Patents

Literature

1021 results about "Design space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

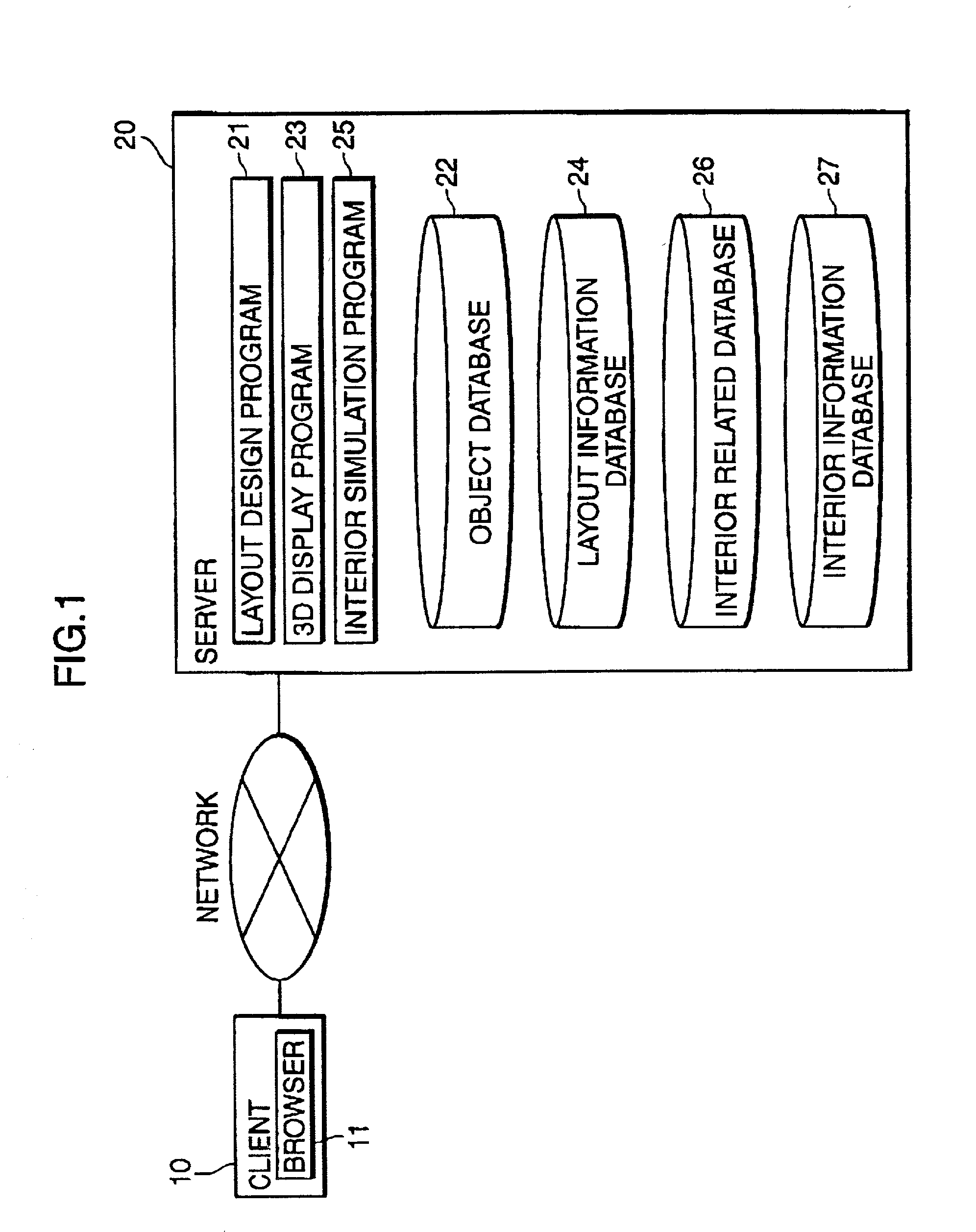

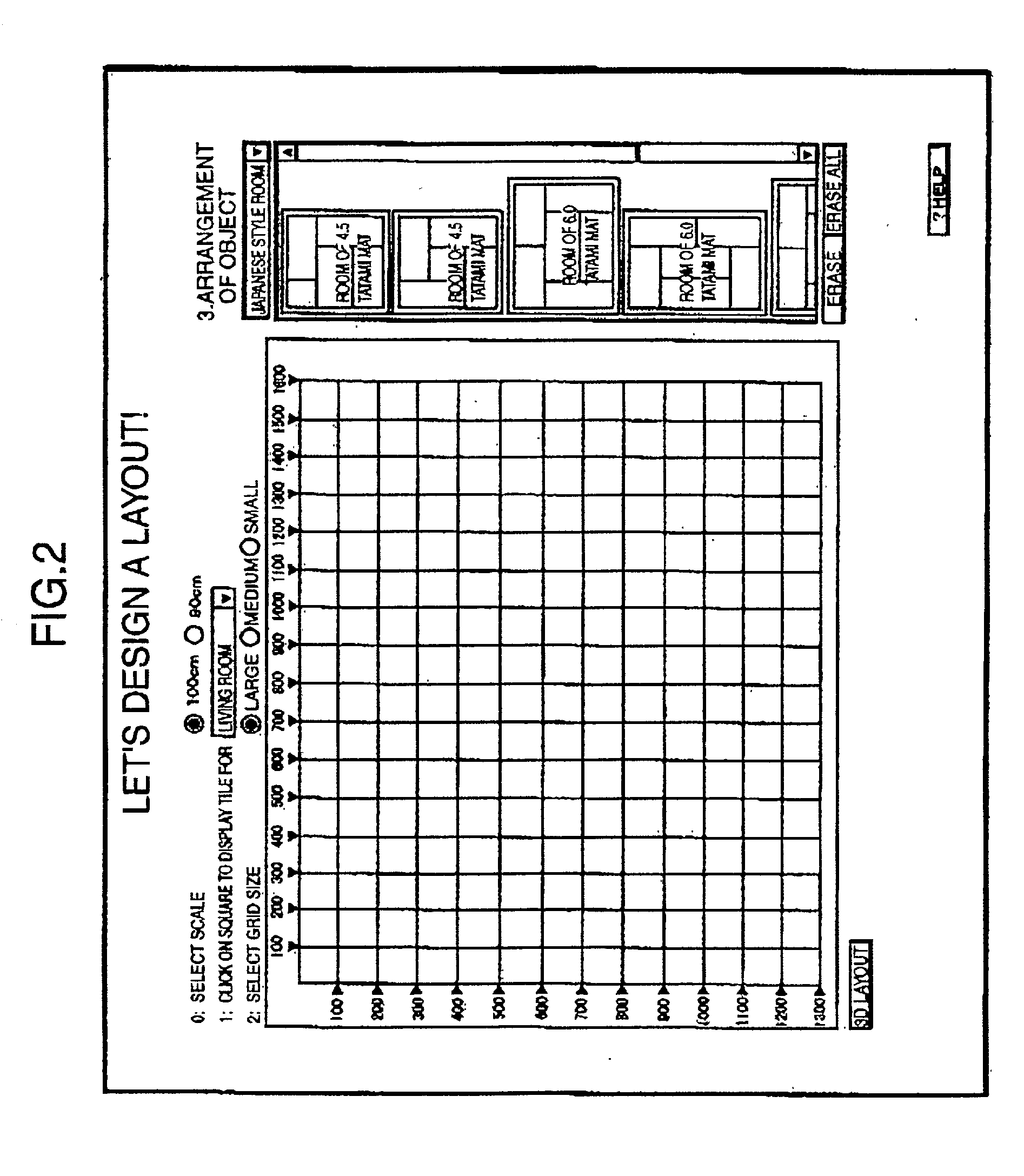

Method for aiding space design using network, system therefor, and server computer of the system

InactiveUS7246044B2Simplify the design processGeometric CADCathode-ray tube indicators3d imageClient-side

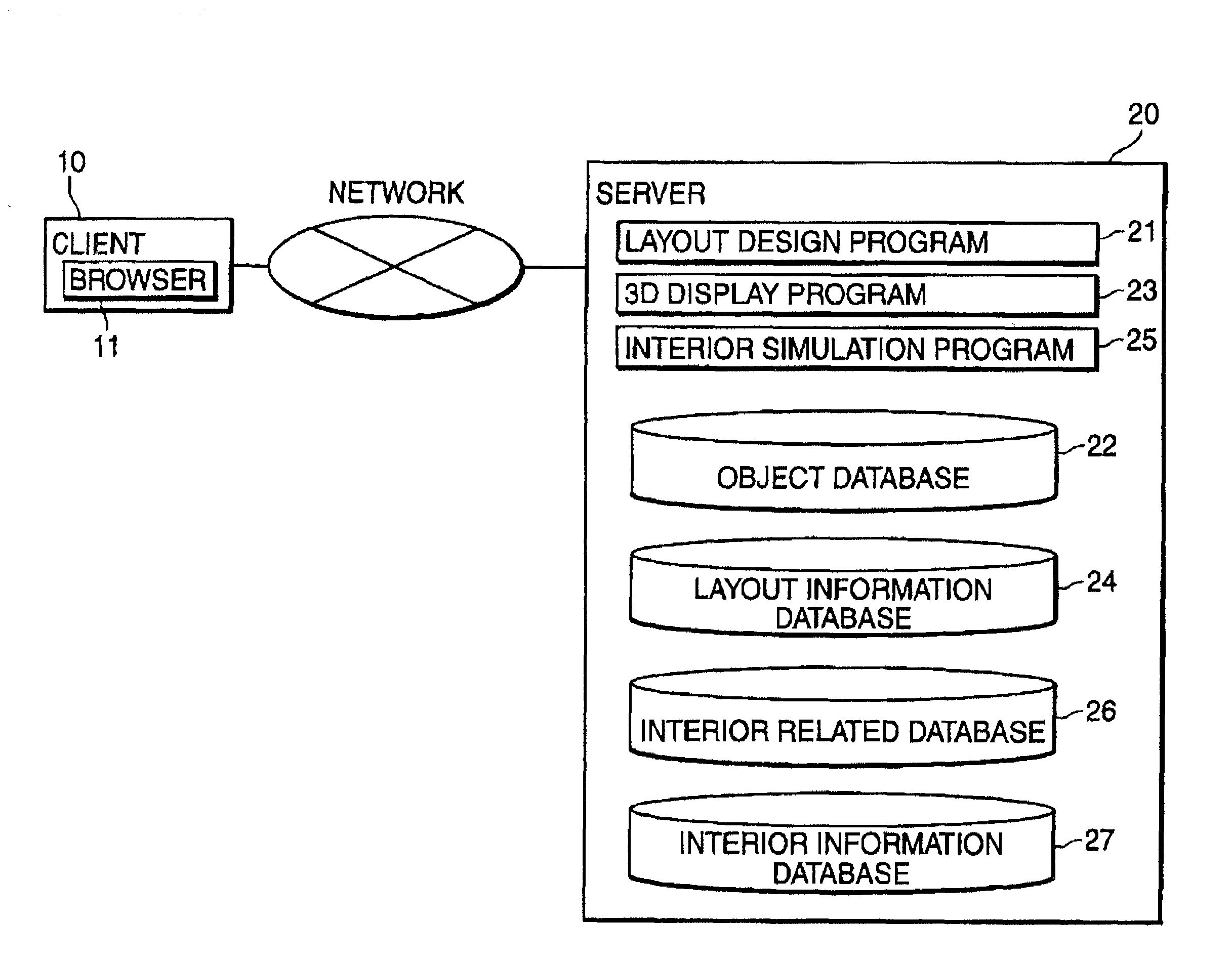

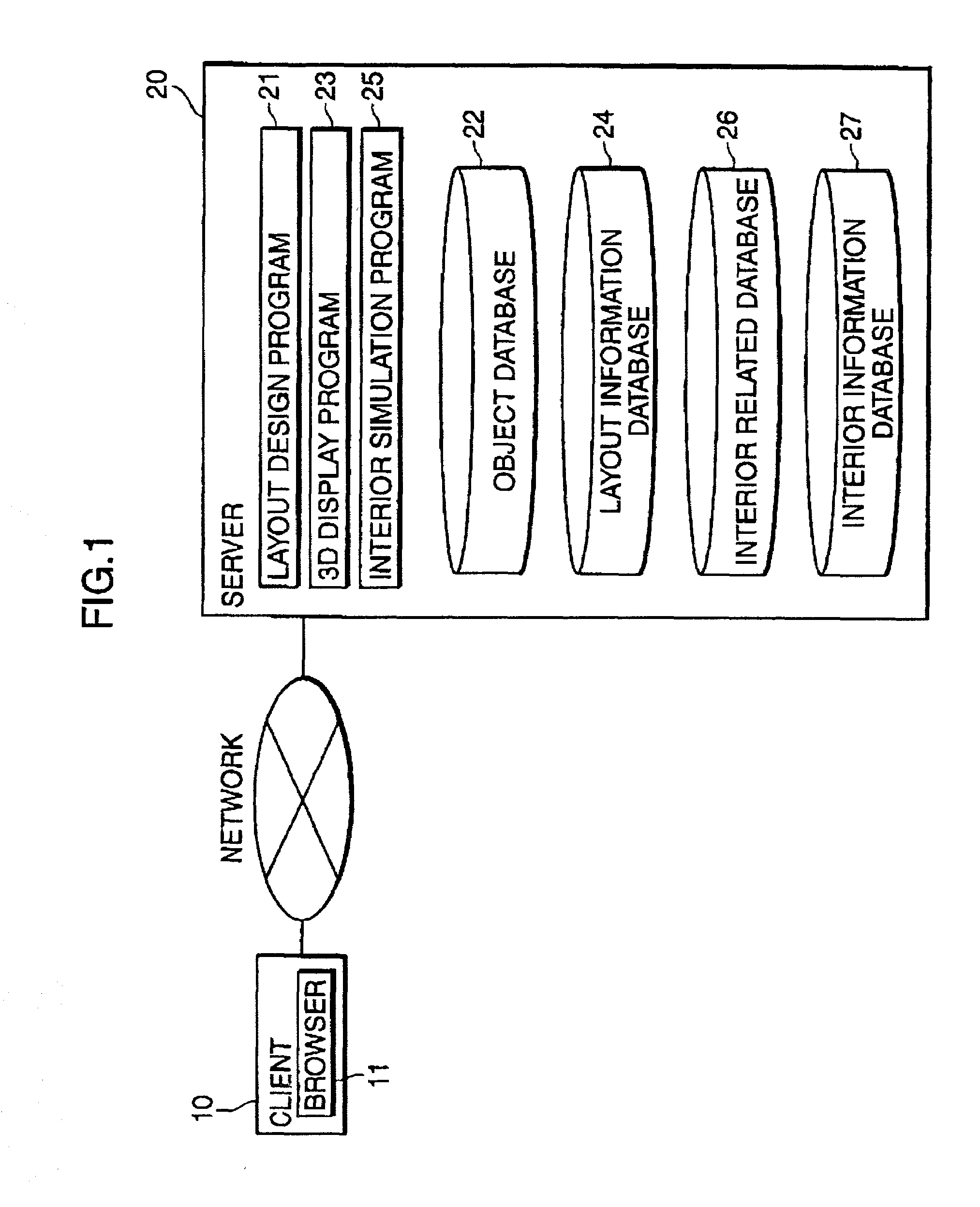

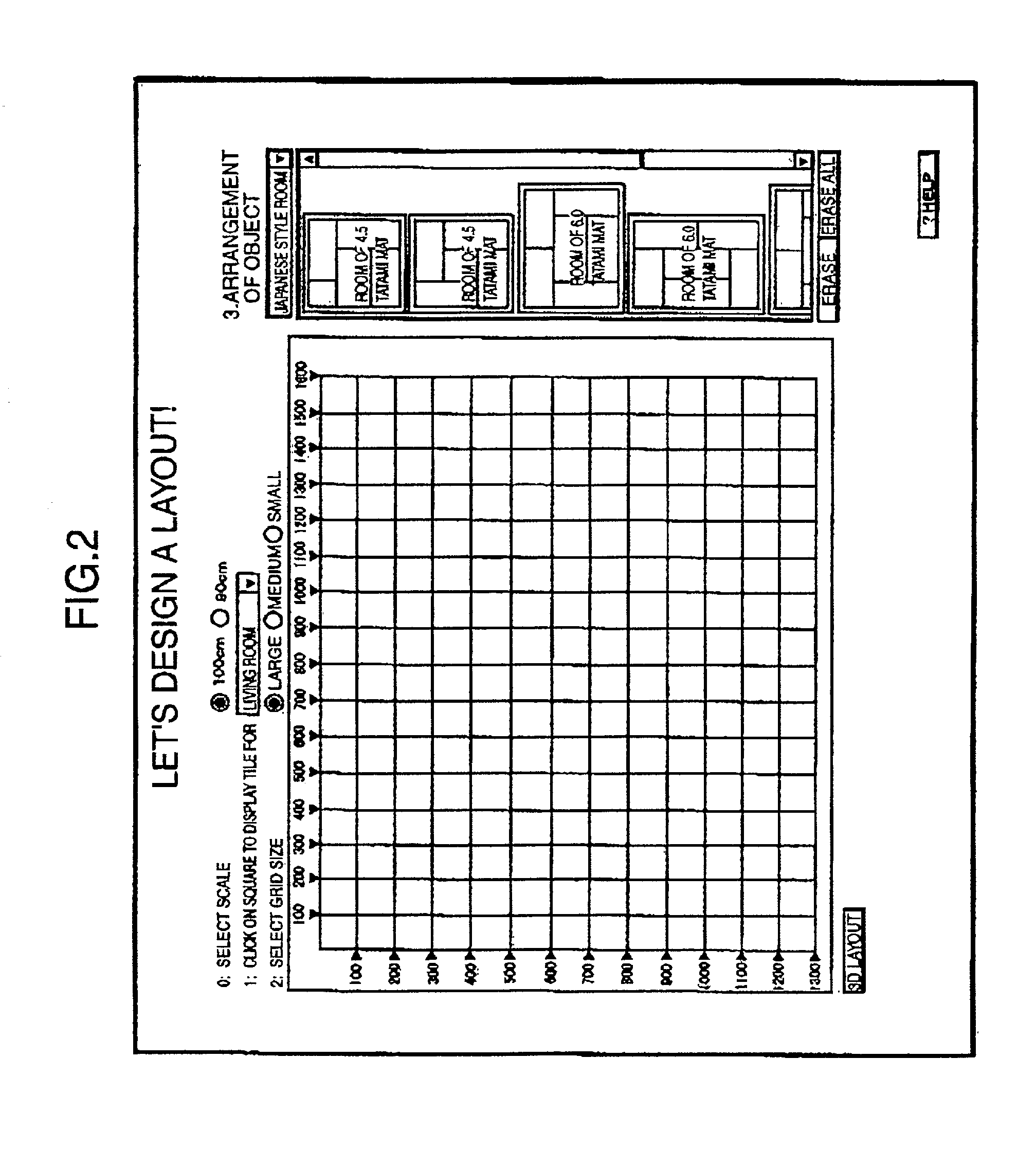

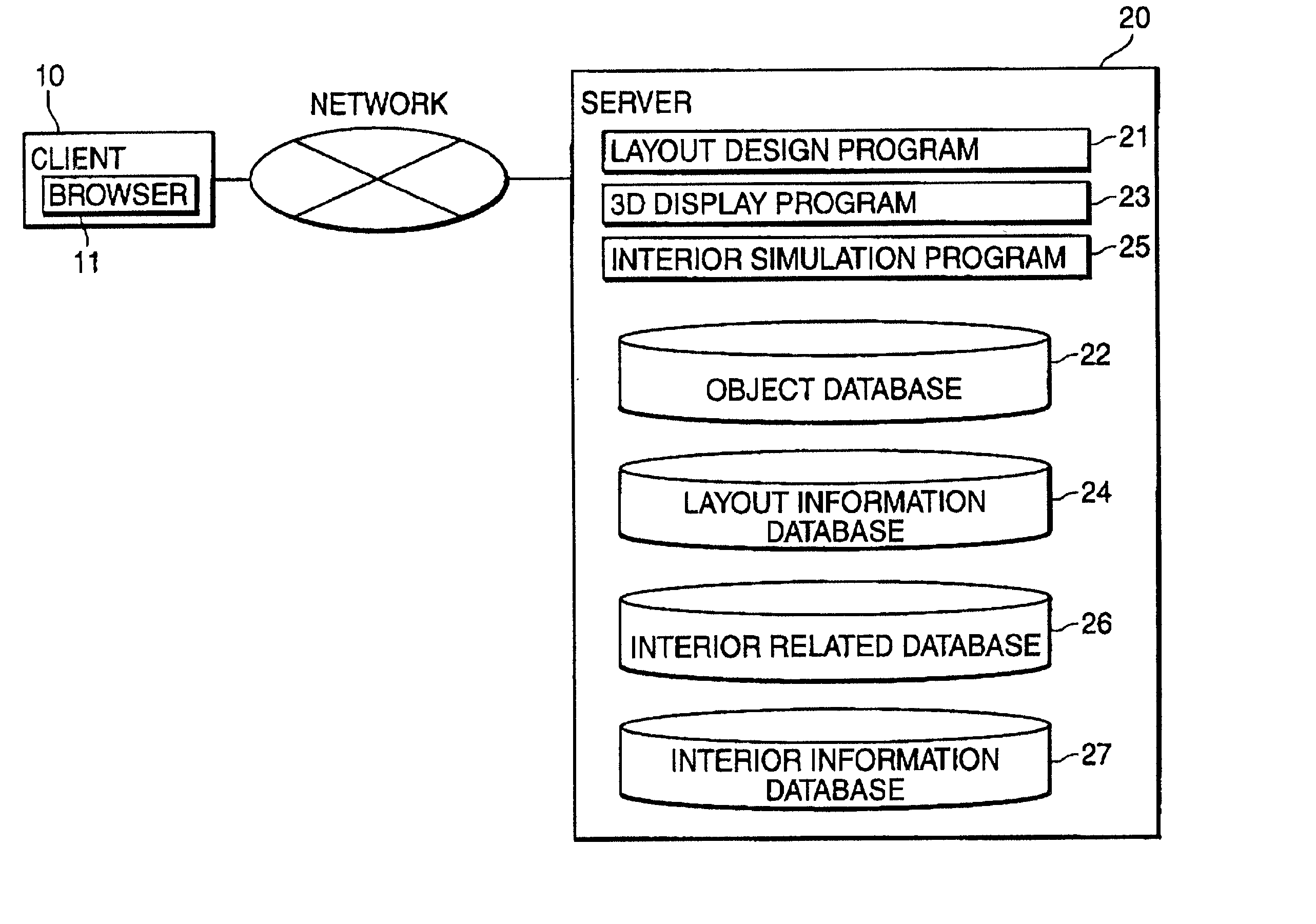

Provided is an environment which enables a user to implement 3D space design on a computer accessible to a server computer via a network. The server computer includes a layout design program which is operable on a screen activated by a browser of the client computer to enable the user to implement space design of a layout in the terms of a 2D image, an object database which stores object data used for layout design for retrieval and extraction, and a 3D display program which is operable on the browser screen of the client computer to display the designed space in the terms of a 3D image. The client computer is equipped with the browser capable of executing programs of the layout design program and the 3D display program. Upon receiving the layout design program and the 3D display program from the server computer via the network, the programs of the layout design program and the 3D display program are executable on the browser screen.

Owner:PANASONIC CORP

Method for aiding space design using network, system therefor, and server computer of the system

Provided is an environment which enables a user to implement 3D space design on a computer accessible to a server computer via a network. The server computer includes a layout design program which is operable on a screen activated by a browser of the client computer to enable the user to implement space design of a layout in the terms of a 2D image, an object database which stores object data used for layout design for retrieval and extraction, and a 3D display program which is operable on the browser screen of the client computer to display the designed space in the terms of a 3D image. The client computer is equipped with the browser capable of executing programs of the layout design program and the 3D display program. Upon receiving the layout design program and the 3D display program from the server computer via the network, the programs of the layout design program and the 3D display program are executable on the browser screen.

Owner:PANASONIC CORP

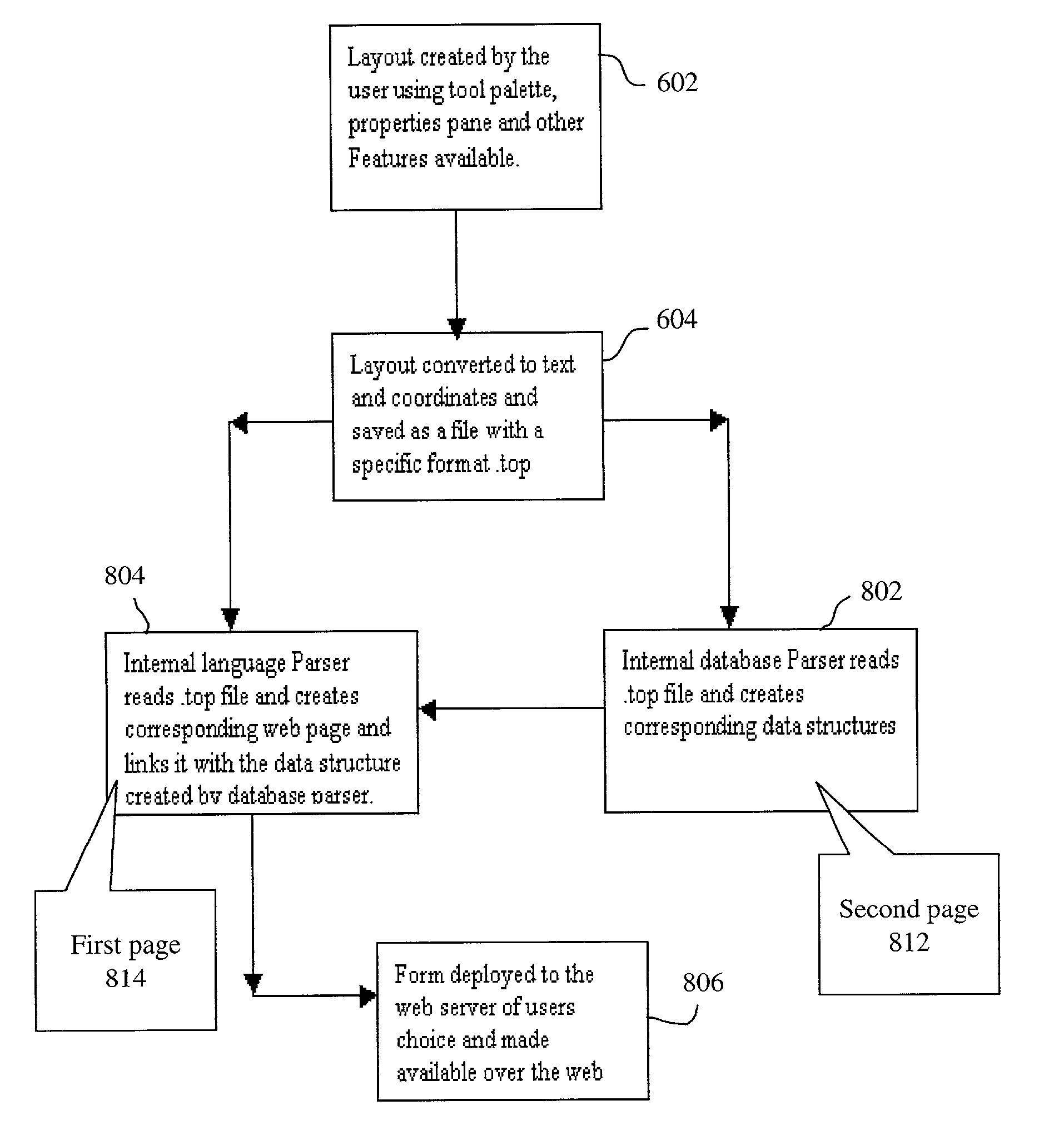

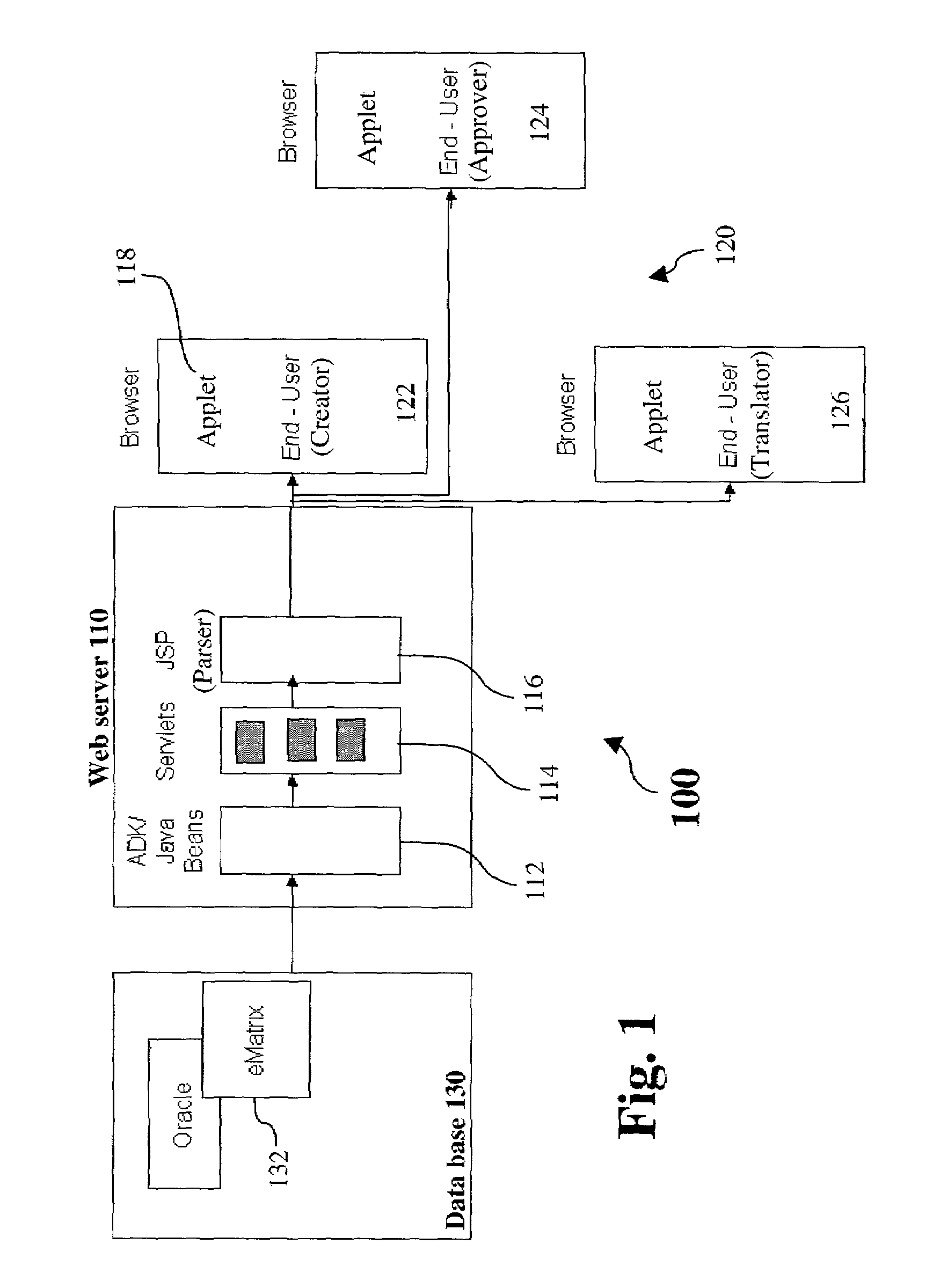

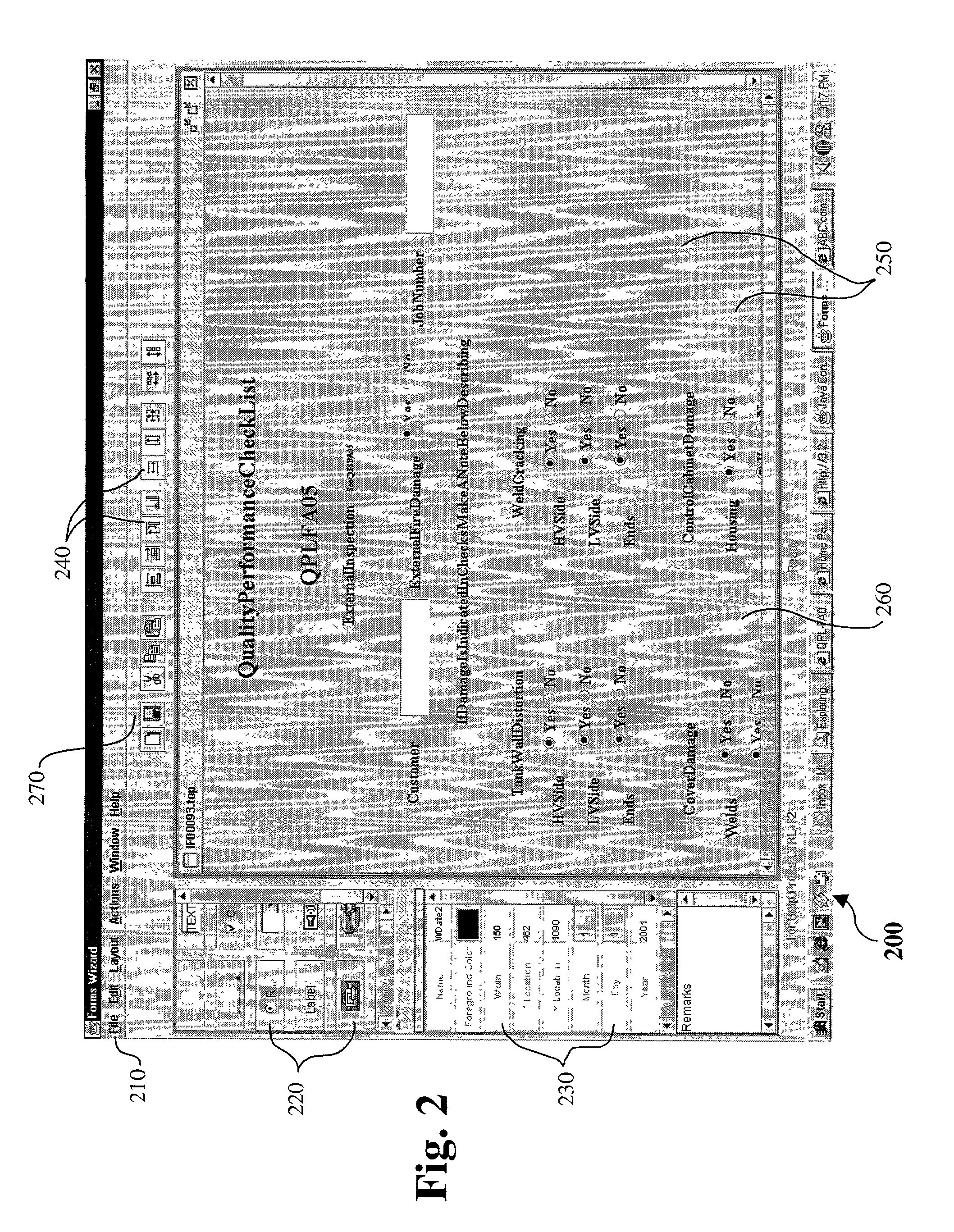

Creating data structures from a form file and creating a web page in conjunction with corresponding data structures

InactiveUS7032170B2Digital data processing detailsNatural language data processingGraphicsArray data structure

The invention provides a system and method for creating a form. The method includes providing a graphical user interface including a plurality of selectable components and a design space; a creator selecting at least one of the selectable components and disposing each of the selected selectable components in the design space to generate a form layout; converting the form layout to data information; and saving the data information to a form file, the form file being output to a database over a network.

Owner:GENERAL ELECTRIC CO

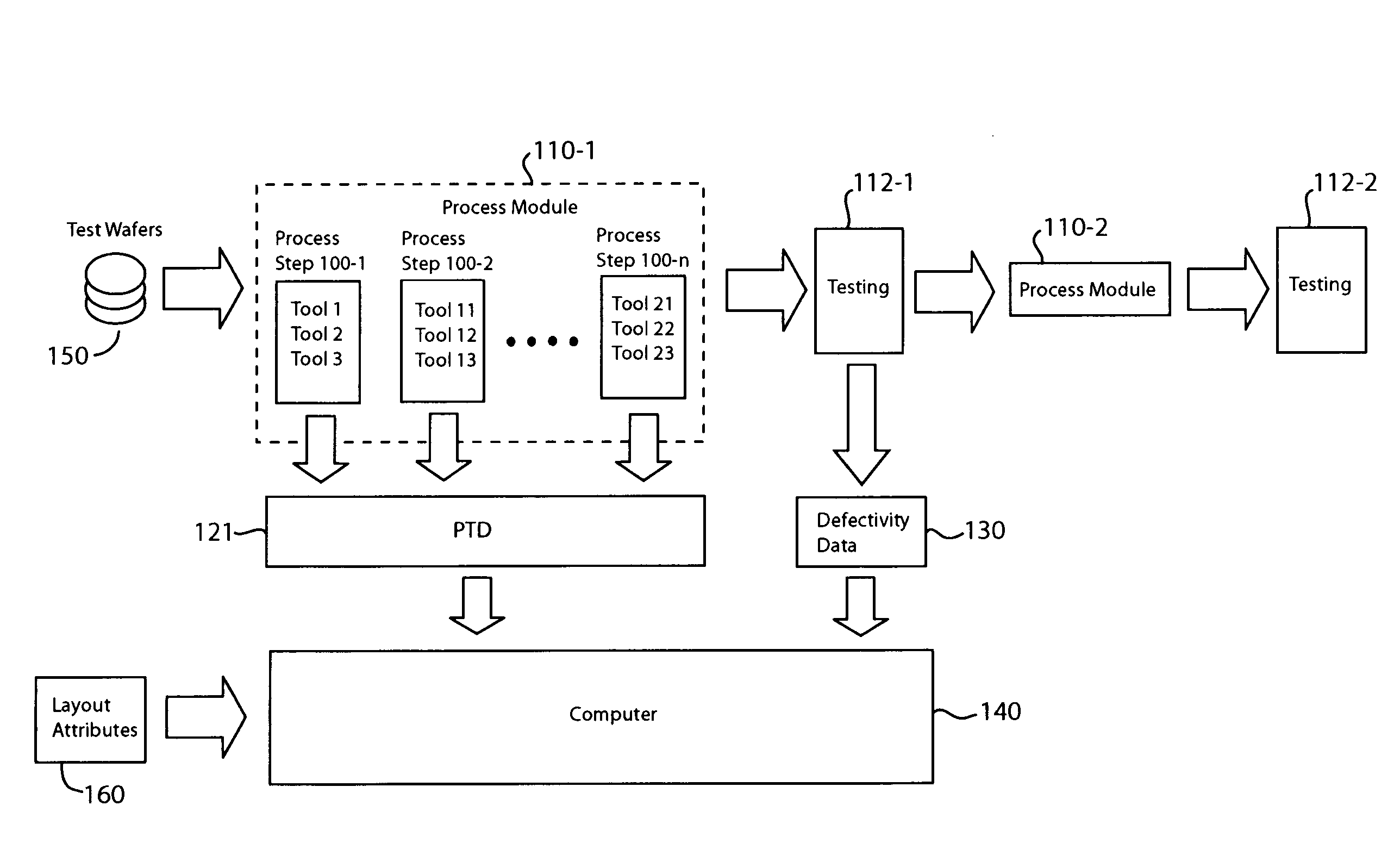

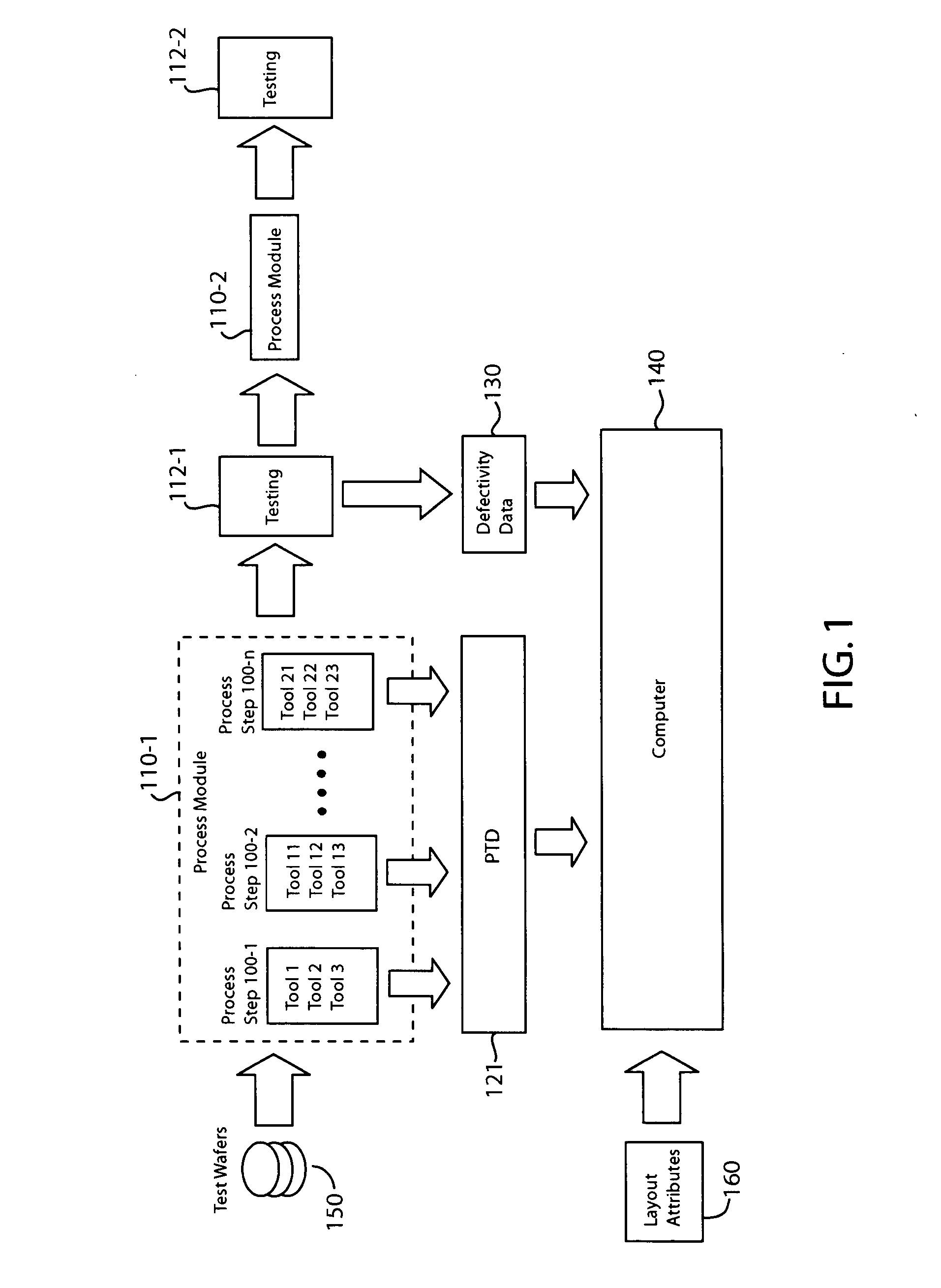

Monitoring and control of integrated circuit device fabrication processes

InactiveUS20080312875A1Programme controlDigital computer detailsDesign informationMonitoring and control

An integrated circuit (IC) device fabrication process may be monitored by processing product wafers to fabricate product IC devices, collecting process tool data from tools used to fabricate the product IC devices, and testing the product IC devices. To predict and monitor yield, the process tool data collected during processing and the defectivity data from testing the product IC devices may be input to a yield model that also takes into account design information particular to the product devices. The design information may comprise layout attributes of the product devices. The yield model may be generated from a defectivity model created by processing test wafers to fabricate test structures, collecting process tool data from tools used to fabricate the test structures, and testing the test structures. The test structures may have varying layout attributes to cover a design space allowed by design rules for particular product IC devices.

