Patents

Literature

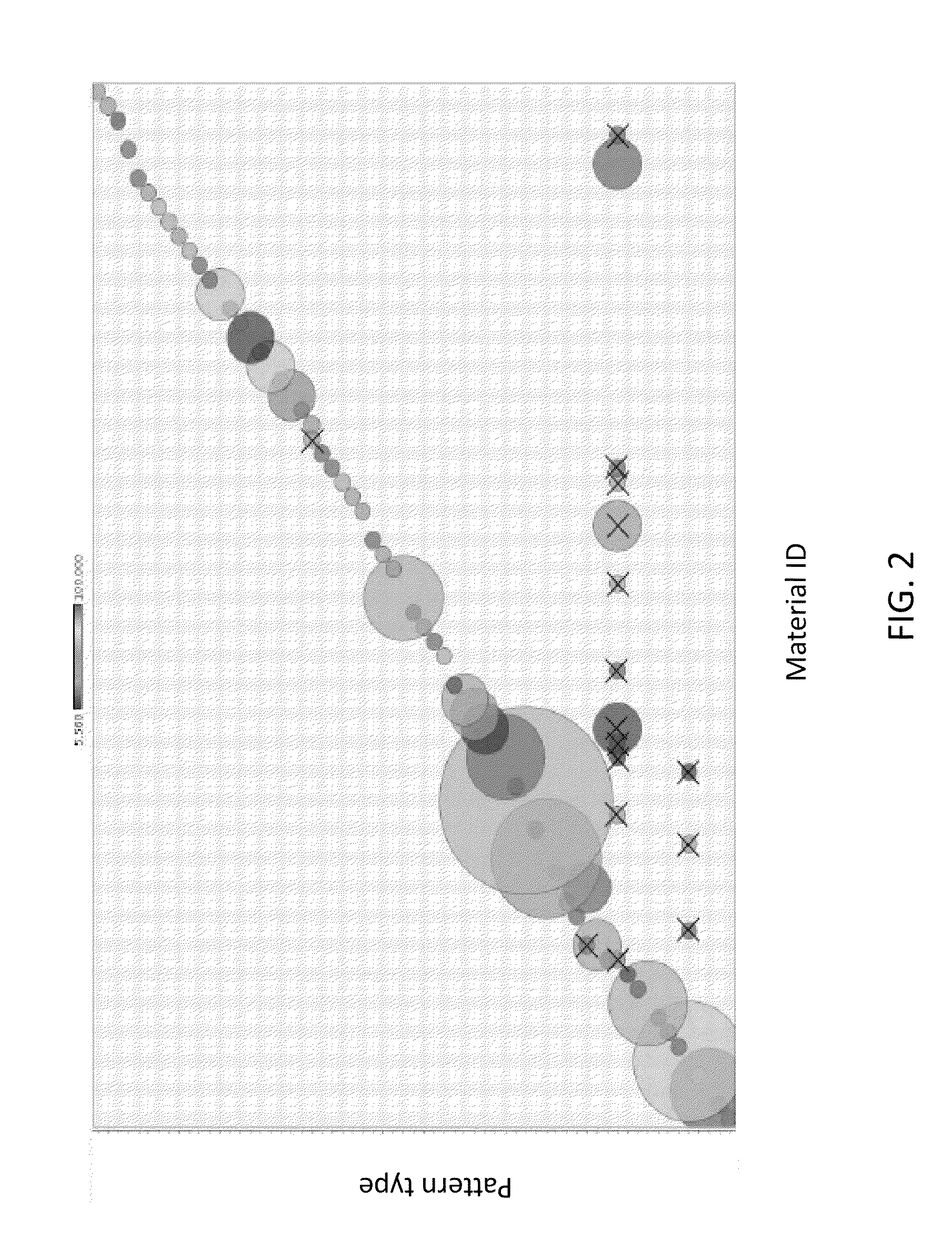

570 results about "Installed base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Installed base (also install base, install[ed] user base or just user base) is a measure of the number of units of a product or service that are actually in use, especially software or an Internet or computing platform, as opposed to market share, which only reflects sales over a particular period. Although the install base number is often created using the number of units that have been sold within a particular period, it is not necessarily restricted to just systems, as it can also be products in general. For products which are in use on some machines for many years, the installed base count will be higher than sales over a given period. Some people see it as a more reliable indicator of a platform's usage rate.

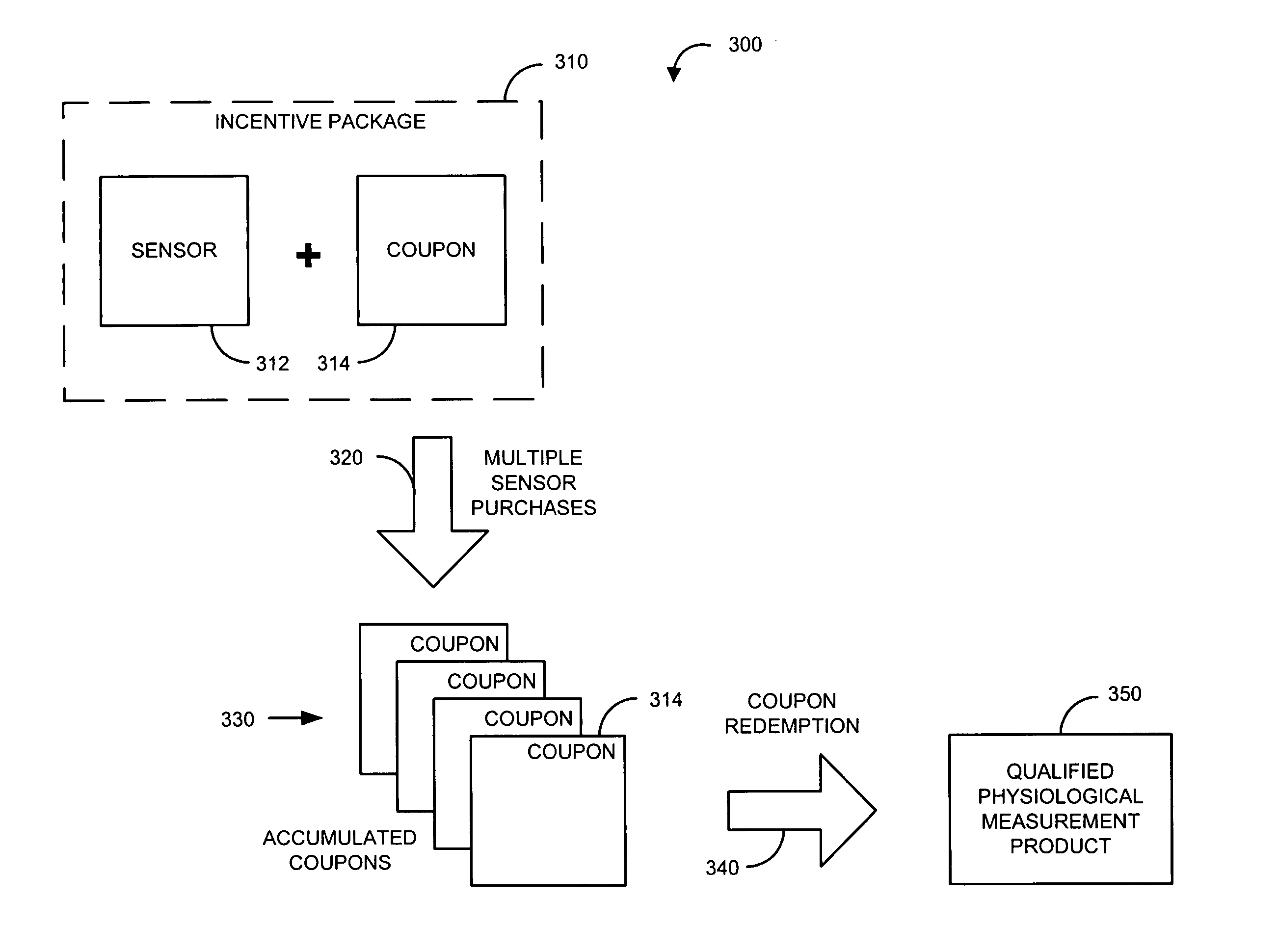

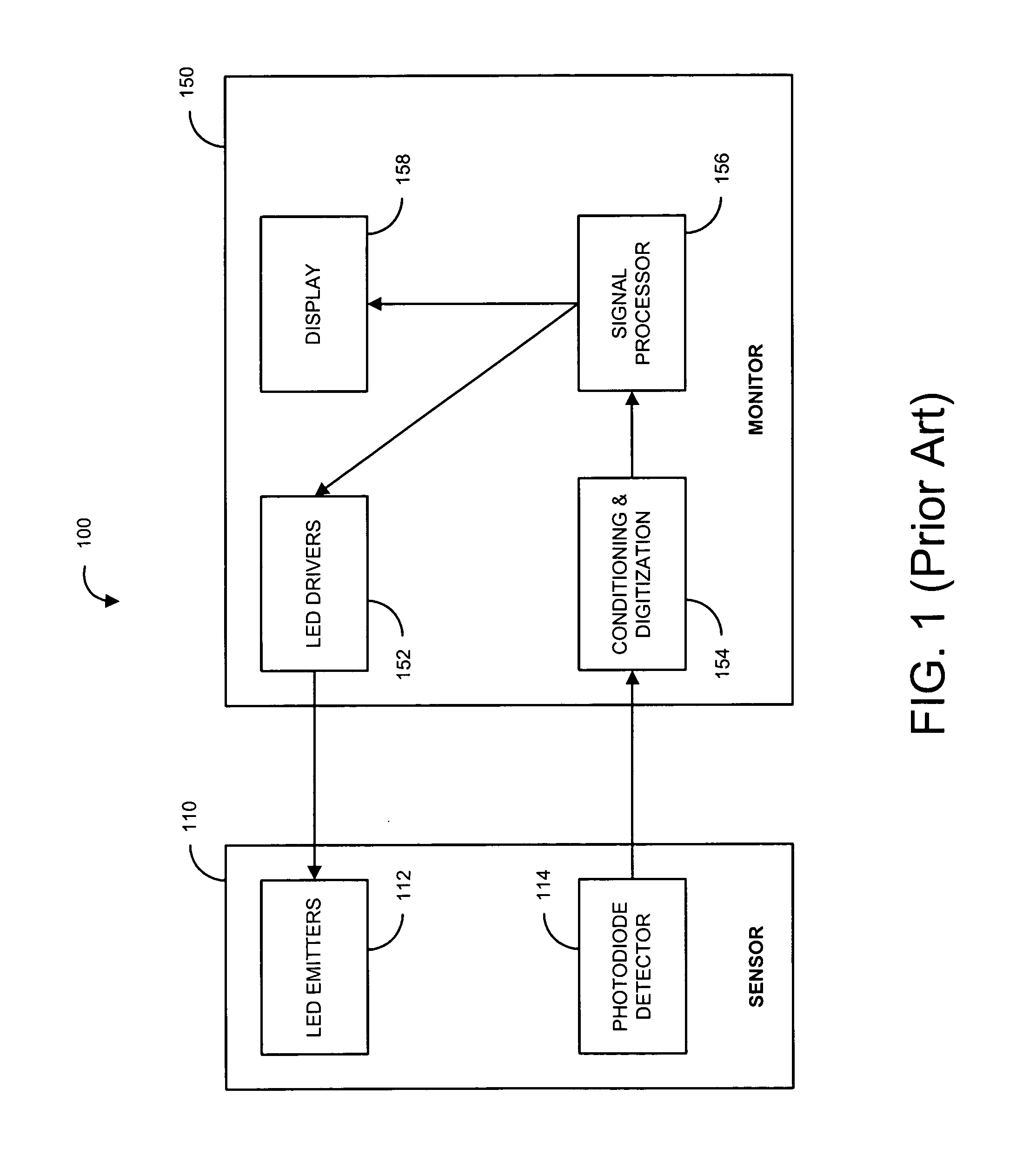

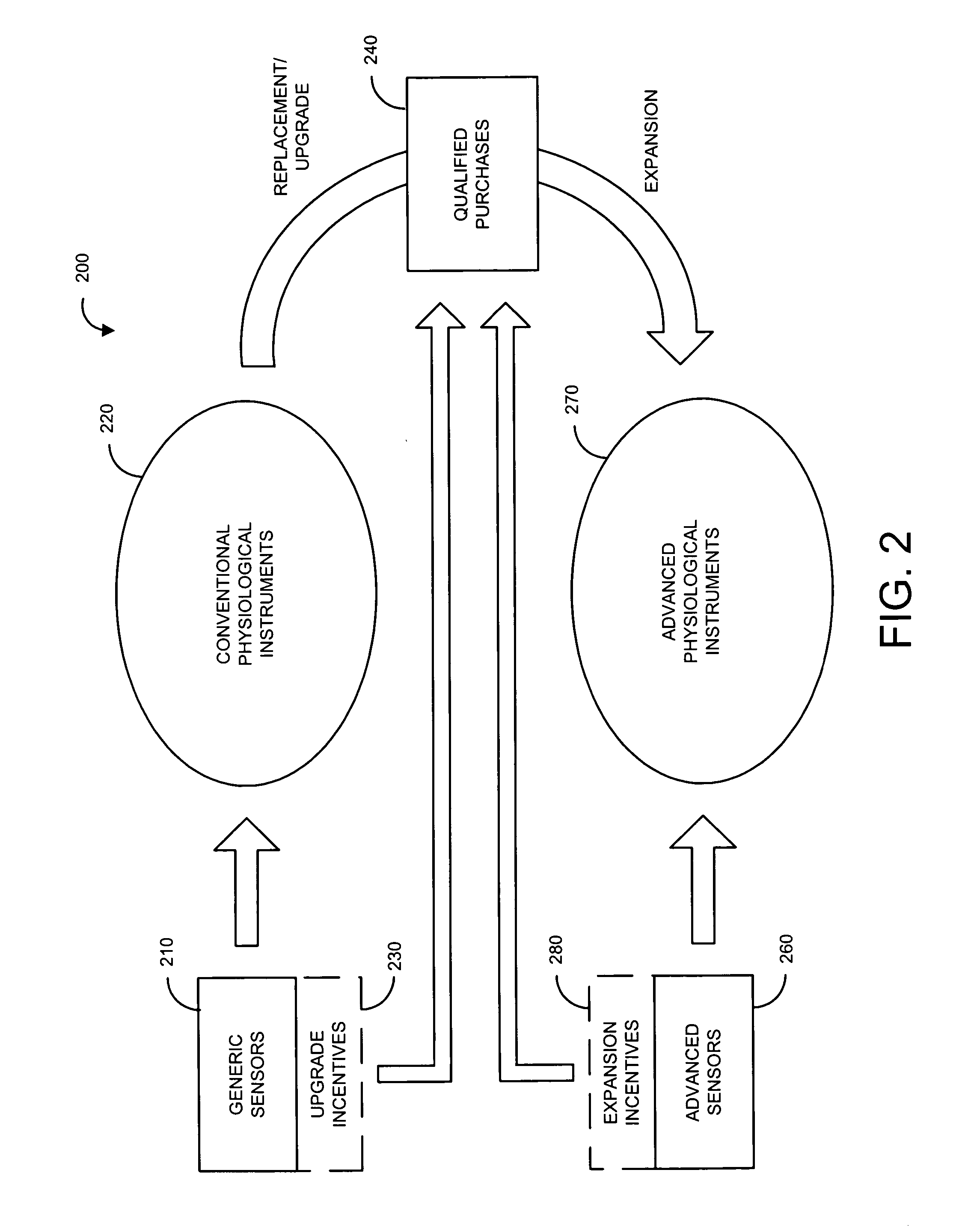

Sensor incentive method

InactiveUS20050055276A1Improve featuresImprove performanceDiscounts/incentivesSpecial data processing applicationsEngineeringMonetary value

A sensor incentive method provides a sensor adapted to function with an installed base of conventional physiological instruments. An incentive is associated with the sensor in connection with a sensor purchase. The incentive is applied to a qualified physiological instrument purchase so as to motivate or otherwise enable the upgrade or replacement of the installed base with advanced physiological instruments. The accumulation of multiple incentives may also apply to the purchase. In one embodiment, a coupon is associated with the sensor purchase, the coupon having a monetary value applicable to the purchase of advanced physiological instruments. The coupon is redeemed for the monetary value during the qualified purchase. Multiple coupons may be accumulated and redeemed for the monetary value times the number of coupons.

Owner:MASIMO CORP

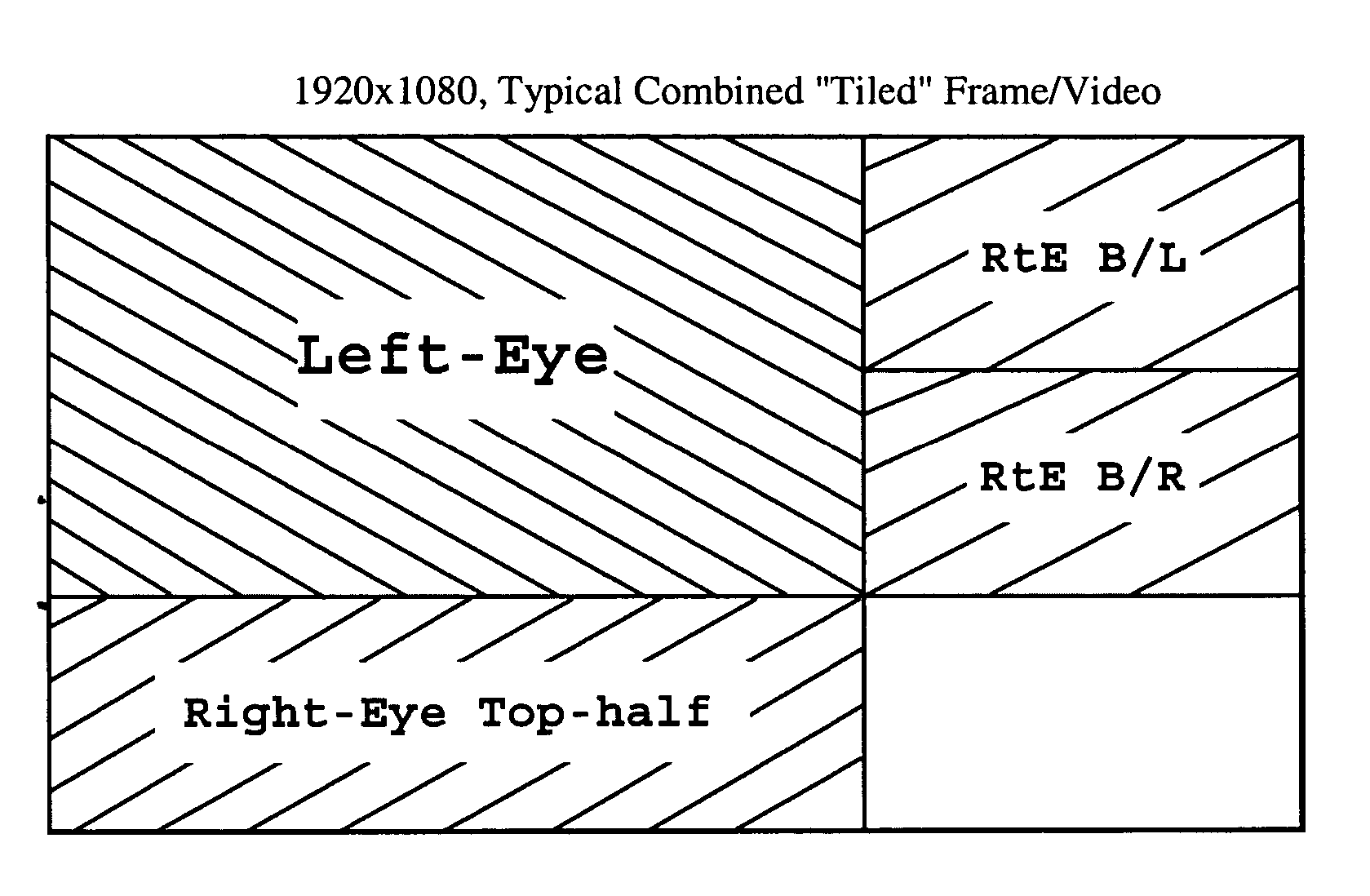

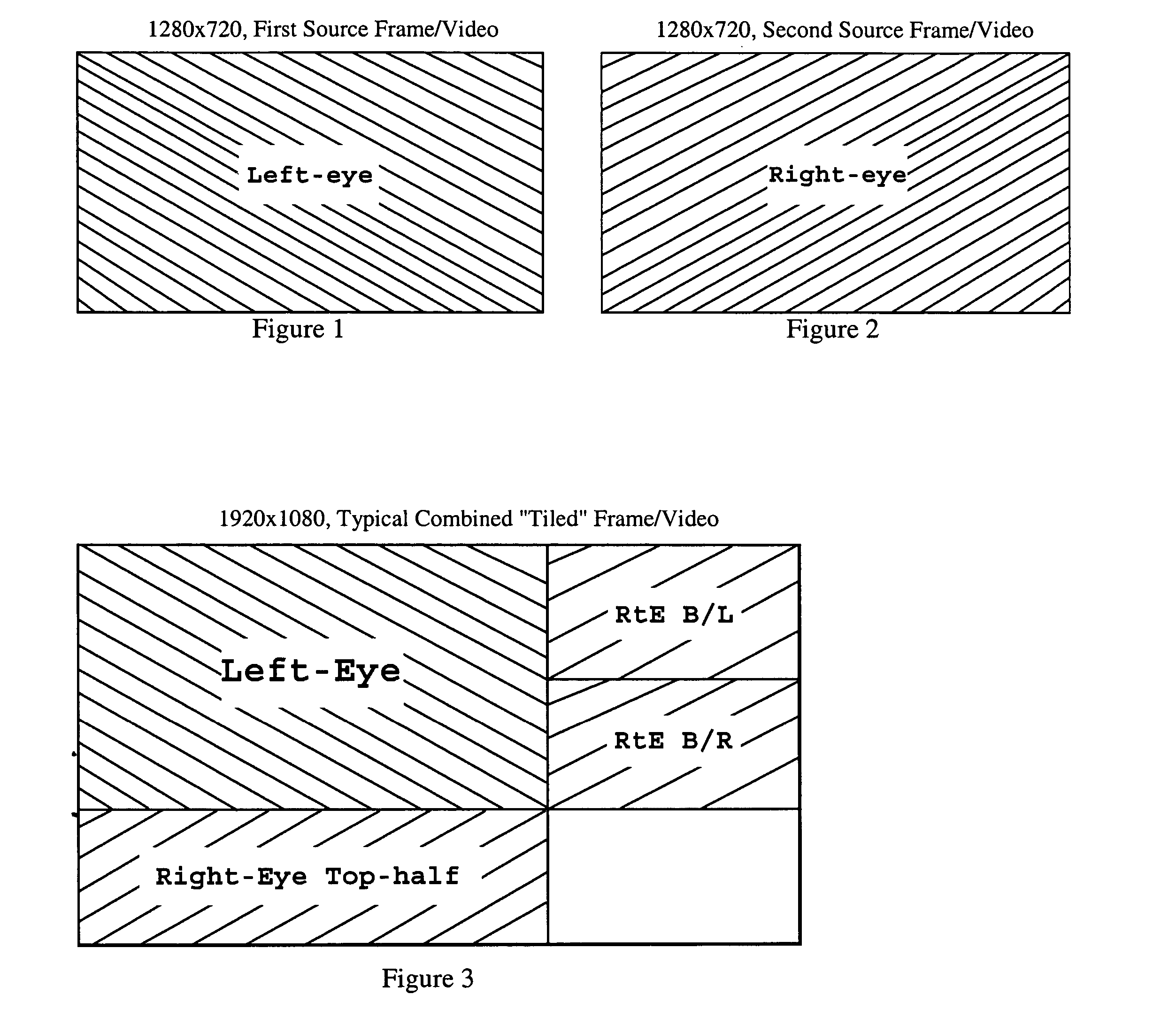

Stereoscopic television signal processing method, transmission system and viewer enhancements

InactiveUS20050041736A1Encode more efficientlyEasy to compressColor television with pulse code modulationColor television with bandwidth reductionComputer graphics (images)High-definition video

This invention provides a method of combining two standard video streams, into one standard video stream, in such a way that it can be encoded efficiently, and that it can enhance the TV viewing experience by presenting Stereoscopic 3D imagery, dual-view display capability, panoramic viewing, and user interactive “pan-and-scan”. The video standards for High Definition Video are used, which are governed by the ATSC and SMPTE standards bodies. Having a dual stream of standard video, which occupies now a single stream of standard video, provides a means to use the standard installed base of equipment for recording, transmission, playback and display.

