Patents

Literature

264 results about "Piezoresistive pressure sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

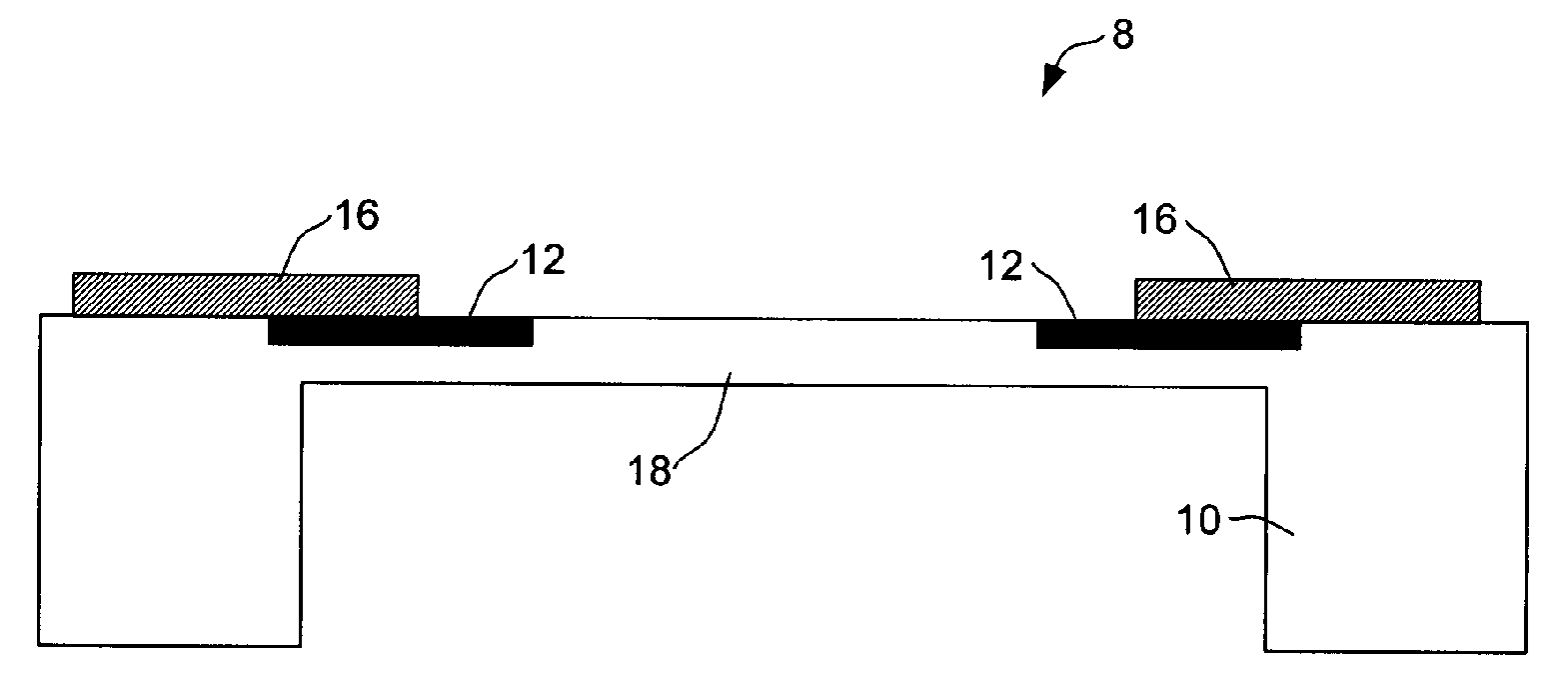

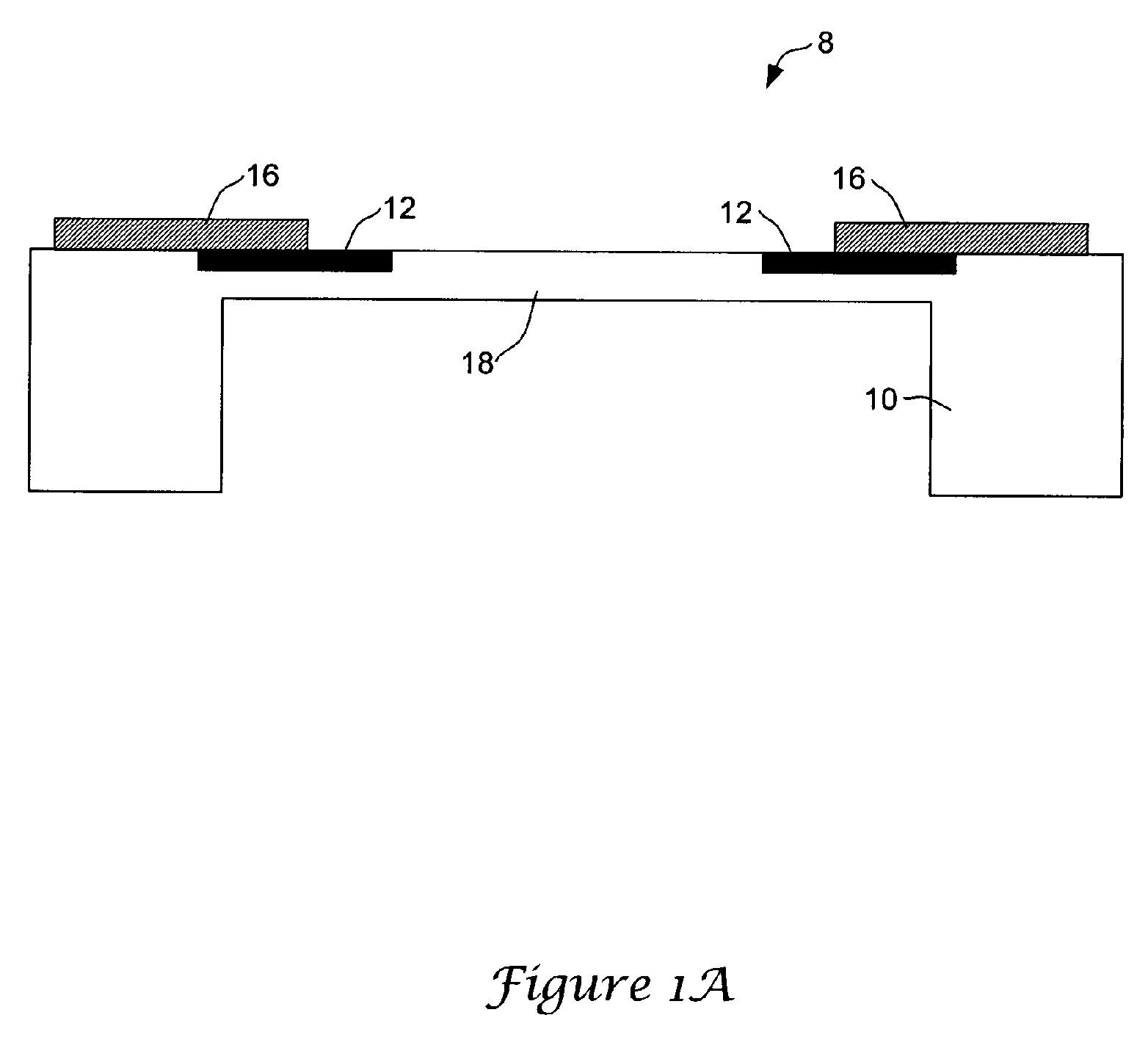

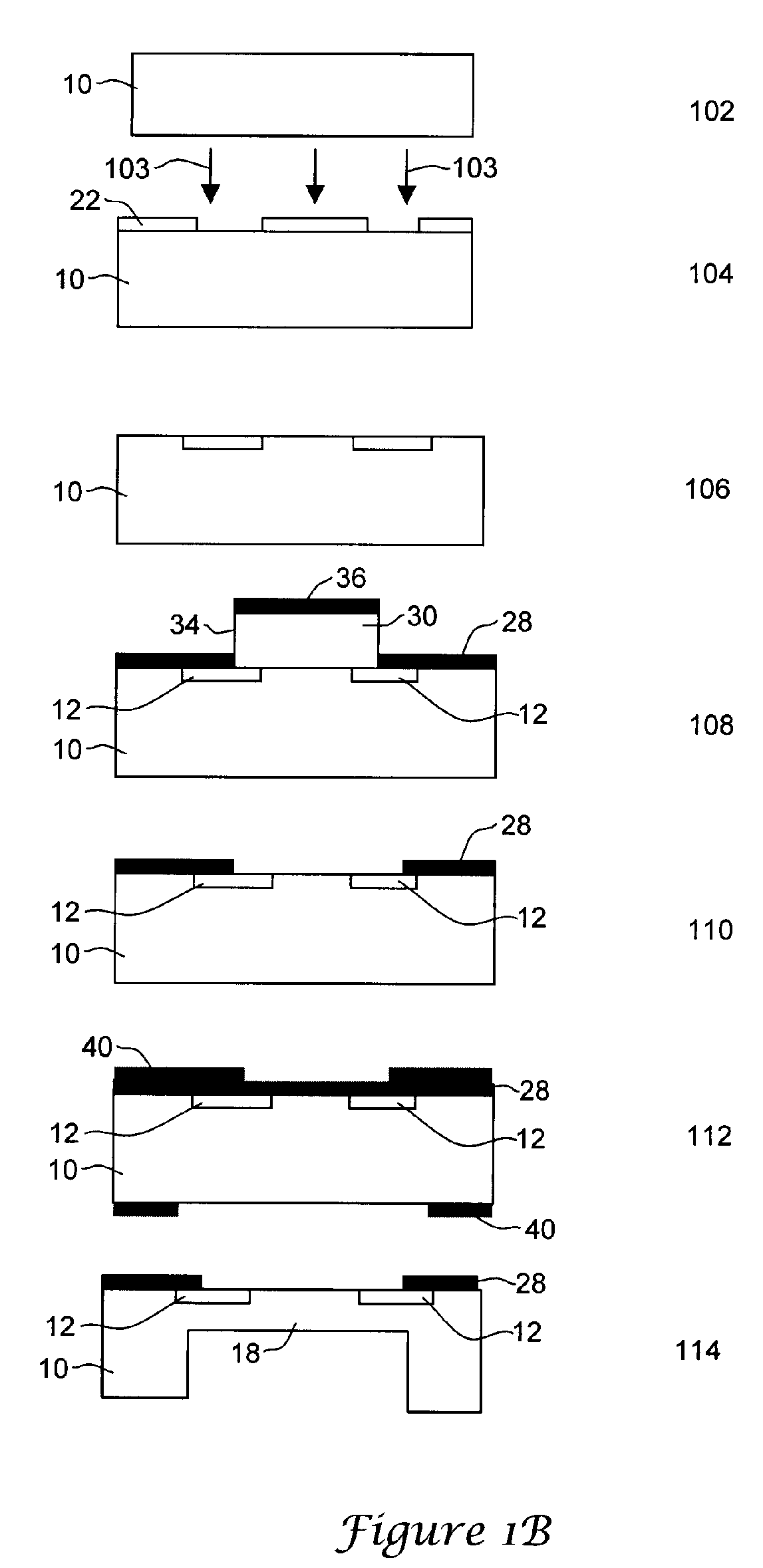

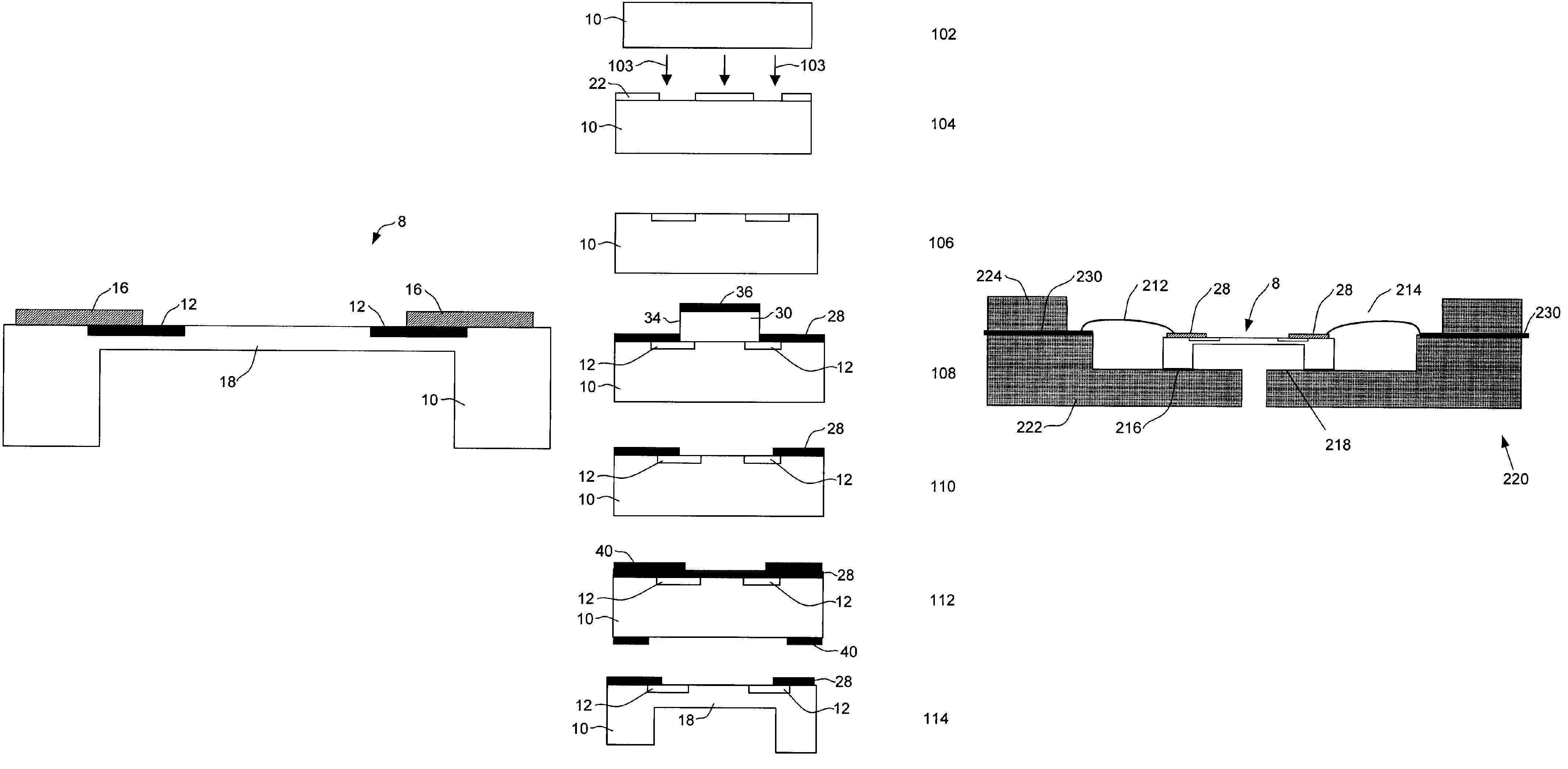

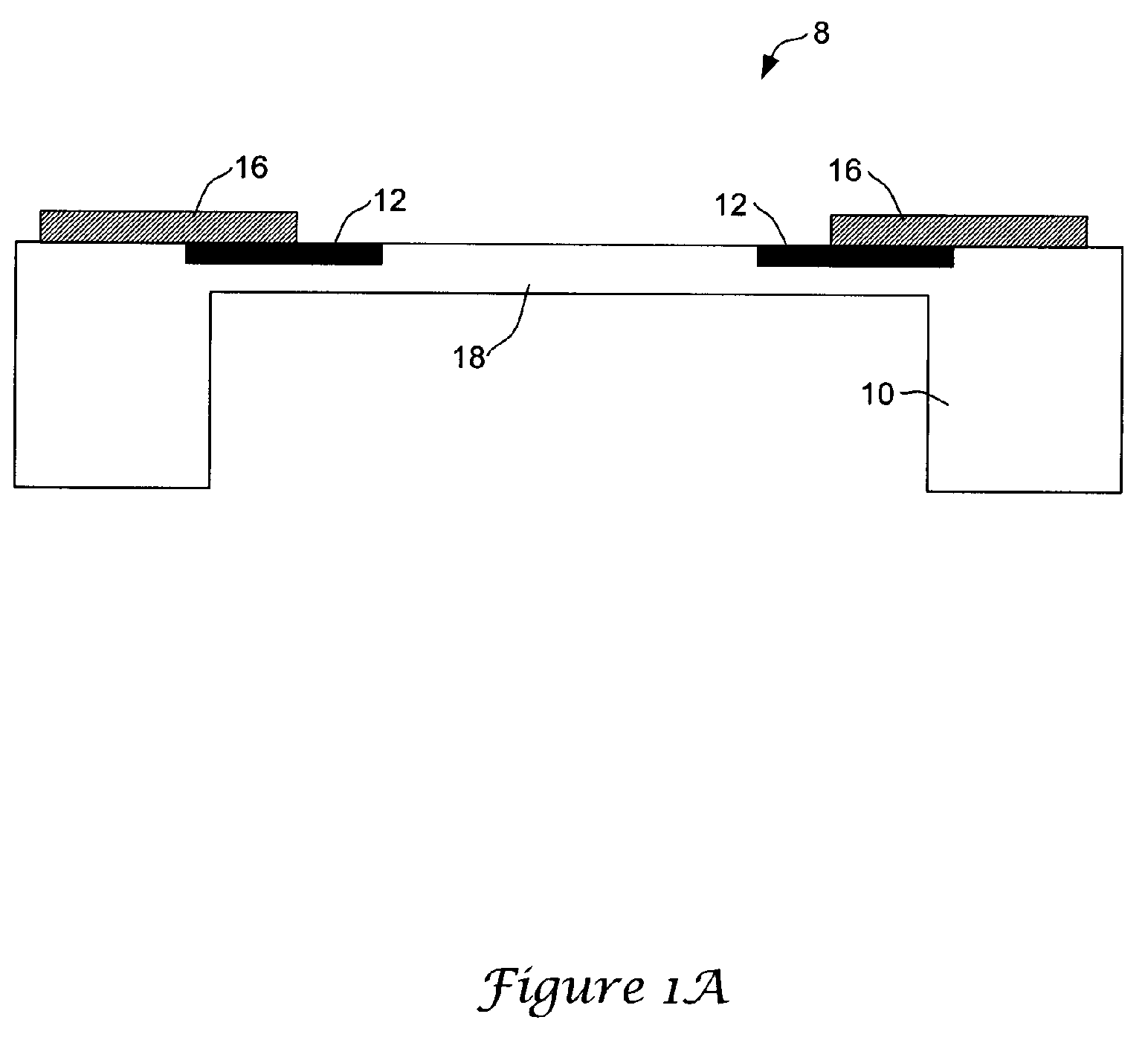

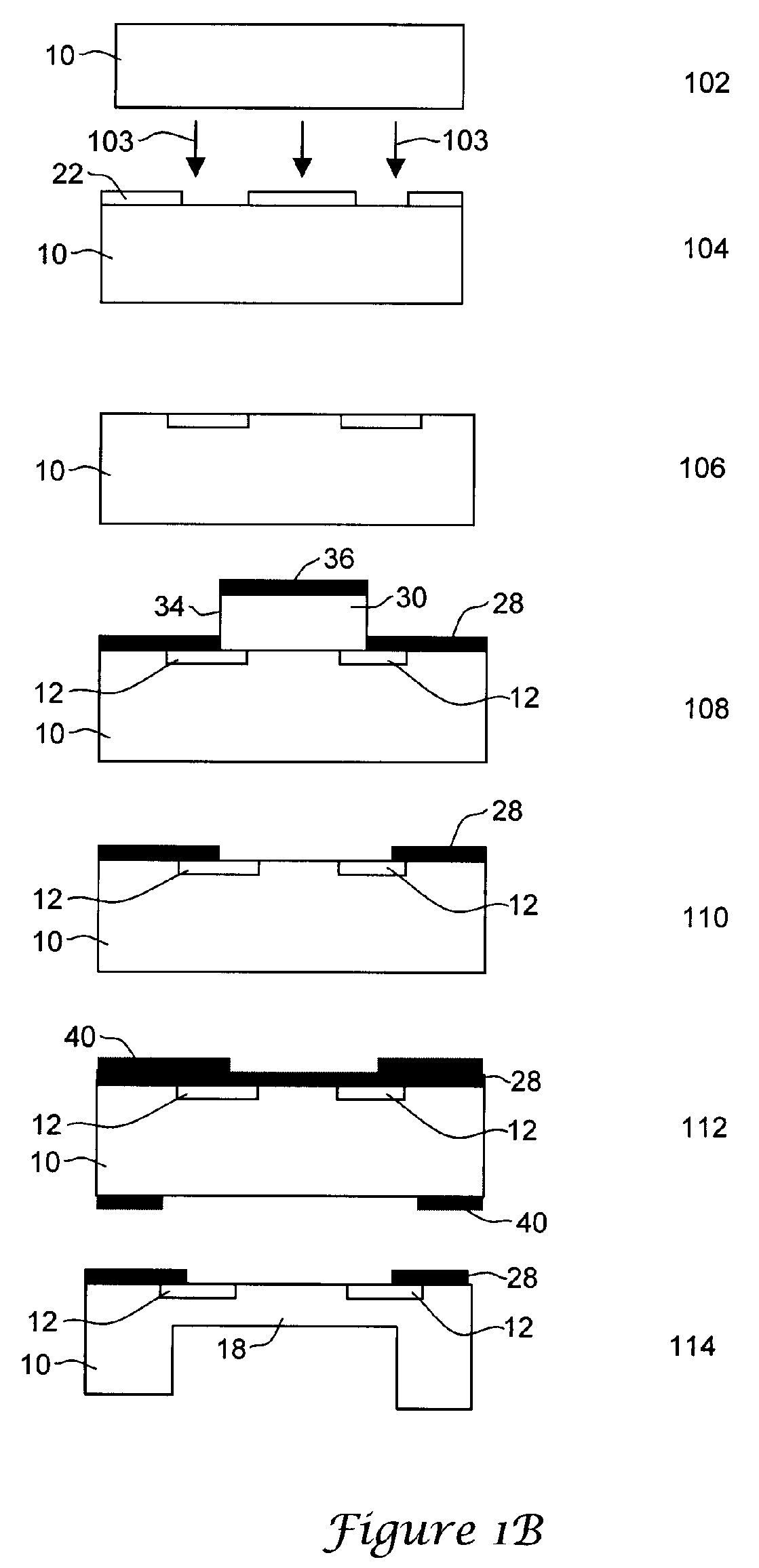

Method of manufacturing a thin piezo resistive pressure sensor

InactiveUS6912759B2Small widthReduce thicknessPiezoelectric/electrostrictive device manufacture/assemblyPaper/cardboard articlesEngineeringPiezoresistive pressure sensors

A method for forming a sensor including the steps of providing a base wafer and forming a sensor cavity in the base wafer. The method further includes the step of coupling a diaphragm wafer to the base wafer, the diaphragm wafer including a diaphragm portion and a sacrificial portion. The diaphragm wafer is coupled to the base wafer such the diaphragm portion generally covers the sensor cavity. The method further includes the steps of reducing the thickness of the diaphragm wafer by removing the sacrificial portion, and forming or locating at least one piezo resistive portion on the diaphragm portion.

Owner:ROSEMOUNT AEROSPACE

Flexible piezocapacitive and piezoresistive force and pressure sensors

InactiveUS8904876B2Facilitate measuring and mapping forcesFluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsCapacitanceDielectric

Owner:PATIENTECH LLC

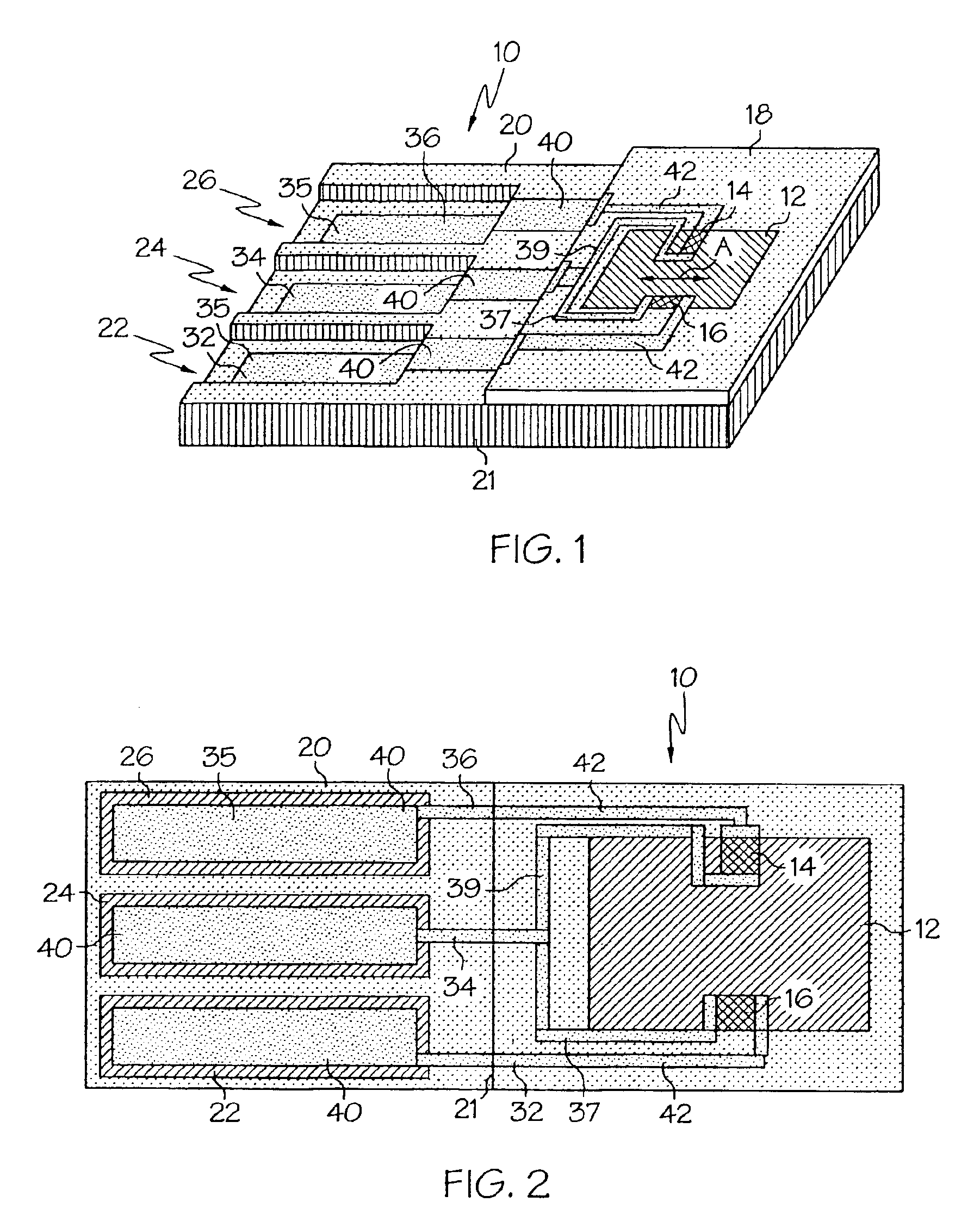

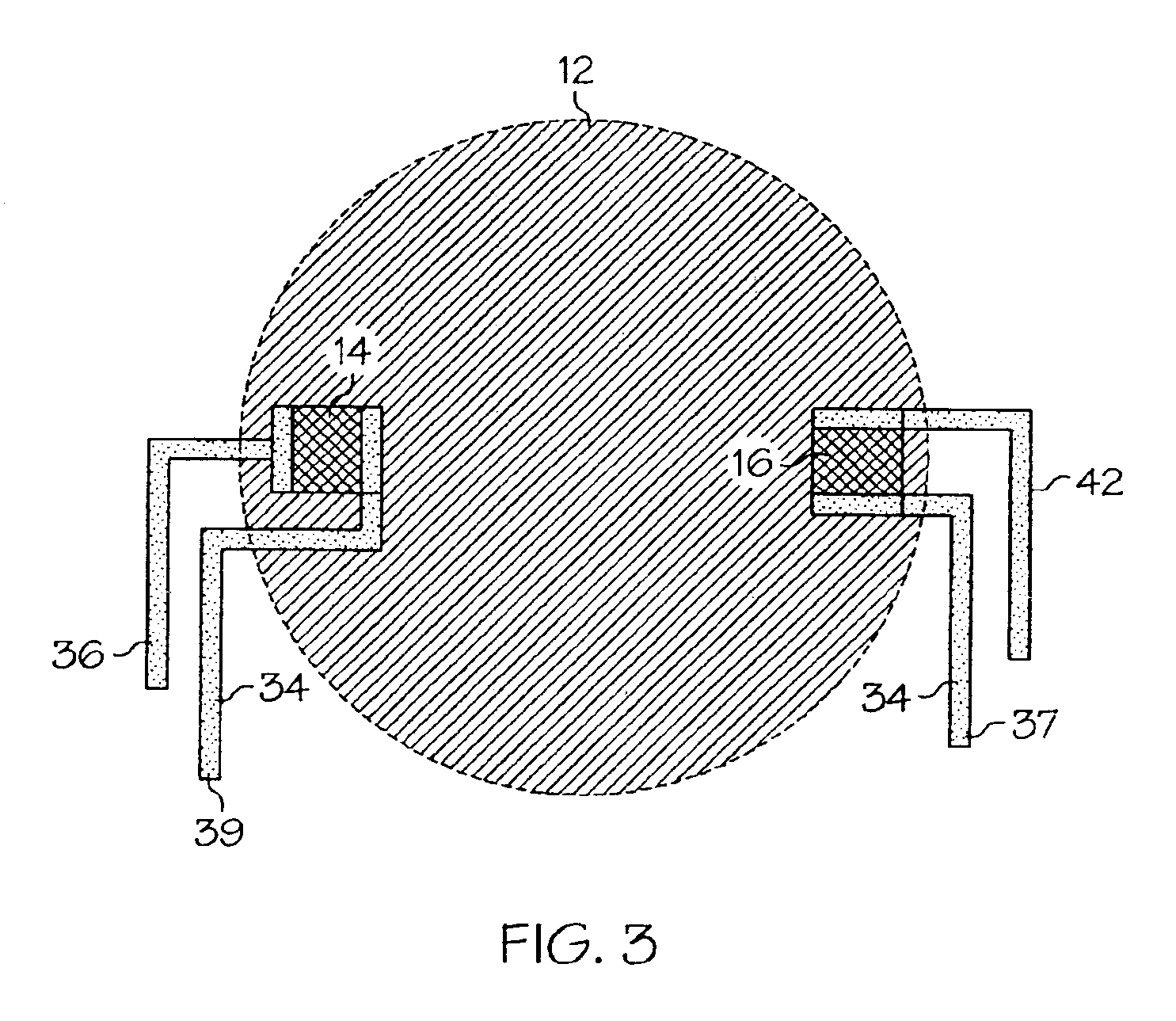

Monolithic silicon intra-ocular pressure sensor and method therefor

InactiveUS6010461ASimplify the viewing processElectrotherapyDiagnostic recording/measuringIntra ocular pressureElectricity

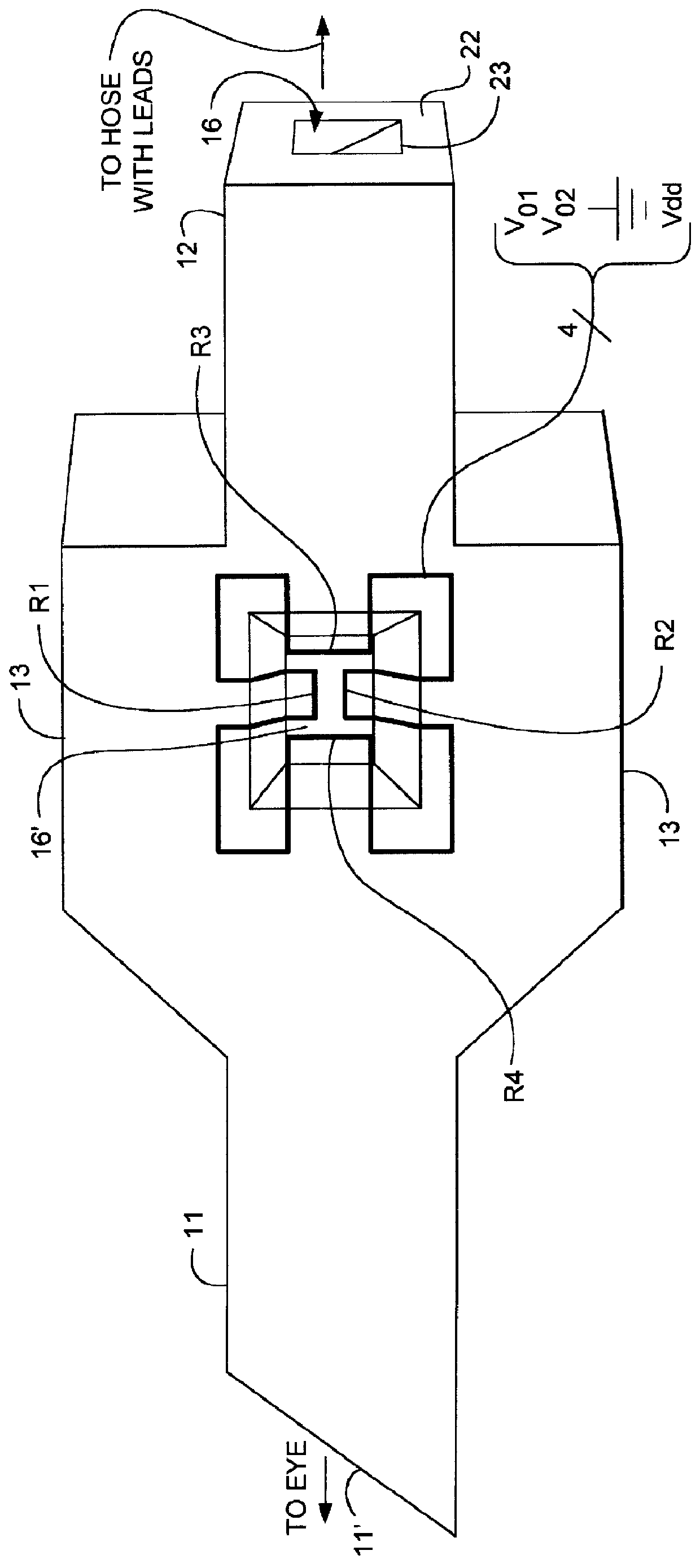

A silicon monolithic miniature intra-ocular pressure sensing probe utilizes pressure sensing piezoresistors attached to a silicon pressure sensing membrane which is directly exposed to the irrigating fluid used during an eye operation, for example. From a silicon fabrication point of view, this is a micro electromechanical (MEM) device and the integration of the piezoresistive pressure sensor directly into the cannula which is inserted into the eye is partially made possible by providing p++ etch stops to gain access for electrical connection to the piezoresistive elements arranged in a Wheatstone bridge configuration. The silicon sensing membrane forms a smooth surface to avoid turbulence and is close to the eye to minimize error.