Owner:PDF SOLUTIONS INC

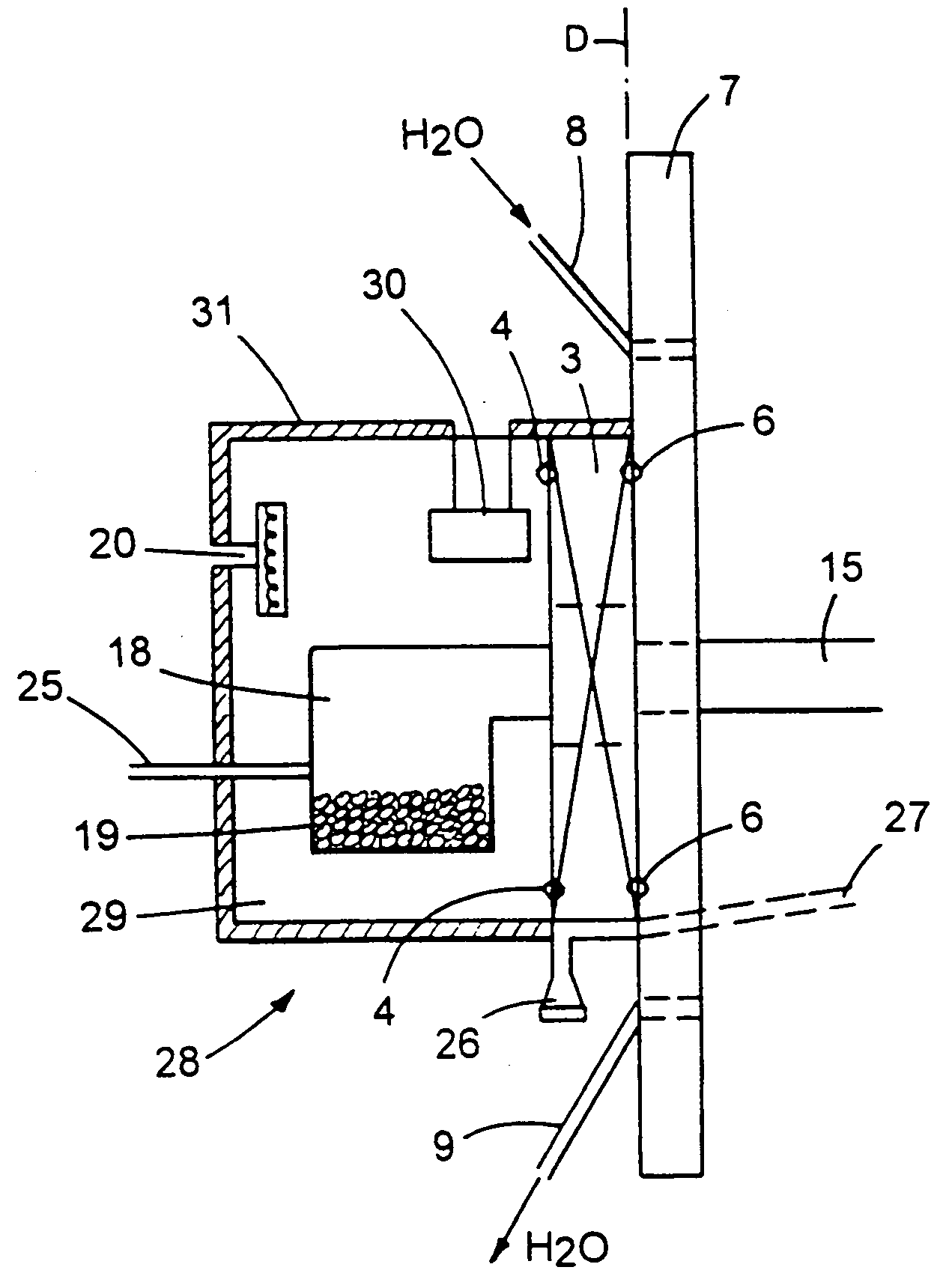

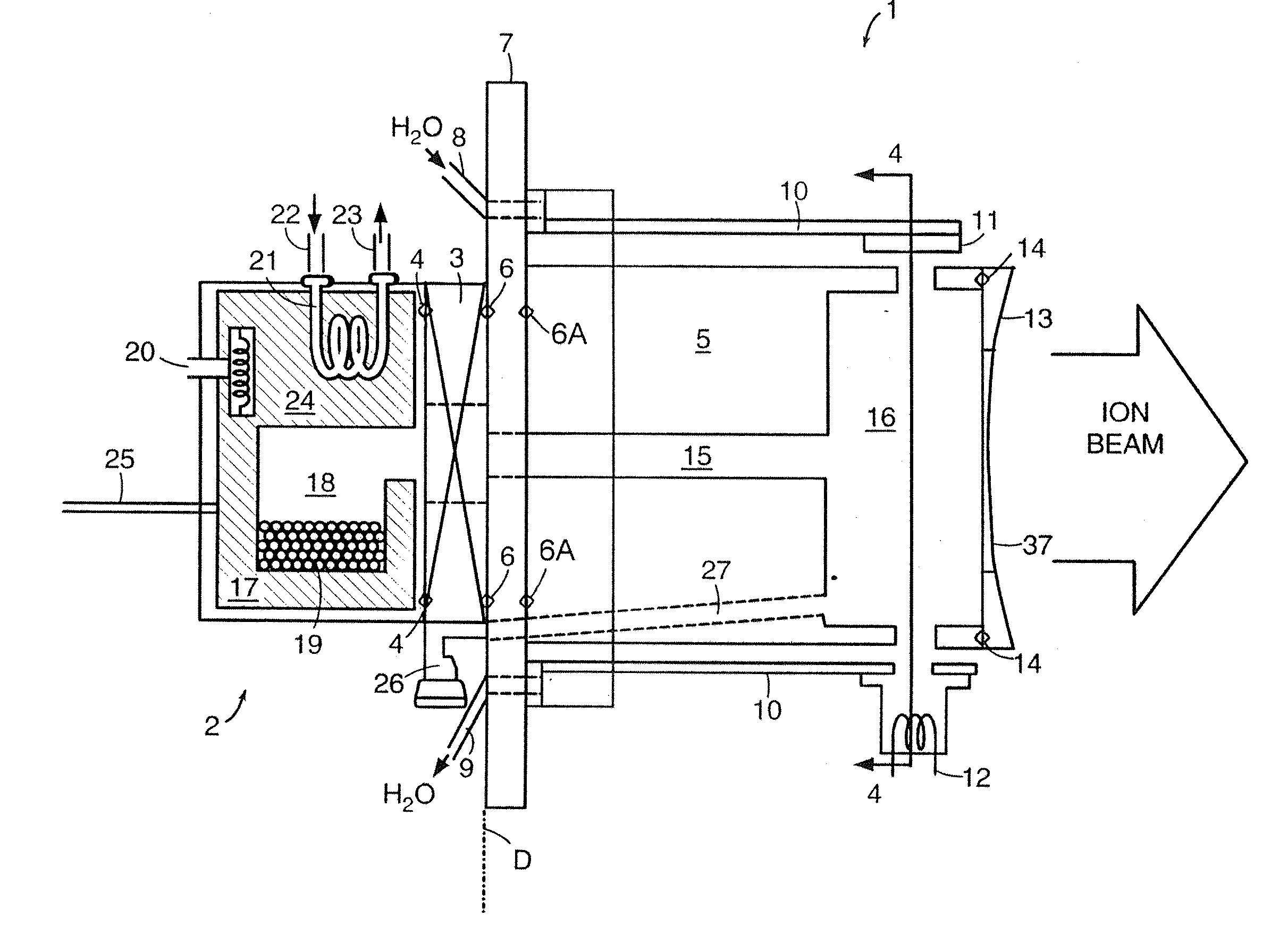

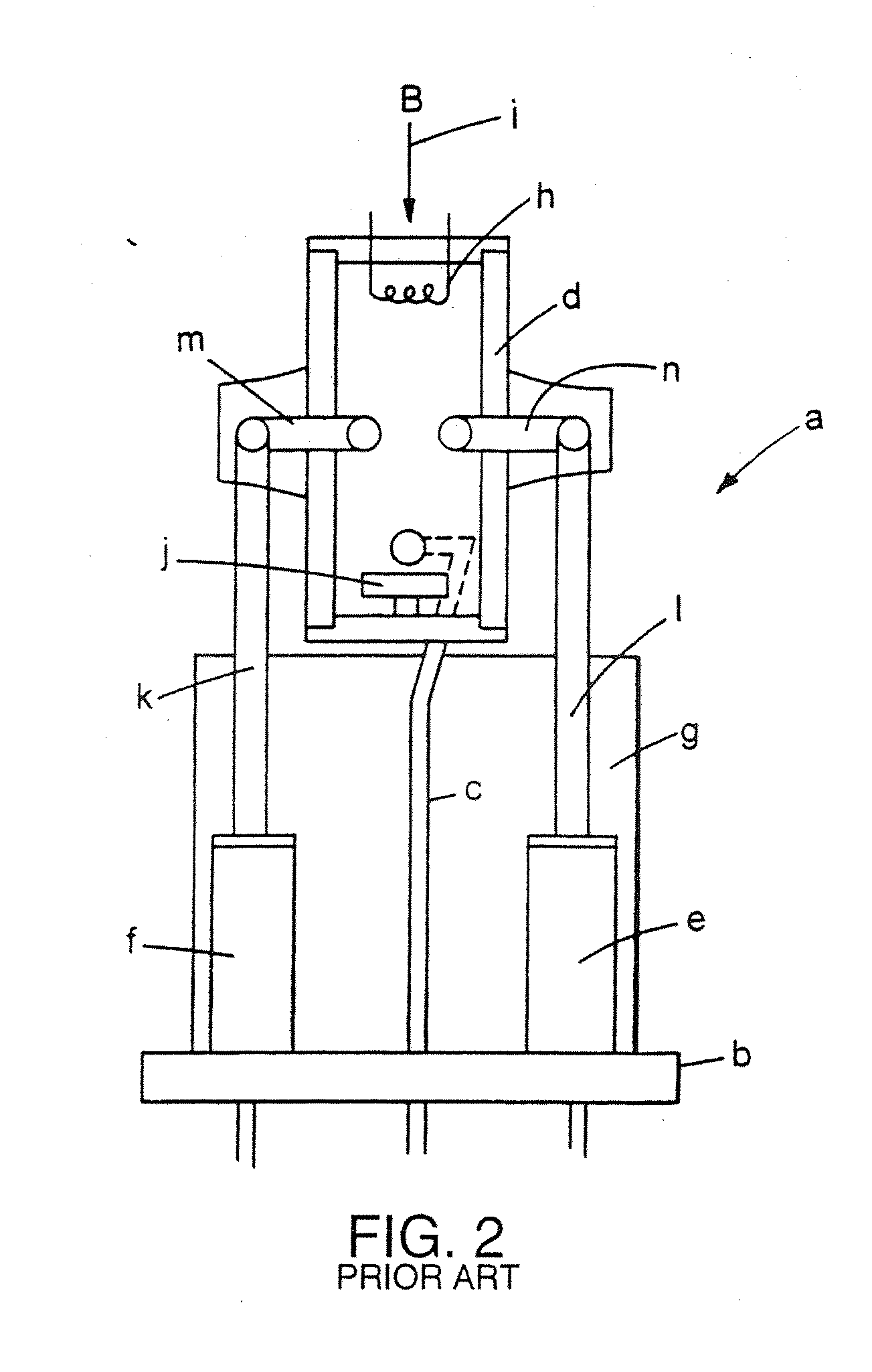

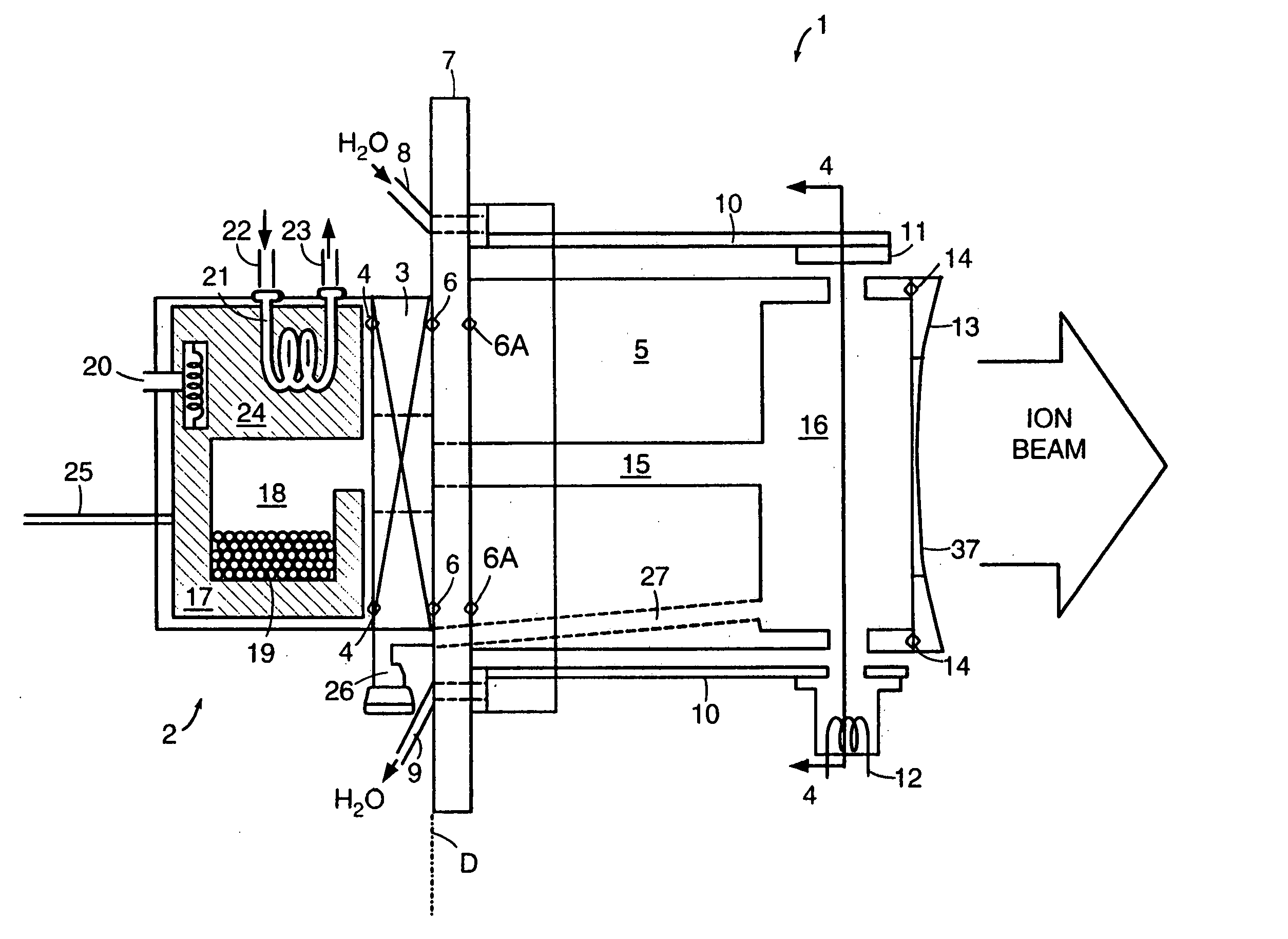

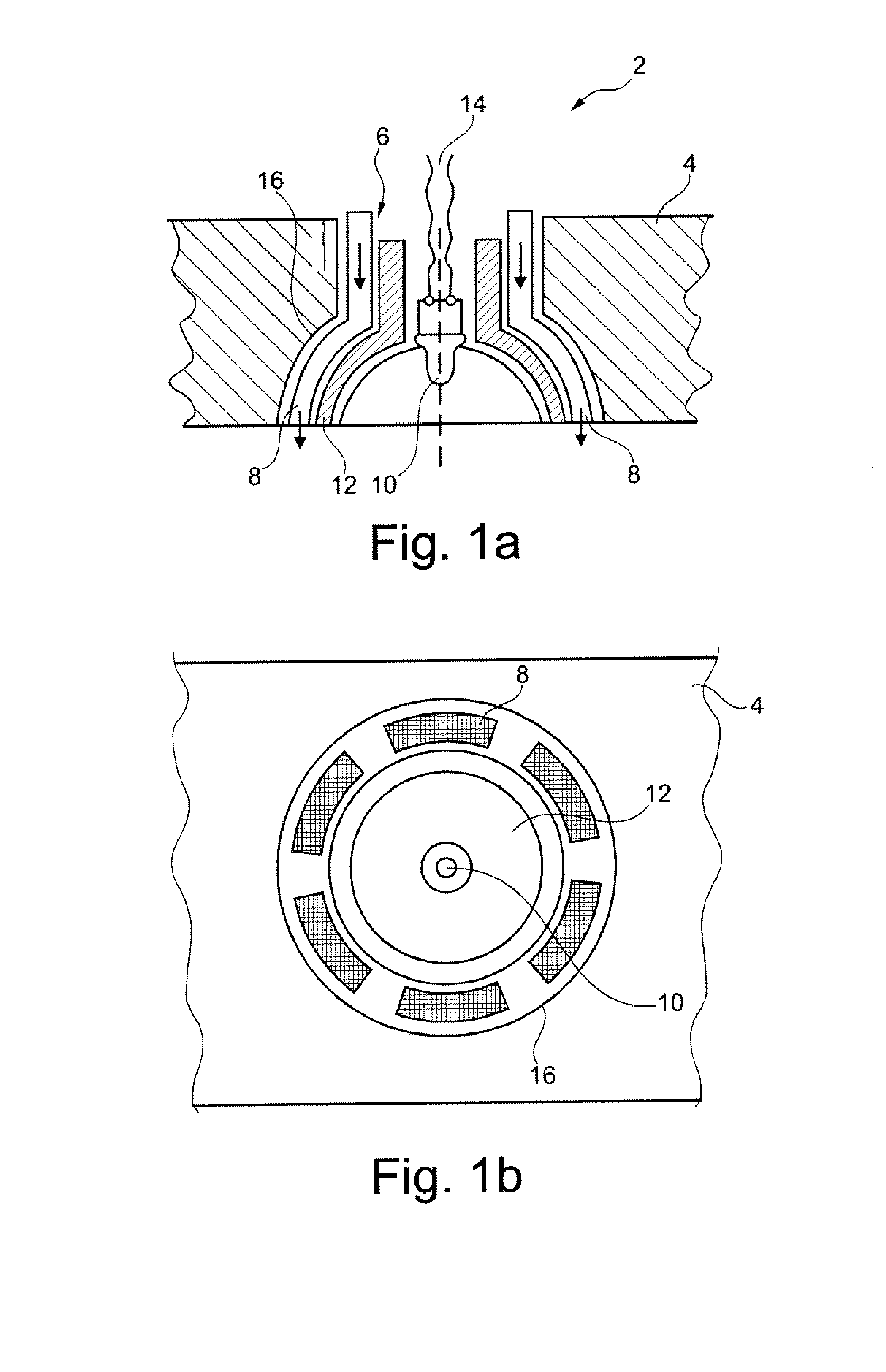

Ion implantation ion source, system and method

InactiveUS20050051096A1Preventing thermal dissociationReduce presenceVacuum evaporation coatingSemiconductor/solid-state device manufacturingLight beamHeat sensitive

An ion implantation device for vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system and delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source. The ion implantation device includes an ion source which can operate without an arc plasma, which can improve the emittance properties and the purity of the beam and without a strong applied magnetic field, which can improve the emittance properties of the beam. The ion source is configured so that it can be retrofit into the ion source design space of an existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs.

Owner:SEMEQUIP +1

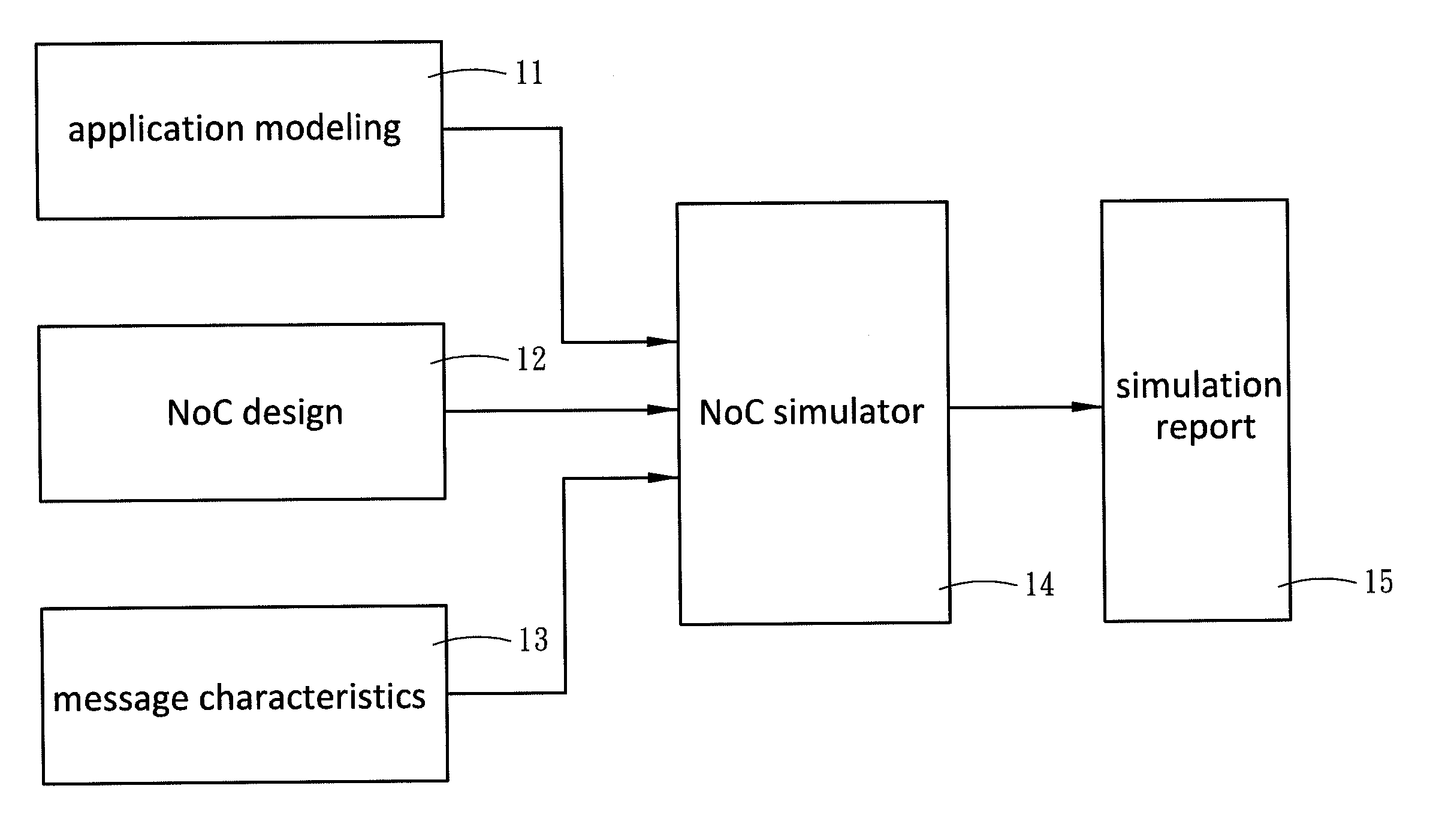

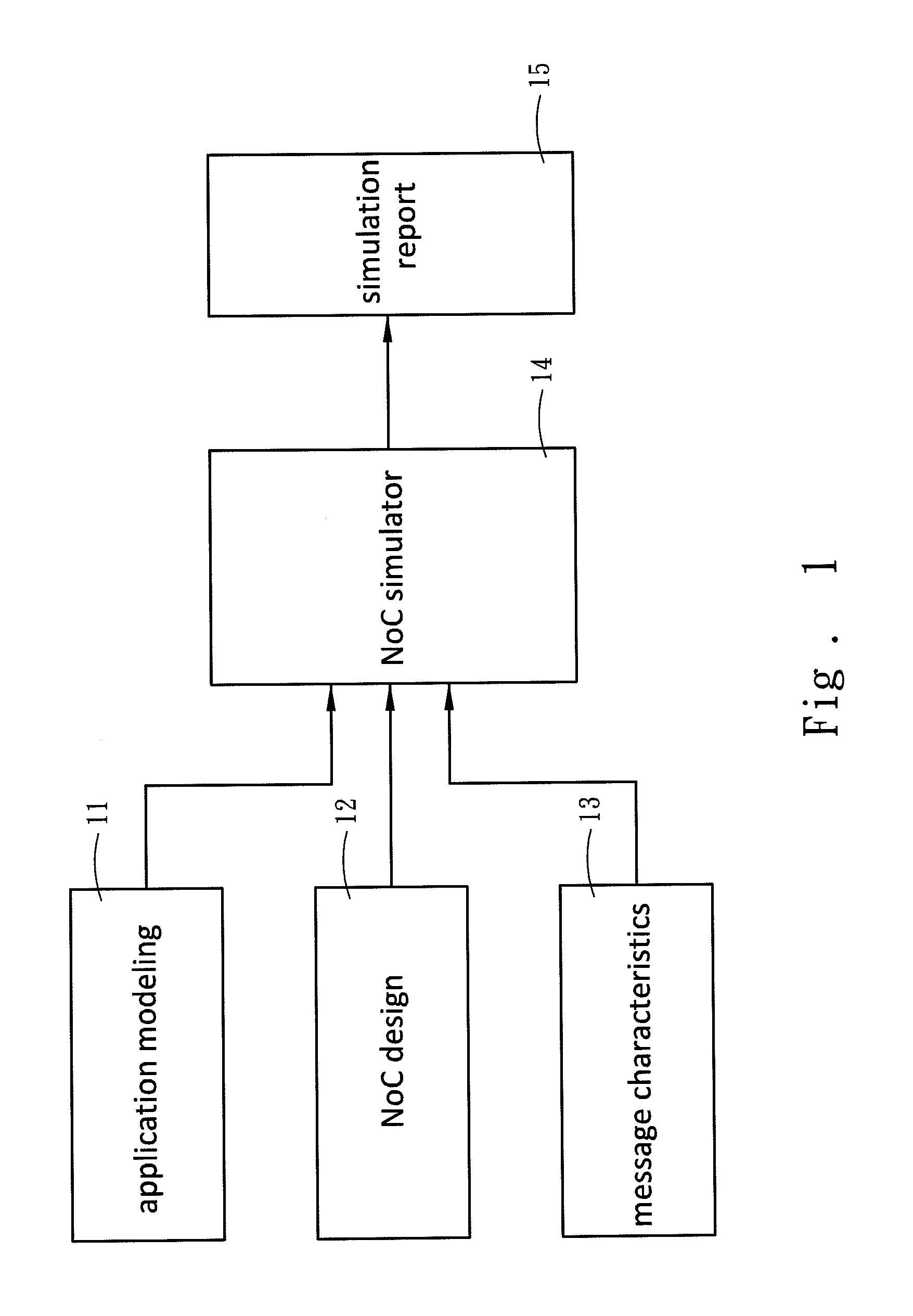

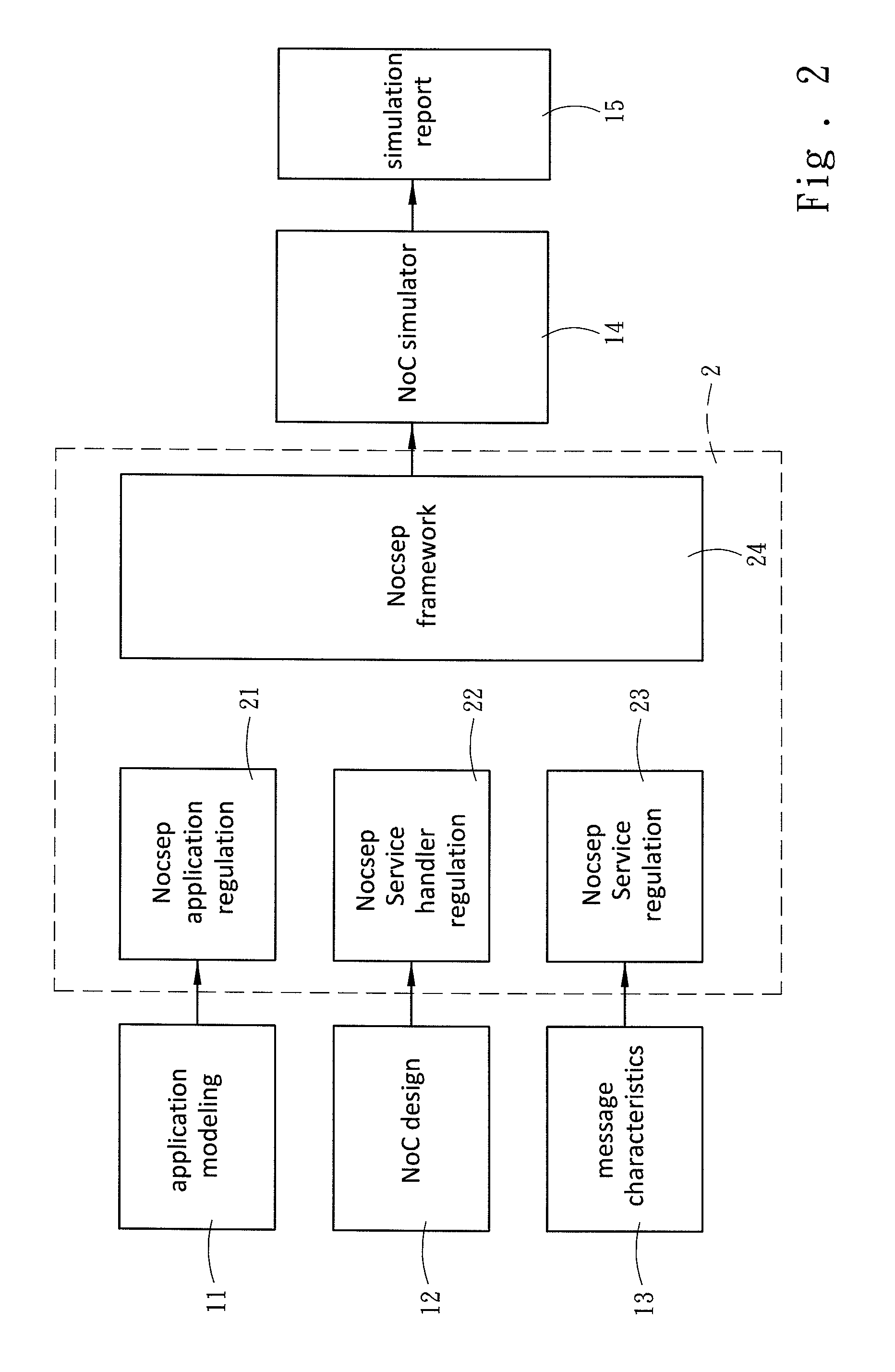

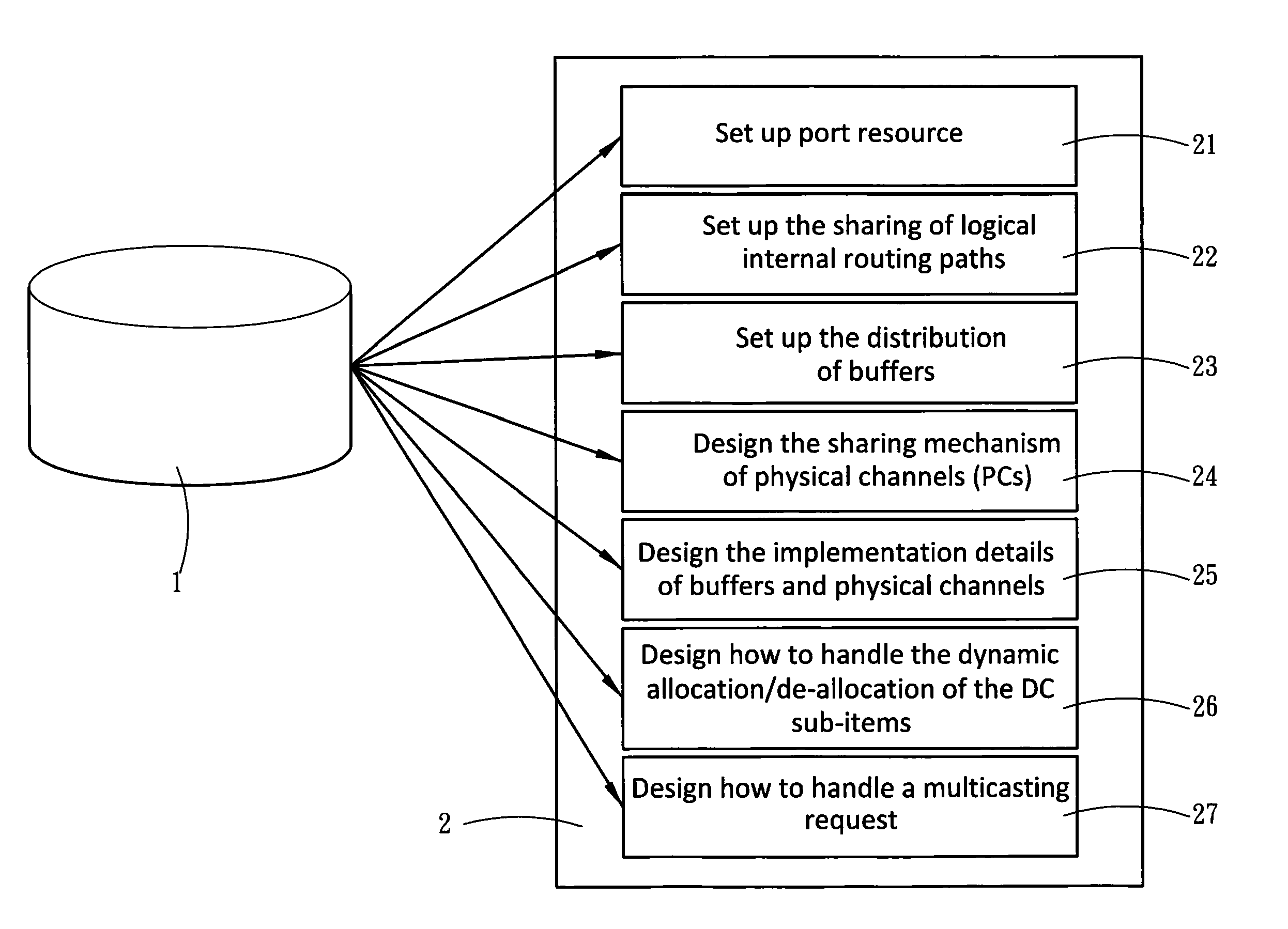

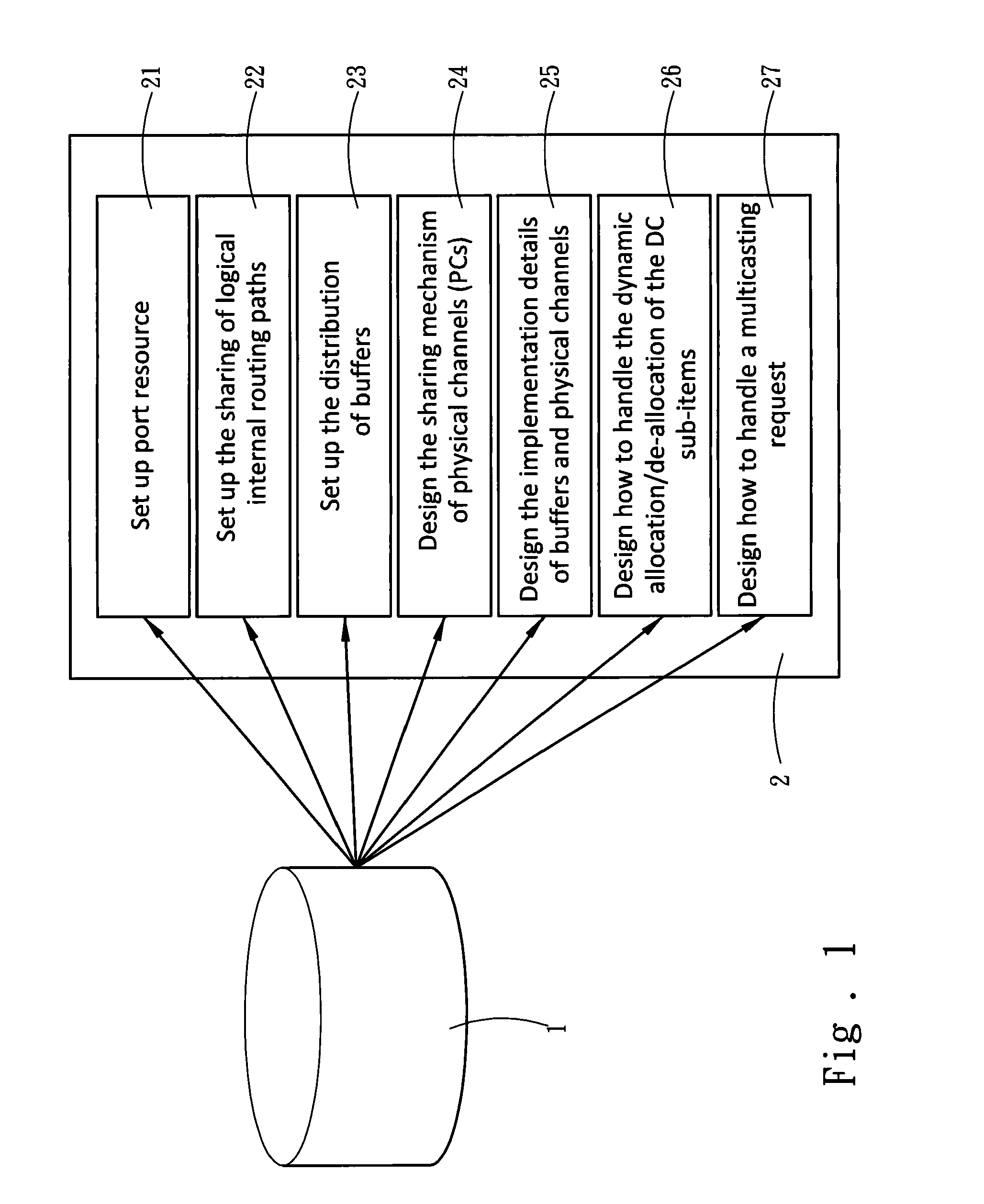

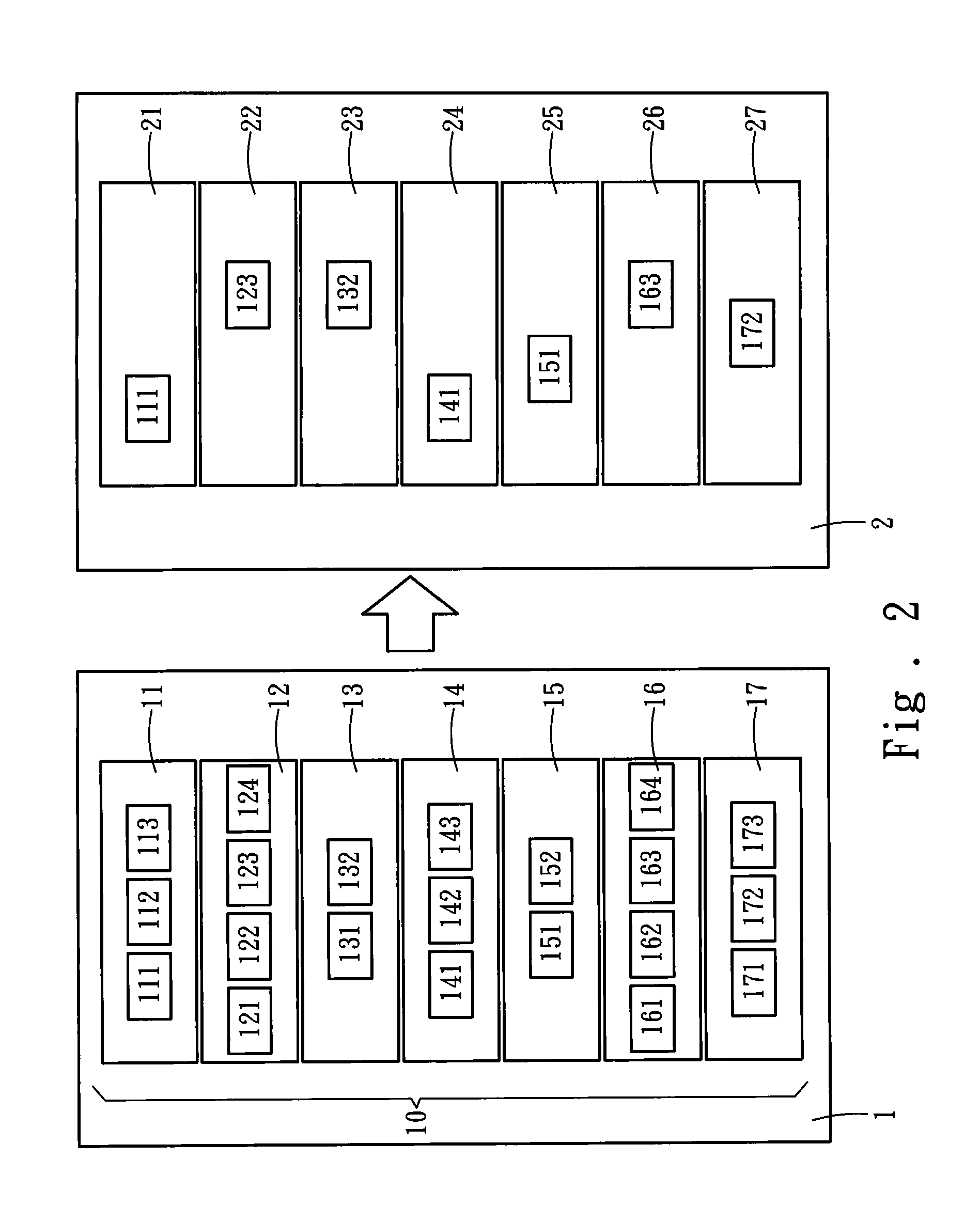

Noc-centric system exploration platform and parallel application communication mechanism description format used by the same

InactiveUS20110191774A1Fast simulationSimplifies some non-critical detailsMultiprogramming arrangementsTransmissionDescription formatComputer architecture

Network-on-Chip (NoC) is to solve the performance bottleneck of communication in System-on-Chip, and the performance of the NoC significantly depends on the application traffic. The present invention establishes a system framework across multiple layers, and defines the interface function behaviors and the traffic patterns of layers. The present invention provides an application modeling in which the task-graph of parallel applications is described in a text method, called Parallel Application Communication Mechanism Description Format. The present invention further provides a system level NoC simulation framework, called NoC-centric System Exploration Platform, which defines the service spaces of layers in order to separate the traffic patterns and enable the independent designs of layers. Accordingly, the present invention can simulate a new design without modifying the framework of simulator or interface designs. Therefore, the present invention increases the design spaces of NoC simulators, and provides a modeling to evaluate the performance of NoC.