Owner:3ALITY DIGITAL SYST

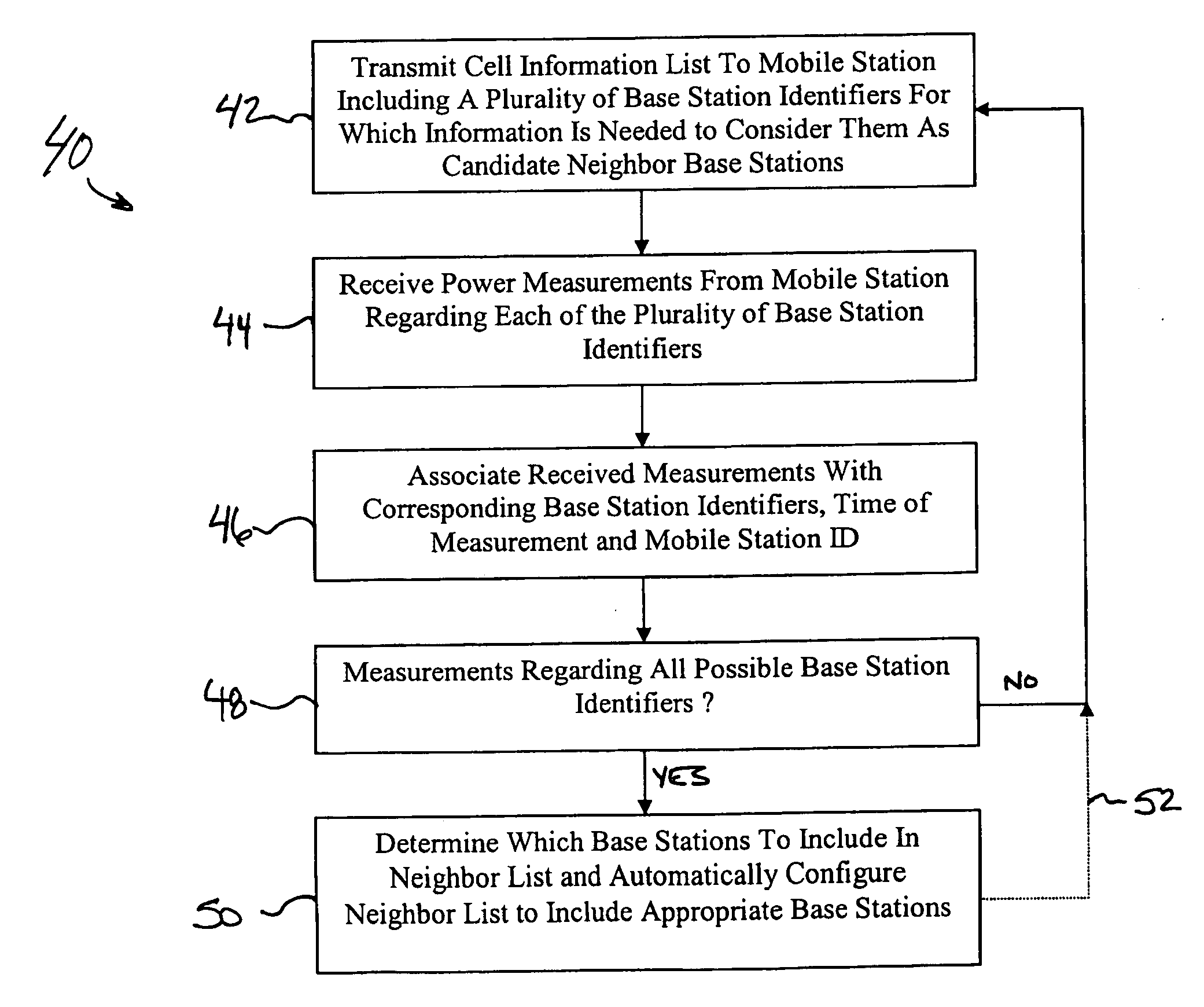

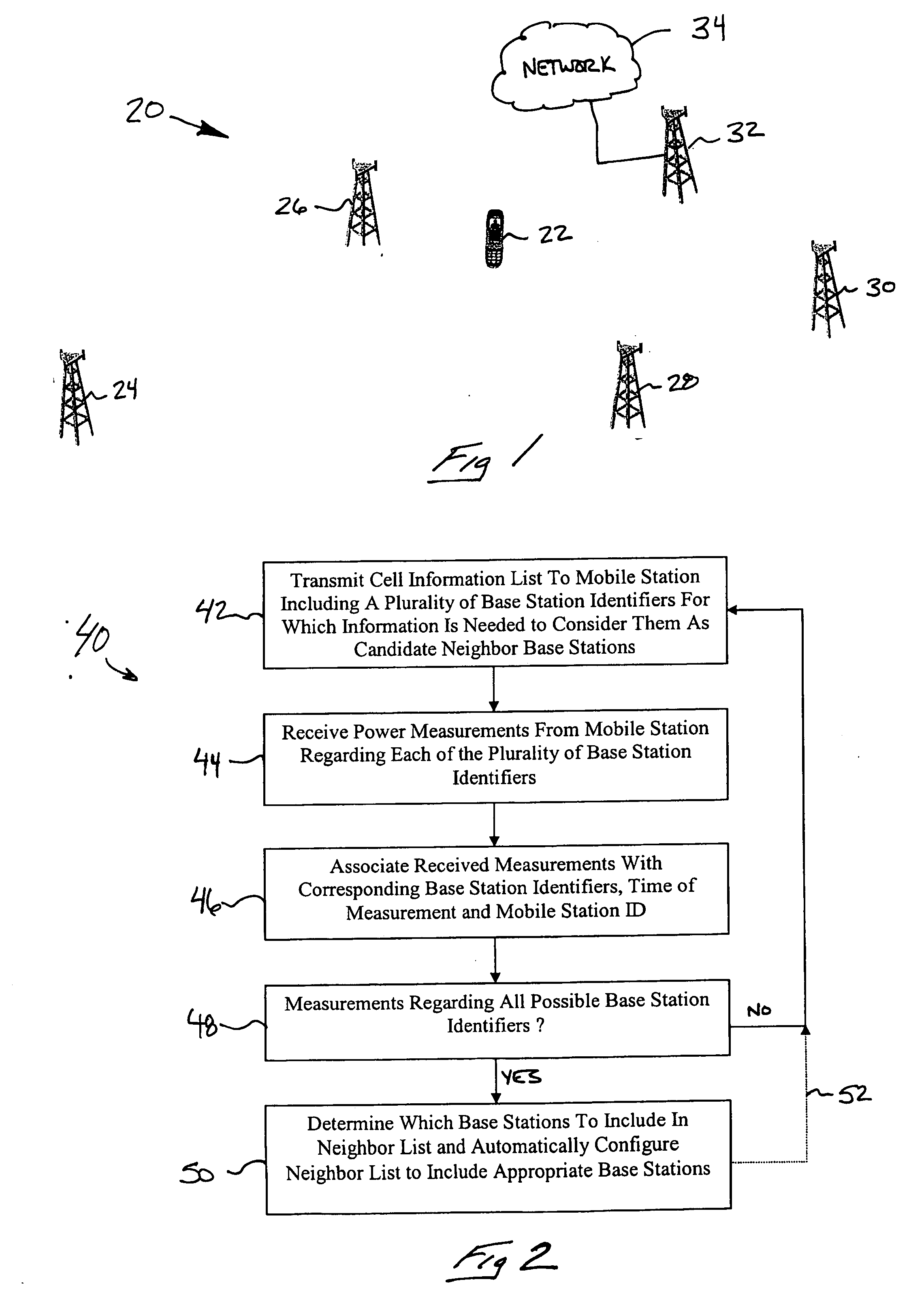

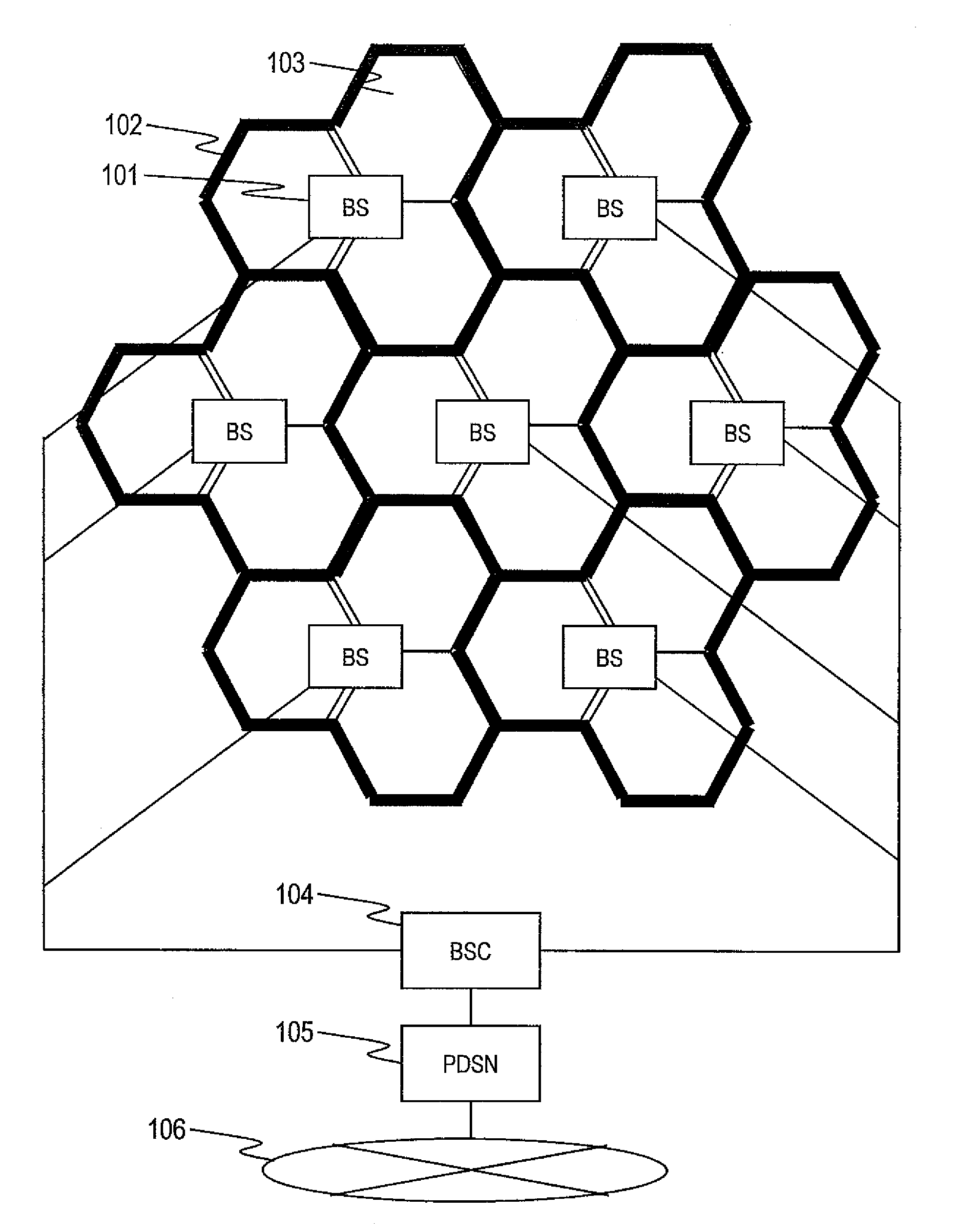

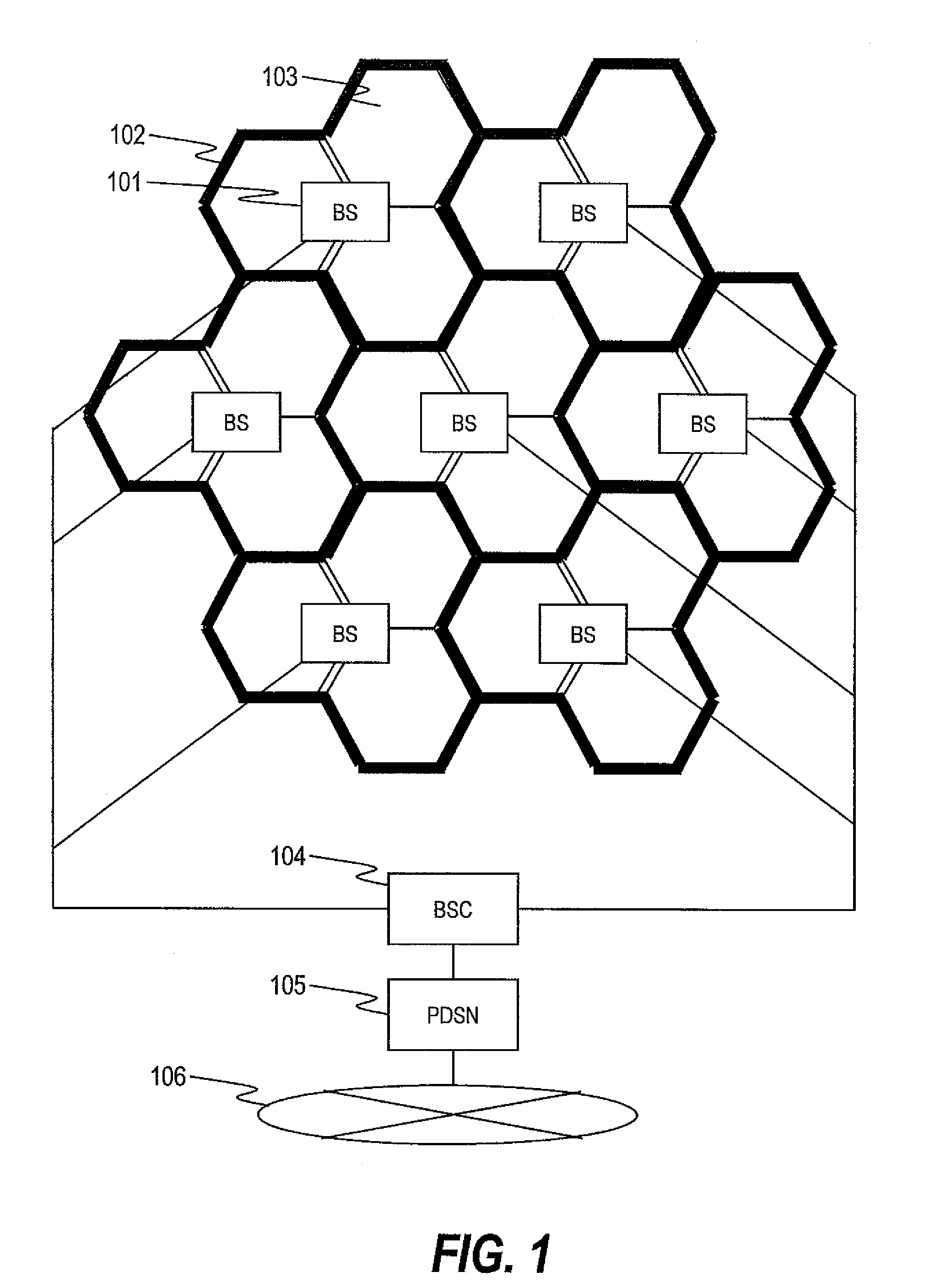

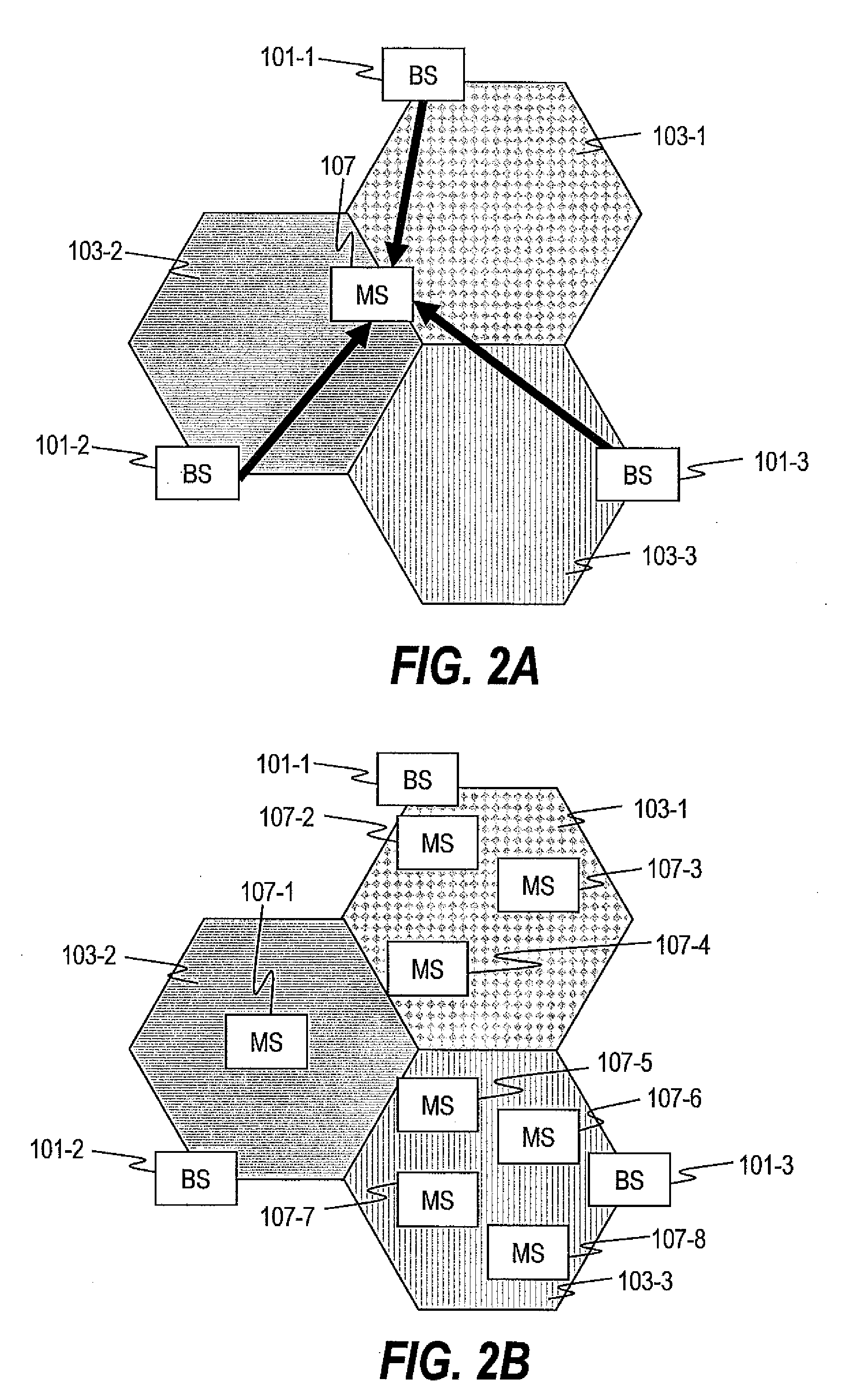

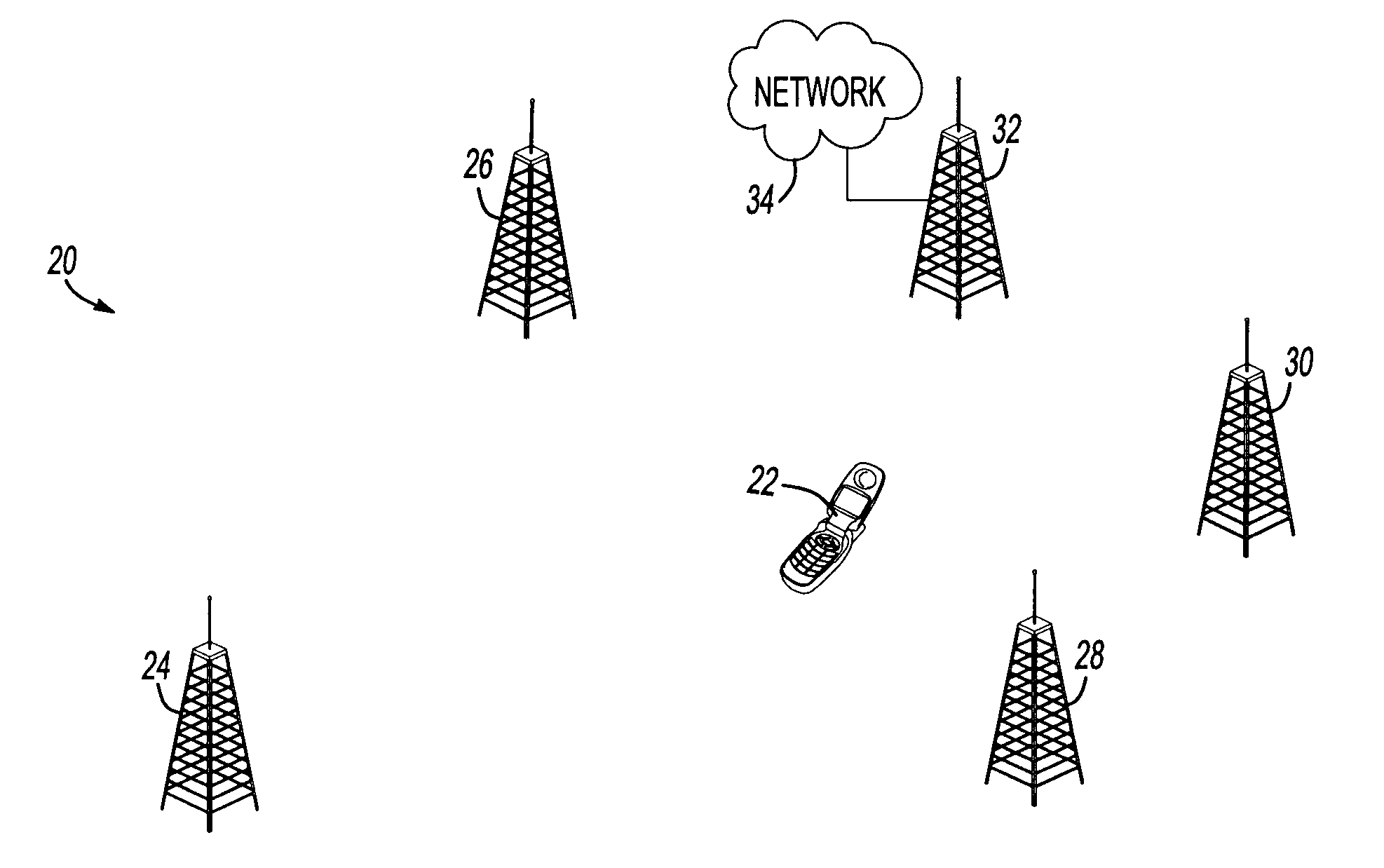

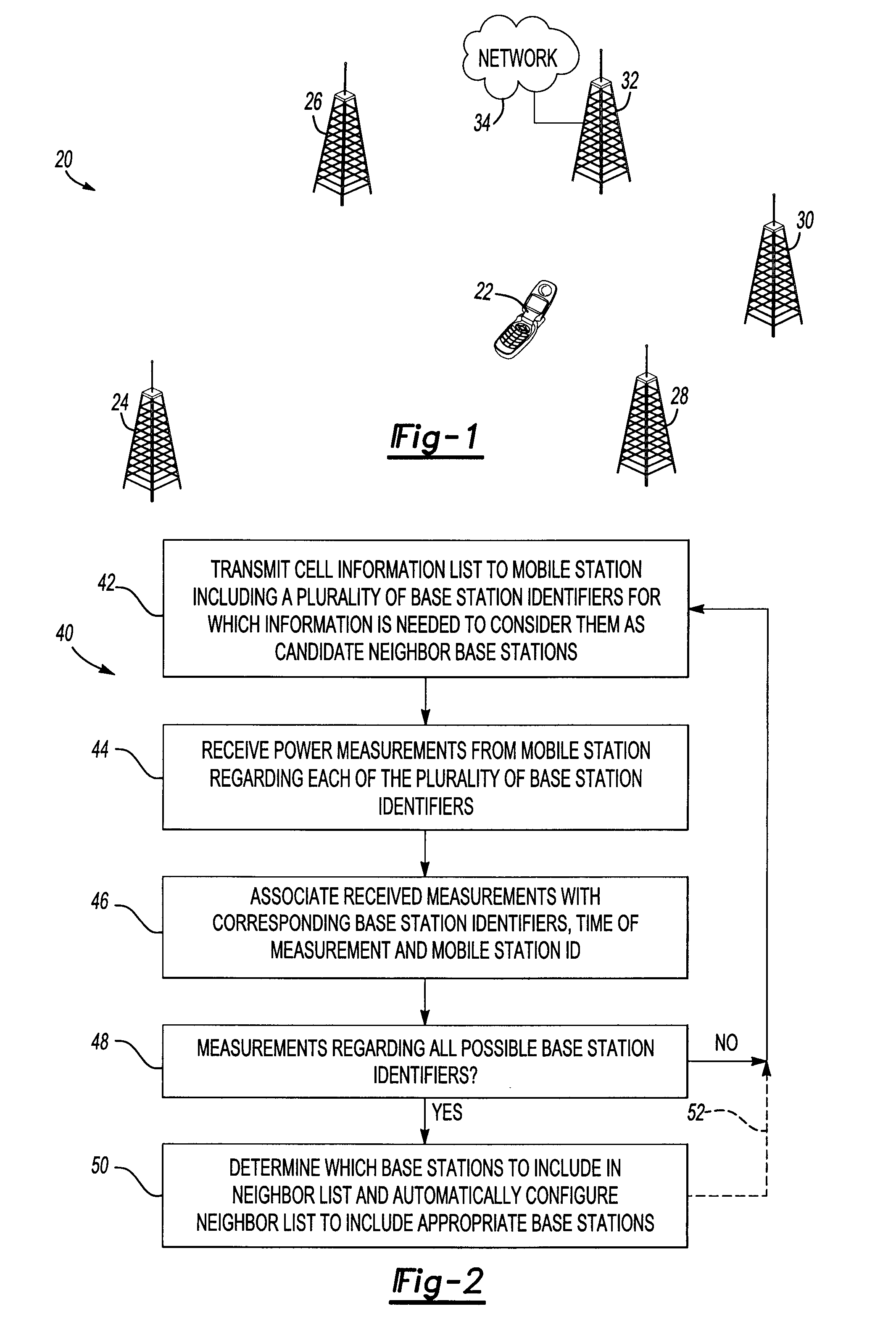

Automatically configuring a neighbor set for a base station

An automated technique for configuring a neighbor set for a base station (32) includes initializing the neighbor set based upon reported measurements from a mobile station (22). In a disclosed example, a newly installed base station (32) transmits a cell information list to a mobile station (22) requesting measurement reports regarding a plurality of candidate base station identifiers. Based upon the reported measurements, a determination is made regarding which of the base stations should be included in the neighbor set for the base station (32). A disclosed example includes the capability of automatically initializing the neighbor set and automatically updating the set. Disclosed examples include utilizing information from a plurality of mobile stations.

