Patents

Literature

127results about How to "Accurate pressure measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

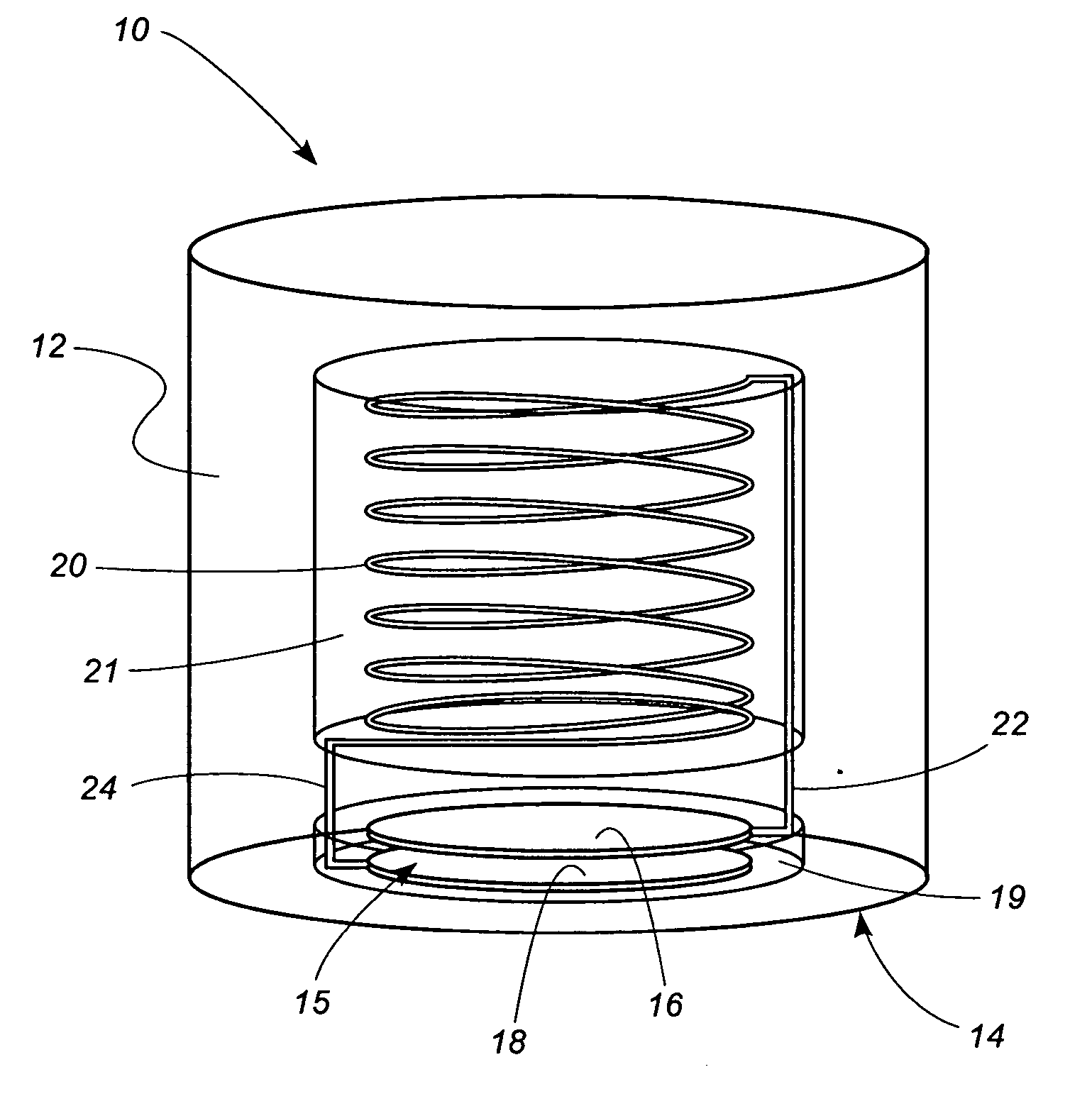

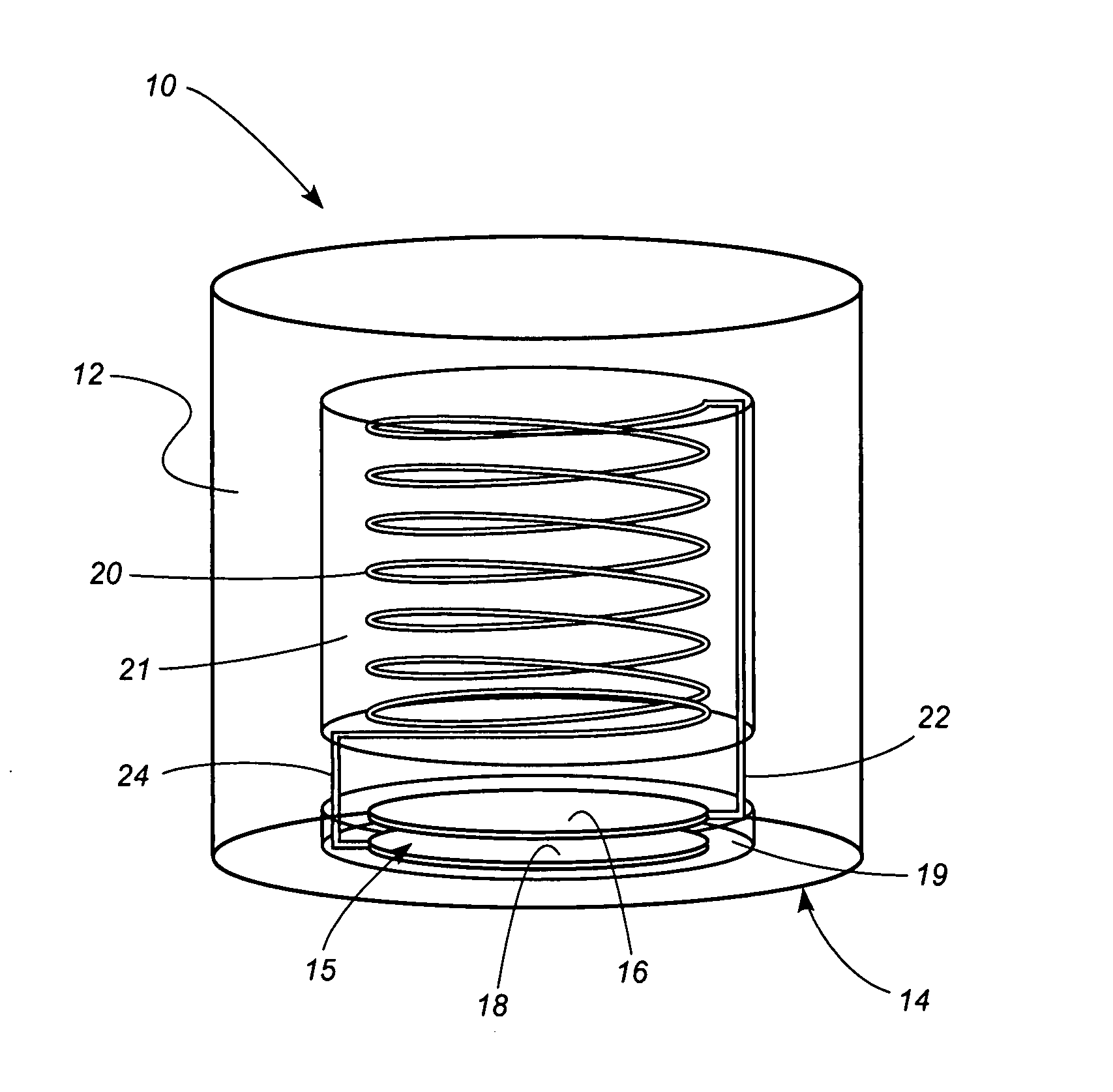

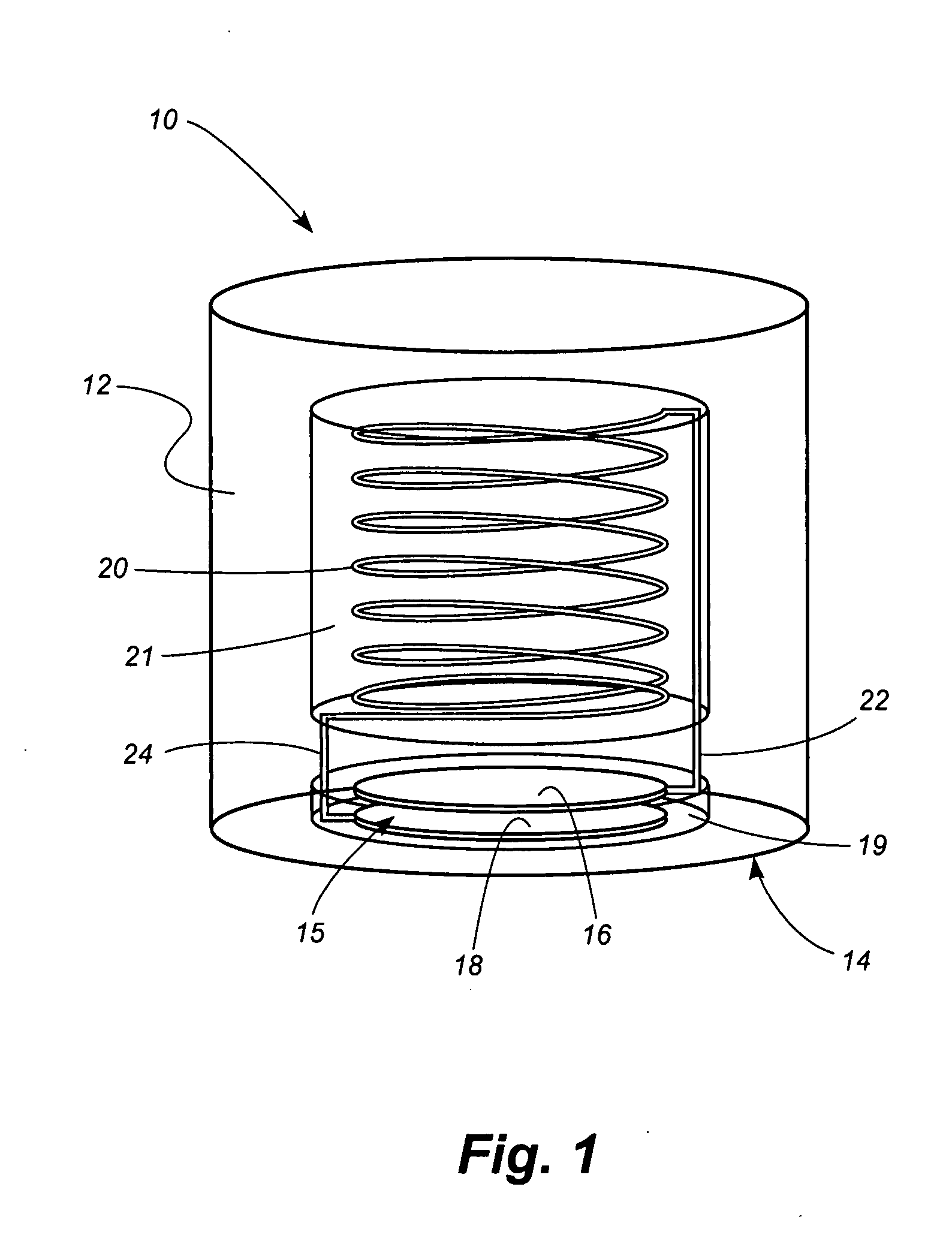

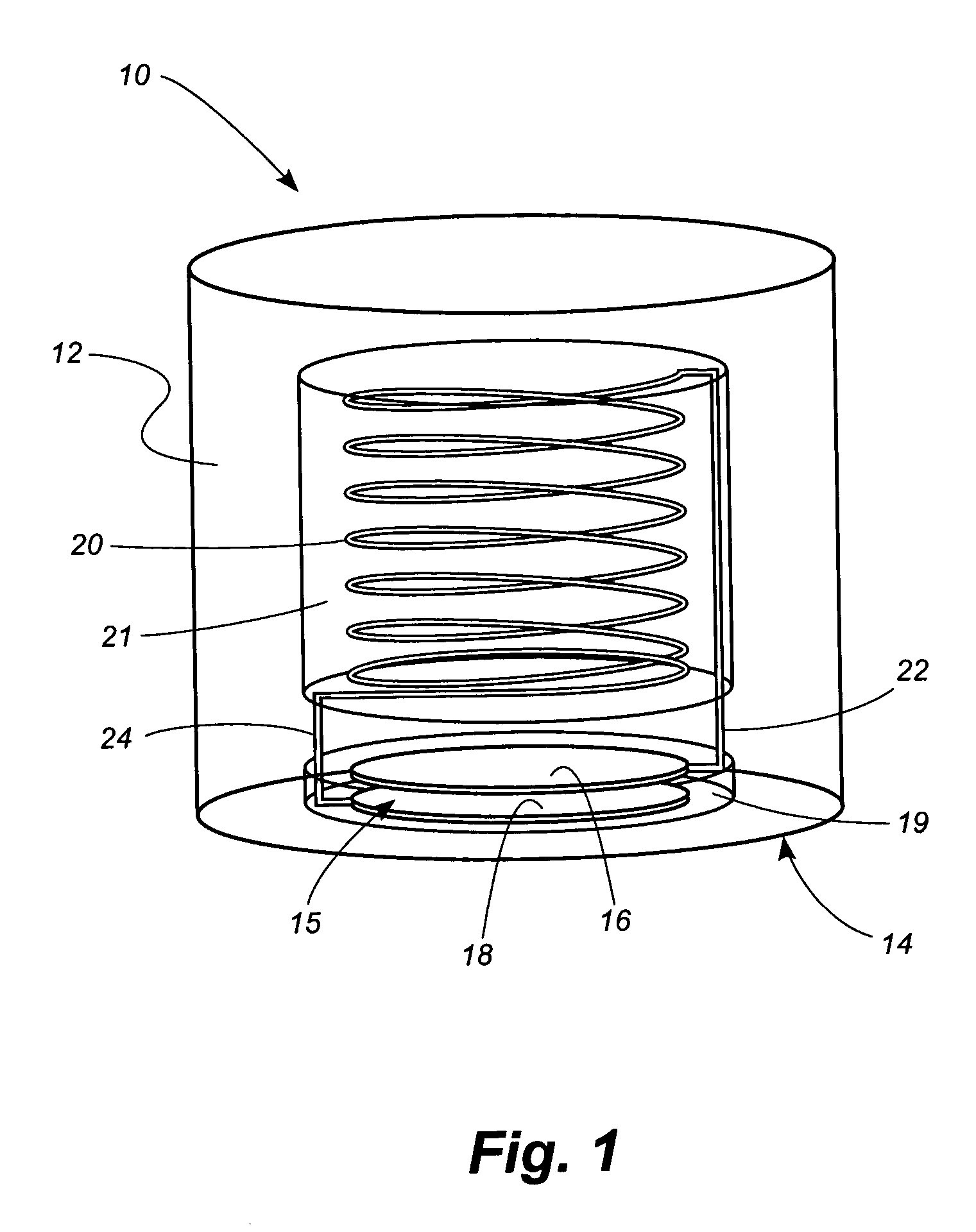

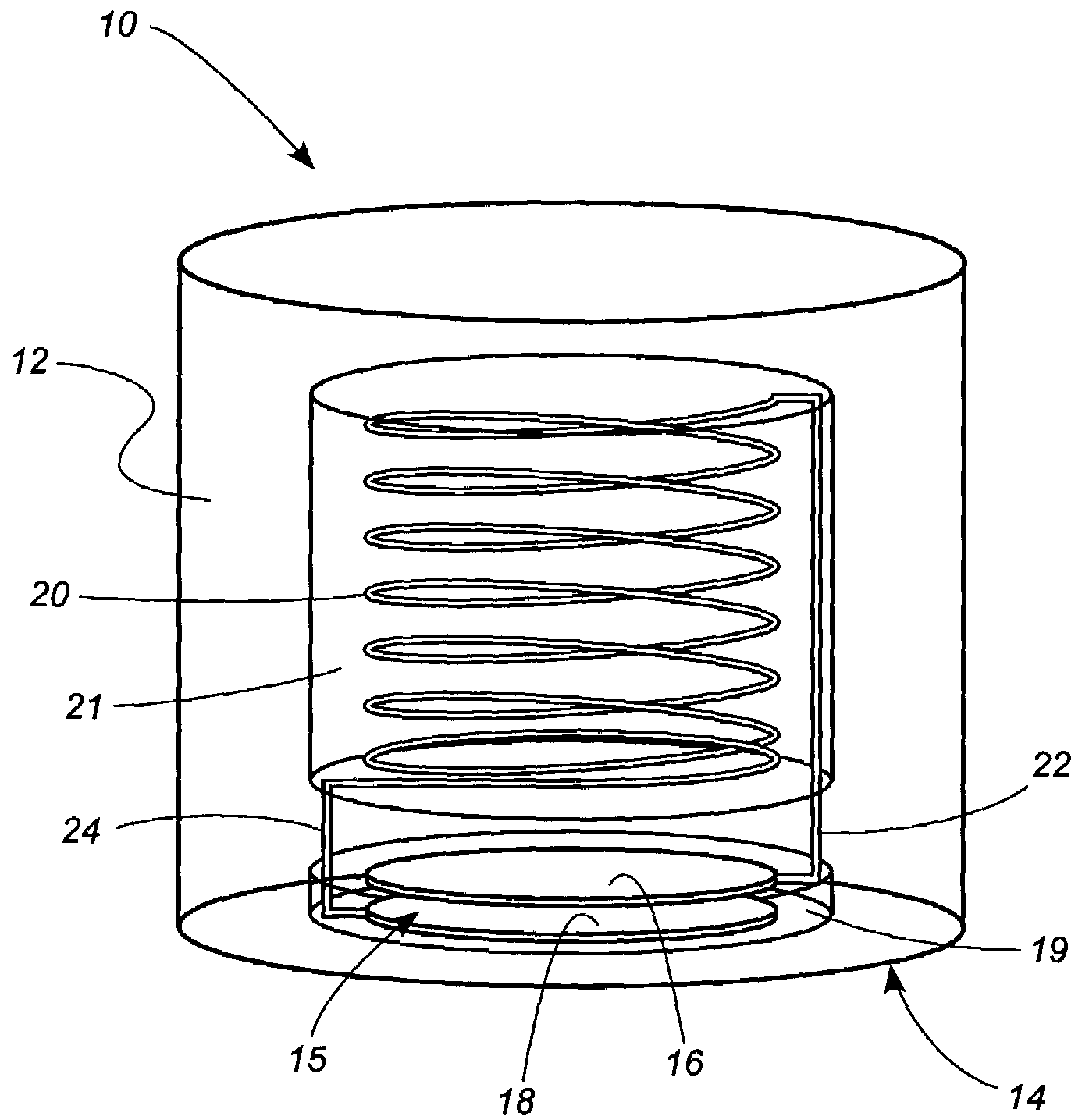

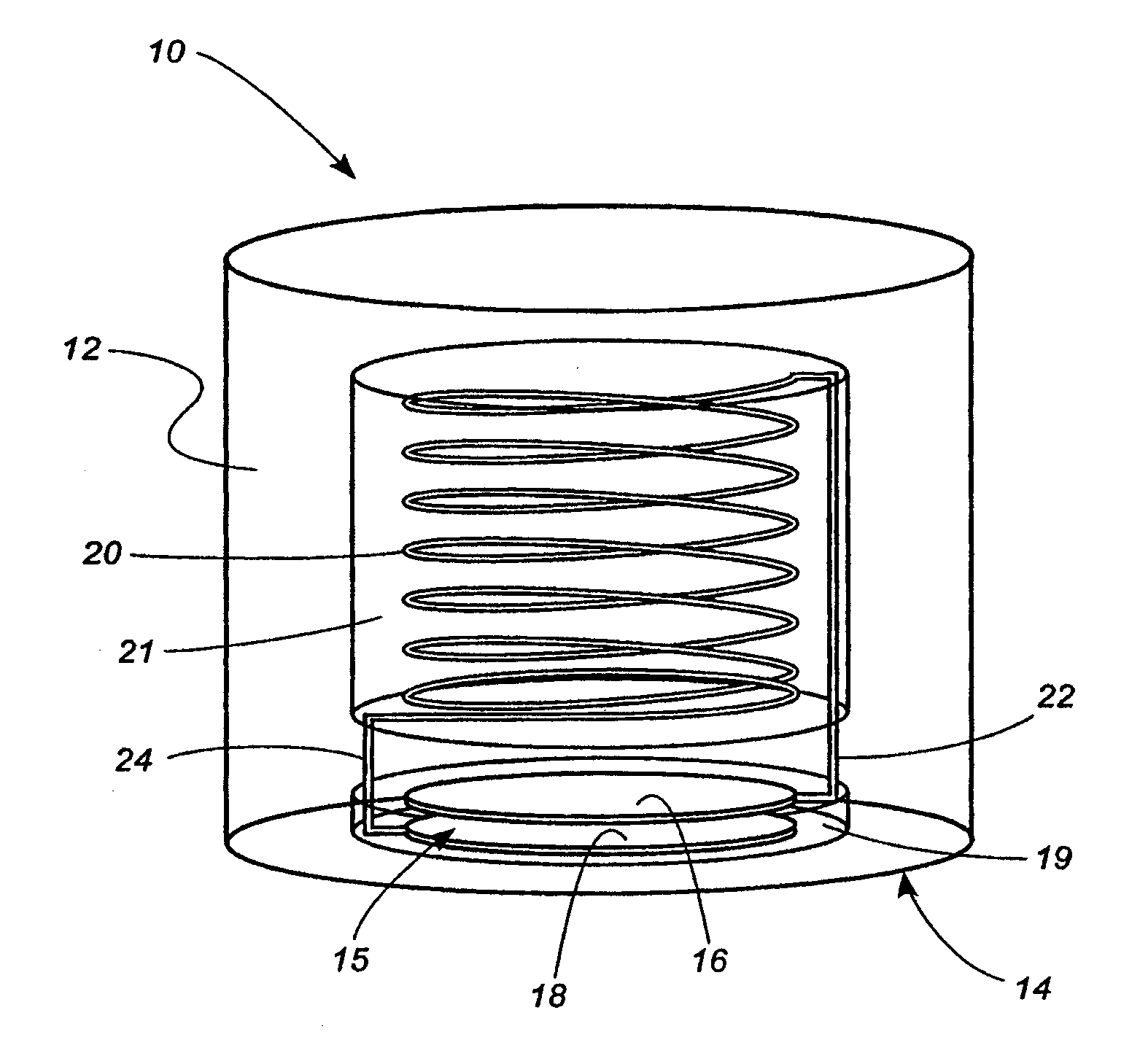

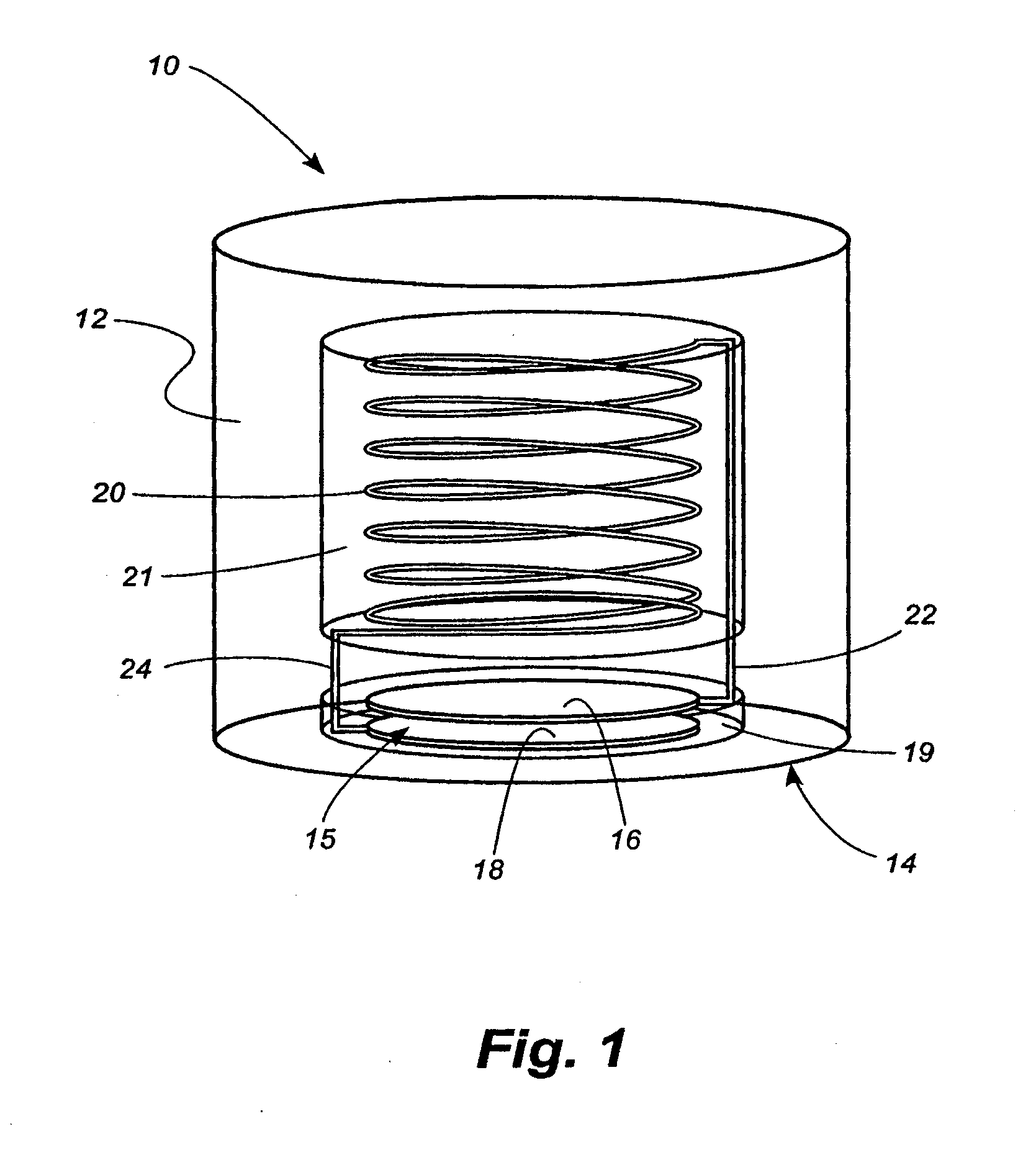

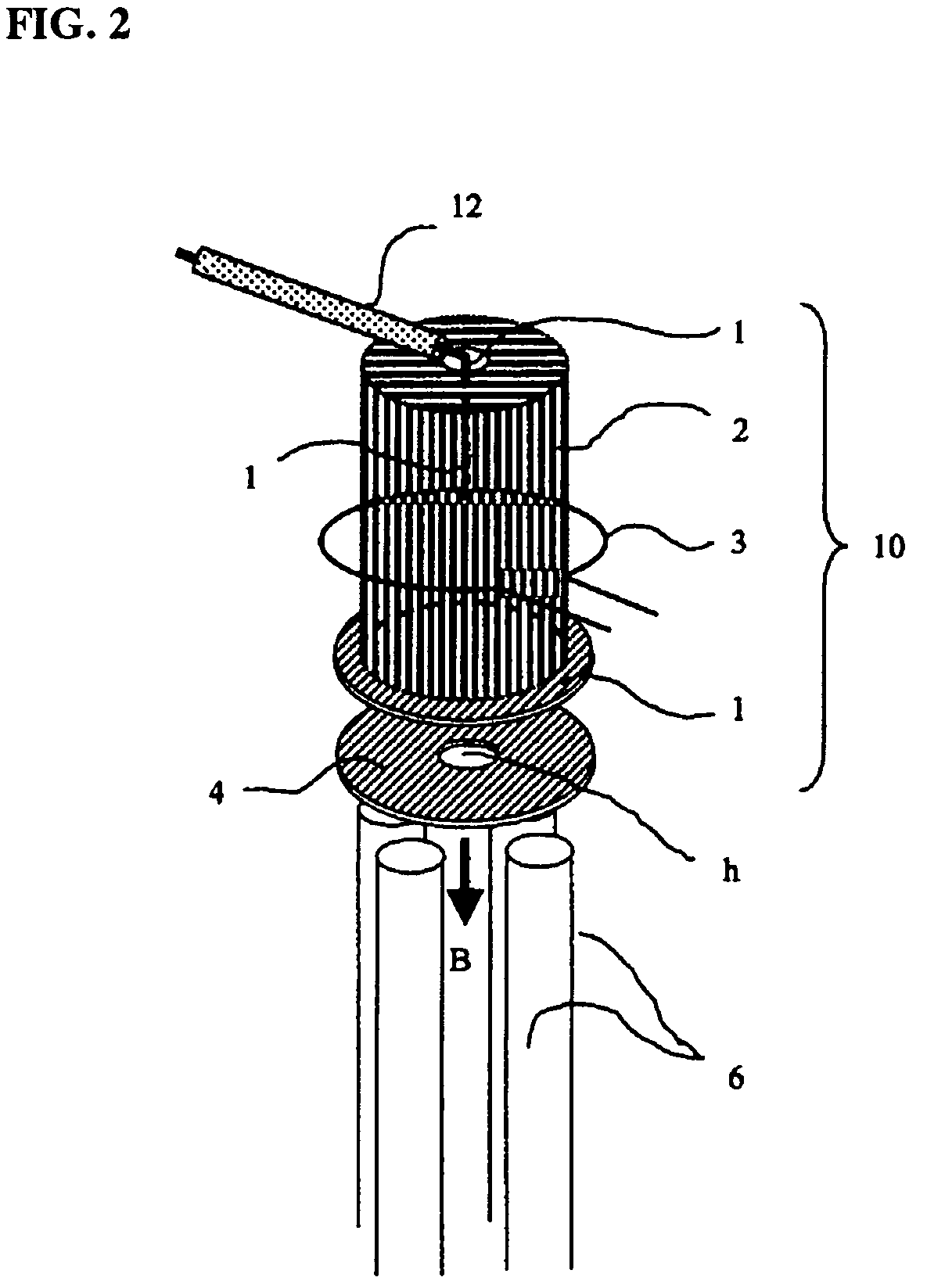

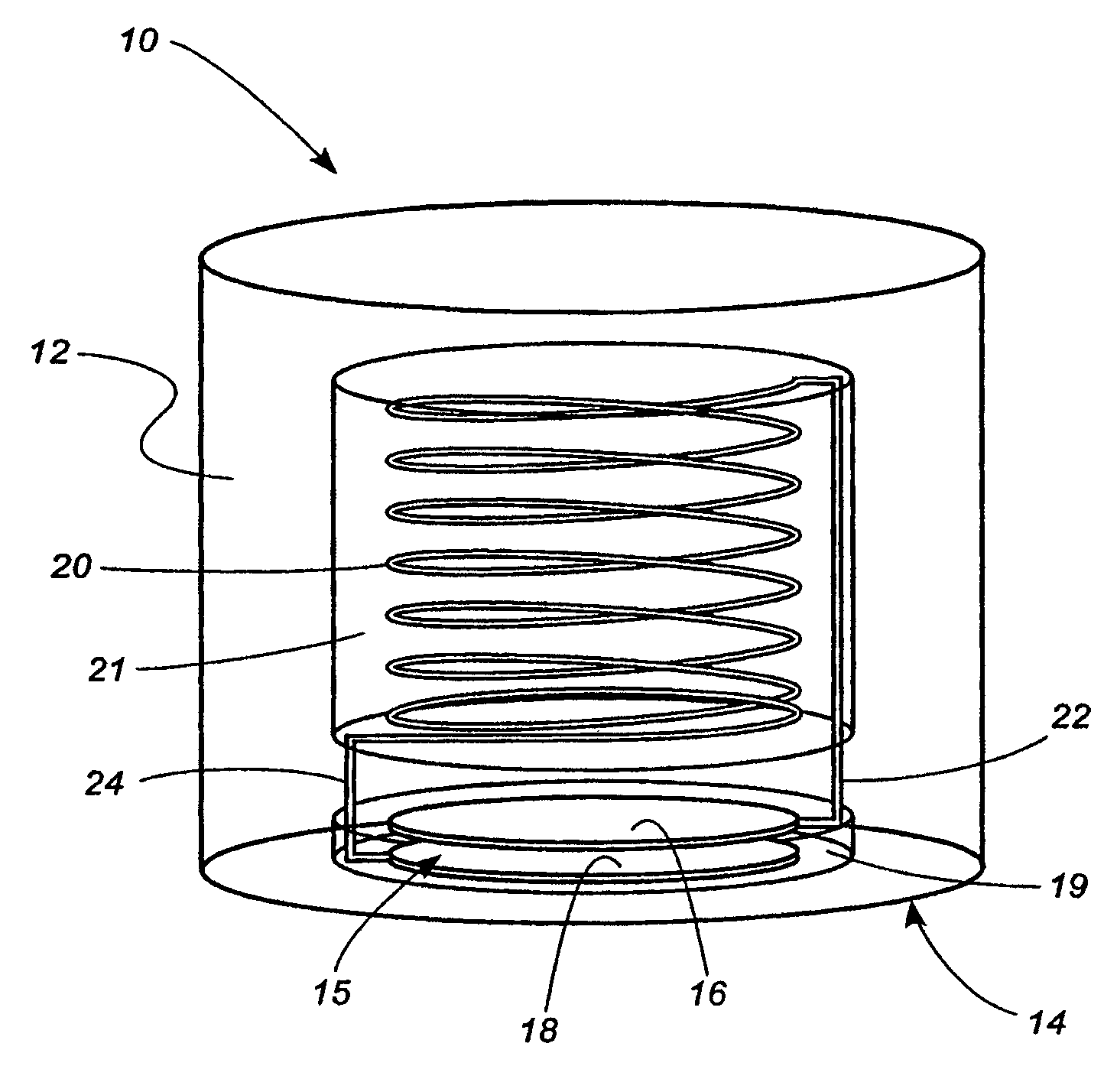

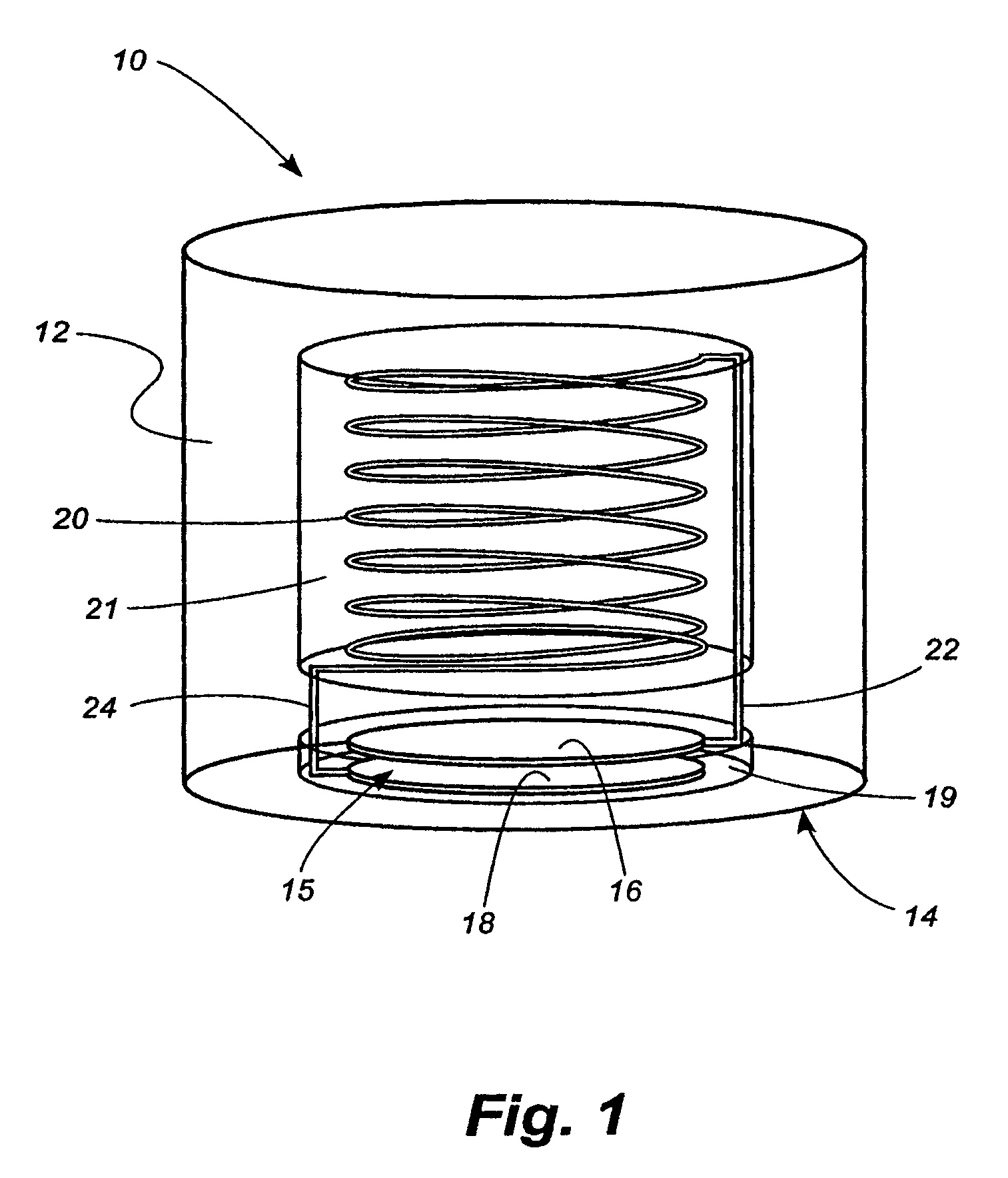

Implantable wireless sensor for in vivo pressure measurement

A sensor suitable for in vivo implantation has a capacitive circuit and a three-dimensional inductor coil connected to the capacitive circuit to form an LC circuit. The LC circuit is hermetically encapsulated within an electrically insulating housing. An electrical characteristic of the LC circuit is responsive to a change in an environmental parameter.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

Implantable wireless sensor for in vivo pressure measurement and continuous output determination

InactiveUS20070282210A1Accurate pressure measurementCatheterDiagnostic recording/measuringLine sensorPeak value

A method and apparatus for determining cardiac parameters within the body of a patient includes a wireless sensor positioned in the patient's pulmonary artery. An external RF telemetry device communicates wirelessly with the sensor and interrogates the sensor to determine changes in pressure in the pulmonary artery over time. The peak pressure difference is determined. Then, assuming zero blood flow velocity at the time of valve opening and at the time of valve closing, a velocity-time function is determined. The velocity-time function is used to determine a velocity-time integral. The velocity-time integral is then used to determine cardiac stroke volume. The cardiac stroke volume is multiplied times the heartbeat rate to determine cardiac output. The cardiac output can be monitored over time to determine continuous cardiac output.

