Patents

Literature

3203results about "Adhesive processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

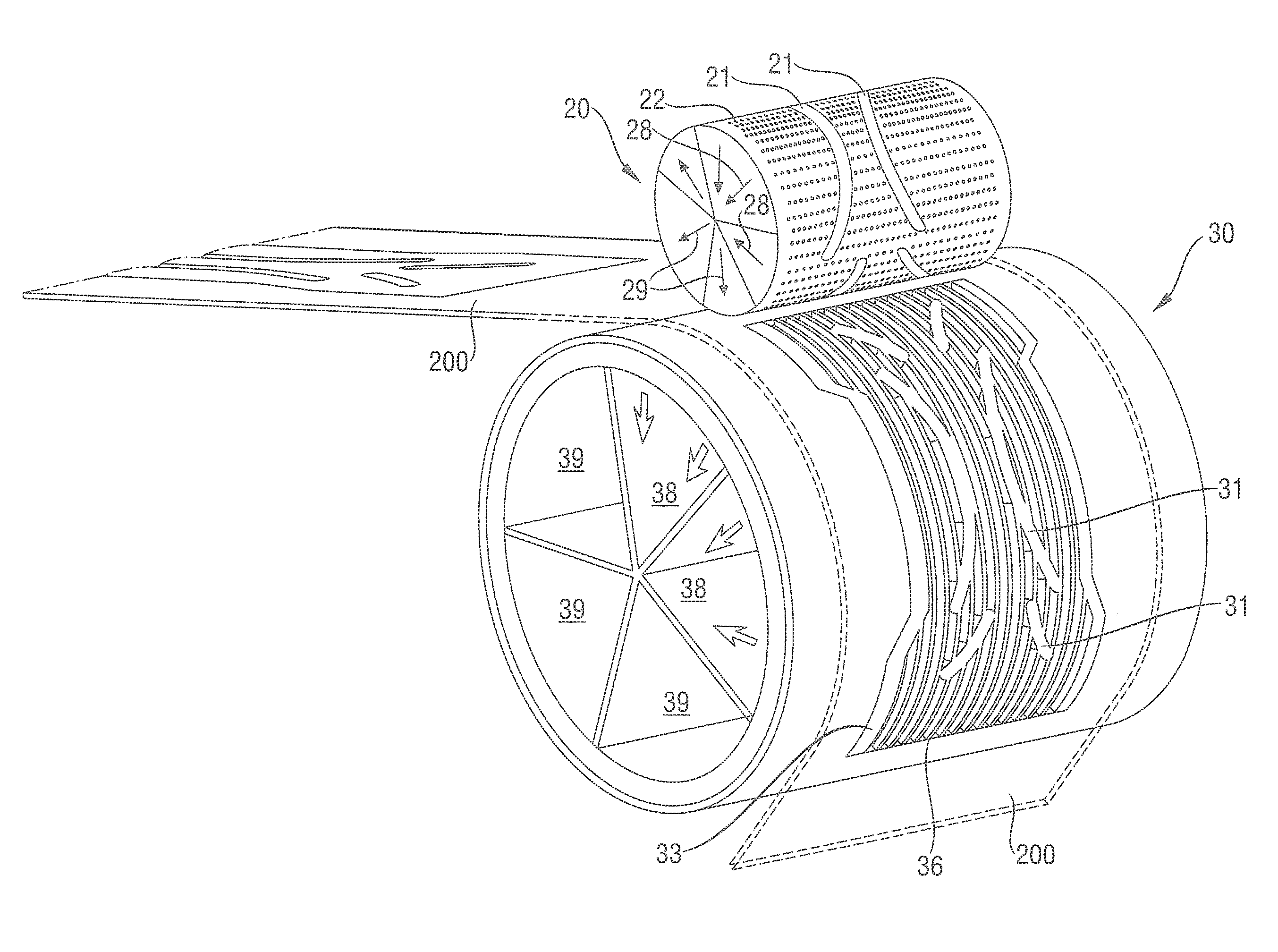

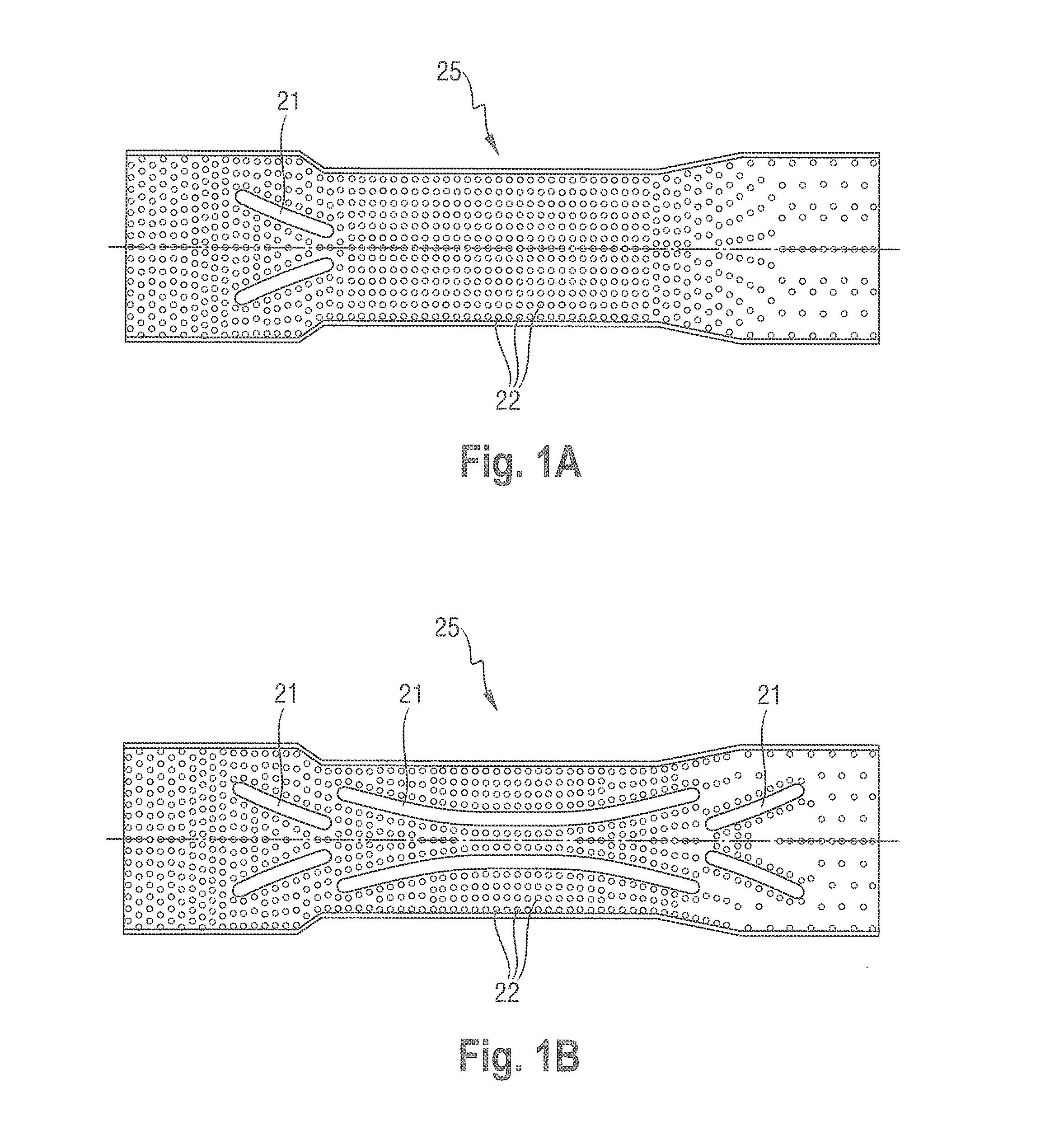

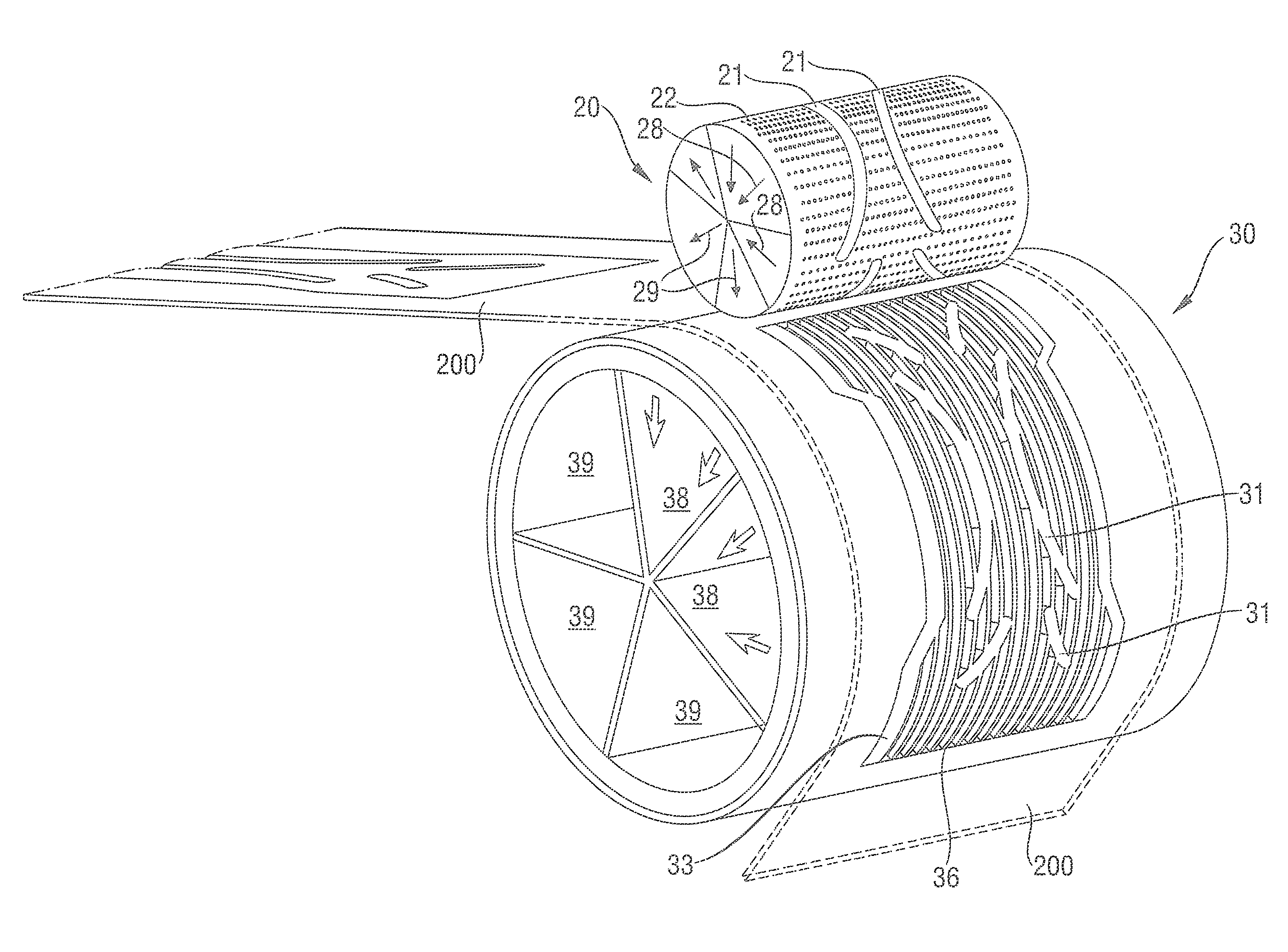

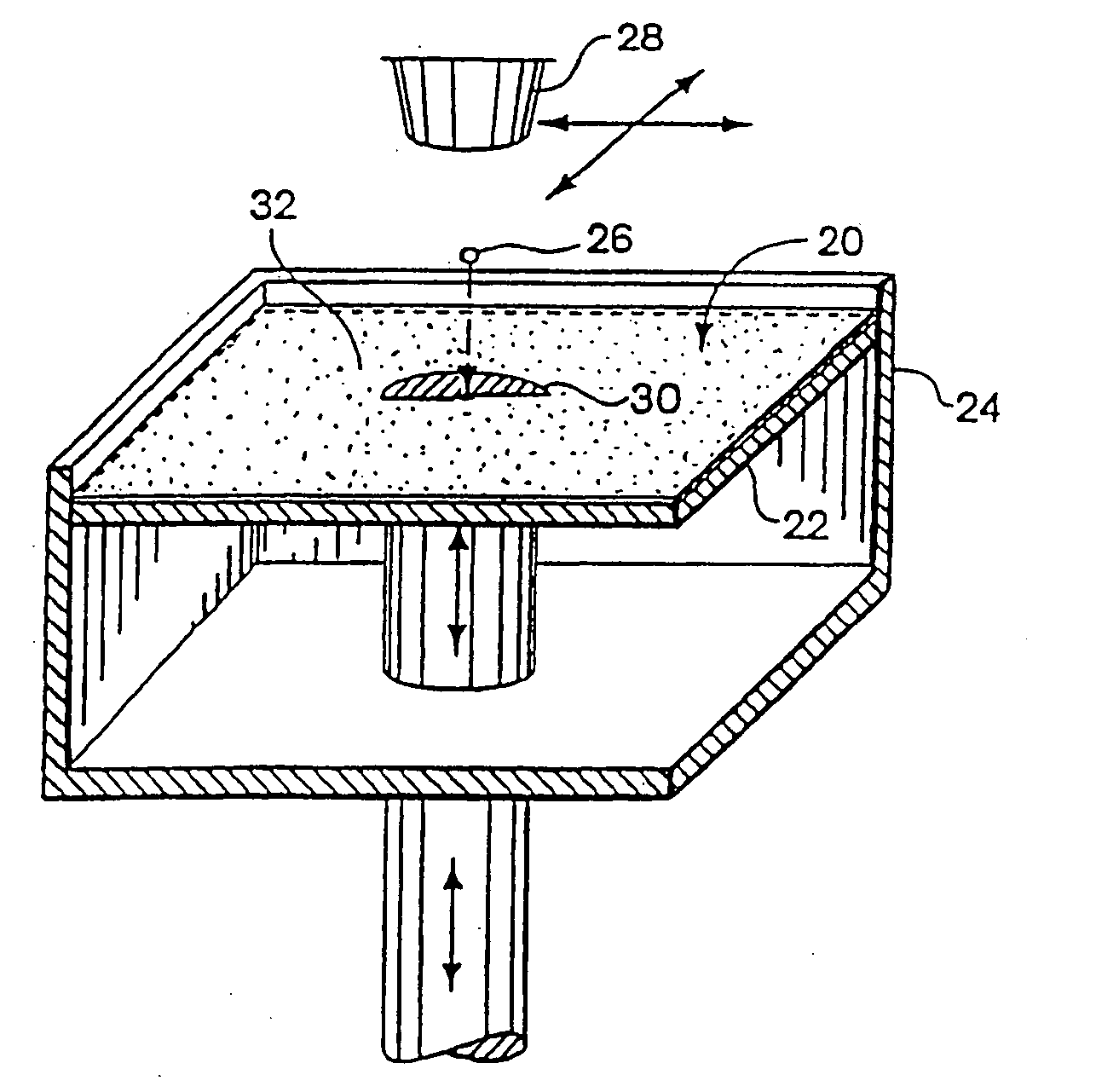

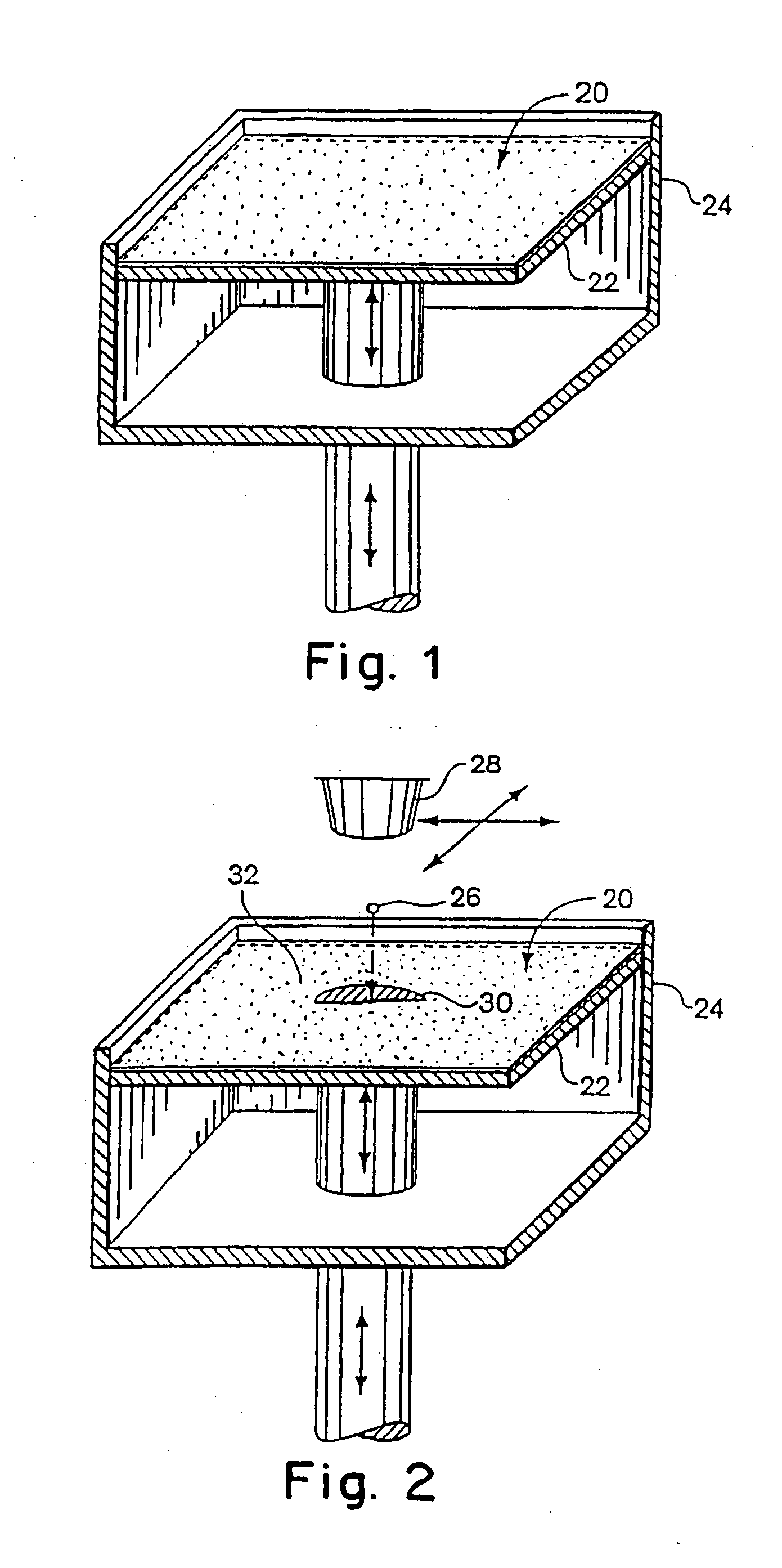

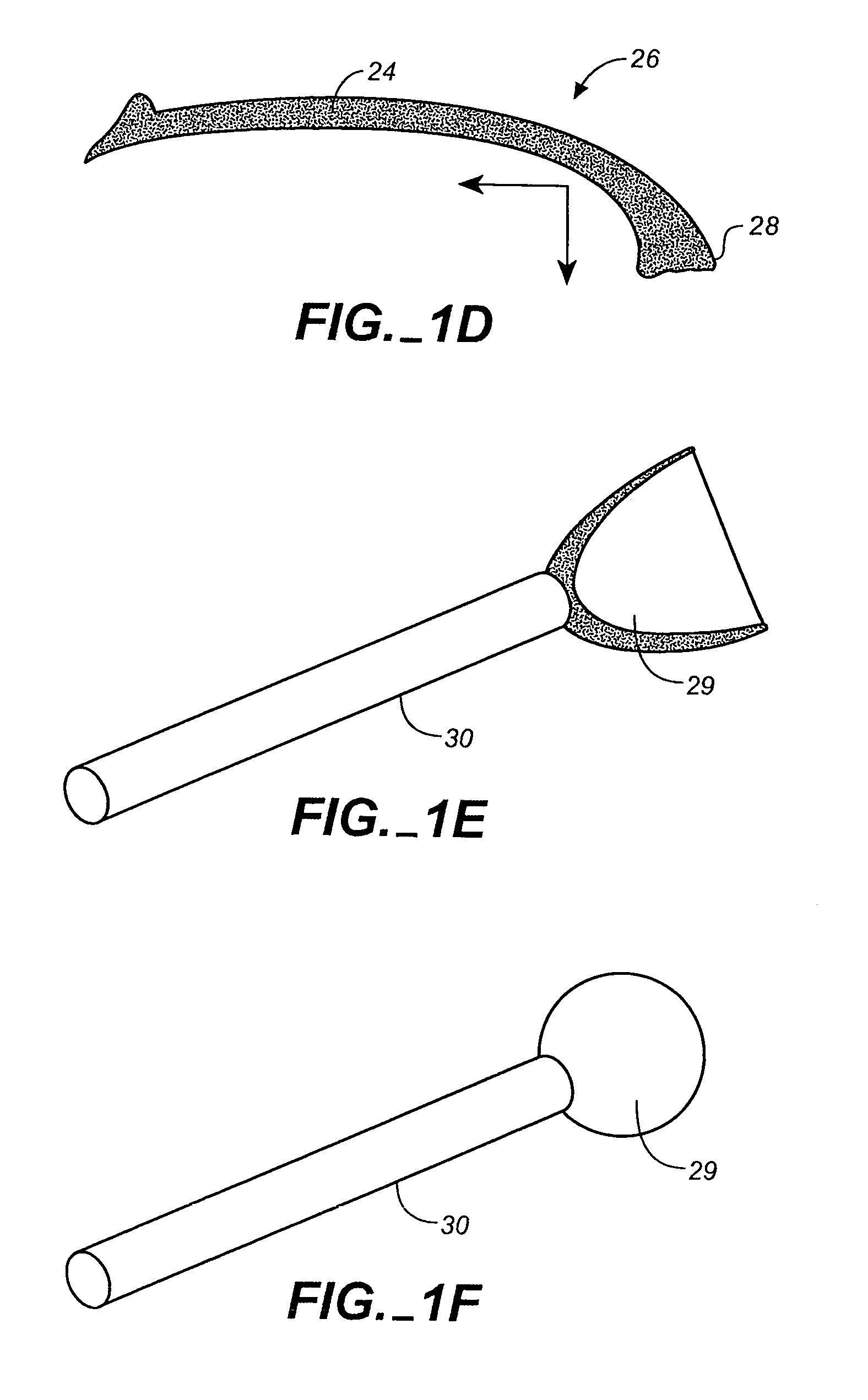

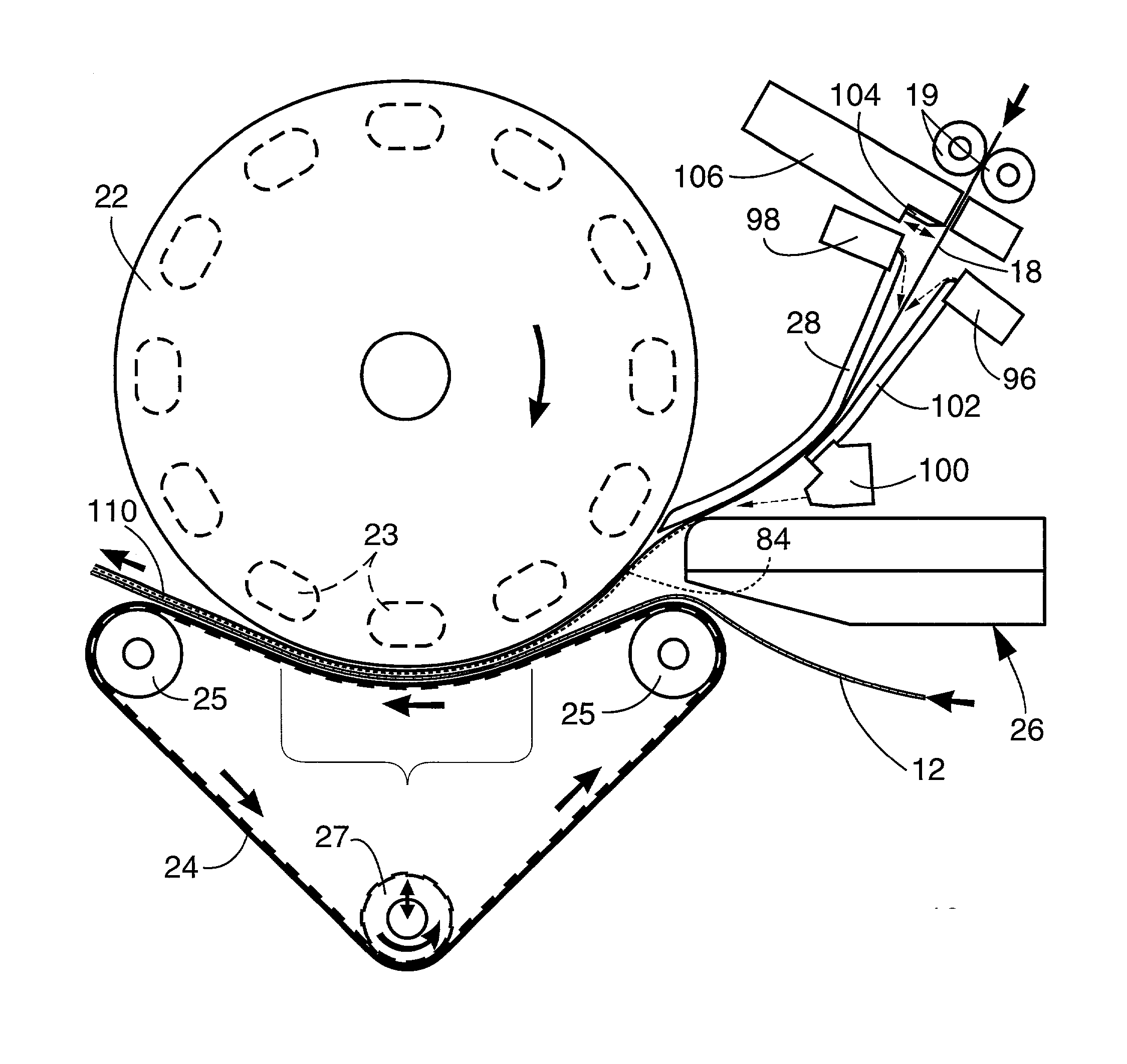

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

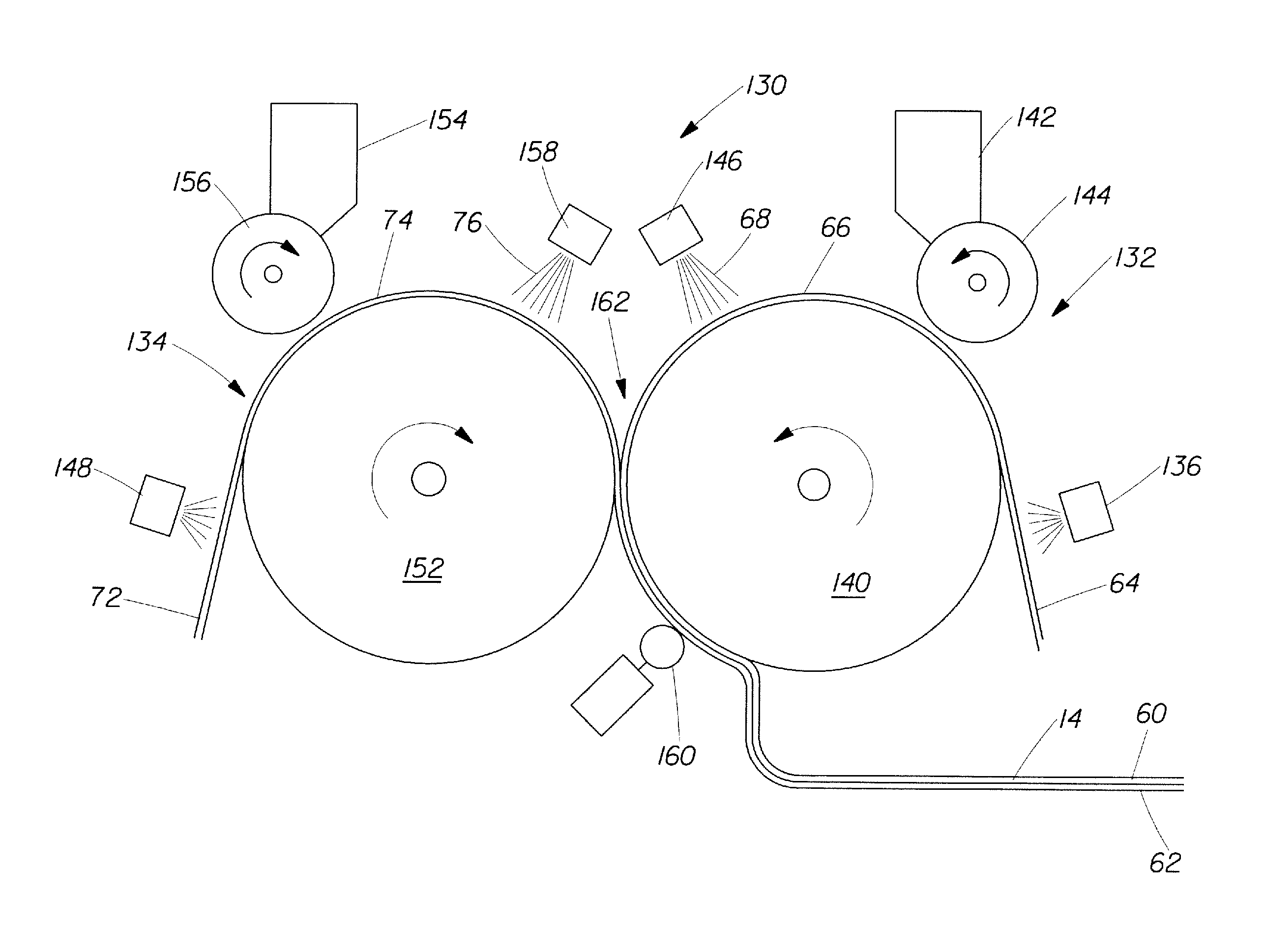

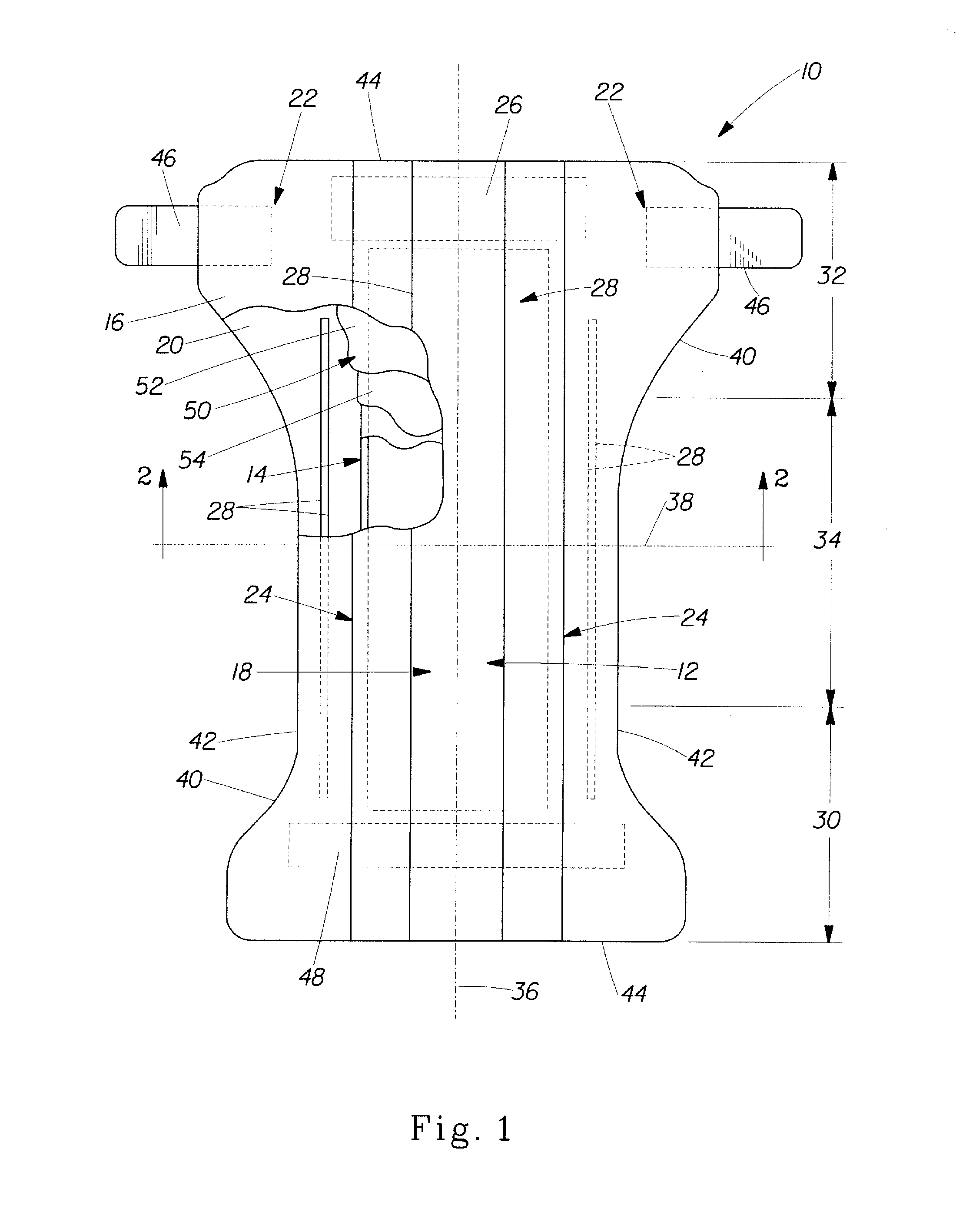

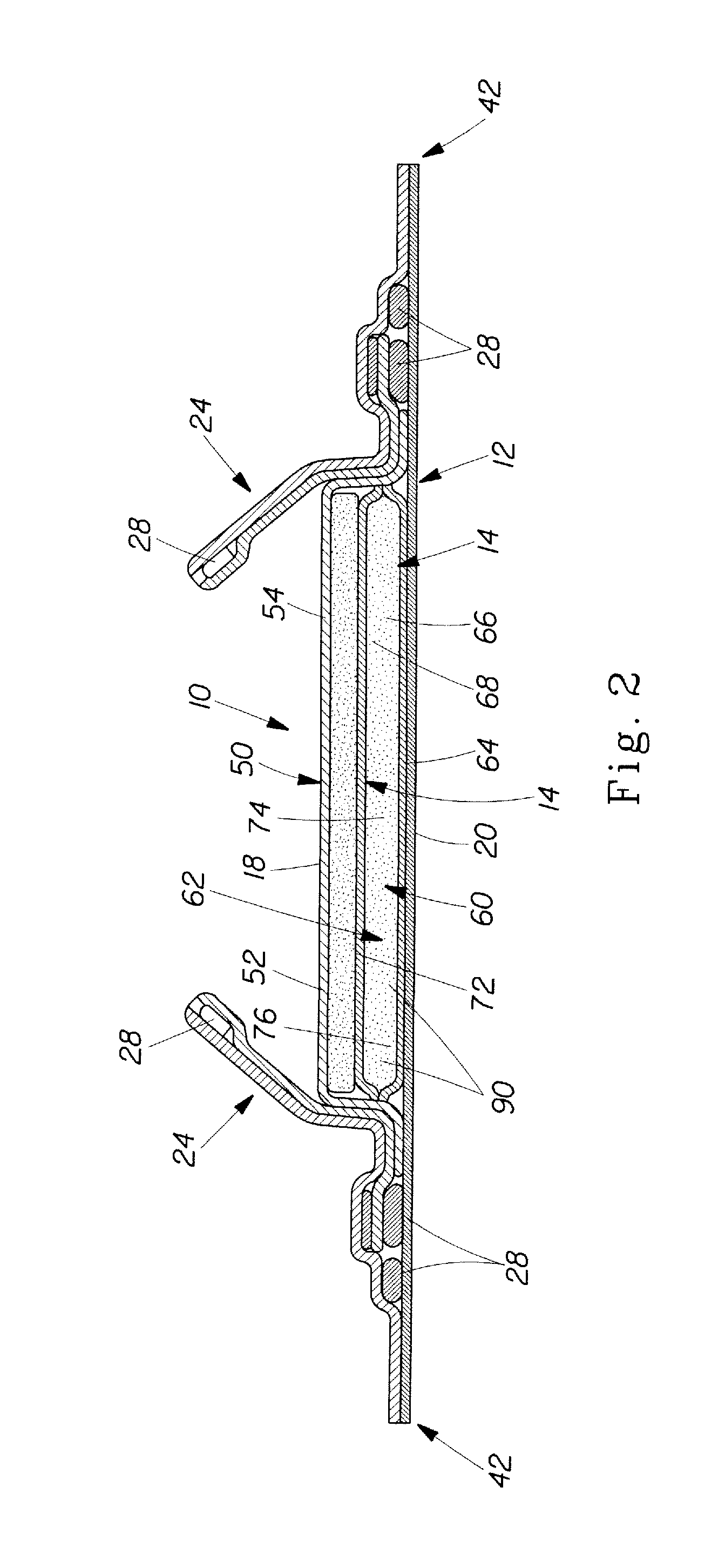

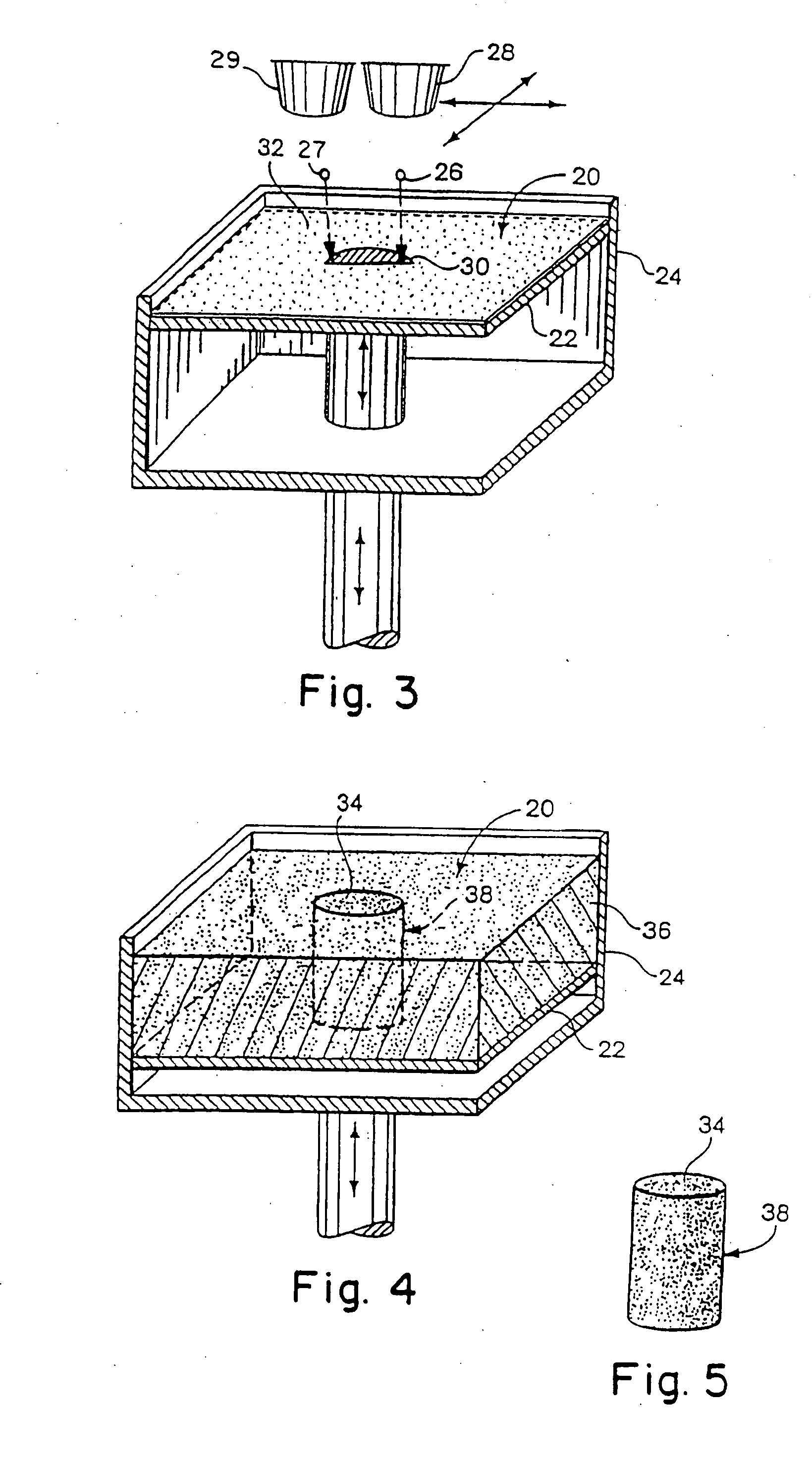

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

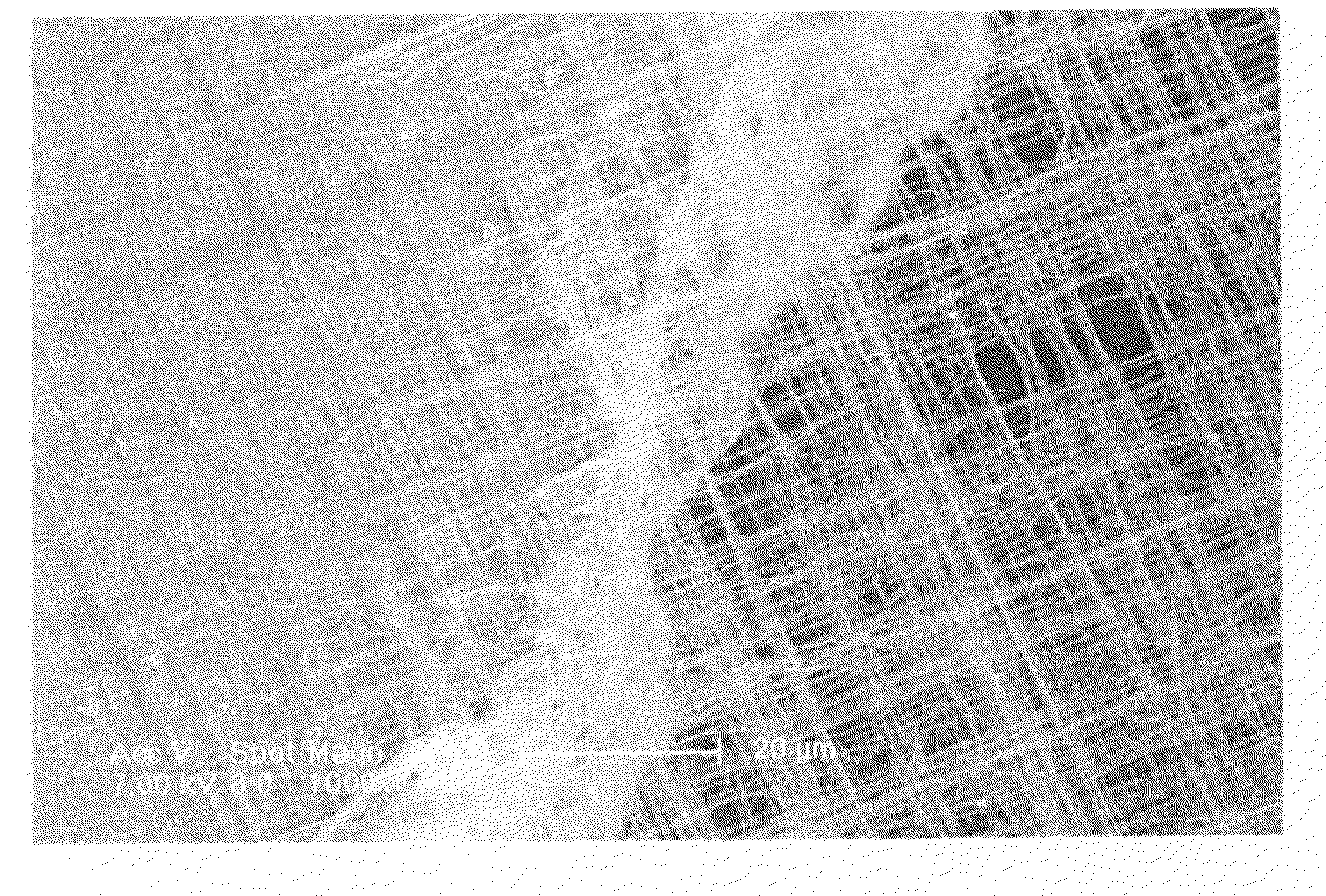

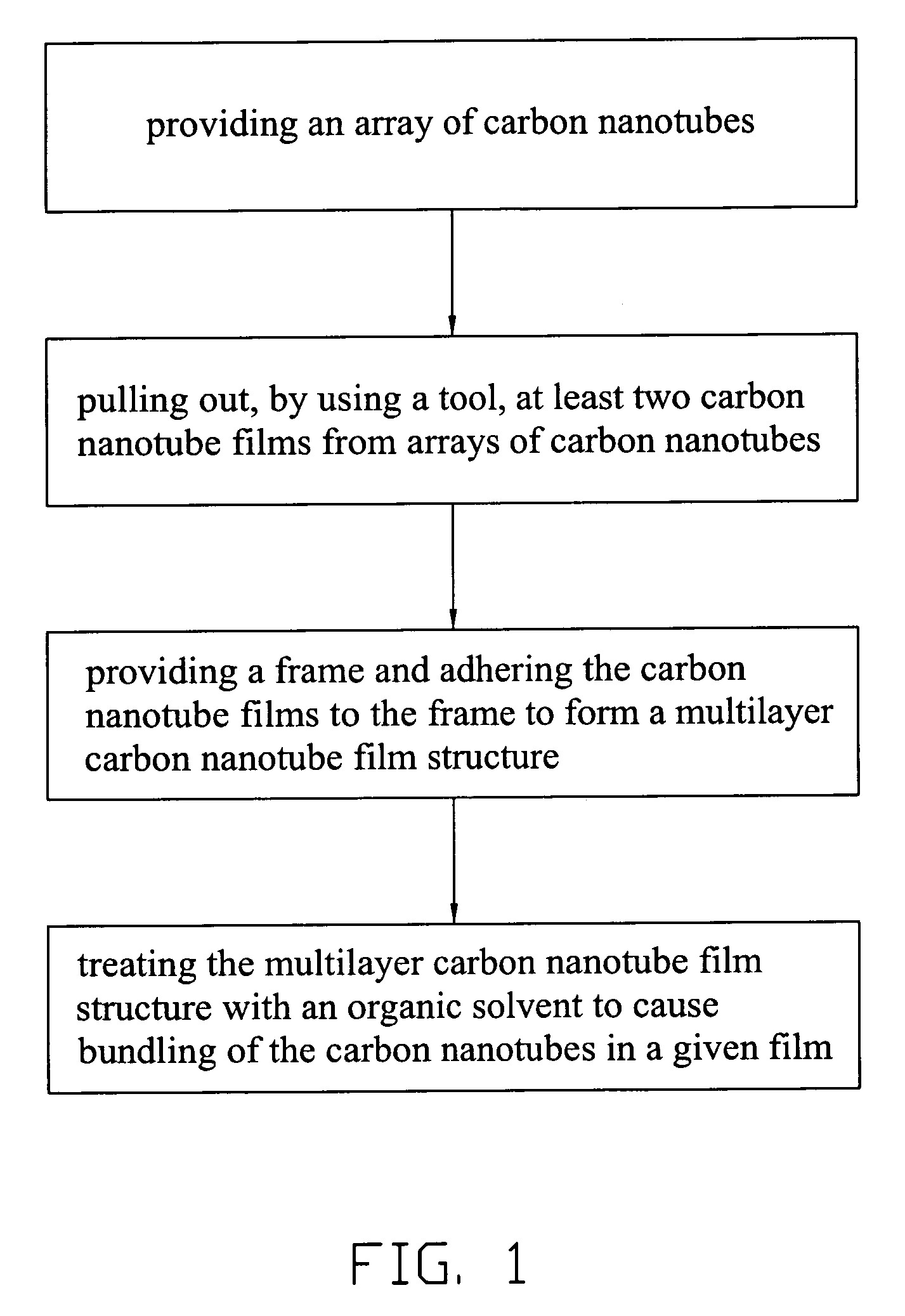

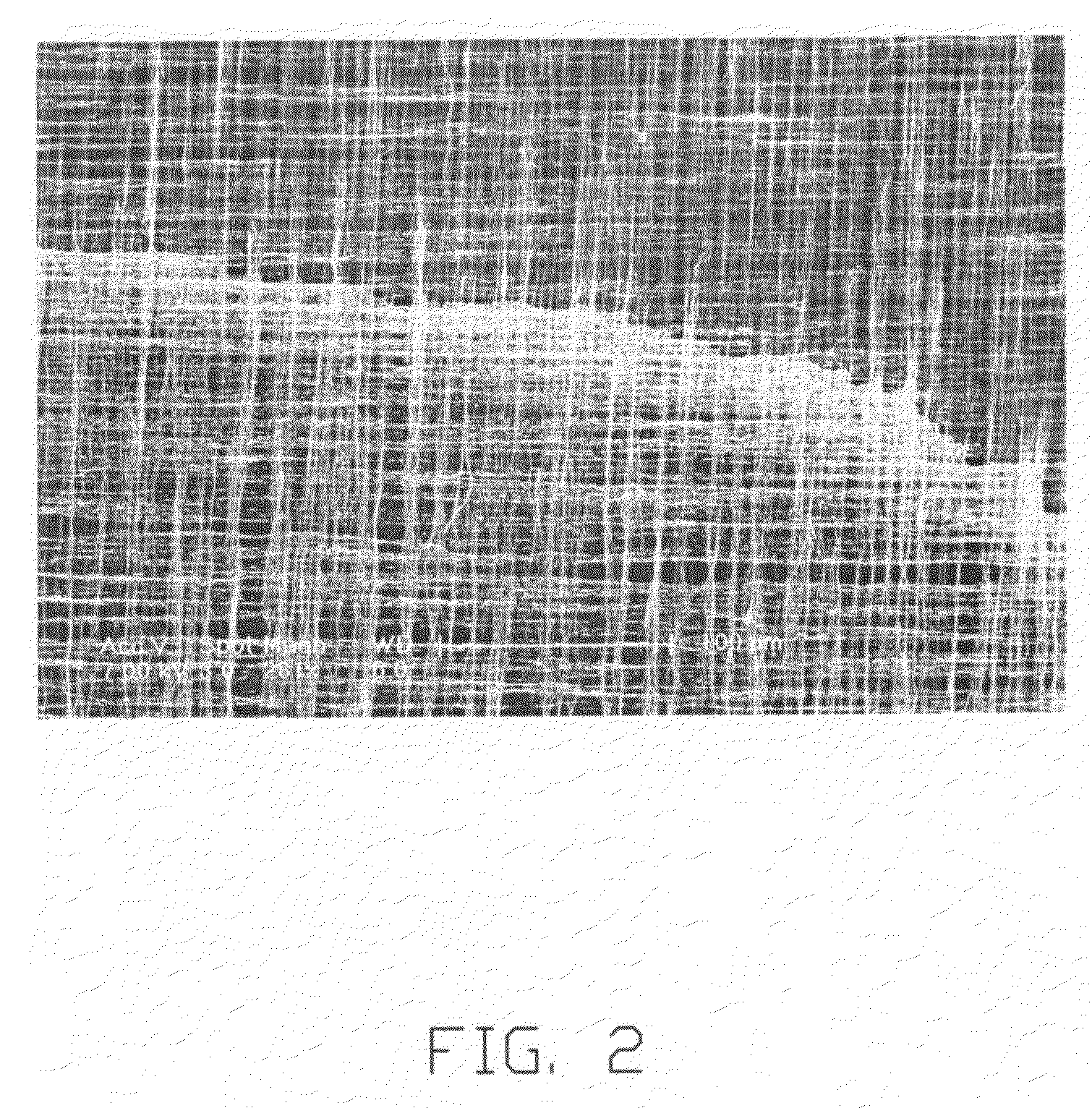

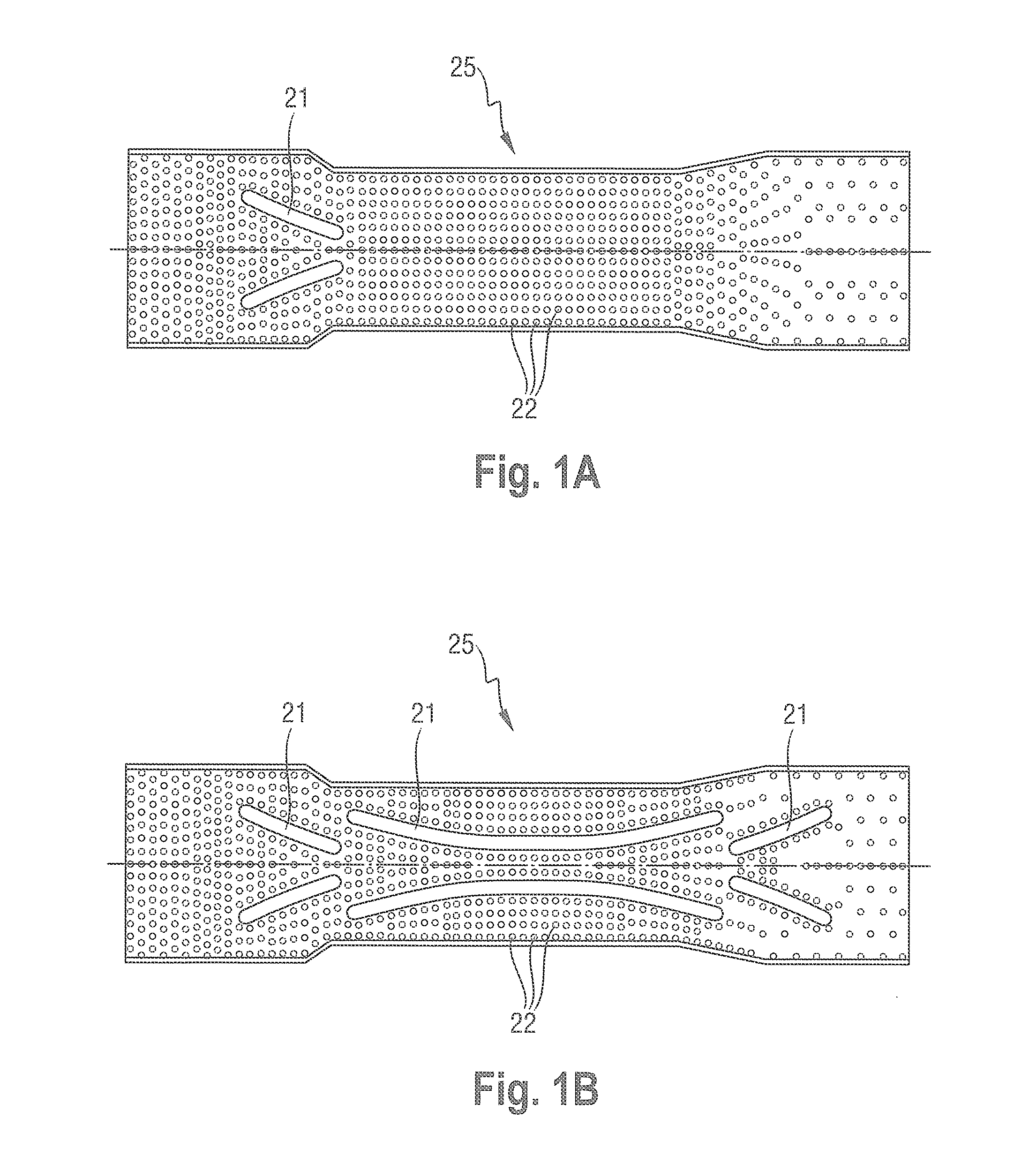

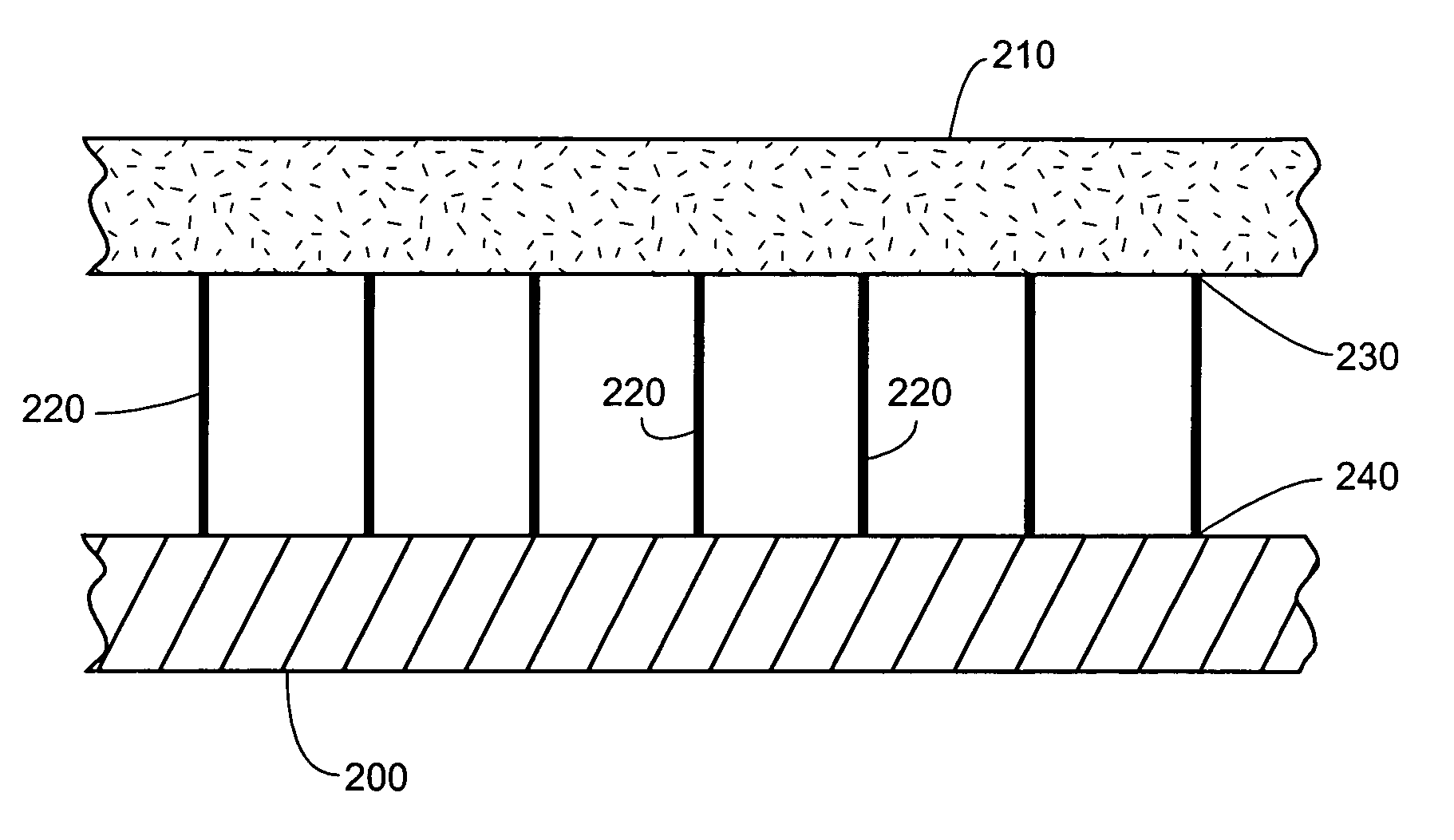

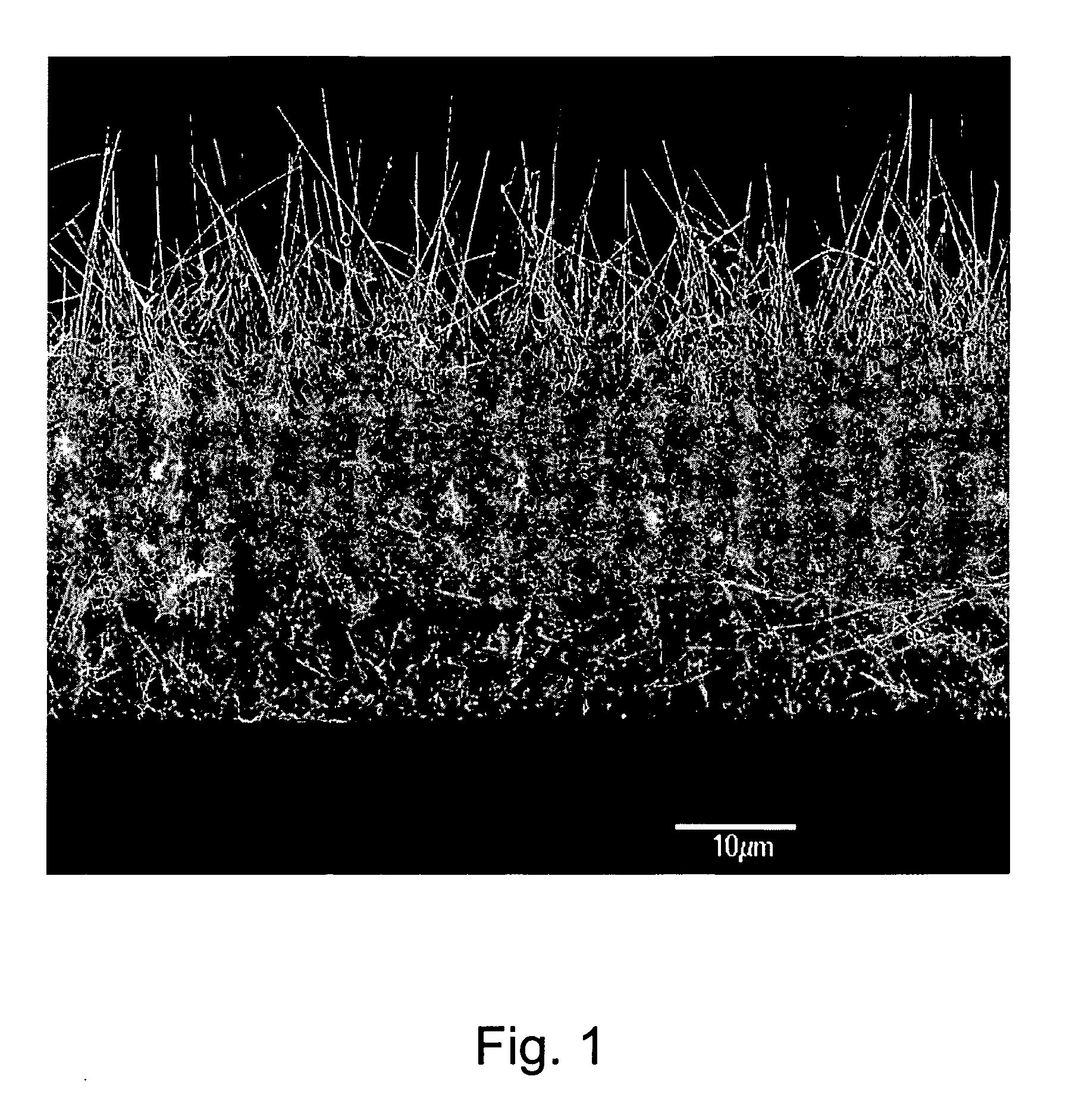

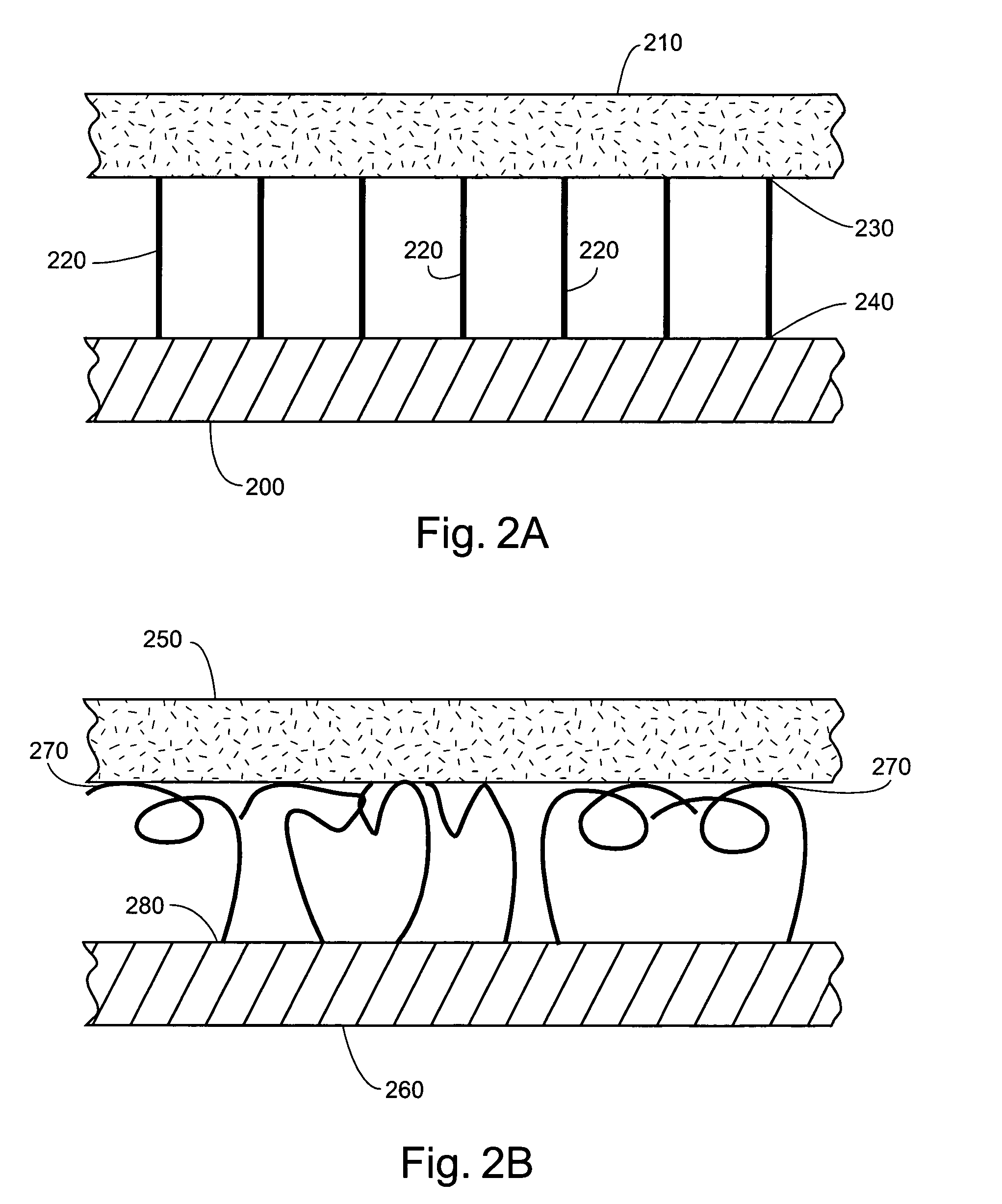

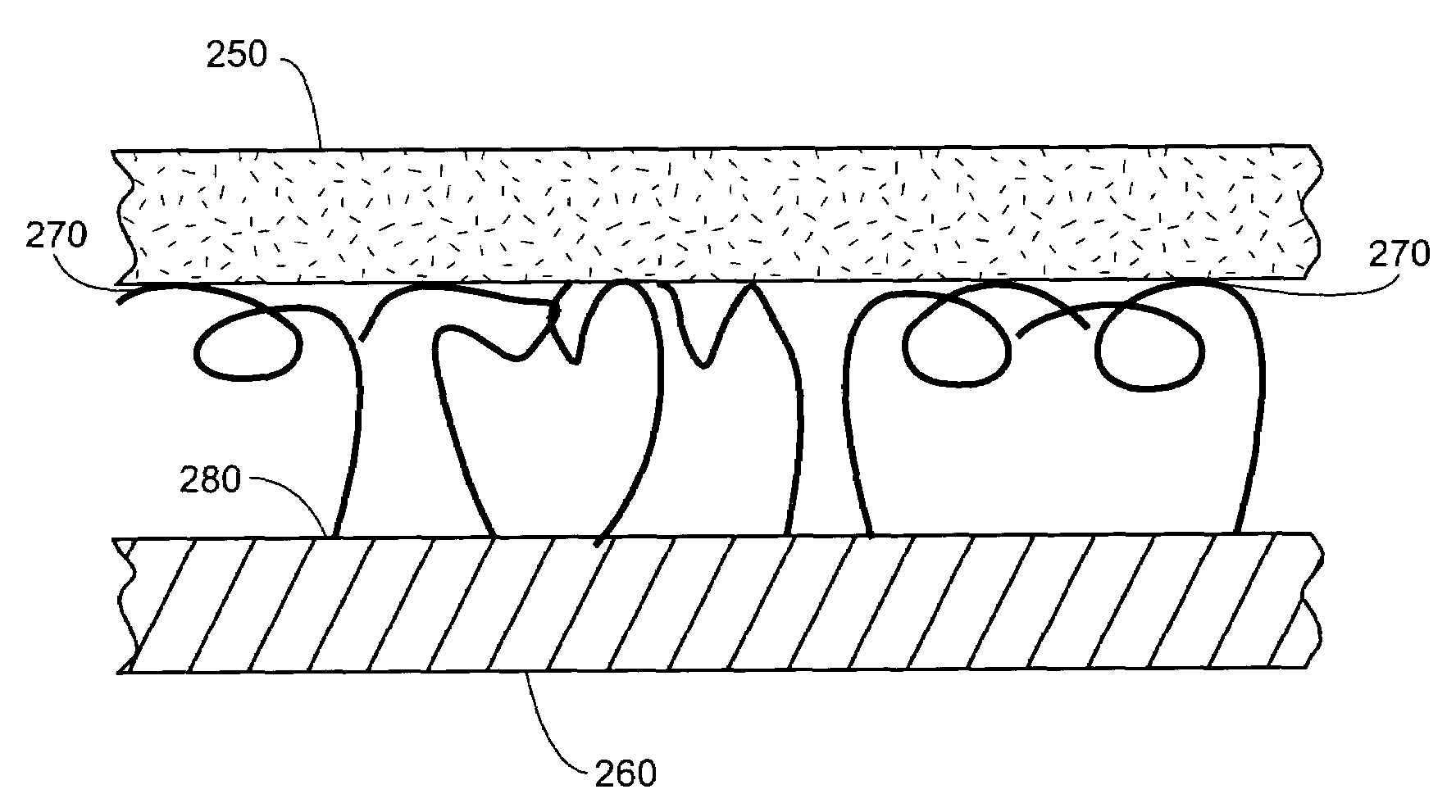

