Patents

Literature

163 results about "Process knowledge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Knowledge processes are methods for creating, acquiring and using knowledge. This is a human-centered process as knowledge is information that exists as human thought. The term knowledge process is extremely broad and is commonly applied to knowledge-intensive business processes, training and events.

Model-free adaptive process control

InactiveUS6055524ALong response delayOvercome limitationsDigital computer detailsDigital dataData miningSelf adaptive

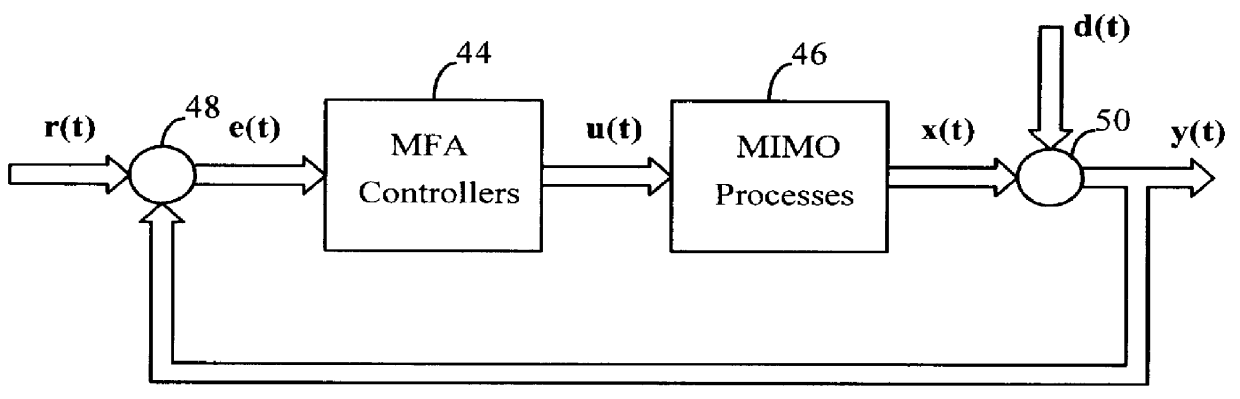

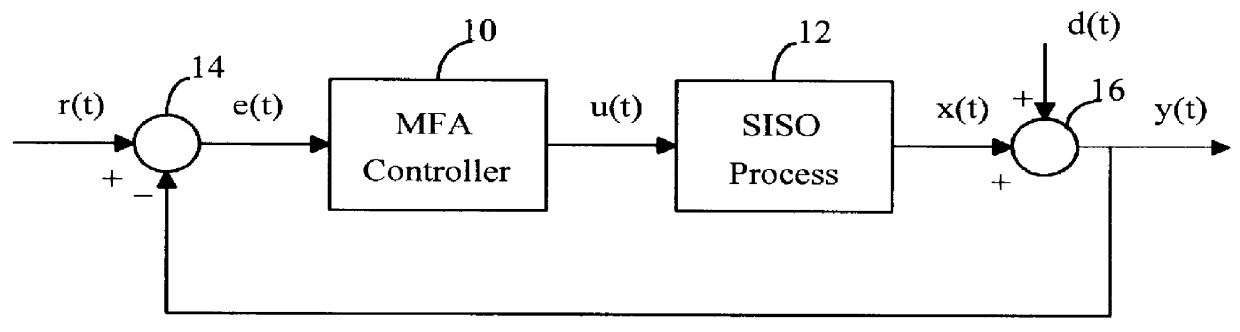

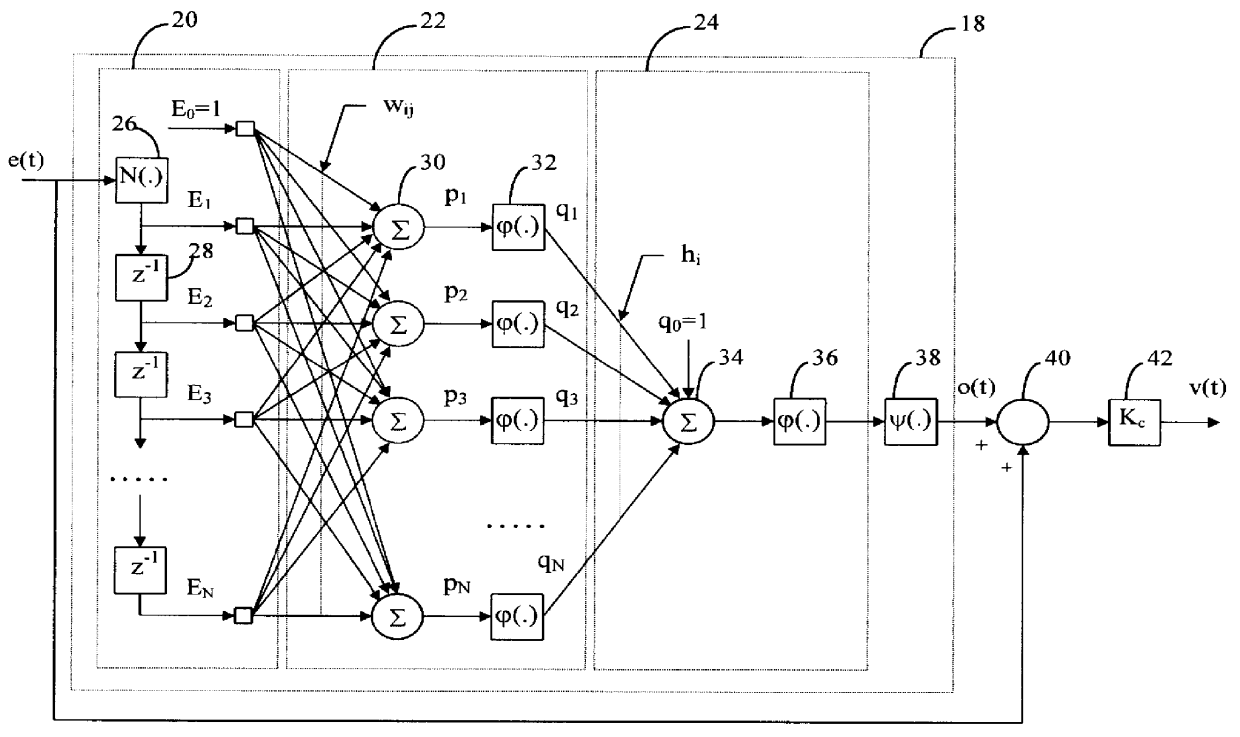

A model-free adaptive controller is disclosed, which uses a dynamic artificial neural network with a learning algorithm to control any single-variable or multivariable open-loop stable, controllable, and consistently direct-acting or reverse-acting industrial process without requiring any manual tuning, quantitative knowledge of the process, or process identifiers. The need for process knowledge is avoided by substituting 1 for the actual sensitivity function .differential.y(t) / .differential.u(t) of the process.

Owner:GEN CYBERNATION GROUP

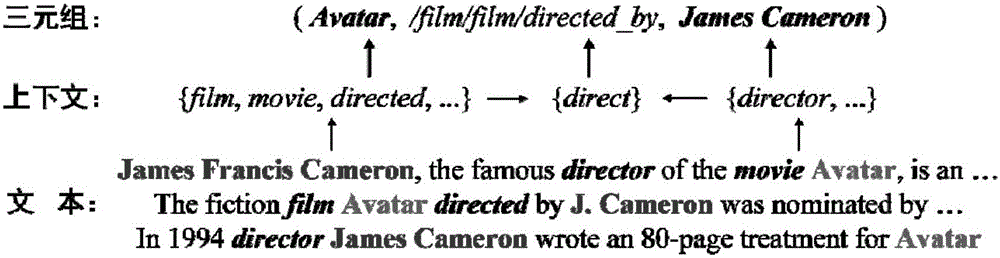

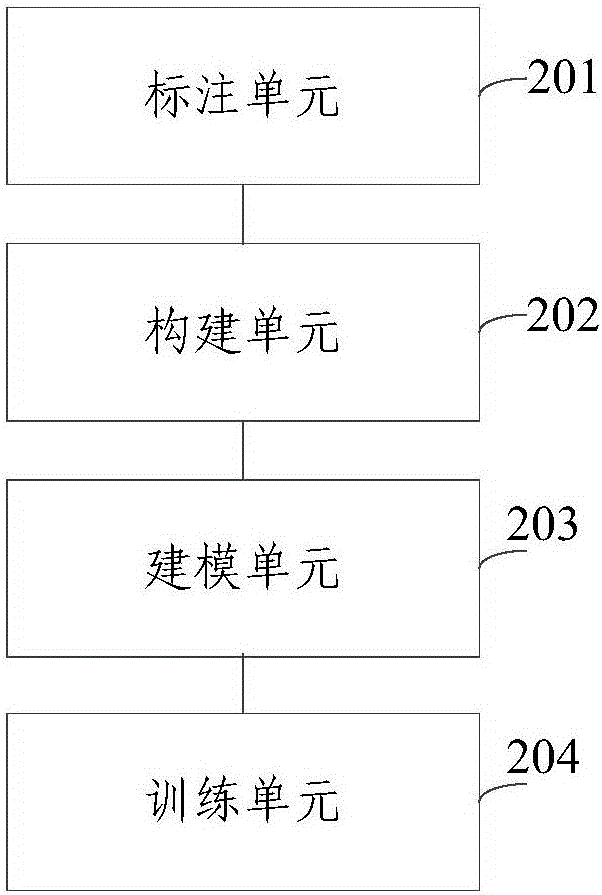

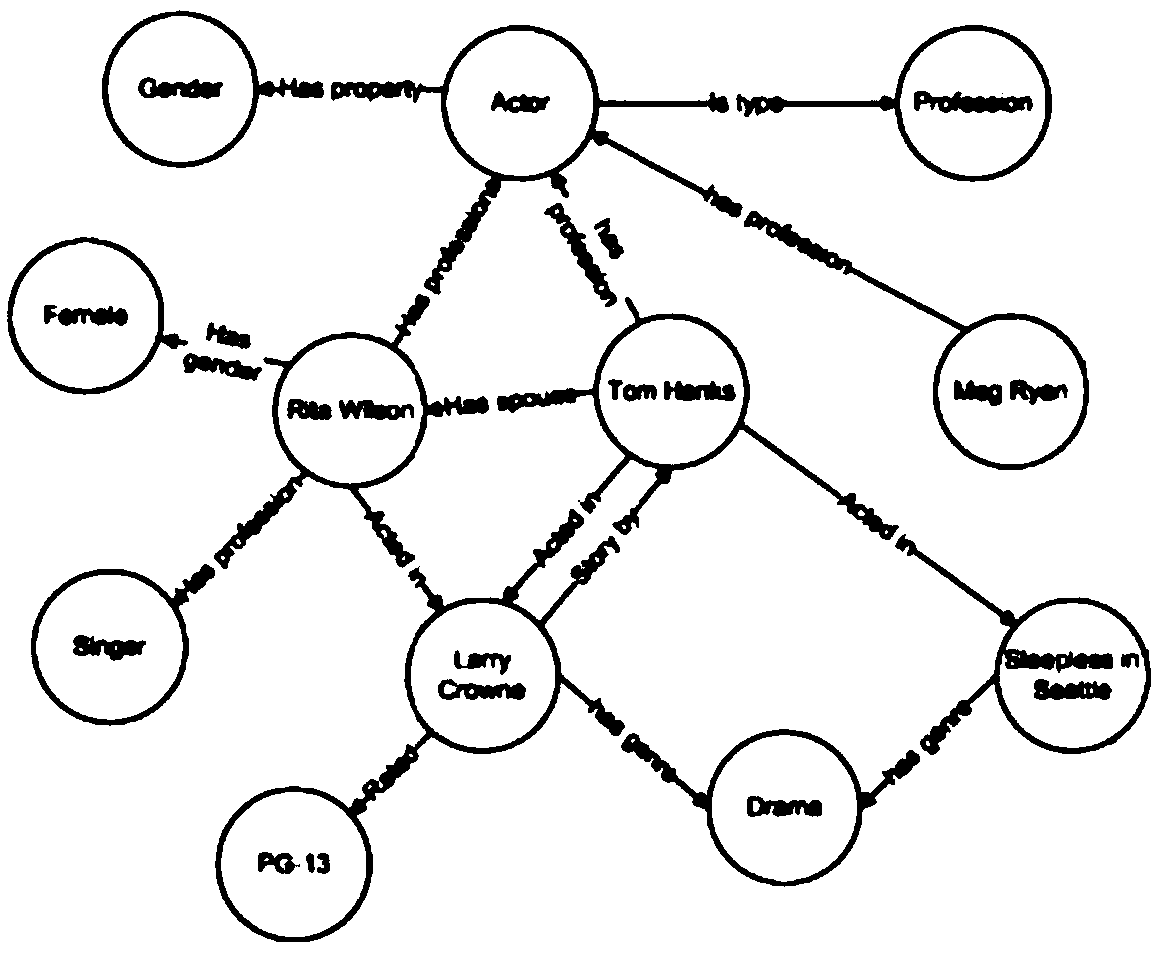

Method and device for acquiring knowledge graph vectoring expression

ActiveCN105824802ARich relevant informationSolve the problem of insufficient representation effect caused by sparsityNatural language data processingSpecial data processing applicationsStochastic gradient descentGraph spectra

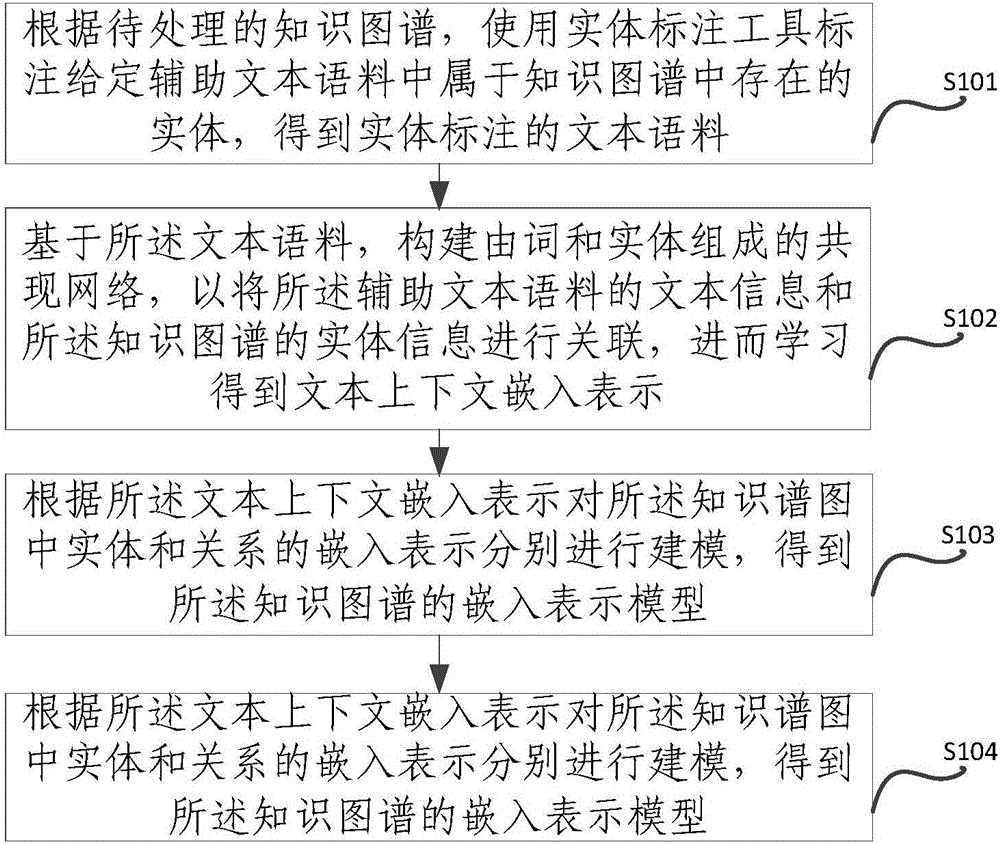

The invention discloses a method and a device for acquiring knowledge graph vectoring expression. The method comprises the following steps of labeling an entity, existed in and belonging to a knowledge graph, in a given auxiliary text corpus by utilization of an entity labeling tool according to a to-be-processed knowledge graph so as to obtain an entity-labeled text corpus; constructing a co-occurrence network comprising words and entities on the basis of the text corpus so as to relate text information of the auxiliary text corpus to entity information of the knowledge graph, and then learning to obtain a text context embedded expression; respectively modeling the embedded expression of the entity and relation in the knowledge graph according to the text context embedded expression so as to obtain an embedded expression model of the knowledge graph; training the embedded expression model by utilization of a stochastic gradient descent algorithm so as to obtain the embedded expression of the entity and relation in the knowledge graph. The method and the device disclosed by the invention have the advantages that not only can the expression capability of the relation be improved, but also the problem of insufficient expression effect caused by sparseness of the knowledge graph can be effectively solved.