Owner:ALCATEL-LUCENT USA INC

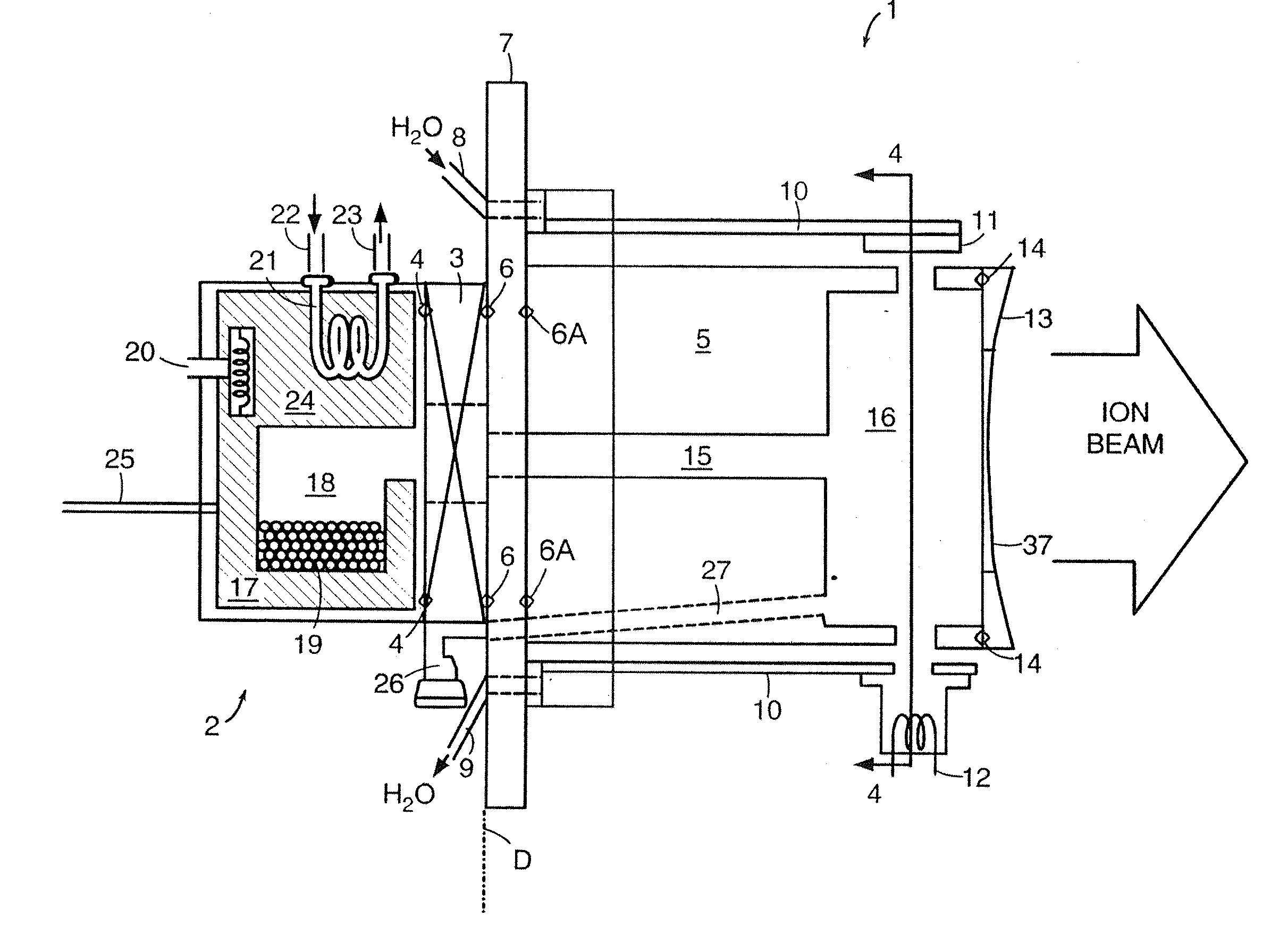

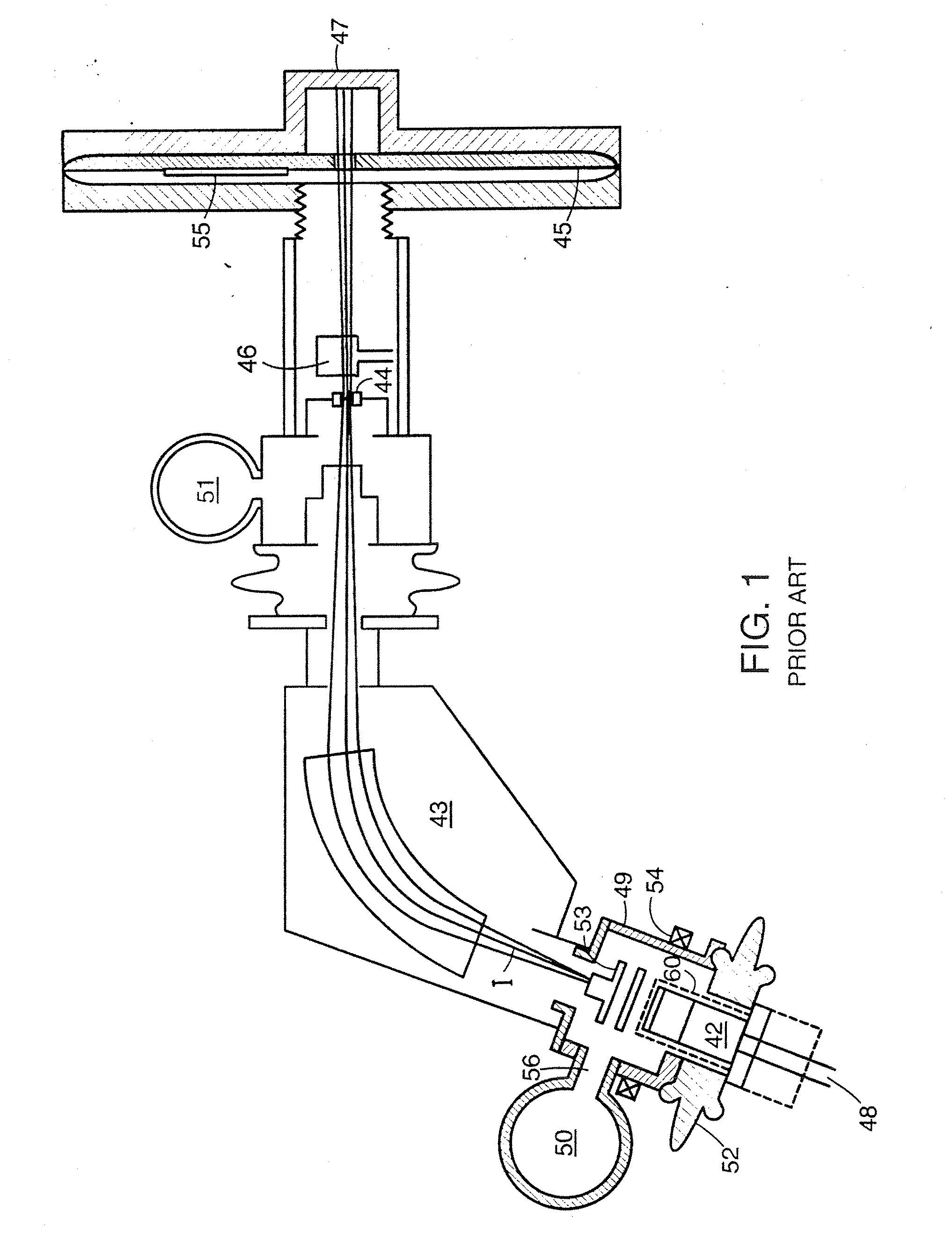

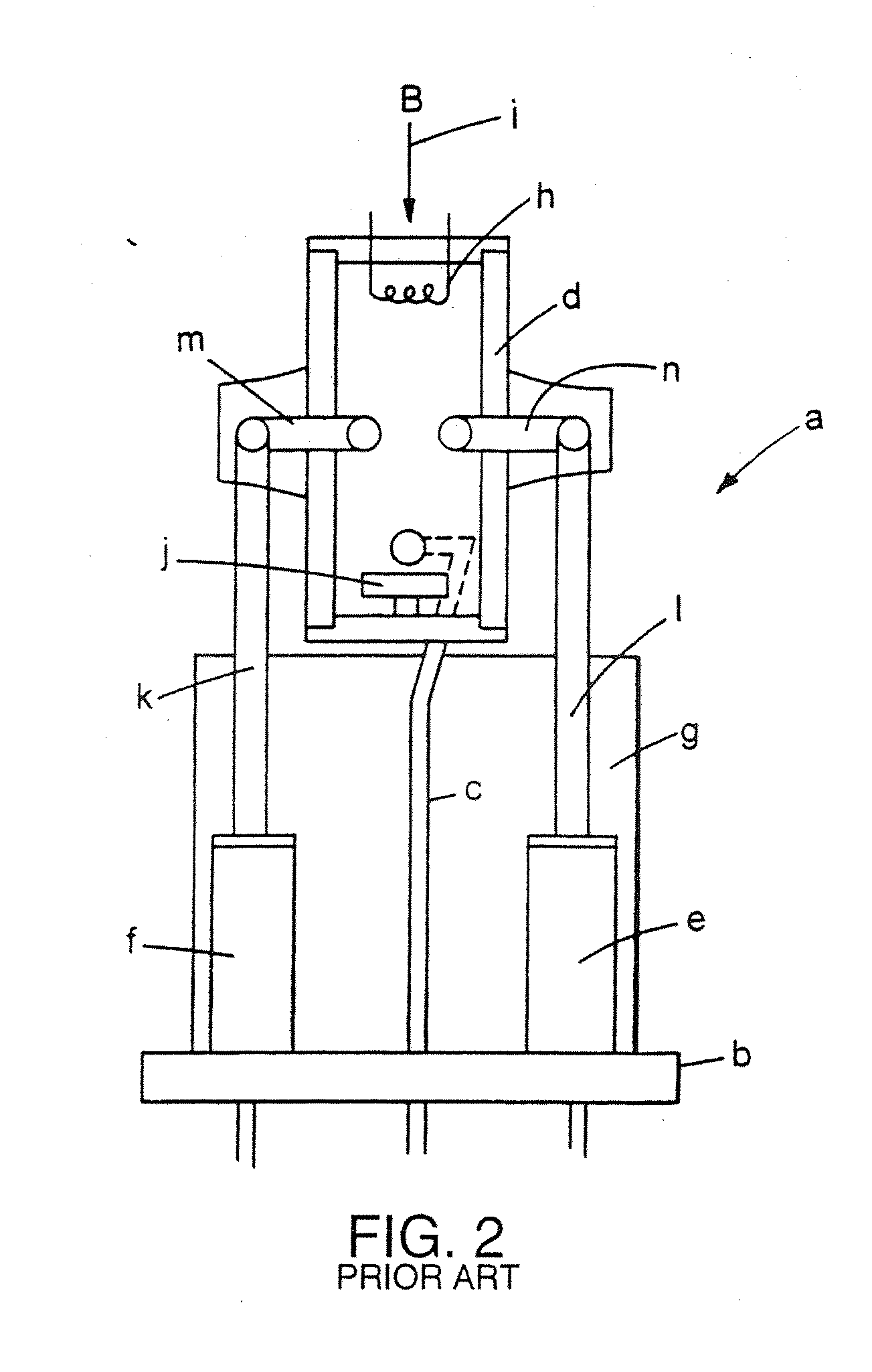

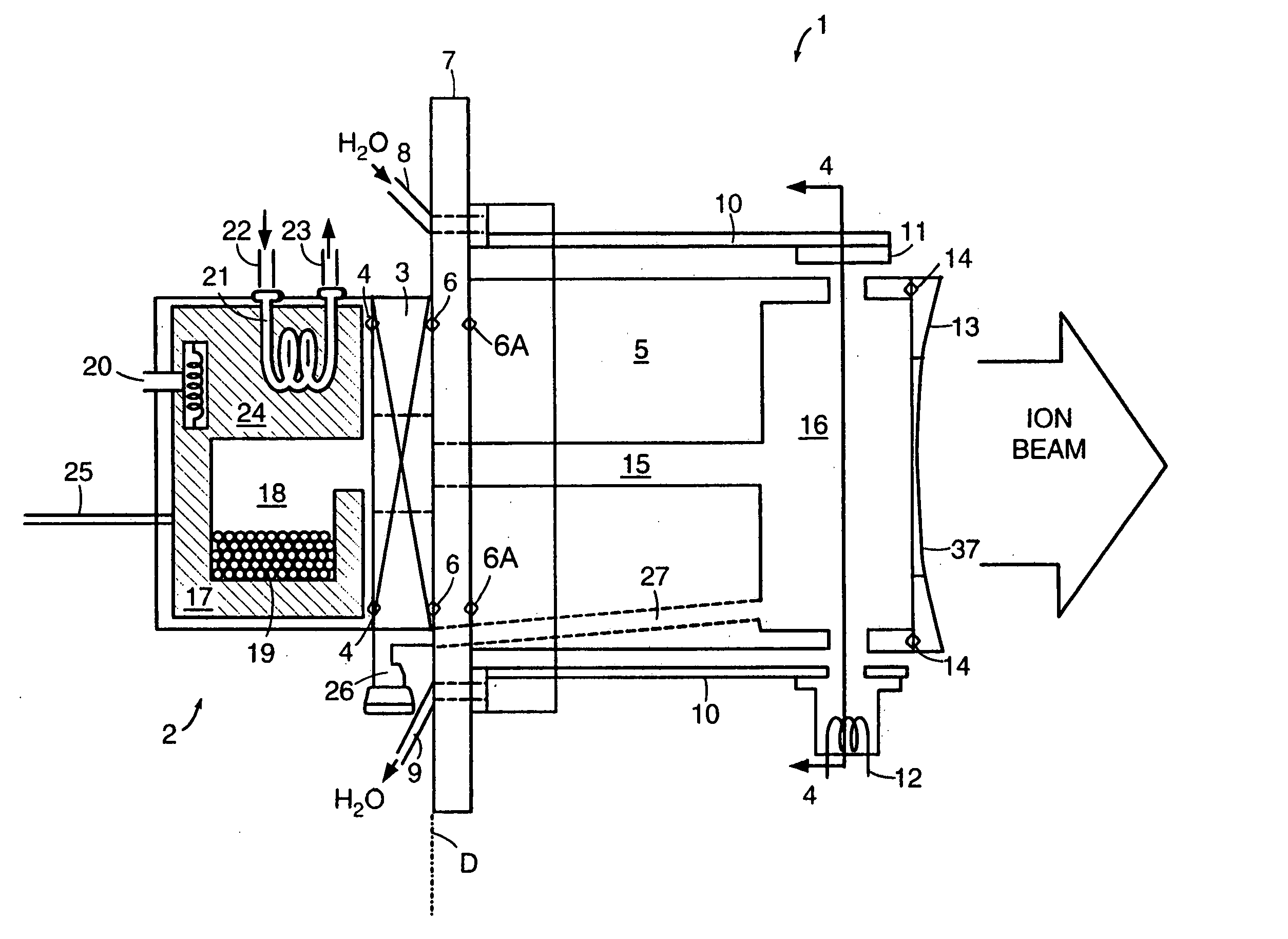

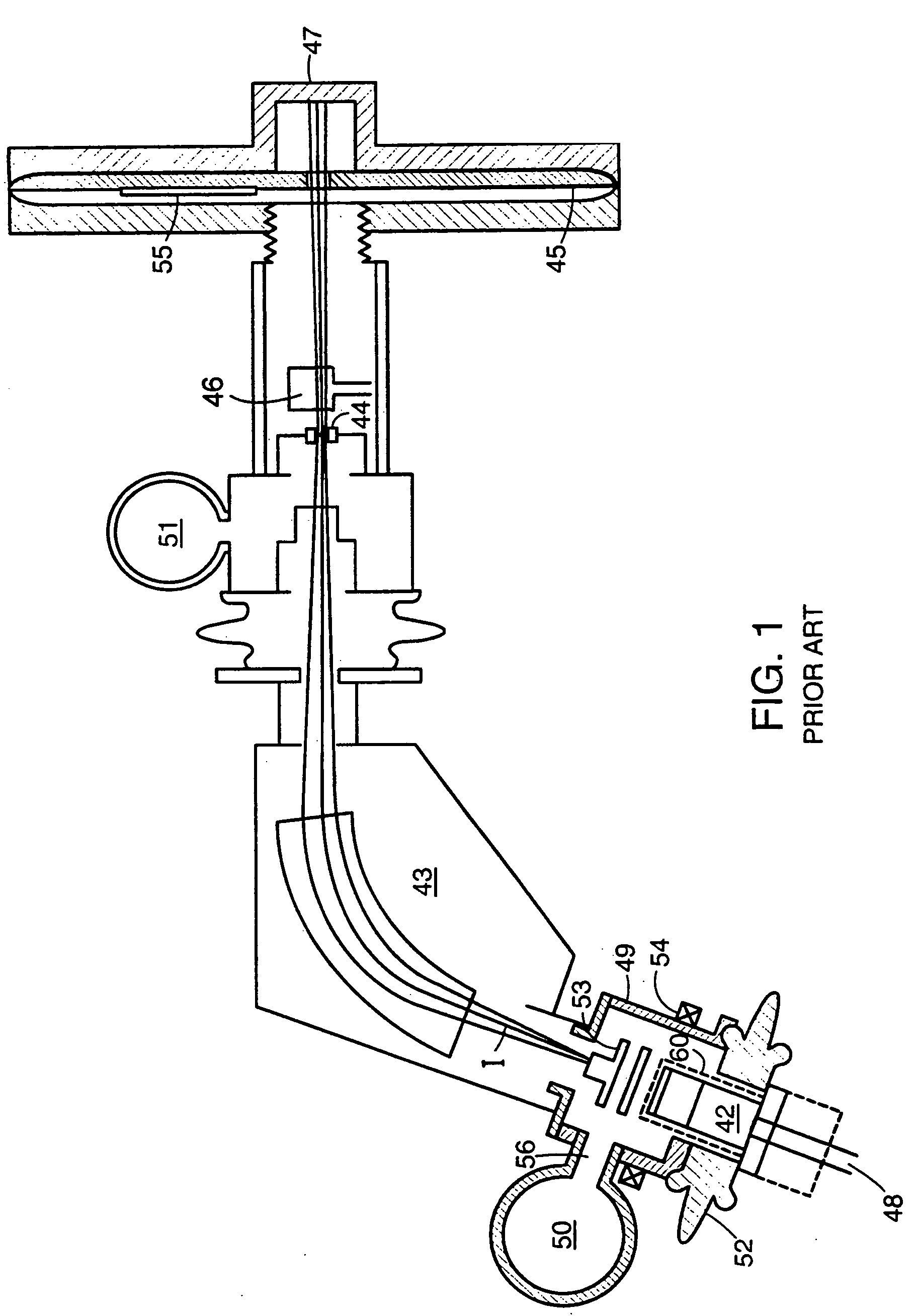

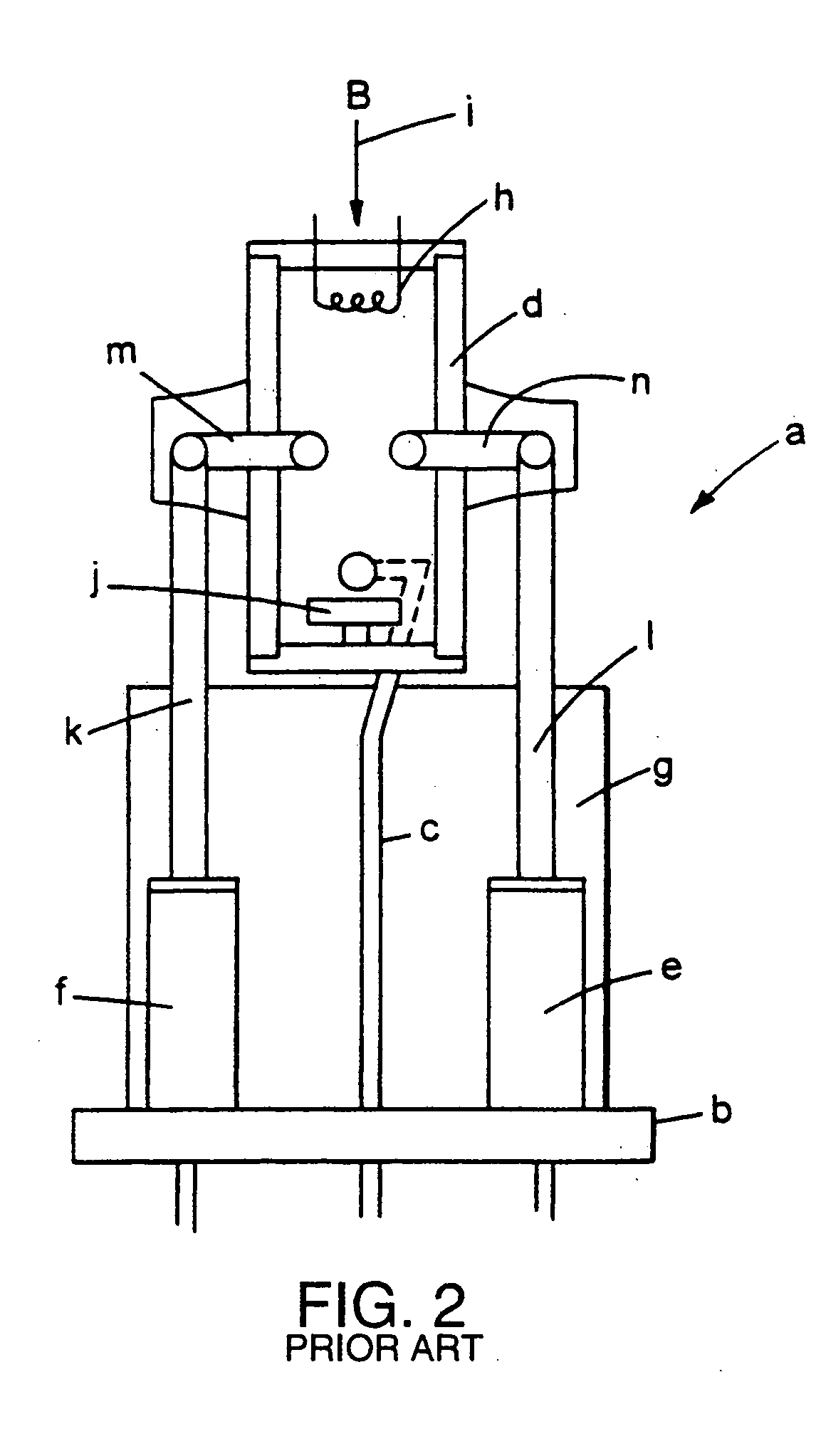

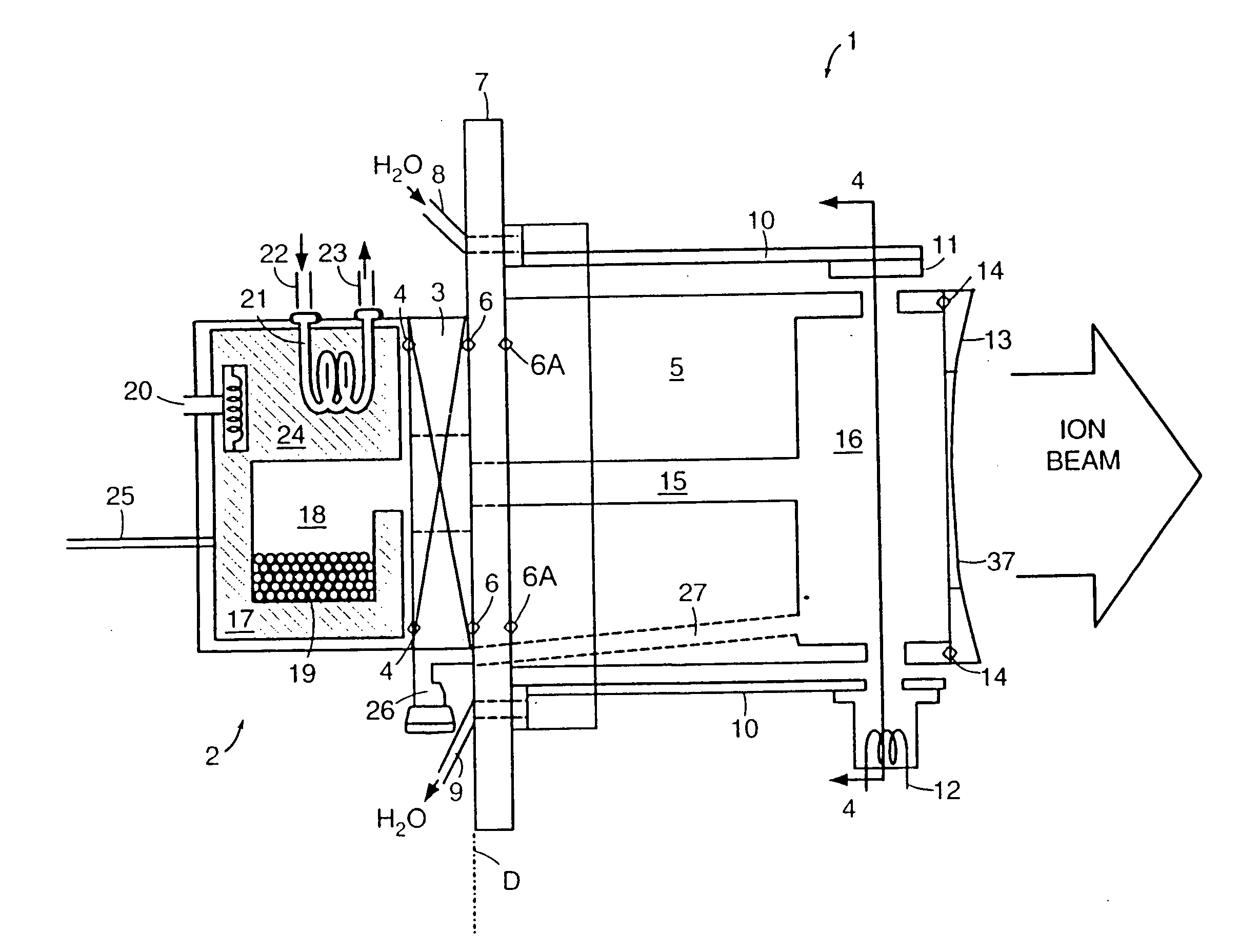

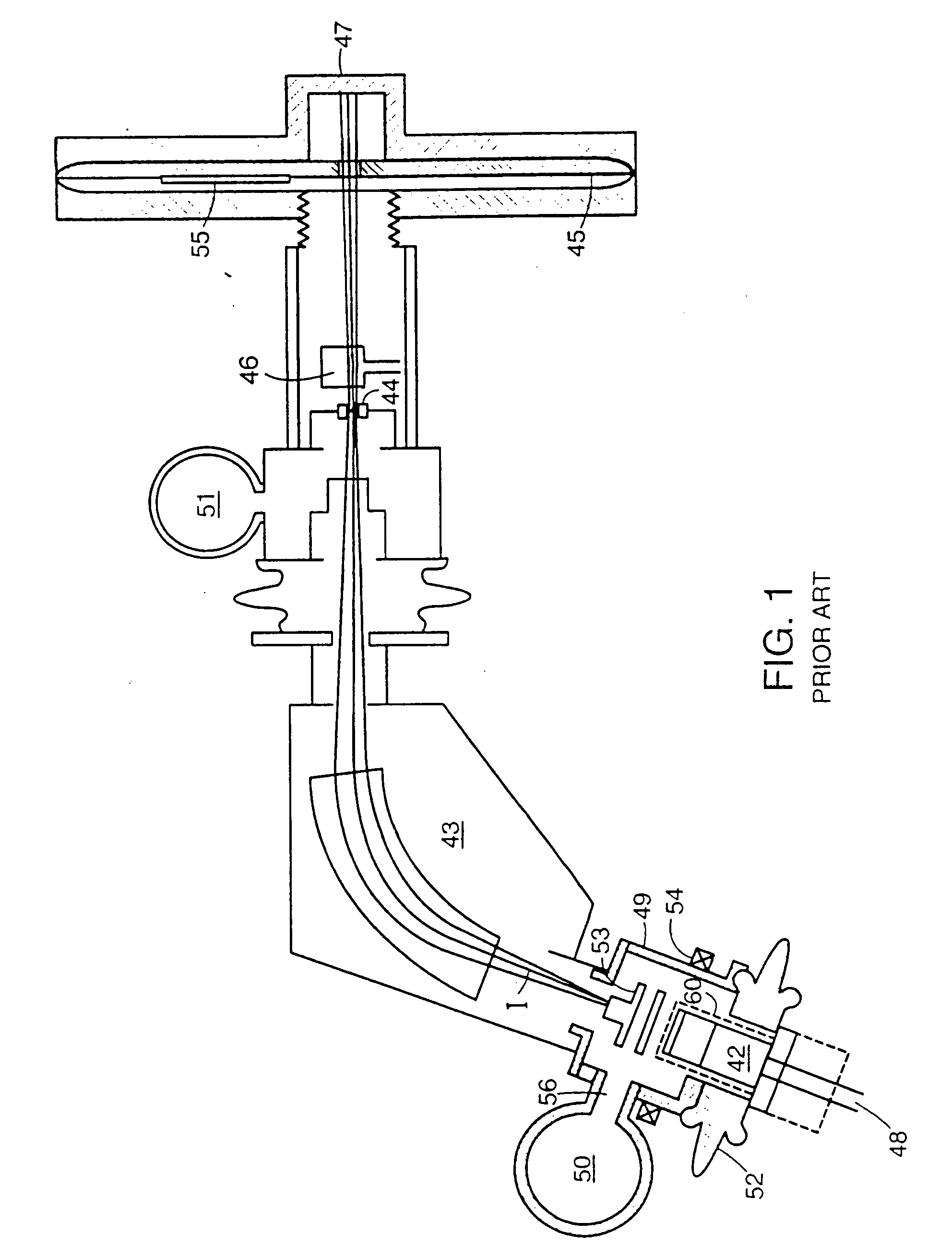

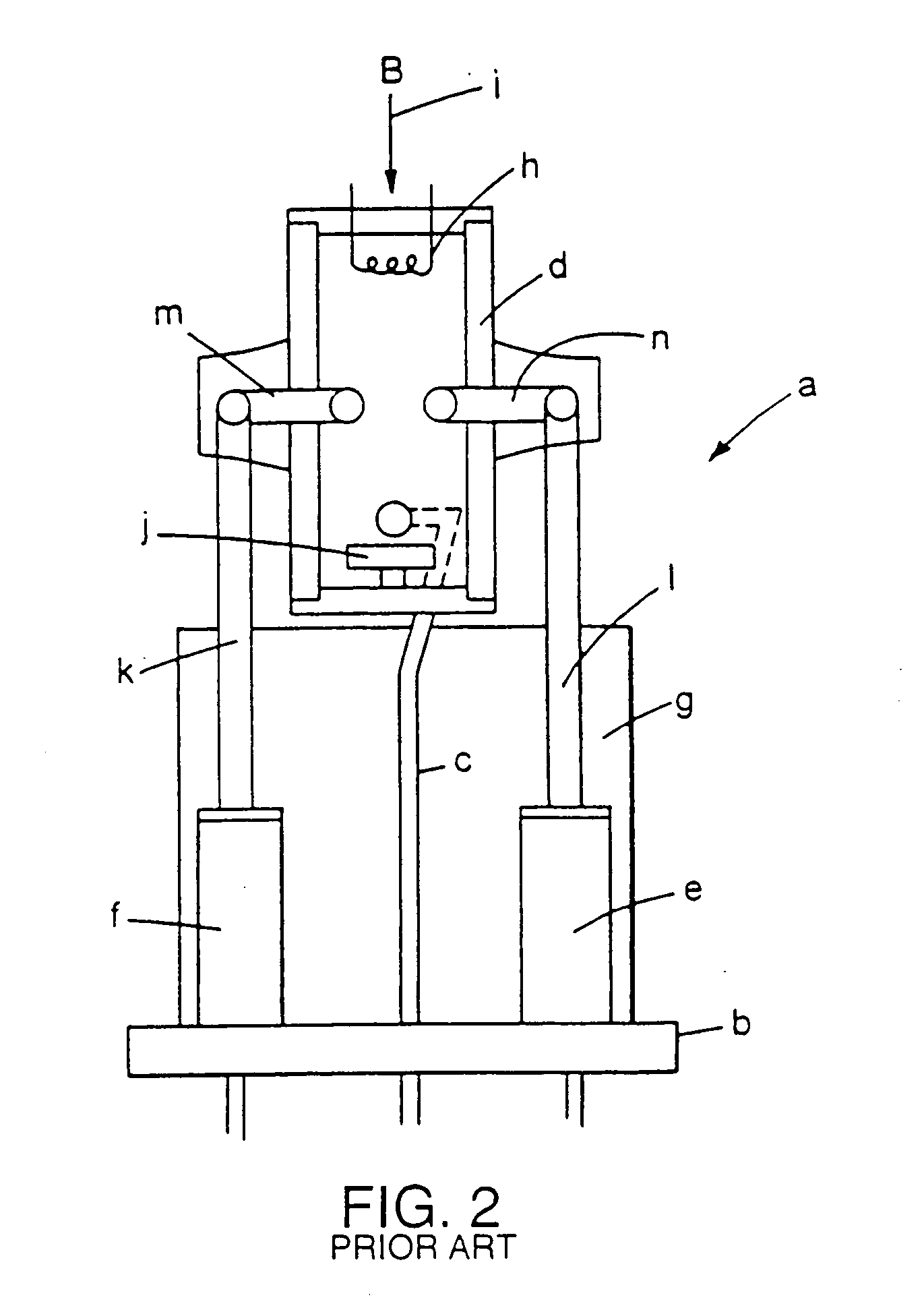

Ion implantation ion source, system and method

InactiveUS20070278417A1Maximizing flow of electronHigh extracted currentMaterial analysis by optical meansIon beam tubesDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

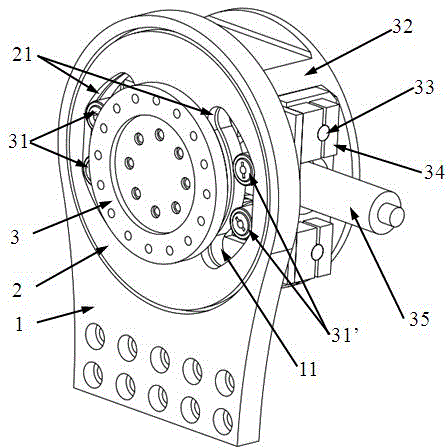

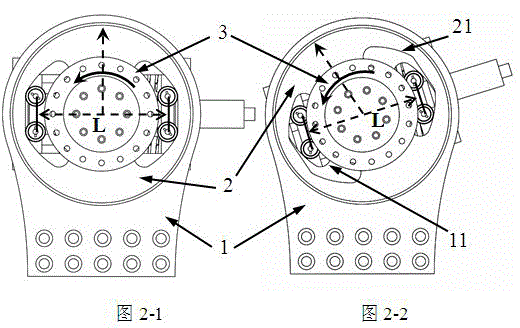

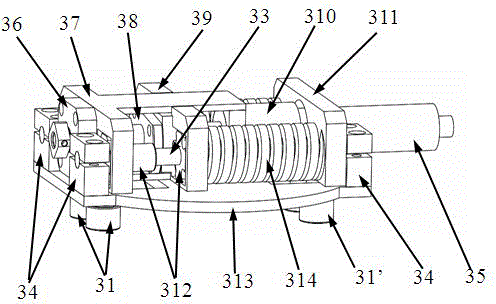

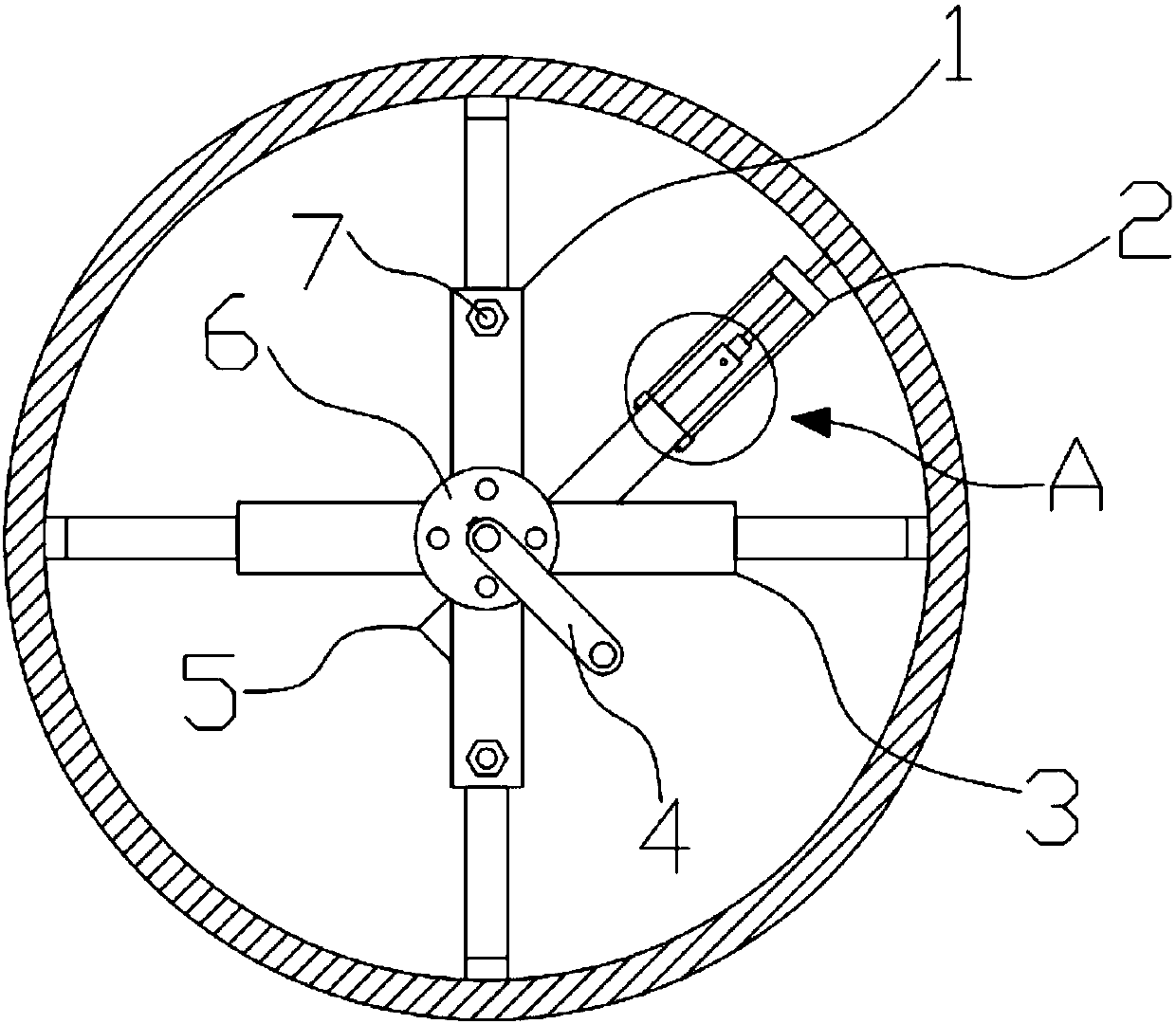

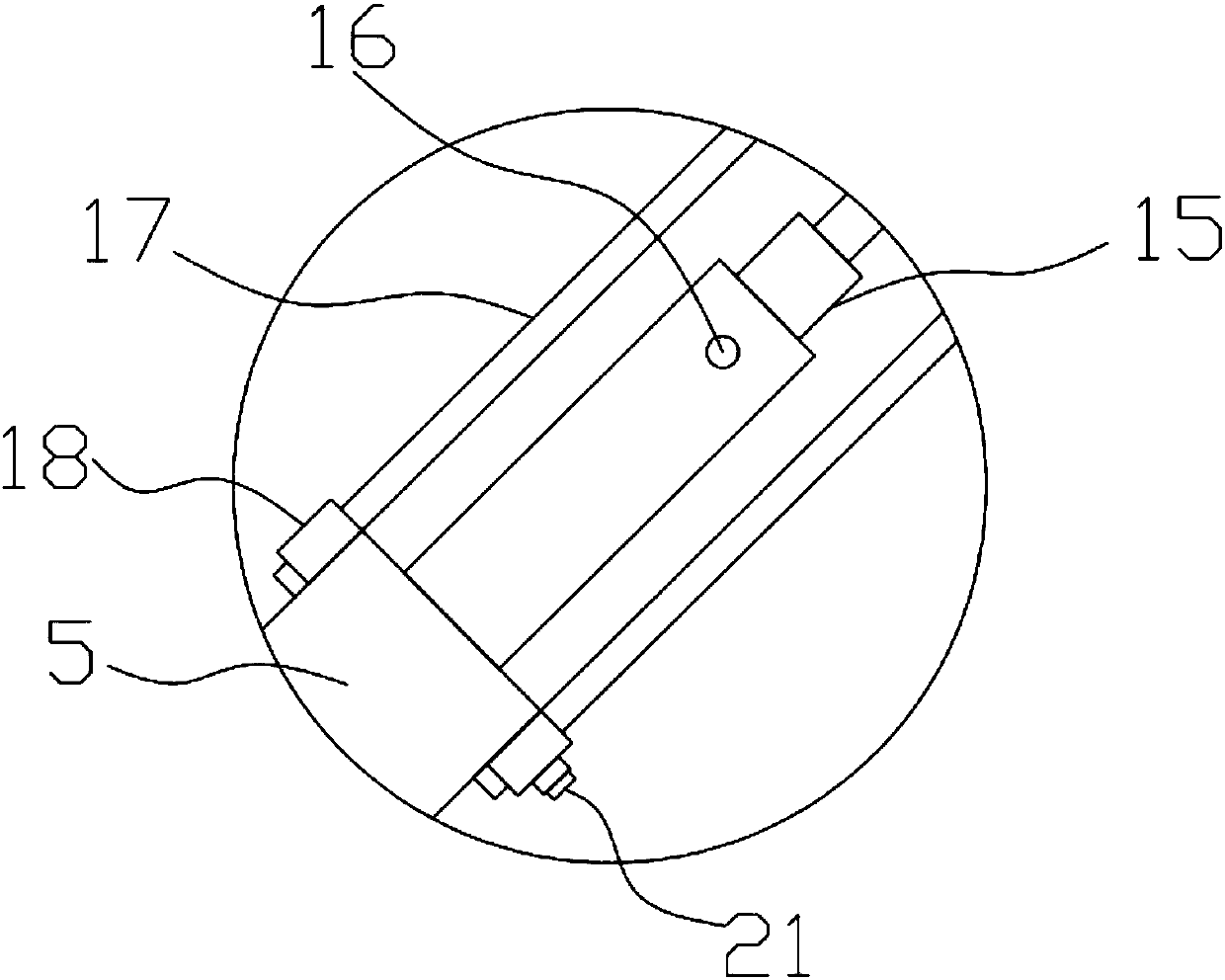

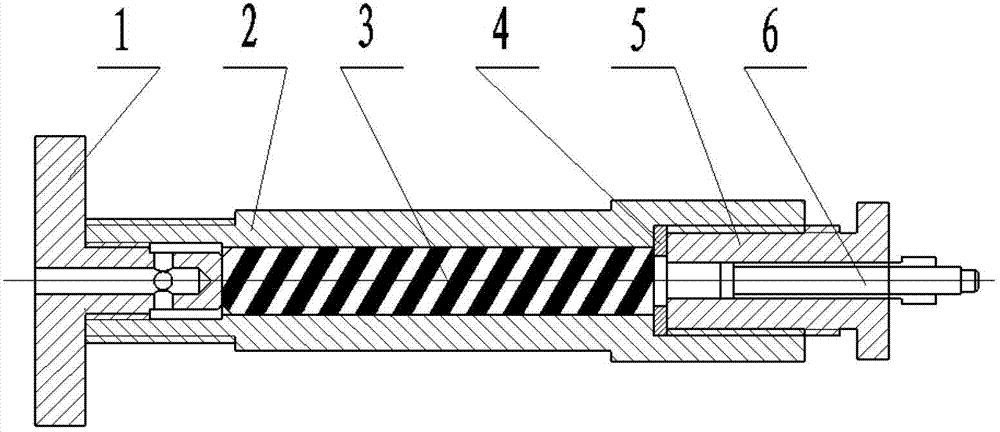

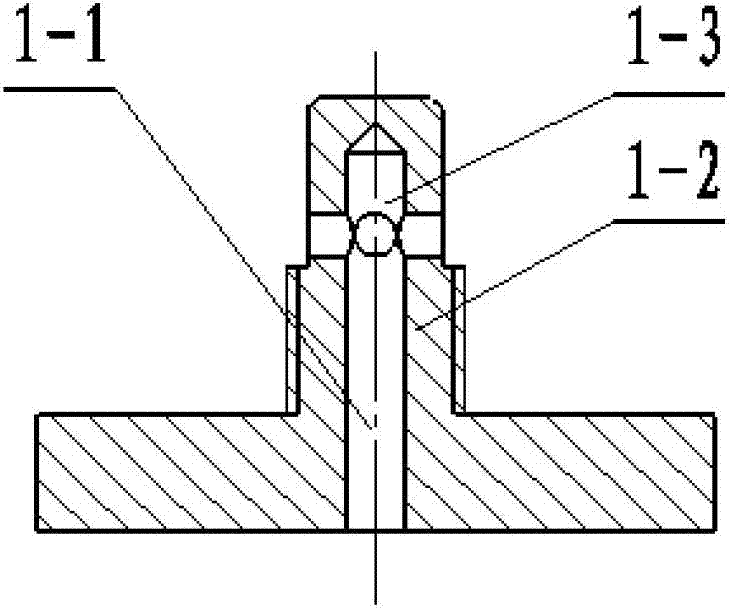

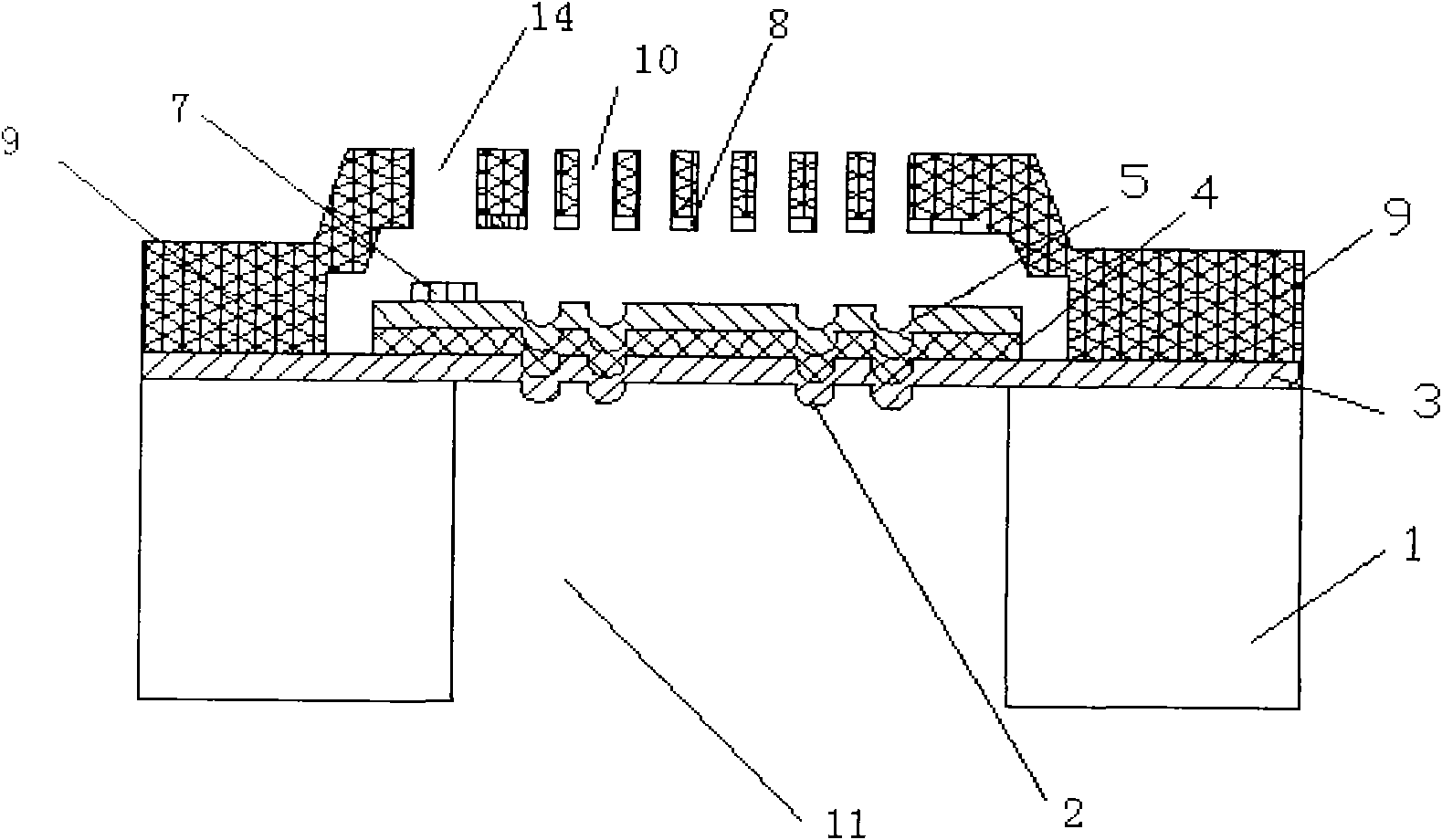

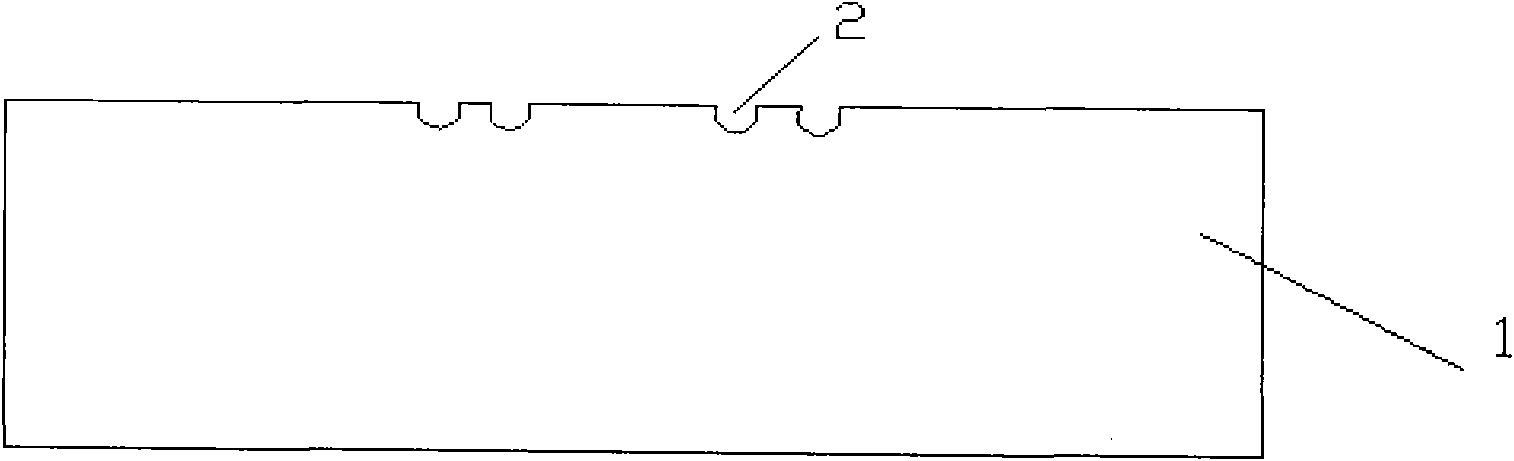

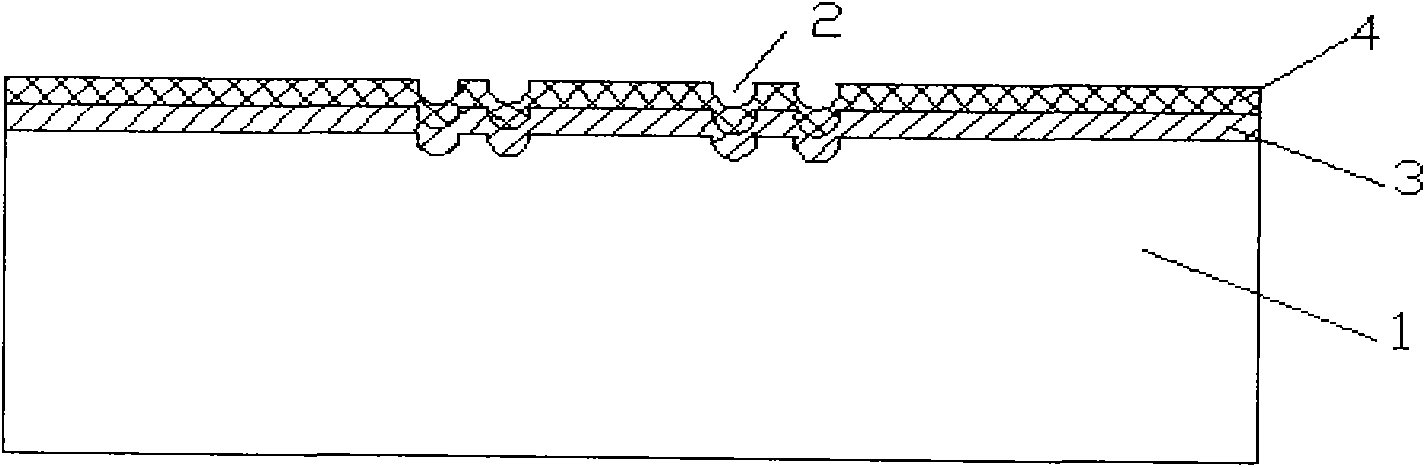

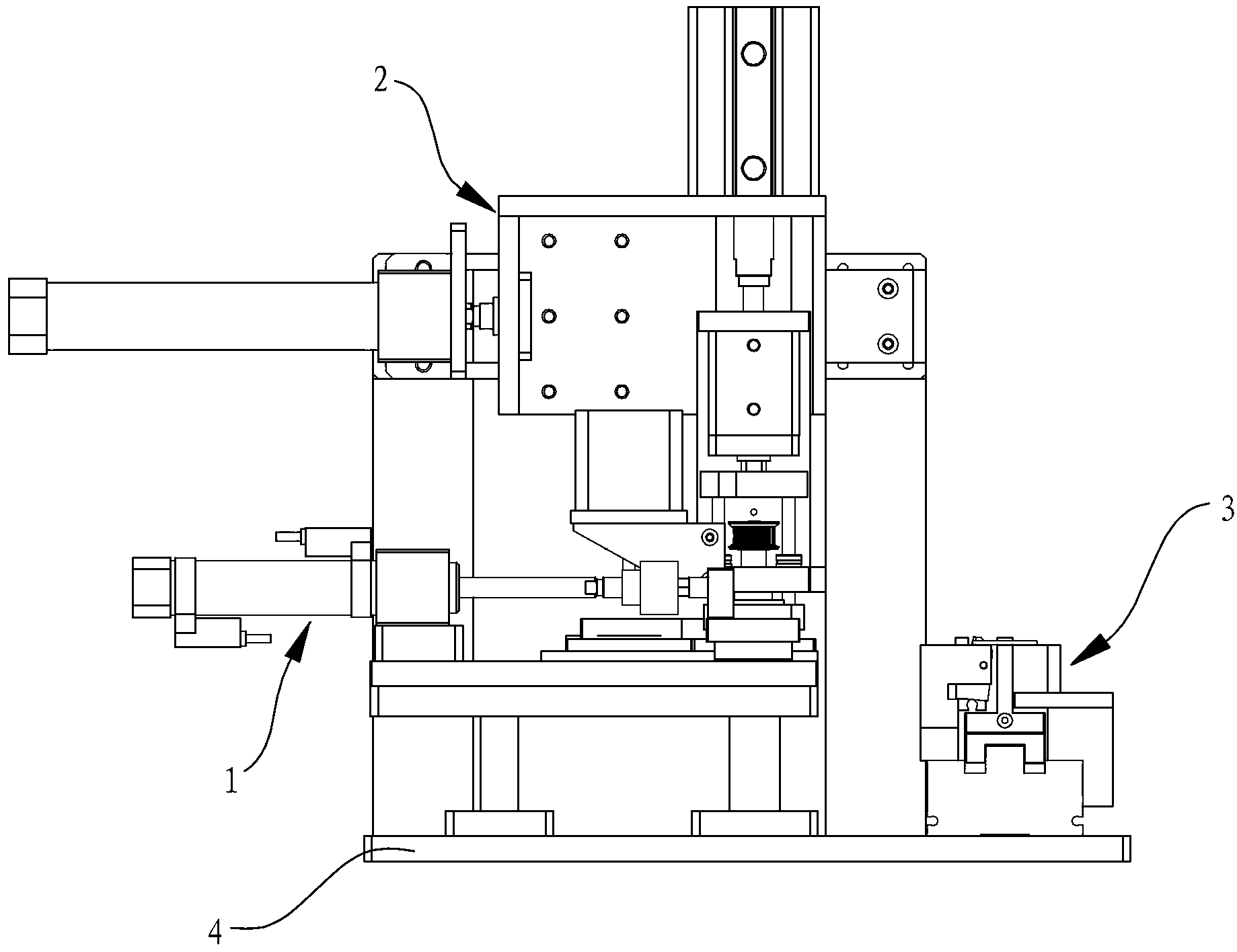

Rotating type rigidity-changing flexible joint

ActiveCN104608142AAchieve stiffnessVariable stiffness flexible joint with compact sizeJointsOptical axisEngineering

The invention discloses a rotating type rigidity-changing flexible joint which comprises a driven rigidity-changing mechanism and a driving flexible drive mechanism. The rotating type rigidity-changing flexible joint is characterized in that the driven rigidity-changing mechanism mainly comprises an output plate of the joint, a first drive plate of the joint, a second drive plate of the joint, a first cam set, a second cam set, a first cam set installing base, a second cam set installing base, a bare shaft, a supporting base of the bare shaft, a rigidity adjusting installing plate, a linear bearing and a spring. The first drive plate of the joint is fixedly connected with the second drive plate of the joint. The second drive plate of the joint and the output plate of the joint are provided with cam grooves with the same outline. By means of the outlines, the equivalent rigidity of the joint can change along with the flexible deformation angle of the joint. Cams of the first cam set and the second cam set can make contact with the second drive plate and the output plate of the joint at the same time. The driving flexible drive mechanism mainly comprises a trapezoidal lead screw, a lead screw supporting base, a lead screw nut, a lead screw bearing, a direct-current servo motor, a motor installing base, a coupler, a rigidity-changing adjusting base, a linear bearing and a spring.