Owner:CARDIOMEMS

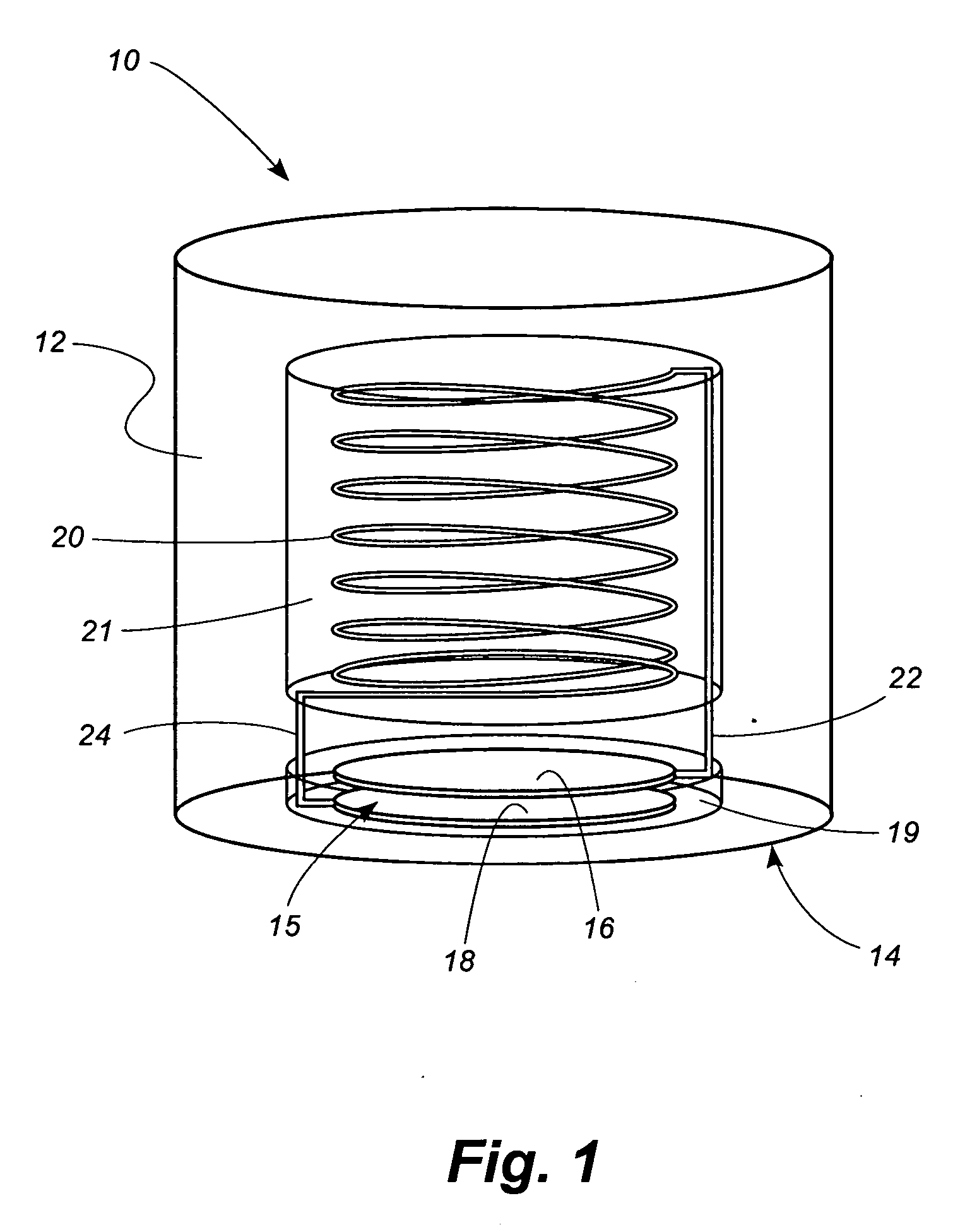

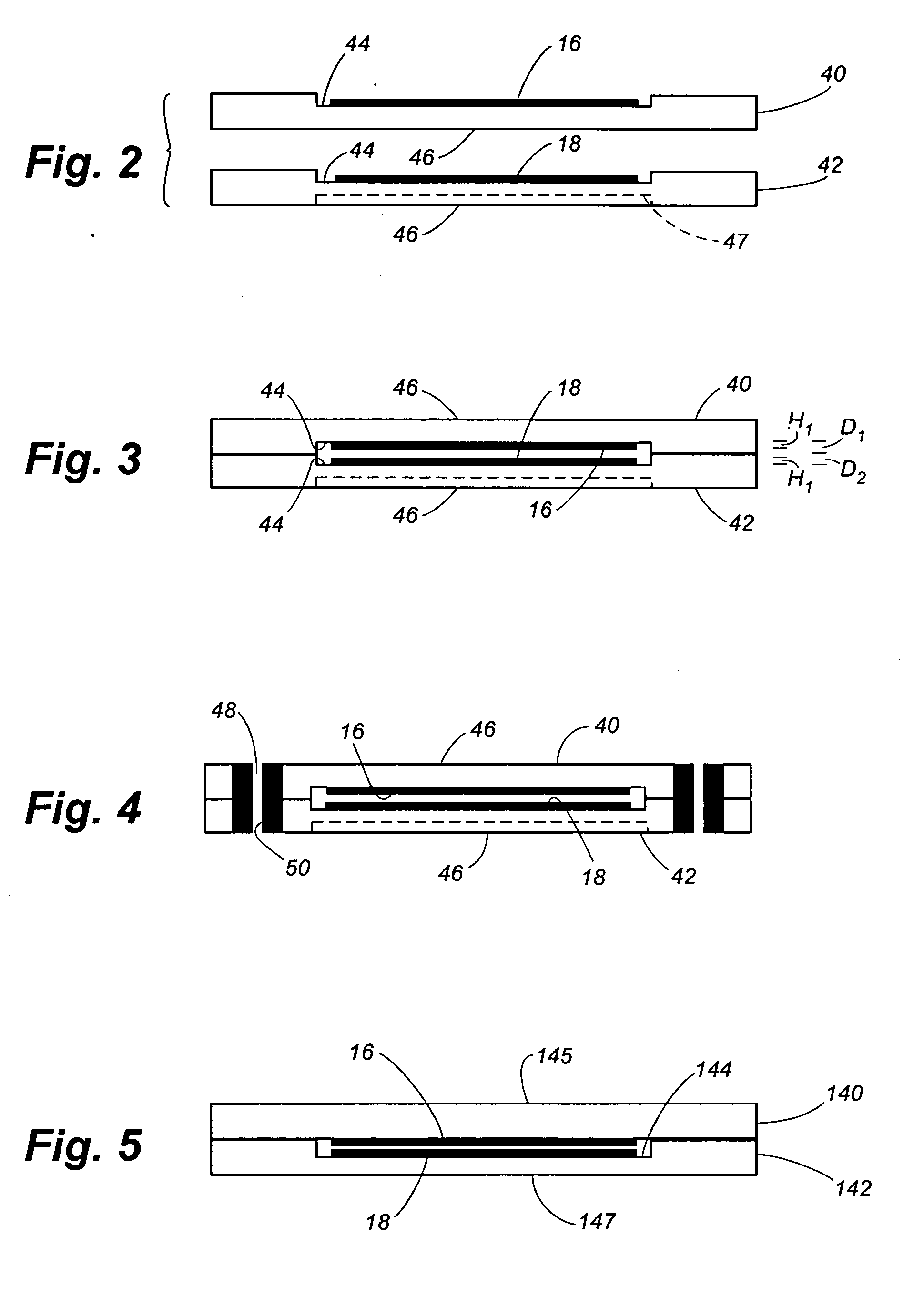

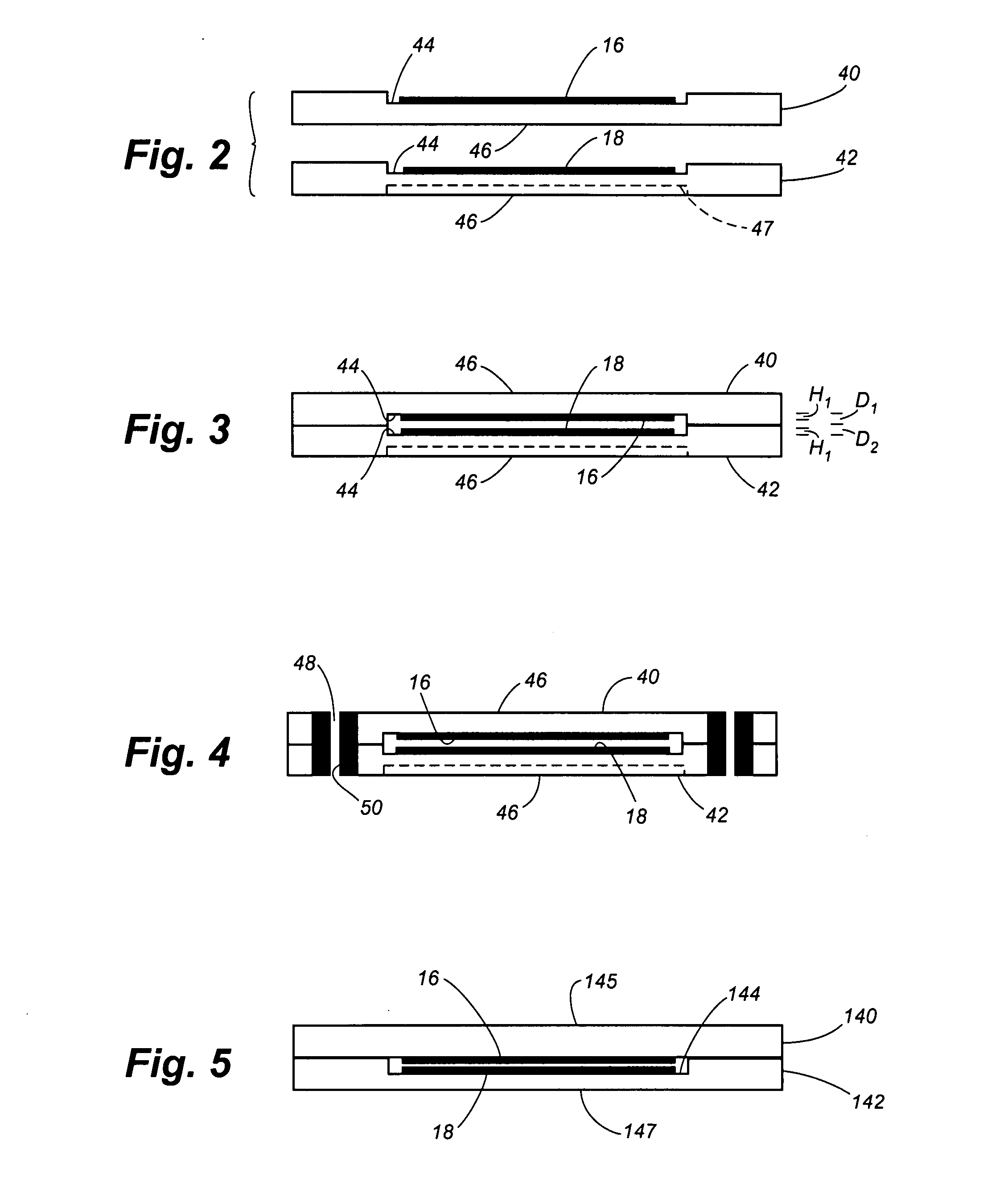

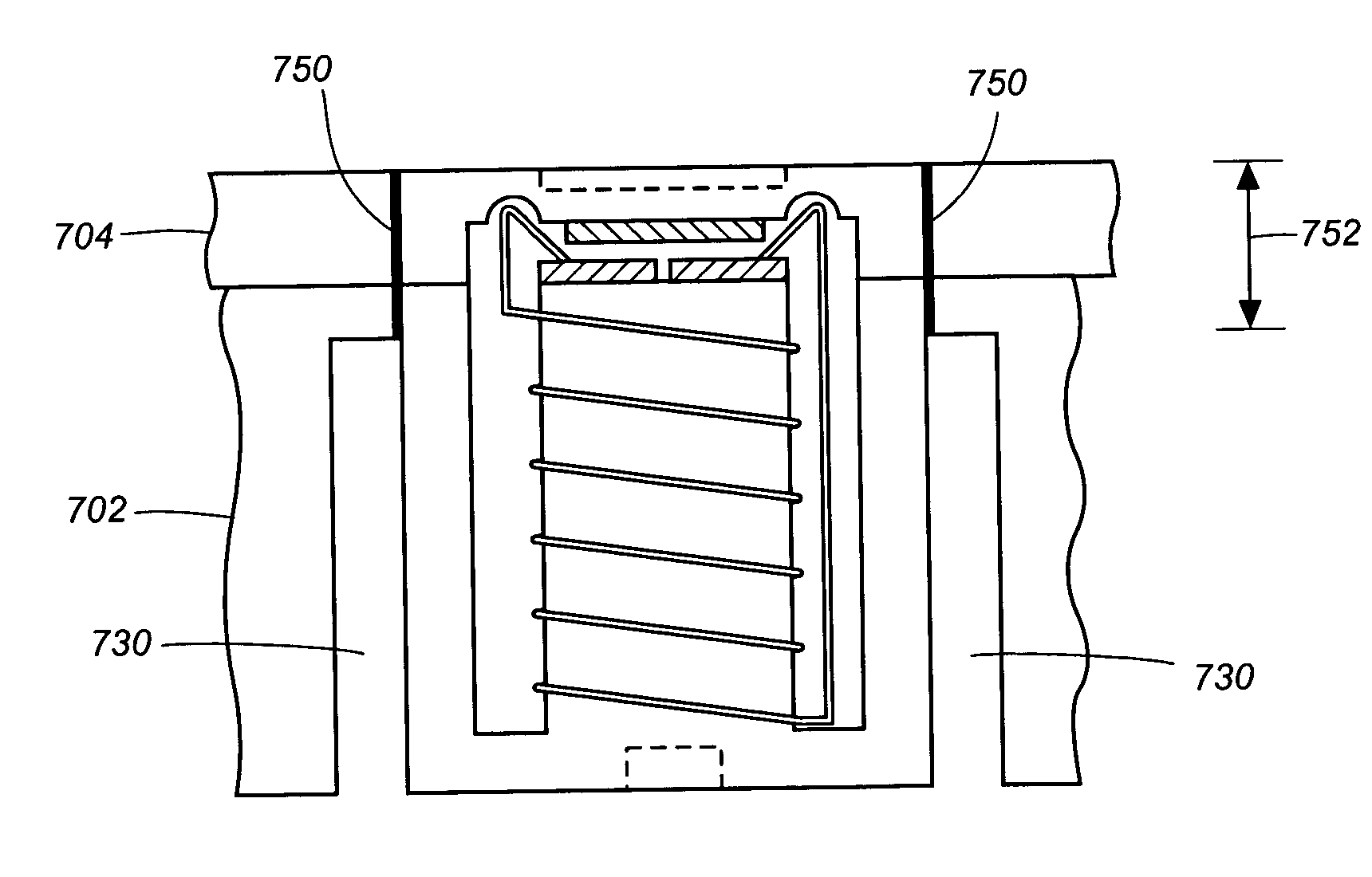

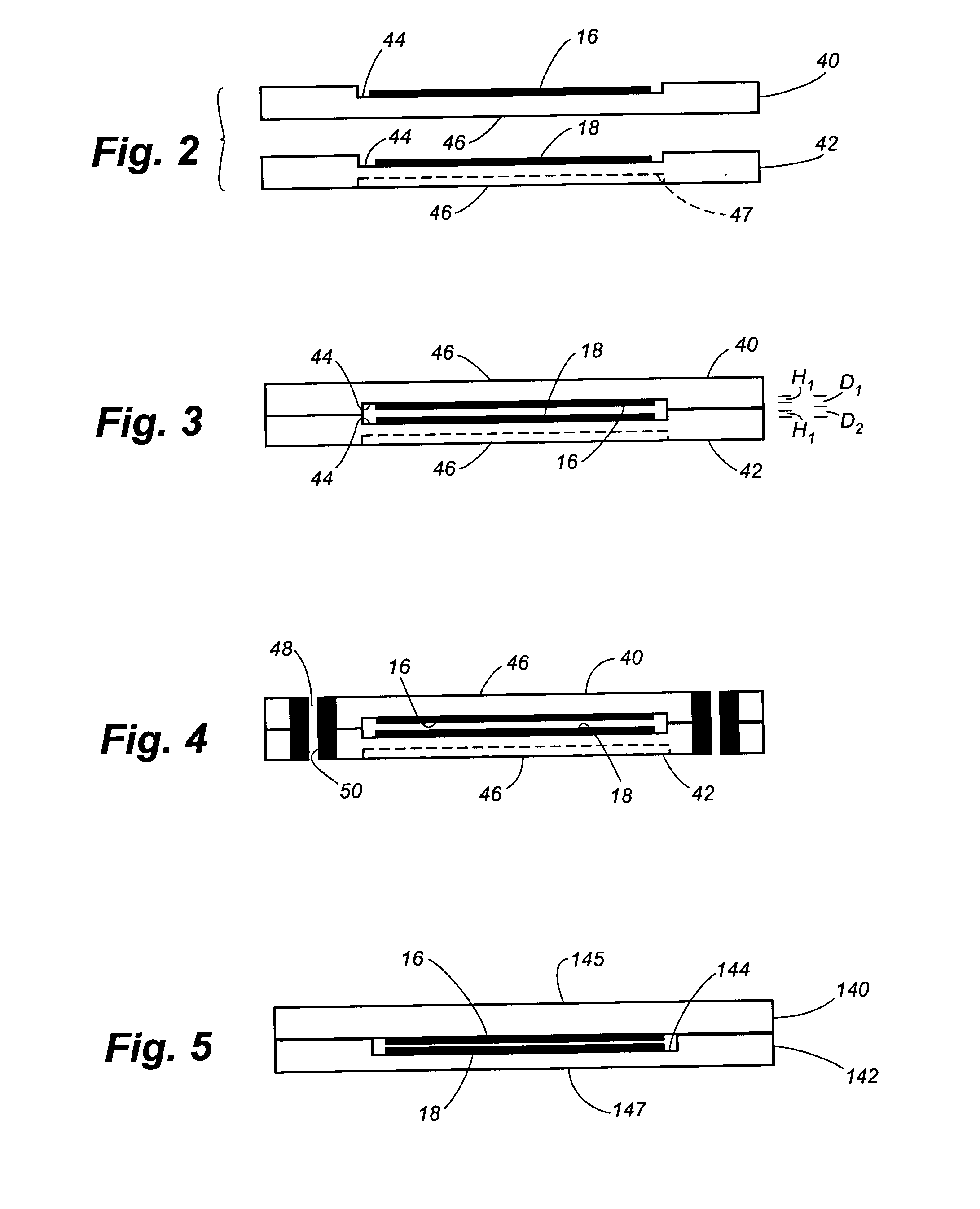

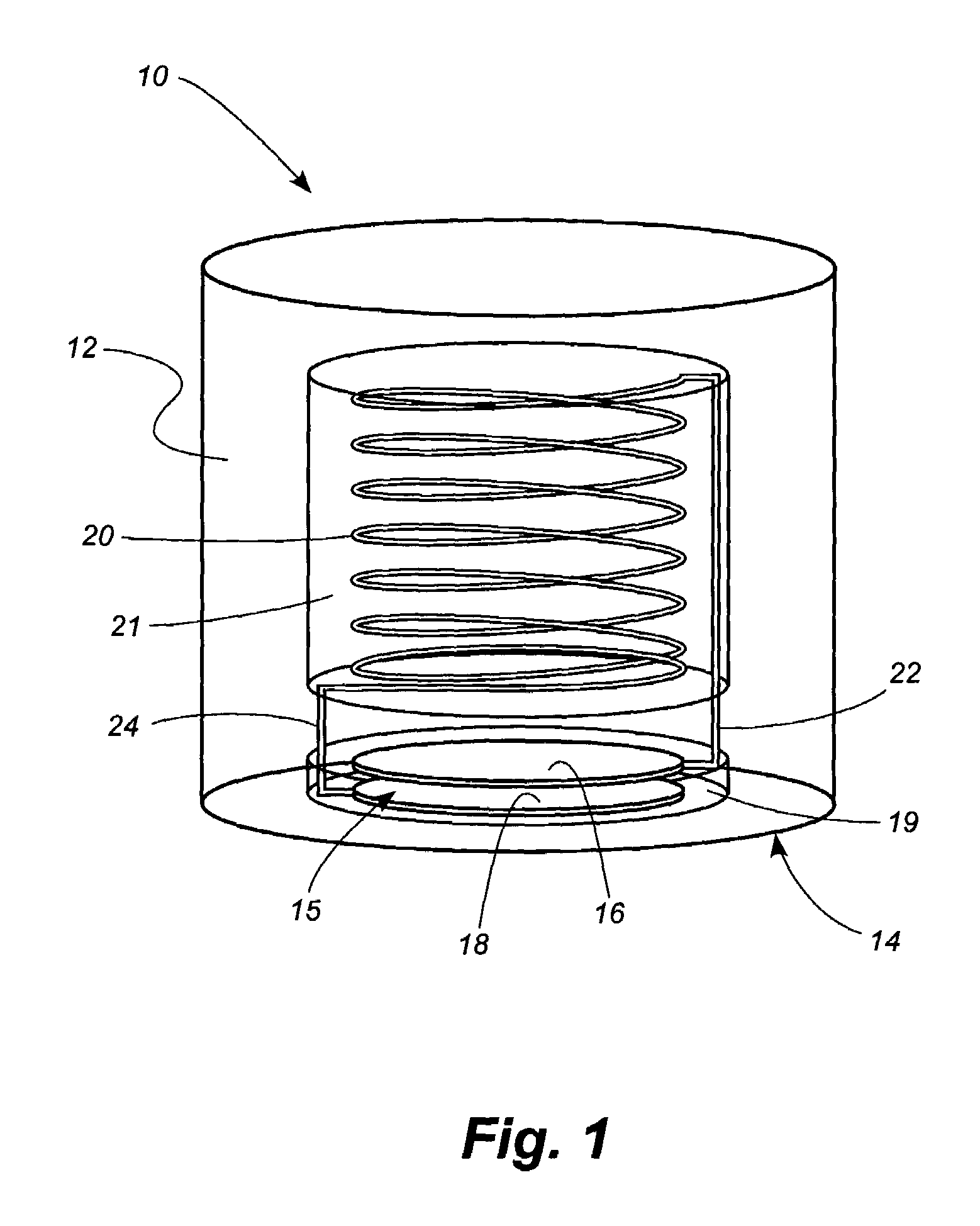

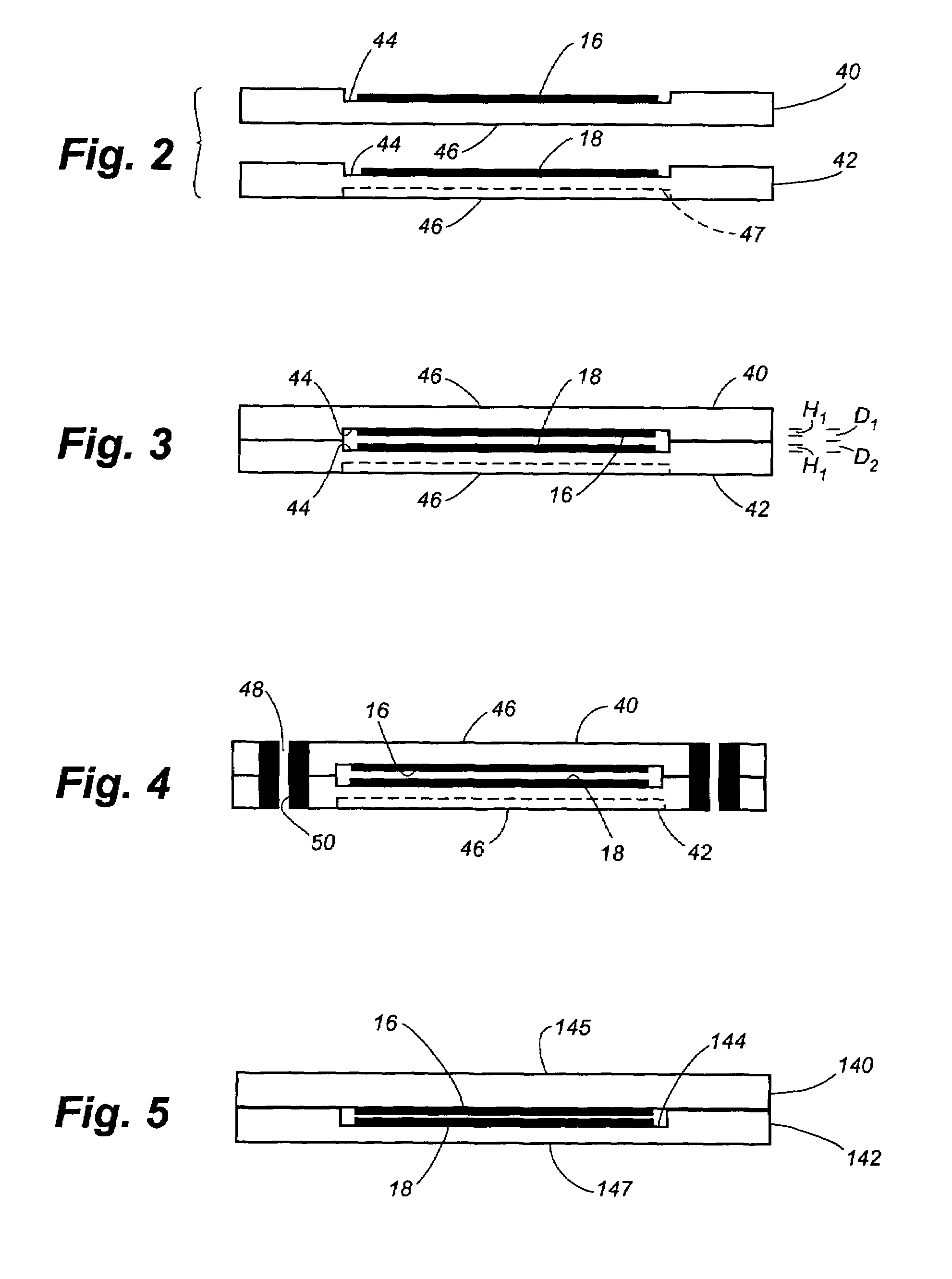

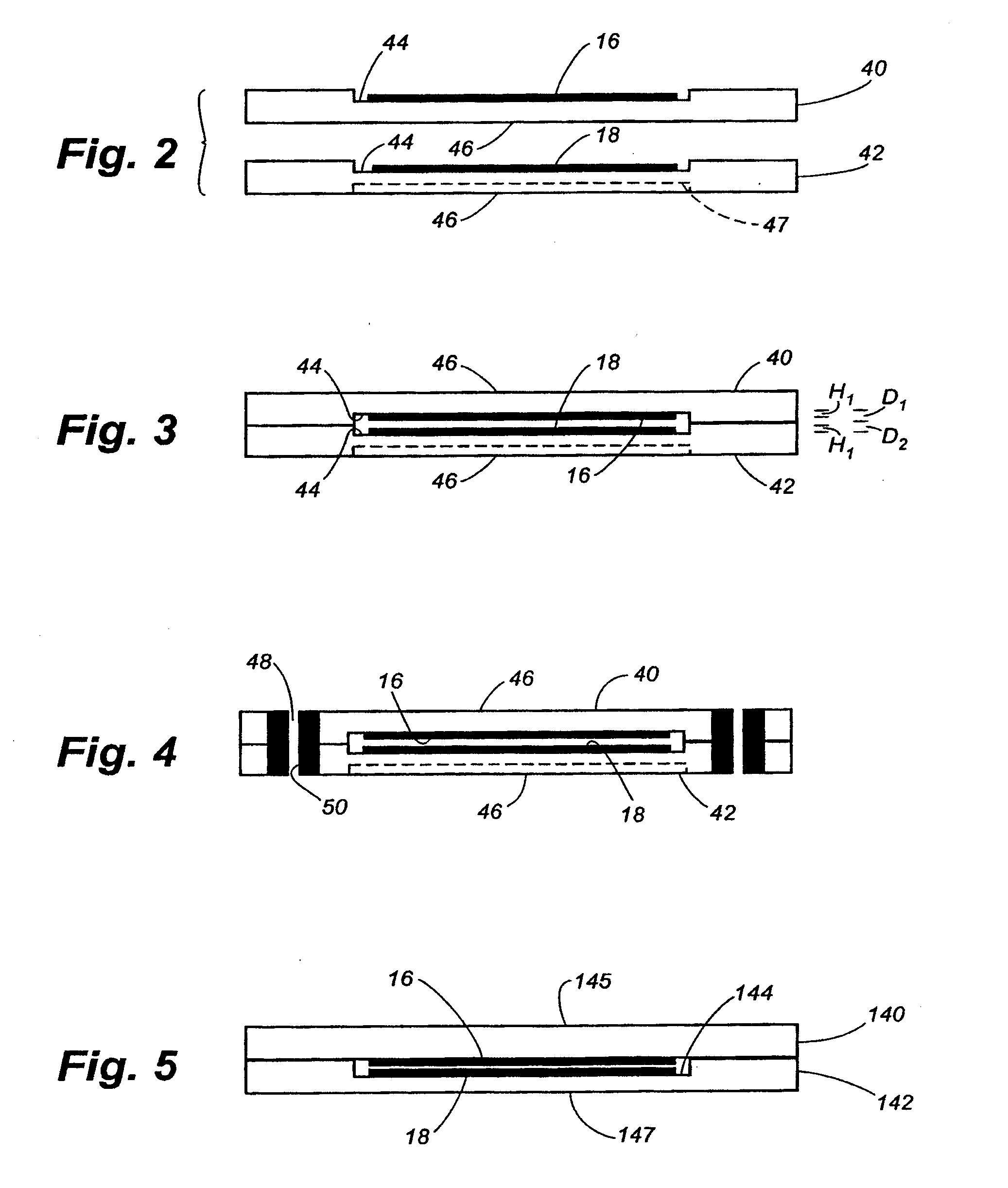

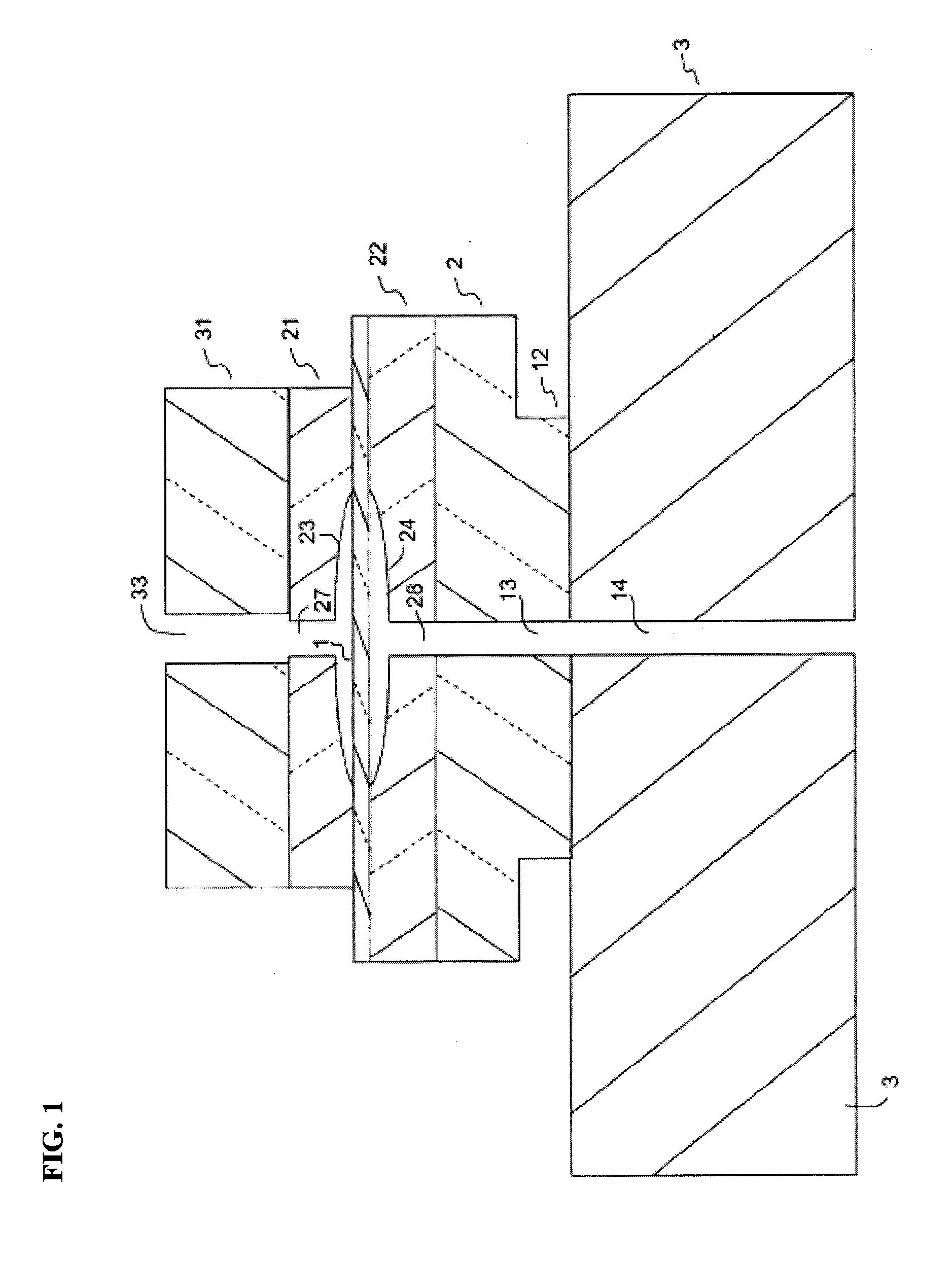

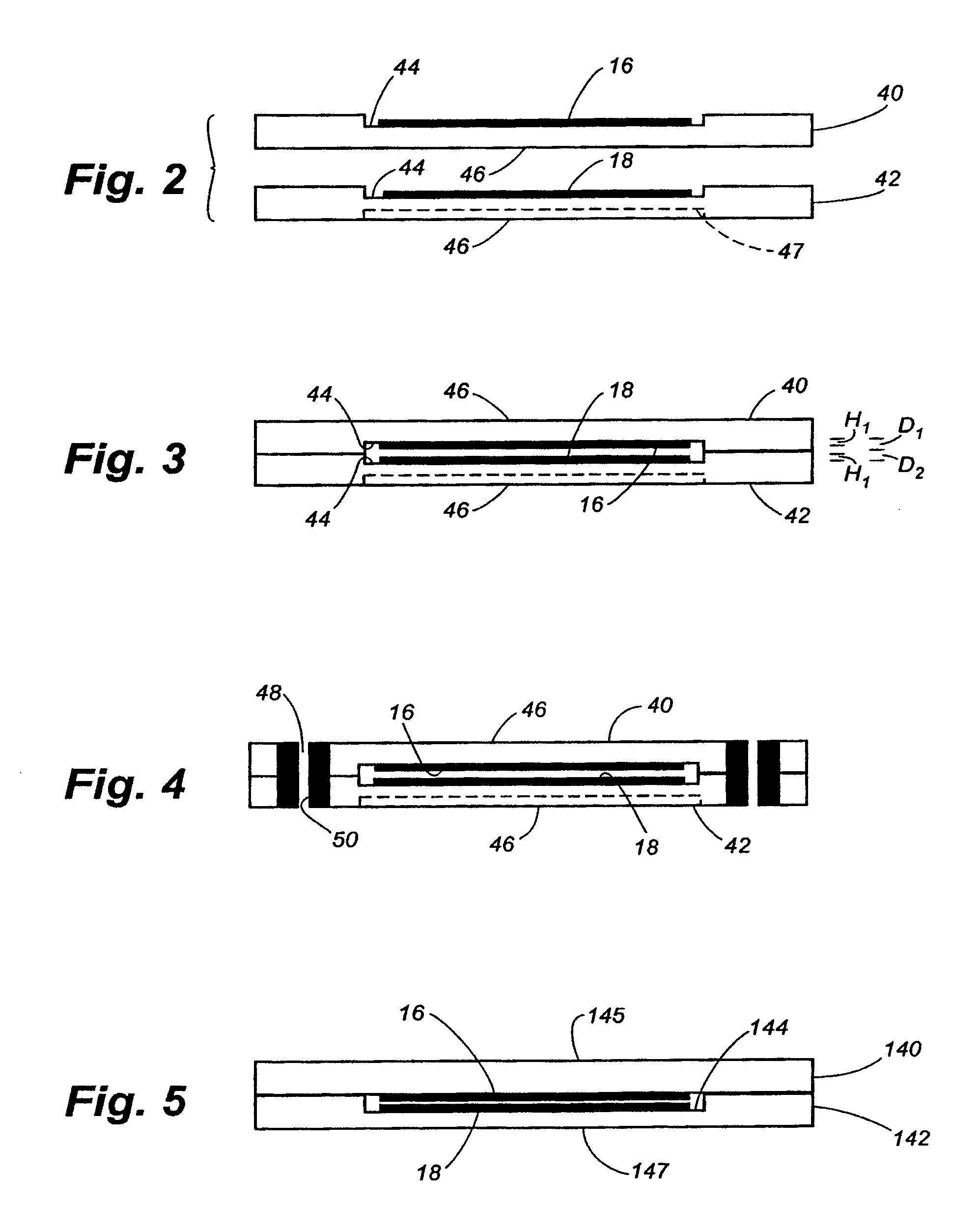

Method of manufacturing implantable wireless sensor for in vivo pressure measurement

ActiveUS20060283007A1Accurate pressure measurementPretreated surfacesManufacture of electrical instrumentsLine sensorEngineering

A method of manufacturing a sensor for in vivo applications includes the steps of providing two wafers of an electrically insulating material. A recess is formed in the first wafer, and a capacitor plate is formed in the recess of the first wafer. A second capacitor plate is formed in a corresponding region of the second wafer, and the two wafers are affixed to one another such that the first and second capacitor plates are arranged in parallel, spaced-apart relation.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

Method of manufacturing implantable wireless sensor for in vivo pressure measurement

ActiveUS7621036B2Accurate pressure measurementPretreated surfacesManufacture of electrical instrumentsLine sensorElectricity

A method of manufacturing a sensor for in vivo applications includes the steps of providing two wafers of an electrically insulating material. A recess is formed in the first wafer, and a capacitor plate is formed in the recess of the first wafer. A second capacitor plate is formed in a corresponding region of the second wafer, and the two wafers are affixed to one another such that the first and second capacitor plates are arranged in parallel, spaced-apart relation.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

