Patents

Literature

18806results about How to "Avoid corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

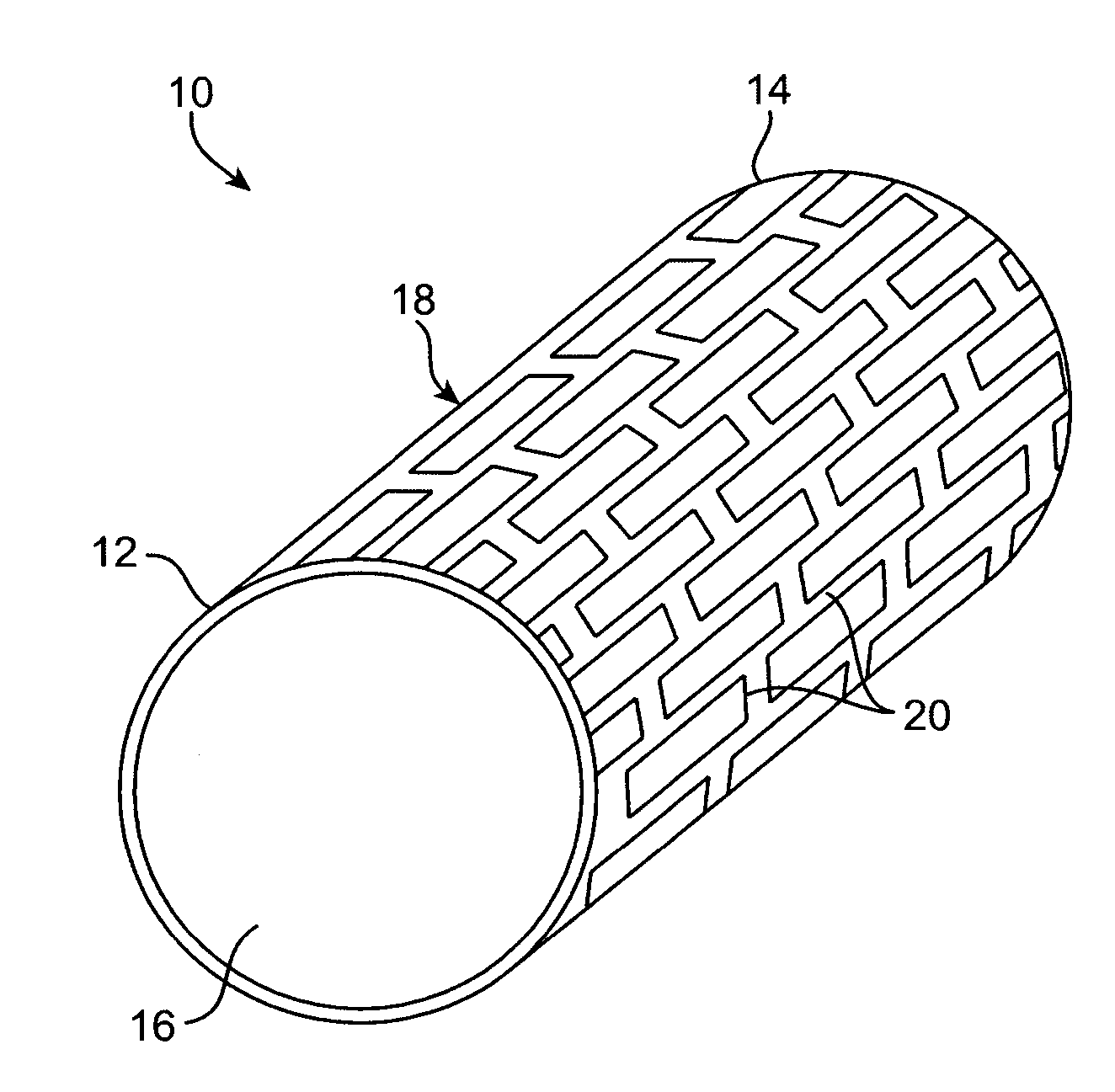

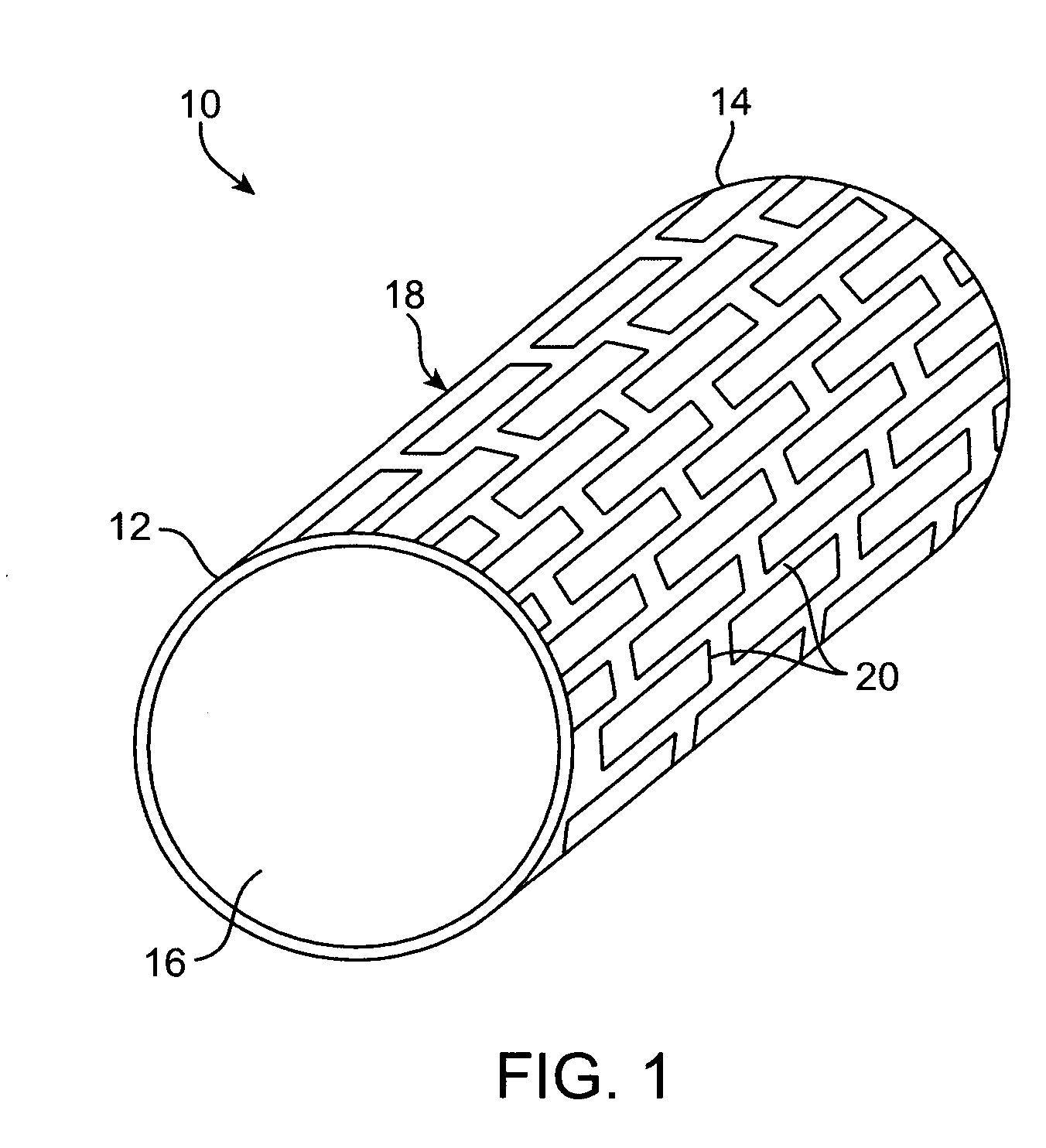

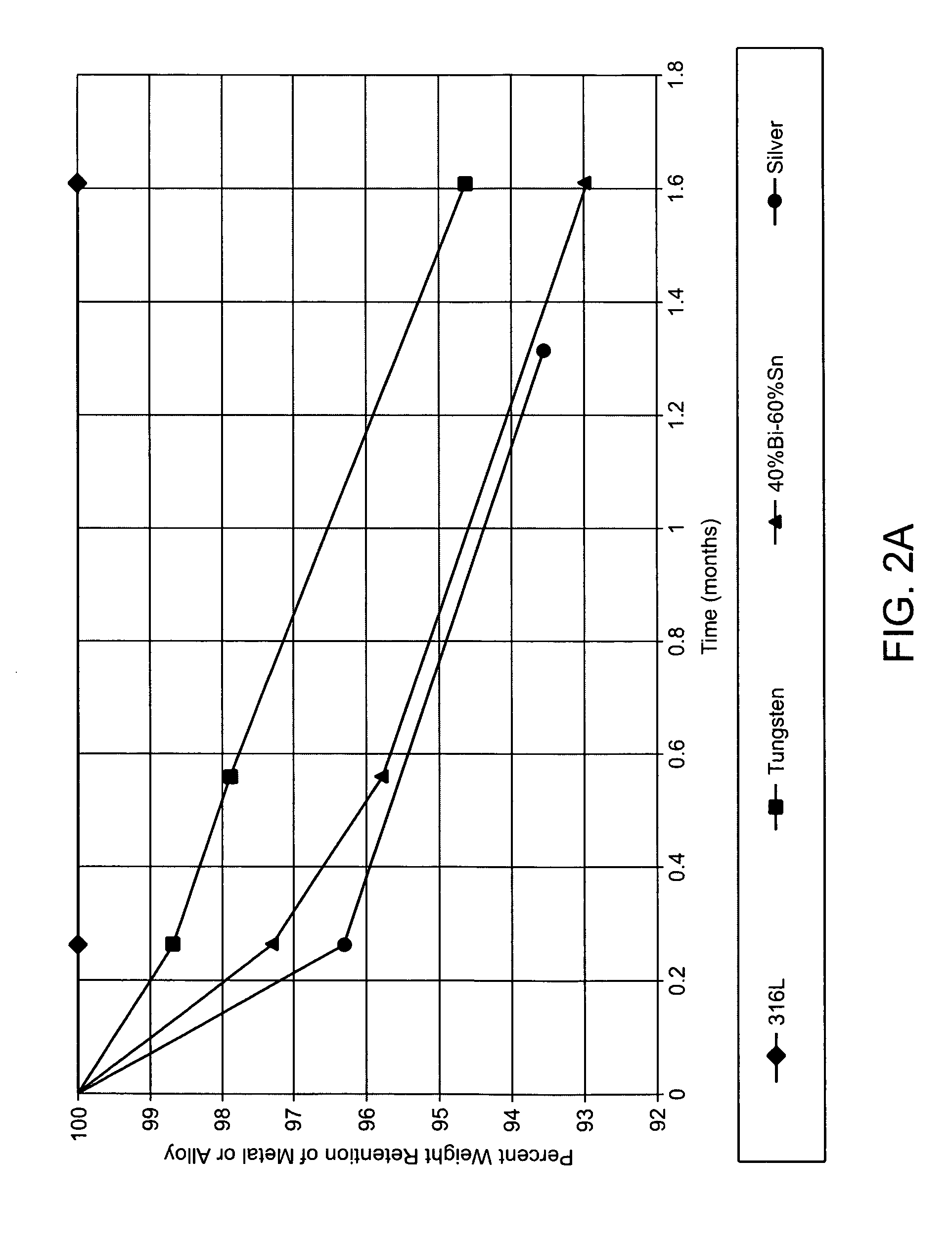

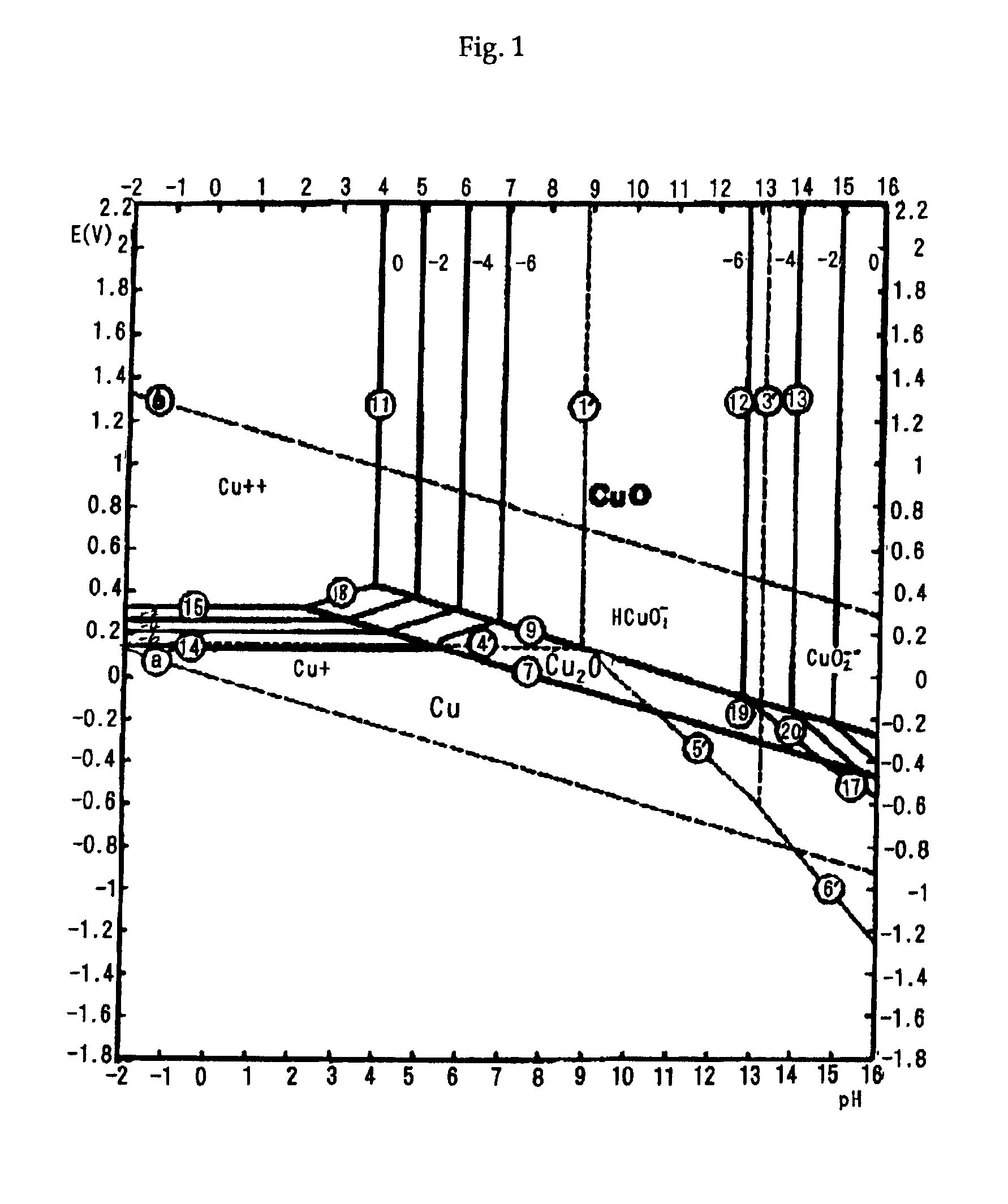

Degradable implantable medical devices

InactiveUS20060229711A1Reduce probabilityLower resistanceStentsBlood vesselsVascular implantBlood vessel

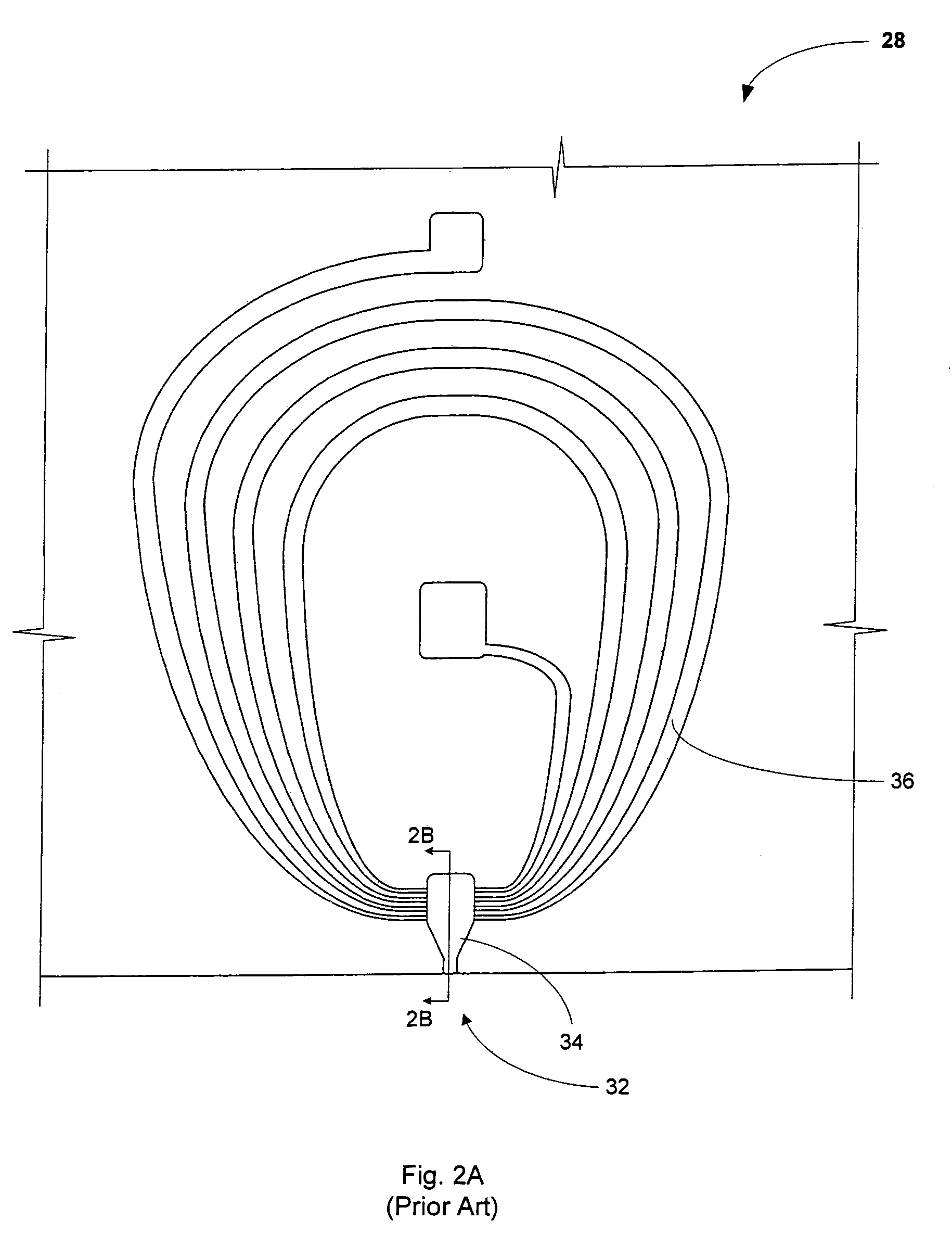

Devices and methods are provided for an implantable medical device which is degradable over a clinically relevant period of time. The medical devices may have the form of implants, graft implants, vascular implants, non vascular implants, wound closure implants, sutures, drug delivery implants, biologic delivery implants, urinary tract implants, inter-uterine implants, organ implants, bone implants including bone plates, bone screws, dental implants, spinal disks, or the like. In preferred embodiments, the implantable medical device comprises an implantable luminal prosthesis, such as vascular and non-vascular stents and stents grafts.