Owner:HEBEI UNIV OF TECH

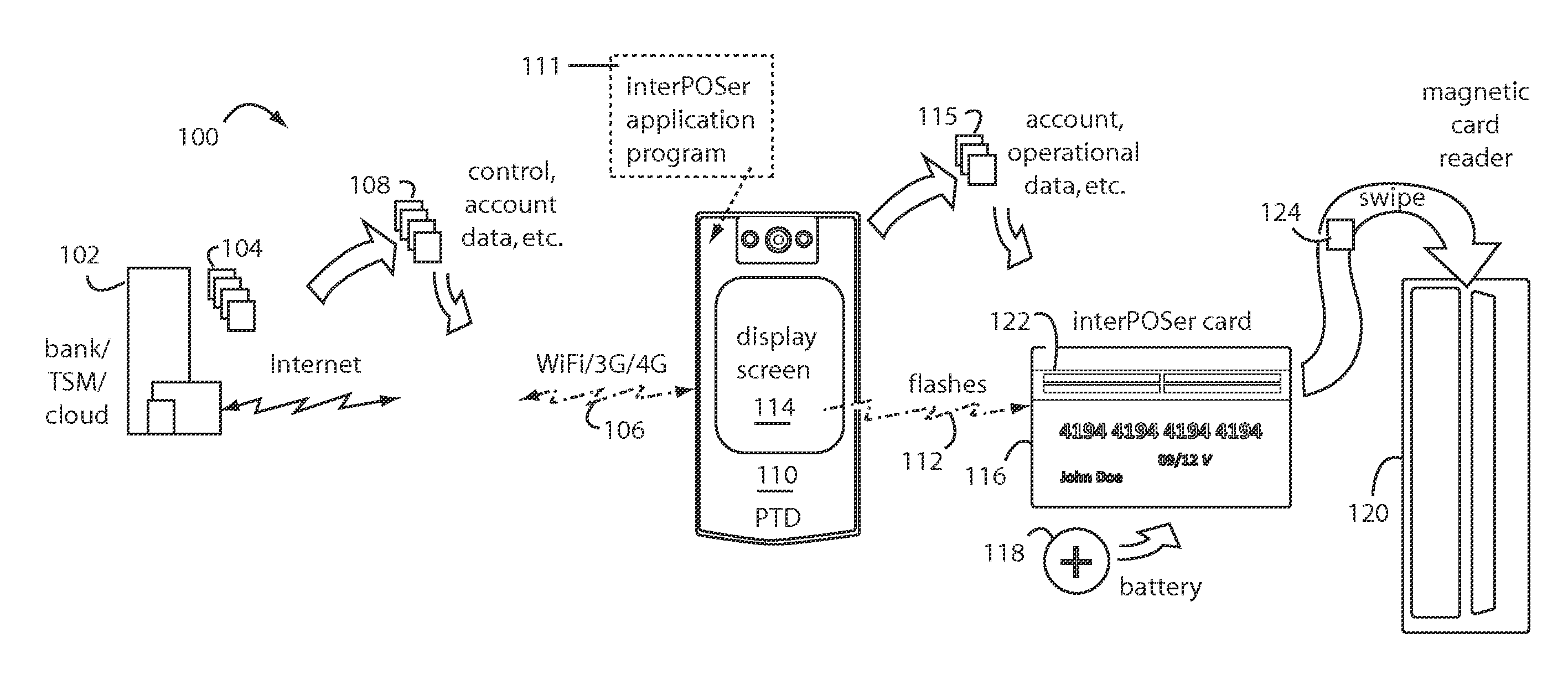

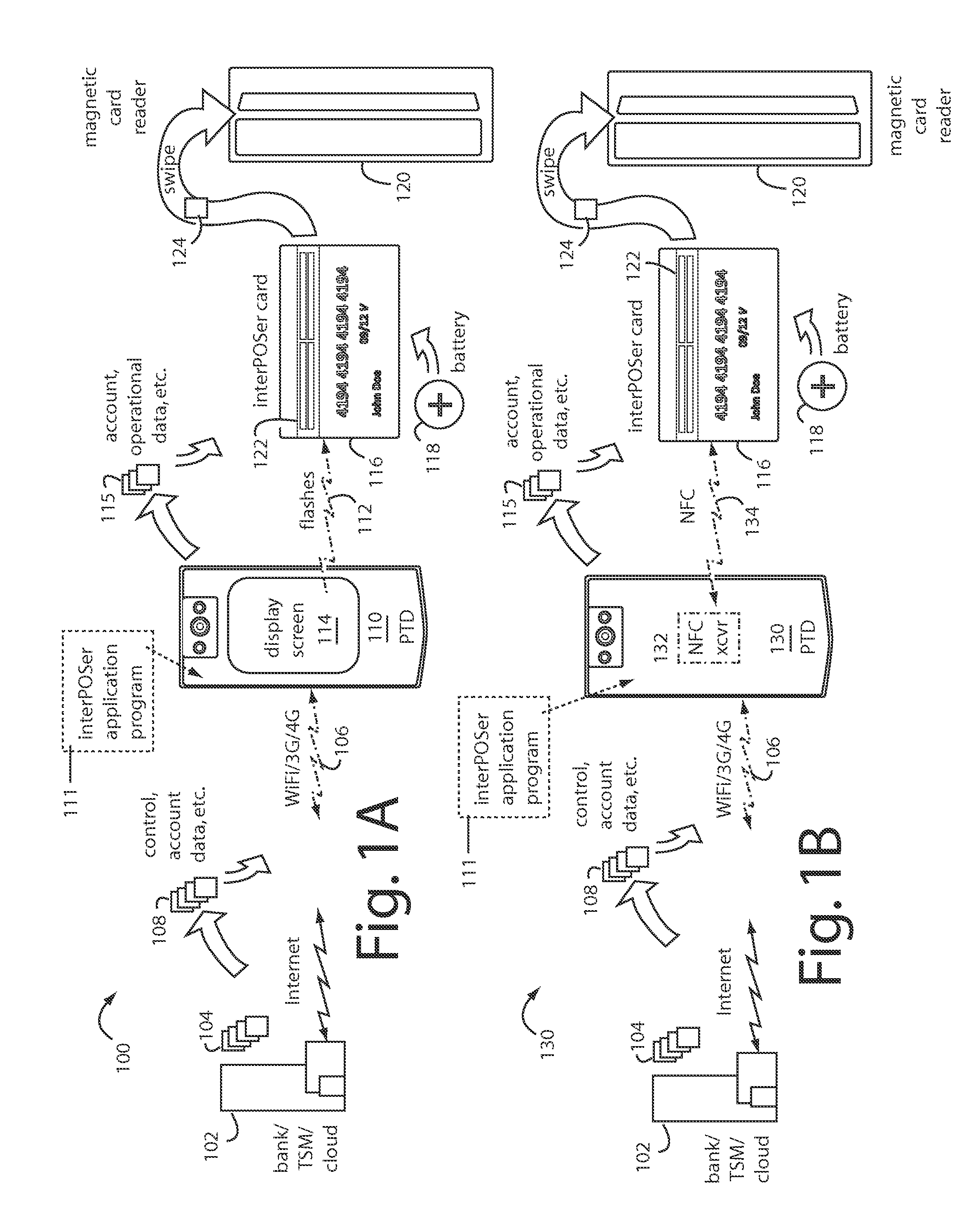

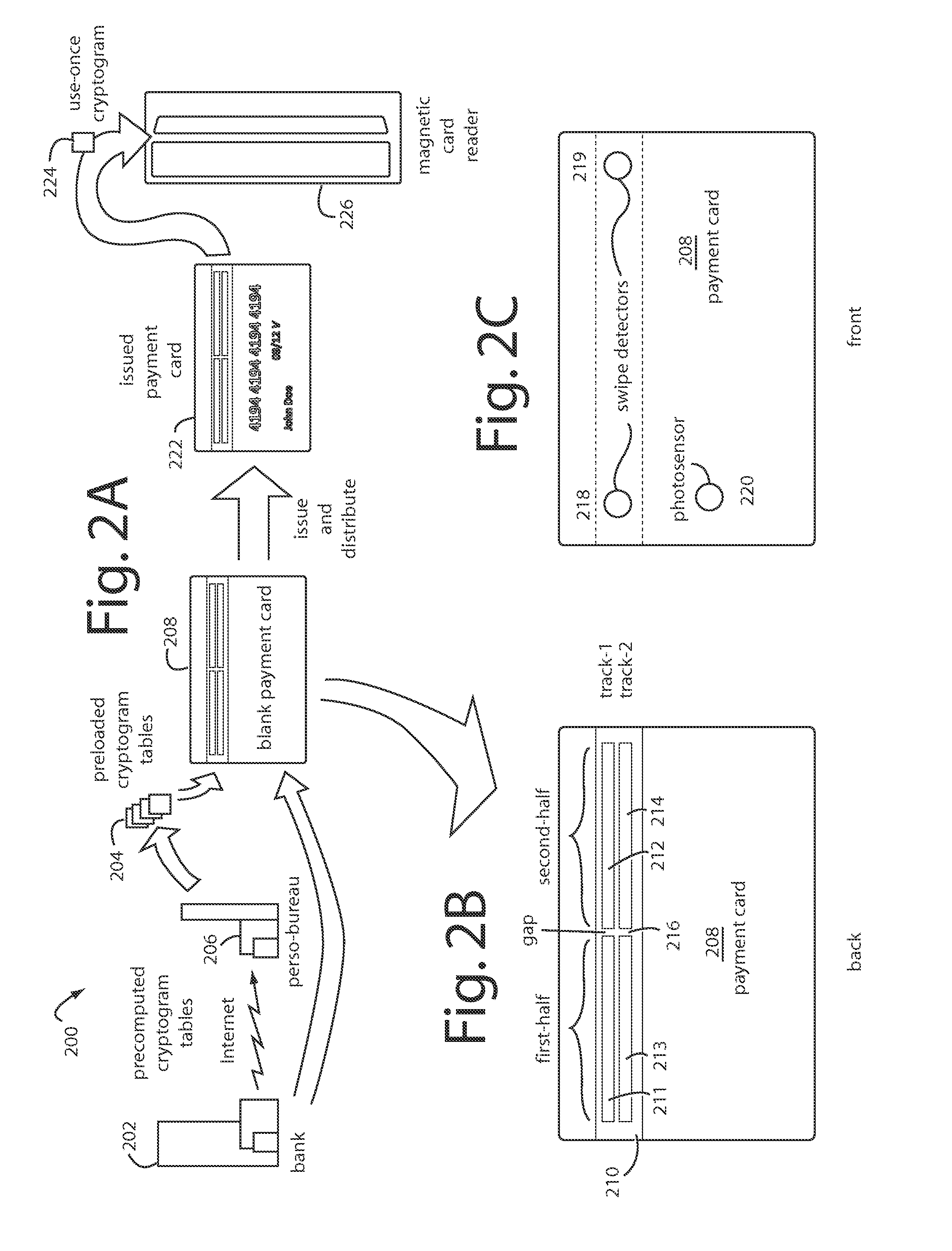

Optical contact loaded magnetic card

ActiveUS20110320314A1Improve securityCommunication securityPayment architectureCommercePayment orderFinancial transaction

A magnetic interface card appears to be a payment card conventionally provided with an electromagnetic stripe and magnetic data tracks. A magnetic emissive element is disposed in the magnetic interface card body under the magnetic data tracks that can emit a variety of ISO-7813 track-2 data strings. A photo-sensor is included to receive a series of optically encoded flashes from a personal trusted device (PTD) smartphone screen that securely communicate one-time-use account information and operational parameters from a financial transaction server. The large installed base of legacy point-of-sale magnetic card readers can continue to be used without any hardware or software modifications, and card security is improved by the change to one-time-use access numbers.

Owner:FITBIT INC

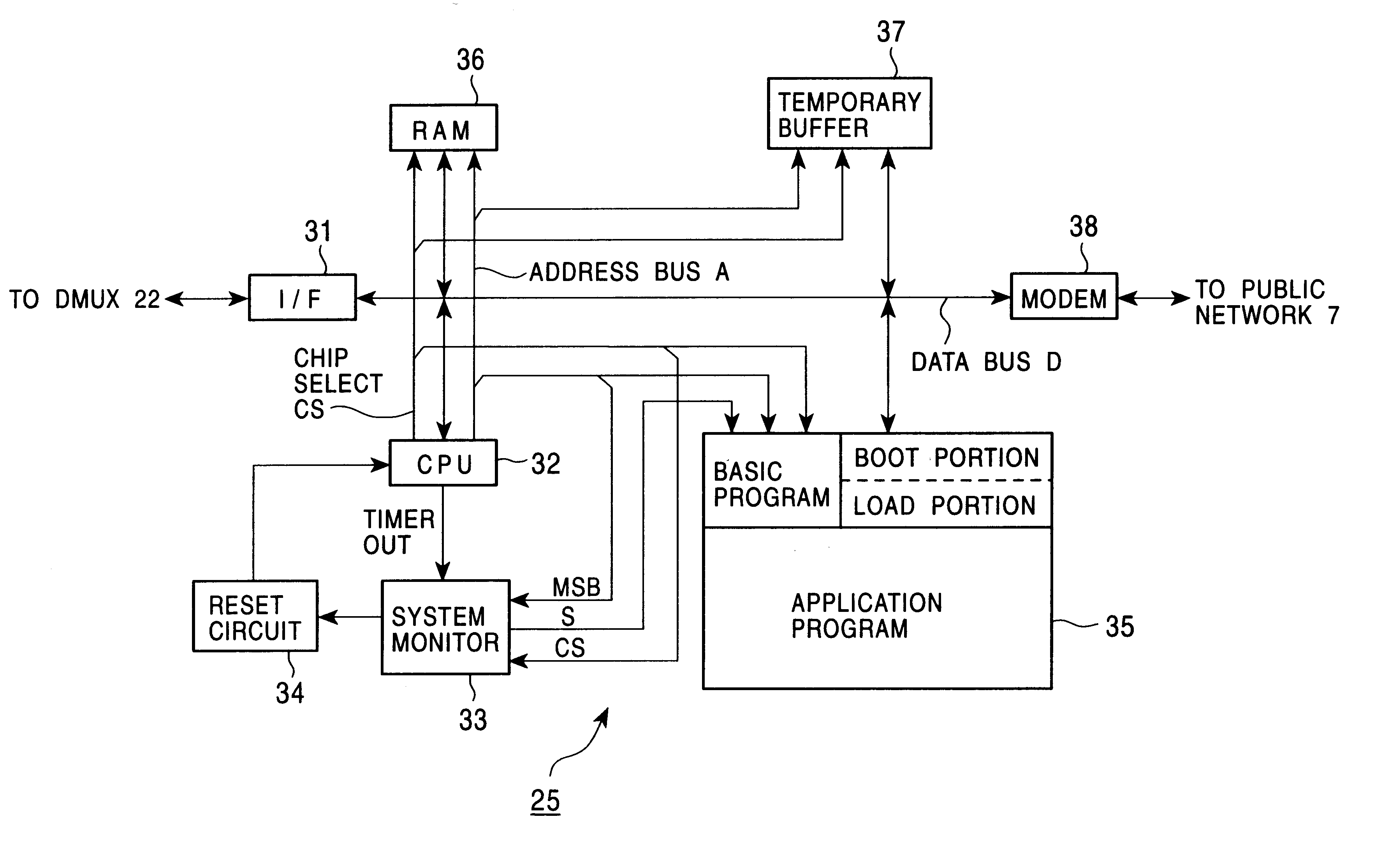

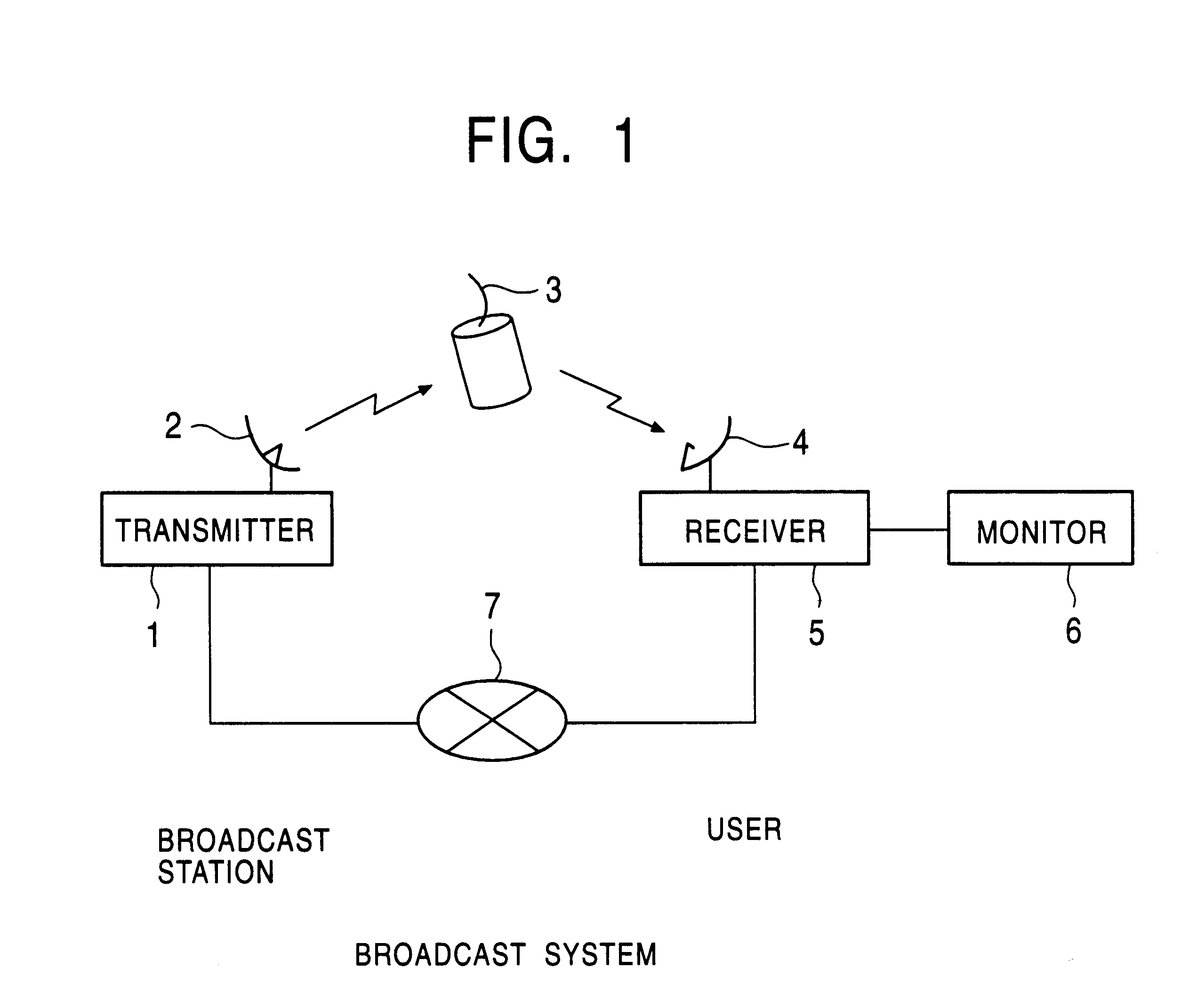

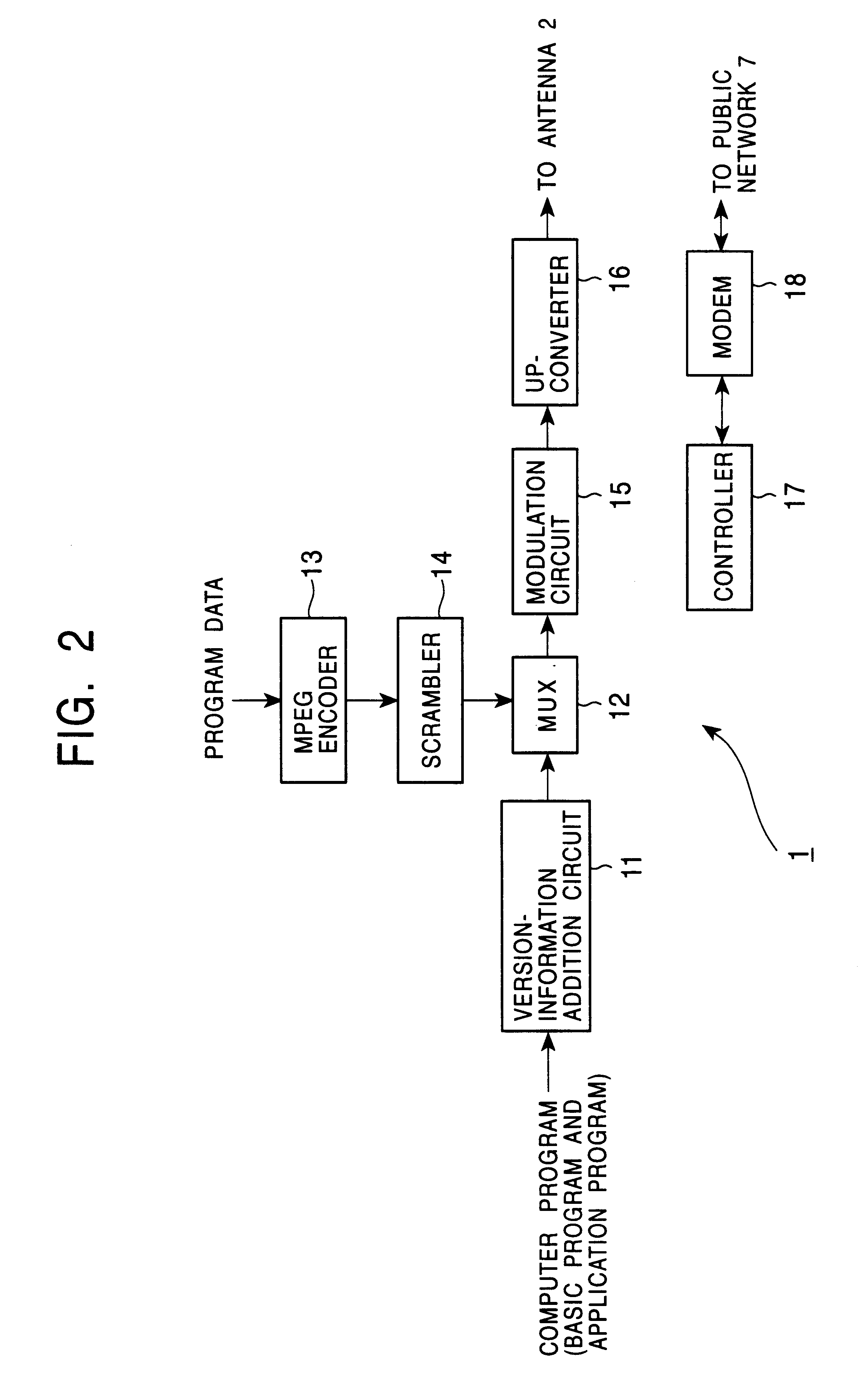

Method and apparatus for determining compatibility of computer programs

InactiveUS6684328B2Guaranteed uptimeData resettingMultiple digital computer combinationsInformation processingComputer compatibility

An information processing apparatus performs predetermined processing by executing a computer program. A program memory stores two boot addresses #1 and #2, each of which serves as an address from which a basic program including a boot program for performing a booting operation is stored. In installing a basic program, the boot addresses #1 and #2 are alternately selected to store the basic program. In starting an apparatus, an error of the computer program stored in the program memory is detected, and upon detection, one of the boot addresses #1 and #2 is selected, and the basic program stored from the selected address is executed. The version compatibilities of a basic program or an application program are described in the basic program or the application program. Upon upgrading the version of the application program, it is determined whether the version of the application program is compatible with the version of the basic program, and vice versa. The application program is then installed based on the result of the determination. With this arrangement, even if the installation of the basic program has failed, the apparatus can be started properly. It is also possible to prevent the installation of an application program whose version is incompatible with the OS and to prevent the installation of an OS whose version is incompatible with the application program.