Owner:SITEK

Flexible piezoresistive pressure sensor with high sensitivity, and preparing method thereof

ActiveCN105092118AHigh sensitivityMake up for the defects of non-bendable deformationForce measurement using piezo-resistive materialsThin membraneGraphite

The invention discloses a flexible piezoresistive pressure sensor with high sensitivity. The pressure sensor comprises the components of a flexible substrate, metal electrodes and a grid-shaped graphene film layer. The metal electrodes are fixedly connected with two ends of the top surface of the flexible substrate. The graphene film layer covers and is connected with the flexible substrate and partial metal electrodes. The pressure sensor has an advantage that the substrate can perform bending deformation and furthermore has high sensitivity. The pressure sensor can be widely used in the fields of biomedicine, wearable device, etc. Furthermore the invention discloses a preparation method for the flexible piezoresistive pressure sensor.

Owner:SOUTHEAST UNIV

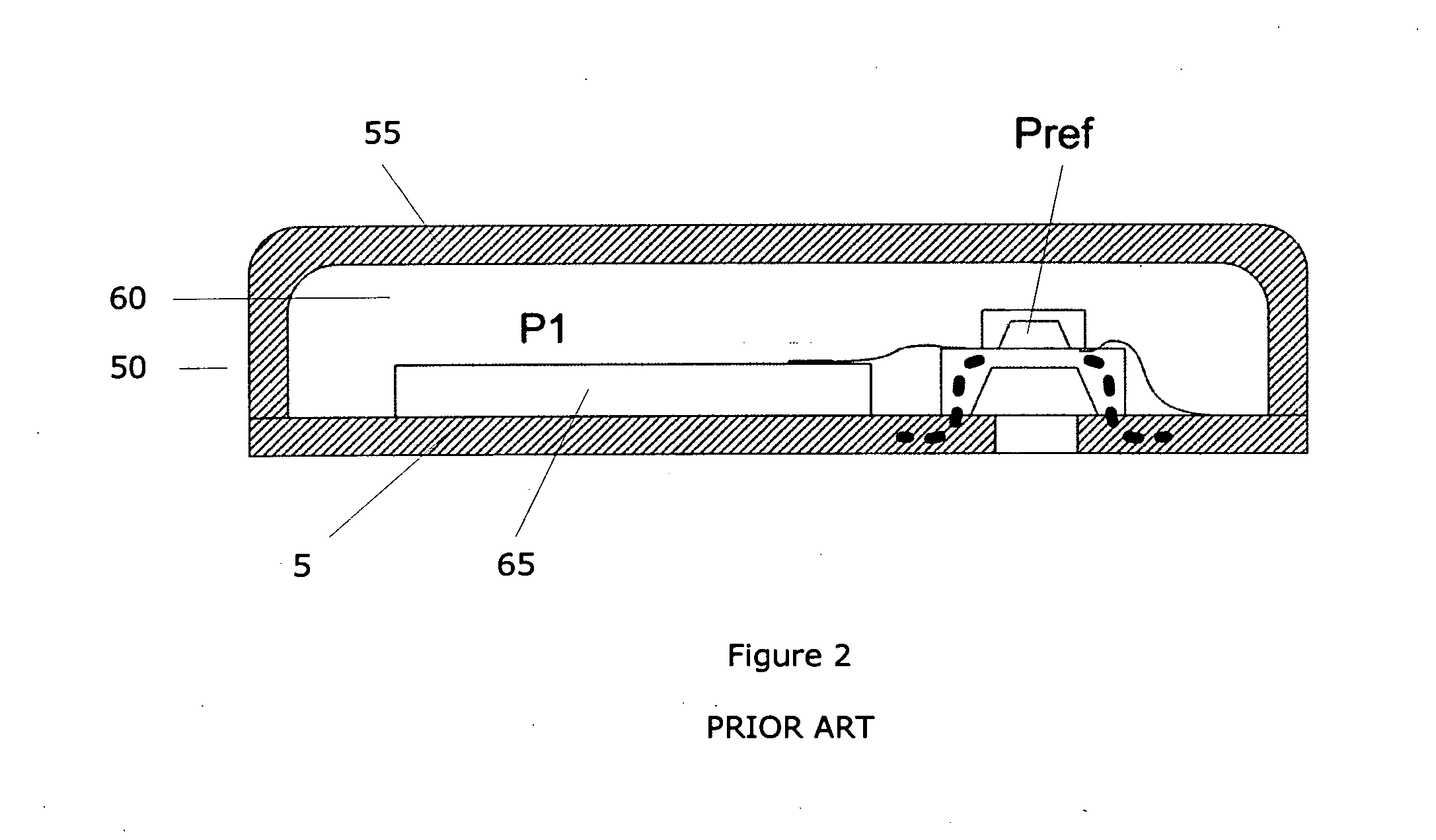

Internal pressure simulator for pressure sensors

InactiveUS20070095146A1Simple and cost-effectiveSimple and cost-effective to and implementFluid pressure measurement using inductance variationFluid pressure measurement using ohmic-resistance variationInternal pressurePressure sense

In oil-filled pressure sensors, the measured pressure is applied to a compliant isolation diaphragm, which causes the pressure of the internal oil to increase until it equals the external pressure. The pressure is sensed by a pressure sensing capsule, such as a MEMS piezoresistive pressure sensor. The invention incorporates an electromagnetic force generator, such as a coil and a magnetic core, within the pressure sensor in order to generate simulated pressure. When the coil is energized, the electromagnetic field creates a uniform distributed force, which moves the isolation diaphragm directly, or via an external flexure, in a manner to cause the pressure of the internal oil to increase, which is sensed by the pressure sensing capsule, which responds by producing an output signal proportional to the electromagnetic force. The simulated pressure is employed in order to perform sensor operation monitoring and self-calibration via measurement of the output signal.

Owner:BROSH AMNON

Micro-machined pressure sensor with polymer diaphragm

ActiveUS20060213275A1Easy to understandElectrical conductivityFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingPolymer substrateNitrogen

A piezoresistive pressure and / or strain sensor micro-machined primarily from plastic and / or glass. In one illustrative embodiment, the piezoresistive pressure sensor is formed on a polymer substrate. A first selectively implanted region is provided in the polymer substrate to create a piezoresistive region in the polymer substrate. A second selectively implanted region is then provided in at least part of the first selectively implanted region to modulate the electrical conductivity of the first selectively implanted region. The illustrative sensor may be selectively implanted with, for example, nitrogen to create the piezoresistive region, and boron to modulate the electrical conductivity of the piezoresistive region. Phosphorus or any other suitable material may also be used to modulate the electrical conductivity of the piezoresistive region, as desired. The piezoresistive pressure / strain sensor may be formed from a single substrate, or two or more substrates, and the resulting pressure / strain sensor may be mounted in a plastic package, if desired.

Owner:HONEYWELL INT INC

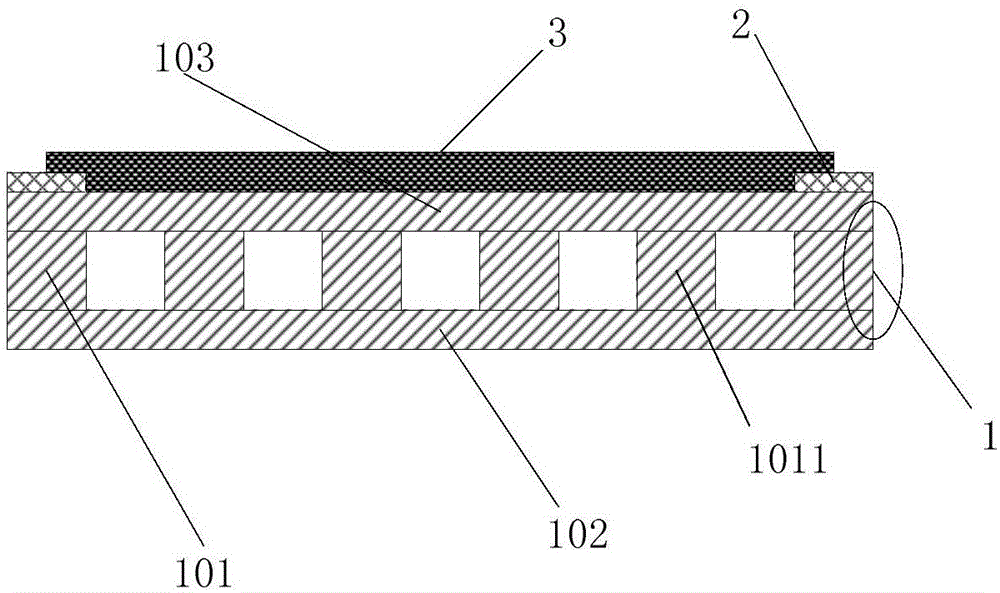

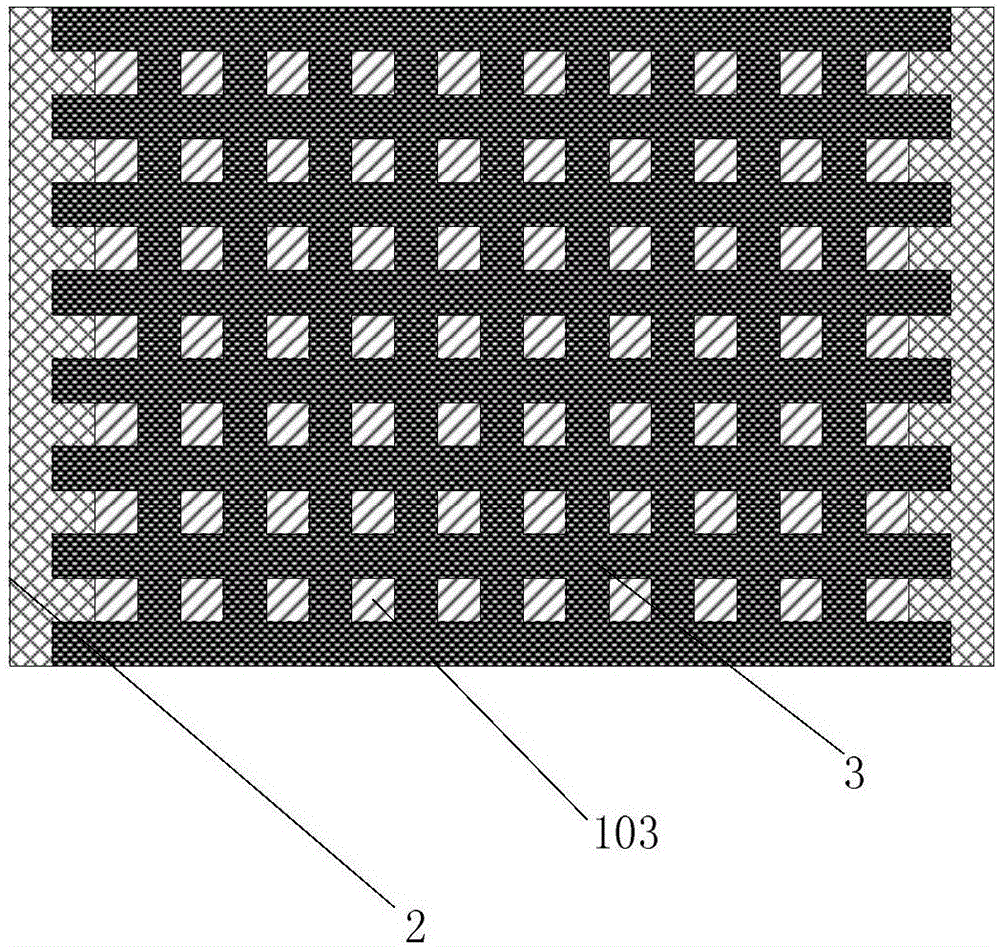

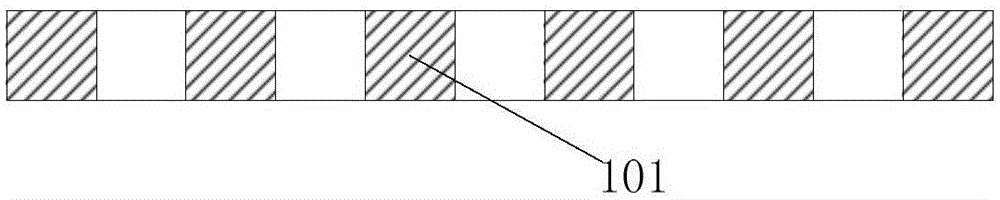

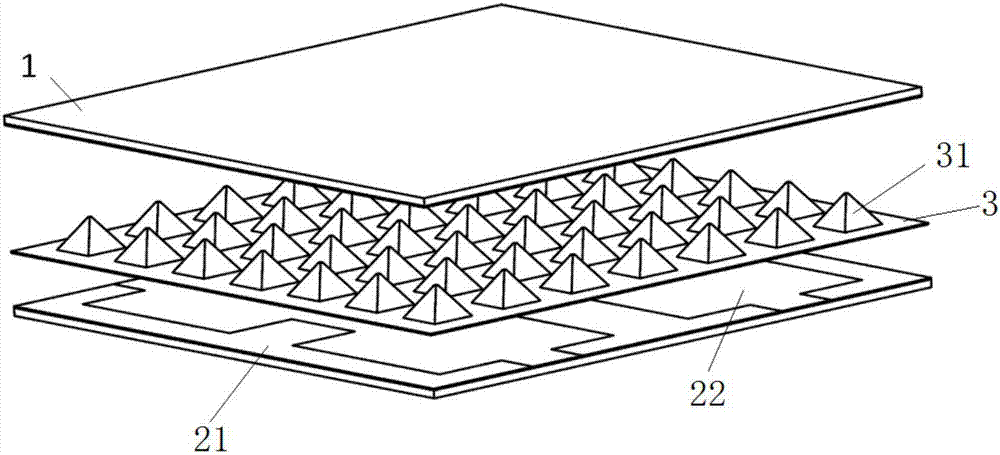

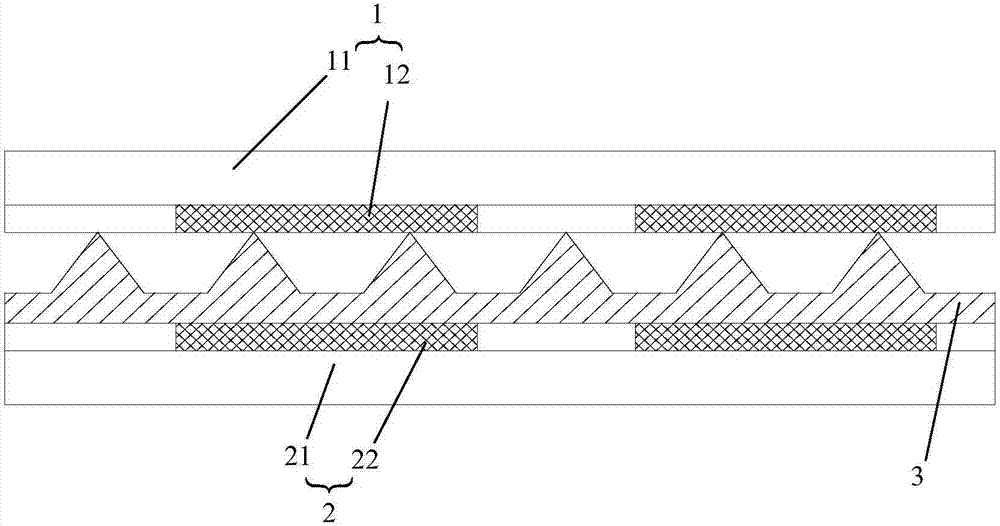

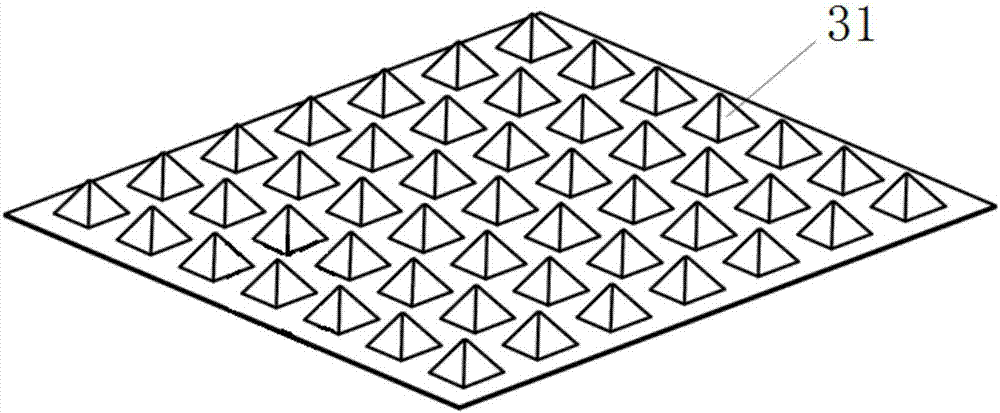

Pressure sensitive layer applied to piezoresistive pressure sensor and piezoresistive pressure sensor

PendingCN106932128AHigh sensitivityGood flexibilityFluid pressure measurement using ohmic-resistance variationForce measurementElastomerElectrical resistance and conductance

The invention discloses a pressure sensitive layer applied to a piezoresistive pressure sensor and the piezoresistive pressure sensor. The pressure sensitive layer comprises a graphene material and a polymer elastomer. The graphene material is loose and porous and has a microstructural array. The polymer elastomer coats the graphene material and penetrates into each hole of the graphene material. The piezoresistive pressure sensor comprises a first electrode plate, a second electrode plate and at least one pressure sensitive layer disposed between the first electrode plate and the second electrode plate, wherein the first electrode plate and the second electrode plate are bonded to each other. The microstructure in the microstructural array contacts electrodes in the first electrode plate and / or the second electrode plate. The piezoresistive pressure sensor provided by the invention can transform the external pressure magnitude into the resistance value of the sensor, senses the change of the external pressure through the change of an electrical signal, and has the advantages of high sensitivity, low cost, high flexibility, easy processing, easy array and miniaturization and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

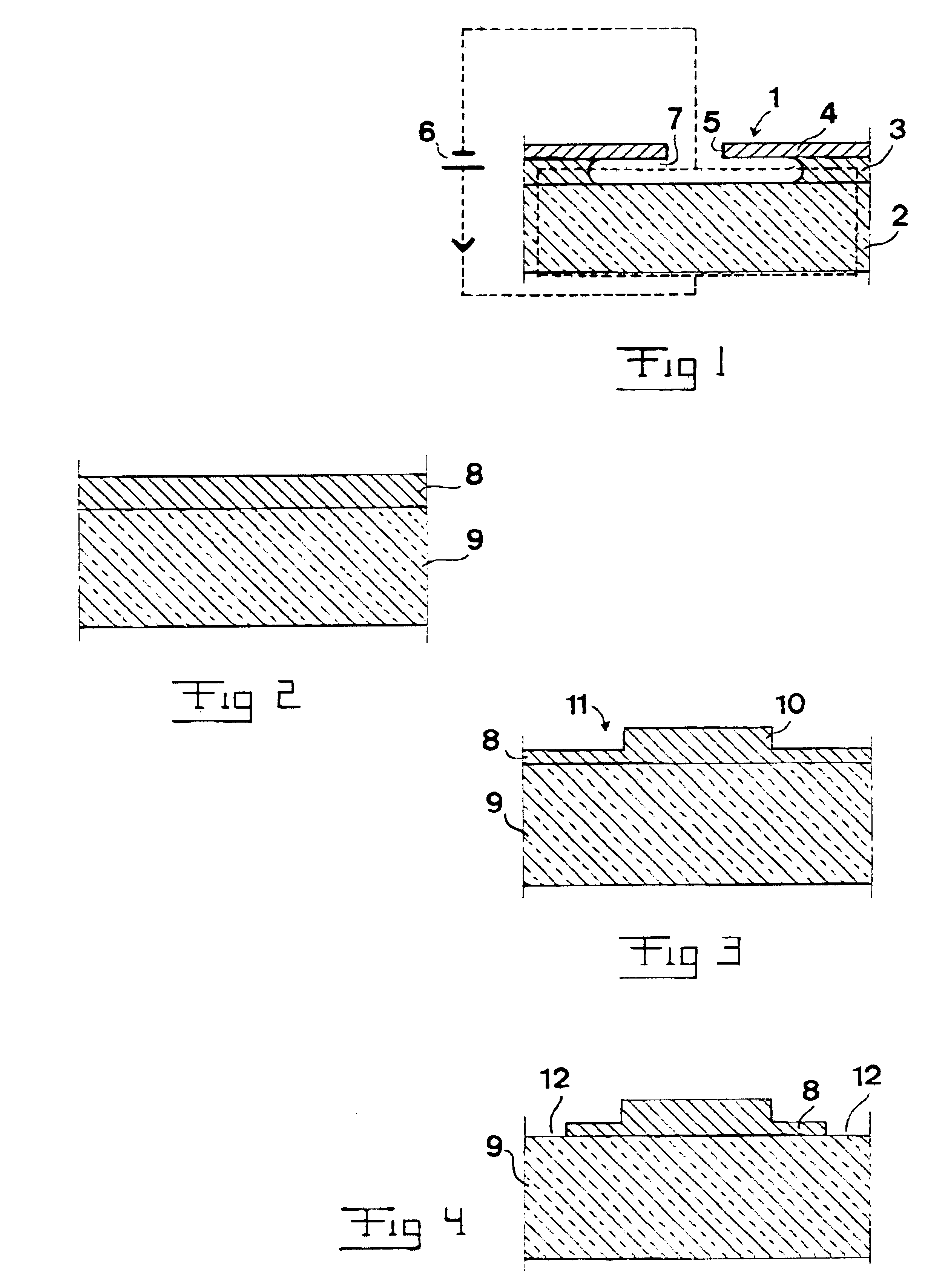

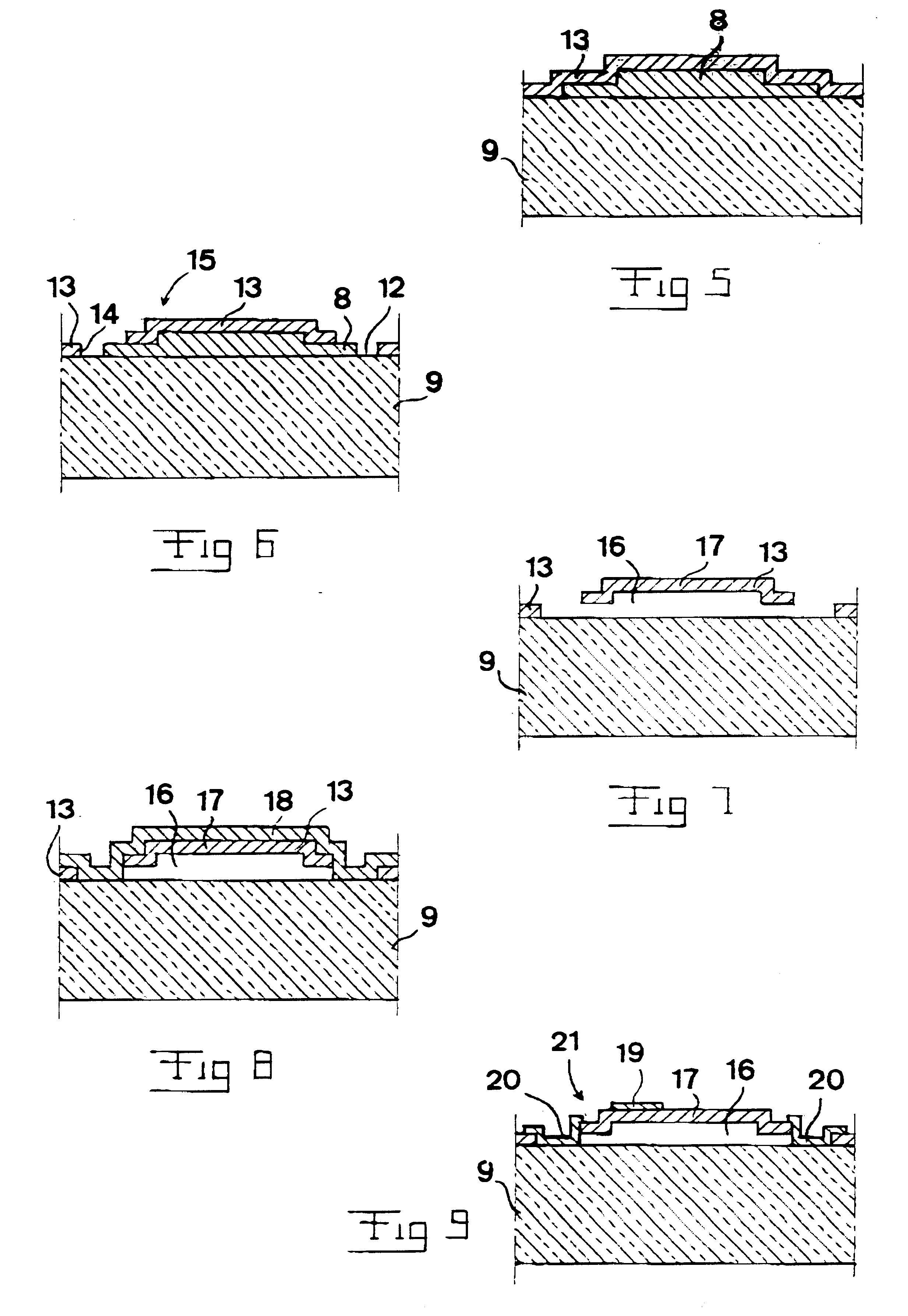

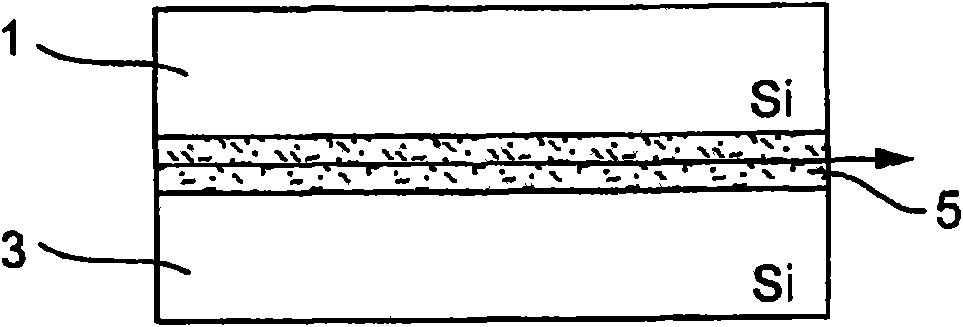

Method of producing a semiconductor device of SiC

InactiveUS6306773B1Promote resultsHigh precisionSemiconductor/solid-state device manufacturingPiezoelectric/electrostrictive devicesMicro structureEtching

The invention relates to a method for selective etching of SiC, the etching being carried out by applying a positive potential to a layer (3; 8) of p-type SiC being in contact with an etching solution containing fluorine ions and having an oxidising effect on SiC. The invention also relates to a method for producing a SiC micro structure having free hanging parts (i.e. diaphragm, cantilever or beam) on a SiC-substrate, a method for producing a MEMS device of SiC having a free hanging structure, and a method for producing a piezo-resistive pressure sensor comprising the step of applying a positive potential to a layer (8) of p-type SiC being in contact with an etching solution containing fluorine ions and having an oxidising effect on SiC.

