Patents

Literature

5832 results about "Pressure measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure measurement is the analysis of an applied force by a fluid (liquid or gas) on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure in an integral unit are called pressure meters or pressure gauges or vacuum gauges. A manometer is a good example, as it uses the surface area and weight of a column of liquid to both measure and indicate pressure. Likewise the widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

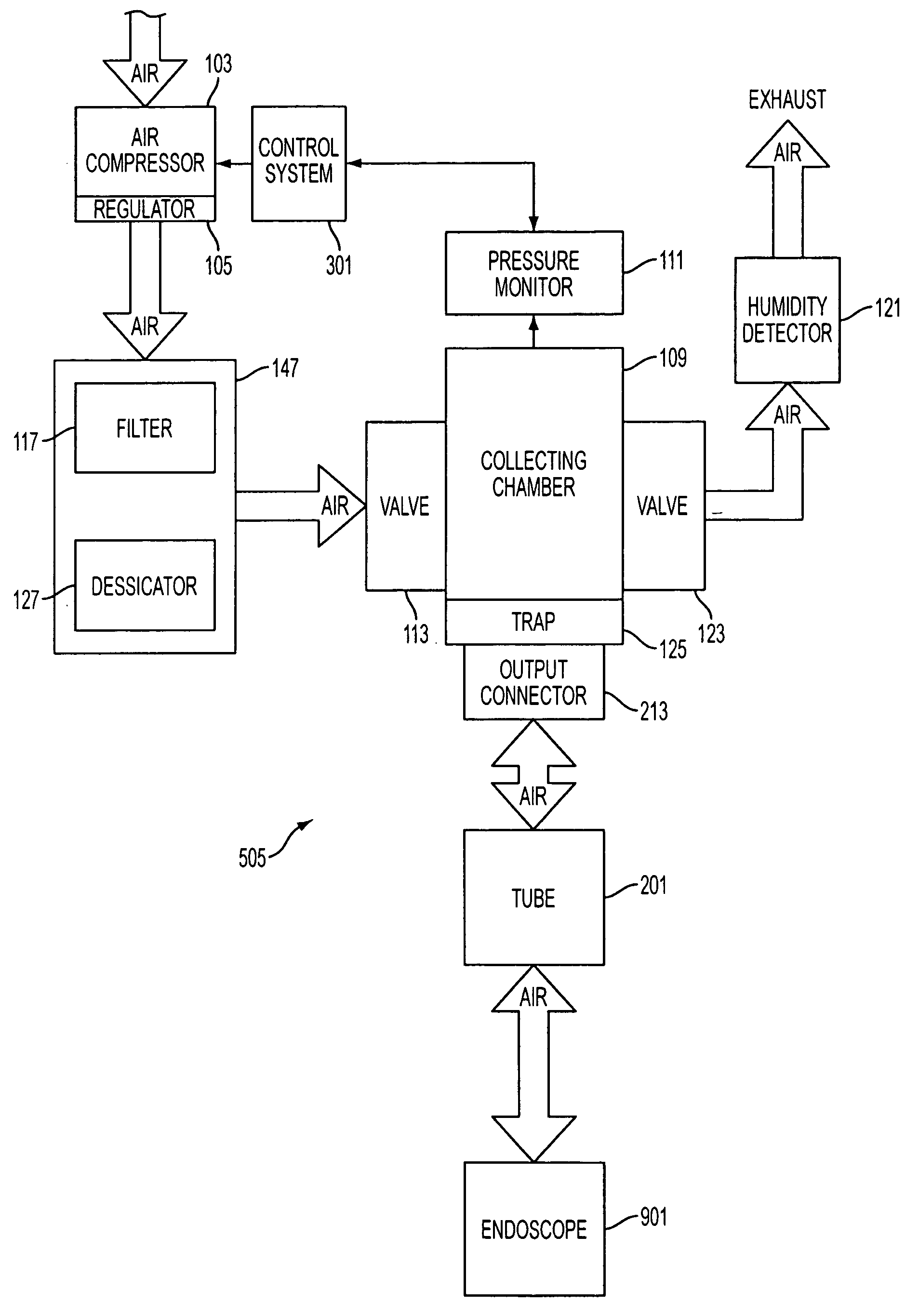

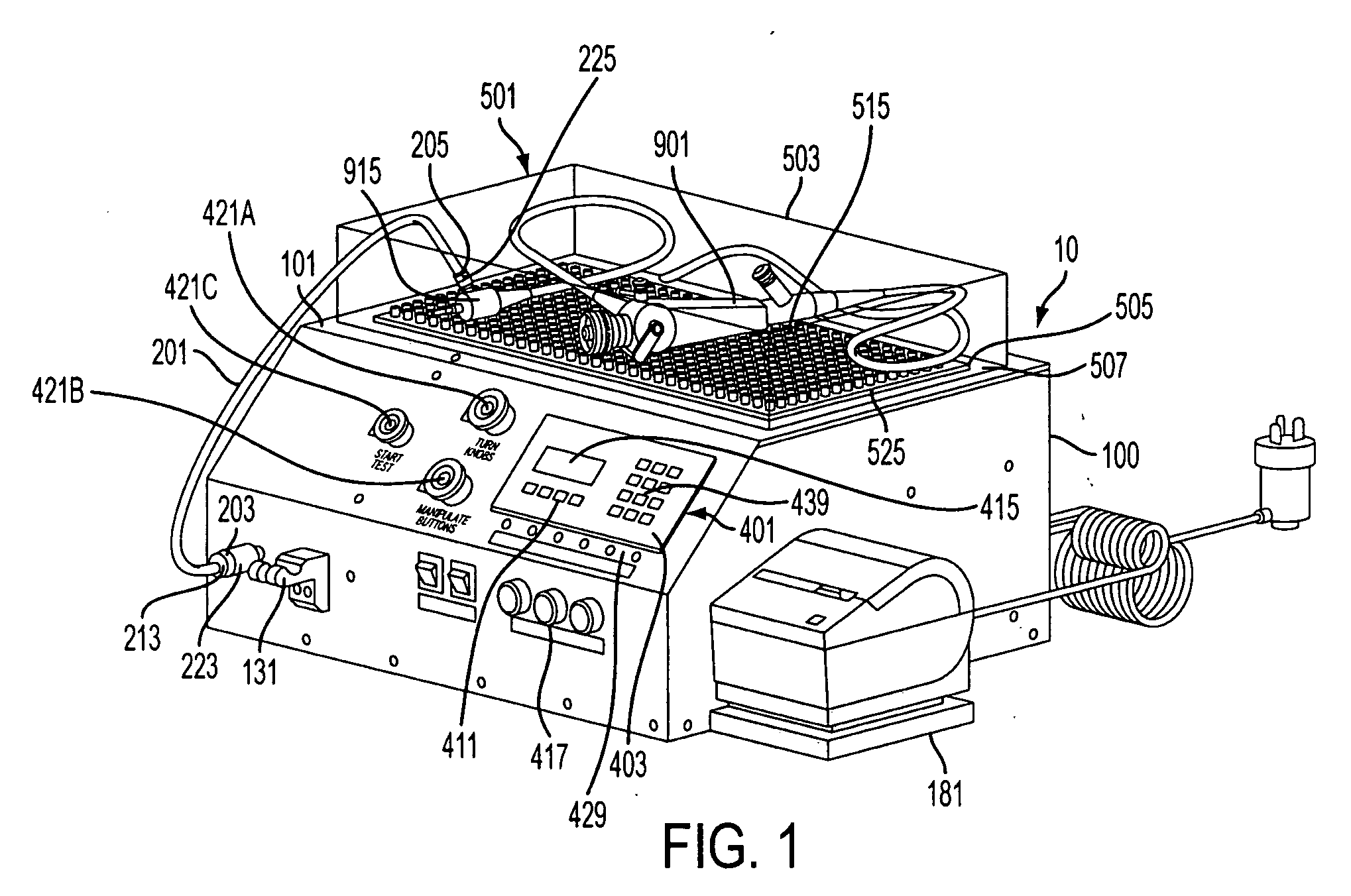

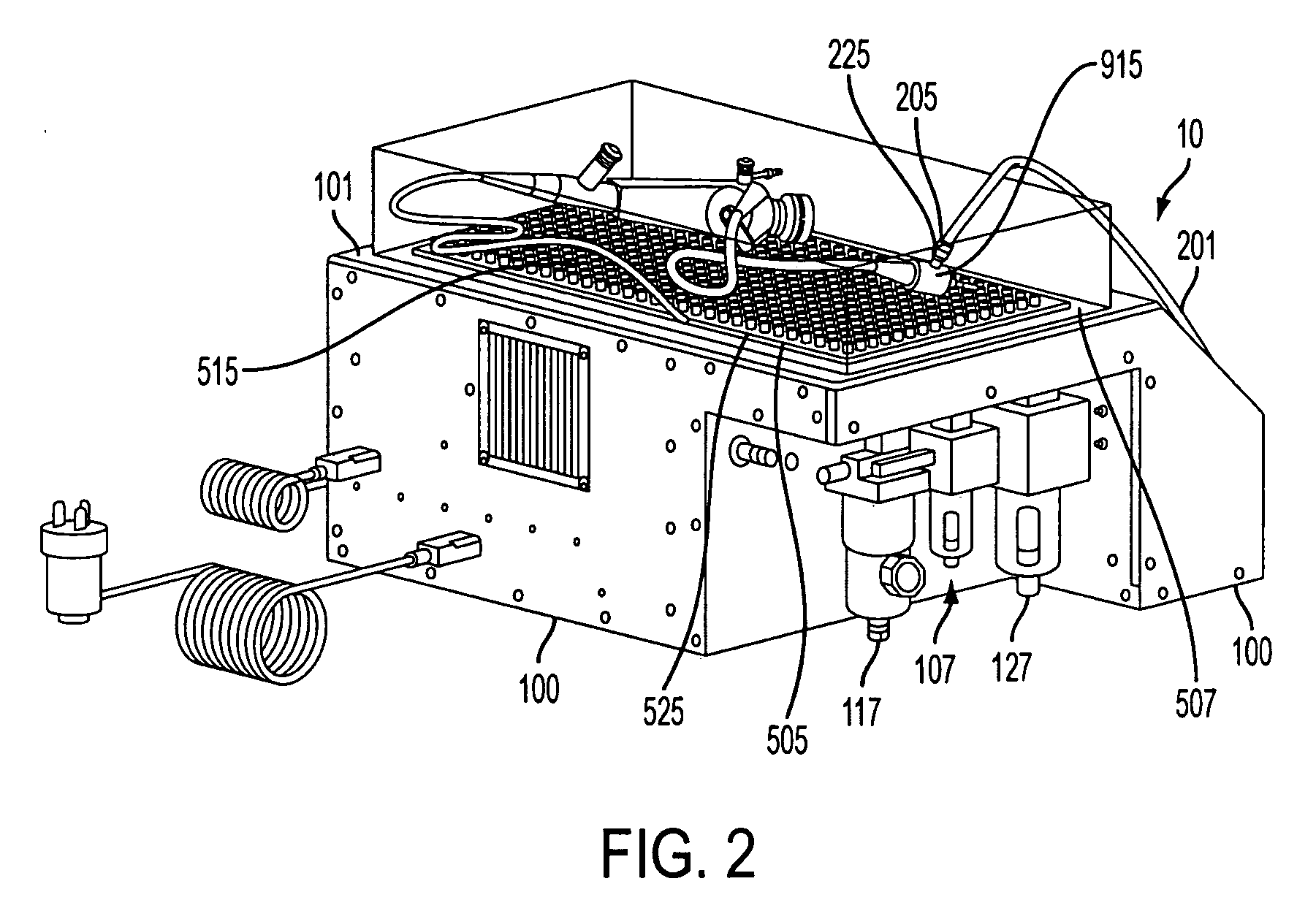

Systems and methods for endoscope integrity testing

Systems and methods for determining the integrity of an endoscope. The systems and methods provide for an air enclosure which includes the internal area of the sleeve or tubing of the endoscope to be pressurized. Pressure measurements of the air enclosure are then taken both before and after the endoscope is manipulated by a user. The systems and methods may also or alternatively vent air from inside the endoscope to a humidity detector to detect the presence of fluid inside the endoscope.

Owner:MINNTECH CORP

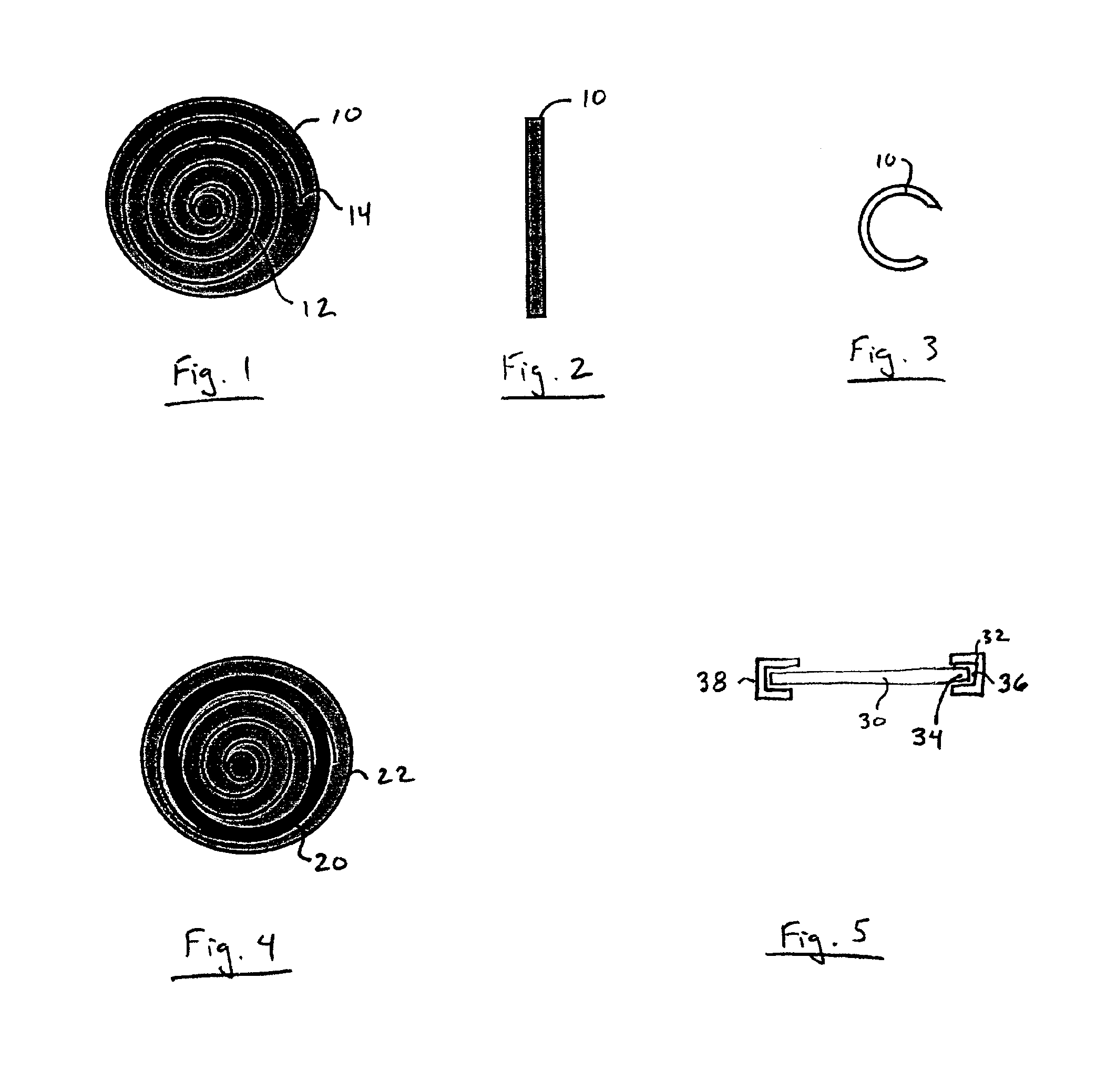

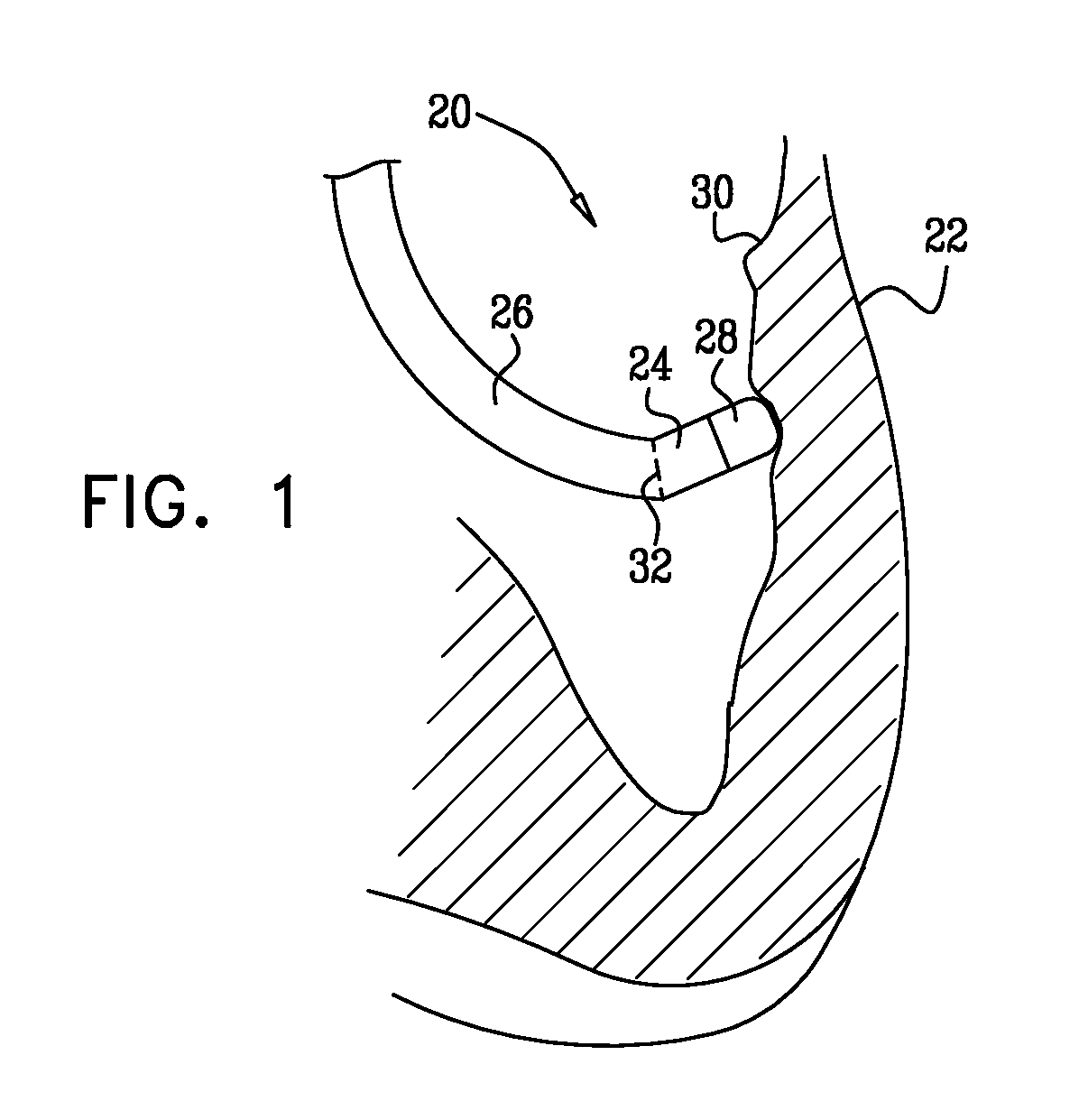

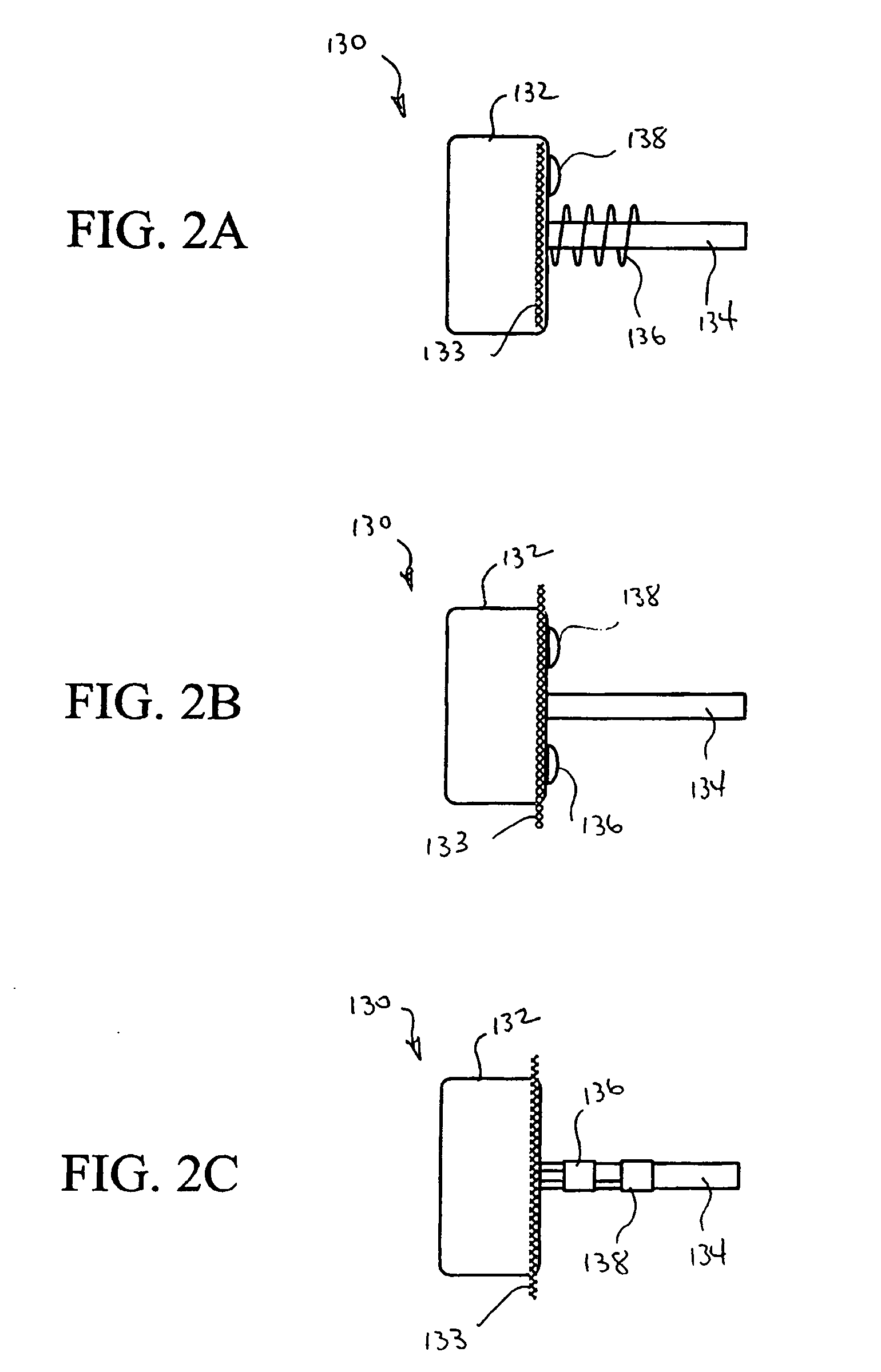

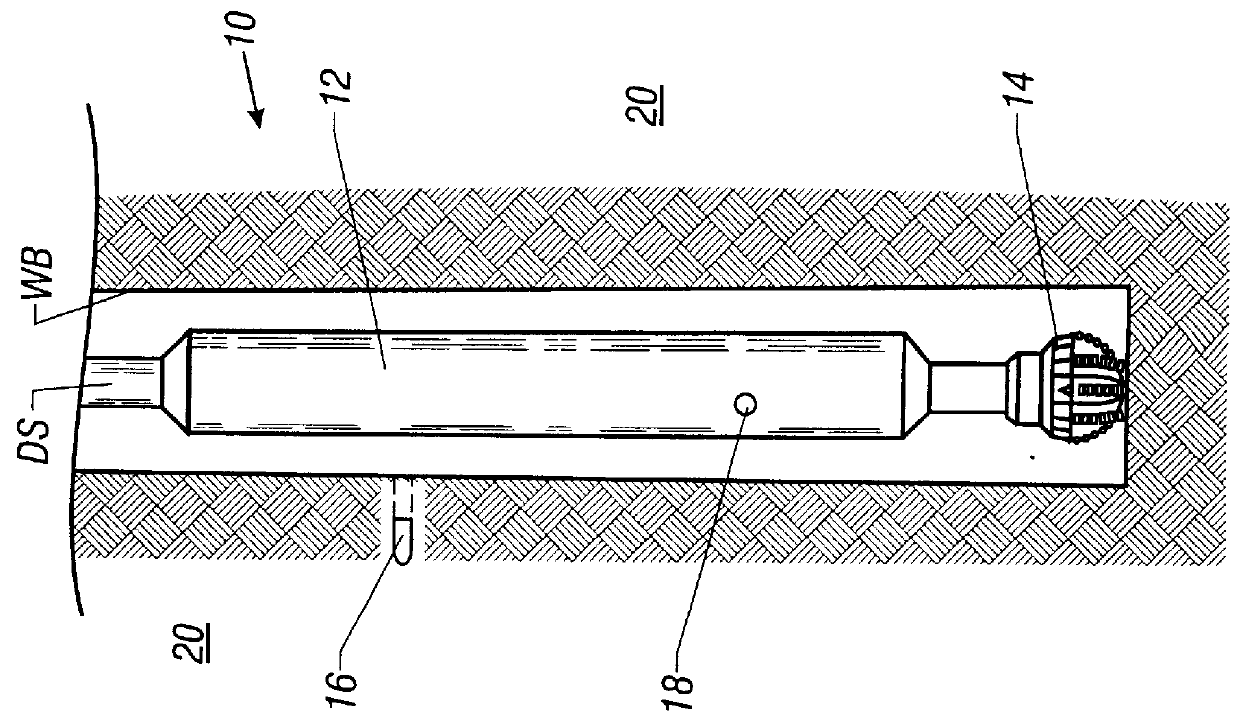

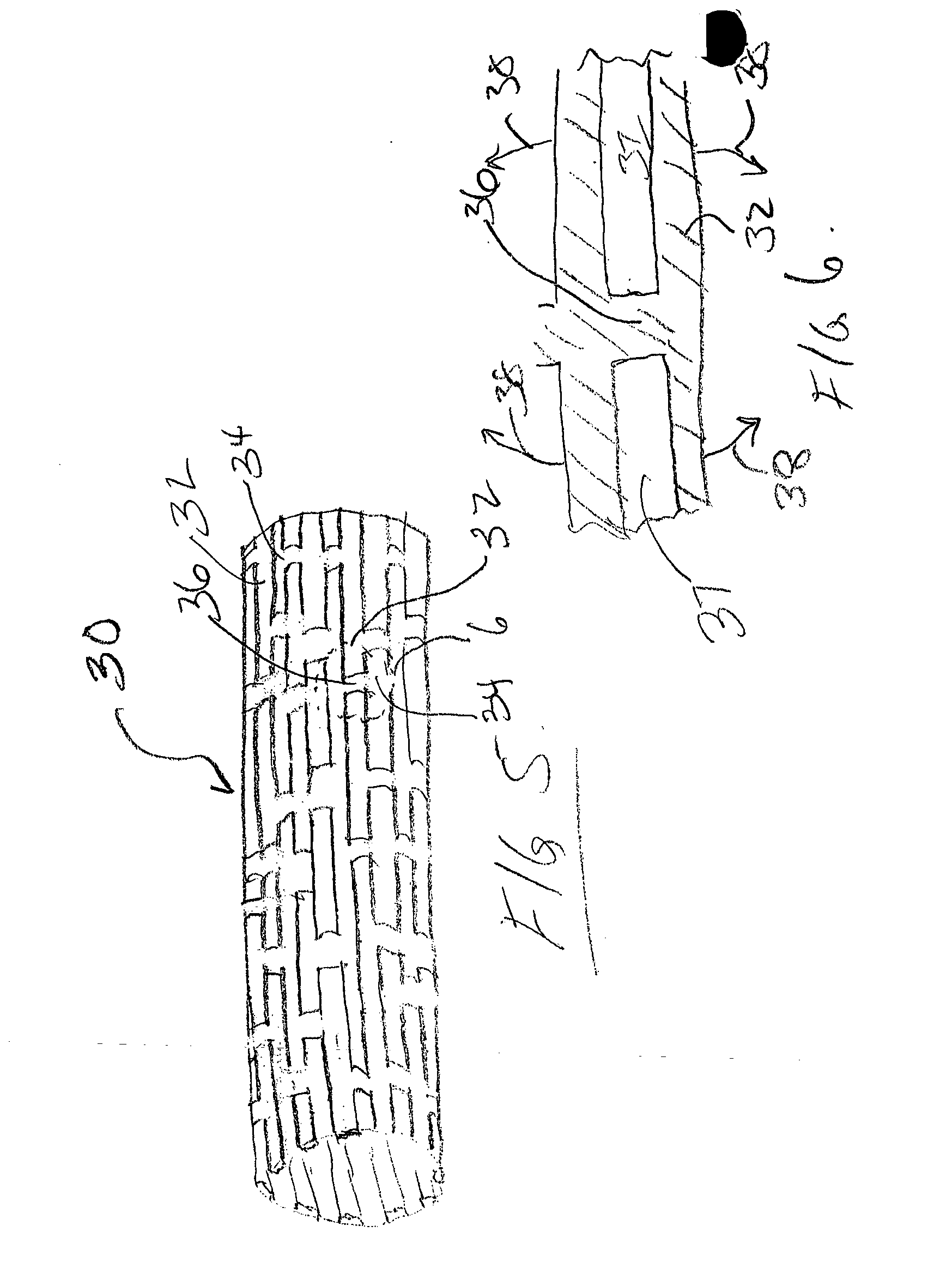

Implantable wireless sensor for pressure measurement within the heart

InactiveUS6855115B2Measure the pressure easily, safely, inexpensively and accuratelyElectrotherapyPerson identificationLine sensorHeart chamber

The progress of a endovascular cardiac repair can be monitored by inserting a pressure transducer sensor using a catheter into a chamber of the heart during endovascular repair and then using a small, hand-held read out device to measure pressure easily, safely, inexpensively and accurately. In one aspect a sensor is introduced into the body by the steps of folding or rolling the sensor into a cylinder, loading it into a catheter, and deploying into the heart chamber by allowing it to unroll or unfold, either by itself or facilitated by the incorporation of a super-elastic alloy component.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