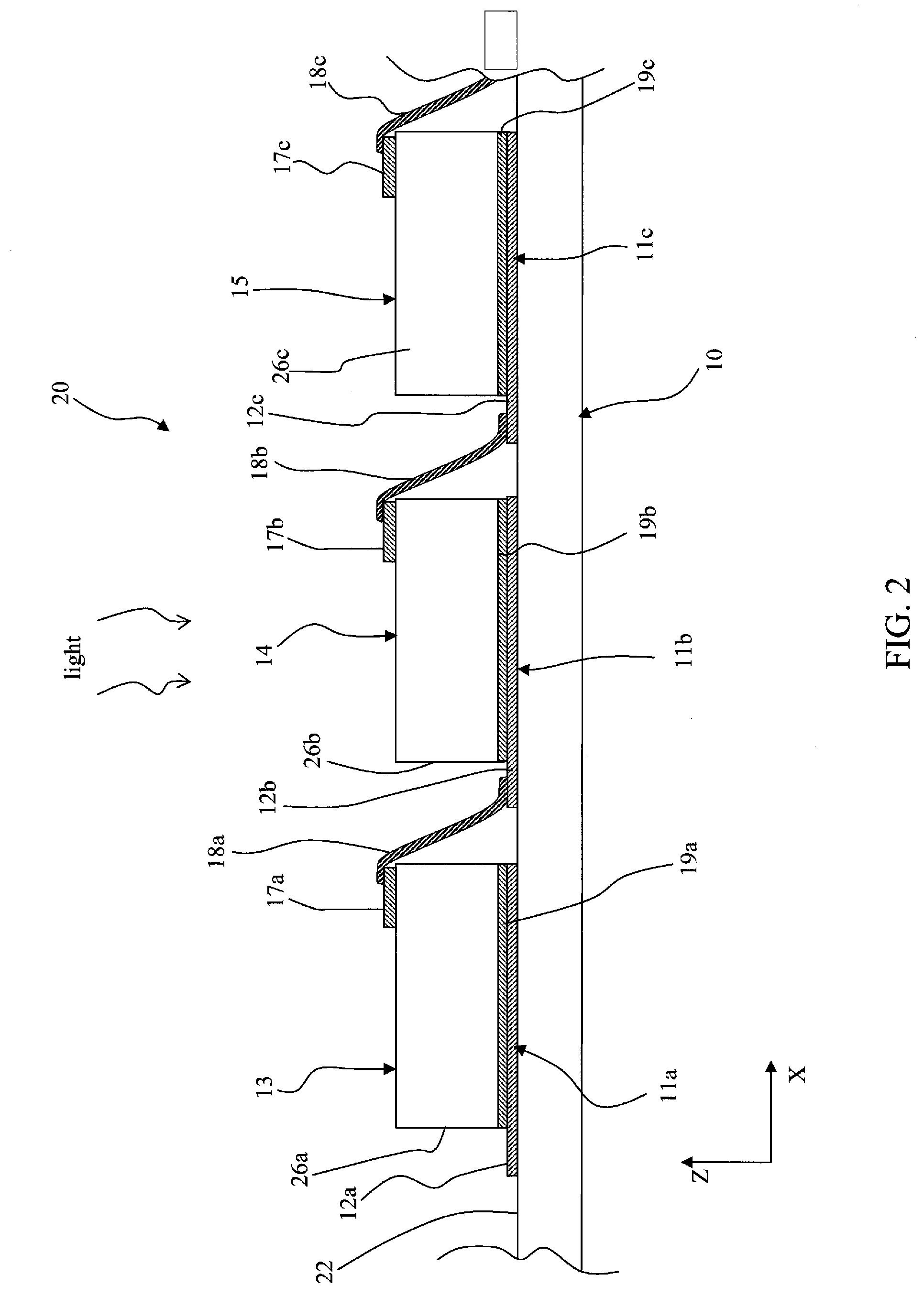

Carbon nanotube film structure and method for fabricating the same

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

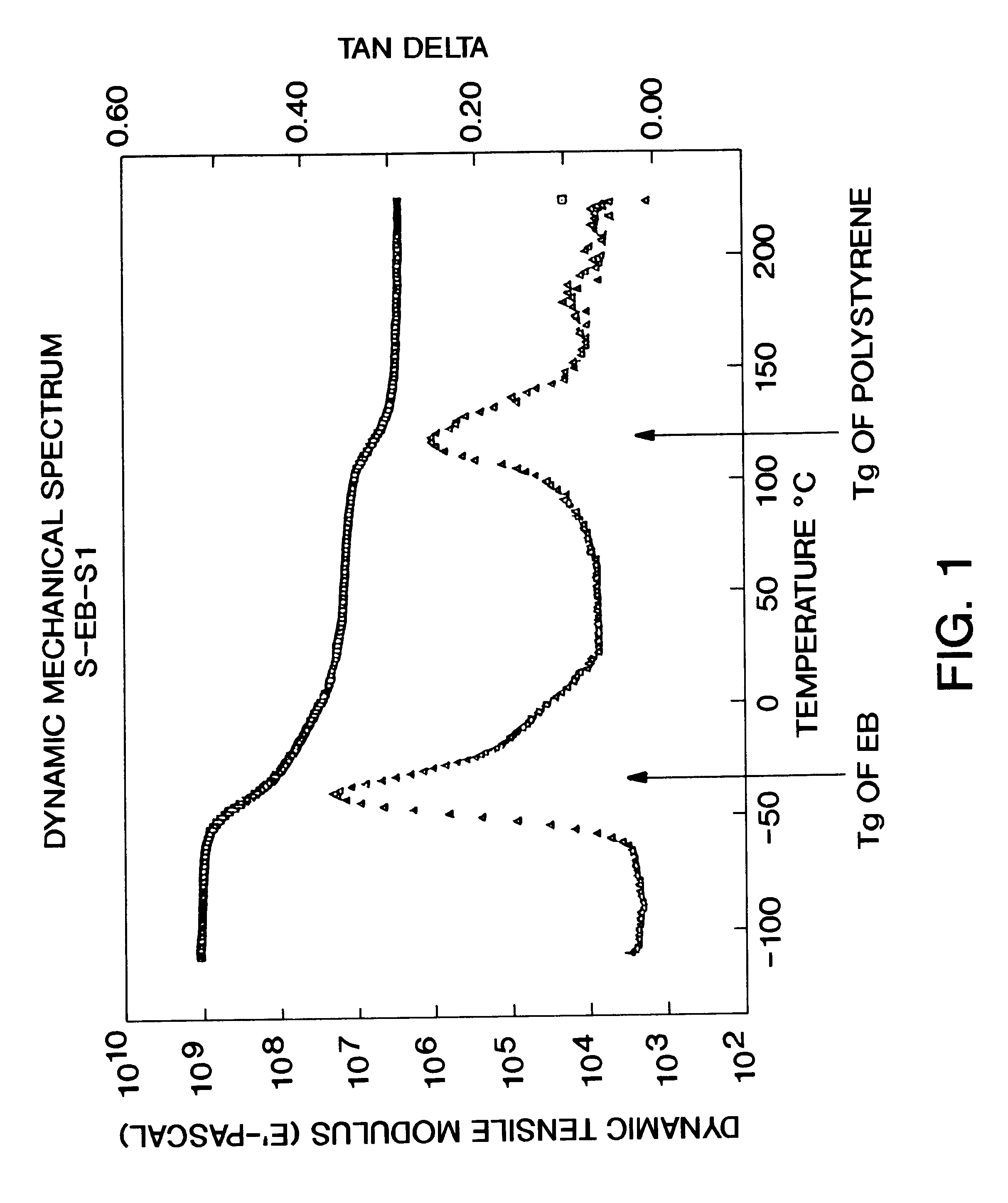

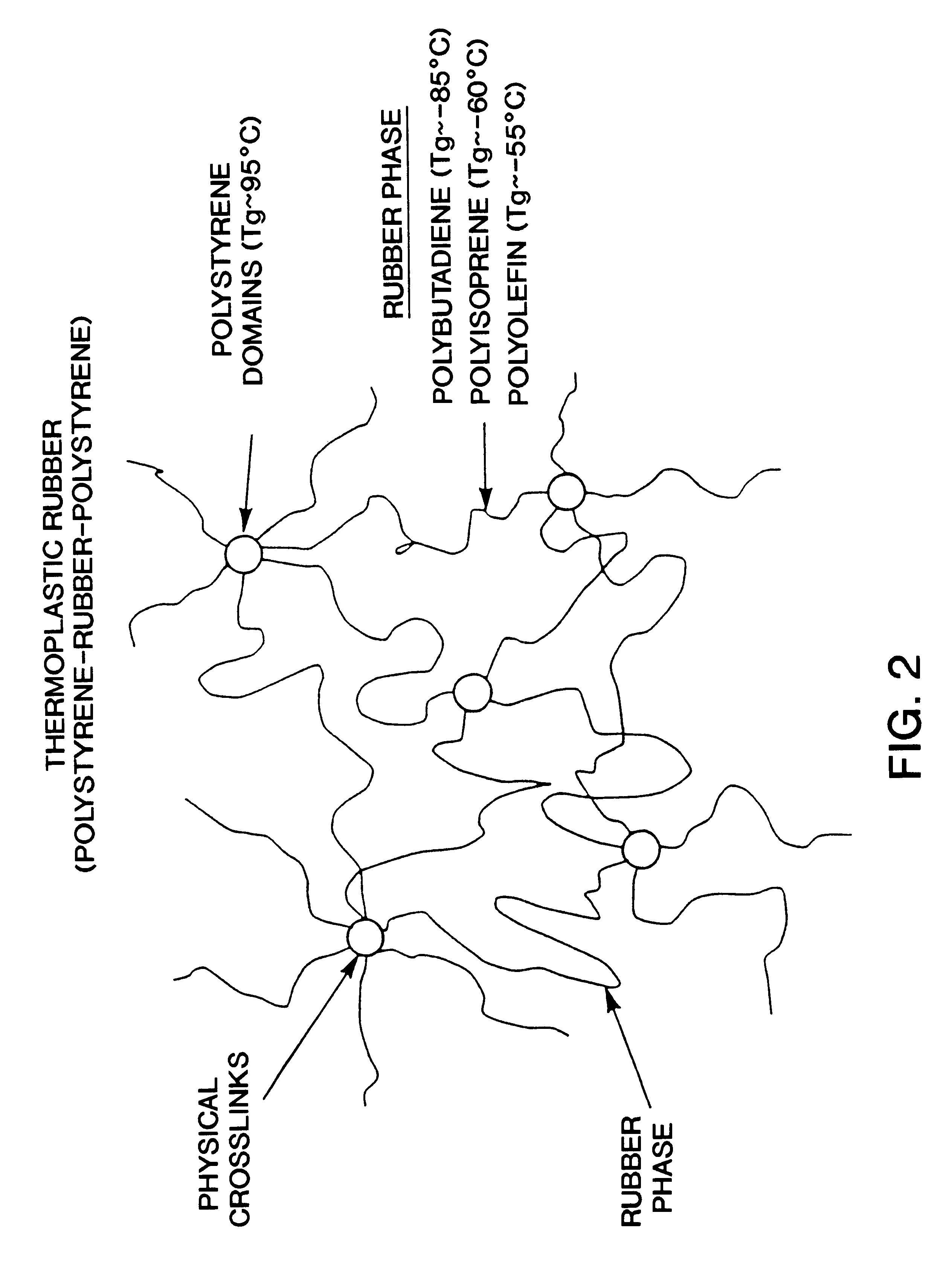

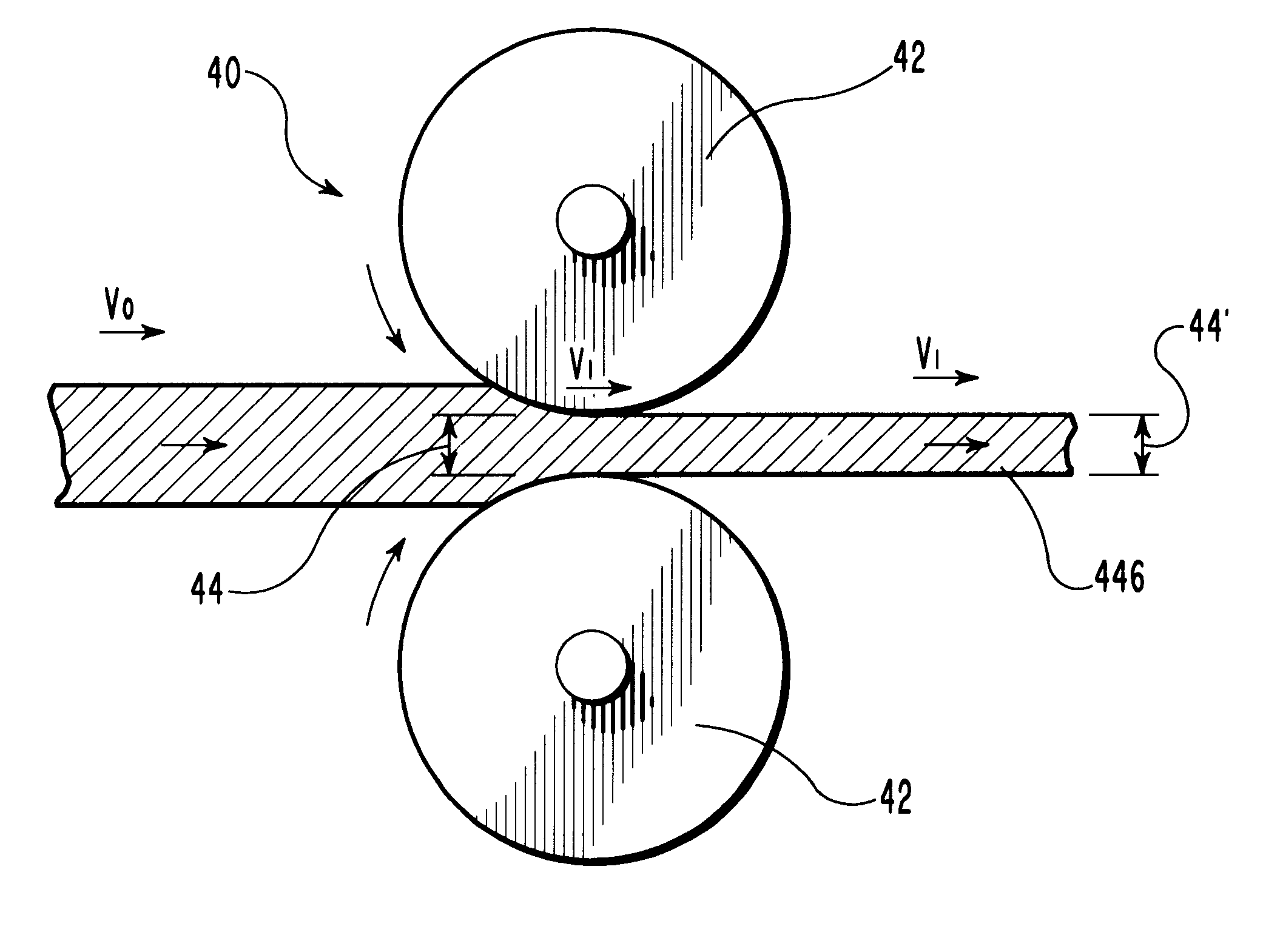

Dimensionally stable, breathable, stretch-thinned, elastic films

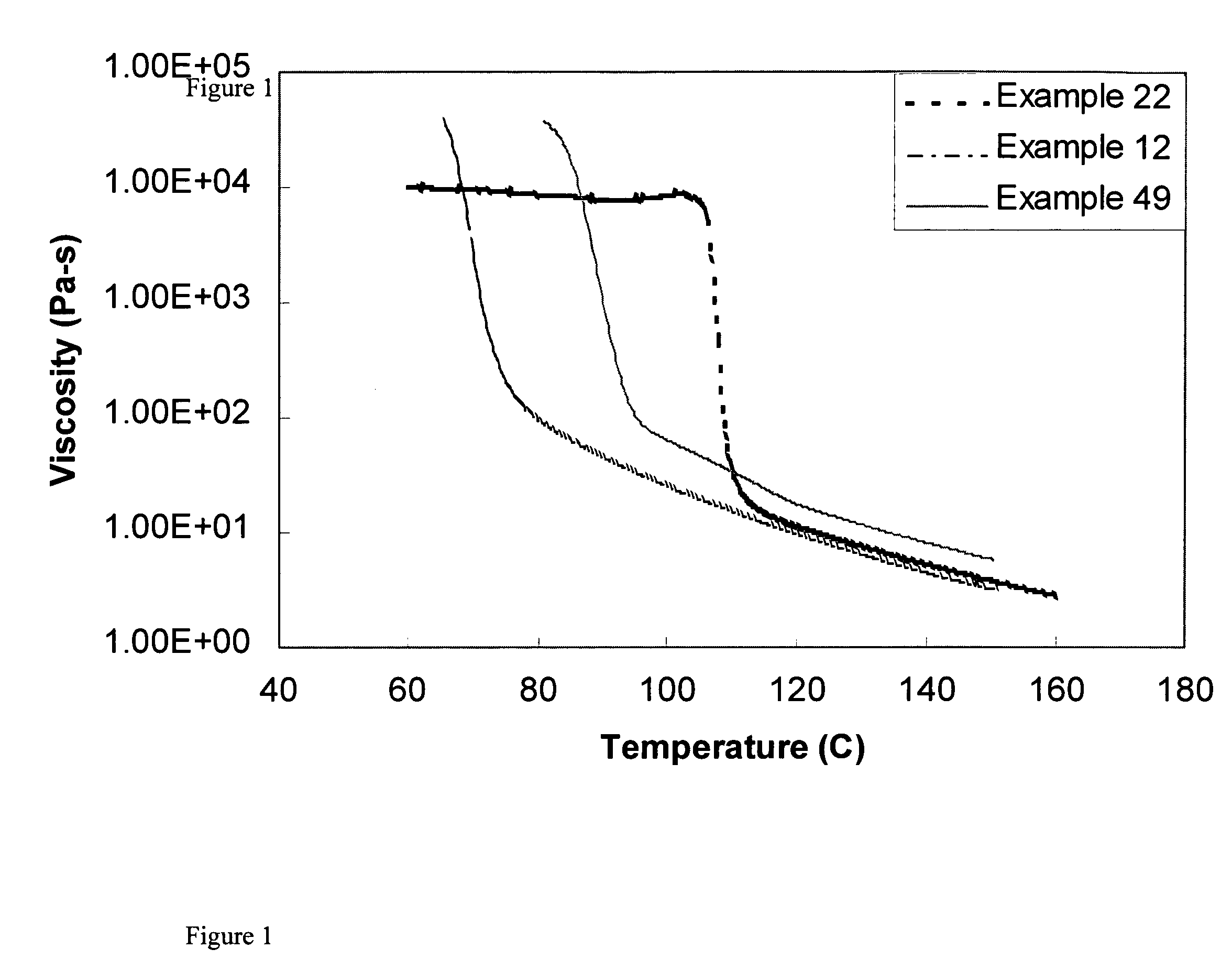

A method for producing a stretch-thinned elastic article having dimensional stability over time and at elevated temperatures in which a thermoplastic block copolymer is melt-processed into a stretchable article such as a film or fiber. The article is then conditioned at an elevated temperature greater than or equal to a glass transition temperature (Tg) of a hard phase of the thermoplastic block copolymer. The article is stretch-thinned at the elevated temperature to a desired percentage stretch, forming a stretch-thinned article, after which it is cooled to a temperature below