Owner:CREE SWEDEN

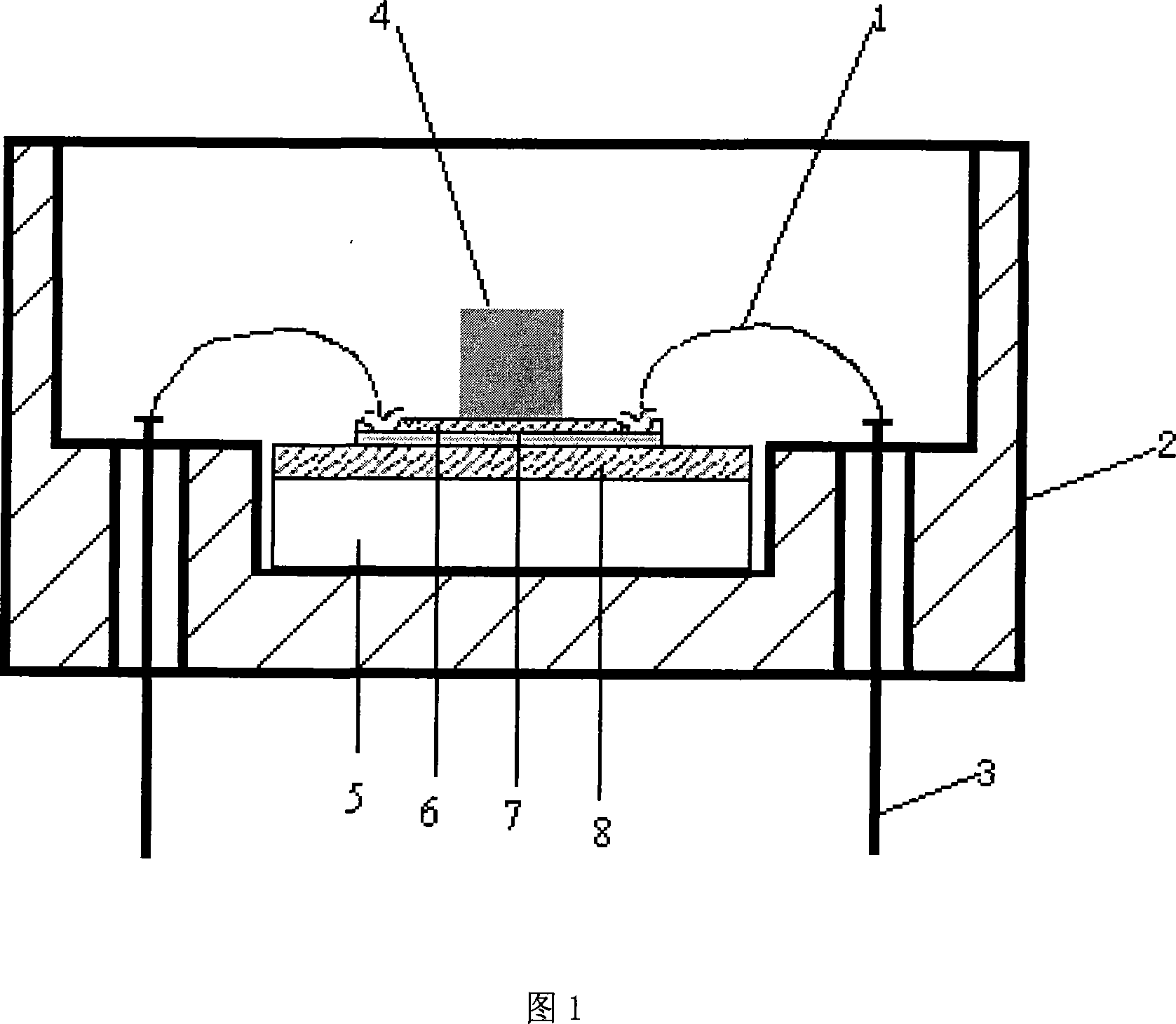

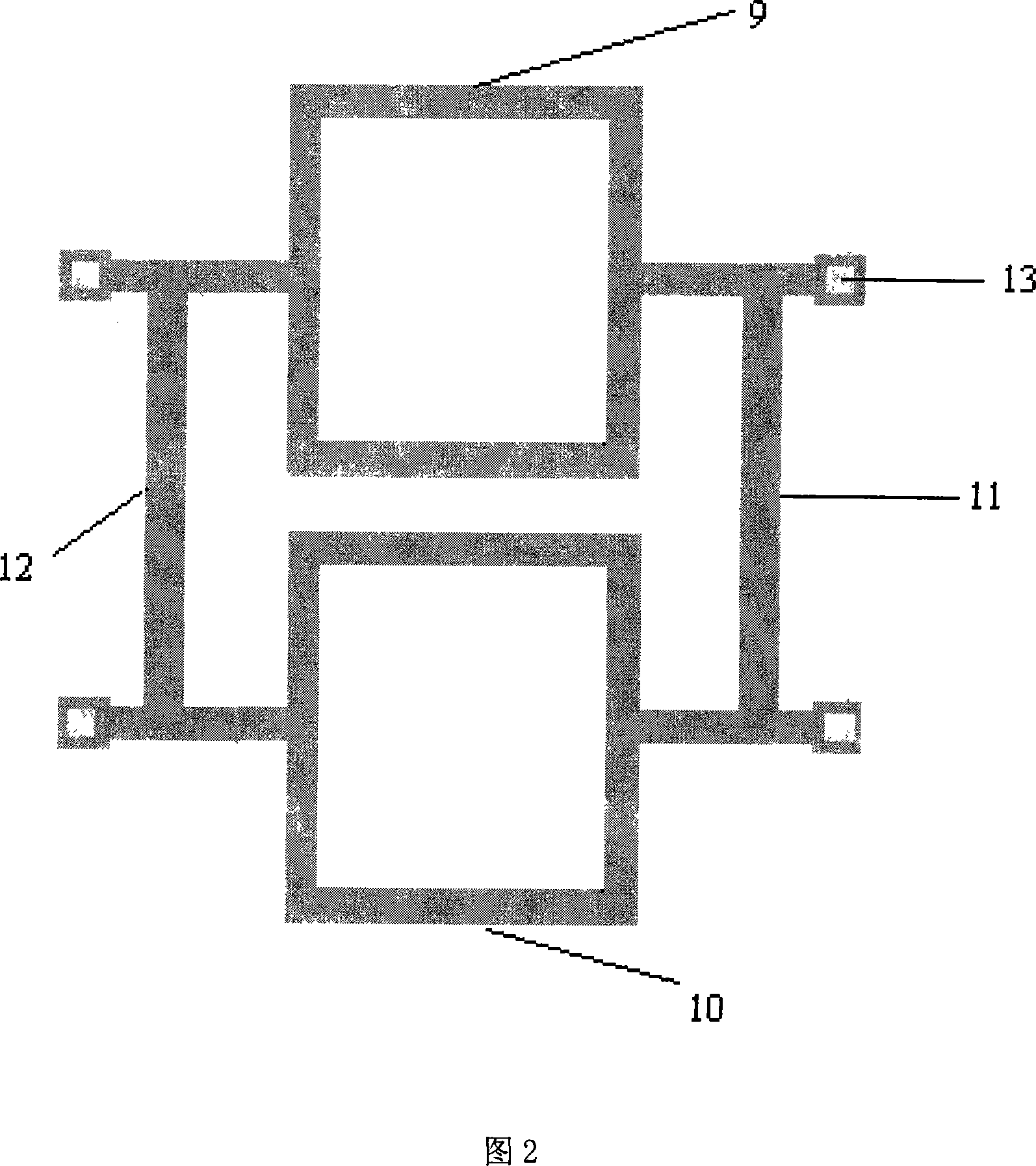

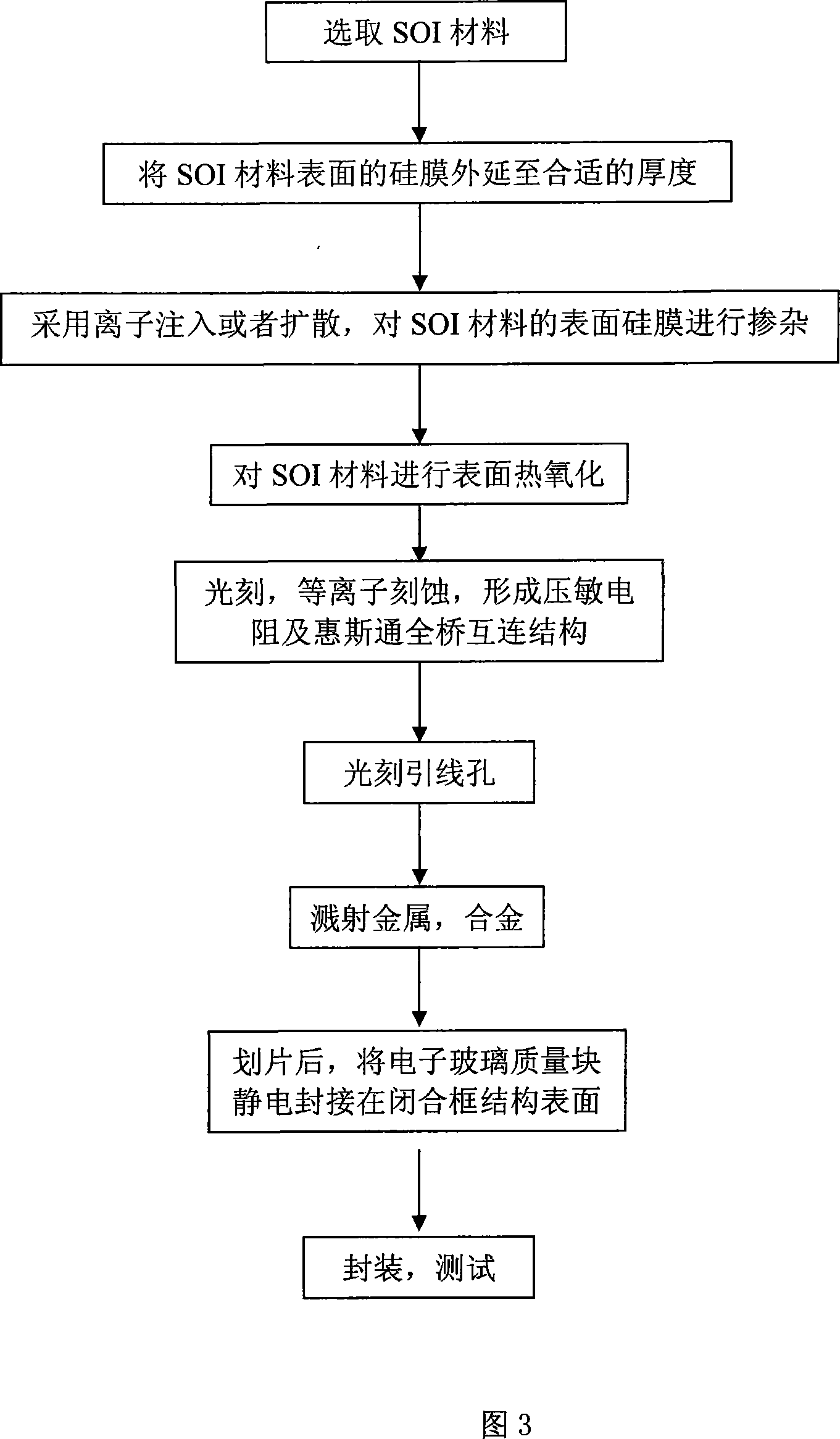

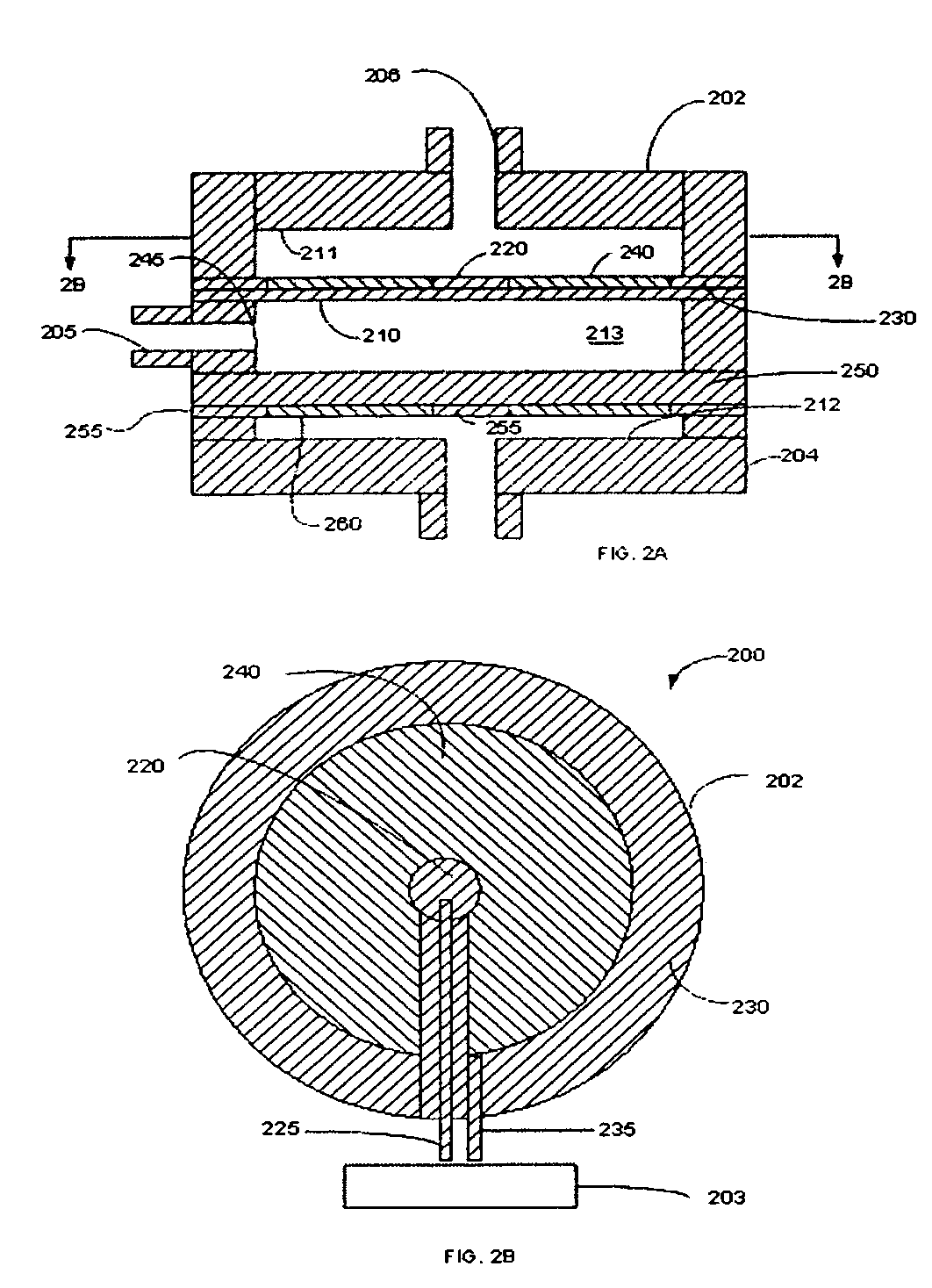

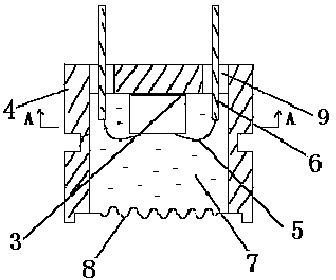

Novel piezoresistance type pressure pickup and method for making same

InactiveCN101082525AWork reliablyEffective galvanic isolationFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsPhotoengravingAlloy

This invention is neotype pressure resistance pressure sensor, including inward-leg wire, package outer, outward-leg wire, pin hole, substrate and the piezoresistor, installing the close structure piezoresistor and the banding piezoresistor,; the four piezoresistors make up of the Wheatstone bridge interconnect structure, a-alloy sputtering from the pin hole, installing the electronic glass mass on the surface of close structure outer. The production method is: (1)mixing; (2)surface thermal oxidization; (3)technic-processing of photoetch and plasma corrosion;(4)photoengraving the pin hole; (5)sputtering a-alloy; (6)static electrostatic encapsulating electronic glass; (7)testing and capsulation. The technic-scheme of this invention makes the production-craft more simple, and compatible with the craft of CMOS integrated circuit plate, and have more high harmonic frequency, and can work in the high temperature circumstance and assuring the compatibility of the production performance.

Owner:TIANJIN UNIV

Micro-machined pressure sensor with polymer diaphragm

ActiveUS7401525B2Fluid pressure measurement by electric/magnetic elementsSolid-state devicesPolymer substrateNitrogen

Owner:HONEYWELL INT INC

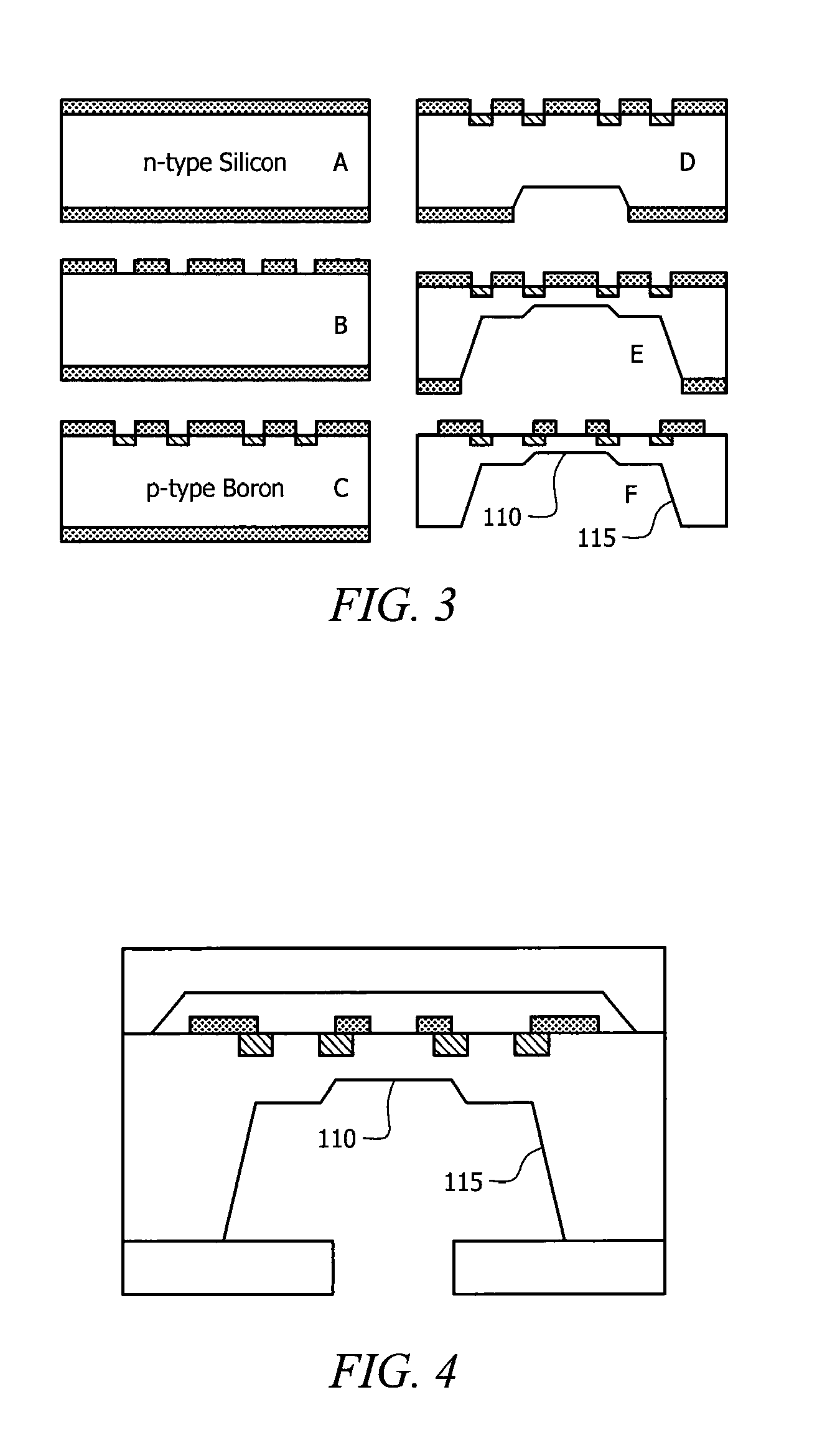

NEMS piezoresistive pressure sensor chip and its making process

InactiveCN1432801AImprove detection accuracyImprove yieldFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceDiffusion

The MEMS piezoresistive pressure sensor chip is one cup-shaped structure including one squared pressure-sensing film, peripheral support and four piezoresistors, which are in the maximum strain area of the pressure-sensing film constitute point bridge to sense pressure change. The piezoresistors are made by ion implantation technology and there is a circle of n+isolating area around each piezoresistor and aligning mark in the edge of the pressure-sensing film to monitor the thickness of the pressure-sensing film. Compared with conventional diffusion technology, the ion implantation technologyhas higher piezoresistor precision, lower zero input and lower zero temperature drift. The increased n+isolating area raises the long-term stability of chip, and the aligning mark makes the etching of the sensing film more controllable.

