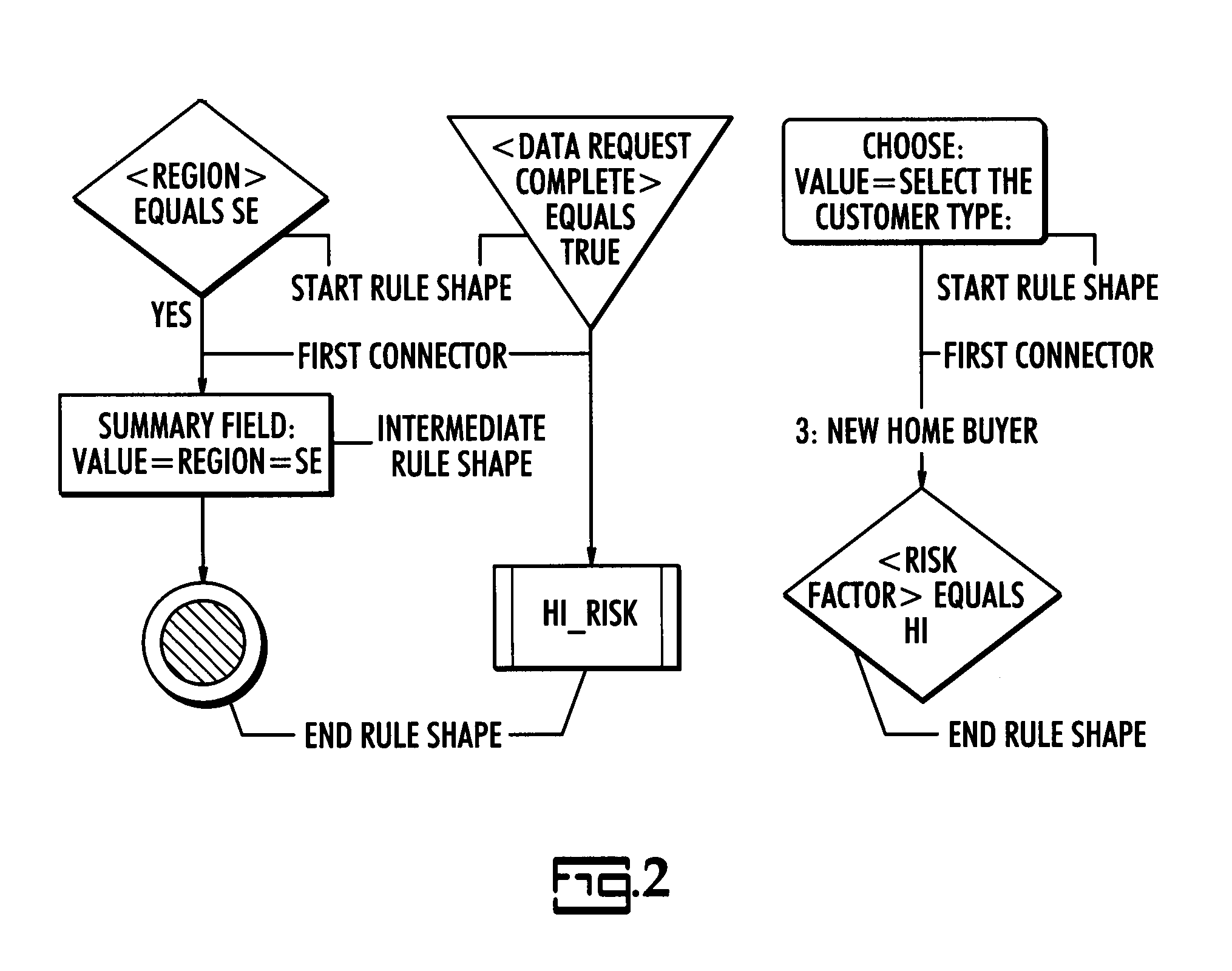

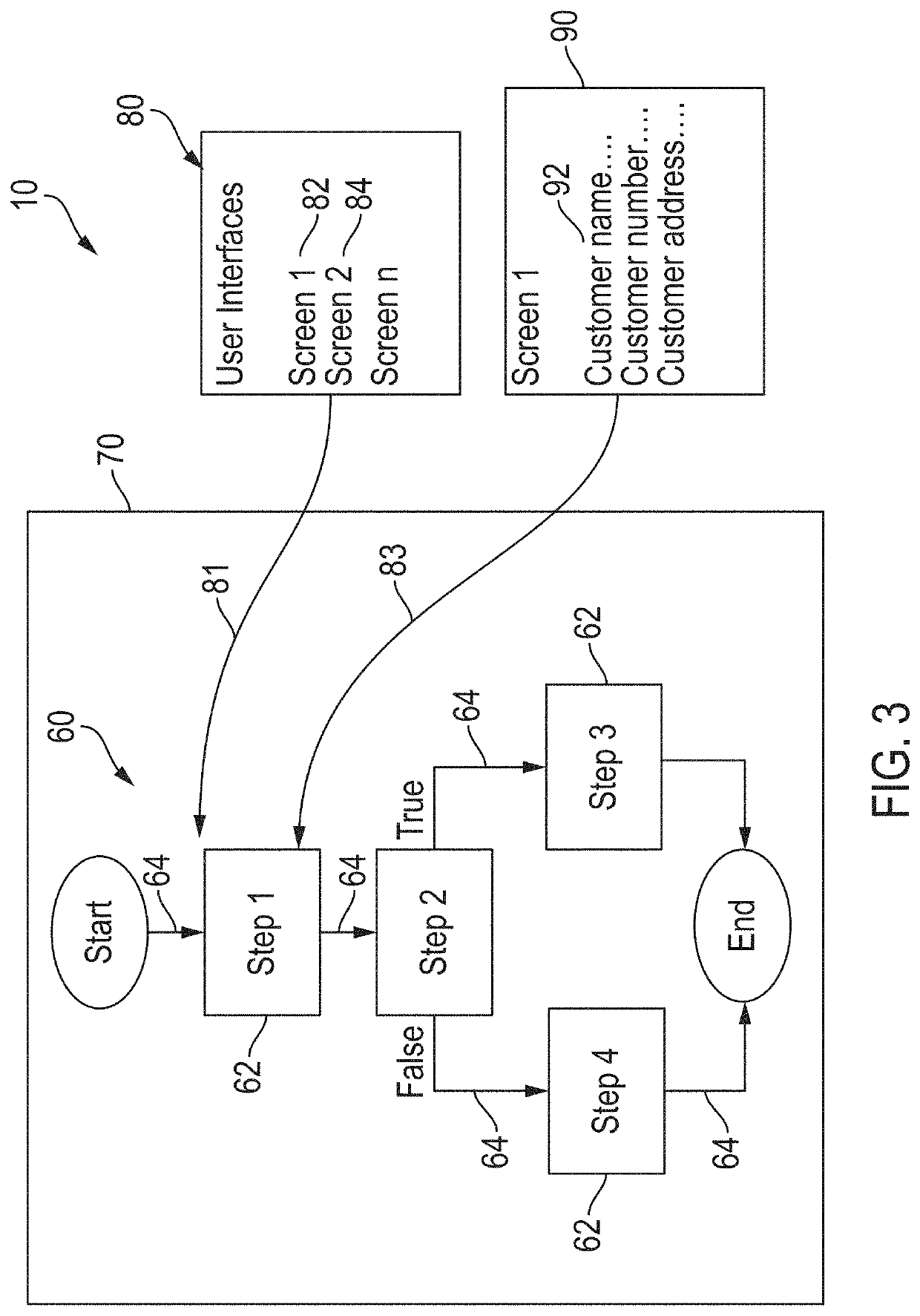

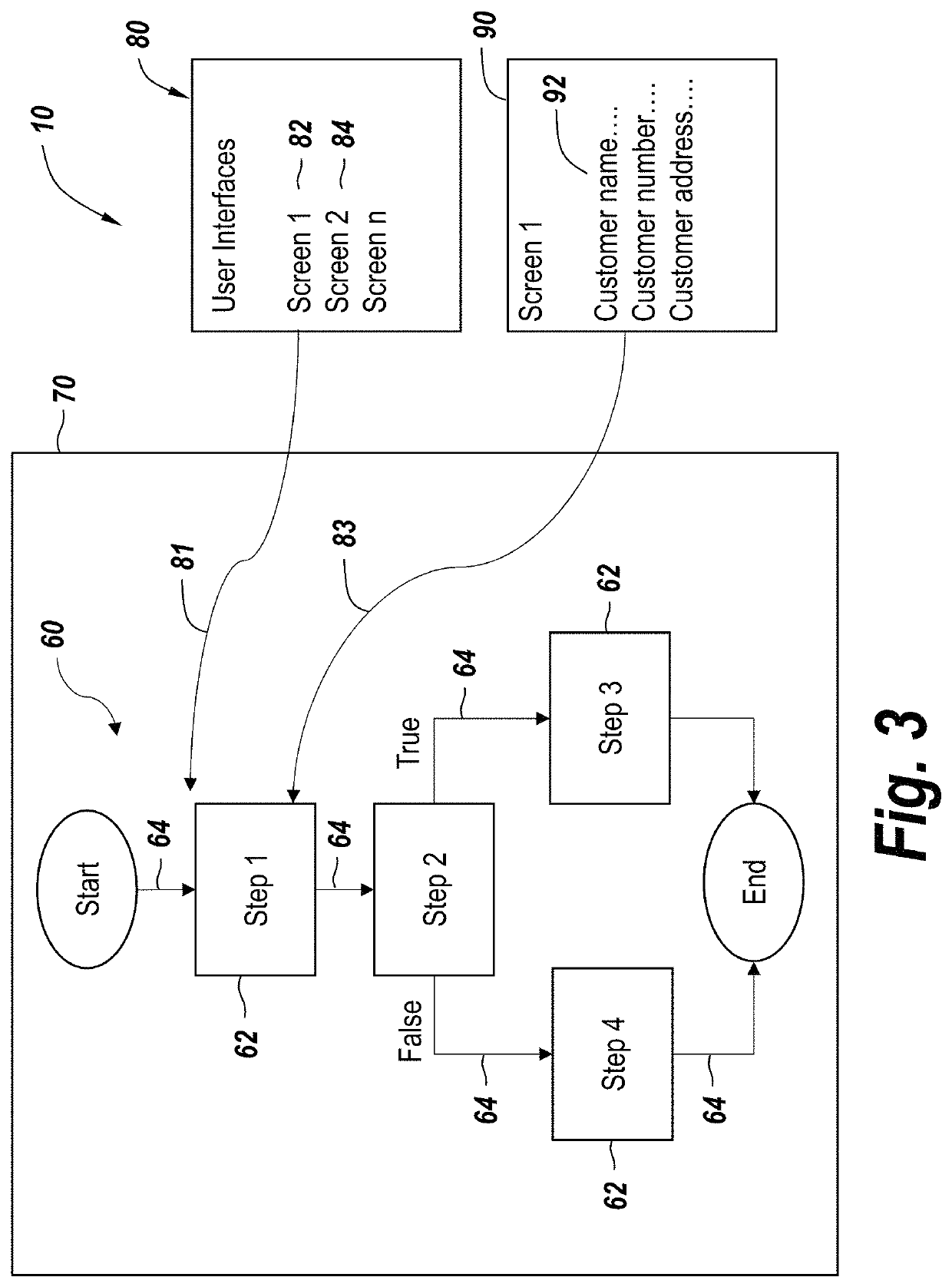

Apparatus for generating software logic rules by flowchart design

ActiveUS8131663B1Improve translationPromote generationChaos modelsNon-linear system modelsSoftware engineeringApplication software

A apparatus implemented using a programmable computer that automatically generates the rules required by a software rules engine as a process flow diagram is designed. The apparatus includes a developer interface; an editing interface, and a rules generator. A developer interface enables the user to define functions and variables together with their properties from the business application. An editing interface allows the user to define the logical rules the business would follow in performing the business application by constructing a process flow diagram and associated tables using the functions and variables defined in the developer interface. The rules generator then automatically parses the flow diagrams and tables defined by the business user and, using the functions and variables defined in the developer interface, generates rules for a rules engine. The rules can then be deployed to a controller that implements the process automatically based on the input rules.

Owner:TAYLOR BLAISE DIEUDONNE

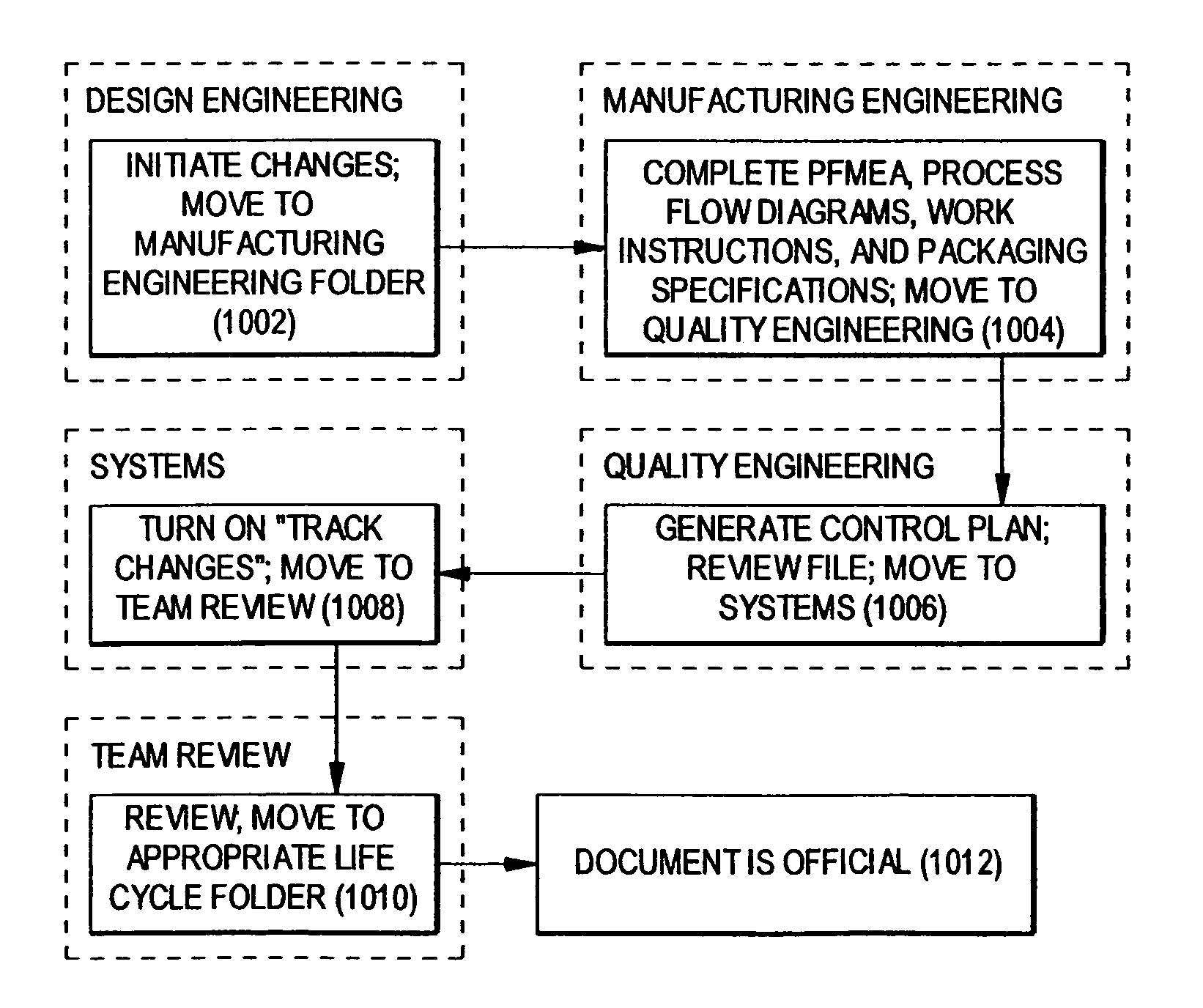

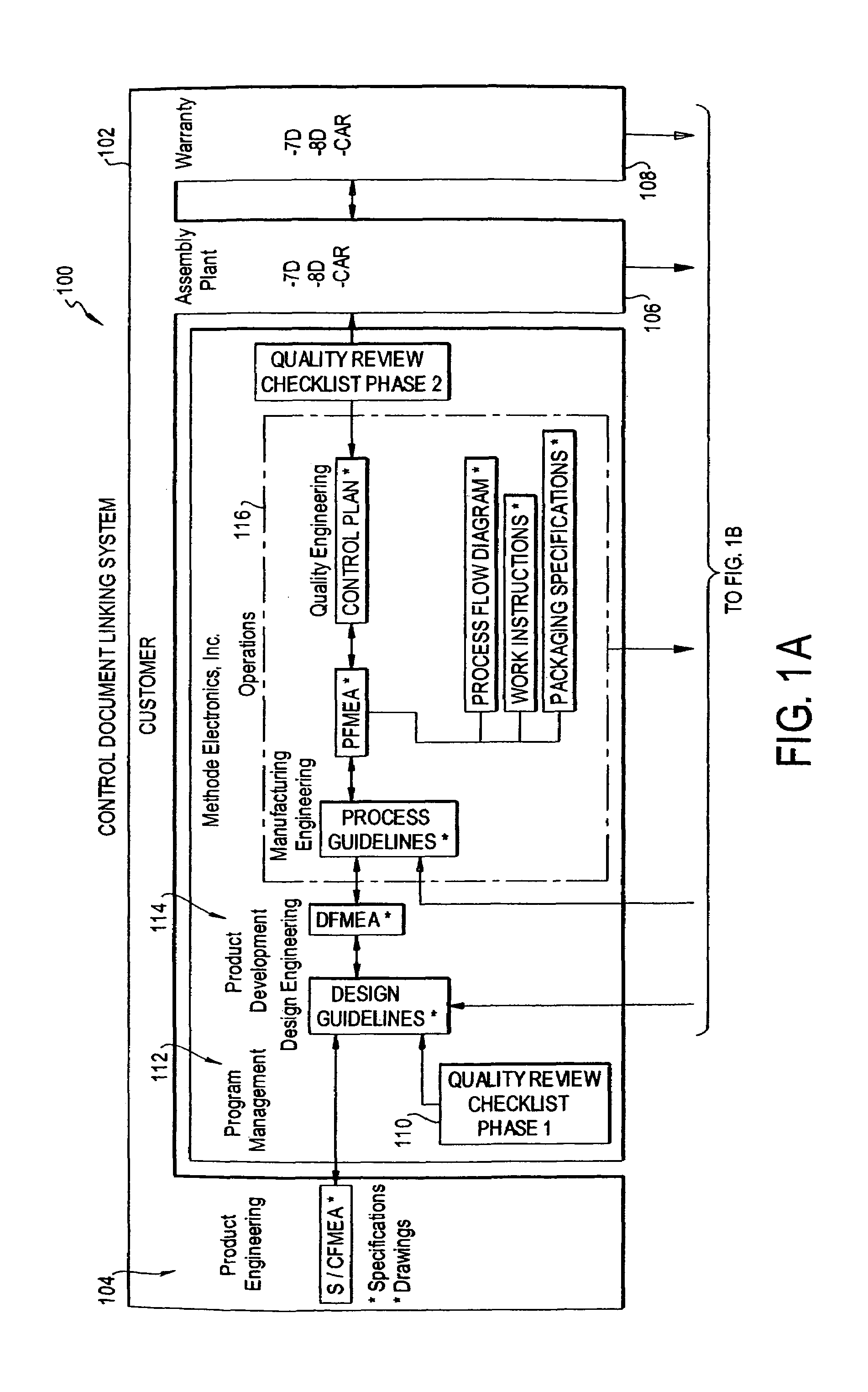

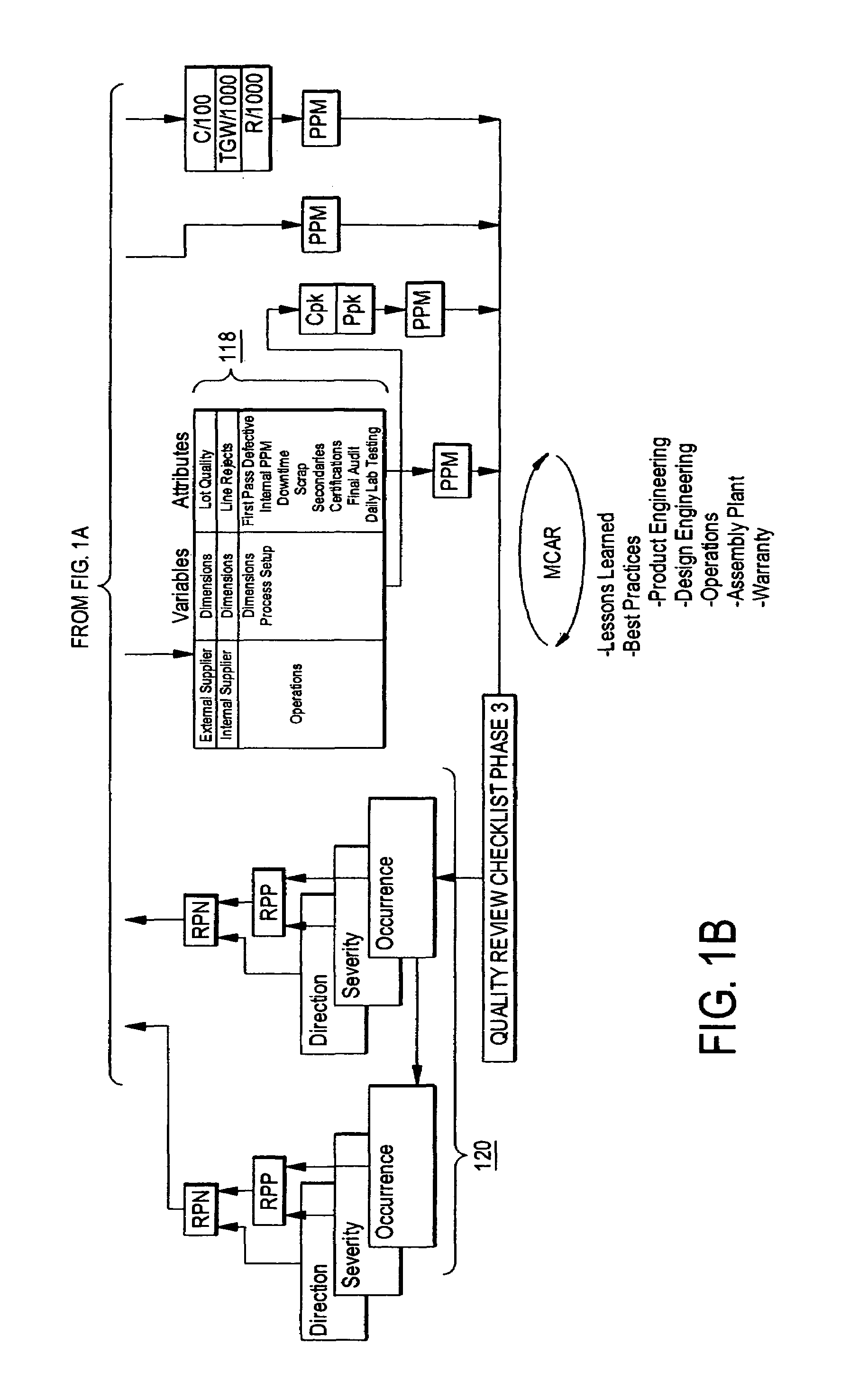

Design control document linking template

InactiveUS7096082B1Facilitate consistent entryWork lessFinanceAnimal feeding devicesOriginal dataElectronic form

A control document template streamlines the creation of control documents and facilitates consistent entry of data. A multi-page spreadsheet file incorporates the design and process failure mode effects analysis pages, the control plan, tools for forming the process flow diagram, the work instructions, and the packaging specifications. A macro sorts the failure mode effects analysis pages by risk priority number without overwriting the original data.

Owner:METHODE ELETRONICS INC

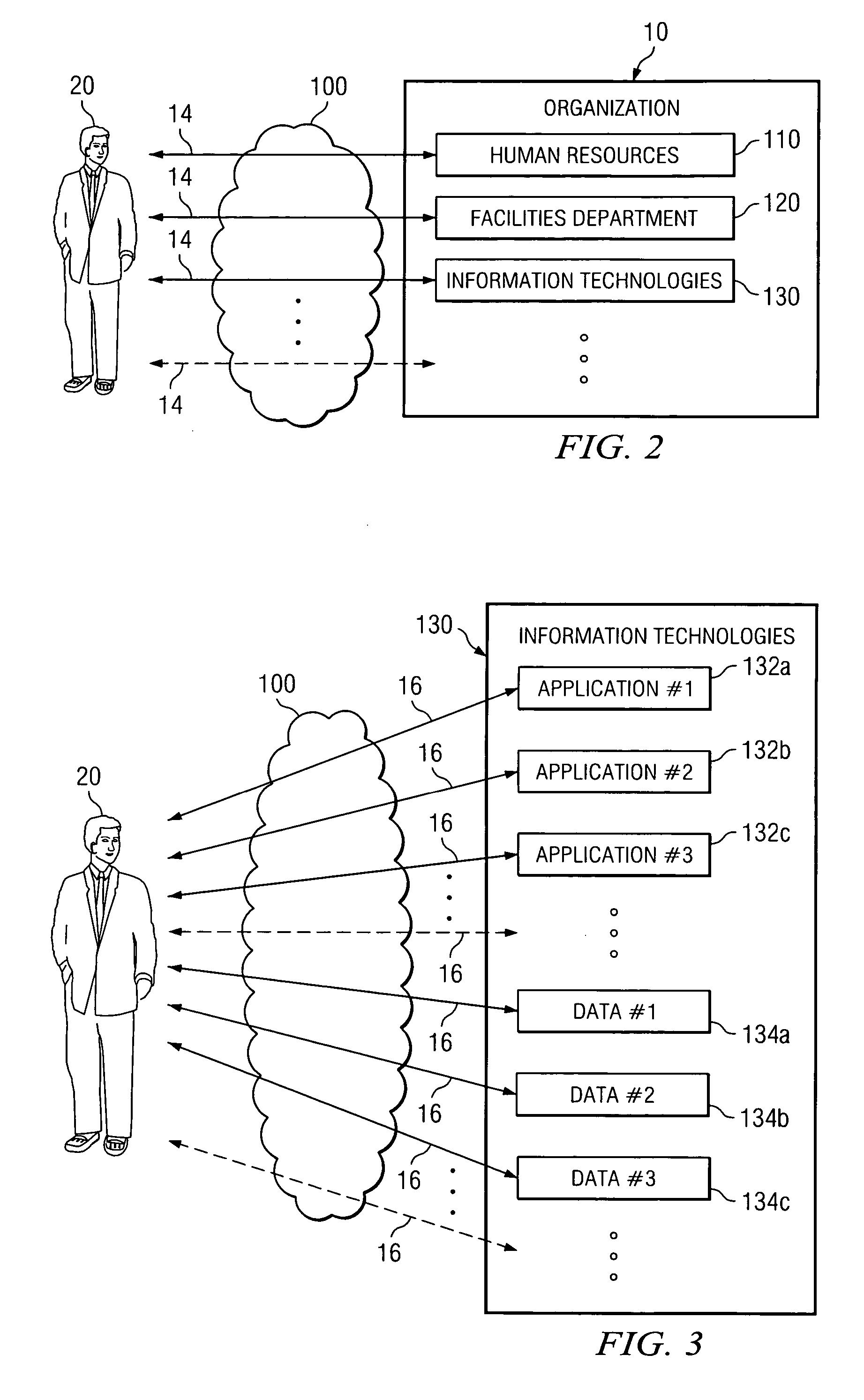

Identity management system and method

InactiveUS20070233531A1Easy to manageTransmissionSpecial data processing applicationsFlow sheetKnowledge management

According to one embodiment, a method for implementing an identity management system for an organization includes developing a process flow diagram, the process flow diagram including one or more icons representing at least one process step for each of the events included in an event group and one or more icons representing at least one process step for each of the functional entities in an entity group, and implementing at least one of the process steps represented in the process flow diagram. The event group includes a status change for a system user, a request for an audit report, and an implementation of a new software application. The entity group includes a human resources department, an information technologies department, and a facilities department.

