Patents

Literature

1251 results about "Optical reflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

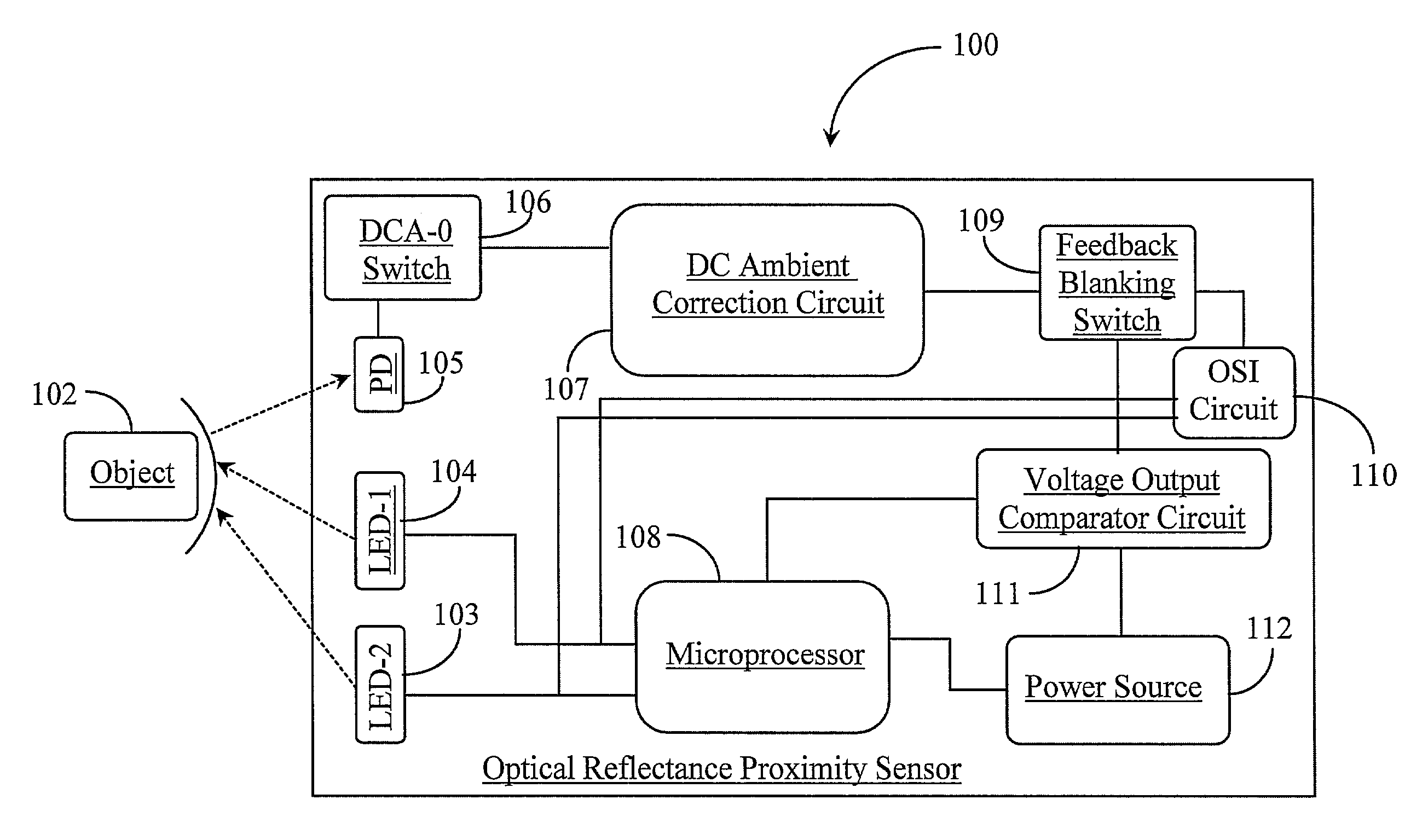

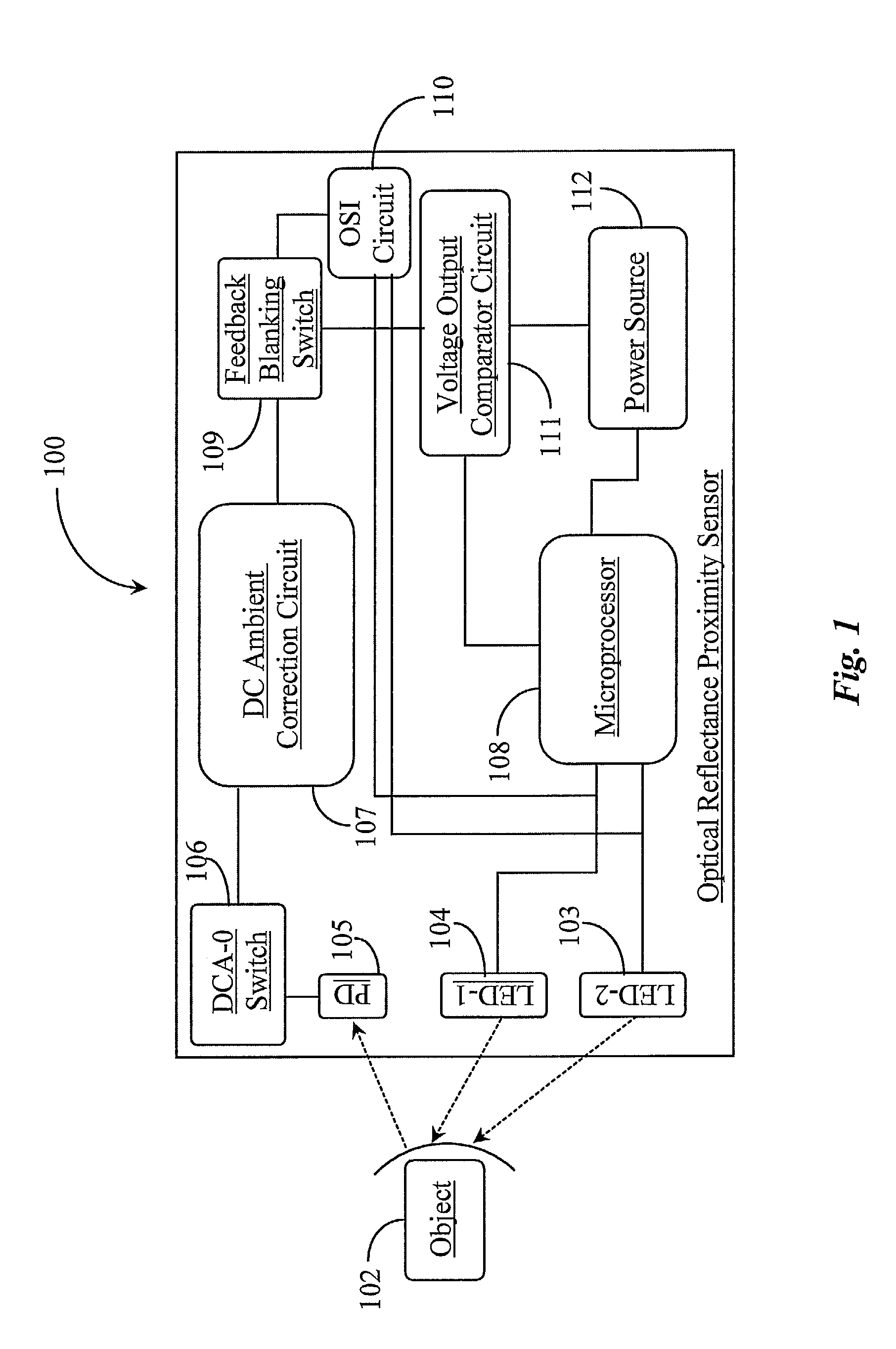

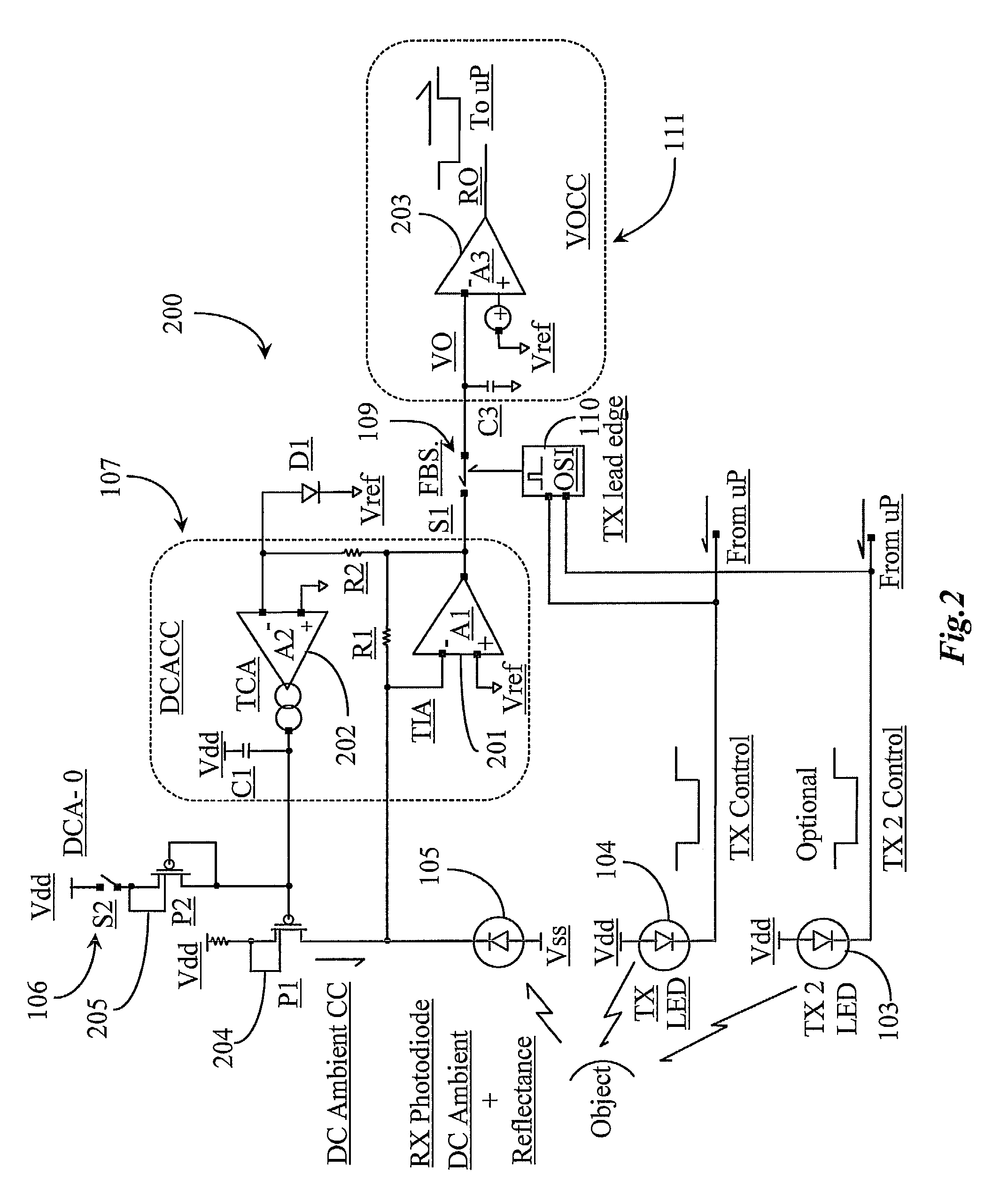

Optical reflectance proximity sensor

ActiveUS7486386B1Enhanced informationOptical rangefindersElectronic switchingOptical reflectionProximity sensor

A method for calibrating an optical reflectance proximity sensor and then measuring proximity in a repeating cycle or on demand, the sensor including one or more wavelength transmitting diodes, one or more wavelength receiving diodes, an ambient correction circuit, and a comparator circuit, and further teaching steps for powering on the sensor, canceling the ambient signal during a calibration period, transmitting wavelengths to and receiving reflectance from an object in the path of the transmitted wavelengths, and measuring a reflectance pulse width and comparing the value to a preset value to determine proximity.

Owner:SILICON LAB INC

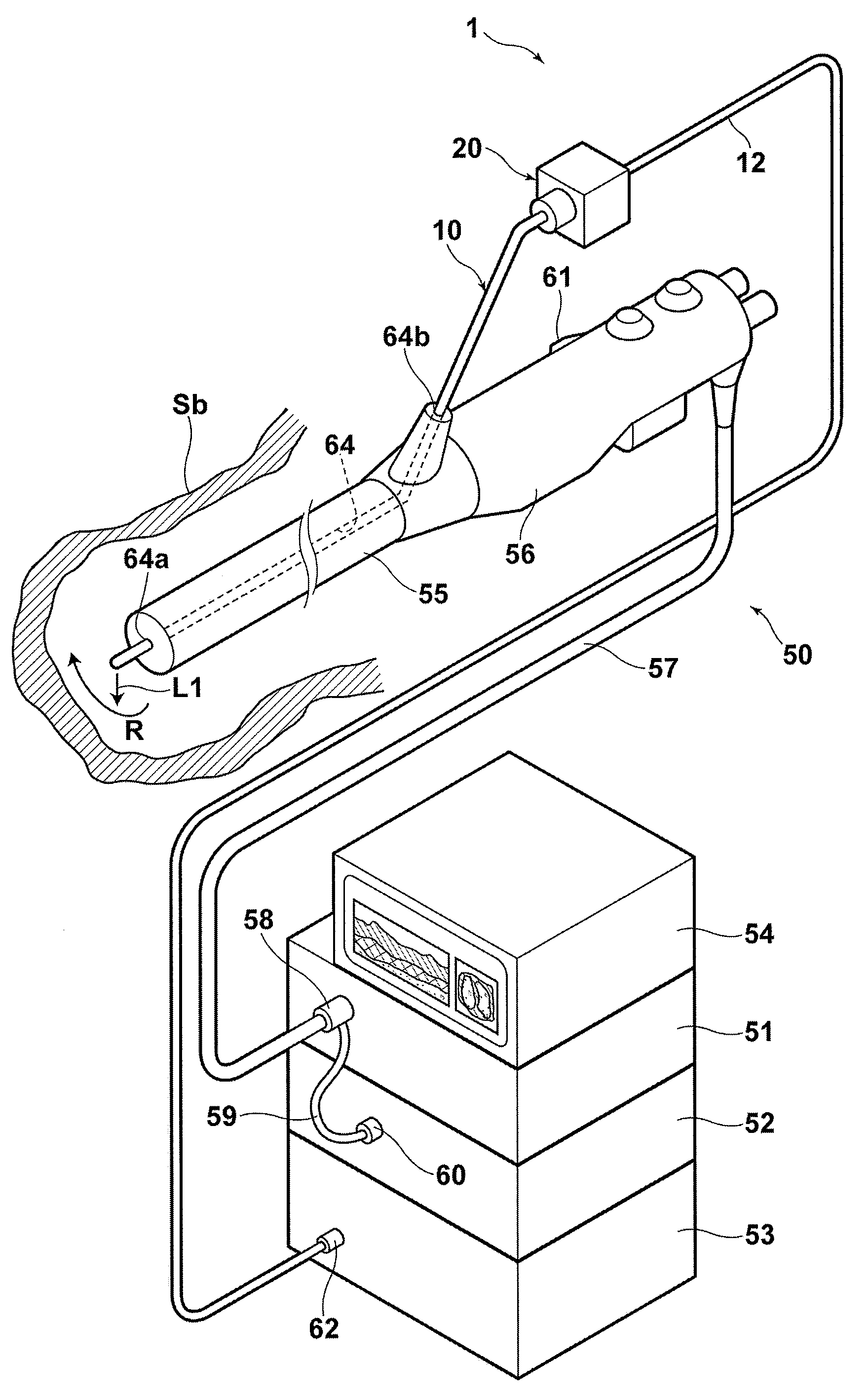

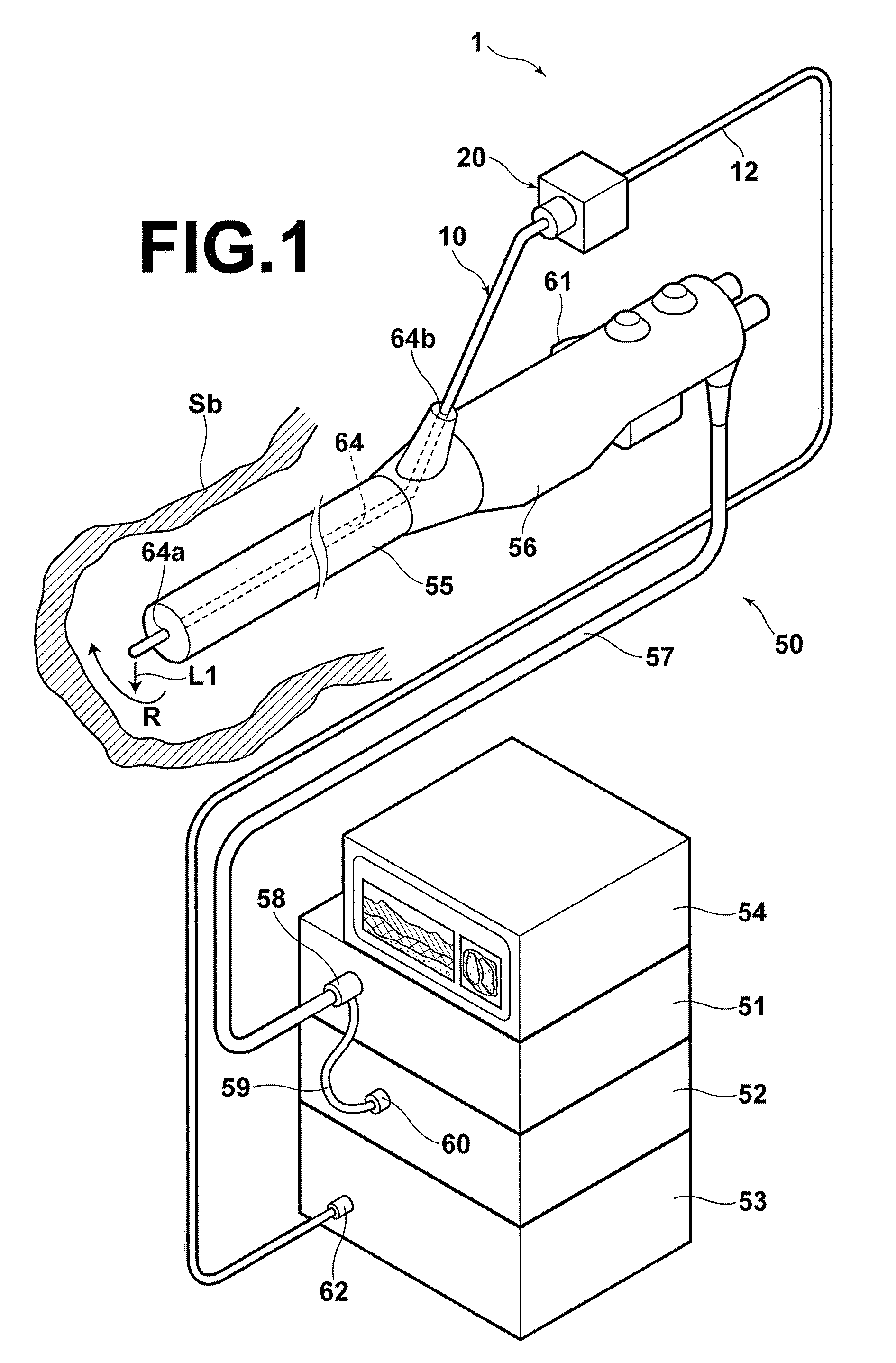

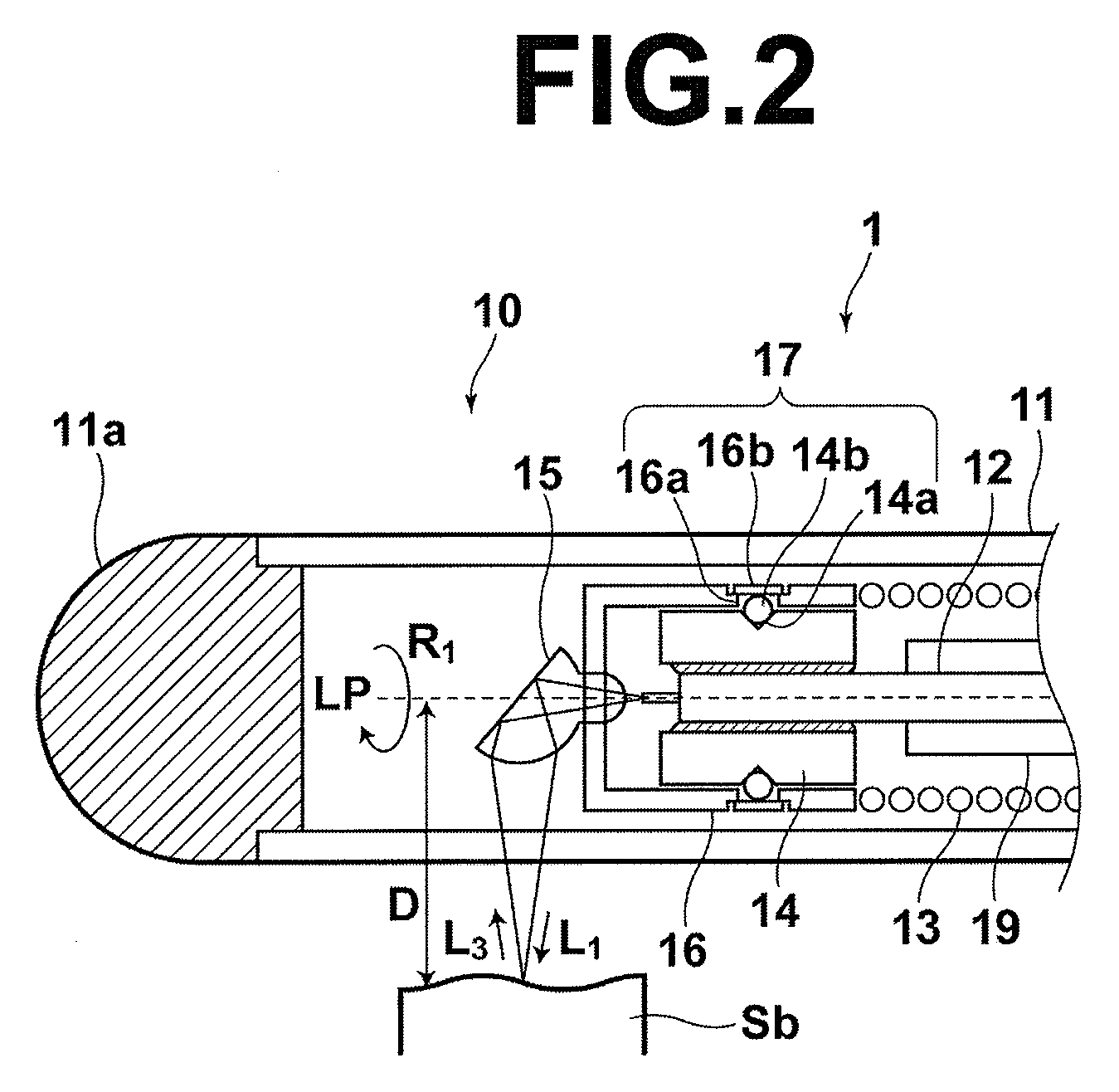

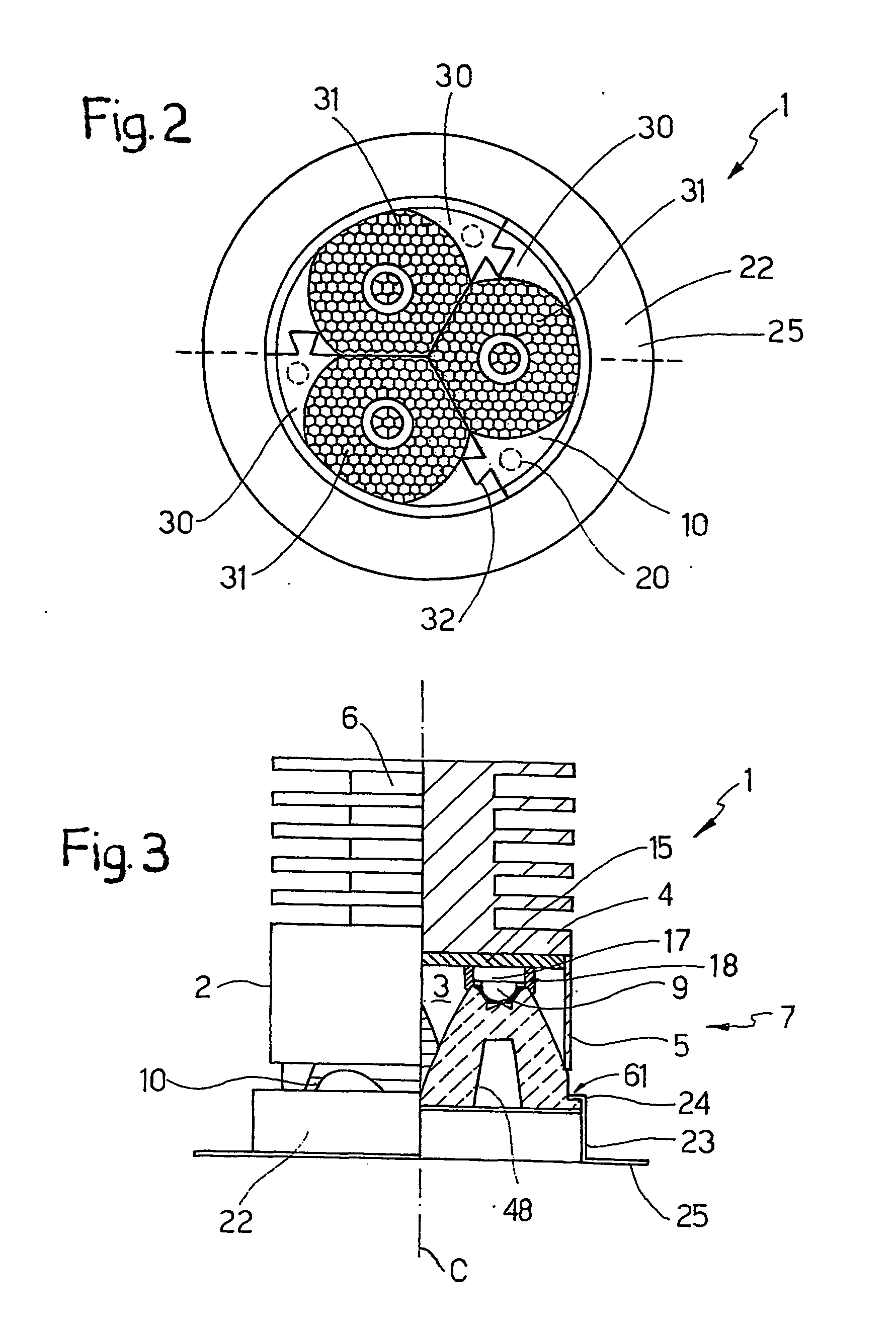

Oct optical probe and optical tomography imaging apparatus

InactiveUS20090198125A1Inexpensive and safeImprove accuracySurgeryEndoscopesOptical reflectionInterior space

An OCT optical probe to be inserted into a subject includes: a cylindrical sheath to be inserted into a subject; an optical fiber disposed in the internal space of the sheath; a rotatably-supporting portion fixed to the optical fiber in the vicinity of a distal end of the optical fiber; a distal optical system to deflect light emitted from the distal end of the optical fiber toward the subject; a holding portion to hold the distal optical system such that the optical system is rotatably supported by the rotatably-supporting portion; and a flexible shaft covering the optical fiber in the internal space, wherein the holding portion is fixed to a distal end of the flexible shaft. Using the OCT optical probe of the invention, the problem of degradation of measurement accuracy due to optical insertion loss and optical reflection loss at a rotary joint can be eliminated inexpensively and safely.

