Patents

Literature

2208 results about "Optical thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

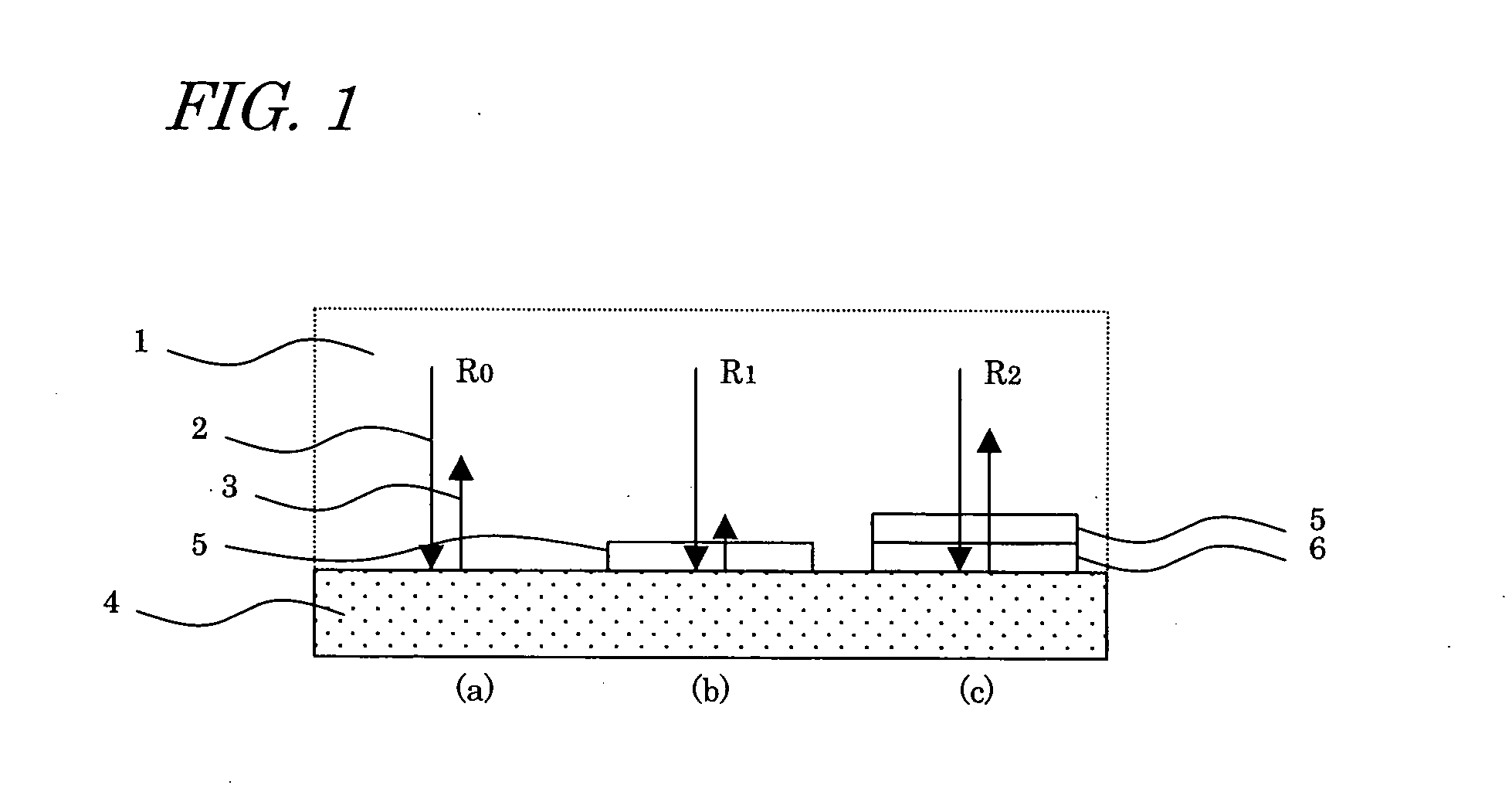

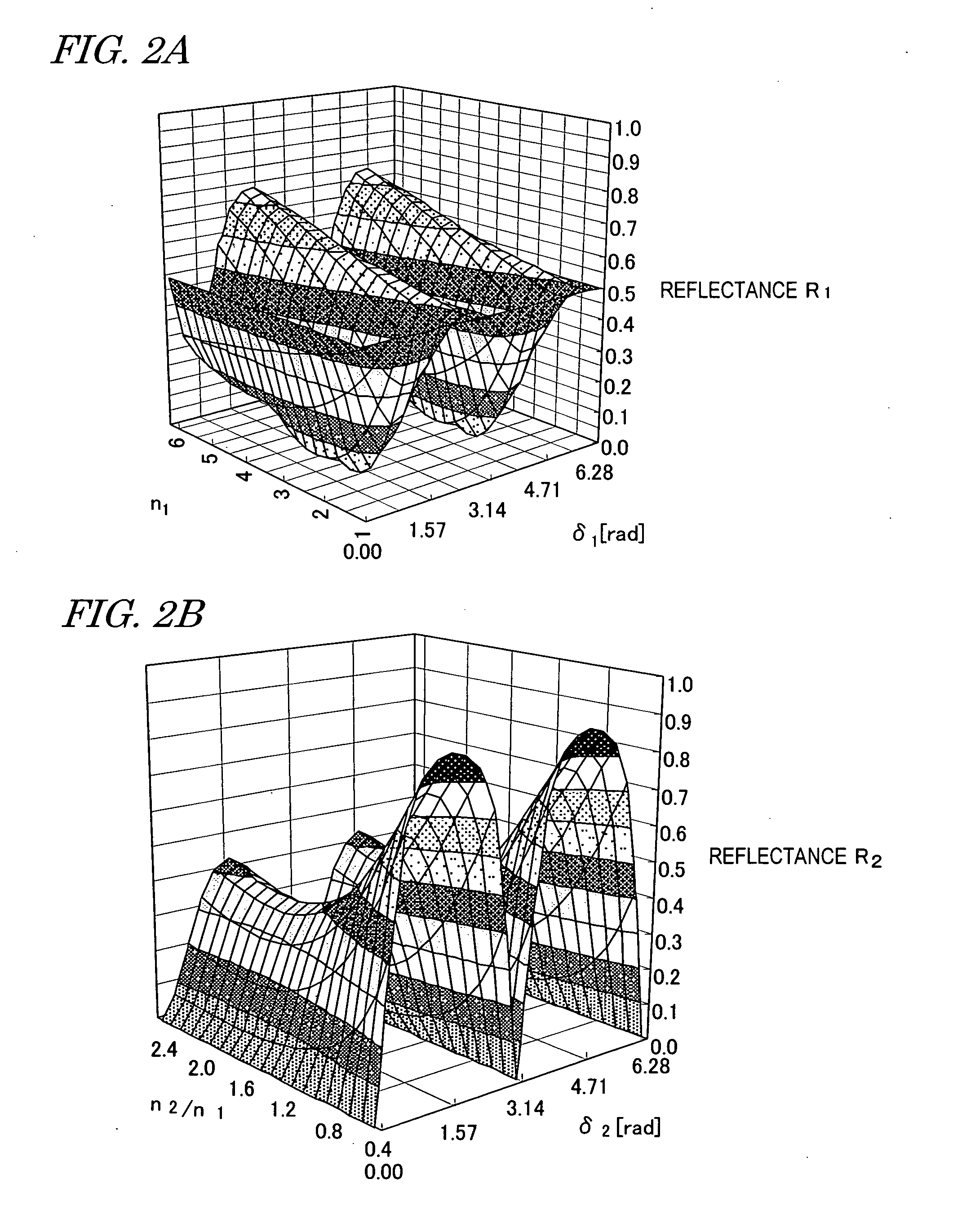

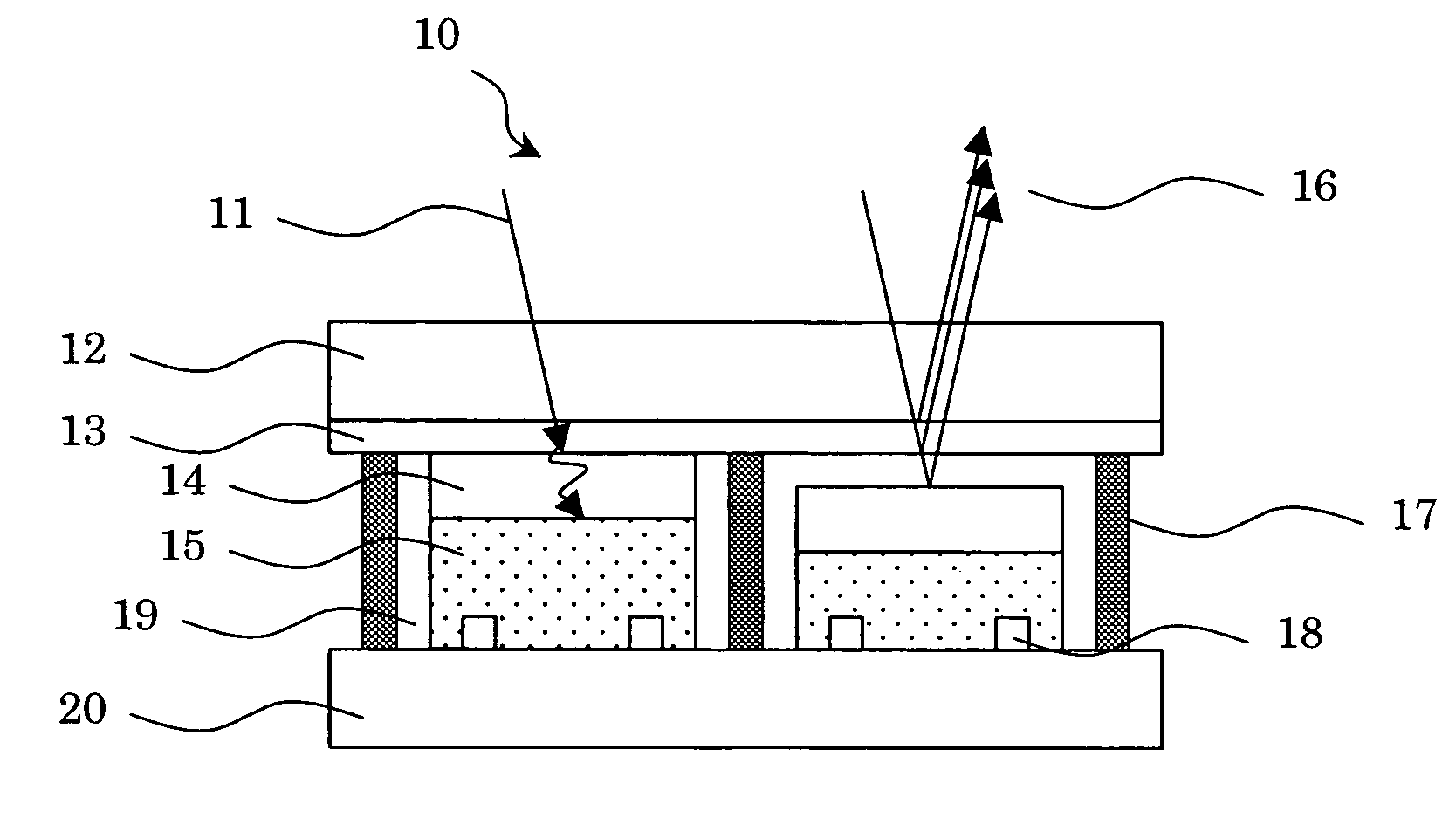

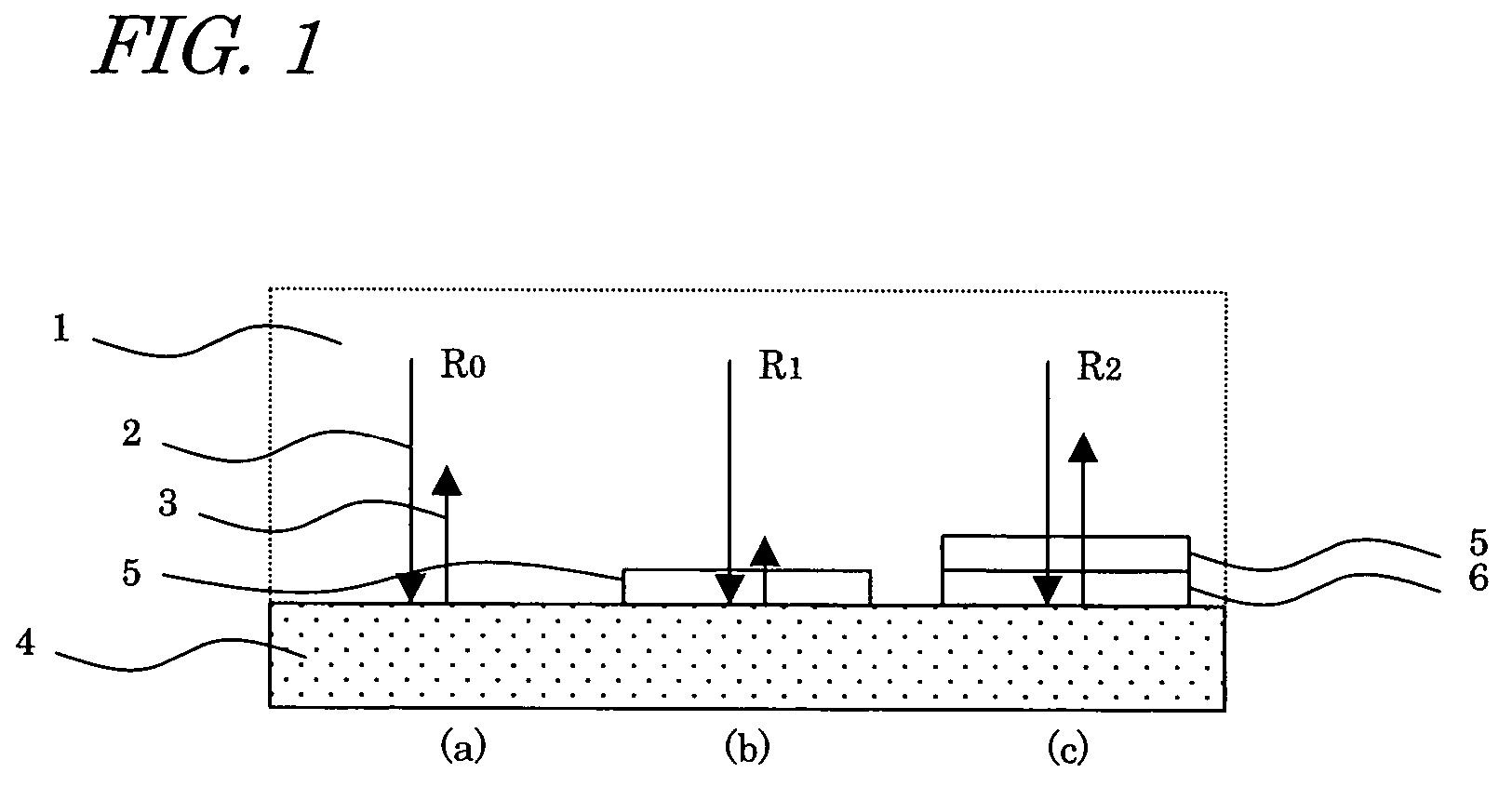

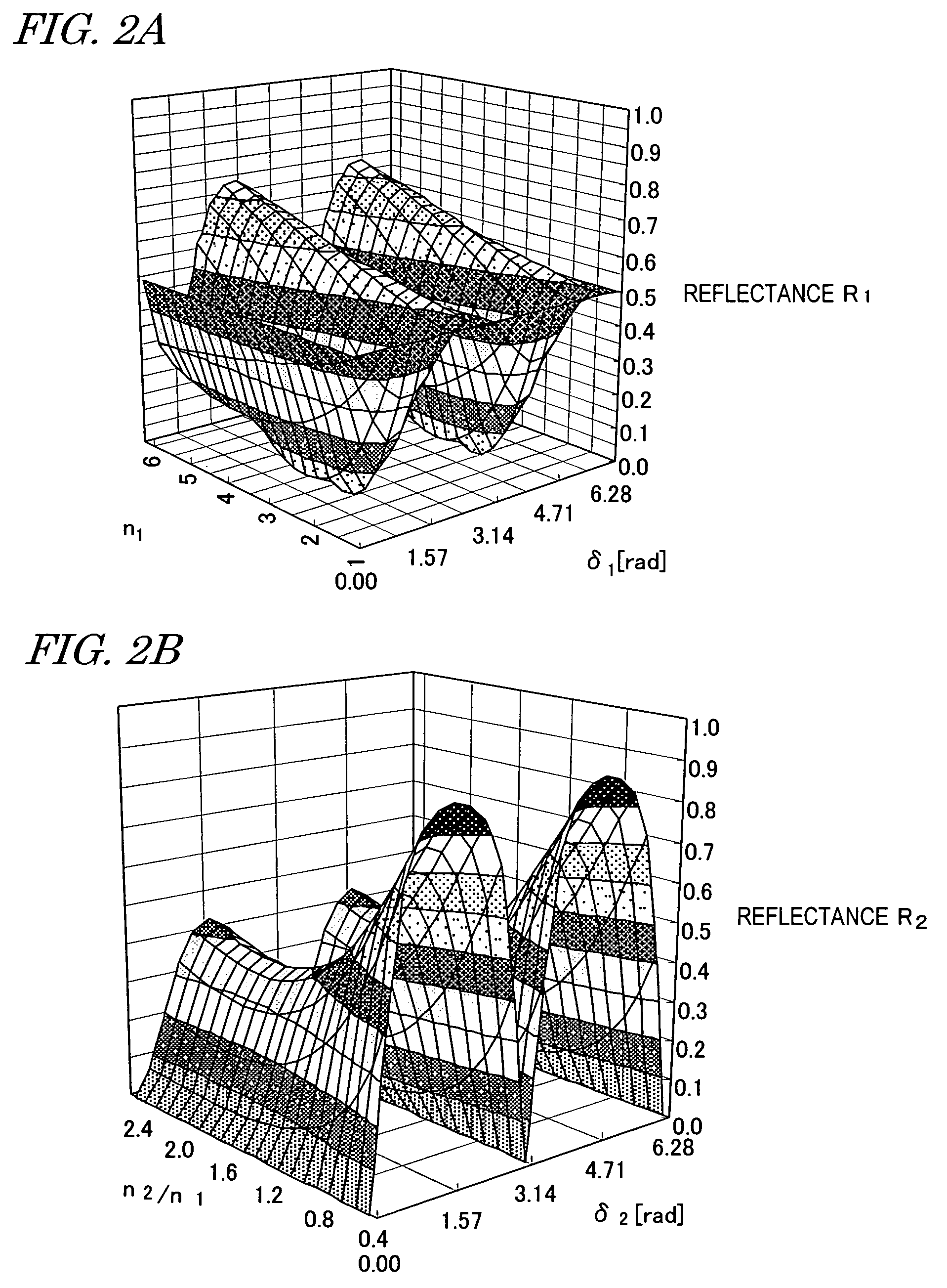

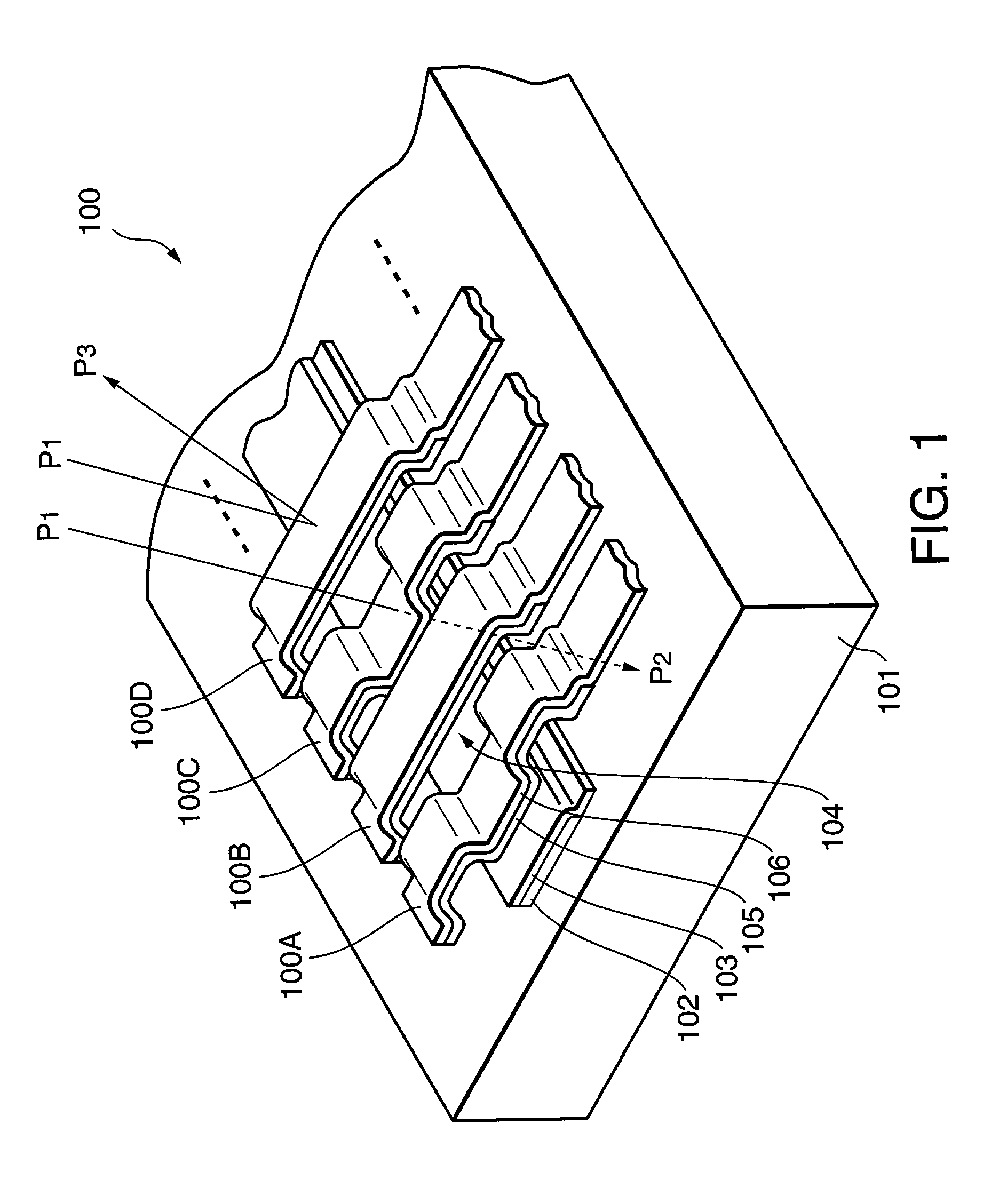

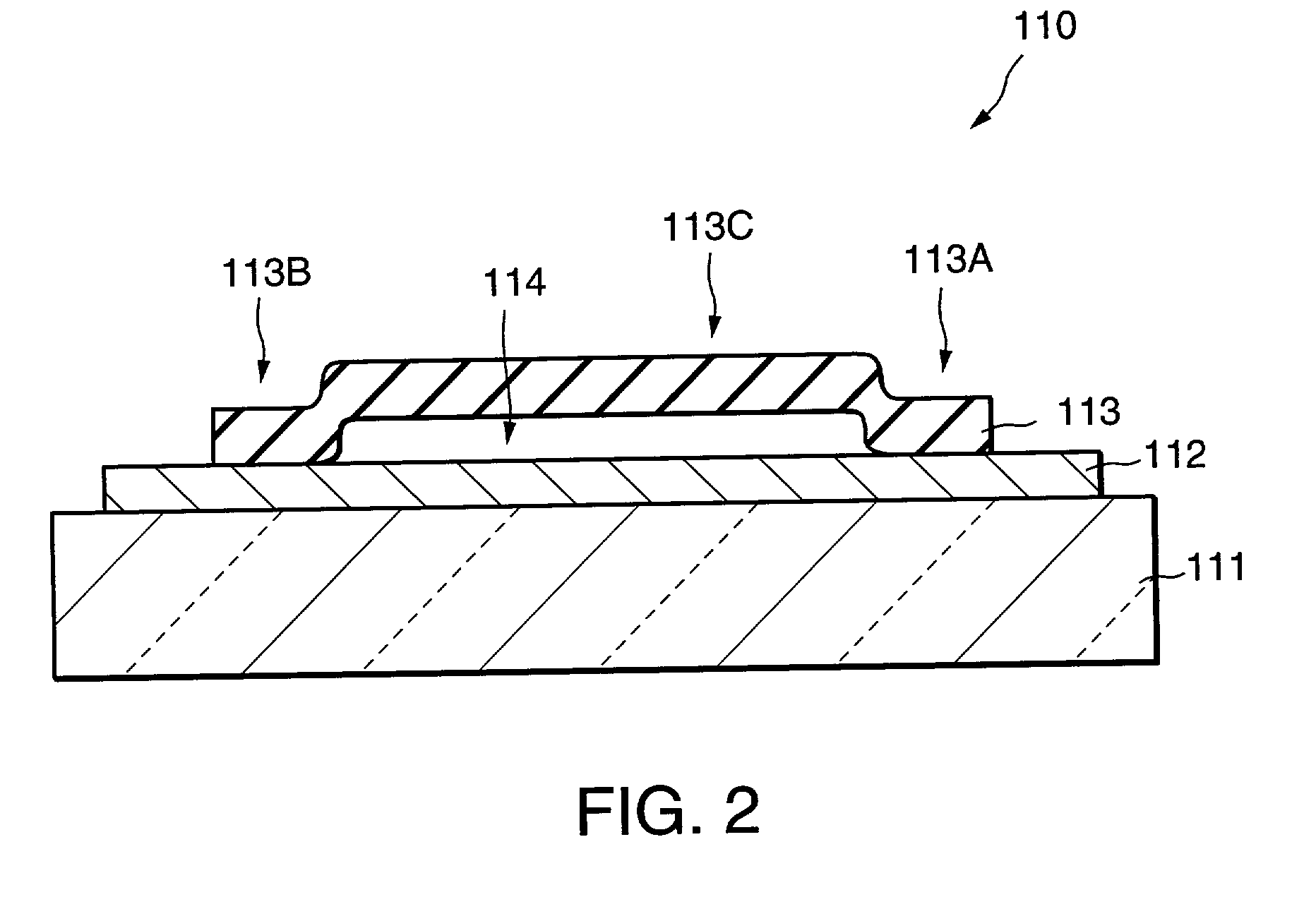

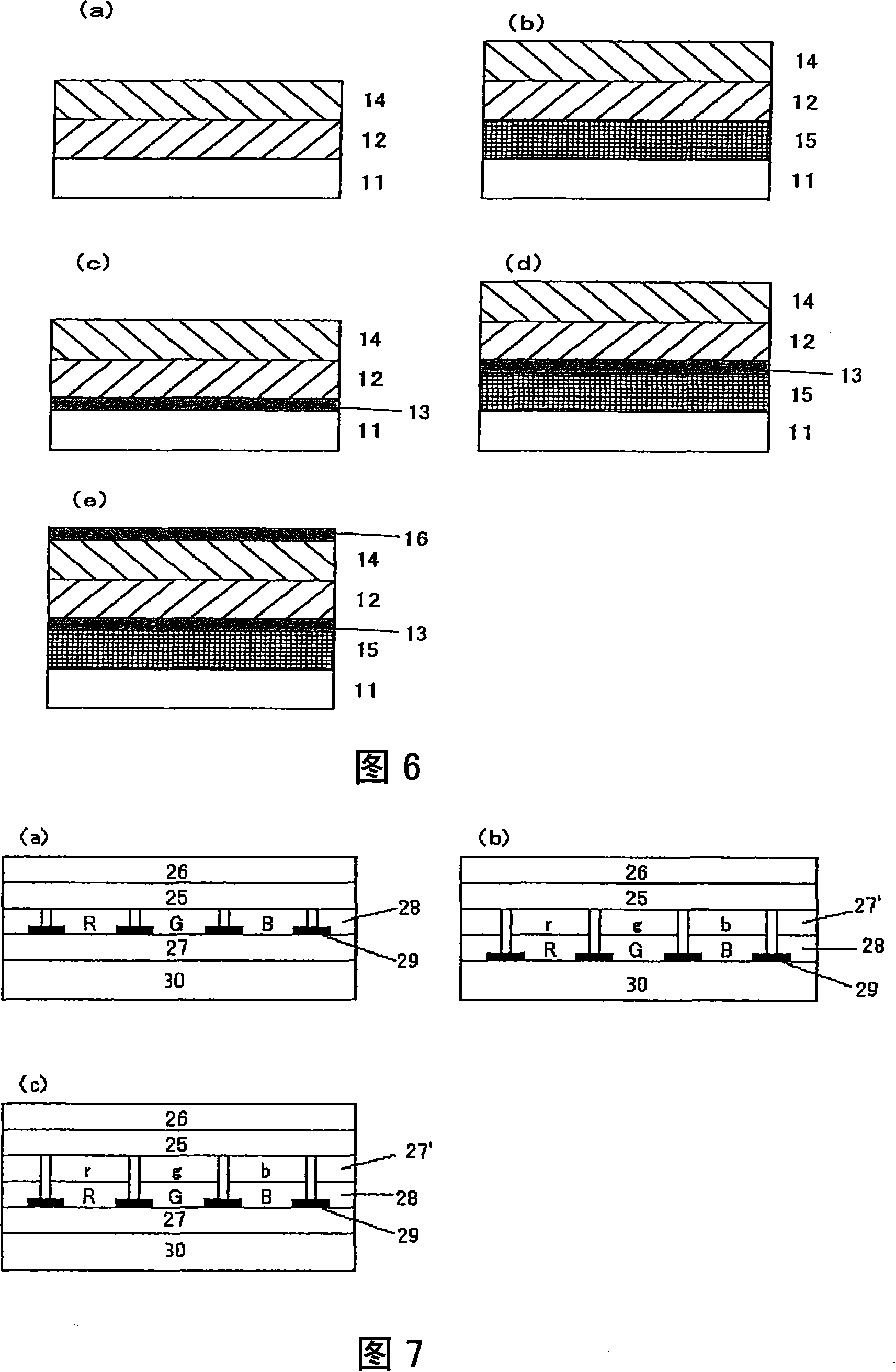

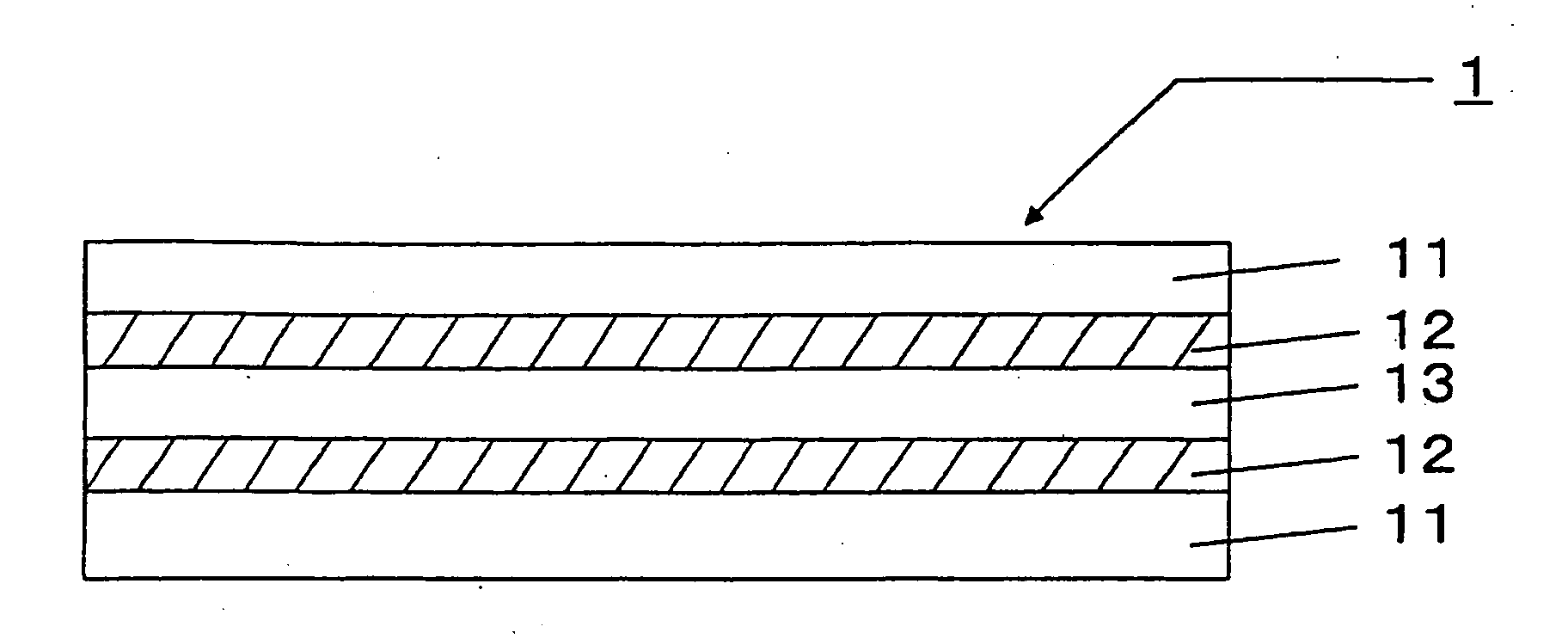

Interferometric modulator and display unit

InactiveUS20050046919A1Improve reflectivityIncrease contrastNon-linear opticsOptical elementsRefractive indexOptical thin film

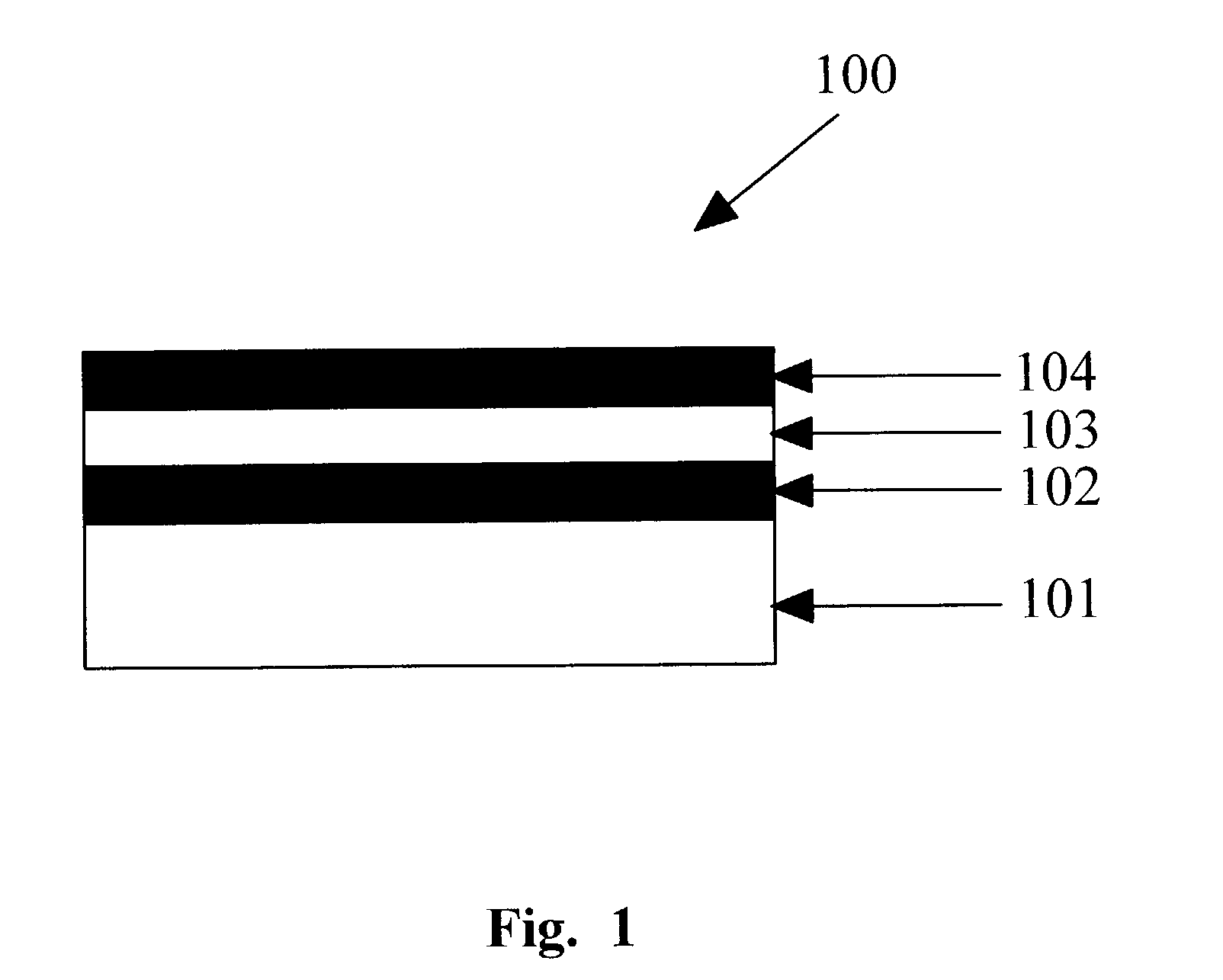

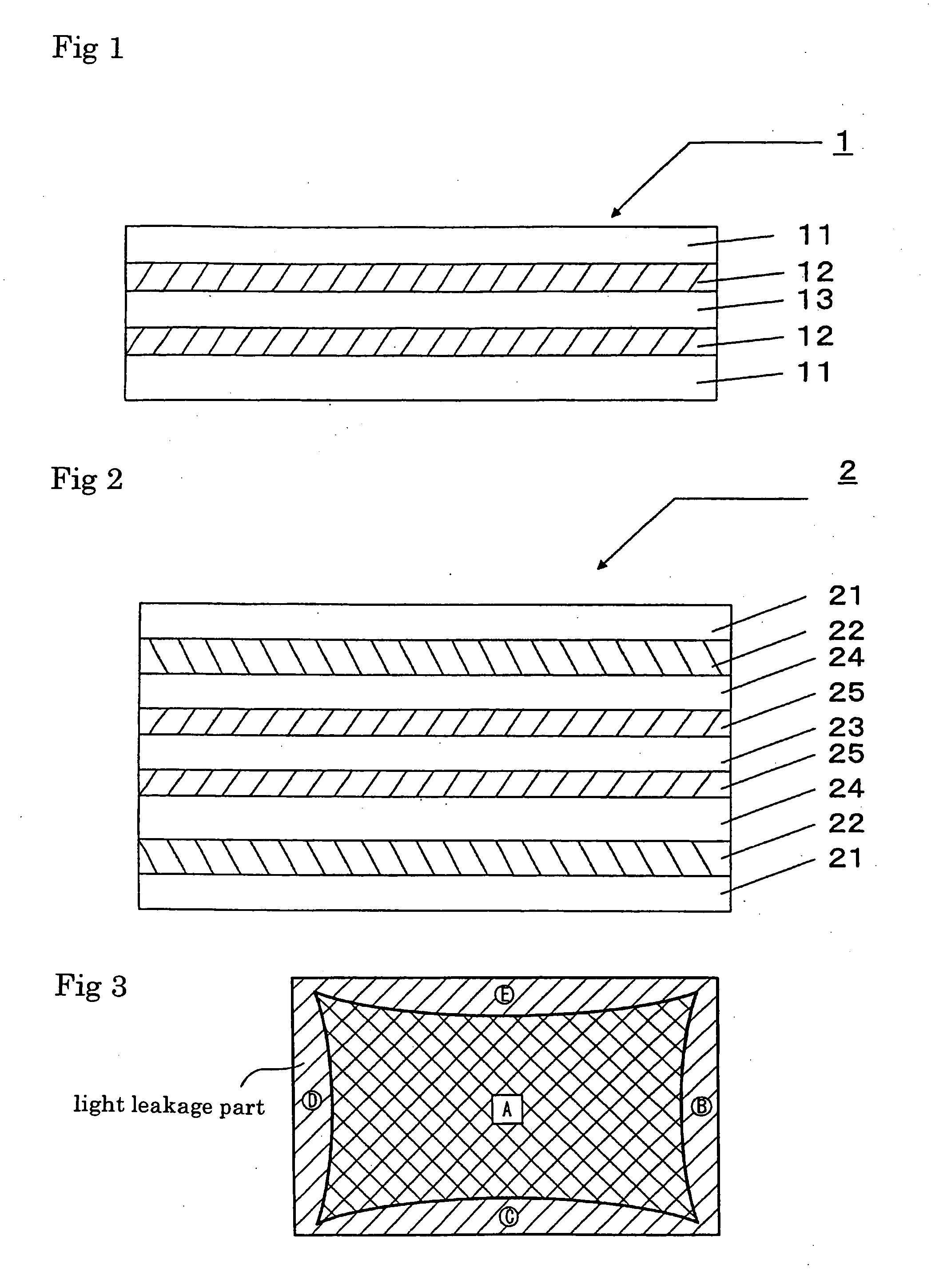

The interferometric modulator of the invention includes a transparent substrate (refractive index: n0) 12, an optical thin film (complex index of refraction: N1=n1−i·k1) 13 provided on the transparent substrate 12, and an absorber layer (complex index of refraction: Ns=ns−i·ks) 14 opposed to the optical thin film 13, the distance of a gap to the optical thin film 13 being variable, wherein the relation n1>n0, k1≅0 and ns>n0 is satisfied.