the glass transition temperature of the hard phase of the thermoplastic block copolymer. Films produced by this method are suitable for use in durable and disposable articles including personal care articles such as diapers, incontinence wear, training pants, and feminine care articles, as well as wound dressings, wipes, towels, napkins, and protective apparel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

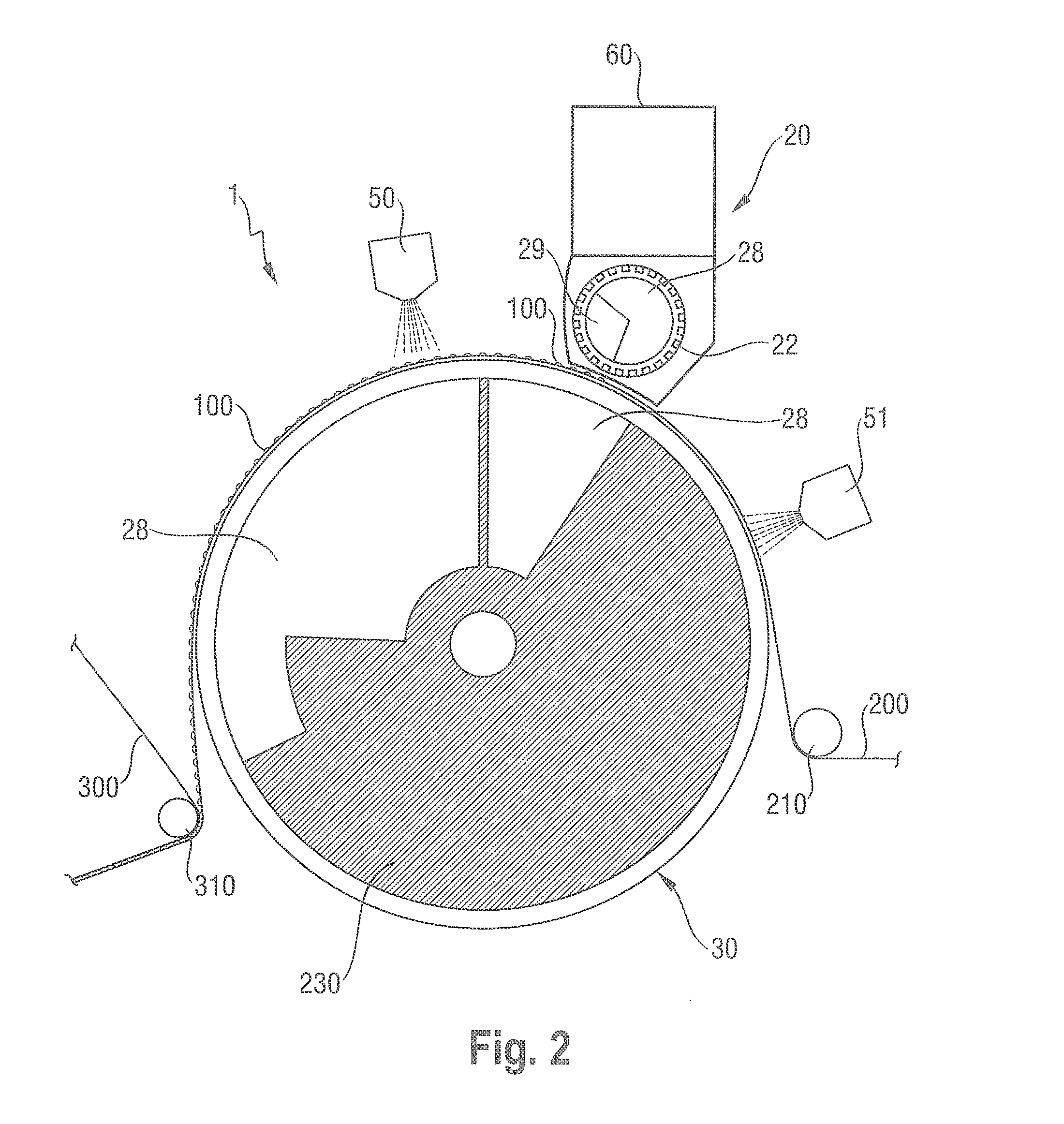

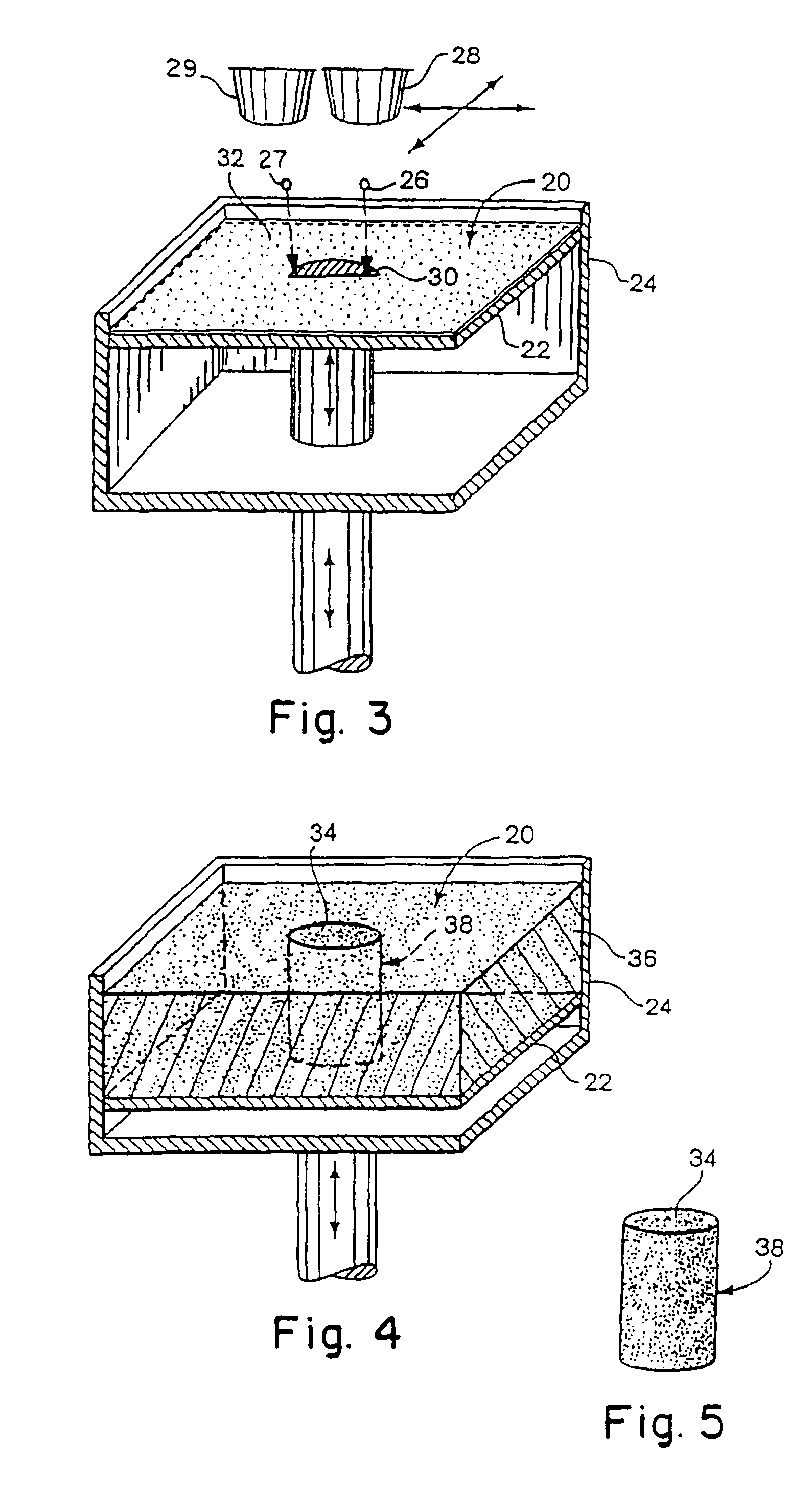

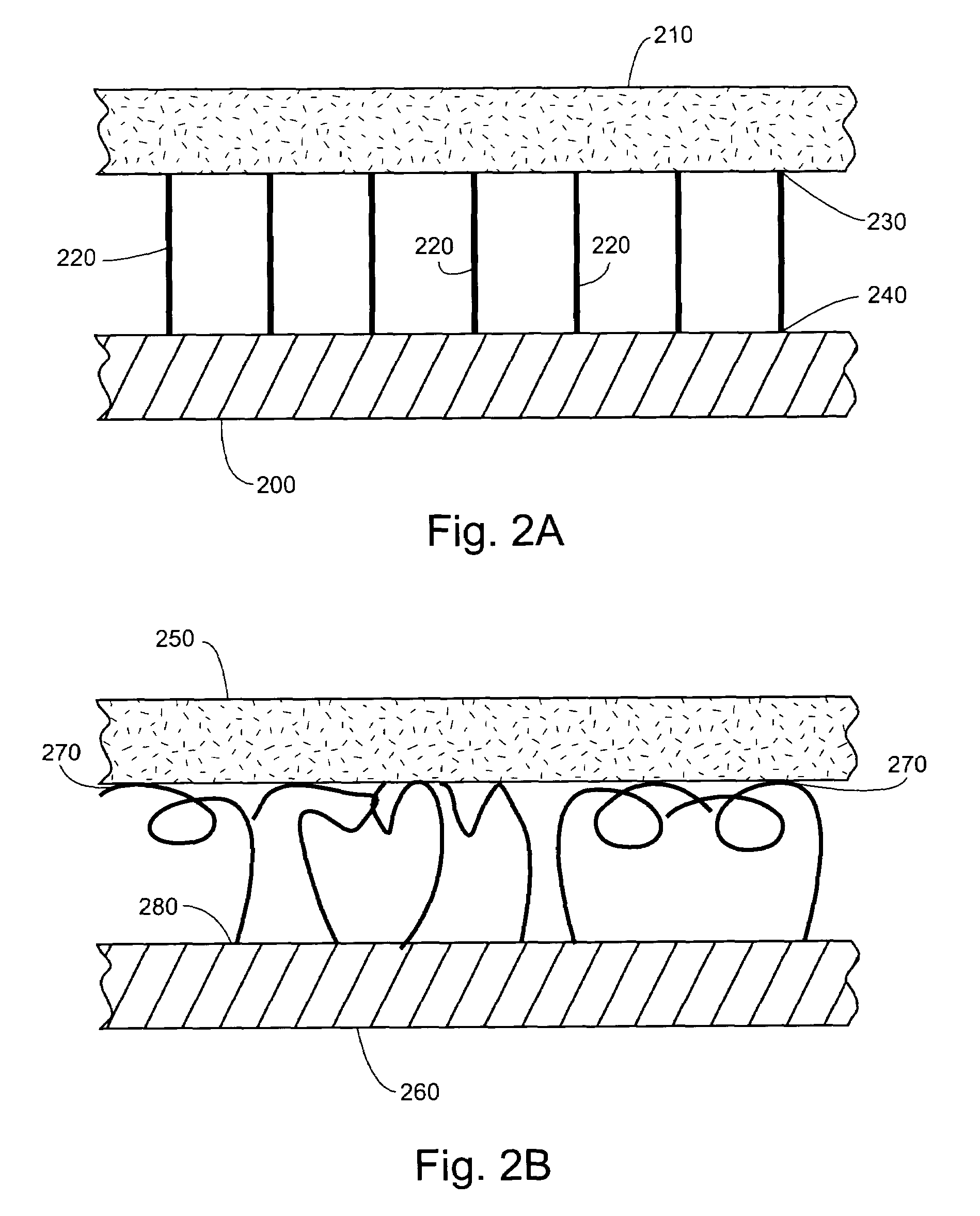

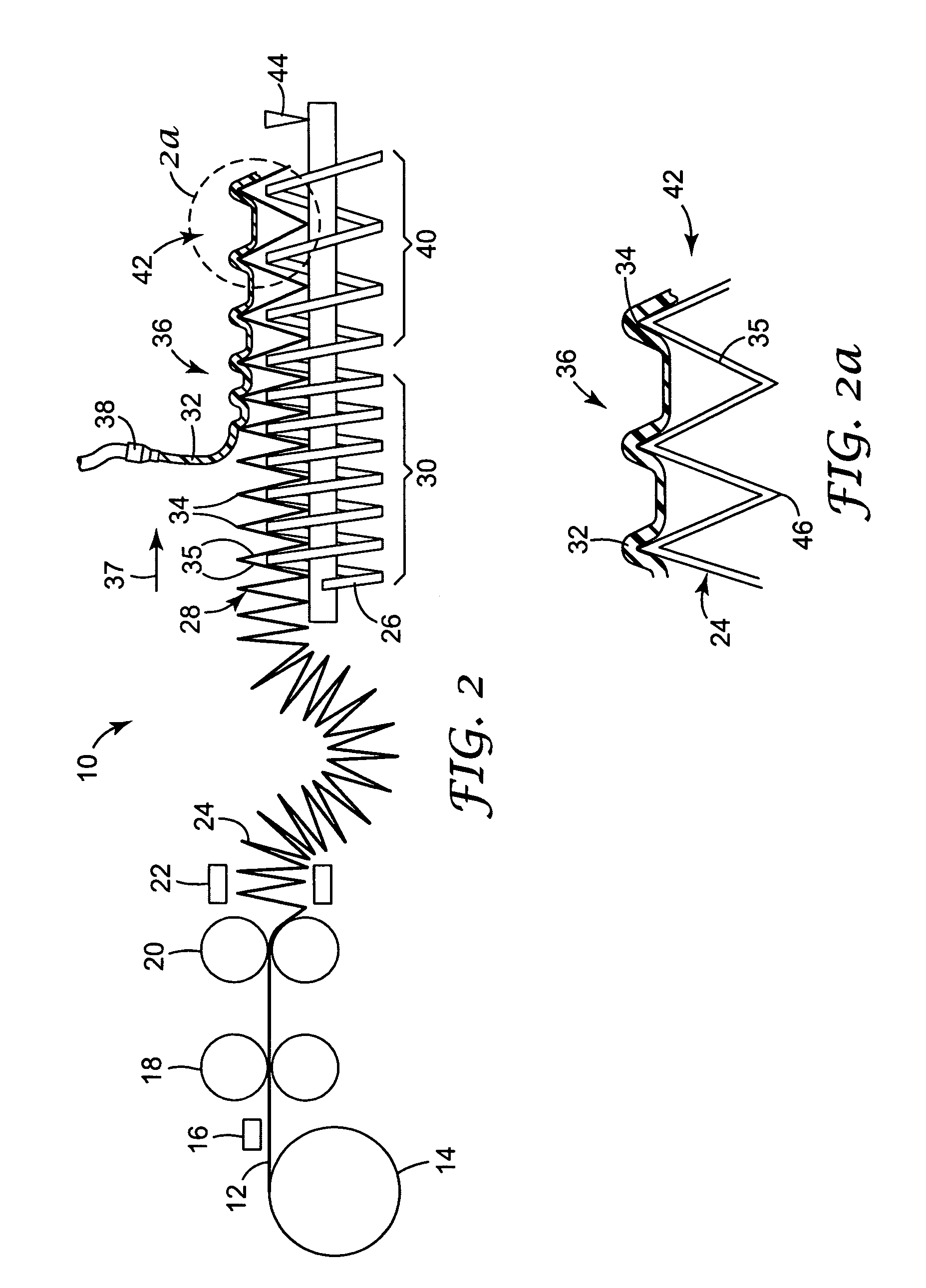

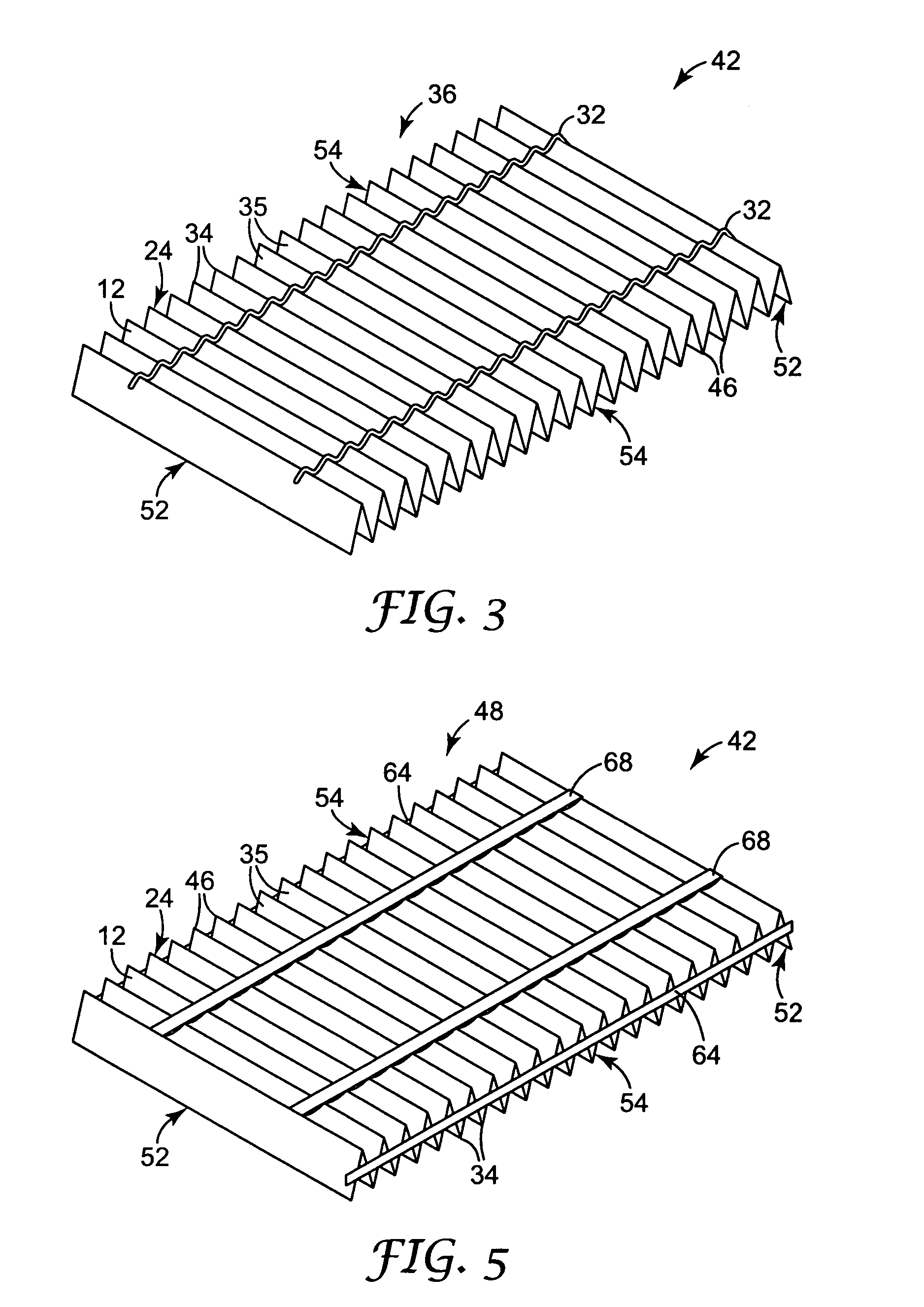

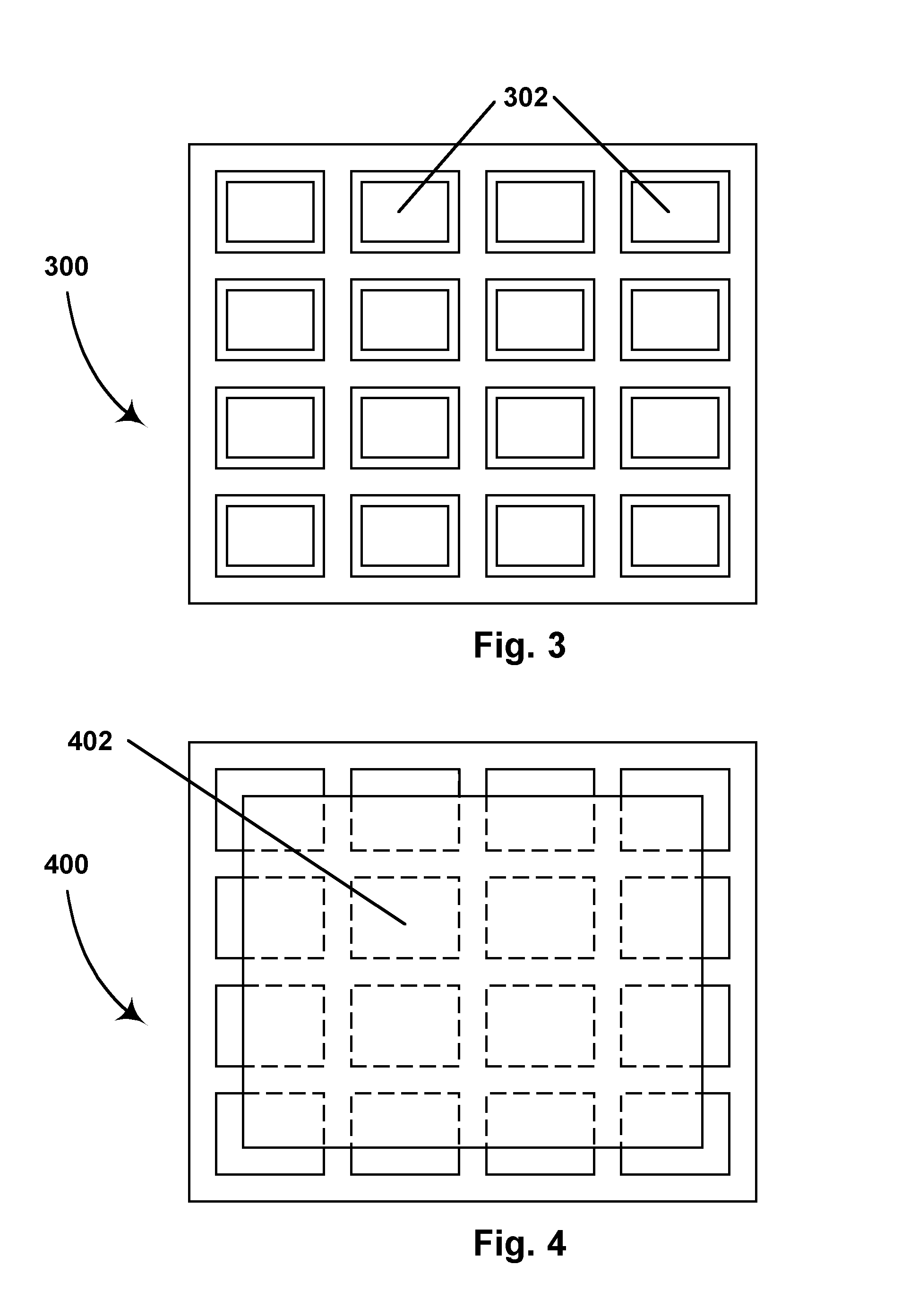

Method and Apparatus for Making Absorbent Structures with Absorbent Material

Apparatus and method for producing absorbent structures with absorbent layers with channel(s) without absorbent material, using a first moving endless surface with specific raised strip(s) and a second moving endless surface with specific mating strip(s).