Owner:NATIONAL TSING HUA UNIVERSITY

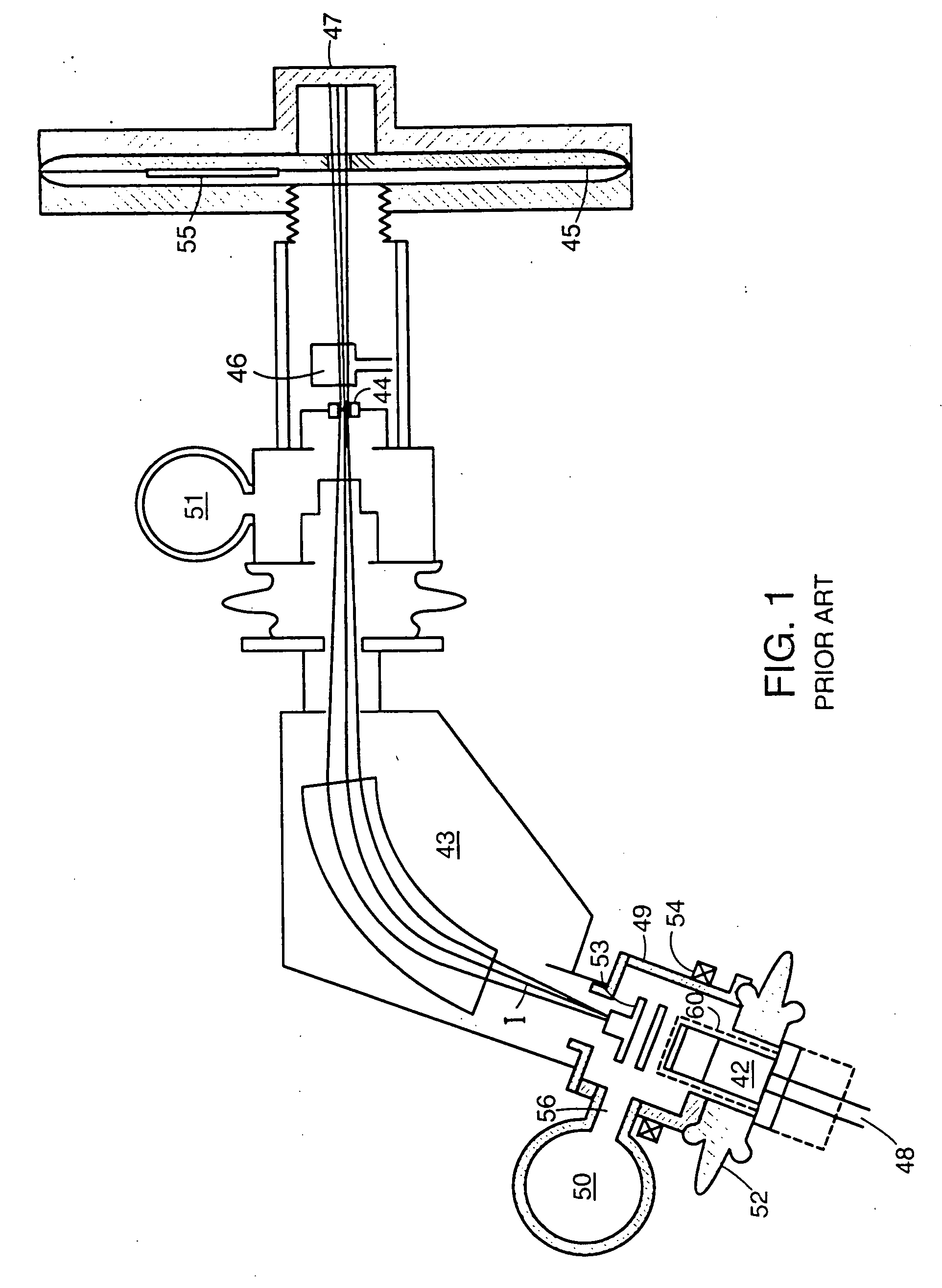

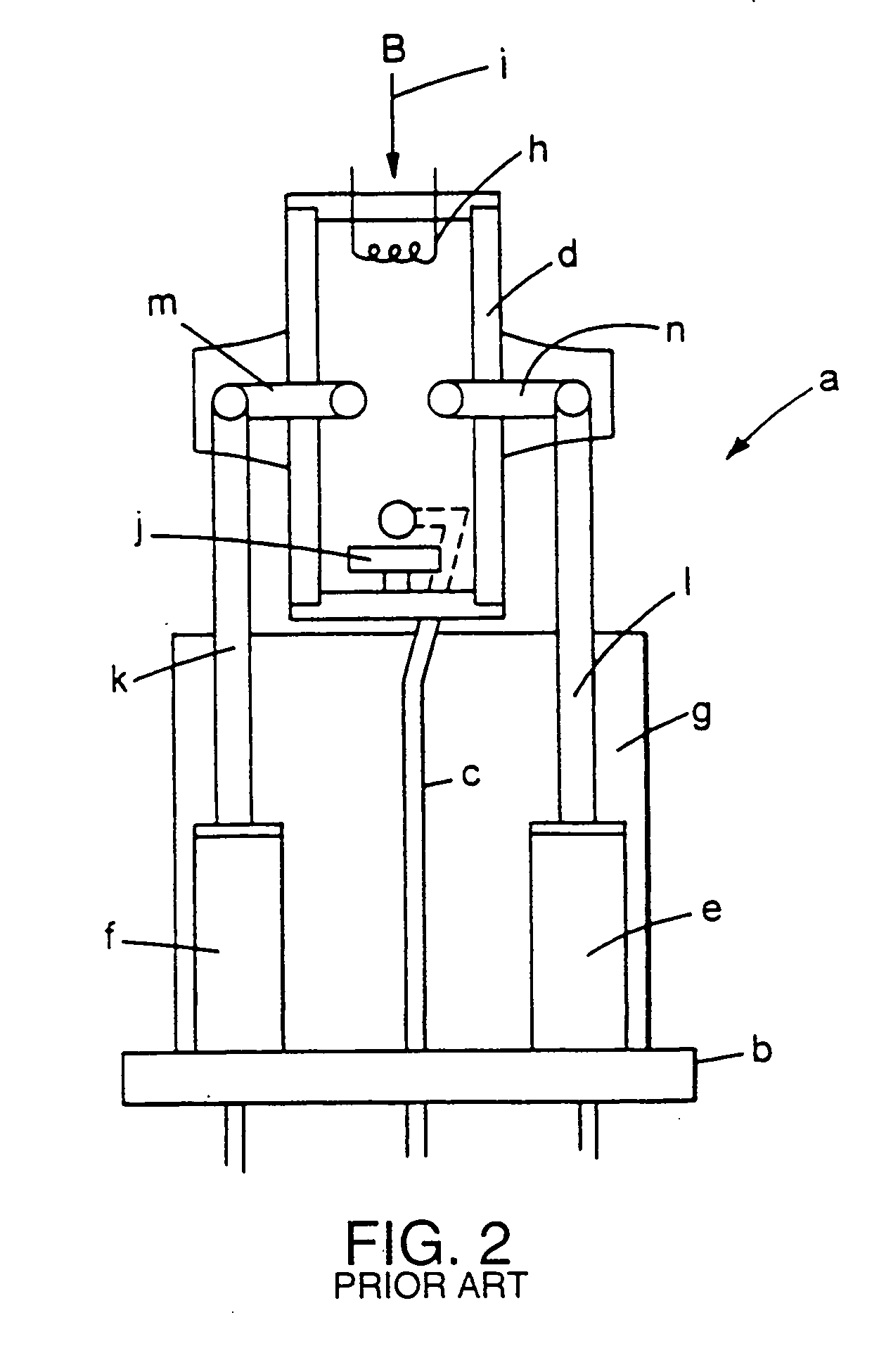

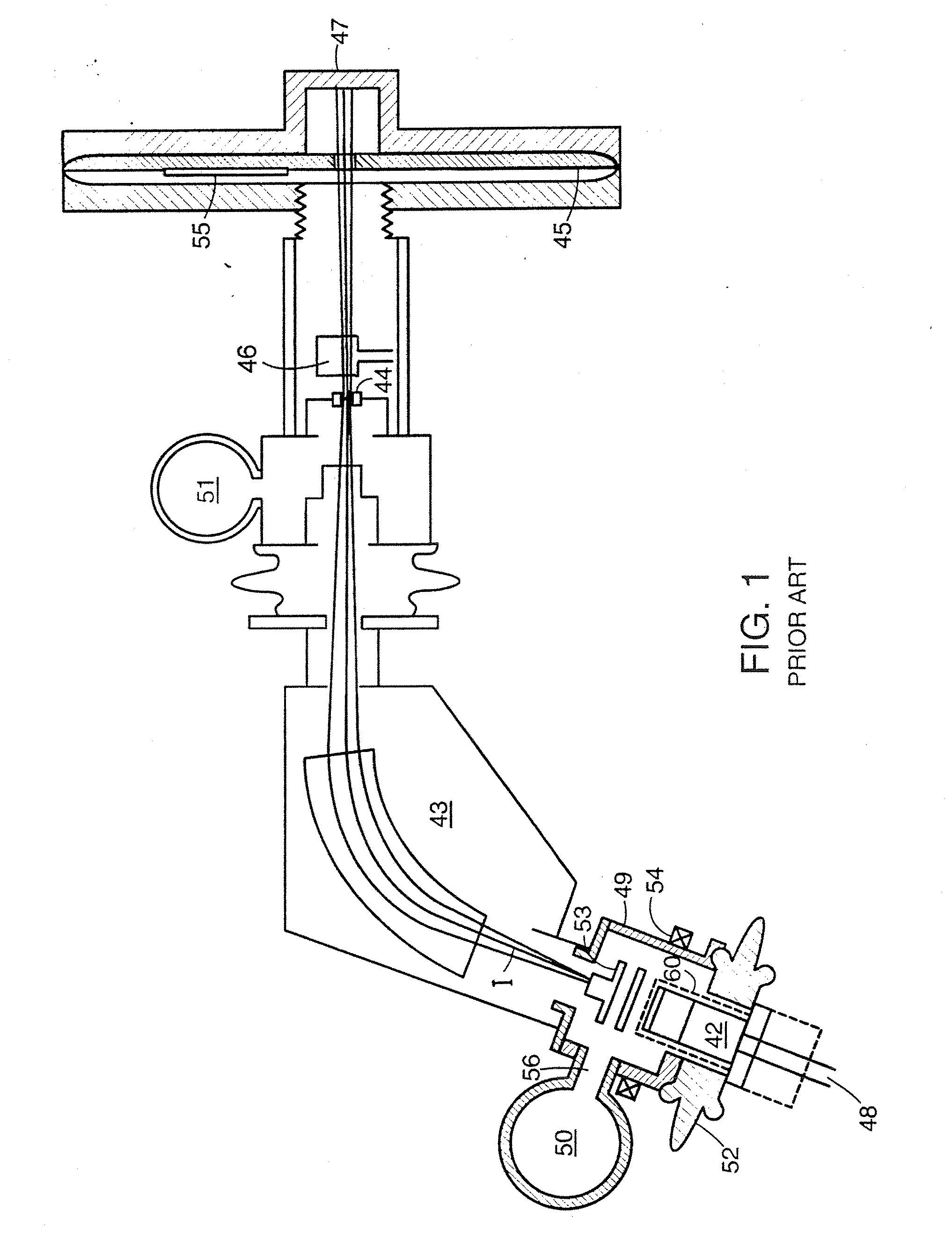

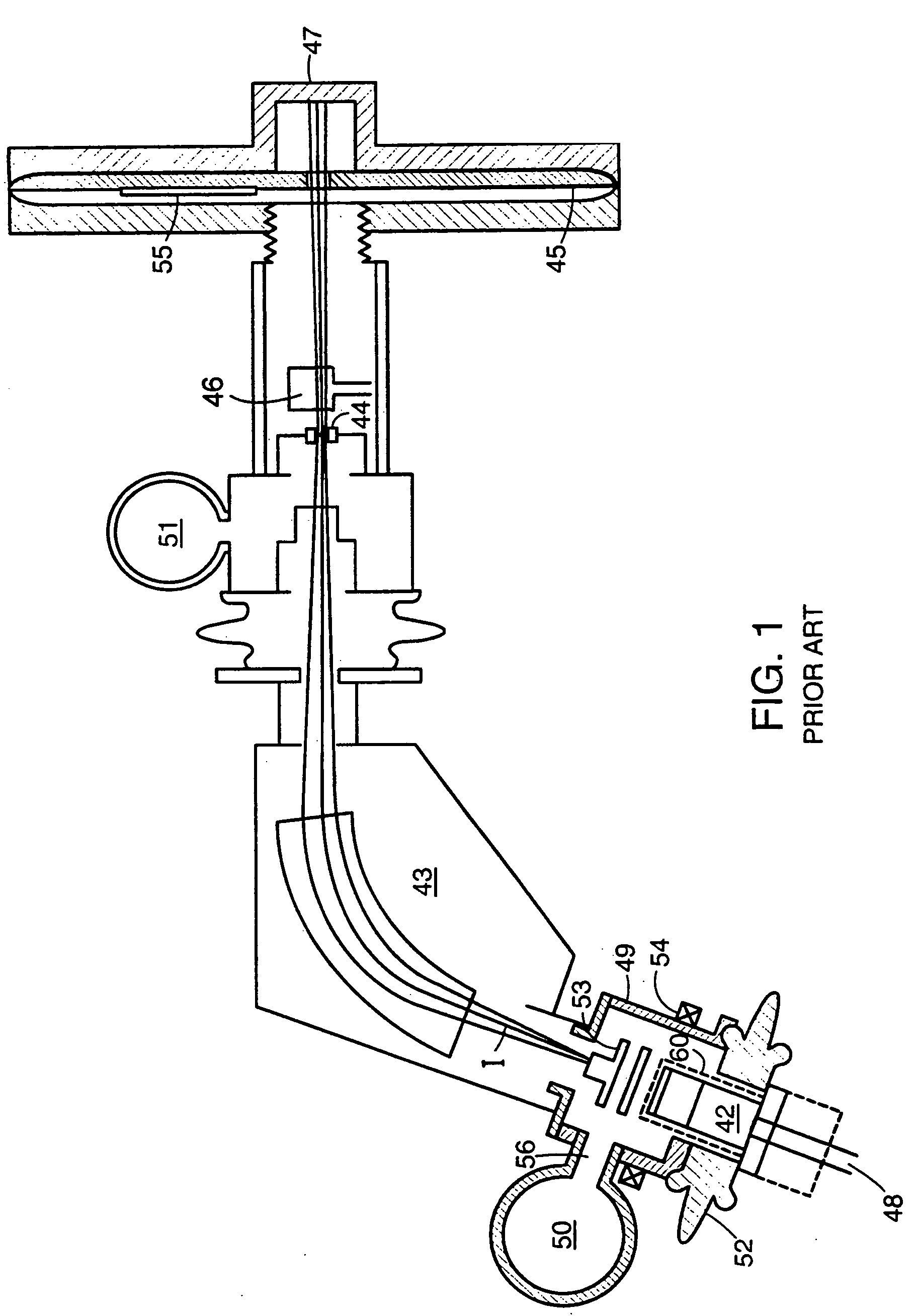

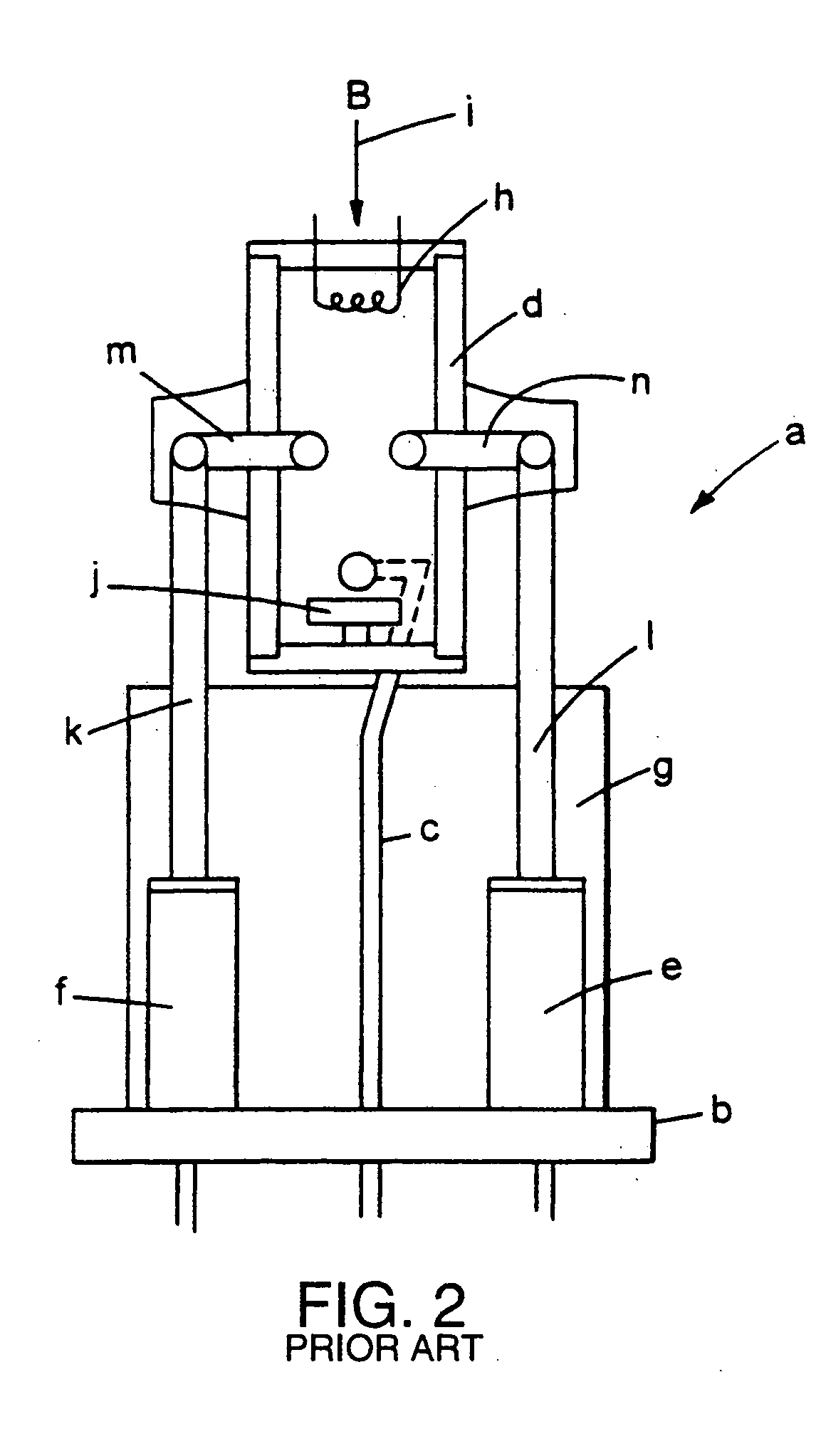

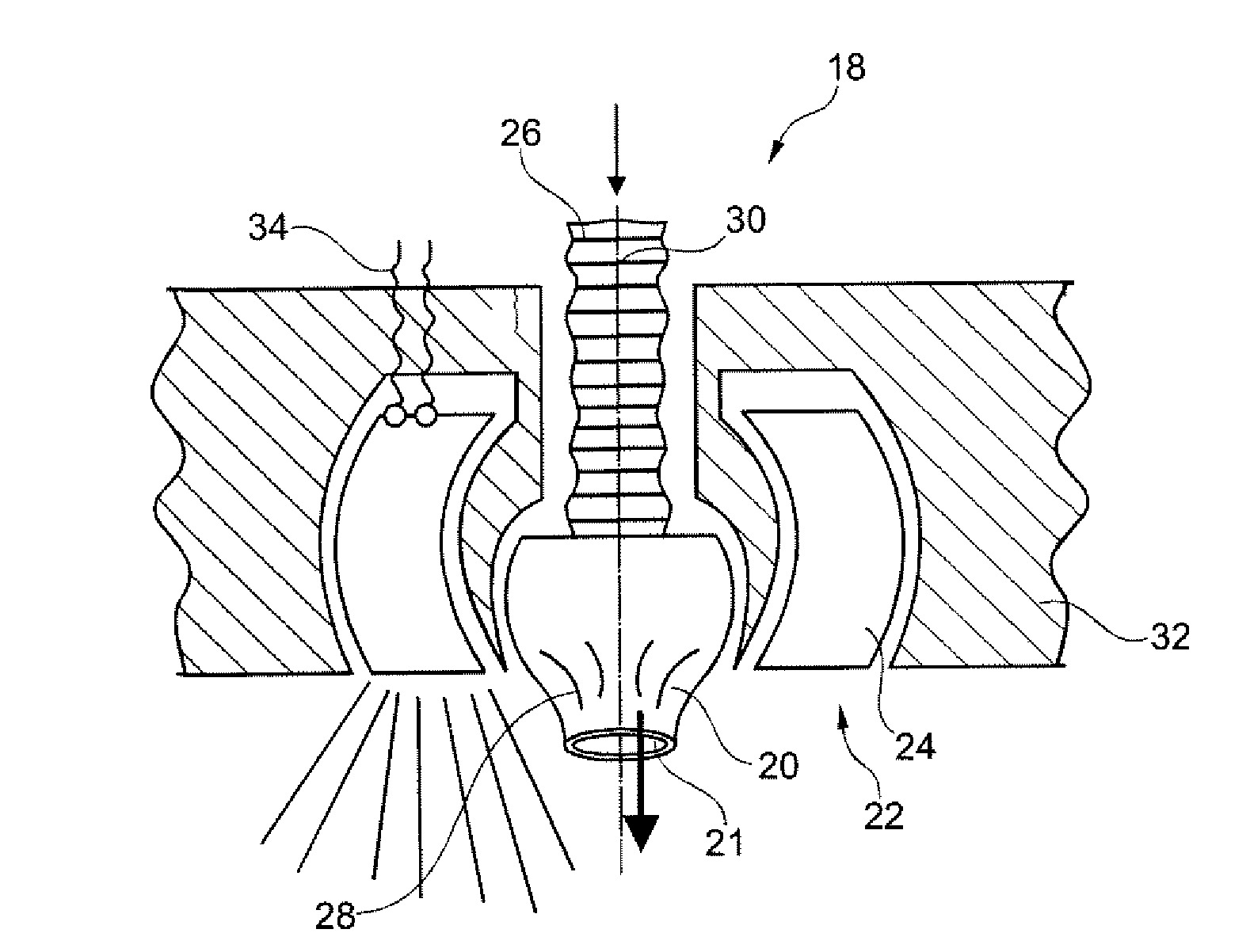

Ion implantation ion source, system and method

InactiveUS20070278417A1Maximizing flow of electronHigh extracted currentMaterial analysis by optical meansIon beam tubesDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

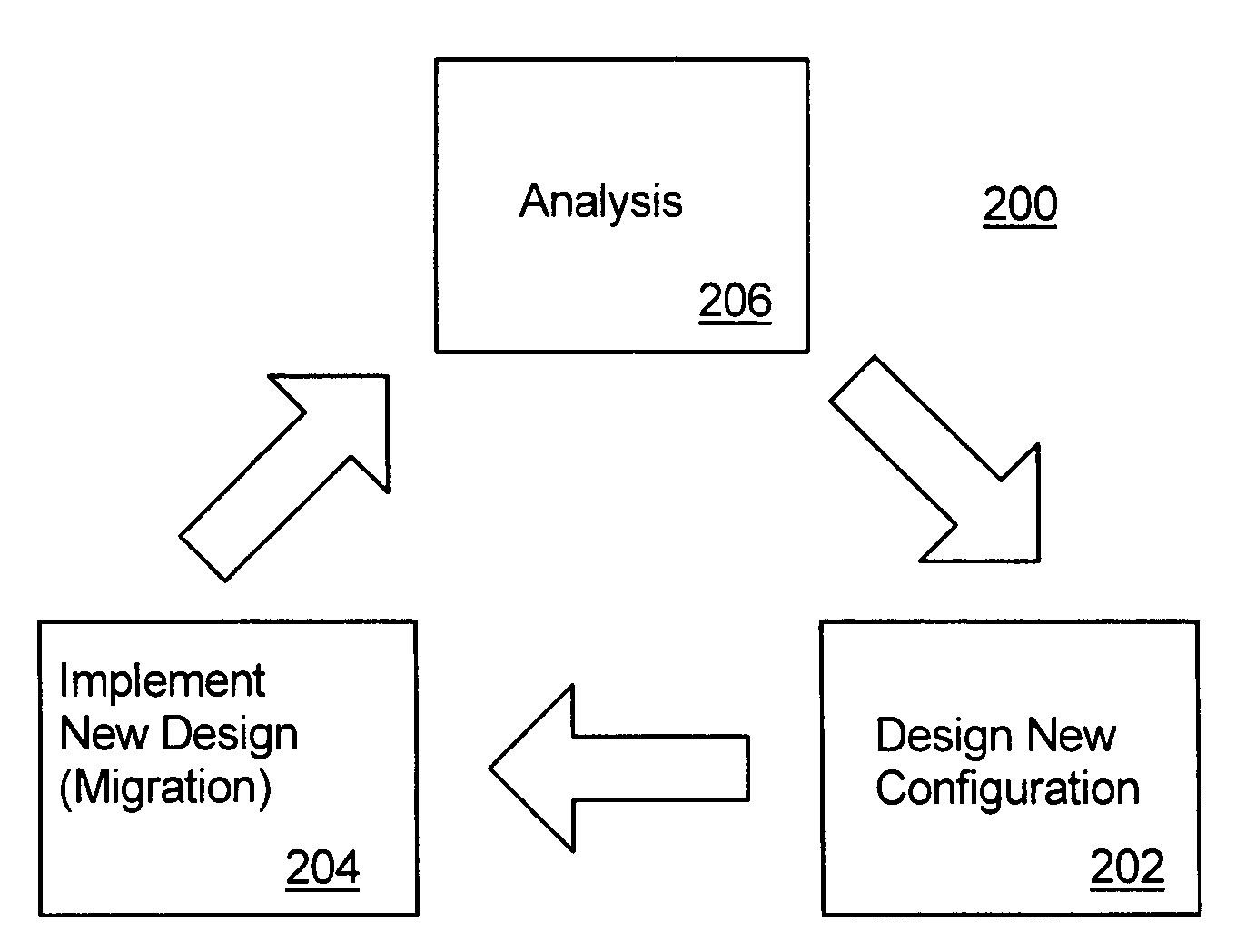

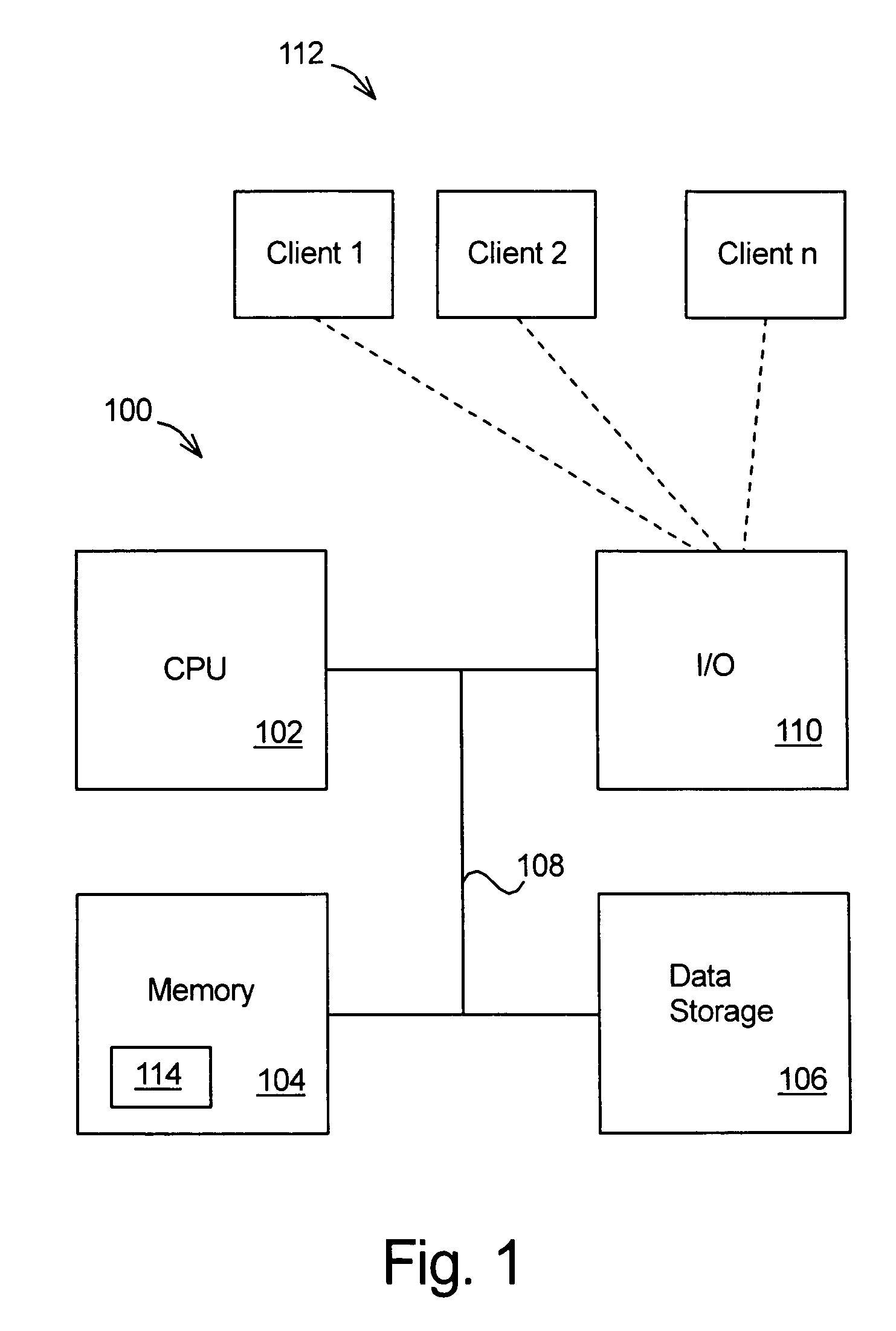

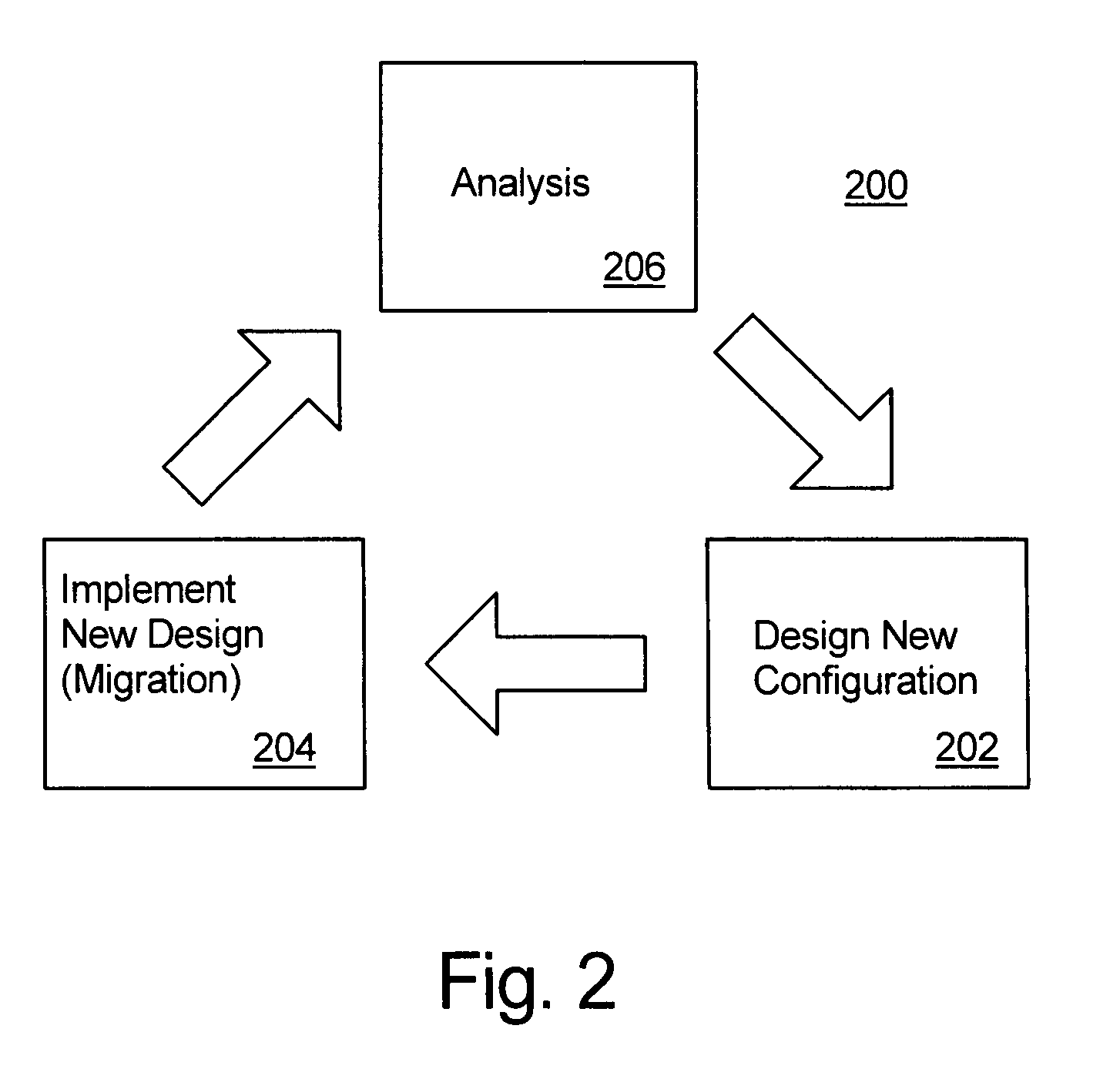

Automated system adaptation technique particularly for data storage systems

InactiveUS6978259B1Simple designInput/output to record carriersError detection/correctionComputerized systemAnalysis working

An automated system adaptation technique for computer systems, networks and subsystems generally and, more particularly, for data storage systems. The invention programmatically designs, configures and manages a system, such as a data storage system. This is accomplished by performing a sequence of steps in an iterative loop, including analyzing the operation of the system under a workload, generating a new design based on the analysis and migrating the existing system to the new design. By systematically exploring a large design space and developing designs based on analyses of the workload, the invention generates designs that are improved in comparison to conventional design techniques. By programmatically repeating these tasks, the invention causes the system to converge to one that supports the workload without being over-provisioned.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