Owner:SHARP KK

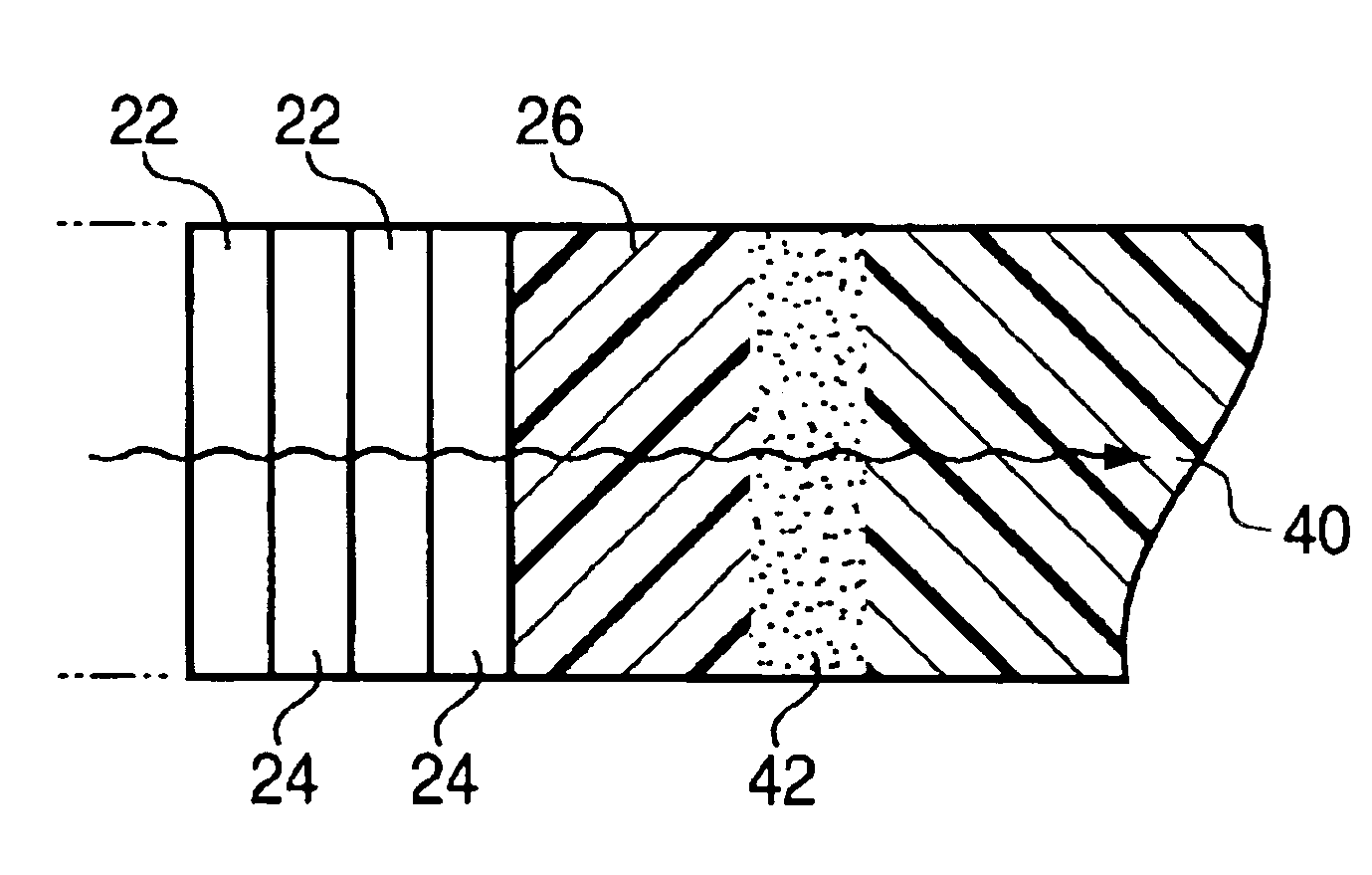

Substrate mounting for organic, dielectric, optical film

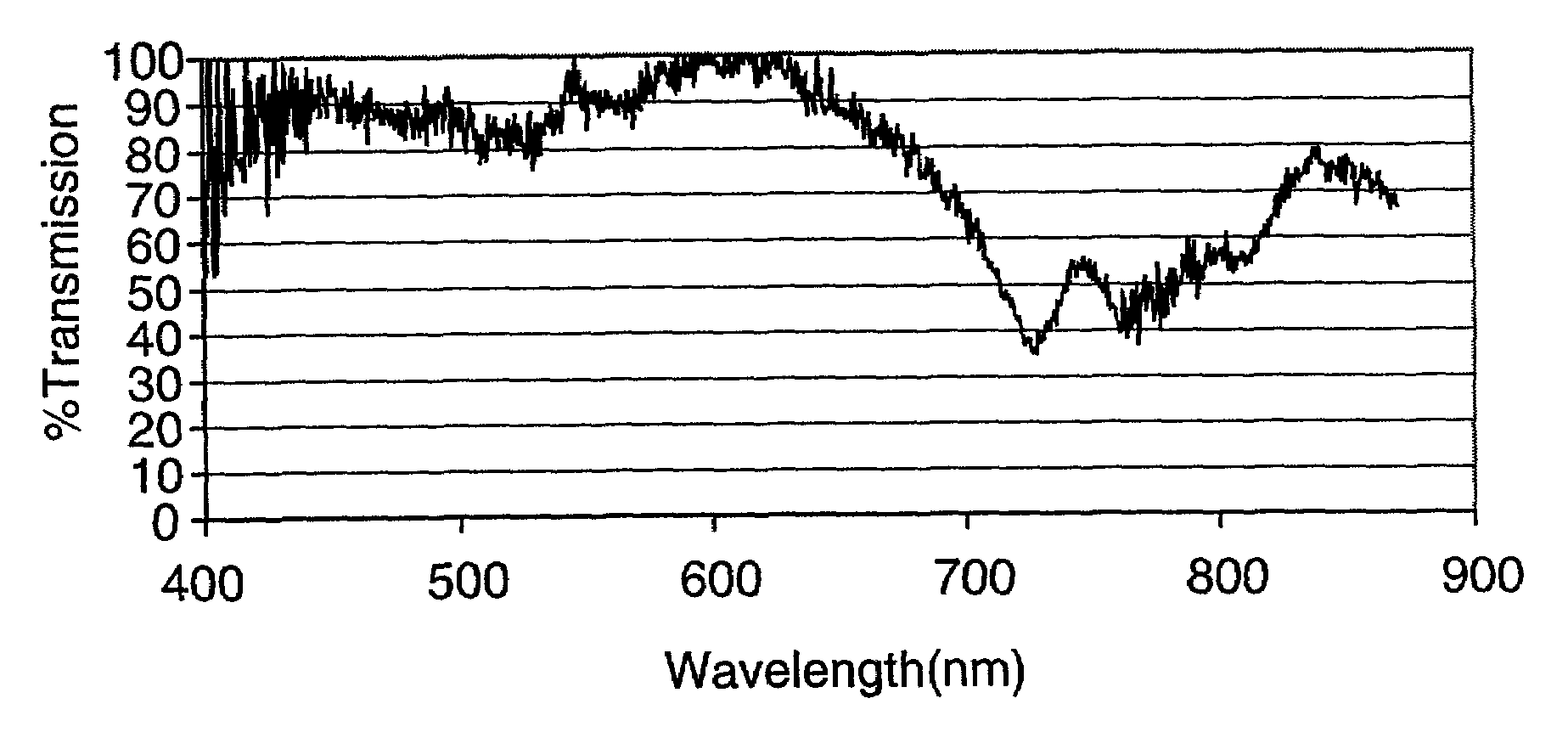

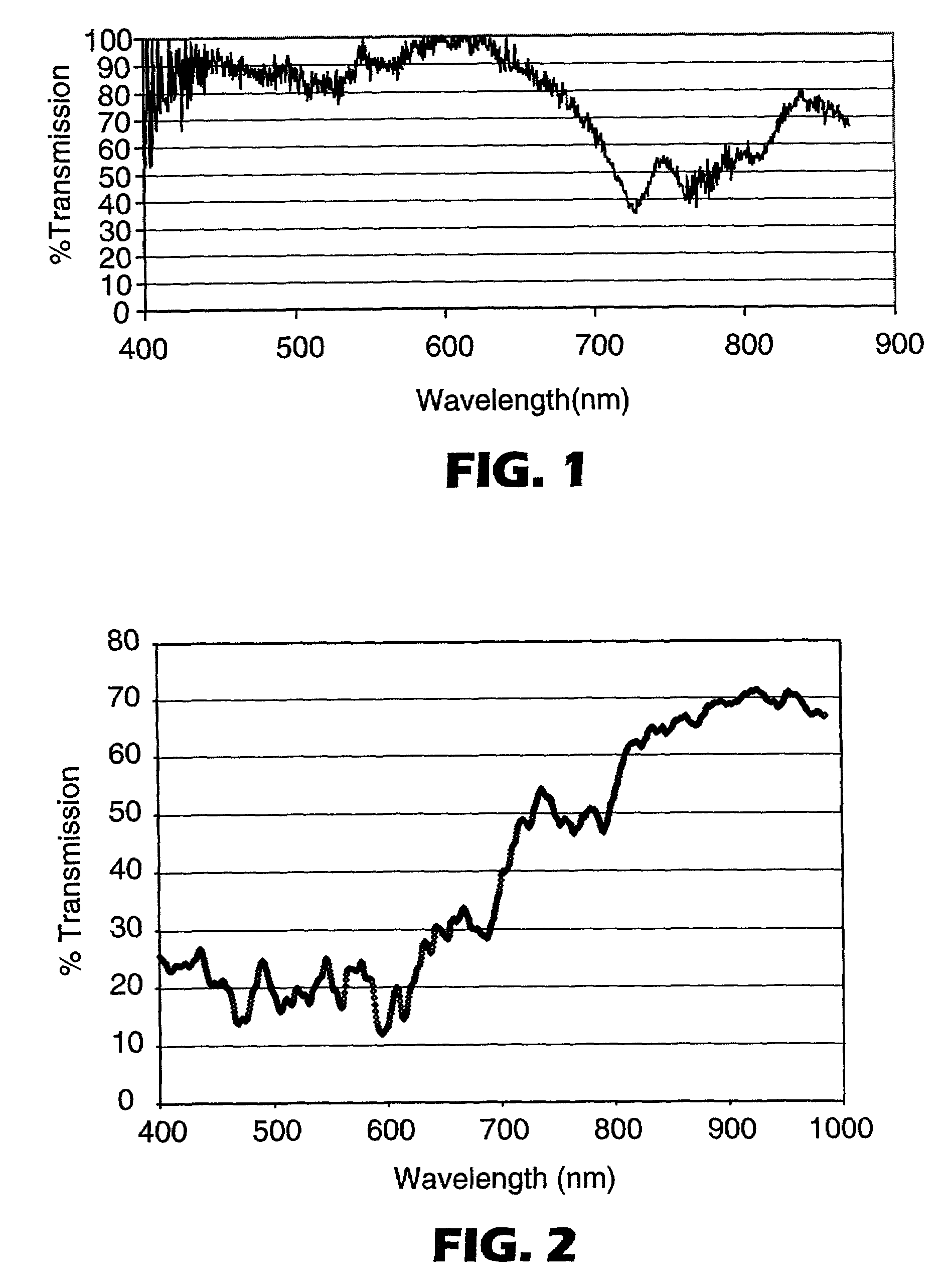

A method for optically coupling a thermoplastic material to an outer surface layer of an organic, dielectric, optical film and the resulting optical filter. Initially, a dielectric film is selected that includes (i) repeating optical layers of at least two polymers having different refractive indexes from each other, (ii) an exterior film surface, (iii) a refractive boundary along the exterior film surface, and (iv) a delamination threshold based on total thermal energy delivered to the film. A thermoplastic material which is miscible with the exterior film surface is fused to the refractive boundary with thermal energy below the delamination threshold to form a polydisperse region having a higher optical transmission than the refractive boundary. Add-on filters in the form of hardcoat layers, anti-reflection layers, holograms, metal dielectric stacks and combinations of these may be combined with the thermoplastic-film construct.

Owner:GENTEX CORP

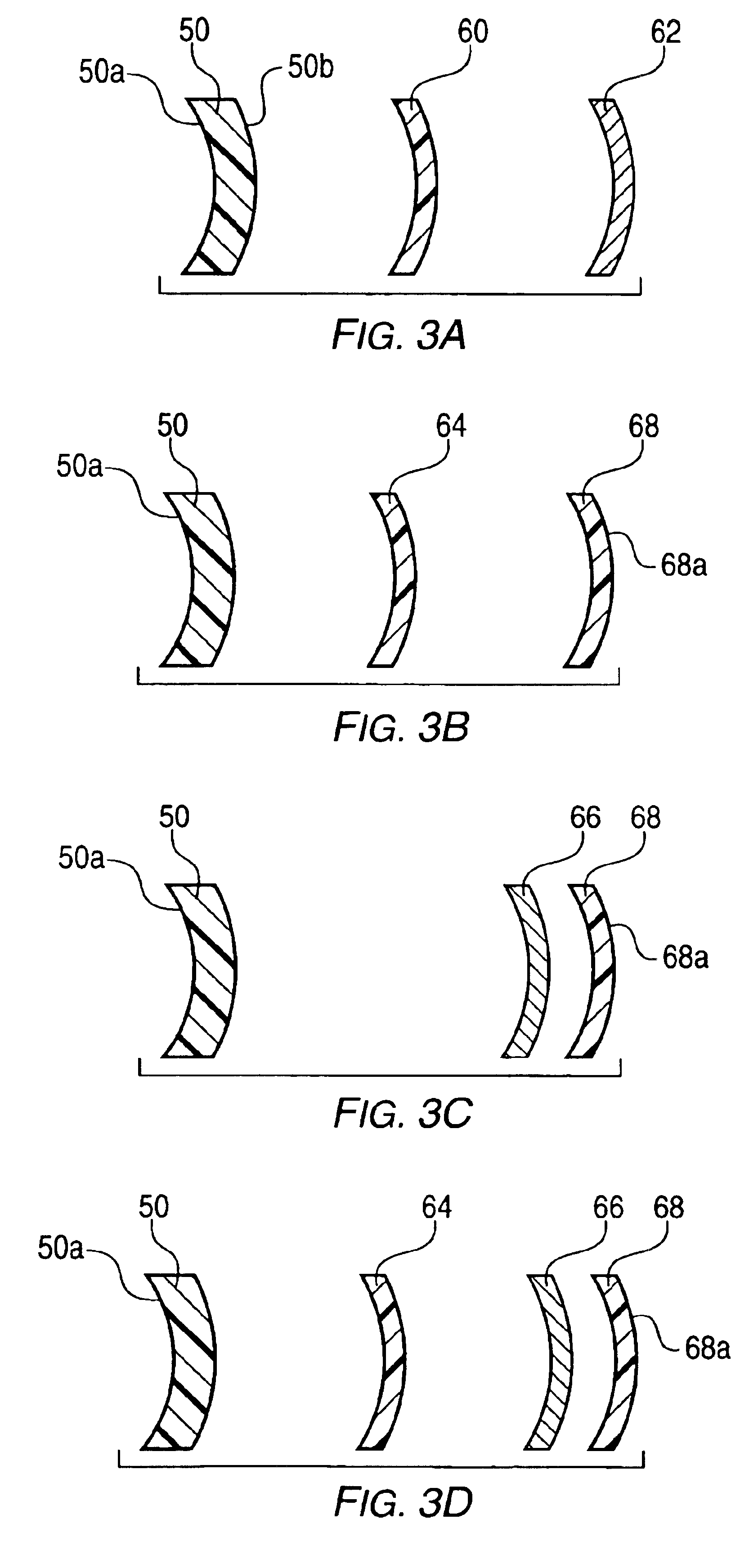

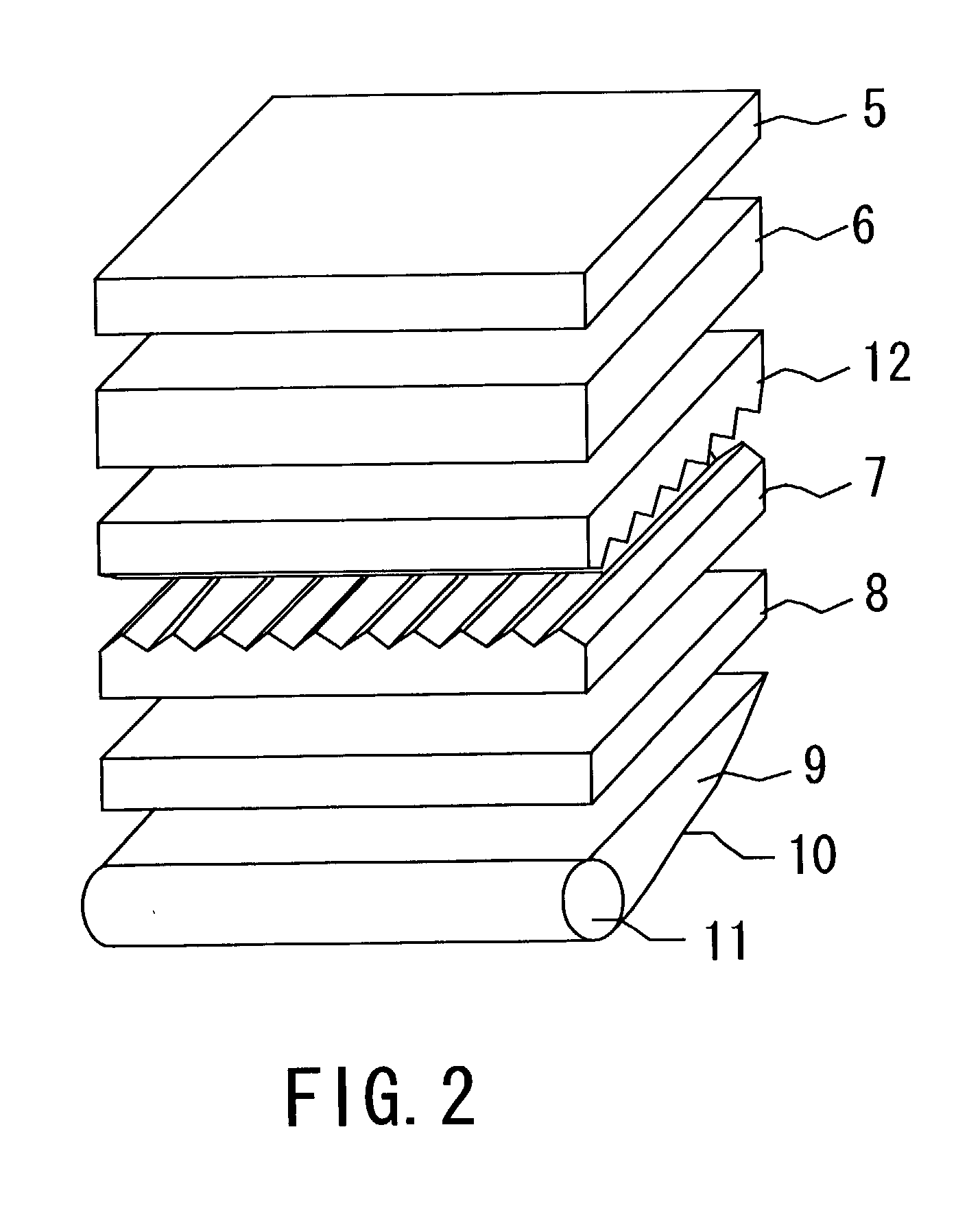

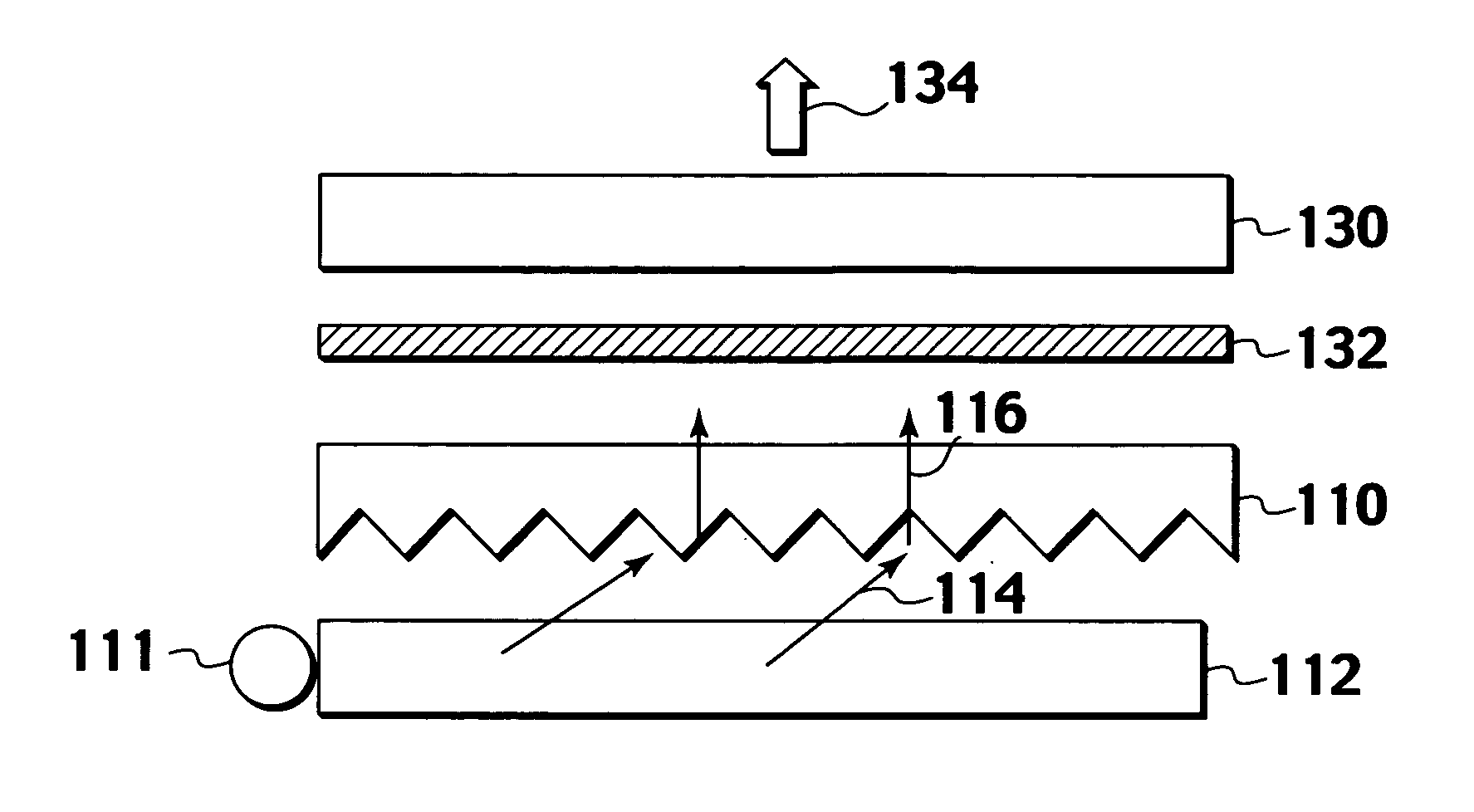

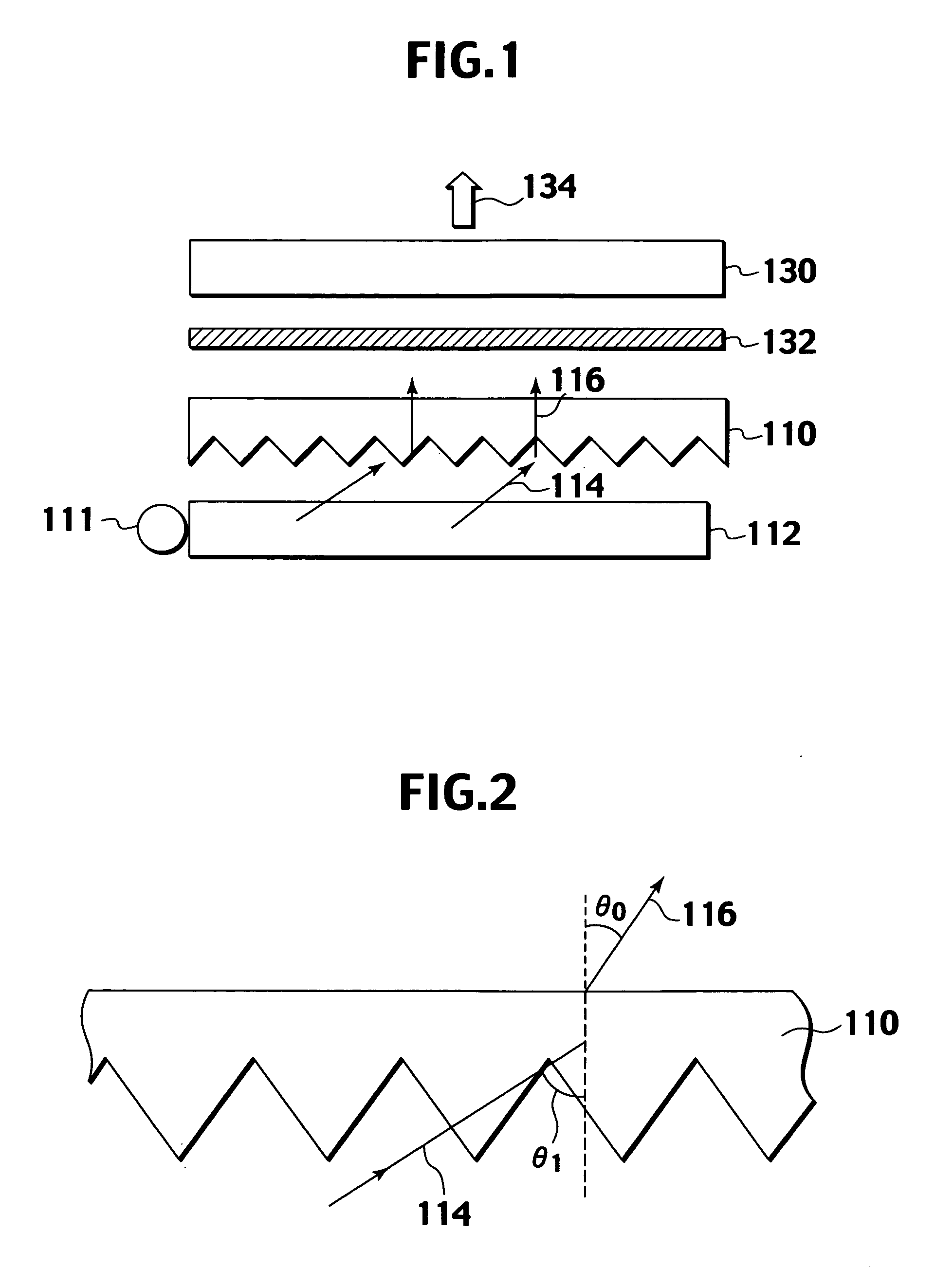

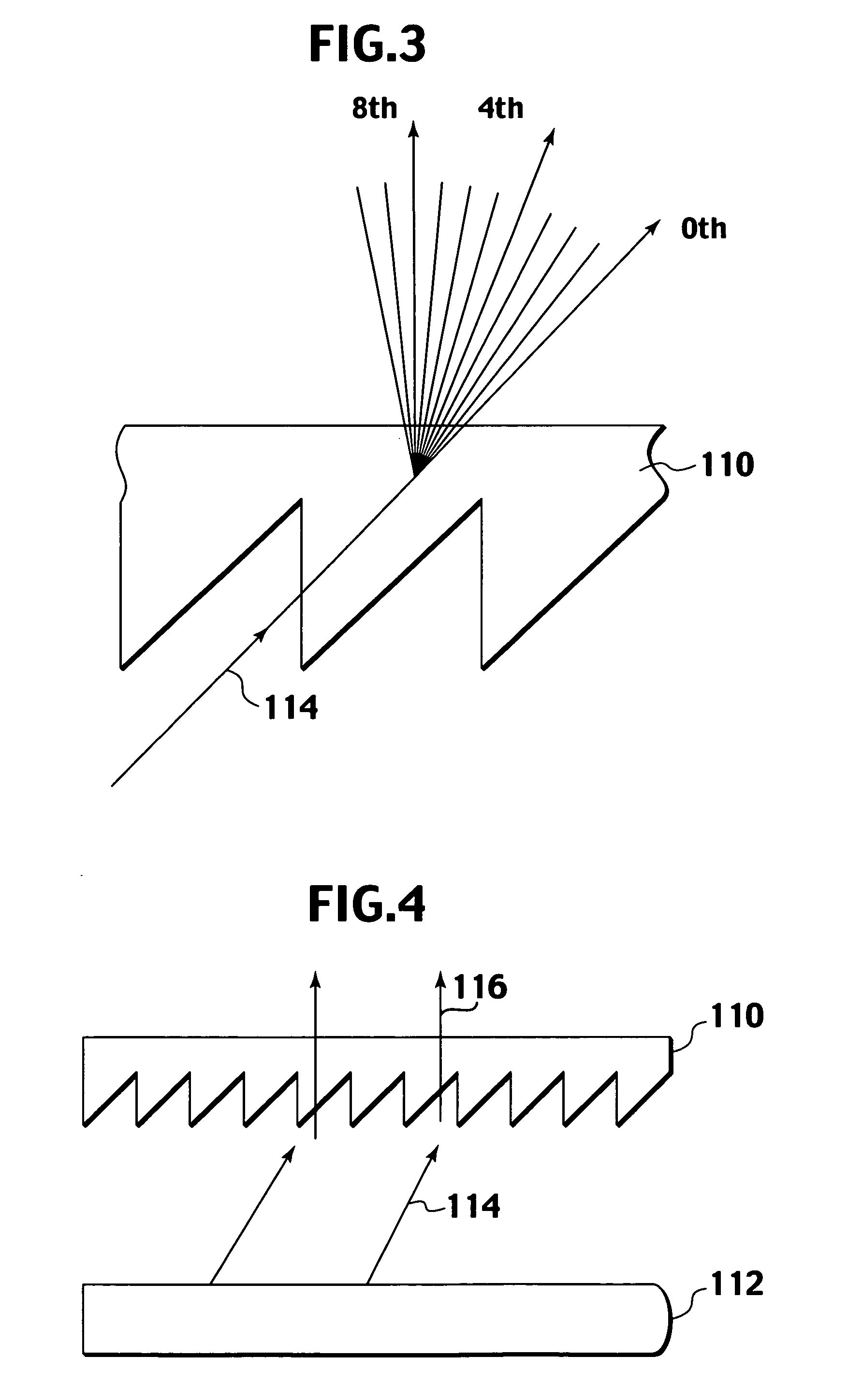

Liquid crystal display device and backlight module thereof

InactiveUS20050270766A1Improve uniformityIncrease brightnessNon-electric lightingPoint-like light sourceLiquid-crystal displayOptical thin film

A backlight module comprises a light transmissive substrate, an optical film, and at least one light source. In this case, the optical film has a first surface and a second surface opposite to the first surface. The first surface of the optical film is connected to the transparent surface, and the second surface of the optical film has at least one fresnel area. The light source is disposed at one side of the light transmissive substrate.

Owner:PRODISC TECH INC

Interferometric modulator and display unit

InactiveUS7113339B2Improve reflectivityIncrease brightnessNon-linear opticsOptical elementsRefractive indexOptical thin film

The interferometric modulator of the invention includes a transparent substrate (refractive index: n0) 12, an optical thin film (complex index of refraction: N1=n1−i·k1) 13 provided on the transparent substrate 12, and an absorber layer (complex index of refraction: Ns=ns−i·ks) 14 opposed to the optical thin film 13, the distance of a gap to the optical thin film 13 being variable, wherein the relation n1>n0, k1≅0 and ns>n0 is satisfied.

Owner:SHARP KK

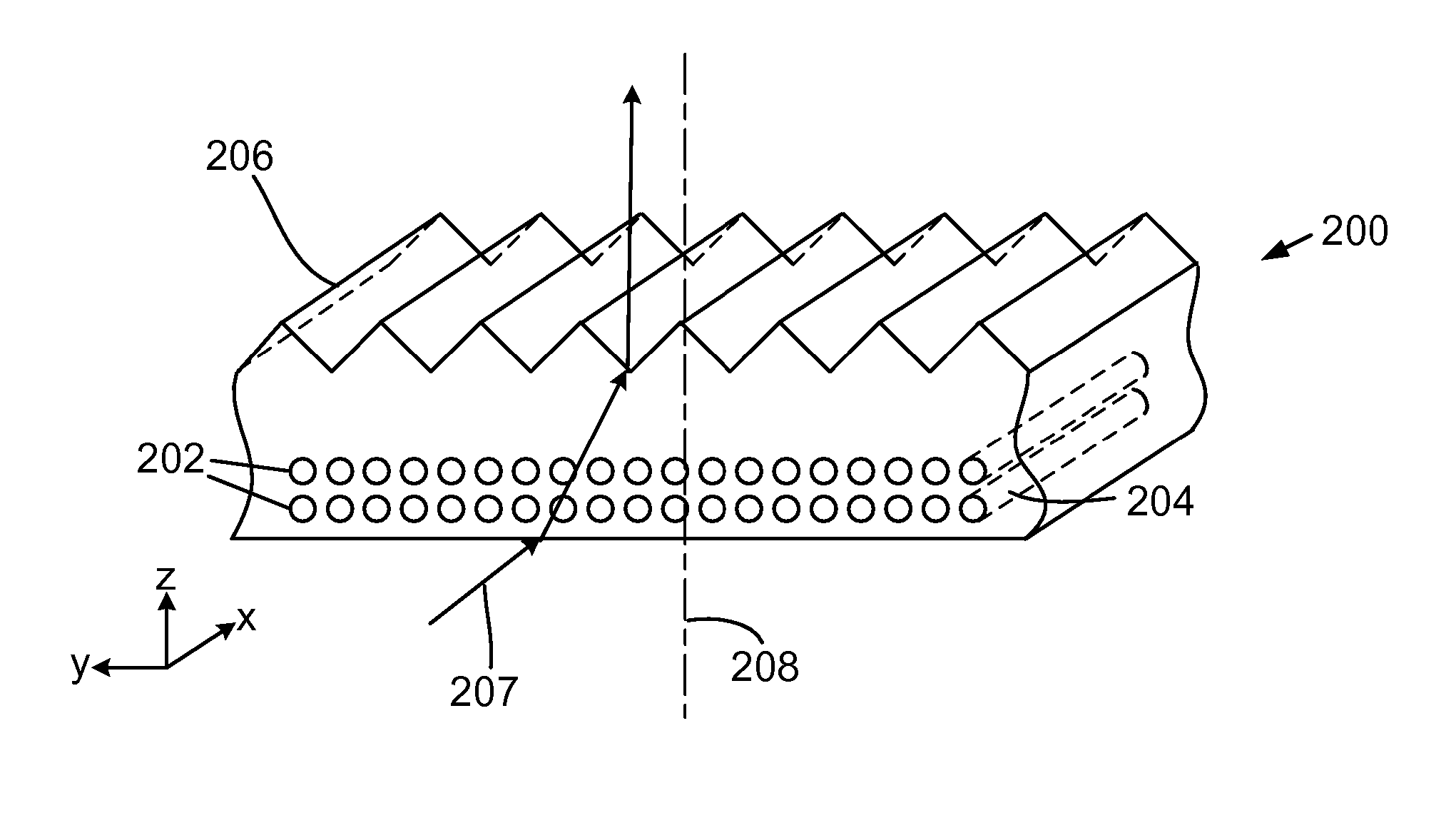

Optical film having microeplicated structures; and methods

An optical film for use in transparent displays, such as reflective LCDs. The optical film has three-dimensional, prismatic structures that reflect incoming light. The prismatic structures are configured so that the reflecting facets orient the reflected light in desired reflective light pattern. The pattern shape and intensity can be controlled by the shape and dimensions of the various reflecting facets. In one embodiment, the height of the prismatic structure varies along two dimensions of the structure.

Owner:3M INNOVATIVE PROPERTIES CO

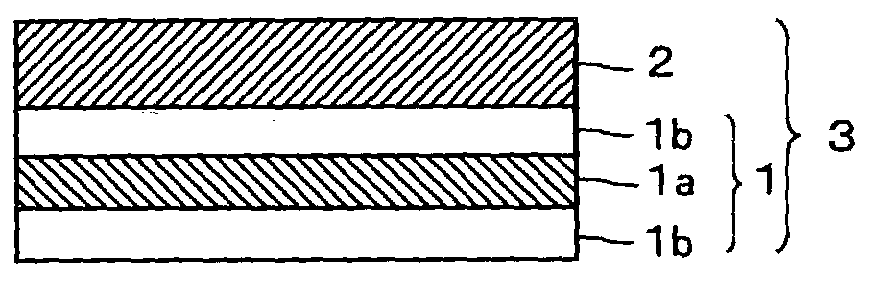

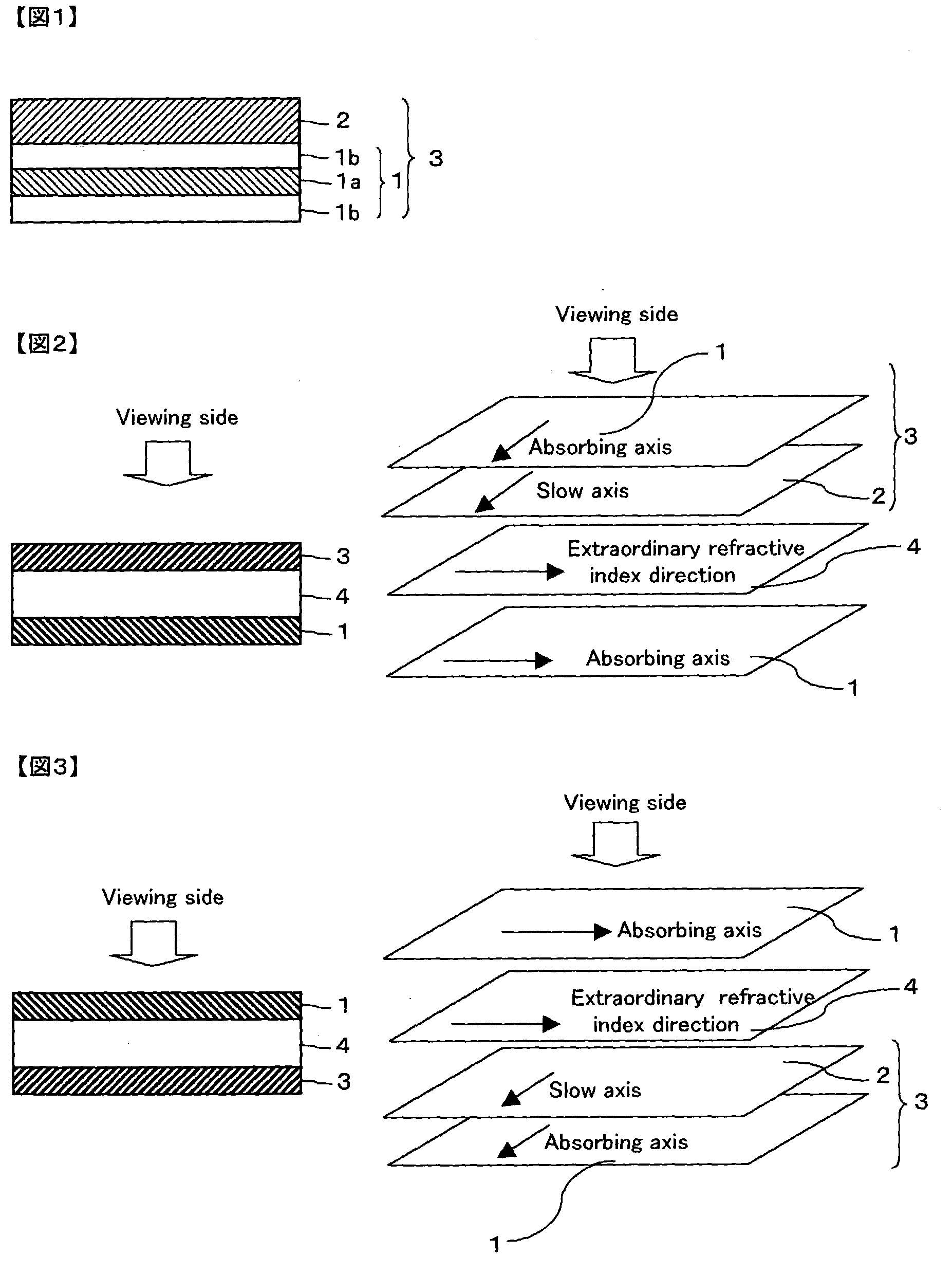

Optical film and a liquid crystal display using the same

InactiveUS20030071947A1Mechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayDisplay device

An optical film having excellent light utilization efficiency and high brightness, and a liquid crystal display using the optical film. The optical film is formed by laminating integrally a brightness enhancement film (A) that separates natural light into transmitted light and reflected light and a collimating film (B) having an uneven portion on a surface thereof. Since an air interface is eliminated by the integral lamination of the brightness enhancement film and the collimating film, stray light is reduced, and the brightness enhancement film has an improved efficiency in reflecting and polarizing light; thereby, enhancing the brightness.