Owner:PEKING UNIV

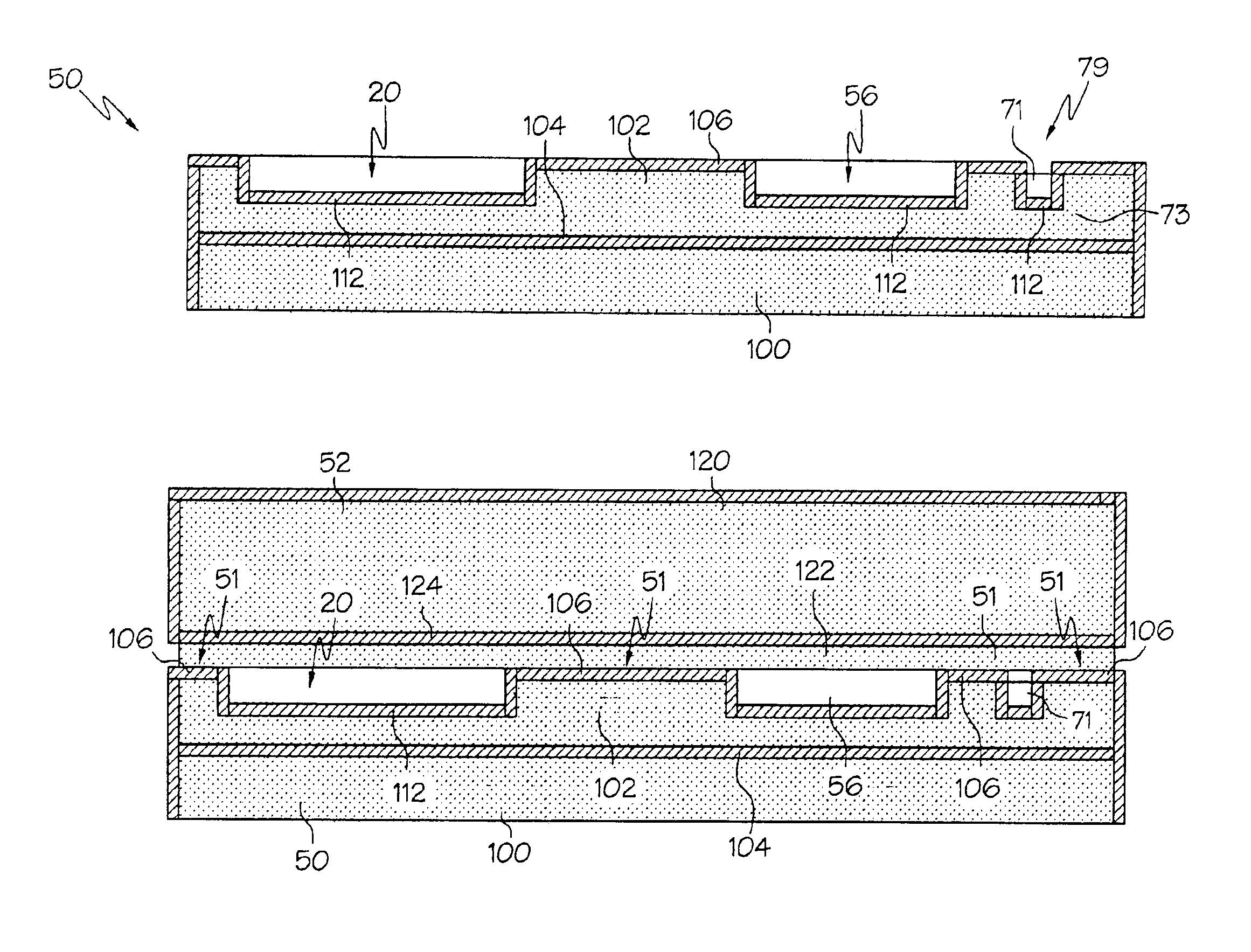

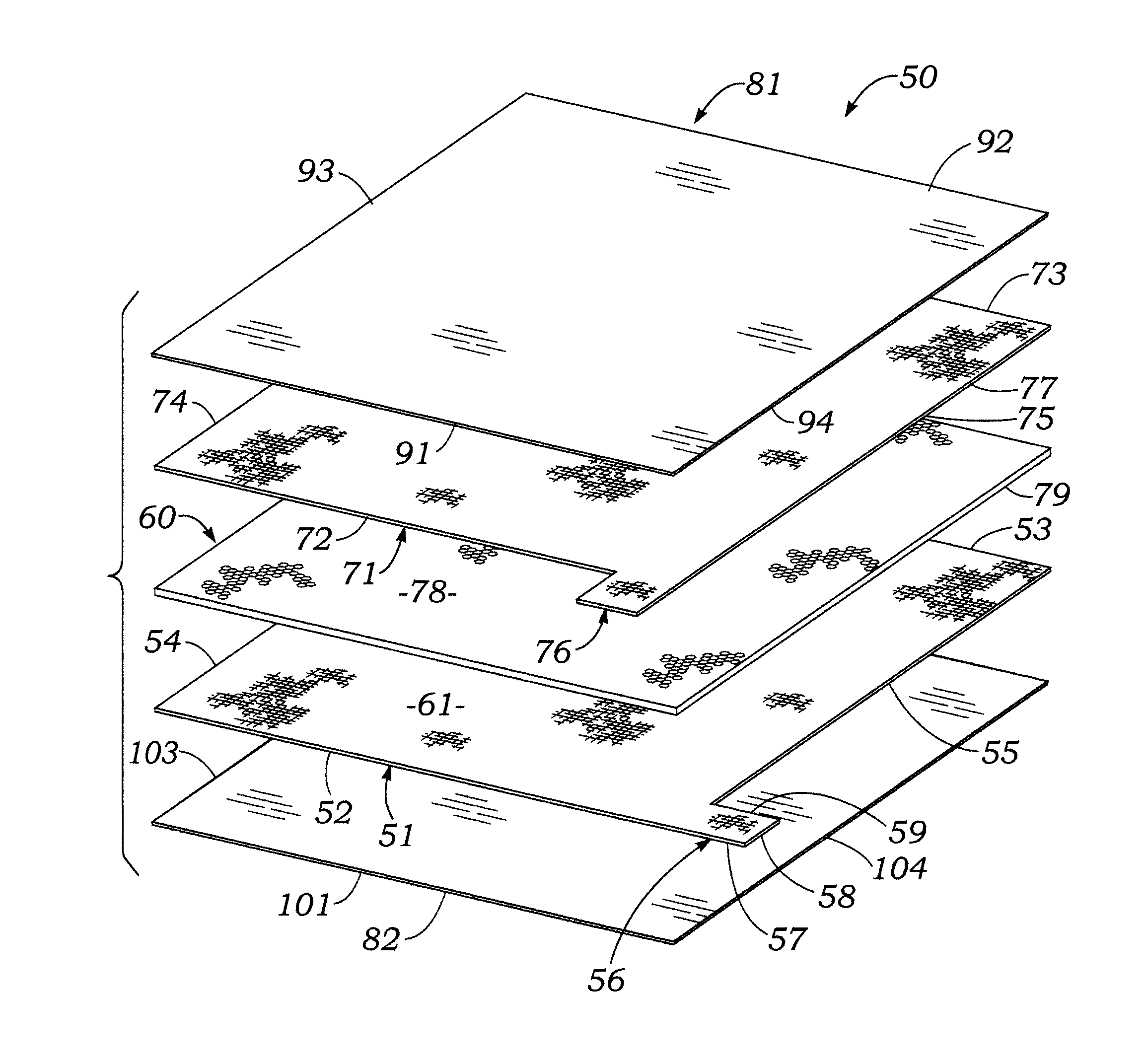

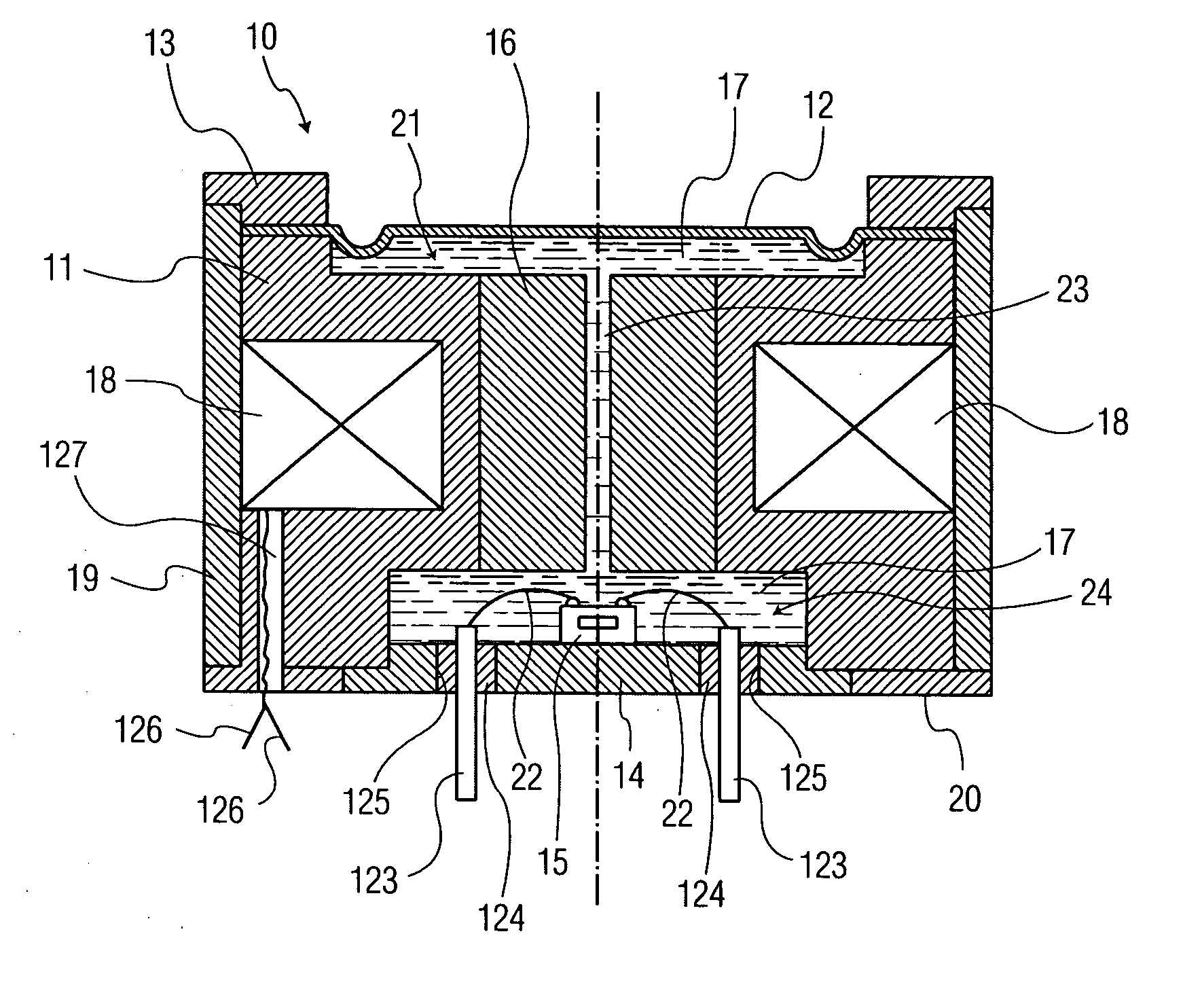

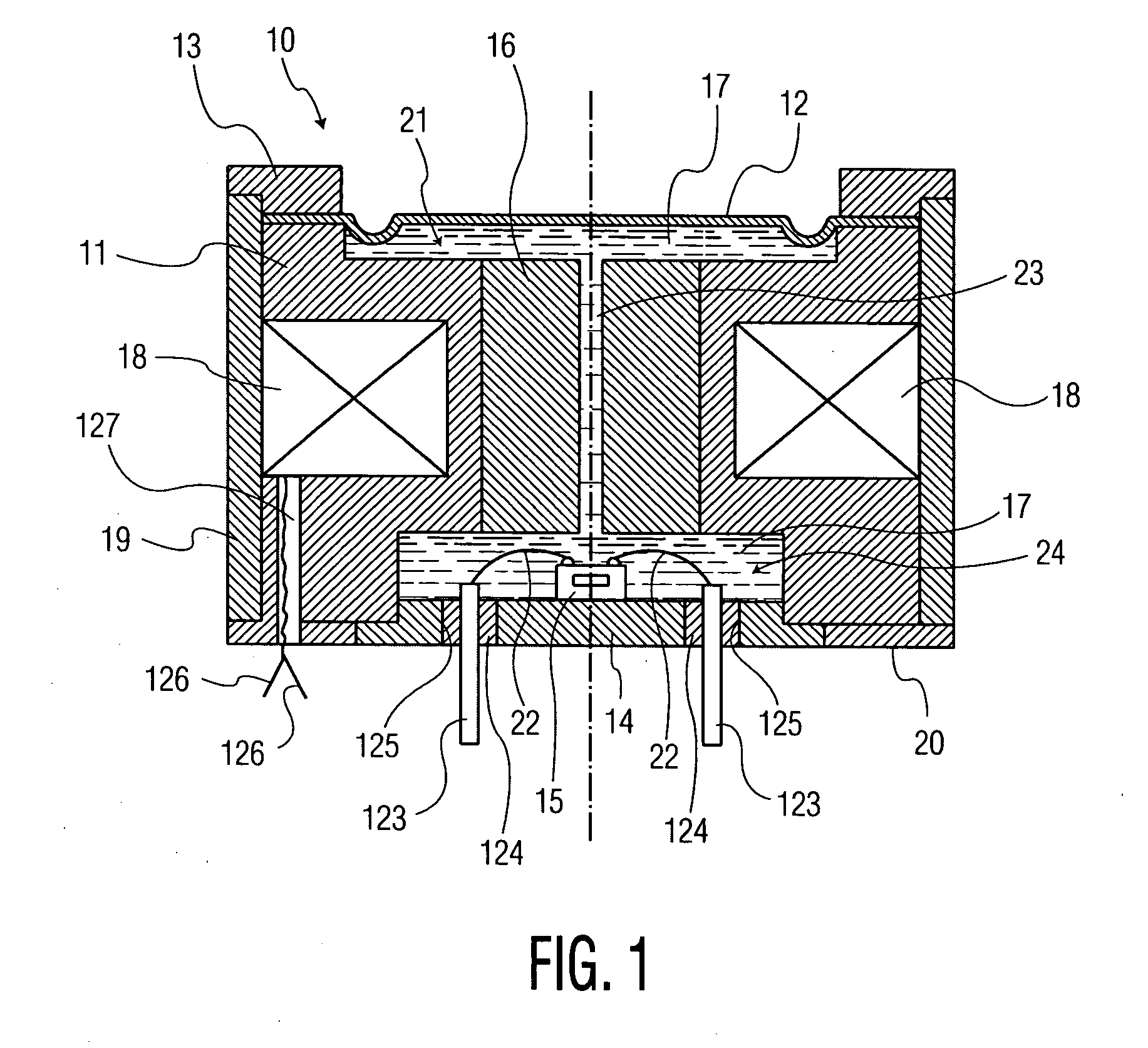

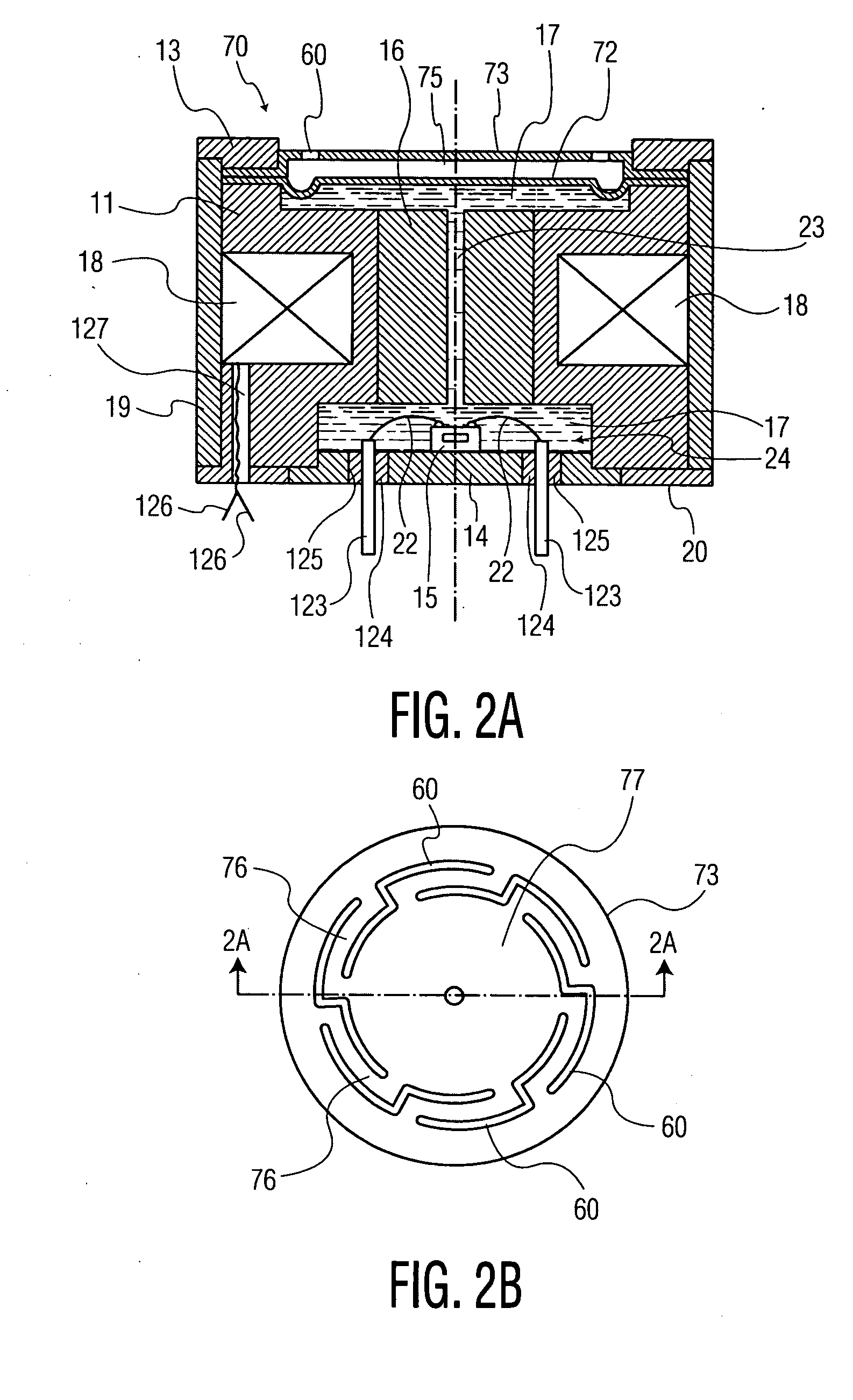

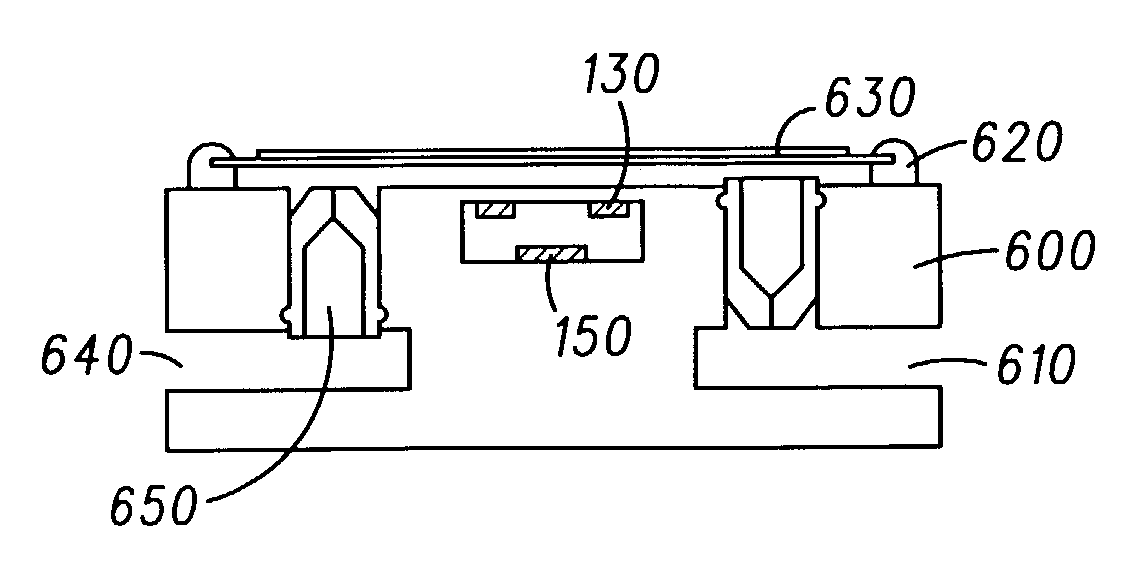

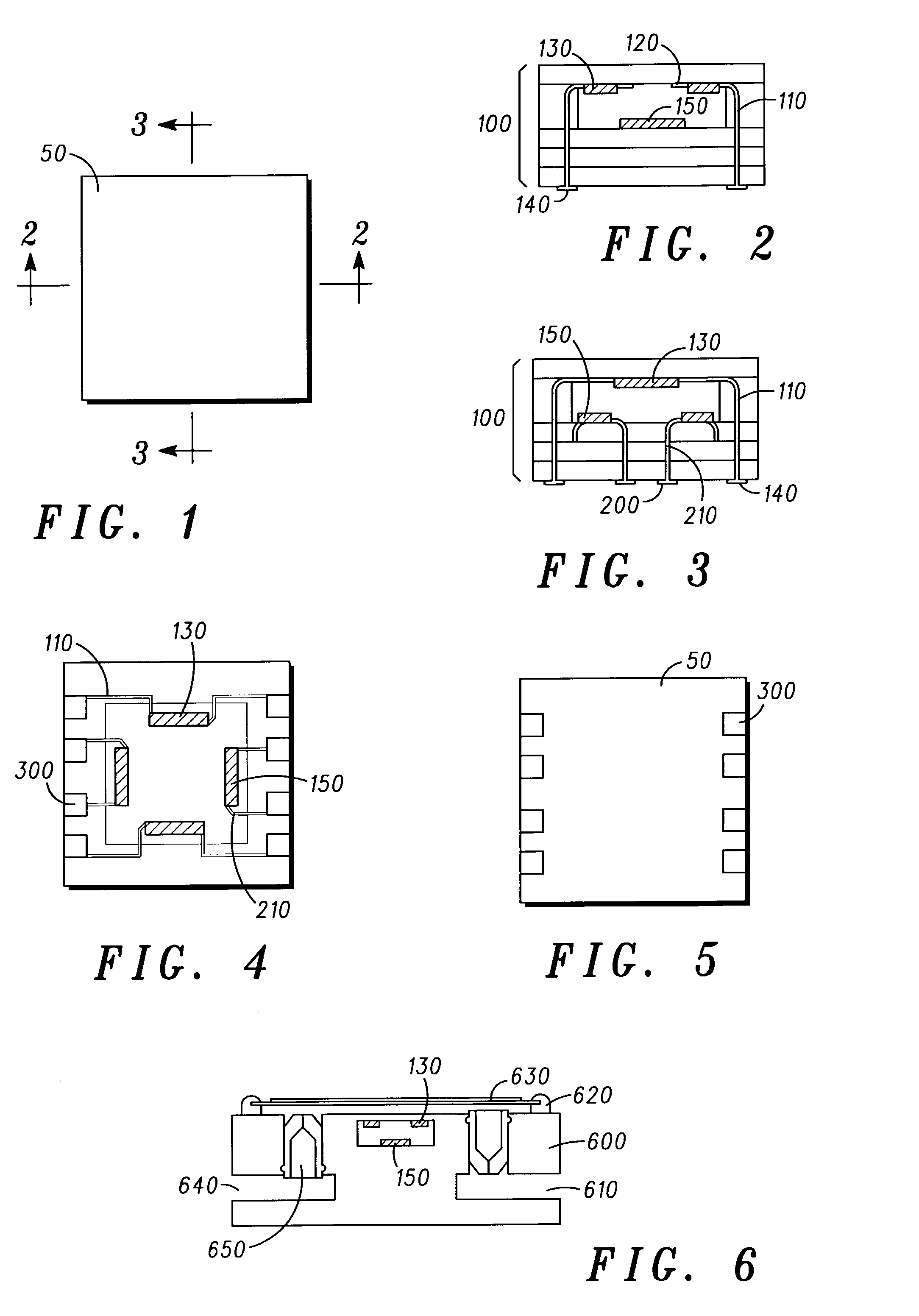

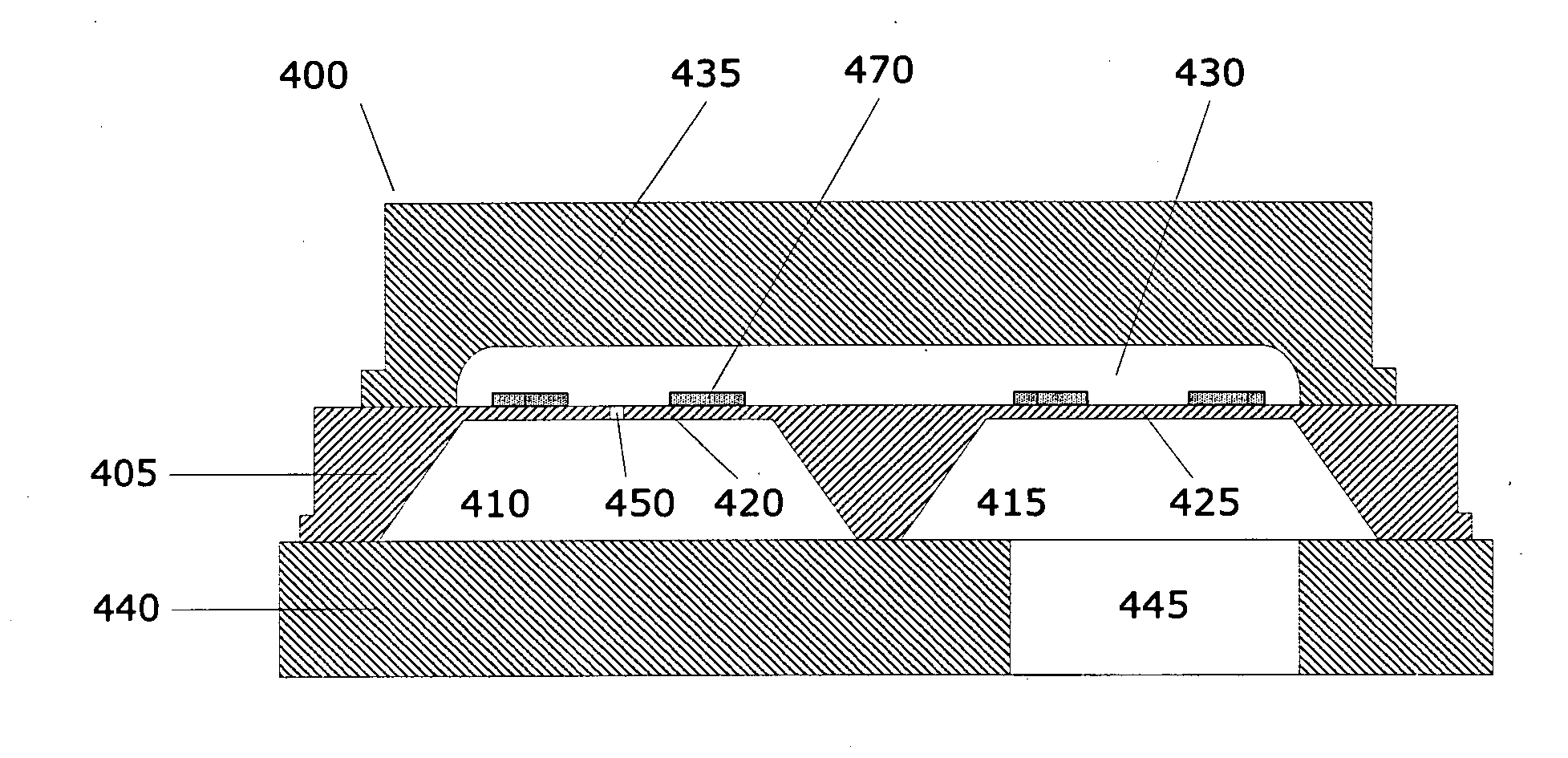

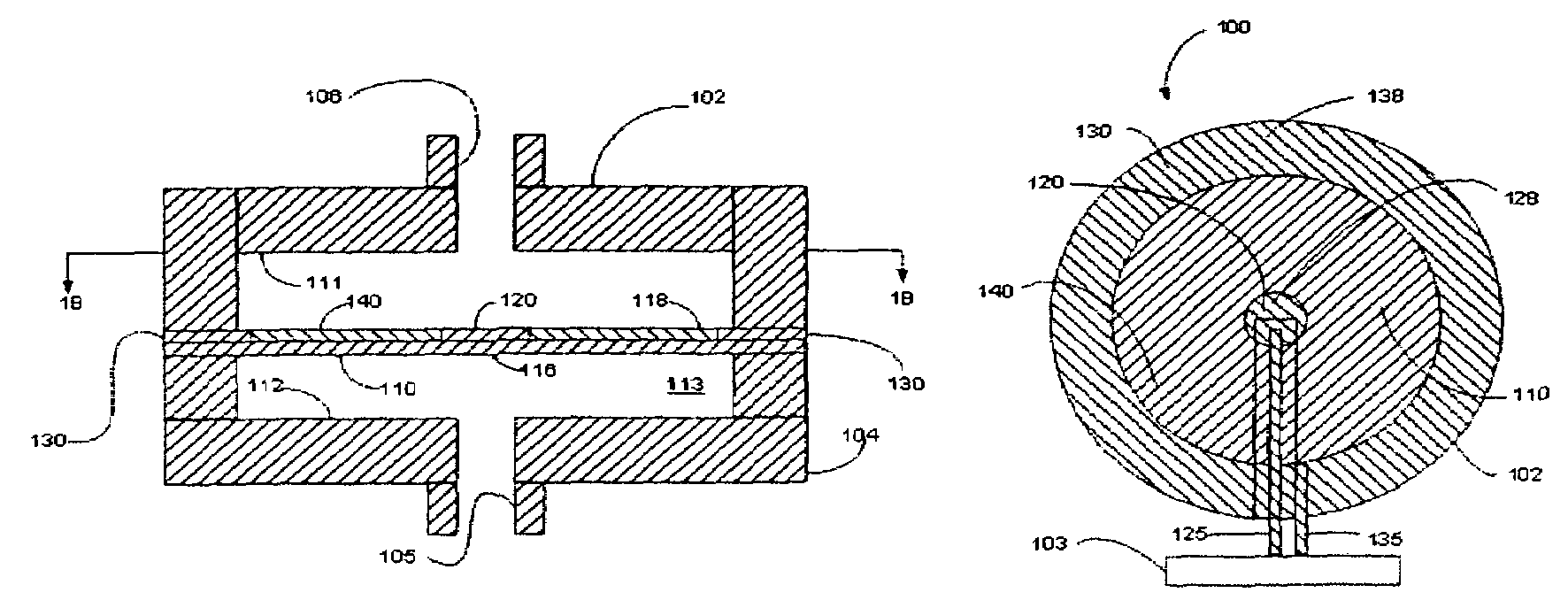

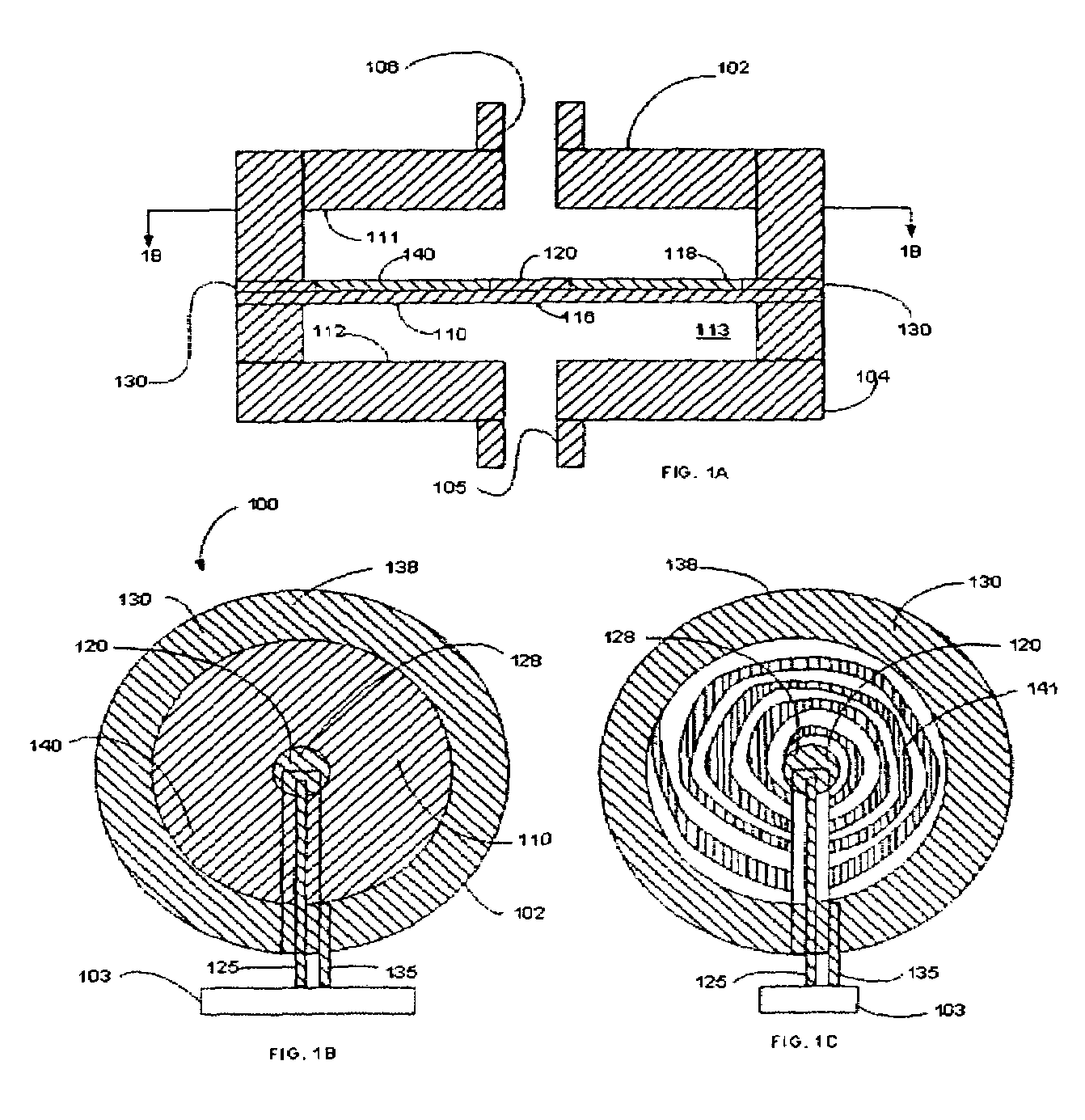

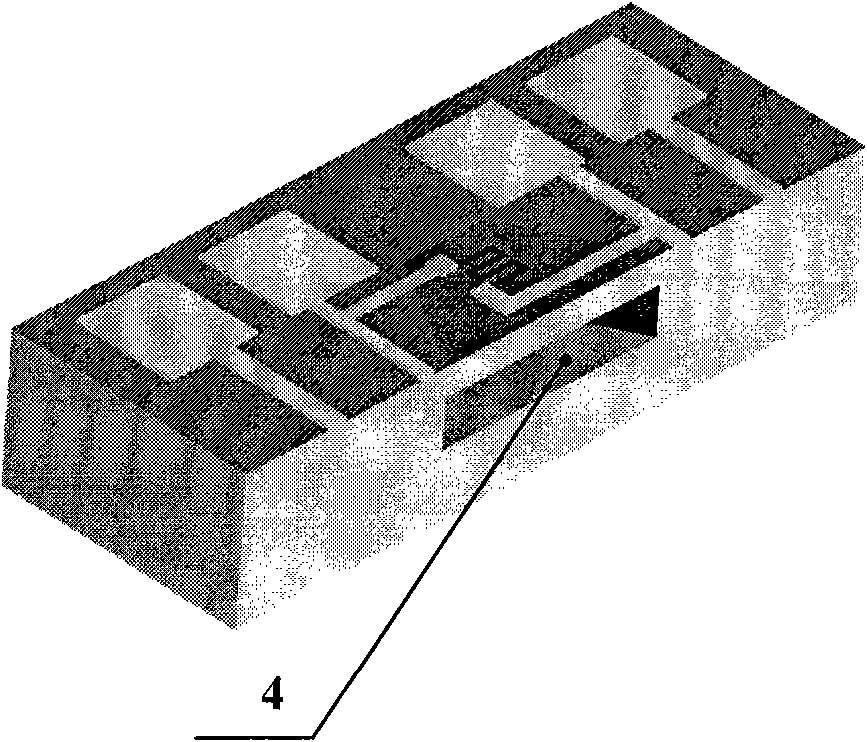

Micropump with integrated pressure sensor

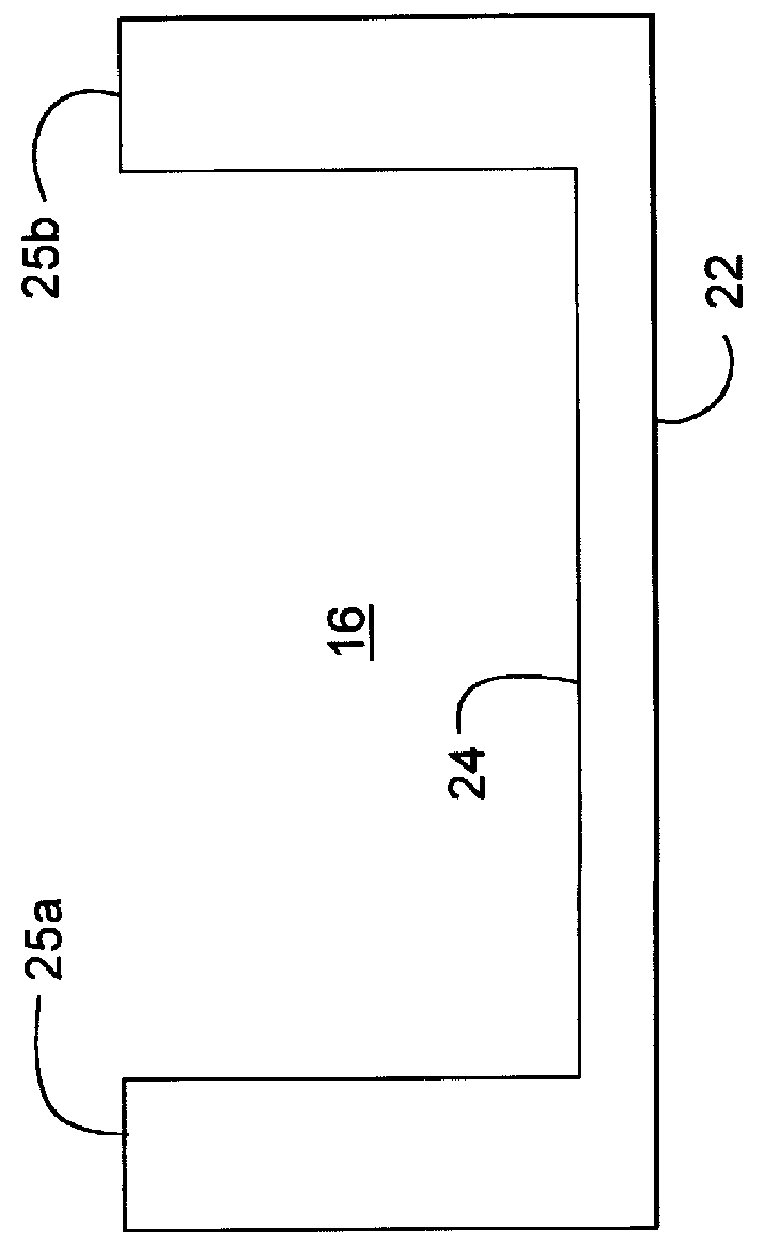

ActiveUS6986649B2Easy to controlLow costPositive displacement pump componentsFlexible member pumpsElectrical resistance and conductanceElectricity

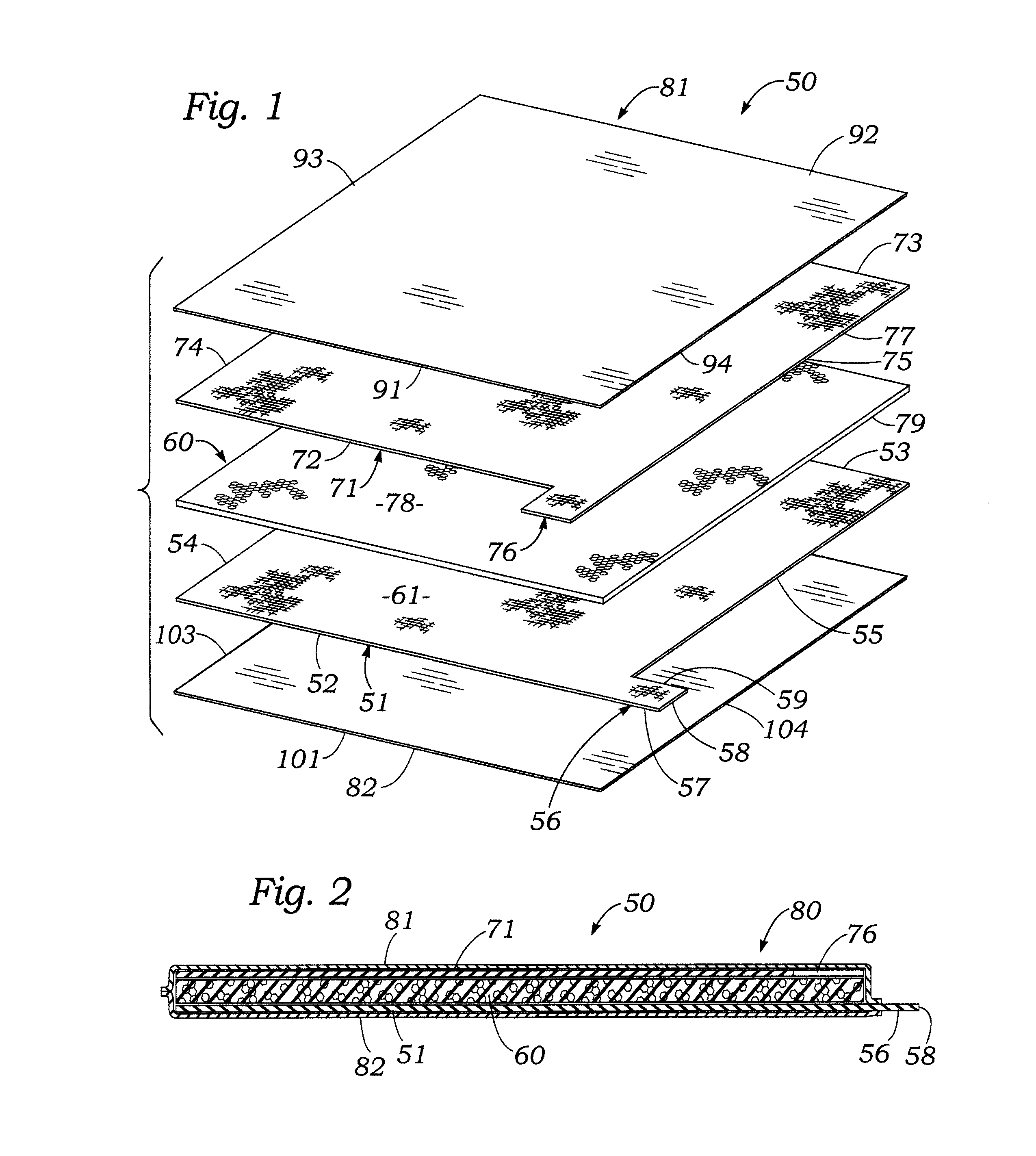

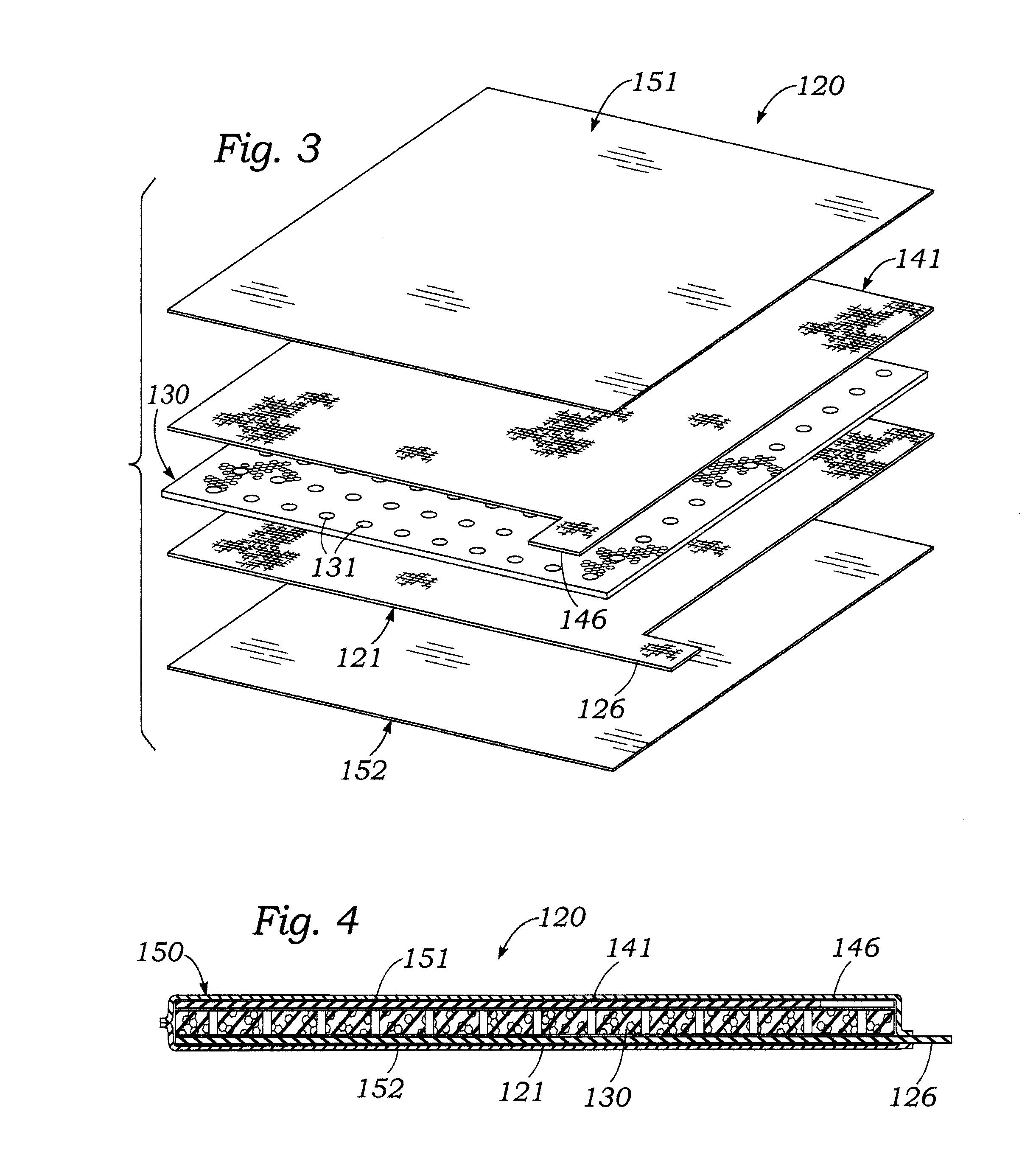

An exemplary system and method for manufacturing micropump systems having integrated piezoresistive sensors is disclosed as including inter alia: a substrate, an inlet channel, an outlet channel, a pumping cavity, a first valve for permitting fluid flow from the inlet channel to the pumping cavity and restricting backflow of purged fluid from the pumping cavity to the inlet channel; a second valve for permitting fluid flow from the pumping cavity to an outlet channel and restricting backflow of purged fluid from the outlet channel to the pumping cavity; a pump actuator element; a pressure sensing cavity surface capable of at least partial mechanical deformation; a plurality of piezoresistors disposed within the sensing cavity; a plurality of contact pads; a plurality of conductive pathways connecting the piezoresistors and the contact pads; and a substantially monolithic device package, wherein the sensing cavity is substantially contained within the micropump device package. Disclosed features and specifications may be variously controlled, adapted or otherwise optionally modified to improve micropump operation in any microfluidic application. Exemplary embodiments of the present invention representatively provide for piezoresistive pressure sensors that may be readily integrated with existing portable ceramic technologies for the improvement of device package form factors, weights and other manufacturing and / or device performance metrics.