Owner:THE PROCTER & GAMBLE COMPANY

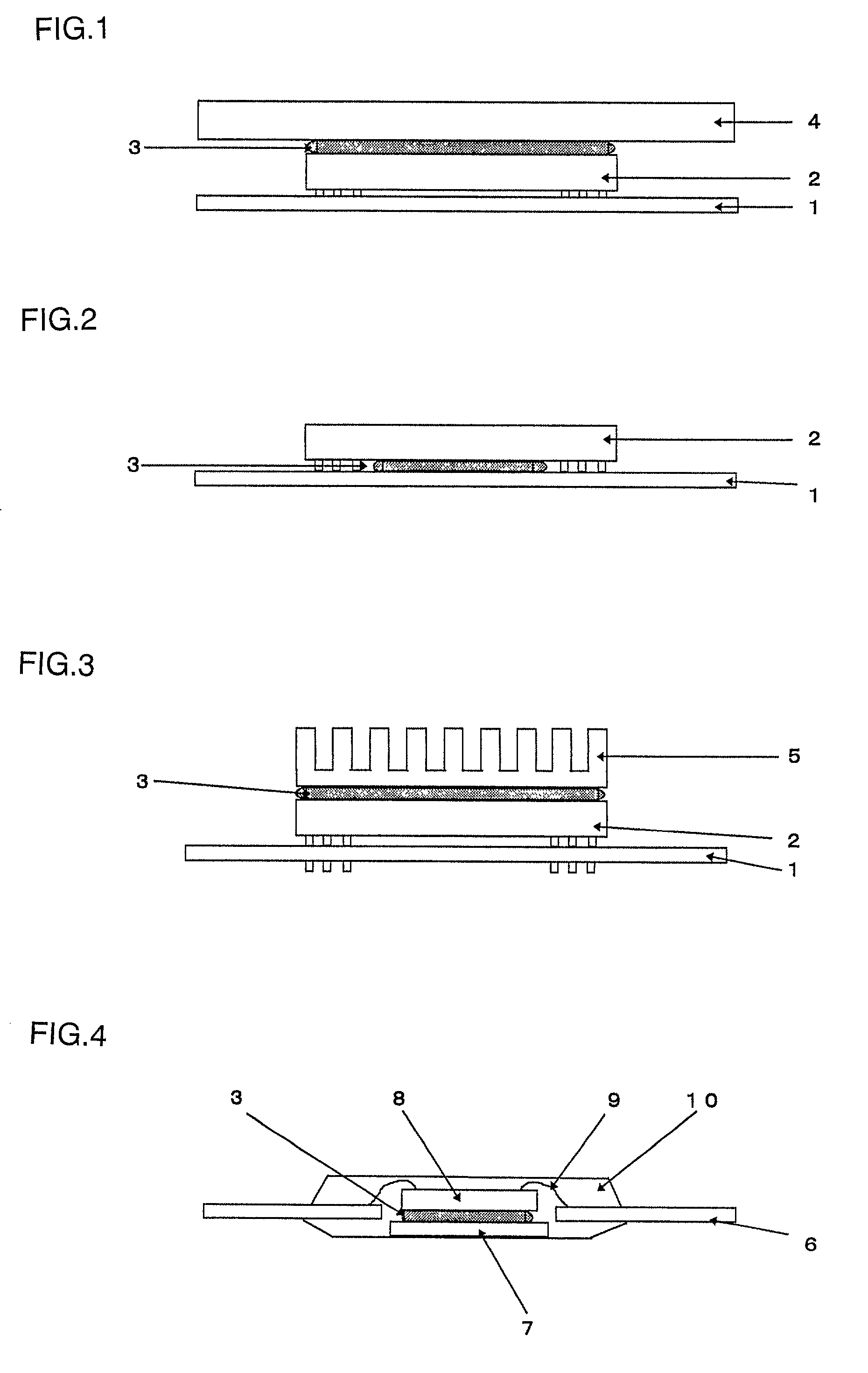

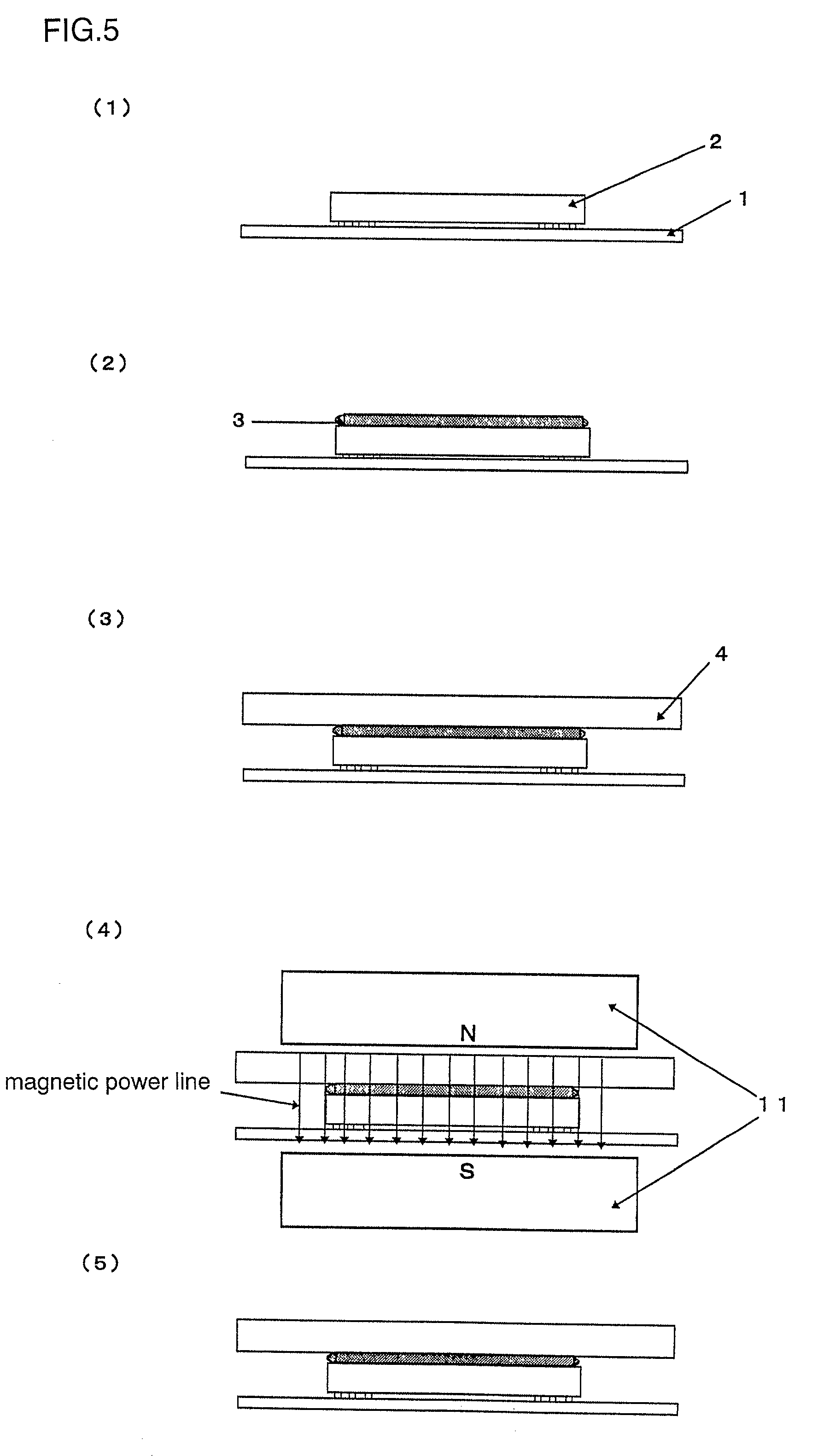

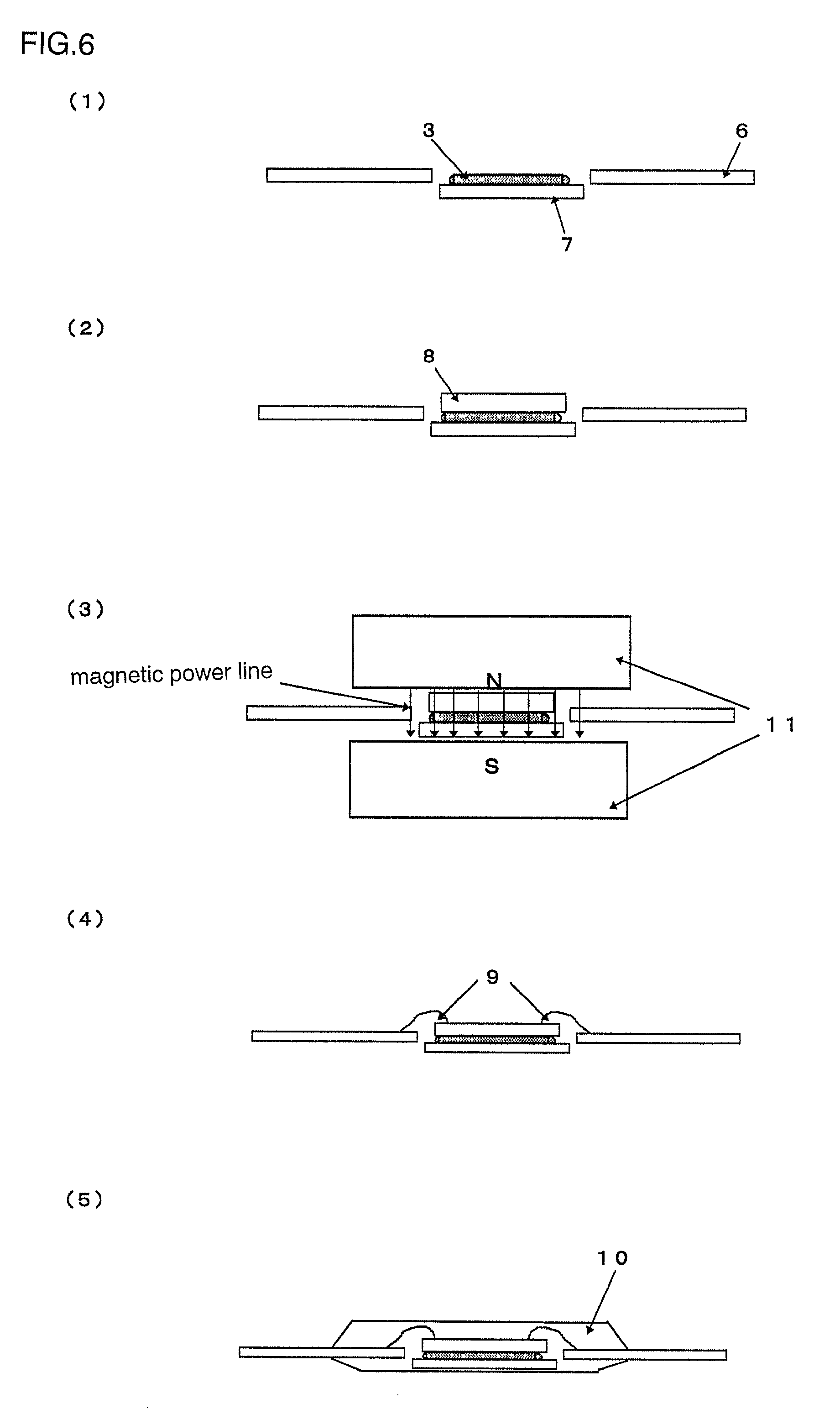

Adhesion method and electronic component

InactiveUS20010004131A1Efficiently dissipatedEnhanced radiationAdhesive processesLamination ancillary operationsAdhesiveBoron nitride

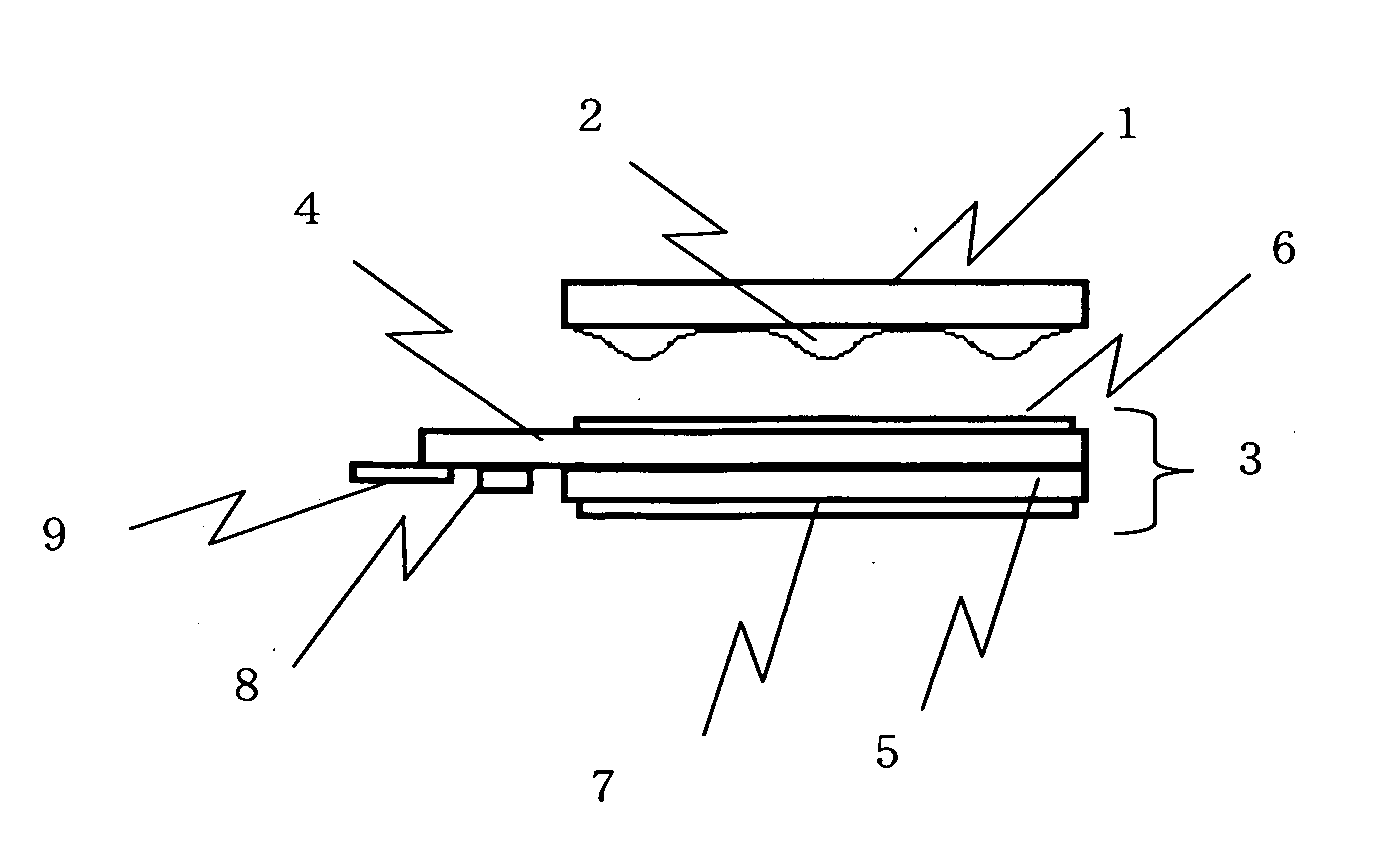

The present invention provides an adhesion method of improving the heat conduction in a fixed direction by using a heat conductive adhesive made by blending boron nitride powder and adhesive polymer and adhering by orienting boron nitride powder in the heat conductive adhesive to the fixed direction under the magnetic atmosphere and an electronic component for effectively dissipating heat generated from semiconductor device 2, power source 4, light source or other components used for the electric products, and an electronic component excellent in radiation.

Owner:POLYMATECH CO LTD

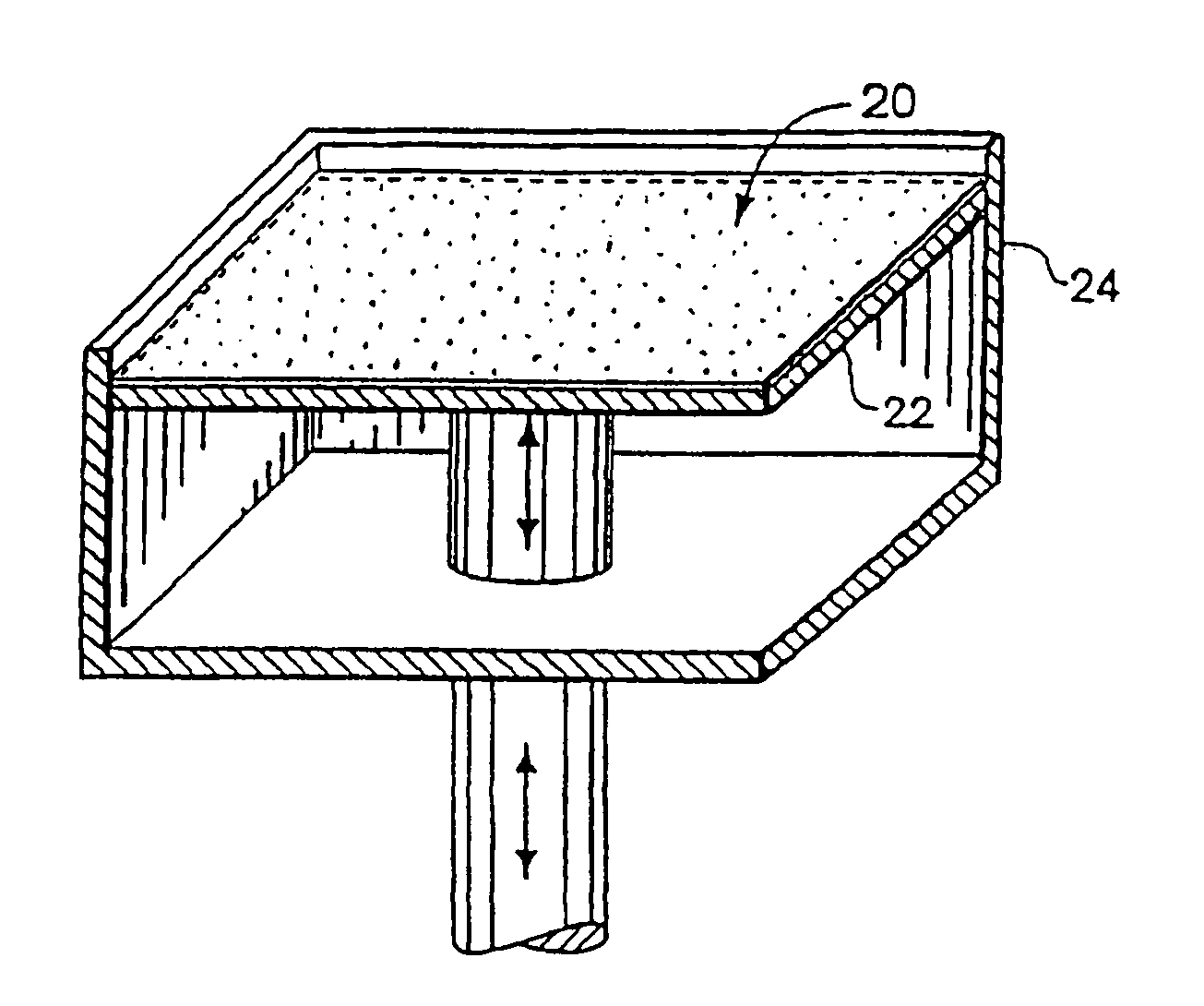

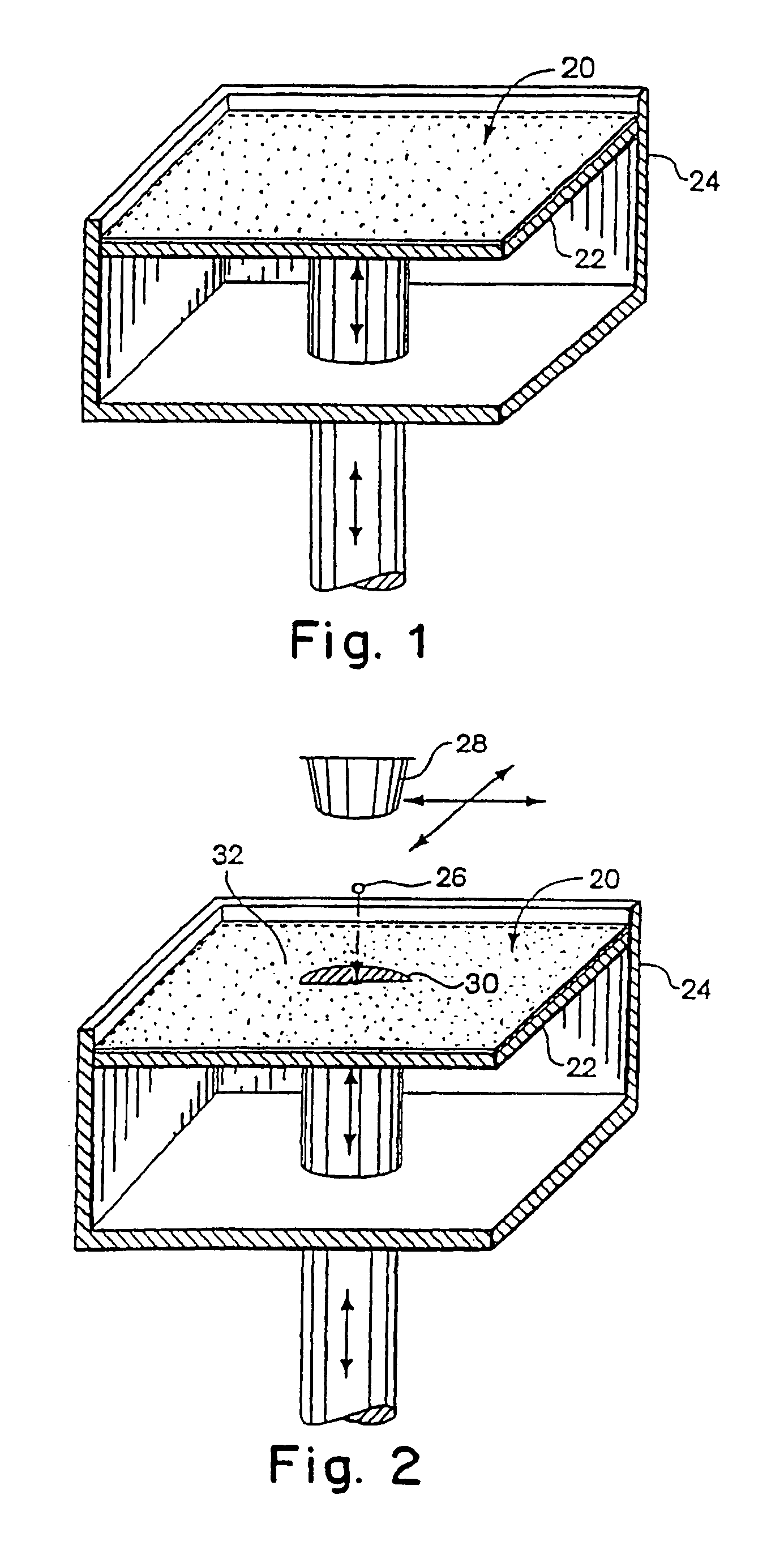

Material systems and methods of three-dimensional printing

InactiveUS7795349B2Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

Method and apparatus for making absorbent structures with absorbent material

Owner:PROCTER & GAMBLE CO

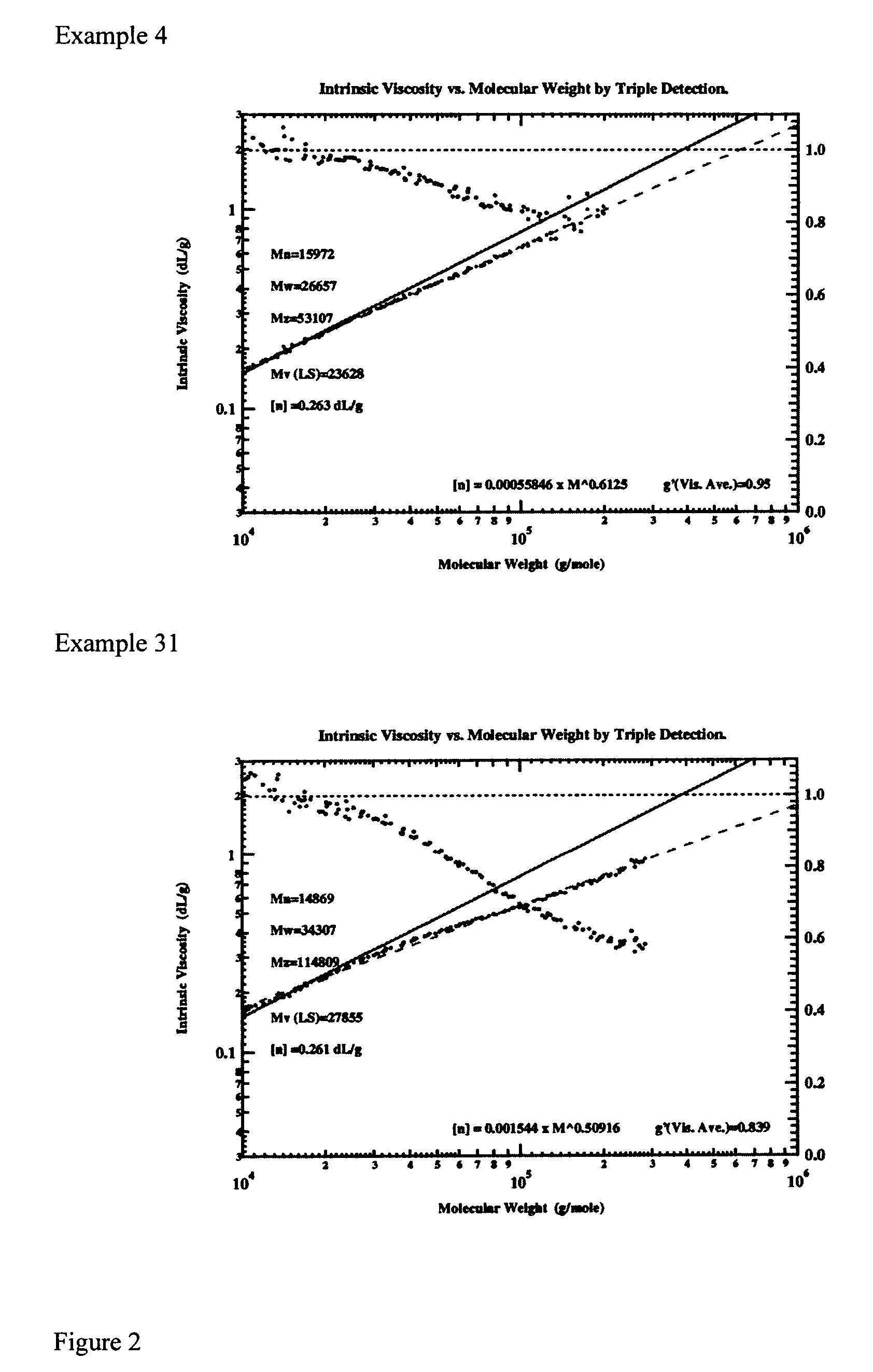

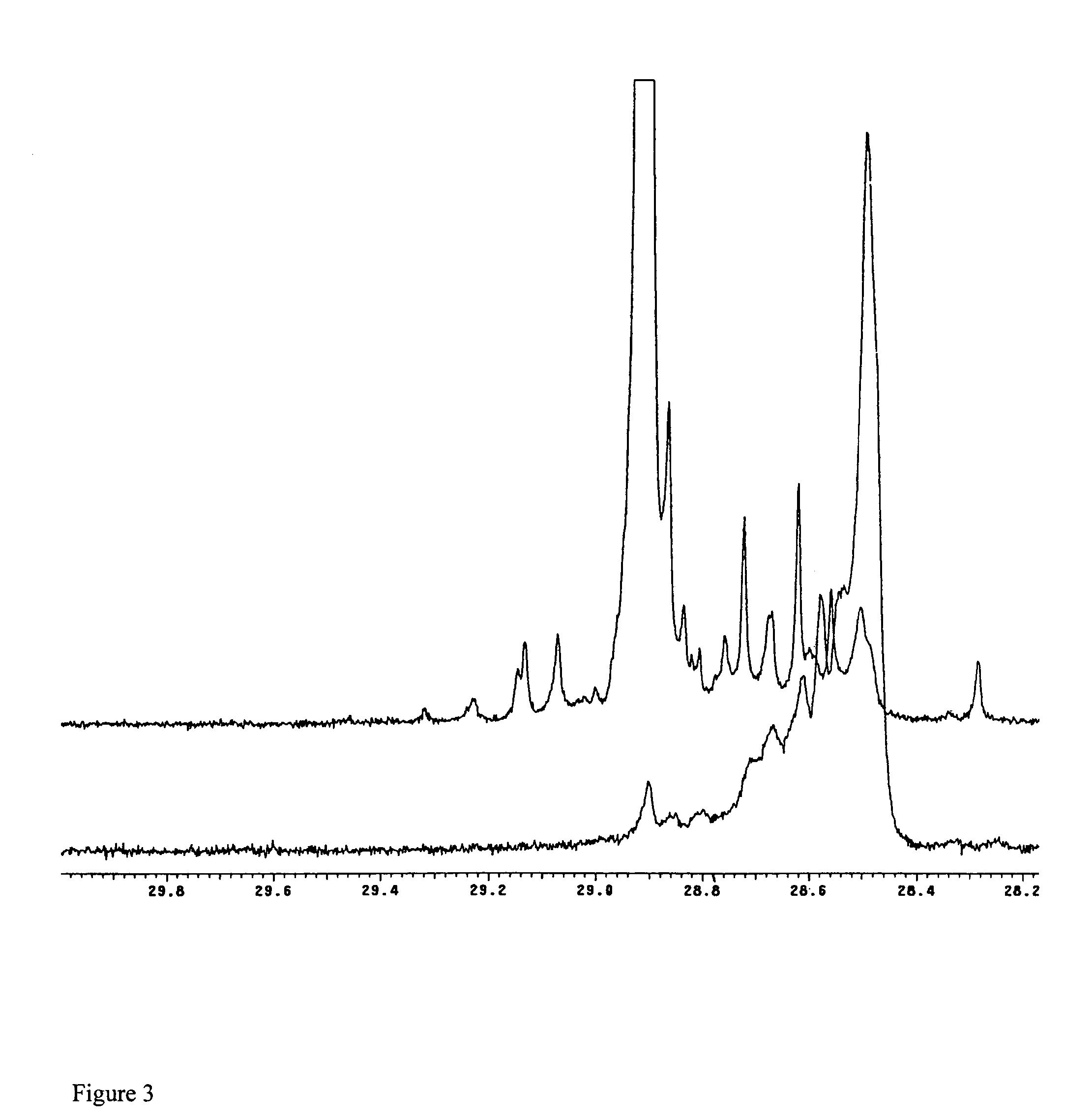

Mutliple catalyst system for olefin polymerization and polymers produced therefrom

This invention relates to a polymer of one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ethylene, and polymerization processes for producing the same.