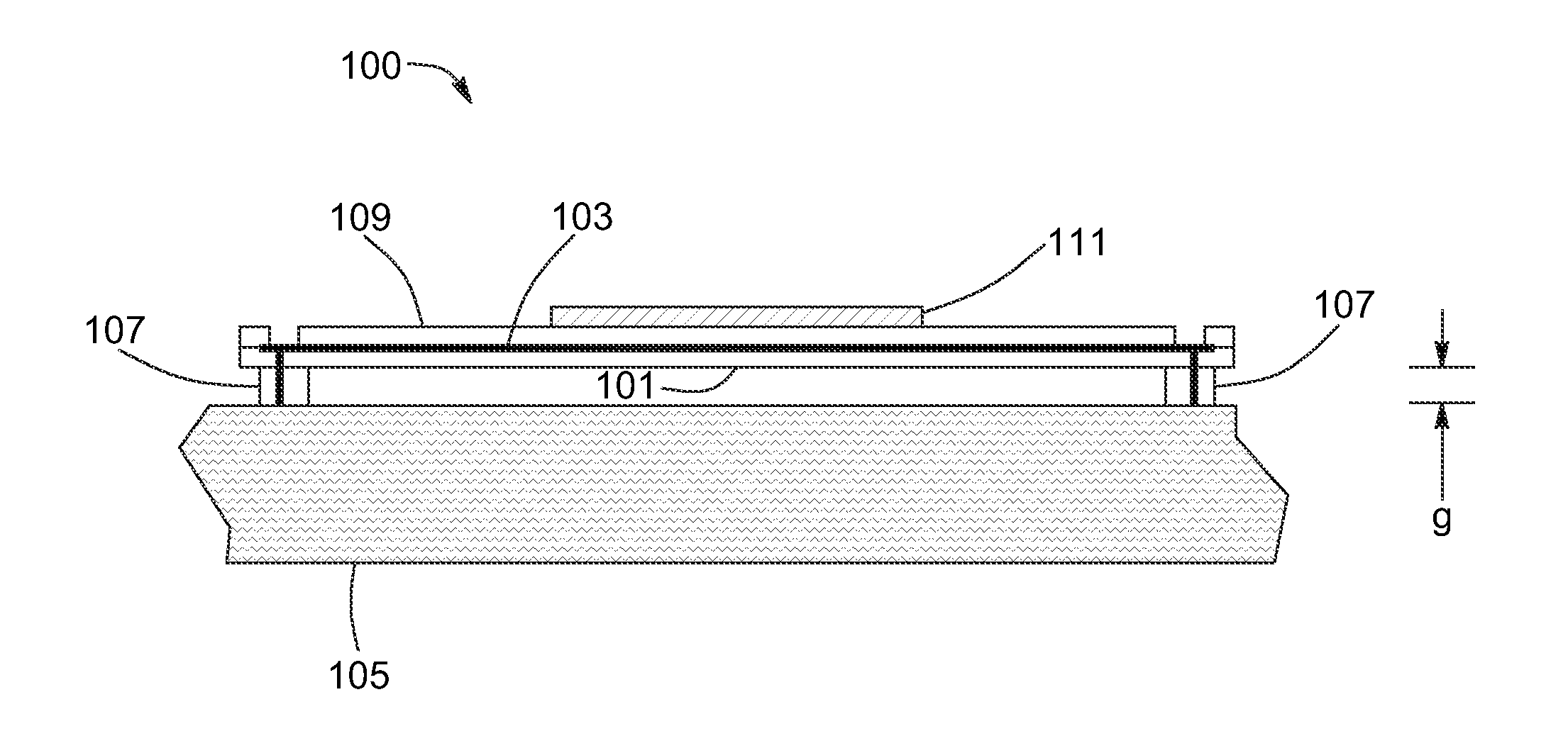

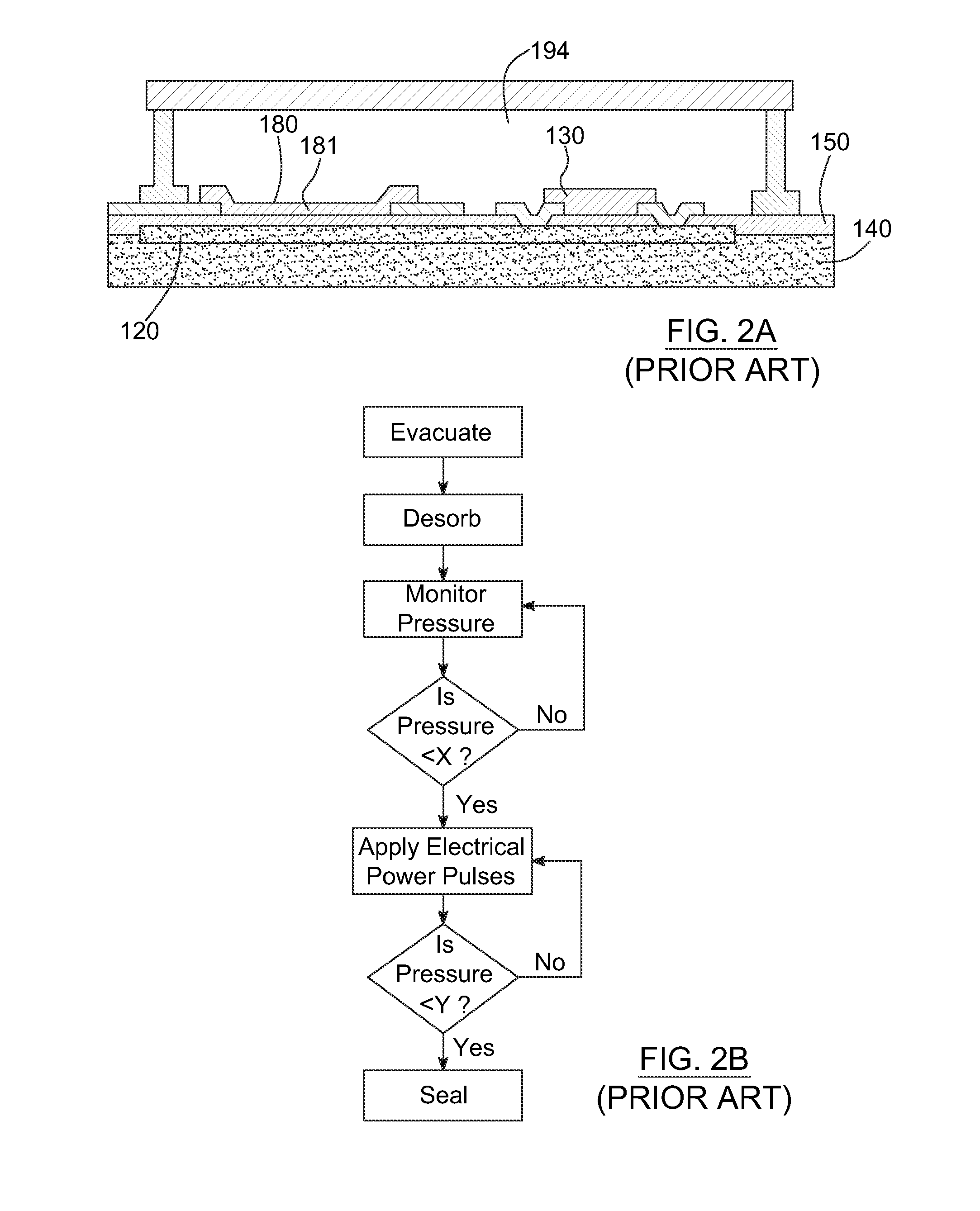

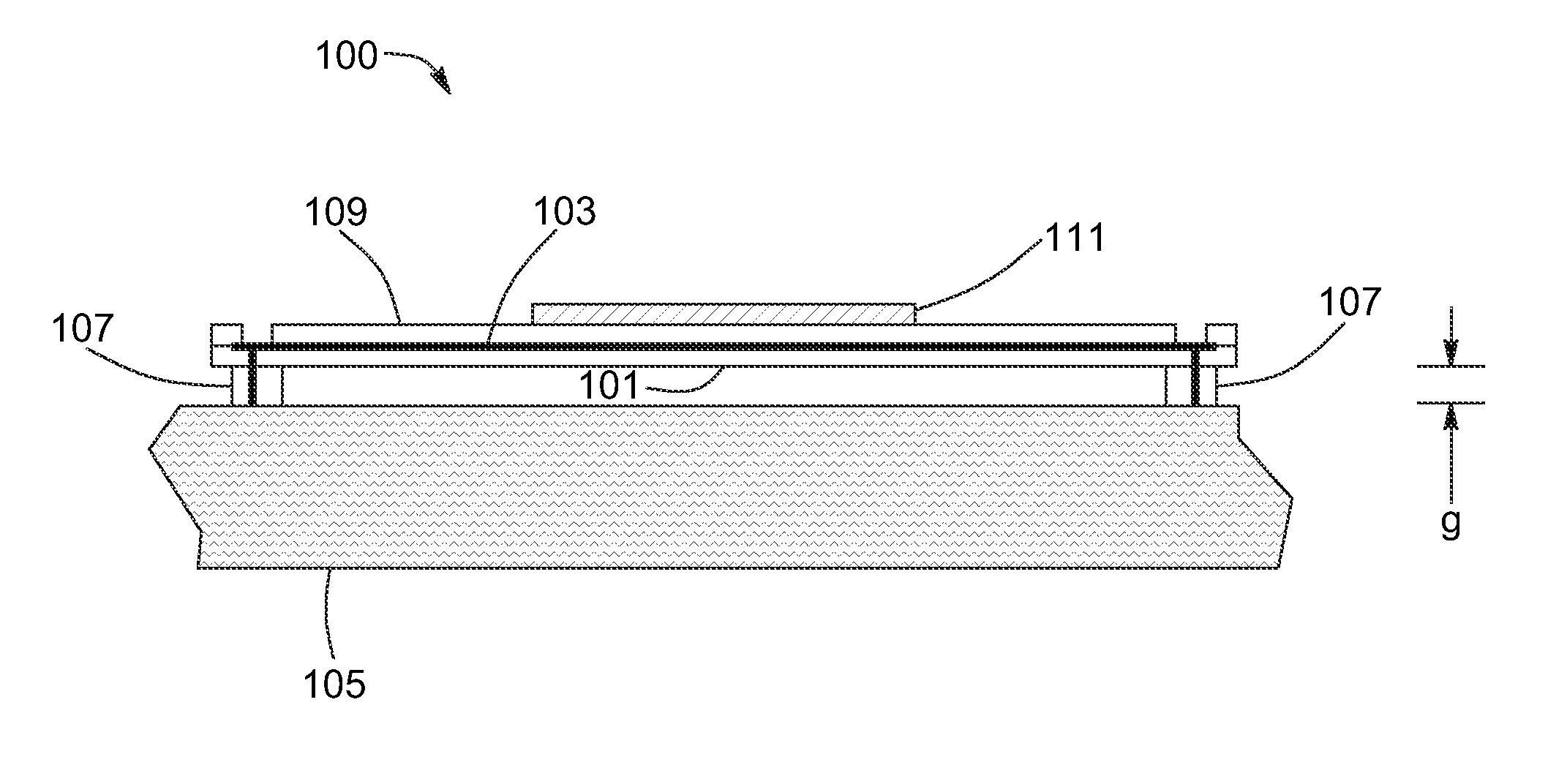

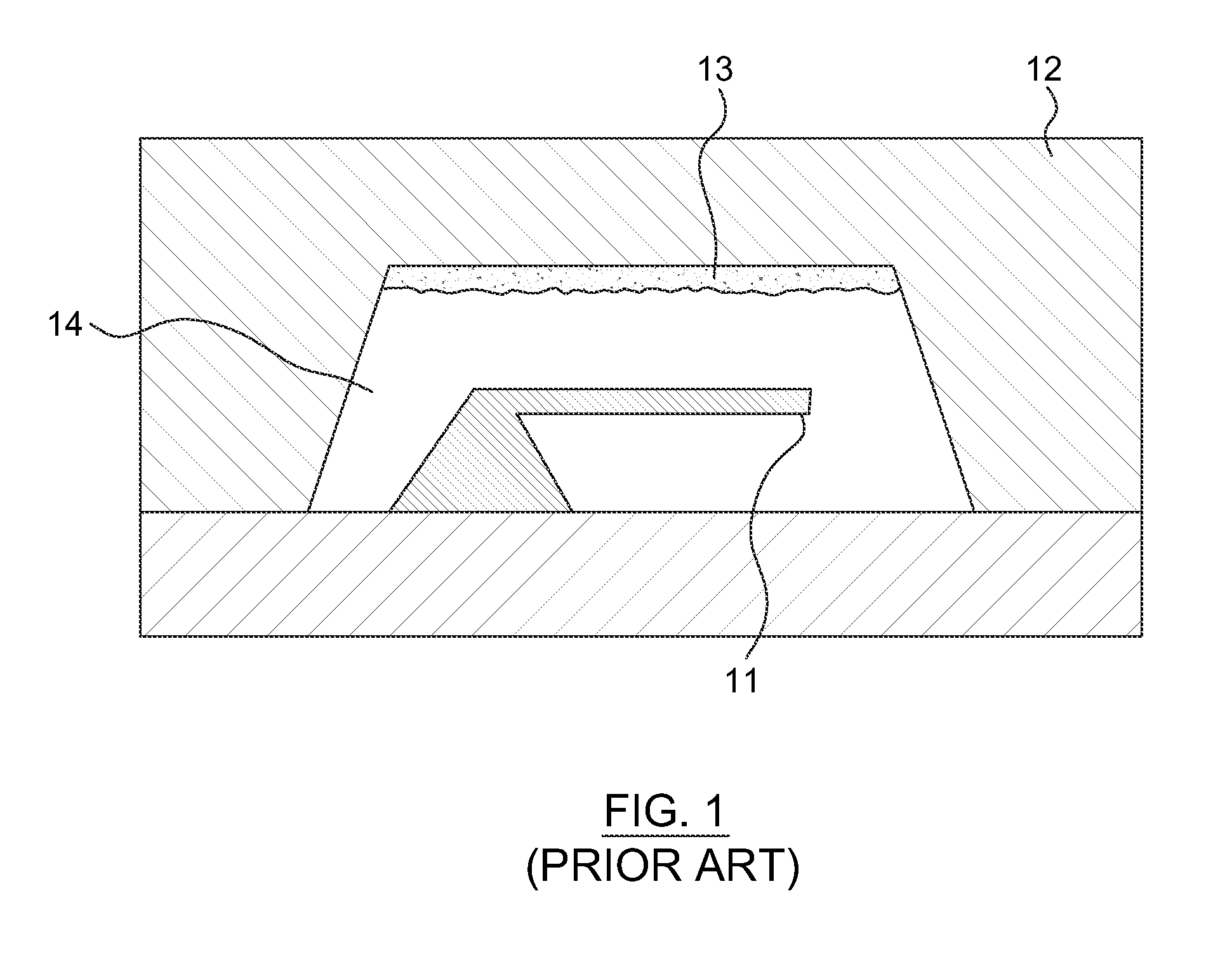

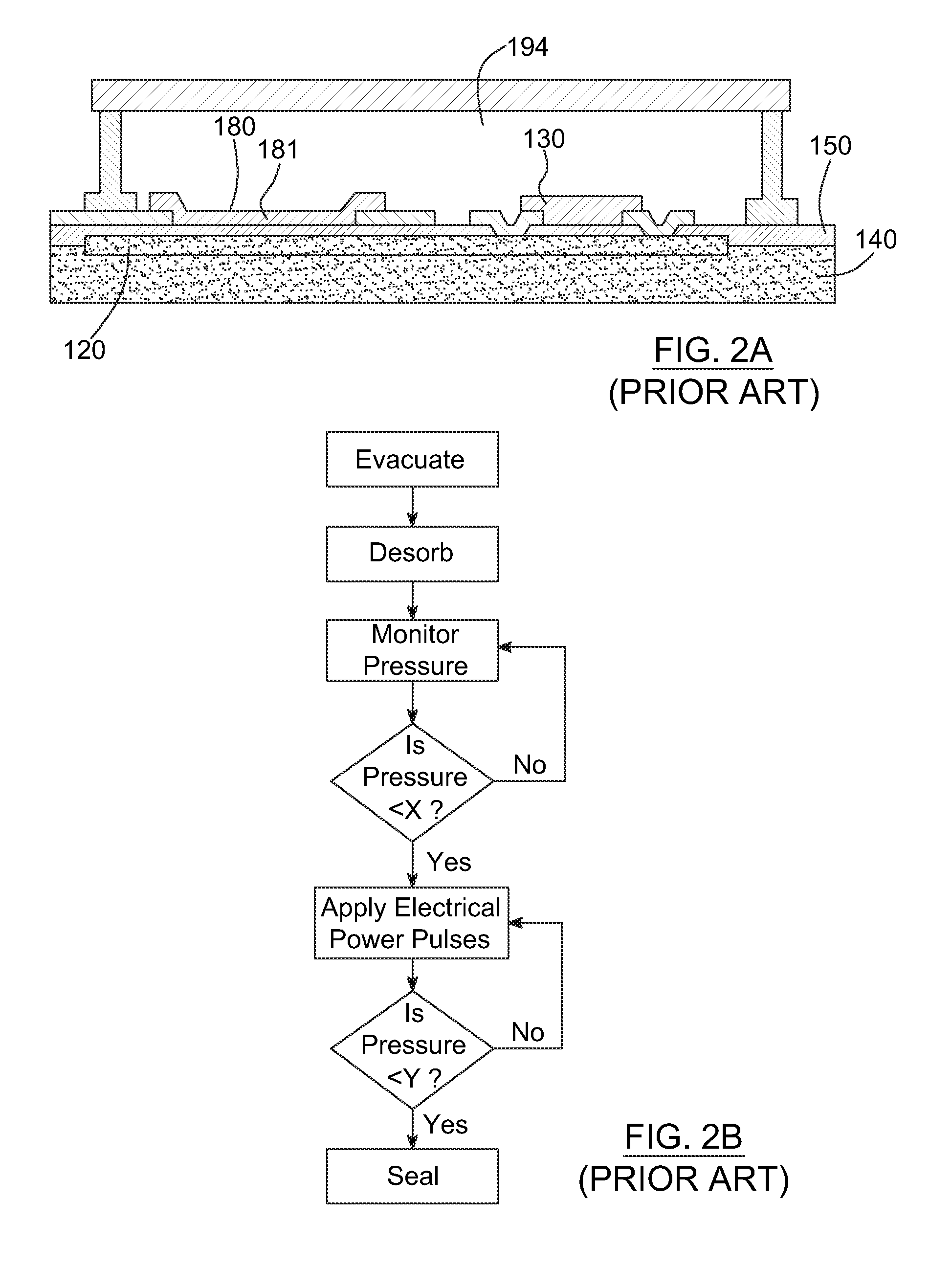

MEMS-based getter microdevice

ActiveUS20120228733A1Prevent degradationAccurate pressure measurementPhotovoltaicsMicrostructural devicesPower flowAmbient pressure

A MEMS (micro-electro-mechanical system) getter microdevice for controlling the ambient pressure inside the hermetic packages that enclose various types of MEMS, photonic, or optoelectronic devices. The getter microdevice revolves around a platform suspended at a height above a substrate, and which is supported by supporting legs having low thermal conductance. Layers are deposited on the platform, such layers including a properly patterned resistor element, a heat-spreading layer and, finally, a thin-film getter material. When an electrical current flows through it, the resistor element heats the thin-film getter material until it reaches its activation temperature. The getter material then absorbs the gas species that could be present in the hermetic package, such gas species possibly impairing the operation of the devices housed in the packages while reducing their lifetime. The weak thermal conductance between the platform and the substrate helps in preventing damages to the surrounding devices when the MEMS getter microdevice is heated at its activation temperature, and it reduces the electrical power required for reaching the activation temperature as well.

Owner:INSTITUT NATIONAL D'OPTIQUE

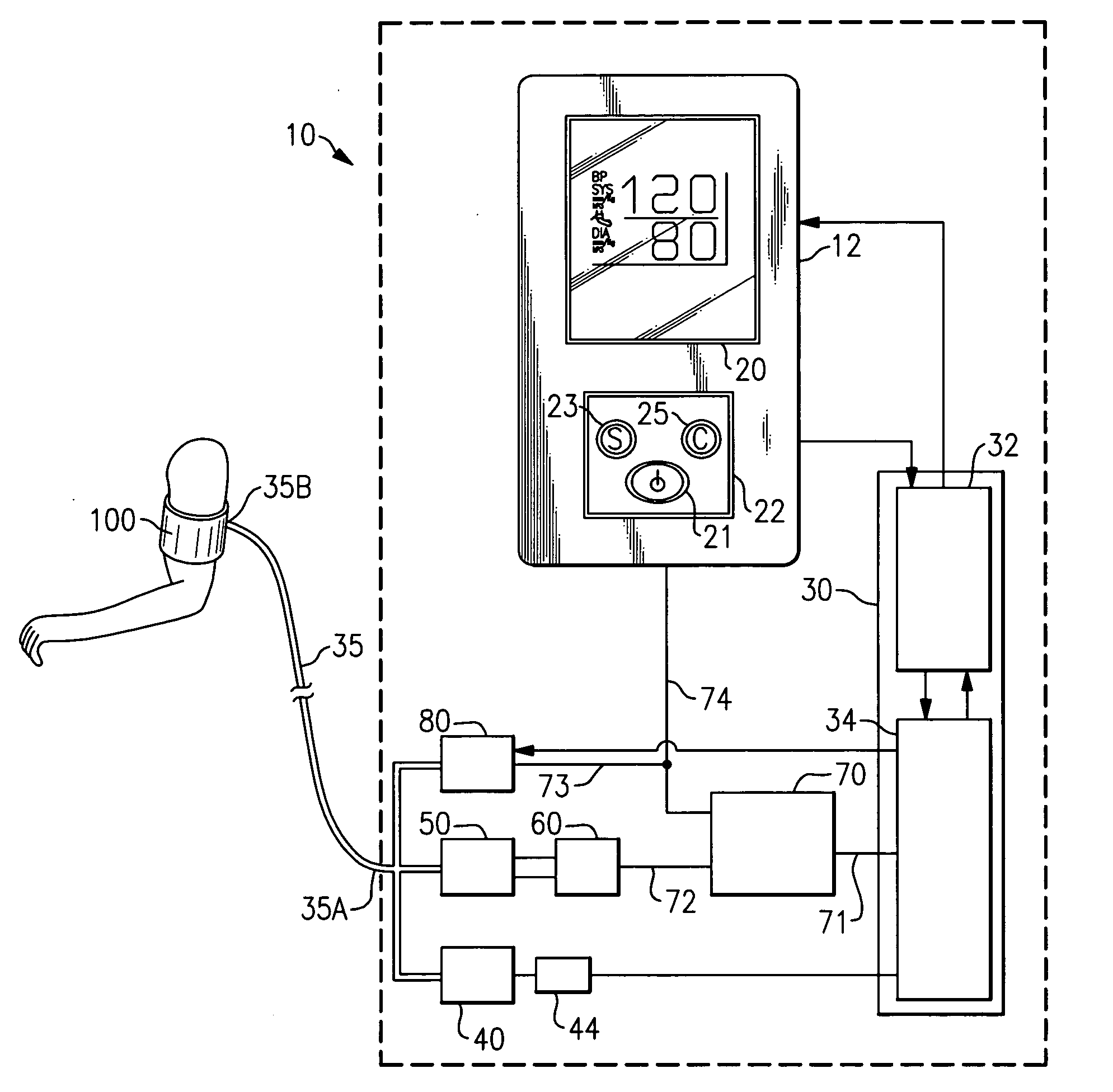

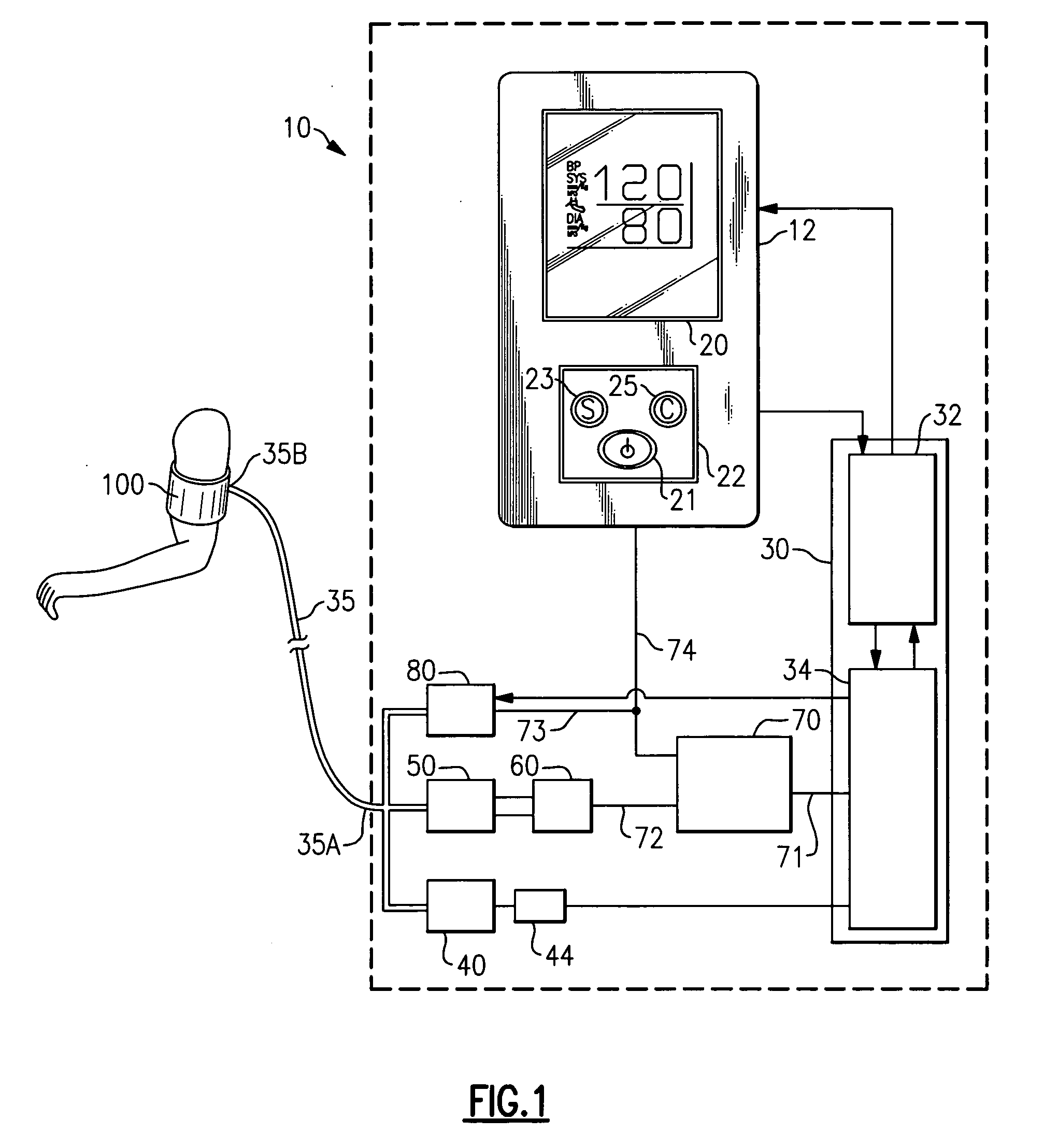

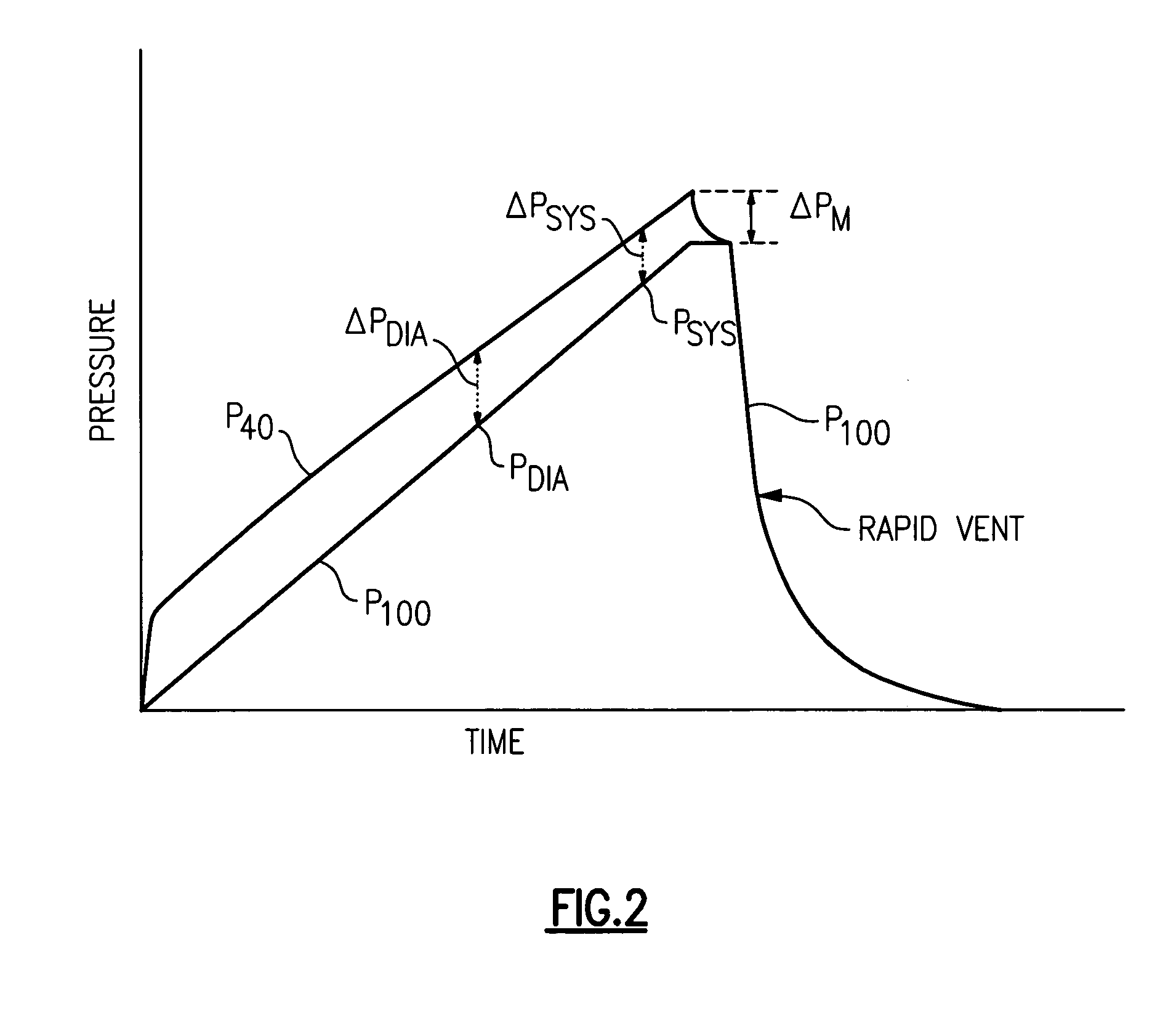

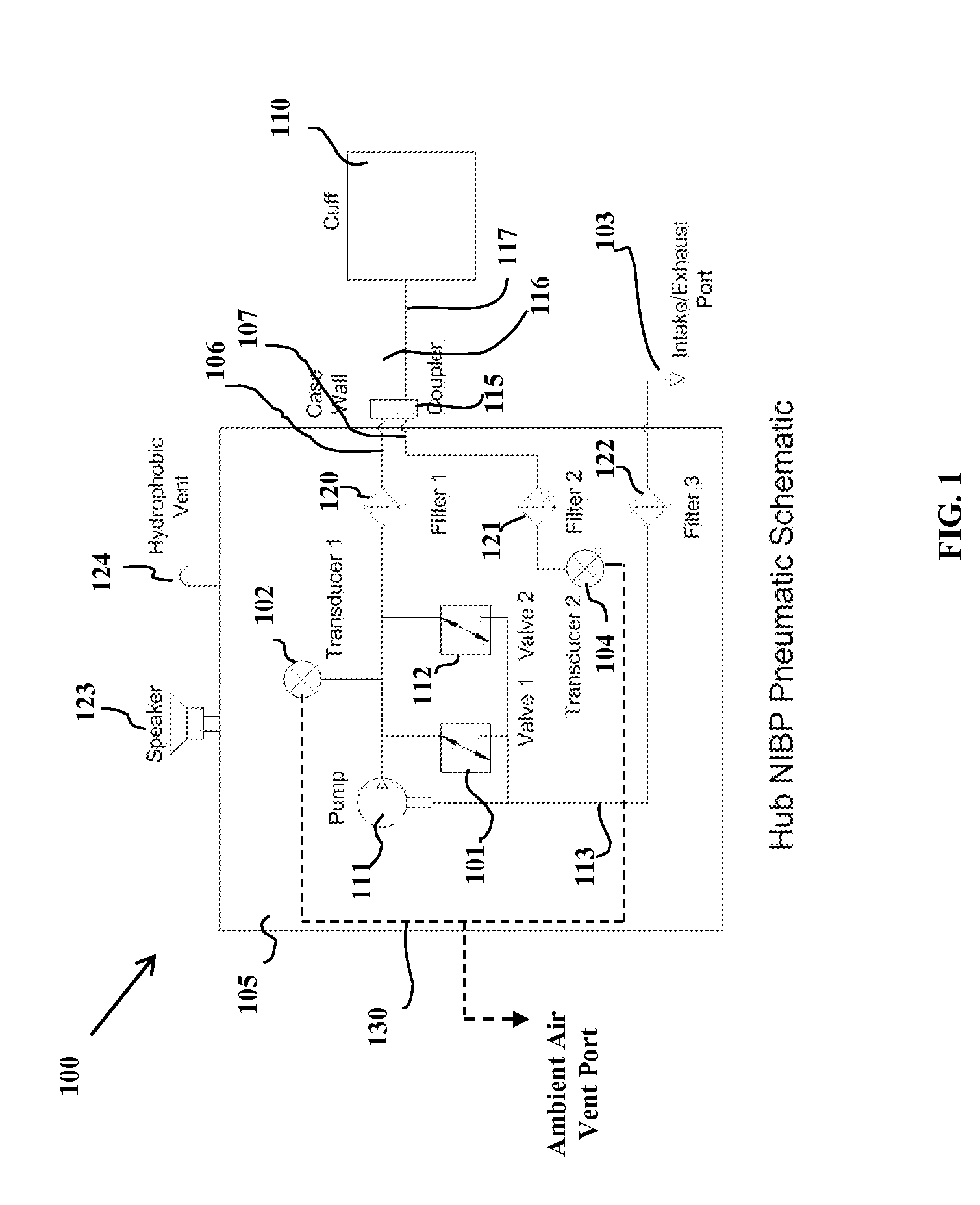

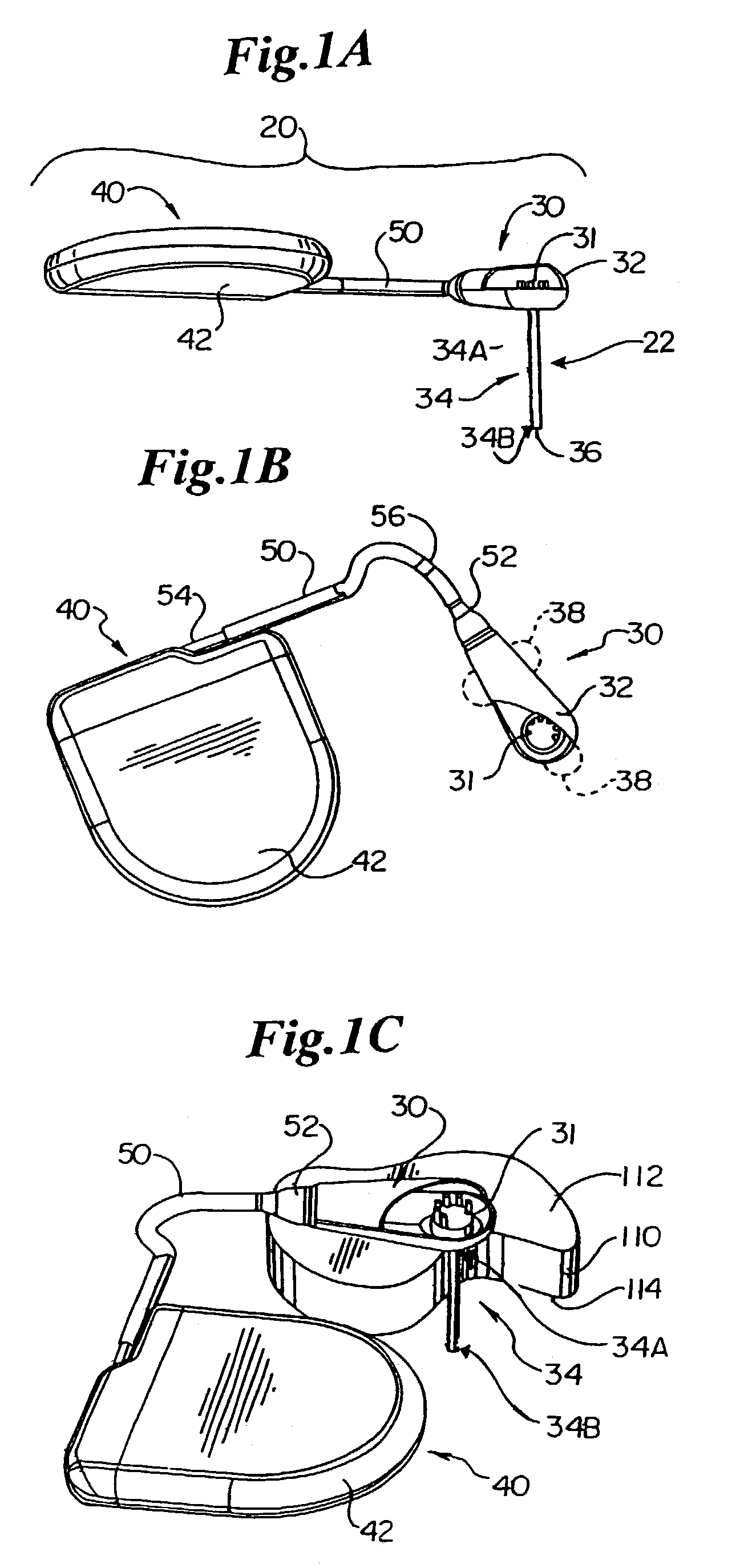

Blood pressure measurement

ActiveUS20070185401A1Accurate pressure measurementCatheterDiagnostic recording/measuringPressure sensorMedicine

The diastolic blood pressure and a systolic blood pressure of a vertebrate are measured using an inflatable pressure cuff disposed about a limb of the vertebrate and connected to an inflation device through a single conduit. A pressure sensor is pneumatically connected to the cuff through the same common conduit. The sensed pressures at the diastolic and systolic points are corrected for a pressure differential associated with the flow of an inflation fluid through the common conduit. The sensed pressures at the diastolic point and the systolic point may be measured during inflation of the cuff or during controlled deflation of the cuff.

Owner:WELCH ALLYN INC

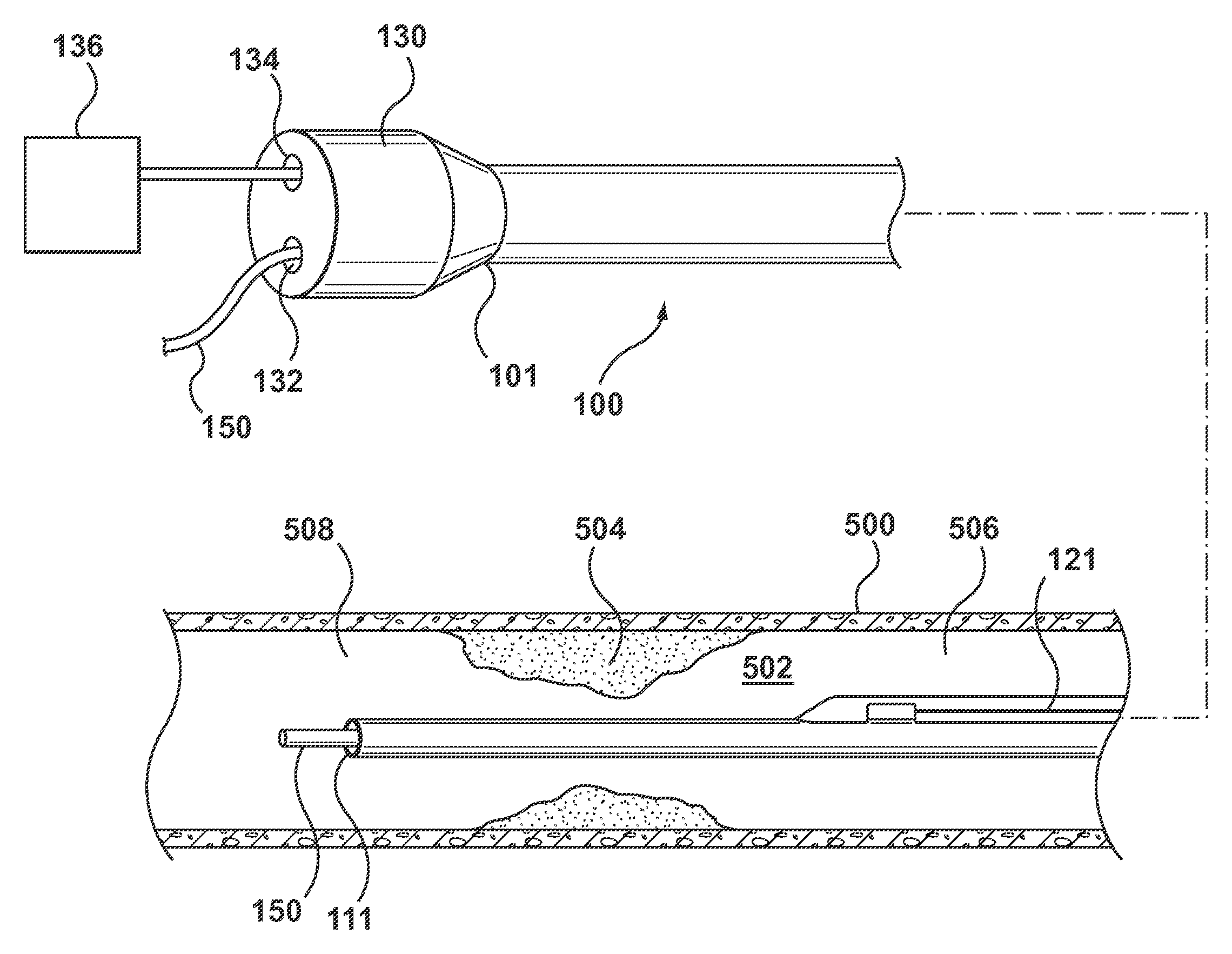

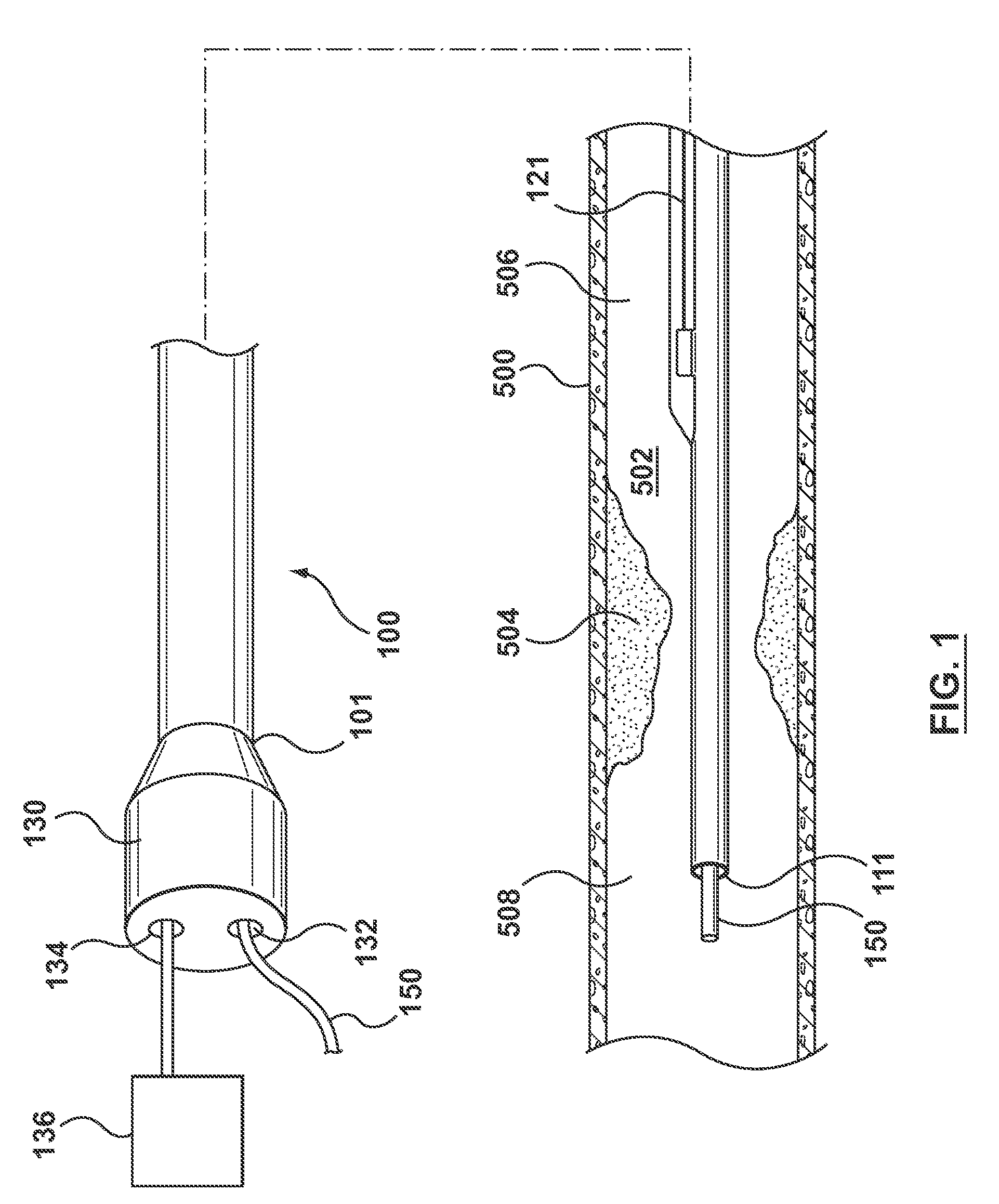

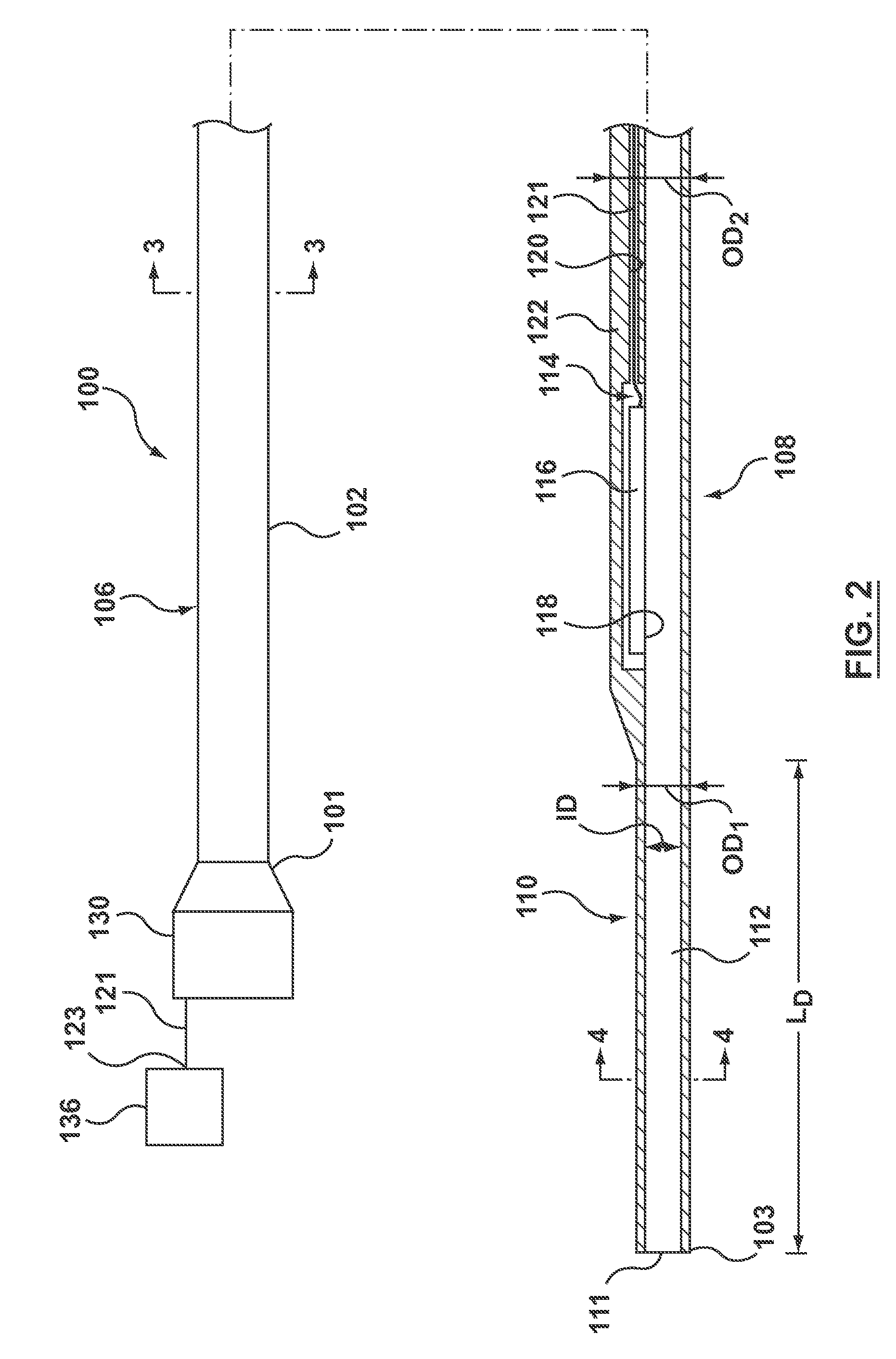

Catheter With Inner Surface Pressure Sensor for Providing a Vascular Pressure Measurement for Determining Fractional Flow Reserve

InactiveUS20150305633A1Accurate pressure measurementAccurate differential pressureGuide wiresDiagnostic recording/measuringDistal portionSurface pressure

A catheter includes an elongate shaft including a proximal portion and a distal portion extending from the proximal portion to a distal opening at a distal end of the shaft. The proximal portion defines a proximal guidewire lumen and has a first outer diameter. The distal portion defines a distal guidewire lumen in communication with the proximal guidewire lumen and has a second outer diameter smaller than the first outer diameter. A pressure sensor is coupled to the proximal portion such that the pressure sensor faces the proximal guidewire lumen. When the catheter is tracked to a treatment site within the vasculature, the pressure sensor is disposed proximal the treatment site, the distal opening is disposed distal to the treatment site, and the distal guidewire lumen fills with blood such that the pressure sensor senses a pressure of the blood at the distal end of the shaft.

