Patents

Literature

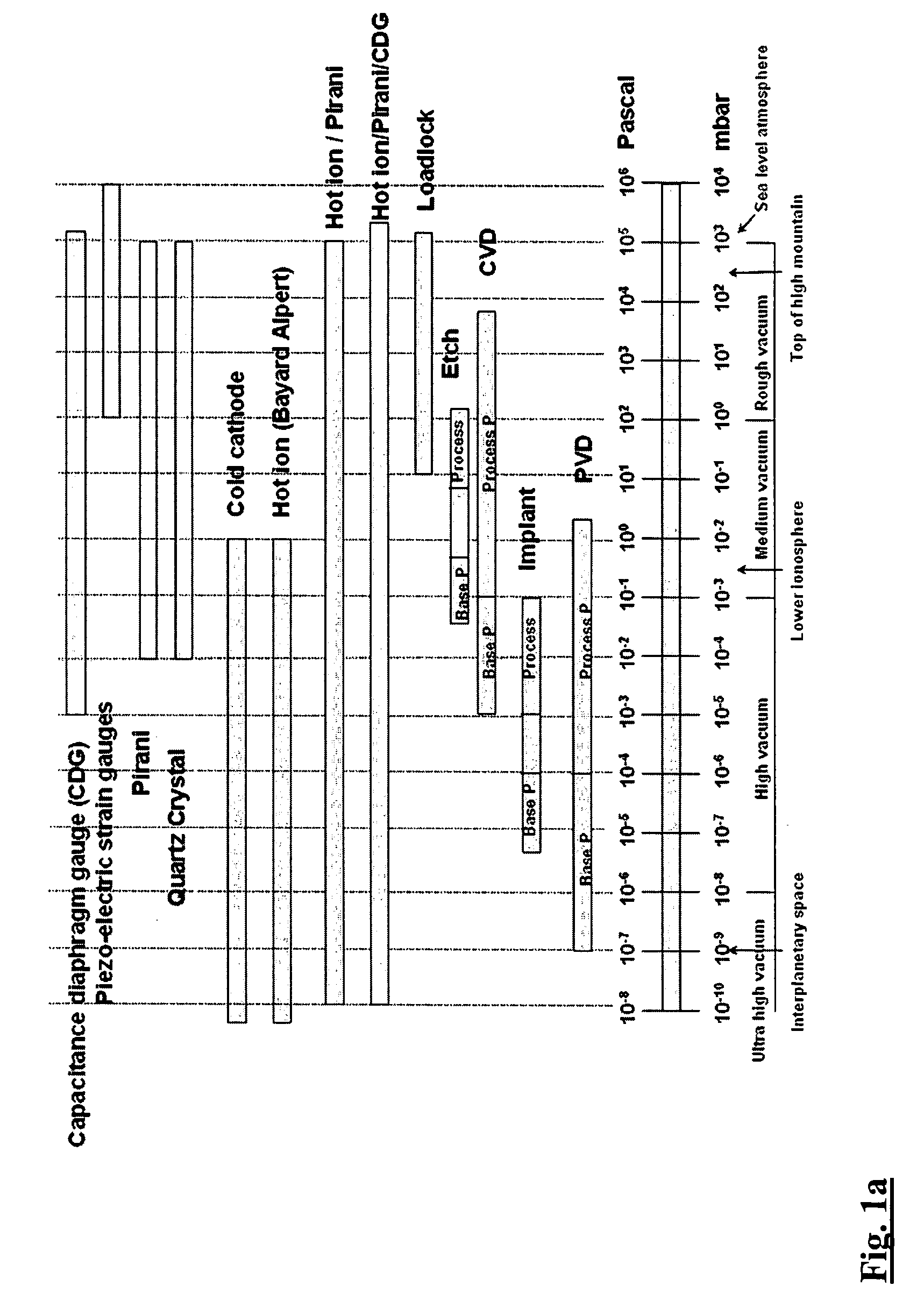

1241results about "Fluid pressure measurement using capacitance variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

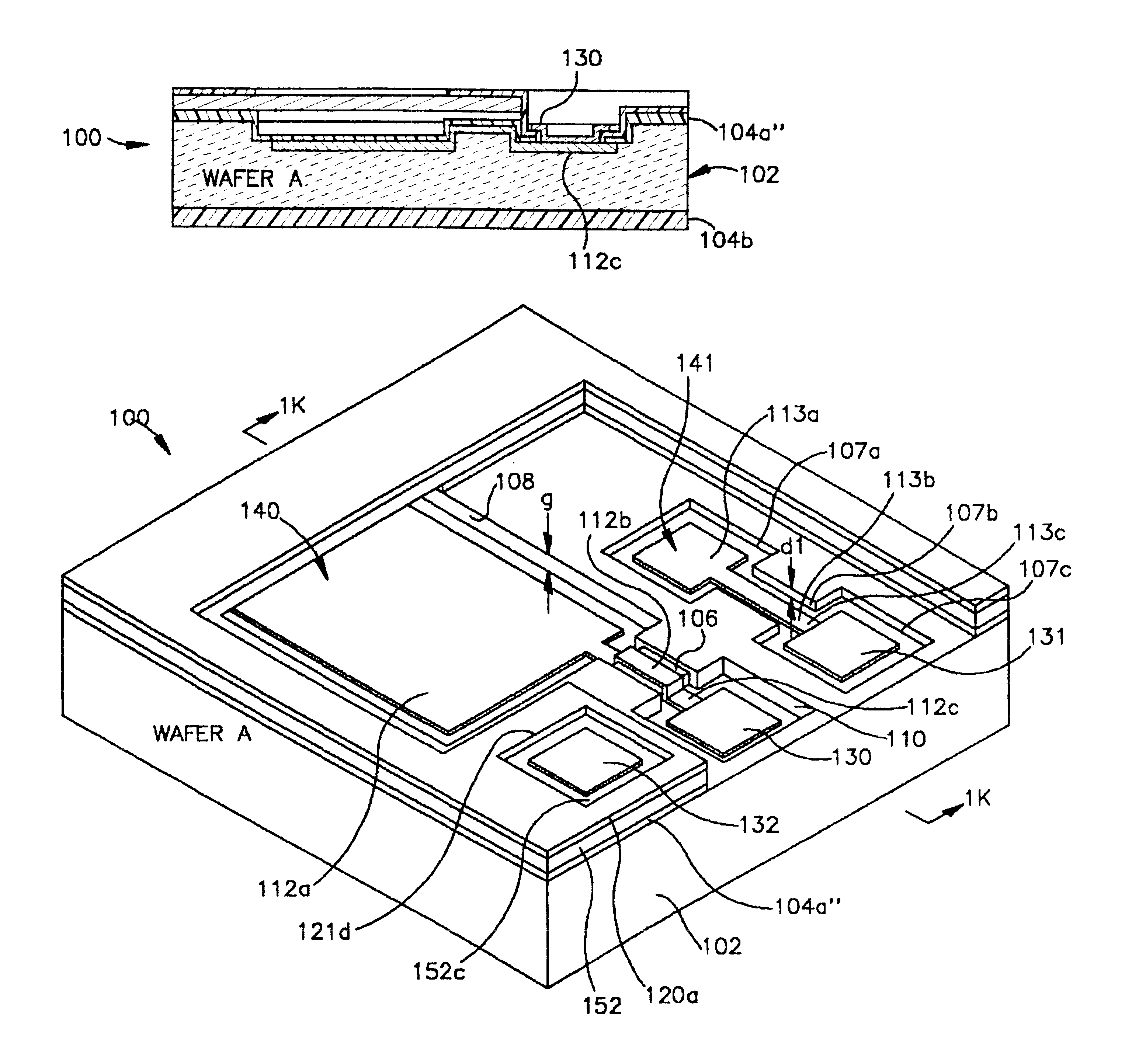

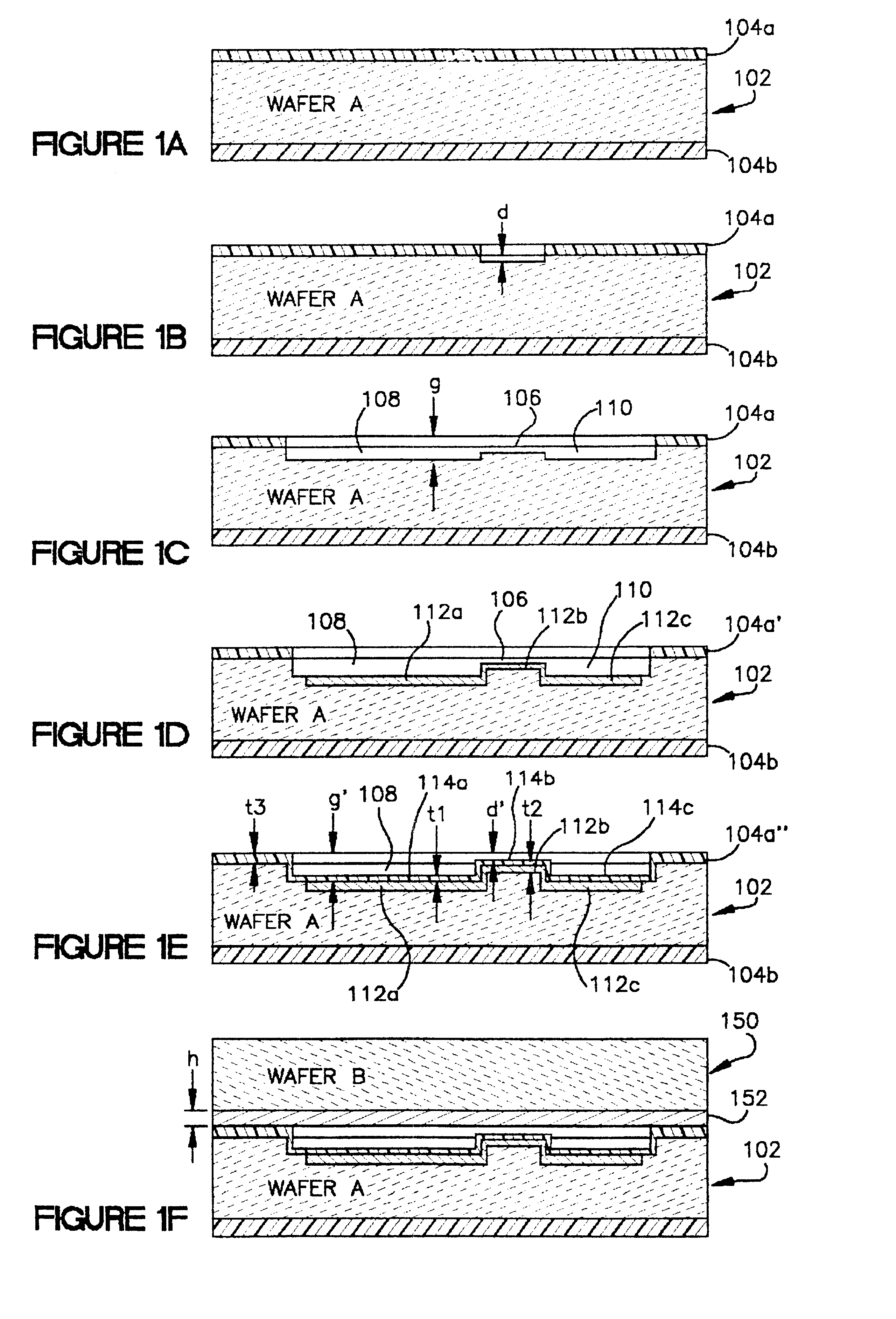

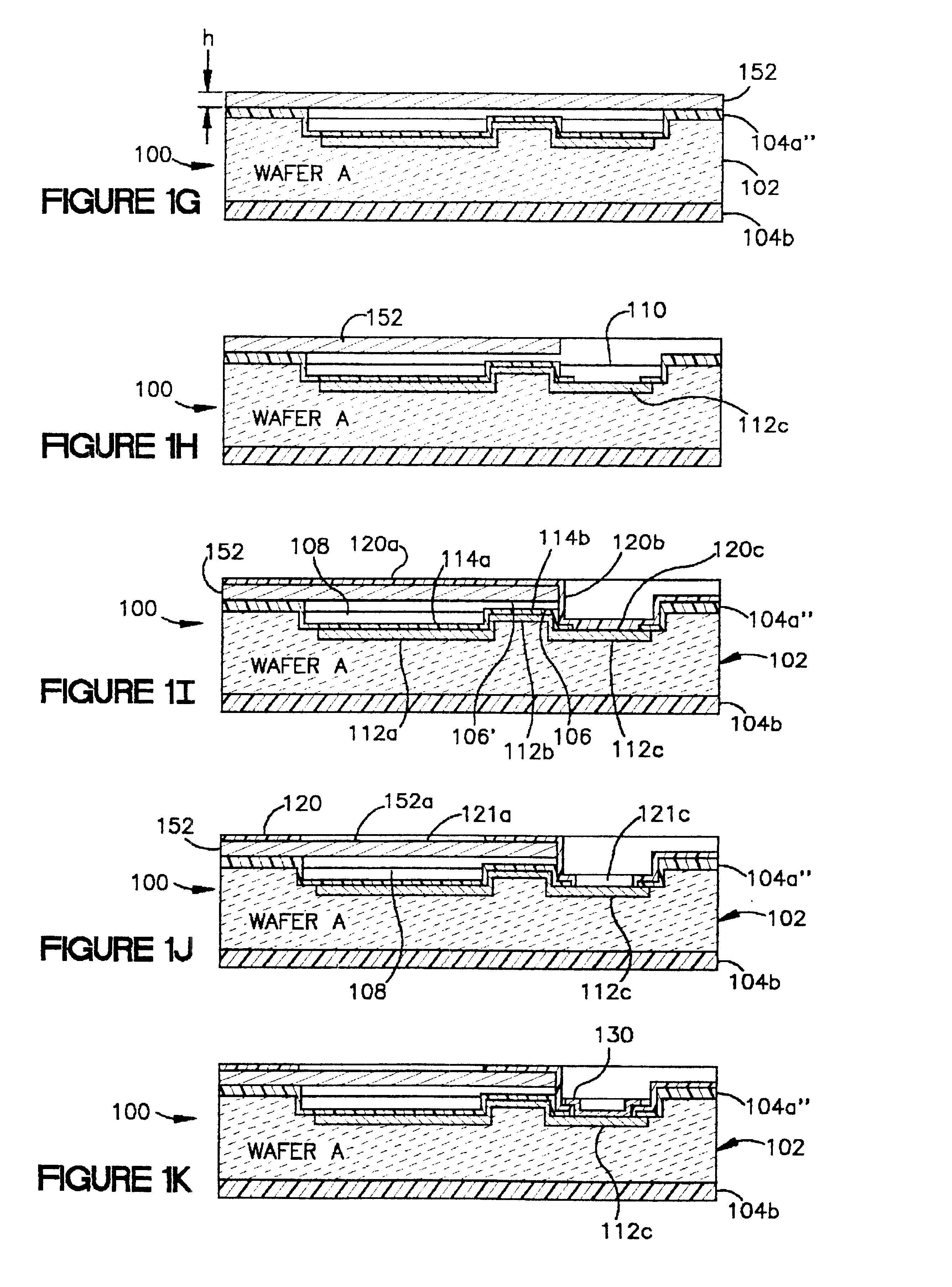

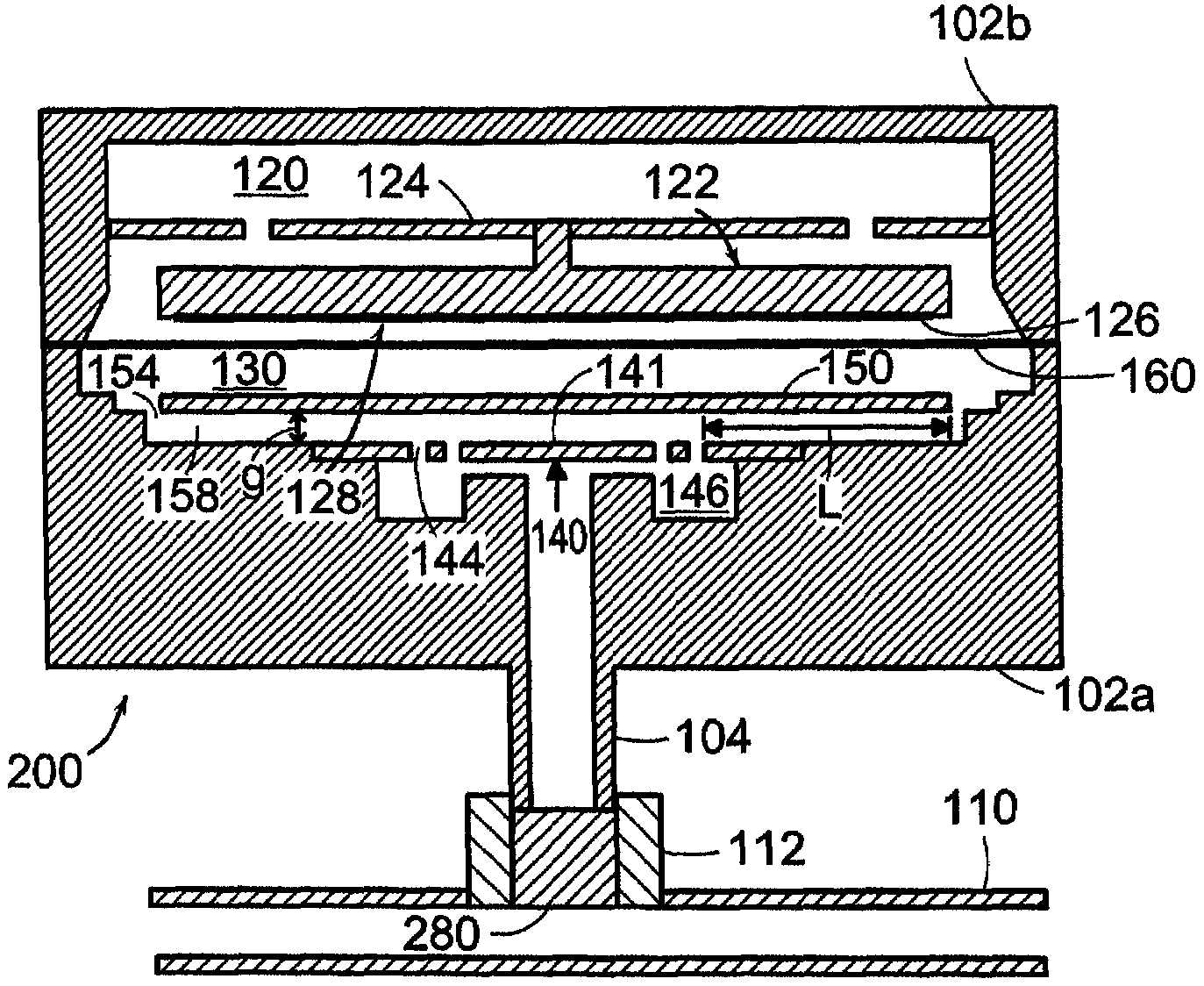

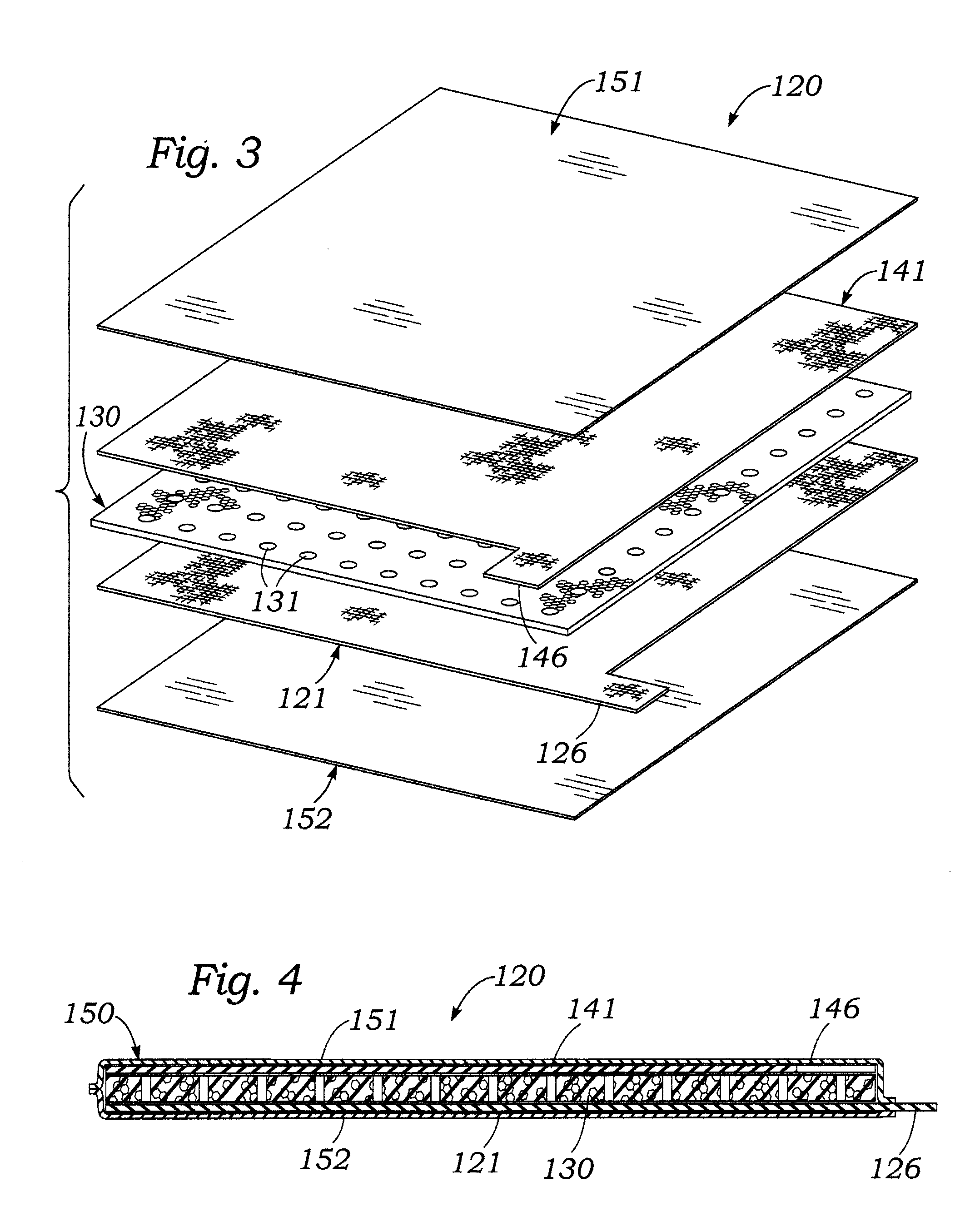

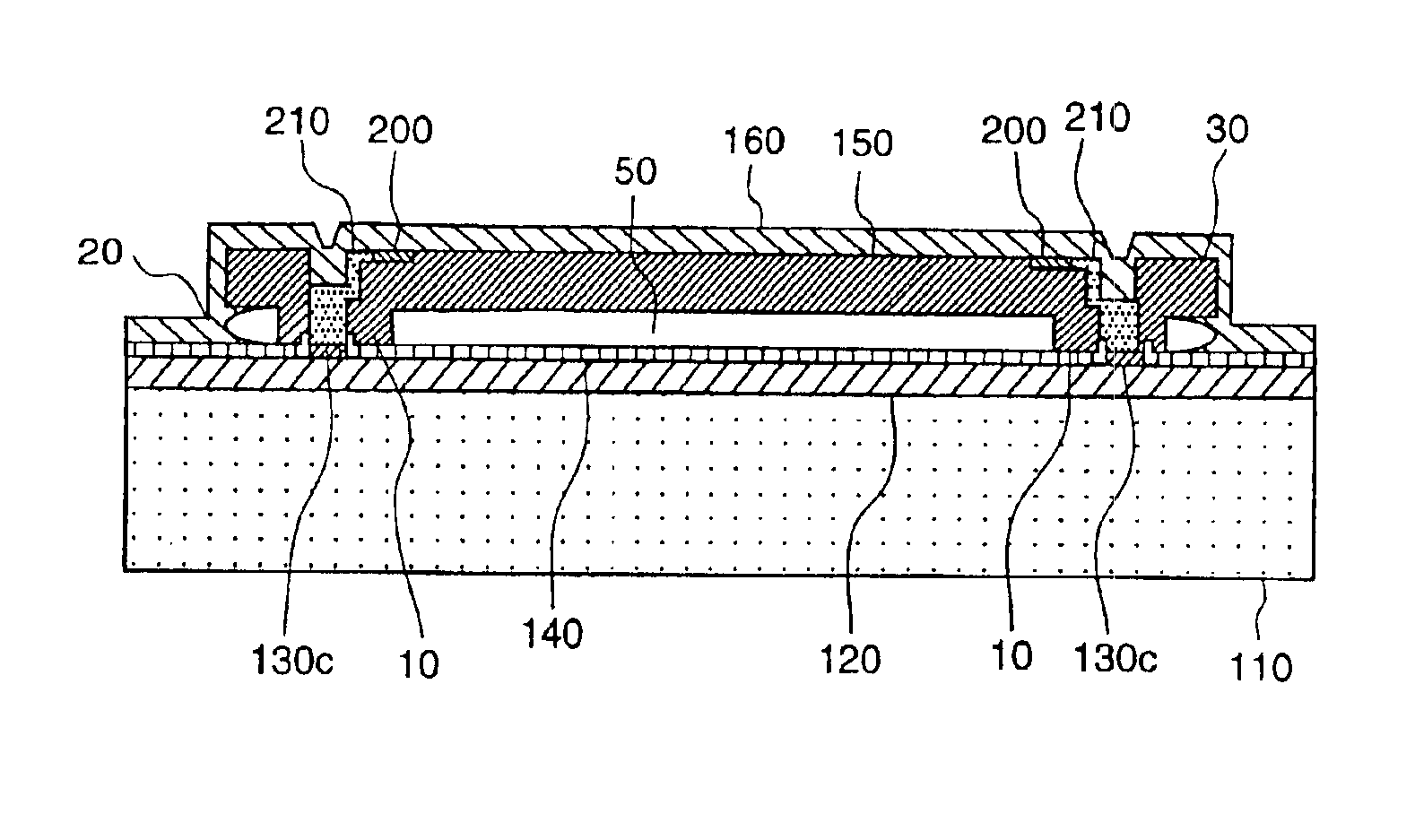

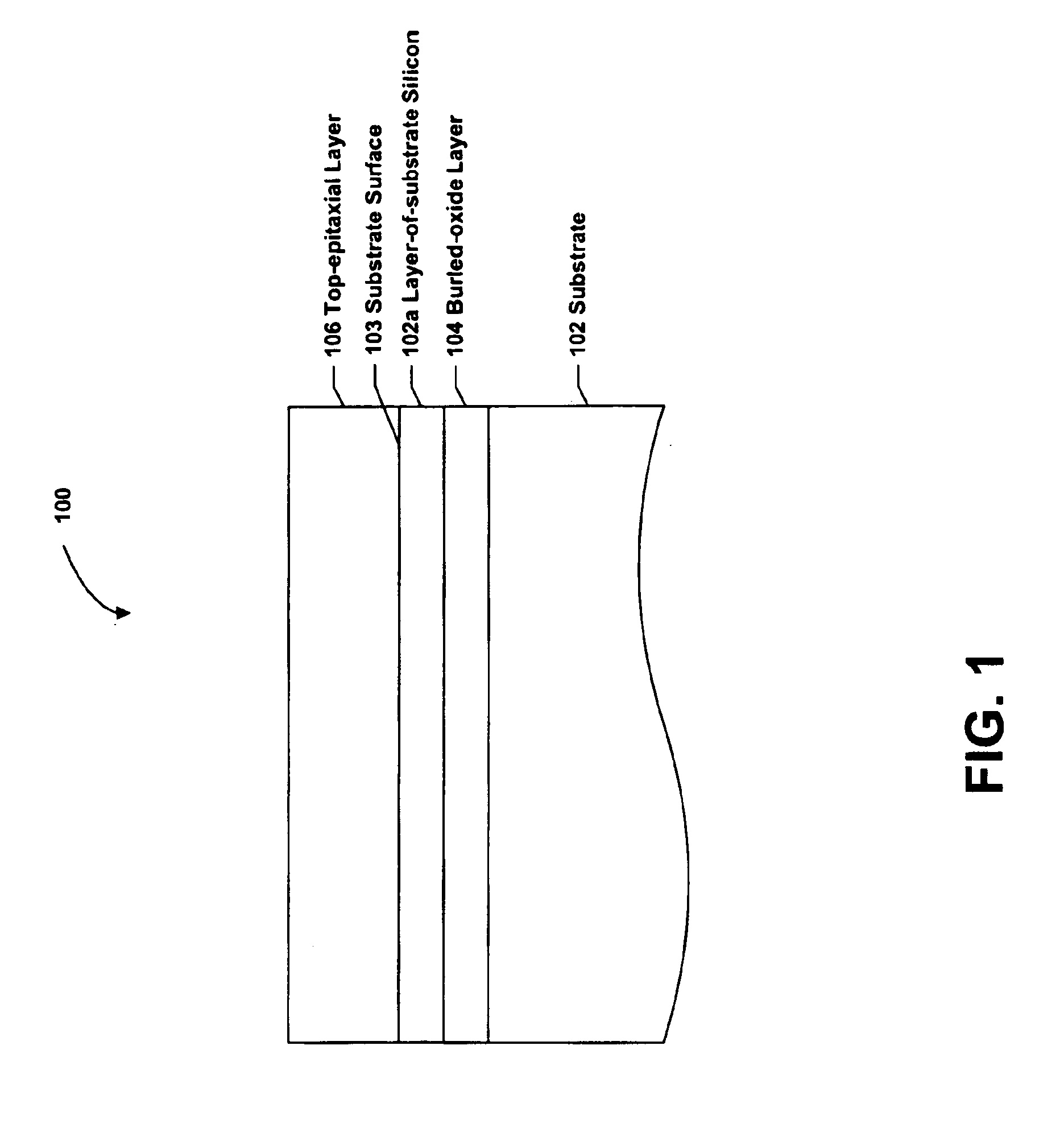

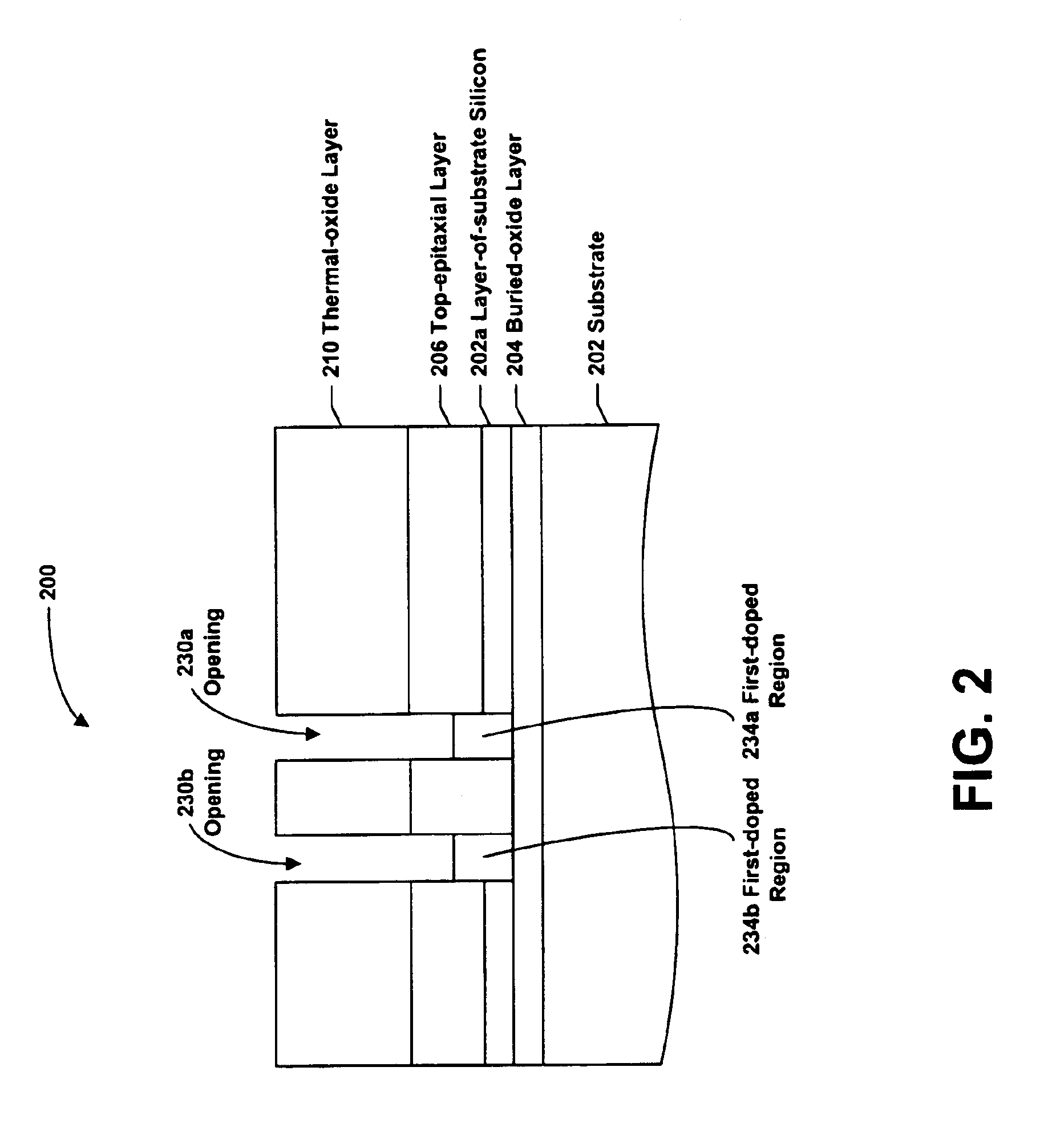

Method of fabricating silicon capacitive sensor

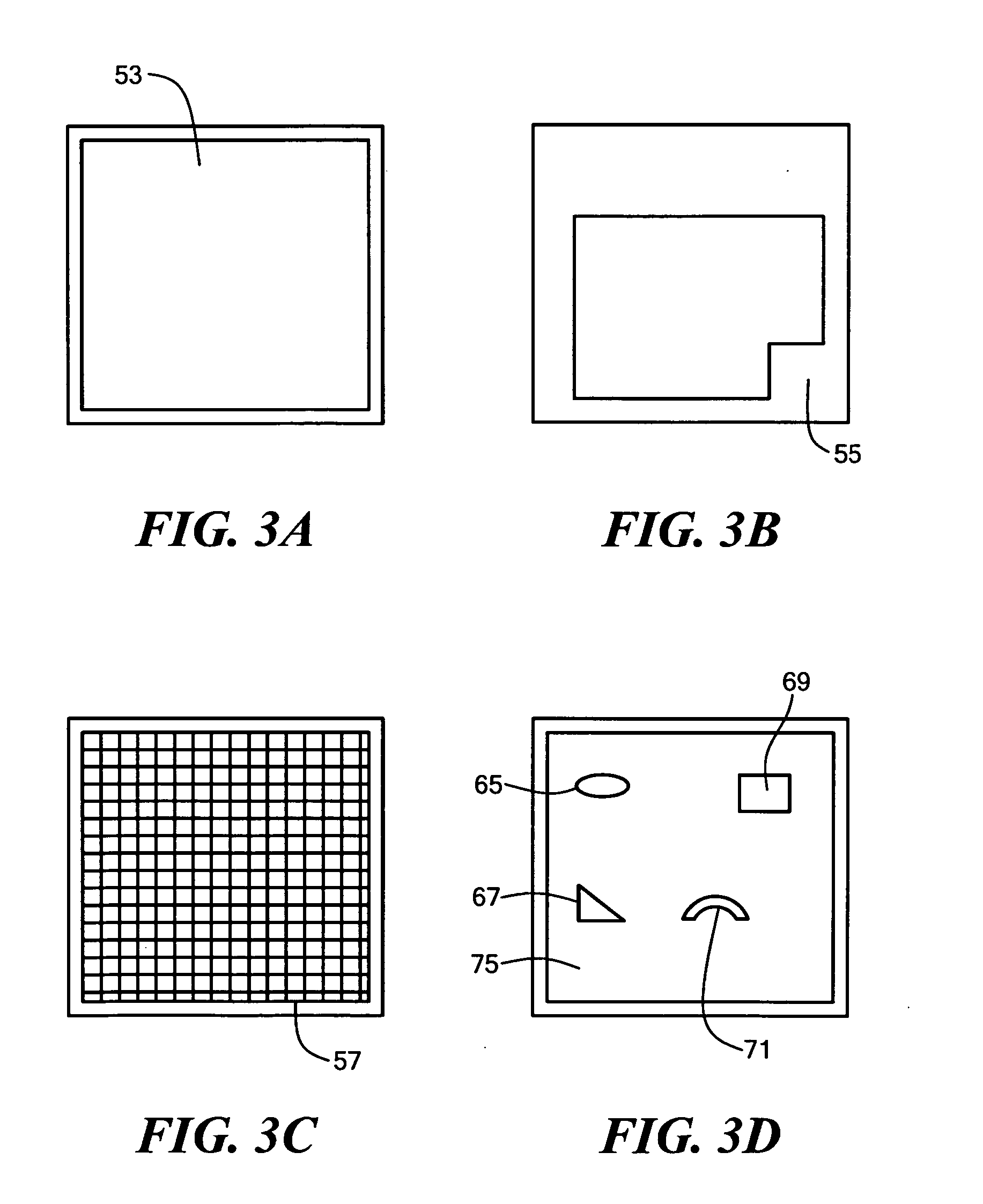

InactiveUS6465271B1Good linear sensitivityLong-term stabilityInflated body pressure measurementSemiconductor/solid-state device manufacturingCapacitive pressure sensorDiffusion

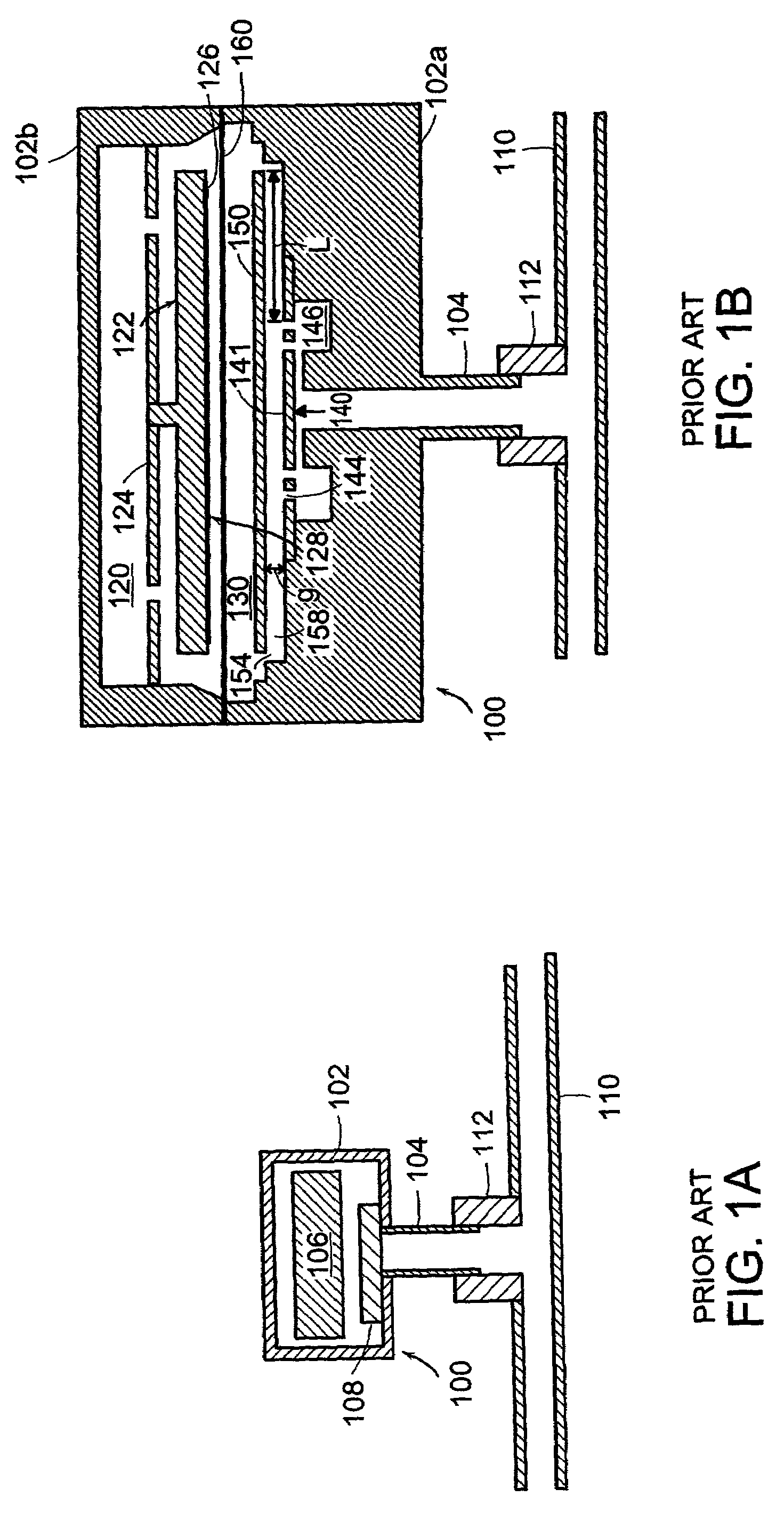

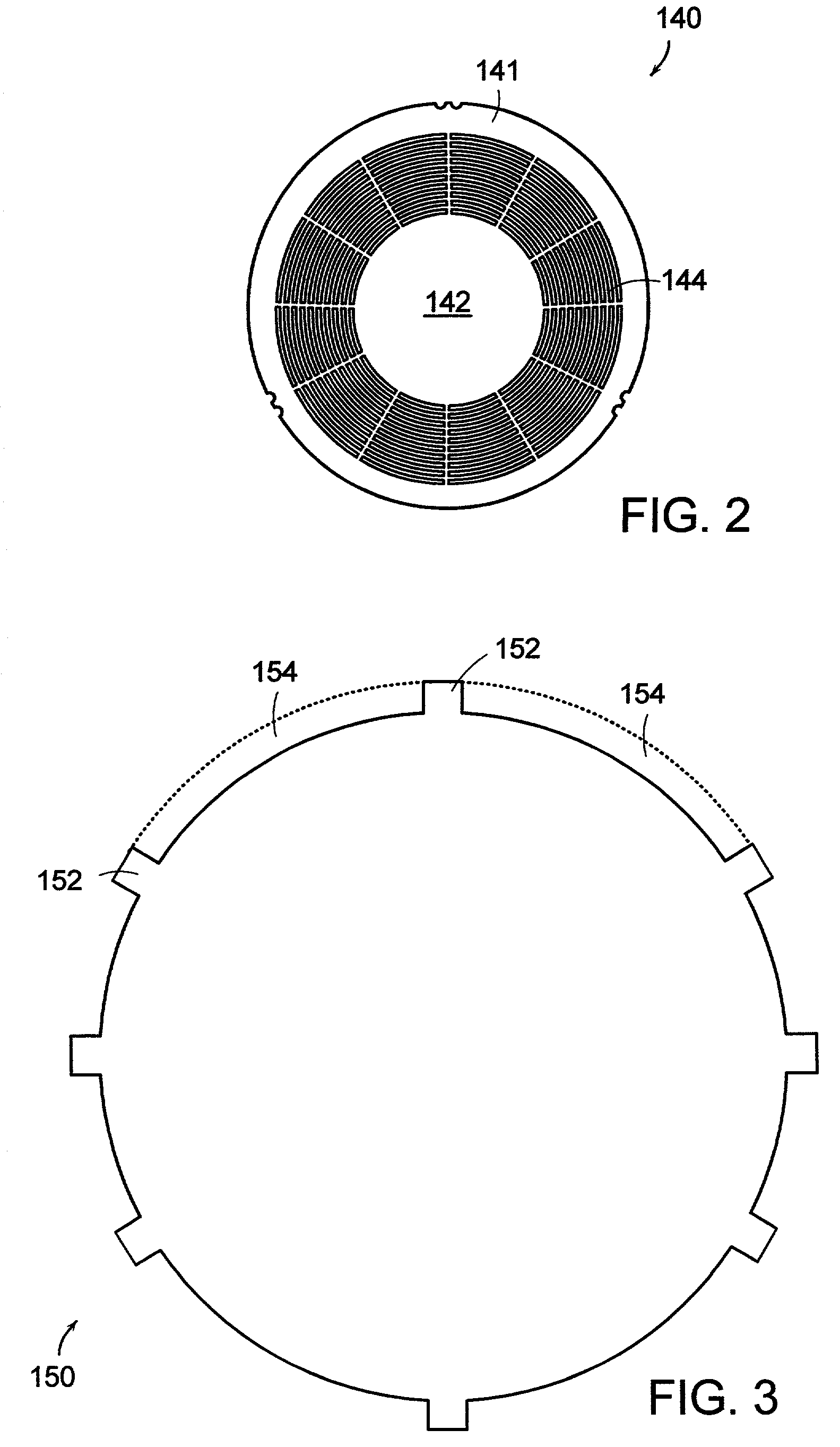

Manufacturing all-silicon force sensors, such as capacitive pressure sensors (100, 200) that have long term stability and good linear sensitivity, and can be built into of a pneumatic tire. The sensors include buried electrical feedthrough (112b) to provide an electrical connection into a sealed silicon cavity (108). The buried feedthrough consists of a conductor (112b) in a shallow groove (106) in a substrate (102), communicating between the sensing cavity (108) and an external contact area (110). The sensor designs also feature a method for forming a silicon-to-silicon fusion bond (SFB) wherein at least one of the two surfaces (152, 252) to be has a tough silicon surface unsuitable for good SFB joints because it was bonded heavily boron-doped by means of diffusion. The method of this invention includes preparing each doped surface (152, 252) for SFB by polishing the surface with a Chemical-Mechanical Polishing (CMP) process. The sensor designs can also include optional reference capacitors (141, 241) on the same chip (100, 200) as the sensing capacitor (140, 240). The reference capacitors (141, 241) are insensitive to pressure (force), but respond to ambient temperature changes in the same way as the sensing capacitor. Suitable external interface circuits can utilize the reference capacitors (141, 241) to pull out the majority of ambient temperature effects.