Owner:TSINGHUA UNIV

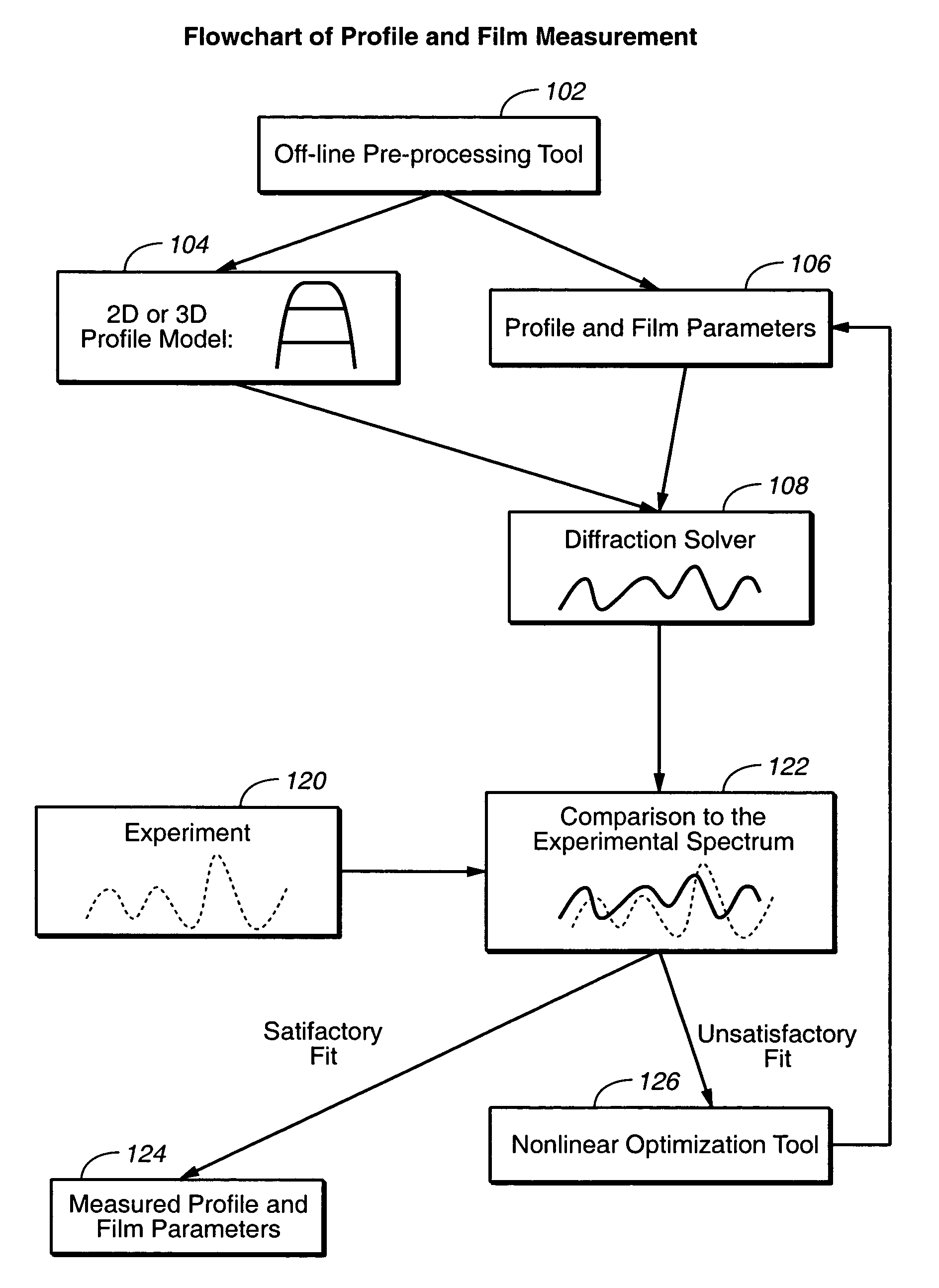

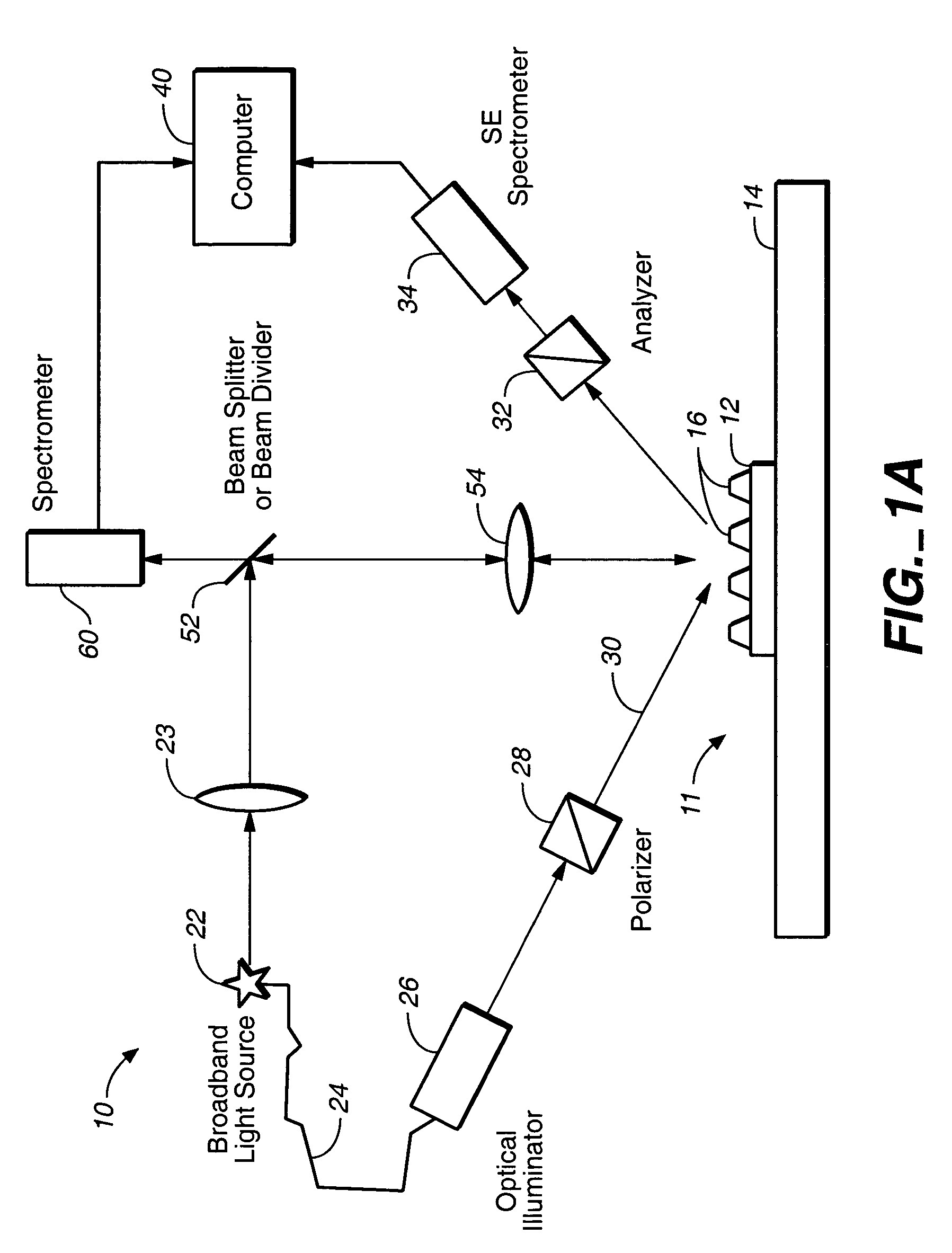

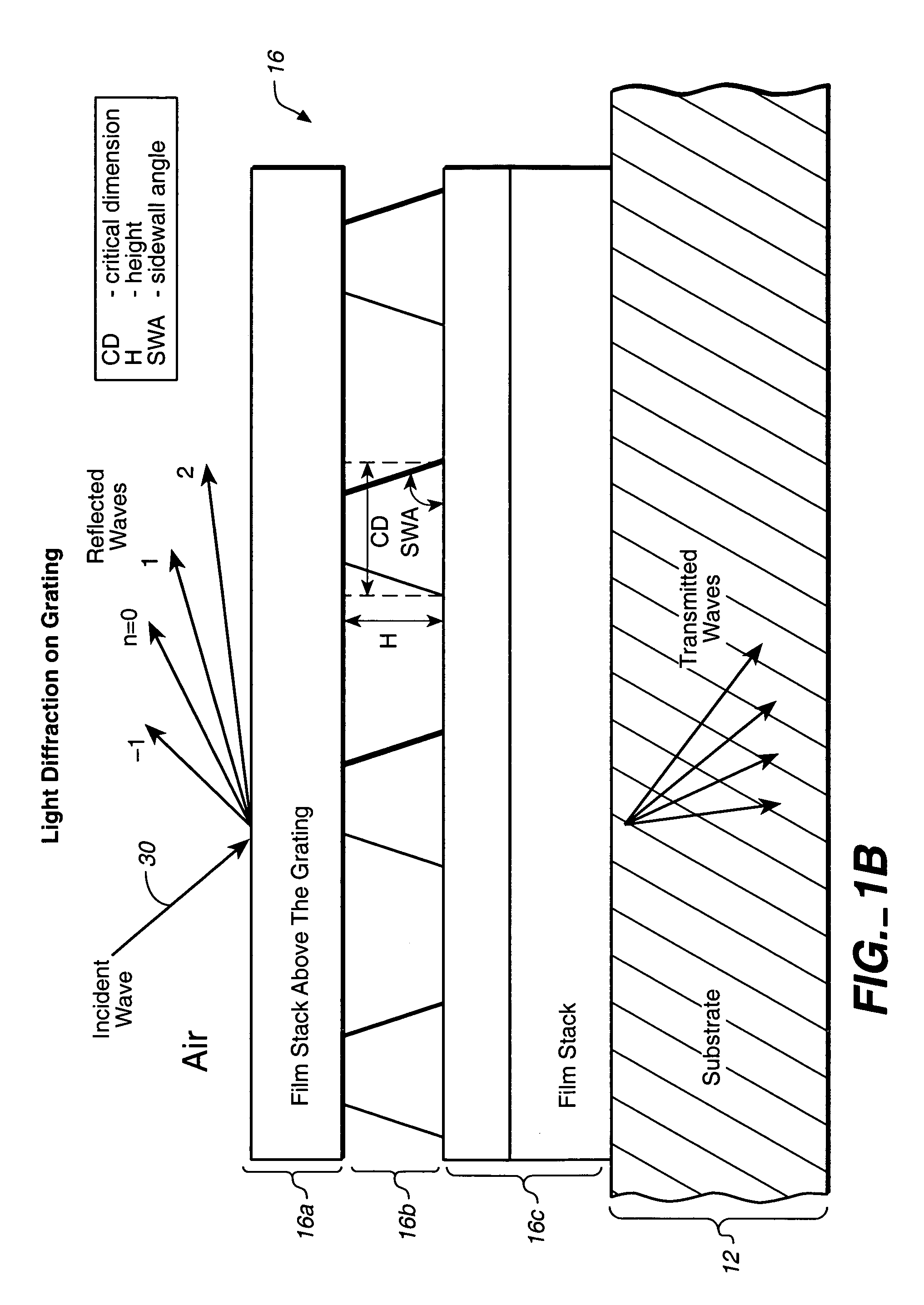

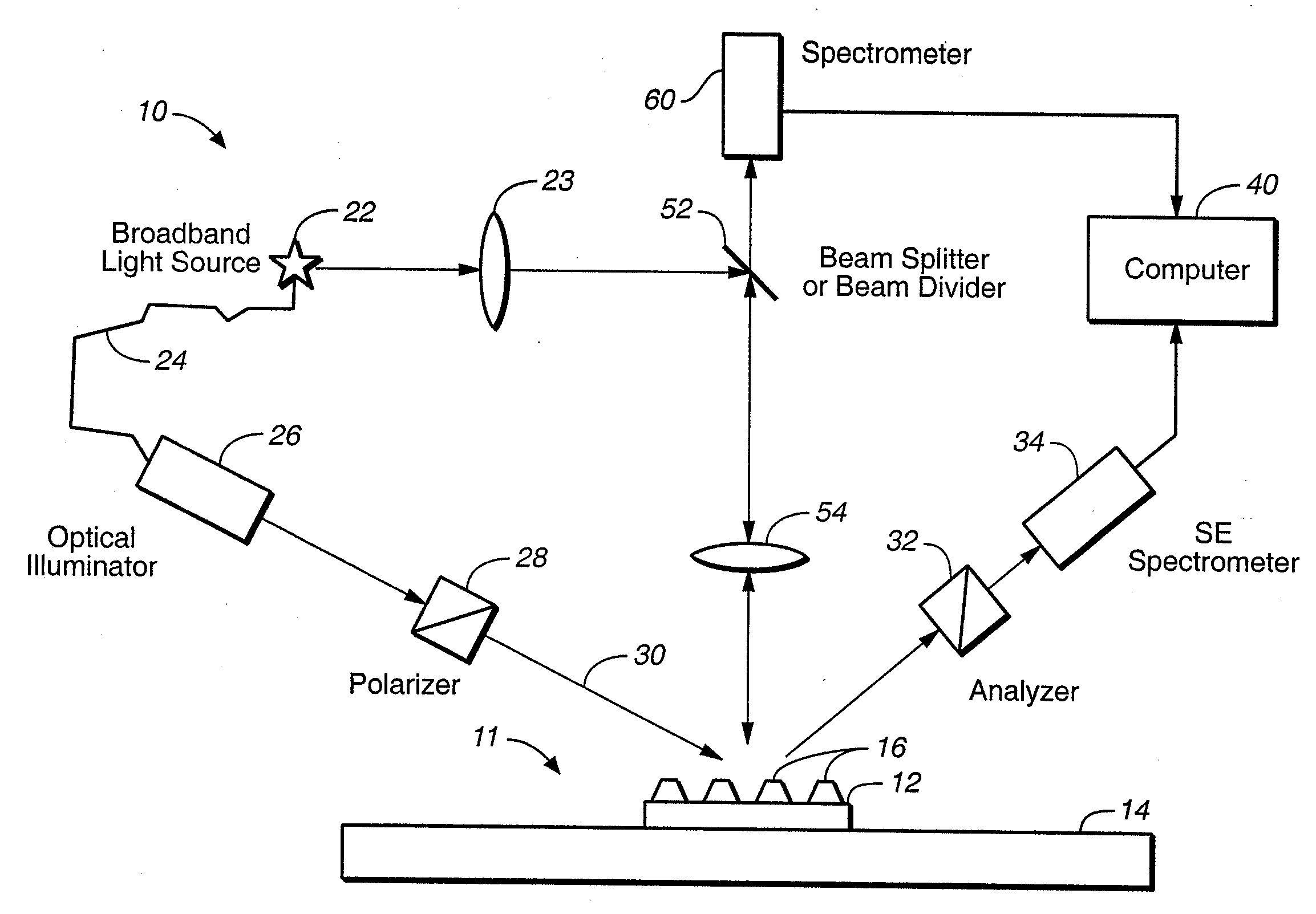

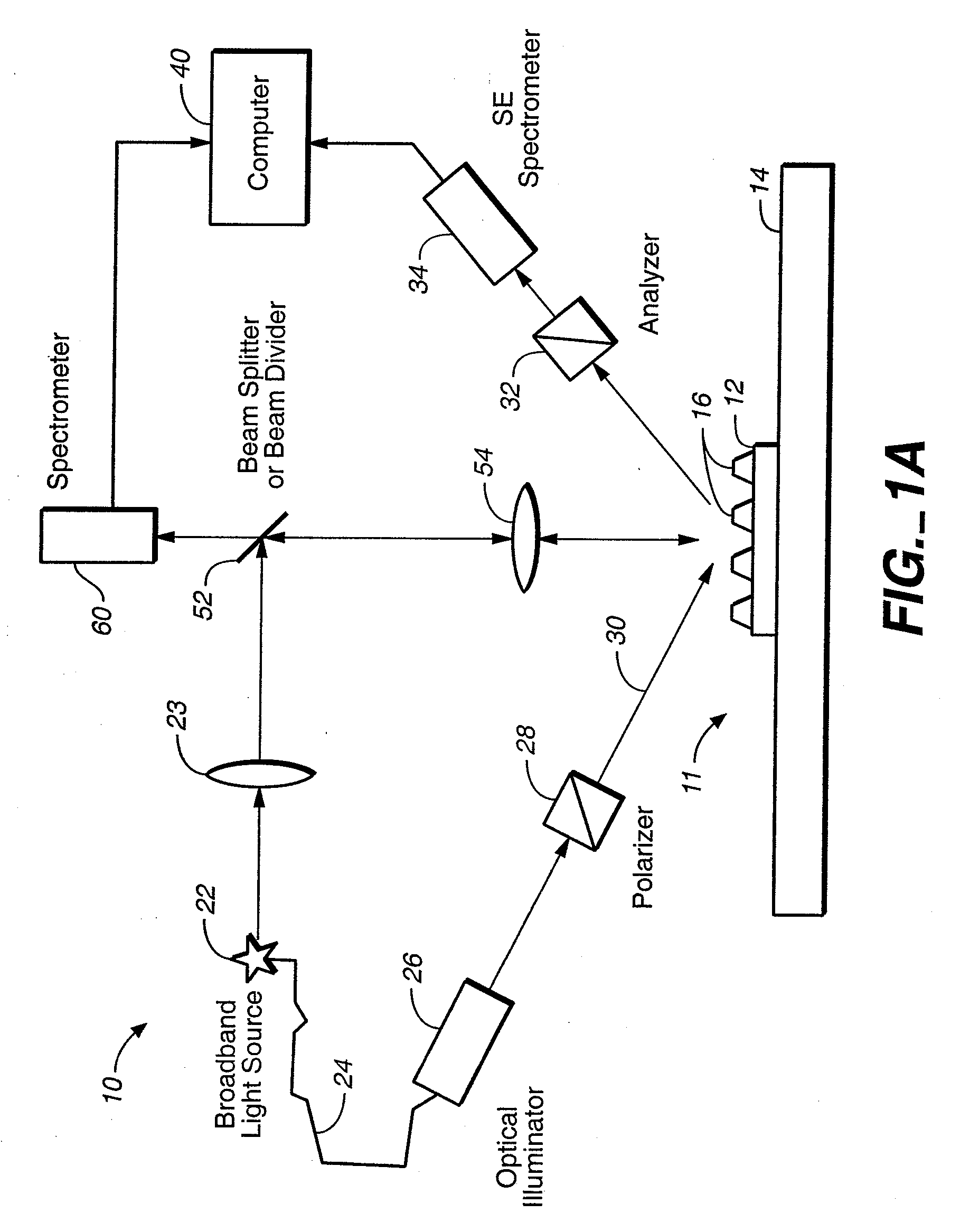

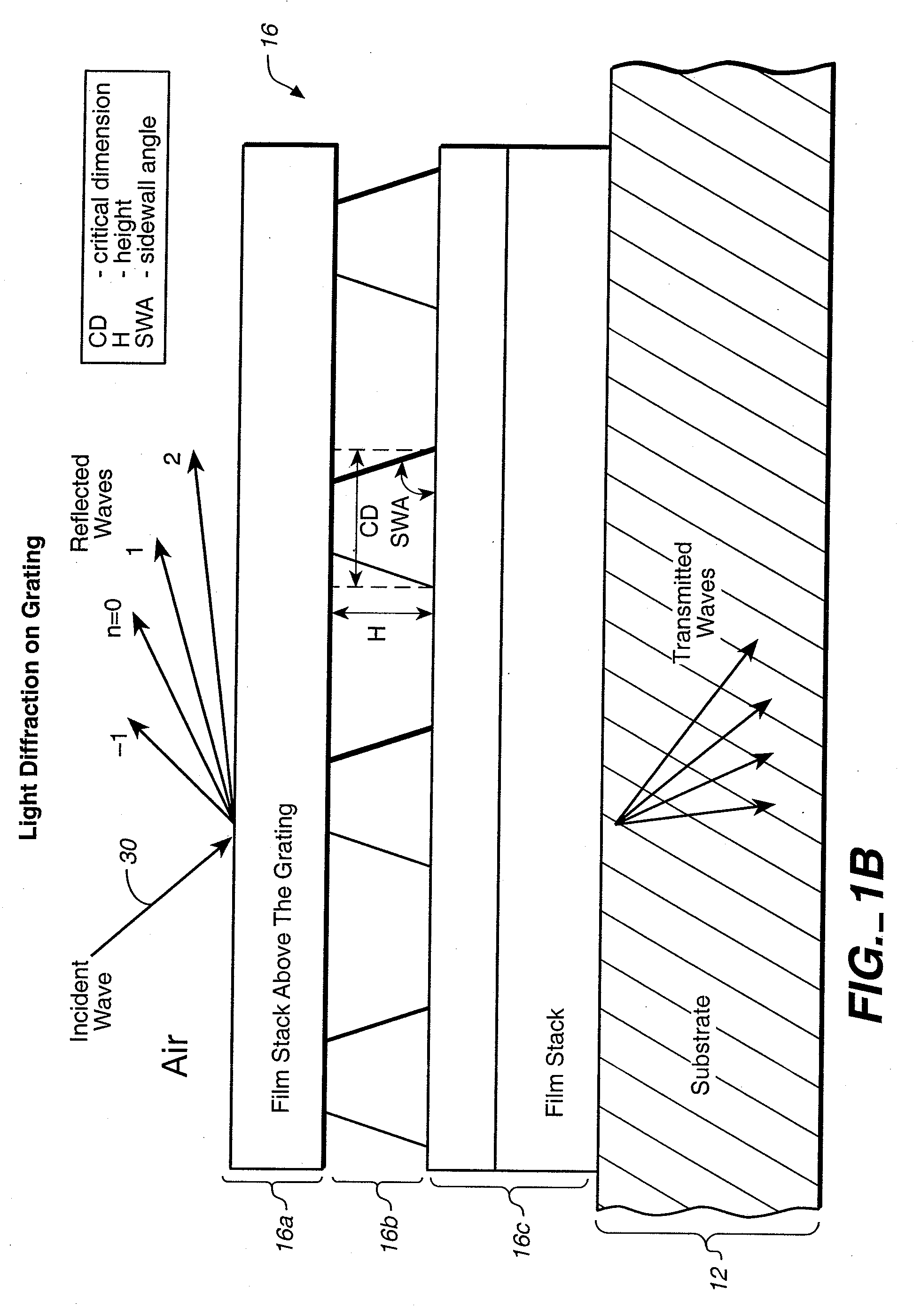

Parametric profiling using optical spectroscopic systems

InactiveUS7280230B2Simplify profile measurementRemove uncertaintyPolarisation-affecting propertiesScattering properties measurementsComputer scienceSemiconductor

A gallery of seed profiles is constructed and the initial parameter values associated with the profiles are selected using manufacturing process knowledge of semiconductor devices. Manufacturing process knowledge may also be used to select the best seed profile and the best set of initial parameter values as the starting point of an optimization process whereby data associated with parameter values of the profile predicted by a model is compared to measured data in order to arrive at values of the parameters. Film layers over or under the periodic structure may also be taken into account. Different radiation parameters such as the reflectivities Rs, Rp and ellipsometric parameters may be used in measuring the diffracting structures and the associated films. Some of the radiation parameters may be more sensitive to a change in the parameter value of the profile or of the films then other radiation parameters. One or more radiation parameters that are more sensitive to such changes may be selected in the above-described optimization process to arrive at a more accurate measurement. The above-described techniques may be supplied to a track / stepper and etcher to control the lithographic and etching processes in order to compensate for any errors in the profile parameters.

Owner:KLA TENCOR TECH CORP

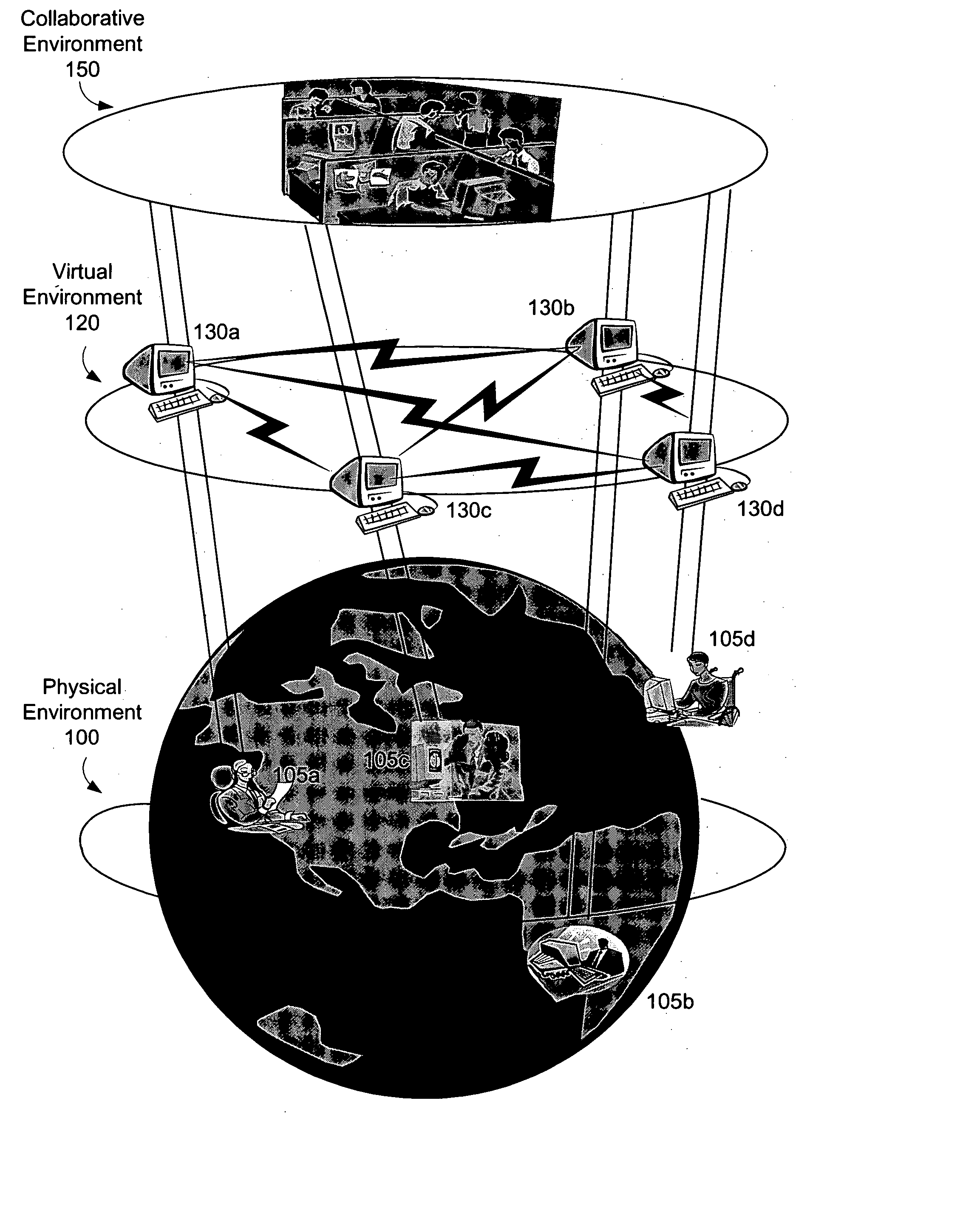

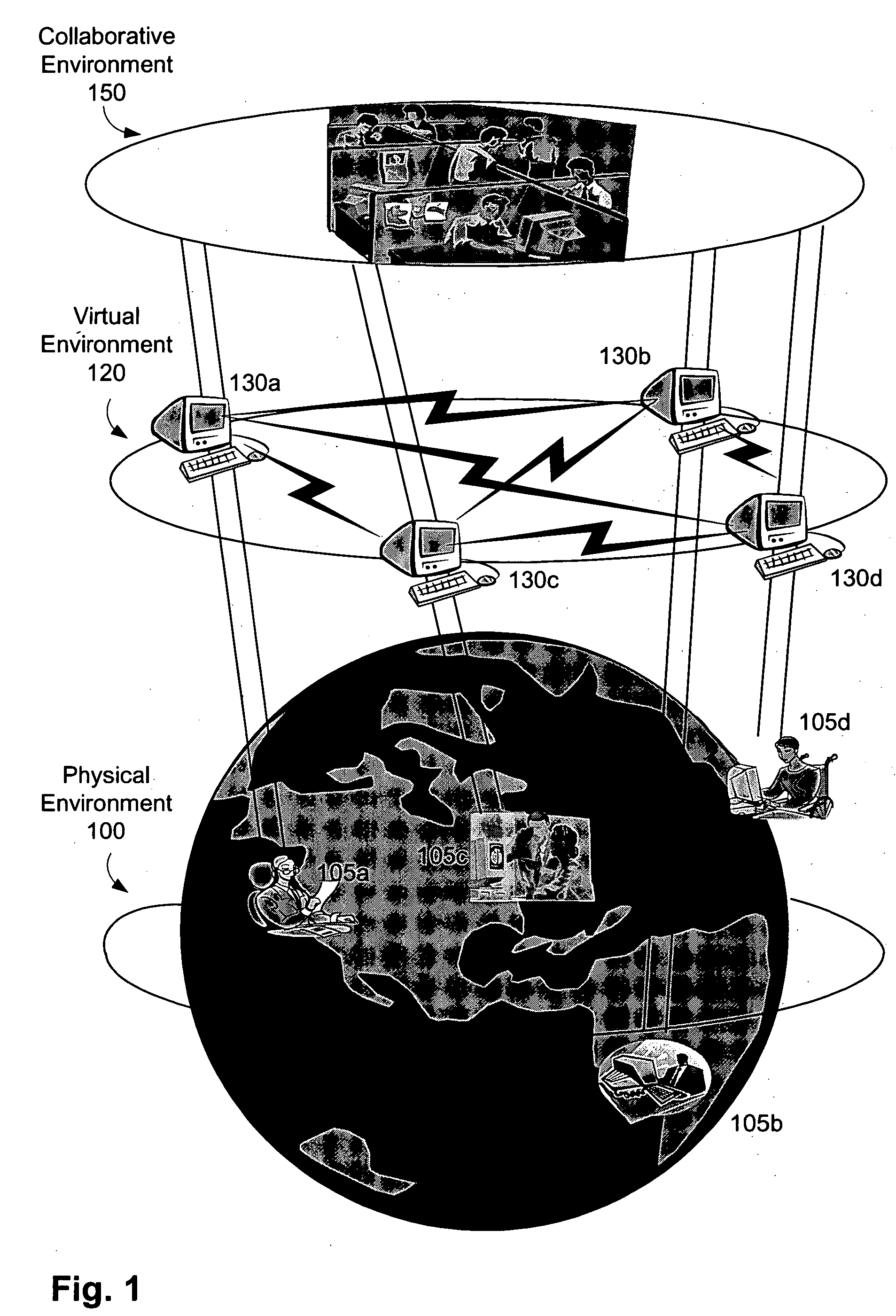

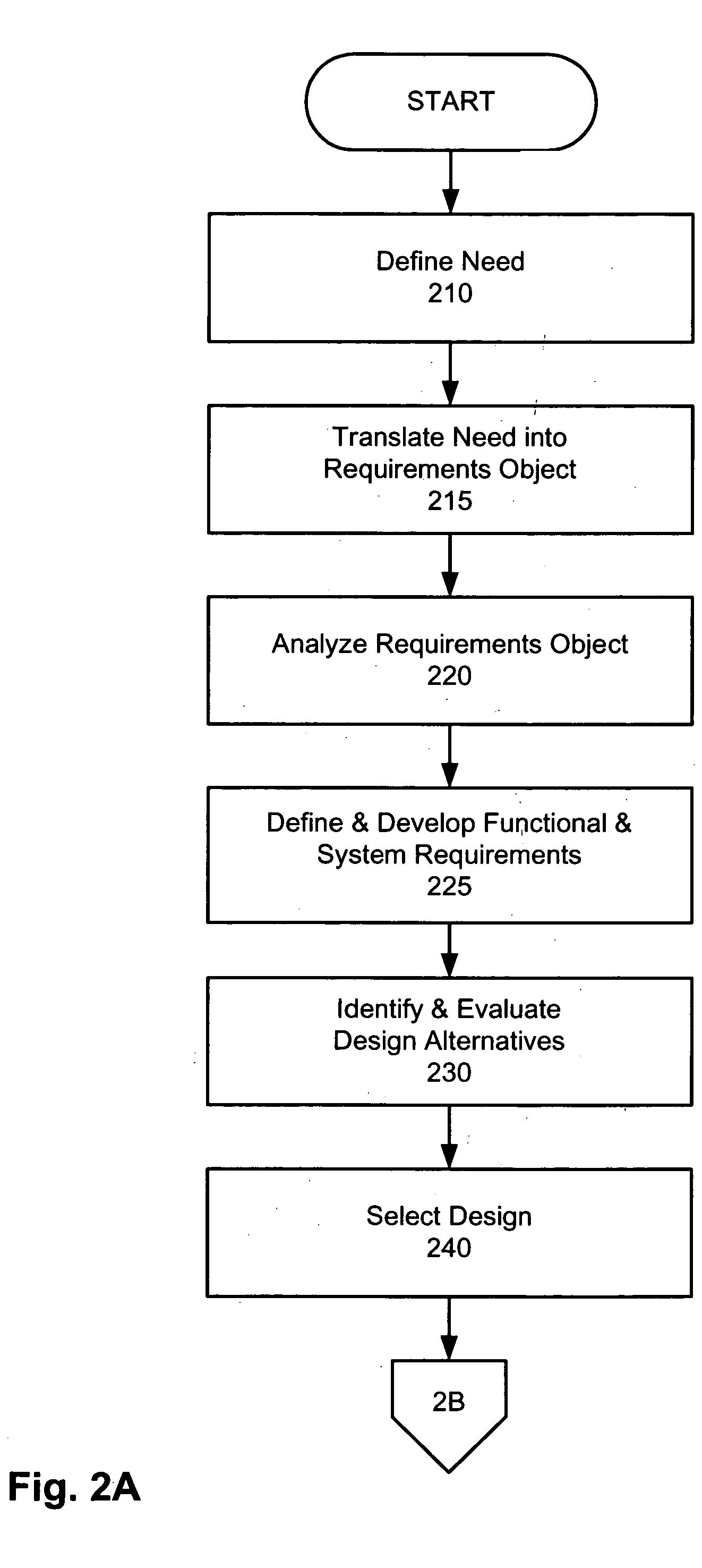

System and method for collaborative systems engineering

InactiveUS20050216429A1Costs associated with methodAvoid mistakesDigital data processing detailsResourcesInterconnectivityError processing

A process converts stand-alone data sources to an open standard based architecture and integrates data throughout disparate departments and organizations. Once the data is in an open environment, it is made available in a collaborative environment via Web-based applications. The process does not require that the data come under the control of a central database, rather each data owner retains control. The invention allows users to maintain original processes for conducting their day-to-day activities. With minor modification to client applications, role-based interconnectivity of data can be established to allow data elements to be re-used by all downstream users without re-entering data, thereby improving product and process knowledge, preventing errors, handling data arbitration, improving data visibility and flexibility for decision makers, and saving resources thereby allowing collaborators to focus on core business competencies.

Owner:LOCKHEED MARTIN CORP

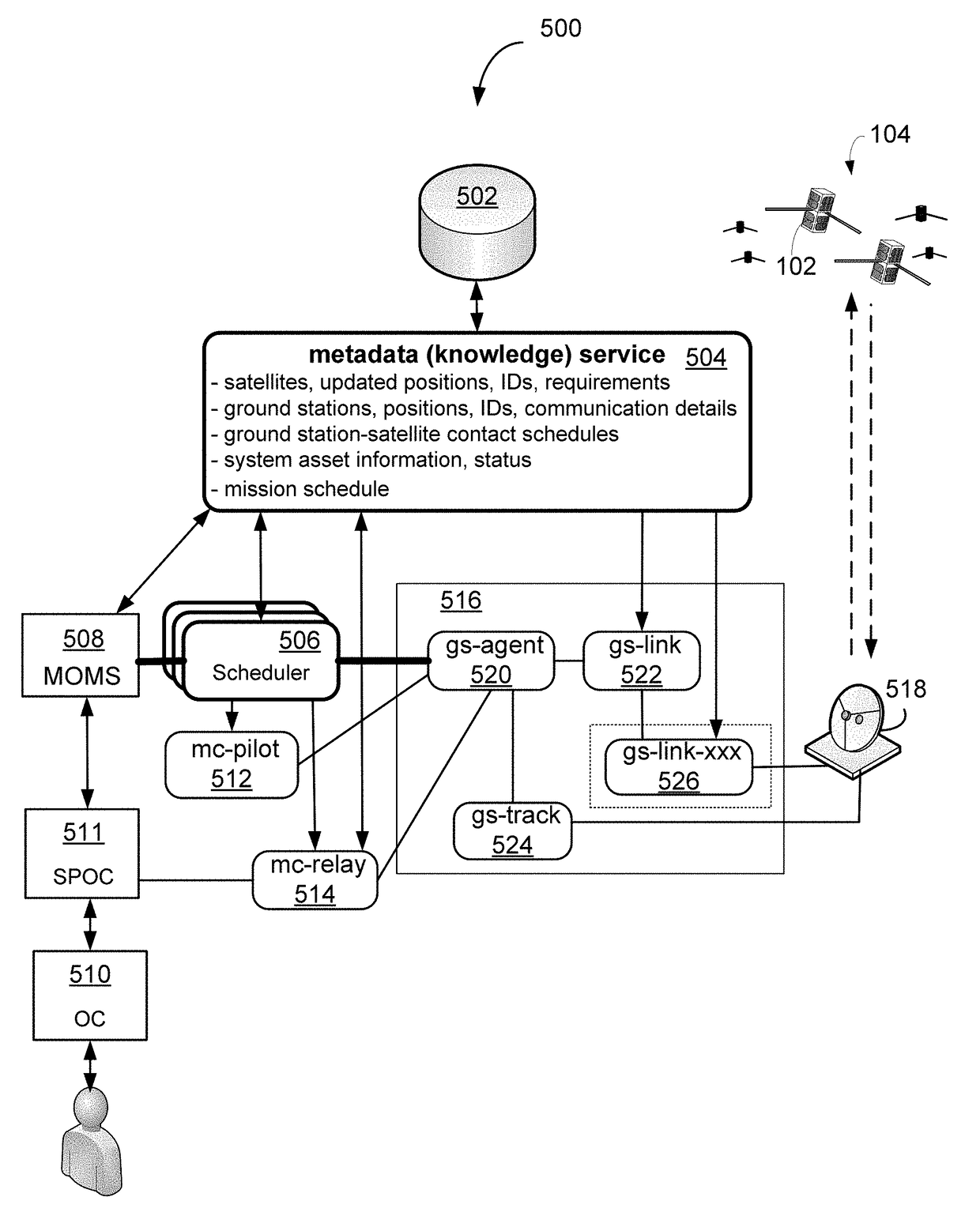

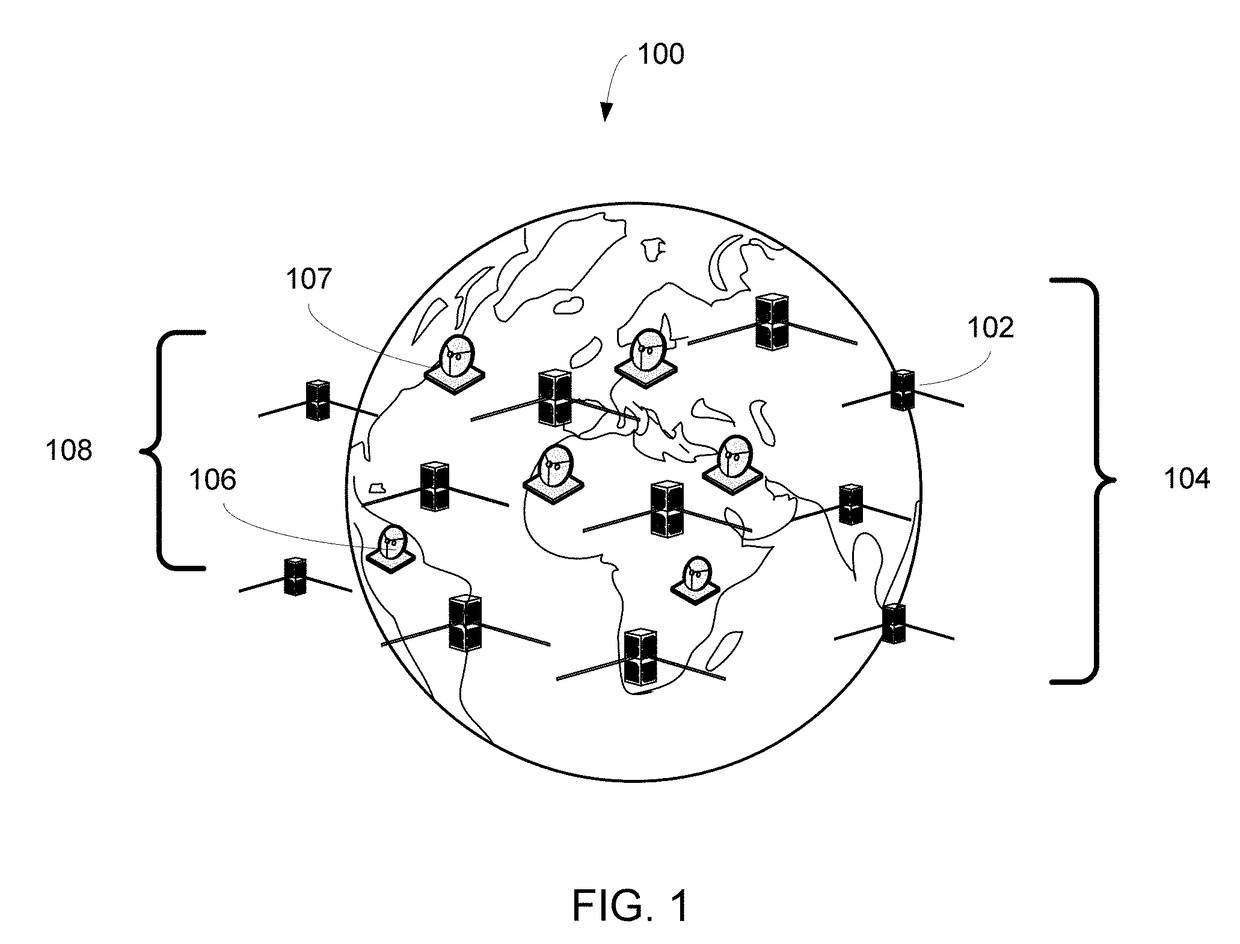

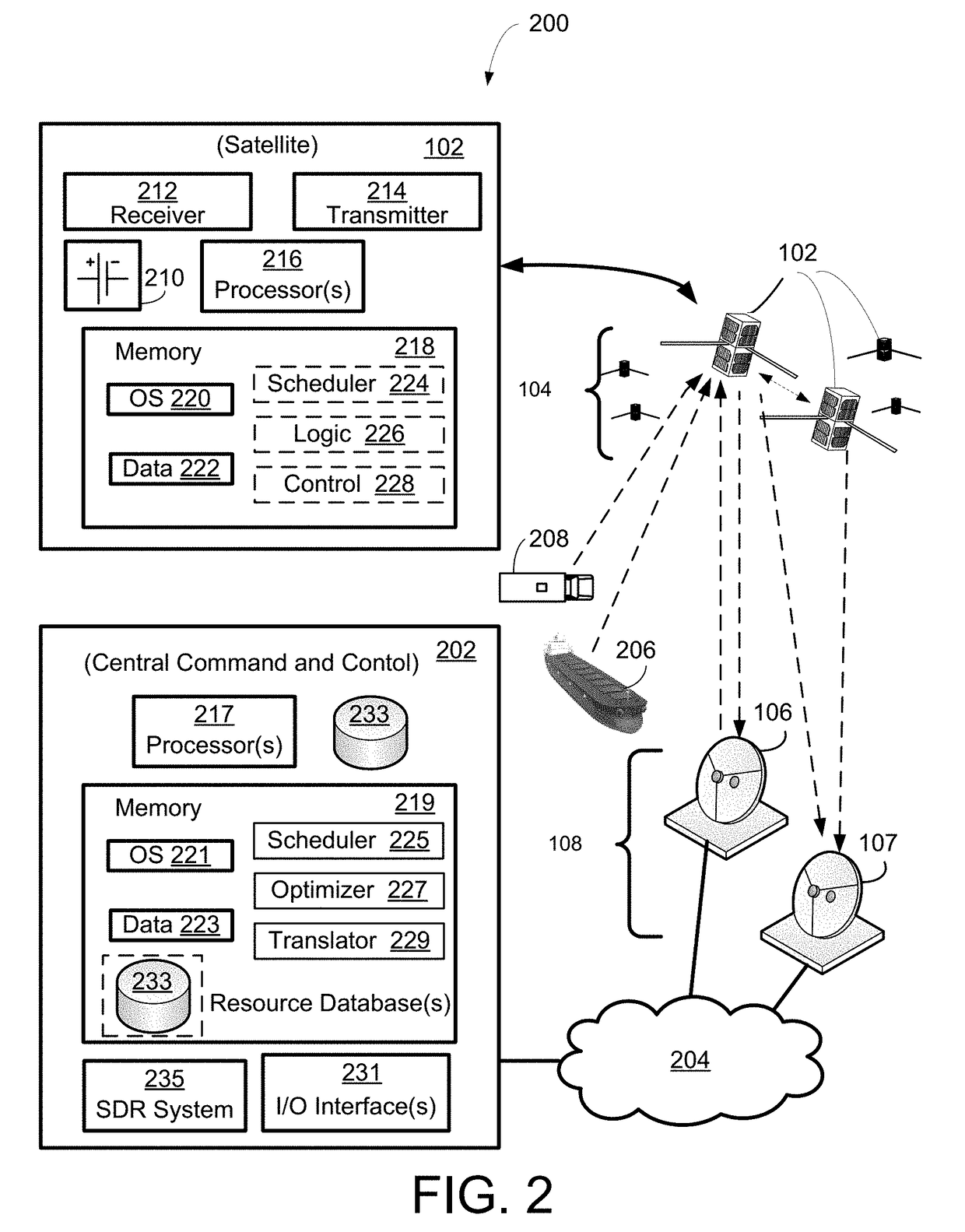

Systems and methods for command and control of satellite constellations

The disclosed technology relates to systems and methods for tasking satellite constellations. A method is disclosed herein for receiving, from a resource database of a satellite control system, knowledge data corresponding to a plurality of components associated with a satellite constellation communications system. The plurality of components can include one or more satellites associated with a constellation. The method includes processing the knowledge data according to at least one received mission objective. Processing the knowledge data can include determining a status of at least one satellite in the constellation. The method includes scheduling the satellite control system based at least in part on the received mission objective and the processed knowledge data; initiating communication with the at least one satellite in the constellation according to the scheduling; receiving updated status information for at least one component of the plurality of components; and storing, in the resource database, the updated status information.