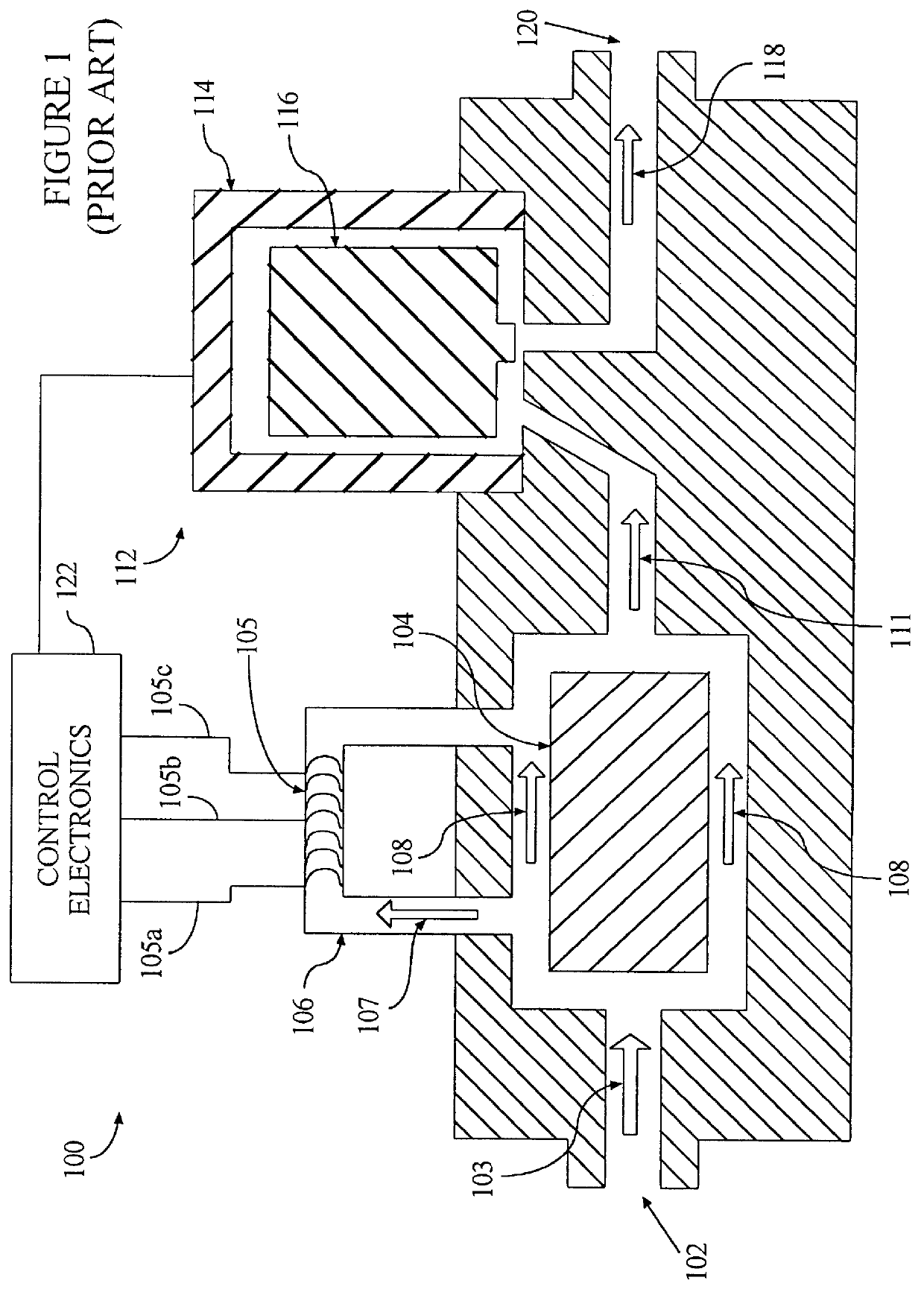

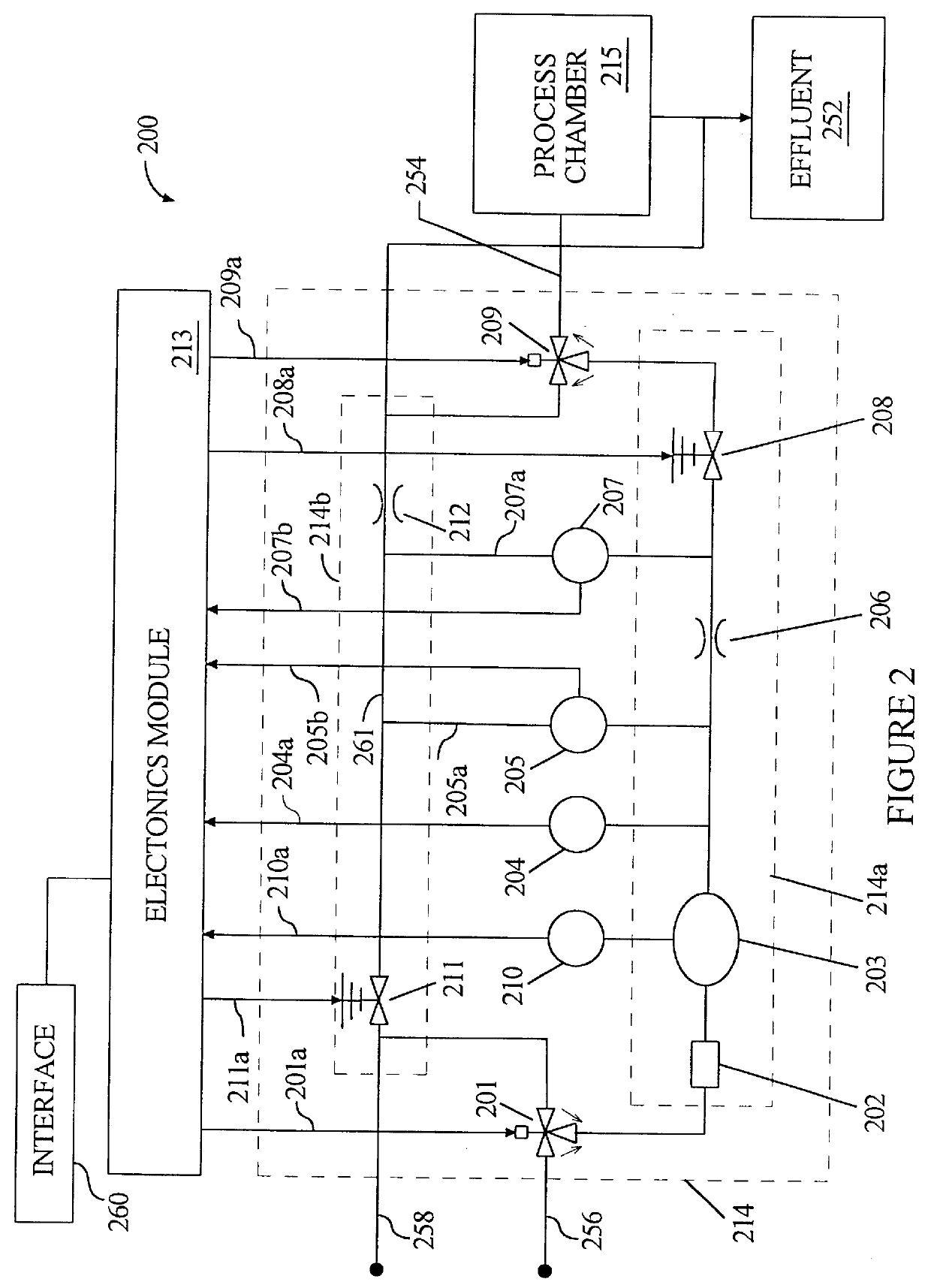

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

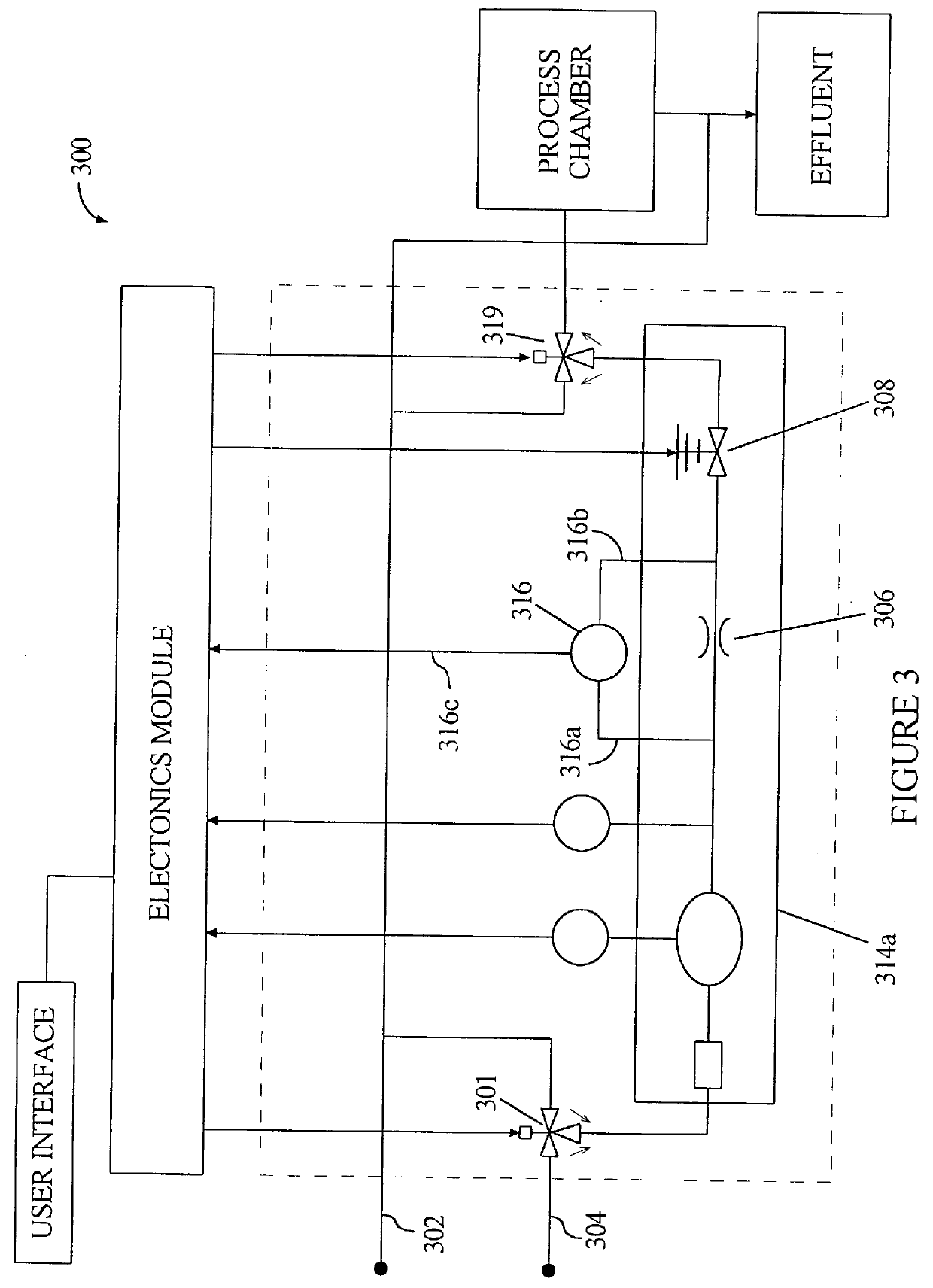

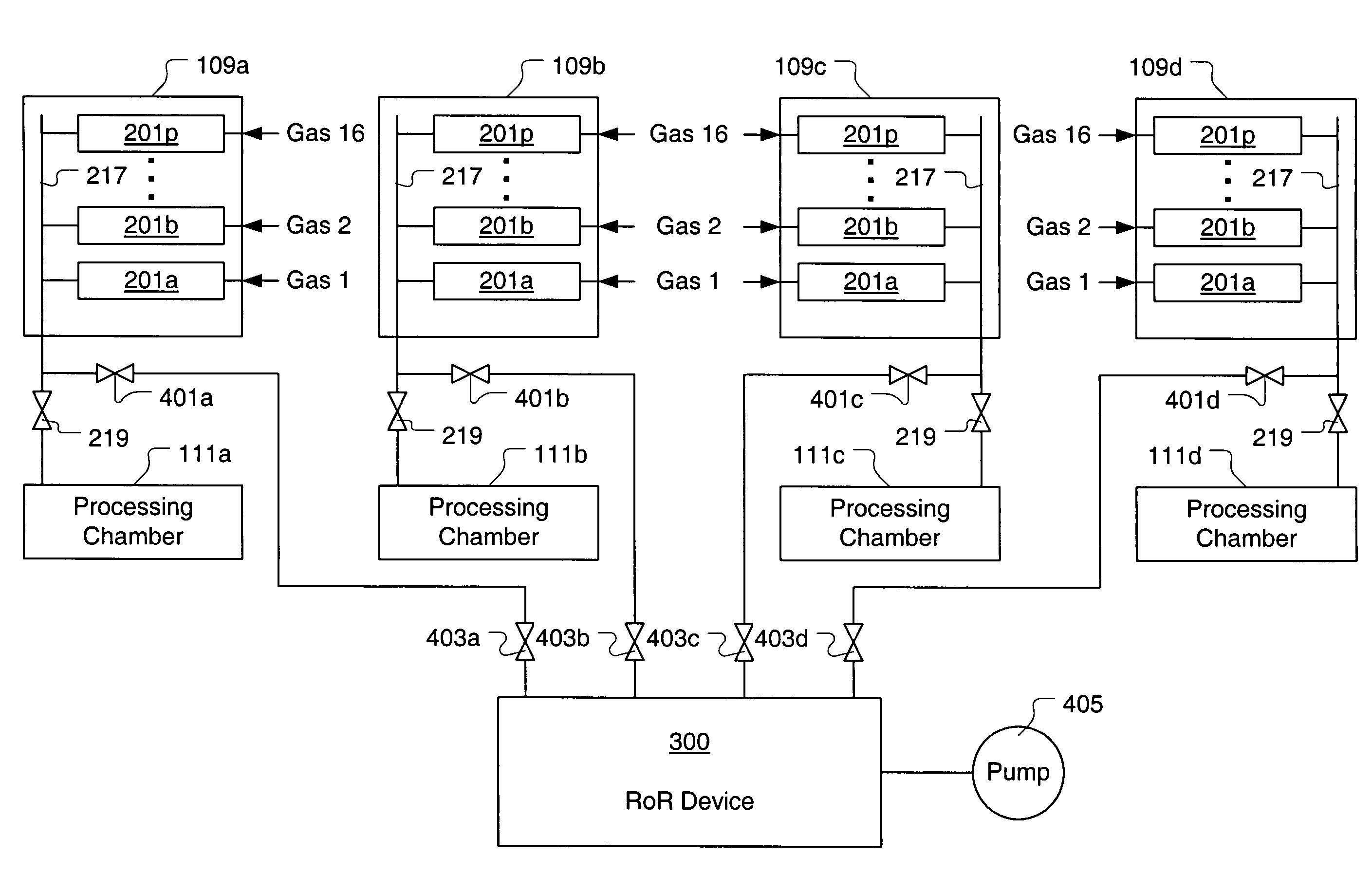

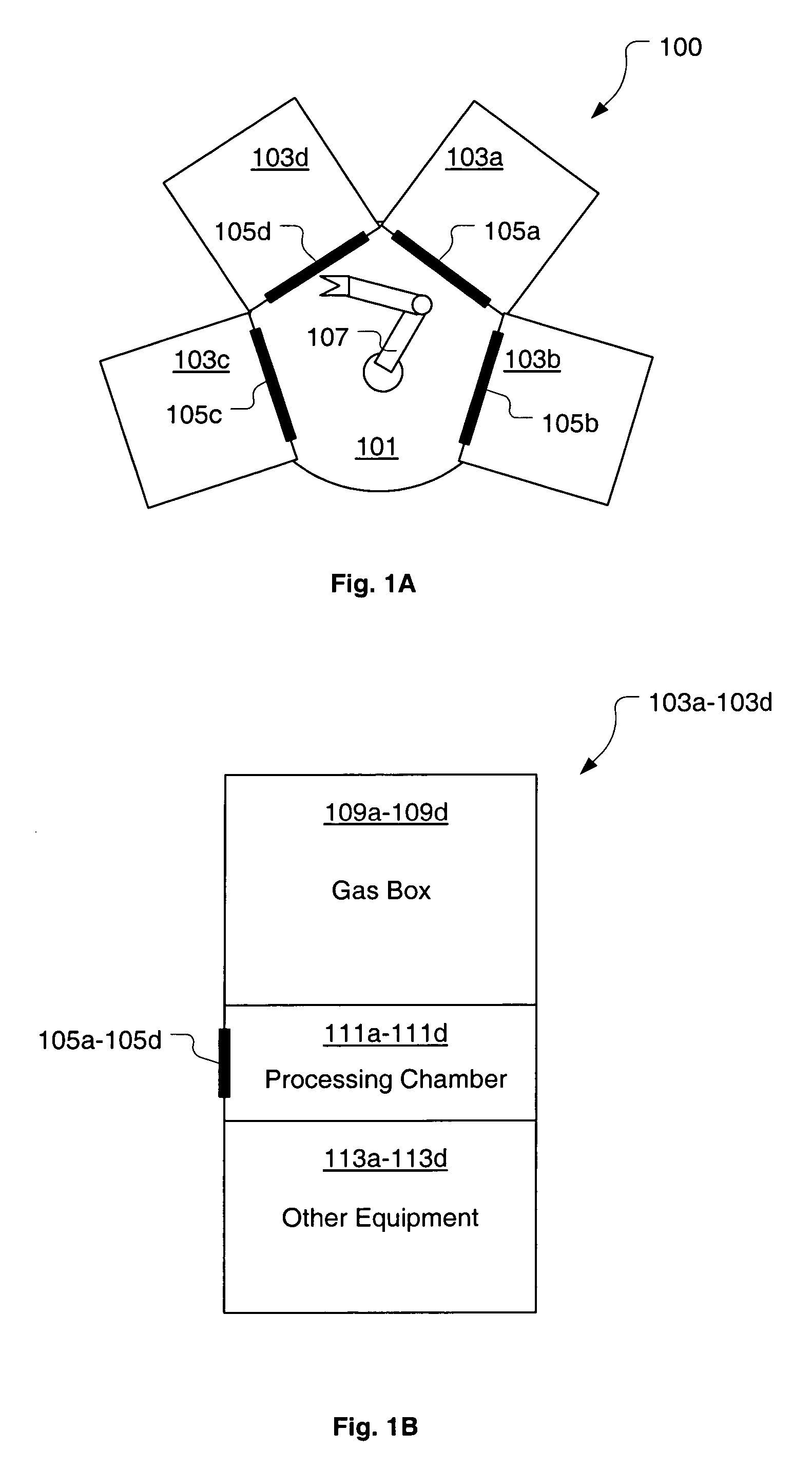

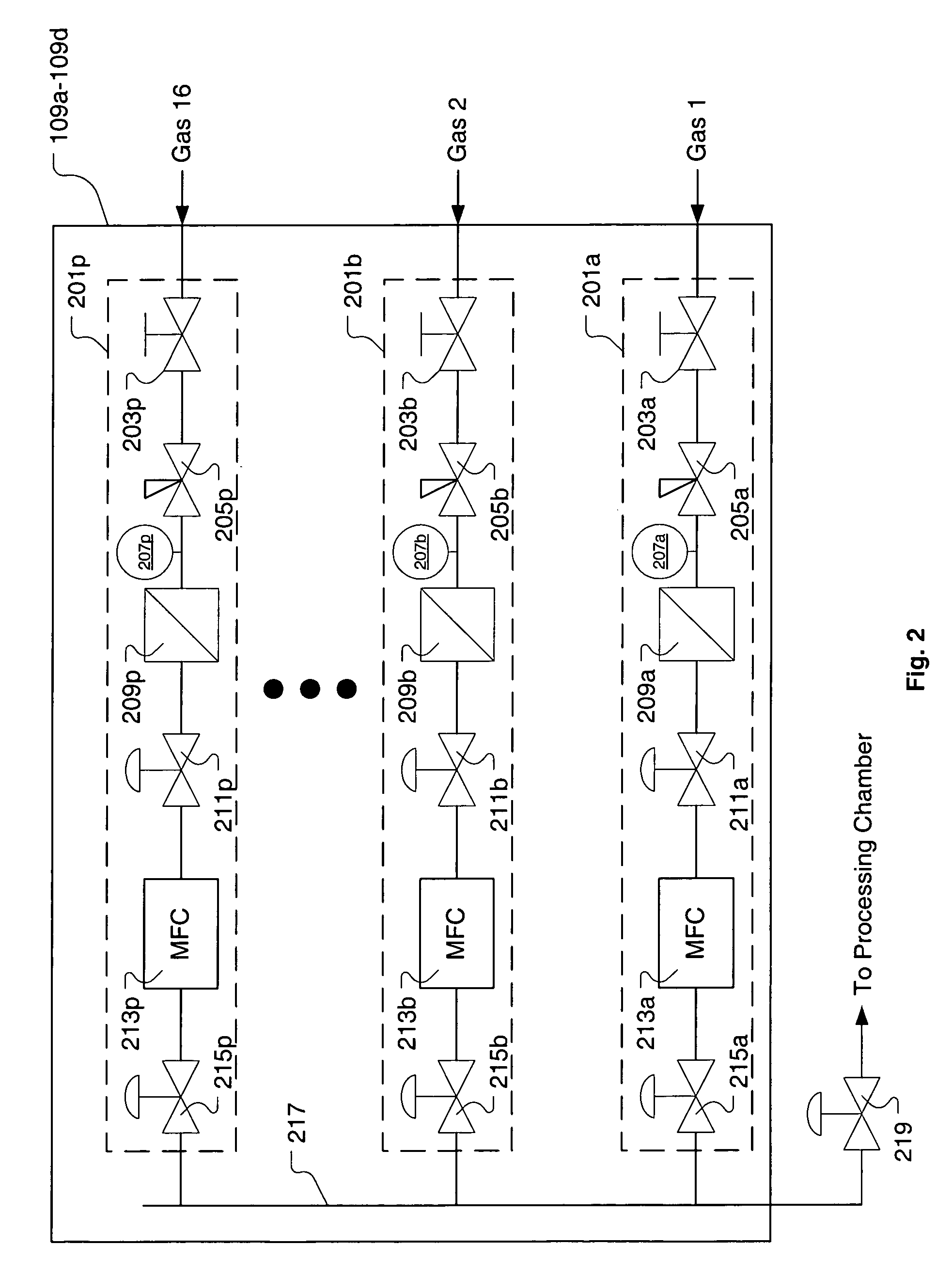

System and method for gas flow verification

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

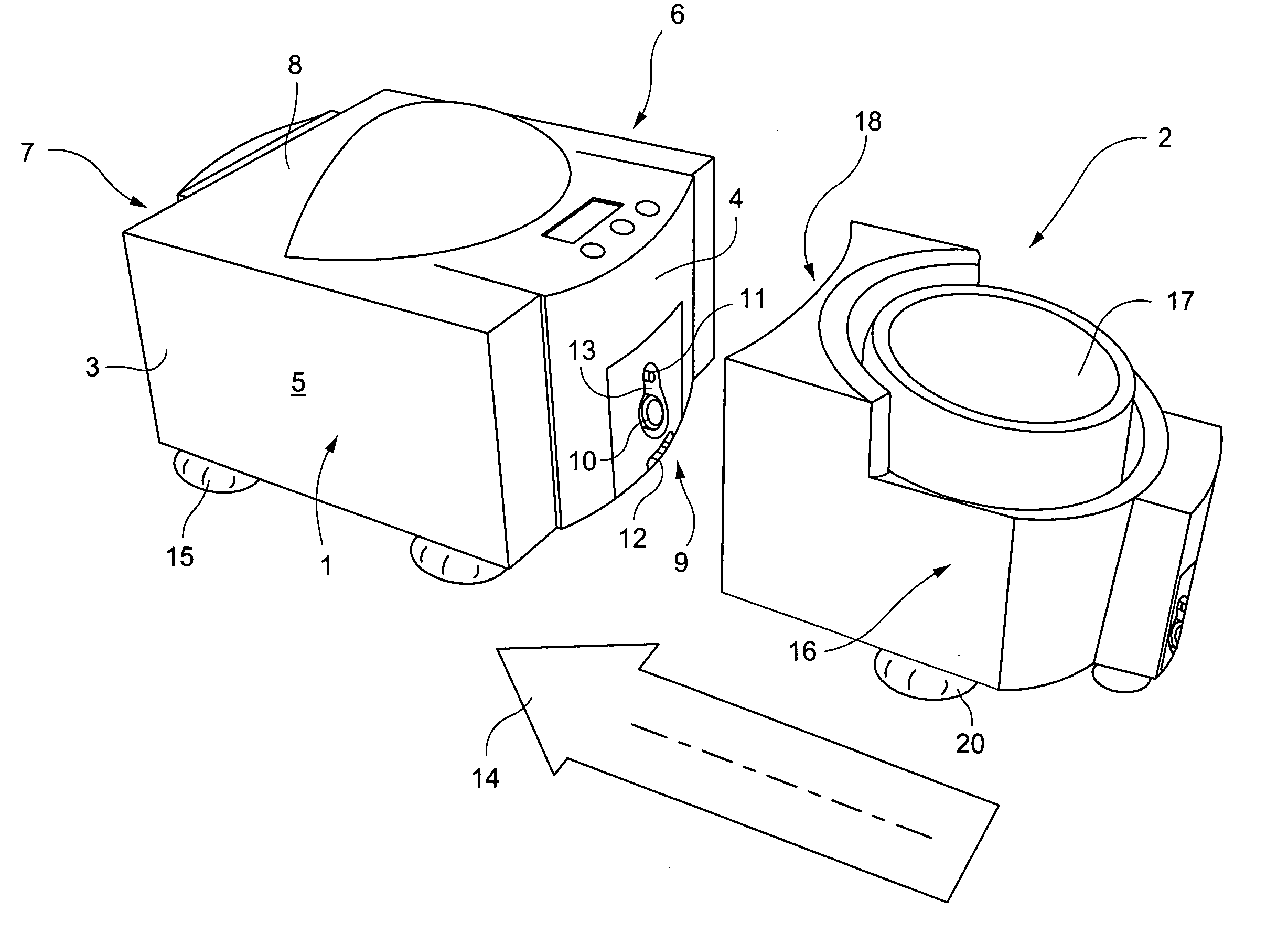

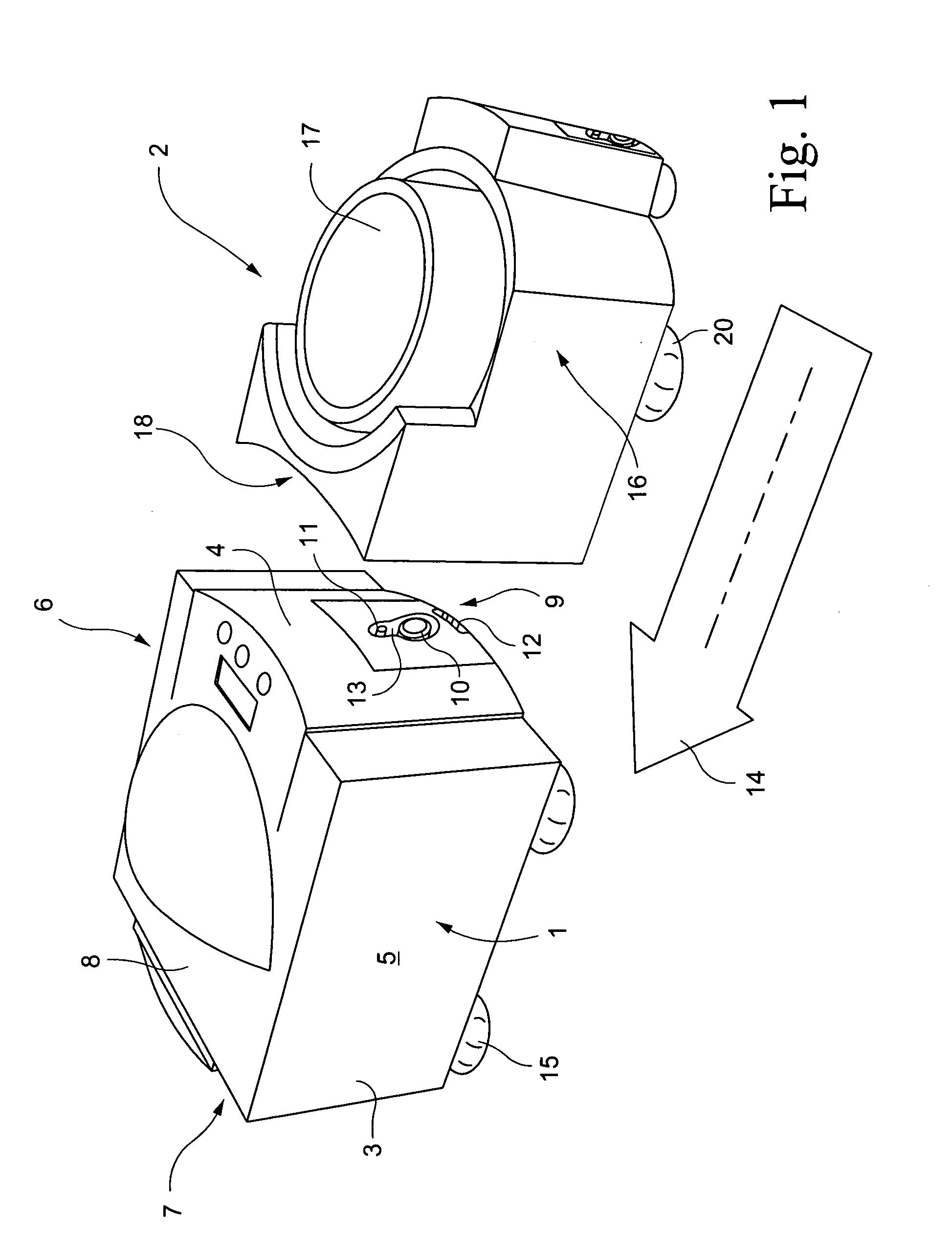

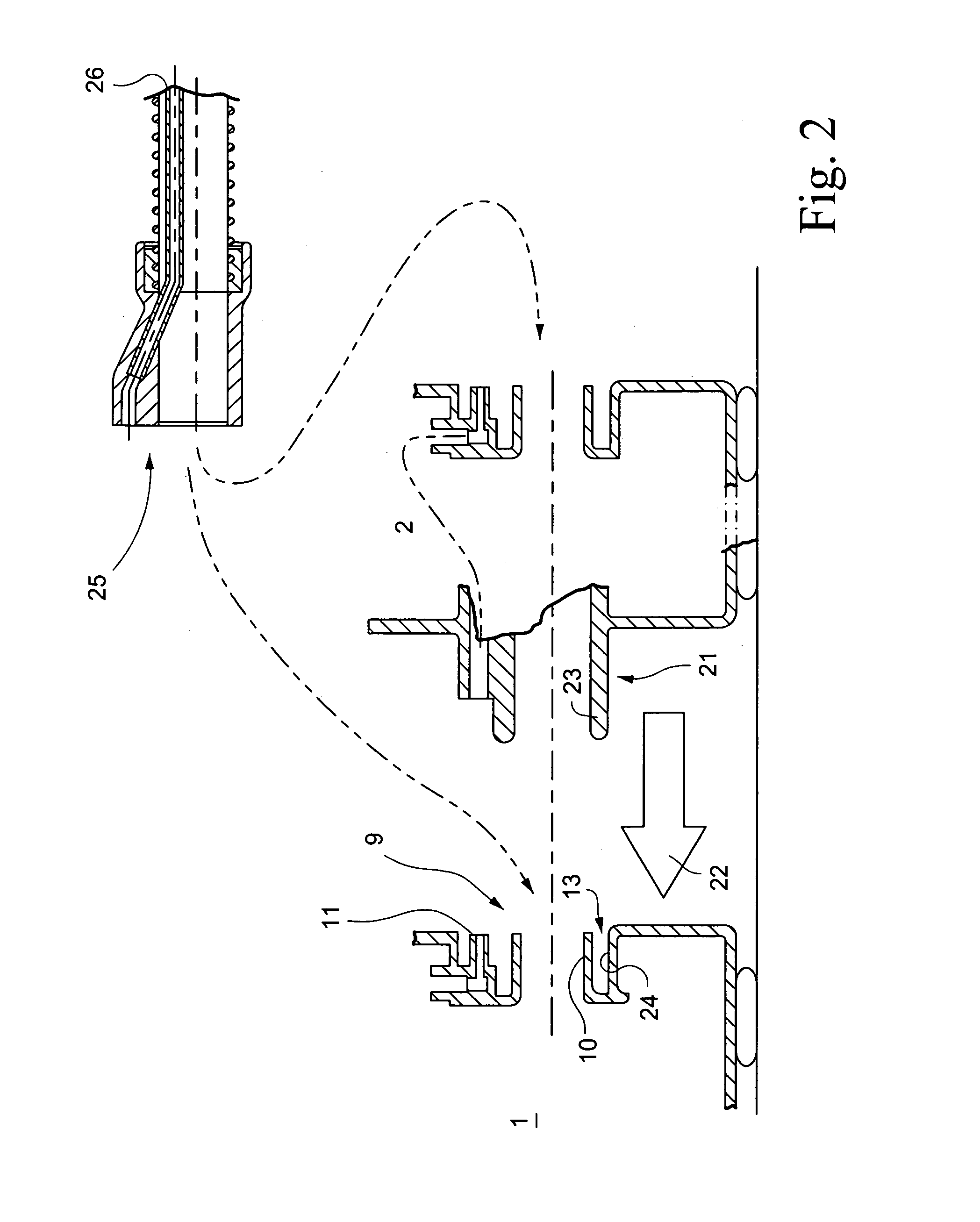

Device for supplying respiratory gas

An apparatus for supplying a respiratory gas includes a blowing device for delivering the respiratory gas, a housing device having a bottom region, a top surface region and a side region extending upwardly between the top surface region and the cover region, as well as a connecting device for connecting a humidifying apparatus. The connecting device is arranged in the side region of the apparatus in such a way that the humidifying apparatus can be laterally coupled thereto. The humidifying apparatus may include a partial amount discharge device for passing a partial amount of the liquid pre-stored in a liquid storage space into a humidifying region. A respiration tube includes a connecting plug structure which has both a respiratory gas connecting portion and a pressure measuring tube connecting portion.

Owner:RESMED HUMIDIFICATION TECH

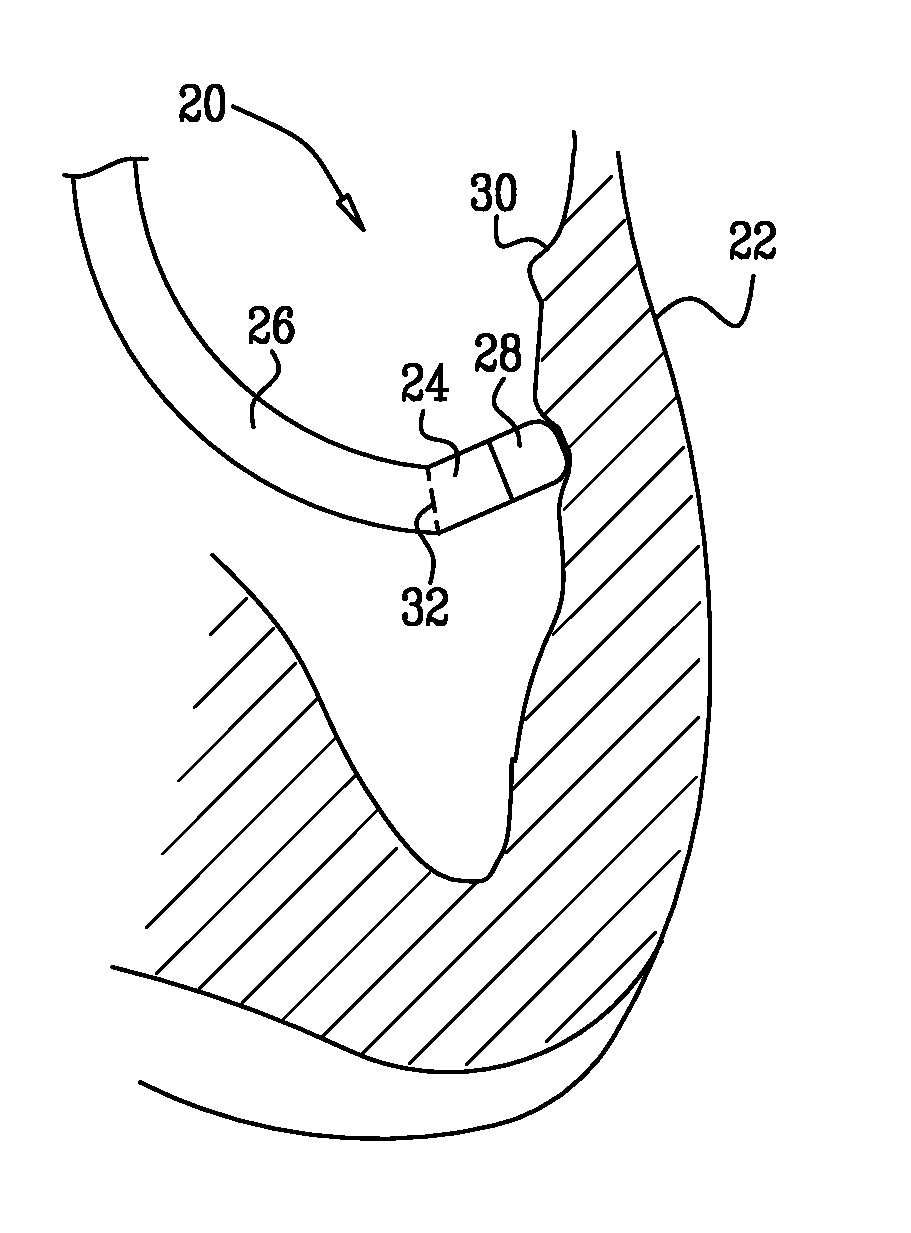

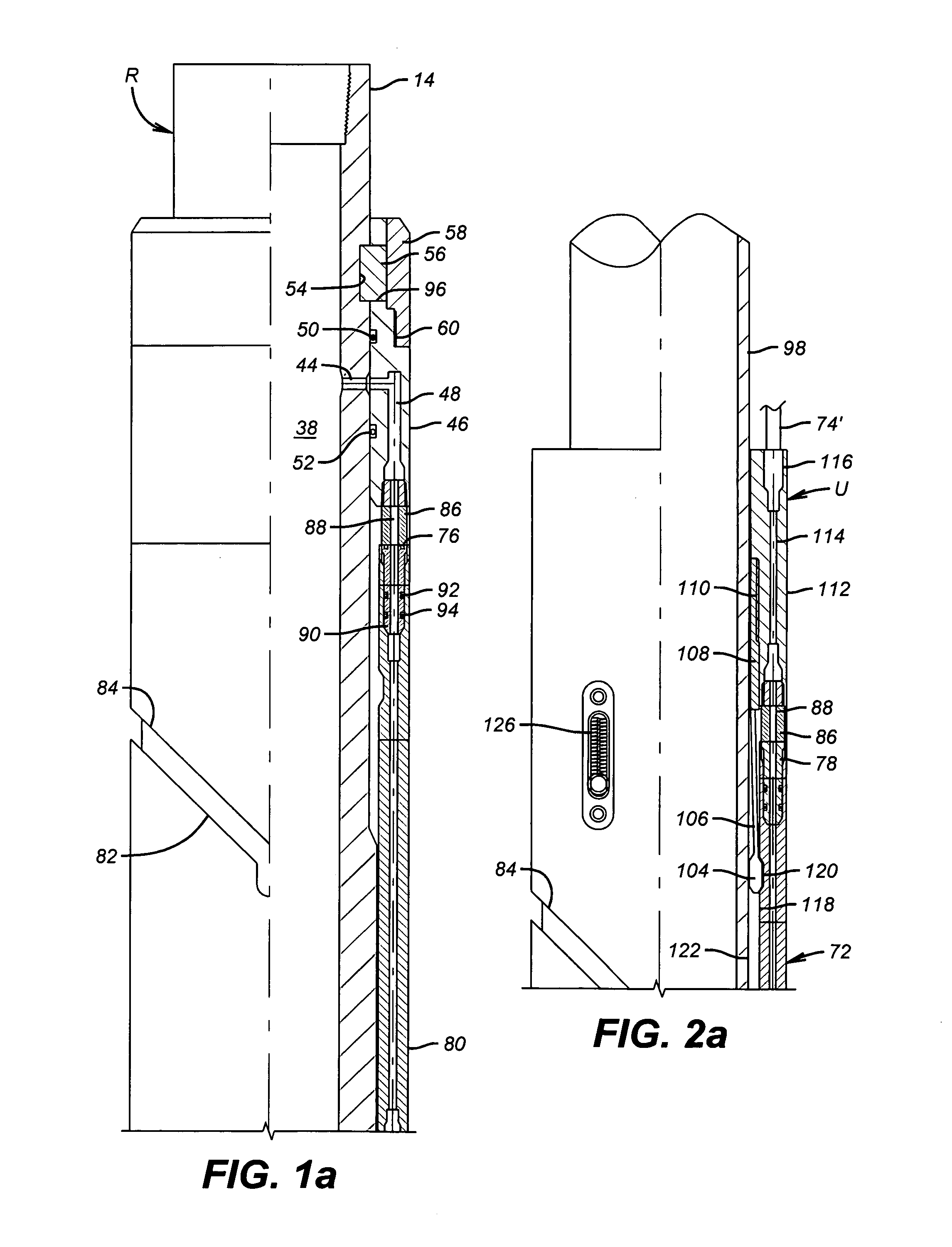

Catheter with pressure measuring tip

A medical probe, consisting of a flexible insertion tube, having a distal end for insertion into a body cavity of a patient, and a distal tip, which is disposed at the distal end of the flexible insertion tube is configured to be brought into contact with tissue in the body cavity. The probe also includes a coupling member, which couples the distal tip to the distal end of the insertion tube and which consists of a tubular piece of an elastic material having a plurality of intertwined helical cuts therethrough along a portion of a length of the piece.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

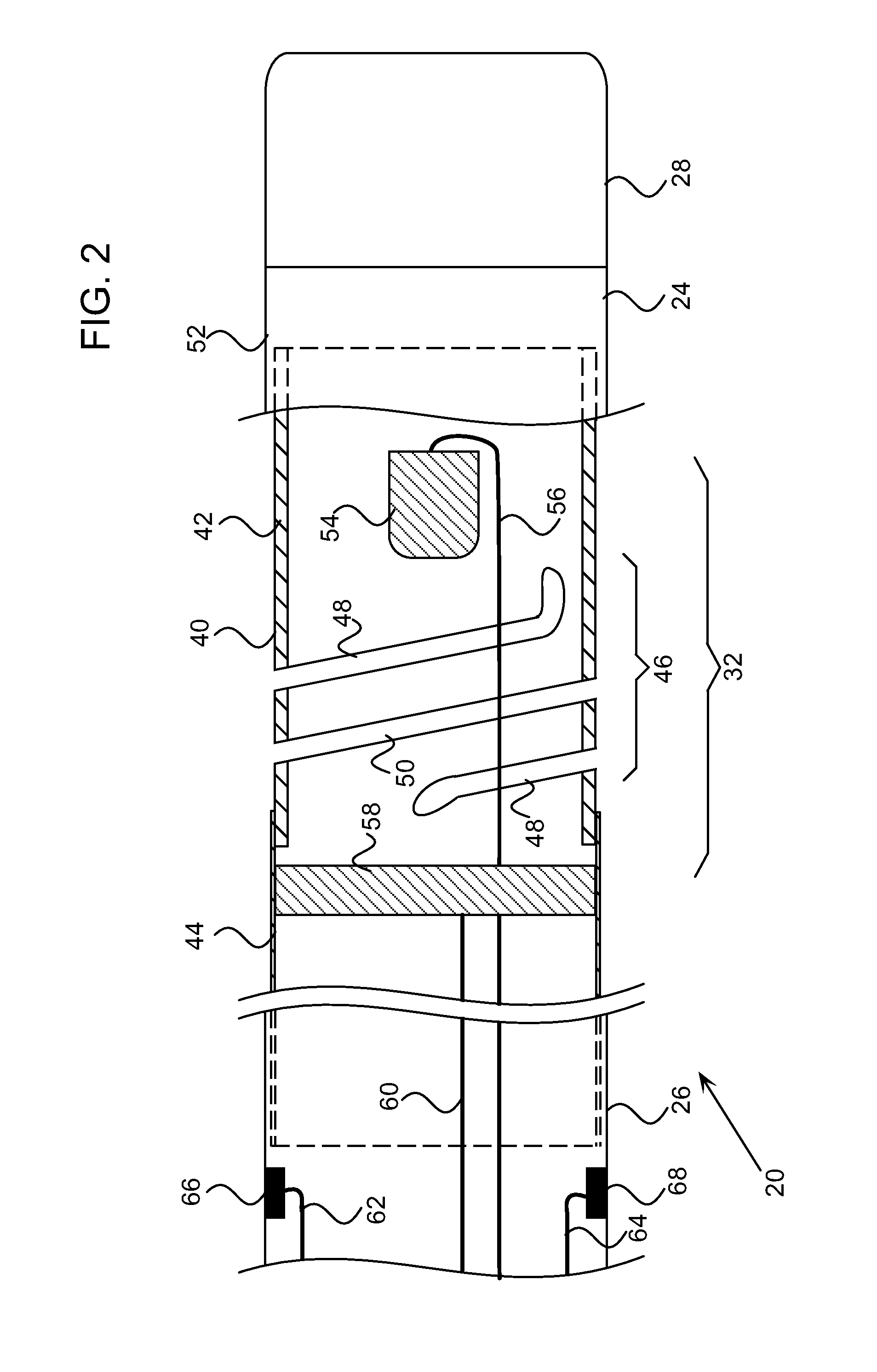

Method of providing hydraulic/fiber conduits adjacent bottom hole assemblies for multi-step completions

A technique for providing auxiliary conduits in multi-trip completions is disclosed. The technique has particular applicability to liner mounted screens which are to be gravel packed. In the preferred embodiment, a protective shroud is run with the gravel pack screens with the auxiliary conduits disposed in between. The auxiliary conduits terminate in a quick connection at a liner top packer. The gravel packing equipment can optionally be secured in a flow relationship to the auxiliary conduits so as to control the gravel packing operation. Subsequent to the removal of the specialized equipment, the production tubing can be run with an auxiliary conduit or conduits for connection down hole to the auxiliary conduits coming from the liner top packer for a sealing connection. Thereafter, during production various data on the well can be obtained in real time despite the multiple trips necessary to accomplish completion. The various completion and / or production activities can also be accomplished using the auxiliary conduits such as actuation of down hole flow control devices, chemical injection, pressure measurement, distributed temperature sensing through fiber optics, as well as other down hole parameters.

Owner:BAKER HUGHES INC

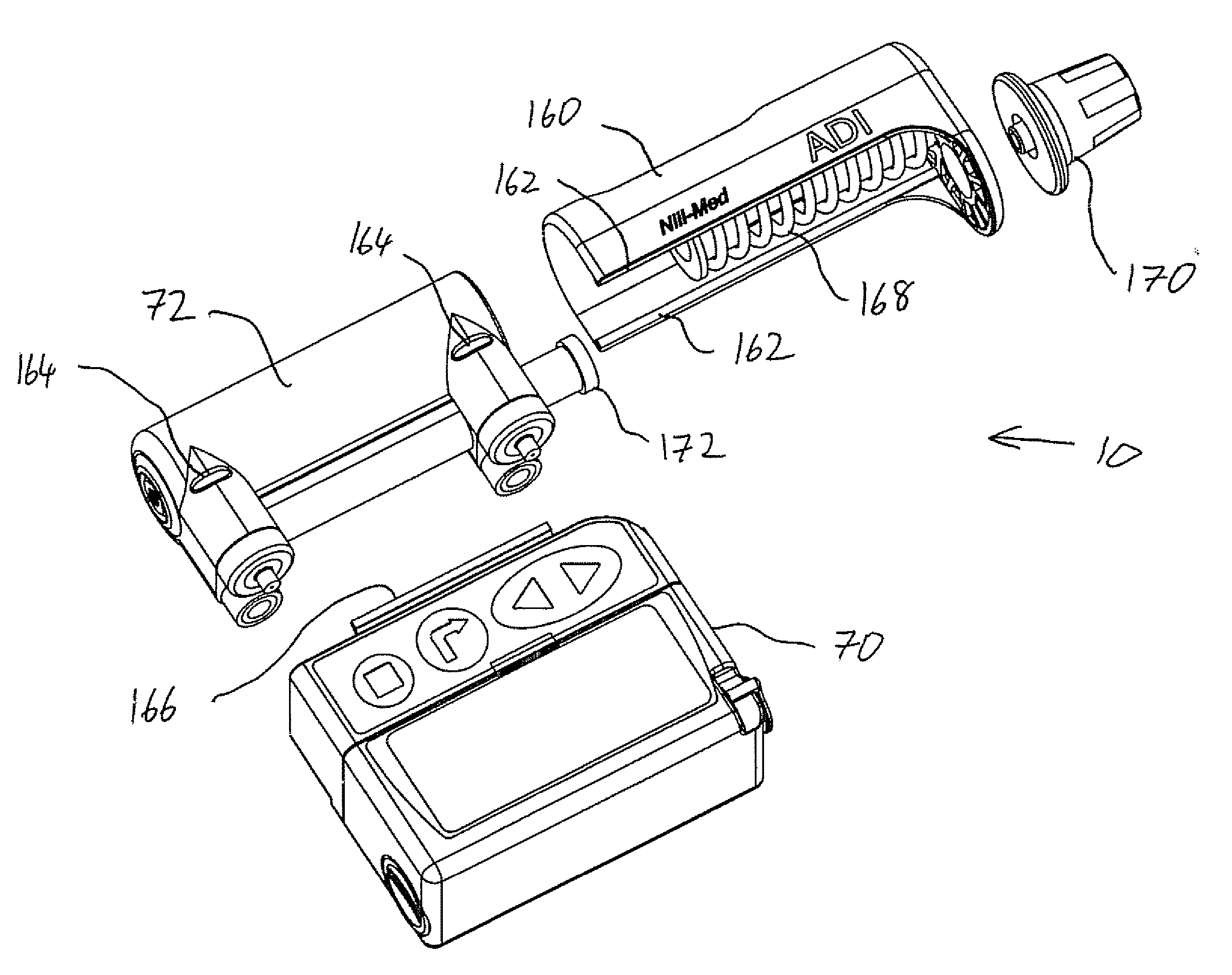

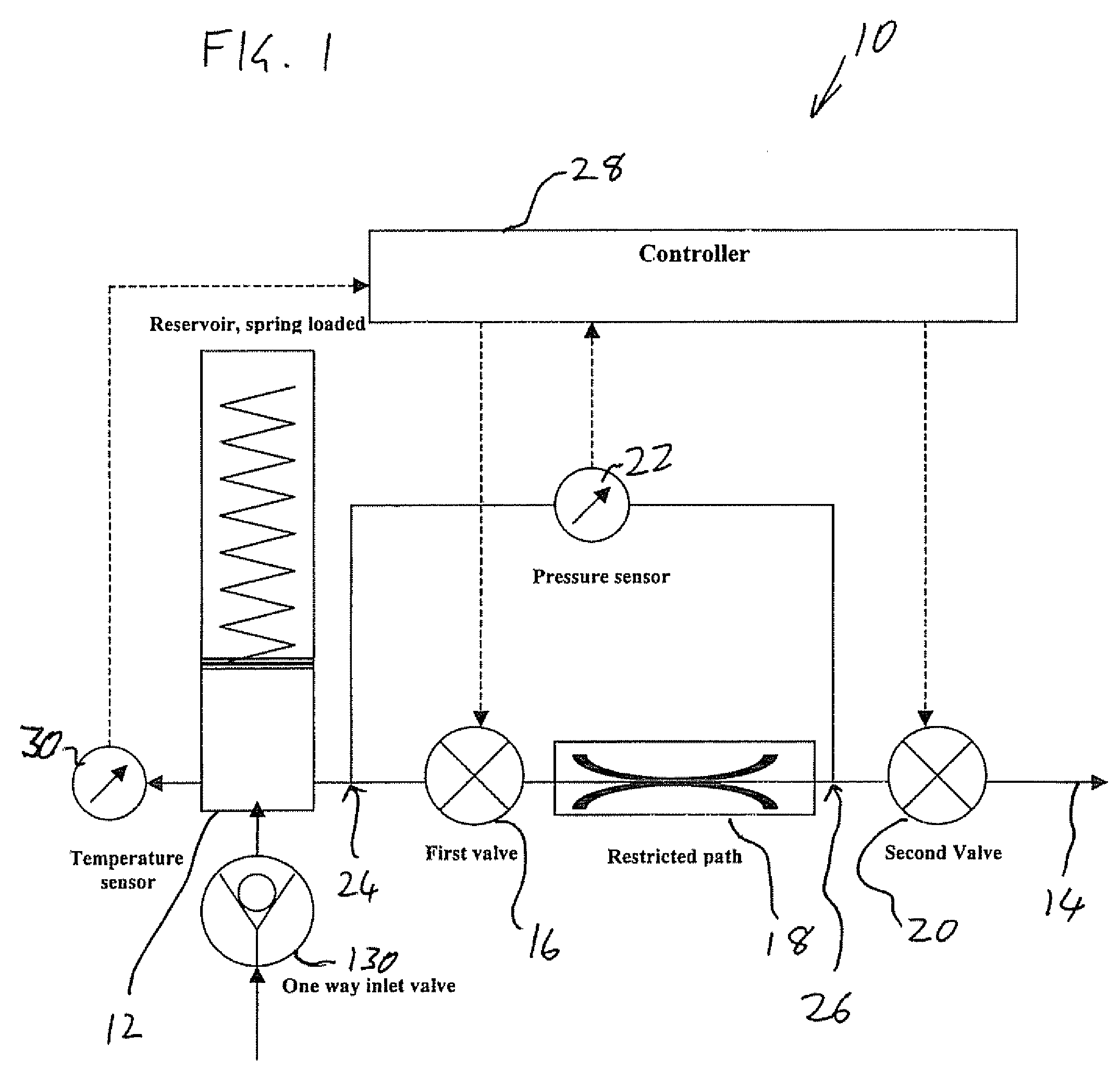

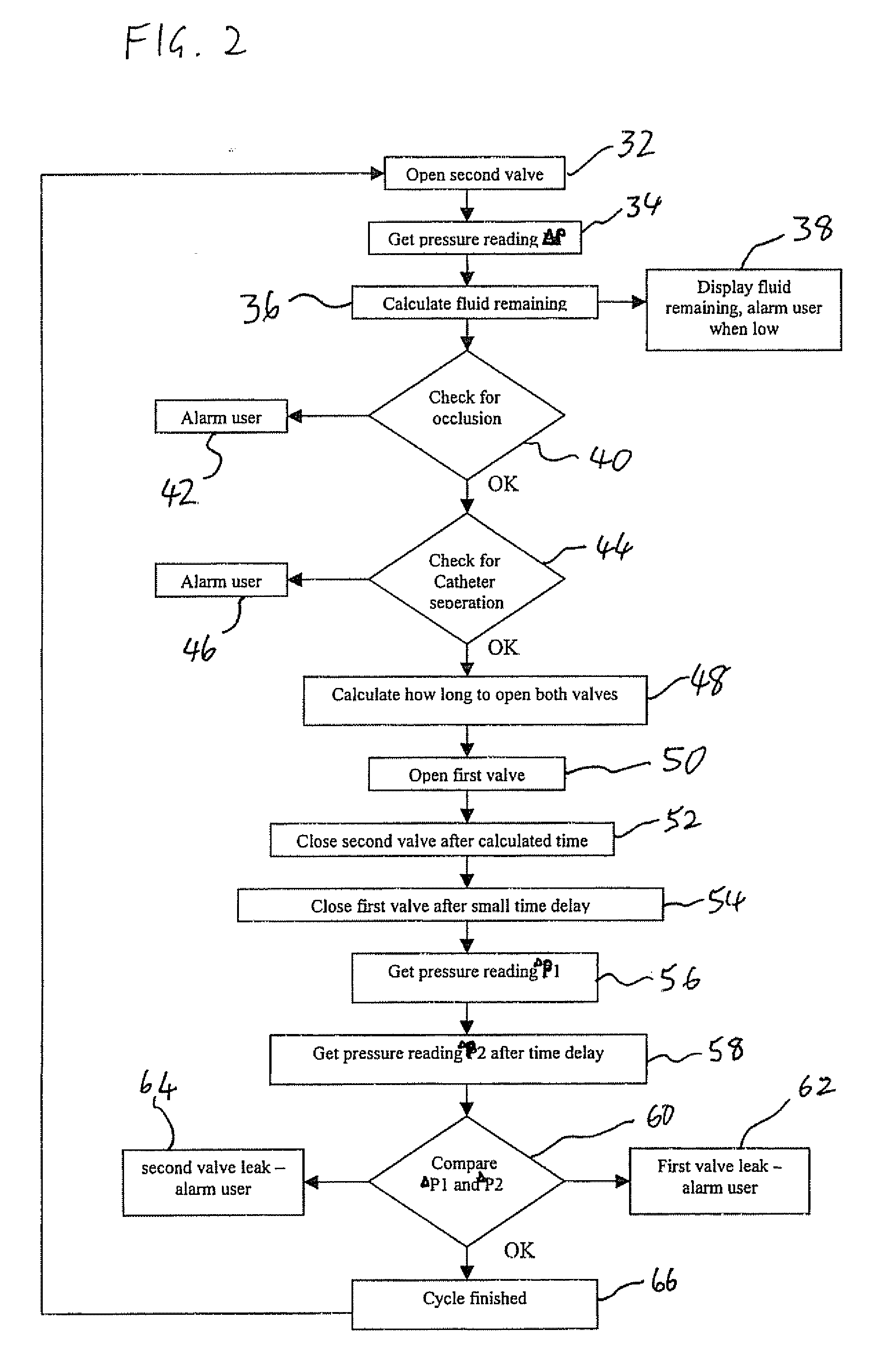

Drug delivery device and method

A drug delivery device includes a pressurized reservoir in communication with a flow path to an outlet. The flow path includes two normally-closed valves and a flow restriction. A pressure measurement arrangement measures a differential fluid pressure between two points along the flow path which span at least part of the flow restriction, one of the points being between the valves. A controller selectively opens the valves to deliver a defined quantity of the liquid medicament to the outlet.