Owner:EXXONMOBIL CHEM PAT INC

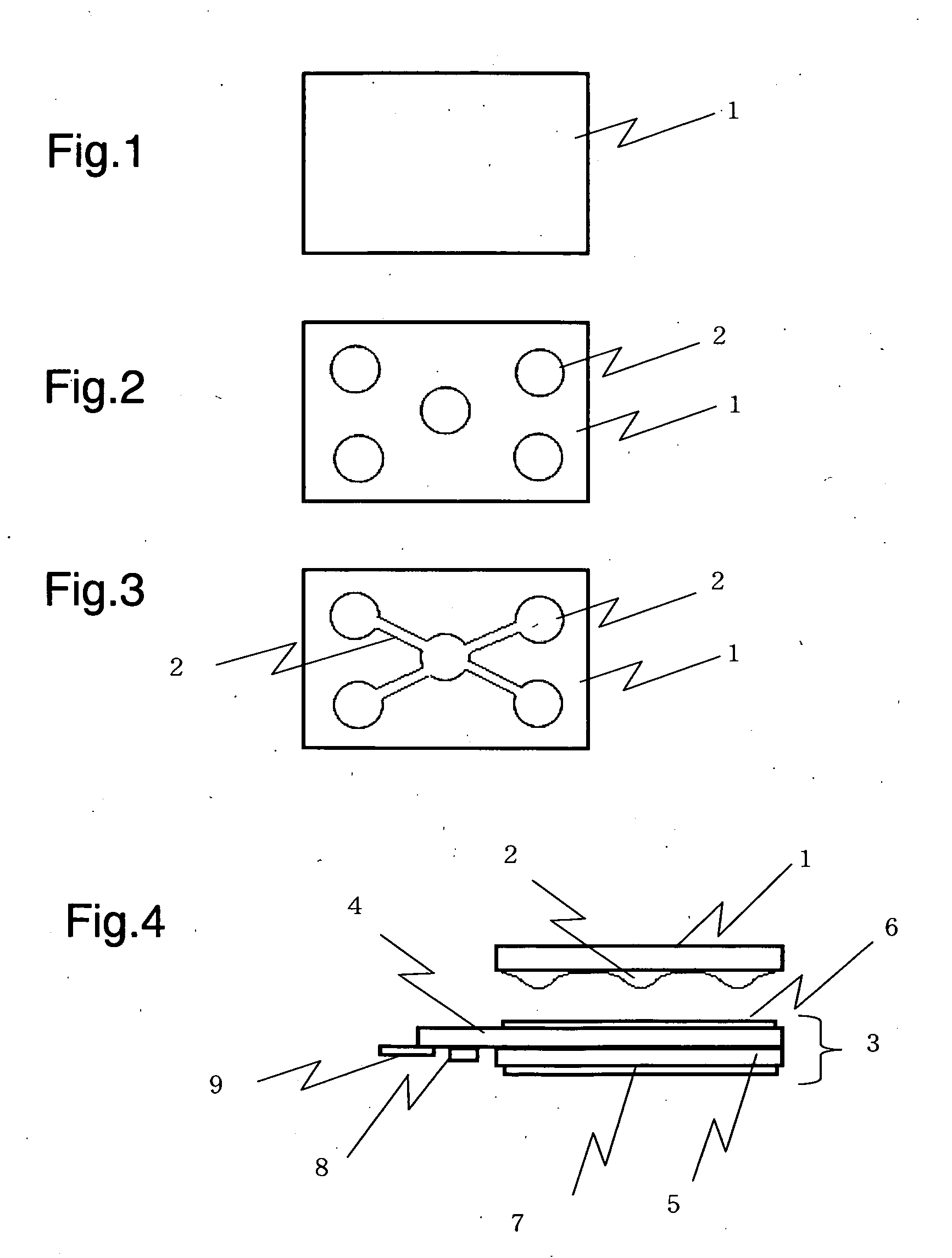

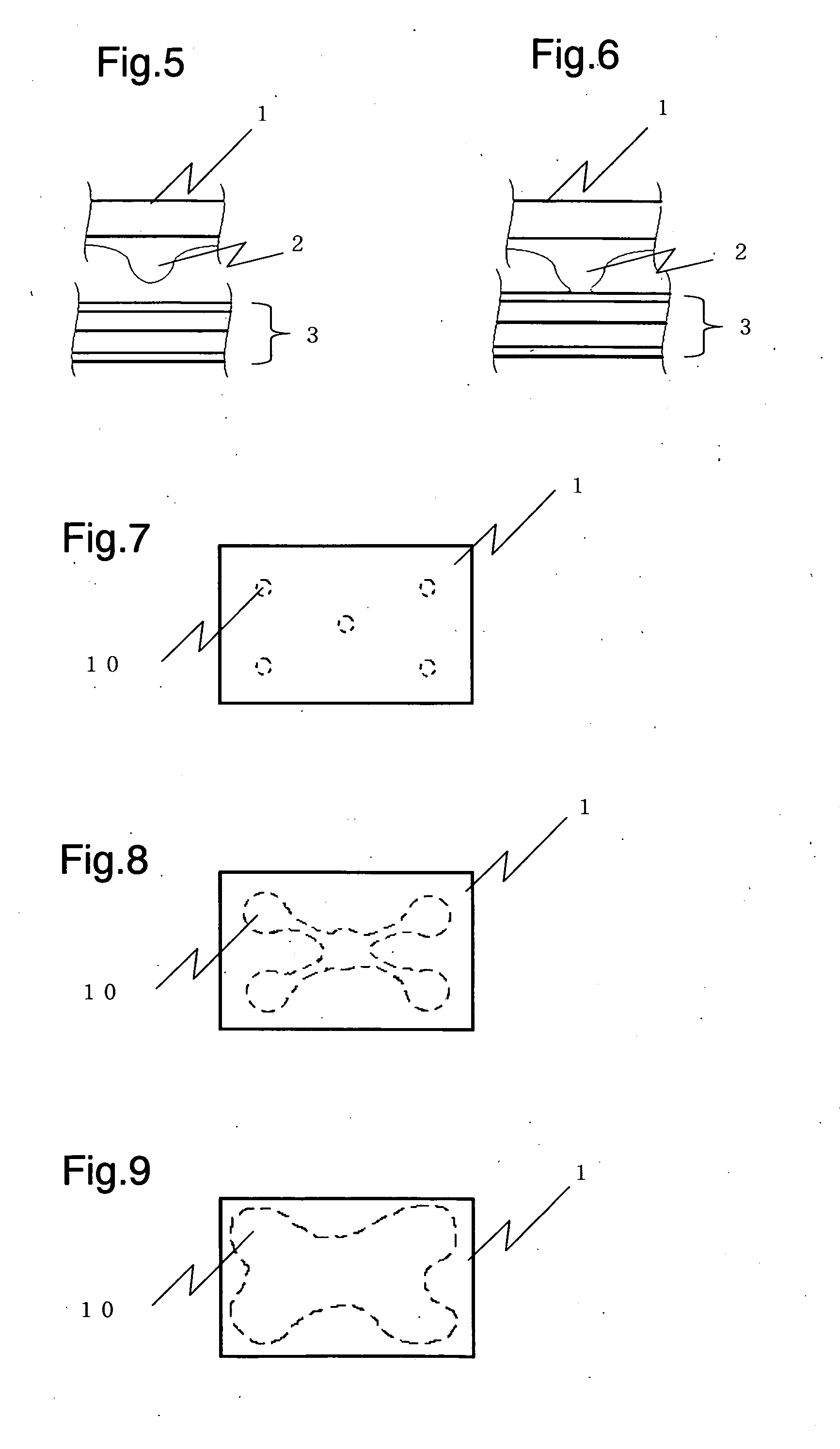

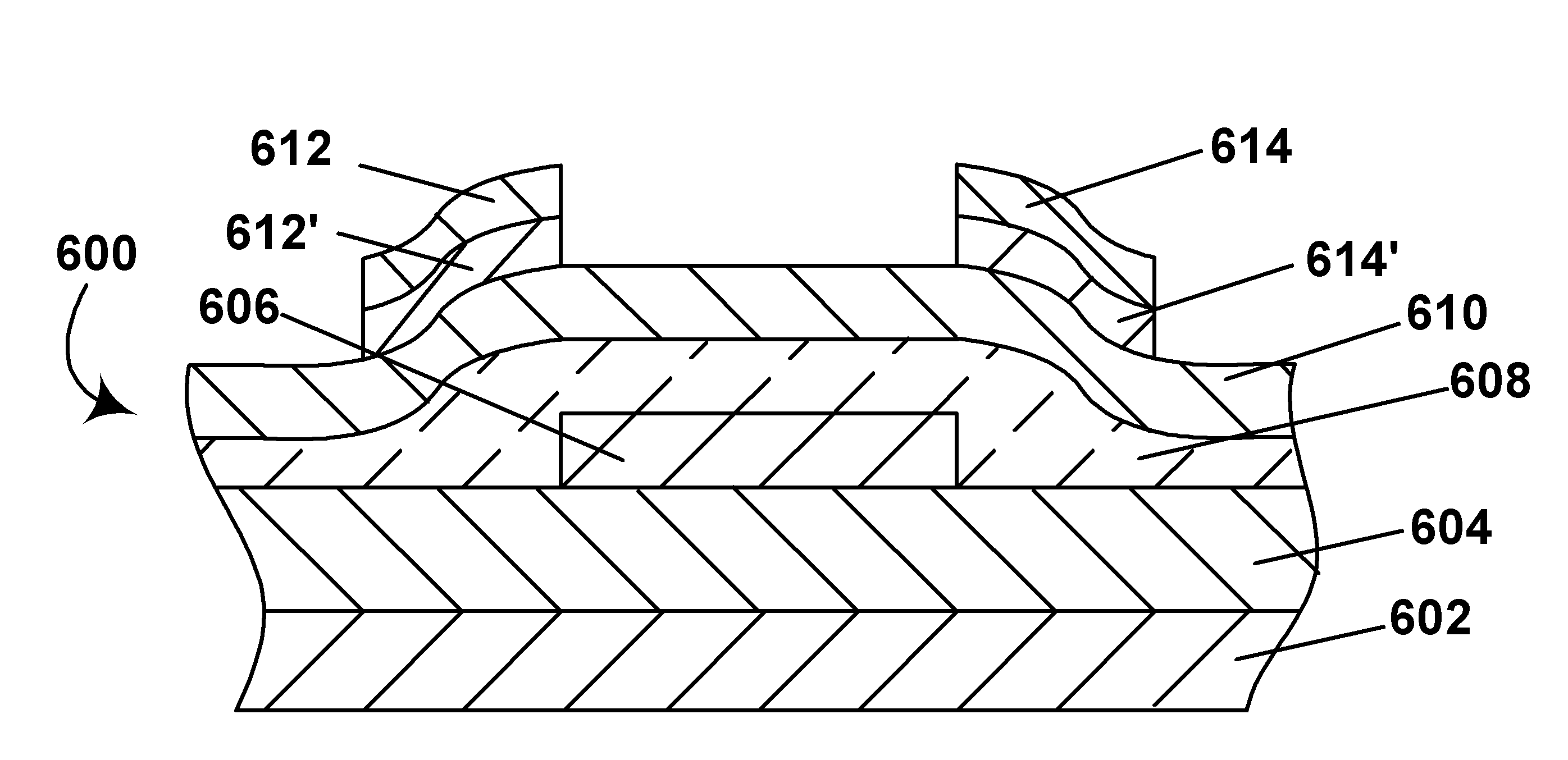

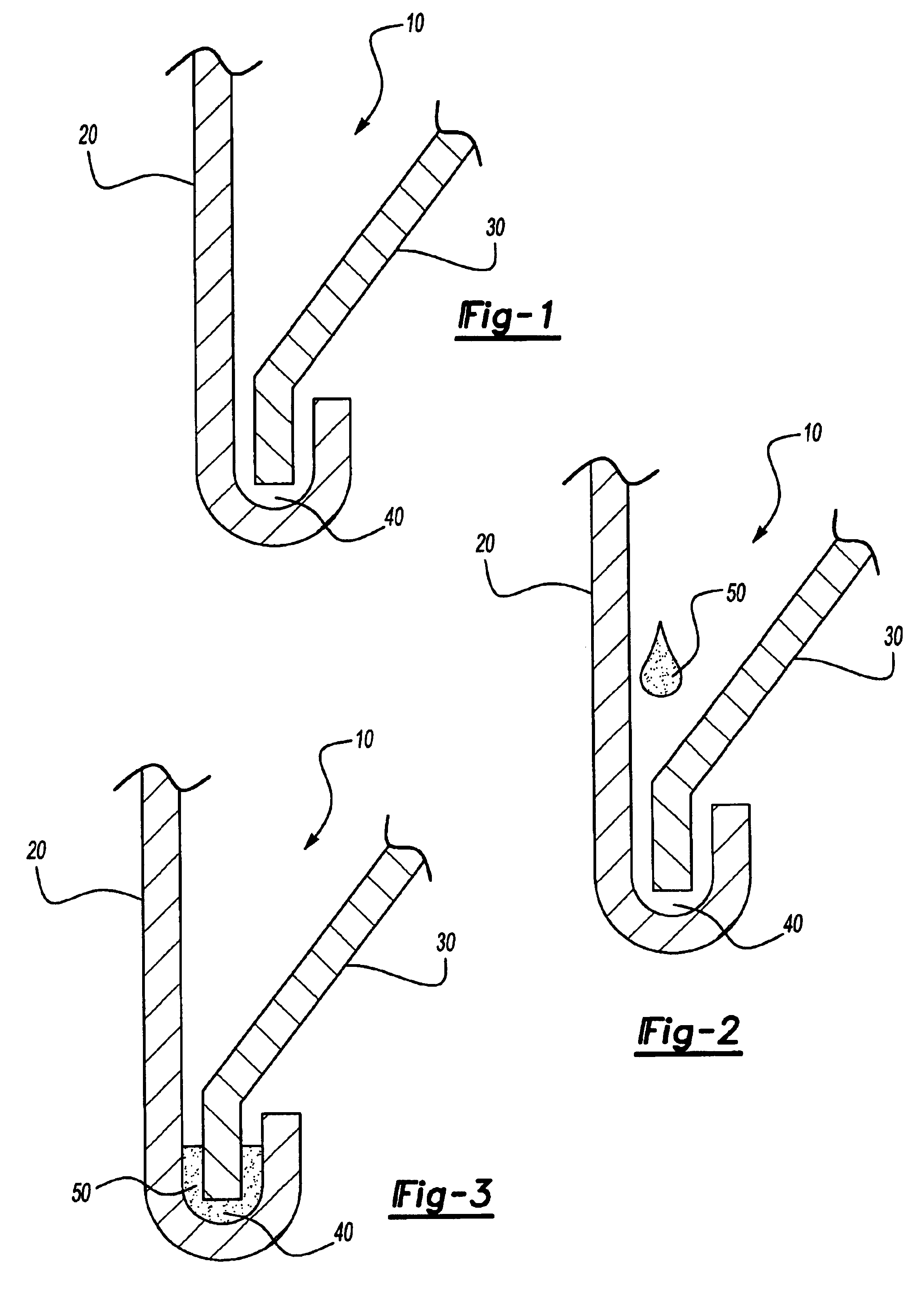

Method of Manufacturing a Display Device and Bonding Method

Provided is a method of bonding a transparent plate or a touch panel to a flat display without allowing air bubbles to form. A fixed amount of liquid adhesive is applied in dots to a bonding surface around corners and at the center. More adhesive is applied to connect the dots of applied adhesive with lines. The bonding surface is then reversed, causing the adhesive to drip, and the dripping adhesive is brought into contact with an opposite bonding surface to fill a gap between the bonding surfaces with the adhesive. The adhesive is cured by irradiation with light incident from a transparent plate side. In short, after dots of adhesive are brought into contact with the opposite bonding surface and the adhesive flows into a pattern that does not let in air bubbles, the gap between the bonding surfaces is filled with the adhesive.

Owner:SEIKO INSTR INC

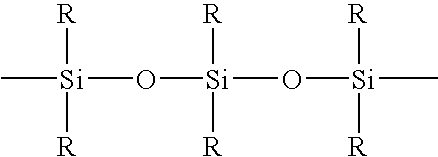

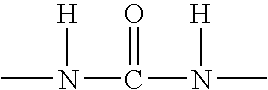

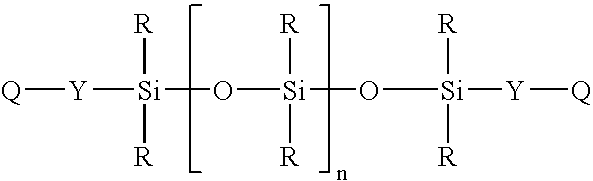

Method for adhering substrates using adhesive devices containing silicone gels

InactiveUS6846508B1Reduce viscosityEasy to disassembleAdhesive processesSurgical adhesivesSilicone GelsProsthesis

A method for adhering a first substrate to a second substrate using a double sided adhesive device based on silicone gels. The method is particularly useful for adhering a medical prosthesis to a human or animal body.

Owner:DOW CORNING FRANCE

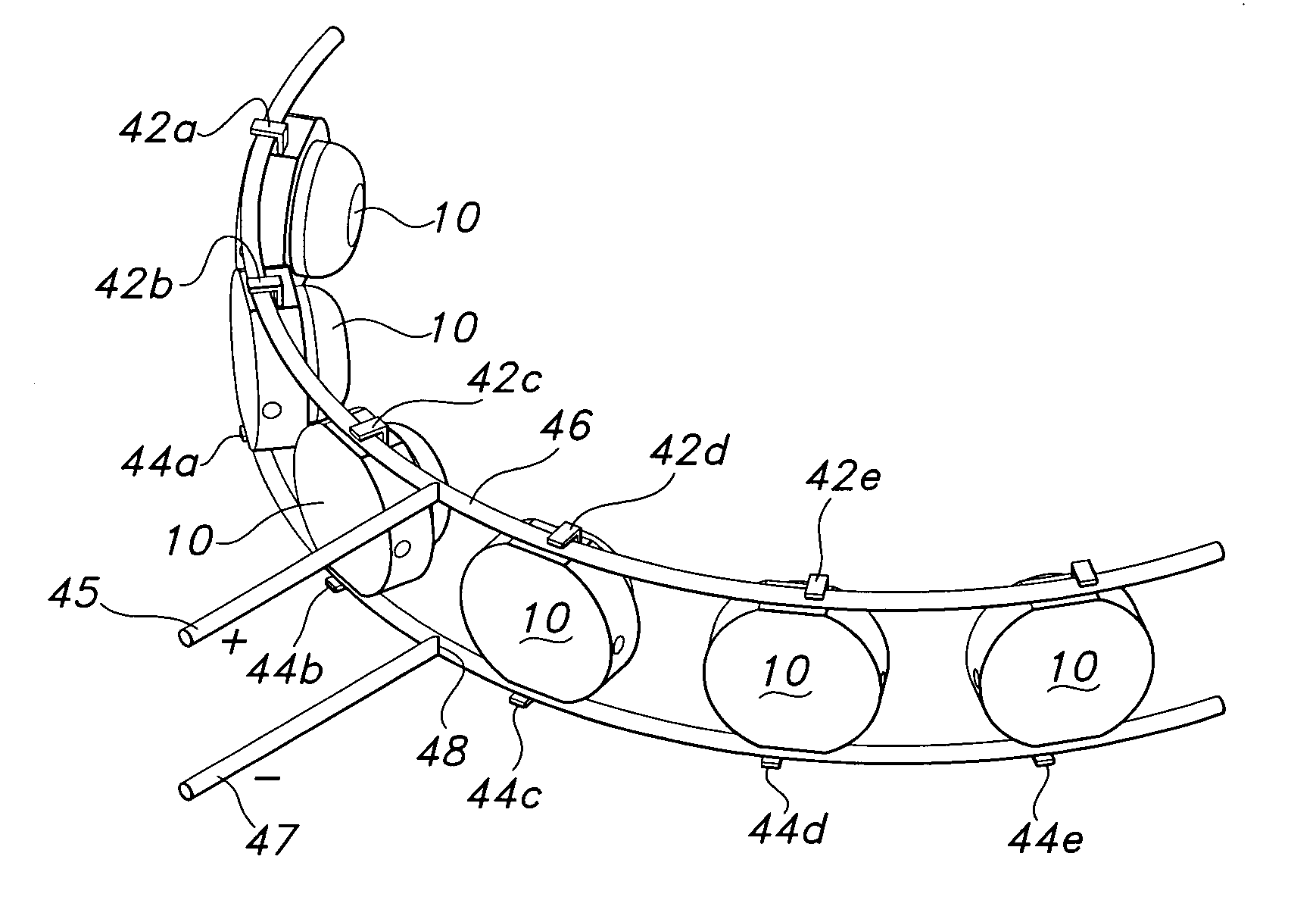

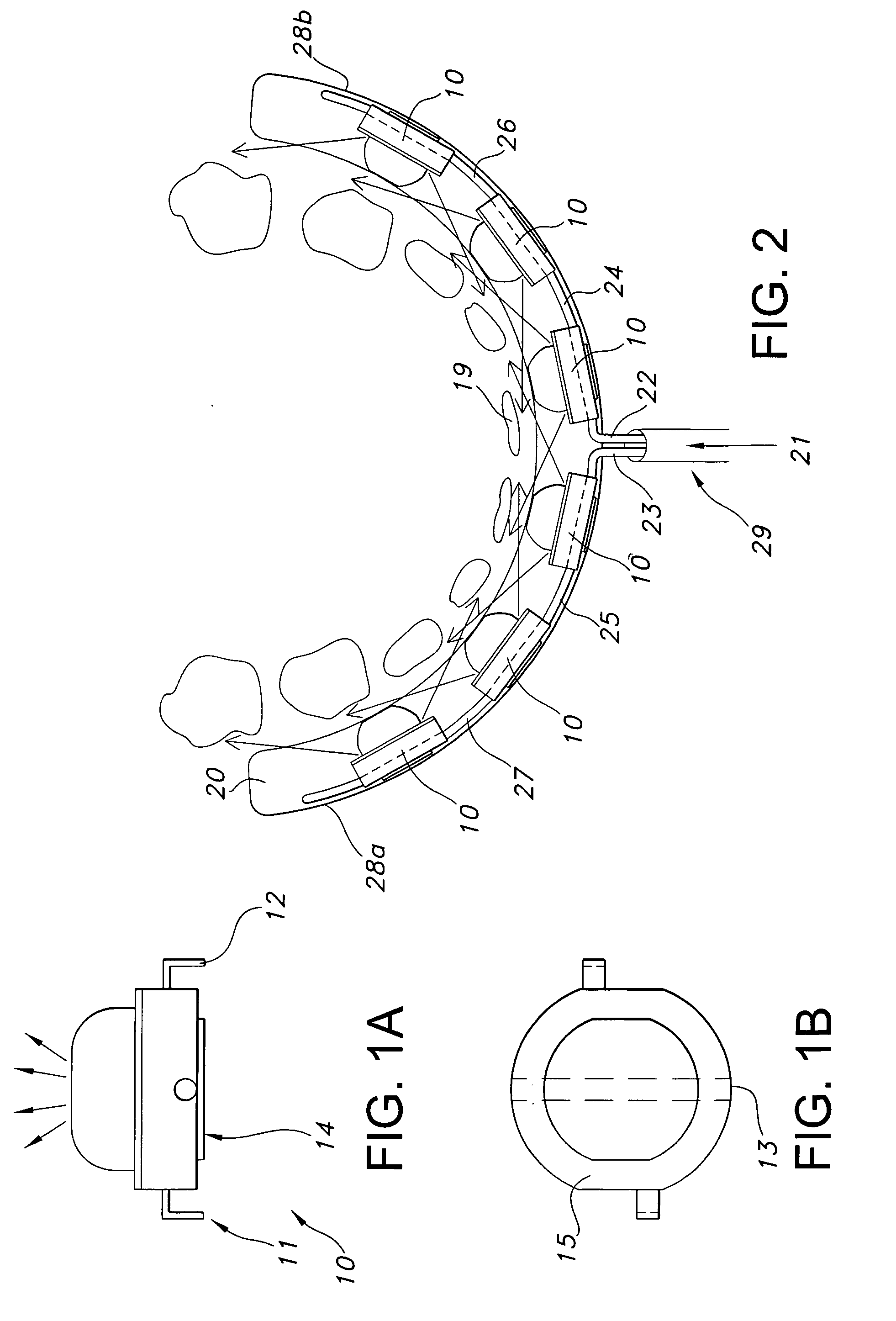

Method and apparatus for using light emitting diodes for curing

The present invention provides a method and apparatus for using light emitting diodes for curing in various applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention that utilizes heat pipes performs far more efficiently in much more compact space. This allows much more closely spaced LEDs operating at higher power and brightness.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

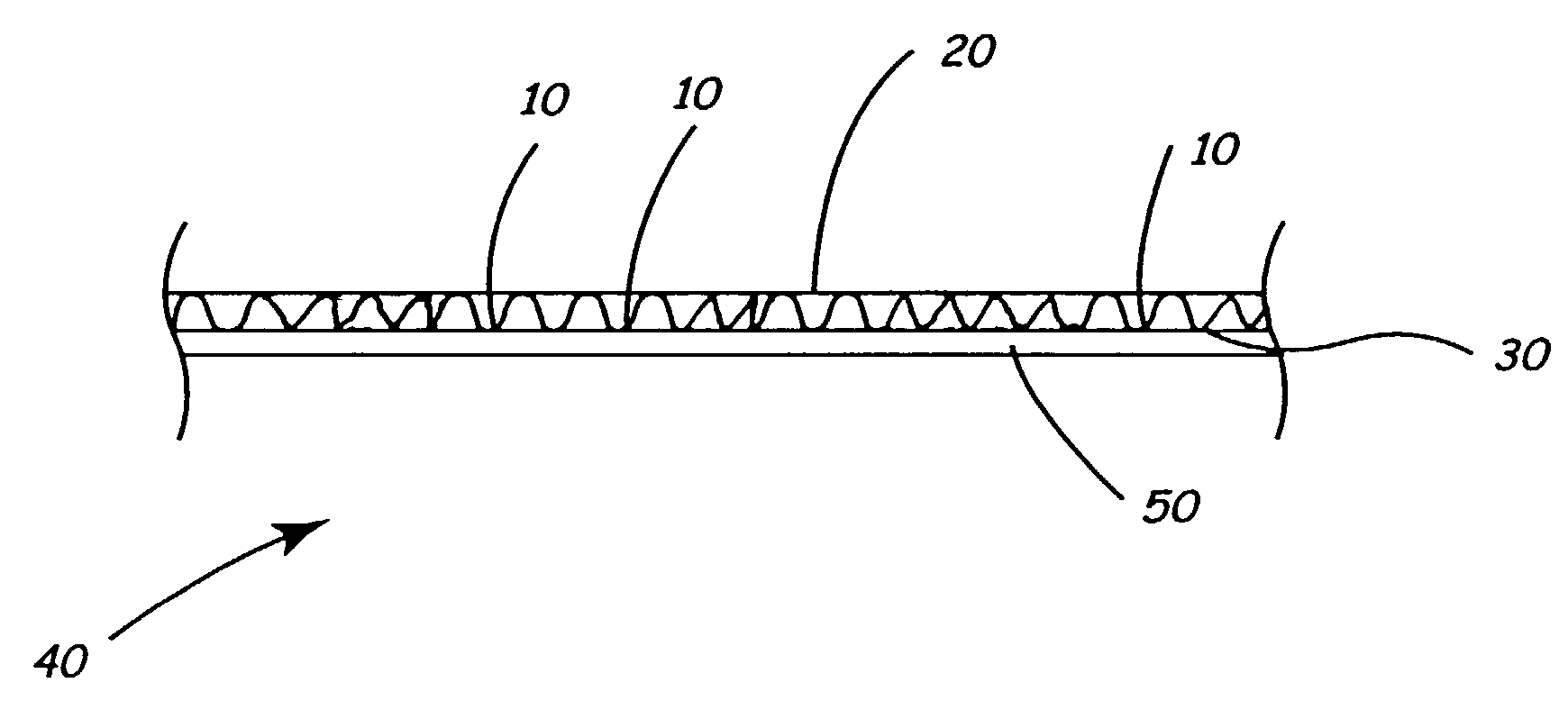

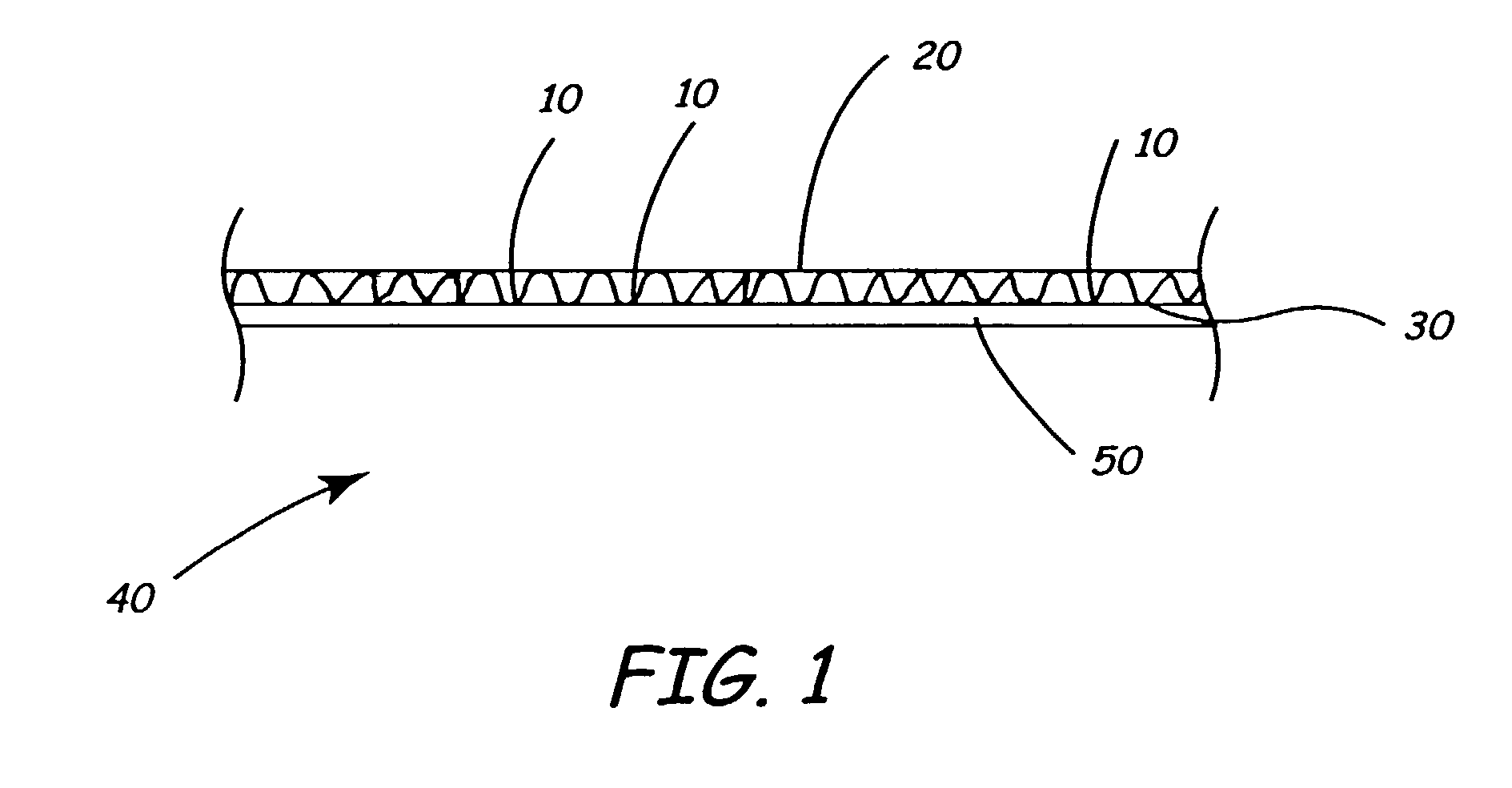

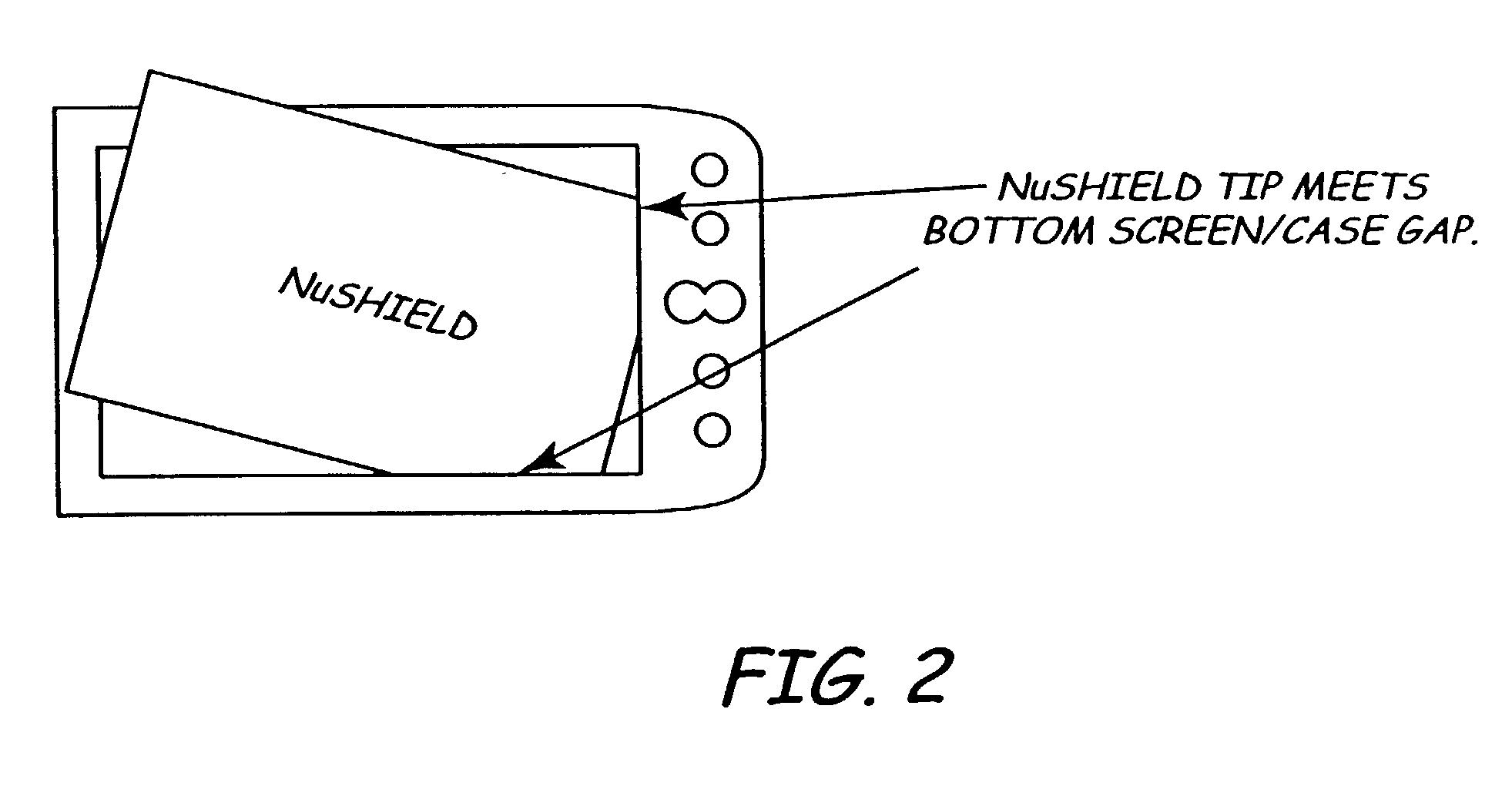

Screen protector

InactiveUS7070837B2Prevents orMinimize formationLiquid crystal compositionsAdhesive processesRefractive indexEngineering

A plastic film screen protector that prevents interference patterns from arising when the film touches the screen is described. The advantages are accomplished by the film having a slightly roughened surface so that the majority of the film facing an electronic device screen does not substantially touch the screen. These physical aberrations prevent Newton ring interference patterns and spots caused by refractive index differences between air and the film material.