Owner:SPIRE GLOBAL

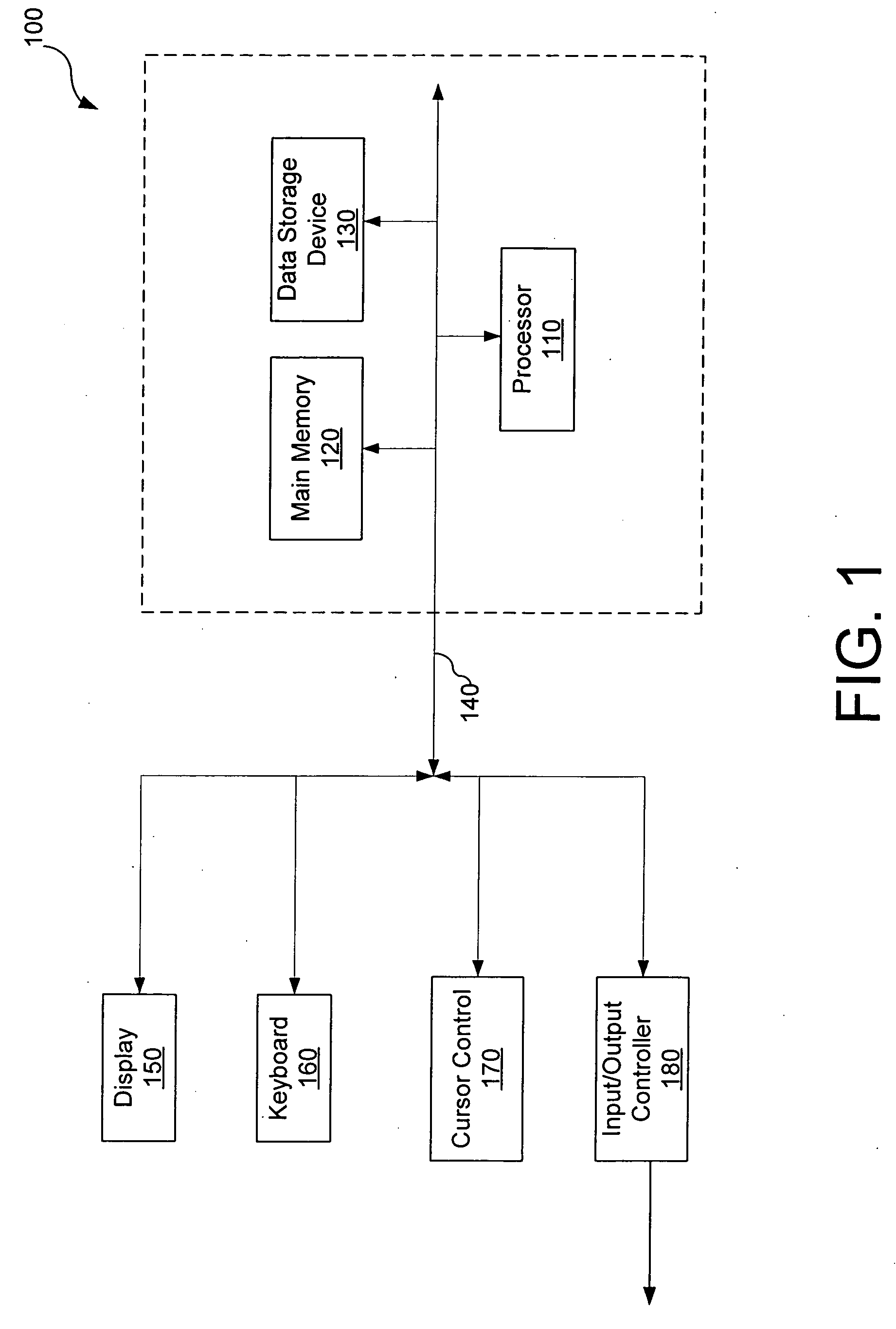

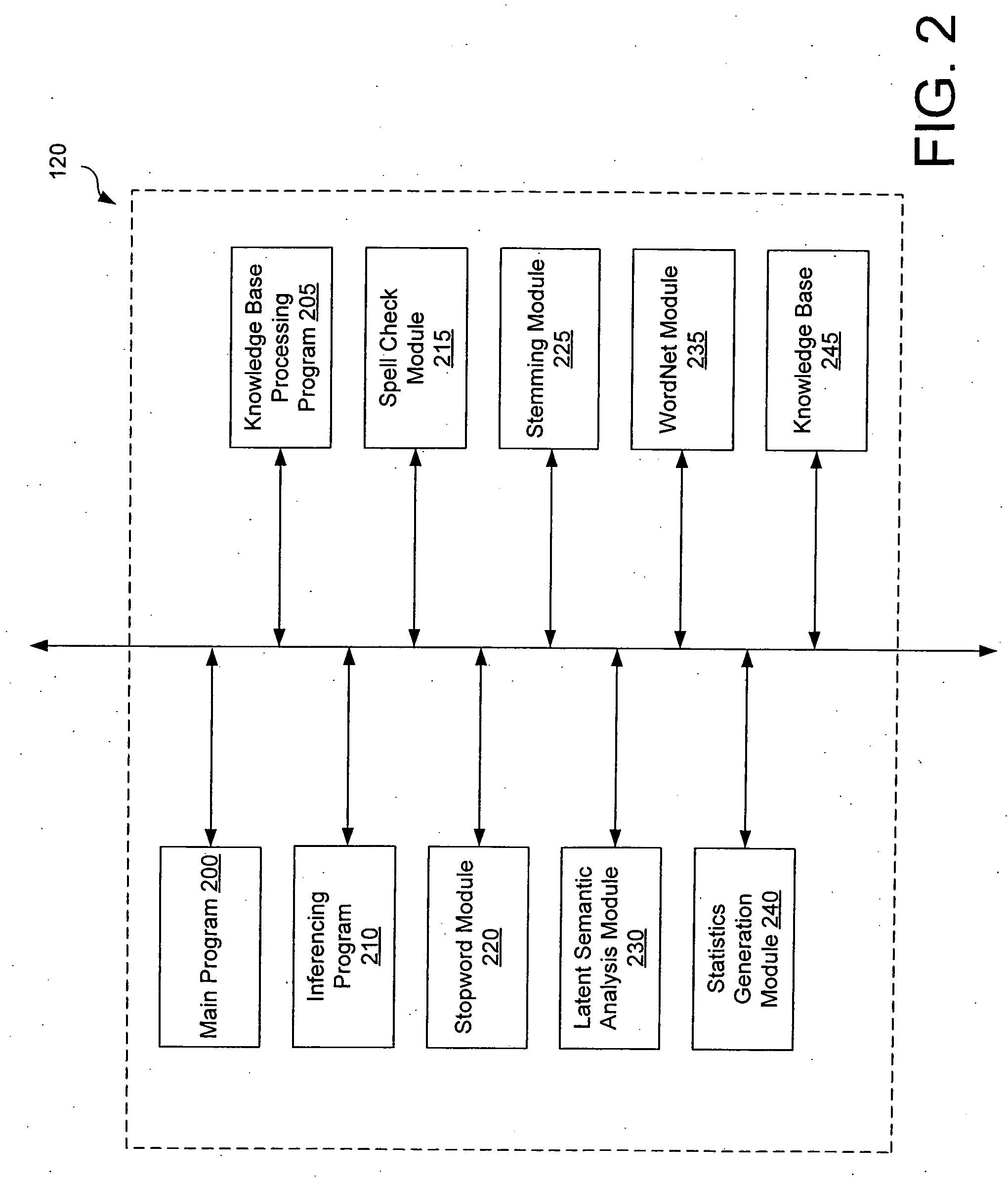

Systems and methods for using statistical techniques to reason with noisy data

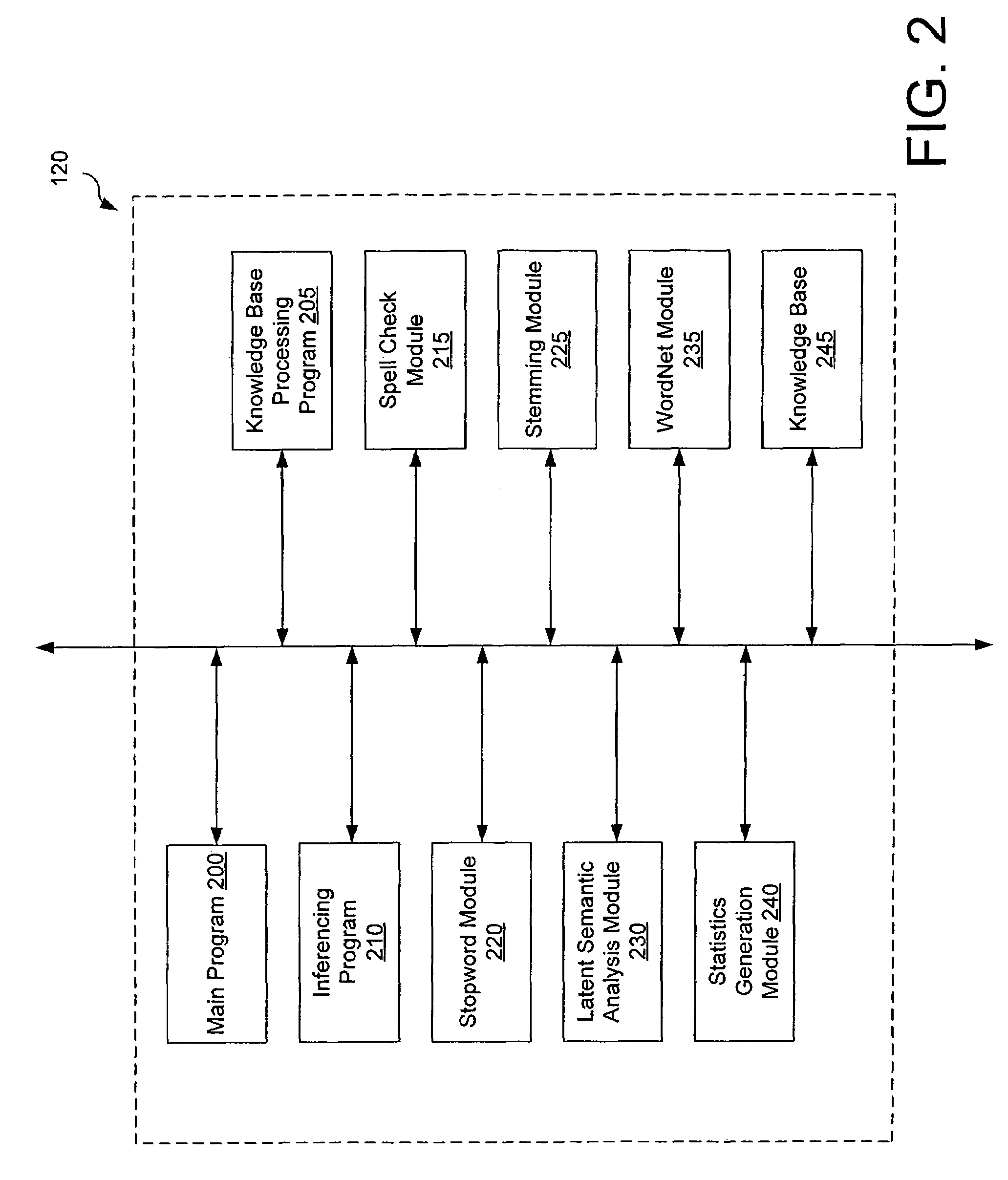

Systems and methods are presented that enable logical reasoning even in the presence of noisy (inconsistent) data. The knowledge base is processed in order to make it consistent and is also compiled. This processing includes checking and correcting spelling, removing stopwords, performing, grouping words of similar and related meaning, and compacting the knowledge base. A robot can use the processed knowledge base to perform many different types of tasks, such as answering a query, determining a course of action that is designed to achieve a particular goal, and determining its own location.

Owner:HONDA MOTOR CO LTD

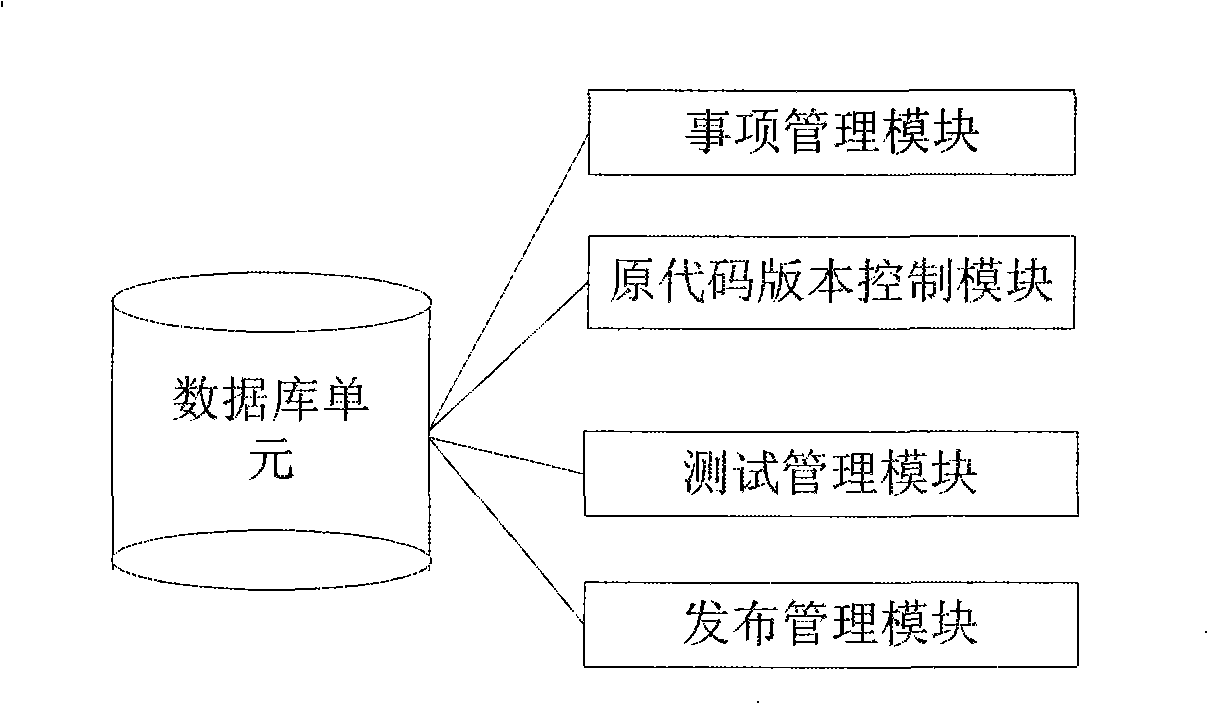

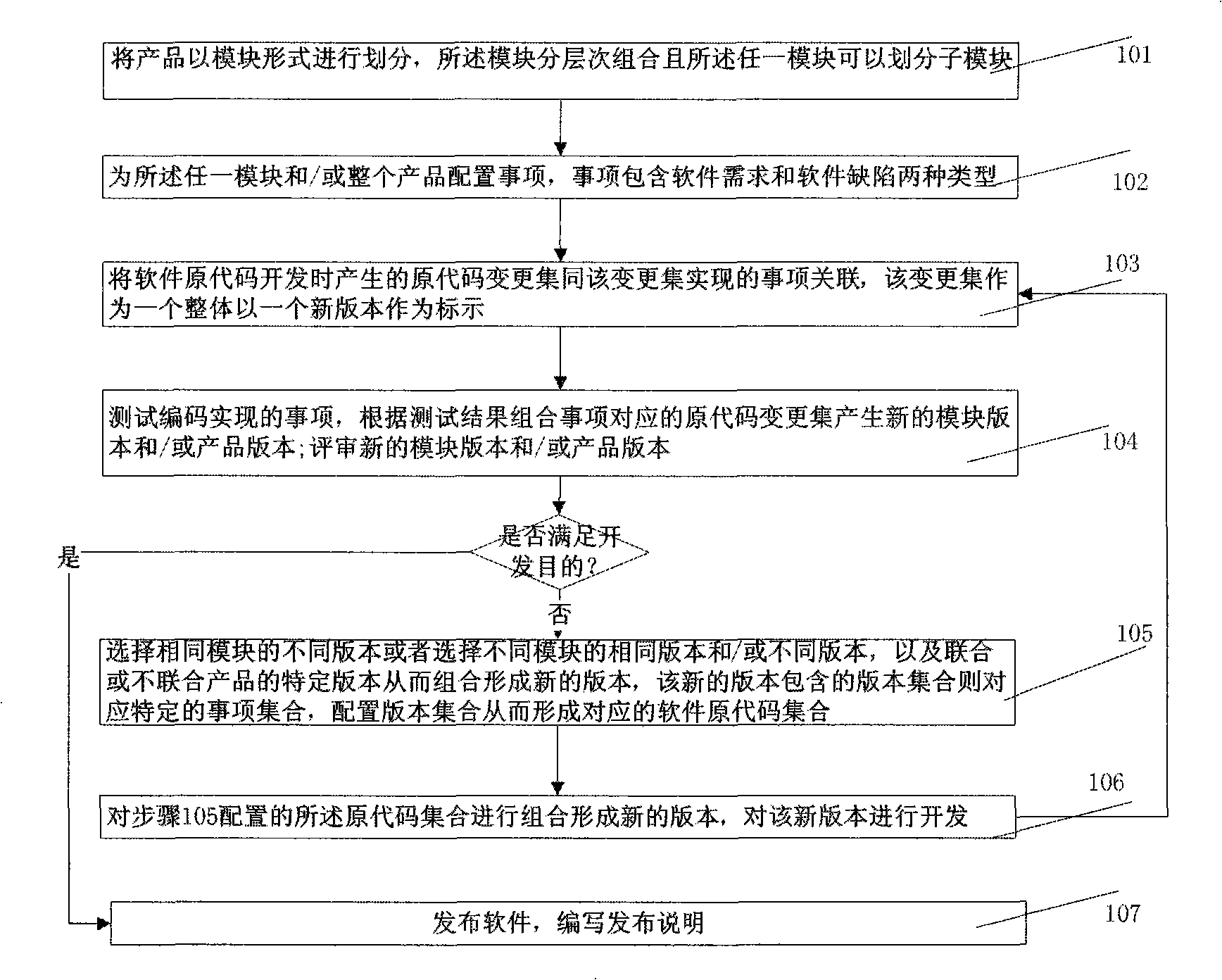

Integration type software configuration management method based on transaction management

InactiveCN101403964AEfficient testingImprove good performanceSpecific program execution arrangementsTransaction managementSoftware configuration management

The invention relates to the field of software development process control and discloses an integrated software configuration management method based on items. The method comprises the following steps: a product is divided in a form of the module; a combination product and / or a module edition form(s) a new edition, and the new edition is corresponding to specific item set; primary code changing set produced by development is related with the items realized by the changing set; the items realized by testing codes produce a new module edition and / or a new product edition; the software is released. The method has the advantages that the software configuration management is carried out by the method and the problem that the software primary code is lack of item process knowledge is solved, thus leading the developed software primary code to be easy to manage, test and release; the development process is easy to trace back and the primary code is easy to expand and maintain, the software quality can be controlled; meanwhile, the efficiency of the software development is improved, and the development cost and the maintenance cost are reduced.

Owner:SICHUAN SEVENUC SOFTWARE

Multi-process scheme planning method based on combination weighting method

The invention discloses a multi-process scheme planning method based on a combination weighting method. The multi-process scheme planning method comprises the following steps: analyzing various factors influencing the quality of a process scheme, and establishing two layers of evaluating systems; carrying out standardizing treatment on evaluating index data by adopting a subjection function; respectively weighting evaluating indexes by adopting a fuzzy integrated evaluating method and a variation coefficient method based on process knowledge data; in combination with the weighting results of the fuzzy integrated evaluating method and the variation coefficient method, taking minimal sum of weight error squares as a target function, and calculating combination weight by adopting a Lagrangian multiplier method; based on the combination weight, in combination with a gray relative analysis method, according to the design of two layers of evaluating structures, establishing two layers of gray relative analysis models, and selecting an optimal process scheme by correlation degree of candidate process schemes obtained by calculating the models. According to the multi-process scheme planning method disclosed by the invention, the distribution deviation of optimized target weights is reduced, and the performability of the process scheme is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

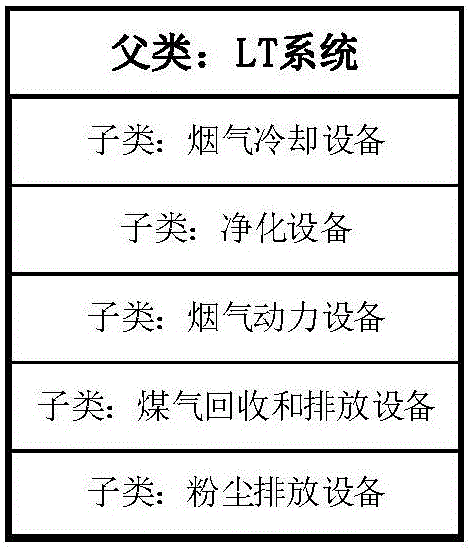

Semantic web based method for acquiring implicit relationship among steel iron making process knowledge

InactiveCN105808734AObtain implicit association informationEasy maintenanceRelational databasesSpecial data processing applicationsState of artReusability

The invention relates to a semantic web based method for acquiring an implicit relationship among steel iron making process knowledge. The method is used for accurately expressing the implicit relationship among the steel iron making process knowledge. The method comprises the following steps of 1) performing triple expression on the steel iron making process knowledge to establish an initialized model of a concept and the relationship of the steel iron making process knowledge; 2) converting the initialized model to construct an ontology base; 3) performing semantic mapping on production standard data and the ontology base to construct a semantic web model; 4) performing formalized expression on a constraint condition of the concept and the relationship in the steel iron making process knowledge by adopting a semantic web rule language (SWRL) to establish a knowledge reasoning-oriented rule base; and 5) according to the semantic web model and the rule base, obtaining implicit associated information of the steel iron making process knowledge. Compared with the prior art, the method has the advantages of reusability, easiness for maintenance, flexibility for expression, fullness for discovery, strong data correlation and the like.