Owner:ELIXIR MEDICAL CORP

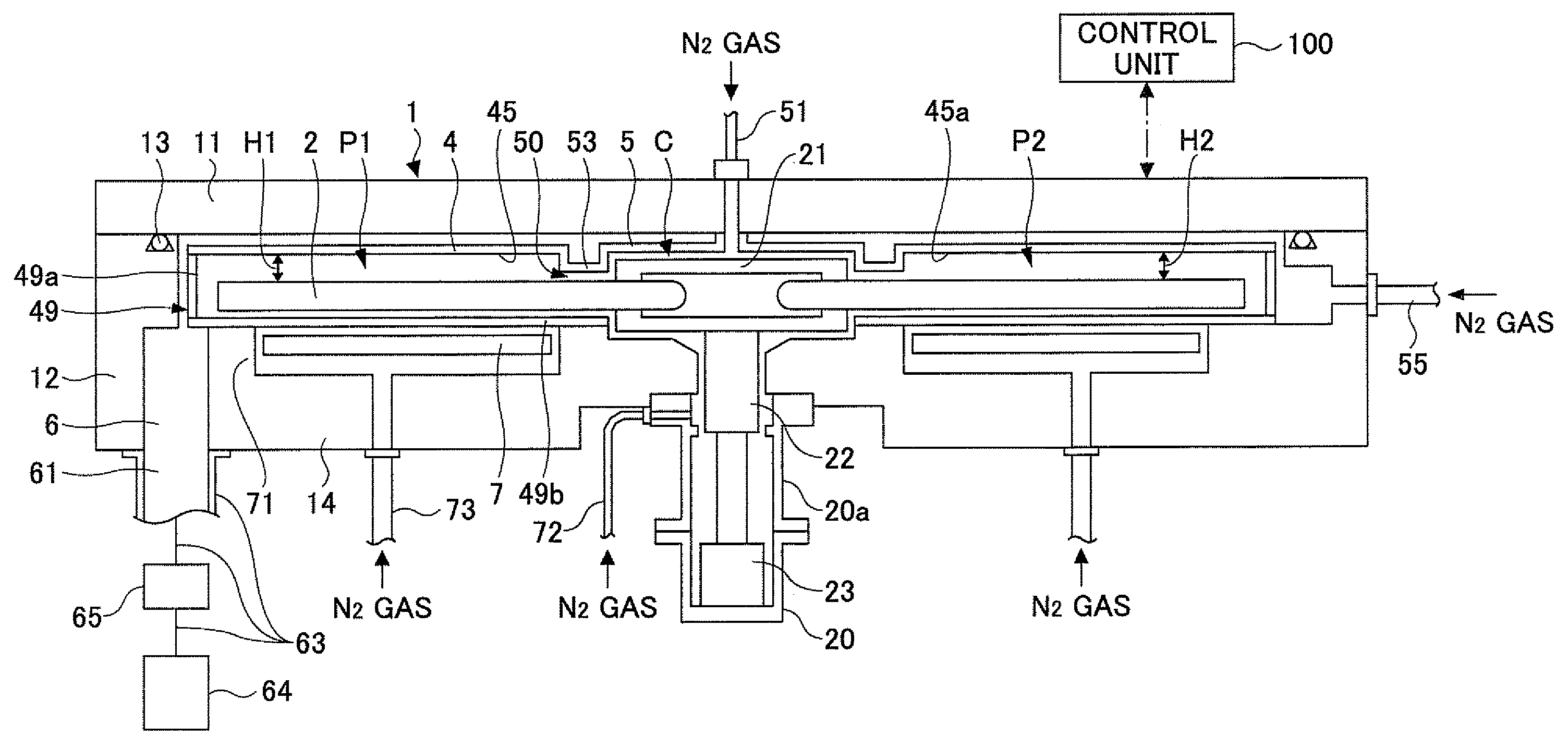

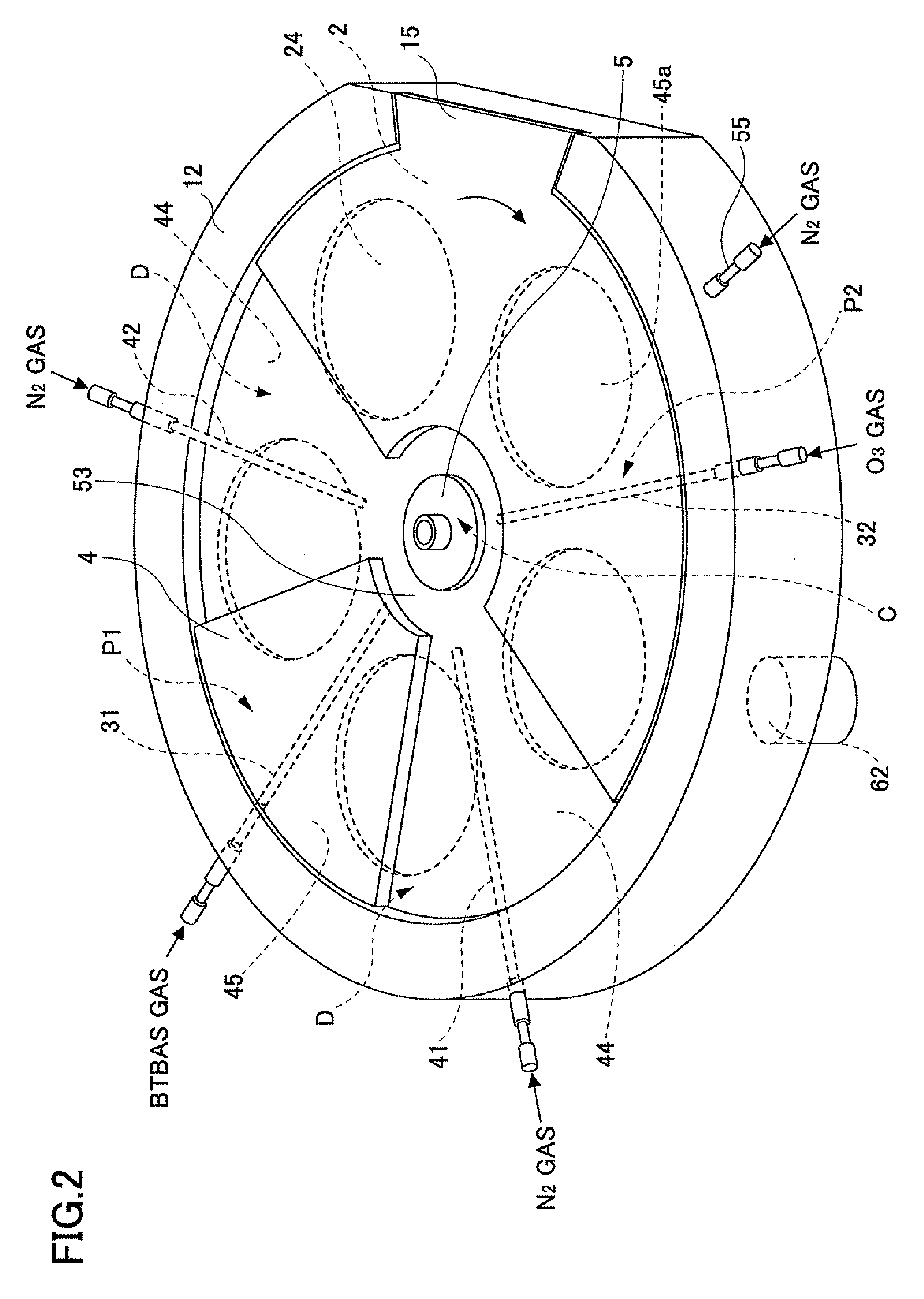

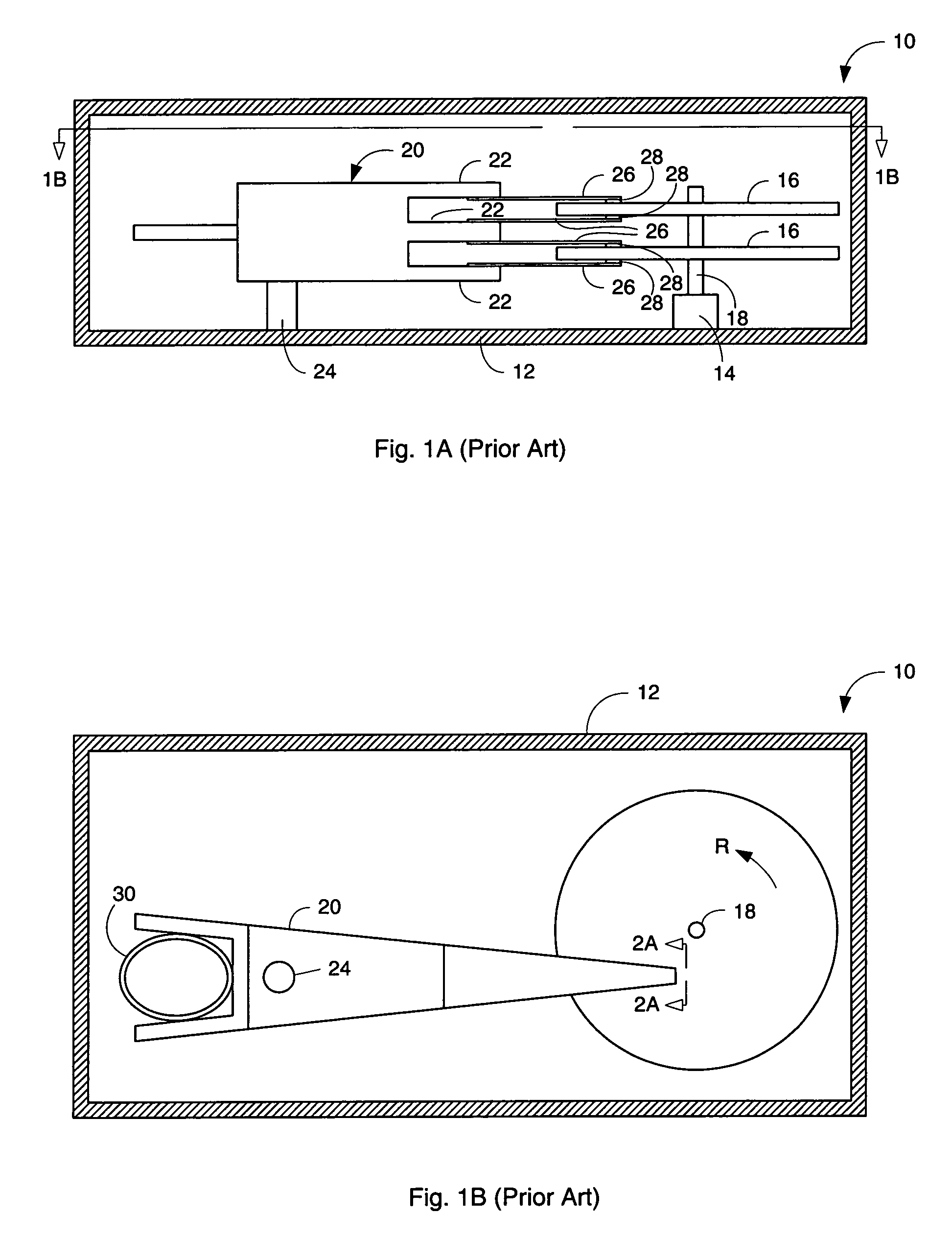

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS20100055316A1Improve throughputSatisfy processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas supplyVacuum chamber

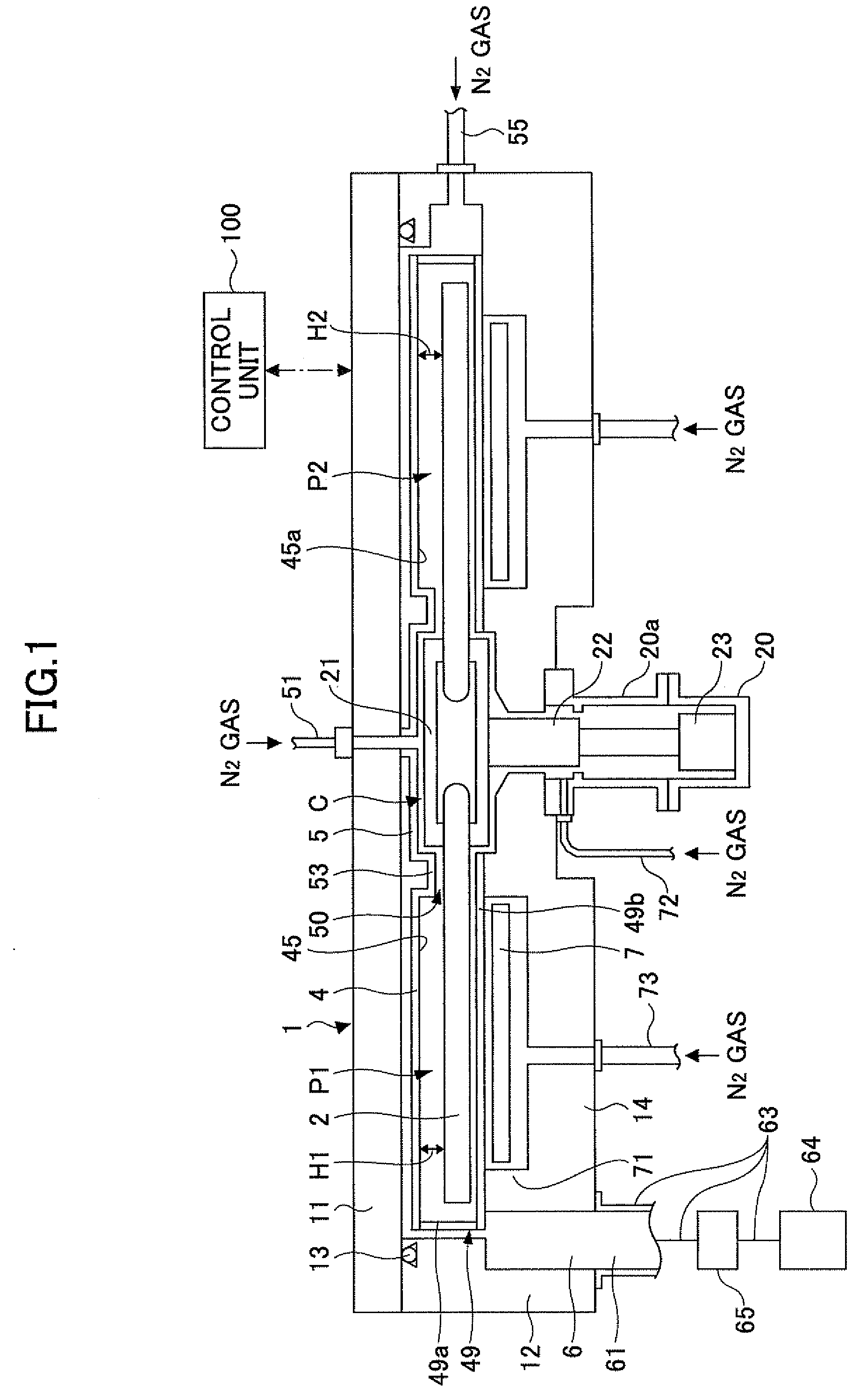

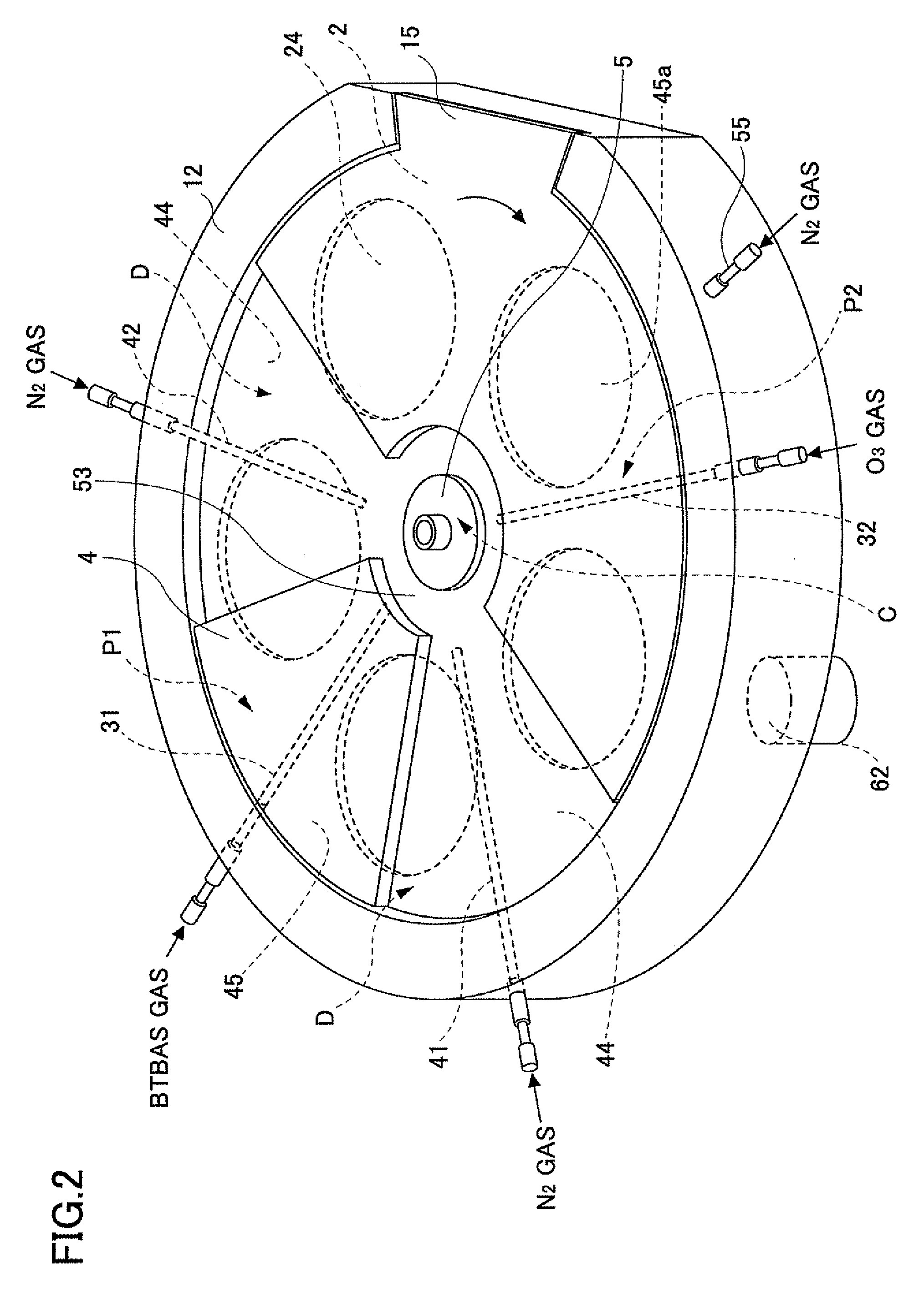

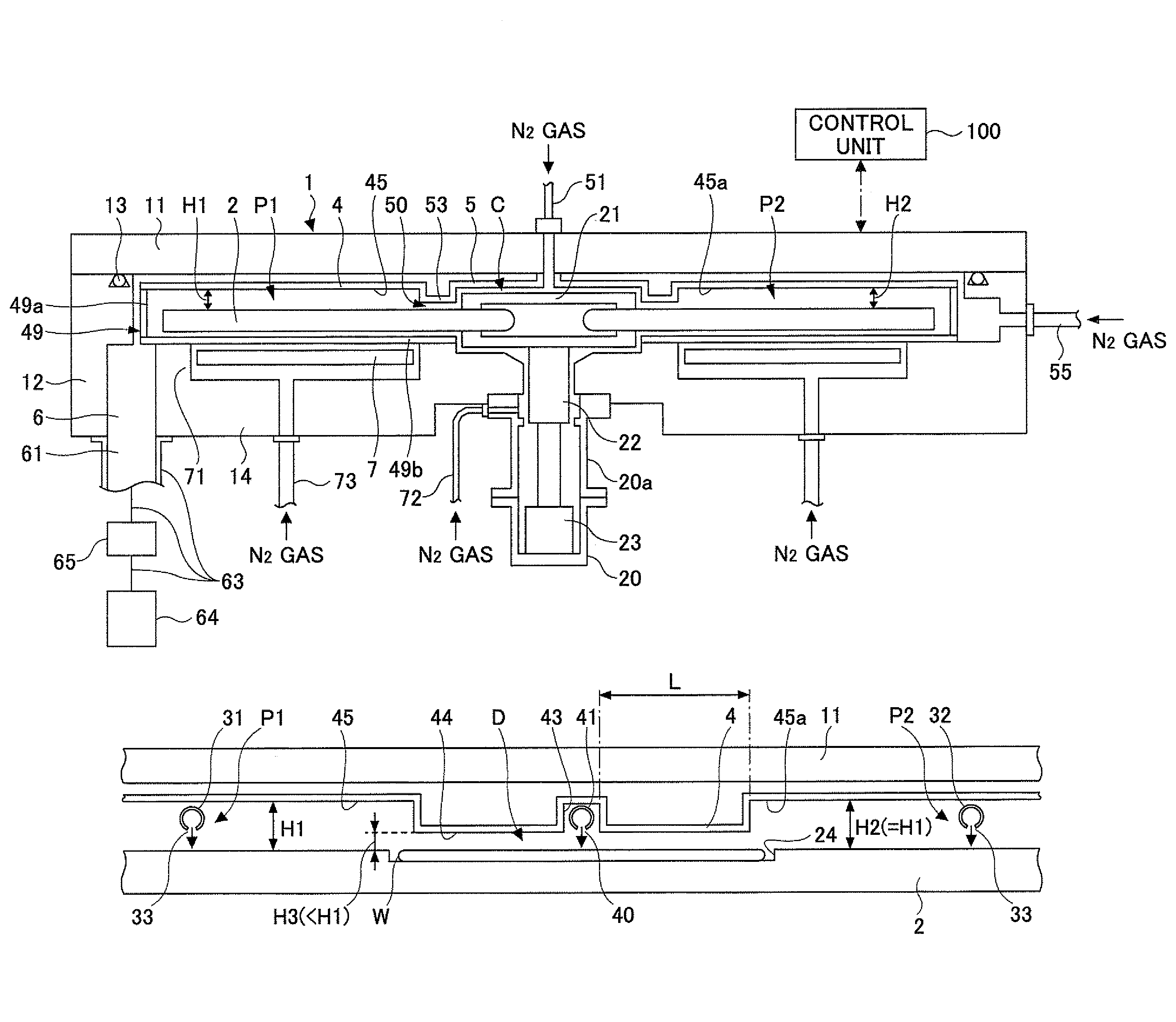

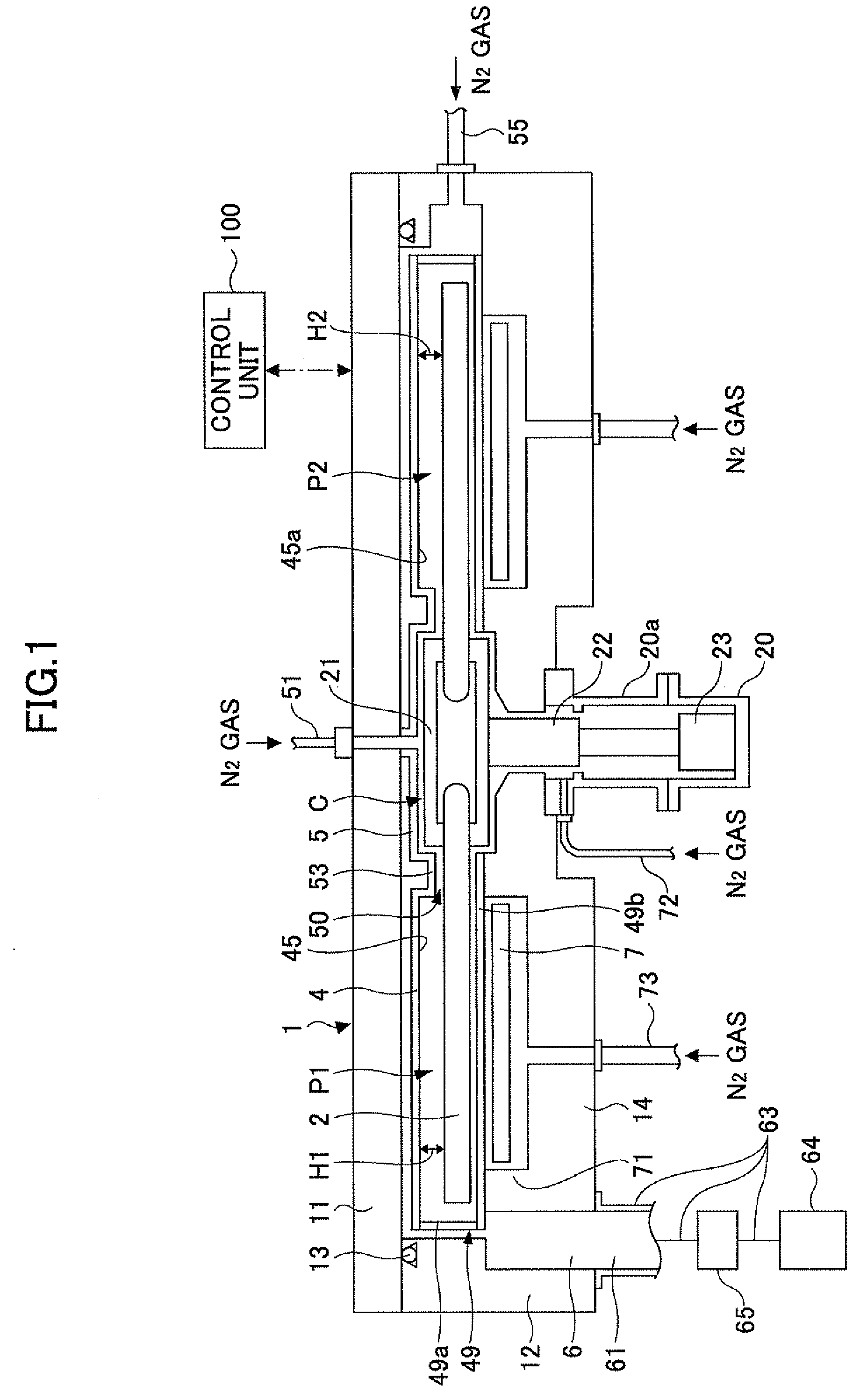

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS9267204B2Improve throughputAvoid mixingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

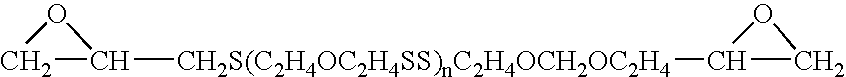

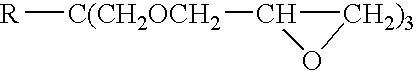

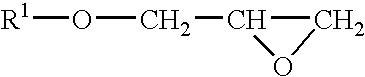

Epoxy coating

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

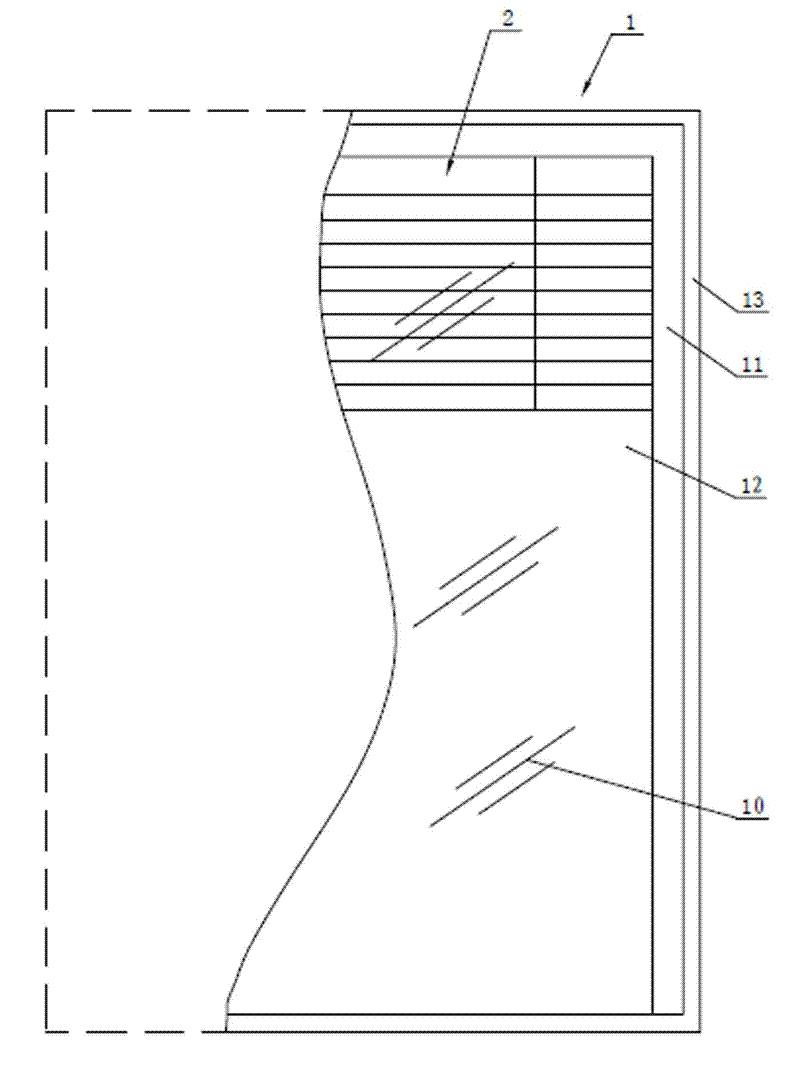

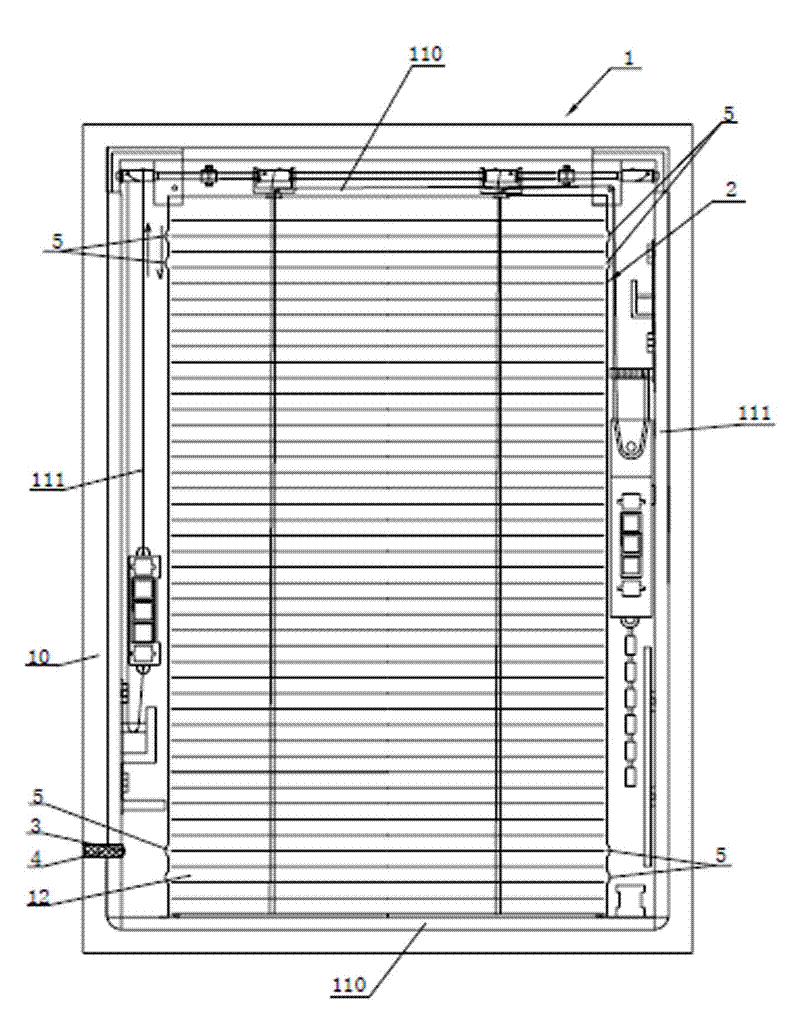

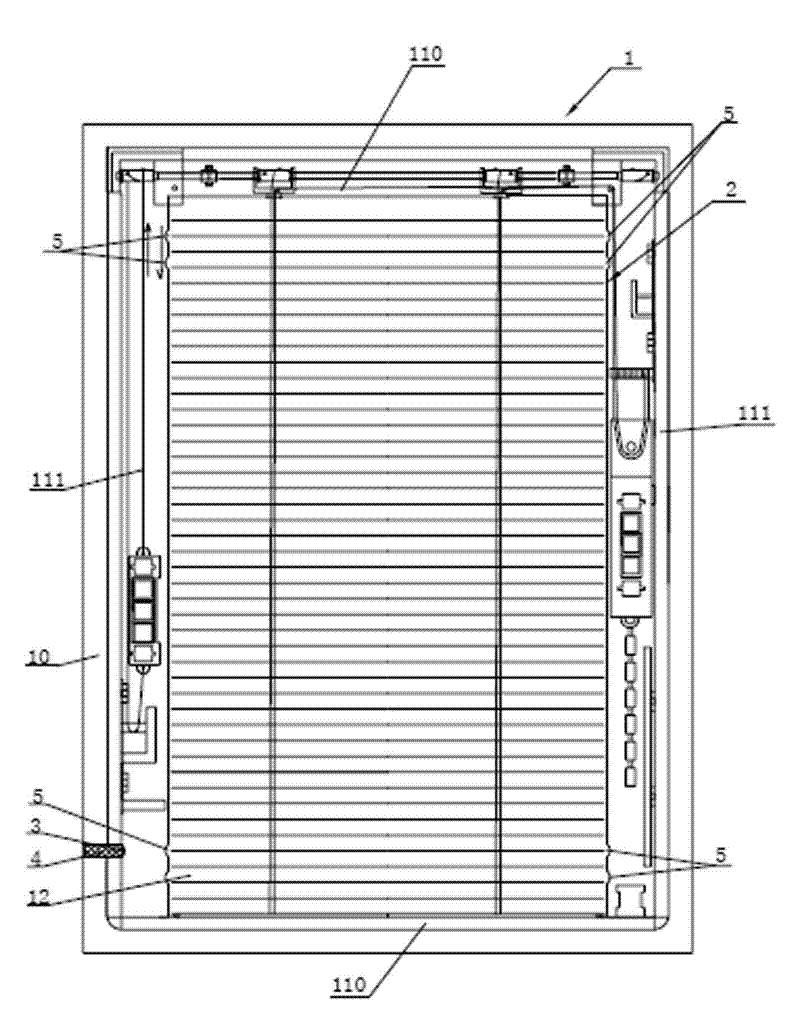

Internally-arranged sun-shading hollow shutter

InactiveCN102444372AExtended service lifePrevent oxidationDoor/window protective devicesClimate change adaptationWindow shutterEngineering

The invention relates to an internally-arranged sun-shading hollow shutter, which comprises hollow glass, a shutter curtain and a control mechanism. The hollow glass comprises a two glass original sheets which are parallel to each other, a metal hollow frame clamped between the two glass original sheets, a hollow portion enclosed by the two glass original sheets and the metal hollow frame, and sealing glue. The shutter curtain is arranged in the hollow portion. The internally-arranged sun-shading hollow shutter further comprises a port arranged on the outer lateral side of the metal hollow frame and a sealing plug for sealing the port. The inner lateral side of the metal hollow frame is provided with an air vent hole for communicating the metal hollow frame and the hollow portion, wherein the hollow portion is filled with inertia gas. The port can be connected with a vacuumizing device to vacuumize the inside of the hollow portion, the inertia gas is delivered into the hollow portion through the port, and inertia gas environment can prevent parts such as a pull rope and a ladder rope in the hollow glass from being oxidized so as to prolong service life of the internally-arranged sun-shading hollow shutter.