Owner:CA TECH INC

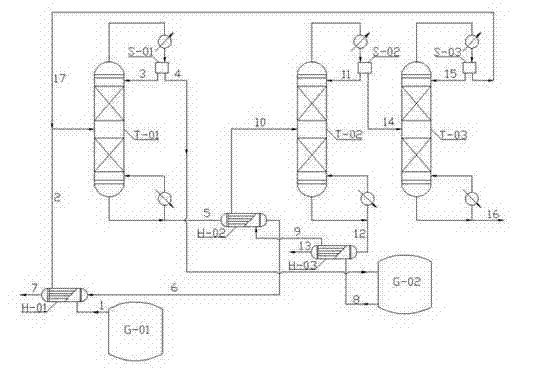

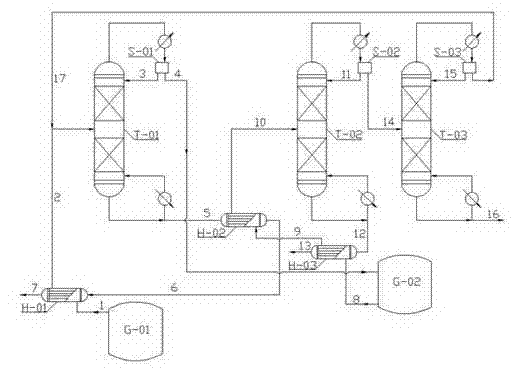

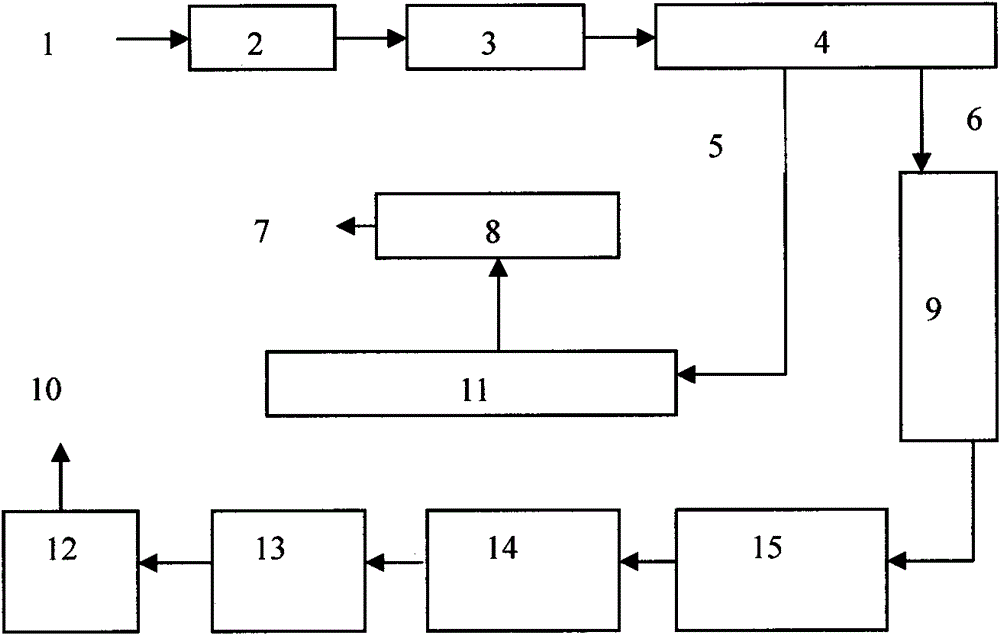

High purity recycling and energy integration technology for different concentrations of dichloromethane wastewater

InactiveCN102126917AHigh puritySolve the azeotropic problemWater/sewage treatment by heatingHalogenated hydrocarbon preparationWastewaterEnergy integration

The invention relates to a high purity recycling and energy integration technology for different concentrations of dichloromethane wastewater. The process flow diagram is shown in the figure 1. The technology is as follows: different concentrations of dichloromethane wastewater performs rectification three times, water is removed from the three fractions and dichloromethane of which purity is 99.95% can be obtained finally. In the technological process, the waste heat of the discharged material in the tank bottom can be fully utilized to preheat the material to be distilled, thus the energy can be fully utilized. The technology can be suitable for all the occasions of the high purity recycling of dichloromethane wastewater.

Owner:NANJING UNIV

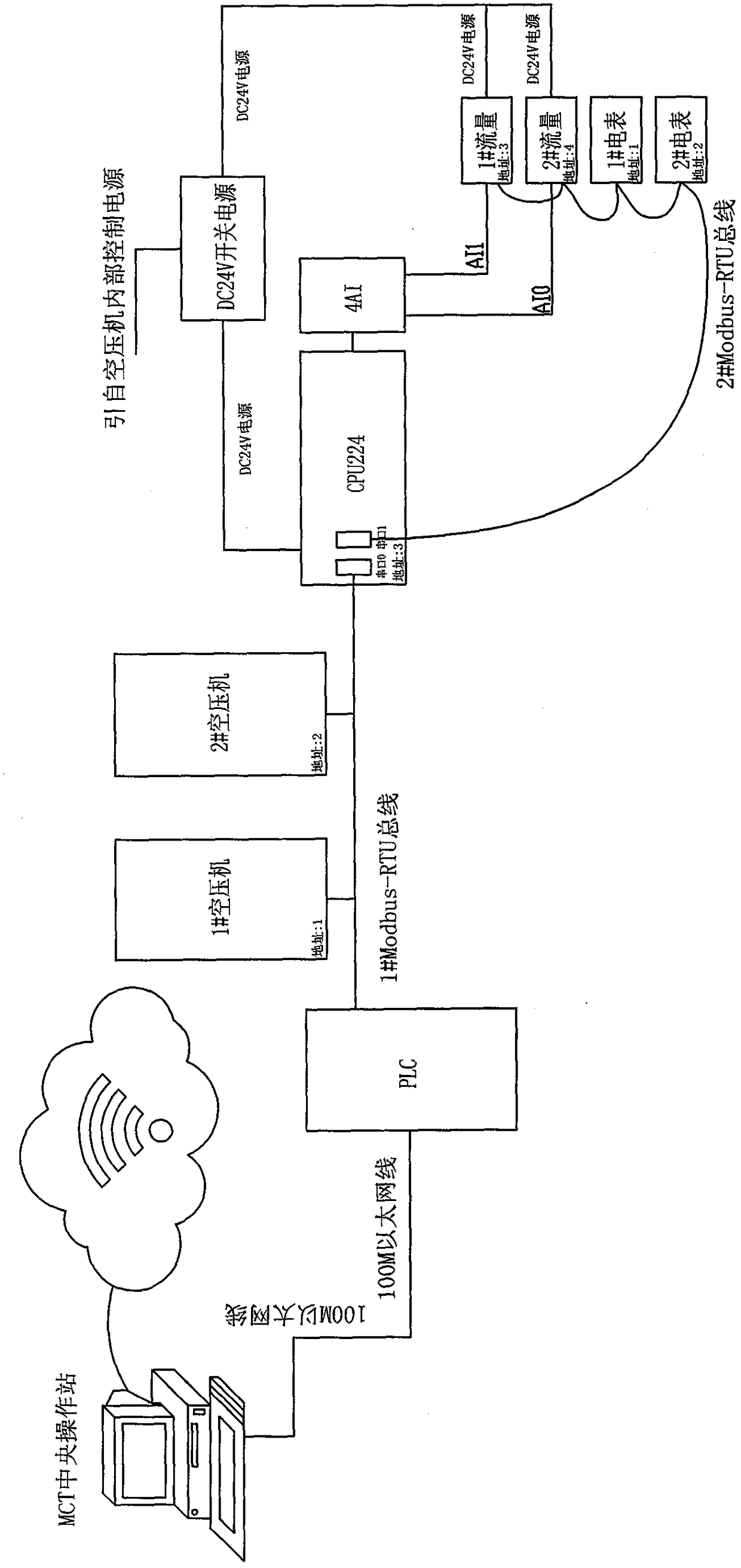

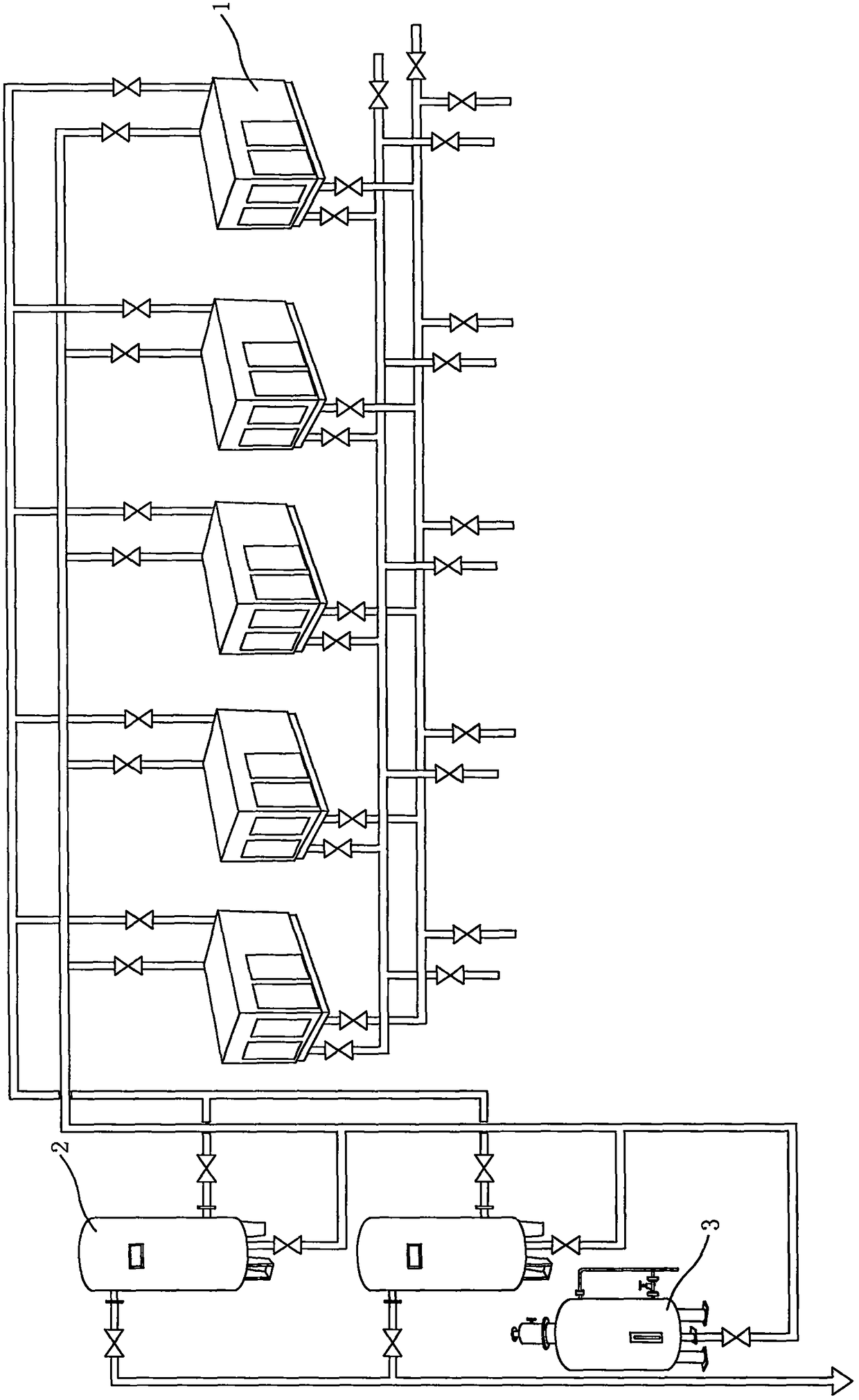

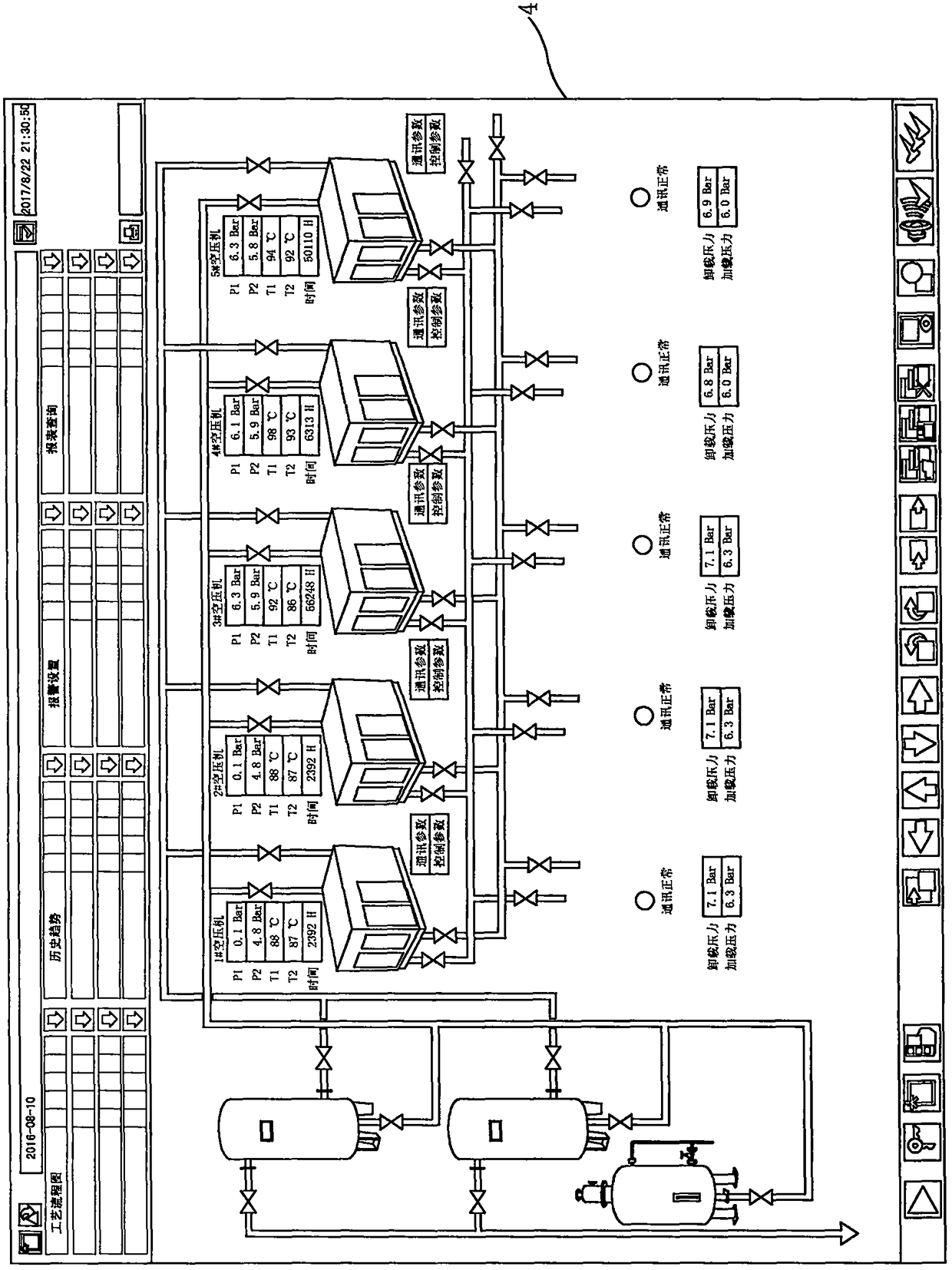

Remote monitoring system of air compressor

ActiveCN108916019AEasy to monitor remotelyRemote Monitoring AccuratePump testingPositive displacement pump componentsEngineeringAir compressor

The invention relates to a remote monitoring system of an air compressor. The system is designed regarding the technical problems that remote monitoring operations of similar products are inconvenient, and the energy saving effect is poor. The system is characterized in that a system navigation composed of grouping pull-down menus is arranged on the upper portion of a system flow main page on an air compressor automatic monitoring system of the system and comprises a process flow diagram, a historical trend, an alarming setting and a statement querying button, the process flow diagram is arranged on the lower portion of the system flow main page, and an air compressor icon of the process flow diagram is provided with a remote control operation panel of the air compressor; a dryer and a pipeline of an air storing tank are arranged on an air pipe hanging frame railway in a workshop, an air-operated connecting control cabinet is arranged above the air pipe hanging frame railway of a workarea, and the air pipe hanging frame railway is provided with a work radio frequency sensing area; an interface pressure sensor and an interface temperature sensor of the air-operated connecting control cabinet are connected with an MCT central operation station through wireless transmitters, and a connecting pipeline of an air-operated screw driver is connected with a pipe joint of the air-operated connecting control cabinet.

Owner:杭州裕达自动化科技有限公司

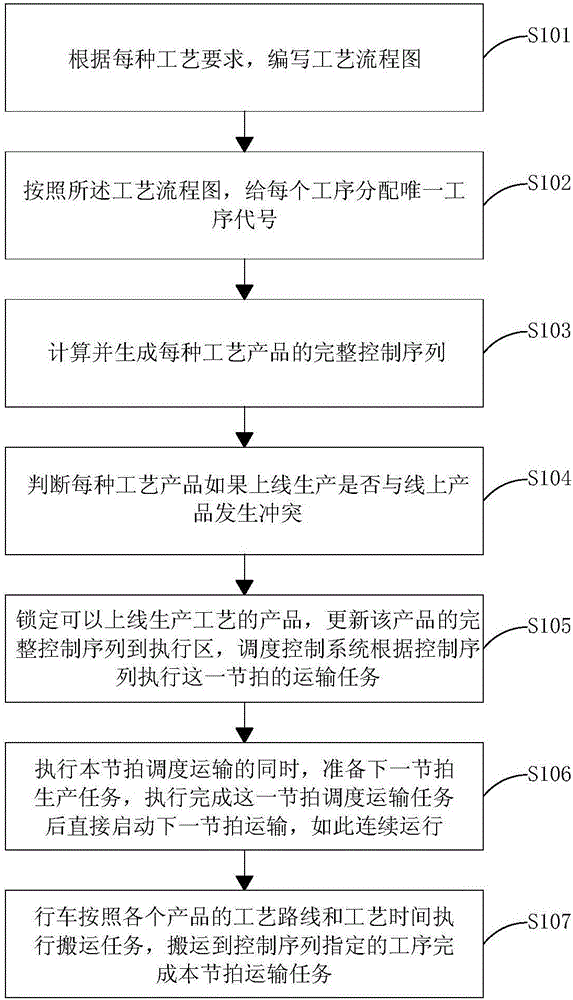

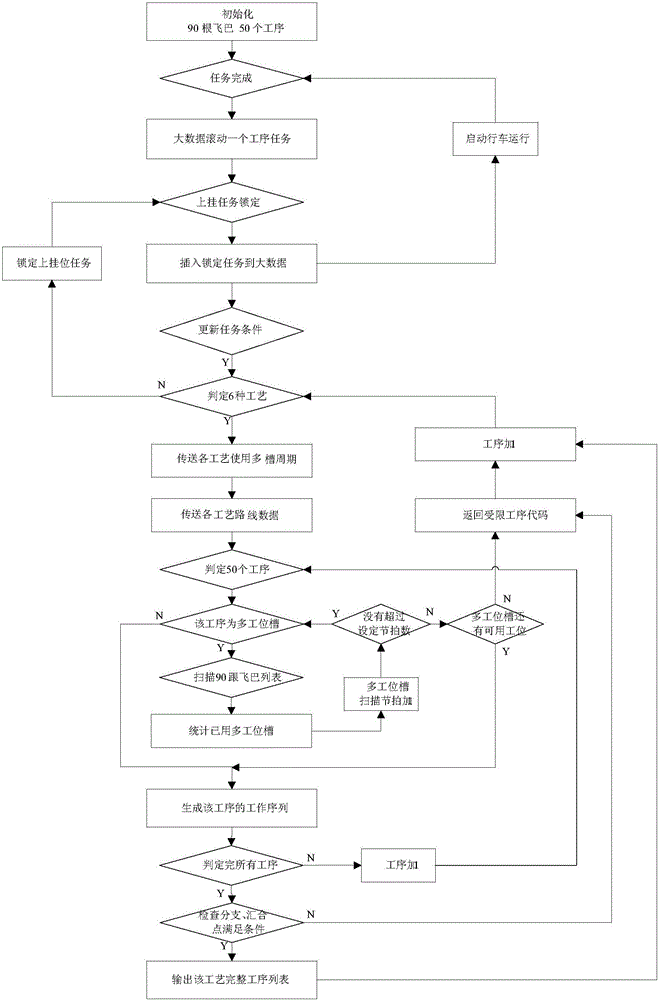

Travelling crane pre-judging, scheduling and controlling method for electroplating production line

ActiveCN105821468AIncrease productivityGuarantee product qualityCellsProduction lineComputer science

The invention discloses a travelling crane pre-judging, scheduling and controlling method for an electroplating production line. The method comprises the steps that a process flow diagram is compiled according to each process requirement; a unique procedure code is distributed to each procedure according to the process flow diagram; a complete control sequence of each process product is calculated and generated; whether each process product conflicts with an on-line product during on-line production or not is judged; products capable of being subjected to an on-line production process are locked, the complete control sequences of the products are updated to an execution area, and the transporting task of the takt is executed according to the control sequences; scheduling and transporting of the takt are executed, meanwhile, the production task of the next takt is prepared, and transporting of the next takt is directly started after the scheduling and transporting task of the takt is executed; and a travelling crane executes carrying tasks according to the process paths and process time of all the products, and the products are carried to procedures specified by the control sequences to complete the transporting task of the takt. According to the method, multiple process products can be produced in a mixed manner at the same time, the production efficiency is improved, and the product quality is guaranteed.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

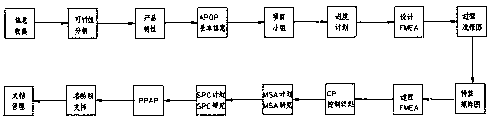

Method for product quality advanced planning of automobile industry

InactiveCN107563675AImprove quality management levelImprove efficiencyResourcesManufacturing computing systemsProgram planningResearch plan

The present invention discloses a method for product quality advanced planning of an automobile industry. An automobile industry product quality advanced planning published by AIAG such as feasibilityanalysis, project teams, project schedule plans, DFMEA, process flow diagrams, characteristic matrix diagrams, PFMEA, CP, MSA, SPC and the like in an APQP reference manual is associated when a new project is developed and changed. The method for product quality advanced planning of an automobile industry determines product features aiming at products and develop APQP basic information according to the product features, the APQP basic information is employed to realize automatic generation of related files such as feasibility analysis, DFMEA, process flow diagrams, characteristic matrix diagrams PFMEA, CP, MSA analysis plans, SPC research plans, operation instructions and the like so as to prompt enterprises to really and solidly perform requirement identification and analysis in the product quality advanced planning and improve an enterprise quality management level.