Owner:TONGJI UNIV

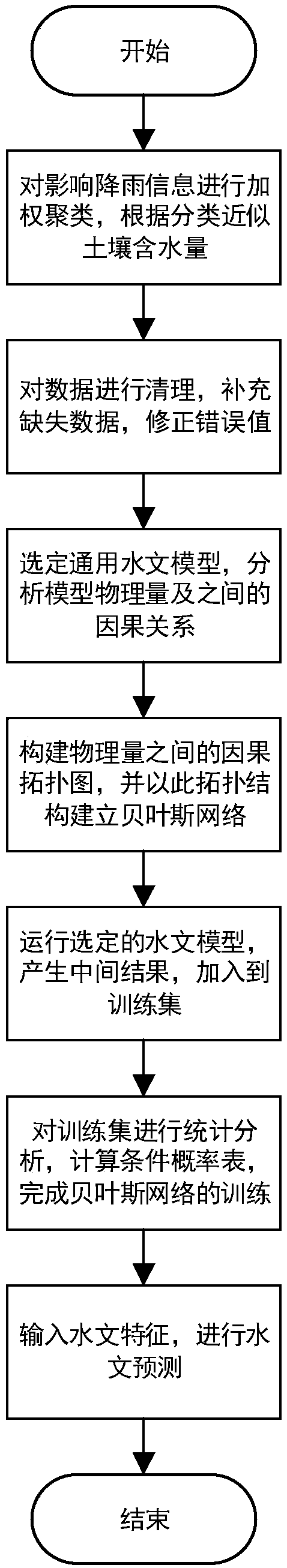

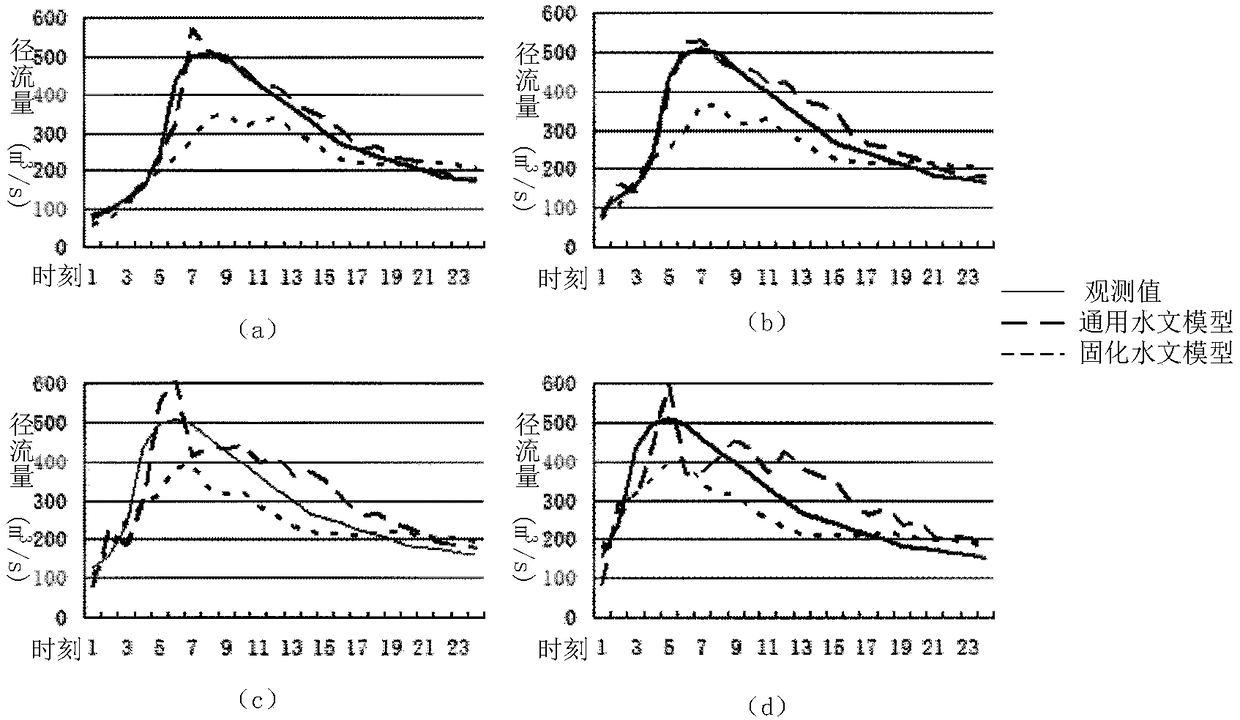

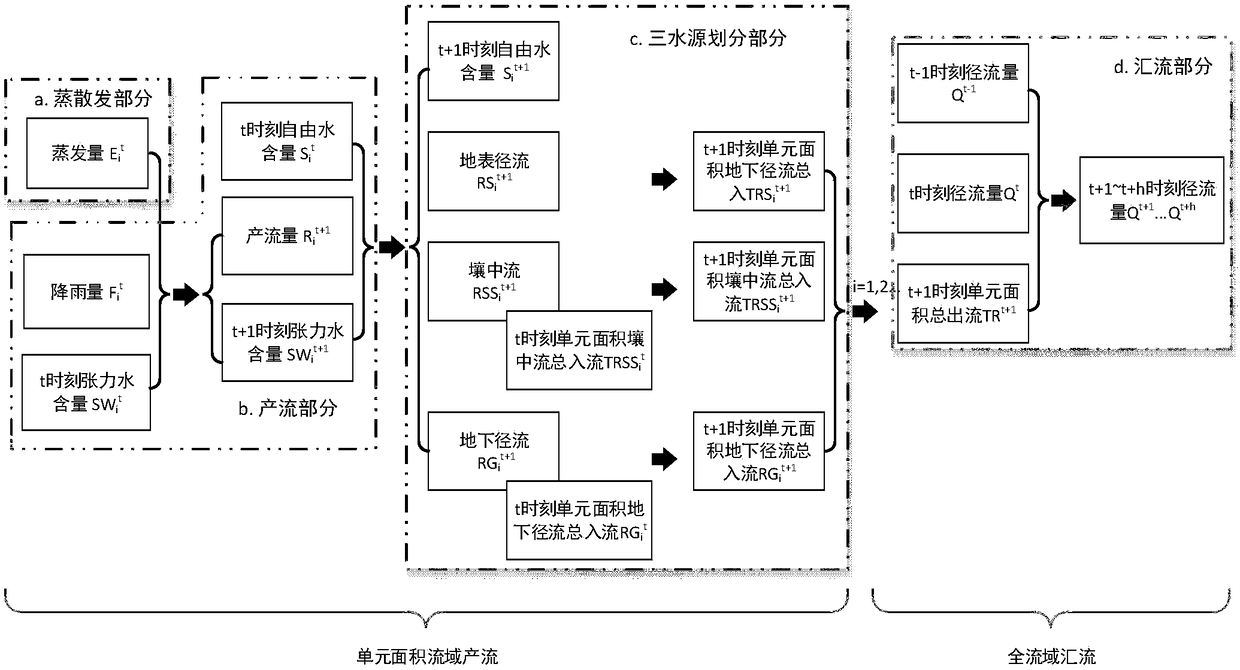

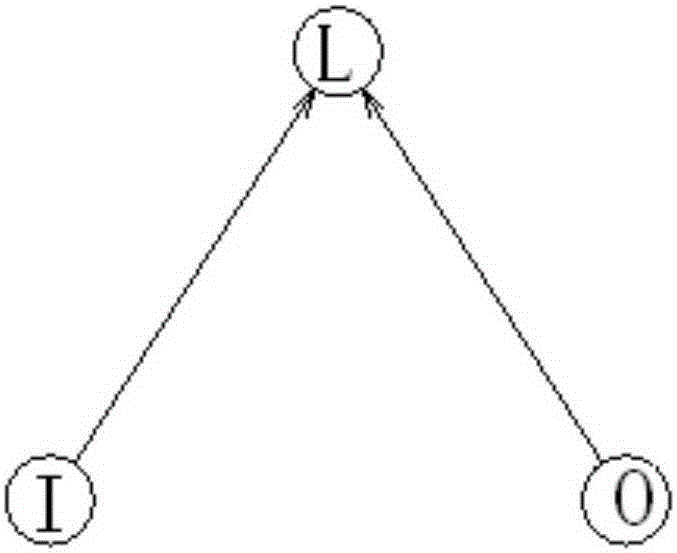

Hydrologic process data and historical prior data combined flood prediction method

ActiveCN108304668AAchieve trainingAchieve solidificationClimate change adaptationForecastingNODALMissing data

The invention discloses a hydrologic process data and historical prior data combined flood prediction method. A weighted clustering algorithm is adopted to perform cluster analysis on rainfall information to approximate water content information; cleaning is conducted on data, missing data is supplemented, and wrong data is corrected; a general hydrologic model is selected according to the basin characteristics to obtain causal reasoning relationships between variables in the hydrologic process; a directed graph manner is adopted to represent each set of reasoning relationship, wherein nodes represent physical variables, the direction of edges indicates the causal reasoning relationships, and a bayesian network is constructed by using a topological structure; historical data is utilized incombination with the general hydrologic model for simulation to generate intermediate result data to form a sample set together; historical prior knowledge is obtained according to the sample set, and a conditional probability table is calculated to achieve training on the network and complete the comprehensive modeling of hydrologic process knowledge and the historical prior knowledge; test datais input to achieve flood prediction.

Owner:HOHAI UNIV

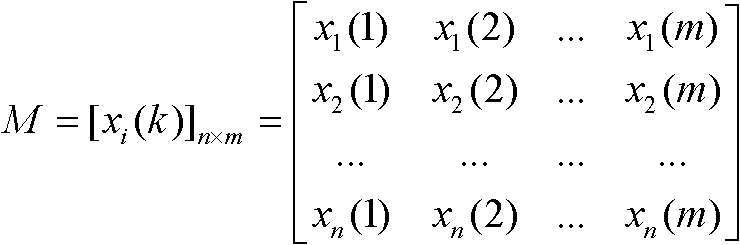

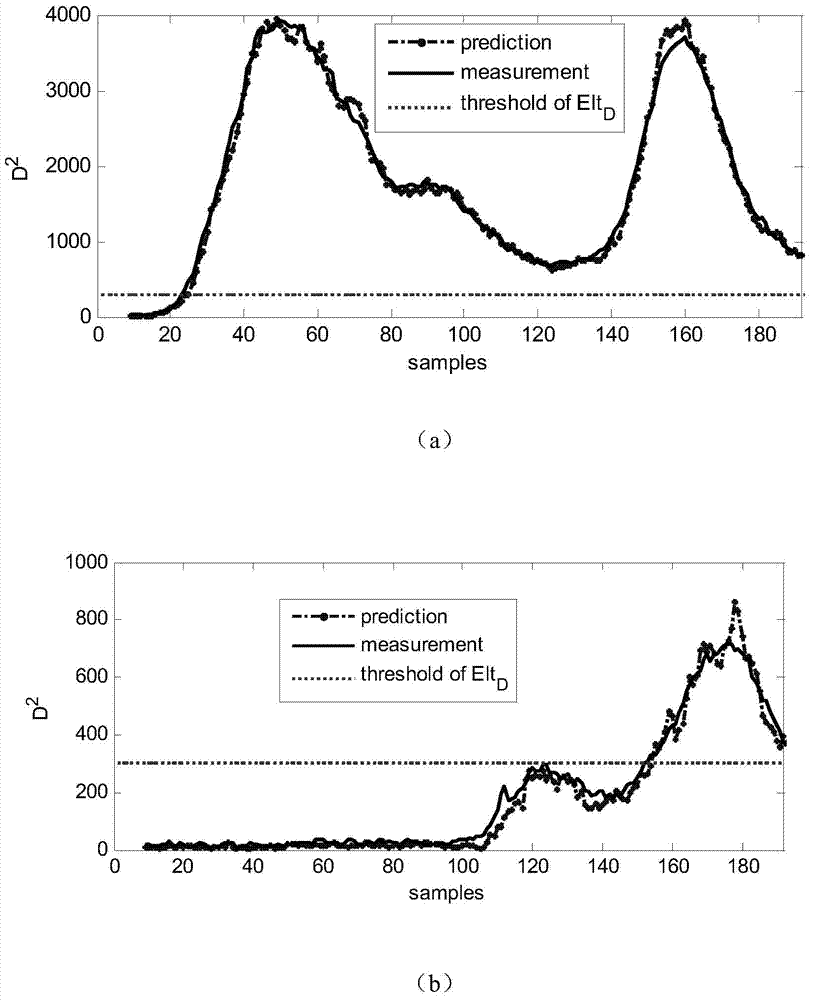

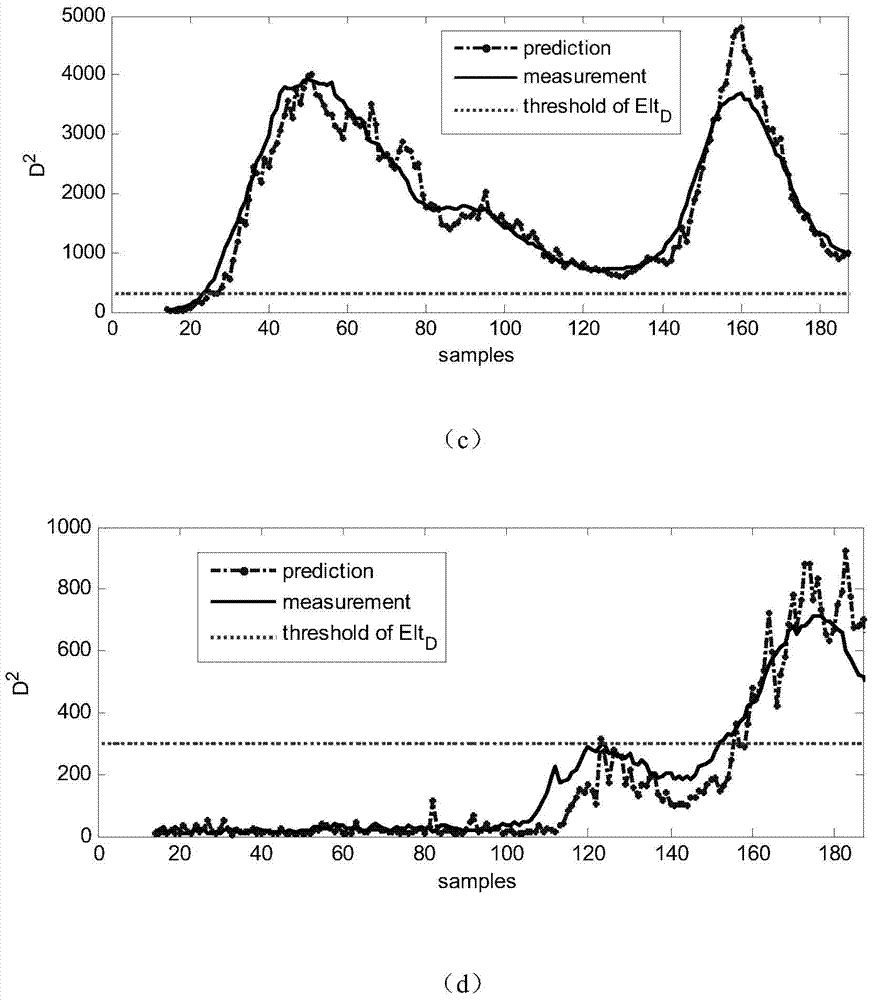

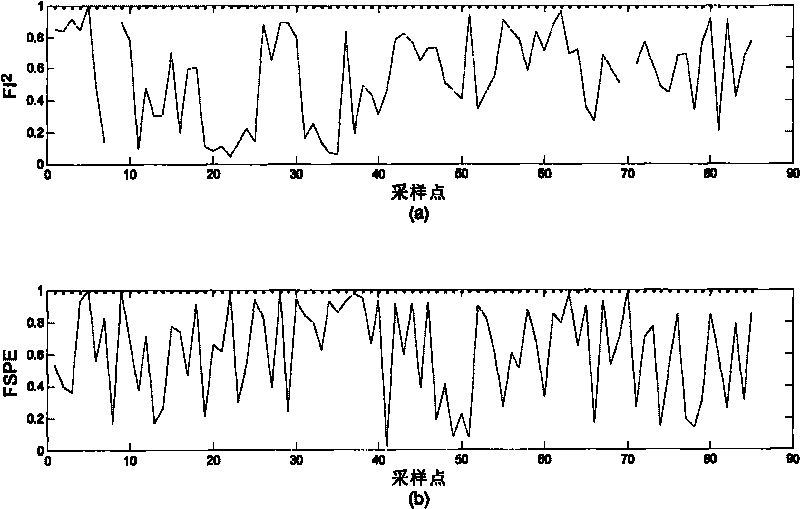

Fault prediction method based on joint relative change analysis and autoregression model

ActiveCN104714537AExtended reaction timeElectric testing/monitoringHypothesisPrincipal component analysis

The invention discloses a fault prediction method based on joint relative change analysis and autoregression modeling. According to the method, on the basis of principal component analysis, the fault influences are decomposed based on a joint relative change analysis method, and the fault direction is determined; then the fault amplitude is evaluated based on a reconstruction technology according o the determined fault direction, and data recovery of the normal portion is conducted; new monitoring statistical magnitude D<2> covering the normal data fluctuation is defined, and accordingly the event alarm limit (please see the formula in the specification) is established; finally an autoregression model is established based on the new monitoring statistical magnitude D<2> to be used for predicting the on-line monitoring statistical magnitude, and alarming in advance of the fault is achieved. The fault prediction method is easy and convenient to implement, efficient and free of depending on prior process knowledge and hypothesis. The fault prediction result is significant to subsequent fault diagnosis and repair, process engineers judge the process operation state timely and easily, and thus safe and reliable industrial production and pursuit for high-quality products are guaranteed.

Owner:ZHEJIANG UNIV

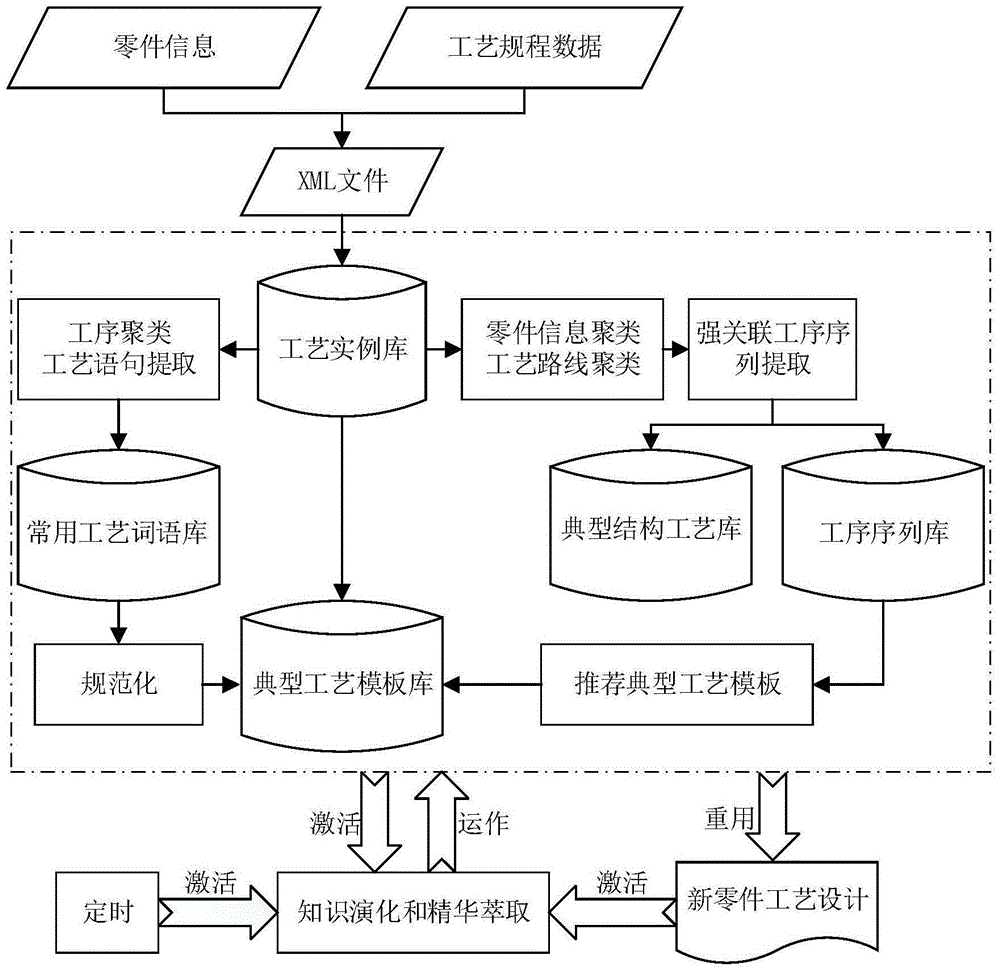

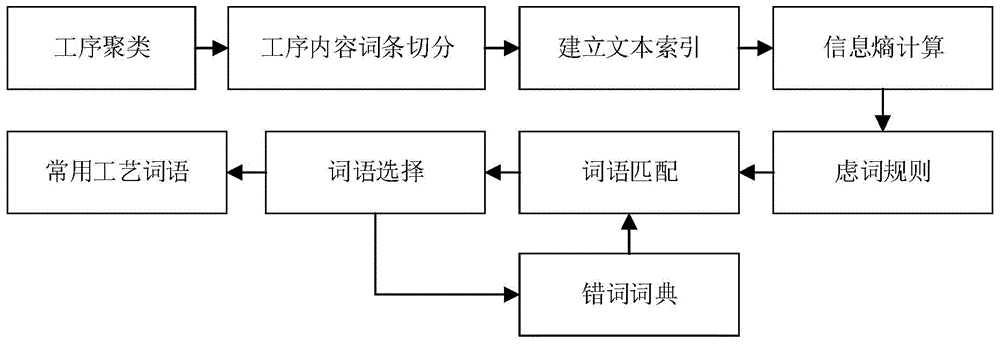

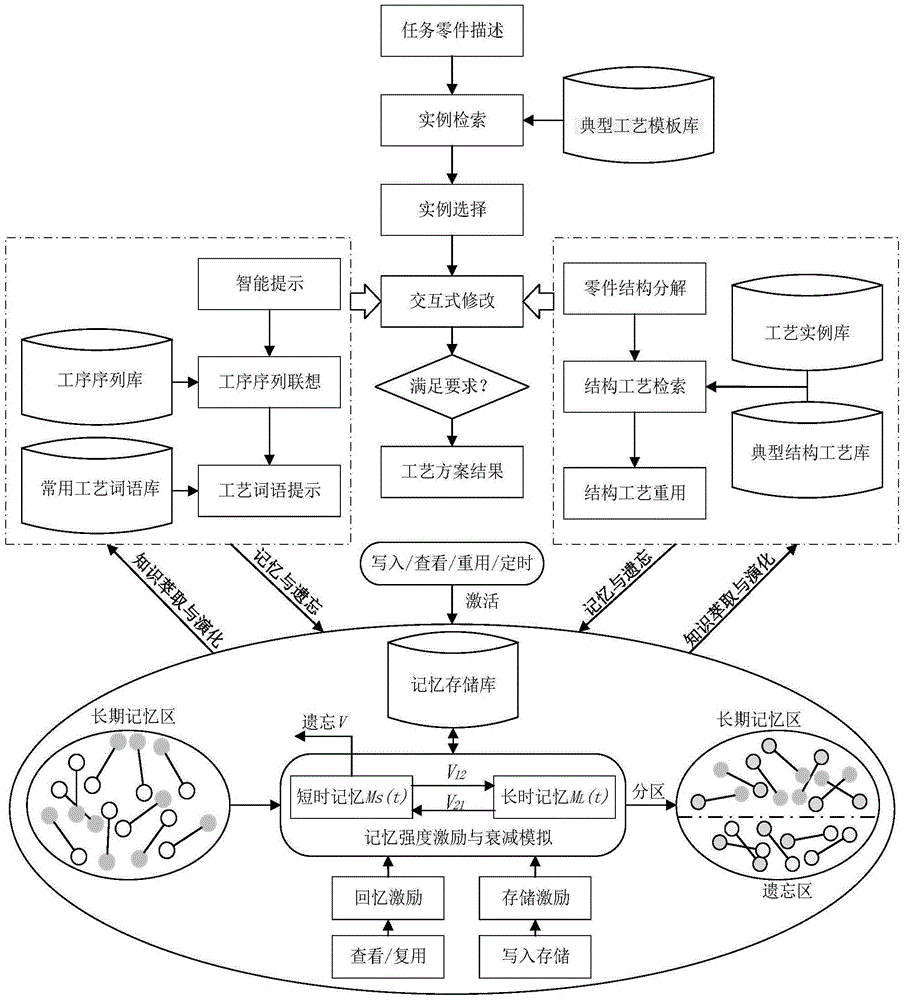

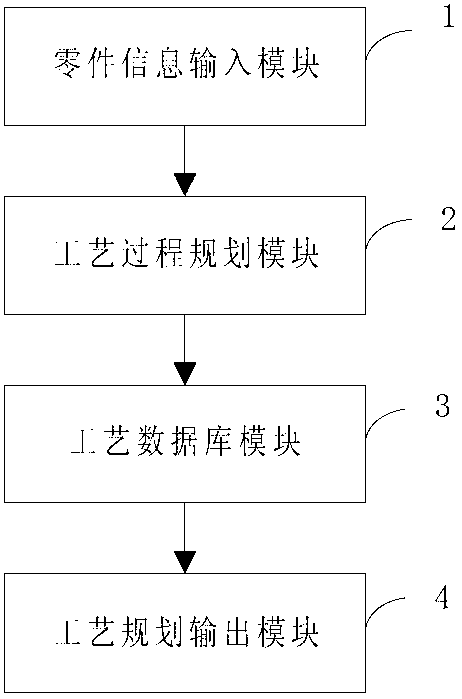

Method for knowledge extraction and evolution in machine parts processing technological procedure

InactiveCN105224953AAchieve standardizationImprove efficiencyCharacter and pattern recognitionMachine partsDecomposition

The present invention provides a method for knowledge extraction and evolution in a machine parts processing technological procedure. The method comprises: building a machine parts information description model, arranging corresponding technological procedure data, and uniformly expressing the model and the data by adopting an XML technology; establishing a snowflake model process case base, and mapping the data in XML into a corresponding table; establishing a data mining system to perform clustering according process names and extract common process words in the technological procedure; complementing the first clustering of parts process cases according to parts information, performing clustering according to a technological route, extracting a typical process sequence and a typical structure process in the technological procedure, and recommending a typical process template; reusing process knowledge in the common process words, the process sequence, the typical structure process and the typical process template based on a case reasoning technology and by means of a part structure decomposition policy and a smart prompting technology; and establishing a memory and forgetting model for realizing evolution and essence extraction of the process knowledge. According to the method provided by the present invention, the reuse of the process knowledge in different granularity levels and the standardization of the process design are achieved.

Owner:TIANJIN UNIV

Systems and methods for using statistical techniques to reason with noisy data

Systems and methods are presented that enable logical reasoning even in the Presence of noisy (inconsistent) data. The knowledge base is processed in order to make it consistent and is also compiled. This processing includes checking and correcting spelling, removing stopwords, performing, grouping words of similar and related meaning, and compacting the knowledge base. A robot can use the processed knowledge base to perform many different types of tasks, such as answering a query, determining a course of action that is designed to achieve a particular goal, and determining its own location.

Owner:HONDA MOTOR CO LTD

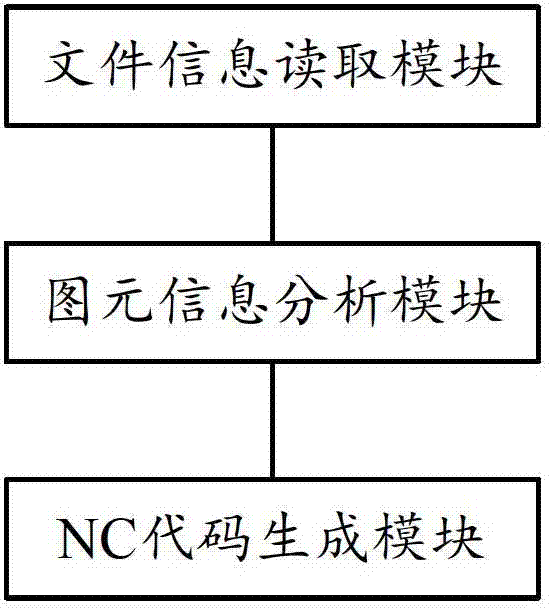

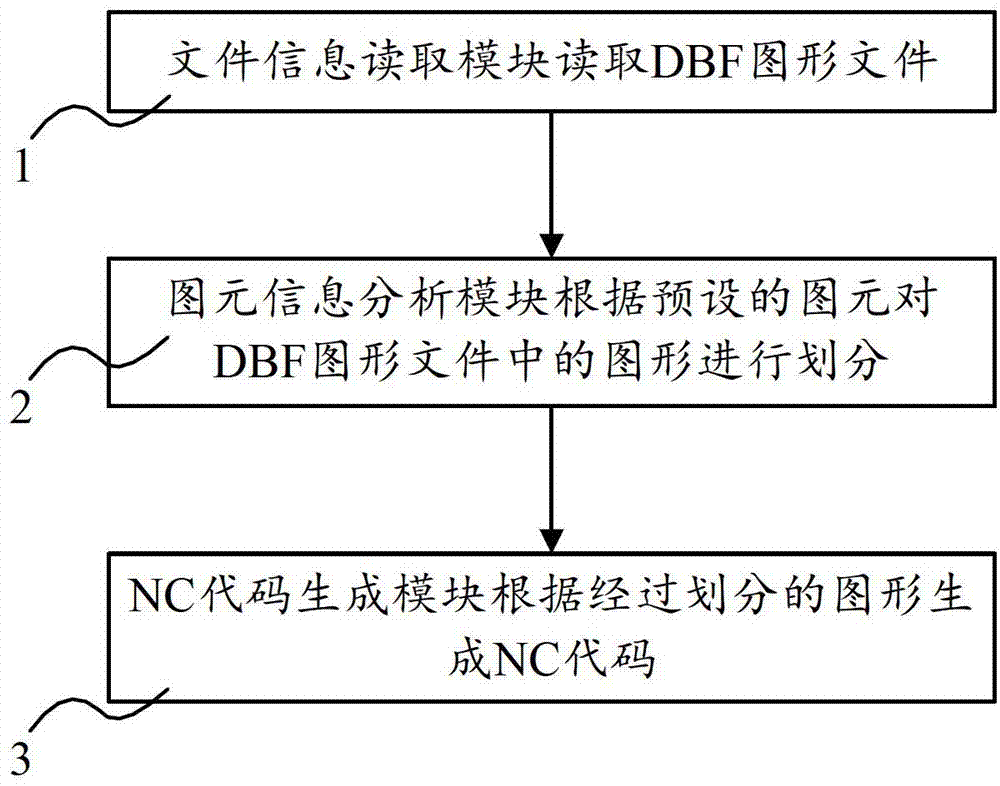

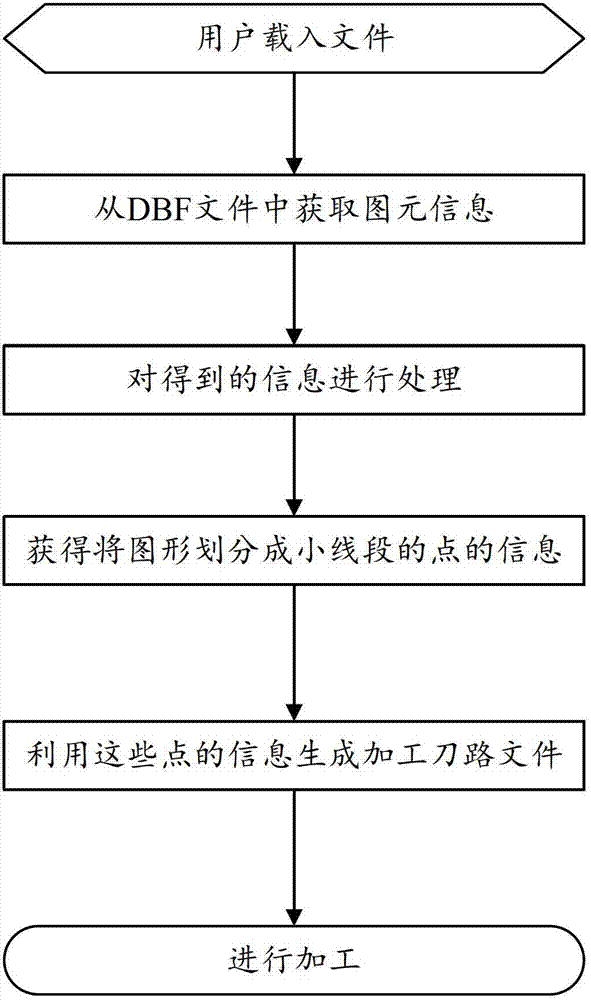

Numerical control system and control method for achieving automatic optimization of tool paths based on DBF

ActiveCN103197604AEasy to implementLow costProgramme controlComputer controlGraphicsInformation analysis