Owner:NITTO DENKO CORP

Optical film and display system

InactiveUS20030210370A1Easy to viewIncrease contrastPolarising elementsNon-linear opticsIn planeTectorial membrane

An optical film in which a retardation film is laminated on one side of a polarizing plate, in which a transparent protective film is laminated on both sides of a polarizer, so that an absorbing axis of the polarizing plate and a slow axis of the retardation film may be perpendicular or may be parallel to each other, wherein a value Nz represented by Nz=(nx1-nzi) / (nx1-ny1) satisfies a range of 0.4 through 0.6, and an in-plane retardation Re1=(nx1-ny1)xd1 is 200 through 350 nm, where, a direction of the retardation film in which an in-plane refractive index within the film surface concerned gives a maximum is defined as X-axis, a direction perpendicular to X axis is defined as Y-axis, a thickness direction of the film is defined as Z-axis, refractive indexes in axial direction are defined as nx1, ny1, nz1, respectively, and a thickness of the film is defined as d1 (nm), and the transparent protective films comprise a thermoplastic saturated norbornene resin, may realize an easily viewable display with high contrast ratio in a wide range when applied to a display system and that may provide a retardation value stabilized under conditions of high temperature or high humidity.

Owner:NITTO DENKO CORP

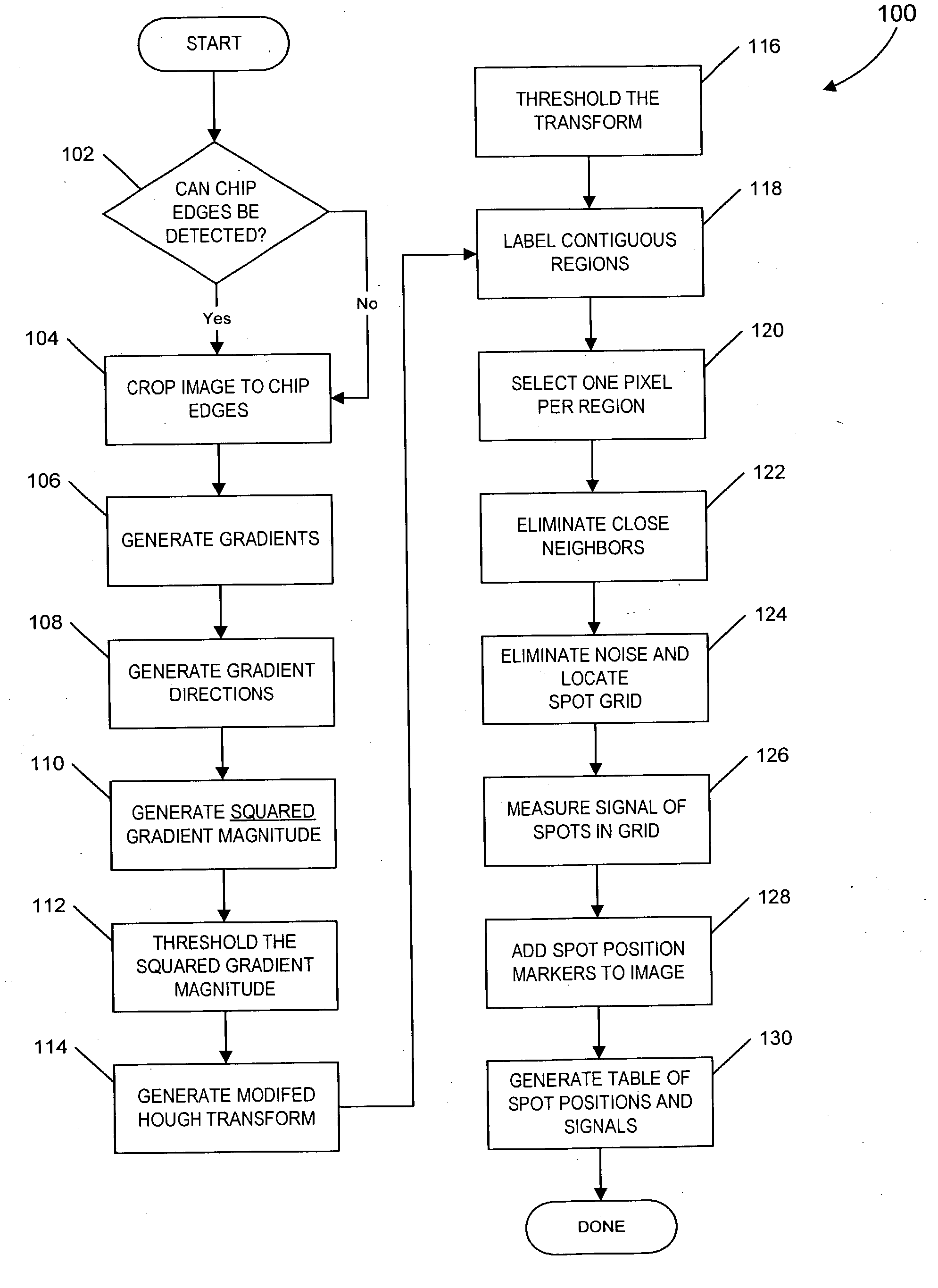

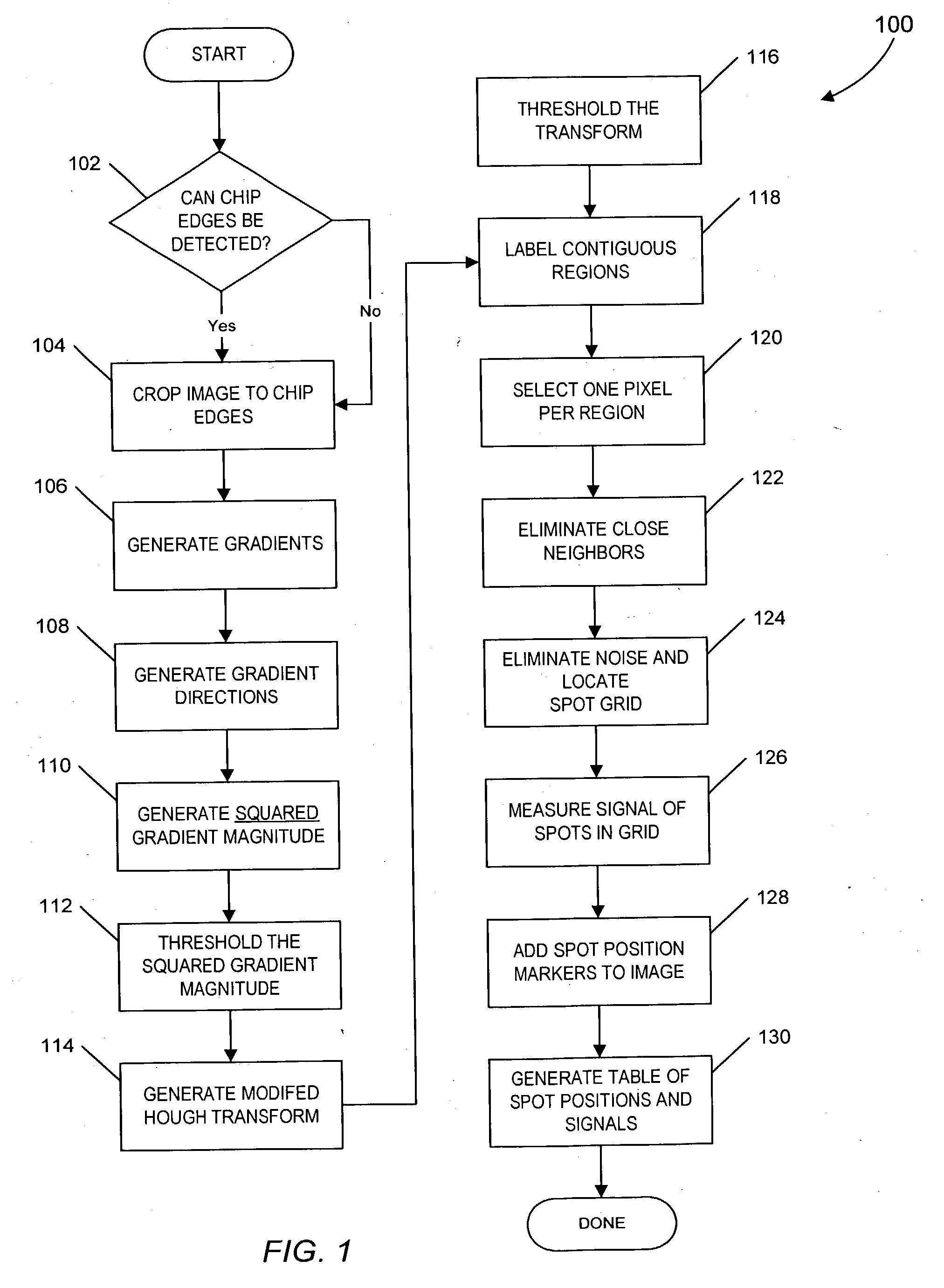

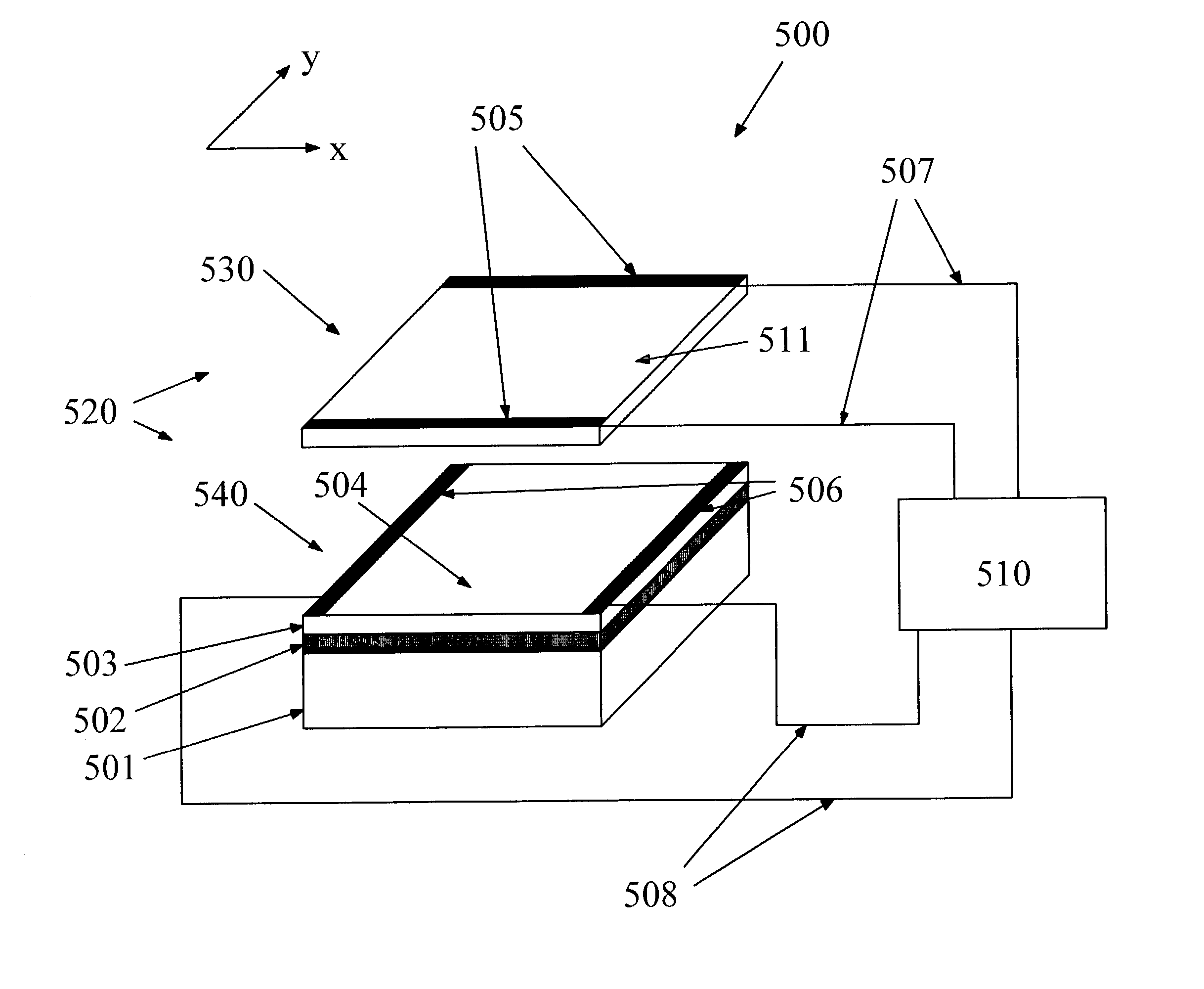

Detection, resolution, and identification of arrayed elements

An image analysis workstation for analyzing optical thin film arrays is disclosed. One disclosed embodiment relates to individual arrays that comprise a single optical thin film test surface that provides a plurality of discretely addressable locations, each comprising an immobilized capture reagent for an analyte of interest. These are referred to herein as "arrayed optical thin film test surfaces." Preferably, an individual arrayed optical thin film test surface comprises at least 4, more preferably at least 16, even more preferably at least 32, still more preferably at least 64, and most preferably 128 or more discretely addressable locations. One or more of the discretely addressable locations may provide control signals (e.g., for normalizing signals and / or that act as positive and / or negative controls) or fiducial signals (i.e., information that is used to determine the relative alignment of the arrayed optical thin film test surface within the device.

Owner:INVERNESS MEDICAL - BIOSTAR

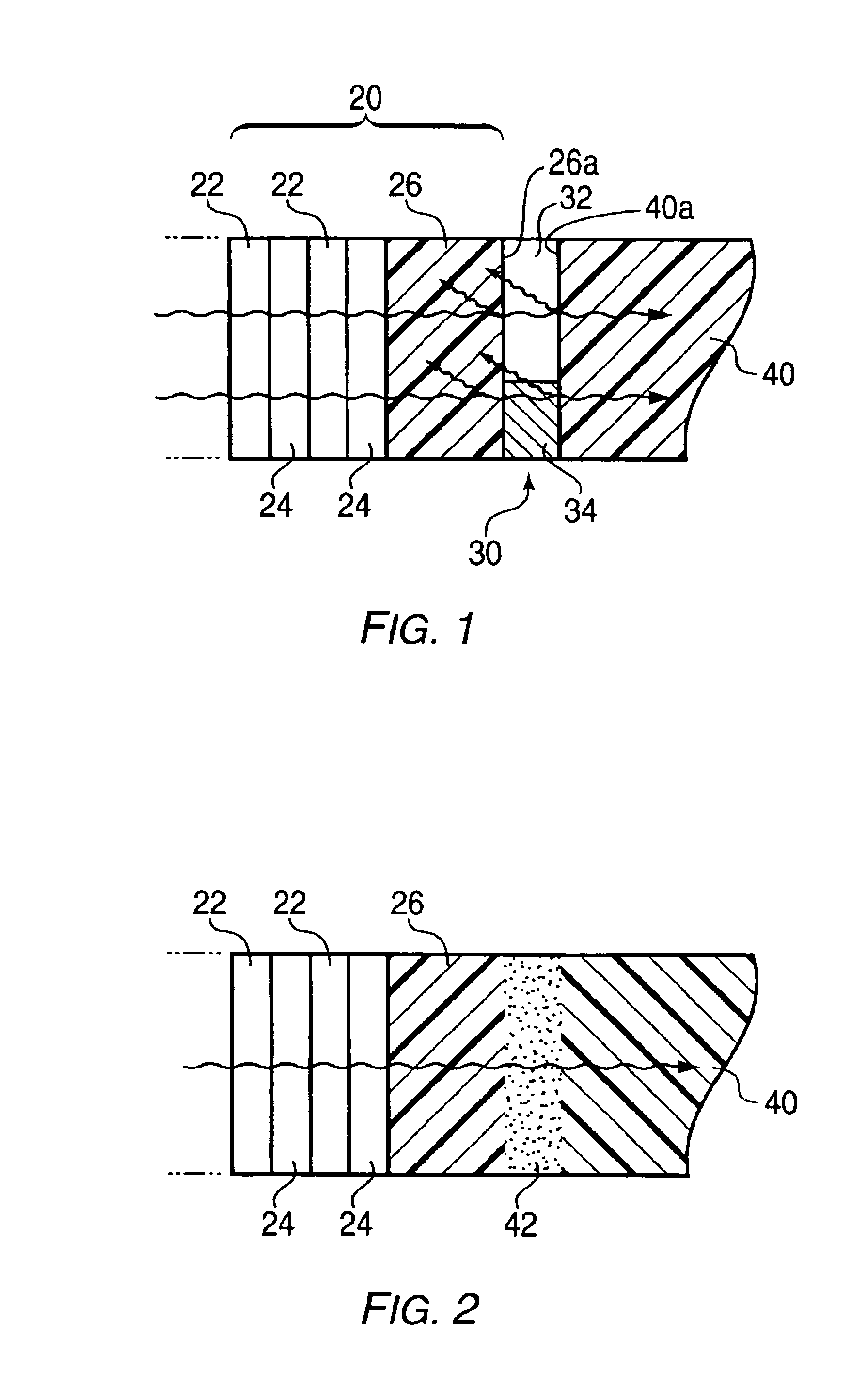

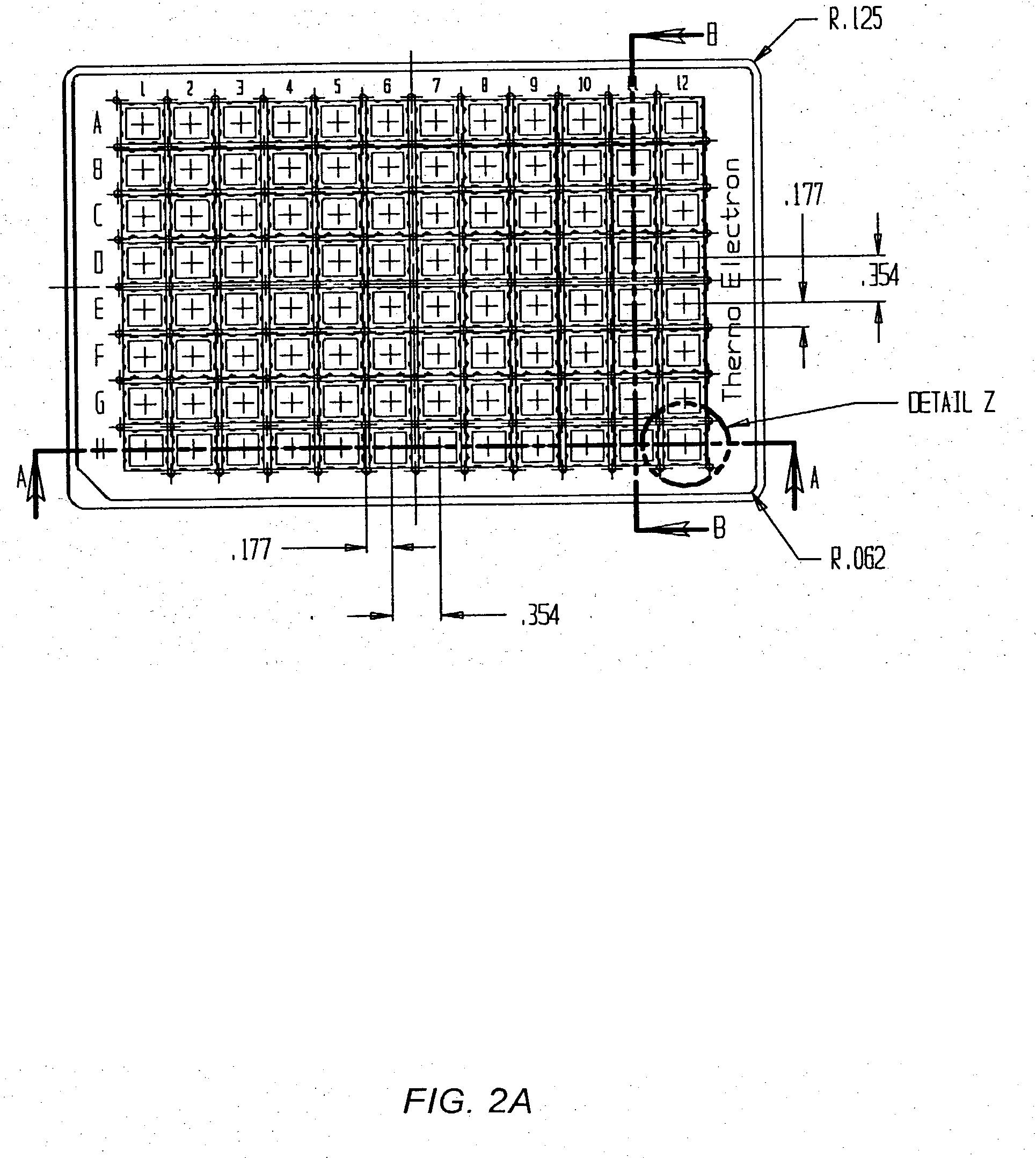

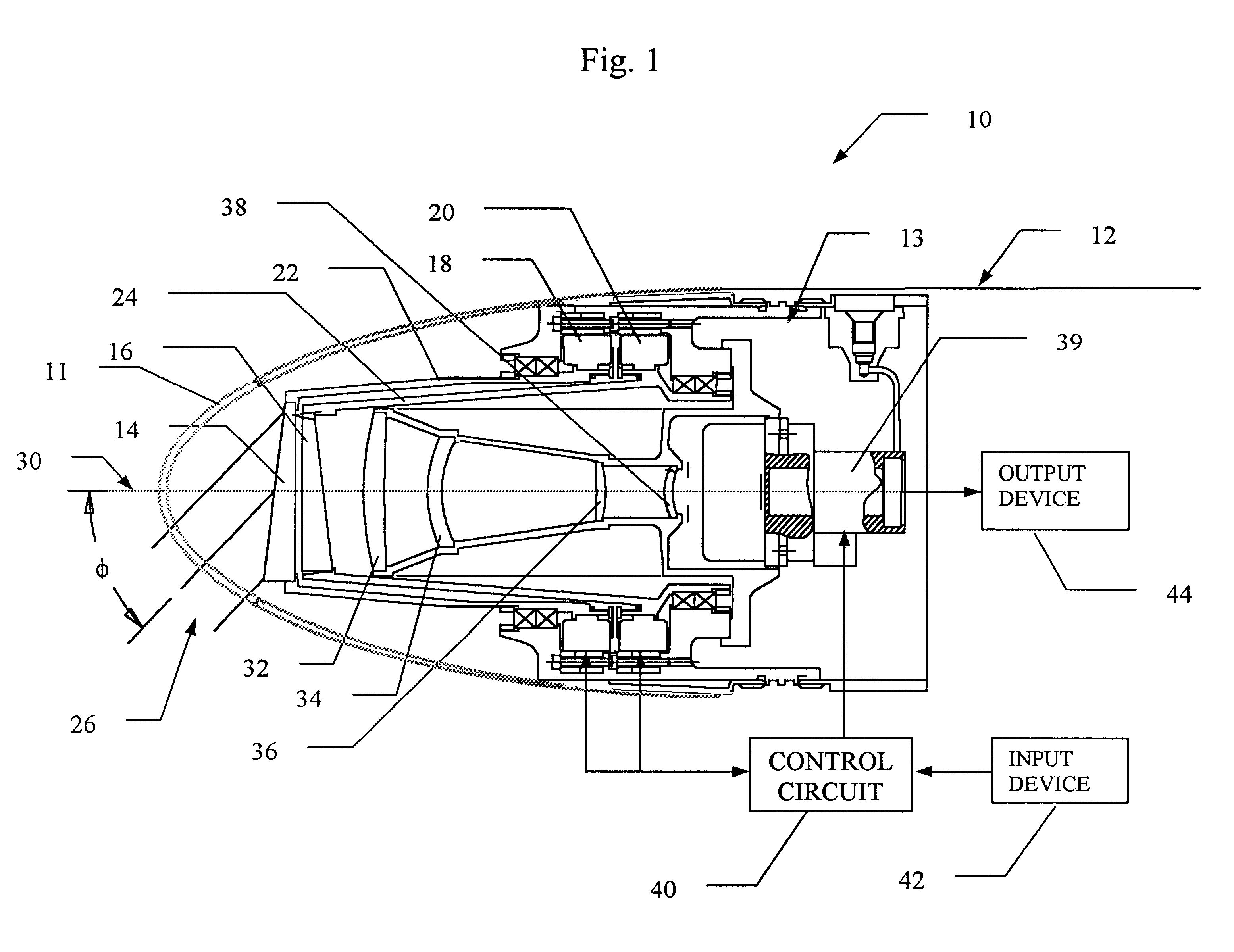

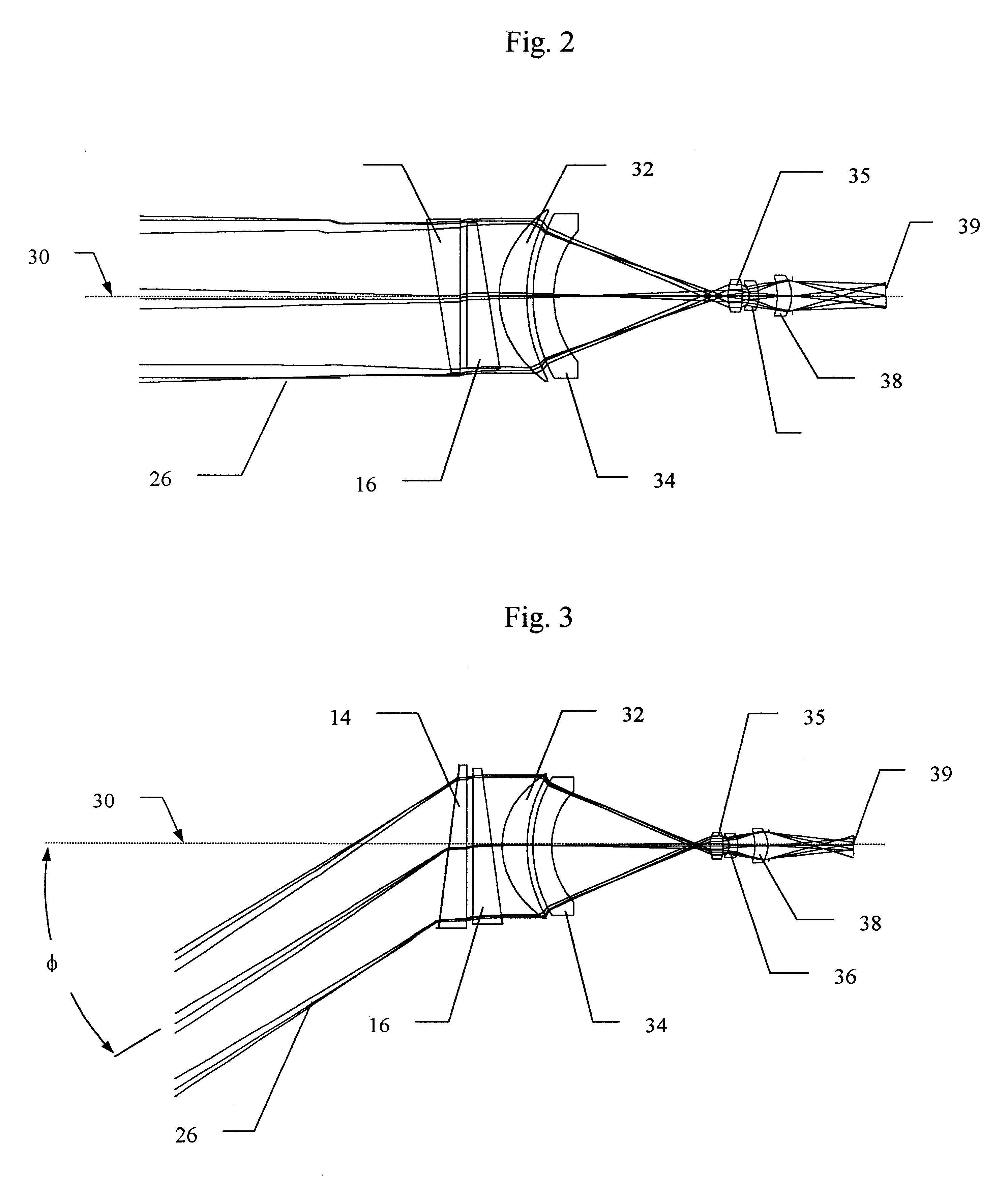

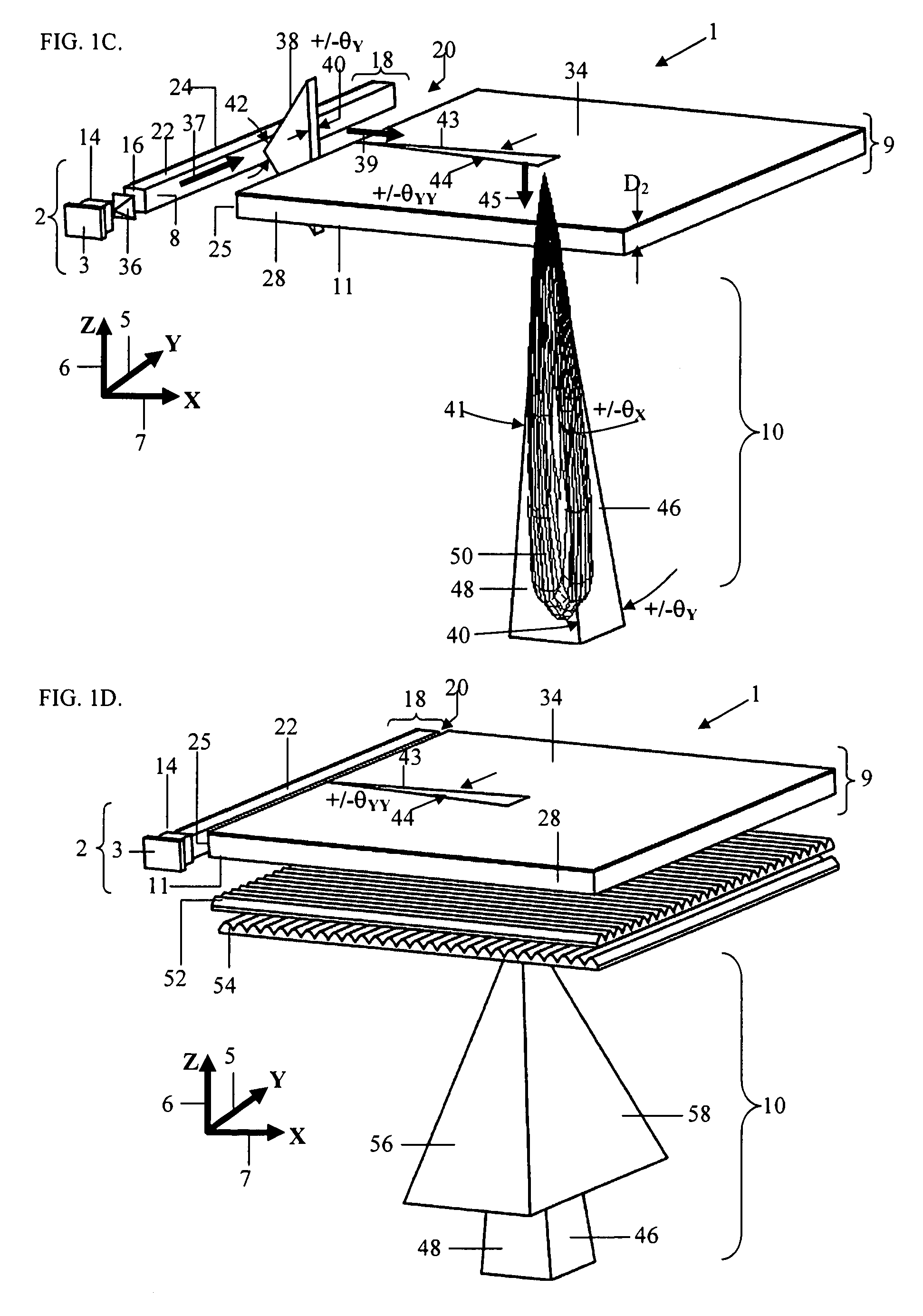

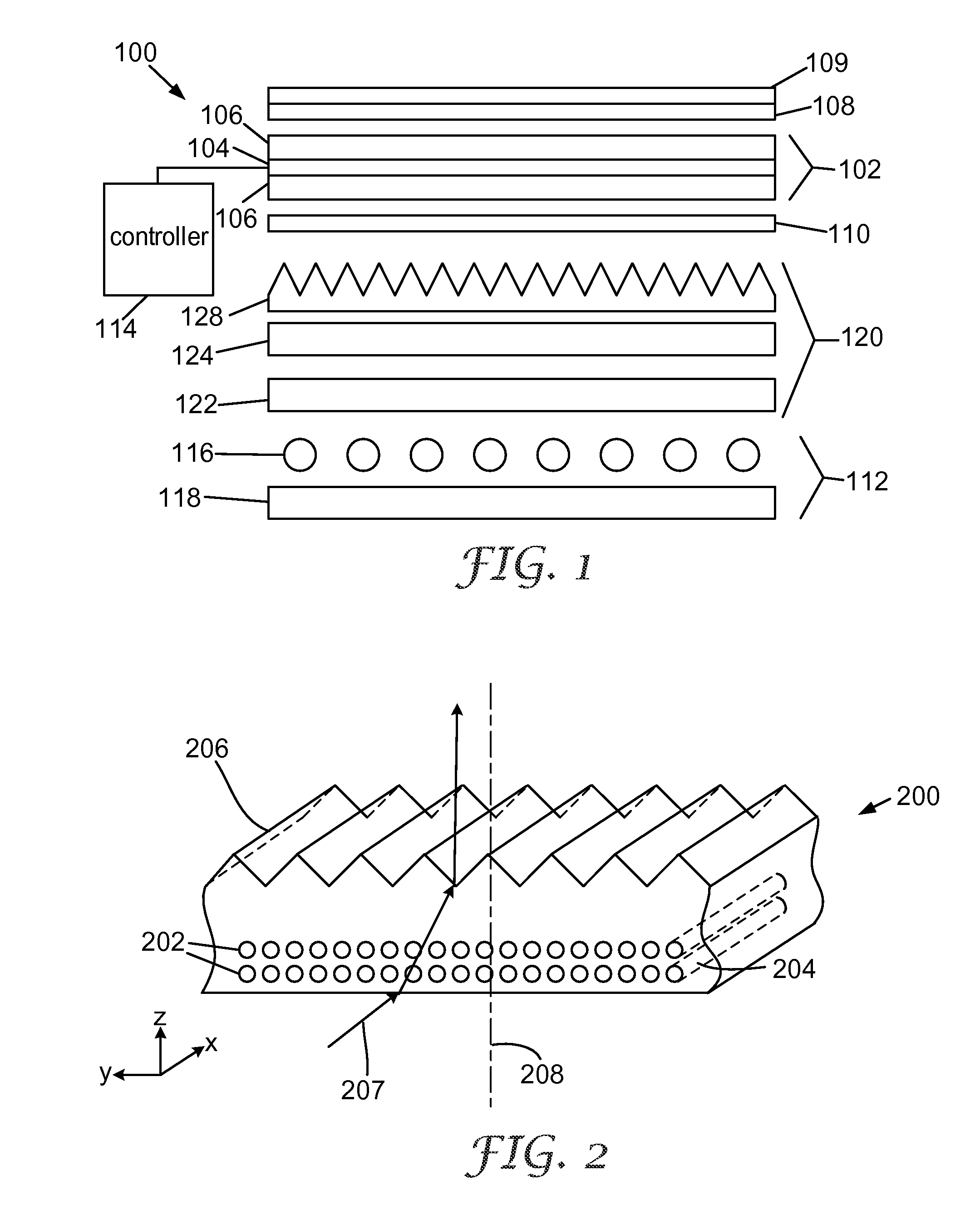

Beam steering optical arrangement using Risley prisms with surface contours for aberration correction

A steerable optical arrangement. The inventive arrangement includes a first prism mounted for rotation about an optical axis and a second prism mounted for rotation about the optical axis. In accordance with the inventive teachings, the first prism and / or the second prism have at least one surface contoured to correct for optical aberration. In the illustrative embodiment, the first and second prisms are Risley prisms. In addition, the illustrative implementation includes a first motor arrangement for rotating the first prism about the optical axis and a second motor arrangement for rotating the second prism about the optical axis. A controller is provided for activating the first and second motors to steer the beam at an angle phi and nod the beam at an angle theta. At least two surfaces at least one prism is contoured to correct for astigmatism, coma, trefoil and other non-rotationally symmetric aberration. The contour is effected by laser etching, micro-machining or optical thin-film coating of the prisms in the manner disclosed herein.