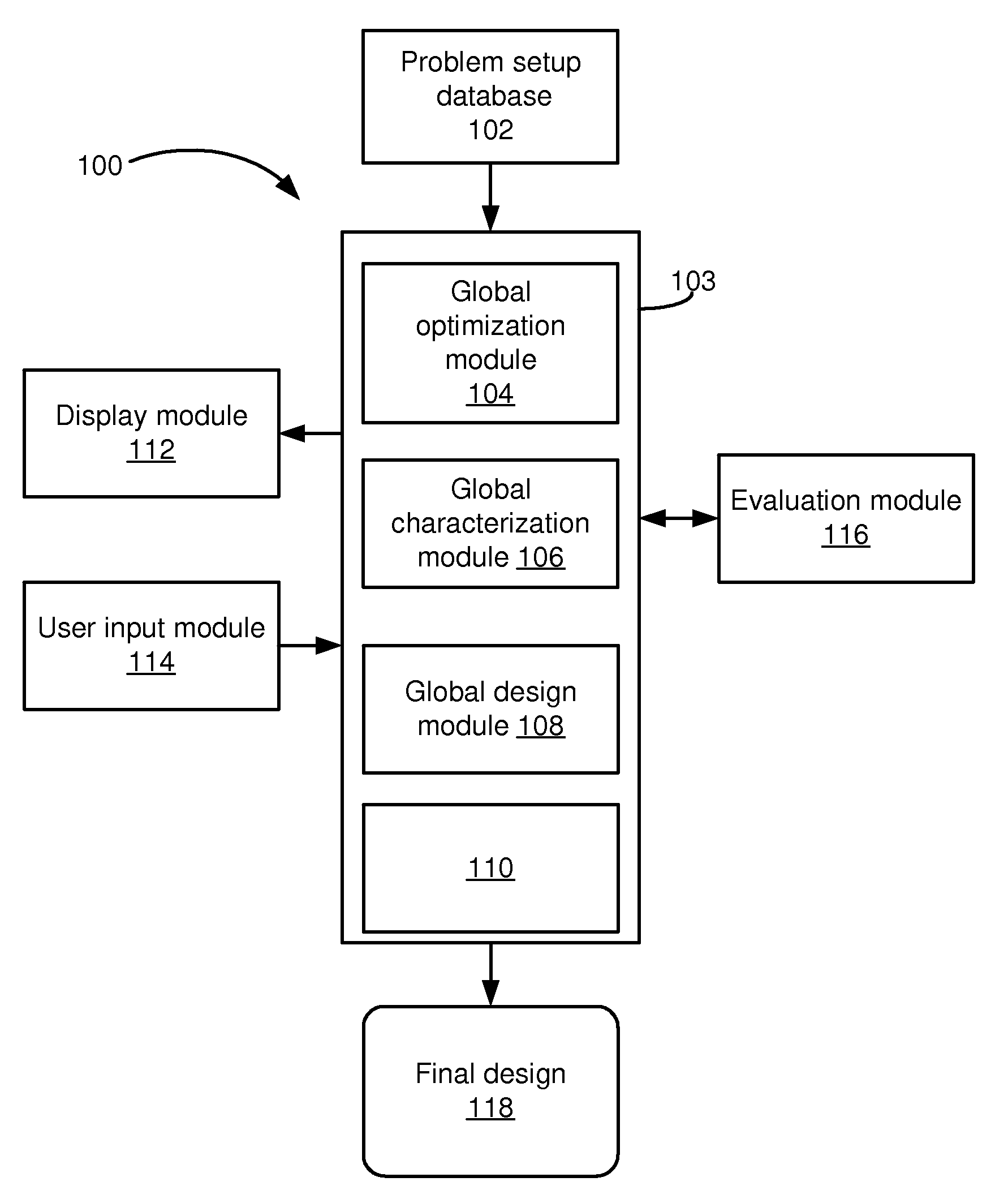

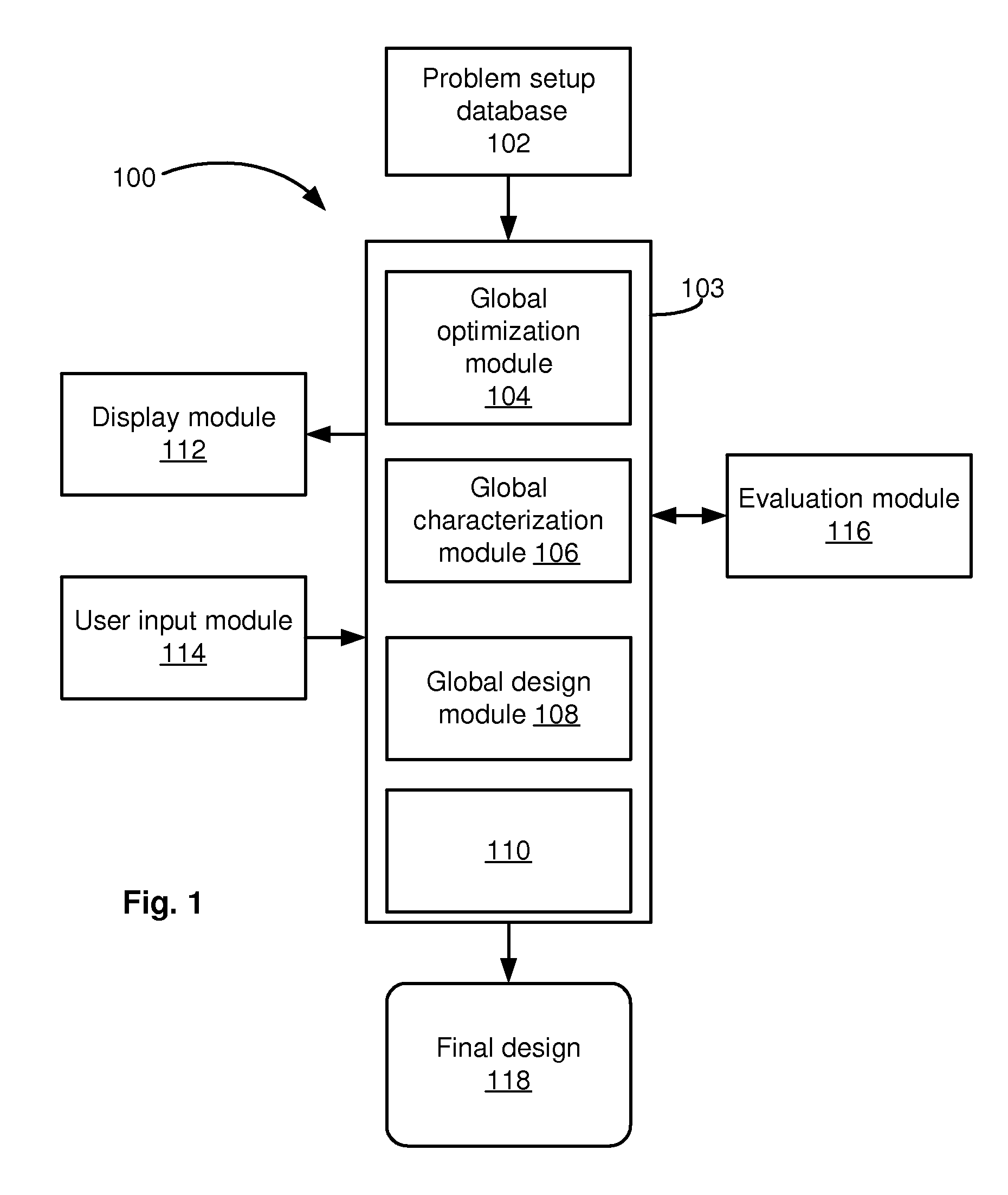

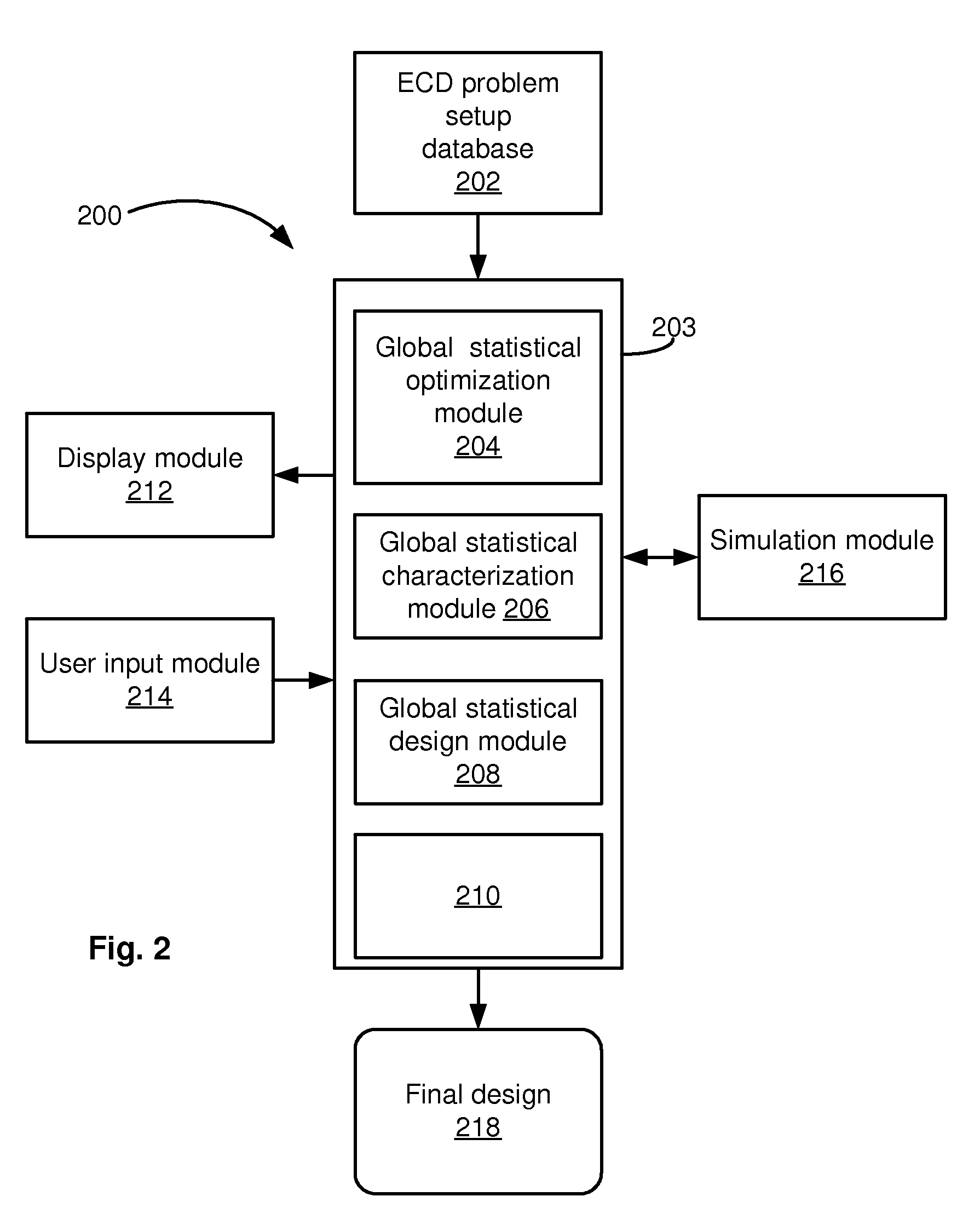

Global statistical optimization, characterization, and design

ActiveUS20090228846A1Low costChange its valueDetecting faulty computer hardwareCAD circuit designTime rangeTheoretical computer science

For application to analog, mixed-signal, and custom digital circuits, a system and method to do: global statistical optimization (GSO), global statistical characterization (GSC), global statistical design (GSD), and block-specific design. GSO can perform global yield optimization on hundreds of variables, with no simplifying assumptions. GSC can capture and display mappings from design variables to performance, across the whole design space. GSC can handle hundreds of design variables in a reasonable time frame, e.g., in less than a day, for a reasonable number of simulations, e.g., less than 100,000. GSC can capture design variable interactions and other possible nonlinearities, explicitly capture uncertainties, and intuitively display them. GSD can support the user's exploration of design-to-performance mappings with fast feedback, thoroughly capturing design variable interactions in the whole space, and allow for more efficiently created, more optimal designs. Block-specific design should make it simple to design small circuit blocks, in less time and with lower overhead than optimization through optimization.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

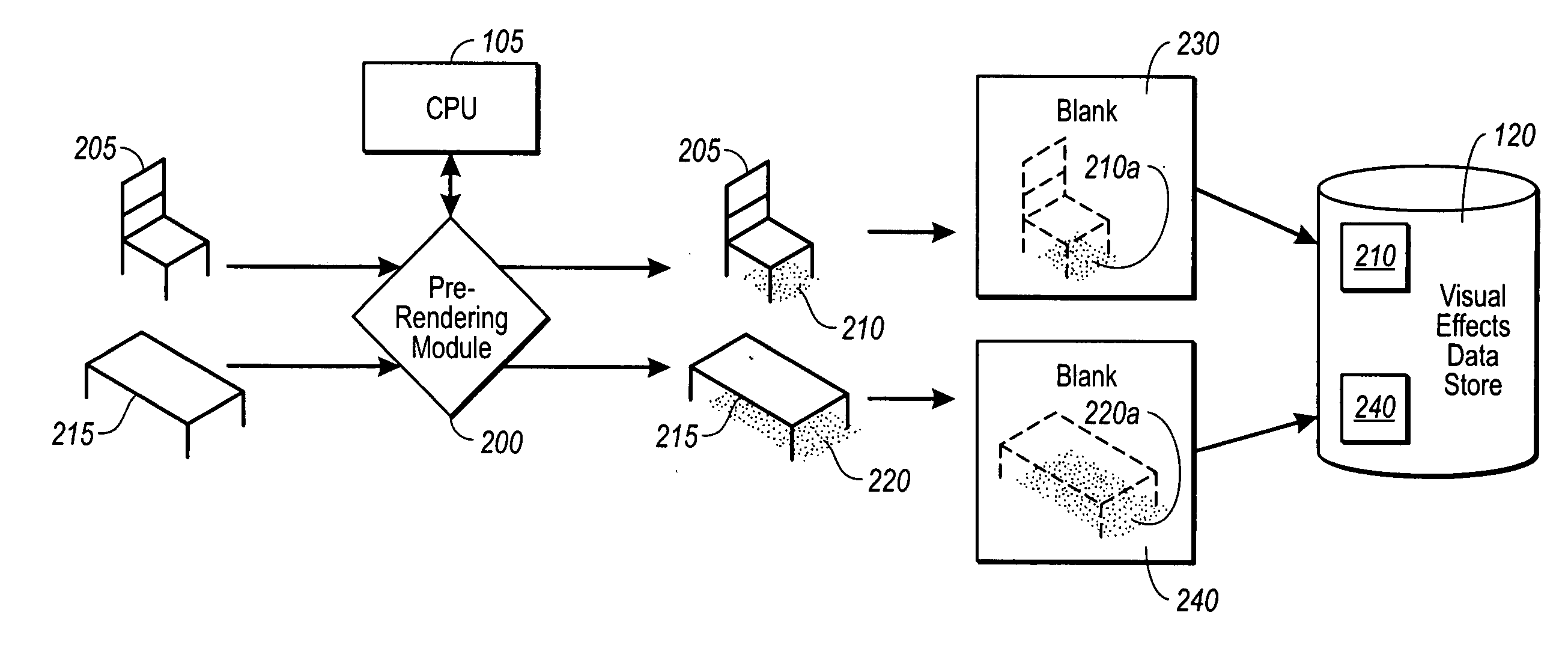

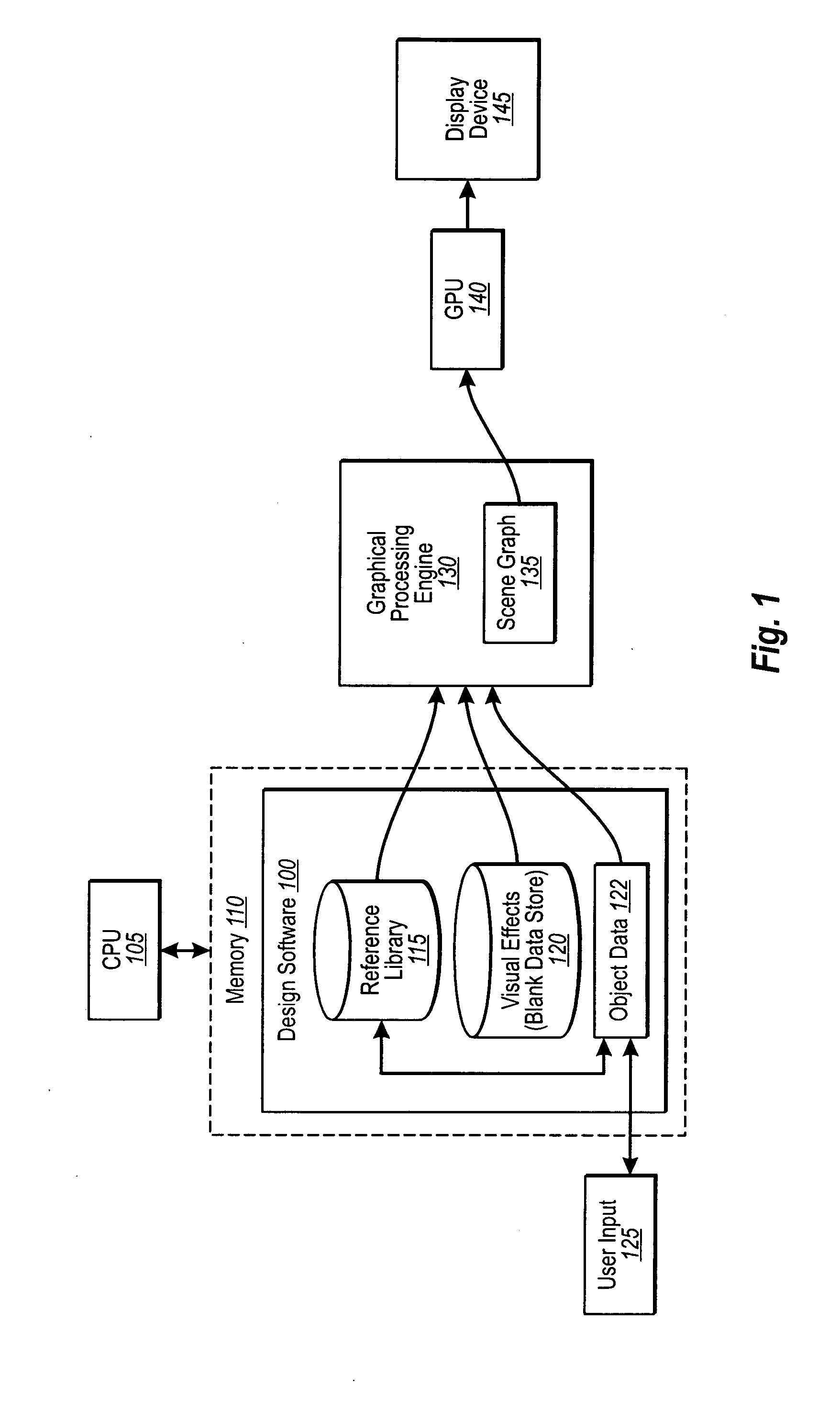

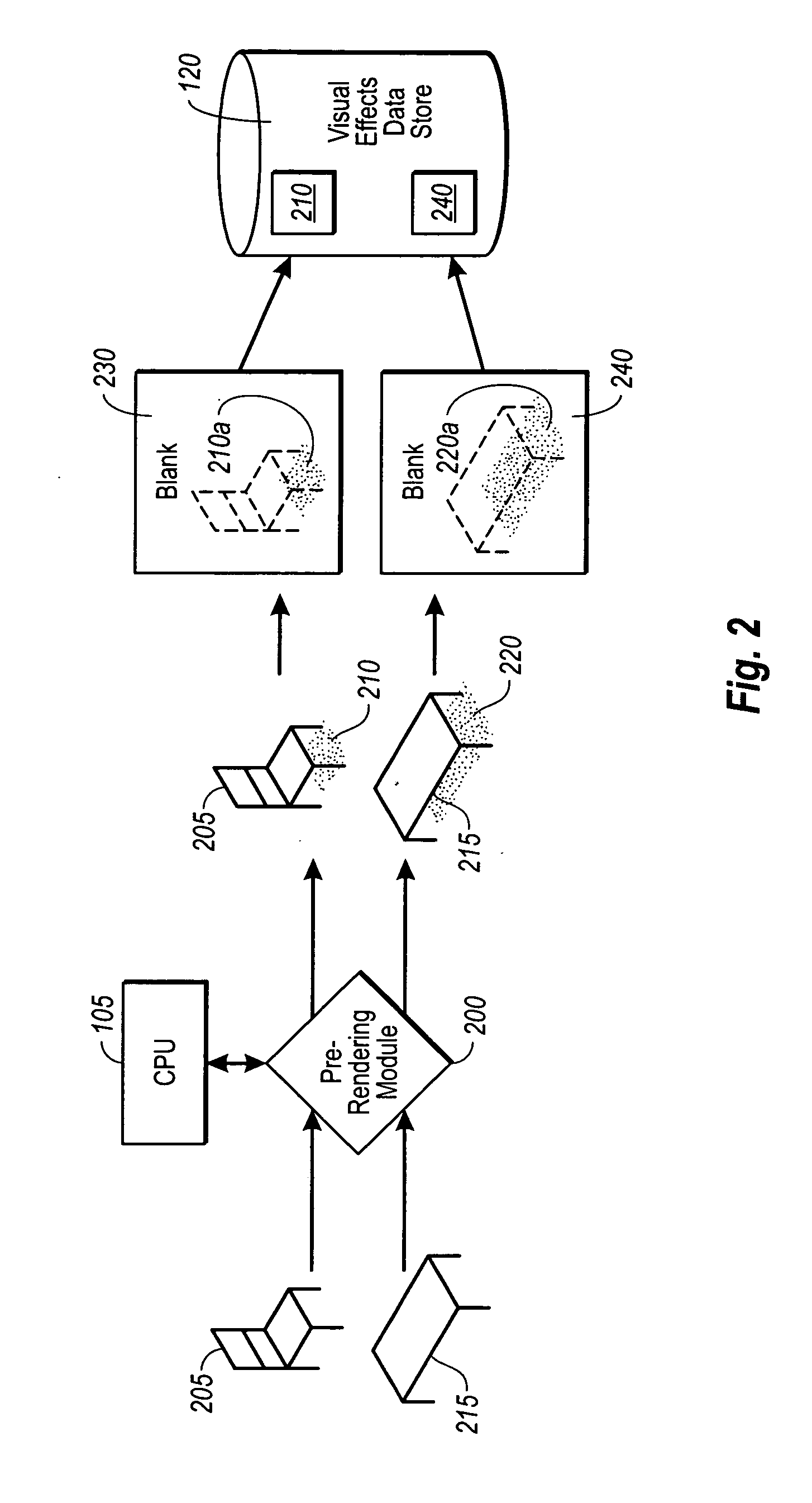

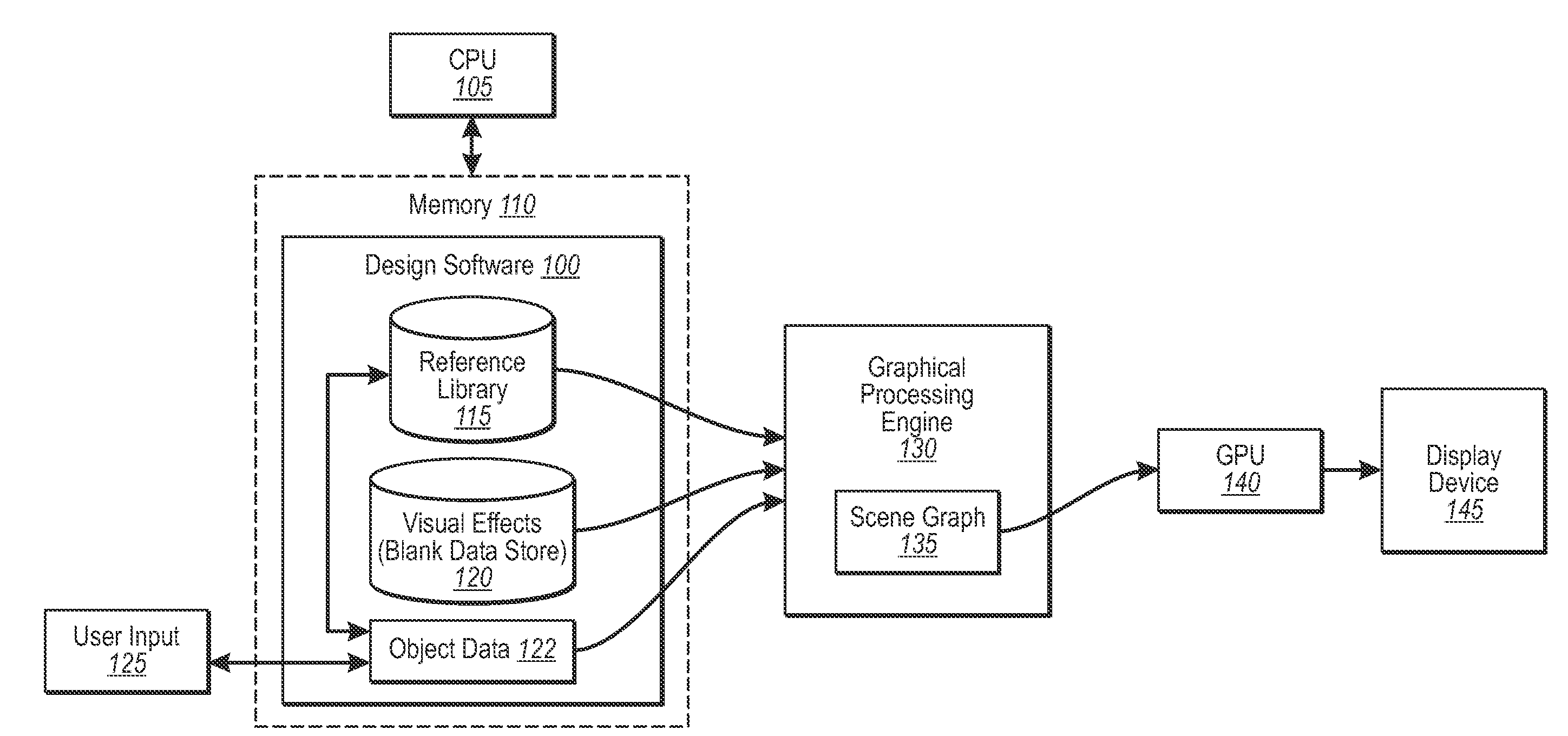

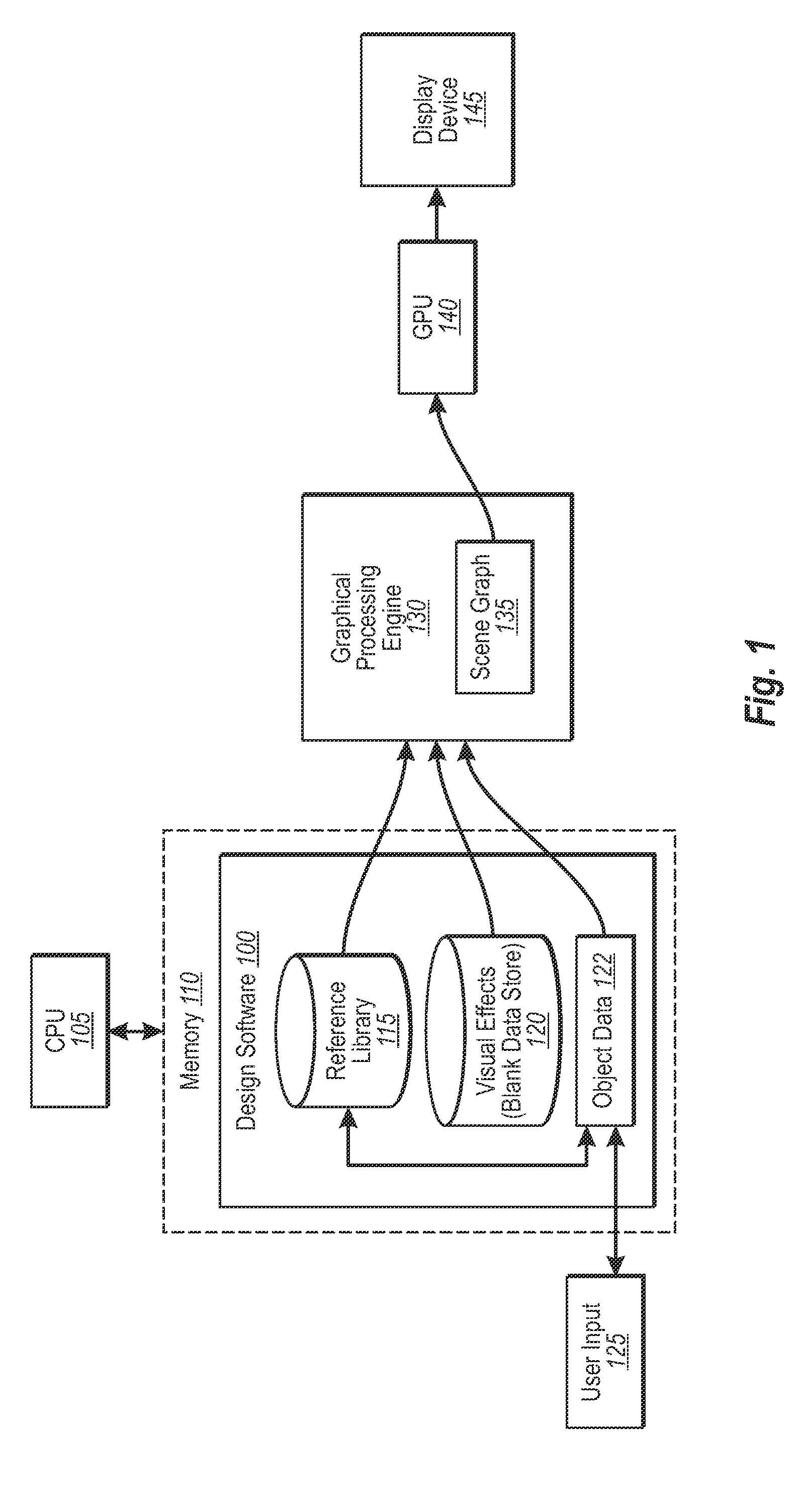

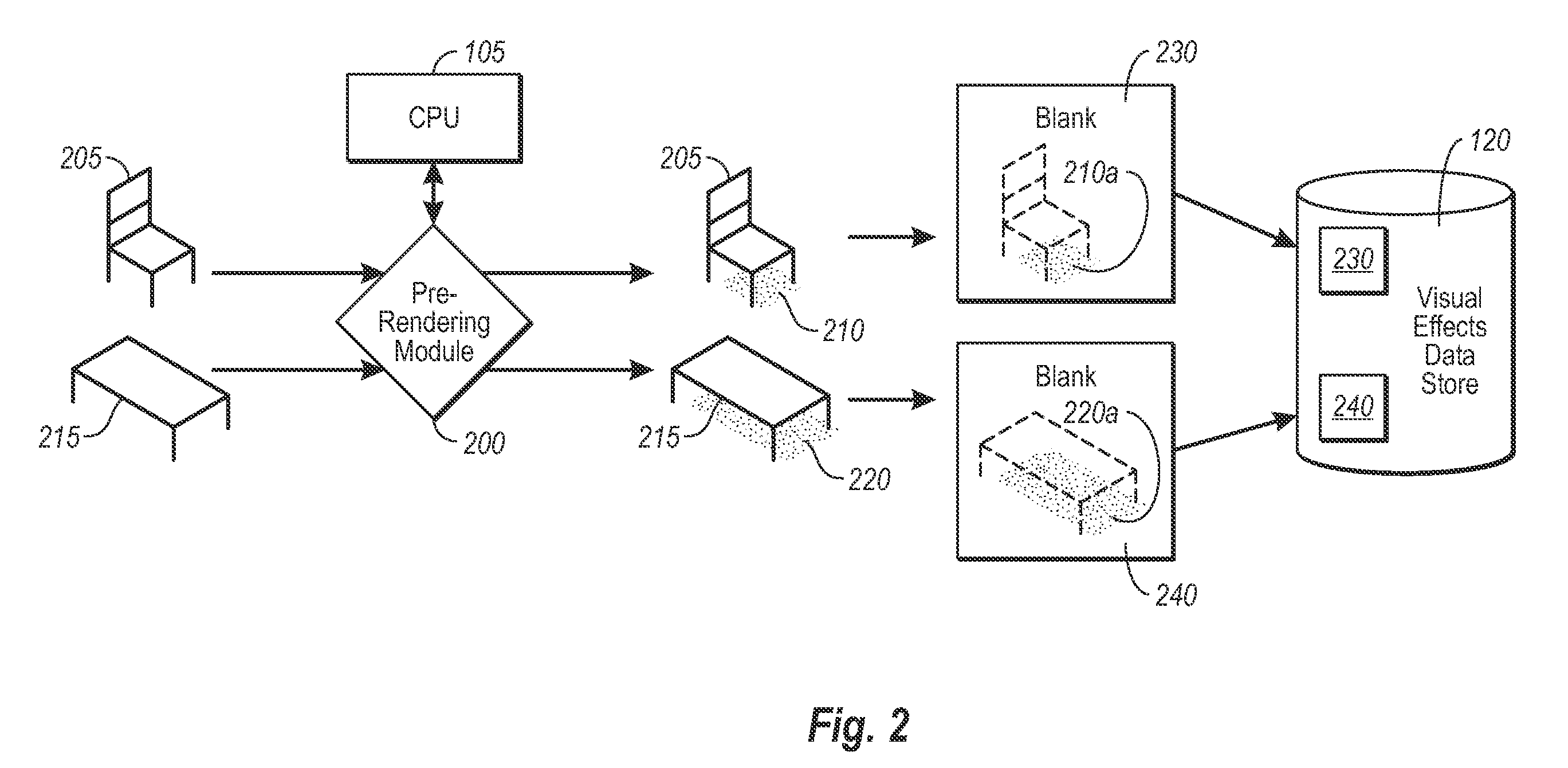

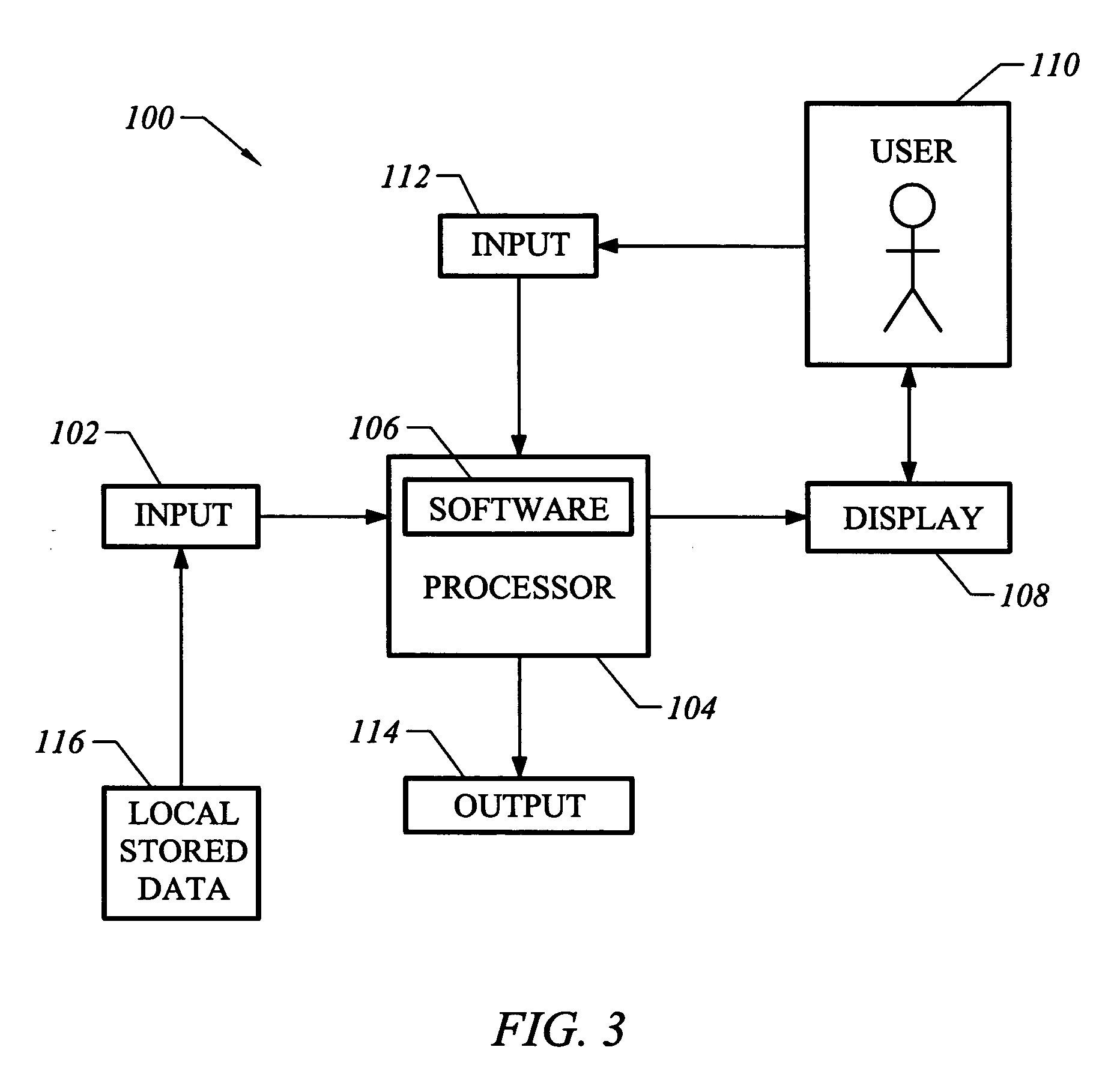

Design software incorporating efficient 3-D rendering

ActiveUS20060055696A1Efficient and accurateAccurate dataCathode-ray tube indicatorsEducational modelsComputer graphics (images)Design software

Design software in accordance with an implementation of the present invention is configured to provide believable three-dimensional representations of user selections in real-time. Design elements that would otherwise be difficult to efficiently render three-dimensionally in real-time are prerendered for realistic visual effects, such as realistic shading, which correspond to various positions of the elements in a design space. Blanks of the visual effects for each position are then stored in a data store for visual effects. At run time, data associated with user design choices, as well as the blanks for any corresponding design elements are fed in one implementation to peripheral processing hardware, such as a GPU, which sends the processed data to a display device. The user is therefore able to view complex visual data of certain design choices efficiently with added realism.