Owner:陈远景

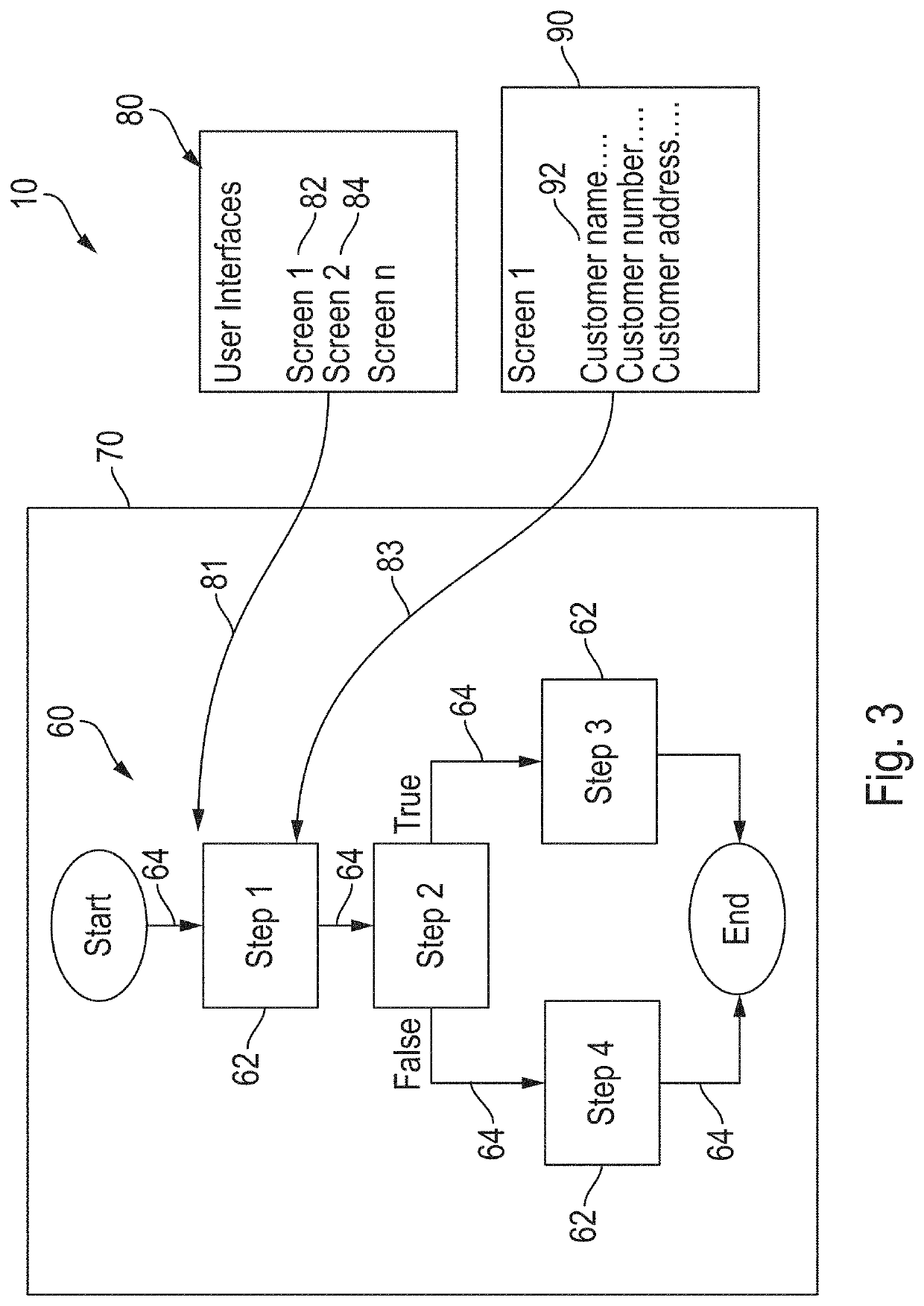

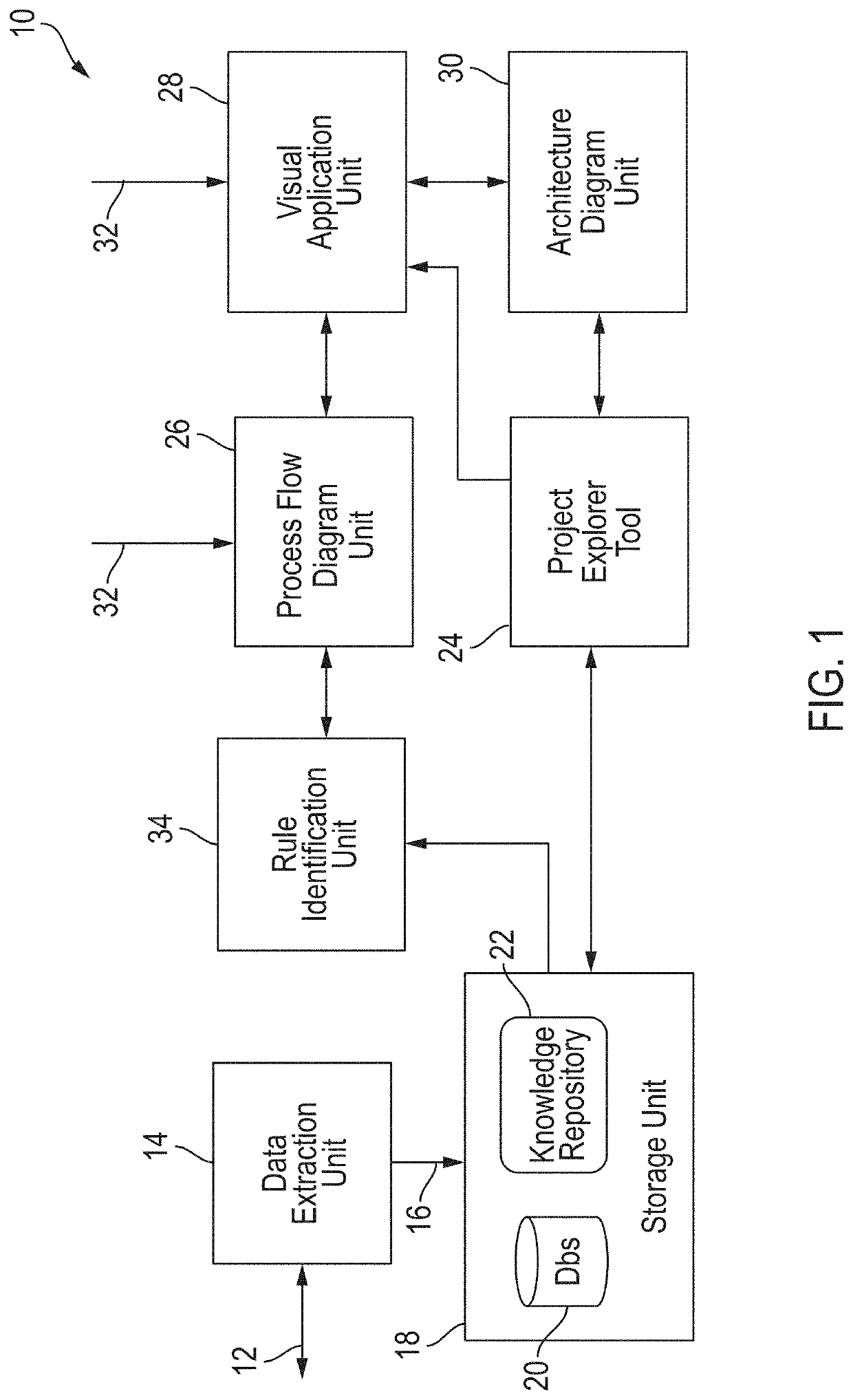

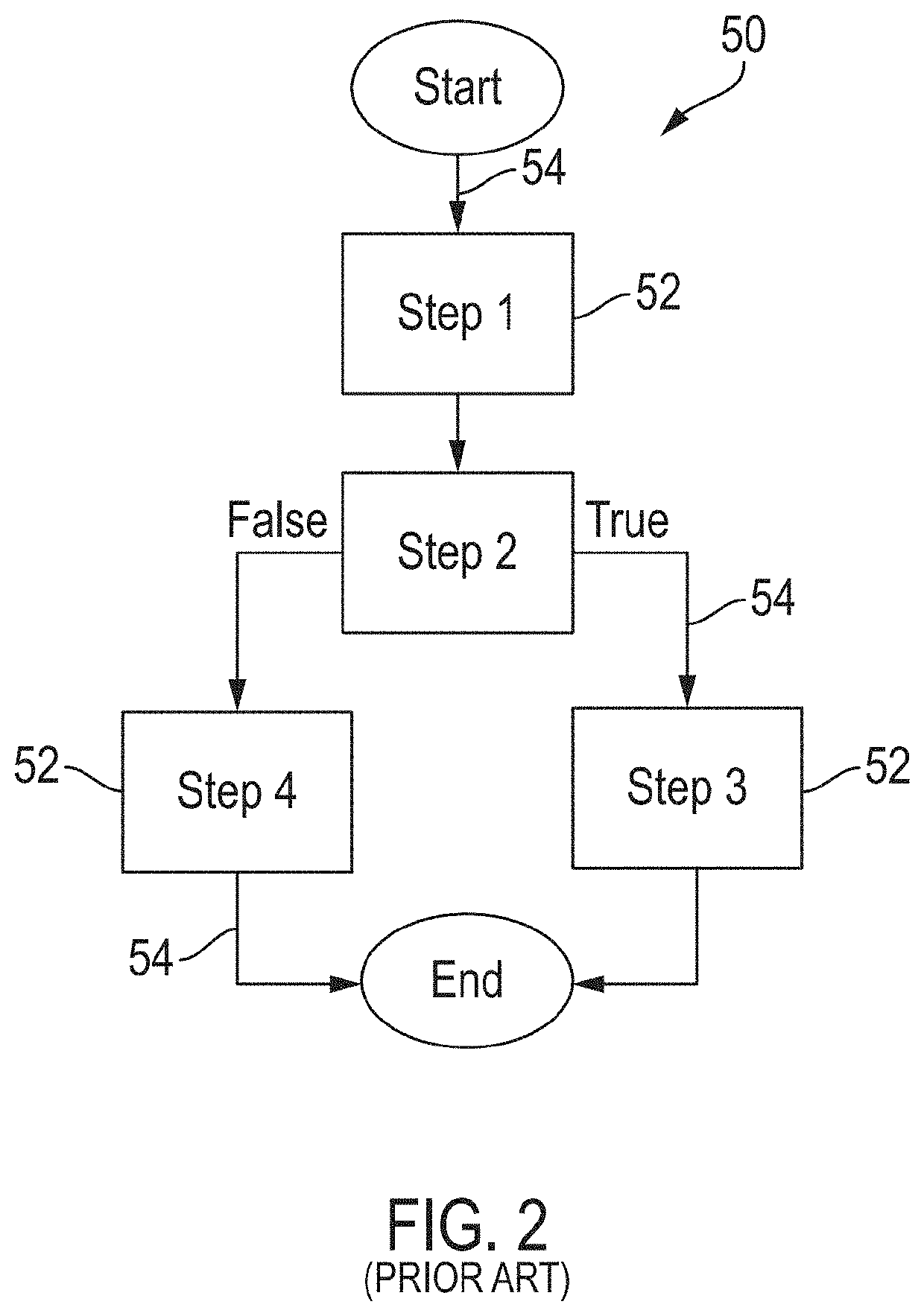

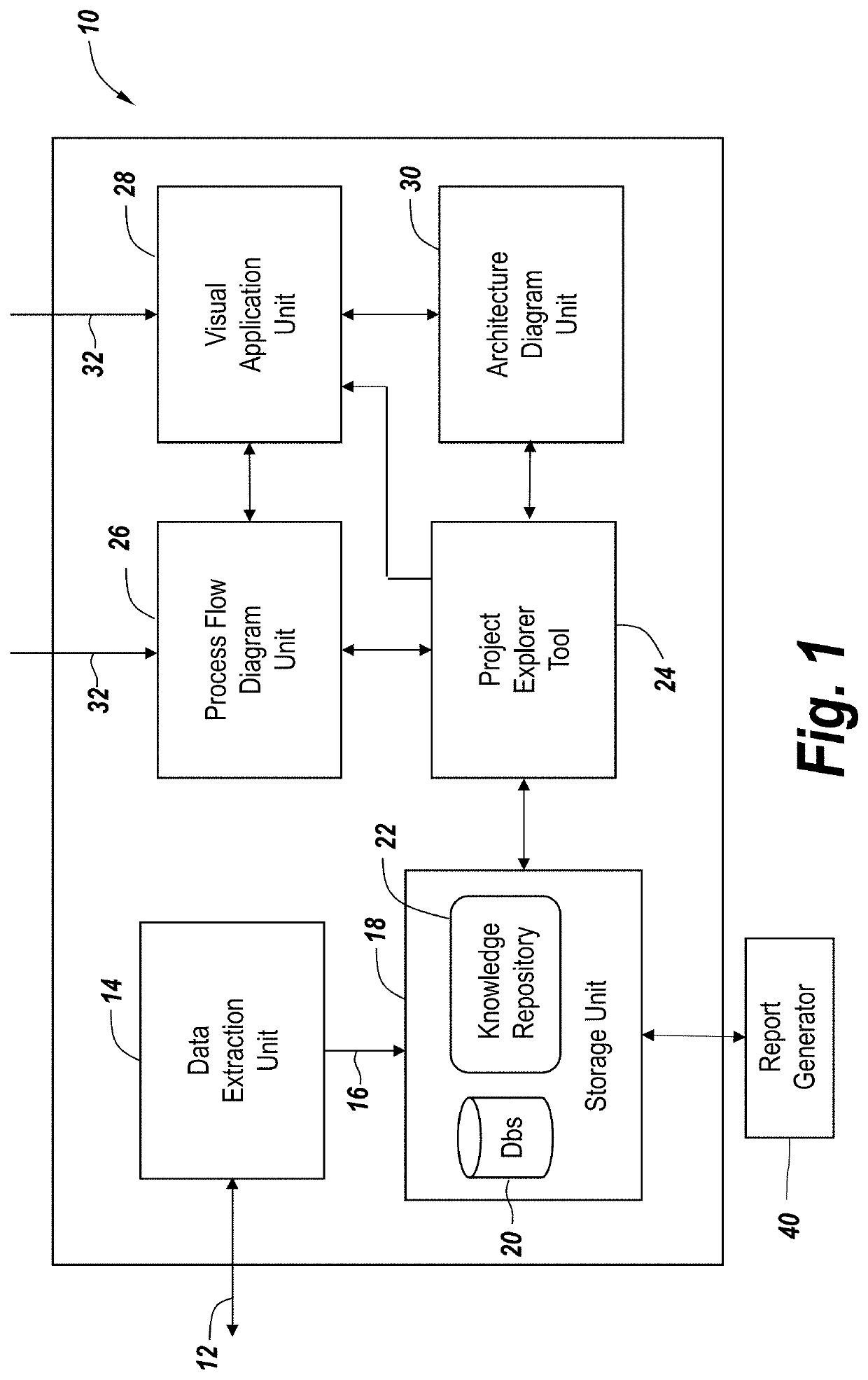

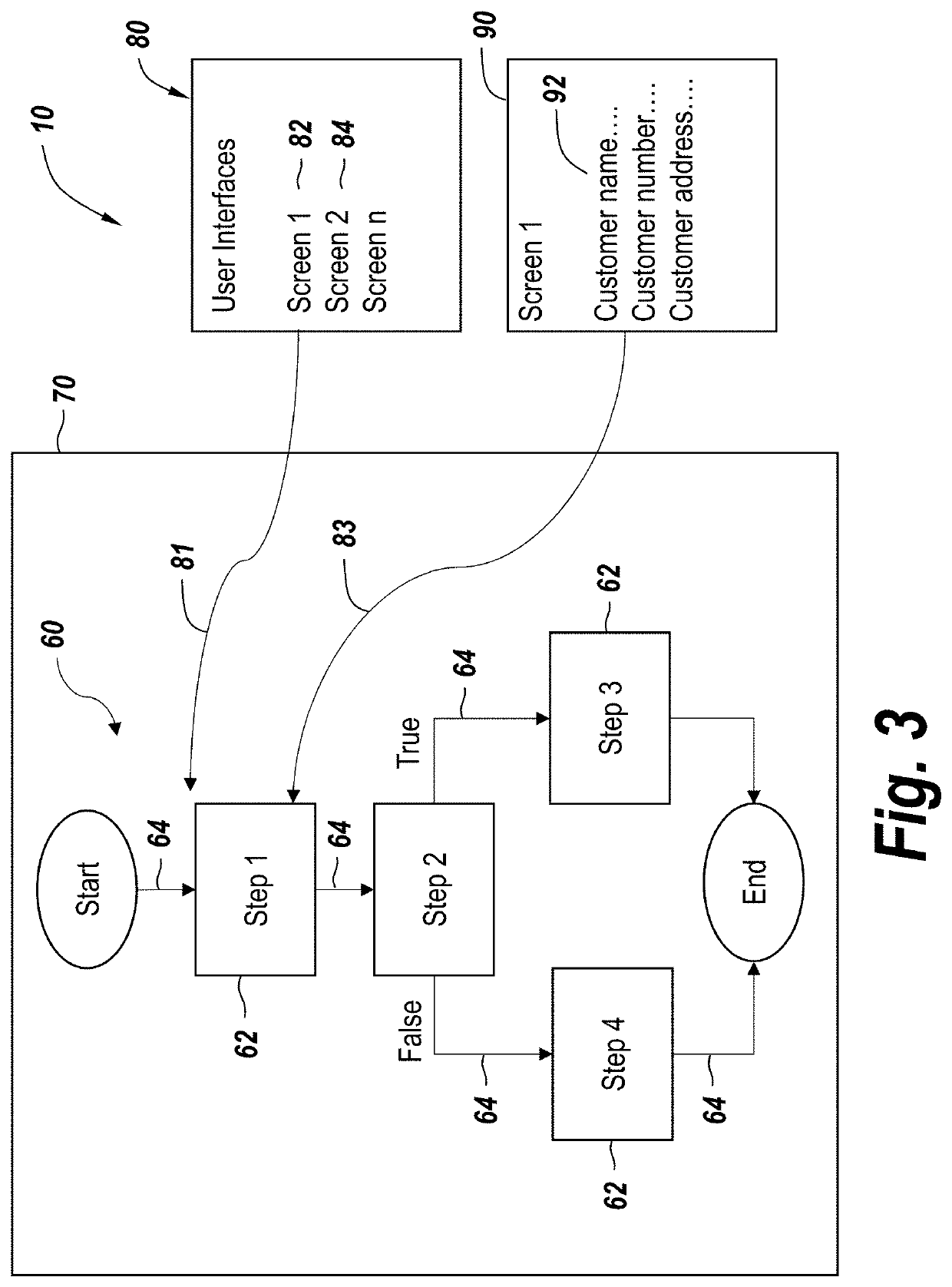

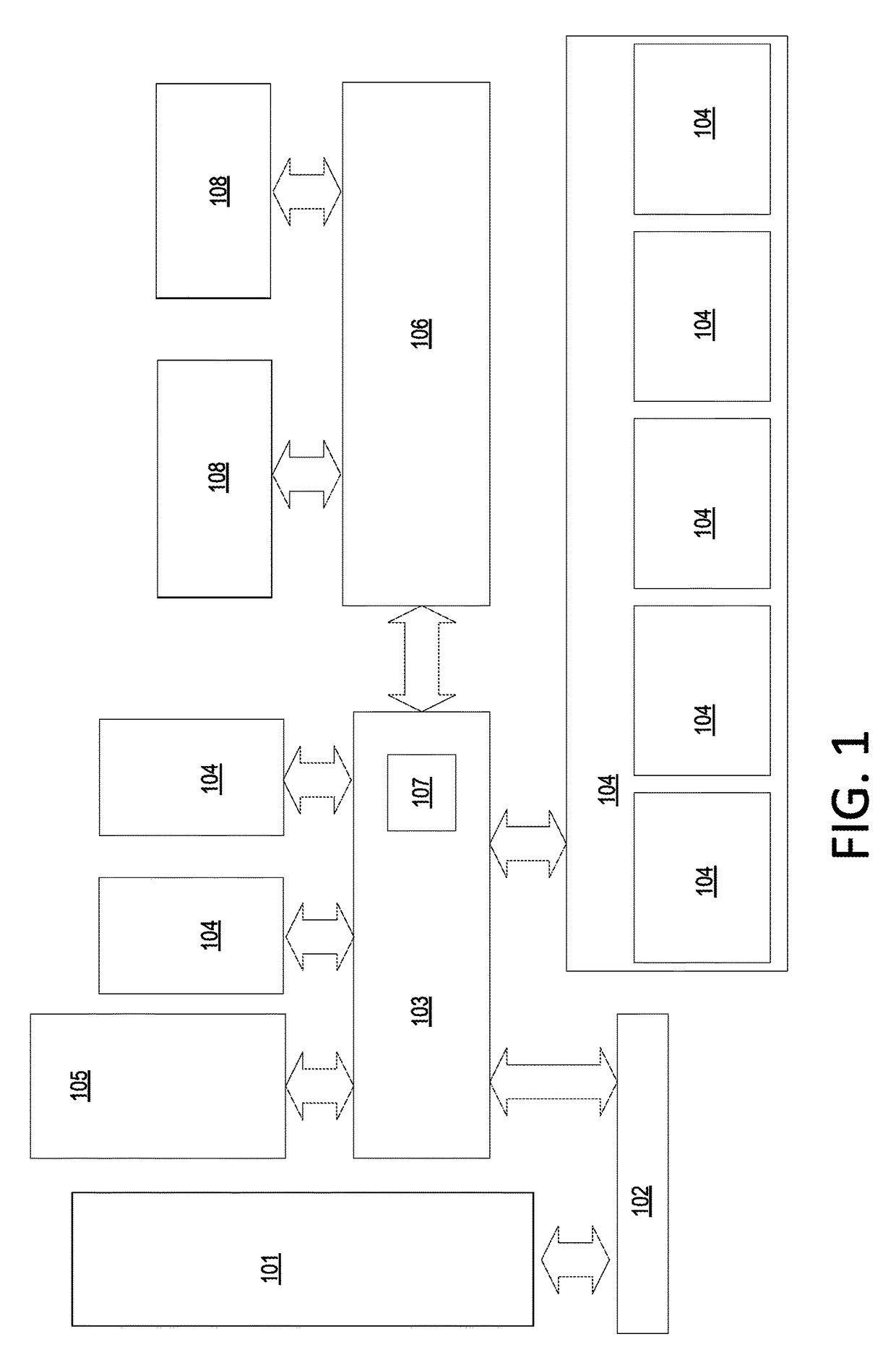

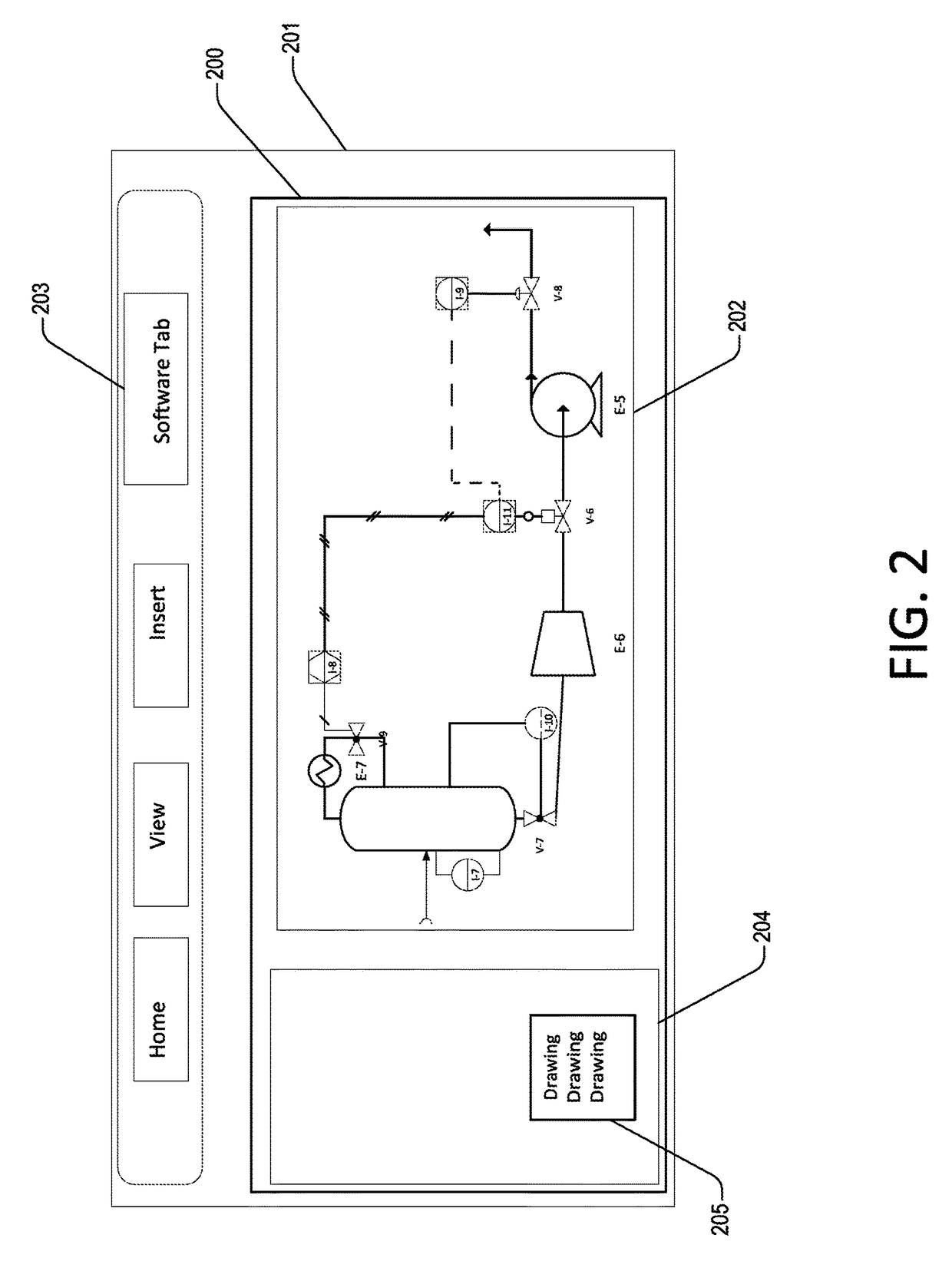

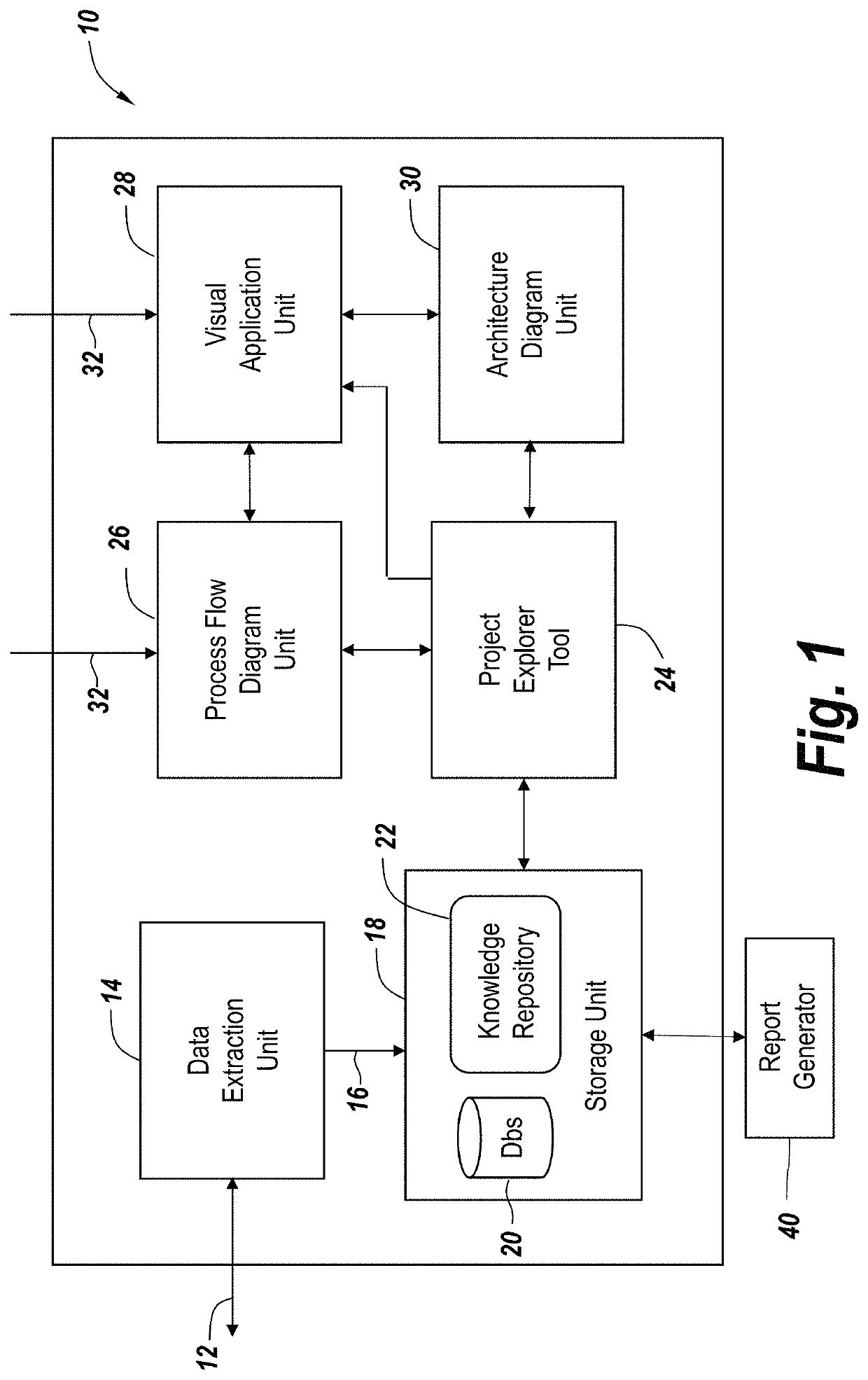

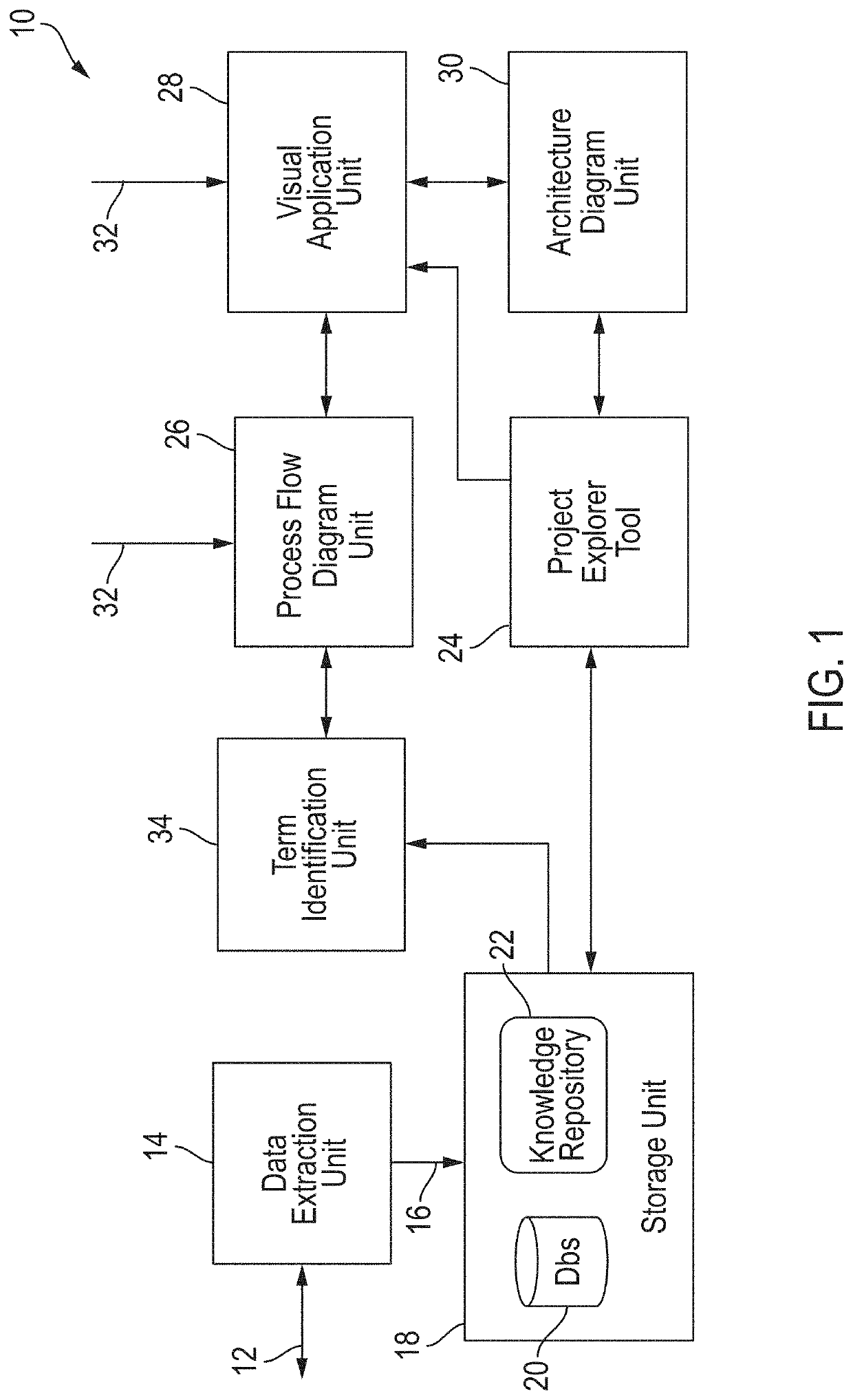

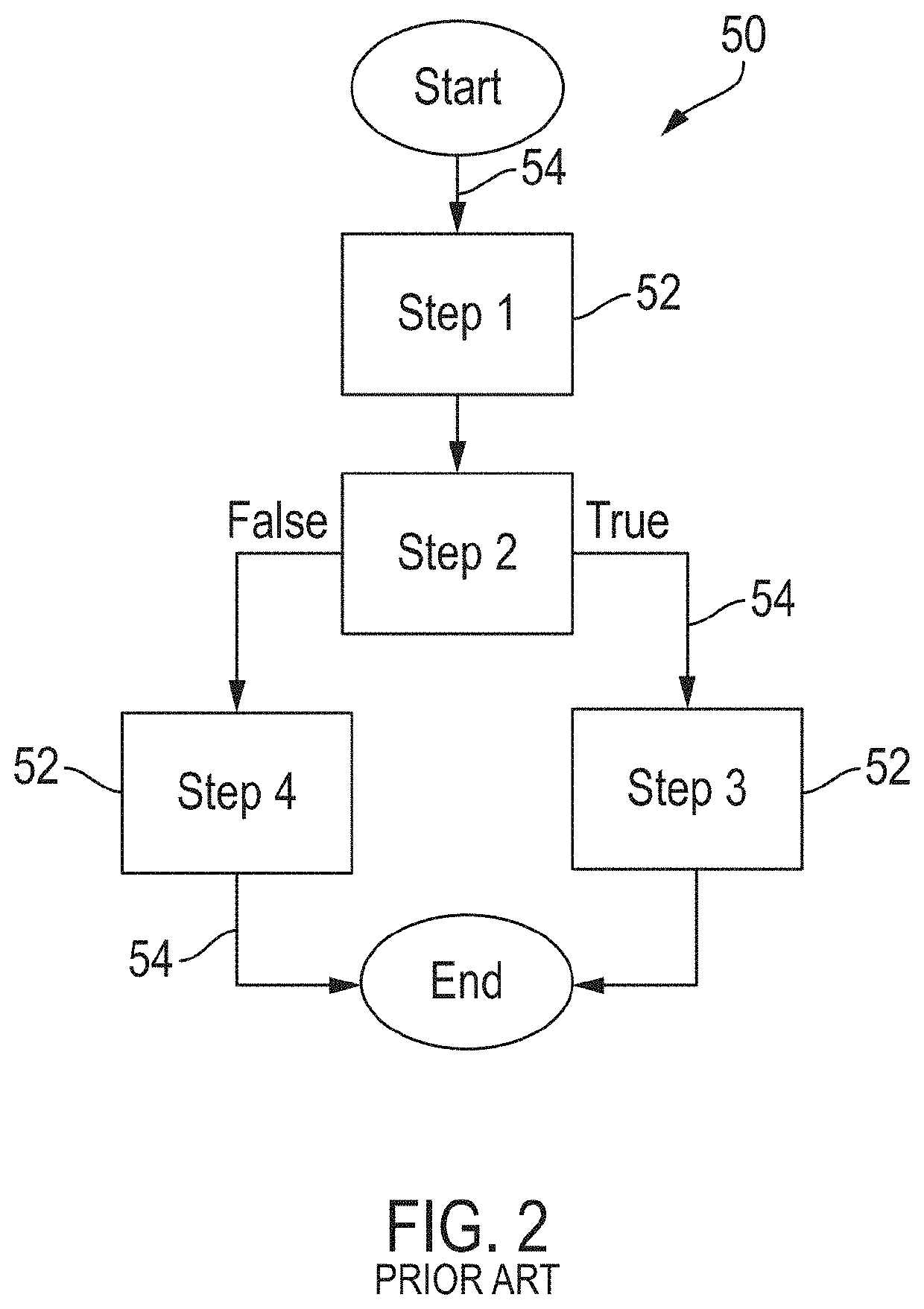

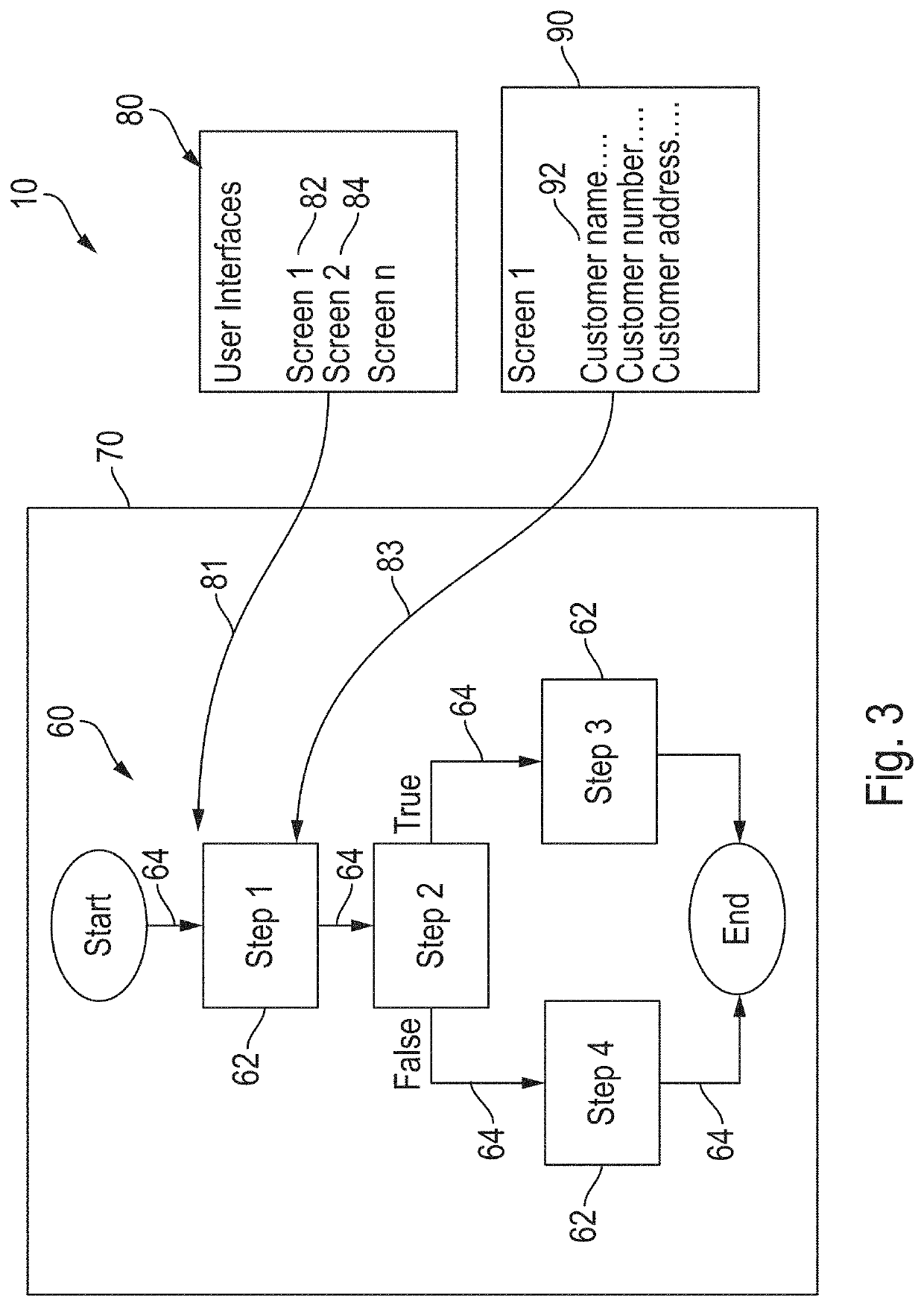

System and method for creating a process flow diagram which incorporates knowledge of business terms

ActiveUS20210241191A1Sure easyOffice automationVisual/graphical programmingSoftware engineeringData mining

A system and method for associating a technical artifact and one or more business terms with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

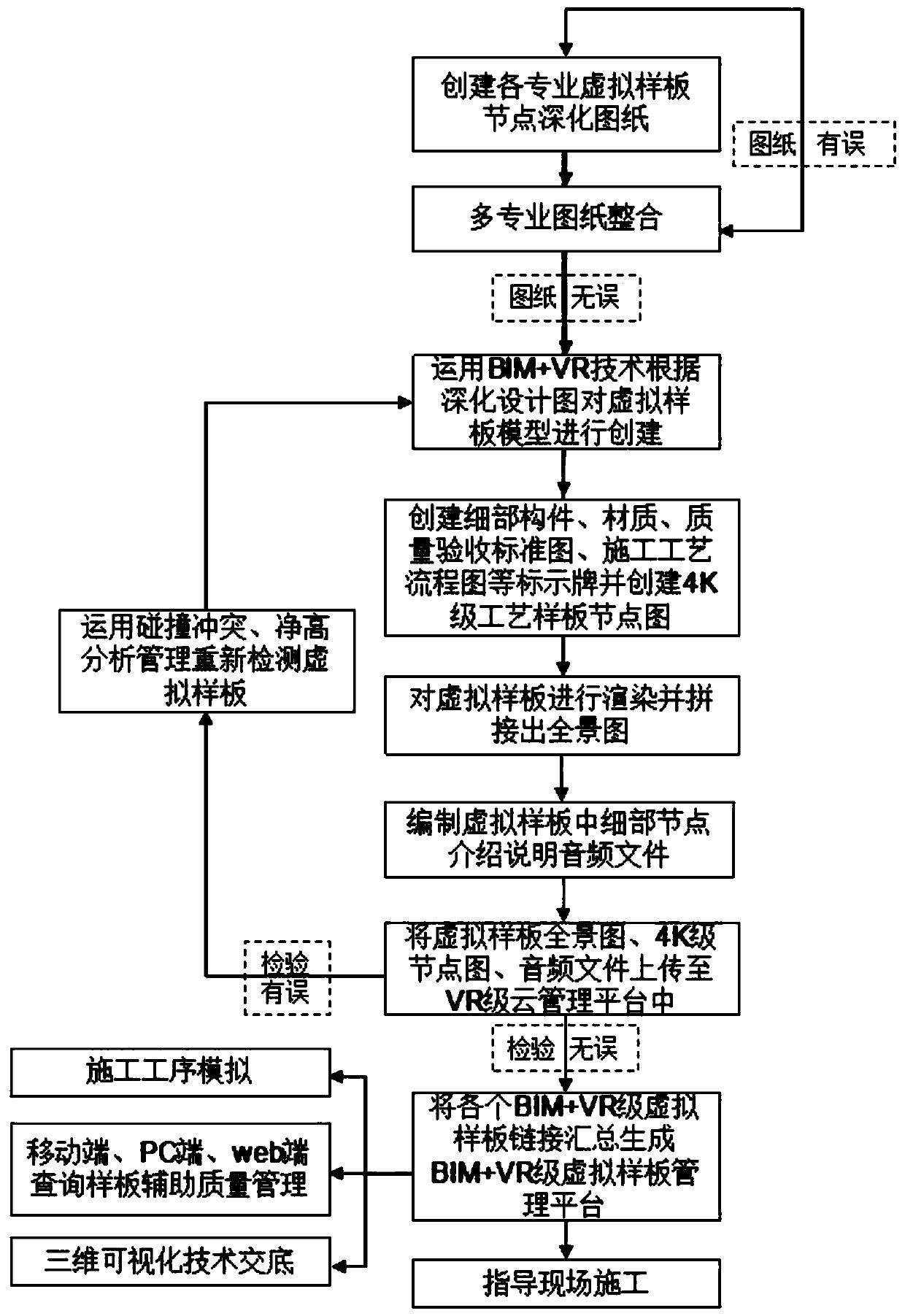

A building construction quality control method based on BIM and VR technologies

PendingCN109583085AIncrease construction costsOvercome the investmentGeometric CADResourcesSocial benefitsQuality control

The invention discloses a building construction quality control method based on BIM and VR technologies. The method comprises the following steps: creating a node deepening graph of each professionalvirtual process sample plate; Creating a visual process sample plate based on the BIM technology; Based on the BIM technology, marking the detail component, the material, the quality acceptance standard diagram and the construction process flow diagram in the virtual process sample plate, and rendering and creating a 4K-level process node diagram; Creating a virtual process sample plate three-dimensional panorama by using a VR technology; Compiling detail node introduction and description audio files in the virtual process template; Uploading the BIM + VR virtual process template drawing and the audio file to a VR-level cloud management platform; Adding a virtual process template construction process