Owner:CASE WESTERN RESERVE UNIV

Surface area deposition trap

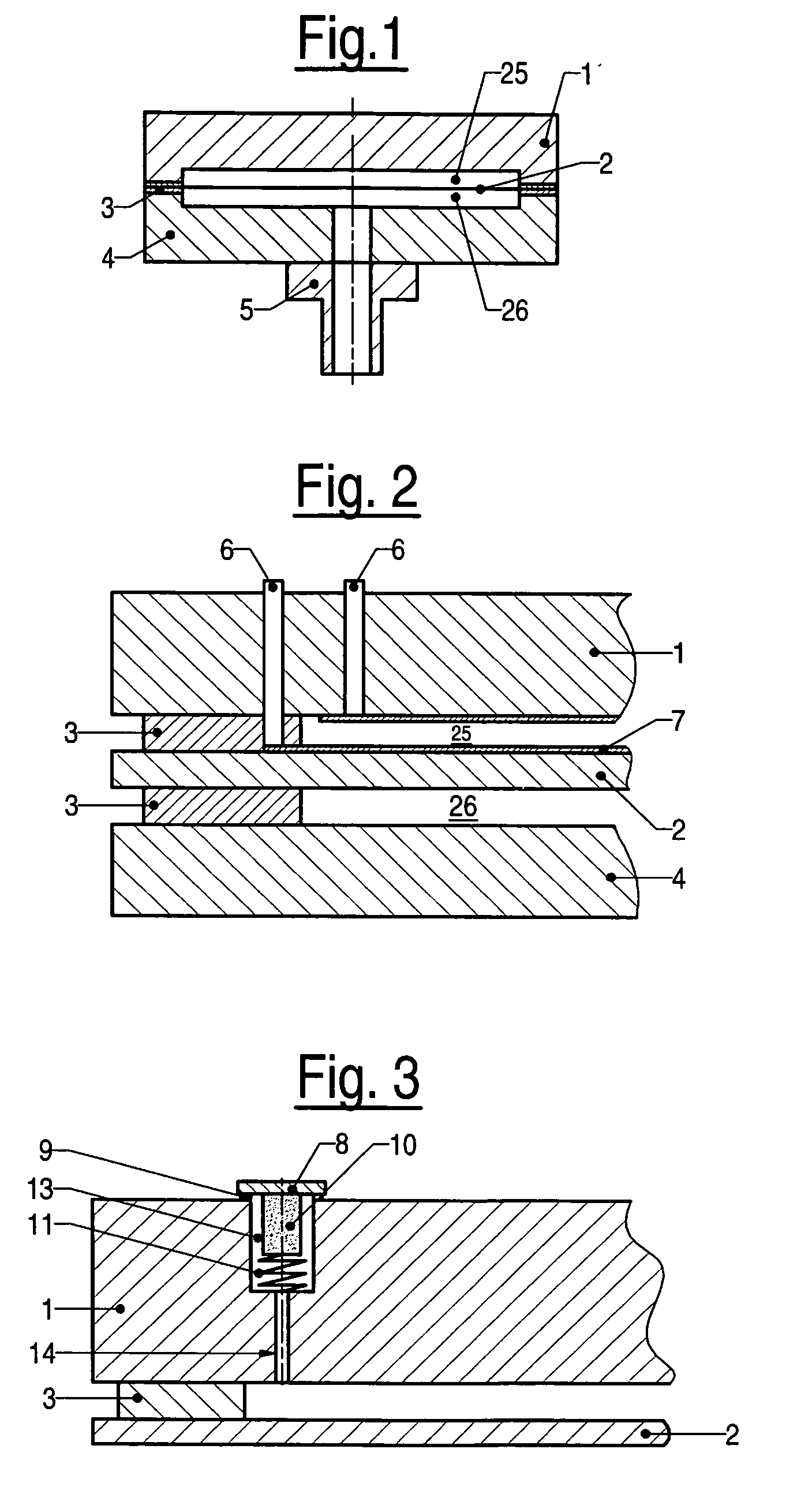

InactiveUS7252011B2Raise the possibilityEasy to addFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement using capacitance variationCouplingTransducer

The disclosed pressure transducer assembly includes a housing, a pressure sensor disposed within the housing, a coupling establishing a sealed pathway between the housing and an external source of gas or fluid, and a deposition trap disposed in the pathway. The deposition trap provides a plurality of channels, each of the channels being narrower than the pathway.

Owner:MKS INSTR INC

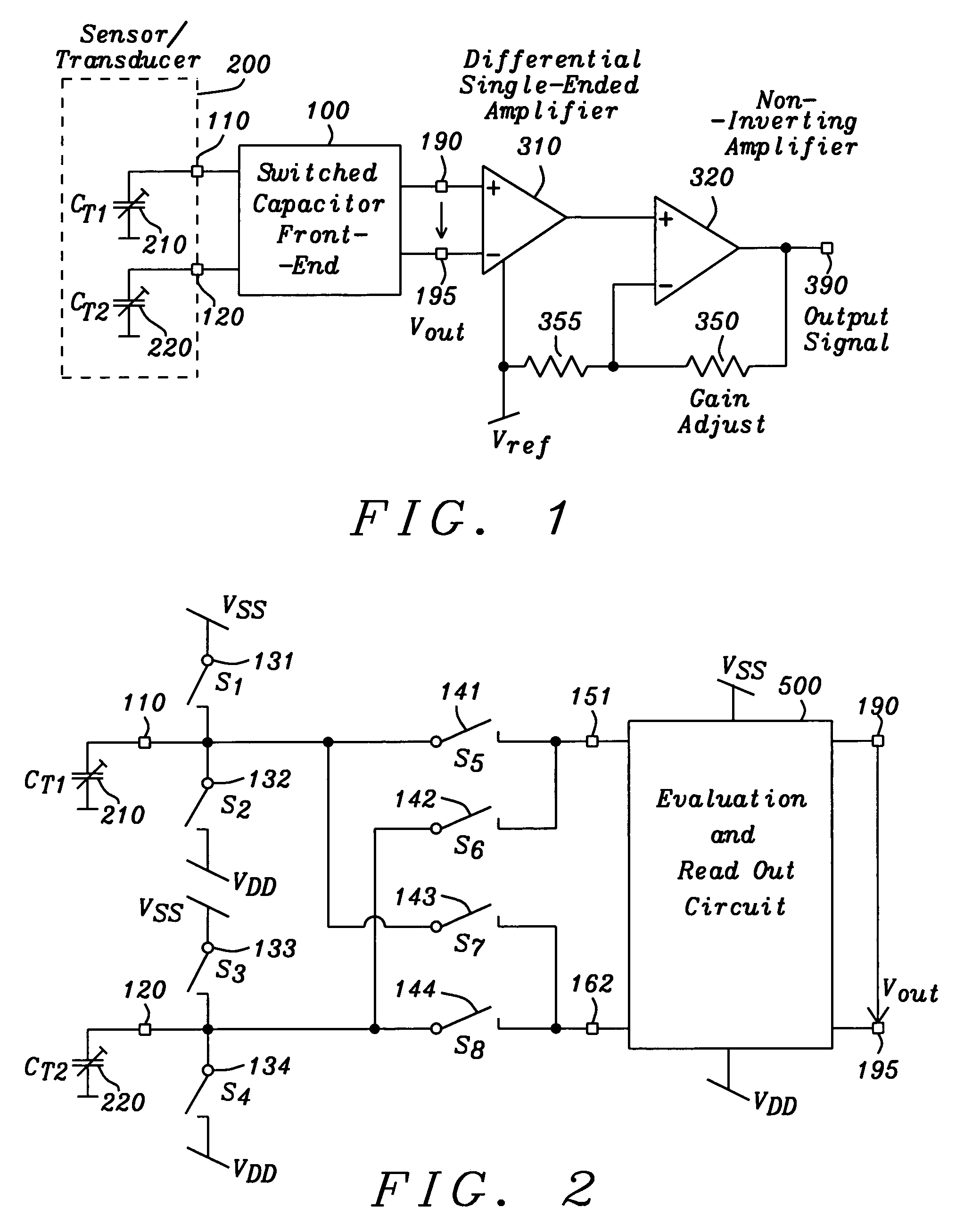

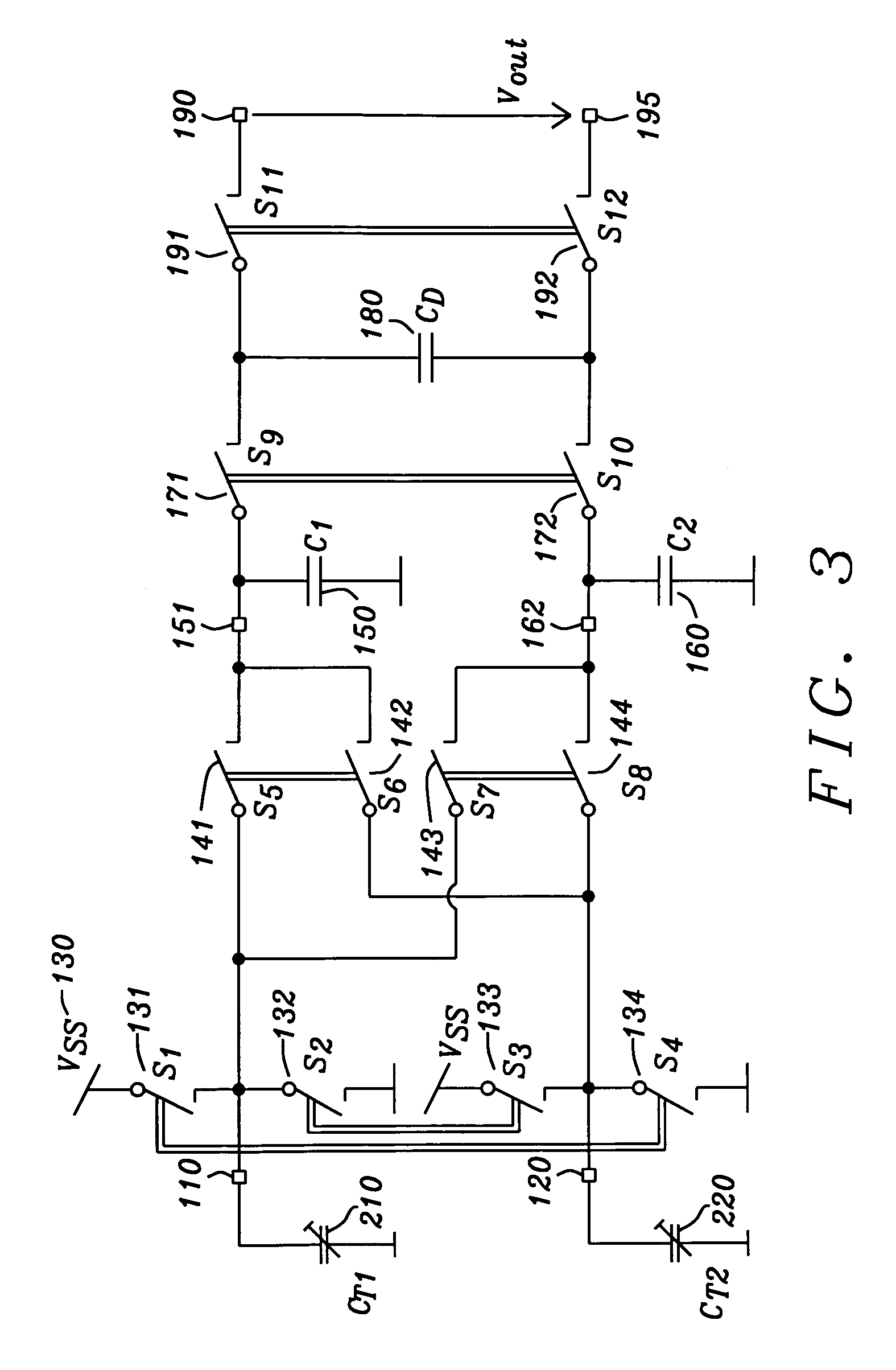

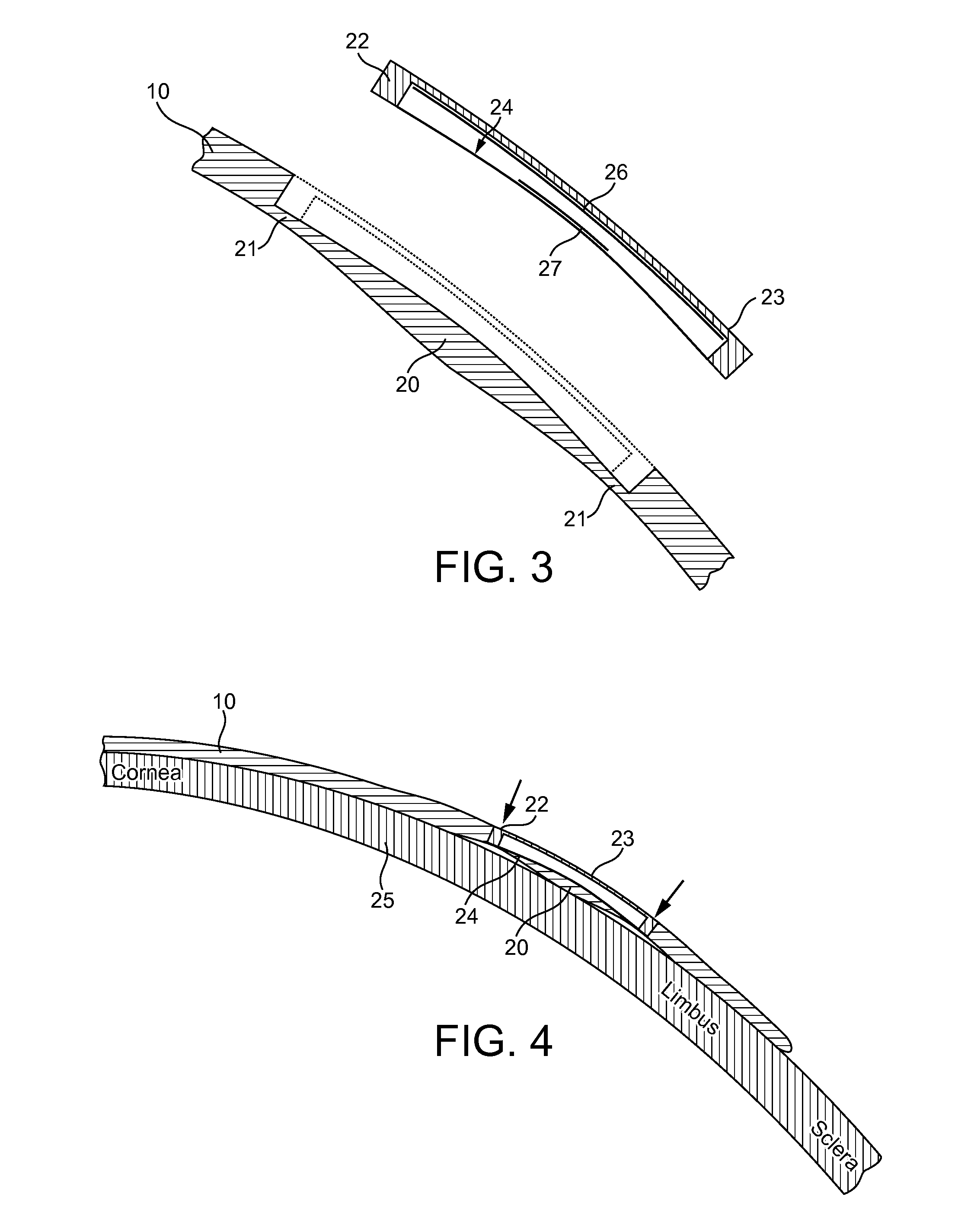

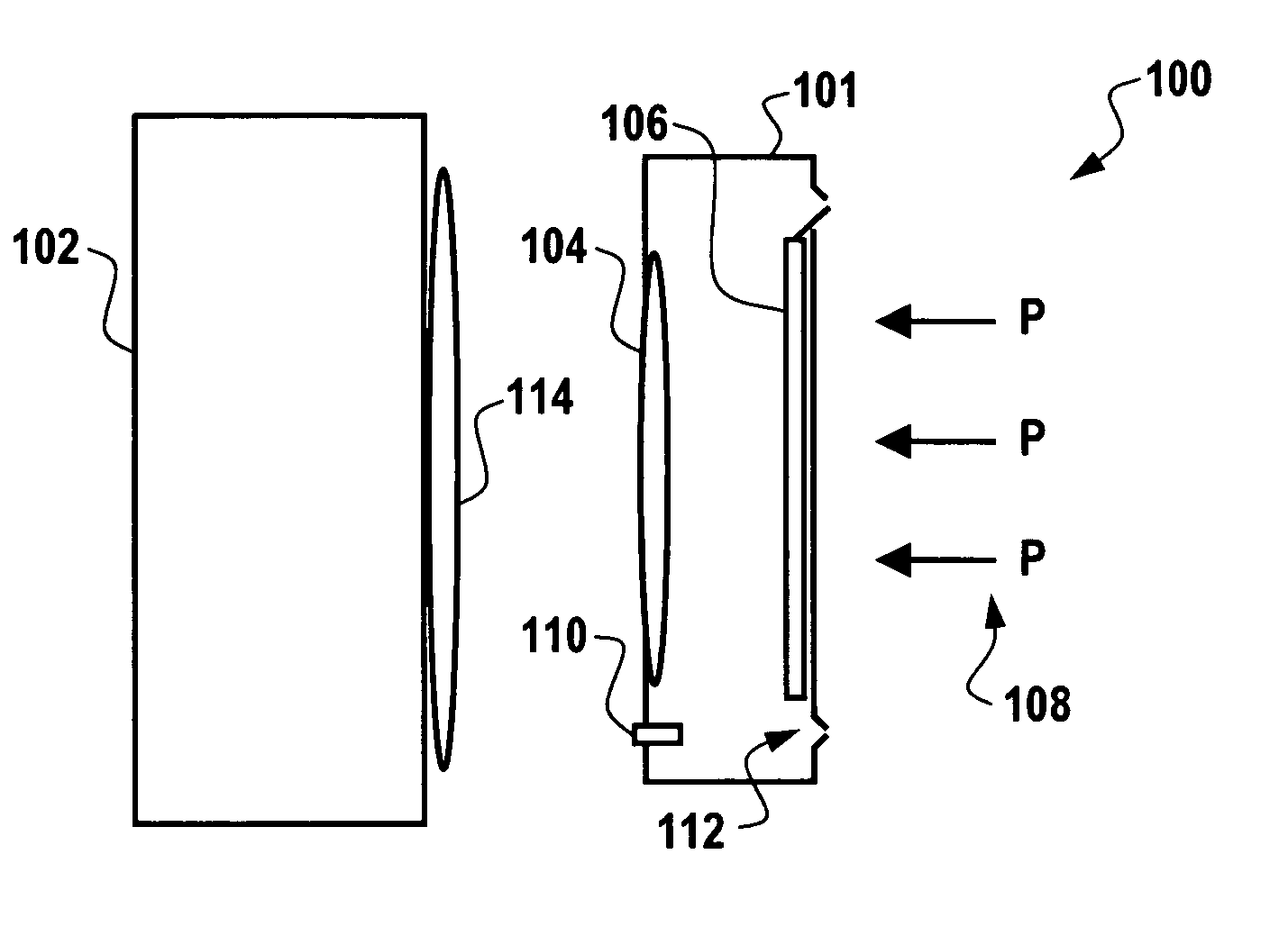

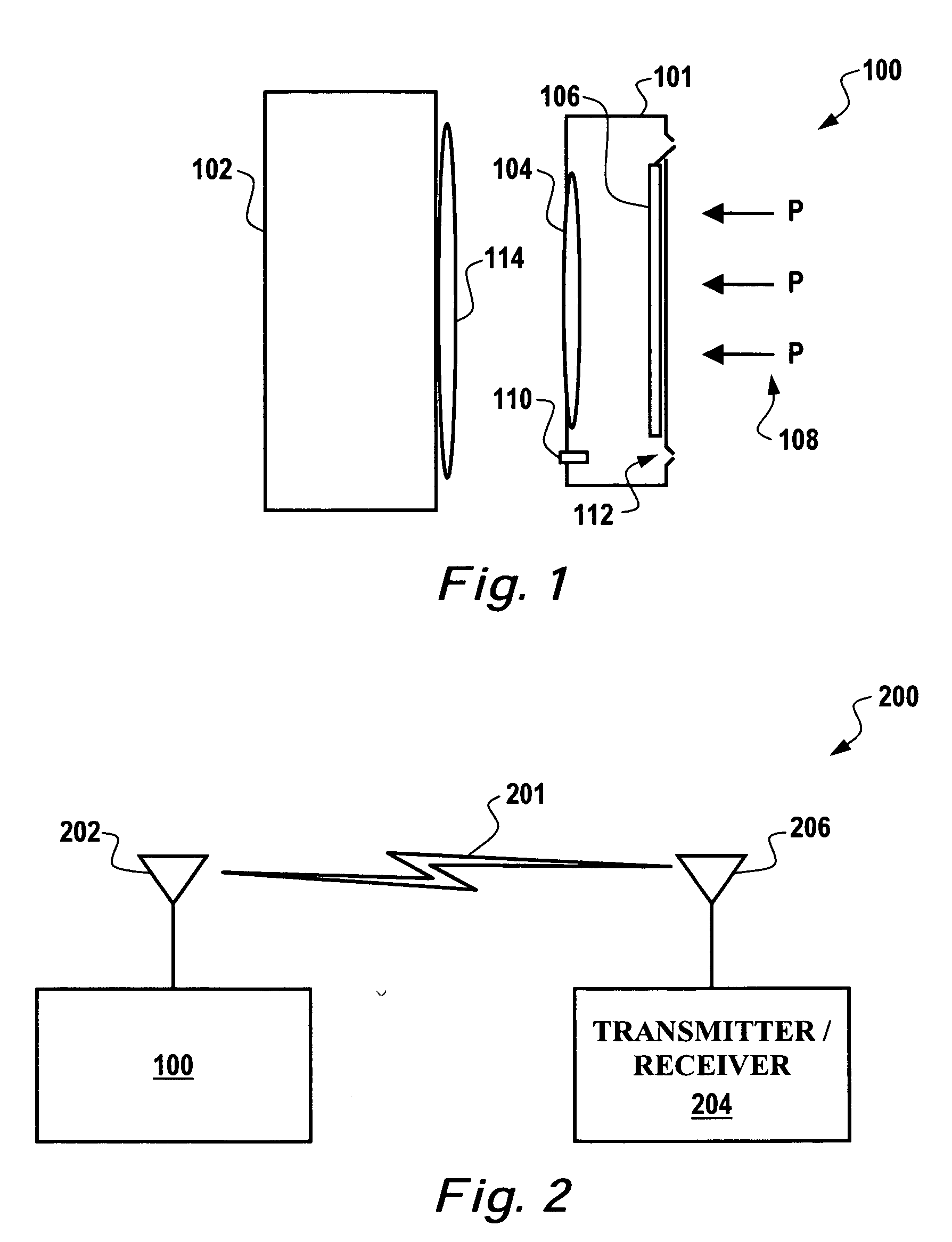

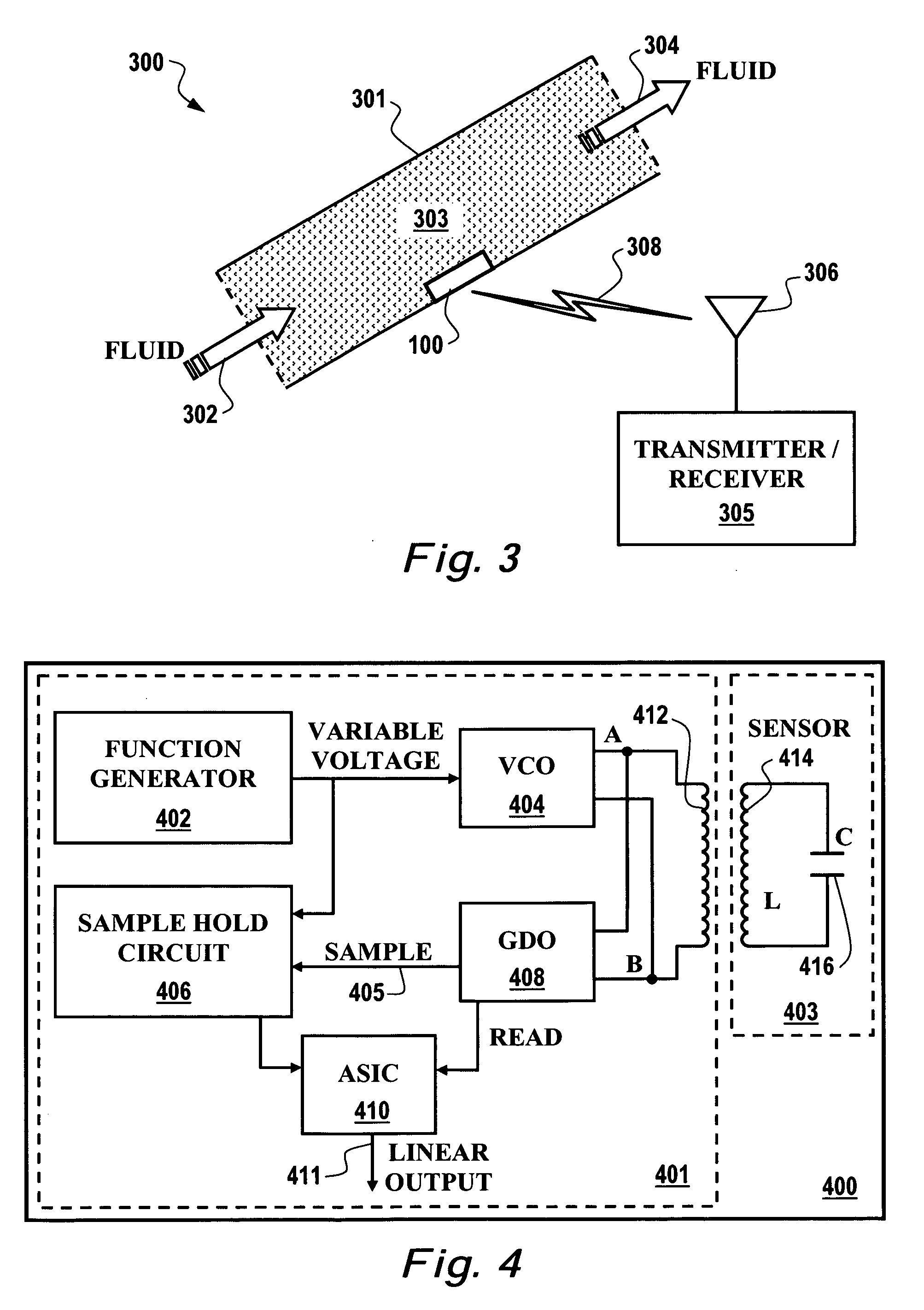

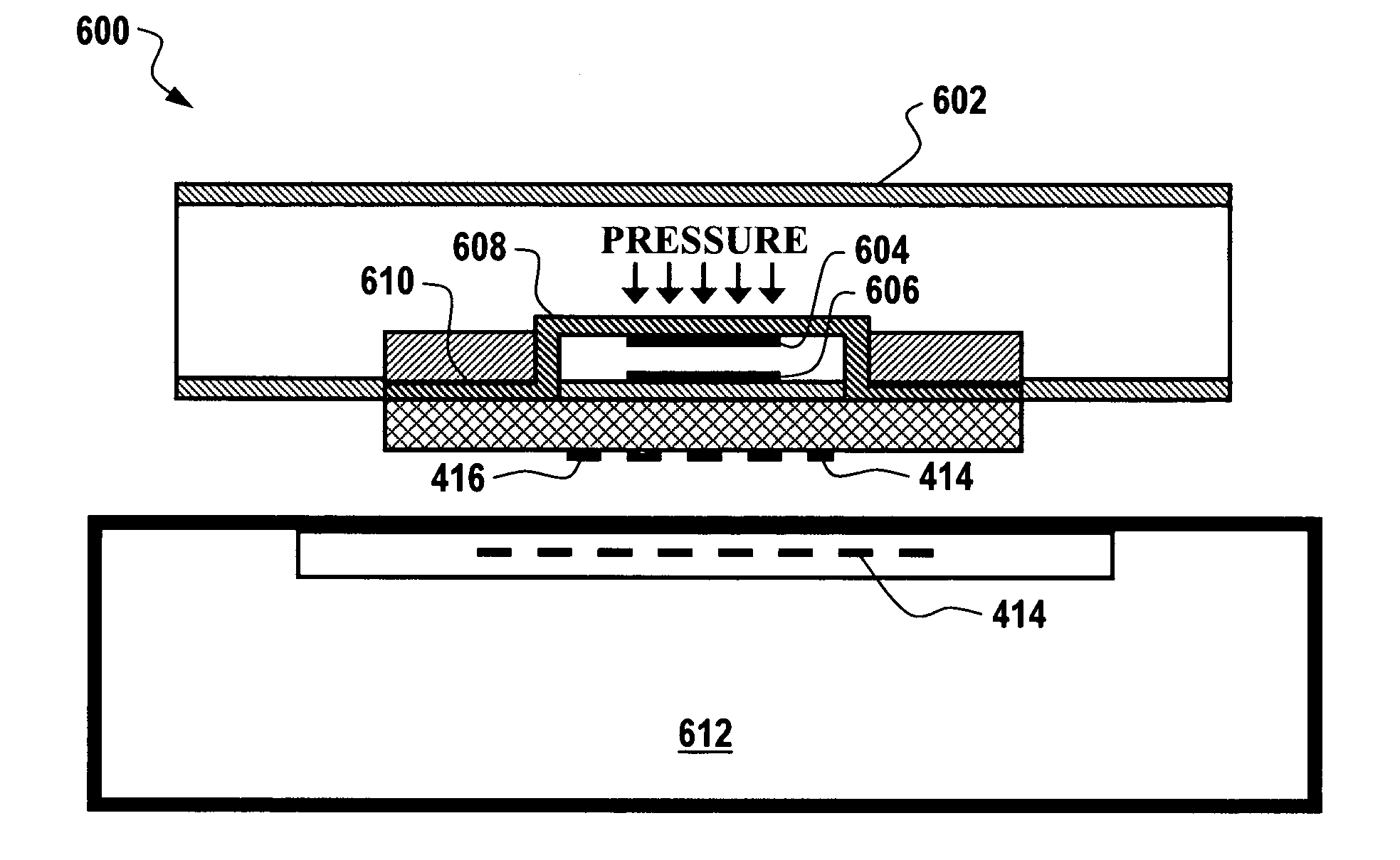

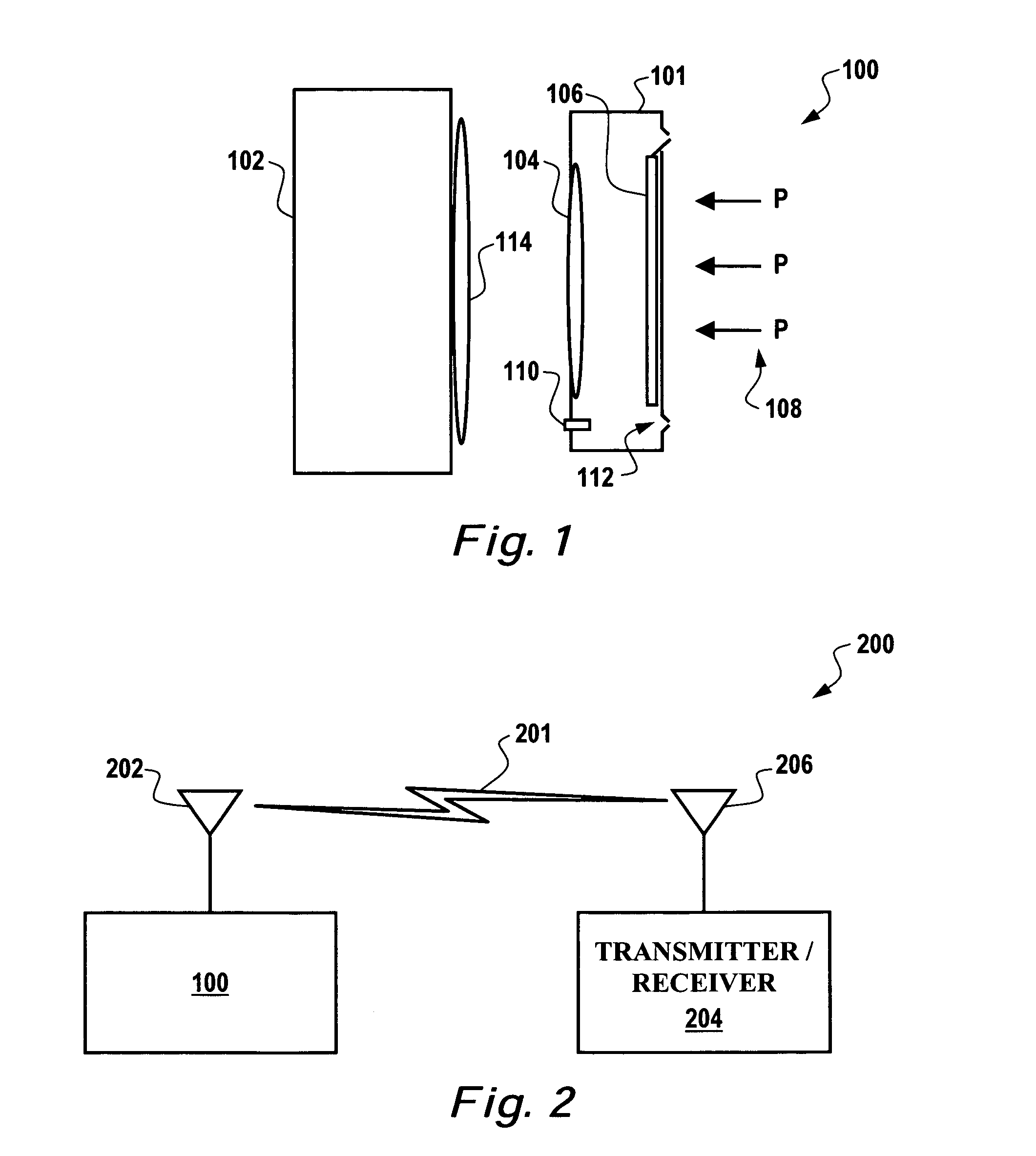

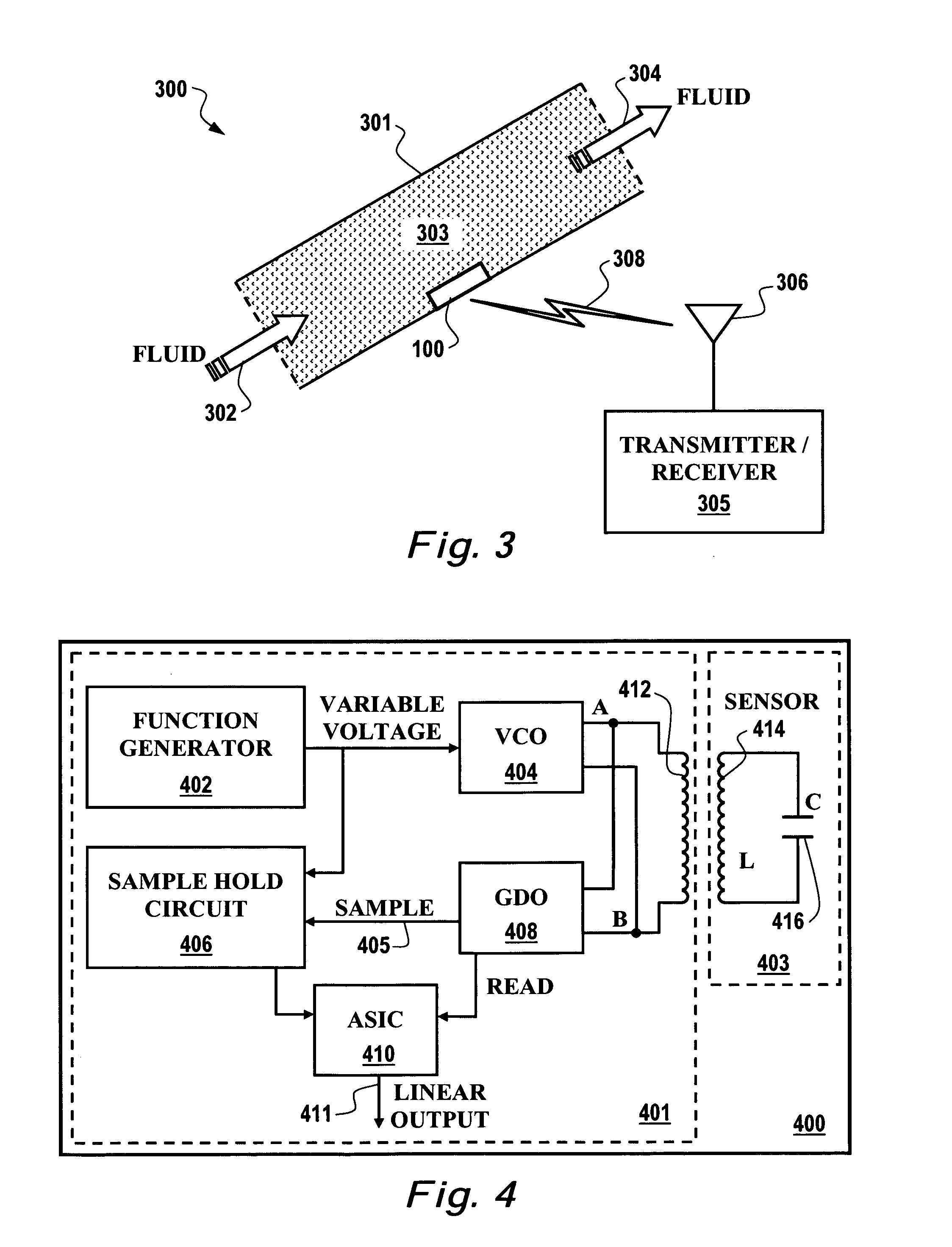

Disposable and trimmable wireless pressure sensor

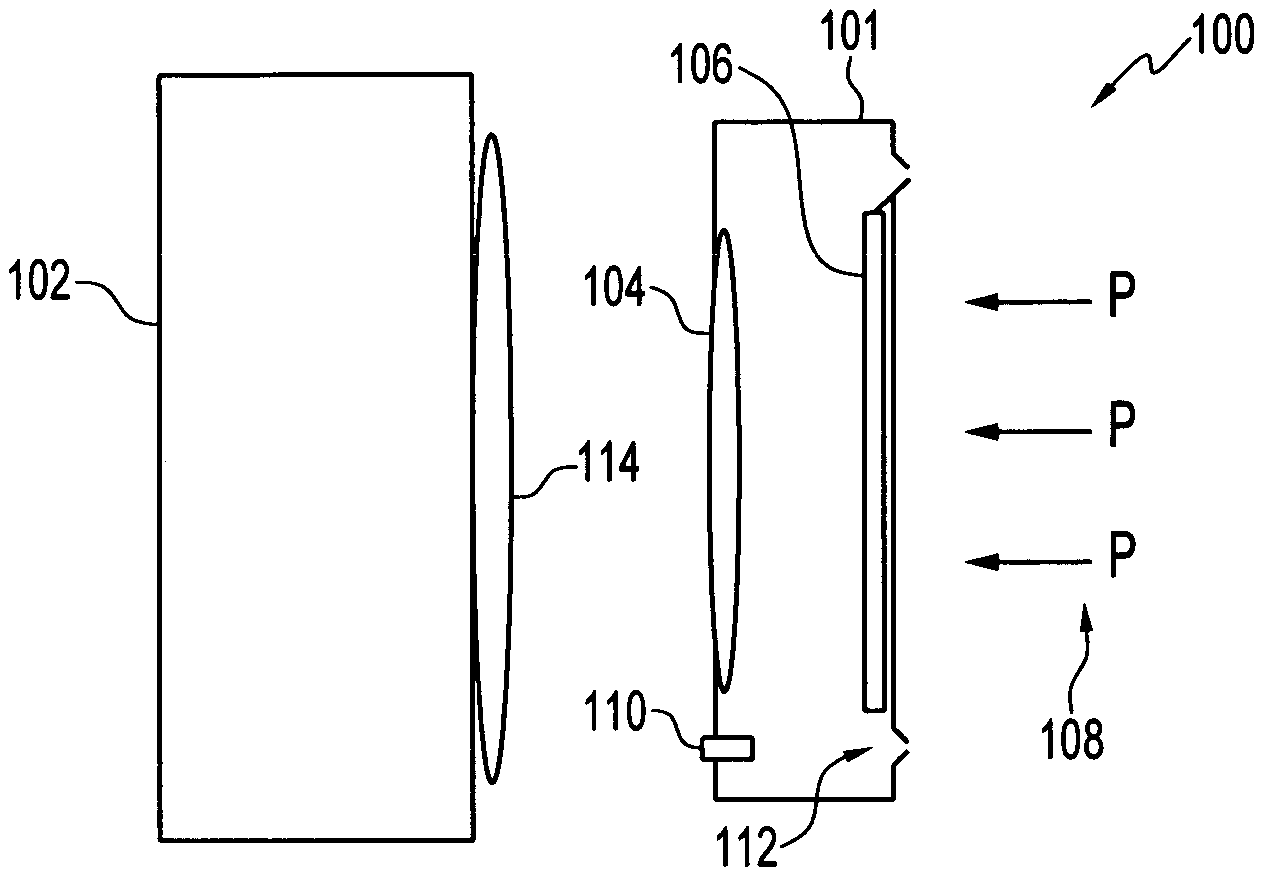

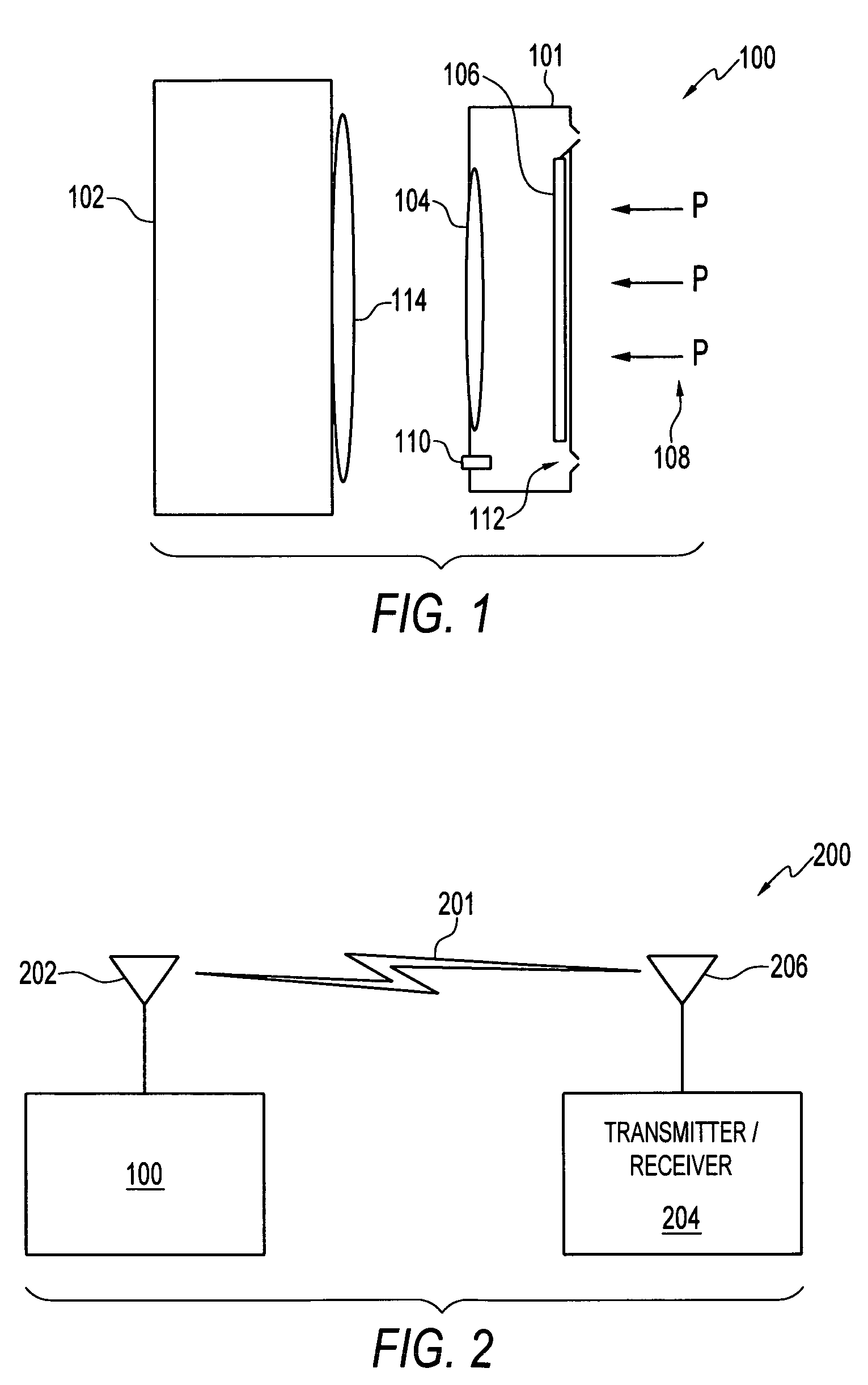

InactiveUS7146861B1Easy to understandFluid pressure measurement using piezo-electric devicesFluid pressure measurement using inductance variationEngineeringInductor

A disposable pressure sensor includes a substrate and a pressure diaphragm formed upon the substrate. A sensor coil can be provided, comprising a capacitor and an inductor formed on the substrate and surrounded by the pressure diaphragm. The ferrite core is located proximate to the sensor coil, such that when the pressure diaphragm is exposed to a pressure, the diaphragm moves close to the inductor or the capacitor, thereby resulting in a change in the capacitor or the inductor and an indication of pressure. The capacitor can be implanted as an adjustable, trimmable or variable capacitor. The inductor may also be provided as an adjustable or variable inductor and can include the use of a variable capacitor and a PVDF based piezoelectric transducer. When the PVDF layer is under pressure, it can generate an electric field across the interdigital transducer and transmit a signal thereof through an antenna.