Owner:RAYTHEON CO

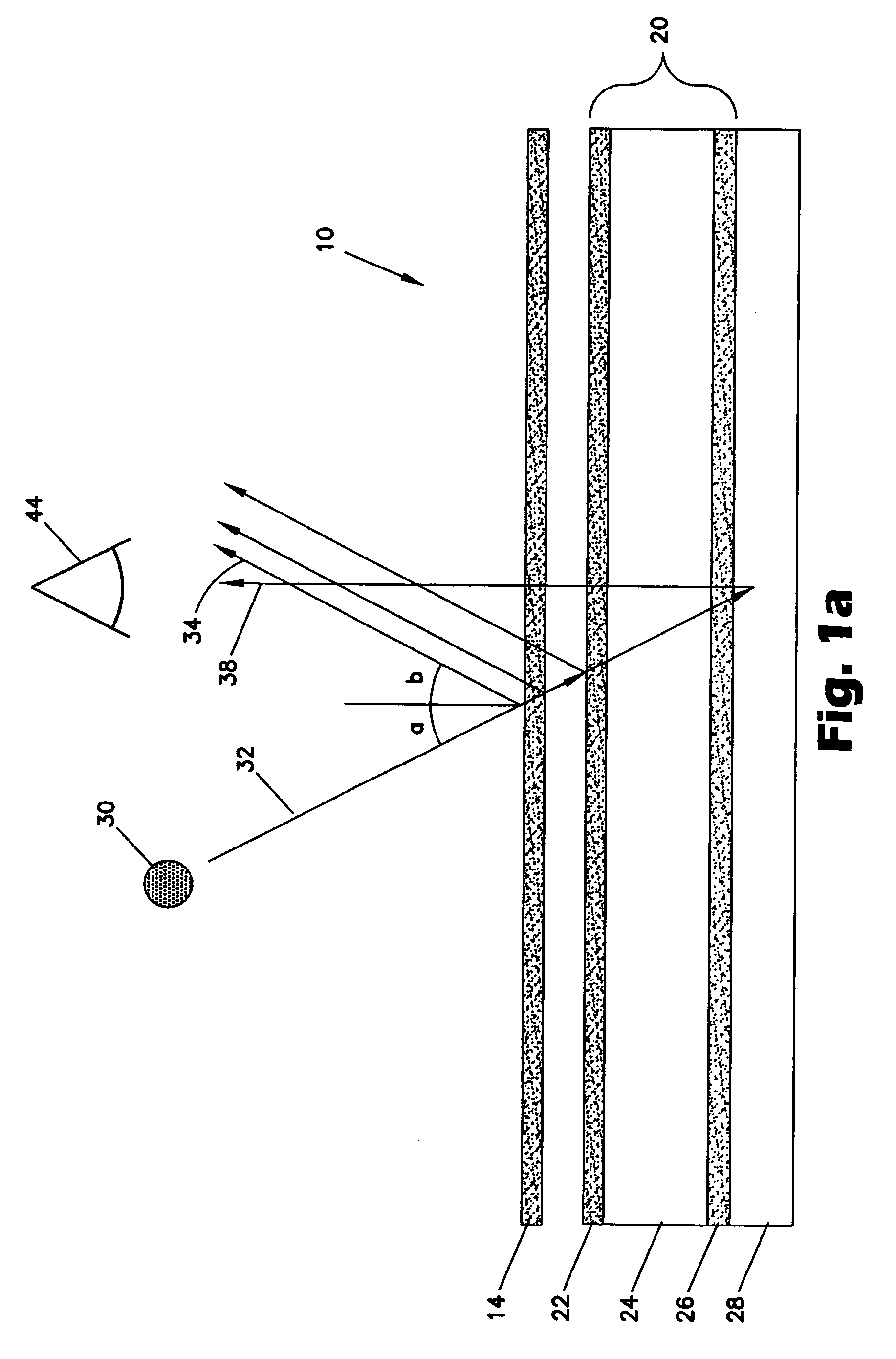

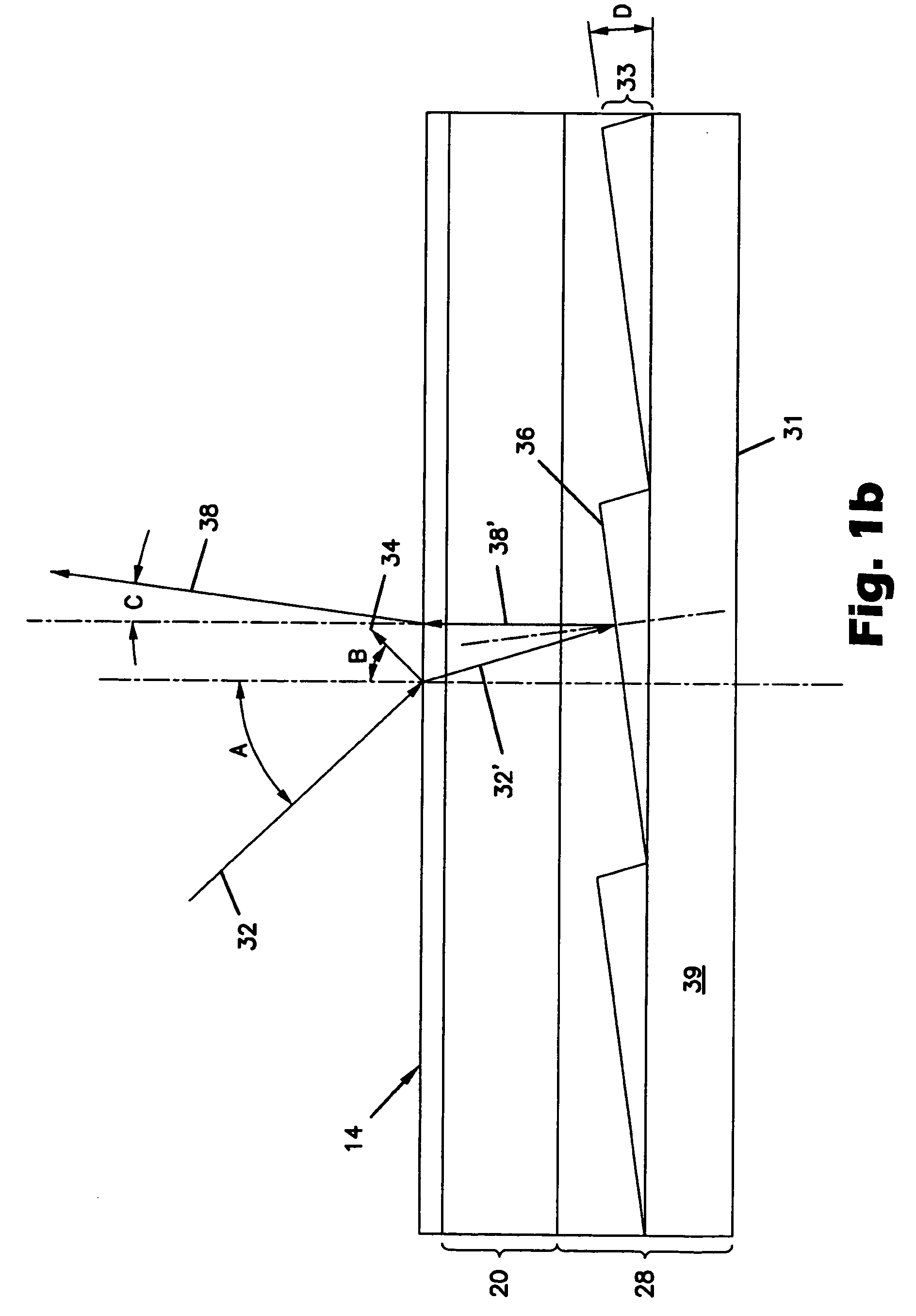

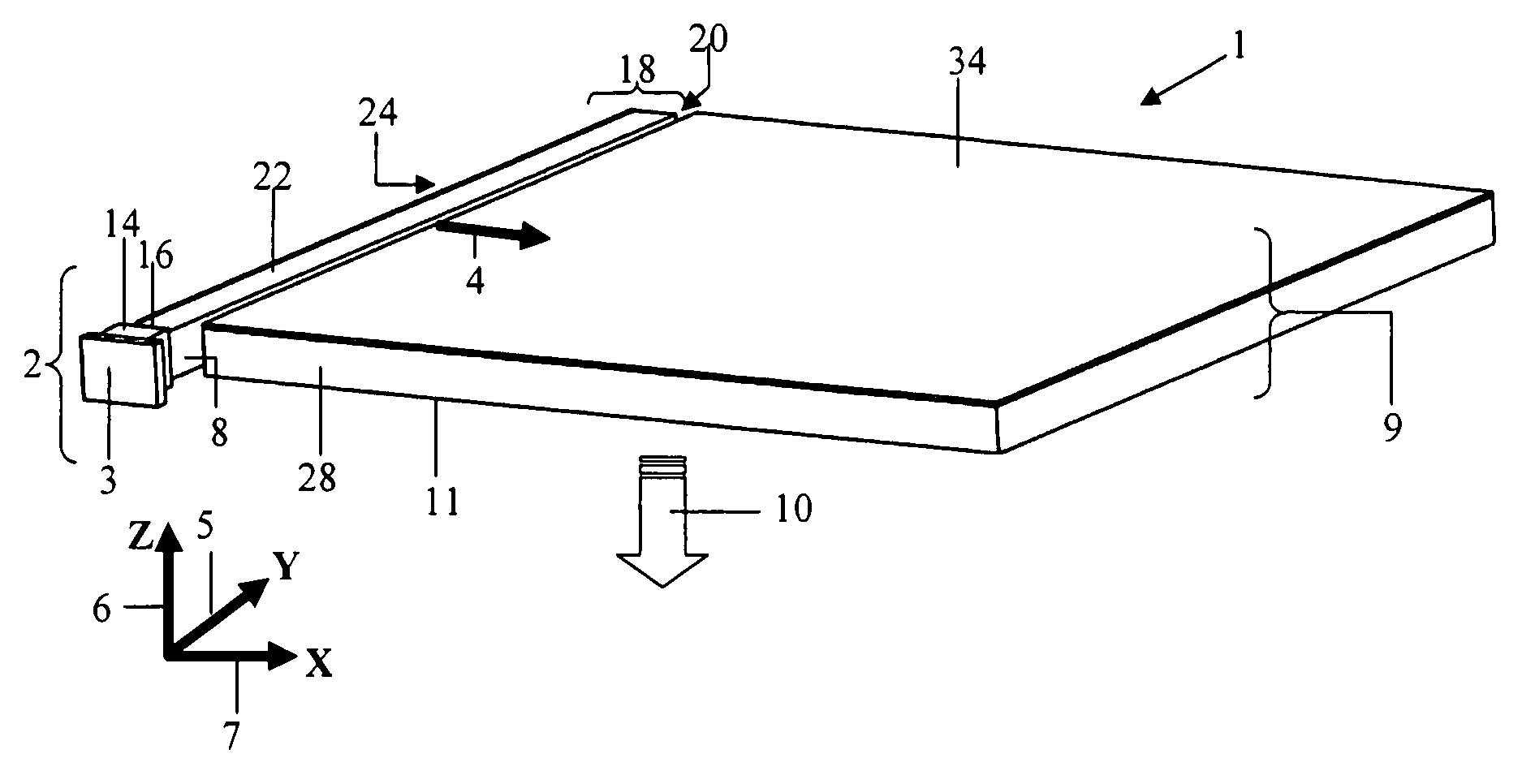

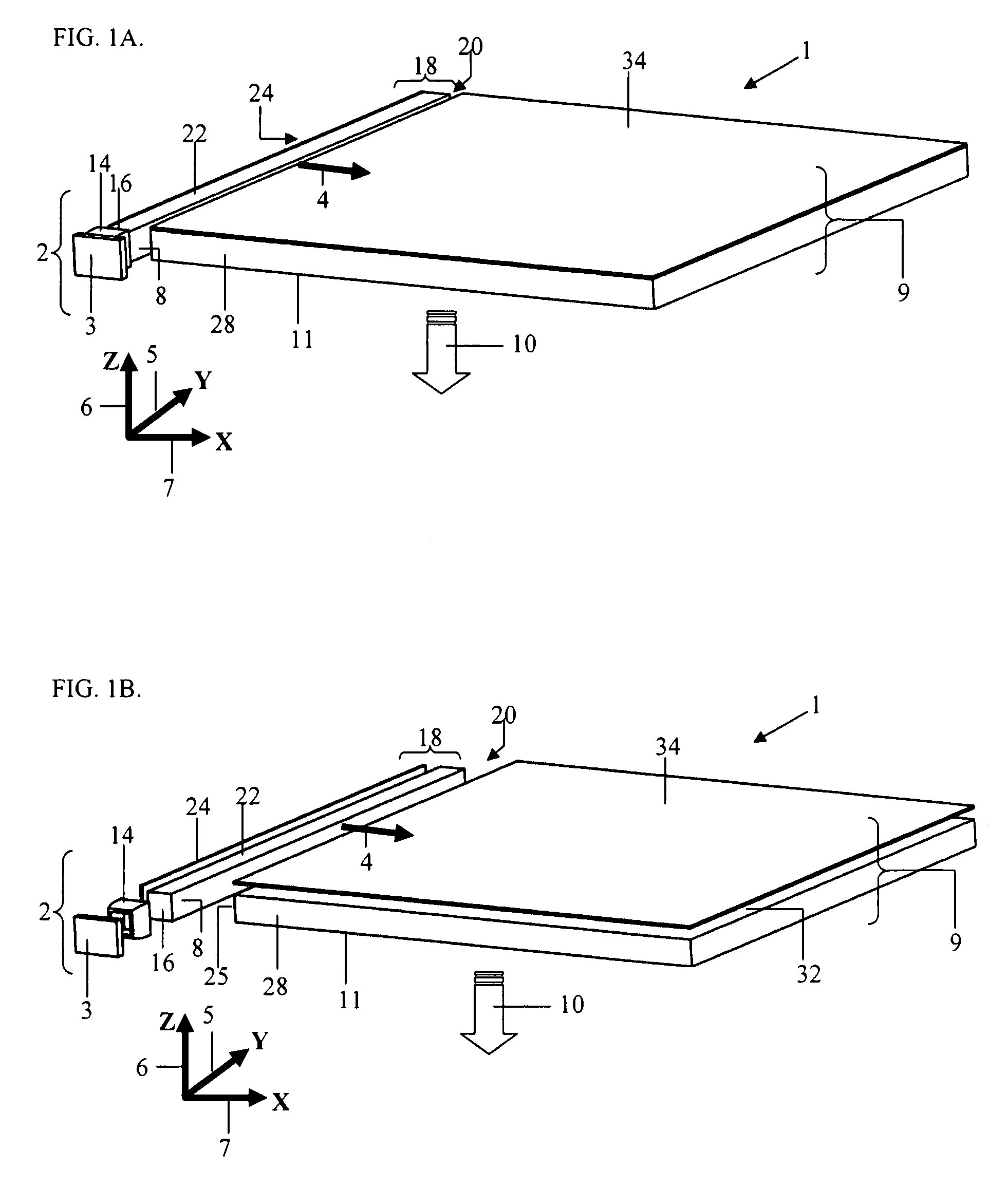

Thin illumination system

The present invention introduces a new class of thin doubly collimating light distributing engines for use in a variety of general lighting applications, especially those benefiting from thinness. Output illumination from these slim-profile illumination systems whether square, rectangular or circular in physical aperture shape is directional, square, rectangular or circular in beam cross-section, and spatially uniform and sharply cutoff outside the system's adjustable far-field angular cone. Field coverage extends from + / −5- to + / −60-degrees and more in each meridian, including all asymmetric combinations in between, both by internal design, by addition of angle spreading film sheets, and angular tilts. Engine brightness is held to safe levels by expanding the size of the engine's output-aperture without sacrifice in the directionality of illumination. One form of the present invention has a single input light emitter, a square output aperture and the capacity to supply hundreds of lumens per engine. A second multi-segment form of the invention deploys one light emitter in each engine segment, so that total output lumens is determined by the number of segments. Both types of thin light distributing engines provide input light collimated in one meridian and a light distributing element that maintains input collimation while collimating output light in the un-collimated orthogonal meridian, in such a manner that the system's far-field output light is collimated in both its orthogonal output meridians. The present invention also includes especially structured optical films that process the engine's doubly collimated output illumination so as to increase its angular extent one or both output meridians without changing beam shape or uniformity.

Owner:SNAPTRACK +1

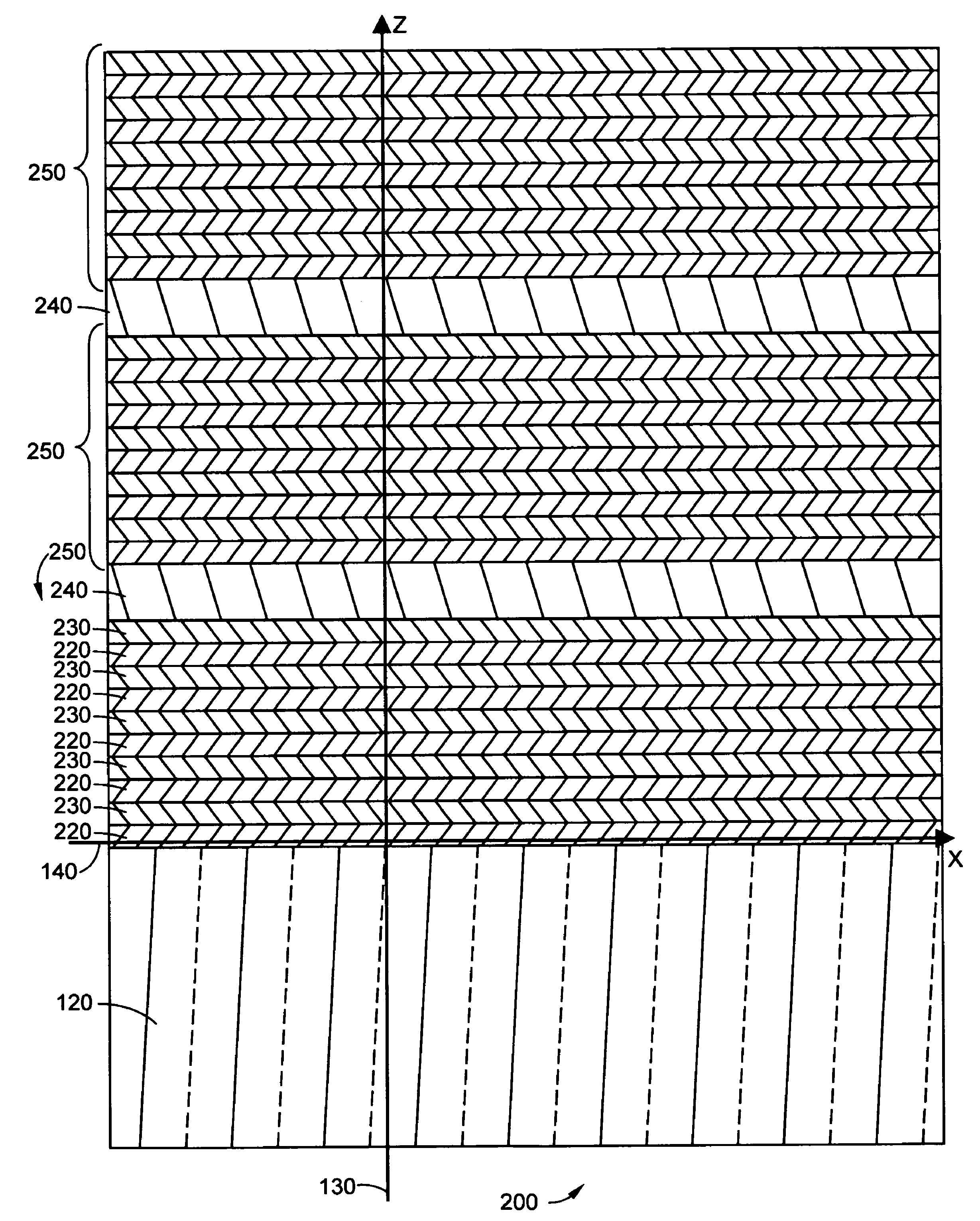

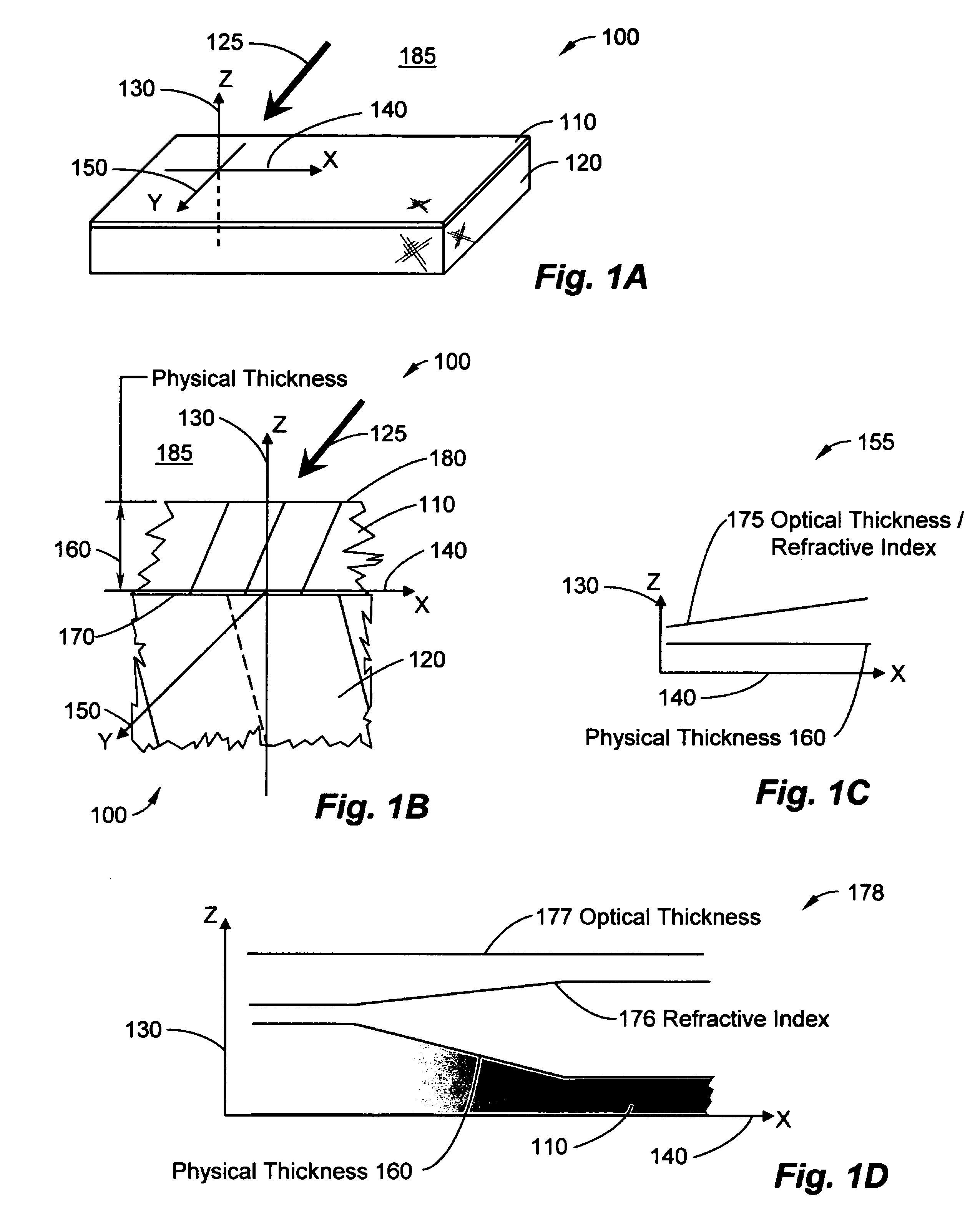

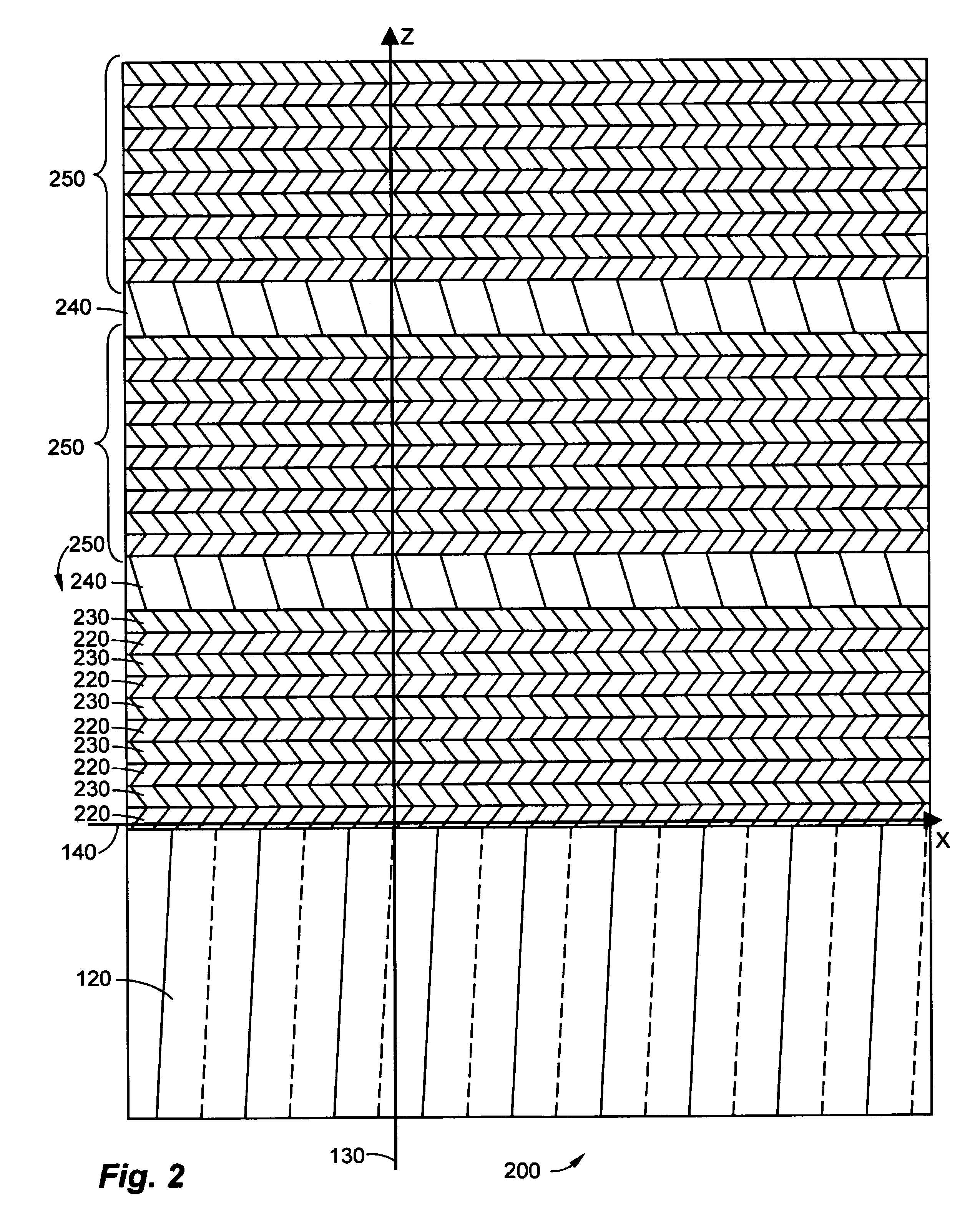

Adjusting optical properties of optical thin films

InactiveUS7901870B1High sensitivityChange the refractive indexCladded optical fibrePhotomechanical apparatusOptical propertyHydrogen

An optical thin film can have a refractive index variation along a dimension that is perpendicular to its thickness. Two areas that have equal physical thicknesses can have different optical thicknesses. Including the thin film as a layer in a thin film optical filter can provide a corresponding variation in the filter's spectral properties. Dosing an optical thin film with ultraviolet light can cause the refractive index variation. Subjecting the film to hydrogen can increase the refractive index's response to the dose of light. Dosing a region of a thin film optical filter with ultraviolet light can change the spectral properties of the region, for example shifting an out-of-specification optical filter into specification thereby increasing manufacturing yield. An agent can promote the film's response to the dose.

Owner:CIRREX SYST

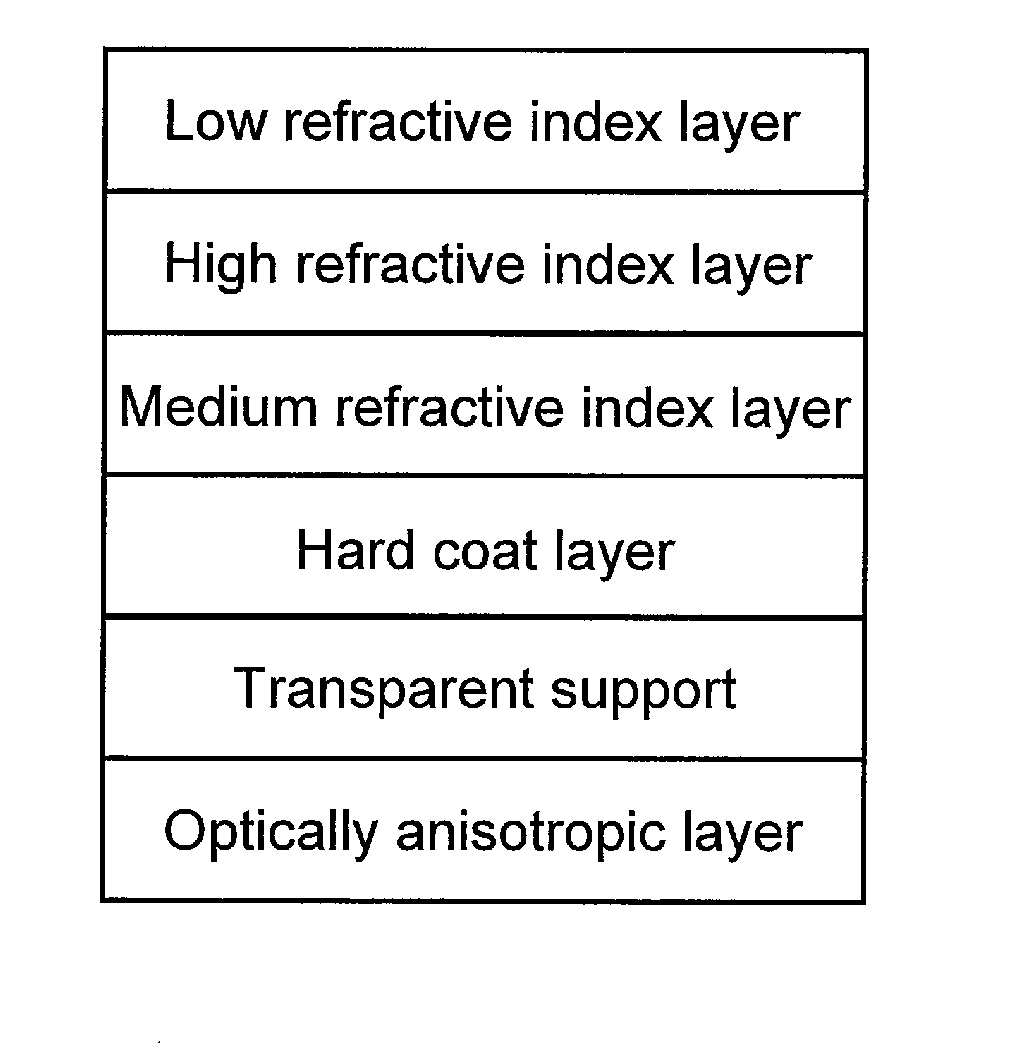

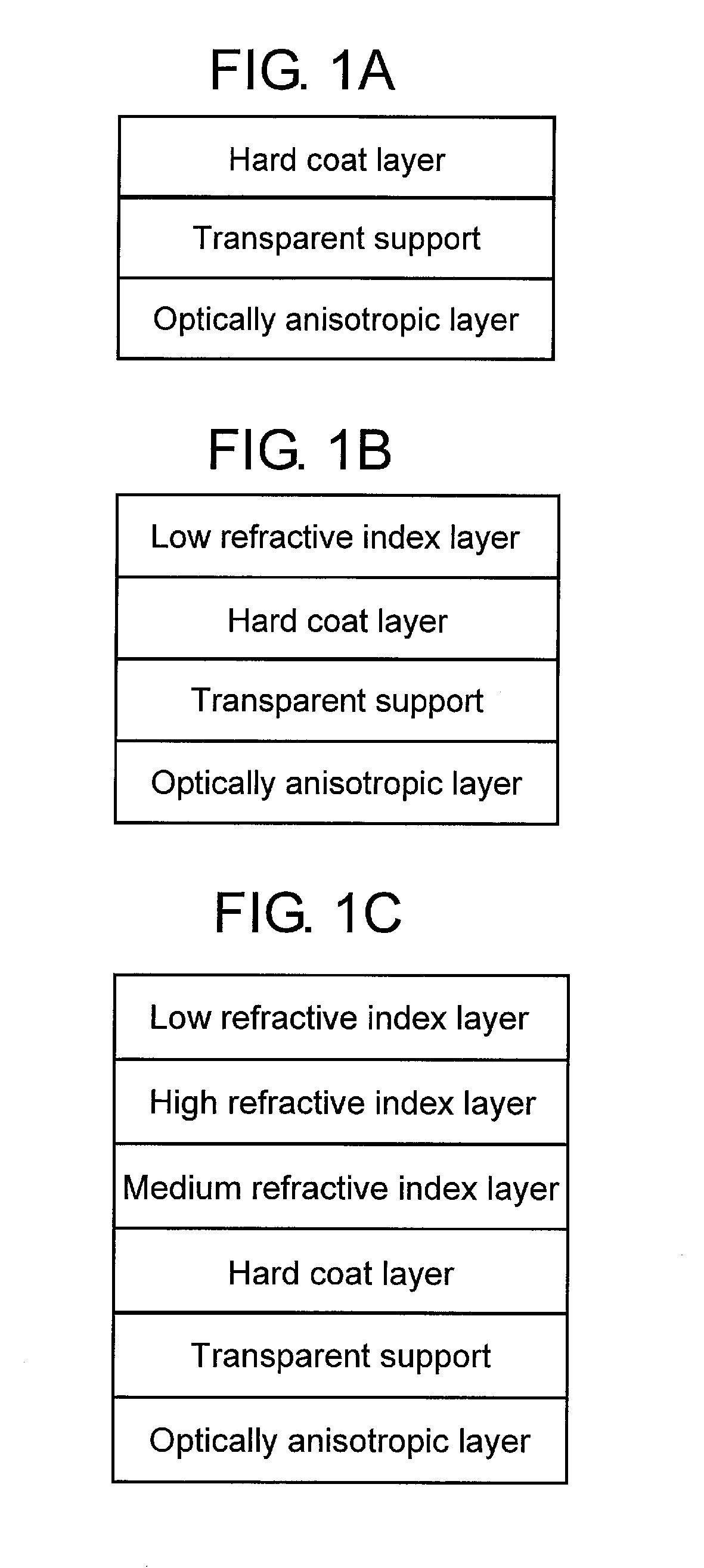

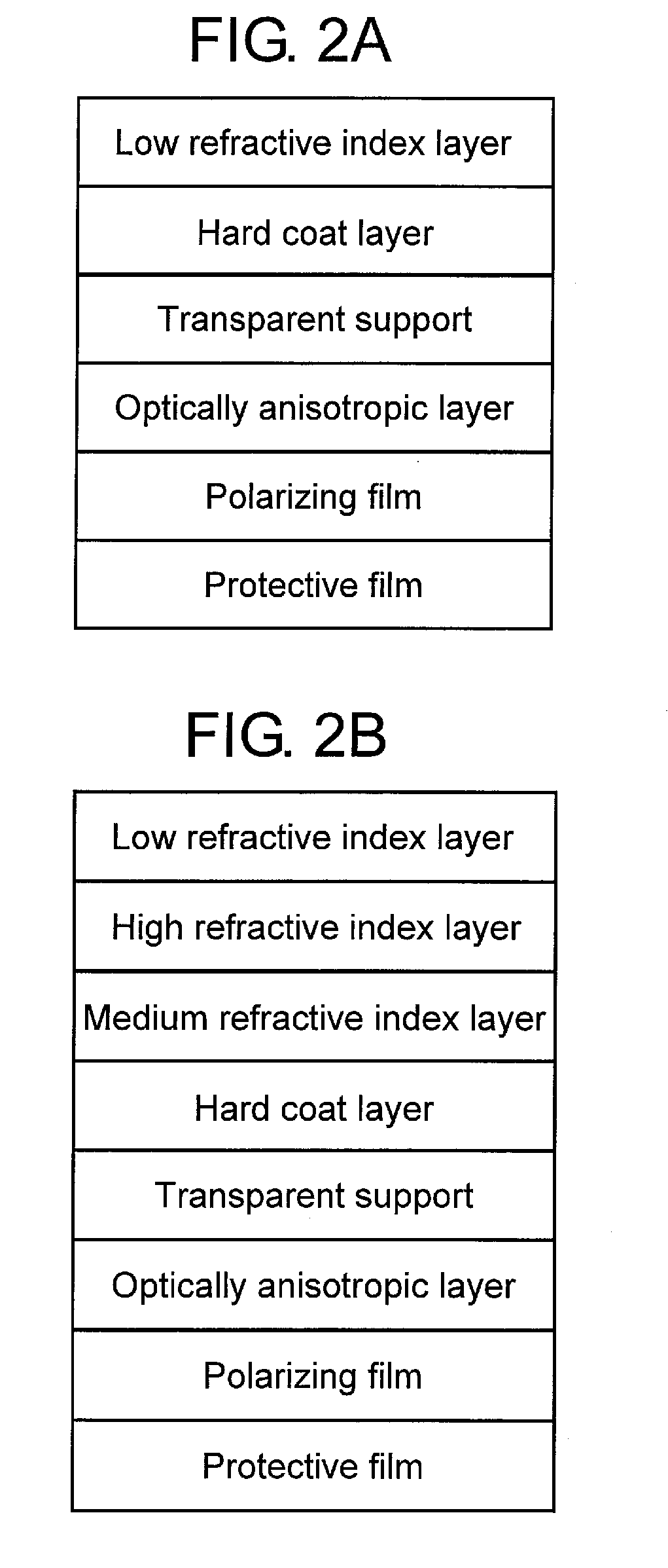

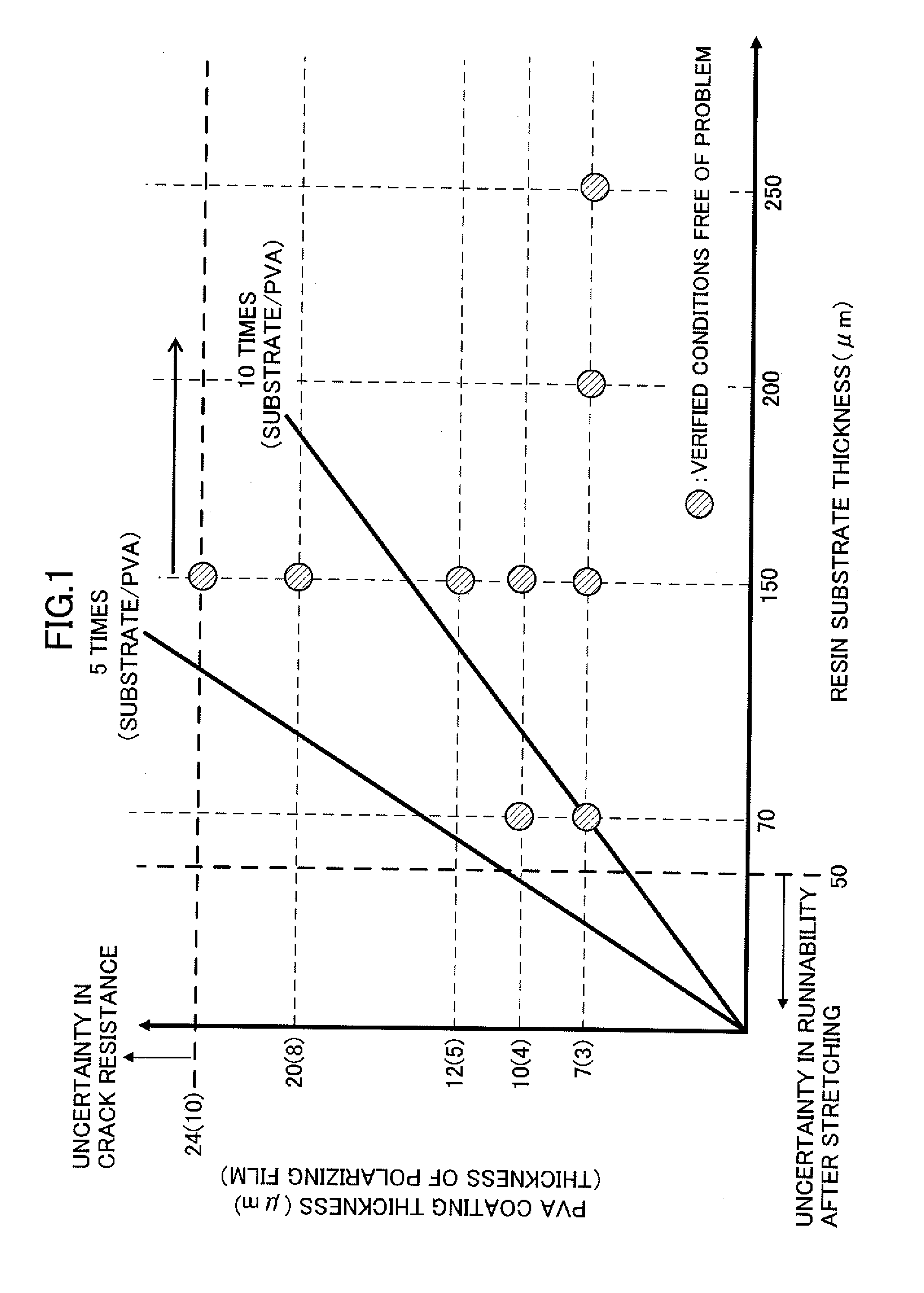

Method for producing optical film, optical film produced by the method, and polarizing plate and image-forming display device having the film

InactiveUS20130293824A1Good physical propertiesImprove productivitySynthetic resin layered productsCellulosic plastic layered productsImage formationDisplay device

A method for producing an optical film including: laminating a hard coat layer on one side of an optical substrate in roll form, the hard coat layer having a transparent support and an optical anisotropic layer. The transparent support is laminated on the optical anisotropic layer, the one side is a transparent support-side of the optical substrate, the hard coat layer is obtained by coating, drying and curing a composition for forming a hard coat layer containing a curable monomer, a photo-polymerization initiator, and a solvent. The solvent is a mixture of at least one solvent selected from (S-1) and (S-2) and at least one solvent selected from (S-3), or a mixture of at least one solvent selected from (S-1) and at least one solvent selected from (S-2): (S-1) solvents dissolving the transparent support; (S-2) solvents swelling the transparent support; and (S-3) solvents neither dissolving nor swelling the transparent support.

Owner:FUJIFILM CORP

Multifunctional multilayer optical film

ActiveUS7151532B2Reduce glareReduce manufacturing costCathode-ray tube indicatorsInput/output processes for data processingOptical thin filmManufacturing line

Optical component for use in a touch sensor and method of fabrication of same are disclosed. Optical component includes a multilayer optical film at least some layers of which are fabricated on the same manufacturing line and using the same manufacturing method. Each layer of the multilayer optical film is designed primarily to provide a desired associated property.