Owner:MEDTRONIC VSACULAR GALWAY

MEMS-based getter microdevice

ActiveUS8395229B2Prevent degradationAccurate pressure measurementSemiconductor/solid-state device detailsSolid-state devicesPower flowAmbient pressure

A MEMS (micro-electro-mechanical system) getter microdevice for controlling the ambient pressure inside the hermetic packages that enclose various types of MEMS, photonic, or optoelectronic devices. The getter microdevice revolves around a platform suspended at a height above a substrate, and which is supported by supporting legs having low thermal conductance. Layers are deposited on the platform, such layers including a properly patterned resistor element, a heat-spreading layer and, finally, a thin-film getter material. When an electrical current flows through it, the resistor element heats the thin-film getter material until it reaches its activation temperature. The getter material then absorbs the gas species that could be present in the hermetic package, such gas species possibly impairing the operation of the devices housed in the packages while reducing their lifetime. The weak thermal conductance between the platform and the substrate helps in preventing damages to the surrounding devices when the MEMS getter microdevice is heated at its activation temperature, and it reduces the electrical power required for reaching the activation temperature as well.

Owner:INSTITUT NATIONAL D'OPTIQUE

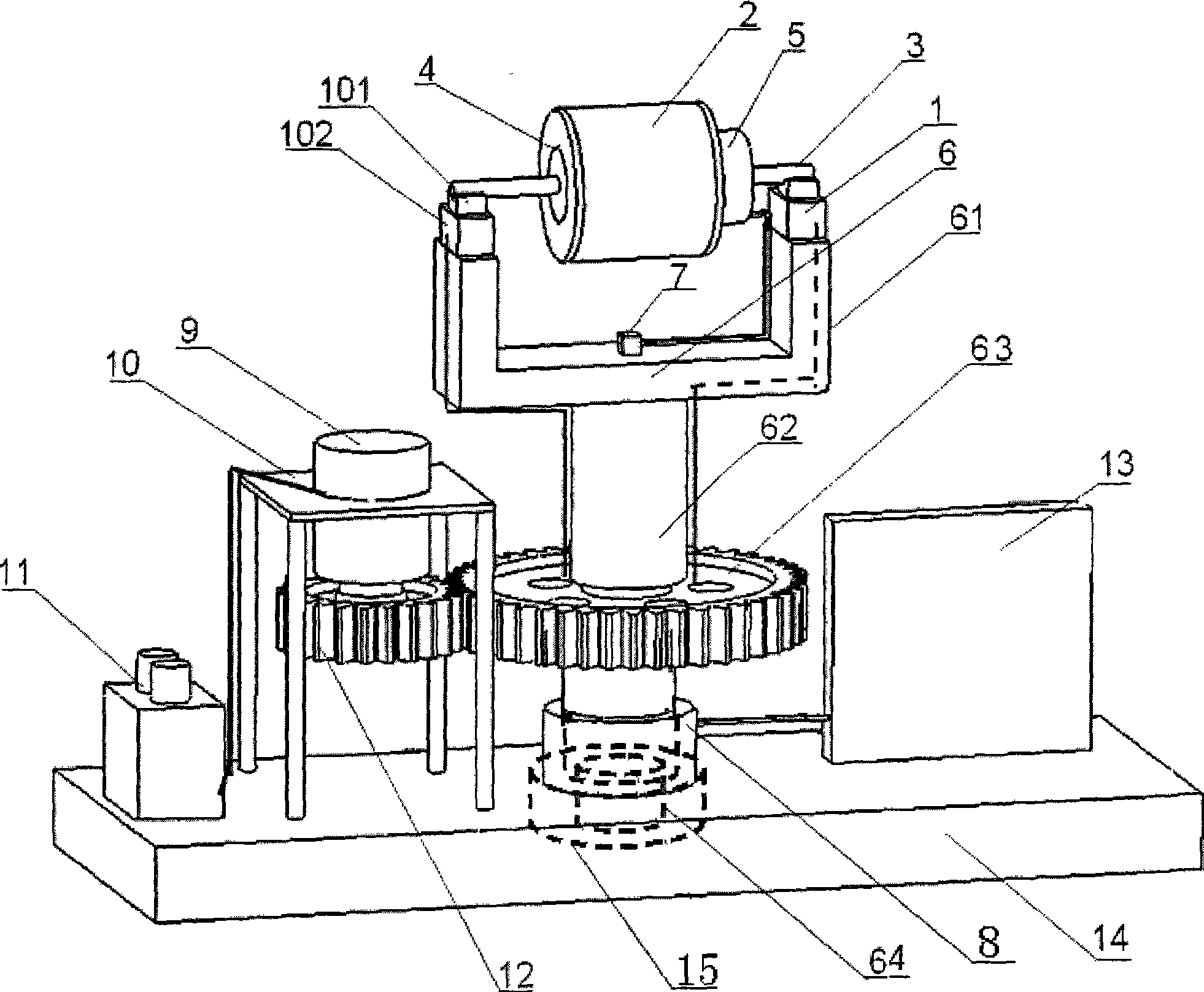

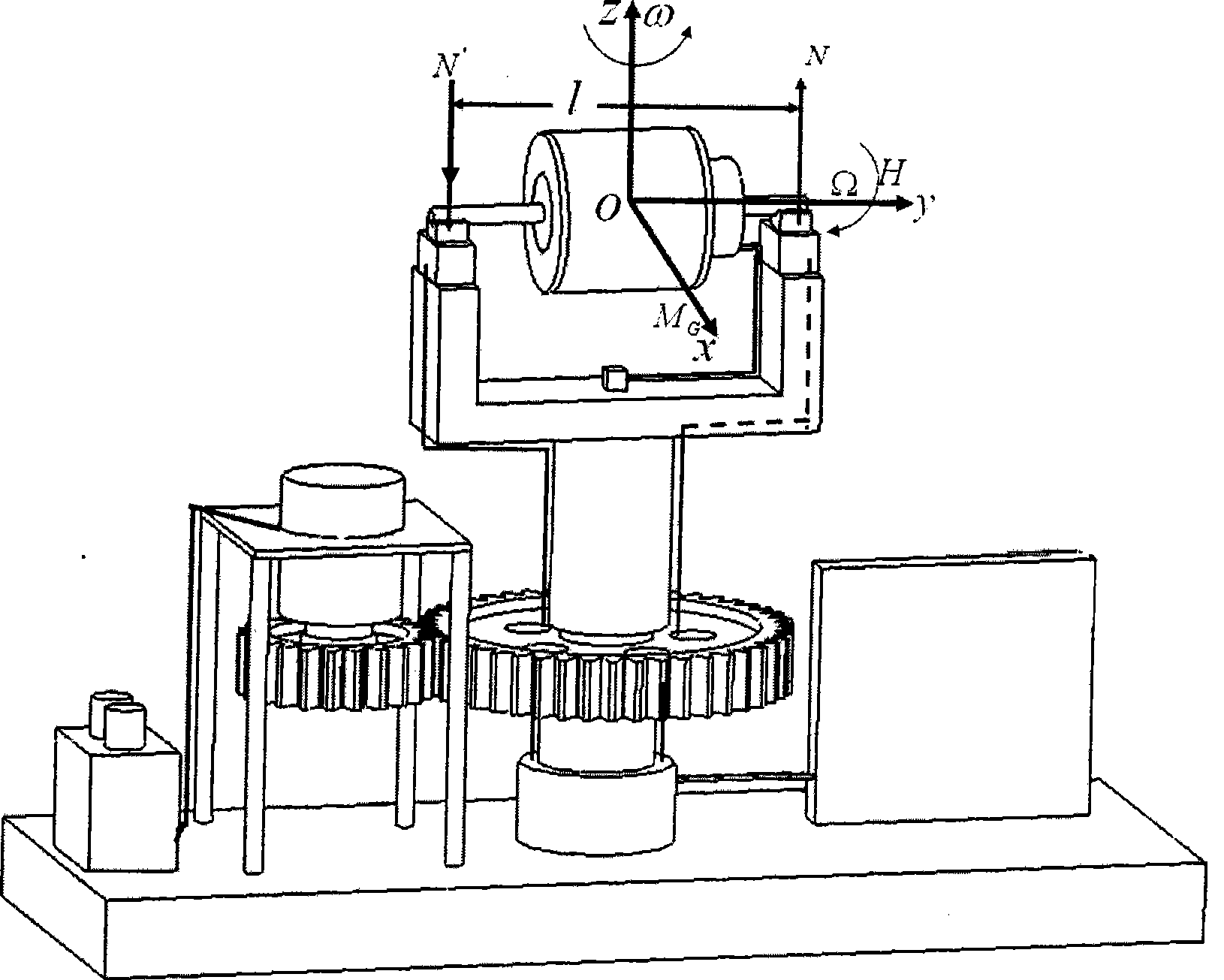

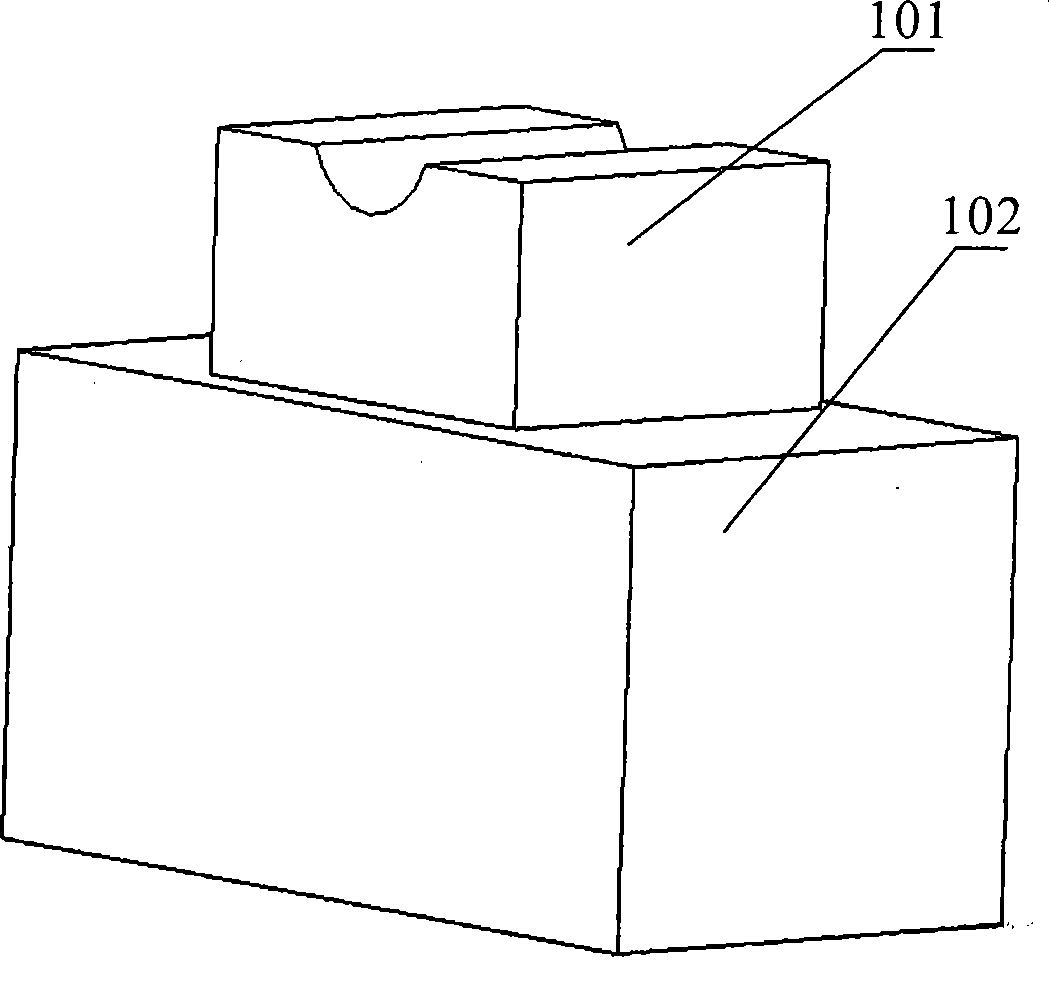

Apparatus and method for measuring gyro moment

InactiveCN101436356AAccurate pressurePrecise Gyro MomentCurrent/voltage measurementEducational modelsBall bearingDisplay device

The invention relates to a gyro moment measuring device, which mainly comprises a force transducer, a gyro rotor, a gyro stator shaft component, a ball bearing, a gyro power supply slip ring, a gyro bracket, a gyro power supply battery, a signal slip ring of the force transducer, a frame rotating motor, a bracket for the frame rotating motor, a revolution stepping switch for the frame rotating motor, a transmission device, a display device, a base and a deep groove ball bearing. The gyro stator shaft component is connected with the gyro rotor through the ball bearing and is fixedly connected with the force transducer, the force transducer is fixedly connected with the gyro bracket which is connected with the base through a rotating shaft, an output rotating shaft of the frame rotating motor is connected with the transmission device which is engaged with a gear on the gyro bracket, and the bracket for the frame rotating motor and the display device are fixedly connected with the base. The gyro moment measuring device uses the force transducer to measure pressure, calculate gyro moment and display the gyro moment in the display device, and can intuitively learn gyro moment effect.

Owner:BEIHANG UNIV

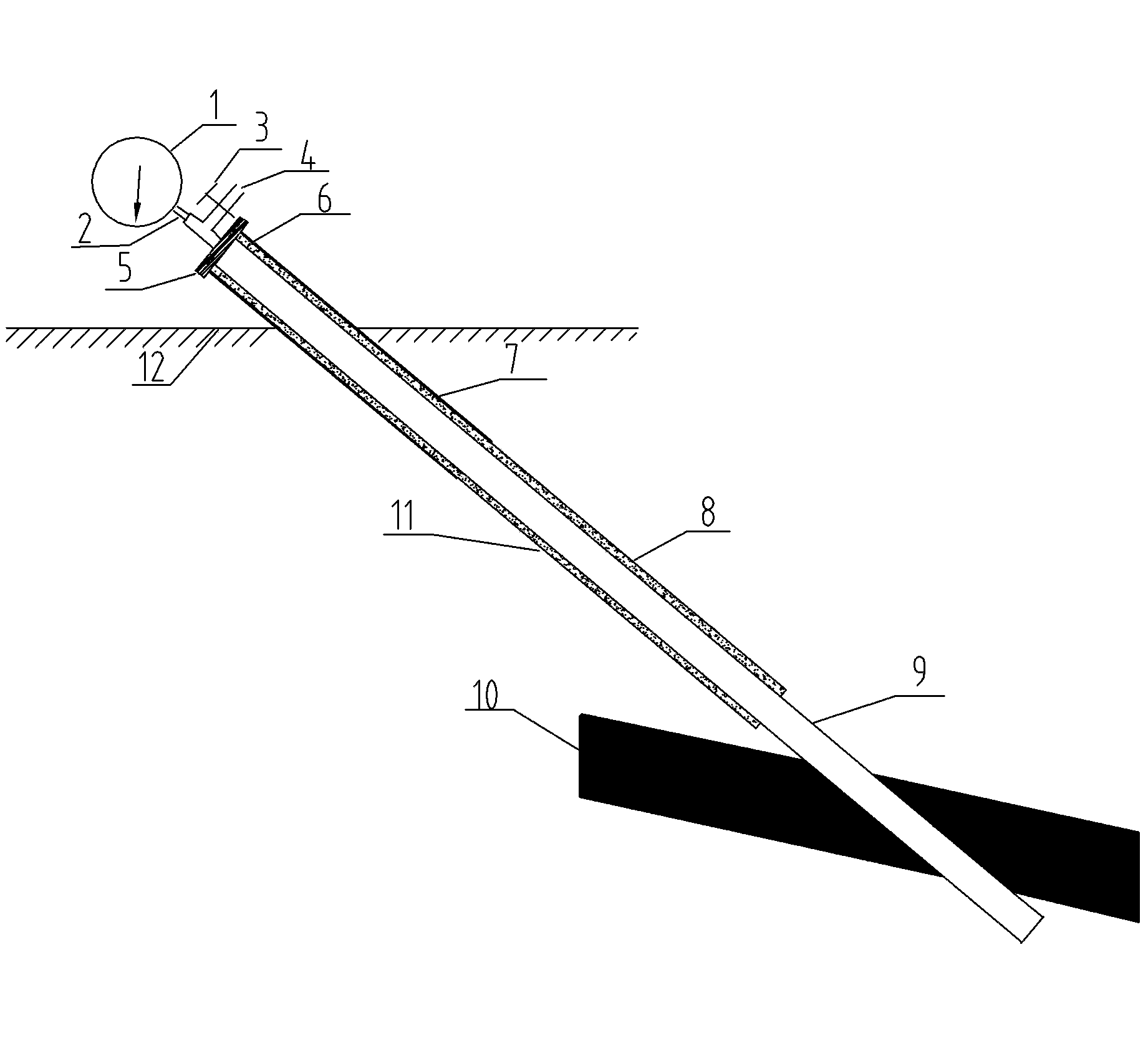

Method for measuring gas pressure of coal seam by casing high-pressure hole sealing method

The invention discloses a method for measuring gas pressure of a coal seam by a casing high-pressure hole sealing method. The method comprises the following steps: a, a hole is opened with a large-diameter drill bit, the depth of a casing can be increased by drilling, and then the casing with a flange at the outer end is sent into the hole; b, expansive cement mortar is injected into the hole in a grouting mode to enhance the casing; c, after the expansive cement mortar is solidified, drilling is carried out with a drill bit which is one size smaller than the large-diameter drill bit in step a along the original drilling center, the drilling is stopped when a coal seam is approached, and the expansive cement mortar is injected into a whole-hole section in a grouting mode for reinforcement after drilling cuttings are removed; d, after the expansive cement mortar is solidified, the hole is drilled with a drill bit which is one size smaller than the drill bit in step c along the original drilling center until the coal seam is penetrated; and e, the flange at the outer end of the casing is connected with a pressure gage to measure gas pressure. Large and small gaps and gap water around the drill hole can be effectively blocked in a high-pressure grouting method, an air leak channel is sealed, and rapid and accurate pressure measurement is realized.

Owner:河南焦煤能源有限公司科学技术研究所

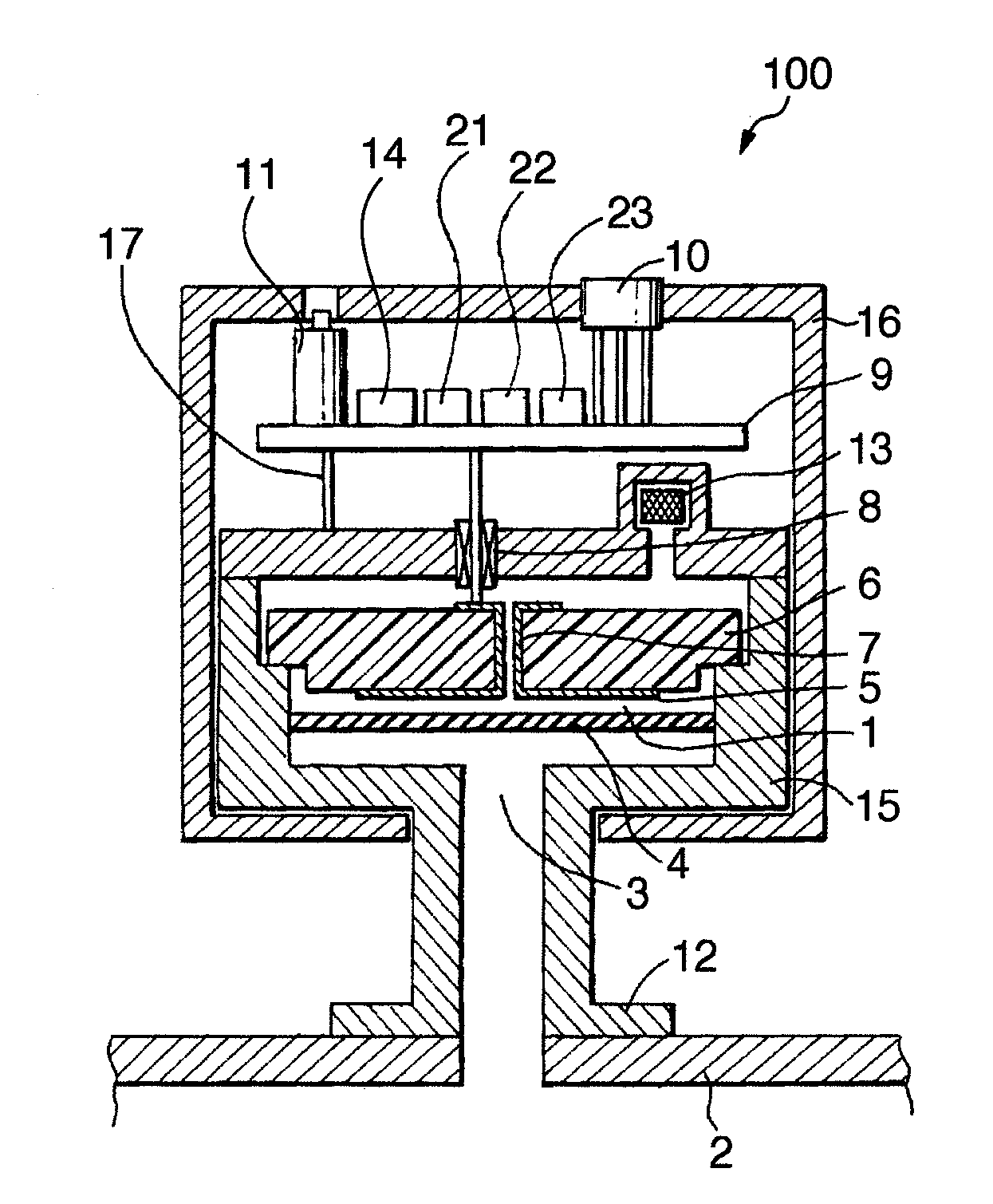

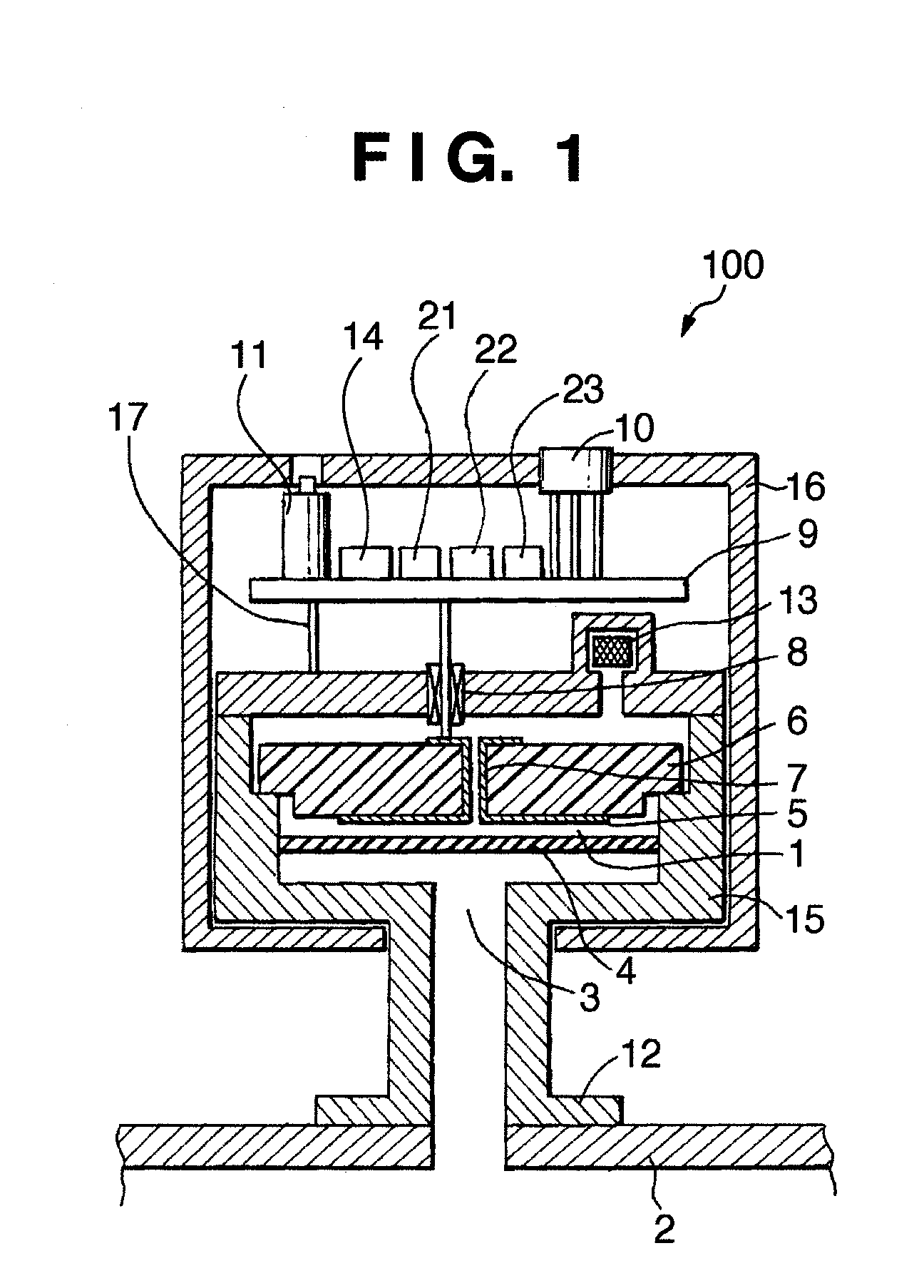

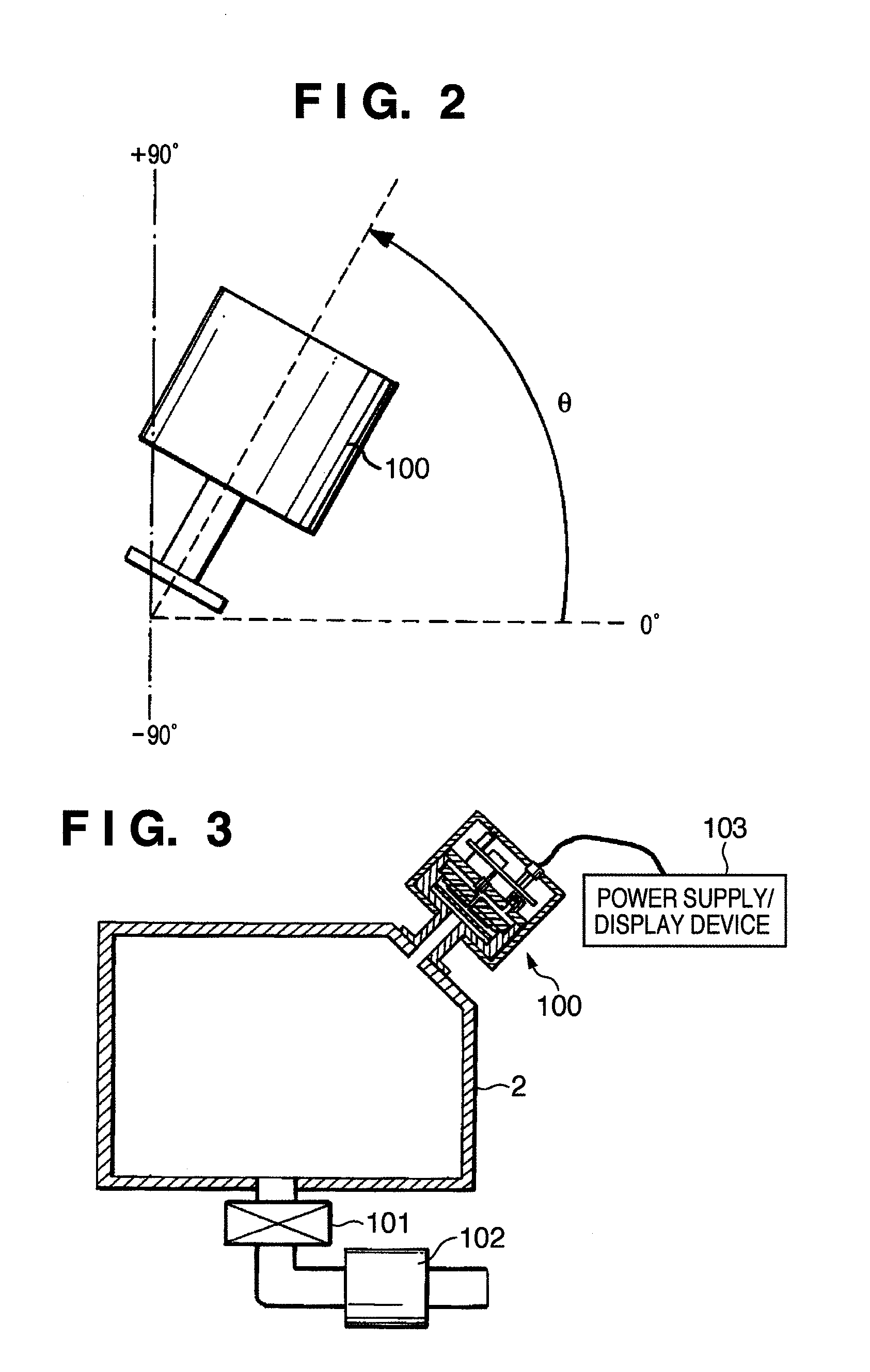

Capacitance diaphragm gauge and vaccum apparatus

InactiveUS20100154552A1Accurate pressure measurementAccurate measurementFluid pressure measurement using capacitance variationCapacitancePressure dependence

A capacitance diaphragm gauge includes an inclination angle sensor which detects the inclination angle of the gauge. The pressure dependences of capacitance obtained when the capacitance diaphragm gauge is mounted on a vacuum apparatus at the first inclination angle (+90°), the second inclination angle (0°), and the third inclination angle (−90°) are stored in a storage unit in advance. A pressure measurement value is then corrected based on the inclination angle information detected by the inclination angle sensor and the capacitance-pressure characteristic data is actually measured at the first, second and third inclination angles, and stored in the gauge.