introduction audio file into the VR-level cloud management platform; The application of the BIM technology and the VR technology in the virtual process sample plate is realized, the land-saving, material-saving and energy-saving green construction management concept is realized, and the economic benefit and the social benefit are very high.

Owner:中建五局第三建设有限公司

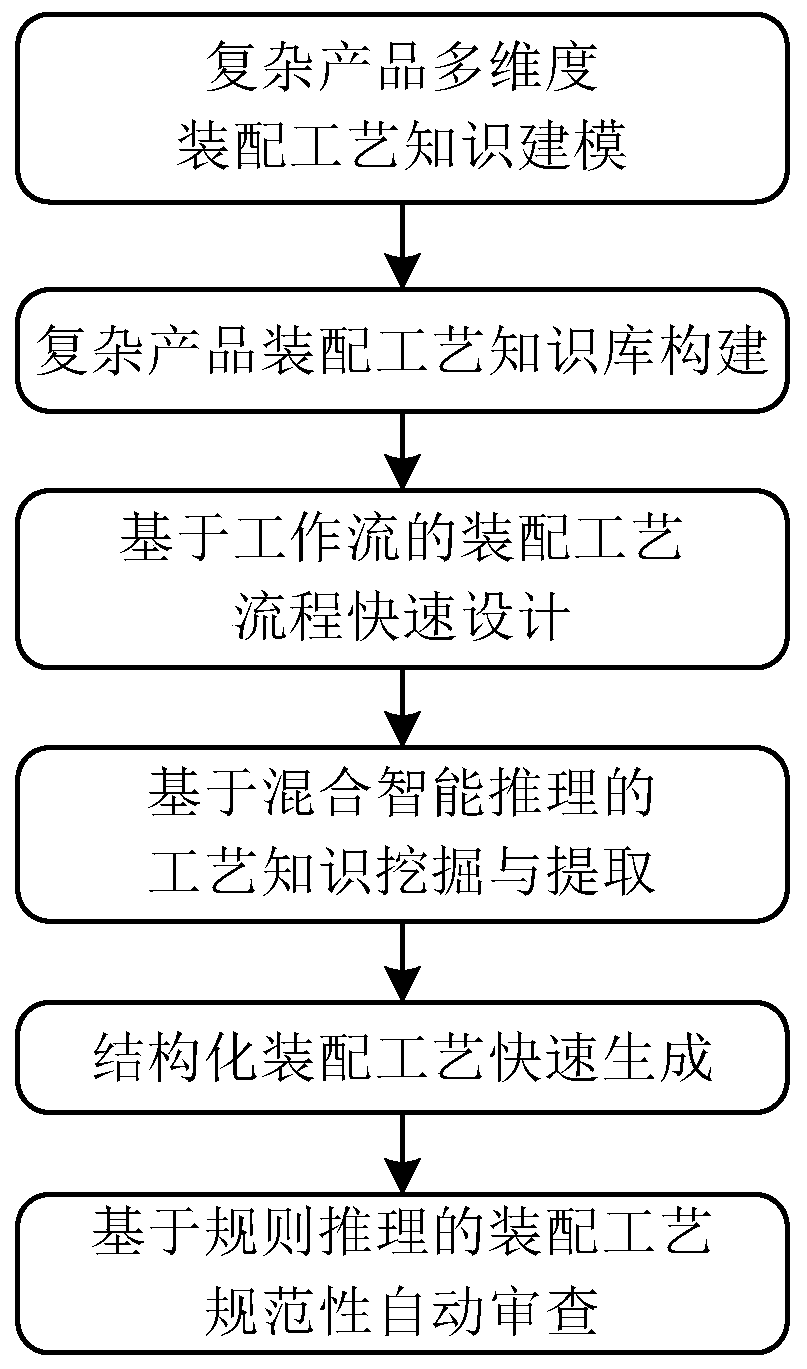

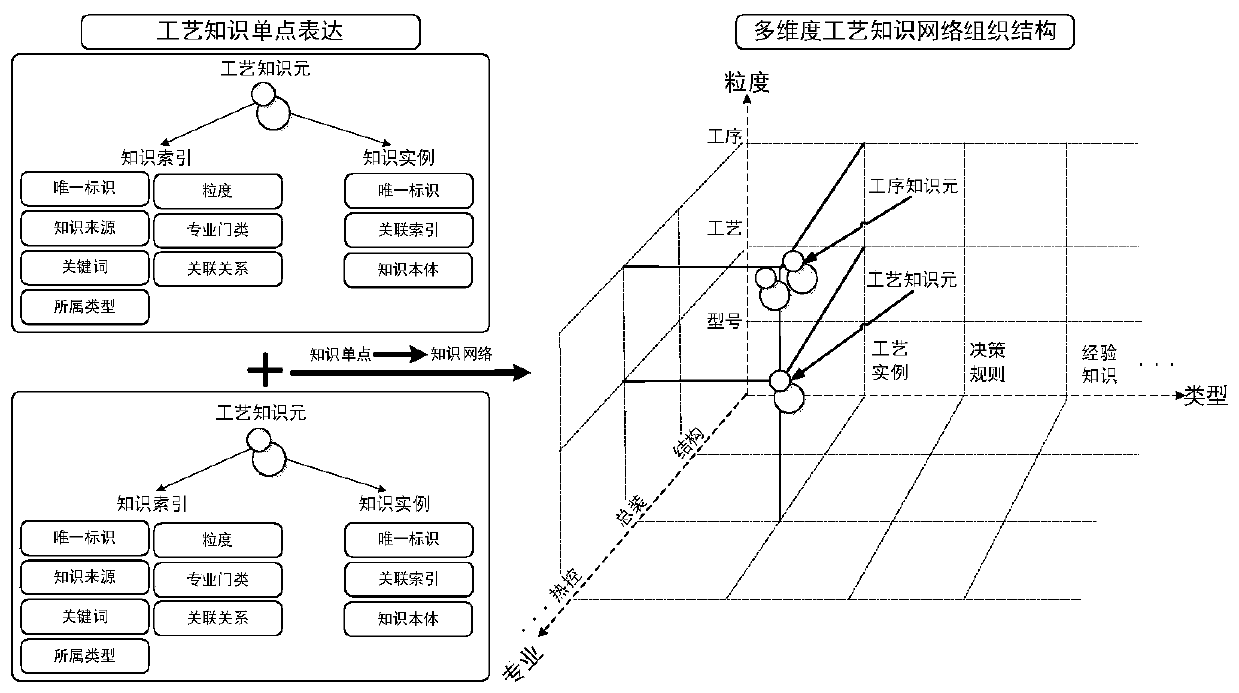

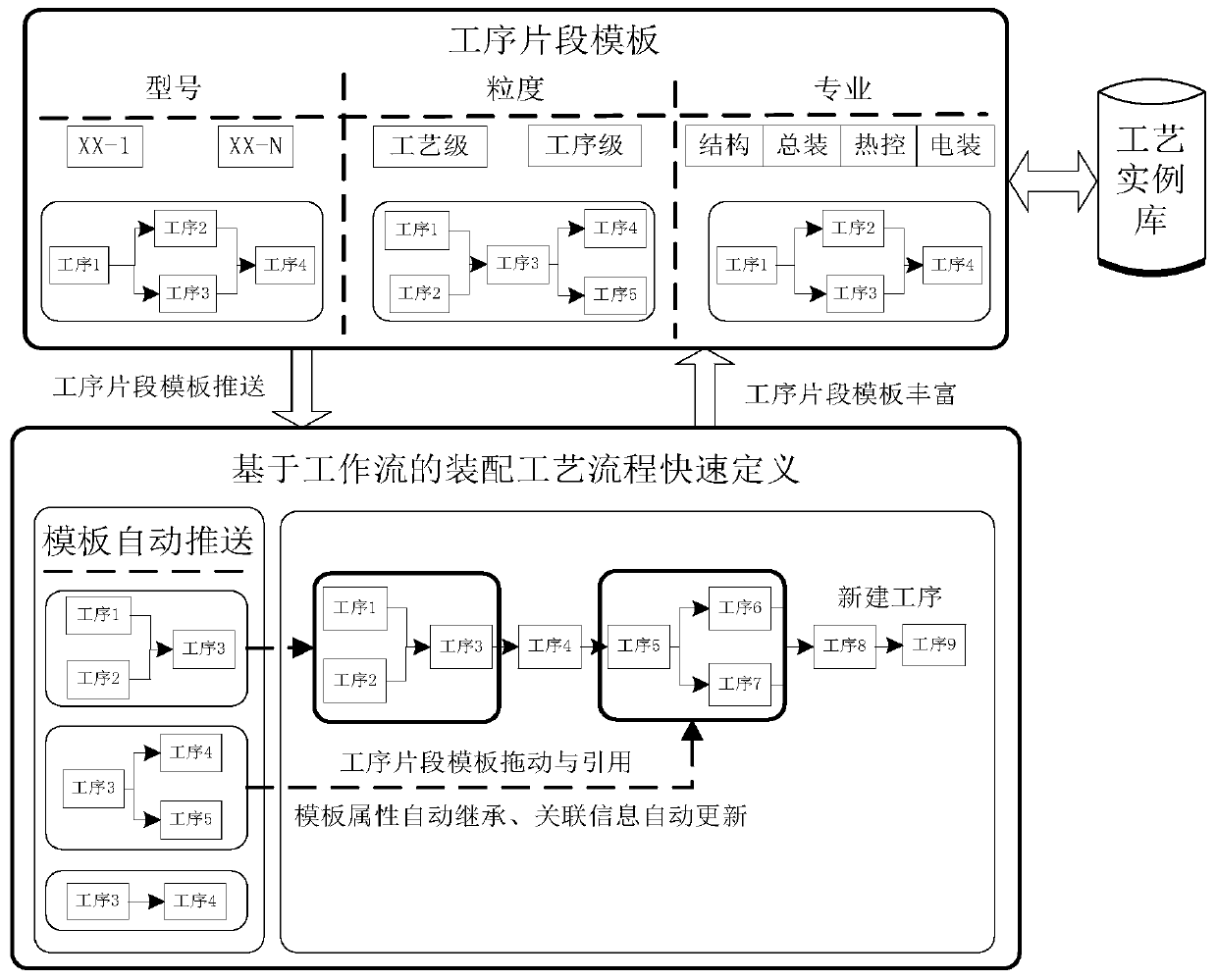

Knowledge-based assembly process design method and system and medium

PendingCN110851499ARapid process designIntelligent assembly process designRelational databasesKnowledge representationProcess engineeringProcess definition

The invention provides a knowledge-based assembly process design method and system and a storage medium. The knowledge-based assembly process design method comprises the following steps: a process knowledge modeling step: constructing an assembly process knowledge model; a process knowledge base building step: building an assembly process knowledge base; a process flow defining step: defining an assembly process flow to obtain an assembly process flow diagram; a process knowledge screening step: screening the assembly process knowledge to obtain an optimal process instance; an assembly processstructuralization step: generating a structuralized assembly process according to the optimal process instance; and a normativity examination step: automatically examining the normativity of the assembly process. Expression, association and storage of a large amount of complex heterogeneous process knowledge are realized, a unified spacecraft assembly process knowledge base is constructed, and knowledge-based rapid process design is supported. Knowledge-based and intelligent assembly process design based on the process flow and knowledge is realized, so that the process design efficiency is greatly improved. The design quality of the process file is effectively ensured.