Owner:3M INNOVATIVE PROPERTIES CO

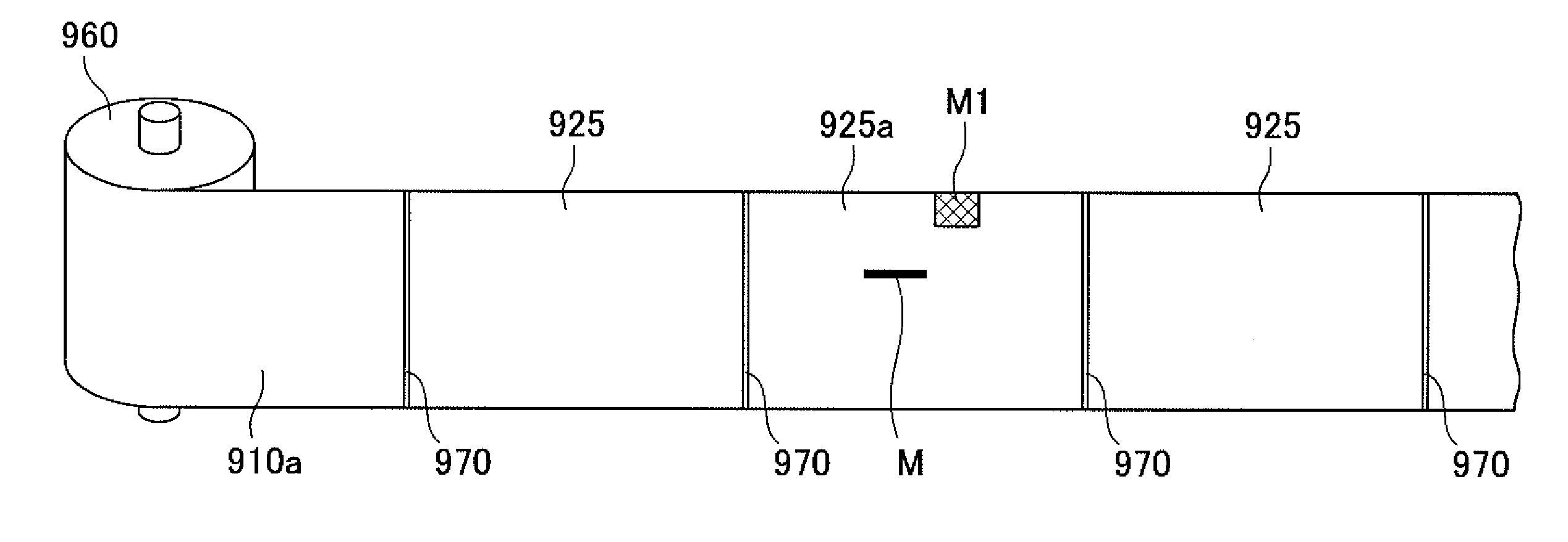

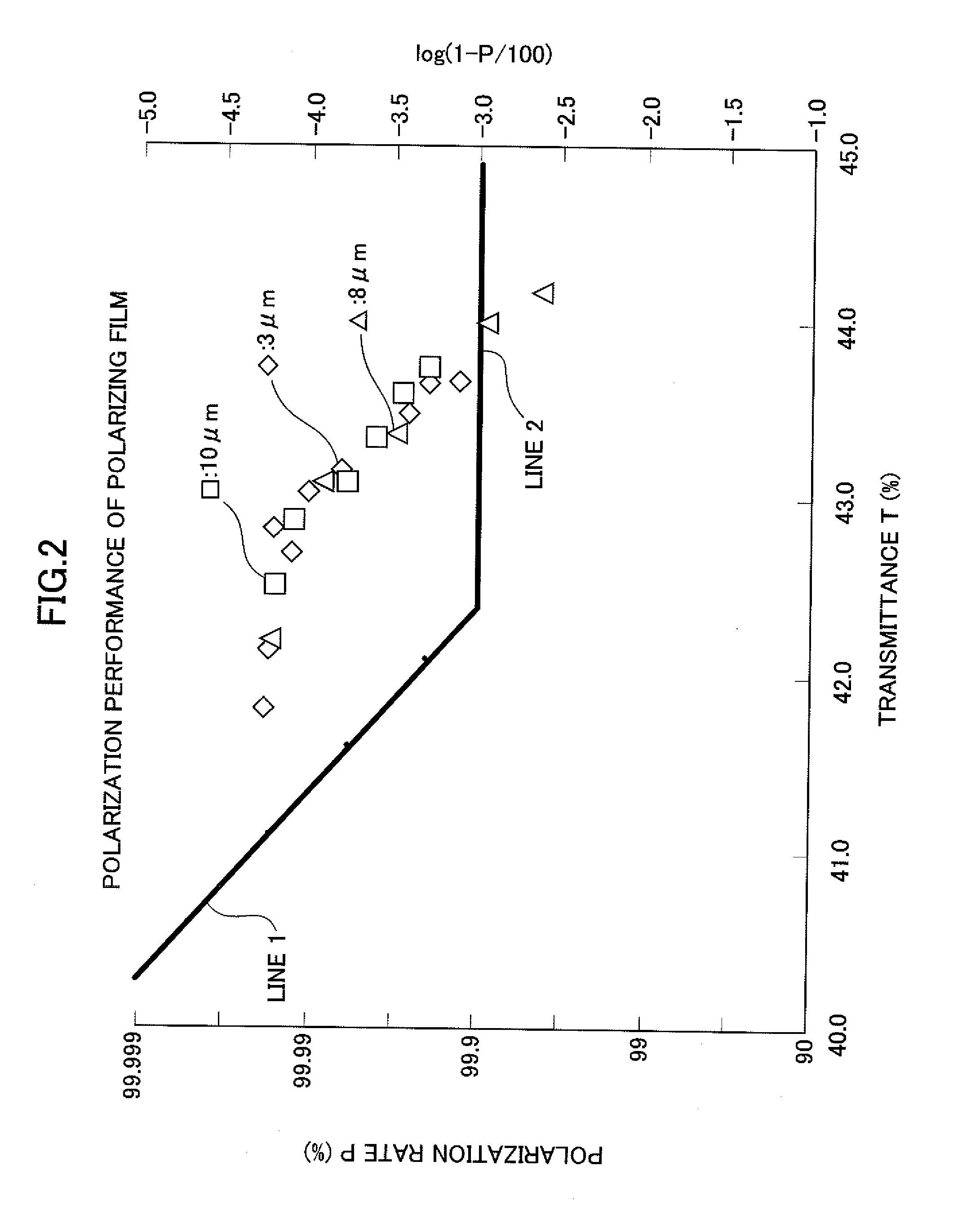

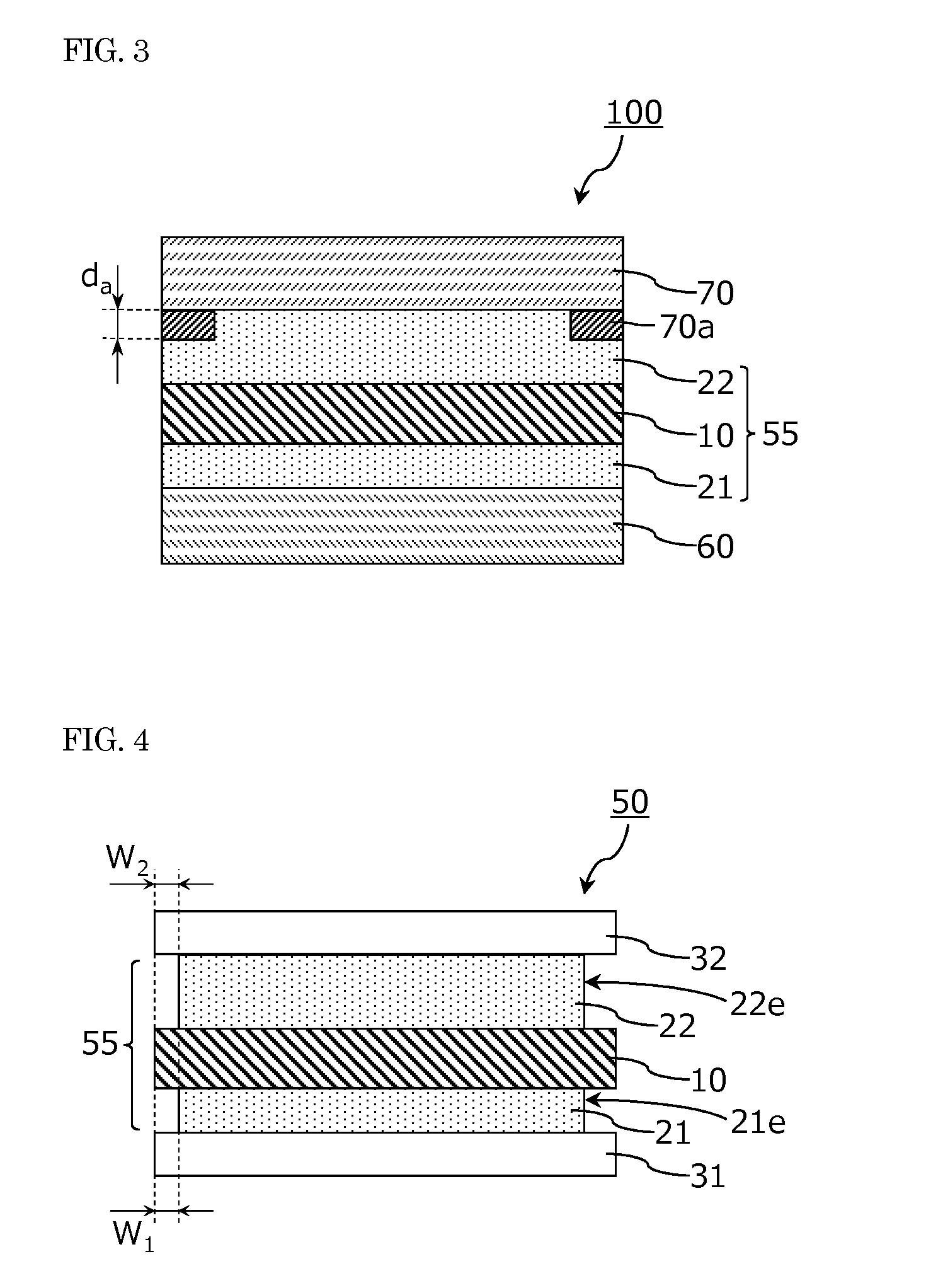

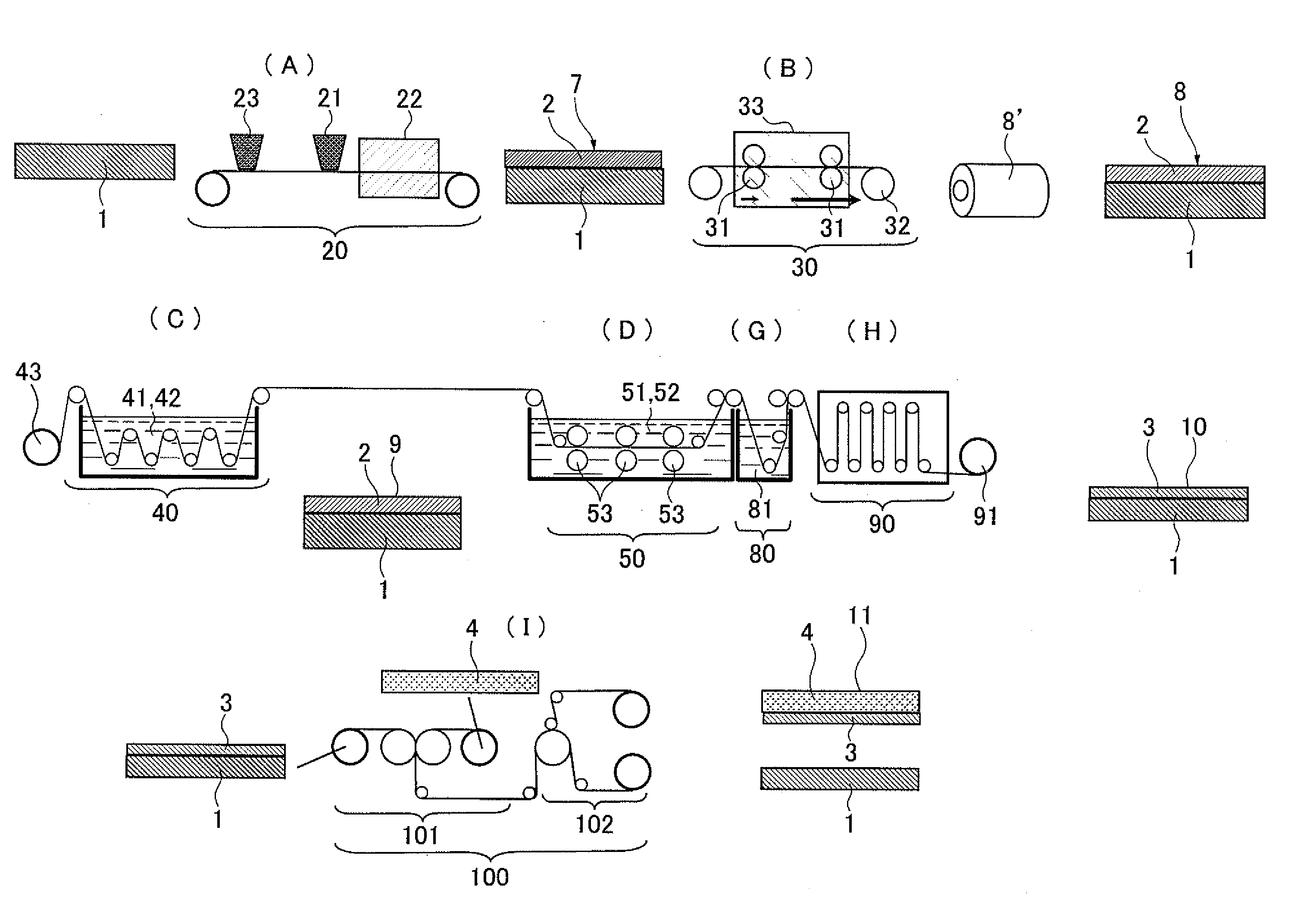

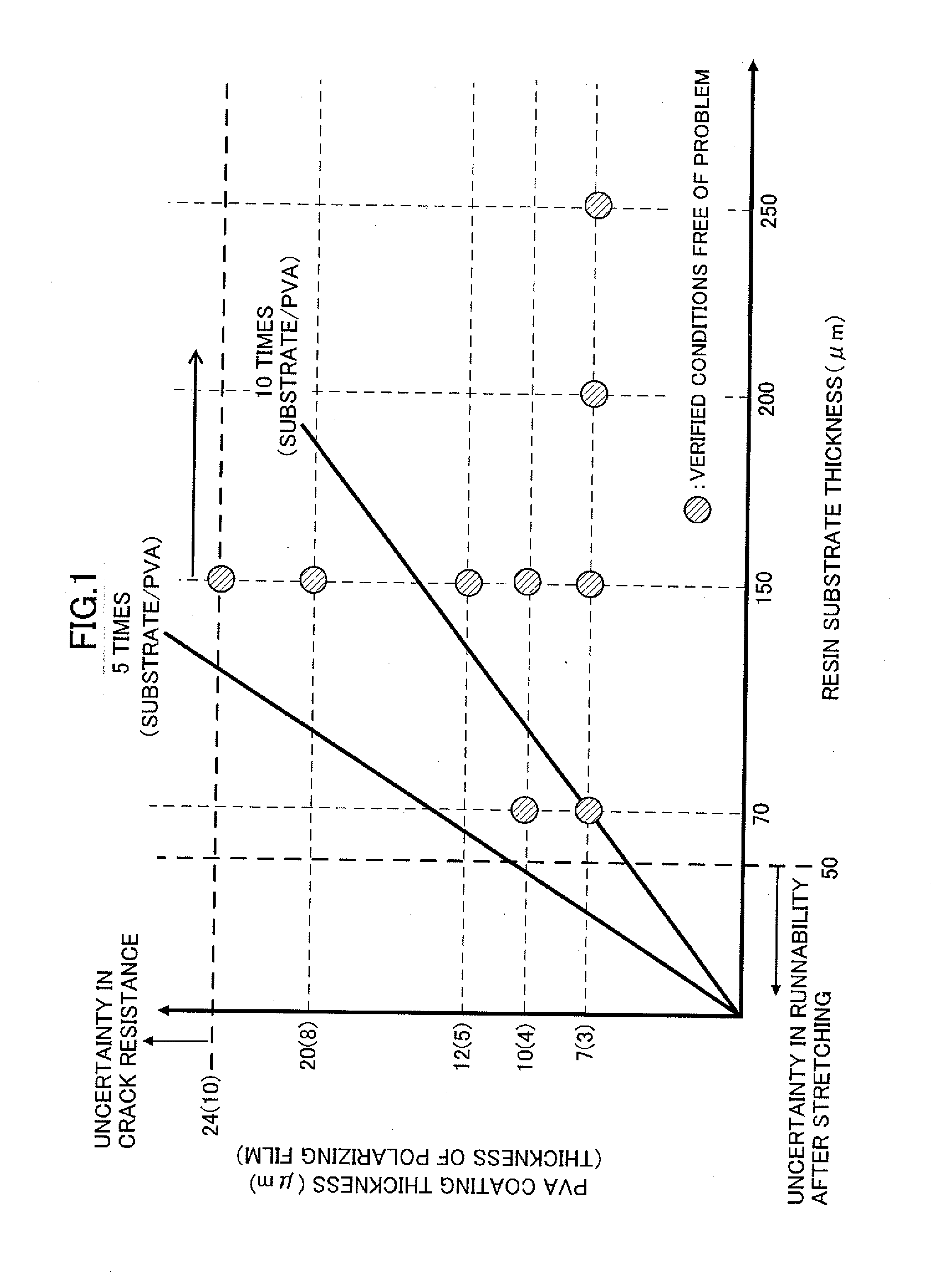

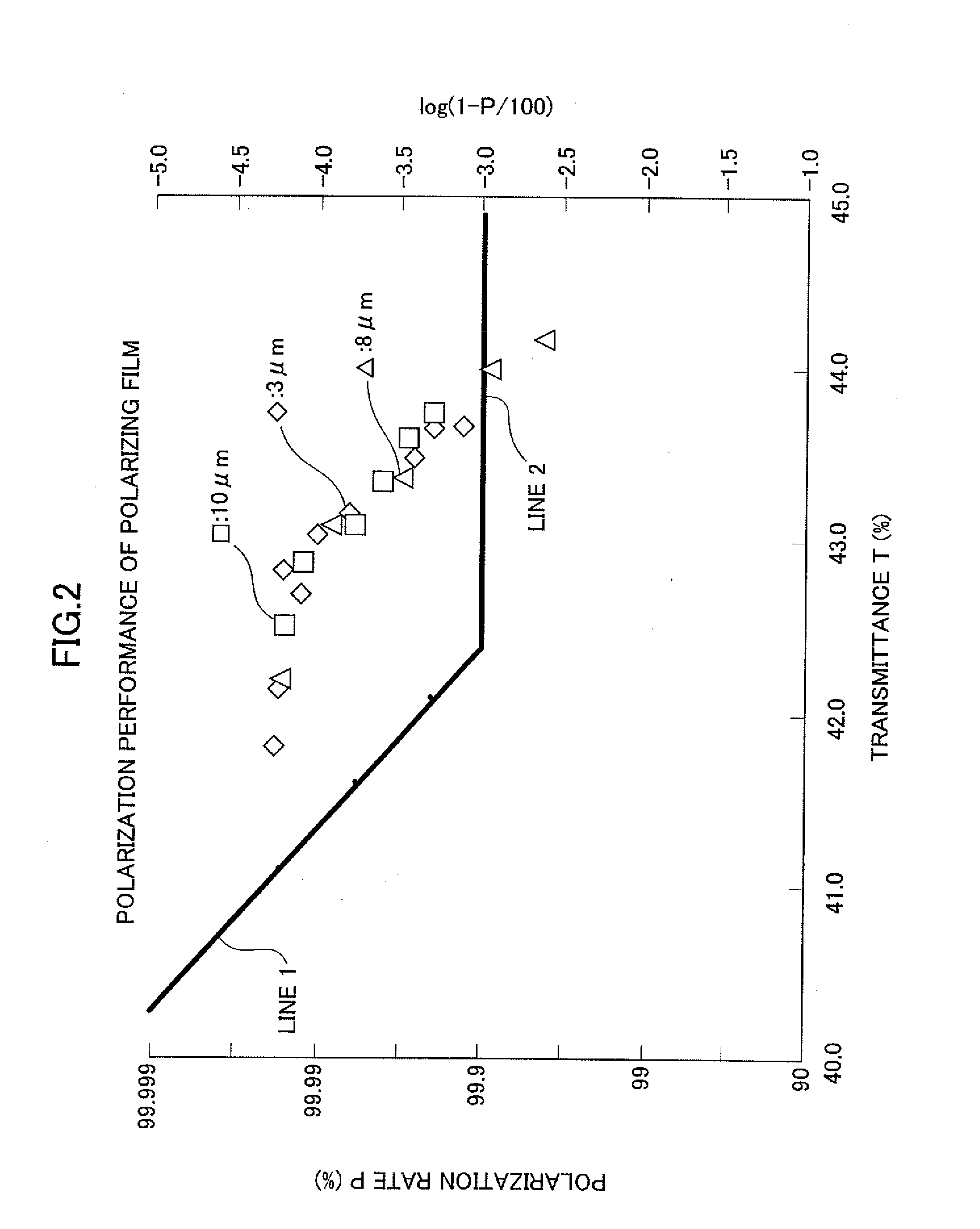

Roll of continuous web of optical film laminate and production method therefor

InactiveUS20120058291A1Thickness minimizationIncreasing the thicknessStampsFlexible coversEngineeringMethods of production

A method of producing a roll of a continuous web of an optical film laminate, usable in a process of laminating an optical film sheet including a polarizing film and formed to a size corresponding to that an optical panel to a surface of the optical panel being fed to a lamination position, is disclosed. The polarizing film is prepared by subjecting a laminate including a thermoplastic resin substrate and a PVA type resin layer formed on the substrate, to uniaxial 2-stage stretching to reduce a thickness of the PVA type resin layer to 10 μm or less, and causing a dichroic material to be absorbed in the PVA type resin layer. A carrier film is releasably attached to the continuous web of optical film laminate including the polarizing film, through an adhesive layer. A defect inspection is performed for the optical film laminate and the adhesive layer.

Owner:NITTO DENKO CORP

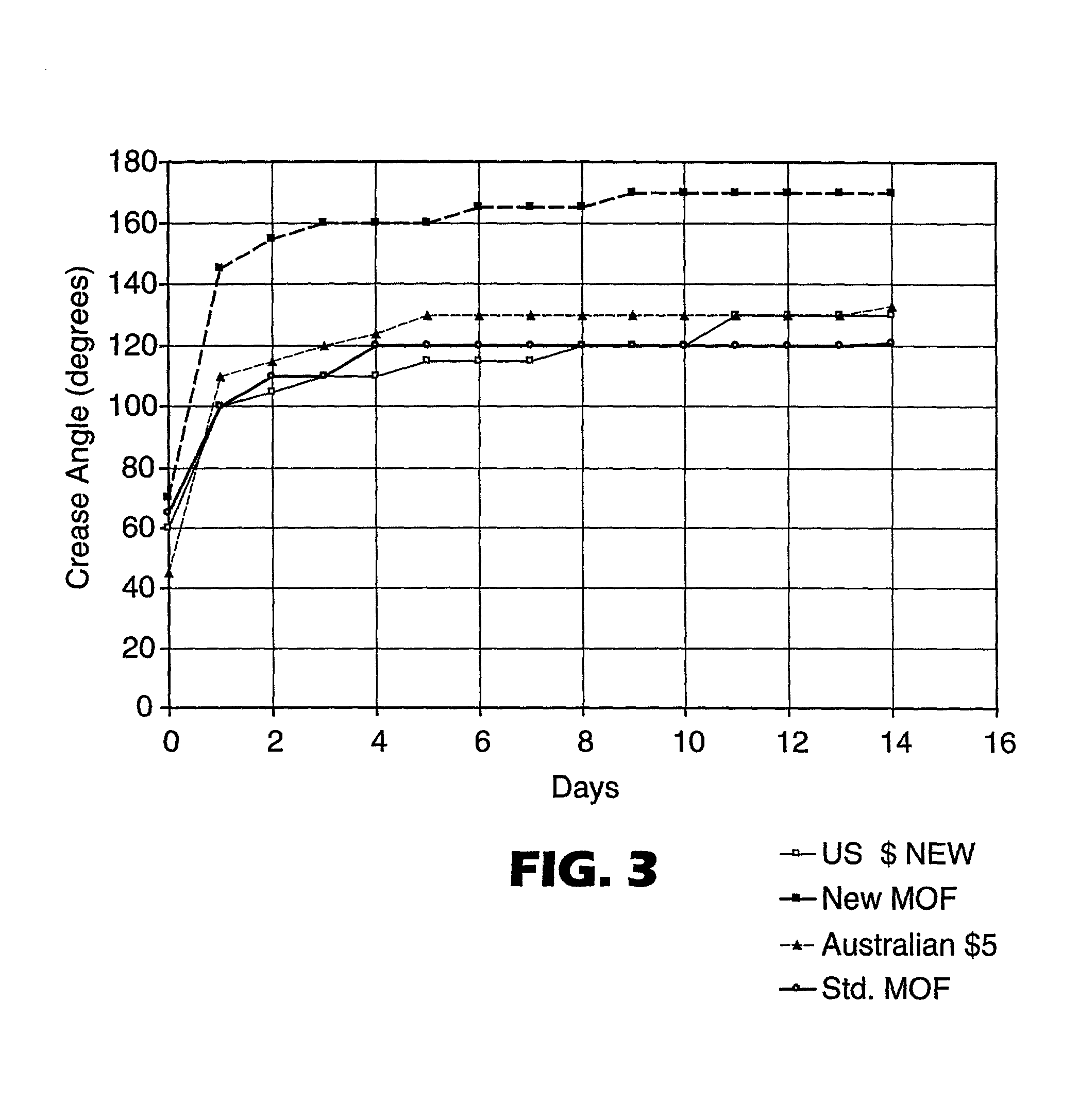

Low Tg multilayer optical films

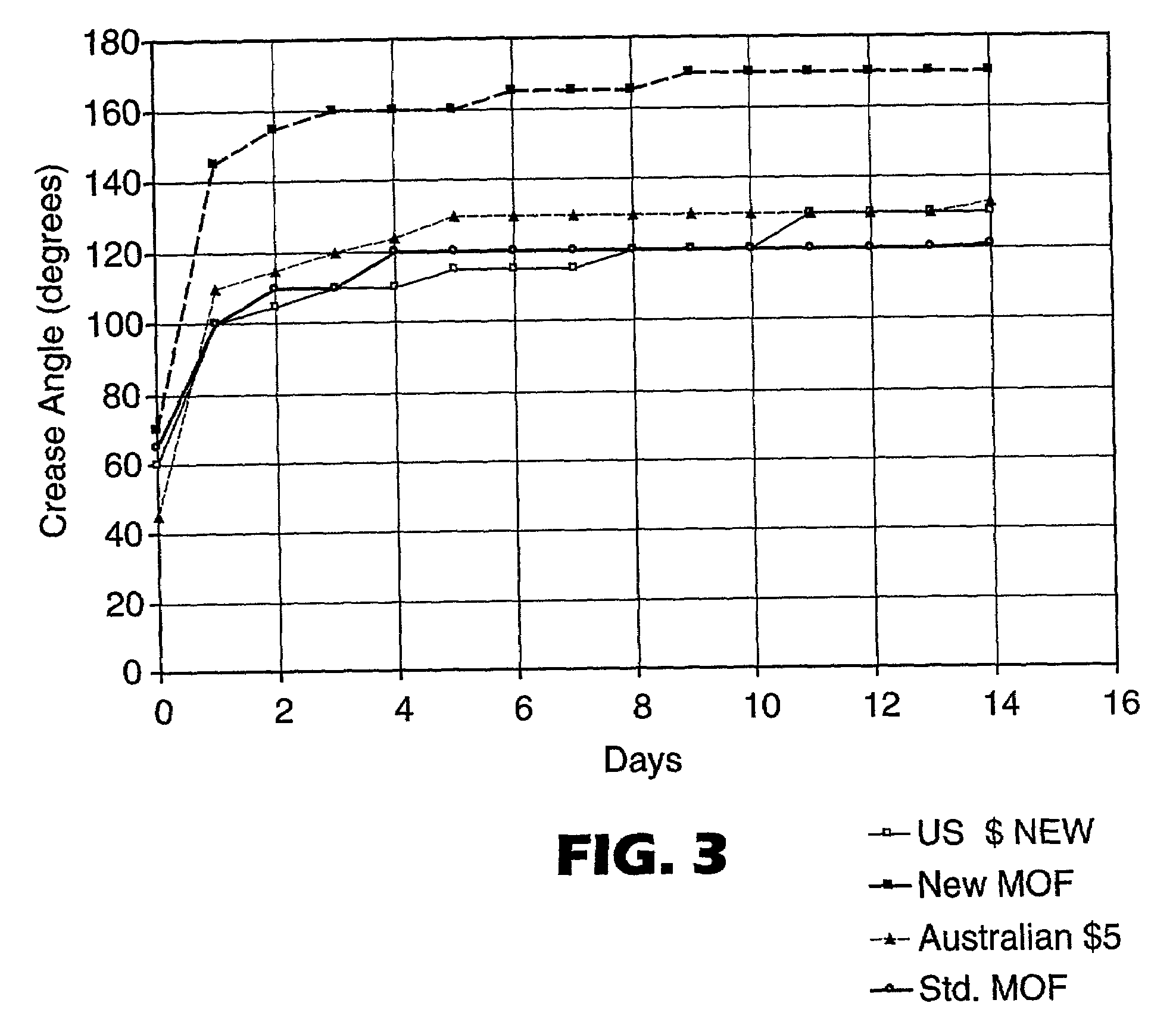

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

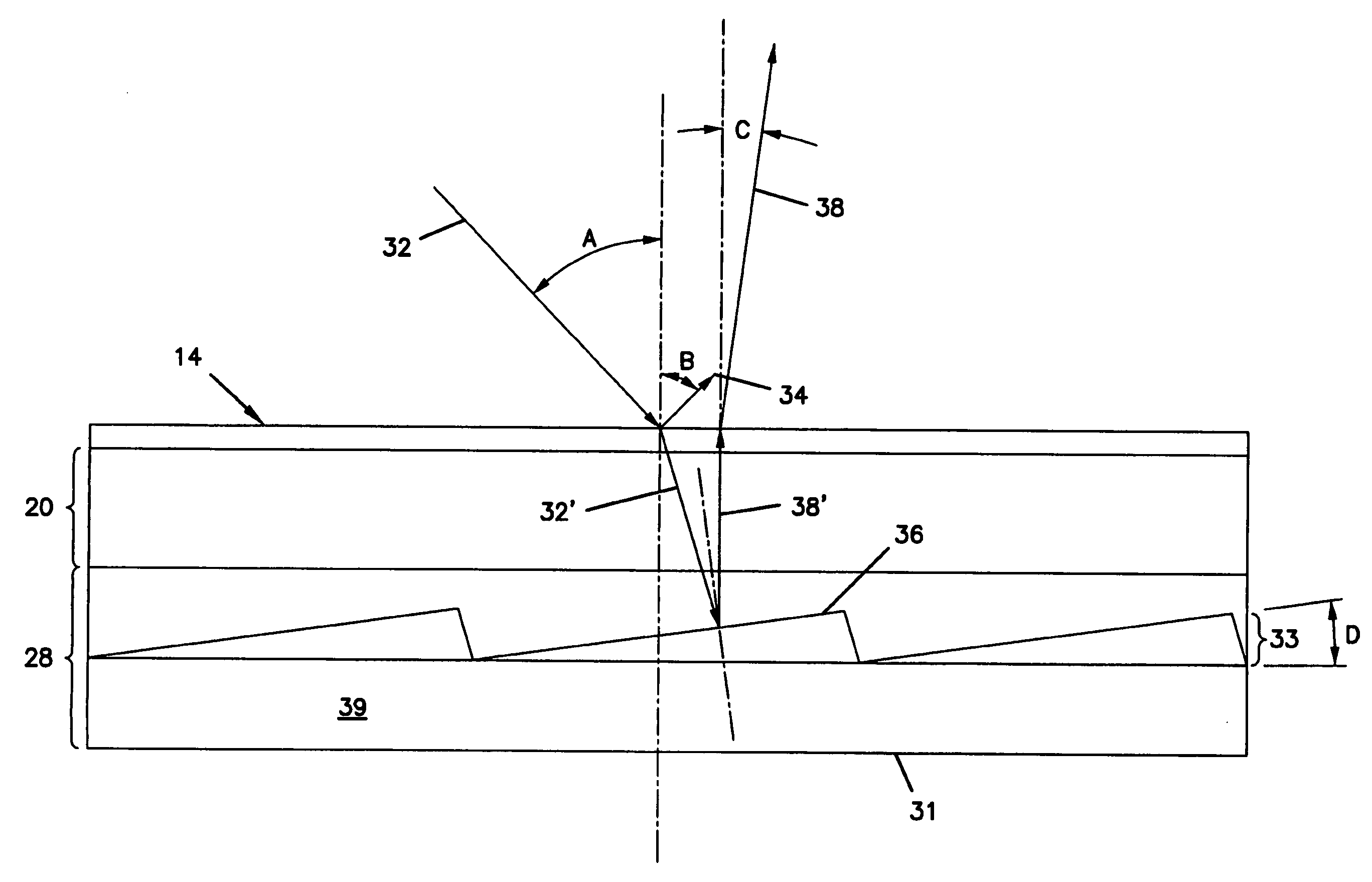

Long curved wedges in an optical film

InactiveUS20060092490A1Reduce moiréHigh on-axis gainDiffusing elementsPlanar/plate-like light guidesMicrometerOptical thin film