Owner:HONEYWELL INT INC

Differential capacitance measurement

InactiveUS6949937B2Efficient methodPrecise and sensitive and yet stable evalutionCapacitance measurementsConverting sensor output electrically/magneticallyCMOSSoi cmos technology

Owner:DIALOG SEMICONDUCTOR GMBH

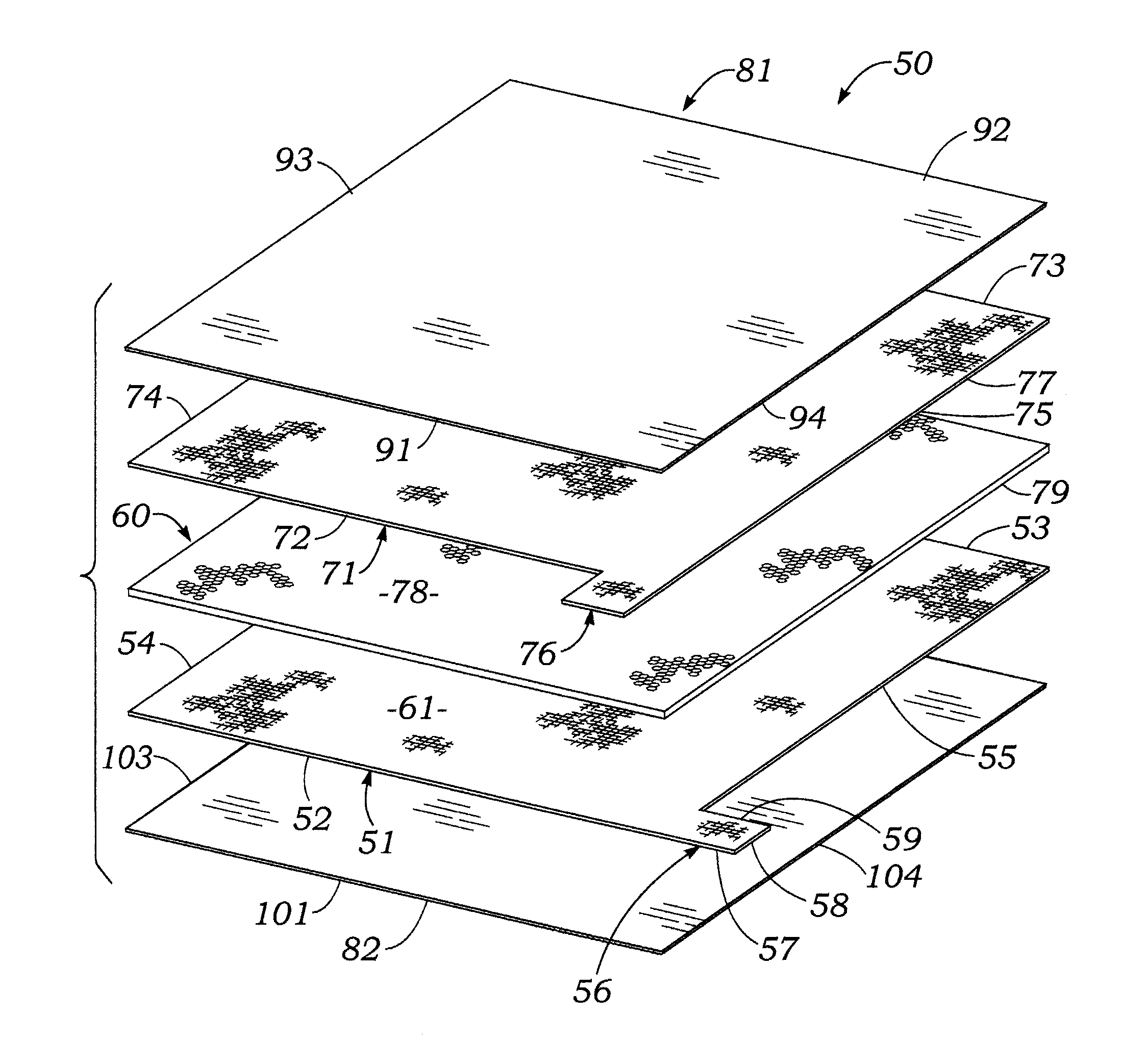

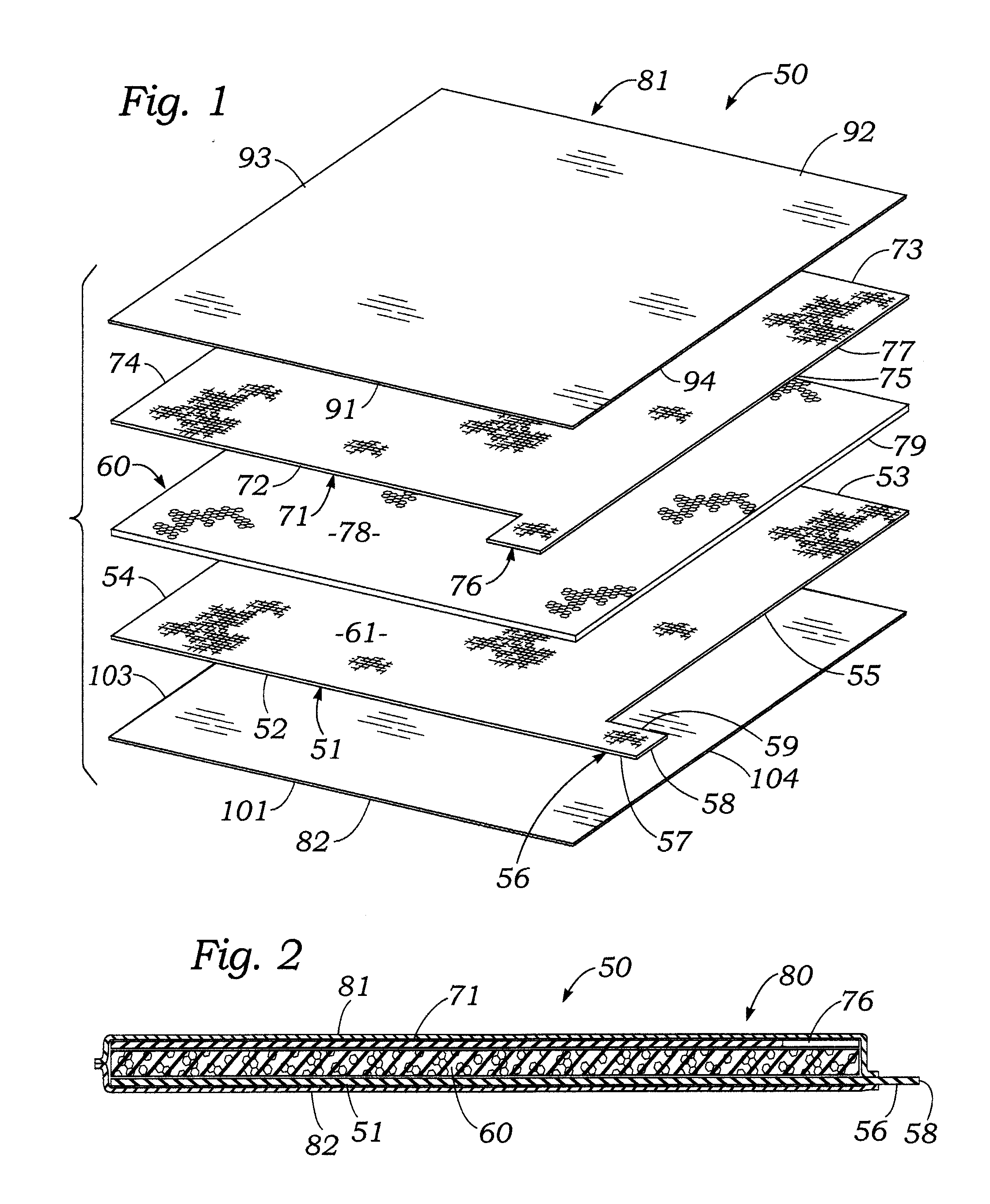

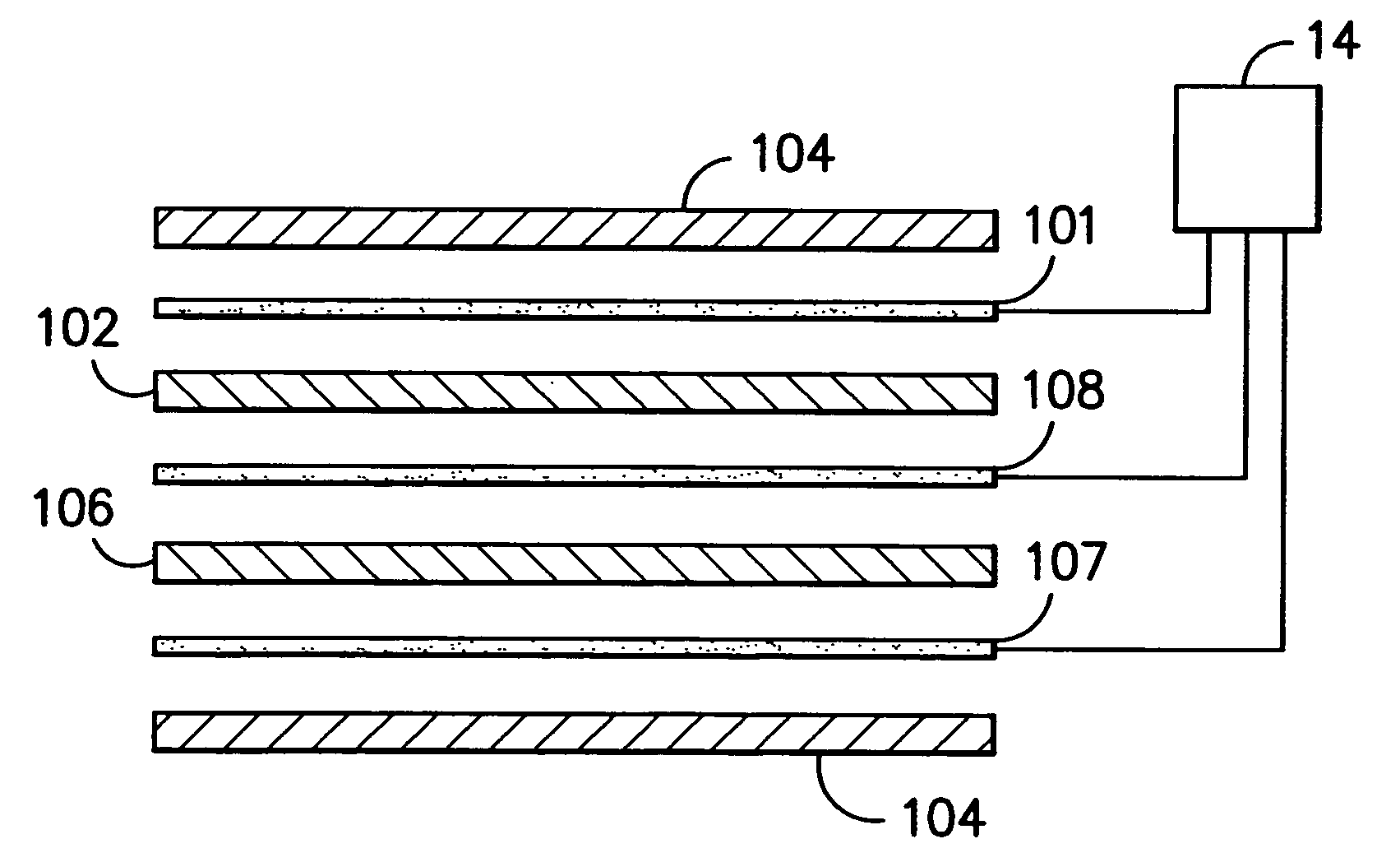

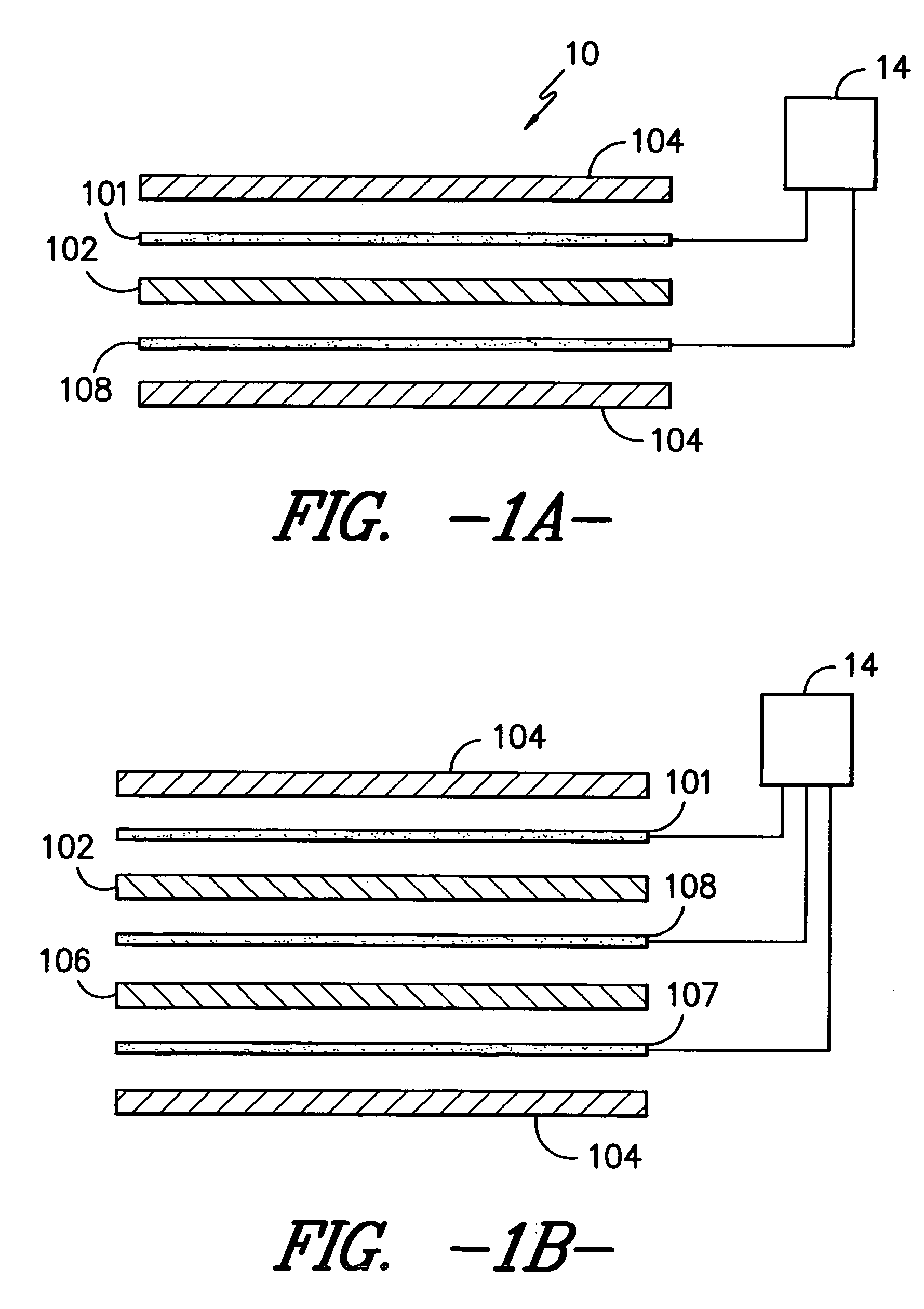

Flexible Piezocapacitive And Piezoresistive Force And Pressure Sensors

InactiveUS20140090488A1Facilitate measuring and mapping forcesForce measurement by measuring frquency variationsForce measurement using piezo-resistive materialsCapacitanceElectricity

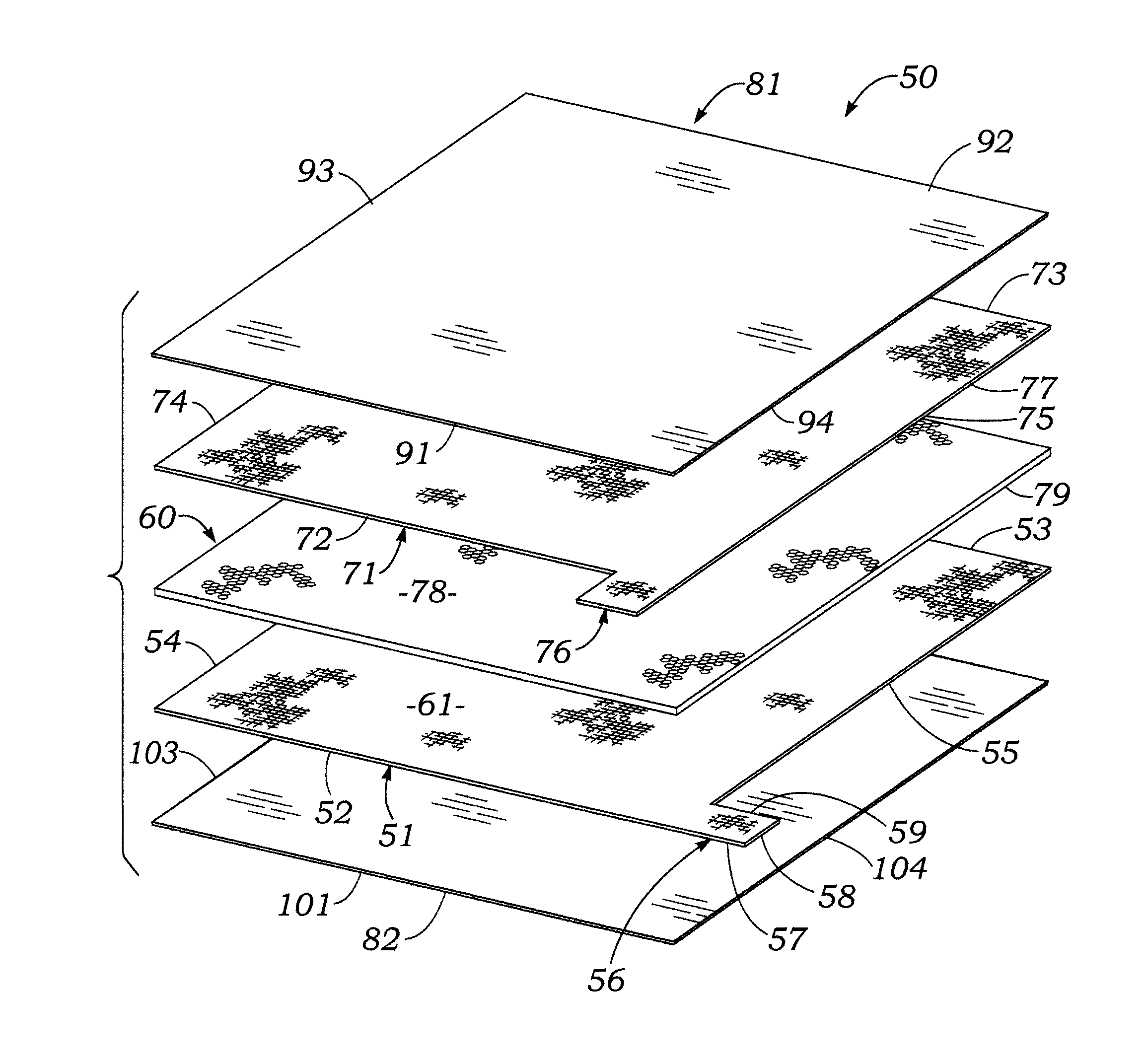

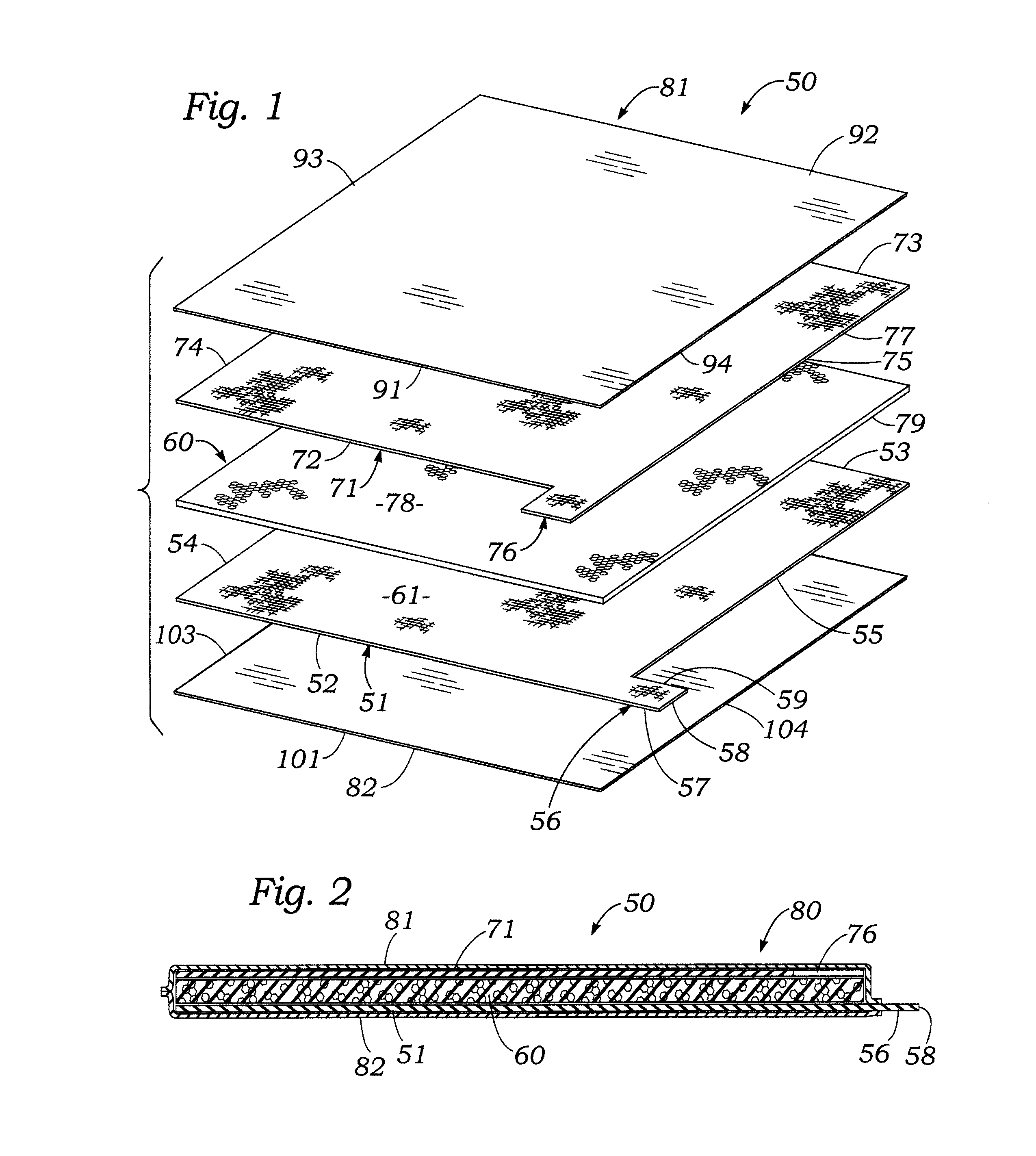

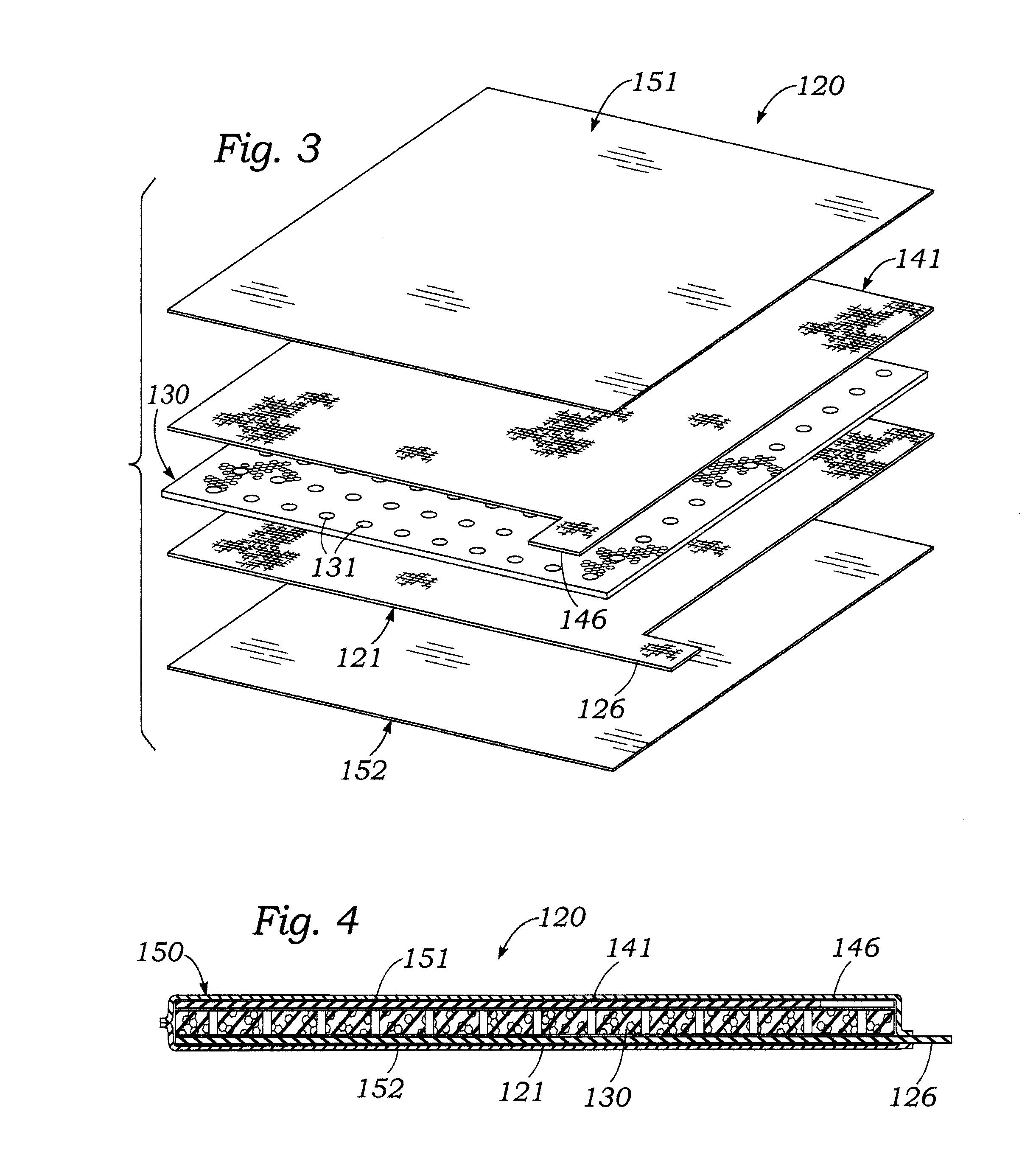

Flexible force / pressure sensors for producing electrical output signals proportional to forces or pressures exerted on the sensor include a thin, elastically deformable foam pad laminated between a pair of electrically conducive fabric sheets. A piezocapacitive embodiment of the sensor utilizes an elastically deformable perforated open-cell polyurethane foam pad preferably saturated with glycerin to increase the capacitance of the sensor. The piezocapacitive sensor section is preferably stacked onto a piezoresistive section having a second open-cell foam pad containing piezoresistive carbon particles to form a hybrid piezocapacitive / piezoresistive sensor. A third, “leaky dielectric” embodiment of a sensor includes a single open-cell foam pad which contains both a dielectric liquid and conductive particles. A low frequency such as d.c. to a few hertz is applied to a sensor to determine piezoresistive response of the sensor to forces or pressures and a higher frequency such as 30 KHz is applied to determine piezocapactive response.