Owner:NILI MED LTD

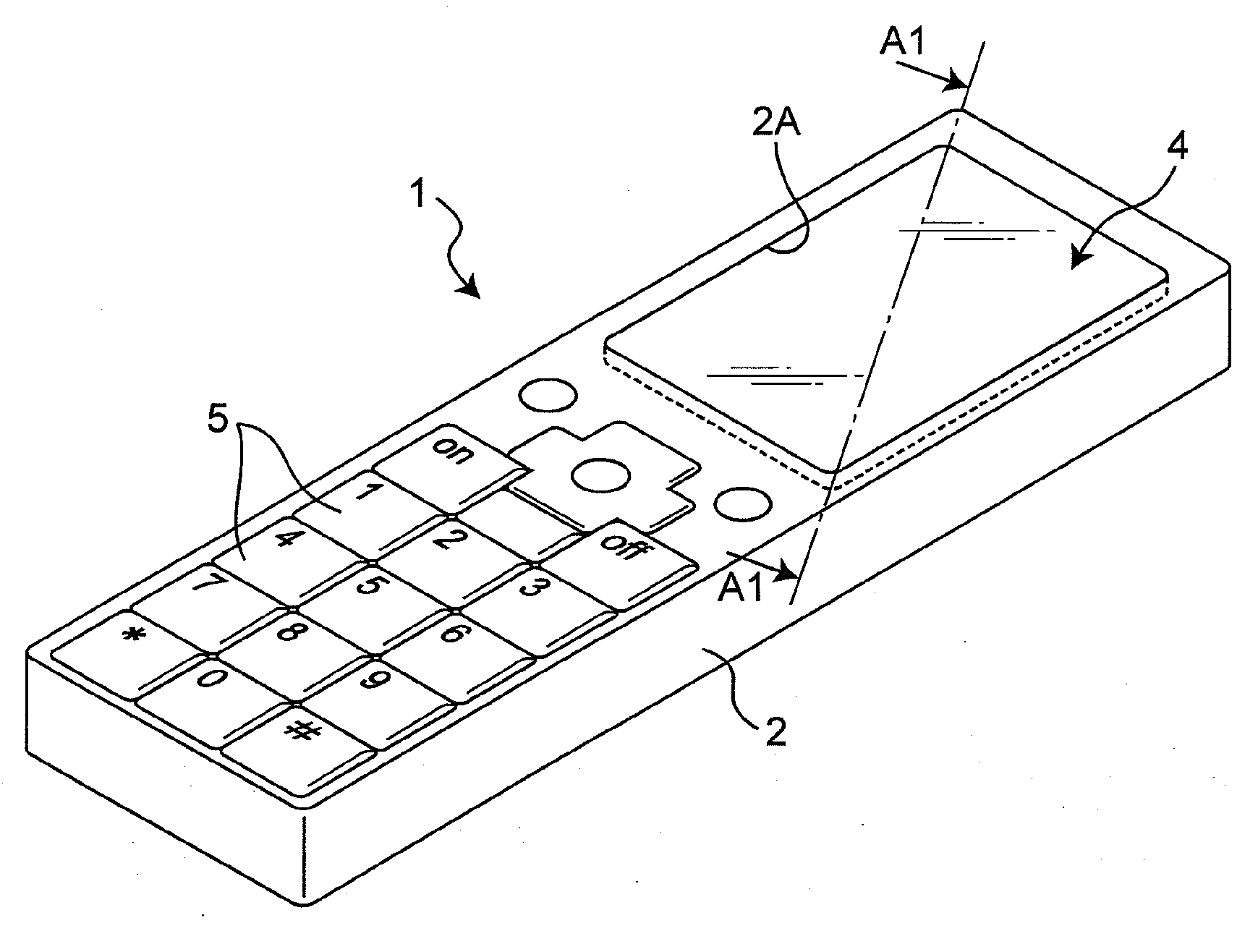

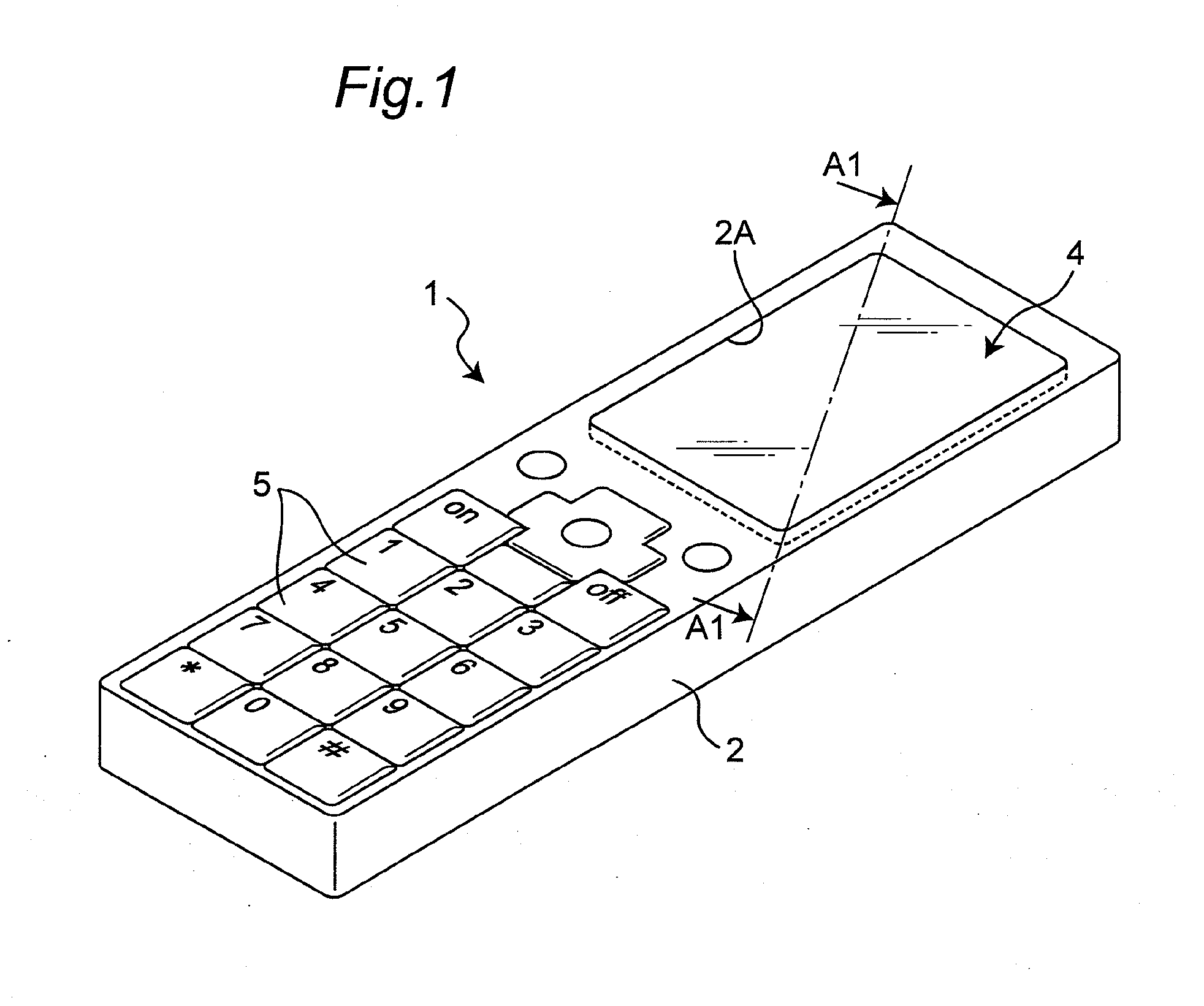

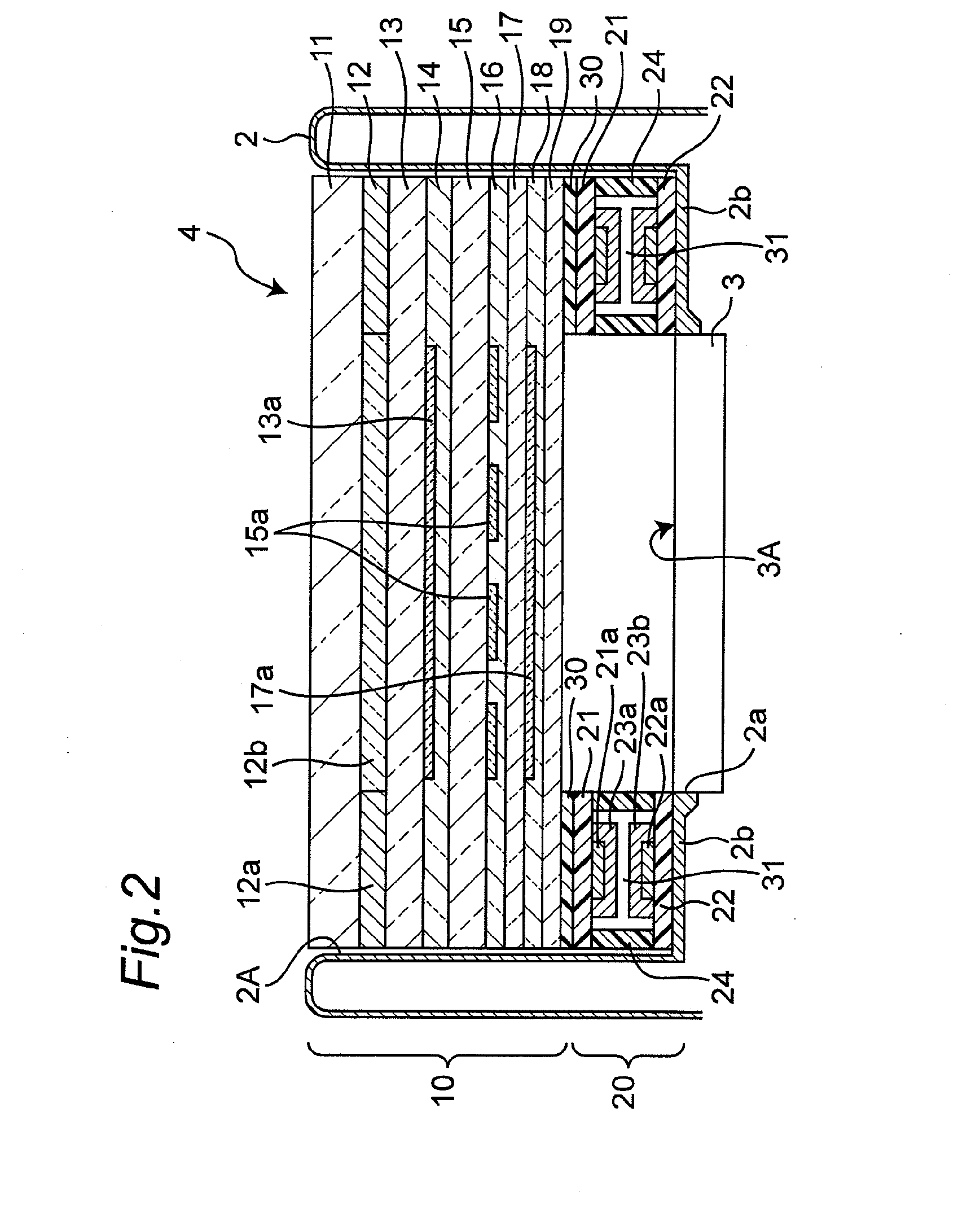

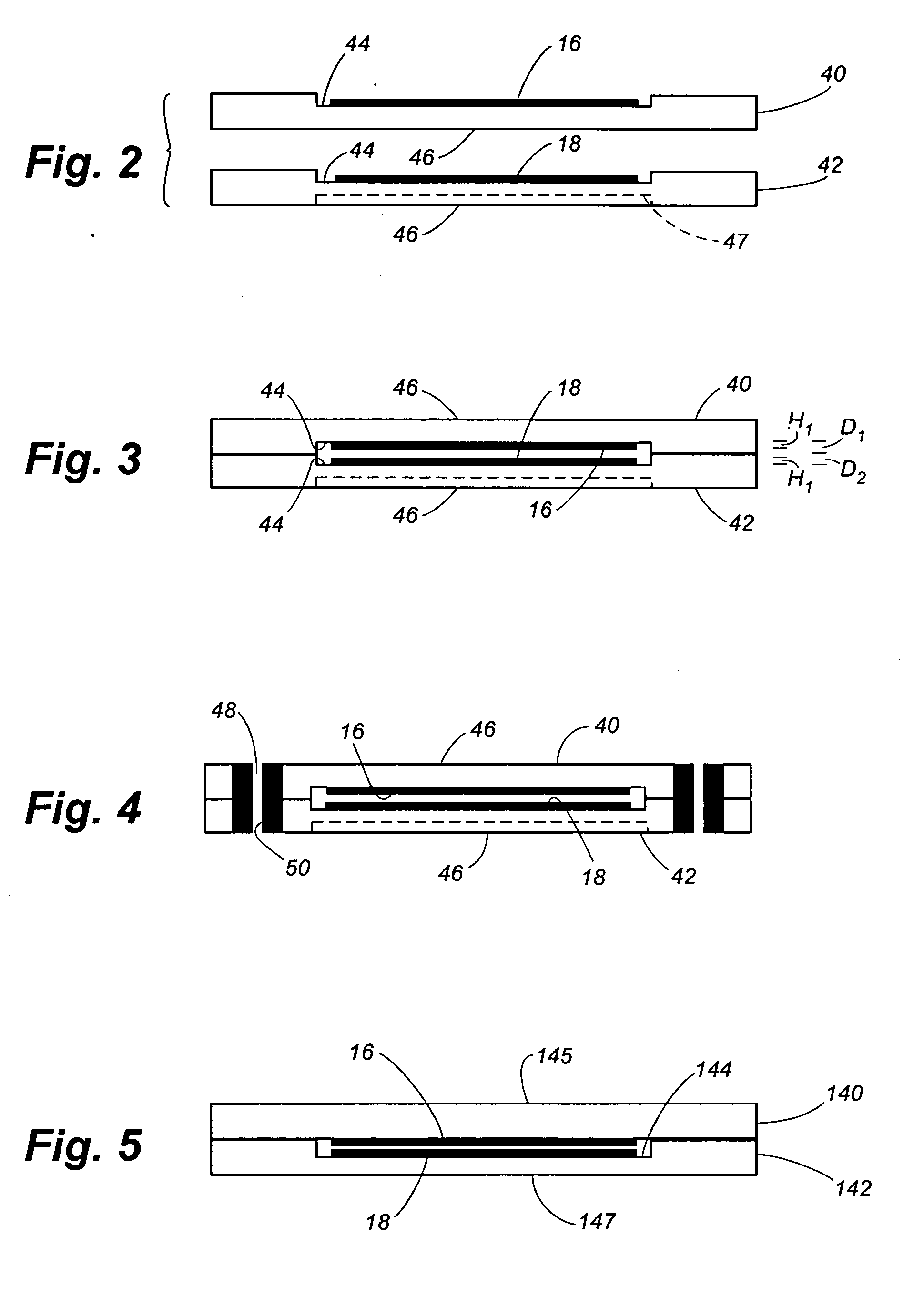

Touch panel having press detection function and pressure sensitive sensor for the touch panel

InactiveUS20110115738A1Degradation of visibility can be suppressedInhibition biasForce measurement by measuring frquency variationsApparatus for force/torque/work measurementVisibilityDisplay device

An object of the present invention is to provide a touch panel having a press detection function, which makes it possible to suppress degradation of visibility of a display unit of a display device even when mounted on an electronic device, and also to improve a pressure measuring precision. For this purpose, the touch panel of the present invention includes a first substrate, a second substrate disposed oppose to the first substrate, a pair of electrodes disposed on either one of opposed surfaces of the respective substrates or disposed separately on both of the surfaces, pressure sensitive ink members disposed with a gap from at least one of the pair of electrodes, each of the pressure sensitive ink members having an electrical characteristic varied by a pressing force applied thereto, and a gap retaining member for bonding the first and second substrates to each other and for retaining a gap between each of the pressure sensitive inks and at least one of the pair of electrodes, wherein the pair of electrodes are disposed in a frame shape along an edge portion of the first or second substrate, and the pressure sensitive ink members are scattered along the edge portion of the first or second substrate so that, when the first or second substrate is deformed upon an application of an external force, at least one of them is made in contact with both of the pair of electrodes so as to make the two electrodes conductive to each other.

Owner:NISSHA PRINTING COMPANY

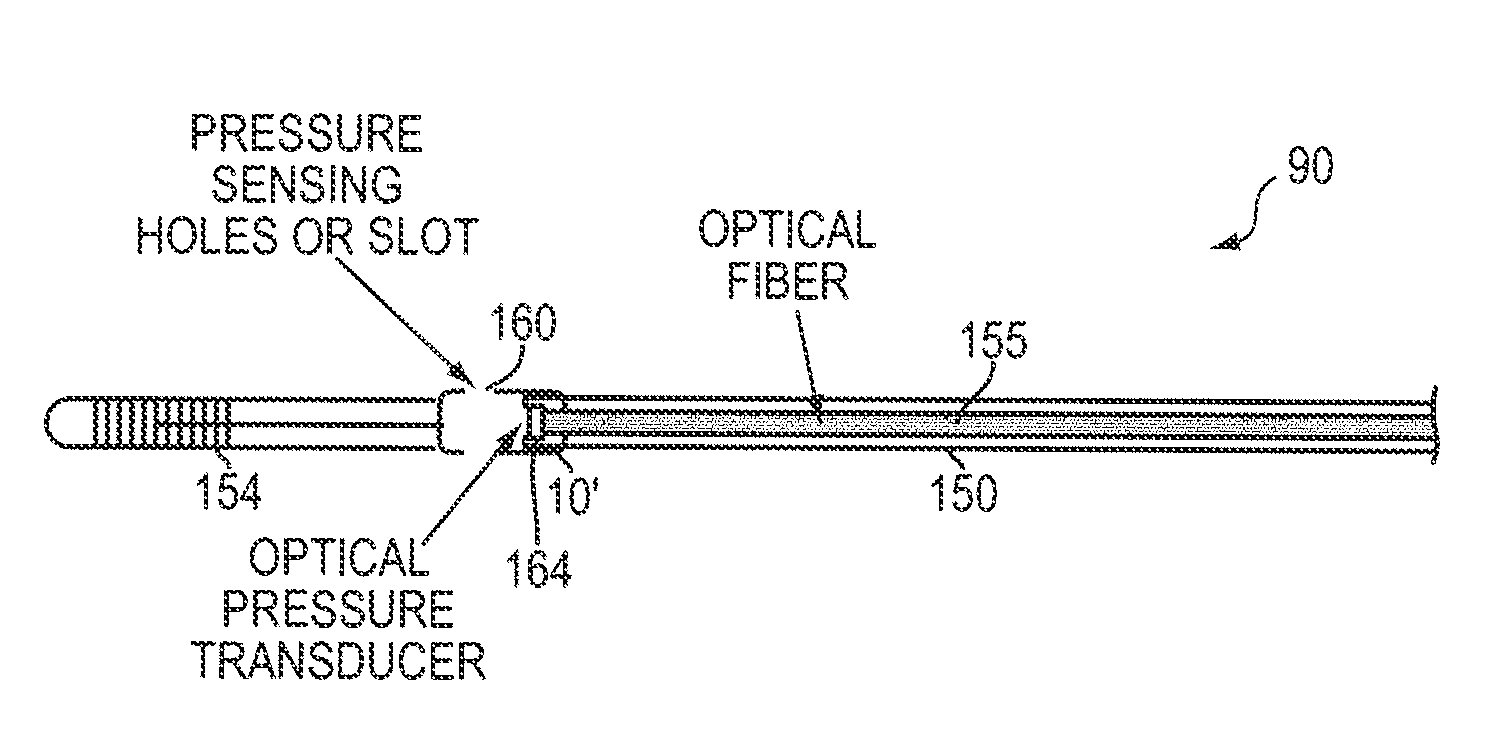

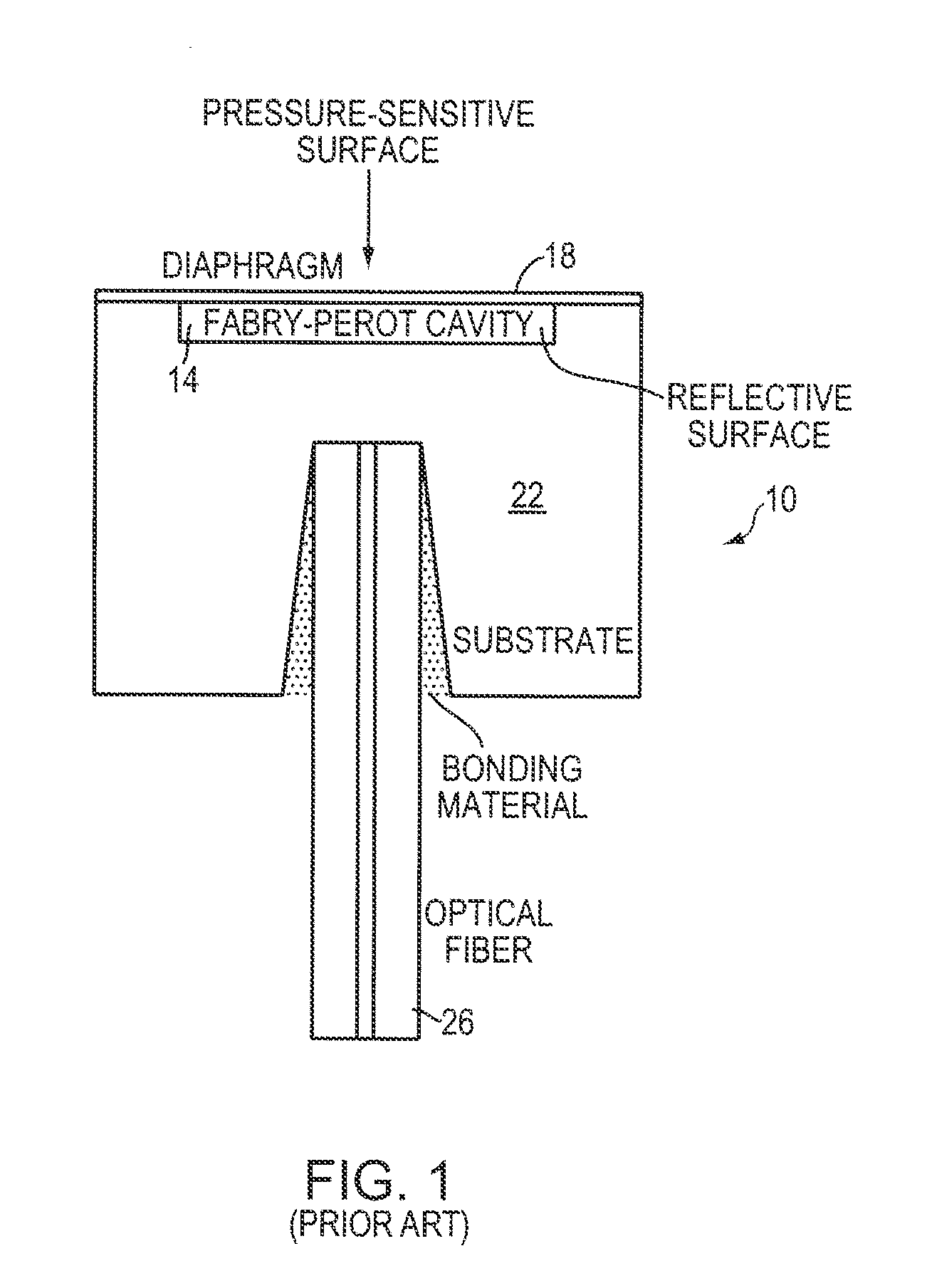

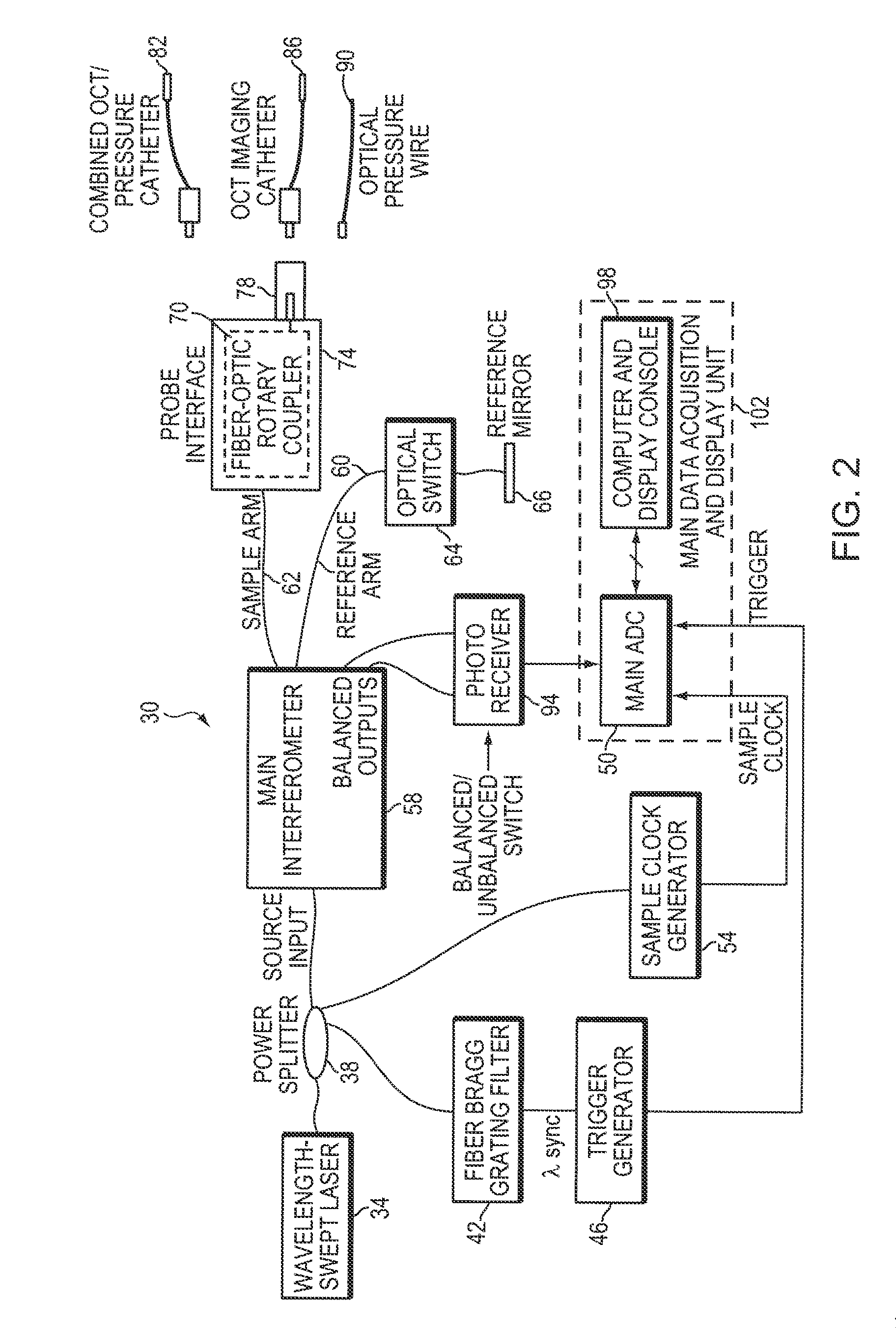

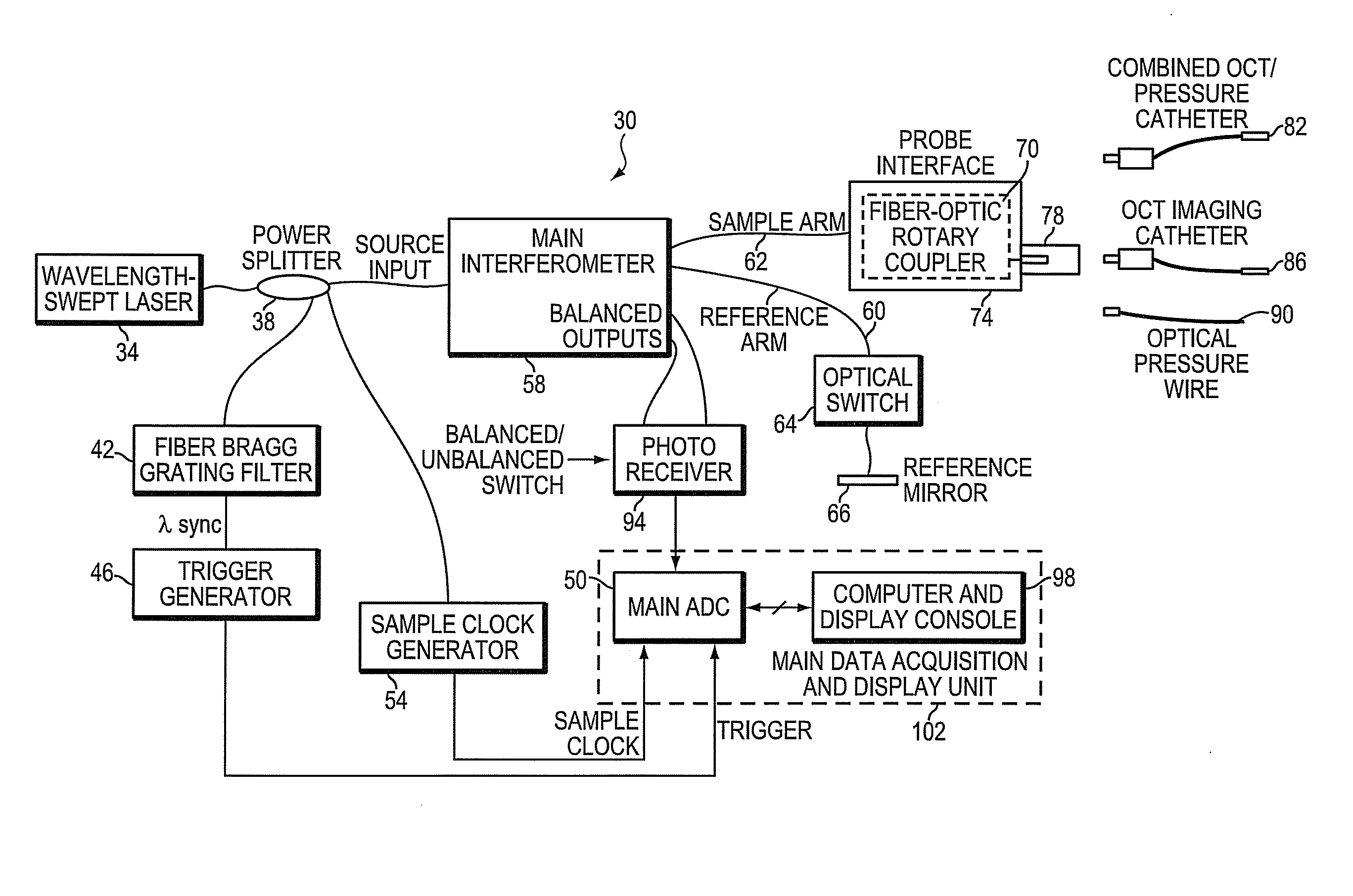

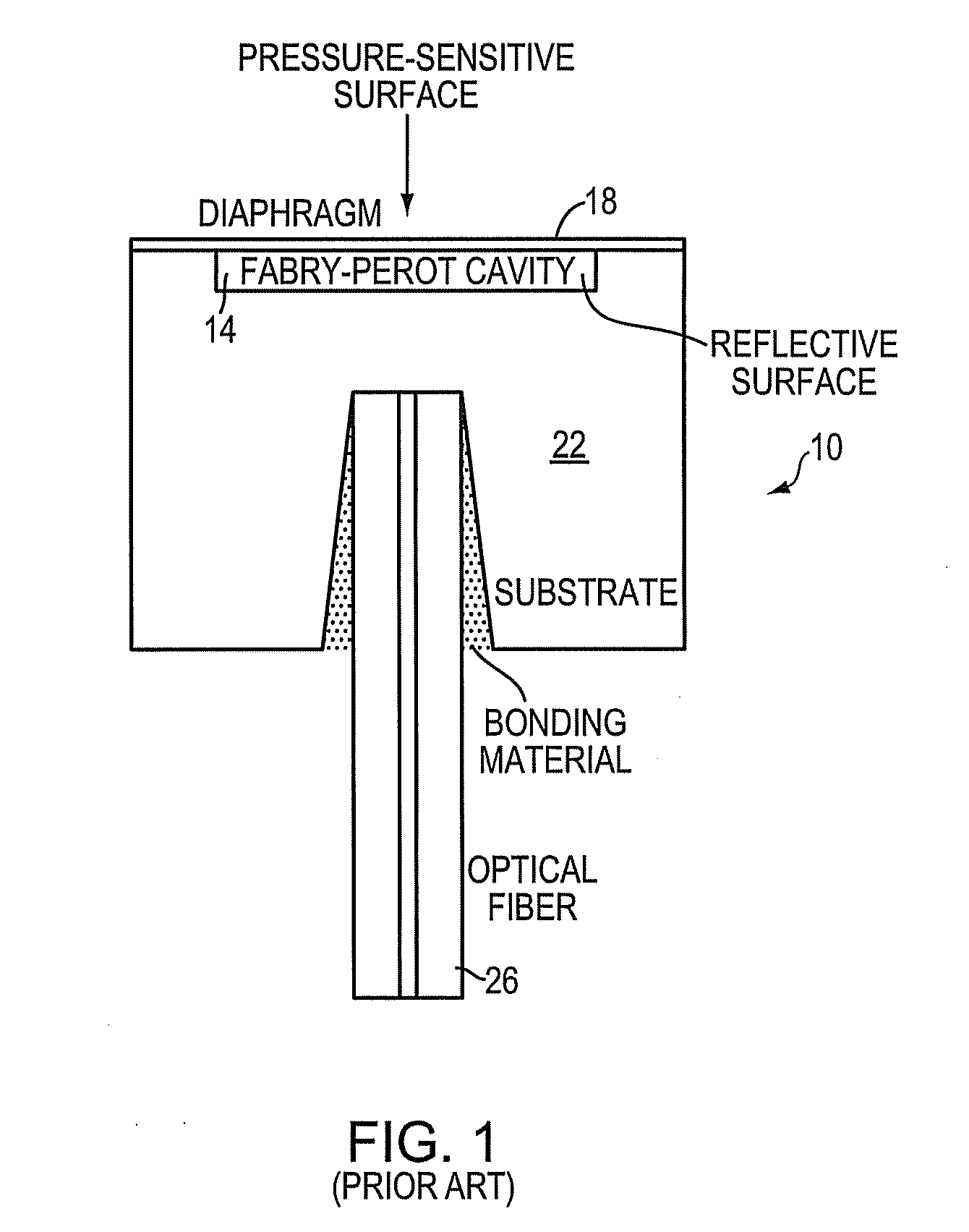

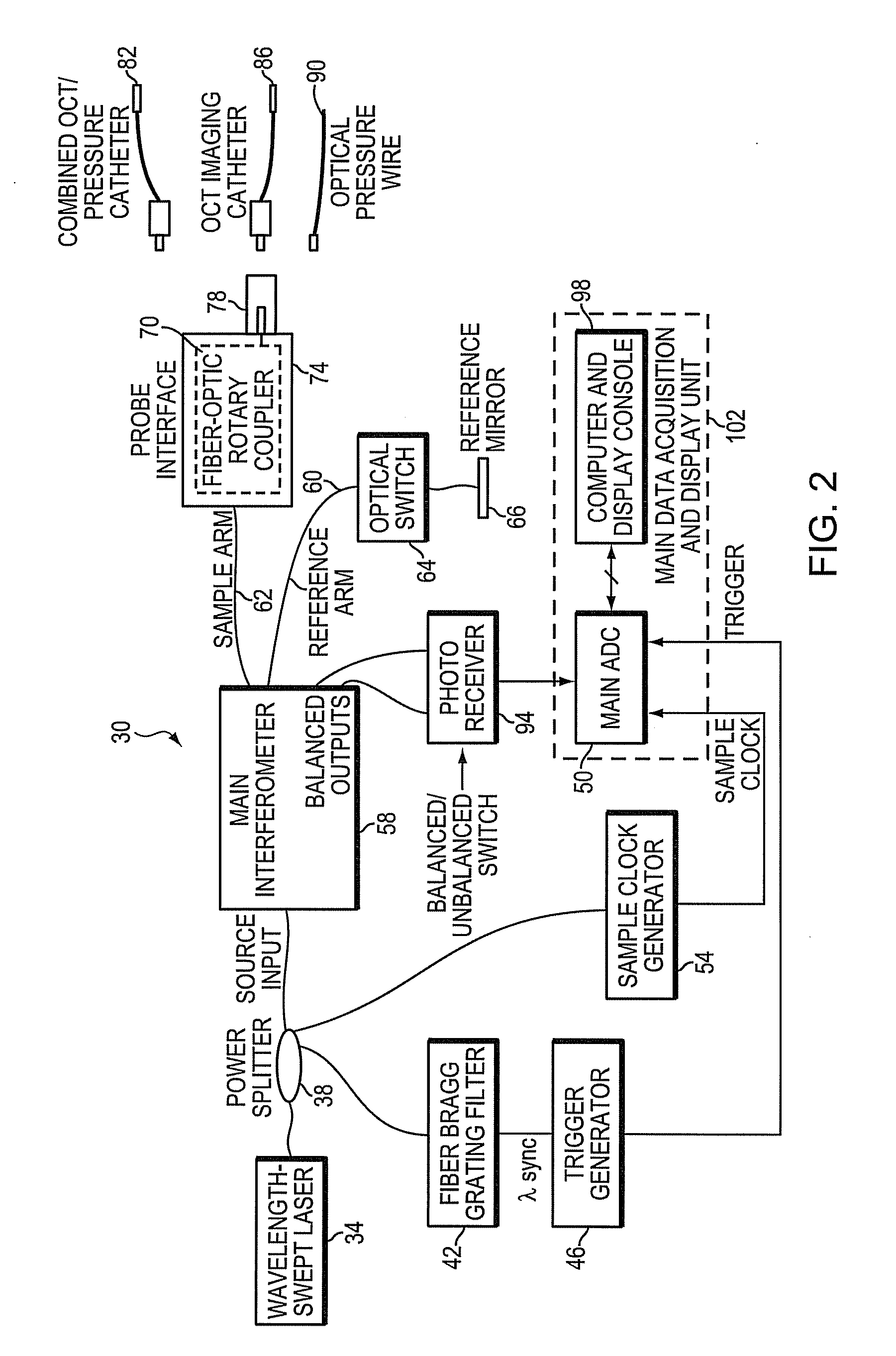

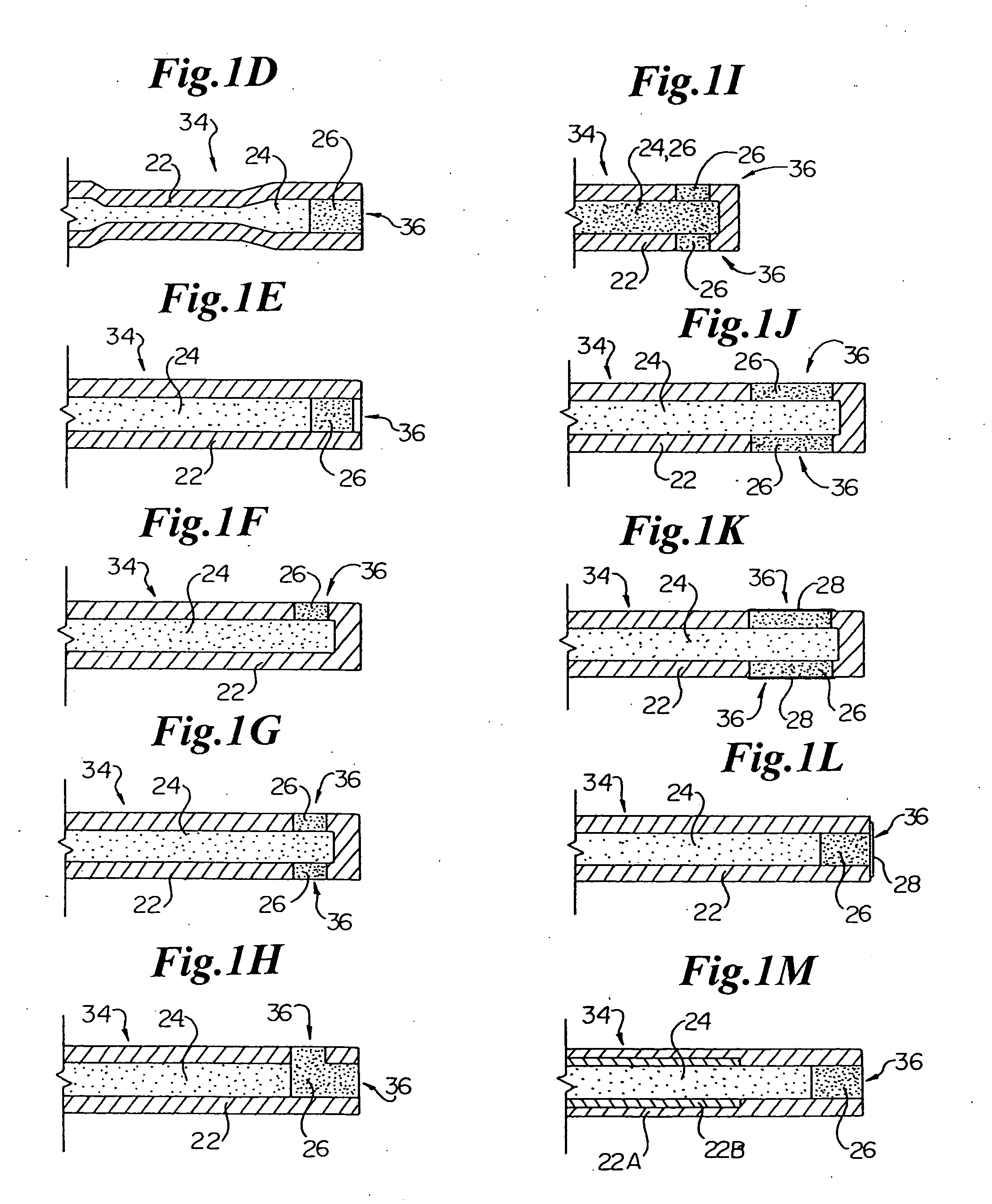

Intravascular Optical Coherence Tomography System with Pressure Monitoring Interface and Accessories

ActiveUS20120238869A1PressureEasy to useDiagnostics using spectroscopyCatheterPhotovoltaic detectorsPhotodetector

An optical coherence tomography system and method with integrated pressure measurement. In one embodiment the system includes an interferometer including: a wavelength swept laser; a source arm in communication with the wavelength swept laser; a reference arm in communication with a reference reflector; a first photodetector having a signal output; a detector arm in communication with the first photodetector, a probe interface; a sample arm in communication with a first optical connector of the probe interface; an acquisition and display system comprising: an A / D converter having a signal input in communication with the first photodetector signal output and a signal output; a processor system in communication with the A / D converter signal output; and a display in communication with the processor system; and a probe comprising a pressure sensor and configured for connection to the first optical connector of the probe interface, wherein the pressure transducer comprises an optical pressure transducer.