Owner:FUJIFILM CORP +1

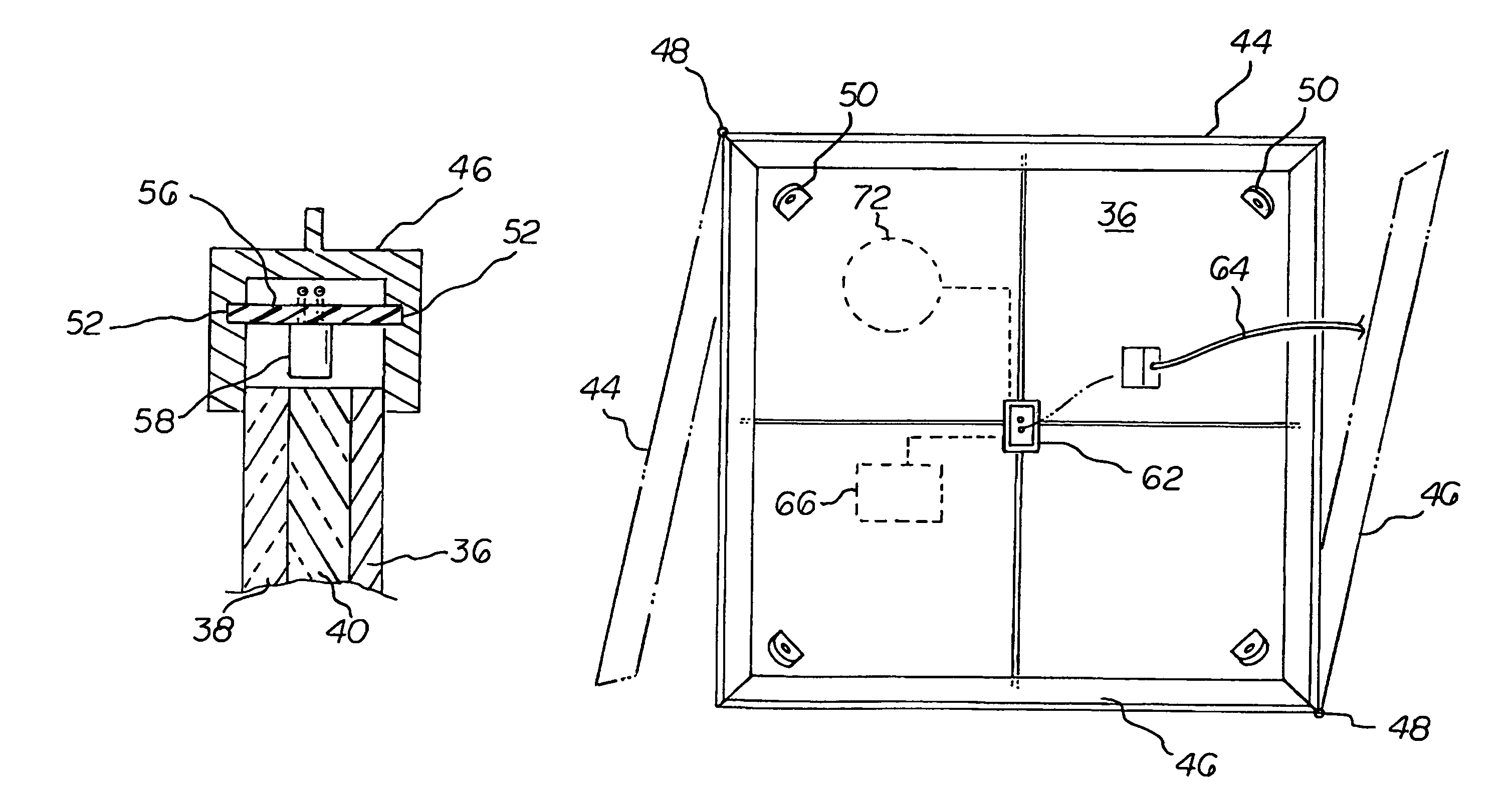

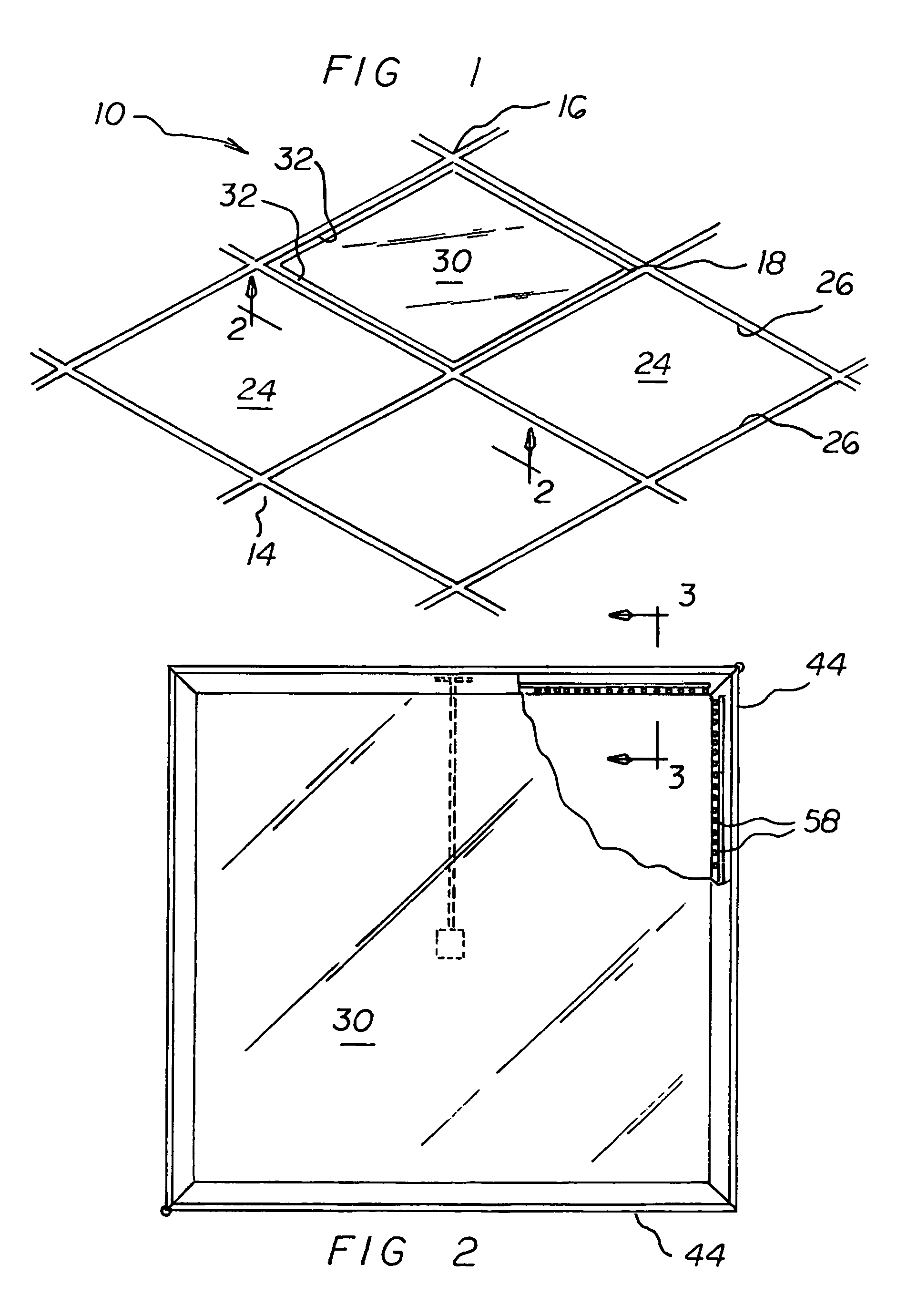

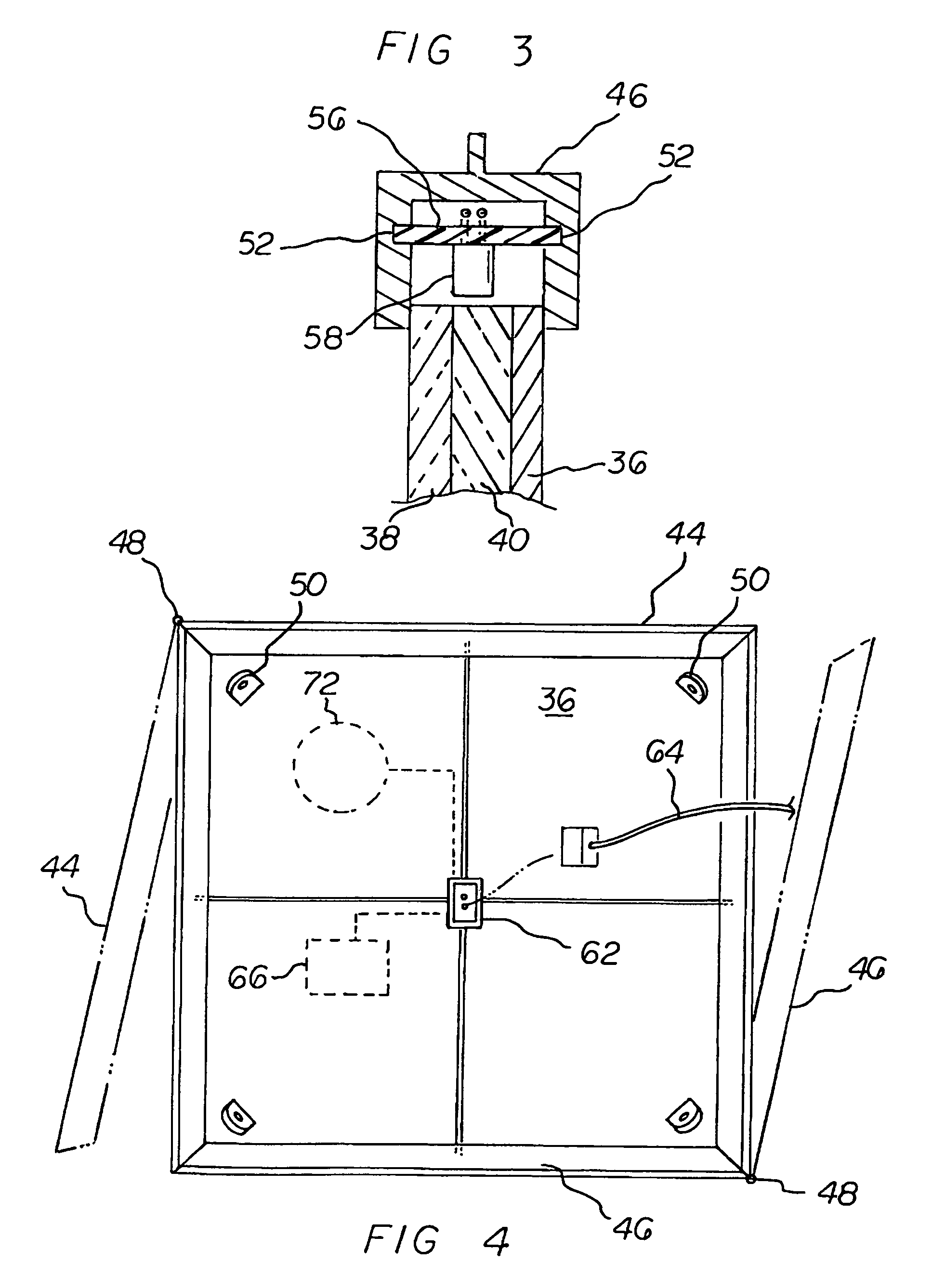

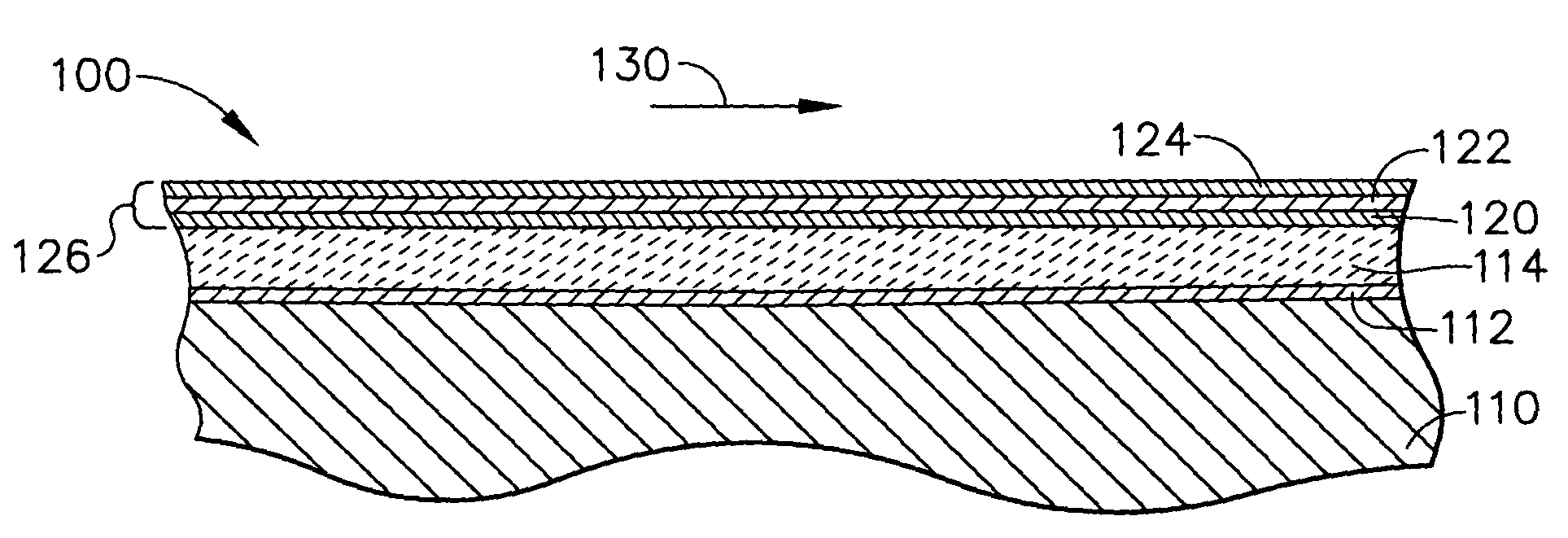

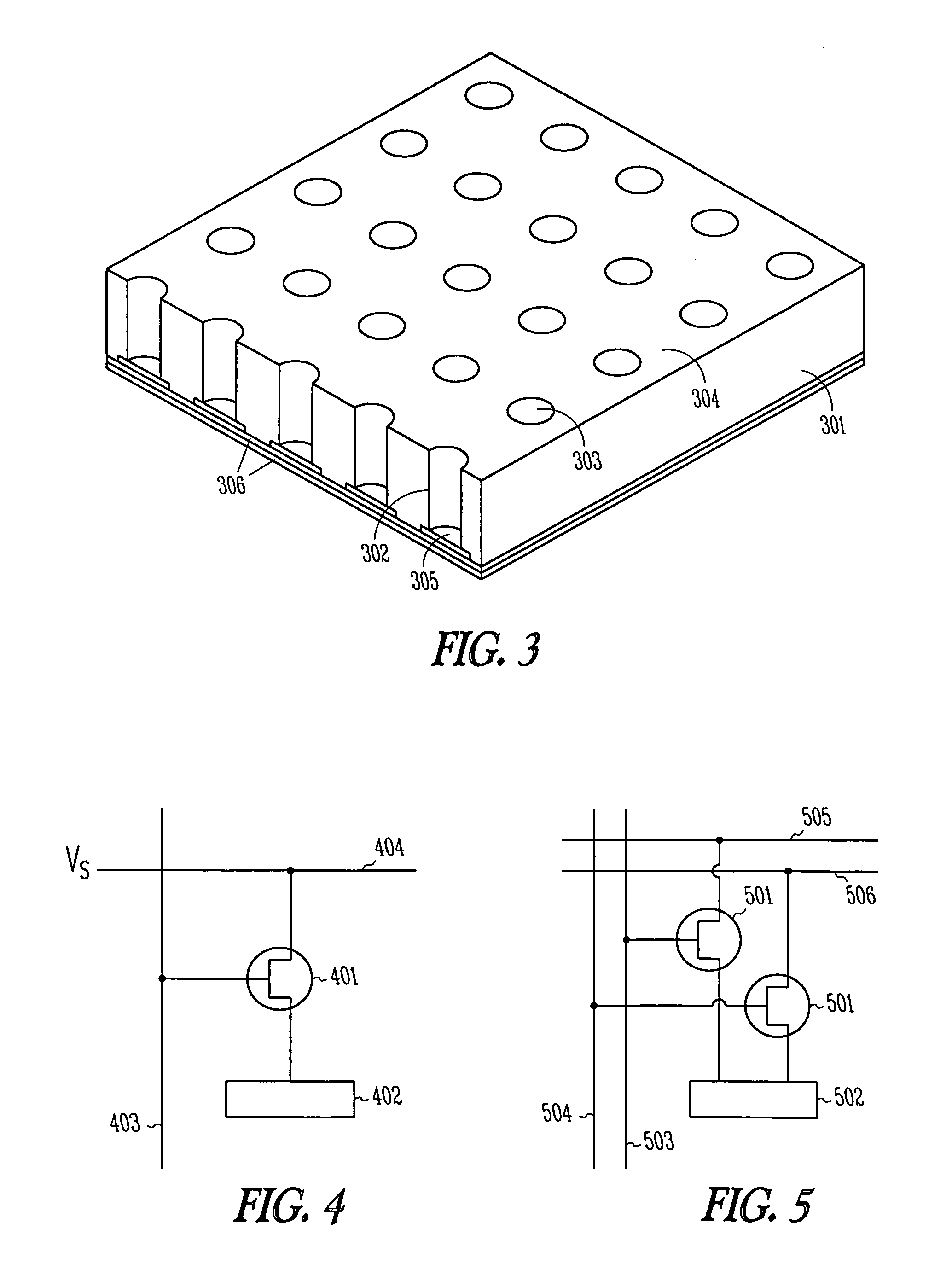

Light emitting diode illumination system

InactiveUS8096671B1Safe and compact and convenient and economical mannerEasily and efficiently manufactured and marketedPlanar light sourcesCeilingsOptical reflectionEngineering

An illumination panel has four peripheral edges constructed of an upper plate and a lower plate. Each of the plates has aligned peripheral edges and an upper and lower surface. The upper plate is fabricated of an optically reflective material. The lower plate is fabricated of an optically diffusive material. Each of the illumination panels includes a peripheral frame formed of four edge pieces. Each of the edge pieces is in a cross sectional configuration to receive and support the peripheral edges of the plates. A pair of opposed recesses face each other in the edge pieces. A printed circuit board with a plurality of light emitting diodes is supported in the edge pieces by the recesses. An electrical connector is adapted to disperse electrical power to the light emitting diodes.

Owner:STEPHENS OWEN

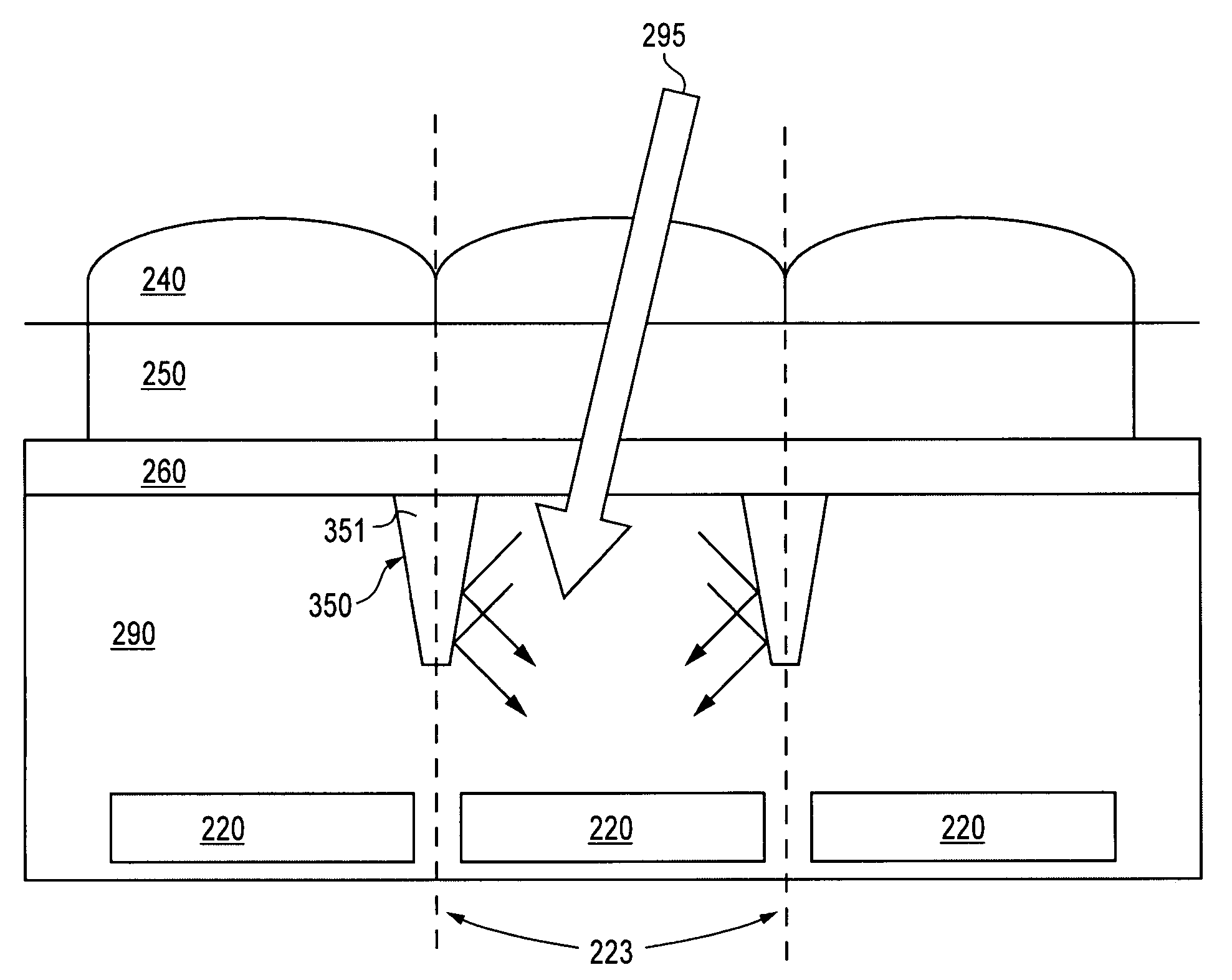

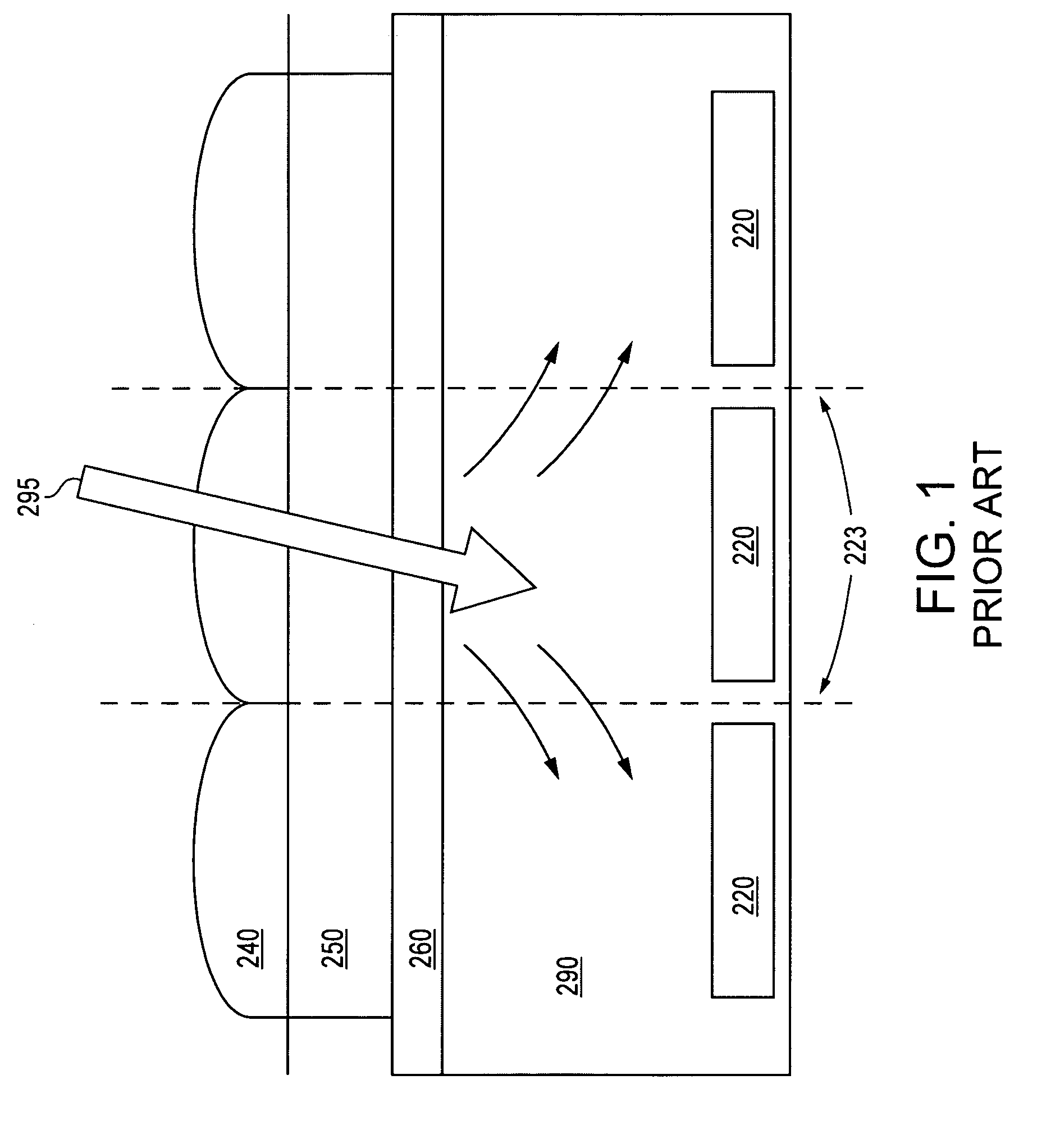

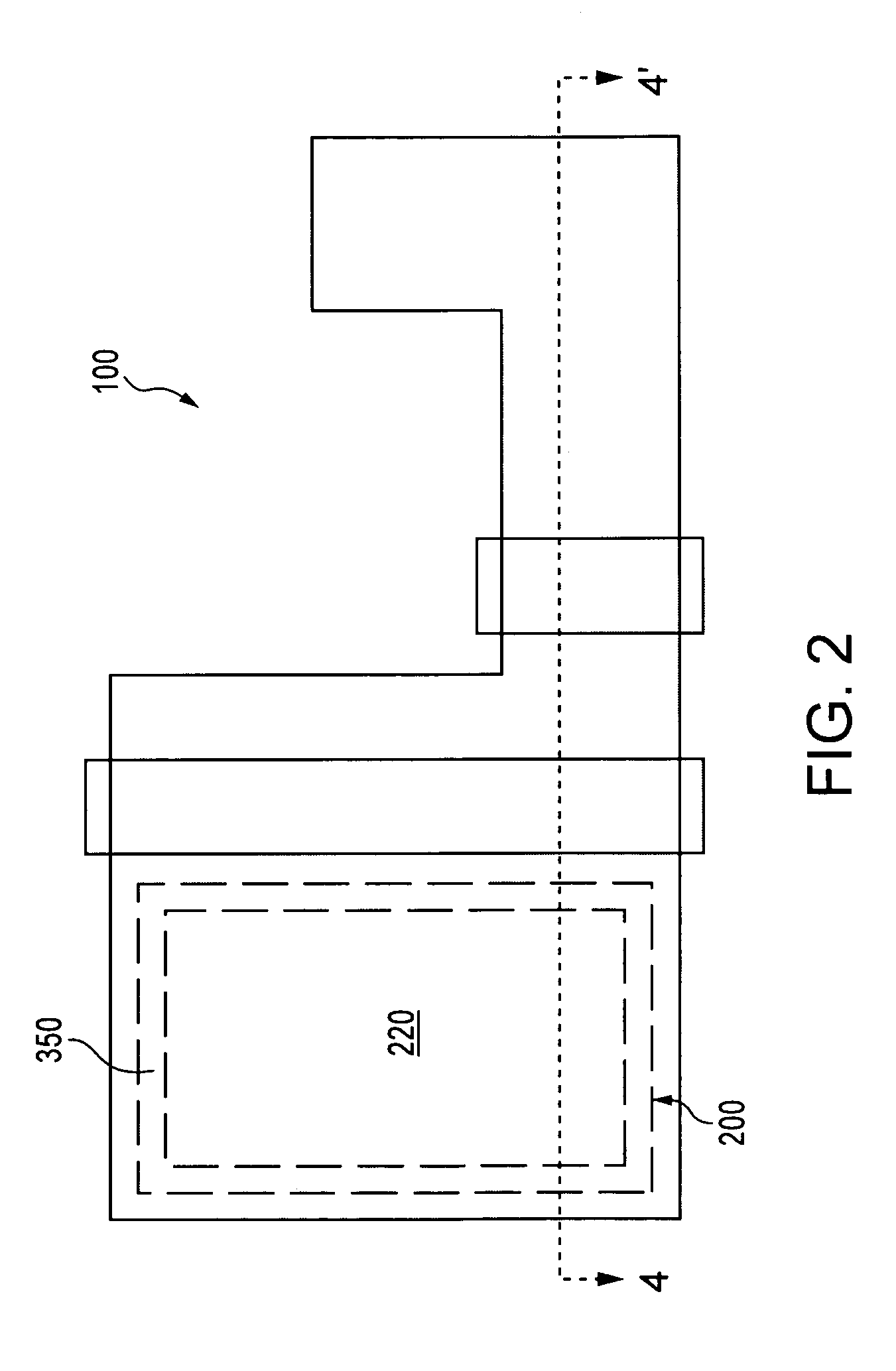

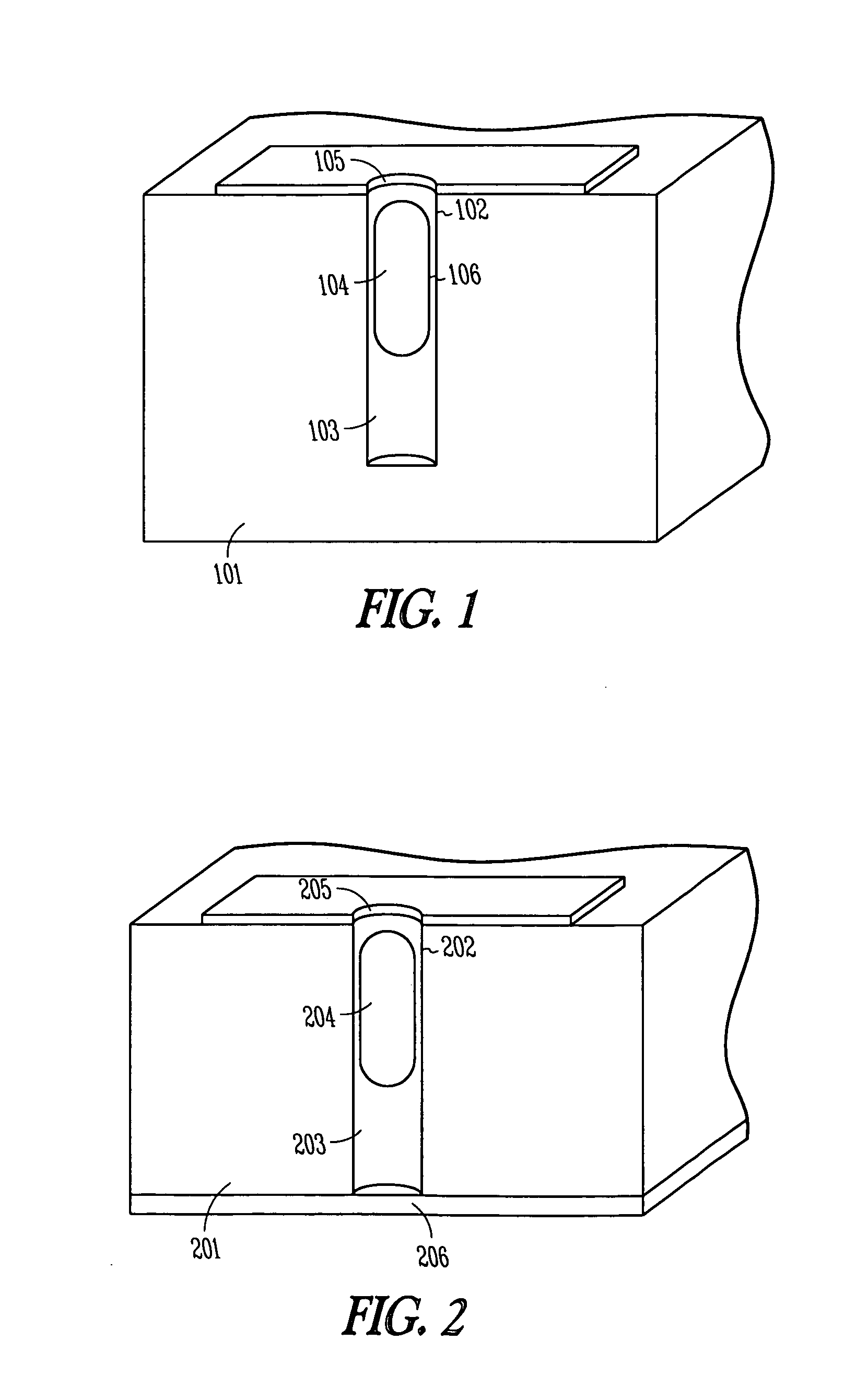

Image sensors with optical trench

ActiveUS7315014B2Mitigates optical crosstalkImprove difference in index of refractionSolid-state devicesMaterial analysis by optical meansOptical reflectionRefractive index

A device and method for providing an optical trench structure for a pixel which guides incoming light onto the photosensor of the pixel. The optical trench structure has an optically reflecting barrier that substantially mitigates optical crosstalk. The optical trench structure is made of low dielectric constant material with an index of refraction that is less than the index of refraction of the material of surrounding layers (e.g., the substrate). This difference in refractive index causes an internal reflection into an optical path existing between a lens and pixel.

Owner:APTINA IMAGING CORP

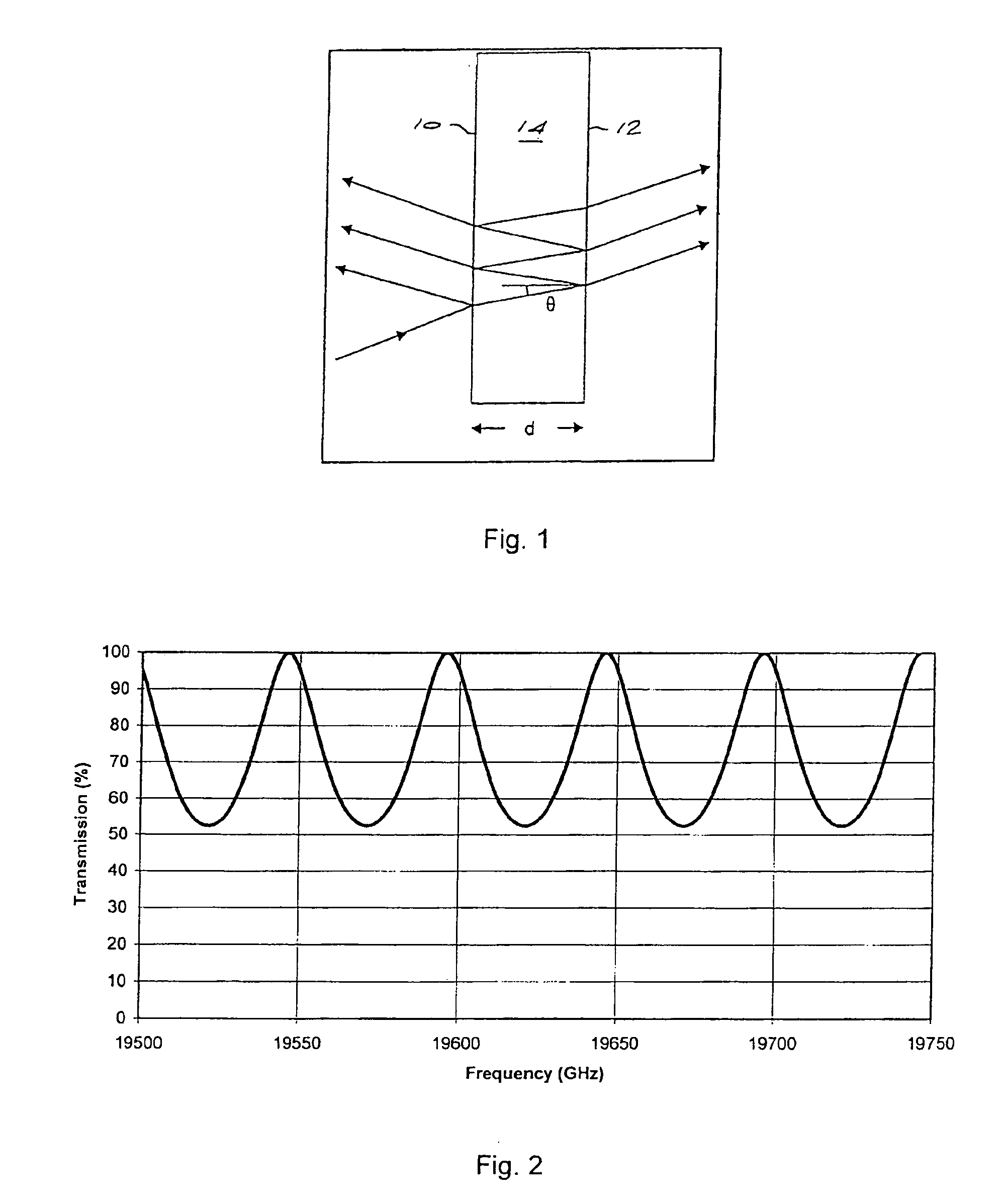

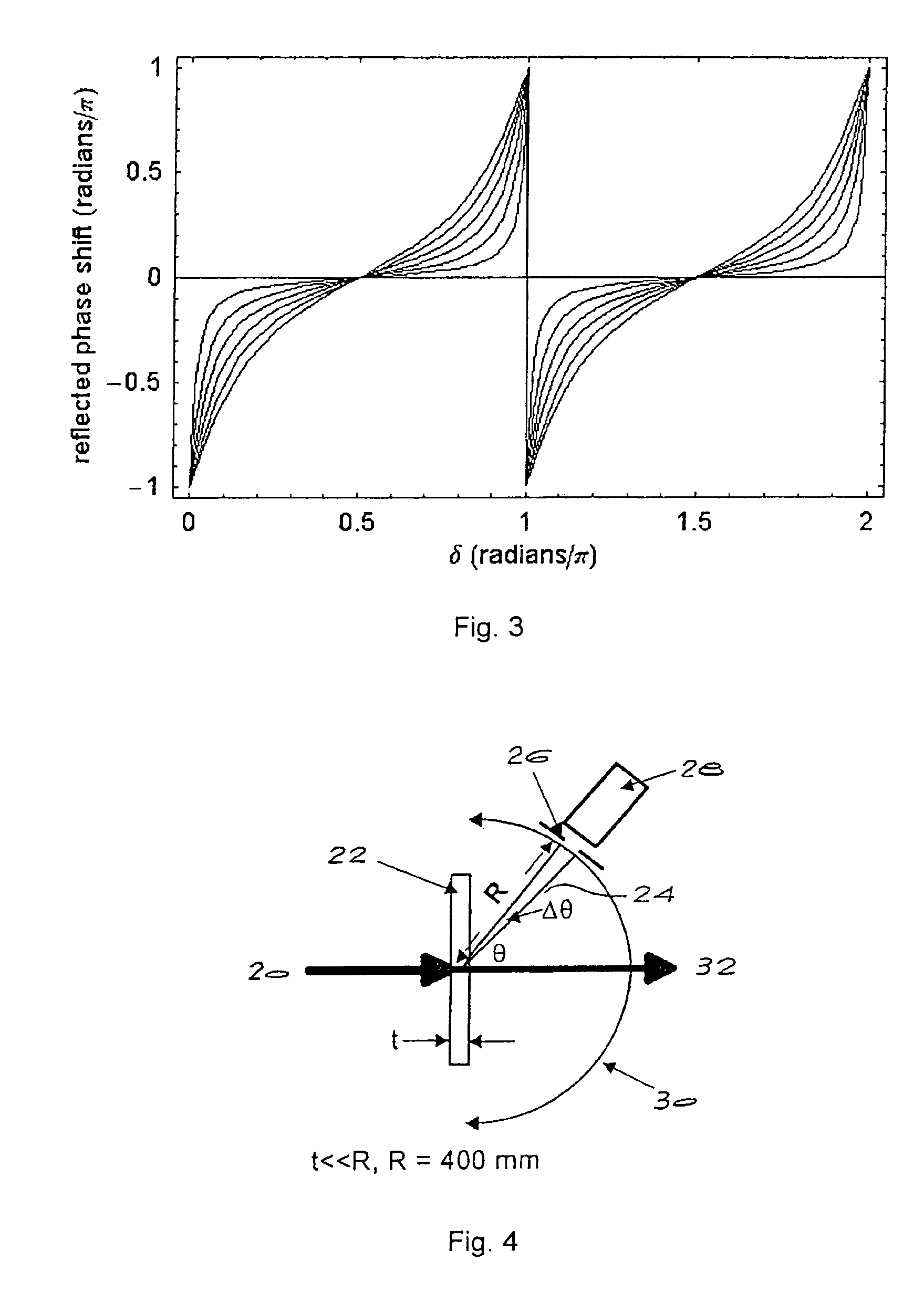

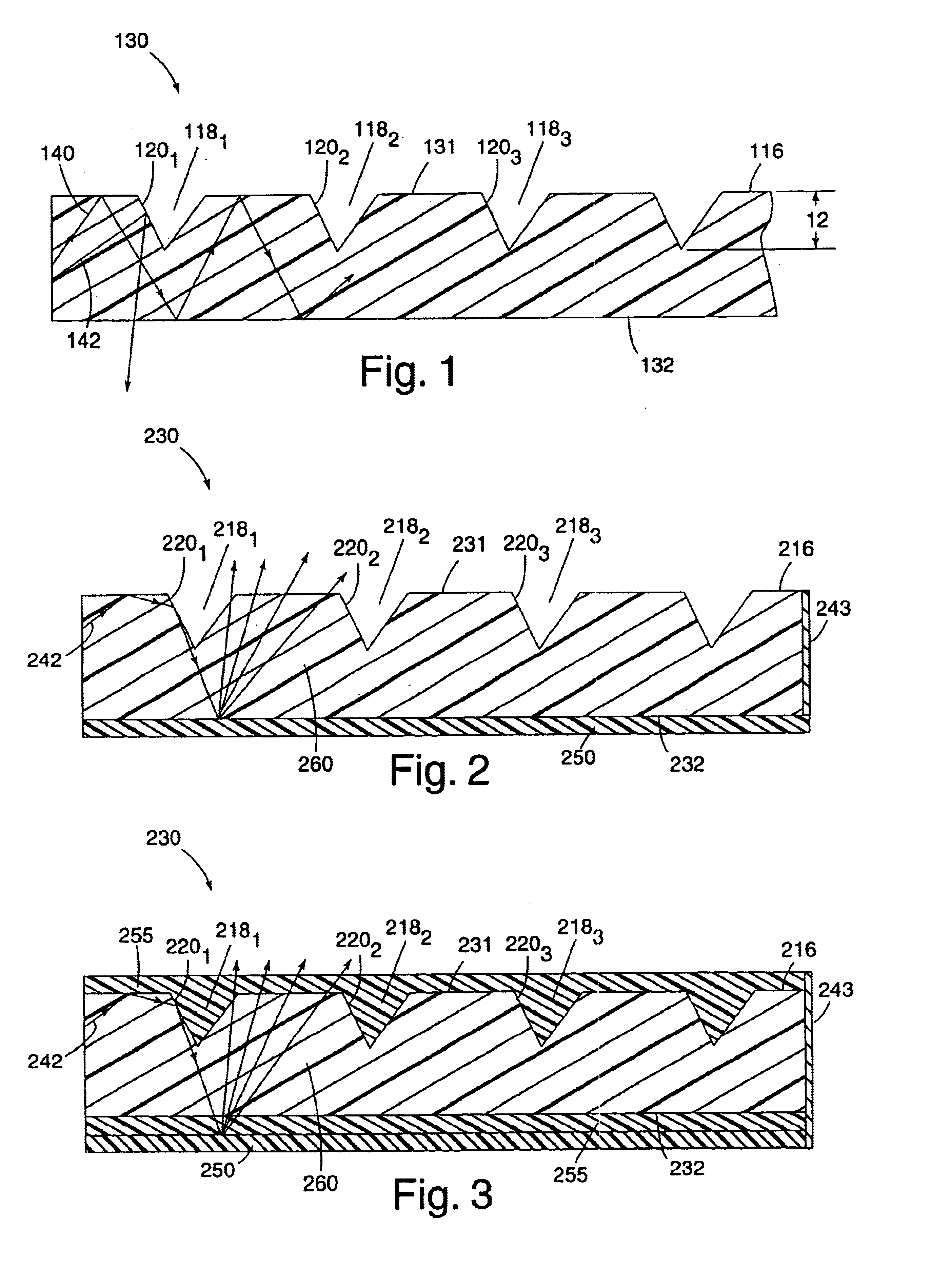

Optical pulse stretching and smoothing for ArF and F2 lithography excimer lasers

InactiveUS6389045B1Easy to stretchFlat shapeOptical resonator shape and constructionGenerators/motorsOptical reflectionLithographic artist

A method and apparatus are provided for temporally stretching and smoothing of the pulses of an output beam of excimer and lithography lasers. The method and apparatus are based upon providing an optical delay line or circuit having a plurality of optical reflectors and a plurality of beam recombiners or splitters so arranged as to divide the pulse into numerous portions which vary in their travel time through the circuit. As a result, the energy of the incident pulse is greatly stretched and smoothed.