Owner:CANON ANELVA CORP

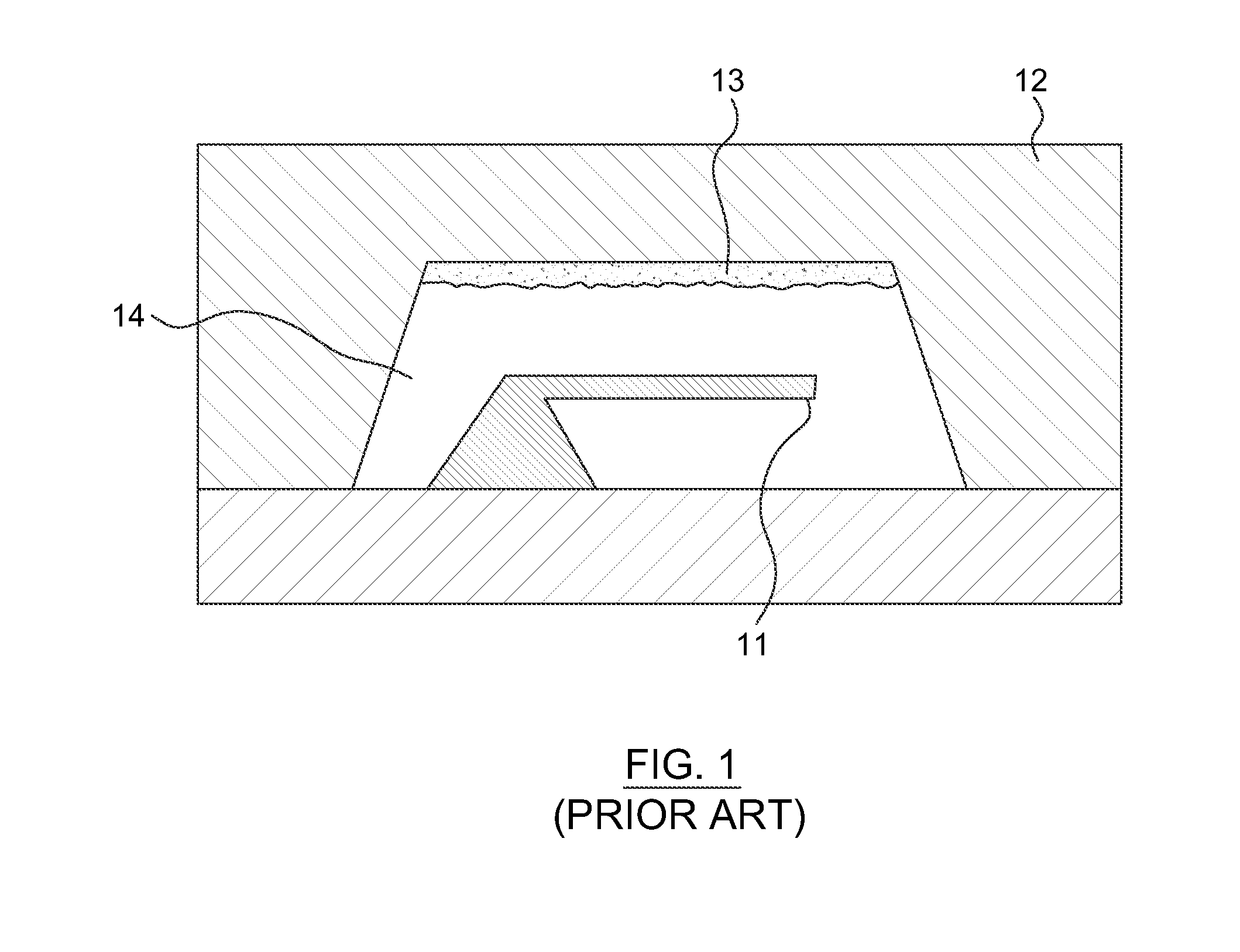

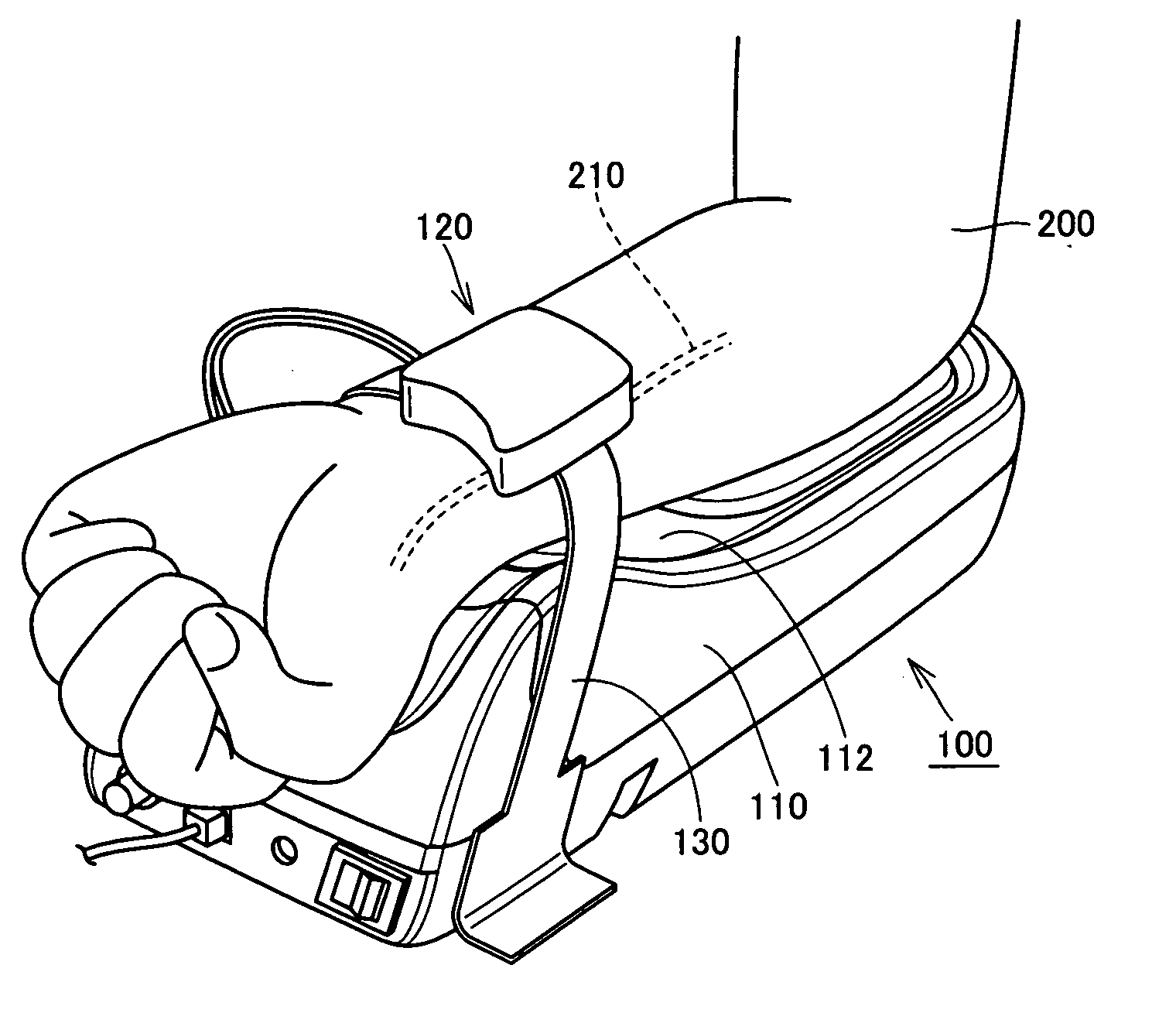

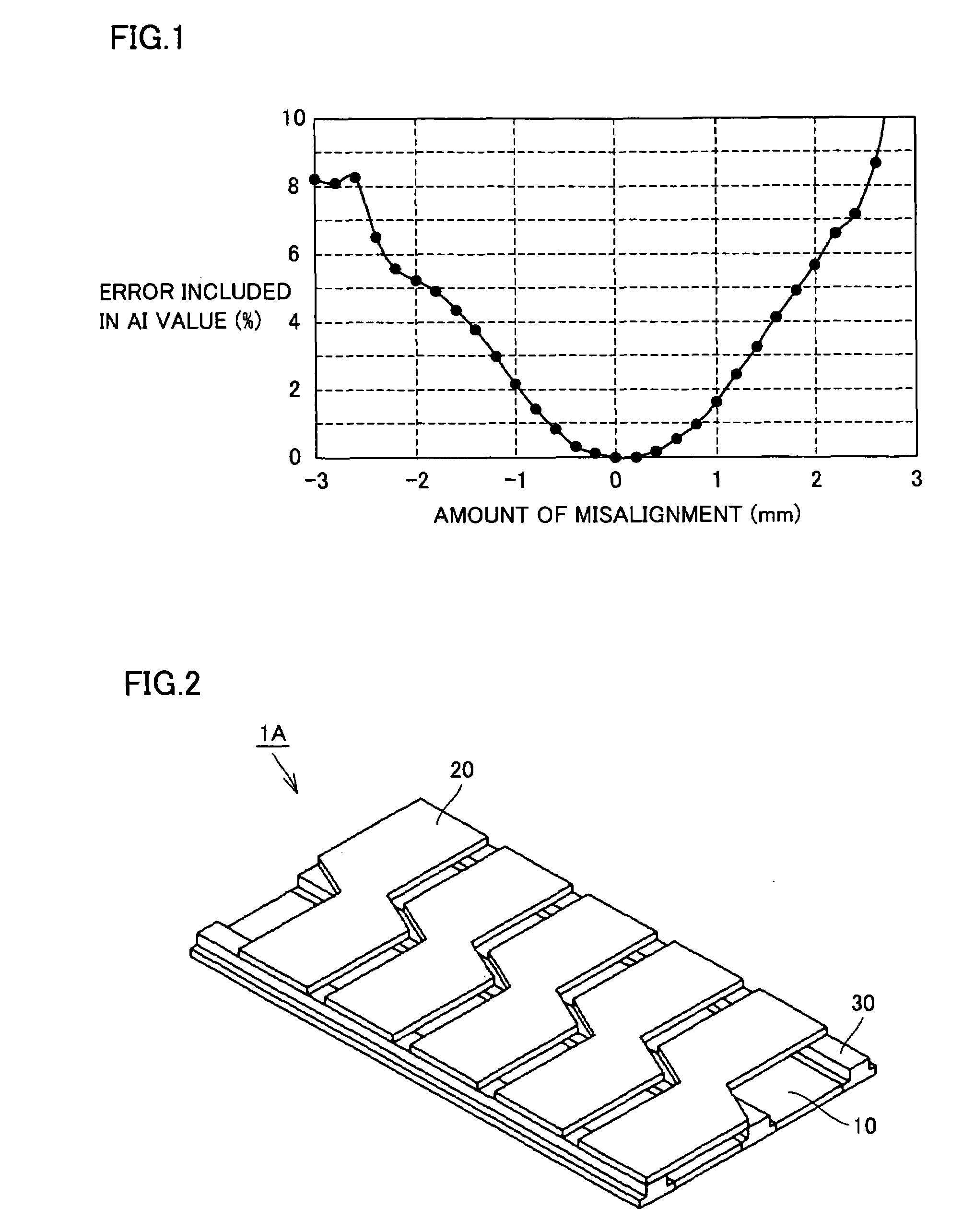

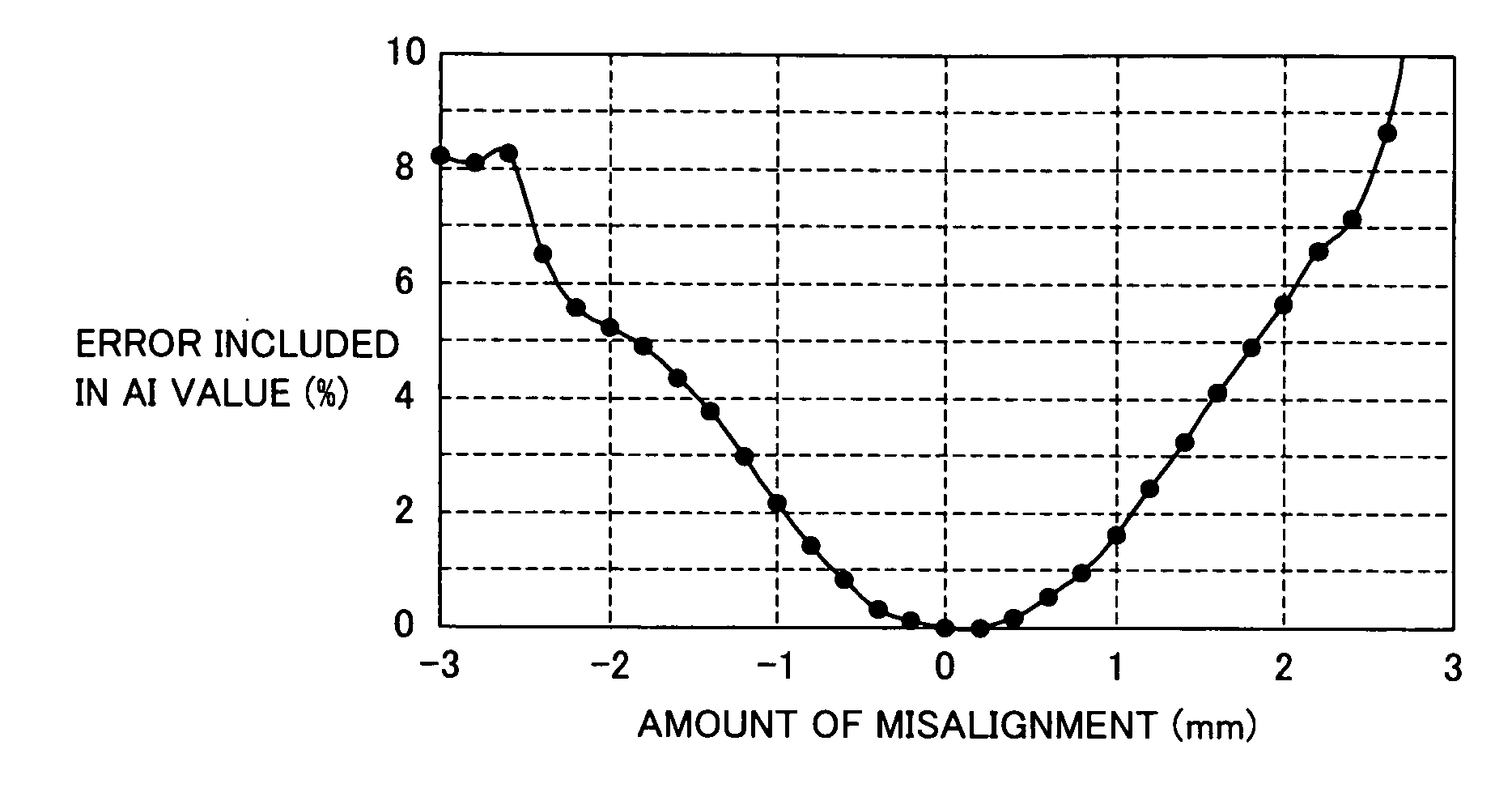

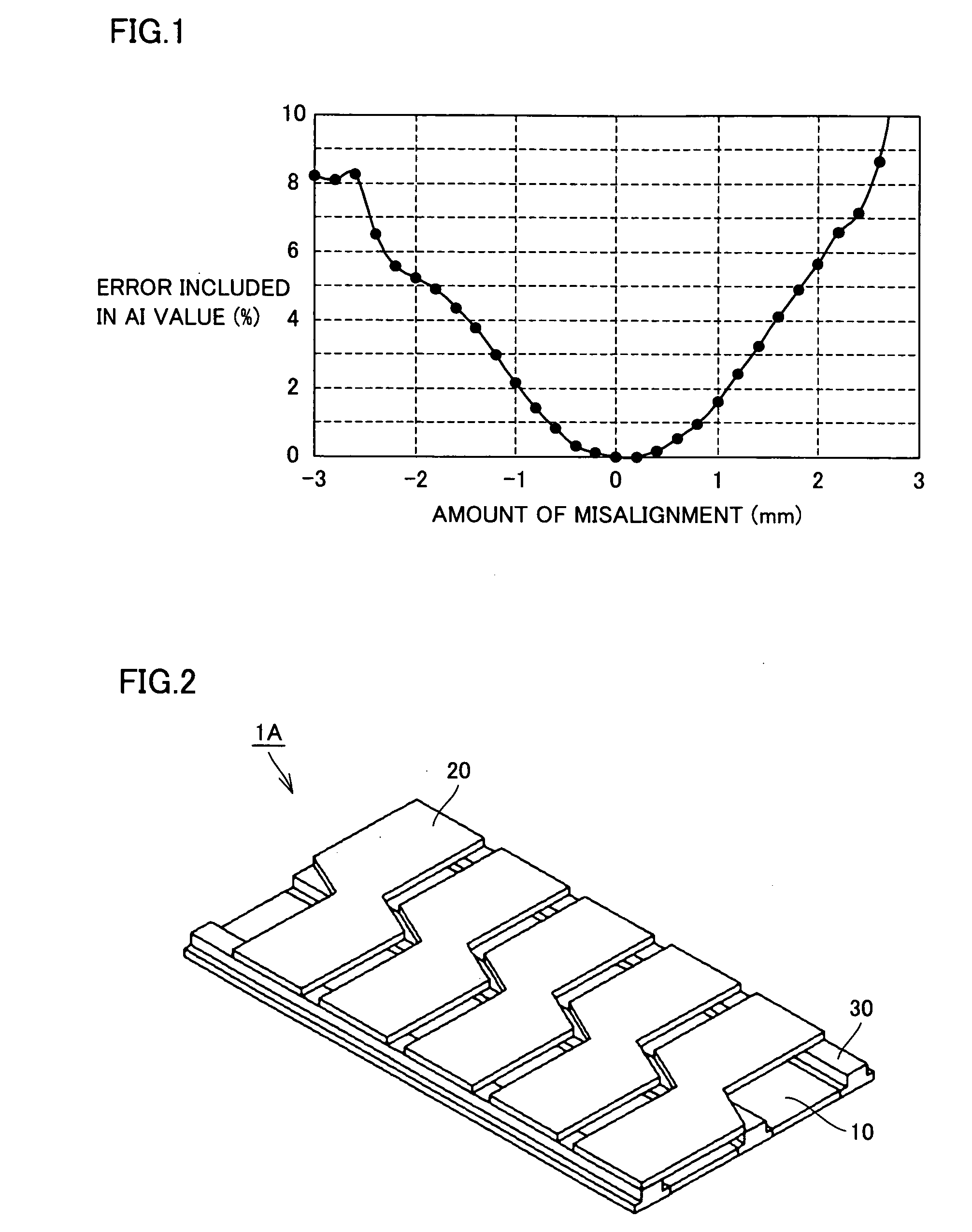

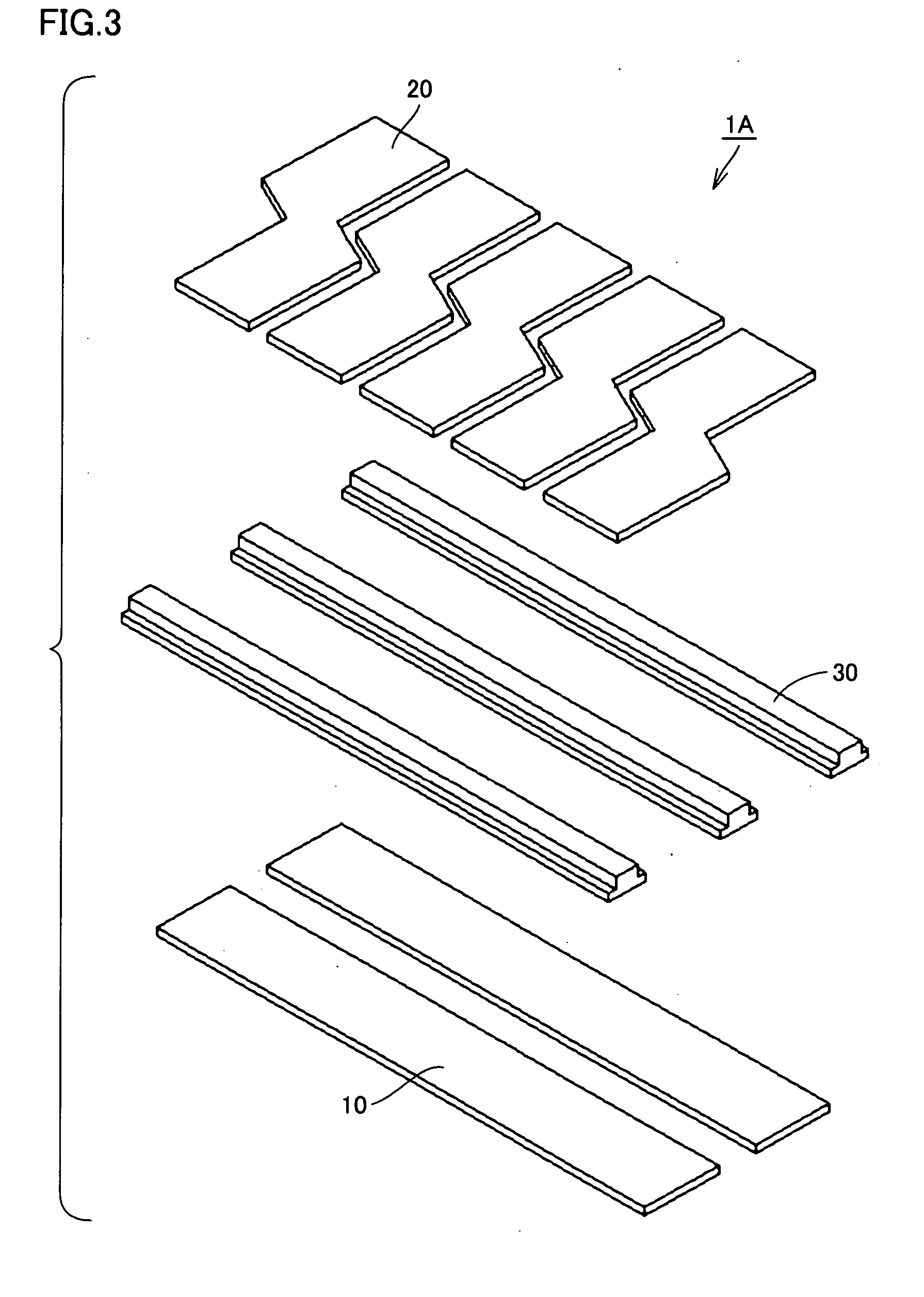

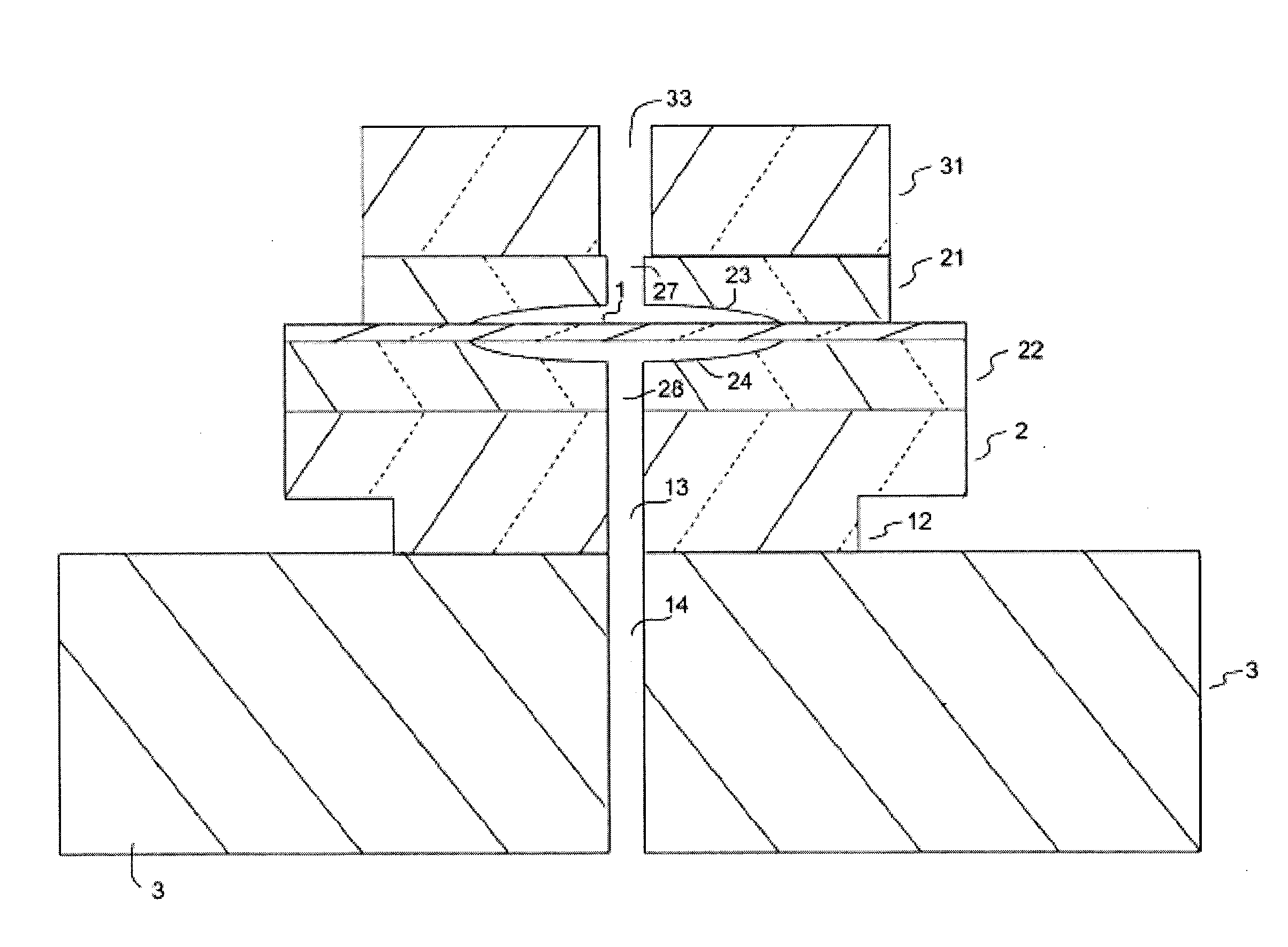

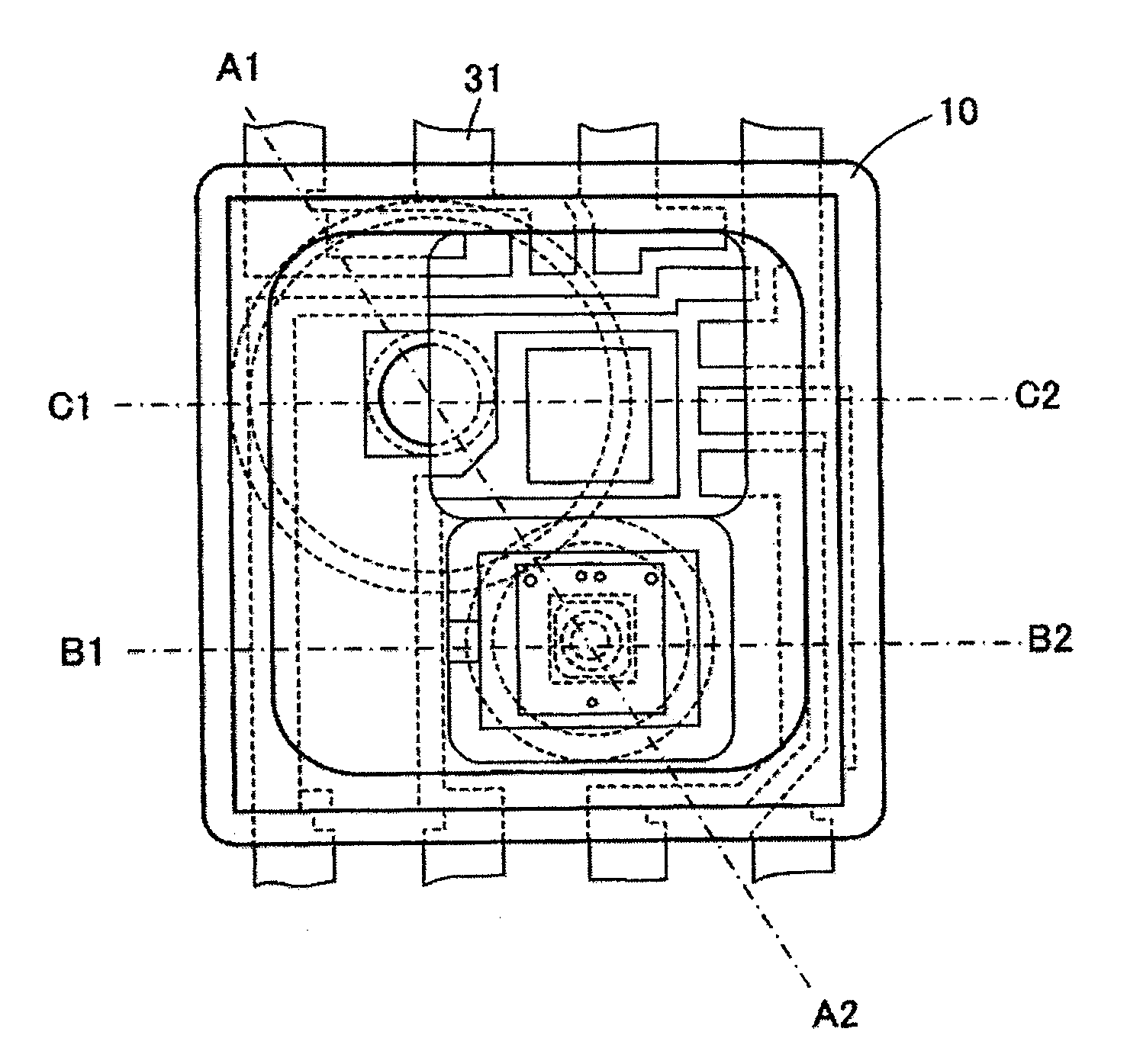

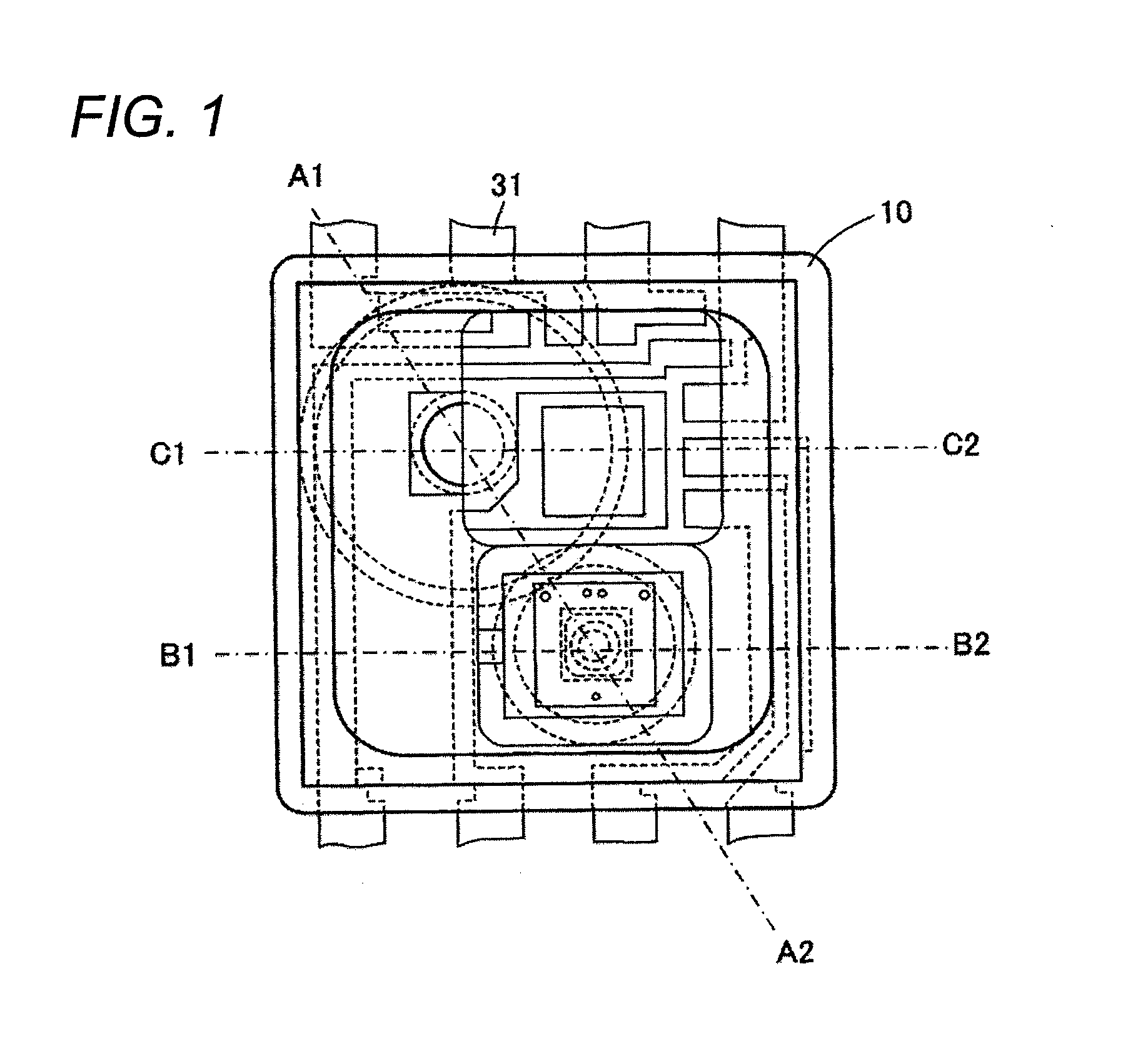

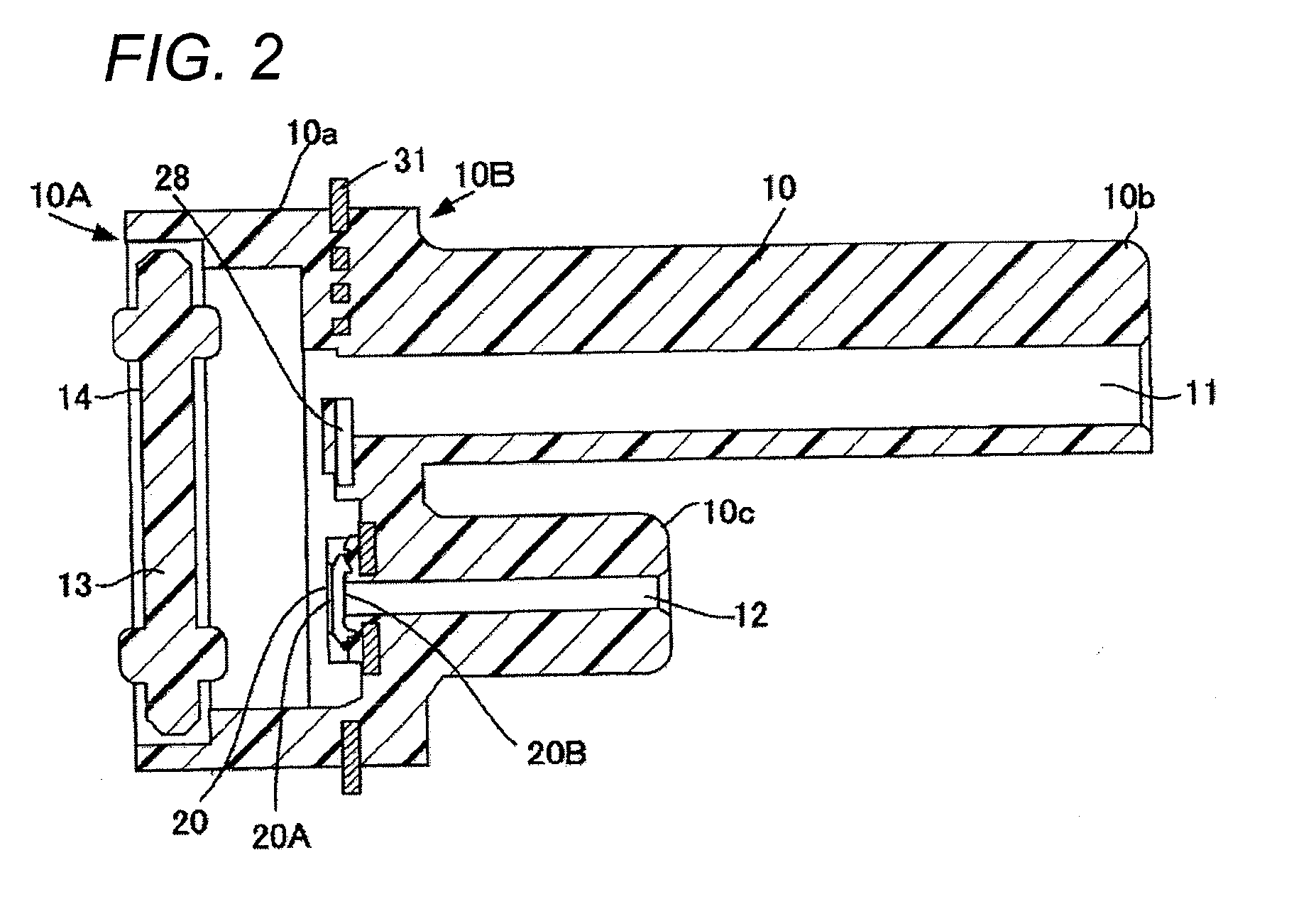

Array-type capacitive pressure pulse wave sensor, and pulse wave measuring apparatus having the same

InactiveUS7069791B2Reduce manufacturing costAccurate pressure measurementForce measurementEvaluation of blood vesselsCapacitanceMeasurement device

An array-type capacitive pressure pulse wave sensor includes m rows of lower electrodes arranged in parallel with each other to extend substantially linearly in a direction approximately orthogonal to the extending direction of the artery at the time of measurement, n columns of upper electrodes arranged in parallel with each other at a prescribed distance from the m lower electrodes to extend in a direction crossing the extending direction of the m lower electrodes, and m×n capacitive elements formed at intersections of the m lower electrodes and the n upper electrodes. The m×n capacitive elements are arranged in a staggered manner when the pressure detecting portion is seen in two dimensions. Thus, it is possible to provide an array-type capacitive pressure pulse wave sensor that can be manufactured inexpensively and that ensures accurate and stable measurement of the pressure pulse wave.

Owner:OMRON HEALTHCARE CO LTD

Method of manufacturing implantable wireless sensor for in vivo pressure measurement

ActiveUS20100058583A1Accurate pressure measurementPrinted circuit assemblingLine/current collector detailsLine sensorPressure measurement

A method of manufacturing a sensor for in vivo applications includes the steps of providing two wafers of an electrically insulating material. A recess is formed in the first wafer, and a capacitor plate is formed in the recess of the first wafer. A second capacitor plate is formed in a corresponding region of the second wafer, and the two wafers are affixed to one another such that the first and second capacitor plates are arranged in parallel, spaced-apart relation.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