Owner:INNOVATIVE DISPLAY TECH

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

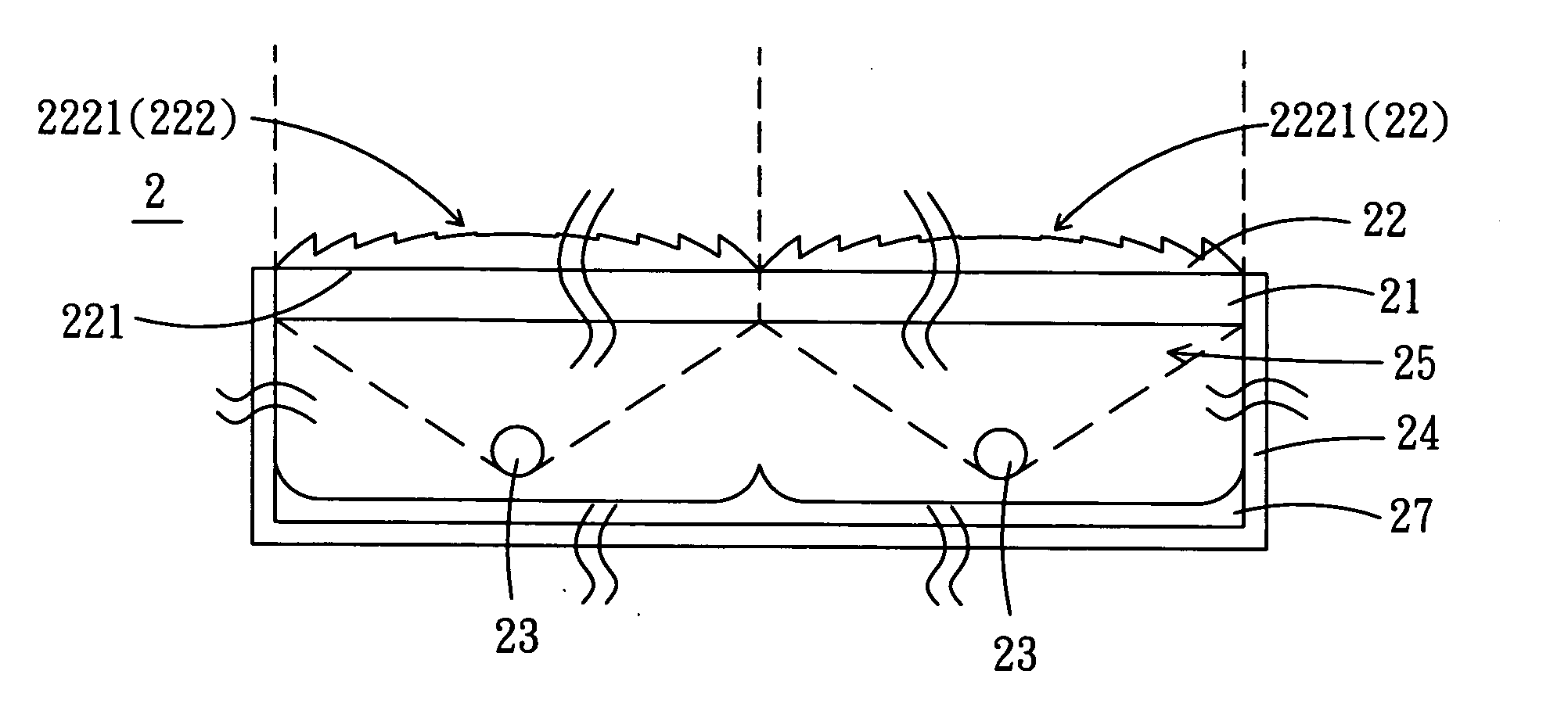

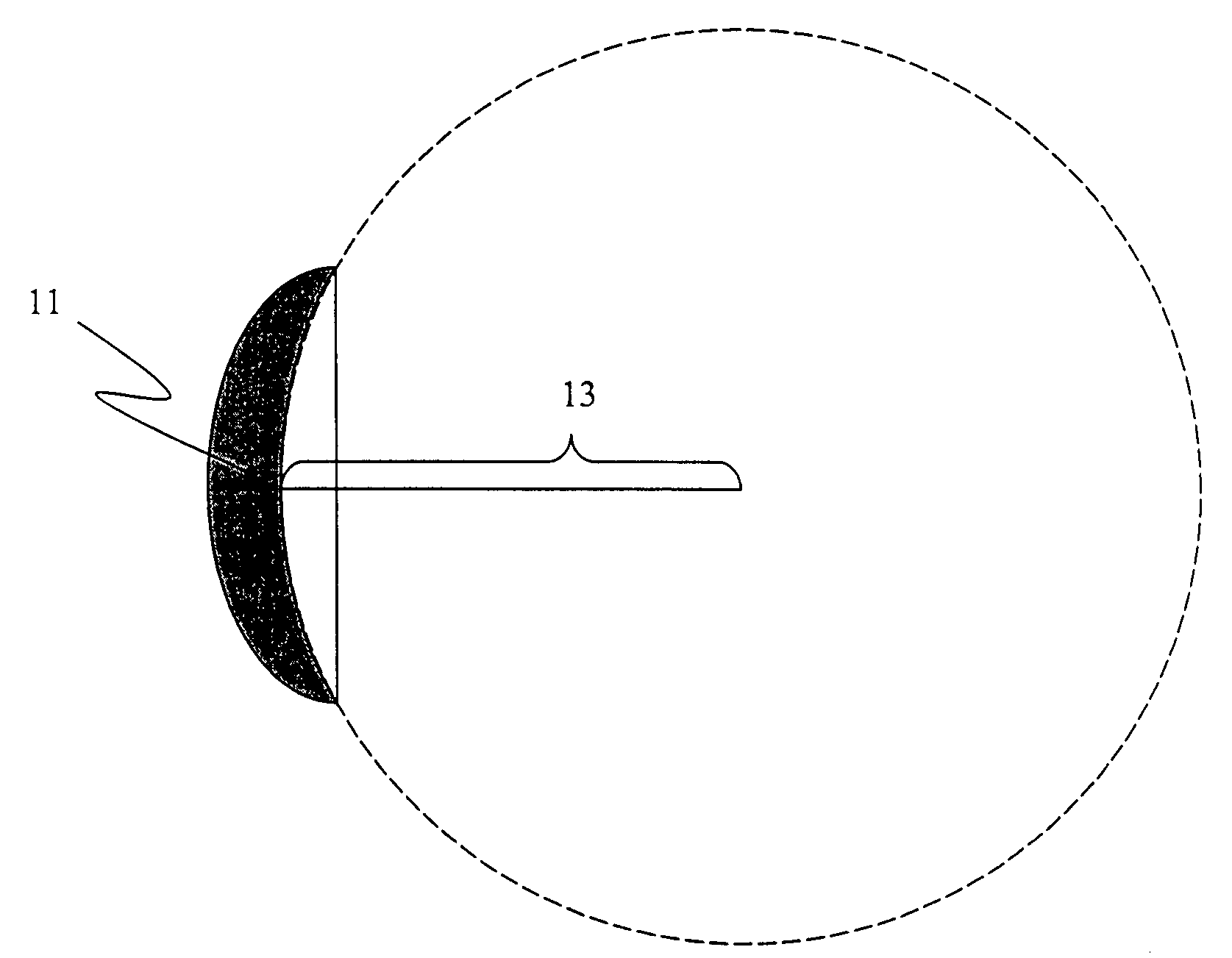

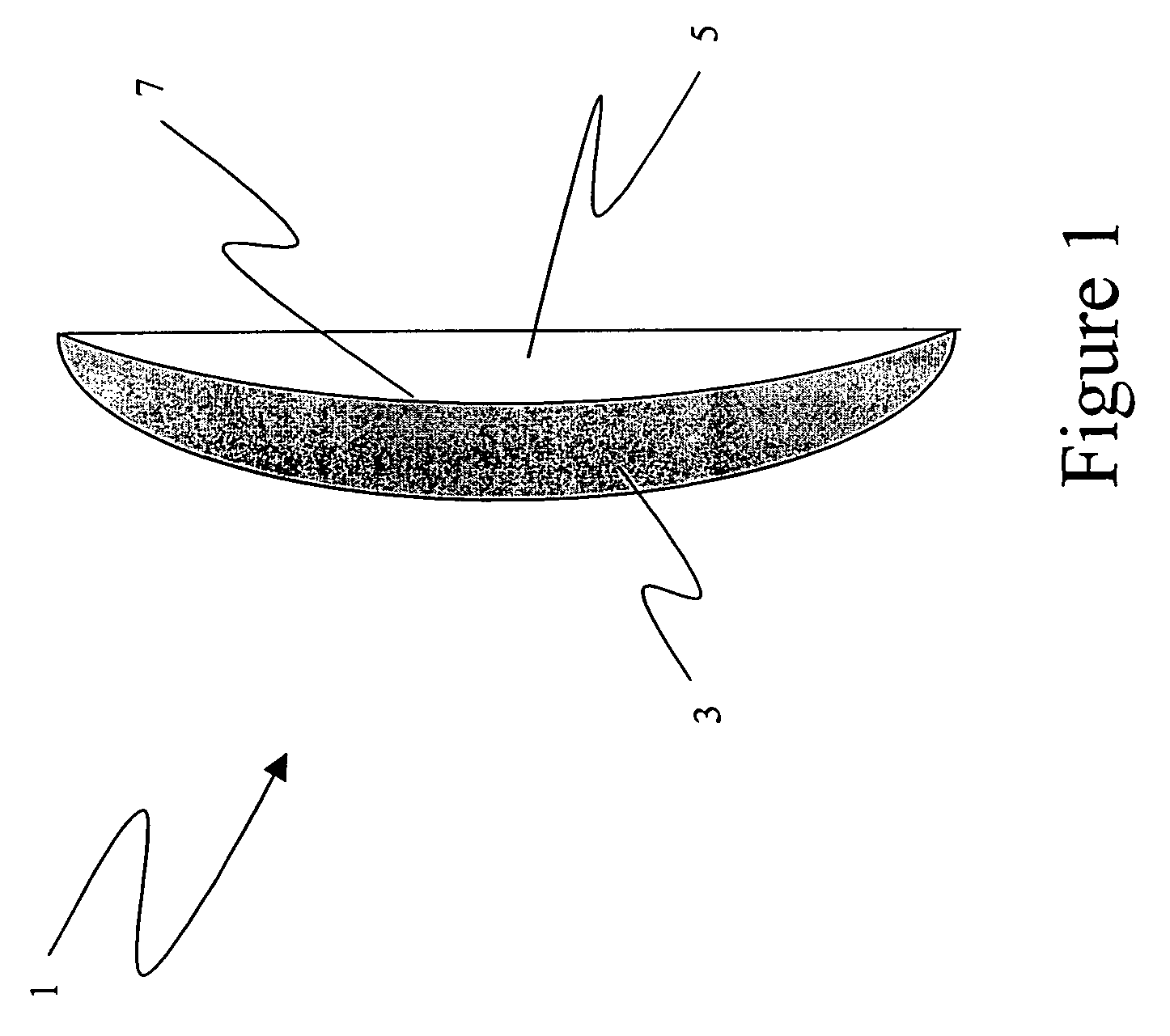

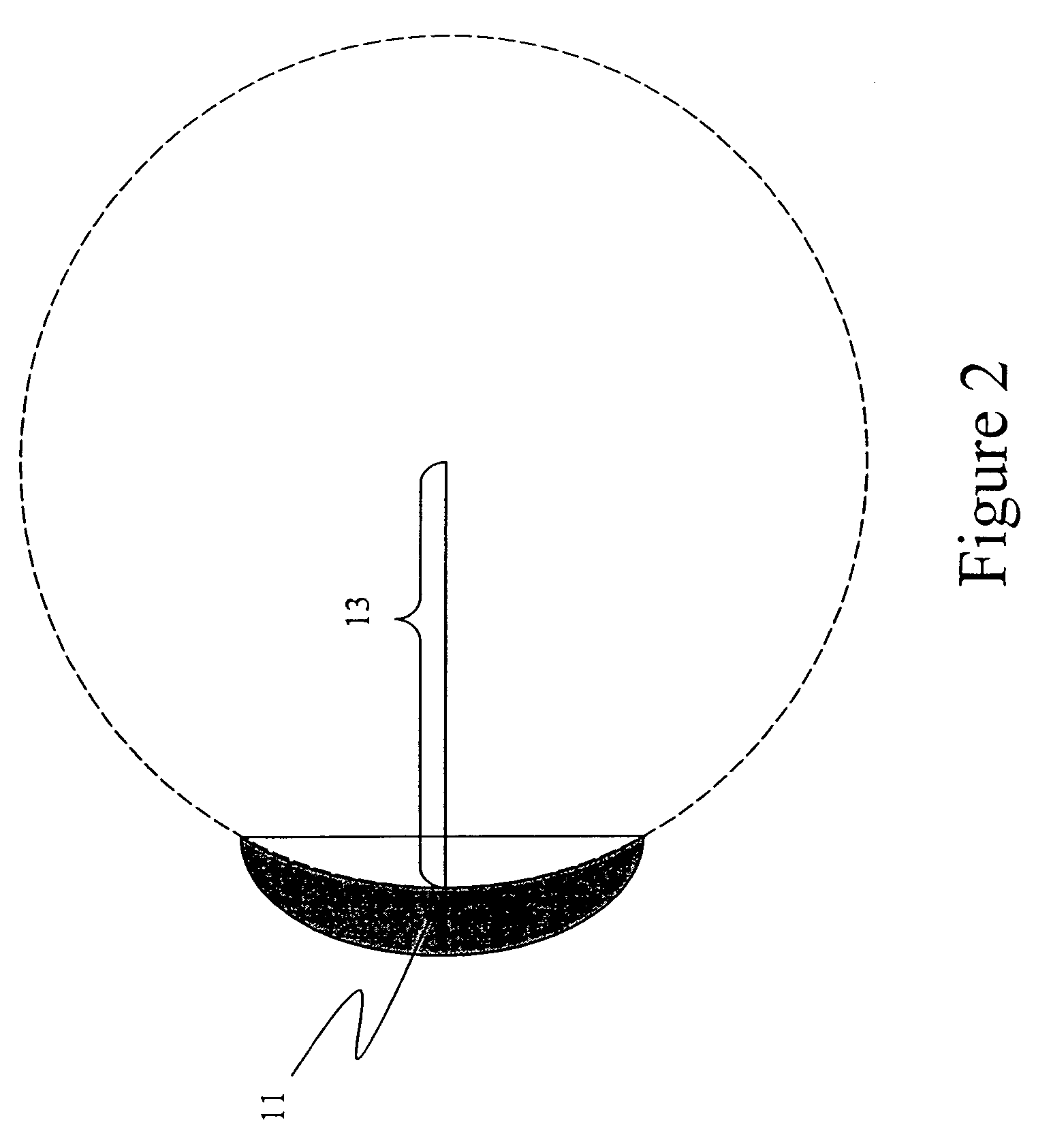

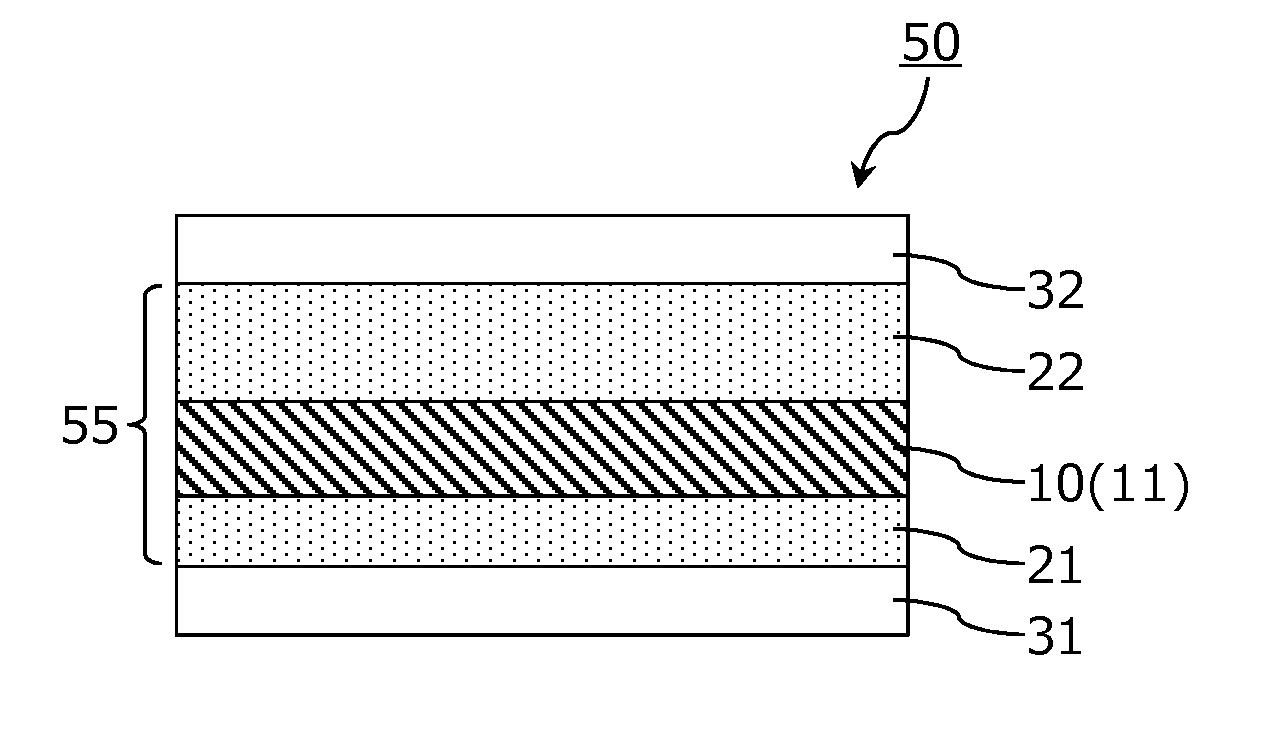

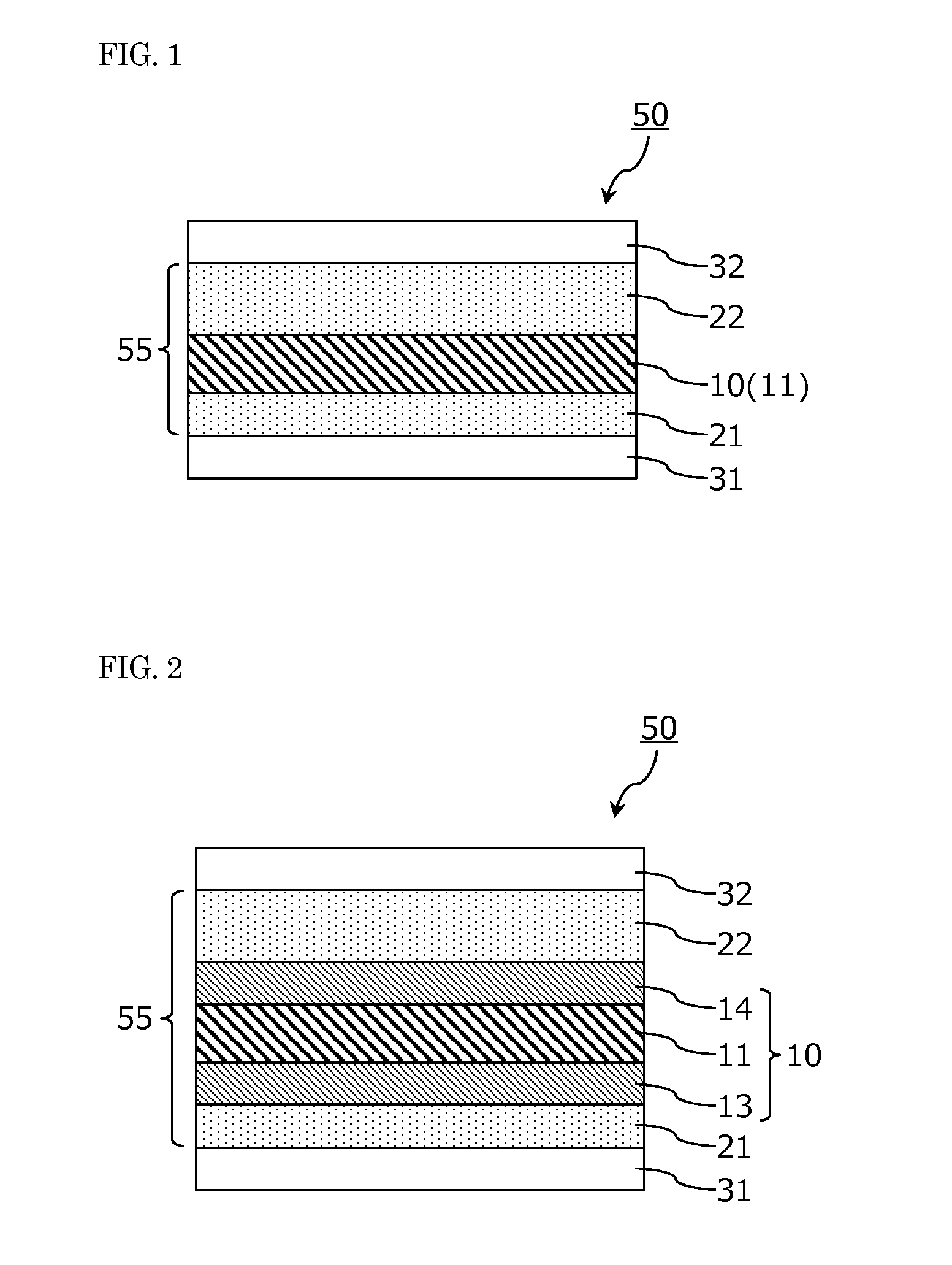

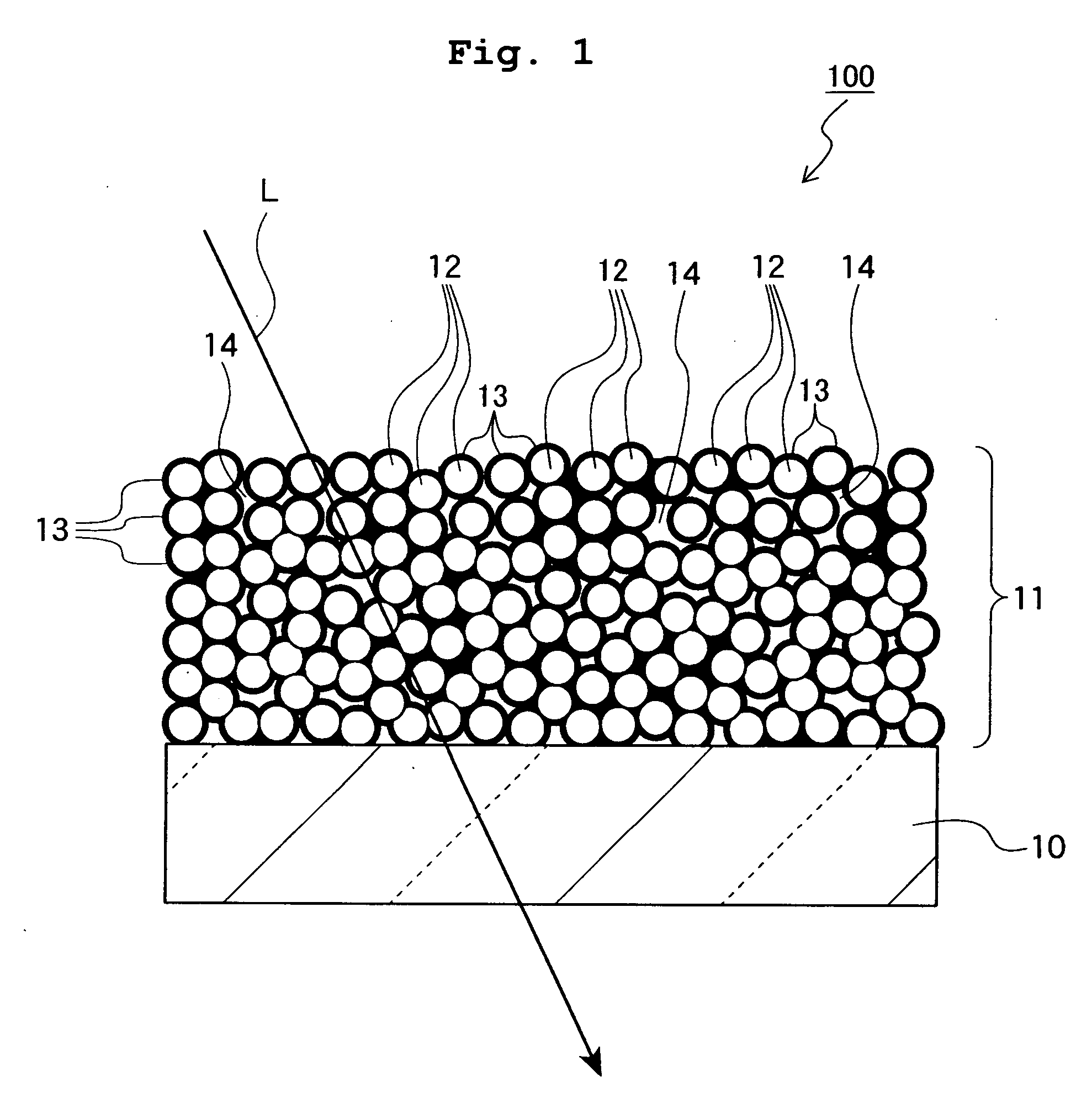

Optical film and surface light source using it

InactiveUS20070064294A1Secure high brightnessEvenly diffused lightMechanical apparatusElongate light sourcesEpoxyPolyethylene terephthalate

An optical film 10 has a transparent base film 11 made of polyethylene terephthalate (PET), a prism made of photo-curing resin such as acryl modified epoxy on an incident surface 12 that is one face of the base film 11, and a hologram similarly made of photo-curing resin on an exit surface 13 opposing the incident surface 12. The prism has grooves or ridges each having a substantially triangular cross section to totally reflect incident light so as to bend the light into a direction perpendicular to the exit surface 13. The hologram anisotropically diffuses light exiting from the exit surface 13, to improve brightness.

Owner:HITACHI CHEM CO LTD

Low Tg multilayer optical films

InactiveUS7052762B2Excellent crease and crumple recoveryHigh refractive indexOther printing matterLayered productsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

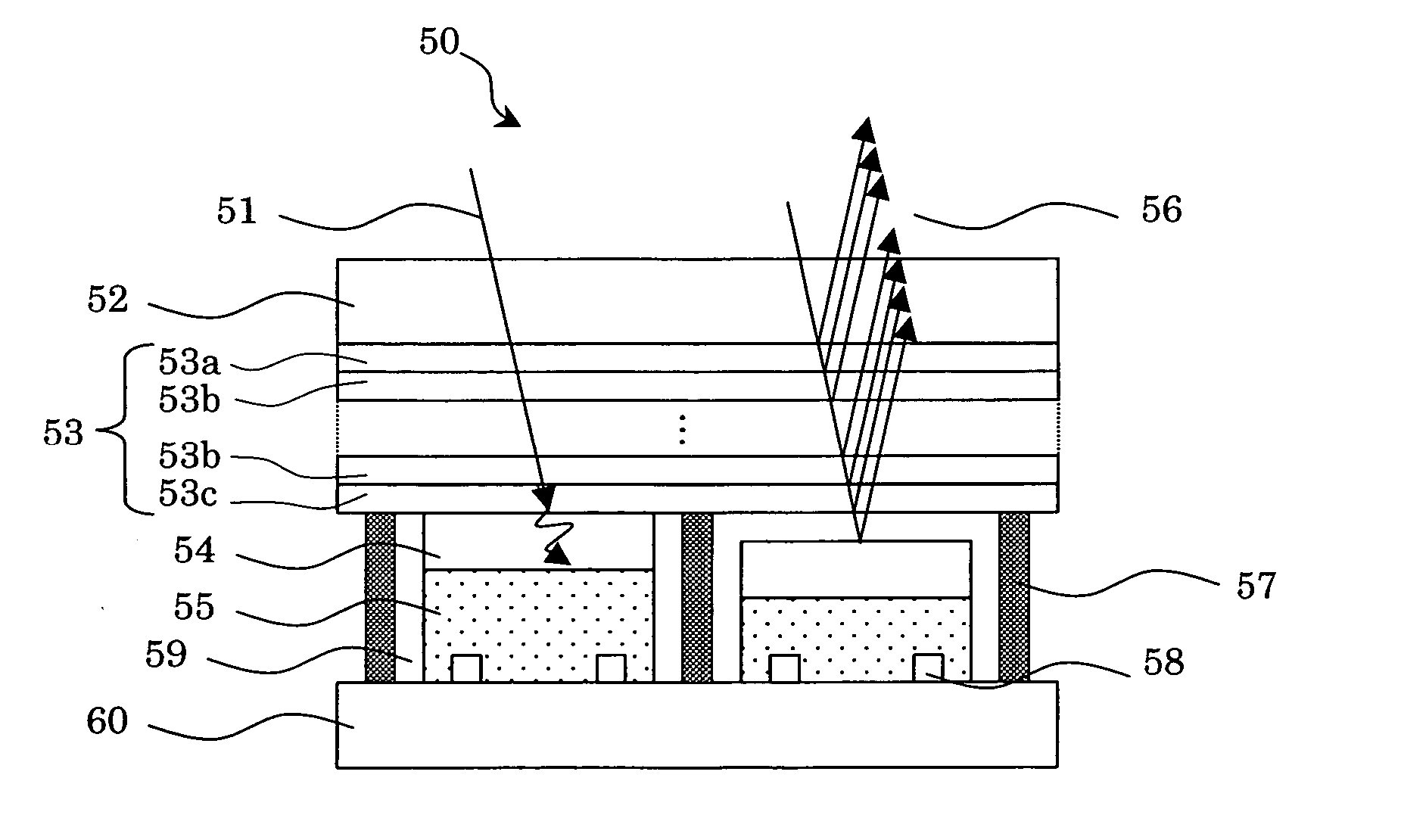

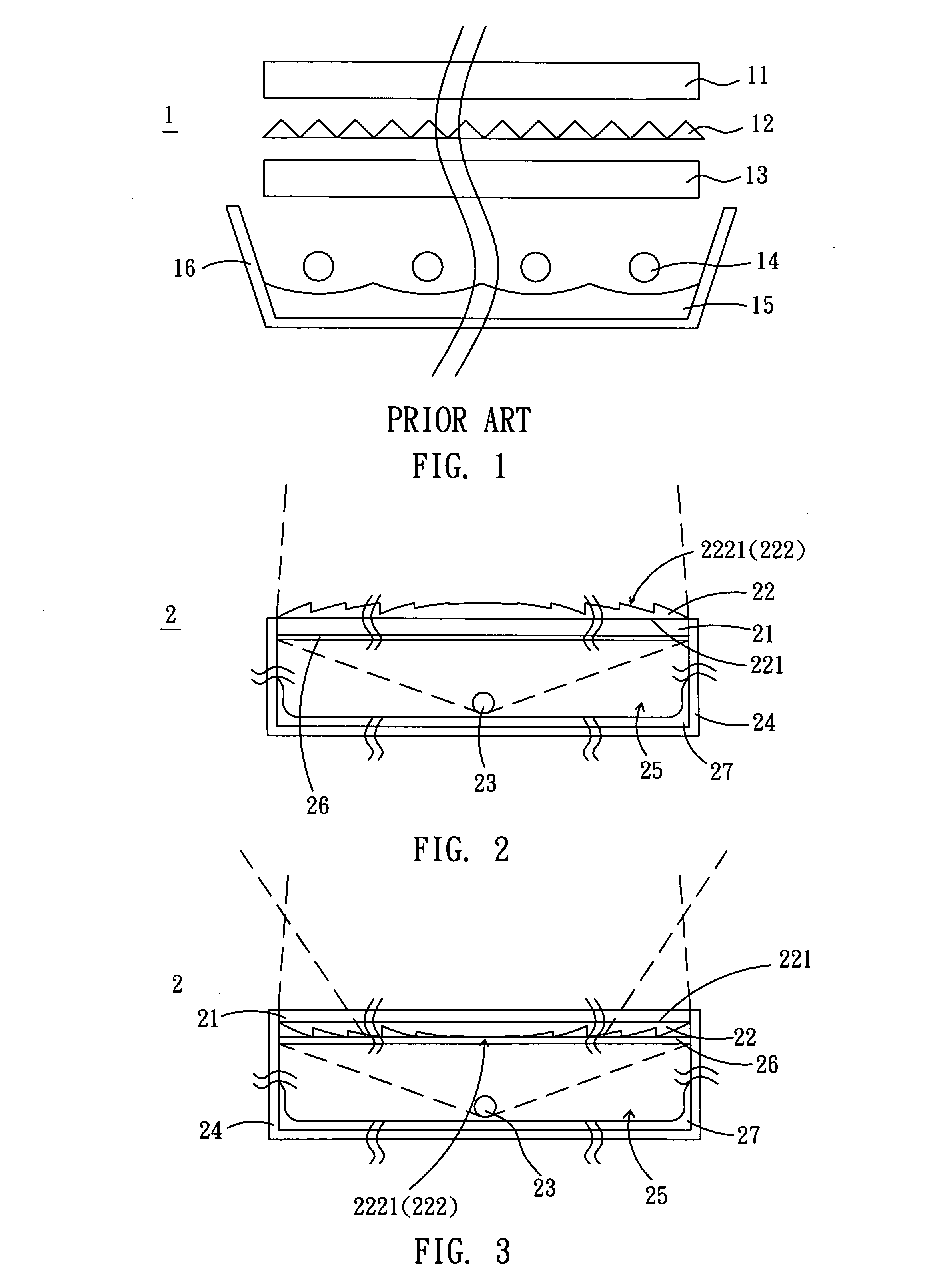

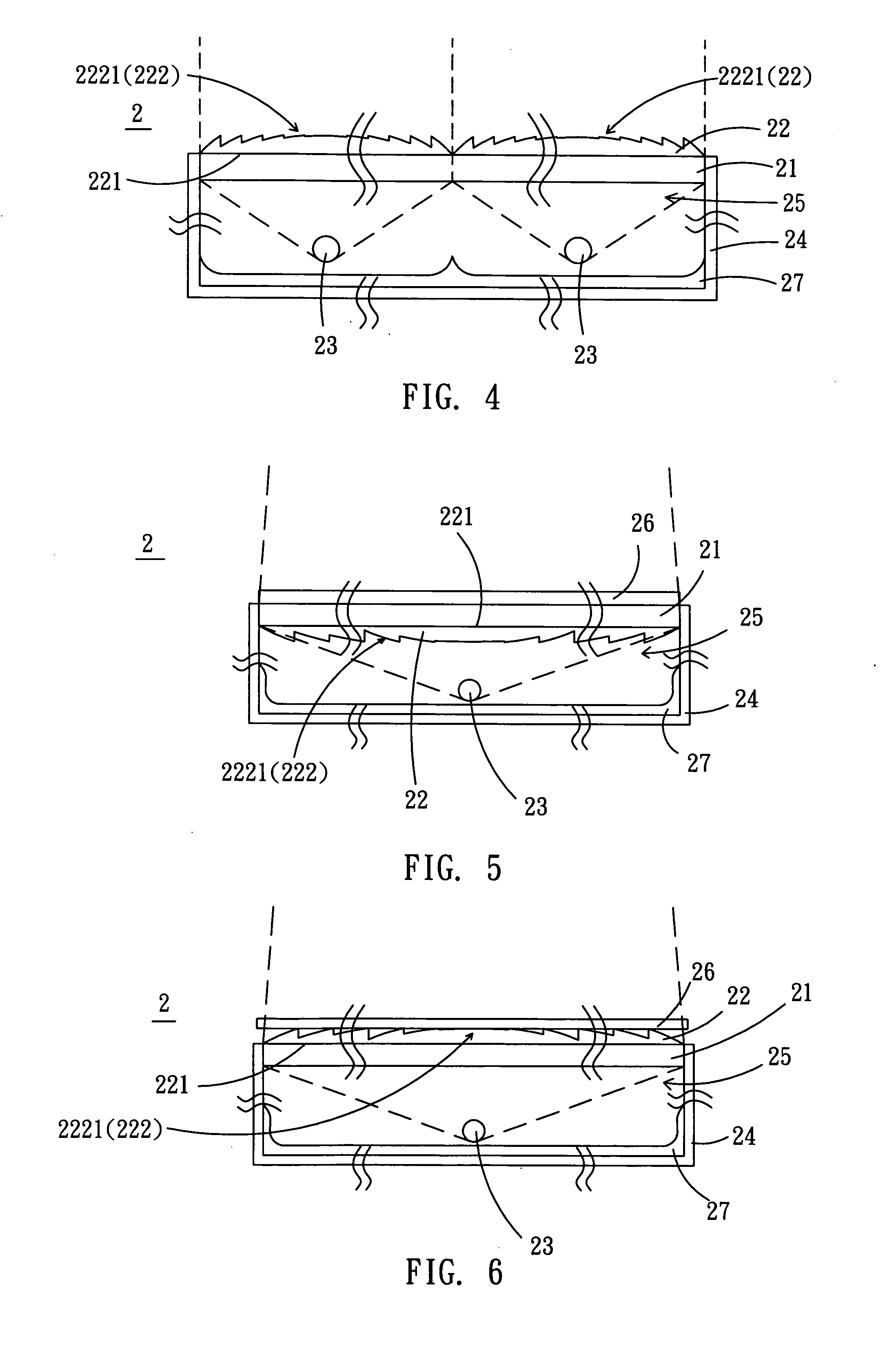

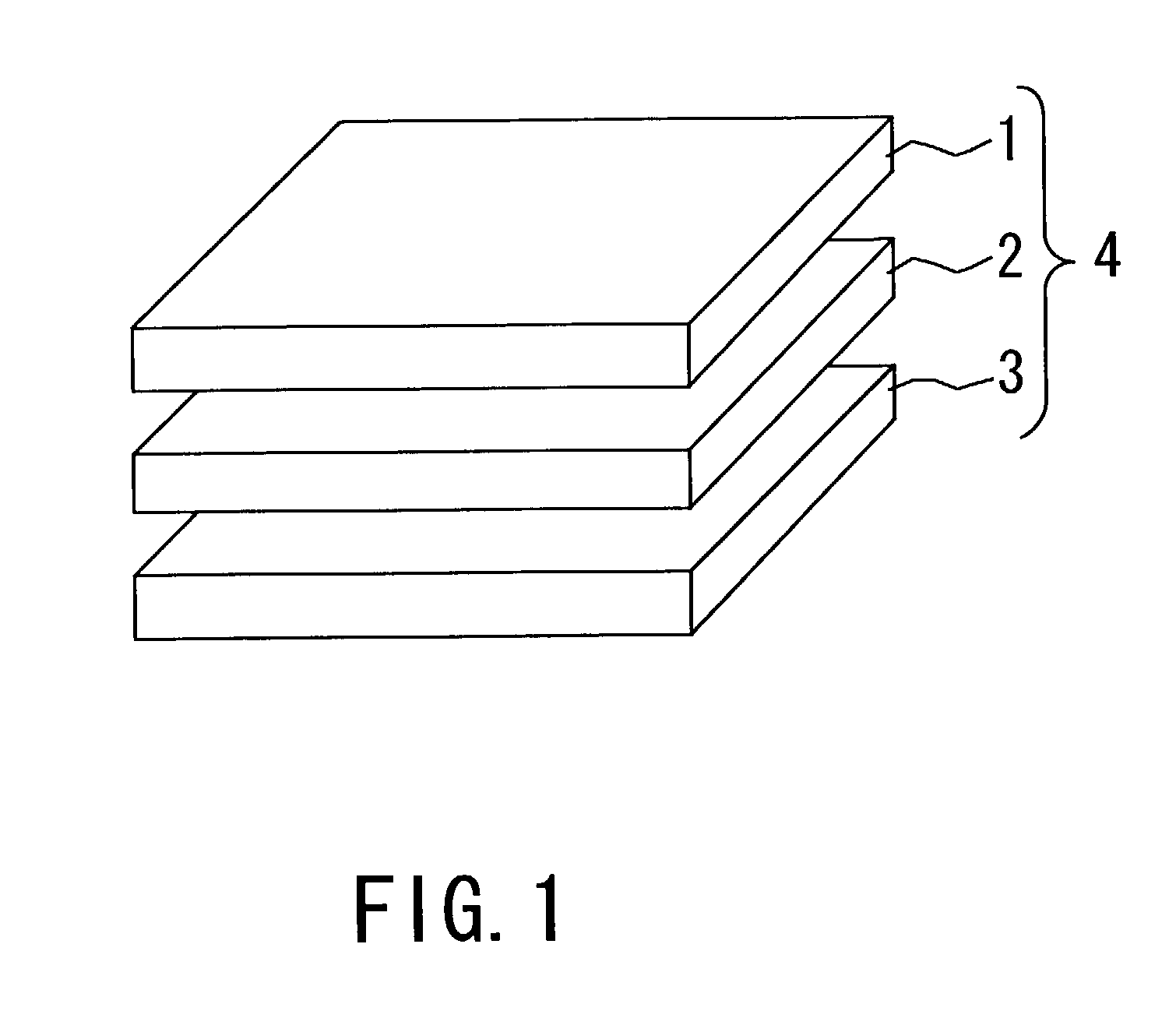

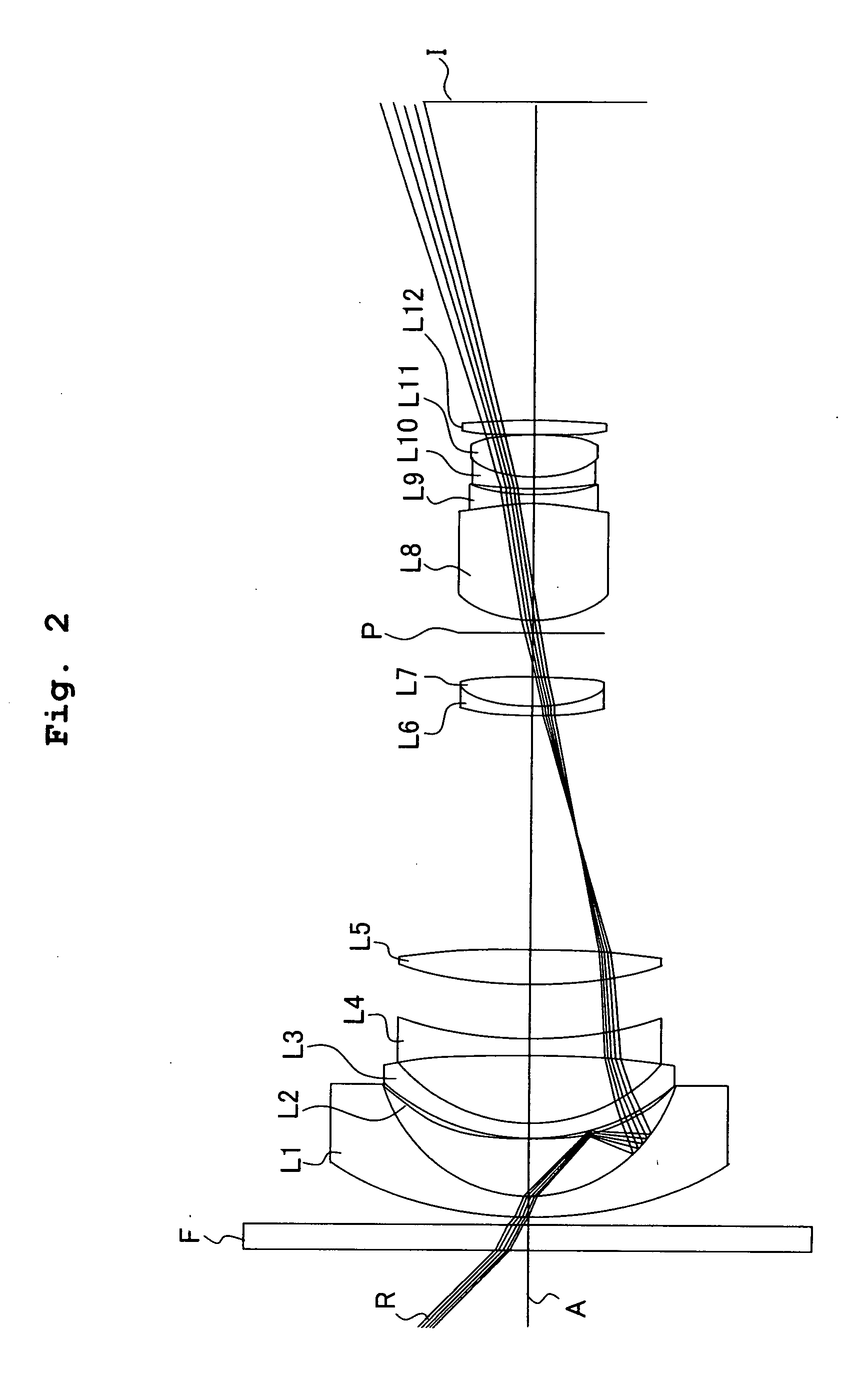

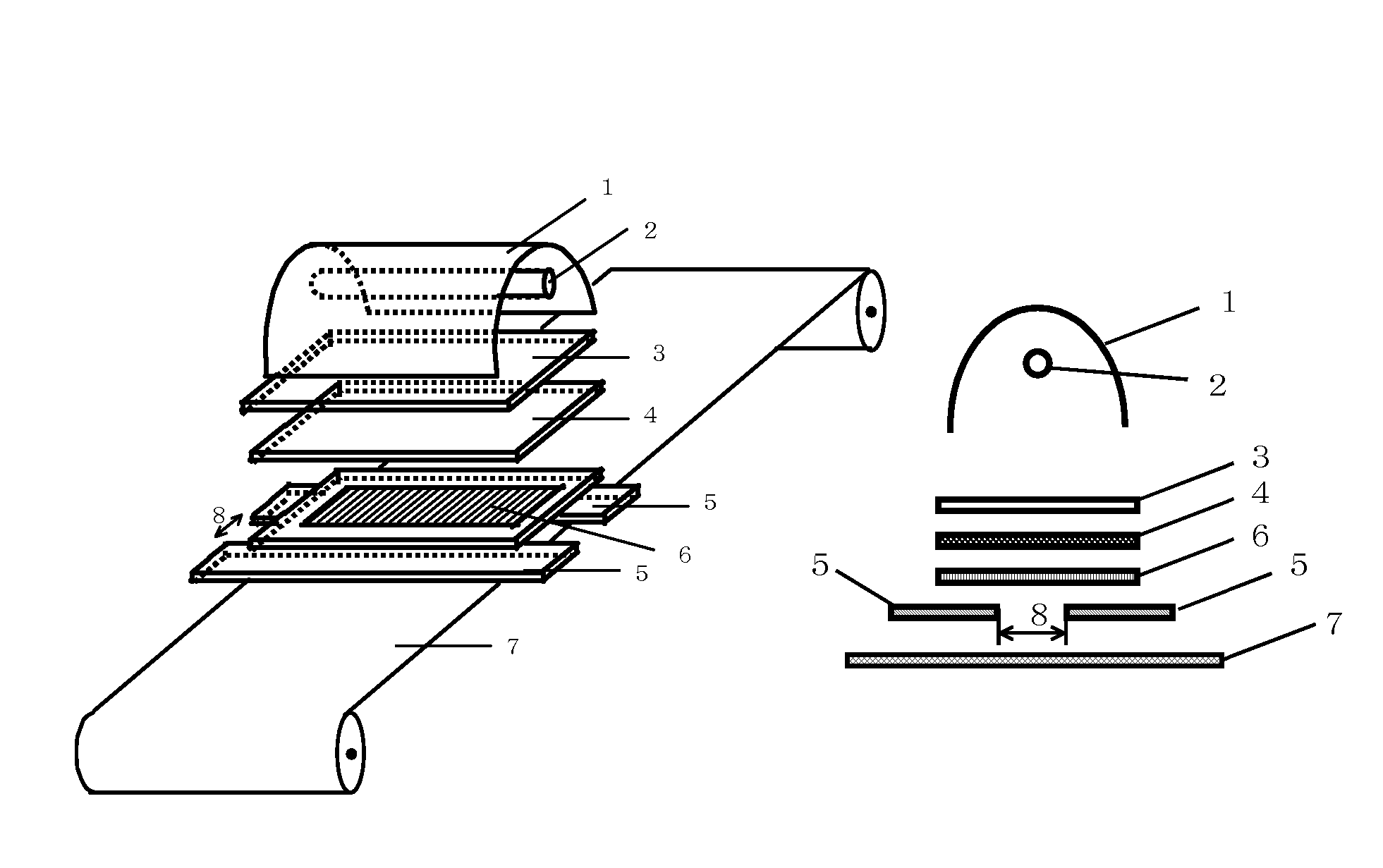

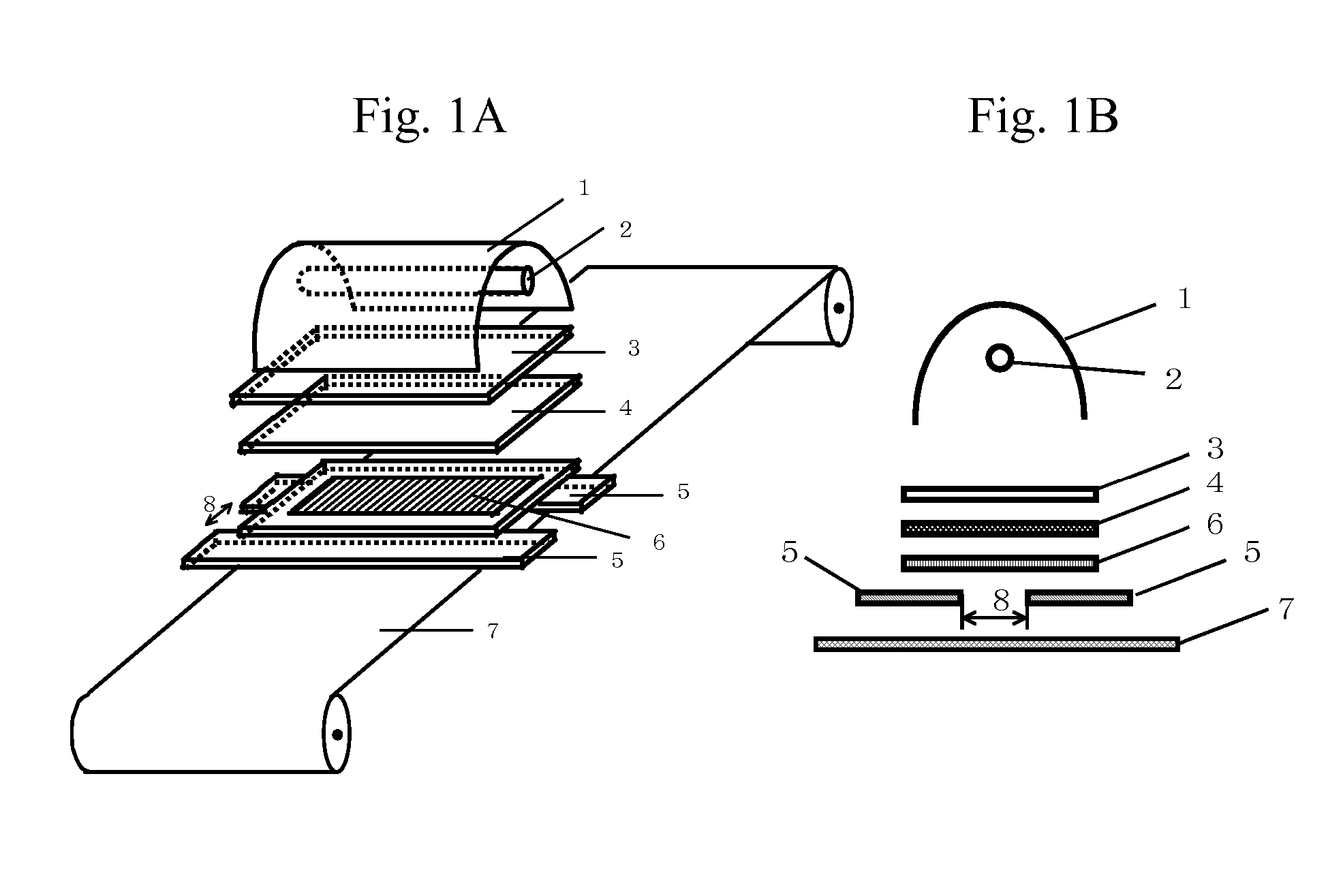

Optical multilayer structure material and process for producing the same, light switching device, and image display apparatus