Owner:COHERENT GMBH

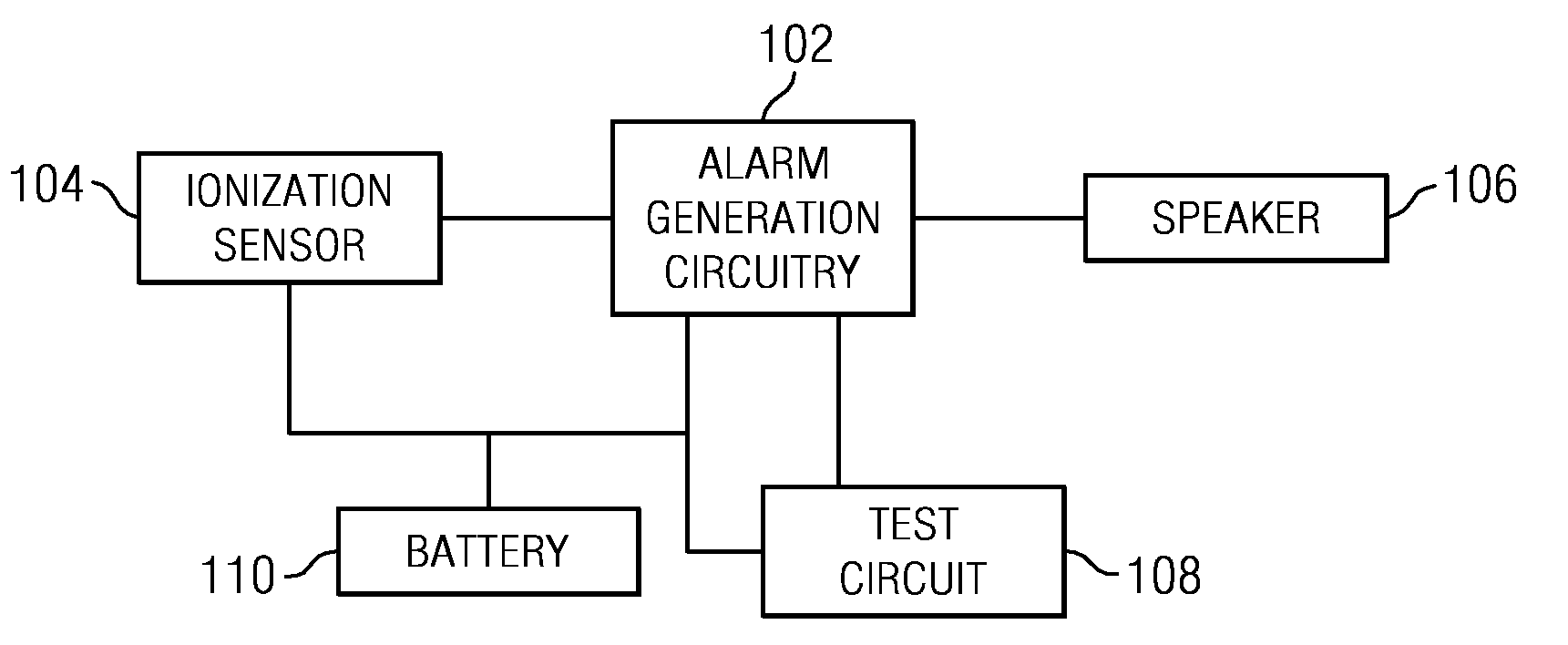

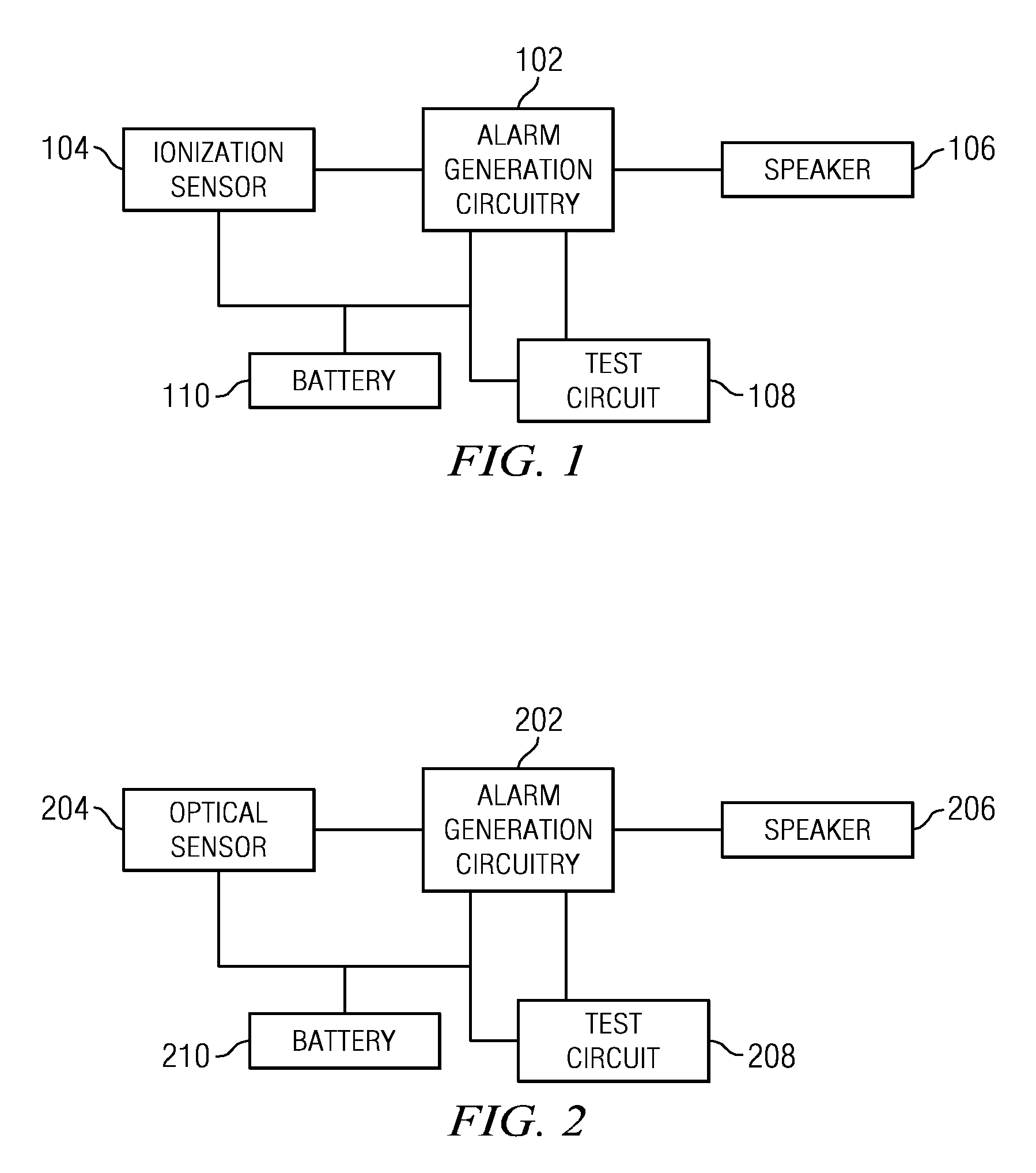

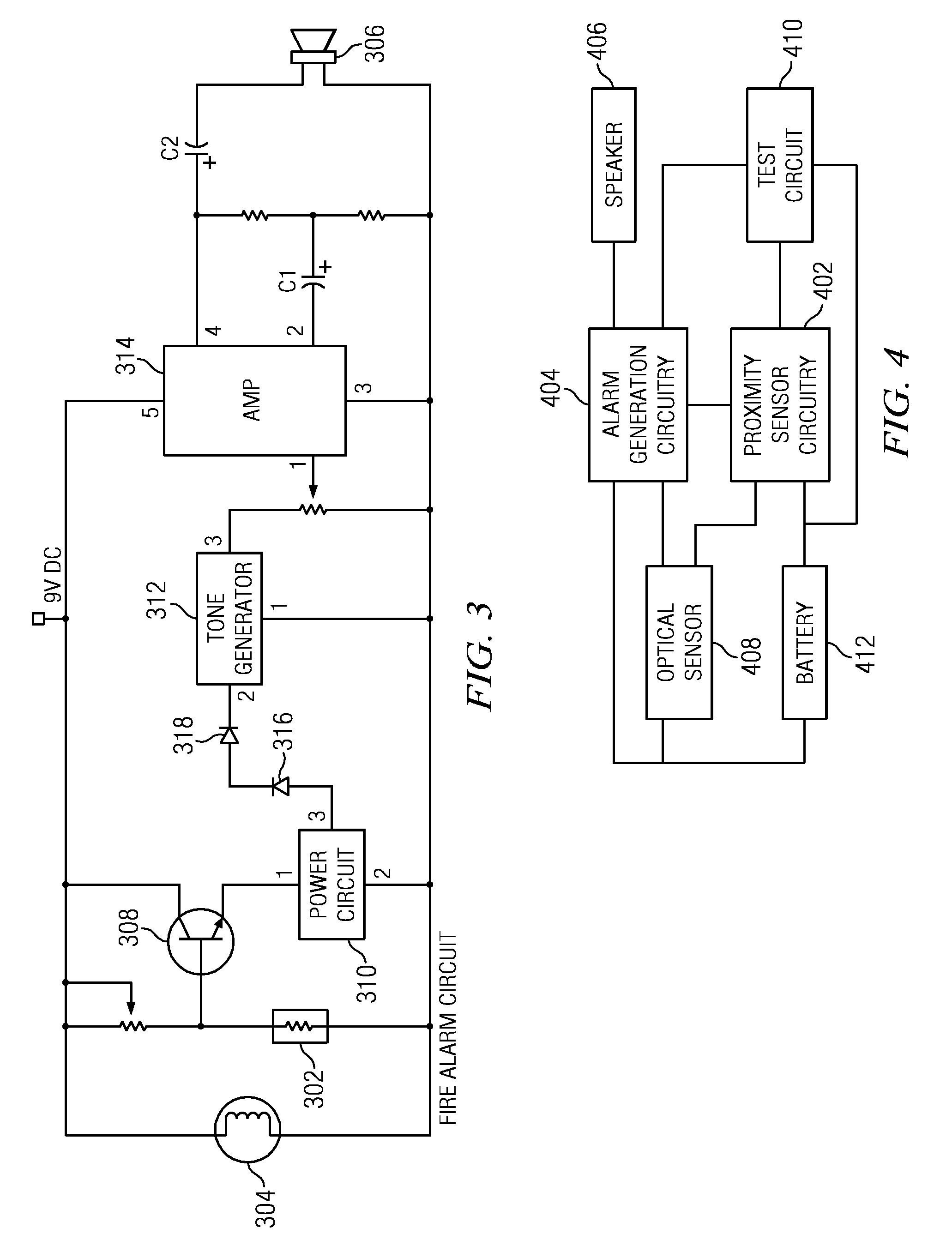

Use of optical reflectance proximity detector for nuisance mitigation in smoke alarms

ActiveUS20100238036A1Fire alarm smoke/gas actuationElectric/electromagnetic audible signallingOptical reflectionEngineering

A smoke alarm comprises smoke detection circuitry for detecting smoke and generating a detection signal responsive thereto. Proximity detection circuitry generates a proximity detection signal responsive to detection of an object within in a selected distance of the smoke alarm. Alarm generation circuitry generates an audible alarm responsive to the detection signal. The audible alarm may be deactivated for a predetermined period of time responsive to at least one proximity detection signal.

Owner:GOOGLE LLC

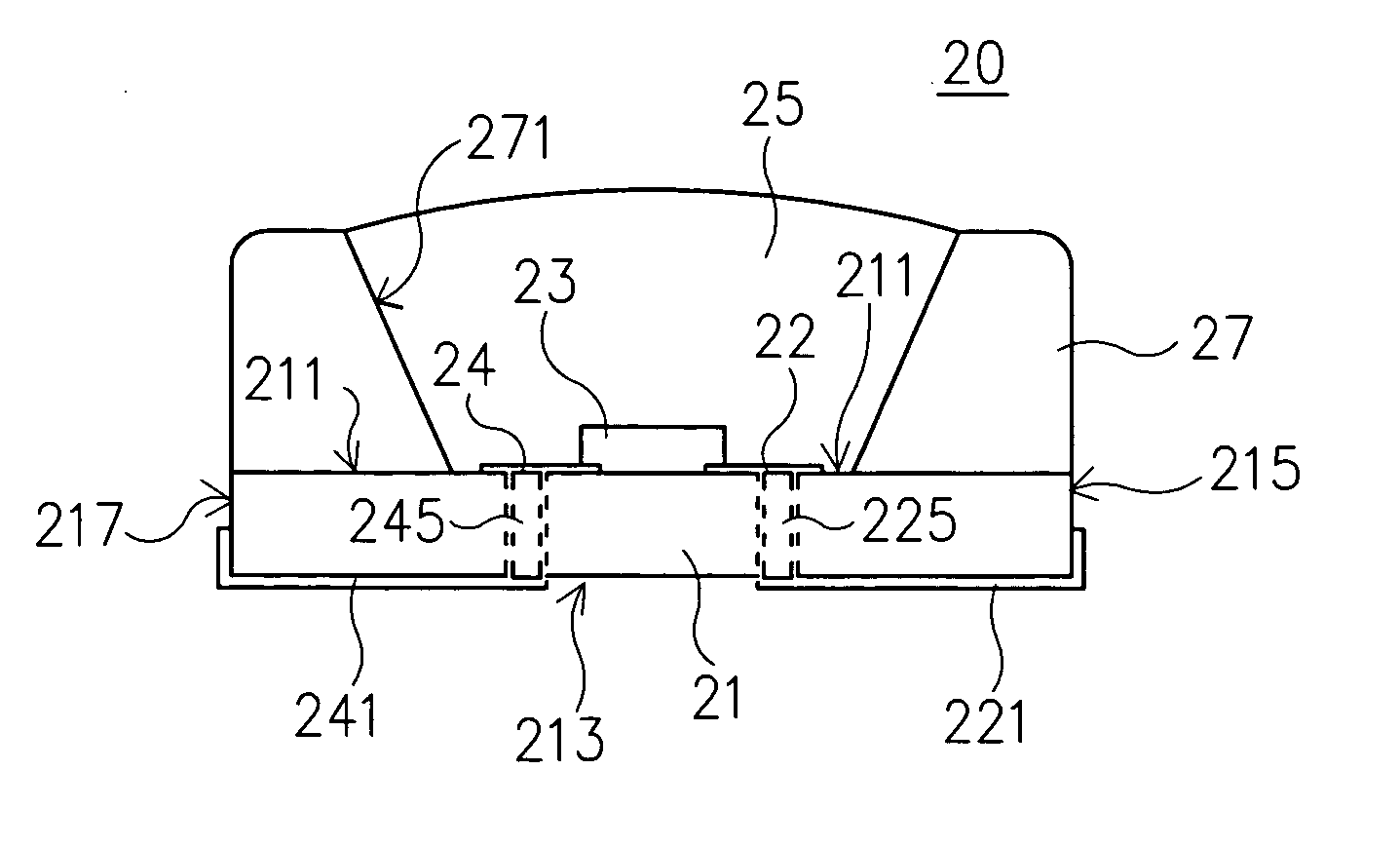

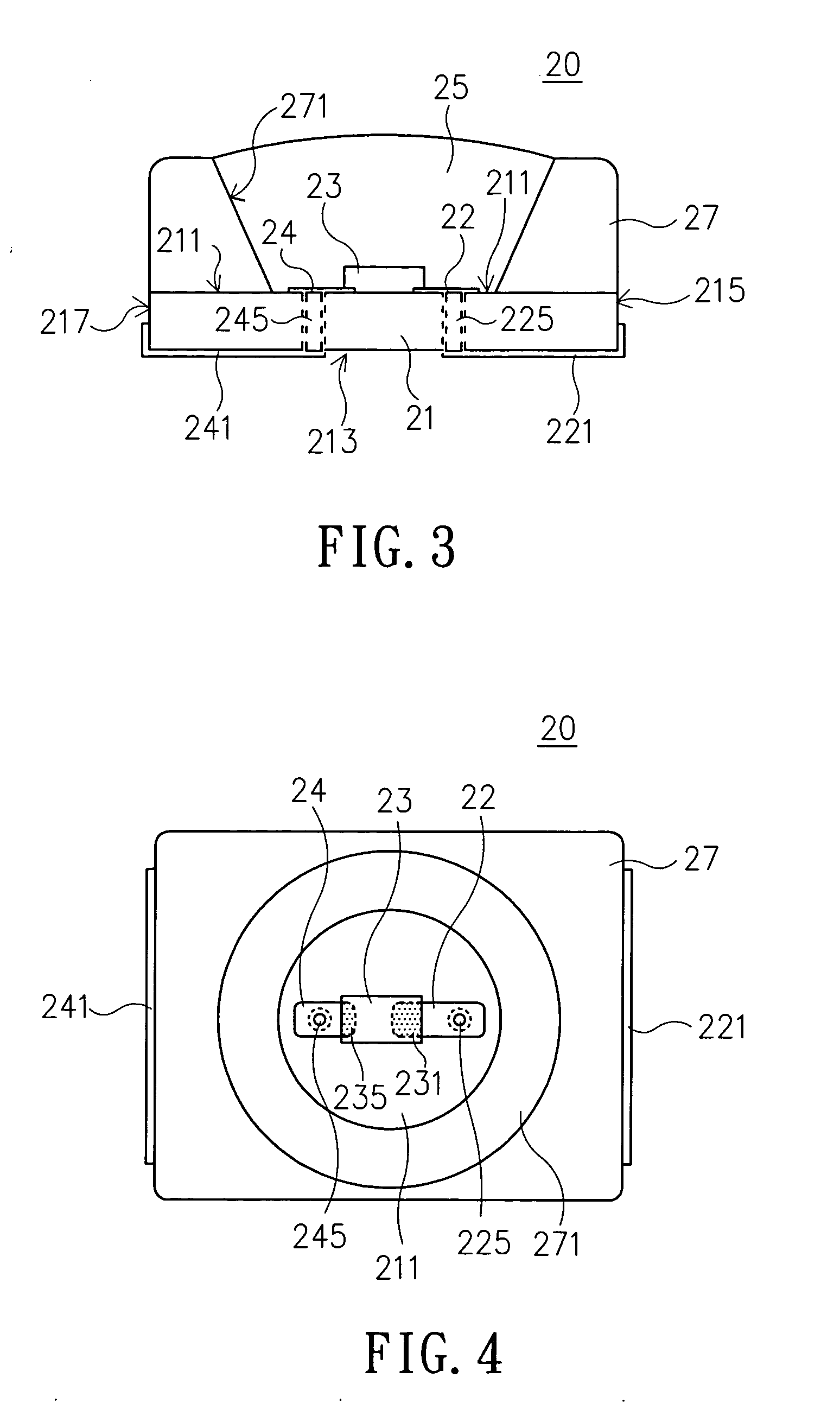

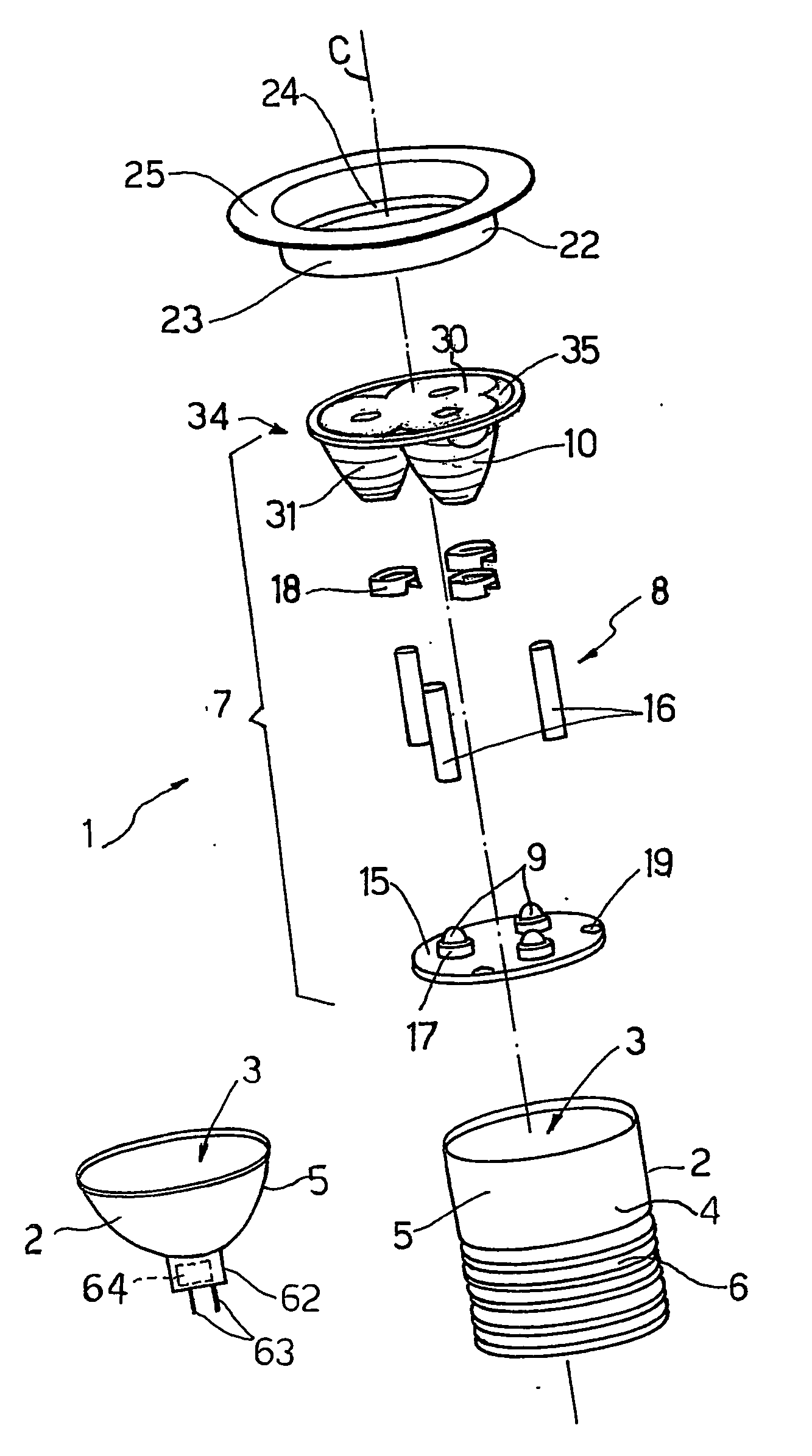

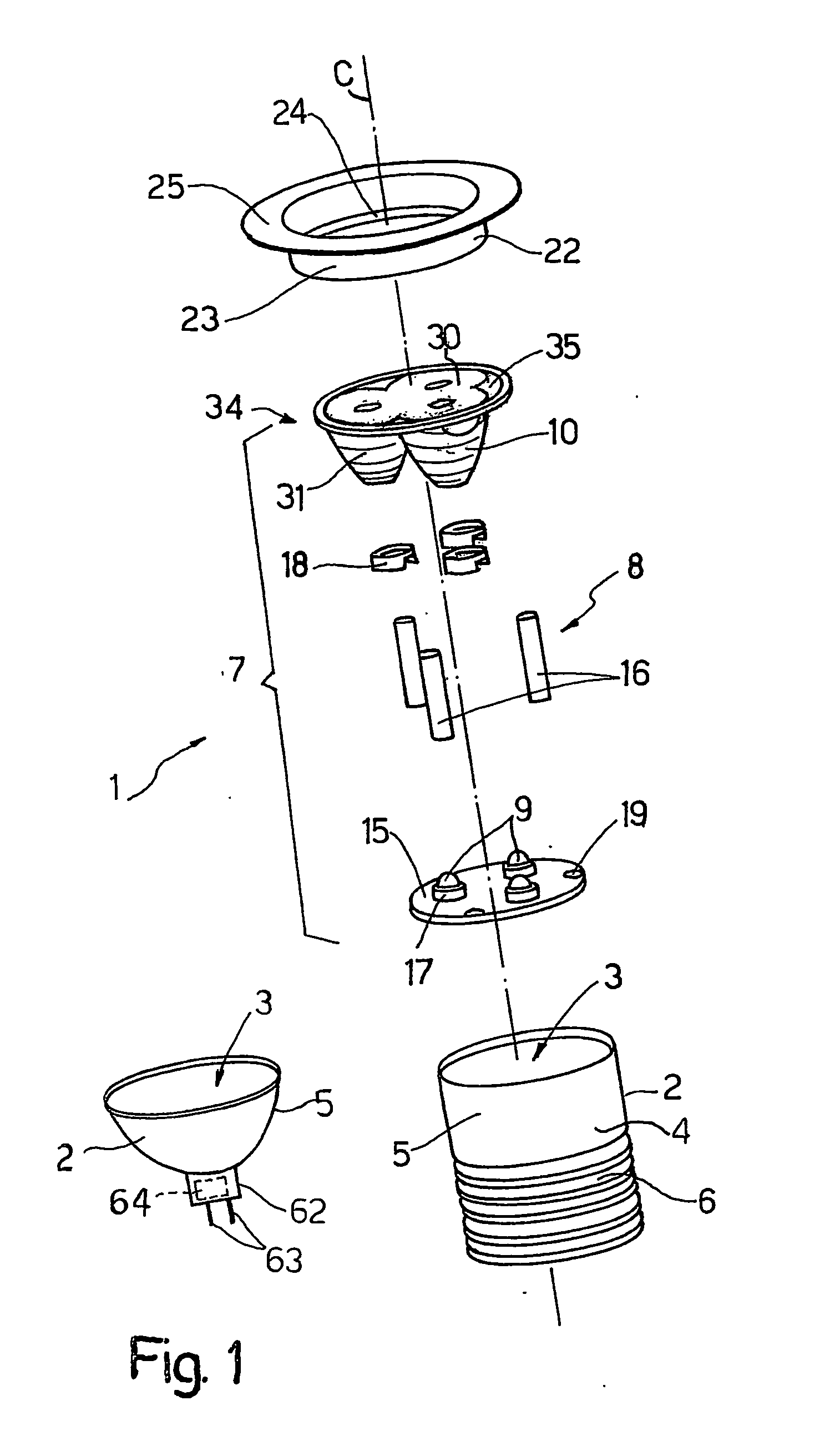

Light-emitting device with high heat-dissipating efficiency

InactiveUS20050199900A1Ensure safe operationReduce manufacturing costSolid-state devicesSemiconductor devicesOptical reflectionLight guide

A light-emitting device with high heat-dissipating efficiency, includes a ceramic substrate having at least one pair of power-supply circuits mounted at a specific location of the substrate, a light-emitting die fixedly mounted on the ceramic substrate by flip-chip mounting, wherein the two electrodes of the light-emitting die are electrically connected to a corresponding power-supply circuit, respectively, and an optical reflector which is adjacently mounted in the periphery of the light-emitting die and made up of a metallic material or a material with a high coefficient of thermal conductivity for increasing the heat-dissipating area and providing a light-guiding mechanism.

Owner:OPTO TECH

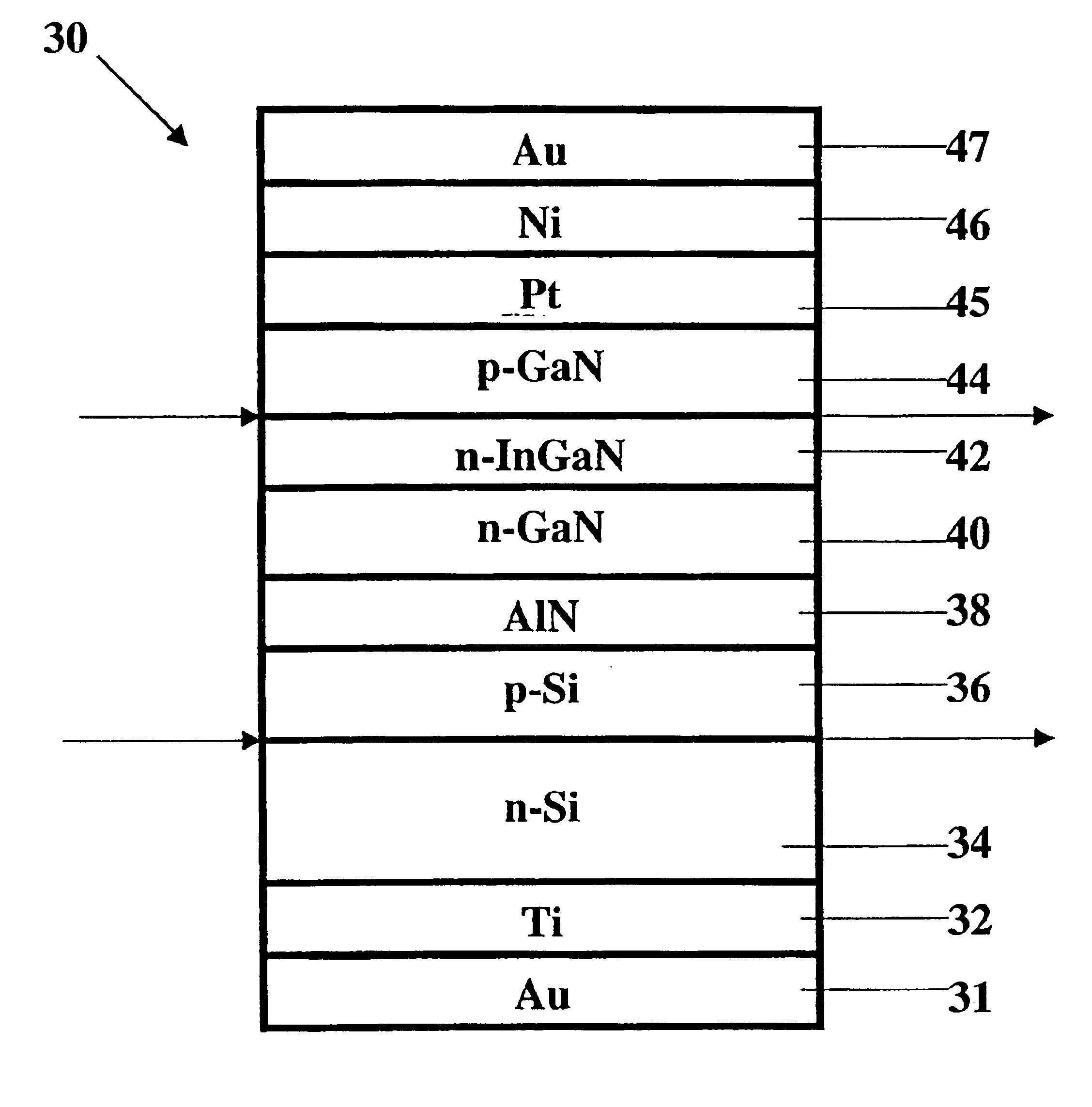

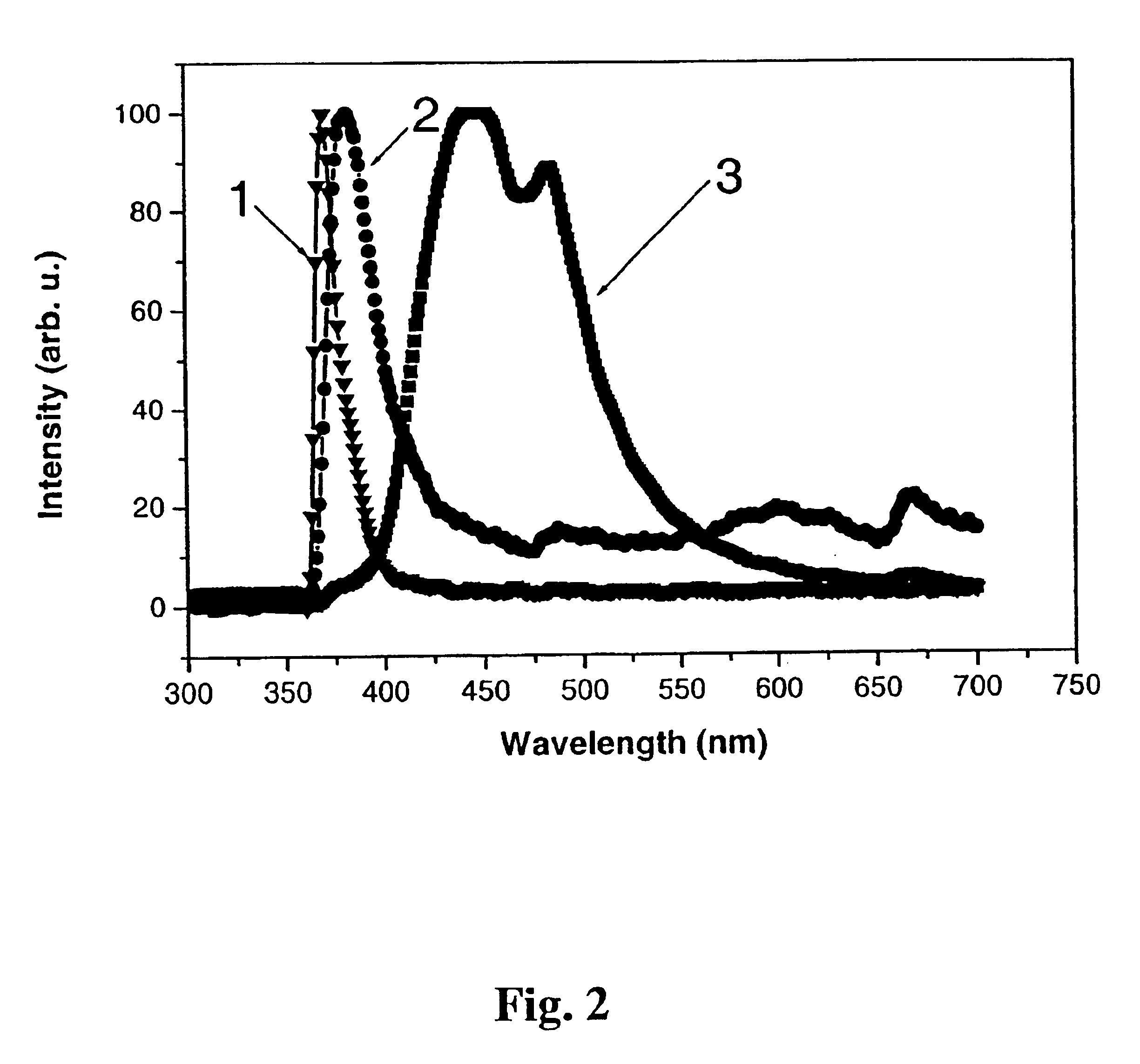

One-chip micro-integrated optoelectronic sensor

InactiveUS6881979B2High sensitivityLaser detailsFinal product manufactureOptical reflectionPhotovoltaic detectors

This disclosure describes one-chip micro-integrated optoelectronic sensors and methods for fabricating and using the same. The sensors may include an optical emission source, optical filter and a photodetector fabricated on the same transparent substrate using the same technological processes. Optical emission may occur when a bias voltage is applied across a metal-insulator-semiconductor Schottky contact or a p-n junction. The photodetector may be a Schottky contact or a p-n junction in a semiconductor. Some sensors can be fabricated on optically transparent substrate and employ back-side illumination. In the other sensors provided, the substrate is not transparent and emission occurs from the edge of a p-n junction or through a transparent electrode. The sensors may be used to measure optical absorption, optical reflection, scattering or fluorescence. The sensors may be fabricated and operated to provide a selected spectrum of light emitted and a multi-quantum well heterostructure may be fabricated to filter light reaching the photodetector.