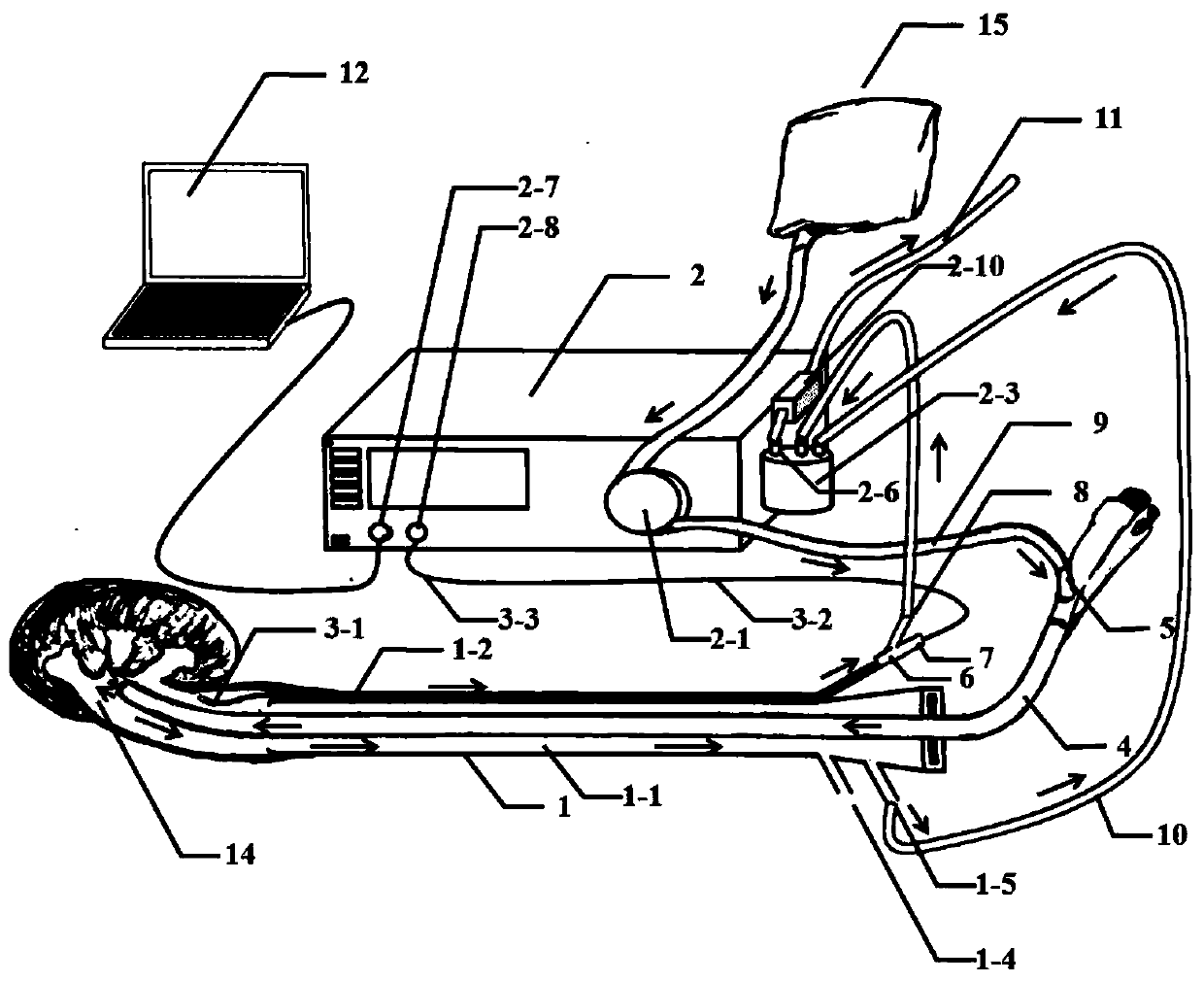

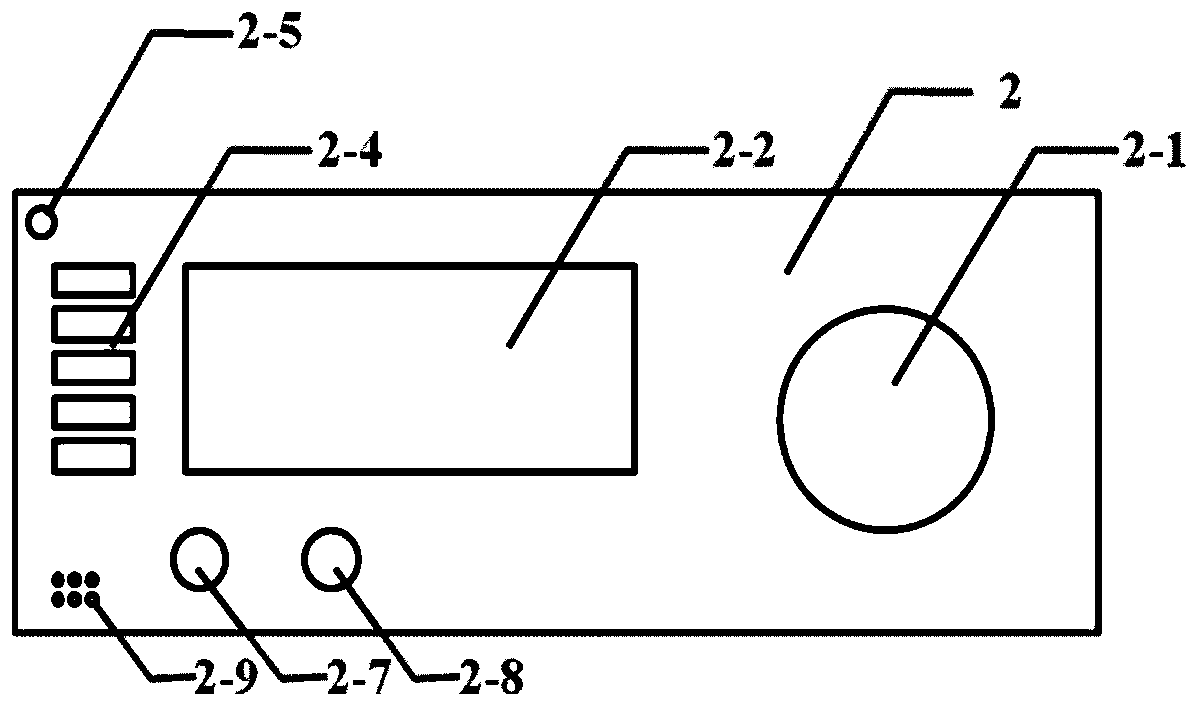

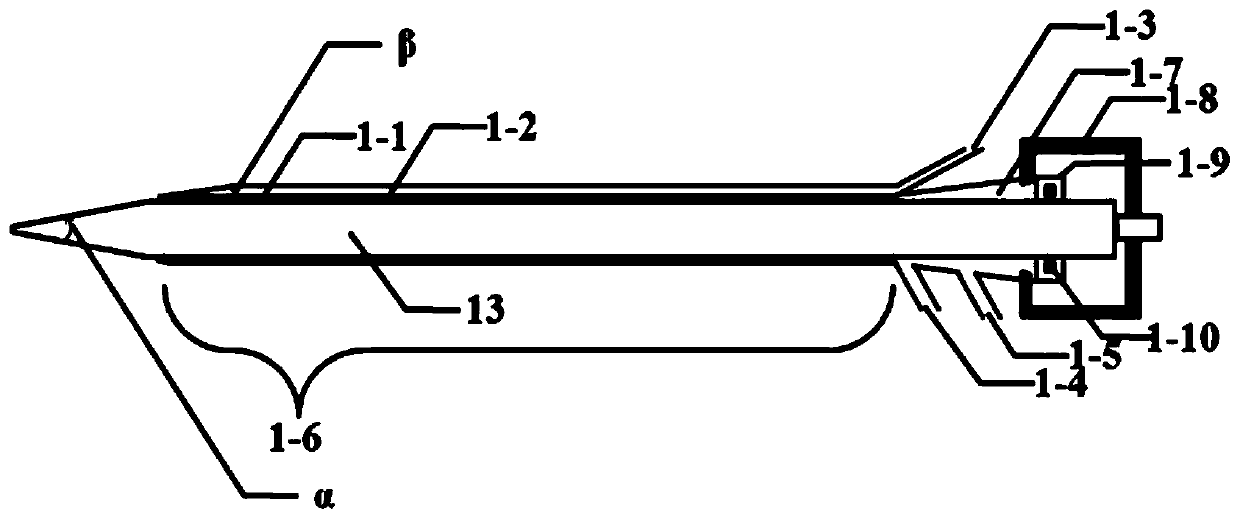

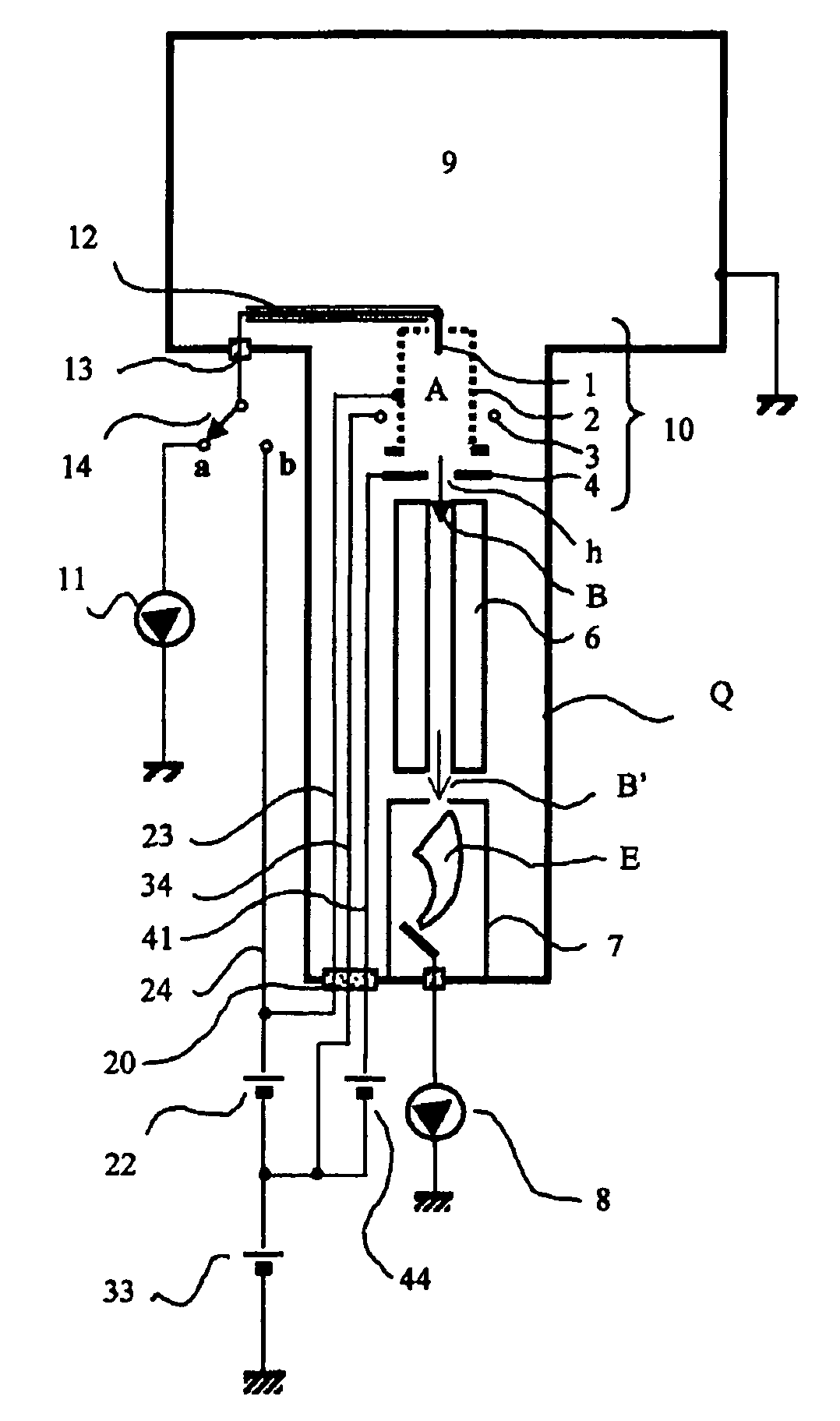

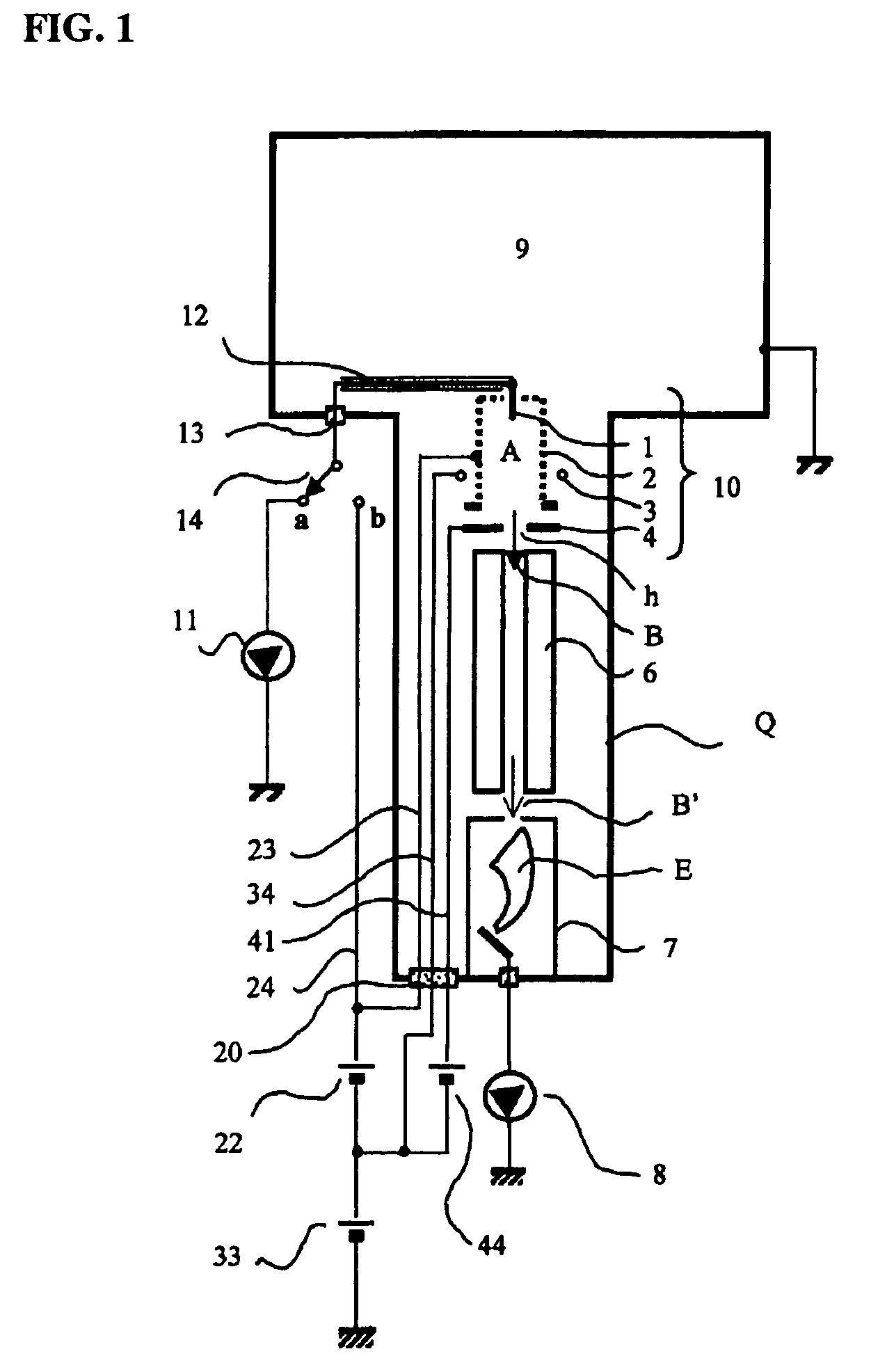

Numerical control system capable of performing real-time control on renal pelvis pressure in ureteroscopy based on sheath-side optical fiber pressure sensor monitoring

PendingCN109998698AAvoid inhalationIncrease the difficultyDiagnosticsSurgeryMain channelHigh pressure

The invention discloses a numerical control system capable of performing real-time control on renal pelvis pressure in ureteroscopy based on sheath-side optical fiber pressure sensor monitoring, whichcomprises an optical fiber pressure measuring system, an independent double-channel ureter leading-in sheath, a numerical control platform with a perfusion / attraction function and an intelligent terminal. In the system, a perfusion pump of a soft mirror connected with the numerical control platform enters a kidney through a main channel of the ureter leading-in sheath; an optical fiber pressure sensor enters a renal pelvis through a side channel to monitor the pressure of the renal pelvis, and both channels can be connected with negative pressure suction of the numerical control platform. According to the measured pressure feedback, the numerical control platform carries out data interaction with the intelligent terminal through wire / wireless; the intelligent terminal collects and analyzes the data in the operation, synchronously optimizes the working mode and can carry out later maintenance on the numerical control platform. The numerical control system has the advantages of real-time accurate pressure control, convenient adjustment and maintenance and the like, can effectively prevent complications such as kidney injury, serious infection and the like caused by high pressure inthe soft mirror operation, and improves the safety and the efficiency of the operation.

Owner:FUJIAN MEDICAL UNIV UNION HOSPITAL

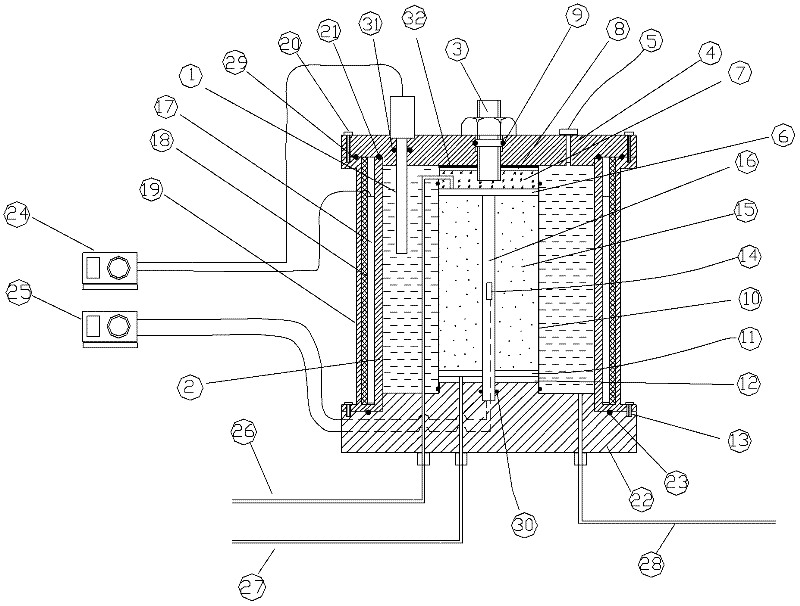

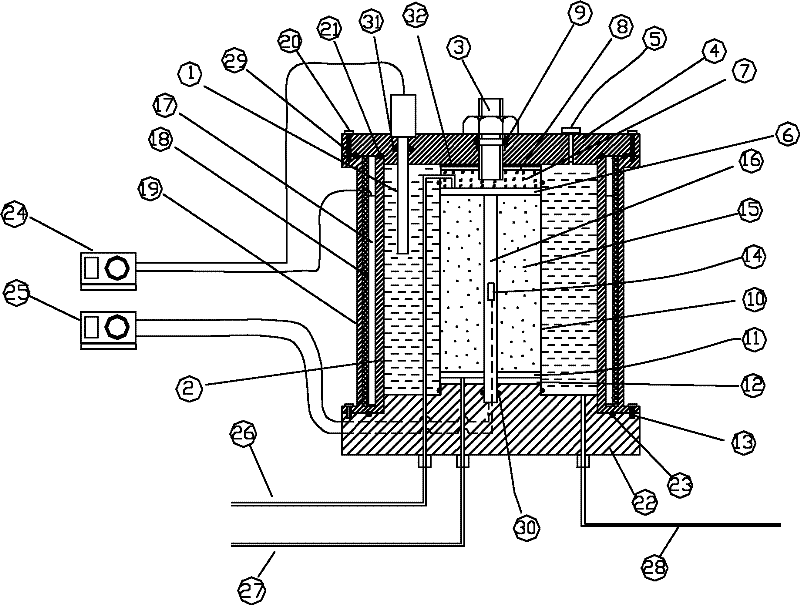

Thermal consolidation pressure room of hollow column sample

InactiveCN102507904AAccurate determination of thermal consolidation deformationAccurate pressure measurementEarth material testingAxial pressurePore water pressure

The invention discloses a thermal consolidation pressure room of a hollow column sample, relating to a thermal consolidation pressure room of a saturated soil sample, which is used for testing thermal consolidation deformation amount of the sample under the condition that the internal and the external temperatures change. The thermal consolidation pressure room solves the disadvantage that the thermal consolidation experiment cannot be carried out by a traditional thermal consolidation pressure room under the condition of coupling change of internal and external temperatures of the sample. A column sample (15) in the pressure room is a hollow column sample and a hot rod (16) is arranged in the hollow part of the column sample; a temperature sensor (14) is arranged on the hot rod; a lead of the hot rod and the lead of the temperature sensor are connected with a sample centre temperature controller (25); one end of an axial pressure rod (3) is connected with a screw socket in a sample cap and the other end of the axial pressure rod (3) is connected with a nut; a second O-shaped rubber pad sealing ring (9) is arranged between a middle section column part and a hole on a top cover (4) of a pressure room; a sample drainage pipe led from the pressure room is connected with a volume changing tube; and a hole water pressure measuring pipe is connected with a hole water pressure measuring system, and an ambient pressure connection pipe is connected with an ambient pressure measuring system.

Owner:BEIJING JIAOTONG UNIV

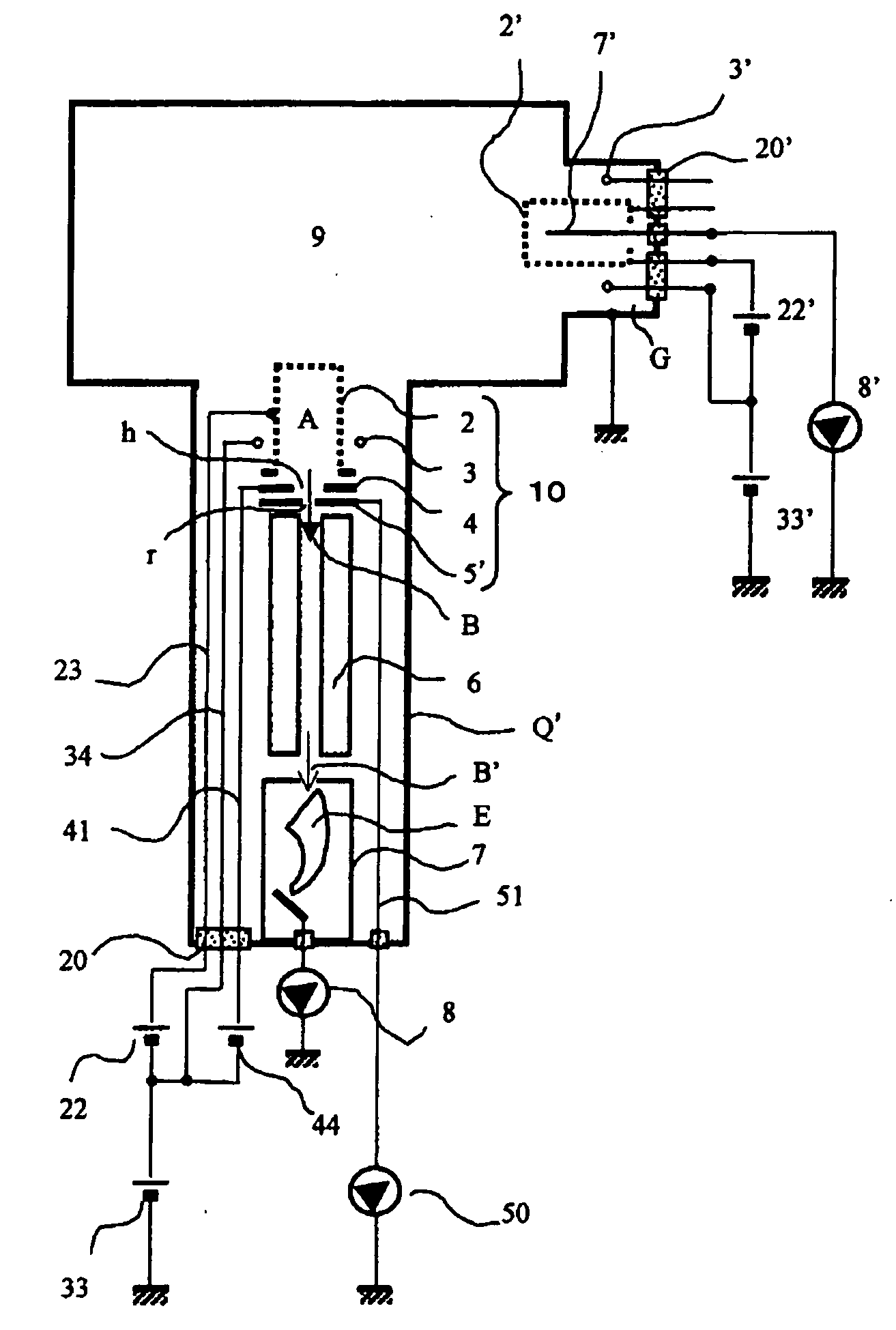

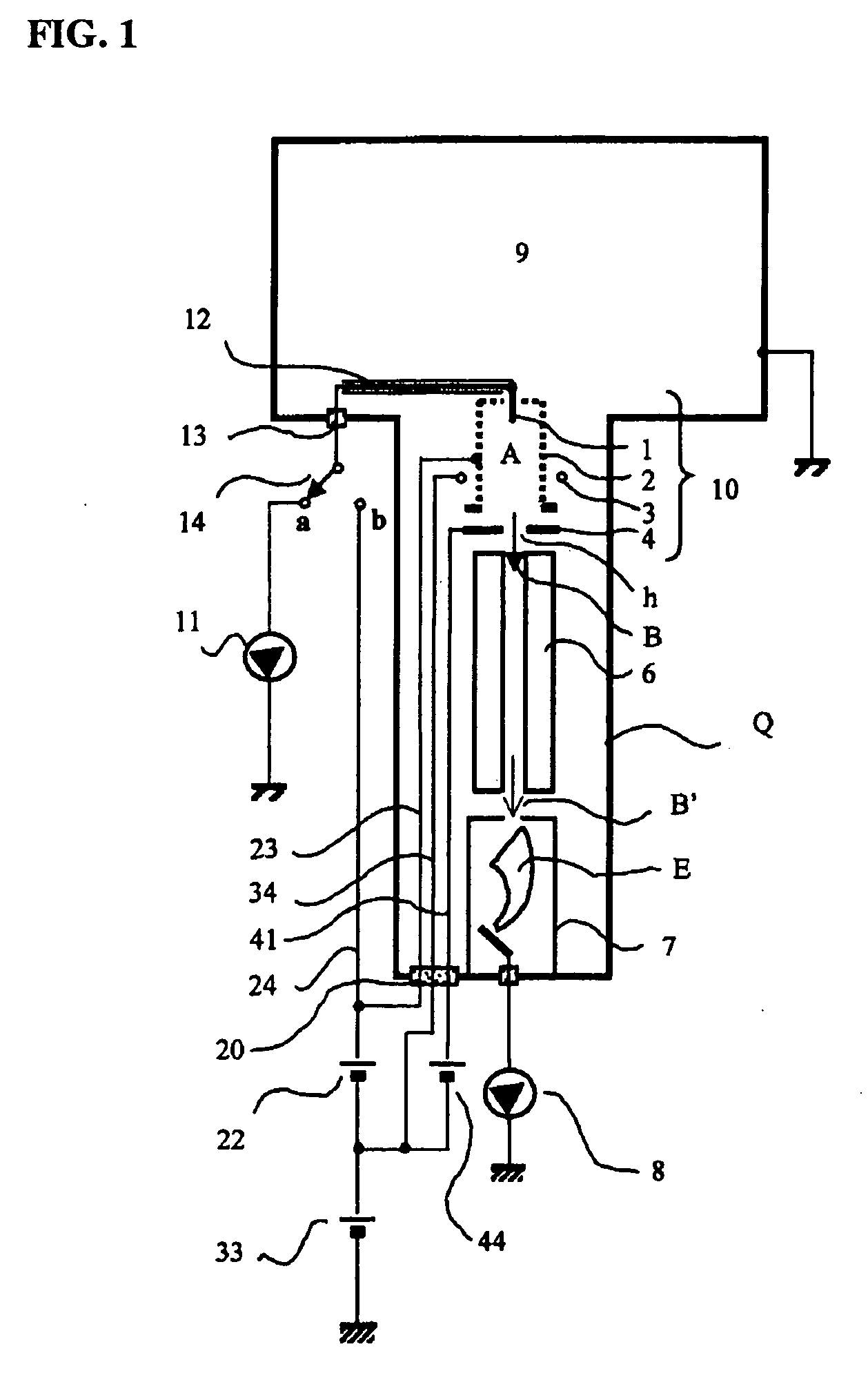

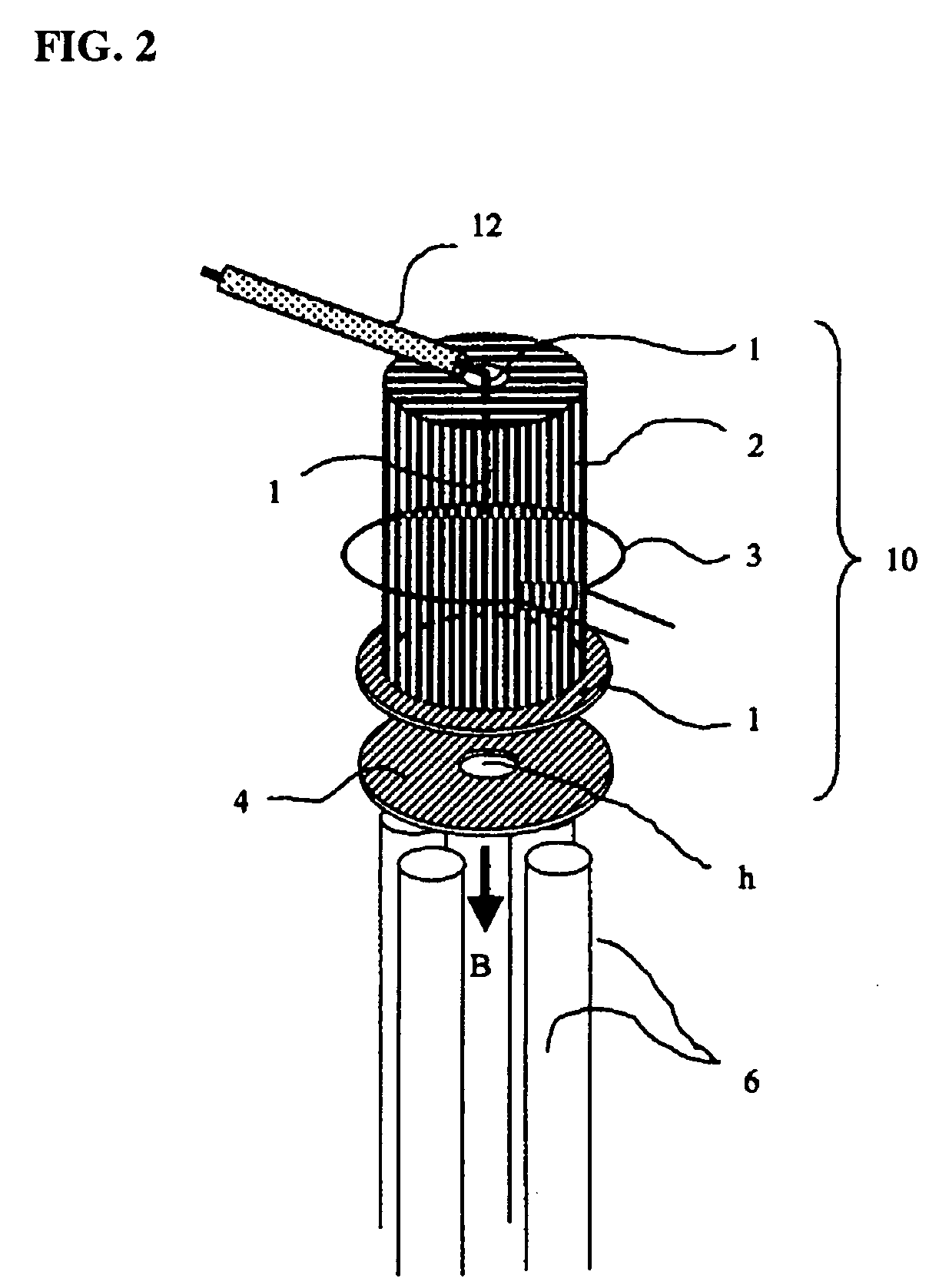

Quadrupole mass spectrometer and vacuum device using the same

InactiveUS20060226355A1Avoid it happening againRemove background noiseThermometer detailsTime-of-flight spectrometersIon currentIon density

In a quadrupole mass spectrometer which measures partial pressure strength according to a gas type in a vacuum system from ion current intensity, a quadrupole mass spectrometer with a total pressure measurement electrode has a total pressure measurement electrode for examining an ion density disposed in a demarcation space which is comprised of a grid electrode and an ion focusing electrode. And, a vacuum system is provided with only the quadrupole mass spectrometer which measures partial pressure strength according to a gas type in the vacuum system from an ion current intensity and does not have an ionization vacuum gauge other than the quadrupole mass spectrometer.

Owner:VACLAB

Array-type capacitive pressure pulse wave sensor, and pulse wave measuring apparatus having the same

InactiveUS20060005631A1Reduce manufacturing costAccurate pressure measurementForce measurementEvaluation of blood vesselsCapacitancePulse wave

An array-type capacitive pressure pulse wave sensor includes m rows of lower electrodes arranged in parallel with each other to extend substantially linearly in a direction approximately orthogonal to the extending direction of the artery at the time of measurement, n columns of upper electrodes arranged in parallel with each other at a prescribed distance from the m lower electrodes to extend in a direction crossing the extending direction of the m lower electrodes, and m×n capacitive elements formed at intersections of the m lower electrodes and the n upper electrodes. The m×n capacitive elements are arranged in a staggered manner when the pressure detecting portion is seen in two dimensions. Thus, it is possible to provide an array-type capacitive pressure pulse wave sensor that can be manufactured inexpensively and that ensures accurate and stable measurement of the pressure pulse wave.

Owner:OMRON HEALTHCARE CO LTD

Quadrupole mass spectrometer and vacuum device using the same

InactiveUS7332714B2Accurate pressure measurementImprove accuracyThermometer detailsStability-of-path spectrometersIon currentIon density

Owner:VACLAB

Pressure measuring device

InactiveUS20120006129A1Accurate pressure measurementAccurate measurementFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesSiliconPressure measurement

Provision of a pressure measuring device having a flexible membrane that receives the pressure; a pedestal, provided with a raised portion having a bottom face that is circular that supports the flexible membrane; and a supporting member that is bonded to the circular bottom face of the raised portion. The flexible membrane is made out of, for example, silicon, and has the (100) face as the primary face. Moreover, the flexible membrane is provided held between a silicon substrate, which is provided with a recessed portion, and a silicon substrate, which is provided with a recessed portion. Because of this, the flexible membrane is held on the pedestal with the silicon substrate interposed therebetween.

Owner:YAMATAKE HONEYWELL CO LTD

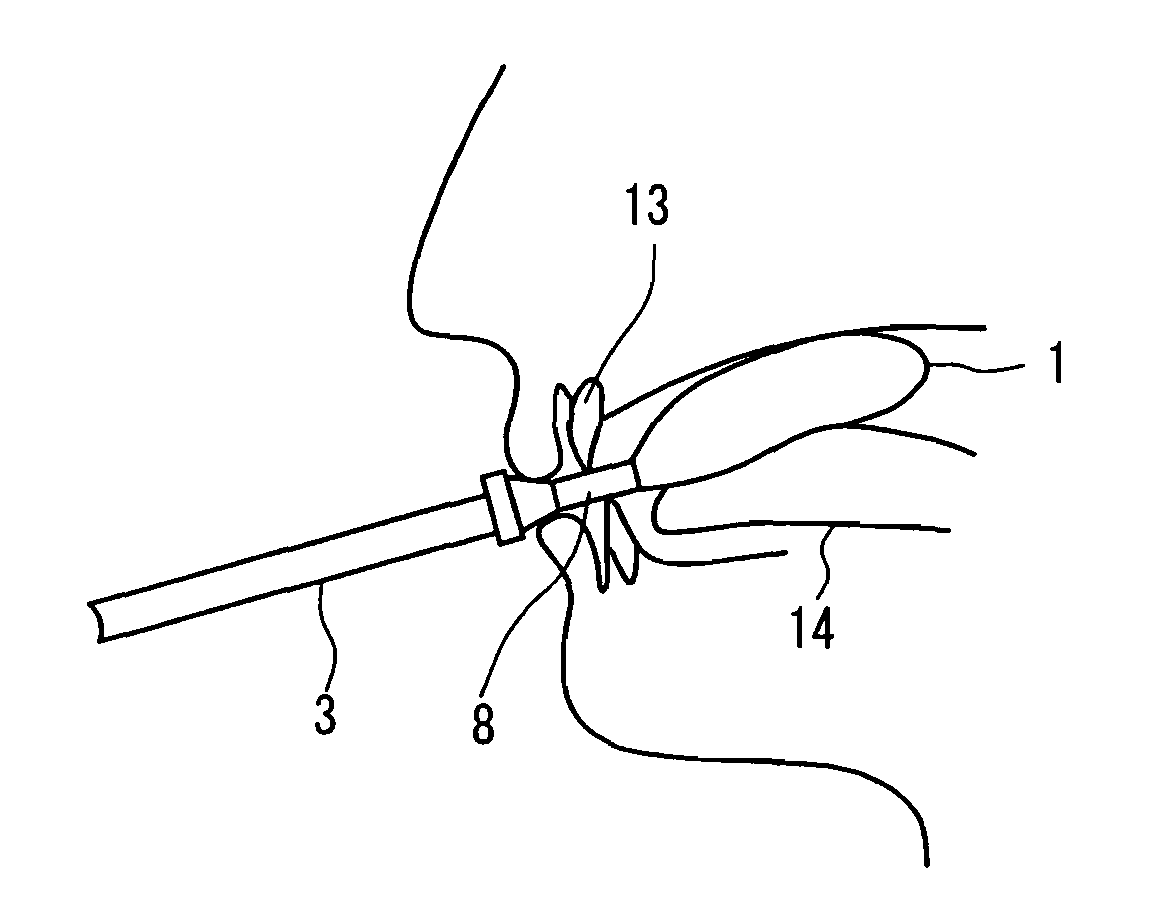

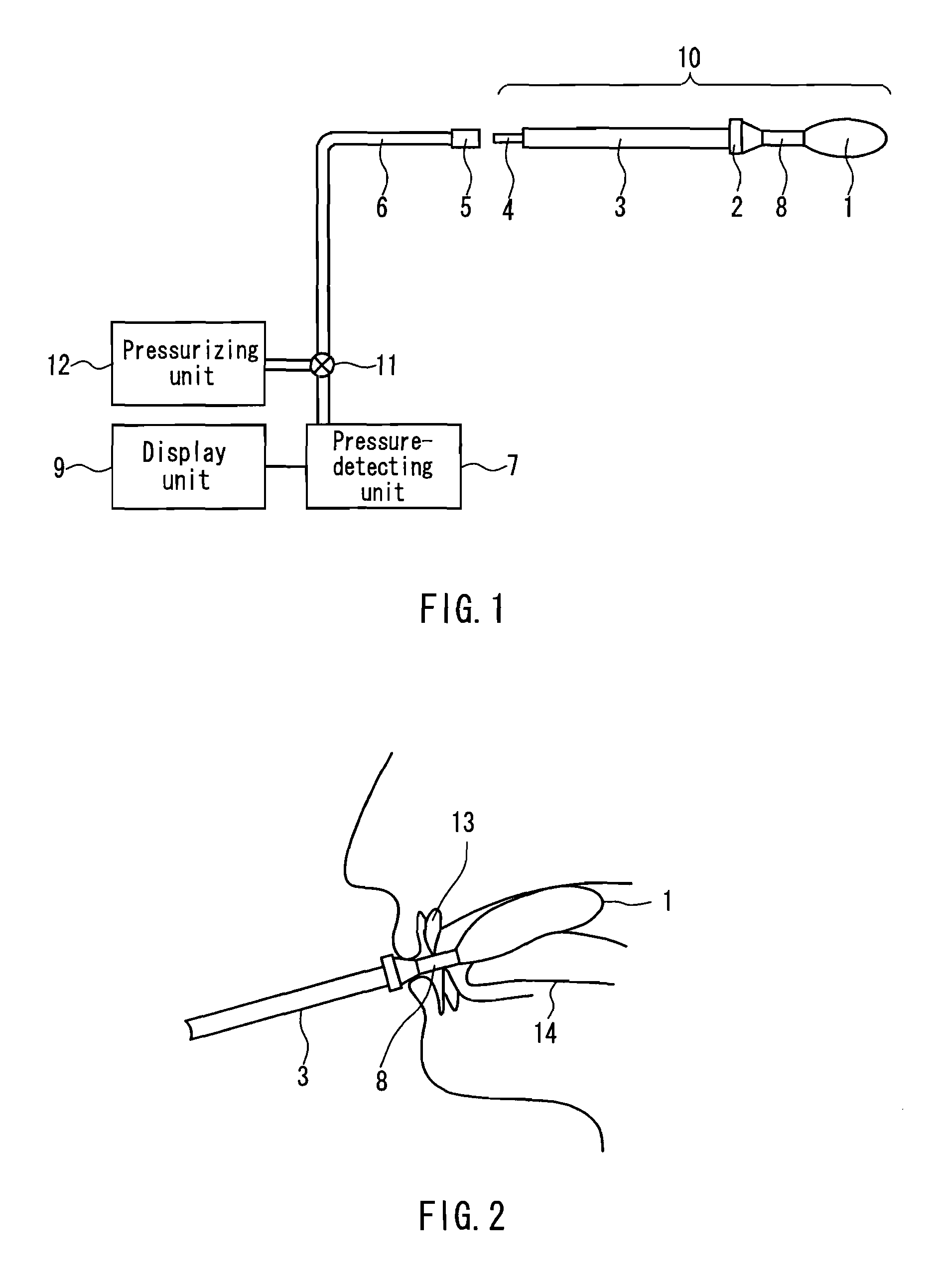

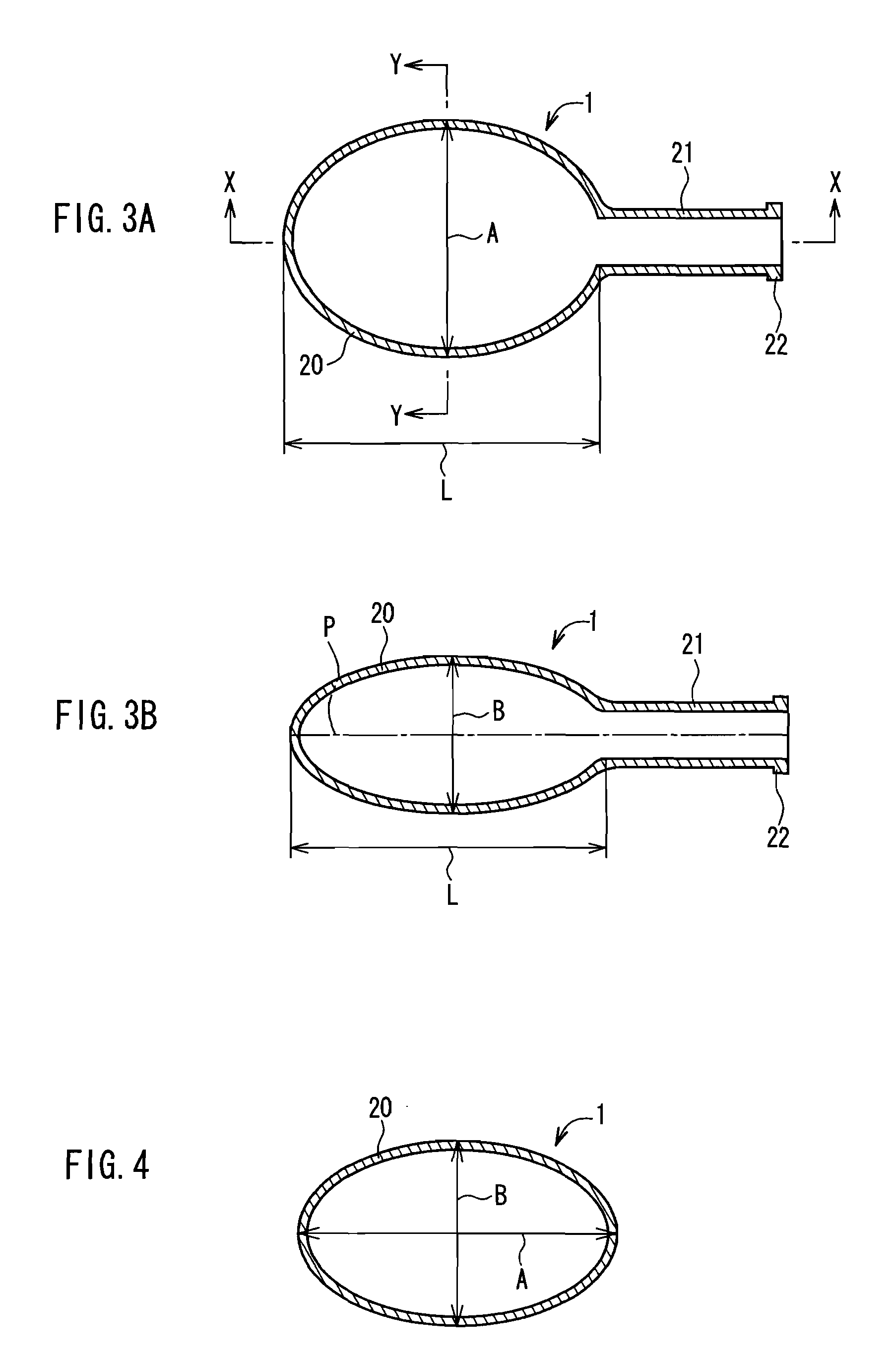

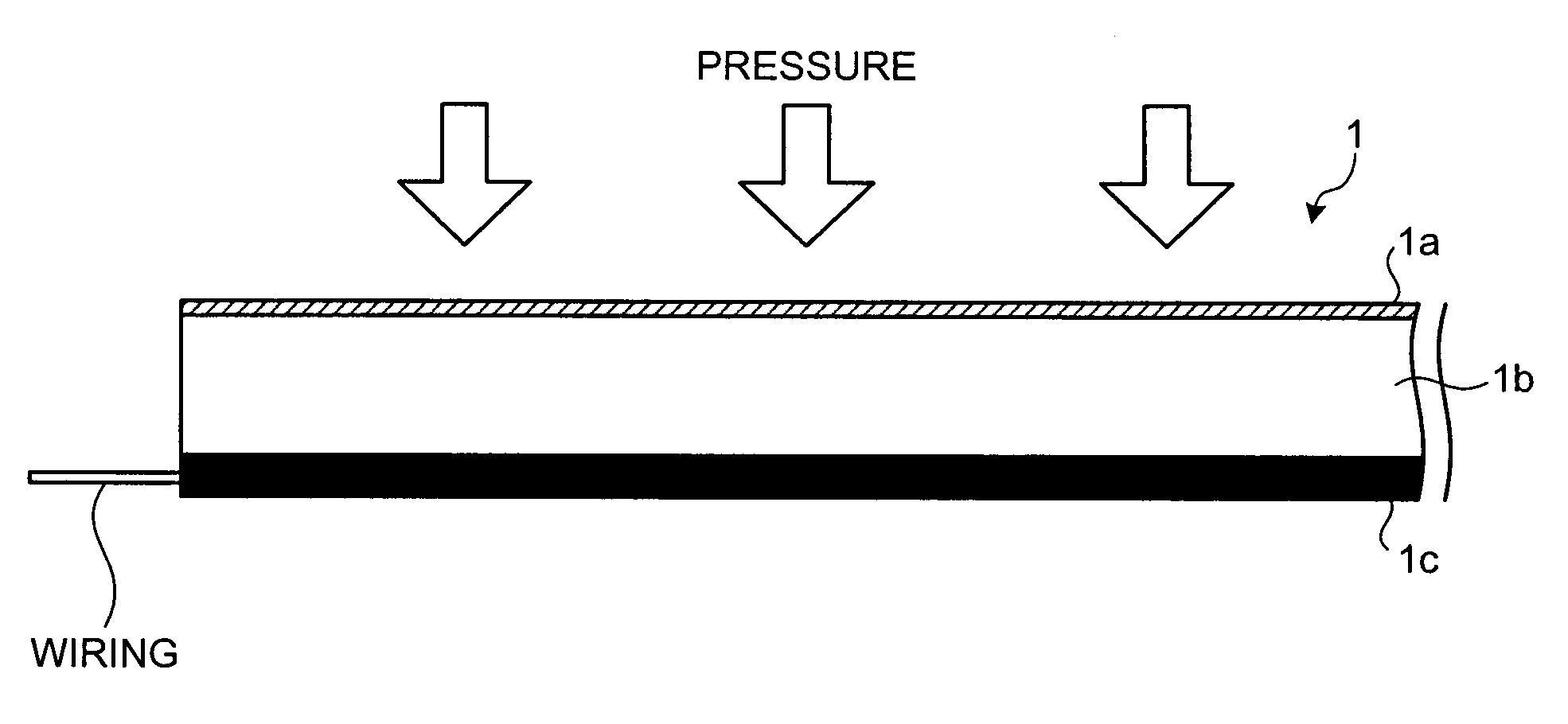

Balloon for measuring pressure related to oral cavity and method for producing the same

ActiveUS8366639B2Stable positionLinearity of the relationship between the load and the detected pressure can be improvedPerson identificationSensorsLong axisAtmospheric pressure

A balloon including: a pressure-receiving portion formed of an elastic material and forming an enclosed space; and a tubular portion formed integrally therewith. The balloon is configured to detect the air pressure in the pressure-receiving portion due to communication with a pressure detector through an opening end of the tubular portion. A transverse cross-section of the pressure-receiving portion orthogonal to the axial direction of the tubular portion has a flattened outer circumferential shape with an oblateness f=(A−B) / A, where A represents the length of a major axis of the outer circumferential shape and B represents the length of a minor axis thereof, being set to a range of 0.1≦f≦0.7 at a position at which the length A is at a maximum. The air pressure can be changed significantly and stably, and the precision of the pressure measurement can be increased.