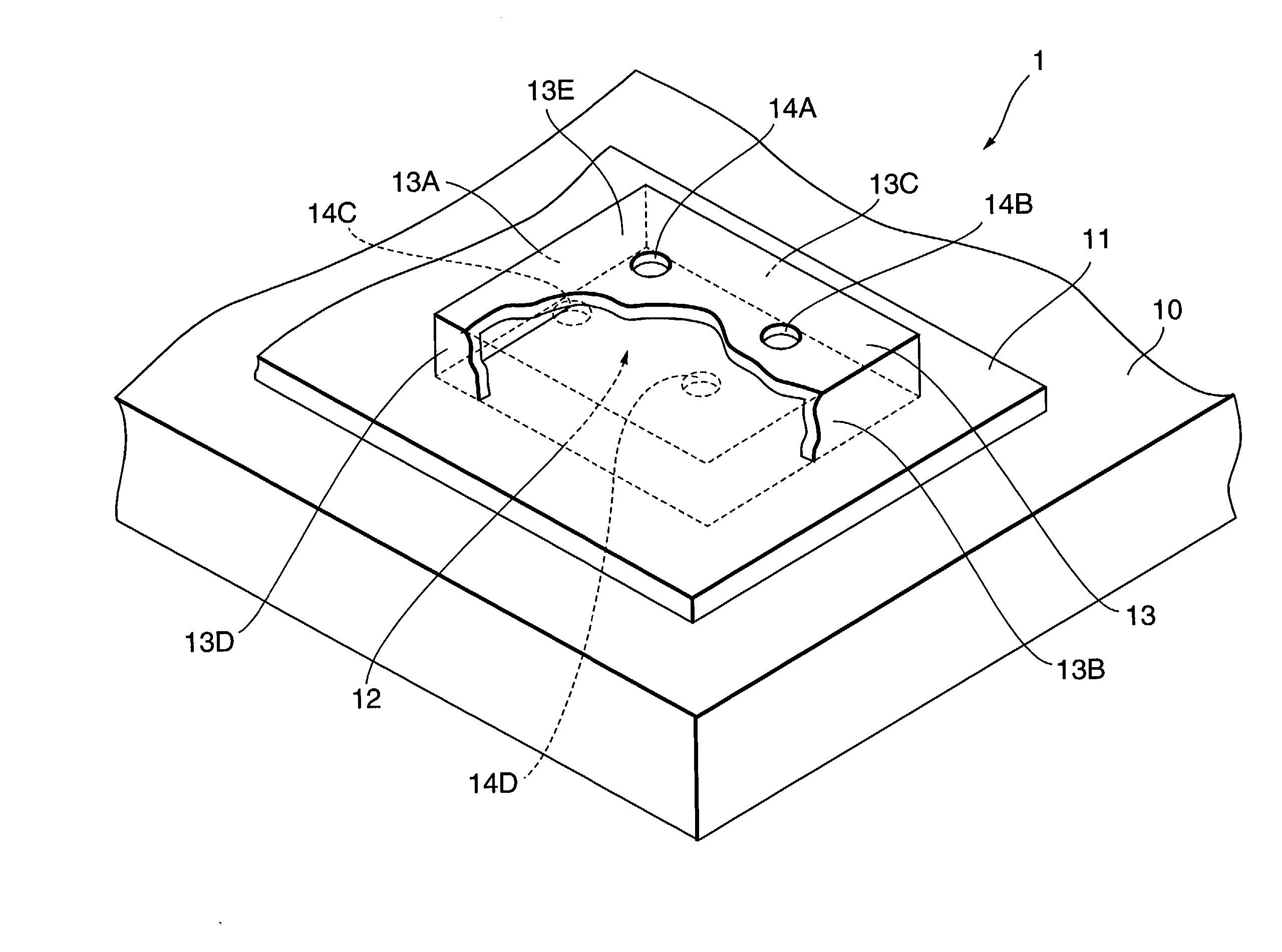

InactiveUS20020126387A1Stable fast responseImprove support strengthPiezoelectric/electrostrictive devicesFlexible microstructural devicesOptical thin filmOptoelectronics

An optical multilayer structure material has a structure such that, on a substrate, a conductive layer in contact with the substrate, a gap portion having a size that enables an interference phenomenon to occur and can be changed, and an optical thin film are formed in this order. The circumference of a movable portion in the optical thin film is uniformly supported by supporting portions, suppressing generation of strain due to an internal stress. Through holes are formed in the movable portion to allow an etchant to easily reach a sacrifice layer when forming a gap portion by etching for sacrifice layer. There is provided an optical multilayer structure material having a simple construction, which can suppress generation of strain due to an internal stress and can be advantageously used in an image display apparatus.

Owner:SONY CORP

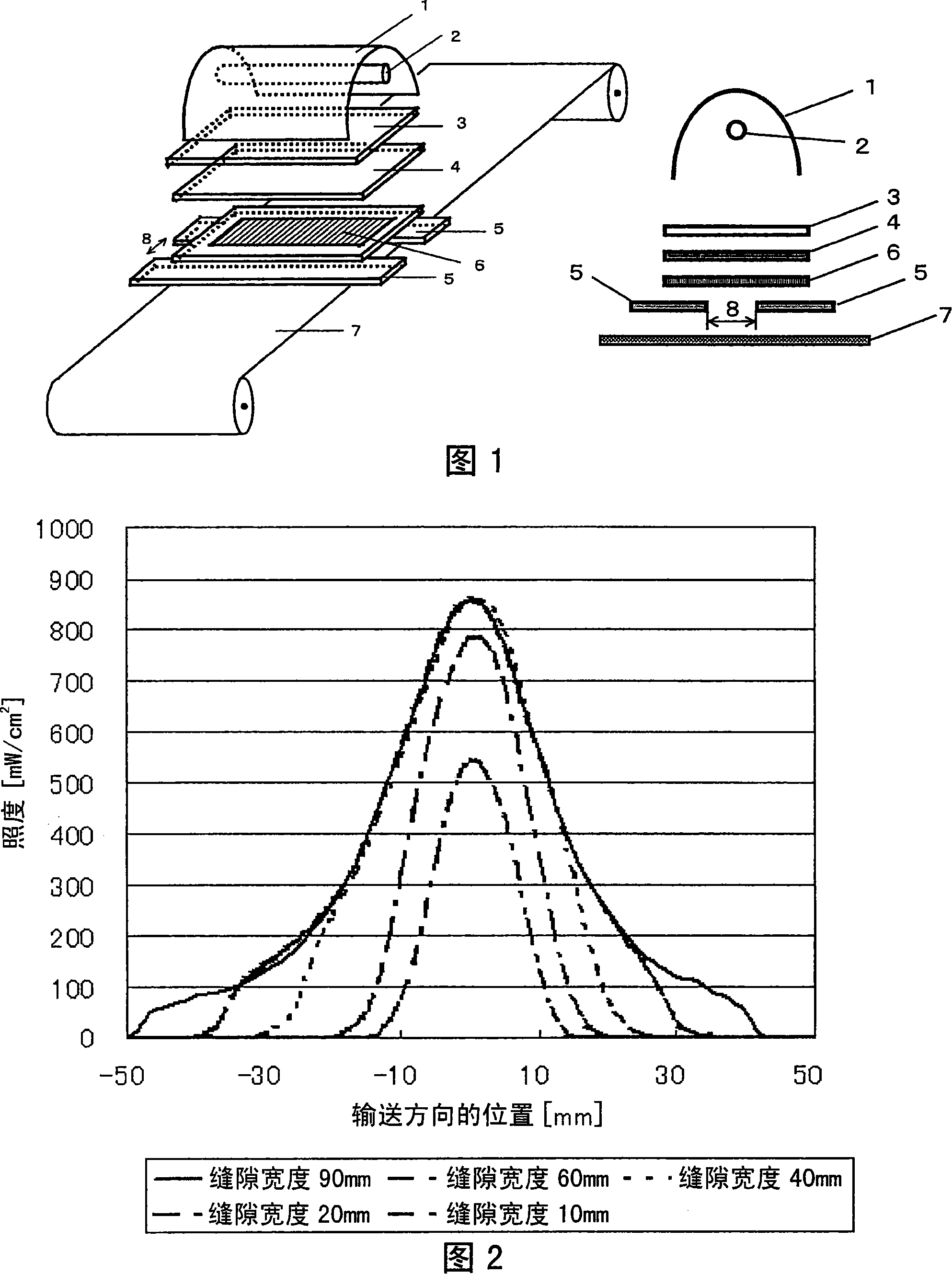

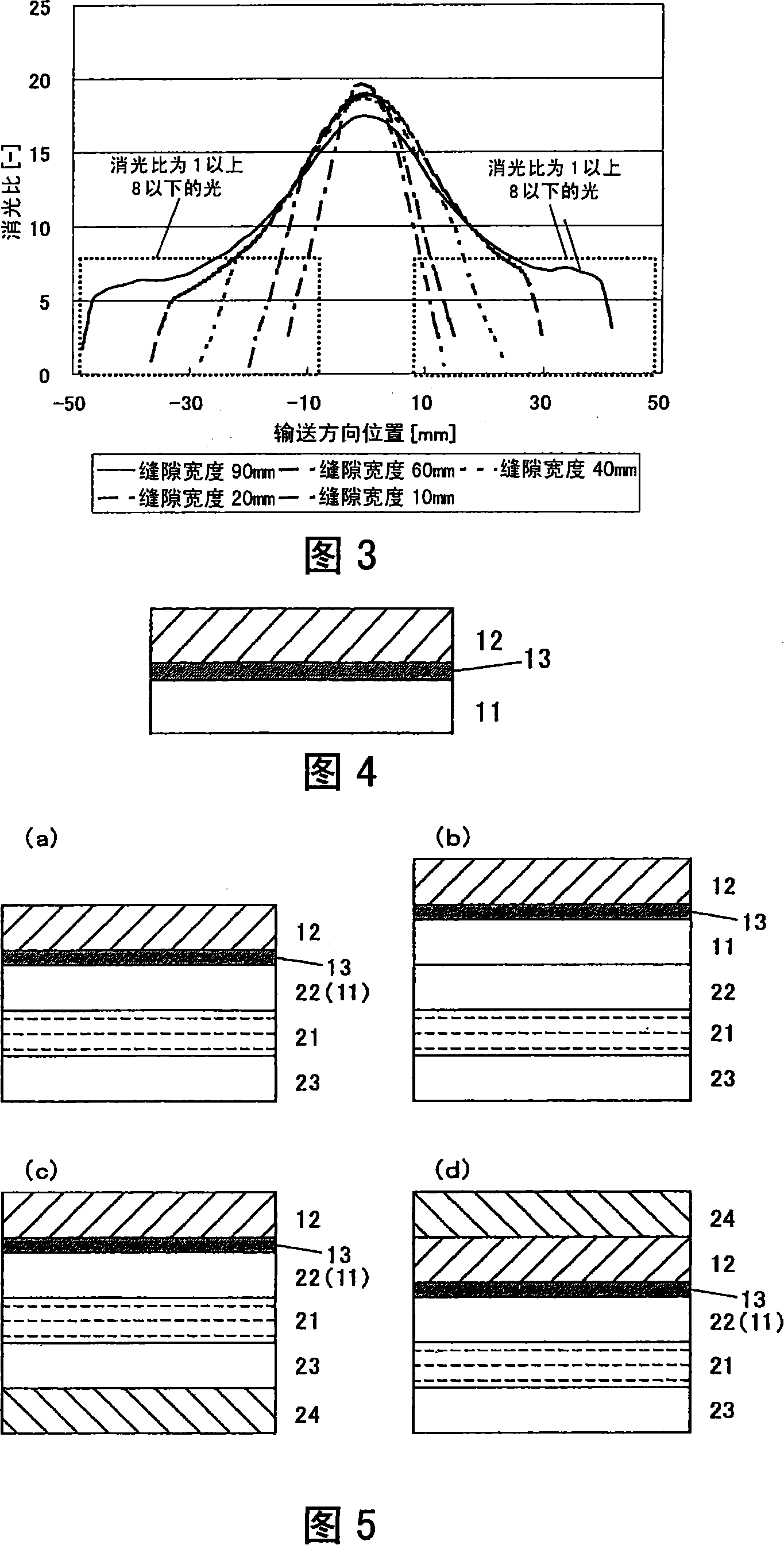

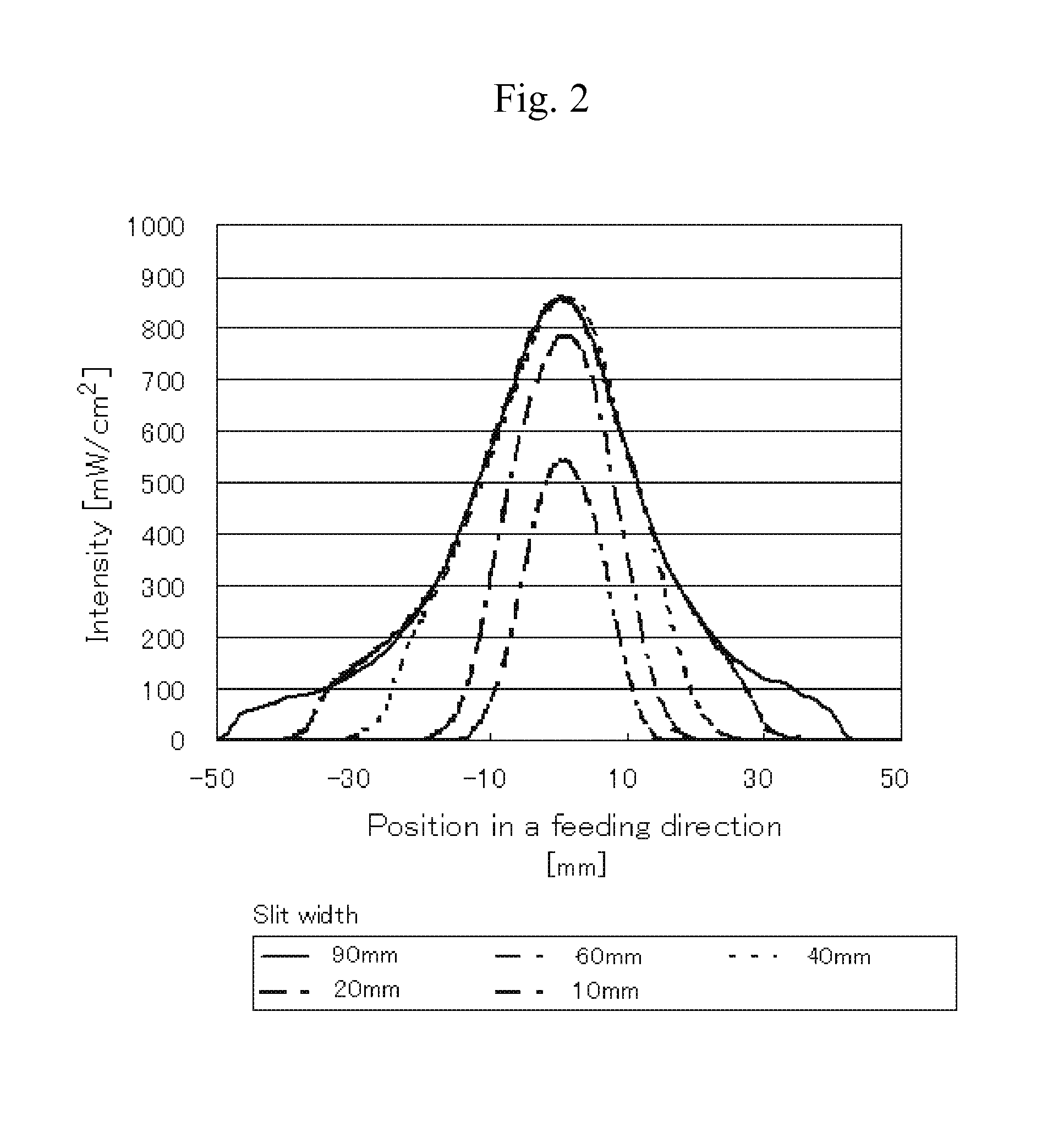

Method of producing optical film, optical film, polarizer plate, transfer material, liquid crystal display device, and polarized ultraviolet exposure apparatus

InactiveCN101131436AExcellent optical propertiesHigh film strengthPolarising elementsNon-linear opticsUltraviolet lightsPolarizer

The present invention provides a method for producing an optical film exhibiting excellent optical characteristics and film strength with high productivity in a production method of an optical film including a step of irradiating polarized ultraviolet rays. The method for producing an optical film is characterized in that it is a method for producing an optical film comprising the following steps (1) to (3) in the order of (1) to (3): (1) A layer composed of a polymerizable composition containing a polymerizable liquid crystal compound and a dichroic polymerization initiator is formed on the surface; (2) the molecules of the polymerizable liquid crystal compound in the layer are formed into a first alignment state; (3) The layer is irradiated with polarized ultraviolet rays to polymerize the polymerizable liquid crystal compound, and fix the molecules of the polymerizable liquid crystal compound in the second alignment state to form an optically anisotropic layer. Exposure to area (J / cm 2 ), the proportion of polarized ultraviolet rays with an extinction ratio of 1 to 8 is 15% or less.

Owner:FUJIFILM CORP

Structured Composite Optical Films

Optical films having structured surfaces are used, inter alia, for managing the propagation of light within a display. As displays become larger, it becomes more important that the film be reinforced so as to maintain rigidity. An optical film of the invention has a first layer comprising inorganic fibers embedded within a polymer matrix. The first layer has a structured surface to provide an optical function to light passing therethrough. The film may have various beneficial optical properties, for example, light that propagates substantially perpendicularly through the first layer may be subject to no more than a certain level of haze or light incident on the film may be subject to a minimum value of brightness gain. Various methods of manufacturing the films are described.

Owner:3M INNOVATIVE PROPERTIES CO

Optical film with pressure sensitive adhesive on both sides and method for producing image display device using same

InactiveUS20150346408A1Simple processAvoid pollutionLamination ancillary operationsElectrical apparatusDisplay devicePolarizer

According to the invention, an optical film with adhesive on both sides comprises: an optical film including a polarizing plate; a first pressure sensitive adhesive layer provided on a surface of the optical film at a side configured to be bonded to an image display cell; and a second pressure sensitive adhesive layer provided on a surface of the optical film at a side configured to be bonded to a transparent plate or the touch panel. Further, a protective sheet is releasably attached on each of the first pressure sensitive adhesive layer and the second pressure sensitive adhesive layer. A thickness of the second pressure sensitive adhesive layer is preferably 30 μm or more. In a practical use, the optical film with adhesive on both sides according to the present invention is, for example, disposed between a front transparent plate or a touch panel and an image display cell.

Owner:NITTO DENKO CORP

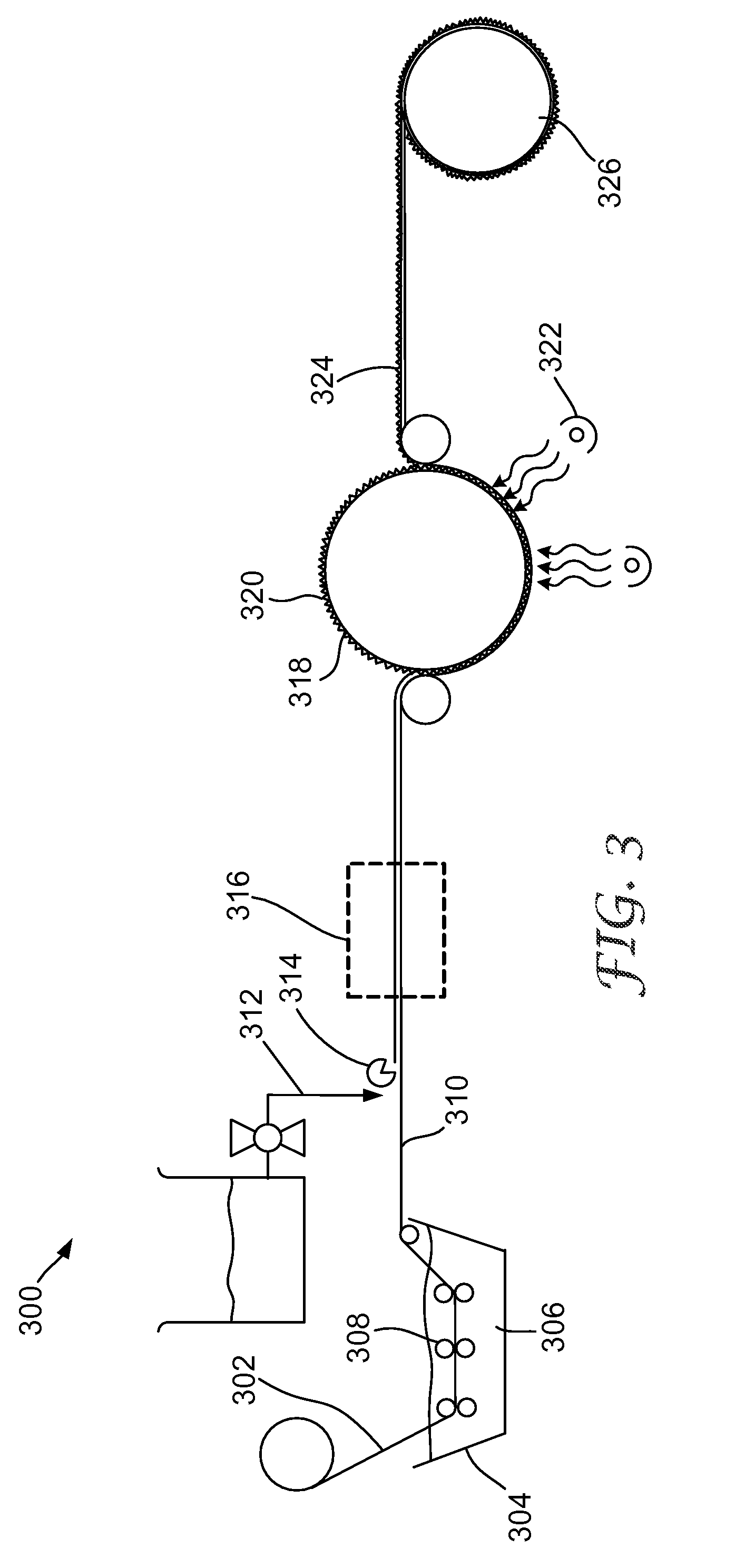

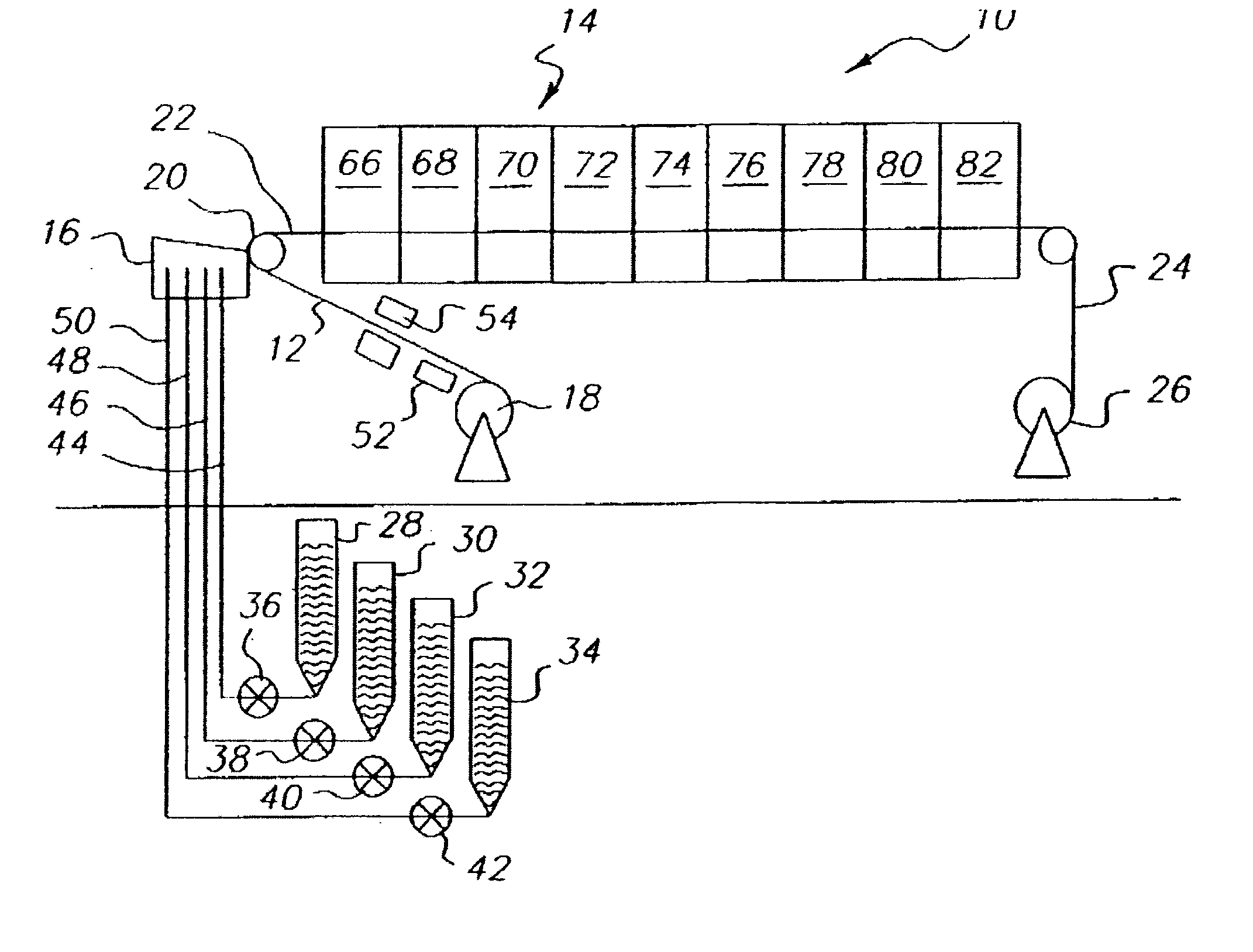

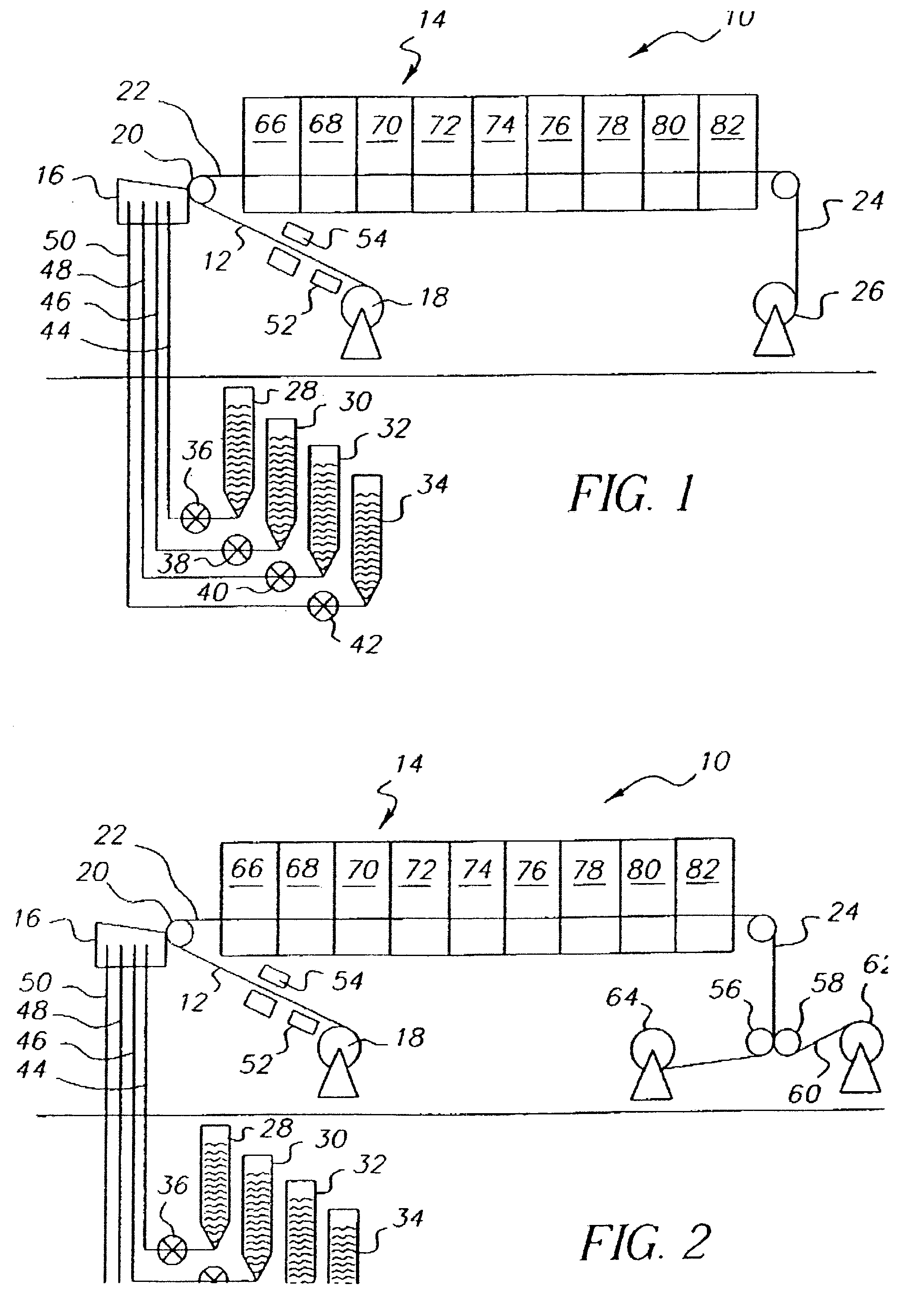

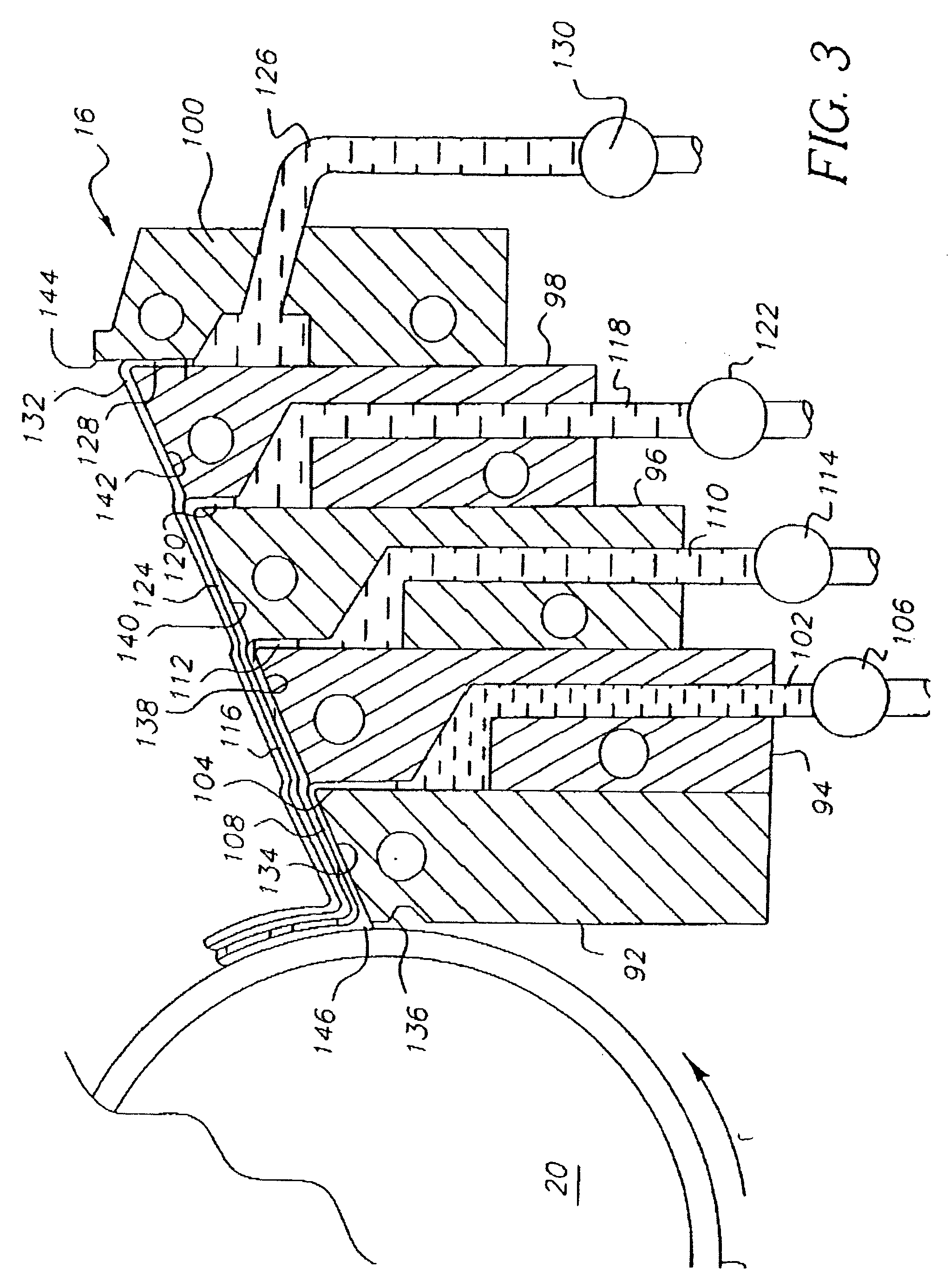

Method and apparatus for sequentially laminating optical film including polarizing film, to rectangular-shaped panel

InactiveUS20120055622A1Adhesive processesLamination ancillary operationsOptical thin filmEngineering

A method of sequentially laminating a carrier film-attached optical film laminate to a rectangular-shaped panel having a long side and a short side, is provided. The optical film laminate includes an optical film including a thin polarizing film, and a carrier film attached to the optical film through an adhesive layer. The method includes the steps: forming a plurality of slits in the carrier film-attached optical film laminate in a width direction thereof at lengthwise given intervals to extend from a surface of the optical film on a side opposite to the carrier film to a depth reaching a surface of the carrier film adjacent to the optical film to thereby form an optical film sheet supported by the carrier film, between lengthwisely adjacent two of the slits; and laminating each of the optical film sheets to a respective one of the panels through the adhesive layer.