Owner:HOUSTON UNIV OF

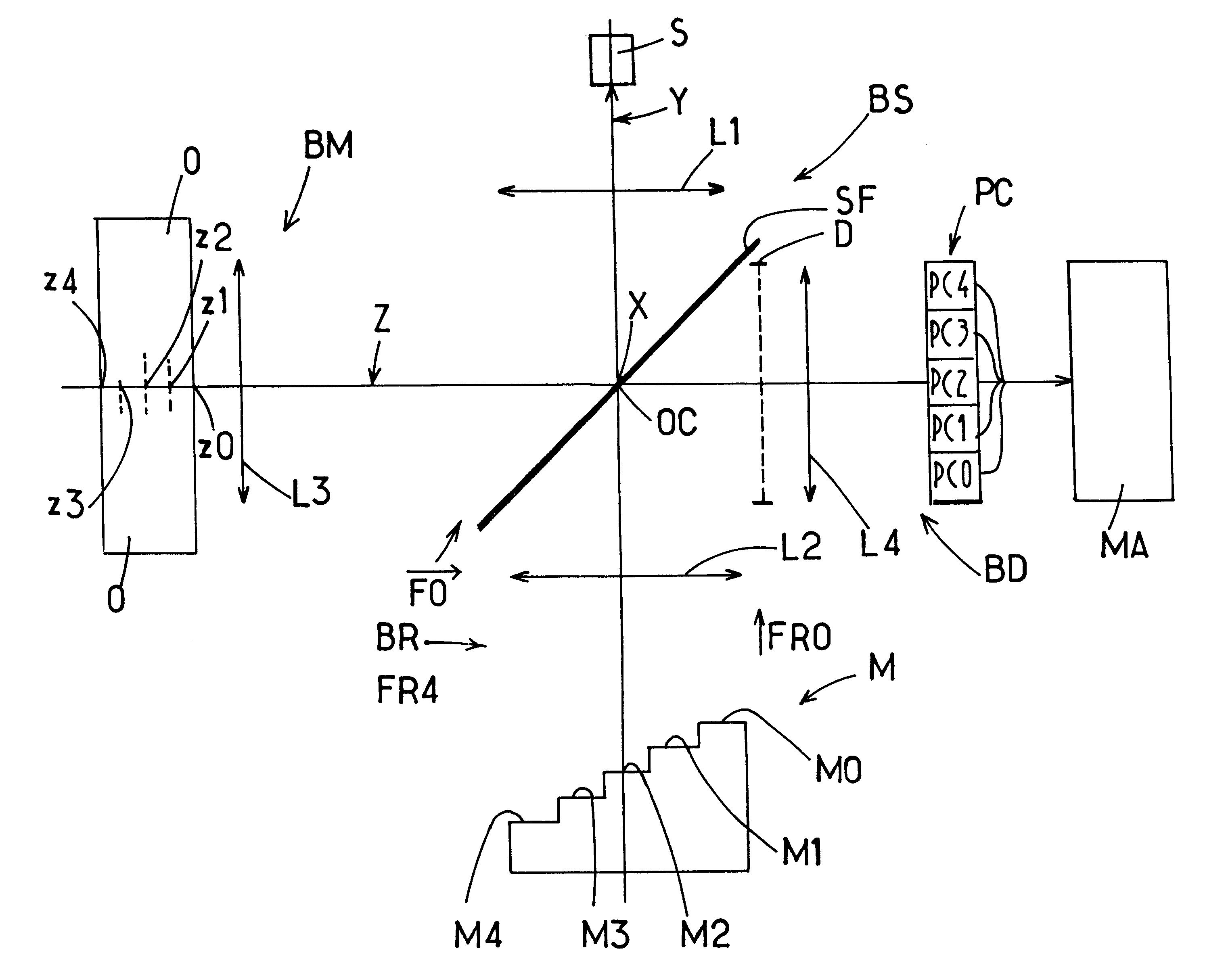

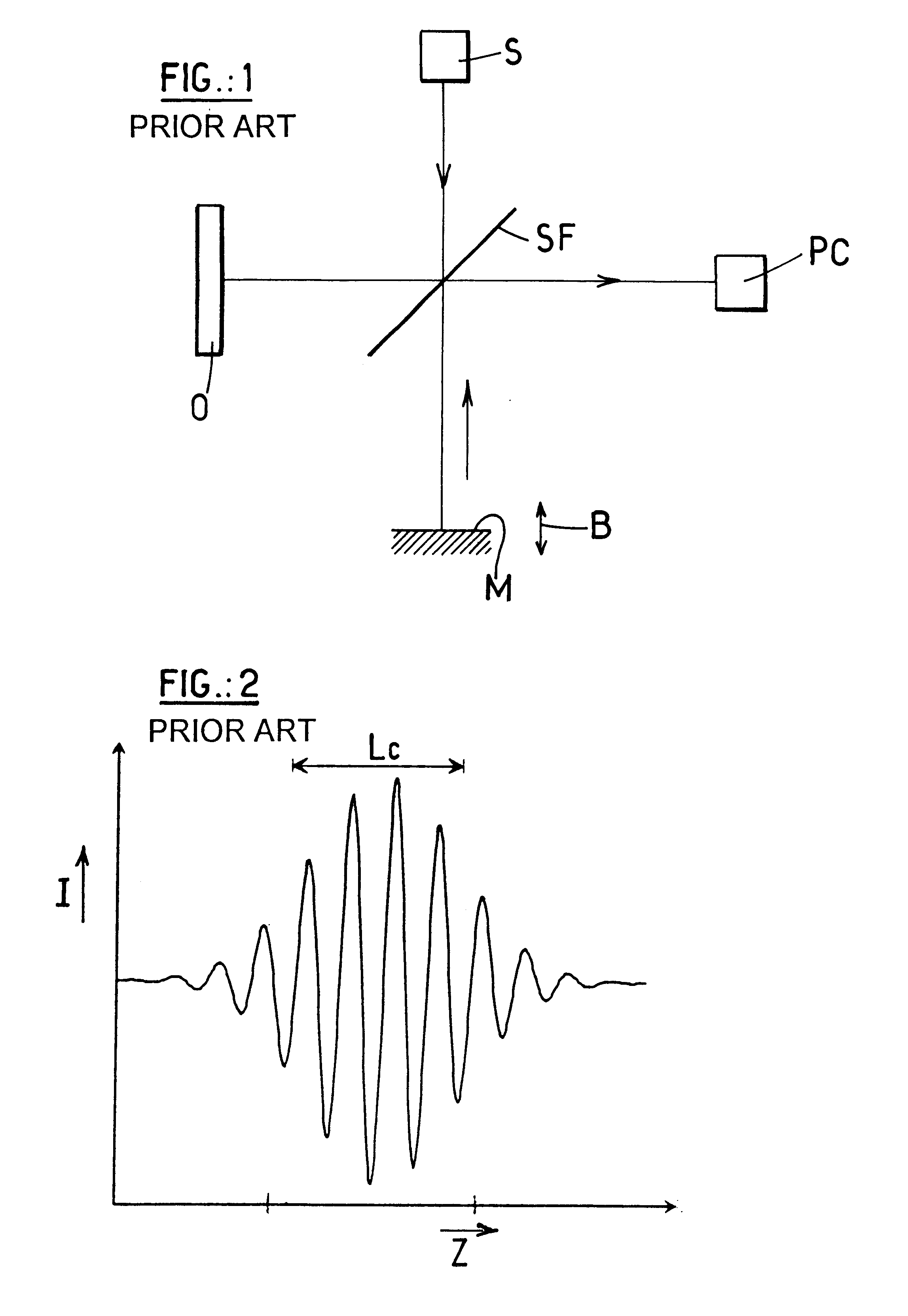

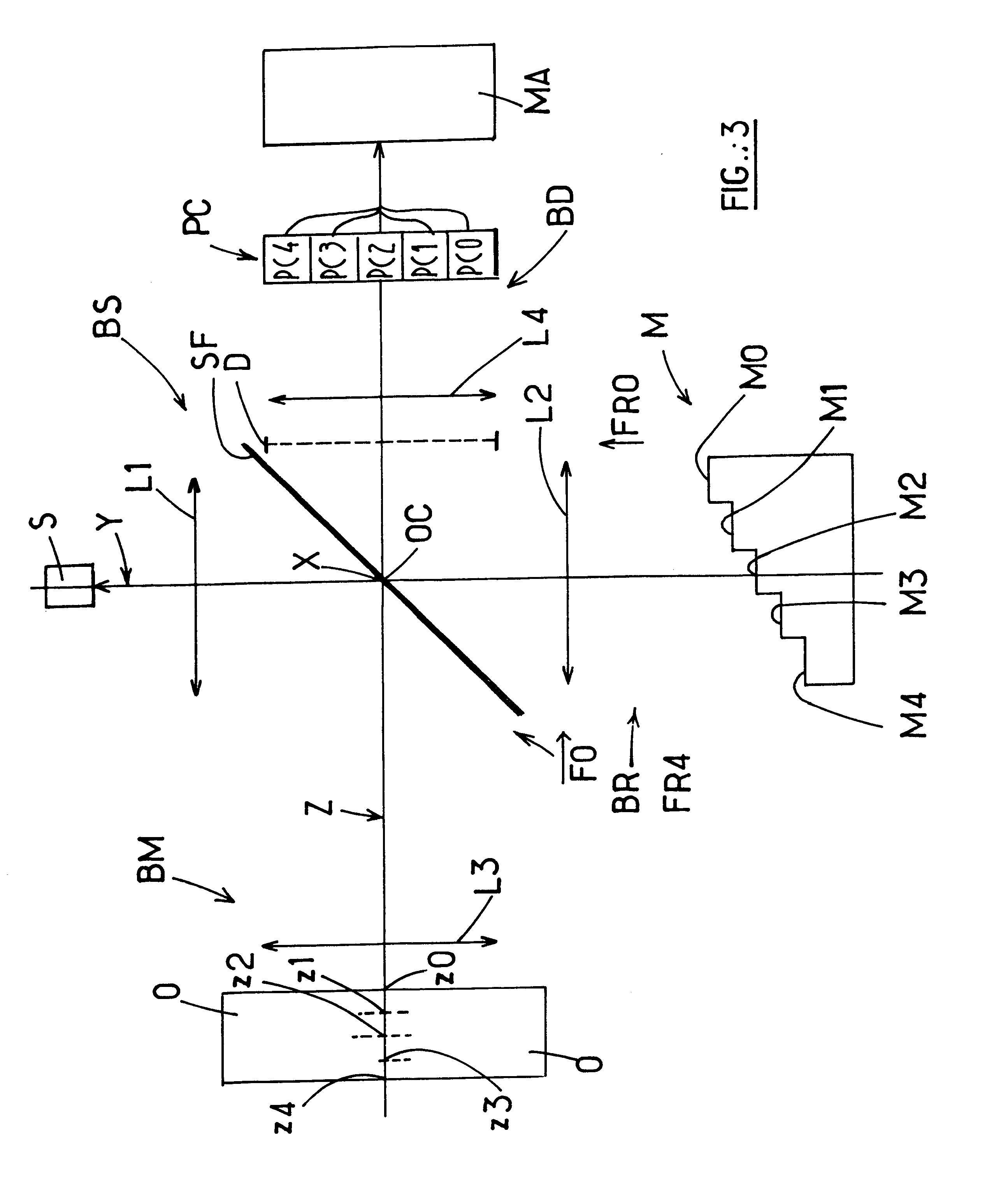

Interferometric device for recording the depth optical reflection and/or transmission characteristics of an object

InactiveUS6268921B1InterferometersColor/spectral properties measurementsOptical reflectionPath length

A tomographic interferometer device in which a spectral light source lights an object to create an object beam originating from that object. A stepped optical block is also exposed to the source to create a plurality of individual reference beams having different path lengths. The object beam and reference beams are made to interfere and the resulting light is sent to an array of side by side photodetectors. A plurality of lenses steer the light generated by the interference of each of the individual reference beams with the object beam to different photodetector cells of the array for generating a tomographic image of the object

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

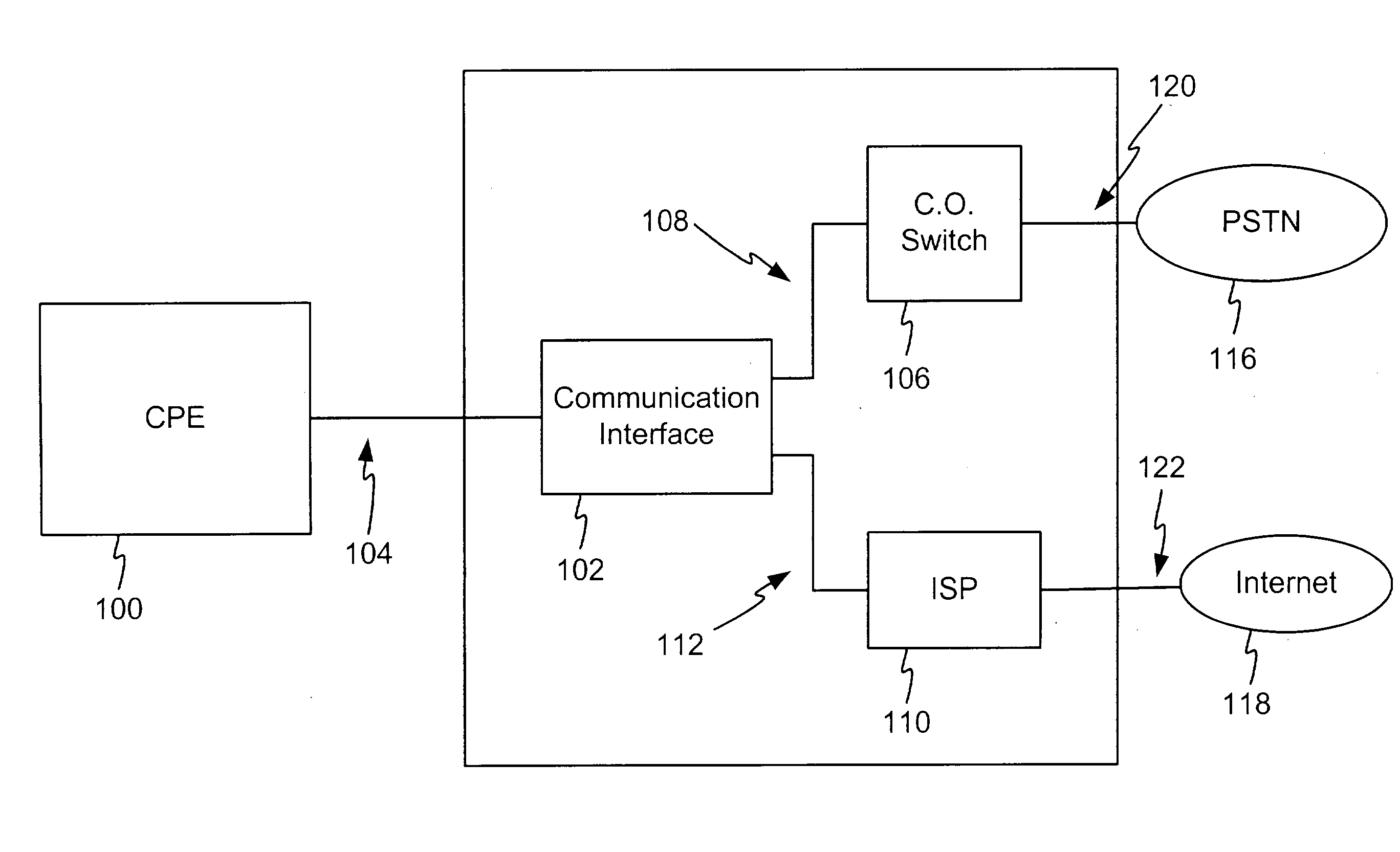

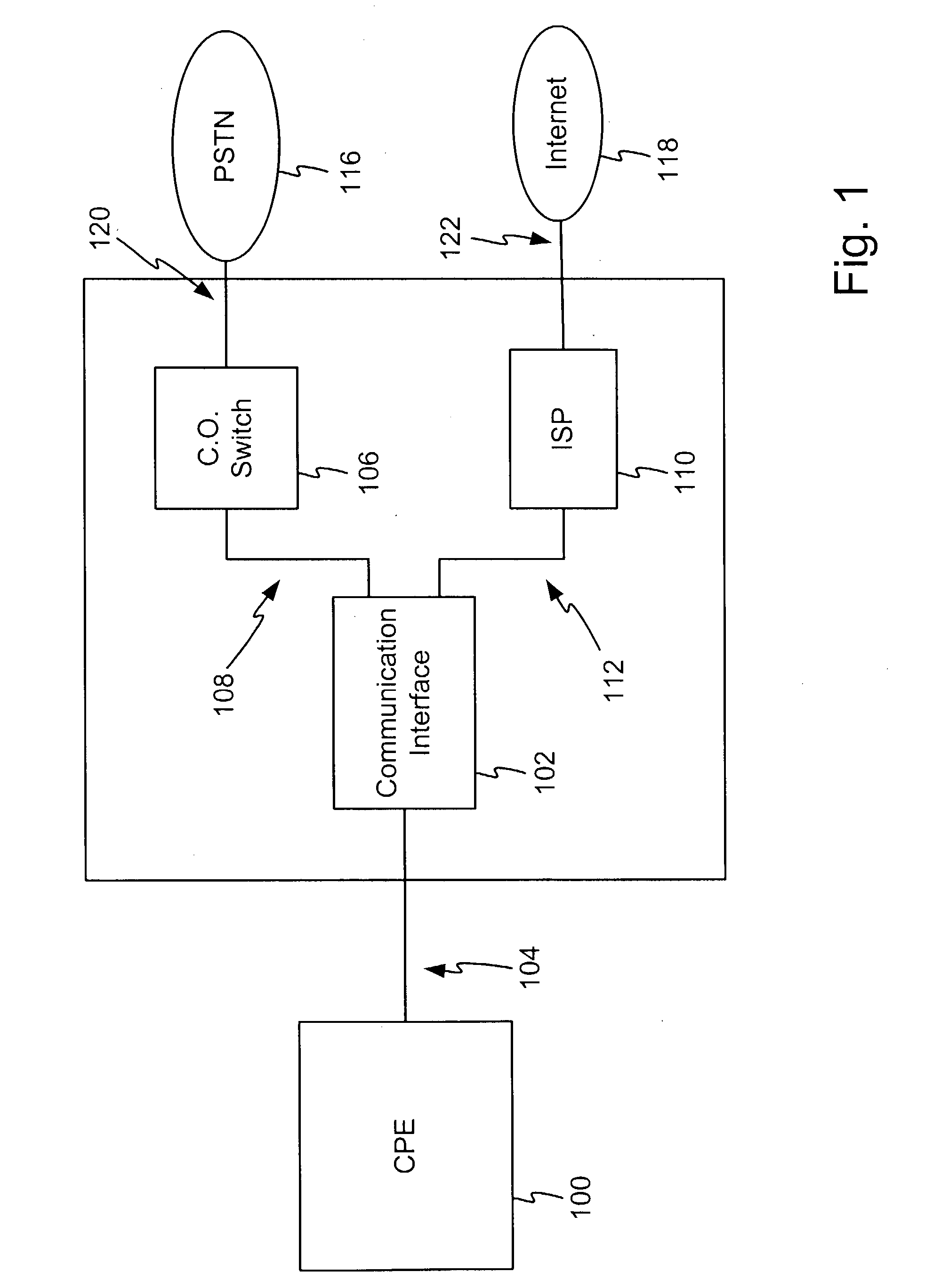

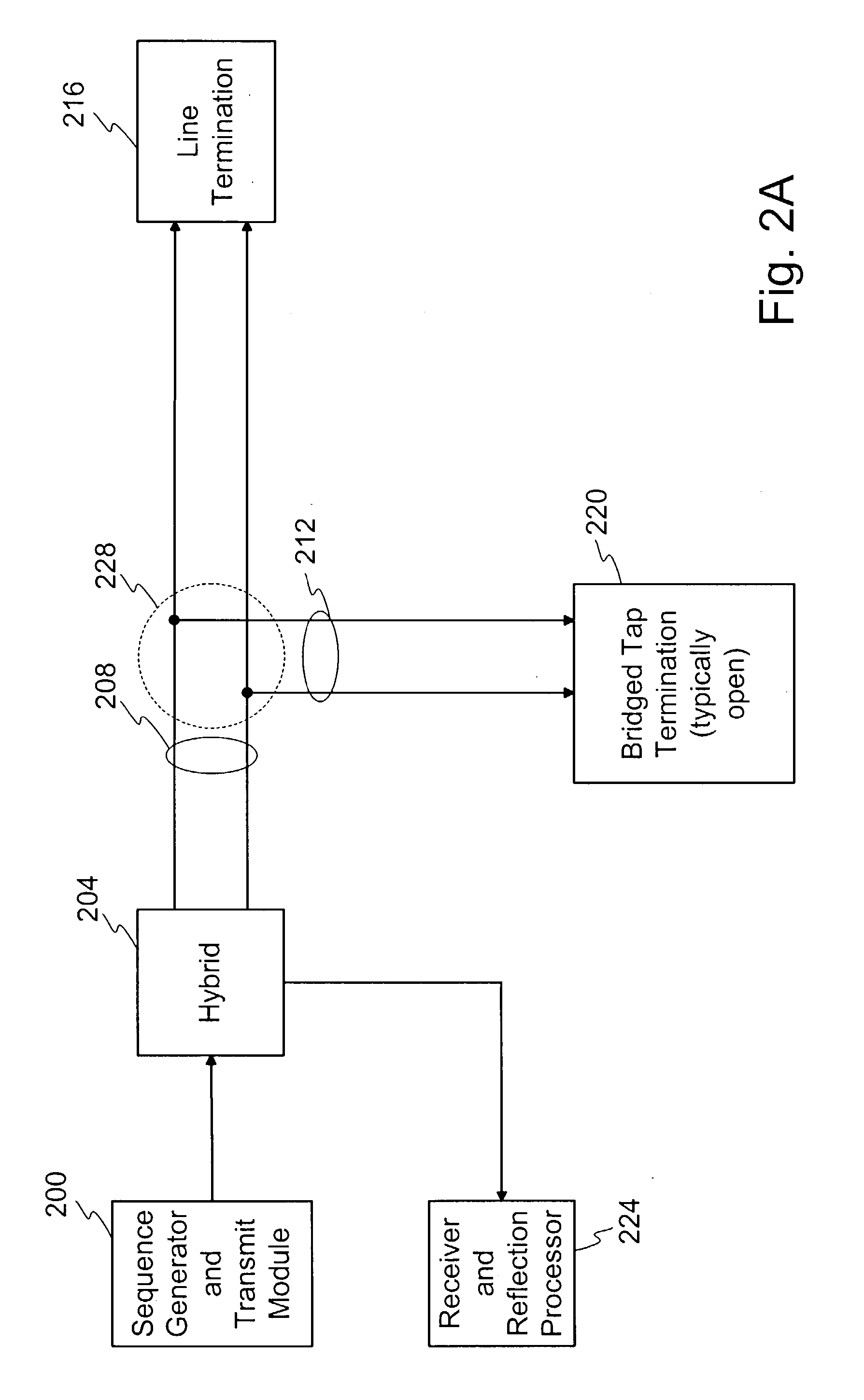

Optical sequence time domain reflectometry during data transmission

InactiveUS20040044489A1Resistance/reactance/impedenceVoltage-current phase angleOptical reflectionSequence signal

A method and system for performing sequence time domain reflectometry over a communication channel to determine the location of line anomalies in the communication channel is disclosed. In one embodiment, the system generates a sequence signal and transmits the sequence signal over an optical channel. The system receives one or more reflection signals over the optical channel and performs reflection signal processing on the reflection signal. In one embodiment, the optical reflection is transformed to an electrical signal and correlated with the original sequence signal to generate a correlated signal. The time between the start of the reflection signal and a subsequent point of correlation and the rate of propagation reveals a line anomaly location. In one or more embodiments sequence signal time domain reflectometry occurs during data transmission.

Owner:MACOM TECH SOLUTIONS HLDG INC

Multiple optical assembly for a led lighting device, and red lighting device comprising such an optical assembly

InactiveUS20060291206A1Improve performanceHighly compactNon-electric lightingPoint-like light sourceOptical reflectionTotal internal reflection

A LED lighting device has a number of LED's, and a multiple optical assembly defined by a number of modular units; each modular unit has a total-internal-reflection lens associated with a LED, and the modular units are connected to one another so as the lenses have respective distinct optical reflecting surfaces.

Owner:FRAEN CORPORATION

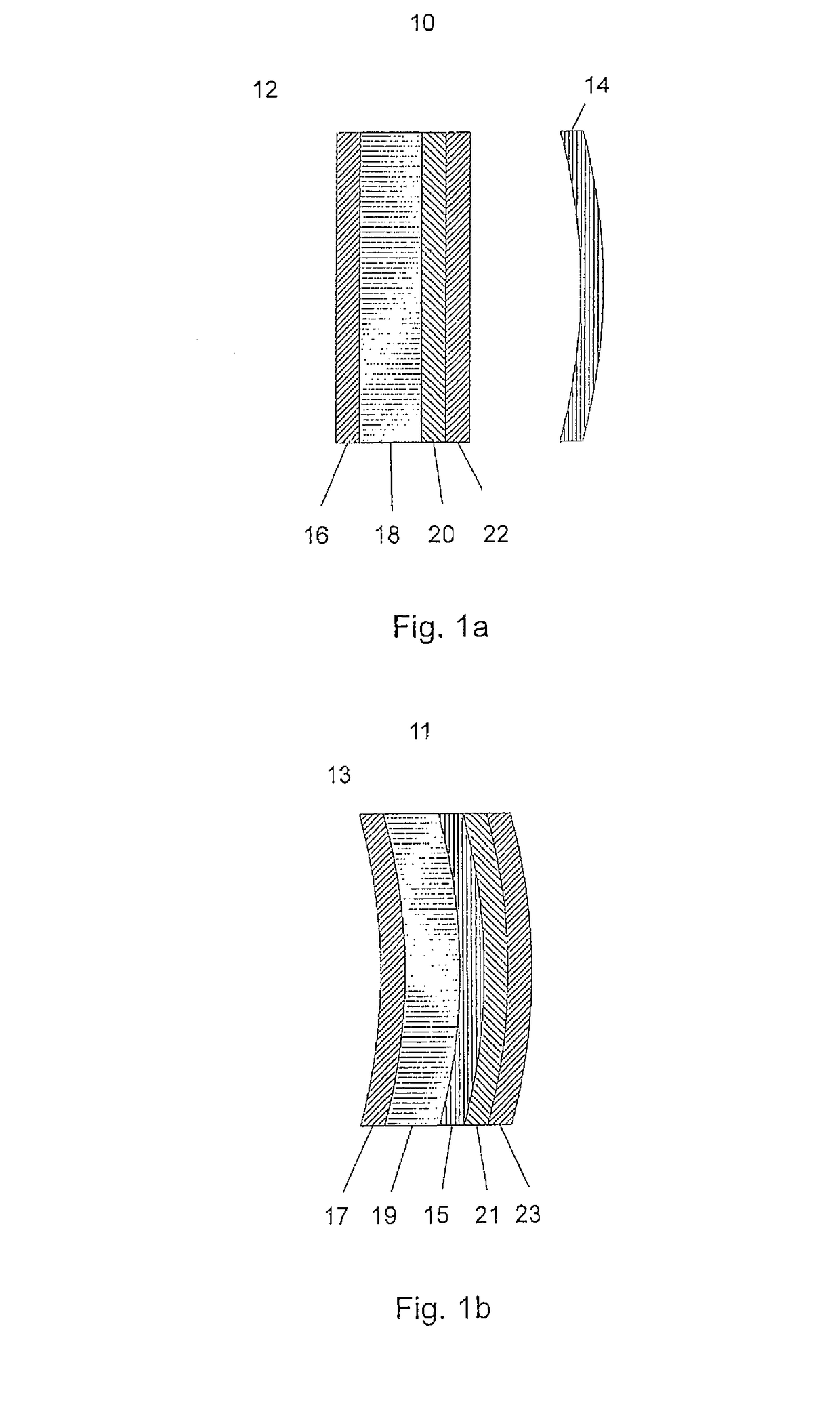

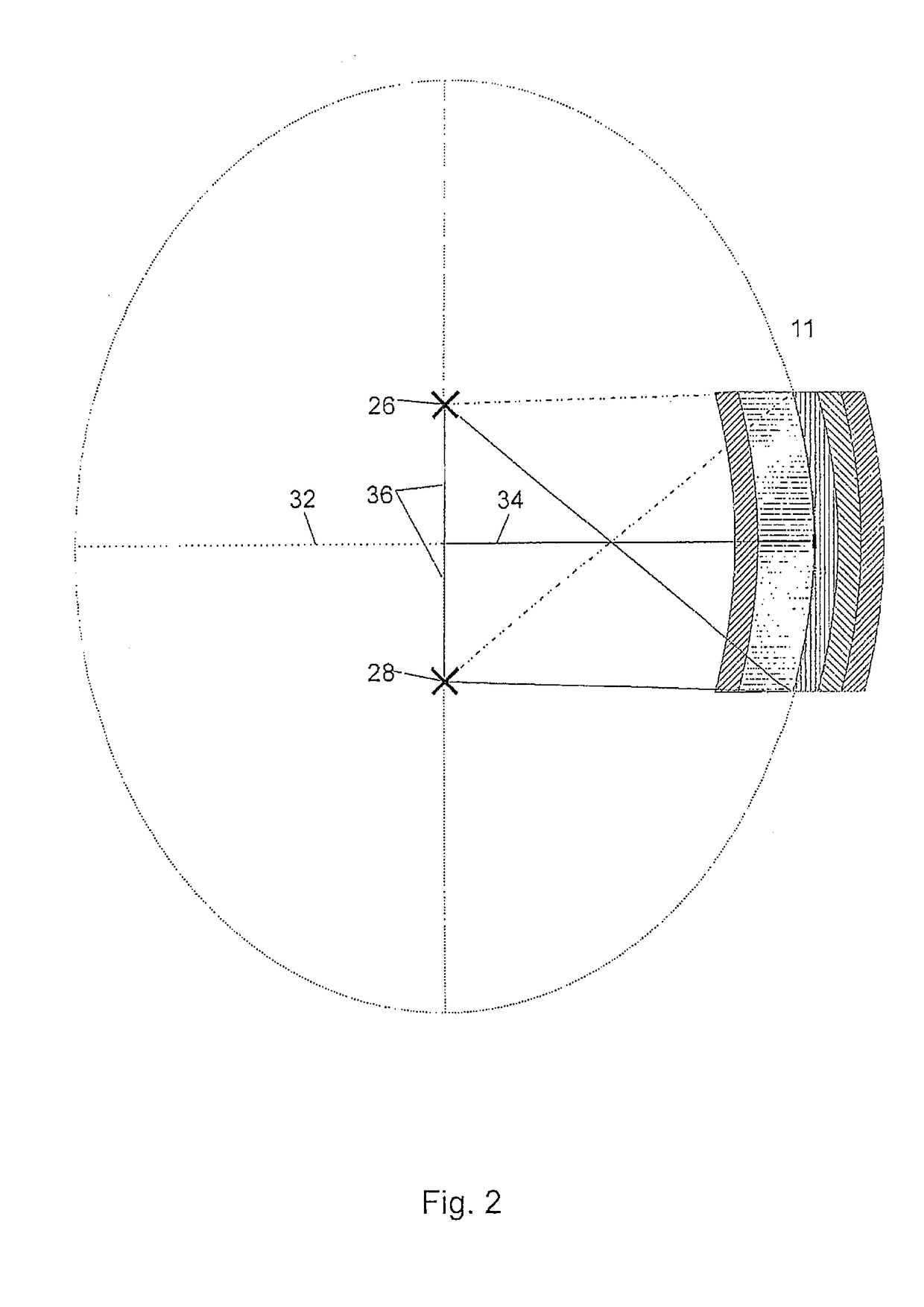

Reflective optical system, tracking system and holographic projection system and method

ActiveUS8120828B2Computational load requiredReduce demandStatic indicating devicesNon-linear opticsOptical reflectionVisibility

The invention relates to an optical reflection system with a reflection element for reflecting reconstruction light waves, an entry-side focal point, from which the reconstruction light waves come when they hit the reflection element, and an exit-side focal point, to which the reconstruction light waves propagate after being reflected from the reflection element. The invention further relates to a tracking system and a holographic projection system with such optical reflection system, and a corresponding holographic projection method. In order to achieve with such an optical reflection system an aberration correction and a tracking of the visibility region and a reconstruction larger than with prior art devices, the optical reflection system according to this invention comprises a deflection element with optically controllable deflection properties and a deflection control means for optically controlling the deflection properties of the deflection element which controls the position of at least the exit-side focal point of the optical reflection system.

Owner:SEEREAL TECHNOLOGIES

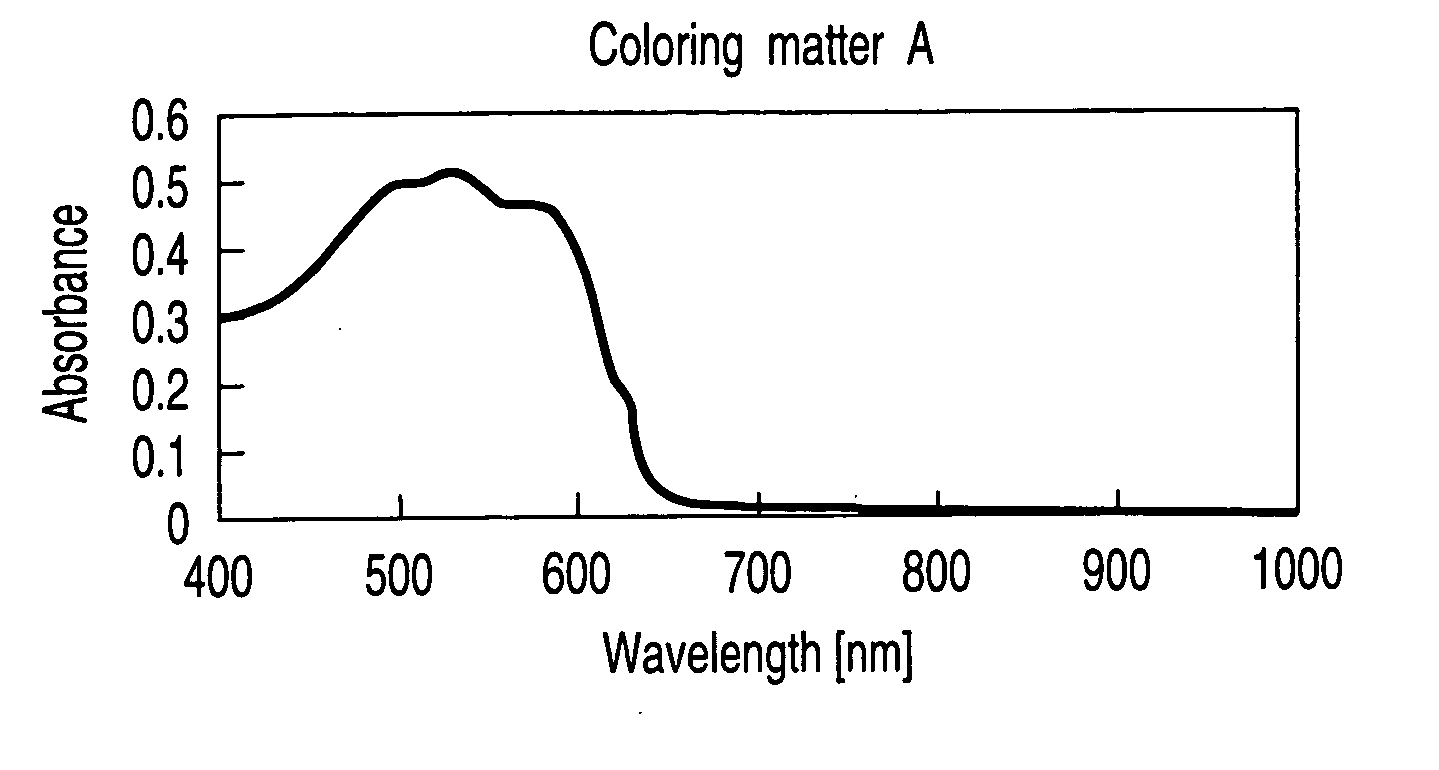

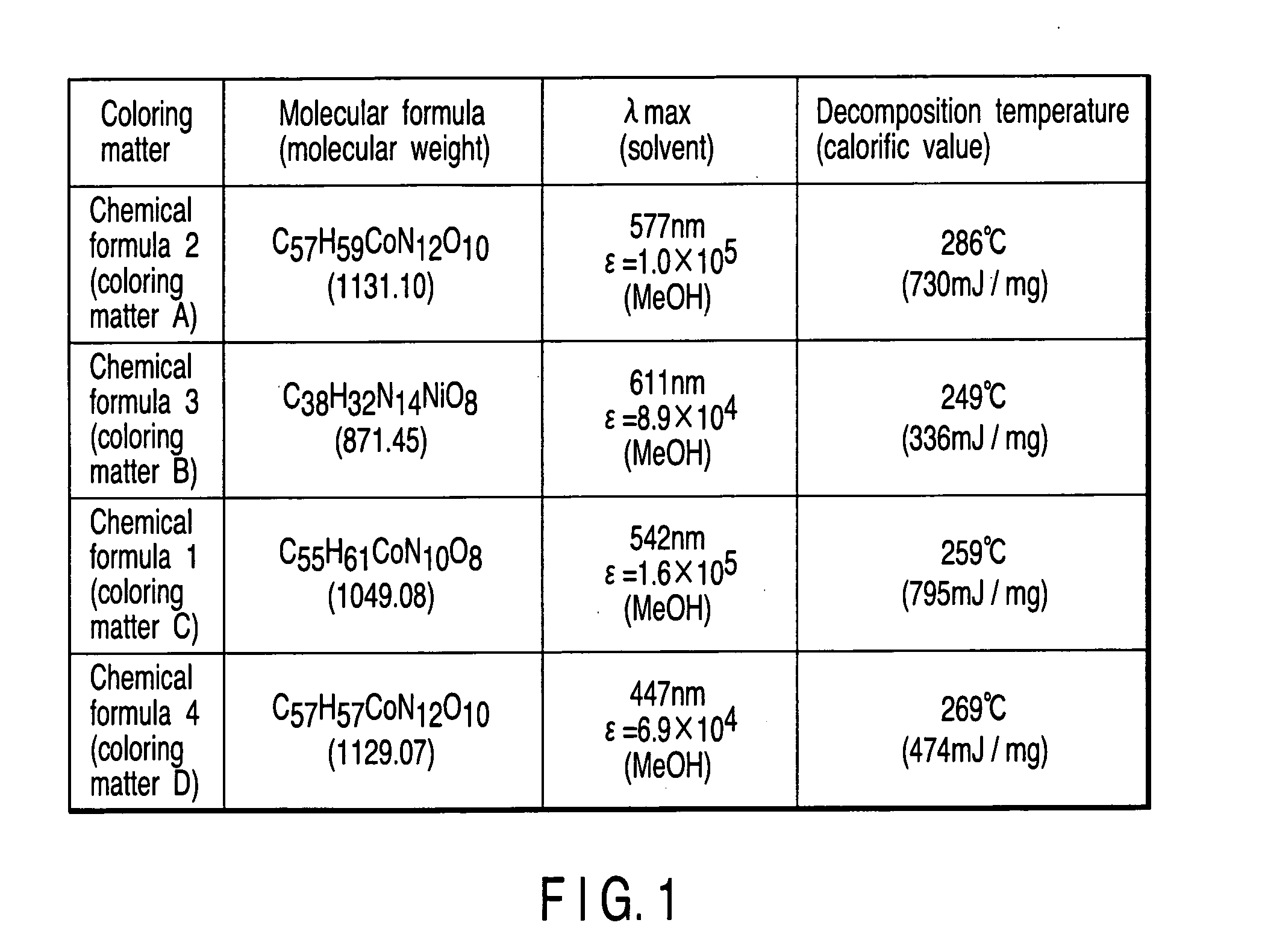

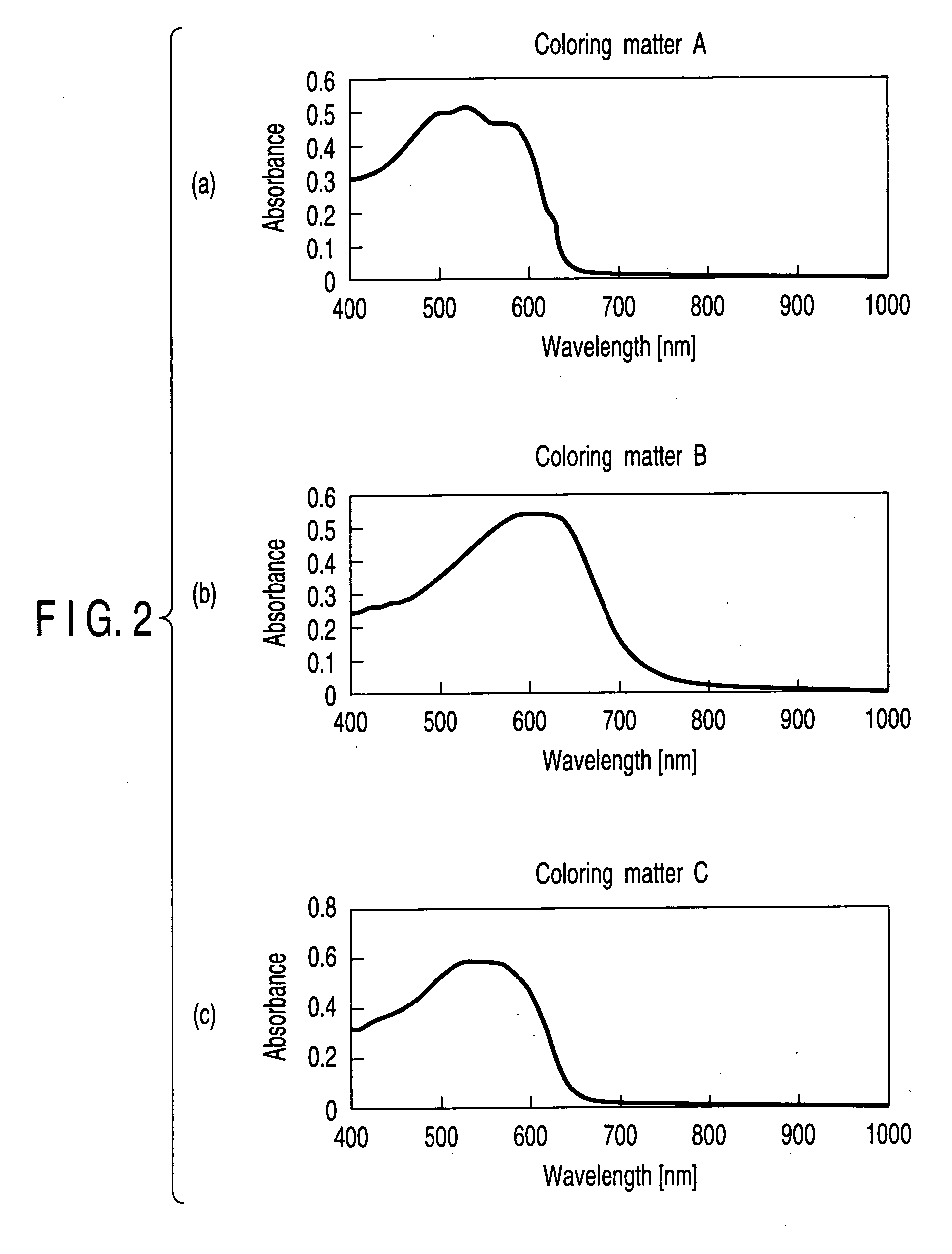

Recording material for medium

InactiveUS20050227178A1Reflection coefficientStyryl dyesLayered productsOptical reflectionLength wave

A recording material for a medium used for the recording film of a write-once type information recording disk equipped with a transparent resin substrate on which concentric or spiral grooves were formed and a recording film which was formed on the grooves, characterized in that it is formed by one organic coloring matter having an anion portion and a coloring matter portion in which the maximum absorption wavelength zone exists at a longer wavelength side than the wavelength of short wavelength laser beam irradiated on the recording film and forms a record mark on the recording film by irradiation of the short wavelength laser beam, and the record mark has a higher optical reflection coefficient than the optical reflection coefficient of the recording film before irradiation of the short wavelength laser beam. This material realizes so-called Low to High property.