Owner:JMS CO LTD

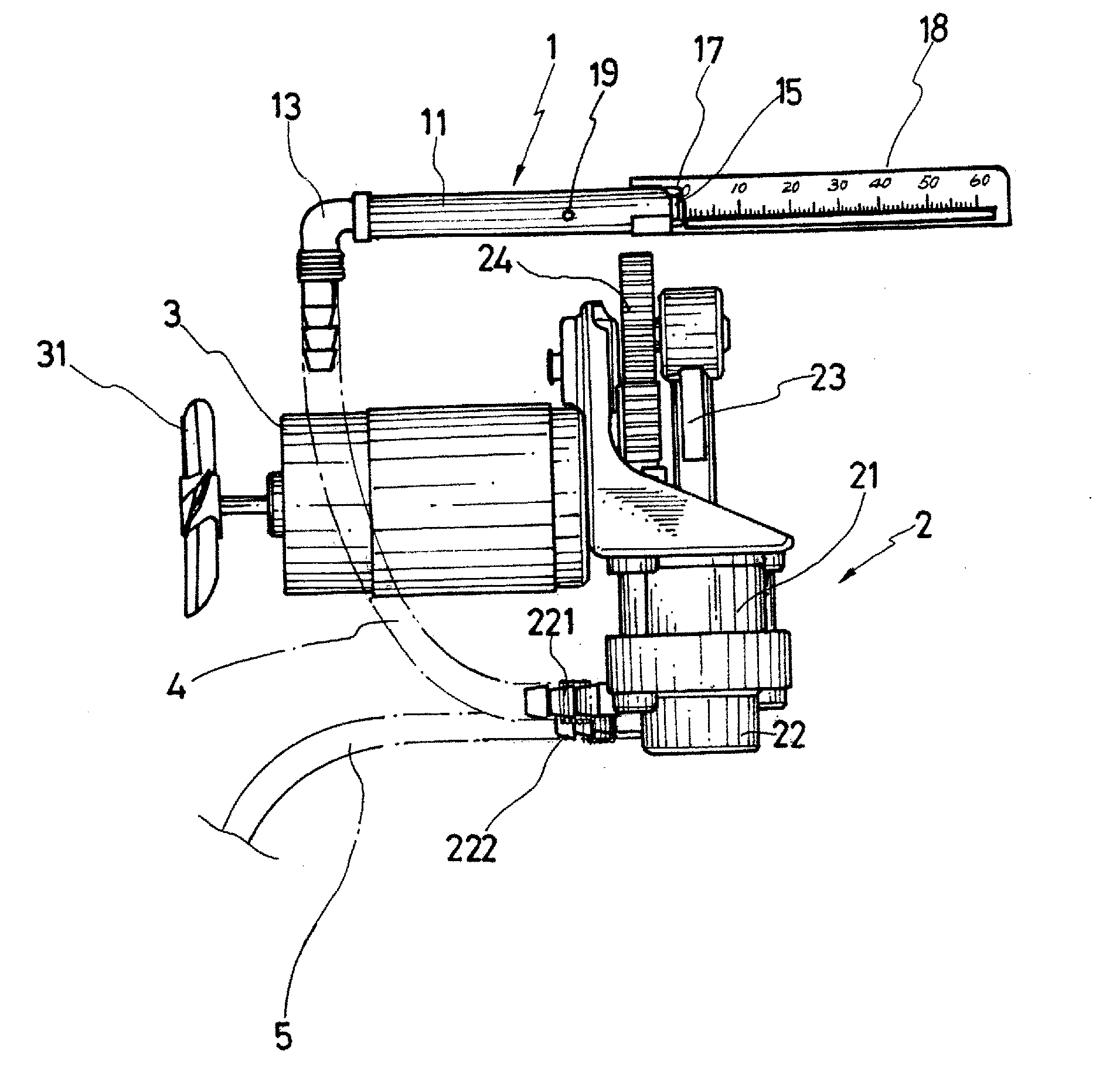

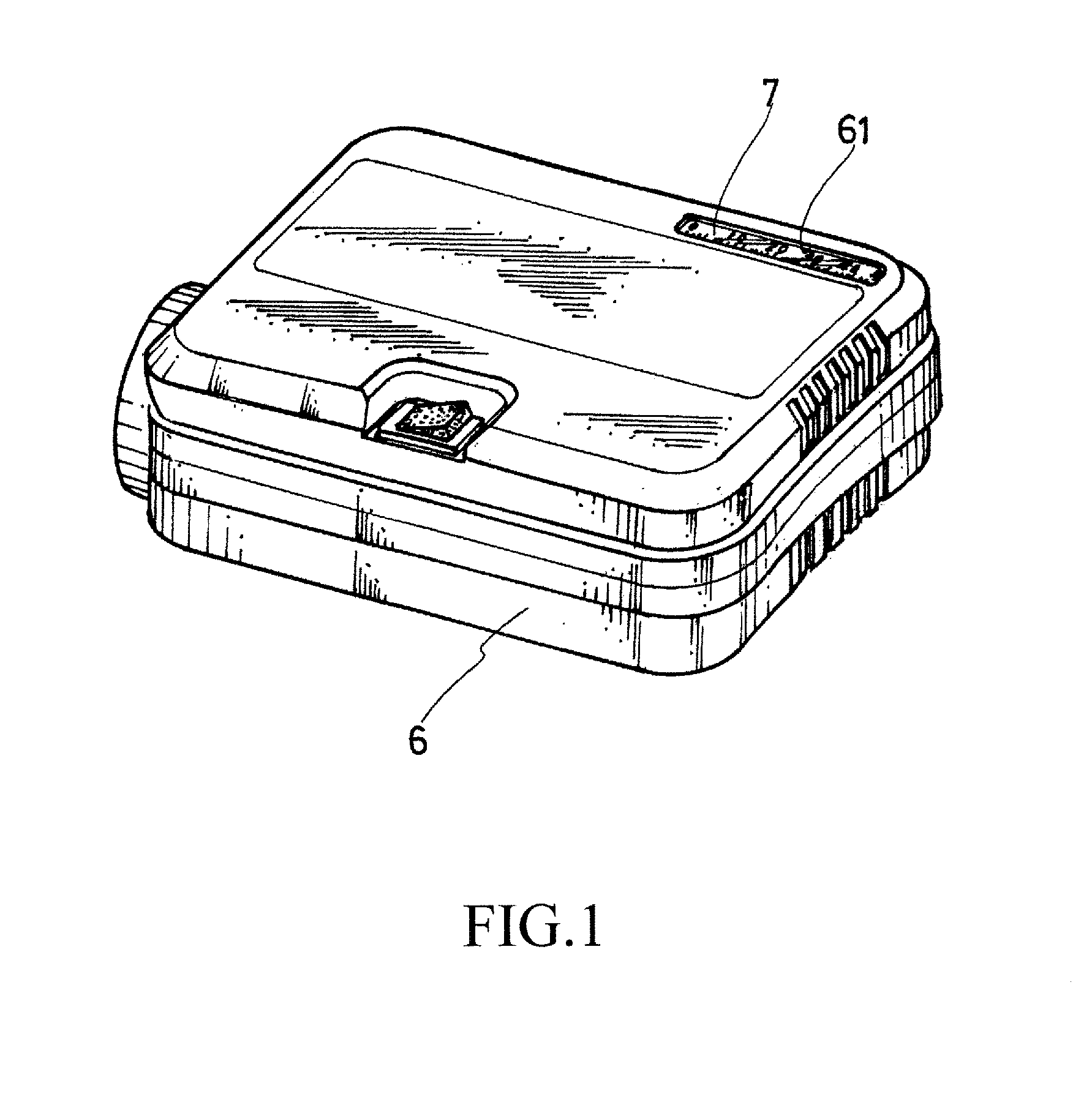

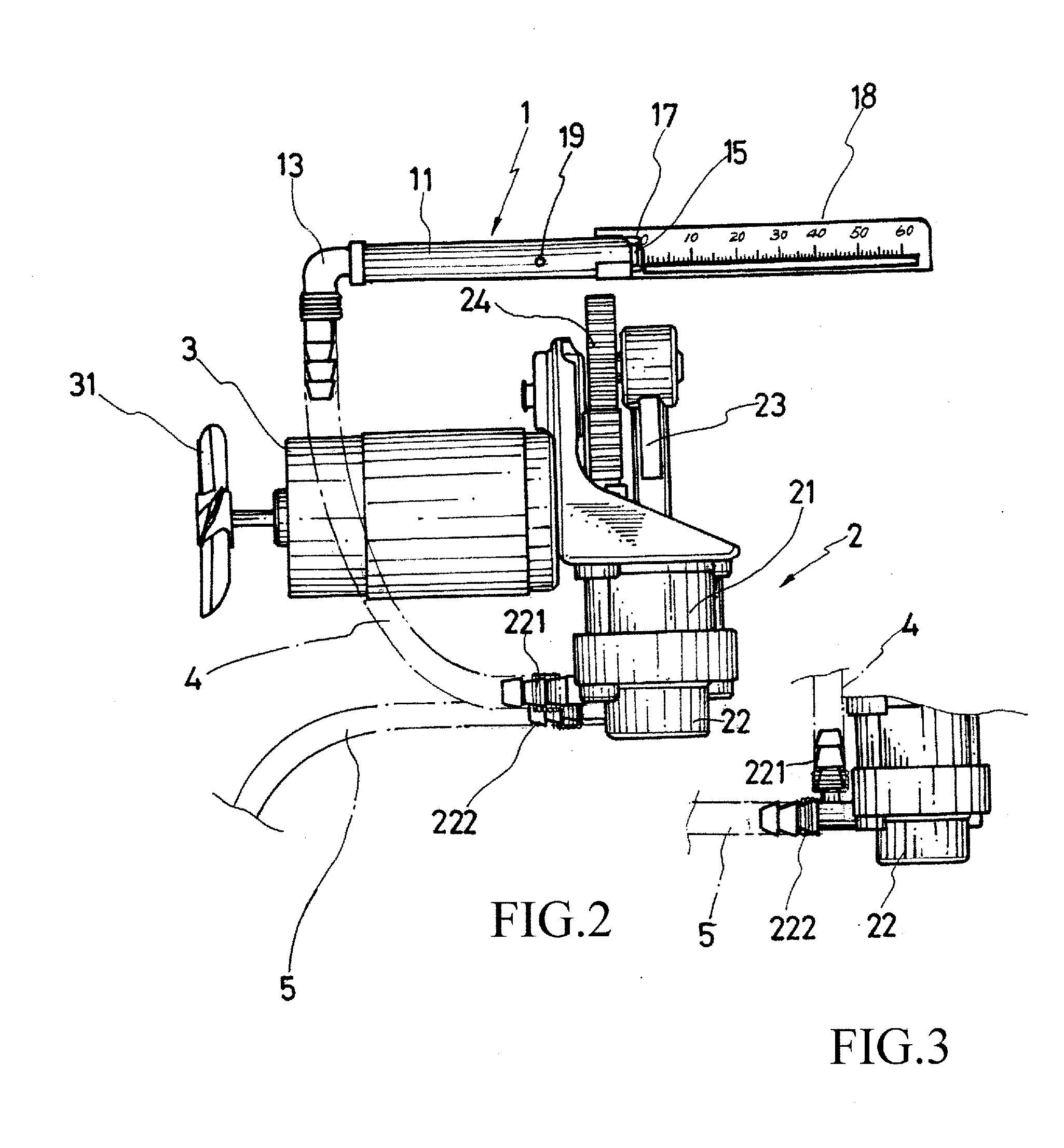

Pressure indication device of inflation machine with safety pressure relief

ActiveUS20140318260A1Precise measurementDurableInflated body pressure measurementFluid pressure measurement using elastically-deformable gaugesPressure levelEngineering

A pressure indication device is provided to connect to an inflation mechanism of an inflation machine. The pressure indication device includes a hollow tubular body in which a push bock is received in a manner of being movable by a pressure conducted into the hollow tubular body and connected to a linearly movable plate and biased by an elastic element. The hollow tubular body has a tubular wall forming a pressure relief hole at a preset position corresponding to a maximum allowable pressure level. A scale bar having graduations is provided along a moving path of the plate. The elastic force of compression of the elastic element serves as a reaction force (restoration and returning force) for the linear movement of the plate. A pressure conducted into the hollow tubular body from the inflation machine drives the plate to move and thus indicates the pressure level.

Owner:ANHUI FUYANG FENGJINBA MASCH & ELECTRIC CO LTD

Semiconductor pressure sensor

ActiveUS20120144923A1Easy to installAccurate pressure measurementFluid pressure measurement using ohmic-resistance variationFlexible microstructural devicesPressure sensorSemiconductor

A semiconductor pressure sensor includes: a case; a pressure inlet port through which a measurement target fluid is introduced into the case; an atmosphere inlet port through which atmosphere is introduced; and a sensor chip configured to measure the pressure of the fluid with respect to atmospheric pressure. The pressure inlet port and the atmosphere inlet port are disposed on the same surface side of the case. The pressure inlet port is communicated with the inside of the case.

Owner:PANASONIC CORP

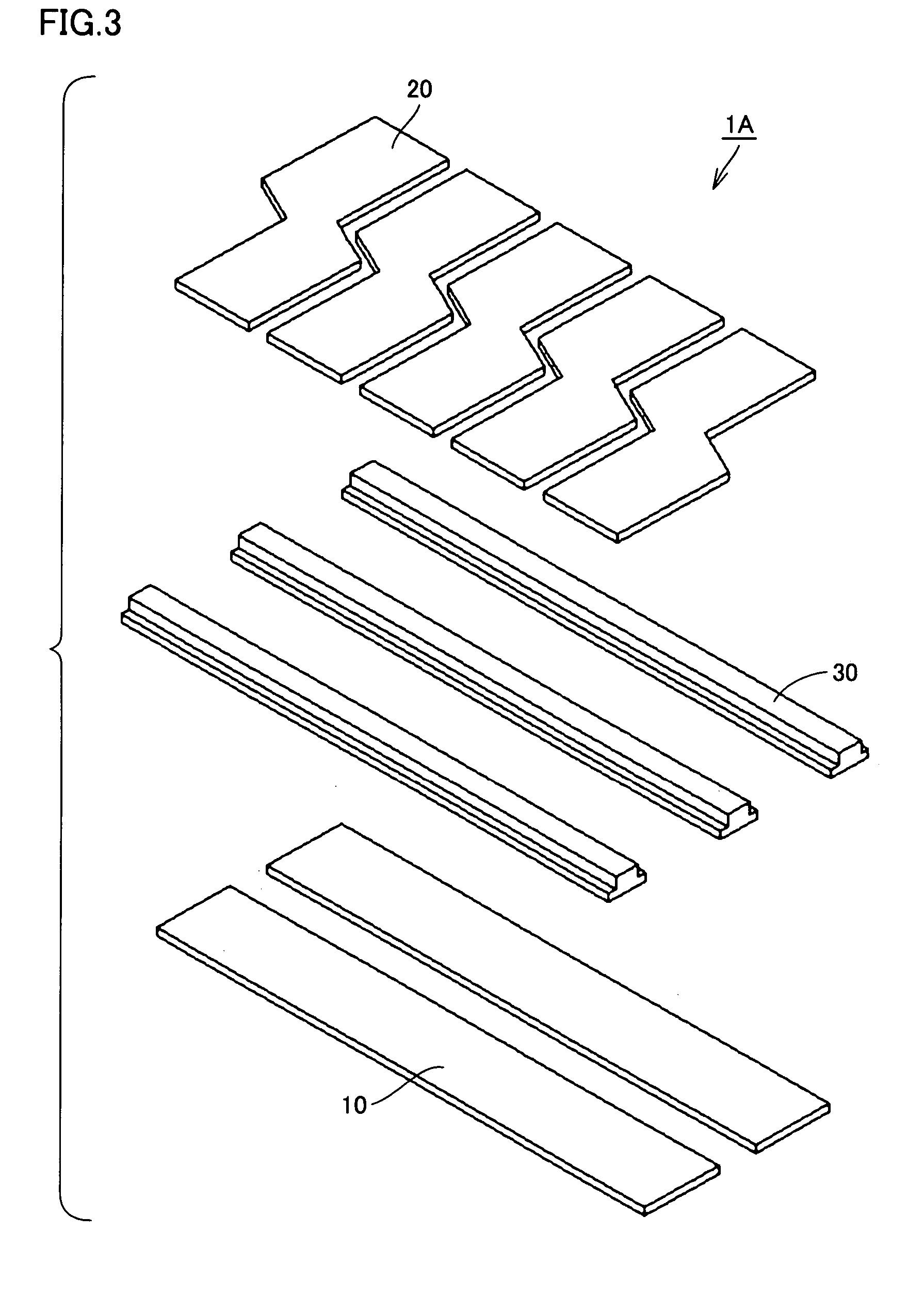

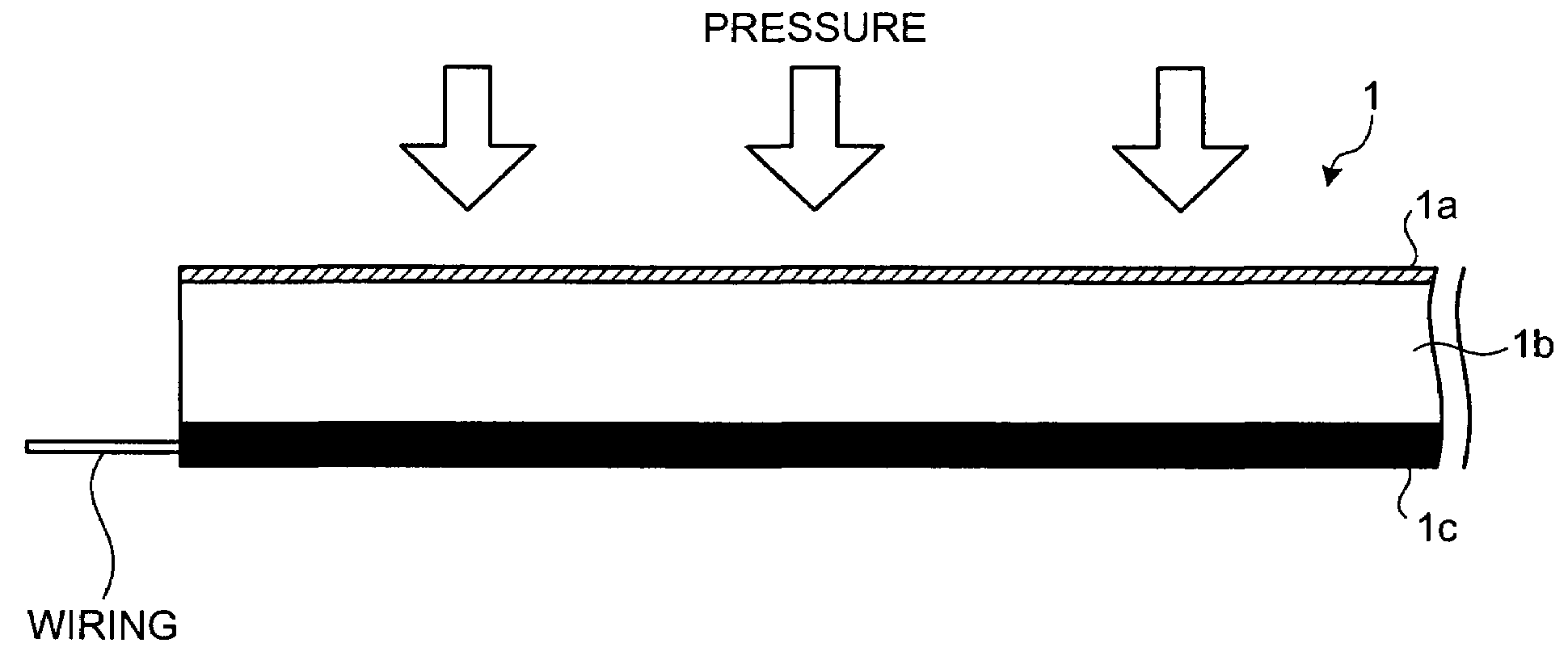

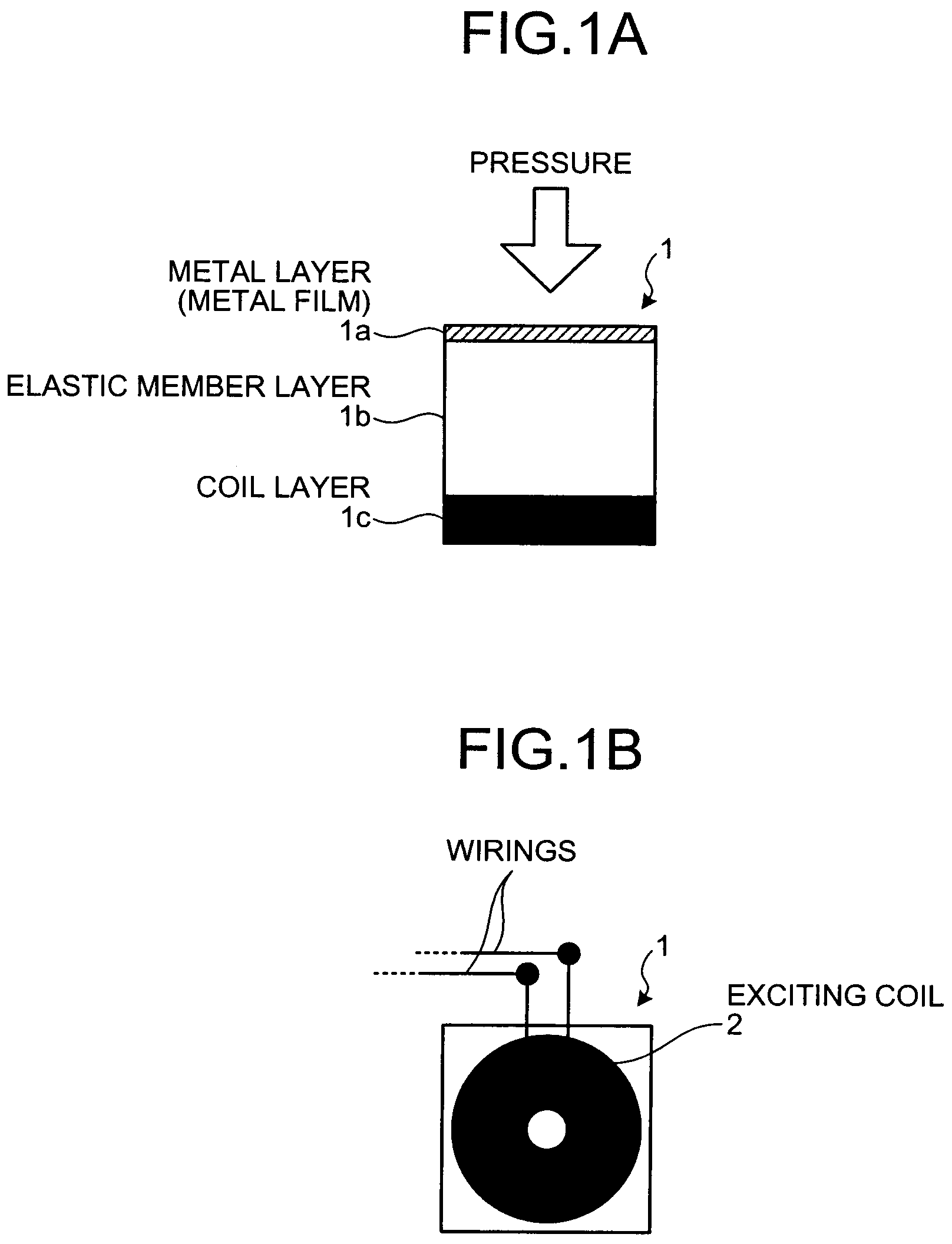

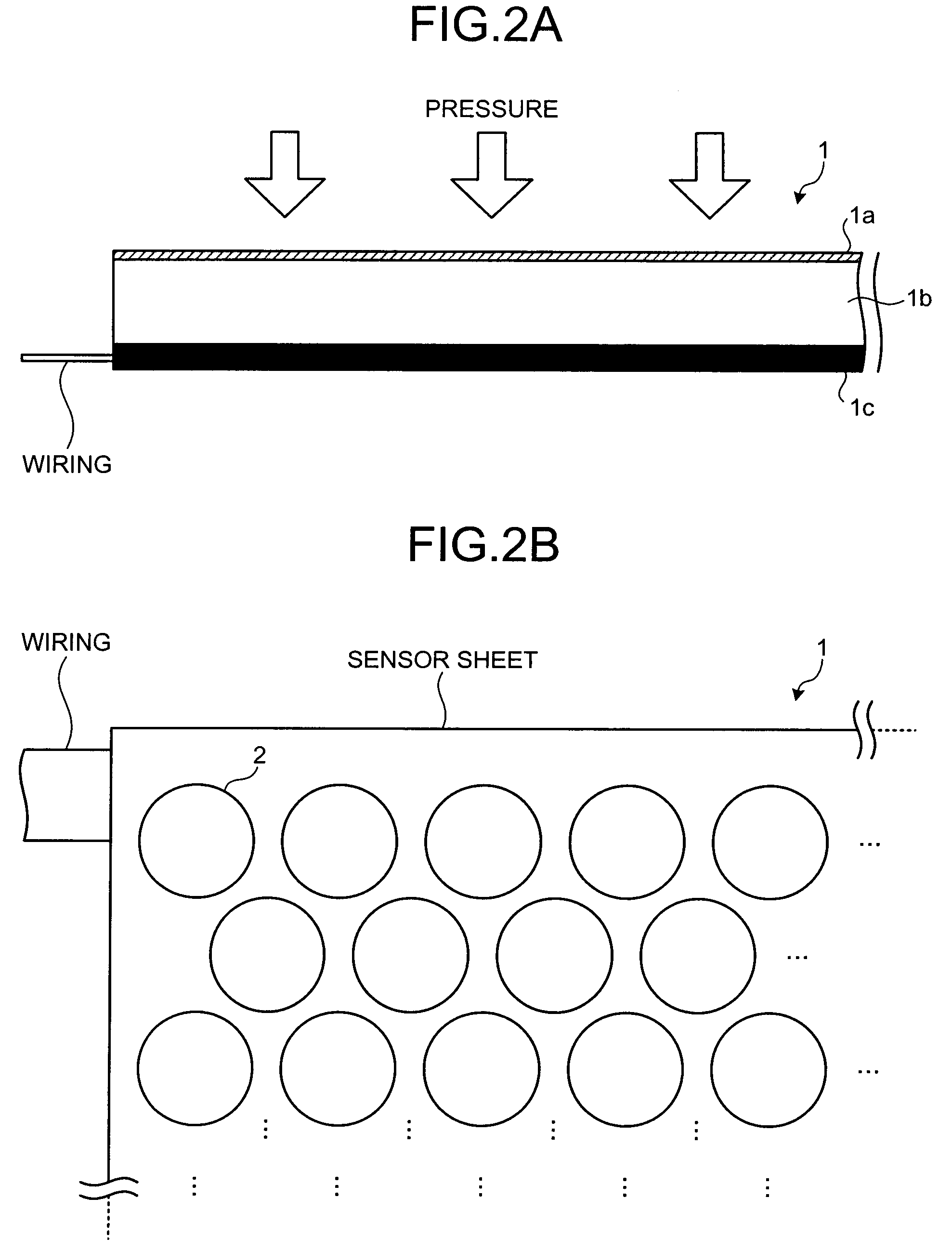

Pressure sensor and device for measuring pressure

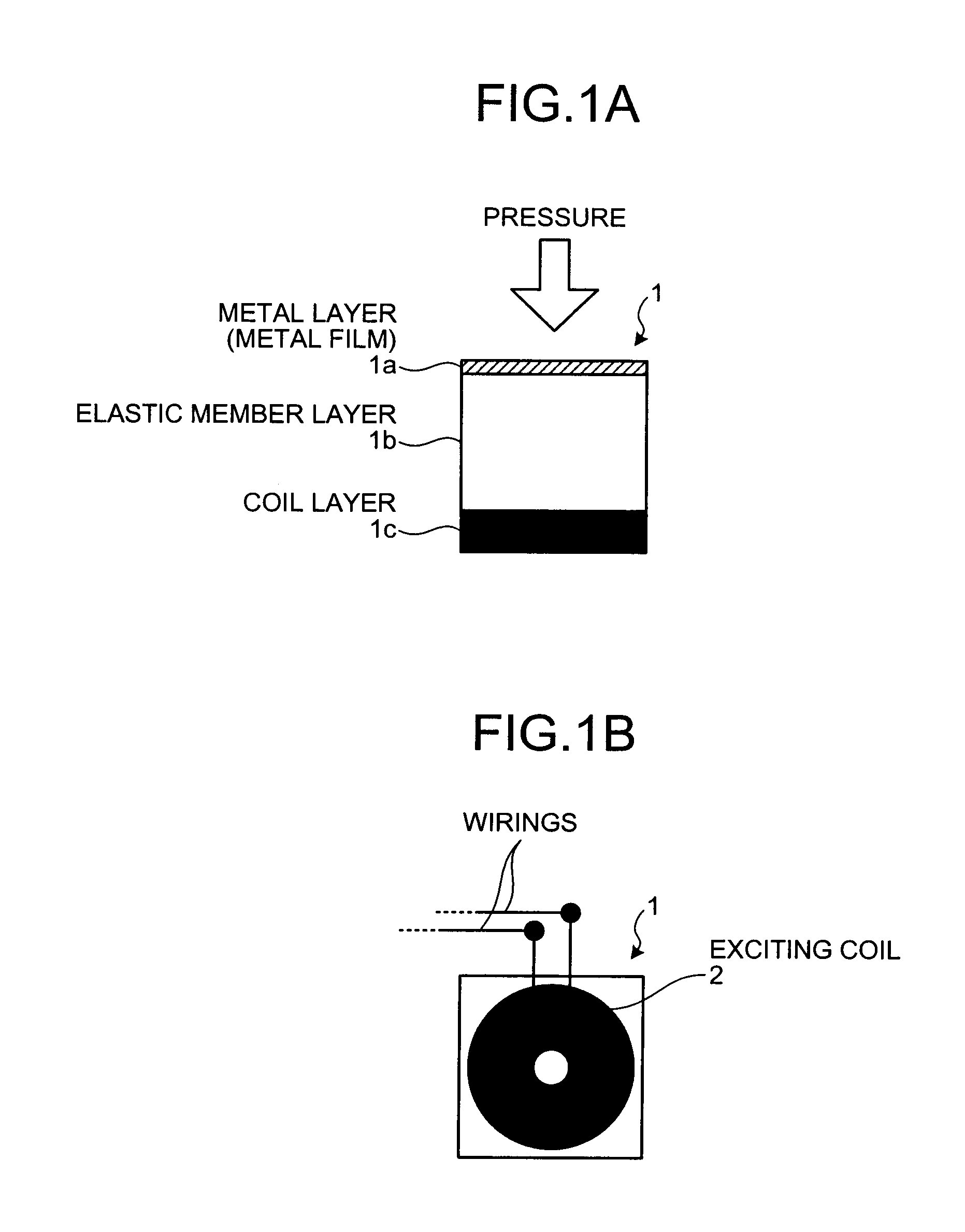

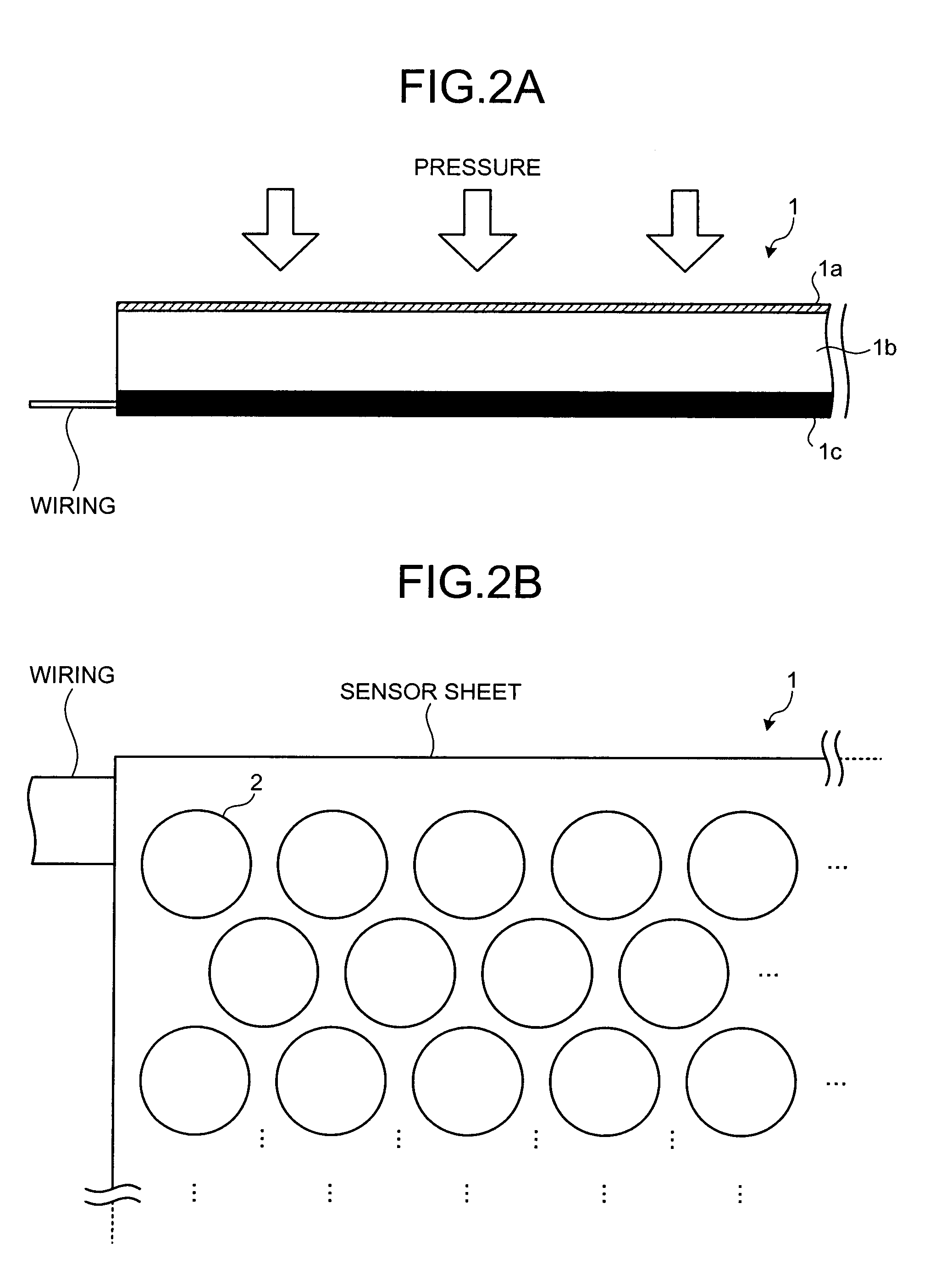

InactiveUS20070204698A1Improve Manufacturing AccuracyReduce manufacturing costFluid pressure measurement using inductance variationForce measurementMeasurement pointMetallic materials

A pressure sensor and a pressure measuring device are provided applicable to a variety of pressure detection targets and capable of measuring a surface pressure. The pressure sensor is configured by laminating a metal layer made of a metal film, an elastic member layer made of a non-metal material, and a coil layer including an exciting coil. Also, as for a sensor sheet on which sensors that each measure point pressure are arranged in an array, variable elements of the elastic member layer and the coil layer are appropriately changed, thereby forming sensors with a single sheet that are different in pressure detection accuracy or pressure detection range for predetermined areas. Also provided is a pressure measuring device that controls exciting timing or frequency of applied voltage of each exciting coil on a sensor sheet.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

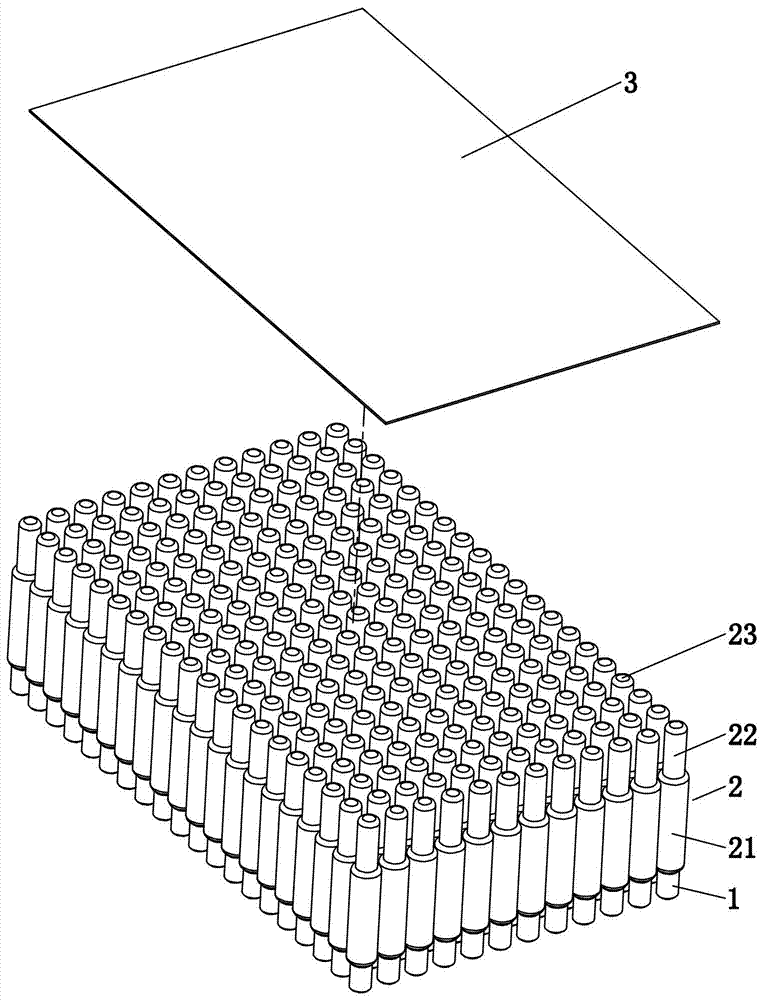

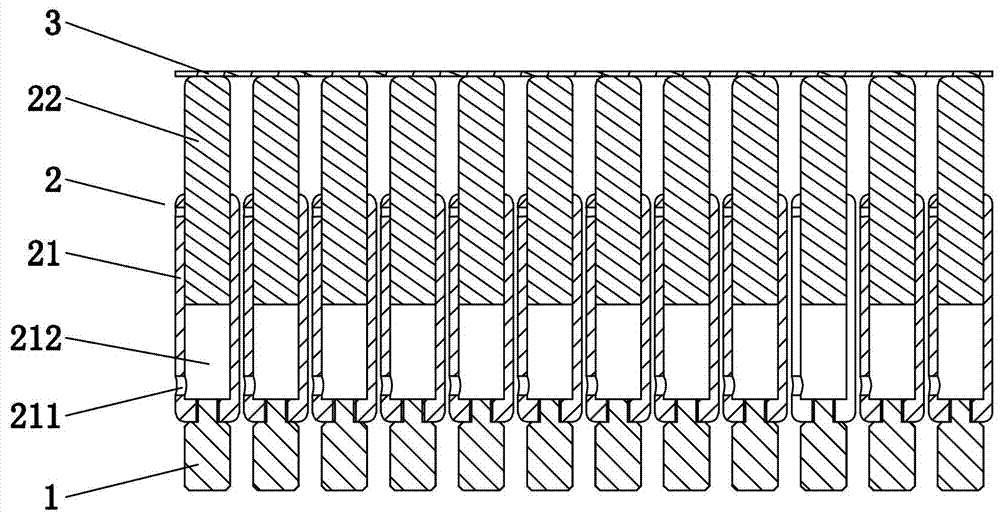

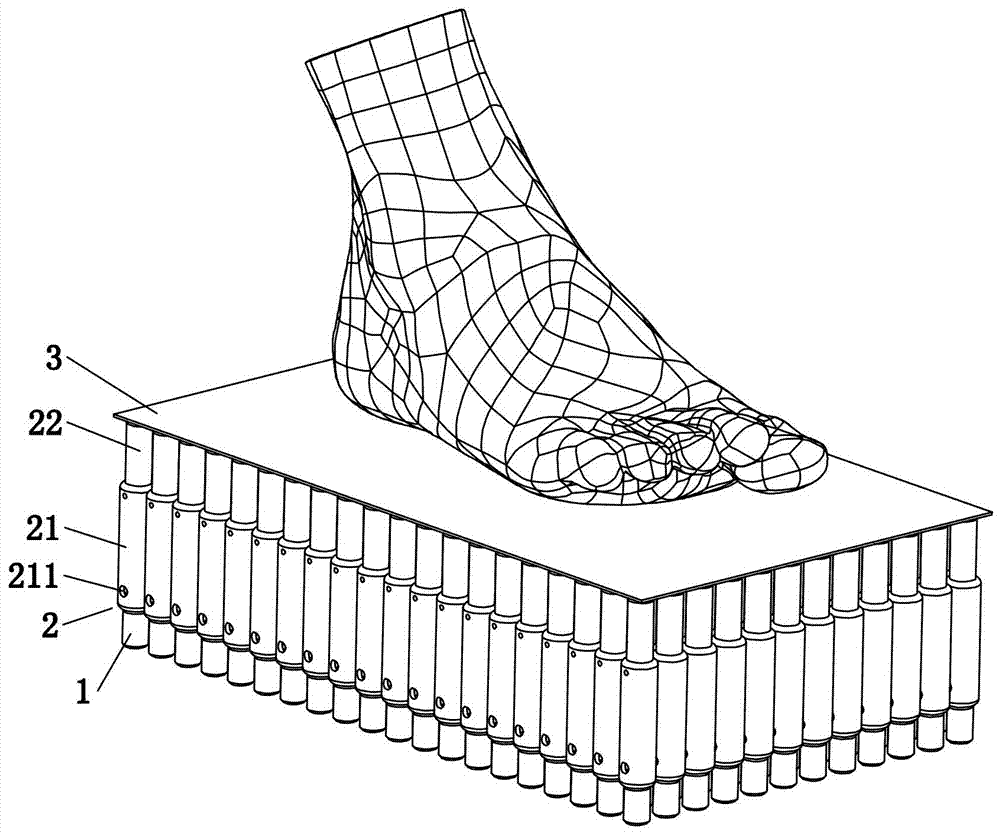

Dot-matrix sole pressure measuring device and detection method thereof

PendingCN107049319AAccurate pressure measurementDiagnostic recording/measuringSensorsEngineeringThree dimensional shape

The invention relates to a dot-matrix sole pressure measuring device and a detection method thereof. The structure of the device comprises pressure measuring devices and an electric control system. The pressure measuring devices are electrically connected with the electric control system and arranged on a panel in an array. The pressure measuring devices are rod-shaped. Sole supporting surfaces are formed by the top ends of the pressure measuring devices and separated from each other. The sole supporting surfaces perform up-down motion with changes of supporting weight. The dot-matrix sole pressure measuring device comprises the multiple pressure measuring devices in shapes of rods. The pressure measuring devices are distributed in a dot-matrix form. The heights of the top ends of the pressure measuring devices can change according to different support weight. Therefore, pressure of all positions of the sole can be precisely measured. Furthermore, no matter what the shape and the size of the sole are, the sole can be within the measurement range. In addition, absolute value of sole pressure distribution is calculated according to an internal software algorithm of a master control unit and a sole three-dimensional shape can be scanned.