Owner:张家港市虹壹玻璃制品有限公司

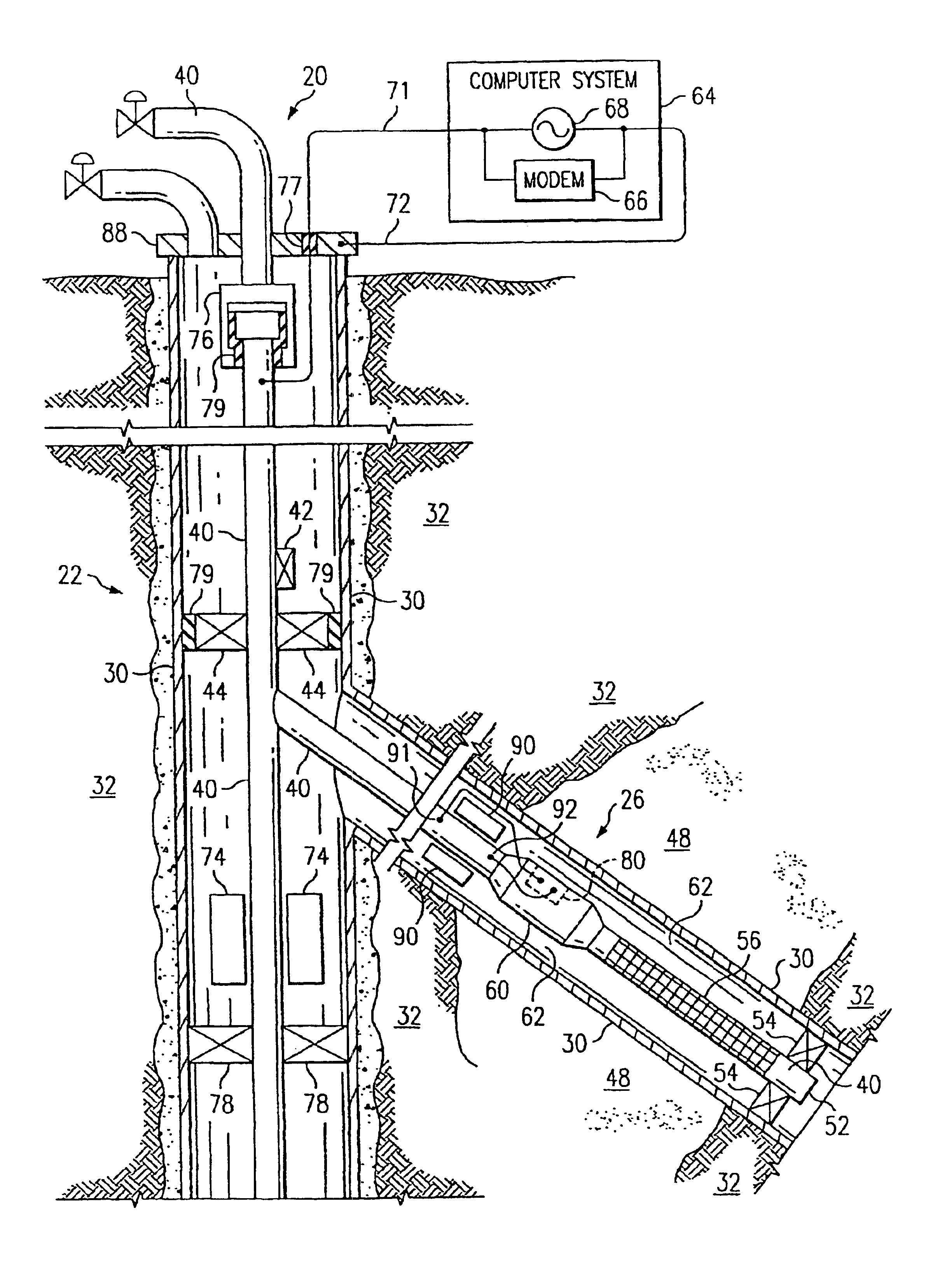

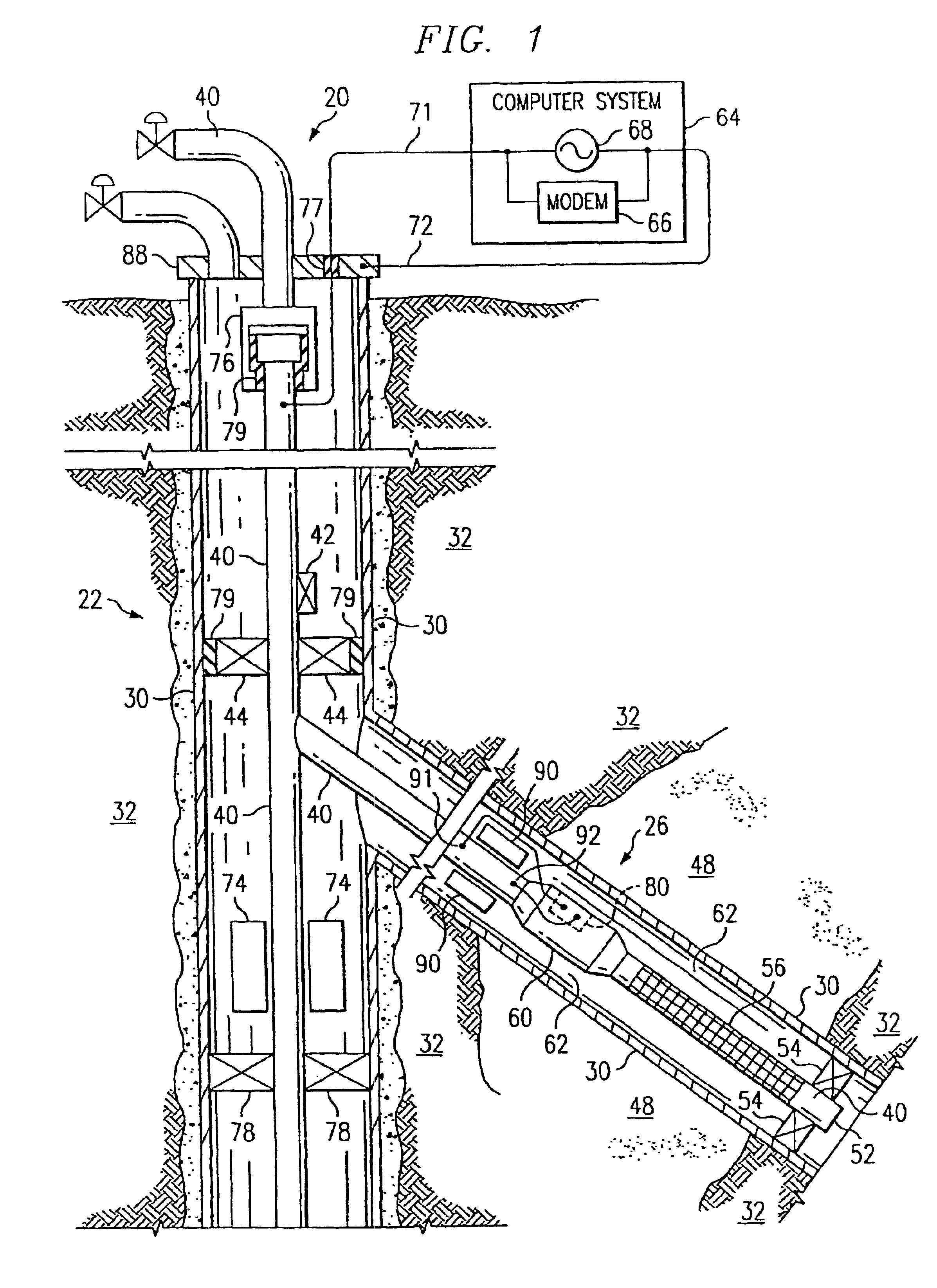

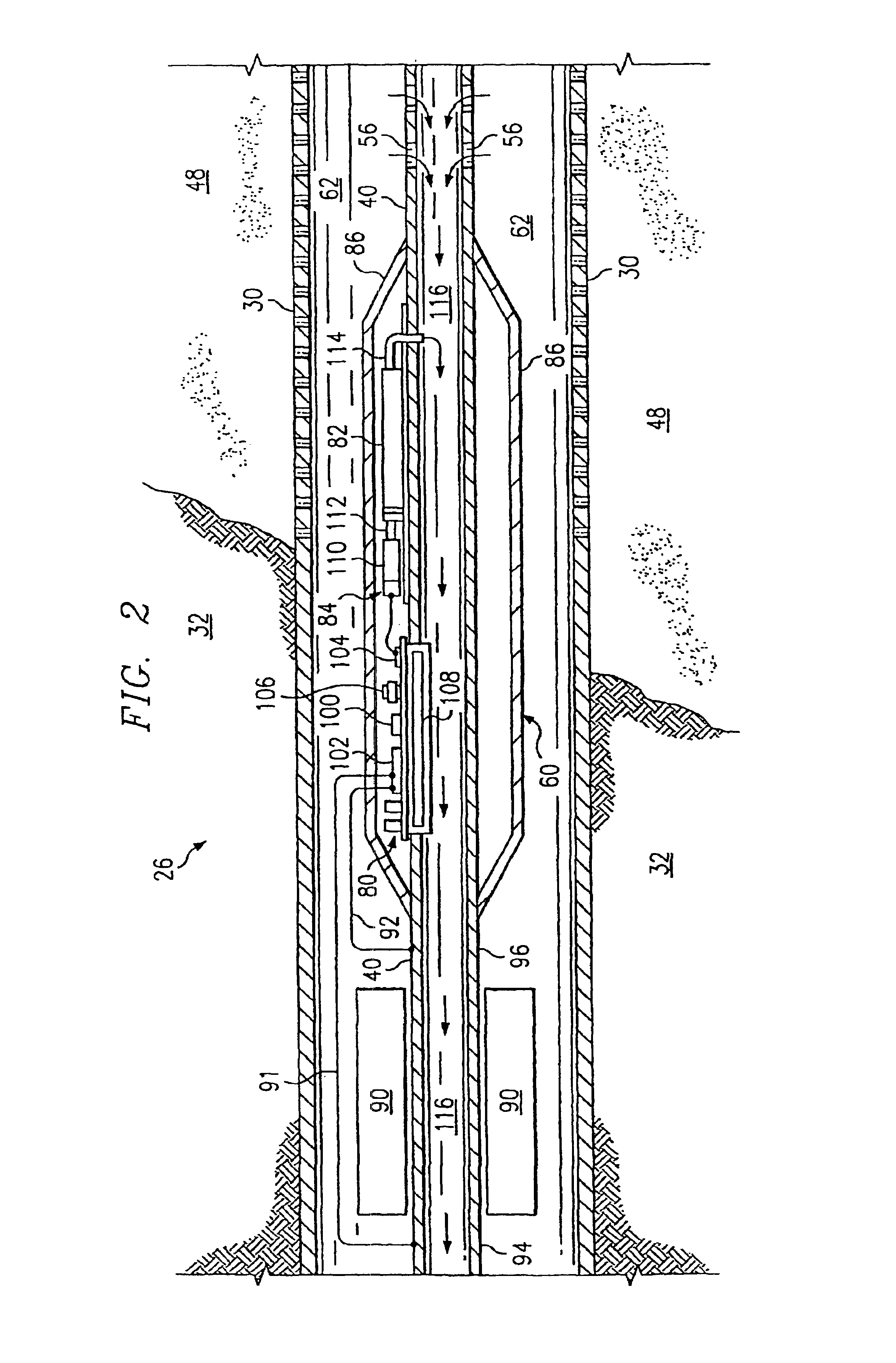

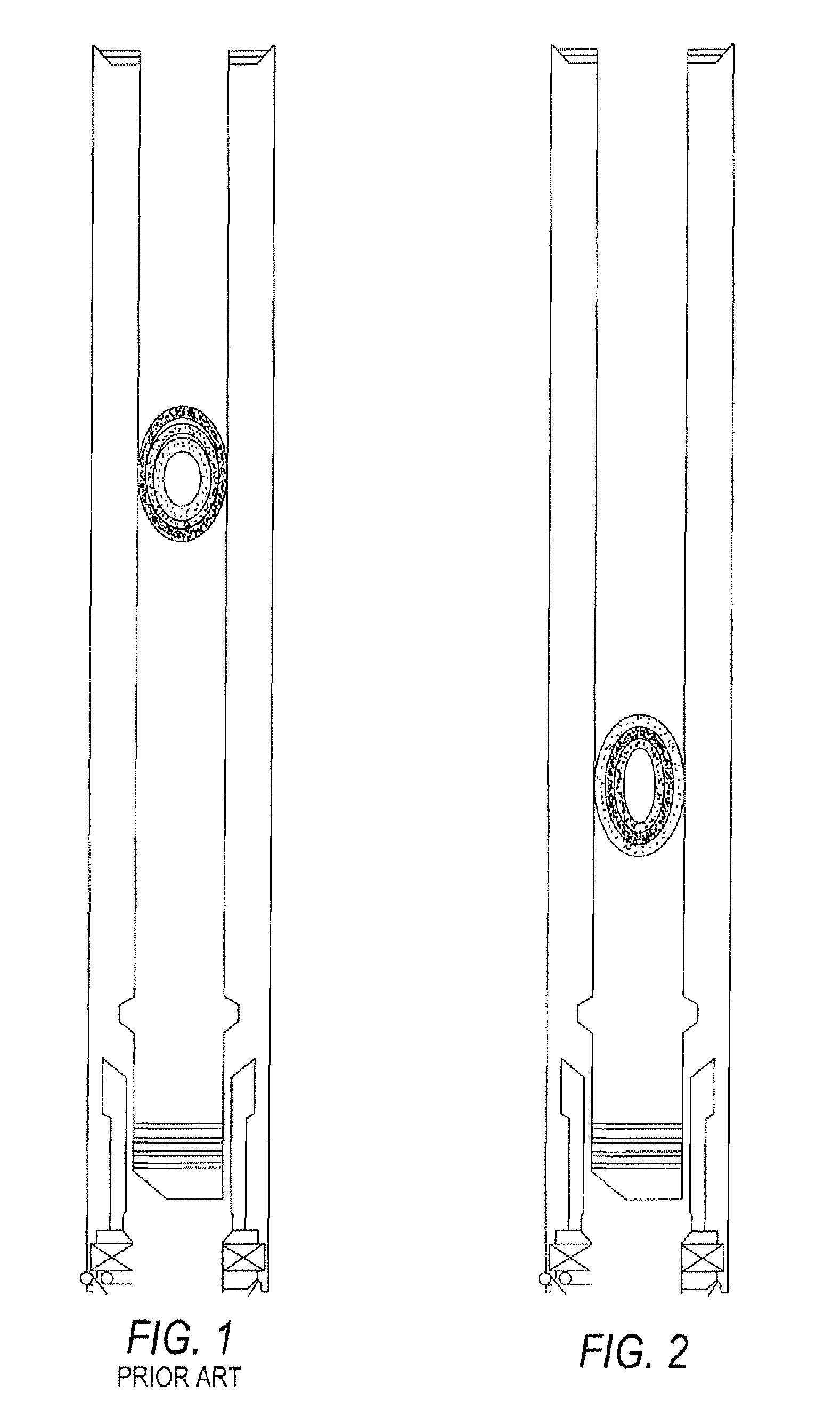

Controlled downhole chemical injection

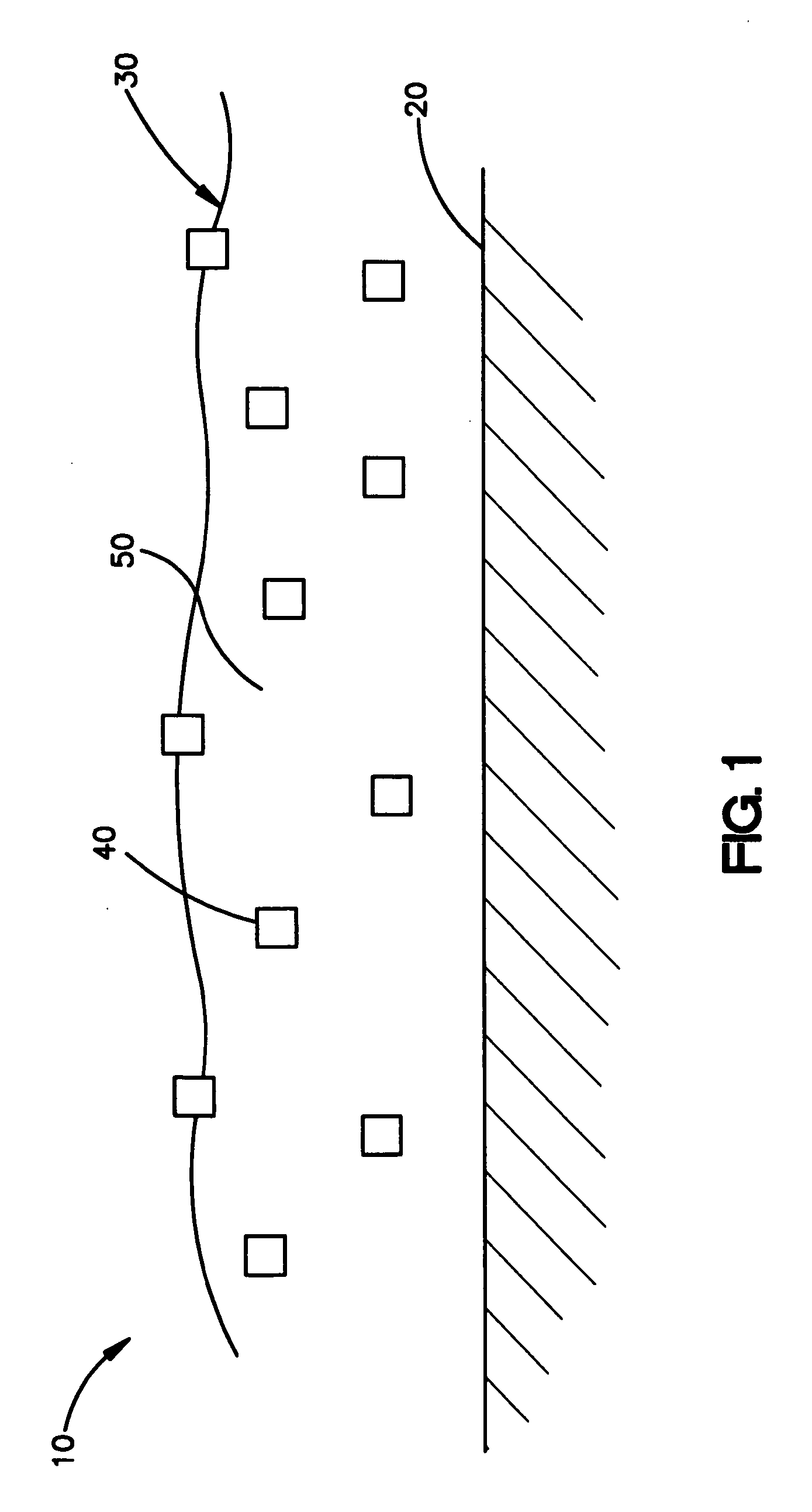

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

Inductive write head having high magnetic moment poles and low magnetic moment thin layer in the back gap, and methods for making

InactiveUS6989962B1Avoid corrosionNegligible effectHeads using thin filmsRecord information storageMagnetic polesThin layer

The present invention provides a write element for use in magnetic data recording system such as a computer disk drive. The write head utilizes the advantageous properties of high magnetic moments while overcoming the corrosion problems engendered by such materials. The write element includes a magnetic yoke constructed of first and second magnetic poles joined to one another at a back gap. While the majority of the poles are constructed of a high magnetic moment material a layer of relatively low magnetic moment material is provided on the first pole at the back gap portion of the first pole. The relatively low magnetic moment material prevents corrosion of the first pole during subsequent manufacturing of the write head. An electrically conductive coil passes through the magnetic yoke and is insulated there from. By passing an electrical current through the electrical coil, a magnetic flux is generated in the yoke. This magnetic flux then generates a magnetic fringing field in at a write gap of the yoke. The fringing field imparts magnetic data onto a recording medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

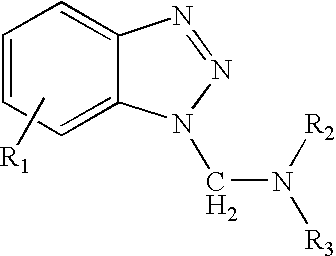

Material for electrolytic solutions and use thereof

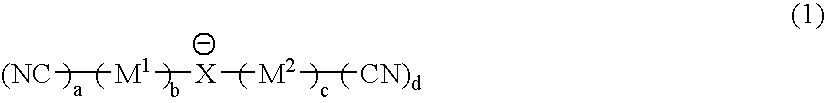

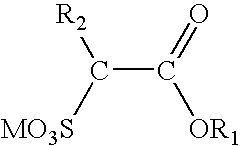

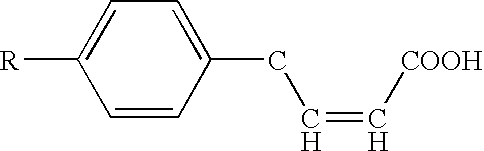

InactiveUS20040002002A1Avoid corrosionImprove ionic conductivityHybrid capacitor electrolytesAlkaline accumulatorsOrganic linkingElectrical conductor

It is an object of the present invention to provide a material for electrolytic solutions suited for use as material in electrolytic solutions serving as ionic conductors in electrochemical devices, such as large-capacity cells or batteries. The present invention is related to a material for electrolytic solutions which comprises, as an essential constituent, an anion represented by the general formula (1): wherein X represents at least one element selected from among B, N, O, Al, Si, P, S, As and Se; M<1 >and M<2 >are the same or different and each represents an organic linking group; a is an integer of not less than 1, and b, c and d each independently is an integer of not less than 0.