Owner:SHANGHAI INST OF SATELLITE EQUIP

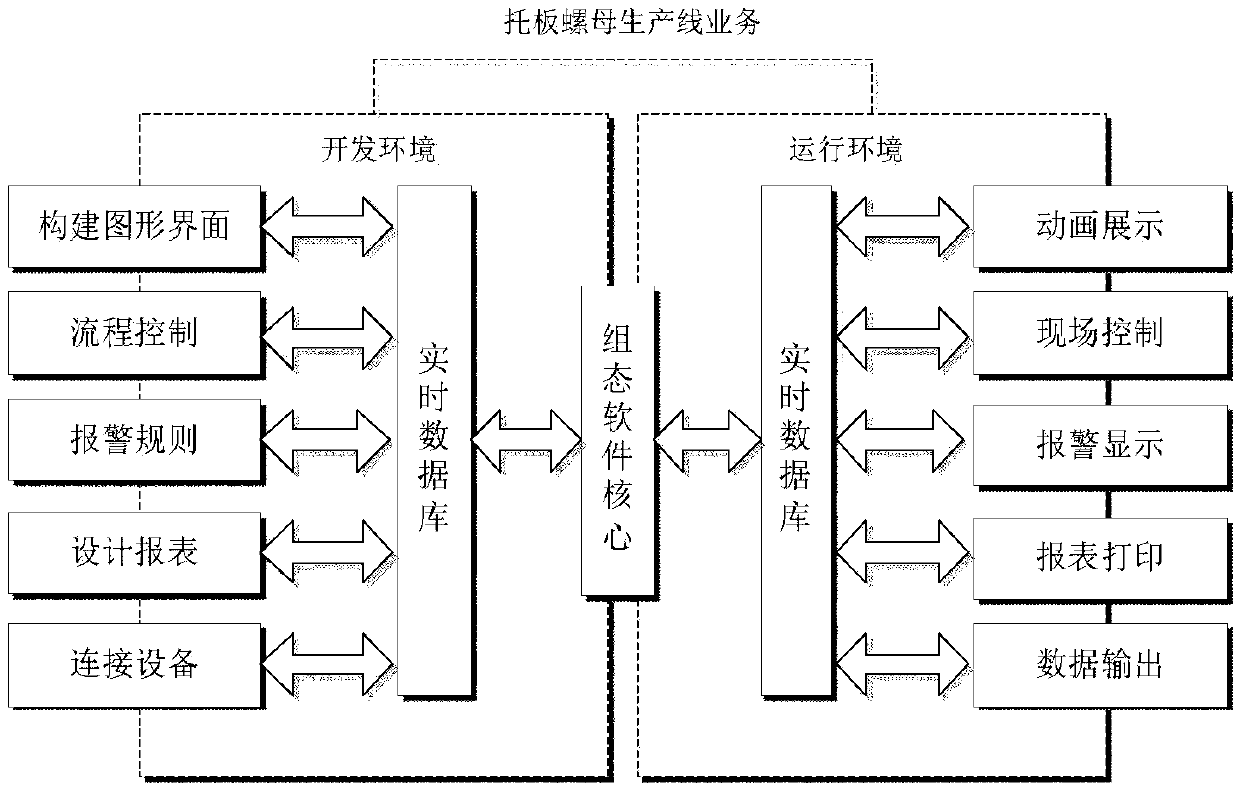

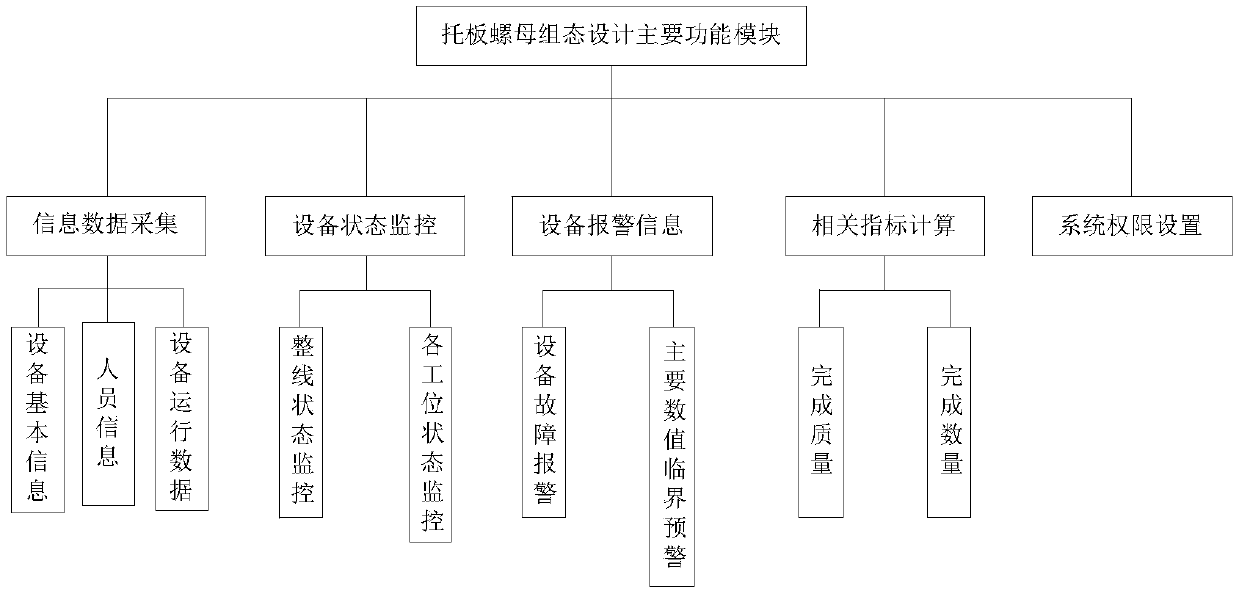

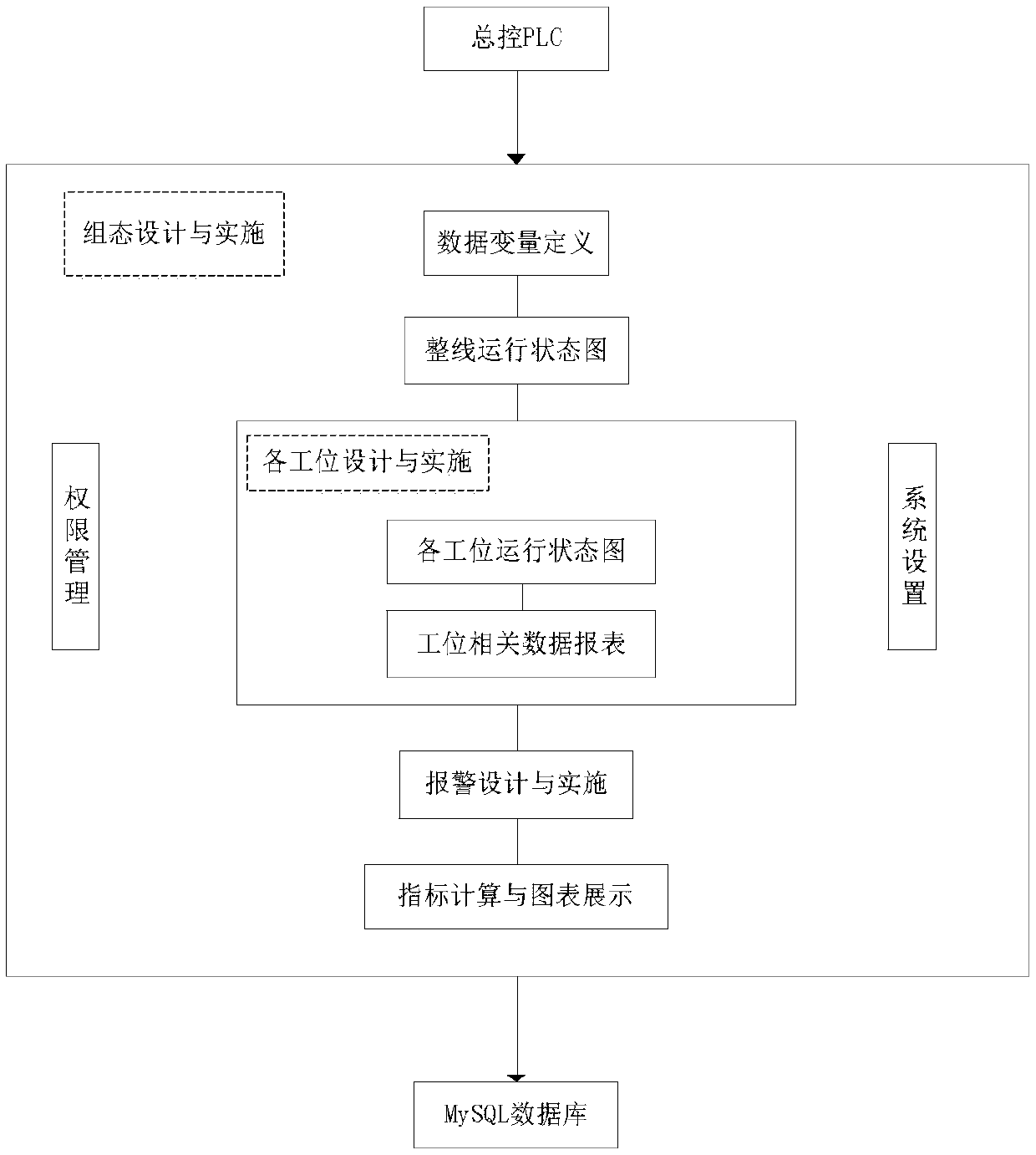

A configuration design method for a supporting plate nut production line

PendingCN109583783AFast emergencyAchieve the goal of personalized configuration monitoring and managementResourcesDatabase modelsProduction lineConfiguration design

The invention discloses a configuration design method of a supporting plate nut production line. The aim of automation of a supporting plate nut production line is achieved. By arranging related application requirements, based on the configuration program, a production process flow chart is designed and displayed for monitoring the state of each station device, automatically alarming and the like,data and reports can be inquired according to time, historical trend chart display of important parameters is supported, numerical values and chart display of important indexes are provided, and finally the data are stored in a designated MySQL database to provide a basis for assistant decision making of managers. Meanwhile, corresponding authority management is set; Development and use personnelare distinguished, a configuration system oriented to a supporting plate nut production line is formed, pictures are clear and interactive, use by users is facilitated, unified storage of equipment-related data and personnel data is achieved, an autonomous alarm function and self-diagnosis of faults are provided, and the users can find equipment abnormity in time and conduct corresponding processing conveniently.

Owner:JIANGXI HONGDU AVIATION IND GRP

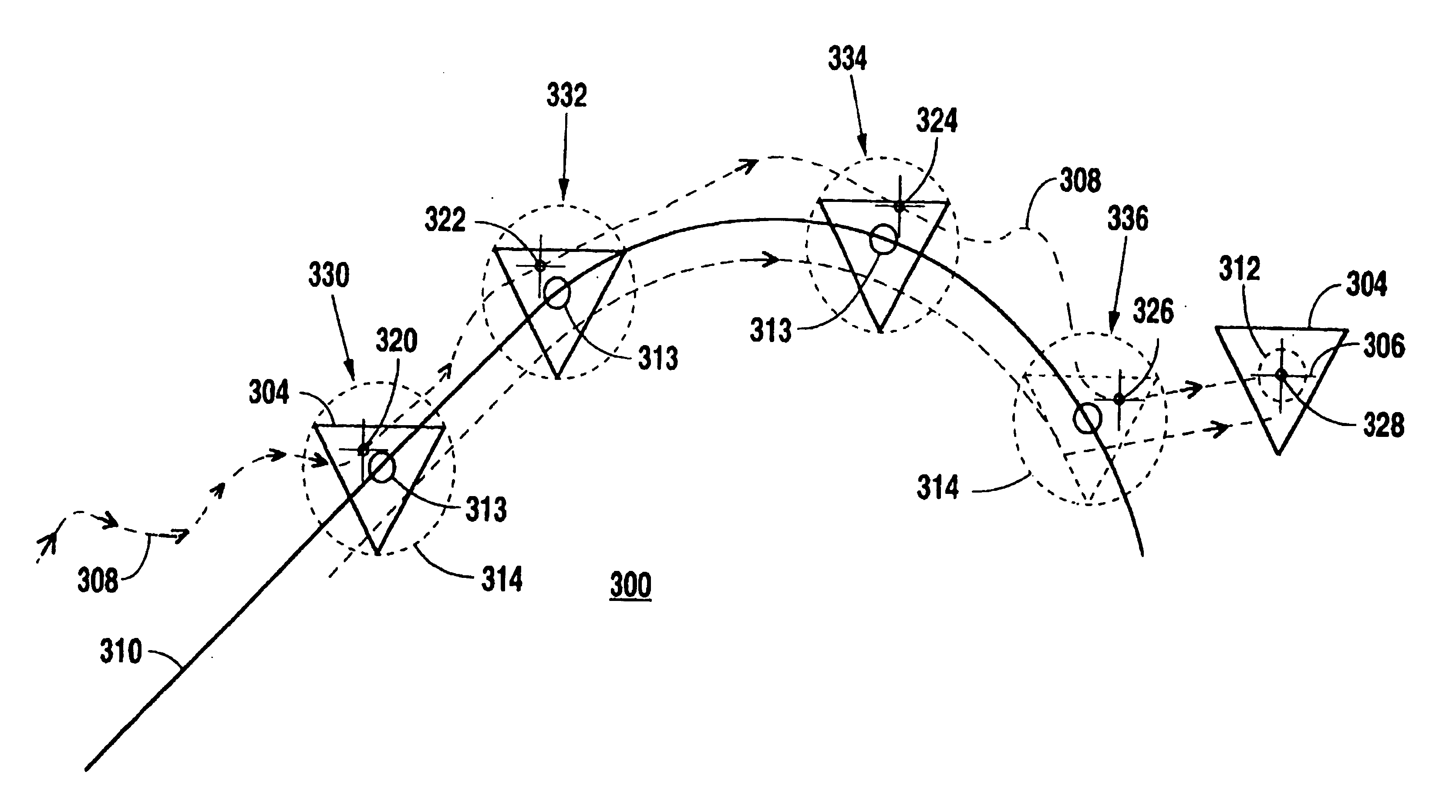

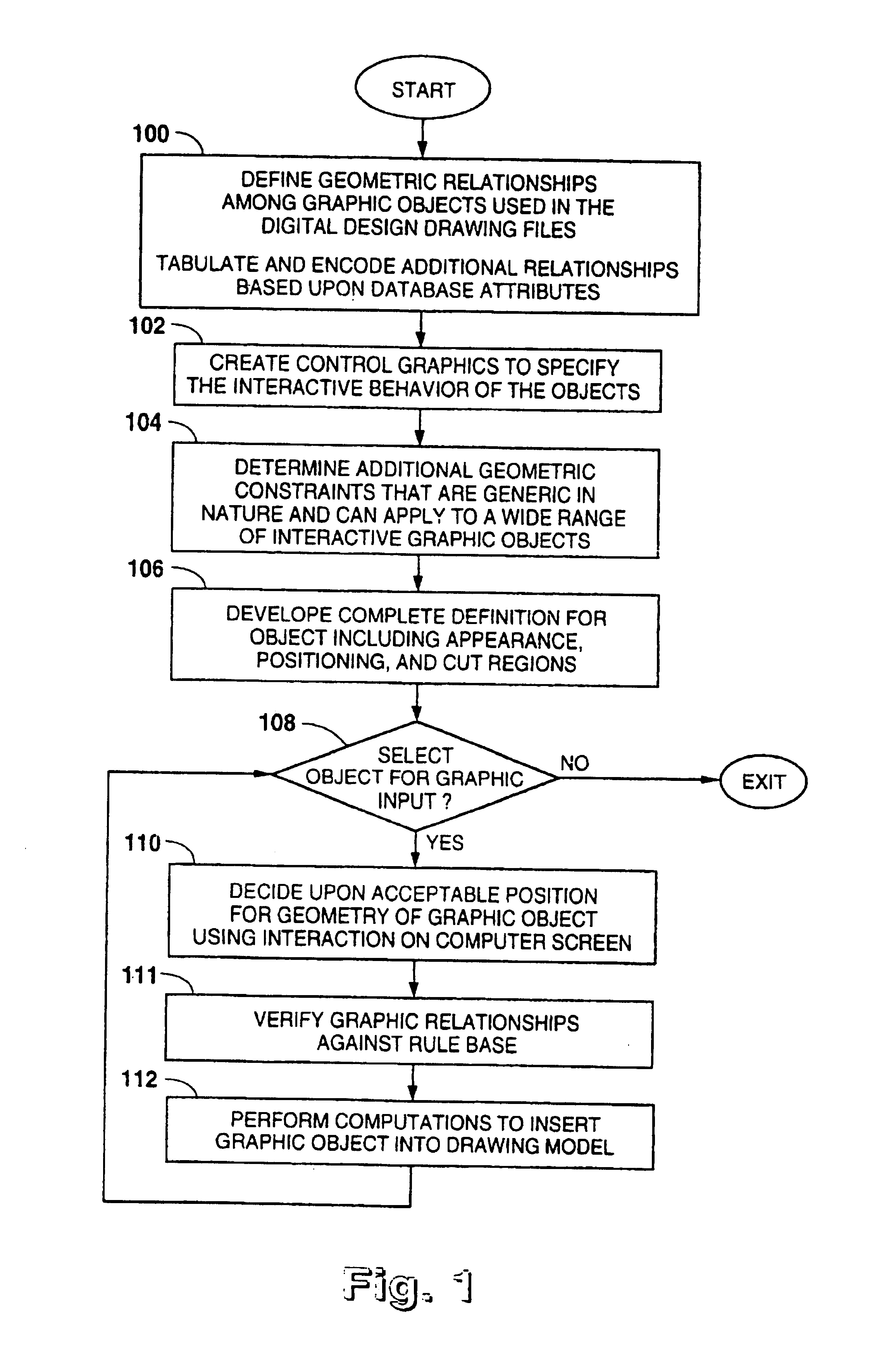

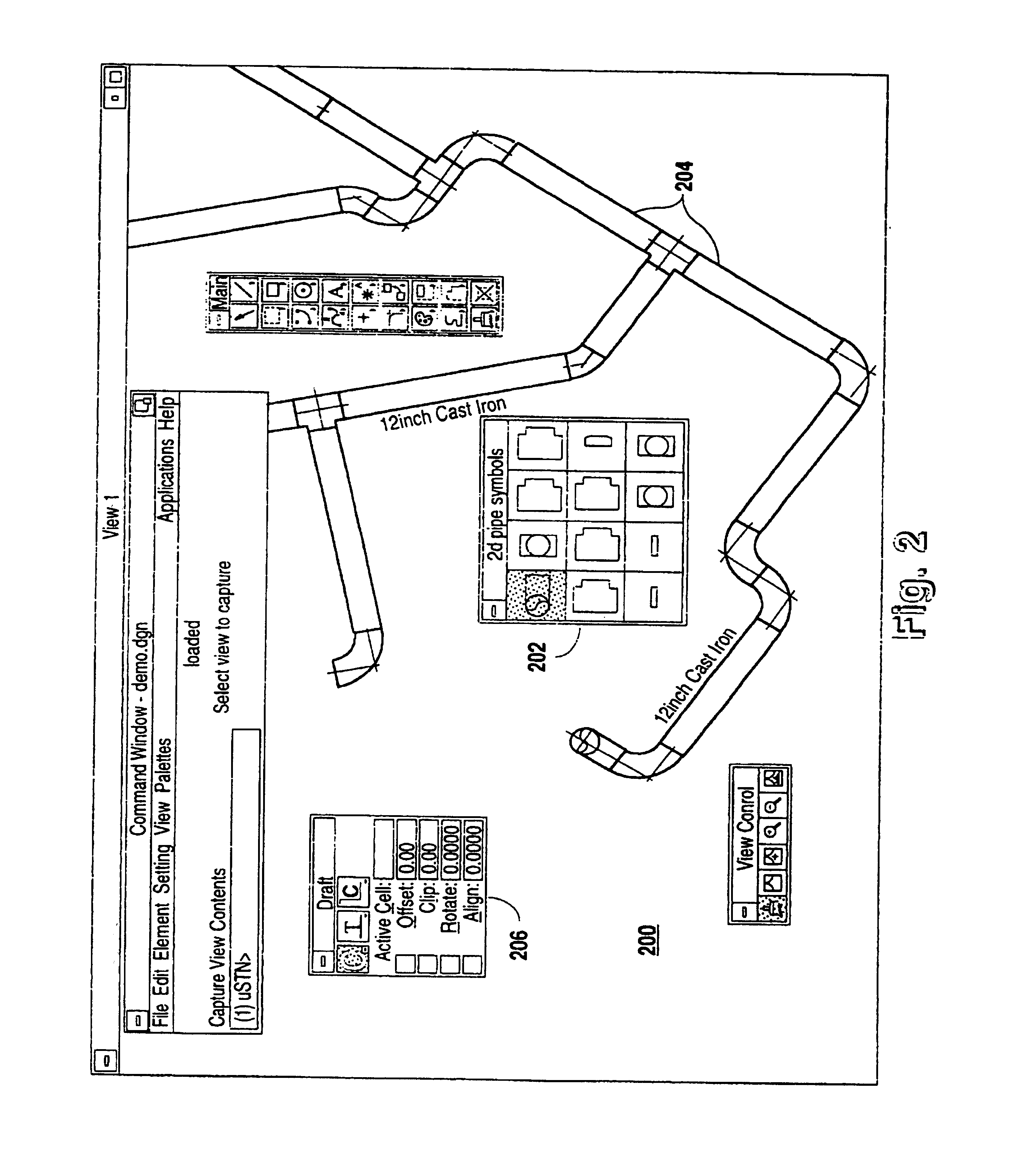

Method and apparatus for interactively manipulating and displaying presumptive relationships between graphic objects

InactiveUSRE39950E1Rapid productionAssembly precisionCathode-ray tube indicatorsImage data processingGraphicsComputer Aided Design

Owner:AUTODESK INC

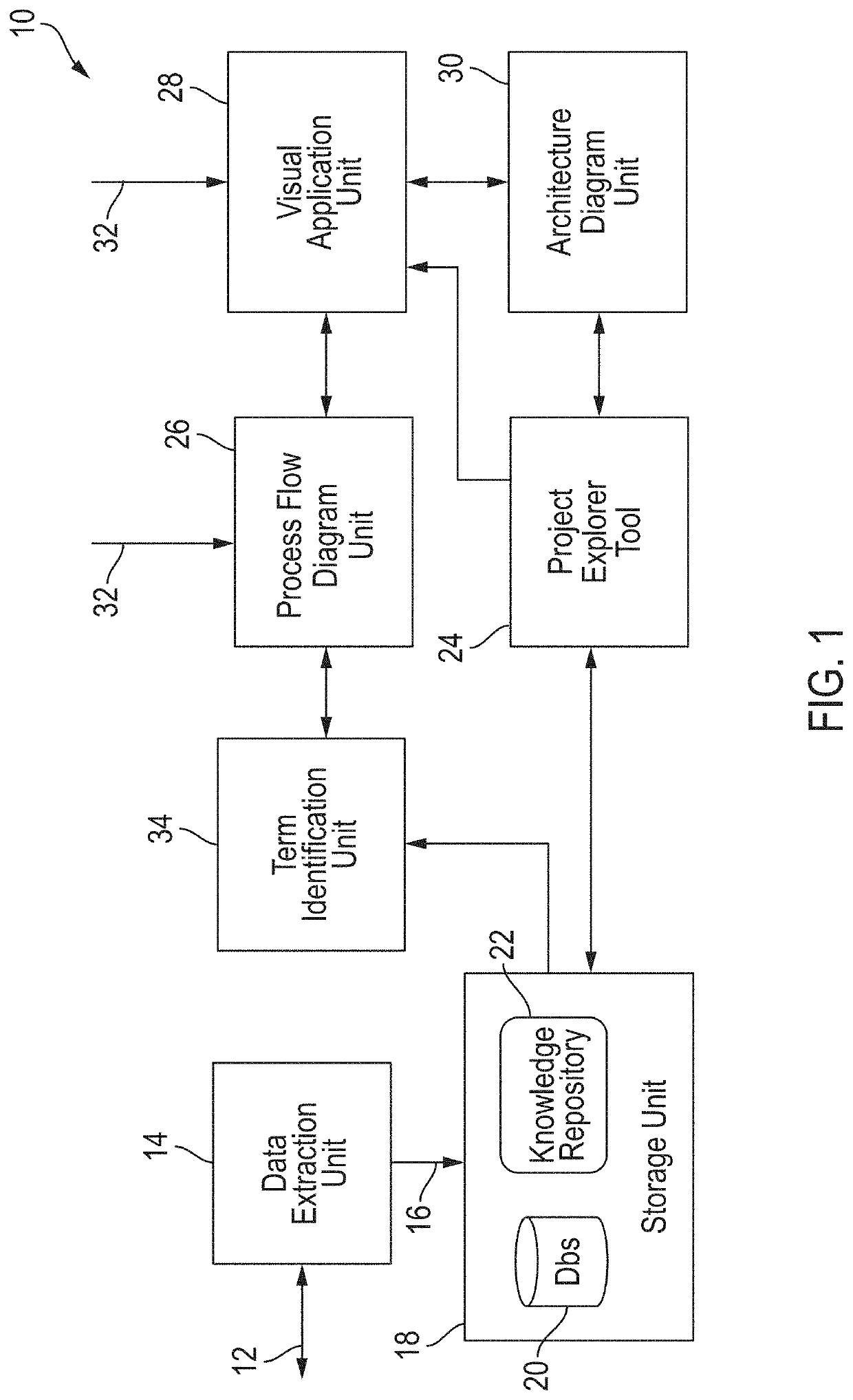

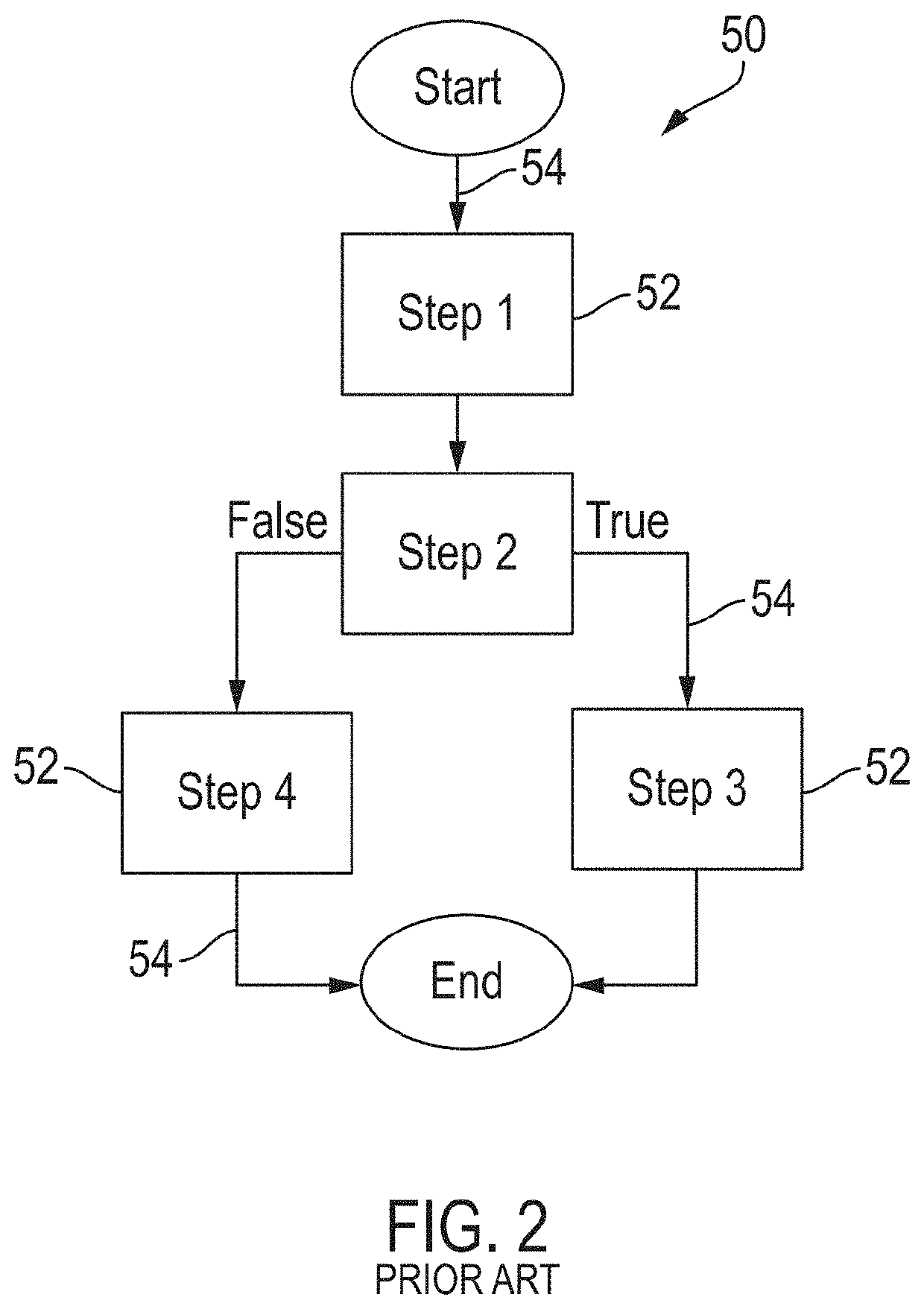

System and method for creating a process flow diagram which incorporates knowledge of business rules