Owner:SONY CORP

Icon implantation ion source, system and method

InactiveUS20050269520A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

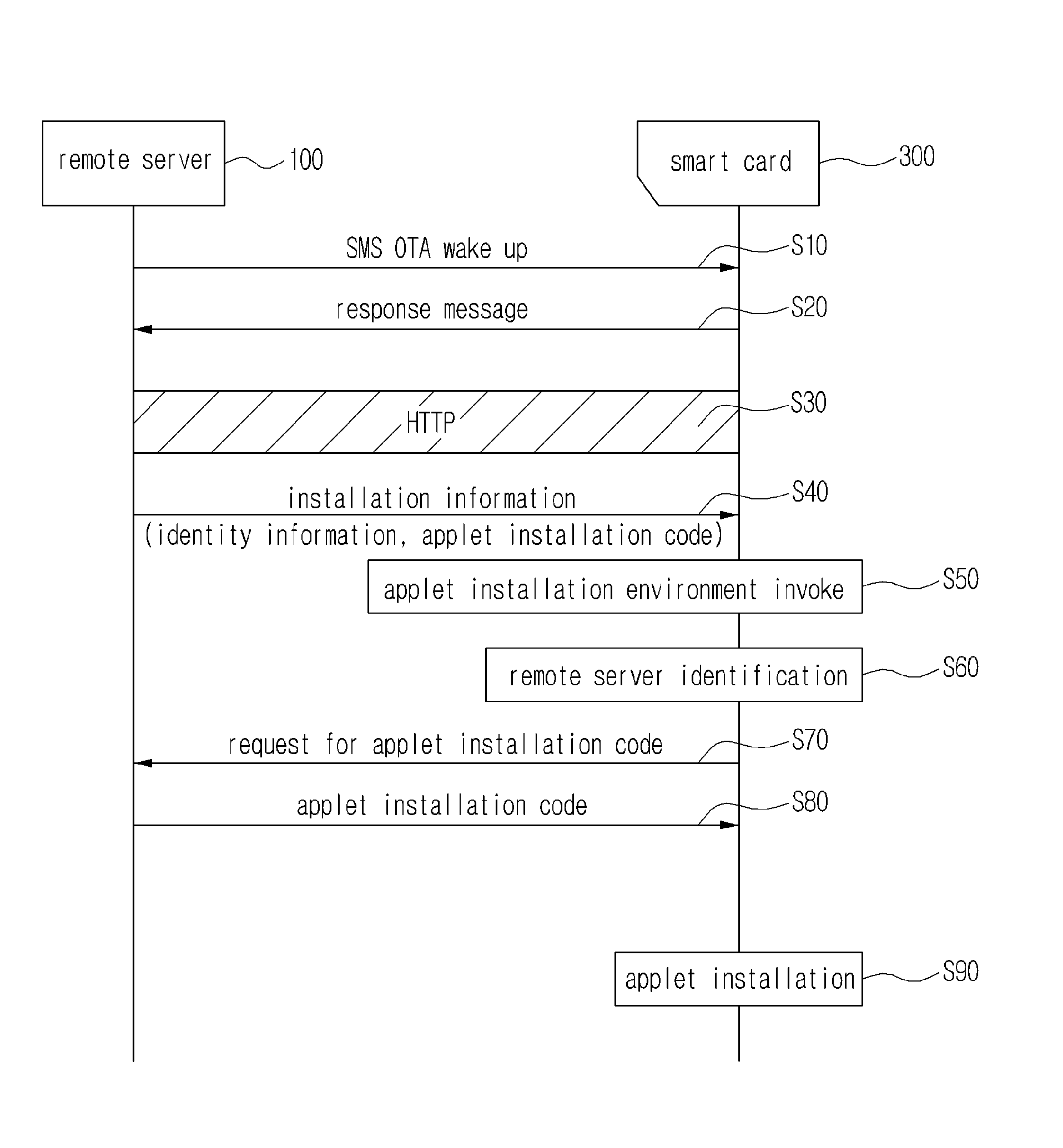

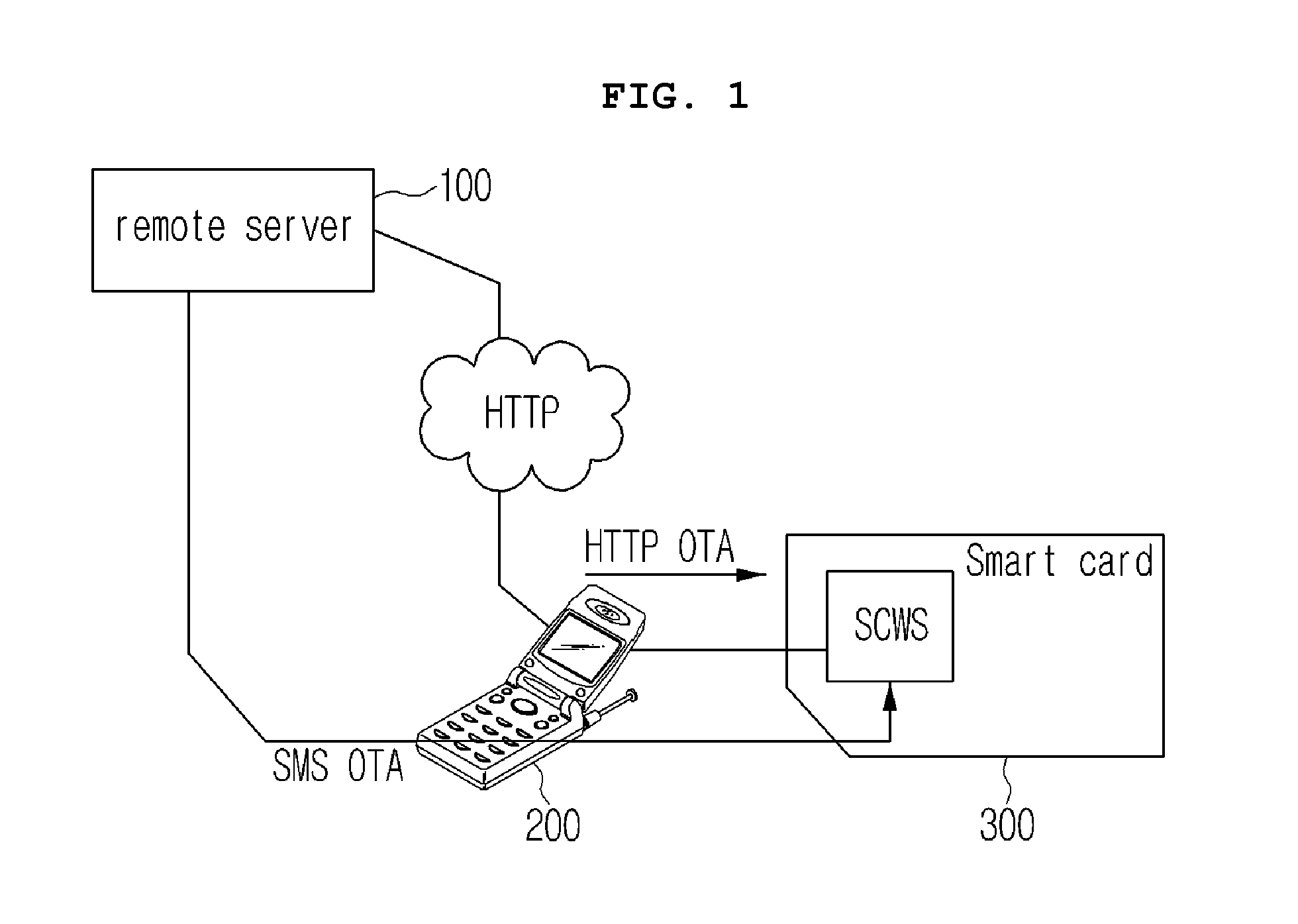

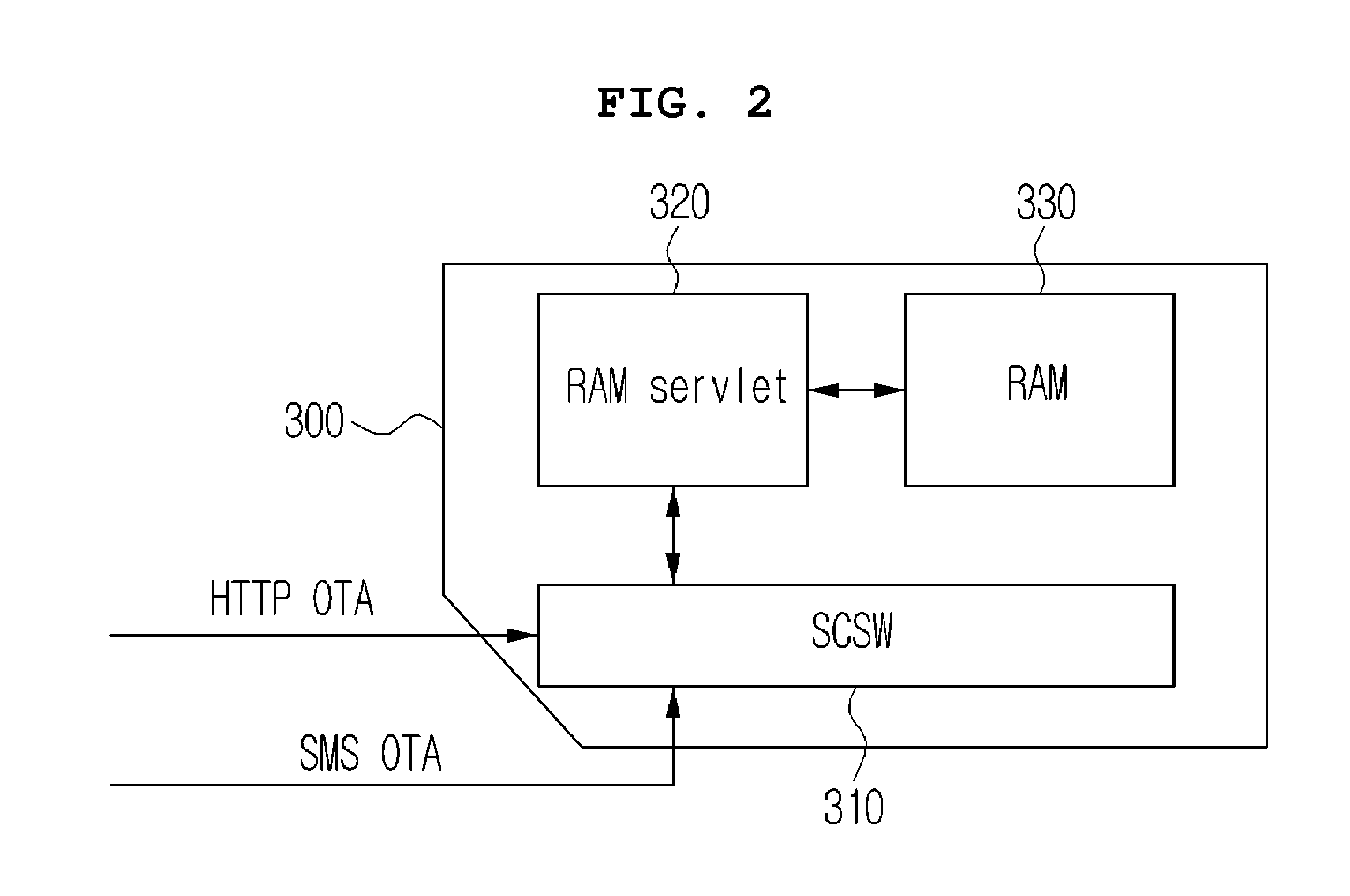

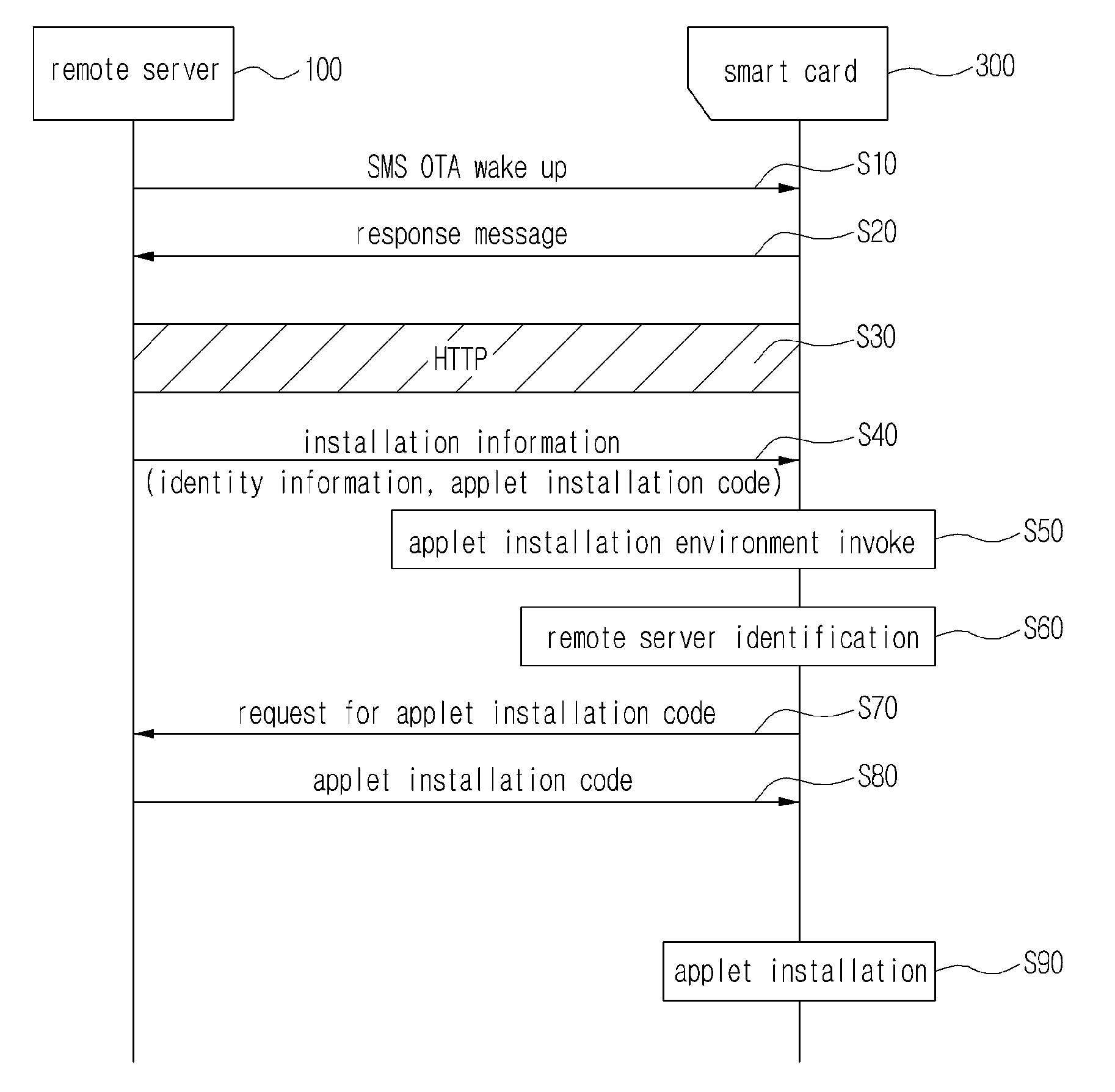

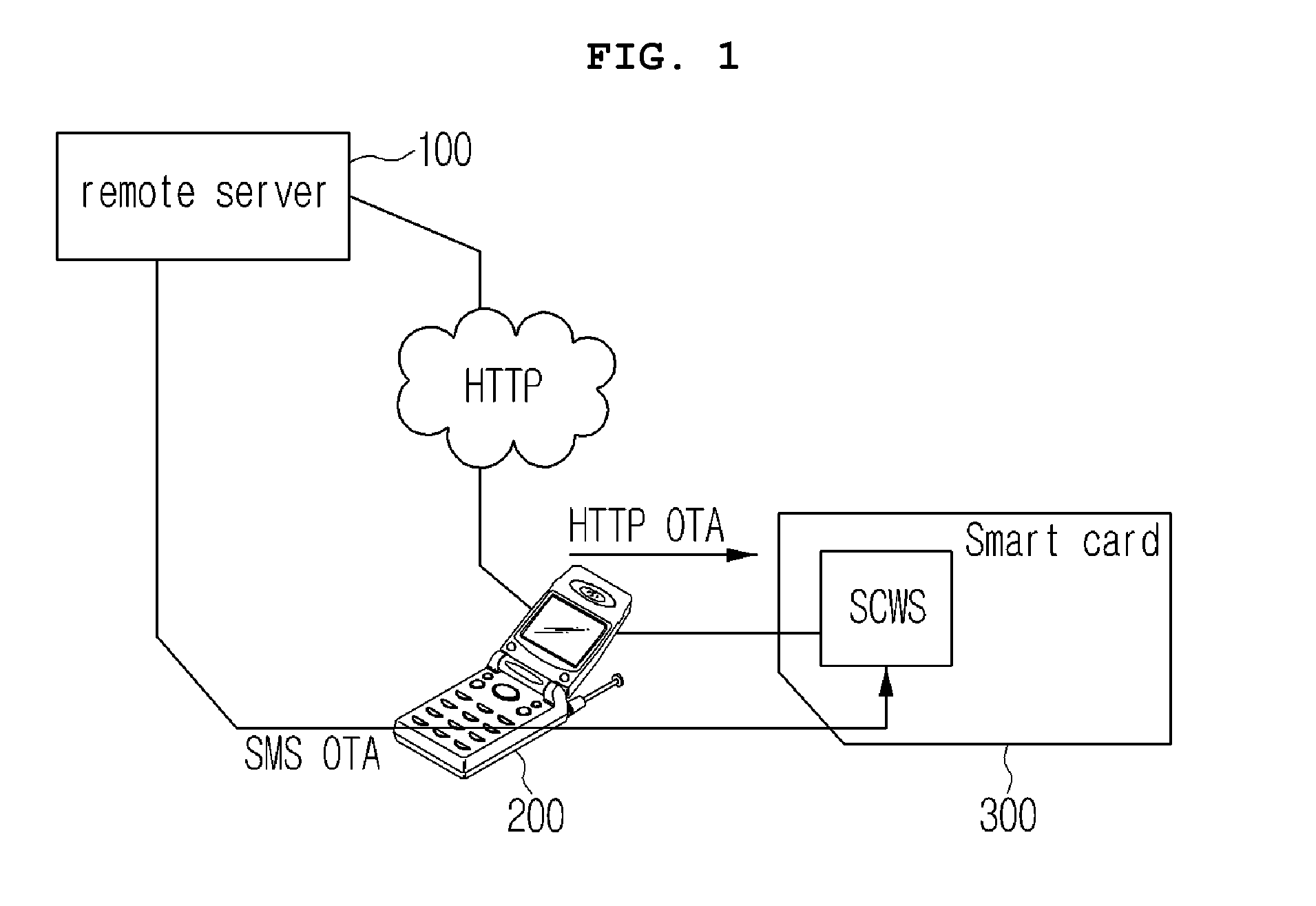

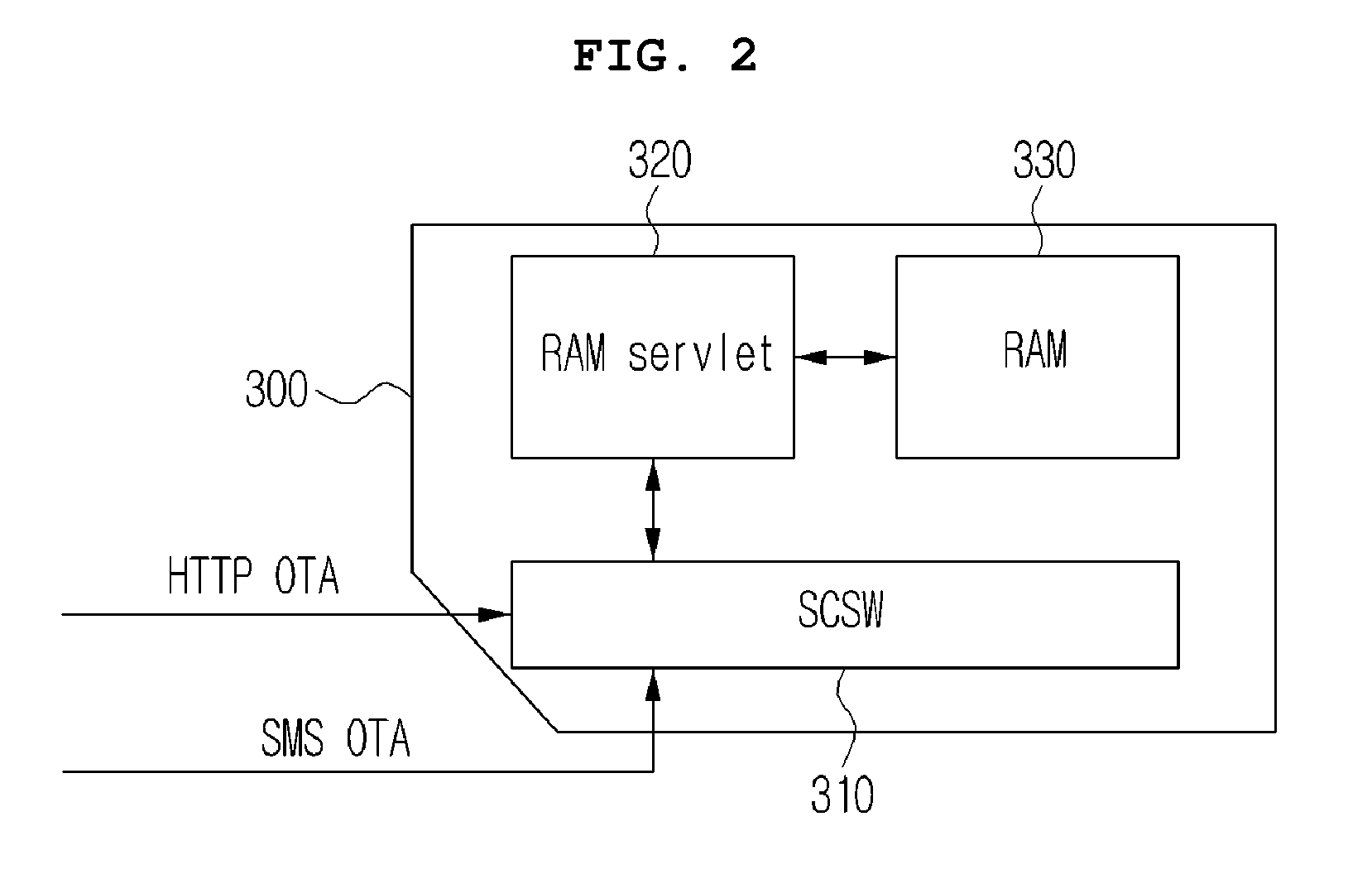

System and method for installing smart card applet

InactiveUS20120311563A1Acutation objectsMultiple digital computer combinationsSmart cardApplication software

Disclosed are a system and a method for installing a smart card applet. A response message for an OTA message received from an external remote server is transmitted to form a communication channel based on HTTP (hyper text transfer protocol) between a smart card and the remote server. The applet is installed based on applet installation information received through the communication channel. A large scale applet is installed in a card within a short period of time.

Owner:SK TELECOM CO LTD

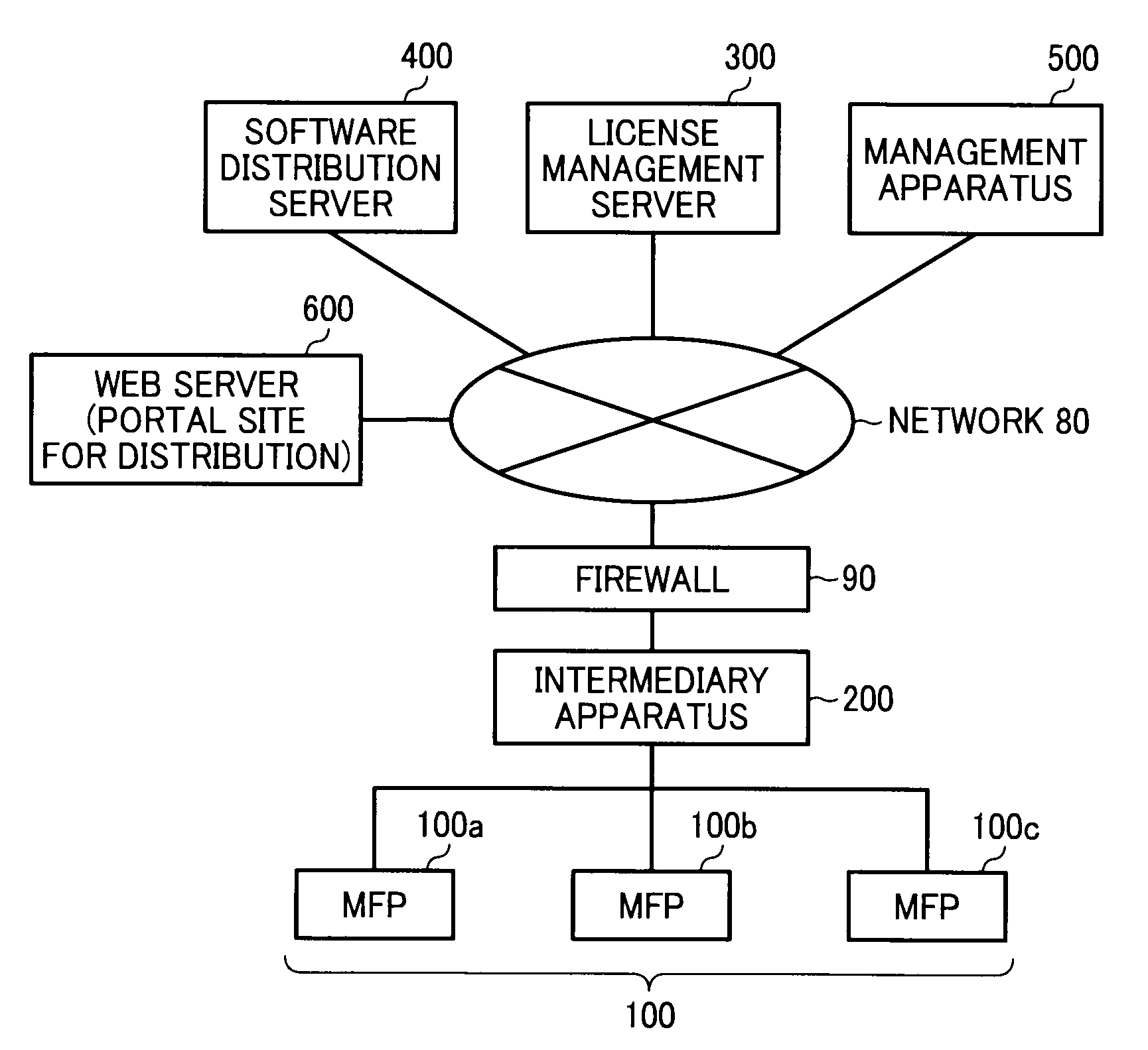

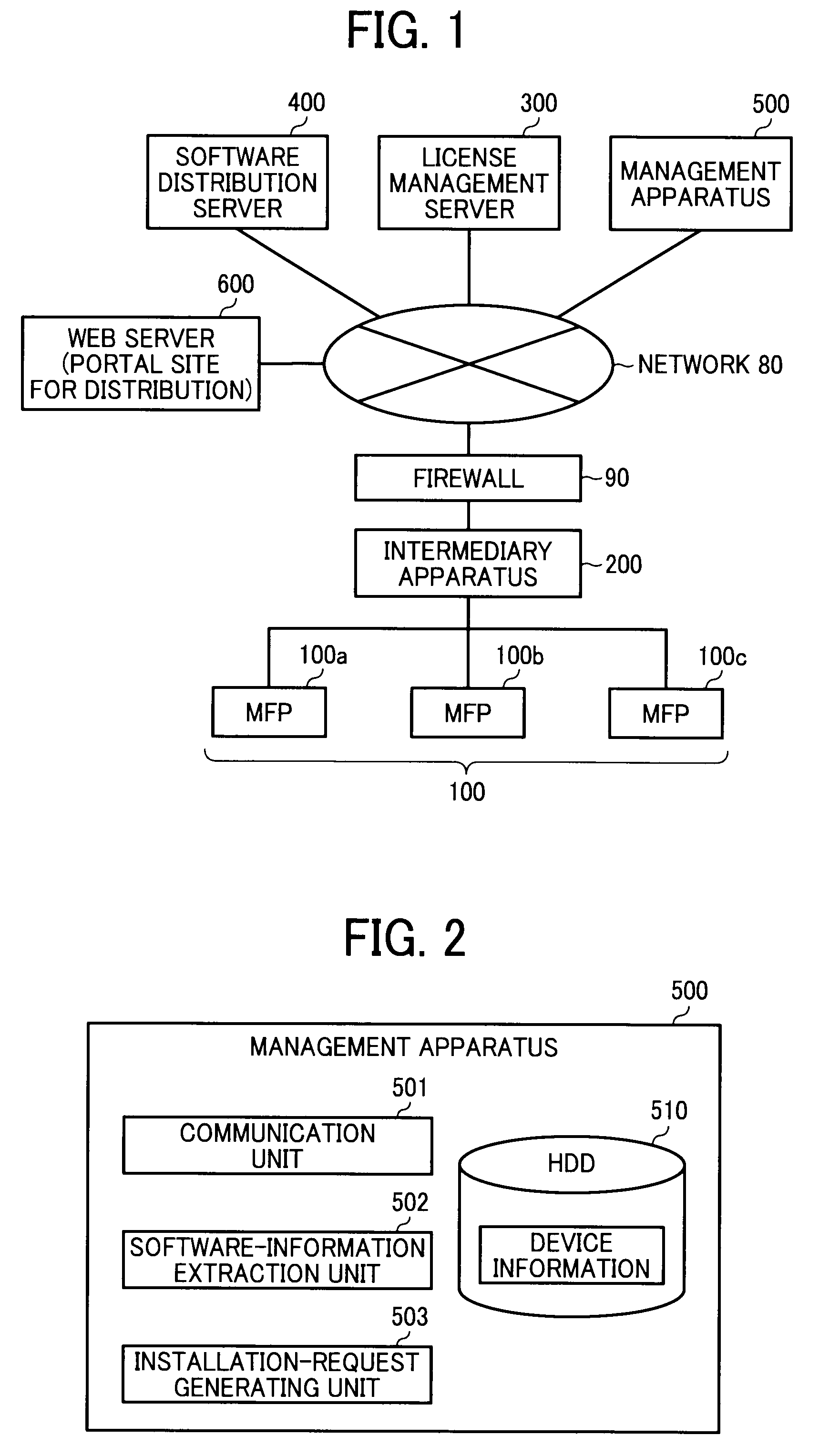

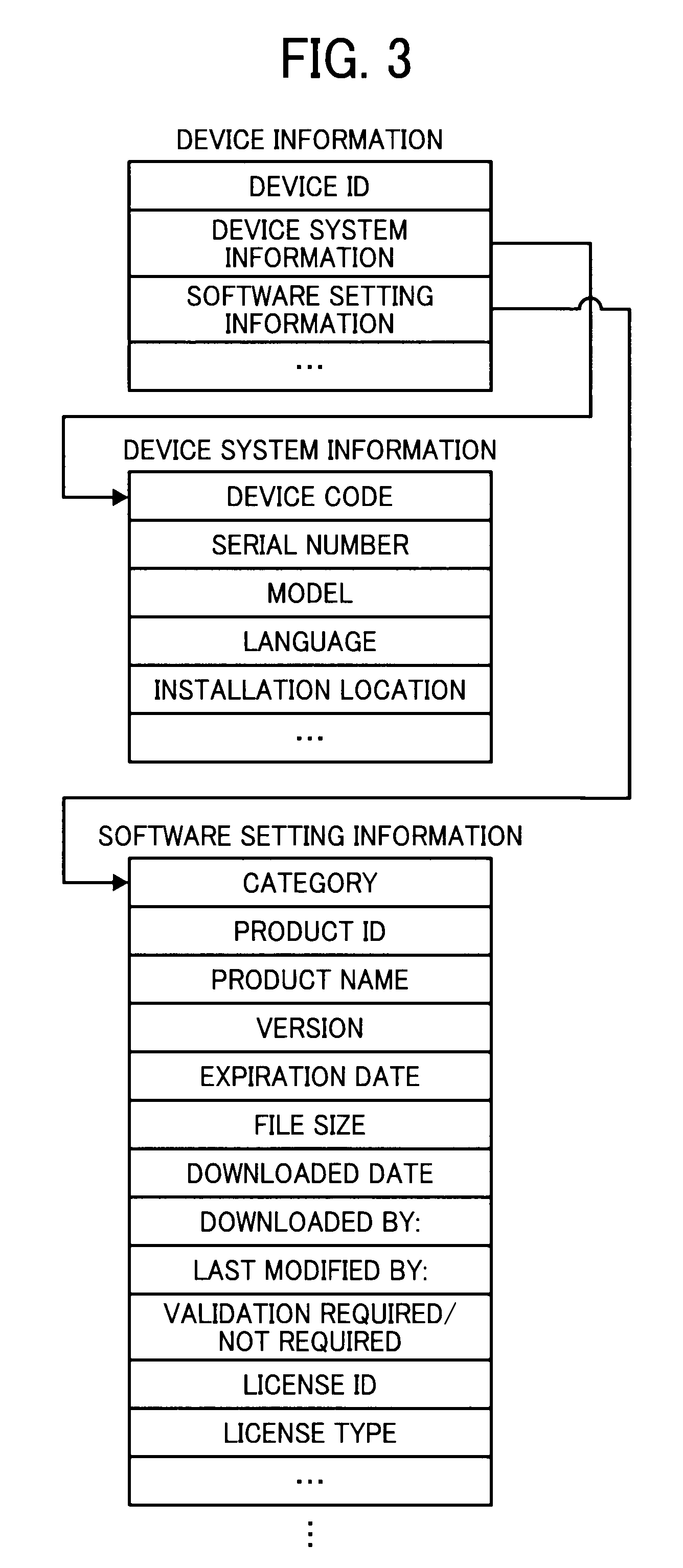

Software management apparatus, software distribution server, software distribution system, and software installation method

InactiveUS20110067023A1Solve problemsElectrographic process apparatusProgram loading/initiatingSoftware distributionImage formation

A software management apparatus includes a software-information obtaining unit that, when receiving a first installation request for installation of a software component onto an image forming apparatus specified by a user, obtains software information on the software component requested to be installed from a software distribution server; a request generating unit that generates a second installation request for installation of the software component requested to be installed based on the software information on the software component requested to be installed and the device information on the specified image forming apparatus; and a request transmitting unit that transmits the second installation request to the specified image forming apparatus so as to cause the software component, which is requested to be installed, to be installed onto the specified image forming apparatus.

Owner:RICOH KK

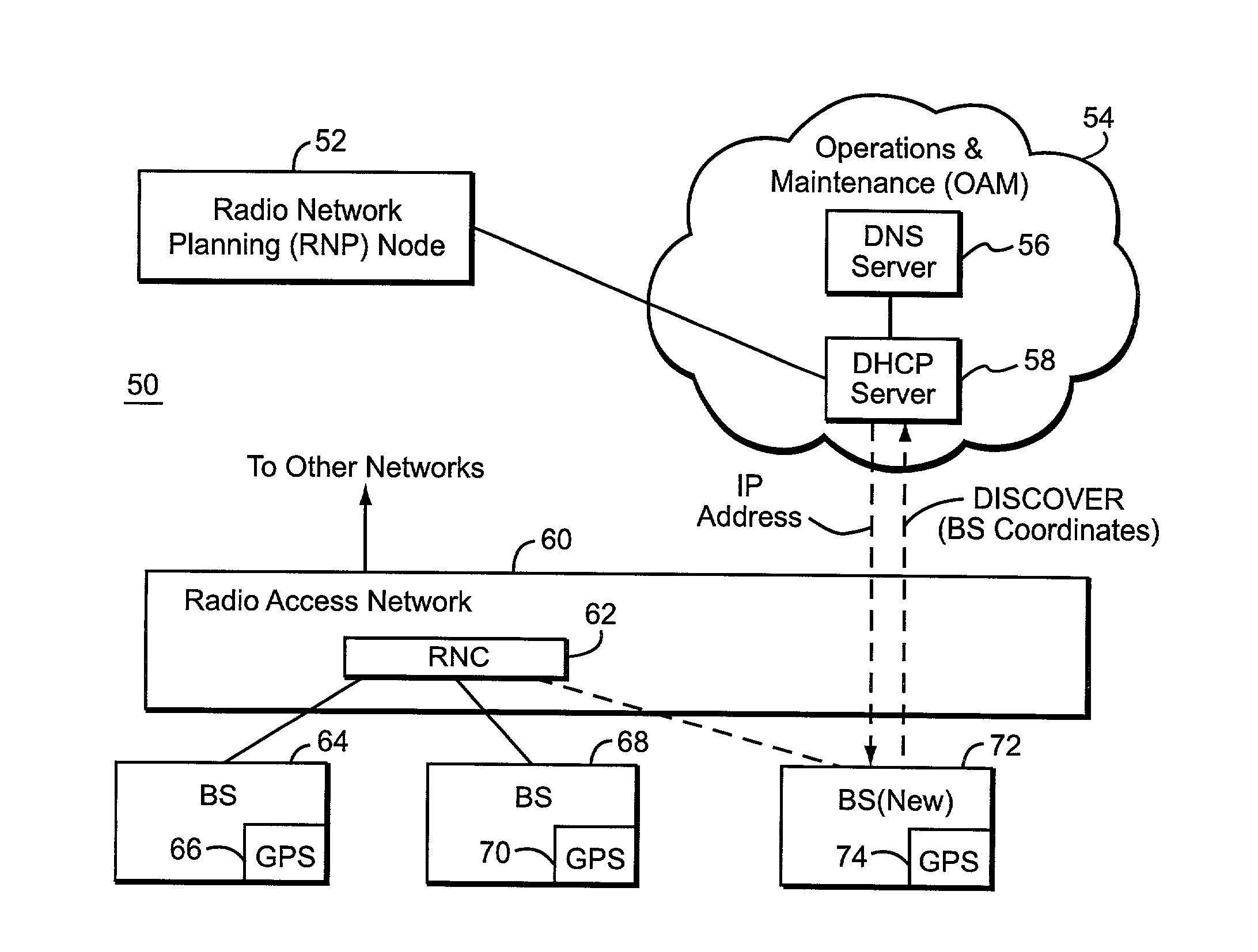

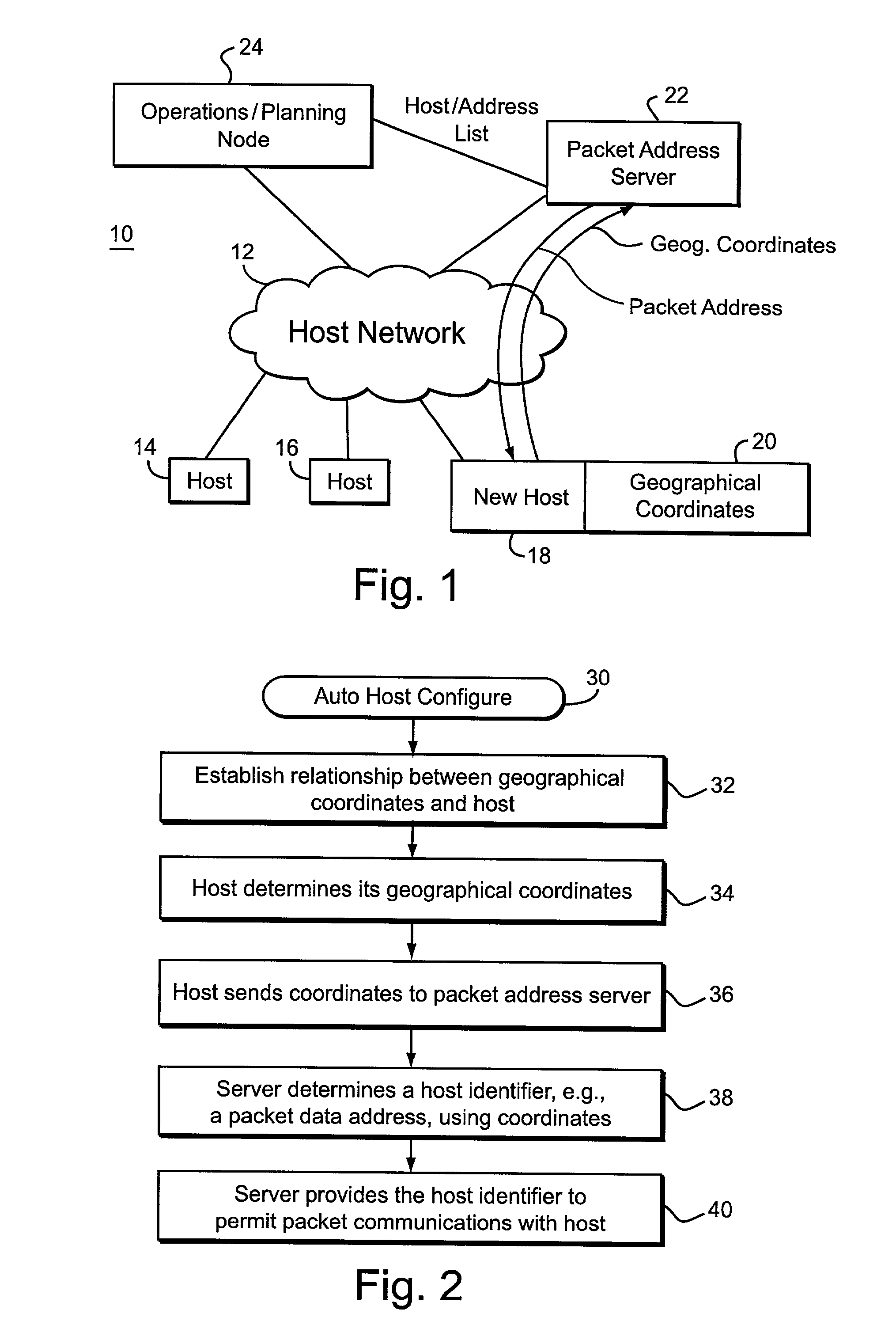

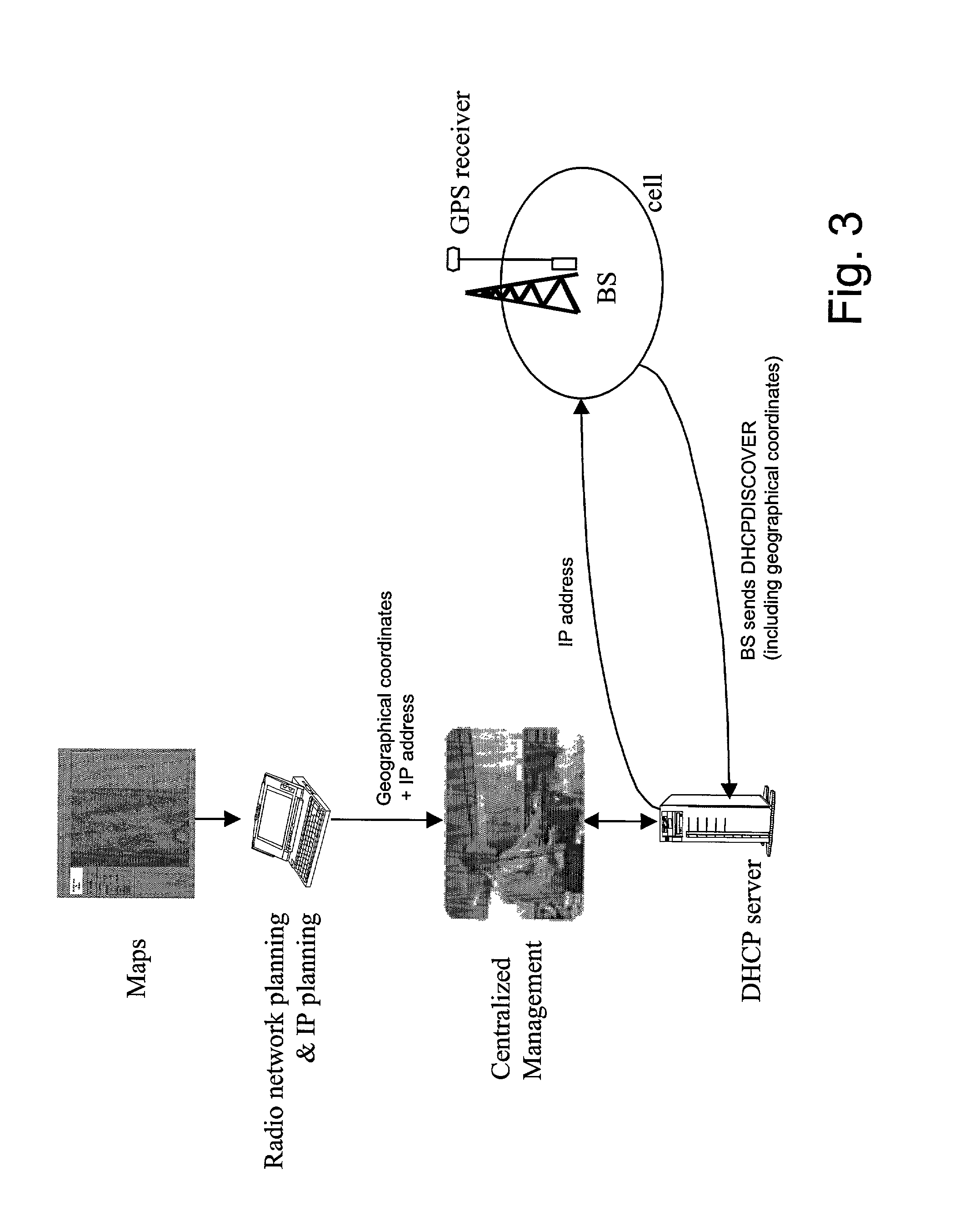

Method and apparatus for identifying a node for data communications using its geographical location

ActiveUS7103040B2Multiplex system selection arrangementsTime-division multiplexEntity identifierIp address

The present invention overcomes drawbacks with on-site, manual configuration of IP addresses for network nodes (like newly-installed base stations) with a method to automatically assign an identifier like a packet data address to a new node. In general., the automatic assignment of such an identifier to a network entity, node, or host includes two steps. First, an initial message is transmitted by the entity which specifies or indicates in some way geographical location information for the entity. Second, using the geographical location information in that message, an identifier is assigned and provided to that entity. In other words, a relationship is established between the geographical location of an entity identifier and its associated identifier. The geographical location information uniquely identifies the entity in the automatic identifier assignment process.

Owner:TELEFON AB LM ERICSSON (PUBL)