Owner:NIPPON SHOKUBAI CO LTD

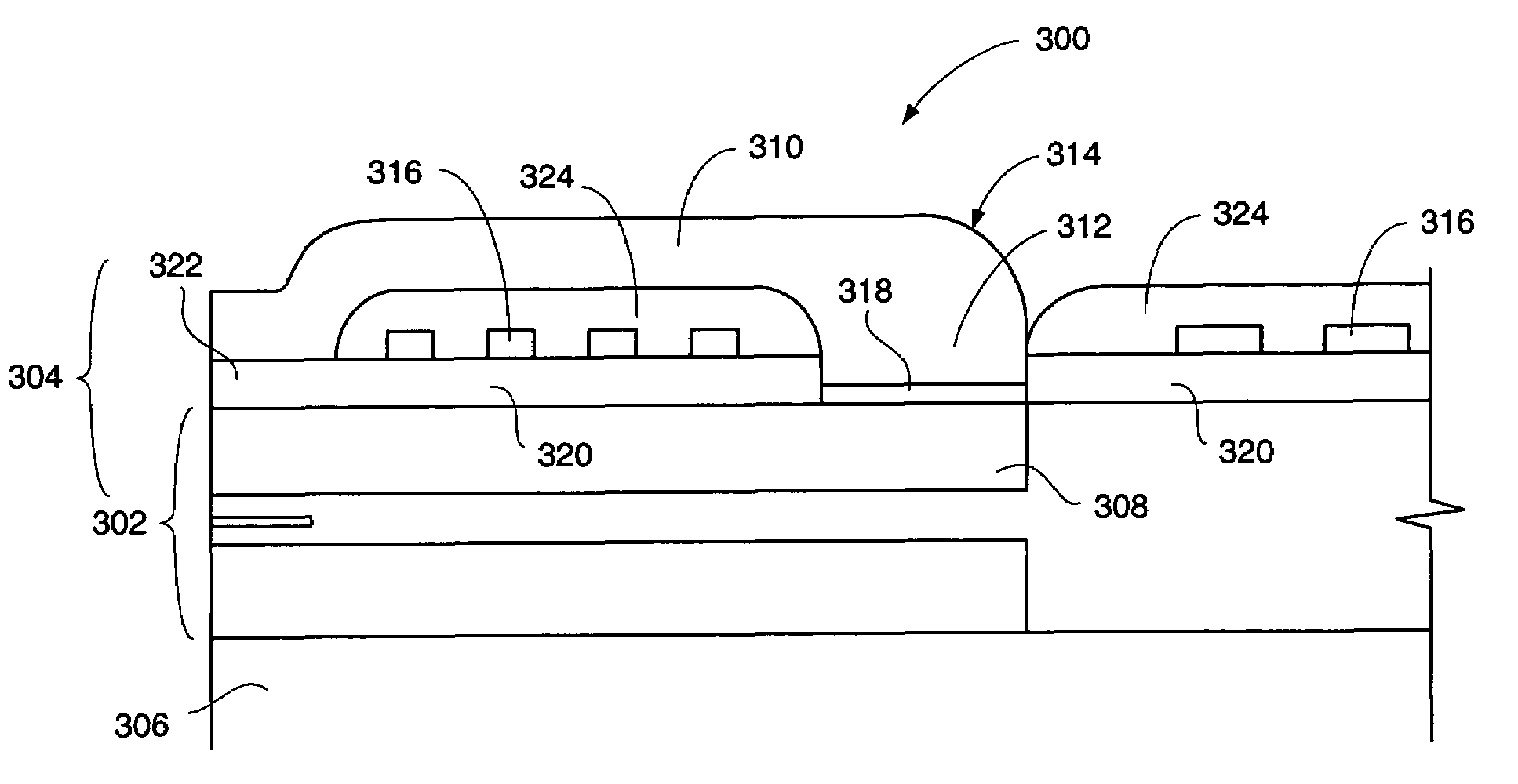

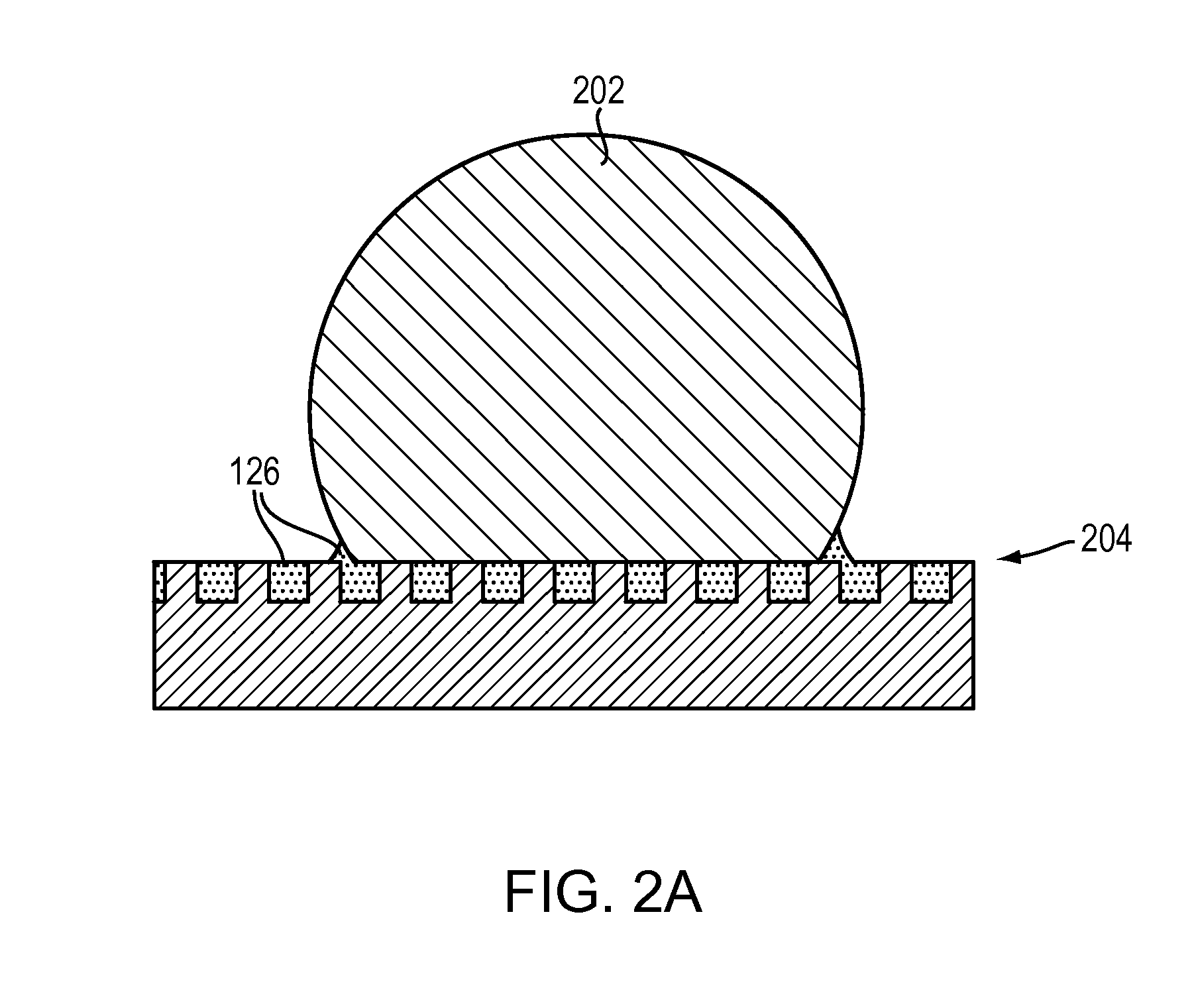

Multilevel semiconductor module and method for fabricating the same

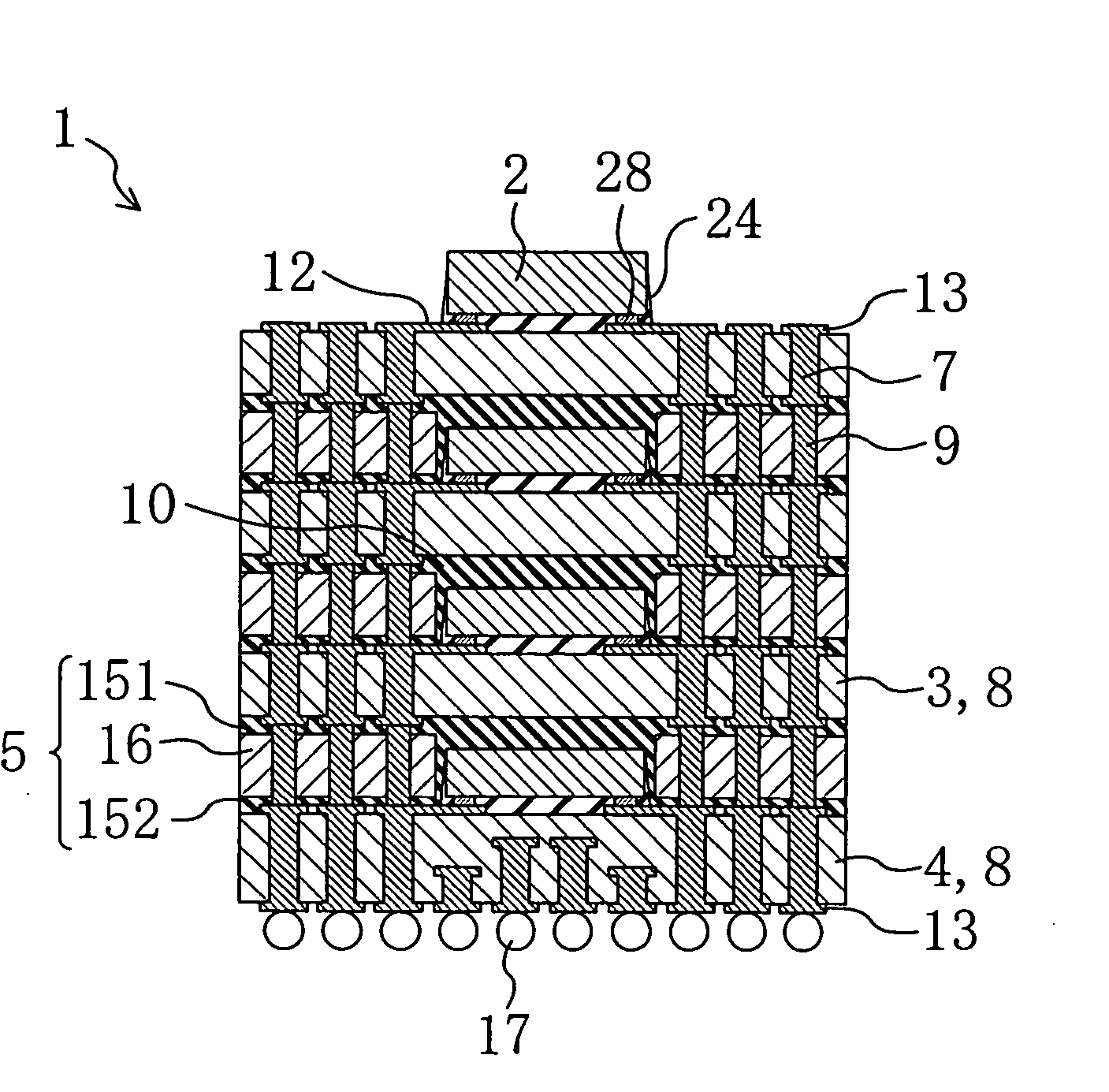

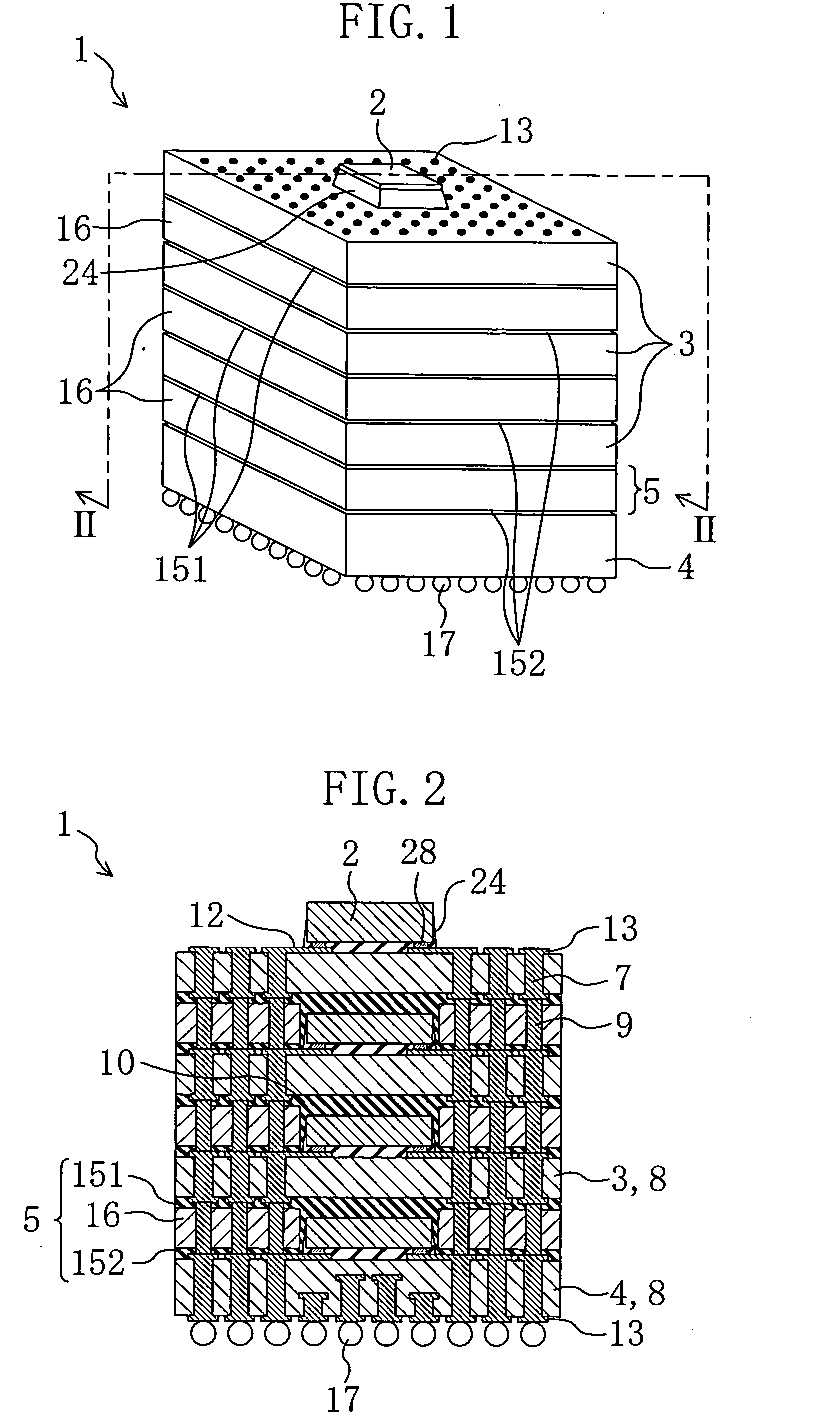

InactiveUS20060231939A1InhibitionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A semiconductor module is formed by alternately stacking resin boards and sheet members. Each of the resin boards includes first buried conductors. A semiconductor chip is mounted on the upper face of each of the resin boards. Each of the sheet members having an opening for accommodating the semiconductor chip and including second buried conductors electrically connected to the first buried conductors. A first resin board located at the bottom is thicker than second resin boards. Each of the sheet members includes an adhesive member covering the upper and side faces of the semiconductor chip.