Owner:PATIENTECH LLC

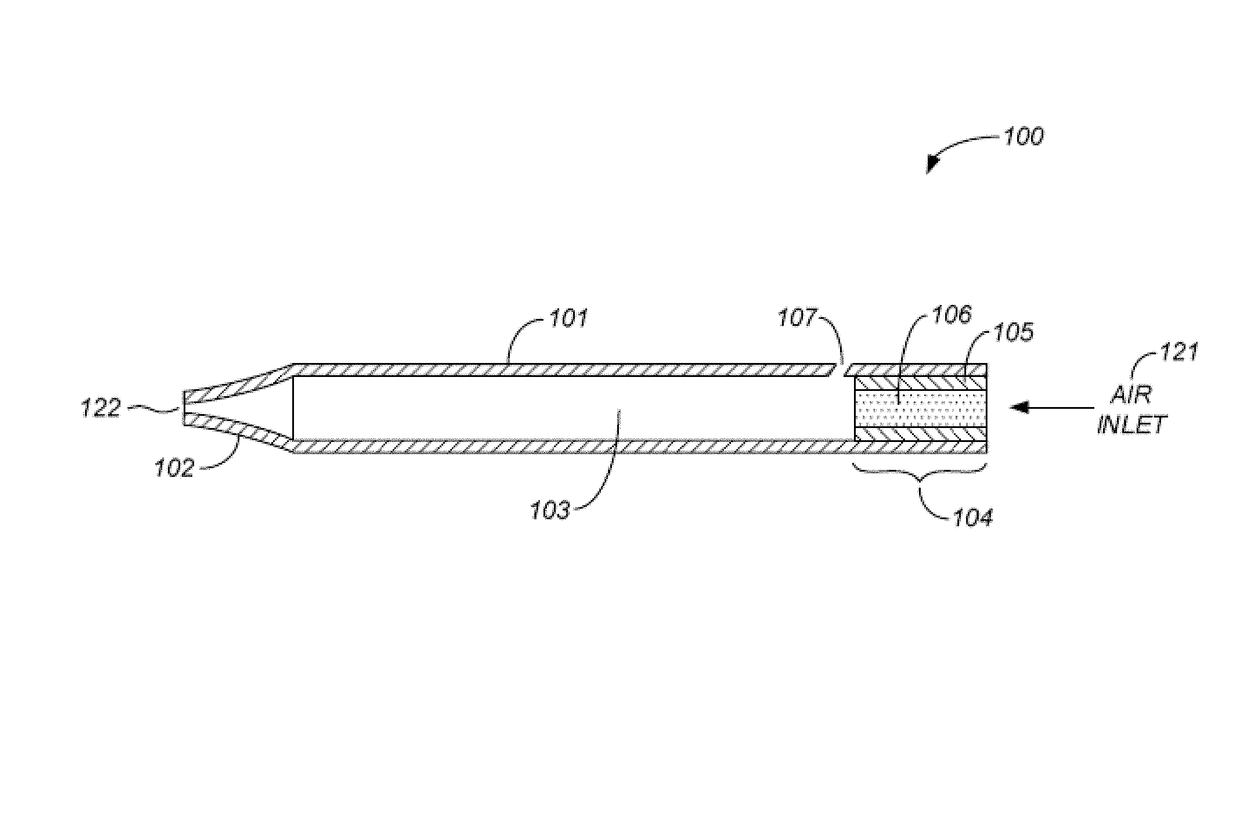

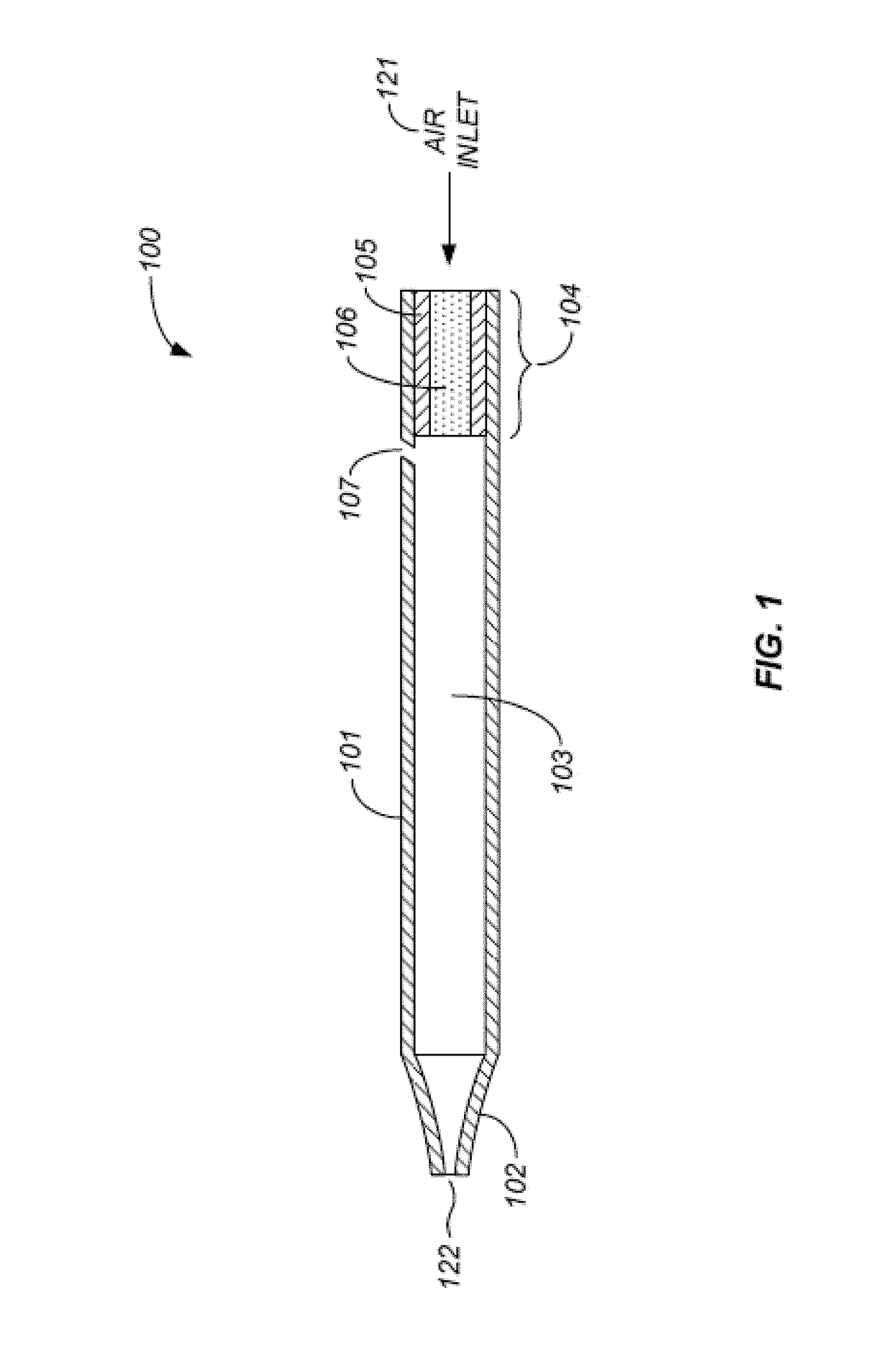

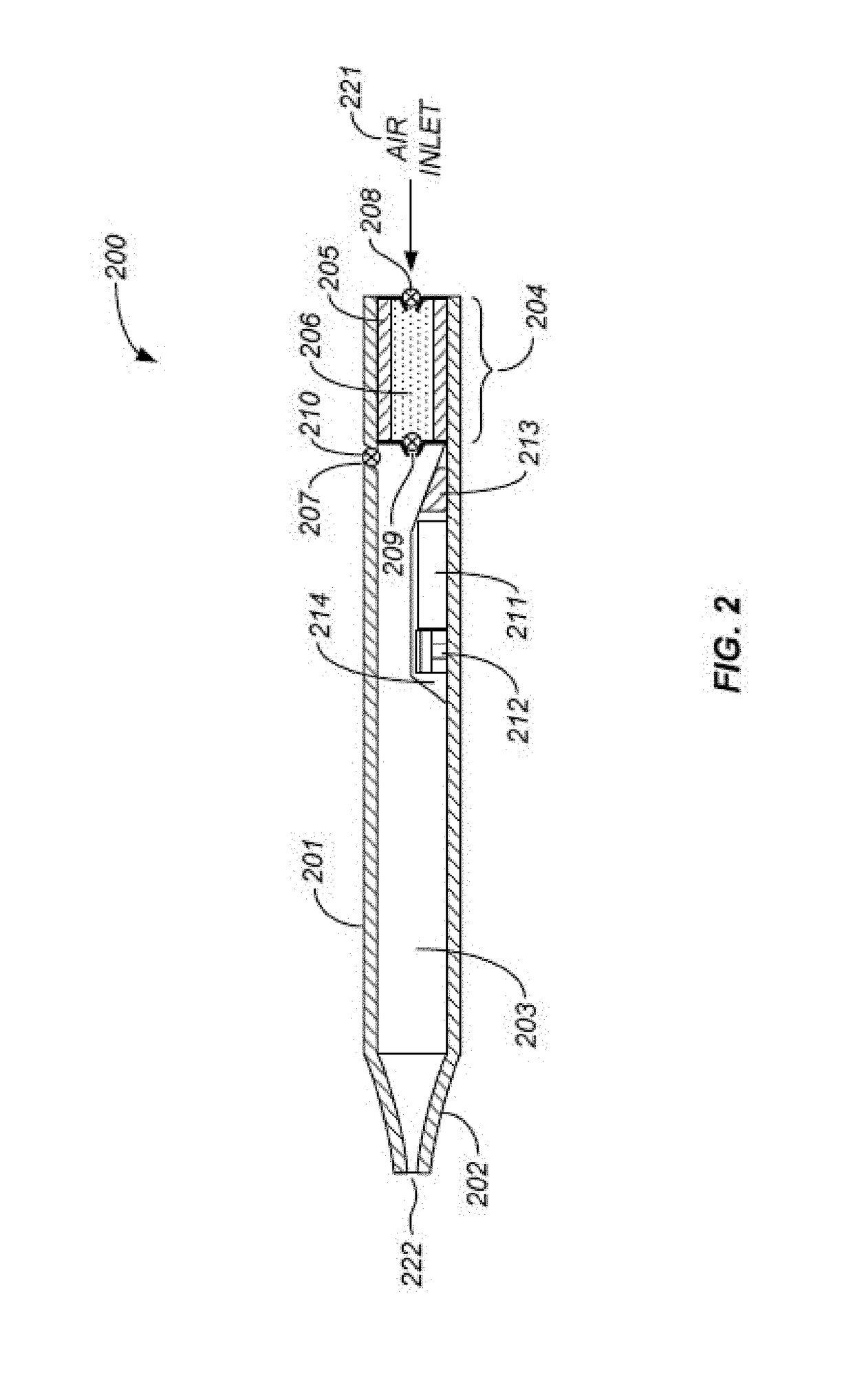

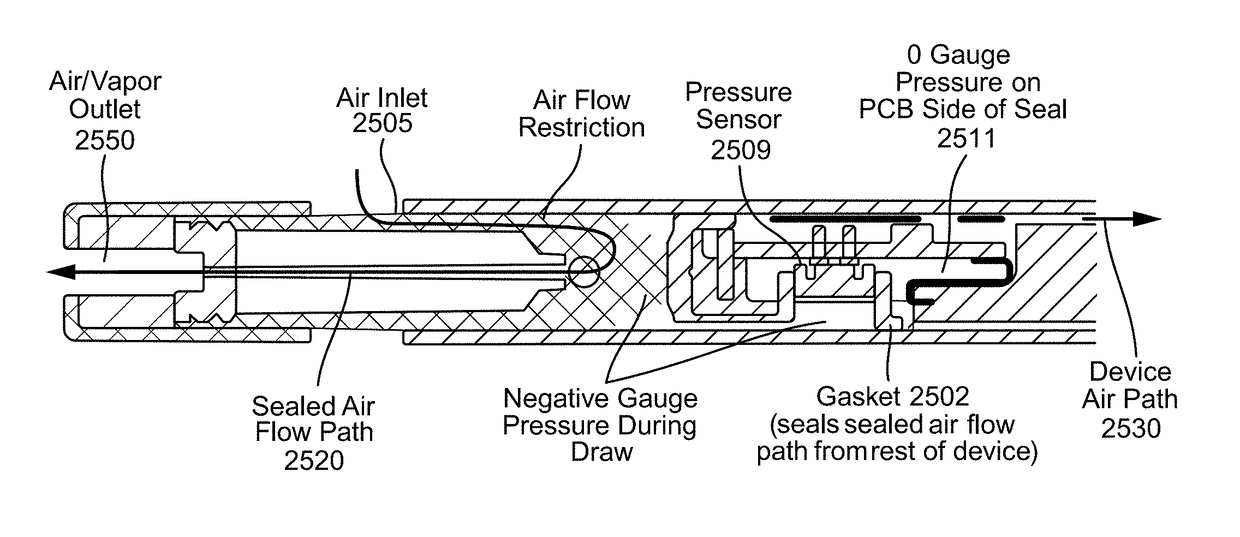

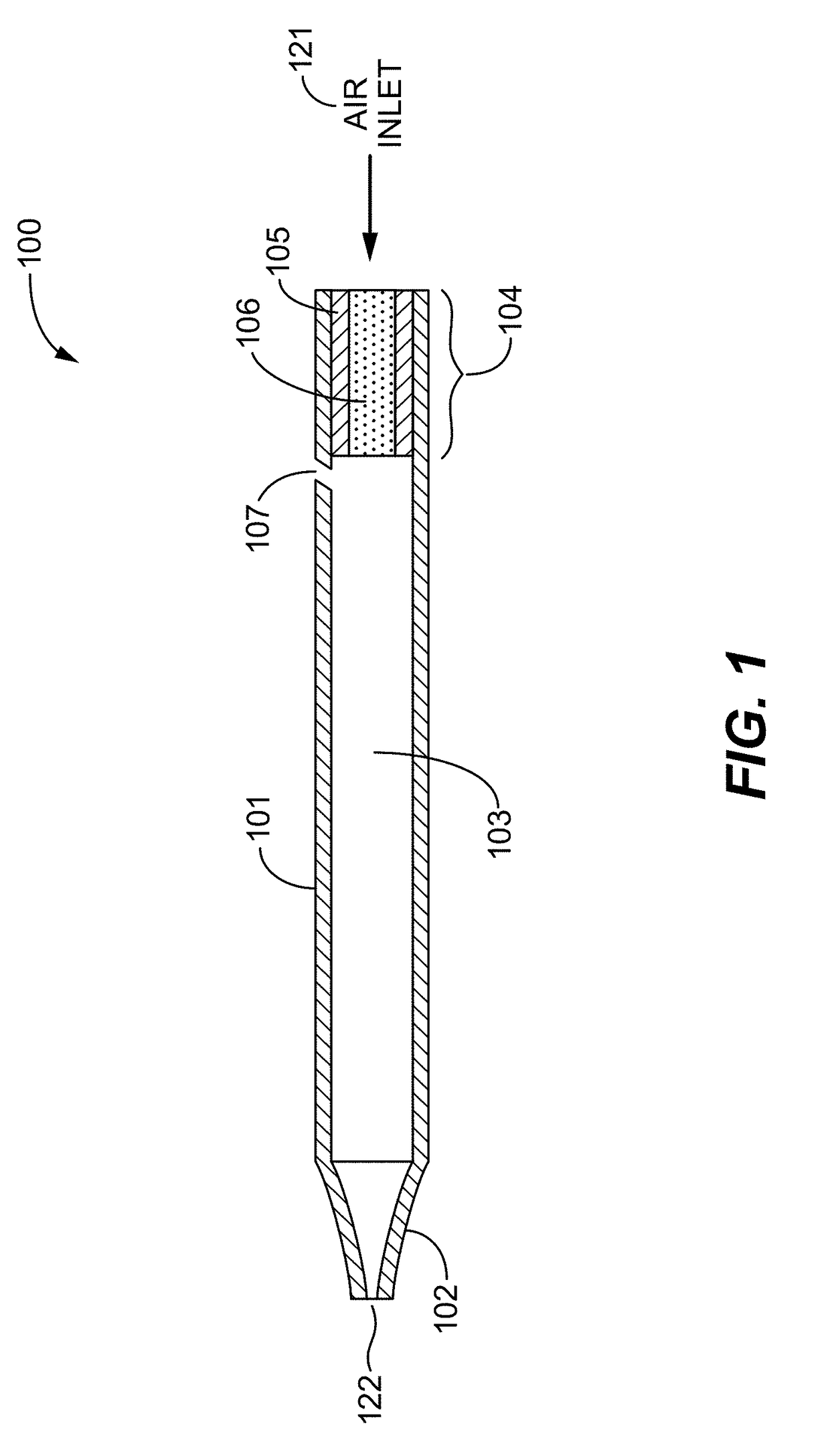

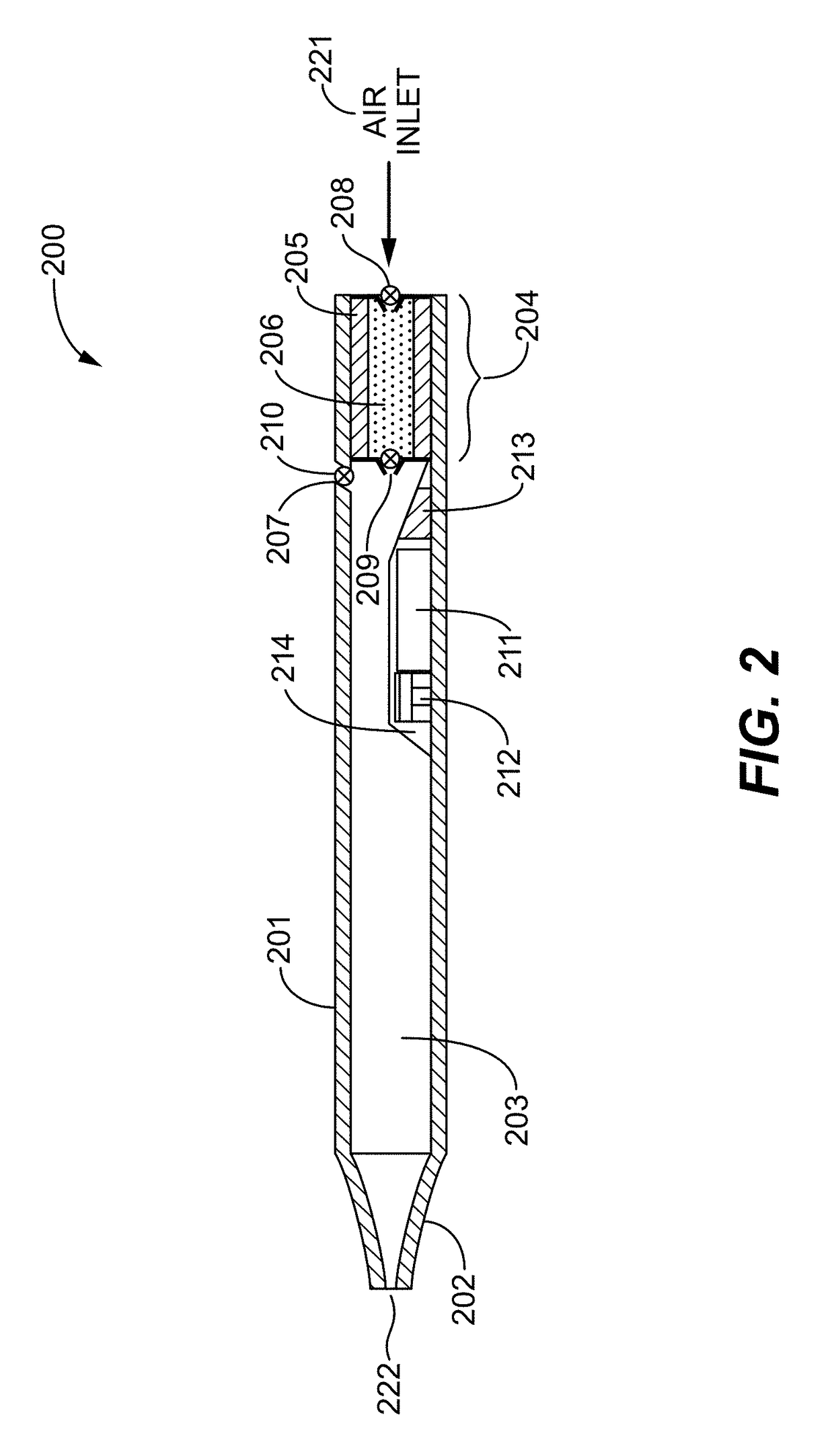

Vaporizer devices with blow discrimination

ActiveUS20170231281A1Absorbs excessive heatDissipates excessive heatElectric heatingTobacco devicesEngineeringVaporization

Methods and apparatuses for discriminating between user blowing and drawing (sucking) in an electronic vaporization device. Described herein are electronic aerosol devices and methods of controlling or operating them which can accurately differentiate between blowing and drawing (sucking) through the mouthpiece and adjust the control of the vaporizer accordingly.

Owner:JLI NAT SETTLEMENT TRUST

Flexible capacitive sensor

InactiveUS20070248799A1Large capacityLarge fabricFluid pressure measurement using inductance variationForce measurementElectricityEngineering

The invention relates to a flexible, resilient capacitive sensor suitable for large-scale manufacturing. The sensor comprises a dielectric, an electrically conductive layer on the first side of the dielectric layer, an electrically conductive layer on a second side of the dielectric layer, and a capacitance meter electrically connected to the two conductive layers to detect changes in capacitance upon application of a force to the detector. The conductive layers are configured to determine the position of the applied force. The sensor may be shielded to reduce the effects of outside interference.

Owner:MILLIKEN & CO

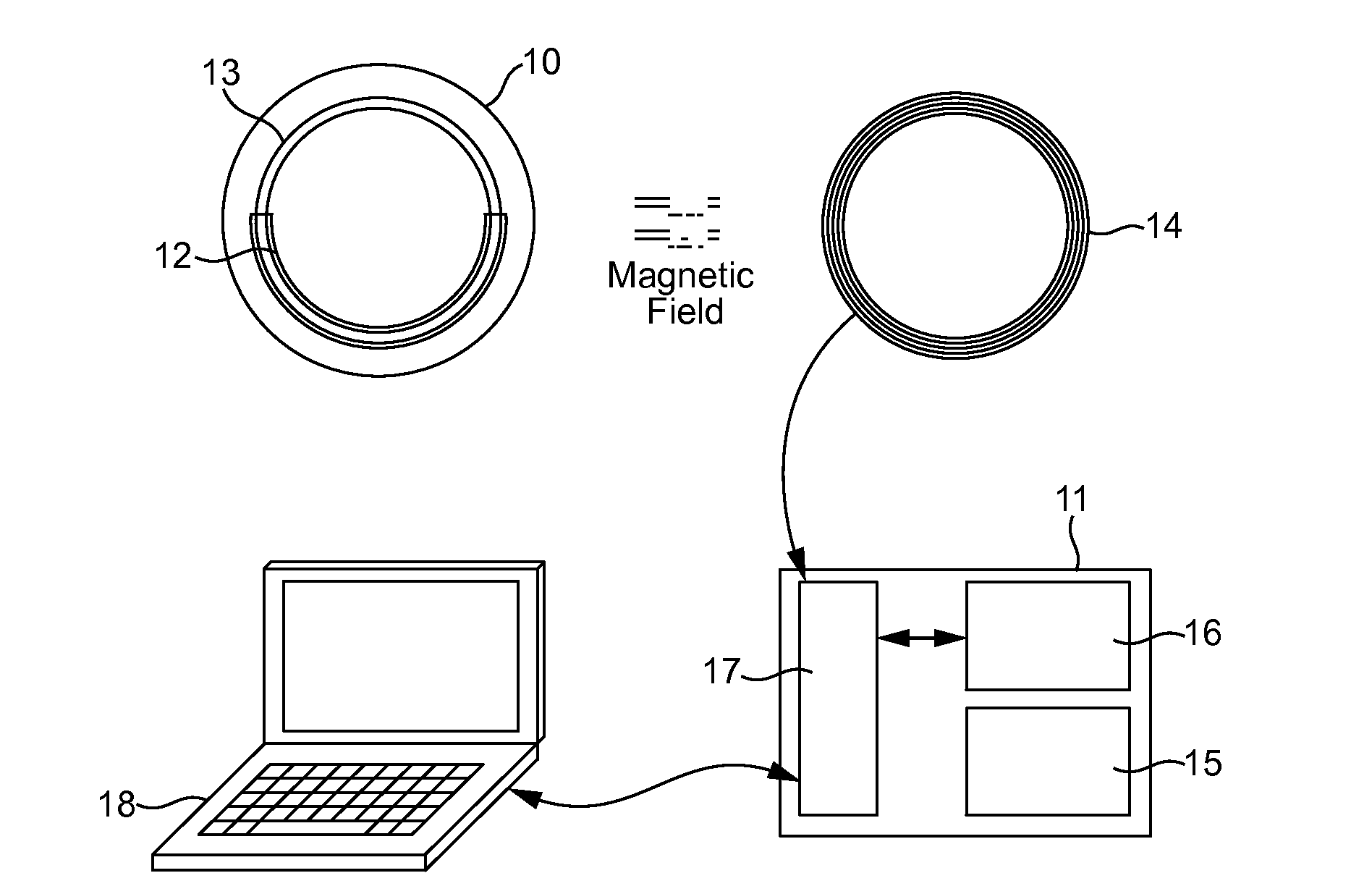

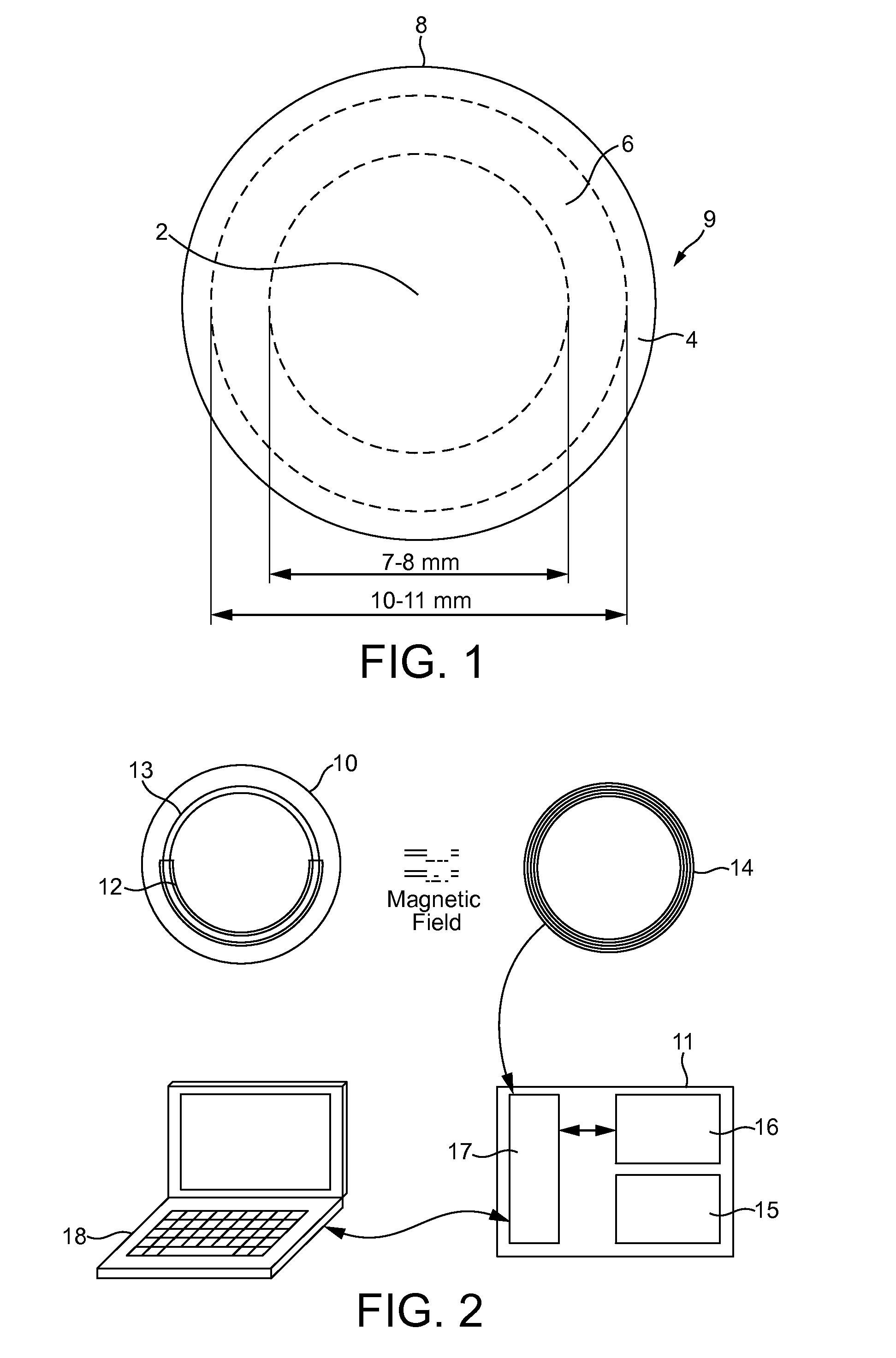

Device for monitoring intraocular pressure

ActiveUS20130184554A1Improve accuracyImprove consistencyTonometersOptical partsIntraocular pressurePressure sensor

Disclosed is a device adapted to measure intraocular pressure comprising: a corneal contact lens having a pressure sensor mounted in a recess or cavity in the contact lens, and wherein the contact lens has a back surface which is formed so as to protrude in a desired portion beyond the profile of the adjacent part of the lens and thus to press against the cornea, which protruding portion experiences a reactive deformation which is detected directly or indirectly by the pressure sensor.

Owner:UNIVERSITY OF DUNDEE +1

Disposable and trimmable wireless pressure sensor for medical applications

ActiveUS20060117859A1Low costLower resonance frequencyFluid pressure measurement using inductance variationCatheterCapacitanceEngineering

Disposable pressure sensor methods and systems are disclosed. A substrate can be provided, along with a capacitor and an inductor fixed to the substrate to form a pressure sensor thereof. In a variable L configuration, the inductor can be configured to comprise an inductor surface and a diaphragm, such that when the diaphragm is exposed to a pressure, the diaphragm moves close to the inductor surface, thereby resulting in an increase in the inductance and a decrease in the resonant frequency associated with the capacitor and the inductor and any associated circuitry. In a variable C configuration, the capacitor can be configured to comprise one electrode on the surface and one on the diaphragm, such that when the diaphragm is exposed to a pressure, the diaphragm moves close to the capacitor surface, thereby resulting in an increase in the capacitance and a decrease in the resonant frequency associated with the capacitor and the inductor and any associated circuitry. Such increase and / or decrease data are detectable by external interrogation.

Owner:HONEYWELL INT INC

Disposable and trimmable wireless pressure sensor for medical applications

ActiveUS7059195B1Low costLower resonance frequencyFluid pressure measurement using inductance variationCatheterCapacitanceInductor

Disposable pressure sensor methods and systems are disclosed. A substrate can be provided, along with a capacitor and an inductor fixed to the substrate to form a pressure sensor thereof. In a variable L configuration, the inductor can be configured to comprise an inductor surface and a diaphragm, such that when the diaphragm is exposed to a pressure, the diaphragm moves close to the inductor surface, thereby resulting in an increase in the inductance and a decrease in the resonant frequency associated with the capacitor and the inductor and any associated circuitry. In a variable C configuration, the capacitor can be configured to comprise one electrode on the surface and one on the diaphragm, such that when the diaphragm is exposed to a pressure, the diaphragm moves close to the capacitor surface, thereby resulting in an increase in the capacitance and a decrease in the resonant frequency associated with the capacitor and the inductor and any associated circuitry. Such increase and / or decrease data are detectable by external interrogation.

Owner:HONEYWELL INT INC

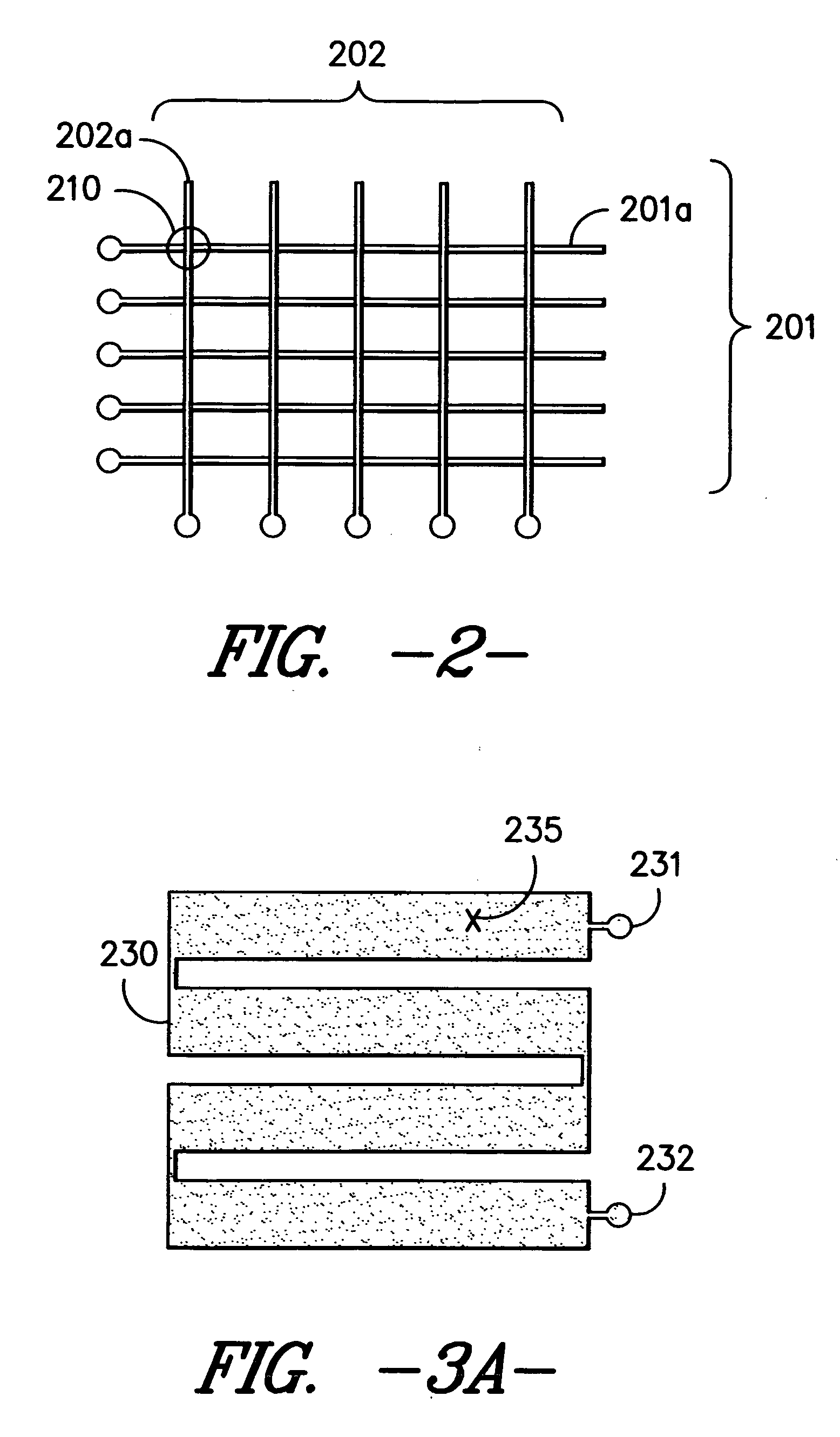

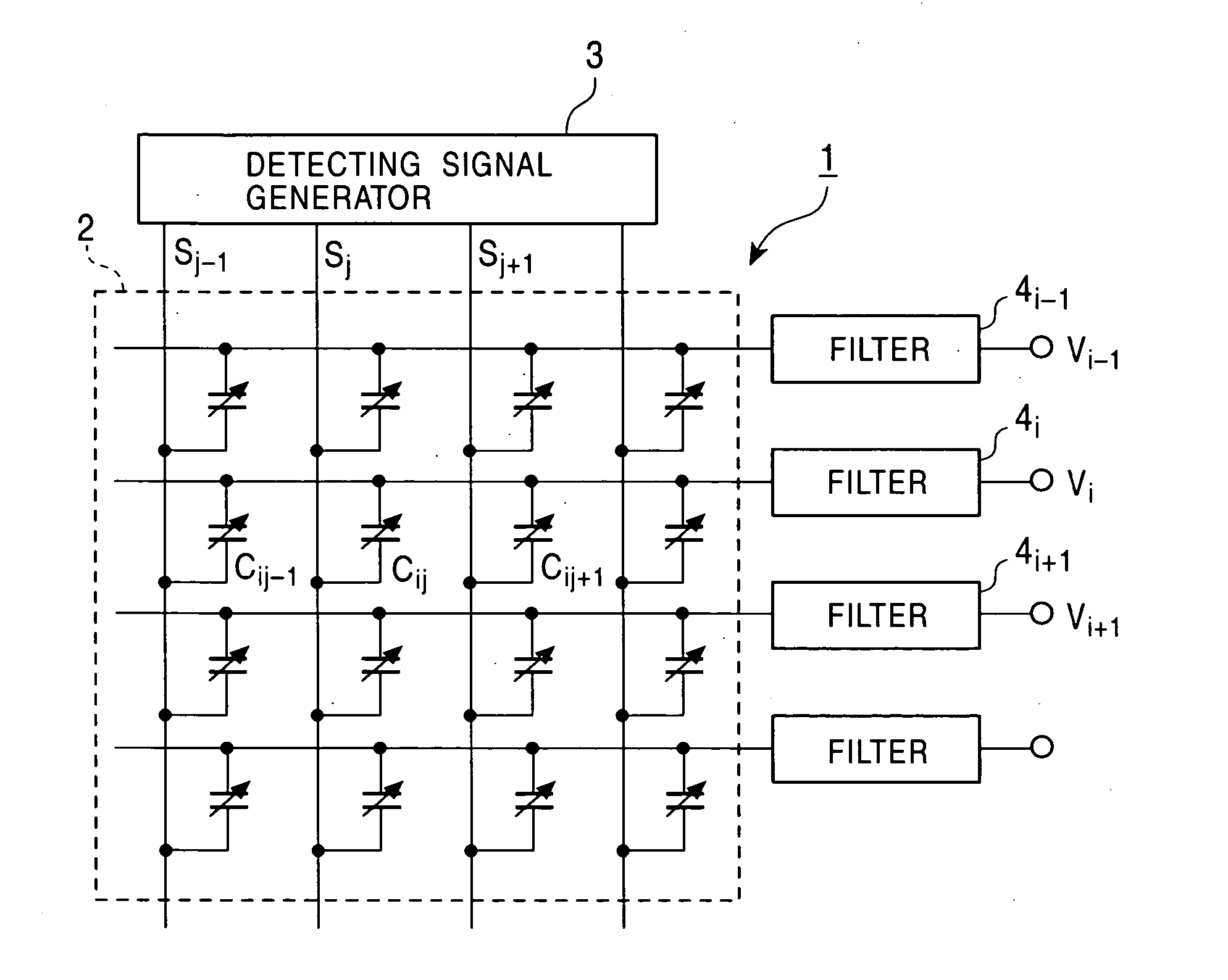

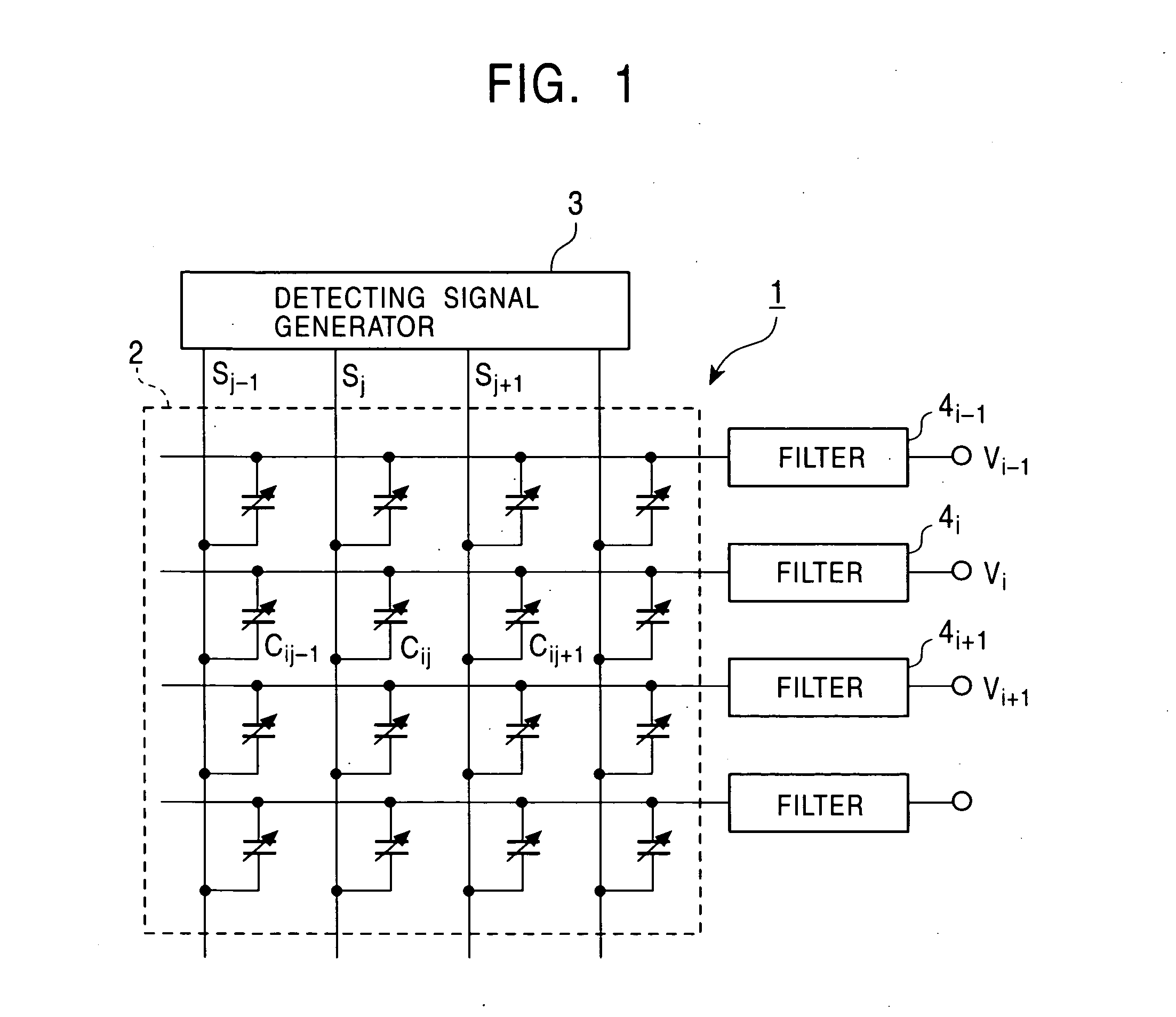

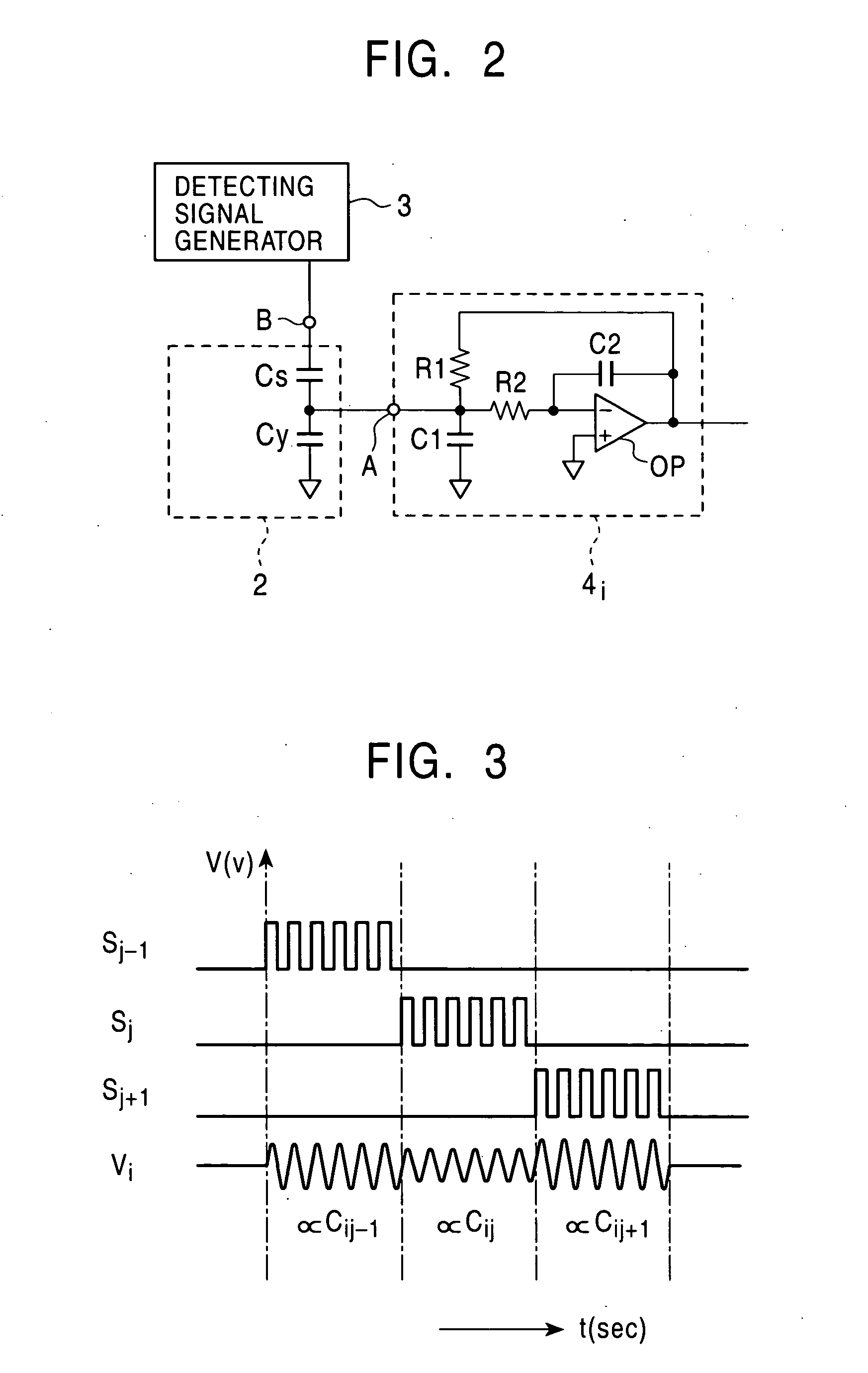

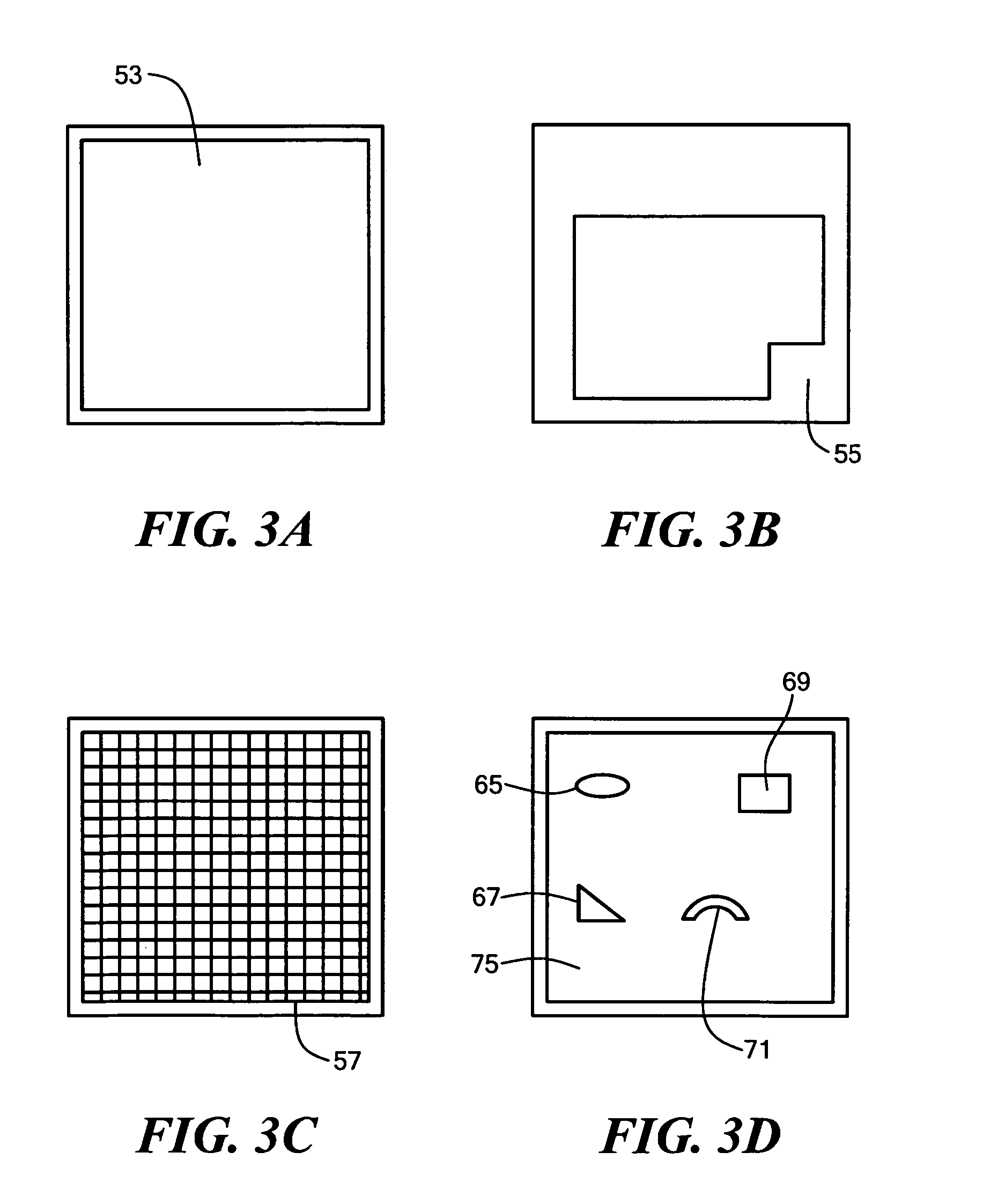

Capacitive sensor

InactiveUS20050005703A1Low frequency noiseReduce low frequency noisePerson identificationForce measurementCapacitive sensingSignal generator

A pressure-sensitive capacitive sensor includes a sensing unit in which a plurality of column wires and a plurality of row wires are formed in a matrix, a detecting signal generator, and filters. Capacitances at intersections between the column wires and the row wires change in accordance with externally applied pressure. The detecting signal generator sequentially outputs pulse signals of a predetermined frequency to the column wires of the sensing unit. The filters are connected to the respective row wires of the sensing unit and extract amplitudes of signals of the predetermined frequency. The amplitude is proportional to the capacitance at the intersection.