Owner:KK TOSHIBA +1

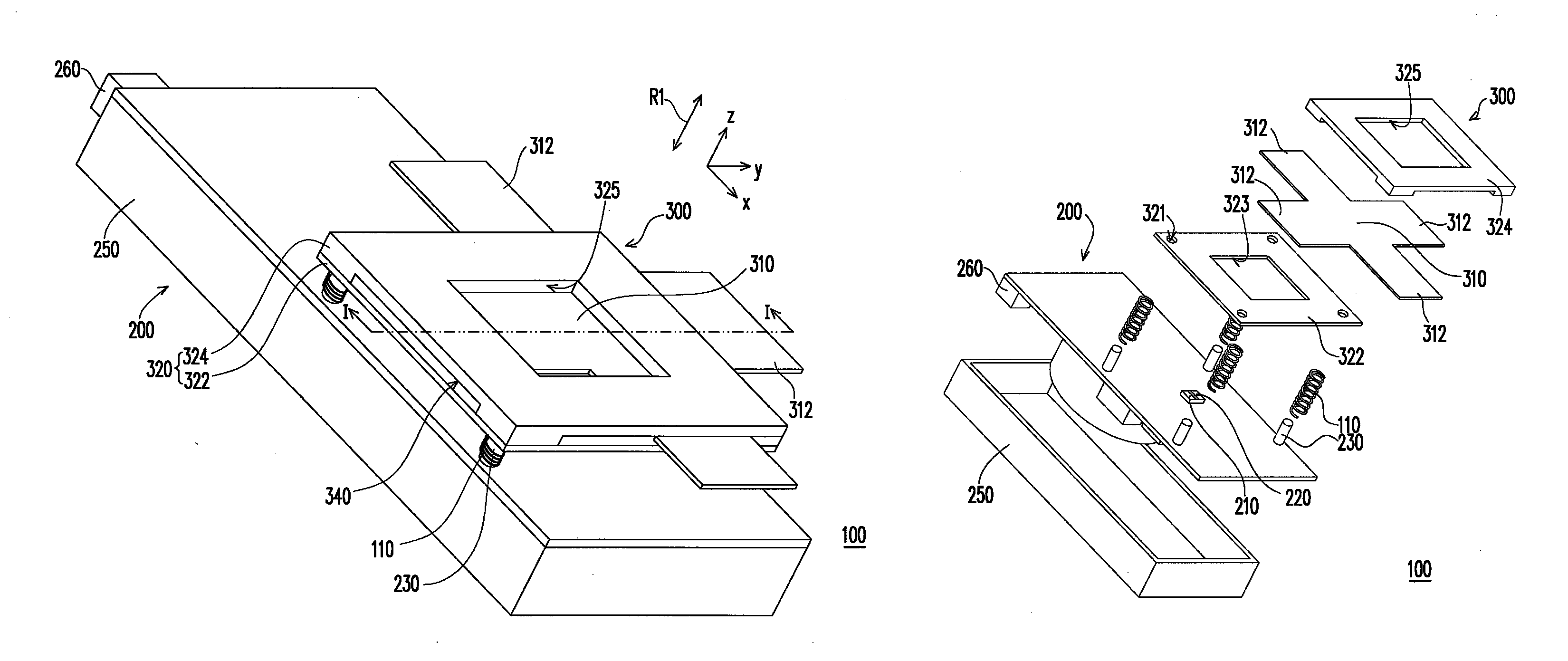

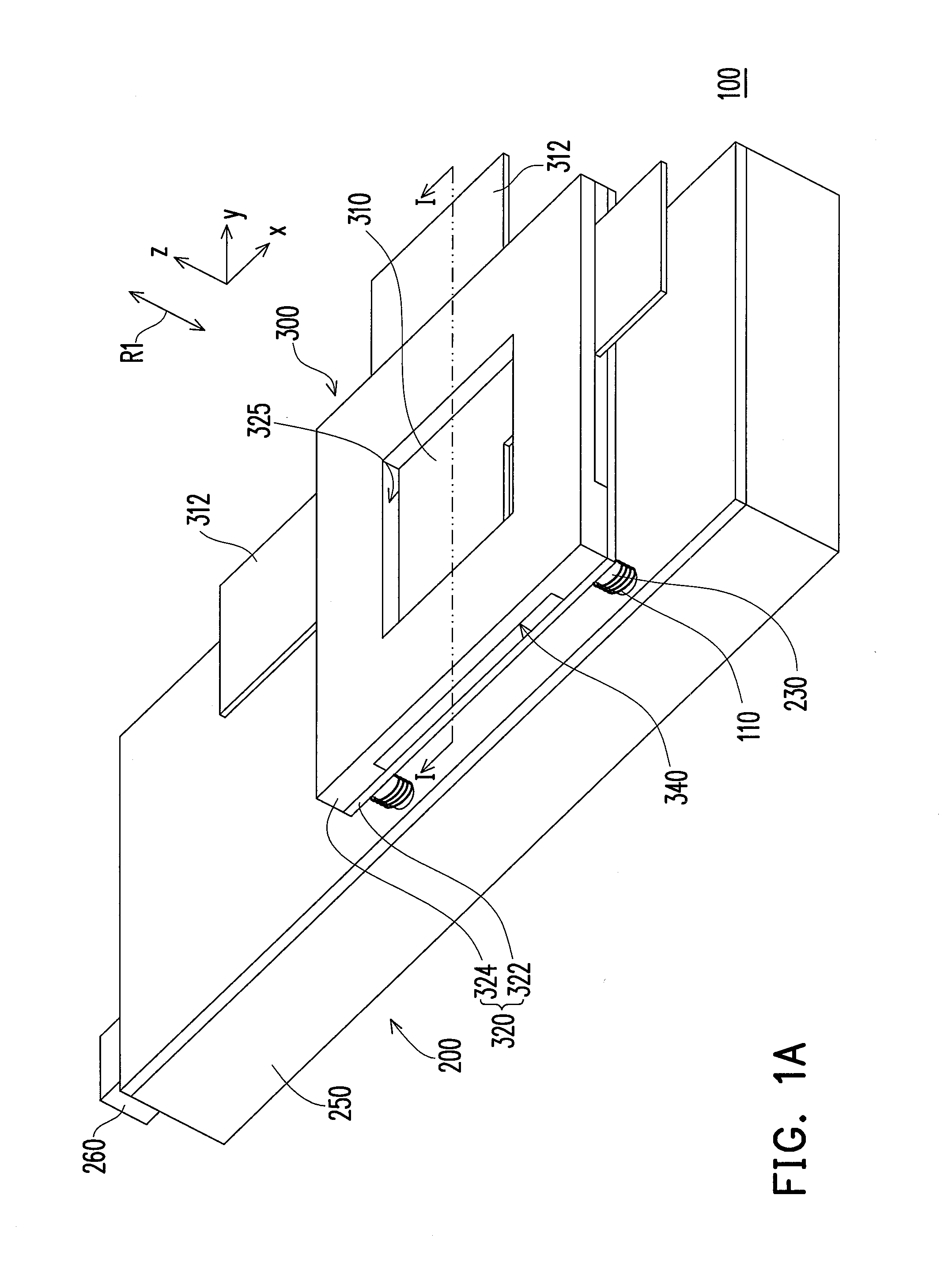

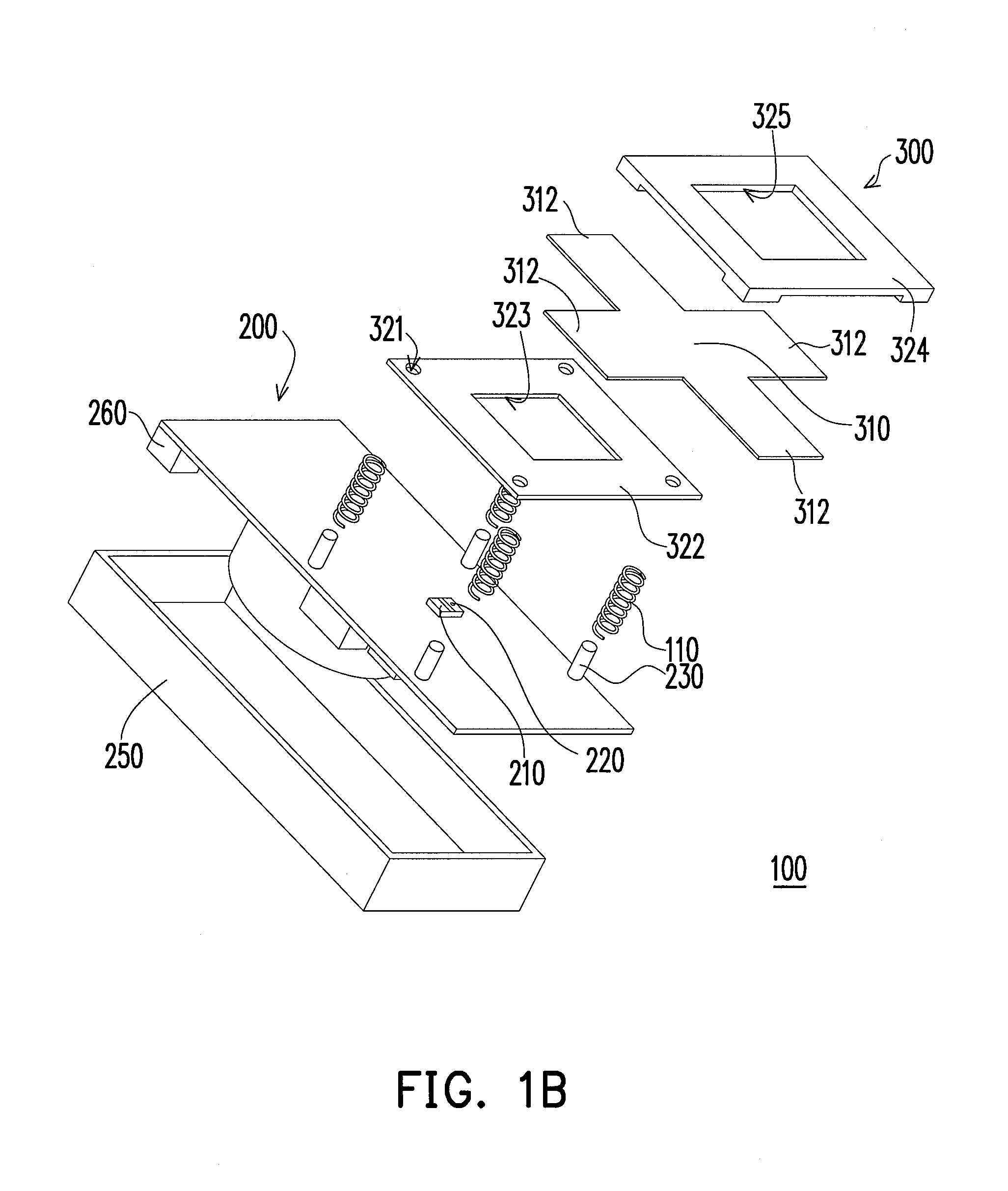

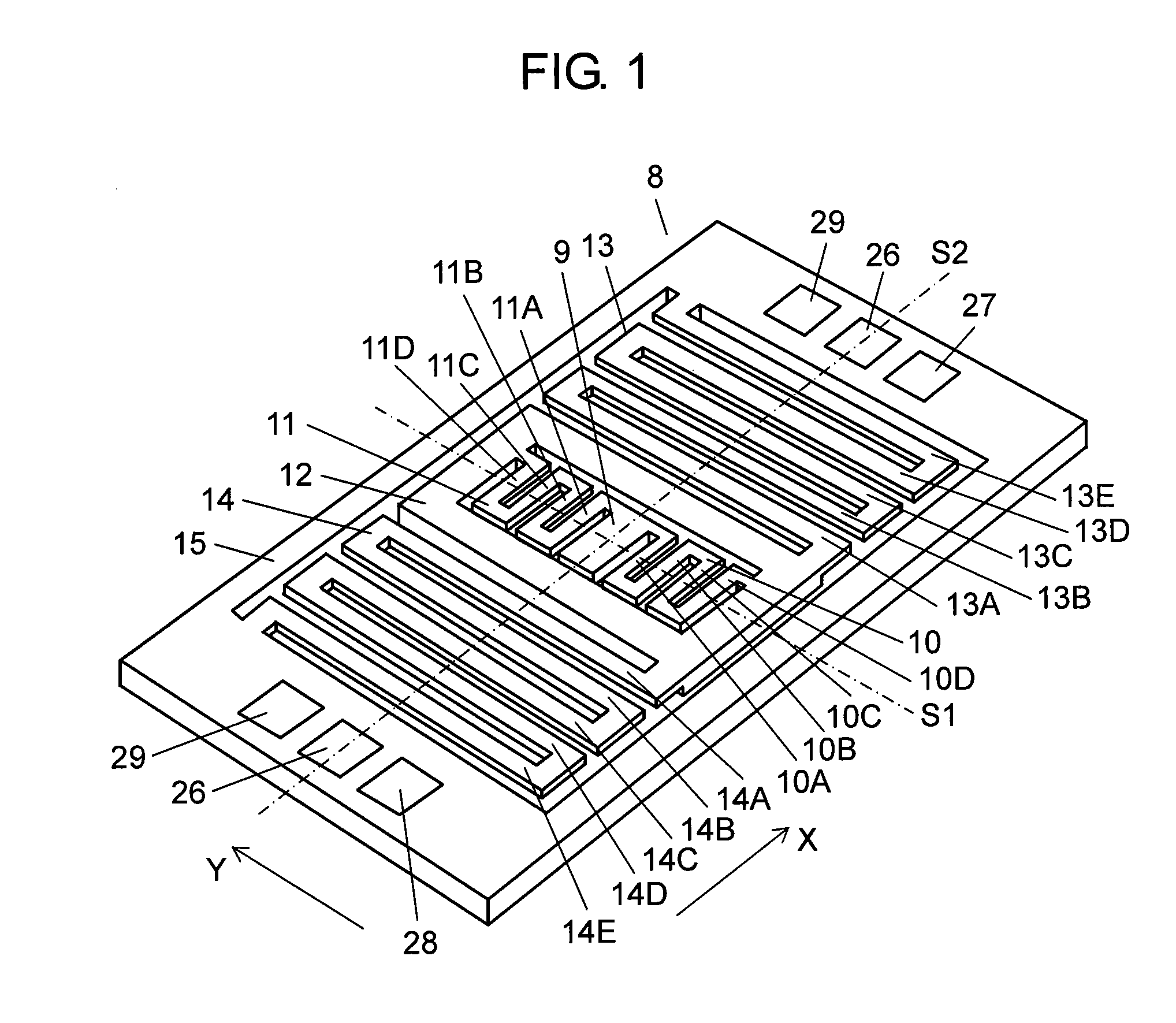

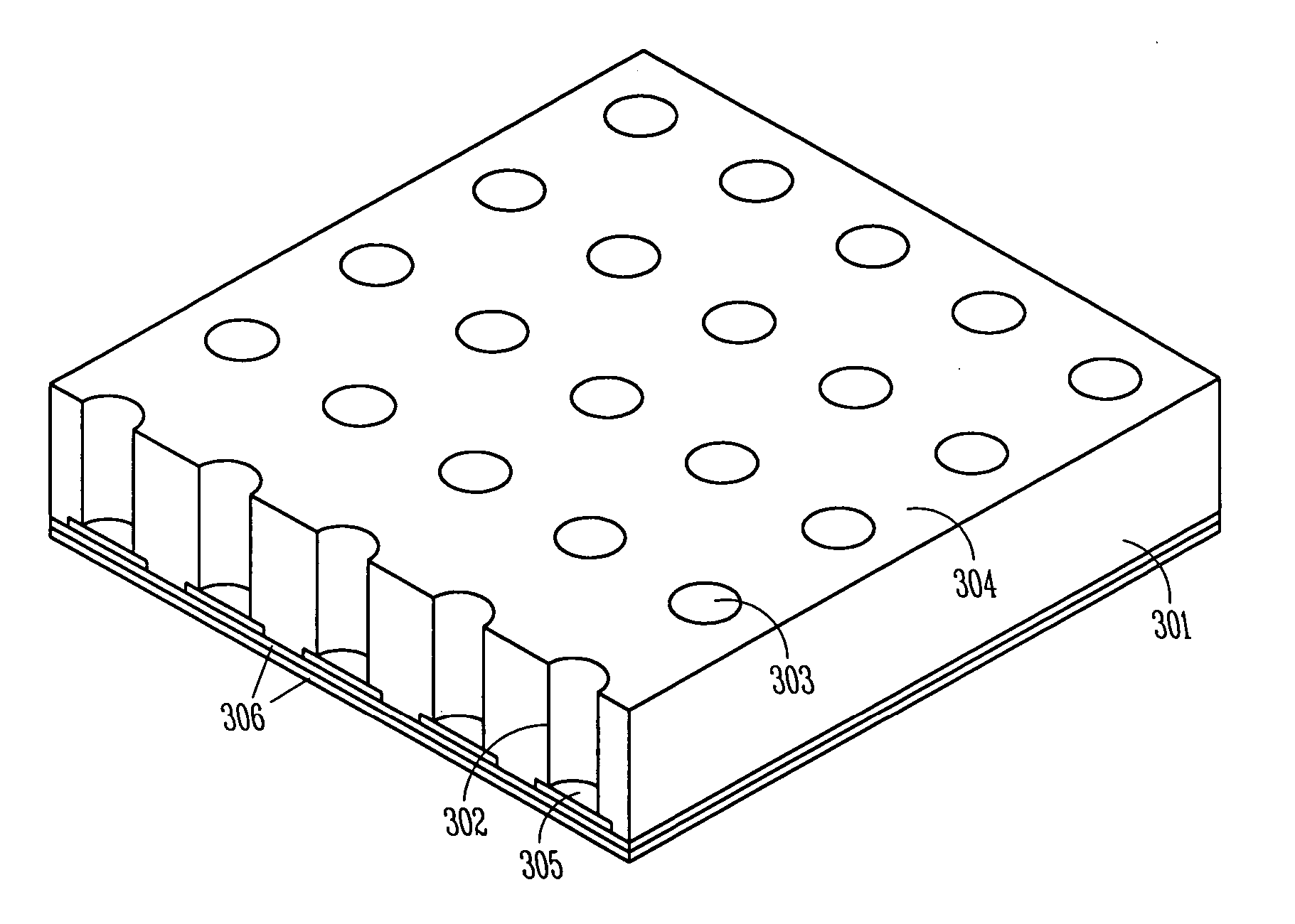

Input apparatus and optical reflection panel module

ActiveUS8477118B2Improve ease of useCathode-ray tube indicatorsInput/output processes for data processingOptical reflectionOptical Module

An input apparatus including an optical mouse module and a mouse pad module is provided. The optical mouse module includes a light source and an optical sensor. The light source is adapted to emit a light beam. The optical sensor has a sensible distance. The mouse pad module is disposed on the optical mouse module. The mouse pad module includes a sliding sheet elastically coupled to the optical mouse module. The sliding sheet is adapted to move in a three-dimensional space. The optical sensor and the sliding sheet are arranged in an arrangement direction. An operation method of the input apparatus is also provided.

Owner:IND TECH RES INST

Optical quality diamond material

ActiveUS7740824B2Prevent or reduce local strain generating defectsPrevent and reduce absorptionPolycrystalline material growthAfter-treatment detailsOptical reflectionGrating

Owner:ELEMENT SIX TECH LTD

Optical reflecting element and actuator

ActiveUS20140368896A1Reduce power consumptionHigh degree of design freedomPictoral communicationOptical elementsOptical reflectionEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

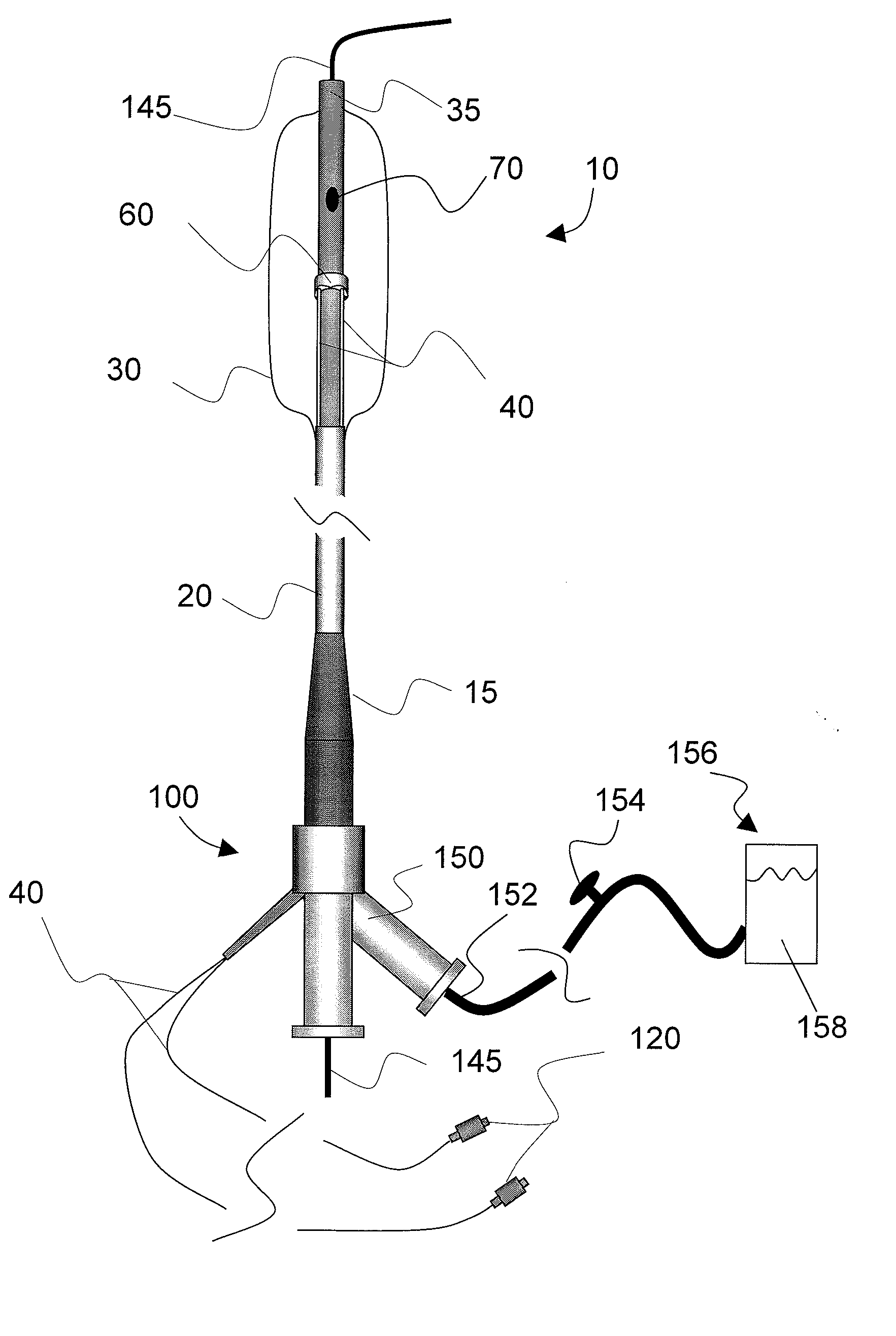

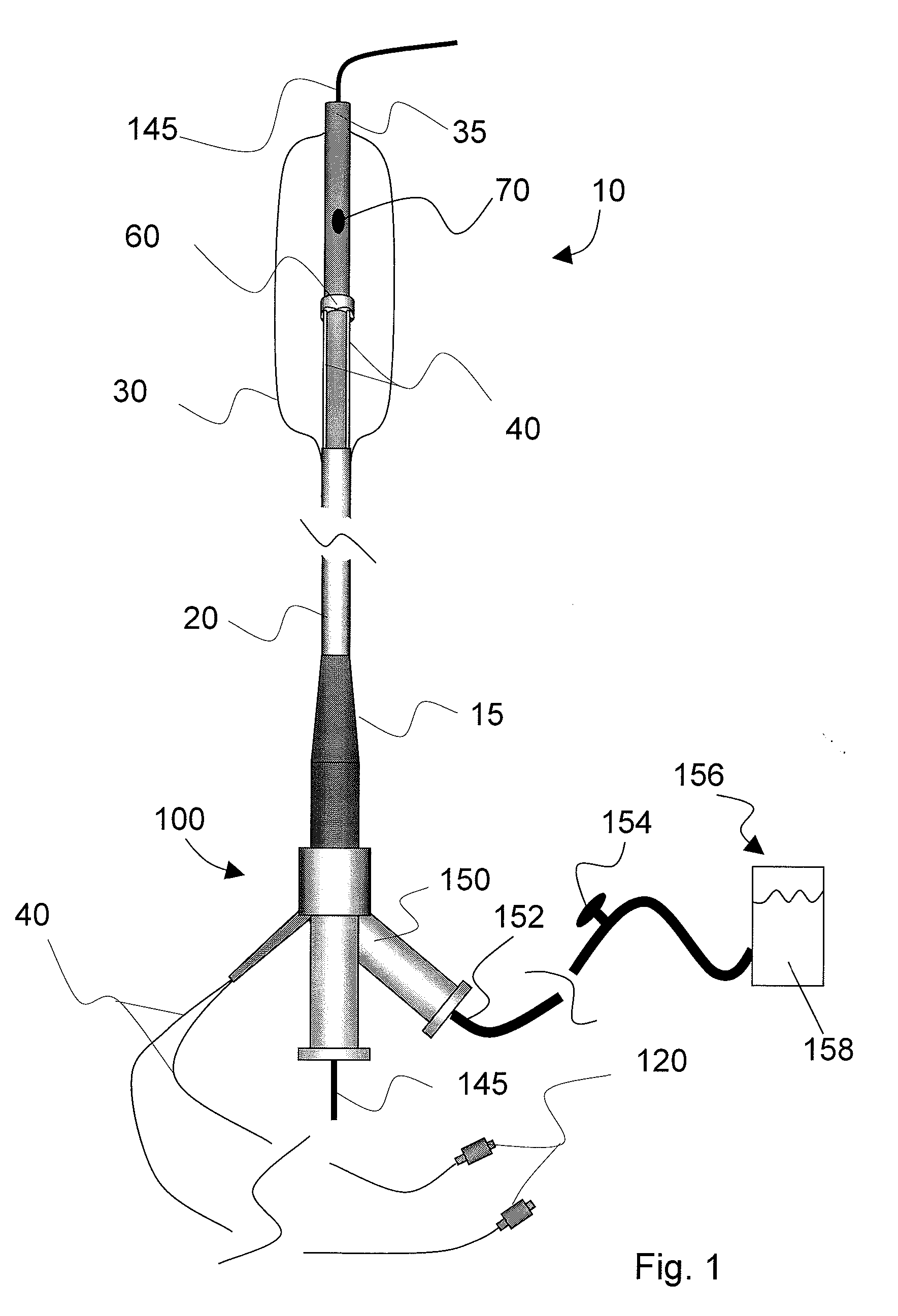

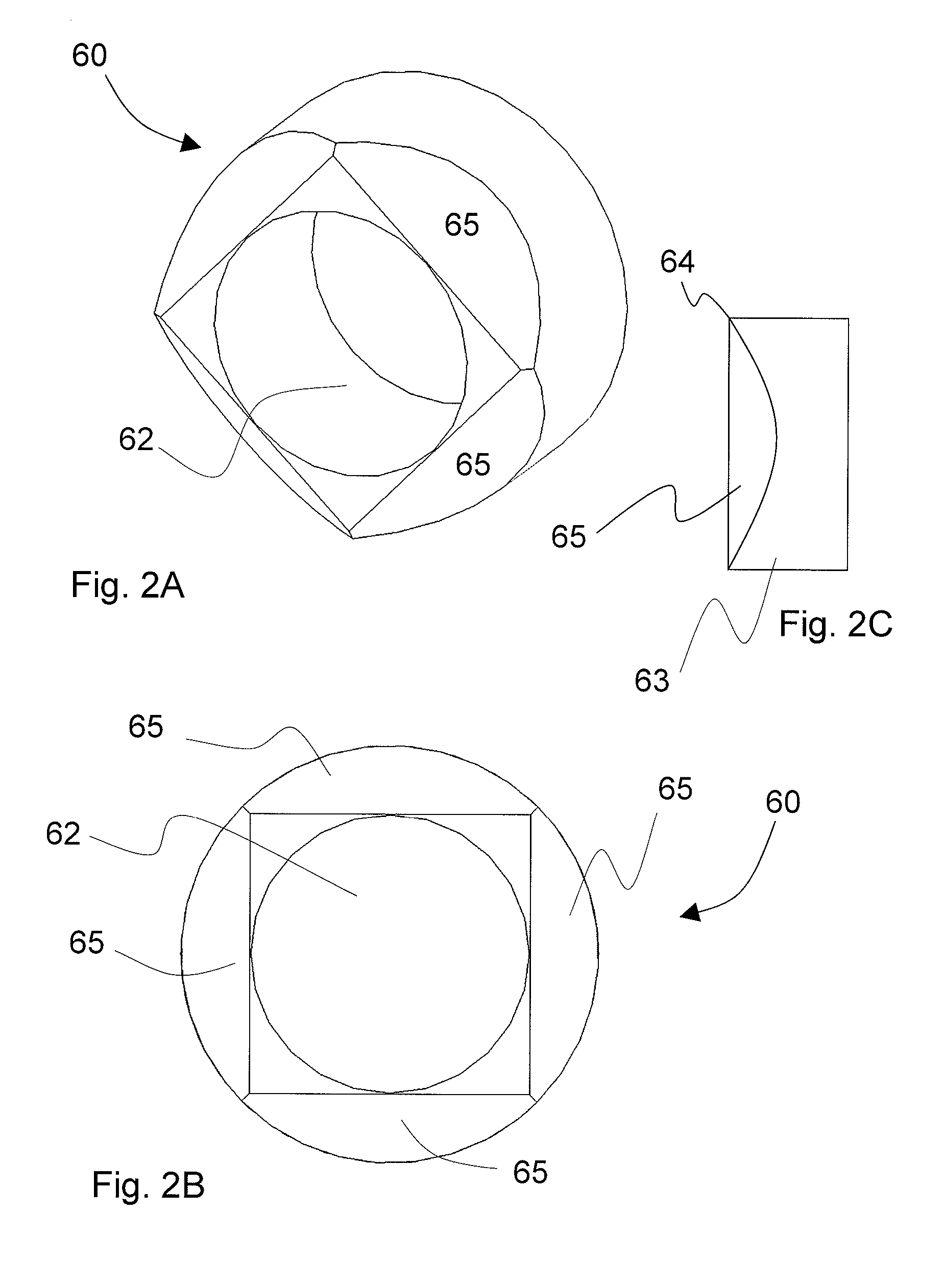

Multi-faceted optical reflector

InactiveUS20070270717A1Reliable and simplified and cost-effectiveSuppress luminescenceGlass making apparatusBalloon catheterFiberOptical reflection

A reflecting element with multiple reflective facets is integrated with the distal end of a multi-fiber optical probe. The facets are shaped depending on the type of analysis performed and according to the desired distribution of radiation to and from internal body tissues and fluids. The probe can include a protective transparent balloon or other covering that separates the reflecting element from interior tissue walls and provides a window for radiation to be transmitted between the reflecting facets and a region of interest. The probe can be integrated with treatment-based devices, including lumen-expanding angioplasty balloon catheters. The probe can also be adapted as an imaging device such as an endoscope.

Owner:CORNOVA

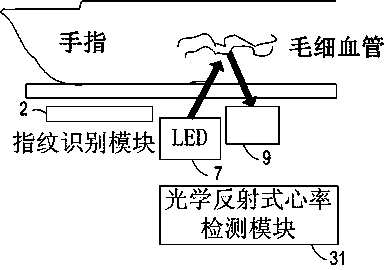

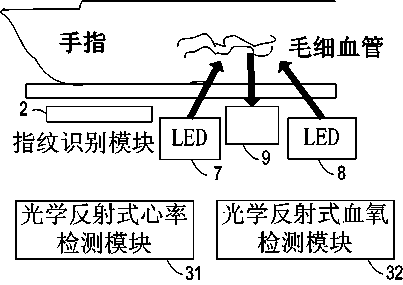

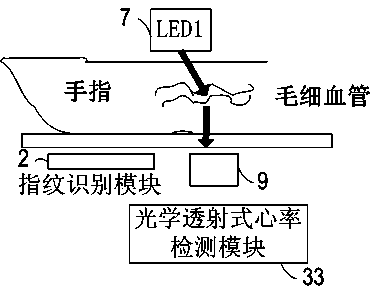

Intelligent fingerprint identification device and device

ActiveCN104239869AImprove securityCharacter and pattern recognitionOptical reflectionIdentification device

The invention provides an intelligent fingerprint identification device and device. The device comprises an intelligent fingerprint identification control unit, a fingerprint identification module, a physiological parameter detecting module and a power supply unit. The fingerprint identification module is used for performing conventional fingerprint identification. The physiological parameter detecting module is used for detecting the physiological parameters of a living body, wherein the physiological parameters include blood oxygen, heart rate and the like. The physiological parameter detecting module can be one or more of an optical reflective heart rate detecting module, an optical reflective blood oxygen detecting module, an optical transmission-type heart rate detecting module, an optical transmission-type blood oxygen detecting module, and an electrocardiogram type heart rate detecting module. The method includes: setting comparison data; detecting the physiological parameters; judging whether living body tissues is the tissues with pulse signals or not; identifying fingerprints; judging whether the fingerprints conform to set fingerprints or not; executing set actions. The device and the method have the advantages that heart rate or blood oxygen saturation identification is performed before conventional fingerprint identification, verification passing by using a cut-off finger or a simulated fingerprint film is avoided, and safety of the fingerprint identification device is increased.

Owner:武汉华和机电技术有限公司

Pseudo-reflective read inhibitor for optical storage media

InactiveUS6839316B2Low costChange is minimalCombination recordingLayered productsOptical reflectionTime function

System and methods are described for inhibiting the readability of an optical media due to changes in a pseudo-reflective material that composes the optical media after the optical media has been exposed to air for a predetermined time. An optical media includes a data encoded component. At least a fraction of the data encoded component transforms from a substantially optically reflective state to a substantially optically non-reflective state as at-least-in-part a function of time from an initializing event. The systems and methods provide advantages because of low cost, limited content lifetime, avoidance of rental returns and minimum changes to existing manufacturing processes.