Owner:PANASONIC CORP

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

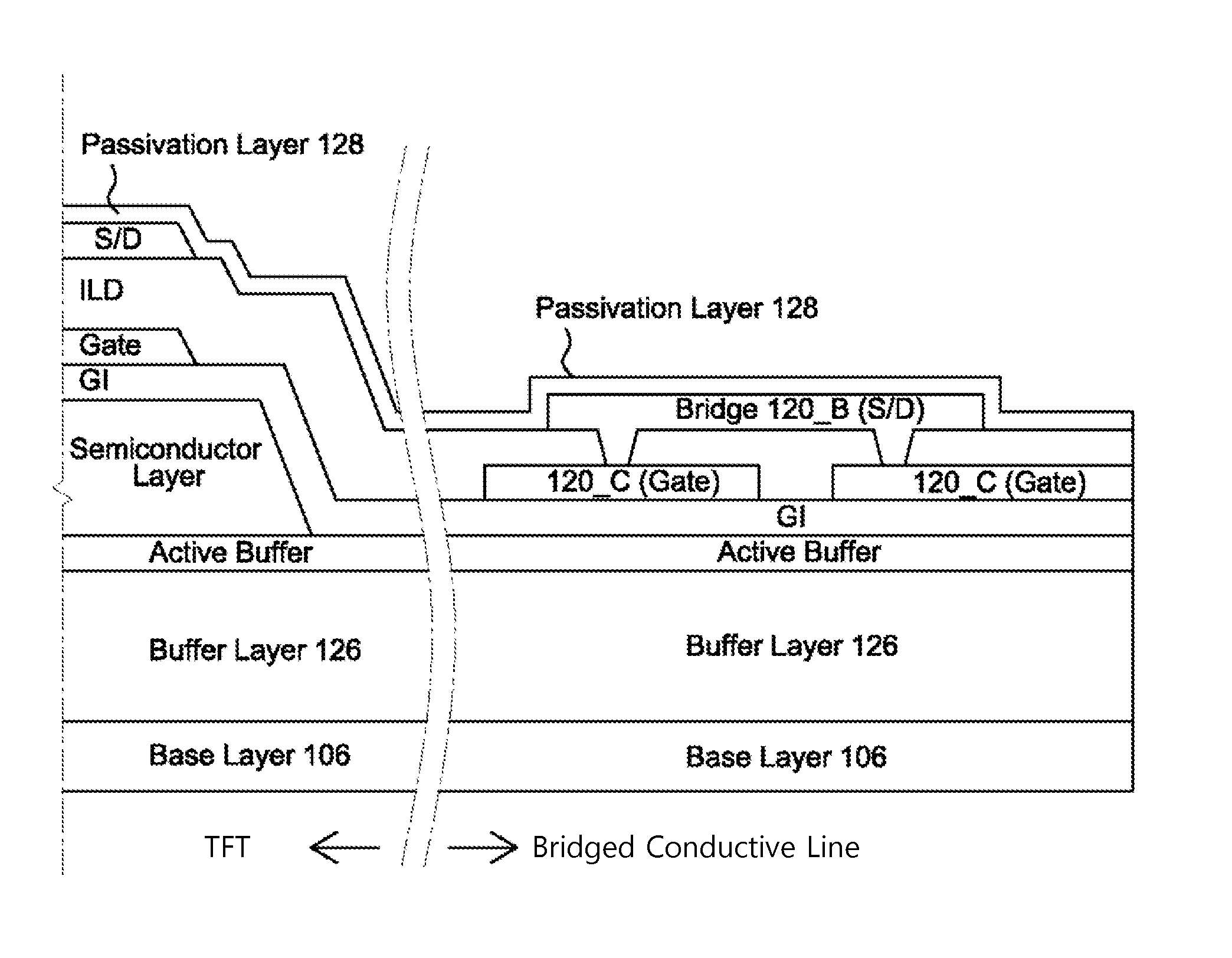

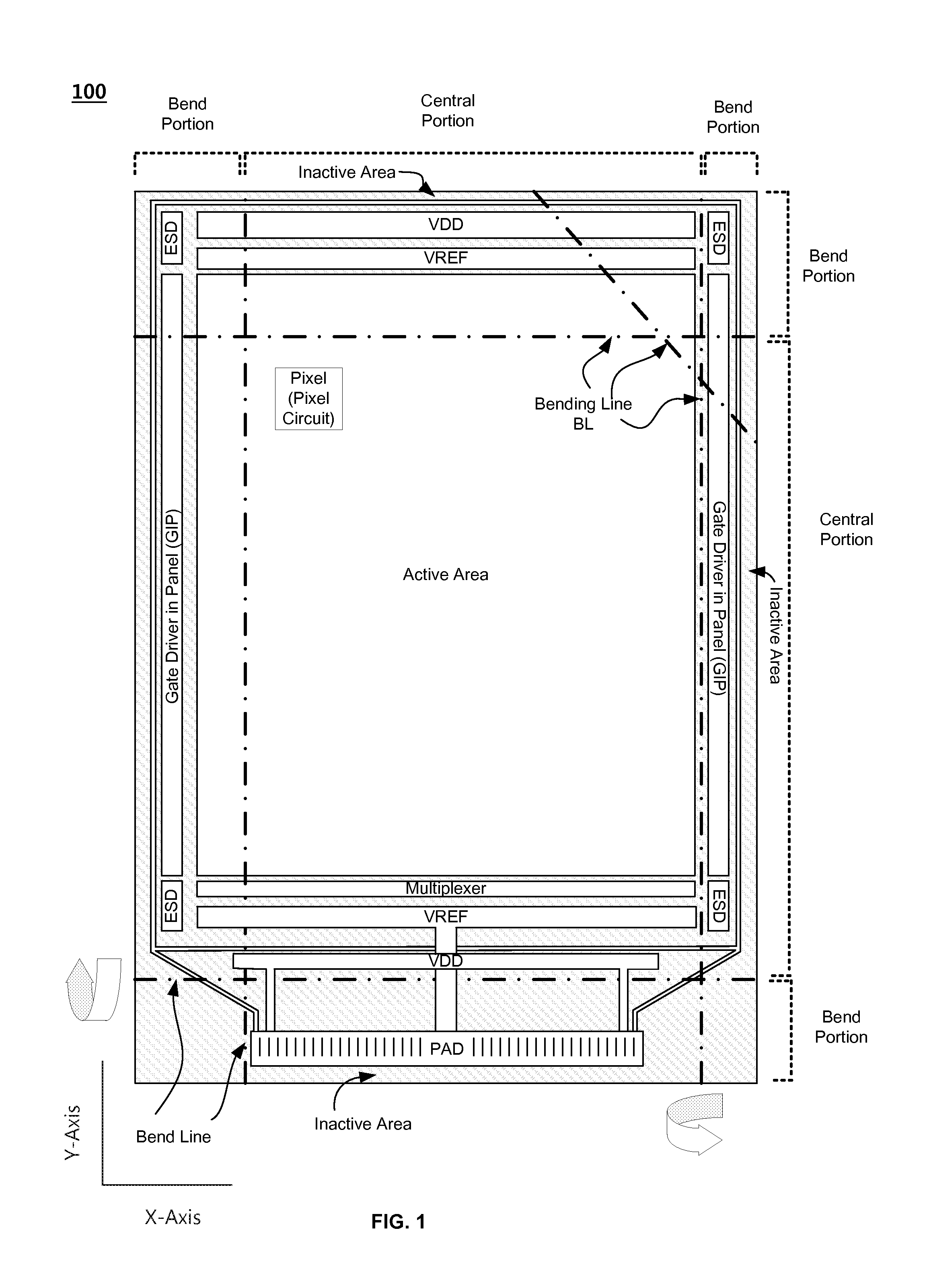

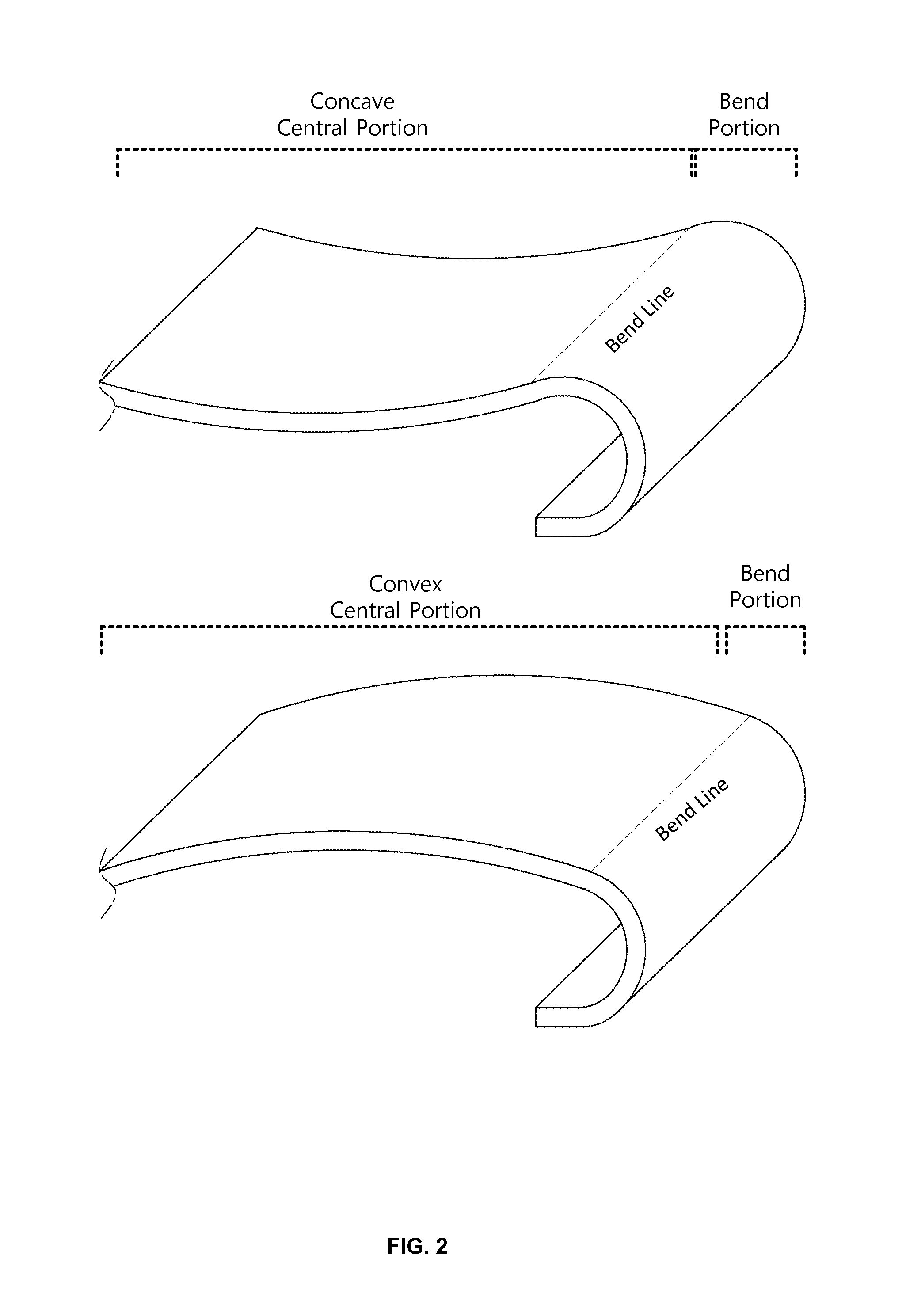

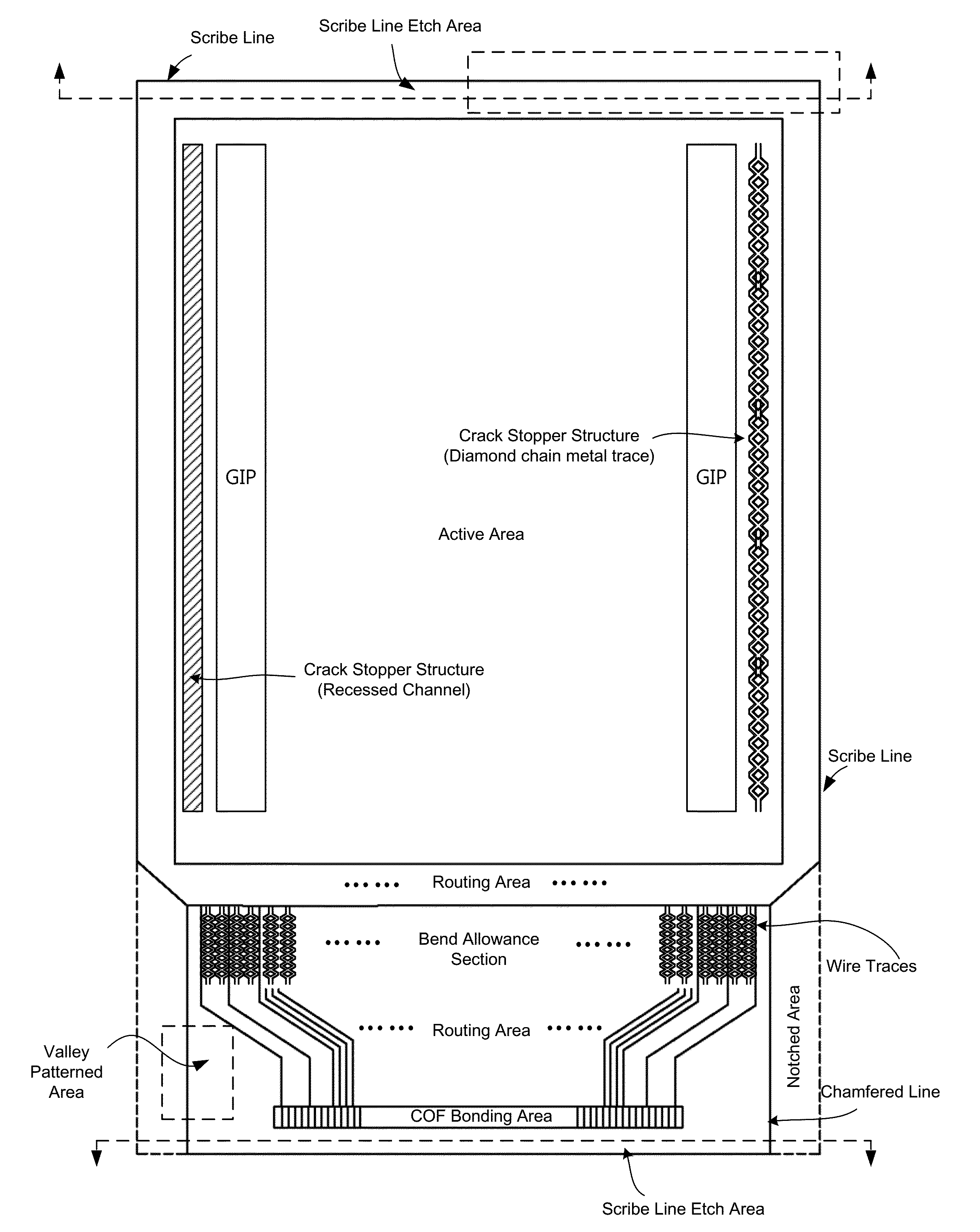

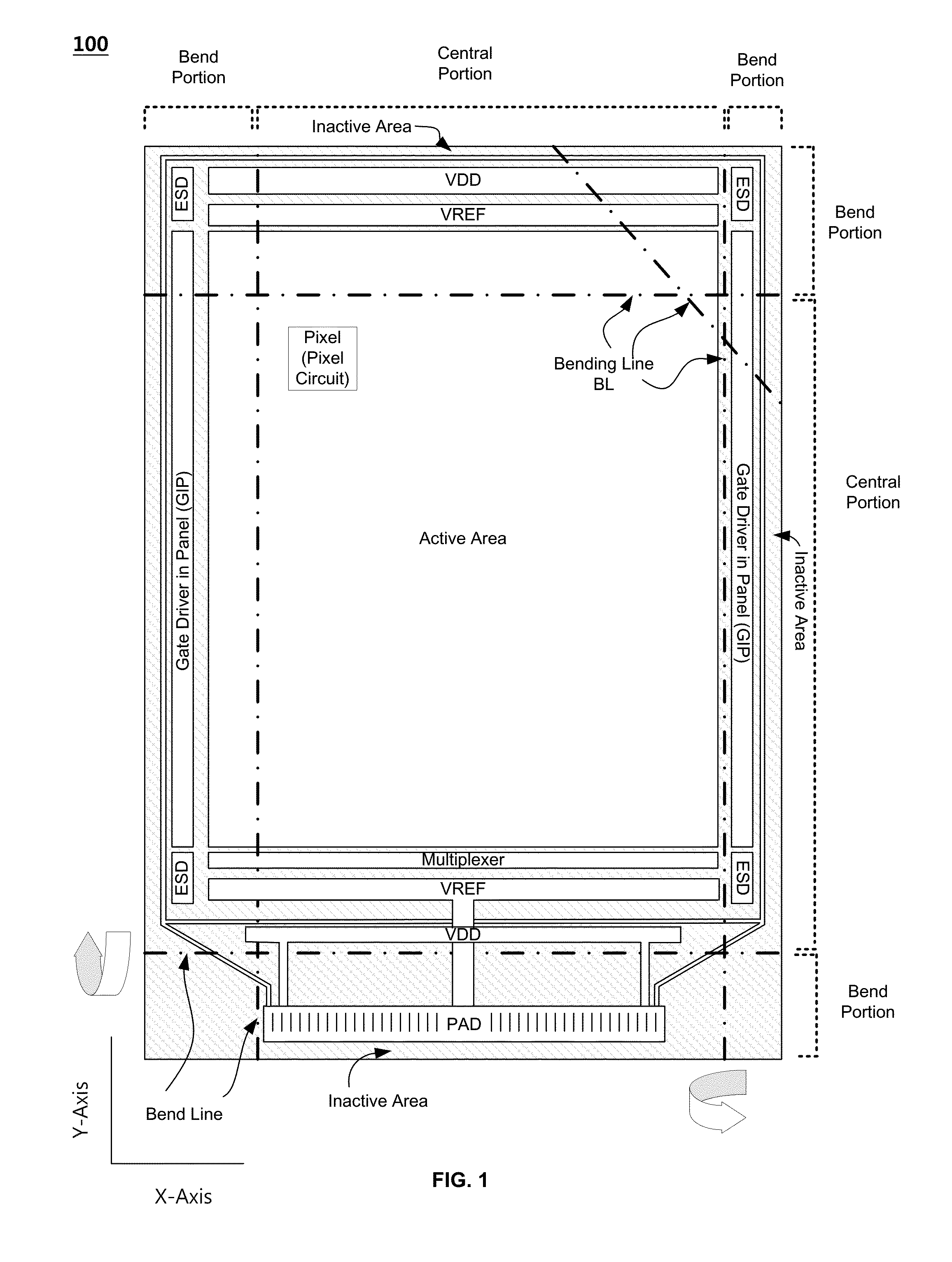

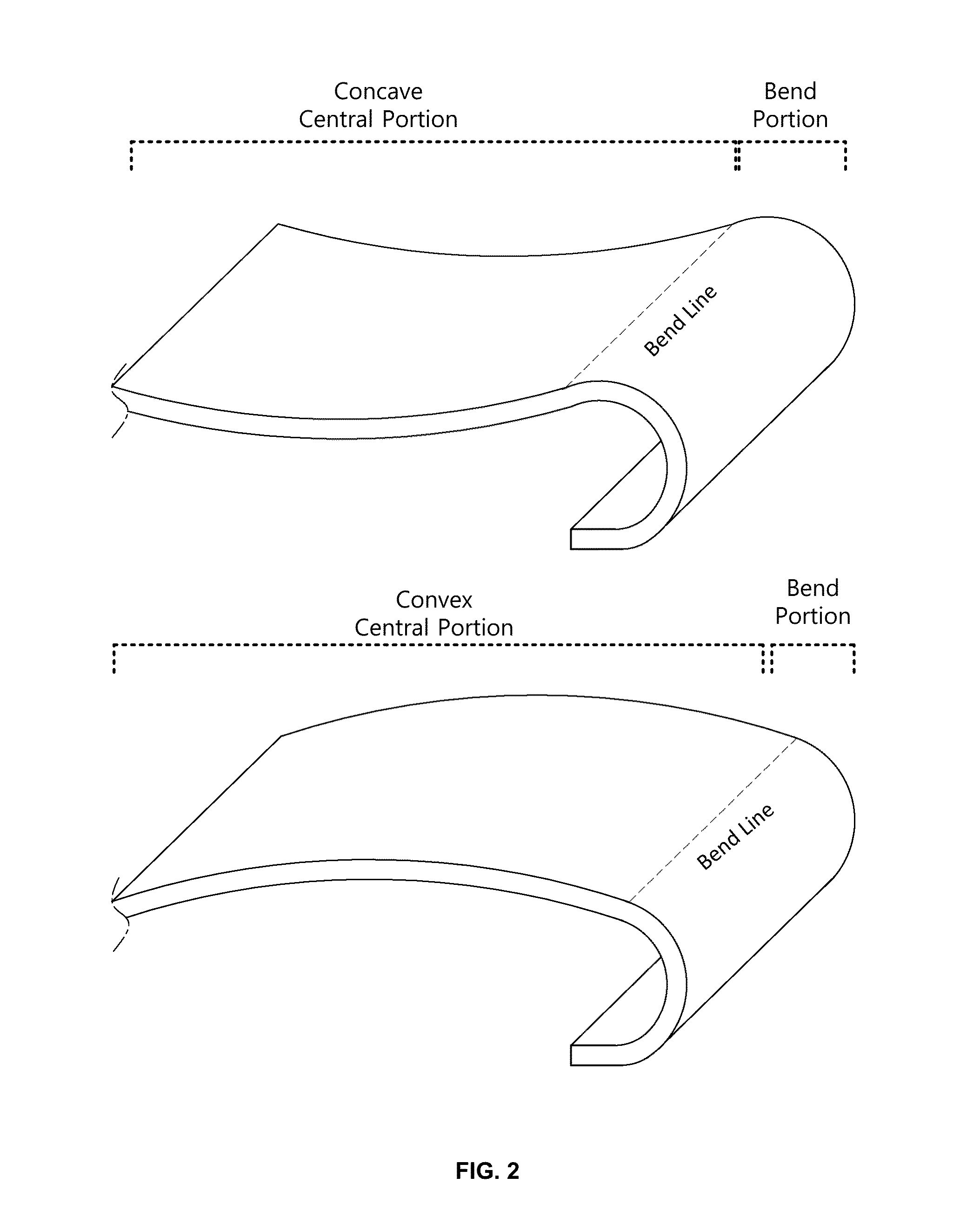

Flexible display device with bridged wire traces

ActiveUS9356087B1Reduce areaArea minimizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDisplay deviceEngineering

There is provided a flexible display having a plurality of innovations configured to allow bending of a portion or portions to reduce apparent border size and / or utilize the side surface of an assembled flexible display.

Owner:LG DISPLAY CO LTD

Flexible display device with corrosion resistant printed circuit film

InactiveUS20160172428A1Reducing and eliminatingMinimizing size of areaFinal product manufactureSolid-state devicesCorrosion resistantDisplay device

There is provided a flexible display having a plurality of innovations configured to allow bending of a portion or portions to reduce apparent border size and / or utilize the side surface of an assembled flexible display.

Owner:LG DISPLAY CO LTD

Epoxidized ester additives for reducing lead corrosion in lubricants and fuels

Fuels, especially hydrocarbon fuels, and lubricants, especially lubricating oils, contain a class of anti-corrosion, anti-fatigue, and anti-wear additives that are derived epoxidized esters of fatty acids. Epoxidized 2-ethylhexyl tallate is particularly effective.

Owner:CHEMTURA CORP

Water heater

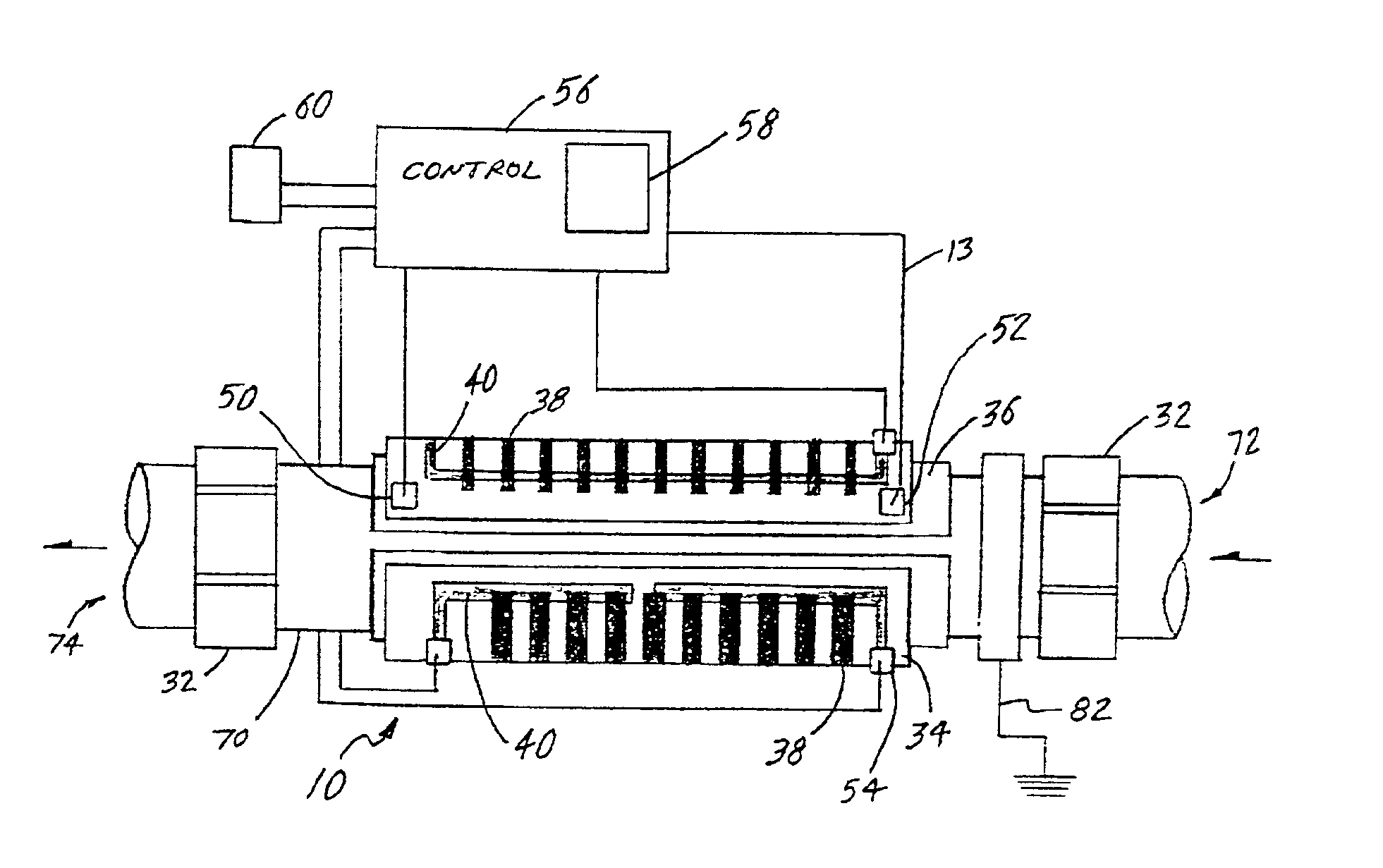

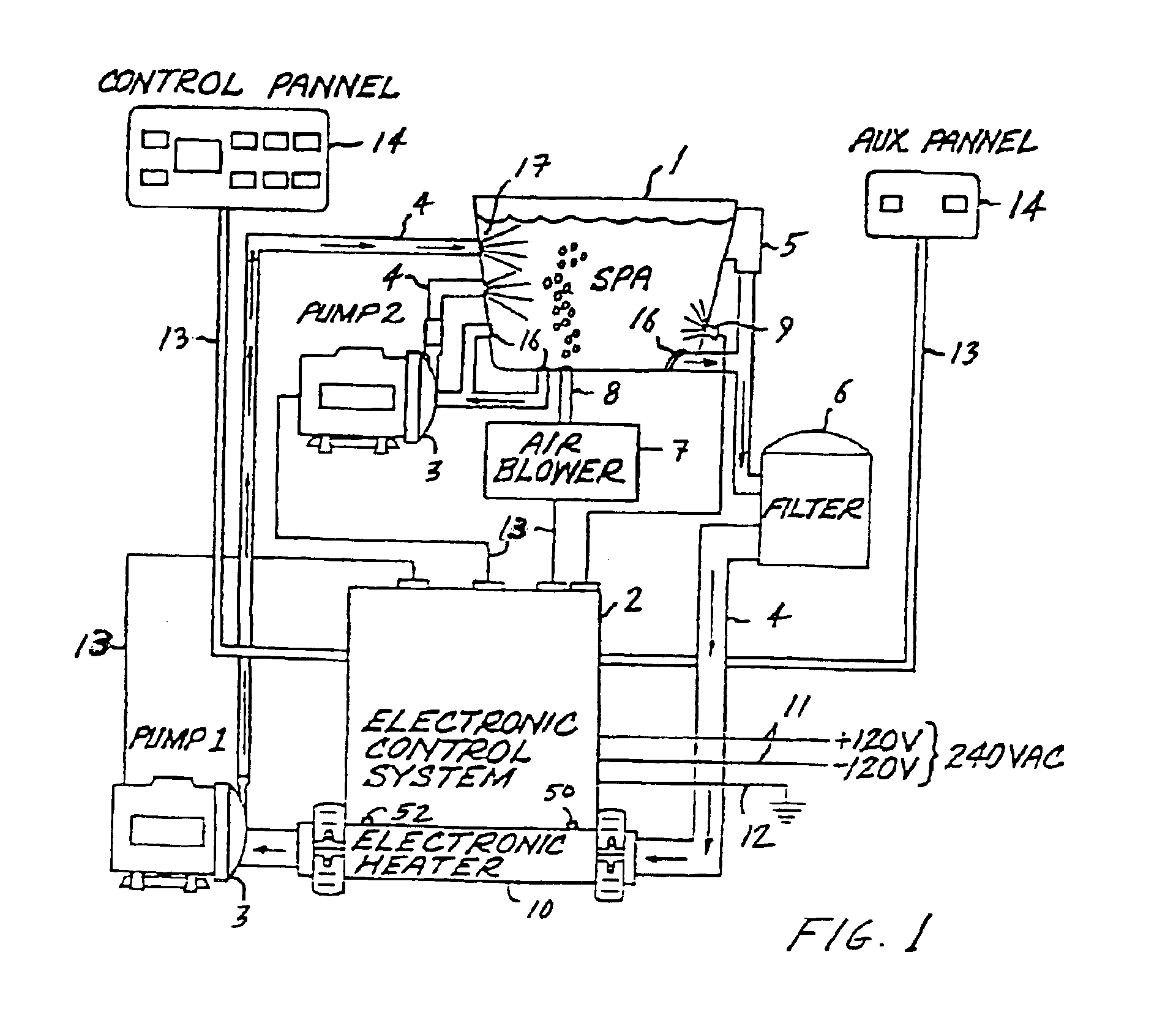

InactiveUS6943325B2Eliminate riskEliminate the risk of corrosionBathsDouchesWater useElectronic controller

An improved water heater for use in spas, hot tubs, pools, hydrotherapy pools, bath tubs, and similar bodies of water used indoors, outdoors, or both indoors and outdoors are used for both therapeutic and recreational purposes. The water heater uses heating element technology know as thick film on substrate comprising resistive elements bonded to the outer dry surface of a pipe to heat the pipe which in turn heats the water flowing therethrough. The heater is highly efficient due to the direct contact of the wet heating surface with the water and provides a smooth seamless inner heating surface by eliminating the need to pass electrical leads into the wet region of the heater. This virtually eliminates the risk of leaks in the water heater due to bulkhead fittings. The invention further eliminates the need for a heating element to be contained in the inner wet region of a spa heater, thereby reducing the risk of corrosion. The water heater is used in combination with an electronic controller having a microprocessor to control and regulate the operation of the water heater. The water heater can be used with electrical, electro-mechanical, and mechanical control systems for spas and can be retrofitted into existing spa applications.

