Hexagonal silicon membrane piezoresistive pressure sensor for embedded monocrystal silicon cavity and method

A pressure sensor and hexagonal technology, which is applied in the field of silicon micromechanical sensors, can solve the problems that the deposited film affects the output characteristics of the sensor, cannot process the pressure sensor, and is not easy to integrate piezoresistive devices, etc., and achieves high sensitivity, simple manufacturing process and size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The substantive features and remarkable progress of the present invention will be further described below through specific implementation, but the present invention is by no means limited to the described embodiments.

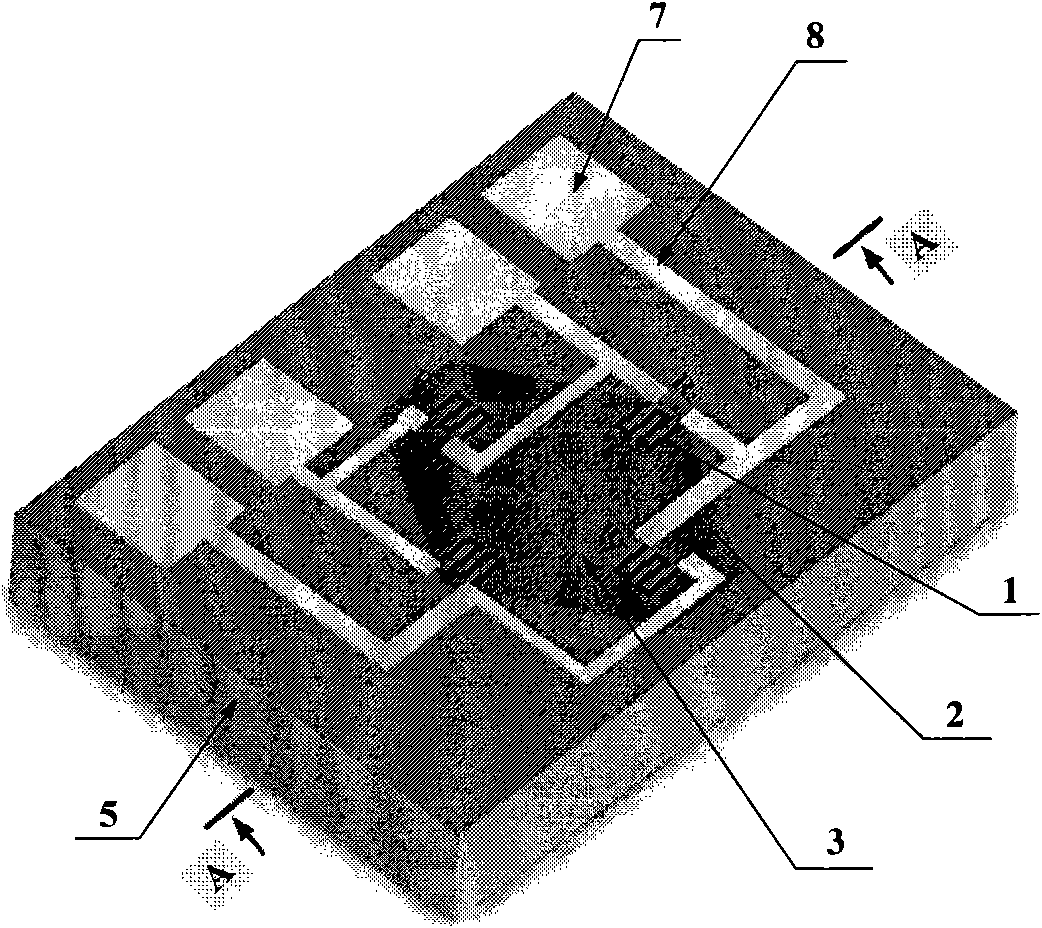

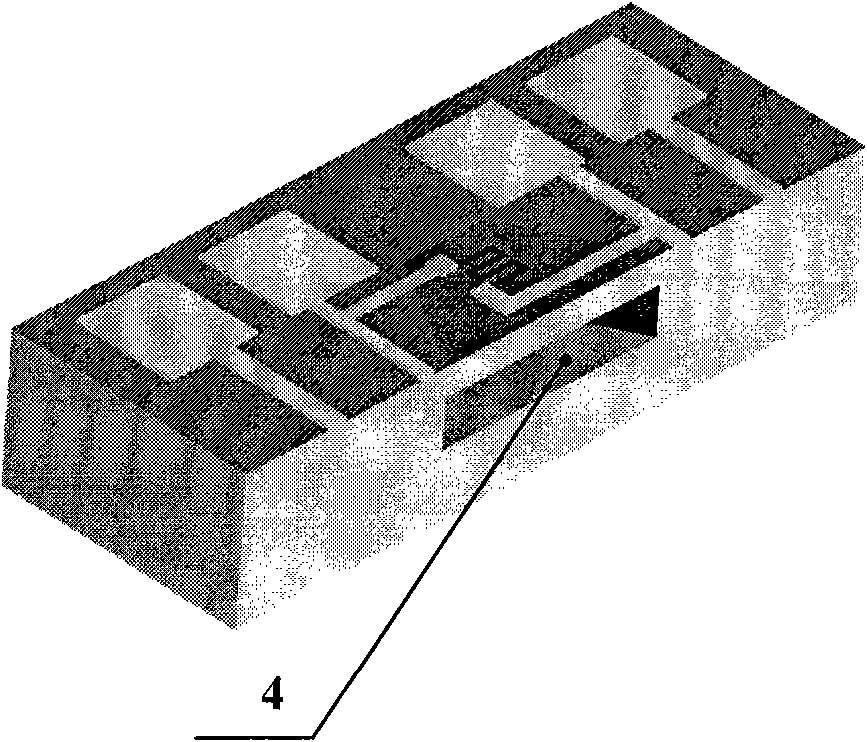