Owner:ARMSTRONG WORLD INDUSTRIES +1

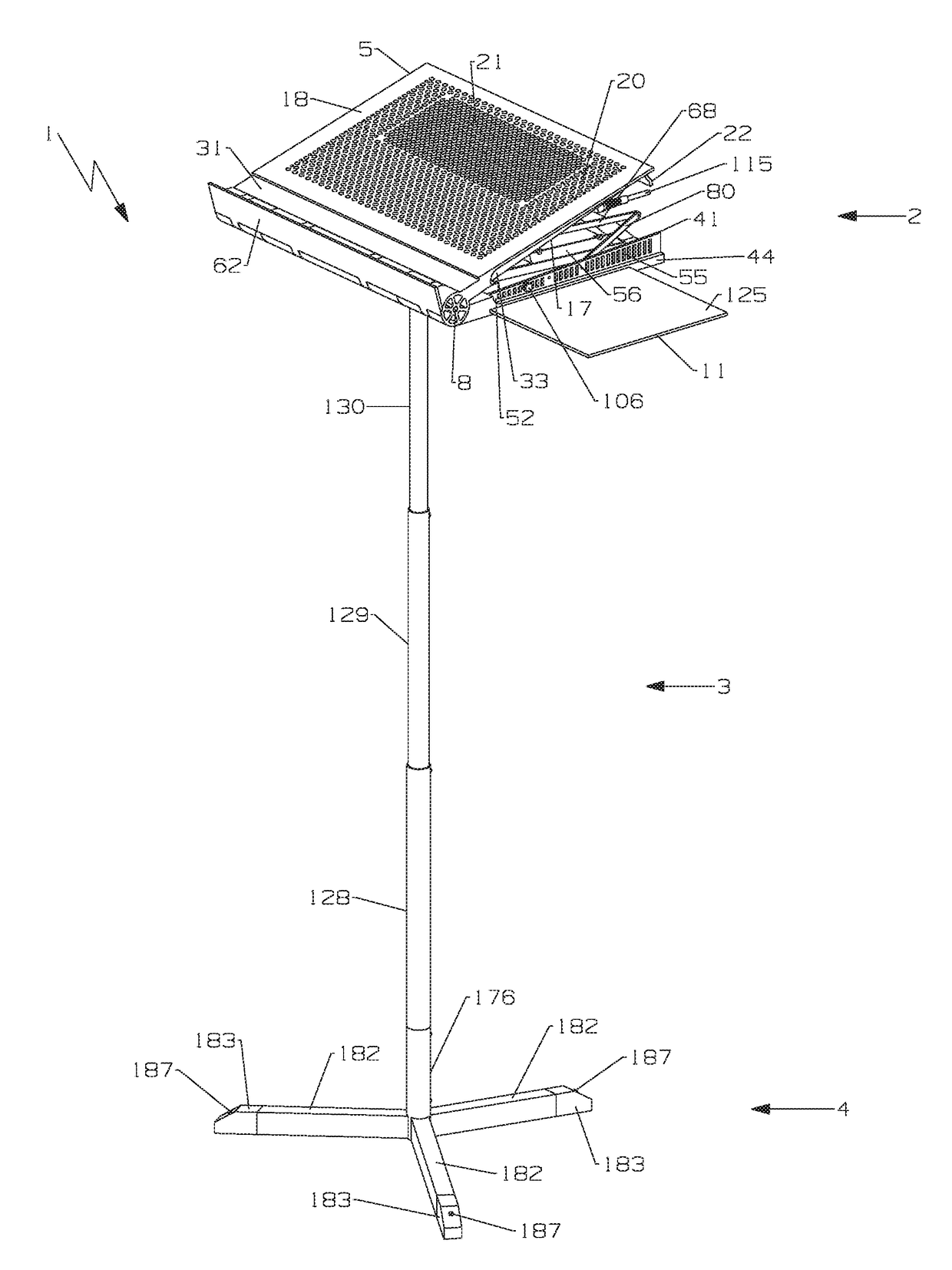

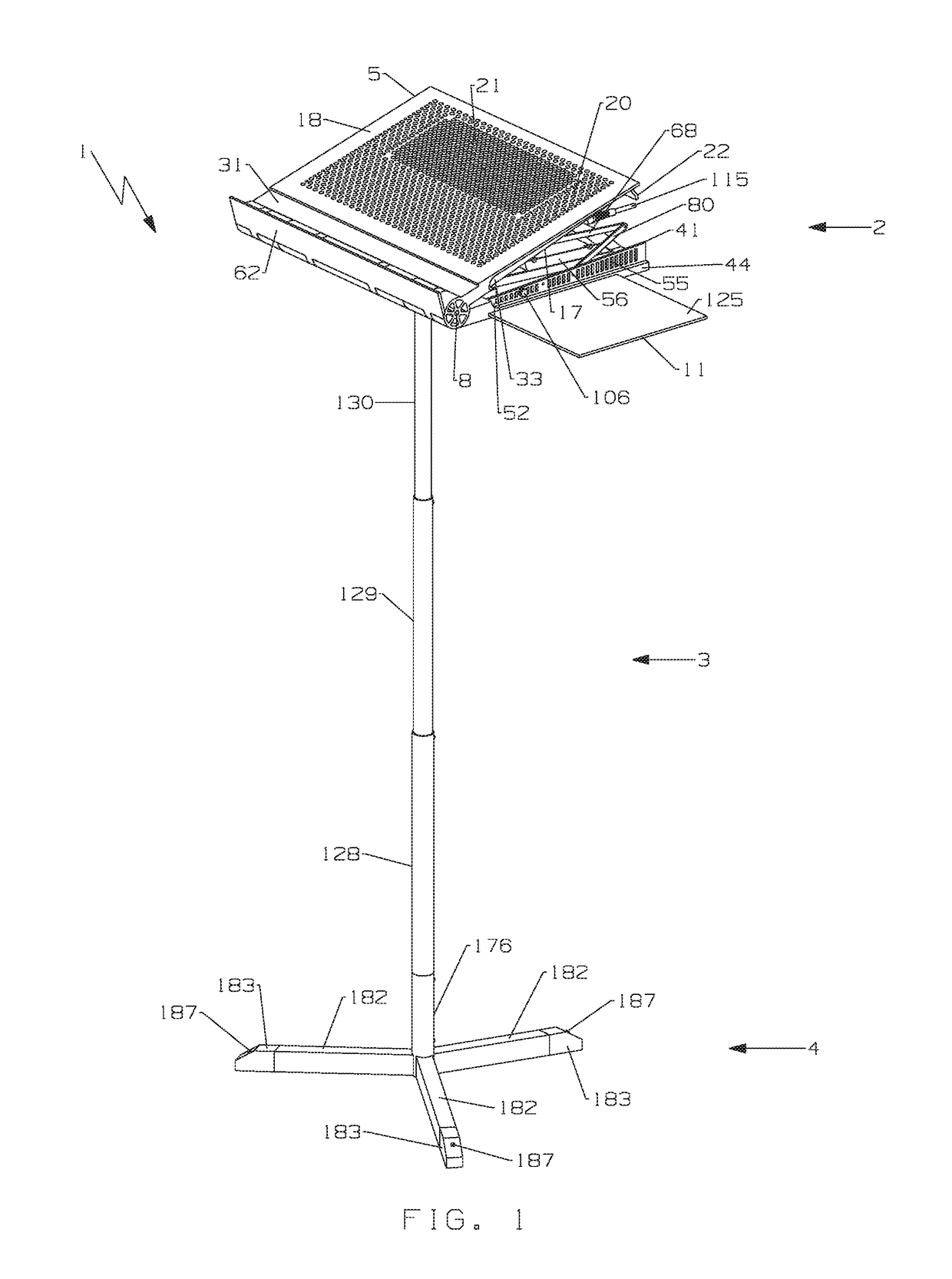

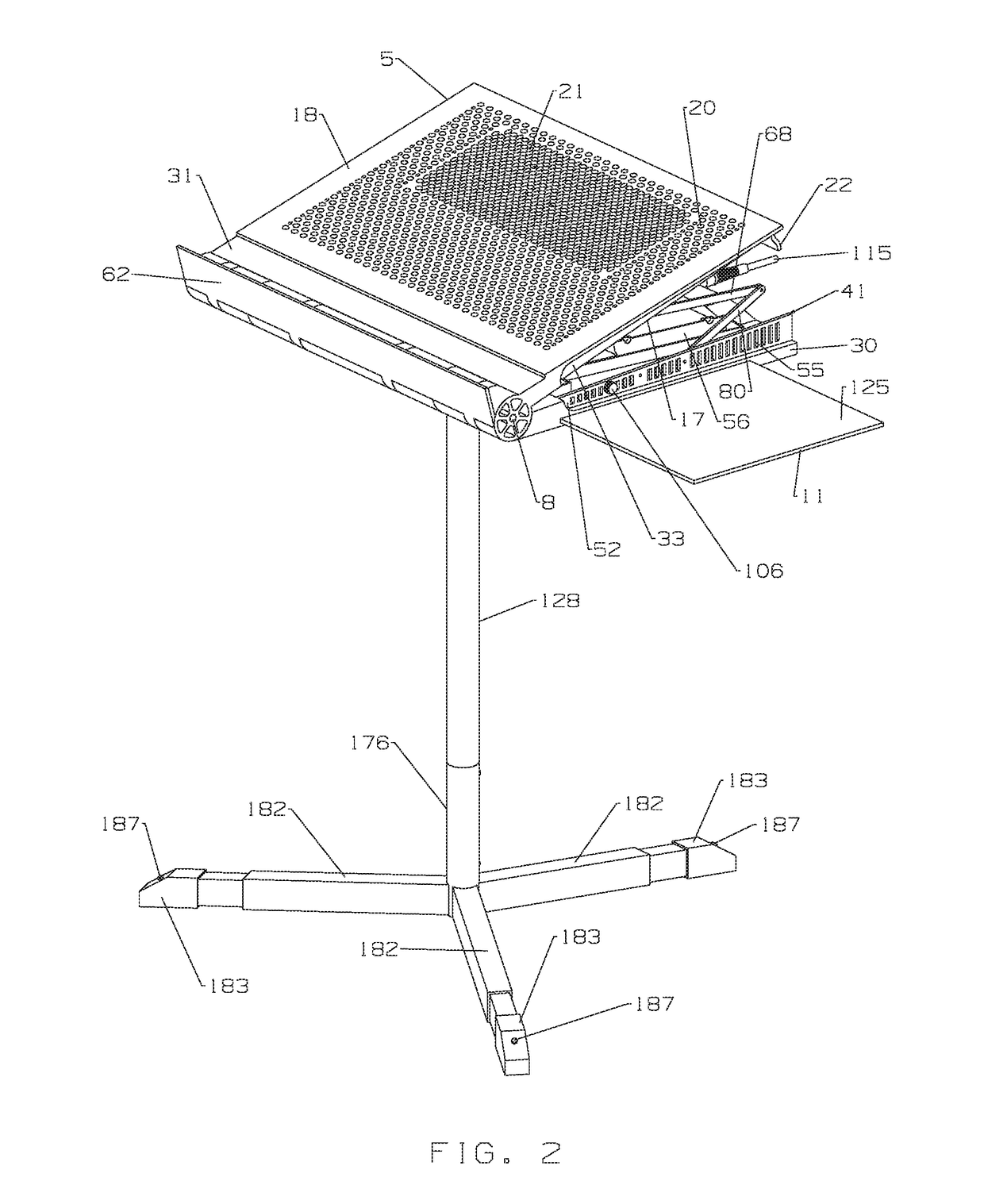

Multi-function travel-friendly workstation with cooling and ventilation

An ergonomically designed space saving, collapsible multi-function travel-friendly modular workstation for supporting a broad range of electronic systems, reading materials and the like for users while standing, sitting or on-the-go, and fits in anywhere, anytime is presented. The workstation comprises a support unit, telescopic rod and tripod and is designed to provide needed cooling and ventilation for electronic systems, support healthy postures, and complete comfort and versatility of a multi-function workstation with all the important things needed when working at a desk, thereby improving a user's comfort when using the workstation. Further, the workstation is designed for easy transportation, storage and set up, as well as provide a versatile workspace for a user in many different environments, for everyday use such as note taking, writing, reading, presentations, performing arts and rehearsing while playing a musical instrument, music or conductor stand, etc.

Owner:ASANTE JAMES NATHANIEL

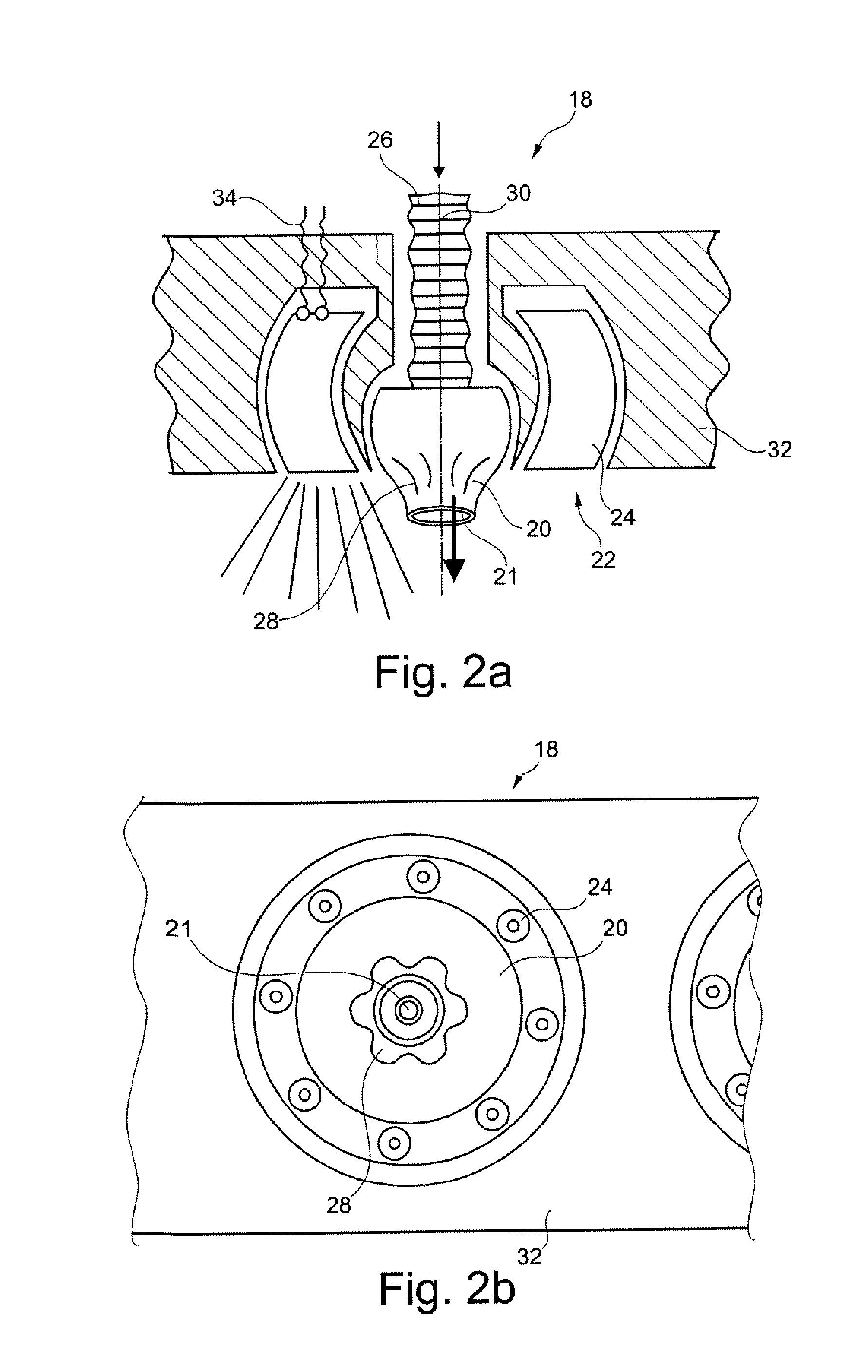

Icon implantation ion source, system and method

InactiveUS20050269520A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

Object-oriented network-on-chip modeling

InactiveUS20110191088A1Shorten the timeReduce construction of hardwareAnalogue computers for electric apparatusCAD circuit designComputer architectureDesign space

Network-on-Chip (NoC) is an oncoming solution to the communication bottleneck of System-on-Chip (SoC). For a good design, it runs a simulation verification before the design is realized. The key factors to the accuracy and simulation speed of a simulator depend on how the simulator abstracts the NoC design. The present invention provides an object-oriented NoC modeling, which divides the NoC design space into many design blocks and models them into many abstraction levels. The present invention defines these models carefully to obtain good hardware accuracy. The present invention also provides an object implementation library of different abstraction levels. Thereby, the present invention can reduce the coding time via selecting required components from the object implementation library, inheriting them with some modifications or using them directly. The present invention extends the design exploration space of NoC, preserves good hardware characteristics, and significantly reduces coding effort of a new NoC design.

Owner:NATIONAL TSING HUA UNIVERSITY

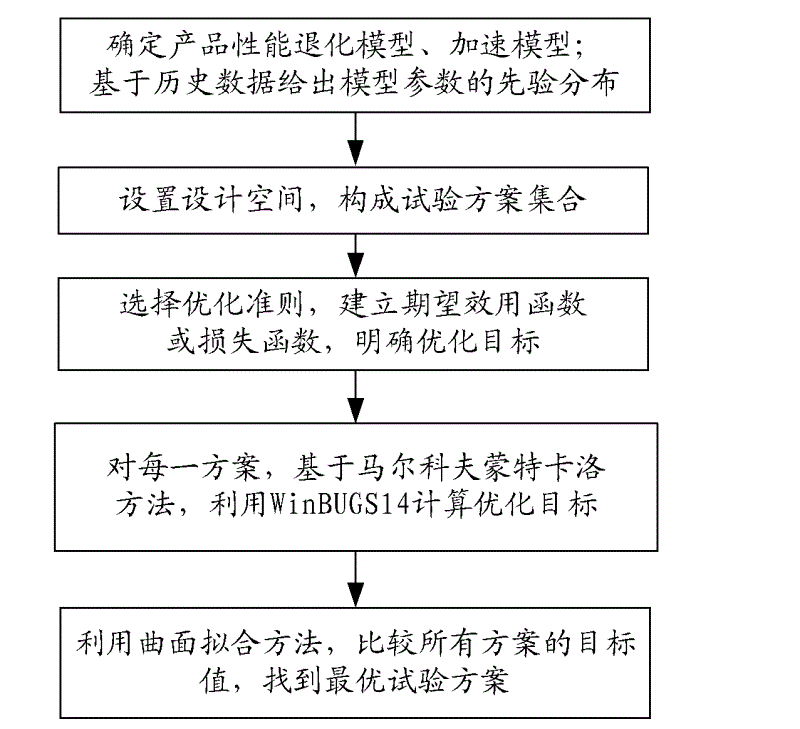

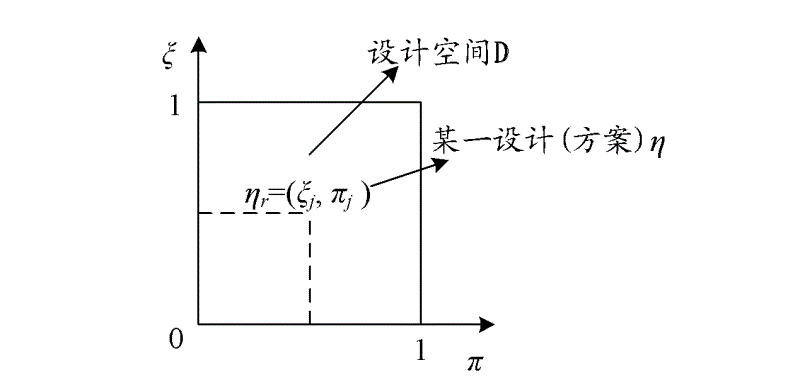

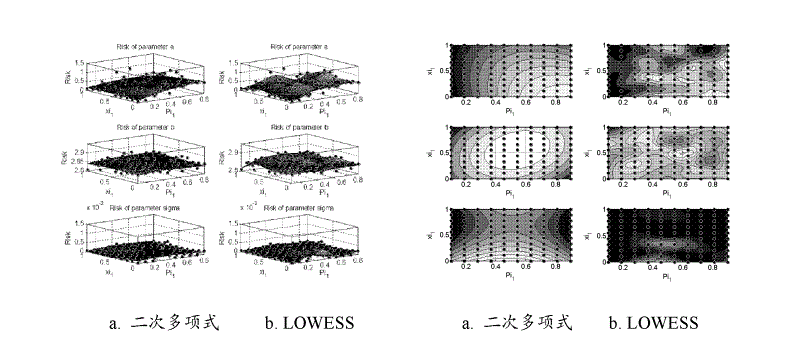

Optimization design method for step stress accelerated degradation test based on Bayesian theory

ActiveCN102622473AAvoid the disadvantage of being prone to large deviationsTaking into account the amount of informationSpecial data processing applicationsAlgorithmOptimal test

The invention discloses an optimization design method for a step stress accelerated degradation test based on a Bayesian theory, and is applied to the technical field of the accelerated degradation test. The optimization design method comprises the steps as follows: firstly, determining product performance degradation and acceleration models, and based on the historical data, giving prior distribution of model parameters; secondly, determining an optimization design space, and forming a test scheme set; thirdly, creating an expected utility function or an expected loss function, determining optimization goals, and based on a Markov Chain Monte Carlo method, determining optimization goal values of designs in the test scheme set; and lastly, finding the optimal test scheme by using a curve fitting method. According to the optimization design method, the shortcoming of high possibility of larger deviation due to the implementation of the traditional (local) test optimization design method when the values of the model parameters are supposed to be known is avoided, and the optimization scheme obtained in the implementation of the test optimization design when the prior distribution of the model parameters is given is more reasonable and more actual.

Owner:BEIHANG UNIV

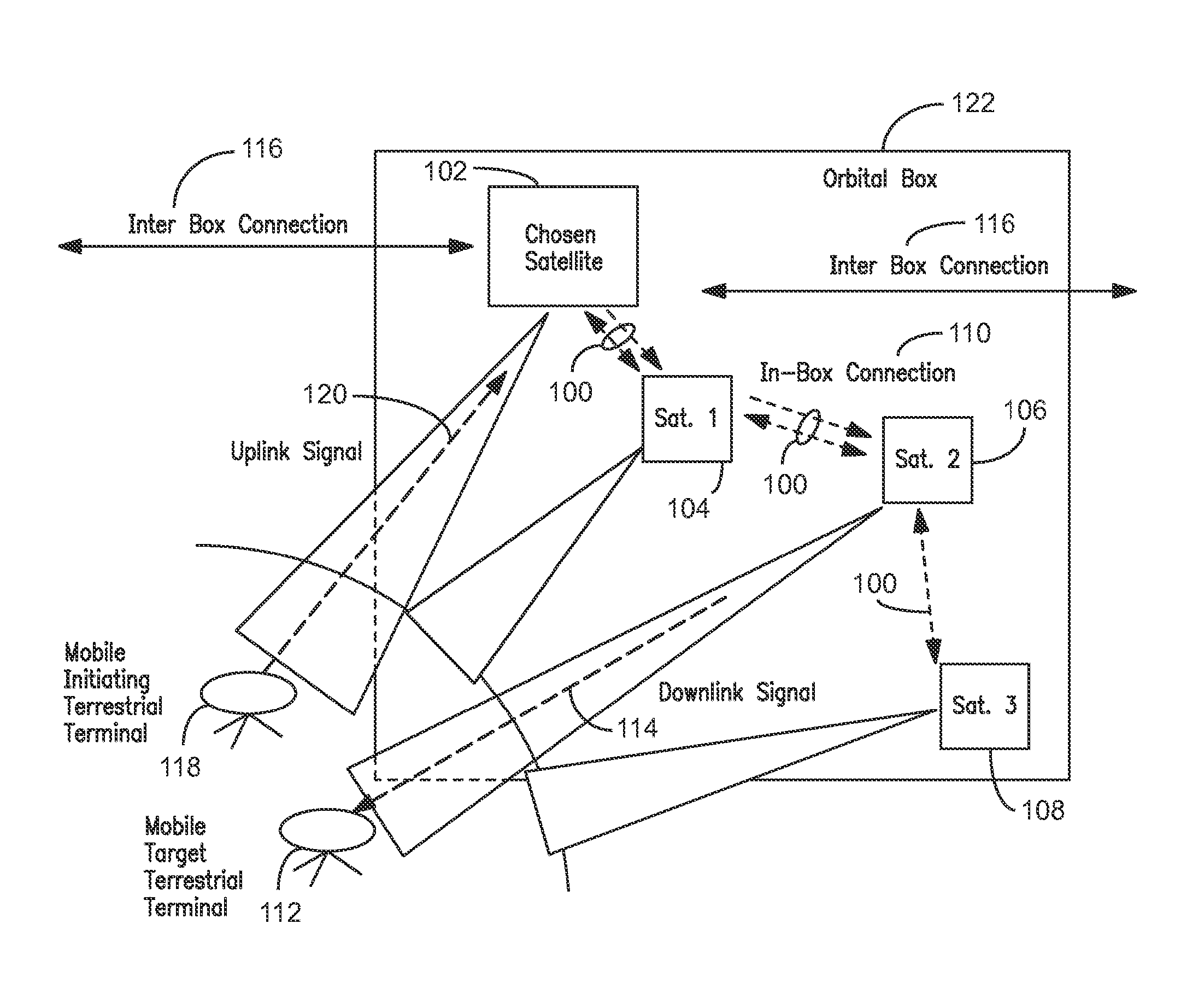

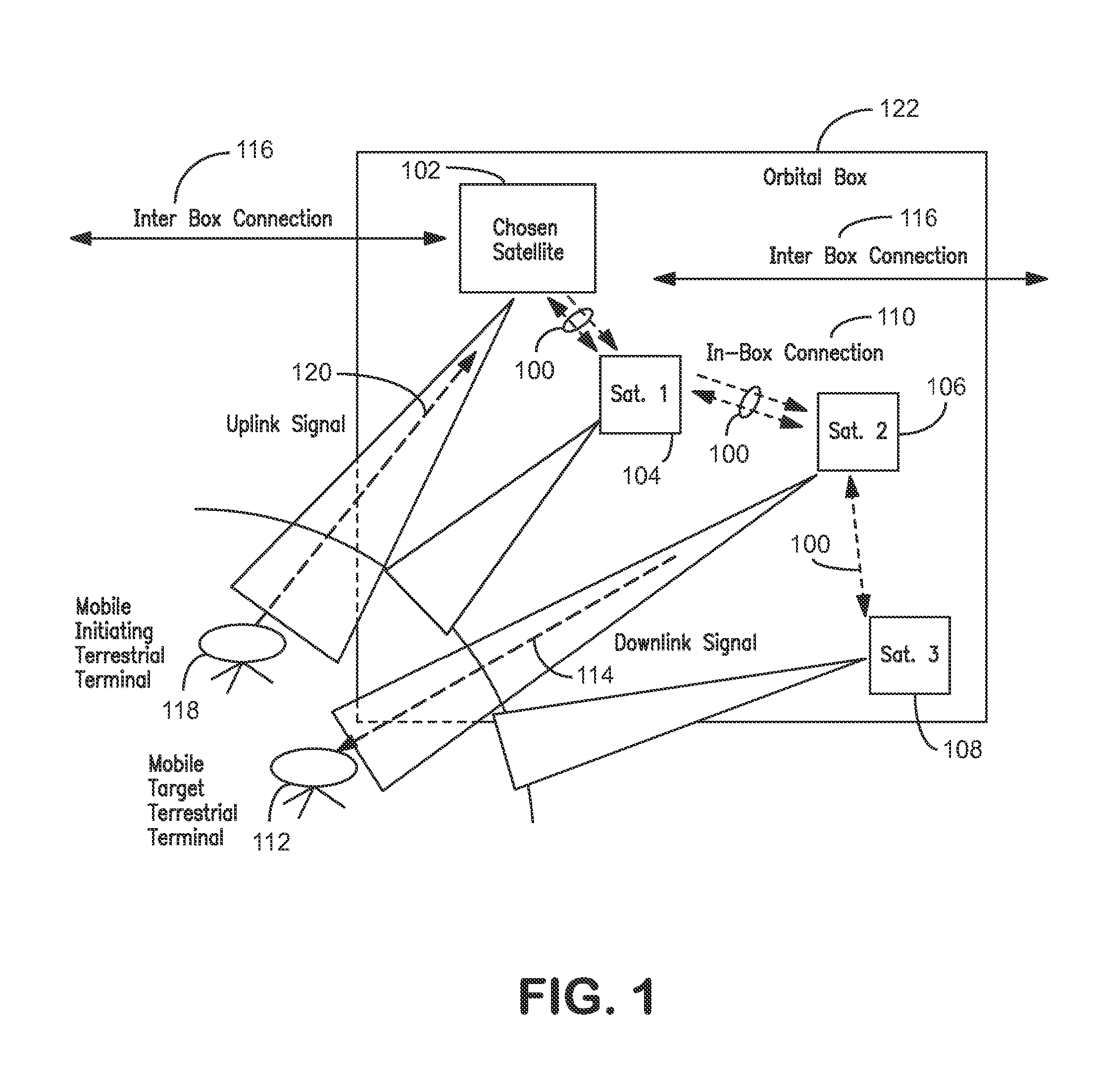

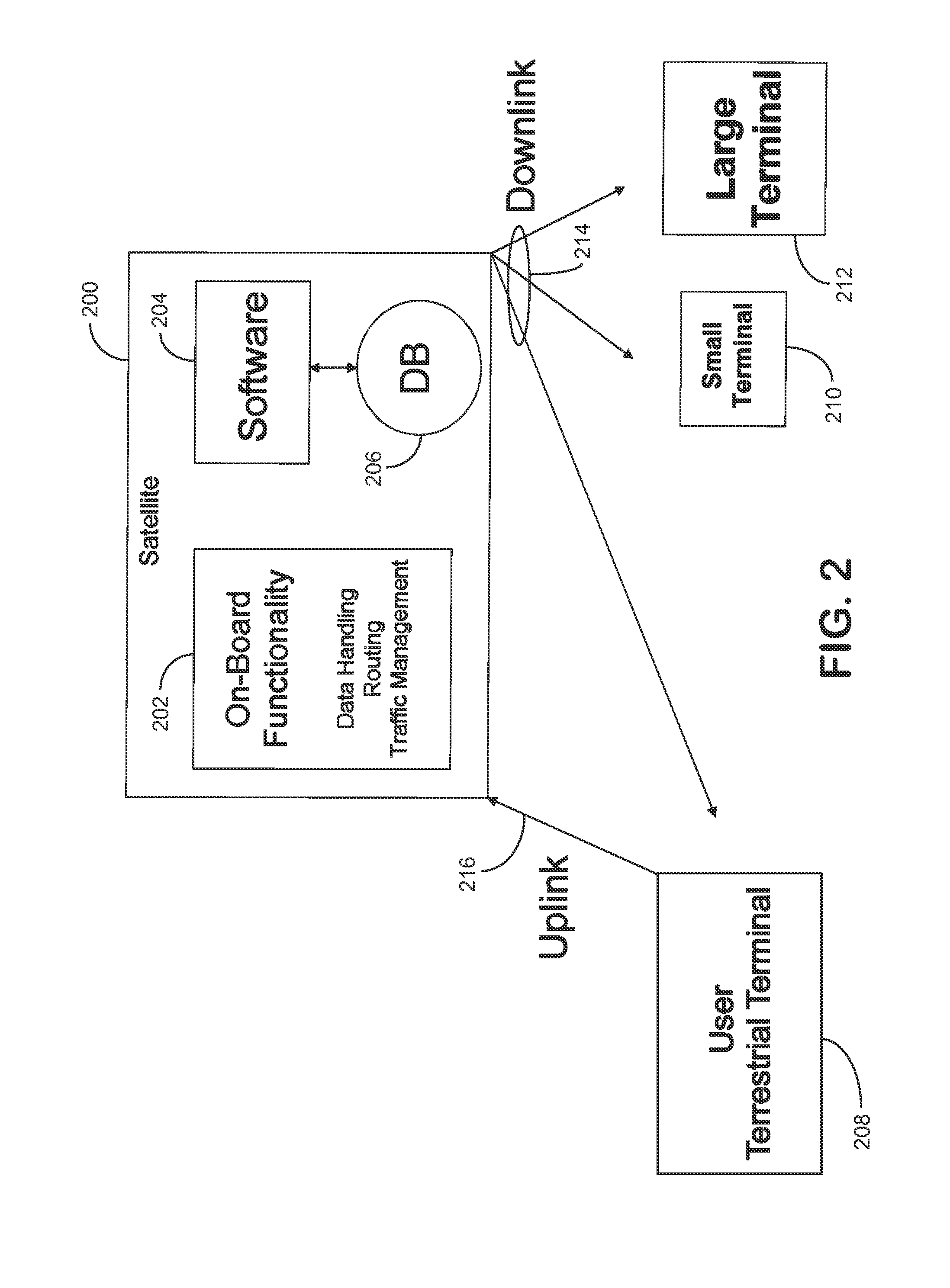

Systems and methods for establishing modular and flexible satellite communications networks

InactiveUS20080045146A1Small sizeLow costBroadcast transmission systemsRadio/inductive link selection arrangementsOn boardModularity

A system and method of building a satellite communications network provides a customer-driven, modular and flexible approach to providing satellite communications services. The satellite network provider carves out a solution for a customer problem from a design space constrained by satellite size, lifetime and payload given a set of specifications from a customer. The satellite network provider may continually gauge the needs of the users of the system in order to adapt the network to the current and future needs of the customer(s). Further, the use of small satellites utilizing on-board functionality provides modularity while maintaining economic feasibility.

Owner:OVERHORIZON (CYPRUS) PLC

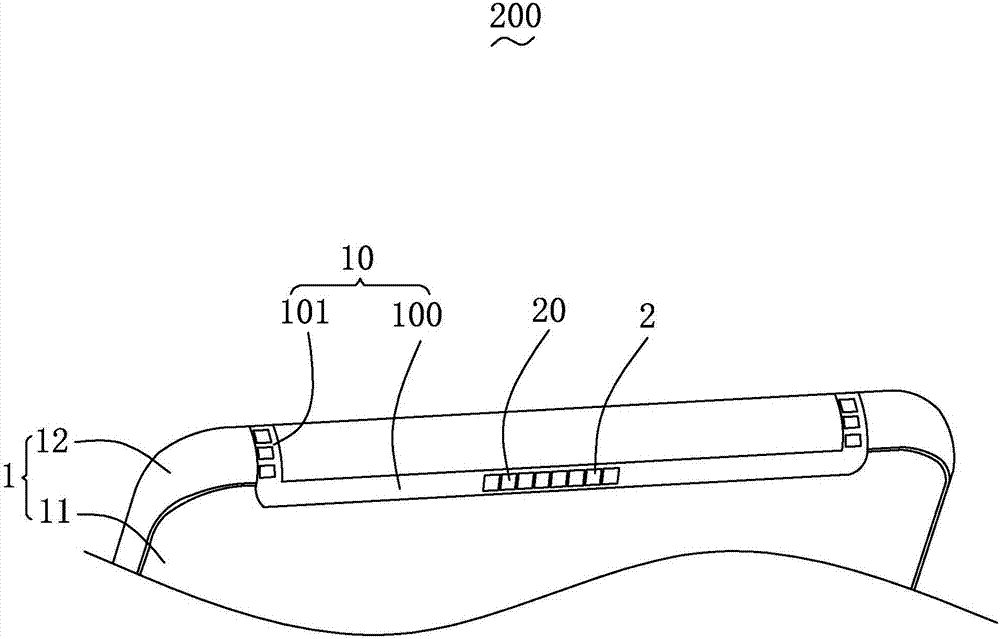

Service apparatus for a transportation means

InactiveUS20100093267A1Less design spaceReadily availableLighting circuitsPoint-like light sourceForced-airEngineering

A service apparatus for a transportation means comprises a first component in the form of an air shower with an air inlet and at least one air outlet, and a second component in the form of an illumination device. The first component and the second component are arranged essentially centrically in relation to each other, wherein one of the two components encloses the other component essentially in a ring-shaped manner. In this way an integral reading light with a forced-air nozzle, or an integral forced-air nozzle with a reading light, is implemented that uses little design space.

Owner:AIRBUS OPERATIONS GMBH

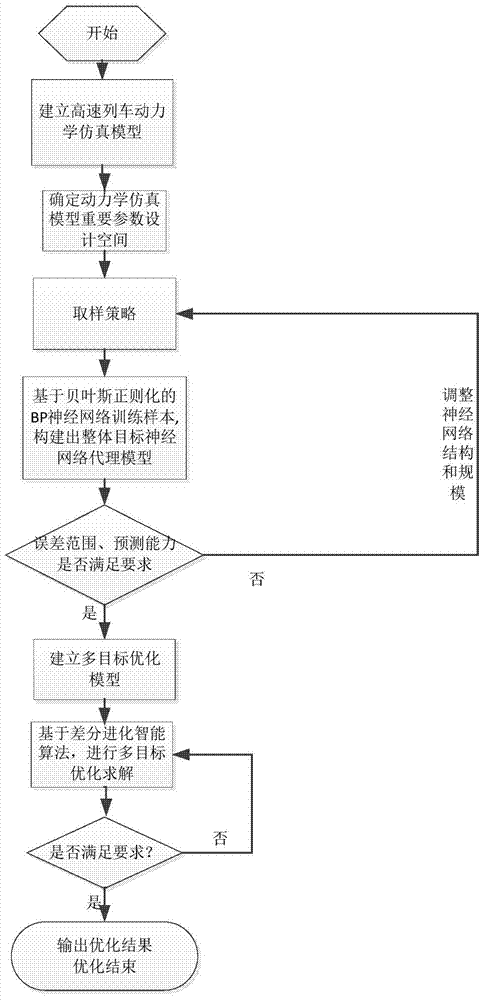

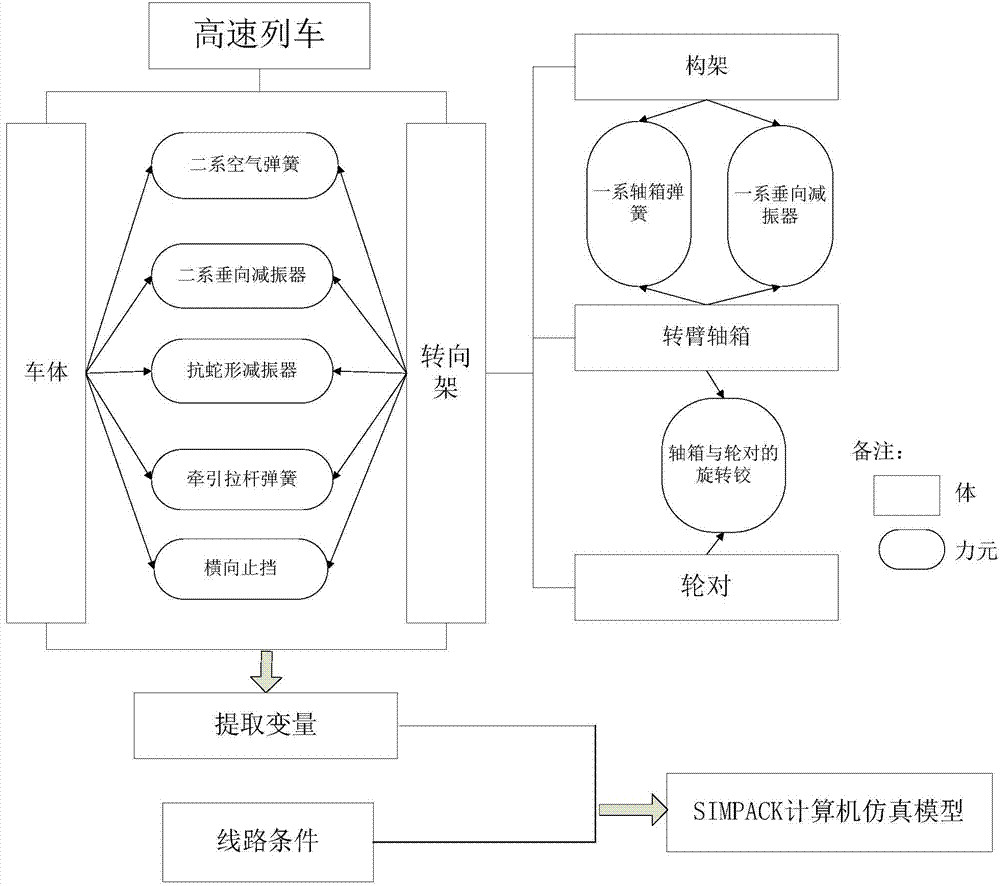

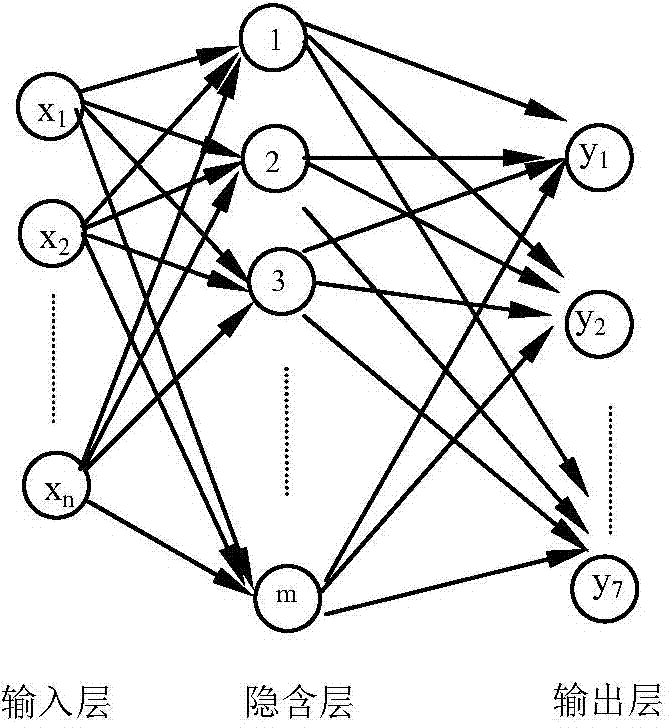

Dynamics performance parameter optimizing method of high-speed train

ActiveCN104765916AImprove operational safetyImproved smoothness and comfortSpecial data processing applicationsNetwork modelDesign space

The invention provides a dynamics performance parameter optimizing method of a high-speed train, relates to the field of parameter design optimizing based on the dynamics simulation analysis of the high-speed train, and aims at effectively replacing a dynamics simulation model of the high-speed train by a comprehensive target neural network agent model and combining the design analysis and the multi-target optimization algorithm of the high-speed train in the multi-disciplinary field to analyze and optimize the dynamics simulation approximation model of the high-speed train. The method specifically comprises the steps of building a multi-rigidity dynamics simulation model for the high-speed train; determining related important input / output design spaces; selecting sampling strategy to obtain a design space sample set suitable for the dynamics performance analysis of the high-speed train; improving the generalization accuracy of the comprehensive target neural network by the bayesian regularization method; adjusting the number of nodes in a hidden layer to build the comprehensive target neural network agent network model of which the error is controlled to be within a certain of range; performing multi-target optimization through the intelligent differential evolution algorithm by using the improved comprehensive target neural network agent network model to obtain the optimized high-speed train design parameters. The method is mainly applied to the dynamics analysis and design optimization of the high-speed train.