Owner:FLEXPLAY TECH INC

Directory read inhibitor for optical storage media

InactiveUS6838144B2Low costChange is minimalLayered productsPhotomechanical apparatusOptical reflectionTime function

Systems and methods are described for inhibiting the readability of an optical media due to changes in a pseudo-reflective material that composes the optical media after the optical media has been exposed to air for a predetermined time. An optical media includes a data encoded component. At least a fraction of the data encoded component transforms from a substantially optically reflective state to a substantially optically non-reflective state as at-least-in-part a function of time from an initializing event. The systems and methods provide advantages because of low cost, limited content lifetime, avoidance of rental returns and minimum changes to existing manufacturing processes.

Owner:FLEXPLAY TECH INC

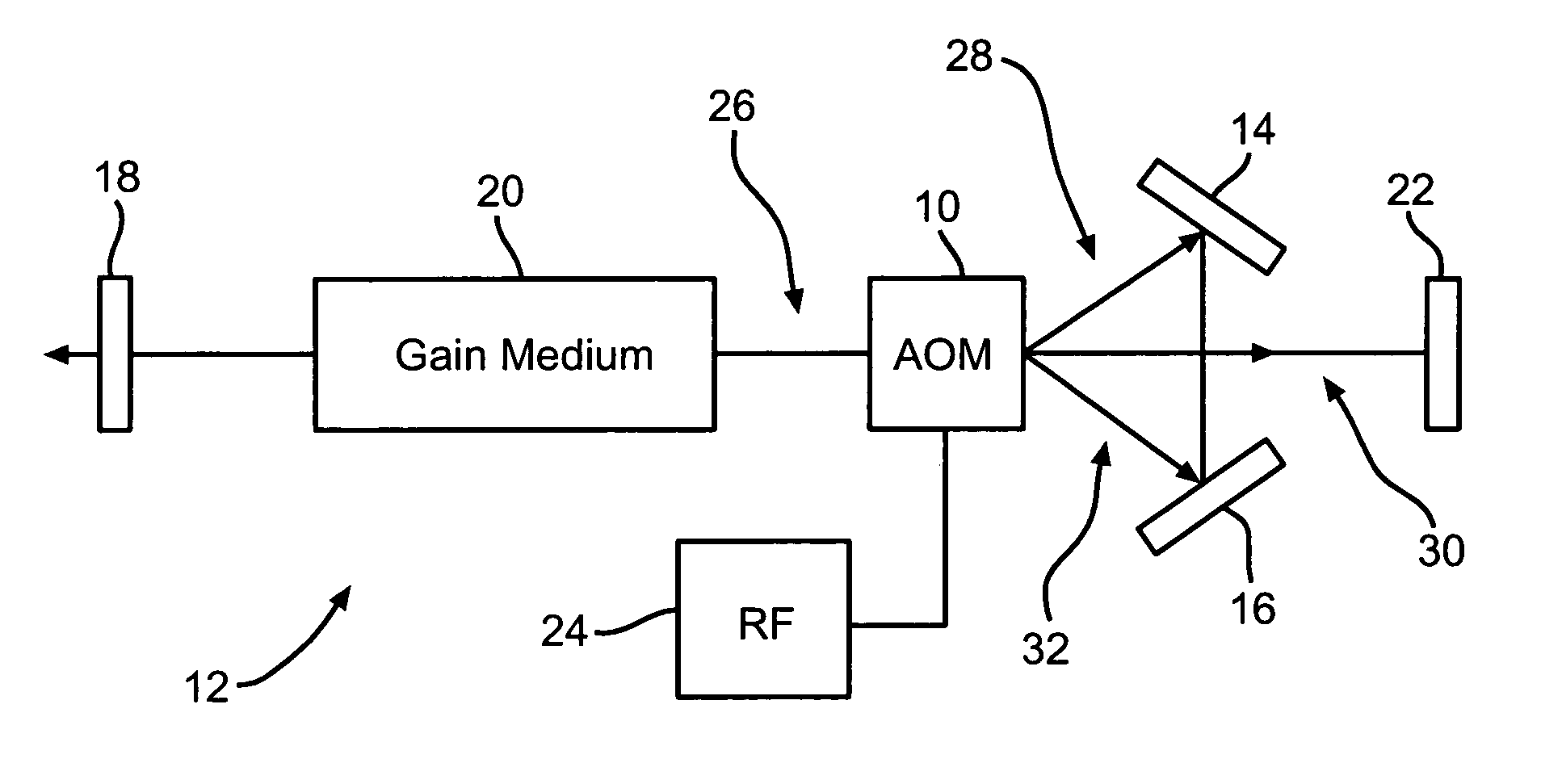

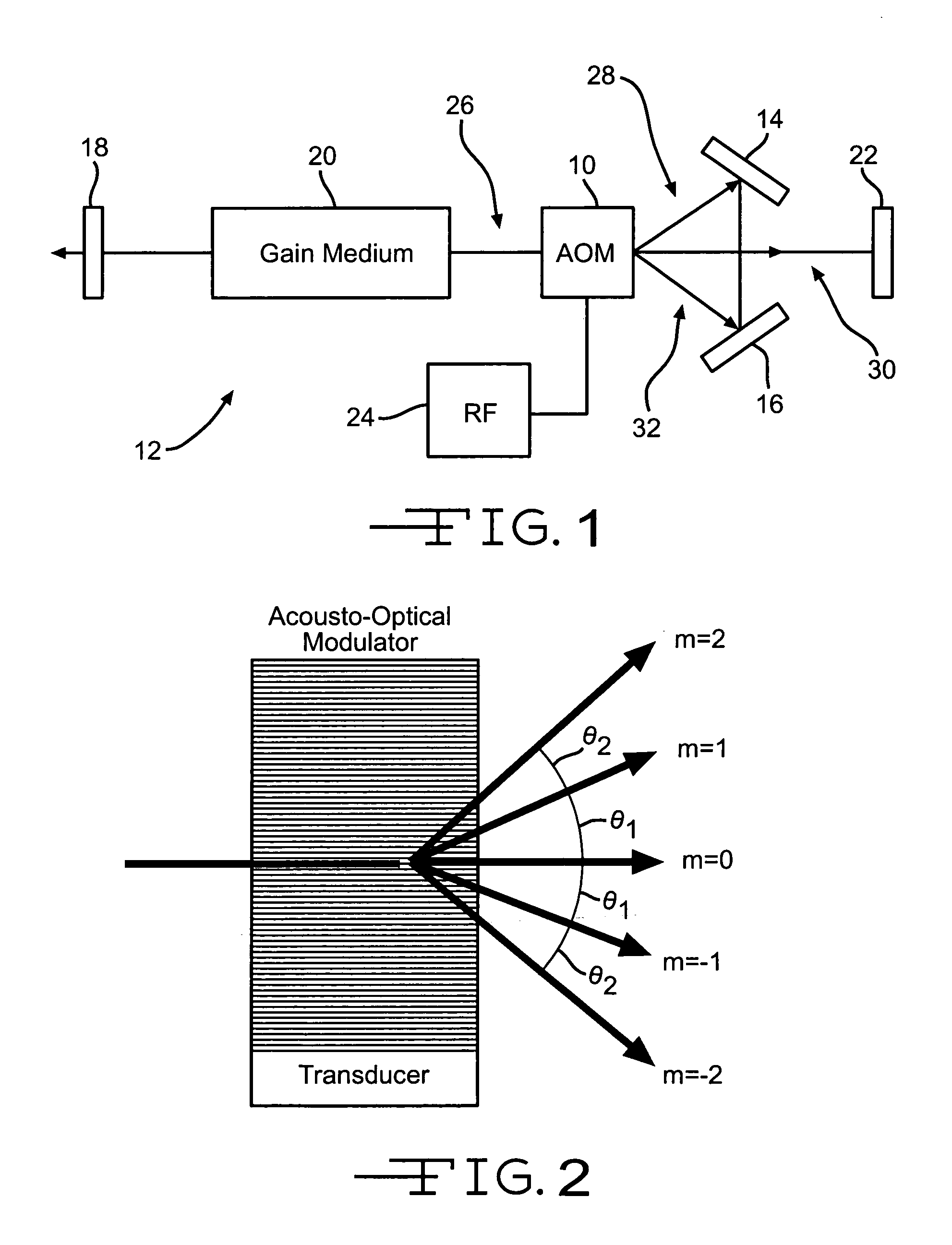

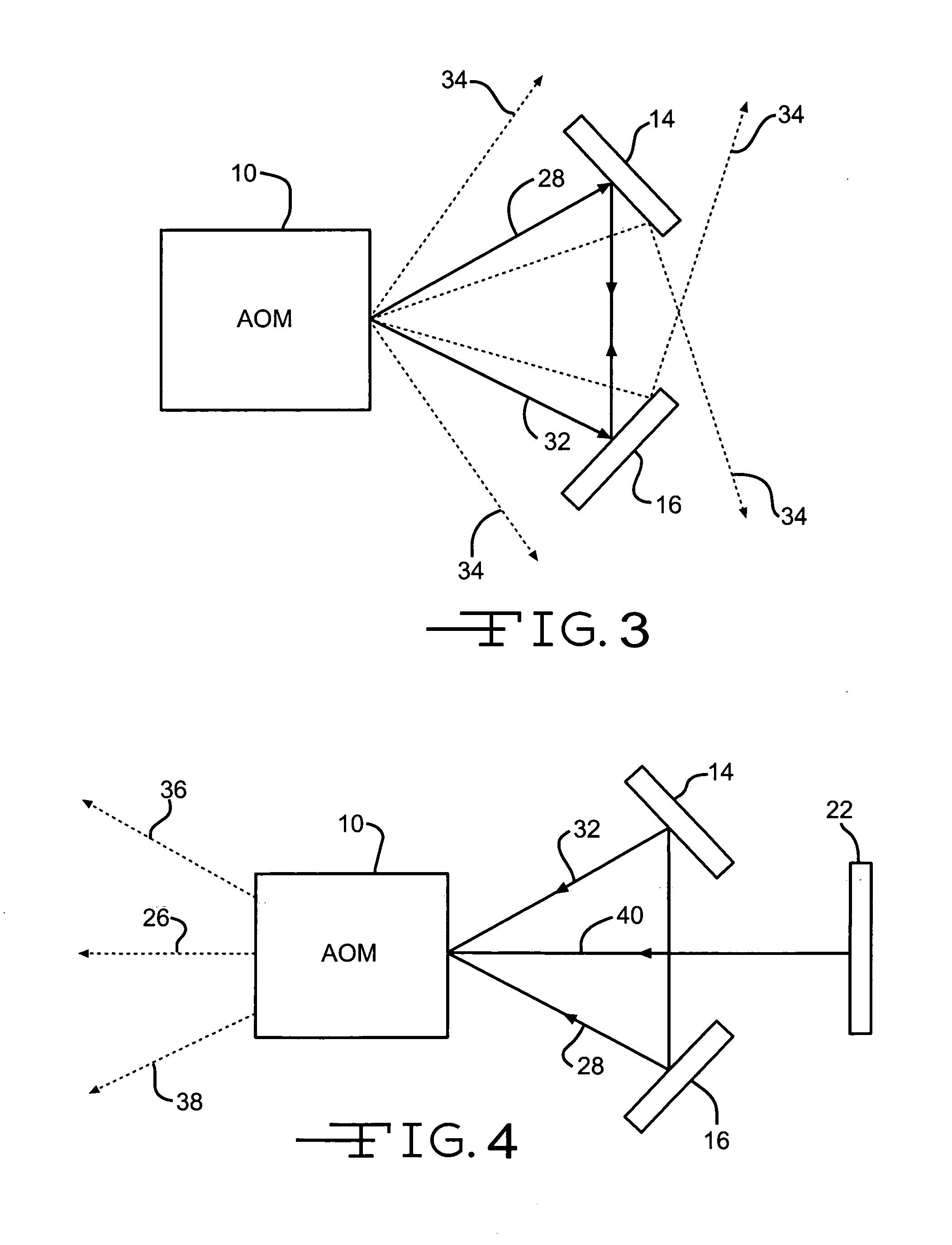

Laser intra-cavity electronic wavelength tuner

An apparatus for adjusting the wavelength of a laser capable of lasing at multiple wavelengths by using a single acousto-optical modulator and a pair of optical reflectors inside a laser cavity. By adjusting the frequency and amplitude of the radio-frequency source to the acousto-optical modulator, undesired wavelengths are suppressed in the laser cavity, leaving appreciable gain only at the desired wavelength.

Owner:THE BOEING CO

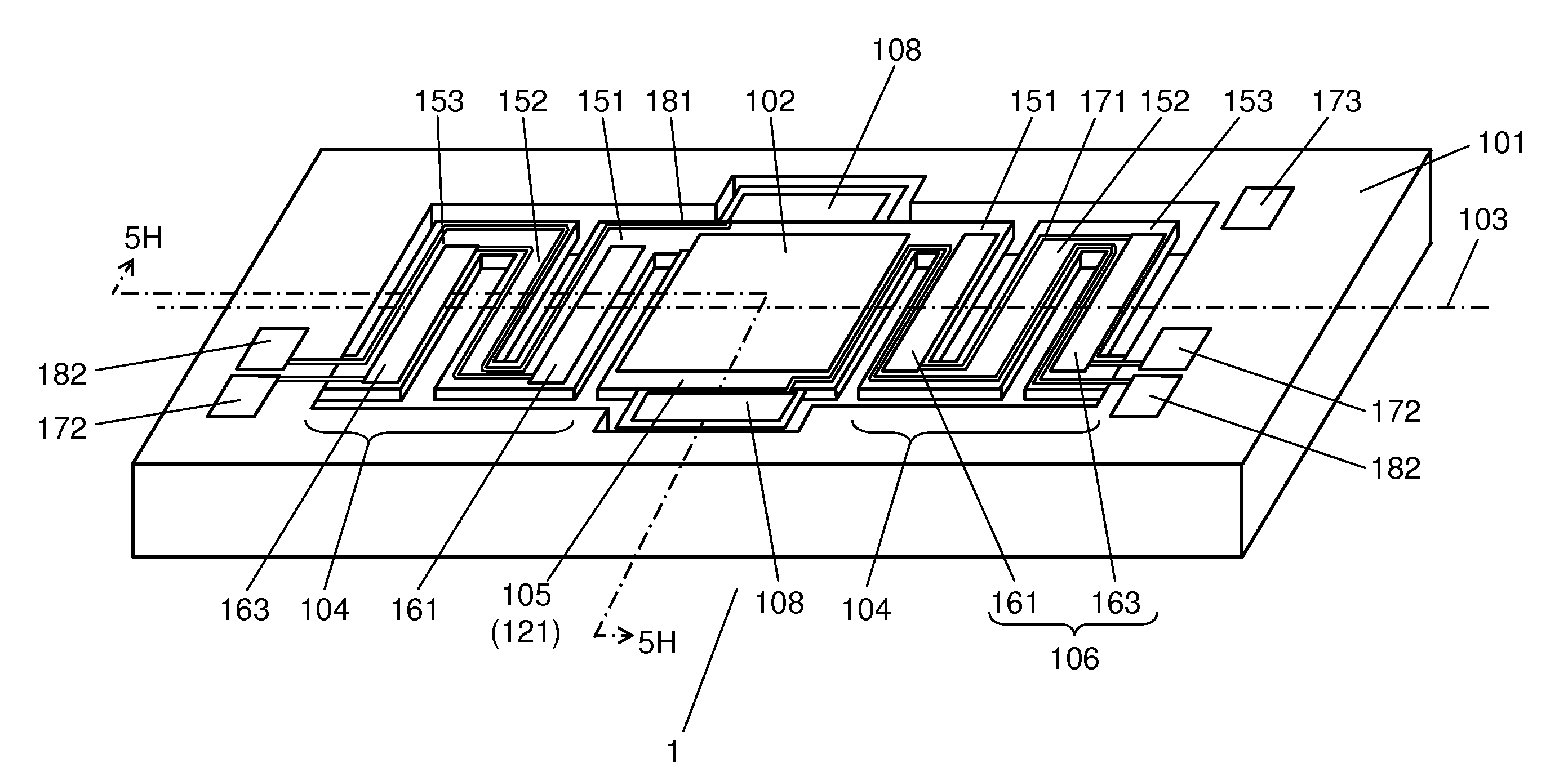

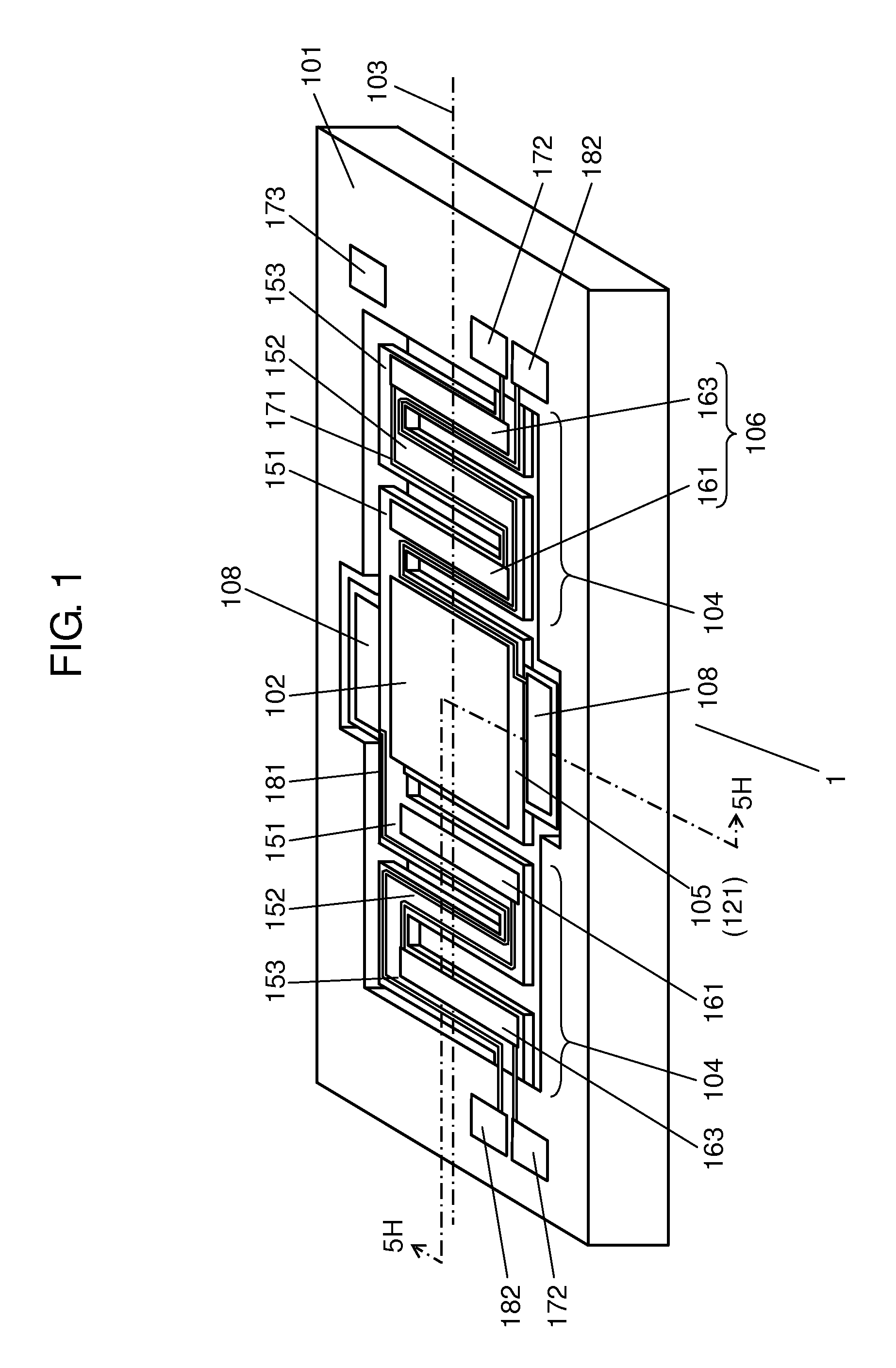

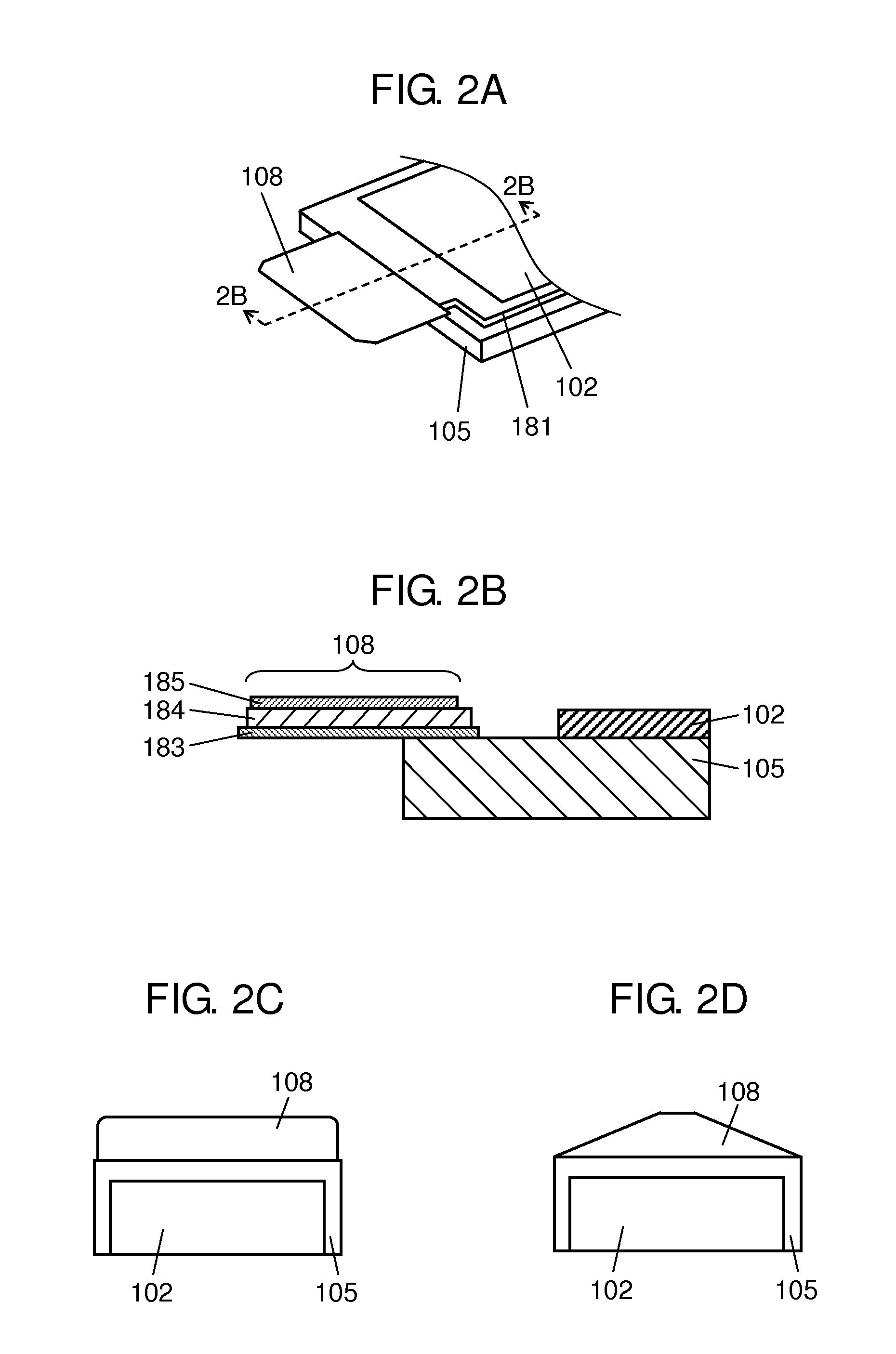

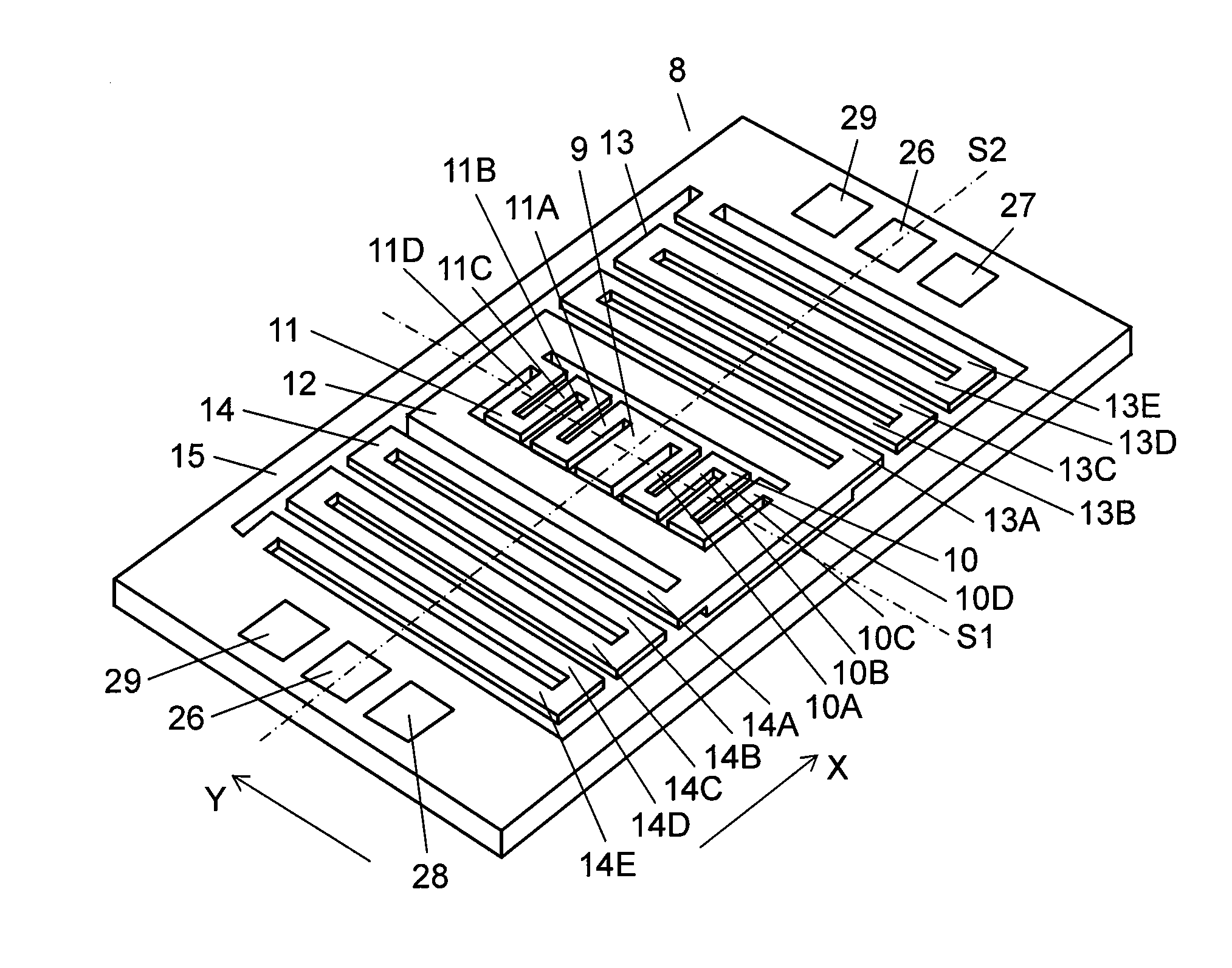

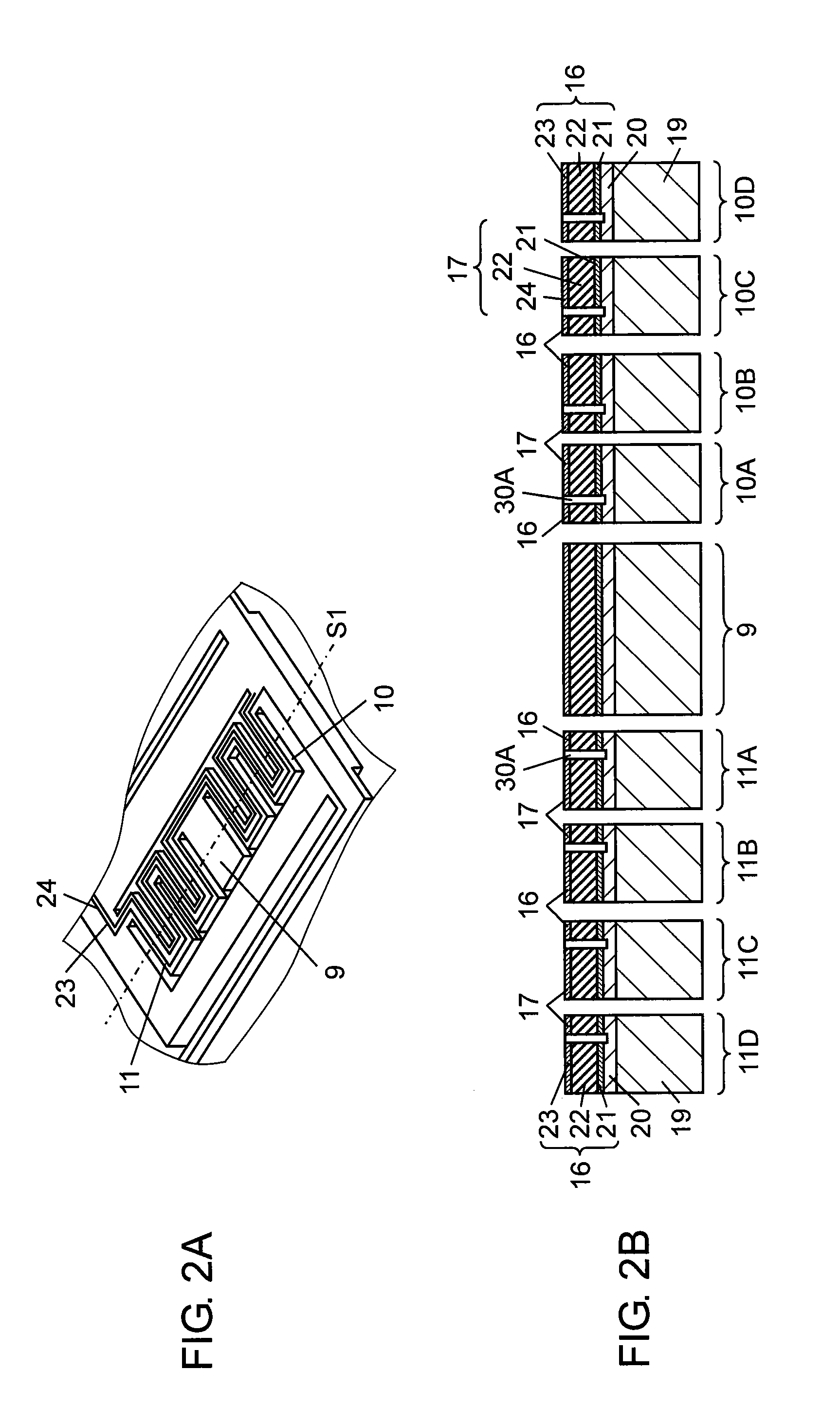

Optical reflection element

ActiveUS20110292479A1Improve detection accuracyImprove accuracyMirrorsPiezoelectric/electrostriction/magnetostriction machinesOptical reflectionSelf excited

An optical reflection element includes a mirror portion and an oscillator coupled to the mirror portion. The oscillator includes a base, an insulating layer, a drive element, and a monitor element. The insulating layer is formed on the base. The drive element and the monitor element are formed on the insulating layer, and are separated from each other by a separation groove. Each of the drive element and the monitor element includes a lower electrode layer, a piezoelectric layer, and an upper electrode layer formed in that order on the insulating layer. The monitor element has high detection accuracy, allowing the optical reflection element to perform self-excited driving with high accuracy.