Owner:WATERS TECH CORP

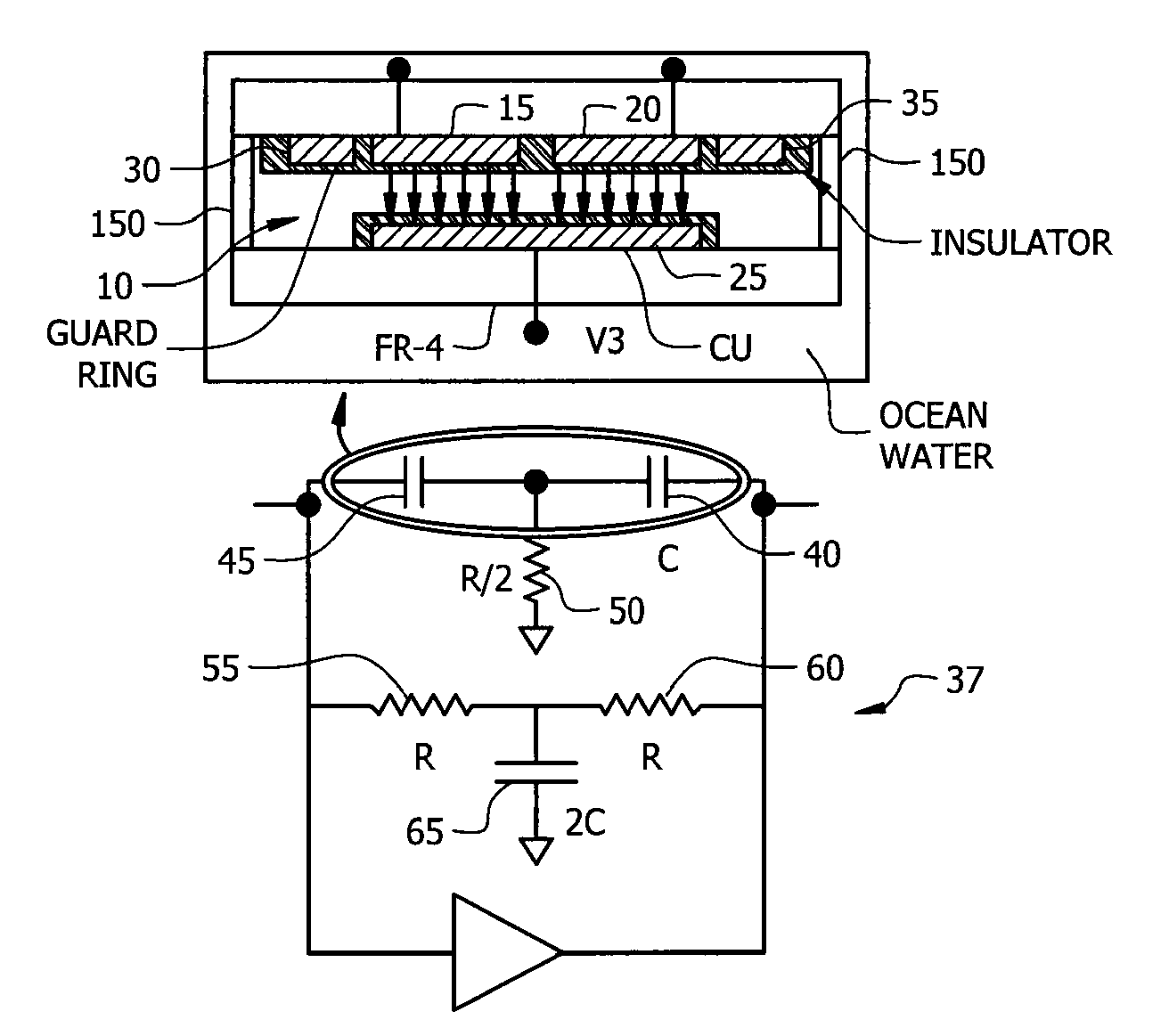

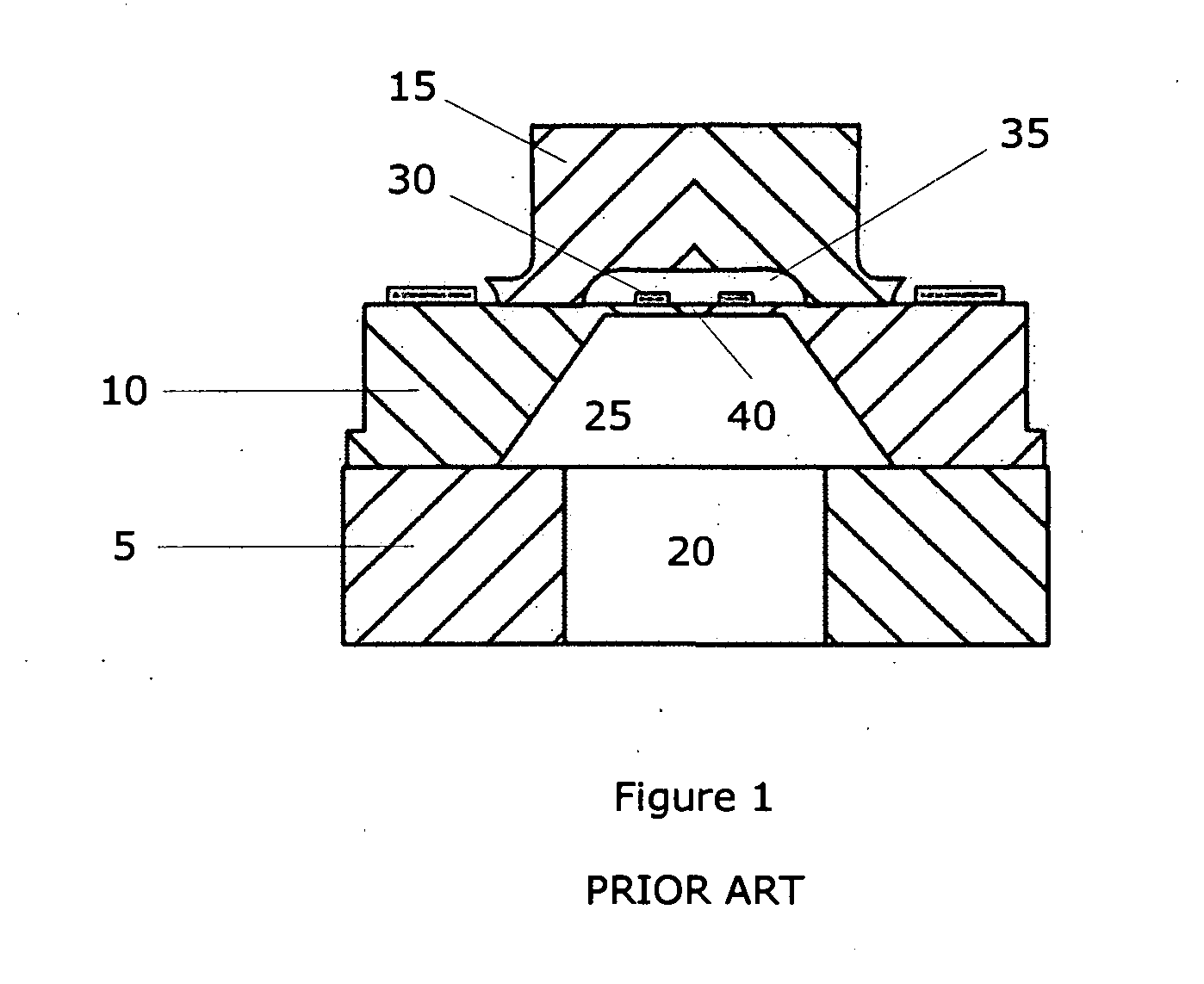

Reinforced piezoresistive pressure sensor

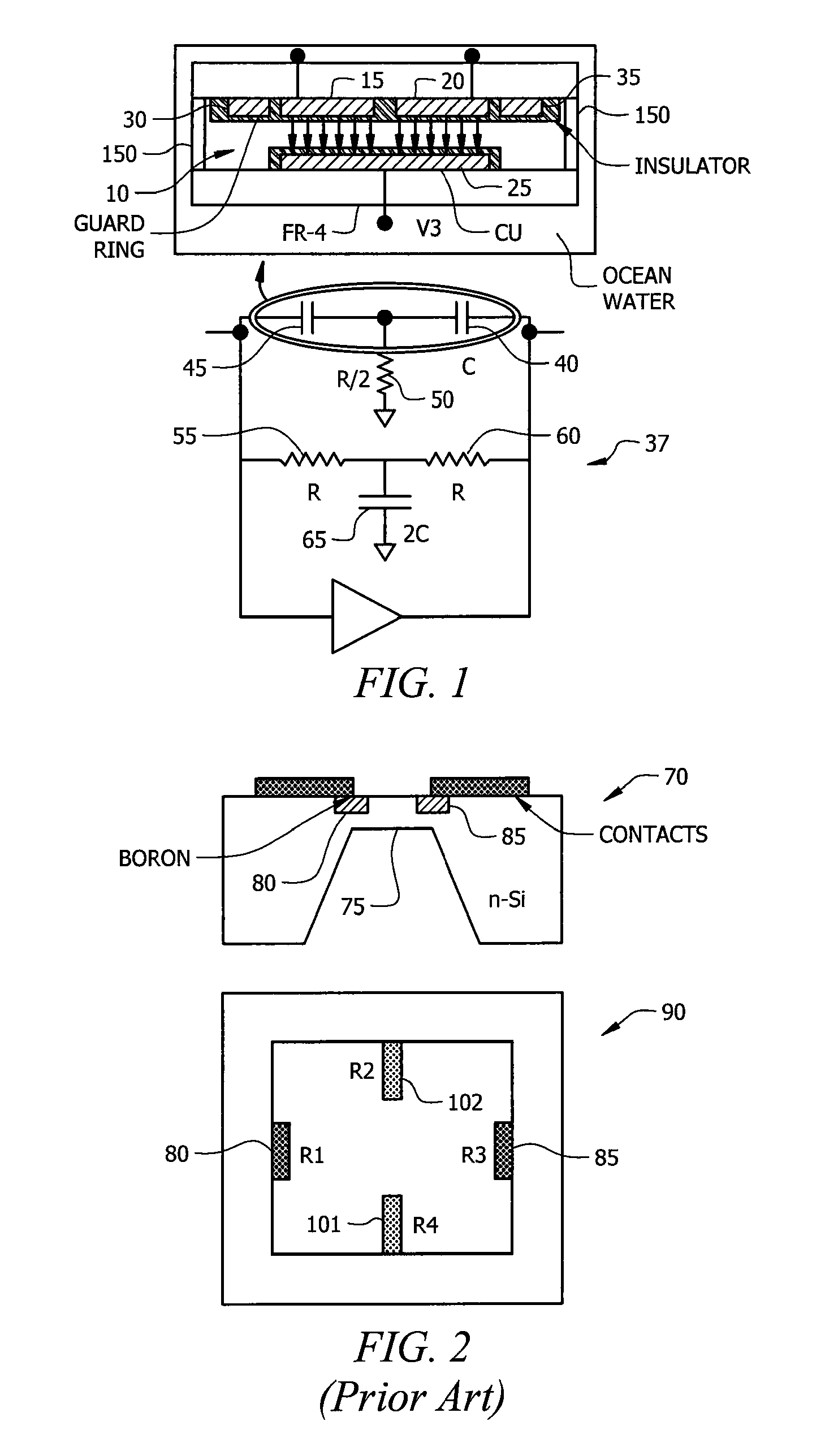

InactiveUS7856885B1Protect environmentHigh measurement accuracyMeasurement apparatus componentsFluid pressure measurement using ohmic-resistance variationEngineeringPiezoresistive pressure sensors

A MEMS-based silicon pressure sensor for the ocean environment is presented. The invention is a multiple diaphragm piezoresistive pressure sensor for measuring the pressure of a liquid, comprising an inner deformable diaphragm formed on a silicon substrate, the inner deformable diaphragm having a first thickness an outer deformable diaphragm formed on the silicon substrate, the outer deformable diaphragm having a second thickness which is greater than the first thickness, positioned below the inner deformable diaphragm to support the inner deformable diaphragm, a first piezoresistive bridge embedded in the inner deformable diaphragm, a second piezoresistive bridge embedded in the outer deformable diaphragm and possibly a third piezoresistive bridge embedded in the silicon substrate to compensate for temperature variations.

Owner:UNIV OF SOUTH FLORIDA

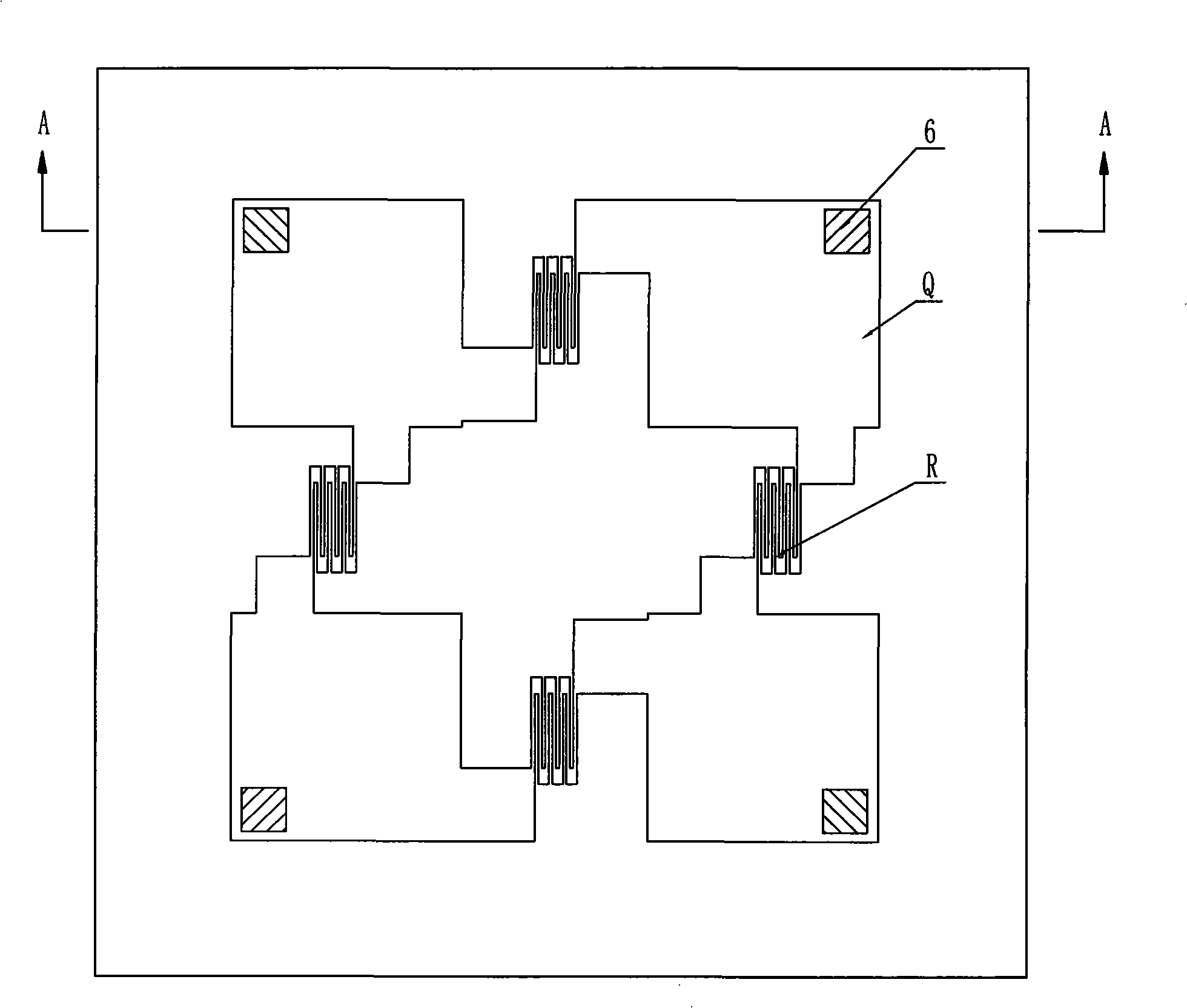

High doping point electrode SOI piezoresistance type pressure sensor and manufacturing method thereof

InactiveCN101349602AHigh precisionImprove dynamic characteristicsFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsOhmic contactPiezoresistive pressure sensors

The invention relates to a highly-doped pointed electrode SOI piezoresistive pressure sensor and a manufacturing method thereof, namely a piezoresistive pressure sensor. The piezoresistive pressure sensor solves the problems that the length of a metal electrode is longer and the reliability of products is lowered through utilizing in high temperature. A SOI diaphragm is formed by a silicon substrate, a first silicon dioxide layer and a highly-doped layer. A thin silicon layer, a second silicon layer and a silicon nitride layer are arranged on the outer portion of the piezoresistive pressure sensor from inside to outside in turn. An electrode is bonded with the highly-doped layer through the upper three layers, and the silicon substrate and the lower three layers are corroded to form a bottom groove. The manufacturing method comprises the flowing steps in turn: injecting heavy boron in the SOI diaphragm, etching to form a highly-doped area Q and a sensitive resistance R, secondarily oxygenizing, generating silicon nitride, and then, making a lead wire and etching the bottom groove, and finally, finishing the conventional process. The sensitive resistor and the lead wire are made through adopting a highly-doped technique, independent high doping is not needed to be done on the extraction portion of an electrode to do ohmic contact, and meanwhile, an annealing process is reduced, the production cost is lowered, and the reliability of products is improved.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

Apparatus and method for minimizing drift of a piezo-resistive pressure sensors due to progressive release of mechanical stress over time

ActiveUS20110209553A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesPressure senseEngineering

An absolute piezo-resistive pressure sensor system and method employing multiple pressure sensing elements operating simultaneously to detect pressure. Both pressure sensing elements being subject to a common reference pressure within a sealed cavity. The first pressure sensing element detecting an offset voltage resulting from the progressive release of mechanical stress at an assembly interface between the sensing element and a base plate on which the sensing elements are assembled. Electronic circuitry compensates the pressure measured by the second pressure sensing element based on the offset voltage detected by the first pressure sensing element.

Owner:CODMAN NEURO SCI

Piezoresistive pressure sensor

InactiveUS7546772B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringPiezoresistive pressure sensors

A pressure sensor includes a housing portion with a fluid inlet and a polymer element within the housing portion. The polymer element may be coated with piezoresistive material to form a first resistor and may have associated electrodes. The polymer element includes a first resistance value that changes to a second resistive value in a response to a predetermined condition. The pressure sensor may also include a second polymer element that includes a first resistance value that changes to a second resistive value in a response to a predetermined condition.

Owner:HONEYWELL INT INC

Pressure sensitive core with thermistor

InactiveCN103454032ATemperature drift compensation facilitatesFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceElectricity

The invention discloses a pressure sensitive core with a thermistor, and belongs to the field of pressure measurement. In order to solve the problem that an existing silicon piezoresistive pressure sensor is large in temperature excursion, the pressure sensitive core with the thermistor comprises a tube base with an inner cavity, a pressure sensitive chip and the thermistor, wherein the pressure sensitive chip and the thermistor are installed in the inner cavity of the tube base. A plurality of pins are installed on the tube base, the pressure sensitive chip is electrically connected with a part of pins, the thermistor is electrically connected with the other part of pins. A corrugated diaphragm is arranged at the bottom of the tube base, a closed cavity is formed between the corrugated diaphragm and the tube base, and silicon oil is contained in the closed cavity. The pressure sensitive core with the thermistor solves the problem that the temperature excursion of the pressure sensor can not be compensated for with high precision when a pure-resistance network is adopted, the NTC thermistor provides signal output in nonlinear relation with temperature, and the nonlinear output signal can compensate for the temperature excursion of the pressure sensitive chip with high precision.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

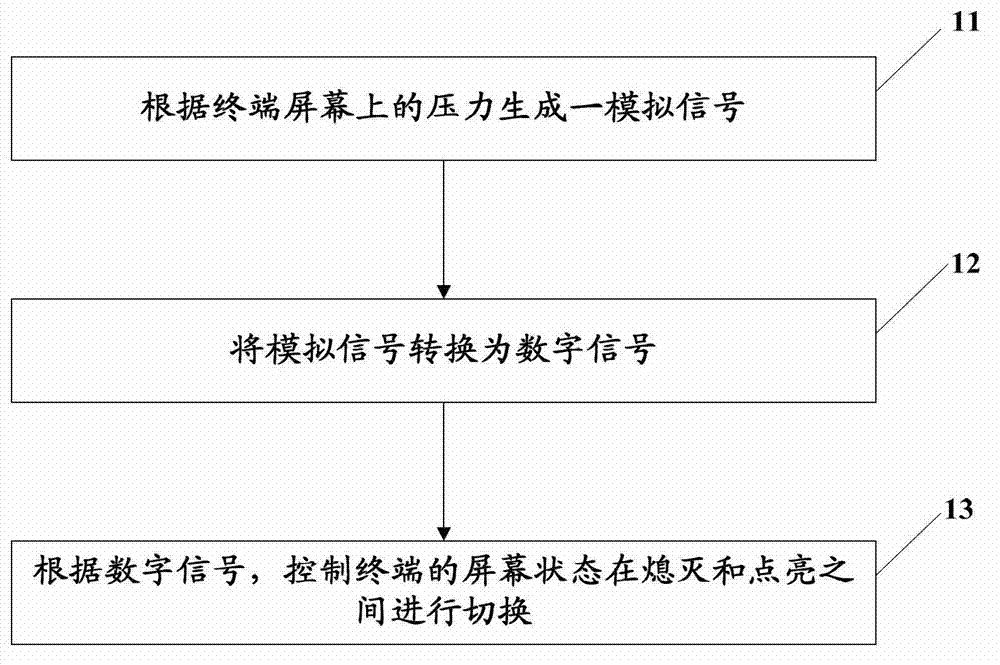

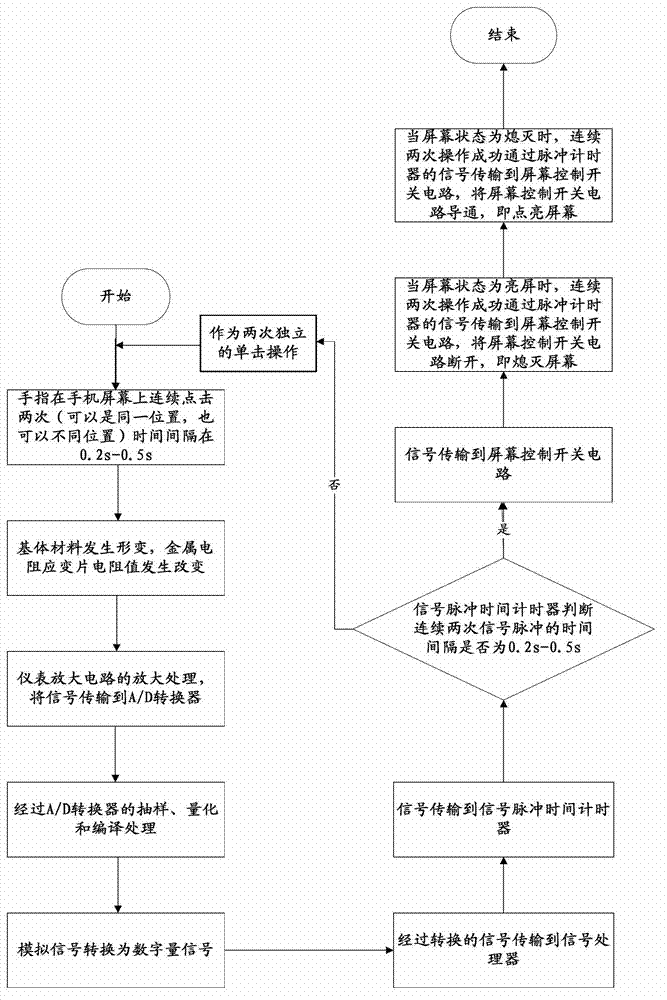

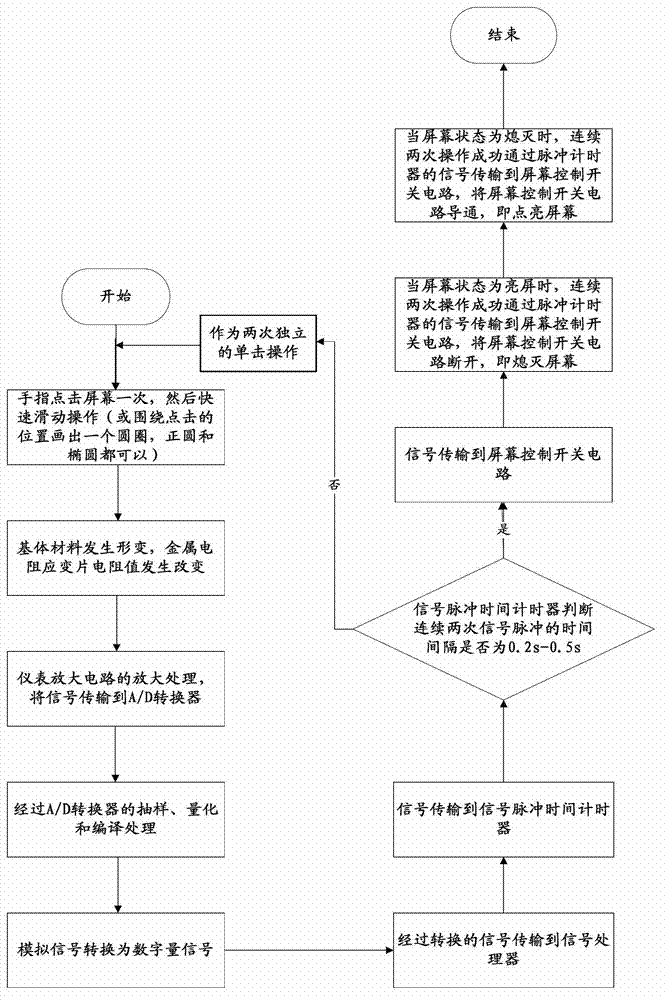

Screen state control method, screen state control device and touch screen terminal

InactiveCN102968242AImprove experienceNo physical lossDigital data processing detailsInput/output processes for data processingElectrical resistance and conductanceTransducer

The invention provides a screen state control method, a screen state control device and a touch screen terminal. The screen state control method is used for the touch screen terminal. The touch screen terminal is characterized in that a piezoresistive pressure transducer is arranged below a screen of the terminal, wherein a metal resistance strain gauge is adsorbed on a matrix material of the piezoresistive pressure transducer. The screen state control method comprises the following steps of: according to a pressure on the screen of the terminal, generating an analog signal; converting the analog signal into a digital signal; and according to the digital signal, controlling to switch the screen state of the terminal between switch-off and switch-on. According to the invention, the screen state can be controlled to be switched between switch-off and switch-on without being operated by a physical power button.