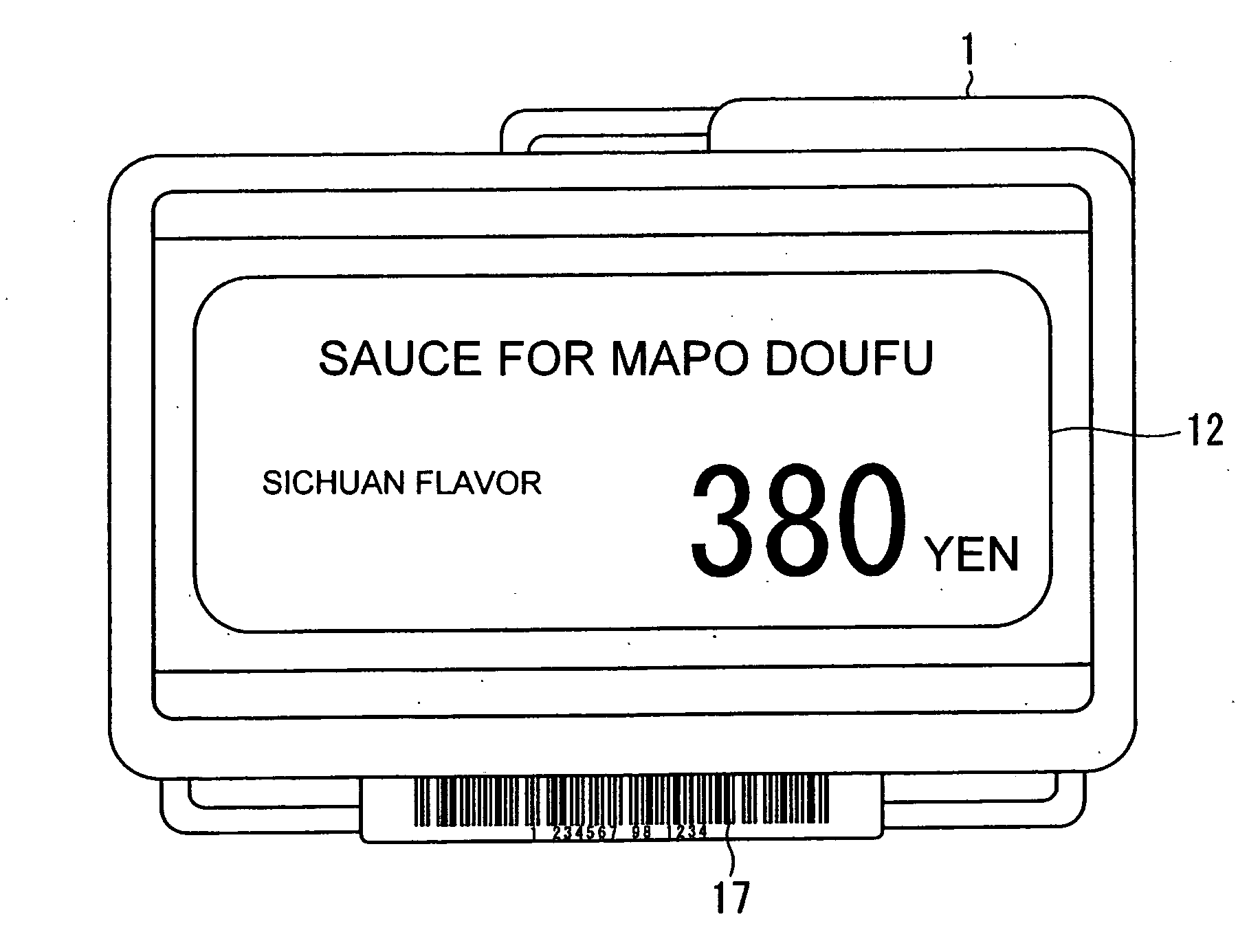

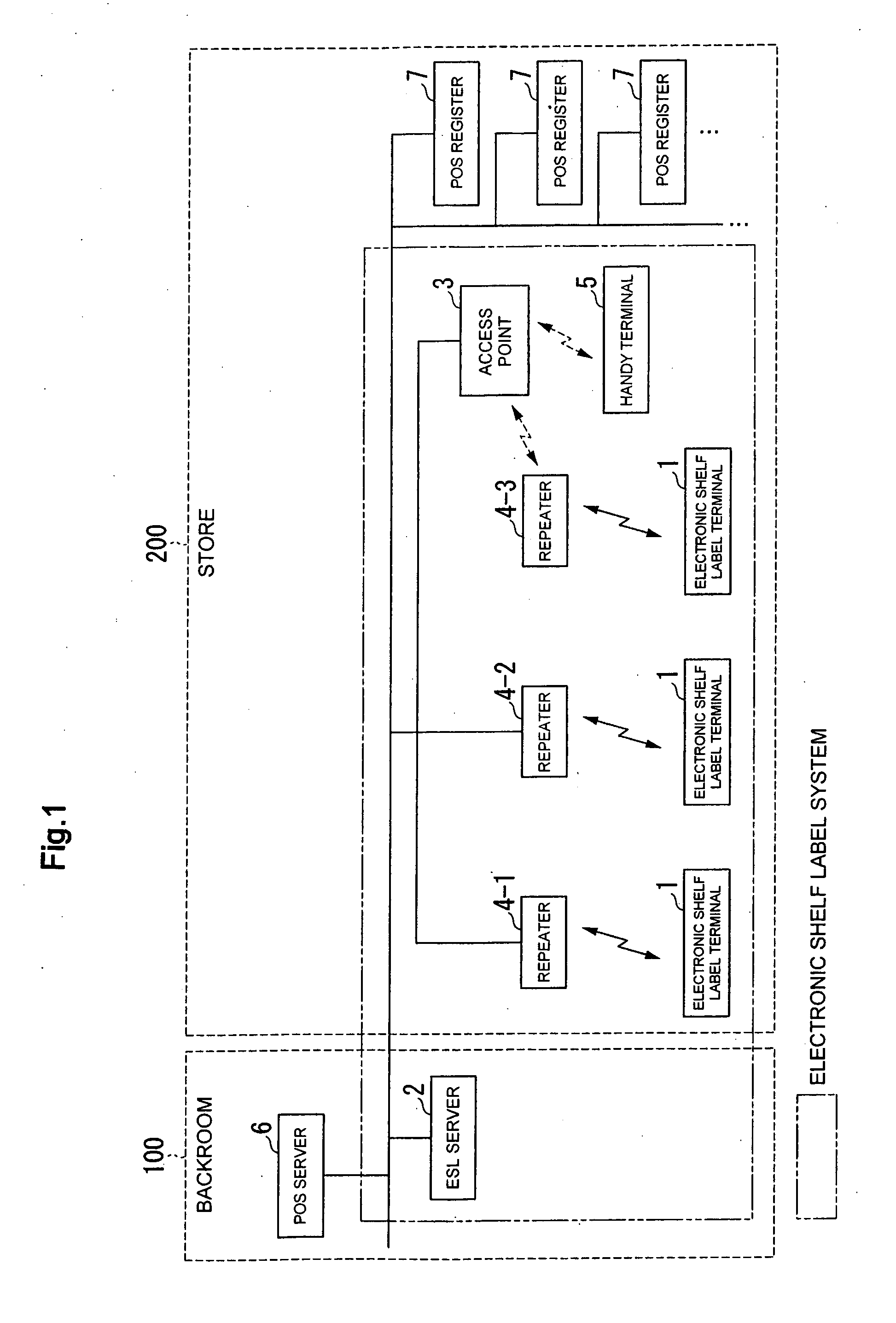

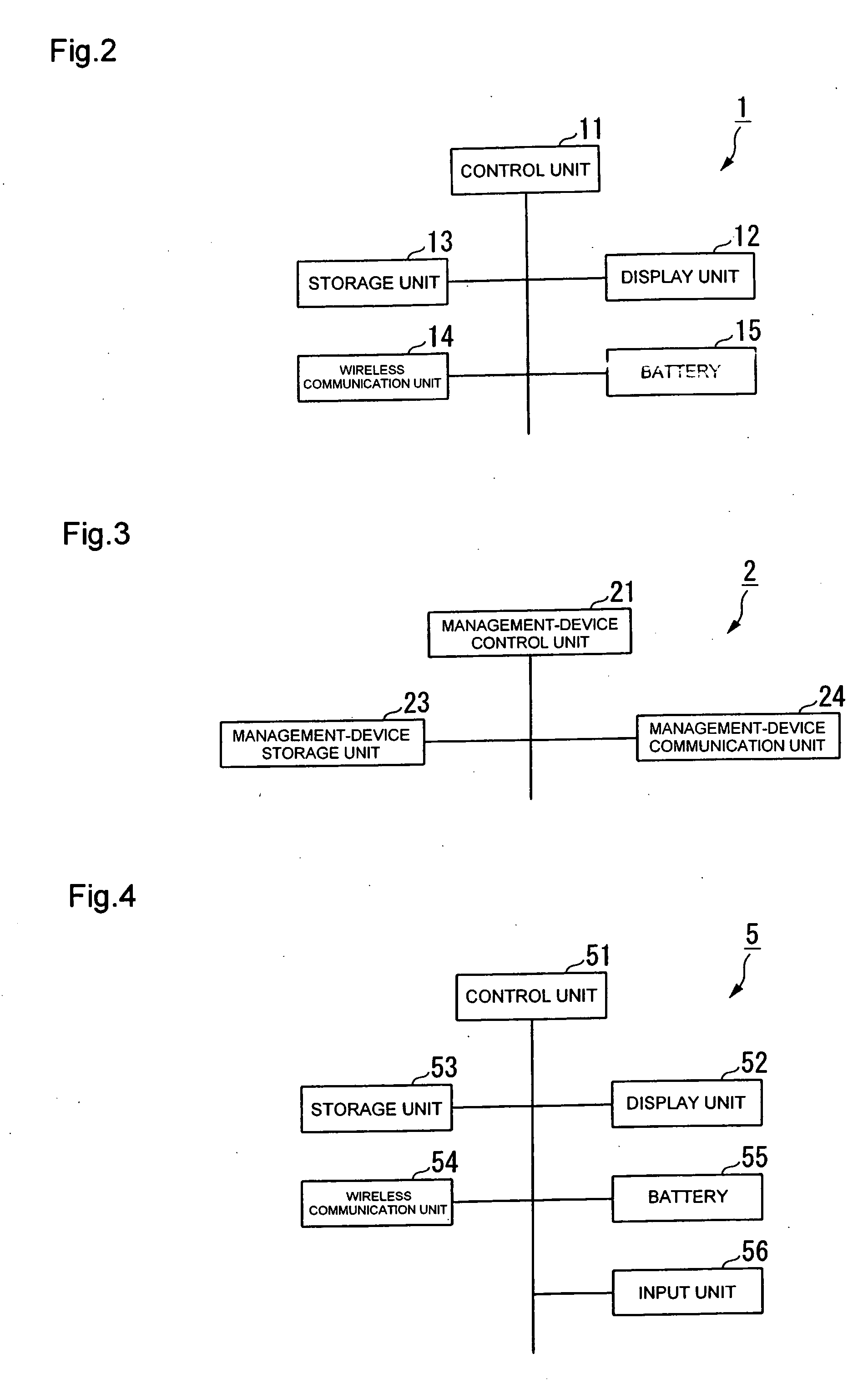

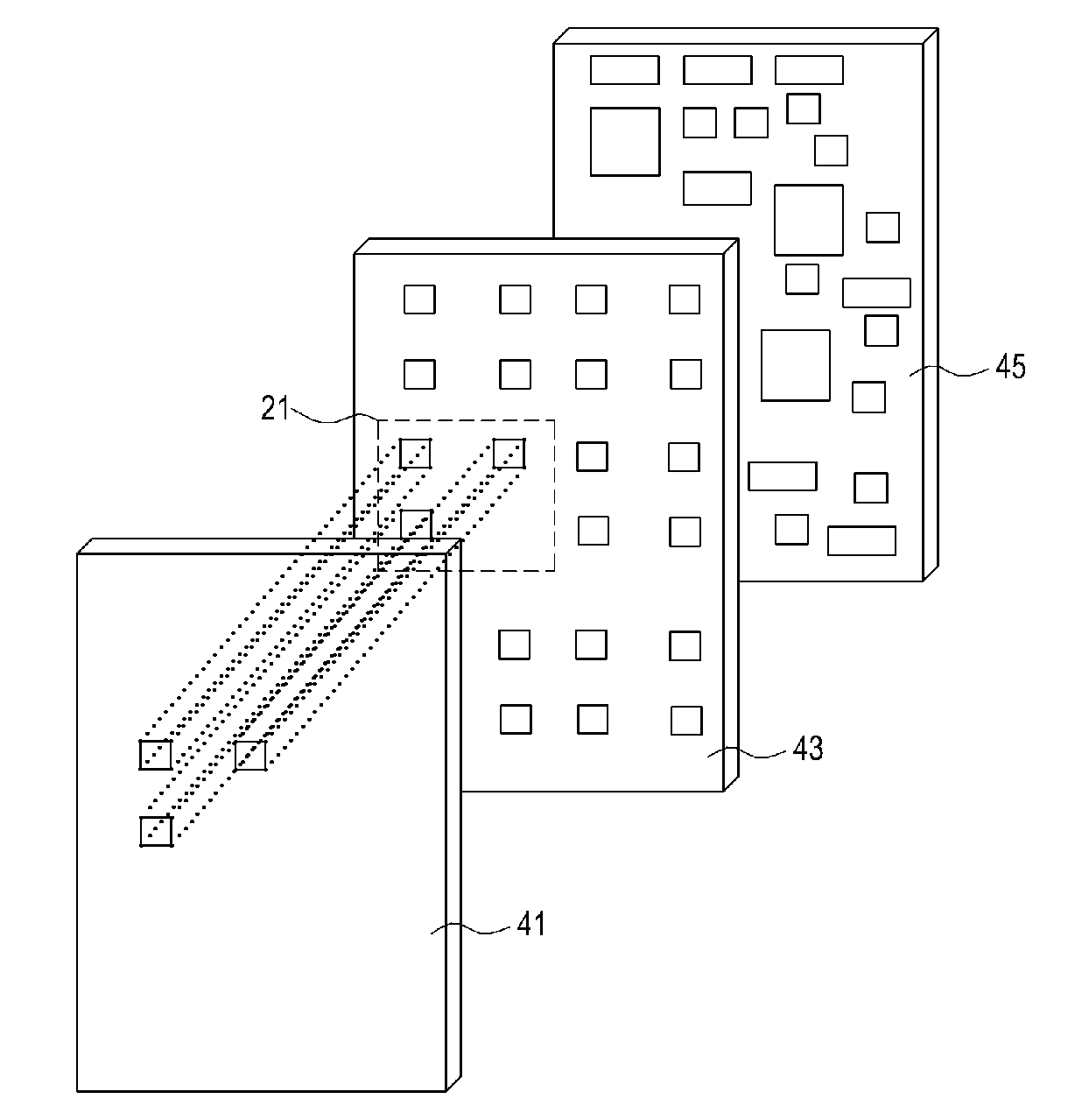

Information display system and management device

InactiveUS20110102144A1Programme controlElectric signal transmission systemsInformation display systemsElectronic shelf label

An ESL server (3) includes a management-device storage unit for storing information indicating a position at which a second electronic shelf label terminal (1) is installed, a management-device reception unit for receiving information transmitted from a transmission unit of a handy terminal (5), and a management-device control unit for identifying a position at which a first electronic shelf label terminal (1) is installed based on information for uniquely identifying the first electronic shelf label terminal (1), information for uniquely identifying the second electronic shelf label terminal (1), information indicating relative position between the position at which the second electronic shelf label terminal (1) is installed and the position at which the first electronic shelf label terminal (1) is installed, and the information indicating the position at which the second electronic shelf label terminal (1) is installed.

Owner:SEIKO INSTR INC

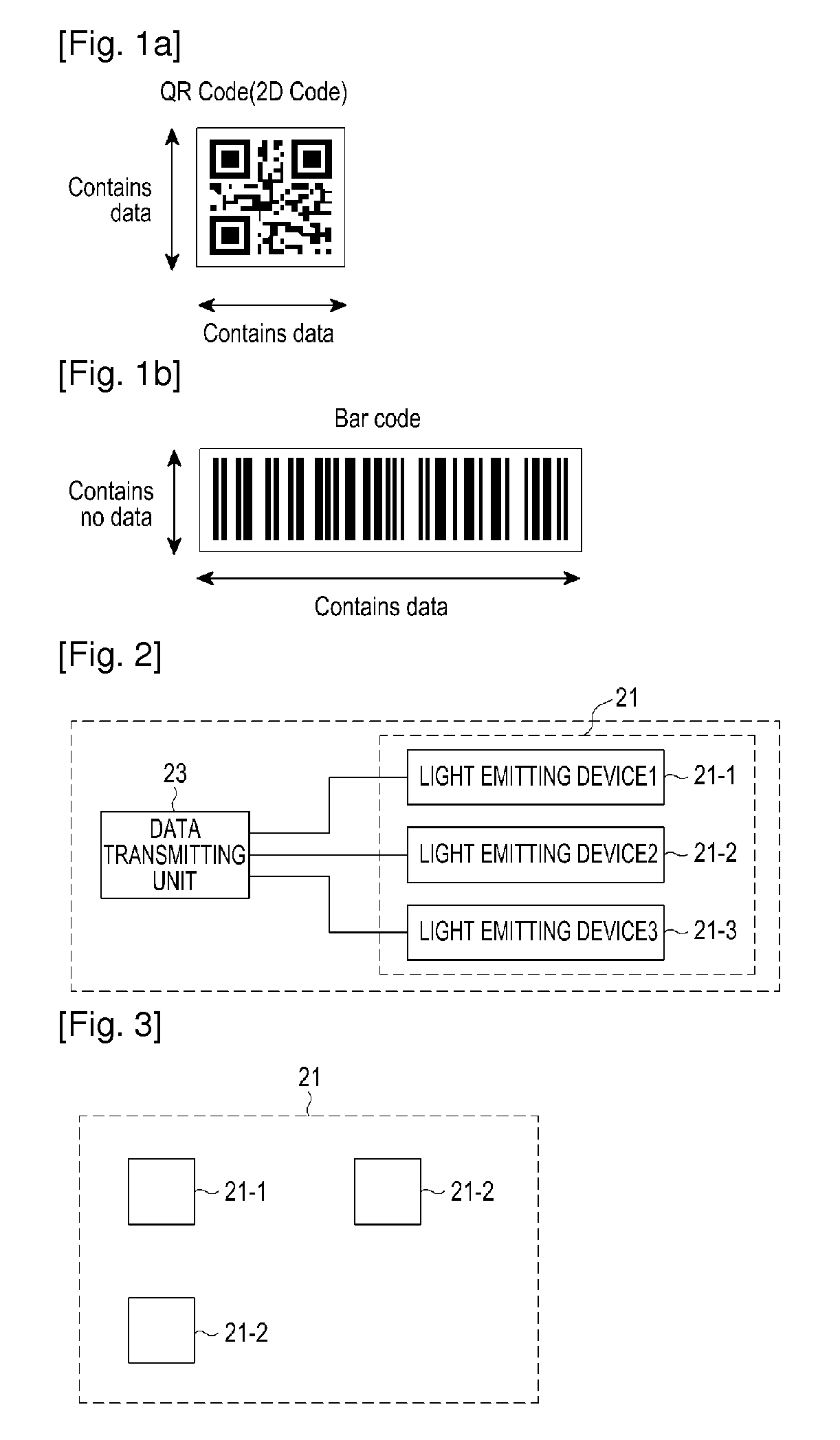

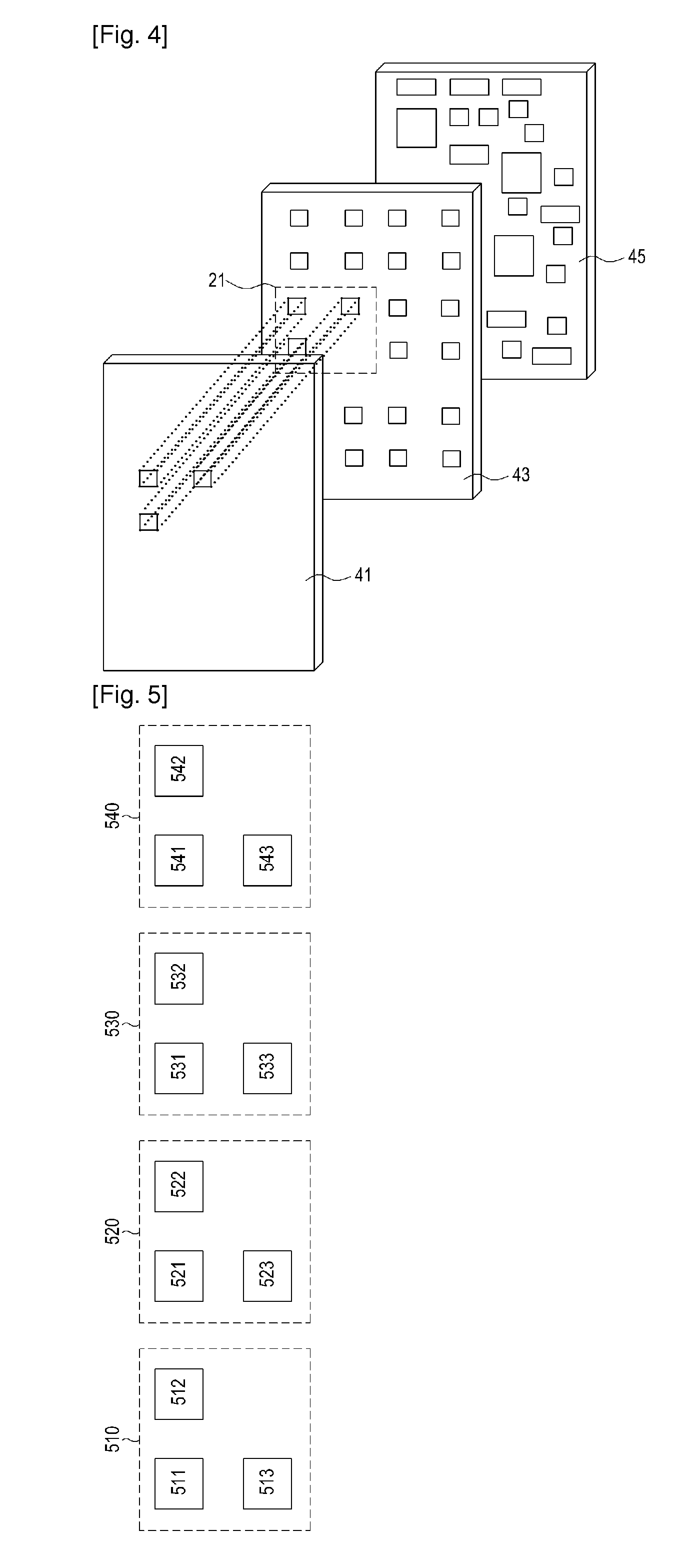

Apparatus for receiving and transmitting optical information

ActiveUS20150030335A1Data is very largeImprove data transfer efficiencyCharacter and pattern recognitionClose-range type systemsLight emitting deviceInstalled base

Owner:SAMSUNG ELECTRONICS CO LTD

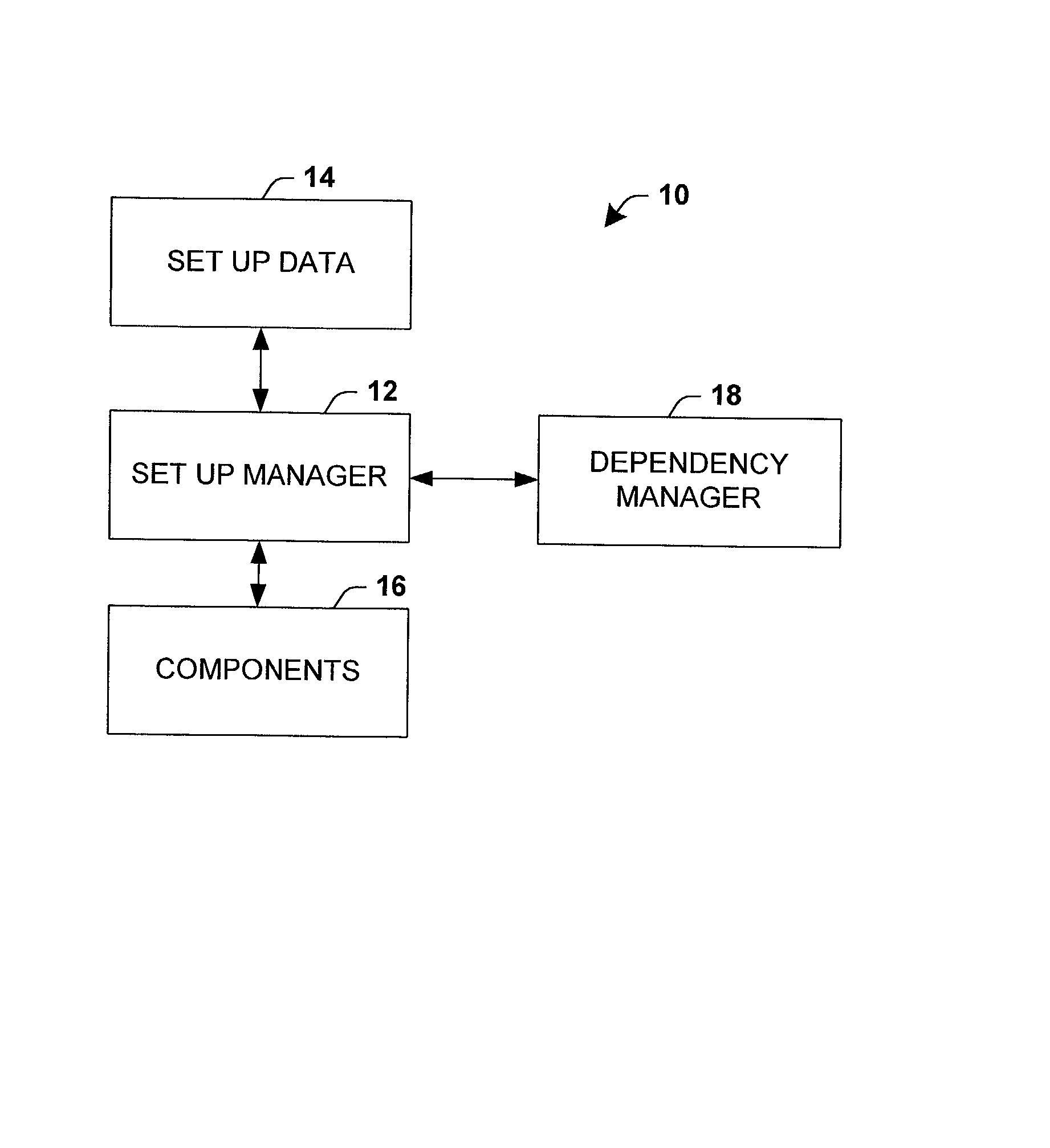

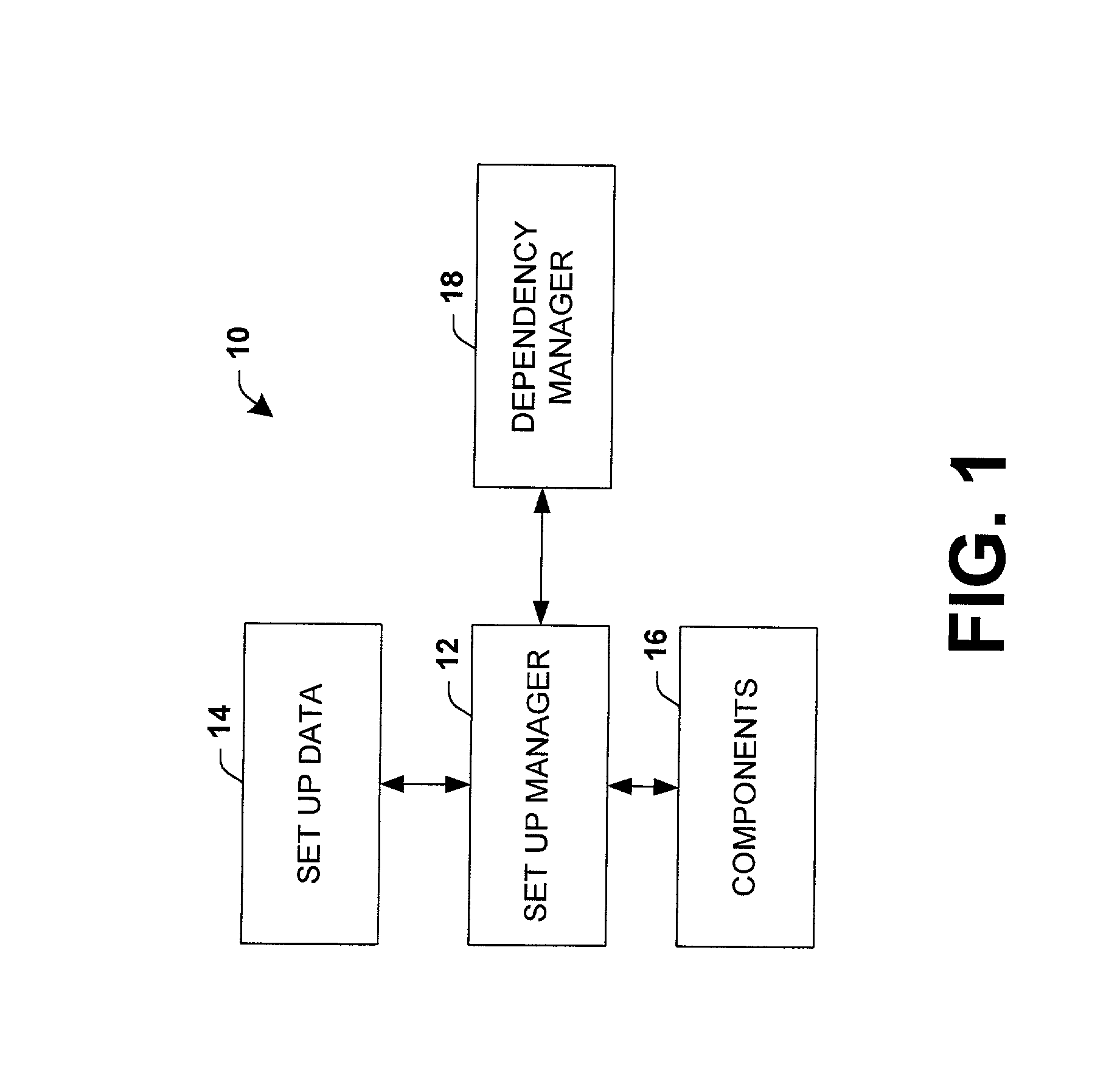

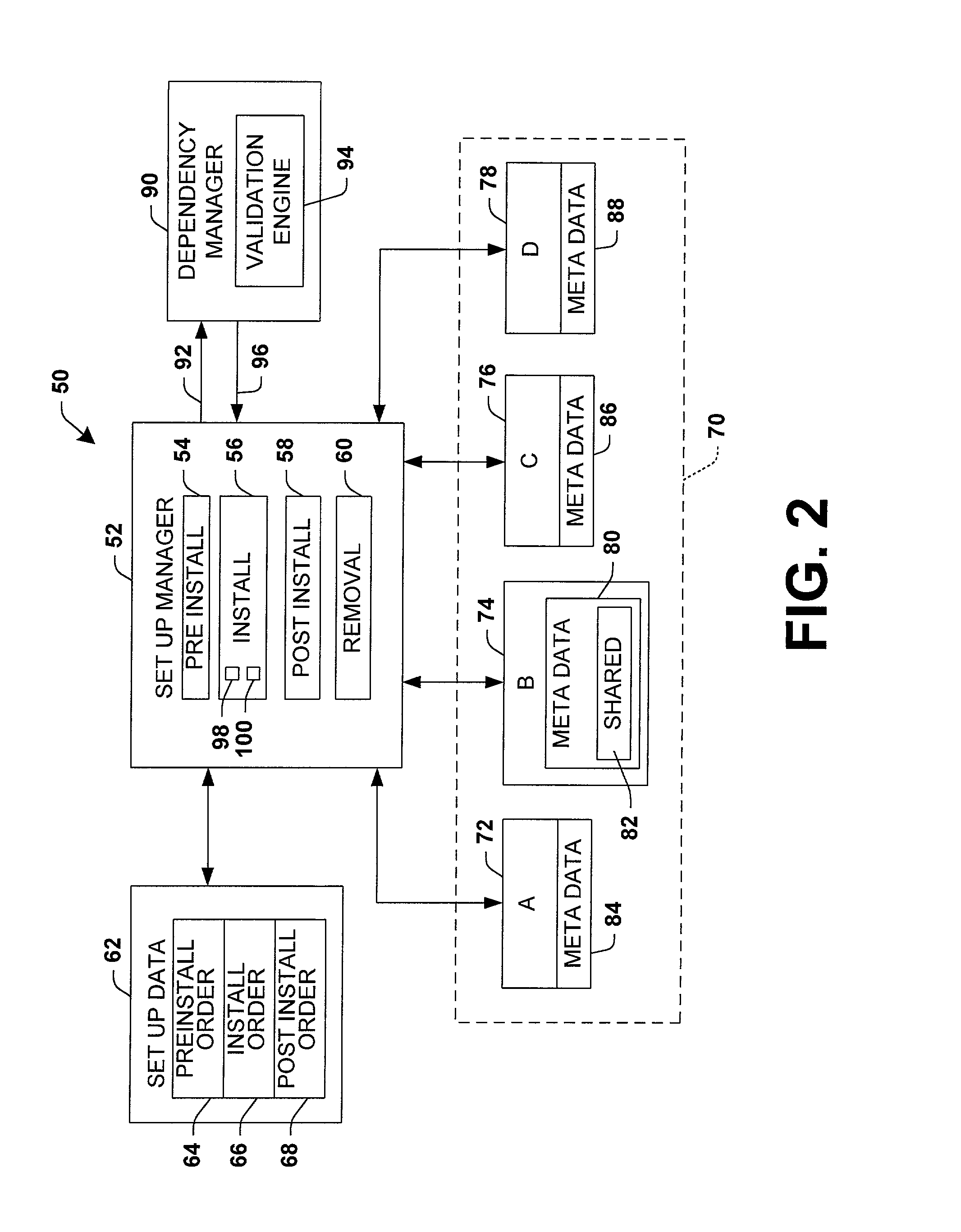

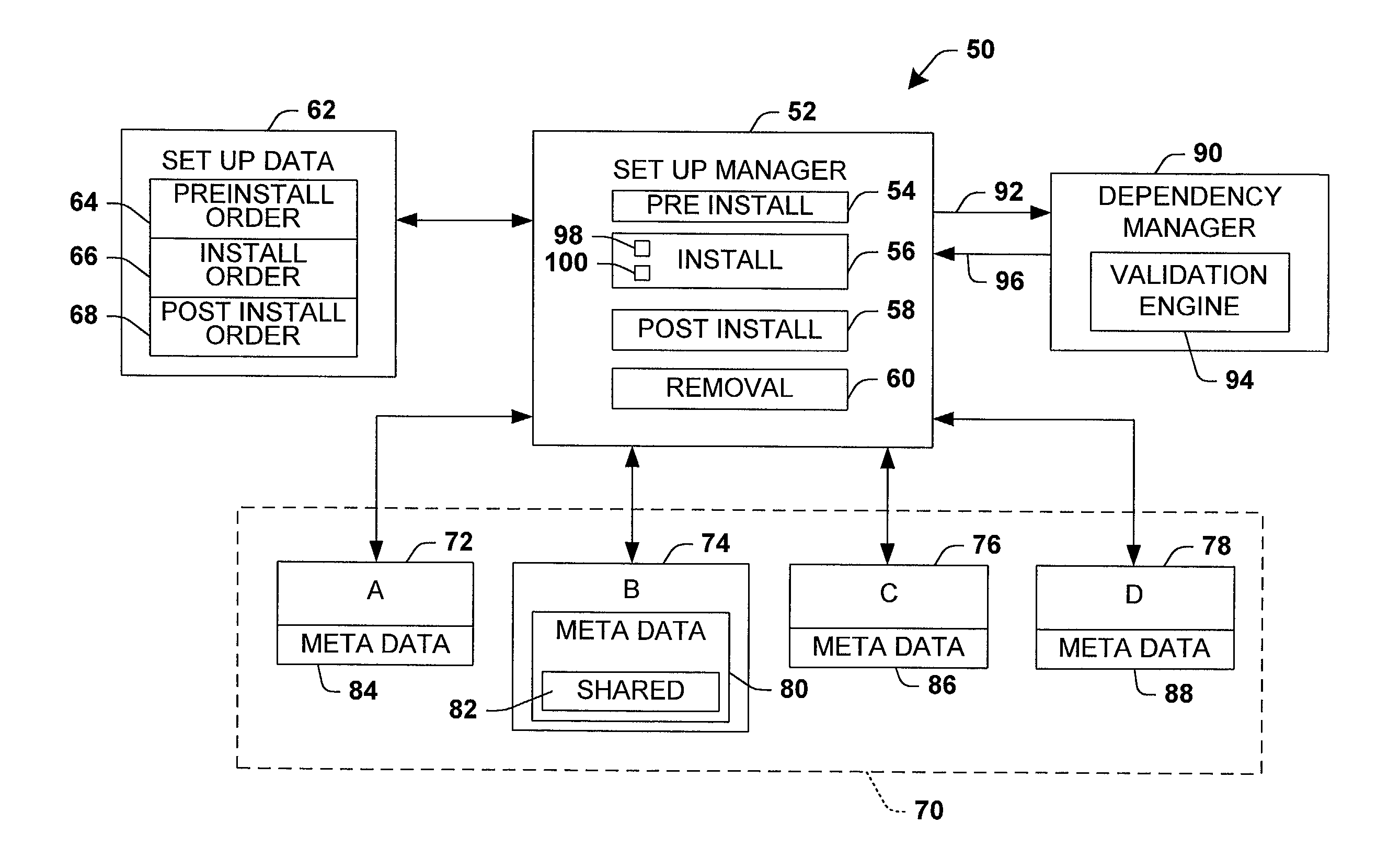

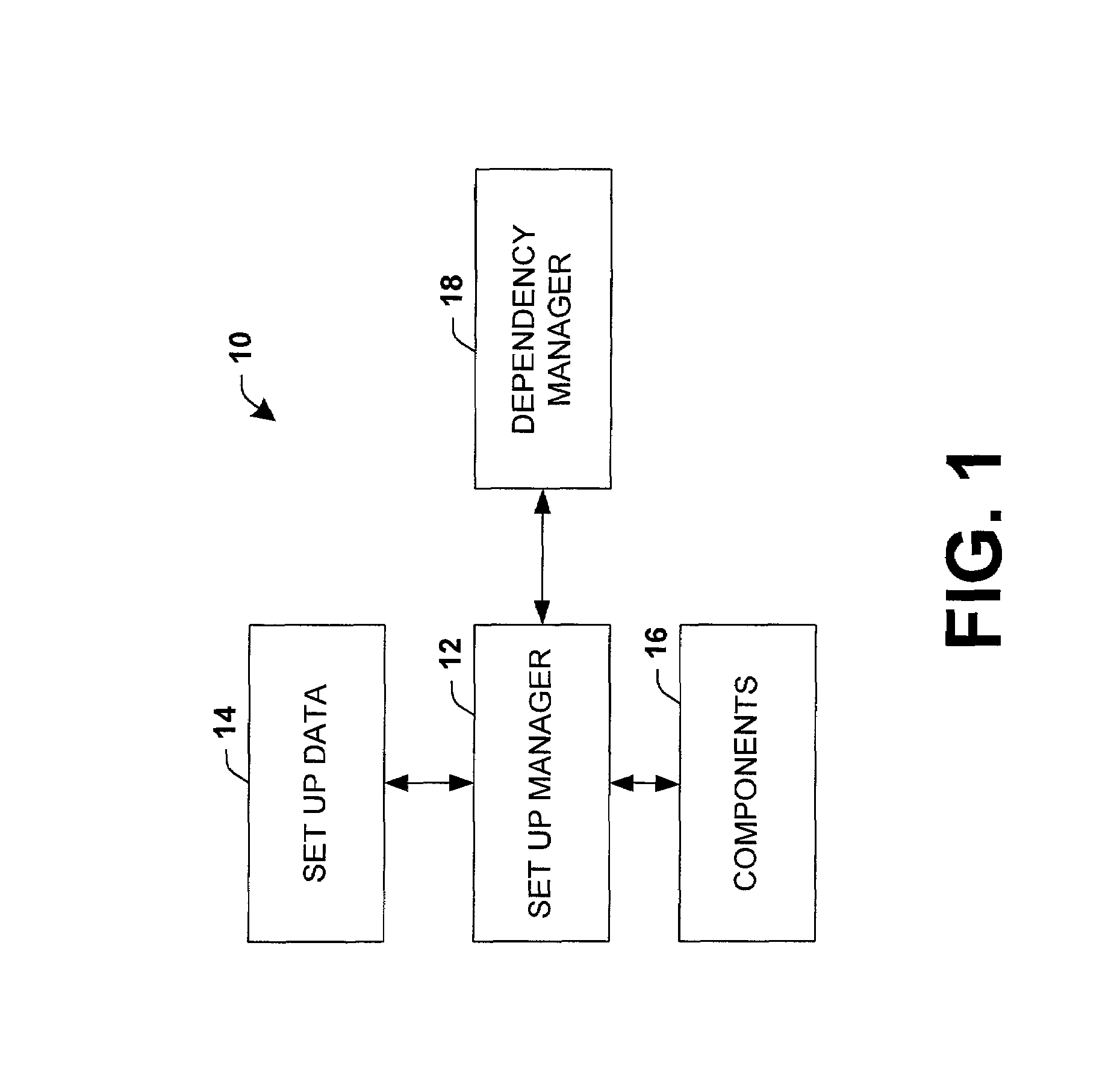

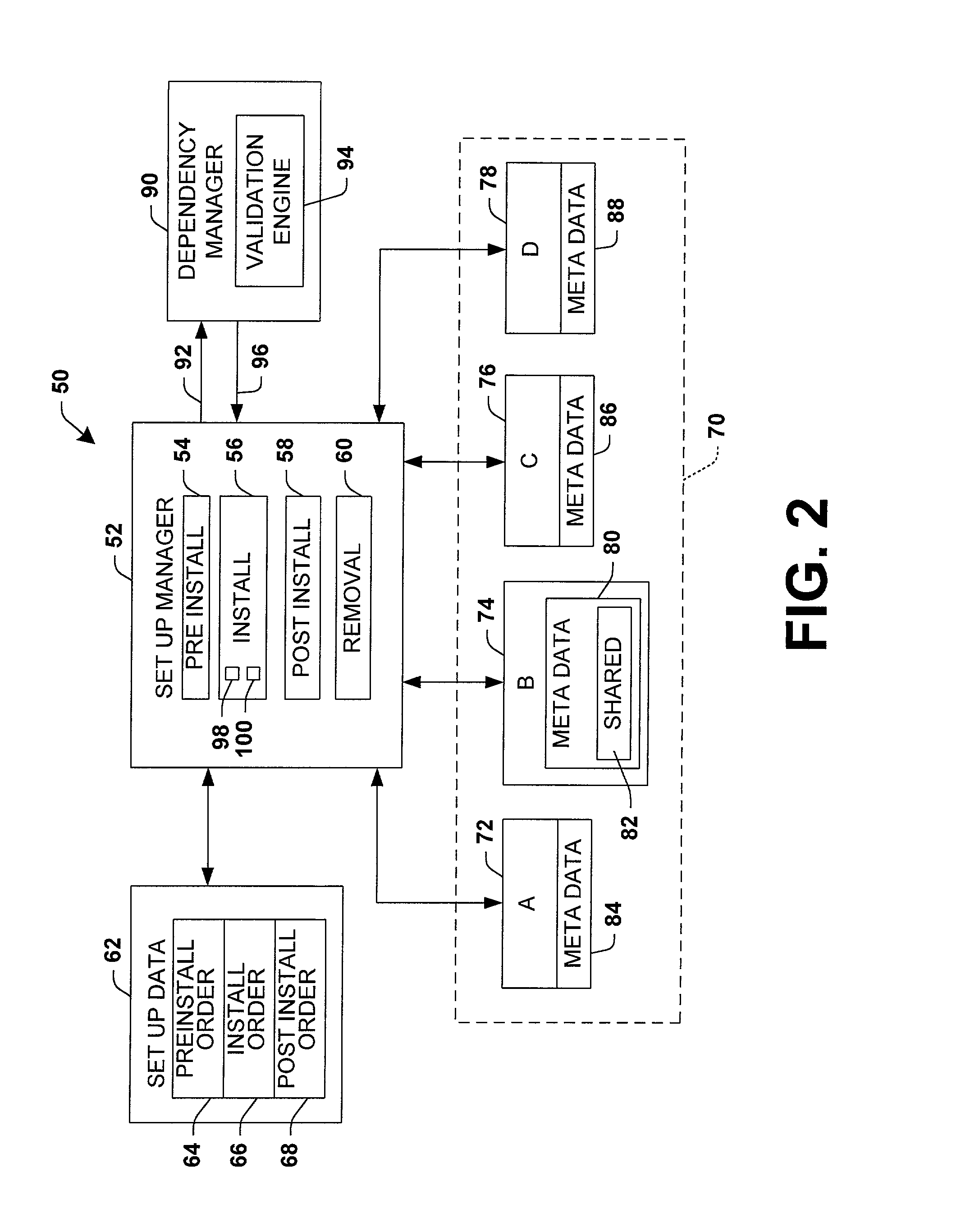

System and method to facilitate installation and/or removal of components

InactiveUS20020103973A1Easy to installEasy to removeMemory loss protectionError detection/correctionOrder formEngineering

The present invention provides a system and method to facilitate installation and / or removal of components in which one of the components is a shared component. The components are installed based on a valid order, such that shared components are installed after other components have been installed. According to one aspect, one or more properties associated with a shared component may be manipulated to facilitate installation and / or removal of components, including the shared component and dependent components.