Owner:LIGHTLAB IMAGING

Intravascular optical coherence tomography system with pressure monitoring interface and accessories

ActiveUS20110178413A1PressureEasy to useRadiation pyrometryInterferometric spectrometryPhotovoltaic detectorsPhotodetector

An optical coherence tomography system and method with integrated pressure measurement. In one embodiment the system includes an interferometer including: a wavelength swept laser; a source arm in communication with the wavelength swept laser; a reference arm in communication with a reference reflector; a first photodetector having a signal output; a detector arm in communication with the first photodetector, a probe interface; a sample arm in communication with a first optical connector of the probe interface; an acquisition and display system comprising: an A / D converter having a signal input in communication with the first photodetector signal output and a signal output; a processor system in communication with the A / D converter signal output; and a display in communication with the processor system; and a probe comprising a pressure sensor and configured for connection to the first optical connector of the probe interface, wherein the pressure transducer comprises an optical pressure transducer.

Owner:LIGHTLAB IMAGING

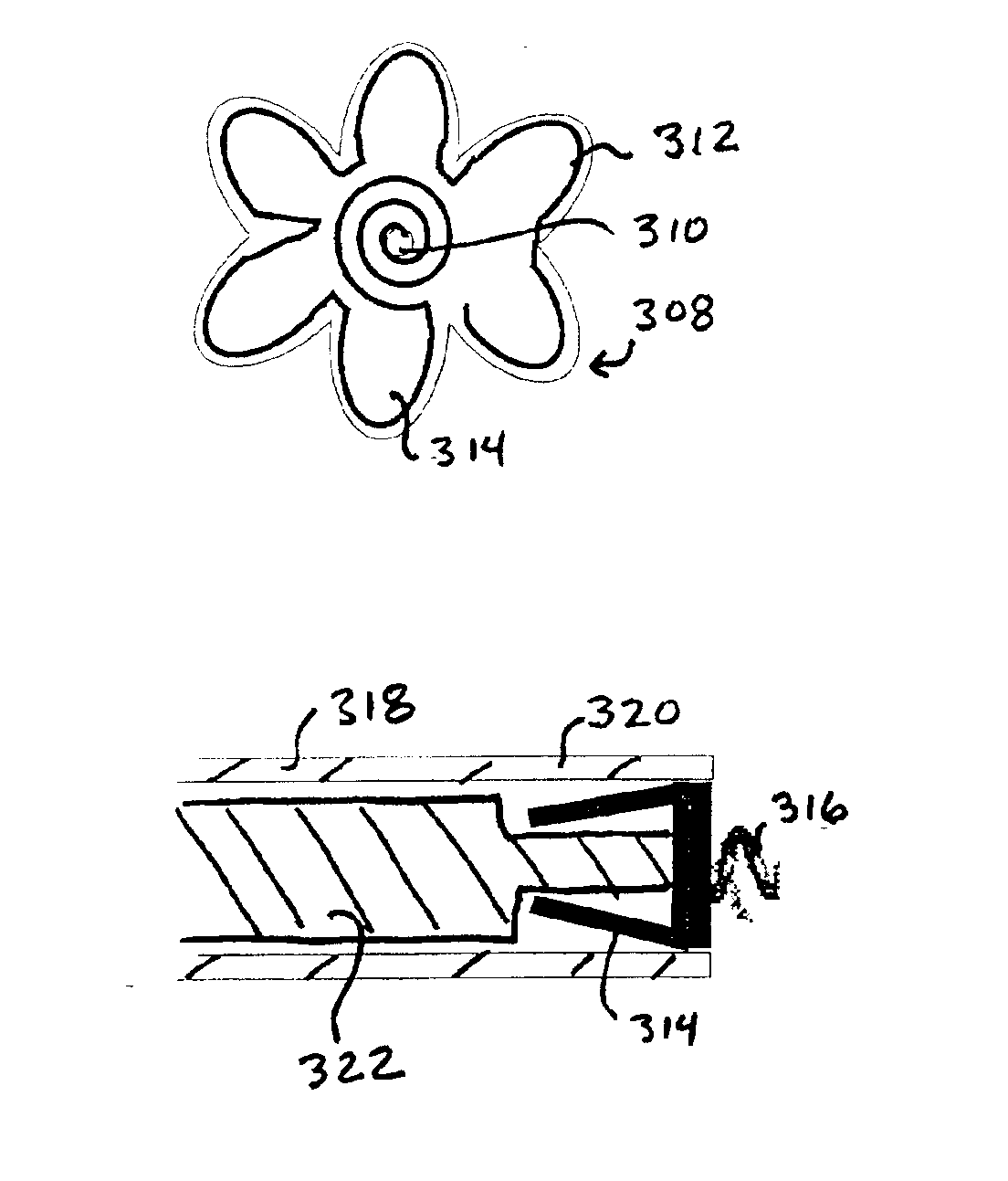

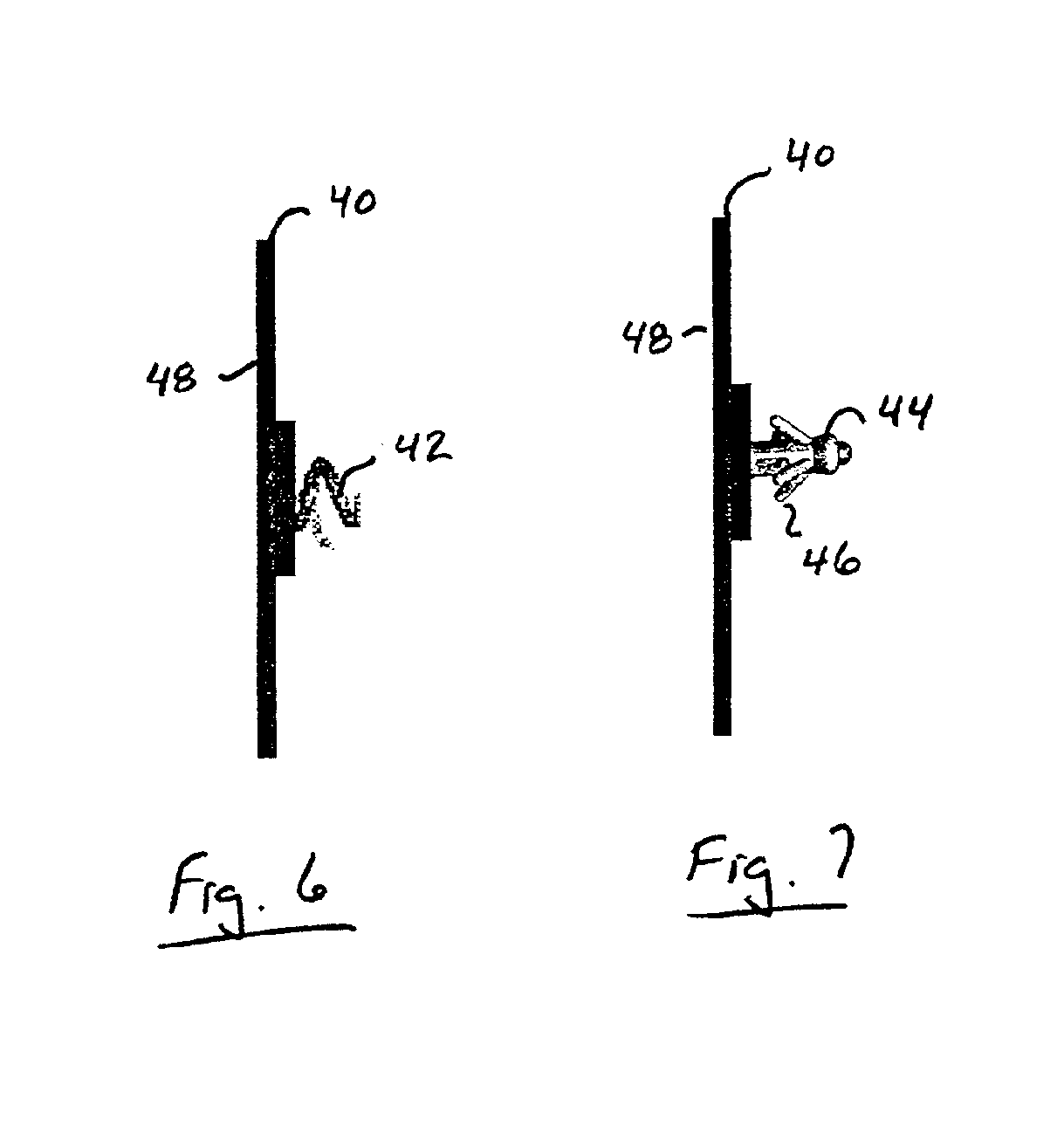

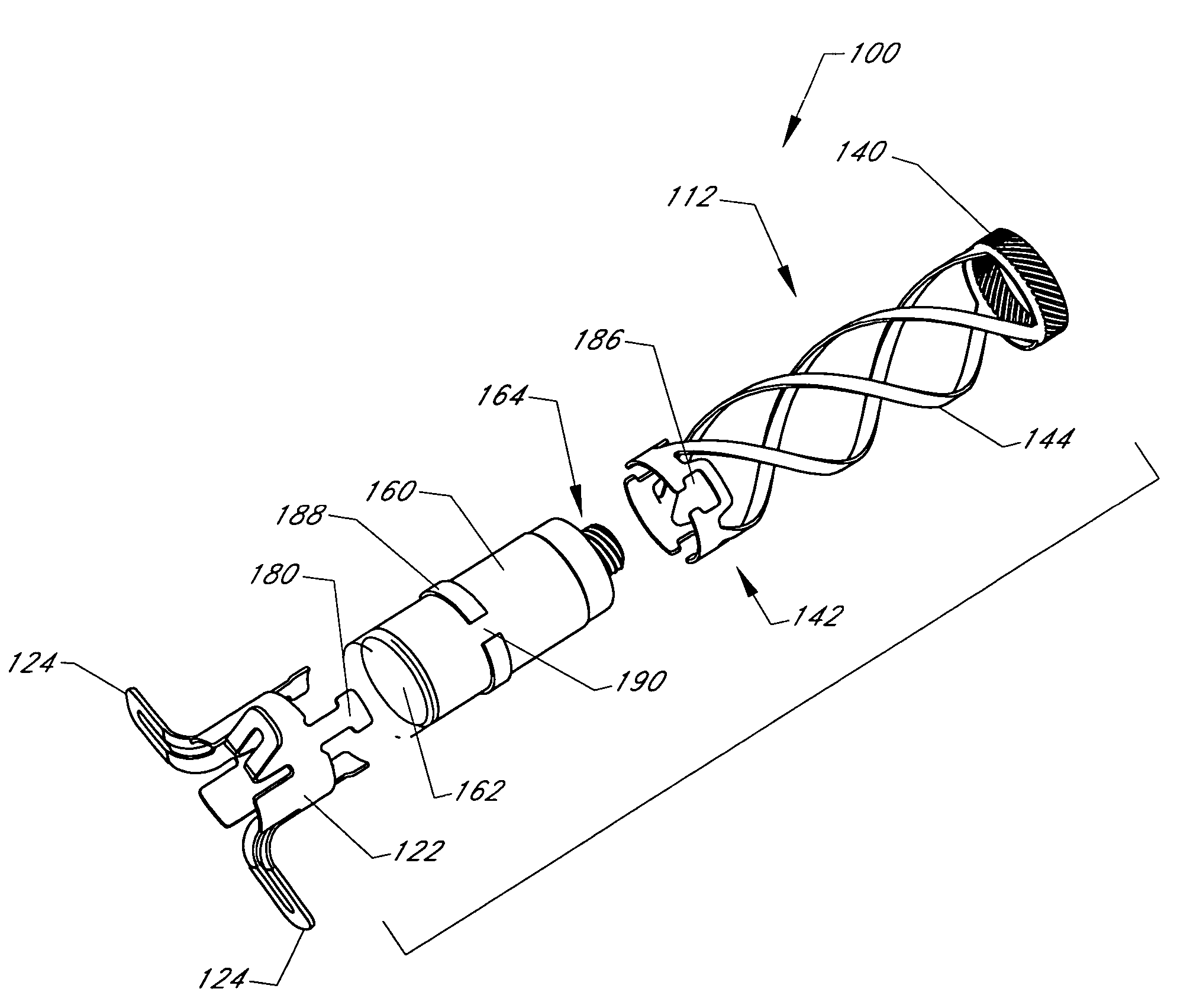

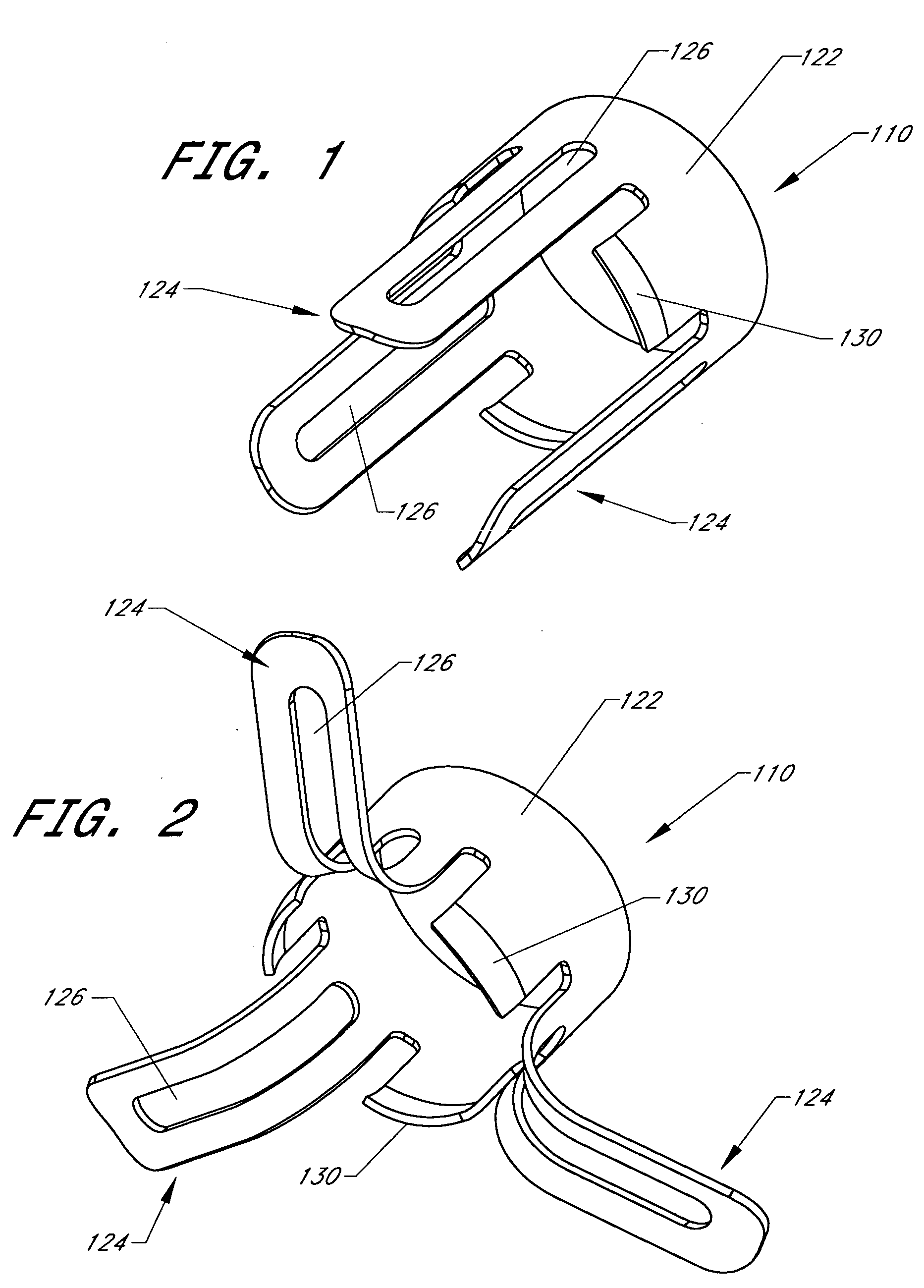

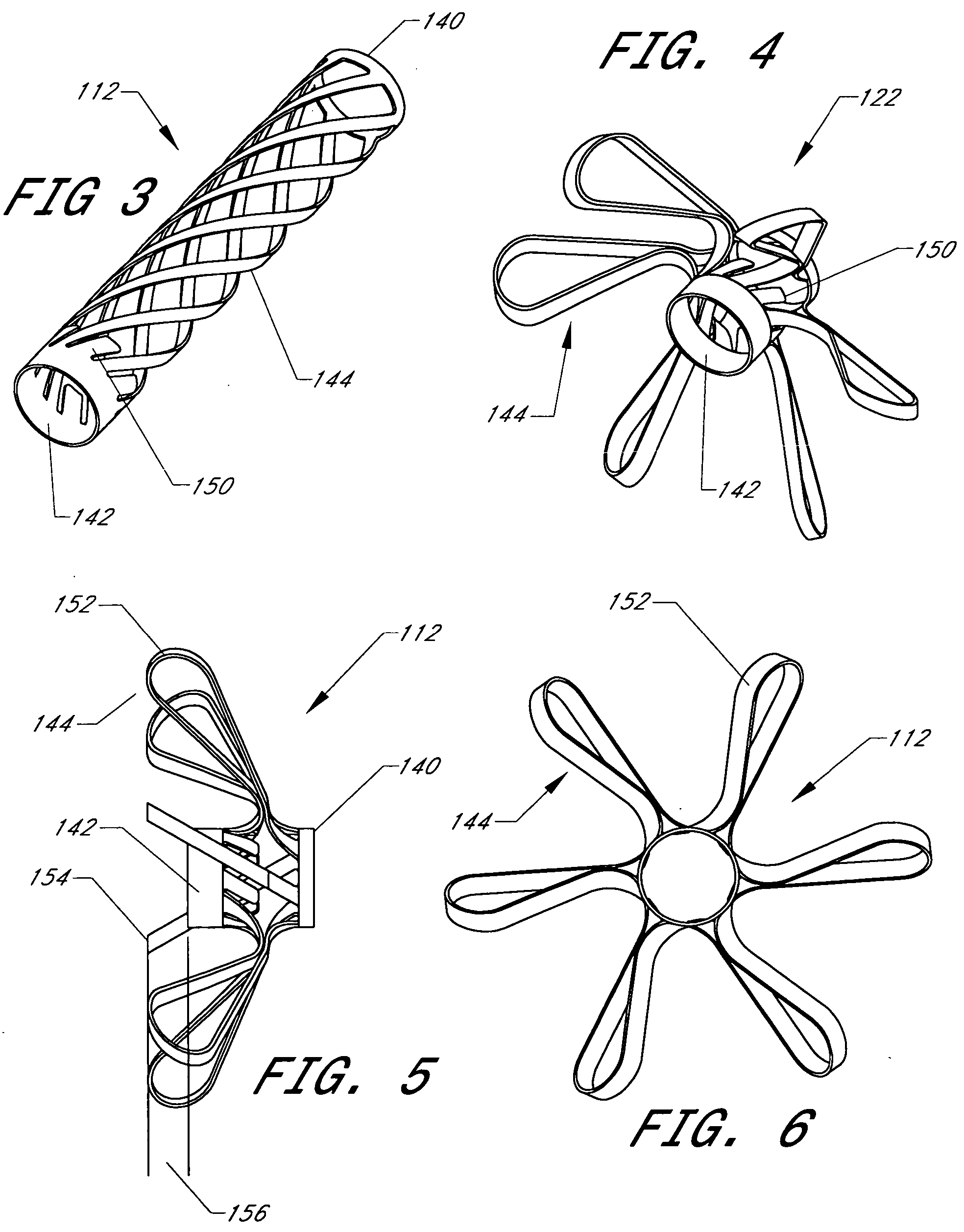

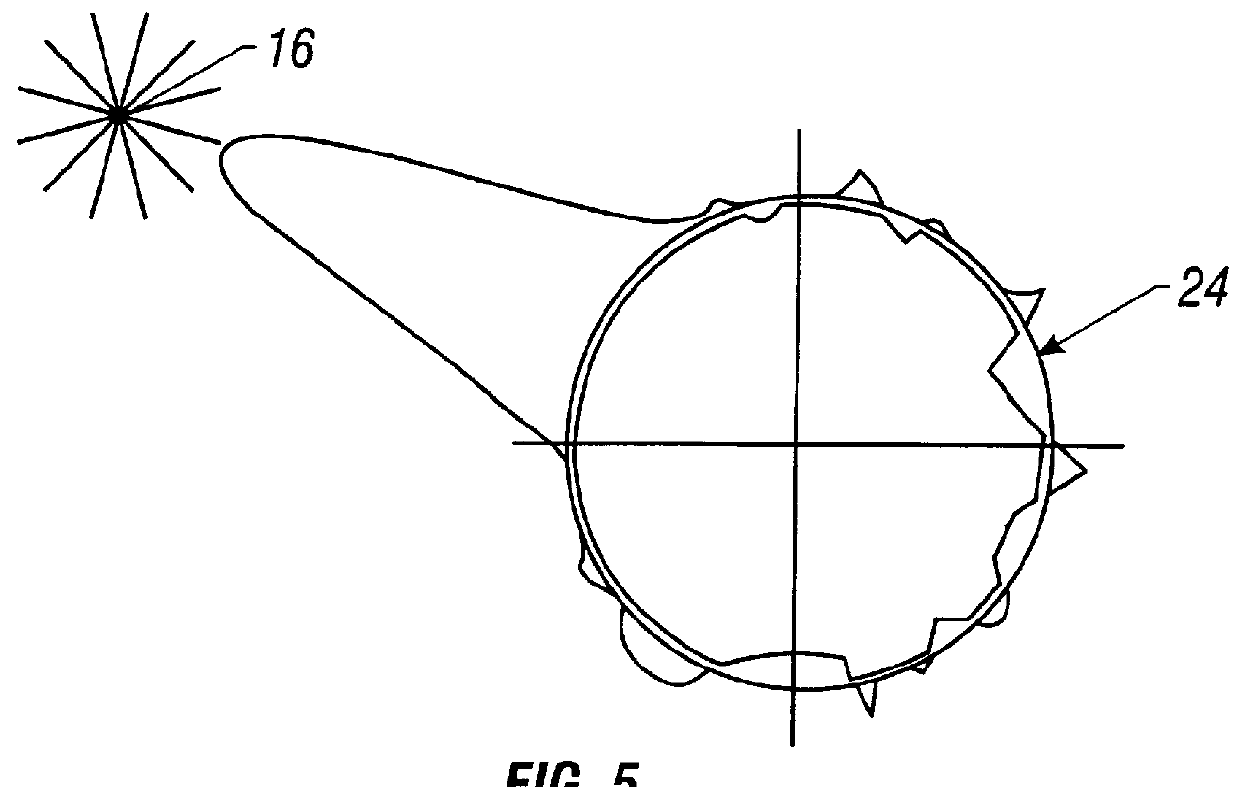

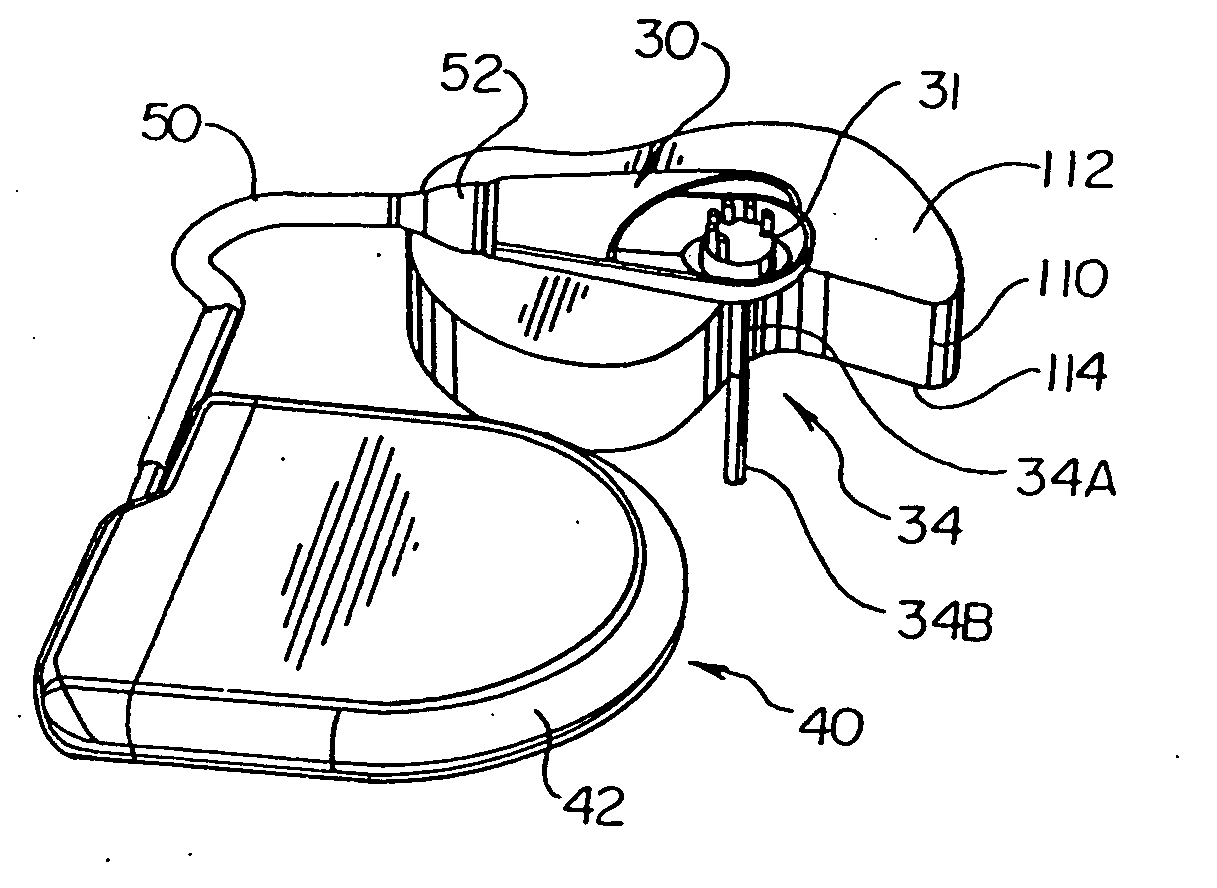

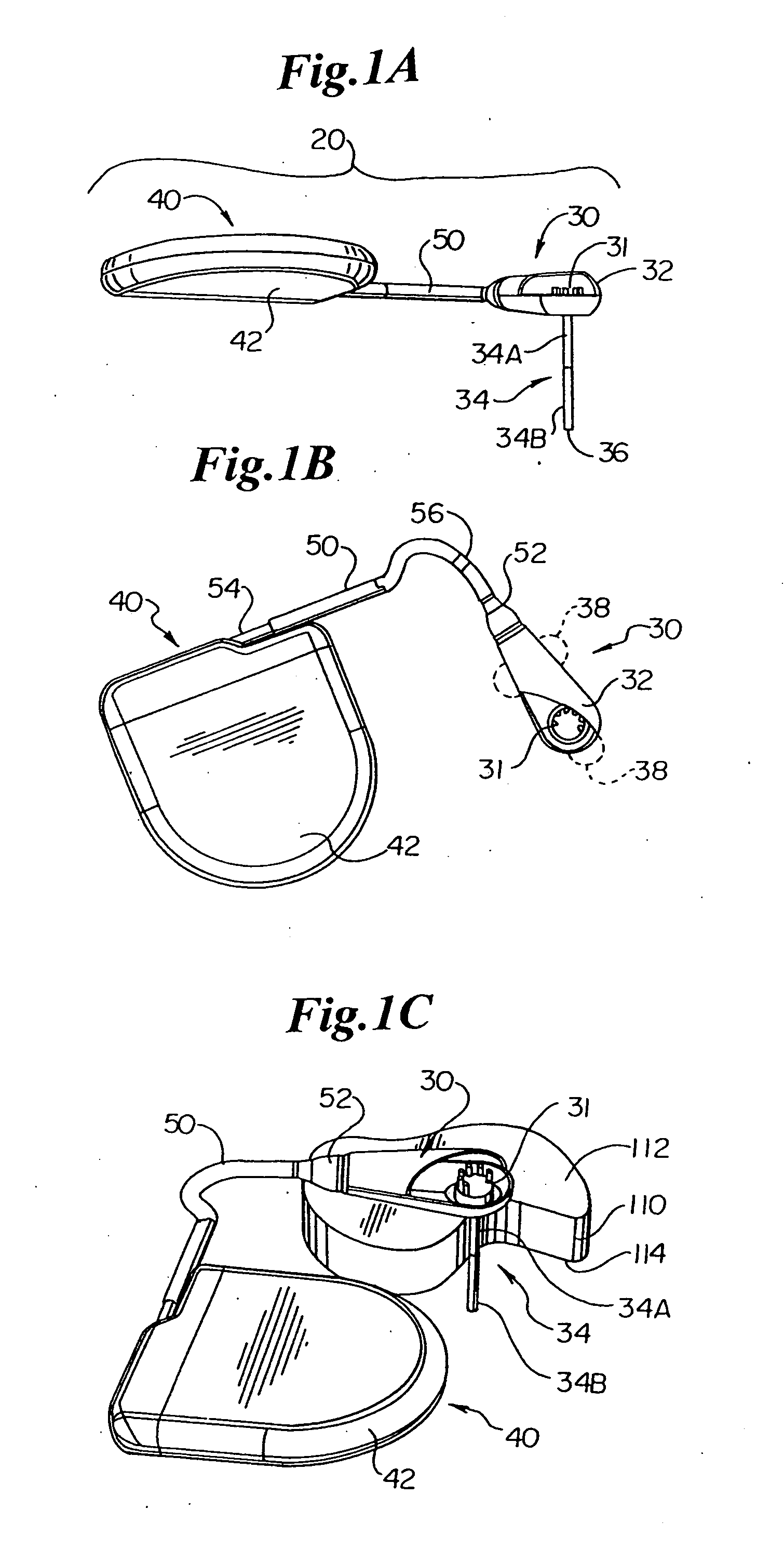

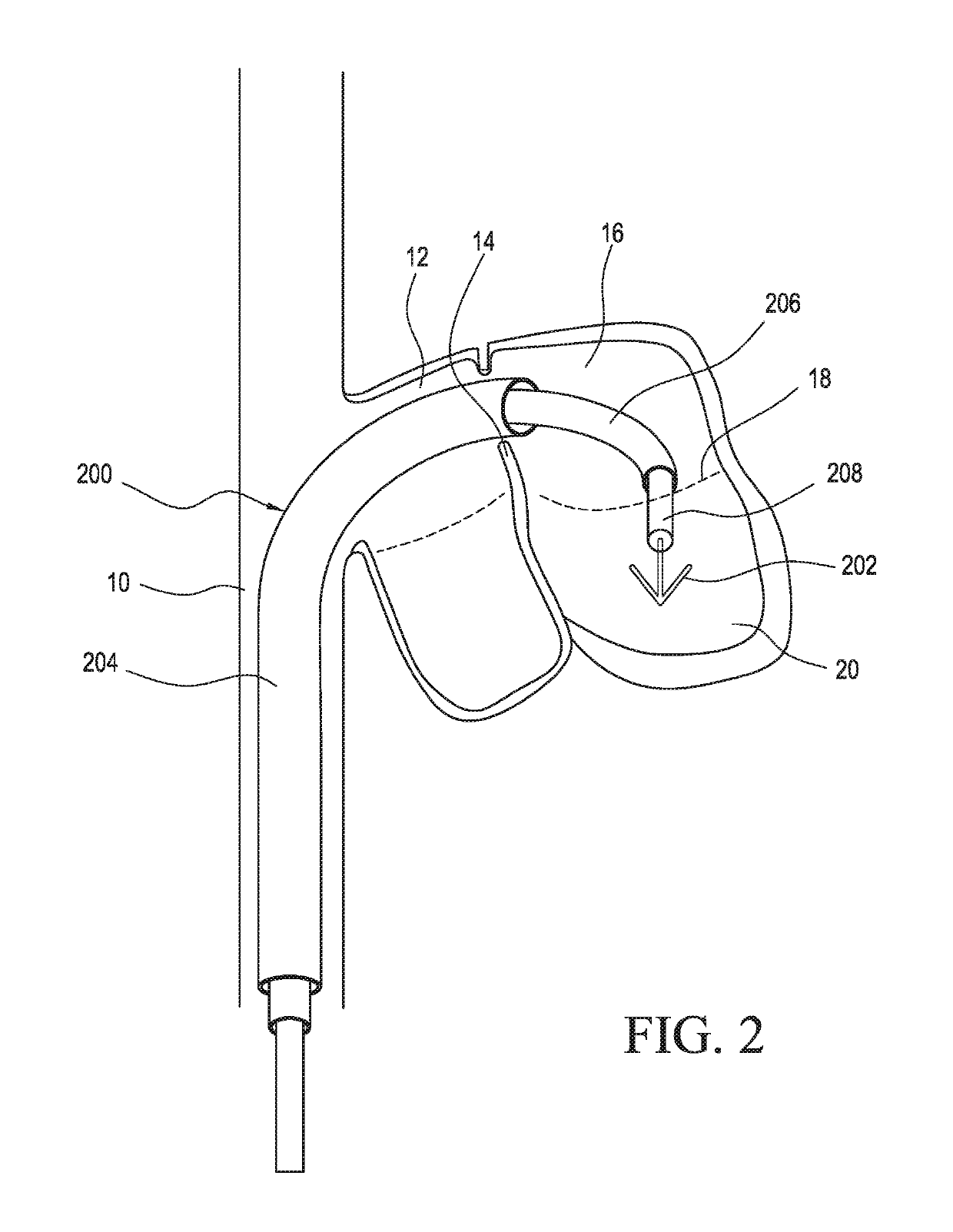

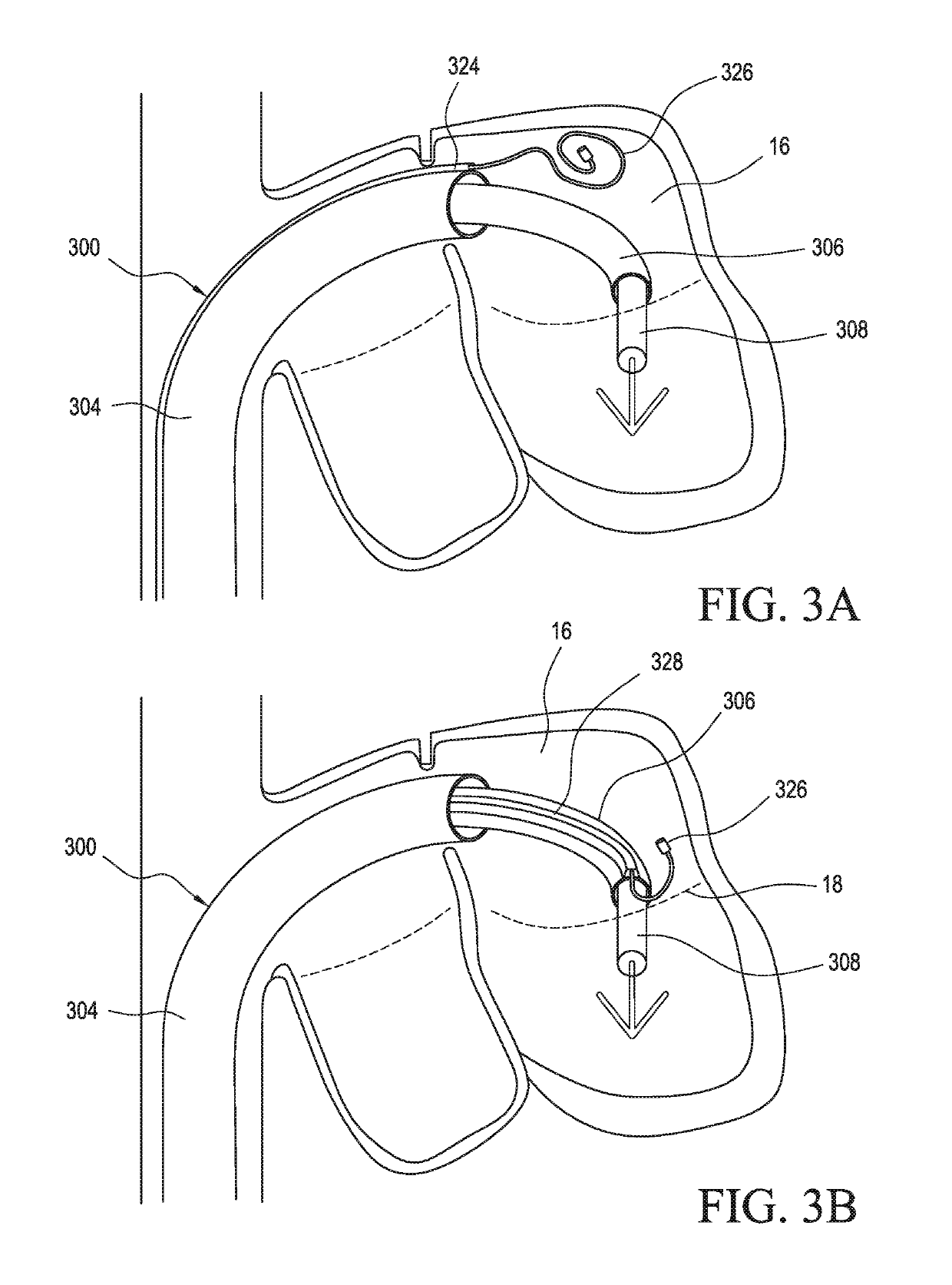

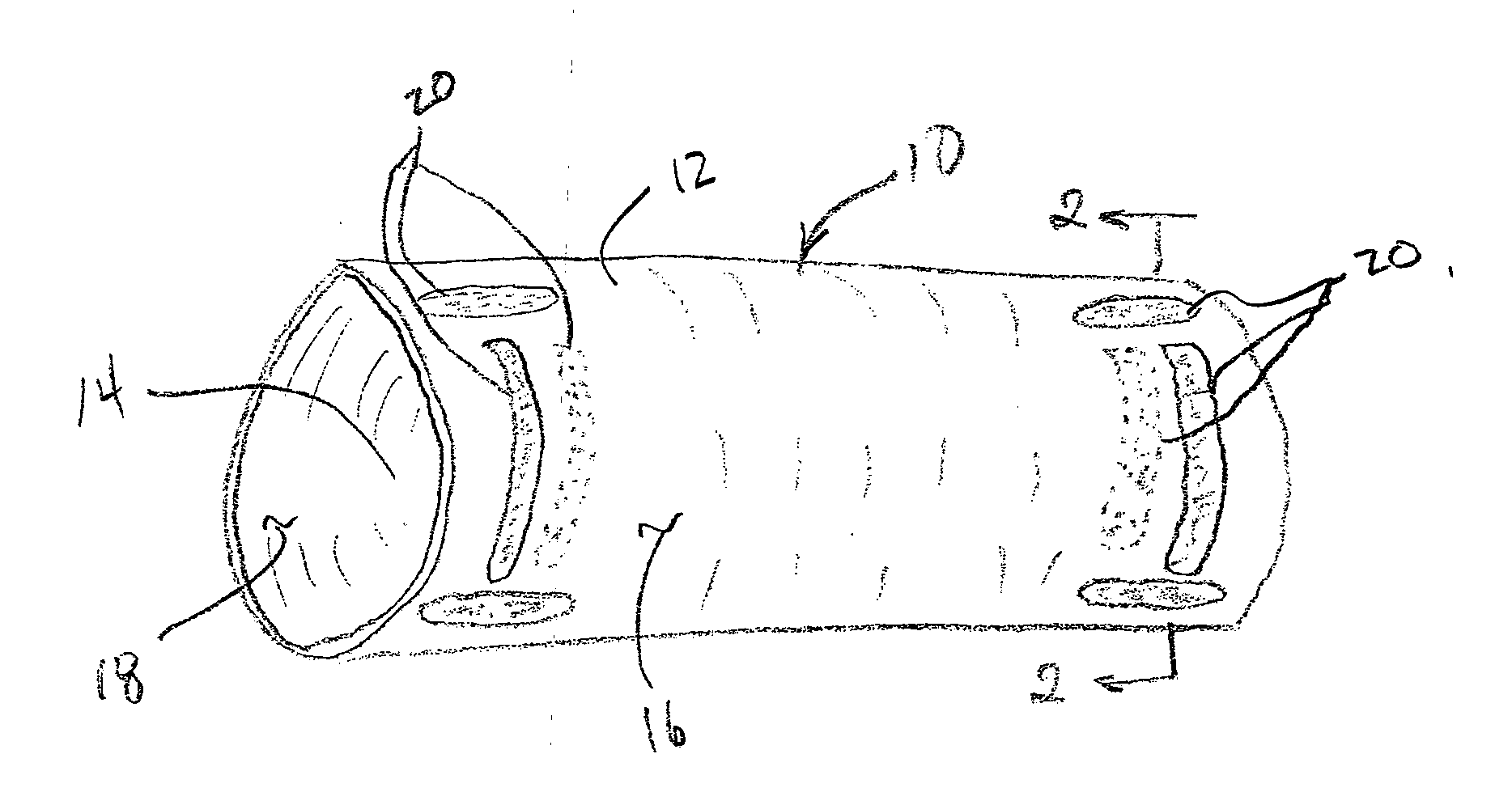

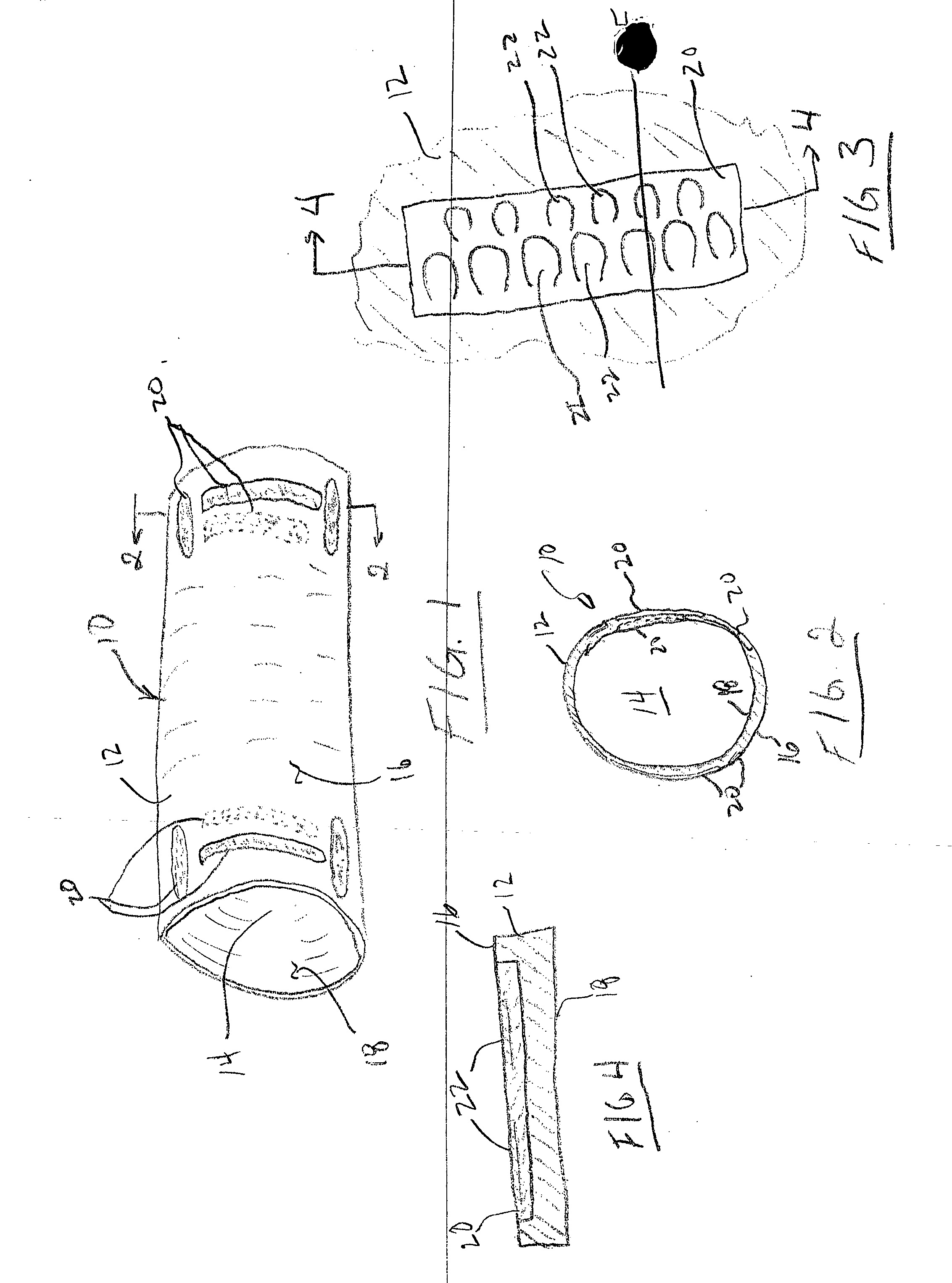

Retrieval devices for anchored cardiovascular sensors

ActiveUS20070106328A1Efficient deploymentPharmaceutical delivery mechanismStaplesOrgan wallMeasurement device

An anchoring device and a delivery method thereof can effectively provide a means for securing an implant to a wall of an internal organ within a patient in a variety of clinical applications. In one embodiment, an anchoring device used to retain a cardiac pressure measurement device is provided. The device is implanted in the body by deforming it to a small cross section profile, sliding it through a low profile delivery device and ejecting from the delivery device at a targeted site. The anchoring mechanism, when ejected from the delivery device, reverts back to pre-formed configuration and engages opposite sides of an organ wall, thereby anchoring the implant in the organ wall.