Owner:ZTE CORP

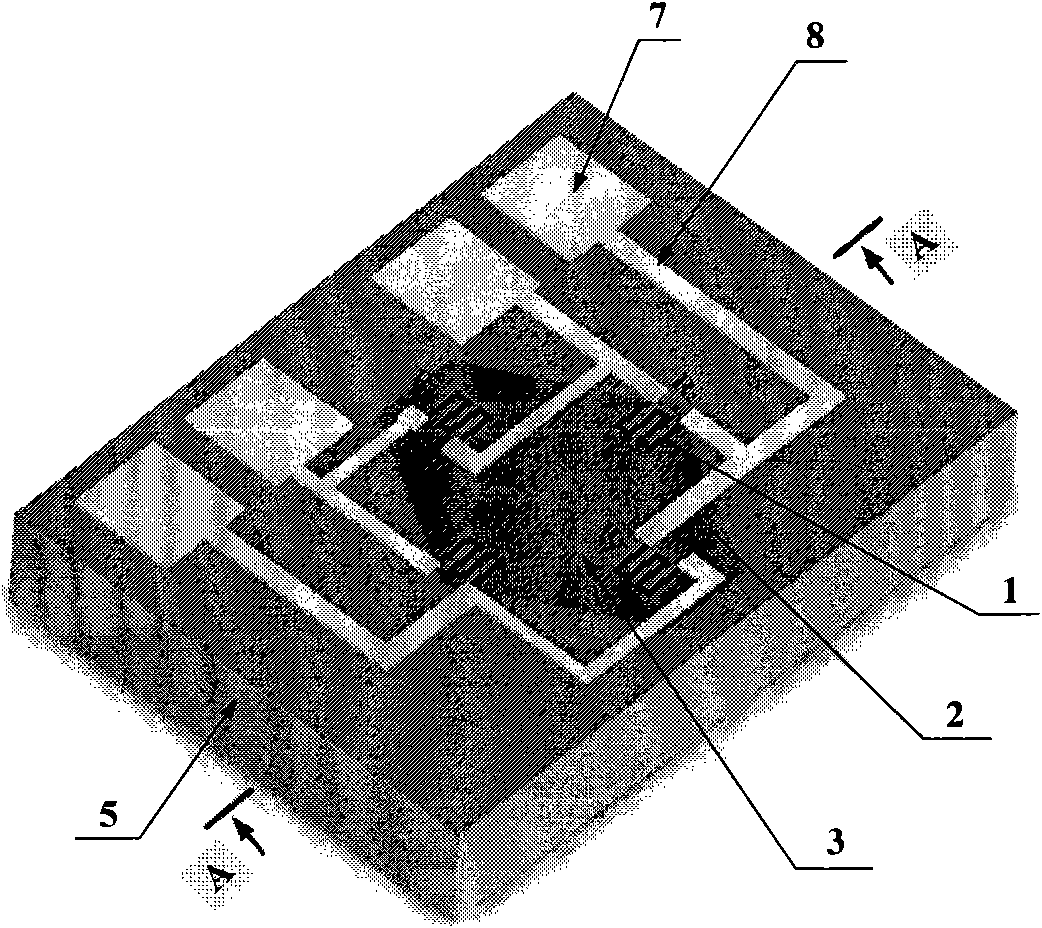

Hexagonal silicon membrane piezoresistive pressure sensor for embedded monocrystal silicon cavity and method

ActiveCN101881676ARealize structural processingHigh sensitivityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStress distributionPressure sense

The invention relates to a hexagonal silicon membrane piezoresistive pressure sensor for an embedded monocrystal silicon cavity and a method. The piezoresistive pressure sensor is characterized in that a micro-machine pressure sensor is obtained by carrying out micro-machine processing on a (111) monocrystalline silicon piece monolithic monohedron silicon; a monocrystal silicon membrane is taken as the pressure sensing membrane of the pressure sensor, the membrane is designed to be a regular hexagon, the angle between each two adjacent sides of the hexagon is 120 degrees; a pressure chamber is positioned under the membrane and is directly embedded to the inner of the silicon piece; the chamber processing respectively utilizes a strip structure way and a grid structure way, and the chamber is formed by transverse etching empty and seaming. According to stress distribution of the membrane area, the longitudinal effect and the transverse effect of piezo-resistance are utilized to respectively design two different types of piezo-resistance configuration ways. A monolithic monohedron silicon micro-machine processing technology is utilized to realize the structure processing of the sensor, and a piezoresistive element integration method is disclosed. The method can be used for manufacturing pressure sensors with the characteristics of large measuring range from 1kPa to 50MPa, high sensitivity, small size and the like, and has broad application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Explosion-field shock wave overpressure filter

InactiveCN102818670ARequirements for Accurate Measurement of Quasi-static PressureAchieving Accurate Measurement RequirementsApparatus for force/torque/work measurementShock waveEngineering

The invention discloses an explosion-field shock wave overpressure filter, which is composed of a cover plate, a tube cavity, a screw rod, a buffer gasket, a sensor installing base and a pressure sensor, wherein one end of the tube cavity is connected with the cover plate, and the other end of the tube cavity is connected with the sensor installing base; the piezoresistive pressure sensor is installed in the sensor installing base; and the inner part of the tube cavity is provided with the screw rod. Explosive is exploded in a closed environment, and shock waves enter from a blind hole in the cover plate, penetrate through cross through holes, and enter into a groove of the screw rod in the tube cavity from gaps around a boss. The shock waves are transmitted along with the screw groove to be weakened, and finally the shock waves are transmitted to the sensitive surface of the pressure sensor. The pressure sensor is subjected to a pressure action and then outputs pressure signals, the pressure signals are amplified through a front adapter, and then a quasi static pressure curve is obtained.