Owner:ALPS ALPINE CO LTD

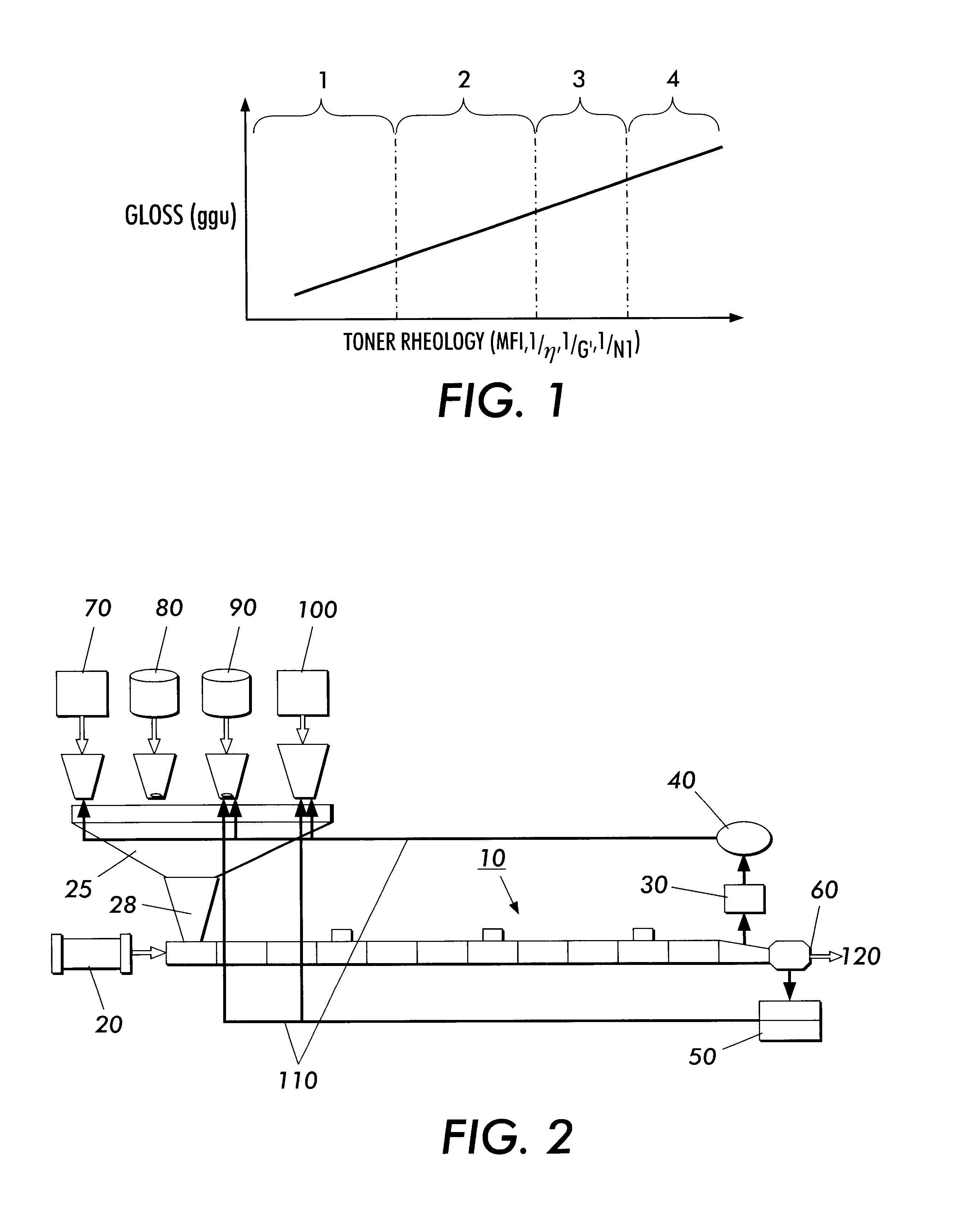

Method for controlling melt rheology of resin mixtures

InactiveUS6593053B1DevelopersFluid pressure measurement using capacitance variationMelt mixingChemistry

A process including: introducing and continuously melt mixing in an extruder a mixture of a first resin feed and a second resin feed; measuring within the extruder the melt rheology of the resulting melt mixture of the first and second resins; determining the relative ratio of the first resin and a second resin from the melt rheology in the resulting melt mixture; and adjusting the relative feed ratio of the first resin and second resin feeds introduced to the extruder.

Owner:XEROX CORP

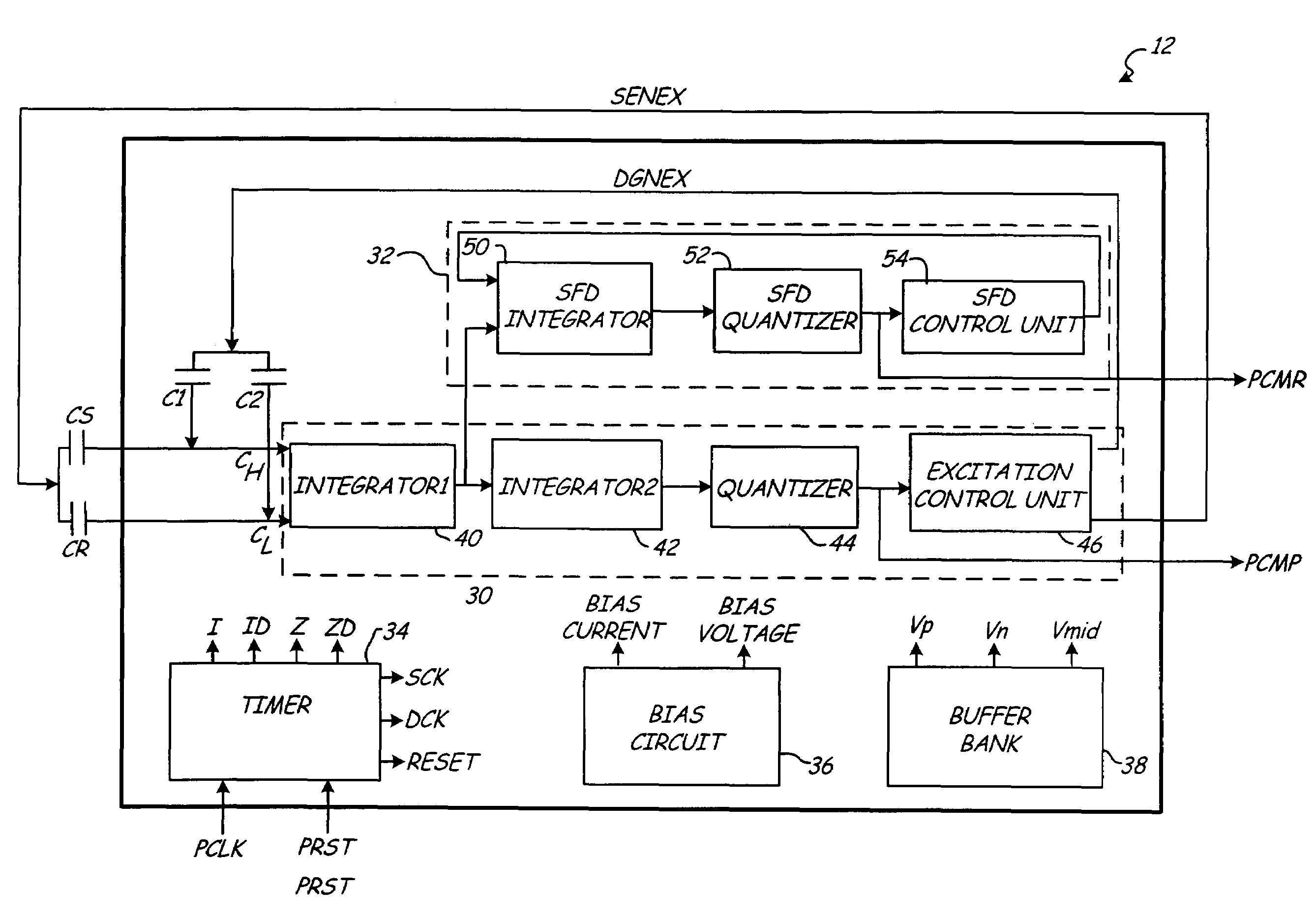

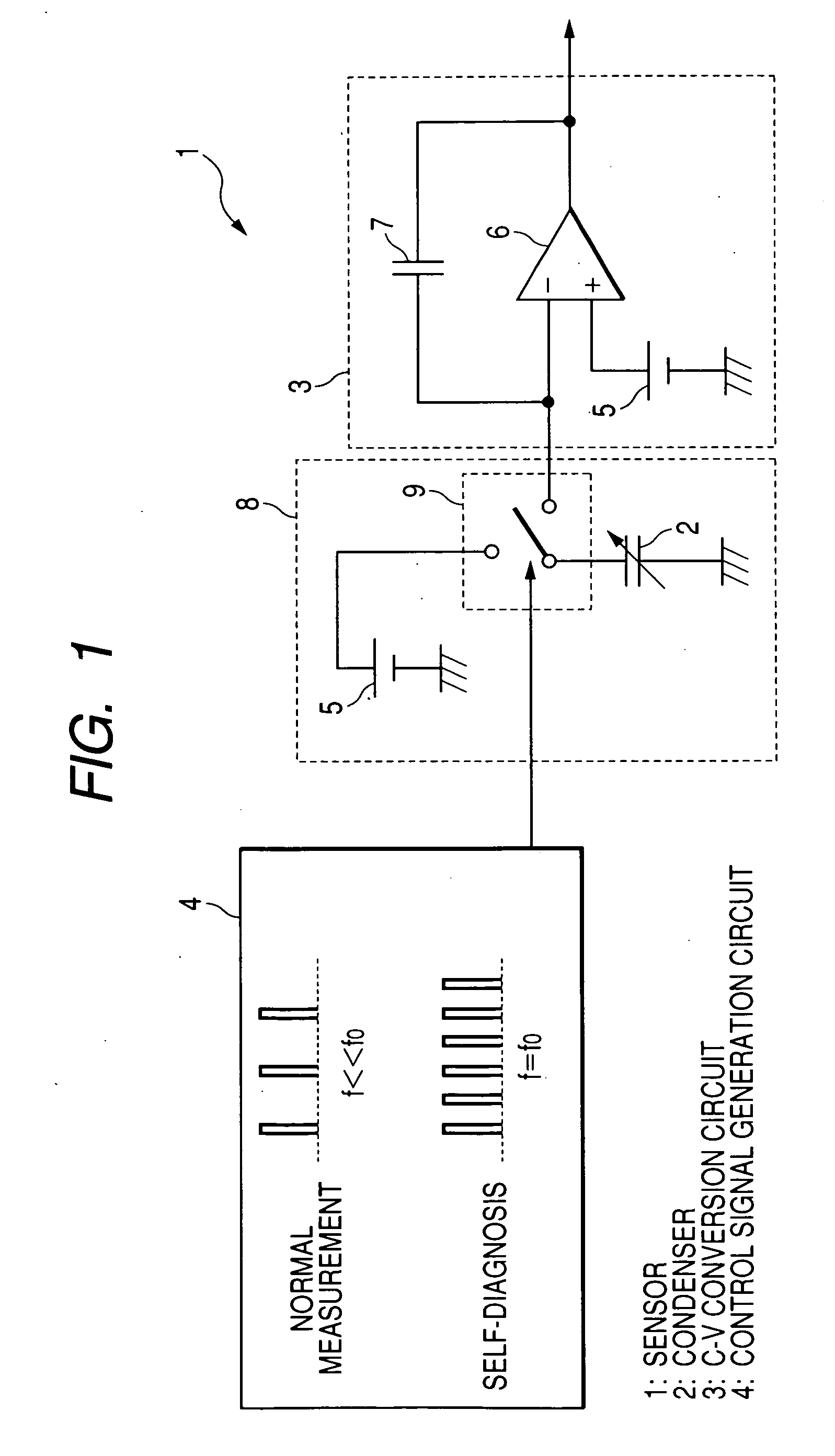

Capacitance-to-digital modulator with sensor failure-mode detection

ActiveUS7236113B1Testing dielectric strengthElectric signal transmission systemsCapacitanceTransmitter

A pressure transmitter having a capacitance-to-digital modulator produces an output as a function of sensor capacitance and a reference capacitance. Transmitter also includes a sensor failure mode detector produces an output signal and identifies failure modes of the sensor capacitance and reference capacitance.

Owner:FISHER-ROSEMOUNT SYST INC

Capacitive sensor

ActiveUS20050229710A1Effective protectionEliminate needSolid-state devicesMachines/enginesEngineeringCapacitor

A capacitive sensor including a housing having a hermetically sealed cavity, a plate in the cavity, a diaphragm forming a part of the cavity and spaced from the plate, a conductive layer on the first diaphragm, and a second conductive layer on the plate, the first and second conductive layers being the electrodes of a capacitor whose capacitance varies with the position of the diaphragm relative to the plate.

Owner:ANALOG DEVICES INC

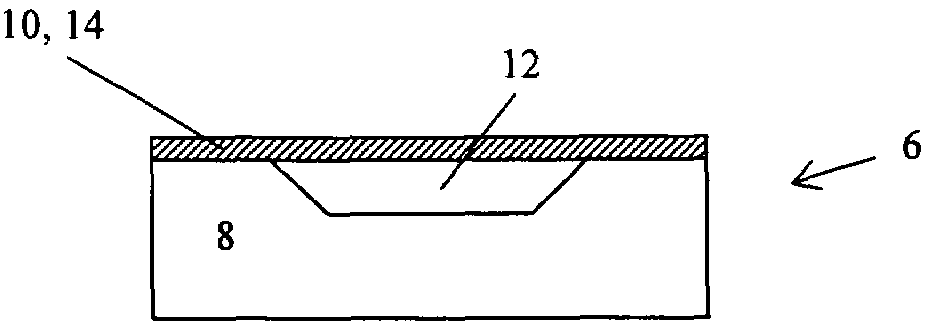

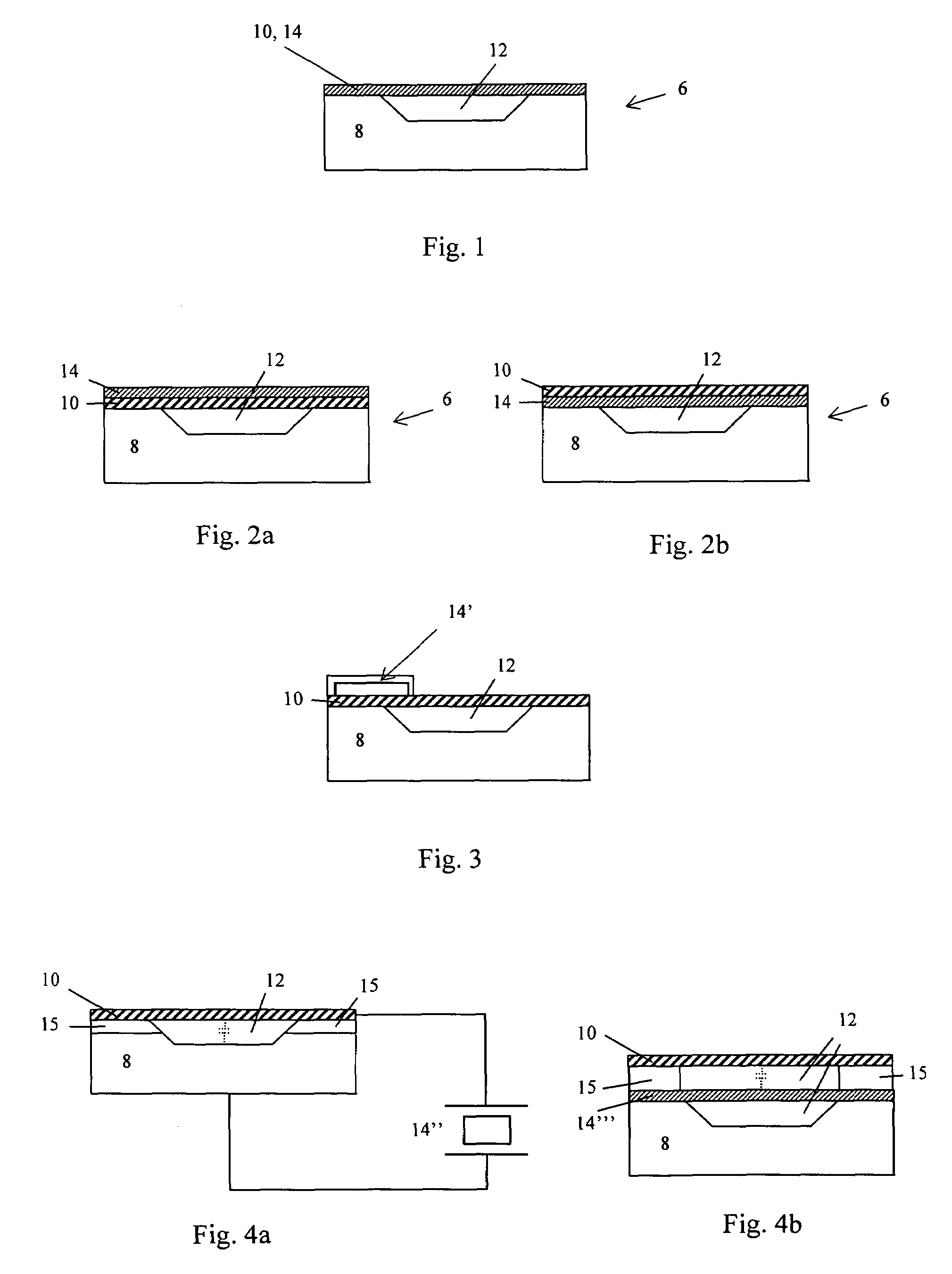

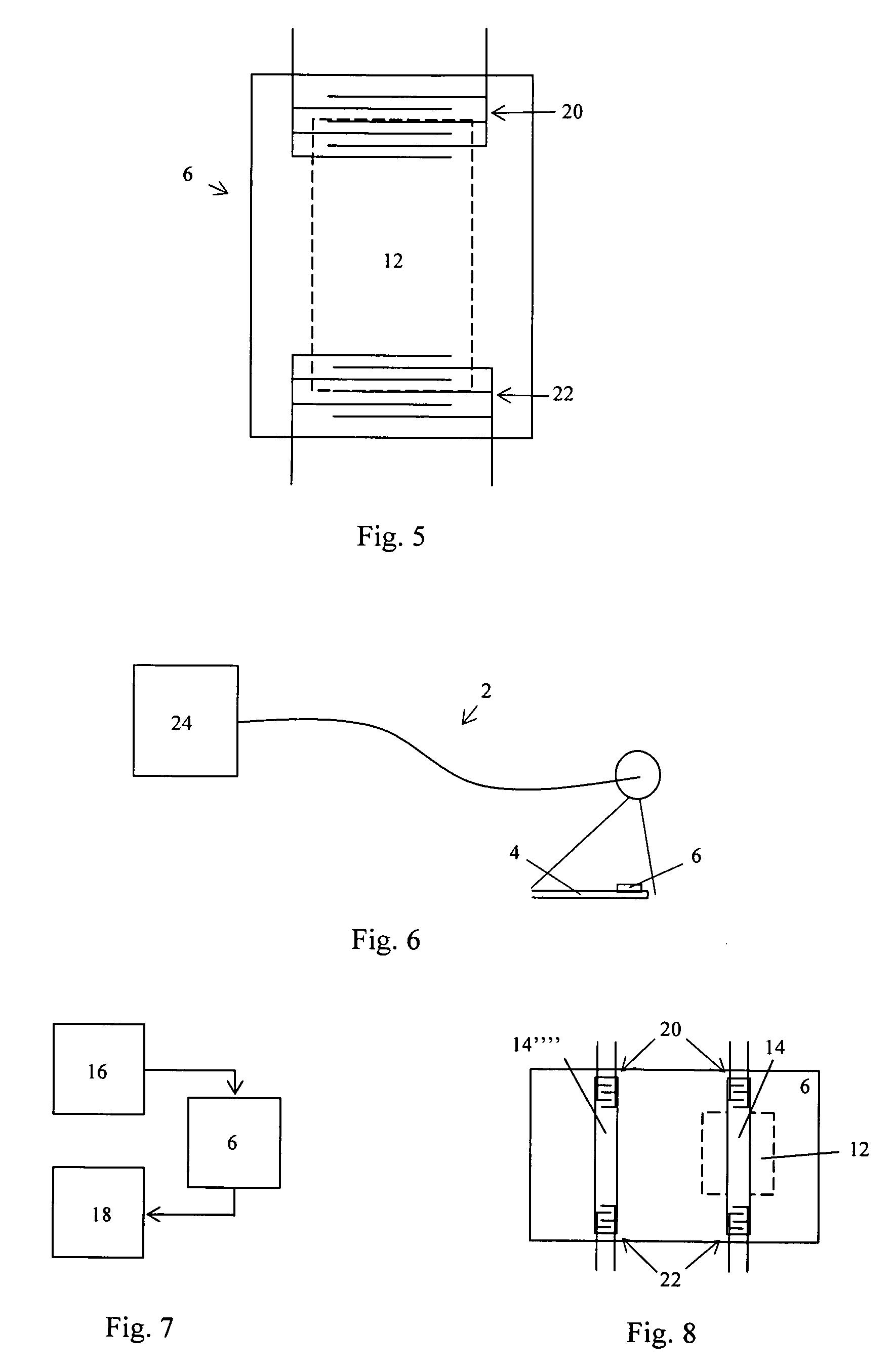

Pressure sensor

InactiveUS7331236B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsAcoustic waveEngineering

A sensor and insertion assembly 2 is used for intravascular measurement of pressure in a living body. The assembly includes, a sensor chip 6 having a substrate body 8 with a recess covered by a pressure sensitive film 10 thereby forming a cavity 12. A piezoelectric element, preferably in the form of a piezoelectric film 14, is arranged in connection with the pressure sensitive film, and energy is applied to the piezoelectric element such that acoustic waves are generated in the element. The piezoelectric element is arranged to generate an output signal, representing the pressure at the film, in dependence on the measured properties of the acoustic waves related to the deflection of the pressure sensitive film.

Owner:ST JUDE MEDICAL COORDINATION CENT

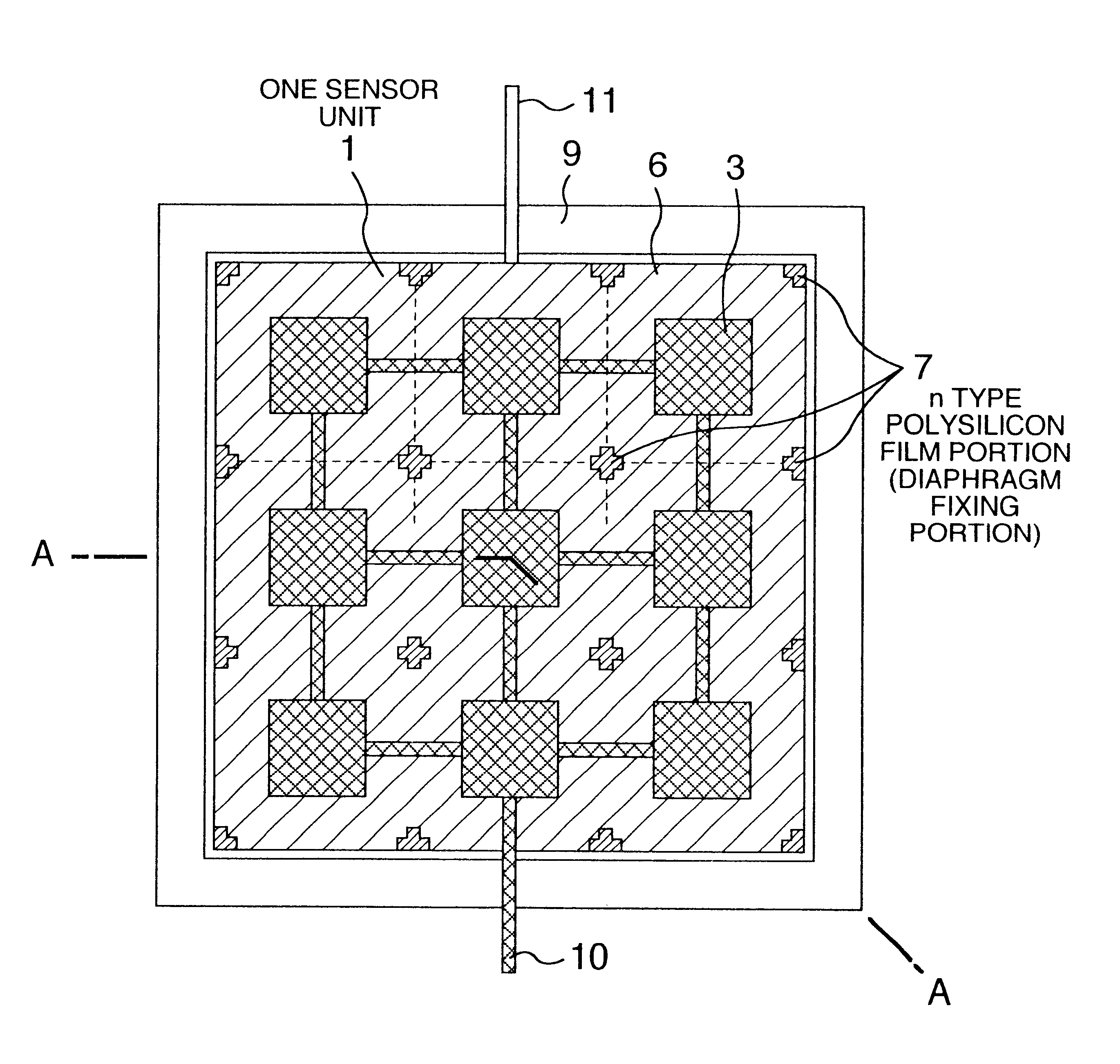

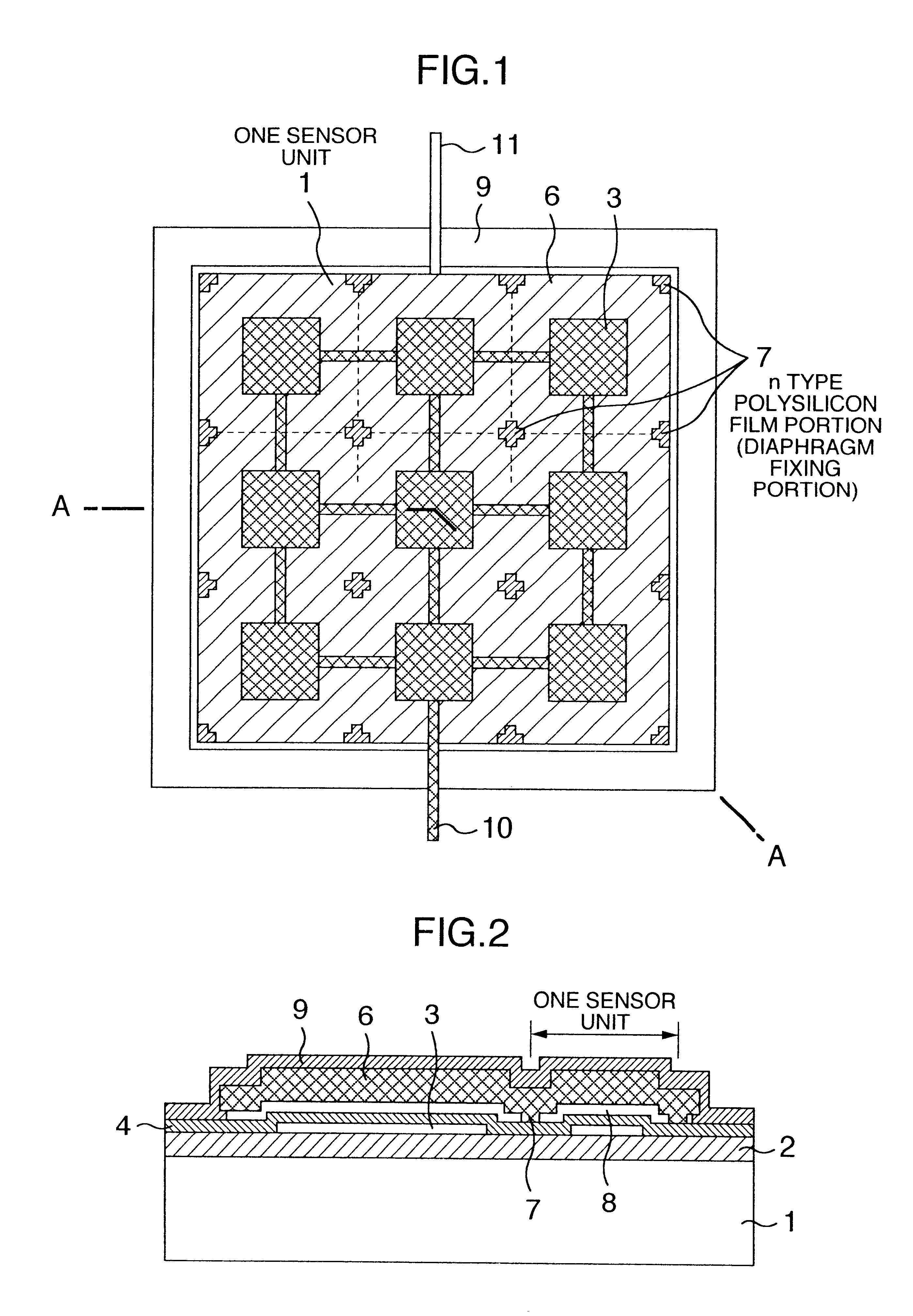

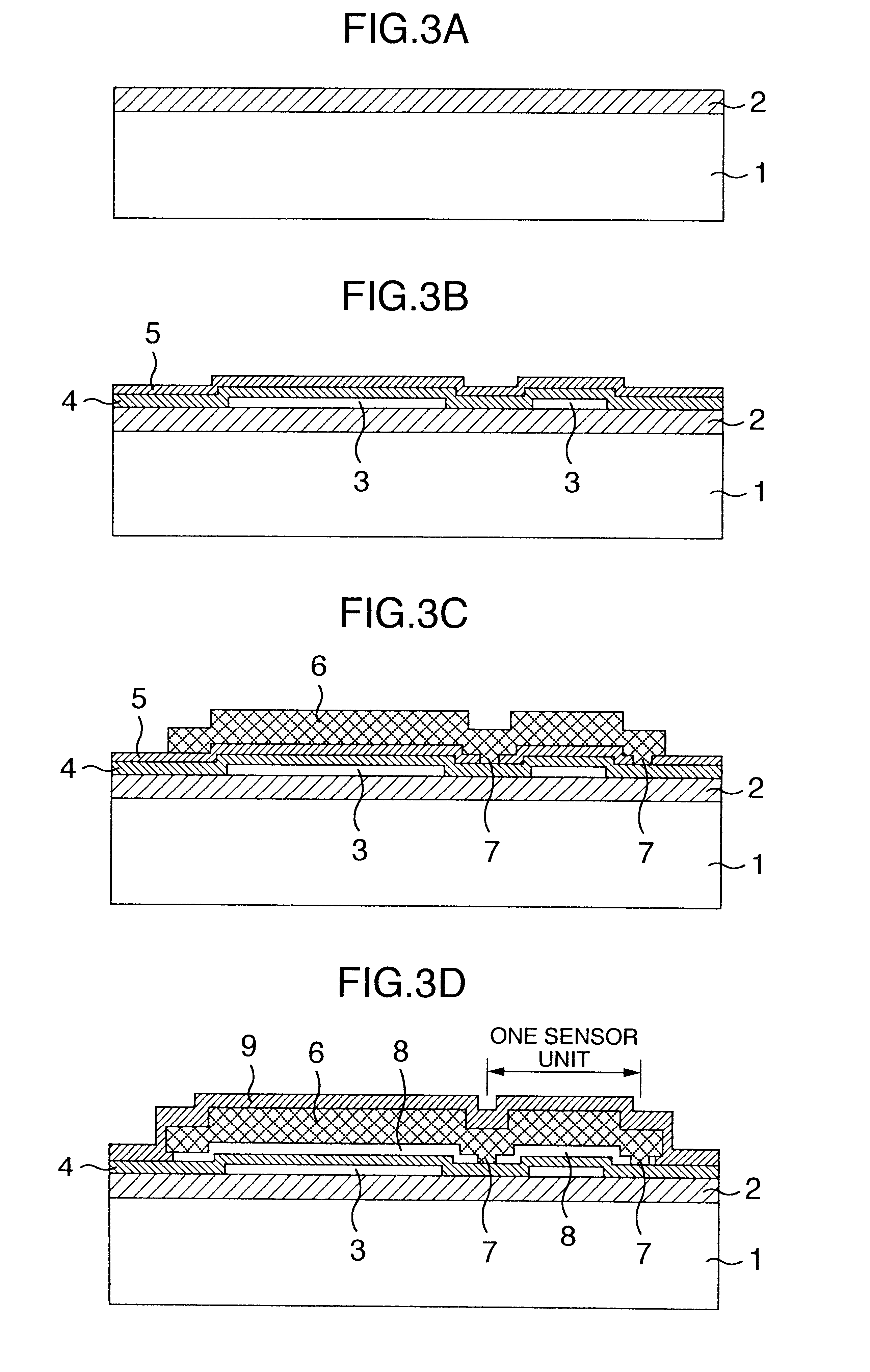

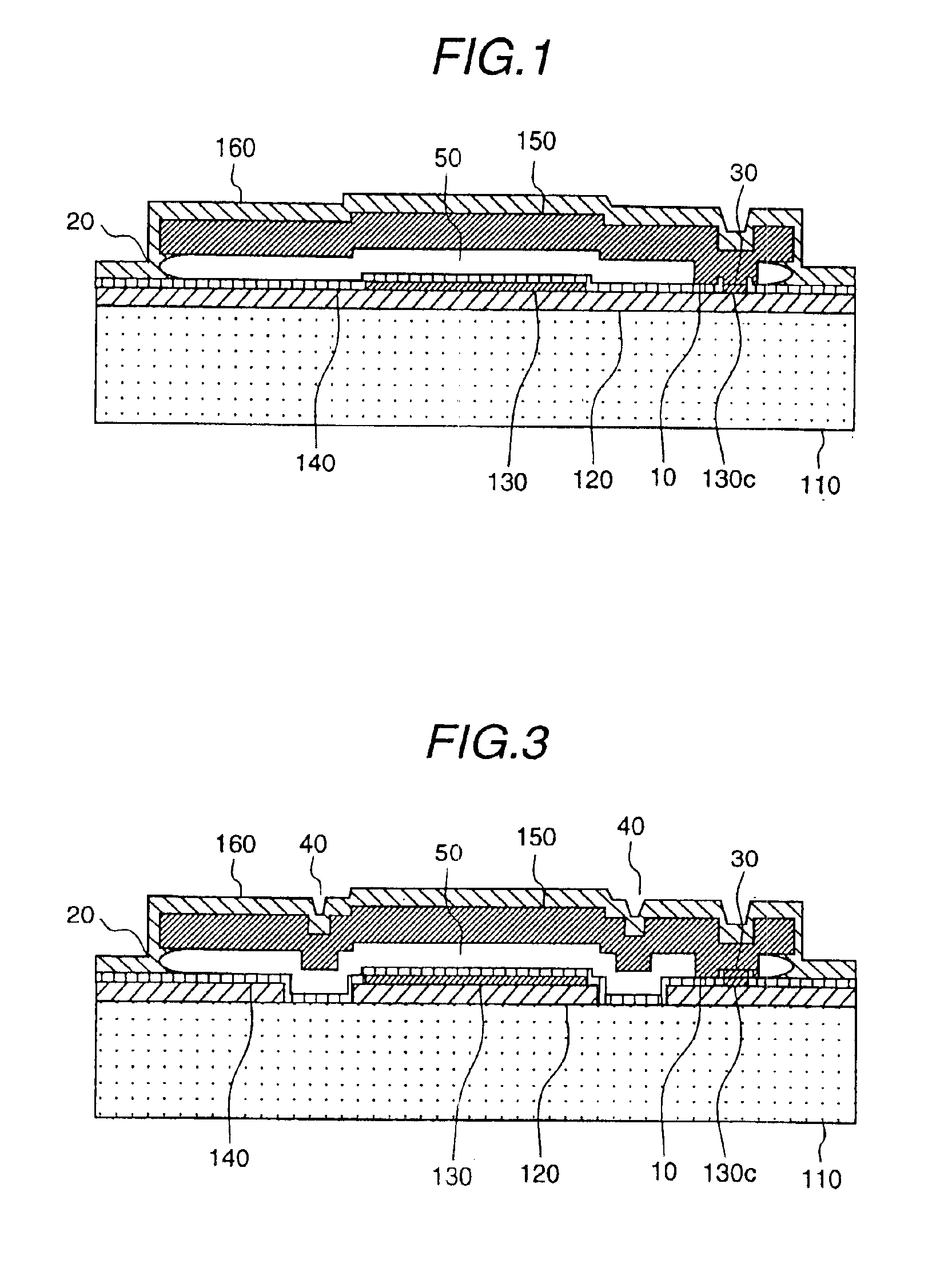

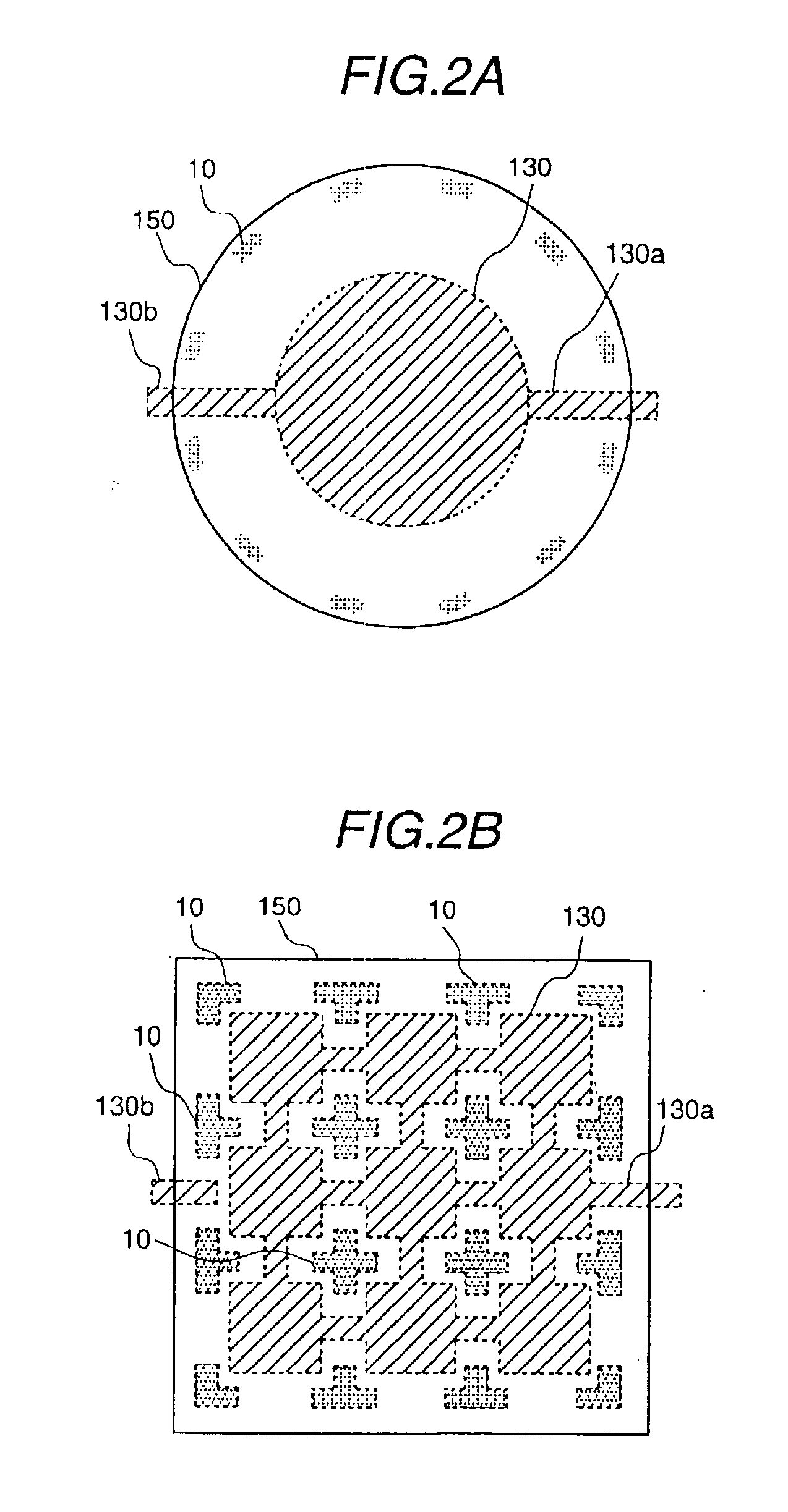

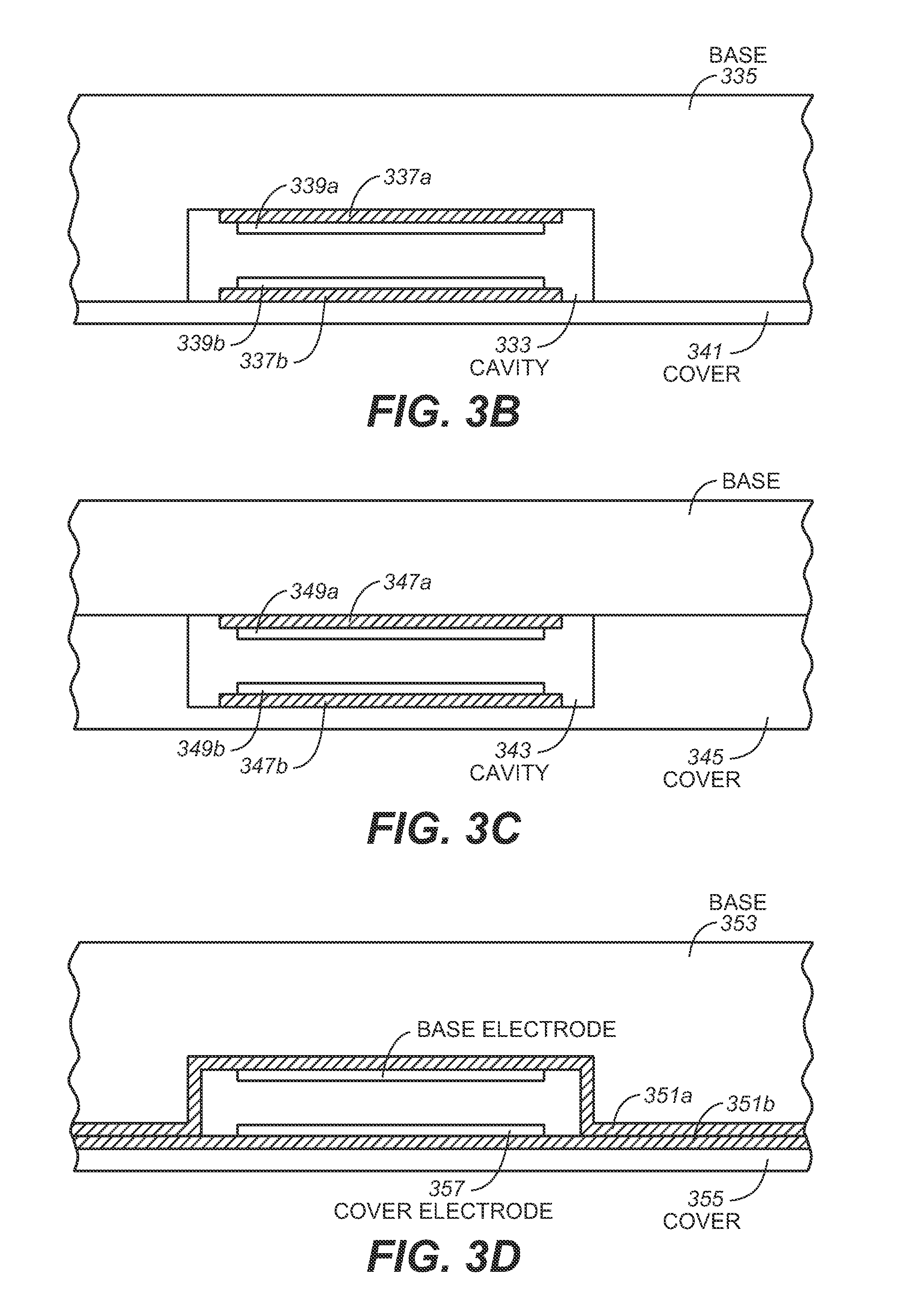

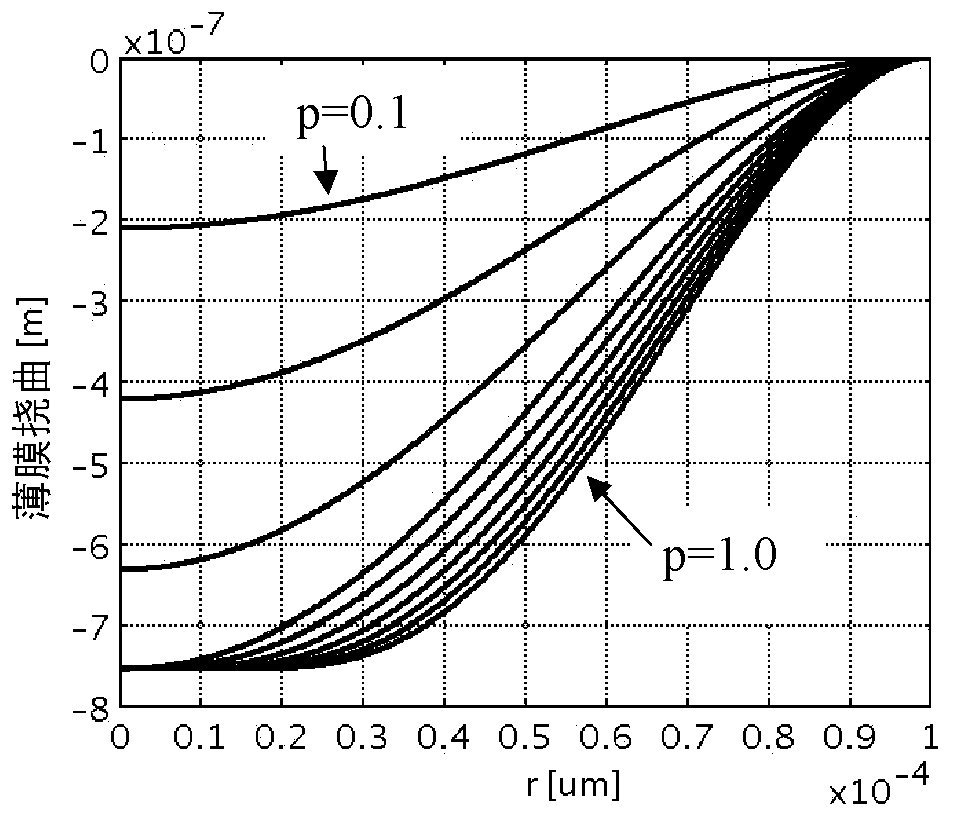

Capacitance-type pressure sensor

InactiveUS6640642B1Improve detection accuracyImprove throughputForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorParasitic capacitance

A pressure sensor of electric capacitance type which includes a plurality of pressure sensor units connected in parallel with one another and each formed on a substrate by an electrode, a cavity region and a diaphragm having an electrically conductive film which is disposed in opposition to the electrode with the cavity region intervening between the electrode and the diaphragm, wherein diaphragm fixing portions are disposed internally of the cavity region so that a single sheet of the diaphragm is partitionarily and regionally allotted to regions of the plural pressure sensor units, respectively. With this structure of the capacitance-type pressure sensor, ineffective region for capacitance detection is minimized and hence the parasitic capacitance can be reduced with the detection accuracy of the sensor being improved.