Owner:PACESETTER INC

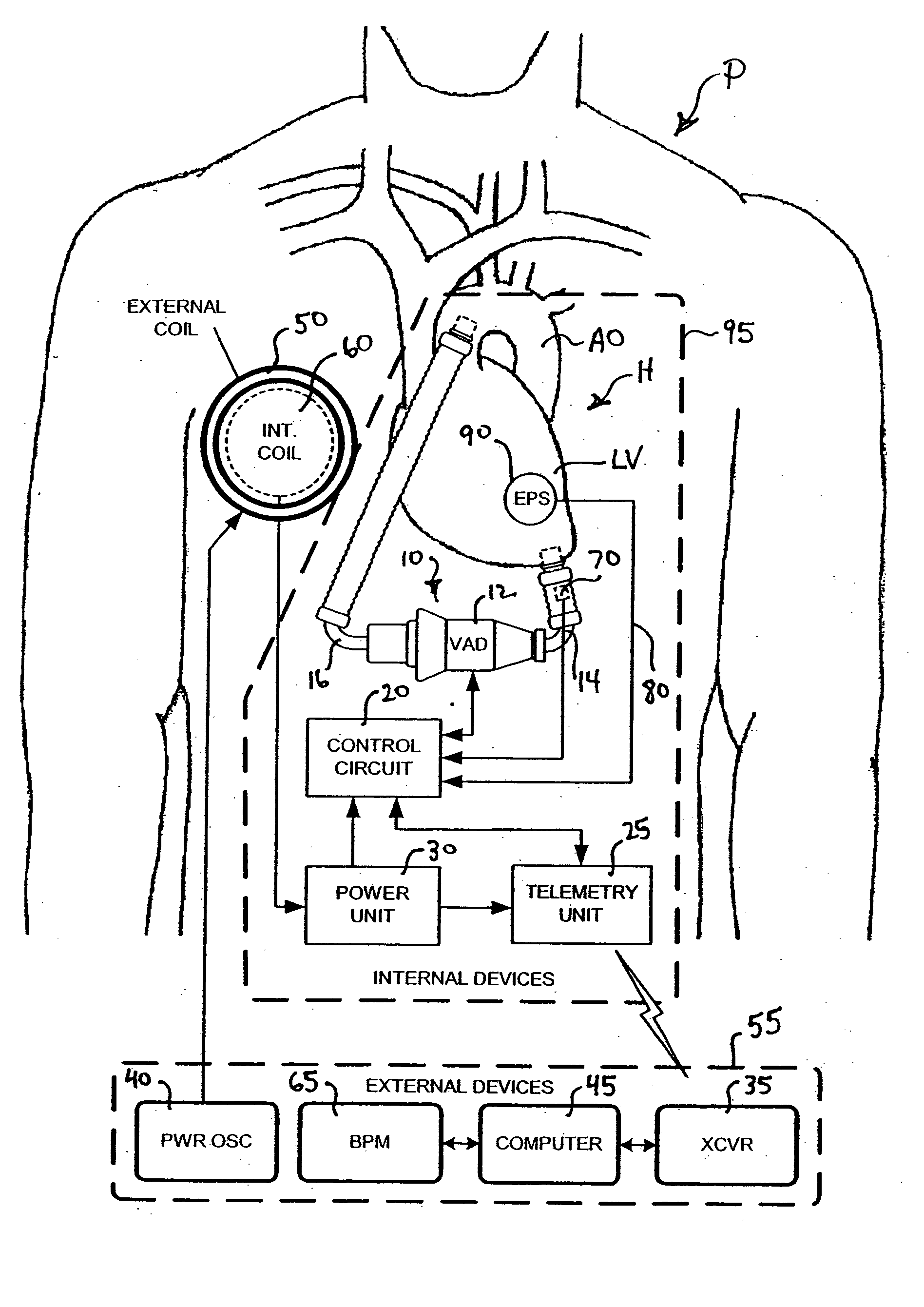

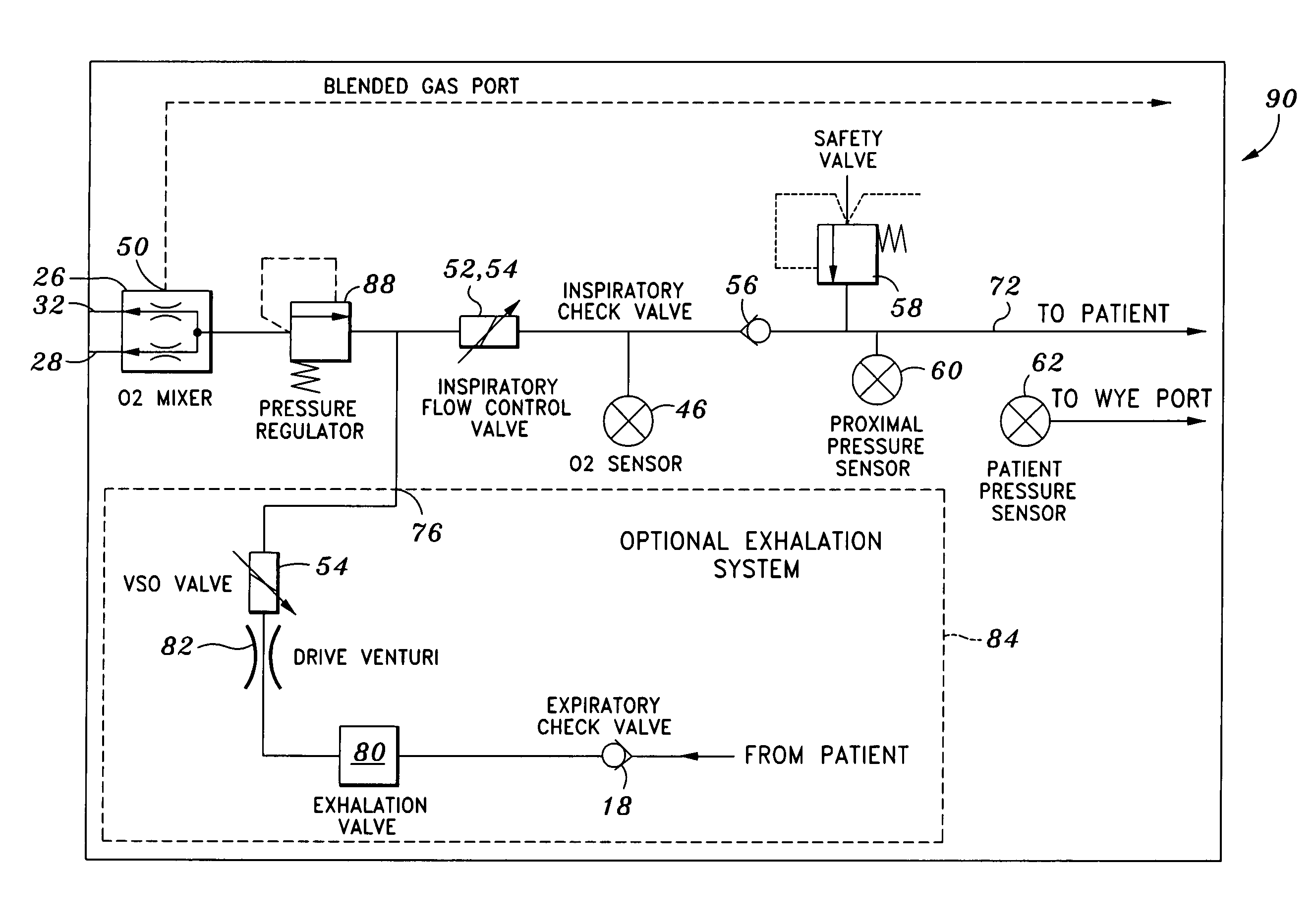

Feedback control of ventricular assist devices

InactiveUS20050107658A1Reliable and accurate pressure feedbackGood curative effectControl devicesBlood pumpsVentricular assistancePhysical therapy

Various devices, systems and methods for providing effective, long term and reliable use of pressure feedback in VADs. Exemplary embodiments are described which provide for direct LV pressure measurement, non-invasive calibration techniques to detect ventricular collapse and recalibrate the feedback mechanism, improved pressure sensor designs with reduced drift, and barometric pressure correction schemes. These devices and methods may be used alone or in combination with each other, and may also be combined with other feedback mechanisms.

Owner:TRANSOMA MEDICAL

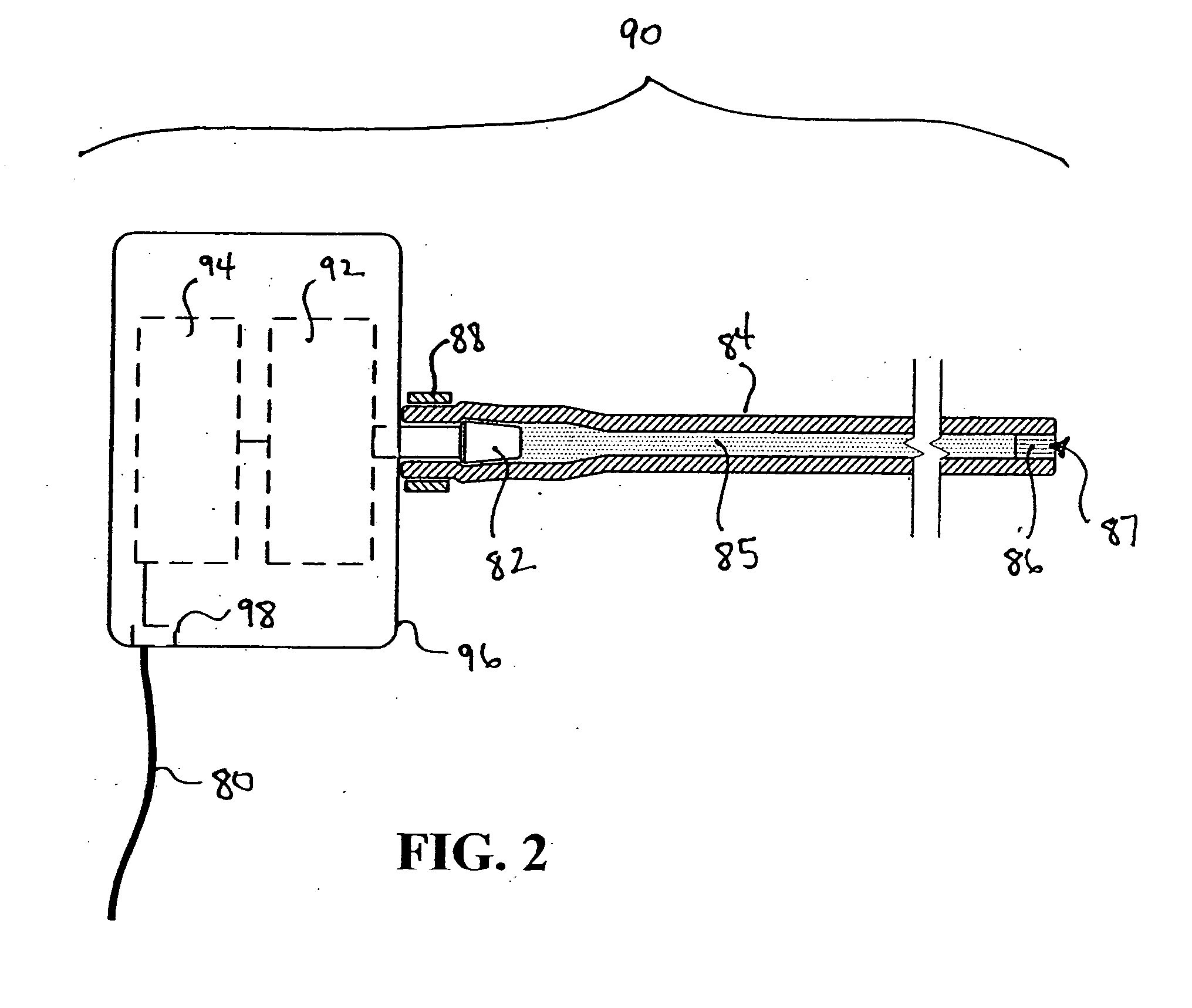

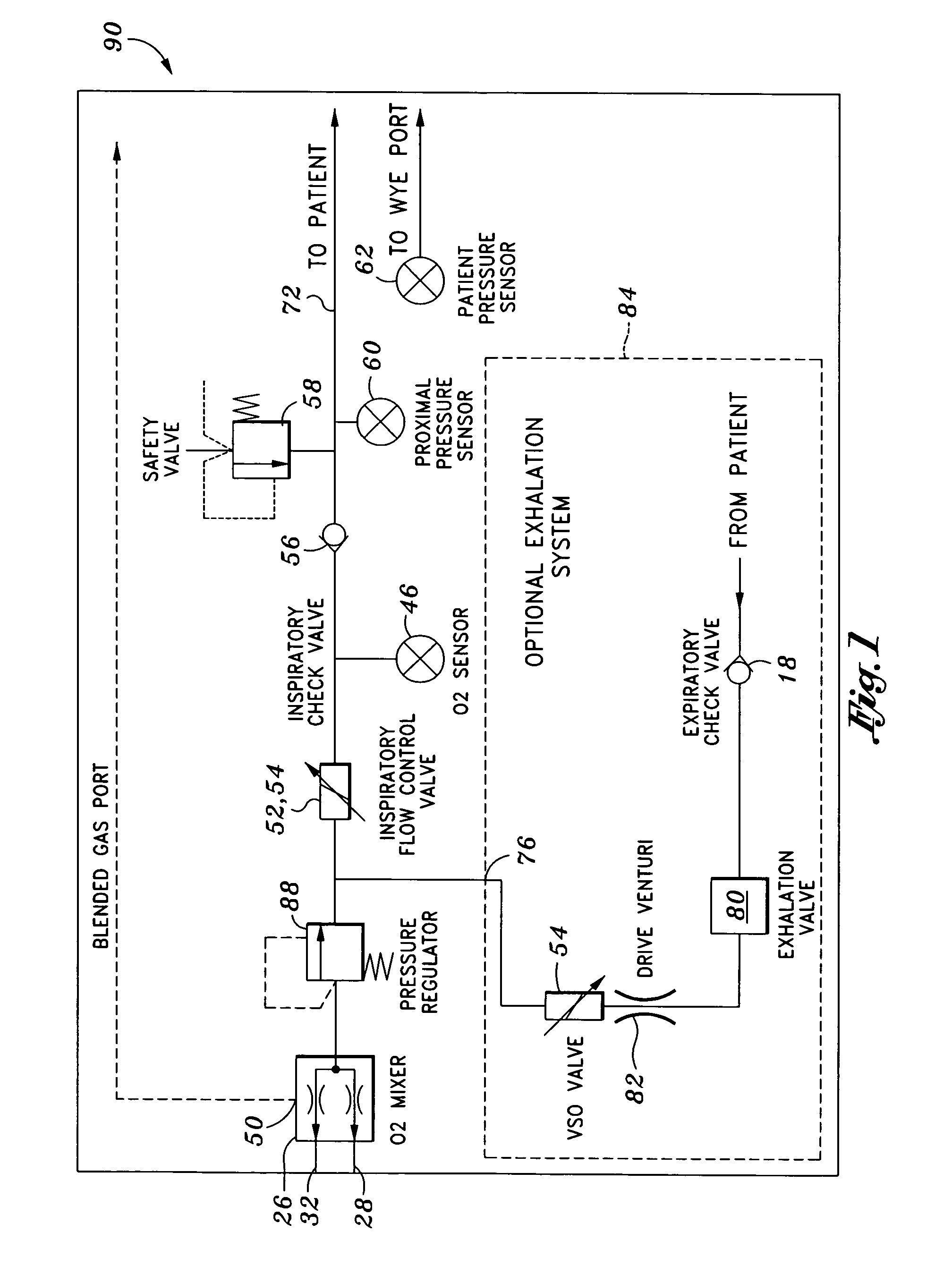

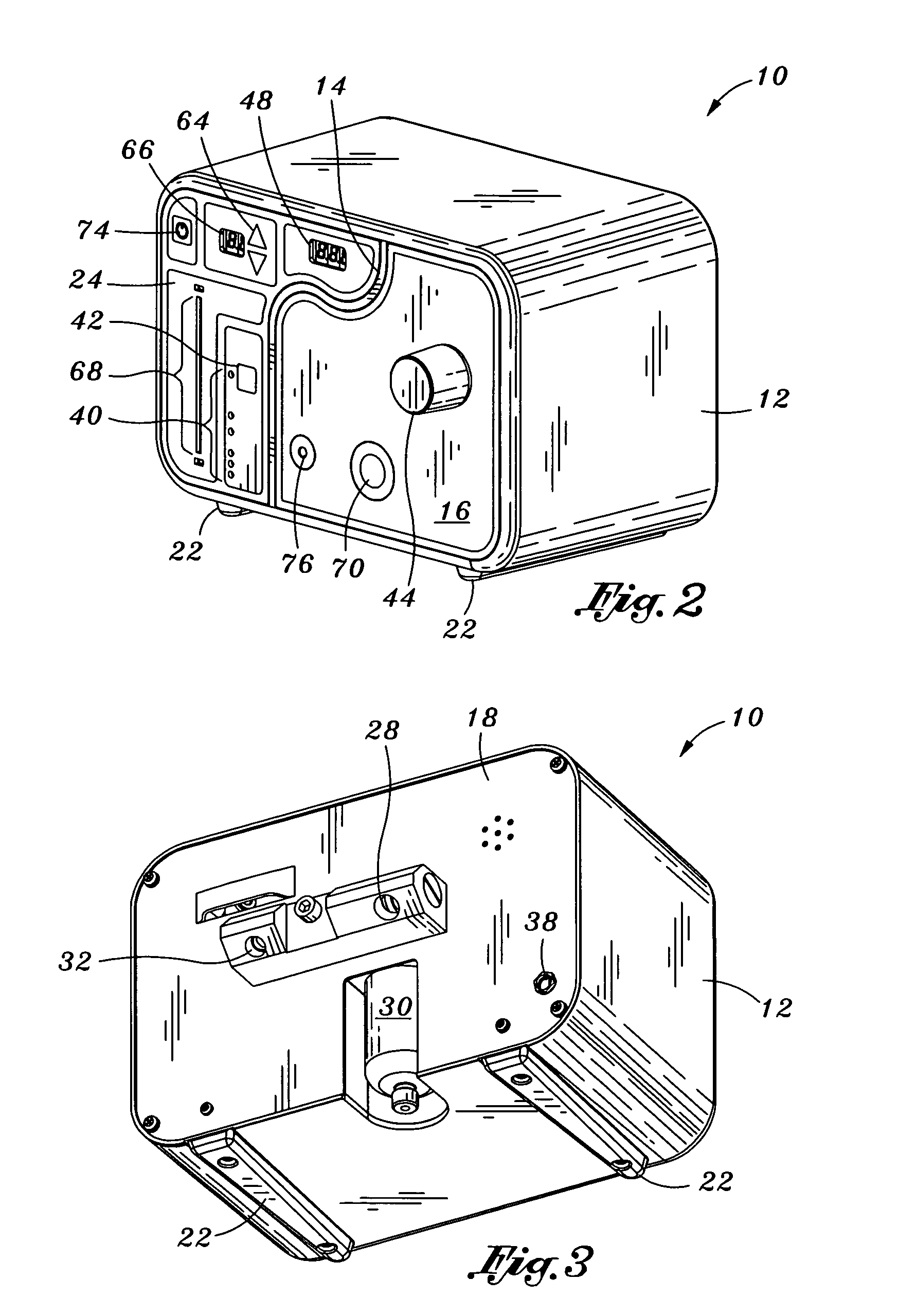

Hardware configuration for pressure driver

ActiveUS7509957B2Reduce oxygen concentrationImprove ventilationRespiratorsOperating means/releasing devices for valvesOxygen sensorControl system

Owner:VYAIRE MEDICAL 211 INC

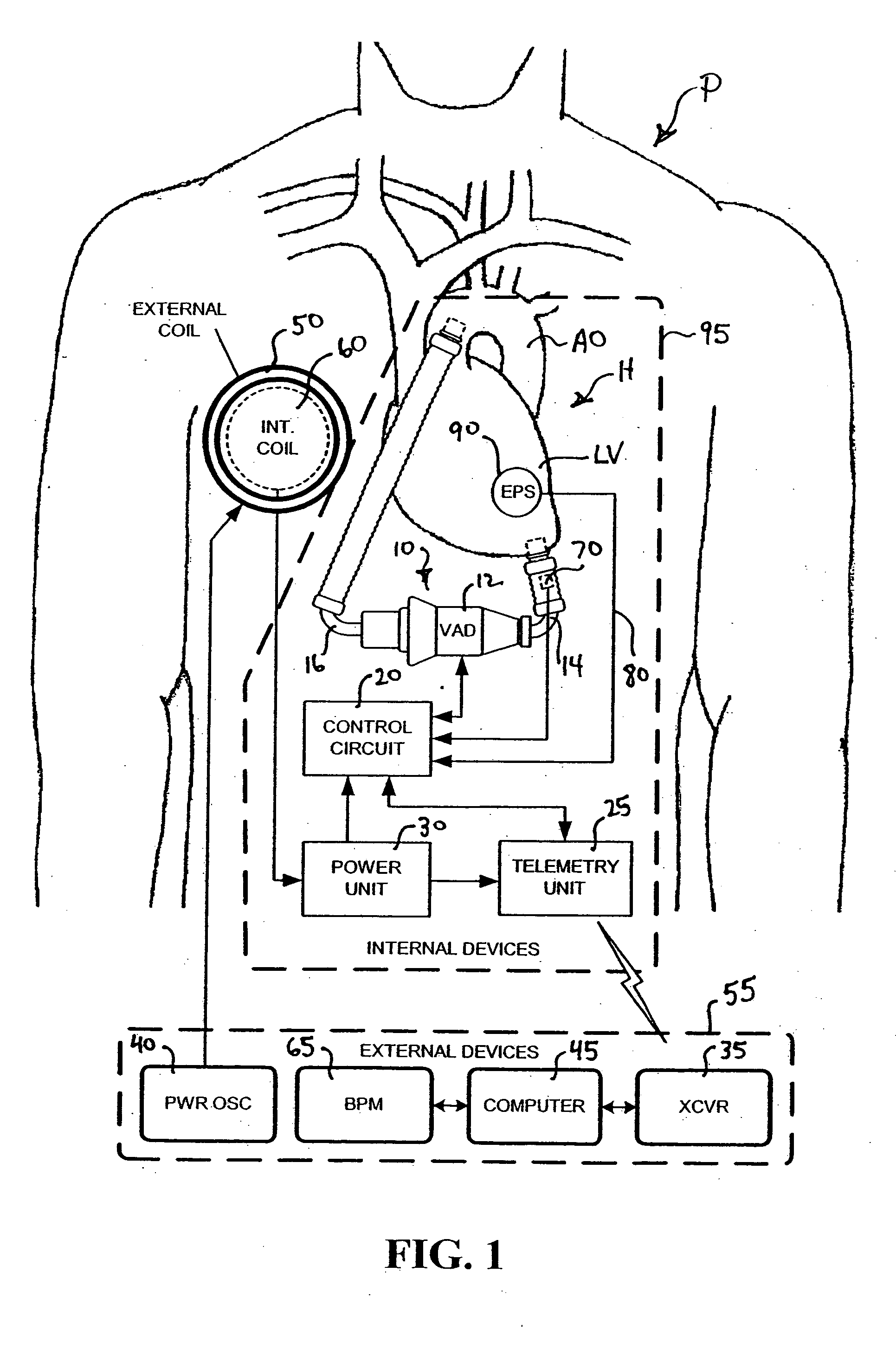

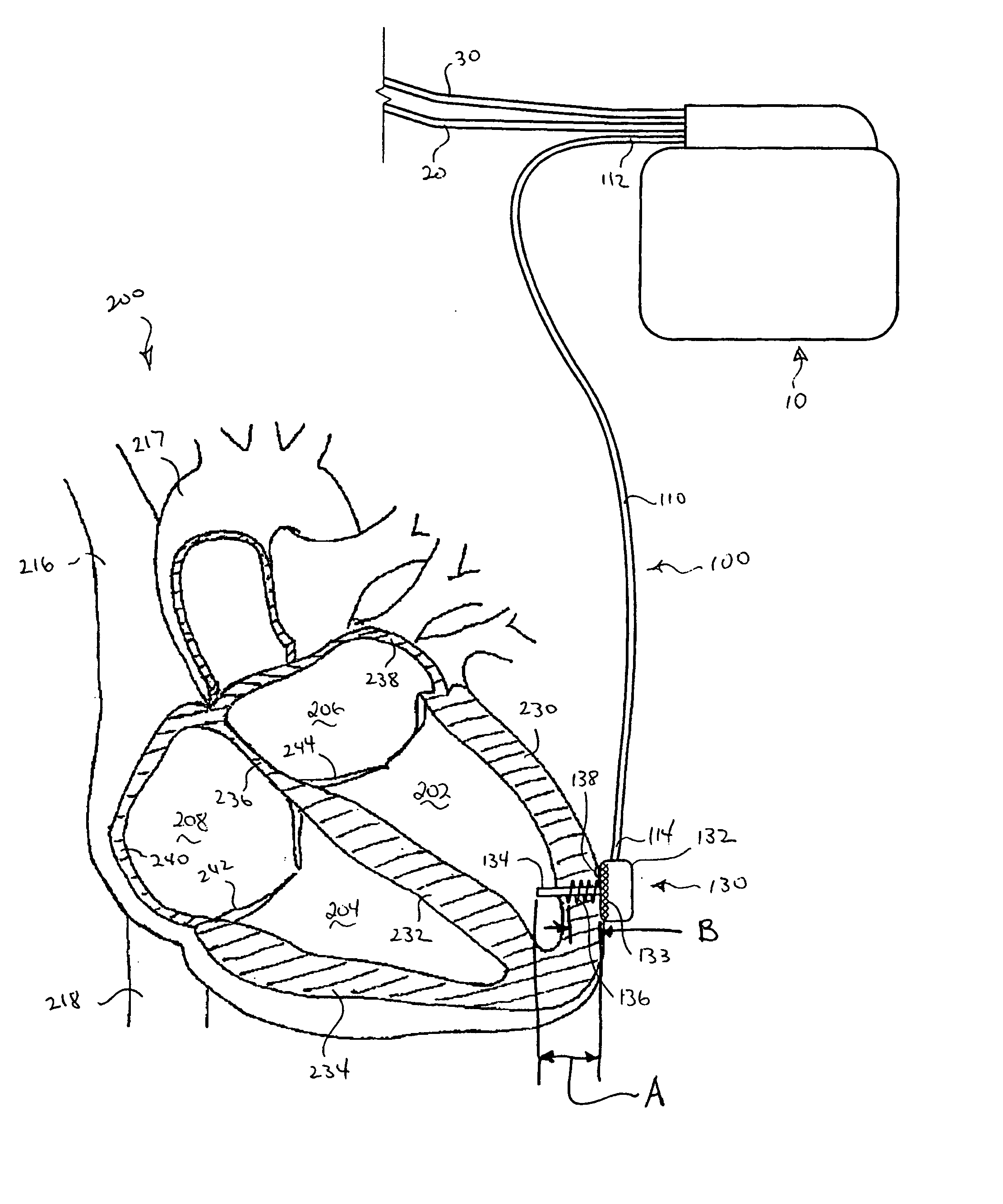

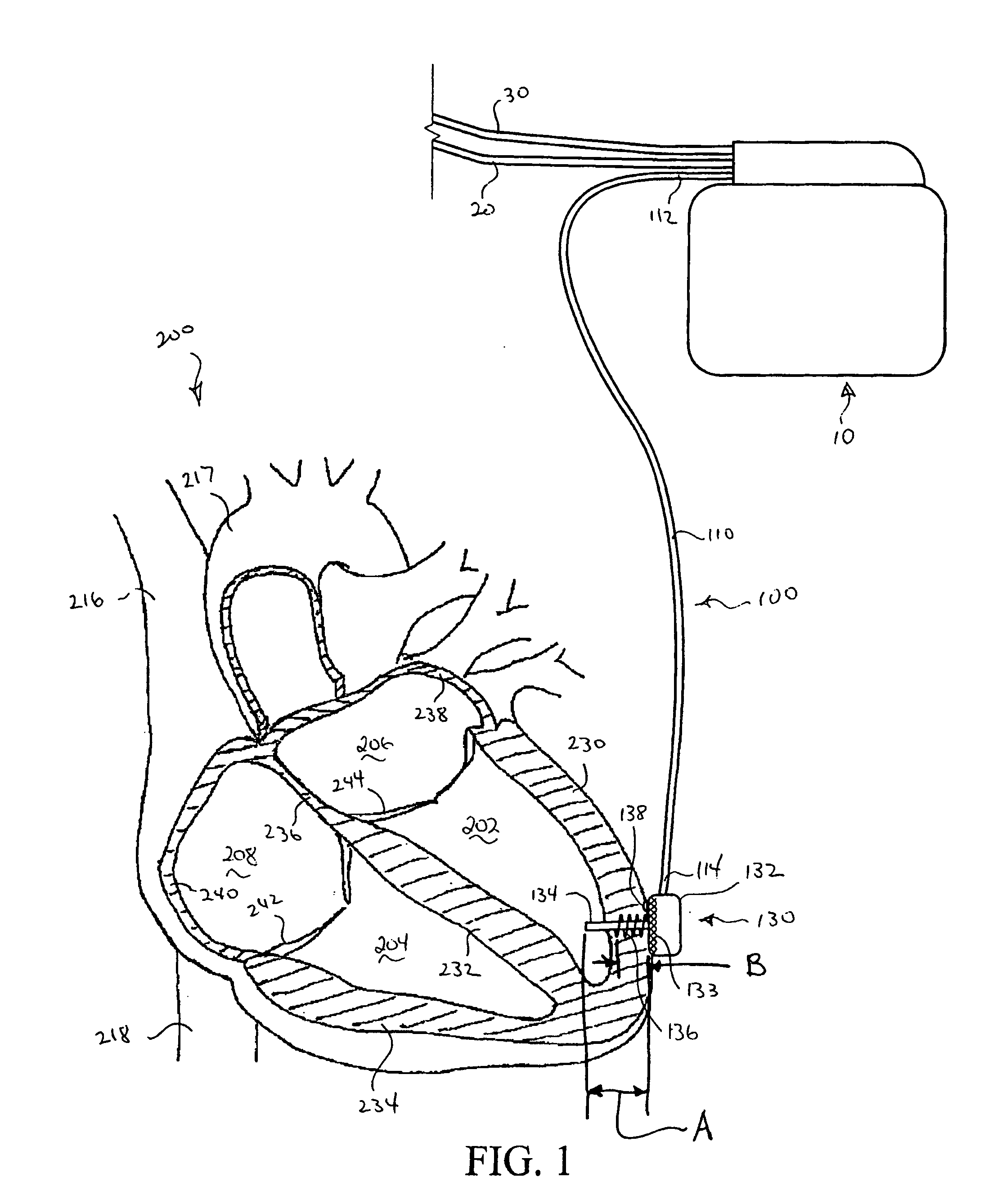

Implantable pressure sensor with pacing capability

Devices and methods for left ventricular or biventricular pacing plus left ventricular pressure measurement. For example, a pacing lead having a combined electrode and pressure sensor assembly may be used for left ventricular (LV) pacing and pressure measurement. The assembly may include one or more electrodes, a pressure sensor, and a pressure transmission catheter. Such a pacing lead is particularly suitable for biventricular pacing and may be incorporated into a cardiac resynchronization therapy (CRT) system, for example.

Owner:TRANSOMA MEDICAL

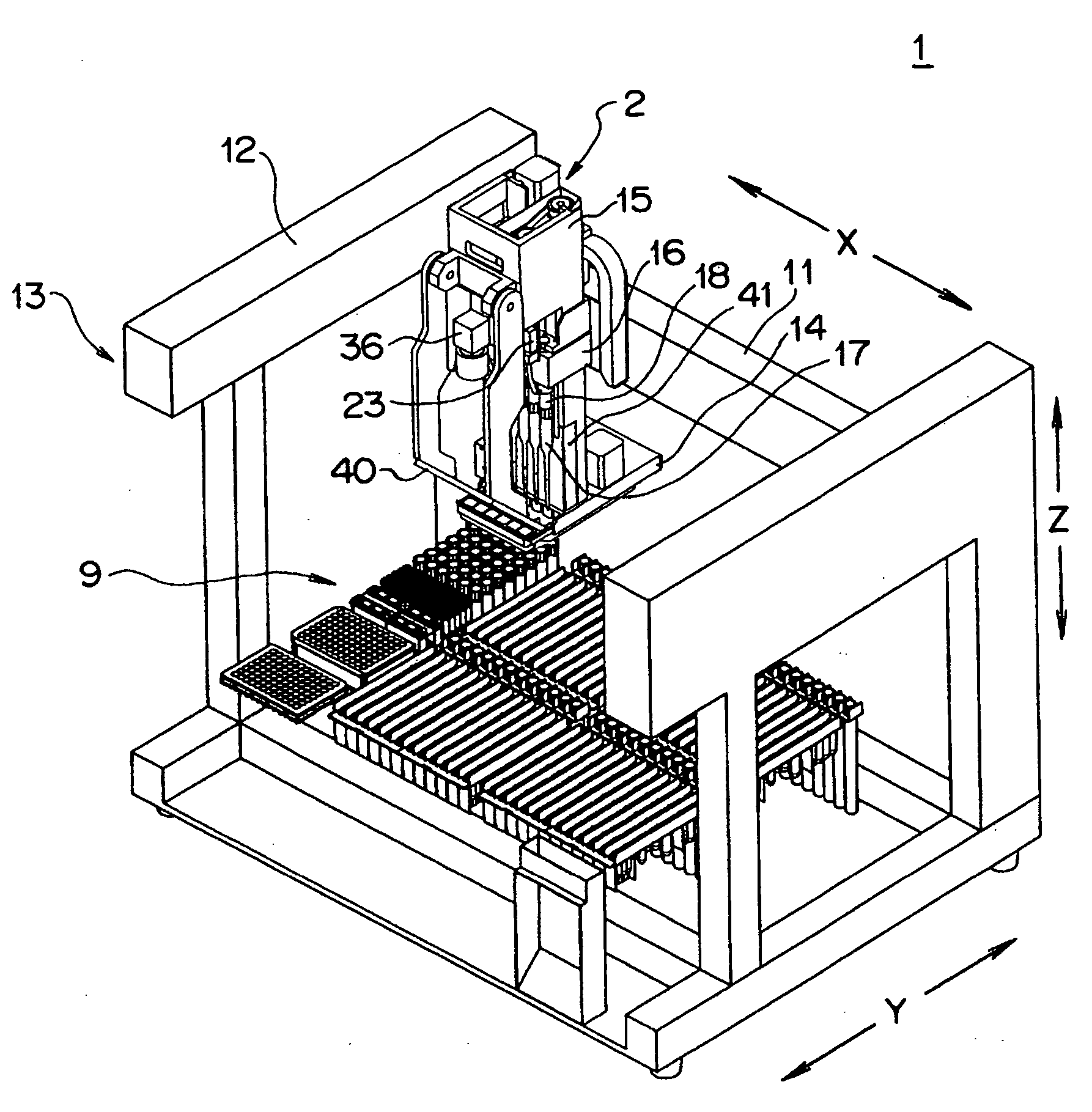

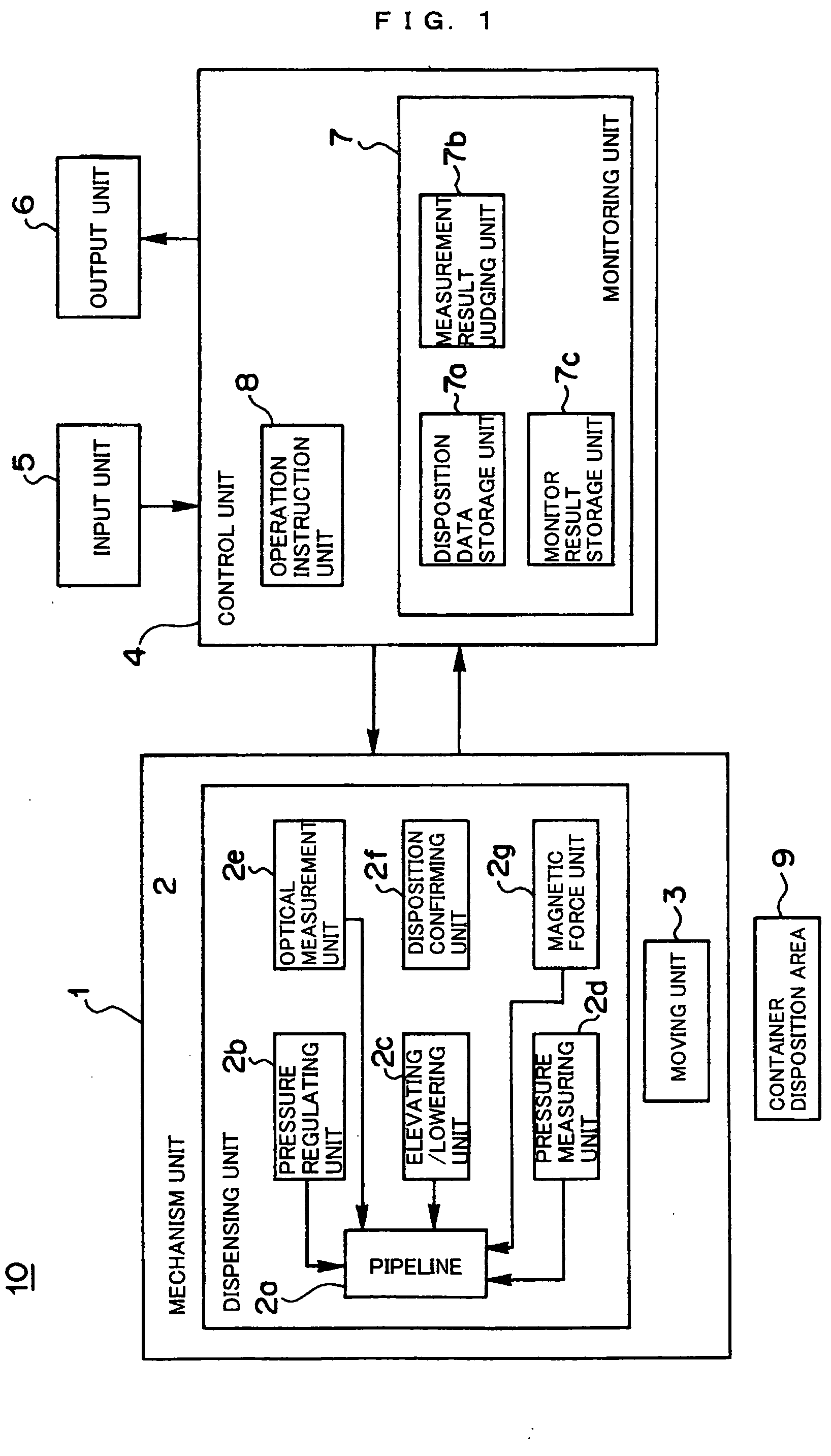

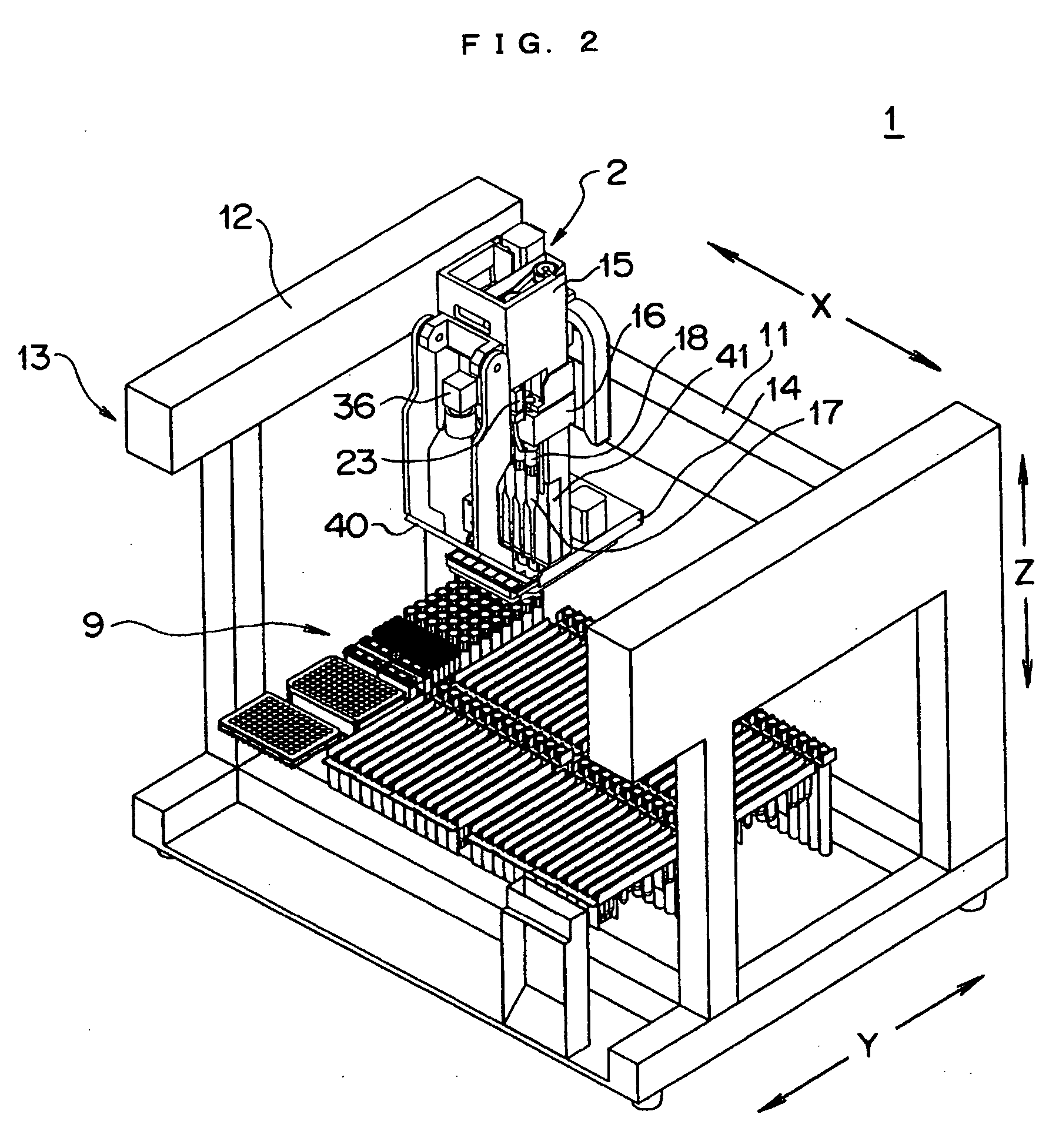

Monitoring function-equipped dispensing system and method of monitoring dispensing device

InactiveUS20060133965A1Ensure correct executionEfficient executionAnalysis using chemical indicatorsLaboratory glasswaresOptical measurementsMonitoring features

A monitoring function-equipped dispensing system and a method of monitoring the dispensing system wherein conditions in a pipeline can be identified accurately and precisely by not only optically measuring conditions in the pipeline, but performing other measurements reinforcing the former. The system comprises: one or more translucent or semi-translucent pipelines; one or more pressure regulating units which respectively regulate the pressures in the pipelines; an elevating / lowering unit which enables the pipelines to be elevated / lowered; a pressure measuring unit which measures the pressures in the respective pipelines when operation instructions are given to the pressure regulating unit; an optical measurement unit which optically measures the conditions of the pipelines above the container disposition area, when operations based on operation instructions including operation instructions to the pressure regulating unit are completed; and a monitoring unit which judges the conditions in the pipelines based on the operation instructions and measurement results of the pressure measuring unit and the optical measurement unit so as to obtain monitoring results that associate the judged results with respective pipelines and the operation instructions.