Owner:NITTO DENKO CORP

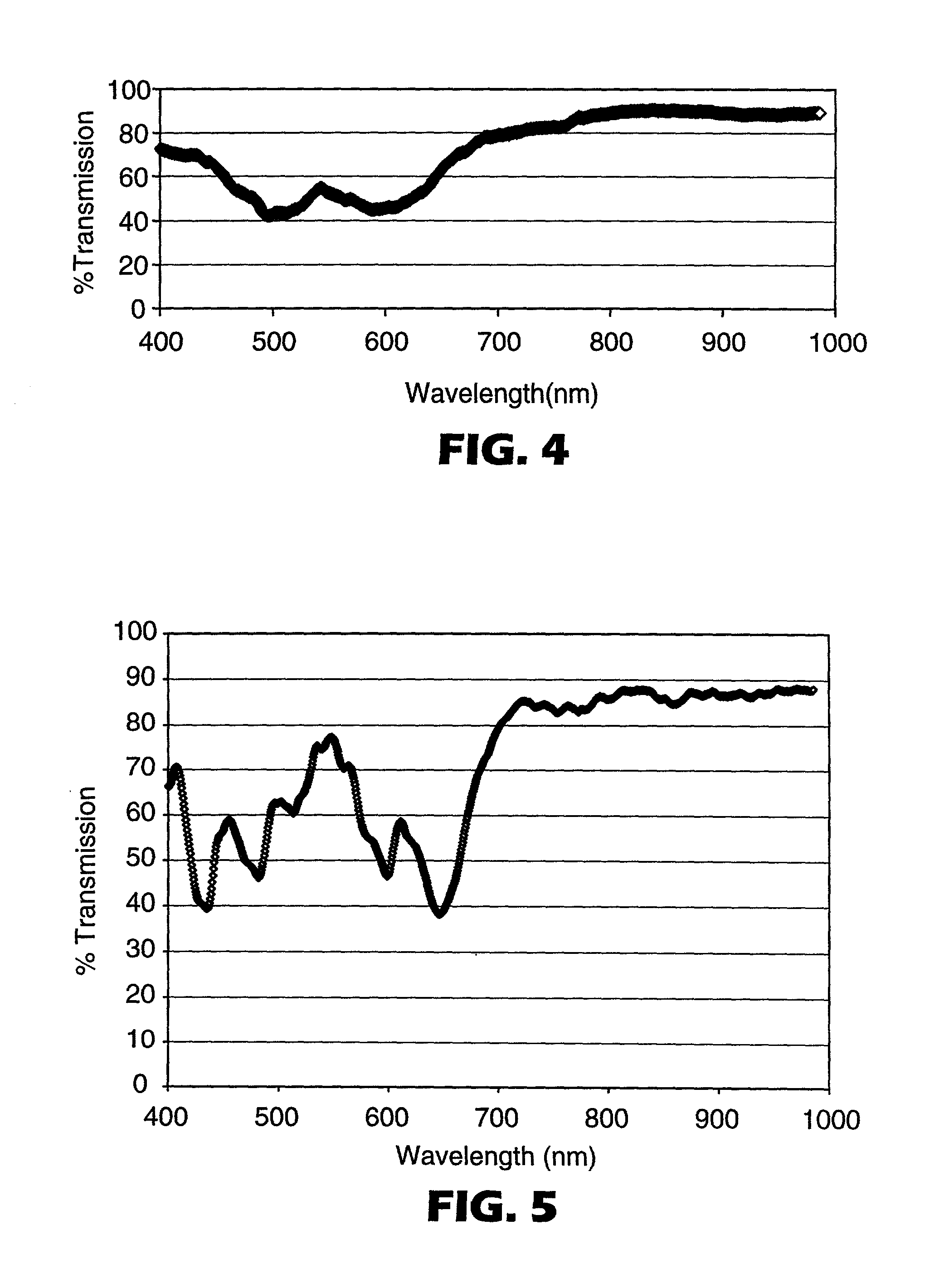

Mgf2 Optical Thin Film Including Amorphous Silicon Oxide Binder, Optical Element Provided With the Same, and Method for Producing Mgf2 Optical Thin Film

InactiveUS20080002259A1Excellent in environment resistance (durability)Secure environment resistanceMagnesium fluoridesMaterial nanotechnologyRefractive indexAmorphous silicon

An MgF2 optical thin film is formed on an optical surface of a base material. The MgF2 optical thin film includes MgF2 particles and an amorphous silicon oxide-based binder which exists on the surfaces of the MgF2 particles and between the MgF2 particles. Owing to this amorphous silicon oxide-based binder, the optical thin film can have high mechanical strength and high adhesion to the base material, while having excellent environment resistance and a lower refractive index.

Owner:NIKON CORP

Pressure sensitive adhesive for polarizing plates, polarizing plate with pressure sensitive adhesive and production process for polarizing plate

ActiveUS20060162857A1Increased durabilityLiquid crystal compositionsOrganic dyesLiquid-crystal displayOptical thin film

The disclosed a pressure sensitive adhesive for polarizing plates which has a storage elastic modulus (G′) at 23° C. of at least 0.3 MPa; a polarizing plate having a pressure sensitive adhesive; a process for producing the above polarizing plate which comprises sticking a polarizing plate on a tacky adhesive material layer formed on a releasing layer of a releasing sheet, and thereafter irradiating with an active energy beam from the releasing sheet side; an optical film which comprises a polarizing plate and a phase difference plate; and a process for producing the above optical film. The pressure sensitive adhesive and polarizing plate having the pressure sensitive adhesive are characterized in that they are capable of sticking with high durability, the polarizing plate to a and phase difference plate, and the resultant liquid crystal display unit is less liable to cause light leakage under the conditions of high temperature.

Owner:LINTEC CORP

Optical films and process for making them

InactiveUS20060068128A1Good dimensional stabilityLow in-planeLiquid crystal compositionsLiquid surface applicatorsLiquid layerSolvent

A method of film fabrication is taught that uses a coating and drying apparatus to fabricate resin films suitable for optical applications. In particular, resin films are prepared by simultaneous application of multiple liquid layers to a moving carrier substrate having low surface energy. After solvent removal, the resin films are peeled from the sacrificial carrier substrate. Films prepared by the current invention exhibit good dimensional stability and low out-of-plane retardation.

Owner:EASTMAN KODAK CO

Method of producing optical film, optical film, polarizer plate, transfer material, liquid crystal display device, and polarized ultraviolet exposure apparatus

InactiveUS20080055521A1High productivityExcellent in optical characteristic and strength of filmPolarising elementsRadiation therapyPolarizerChemistry

A novel method of producing an optical film is disclosed. The method comprises steps (1) to (3) in this order: (1) preparing, on a surface of an alignment film, a layer of a polymerizable composition comprising a polymerizable liquid crystal compound and a dichroic polymerization initiator; (2) aligning molecules of said polymerizable liquid crystal compound in said layer in a first alignment state; and (3) irradiating said layer with polarized ultraviolet light to carry out polymerization of said polymerizable liquid crystal compound and fix molecules of said polymerizable liquid crystal compound in a second alignment state thereby to form an optically anisotropic layer, wherein a percentage of polarized ultraviolet light having an extinction ratio ranging from 1 to 8 is not greater than 15% with respect to an energy density of polarized ultraviolet light per unit area (J / cm2).

Owner:FUJIFILM CORP

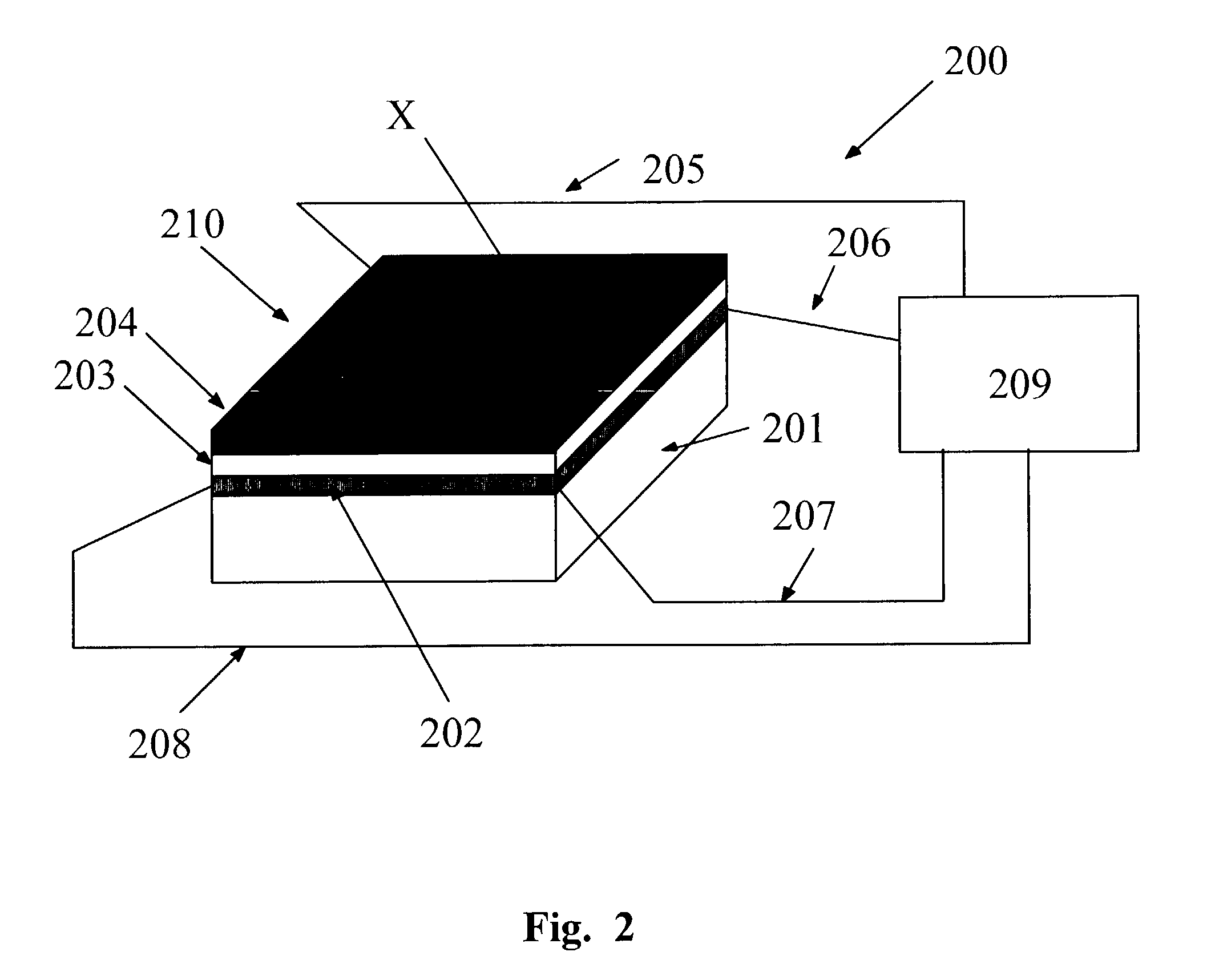

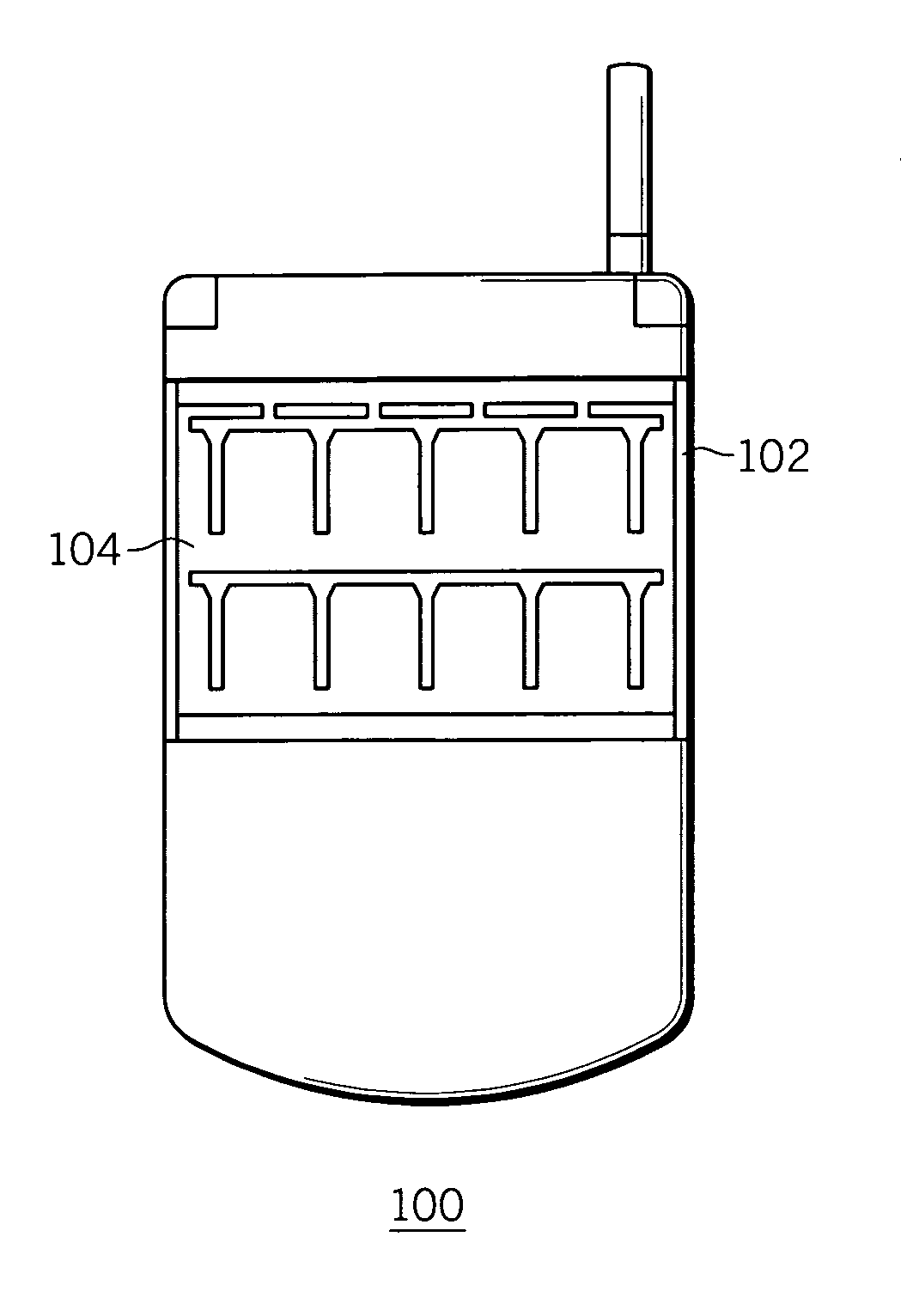

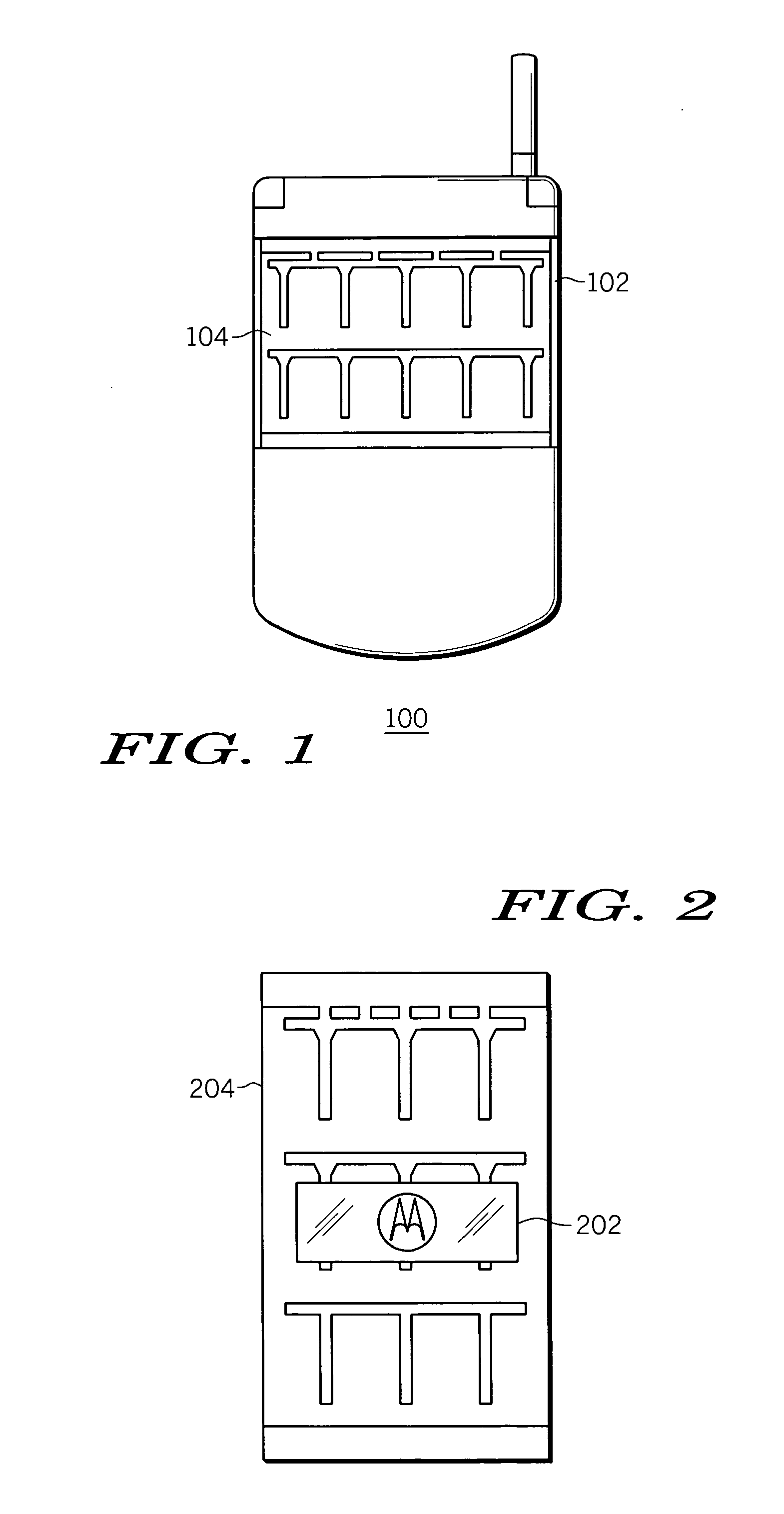

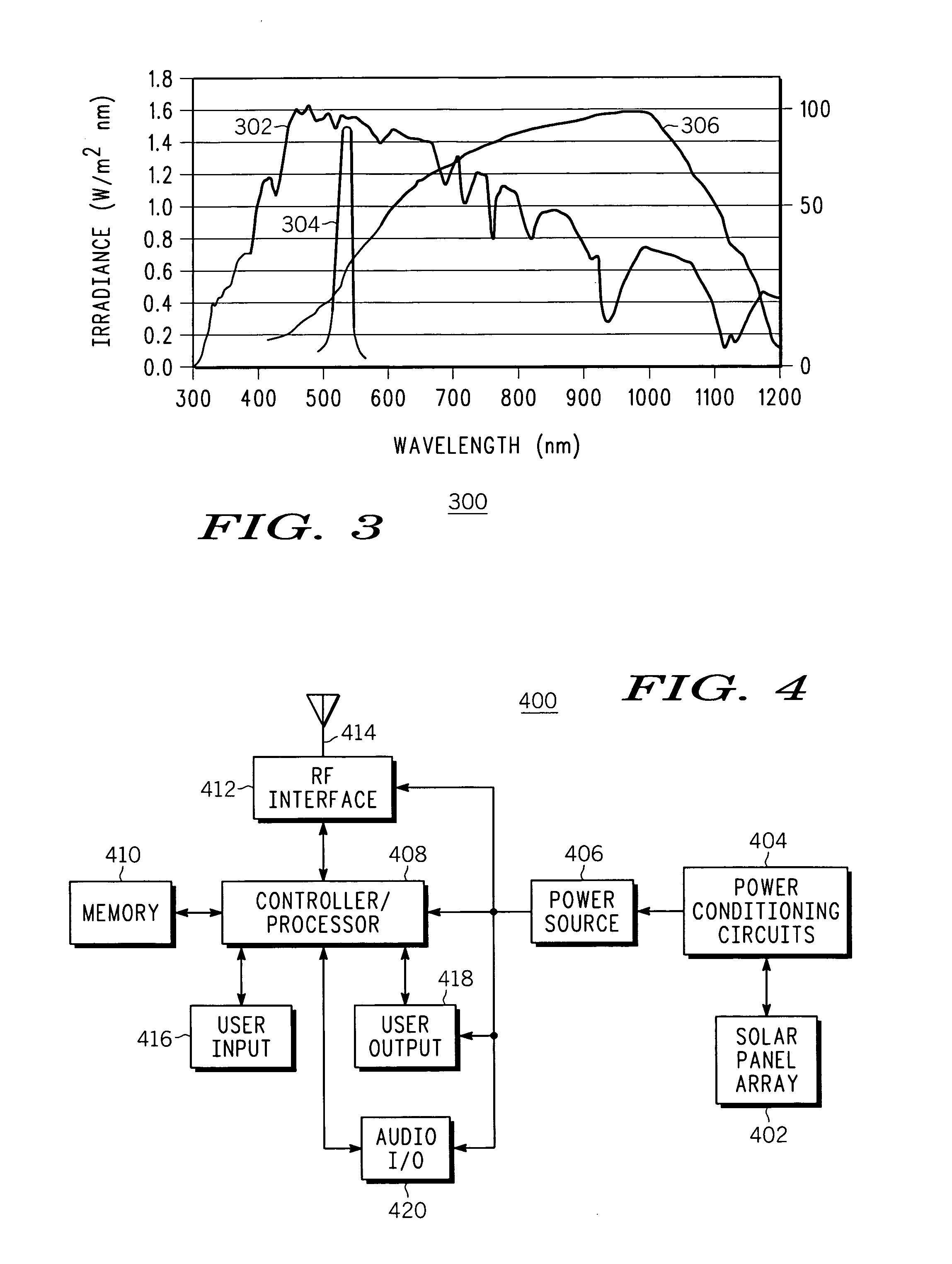

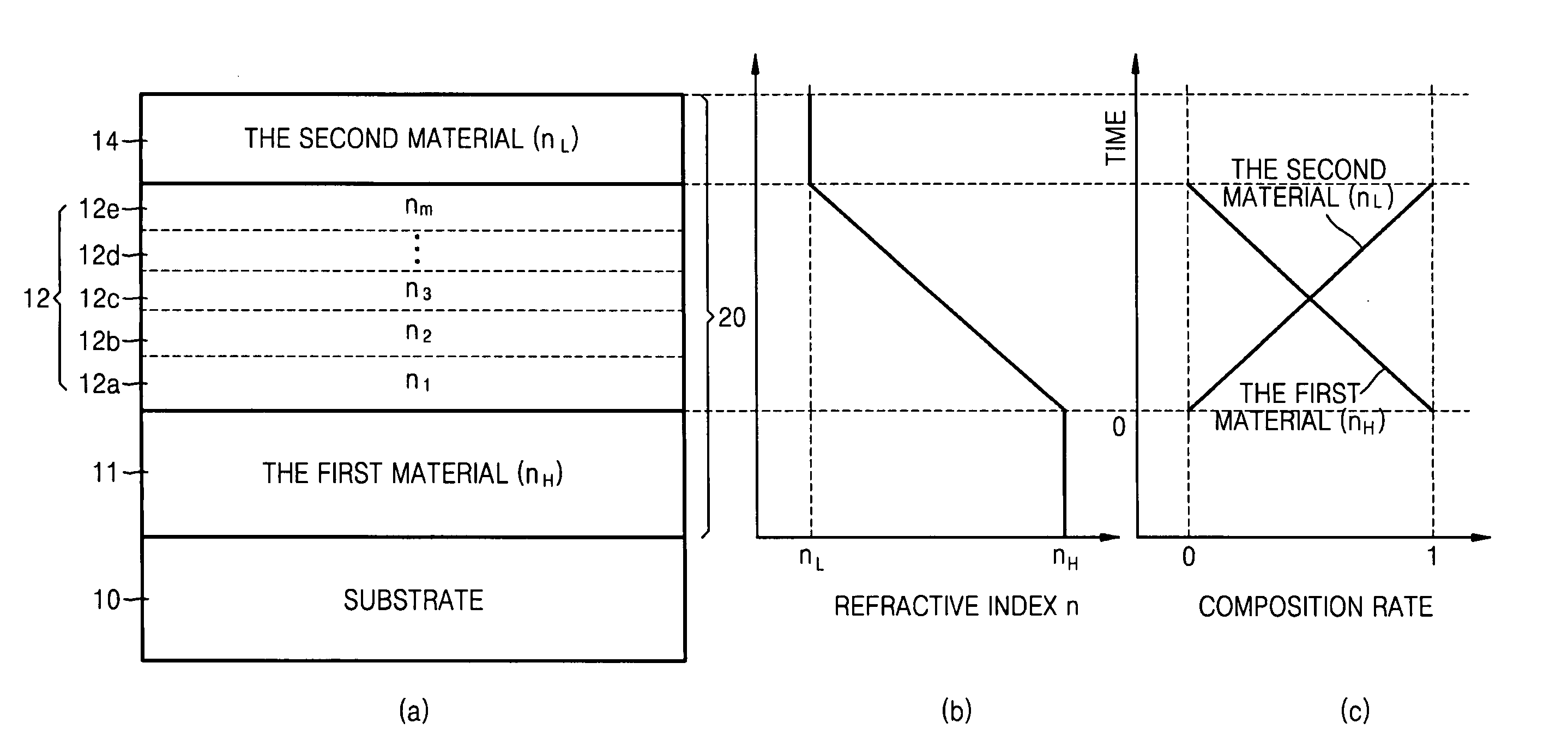

Solar panel with optical films

A solar panel mounting arrangement, and electronic device, and a wireless device, includes a solar panel (204); and a wavelength selectively reflective optical film (202) being disposed in front of the solar panel for the optical film to substantially reflect a pre-selected band (304) of solar irradiation frequencies (302) in the visible light range and incident on a front surface of the optical film (202) while allowing solar irradiation frequencies (302) outside of the pre-selected band (304) to substantially pass through the optical film (202) and irradiate the solar panel (204). The optical film (202) can include at least one of an iconic pattern, a company logo, and a photo, that is visible from the front of the optical film (202). The optical film (202) can include holographic film. The optical film can include a multi-layer film.

Owner:MOTOROLA INC

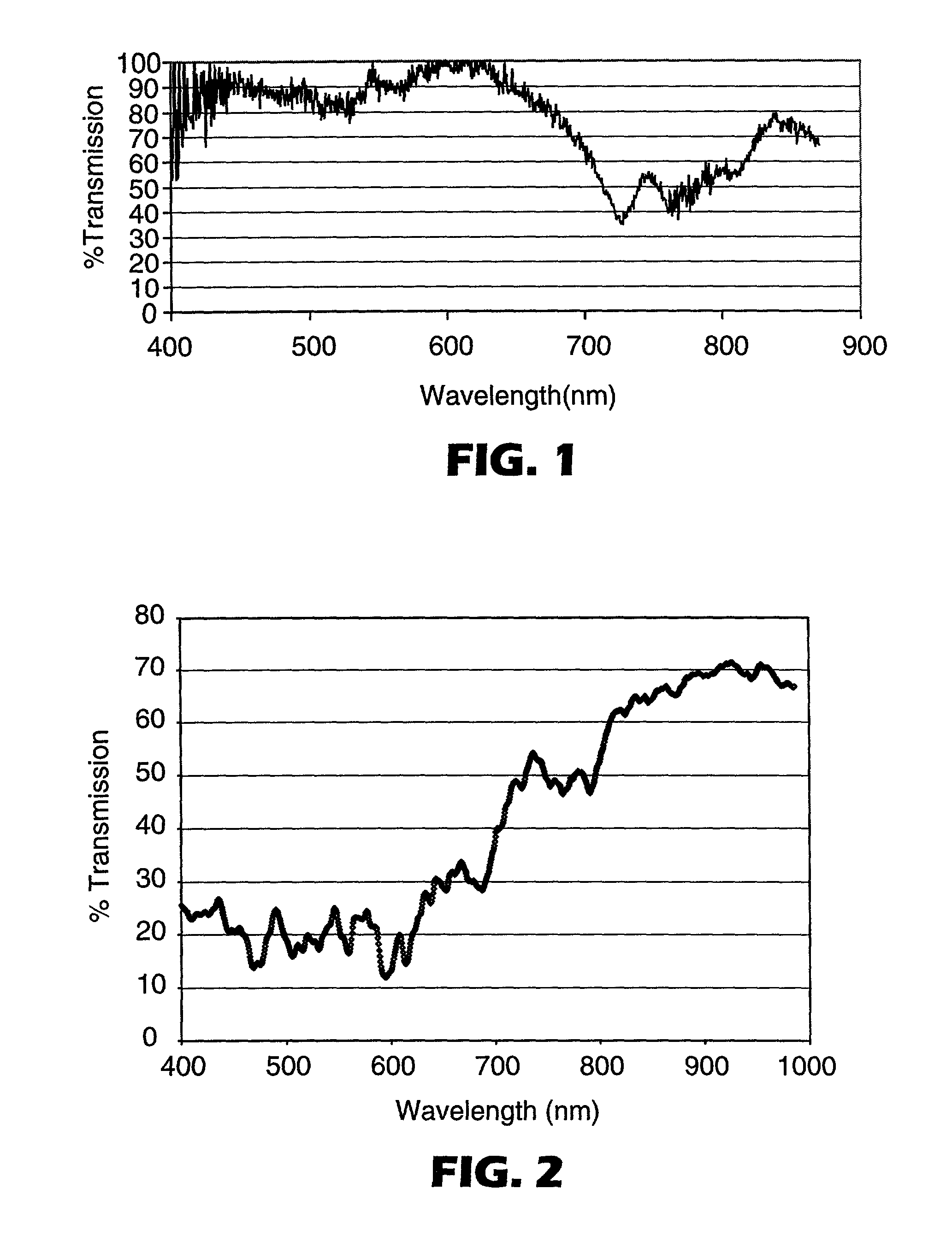

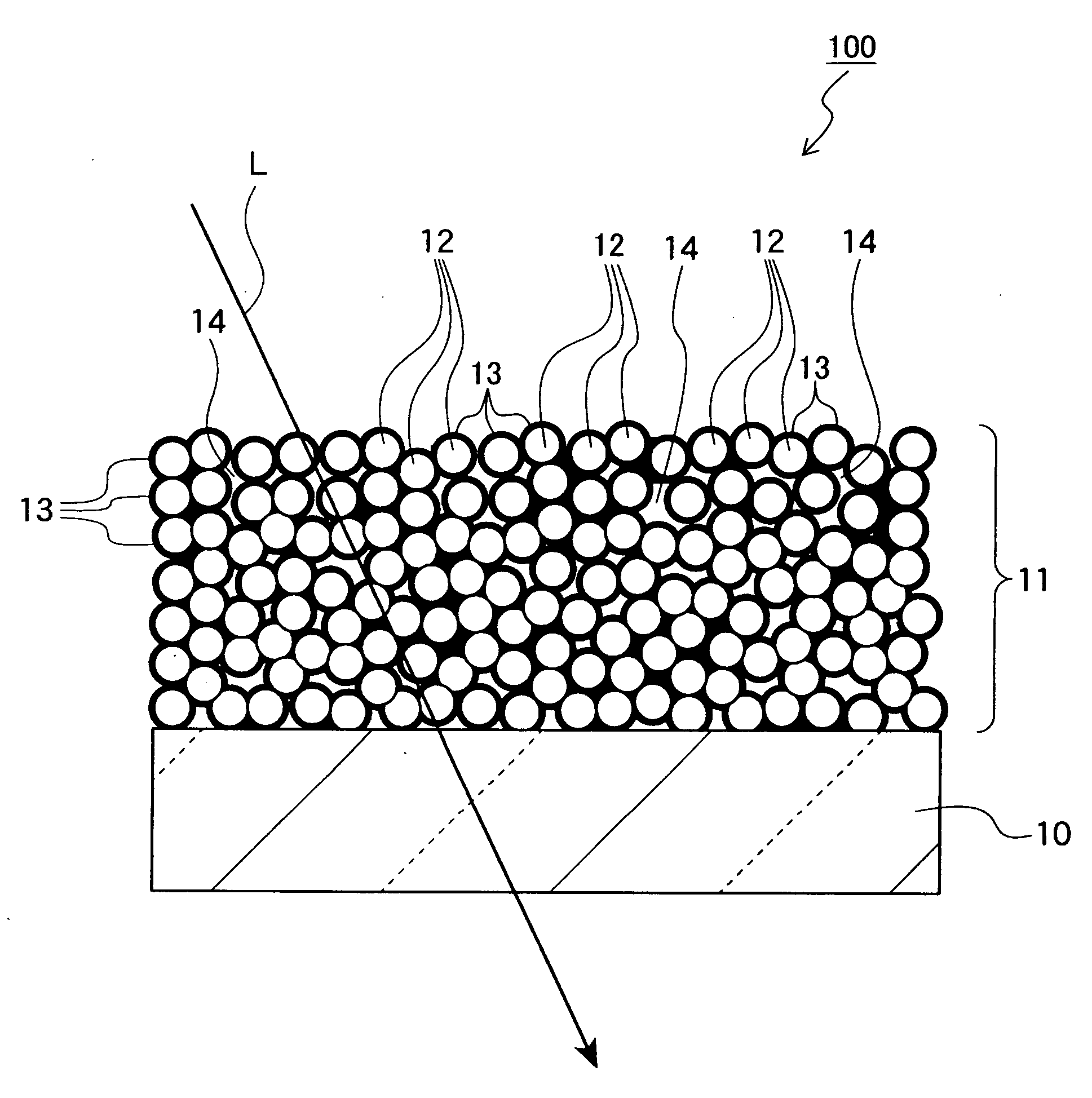

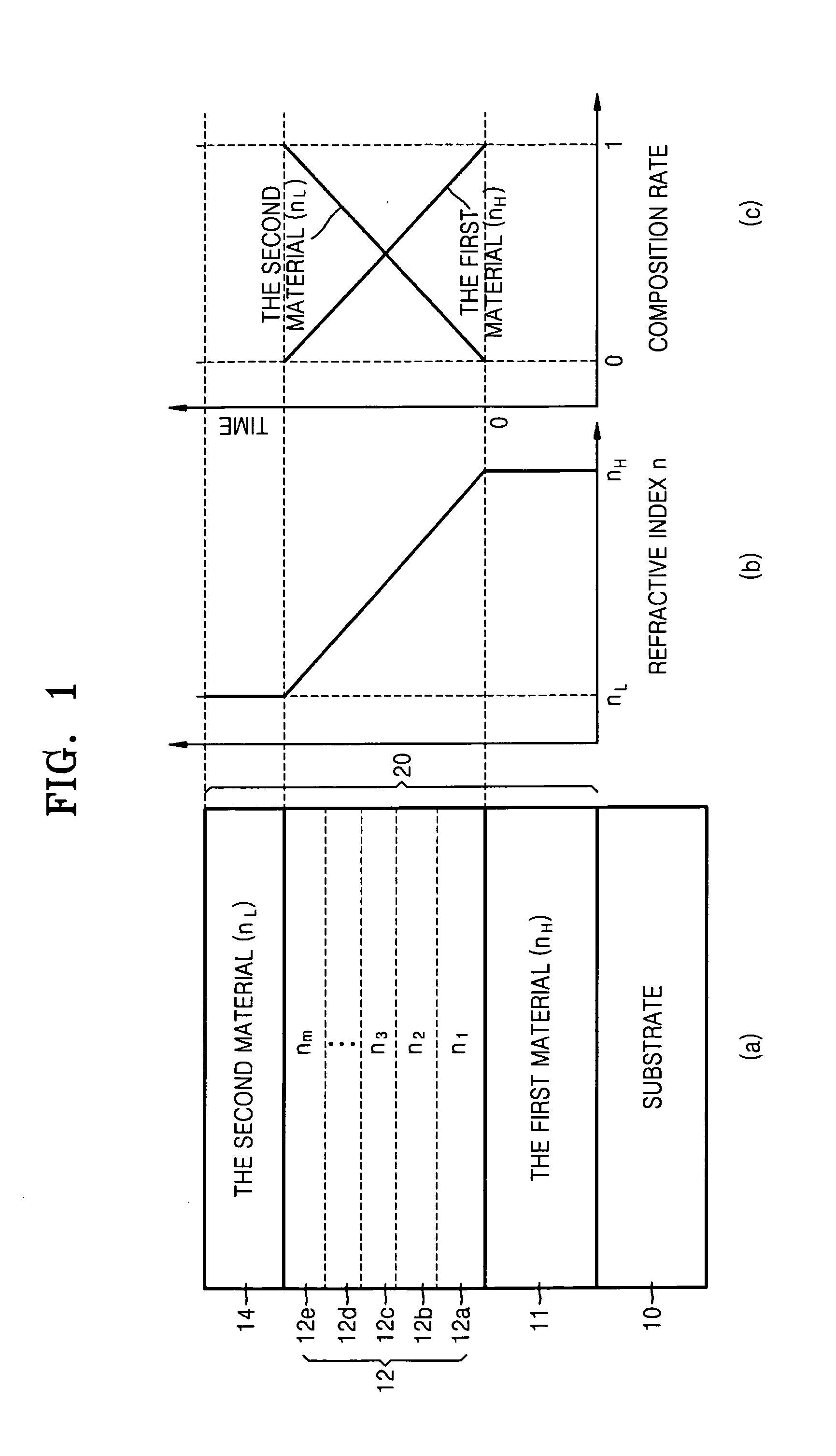

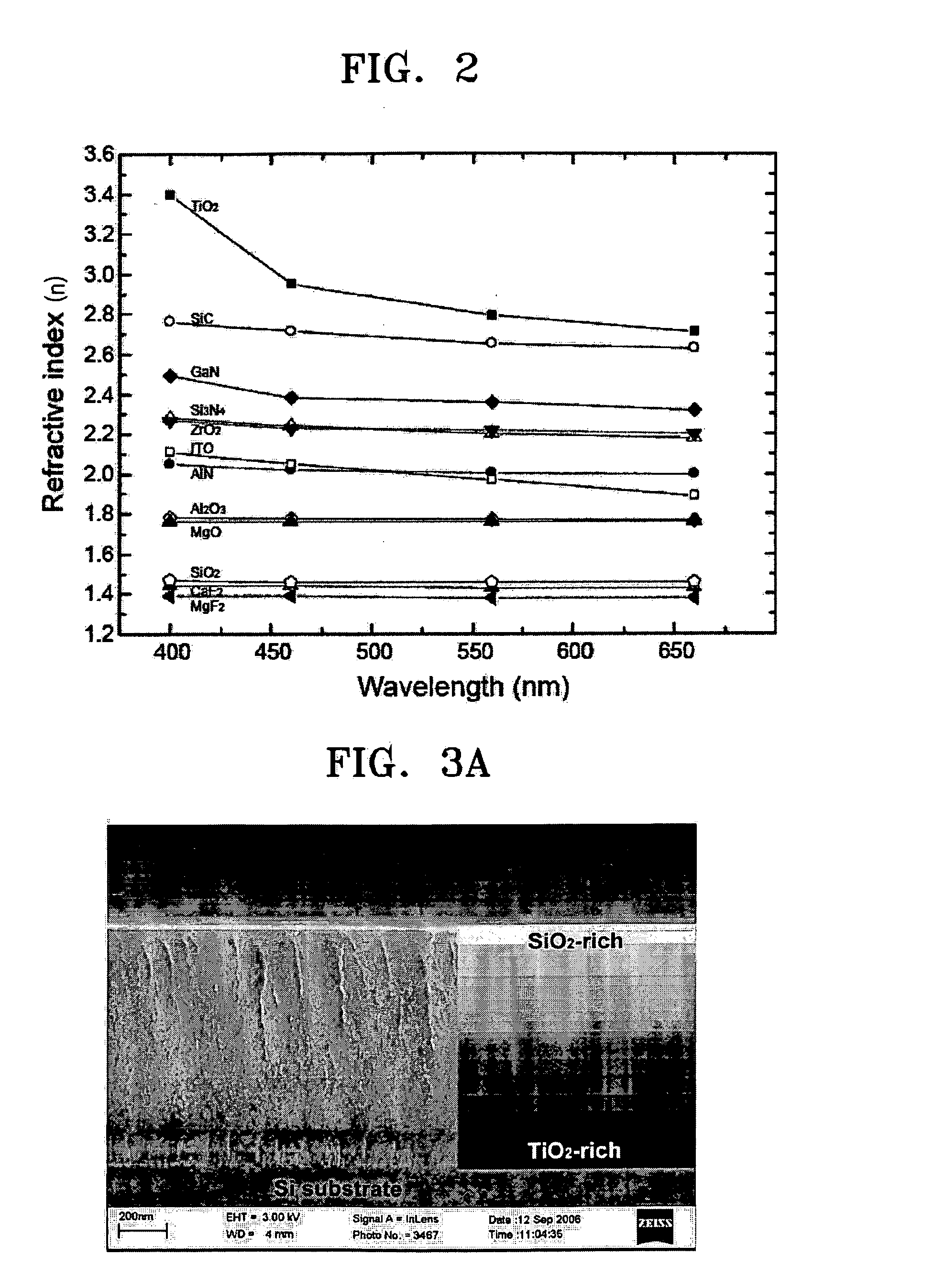

Optical thin film, semiconductor light emitting device having the same and methods of fabricating the same

ActiveUS20080088932A1Simple structureLight transmittance efficiency can be maximized and increasedOptical elementsOptical reflectionSemiconductor materials

Provided are a highly transmissive optical thin film having an improved structure, in which, optical reflection (due to a difference in the refractive index between a semiconductor material and the air, when light is extracted from a semiconductor light emitting device into the air) may be suppressed, an optical output loss may be reduced and light transmittance efficiency may be maximized or increased, a semiconductor light emitting device having the same, and methods of fabricating the same. The optical thin film may include a first material layer having a first refractive index, a second material layer formed on the first material layer and having a second refractive index that is smaller than the first refractive index, and a graded-refractive index layer interposed or inserted between the first material layer and the second material layer and having a multi-layer structure in which refractive index distribution gradually decreases in the range between the first refractive index and the second refractive index as the refractive index distribution progresses from the first material layer toward the second material layer.

Owner:RENESSELAER POLYTECHNIC INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com