Owner:HITACHI LTD +1

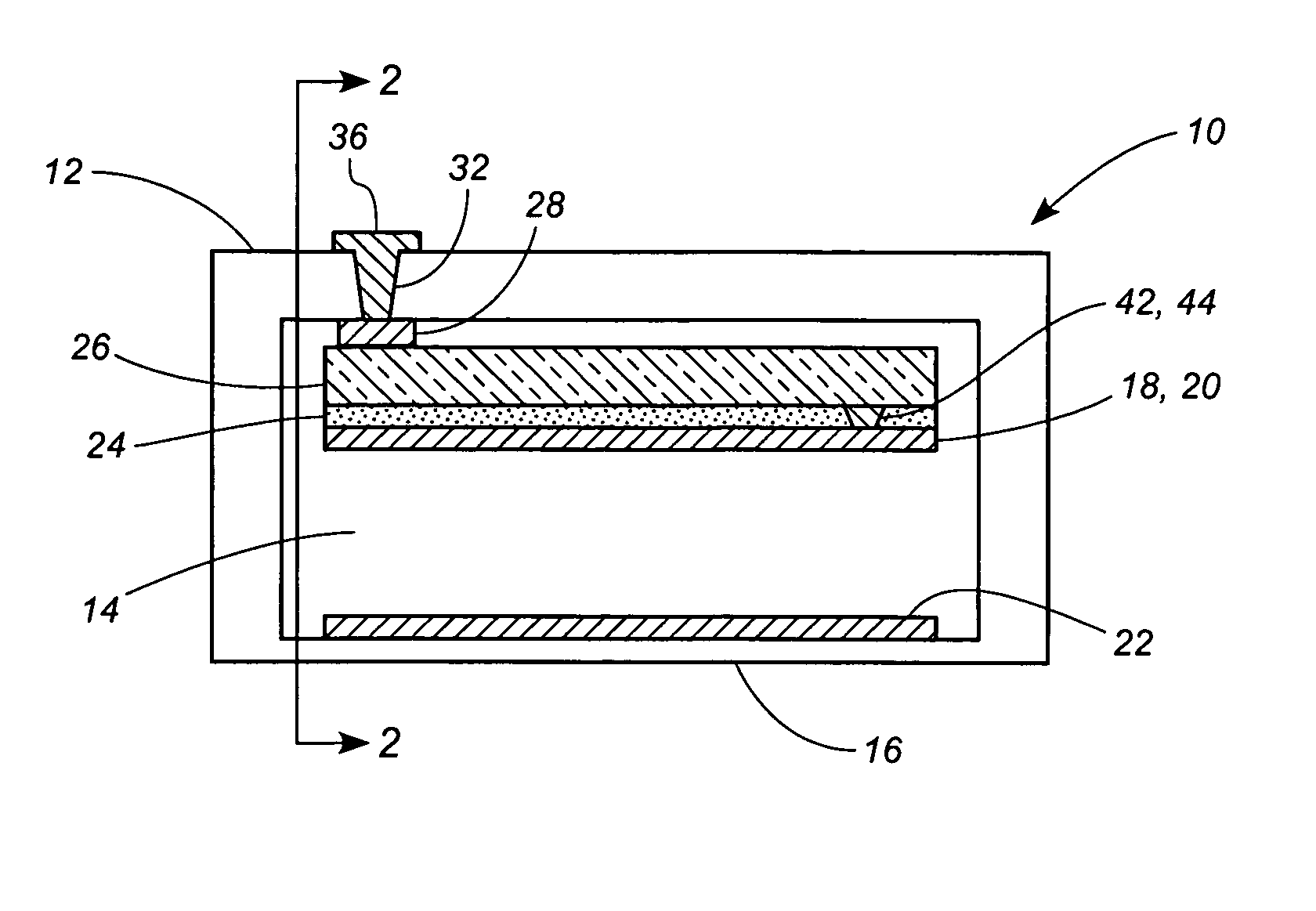

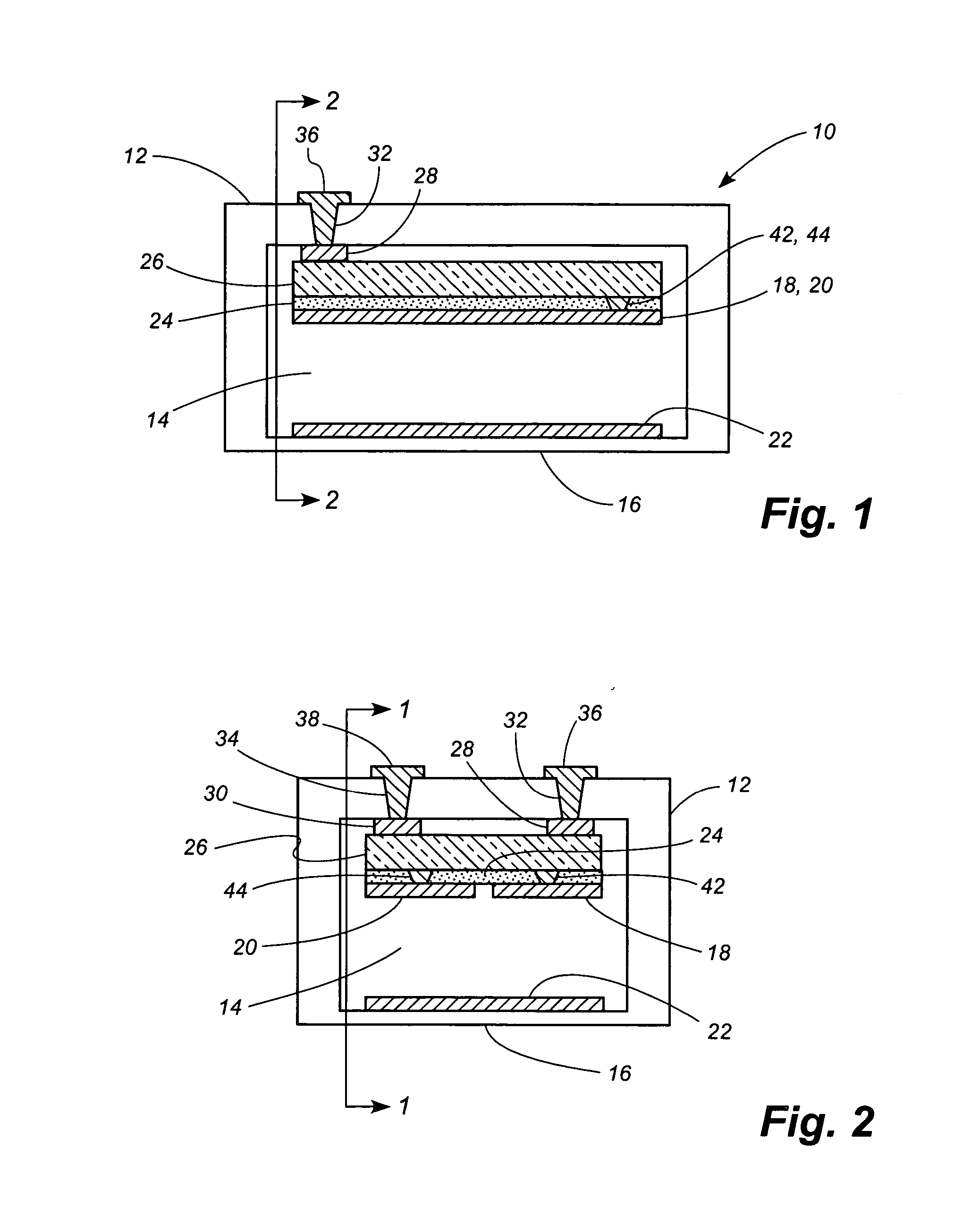

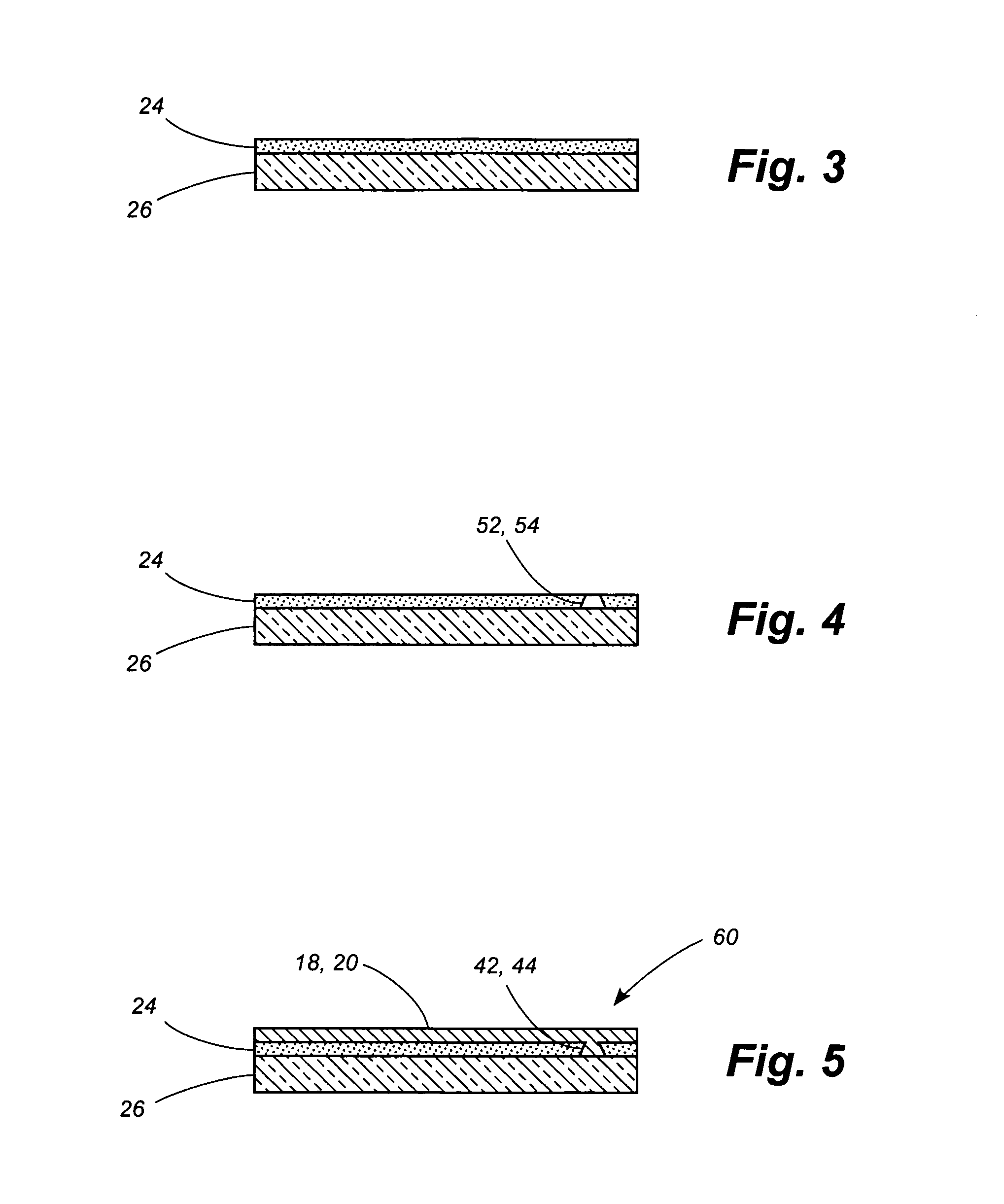

Capacitive sensor

ActiveUS7353711B2Simple designReduce manufacturing costSolid-state devicesMachines/enginesHermetic sealCapacitive sensing

A capacitive sensor including a housing having a hermetically sealed cavity, a plate in the cavity, a diaphragm forming a part of the cavity and spaced from the plate, a conductive layer on the first diaphragm, and a second conductive layer on the plate, the first and second conductive layers being the electrodes of a capacitor whose capacitance varies with the position of the diaphragm relative to the plate.

Owner:ANALOG DEVICES INC

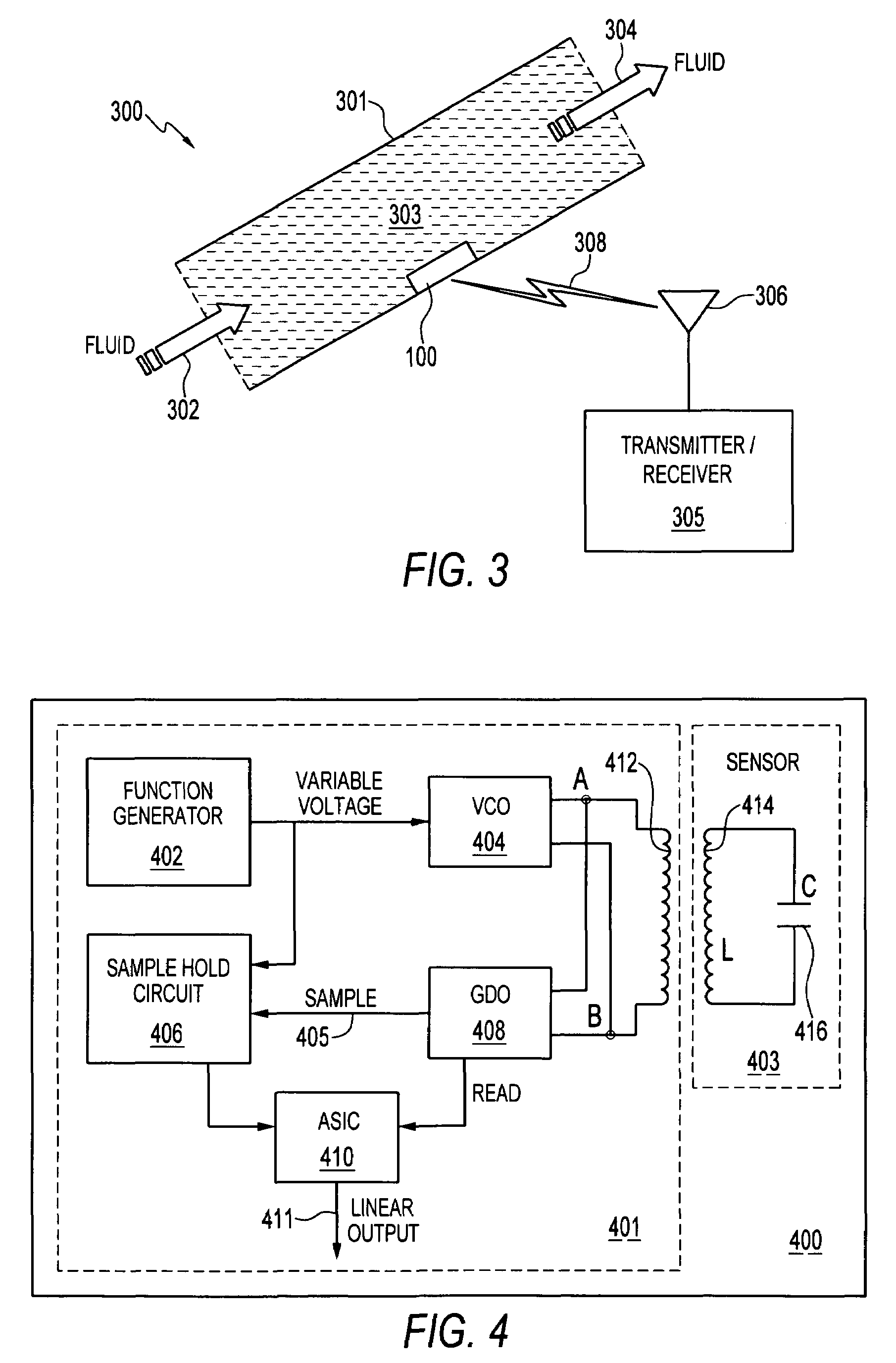

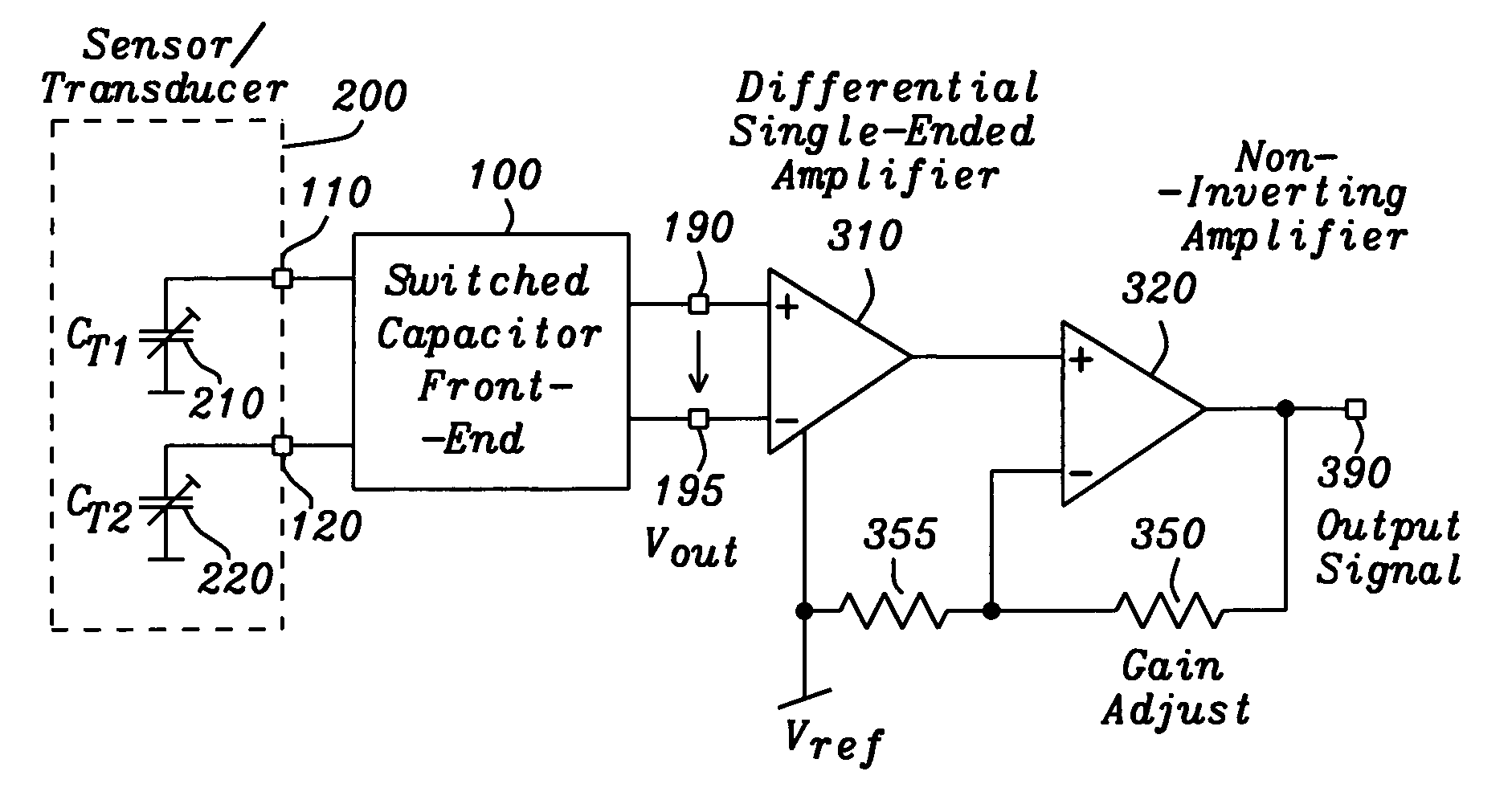

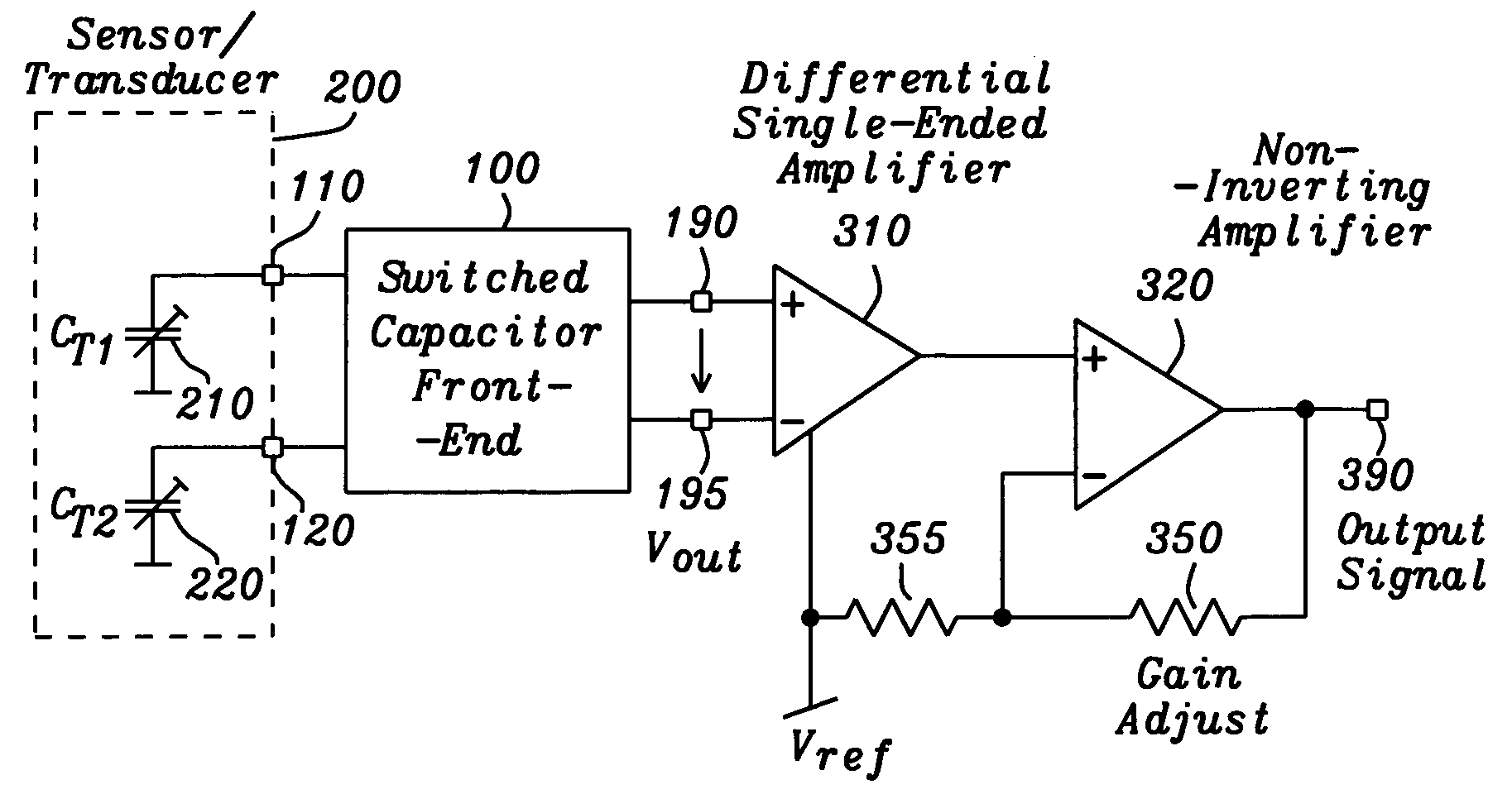

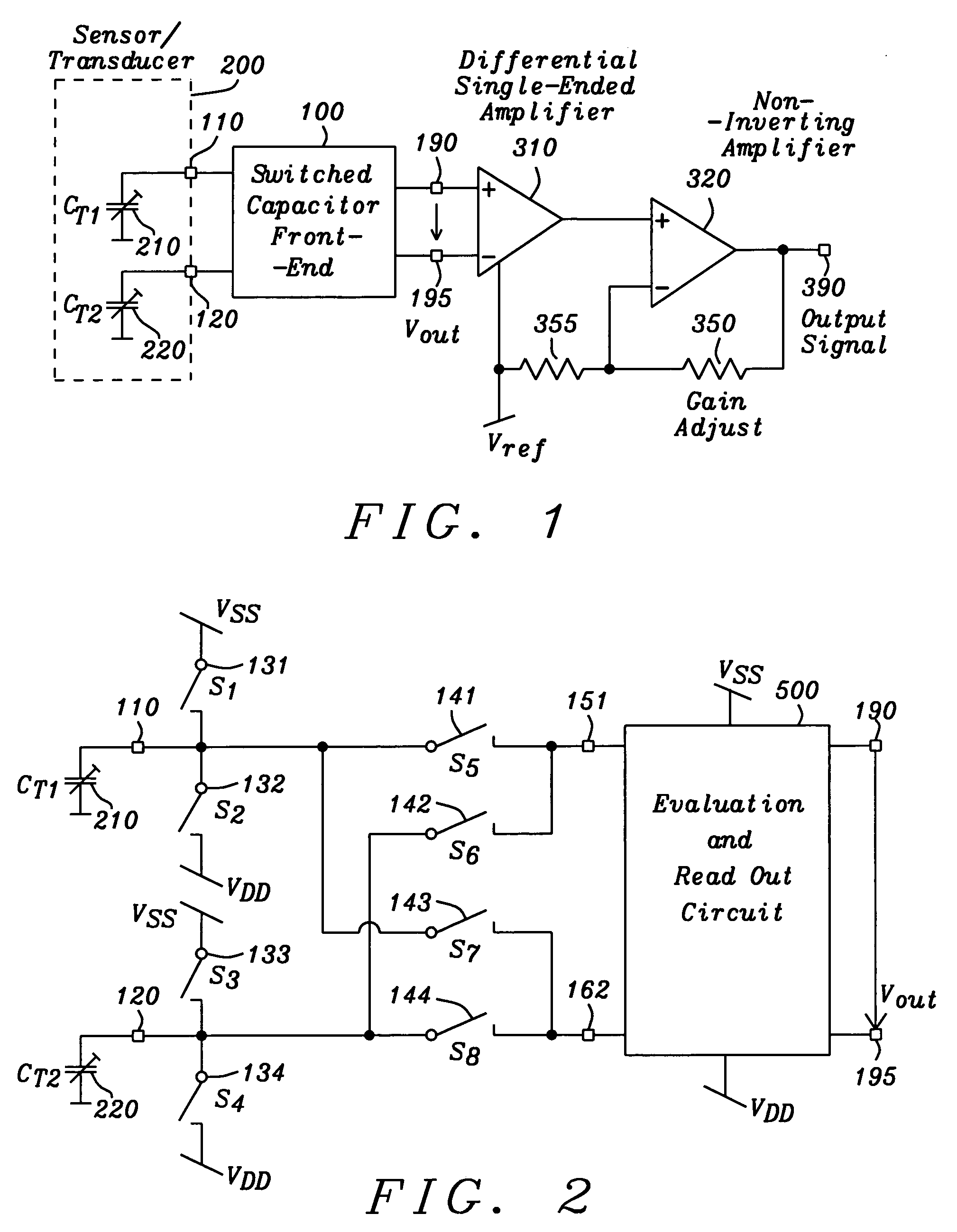

Differential capacitance measurement

InactiveUS20050134292A1Efficient methodPrecise and sensitive and yet stable evalutionCapacitance measurementsConverting sensor output electrically/magneticallyCMOSSoi cmos technology

A circuit and method are given, which realizes a stable yet sensitive differential capacitance measuring device with good RF-suppression and with very acceptable noise features for use in capacitive sensor evaluation systems. By evaluating the difference of capacitor values only—with the help of a switched capacitor front-end—large spreads of transducer capacitor values are tolerable. Furthermore a mode of operation can be set up, where no essential galvanic connection between sensor input and the active read-out input at any given time is existing. The solution found exhibits a highly symmetrical construction. Using the intrinsic advantages of that solution the circuit of the invention is manufactured as an integrated circuit with standard CMOS technology at low cost.

Owner:DIALOG SEMICONDUCTOR GMBH

Flexible piezocapacitive and piezoresistive force and pressure sensors

InactiveUS8904876B2Facilitate measuring and mapping forcesFluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsCapacitanceDielectric

Owner:PATIENTECH LLC

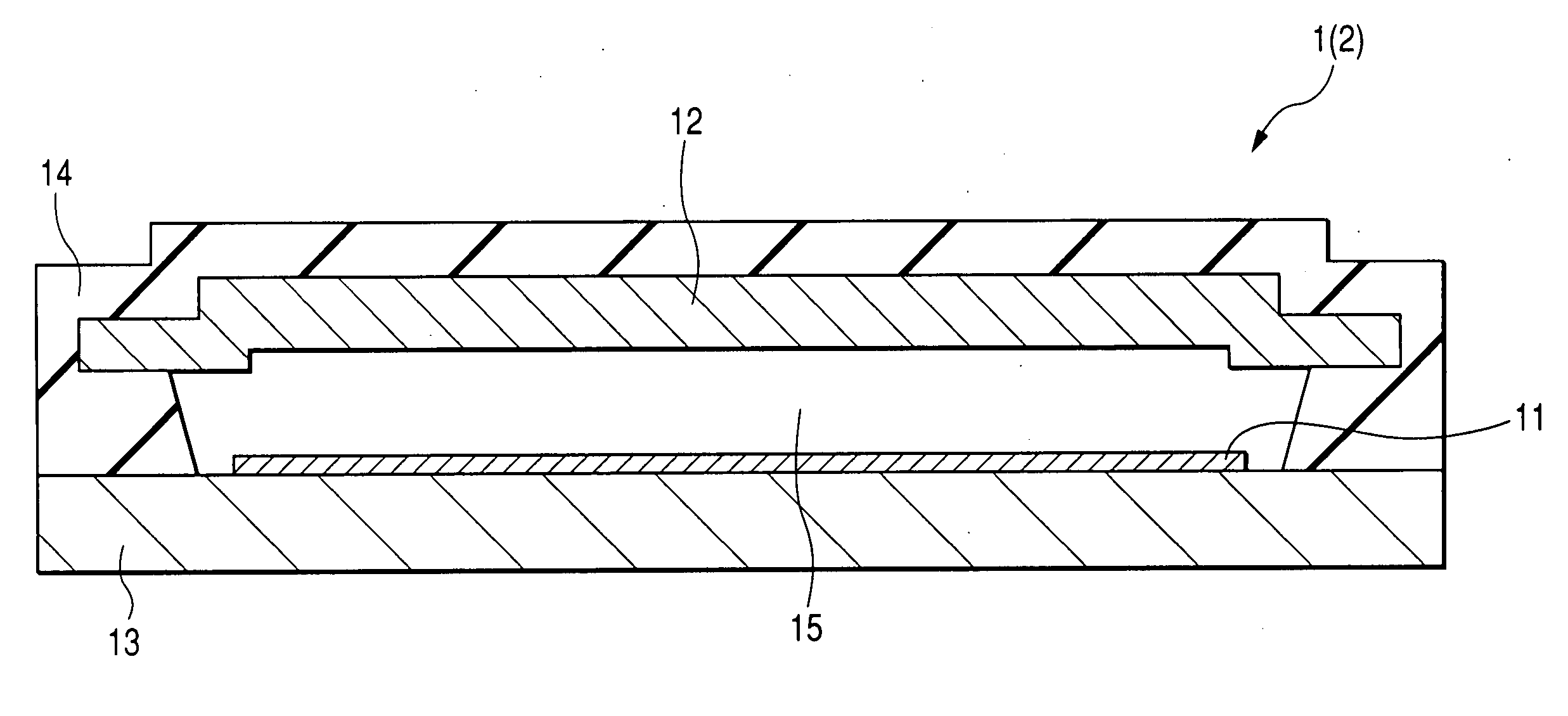

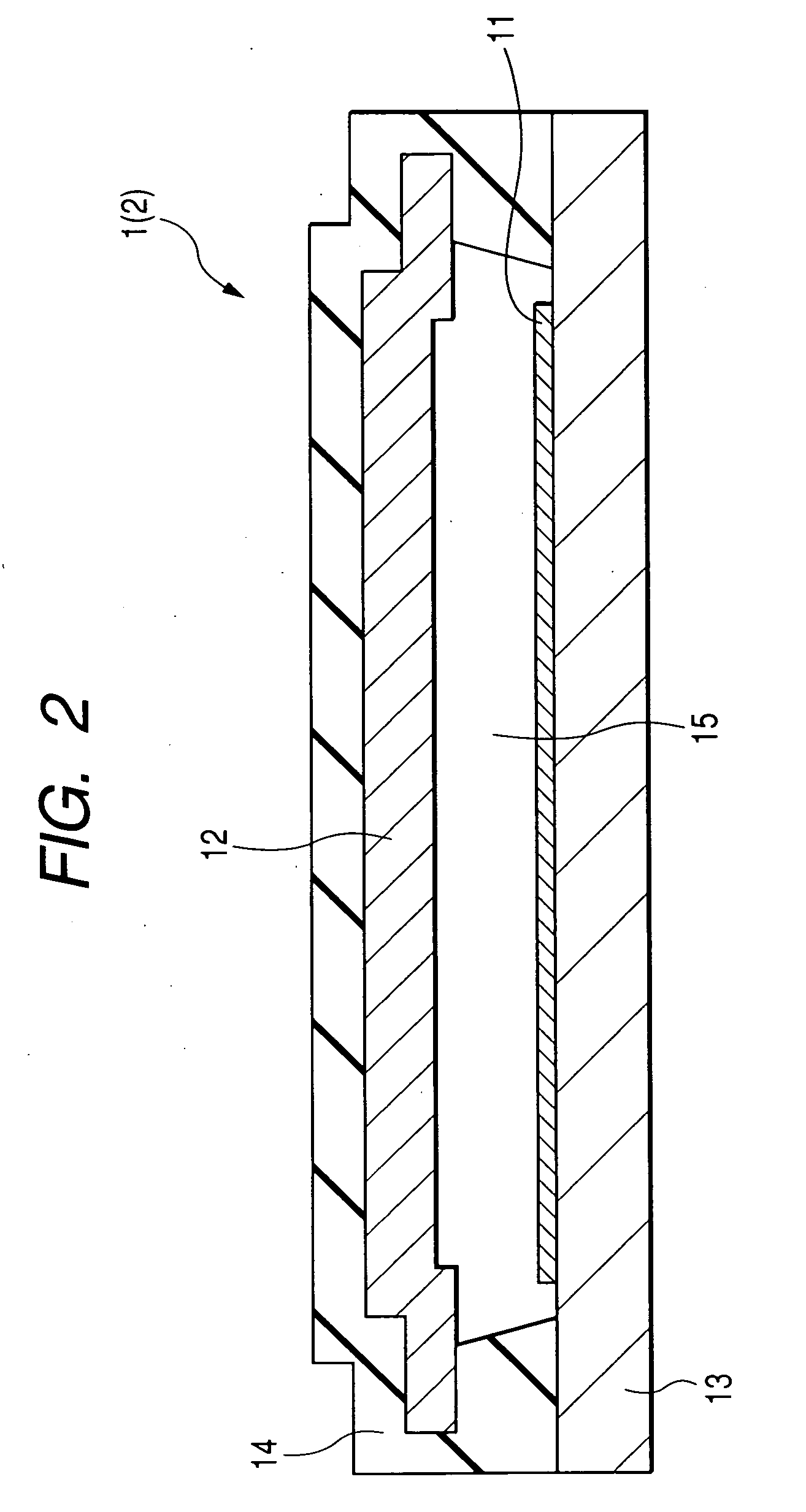

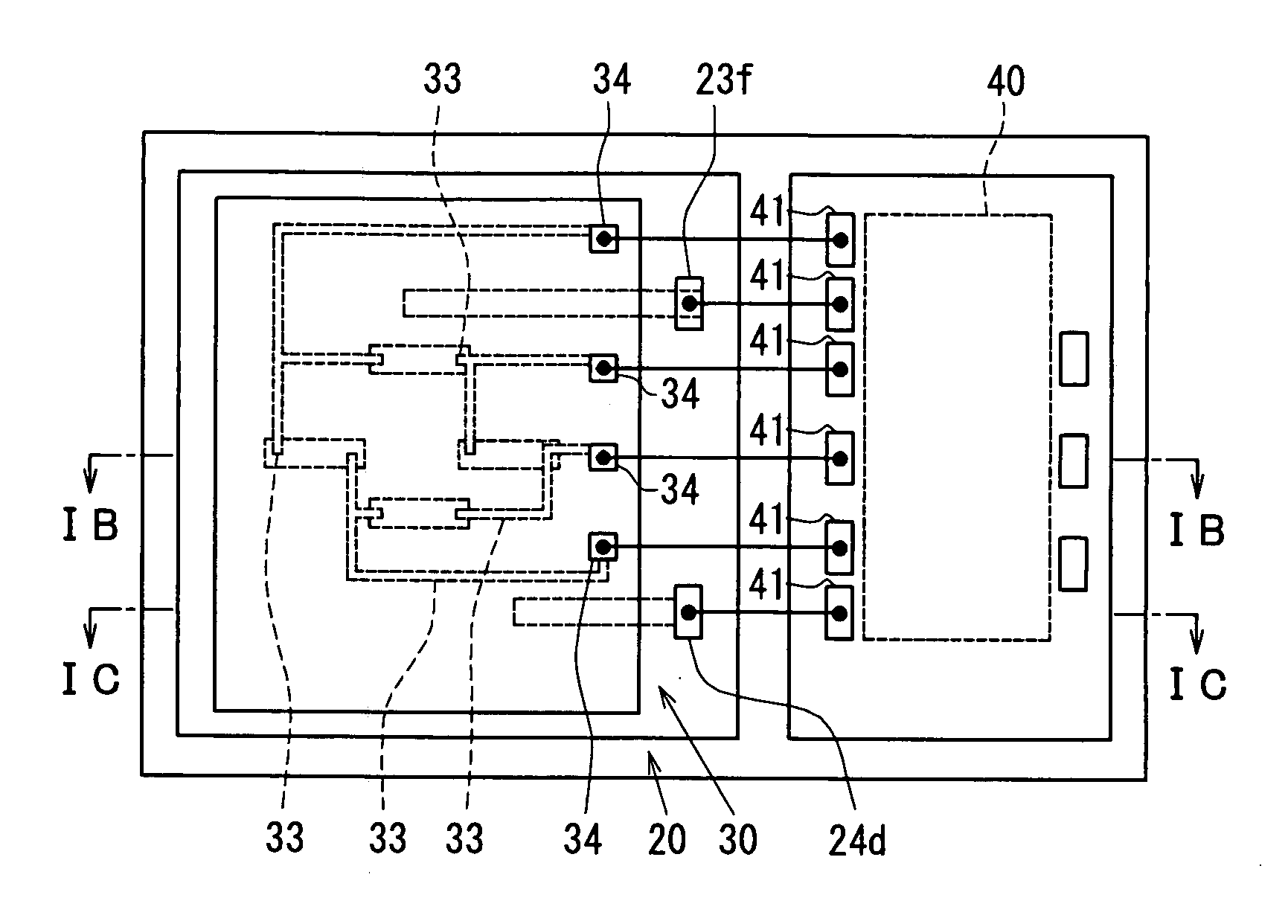

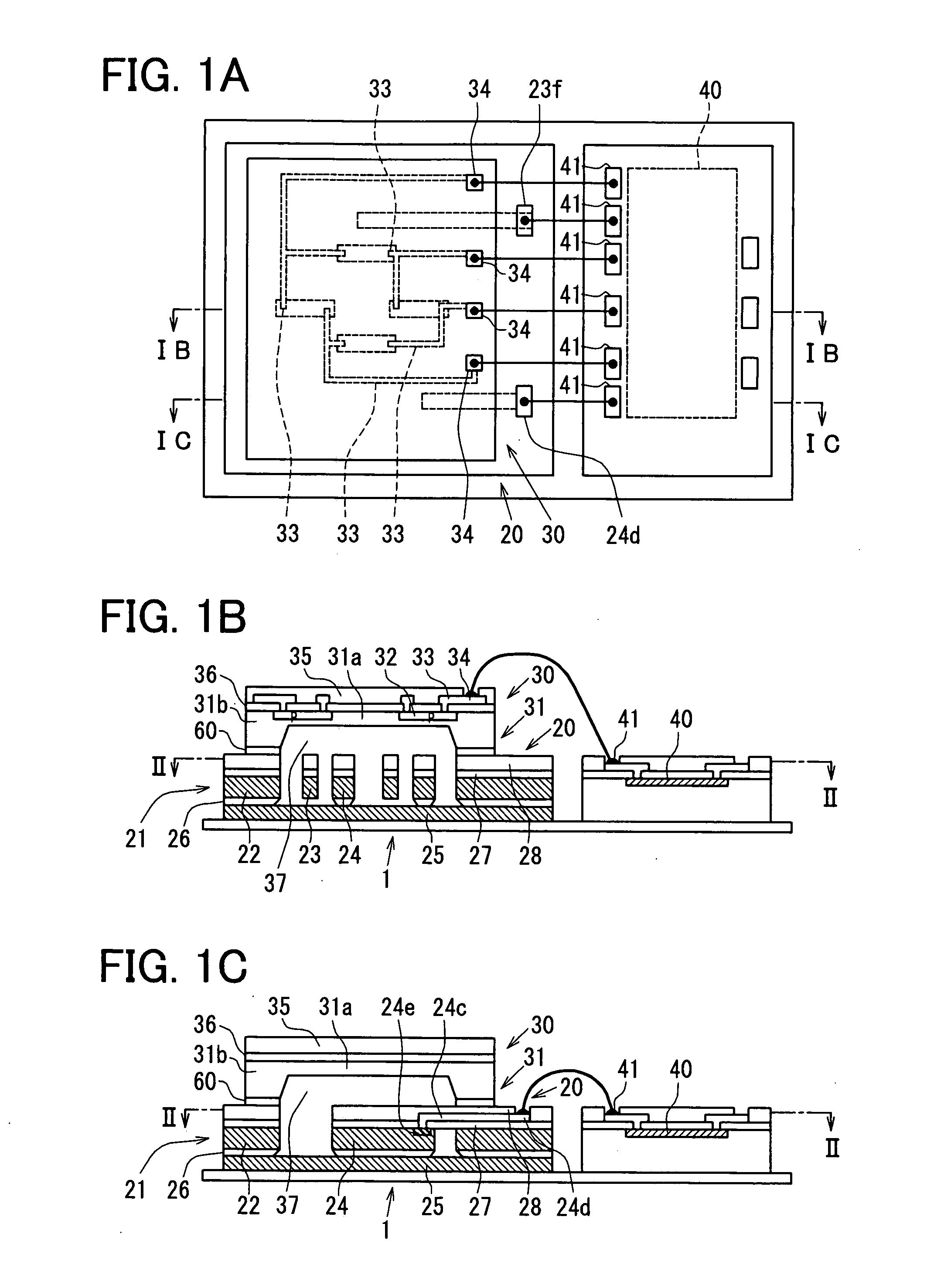

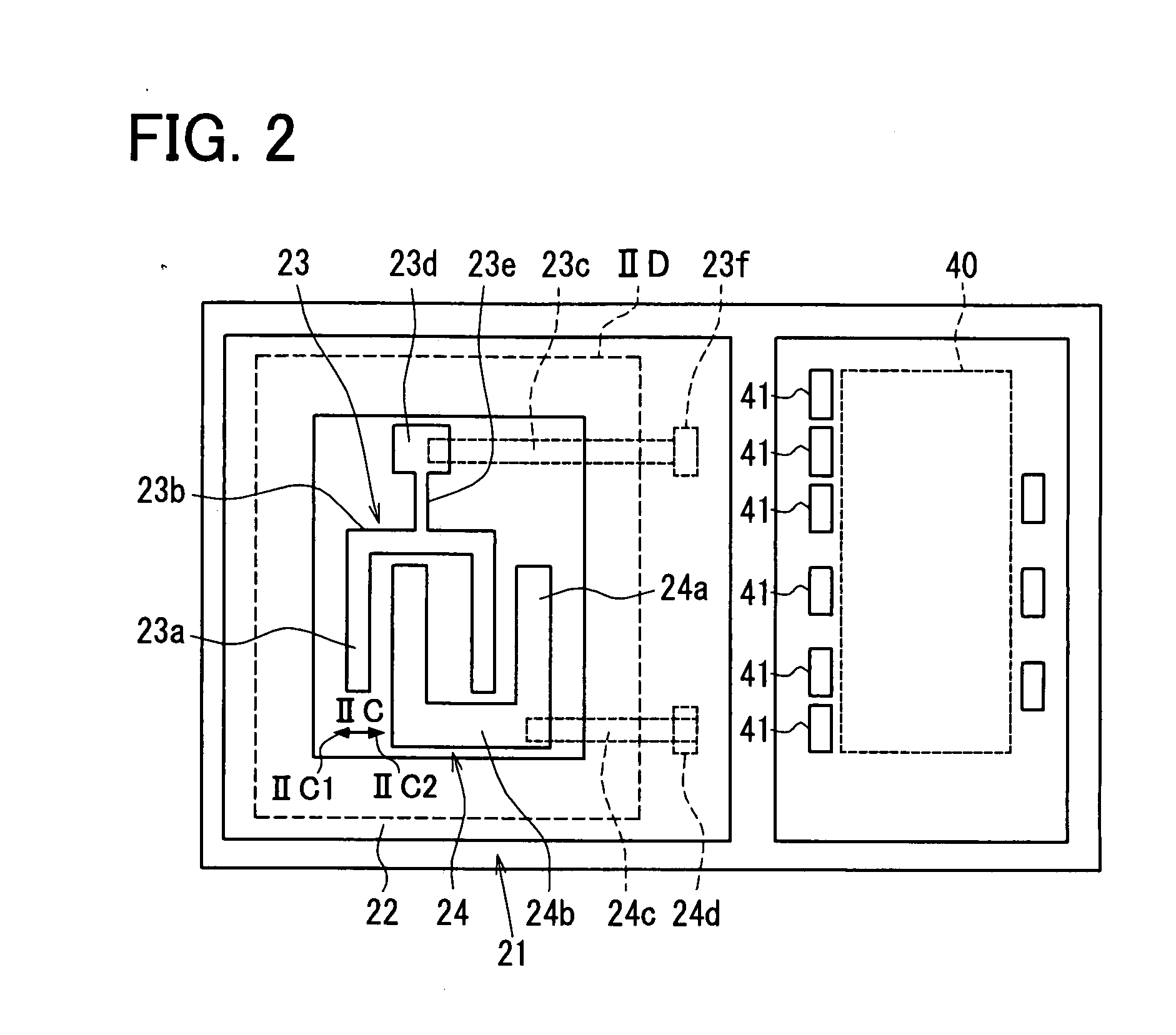

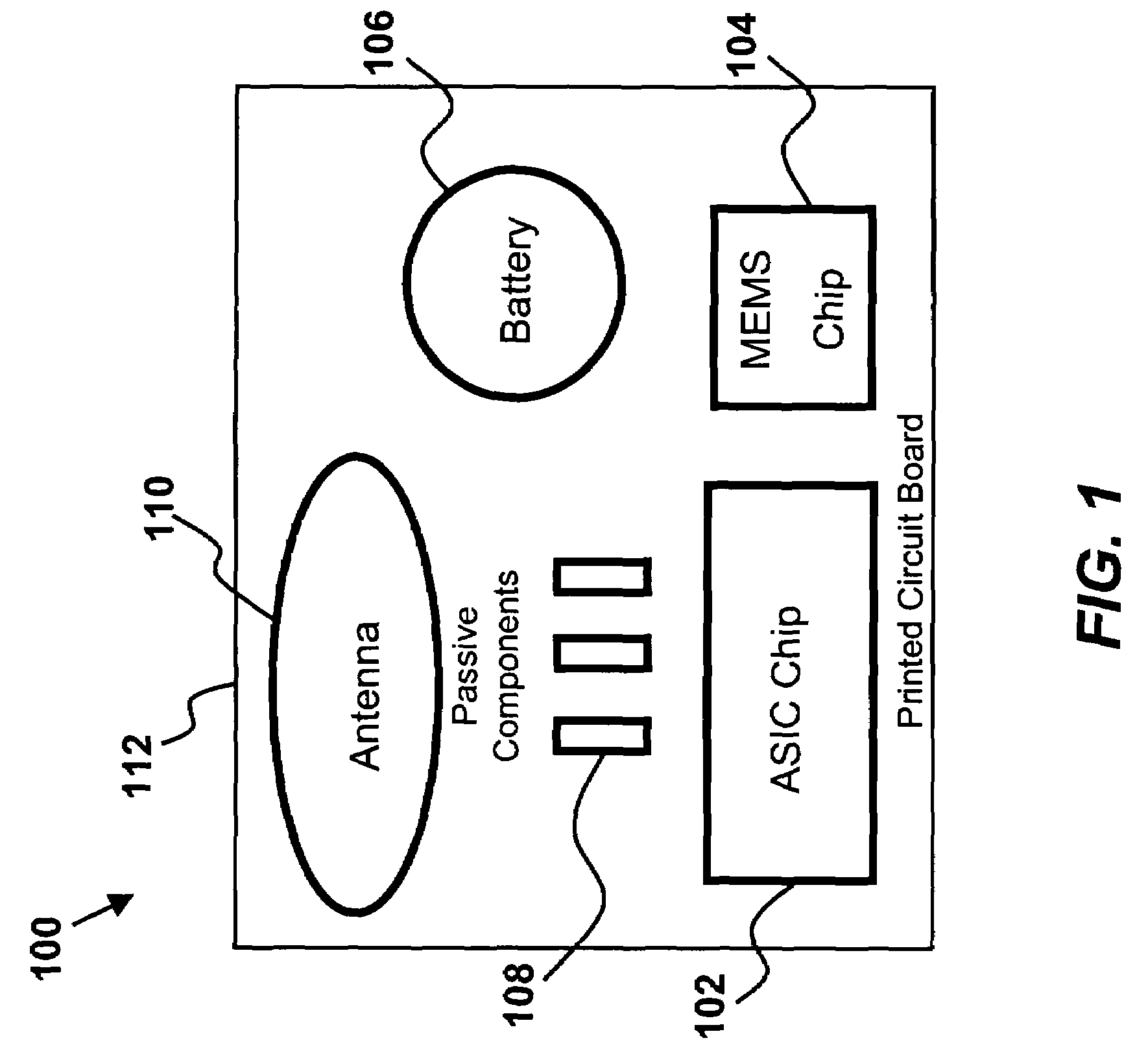

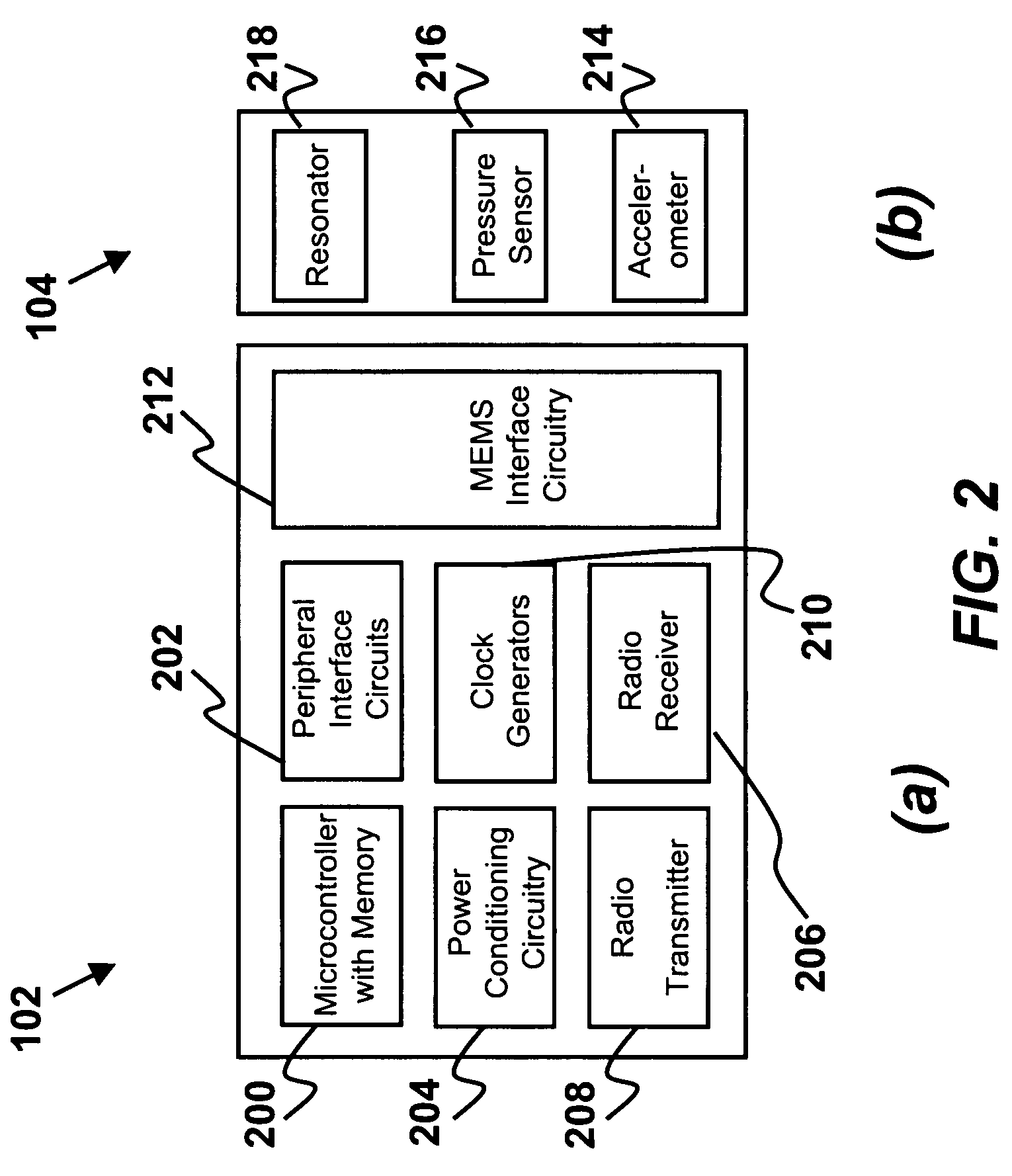

Sensor and sensor module

InactiveUS20070068266A1Solve the large power consumptionImprove reliabilityTyre measurementsConverting sensor outputControl signalEngineering

A sensor and sensor module with small power consumption and high reliability are disclosed. The sensor includes a capacitor having a capacitance varying with a physical quantity, a capacitance-voltage conversion circuit for converting the capacitance of the capacitor into a voltage, and a control signal generation circuit for generating a plurality of control signals. The capacitor has a frequency-capacitance characteristic with a resonant frequency. In a measurement of the physical quantity, the capacitance of the capacitor is measured with one of the control signals having a first frequency which is much higher or much lower than the resonant frequency. In a self-diagnosis of the sensor, the capacitance of the capacitor is measured with another one of the control signals having a second frequency which is equal or close to the resonant frequency.

Owner:HITACHI LTD

Capacitive type pressure sensor

InactiveUS6877383B2Avoid problemsHigh sensitivityFluid pressure measurement using capacitance variationCapacitive pressure sensorEngineering

By sealing a diaphragm with less processes and lower cost and reducing deformation due to remaining stress, a stable and highly reliable pressure sensor construction is proposed. The pressure sensor is low in measurement error and small in floating capacitance and leakage current and good in characteristic. As a means to attain the above object, a polycrystalline silicon diaphragm is sealed with a silicon oxide film deposited through a LPCVD method and then completely covered. The diaphragm is placed on a surface of a semiconductor substrate with a nearly constant gap of 0.15 to 1.3 μm, and has difference-in-grade constructions of a deformation reducing means due to remaining stress.

Owner:HITACHI LTD +1

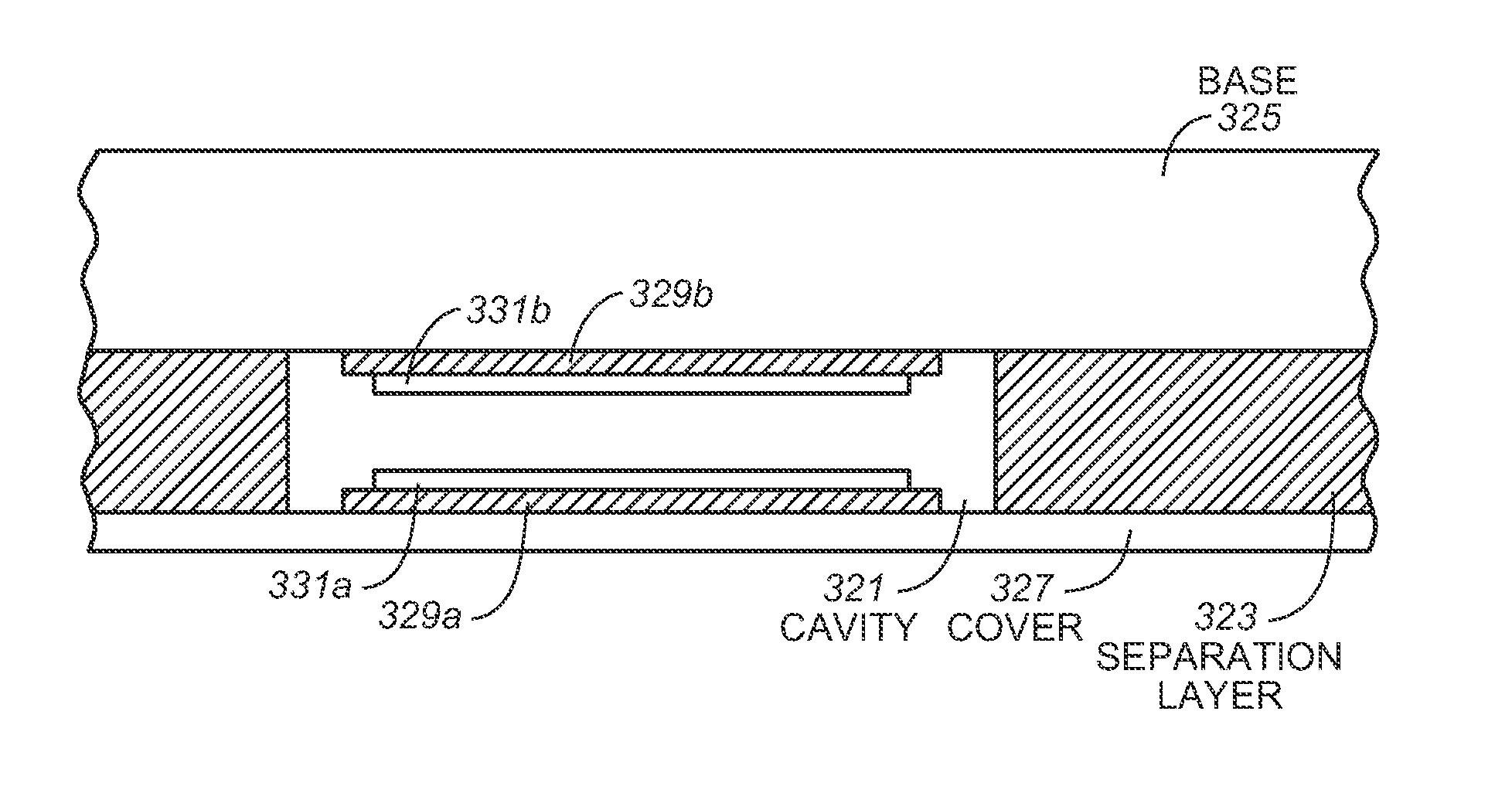

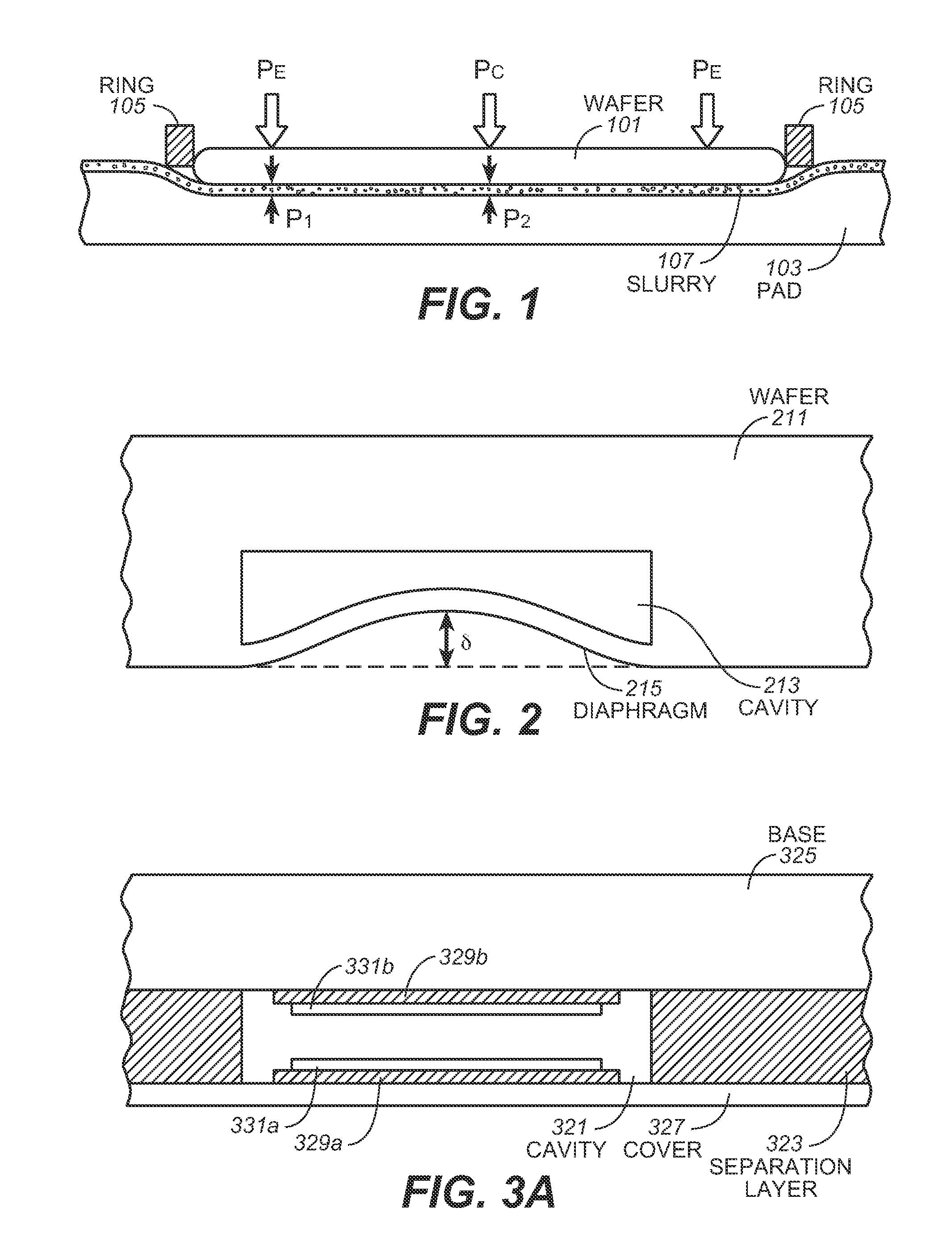

Pressure Sensing Device

ActiveUS20080087069A1Great frictional forceMechanical abrasionForce measurementUsing electrical meansCapacitanceCapacitive coupling

At least one pair of capacitively coupled electrodes contained in a structure is used to sense the deflection of a diaphragm in a pressure or force sensor for measuring the pressure or force exerted on the diaphragm. Preferably the structure has properties (such as one or more of the following: dimensions, hardness, area and flexibility) that are substantially the same as those of a real substrate, such as a semiconductor wafer or flat panel display panel.

Owner:KLA TENCOR TECH CORP

Capacitor electrode formed on surface of integrated circuit chip

A sensor has a sensor housing defining a cavity therein. A first wall partially defining the cavity is deflectable under a physiologically relevant range of pressures. An integrated circuit chip bearing electronics is fixedly mounted within the cavity. A capacitor comprises first and second capacitor plates in generally parallel, spaced-apart relation. The first capacitor plate is physically coupled to the deflectable wall so as to move as the wall deflects, and the second capacitor plate is carried by the chip. The second capacitor plate is in electrical communication with the input pad of the chip.

Owner:CARDIOMEMS

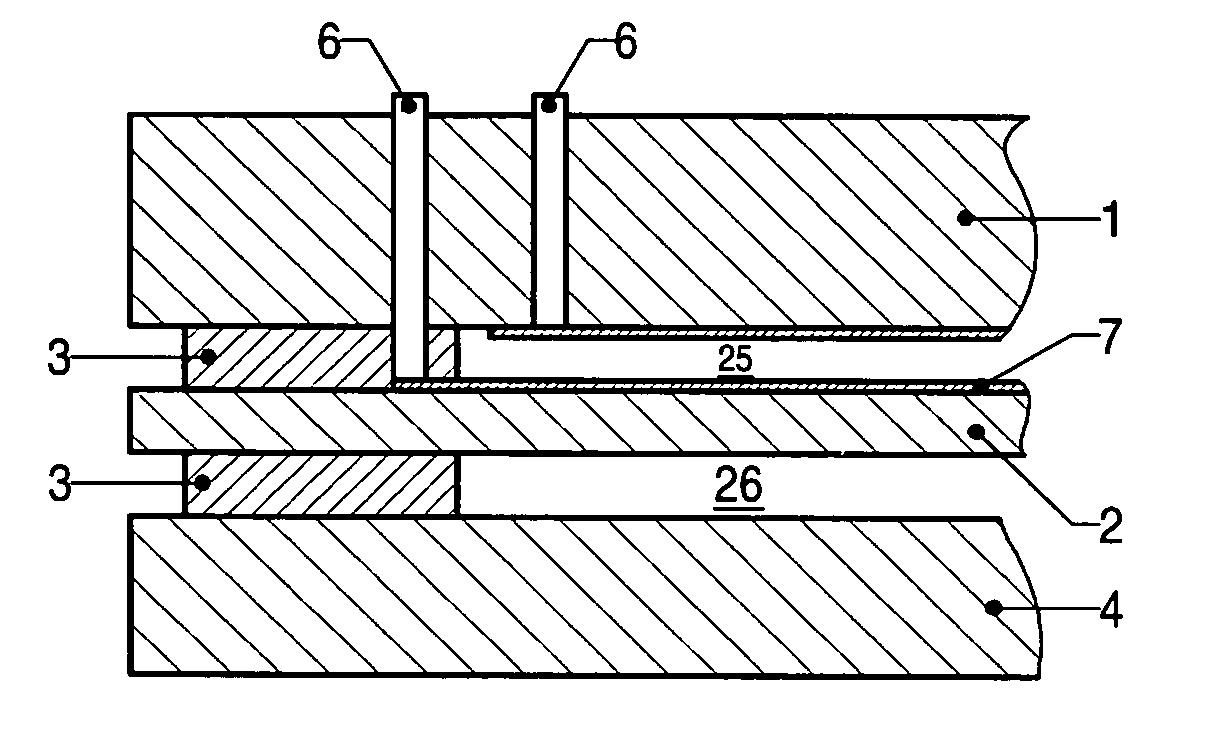

Physical quantity sensor

InactiveUS20080030205A1Easy retrievalLow wireResistance/reactance/impedenceForce measurementEngineeringPhysical quantity

A physical quantity sensor for detecting a physical quantity includes: a first substrate having a first physical quantity detection element; a second substrate having a second physical quantity detection element, wherein the second substrate contacts the first substrate; and an accommodation space disposed between the first substrate and the second substrate. The first physical quantity detection element is disposed in the accommodation space. The first physical quantity detection element is protected with the first substrate and the second substrate since the first physical quantity detection element is sealed in the accommodation space.

Owner:DENSO CORP

Optical interferometric pressure sensor

InactiveUS20070089524A1Raise the gradeFluid pressure measurement by mechanical elementsFluid pressure measurement by optical meansOptical reflectionEngineering

A capacitive vacuum measuring cell has a first housing body and a membrane, both of Al2O3 ceramic or sapphire. The membrane is planar with a peripheral edge joined by a first seal to the first housing body to form a reference vacuum chamber. A second housing body of Al2O3 ceramic or sapphire opposite the membrane, is joined to the peripheral edge of the membrane by a second seal to form a measurement vacuum chamber. A port connects the vacuum measuring cell to a medium to be measured. At least in the central area of the first housing body, an optical transparent window is formed and at least the central region of the membrane has an optically reflective surface. Outside the reference vacuum chamber, in opposition to and at a distance from the window, an optical fibre is arranged for feeding in and out light onto the surface of the membrane.

Owner:INFICON GMBH

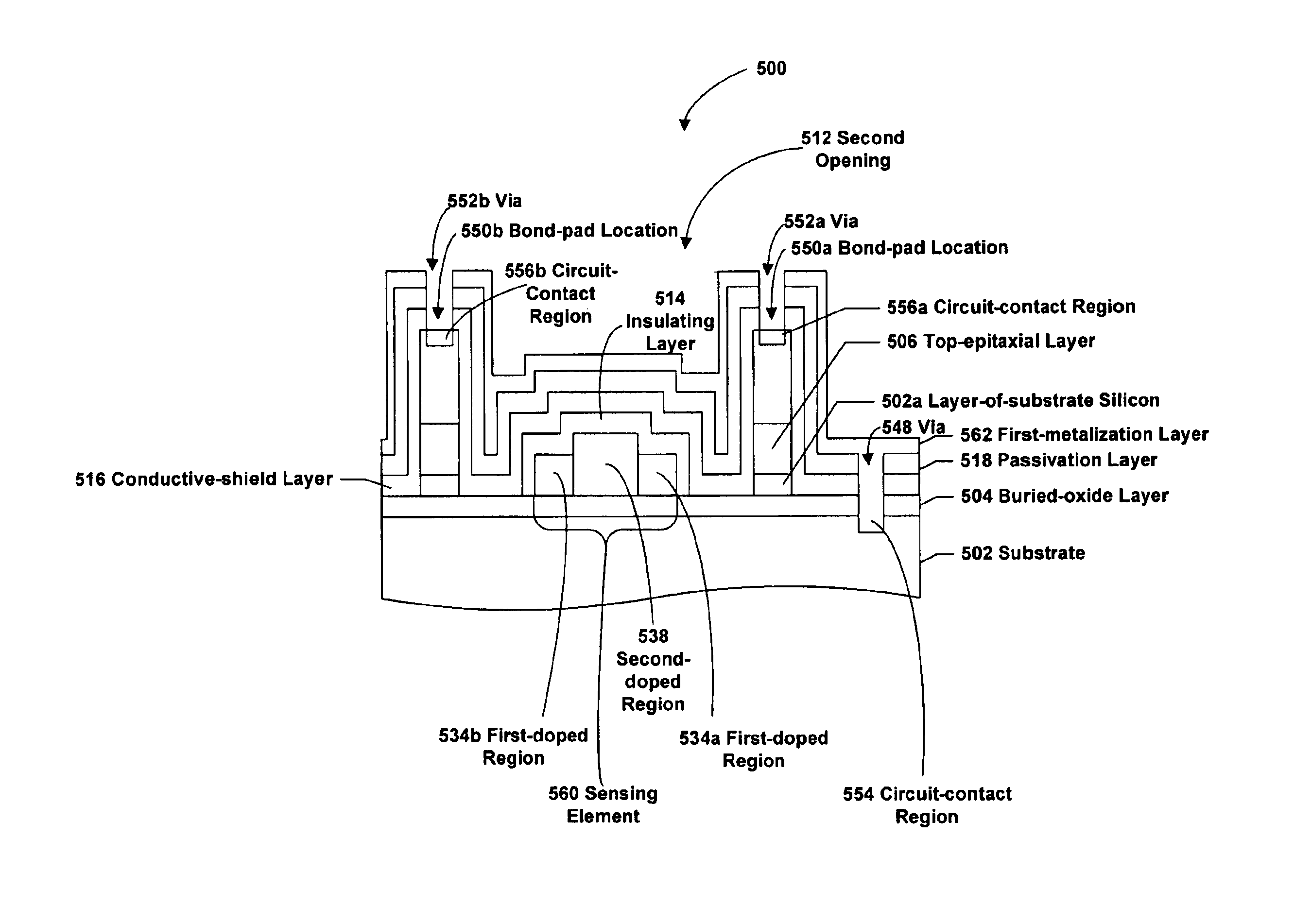

Microelectromechanical device with integrated conductive shield

InactiveUS6952042B2Television system detailsAcceleration measurement using interia forcesMicroelectromechanical systemsEngineering

A microelectromechanical device and method of fabricating the same, including a layer of patterned and deposited metal or mechanical-quality, doped polysilicon inserted between the appropriate device element layers, which provides a conductive layer to prevent the microelectromechanical device's output from drifting. The conductive layer may encapsulate of the device's sensing or active elements, or may selectively cover only certain of the device's elements. Further, coupling the metal or mechanical-quality, doped polysilicon to the same voltage source as the device's substrate contact may place the conductive layer at the voltage of the substrate, which may function as a Faraday shield, attracting undesired, migrating ions from interfering with the output of the device.