Owner:MICROSOFT TECH LICENSING LLC

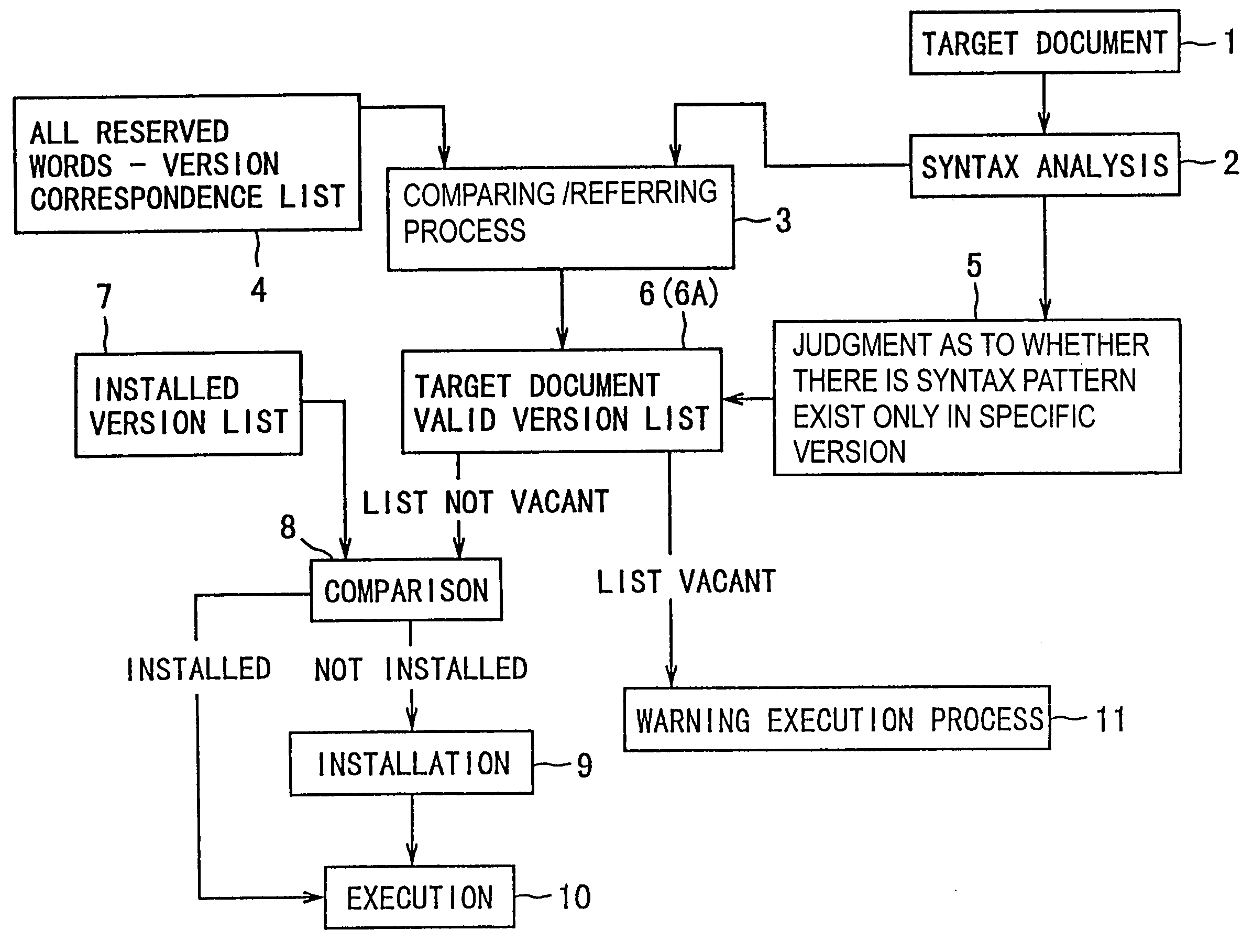

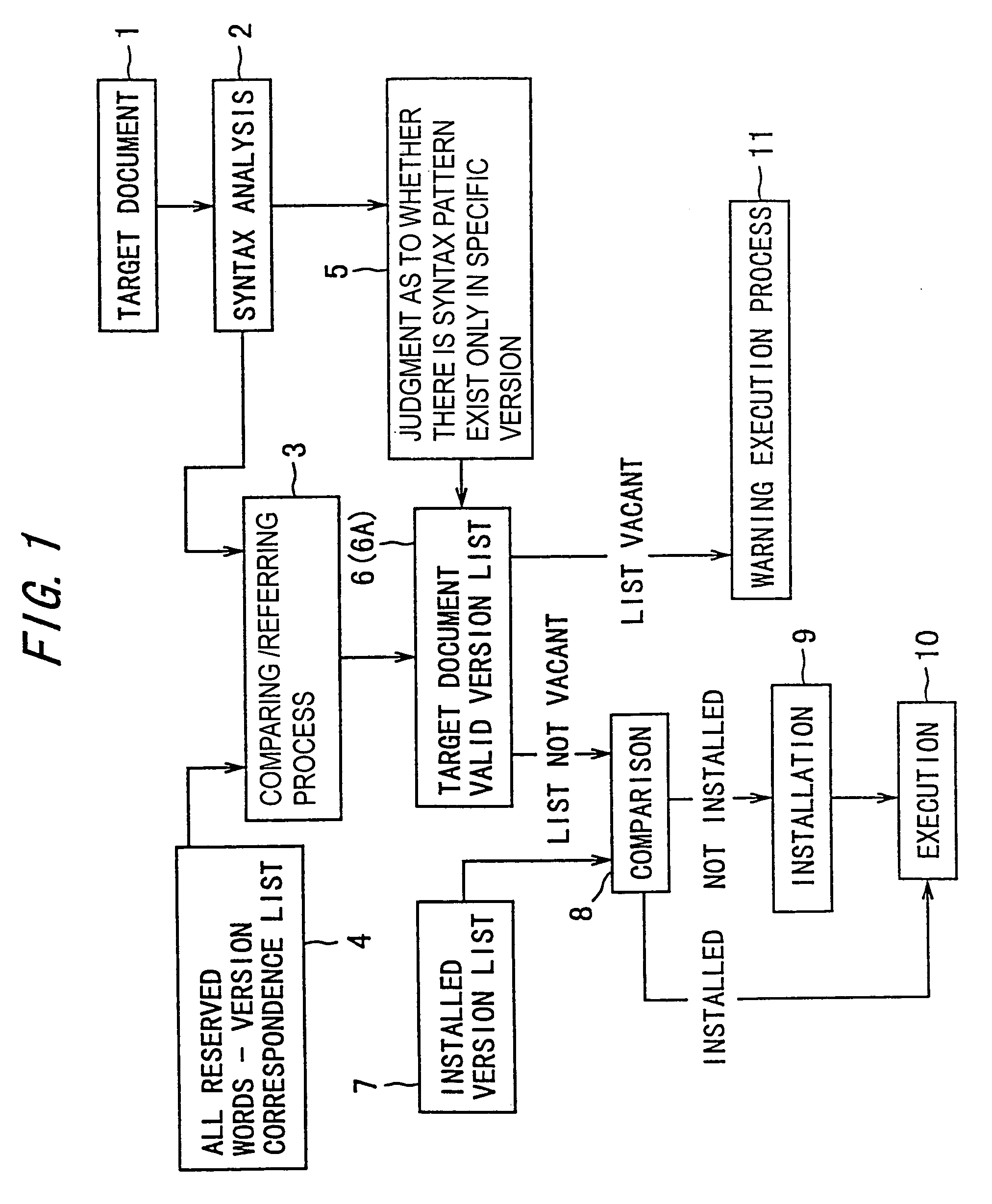

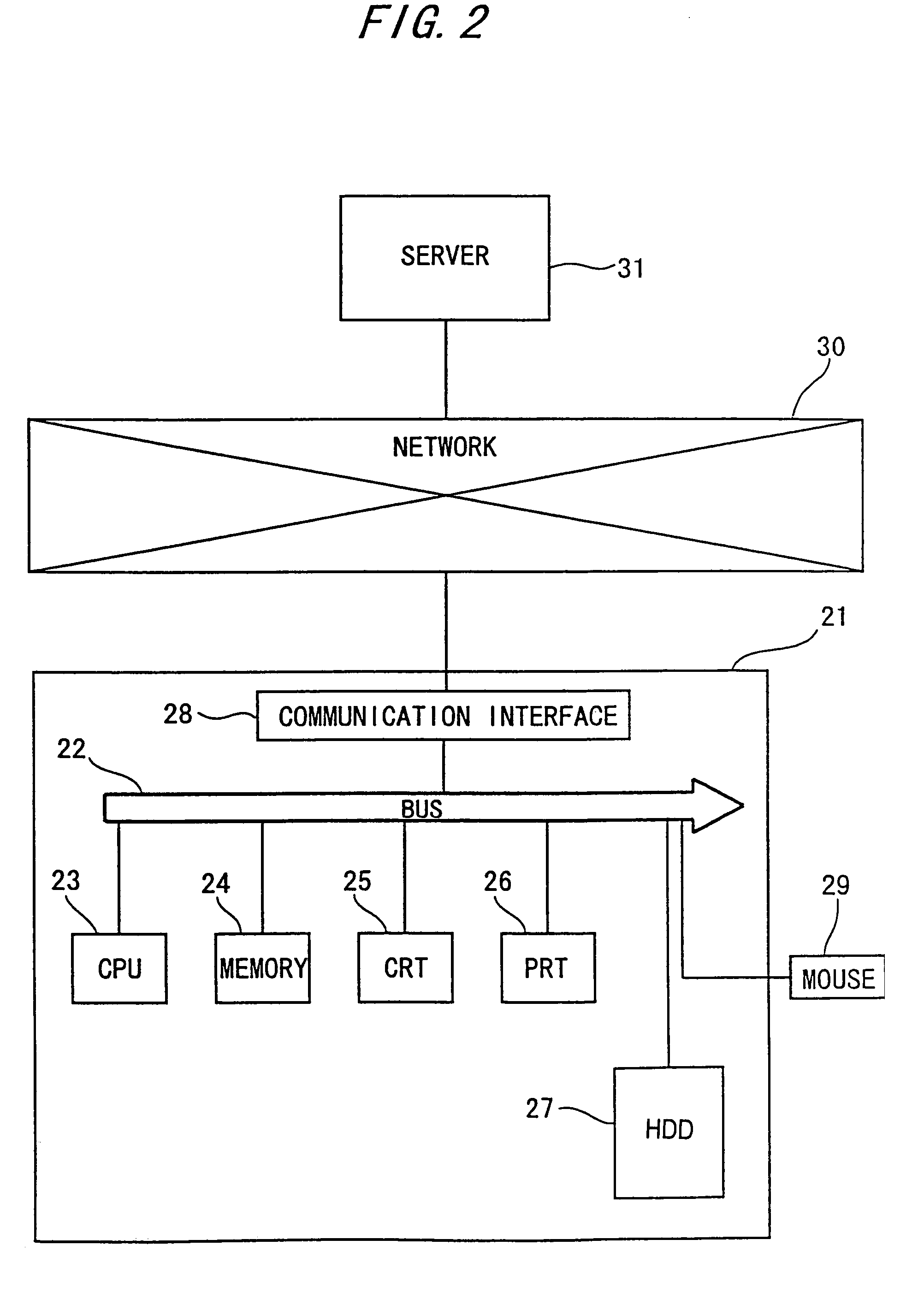

Installation method, activation method, execution apparatus and medium of application program

Without letting a user execute a cumbersome judgment of a version, an application program of the most suitable version is installed for data file automatically, thus an automatic activation of the application becomes possible. Firstly, a document file of a readout target is analyzed, a feature point as reserved word of macro instruction is extracted, and a version of an application suited for the document file is distinguished by an extracted feature point. Secondly, it is judged whether an application program of the version distinguished mentioned above is installed already. When found not being installed based on this judgment result, an application program of the version is newly installed.

Owner:FUJITSU LTD

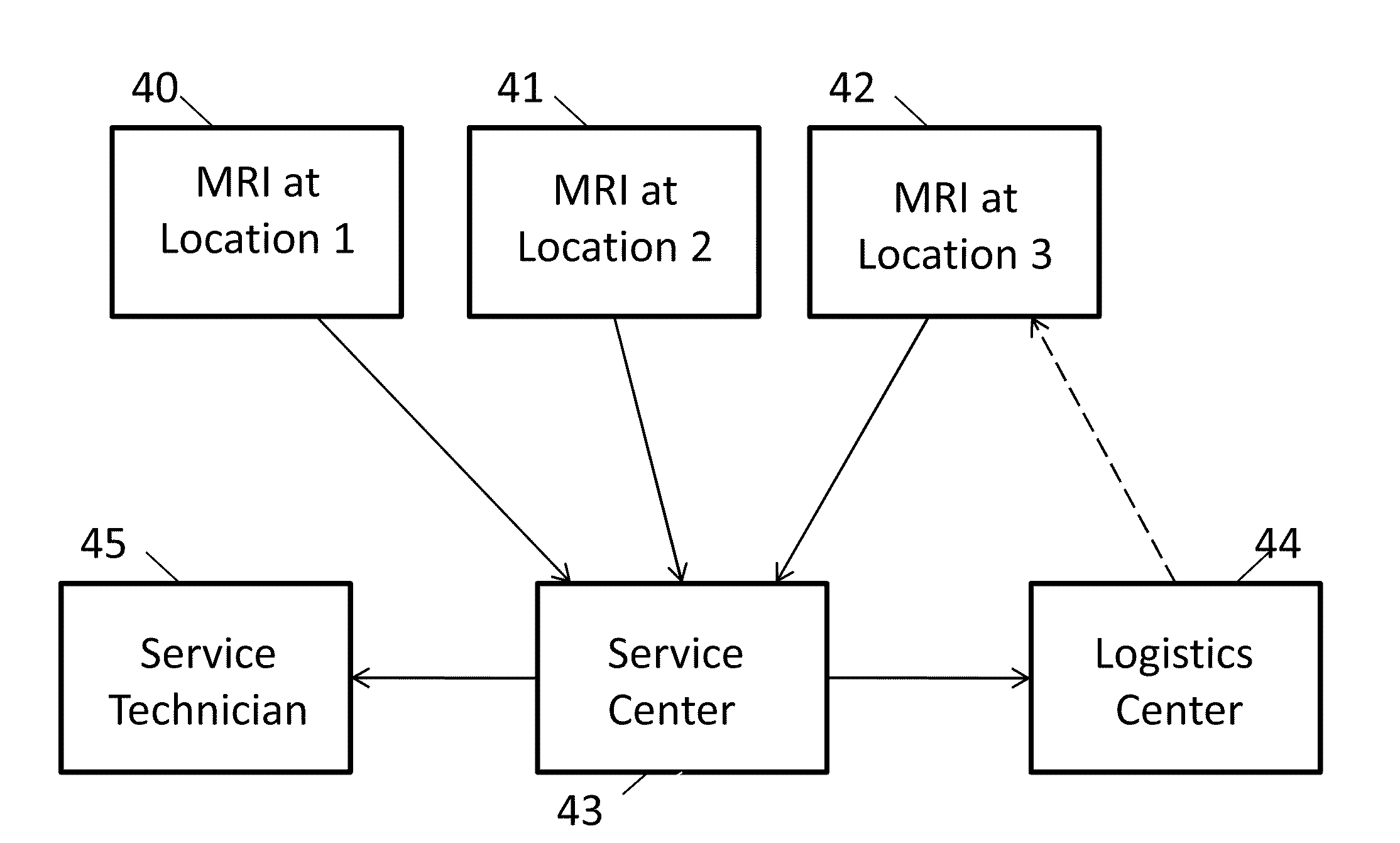

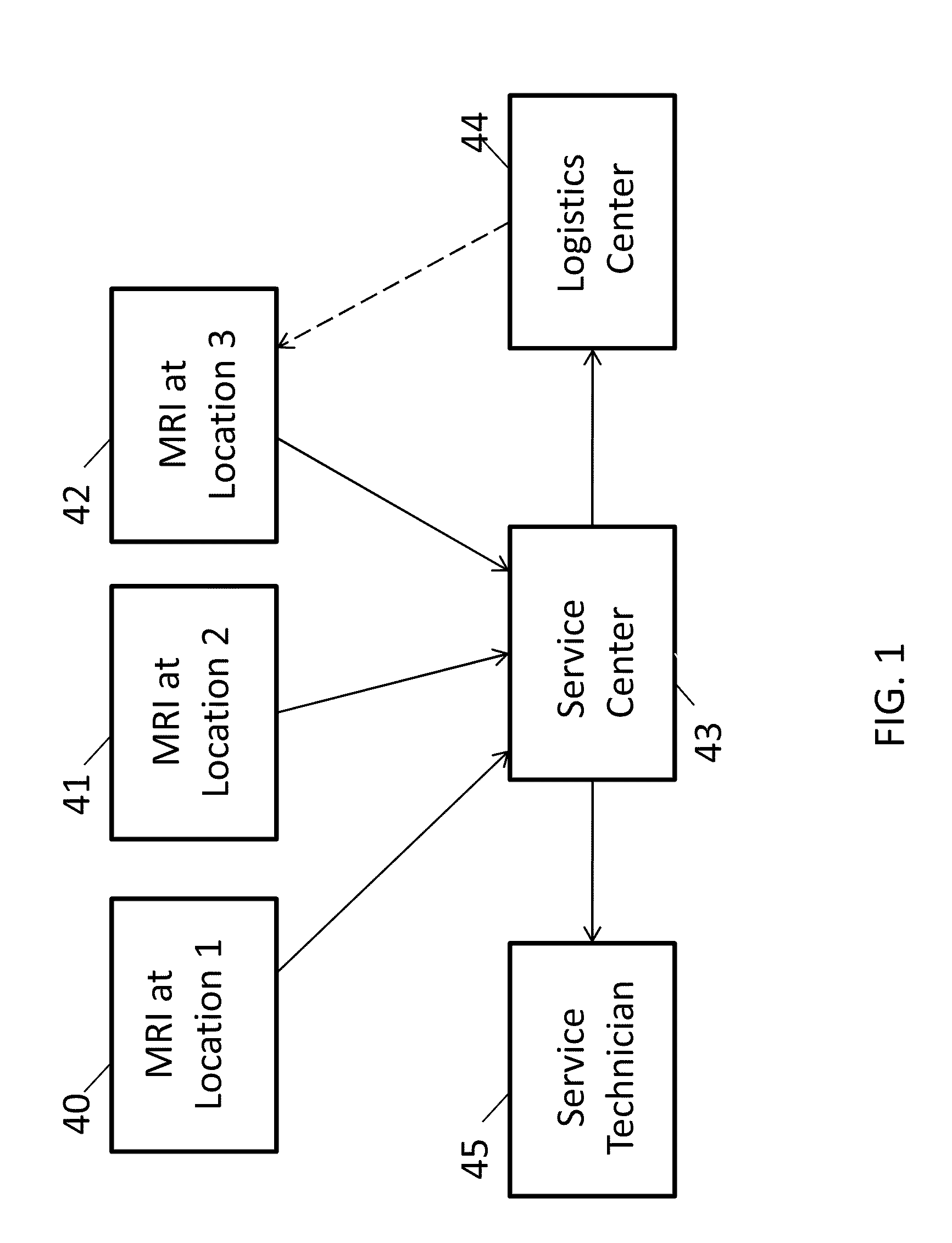

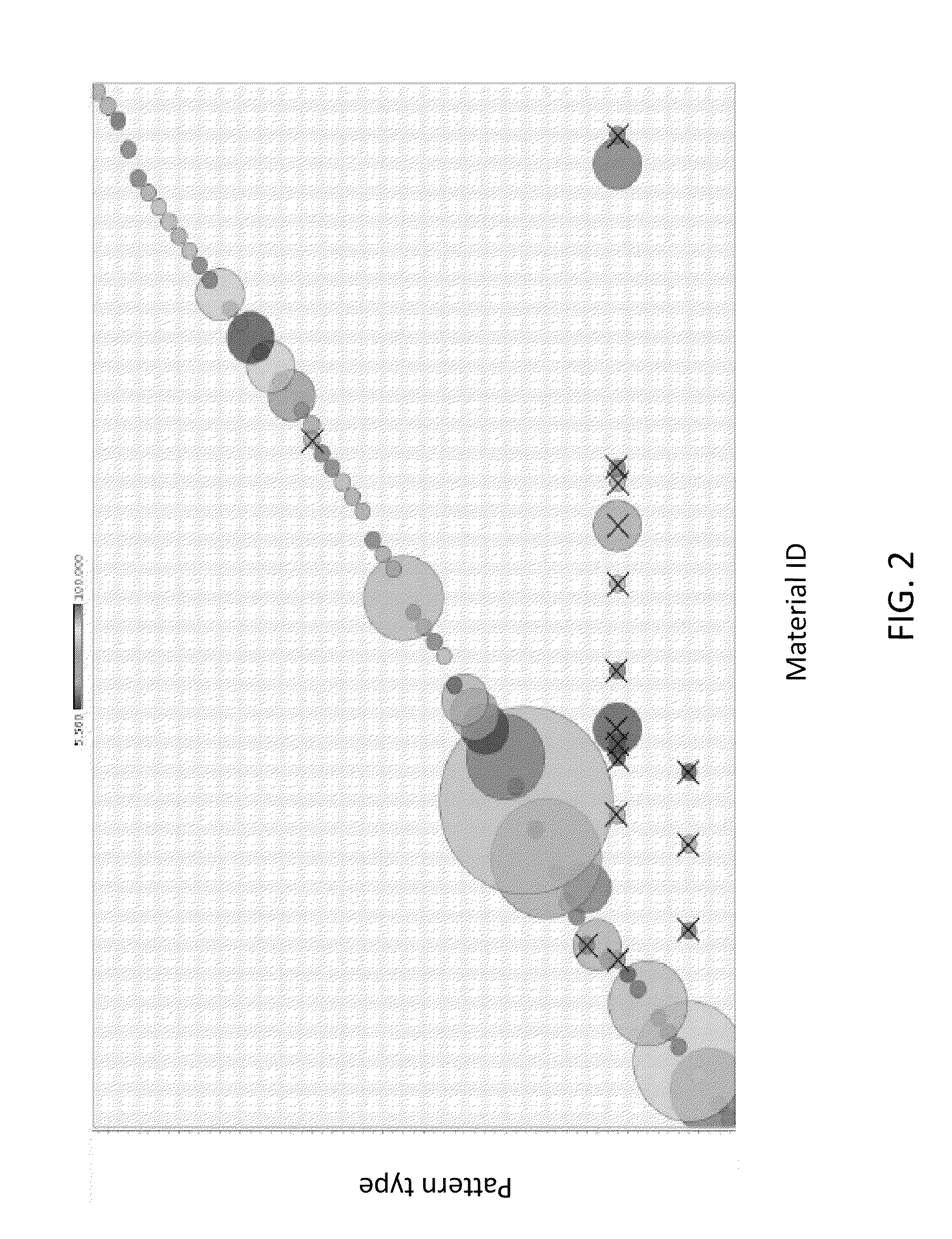

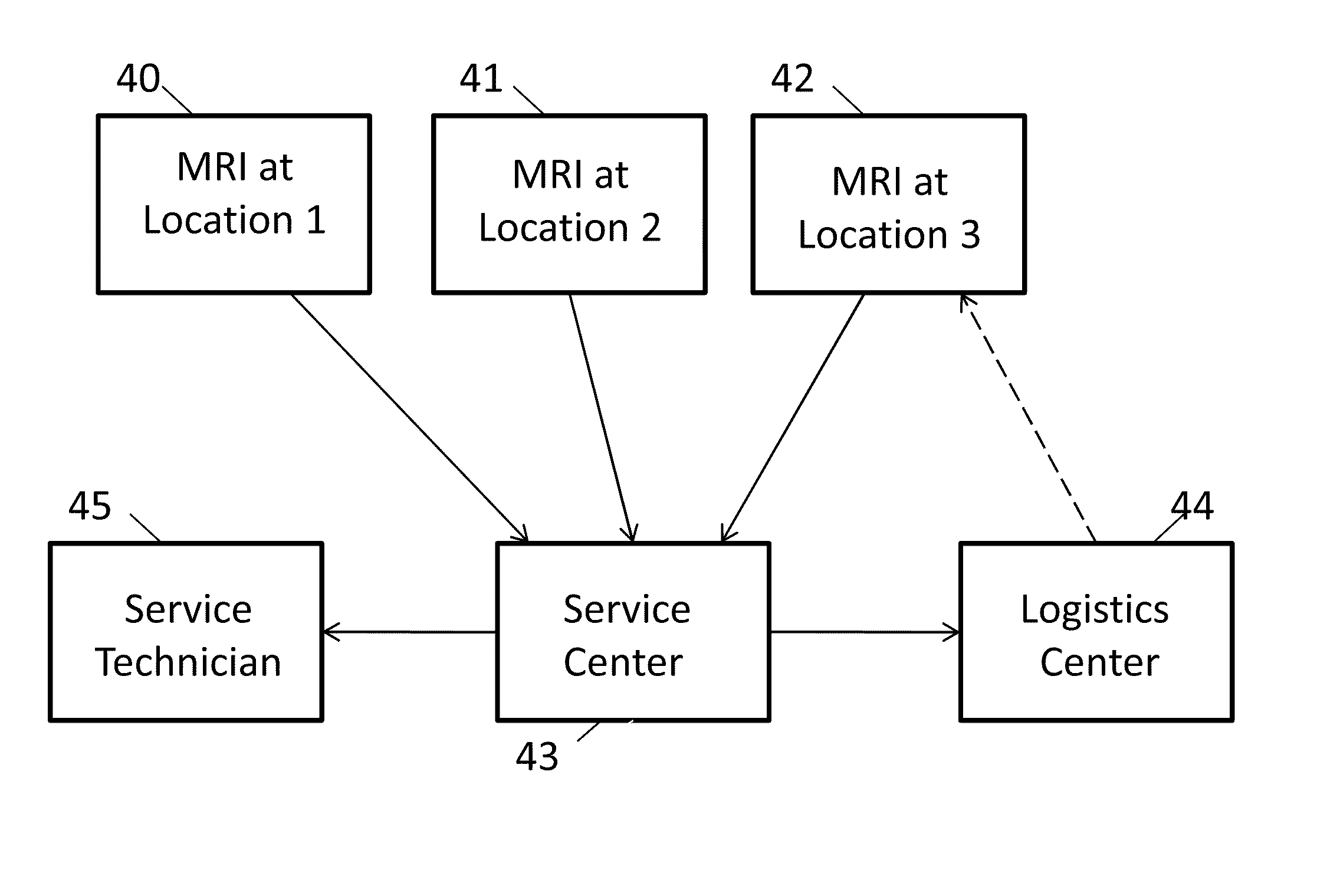

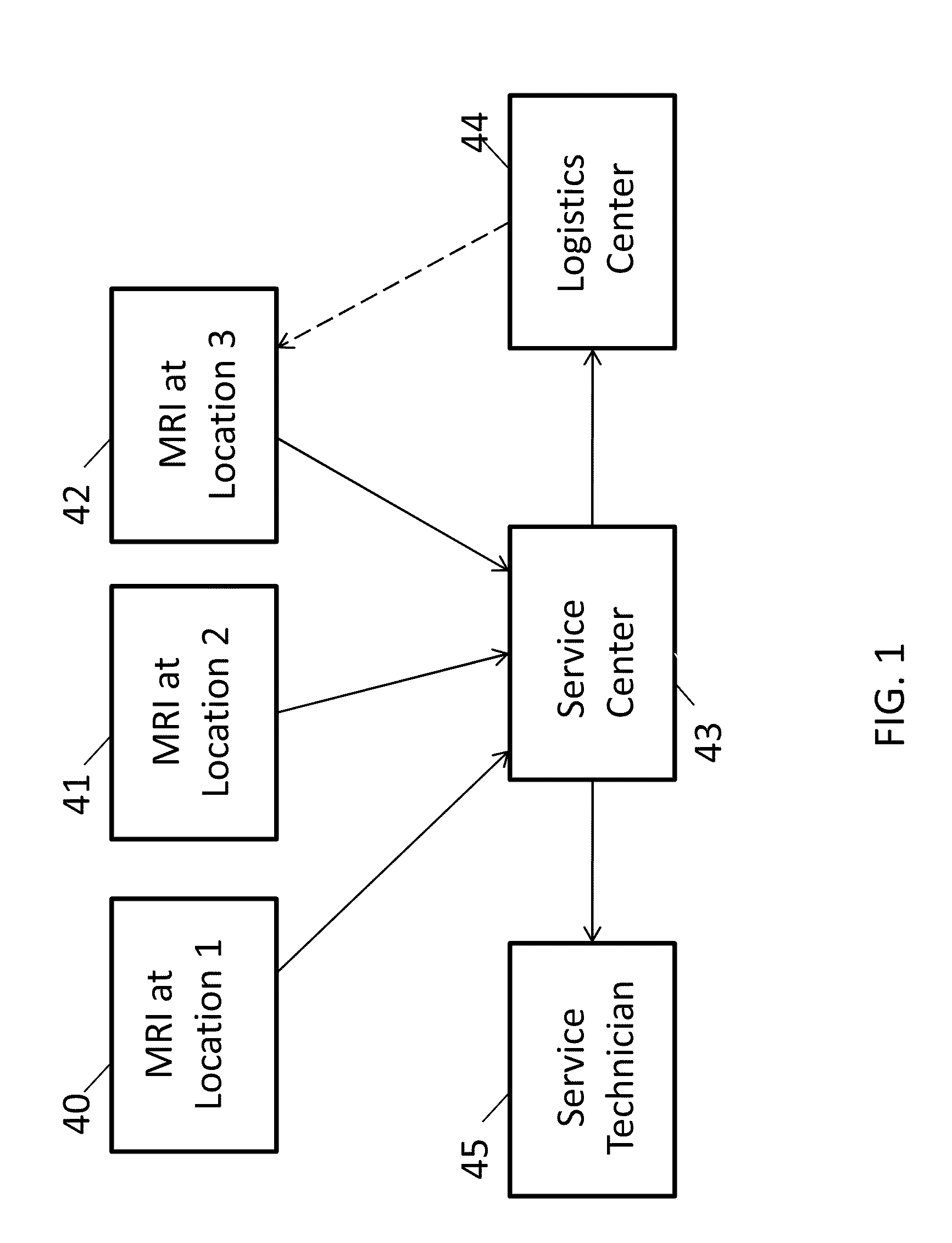

Error pattern identification in an installed base of systems

A system and method of servicing a group of similar types of equipment that maybe installed at geographically separated locations is described. The method makes use of error messages produced by the equipment and service requests received by a servicing center. Data mining techniques are used to establish error patterns associated with specific failure modes so that future error messages may be processed to determine if an identified failure mode has occurred. This will enable the efficient dispatch of spare parts and service personnel to the location where the failure has occurred.

Owner:SIEMENS HEALTHCARE GMBH

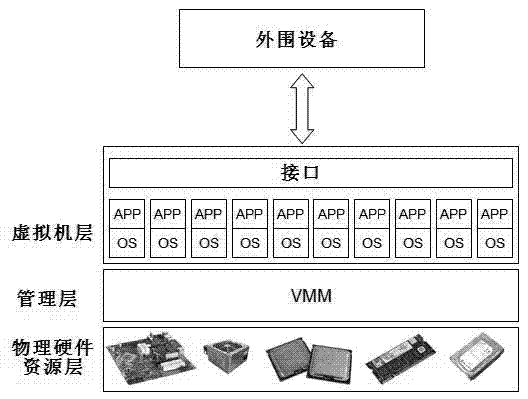

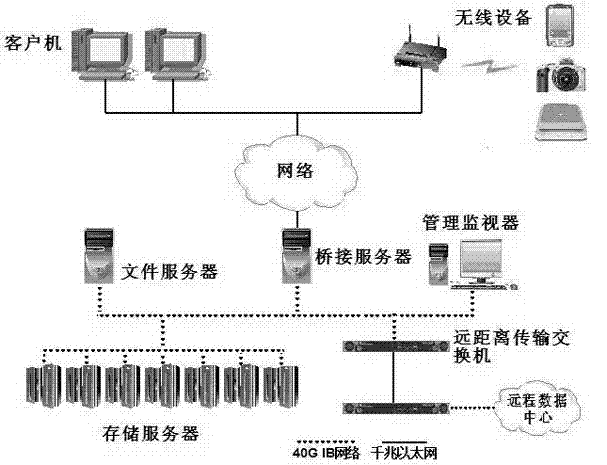

Virtualization system based on InfiniBand cloud computing network

InactiveCN102882864AImprove performanceImprove resource utilizationTransmissionSoftware simulation/interpretation/emulationPersonalizationFar distance

The invention provides a virtualization system based on InfiniBand cloud computing network, comprising a client and an infiniBand cloud computing network. The client is connected to the InfiniBand cloud computing network through an Ethernet. The infiniBand cloud computing network comprises a file server, a bridge server, a storage server and a management monitor, all of which are connected via infiniBand. The management monitor utilizes a virtual machine manager to manage the hardware resource of the cloud computing network, a plurality of virtual machines are installed based on the hardware resources to form a virtual machine layer, and the virtual machines are isolated mutually. The file server is used to store operating system files and user profiles and configure an individualized virtual machine when the user logs in the virtual machine. The bridge server performs protocol transformation and connects the InfiniBand cloud computing network to an external Ethernet so as to achieve virtual table logging within a hyper-far distance. The solution of the invention utilizes the characteristic of an infiniBand cloud computing network, namely the dynamic resource allocation, to improve the resource utilization rate of a virtualization system.

