Explosion-field shock wave overpressure filter

A shock wave and filter technology, which is applied in the field of explosive effect testing, can solve the problems of measurement error, narrow frequency response range, curve attenuation, etc., and achieve the effect of increasing transmission distance, saving installation space and shortening length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

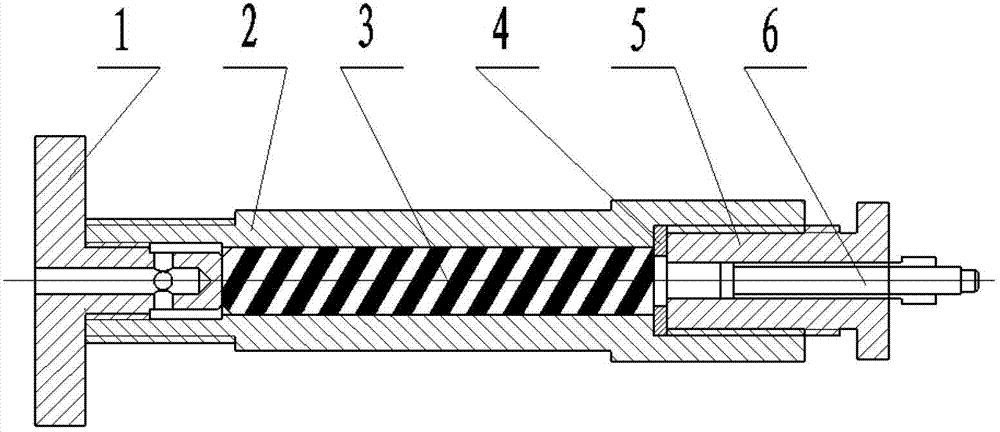

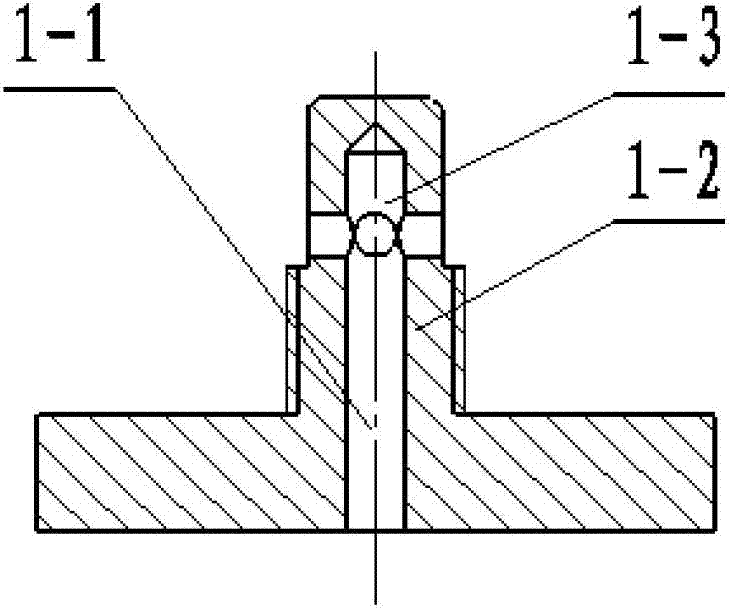

[0021] like figure 1 As shown, this embodiment provides an explosion field shock wave overpressure filter, which is composed of a cover plate 1, a lumen 2, a screw rod 3, a buffer pad 4, a sensor mounting seat 5, and a piezoresistive pressure sensor 6. in:

[0022] The lumen 2 is a cylinder with two central stepped holes. The end of one end of the small stepped hole is provided with an internal thread for matching with the external thread on the cover plate 1. The outer diameter of the small stepped hole is close to the end position An external thread is provided; the inner hole at one end of the large step hole is provided with an internal thread near the end, which is used to cooperate with the external thread on the sensor mounting seat 5, and the outer diameter of the large step hole is hexagonal near the end;

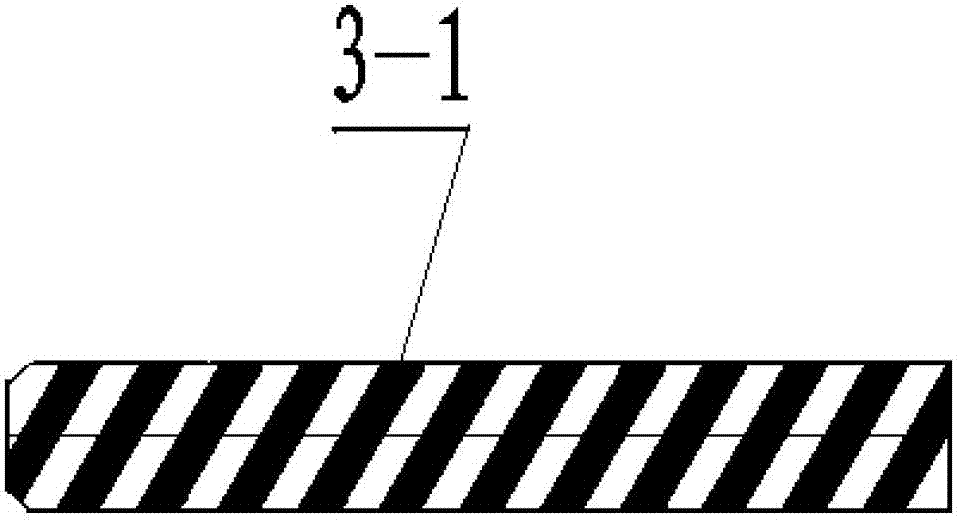

[0023] The screw rod 3 is a cylinder, which is assembled into the inner hole of the small step of the lumen 2;

[0024] The buffer pad 4 is positioned on the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com