Owner:成都天佑创软科技有限公司

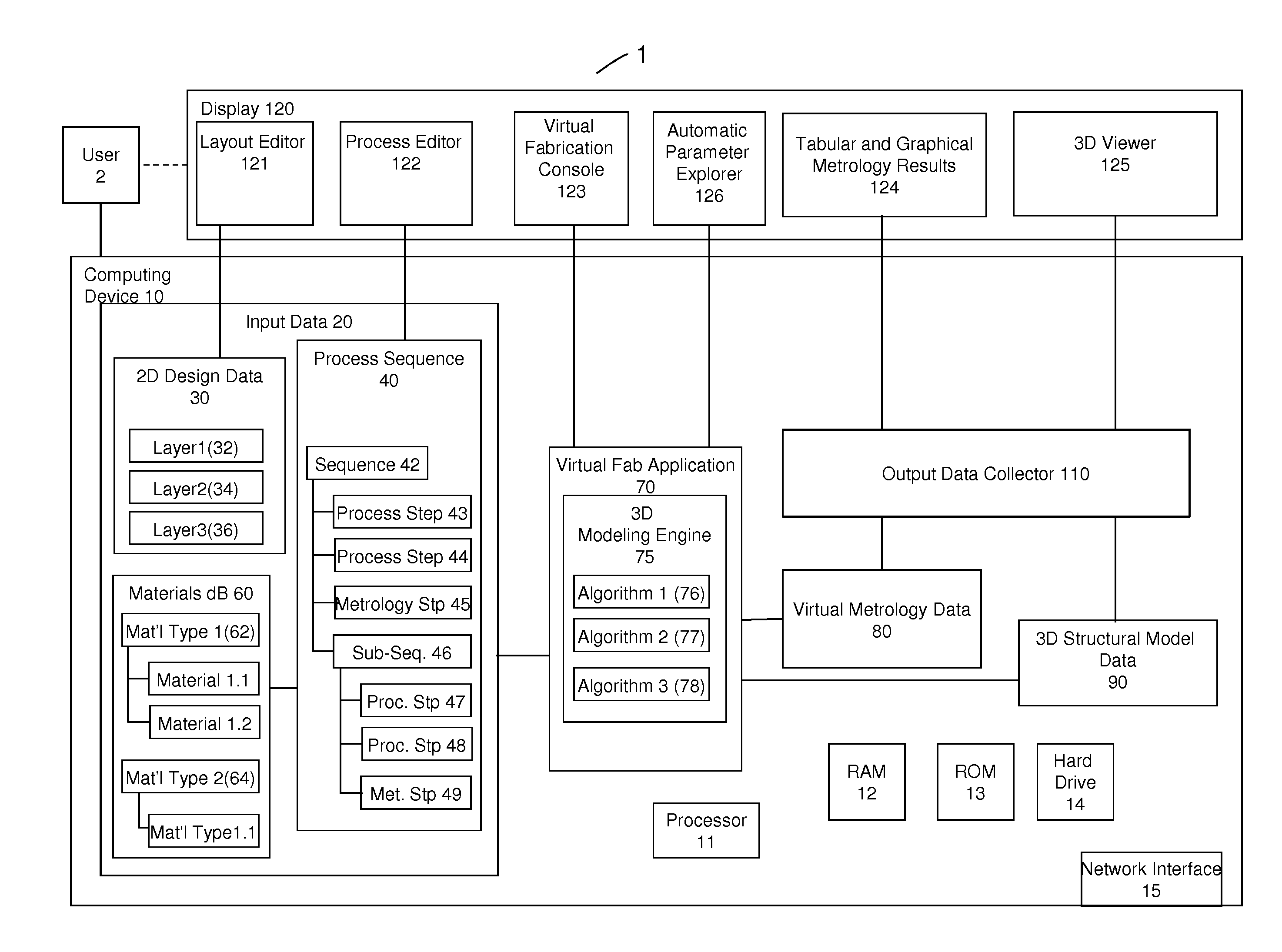

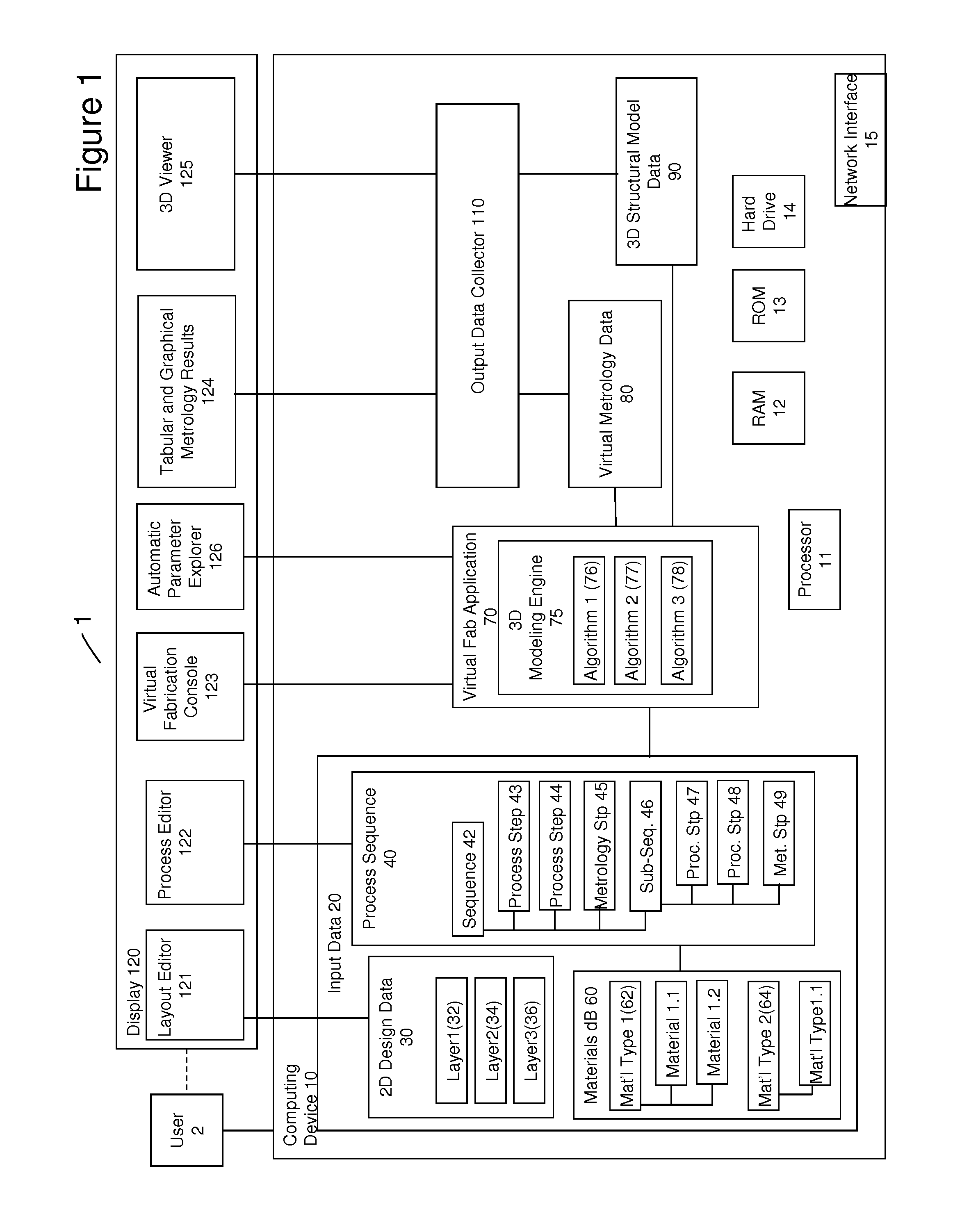

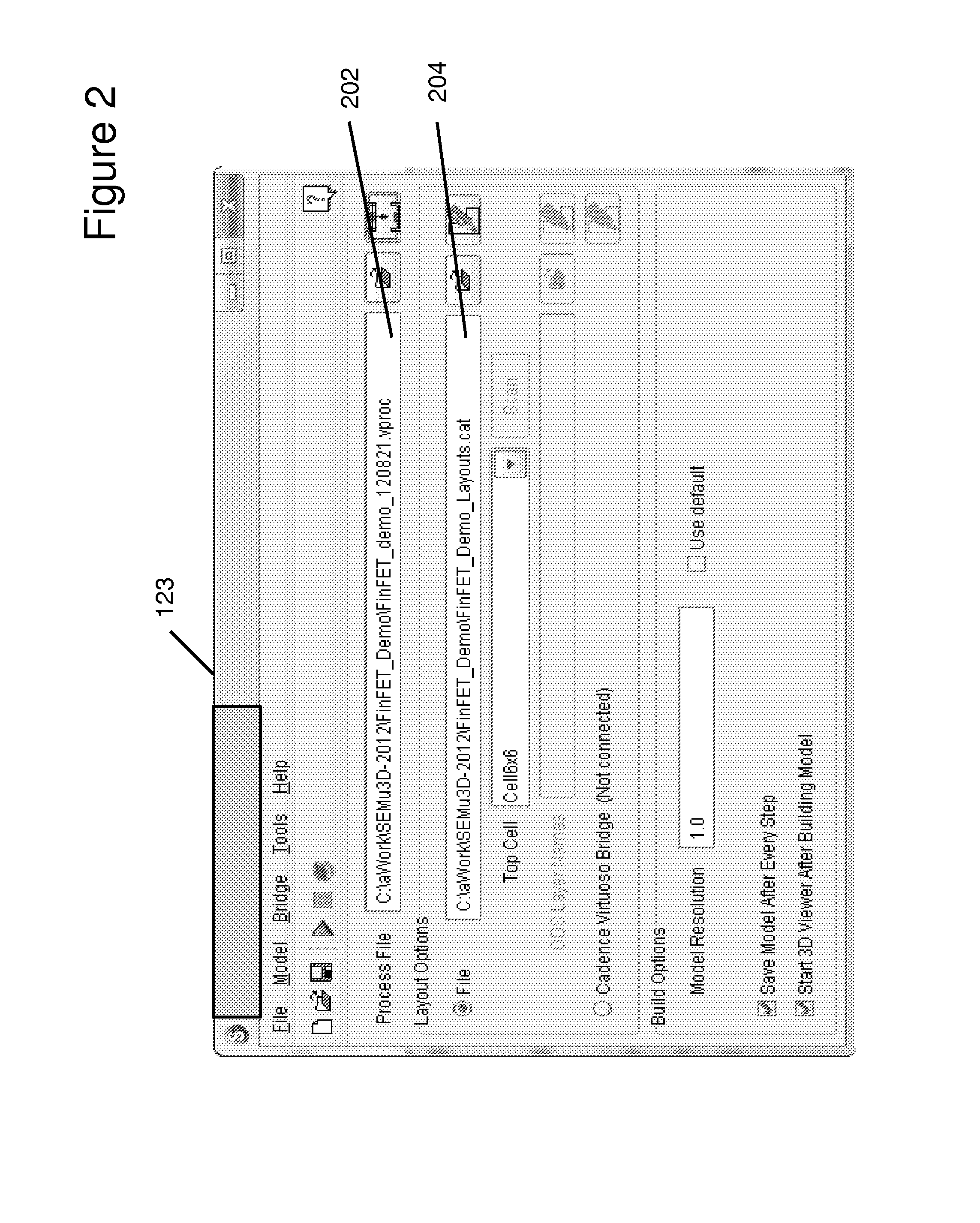

Predictive 3-d virtual fabrication system and method

ActiveUS20140282324A1More physically predictiveGeometric CADCAD circuit designEngineeringDesign space

A virtual fabrication environment for semiconductor device structures that includes the use of virtual metrology measurement data to optimize a virtual fabrication sequence is described. Further, calibration of the virtual fabrication environment is performed by comparing virtual metrology data generated from a virtual fabrication run with a subset of measurements performed in a physical fabrication environment. Additionally, virtual experiments conducted in the virtual fabrication environment of the present invention generate multiple device structure models using ranges of process and design parameter variations for an integrated process flow and design space of interest.

Owner:COVENTOR

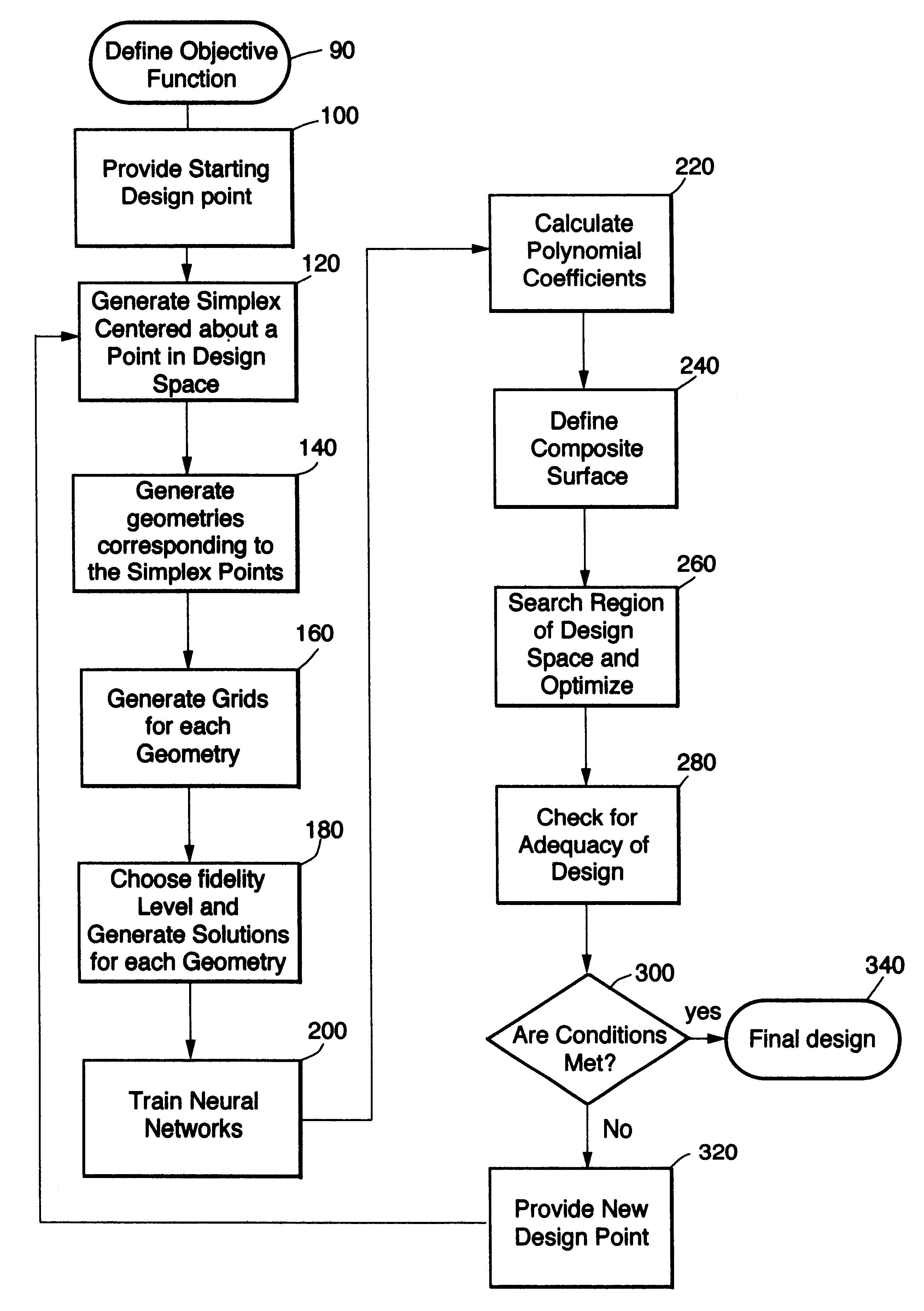

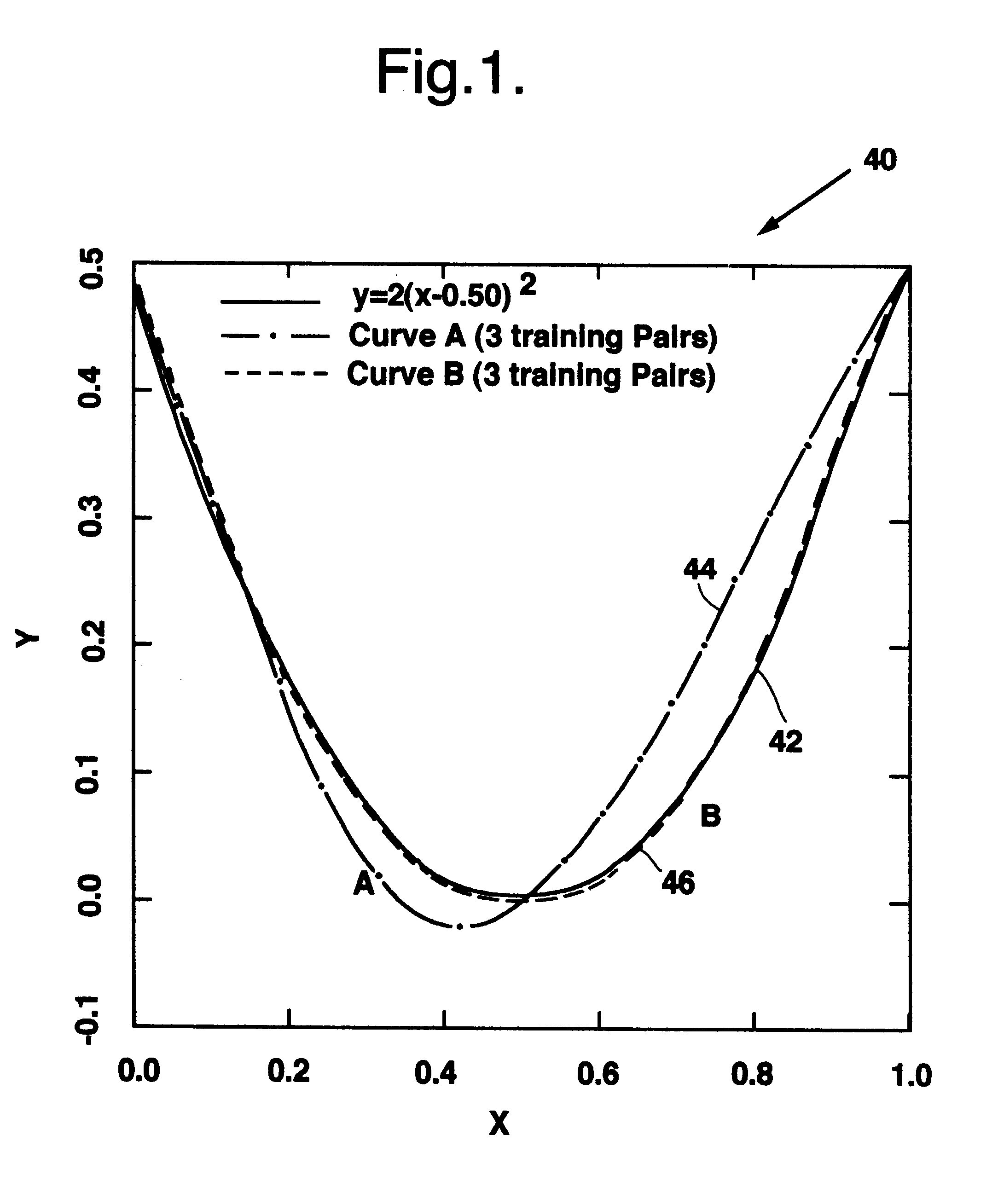

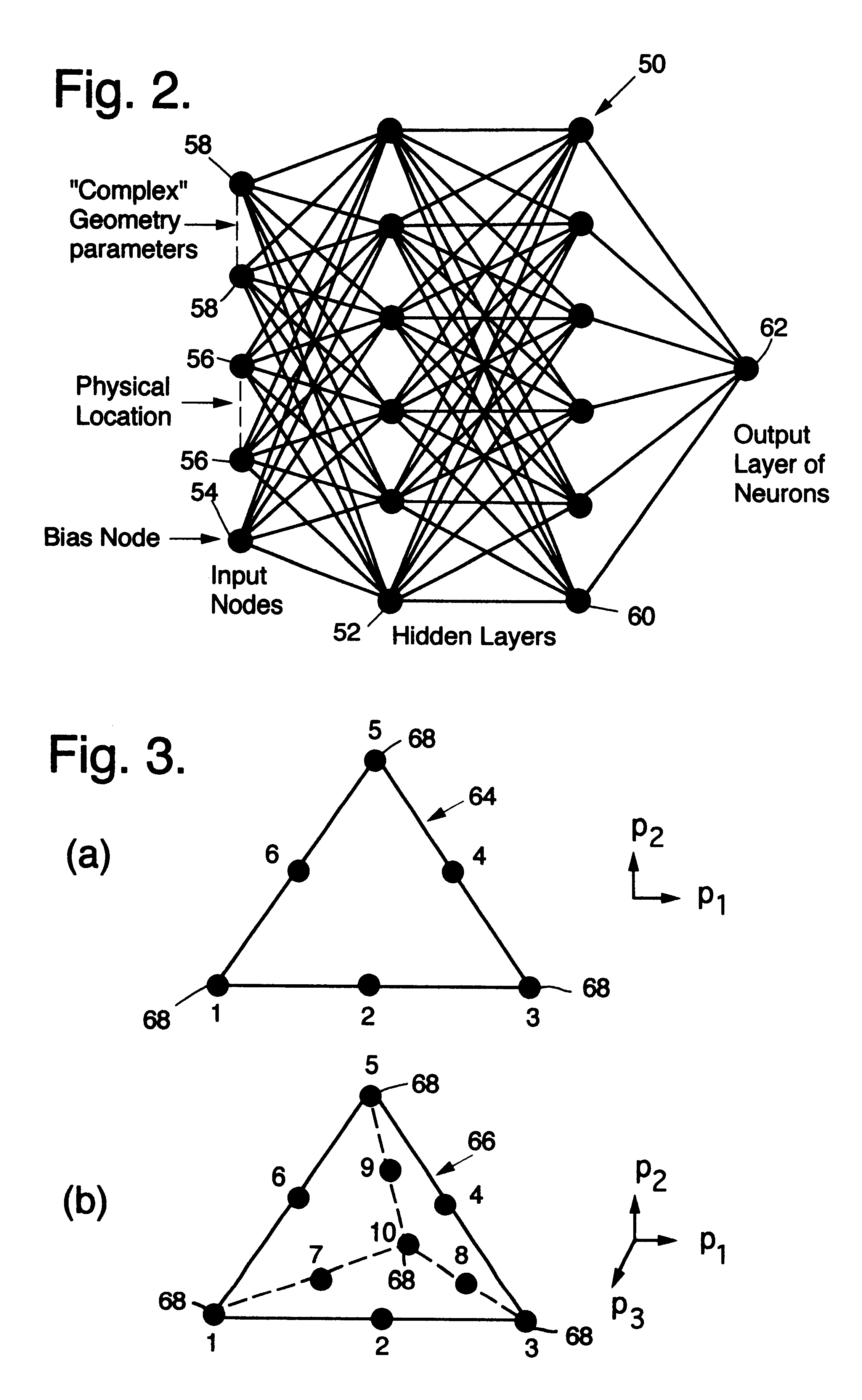

Method for constructing composite response surfaces by combining neural networks with other interpolation or estimation techniques

InactiveUS6606612B1Small amountReduce amountGeometric CADDigital computer detailsAlgorithmEngineering

A method and system for design optimization that incorporates the advantages of both traditional response surface methodology (RSM) and neural networks is disclosed. The present invention employs a unique strategy called parameter-based partitioning of the given design space. In the design procedure, a sequence of composite response surfaces based on both neural networks and polynomial fits is used to traverse the design space to identify an optimal solution. The composite response surface has both the power of neural networks and the economy of low-order polynomials (in terms of the number of simulations needed and the network training requirements). The present invention handles design problems with many more parameters than would be possible using neural networks alone and permits a designer to rapidly perform a variety of trade-off studies before arriving at the final design.

Owner:NASA

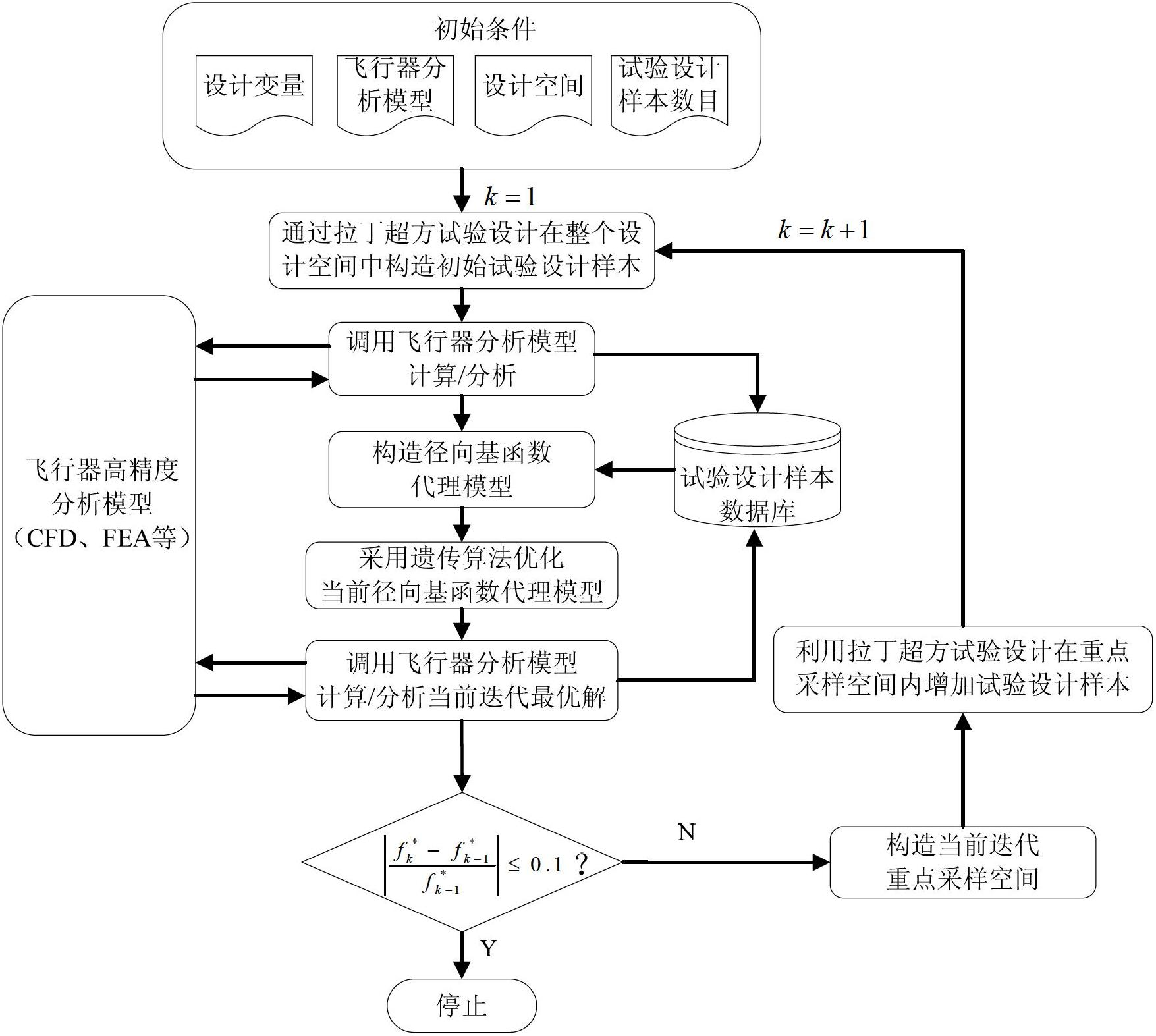

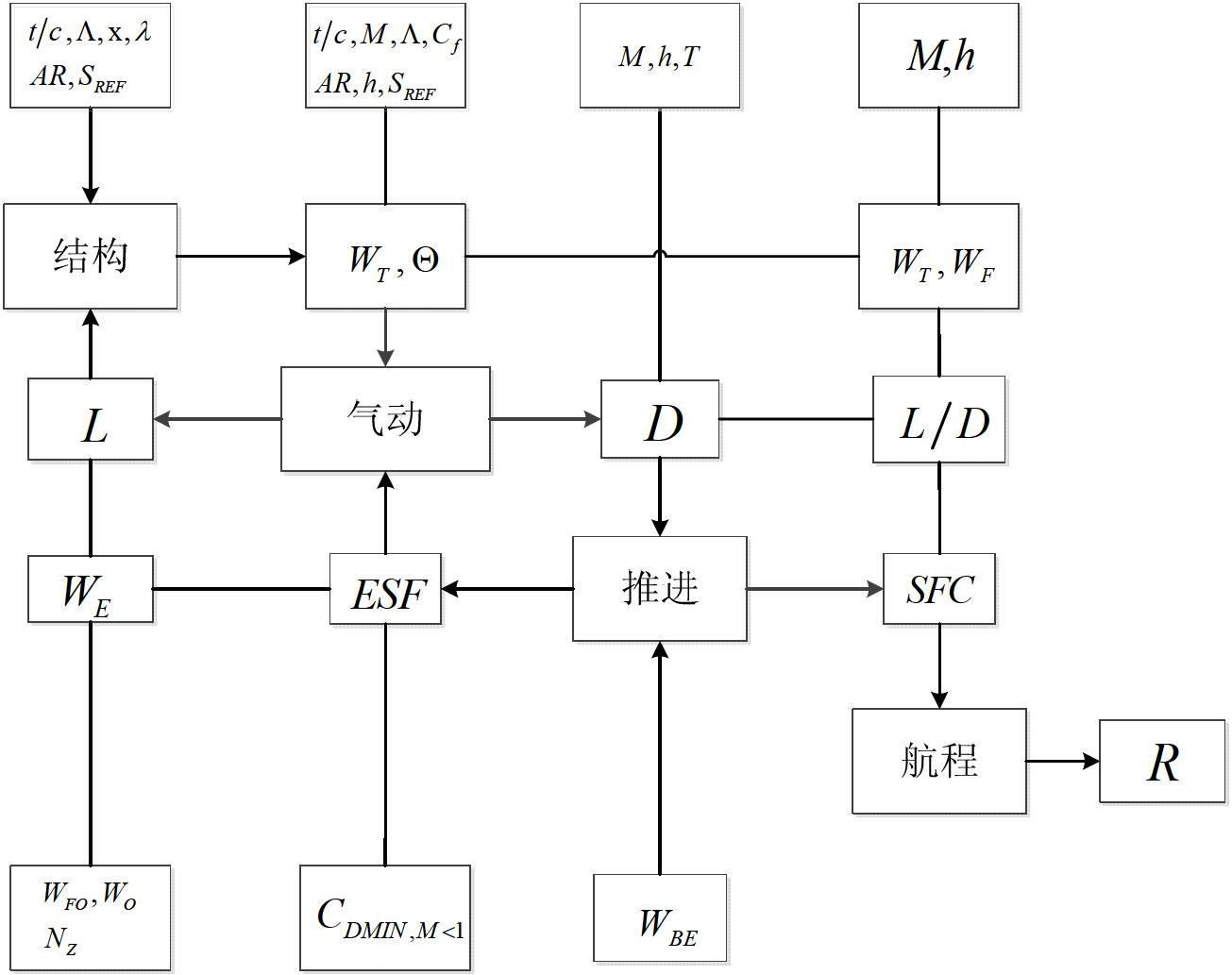

Optimization design method based on self-adaptive radial basis function surrogate model for aircraft

InactiveCN102682173AImprove Global Approximation AccuracySave optimization design costSpecial data processing applicationsAnalytic modelGenetic algorithm

The invention provides an optimization design method based on a self-adaptive radial basis function surrogate model for an aircraft. The optimization design method comprises the following steps of: first, sampling an experimental design sample in a design space by adopting a latin square experimental design method and acquiring an aircraft high-precision analytical model response value corresponding to the experimental design sample; constructing an approximate aircraft high-precision analytic model of the radial basis function surrogate model; acquiring the global optimal solution of a current radial basis function surrogate model by utilizing a genetic algorithm; constructing an aircraft optimization design major sampling space according to current optimization flow information, increasing a few experimental design samples, and updating the radial basis function surrogate model; and acquiring the global optimal solution of the updated radial basis function surrogate model by utilizing the genetic algorithm again, judging whether an optimization flow is converged or not, stopping optimization if the optimization flow is converged, and reconstructing the aircraft optimization design major sampling space until the optimization is converged if the optimization flow is not converged. By using the optimization design method provided by the invention, the optimization efficiency is improved, and the optimization design cost of the aircraft is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

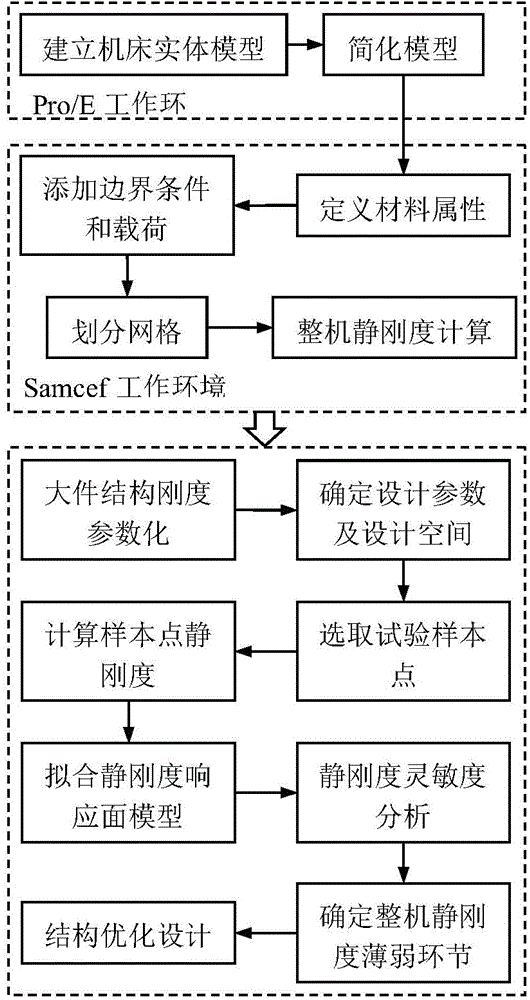

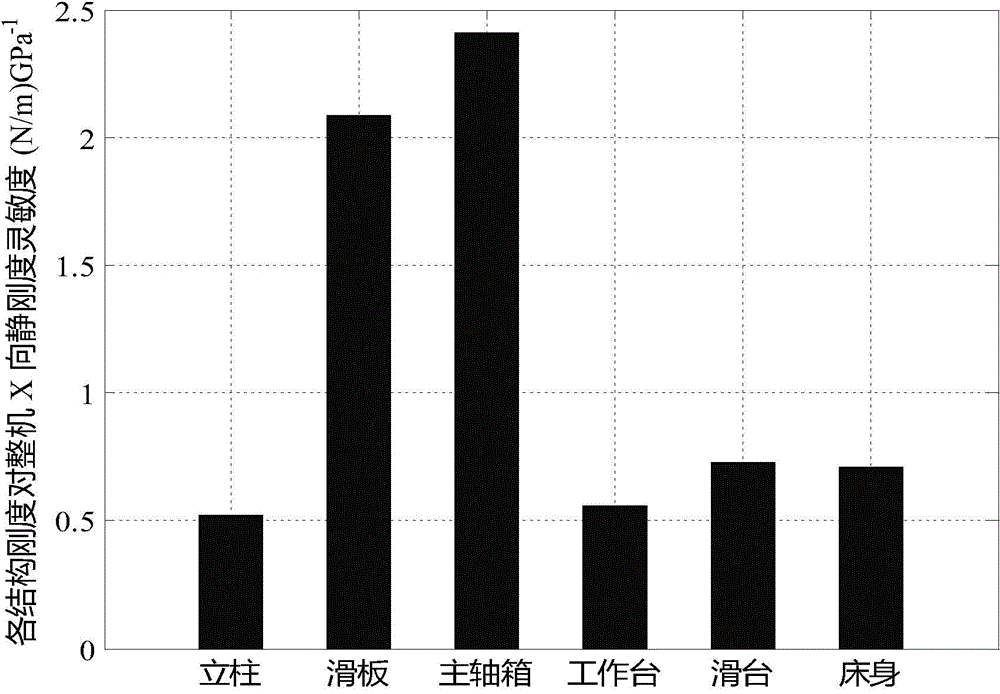

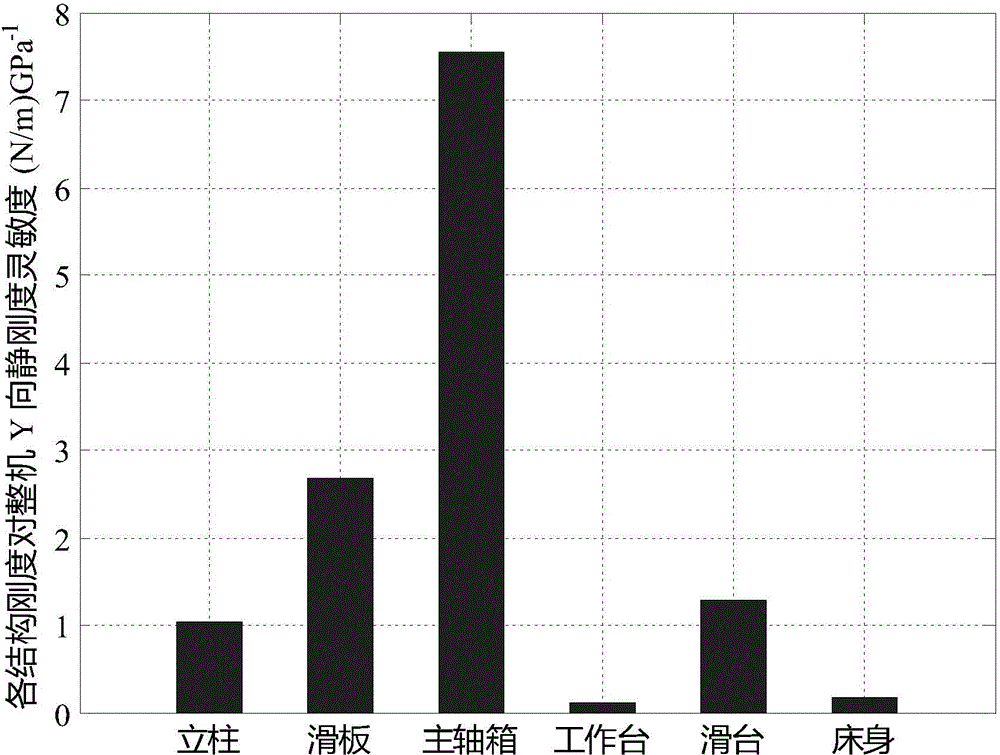

Optimized design method of overall static rigidity of machine

InactiveCN104156501AIncrease the static stiffness value at the end of the machineReduce stress deformationSpecial data processing applicationsReduced modelElement model

The invention discloses an optimized design method of overall static rigidity of a machine. The method includes the steps of establishing a simple machine model by Pro / E software; importing the simple machine model into SAMCEF software to establish a machine finite element model; parameterizing rigidity features of large structures of the machine to determine design parameters and a design space; selecting test sample points for finite element analysis by a central composite experiment design method; subjecting the test sample points to finite element analysis to obtain machine static rigidity response values of the test sample points; establishing a response surface model for large structure rigidity feature parameters and machine static rigidity; analyzing sensitivities of large structure rigidities to the machine static rigidity so as to determine a static rigidity weak link, and performing optimized design. The optimized design method of overall static rigidity of the machine has the advantages that the sensitivities of the structures of the machine to the machine static rigidity are effectively determined, the weak link restricting the improvement of the machine static rigidity is effectively found, and accordingly important basis for the optimized design of machine structure is provided to guide designers to optimally design the weak large structures of the machine.