Owner:ROSS MARK

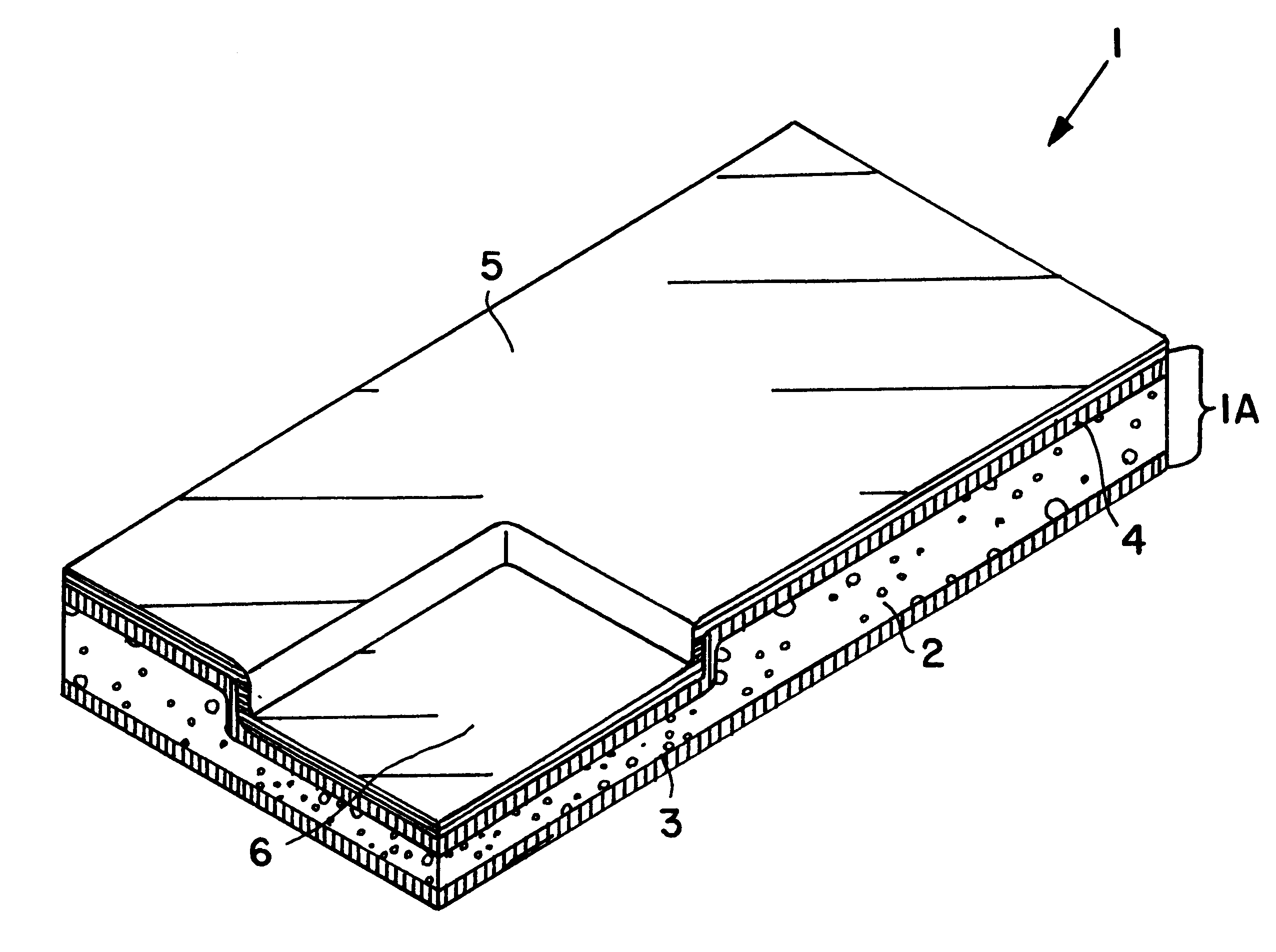

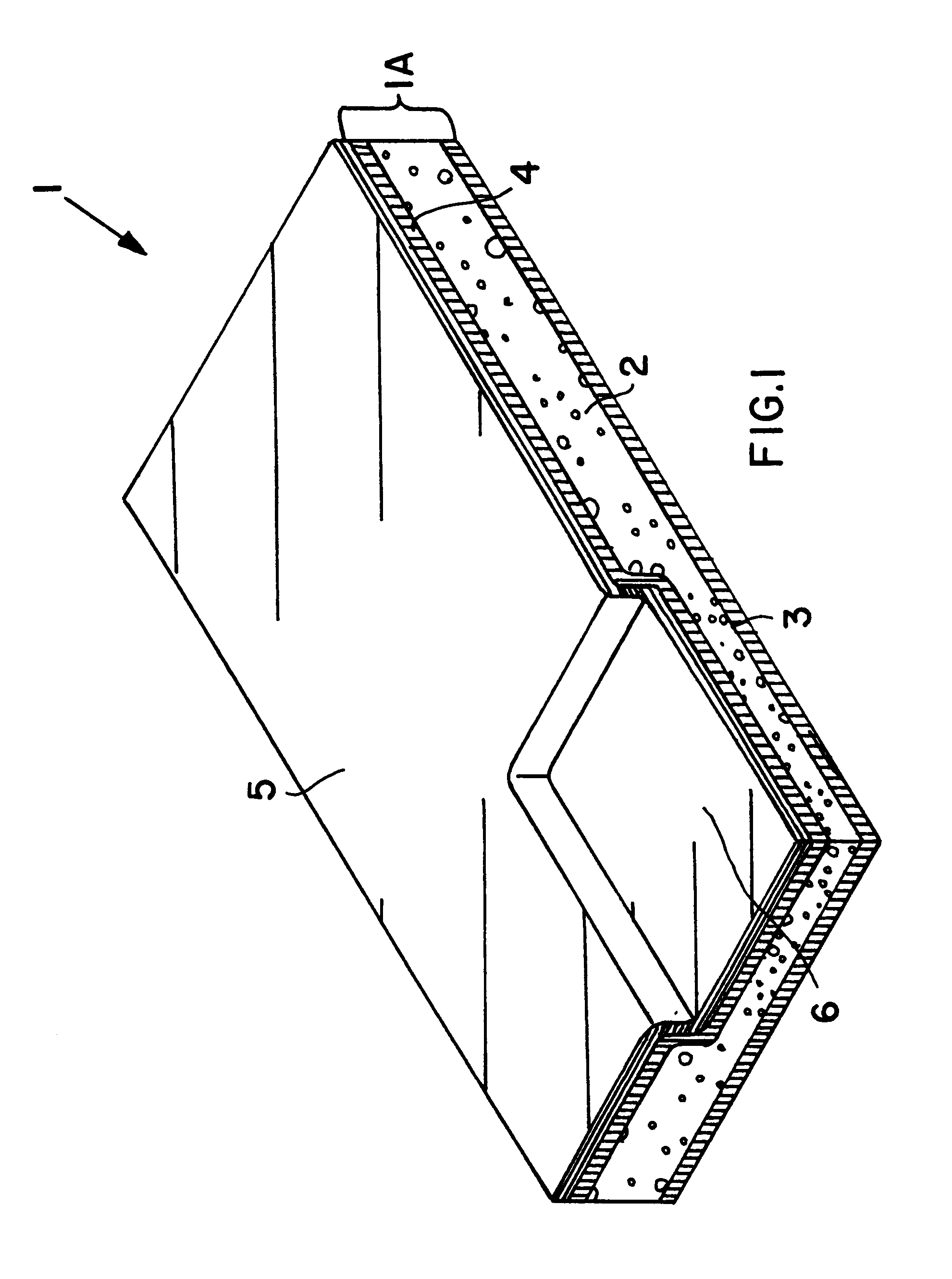

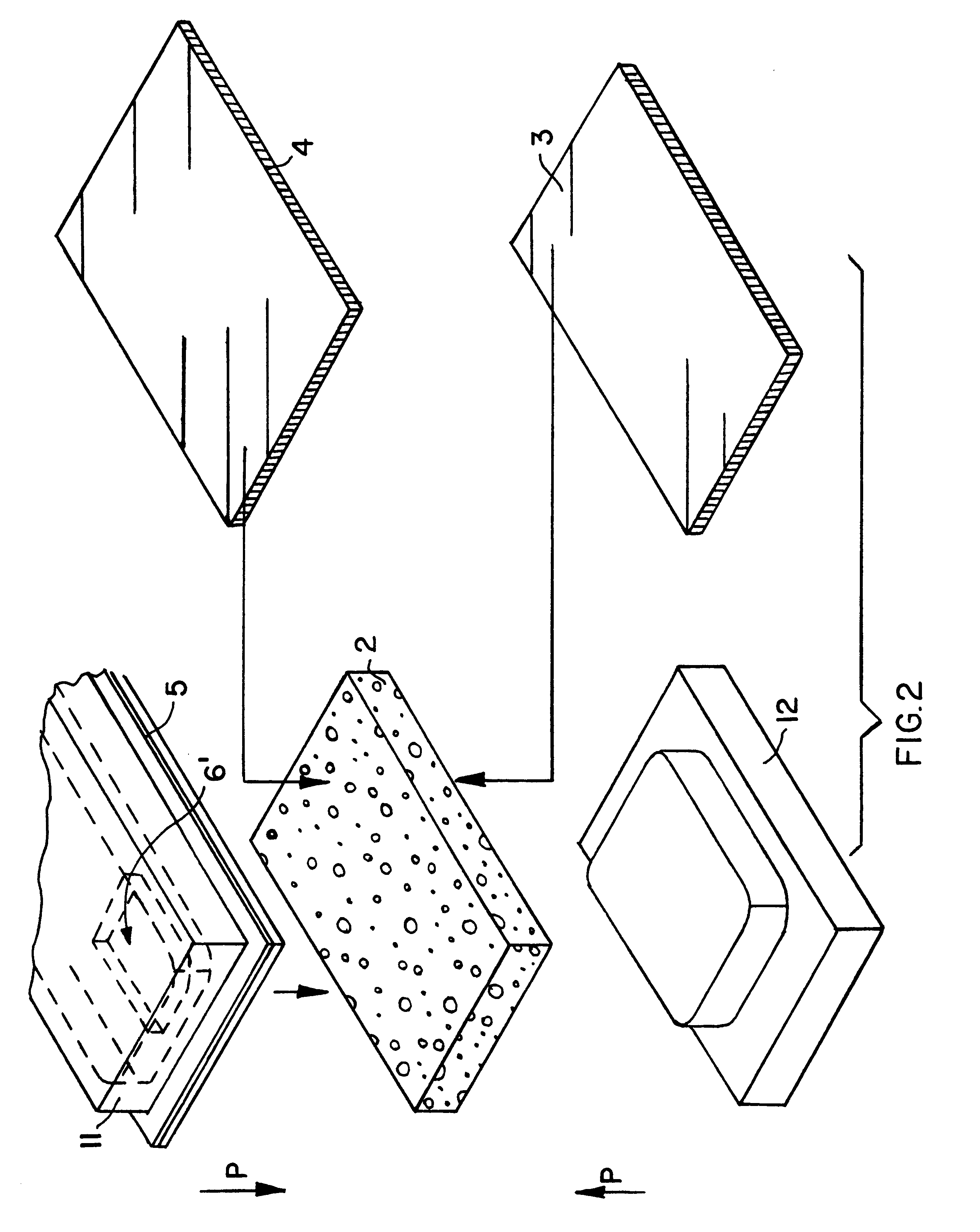

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

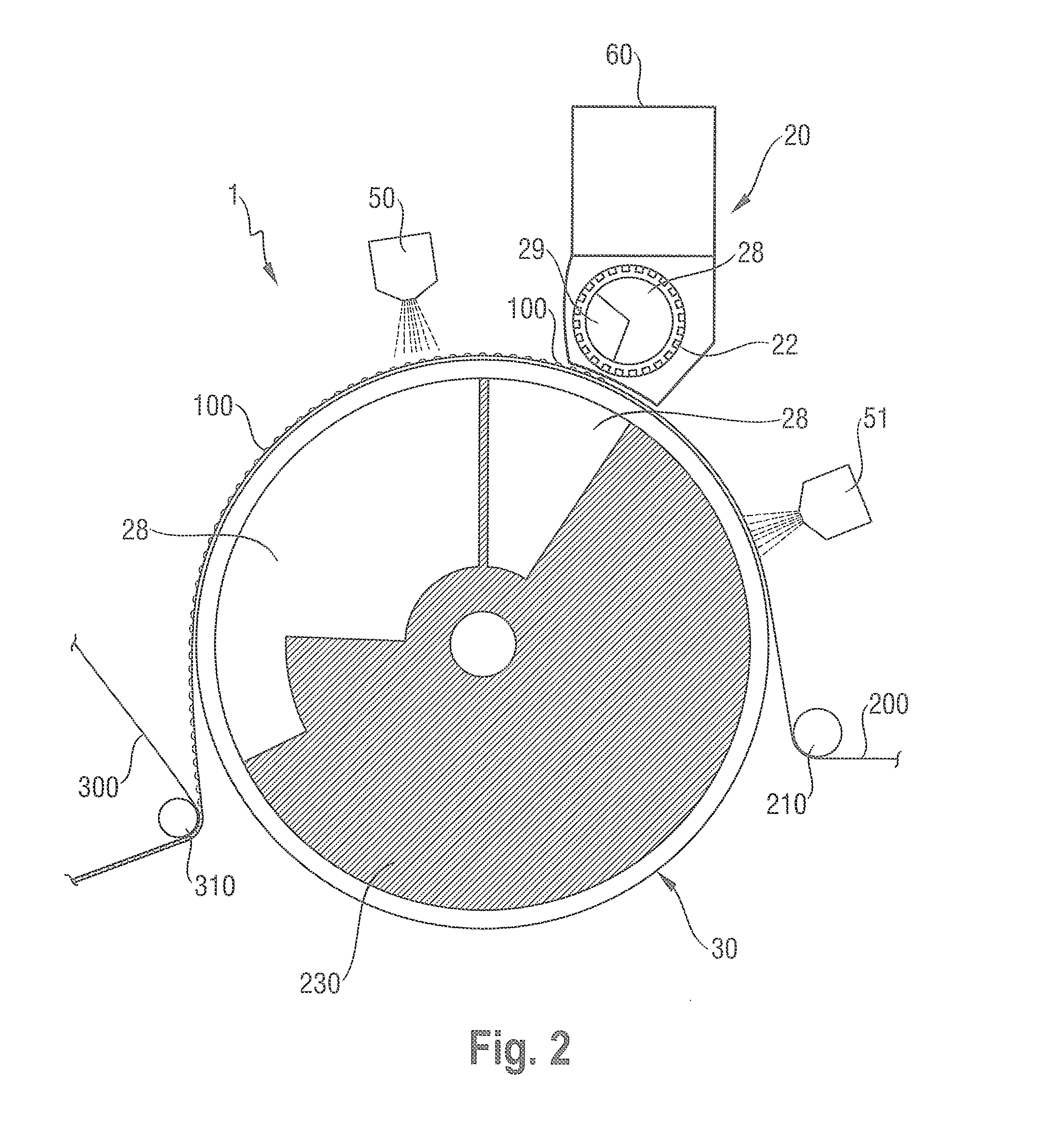

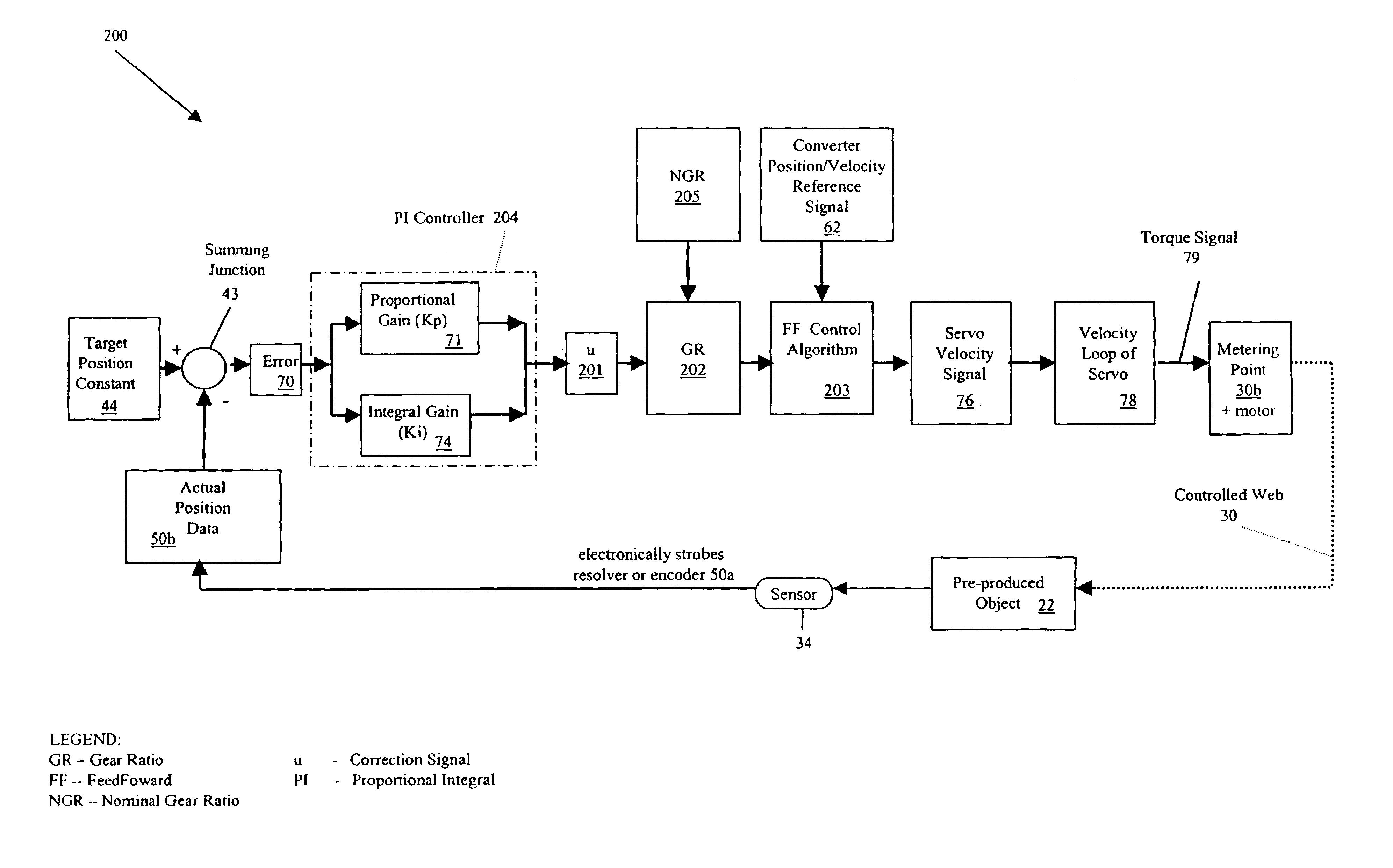

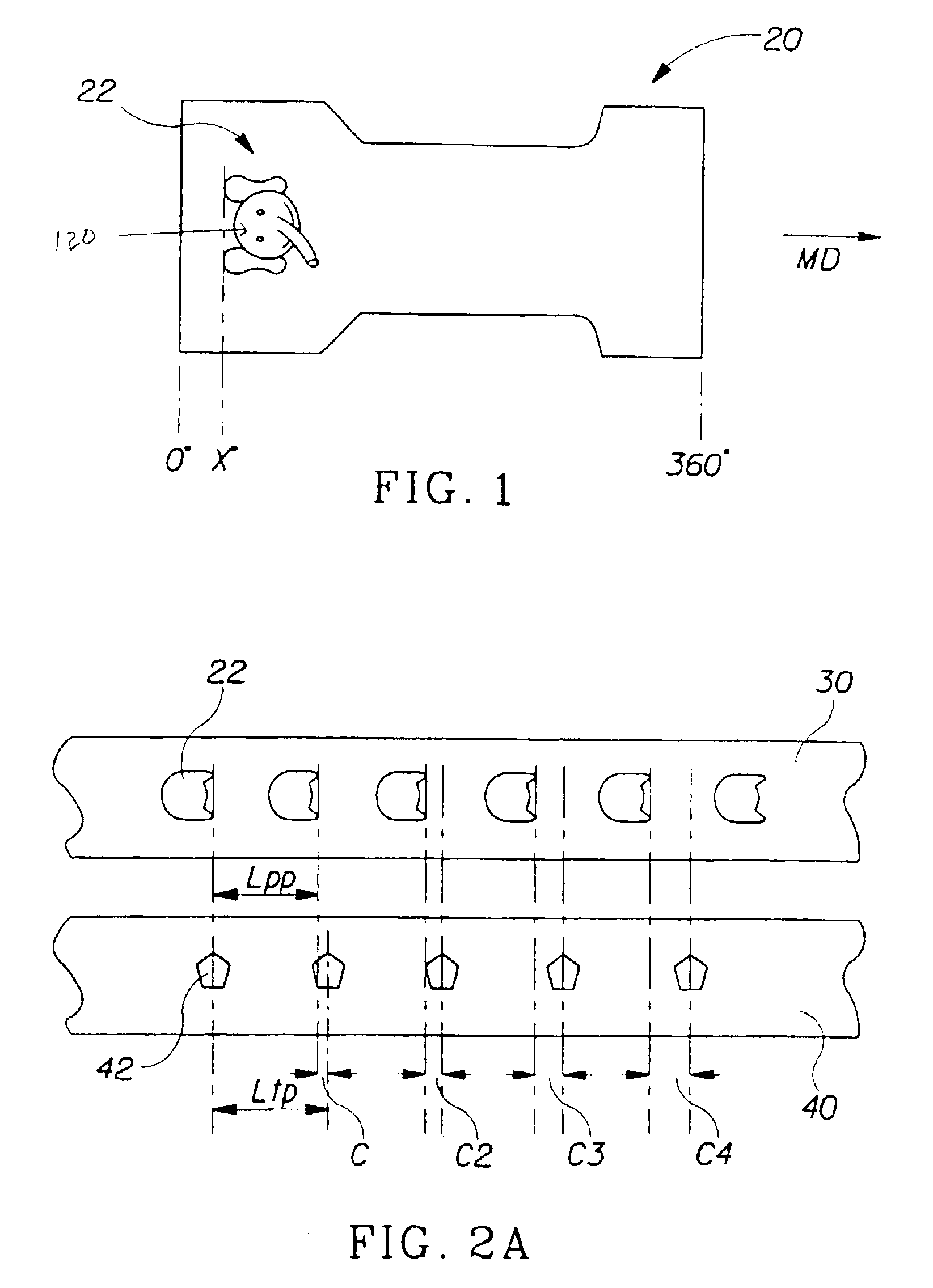

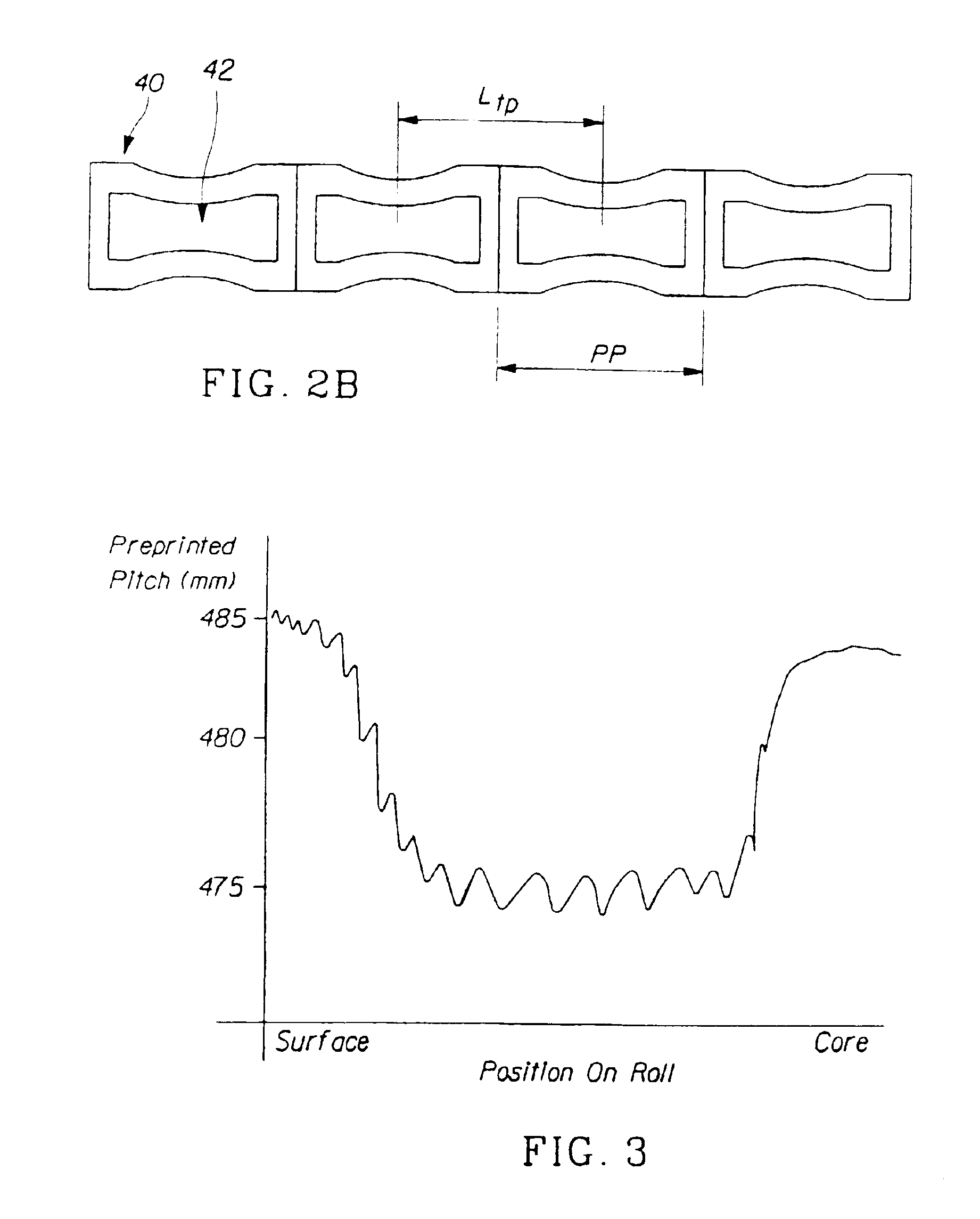

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

Material systems and methods of three-dimensional printing

ActiveUS20060208388A1Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

Structures, systems and methods for joining articles and materials and uses therefor

Owner:NANOSYS INC

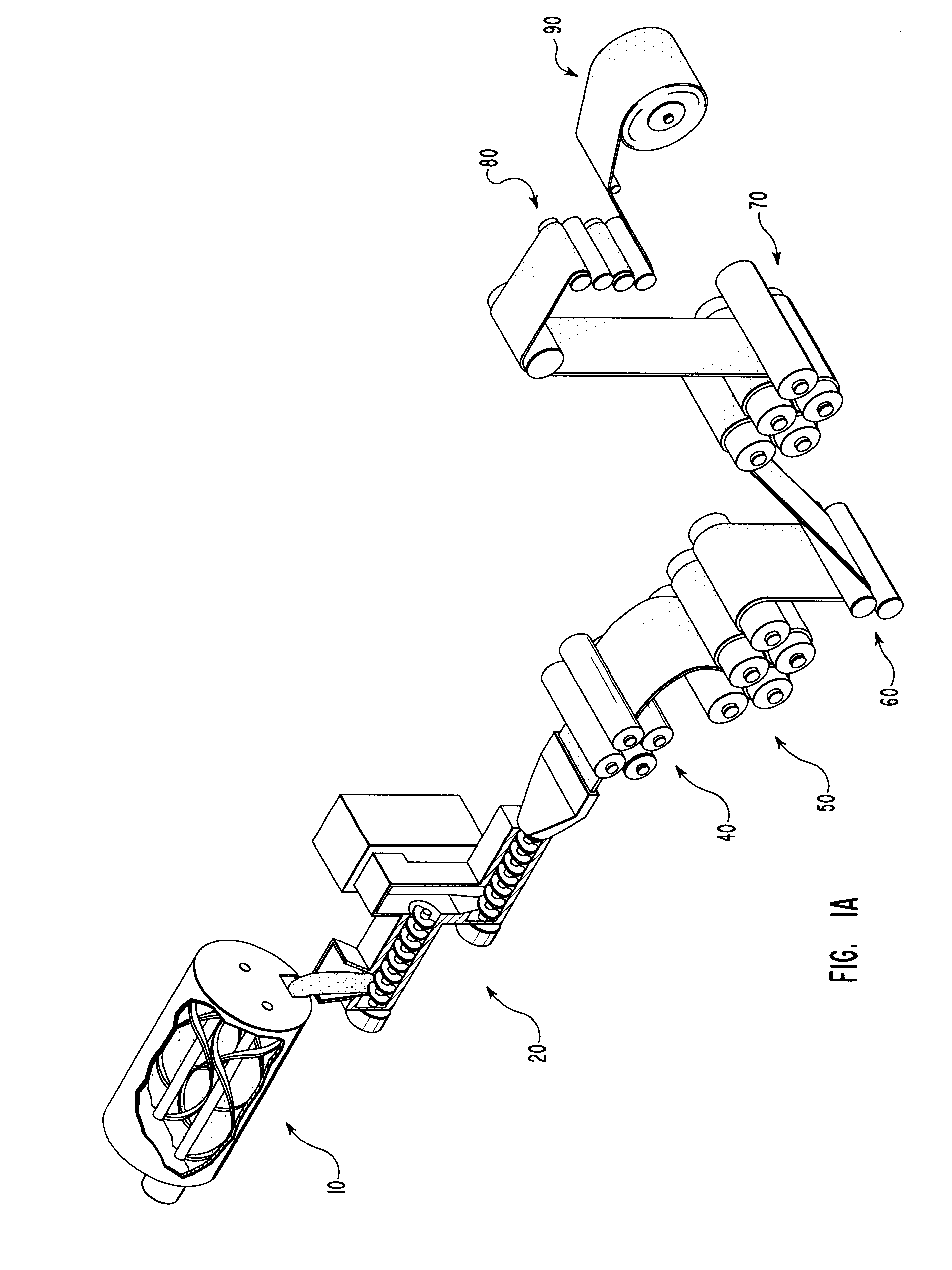

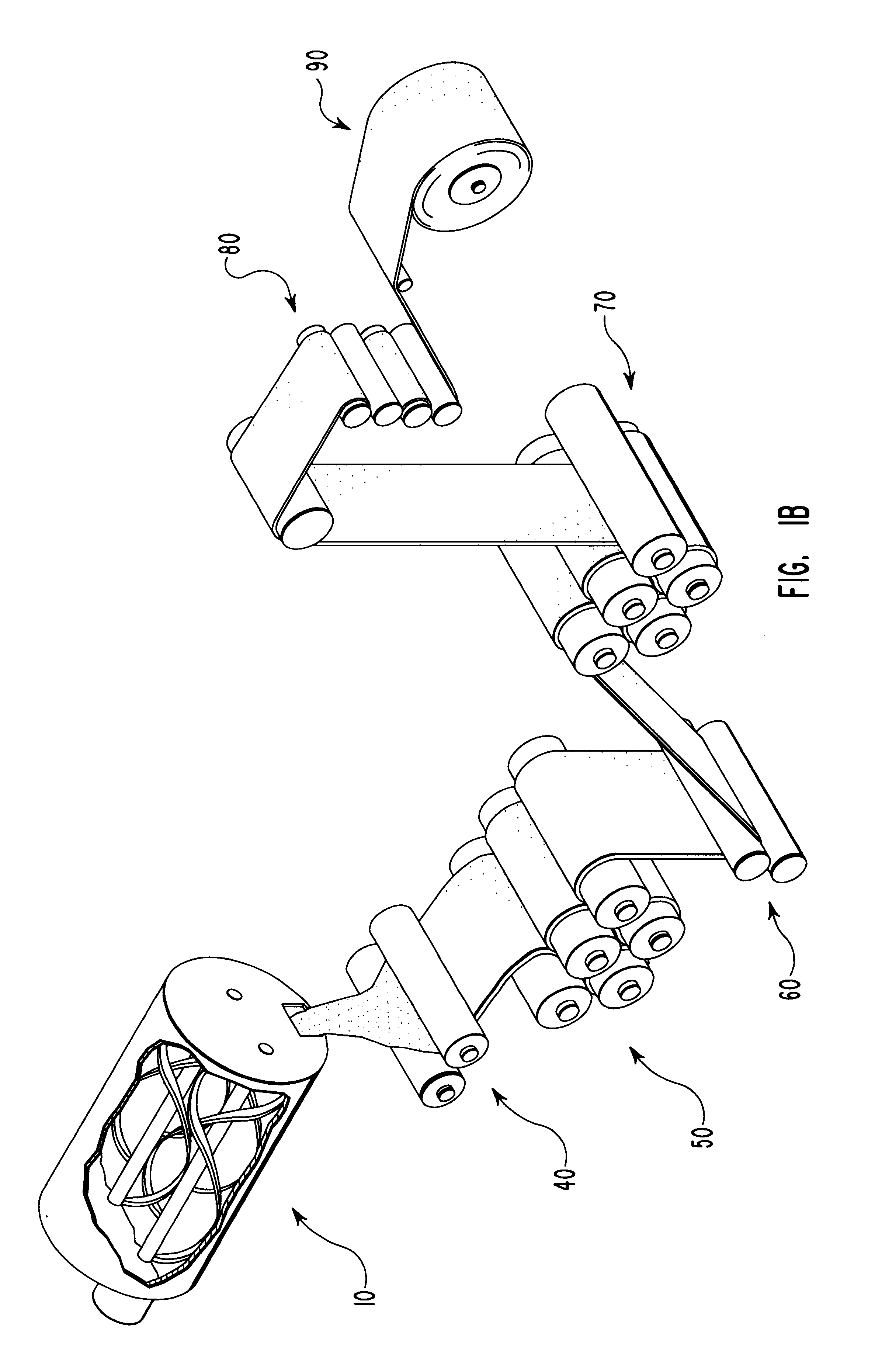

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

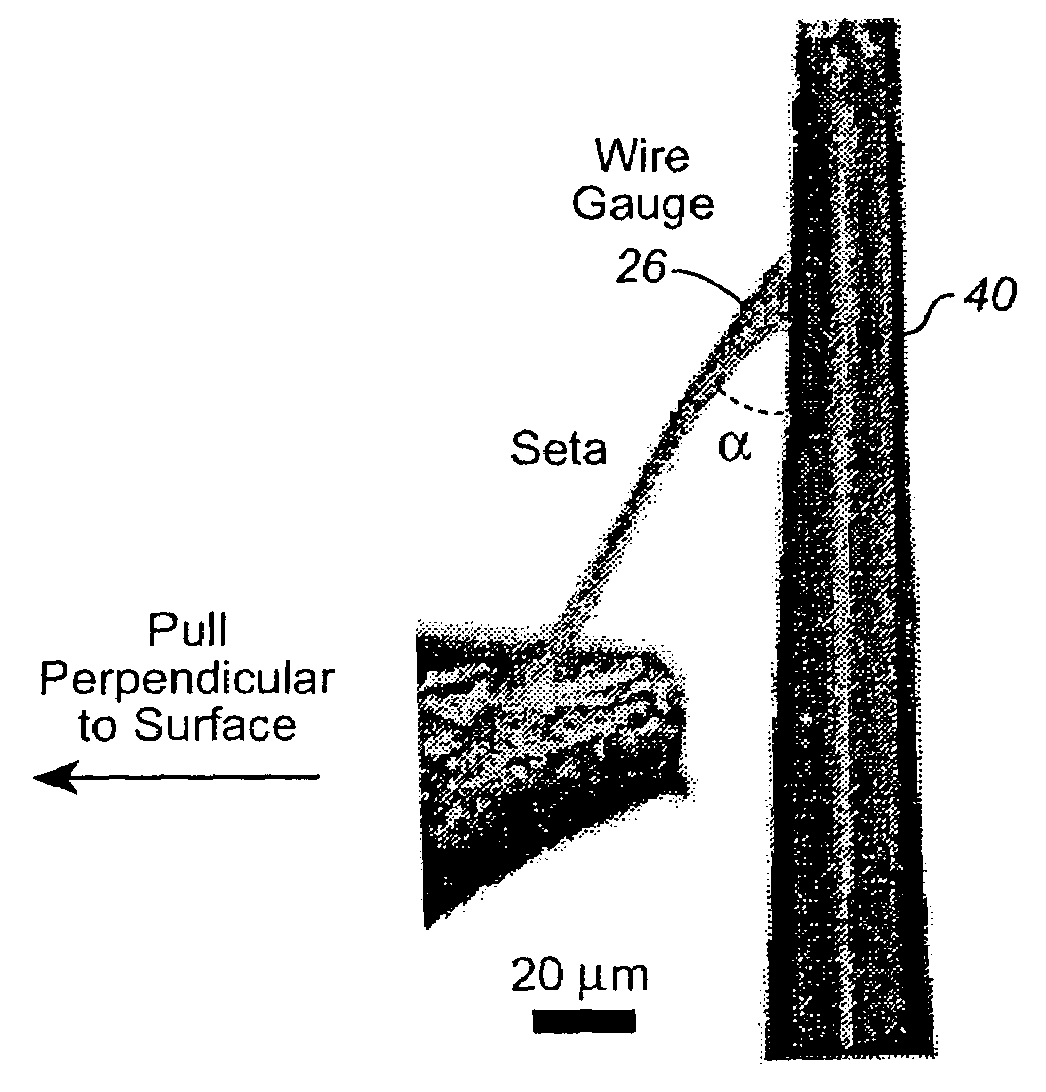

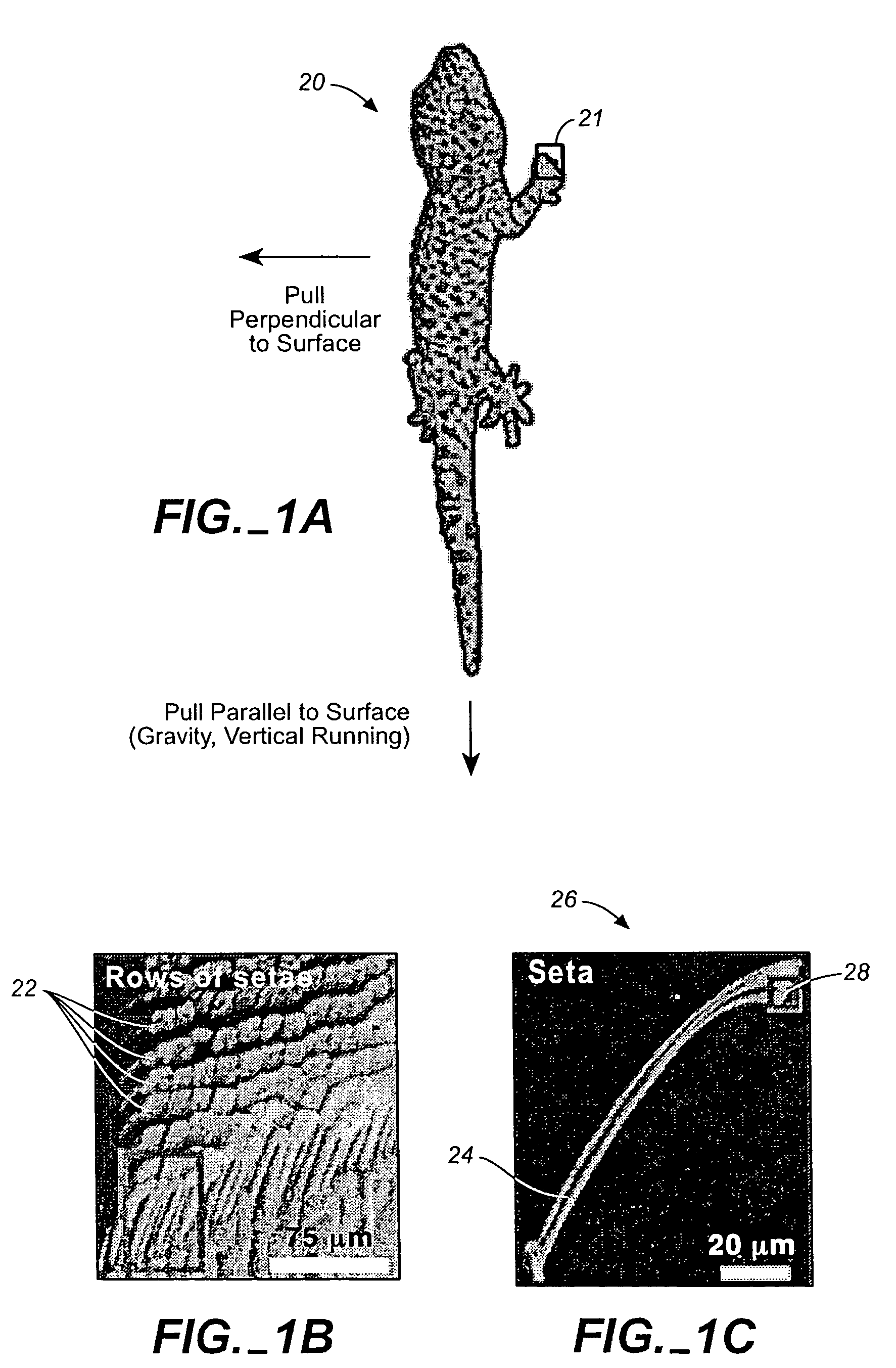

Adhesive microstructure and method of forming same

A method of forming an adhesive force includes removing a seta from a living specimen, attaching the seta to a substrate, and applying the seta to a surface so as to establish an adhesive force between the substrate and the surface. The seta is applied to the surface with a force perpendicular to the surface. The seta is then pulled with a force parallel to the surface so as to preload the adhesive force of the seta.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Structures, systems and methods for joining articles and materials and uses therefor

ActiveUS7056409B2Increase van der Waals attractionIncrease friction forceMaterial nanotechnologyAdhesive processesNanofiberMaterials science

Owner:NANOSYS INC

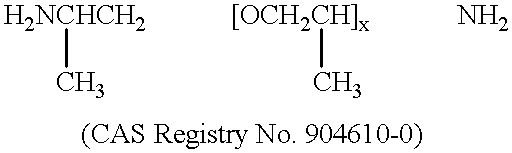

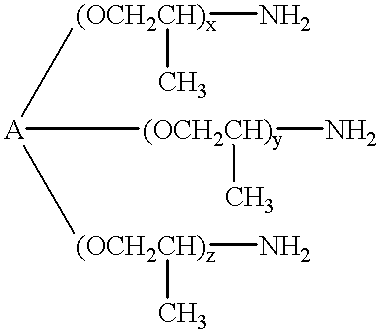

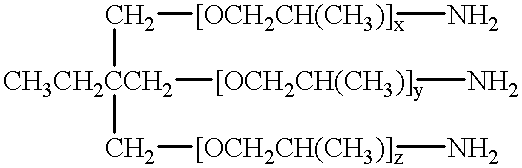

Two part, reinforced, room temperature curable thermosetting epoxy resin compositions with improved adhesive strength and fracture toughness

The present invention provides a room-temperature curable, reinforced thermosetting epoxy resin composition. The composition includes an epoxy resin first component, and an epoxy resin hardener second component. The epoxy resin component includes an epoxy resin, and may further include an inorganic and / or organic filler component, such as a structural reinforcement component. The epoxy resin hardener component includes an amine-based hardener, and may further include an inorganic and / or organic filler component. Cured reaction products of the composition demonstrate at about room temperature an adhesive strength of at least about 6500 psi, such as about 8000 to about 10000, and a fracture toughness of at least about 10 in-lbs / in.sup.2, such as about 20 to about 35 in-lbs / in.sup.2. In addition, the cured reaction products of the composition demonstrate a creep resistance at about room temperature at least about 6000 psi of at least about 1 hour. After mixing together the first and second components and at about room temperature, the composition has a pot life of at least about 3 hours at about room temperature, and after application onto a surface of a substrate has a slump resistance at about 30 minutes of less than about 0.5 inches.