Owner:UNIVERSAL BIO RESEARCH CO LTD

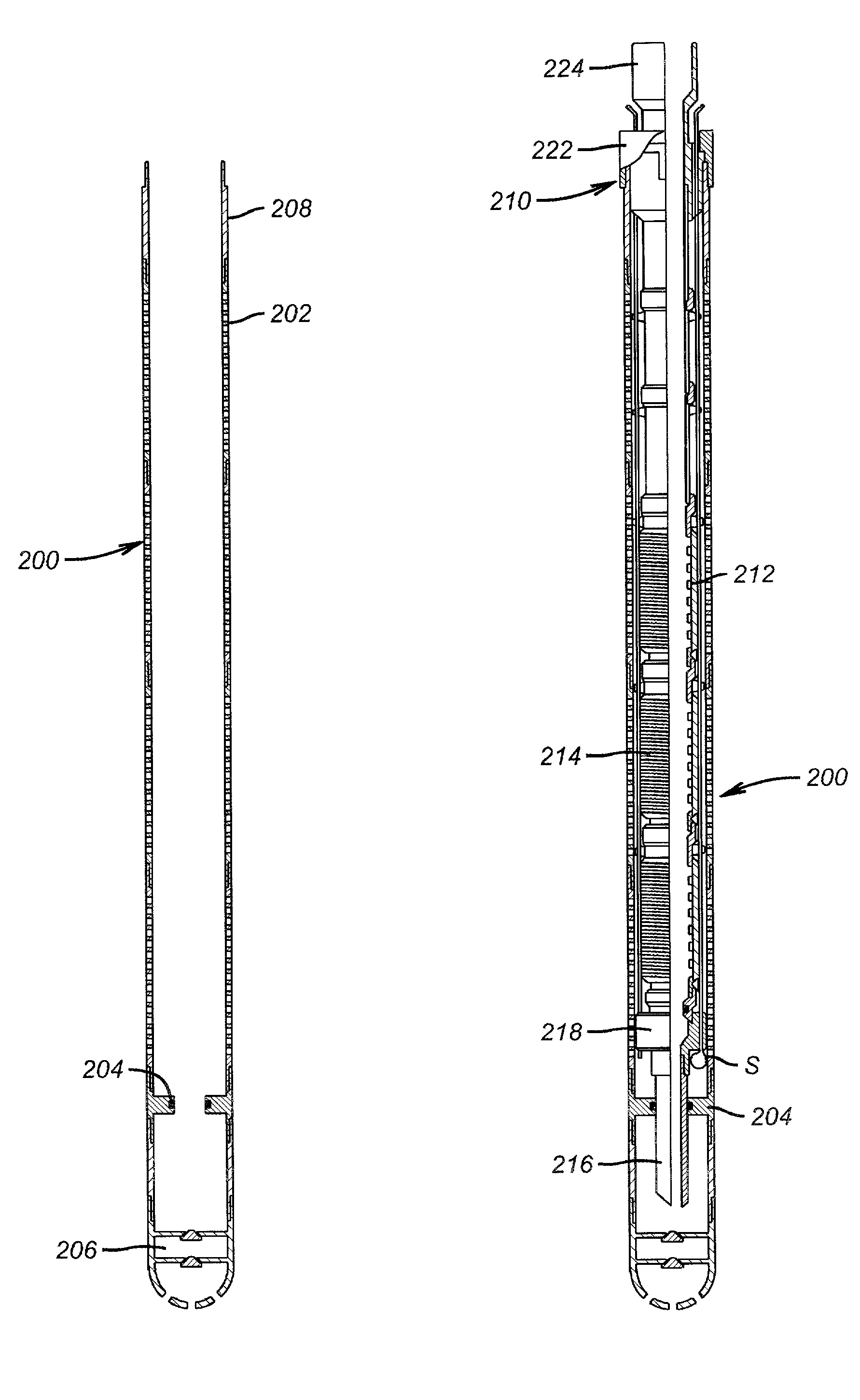

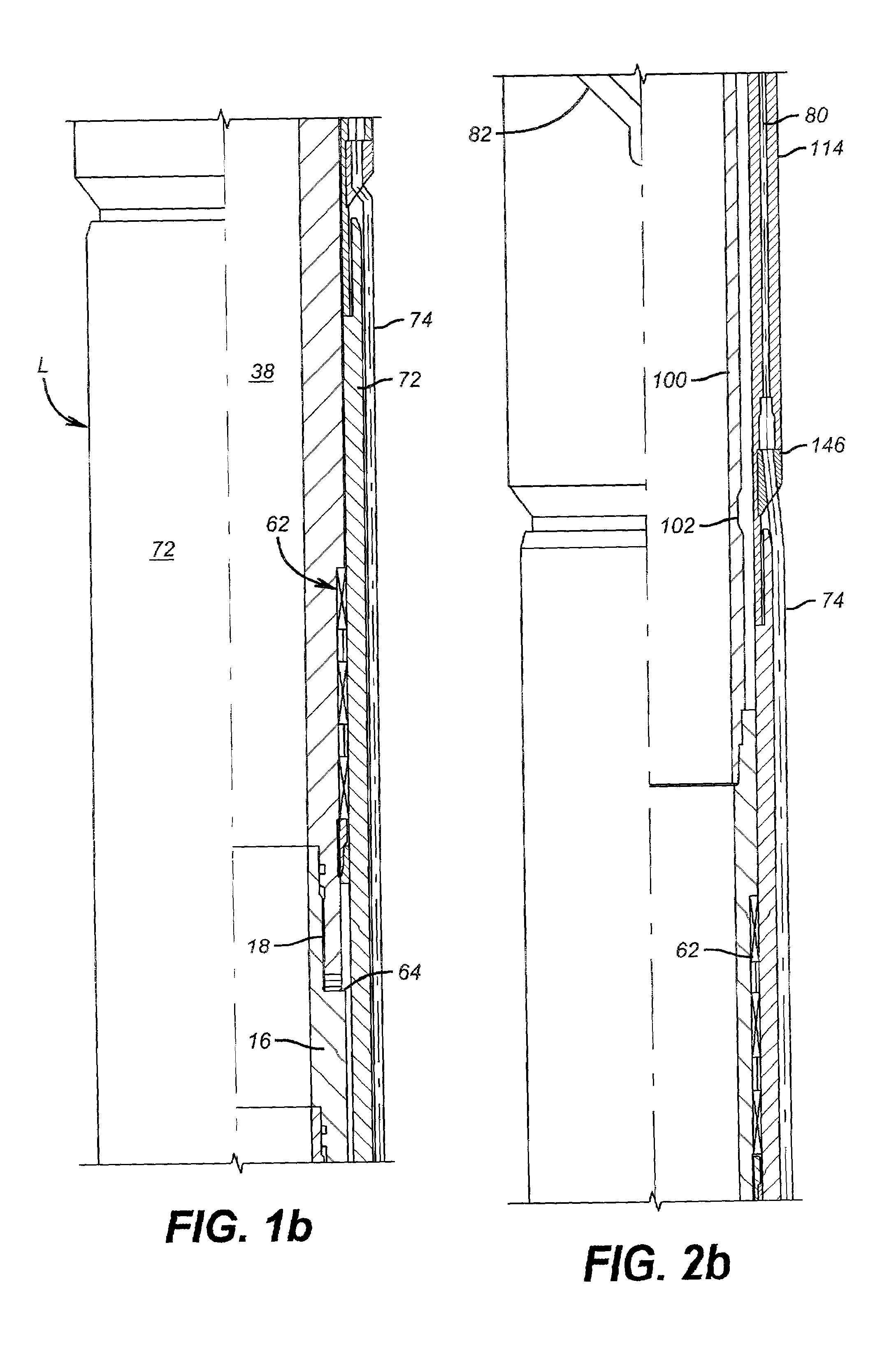

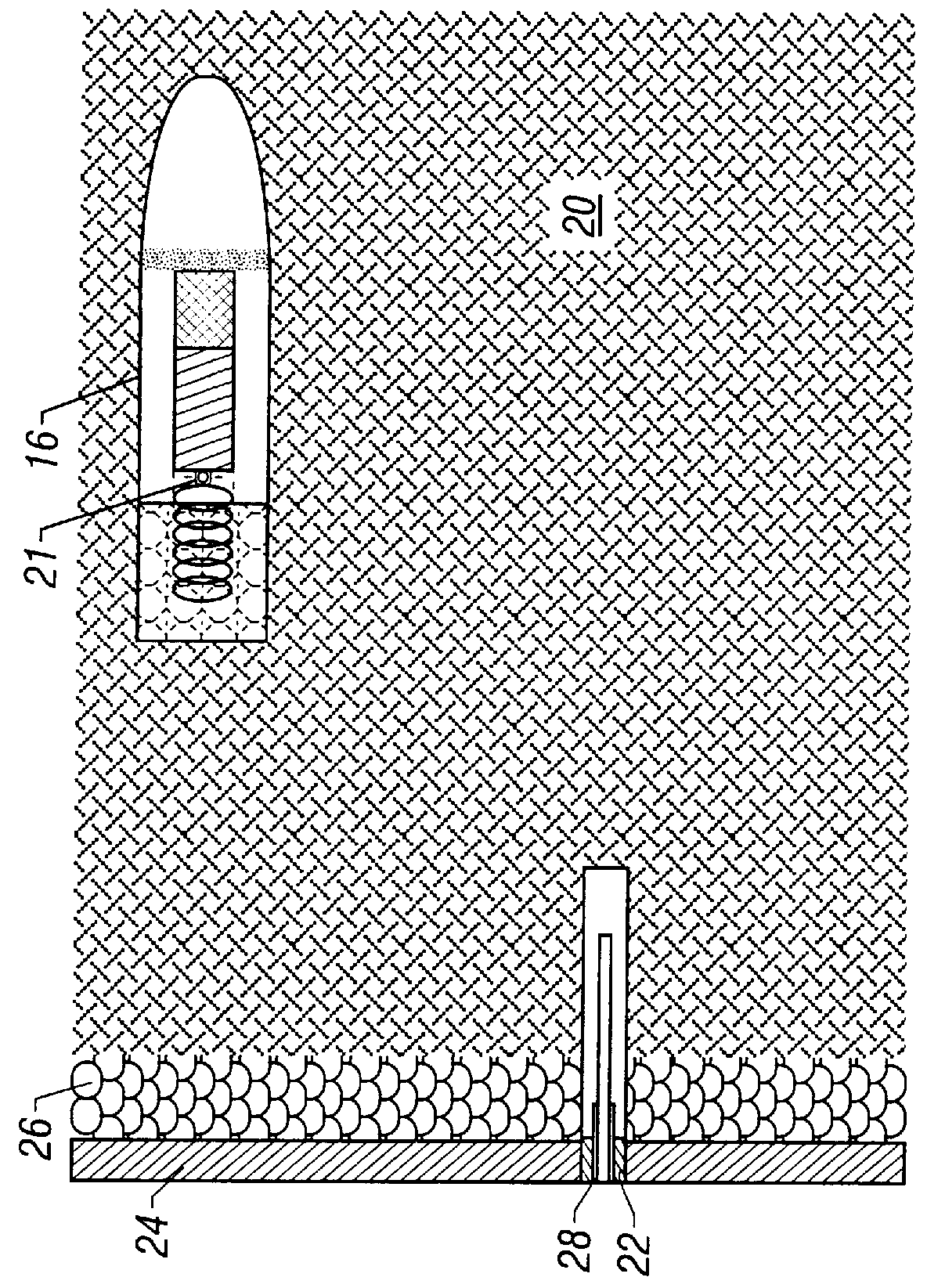

Formation pressure measurement with remote sensors in cased boreholes

The present invention relates to a method and apparatus for establishing communication in a cased wellbore with a data sensor that has been remotely deployed, prior to the installation of casing in the wellbore, into a subsurface formation penetrated by the wellbore. Communication is established by installing an antenna in an opening in the casing wall. The present invention further relates to a method and apparatus for creating the casing wall opening, and then inserting the antenna in the opening in sealed relation with the casing wall. A data receiver is inserted into the cased wellbore for communicating with the data sensor via the antenna to receive formation data signals sensed and transmitted by the data sensor. Preferably, the location of the data sensor in the subsurface formation is identified prior to the installation of the antenna, so that the opening in the casing can be created proximate the data sensor. The antenna can then be installed in the casing wall opening for optimum communication with the data sensor. It is also preferred that the data sensor be equipped with means for transmitting a signature signal, permitting the location of the data sensor to be identified by sensing the signature signal. The location of the data sensor is identified by first determining the depth of the data sensor, and then determining the azimuth of the data sensor relative to the wellbore.

Owner:SCHLUMBERGER TECH CORP

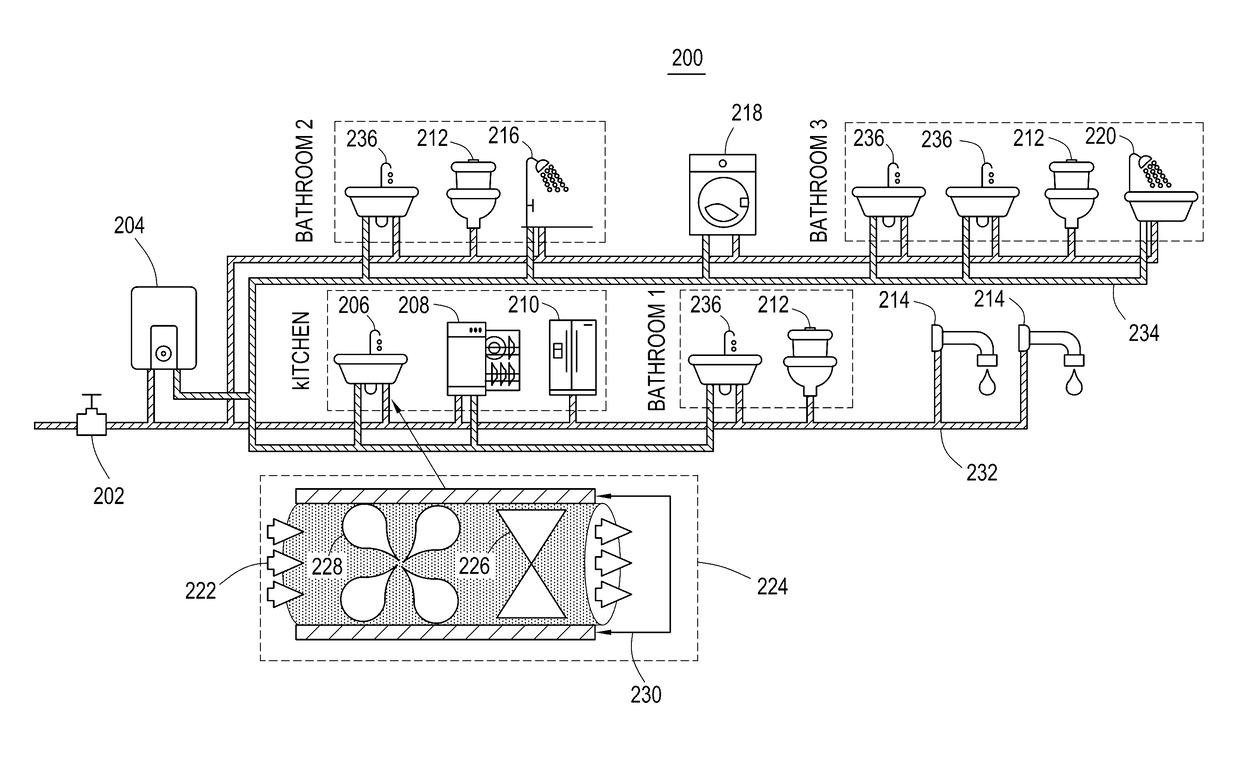

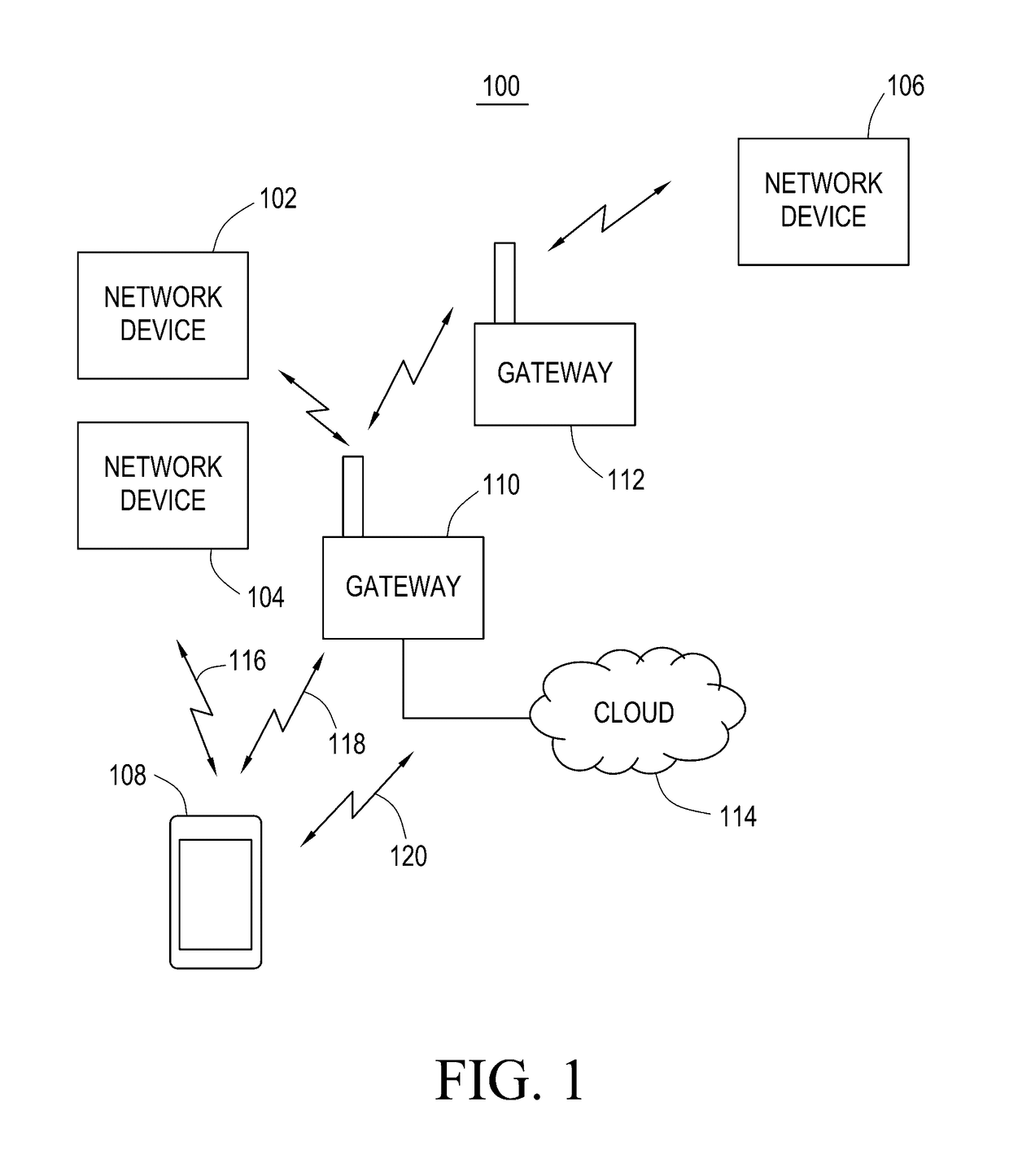

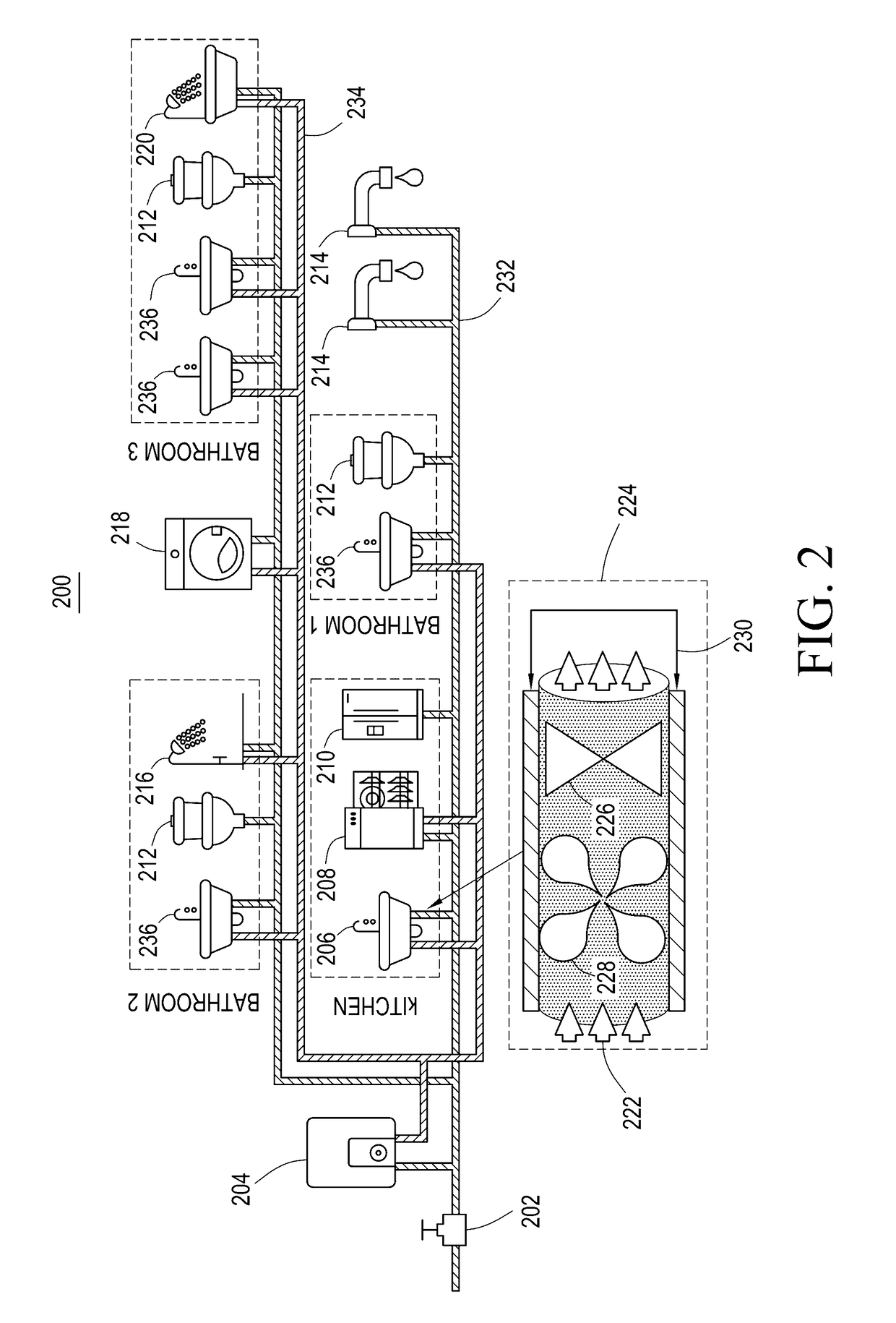

Water leak detection using pressure sensing

ActiveUS20170131174A1Inexpensive to fixWater consumptionMeasurement of fluid loss/gain rateGeneral water supply conservationEngineeringWater leak

A system including a sensing device including a pressure sensor configured to measure pressure of water in a water system of a structure. The sensing device can be configured to generate pressure measurement data representing the pressure of the water as measured by the pressure sensor. The system also can include one or more processing units including one or more processors and one or more non-transitory storage media storing machine executable instructions configured when run on the one or more processors to perform detecting a non-cyclical pressure event corresponding to a water leak in the water system of the structure during a first time period based on an analysis of information including the pressure measurement data. The information analyzed in the analysis does not include any flow measurement data that represents a total amount of flow of the water in the water system of the structure during the first time period. The pressure sensor can be coupled to the water system of the structure at a single location of the water system of the structure when measuring the pressure of the water in the water system of the structure. Other embodiments are provided.

Owner:PHYN LLC

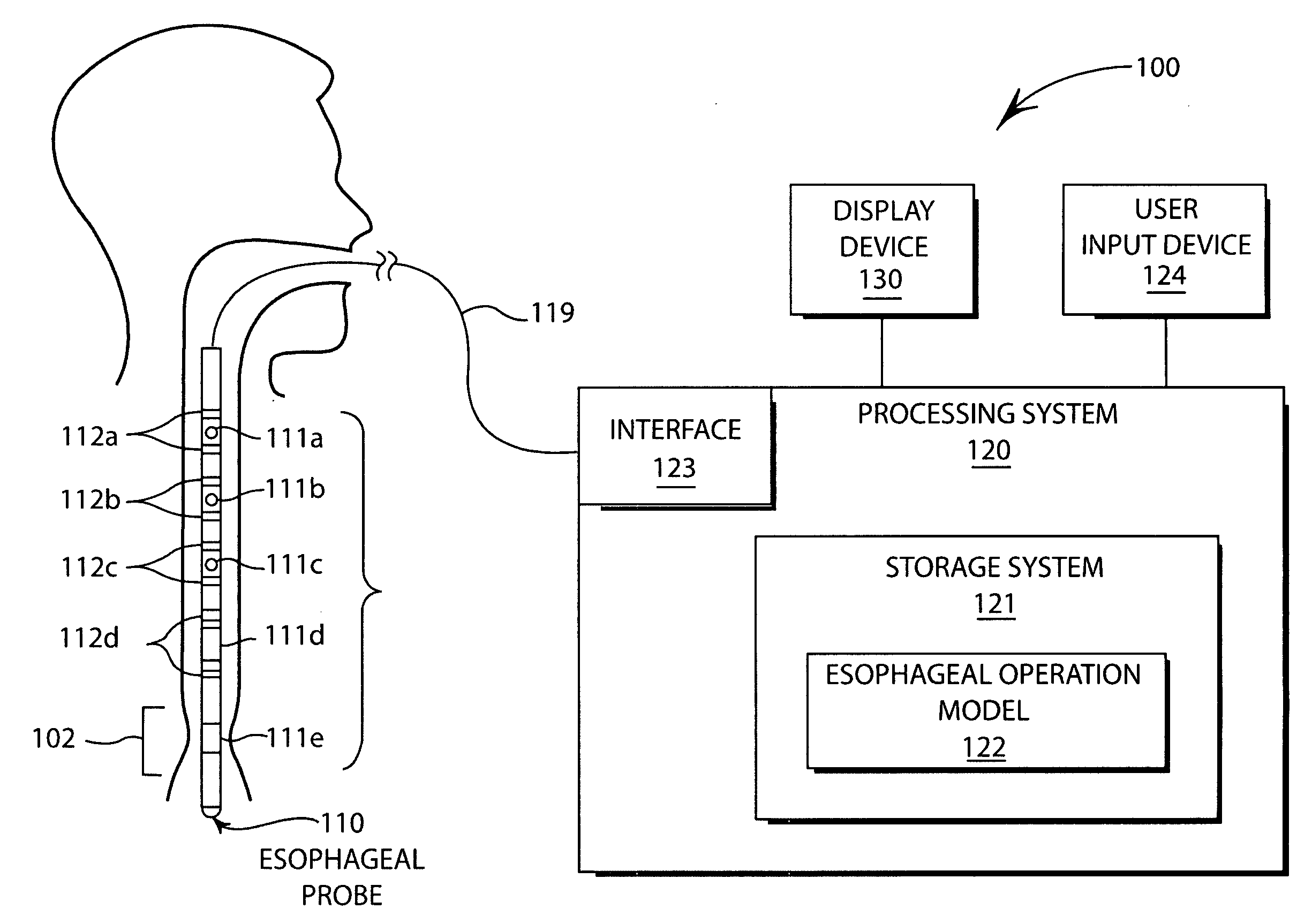

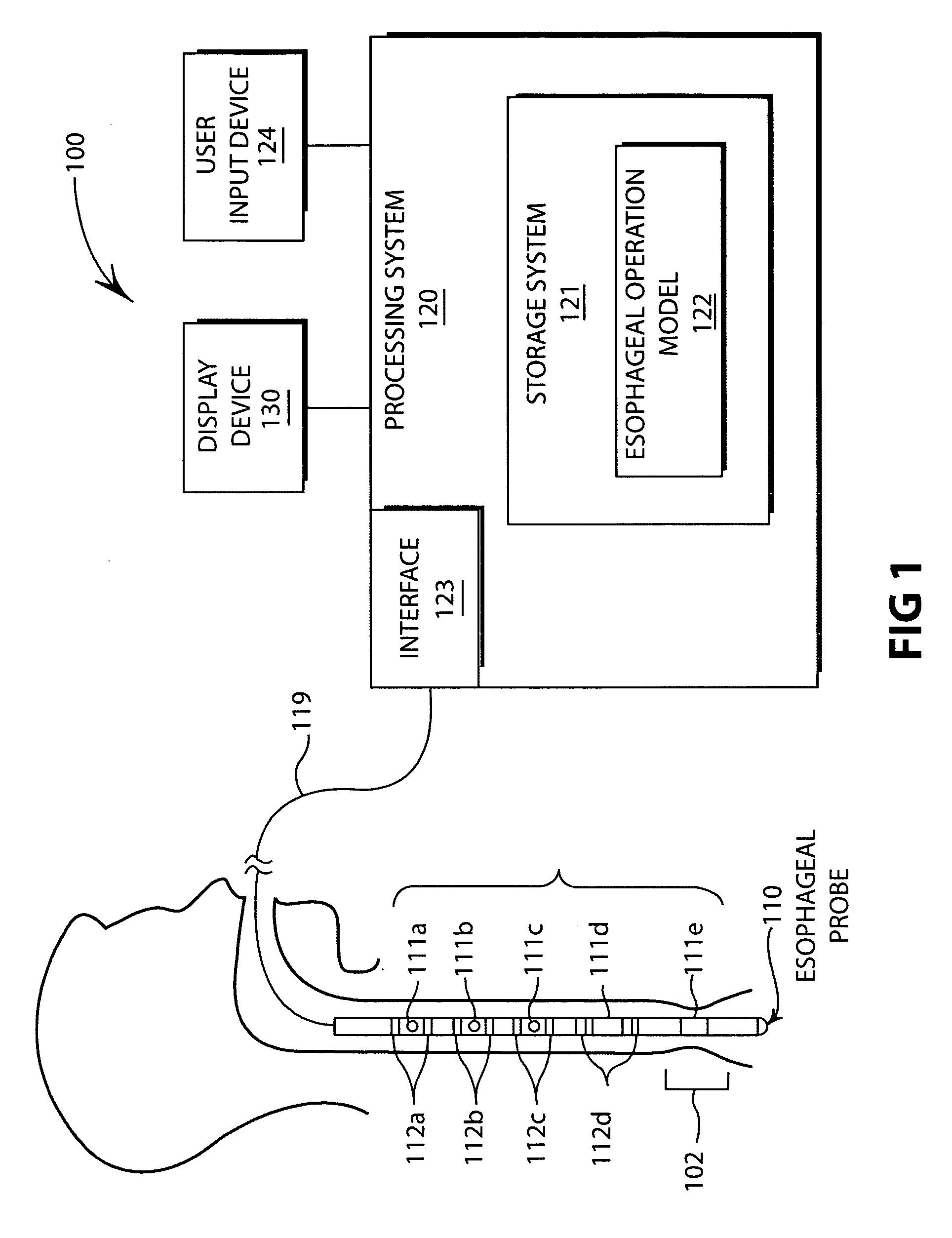

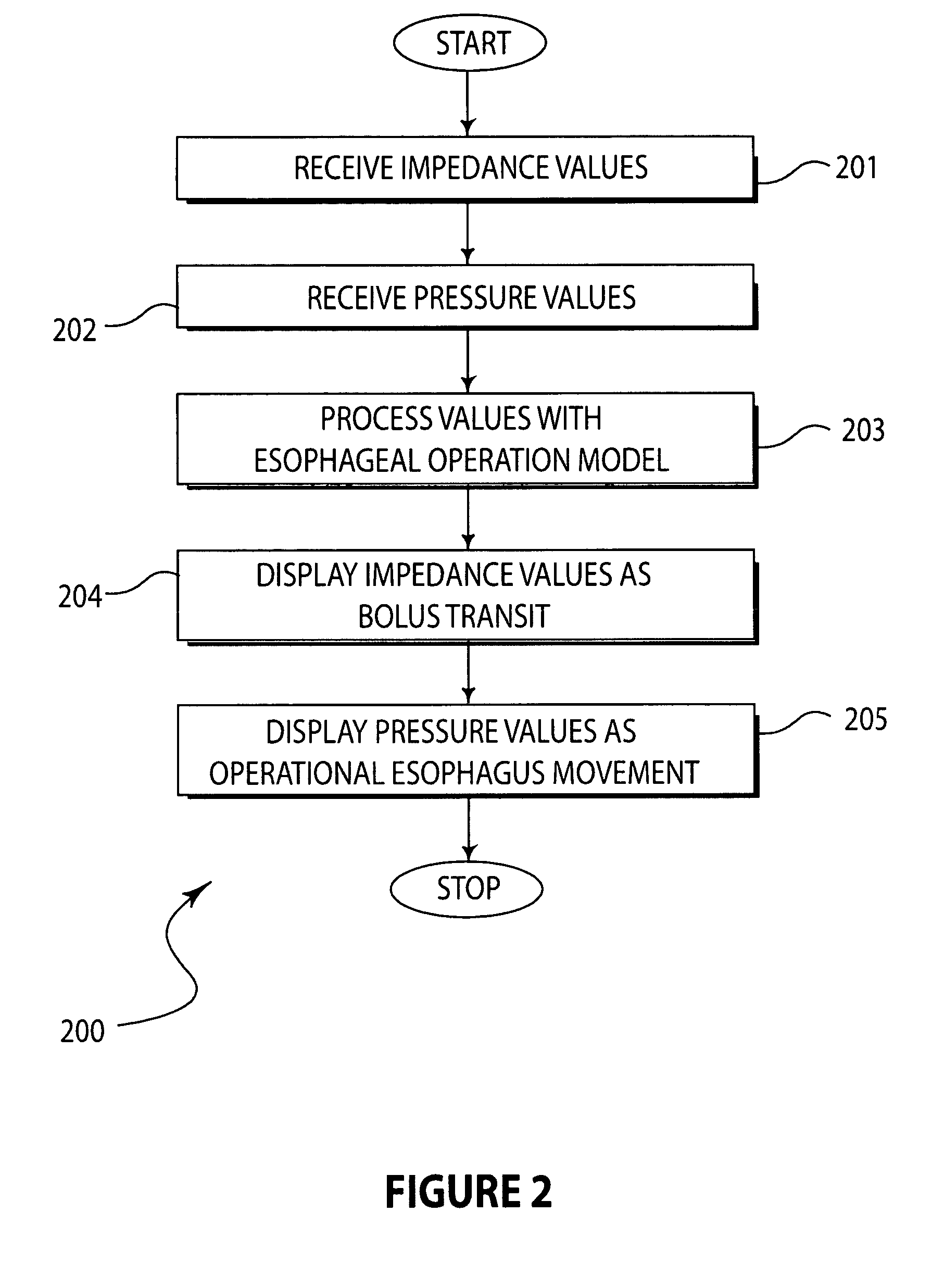

Esophageal function display and playback system and method for displaying esophageal function

A system and method for displaying an esophageal operation includes a display device, an interface capable of receiving esophageal impedance and pressure measurements, and a processing system in communication with the display device, the interface, and an esophageal operation model. The processing system is configured to receive a plurality of impedance values from a first plurality of spaced-apart esophageal locations, receive a plurality of pressure values from a second plurality of spaced-apart esophageal locations, process the plurality of impedance values and the plurality of pressure values with the esophageal operation model, display the plurality of impedance values on the display device as a bolus transit, and display the plurality of pressure values on the display device as operational esophagus movement.