Owner:DYMAS FUNDING COMPANY

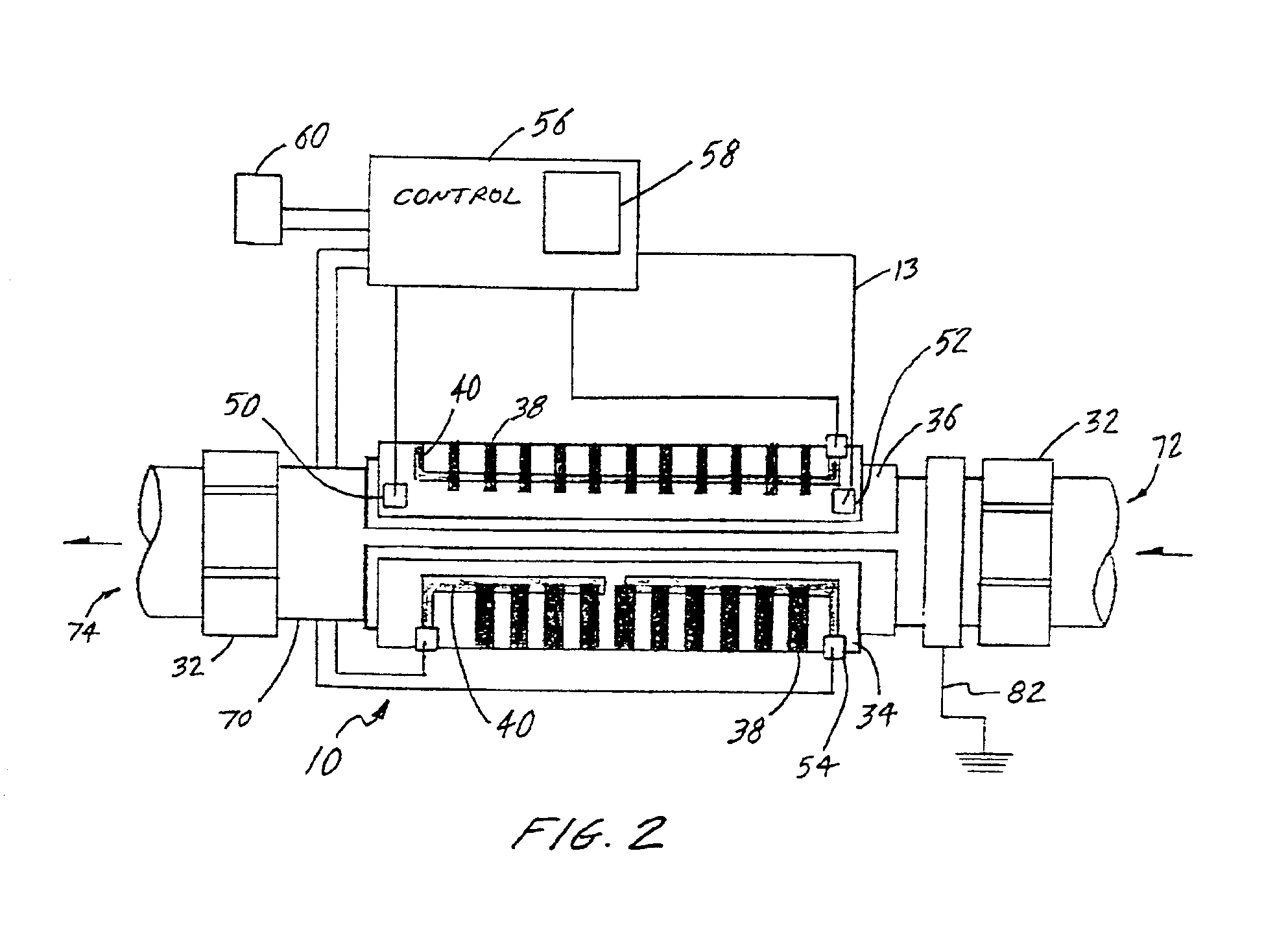

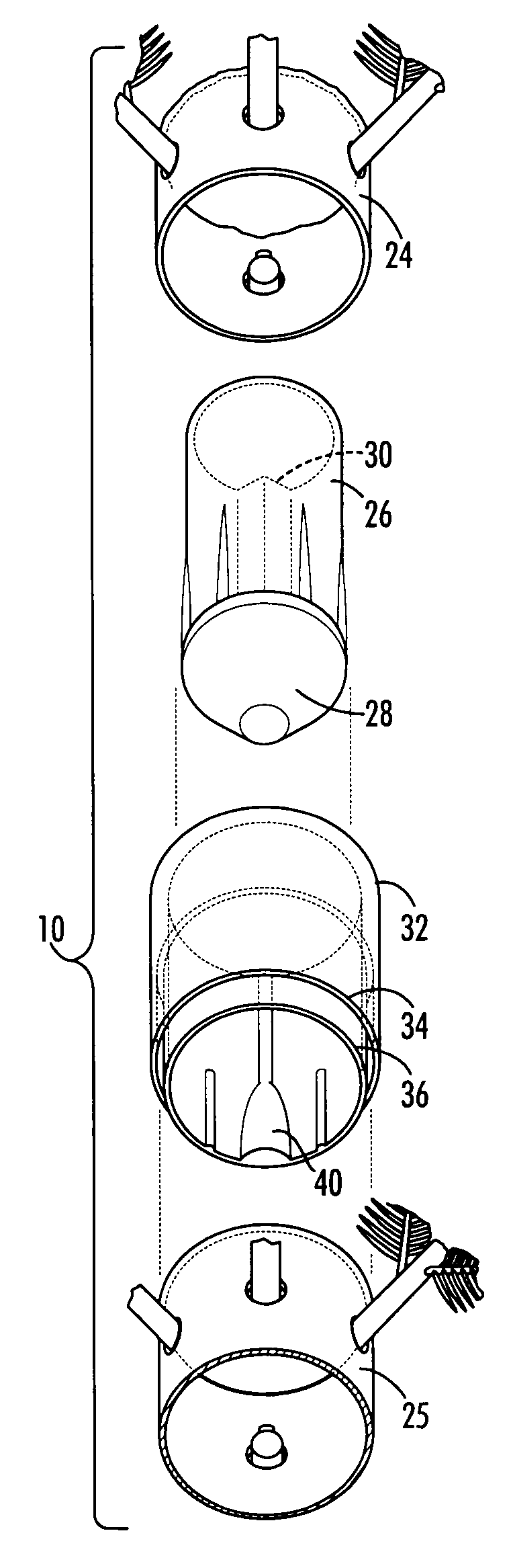

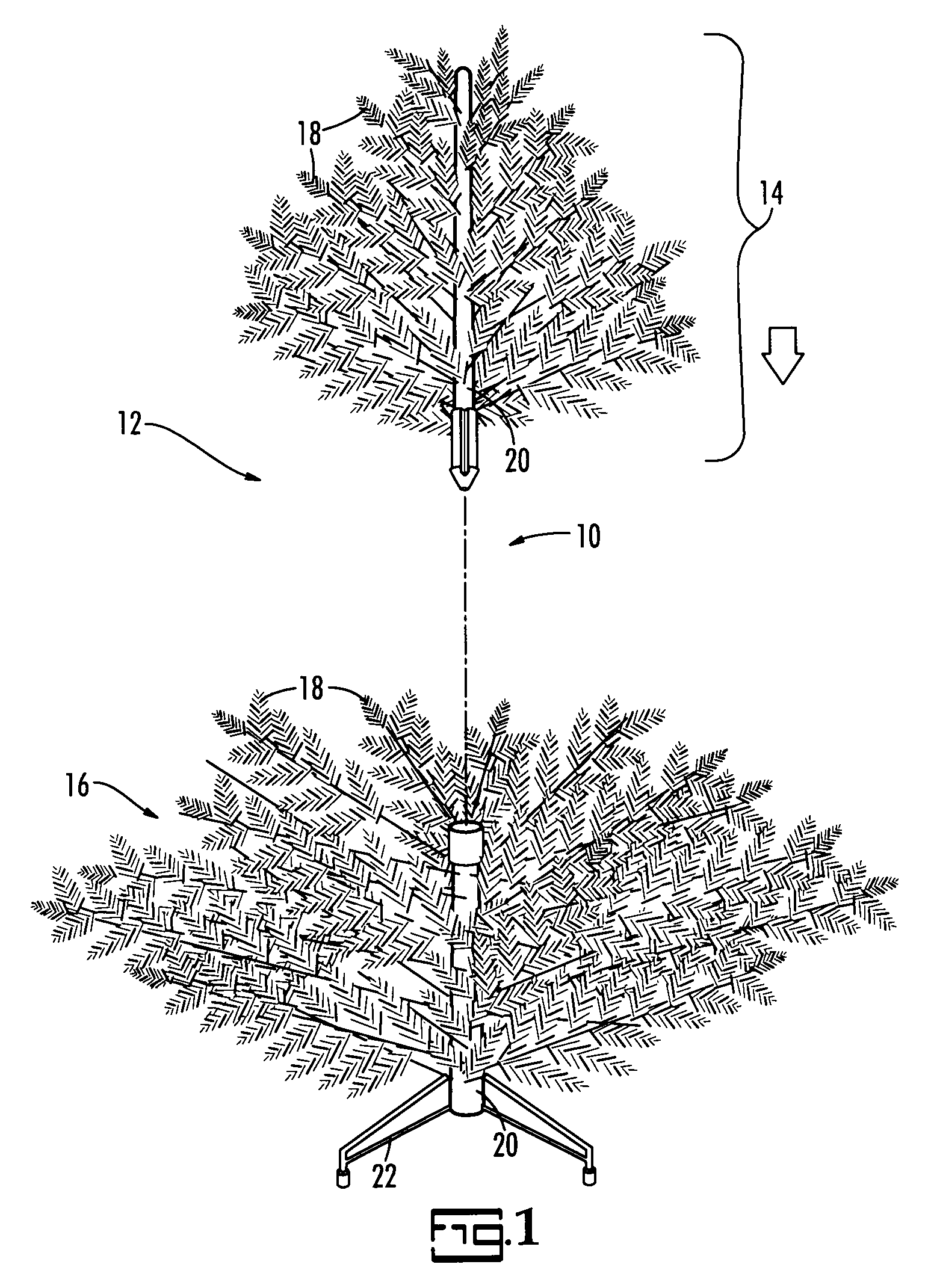

Tree pole coupler system

InactiveUS20100072747A1Easily insertAvoid corrosionSleeve/socket jointsArtificial flowers and garlandsConcentric cylinderTree trunk

A coupler system for use in assembling artificial tree trunks or poles. In particular, the coupler system includes a first part having a cone-shaped end and carrying a wedge-shaped groove parallel to its axis, which is insertable into a second part that is formed as a pair of concentric cylinders. The inner of these cylinders receives the first part of the coupler system and includes a bulge parallel to its axis that aligns with the wedge-shaped groove of the first part when the two are fitted together. Preferably, the end of the first part opposite the cone-shaped end is dimensioned to fit into a first tubular segment that stands as a surrogate for a tree trunk. Additionally, the outer of the concentric cylinders is dimensioned to receive a second tubular segment.

Owner:THE PRE LIT TREE CONCEPT

Coating for medical devices comprising an inorganic or ceramic oxide and a therapeutic agent

InactiveUS20070264303A1Improve coating adhesionGood biocompatibilityStentsHeavy metal active ingredientsIntravascular stentMedical device

The invention relates generally to an implantable medical device for delivering a therapeutic agent to the body tissue of a patient, and a method for making such a medical device. In particular, the invention pertains to an implantable medical device, such as an intravascular stent, having a coating comprising an inorganic or ceramic oxide, such as titanium oxide, and a therapeutic agent.

Owner:BOSTON SCI SCIMED INC

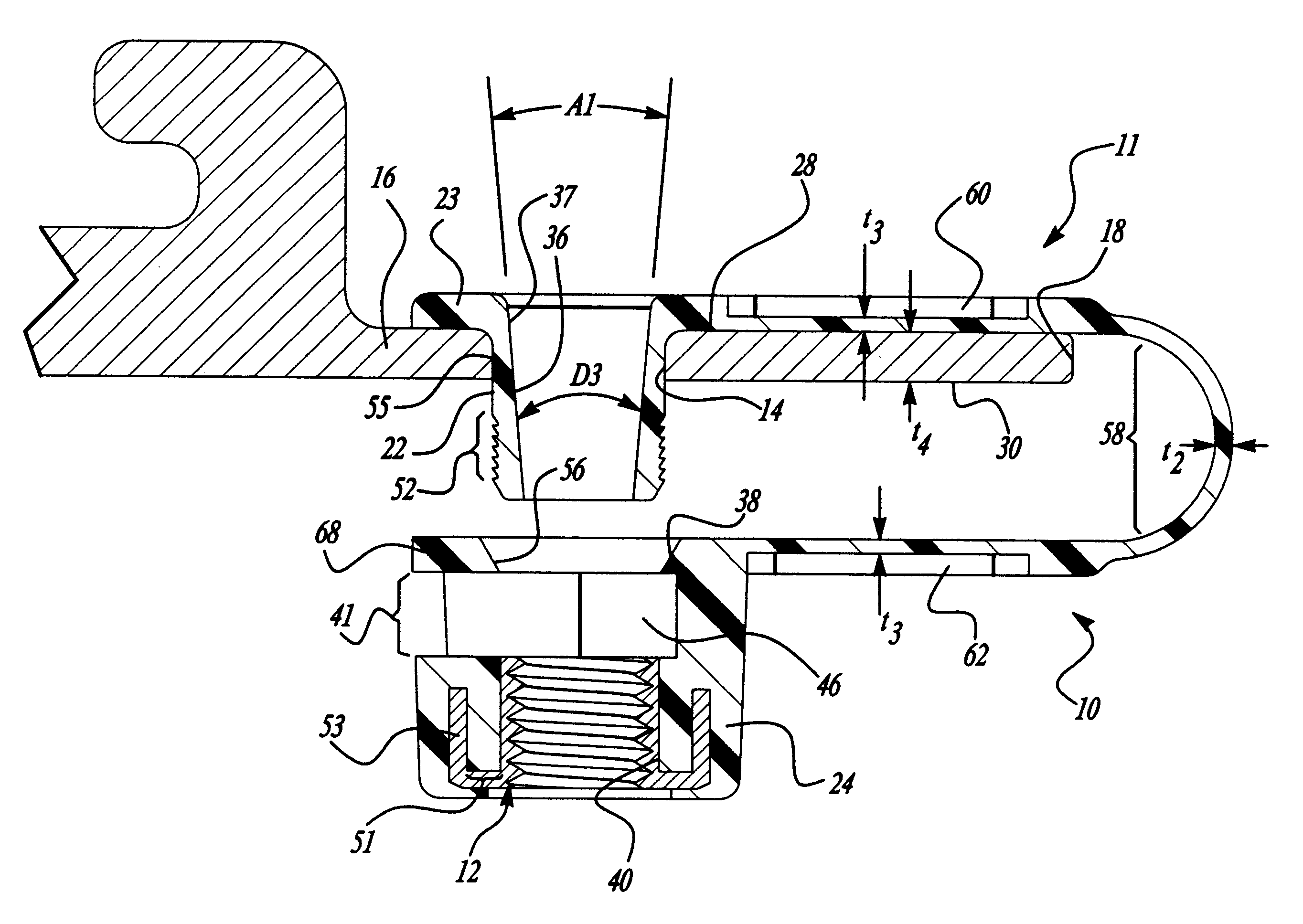

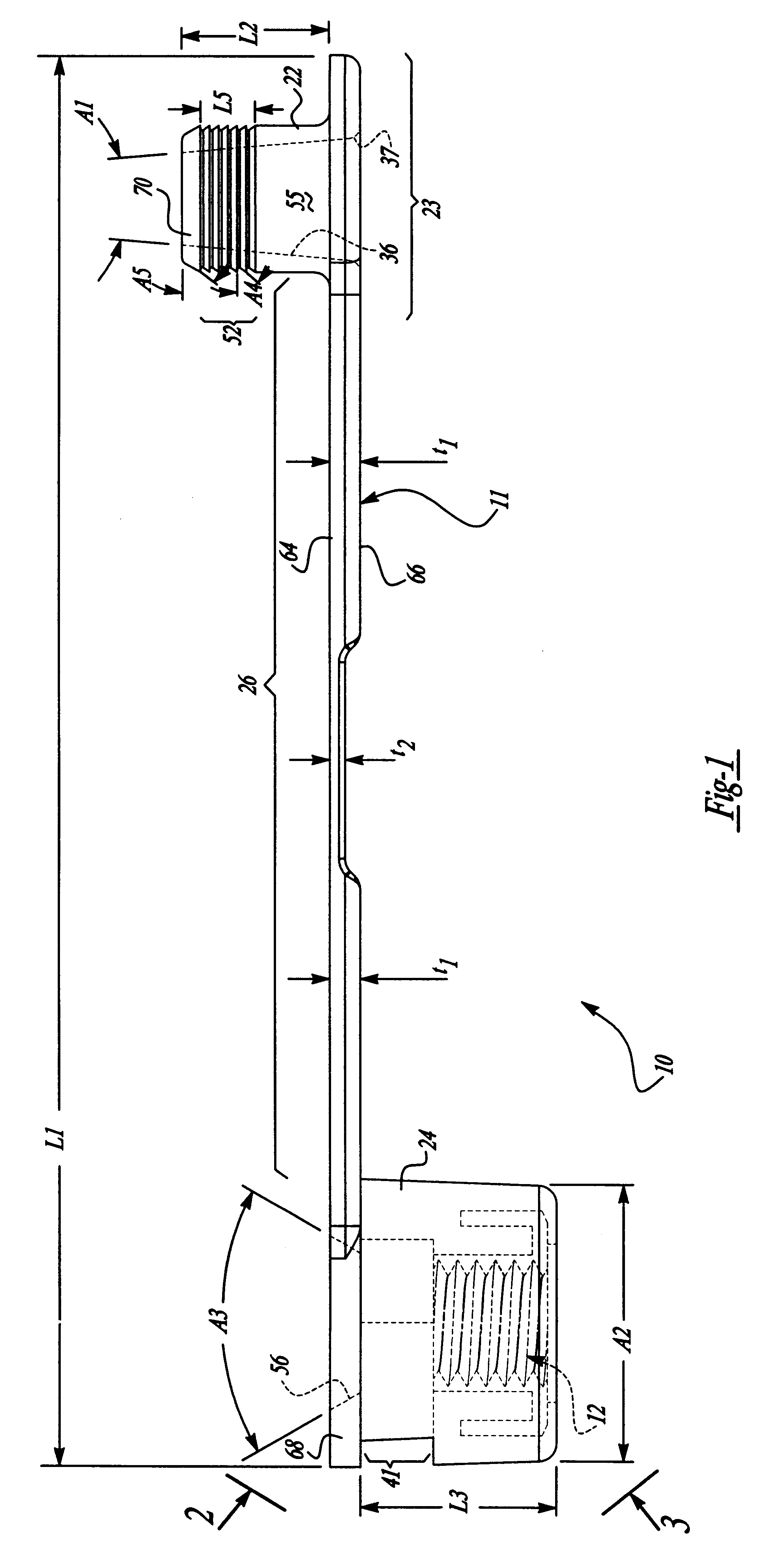

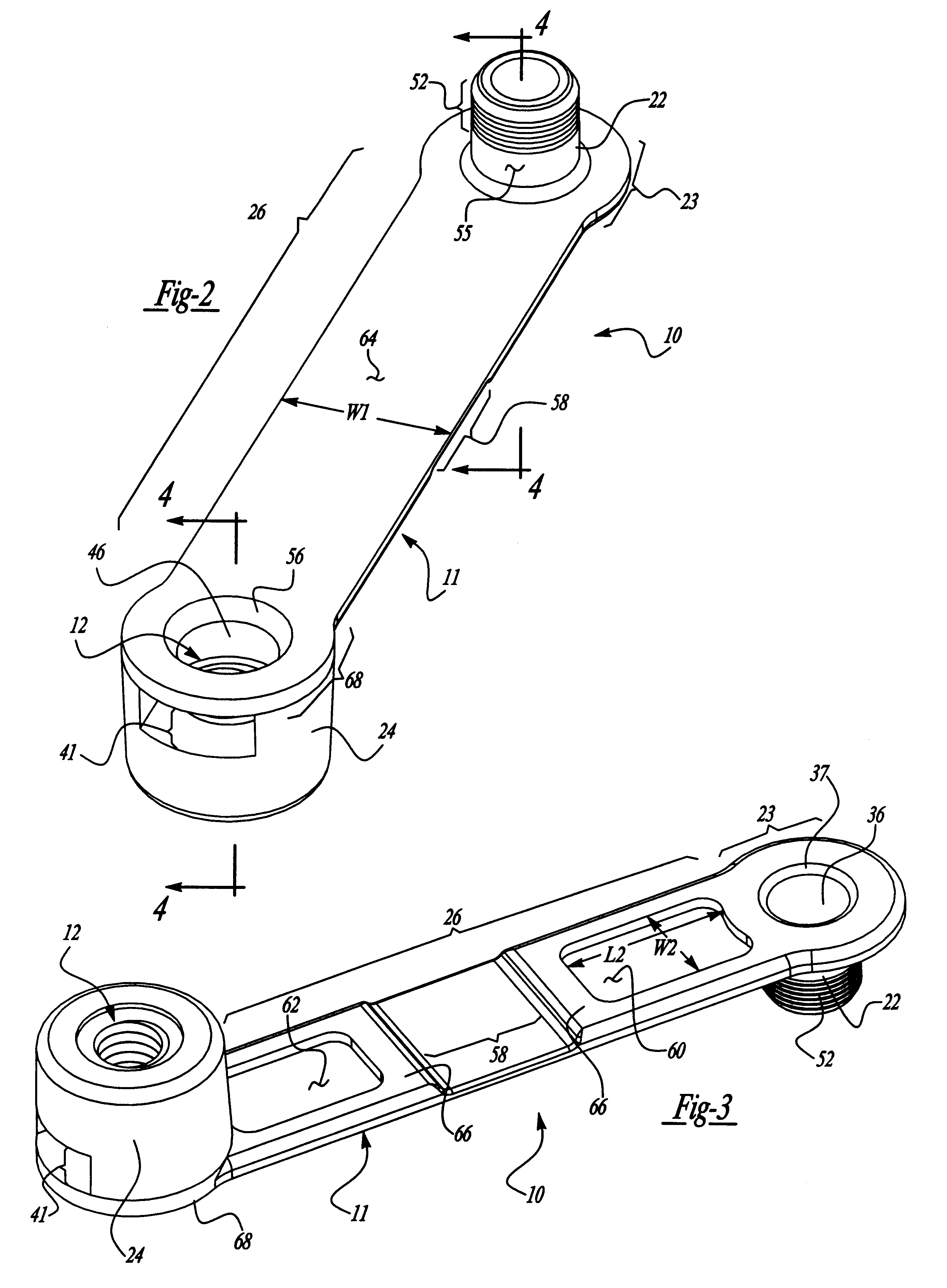

Clip type fastener assembly

A clip type nut device for attachment about an aperture or opening of a support structure is provided with the clip nut device having a resilient main body member having a pair of transversely oppositely extending bushings at opposite ends of a flexible strap with a captured nut member in one bushing. One bushing has a first opening and is receivable within the support structure opening. The other or second bushing has a second opening with the threaded nut member captured in the second opening. A securing structure associated with the first and second bushing is operable to secure the first bushing to the second bushing with the first opening being aligned with the second opening such that the threaded nut member is aligned with the opening through the support structure.