ActiveUS20210240449A1Sure easyDatabase management systemsSoftware designSoftware engineeringData mining

A system and method for associating a technical artifact and one or more business rules with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

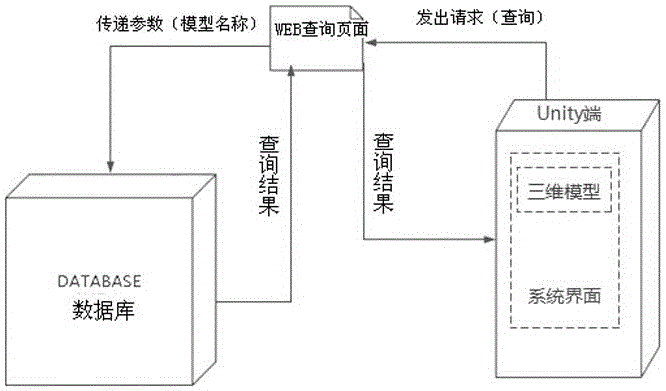

Three-dimensional in-station pipe network and device information three-dimensional display method for unite station

InactiveCN106095840ASolve the problem of equipment information displayReduce training timeWebsite content managementSpecial data processing applicationsPoint cloudData acquisition

The invention discloses a three-dimensional in-station pipe network and device information three-dimensional display method for a unite station. The method comprises the steps of performing data acquisition and arrangement on the unite station once, enabling outdoor workers to carry a professional camera and a three-dimensional laser scanning device, performing non-contact scanning measurement and shooting on supported pipelines of the unite station under the cooperation of oil field unity station technicists, and making sure underground pipeline directions by utilizing pipeline marks and a process flow diagram and querying an oil field worker; performing supported pipeline modeling according to scanned point cloud by utilizing 3D MAX software, and then importing a pipeline model into unity 3D to realize pipeline information display; and finally publishing the unity 3D on a webpage to realize online access. The method has the beneficial effects that three-dimensional in-station pipeline and device three-dimensional display of the unite station is realized through a Unity 3D engine, database access is realized through mouse click event triggering, and pipeline information is displayed on a screen, so that the difficult problem in device information display in the past is solved.

Owner:SHANDONG TIANYUAN INFORMATION TECHNOLOGY CO LTD

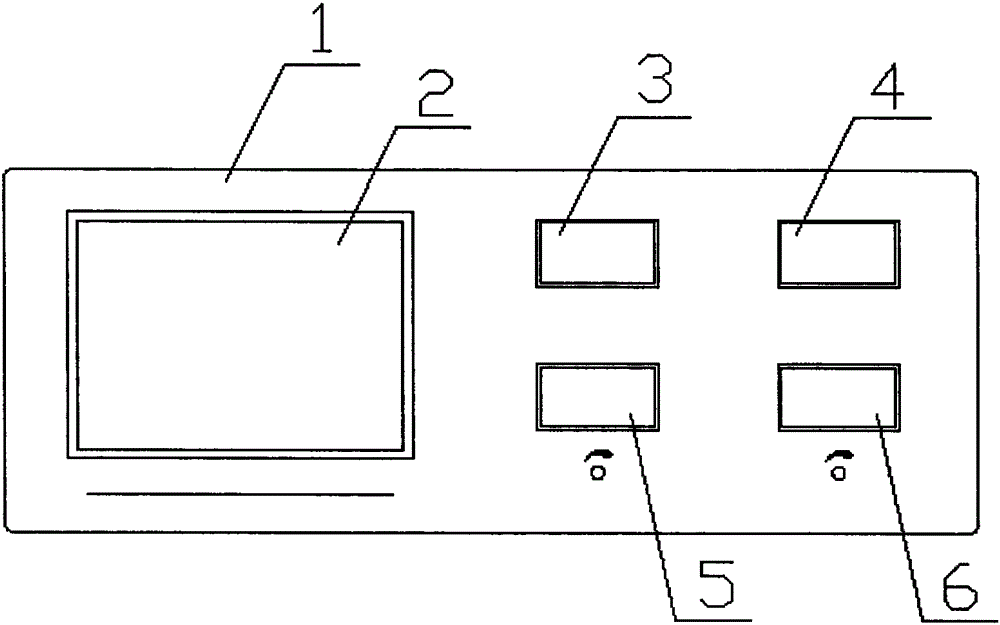

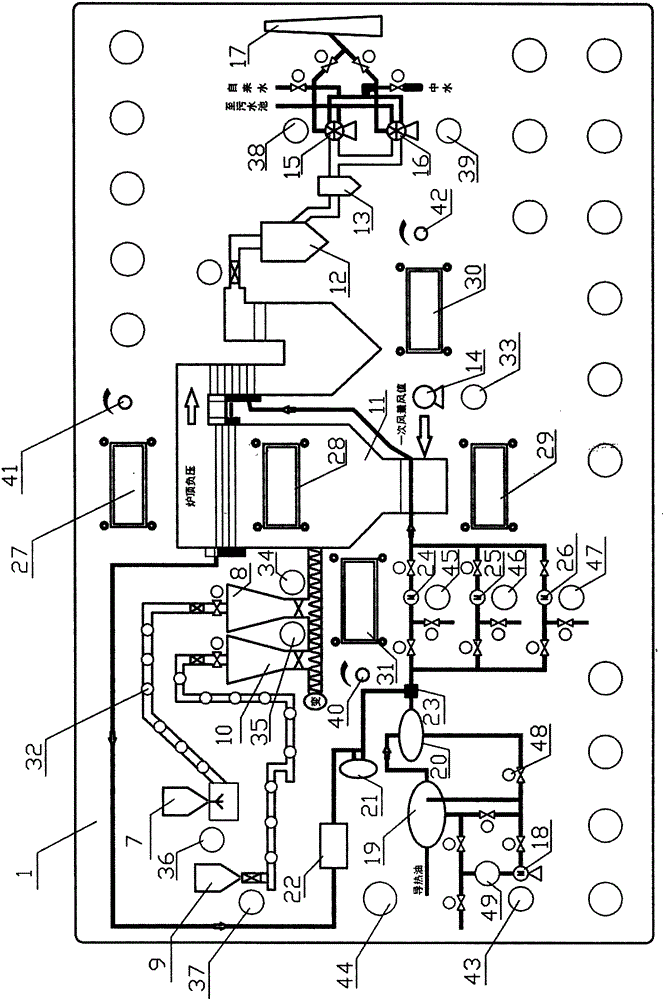

Practical training operating platform for sludge incinerator in sewage treatment plant

ActiveCN105096684AAvoid security issuesHigh technology contentCosmonautic condition simulationsSimulatorsElectricitySludge

The invention discloses a practical training operating platform for a sludge incinerator in a sewage treatment plant. The practical training operating platform comprises a bottom plate and a controller running practical training management software, wherein a touch screen, a material layer pressure difference simulation display meter, a top negative pressure simulation display meter, a draught fan A value simulation display meter and a draught fan B value simulation display meter which are electrically connected with the controller are embedded into the upper part of the front side of the bottom plate; a process flow diagram of the incinerator is drawn at the lower part of the front side of the bottom plate, and a digital display meter, an operating button, a tuning button and a simulation pipeline indicating lamp which are electrically connected with the controller are embedded into the lower part of the front side of the bottom plate; and the controller is arranged on the back of the bottom plate. During practical training operation of a trainee, the operation steps of the trainee are automatically recorded into the software system, and after the operation is completed and a submission button is clicked, all the operation steps of the trainee are automatically displayed on the system interface of the touch screen and compared with an answer database to automatically obtain a practical training result. The practical training operating platform is suitable for teaching and examination of sludge incinerator operation.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

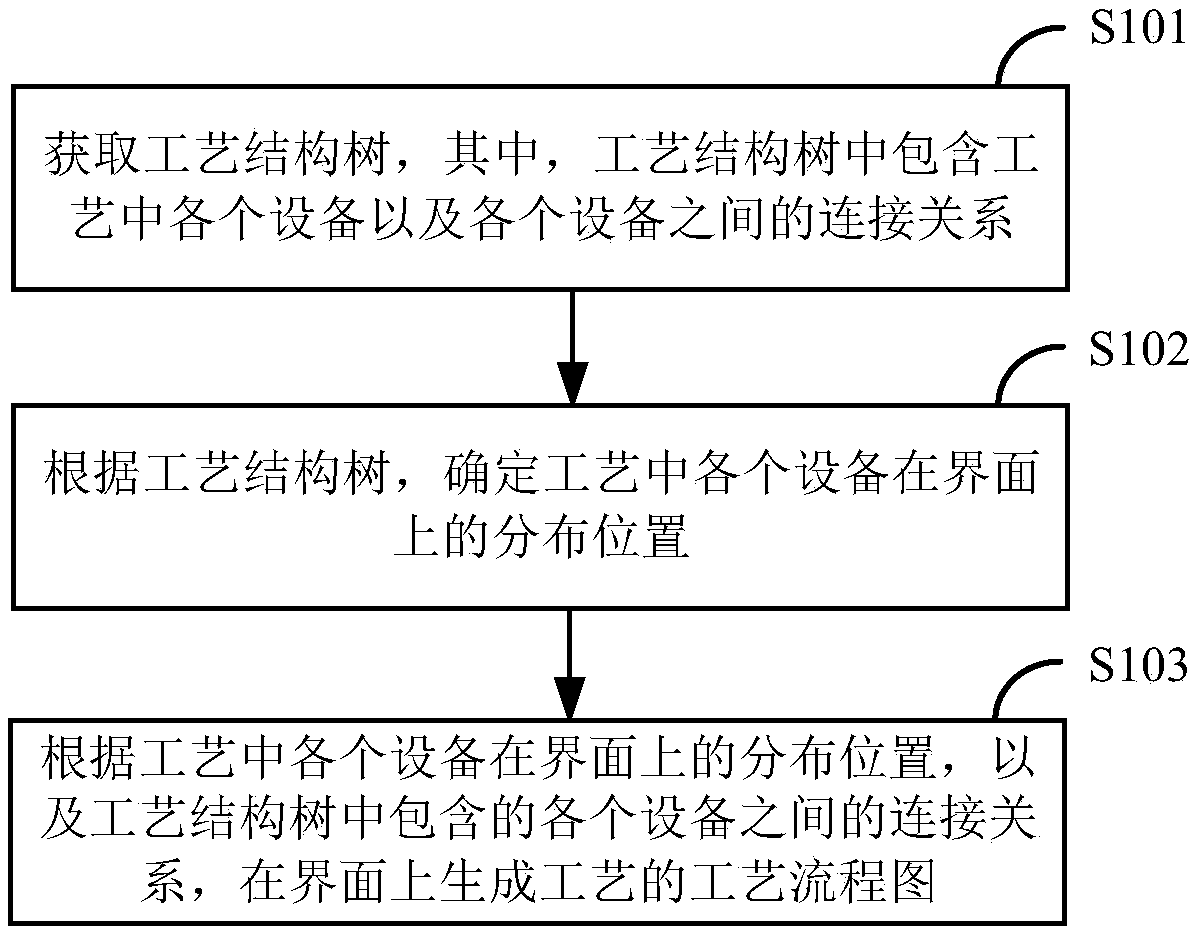

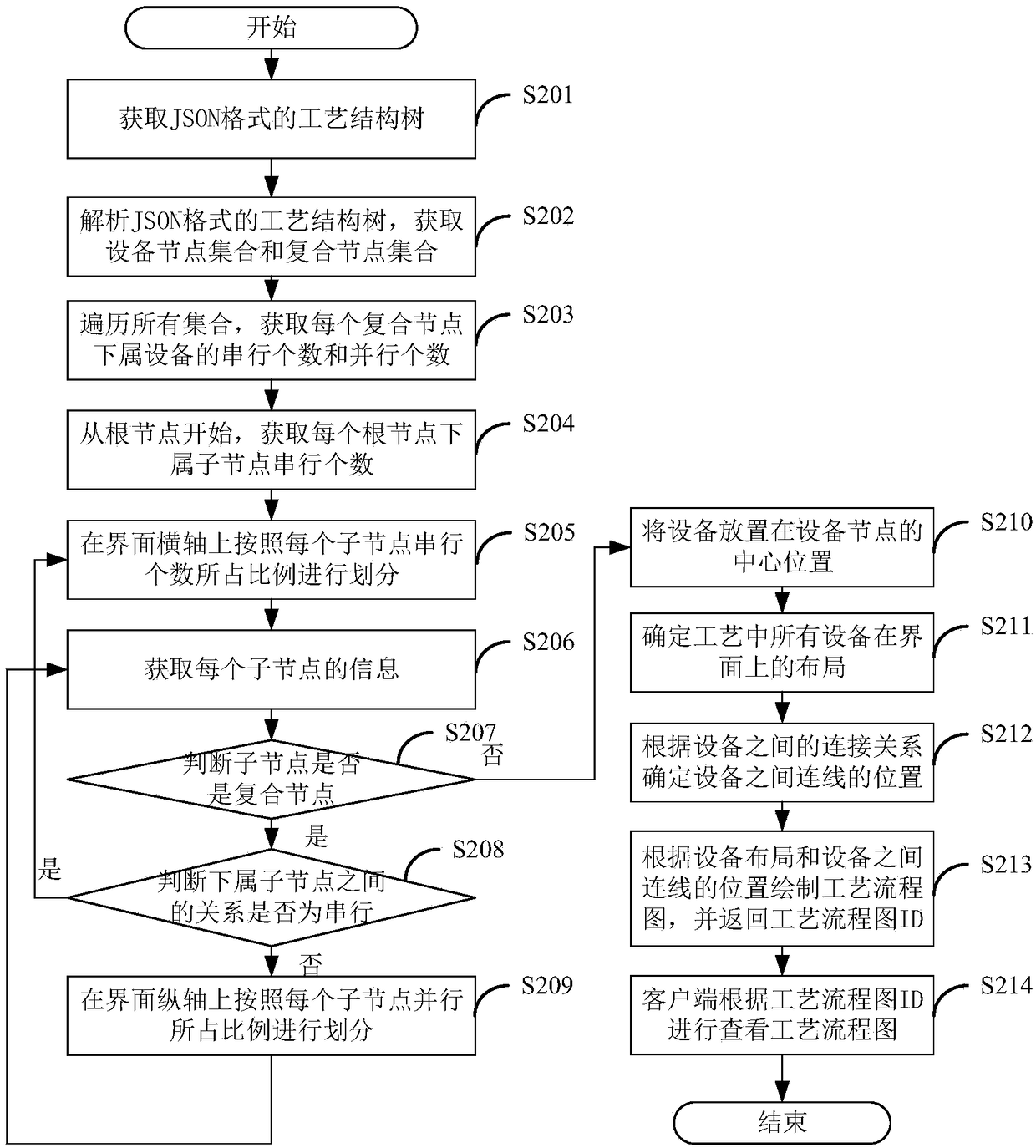

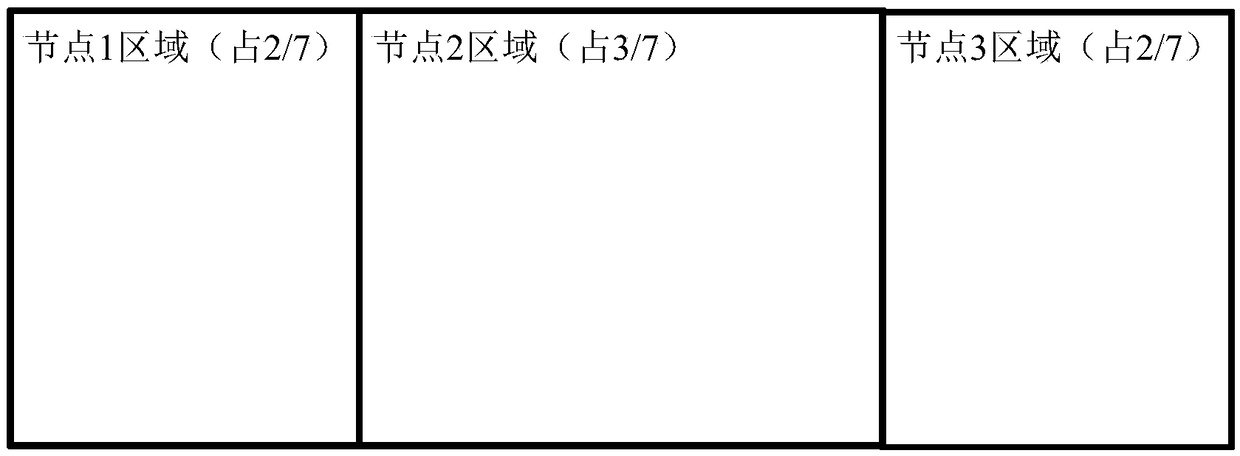

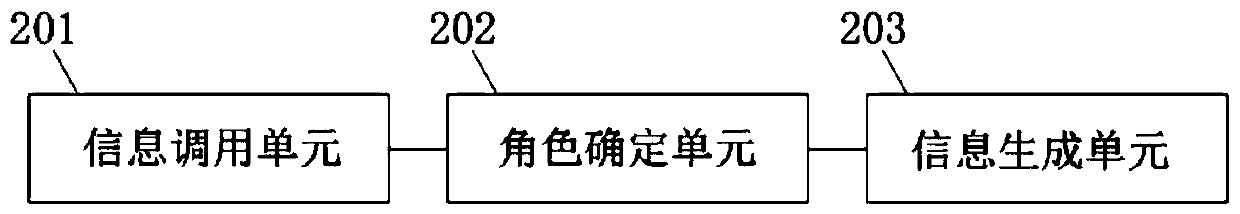

Method and device for generating process flow diagram

PendingCN109190326AImprove drawing efficiencyImprove accuracyComputer aided designSpecial data processing applicationsSoftware engineeringProcess flowsheeting

The invention discloses a method and a device for generating a process flow diagram. The method comprises the following steps: obtaining a process structure tree, wherein, the process structure tree comprises each device in the process and a connection relationship among the devices; according to the process structure tree, determining the distribution position of each device in the process on theinterface. According to the distribution position of each device in the process interface and the connection relationship between each device contained in the process structure tree, the process flowchart of the process is generated on the interface. The invention can automatically generate a process flow diagram according to the process structure tree, thereby improving the drawing efficiency of the process flow diagram and the accuracy of the drawing result.

Owner:NANJING XINLIAN ENERGY CLOUD SERVICES CO LTD

Mobile APP Cooperative Office System

PendingCN109377190AImprove management efficiencyImprove mobile office efficiencyOffice automationMobile appsComputer terminal

The invention discloses a mobile APP collaborative office system, which comprises a mobile terminal office system and a remote collaborative office platform system. The mobile terminal office system is connected with the remote collaborative office platform system. A mobile terminal office system comprises a mobile approval component module, It is used to query all the functions of to-do, done, finished, cc, approval process, initiating process, forwarding process, viewing process flow log and process flow diagram at any time. The mobile approval component module uses fragmentation time to complete important process approval, and the data of process is synchronized with the web end The invention improves the efficiency of the enterprise mobile office and reduces the management cost of theenterprise mobile office.

Owner:湖北宏石科技股份有限公司

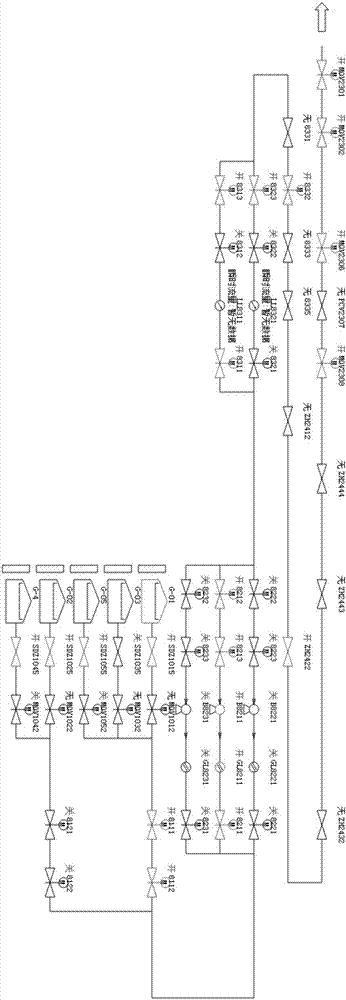

Online configuration method for gas station SCADA system process flow diagrams

ActiveCN105959157AReduce duplication of workReduce workloadData switching networksTotal factory controlSCADAFlow sheet

The invention provides an online configuration method for gas station SCADA system process flow diagrams. The method comprises the following steps: S1, drawing process flow diagram templates for various station types, and initializing the templates in a company level data storage server; S2, during station level process flow diagram configurations, according to a corresponding template file acquired by each gas station type, carrying out S3 when the actual process flow of each station is identical to the corresponding template, and carrying out S4 when the actual process flow of each station is different from the corresponding template; S3, saving the acquired corresponding template file in a station level data storage server to complete station level configurations; and S4, carrying out operations on the corresponding process flow diagram template file according to the actual situations of each gas station to complete the station level configurations, saving each updated process flow diagram in the station level data storage server of the corresponding station, uploading each updated process flow diagram in a real time manner to the company level data storage server for storage through the WCF / TCP communication mode, and releasing received data on the Ethernet through the WEB page mode. The method provided by the invention can greatly reduce the workload and cost.

Owner:中国石化销售股份有限公司 +2

System and method for creating a process flow diagram which incorporates knowledge of the technical implementations of flow nodes

A system and method for associating a technical artifact with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

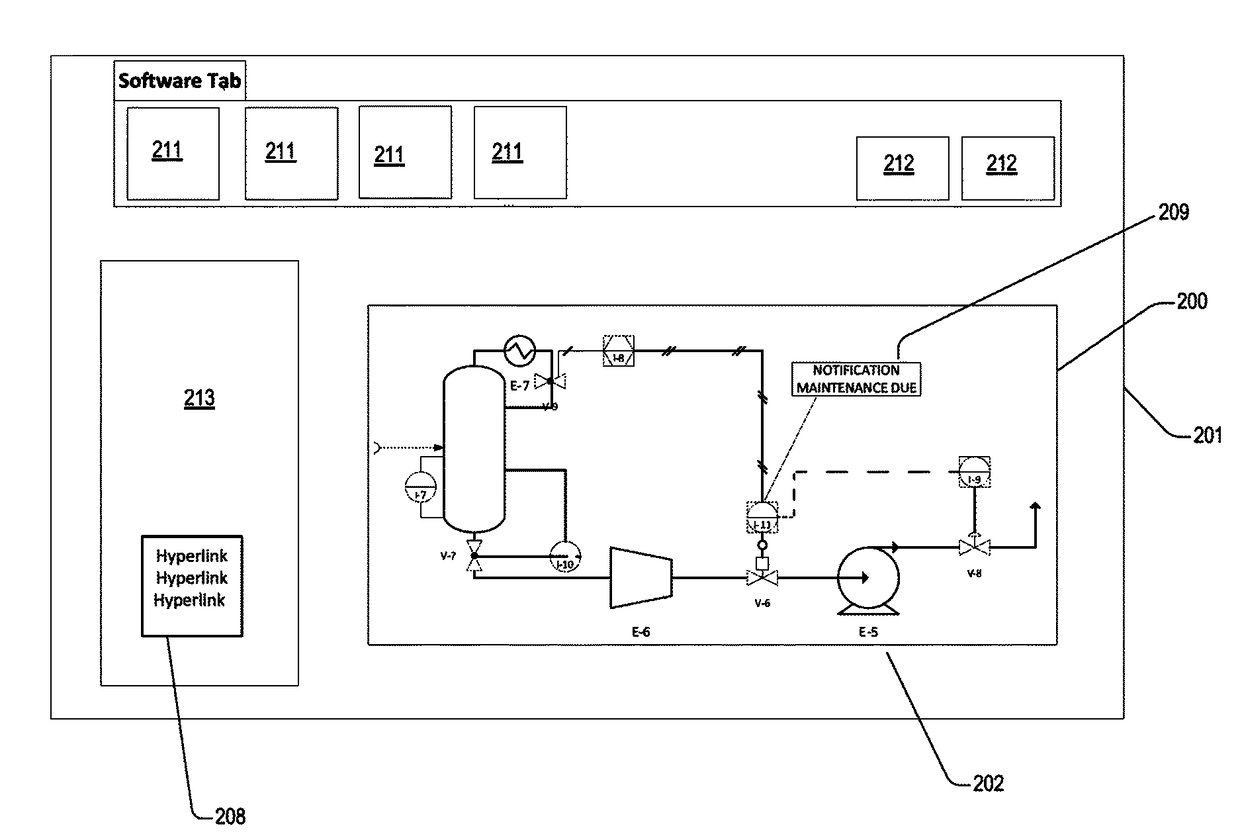

Graphical user interface systems and methods for data integration with data-driven engineering drawings

ActiveUS9811251B2Database management systemsSpecial data processing applicationsData systemUser interface

Described is a system and methodology, in which information is exchanged and / or updated within data-driven engineering schematics and various data management systems within an operating facility. The integration of plant data management systems with data-driven engineering schematics, such as piping and instrumentation diagram (P&ID), process flow diagrams (PFDs) and isometric drawings is an innovation that provides numerous benefits to multiple plant disciplines, including but not limited to Engineering, Operations, Maintenance, Procurement, Environmental, and Safety personnel. In addition to data exchange, described methods and systems within the graphical user interface are capable of generating alerts and initiating to changes to resolve data inconsistencies for a particular component represented in two or more data systems.