Owner:DIVERSATEK HEALTHCARE INC

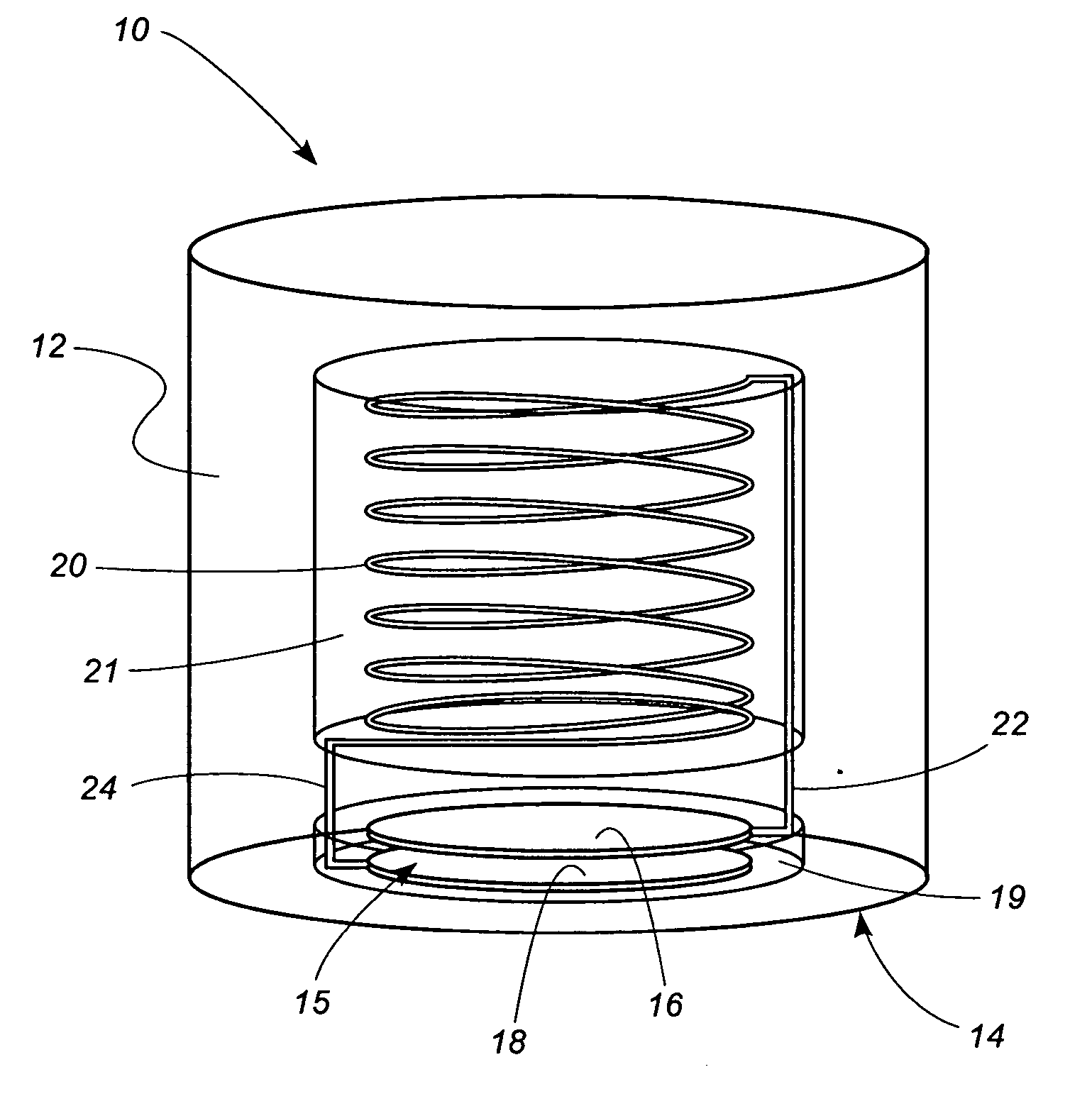

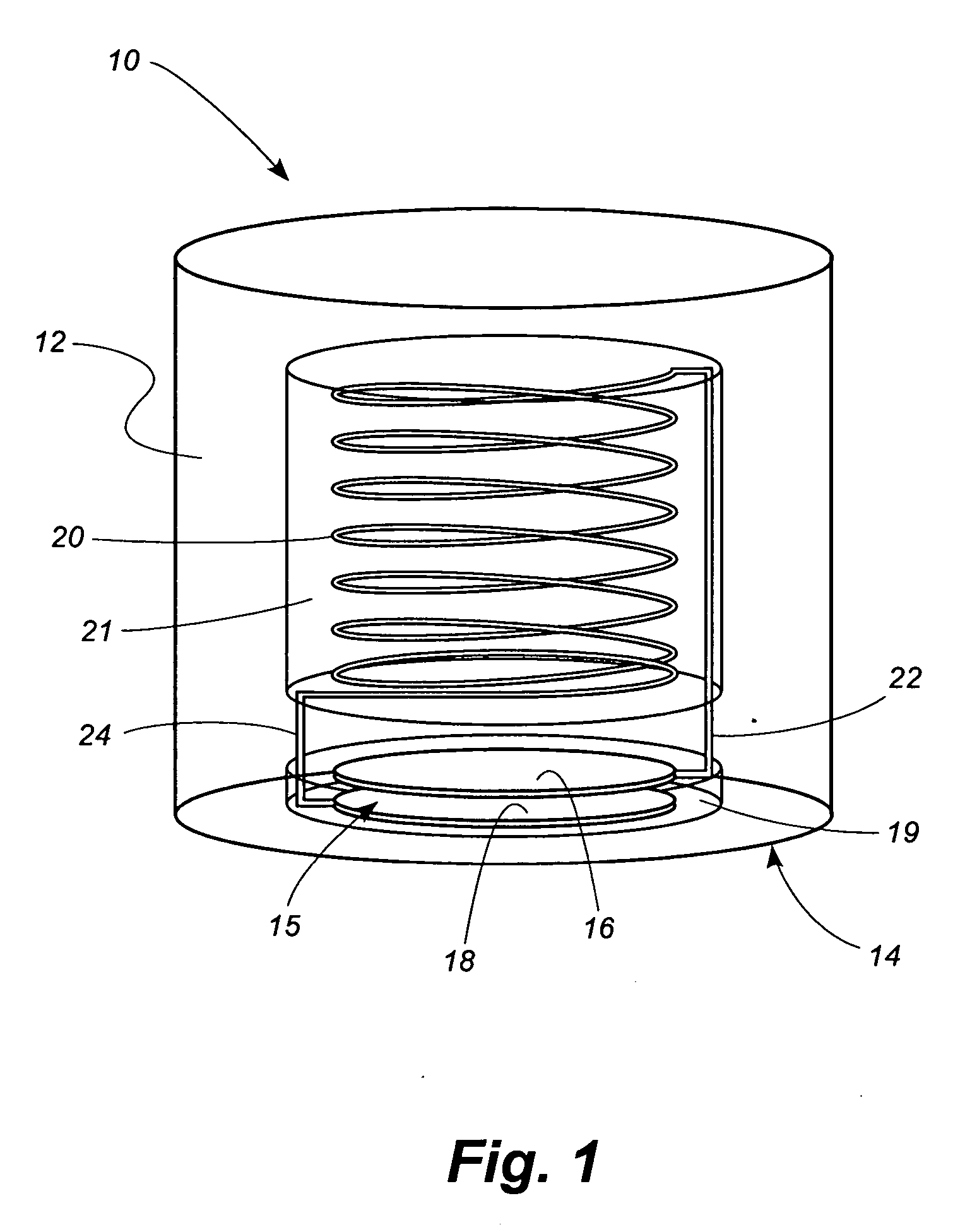

Implantable wireless sensor for in vivo pressure measurement

A sensor suitable for in vivo implantation has a capacitive circuit and a three-dimensional inductor coil connected to the capacitive circuit to form an LC circuit. The LC circuit is hermetically encapsulated within an electrically insulating housing. An electrical characteristic of the LC circuit is responsive to a change in an environmental parameter.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

Devices, systems and methods for endocardial pressure measurement

InactiveUS20050182330A1Electric signal transmission systemsElectrocardiographyCongestive heart failure chfTunica intima

Endocardial pressure measurement devices, systems and methods for the effective treatment of congestive heart failure and its underlying causes, in addition to other clinical applications.

Owner:TRANSOMA MEDICAL

Systems and methods for intra-procedural cardiac pressure monitoring

The present disclosure relates to delivery devices and interventional devices configured to enable monitoring of pressure and other hemodynamic properties before, during, and / or after a cardiac procedure. A guide catheter includes a routing lumen or a routing groove for routing a sensor wire to a desired location during a cardiac procedure. A guide catheter includes one or more pressure sensors positioned to provide desired pressure measurements when the guide catheter is deploying an interventional device. An interventional device may also include one or more associated sensors for providing hemodynamic information before, during, and / or after deployment.

Owner:EVALVE

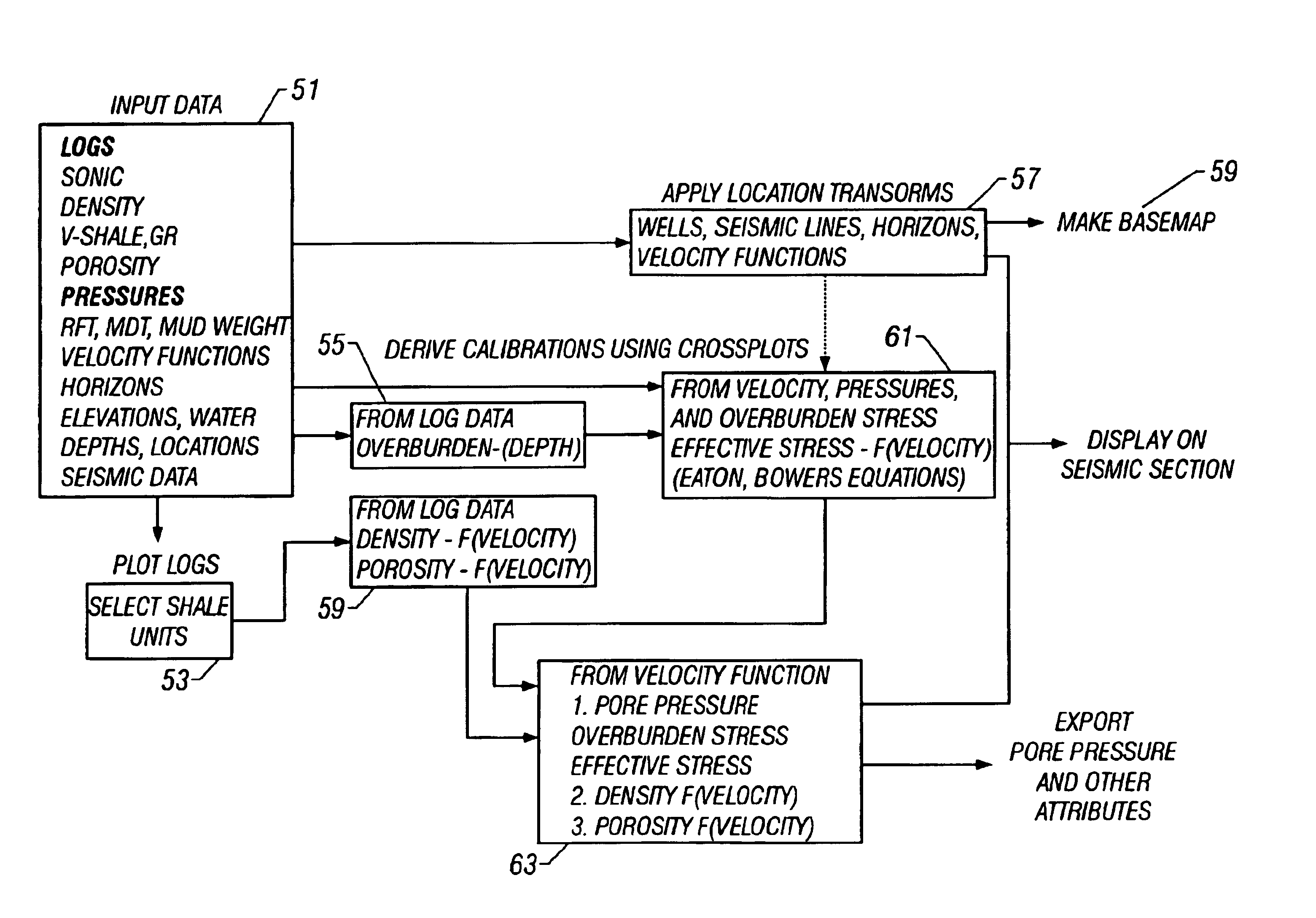

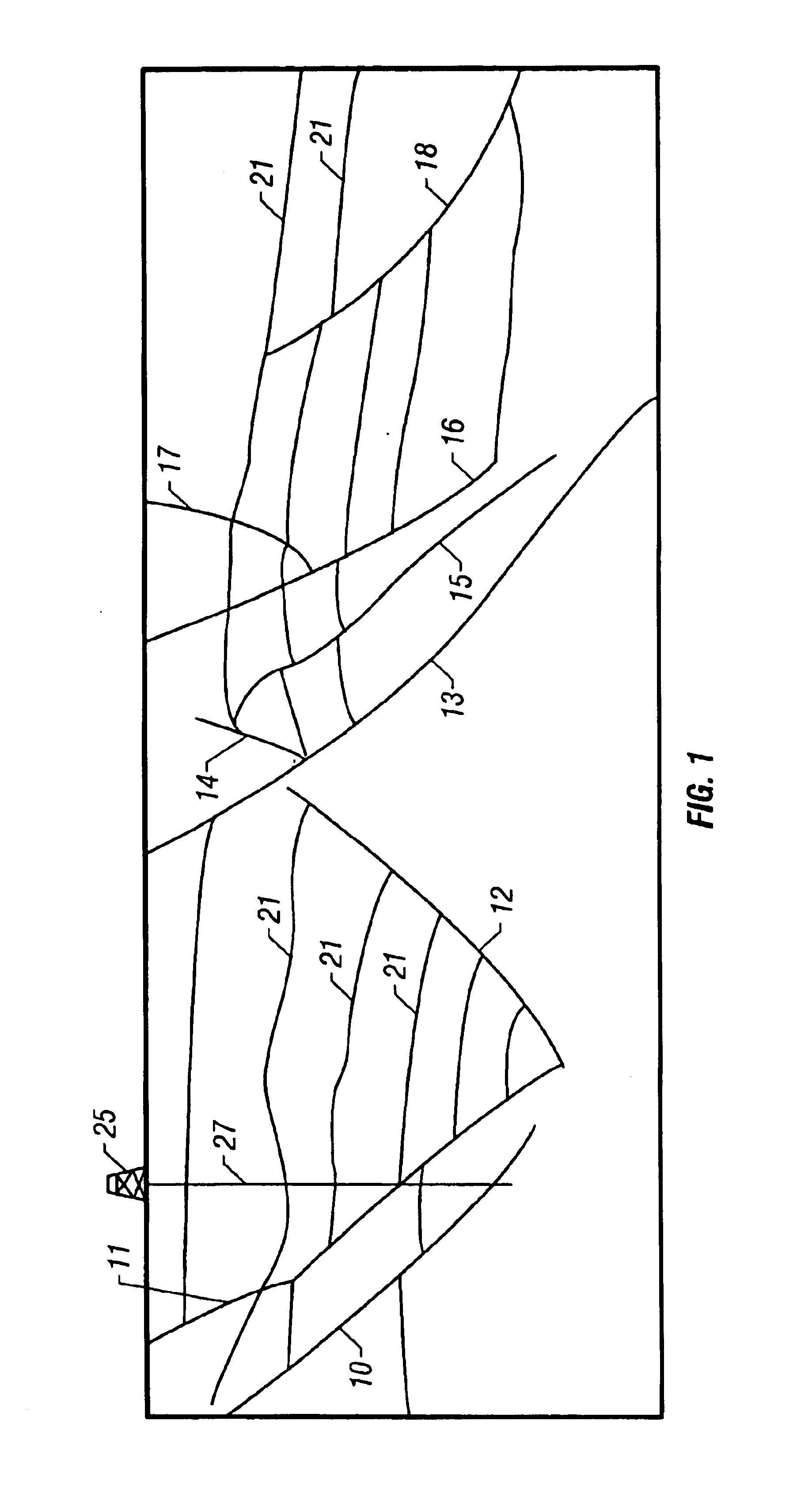

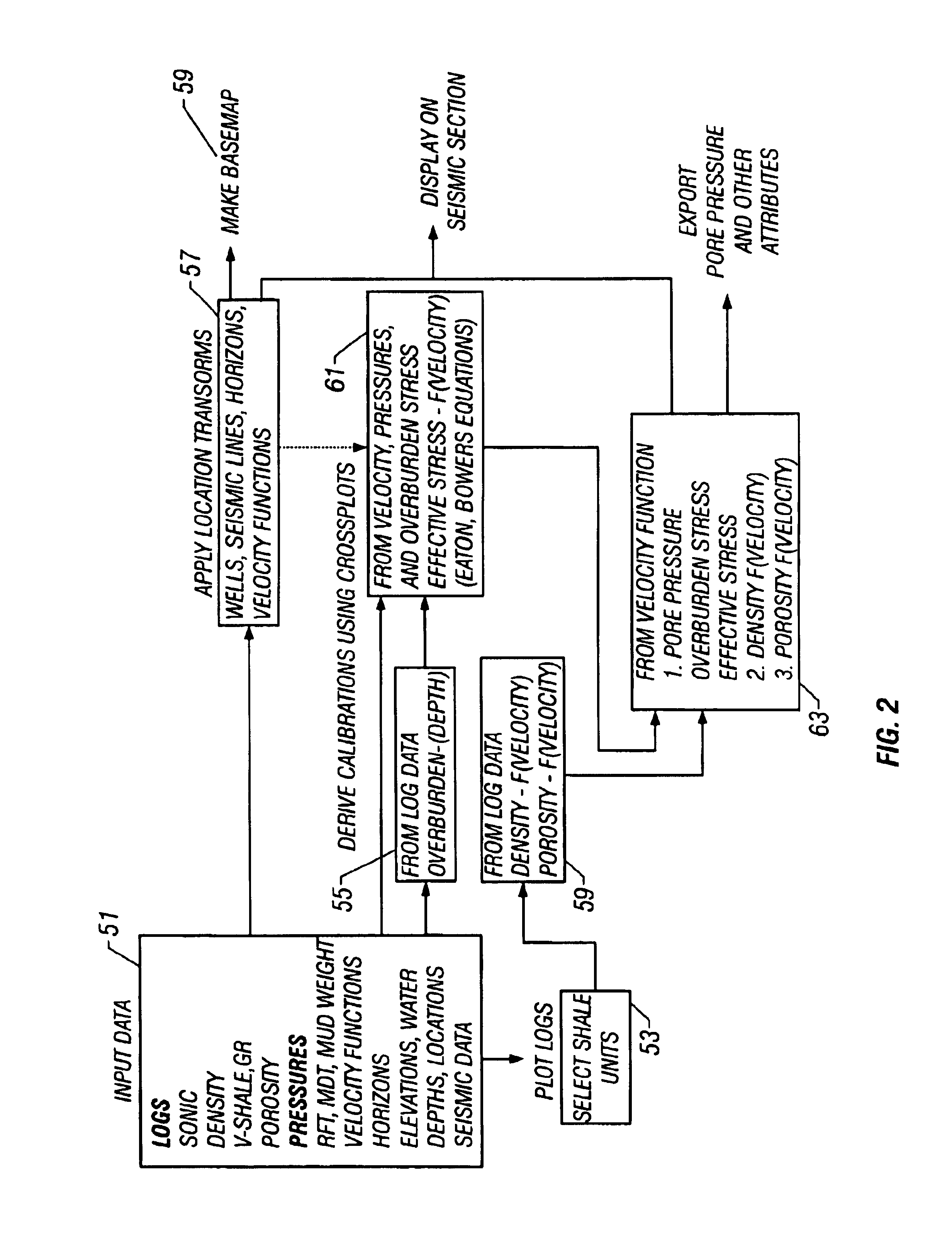

Method and process for prediction of subsurface fluid and rock pressures in the earth

A method of determination of fluid pressures in a subsurface region of the earth uses seismic velocities and calibrations relating the seismic velocities to the effective stress on the subsurface sediments. The seismic velocities may be keyed to defined seismic horizons and may be obtained from many methods, including velocity spectra, post-stack inversion, pre-stack inversion, VSP or tomography. Overburden stresses may be obtained from density logs, relations between density and velocity, or from inversion of potential fields data. The seismic data may be P-P, P-S, or S-S data. The calibrations may be predetermined or may be derived from well information including well logs and well pressure measurements. The calibrations may also include the effect of unloading. The determined pressures may be used in the analysis of fluid flow in reservoirs, basin and prospect modeling and in fault integrity analysis.

Owner:CONOCOPHILLIPS CO

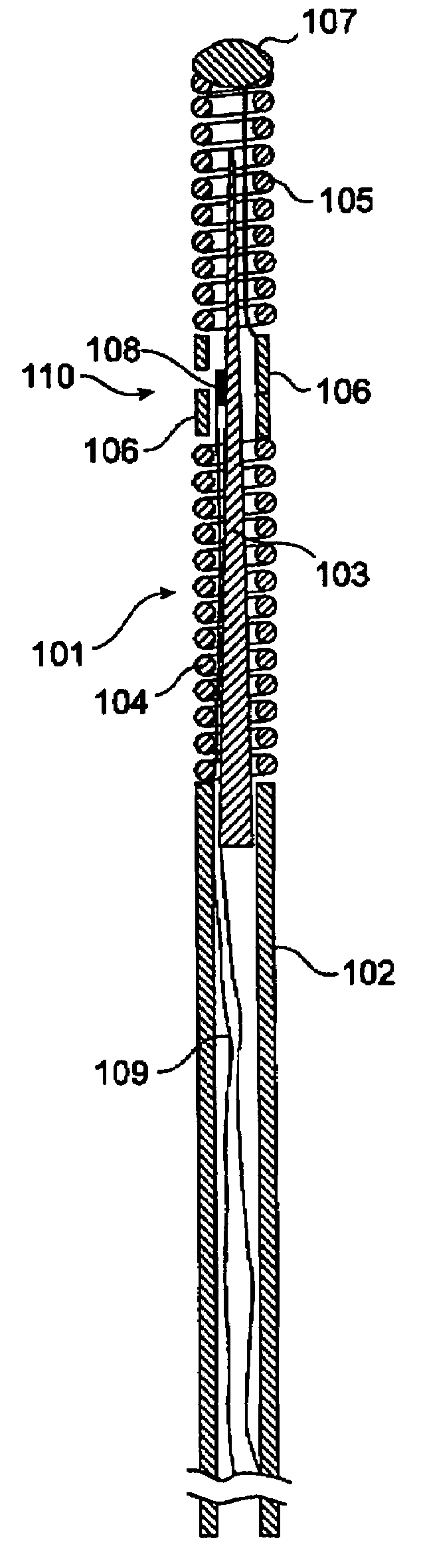

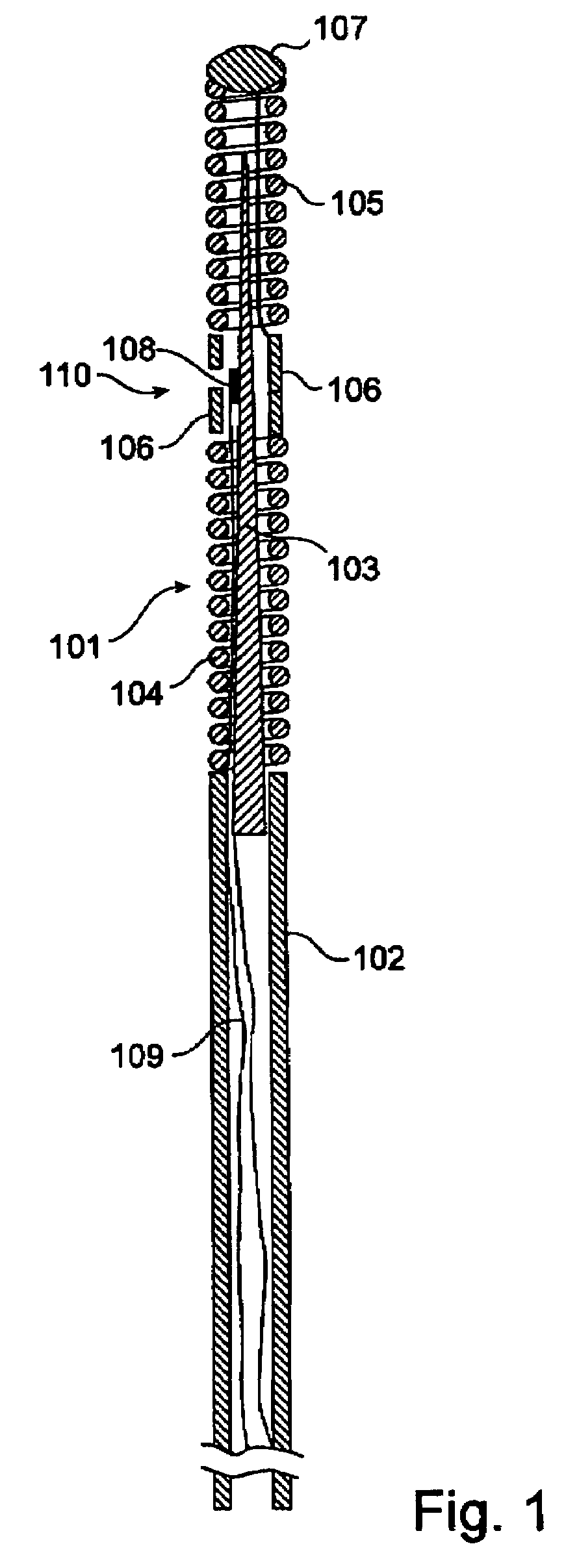

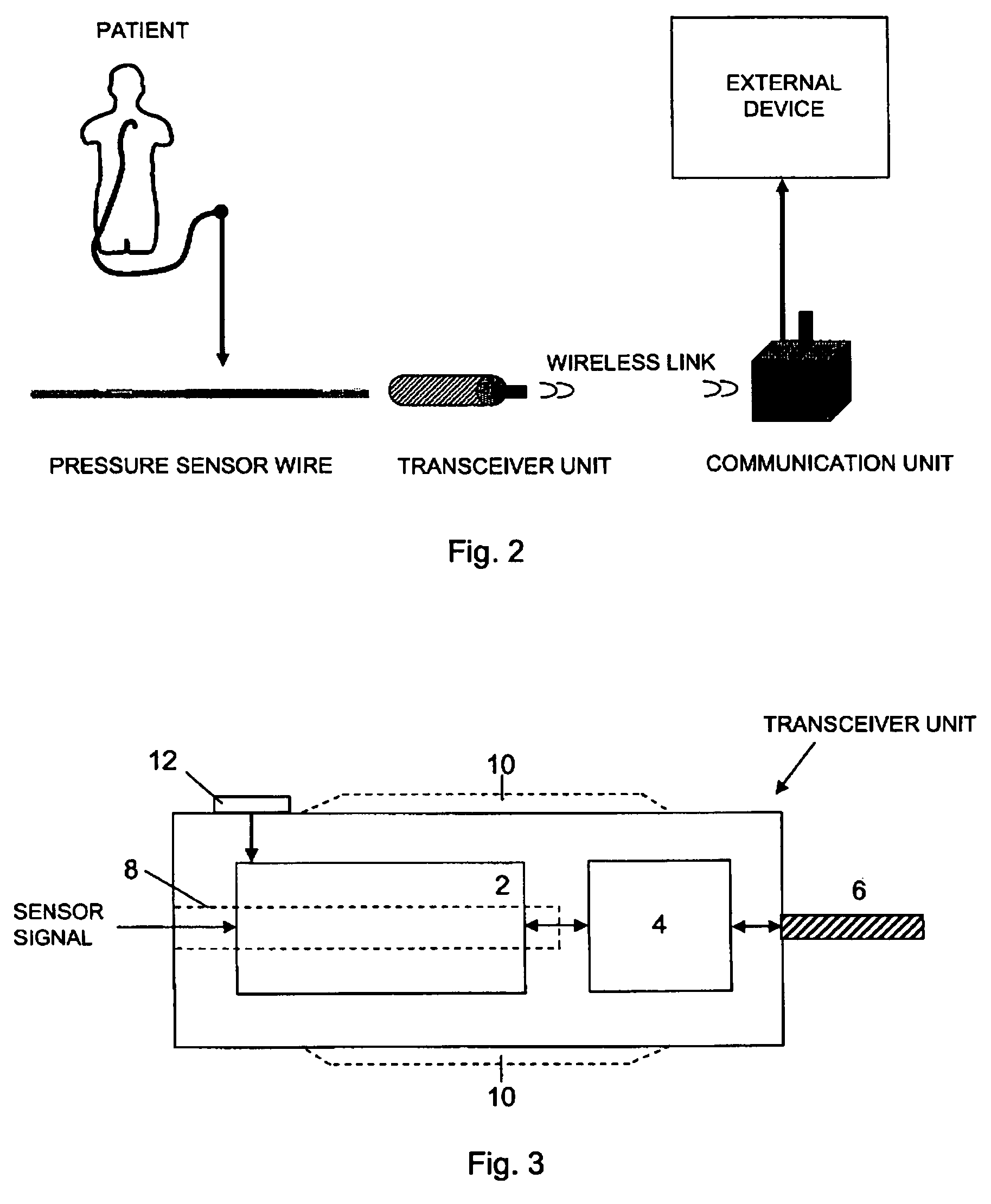

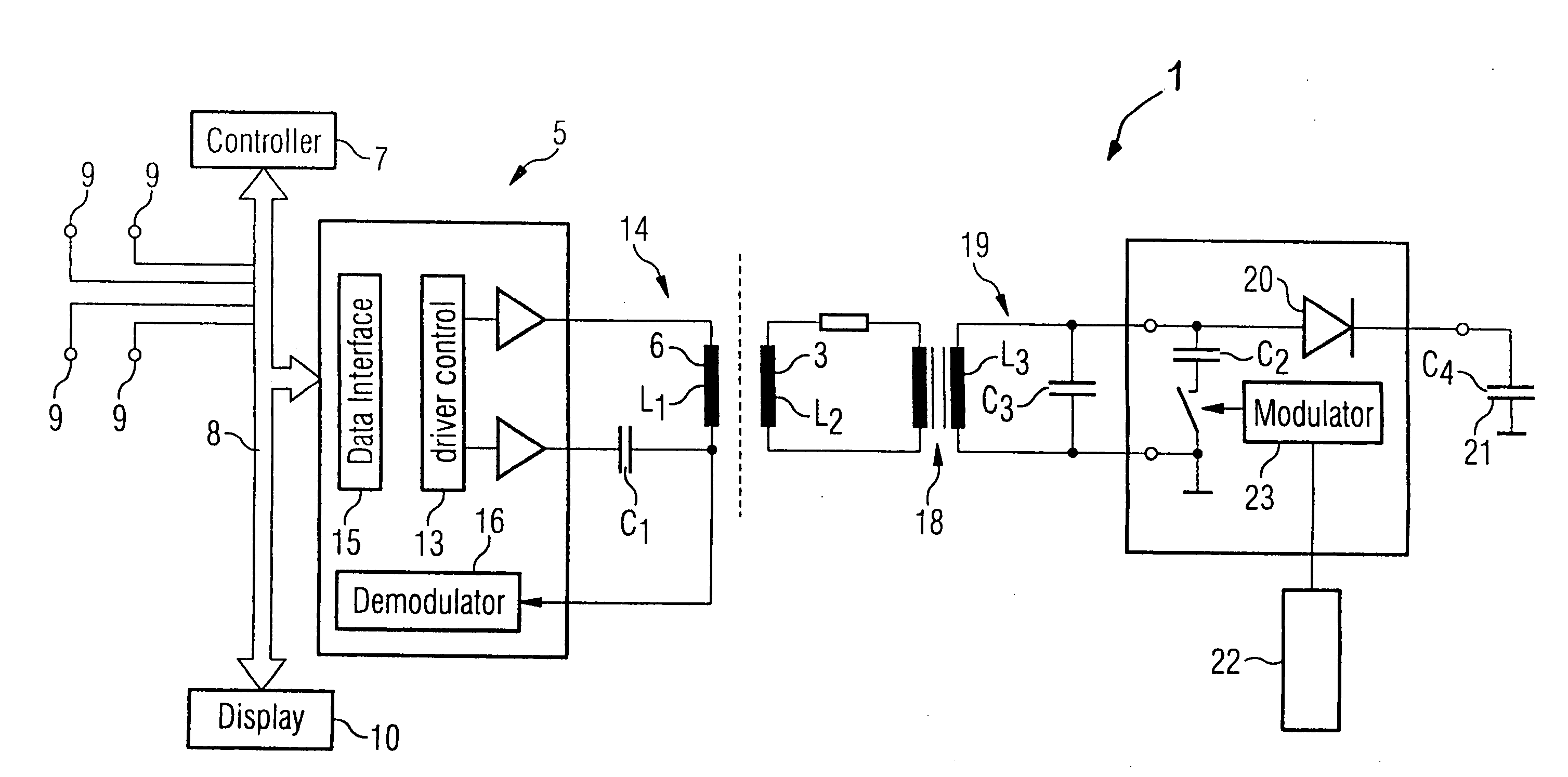

Transceiver unit in a pressure measurement system

Pressure measurement system comprising a pressure sensor wire with a pressure sensor to measure pressure inside a patient, and to provide measured pressure data to an external device. The pressure sensor wire is adapted to be connected, at its proximal end, to a transceiver unit that is adapted to wirelessly communicate via a communication signal with a communication unit arranged in connection with an external device, in order to transfer measured pressure data to the external device. The pressure data to be transferred is generated by the transceiver unit and transferred as a data stream. Preferably, the communication signal is a radio frequency signal.

Owner:ST JUDE MEDICAL COORDINATION CENT

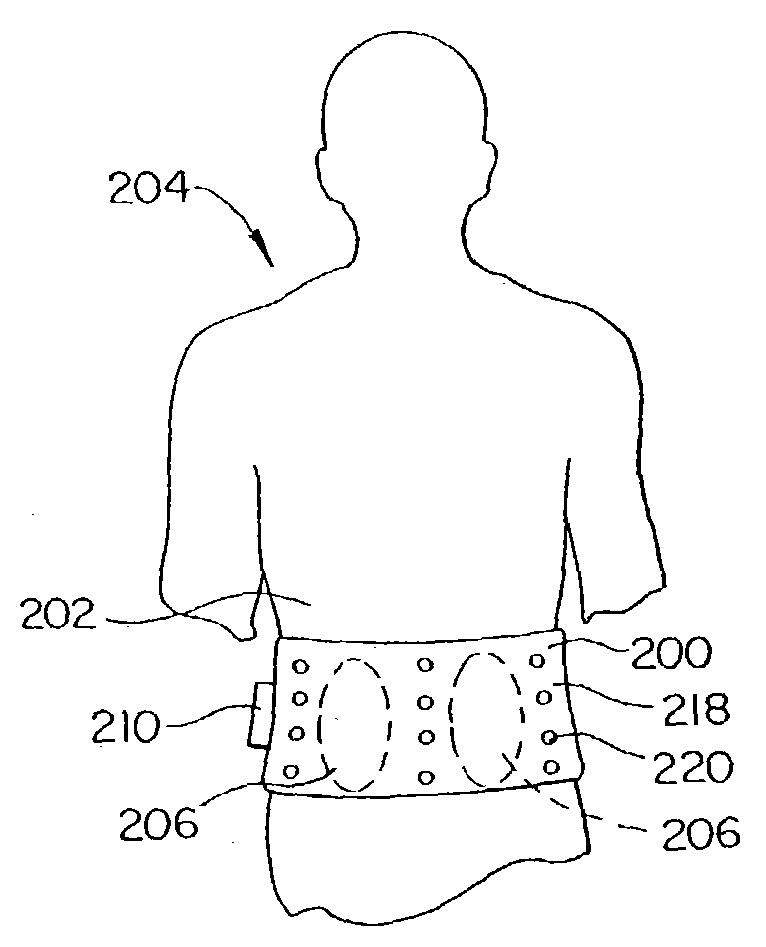

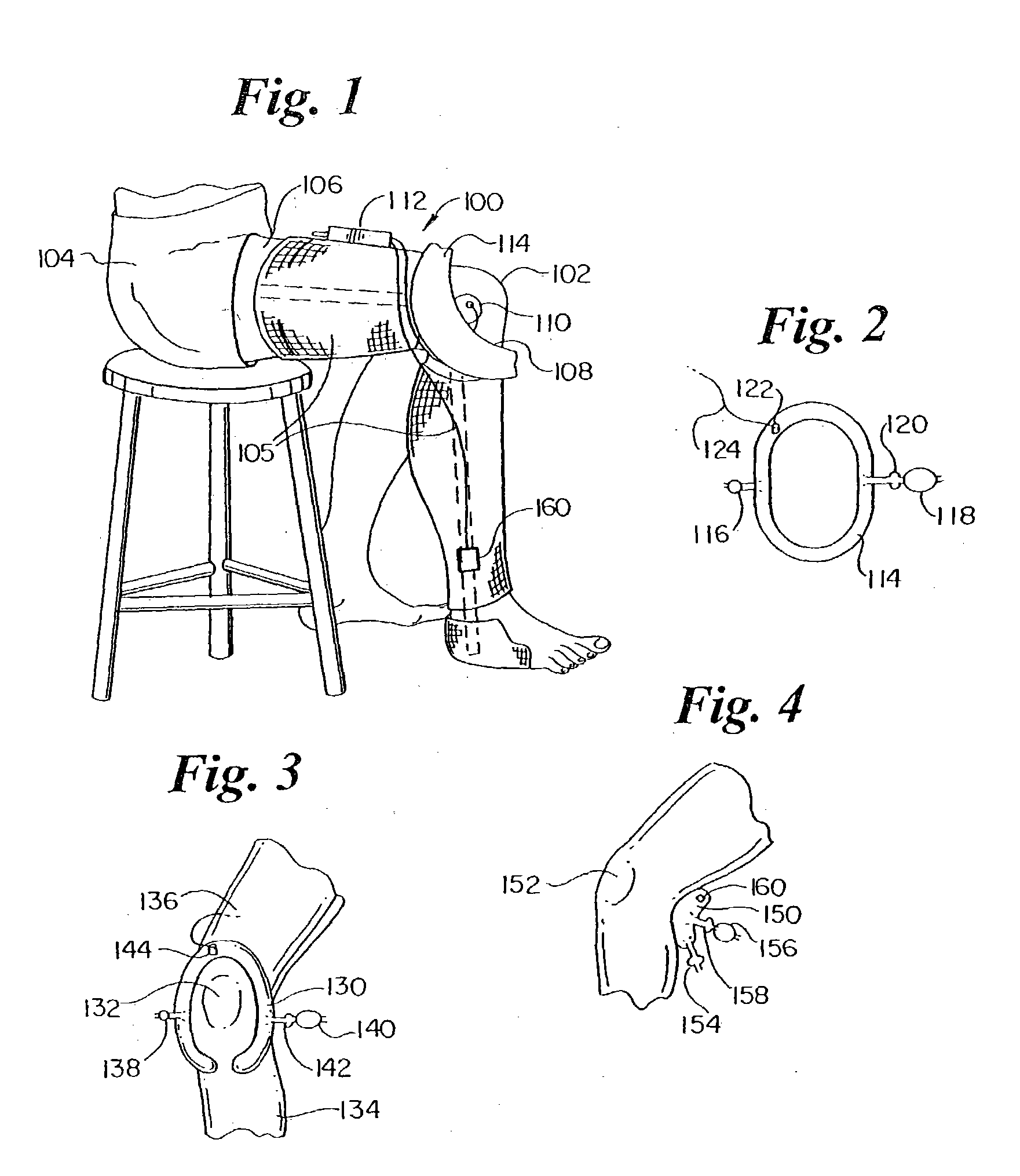

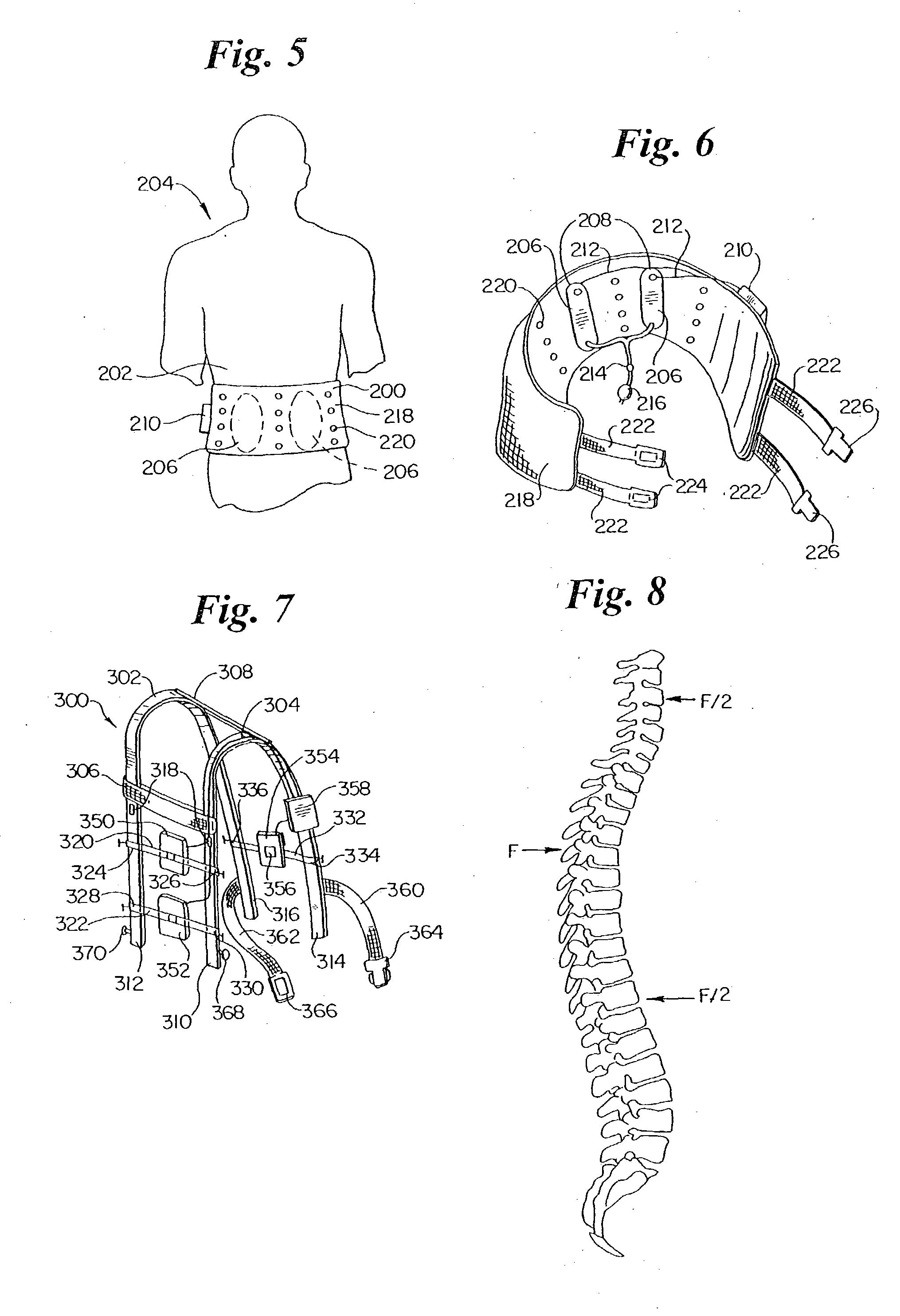

Orthoses

Exercise orthoses are described that include a frame, a fluid bladder held by the frame, a pressure sensor attached to the fluid bladder and a microprocessor receiving the pressure measurements. The microprocessor monitors variations in pressure and determines differences between the measured pressures and predetermined target values. The frame can be designed to support a hinge joint or at least one vertebra. Furthermore, corrective back orthoses are described that include a frame force applicators connected to the frame to apply force to the patient's spine, a sensor that measures forces associated with the force applicators and a control unit that monitors forces measured by the sensor. The corrective back orthosis can include fluid bladders as force applicators. The control unit can include a microprocessor.