Owner:TIANJIN UNIV

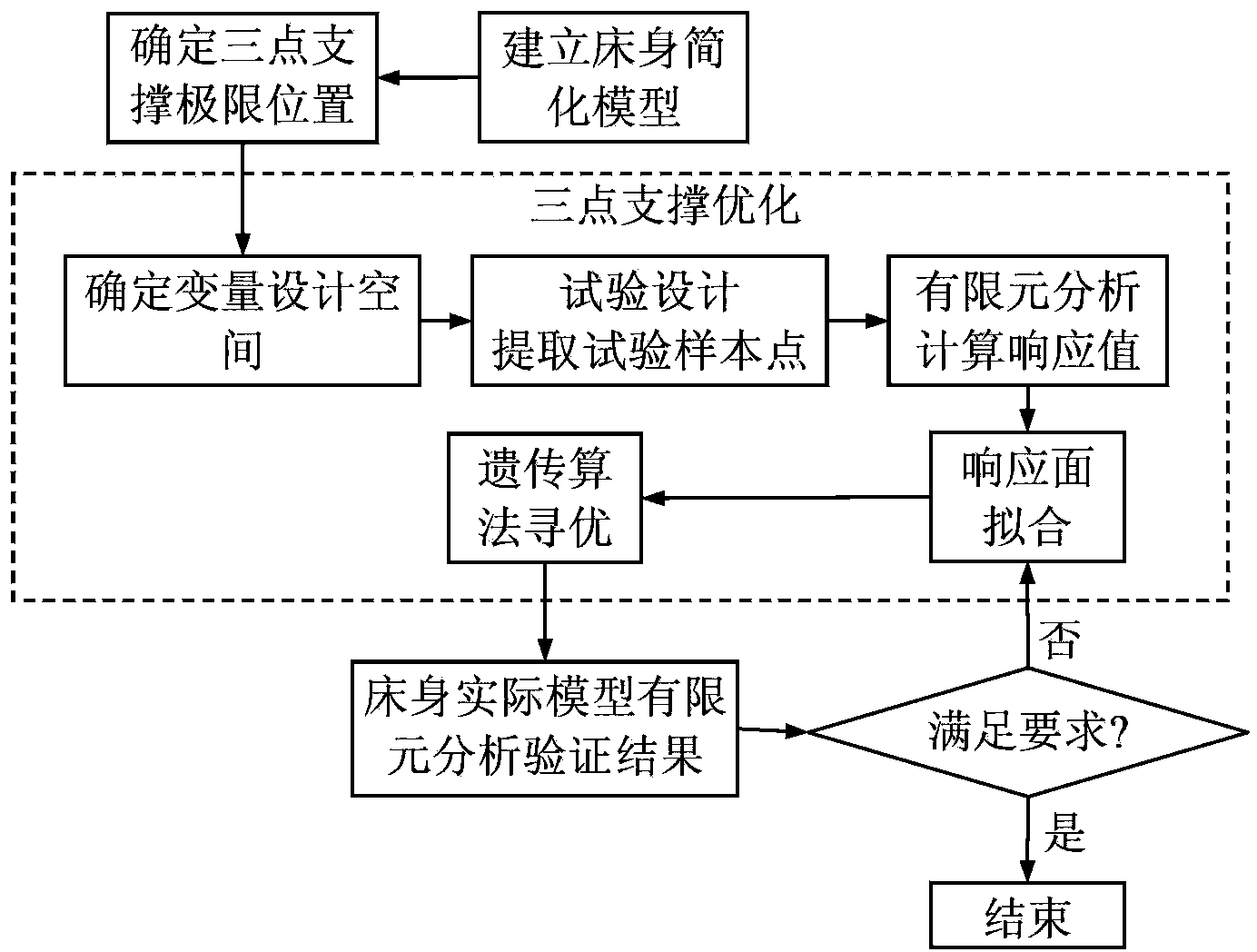

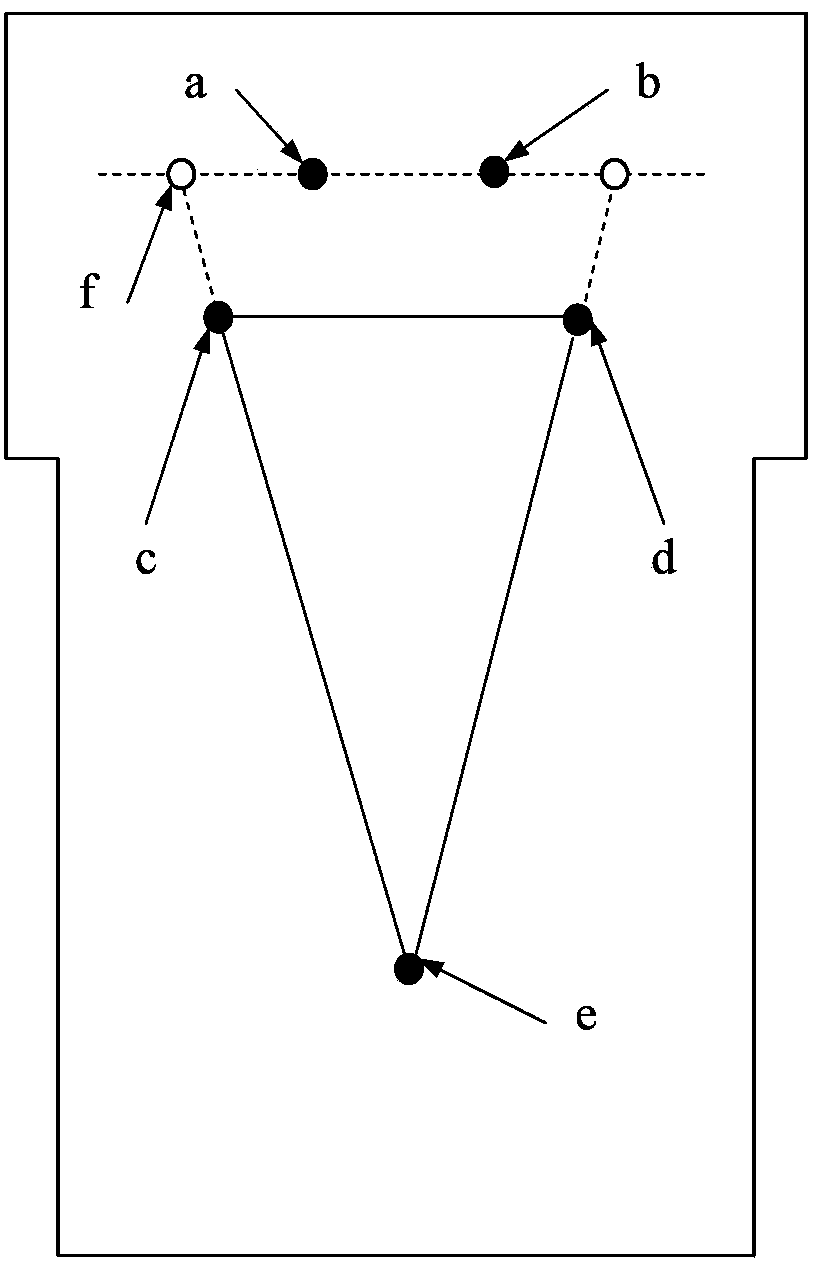

Three-point support optimization design method of machine tool bed based on response surface model

ActiveCN103366043AReduce distortionImprove machining accuracySpecial data processing applicationsReduced modelEngineering

The invention discloses a three-point support optimization design method of a machine tool bed based on a response surface model. The method comprises the steps that a simplified model of a bed structure is established in CAD (Computer-Aided Design) software; three-point support limiting positions are found; a variable design space and an optimization objective are determined; test sample points for statics analysis are selected from the design space, and subjected to the statics analysis by finite element analysis software; a response value is calculated and extracted; a second-order response surface model, reflecting an input-output relation of structural design, of deformation at guide rails of the bed is established according to the response value; an optimal solution of the response surface model is acquired by a genetic algorithm; based on the established second-order response surface model, three-point support positions when the deformation of the guide rails is minimum are found; a practical model of the bed is subjected to the statics analysis; and the reliability of three-point support optimization design is verified. With the adoption of the method, the deformation of a machine tool is reduced; the machining precision of the machine tool is improved; the three-point support optimization efficiency and the optimization precision are improved; and the problems that the calculation amount is large, the efficiency is low, and an optimal result cannot be ensured easily in the existing optimization technique are solved.

Owner:TIANJIN UNIV

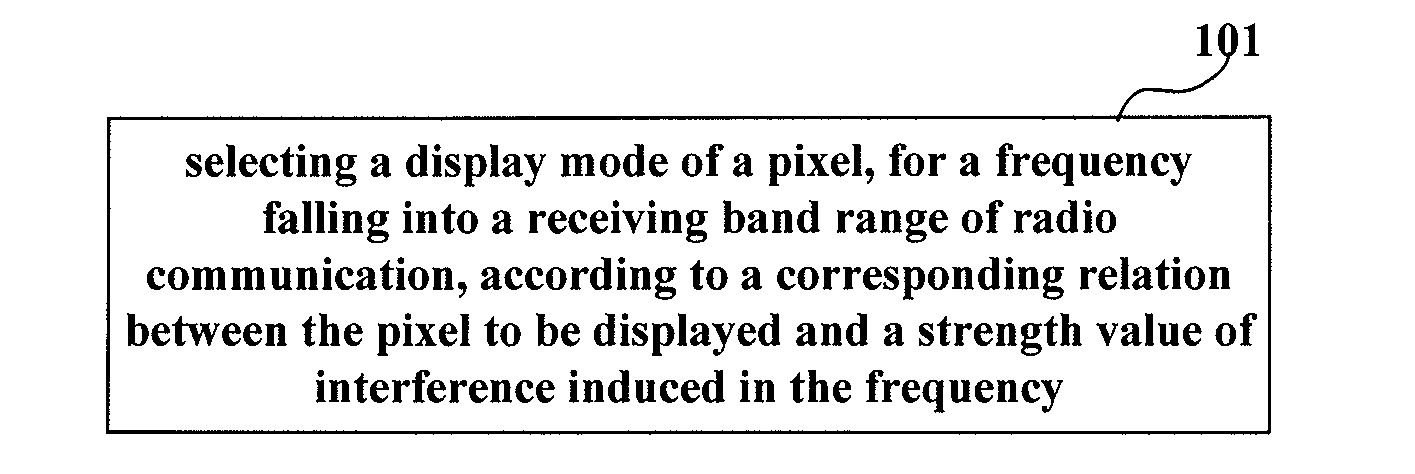

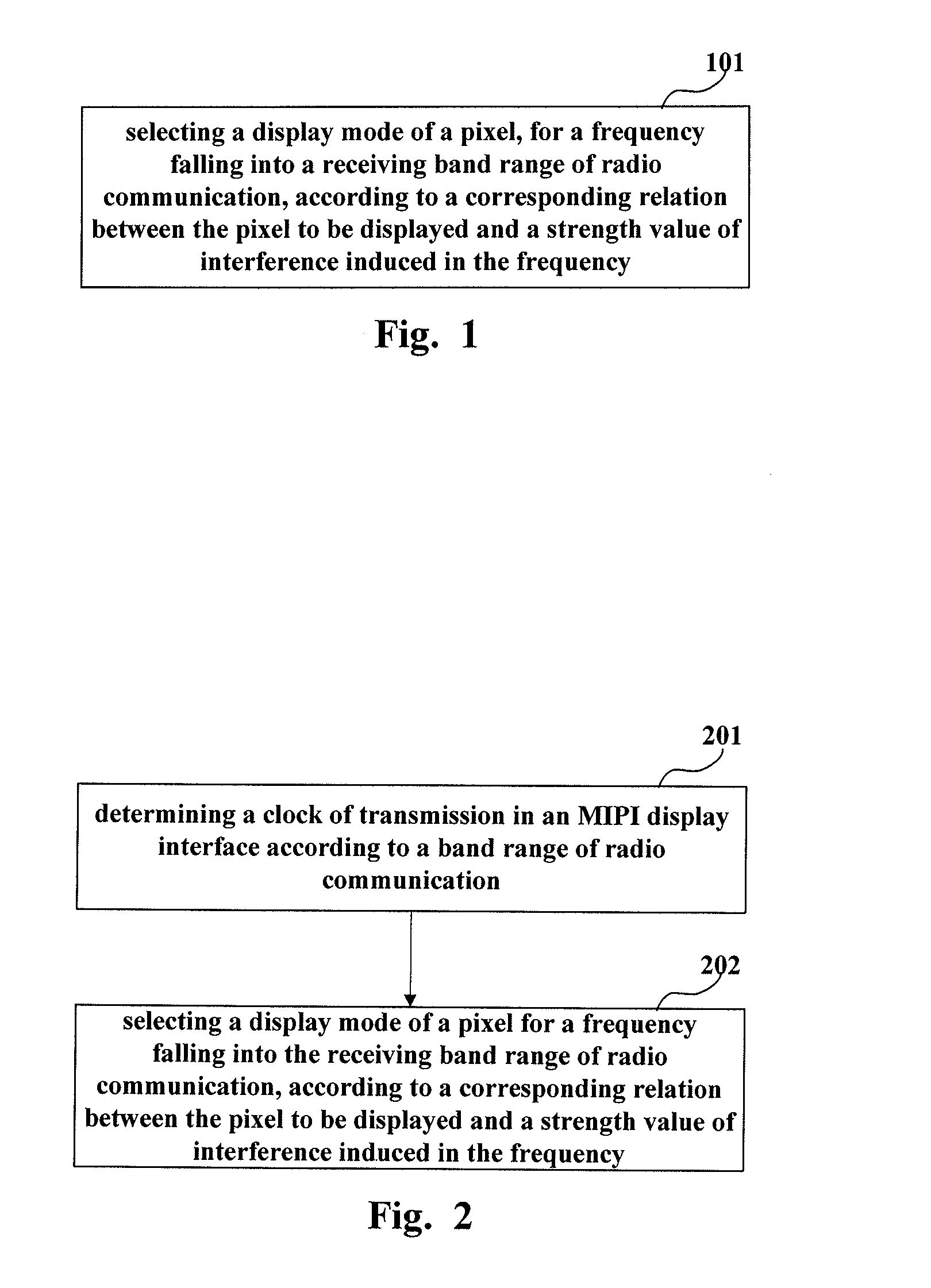

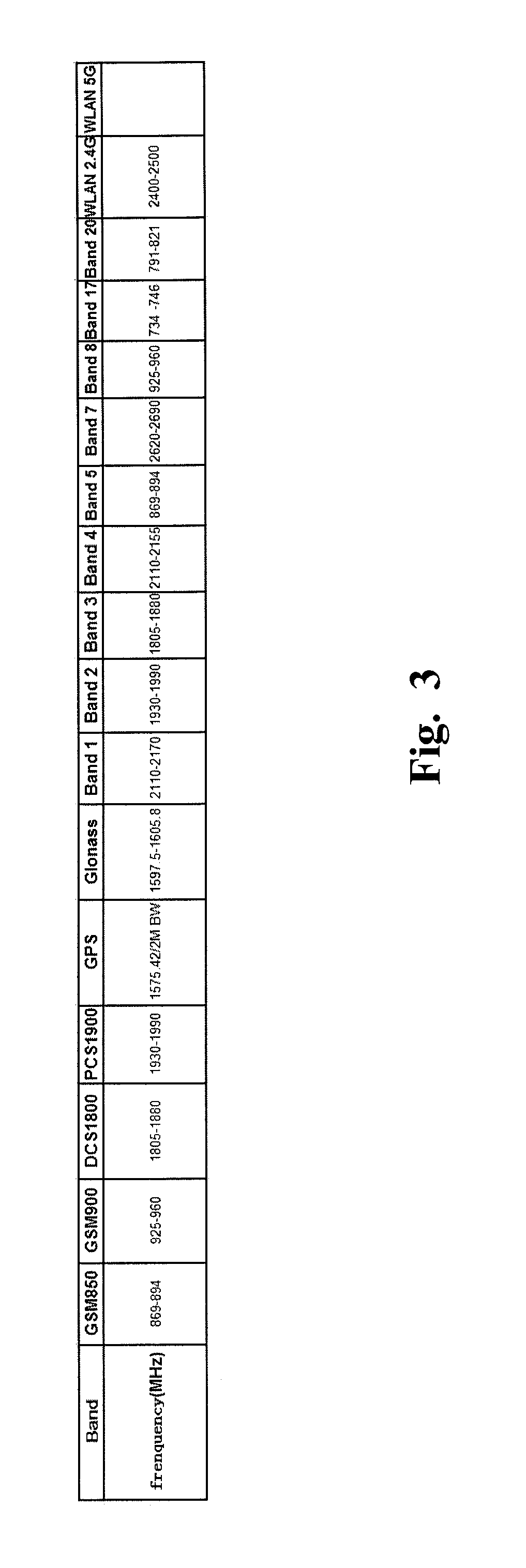

Method and apparatus for reducing interference and mobile terminal

InactiveUS20140218352A1Performance of radio communication is loweredLower performance requirementsPower managementCathode-ray tube indicatorsComputer hardwareDesign space

A method and apparatus for reducing interference and a mobile terminal using the method and apparatus. The method includes: selecting a display mode of a pixel, for a frequency falling into a receiving band range of radio communication, according to a corresponding relation between the pixel to be displayed and a strength value of interference induced in the frequency. The present invention may not only further reduce interference brought by the MIPI high-speed data transmission to radio communication receiver, but also have effect on those bands lower than 1 GHZ, lower the requirements on hardware and hence lower hardware cost, and occupy no design space.

Owner:SONY MOBILE COMM INC +1

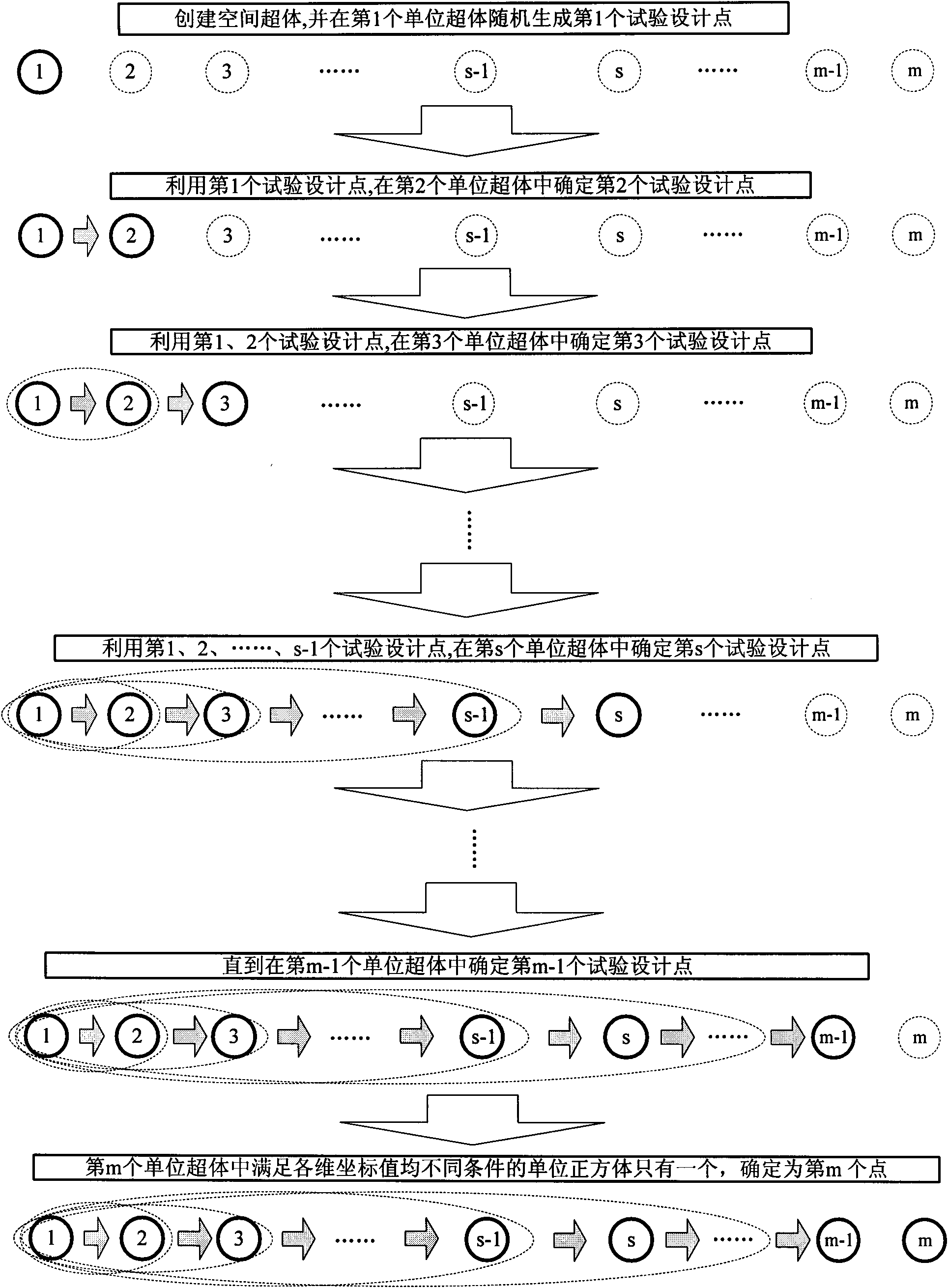

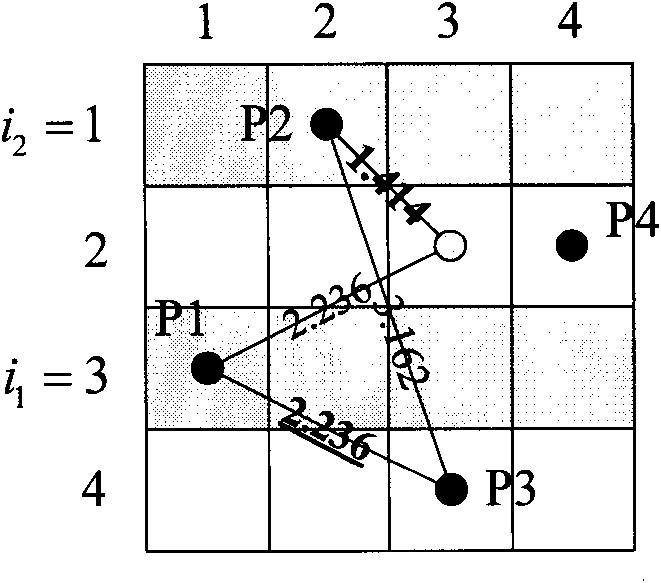

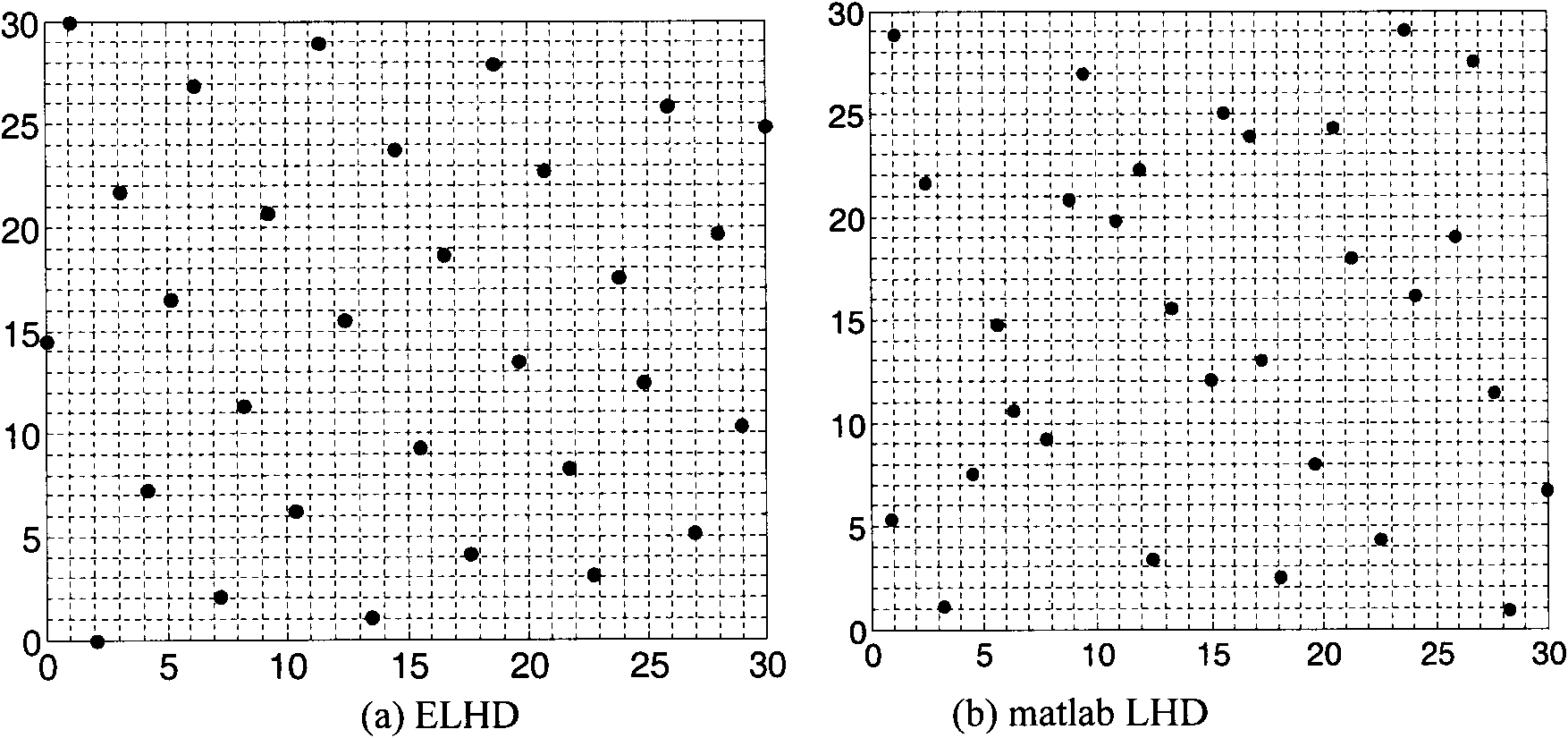

High-efficiency Latin hypercube experimental design method

InactiveCN101923590AImprove sampling efficiencySimple designSpecial data processing applicationsPartition of unityEngineering

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Design software incorporating efficient 3-D rendering

ActiveUS7249005B2Efficient and accurateAccurate visual effect dataCathode-ray tube indicatorsEducational modelsComputer graphics (images)Display device

Design software in accordance with an implementation of the present invention is configured to provide believable three-dimensional representations of user selections in real-time. Design elements that would otherwise be difficult to efficiently render three-dimensionally in real-time are prerendered for realistic visual effects, such as realistic shading, which correspond to various positions of the elements in a design space. Blanks of the visual effects for each position are then stored in a data store for visual effects. At run time, data associated with user design choices, as well as the blanks for any corresponding design elements are fed in one implementation to peripheral processing hardware, such as a GPU, which sends the processed data to a display device. The user is therefore able to view complex visual data of certain design choices efficiently with added realism.

Owner:ARMSTRONG WORLD INDUSTRIES +1

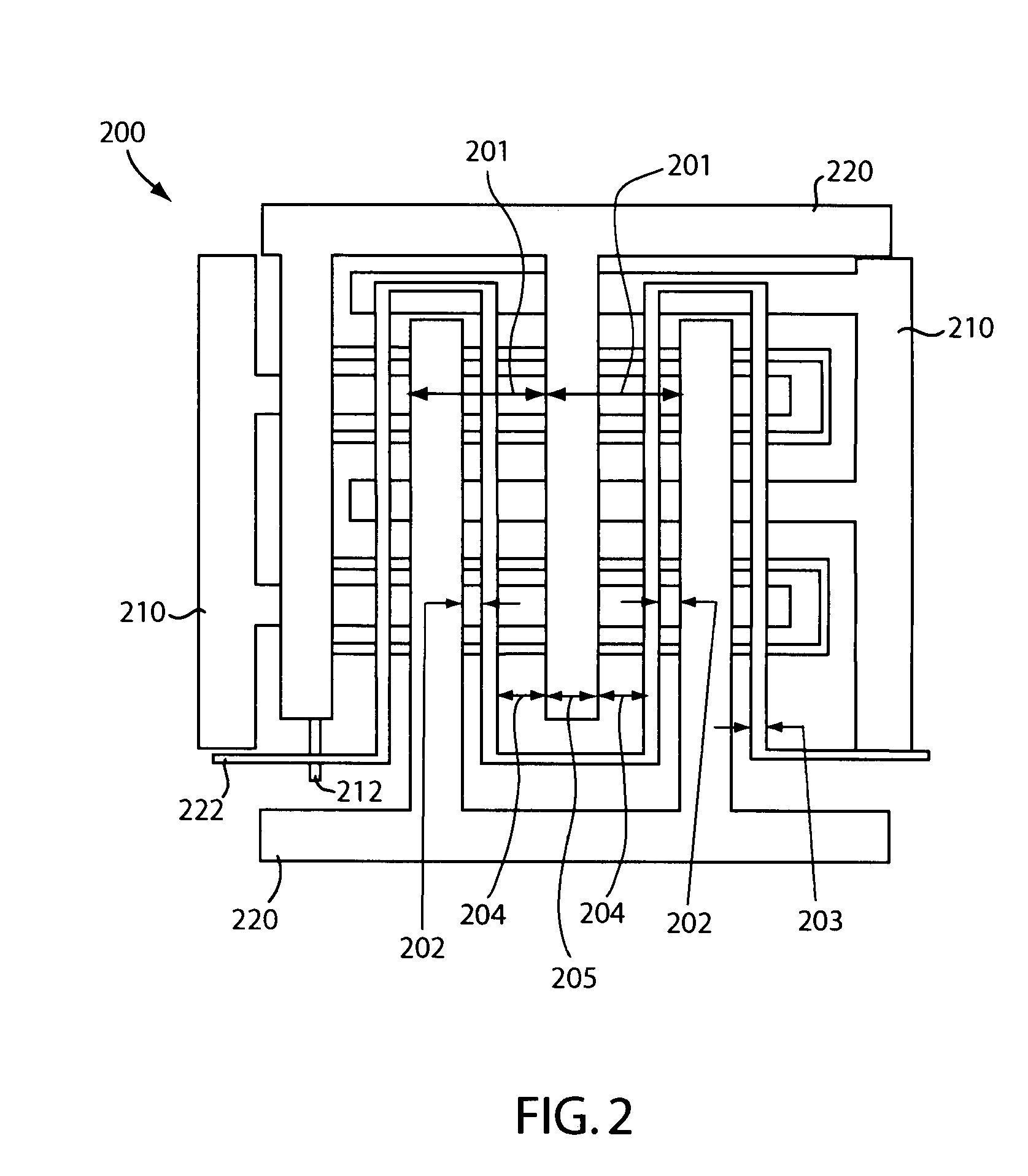

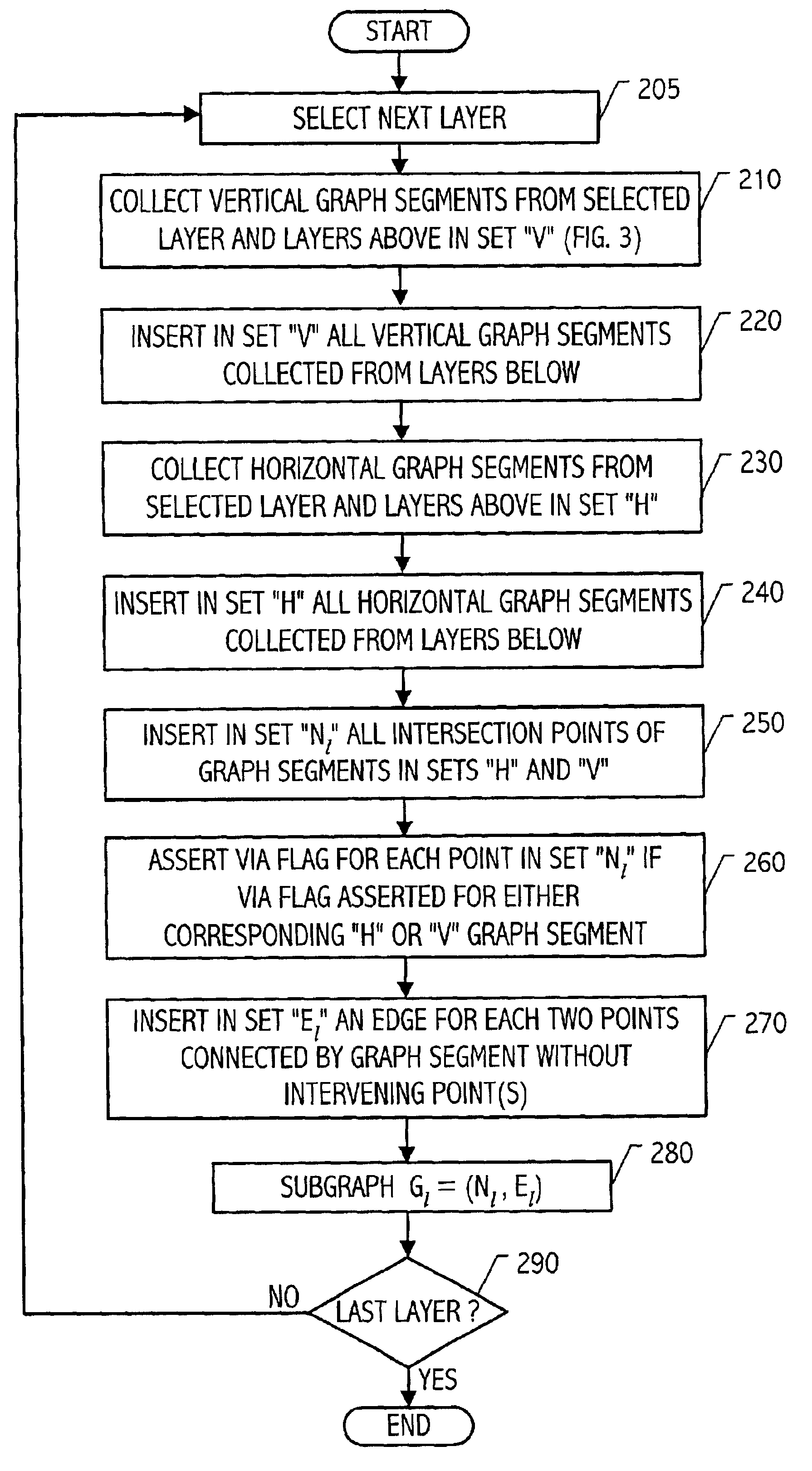

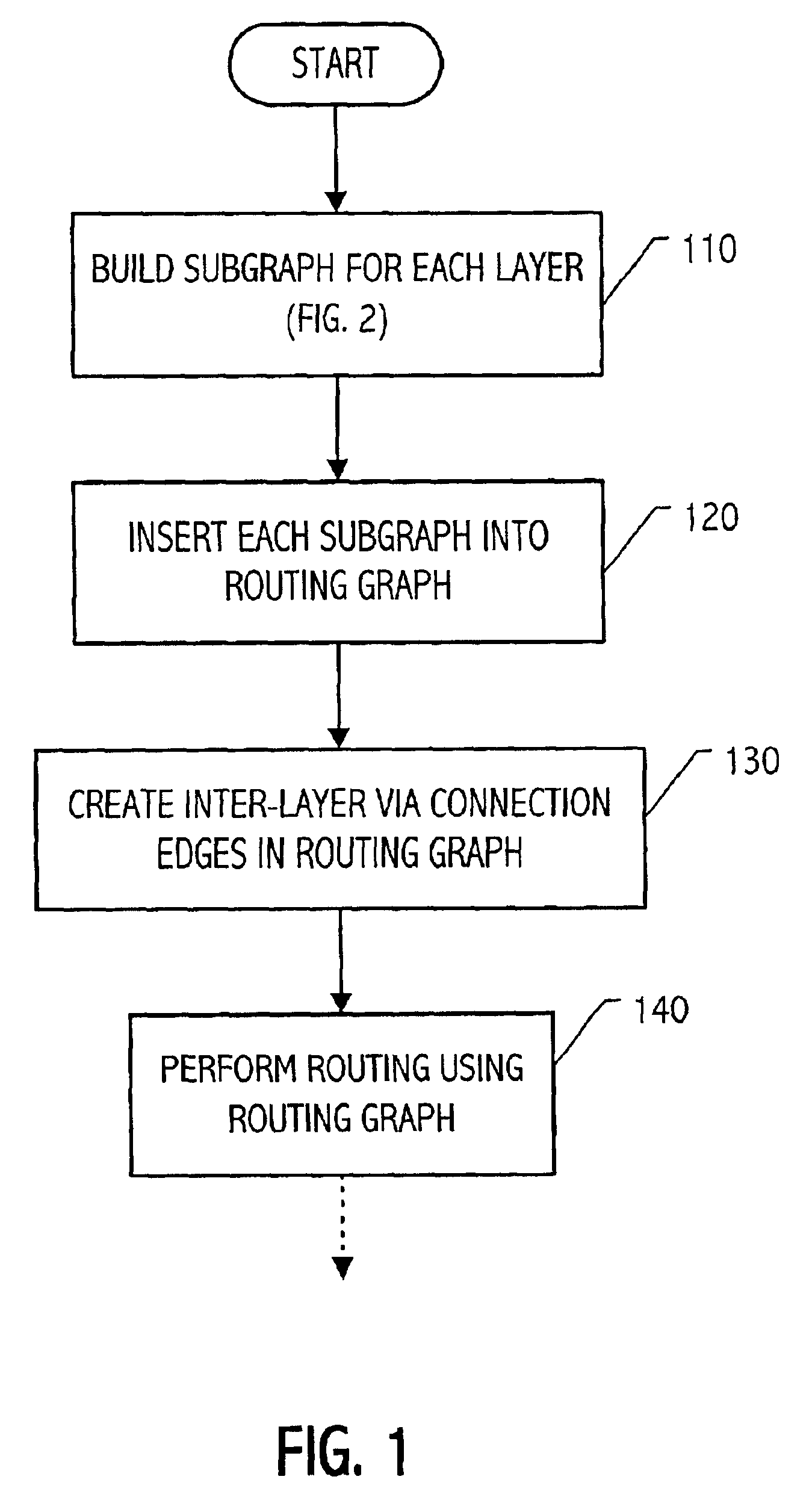

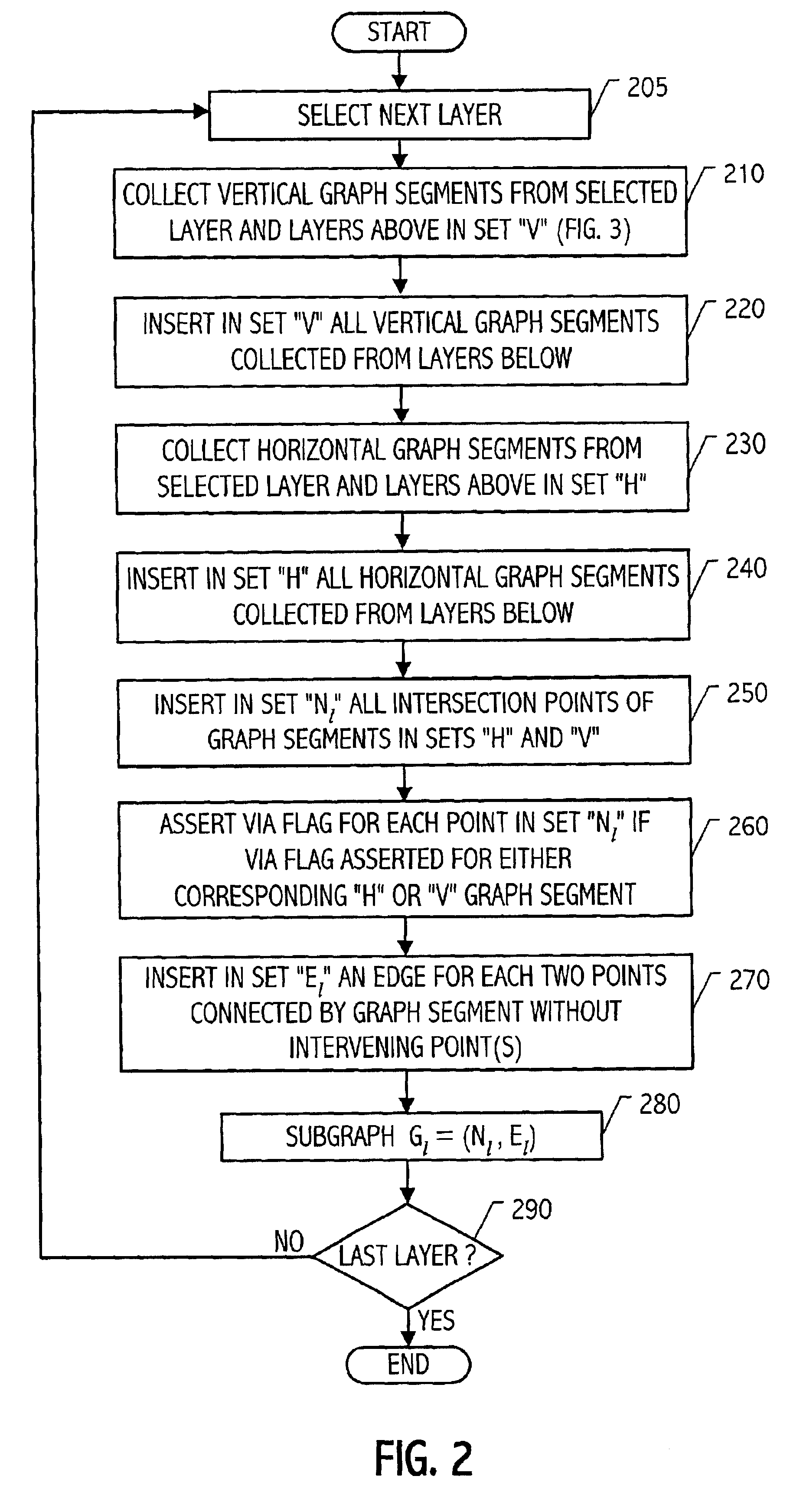

2.5-D graph for multi-layer routing

InactiveUS6792587B2Computer aided designSpecial data processing applicationsTheoretical computer scienceDesign space

A routing graph (e.g., a 2.5-D graph) and a method for generating same is provided for more efficient multiple-layer path searching and routing. Subgraphs are generated for each layer, and then are combined (e.g., through via connections) into a single, multi-layer graph. The resulting 2.5-dimensional graph may be used in VLSI routing, for example, which commonly includes multiple routing layers in a given design space. Each subgraph corresponds to a layer of circuitry and includes segments based on segments from other layers and intersection points of all such segments. Methods of generating subgraph layers are disclosed.