The invention relates to a numerical control system and a control method for achieving automatic optimization of tool paths based on DBF, and belongs to the technical field of numerical control system control. The numerical control system comprises a file information read module, a graphic primitive information analysis module and an NC code generation module. The control method includes that after DBF graphic files are read by the file information read module, graphs in the DBF graphic files are divided by the graphics primitive information analysis module according to a preset graphic primitive, and at last, NC codes are generated by the NC code generation module according to divided graphs. By adoption of the numerical control system and the control method, graphic information can be extracted from CAD graphs and converted to coordinate point data, combined with numerical control machining technique knowledge, the data are converted to the NC codes which can be identified by a machine tool to generate a numerical control program and achieve control of numerical control system machining, moreover according to the numerical control system and the control method for achieving the automatic optimization of the tool paths based on the DBF, the implementation mode is easy and convenient, implementation cost is low, and the application range is relatively wide.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

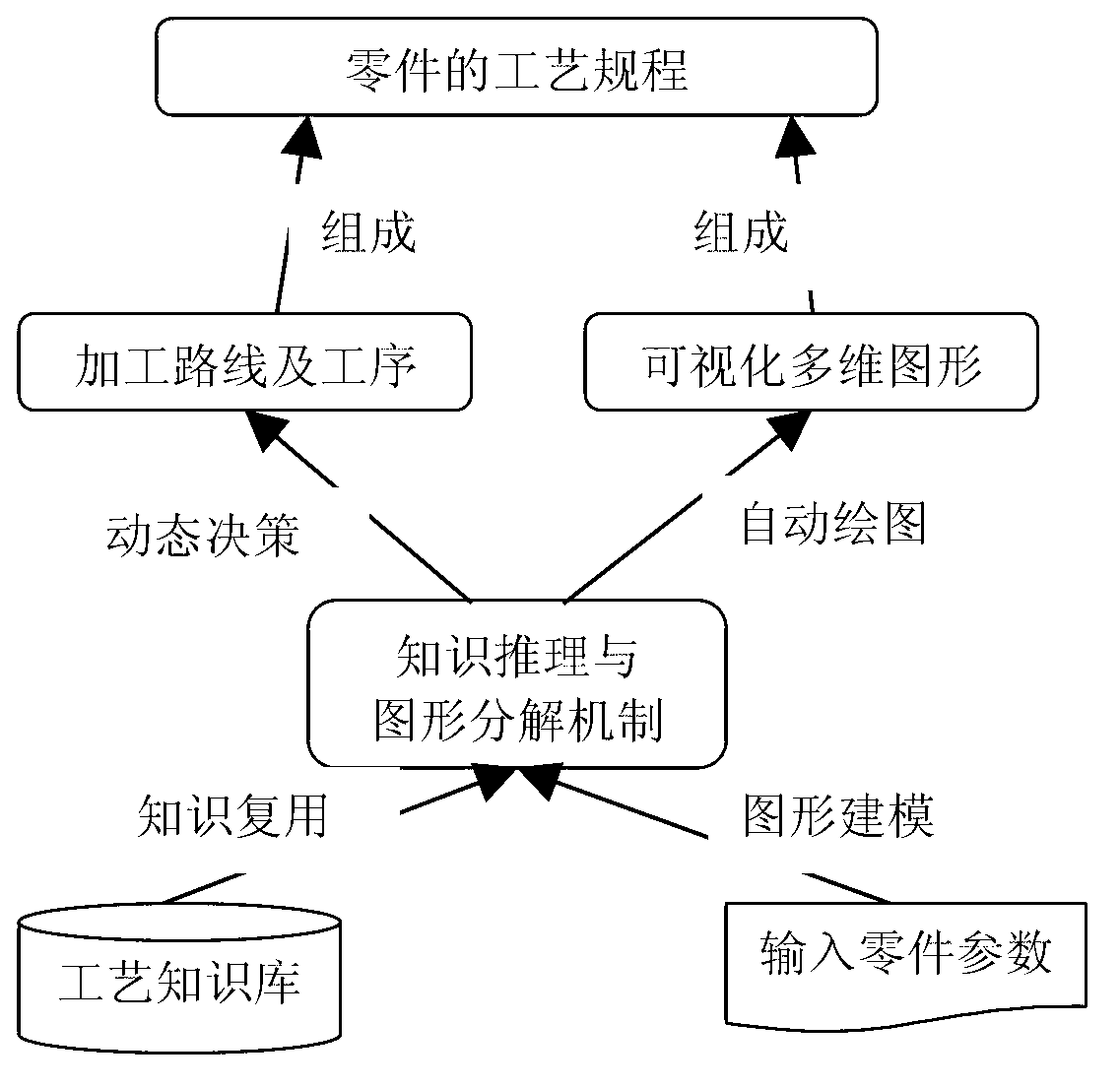

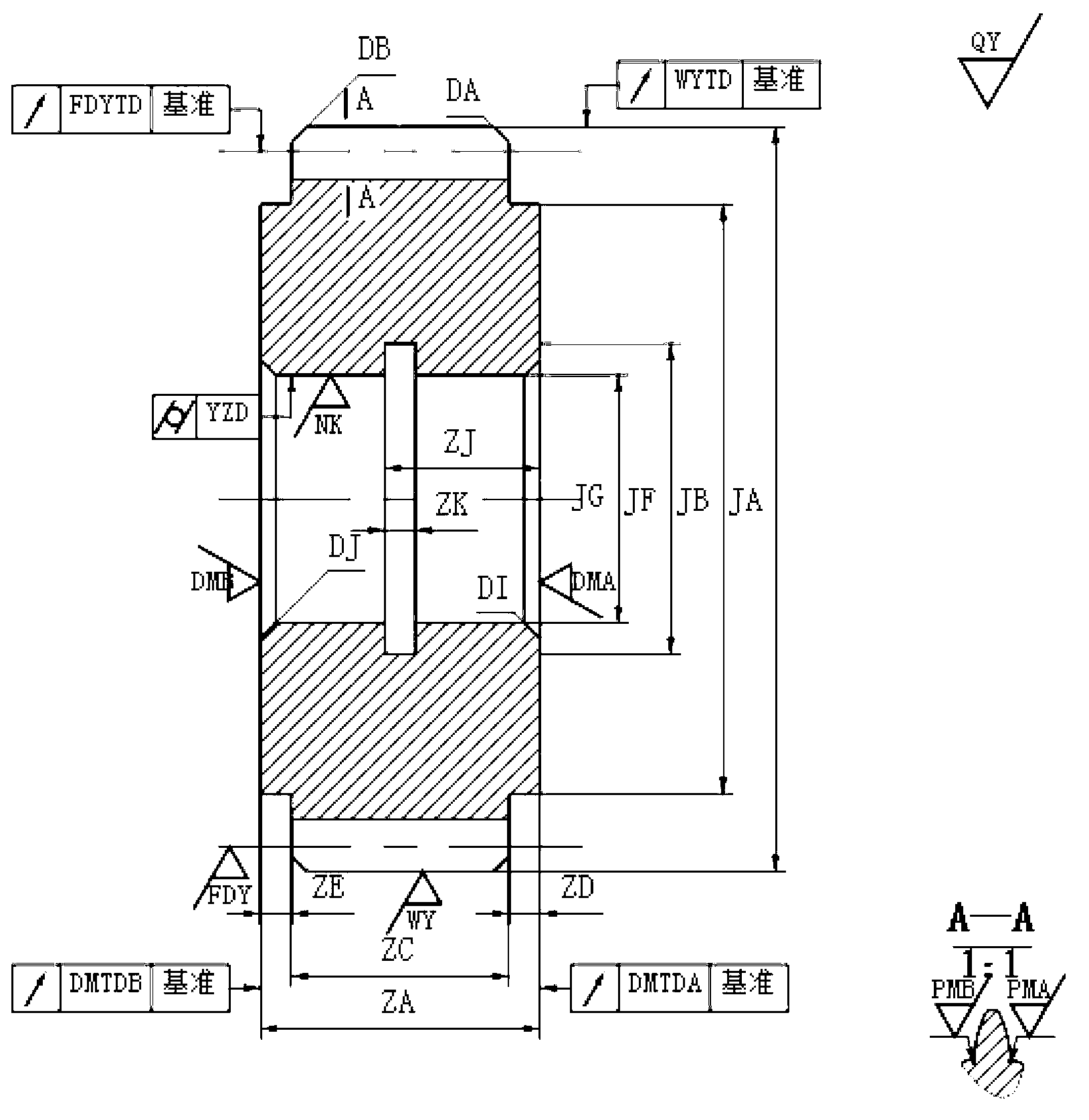

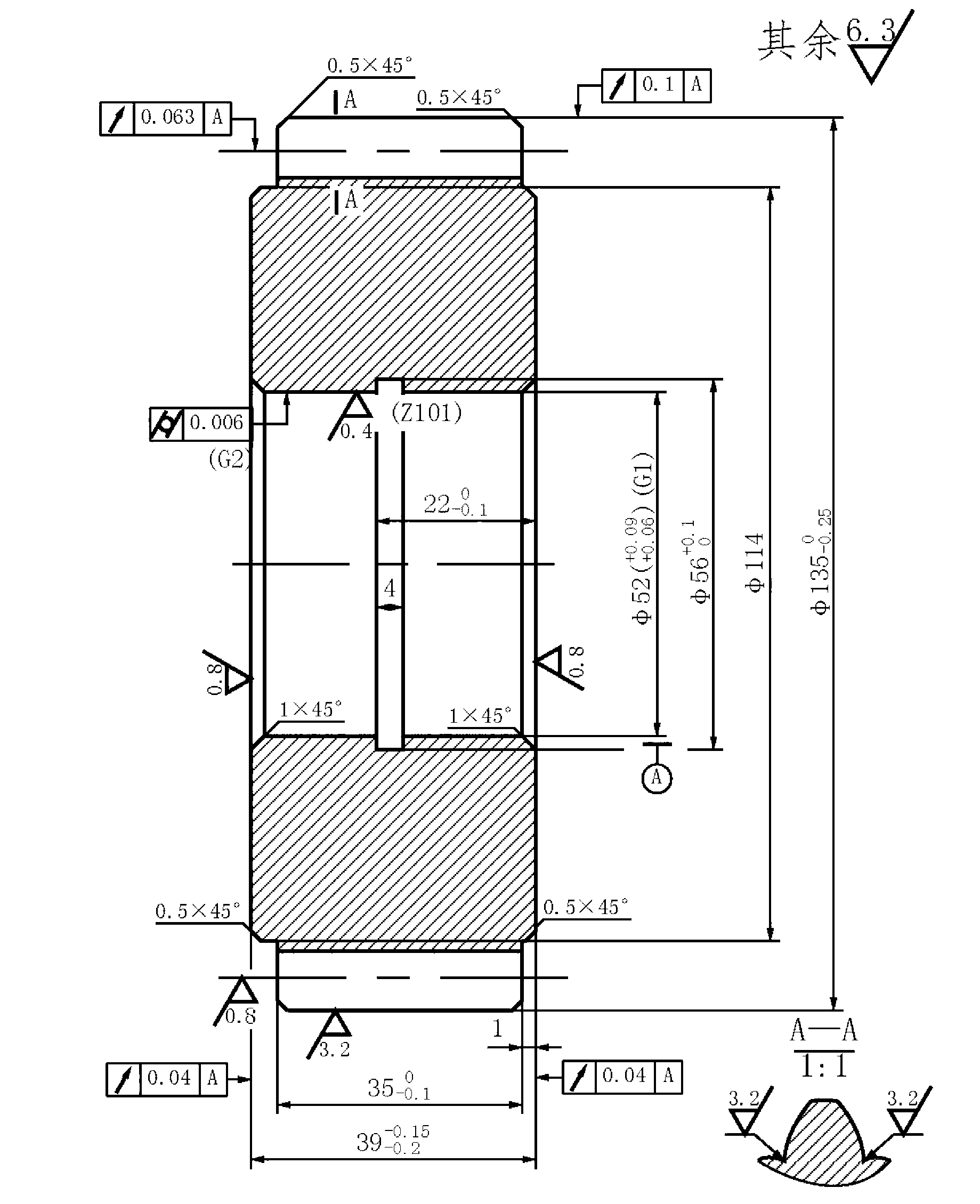

Computer-aided process planning method with graphic function

InactiveCN103268390ASolve problems in process preparationShorten the production cycleSpecial data processing applicationsGraphicsComputer-aided

The invention relates to a computer-aided process planning method with graphic function, belonging to the technical field of manufacturing automaton. The method comprises the steps of: combining visible process graphic drawing with computer-aided process planning, dynamically determining the processing path and each procedure of the parts by taking a process knowledge base as a core and combining process knowledge in the knowledge base according to process parameters of the parts under the support of knowledge reasoning and graphic decomposing mechanisms, meanwhile, automatically drawing the process graphics of the procedures in the processing path, and finally generating an integral process plan. The computer-aided process planning method effectively solves the problems in process planning, releases technologists from a mass of repeated labor, shortens the production period and improves the labor efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

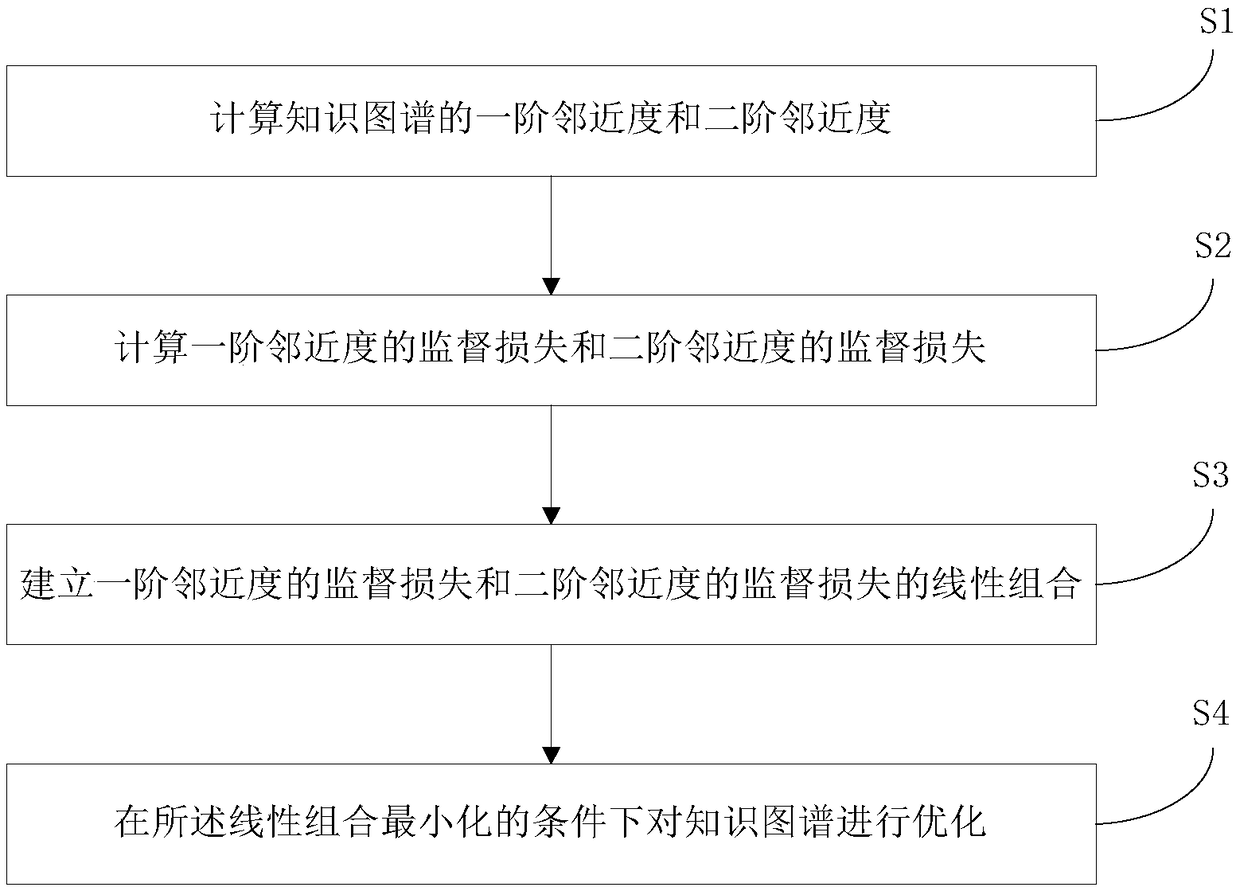

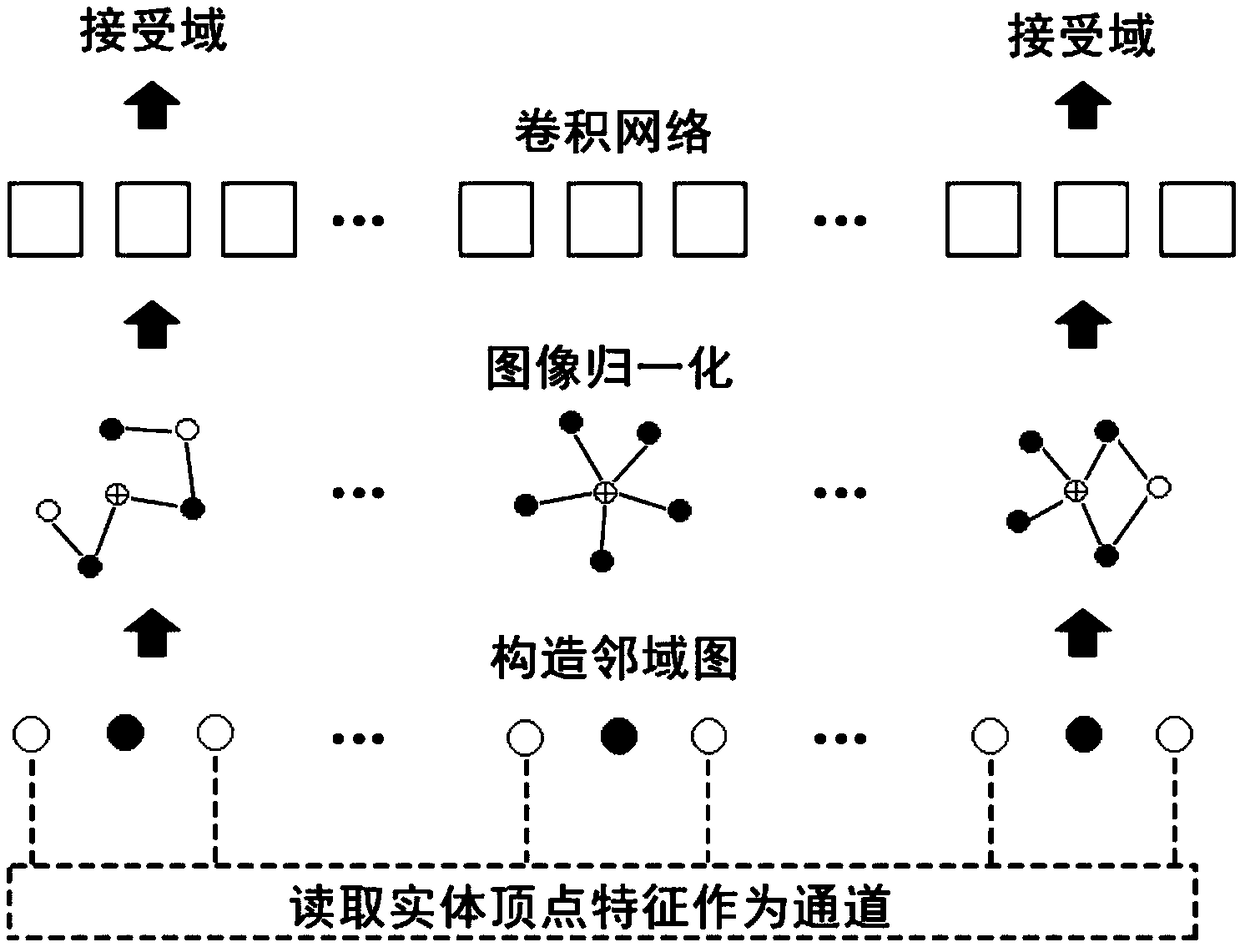

A method and apparatus for processing knowledge map based on semi-supervised embedded representation model

ActiveCN109389151AKeep partRetain structureCharacter and pattern recognitionNeural architecturesGraph spectraImage identification

The invention discloses a knowledge map processing method and a device based on a semi-supervised embedded representation model, the method comprises calculating a first-order proximity and a second-order proximity of a knowledge map, calculating the supervisory loss of the first-order proximity and the supervisory loss of the second-order proximity, establishing a linear combination of the supervisory loss of the first-order proximity and the supervisory loss of the second-order proximity, optimizing the knowledge map under the condition of minimizing the linear combination, and the like. Bycalculating the first-order proximity between any two vertices in the knowledge map, and calculating the second-order proximity according to the neighborhood structure of any two vertices in the knowledge map, At the same time, the first-order proximity and the second-order proximity are considered to jointly optimize the knowledge map so as to retain the local and global structural information ofthe knowledge map, thereby overcoming the defects caused by the dependence of the knowledge map on the characteristics of each vertex and the lack of the relationship information among the vertices in the prior art. The invention is widely applied to the field of image recognition.

Owner:SOUTH CHINA NORMAL UNIVERSITY

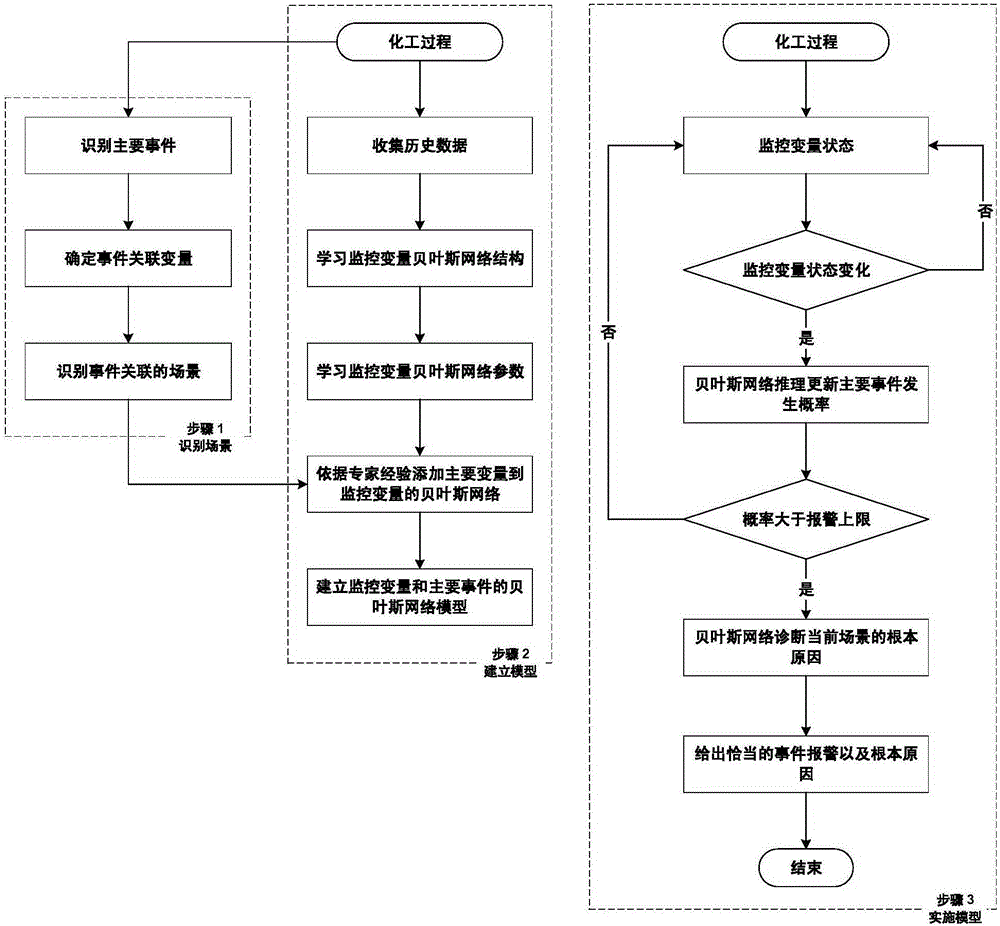

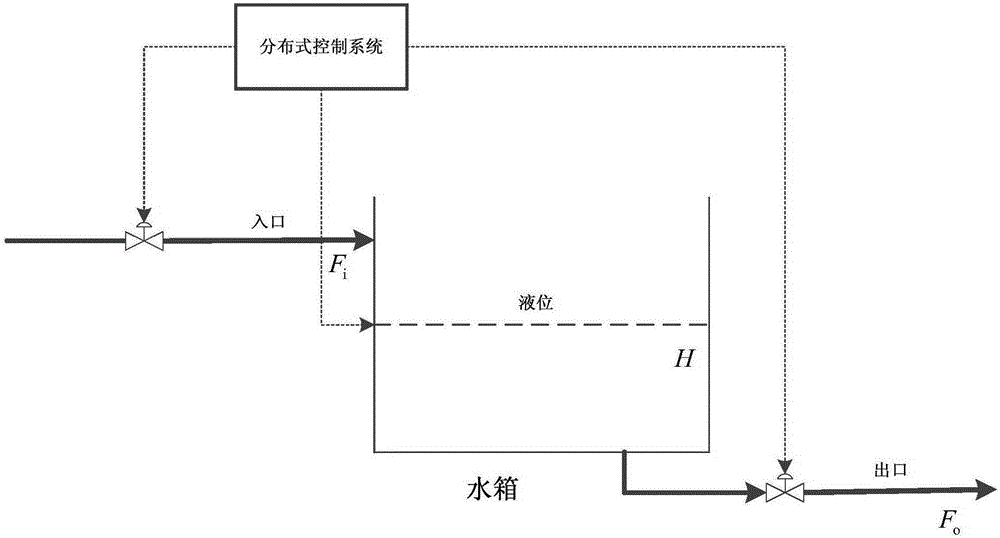

Method for establishing abnormal event early warning system based on expert experience and historical data

The invention discloses a method for establishing an abnormal event early warning system based on expert experience and historical data. The method includes three steps; a model is established offline in the first two steps; and the model is applied in real time and offline in the third step. According to the method, alarm data are continuously acquired, and the expert experience is used in combination, and therefore, an abnormal event early warning system is updated regularly; the system is implemented online, and the state change of variables are continuously monitored; the probability of abnormal events which may occur is predicted in real time, and root causes causing deviation are analyzed continuously; and an operator can be timely informed of the change of the system, and therefore, the operator can be assisted to take appropriate measures in time. With the Bayesian network-based early warning system management method adopted, the randomness and uncertainty of a real process can be embodied, and complexity of consideration on all variables in process knowledge modeling can be omitted, and correlativity between monitoring variables can be reflected, and discovery and judgment of fault sources can be benefitted for the operator.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