Owner:XIAN MODERN CHEM RES INST

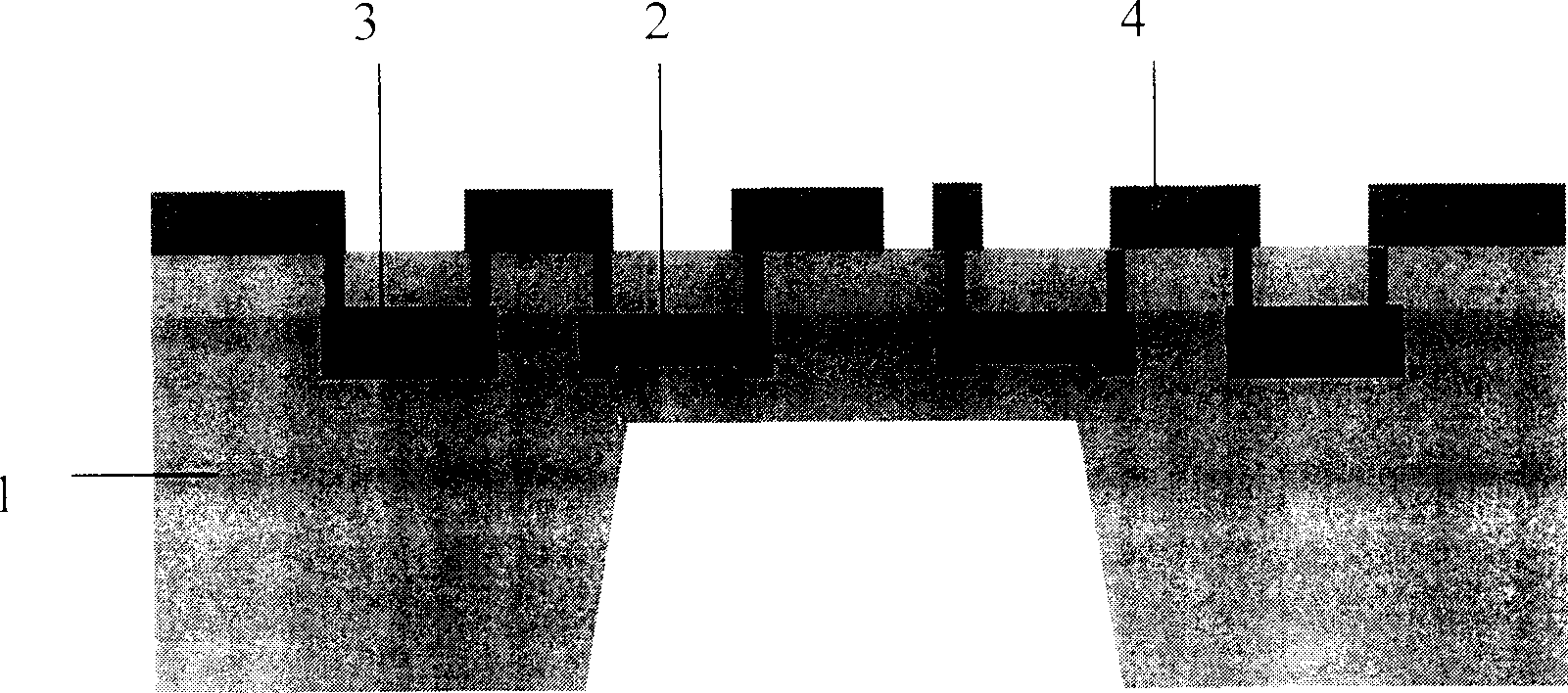

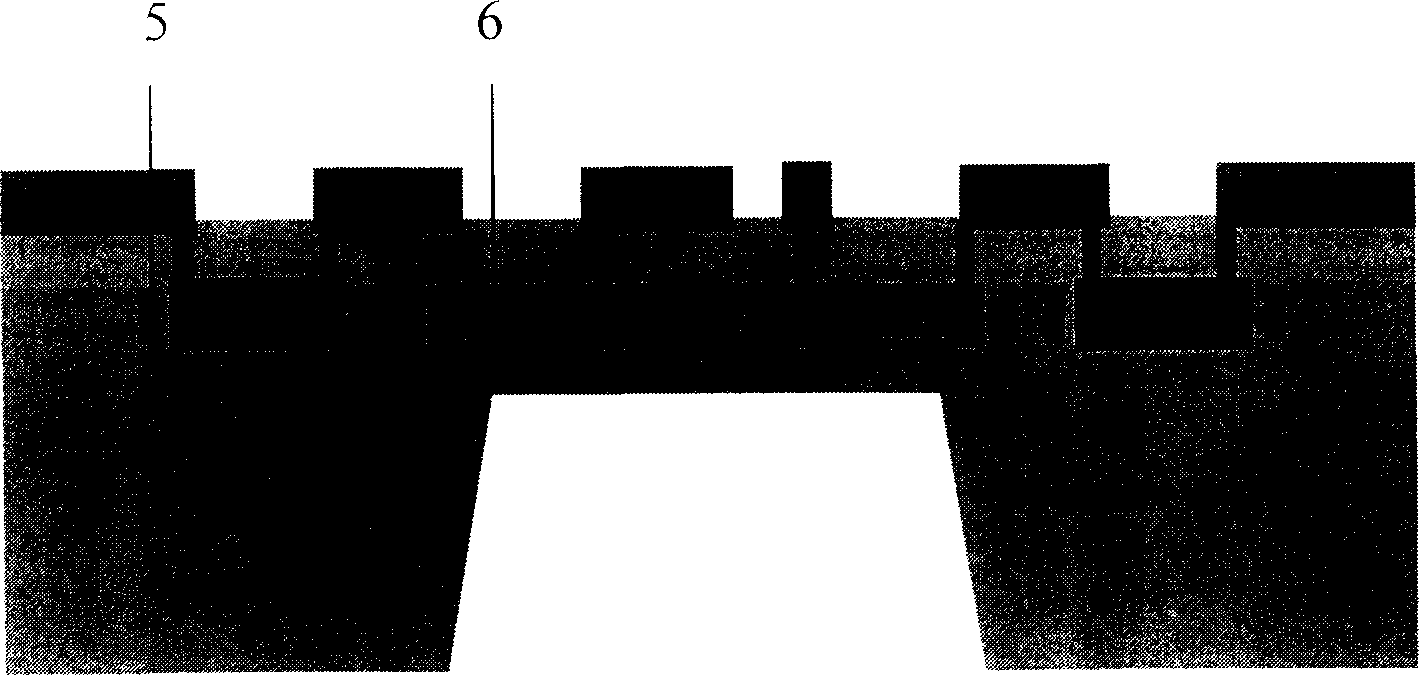

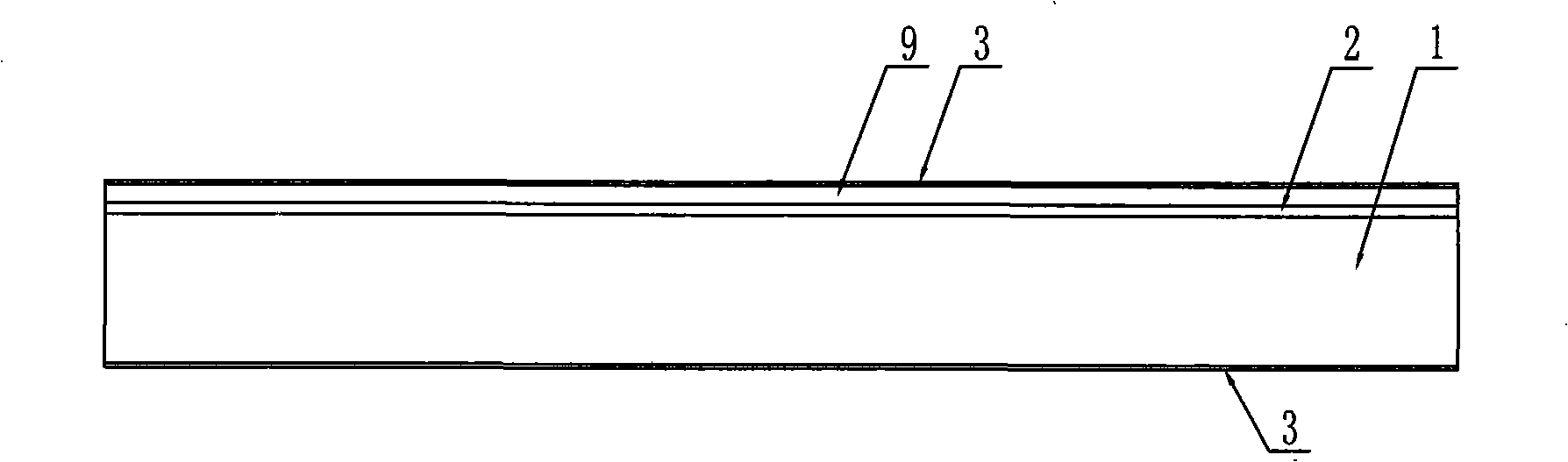

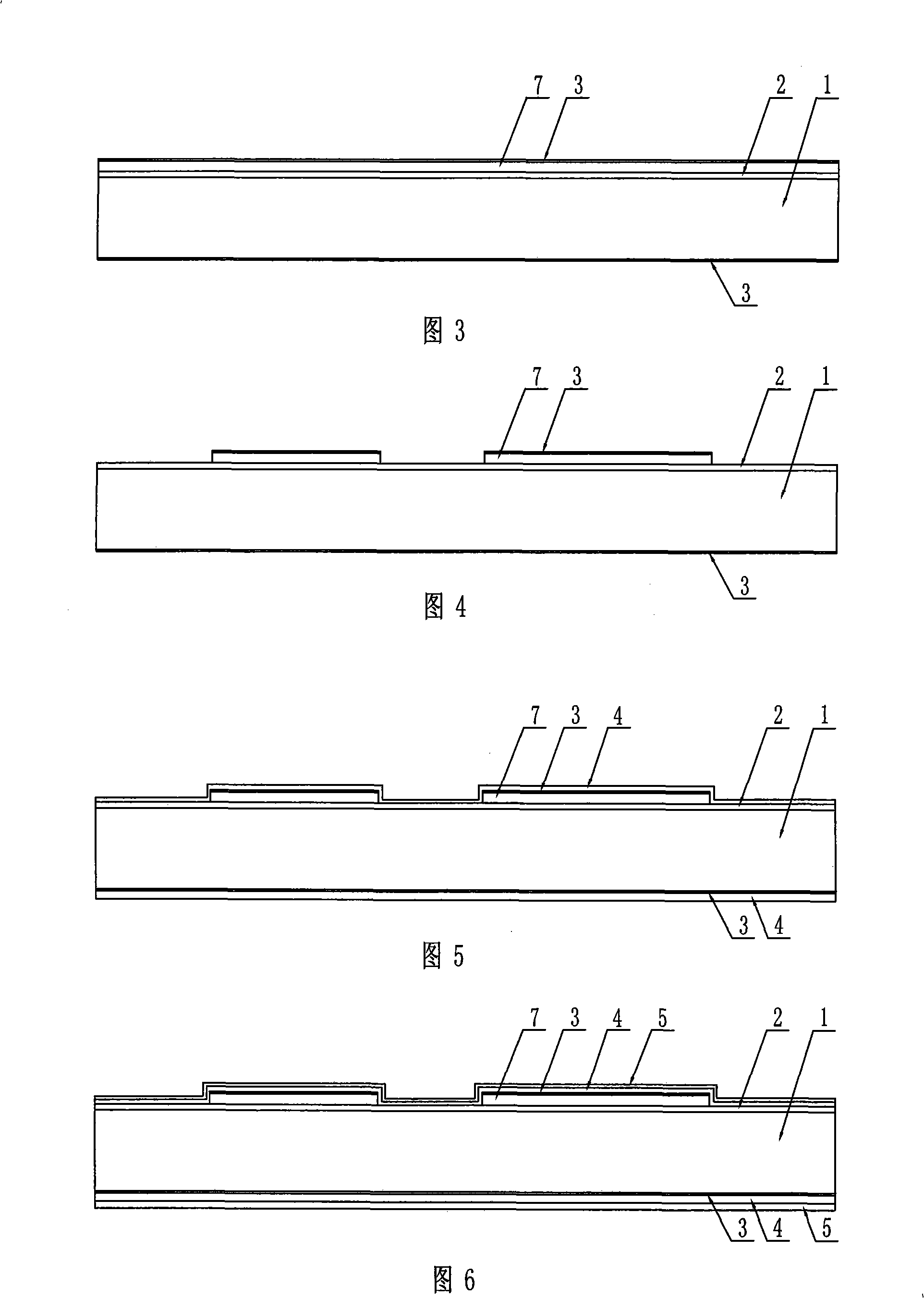

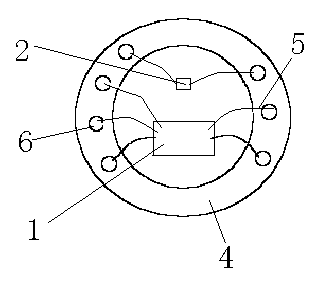

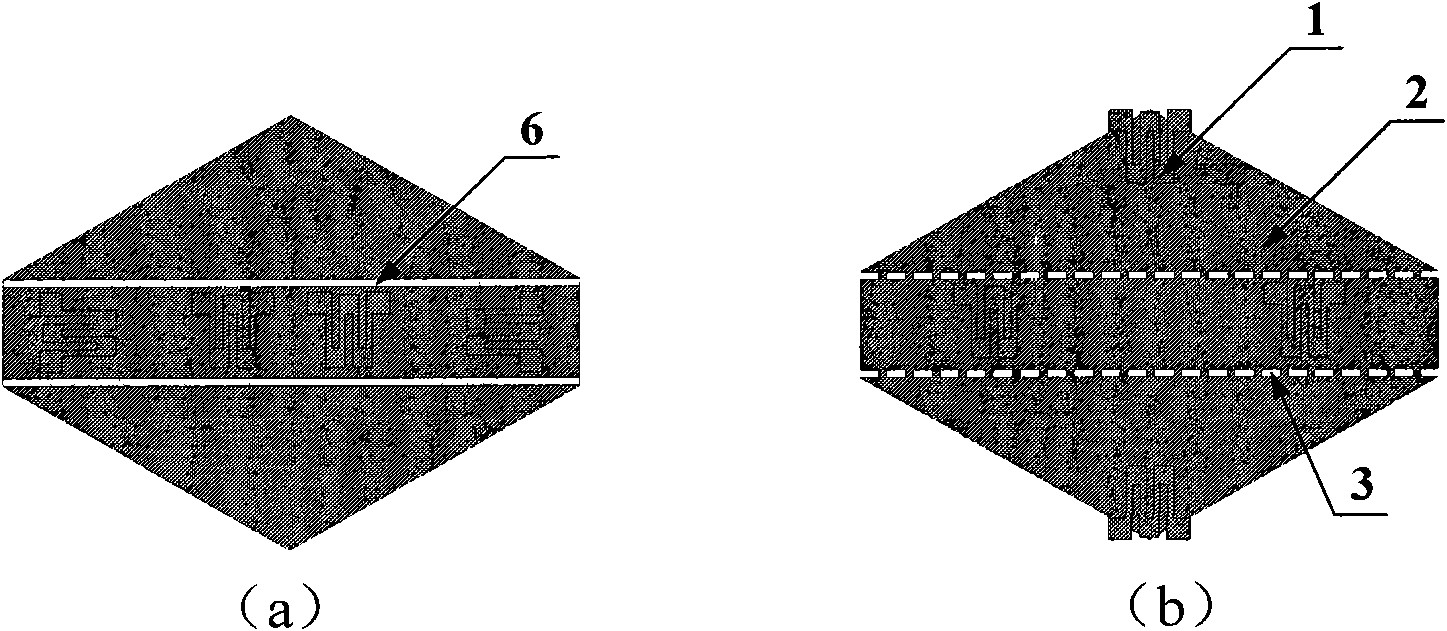

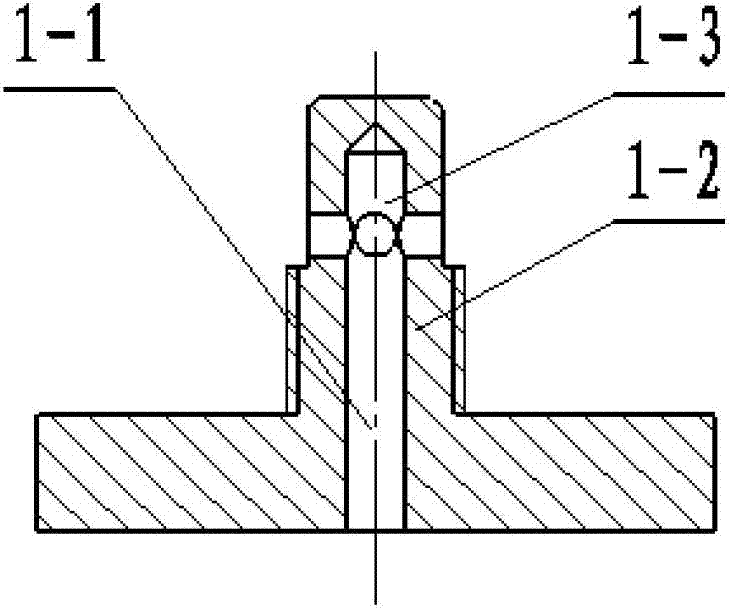

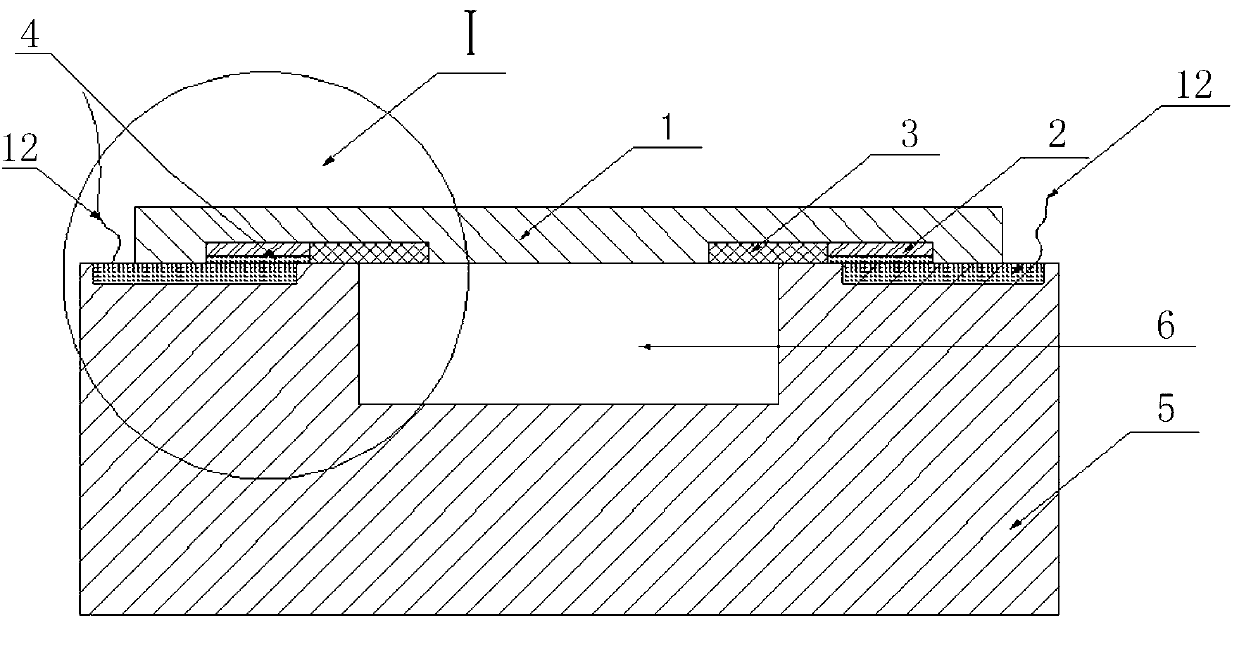

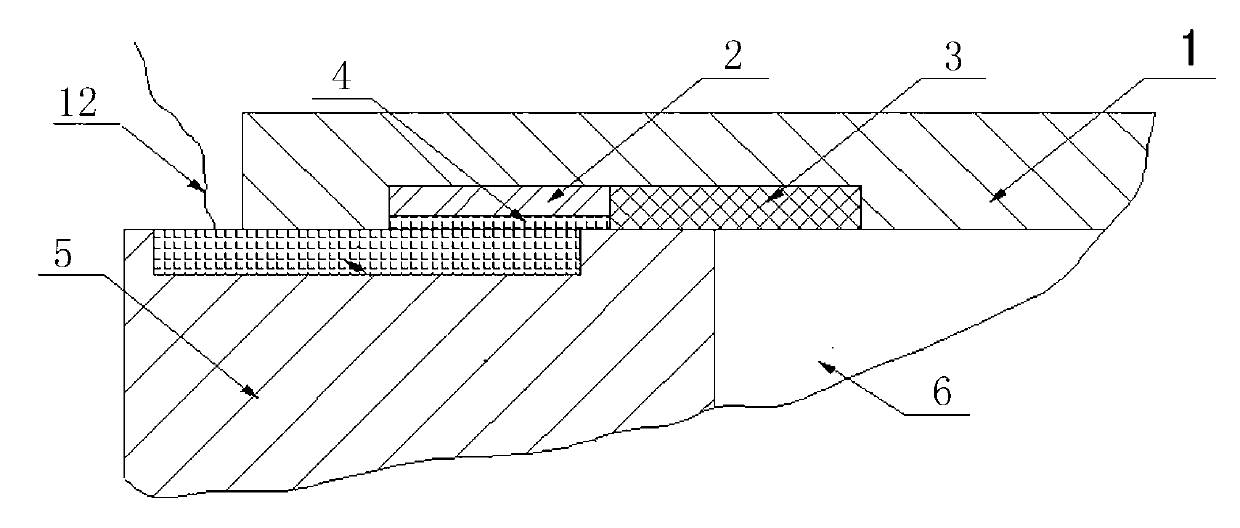

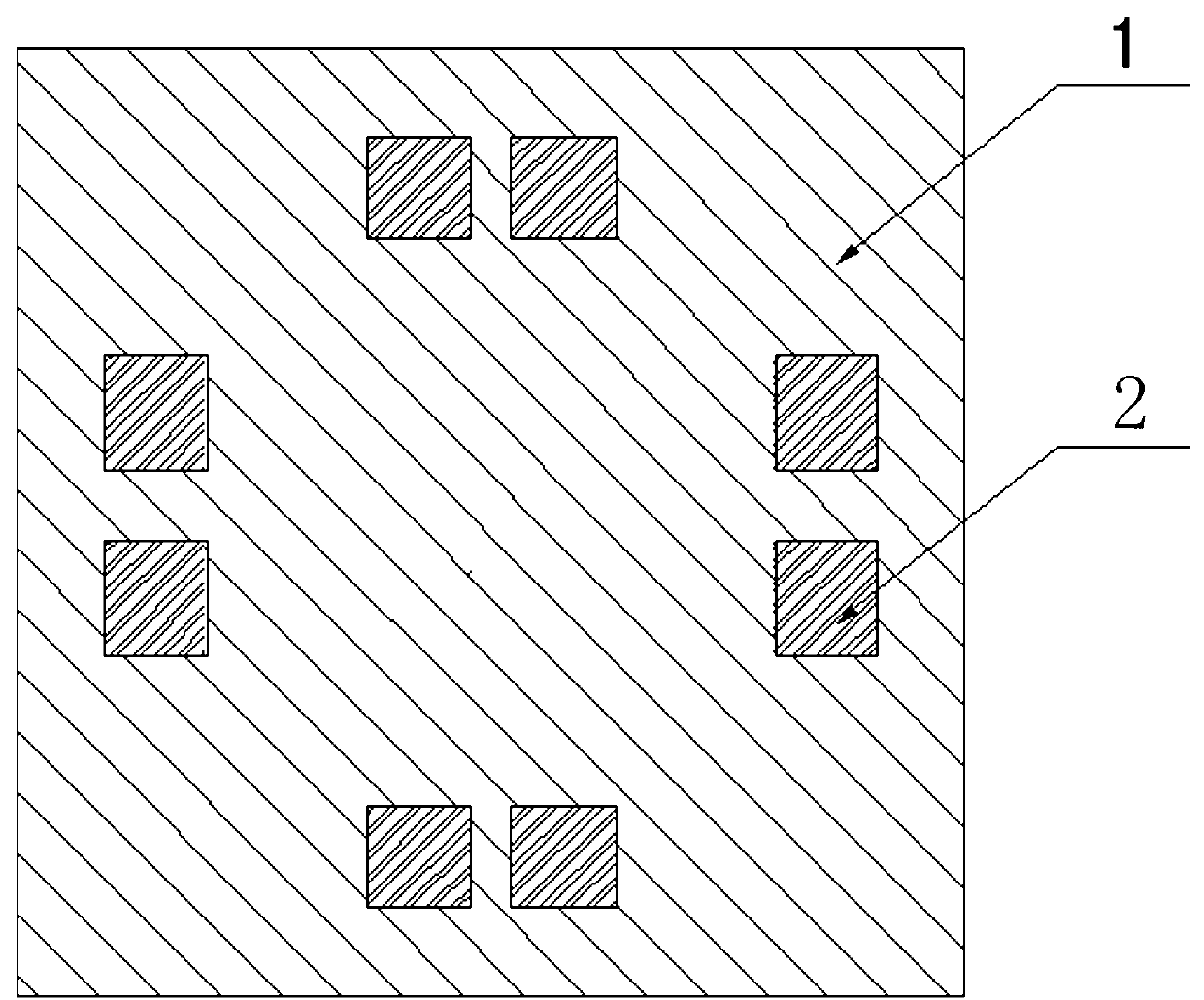

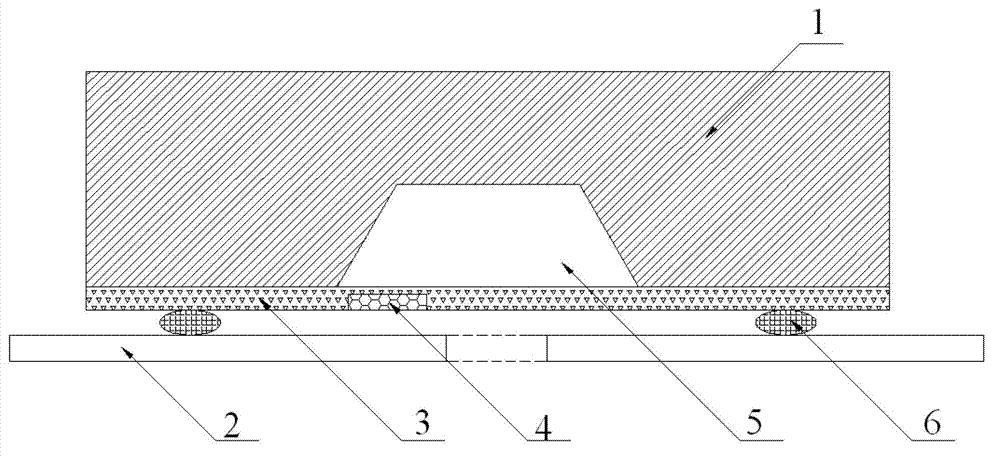

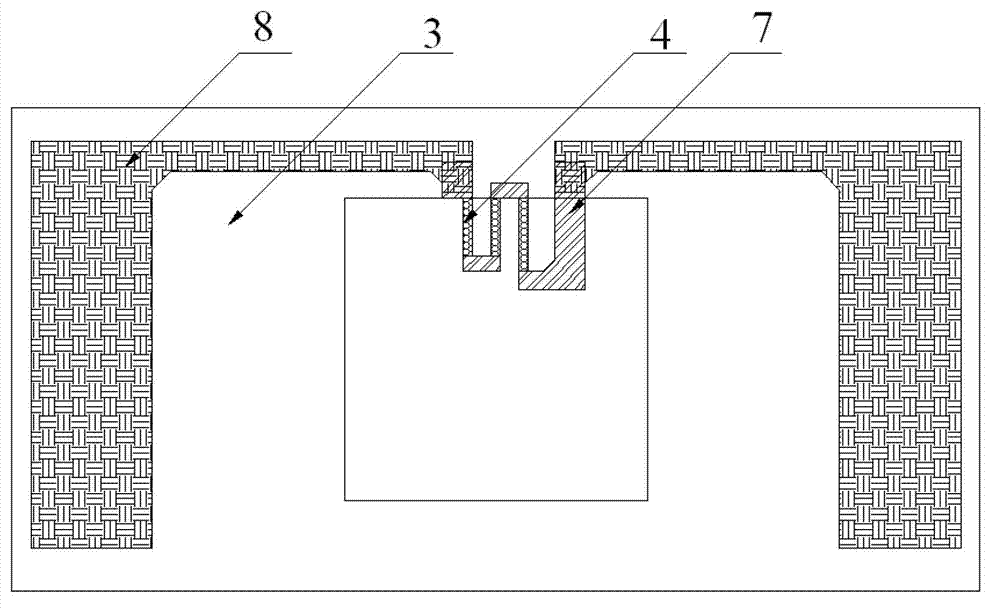

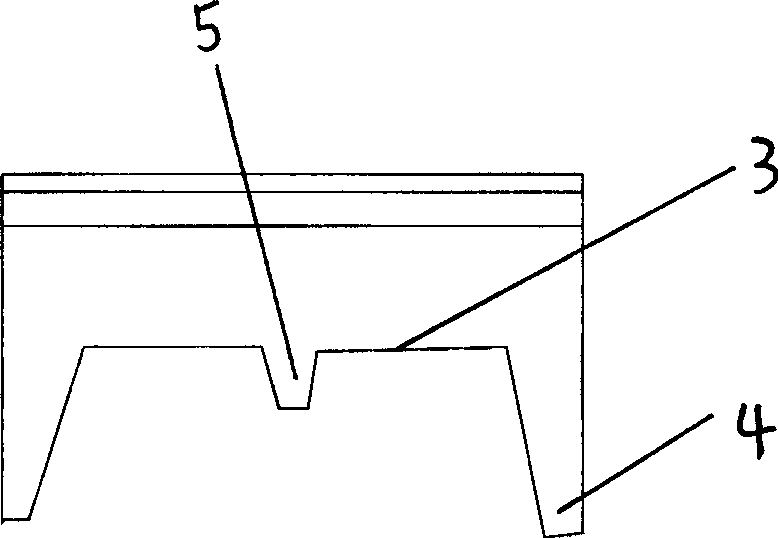

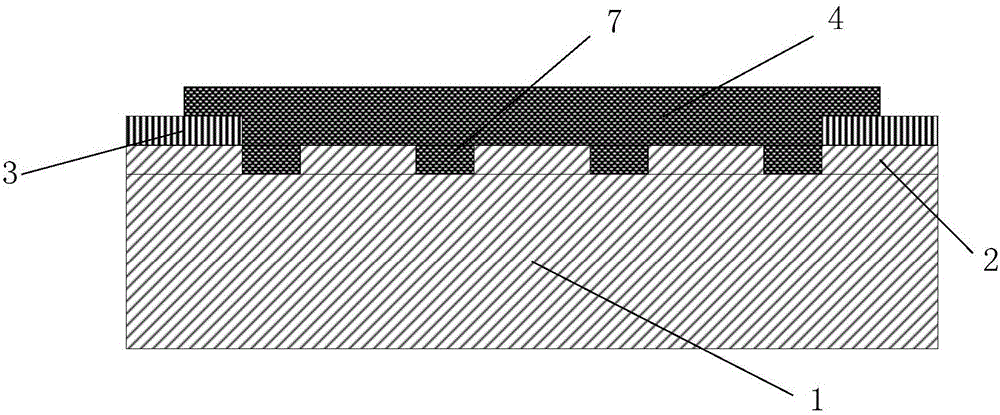

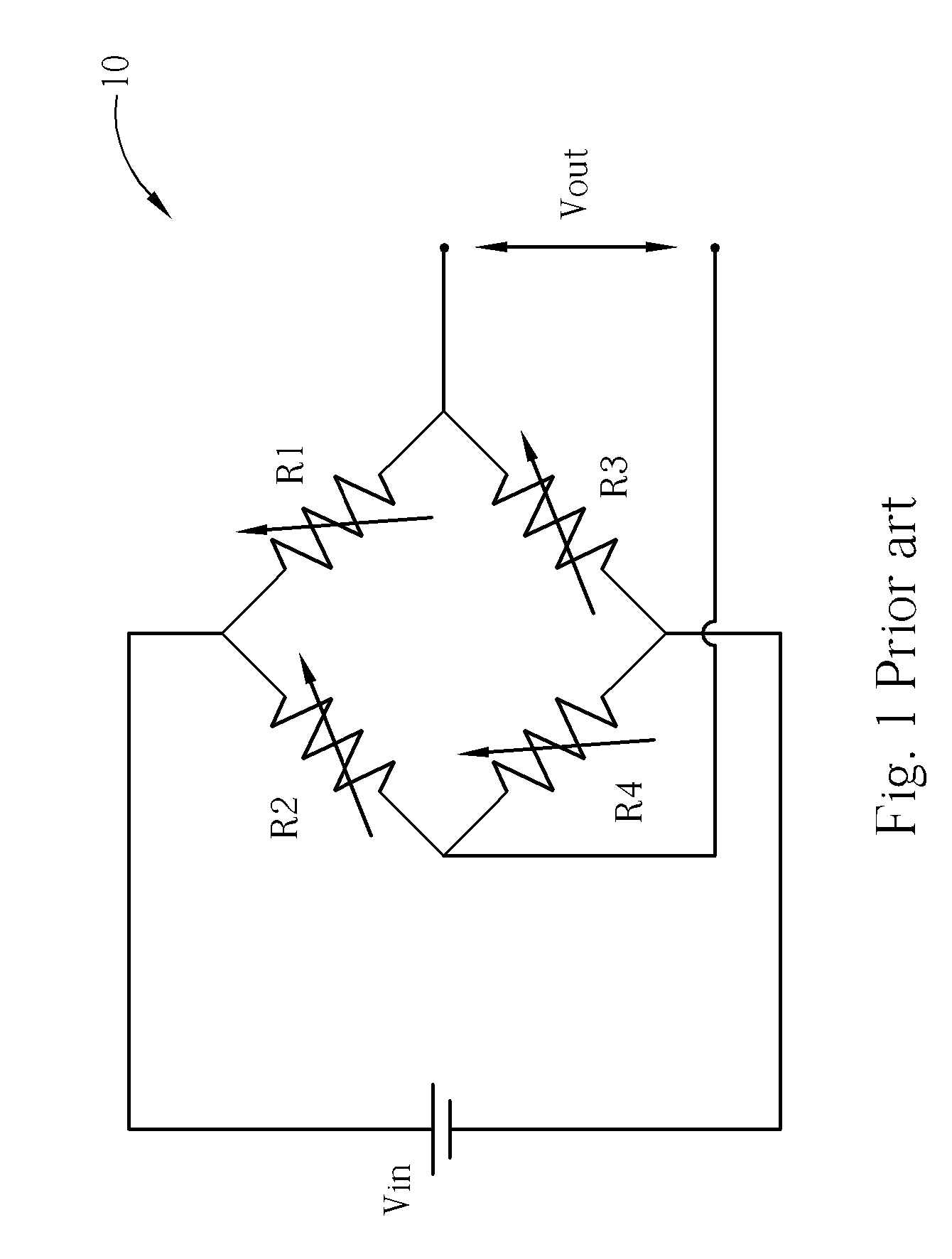

Hidden-type MEMS pressure sensor sensitive chip and manufacturing method thereof

InactiveCN103344374AGuaranteed tightnessMeet basic performance requirementsFluid pressure measurement using ohmic-resistance variationDecorative surface effectsMems pressure sensorHemt circuits

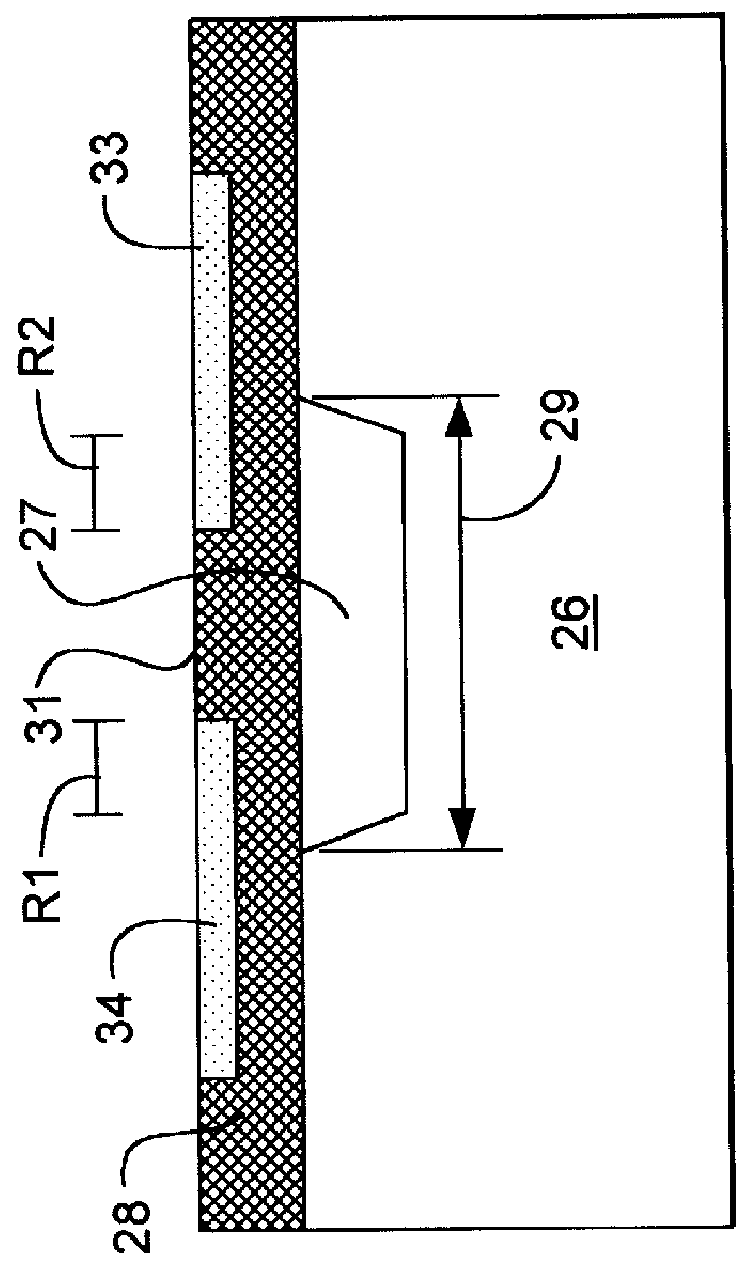

The invention relates to a sensitive chip of a pressure sensor, in particular to a hidden-type MEMS pressure sensor sensitive chip and a manufacturing method thereof. According to the hidden-type MEMS pressure sensor sensitive chip and the manufacturing method, the problem that component performance and service life of an existing silicon piezoresistive pressure sensor are not ideal is solved. The hidden-type MEMS pressure sensor sensitive chip comprises an SOI wafer component layer (1) and a glass substrate (5), wherein the SOI wafer component layer (1) is formed by the practice that a substrate layer of an SOI wafer is etched in an etching process based on a stopping layer, and the BOX layer of the SOI wafer is taken as the stopping layer. Four voltage dependent resistors of the Wheatstone bridge including R1, R2, R3 and R4, eight doping wires (3) and eight connection anchor points (2) are manufactured on the SOI wafer component layer (1). The hidden-type MEMS pressure sensor sensitive chip and the manufacturing method are reasonable in design, the manufacture hidden-type MEMS pressure sensor sensitive chip overcomes influences of external environment factors on a component circuit, the defect that component performance is reduced due to thermal mismatch of materials is eliminated, and service life of components is prolonged.

Owner:山西傲维光视光电科技有限公司

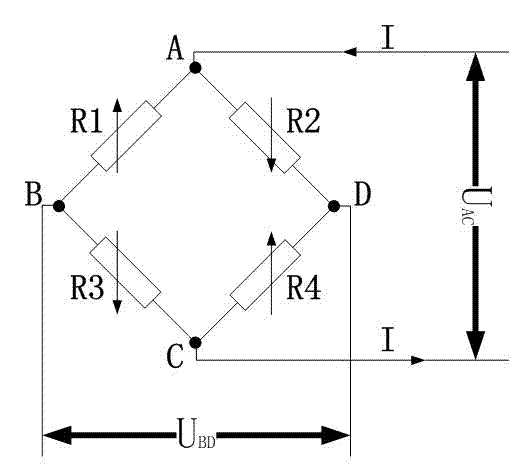

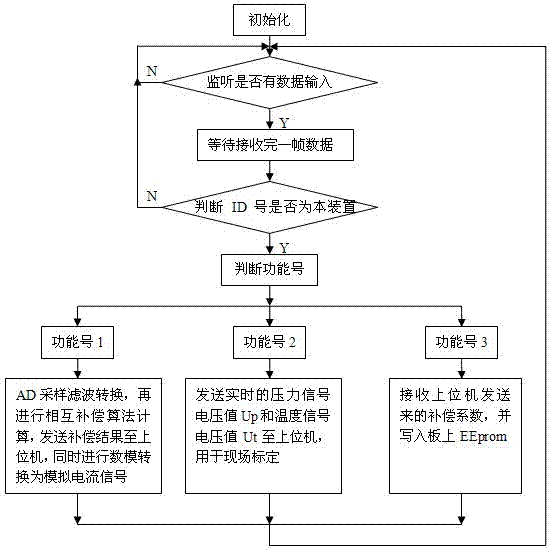

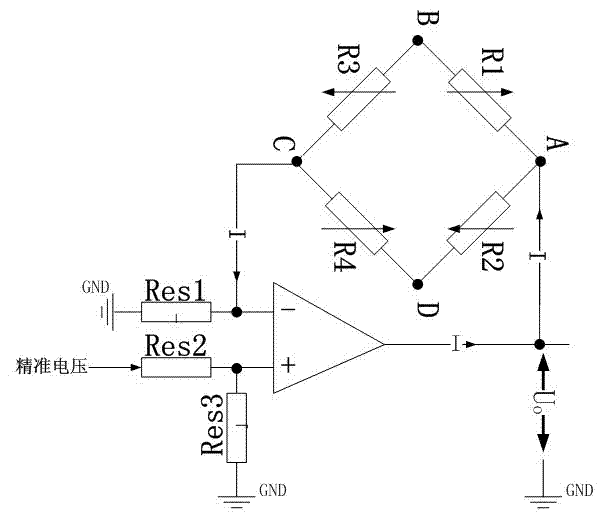

Method and device for complementing temperature and pressure of pressure sensor based on two-dimensional orthogonal function

InactiveCN102353481AA way to achieve mutual compensationSmall amount of calculationForce measurement using piezo-resistive materialsMicrocontrollerEngineering

The invention discloses a method and device for complementing the temperature and pressure of a pressure sensor based on a two-dimensional orthogonal function. The method comprises the following steps of: firstly, establishing a two-dimensional orthogonal function complementary model which can be used for realizing temperature compensation on a pressure signal or conversely carrying out real-timecompensation on a sensor temperature by using the pressure signal; then calculating a compensation factor of the model by using a least square fitting algorithm based on the two-dimensional orthogonal function; and finally substituting sampled data into the model to carry out a compensation calculation. The device comprises a piezoresistive pressure sensor, an MCU (Micro-programmed Control Unit) platform and an upper computer. The MCU platform comprises a single chip, an operational amplifier, a memory, a DA (Digital to Analog) conversion chip and a serial communication chip. In the invention, an ingenious circuit design can be effectively carried out according to the property of the pressure sensor and the implementation method is simple and novel; and the device provided by the invention has the characteristics of low cost, good real-time performance, high robustness and high precision.

Owner:SOUTH CHINA UNIV OF TECH

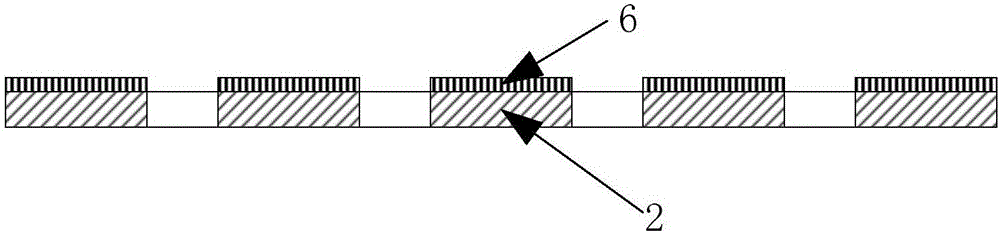

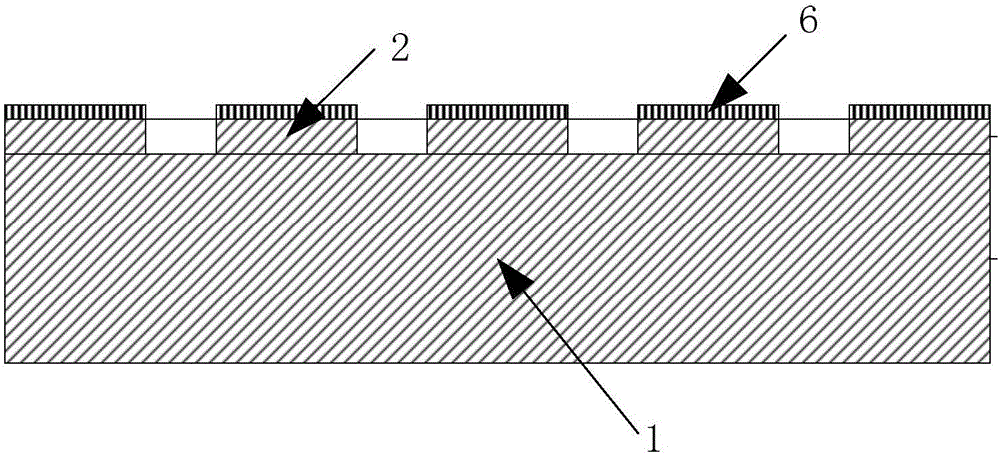

Piezoresistive pressure sensor chip adopting face down bonding and preparing method thereof

ActiveCN102853950AImprove reliabilityRealize surface mount packageForce measurement using piezo-resistive materialsSilicon membranePiezoresistive pressure sensors

The invention relate to a micro electro mechanical system (MEMS) device, and provides a piezoresistive pressure sensor chip adopting face down bonding, which is high in reliability, can avoid inconsistency of varistors and solves the problem that a metal wire for connecting the piezoresistive pressure sensor chip with an external circuit is likely to break, and as well as a preparing method of the piezoresistive pressure sensor chip. The piezoresistive pressure sensor chip adopting face down bonding is provided with a chip main body; the chip main body is provided with a silicon substrate with a square pressure cavity and a silicon membrane; a varistor is arranged on the surface of the silicon membrane; the silicon substrate is combined with the silicon membrane through direct silicon-silicon bonding; the piezoresistive pressure sensor chip is welded on a printed circuit board (PCB) through adopting face down bonding method; and the varistor and three resistors with the resistance values being the same as that of the varistor of the external circuit form an integral comparison bridge. In preparing, the silicon substrate part is prepared at first, and then is assembled and subjected to follow-up process, and is finally is connected with the external circuit of the chip.

Owner:厦门海合达电子信息股份有限公司

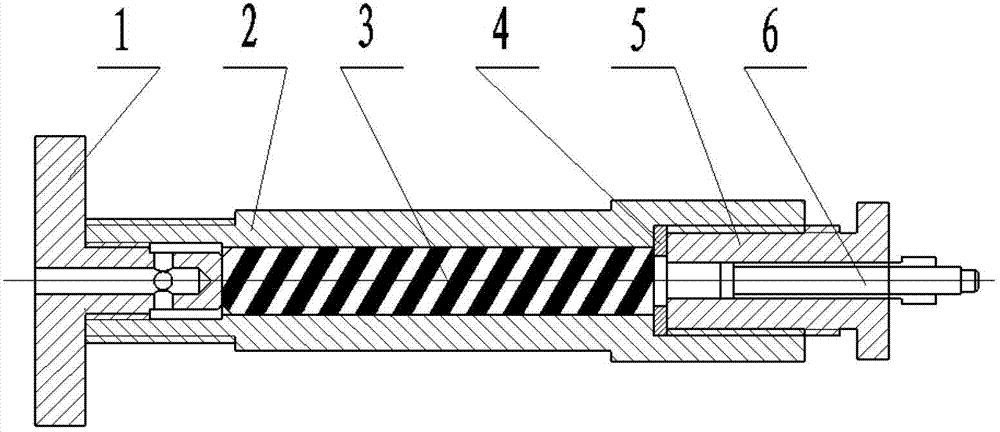

Micro dynamic piezoresistance pressure sensor and manufacturing method thereof

ActiveCN1544901AGuaranteed dynamic frequency response characteristicsExcellent resistance to light interferenceFluid pressure measurement using ohmic-resistance variationEngineeringAlloy

The invention relates to a micro-type dynamic piezoresistive pressure sensor and its making method, using MEMS silicon bulk micromachining method to make a pressure sensitive chip of E-shaped silicon cup structure, the reverse side of the chip is welded with static seal technique, Pyres glass ring and Hitachi alloy ring, to form silicon back contact medium quasi-level packaging, the reverse back of the chip is covered with anti-interference insulating layer, the right side of the chip is connected with a lead cable through connecting circuit, the sensor tube cap with cable drawing-off mouth at the tail is hermetically welded to the Hitachi alloy ring to form sealed isolation between the side pressure surface and the back pressure cavity, the tail of the tube cap squeezes tightly the cable without sealing, the nozzle part of the sleeve covered on the cable is hermetically covered on the tail of the tube cap, the heat-shrinkable tube segment covered on the cable is hermetically fixed with the outer end part of the sleeve nozzle, thus implementing atmosphere connection between the back pressure cavity and the measured environment, and it is used in shrinkage mould test for hydraulic engineering like dam, ship gate, pier, embankment, etc. and has low measuring range, high sensitivity, strong anti-interference performance, and good dynamic performance during fluid dynamic test.

Owner:王文襄

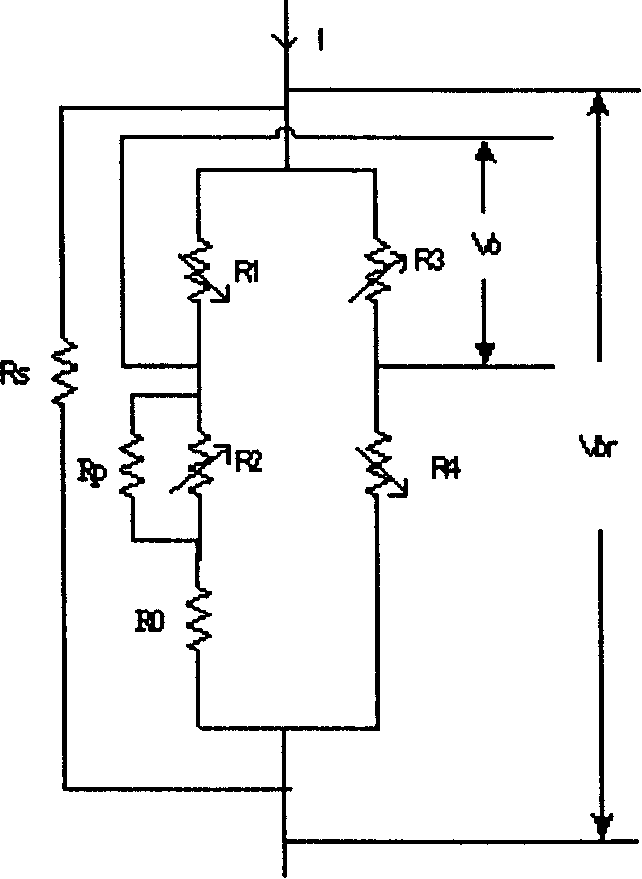

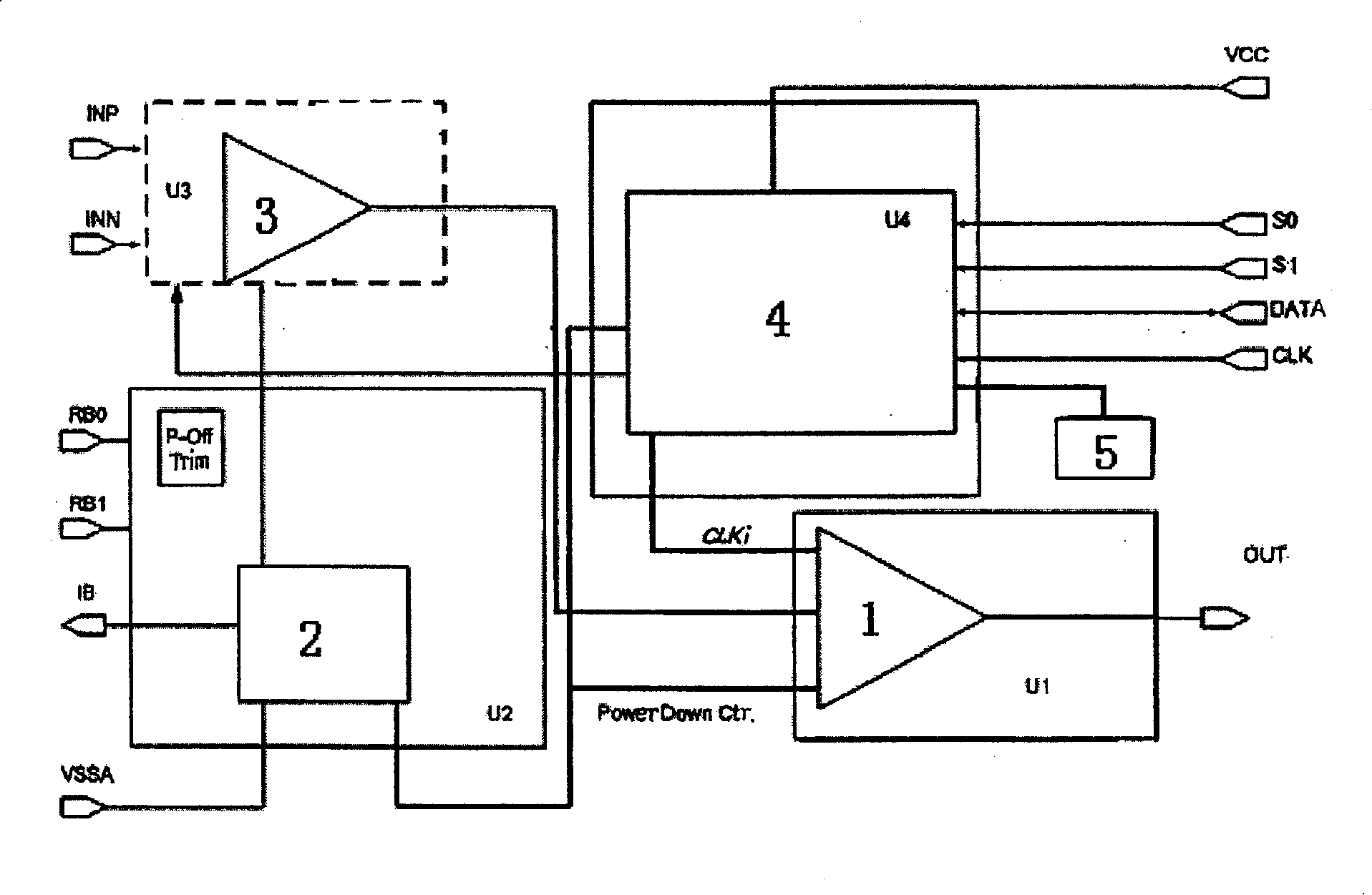

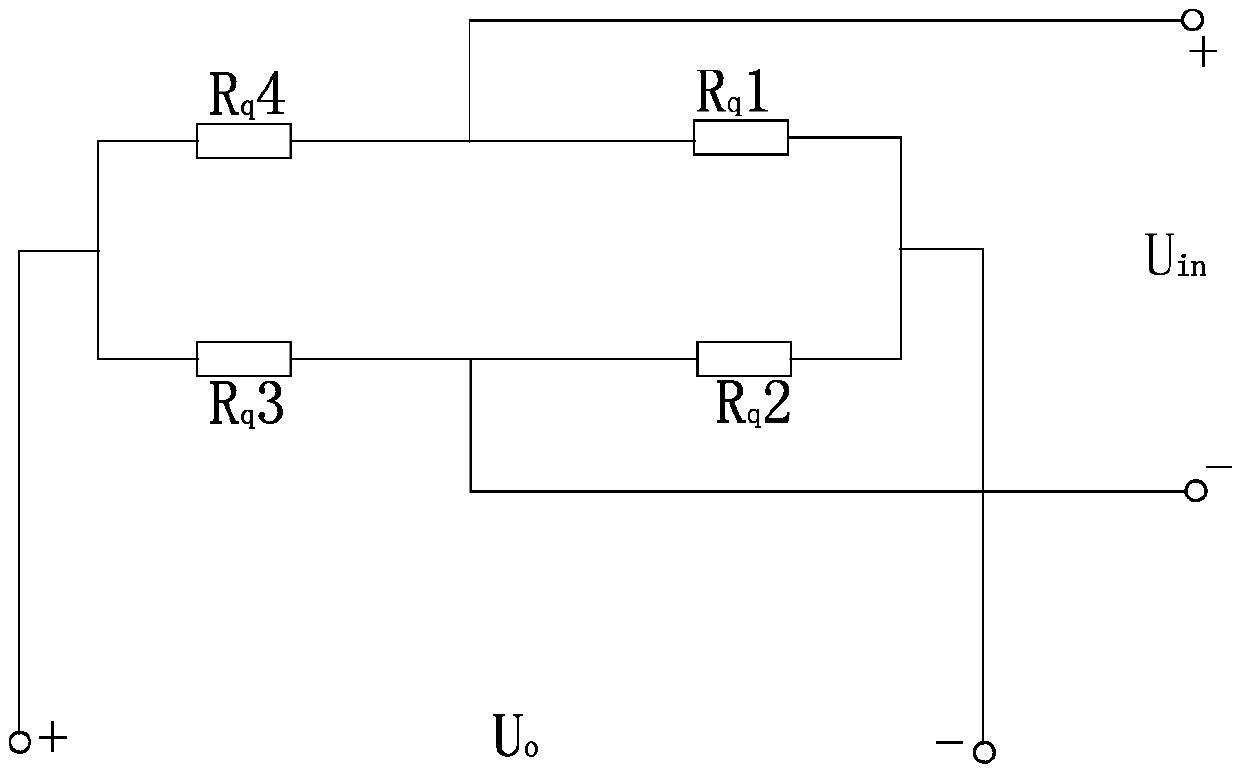

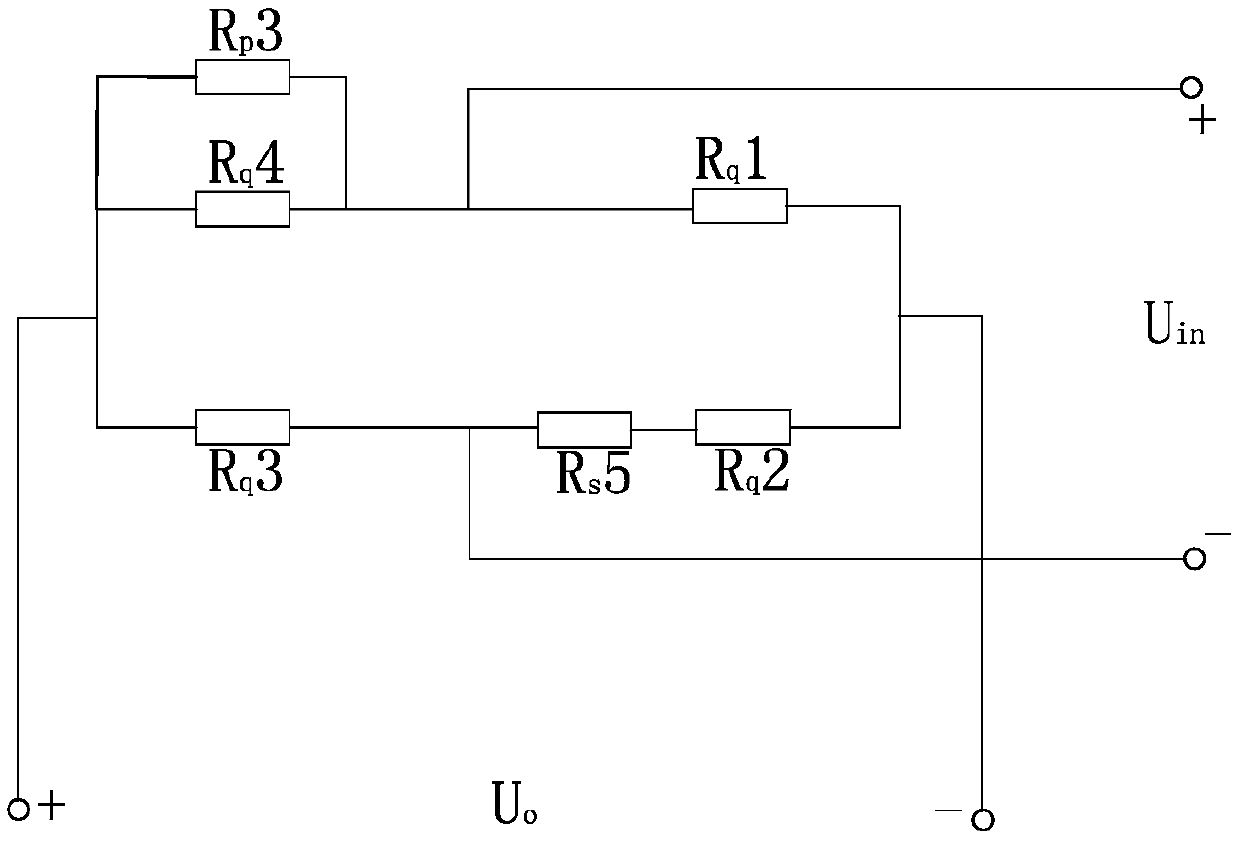

All-bridge type piezoresistance type pressure sensor digital type signal conditioning chip

ActiveCN101236113ALow costHigh conditioning accuracyForce measurement using piezo-resistive materialsCapacitanceFull bridge

Disclosed is a digital signal conditioning chip of a full-bridge and piezoresistive pressure sensor, which mainly comprises a bandgap reference voltage module, an adjustable gain calculation amplifier module and a digital control unit module. The invention is characterized in that a positive temperature coefficient voltage is generated in the bandgap reference voltage module to provide an energizing voltage for the full-bridge and piezoresistive pressure sensor, the digital control unit module is equipped with a memory and an inner clock circuit, the gain in the adjustable gain switch capacity calculation amplifier is confirmed by the digital control unit module according to the parameter of positive temperature coefficient, zero temperature coefficient and zero output value. The digital signal conditioning chip of a full-bridge and piezoresistive pressure sensor has the advantages that the conditioning chip realizes effect compensation of sensitivity, zero drift compensation and adjustment of zero output, and is high in conditioning accuracy and low in cost.