Owner:PANASONIC CORP

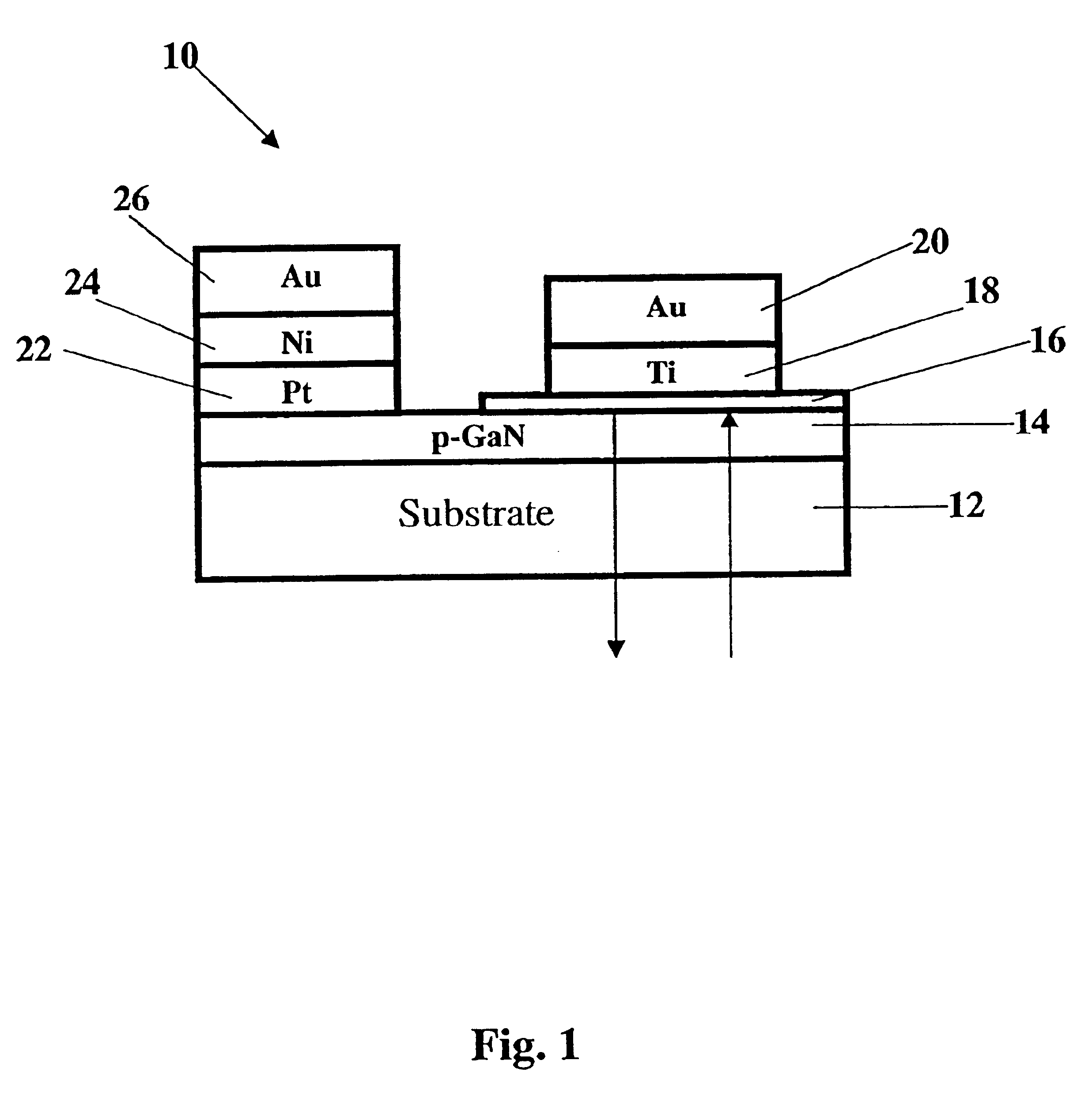

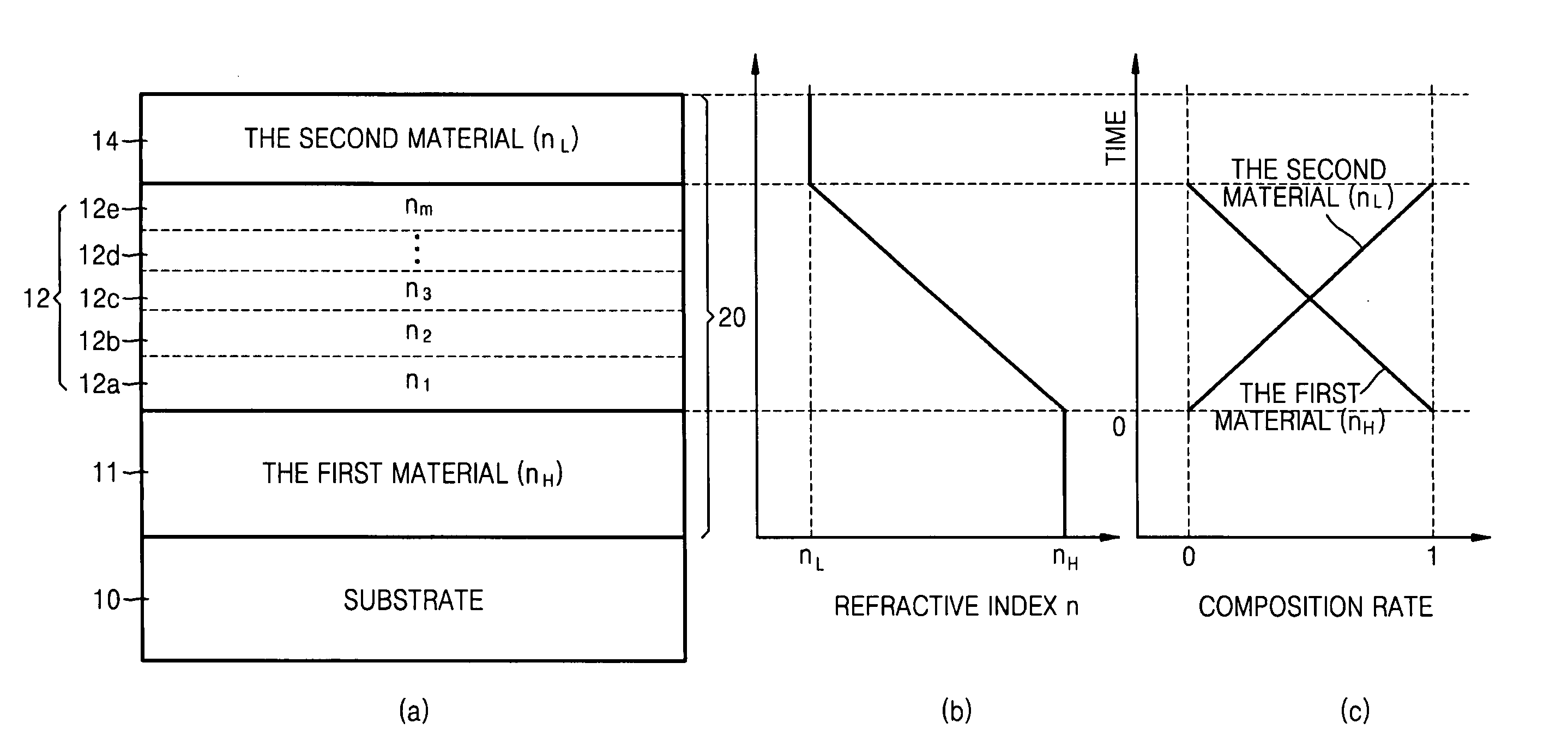

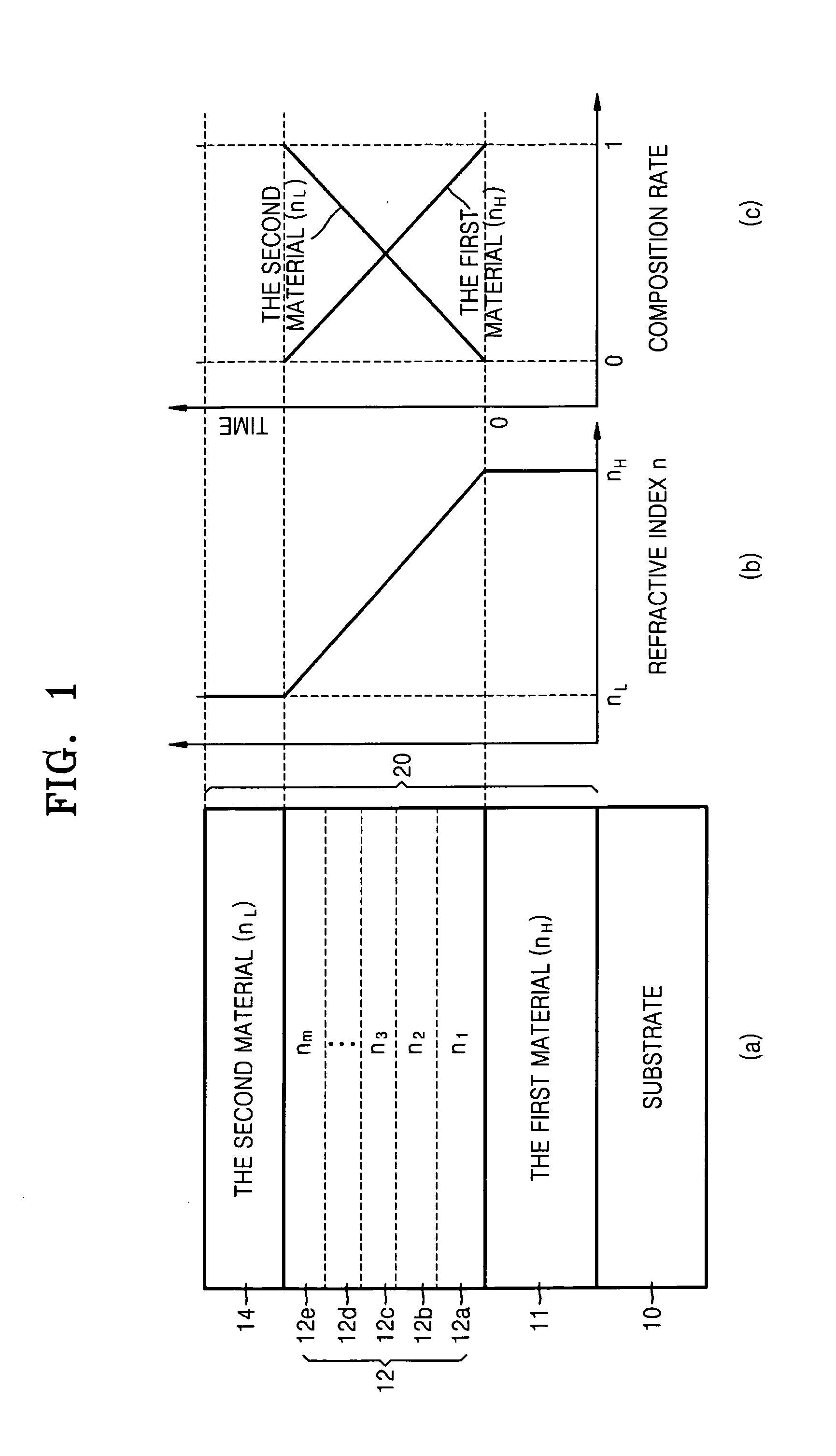

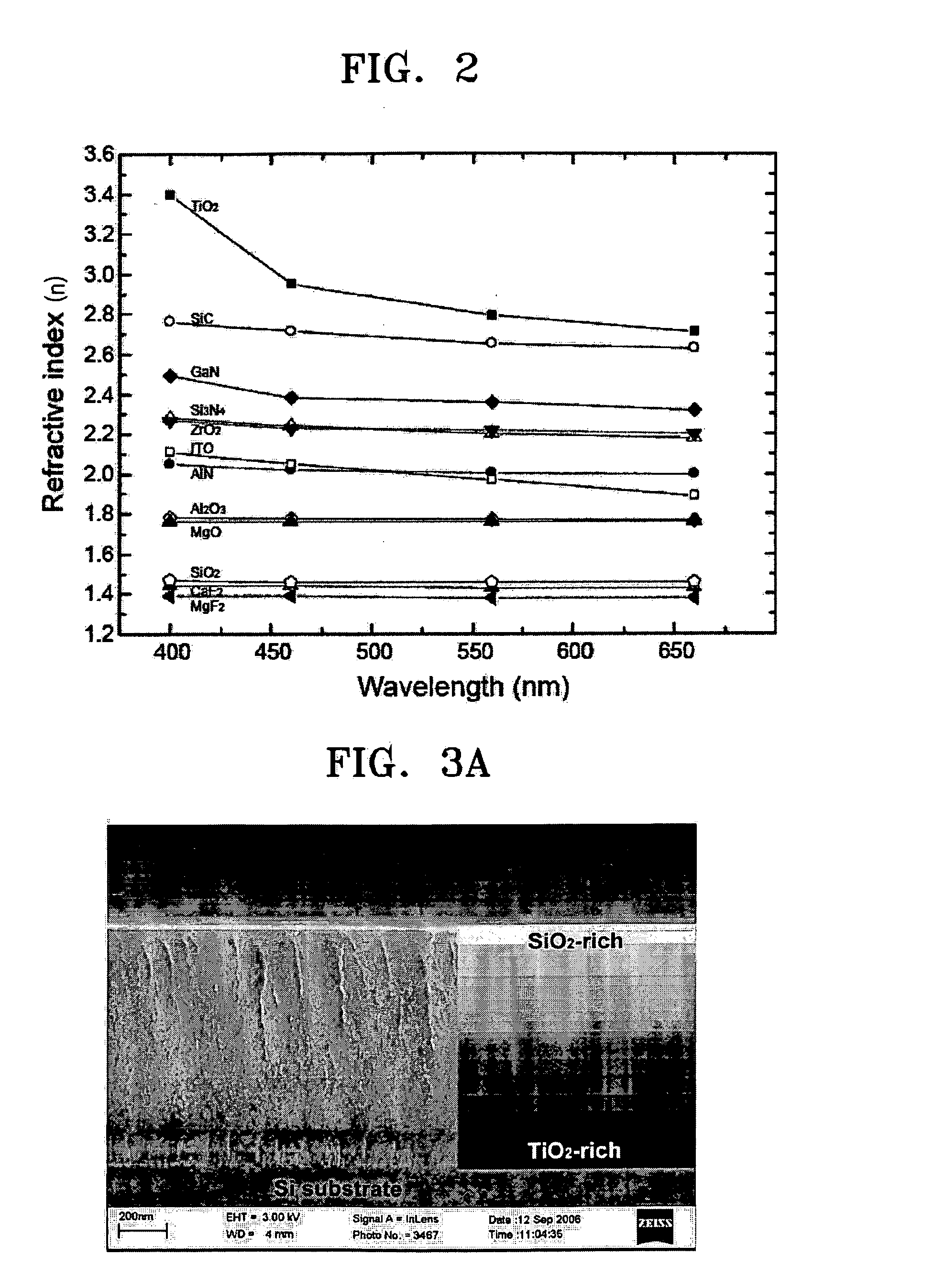

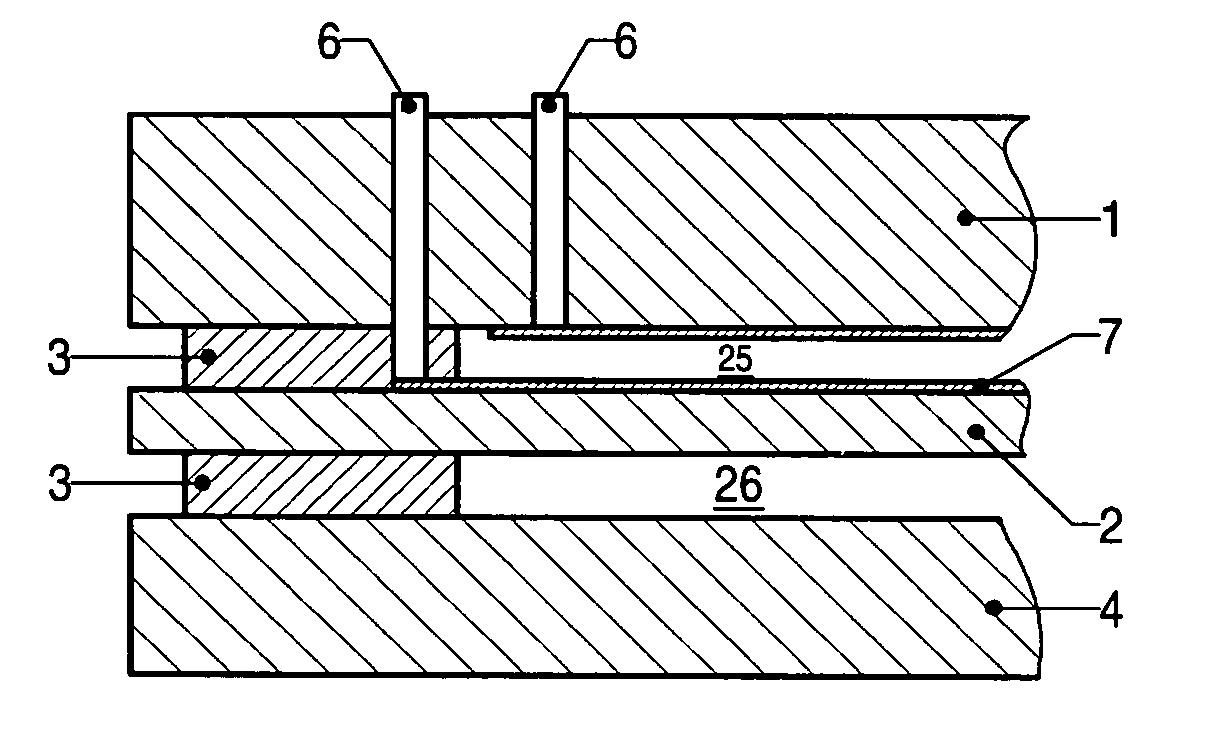

Optical thin film, semiconductor light emitting device having the same and methods of fabricating the same

ActiveUS20080088932A1Simple structureLight transmittance efficiency can be maximized and increasedOptical elementsOptical reflectionSemiconductor materials

Provided are a highly transmissive optical thin film having an improved structure, in which, optical reflection (due to a difference in the refractive index between a semiconductor material and the air, when light is extracted from a semiconductor light emitting device into the air) may be suppressed, an optical output loss may be reduced and light transmittance efficiency may be maximized or increased, a semiconductor light emitting device having the same, and methods of fabricating the same. The optical thin film may include a first material layer having a first refractive index, a second material layer formed on the first material layer and having a second refractive index that is smaller than the first refractive index, and a graded-refractive index layer interposed or inserted between the first material layer and the second material layer and having a multi-layer structure in which refractive index distribution gradually decreases in the range between the first refractive index and the second refractive index as the refractive index distribution progresses from the first material layer toward the second material layer.

Owner:RENESSELAER POLYTECHNIC INST +1

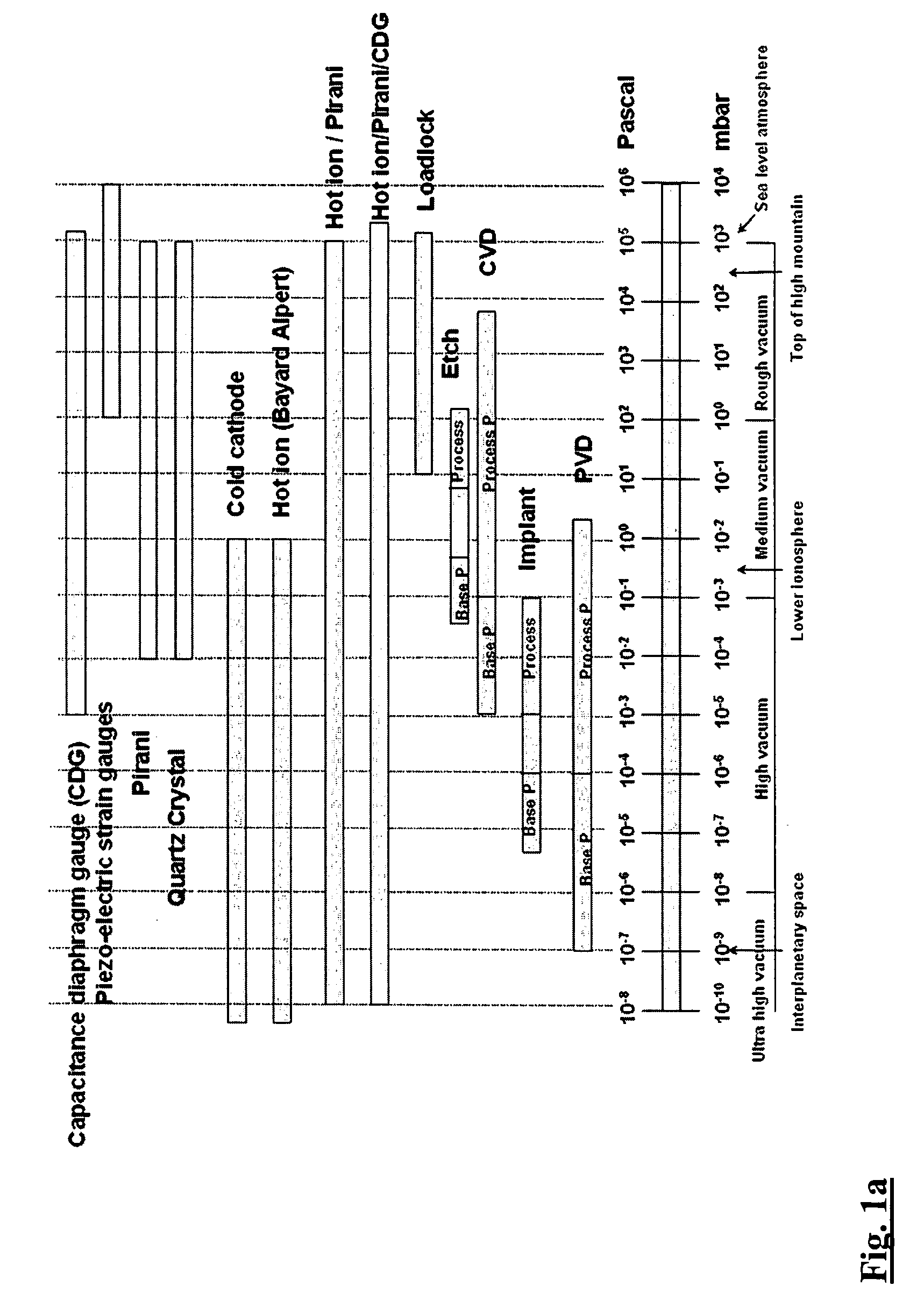

Optical interferometric pressure sensor

InactiveUS20070089524A1Raise the gradeFluid pressure measurement by mechanical elementsFluid pressure measurement by optical meansOptical reflectionEngineering

A capacitive vacuum measuring cell has a first housing body and a membrane, both of Al2O3 ceramic or sapphire. The membrane is planar with a peripheral edge joined by a first seal to the first housing body to form a reference vacuum chamber. A second housing body of Al2O3 ceramic or sapphire opposite the membrane, is joined to the peripheral edge of the membrane by a second seal to form a measurement vacuum chamber. A port connects the vacuum measuring cell to a medium to be measured. At least in the central area of the first housing body, an optical transparent window is formed and at least the central region of the membrane has an optically reflective surface. Outside the reference vacuum chamber, in opposition to and at a distance from the window, an optical fibre is arranged for feeding in and out light onto the surface of the membrane.

Owner:INFICON GMBH

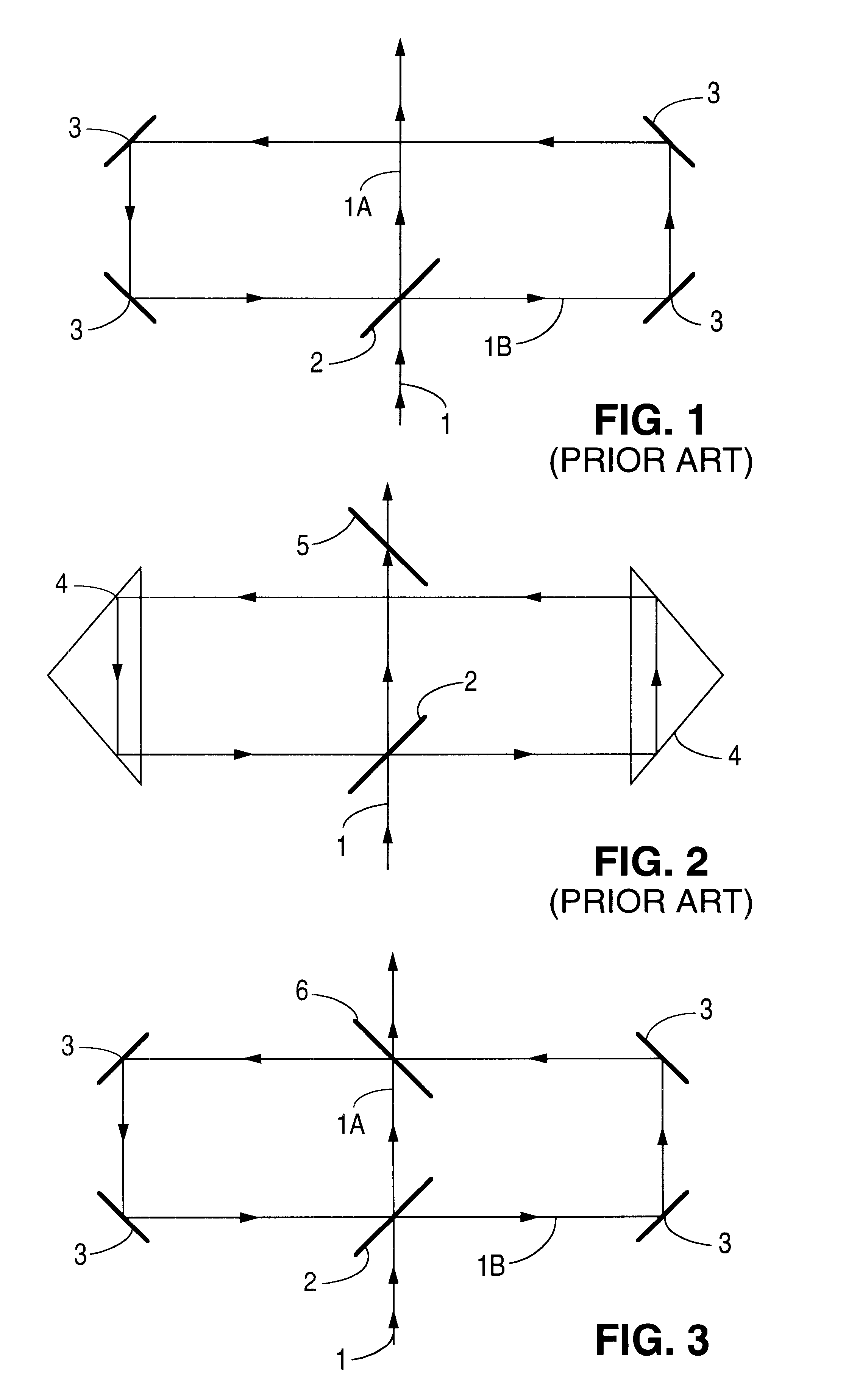

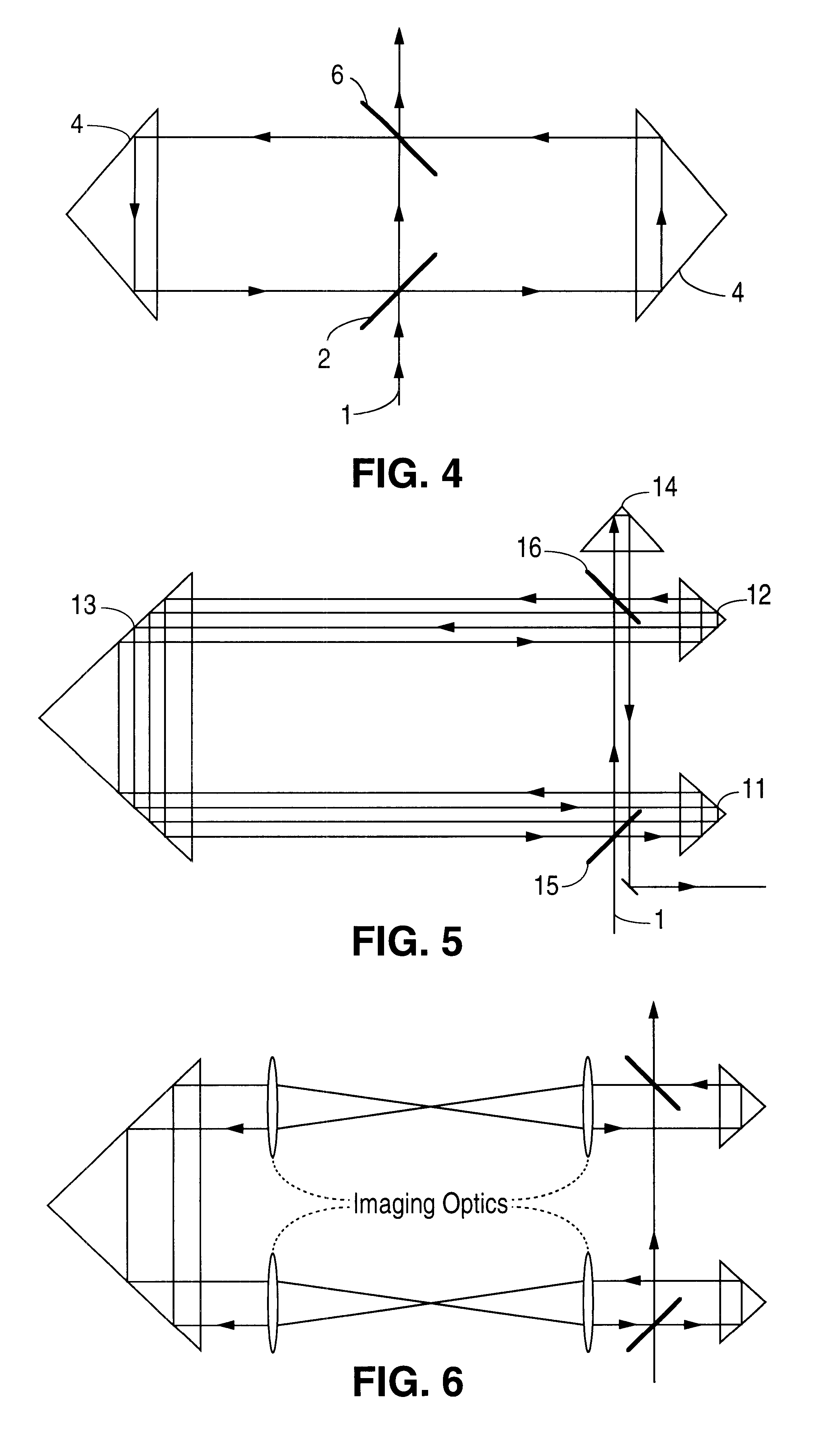

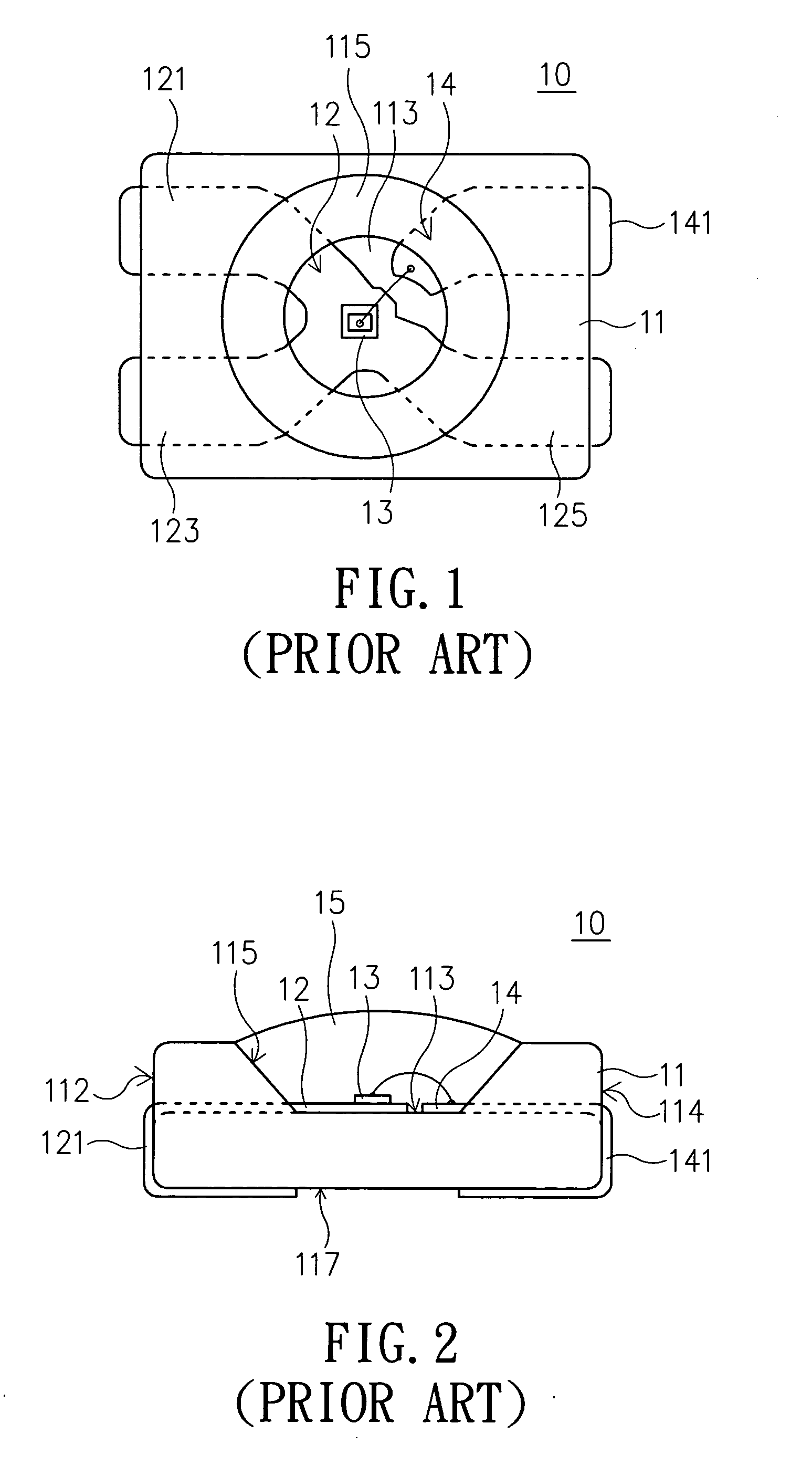

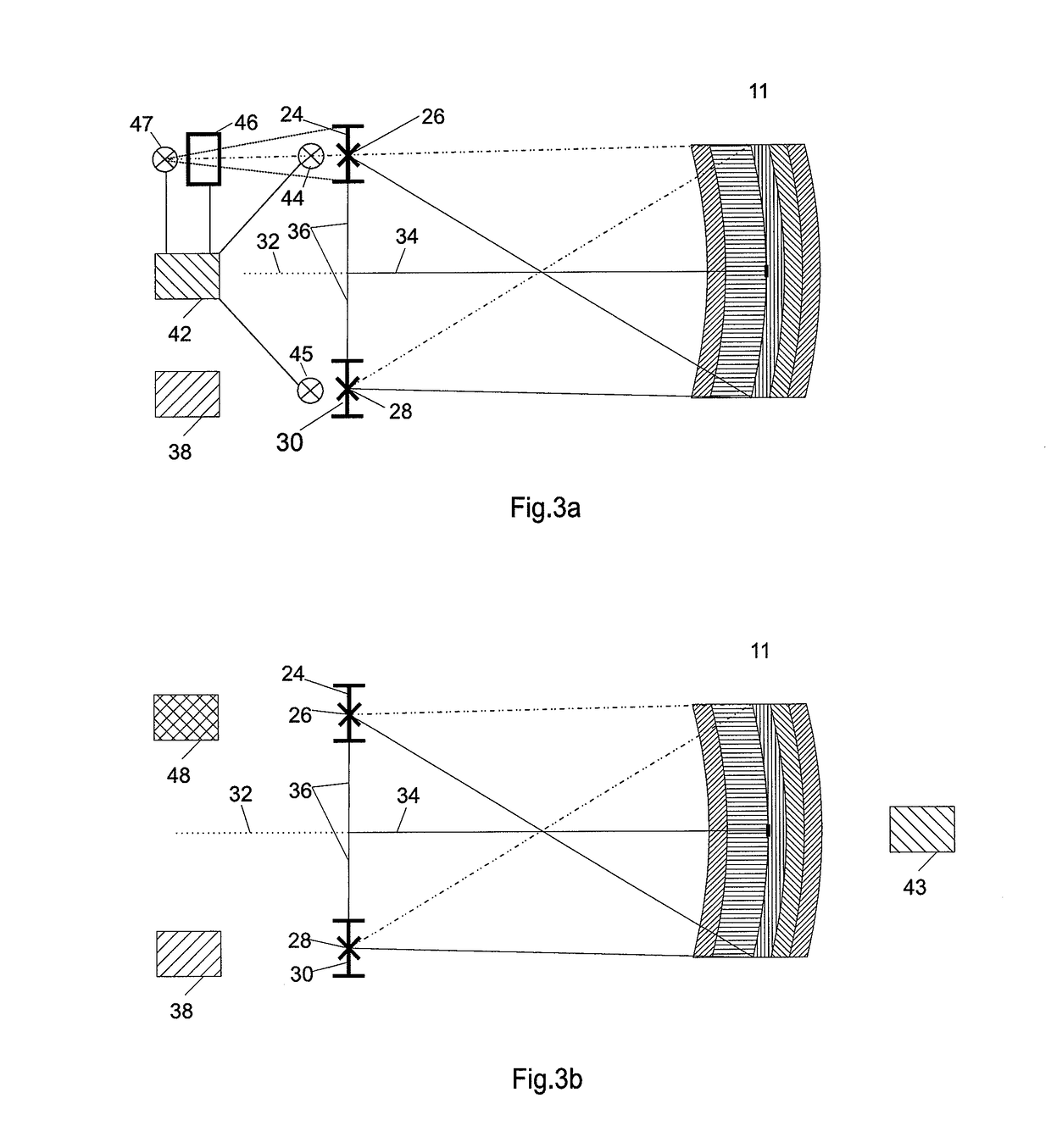

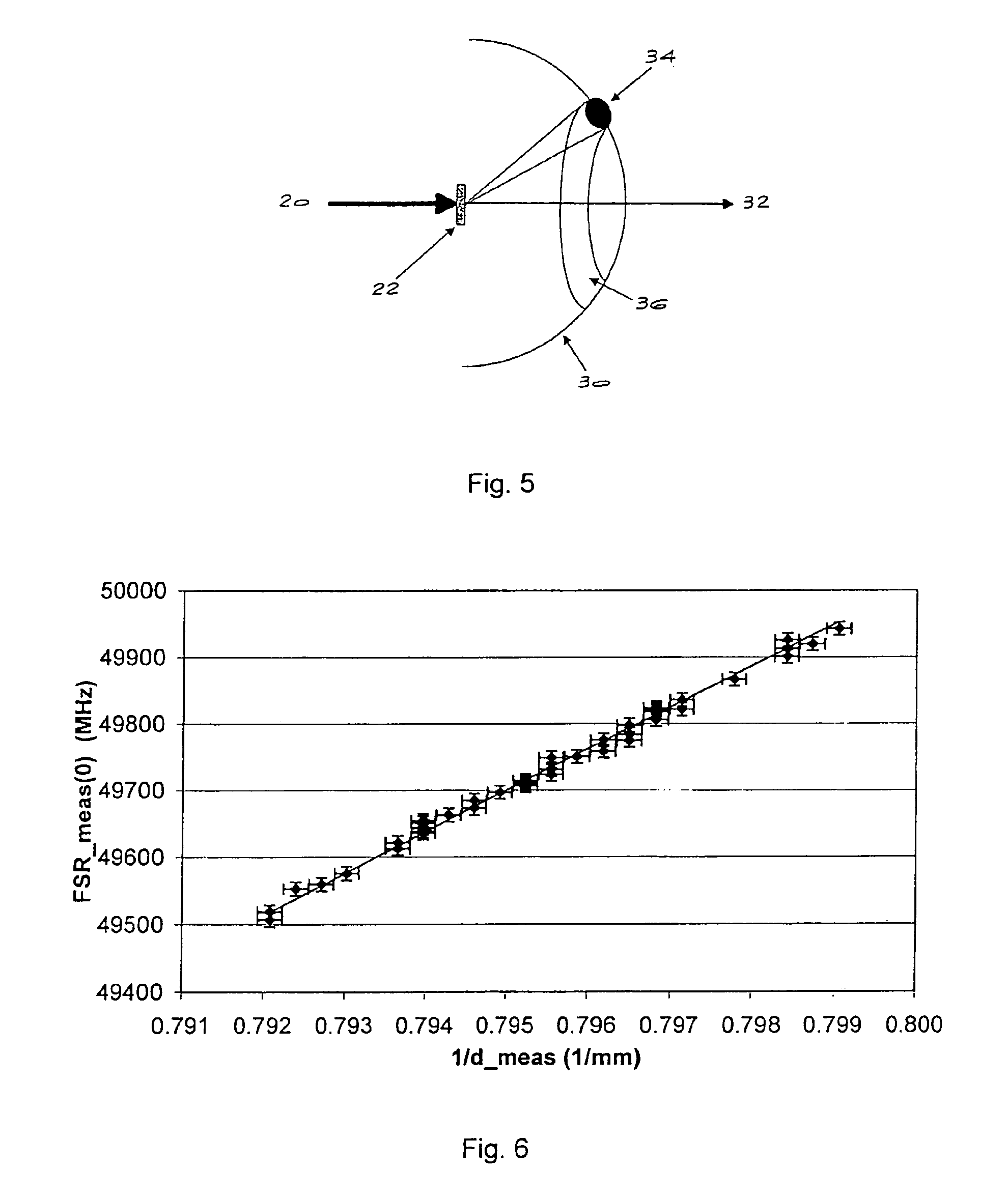

Variable wavelength laser light source

InactiveUS6047008ALaser optical resonator constructionOptical resonator shape and constructionOptical reflectionImage resolution

A variable wavelength laser light source to improve the resolution of the outgoing light and output only pure laser light without the natural emitted light has an optical amplification element (laser) 11, a first optical reflector 12 at one end surface 11a of the optical amplification element 11, and a wavelength selection element (diffraction grating) 13 at the other end surface 11b of the optical amplification element 11 which selects and outputs the desired wavelength light emitted by the optical amplification element 11. A second optical reflector 14 receives the outgoing light from the wavelength selection element 13 to form the optical resonator with the first optical reflector 12. A first rotating mechanism 15 rotates the second optical reflector 14 around its axis, and a second rotating mechanism 16 connected to the first rotating mechanism 15 rotates the second optical reflector 14 around a second axis 16a remote from the second optical reflector 14 by rotating the first rotating mechanism.