Owner:LOCTITE

Spray on bandage and drug delivery system

InactiveUS6958154B2Maximum flexibilityEasy to prepareCosmetic preparationsAdhesive processesDrug deliveryFluid composition

The present invention provides novel “patch in a bottle” technology in which a fluid composition, e.g., an aerosol spray, is applied onto a surface as a fluid, but then dries to form a covering element, such as a patch, having a tack free outer surface covering an underlying adhesive that helps adhere the patch to the substrate. The fluid compositions have a unique chemical formulation that allows such composite patches to form in situ. Specifically, the fluid compositions include a tacky component, such as an adhesive, and a film-forming, non-tacky component. The non-tacky and tacky components are selected to be immiscible with each other so that the components undergo phase separation as the fluid composition dries.

Owner:3M INNOVATIVE PROPERTIES CO

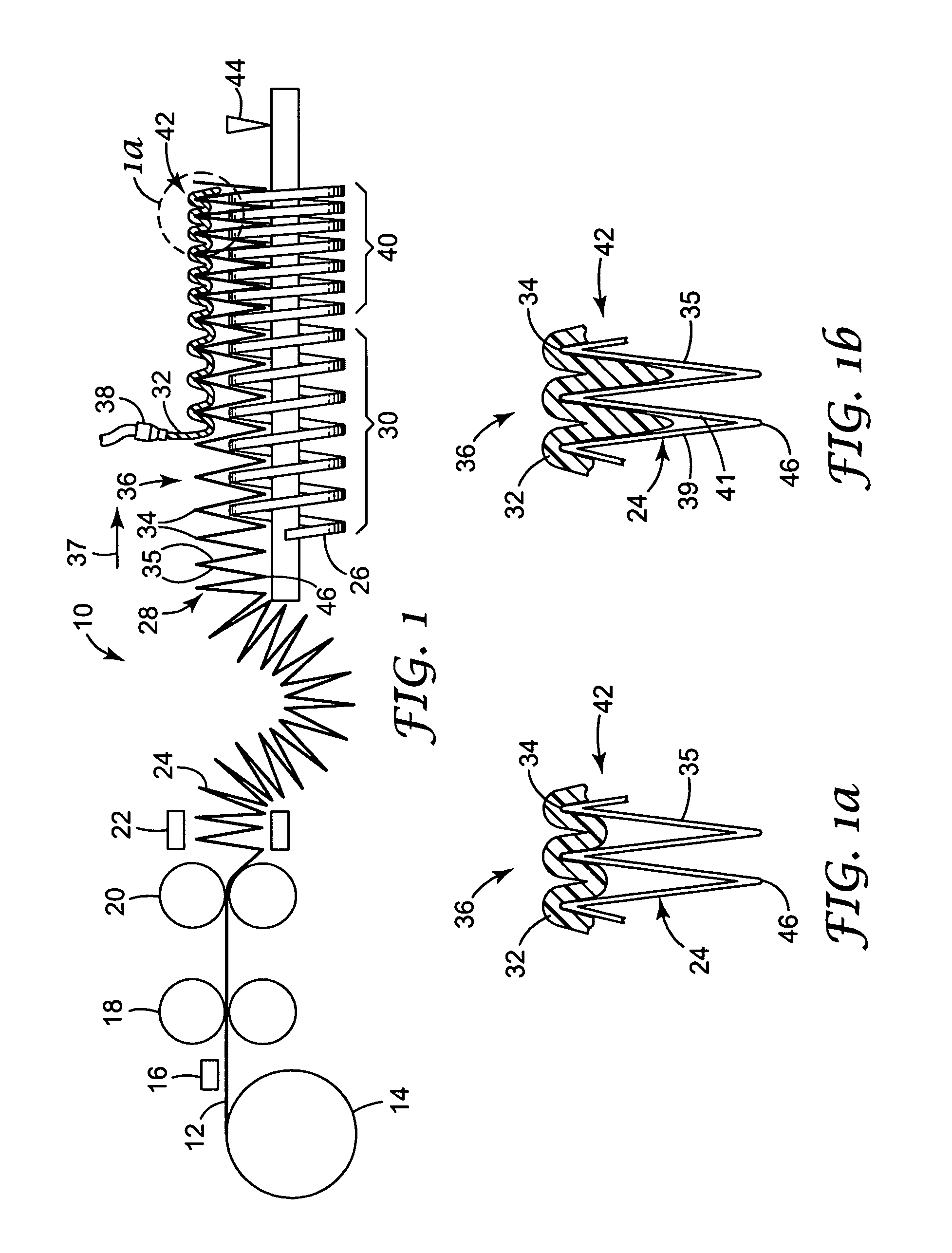

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

Flexible electronic circuits and displays

InactiveUS20110140744A1Adhesive processesSemiconductor/solid-state device manufacturingMetal foilDisplay device

A backplane for use in an electro-optic display comprises a patterned metal foil having a plurality of apertures extending therethrough, coated on at least side with an insulating polymeric material and having a plurality of thin film electronic devices provided on the insulating polymeric material.

Owner:E INK CORPORATION

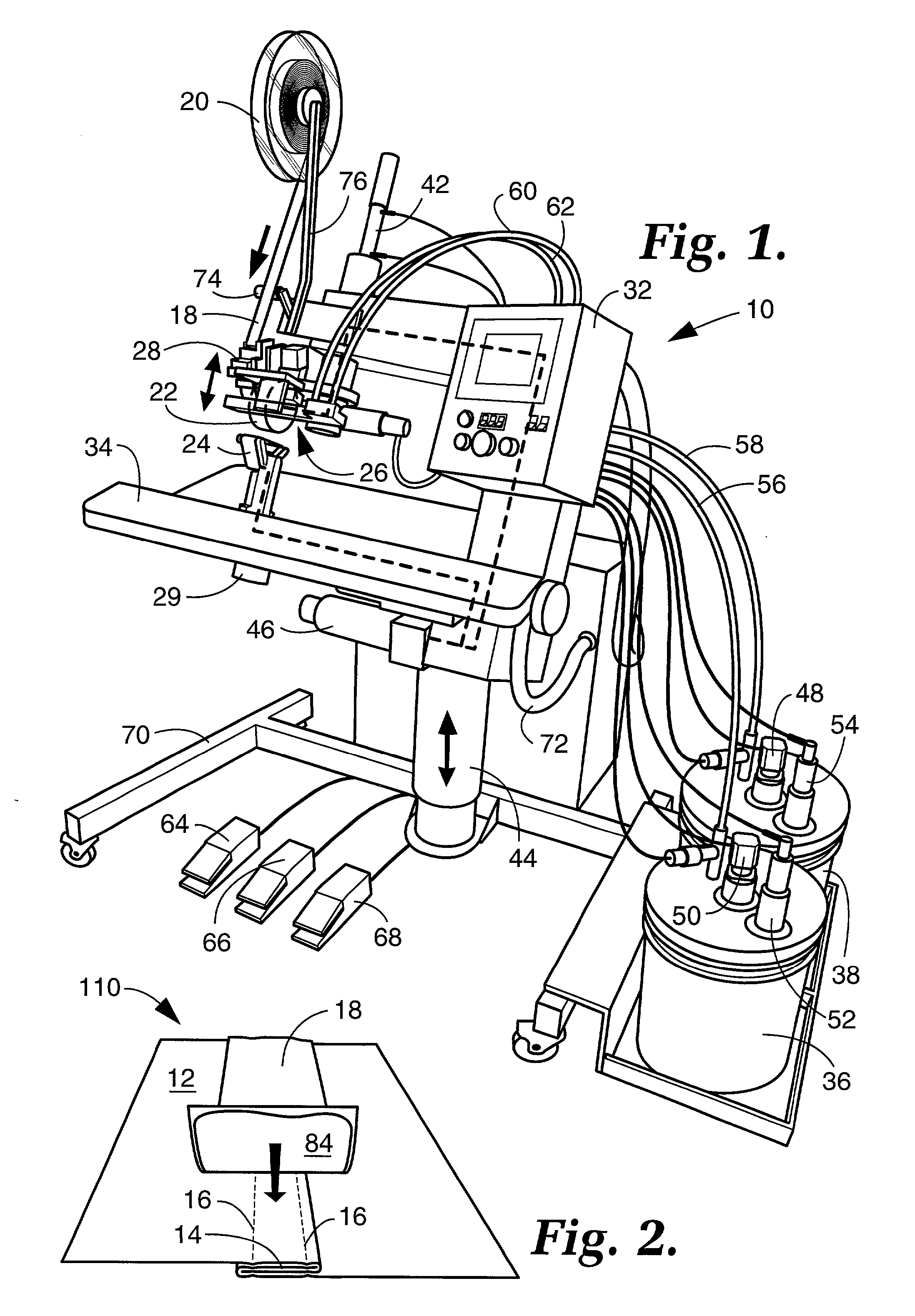

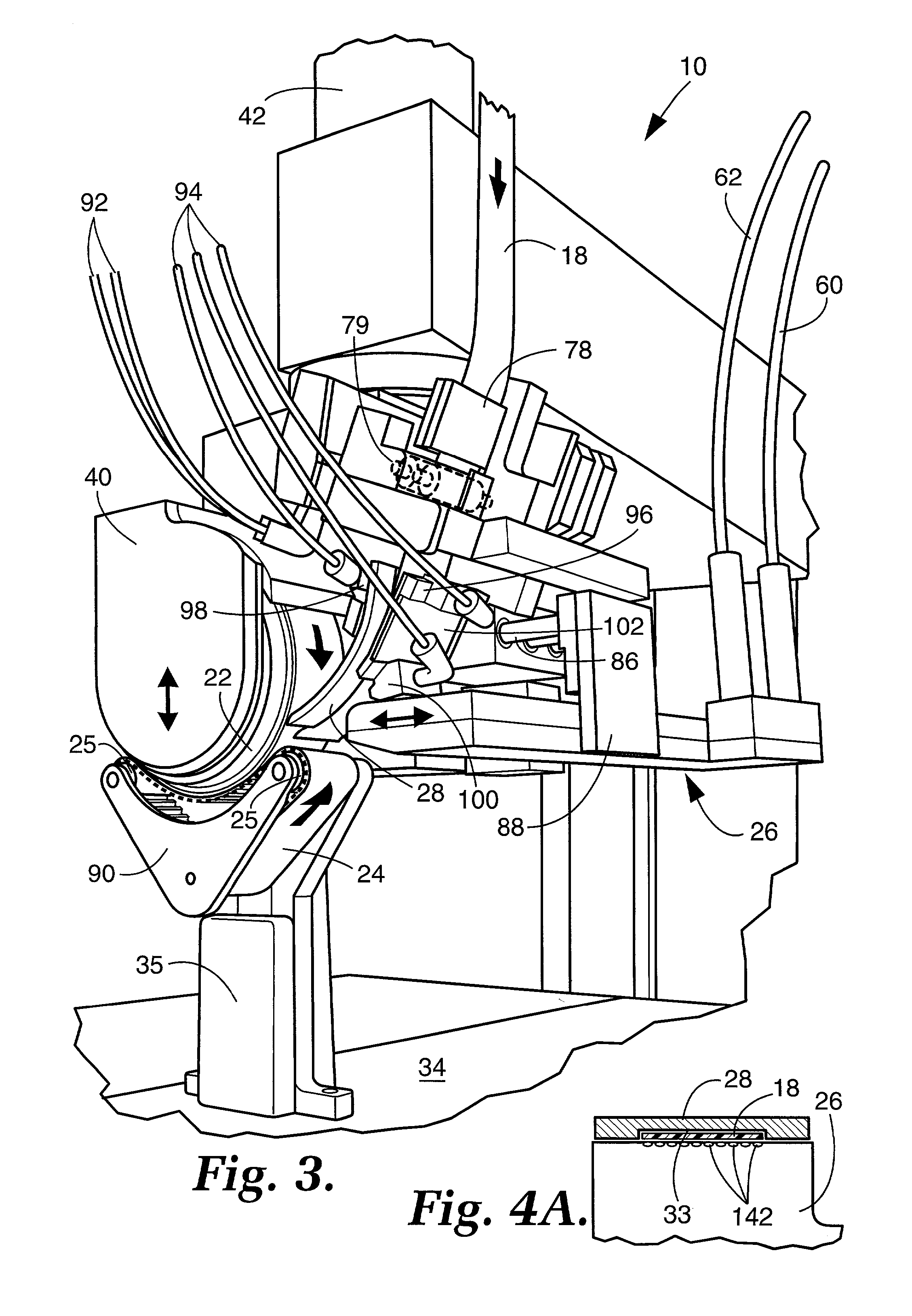

Seam sealing apparatus and process therefor

InactiveUS20030010439A1Easy to cleanWell mixedAdhesive processesManual label dispensersAdhesiveSurgical Gowns

Apparatus and a method for sealing of protective barrier fabric seams in otherwise impermeable articles such as garments, footwear, surgical gowns and the like, are provided, the sealed seams maintaining the imperviousness of the article, including seamed joints, to water, body fluids, pathogens and chemicals. In one pass through the apparatus, a sealed seam in a protective barrier fabric joint, using a curable adhesive sealant, is provided along a predetermined and specified length of the joint. The preferred adhesive is a silicone, most preferably a two-part, thermosetting silicone elastomeric adhesive. Also provided are mixing dies for use, inter alia, in the process which are especially suited for applying the two-part adhesive sealant. In addition, variable-residence-time curing apparatus, which effects variable, controlled, desired cures of the adhesive, all in a one-pass operation, is provided, together with precise metering pumps, especially suited for supplying the seam sealing adhesives in the process of the invention.

Owner:WL GORE & ASSOC INC

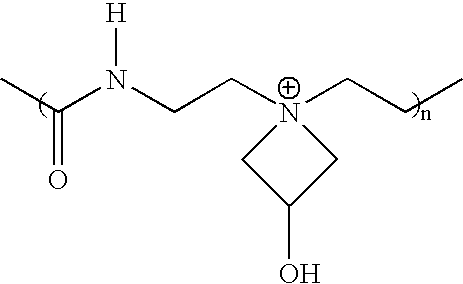

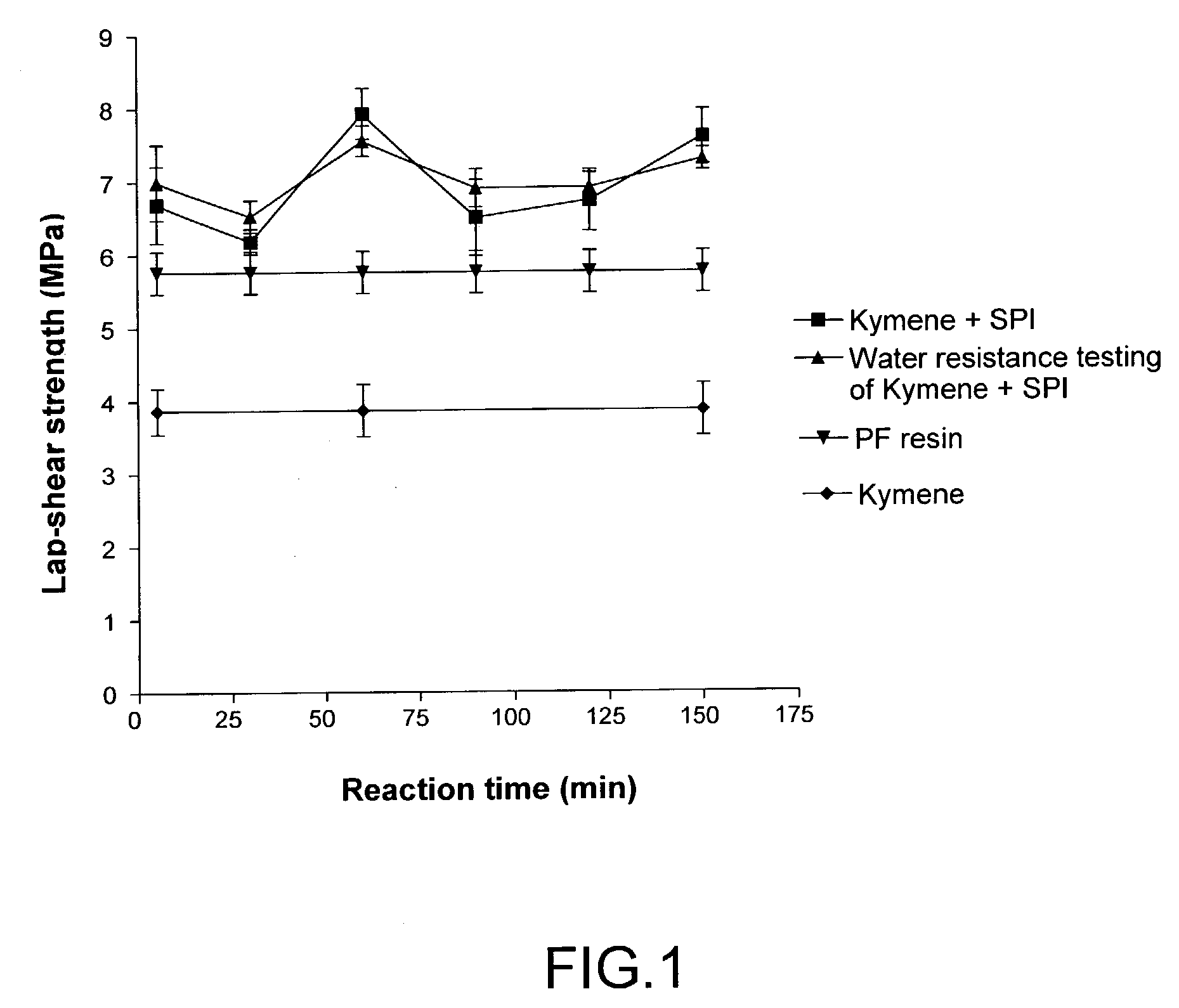

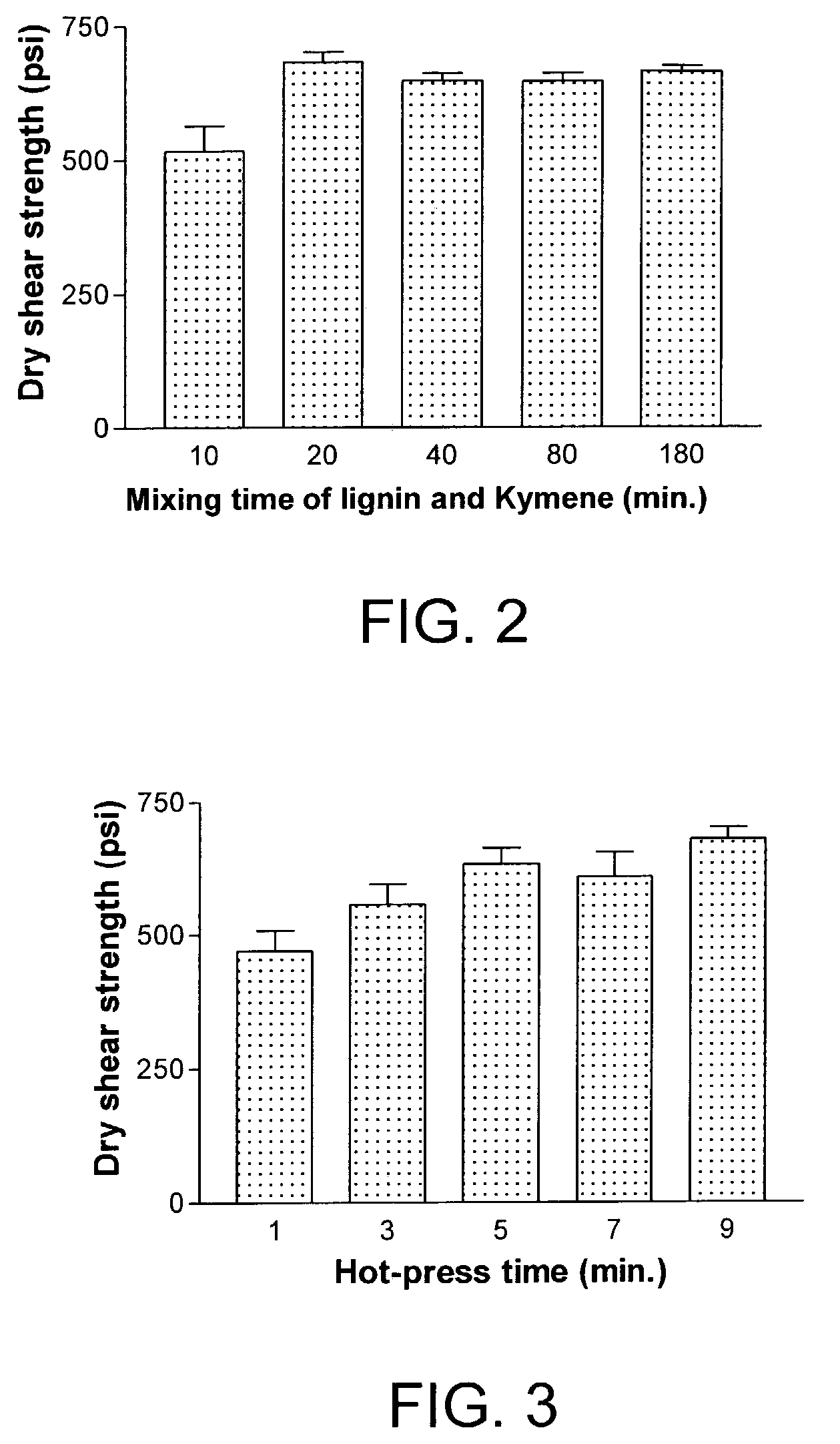

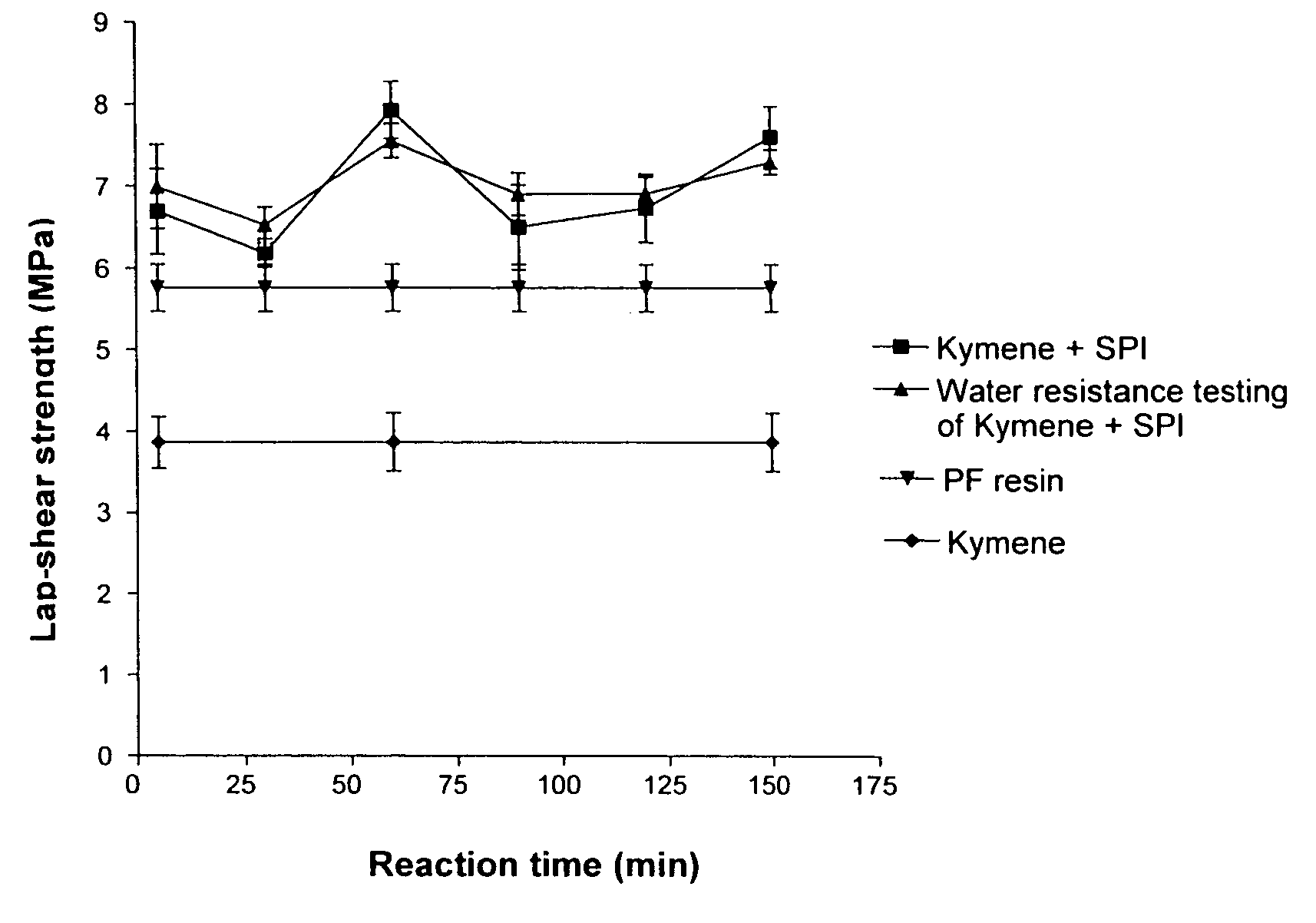

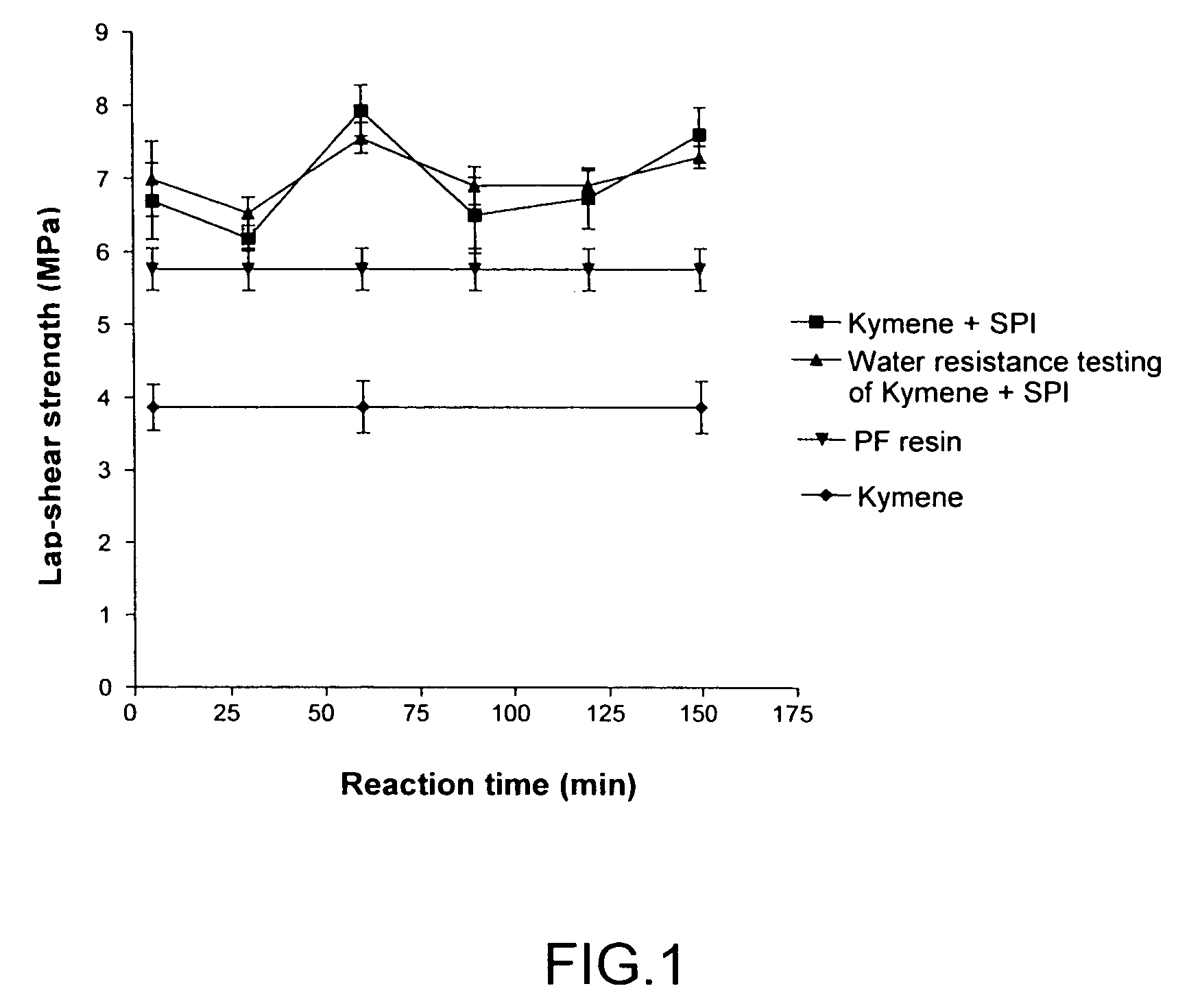

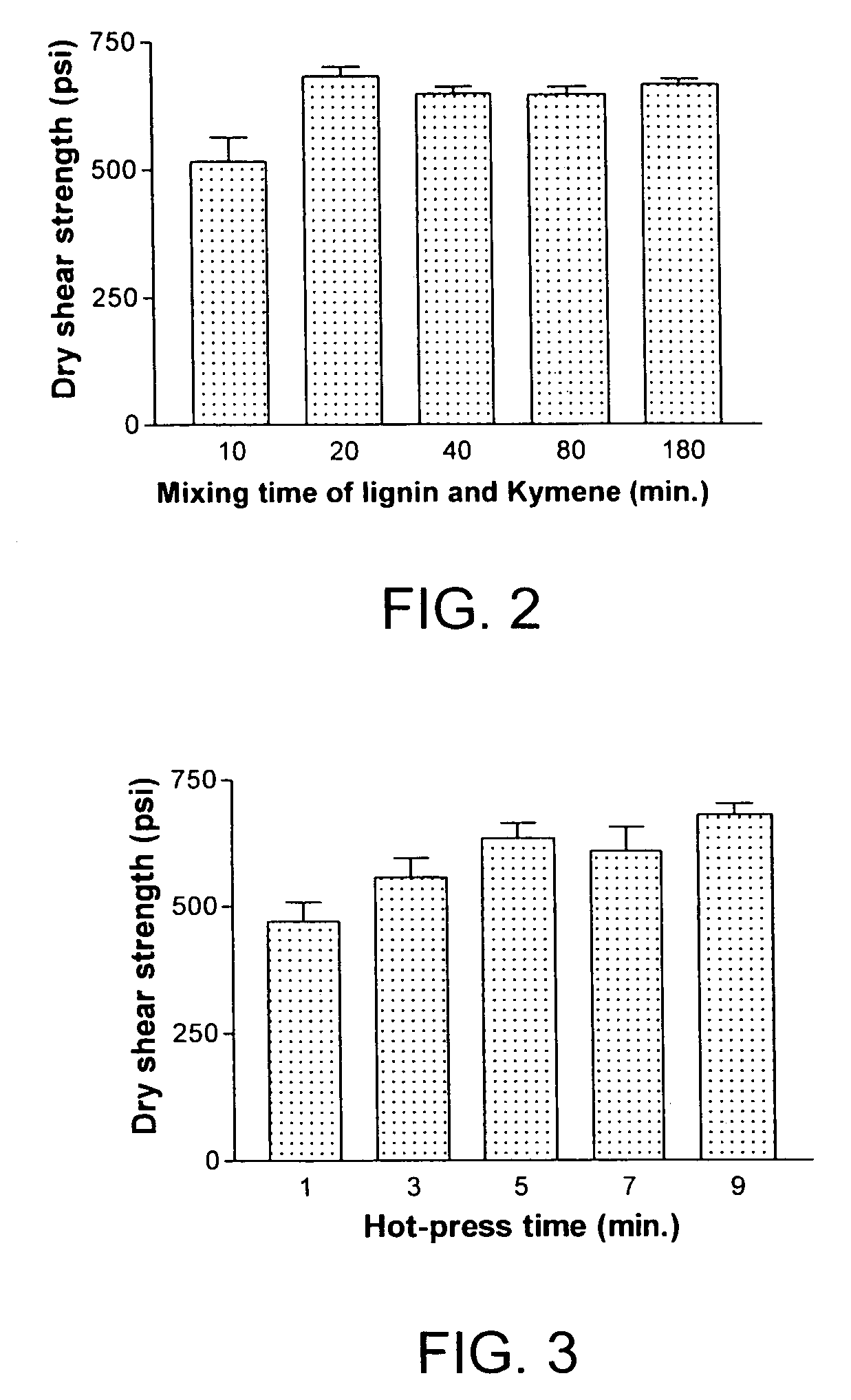

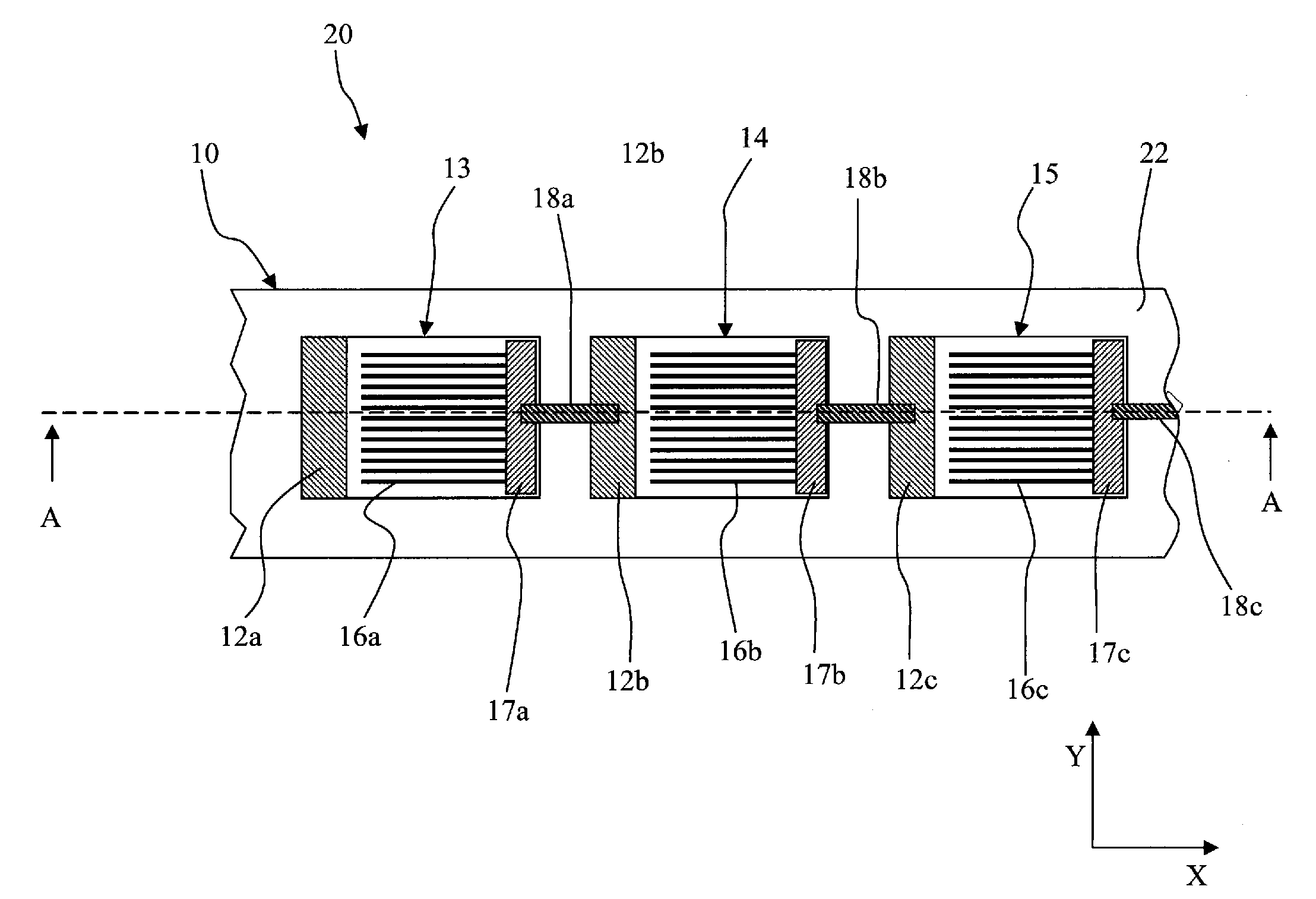

Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives

Method for making lignocellulosic composites by adhering lignocellulosic substrates together. A first variant of the method involves using an adhesive composition that comprises a reaction product of (i) first ingredient selected from a soy protein or lignin and (ii) at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein. A second variant of the method involves using an adhesive composition that comprises a reaction product of (i) a protein or lignin, (ii) a first compound that includes at least one amine, amide, imine, imide or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the protein and (iii) a curing agent.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Structural hot melt material and methods

InactiveUS6887914B2Reduce and eliminate stepAvoid corrosionAdhesive processesNon-macromolecular adhesive additivesEpoxyHot melt

The present invention relates to a material, method, and application for reinforcement of structural members, especially joints such as a hem flange joint of an automobile. The method and material of the present invention comprises of combining, in parts by weight: less than about twenty percent (<20%) ethylene copolymer, less than about forty percent (<40%) epoxy, less than about thirty percent (<45%) epoxy-based resin, less than about two percent (<2%) blowing agent and from about one percent (1%) to about five percent (5%) curing agent (and optionally add any of the following components: less than about two percent (<2%) curing agent accelerator, from about twenty-five percent (25%) to fifty-five percent (55%) filler, and less than about one percent (<1%) of coloring agent). The application of the present invention comprises of: (1) providing a structural member having two substrates forming a space to be joined; (2) placing the material of the present invention in proximity of the space to be joined; (3) exposing the material to a heat source causing it to flow, fill, and cure in the defined area or space to be joined.