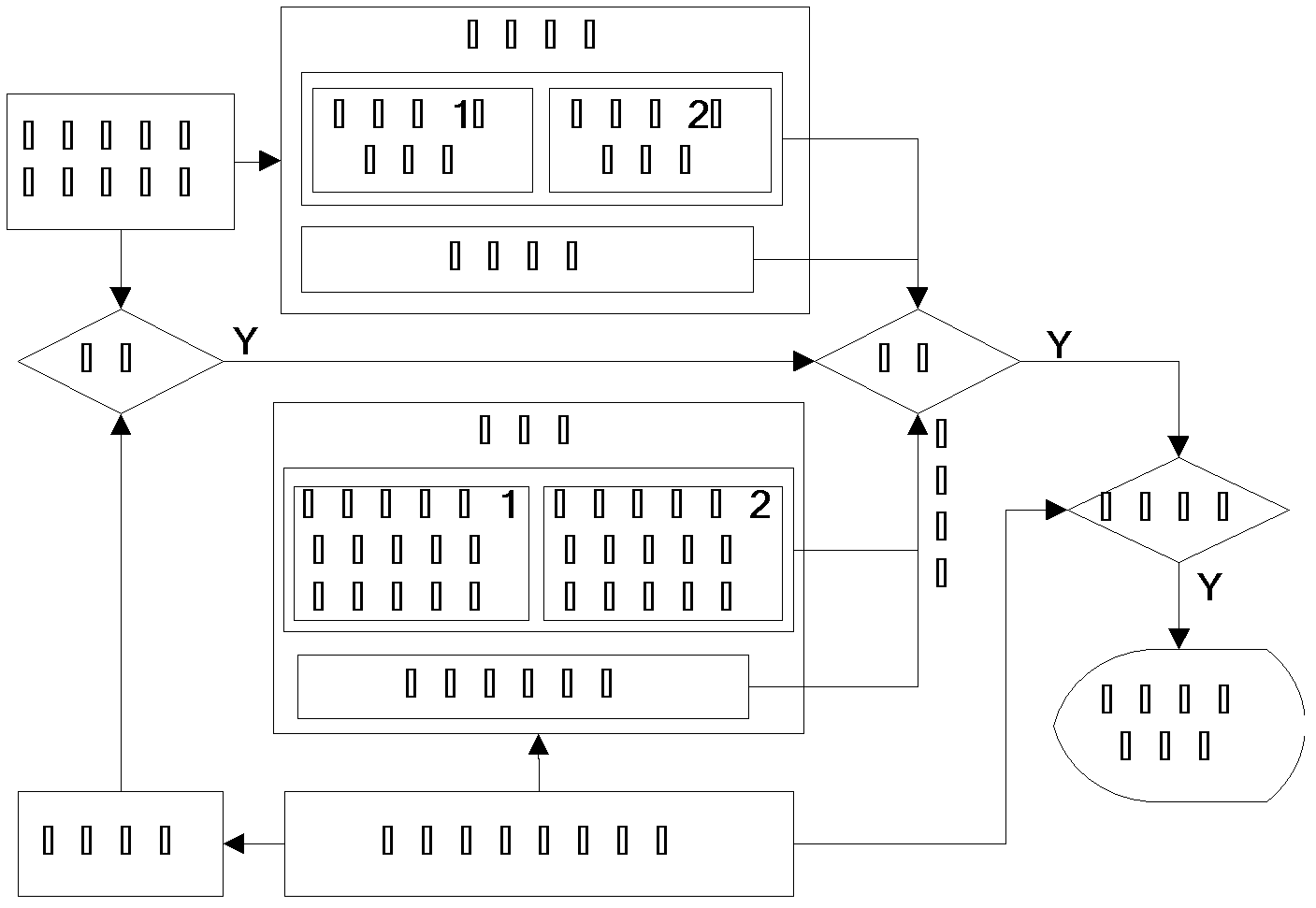

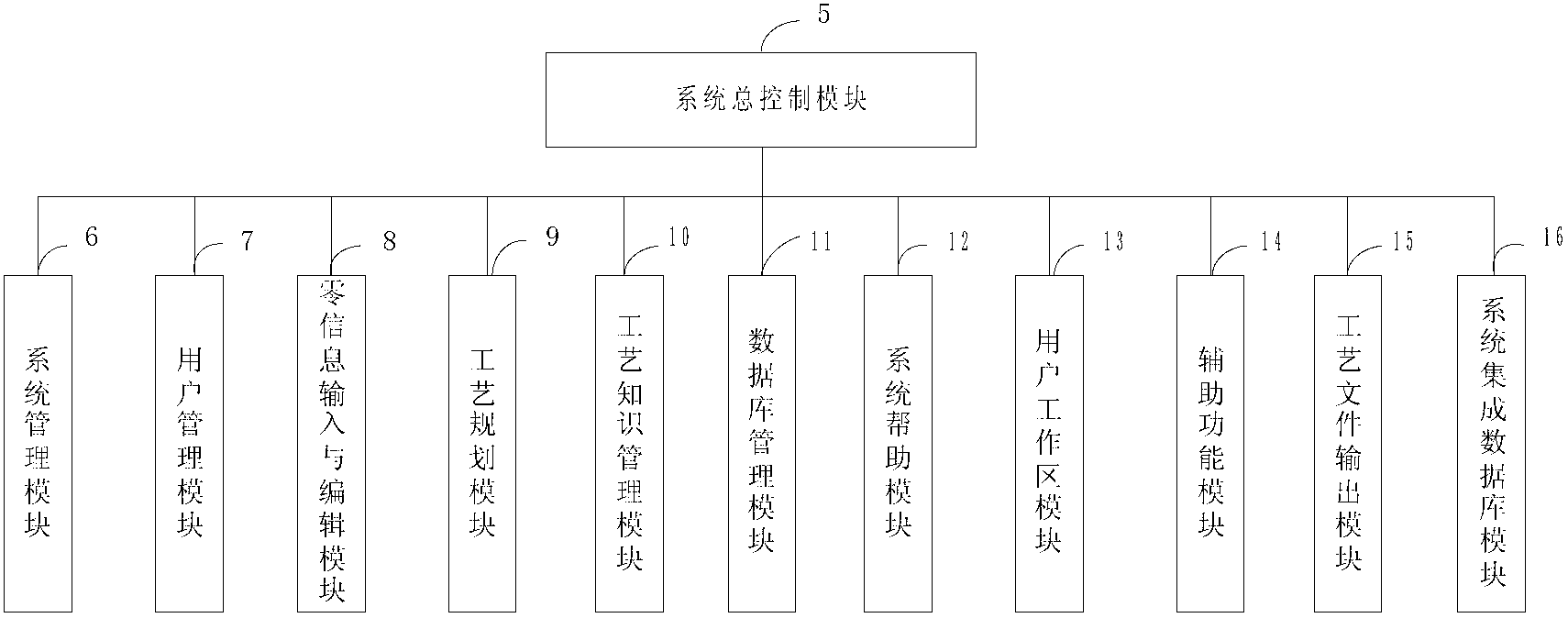

CAPP (computer aided progress planning) system of sheetmetal

InactiveCN103077448ARich management methodsEmphasis on participationResourcesSystems managementComputer-aided

The invention discloses a CAPP (computer aided progress planning) system of sheetmetal, which comprises a system master control module, a system management module, a user management module, a planning module, a process knowledge management module, a database management module, a system help module, a user work area module and the like. The system adopts a modularized concept in design and has higher development flexibility; a system of the system has good expandability and a maintenance function; the system has a powerful man-machine interaction function and a user interface, and simplicity and convenience in operation, meanwhile the system provides help and learning functions so as to guide a user to complete a sheetmetal process planning conveniently and quickly; the system provides a special auxiliary function module, has high openness and directs to requirements of the user; the system can replace handwork of technologists, complete the preparation and the audit of a sheetmetal machining technology, and reduce the labor intensity of the technologists, at the same time, the system also can ensure the consistency of the technology, improve the preparation efficiency of the technology, and shorten a product development cycle.

Owner:XIAN TECHNOLOGICAL UNIV

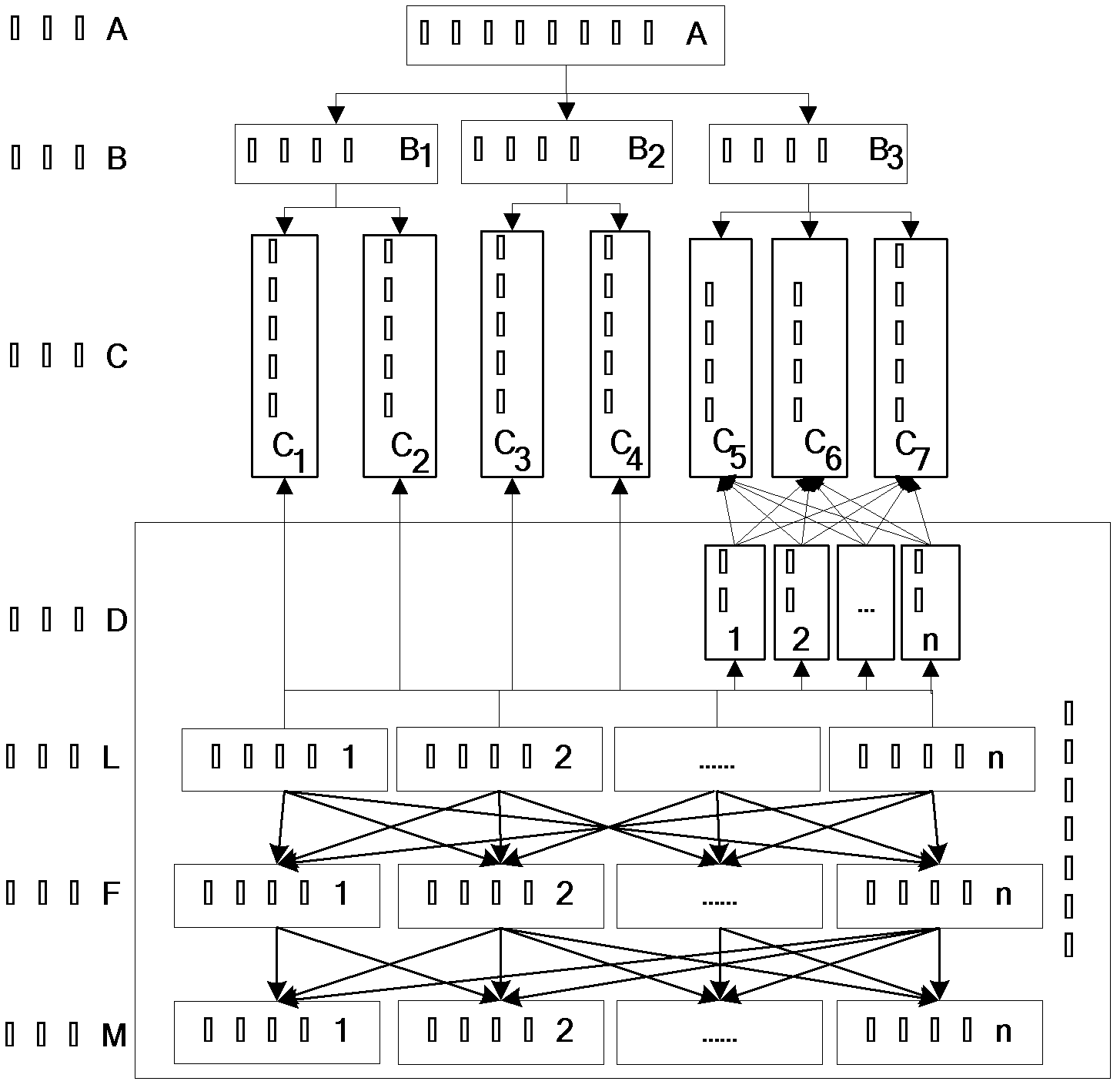

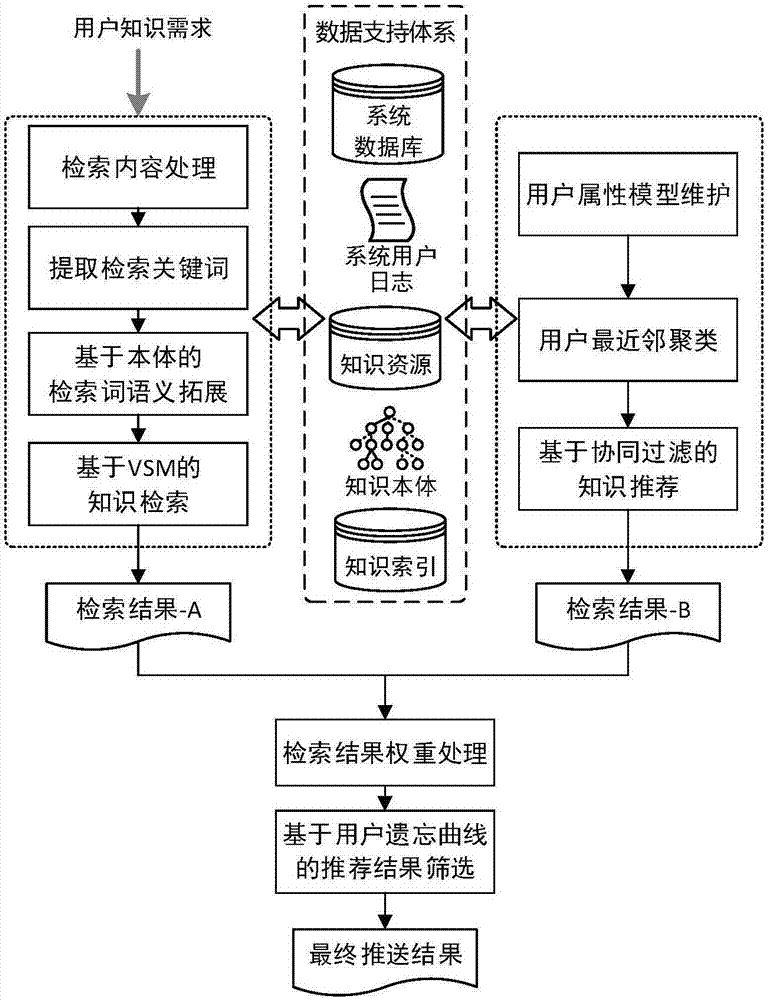

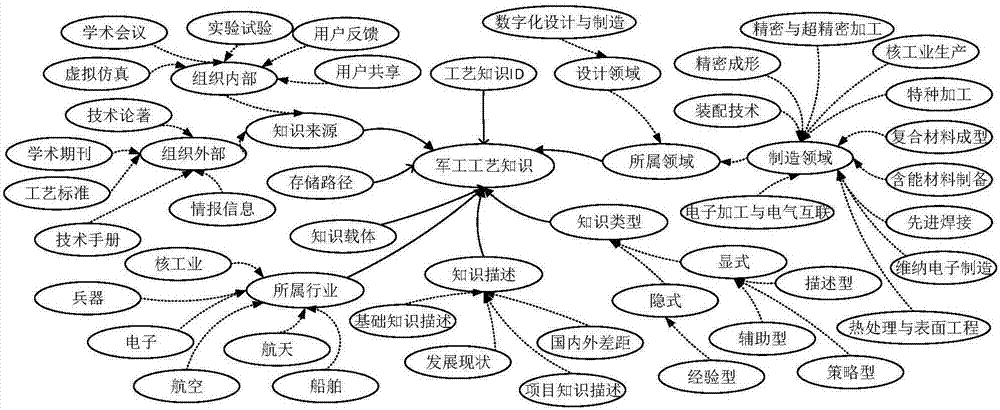

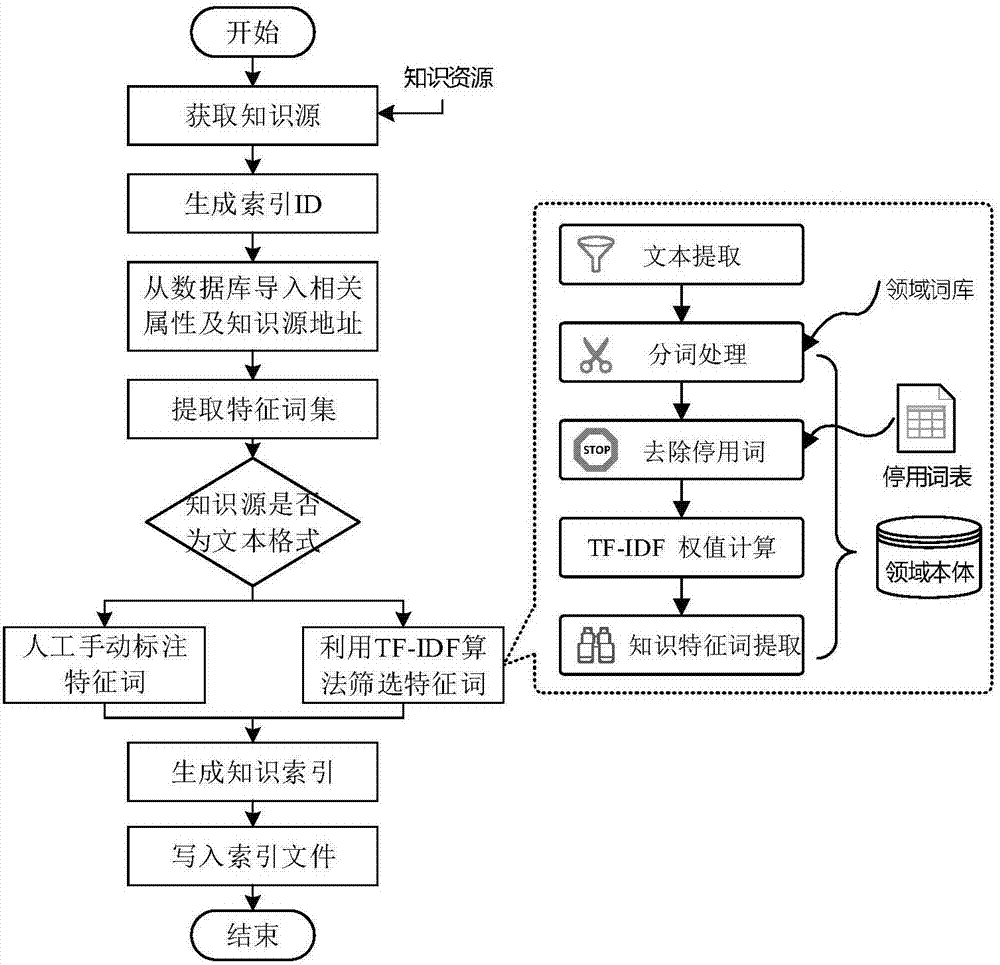

Ontological semantic extension and collaborative filter weighting fused process knowledge retrieval method

ActiveCN107885749AMeet search requirementsPersonalizedSemantic analysisSpecial data processing applicationsPersonalized searchRelevant information

The invention discloses an ontological semantic extension and collaborative filtering weight-fused process knowledge retrieval method. According to the method, weighted fusion is carried out on ontological semantic extension and vector space model-based knowledge matching method and a user attribute collaborative filtering matching method, and finally user personalized retrieval results accordingwith real retrieval intentions of users are obtained through forgetting curve-based weight control. According to the method, advantages of ontological knowledge retrieval and collaborative filtering are combined, dynamic and static attributes of users are sufficiently considered, and related information is integrated, so that retrieval results which more accord with user retrieval requirements andhave user personalization can be obtained and then sharing and reusing of war industry knowledges are improved.

Owner:NANJING UNIV OF SCI & TECH

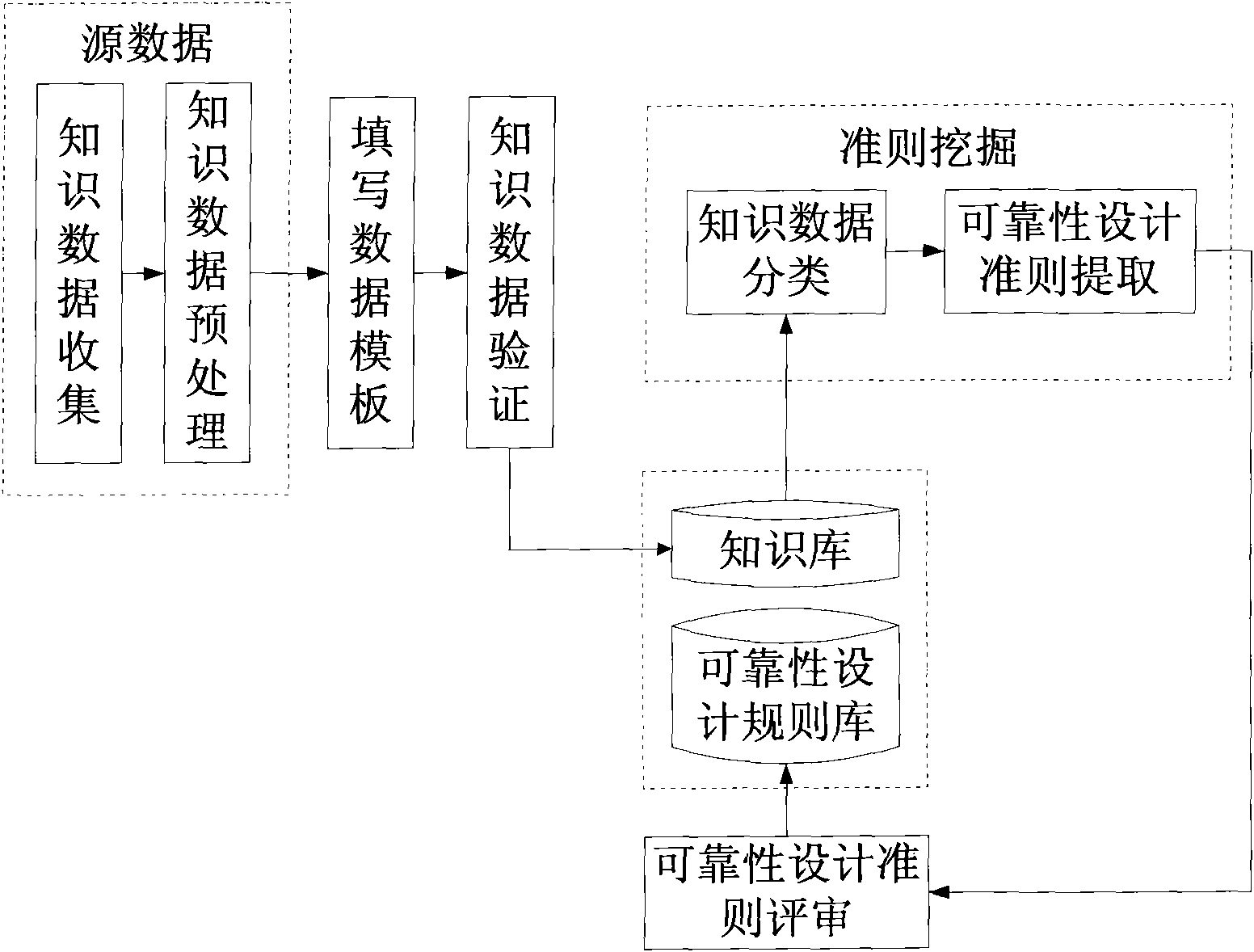

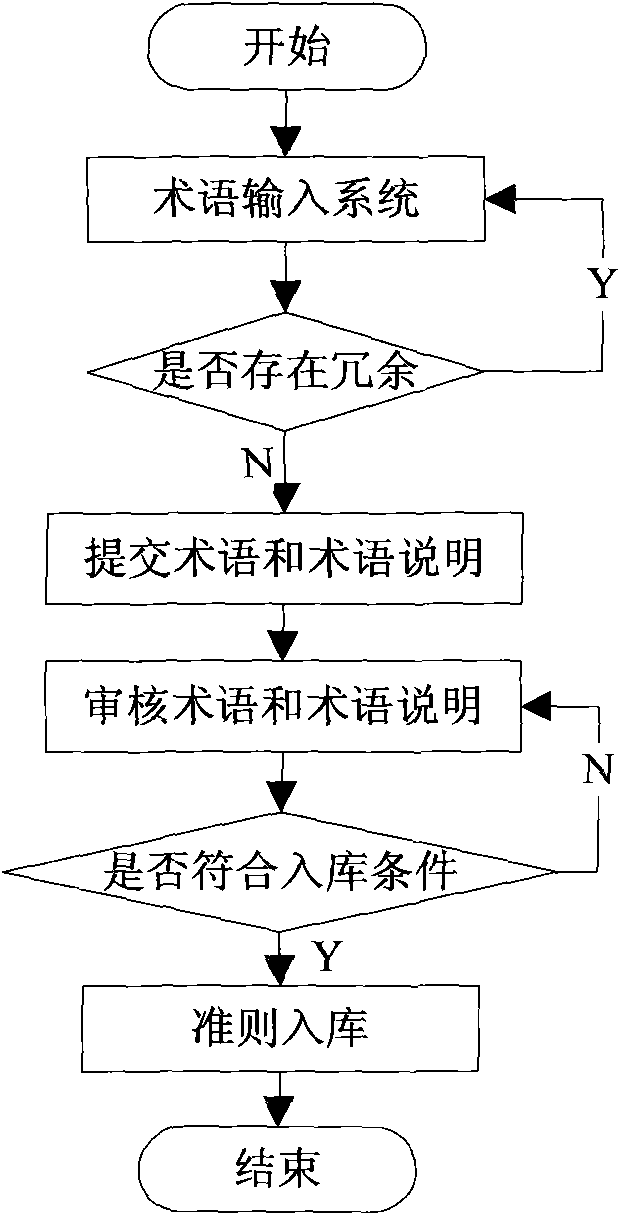

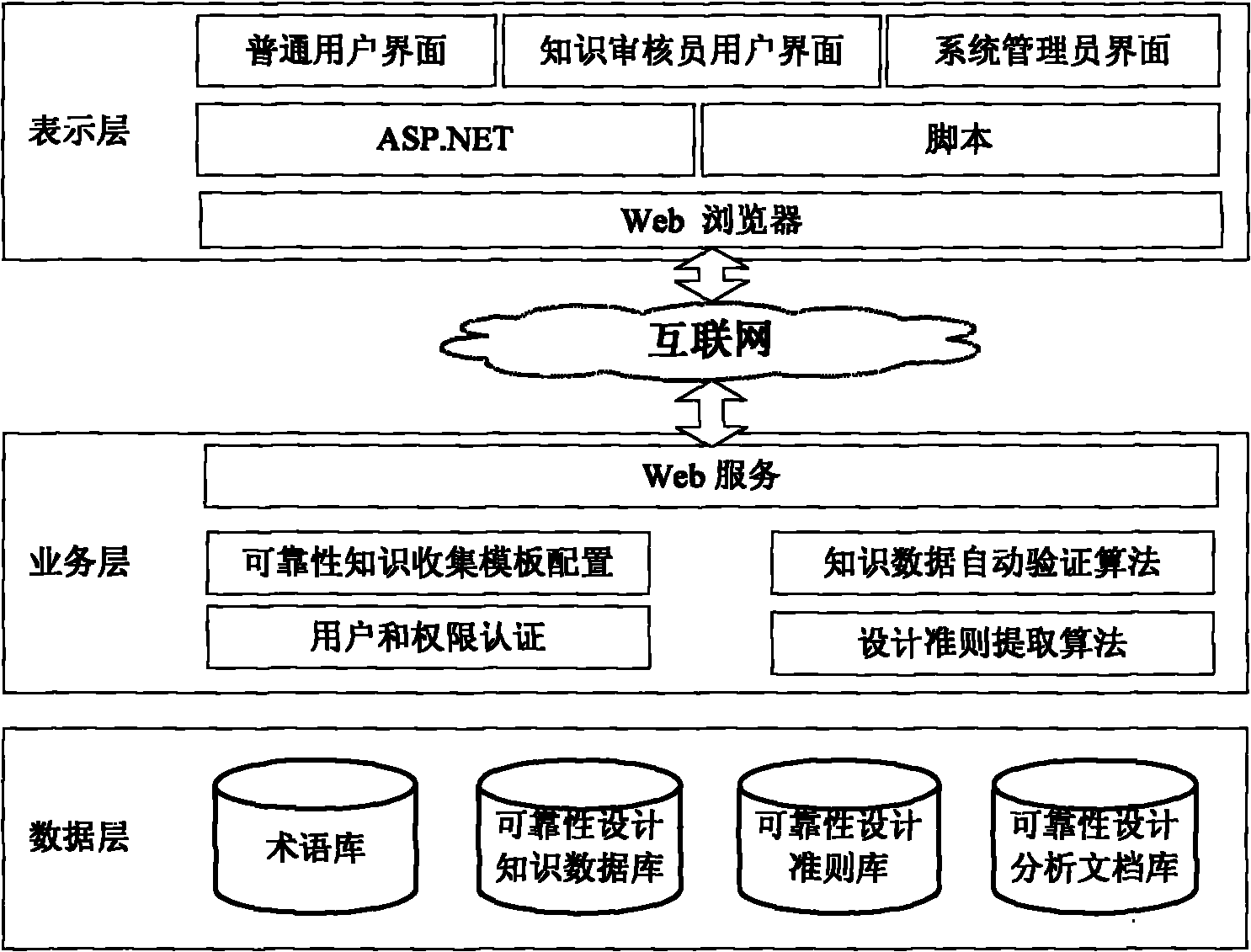

Knowledge acquisition template for product reliability design and criteria extracting method

InactiveCN102044018AAccurate collectionEasy accessSpecial data processing applicationsFeature vectorGuideline

The invention discloses a knowledge acquisition template for product reliability design and a criteria extracting method. The method comprises the following steps of: 1, determining reliability design knowledge data acquisition principles, and describing the reliability design knowledge acquisition principles by using a feature vector representation method; 2, pre-processing knowledge data by using the reliability design knowledge acquisition principles, and standardizing the identified identification features; 3, performing integrity verification and redundancy verification on the pre-processed reliability design knowledge data, and storing the audited data in a knowledge base; and 4, automatically extracting initial reliability design criteria from the reliability design by using a program, then judging the reliability design criteria by a manual judgment method, and storing the reliability design criteria passing the judgment in a criteria base.