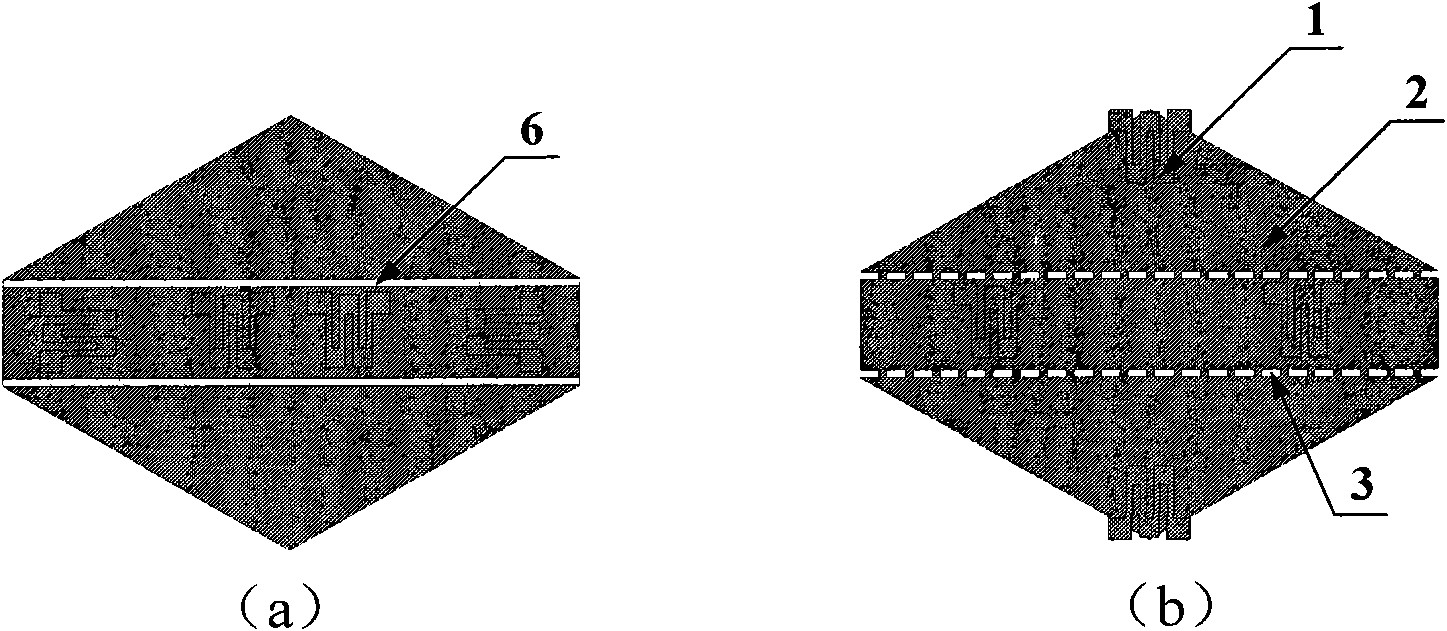

[0038] The pressure sensor provided by the present invention adopts (111) monocrystalline silicon film as the pressure-sensitive diaphragm of the sensor, and the pressure-sensitive diaphragm is designed into a regular hexagon and the included angle between adjacent two sides is 120°, and the thickness of the diaphragm is determined by the silicon wafer The grooves of different depths are determined by dry etching of the front side. The pressure chamber is directly embedded in the silicon substrate, and the sidewalls of the long grooves are respectively etched (such as image 3 (a)) or grid trench sidewall etching (eg image 3 (b)) Two different ways of hollowing out the cavity. The cavity after the side wall is hollowed out uses low-stress polysilicon t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com