Owner:ZEPHYROS INC

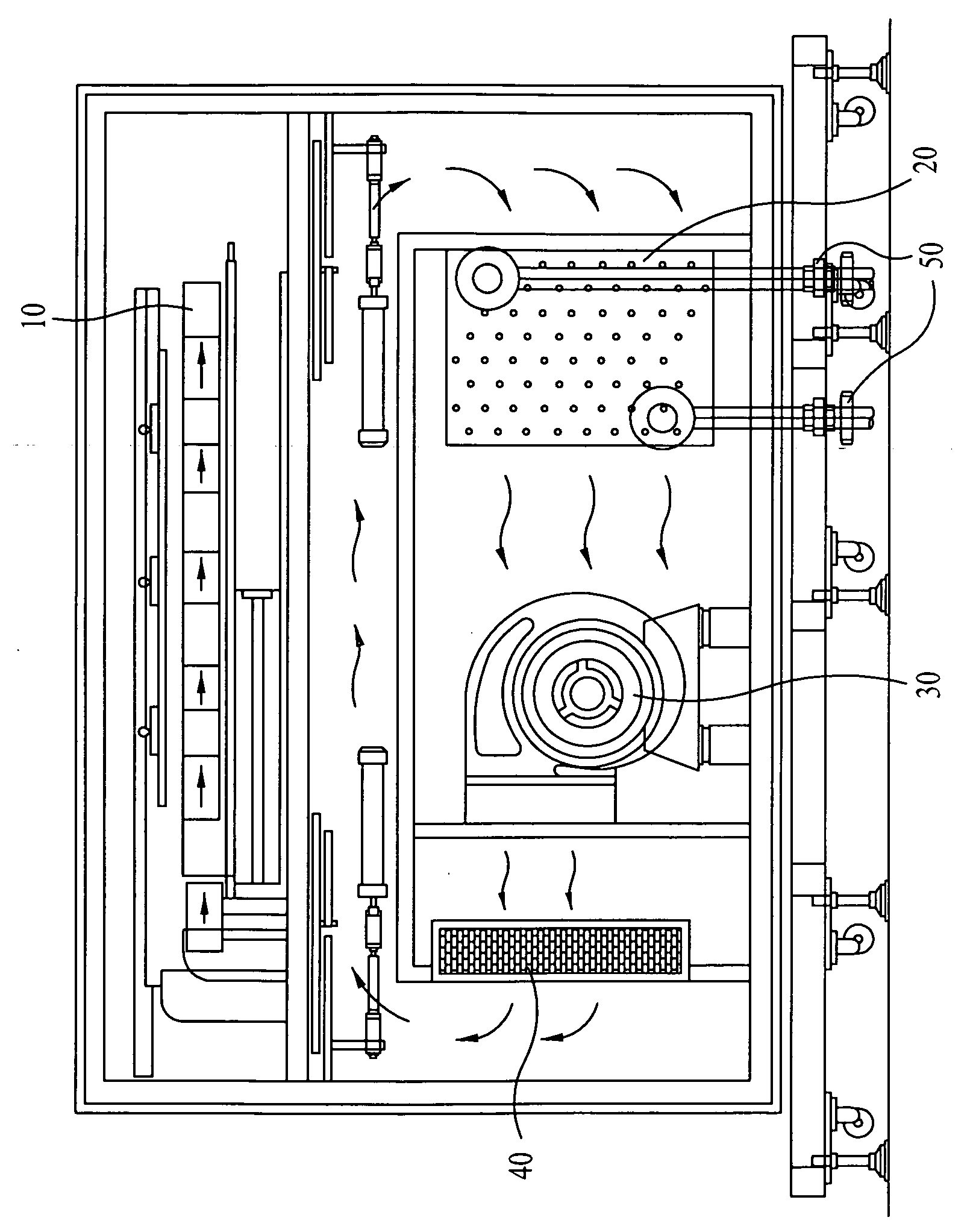

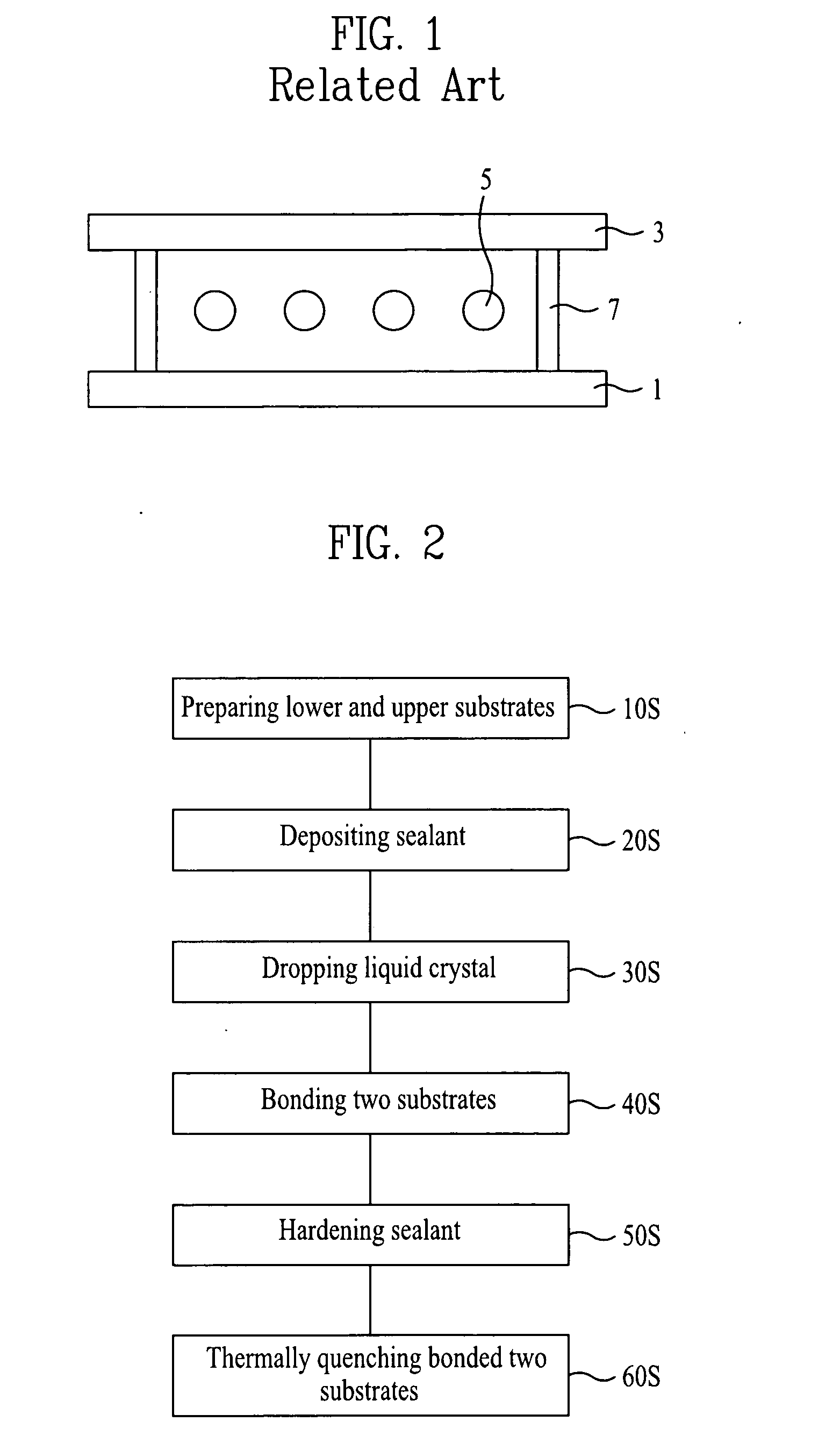

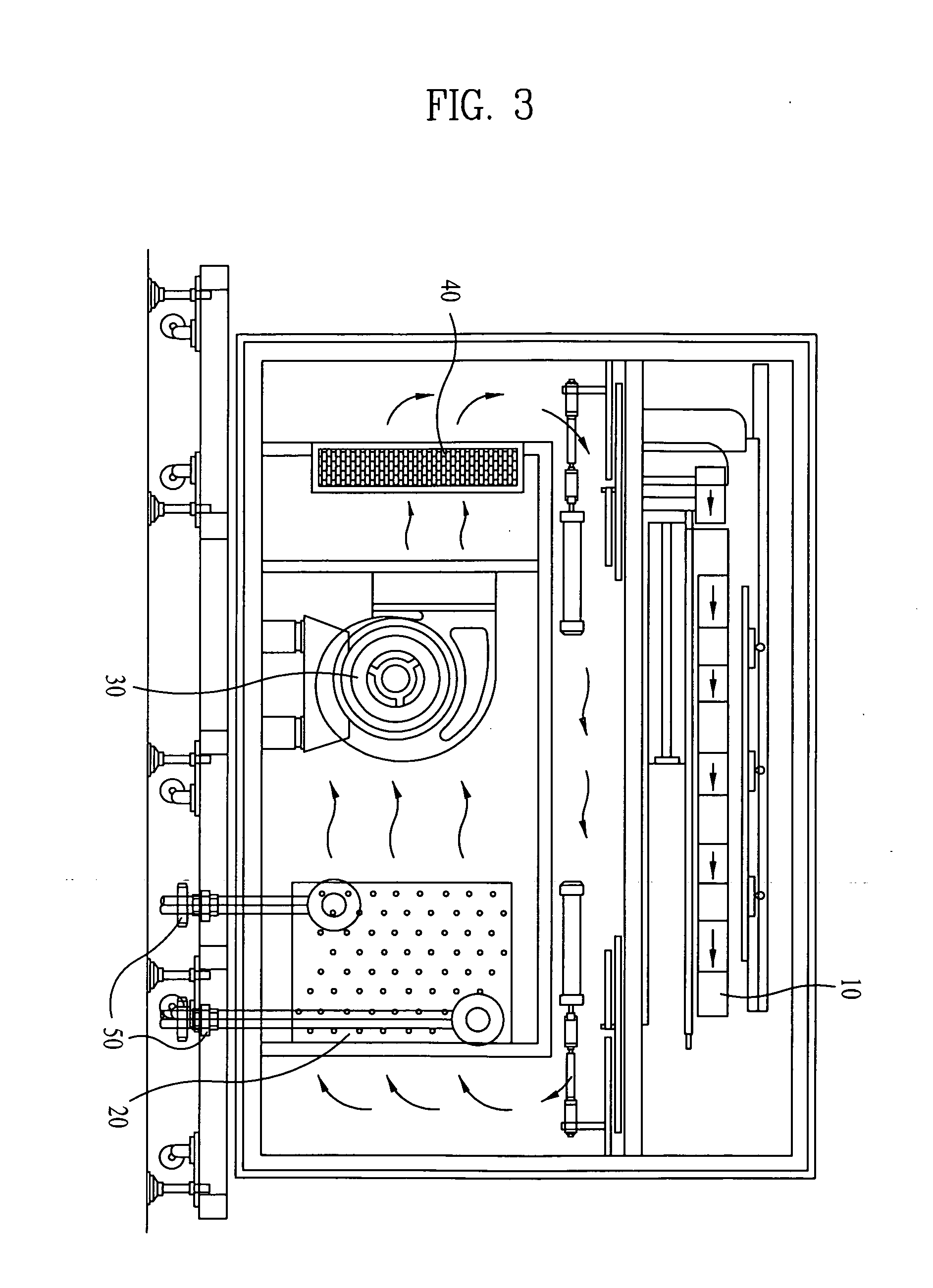

Cooling apparatus and method for manufacturing liquid crystal display device using the same

A method for manufacturing a liquid crystal display device includes preparing a lower substrate and an upper substrate; depositing a sealant on one of the two substrates; dropping a liquid crystal on one of the two substrates; bonding the two substrates to each other; bonding the two substrates to each other by hardening the sealant; and thermal quenching the two bonded substrates. Since thermal quenching of the two bonded substrates is additionally performed after hardening of the sealant is performed using a liquid crystal dropping method, orientation of a liquid crystal layer, which is scattered by the hardening of the sealant, is returned to its original state, thus preventing domain defects.

Owner:LG DISPLAY CO LTD

Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives

Method for making lignocellulosic composites by adhering lignocellulosic substrates together. A first variant of the method involves using an adhesive composition that comprises a reaction product of (i) first ingredient selected from a soy protein or lignin and (ii) at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein. A second variant of the method involves using an adhesive composition that comprises a reaction product of (i) a protein or lignin, (ii) a first compound that includes at least one amine, amide, imine, imide or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the protein and (iii) a curing agent.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

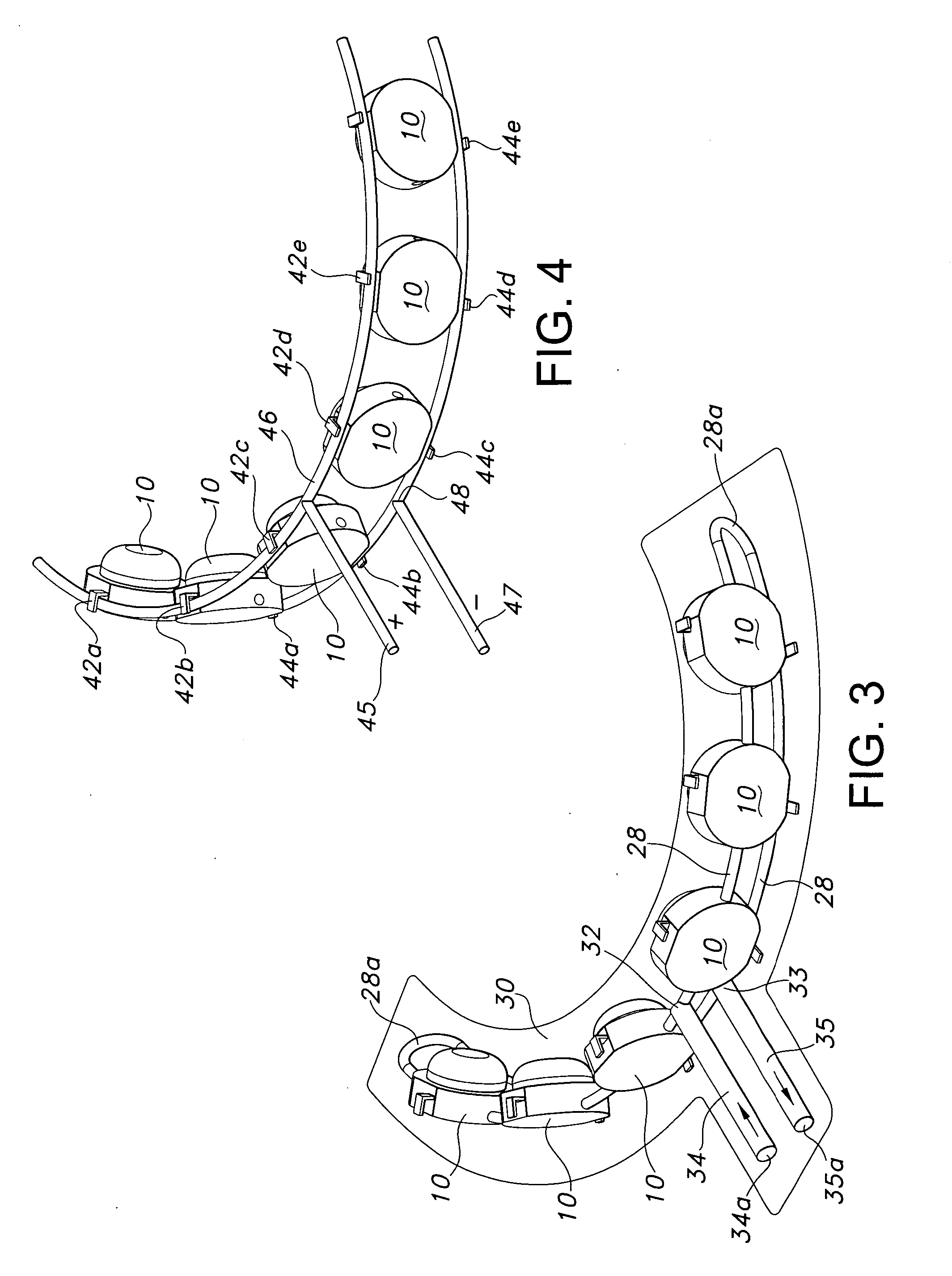

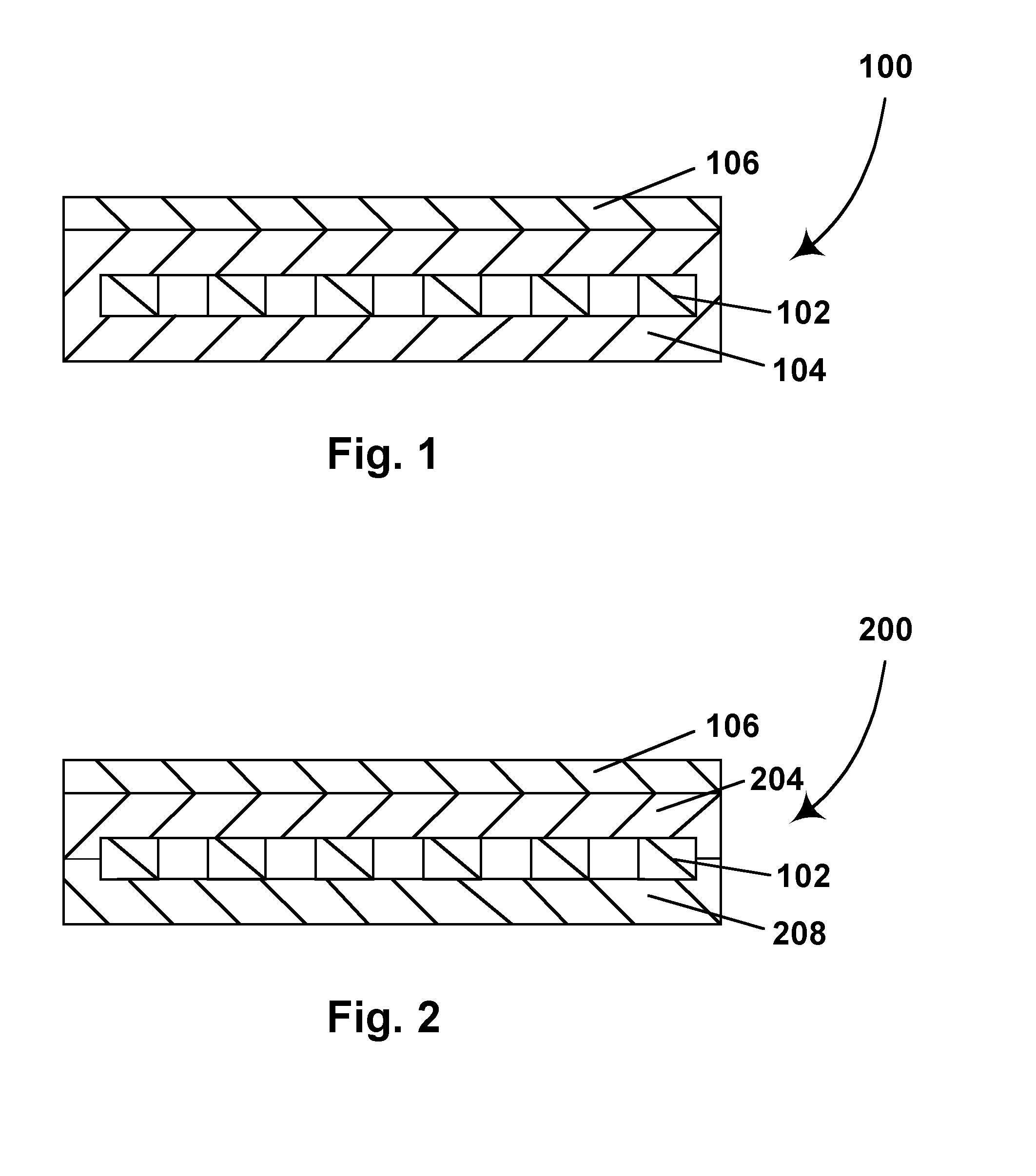

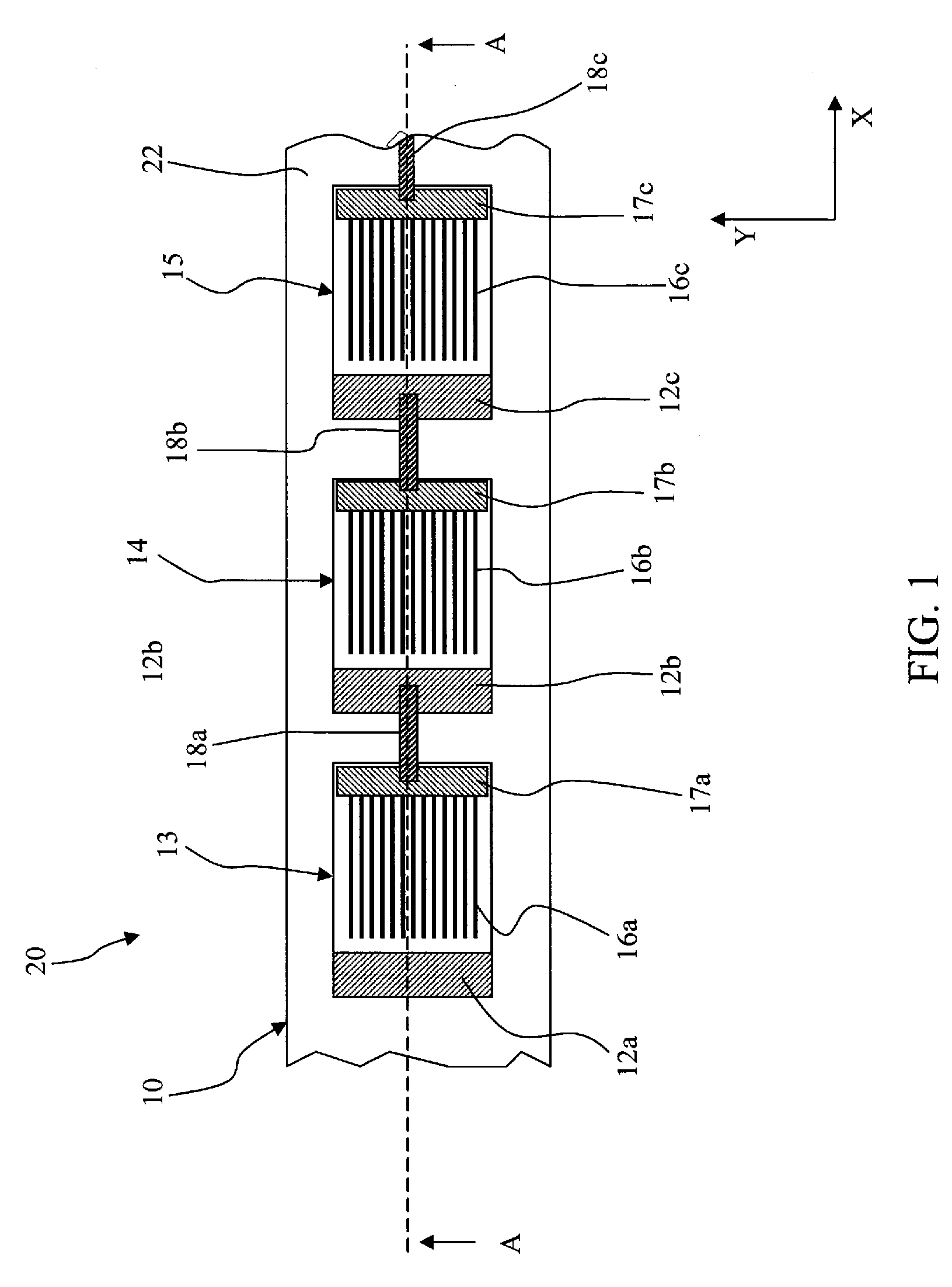

Solar Cell Interconnection on a Flexible Substrate

InactiveUS20100282288A1High bulk densityRobust interconnectionAdhesive processesPV power plantsElectrical batteryEngineering

A solar cell array comprising: a substrate having a carrier surface on which a plurality of electrically conductive bonding pads are provided, the bonding pads being spaced from one another along a main direction; a plurality of solar cells, each solar cell of the plurality including a back electrode bonded to a first portion of a respective bonding pad, wherein each bonding pad comprises a second portion defining an exposed contact region not covered by the back electrode of the respective solar cell, and wherein an interconnecting lead electrically connects the second portion of the bonding pad associated with a first solar cell with an electrode of a directly adjacent second solar cell.The substrate is an electrically insulating substrate and preferably a flexible film, made for instance of polyimide material.

Owner:EMCORE SOLAR POWER

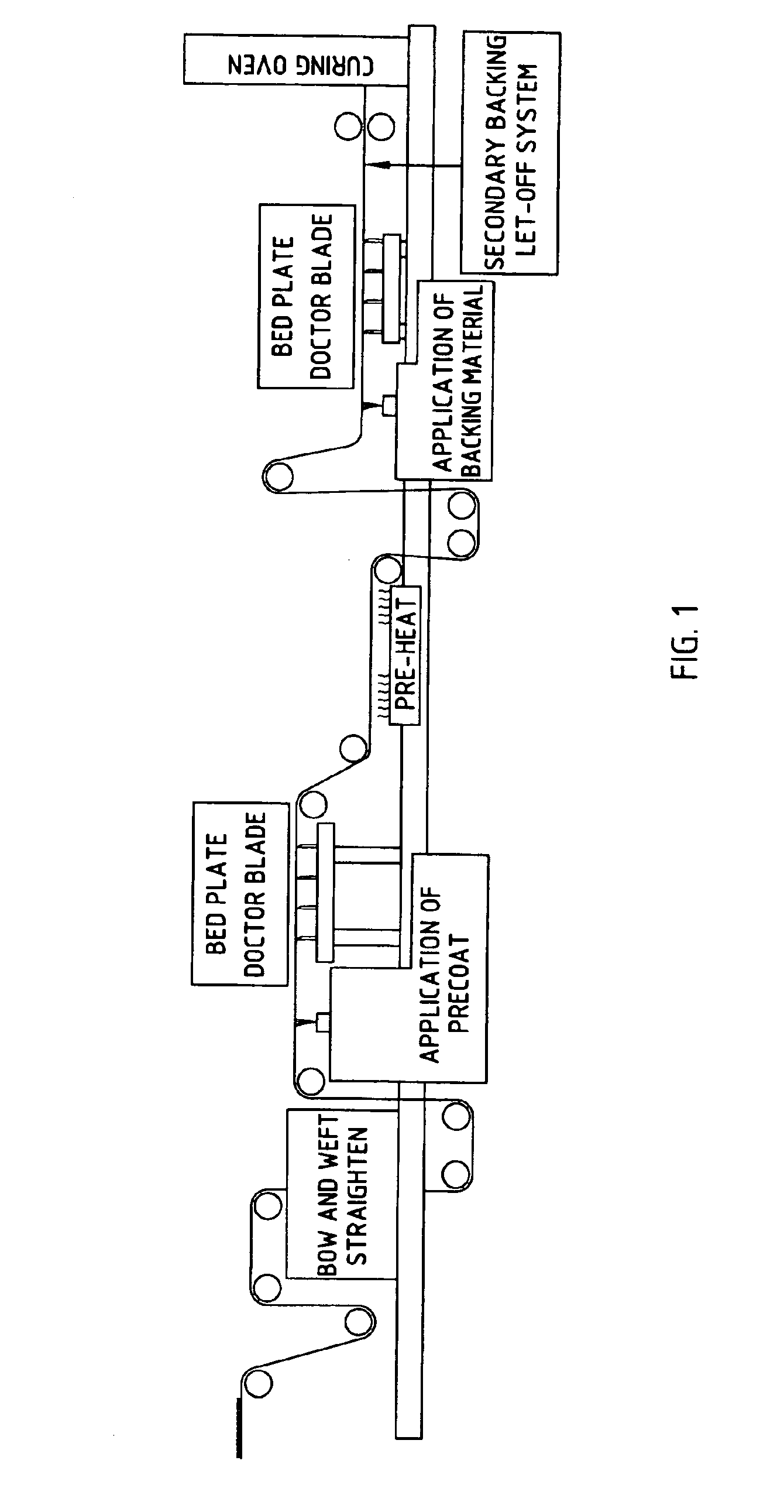

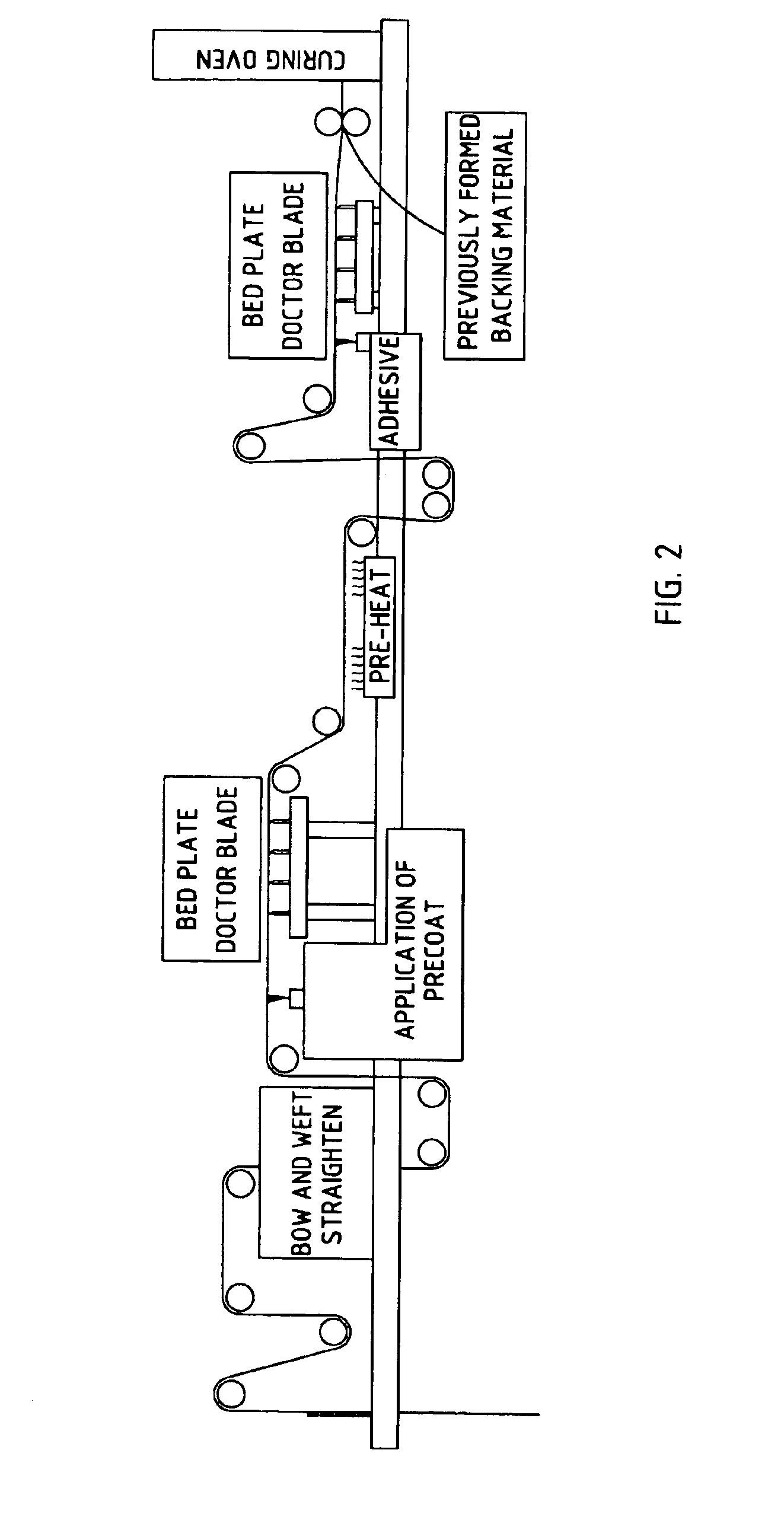

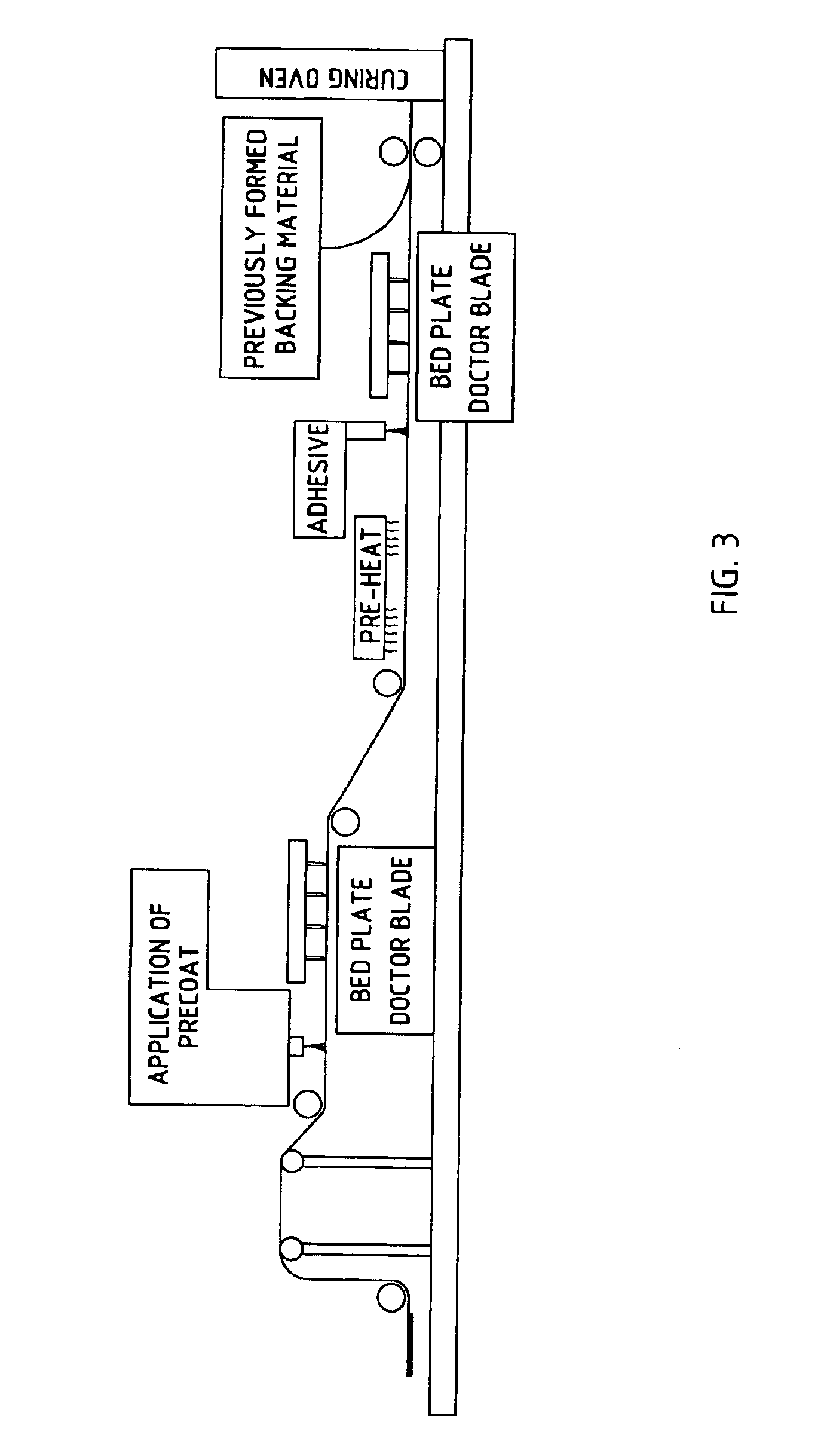

Method of producing a bio-based carpet material

The present invention includes a method for making a bio-based carpet material by providing tufts, a backing, a pre-coat, and a backing material wherein the pre-coat includes the reaction product of a pre-coat A-side having a pre-coat isocyanate and a pre-coat B-side and the backing material includes the reaction product of a backing material A-side having a backing material B-side. The pre-coat B-side and the backing material B-side may include a petroleum based polyol; a vegetable oil, cross-linker, and a catalyst; or a transesterified polyol.

Owner:RHINO LININGS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com