Owner:BEIHANG UNIV

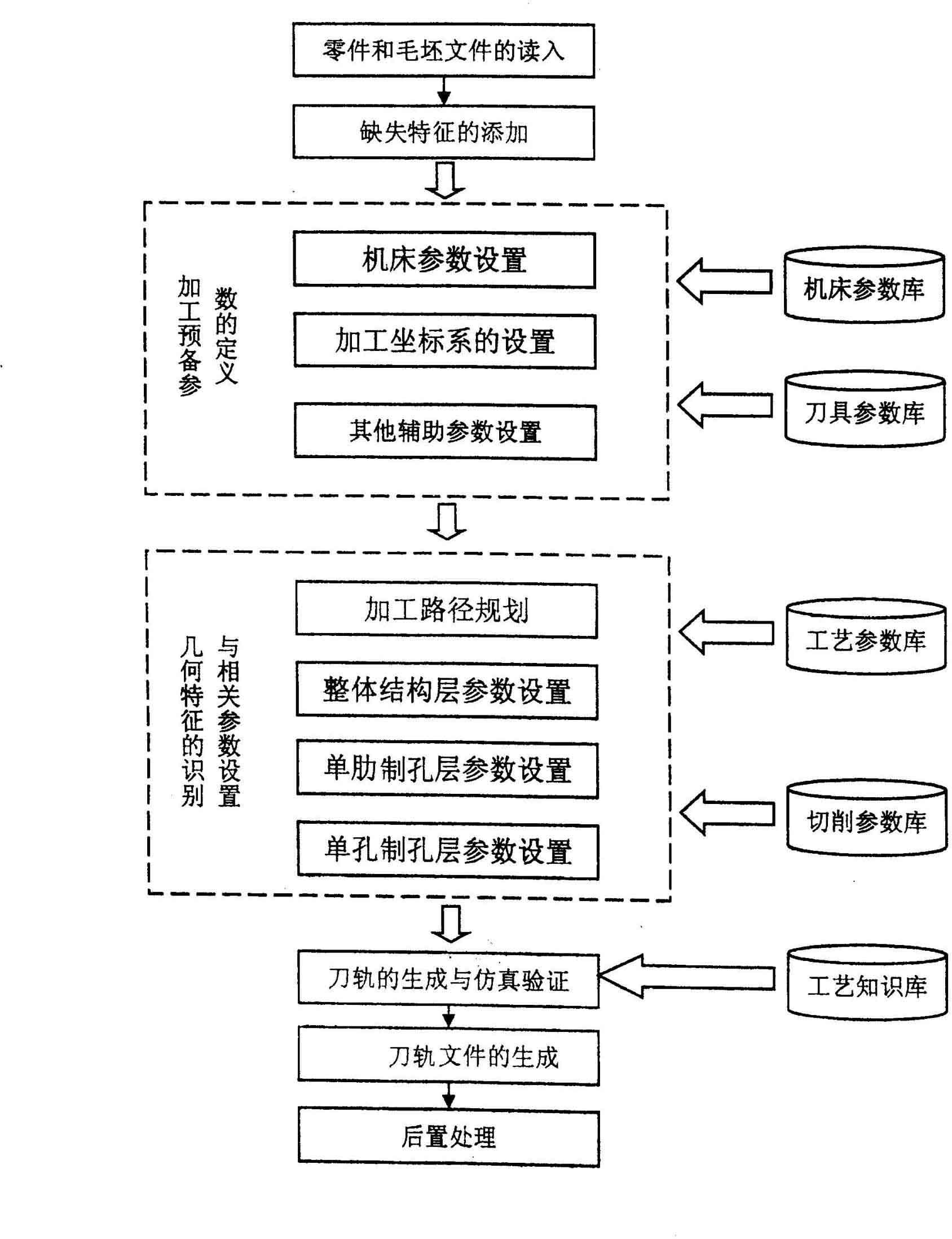

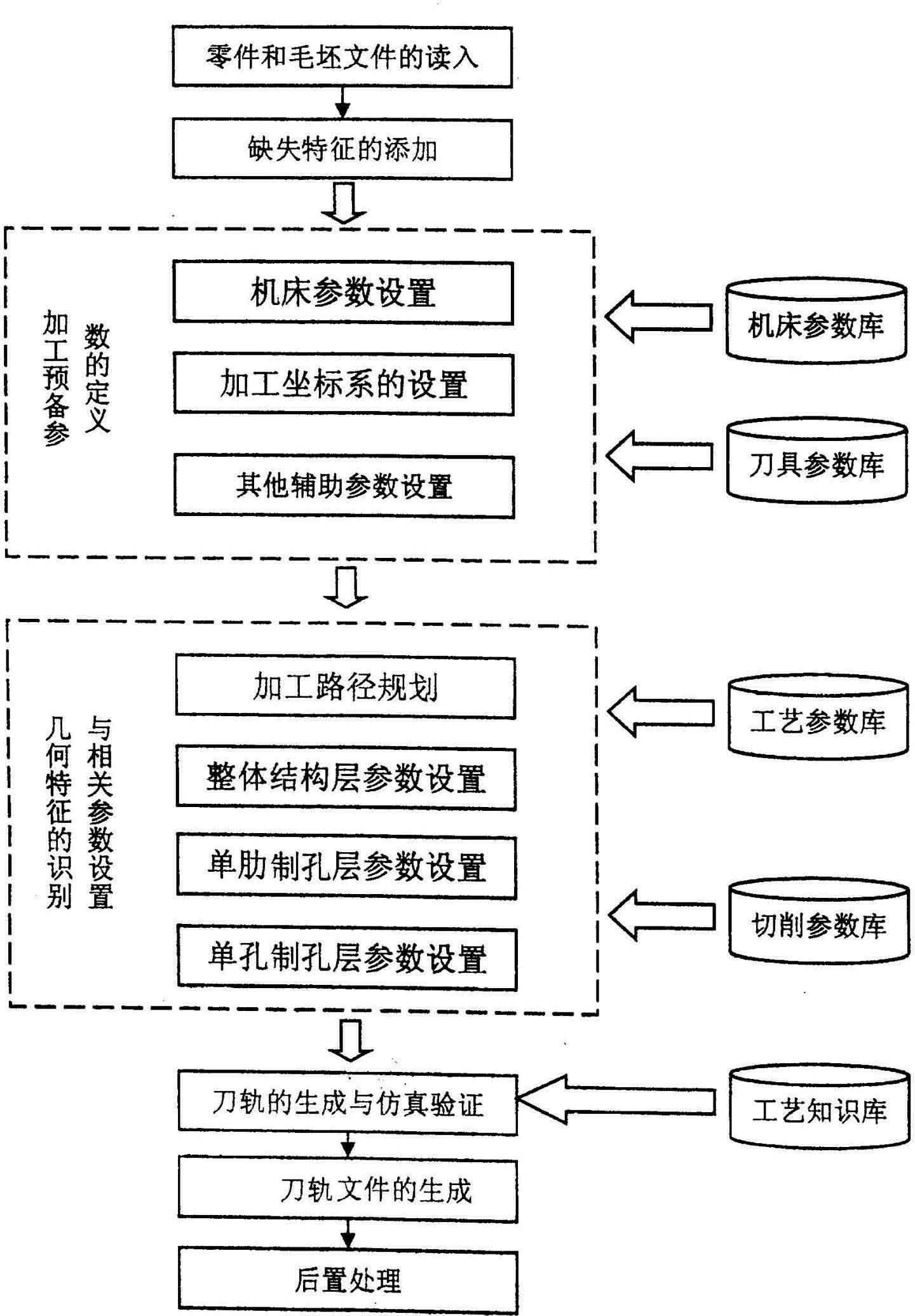

Multilayer numerical control programming method for flexible hole formation on large-scale wing part

ActiveCN102591261ARealize data sharingAchieve integrationProgramme controlComputer controlNumerical controlPath generation

The invention relates to a multilayer numerical control programming method for flexible hole formation on a large-scale wing part. The multilayer numerical control programming method includes the steps as follows: (1) reading part and blank documents; (2) adding missing features, that is, generating needed hole position information in a digital model; (3) extracting related information in a machine tool parameter library and a cutter parameter library, performing definition of machining preparation parameters, that is, setting machine tool parameters, setting a machining coordinate system and setting other auxiliary parameters; (4) extracting related information in a technological parameter library and a cutting parameter library, performing geometrical characteristic recognition and related parameter setting, namely, machining path planning and parameter setting; (5) extracting related information in a technological knowledge library, and performing cutter path generation and simulation verification; (6) generating a cutter path document; and (7) postprocessing. The system is used in the process of flexible hole formation on a wing, can finish skin and rib drilling and dimple programming work in one step, effectively improves the programming efficiency, and meanwhile improves the auxiliary hole position precision.

Owner:SHENYANG AIRCRAFT CORP

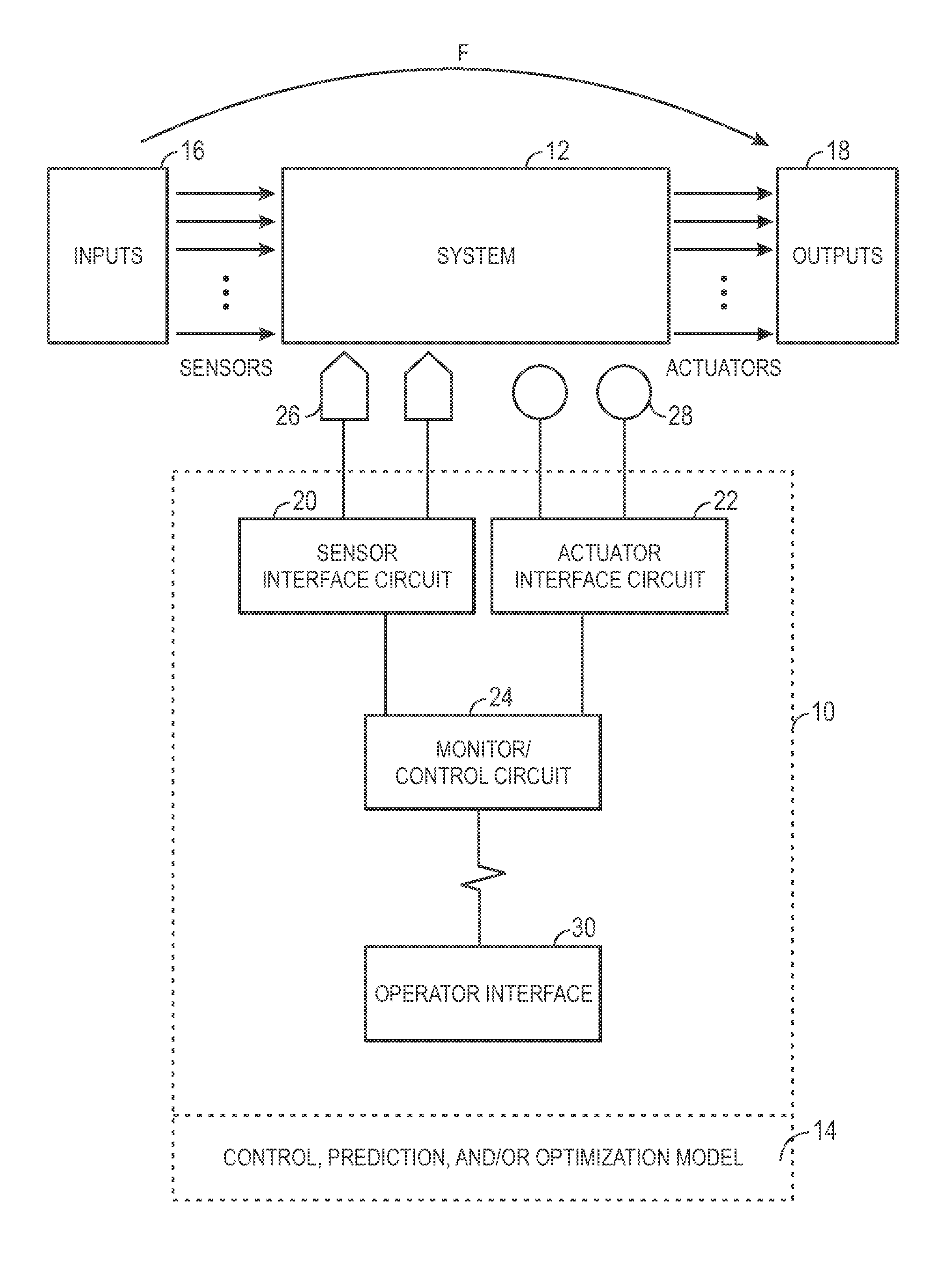

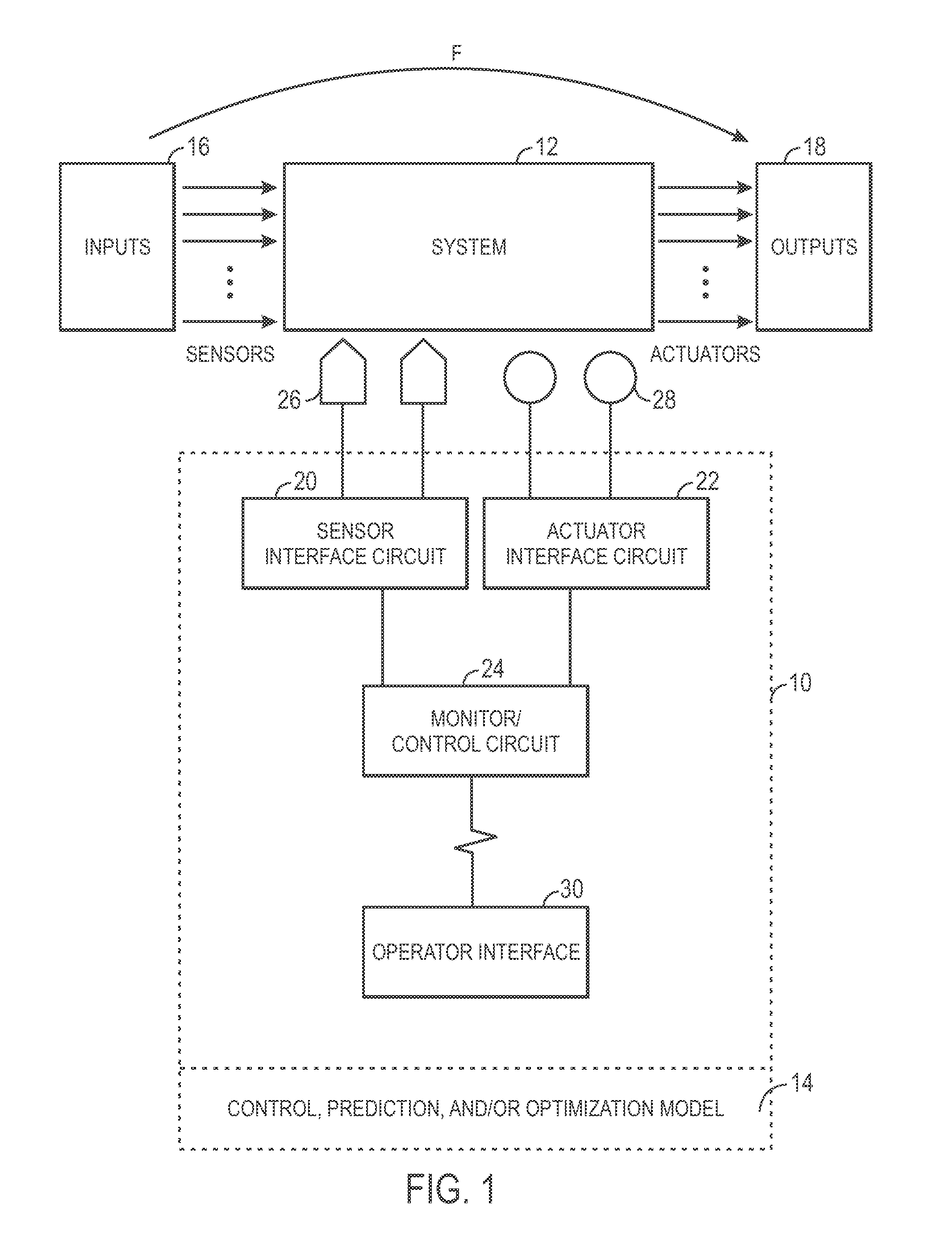

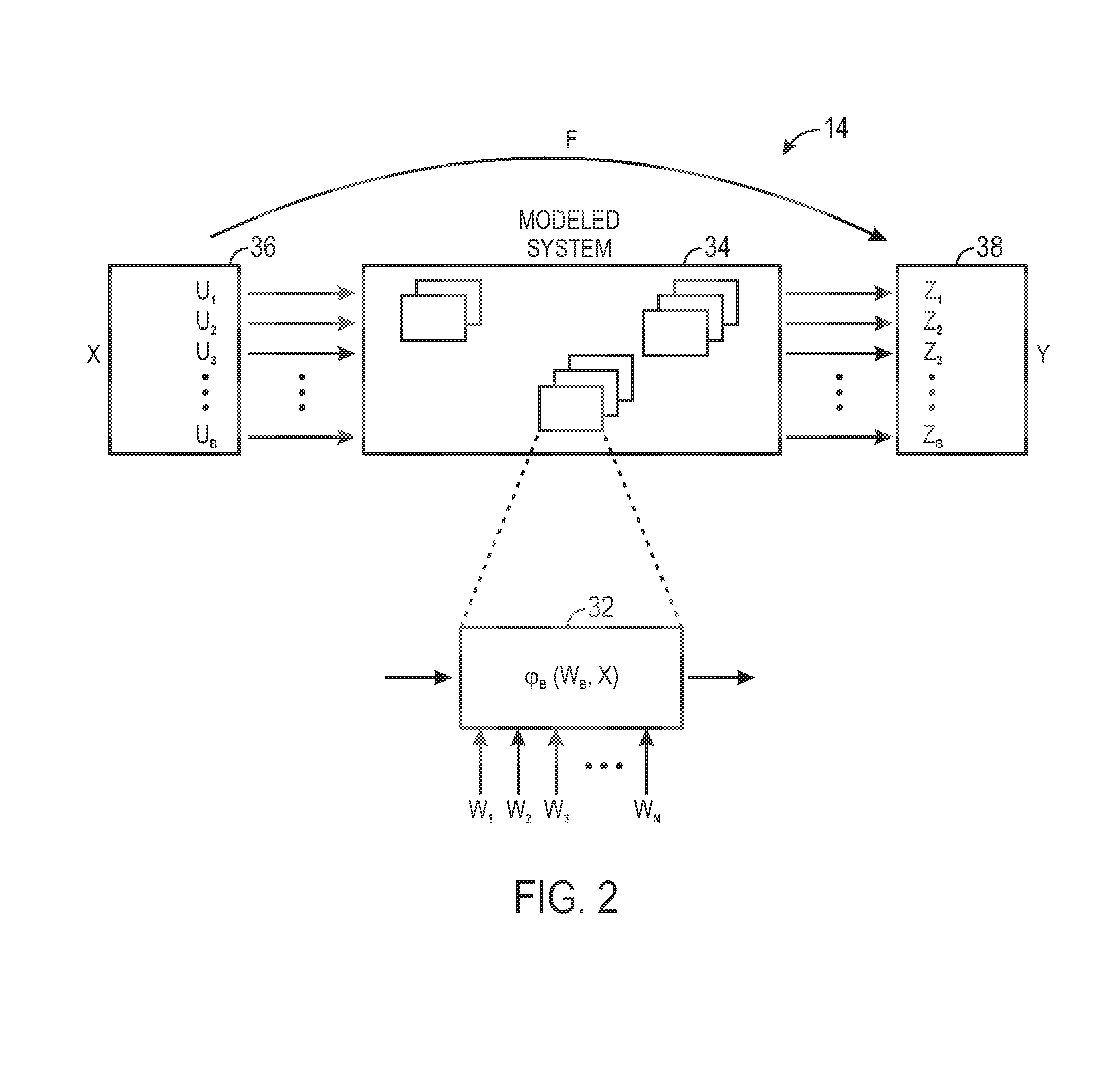

Empirical modeling with globally enforced general constraints

In certain embodiments, a method includes formulating an optimization problem to determine a plurality of model parameters of a system to be modeled. The method also includes solving the optimization problem to define an empirical model of the system. The method further includes training the empirical model using training data. The empirical model is constrained via general constraints relating to first-principles information and process knowledge of the system.

Owner:ROCKWELL AUTOMATION TECH

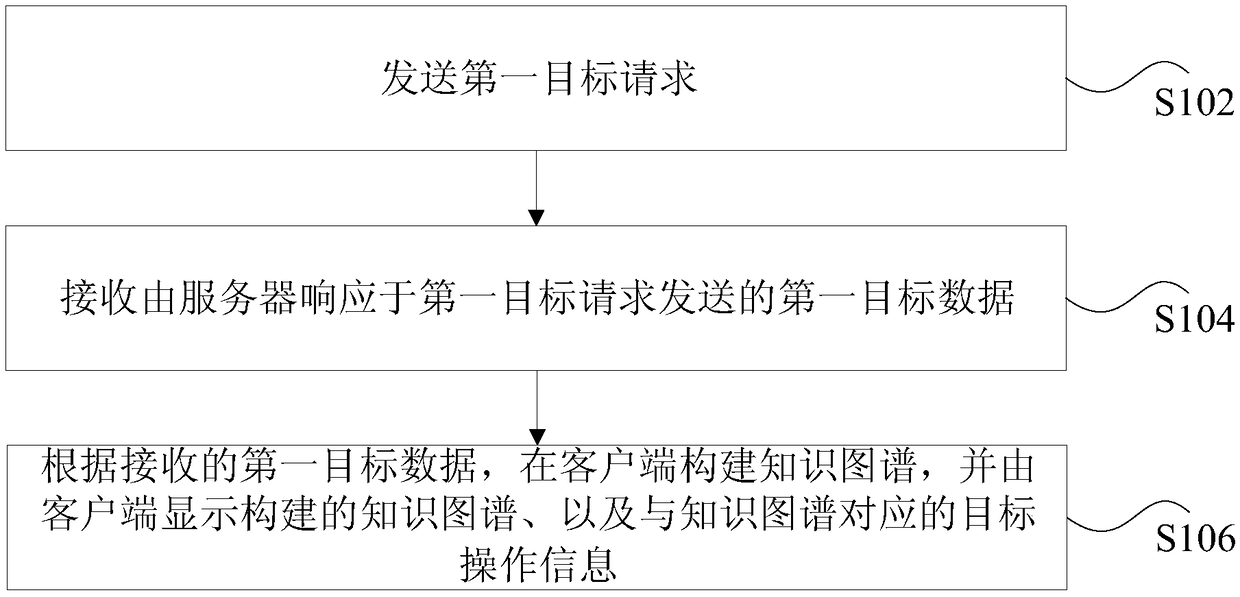

Method, apparatus, storage medium and processor for processing knowledge map

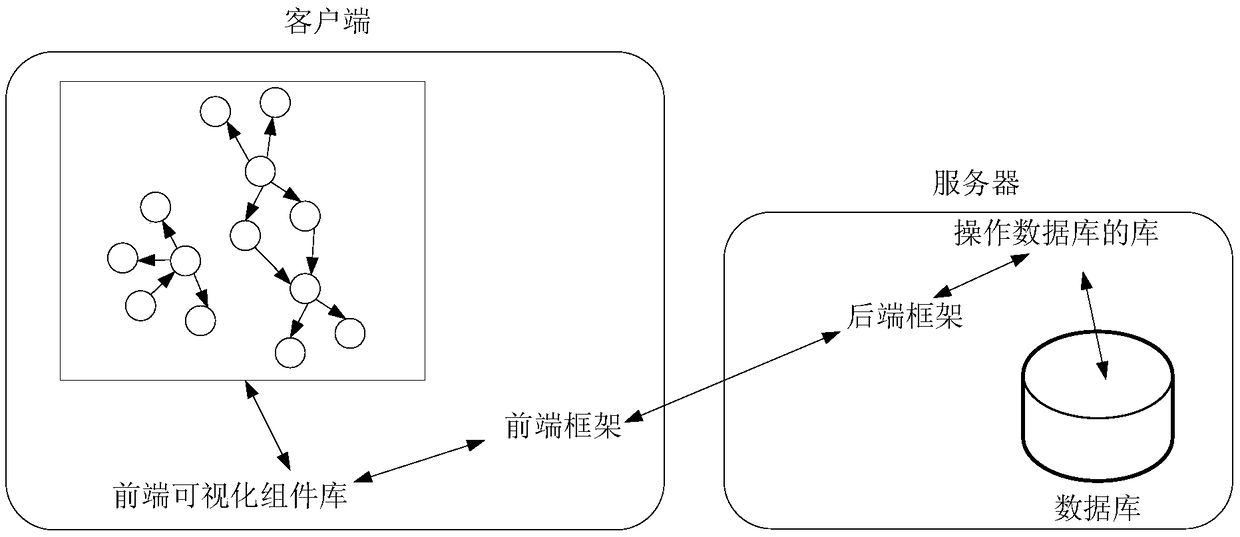

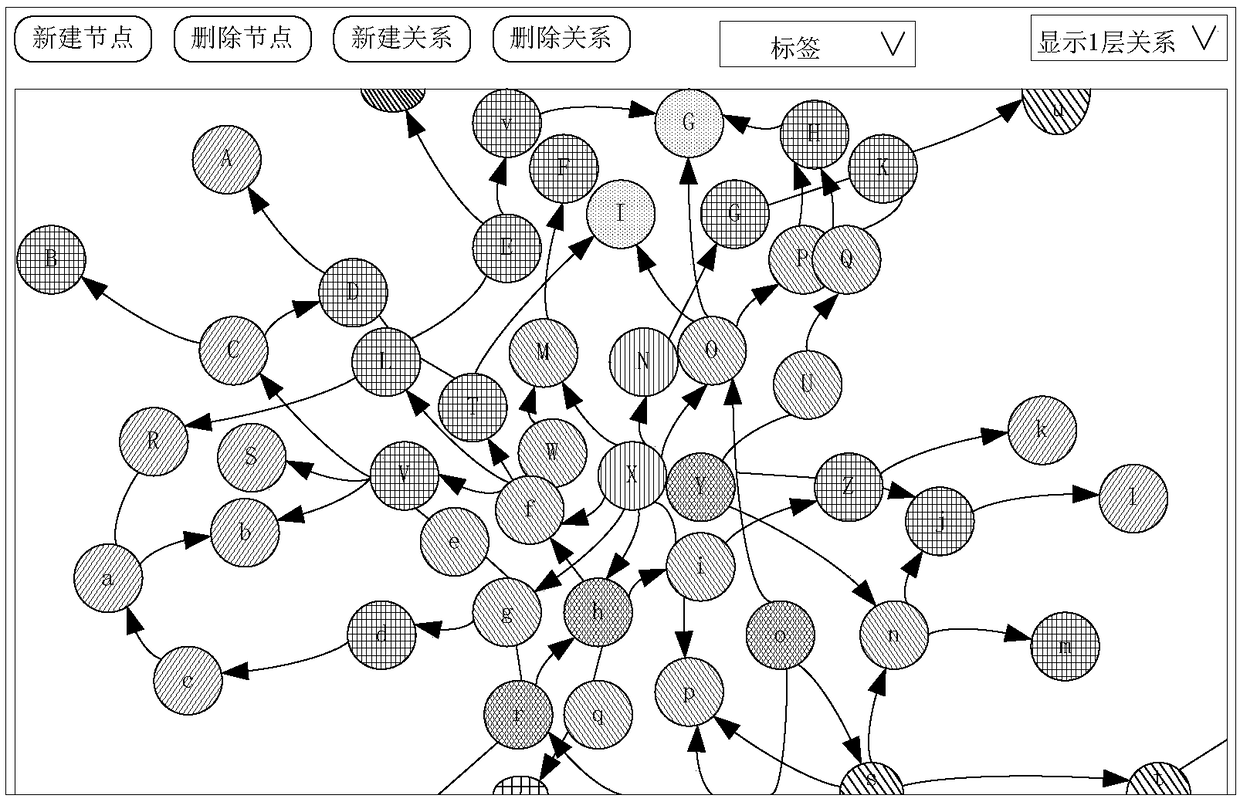

InactiveCN109508384ADisplay richSolve the single technical problem of display comparisonText database browsing/visualisationSemantic tool creationKnowledge contentData science

The invention discloses a Method, apparatus, storage medium and processor for processing knowledge map. The method comprises the following steps: sending a first target request, wherein, the first target request is used for requesting to acquire the first target data, and the first target data is used for constructing a knowledge map; Receiving first target data transmitted by the server in response to the first target request; Based on the received first target data, constructing A knowledge map on the client, and displaying the constructed knowledge map and the target operation information corresponding to the knowledge map on the client, wherein, an interface corresponding to the target operation information is pre-configured on the client, and the interface is used for operating the knowledge map in the case that the corresponding target operation information is triggered. The invention solves the technical problem that the display of the knowledge content is relatively single.

Owner:BEIJING GRIDSUM TECH CO LTD

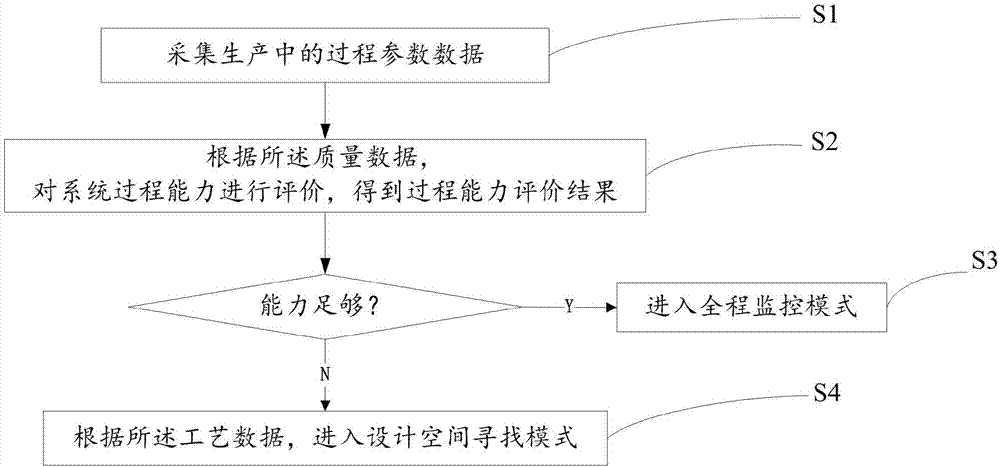

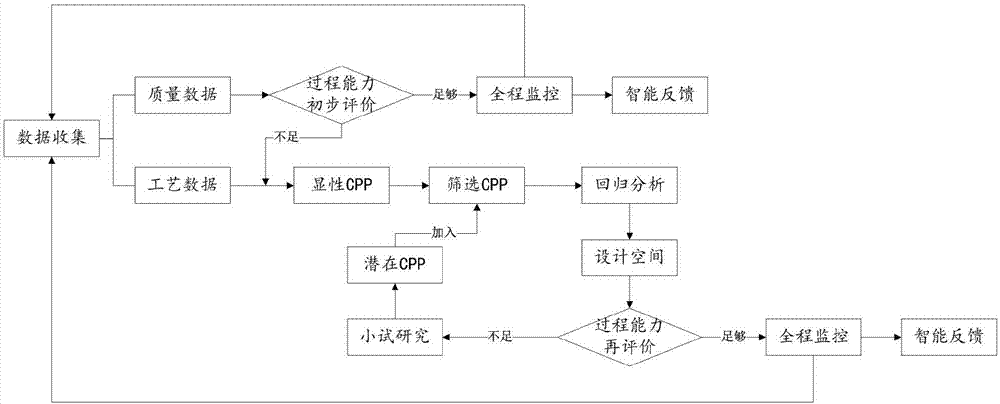

Traditional Chinese medicine production process knowledge system

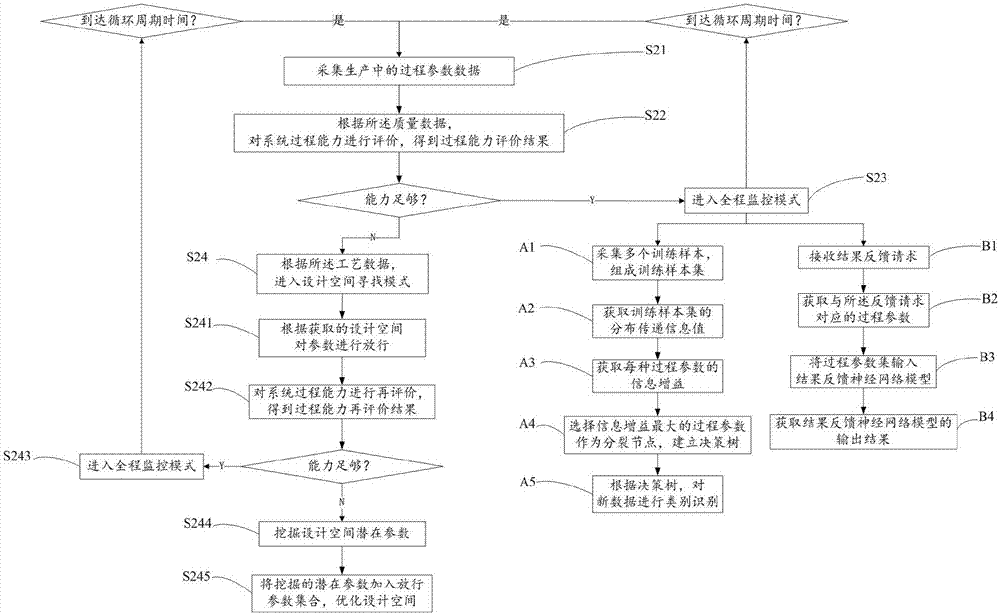

ActiveCN107578104AImprove reliabilityAvoid the effects of multicollinearityAlternative medicinesRegistering/indicating quality control systemsQuality dataDesign space

The invention discloses a traditional Chinese medicine production process knowledge system which comprises a database module, a competency assessment module, a monitoring feedback module and a designspace looking-for module. The database module comprises a production data collection unit and a storage unit, the production data collection unit is used for collecting process parameter data in production, process parameters include quality data and process data, and the storage unit is used for storing the collected process parameter data; the competency assessment module is used for assessing system process capability according to the quality data to acquire process capability assessment results; the monitoring feedback module is used for entering a whole-process monitoring mode when the process capability assessment results are responded adequately; the design space looking-for module is used for entering a design space looking-for module according to the process data when the processcapability assessment results are responded inadequately. The parameters are released or design space is looked for through the process capability assessment, so that the production process knowledgesystem is allowed to gradually returns to the process knowledge system with the traditional Chinese medicine production process adjusted and fed back intelligently.