Owner:WUHAN FINEMEMS

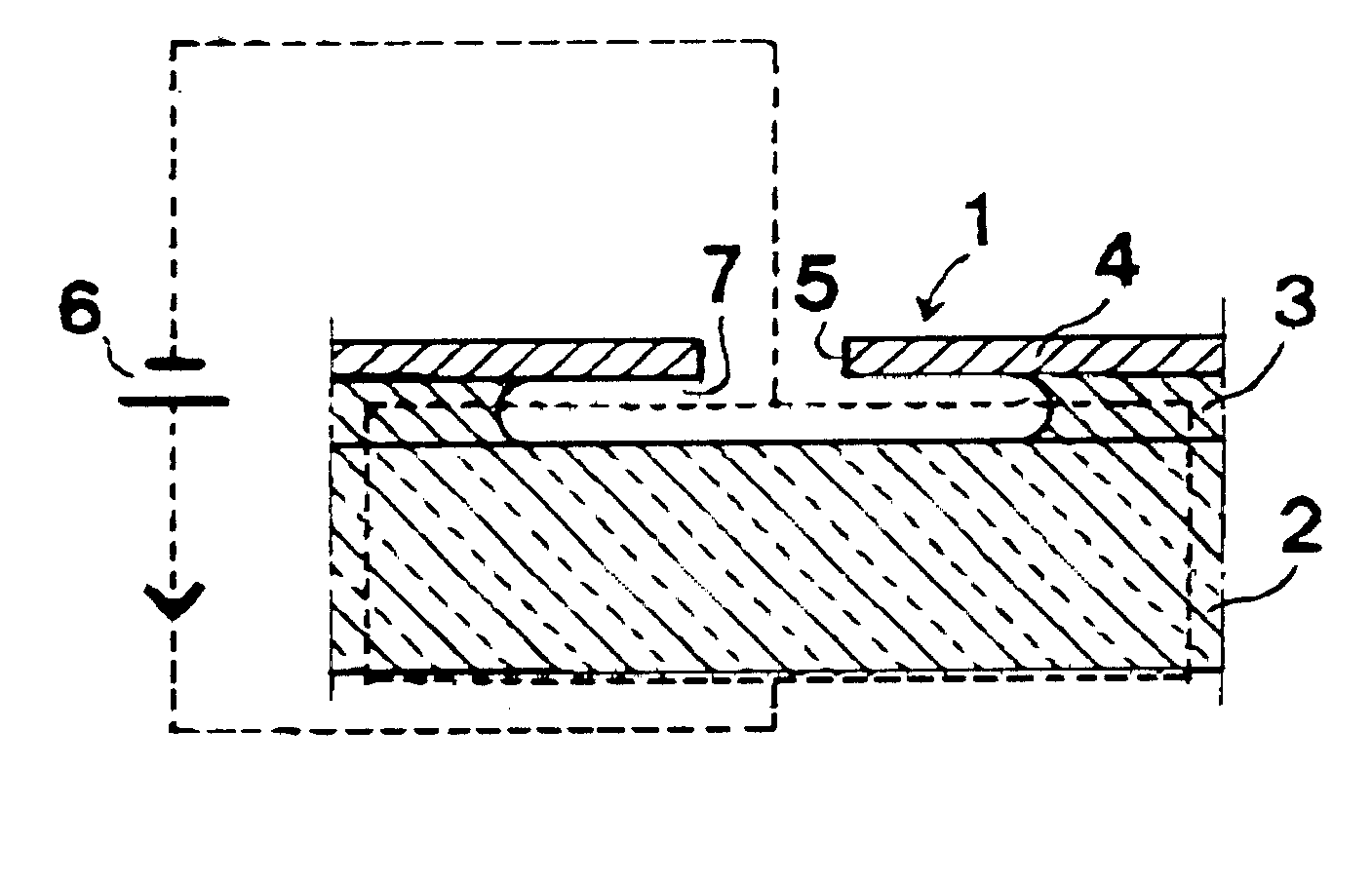

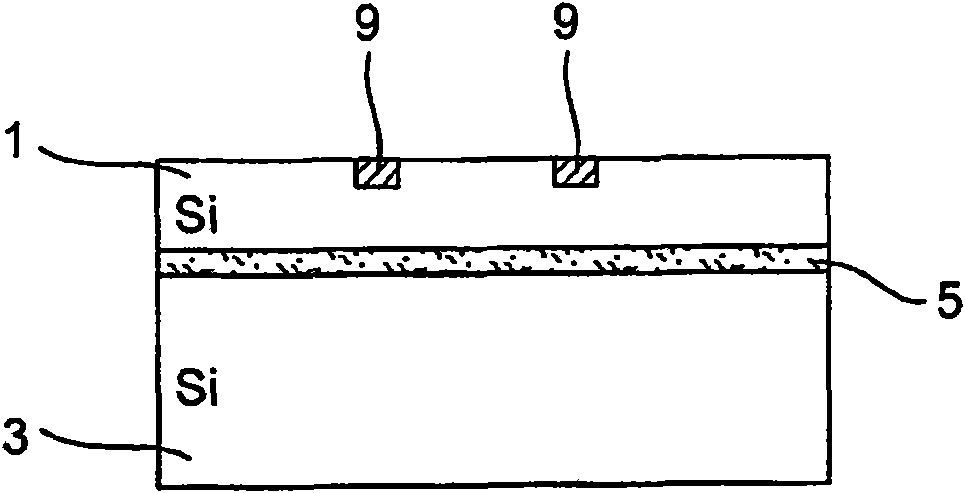

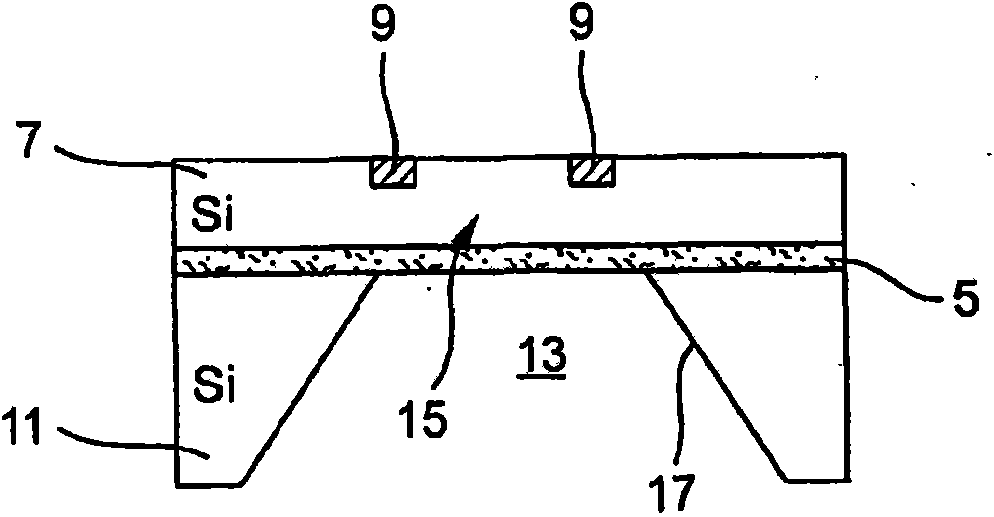

Pressure sensor

InactiveCN101627292AReduce sensitivityHigh hardnessFluid pressure measurement using ohmic-resistance variationOptoelectronicsPiezoresistive pressure sensors

The invention relates to a piezo-resistive pressure sensor in BESOI technology, which is particularly suited for measuring low pressures, has low linearity distortion, is made of a BESOI wafer having a first and a second silicon layer (1, 3) and an oxide layer (5) disposed between the same, has an active layer (7) that is formed by a first silicon layer (1) of the BESOI wafer, piezo-resistive elements (9) being doped in said active layer, and has a membrane carrier (11) formed by the second silicon layer (3) of the BESOI wafer, the carrier surrounding a recess (13) in the second silicon layer (3) on the outside, the recess exposing a region of the active layer (7) forming a membrane (15) and of the associated oxide layer (5), wherein in an outer edge of the region (21) of the oxide layer (5) exposed by the recess (13) a groove (19) surrounding the region (21) is provided.

Owner:EHNDRESS KHAUZER GMBKH KO KG

Piezoresistive pressure sensor and preparation method thereof

ActiveCN105092117AHigh sensitivityWide band gapFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsThin membraneEngineering

The invention discloses a piezoresistive pressure sensor and a preparation method thereof. The pressure sensor comprises an LCP substrate, an LCP thin film layer, metal electrodes, a graphene thin film layer and a graphene array layer. The LCP thin film layer is fixedly connected to the LCP substrate; the LCP thin film layer is provided with through holes in an array structure; the metal electrodes are connected above the two ends of the LCP thin film layer; the graphene thin film layer is connected on the LCP thin film layer; the graphene thin film layer fills a gap between the metal electrodes and covers the metal electrodes; and the graphene array layer fills the through holes in the LCP thin film layer, and the graphene thin film layer is connected with the graphene array layer. The piezoresistive pressure sensor not only has the advantage that the substrate can be bent and deformable, but also has good sensitivity, and can be widely applied to the fields of biomedicine and wearable equipment and the like.

Owner:SOUTHEAST UNIV

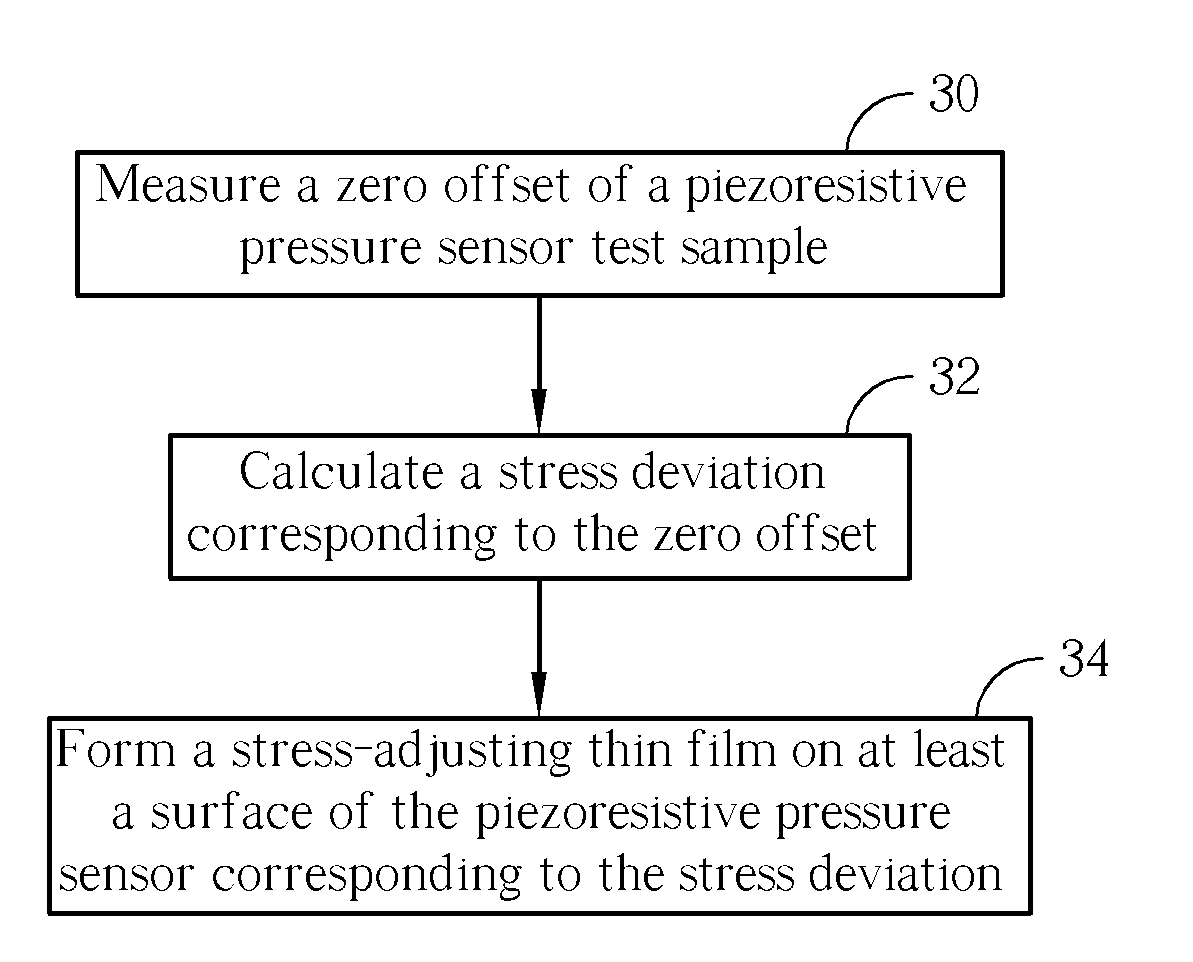

Method of calibrating zero offset of a pressure sensor

InactiveUS20060272383A1Low costImprove efficiencyElectronic circuit testingFluid pressure measurement using ohmic-resistance variationTest sampleEngineering

A piezoresistive pressure sensor test sample is first provided, and a zero offset of the piezoresistive pressure sensor test sample is measured. Subsequently, a stress deviation corresponding to the zero offset is calculated. Thereafter, at least a piezoresistive pressure sensor under the same process condition as the piezoresistive pressure sensor test sample is formed. When forming the piezoresistive pressure sensor, at least a stress-adjusting thin film is formed on at least a surface of the piezoresistive pressure sensor to calibrate the zero offset of the piezoresistive pressure sensor.

Owner:TOUCH MICRO SYST TECH

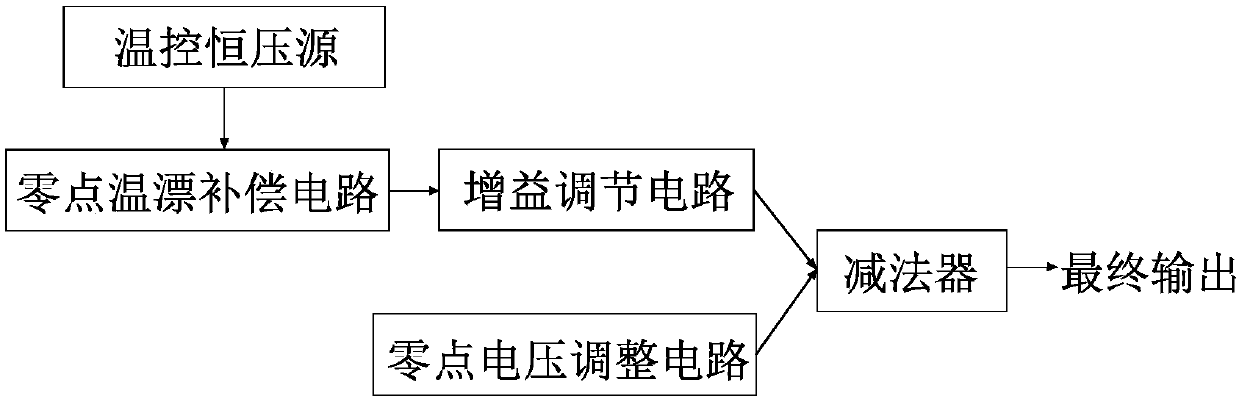

High-precision temperature compensating circuit and method of silicon piezoresistive pressure sensor

ActiveCN109668674ASolve the problem of longevityHigh compensation accuracyFluid pressure measurement using ohmic-resistance variationTemperature controlPiezoresistive pressure sensors

The invention provides a high-precision temperature compensating circuit of a silicon piezoresistive pressure sensor. The high-precision temperature compensating circuit comprises a temperature control constant voltage source, a zero point temperature excursion compensating circuit, a gain adjusting circuit, a zero point voltage adjusting circuit and a subtracter. The zero point temperature excursion compensating circuit is connected with the temperature control constant voltage source and the gain adjusting circuit respectively, and the subtracter is connected with the gain adjusting circuitand the zero point voltage adjusting circuit. The invention further provides a high-precision temperature compensating method of the silicon piezoresistive pressure sensor. The temperature compensating method adopting full analog circuits meets the requirements that FS precision of the silicon piezoresistive pressure sensor reaches 0.4%, and 0.5 V - 4.5 V is output in the full temperature range of-55 DEG C to 125 DEG C.

Owner:XIAMEN NIELL ELECTRONICS

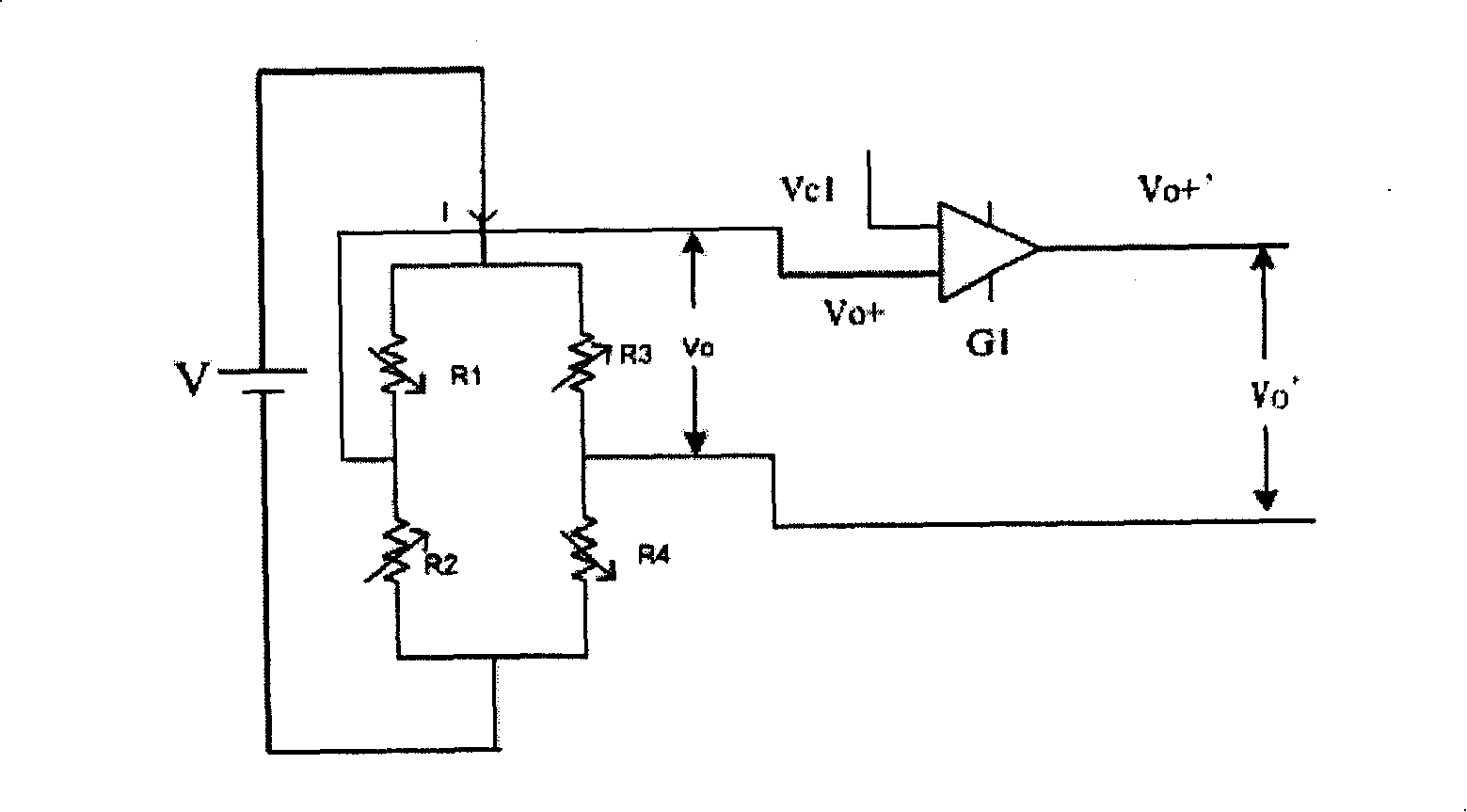

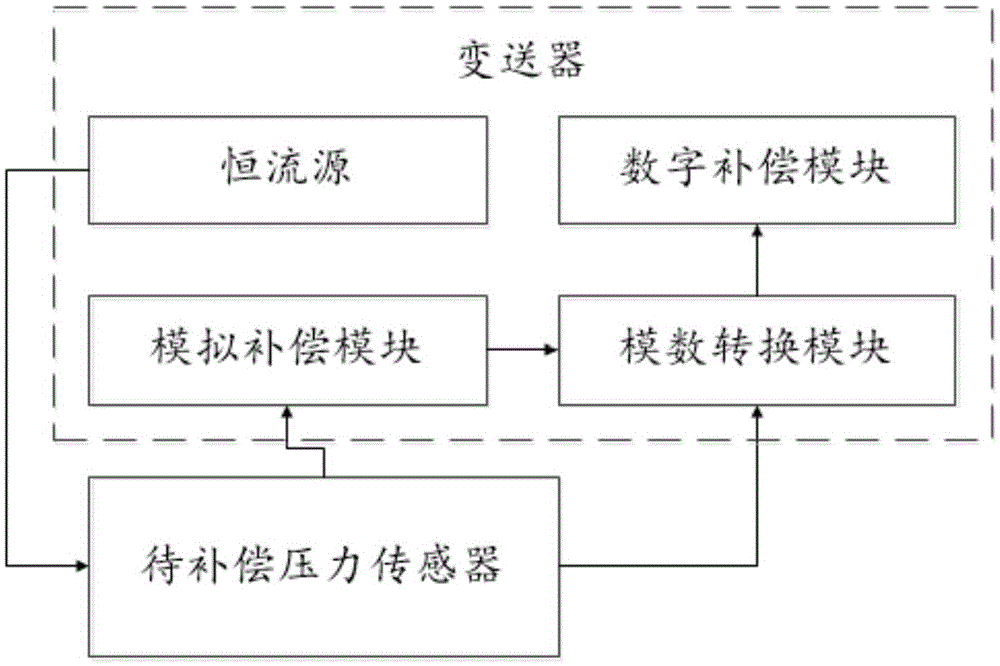

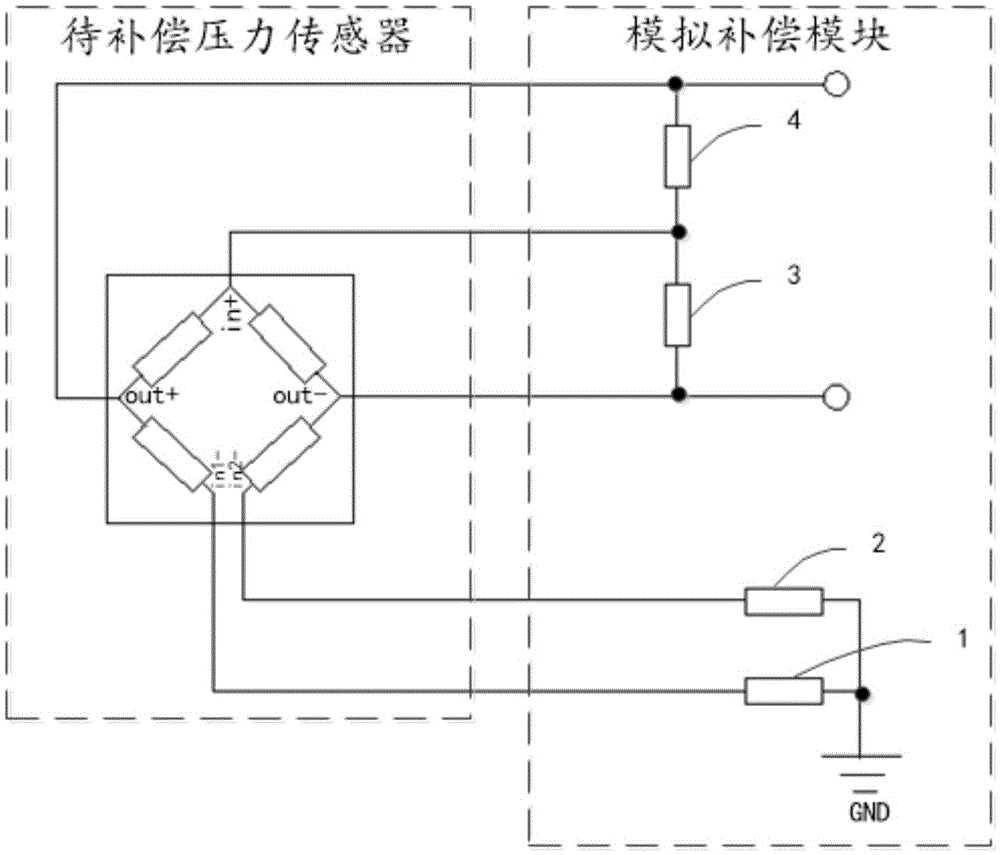

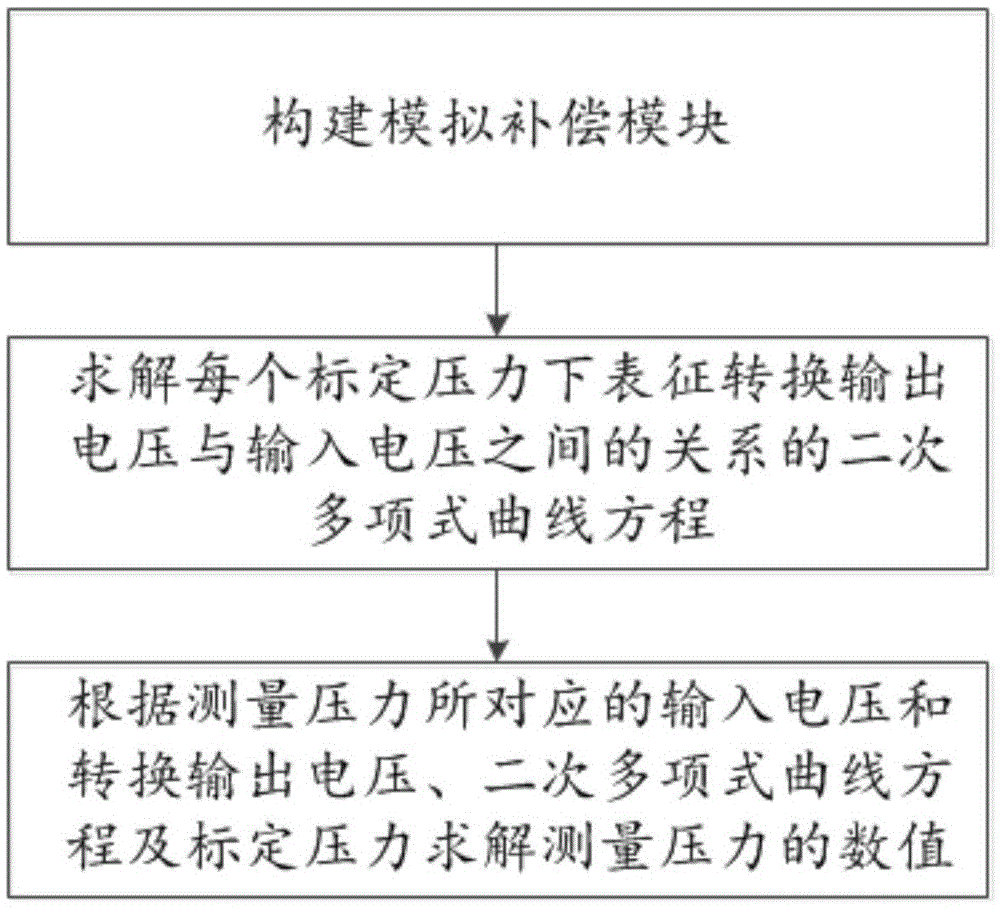

Temperature compensation system and method of pressure sensor

ActiveCN105628266AHigh measurement accuracyReduce generation costForce measurement using piezo-resistive materialsEngineeringPiezoresistive pressure sensors

The invention relates to a temperature compensation system and method of a pressure sensor. By taking input voltages of a pressure sensor to be compensated as temperature signals, an analog compensation module converts output voltages of the pressure sensor to be compensated to enable the relation between the converted output voltages and the input voltages of the pressure sensor to be compensated to be fitted by a quadratic polynomial curve under the condition of certain pressure so that a quadratic polynomial curve equation representing the relation between the converted output voltages and the input voltages under each calibration pressure can be determined only through three calibration temperature points in a digital compensation module, a value of measurement pressure is solved accordingly, and thus a whole temperature compensation process is completed. Through combining analog compensation with digital compensation, high-precision measurement of a constant-current source driving type silicon piezoresistive pressure sensor is realized only through the three calibration temperature points.

Owner:WUHAN AVIATION SENSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com