Owner:ORACLE INT CORP

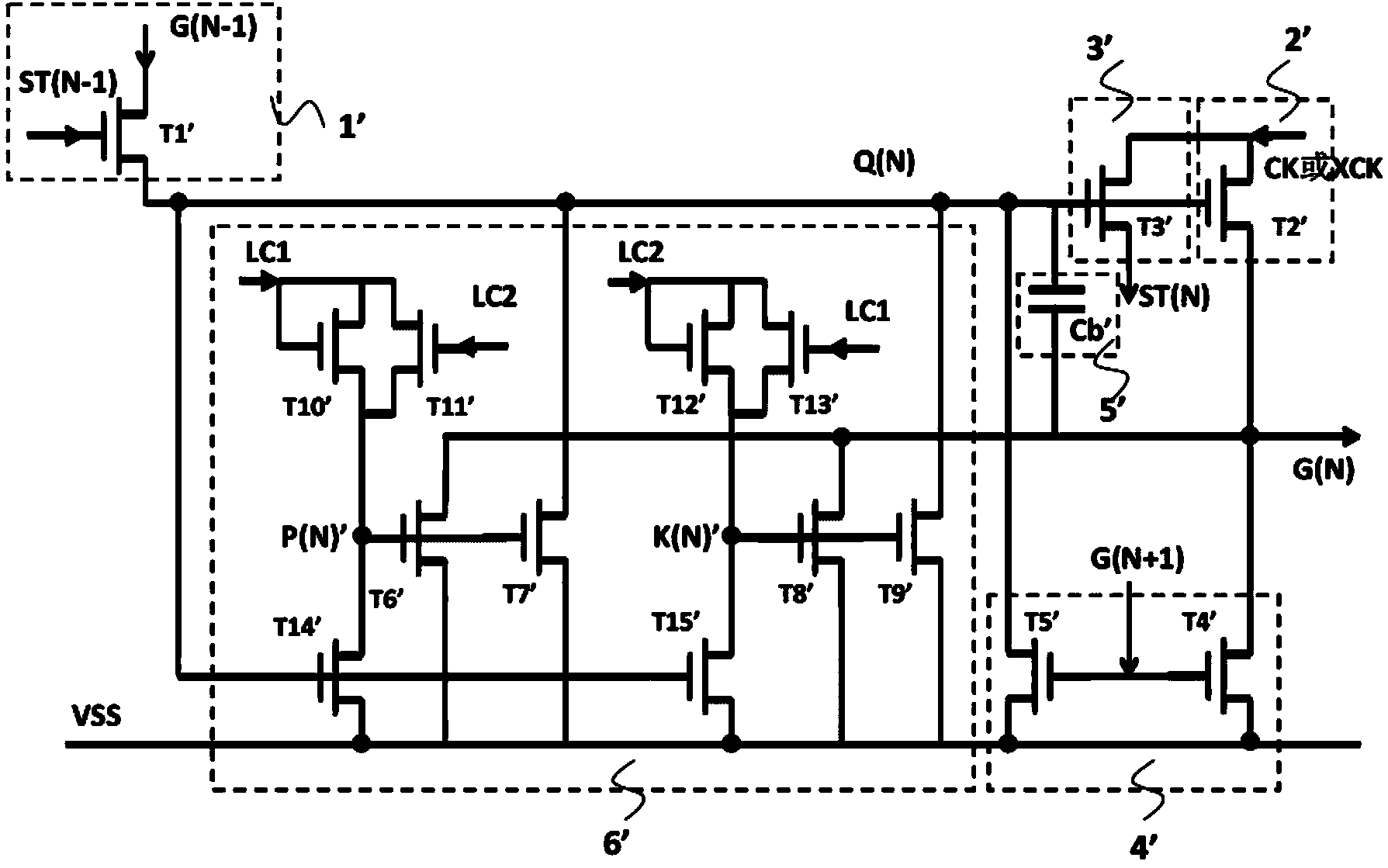

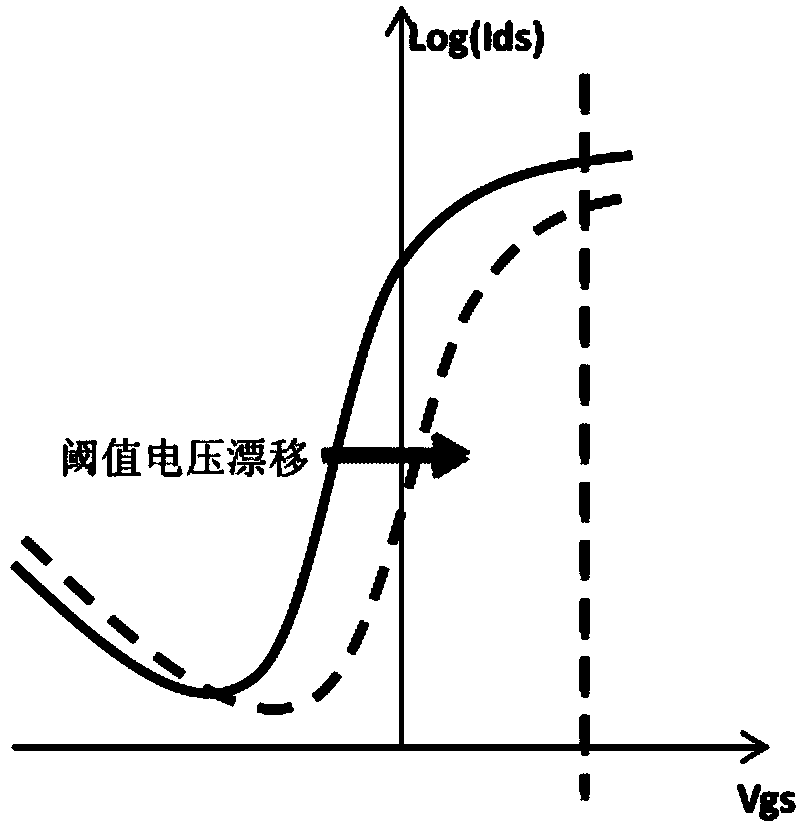

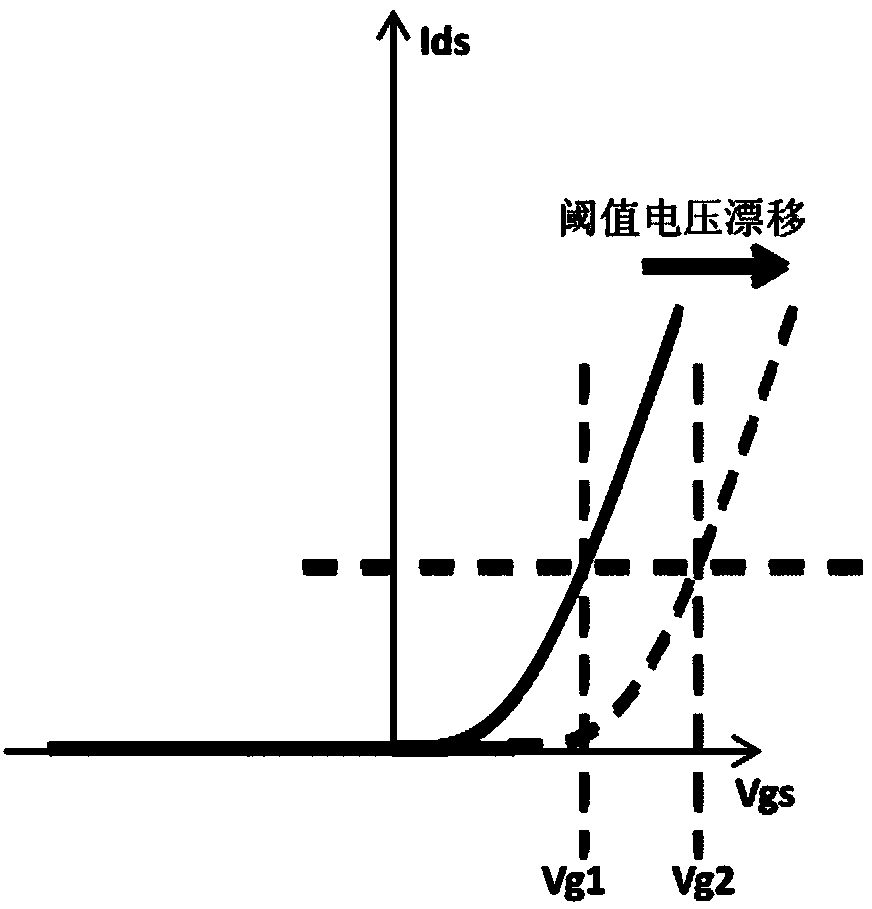

Grid drive circuit with self-compensation function

ActiveCN104064159AImprove reliabilityReduce power consumptionStatic indicating devicesDigital storageCapacitanceLow voltage

The invention provides a grid drive circuit with the self-compensation function. The grid drive circuit comprises a plurality of cascaded grid driver on array (GOA) units. The Nth grade of GOA unit comprises an upward-pull control module, an upward-pull module, a downward-transfer module, a first downward-pull module, a bootstrap capacitor module and a downward-pull maintaining module; the upward-pull module, the first downward-pull module, the bootstrap capacitor module and the downward-pull maintaining module are electrically connected with the Nth grade grid signal point Q(N) and the Nth grade horizontal scanning line G(N), the upward-pull control module and the downward-transfer module are electrically connected with the Nth grade grid signal point Q(N), and the first direct-current low voltage VSS1 and the second direct-current low voltage VSS2 are input into the downward-pull maintaining module. Due to the design of the downward-pull maintaining module with the self-compensation function, reliability of long-term operation of the grid drive circuit is improved; moreover, the design of the downward-pull maintaining module directly controlled by a set of direct-current signal source DC can be adopted for the grid drive circuit with the self-compensation function, and therefore not only can circuit layout design space be saved, but also the overall power consumption of the circuit can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

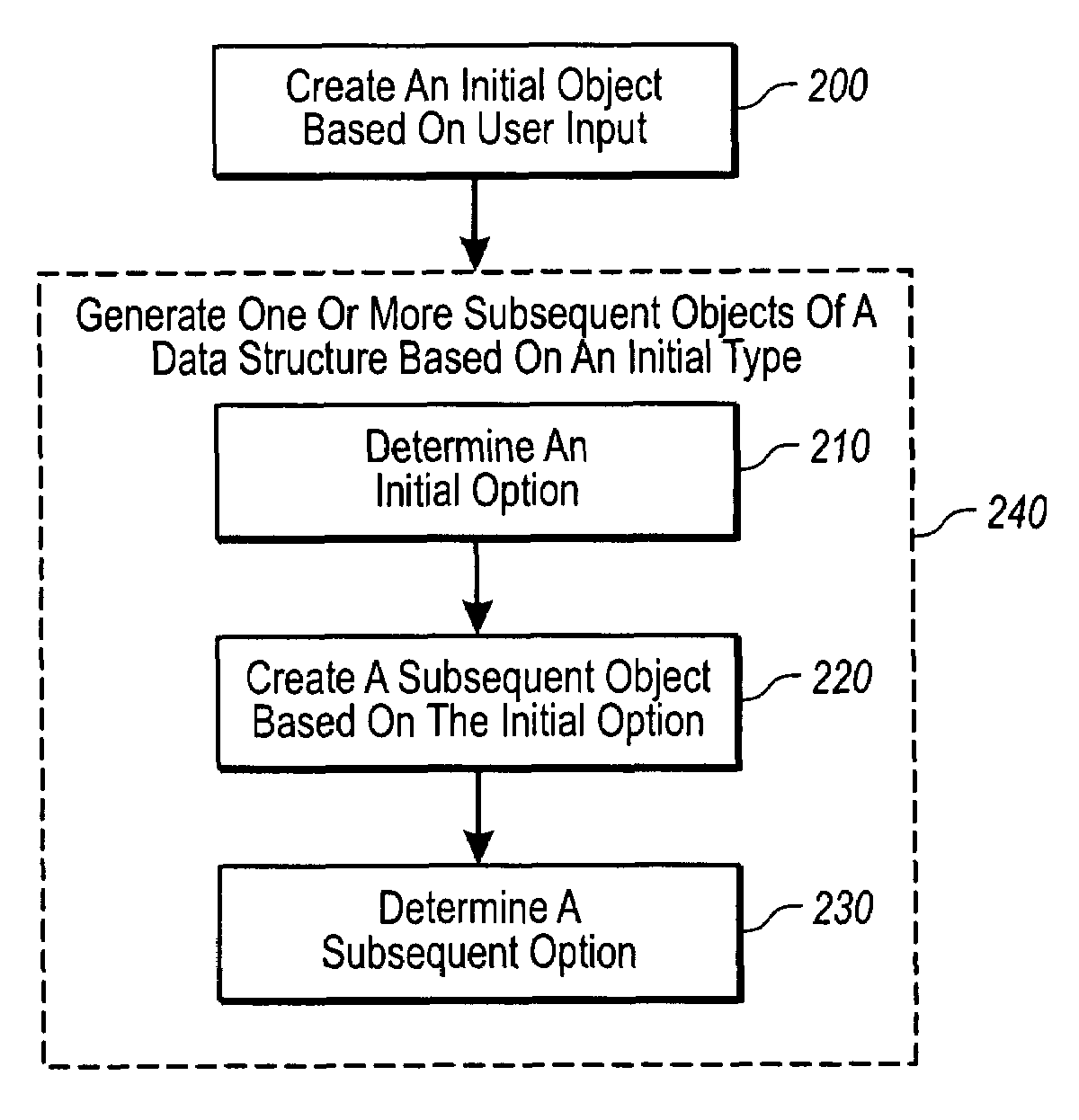

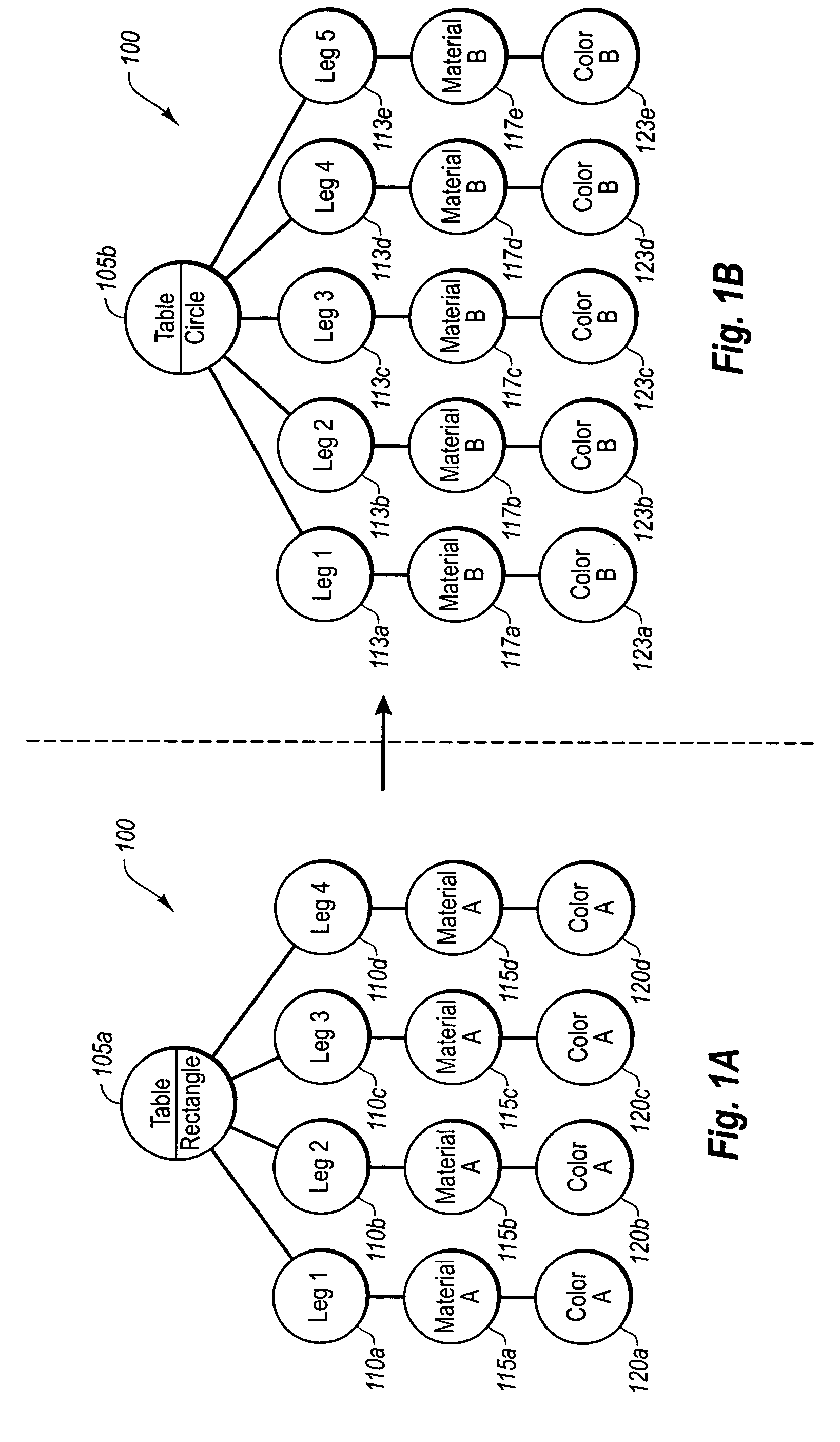

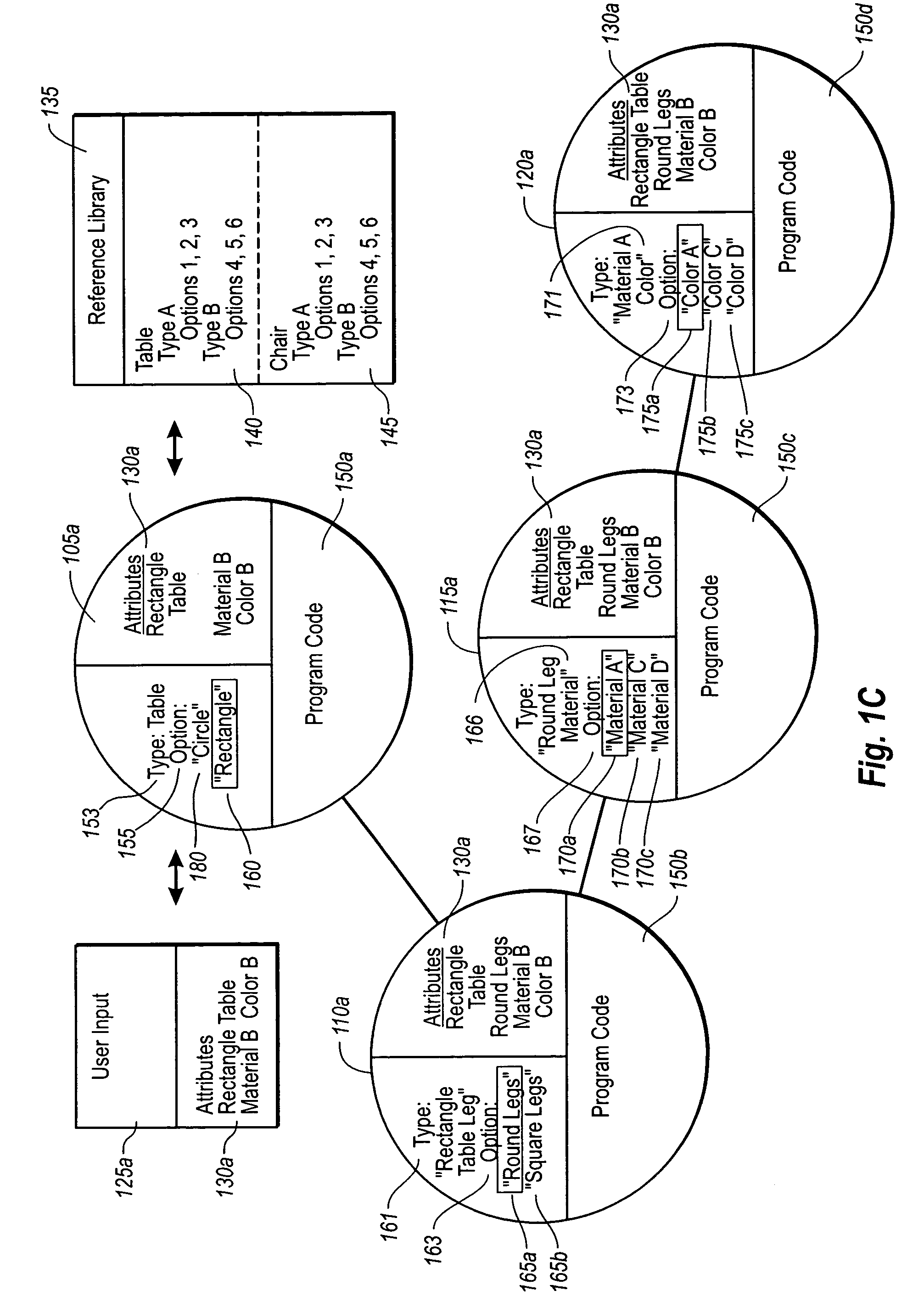

Capturing a user's design intent with resolvable objects

Owner:ARMSTRONG WORLD IND INC

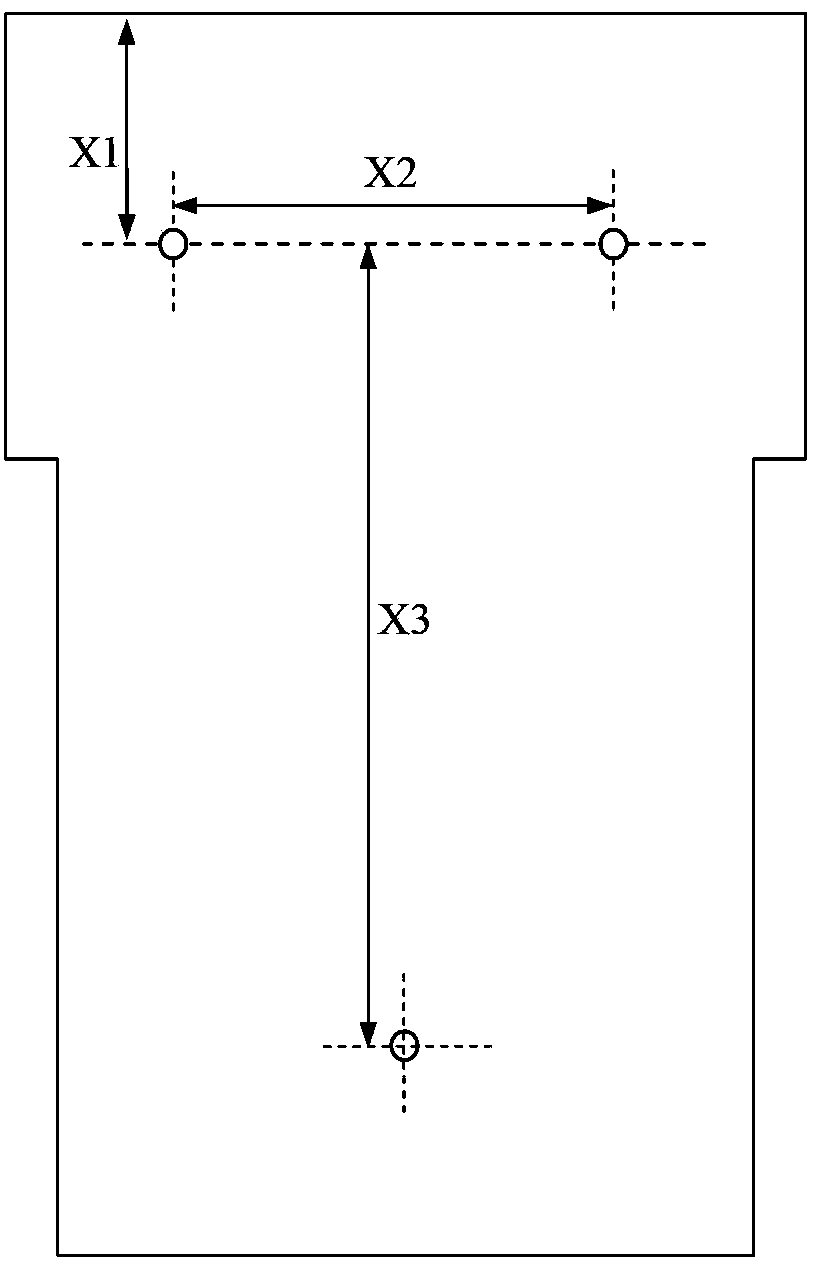

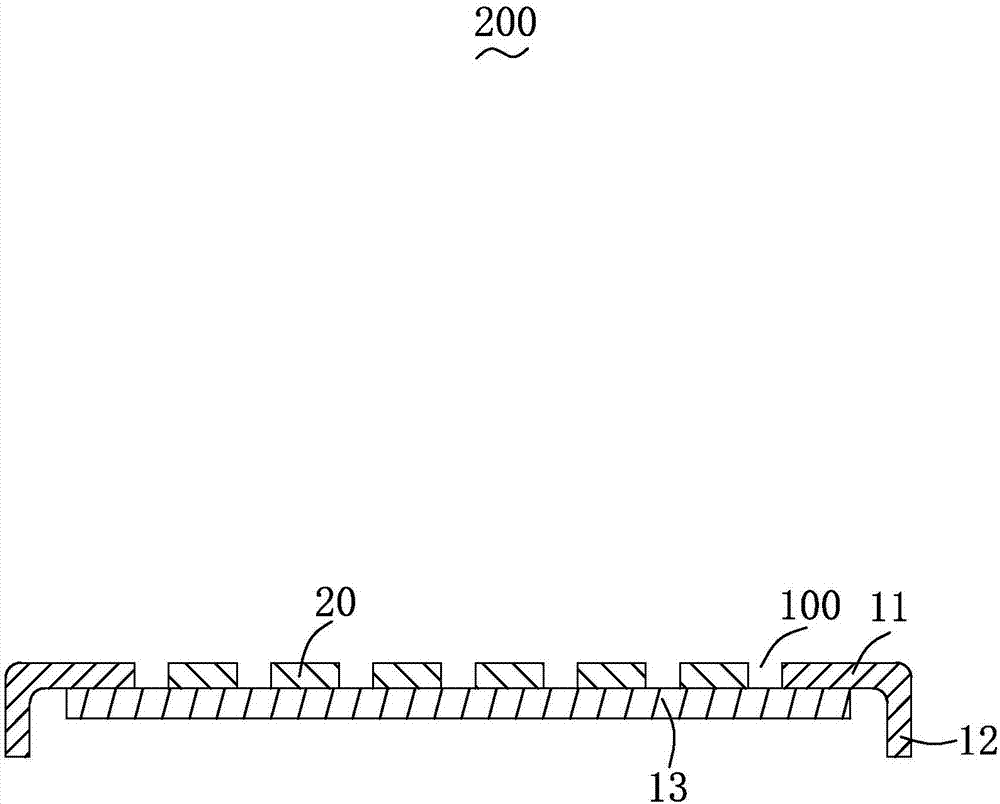

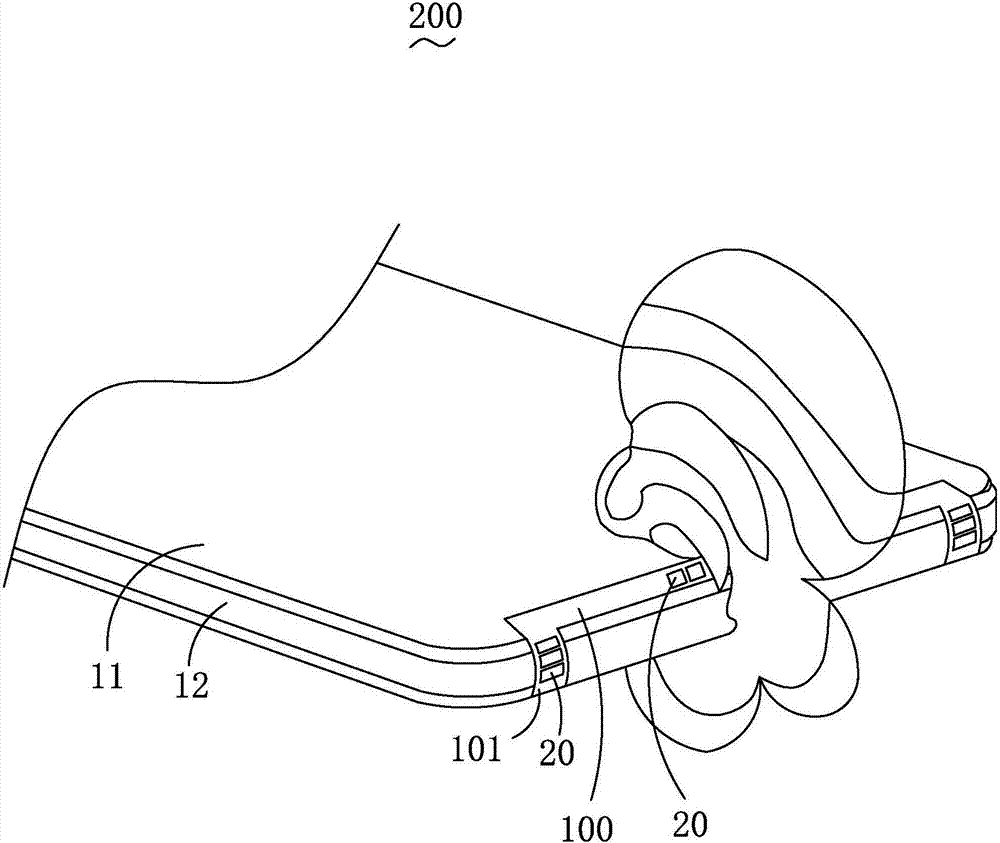

Antenna device

InactiveCN106921023AImprove radiation efficiencyAvoid individual slitsAntenna supports/mountingsAntenna equipments with additional functionsRadiation bandwidthRadio frequency signal

The invention provides an antenna device. The antenna device comprises a millimeter wave microstrip antenna, wherein the millimeter wave microstrip antenna is assembled on a shell of electronic equipment, the electronic equipment comprises a main antenna, the main antenna is arranged in the shell, an antenna gap is formed in the shell and is used for radiation / receiving of a radio frequency signal by the main antenna, the millimeter wave microstrip antenna comprises a plurality of unit antennas, the plurality of the unit antennas are arranged at intervals, and the plurality of the unit antennas and the shell are arranged at an interval and are arranged in the antenna gap in an array way. Compared with prior art, the antenna device provided by the invention has the advantages that the millimeter wave microstrip antenna is arranged in the antenna gap for radiation / receiving of the radio frequency by the main antenna, so that independent gap opening on the millimeter wave microstrip antenna is prevented, the same antenna clearance region can be shared with the main antenna, the design space of the millimeter wave microstrip antenna is saved, and the space utilization ratio is improved; and meanwhile, the radiation bandwidths of the unit antennas can also be effectively expanded, the gain is improved, the side lobe is suppressed, and the radiation efficiency of the antenna device is further improved.

Owner:AAC TECH PTE LTD

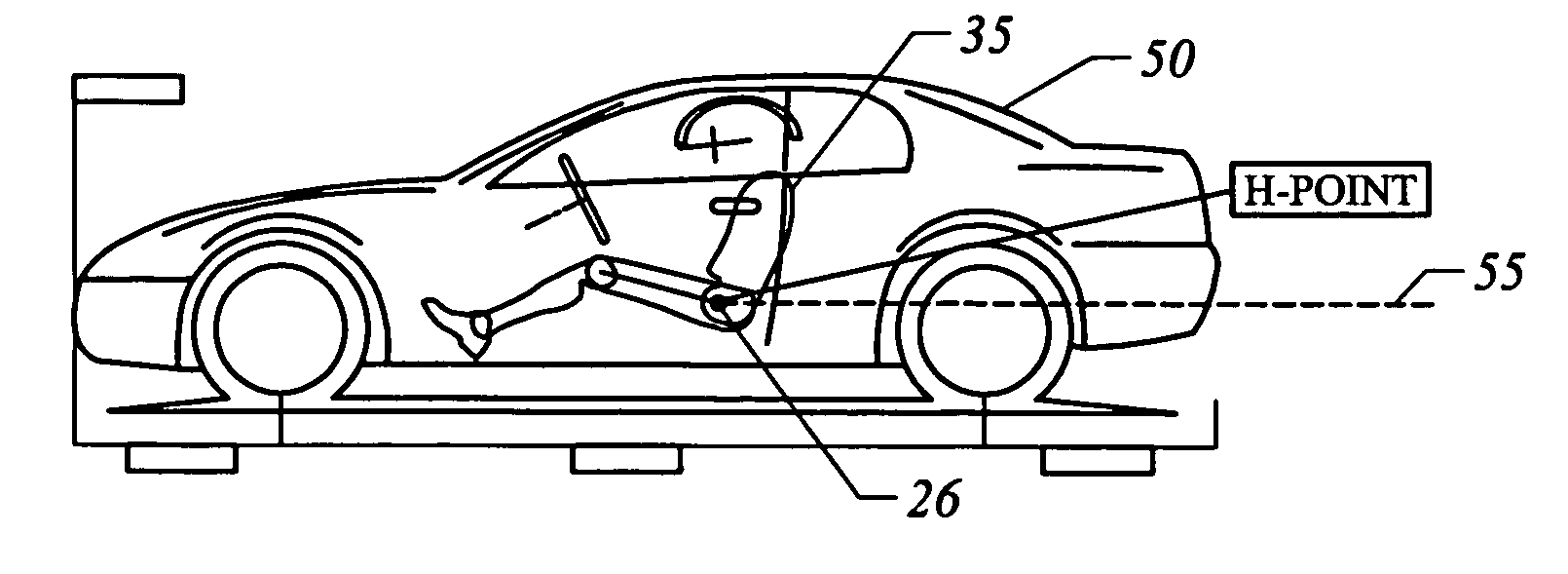

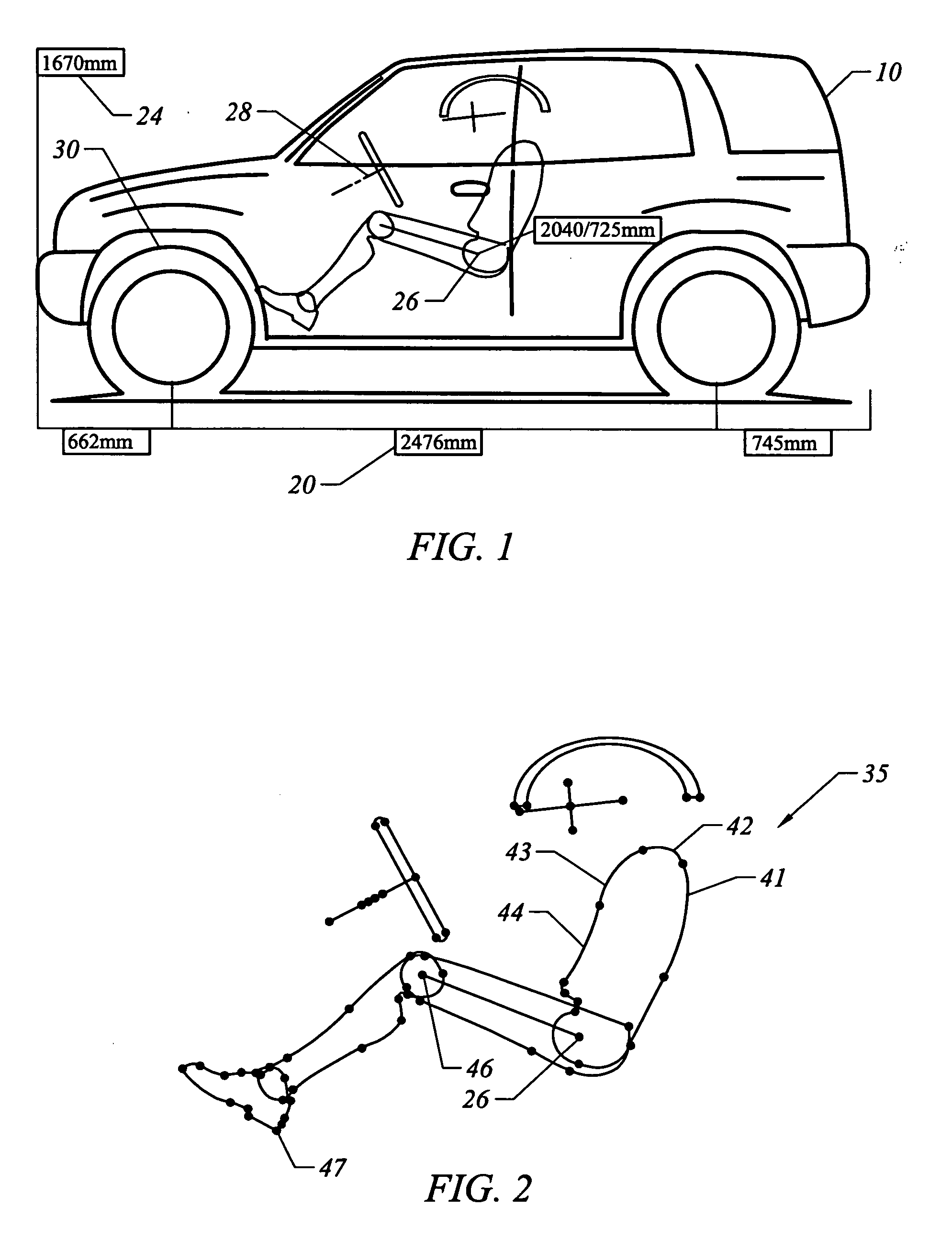

System and method for morphable model design space definition

InactiveUS20060038832A1Geometric CADCathode-ray tube indicatorsStructured modelComputer graphics (images)

A system, method, apparatus and product for designing, on a display device, a geometric shape is disclosed. The method comprises the steps of displaying an initial set of similarly structured model exemplars on a display device, selecting a chosen set of models from the initial set of similarly structured model exemplars to apply to a model mix, mixing the set of models consisting of a first portion and a second portion to form a currently displayed shape, providing on the display device at least one selectable feature for manipulating the currently displayed shape, and applying a constraint of the selectable feature to the displayed shape to update both the first portion and the second portion of the currently displayed shape into a new geometric shape design. In a particular implementation, the first portion of the geometric shape is an automobile and the second portion is a standardized human occupant representation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com