Owner:JIANGSU KANION PHARMA CO LTD +1

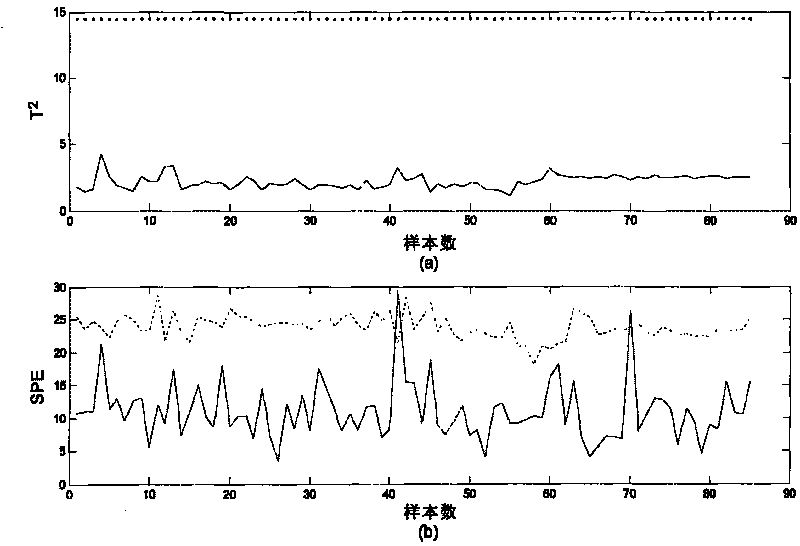

Semiconductor process monitoring method based on independent component analysis and Bayesian inference

InactiveCN101713983AImprove monitoring effectFacilitates automated implementationTotal factory controlProgramme total factory controlIndependent component analysisAnalysis method

The invention discloses a semiconductor process monitoring method based on independent component analysis and Bayesian inference, comprising the following step of: firstly, dividing working conditions according to the mixed data of the semiconductor process, conducting the independent component analysis for each working condition data, and establishing a corresponding independent component analysis model; and then integrating and combining the monitoring information under the different working conditions by a Bayesian inference method to obtain a final monitoring result. In addition, the invention can also acquire the working condition information of current monitoring data by a posterior probability analysis method, that is to say, the invention can judge that the current monitoring data is in what process operation working condition; compared with the present other methods, the invention can not only greatly enhance the monitoring effect of the semiconductor process, but also largely improve the dependence of the monitoring method on process knowledge and enhance the comprehensive ability and the operating confidence of process operators on the process, thereby being more beneficial to the implementation of the automation of the semiconductor process.

Owner:ZHEJIANG UNIV

Parametric Profiling Using Optical Spectroscopic Systems

InactiveUS20090135416A1Reduce complexitySimple methodRadiation pyrometryPolarisation-affecting propertiesComputer scienceSemiconductor

Owner:KLA CORP

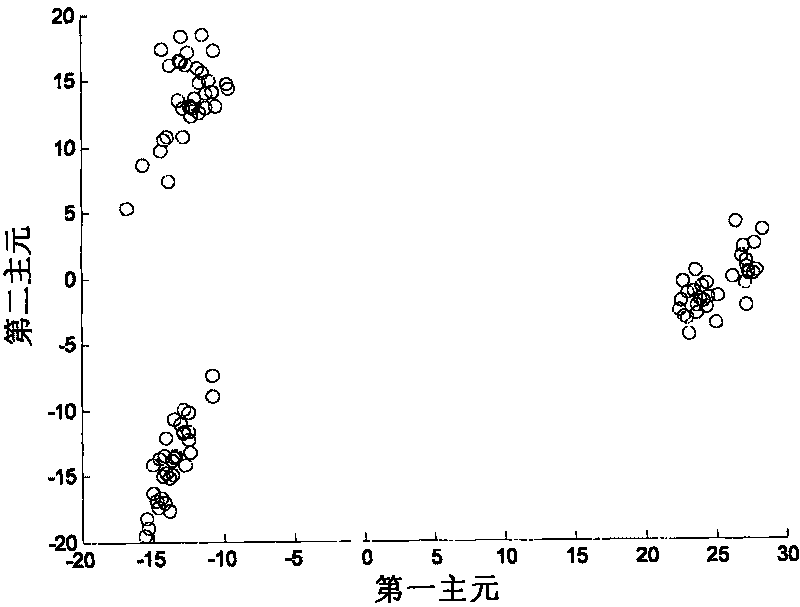

Plant-level process fault detection and diagnosis method based on distributed data model

InactiveCN103389701ARealize accurate fault diagnosisAvoid dependenceTotal factory controlProgramme total factory controlComputer sciencePlant level

The invention discloses a plant-level process fault detection and diagnosis method based on a distributed data model. Aiming at the complex large plant-level production process, the existing commonly used fault detection and diagnosis methods are mostly built on the basis of a data driving model, wherein the most typical method includes first dividing the whole plant-level process into a plurality of sub modules according to operation units and functions and then building corresponding fault detection and diagnosis models aiming at the different sub modules respectively. The methods often rely on process knowledge to a large extent, and the requirement is harsh for the complex plant-level process. A novel method for dividing the sub modules completely based on data analysis is provided, and the corresponding fault detection and diagnosis method is constructed on the basis to achieve the whole situation monitoring of the plant-level process. The method has important application value for improving fault detection and diagnosis performance and product quality in the plant-level production process.

Owner:ZHEJIANG UNIV

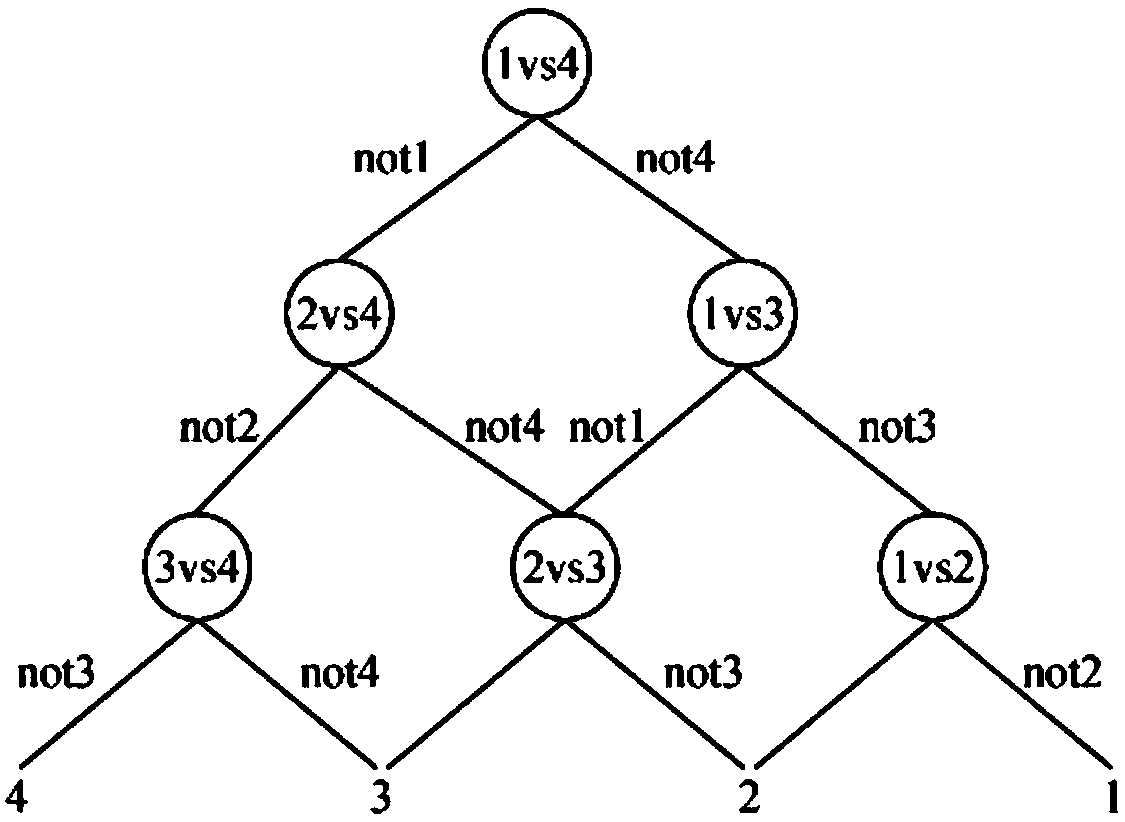

Method and system for core process knowledge intelligent pushing based on multi-model fusion

ActiveCN108846050AThe result is obviousImprove classification performanceCharacter and pattern recognitionSpecial data processing applicationsUser inputData mining

The invention discloses a method and a system for core process knowledge intelligent pushing based on multi-model fusion. The method comprises: preprocessing existing corpus data, and then inputting the data into a classification algorithm model for pre-classification, improving effect of classification through model fusion, when user queries or user feeds back, performing similarity calculation on user input and text categories, to determine the categories to which keywords belong, taking first k1 most similar categories, just retrieving in the categories, for each category, using the input keywords to retrieve respectively using different models in the category, combining all previous results, performing relevancy sorting using a BM25 algorithm, taking first k2 results, and using Jaccardsimilarity to remove texts which are too similar in the results, finally, returning the results to users. The method and the system can further adjust user's keyword models according to the feedbackof the users, and better fit needs of the users, so as to optimize user pushing effect and matching degree in the next pushing.

Owner:CHONGQING WANGJIANG IND +1

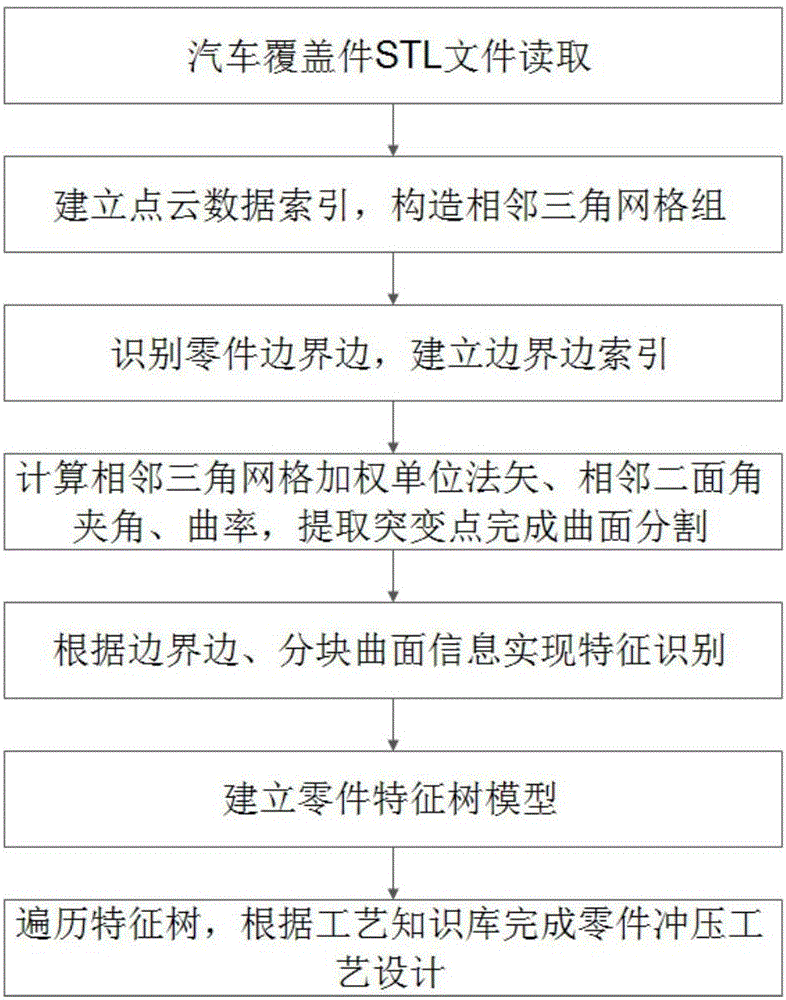

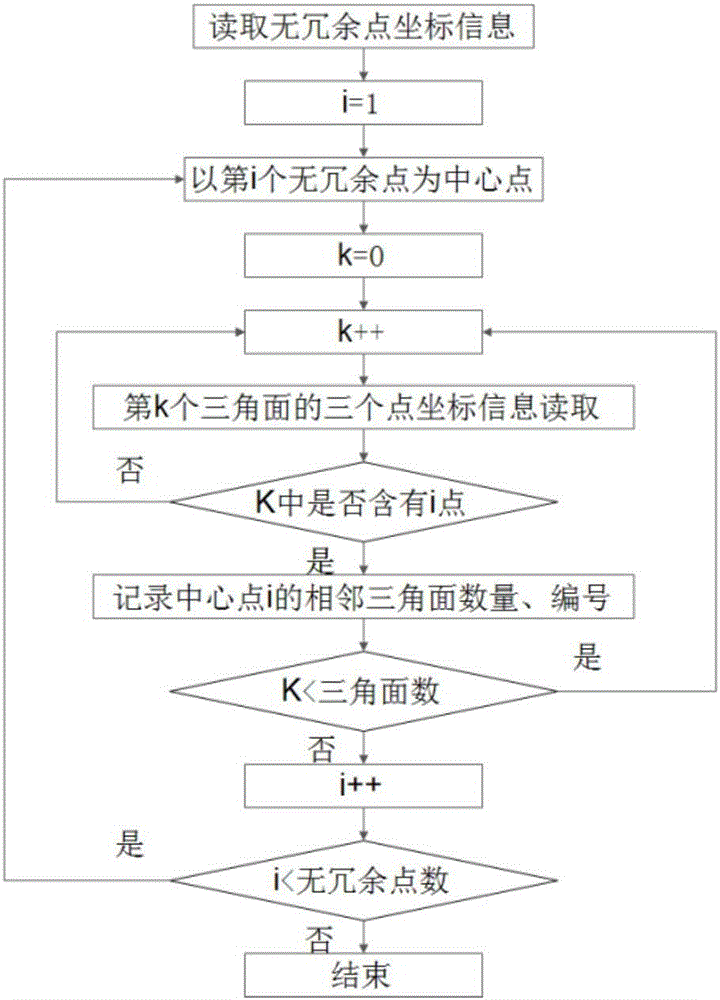

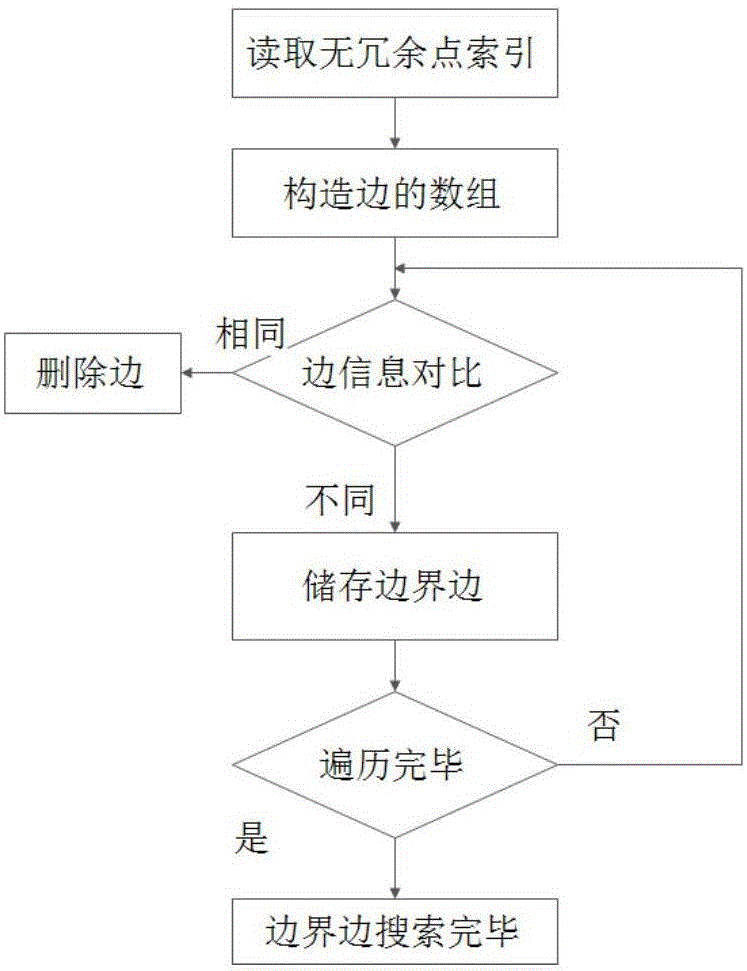

Automobile covering part sheet metal forming technology optimizing method based on STL grid feature recognition

ActiveCN106599515ASolve complex analysis problemsReduce stamping process design timeGeometric CADDesign optimisation/simulationProcess knowledgeDecision-making

The invention discloses an automobile covering part sheet metal forming technology optimizing method based on STL grid feature recognition. The method comprises the following steps: firstly reading a part STL grid model to obtain part curve information, obtaining part shape features through the curve information, constructing a part feature tree according to a feature topological relation, classifying the features according to feature processing categories, and determining respective sheet metal forming technology for different features. According to the method, a process knowledge database is taken as a core, optimization for the part sheet metal forming technology is finally completed depending on the obtained feature tree and the sheet metal forming technology route of each feature parameter decision-making part under the mechanism support of knowledge reasoning, the features can be extracted from the automobile covering part sheet STL model automatically, and the sheet metal forming technology routes are designed, so that a large amount of repeated work of technologists can be reduced, the work efficiency is effectively improved, and the technology preparation time is shortened.

Owner:WUHAN UNIV OF TECH

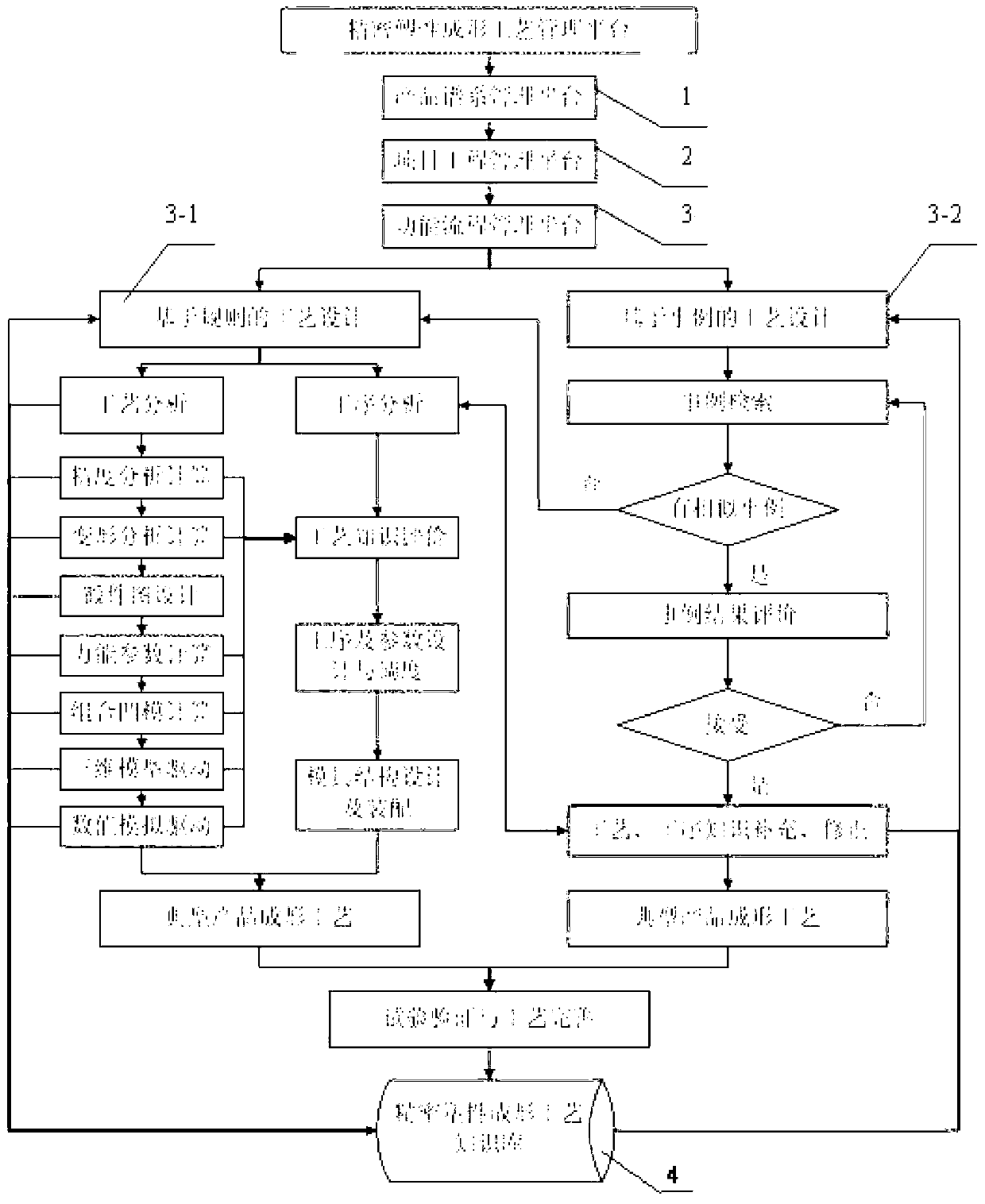

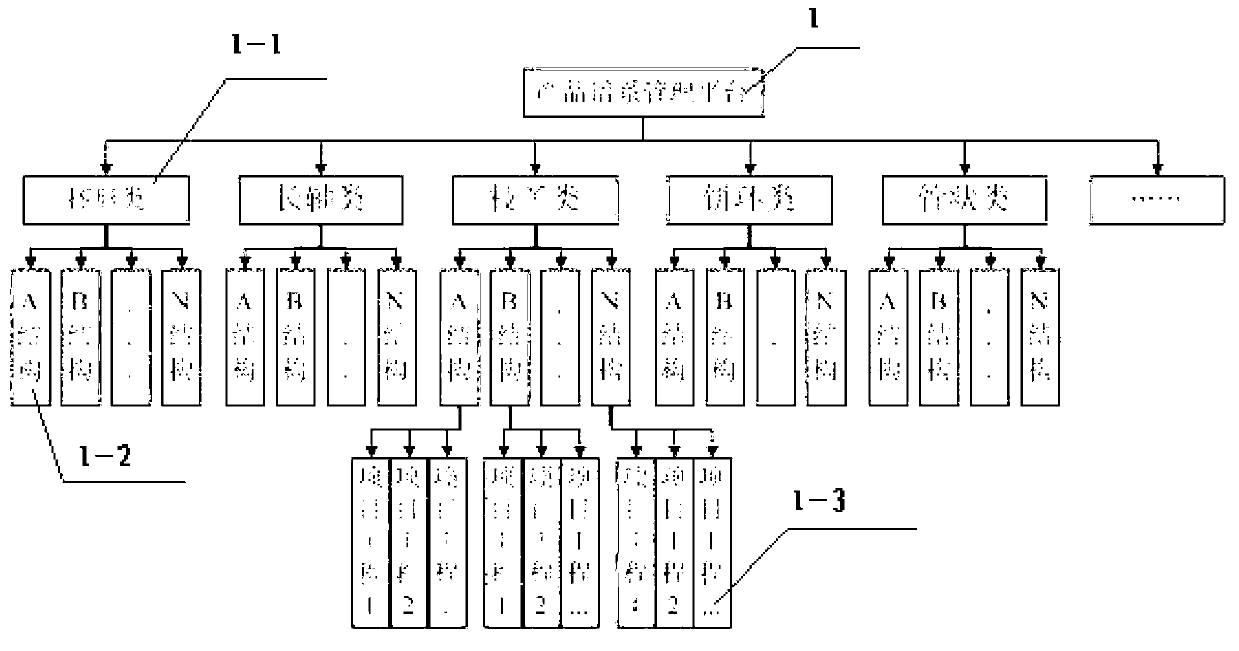

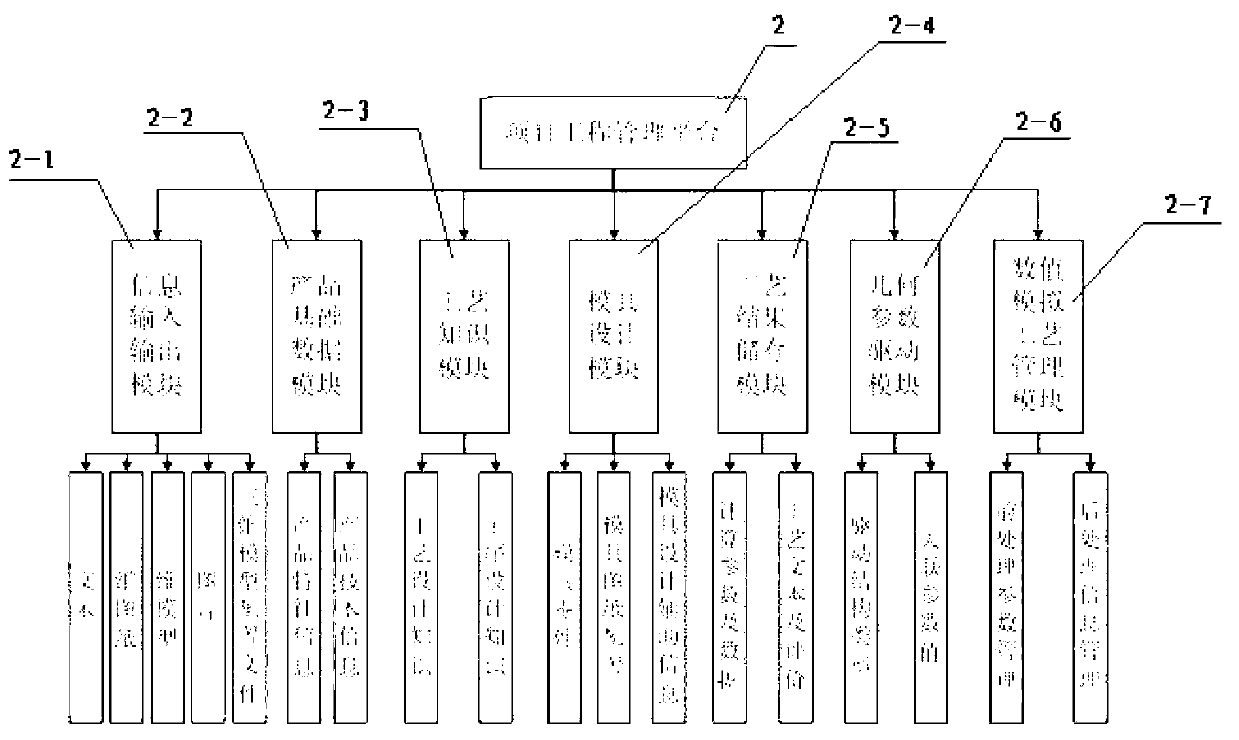

Knowledge-based precision plastic forming knowledge base designing system

ActiveCN103279817AImprove the level ofImprove efficiencyResourcesSpecial data processing applicationsProcess developmentProcess design

The invention discloses a knowledge-based precision plastic forming knowledge base designing system. Key points are that the system comprises a product genealogy management platform, a project engineering management platform, a functional flow management platform and a precision plastic forming process knowledge base. According to the knowledge-based precision plastic forming knowledge base designing system, the shortcomings of inadequate knowledge of precision plastic forming process development designers, design blindness, low-level repetition and the like can be overcome, the problems of complexity in the calculation of a plurality of process key points, long process development cycle and the like of product forming process analysis and procedure analysis can also be solved, and the level and the efficiency of precision plastic forming process design and development can be effectively improved. The system can be used for the development of new plastic forming products and processes, and can also be used in the field of manufacturing of forming parts for automobiles, motorcycles and special equipment.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com