Owner:ENVIRONMENTAL INTELLECT INC

System and method for creating a process flow diagram which incorporates knowledge of the technical implementations of flow nodes

A system and method for associating a technical artifact with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

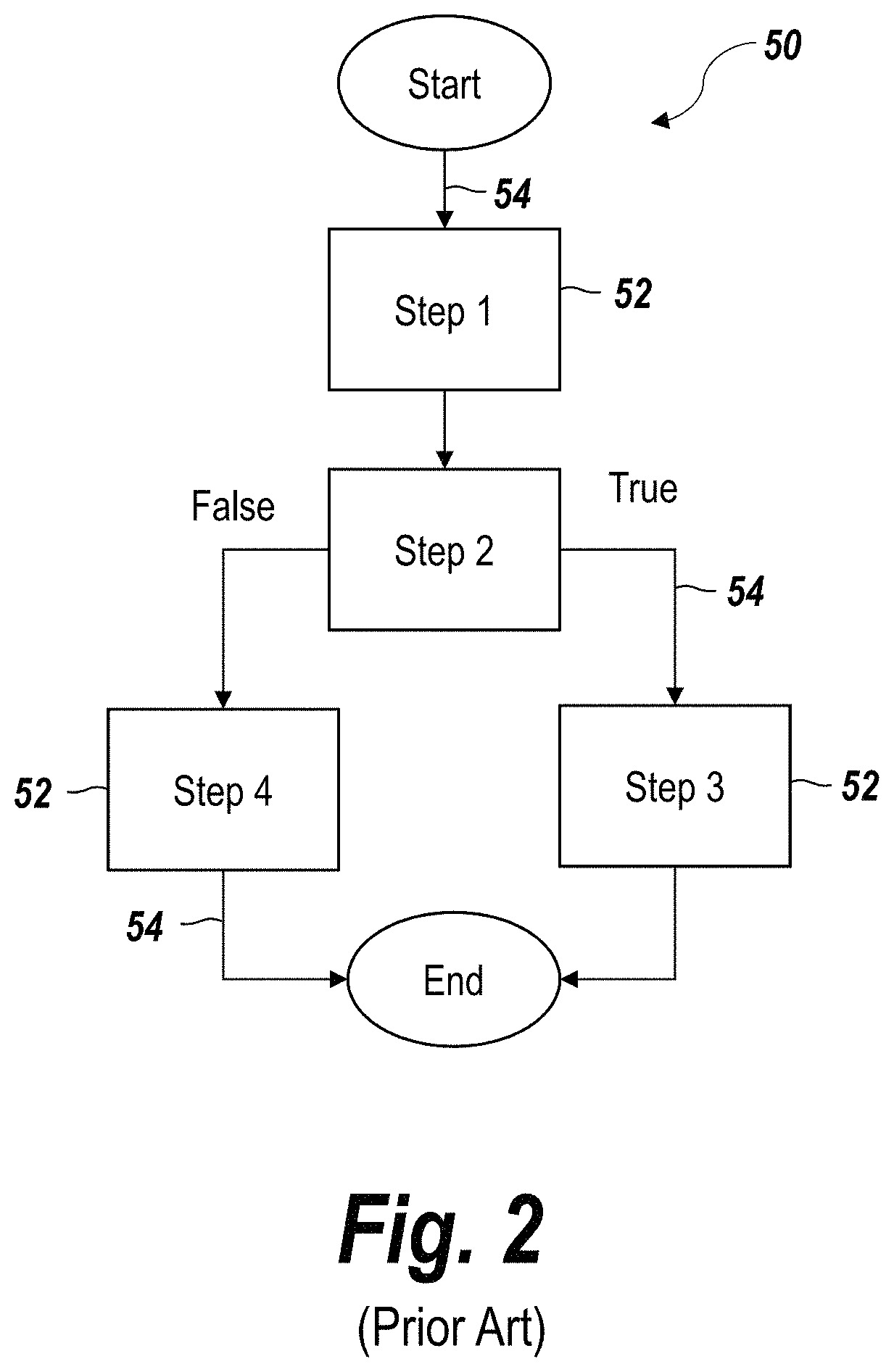

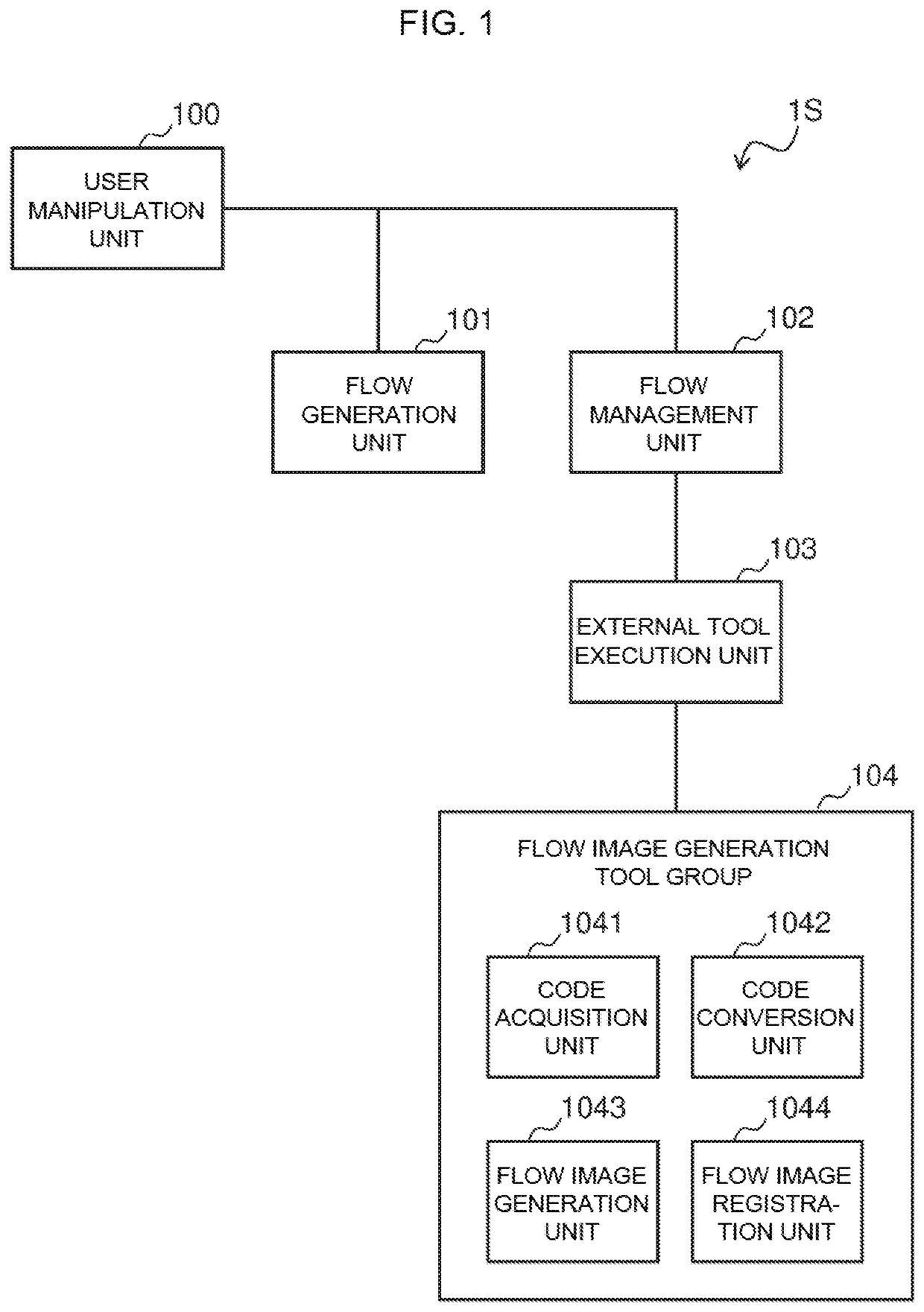

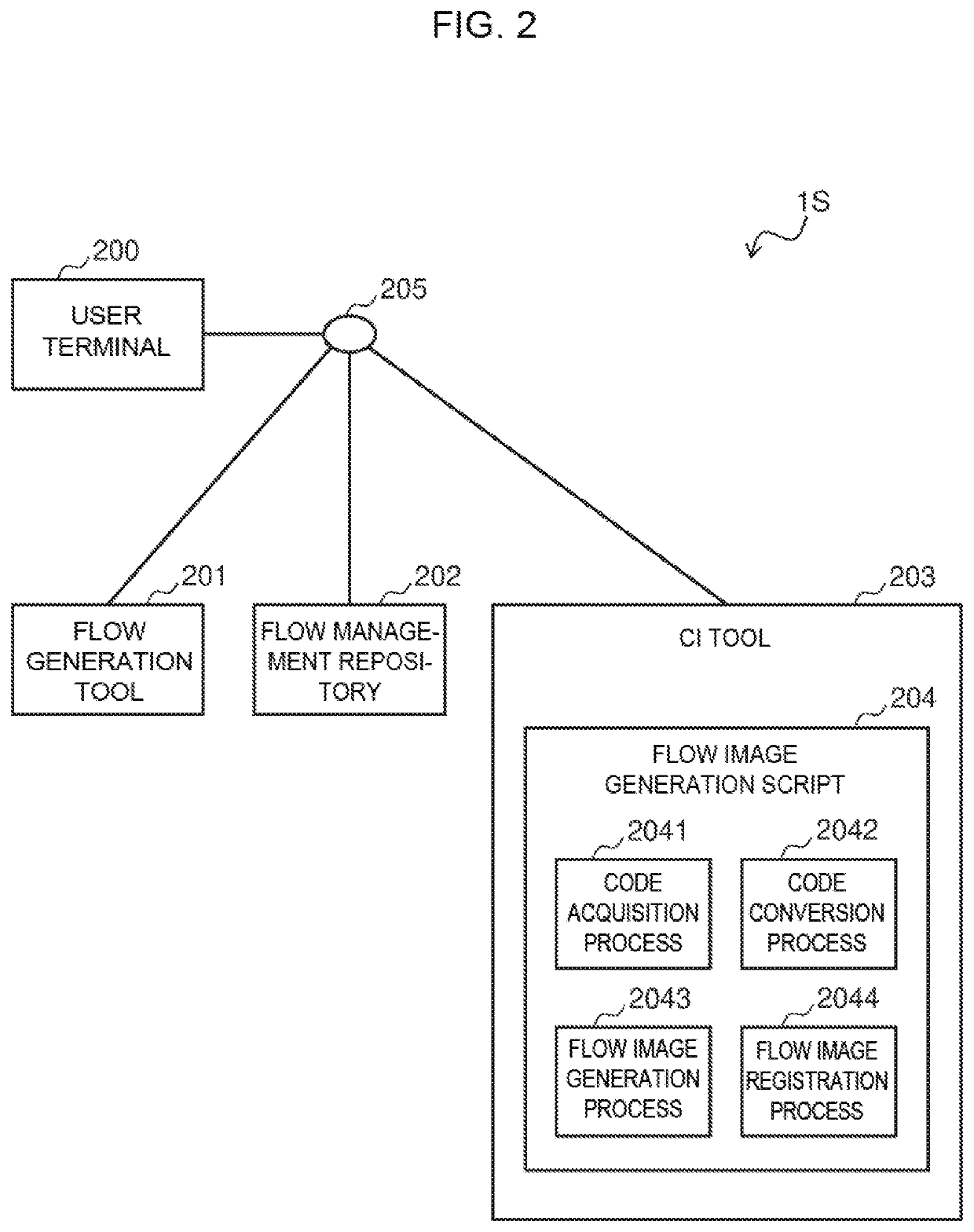

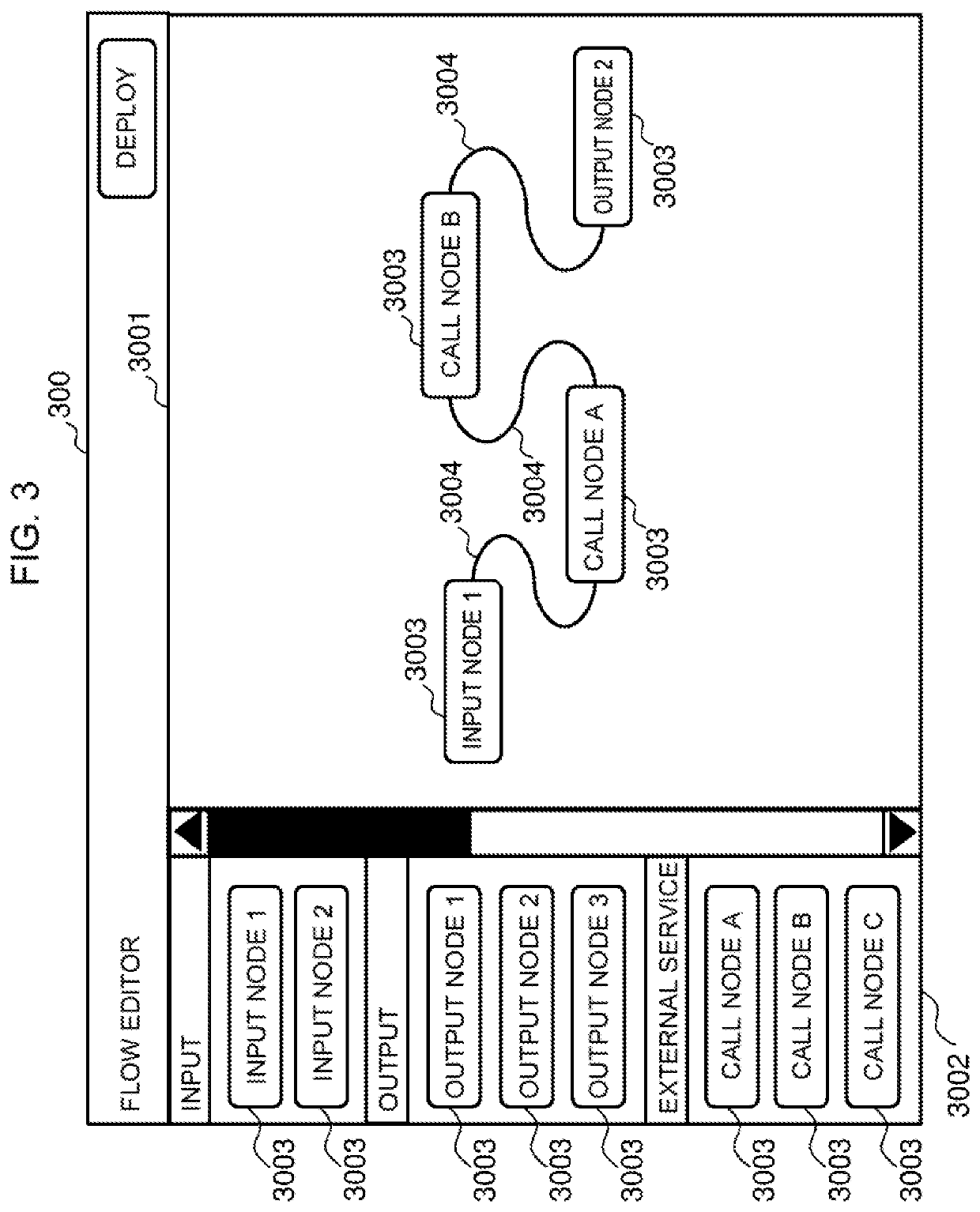

Code Management System and Code Management Method

ActiveUS20200241850A1Improve convenienceReverse engineeringVisual/graphical programmingSoftware engineeringProcess map

The convenience of reusing software generated by a visual programming tool is further improved. A code management system includes a flow generation unit that creates a process flow based on user manipulation and generates code based on the created process flow, a flow management unit that saves the code generated by the flow generation unit, a code acquisition unit that acquires code in response to the code being saved in the flow management unit, a code conversion unit that converts the code acquired by the code acquisition unit to a process flow diagram, a flow image generation unit that generates a flow image of the process flow diagram converted by the code conversion unit, and a flow image registration unit that registers the flow image generated by the flow image generation unit in the flow management unit in association with the code prior to conversion to the process flow diagram by the code conversion unit.

Owner:HITACHI LTD

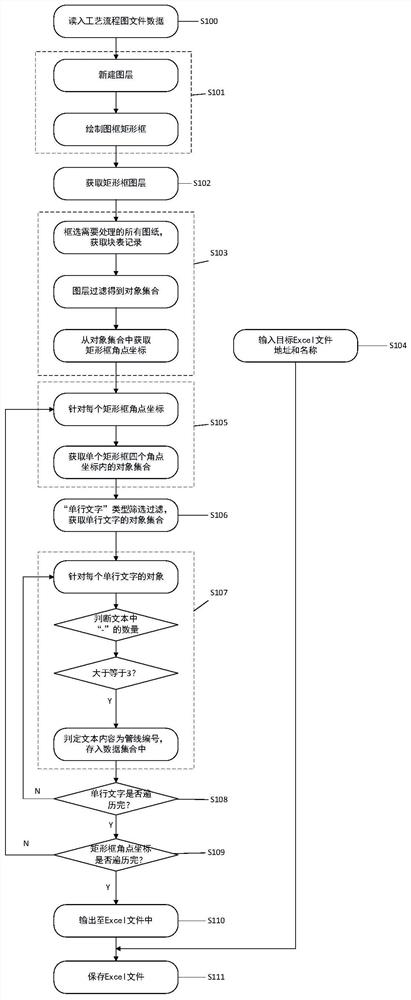

Method for identifying and outputting pipeline number from AutoCAD format process flow diagram

PendingCN112069956APrecise screeningAccurate outputGeometric CADCharacter and pattern recognitionSoftware engineeringProcess map

The invention relates to a method for identifying and outputting a pipeline number from an AutoCAD format process flow diagram, in particular to a process pipeline table compiling part in medical engineering design, and realizes AutoCAD secondary development and a DLL program through VB.Net. The method comprises the implementation steps: opening AutoCAD, loading the DLL program, reading in processflow diagram file data, newly establishing a diagram layer, drawing a diagram frame rectangular frame, selecting a rectangular frame diagram layer, selecting all drawings needing to be processed, obtaining block table records, filtering layers, obtaining a rectangular frame object set and corner coordinates, traversing all rectangular frames, obtaining a single-row character object set in the corner coordinates of the rectangular frames, traversing all single-row character objects, judging whether a single-row character text is a pipeline number or not, storing the single-row character text in a data list, output the data list to an Excel file, and saving the Excel file. The method is rapid, efficient, convenient to use, high in accuracy and good in reliability, the automation degree andaccuracy of process professional work are improved, and the timeliness of process professional pipeline table compiling work is guaranteed.

Owner:SINOPEC SHANGHAI ENG +1

Oil depot oil product moving path automatic planning method

InactiveCN107451696ASimple moving path automatic planningAutomatic planning is simpleForecastingElement modelWeb service

The invention discloses an oil depot oil product moving path automatic planning method comprising the steps that S1, a data model and a graphical element model are established for various types of equipment on the oil product moving path within the range of the oil depot and saved in a database; and S2, an oil product moving path process flow diagram is drawn for different oil products in the oil depot on a Web interface through the configuration mode, and the process flow diagram data are combined into the Json format to be uploaded to a Web server after completion of configuration and saved in the database. The oil product moving path planning operation is enabled to be simpler, the path planning efficiency is higher, the path planning result is more accurate and more visual, and on / off and start / stop control can be accurately performed on the involved equipment in the path according to the specified order so that the problems of negligence or error of manual planning can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP

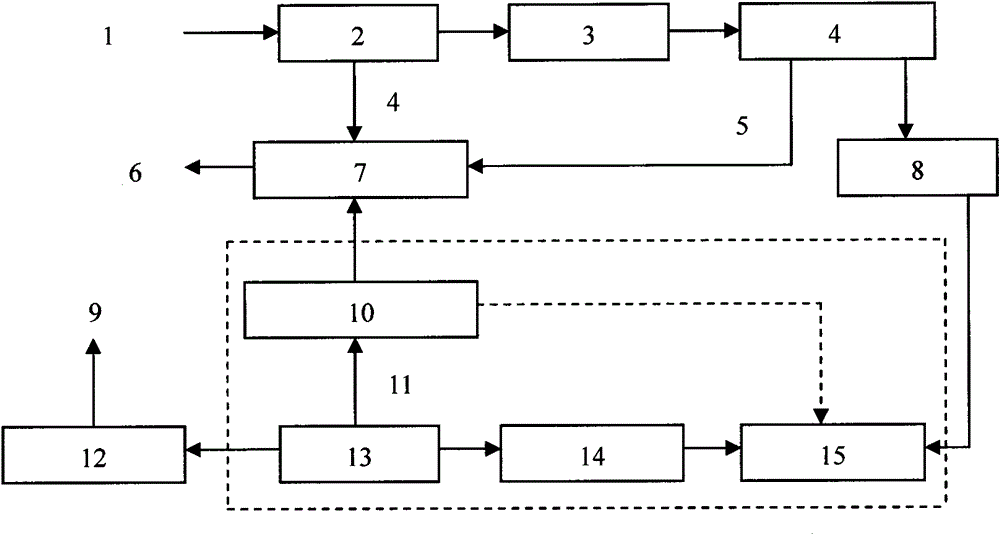

Resource recovery-based automatic corrugated board glue making system

InactiveCN102796467AEasy to adjustThe running screen is accurate and clearStarch adhesivesCycle controlSoftware

The invention discloses a full-automatic glue making system for improving corrugated board glue making performance and resource recovery. The system mainly comprises two aspects, namely a full-automatic corrugated board glue making system and a resource recovery-based corrugated board glue making recycle process (a domestic wastewater recovery process flow diagram is shown as figure 1). The full-automatic corrugated board glue making system mainly comprises software and hardware equipment of the glue making system, and matched large and small cycle control systems; by high process control over pasting temperature, viscosity, solid content and glue temperature, unstable glue quality caused by human factors is radically avoided, the high quality of products is ensured, and high efficiency and low consumption in the production process are ensured. The resource recovery-based corrugated board glue making recycle process mainly comprises steps of using the treated domestic wastewater as production water for the automatic glue making process and treating and recycling glue making wastewater. By the two aspects, water for the whole production system is organically cycled, so that cyclic production is realized, water resources are recycled, the full-automatic glue making system accords with low-carbon production and environmental protection concepts supported by China, and a green idea is combined into the glue making system.

Owner:黄遂兢

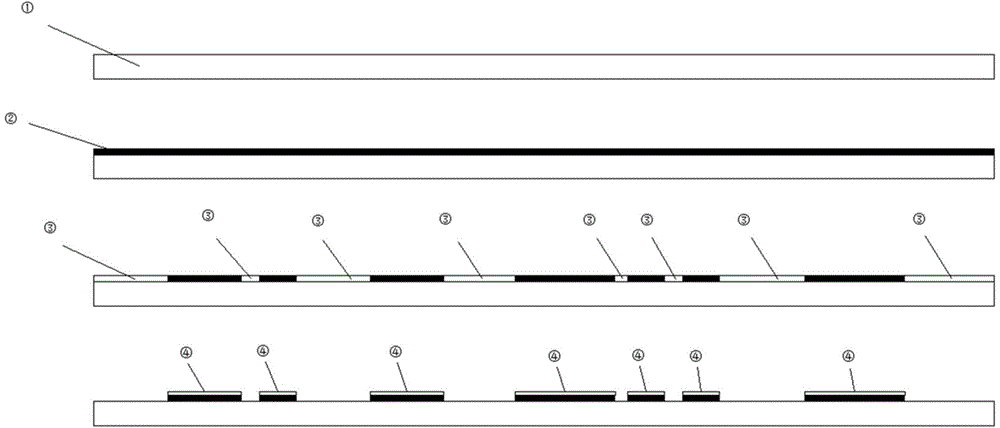

Preparation method of ceramic substrate for medium-free copper-coated gold-deposited light-emitting diode (LED) package

InactiveCN105489713AChemical reaction stabilityImprove thermal conductivitySemiconductor devicesVulcanizationChemical reaction

The invention discloses a preparation method of a ceramic substrate for medium-free copper-cladding gold-deposited light-emitting diode (LED) package. The preparation method comprises the following steps of sintering a ceramic wafer, in which ceramic powder is subjected to die forming and then placed in an environment at 1,000-1,020 DEG C for sintering for 8 to 10 minutes to obtain the ceramic wafer; coating copper, in which copper is coated on the upper surface of the ceramic wafer by a vacuum mist plating method to form a copper foil; etching, in which the useless copper foil is corroded with dilute sulphuric acid according to a process flow diagram to reserve the useful copper foil as a circuit; depositing gold, in which gold liquid medicine passes through the substrate with the circuit already etched so that the gold is deposited on the copper foil to obtain a finished product. According to the preparation method, a medium-free copper cladding technique is adopted, and the excellent heat conduction performance of primary copper and ceramic is maintained; and the gold is deposited on the copper, the chemical reaction of the gold is stable, the vulcanization problem is effectively solved, and the electrical property of the product and the long-term maintenance rate of light refraction are further improved.