Owner:SOUTHCO

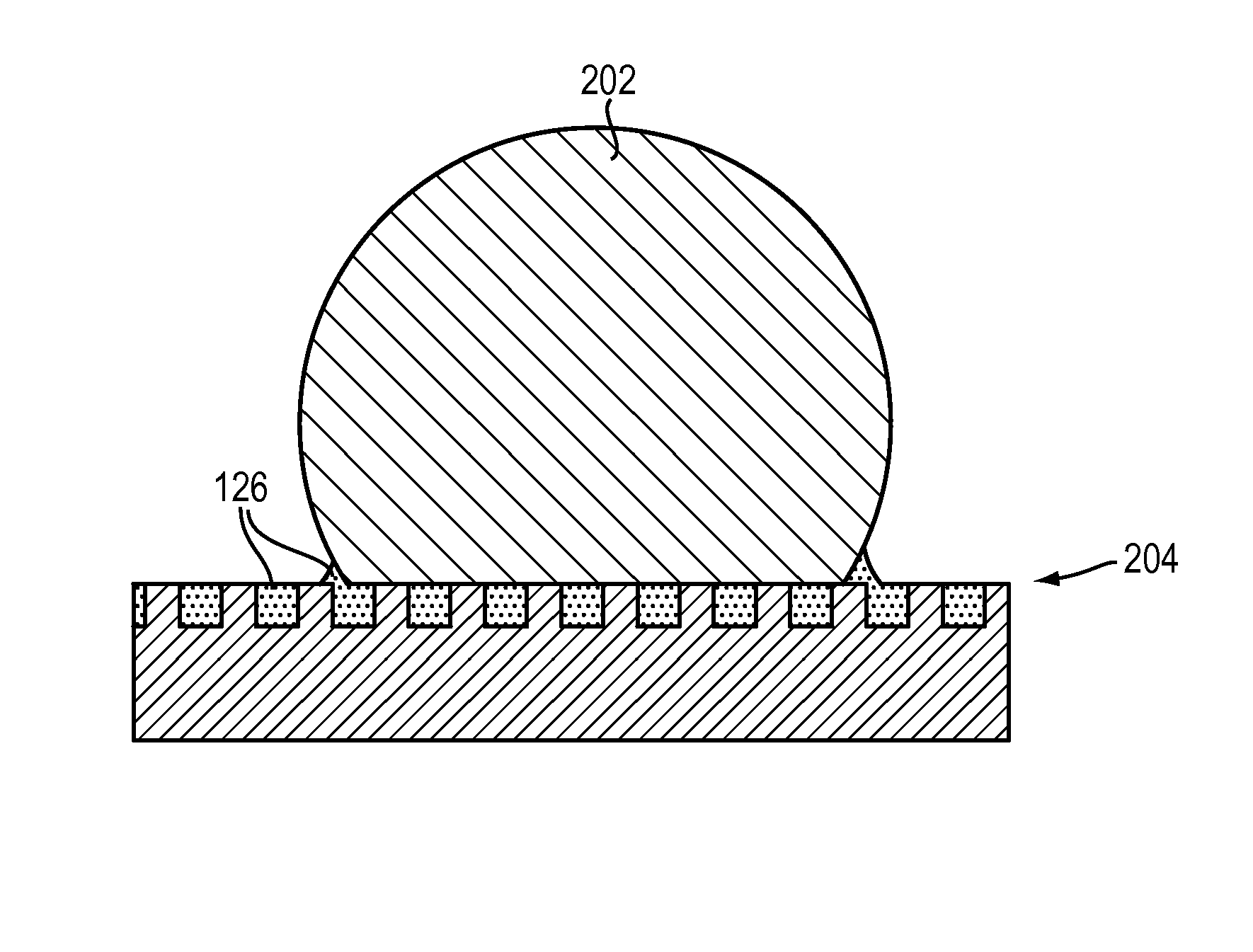

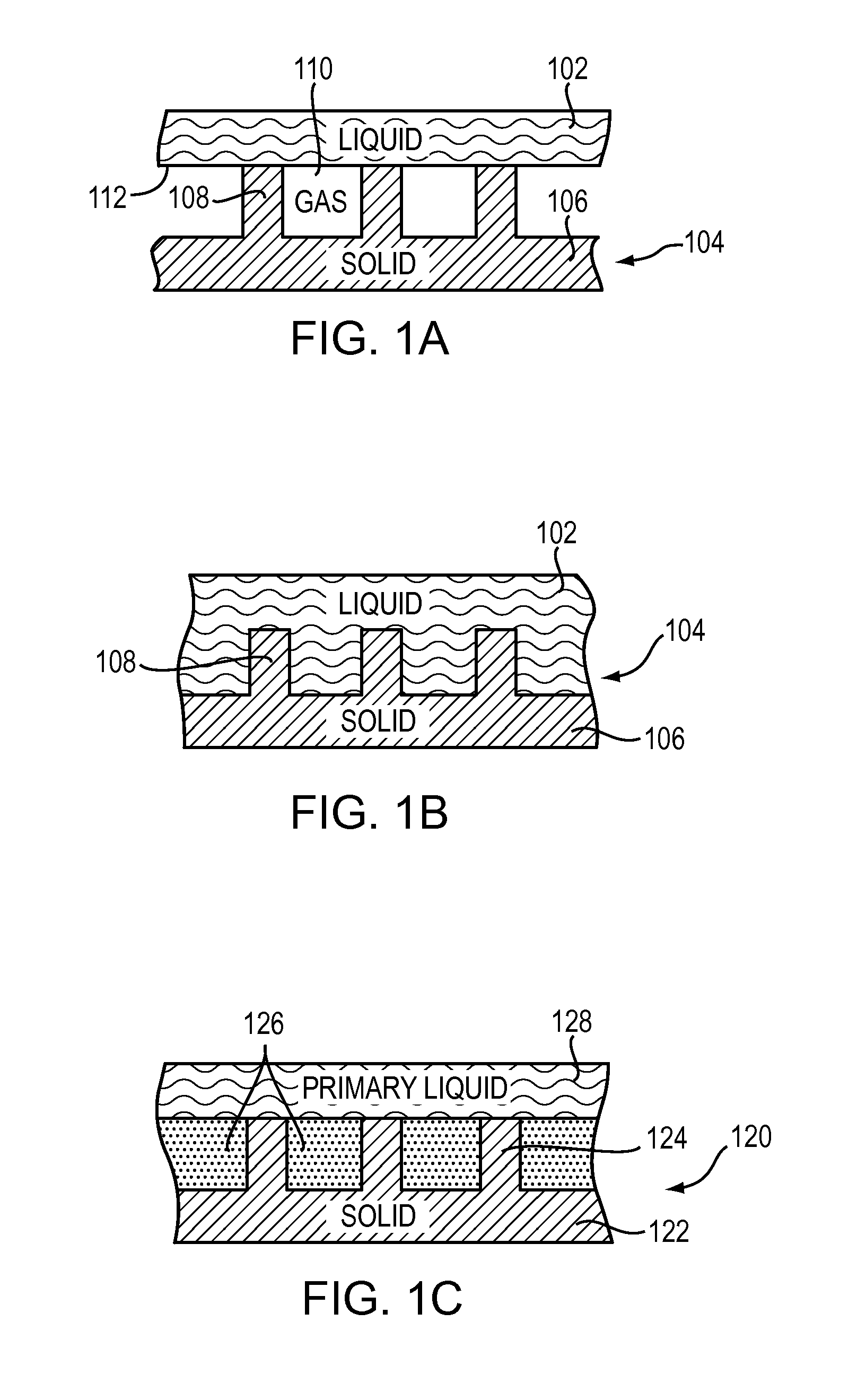

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

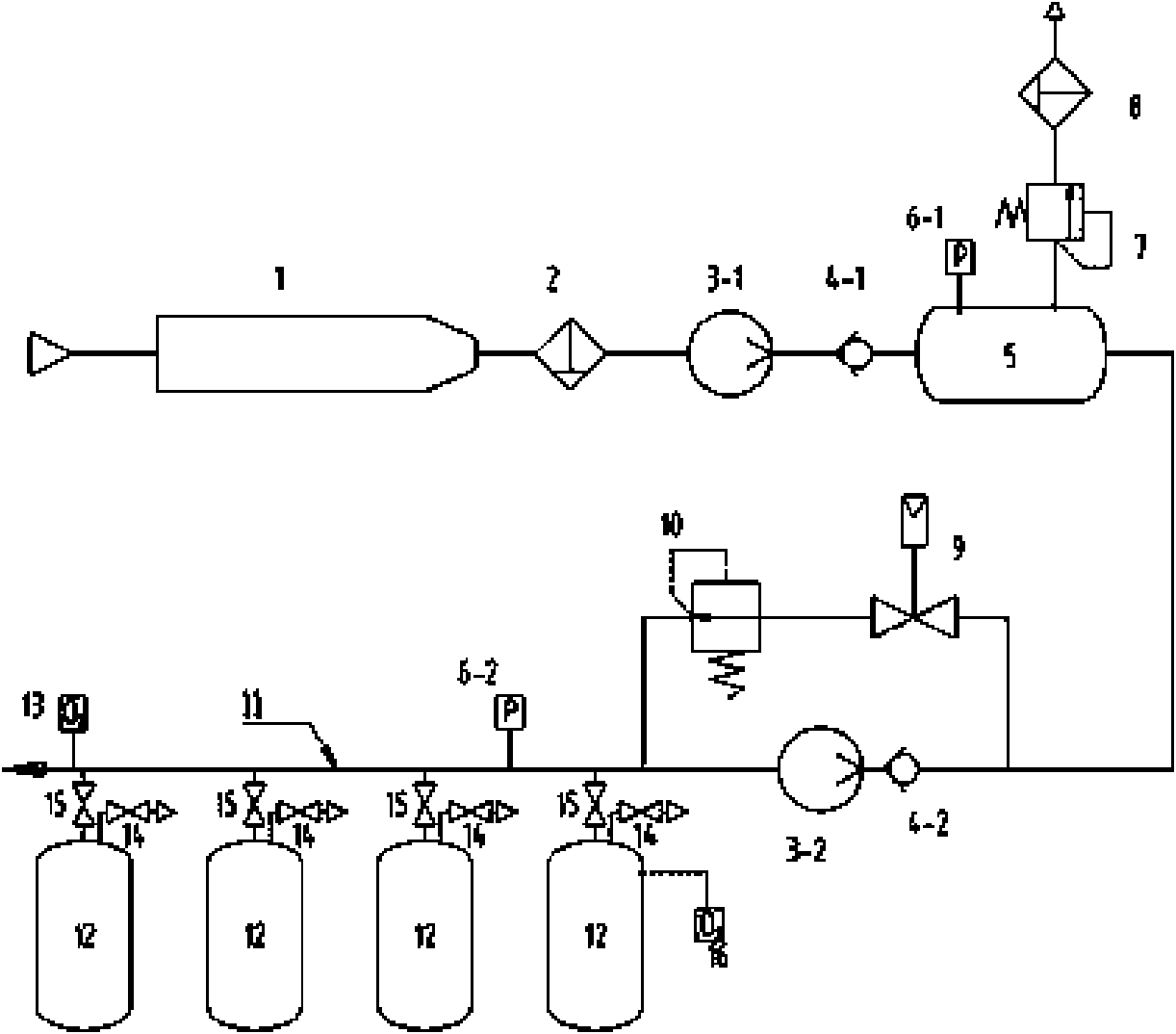

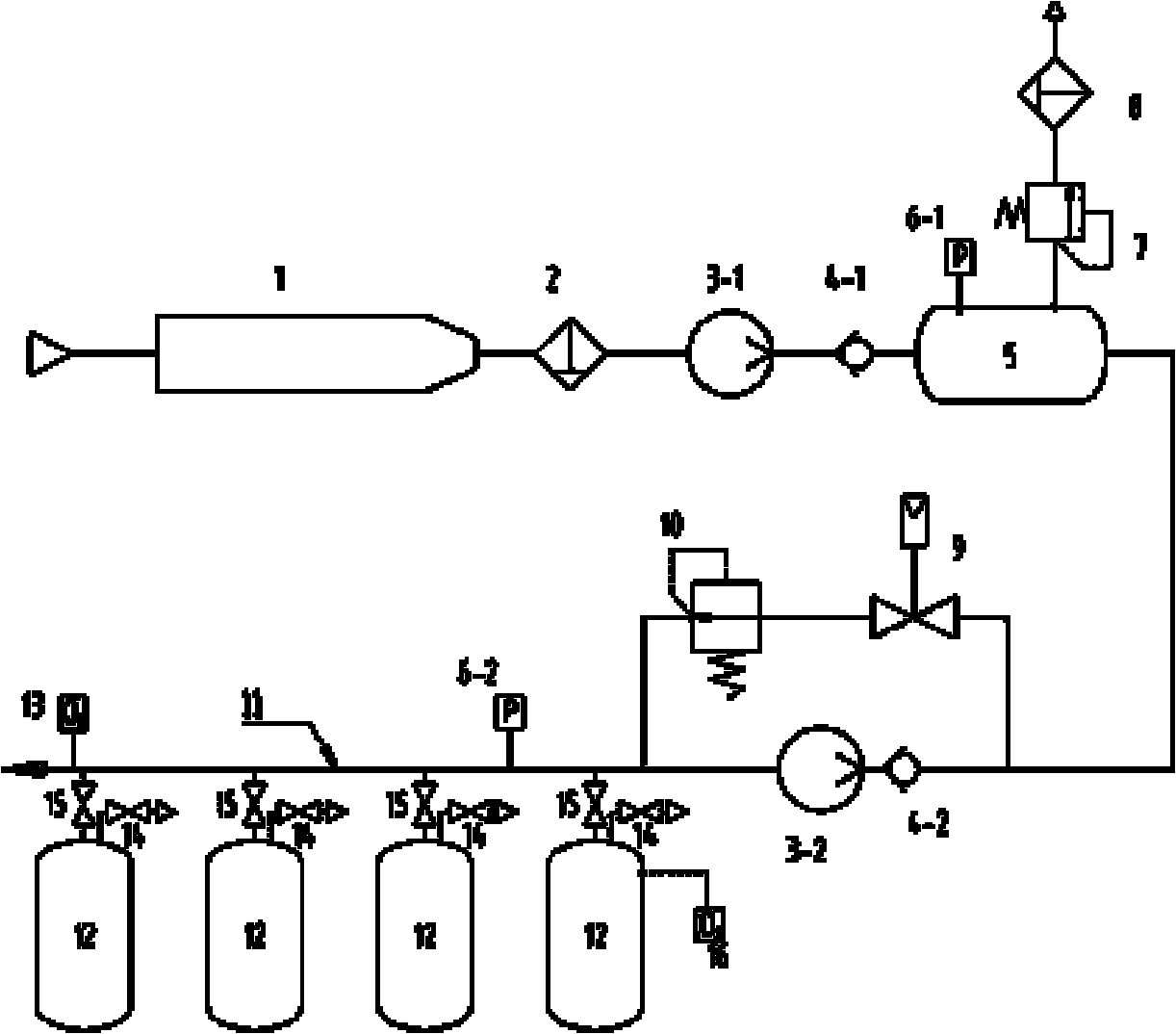

Intrinsically safe inerting protection method and device for oil storage tank

ActiveCN101767697ARealize security protectionImprove real-time performanceLarge containersPipeline systemsEngineeringLimit value

The invention discloses an intrinsically safe inerting protection method and an intrinsically safe inerting protection device for an oil storage tank, relates to a method and a device for active fire and explosion prevention of the oil storage tank, and aims to solve the problem of fire and explosion prevention of the oil storage tank. The method comprises the following steps: a, performing inerting on each oil tank in sequence to ensure that each oil tank achieves an inexplosive condition, namely, the oxygen concentration of gas in the tank is lower than 10 percent; b, detecting the pressure of a pipe network for supplying inert gas to the oil tank, and supplying the inert gas to the pipe network and inputting the inert gas to the oil tank through the pipe network if the pressure is lower than a set lower limit value; c, detecting the pressure of the pipe network for supplying the inert gas to the oil tank, emitting the inert gas in the pipe network if the pressure exceeds a set upper limit value; and d, detecting the oxygen concentration in the pipe network for supplying the inert gas to the oil tank, and repeating the step a if the concentration exceeds the set upper limit value. The device comprises a buffer device, a breathing pipe network, a first pressure transmitter, a second pressure transmitter, an online oxygen analyzer and an electric control device.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

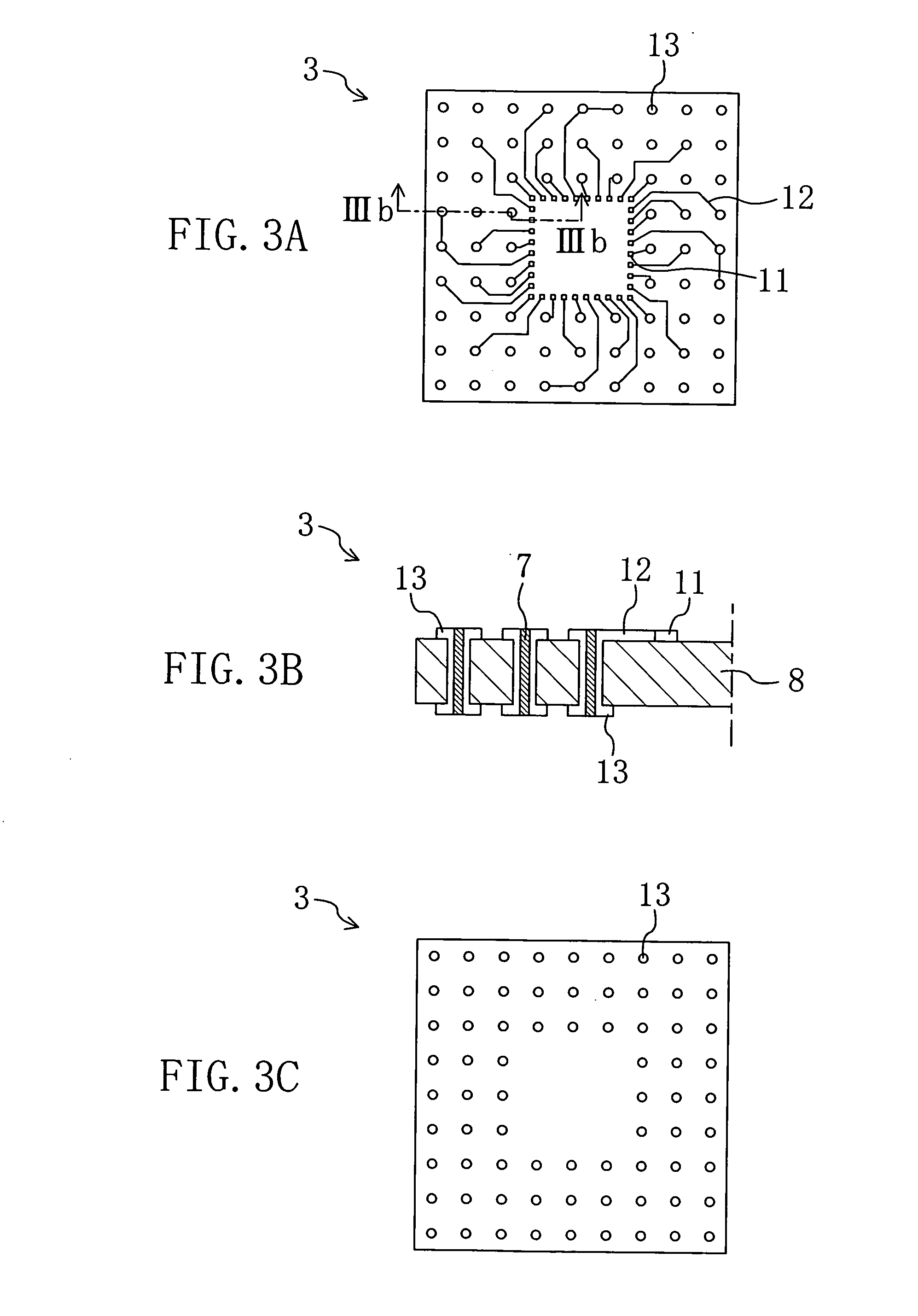

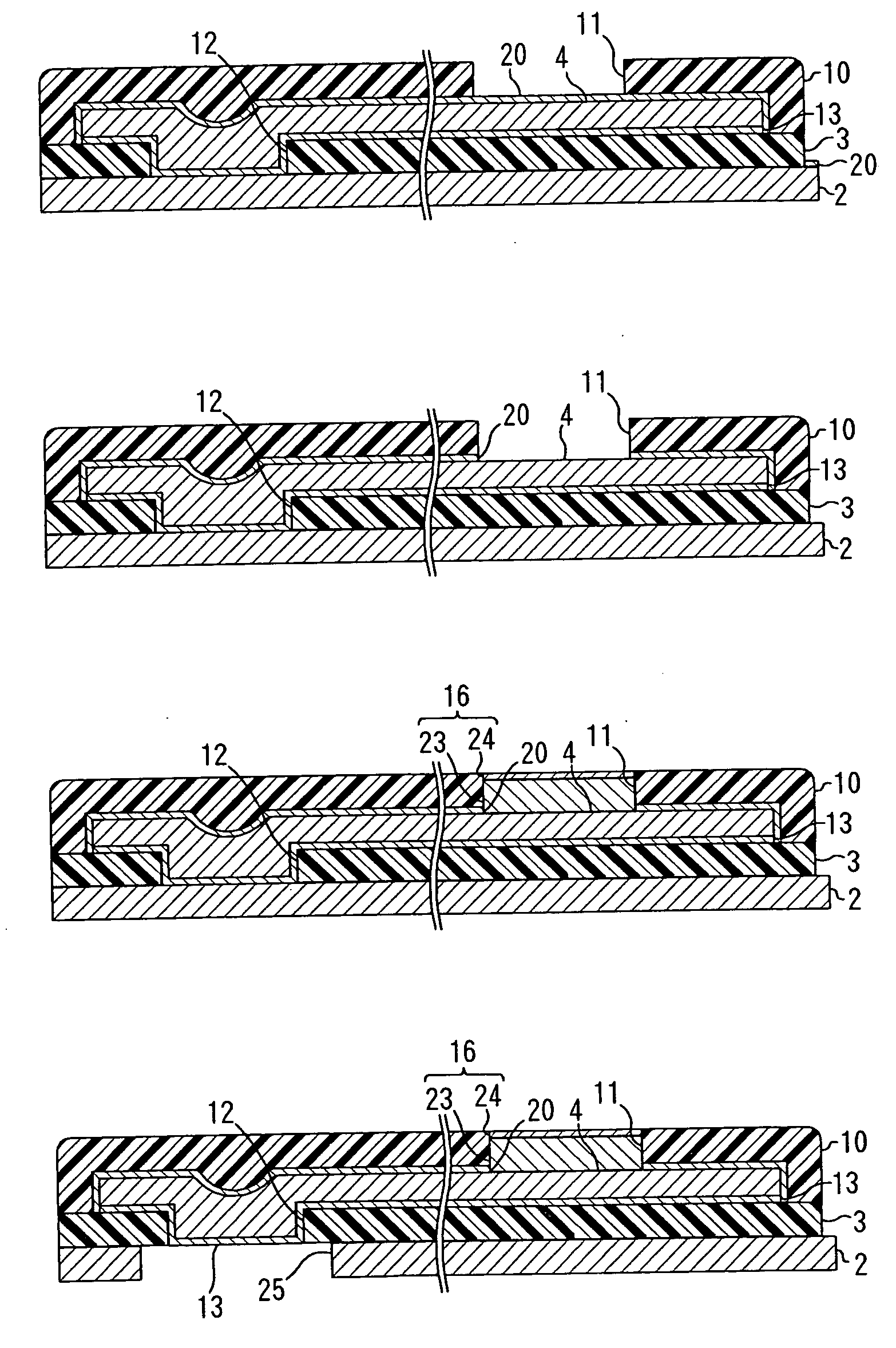

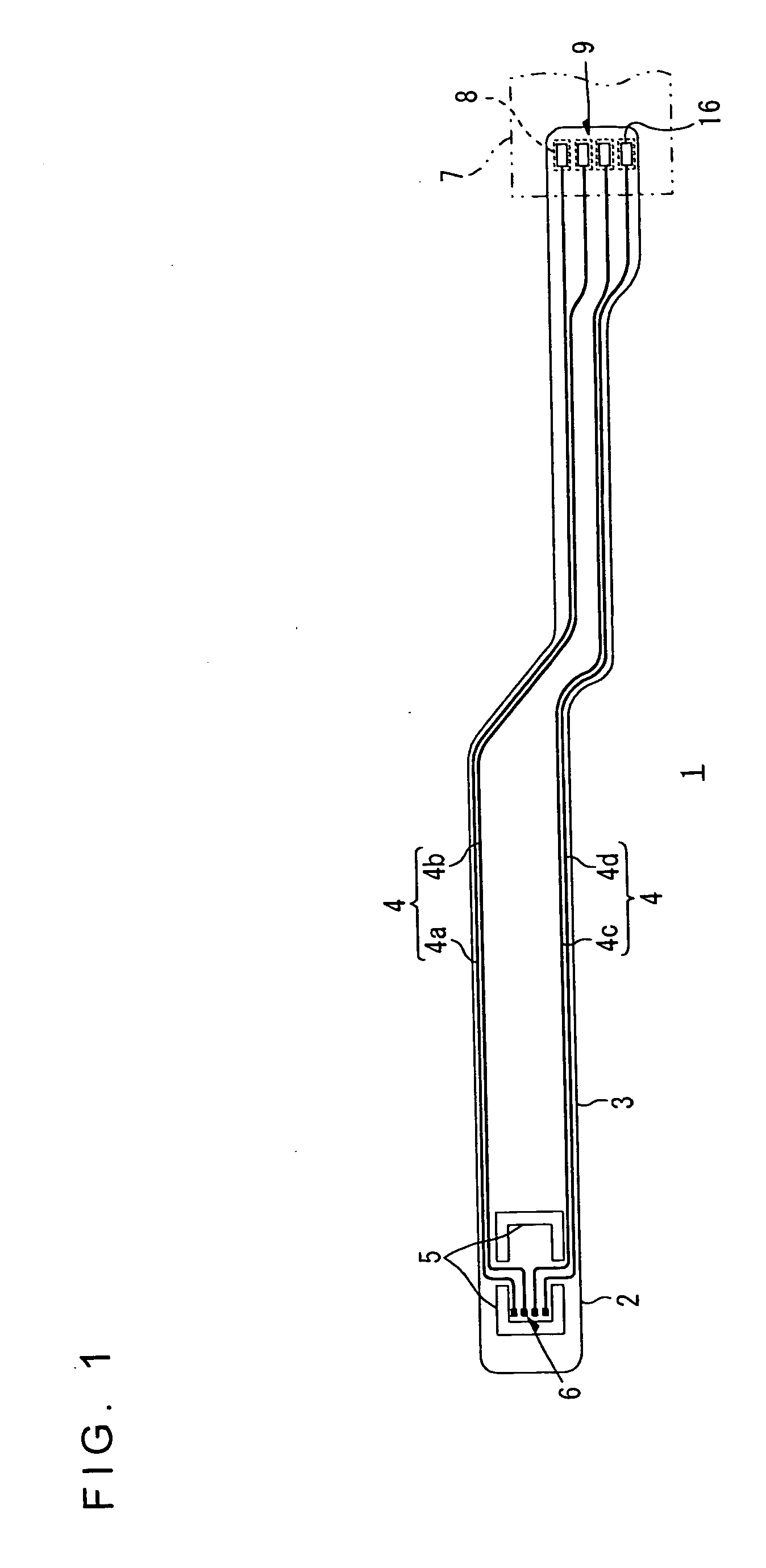

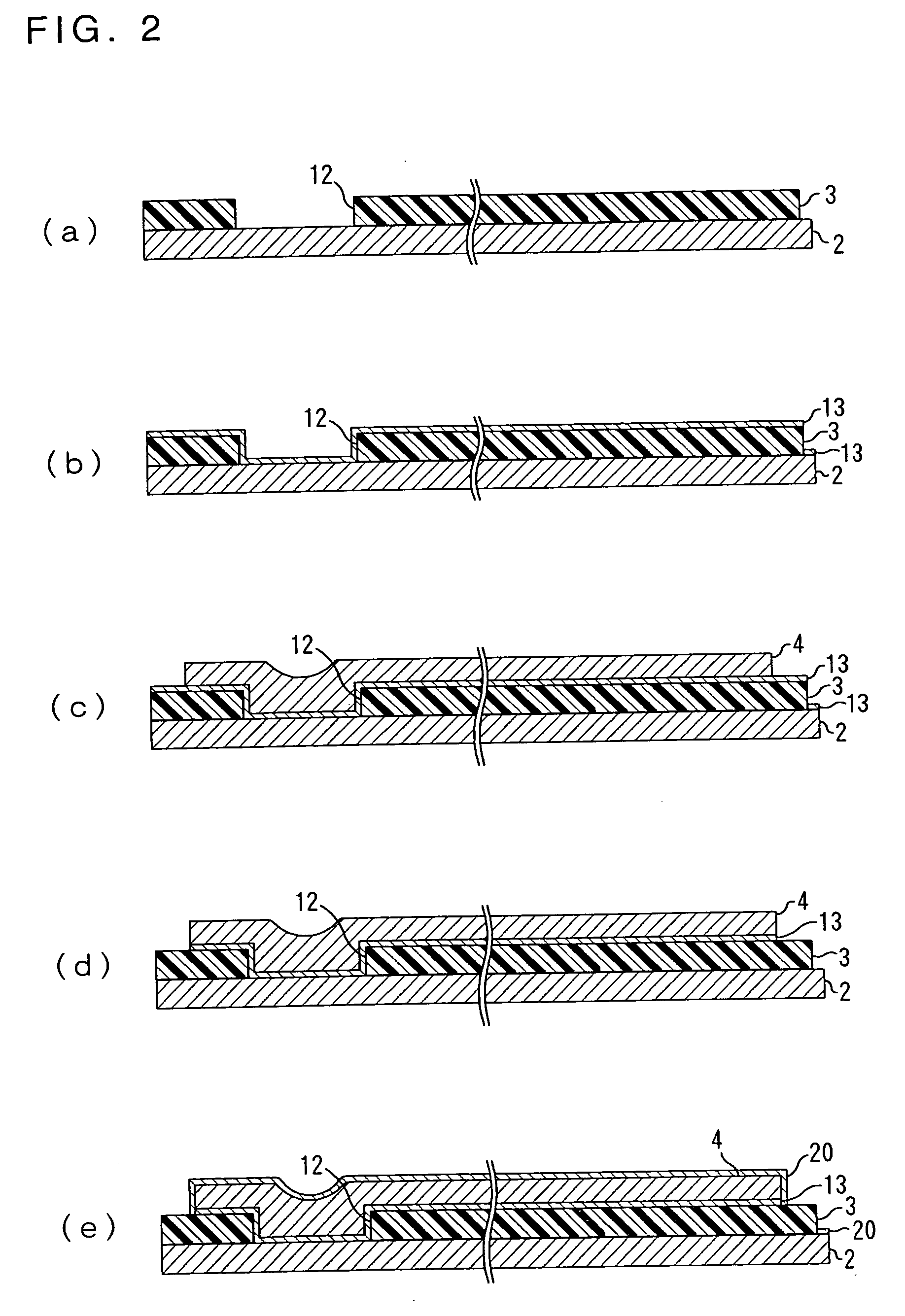

Suspension board with circuit and procuding method thereof

ActiveUS20050061542A1Increase productivityLow costInsulating substrate metal adhesion improvementCircuit arrangements on support structuresThin metalElectrical conductor

A producing method of a suspension board with circuit that can permit a terminal portion to be formed by electrolysis plating without exposing a conductor layer to outside and also can reduce the number of processes, and the suspension board with circuit produced by the same producing method. After an insulating base layer 3 is formed on a suspension board 2 in a specific pattern in which a second opening 12 is formed, a thin metal film 13 is formed on an entire surface of the insulating base layer 3 and on a surface of the suspension board 2 including the second opening 12 exposed from the insulating base layer 3.Then, a conductor layer 4 is formed in the form of a wired circuit pattern on the thin metal film 13. Thereafter, the insulating cover layer 10 is formed in such a manner that a pad opening 11 is formed in the insulating cover layer 10 and then a pad portion 16 is formed in the pad opening 11 using the suspension board 2 as a lead portion of the electrolysis plating. Thereafter, a first opening 25 larger than the second opening 12 is formed in the suspension board 2 at a portion thereof corresponding to the second opening 12.