Owner:IZEX TECH

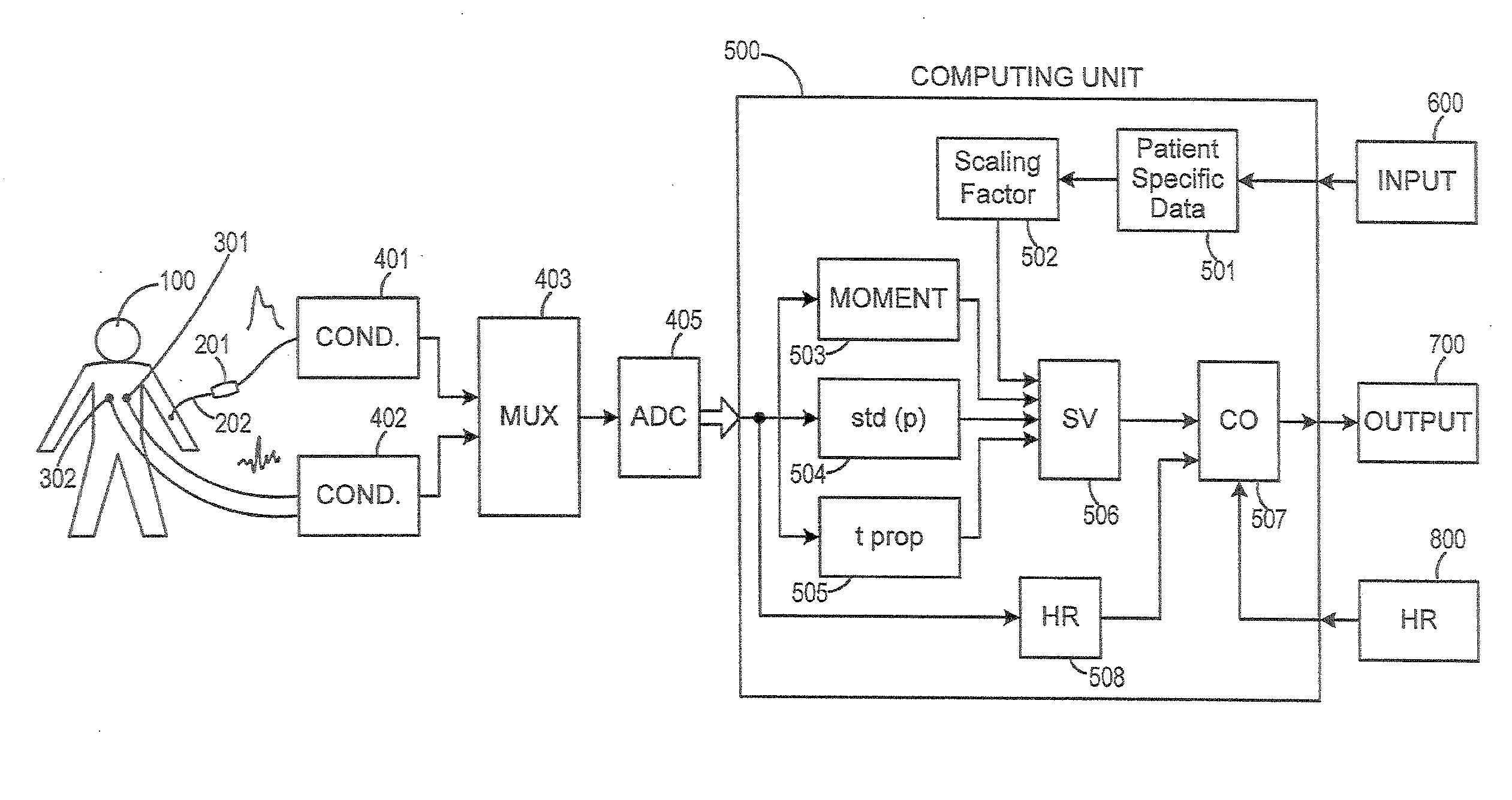

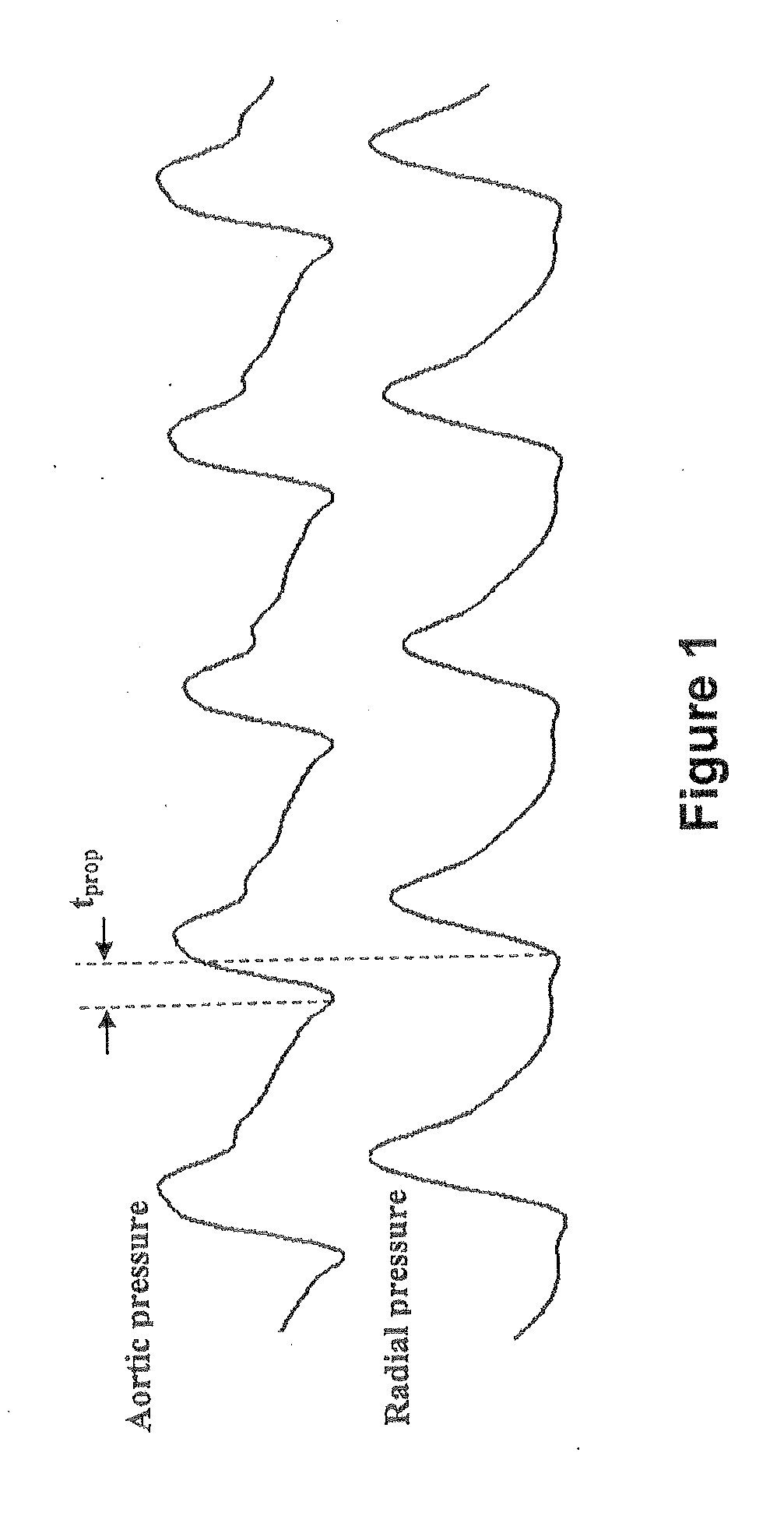

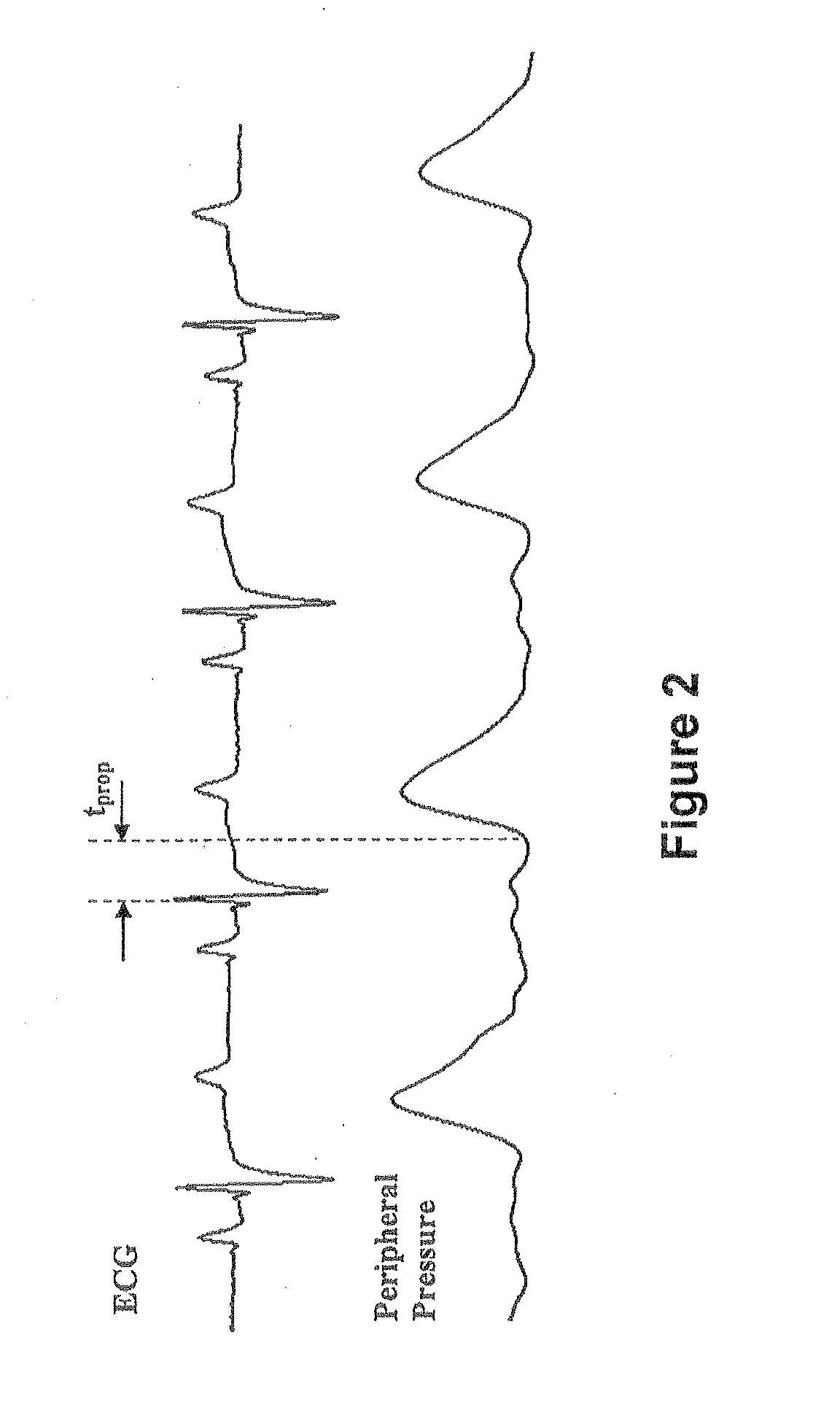

Method and Apparatus for Continuous Assessment of a Cardiovascular Parameter Using the Arterial Pulse Pressure Propagation Time and Waveform

InactiveUS20080015451A1ElectrocardiographyBlood flow measurement devicesCardiac cycleArterial pulse pressure

A method and apparatus for determining a cardiovascular parameter including receiving an input signal corresponding to an arterial blood pressure measurement over an interval that covers at least one cardiac cycle, determining a propagation time of the input signal, determining at least one statistical moment of the input signal, and determining an estimate of the cardiovascular parameter using the propagation time and the at least one statistical moment.

Owner:EDWARDS LIFESCIENCES CORP

In VIVO sensor and method of making same

InactiveUS20060074479A1Easy to detectUltrasonic/sonic/infrasonic diagnosticsSurgeryIn vivoRadio frequency

Implantable in vivo sensors used to monitor physical, chemical or electrical parameters within a body. The in vivo sensors are integral with an implantable medical device and are responsive to externally or internally applied energy. Upon application of energy, the sensors undergo a phase change in at least part of the material of the device which is then detected external to the body by conventional techniques such as radiography, ultrasound imaging, magnetic resonance imaging, radio frequency imaging or the like. The in vivo sensors of the present invention may be employed to provide volumetric measurements, flow rate measurements, pressure measurements, electrical measurements, biochemical measurements, temperature, measurements, or measure the degree and type of deposits within the lumen of an endoluminal implant, such as a stent or other type of endoluminal conduit. The in vivo sensors may also be used therapeutically to modulate mechanical and / or physical properties of the endoluminal implant in response to the sensed or monitored parameter.

Owner:VACTRONIX SCI LLC

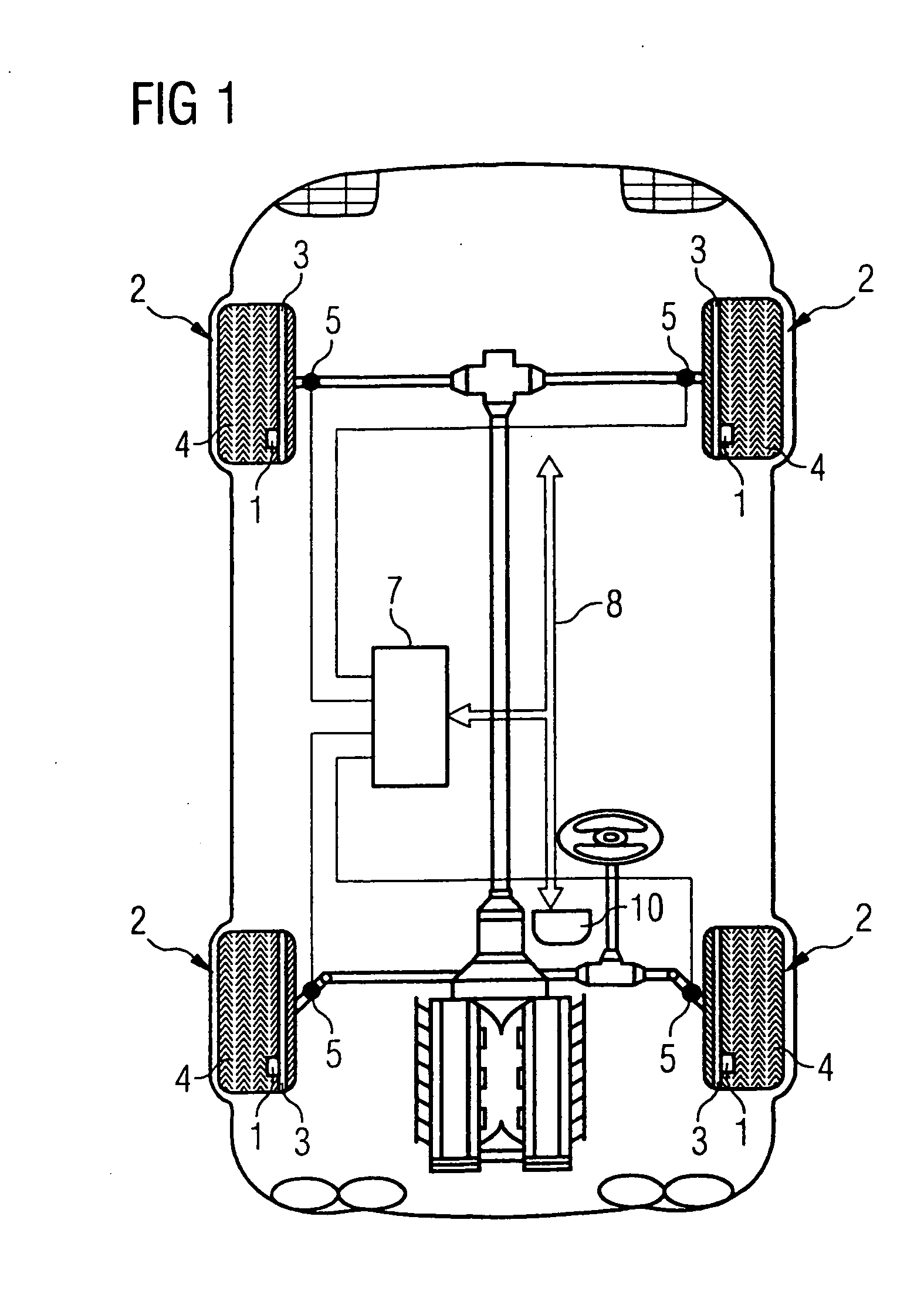

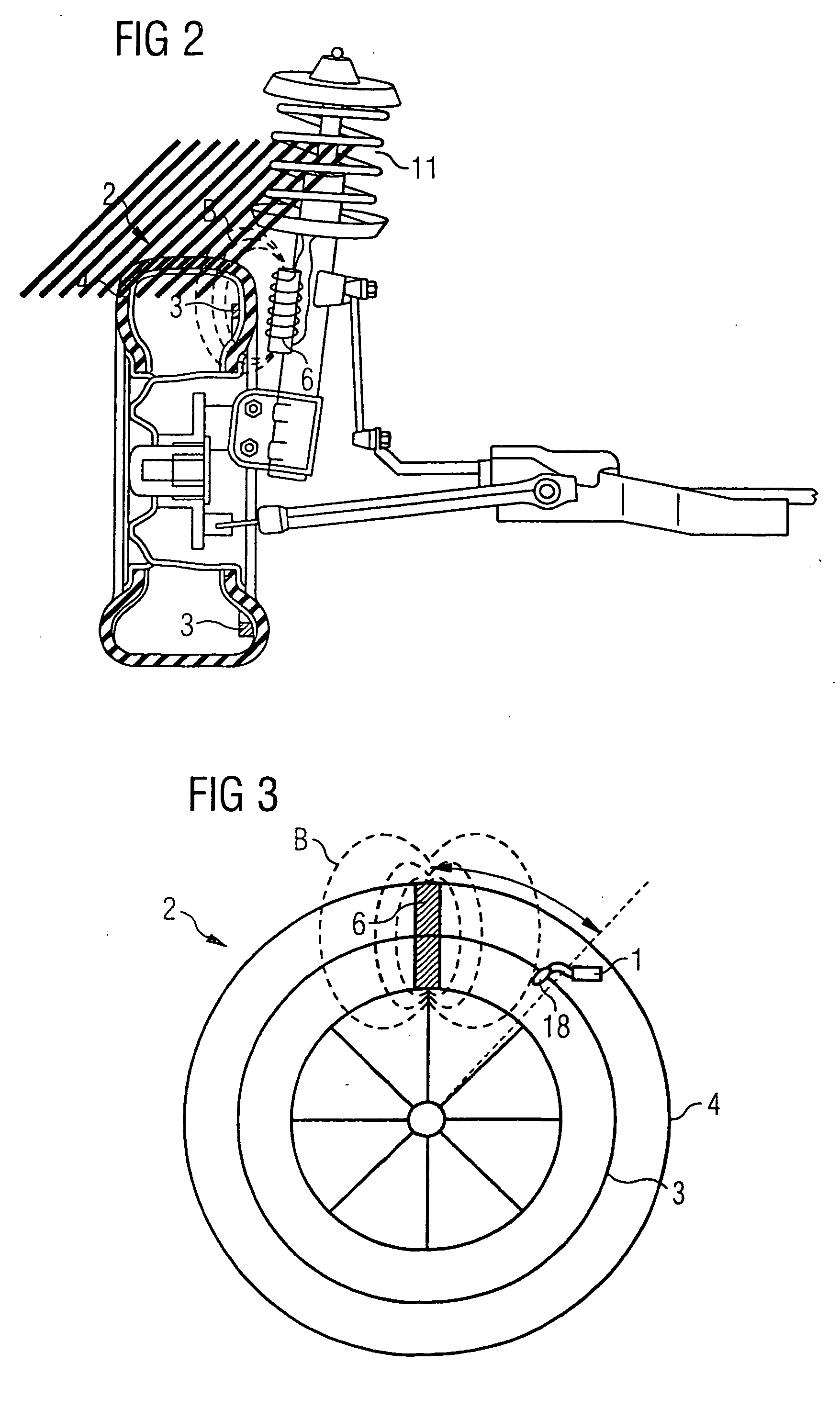

Configuration and method for bidirectional transmission of signals in a motor vehicle

InactiveUS20050163063A1Keep energy smallConvenient distanceTransmission control/equalisingNear-field systems using receiversTransceiverLow speed

A method for operating a tire pressure measuring system uses a transceiver. When triggered, the transceiver transmits an energy signal to a transponder in a tire that then responds with a data signal. So that the energy signals do not interfere with other transceivers on receipt of the data signals, the method makes provision for the repetition rate with which the energy signals are triggered to be a function of the speed of the vehicle. Transmission is more frequent at higher speed than at lower speed.

Owner:SIEMENS AG

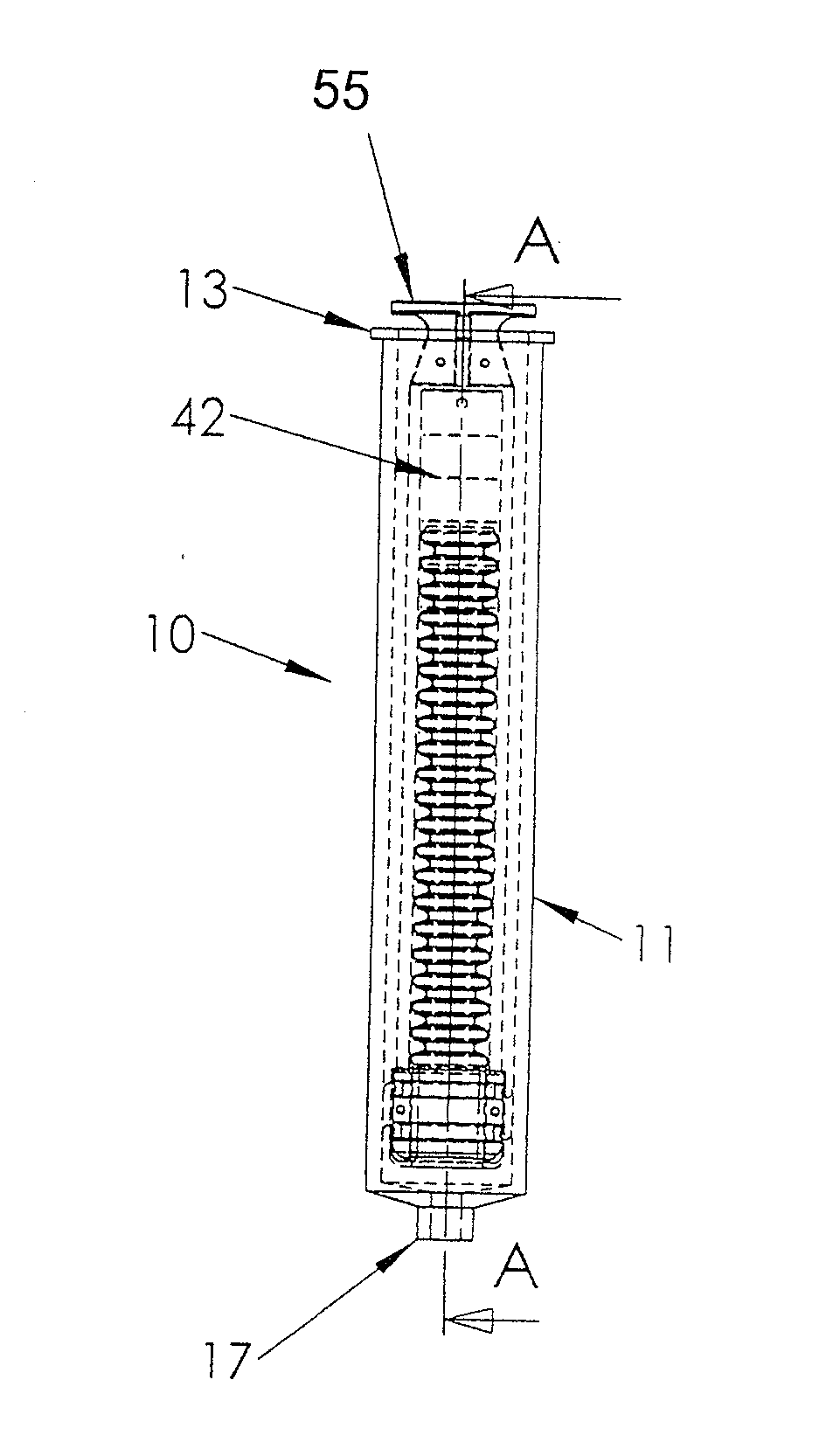

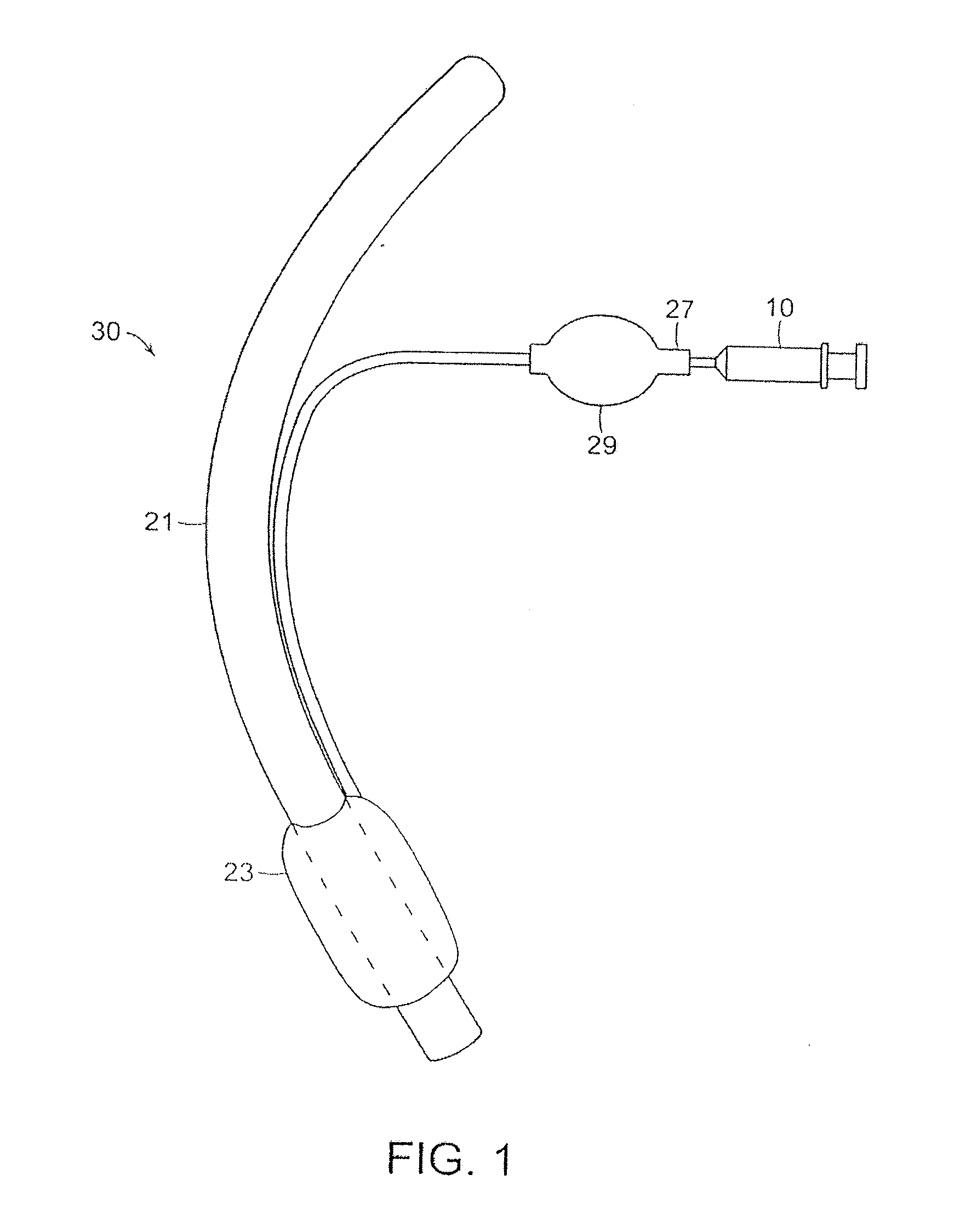

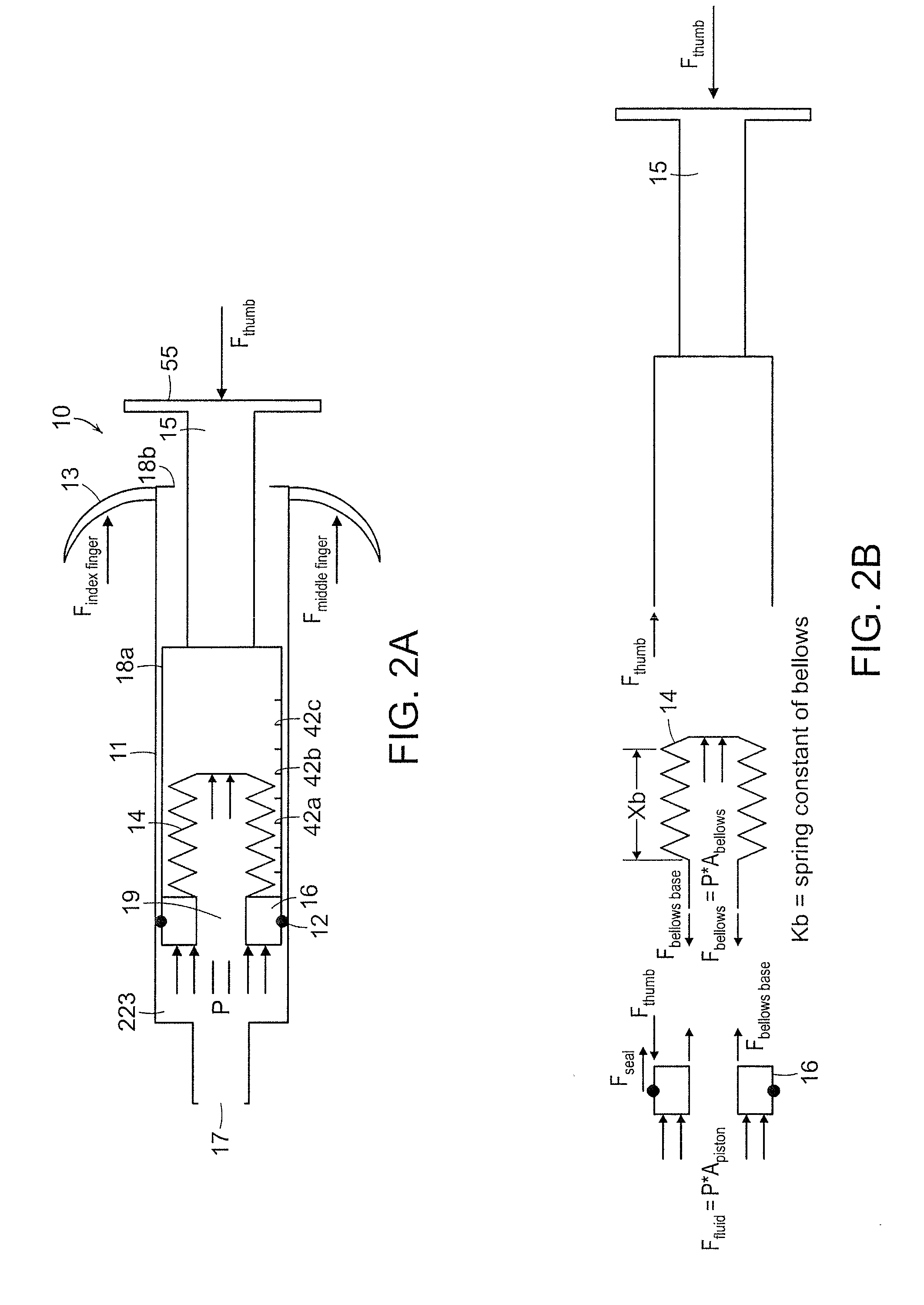

Pressure measuring syringe

InactiveUS20100179488A1Change pressureReduce frictionRespiratorsStentsInternal pressureEndotracheal tube

A syringe having an internal pressure gauge comprises a syringe barrel; a piston within the barrel; a spring coupled to the piston at a first position of the spring, the spring having a second portion that is movable in response to fluid pressure within a syringe cavity; and a pressure gauge having an indicator correlated to a plurality of positions of the second portion of the spring to indicate a pressure of a fluid. The spring can be a bellows. The first portion of the spring can be coupled to the piston to form a sliding seal with an inner wall of the syringe, and the second portion of the spring can move longitudinally within the syringe without sealing contact. The syringe can indicate fluid pressures within a range of at least about 5 to 35 cm H2O, for example. The fluid chamber can be in fluid communication with a cuff of an inflatable medical device, such as an endotracheal tube, such that the measured pressure comprises the fluid pressure within the cuff. Methods of measuring pressure using a syringe are also disclosed.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC +1

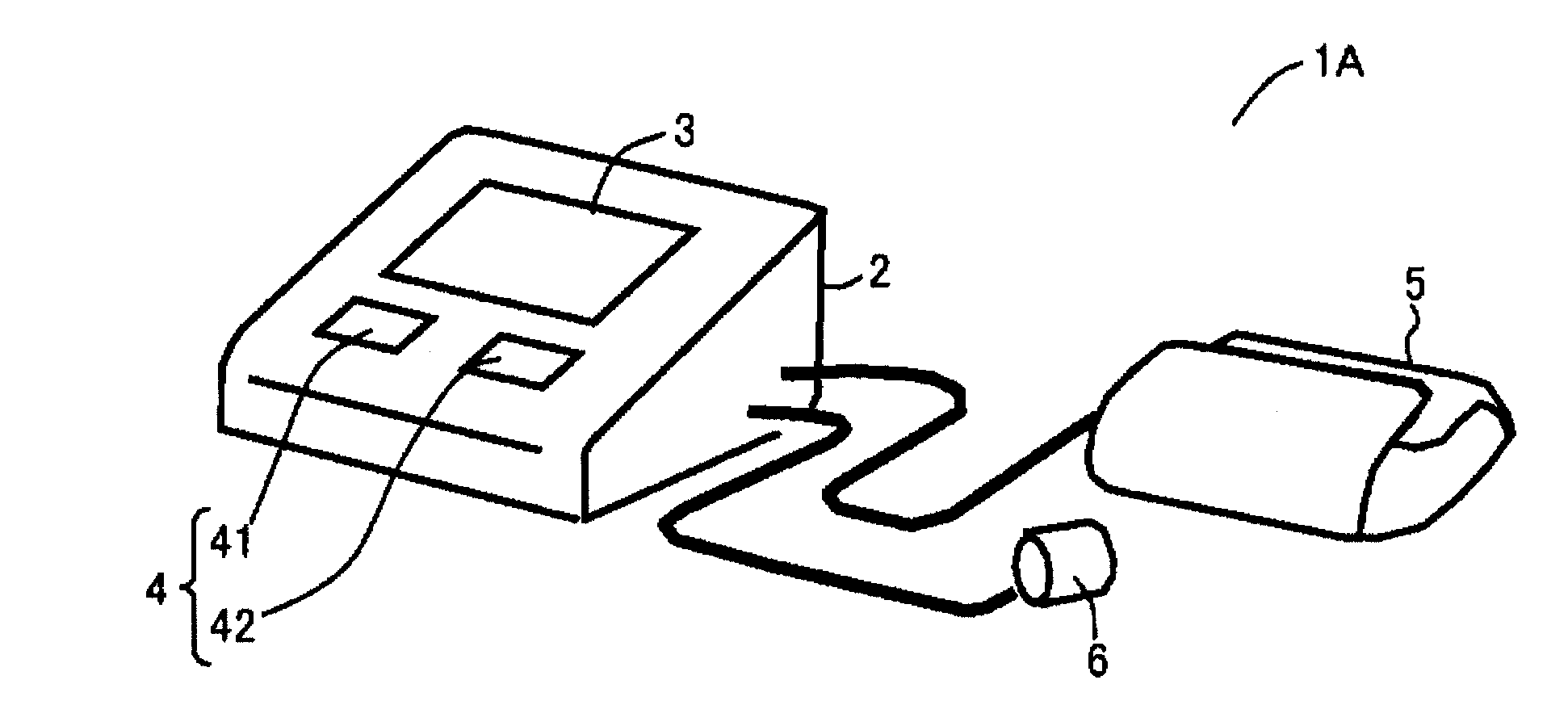

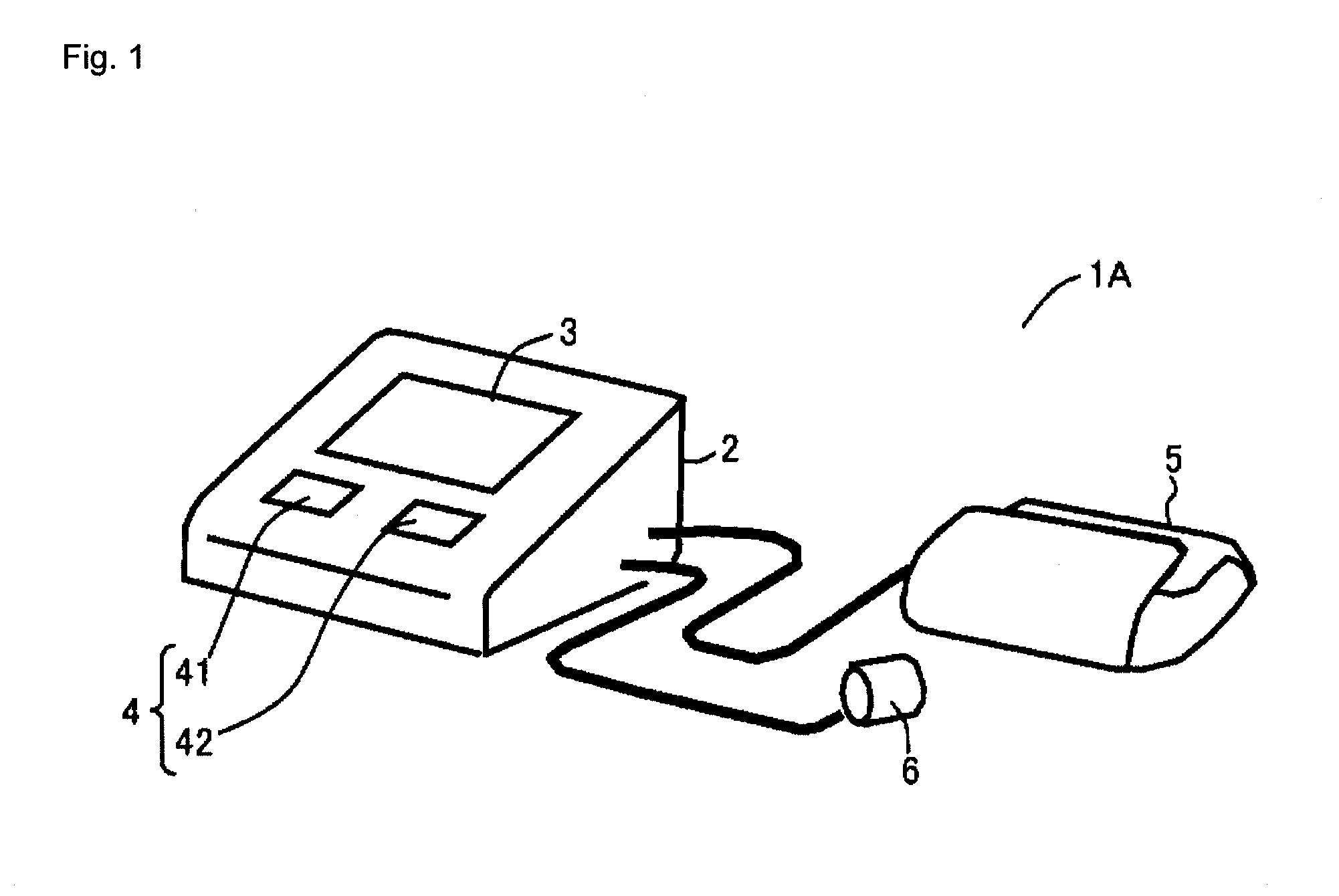

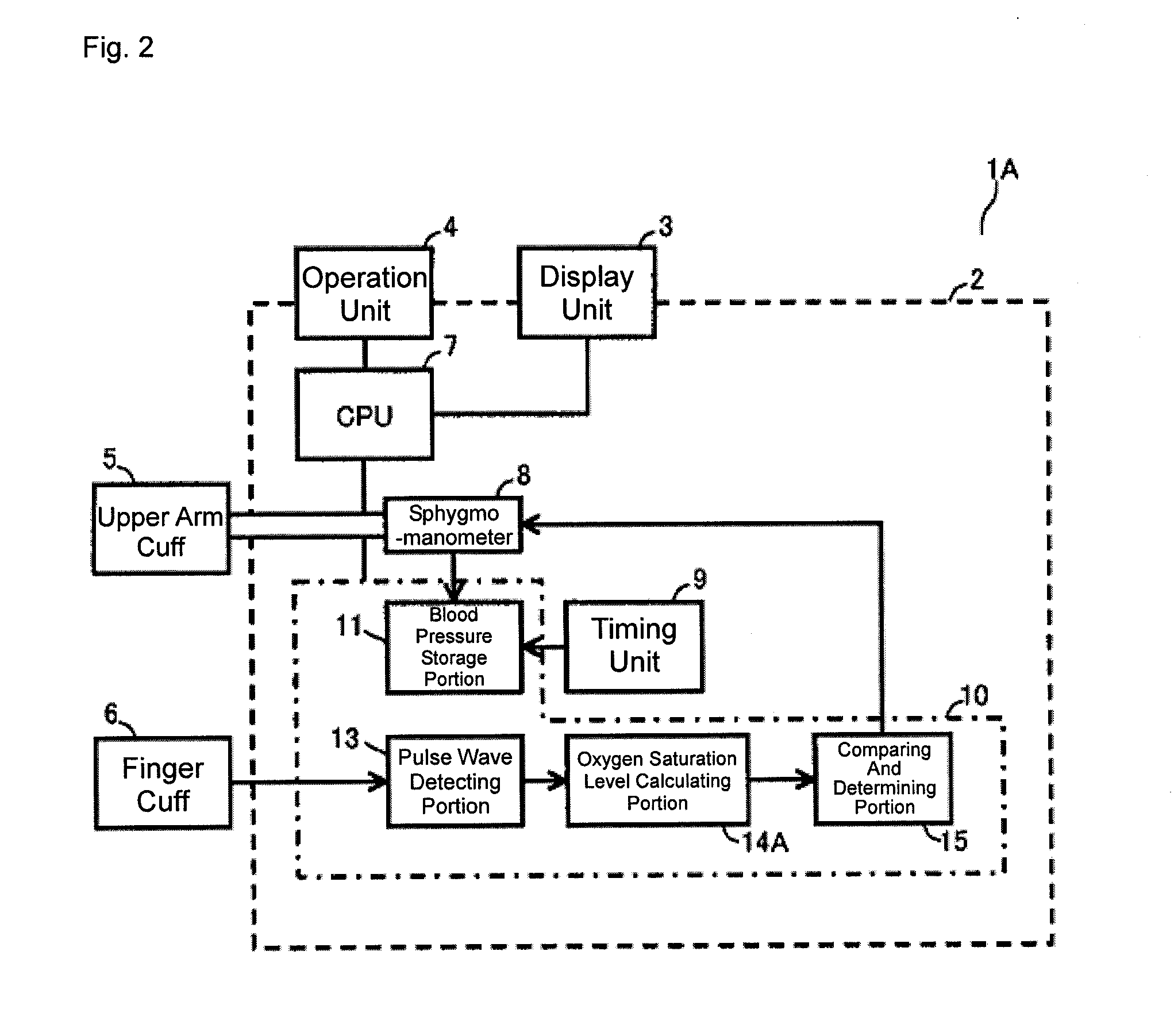

Blood pressure measurement device for measuring at appropriate timing

ActiveUS20110230729A1ElectrocardiographyEvaluation of blood vesselsSphygmomanometerMeasurement device

A blood pressure measurement device includes a finger cuff for measuring a blood oxygen saturation level of a subject as physiological information excluding a blood pressure, a pulse wave detecting portion, and an oxygen saturation level calculating portion, where a start of blood pressure measurement in a sphygmomanometer is determined by a comparing and determining portion when a value becomes greater than or equal to a reference value. After the end of the measurement, a time limit for limiting the start of the blood pressure measurement is set. The comparing and determining portion determines not to start the blood pressure measurement within the time limit even if the blood oxygen saturation level becomes greater than or equal to the reference value.

Owner:OMRON HEALTHCARE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com