Owner:GUANGDONG MENLO ELECTRIC POWER

Pressure sensor and device for measuring pressure

InactiveUS7513163B2Accurate pressure measurementConvenient ArrangementFluid pressure measurement using inductance variationForce measurementMeasurement pointMetallic materials

A pressure sensor and a pressure measuring device are provided applicable to a variety of pressure detection targets and capable of measuring a surface pressure. The pressure sensor is configured by laminating a metal layer made of a metal film, an elastic member layer made of a non-metal material, and a coil layer including an exciting coil. Also, as for a sensor sheet on which sensors that each measure point pressure are arranged in an array, variable elements of the elastic member layer and the coil layer are appropriately changed, thereby forming sensors with a single sheet that are different in pressure detection accuracy or pressure detection range for predetermined areas. Also provided is a pressure measuring device that controls exciting timing or frequency of applied voltage of each exciting coil on a sensor sheet.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

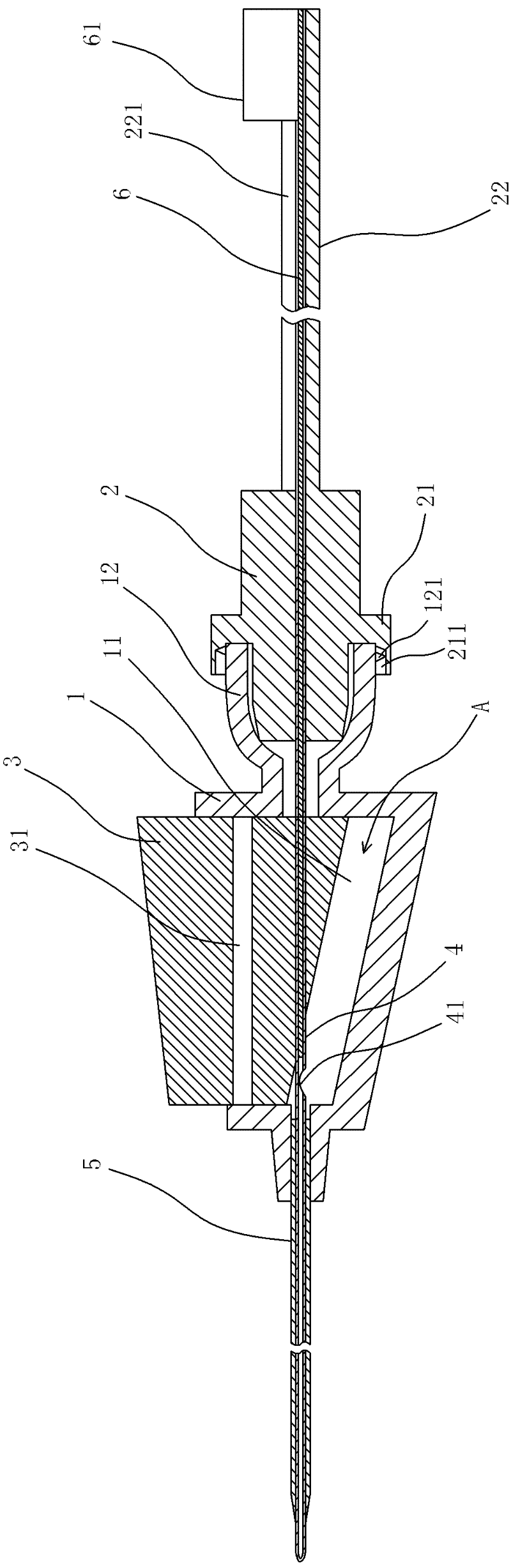

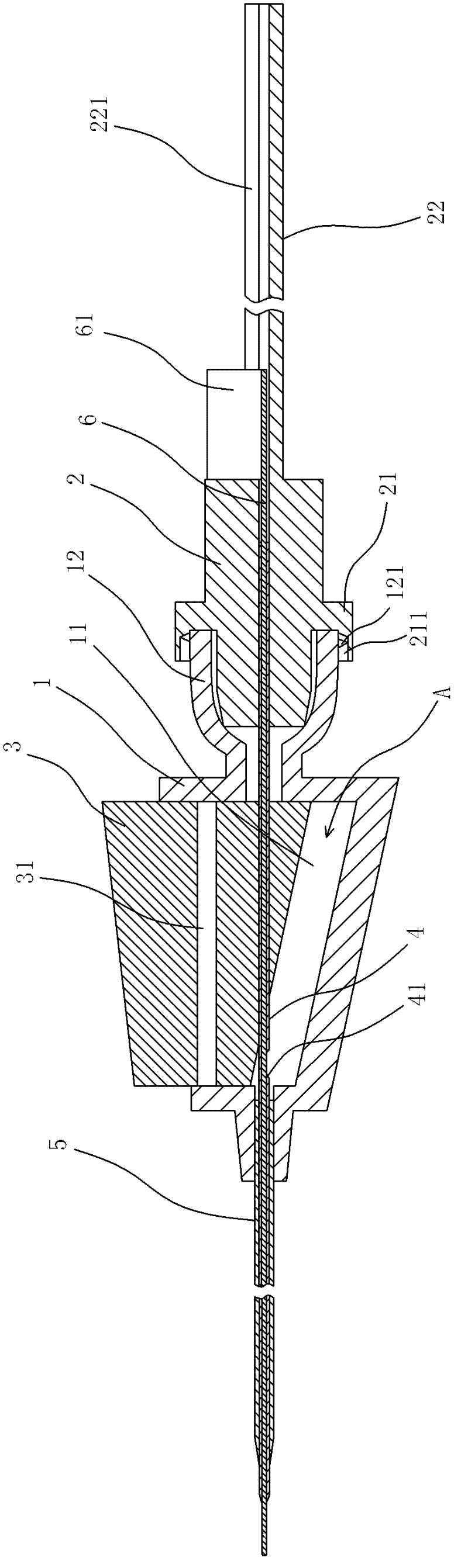

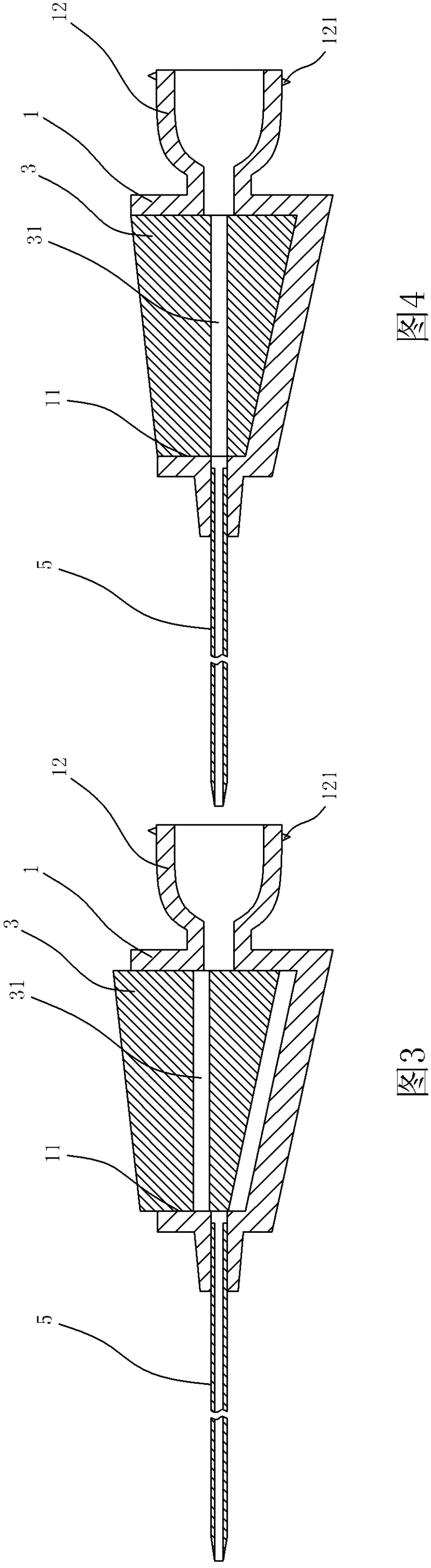

Artery puncture needle

InactiveCN102551692APrevent backflowPrevent sprayingCatheterAngiographyBlood collectionArtery puncture

An artery puncture needle comprises a light-transmission cannula seat, a remaining needle outer cannula, a steel needle seat and a steel needle. A tubular pressure measuring joint is arranged at the rear end of the light-transmission cannula seat, the remaining needle outer cannula is opposite to the pressure measuring joint and arranged at the front end of the cannula seat, the steel needle is disposed on the steel needle seat, a holding groove which is respectively communicated with the remaining needle outer cannula and the pressure measuring joint is formed in the cannula seat, an elastic stop block which can be operated to slide between a puncture position and a pressure measuring position is movably assembled in the holding groove, a pressure measuring channel which runs through transversely is formed on the stop block, and a blood draining hole which is communicated with the holding groove is formed on the cannula seat. The artery puncture needle has the advantages that the artery puncture needle is simple in structure, convenient in operation, capable of preventing blood from spraying outwards, high in puncture success rate, accurate in pressure measurement, convenient in blood collection, and the like.

Owner:谢文钦

Method of manufacturing implantable wireless sensor for in vivo pressure measurement

ActiveUS9078563B2Accurate pressure measurementPrinted circuit assemblingCatheterElectricityEngineering

A method of manufacturing a sensor for in vivo applications includes the steps of providing two wafers of an electrically insulating material. A recess is formed in the first wafer, and a capacitor plate is formed in the recess of the first wafer. A second capacitor plate is formed in a corresponding region of the second wafer, and the two wafers are affixed to one another such that the first and second capacitor plates are arranged in parallel, spaced-apart relation.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

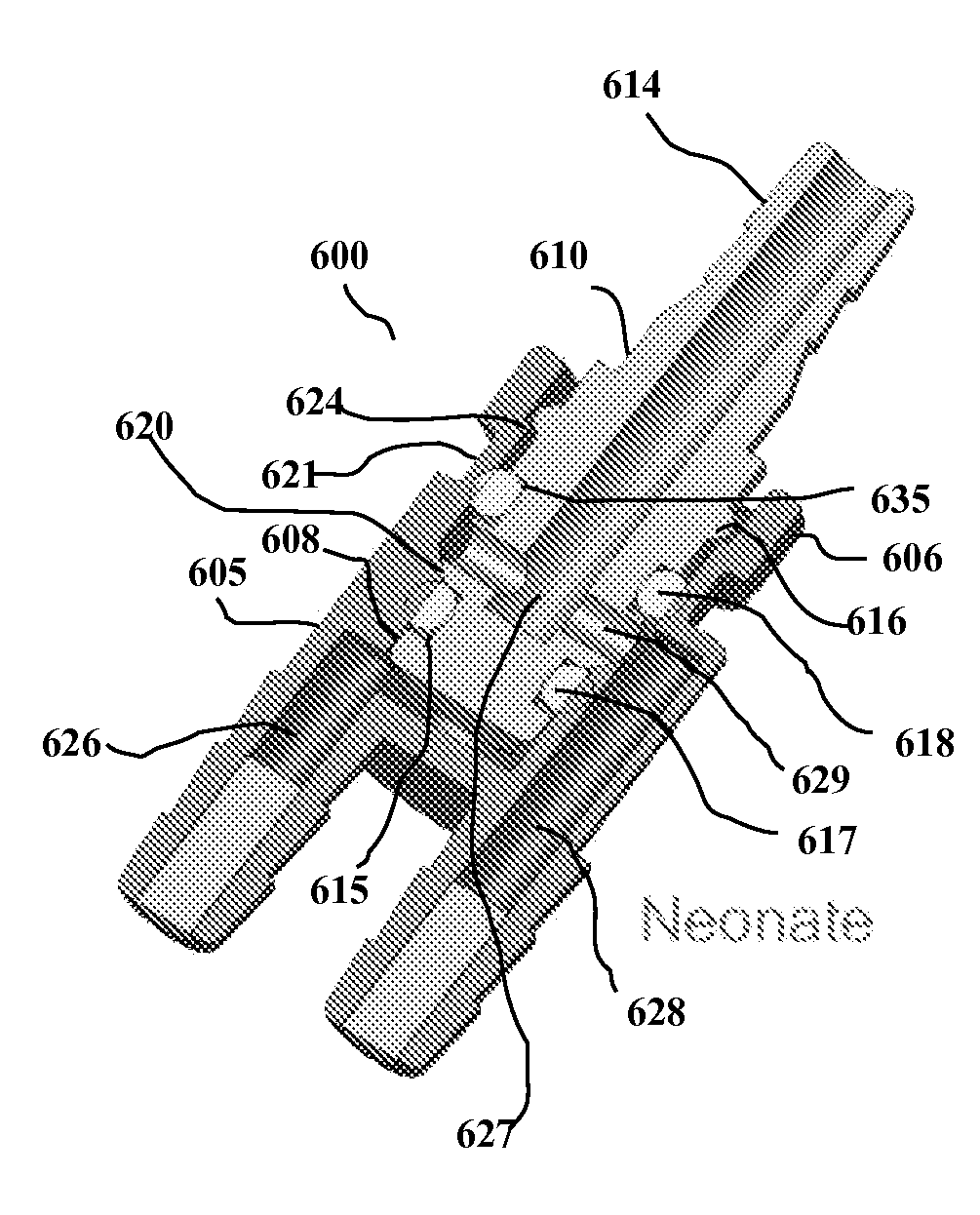

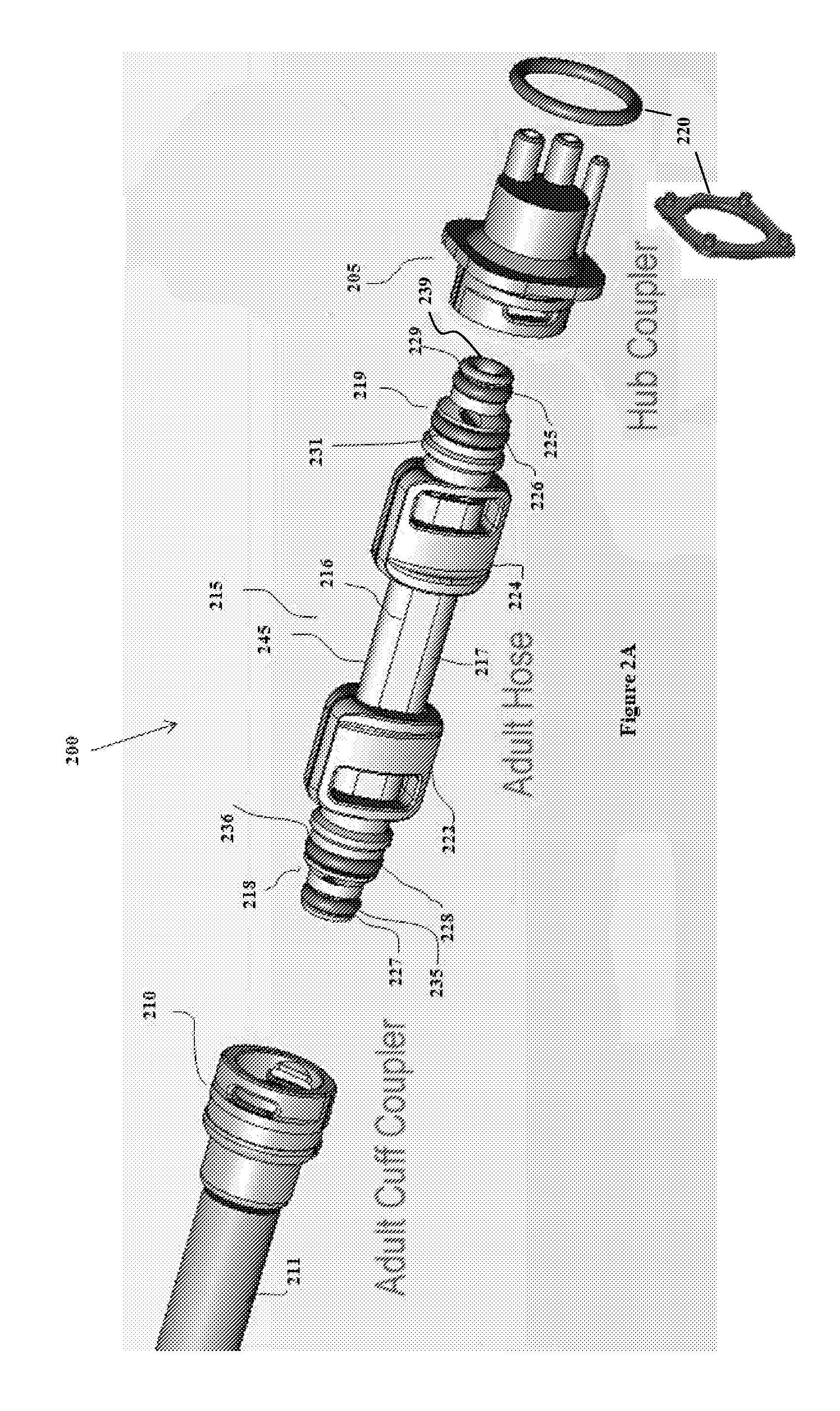

Air-Tight Push-In and Pull-Out Connector System with Positive Latching

InactiveUS20130015654A1Avoid couplingPositive lockEvaluation of blood vesselsPipe elementsBlood pressure cuffsBlood pressure cuff

The present specification discloses an adapter for coupling a blood pressure cuff to a blood pressure manifold. In one embodiment, the adapter includes an elastomeric hose having a first end and a second end and a first lumen and a second lumen. The first and second lumens define a first air pathway and a second air pathway respectively. A first end connector is integrally formed with the first end and the second end connector is integrally formed with the second end. The first end connector includes a first seal and a second seal and the second end connector includes a third seal and a fourth seal. The first end of the first lumen terminates proximate to the first seal, the second end of the first lumen terminates proximate to the third seal, the first end of the second lumen terminates proximate to the second seal, and the second end of the second lumen terminates proximate to the fourth seal. The seals are comprised of O-rings, compressible wipers, or any other equally compressible, sealing material. Optionally, for a neonate adapter, the third and fourth seals at the second end connector are replaced by an integrated single lumen tube with a neonate cuff attached at its end.

Owner:SPACELABS HEALTHCARE LLC

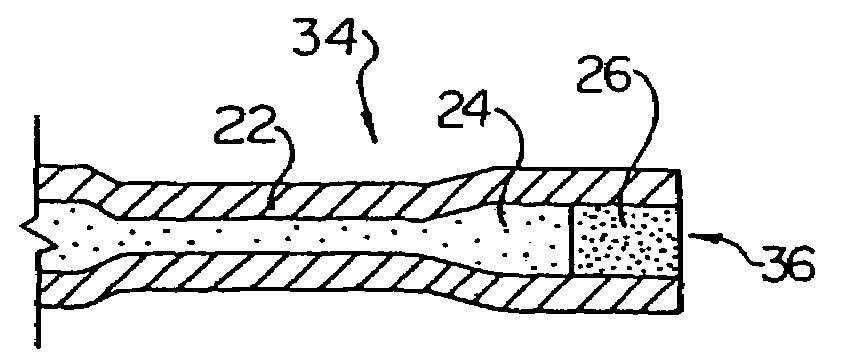

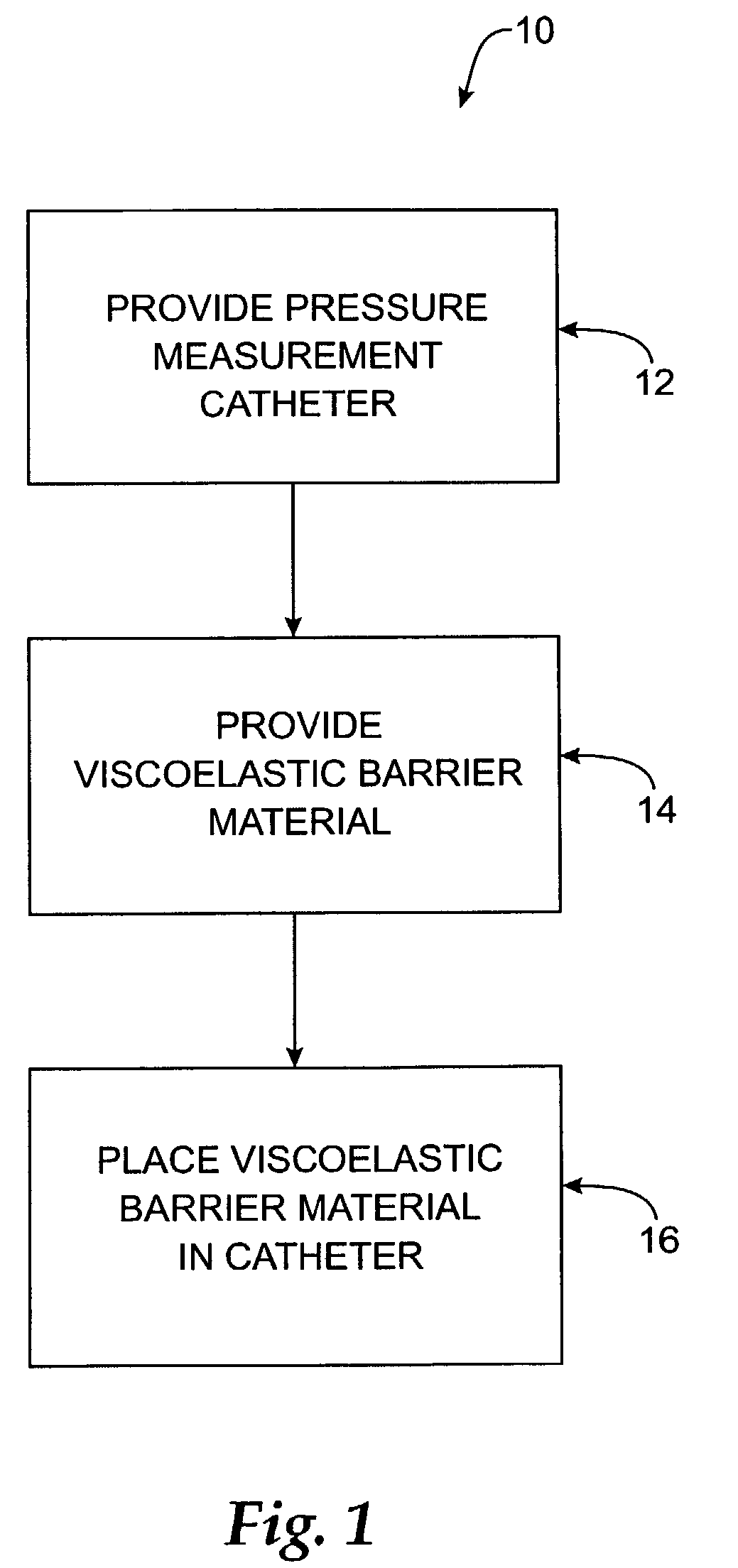

Barriers and methods for pressure measurement catheters

ActiveUS7344505B2Easy to optimizeHigh percentage of cross-linkageCatheterIntracranial pressure measurementCross-linkPressure transmission

Methods and apparatus of the present invention provide viscoelastic barrier materials for use as barriers in devices such as pressure measurement catheters. Improved barrier materials sometimes include at least one barrier material precursor combined with an amount of a softener. In other embodiments, two barrier material precursor components are combined without a softener to provide a fully cross-linked barrier material having certain softness characteristics. In various embodiments, a softener may be dimethyl silicone oil and may be combined with a barrier material precursor in an amount of between about 25% and about 45% by weight, relative to the final barrier material. Once a viscoelastic barrier material is prepared, it may be placed in a pressure transmission catheter or similar device, for example by injecting the gel into a lumen of the catheter via a syringe. Barrier materials of the present invention have one or more advantageous properties, such as a desired softness, full cross-linking, resistance to washout from a catheter, enhanced stability and / or the like.

Owner:DATA SCI INT

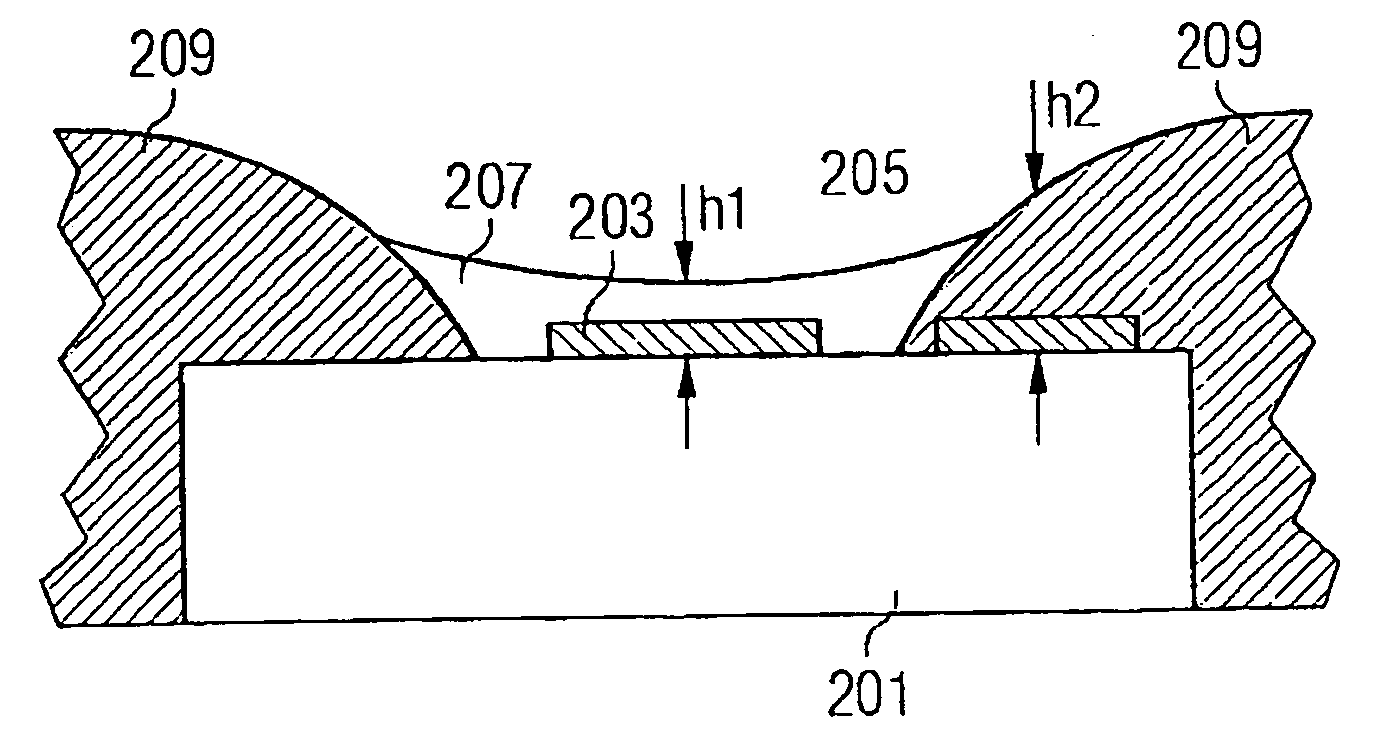

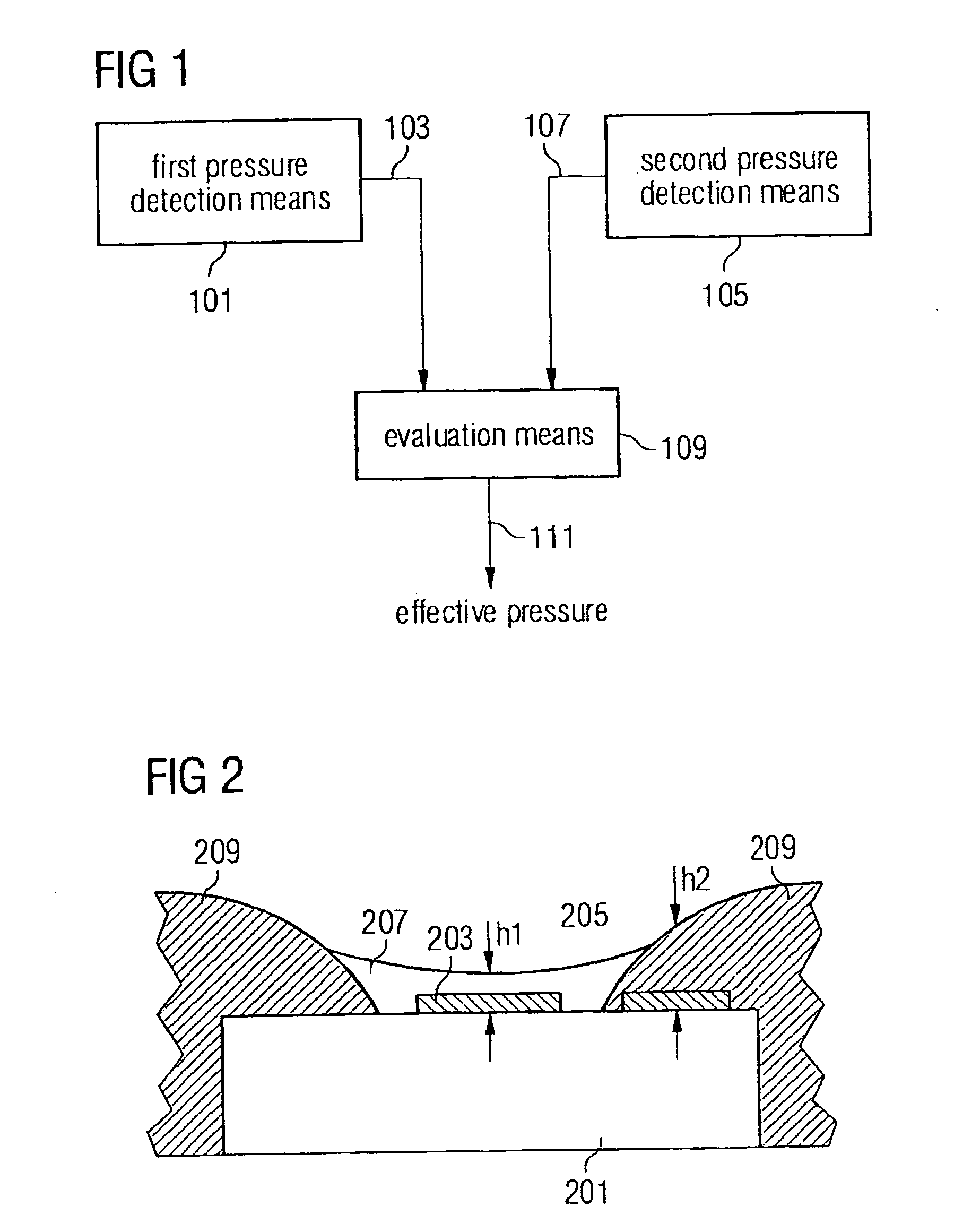

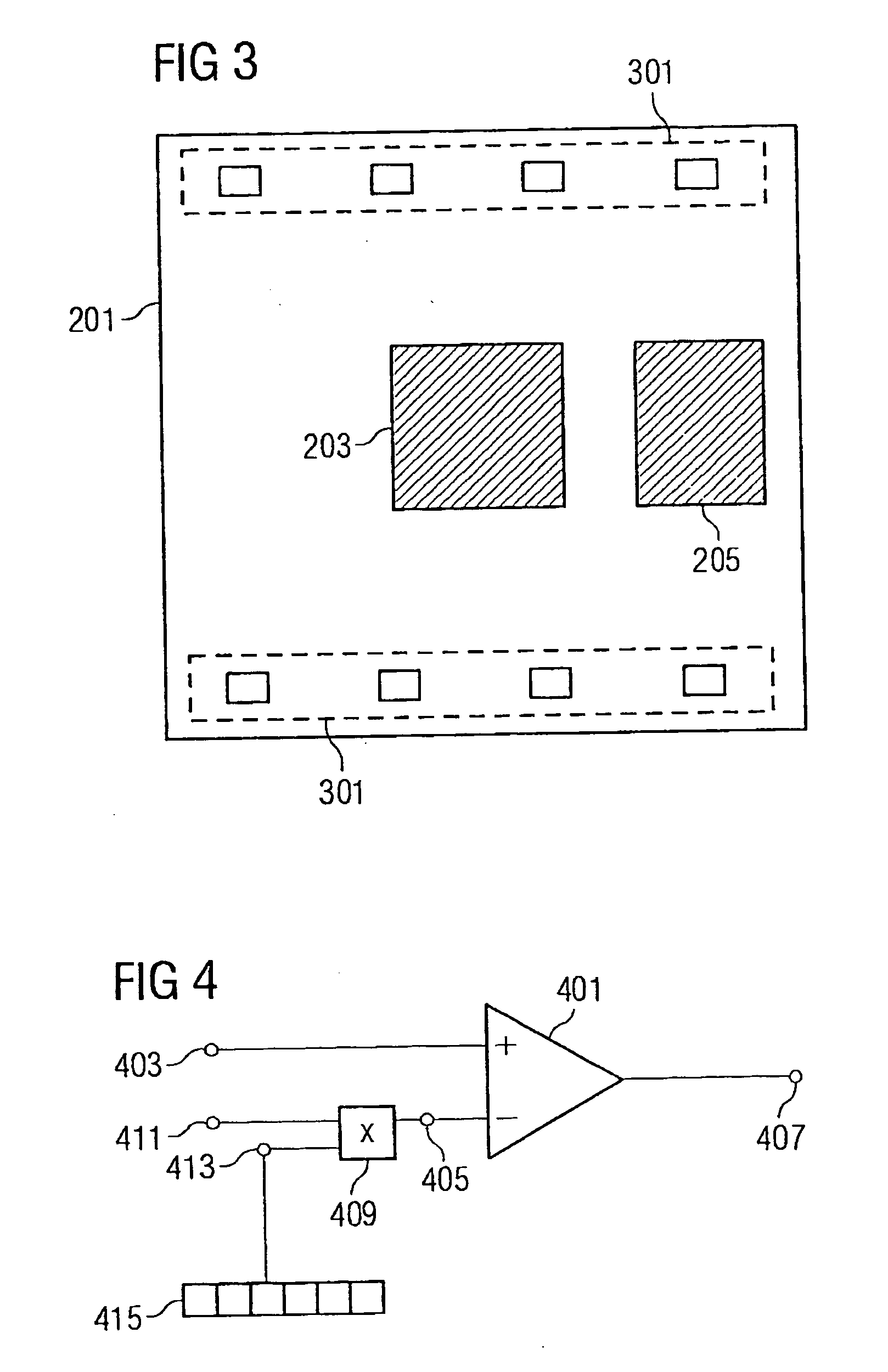

Pressure sensor and method for detecting an effective pressure

ActiveUS20050000293A1Effective compensationAccurate pressure measurementFluid pressure measurement using elastically-deformable gaugesCatheterEngineeringPressure measurement

A pressure sensor for detecting an effective pressure comprises a first pressure detection means for providing a first pressure measurement signal and a second pressure detection means for providing a second pressure measurement signal, wherein the first pressure measurement signal differs from the second pressure measurement signal, as well as an evaluation means for determining the effective pressure based on the first and the second pressure measurement signal. Thereby it is achieved that in a pressure measurement the measurement errors are reduced.

Owner:INFINEON TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com