Owner:ANDO ELECTRIC CO LTD

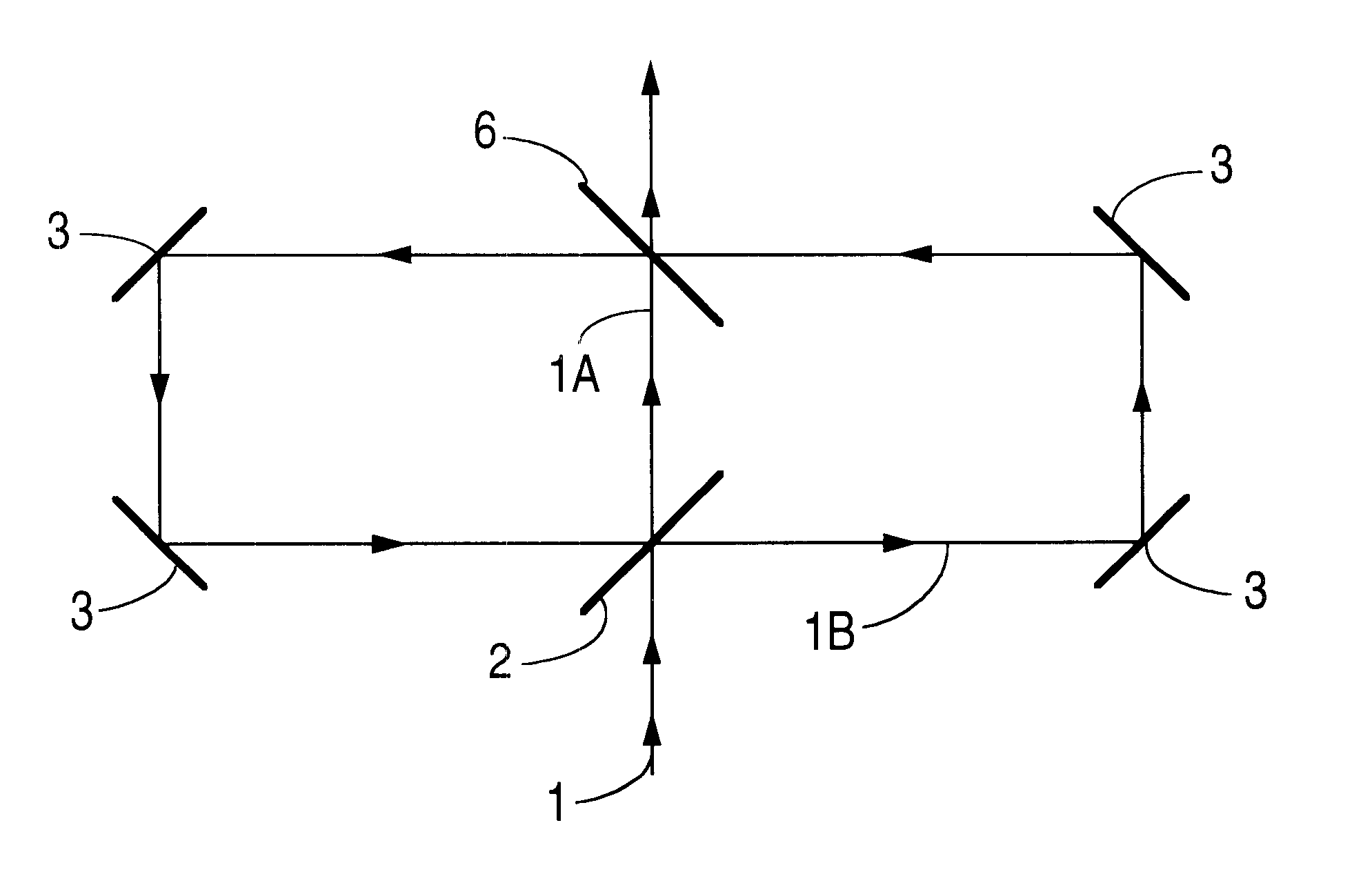

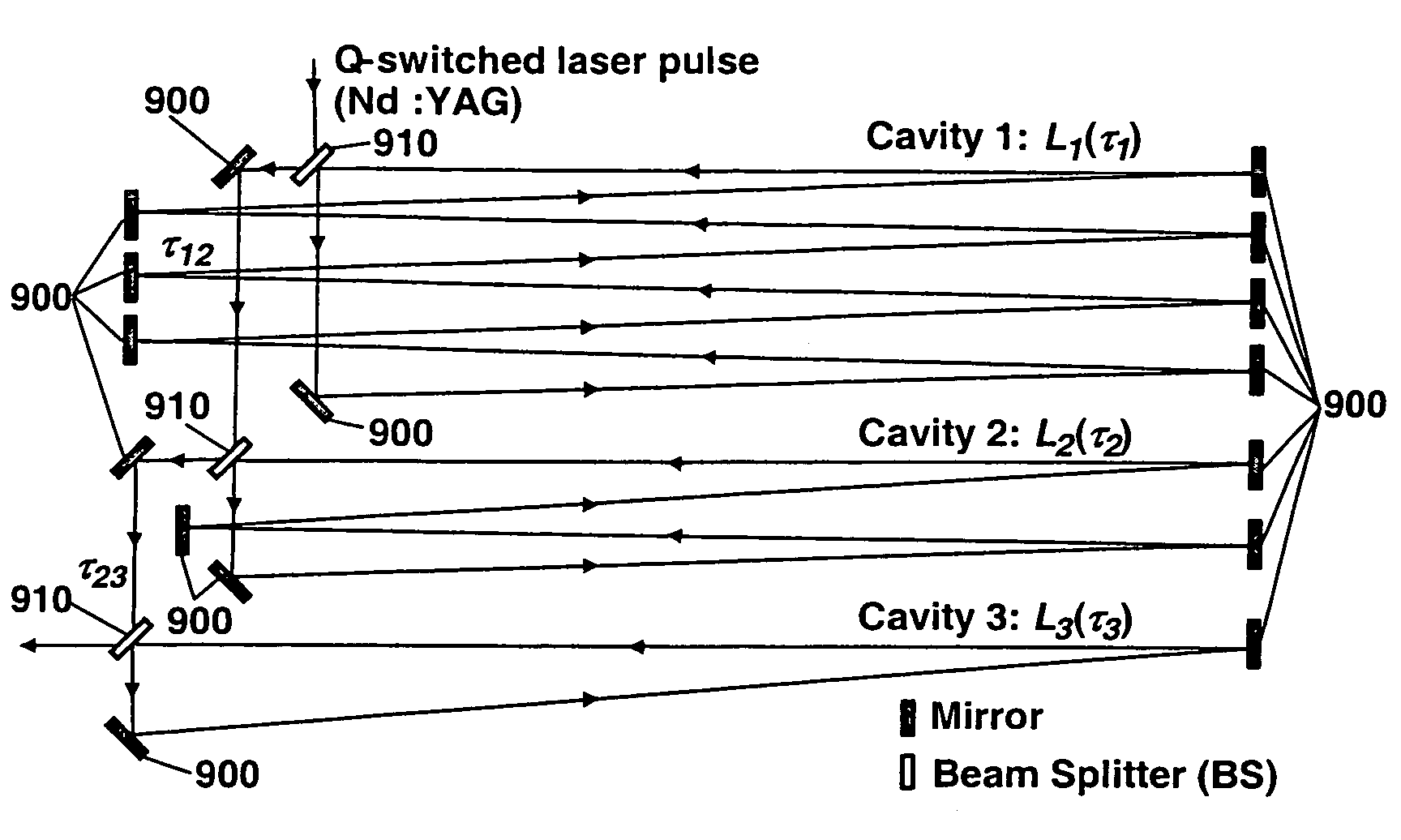

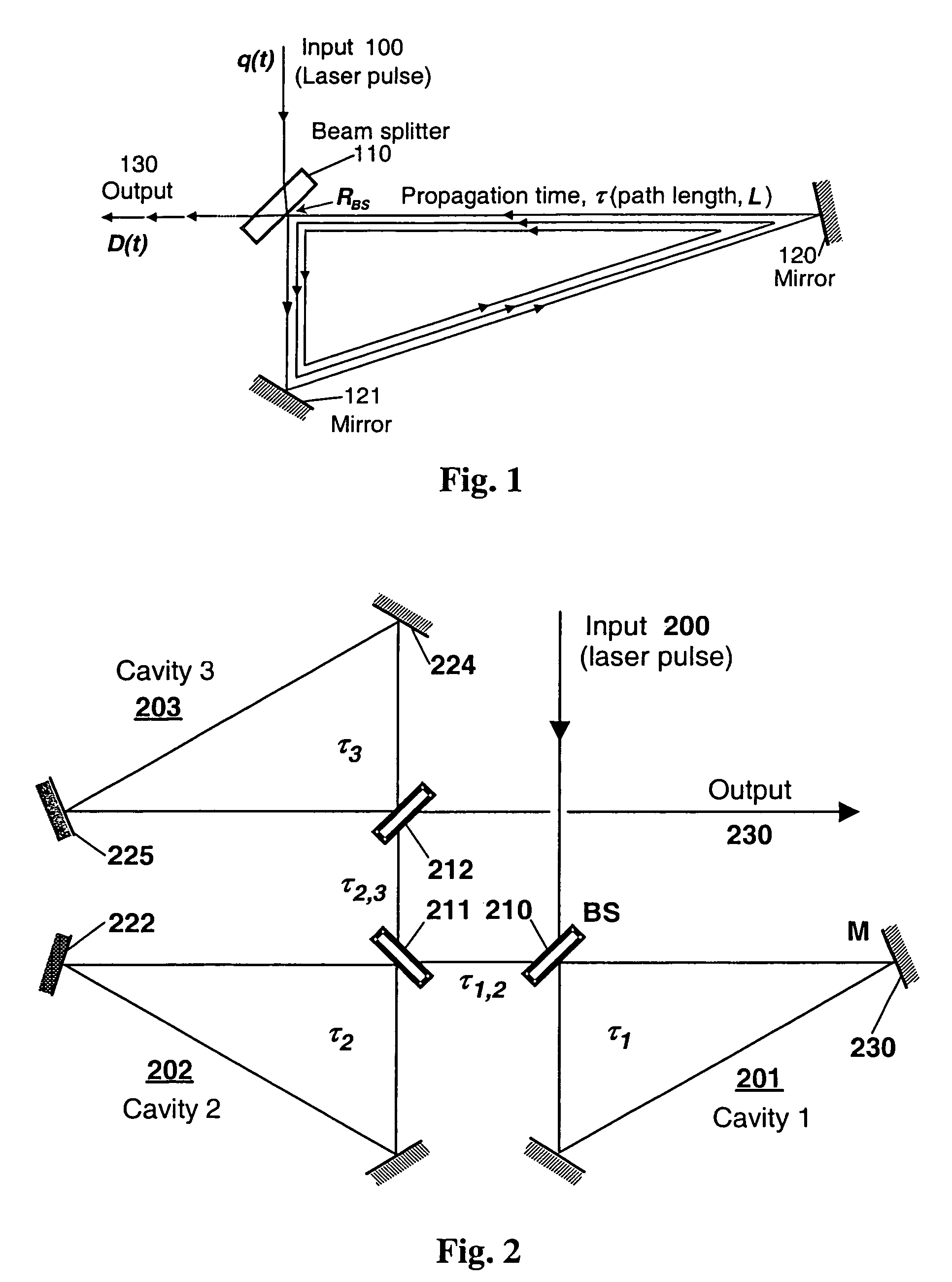

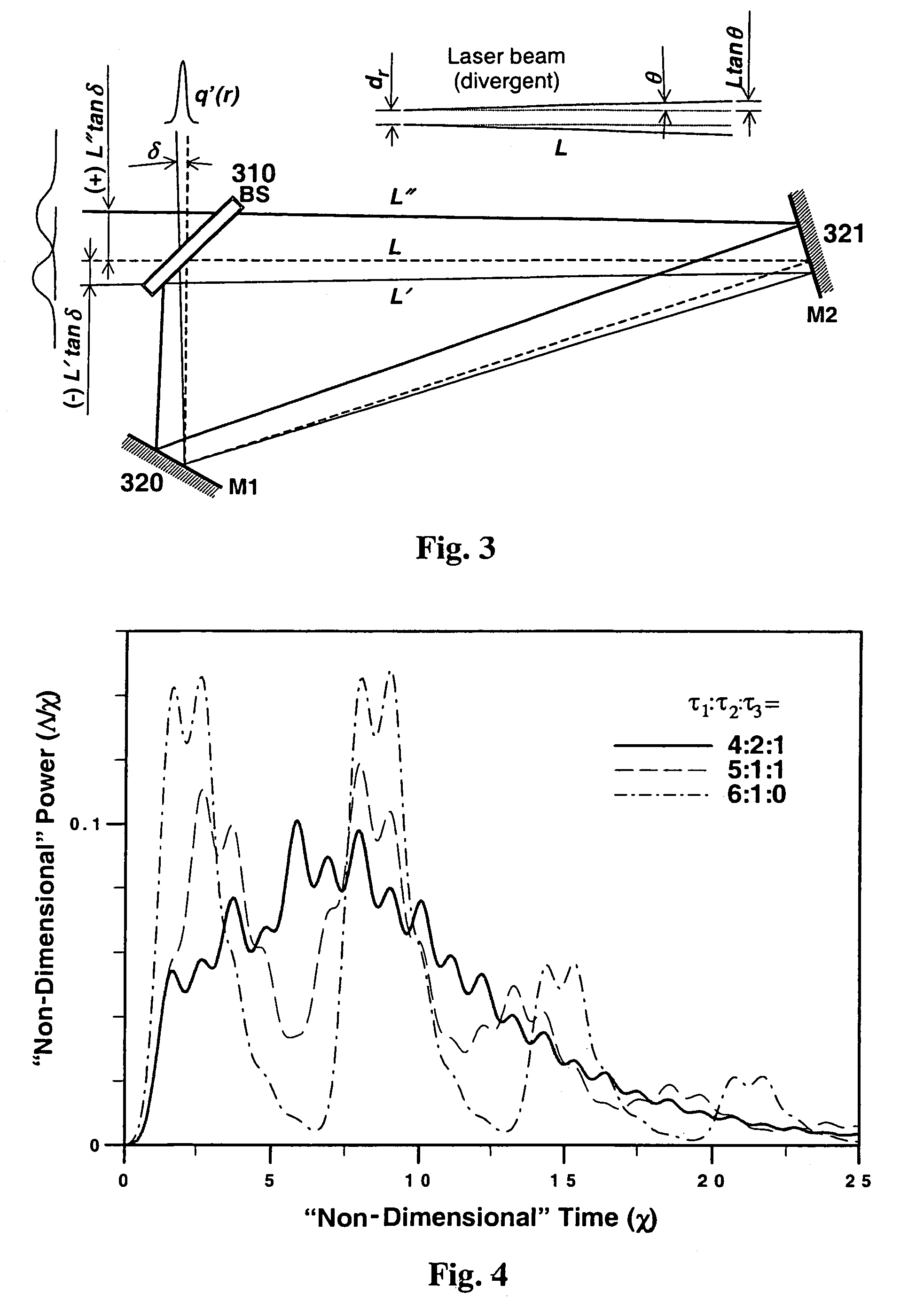

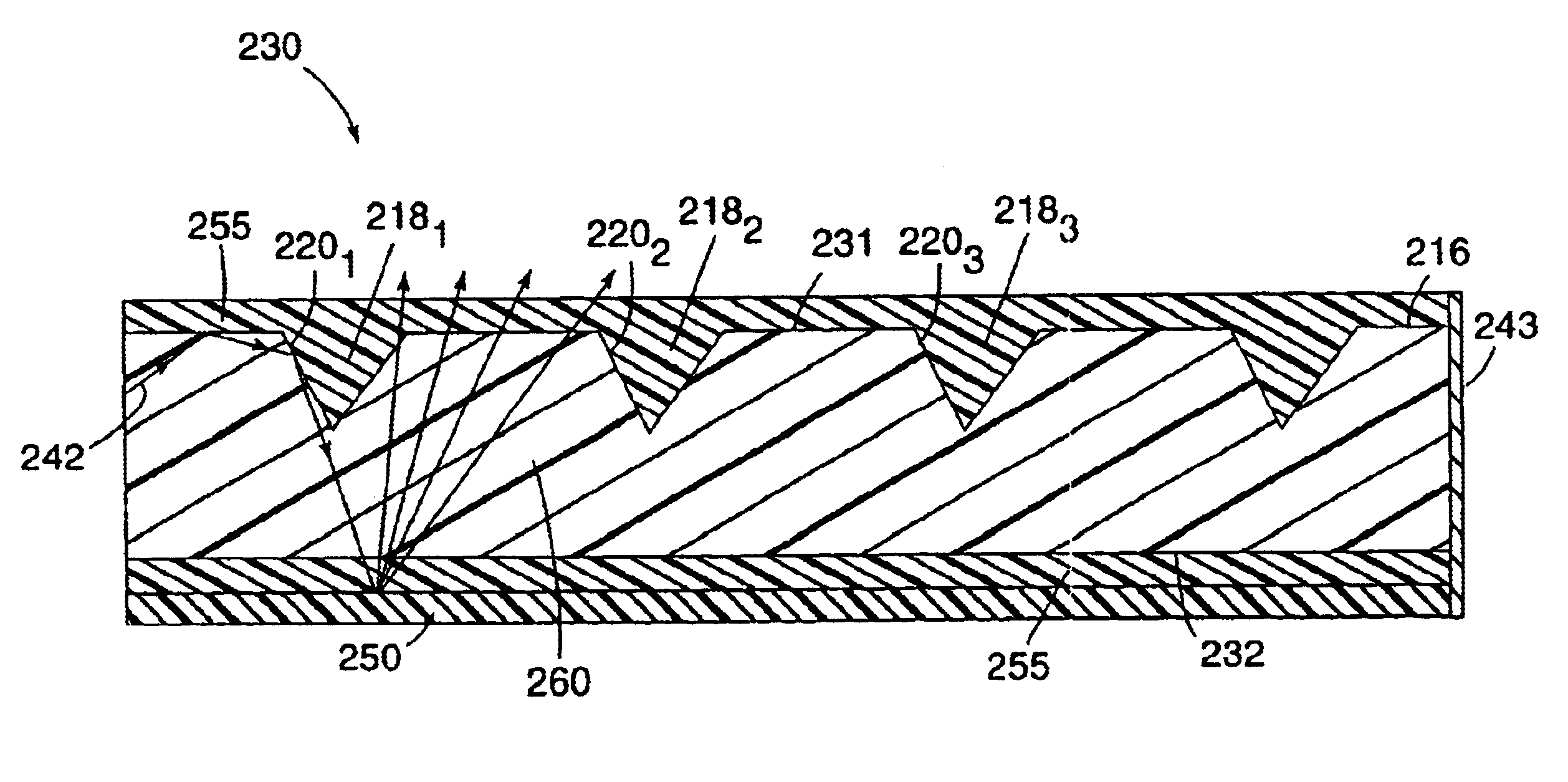

Temporal laser pulse manipulation using multiple optical ring-cavities

An optical pulse stretcher and a mathematical algorithm for the detailed calculation of its design and performance is disclosed. The optical pulse stretcher has a plurality of optical cavities, having multiple optical reflectors such that an optical path length in each of the optical cavities is different. The optical pulse stretcher also has a plurality of beam splitters, each of which intercepts a portion of an input optical beam and diverts the portion into one of the plurality of optical cavities. The input optical beam is stretched and a power of an output beam is reduced after passing through the optical pulse stretcher and the placement of the plurality of optical cavities and beam splitters is optimized through a model that takes into account optical beam divergence and alignment in the pluralities of the optical cavities. The optical pulse stretcher system can also function as a high-repetition-rate (MHz) laser pulse generator, making it suitable for use as a stroboscopic light source for high speed ballistic projectile imaging studies, or it can be used for high speed flow diagnostics using a laser light sheet with digital particle imaging velocimetry. The optical pulse stretcher system can also be implemented using fiber optic components to realize a rugged and compact optical system that is alignment free and easy to use.

Owner:NASA

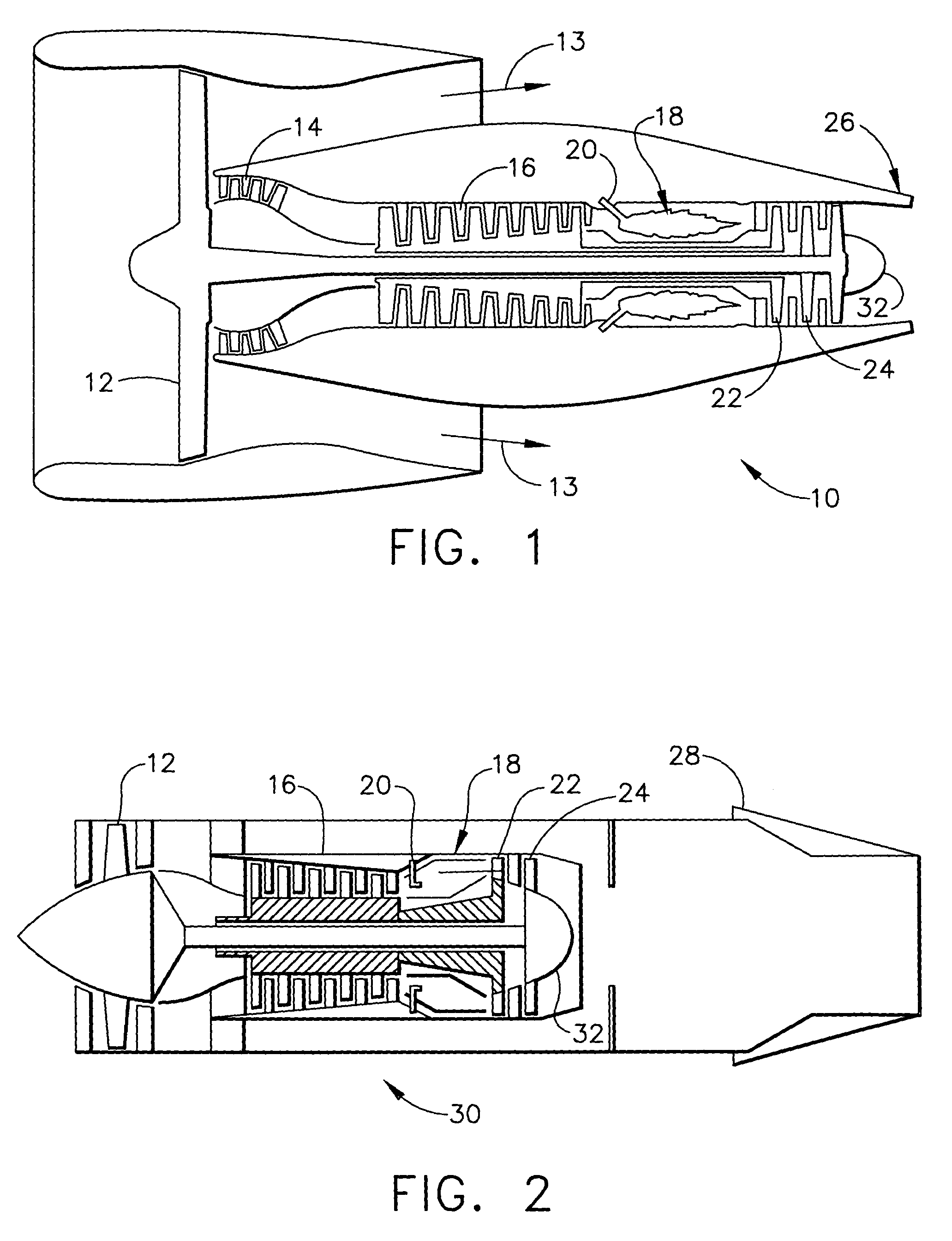

Optical reflector for reducing radiation heat transfer to hot engine parts

InactiveUS7208230B2Prolong lifeLess mean timePropellersMagnetic materialsOptical reflectionCoating system

A high temperature gas turbine component for use in the gas flow path that comprises a specular optical reflector coating system. A thin specular optical reflector coating system is applied to the gas flow path of the component, that is, the surface of the component that forms a boundary for hot combustion gases. The component typically includes a thermal barrier coating overlying the high temperature metallic component that permits the component to operate at elevated temperatures. The thermal barrier coating must be polished in order to provide a surface that can suitably reflect the radiation into the gas flow path. The thin reflector coating system comprises a thin high temperature and corrosion resistant refractory stabilizing layer, which is applied over a thin reflective metal layer, which is applied over a thin high temperature and corrosion resistant refractory sealing layer. The coating system is applied over the polished thermal barrier coating by a process that can adequately adhere the reflector to the polished surface without increasing the roughness of the surface. The coating system reflects radiation back into the hot gas flow path or into the atmosphere. The reflected radiation is not focused onto any other hardware component. The design of the component is such that the radiation is returned to the gas flow path or sent to the atmosphere rather than absorbed into a component that only serves to increase the temperature of such a component.

Owner:GENERAL ELECTRIC CO

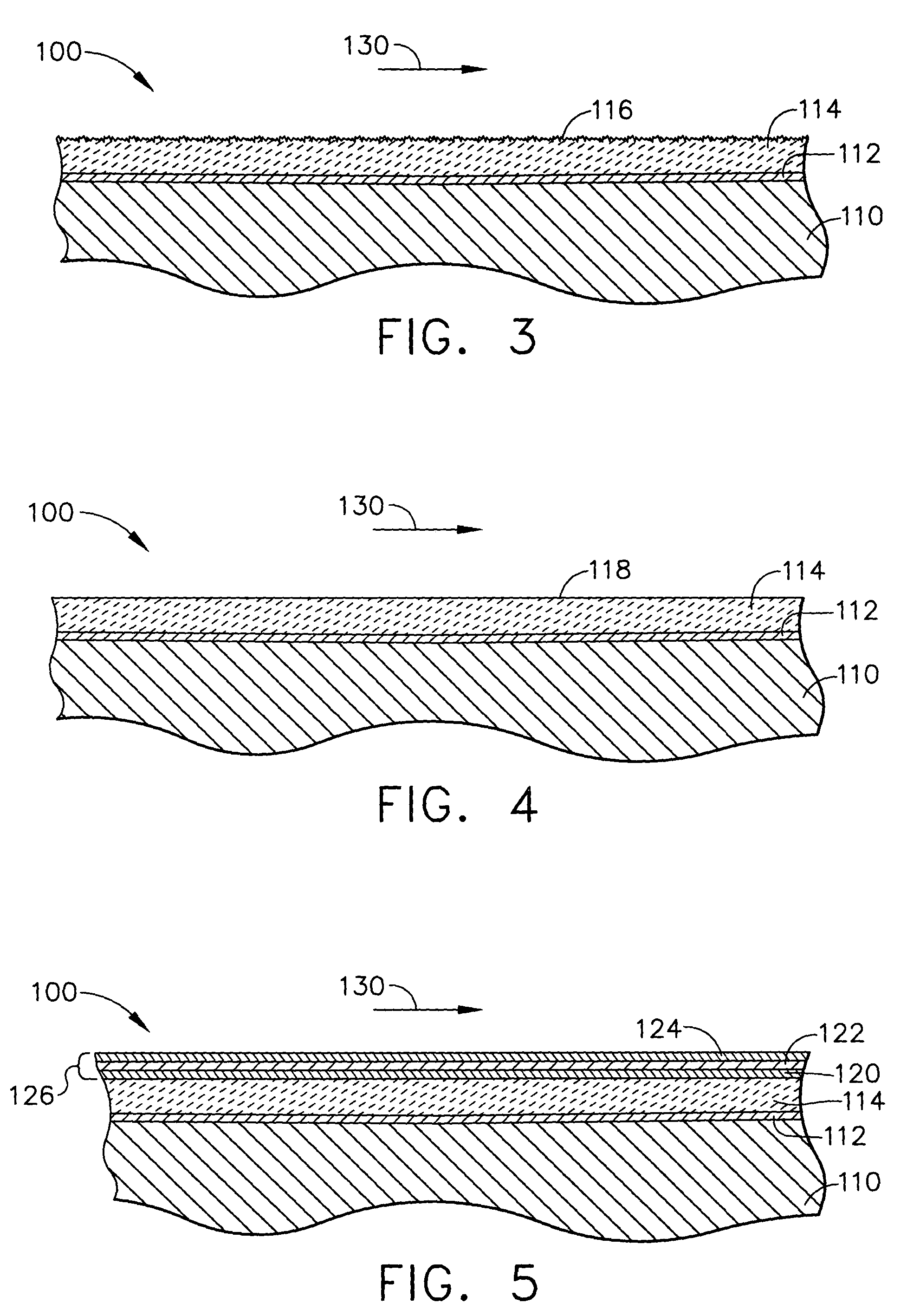

Light guide illumination device appearing uniform in brightness along its length

An illumination device that is relatively bright and uniform in appearance includes a light guide, which has a light guide core having an optically smooth surface for propagating light therethrough. A light emitting region, which extends along a portion of the core, includes at least one light extraction structure located along the optically smooth surface of the light guide core. The light extraction structure, which includes an optically reflective surface extending into the light guide core, is oriented to reflect light at an angle less than a critical angle necessary for light to propagate through the light guide core. A diffuse reflective material is disposed around at least a portion of the light guide. The diffuse reflective material directs at least a portion of the light reflected by the light extraction structure back through the light guide so that light is emitted through the light emitting region of the optically smooth surface.

Owner:3M INNOVATIVE PROPERTIES CO

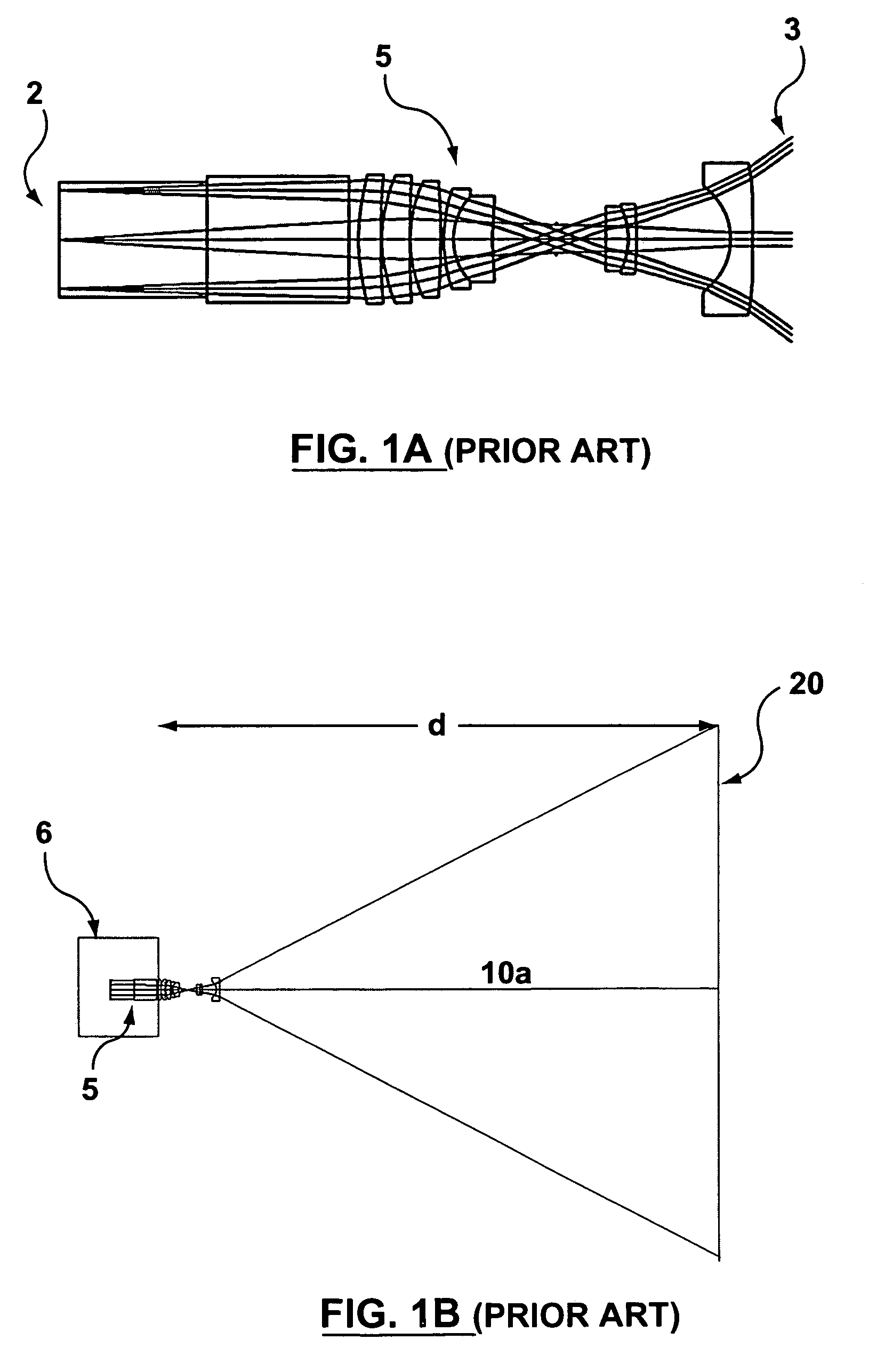

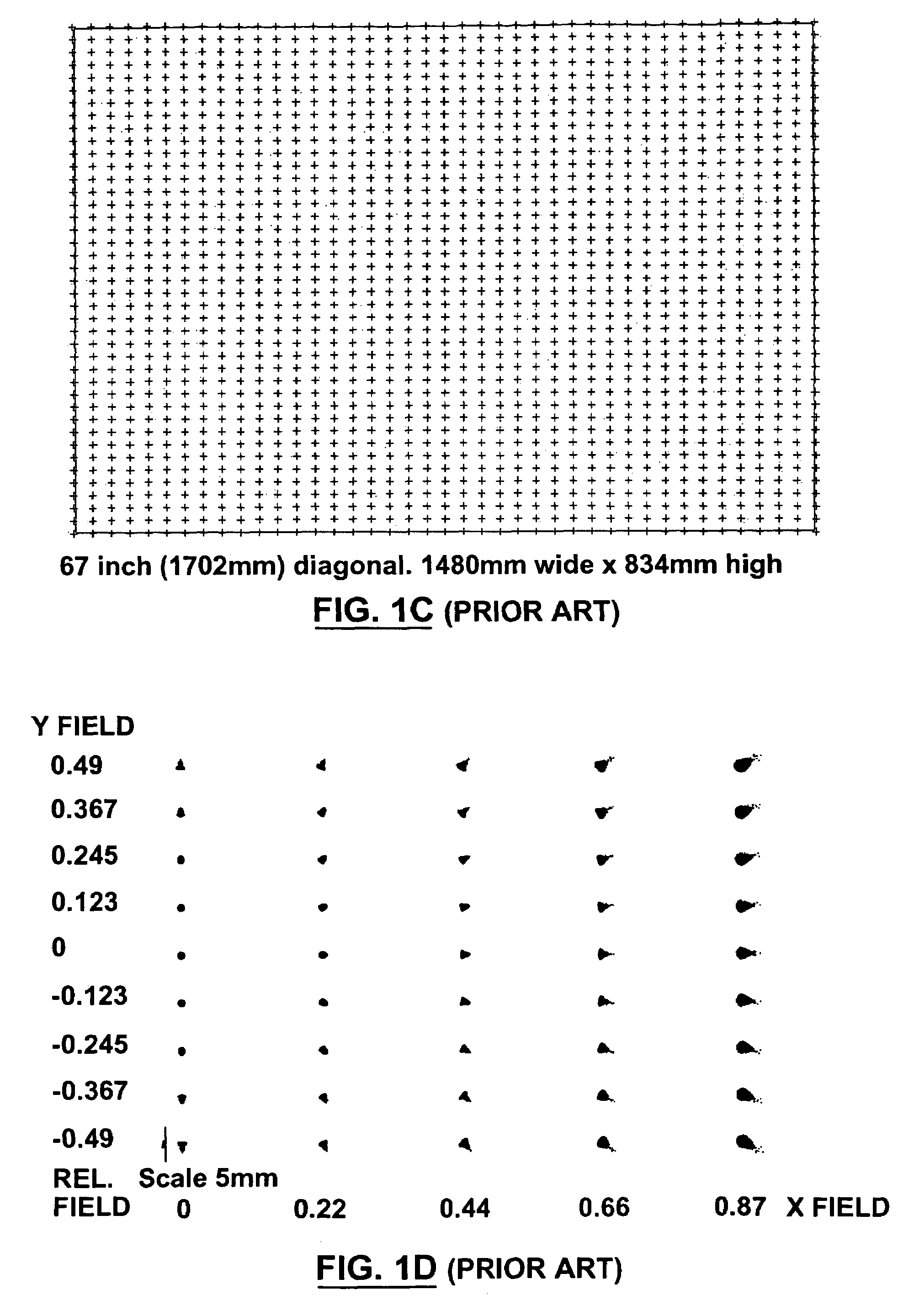

Image projection system and method

ActiveUS7384158B2Improve image qualityShorten the optical path lengthTelevision system detailsMirrorsOptical reflectionImaging processing

An image projection system and method is presented for optically projecting an image onto a display surface with visually correct geometry and optimum image quality. The projection system includes an image processing unit for receiving the input image data and generating distortion-compensated image data to compensate for ensuing spatial distortions in the projection system, a projection light engine for receiving the distortion-compensated image data and projecting a distortion-compensated optical image that corresponds to the distortion-compensated image data; and, an optical reflection assembly comprising at least one curved mirror positioned in the optical path of the distortion-compensated optical image emerging from the projection light engine for producing a displayed optical image with reduced distortion on the display surface. The image processing unit distortion-compensates the input image data such that the optical and spatial distortions associated with the projection light engine and optical reflection assembly are substantially reduced in the displayed optical image.

Owner:APPLE INC +1

Electrowetting display

InactiveUS20050285816A1High resolutionStatic indicating devicesOptical elementsOptical reflectionElectricity

The present invention comprises construction of a display from display elements that are actuated using the physical principle of electrowetting. In one embodiment, pores within porous silicon are filled with an ionic and an optically reflective electronic conductor, and actuated by application of an electric potential across the pore. An image is then formed on an array of such pores by applying an appropriate voltage to each pore of the array to create an optical image in the light reflected off the electronic conductors. Such a display may be constructed to have very high resolution, making it desirable for creating real-time holographic images, or for creating high-resolution mask images for use in photolithography.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com