Owner:HONEYWELL INT INC

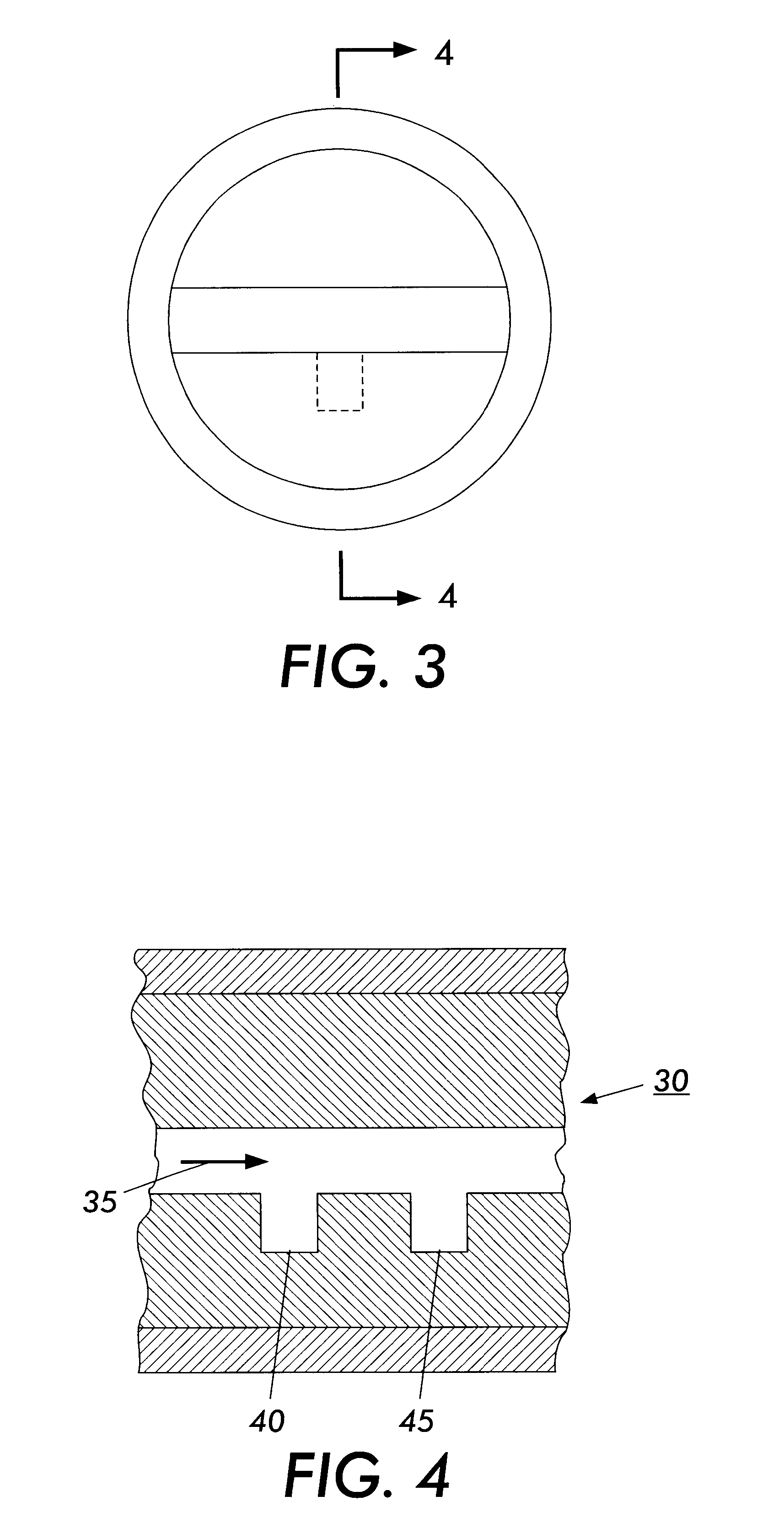

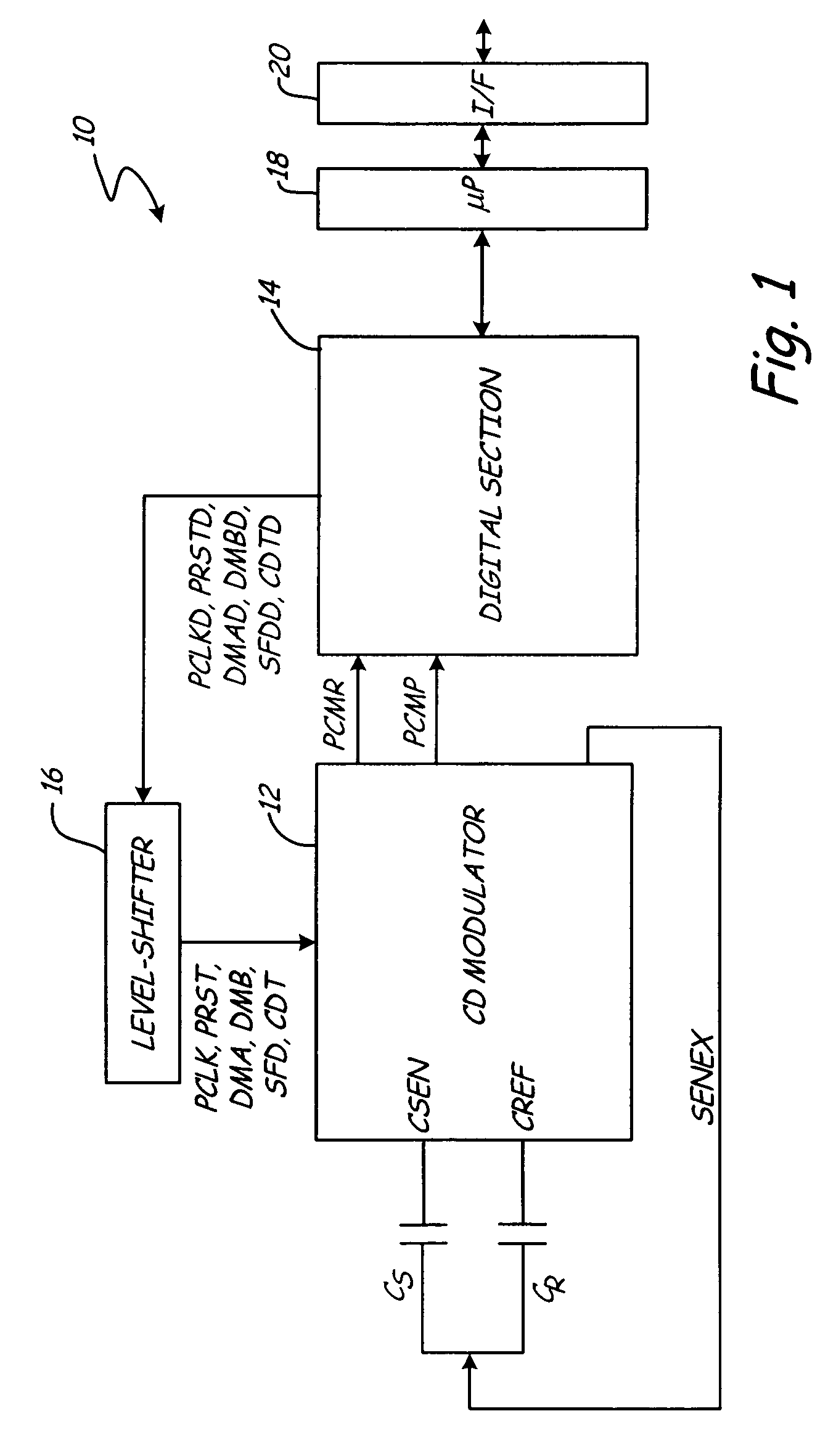

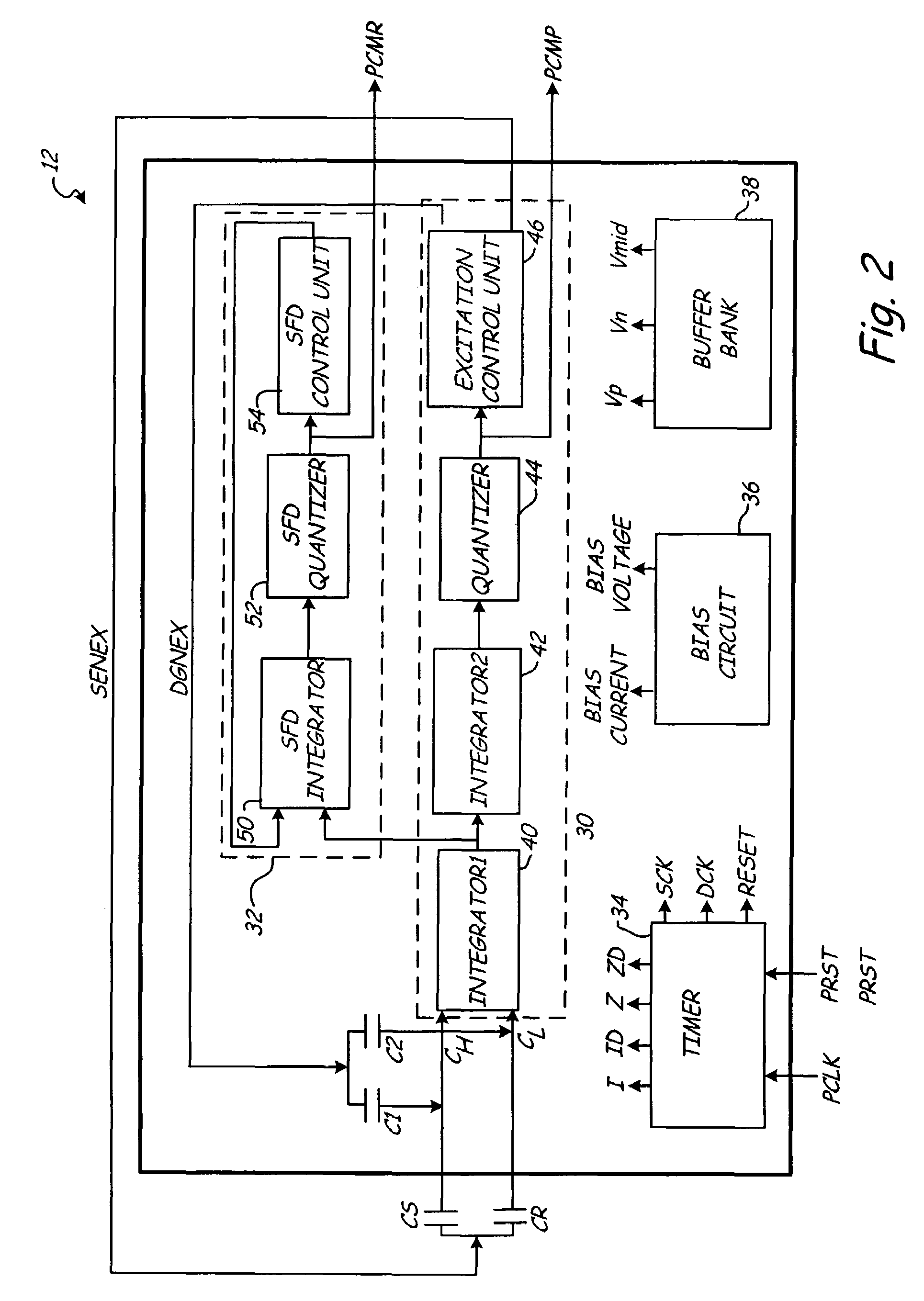

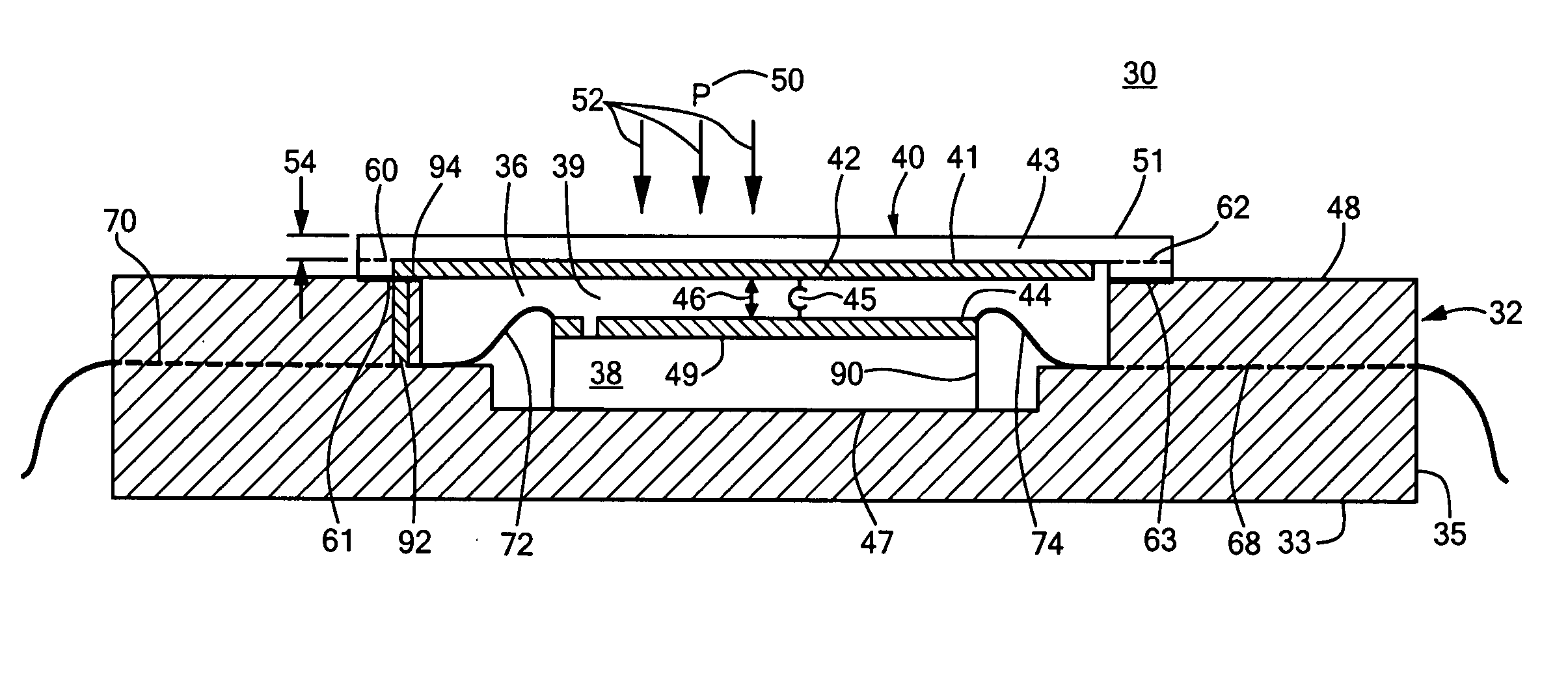

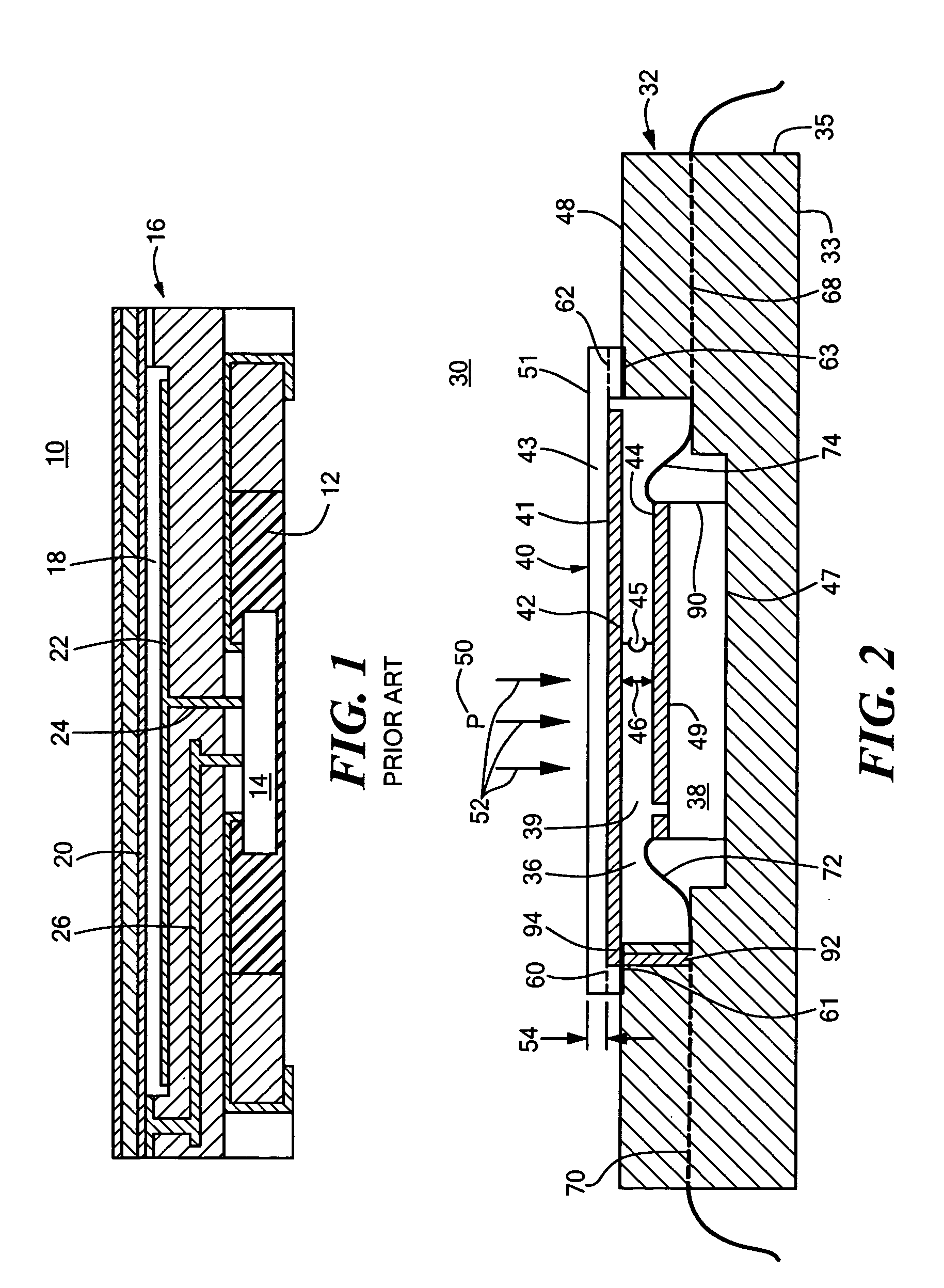

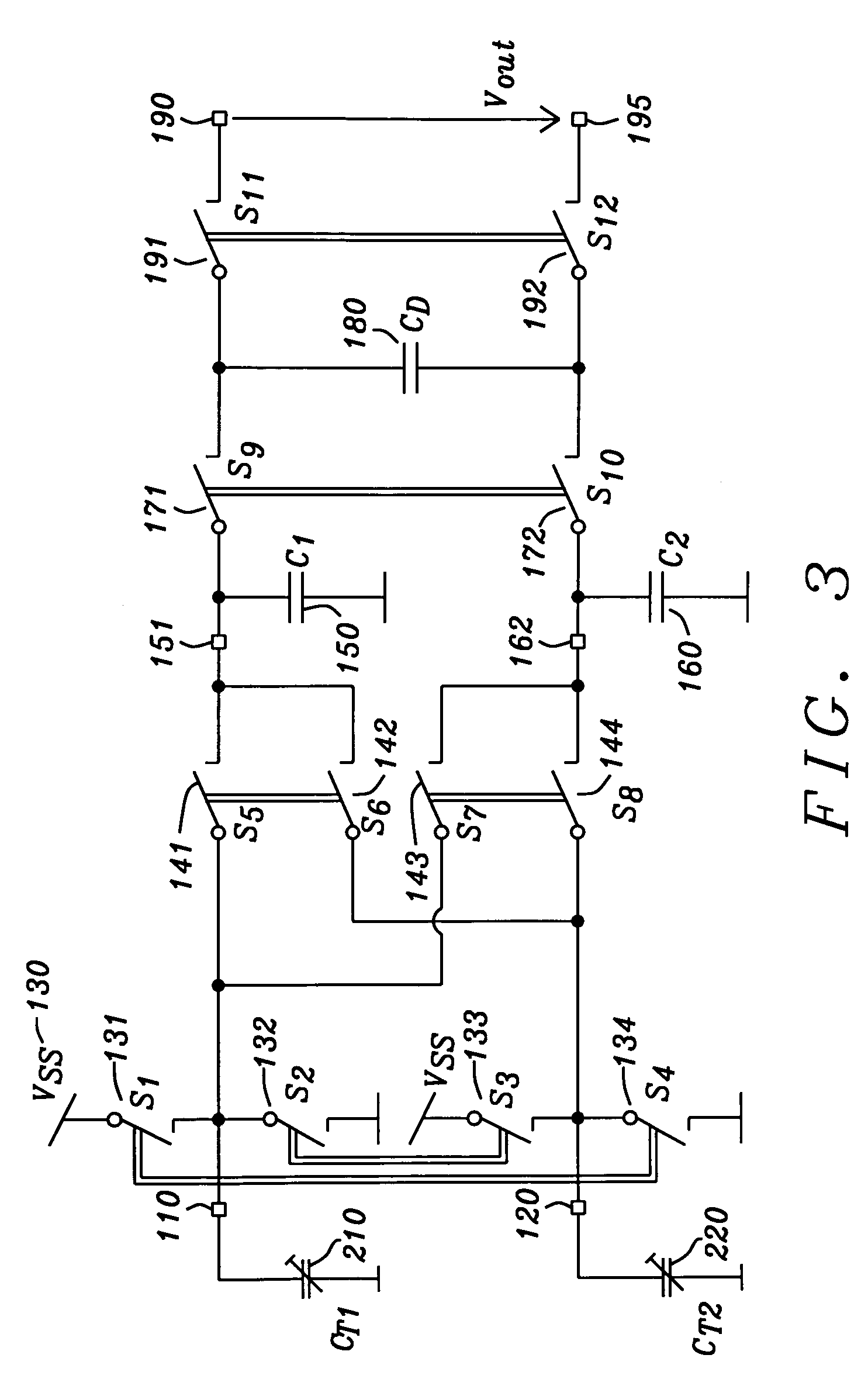

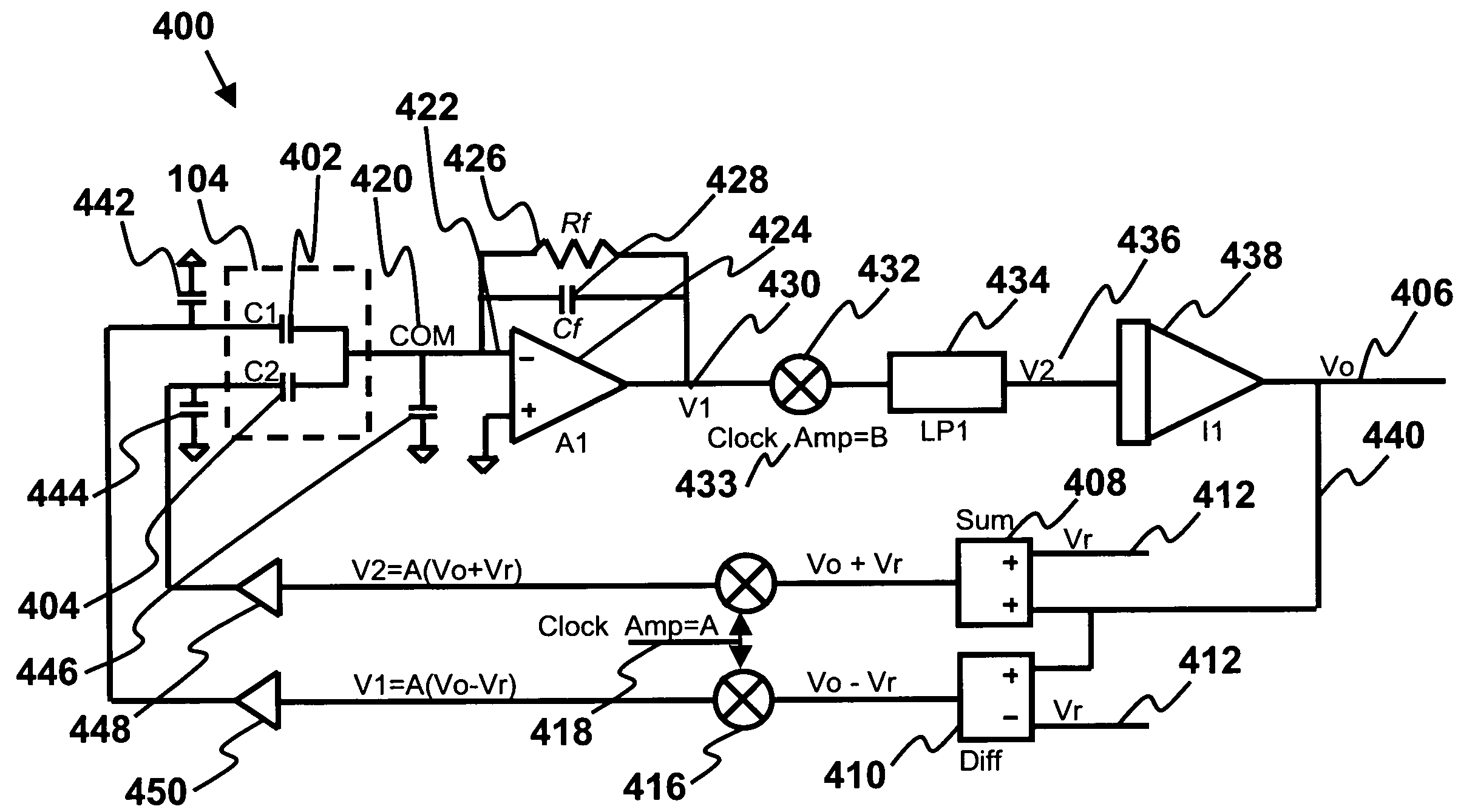

Signal conditioning methods and circuits for a capacitive sensing integrated tire pressure sensor

A tire pressure monitoring system is provided that includes a switched capacitor circuit having a clock with two non-overlapping clock phases that control a state of analog switches of the switched capacitor circuit. The system uses tire pressure sensor MEMS capacitors that are measured differentially. A capacitance-to-voltage converter is connected to the MEMS sense capacitor, and a sigma-delta converter having a comparator with a first digital output state and a second digital output state is used. The first output state is a sum of reference voltages and the second output state is a difference of the reference voltages. An average value of the capacitance-to-voltage converter output is driven to a zero value and a digital output is provided of the average output states that is equal to a difference between the MEMS capacitors divided by their sum multiplied by a ratio of the reference voltages.

Owner:SAMSUNG ELECTRONICS CO LTD

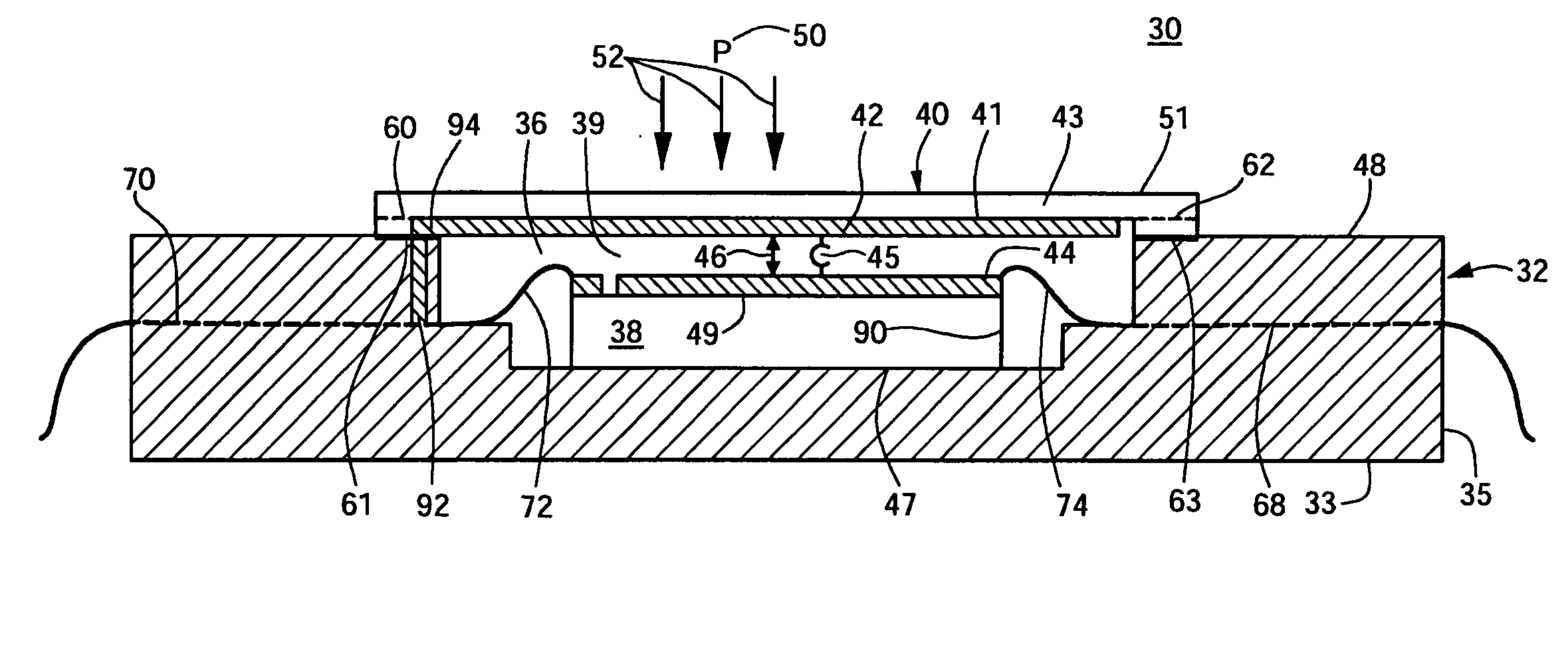

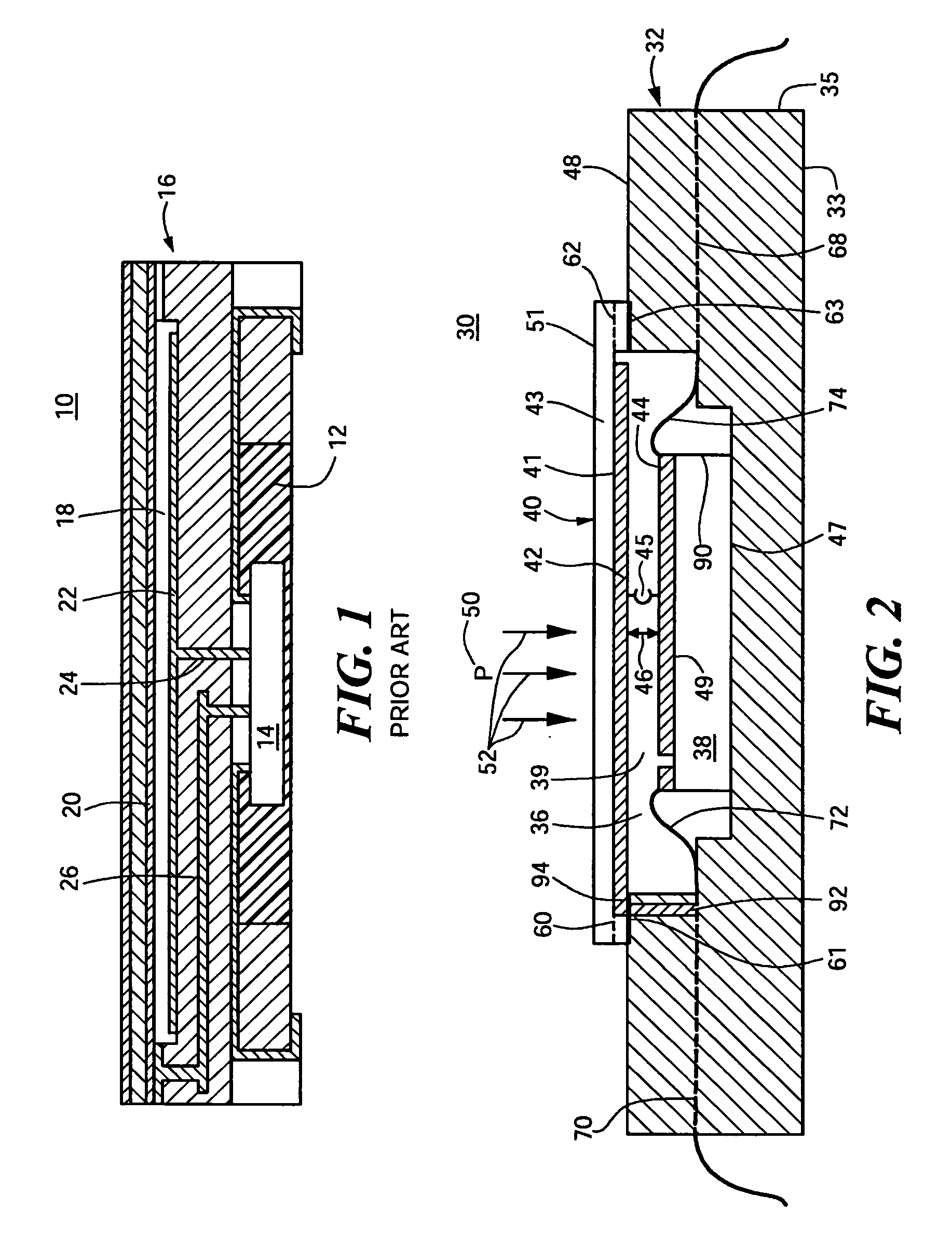

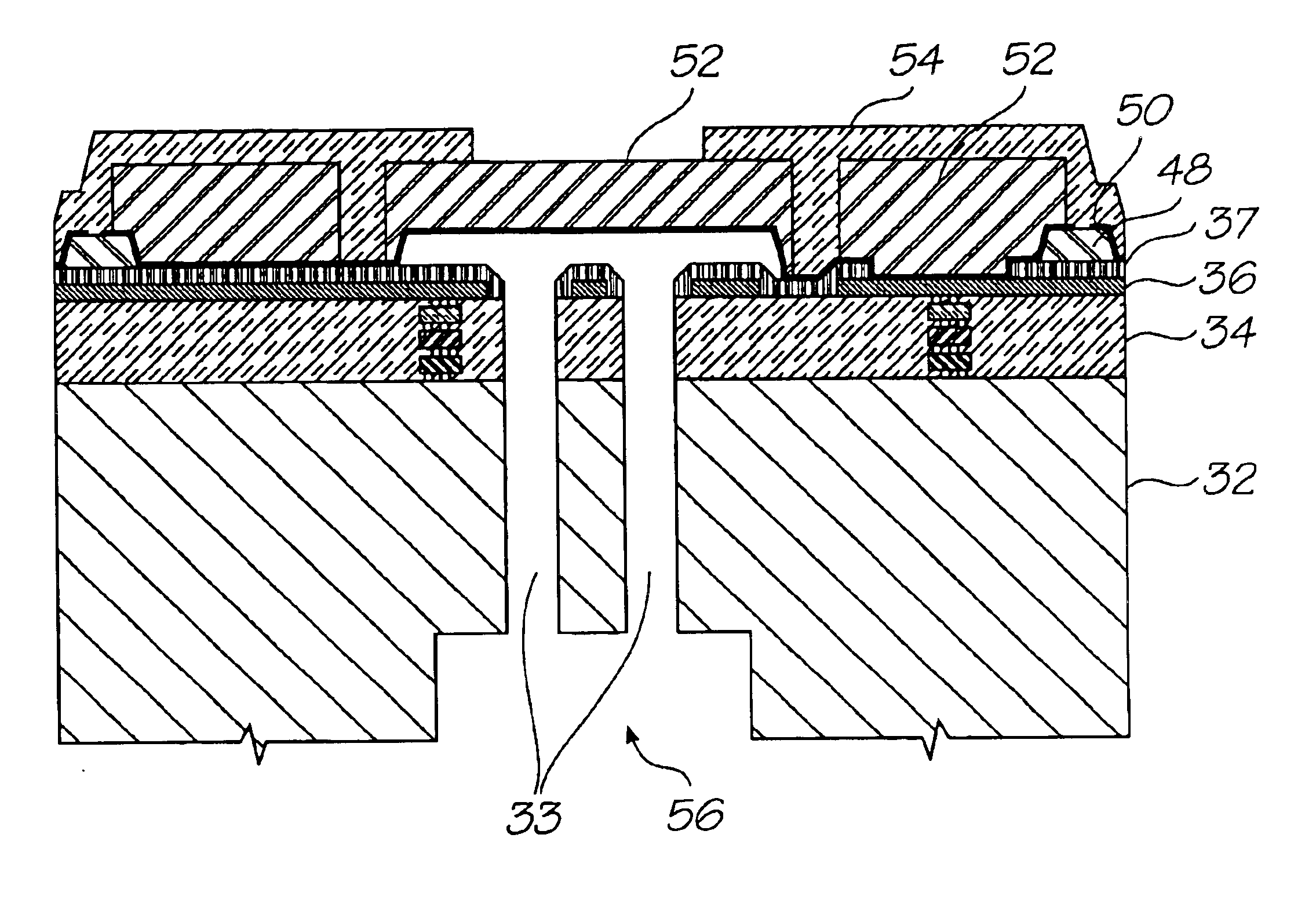

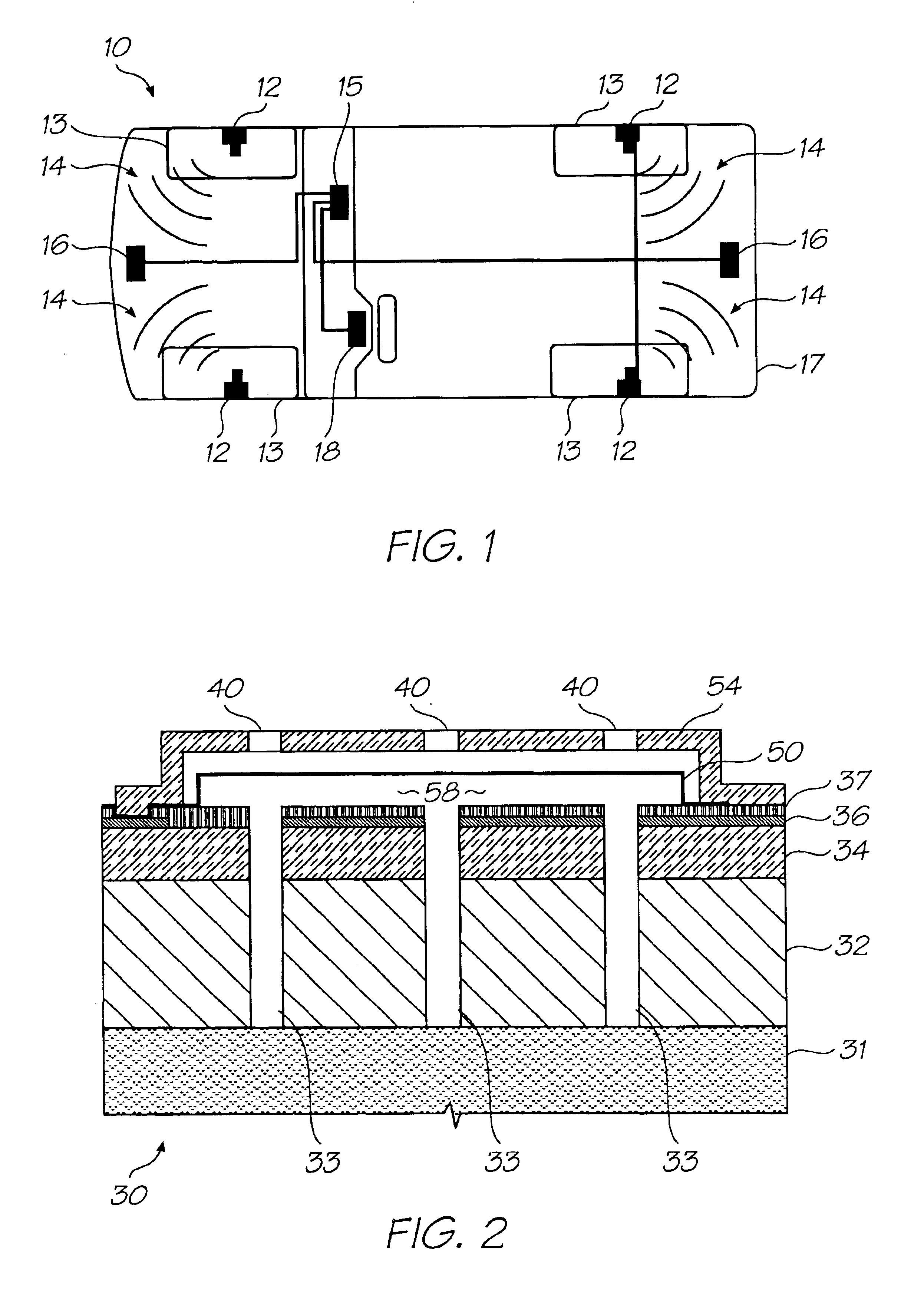

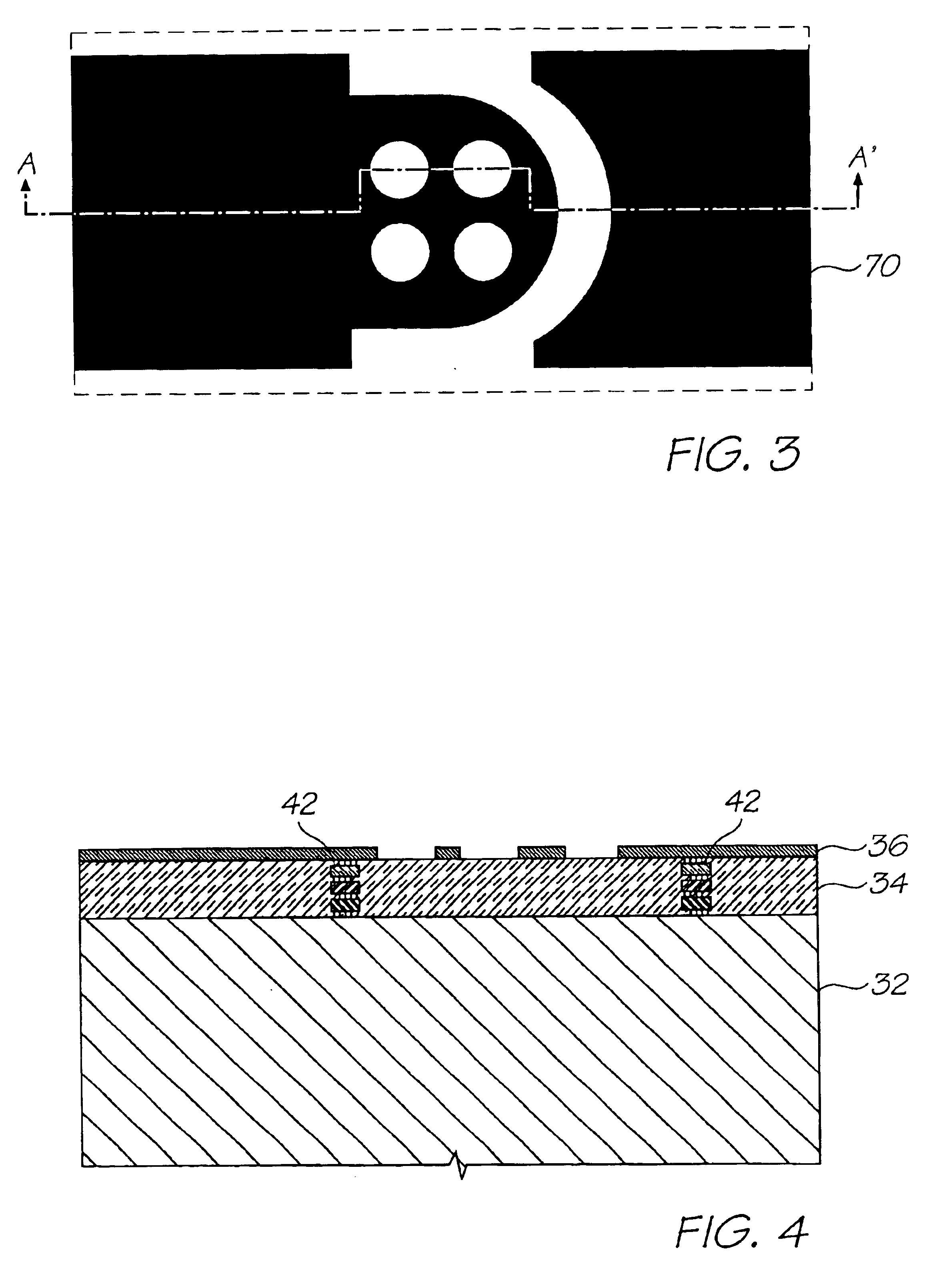

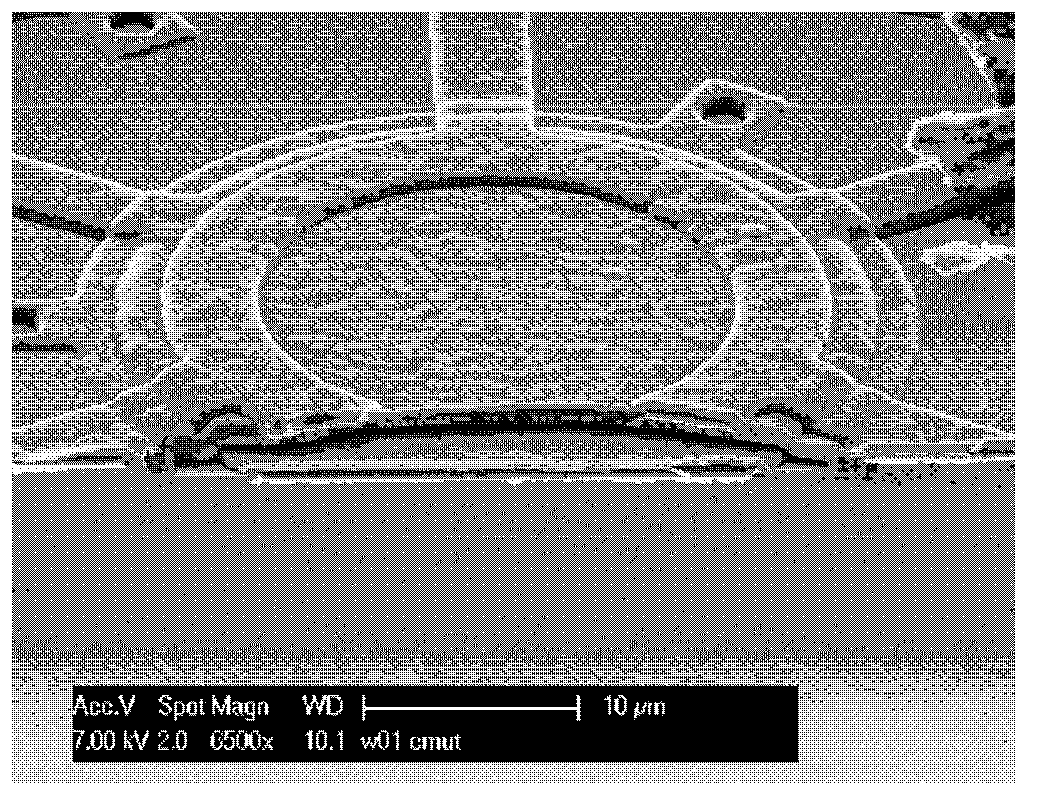

Capacitative pressure sensor with close electrodes

InactiveUS6968744B1Avoids extreme fluid pressureSmall surface area electrodeTyre measurementsMultiple fluid pressure valves simultaneous measurementCapacitive pressure sensorConductive materials

A pressure sensor (30) for harsh environments such as vehicle tires, formed from a chamber (58) partially defined by a flexible membrane (50), the chamber (58) containing a fluid at a reference pressure. In use, the flexible membrane (50) deflects due to pressure differentials between the reference pressure and the fluid pressure, the membrane being at least partially formed from conductive material. A conductive layer (36) is deposited within the chamber (58) spaced from the flexible membrane (50) such that they form opposing electrodes of a capacitor. Associated circuitry (34) is also deposited for converting the deflection of the flexible membrane (50) into an output signal indicative of the fluid pressure. The conductive layer (36) is less than 50 microns from the membrane in its undeflected state because capacitative sensors with closely spaced electrodes can have small surface area electrodes while maintaining enough capacitance for the required operating range. Furthermore, small electrodes reduce the power consumption of the sensor which in turn reduces the battery size needed for the operational life of the sensor.

Owner:PRECISION MECHATRONICS

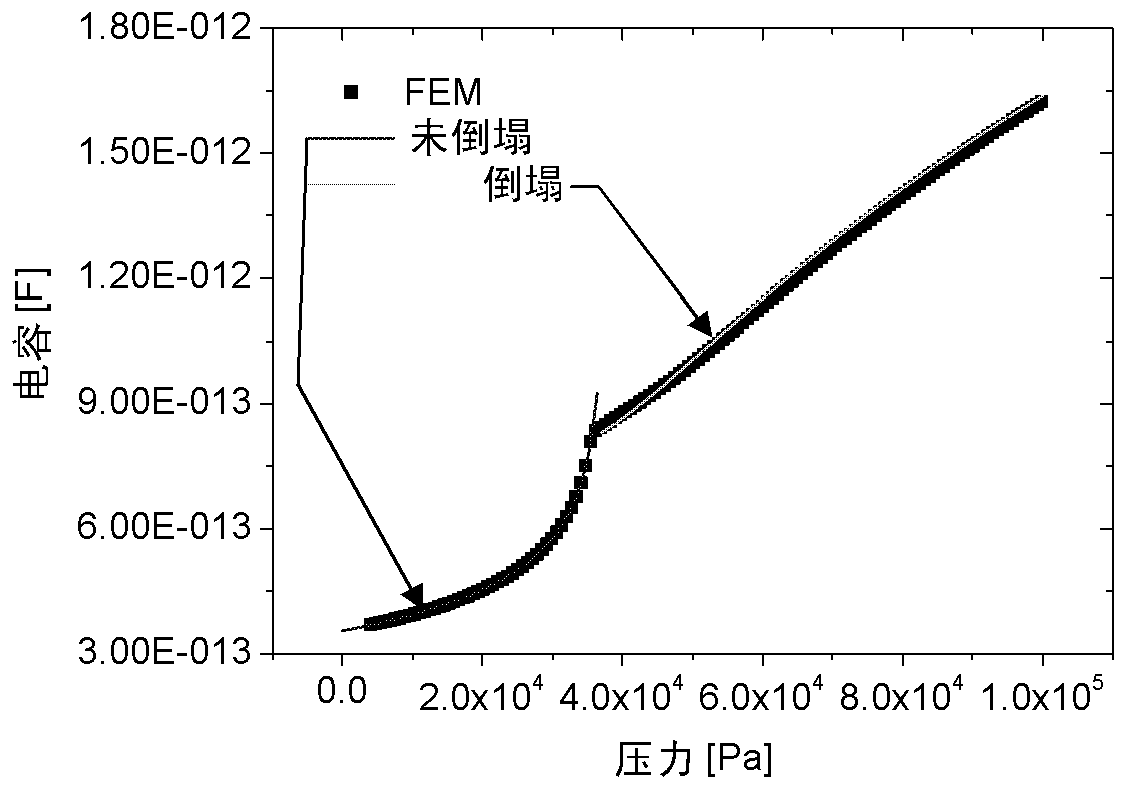

Mems capacitive pressure sensor

ActiveCN103308239AFluid pressure measurement using elastically-deformable gaugesForce measurementInternal pressureCapacitive pressure sensor

A pressure sensor measures pressure by measuring the deflection of a MEMS membrane using a capacitive read-out method. There are two ways to implement the invention. One involves the use of an integrated Pirani sensor and the other involves the use of an integrated resonator, to function as a reference pressure sensor, for measuring an internal cavity pressure.

Owner:希奥检测有限公司

Vaporizer devices with blow discrimination

ActiveUS10130123B2Avoid instabilityAbsorbs and dissipates excessive heatElectric heatingTobacco devicesEngineeringVaporization

Methods and apparatuses for discriminating between user blowing and drawing (sucking) in an electronic vaporization device. Described herein are electronic aerosol devices and methods of controlling or operating them which can accurately differentiate between blowing and drawing (sucking) through the mouthpiece and adjust the control of the vaporizer accordingly.

Owner:JLI NAT SETTLEMENT TRUST

Popular searches

Angle modulation Non-mechanically variable capacitors Angiography Pressure difference measurement between multiple valves Apparatus for force/torque/work measurement Electronic switching Thin material handling Input/output processes for data processing Metal layered products Intracranial pressure measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com