Owner:郭垣成

System and method for creating a process flow diagram which incorporates knowledge of business terms

ActiveUS11348049B2Sure easyOffice automationVisual/graphical programmingSoftware engineeringData mining

A system and method for associating a technical artifact and one or more business terms with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

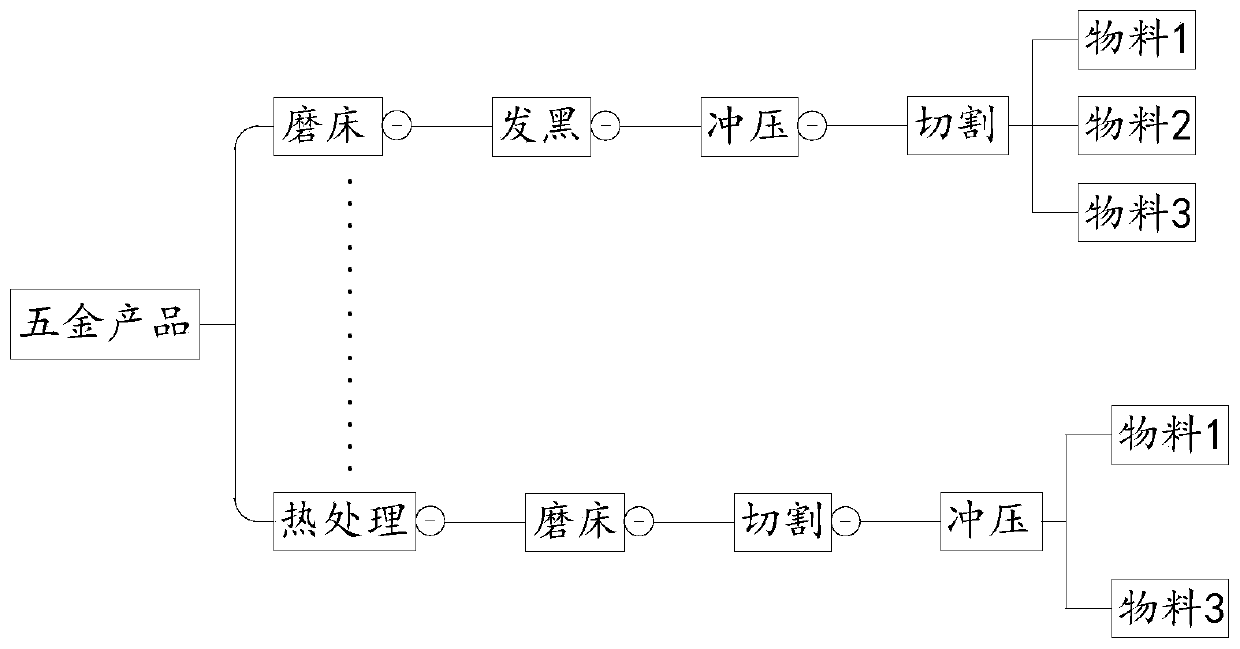

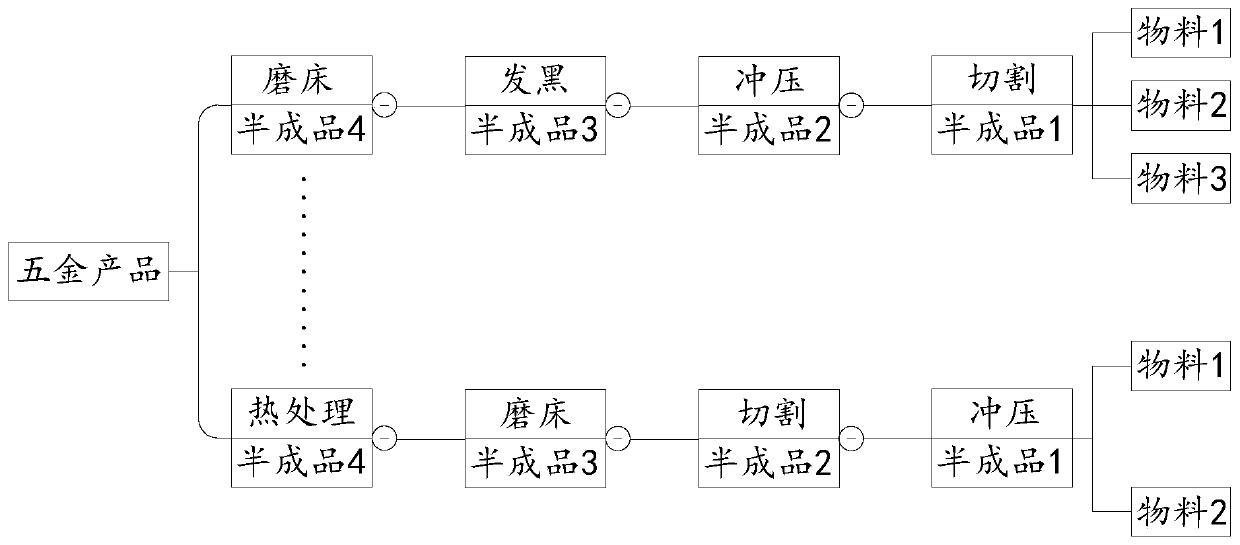

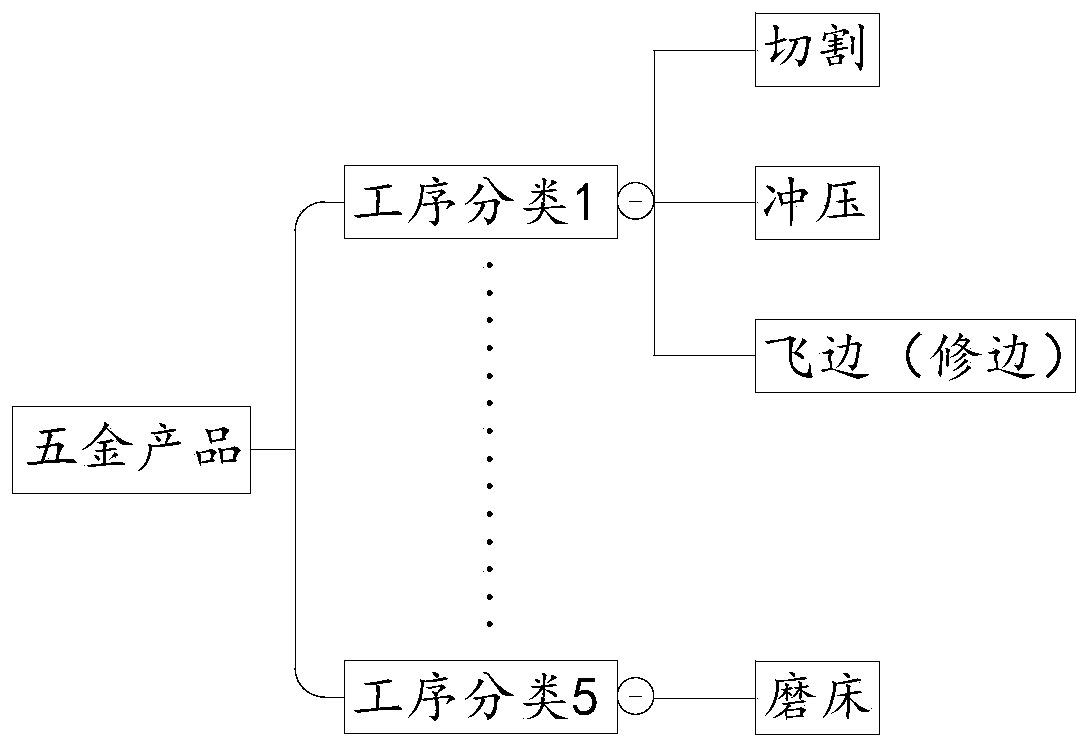

Technological process display method based on mind map, electronic equipment and storage medium

PendingCN111160862AEasy to manageQuick and easy to createOffice automationProcess engineeringProcess map

The invention provides a mind map-based process flow display method, electronic equipment and a storage medium. The method comprises the steps: drawing up a plurality of production technologies according to the features of a to-be-produced product; according to the production sequence of each production process, sequentially arranging the process steps from left to right in an inverted sequence mode, and forming a plurality of process nodes; connecting two adjacent process nodes in series to form a plurality of production process flow diagrams; taking a to-be-produced product as a root node, and connecting a plurality of production process flow diagrams in parallel to form a process flow mind map. According to the method, process nodes of the same level are connected in series to form a process flow diagram, and a plurality of process flow diagrams are associated to the same root node in a parallel connection mode to form a clear and complete process flow mind map.

Owner:广东三扬网络科技有限公司

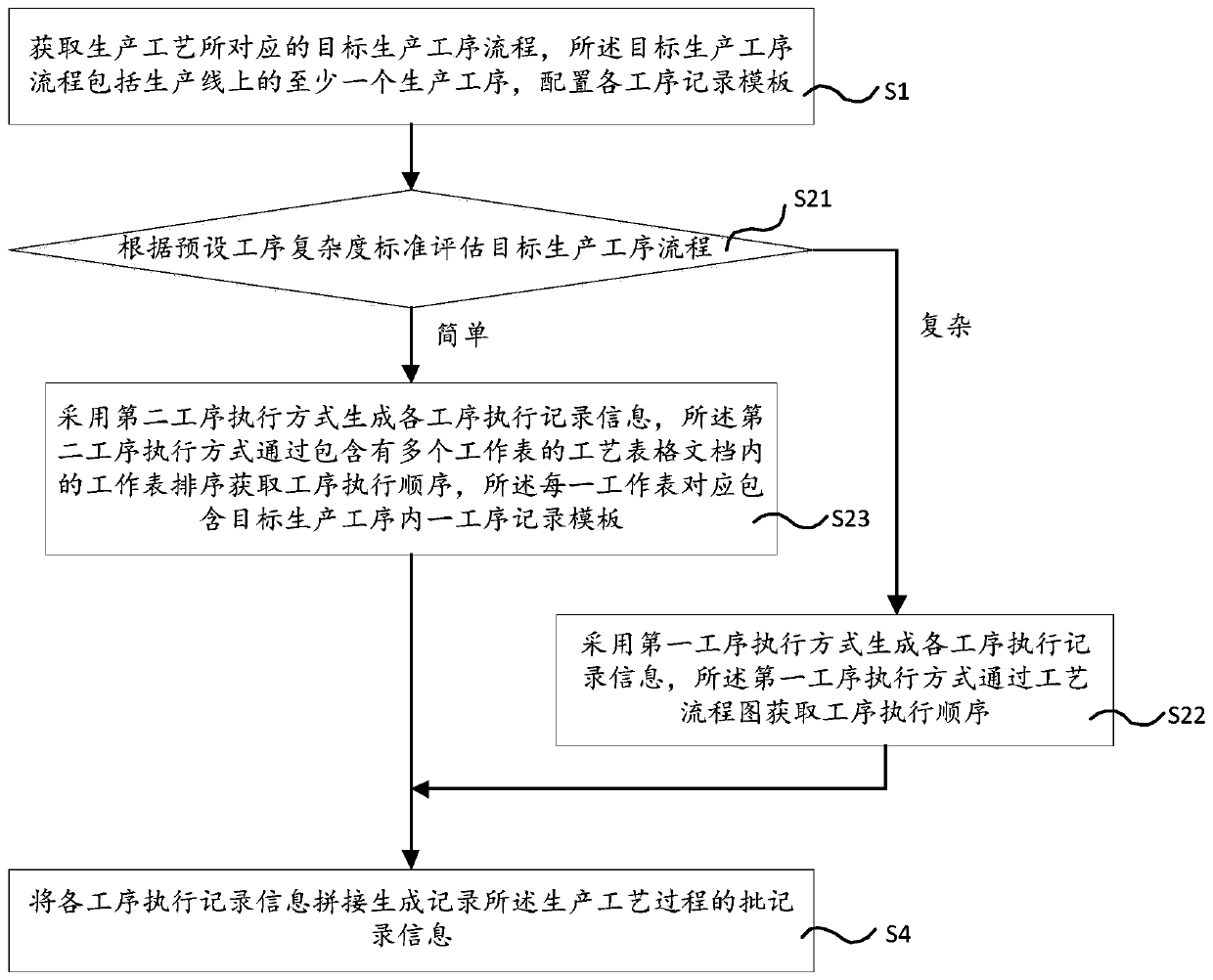

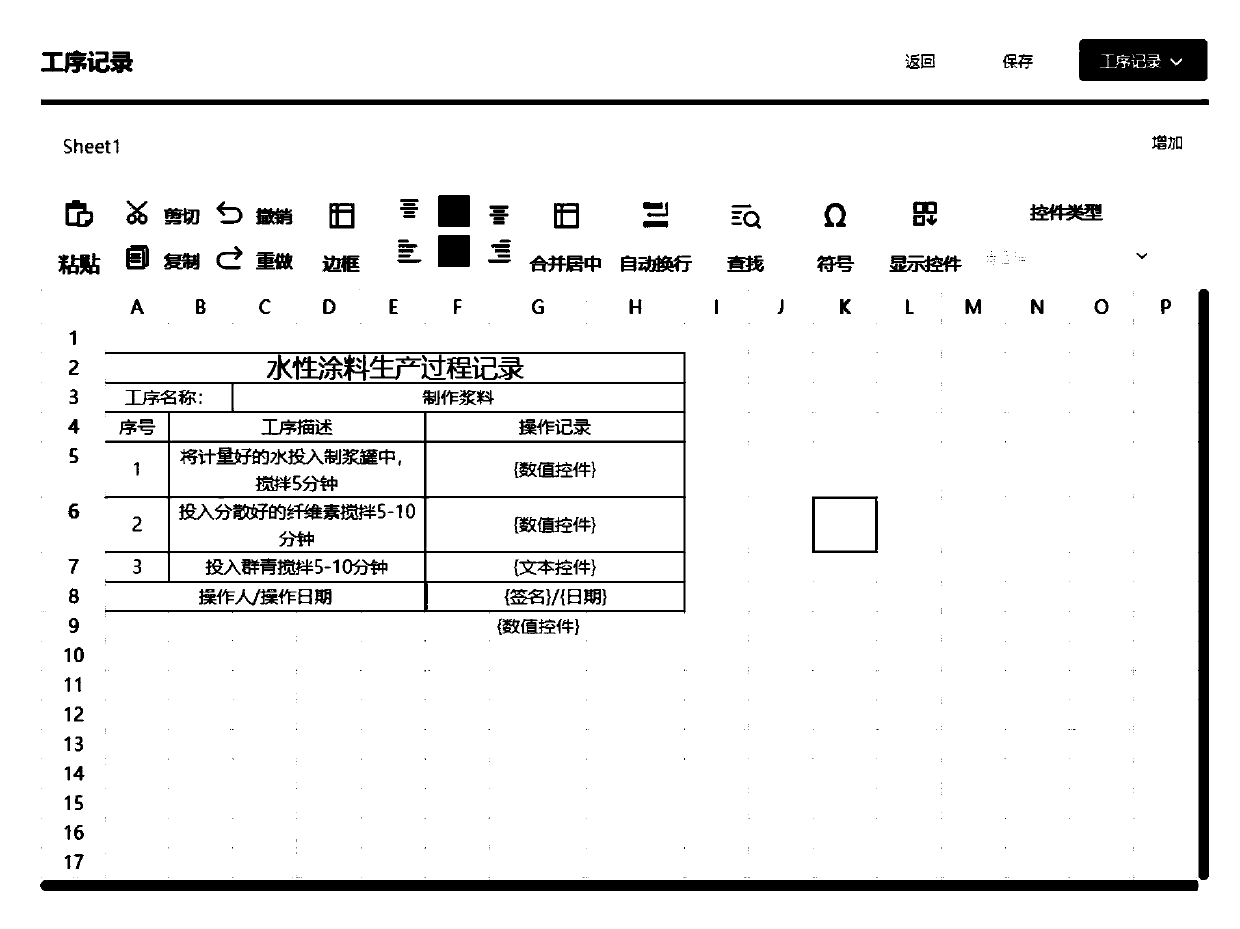

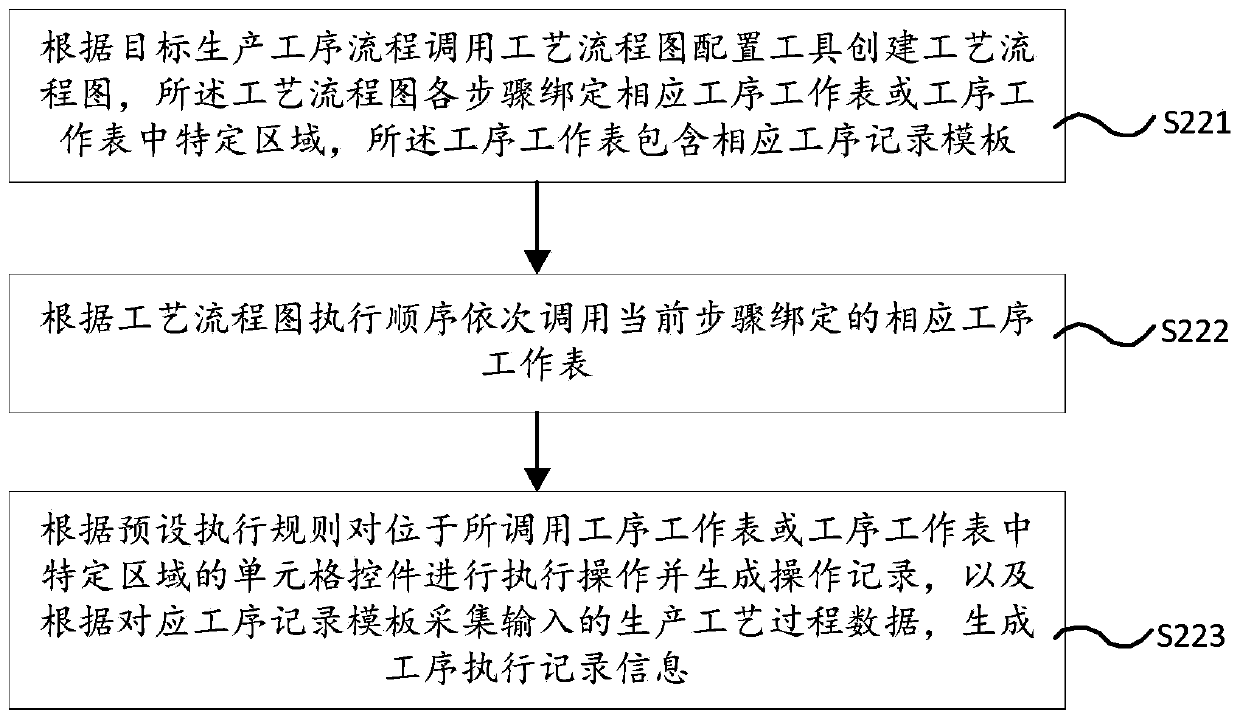

Production process recording method and device based on flow chart and table

ActiveCN110096688AFlexible adjustmentSimple processText processingSpecial data processing applicationsTechnical standardProcess complexity

The invention discloses a process recording method based on a flow chart and a table. The method comprises the steps of obtaining a target production process flow corresponding to a production process, evaluating a target production process flow according to a preset process complexity standard; if so, generating execution record information of each process by adopting a first process execution mode; otherwise, generating execution record information of each process by adopting a second process execution mode, wherein the first process execution mode obtains a process execution sequence through a process flow diagram, the second process execution mode obtains a process execution sequence through a work table sequence in a process table document comprising a plurality of work tables, each work table correspondingly comprises a process record template in a target production process; and finally, splicing the process execution record information to generate batch record information for recording the production process. When the manufacturing process which is diverse and frequently adjusted is generated, the process recording sequence and the recording content can be flexibly adjusted,and the process can be reused in similar processes and processes, so that the customized implementation period is shortened under the condition that the actual production requirements are met.

Owner:MINGDU ZHIYUN (ZHEJIANG) TECH CO LTD

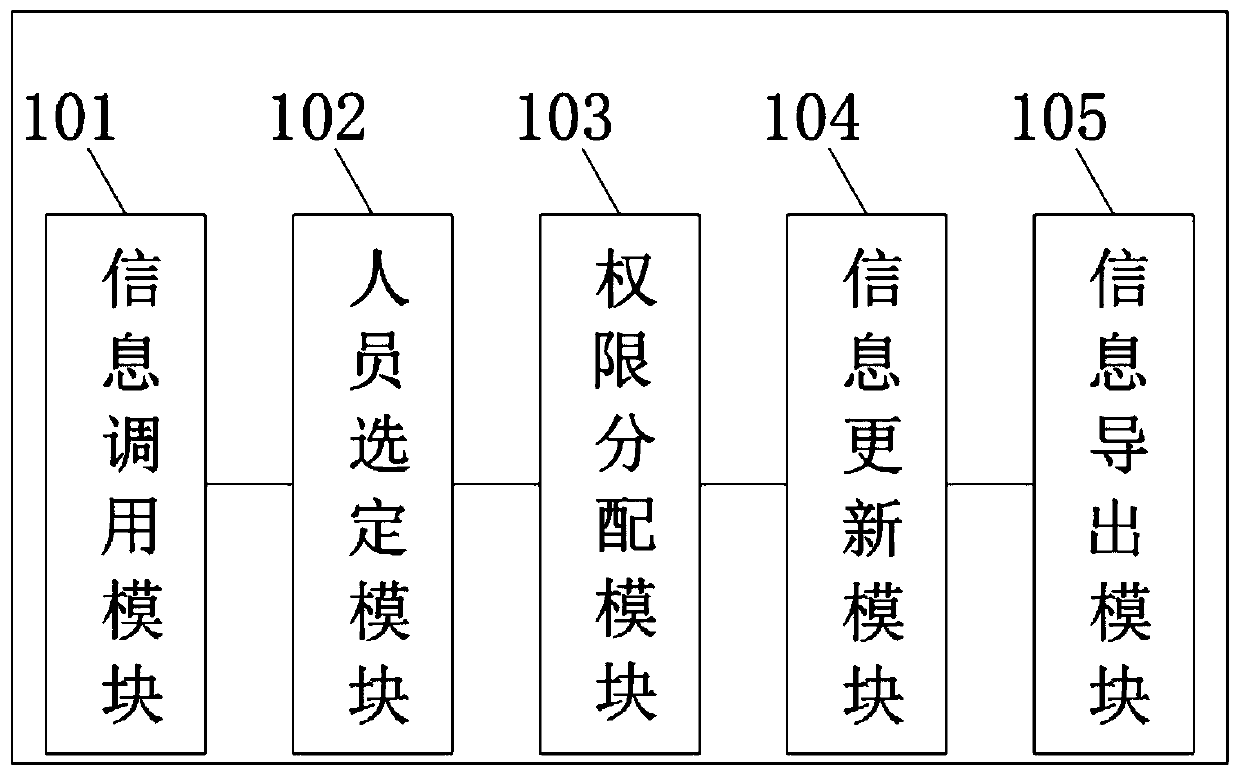

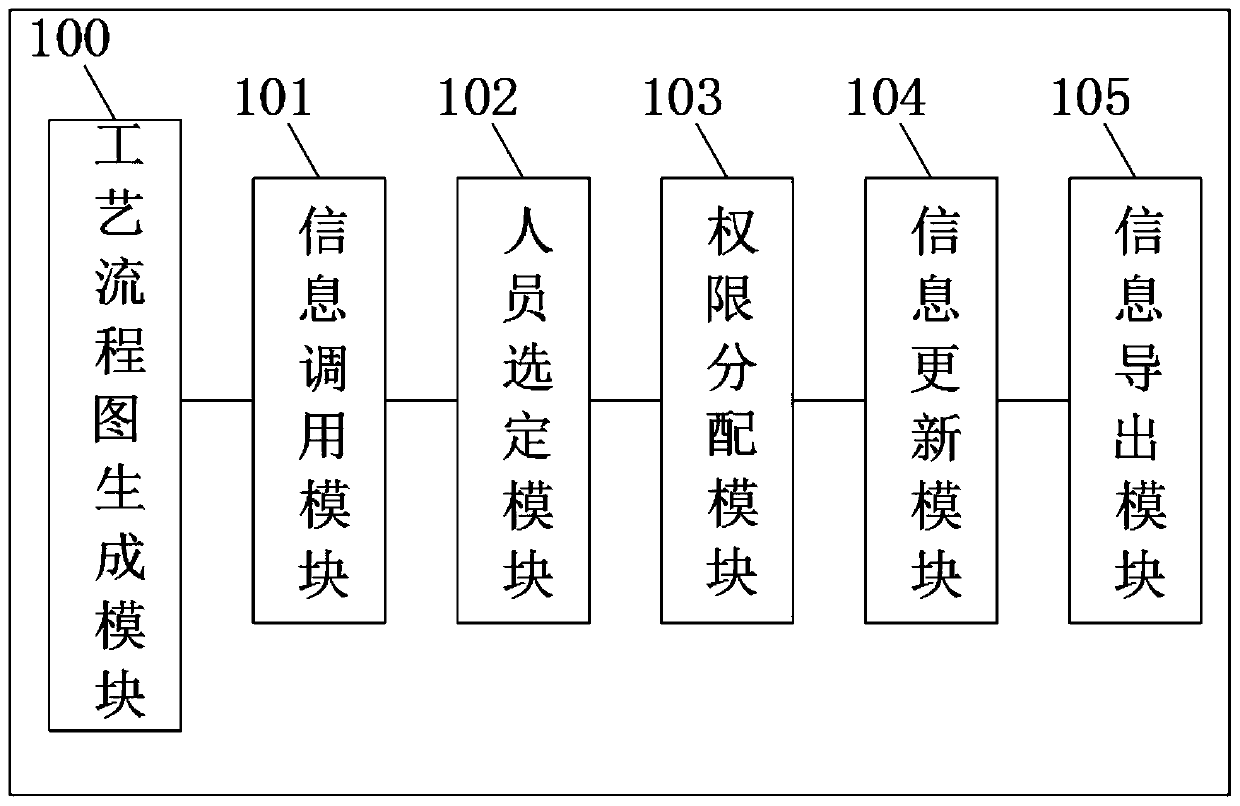

Management system and method for research, development, transformation and production of medical instruments

InactiveCN109800994AStandardized managementTo overcome the problem of information asymmetryResourcesManufacturing computing systemsProduction lineManagement system

The invention discloses a management system and method for research, development, transformation and production of medical apparatuses and instruments, and the system comprises the steps: allocating corresponding production line role permissions to user terminals of production personnel after calling a medical apparatus and instrument process flow chart, and exporting a complete medical apparatusand instrument production record after generating the medical apparatus and instrument production record. Compared with the prior art, the method has the advantages that the cost is low;, According tothe invention, a mode of calling the medical apparatus and instrument process flow diagram formed by research and development conversion data is utilized; paper research and development conversion data with poor readability is visualized; and the research and development are converted into the research and development, the production implementation process is completely integrated and recorded; According to the system and the method, the data chain is closed, the problem of information asymmetry between medical instrument research and development information release and medical instrument production is solved, resources are shared in the production realization process and the research and development conversion process, the consistency of the production realization process and the research and development conversion process is ensured, and the management of research and development conversion production is standardized.

Owner:广州奥咨达医疗器械技术股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com