Owner:南京斯坦德云科技股份有限公司

Ion implantation ion source, system and method

InactiveUS20070107841A1Maximizing flow of electronHigh extracted currentSemiconductor/solid-state device manufacturingIon beam tubesDevice materialDesign space

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using, a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump;. Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

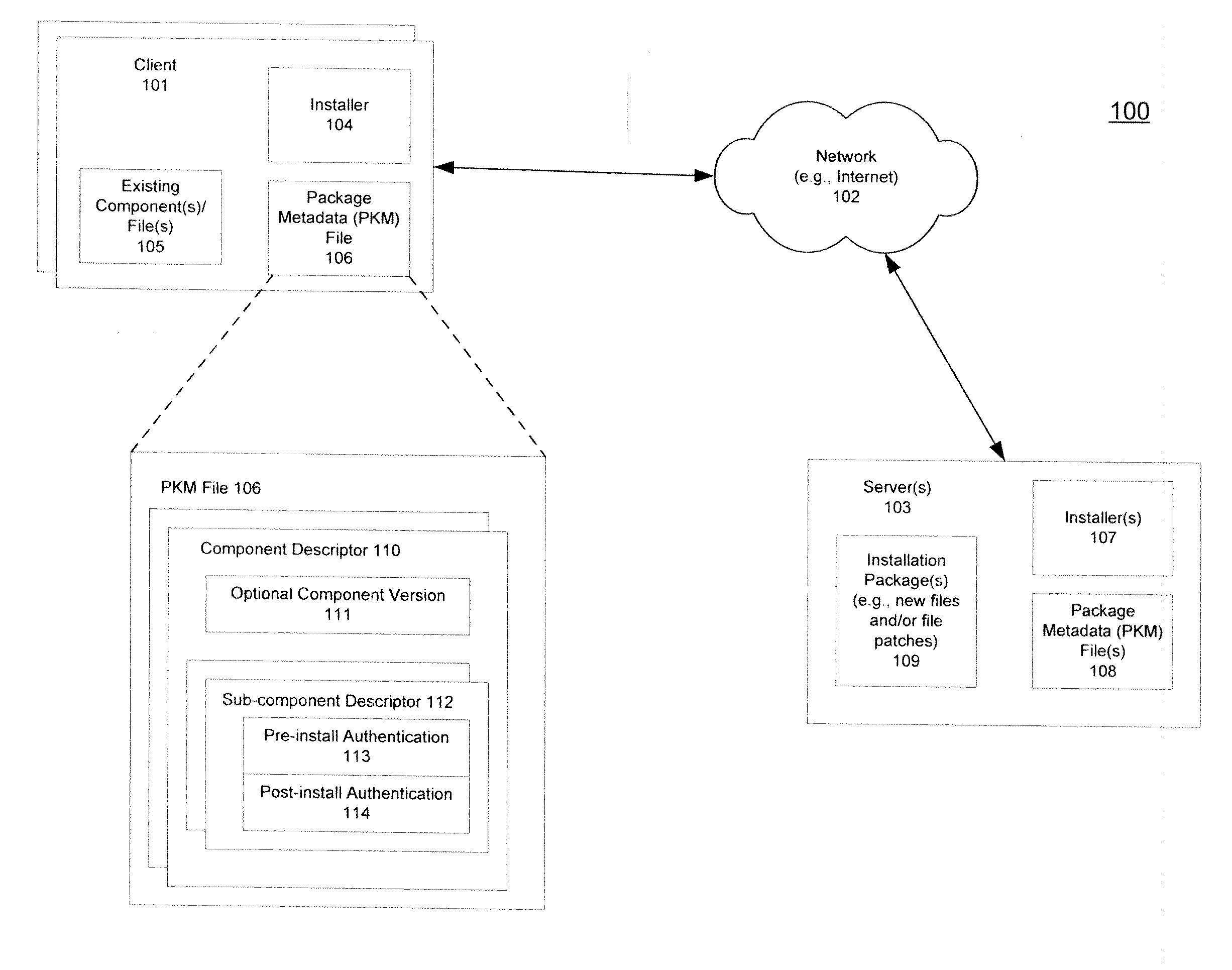

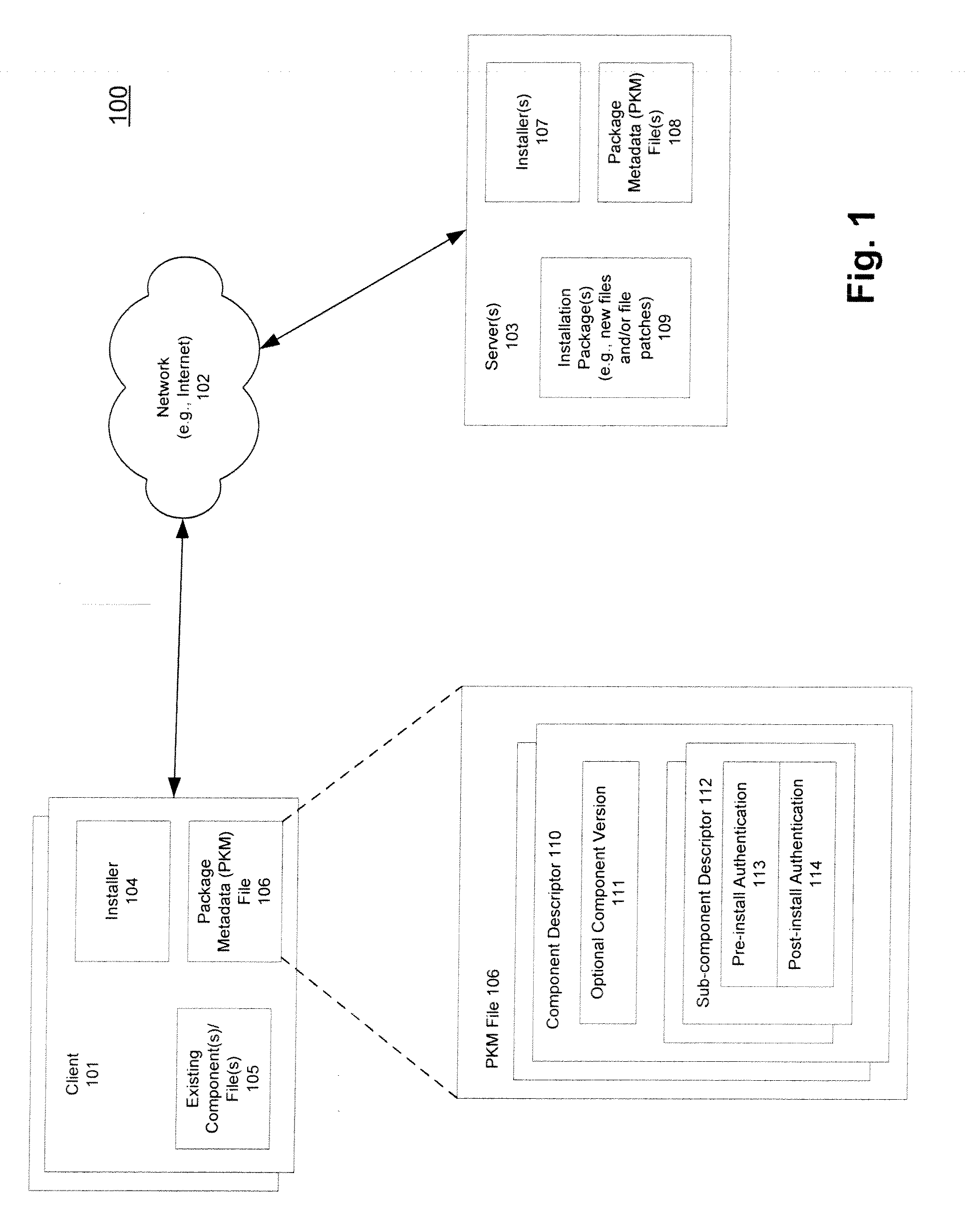

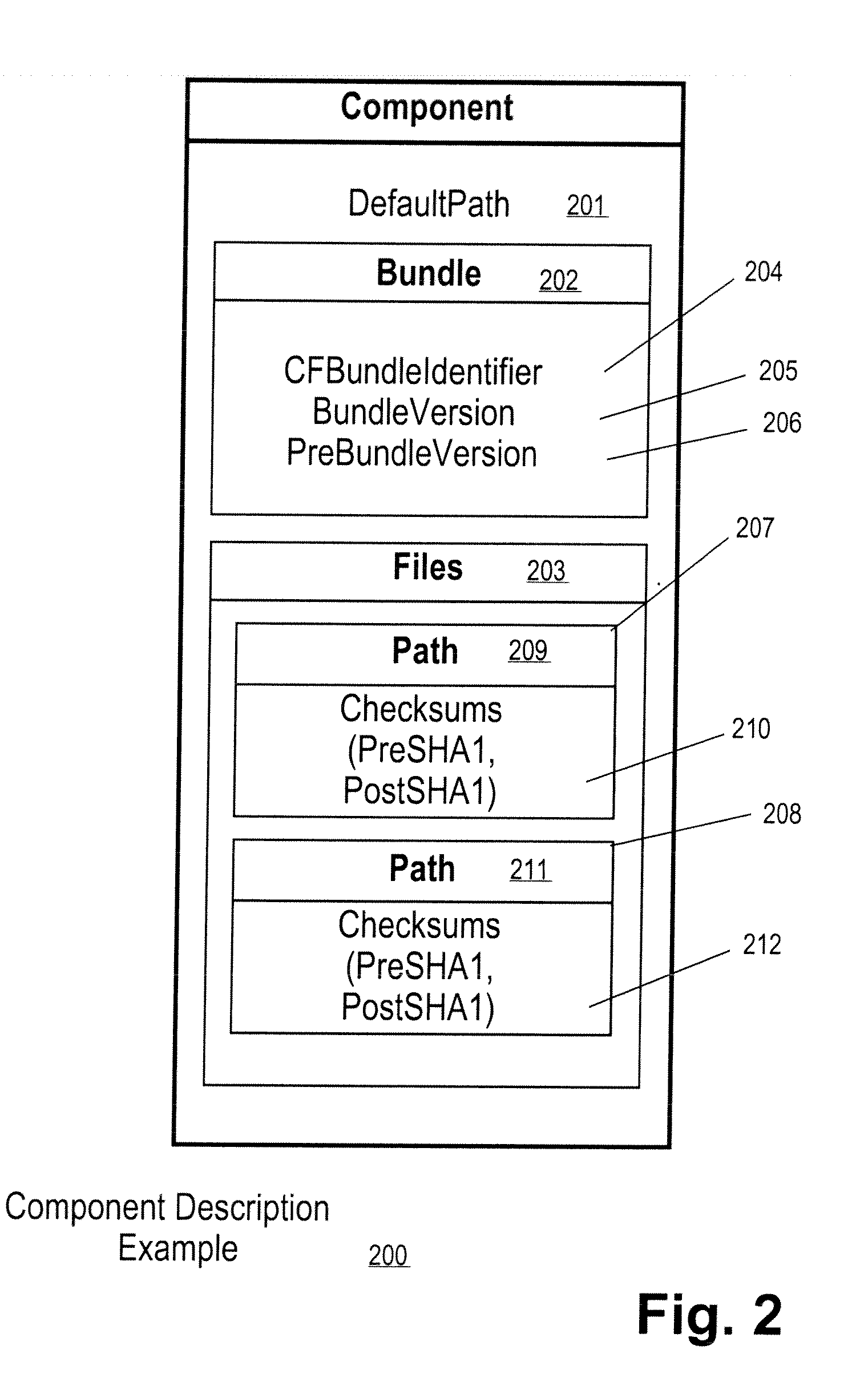

Mechanism for determining applicability of software packages for installation

Mechanism for determining applicability of a software package for installation is described herein. In one embodiment, a process is provided to retrieve authentication information of a component from an installation descriptor file, where the descriptor file describes installation information of the software package. The software package may include one or more components and each component having zero or more sub-components. For at least one sub-component of at least one existing component that has already been installed, an image of the sub-component is authenticated using an authentication key extracted from the authentication information to determine whether the component can be installed based on the existing component. Other methods and apparatuses are also described.

Owner:CIUDAD JEAN PIERRE +2

Error pattern identification in an installed base of systems

InactiveUS8595553B2Local control/monitoringError detection/correctionService personnelInstalled base

A system and method of servicing a group of similar types of equipment that maybe installed at geographically separated locations is described. The method makes use of error messages produced by the equipment and service requests received by a servicing center. Data mining techniques are used to establish error patterns associated with specific failure modes so that future error messages may be processed to determine if an identified failure mode has occurred. This will enable the efficient dispatch of spare parts and service personnel to the location where the failure has occurred.

Owner:SIEMENS HEALTHCARE GMBH

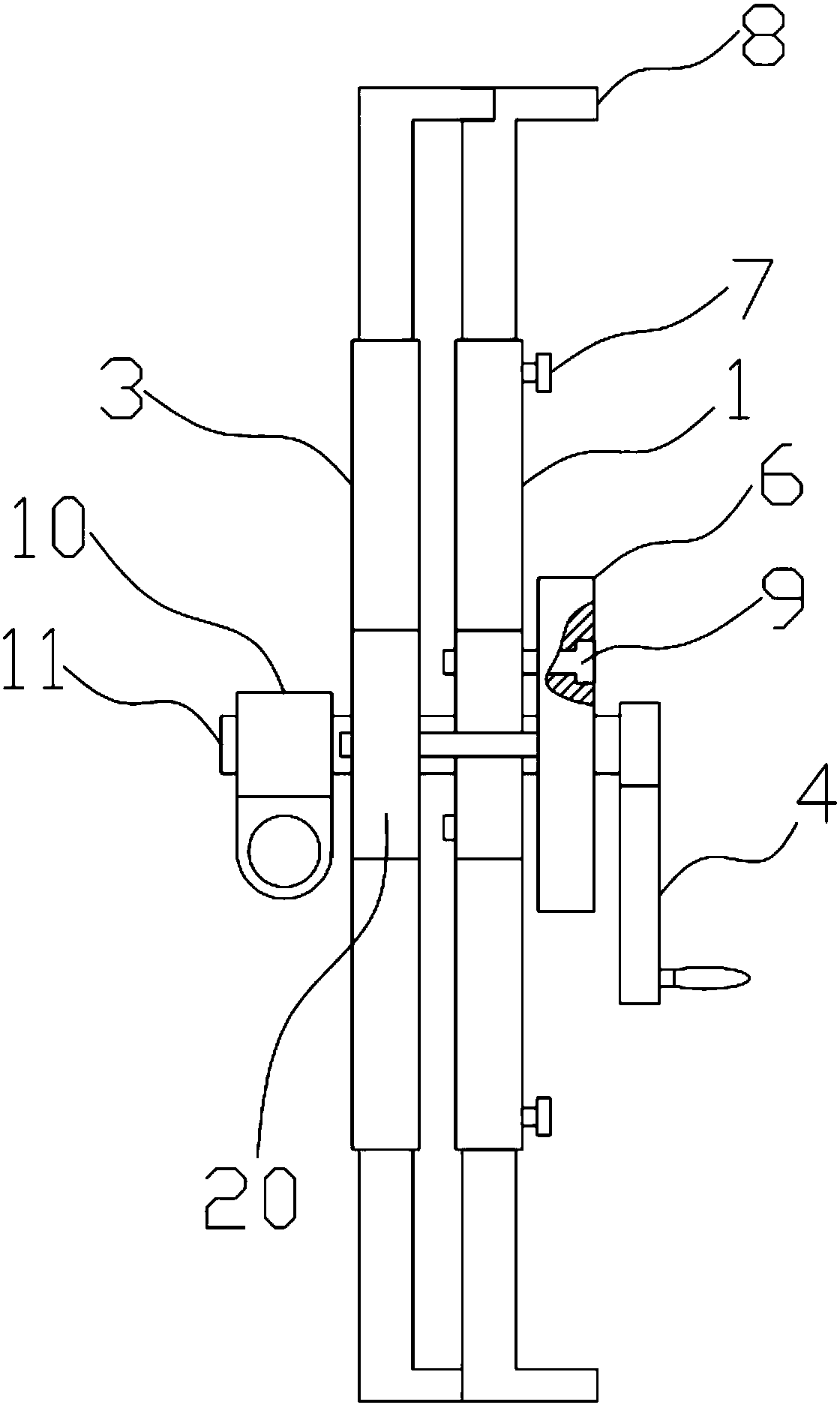

Large pipeline inner wall welding tool

InactiveCN107553023AImprove practicalityEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringInstalled base

The invention discloses a large pipeline inner wall welding tool. The large pipeline inner wall welding tool comprises a rotating shaft, two vertical supporting rods, two transverse supporting rods and a supporting arm, wherein a fixed disc and two installing bases are rotationally connected to the rotating shaft in sequence, a fixed sleeve is fixed to one end of the rotating shaft, and the otherend of the rotating shaft penetrates through the fixed disc to be fixedly provided with a curved bar; and the vertical supporting rods are fixed to the two ends of one installing base separately, thetransverse supporting rods are fixed to the two ends of the other installing base separately, the bottom of the supporting arm is fixed to the fixed sleeve, and a welding rod clamping base is installed at the top end of the supporting arm. According to the large pipeline inner wall welding tool, the rotating shaft can be fixed at the axis of a pipeline through the transverse supporting rods and the vertical supporting rods, the transverse supporting rods and the vertical supporting rods are each of a telescopic structure and can adapt to pipelines which are different in size, and the practicability of the device is improved; and manual welding operation is simulated, the welding effect is guaranteed, welding rods are attached to the inner wall of the pipeline all the time, and therefore continuous welding can be conducted, and the welding efficiency is high.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Explosion-field shock wave overpressure filter

InactiveCN102818670ARequirements for Accurate Measurement of Quasi-static PressureAchieving Accurate Measurement RequirementsApparatus for force/torque/work measurementShock waveEngineering

The invention discloses an explosion-field shock wave overpressure filter, which is composed of a cover plate, a tube cavity, a screw rod, a buffer gasket, a sensor installing base and a pressure sensor, wherein one end of the tube cavity is connected with the cover plate, and the other end of the tube cavity is connected with the sensor installing base; the piezoresistive pressure sensor is installed in the sensor installing base; and the inner part of the tube cavity is provided with the screw rod. Explosive is exploded in a closed environment, and shock waves enter from a blind hole in the cover plate, penetrate through cross through holes, and enter into a groove of the screw rod in the tube cavity from gaps around a boss. The shock waves are transmitted along with the screw groove to be weakened, and finally the shock waves are transmitted to the sensitive surface of the pressure sensor. The pressure sensor is subjected to a pressure action and then outputs pressure signals, the pressure signals are amplified through a front adapter, and then a quasi static pressure curve is obtained.

Owner:XIAN MODERN CHEM RES INST

Radio Communication System, A Repeater Apparatus and a Control Method of the Repeater

InactiveUS20100035542A1Uniform loadImprove throughputTransmission monitoringRadio transmissionCommunications systemA domain

Provided is a radio communication system including a plurality of base stations and a repeater apparatus, in which the repeater apparatus amplifies and transmits a radio signal received from at least one of the plurality of base stations, and controls a domain in which the radio signal is transmitted based on a traffic amount of each of the plurality of base stations. Accordingly, the number of installed base stations which are costly is reduced, and an operating rate of the respective base stations is gained along with the decrease in number of installed base stations.

Owner:HITACHI LTD

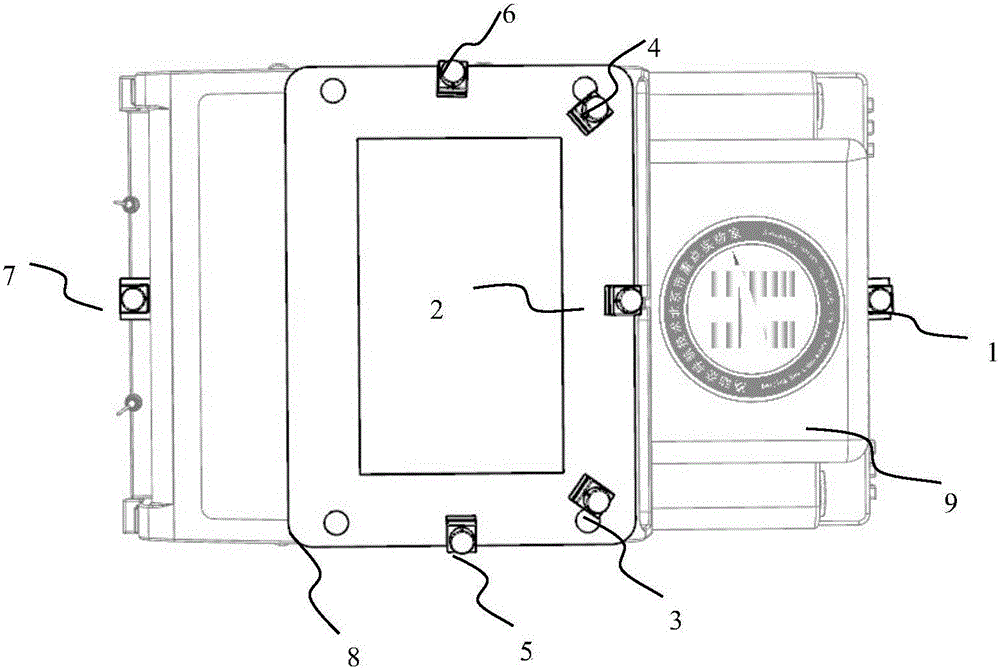

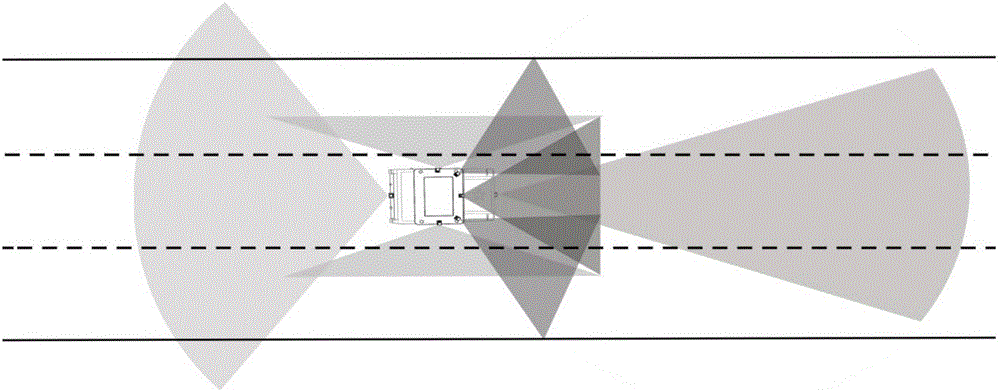

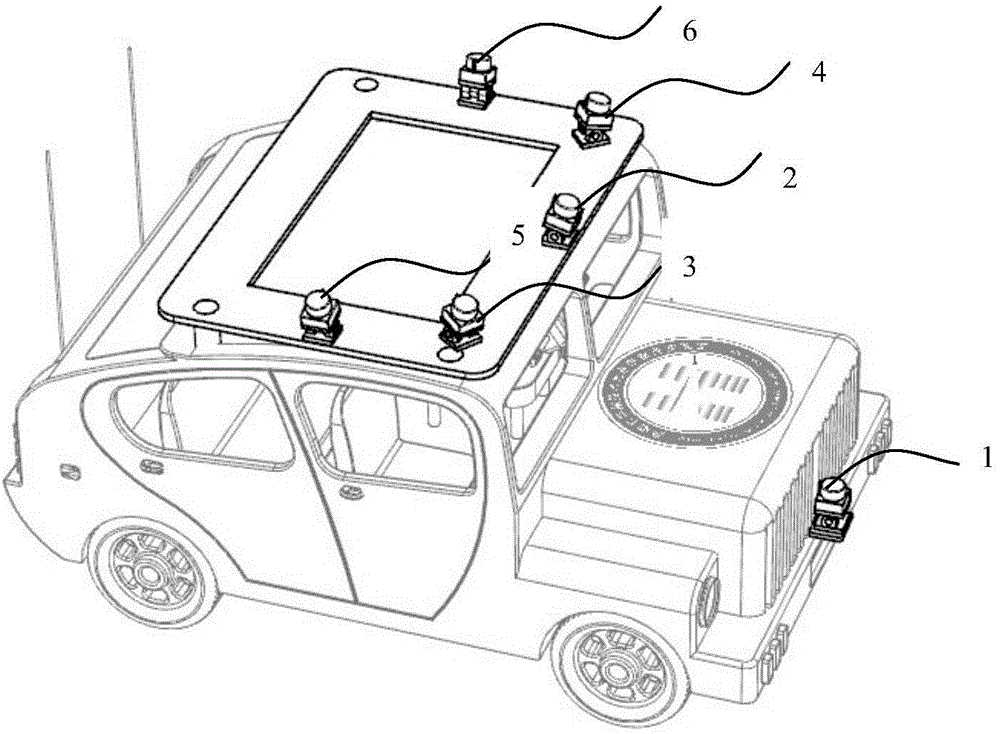

Single-line laser radar device

InactiveCN105699985AIncrease in sizeReal-time perceptionElectromagnetic wave reradiationOptoelectronicsInstalled base

Disclosed in the invention is a single-line laser radar device comprising a radar installation device, a single-line laser radar and a carrier rack. The single-line laser radar is installed on the carrier rack by the radar installation device. The carrier rack with a preset thickness has a flat rectangular shape; at least three single-line laser radars including a first single-line laser radar, a second single-line laser radar, and a third single-line laser radar are distributed uniformly at one side of the carrier rack; and at least one single-line laser radar being a fourth single-line laser radar or a fifth single-line laser radar is distributed at the middle of each of two sides perpendicular to one side with the first single-line laser radar. The installation position and the pitching angle of the radar installation device can be adjusted. When a radar is installed based on the technical scheme, full coverage of the carrier rack in terms of the scanning range can be realized. The provided device is applied to an unmanned vehicle to complete real-time detection on the environment of unmanned driving.

Owner:BEIJING INFORMATION SCI & TECH UNIV

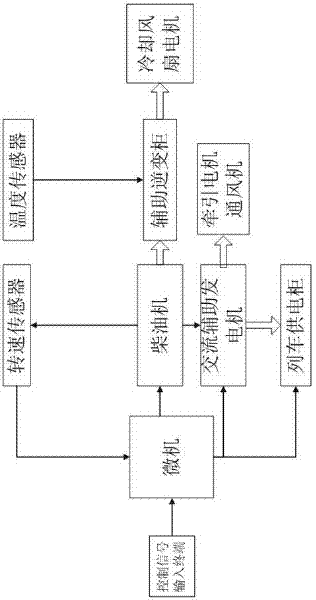

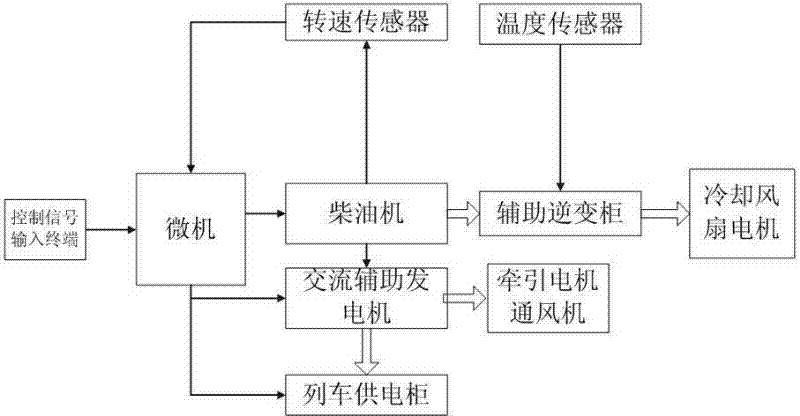

Locomotive AC train power supply system and power supply control method thereof

InactiveCN102416958ALow costImprove reliabilityElectric locomotivesElectric propulsionThrottle controlMicrocomputer

The invention discloses a locomotive AC train power supply system and a power supply control method thereof, relates to the train power supply technology, and provides a locomotive AC train power supply system and a power supply control method thereof aiming at the defect in the prior art that the power energy demand is not ensured when a train breaks down. The technical points of the invention are that: a control signal input terminal, a microcomputer, a rotating speed sensor, and a train power supply cabinet are additionally installed based on an existing diesel engine, and an AV auxiliary generator for locomotive AC auxiliary transmission; the microcomputer is in signal connection with all of the control signal input terminal, the rotating speed sensor, the AV auxiliary generator, a diesel engine throttle control terminal, and the train power supply cabinet; the AV auxiliary generator supplies power to the train power supply cabinet, and a AC power supply output terminal of the train power supply cabinet is used to supply power to the train; the microcomputer adjusts the size of the output voltage of the AV auxiliary generator according to a rotating speed signal of the diesel engine outputted by the rotating speed sensor so as to ensure that the train power supply cabinet outputs stable 380 V three-phase AC power for the train.

Owner:CRRC ZIYANG CO LTD

Capacitance type minitype silicon microphone and preparation method thereof

ActiveCN101835079AFlexible designImprove yieldElectrostatic transducer microphonesCapacitanceEngineering

The invention relates to a capacitance type minitype silicon microphone and a preparation method thereof. The capacitance type minitype silicon microphone comprises a base plate; a vibrating diaphragm is deposited in the central area of the base plate; an insulating material layer is also deposited on the surface of the base plate, which corresponds to an installed base plate; the insulating material layer covers the surfaces of the base plate and the vibrating diaphragm, and a cavity is formed between the insulating material layer and the vibrating diaphragm; the inner wall of the insulatingmaterial layer, which corresponds to the vibrating diaphragm, is provided with fixedly connected back pole plates, and a capacitance structure is formed by the back pole plates and the vibrating diaphragm; the outer wall of the insulating material layer, which corresponds to the vibrating diaphragm, is provided with a plurality of sound holes, and the sound holes are communicated with the cavity formed between the insulating material layer and the vibrating diaphragm; the lower part of the base plate, which corresponds to an installed vibrating diaphragm, is provided with a sound cavity, and the depth of the sound cavity extends from the surface of the base plate, which corresponds to the other end of the installed vibrating diaphragm, to the vibrating diaphragm. The invention has low manufacturing cost, high finished product ratio and easy process operation and meets the requirements for small dimension.

Owner:无锡芯感智半导体有限公司

Automatically configuring a neighbor set for a base station

An automated technique for configuring a neighbor set for a base station (32) includes initializing the neighbor set based upon reported measurements from a mobile station (22). In a disclosed example, a newly installed base station (32) transmits a cell information list to a mobile station (22) requesting measurement reports regarding a plurality of candidate base station identifiers. Based upon the reported measurements, a determination is made regarding which of the base stations should be included in the neighbor set for the base station (32). A disclosed example includes the capability of automatically initializing the neighbor set and automatically updating the set. Disclosed examples include utilizing information from a plurality of mobile stations.

Owner:ALCATEL-LUCENT USA INC

System and method for installing smart card applet

InactiveUS20110047257A1Acutation objectsMultiple digital computer combinationsSmart cardApplication software

Disclosed are a system and a method for installing a smart card applet. A response message for an OTA message received from an external remote server is transmitted to form a communication channel based on HTTP (hyper text transfer protocol) between a smart card and the remote server. The applet is installed based on applet installation information received through the communication channel. A large scale applet is installed in a card within a short period of time.

Owner:SK PLANET CO LTD

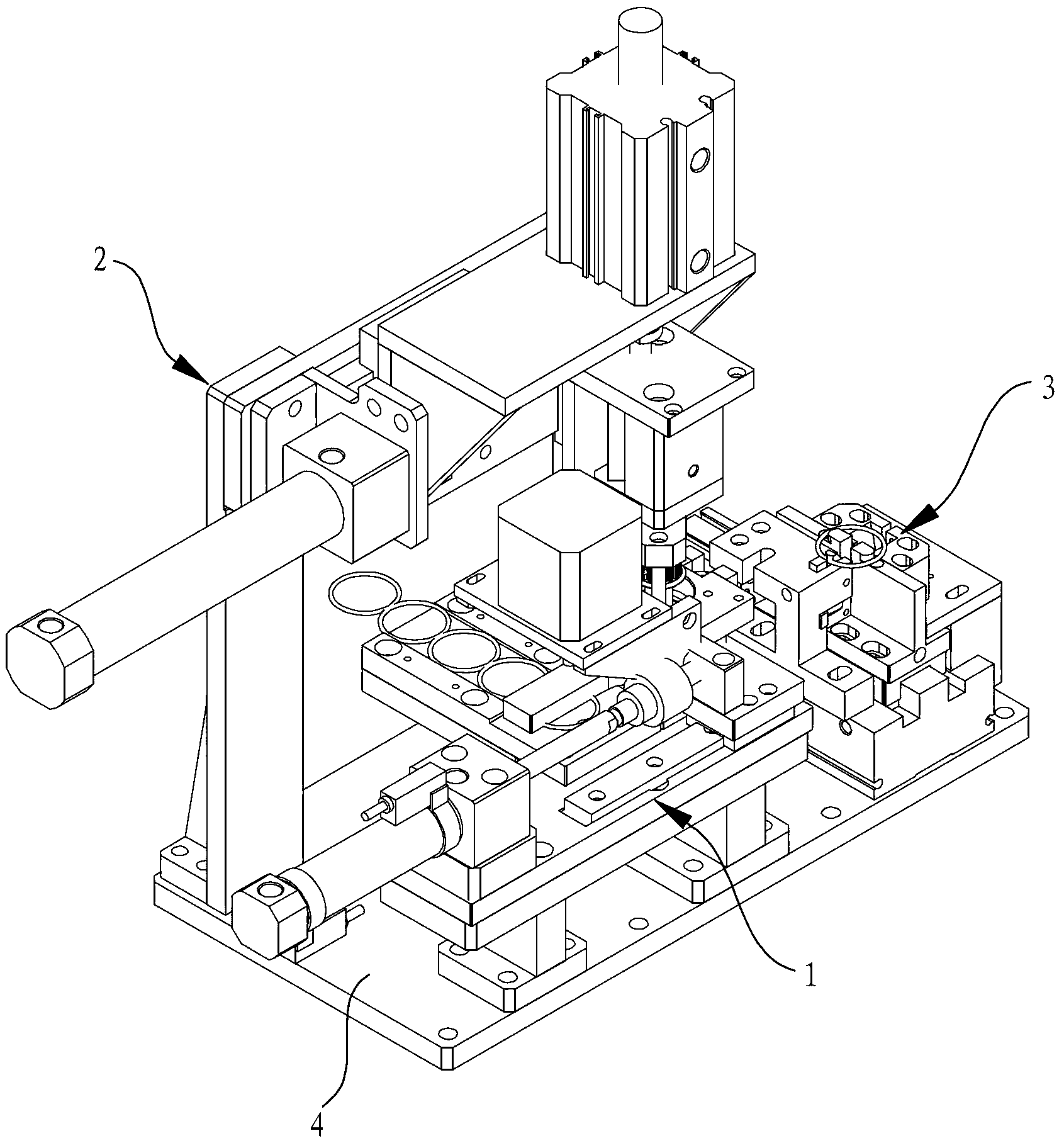

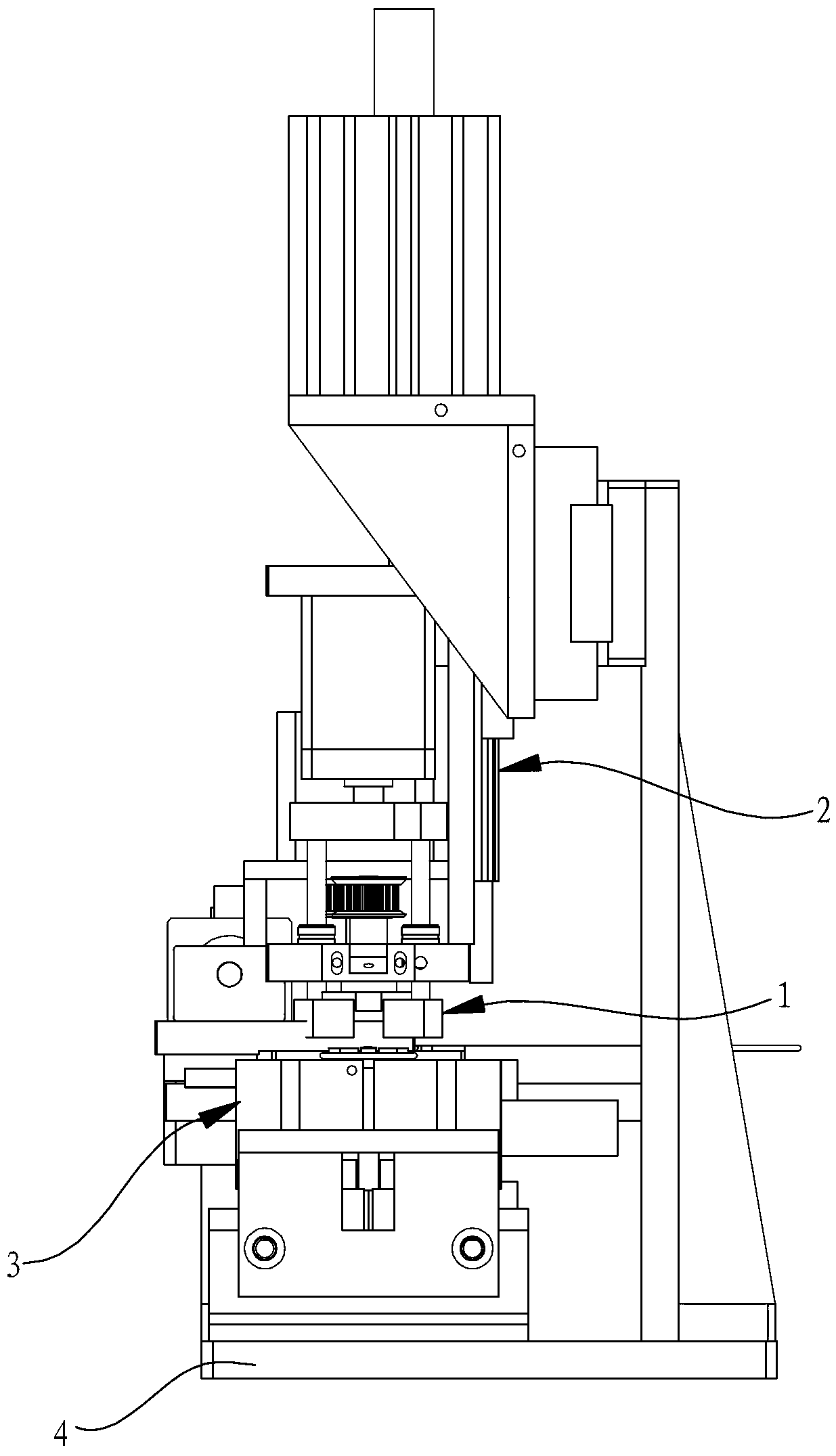

Ring installing mechanism of clamp assembling machine

InactiveCN103273314ASimple structureHigh degree of automationAssembly machinesEngineeringInstalled base

The invention discloses a ring installing mechanism of a clamp assembling machine. The ring installing mechanism is characterized by comprising a ring installing base plate, a ring distributing device, a ring taking device and a ring opening device, wherein the ring distributing device, the ring taking device and the ring opening device are arranged on the ring installing base plate. The ring distributing device obtains the O-shaped ring input from a vibrating disc, and the ring taking device obtains the O-shaped ring from the ring distributing device and conveys the O-shaped ring to the ring opening device. Compared with the prior art, the ring installing mechanism has the advantage that the ring distributing device, the ring taking device and the ring opening device of the ring installing mechanism of the clamp assembling machine are sequentially matched, and the O-shaped ring is input from the vibrating disc and finally sent to the ring opening device to be opened. The whole ring installing mechanism is simple in structure, high in automation degree and capable of achieving fast ring installing of the O-shaped ring.

Owner:NINGBO TIANQI MOLDING

System and method to facilitate installation and/or removal of components

The present invention provides a system and method to facilitate installation and / or removal of components in which one of the components is a shared component. The components are installed based on a valid order, such that shared components are installed after other components have been installed. According to one aspect, one or more properties associated with a shared component may be manipulated to facilitate installation and / or removal of components, including the shared component and dependent components.

Owner:MICROSOFT TECH LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com