Owner:NITTO DENKO CORP

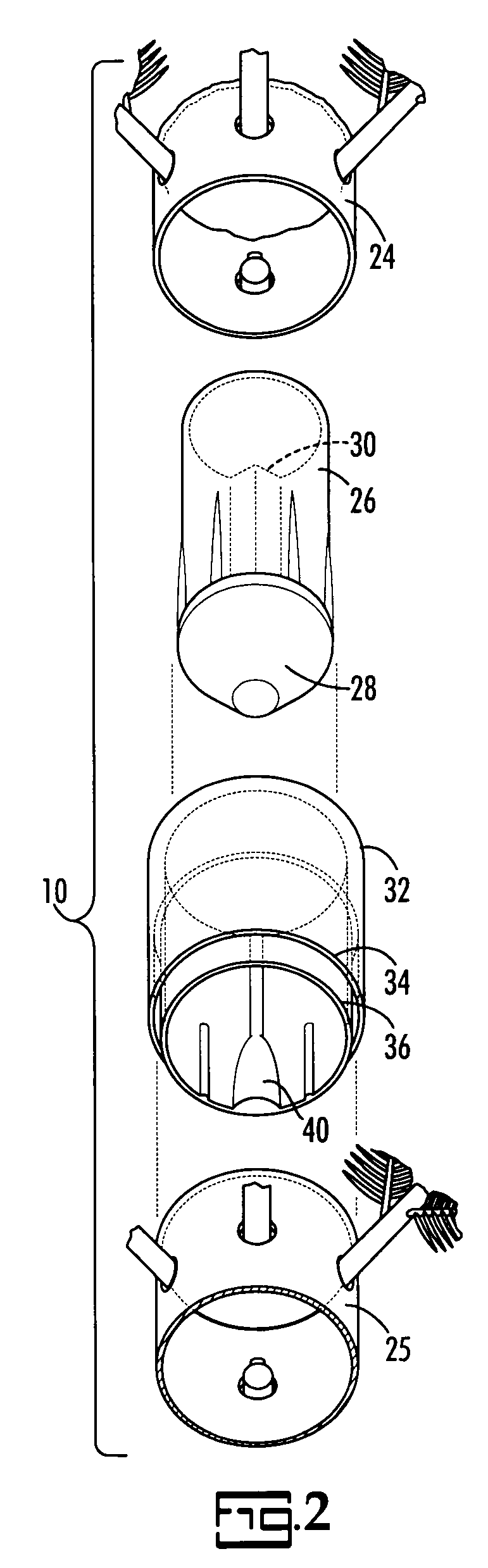

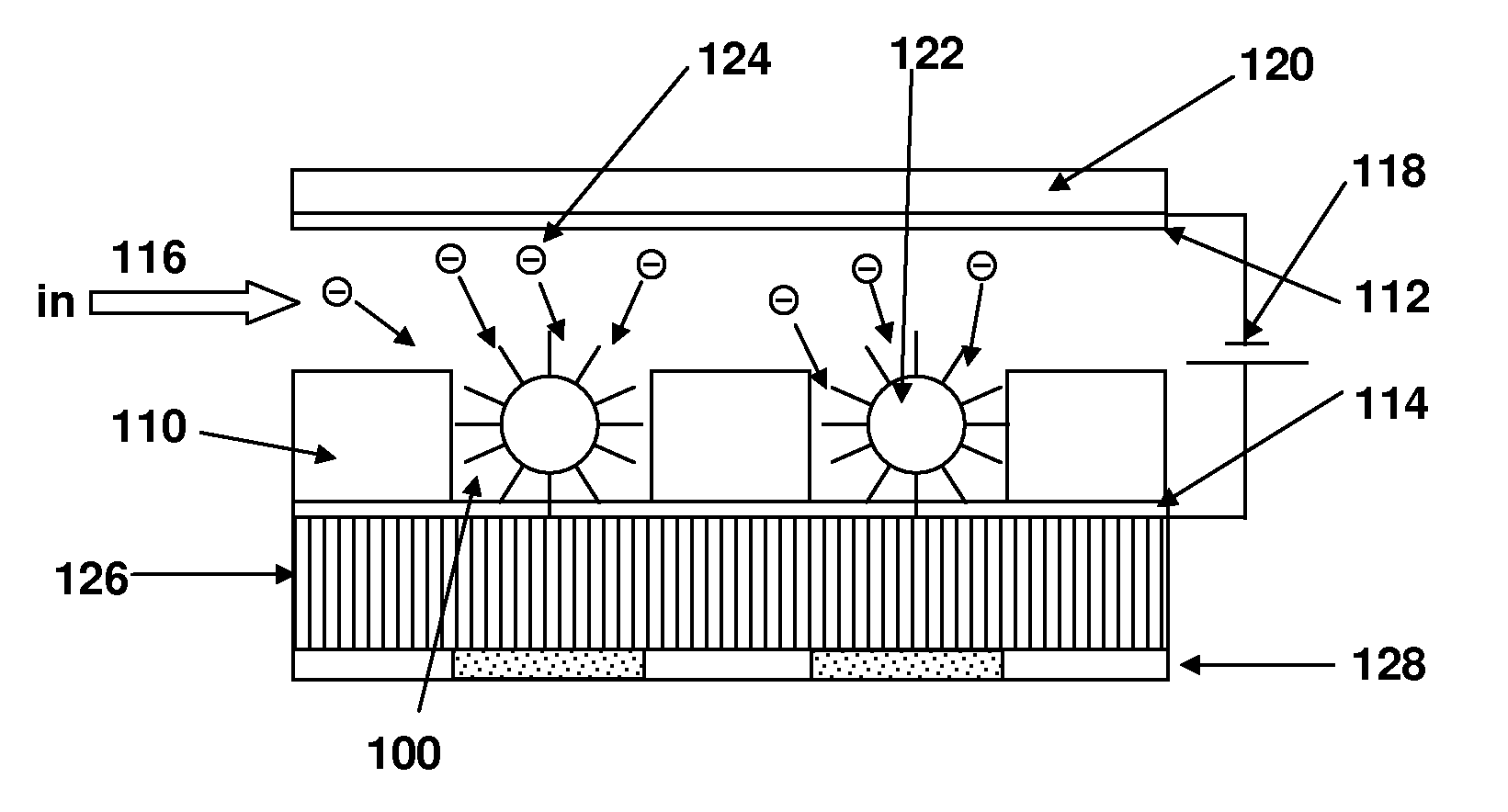

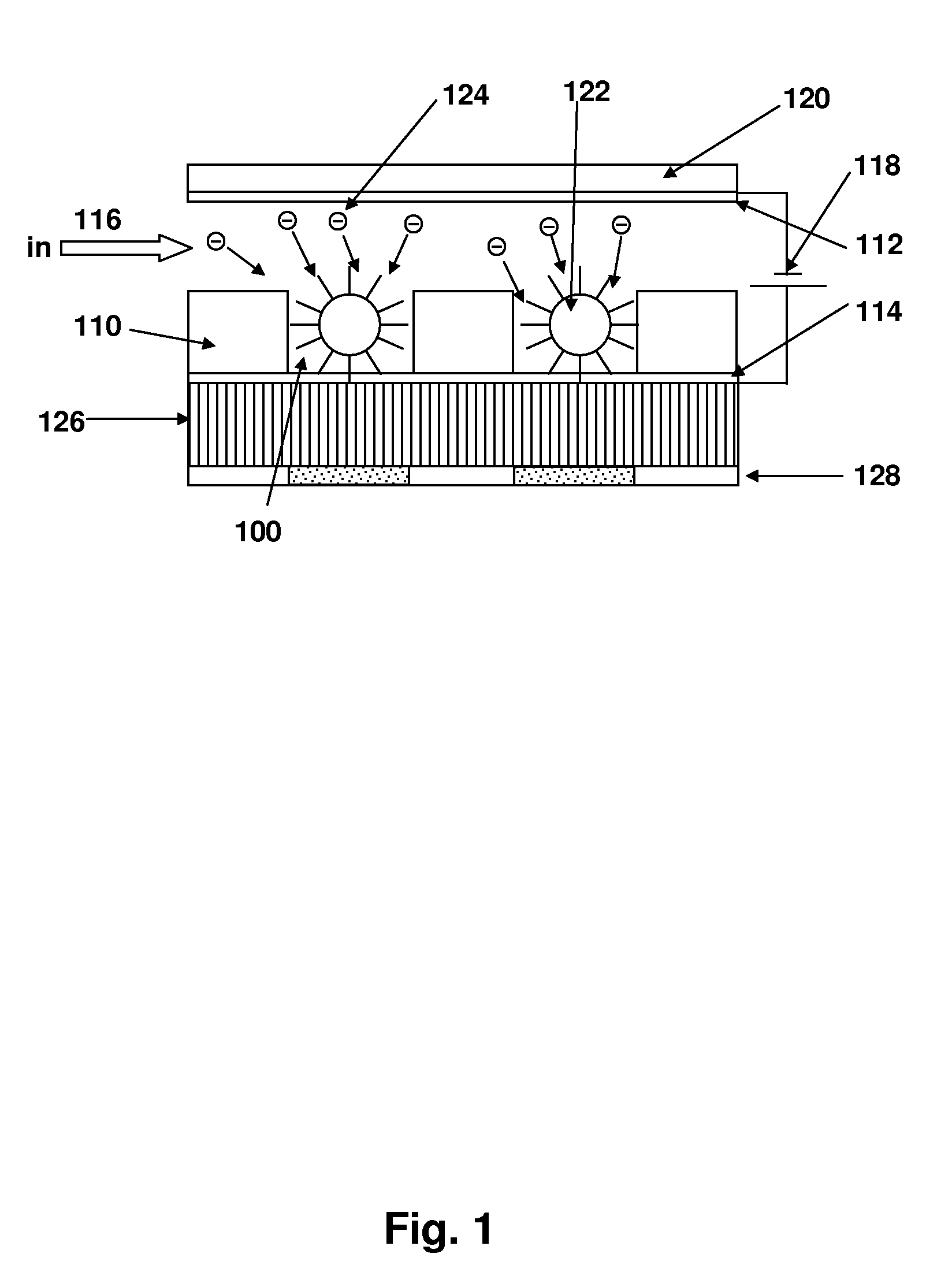

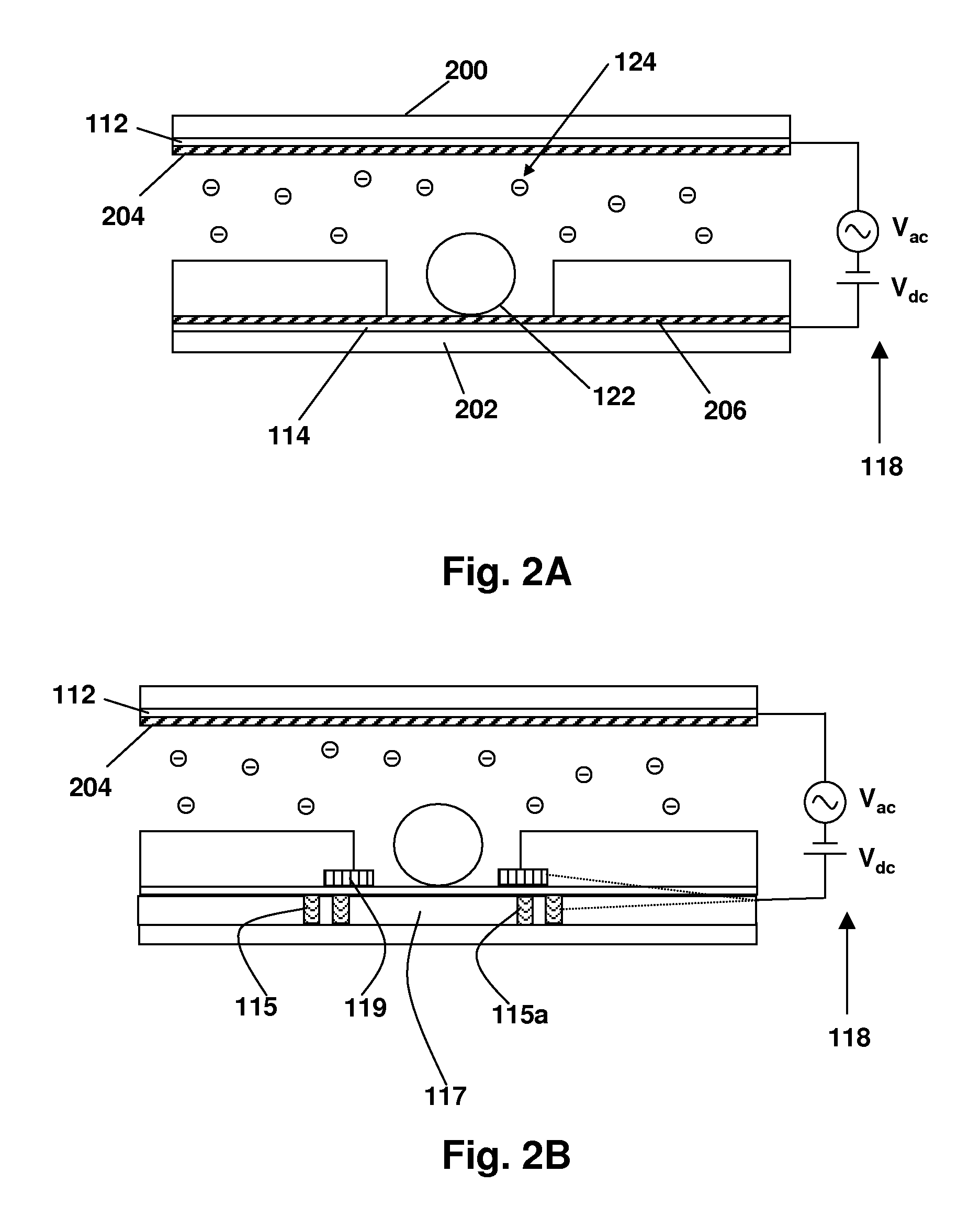

Method and apparatus using electric field for improved biological assays

ActiveUS8277628B2Quality improvementEfficient removalElectrostatic separatorsSludge treatmentPresent methodEngineering

Disclosed are a method and apparatus that use an electric field for improved biological assays. The electric field is applied across a device having wells, which receive reactants, which carry a charge. The device thus uses a controllable voltage source between the first and second electrodes, which is controllable to provide a positive charge and a negative charge to a given electrode. By controlled use of the electric field charged species in a fluid in a fluid channel are directed into or out of the well by an electric field between the electrodes. The present method involves the transport of fluids, as in a microfluidic device, and the electric field-induced movement of reactive species according to various assay procedures, such as DNA sequencing, synthesis or the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

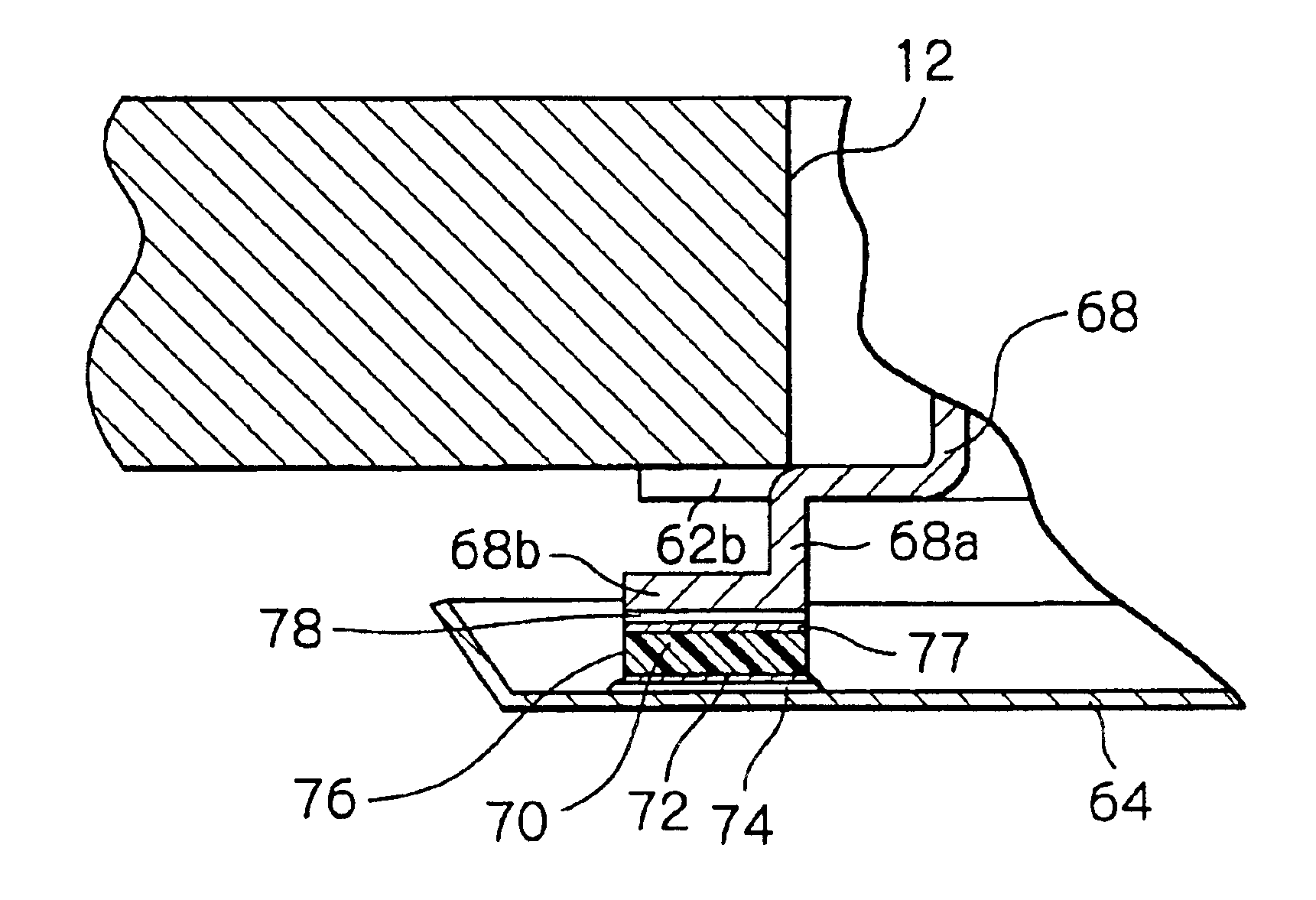

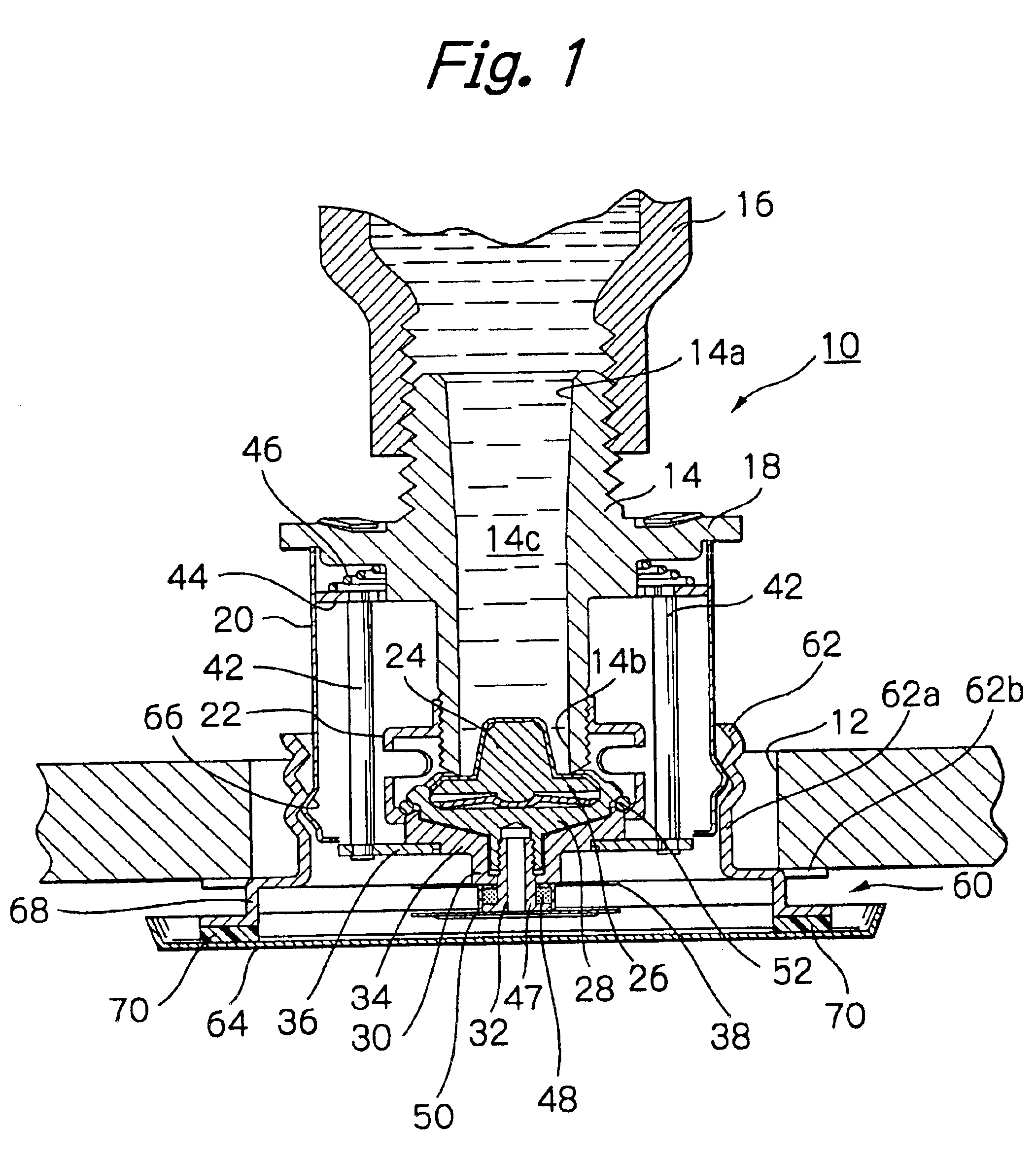

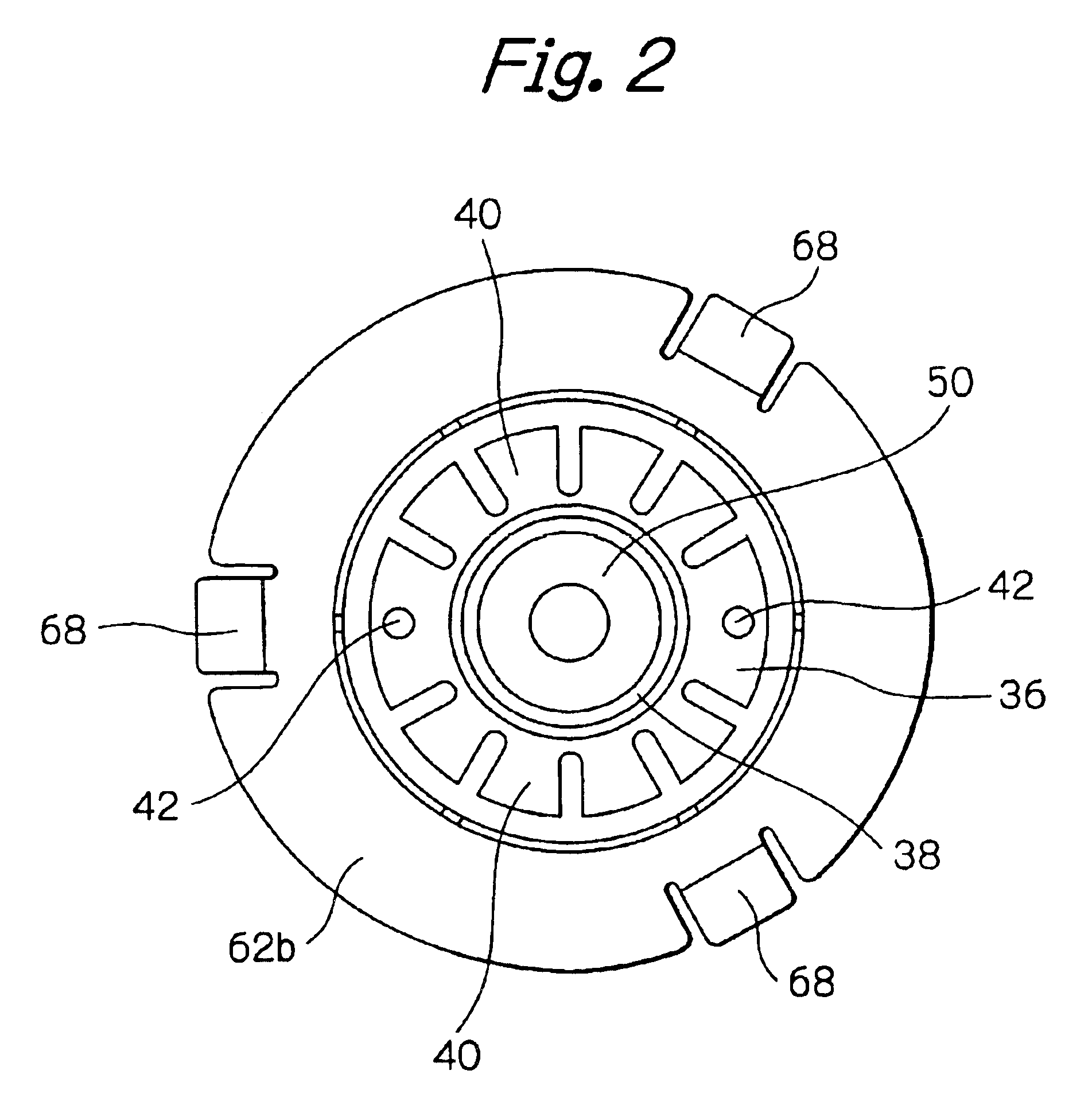

Cover assembly for a concealed sprinkler head

A concealed sprinkler head is mounted above the ceiling of a fire protected zone. The sprinkler head includes a housing within which a valve and other operative parts are contained. A decorative cover plate is secured to the housing to conceal the sprinkler head within the ceiling so that none of the operative parts is visible. The cover assembly includes a thin metallic cover plate made of a heat conductive material such as copper, and a metallic skirt including a cylindrical wall threaded on the housing, an annular flange extending outwardly from one end of the cylindrical wall, and a plurality of tabs extending downwardly from the flange. A plurality of heat insulative elements are disposed between the tabs and the cover plate. A metallic layer is attached to the lower surface of each of the insulative elements. A layer of fusible material is disposed between the metallic layer and the cover plate to secure each of the insulative elements to the cover plate through the metallic layer.

Owner:SENJU SPRINKLER

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

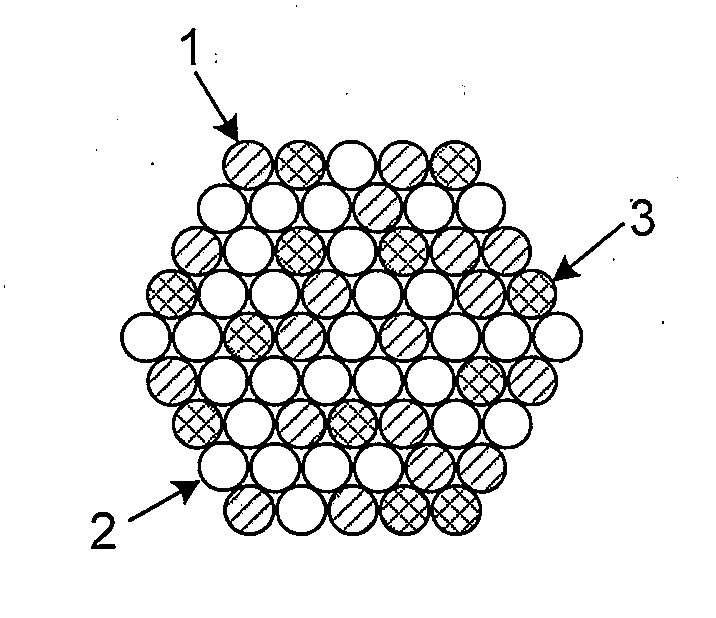

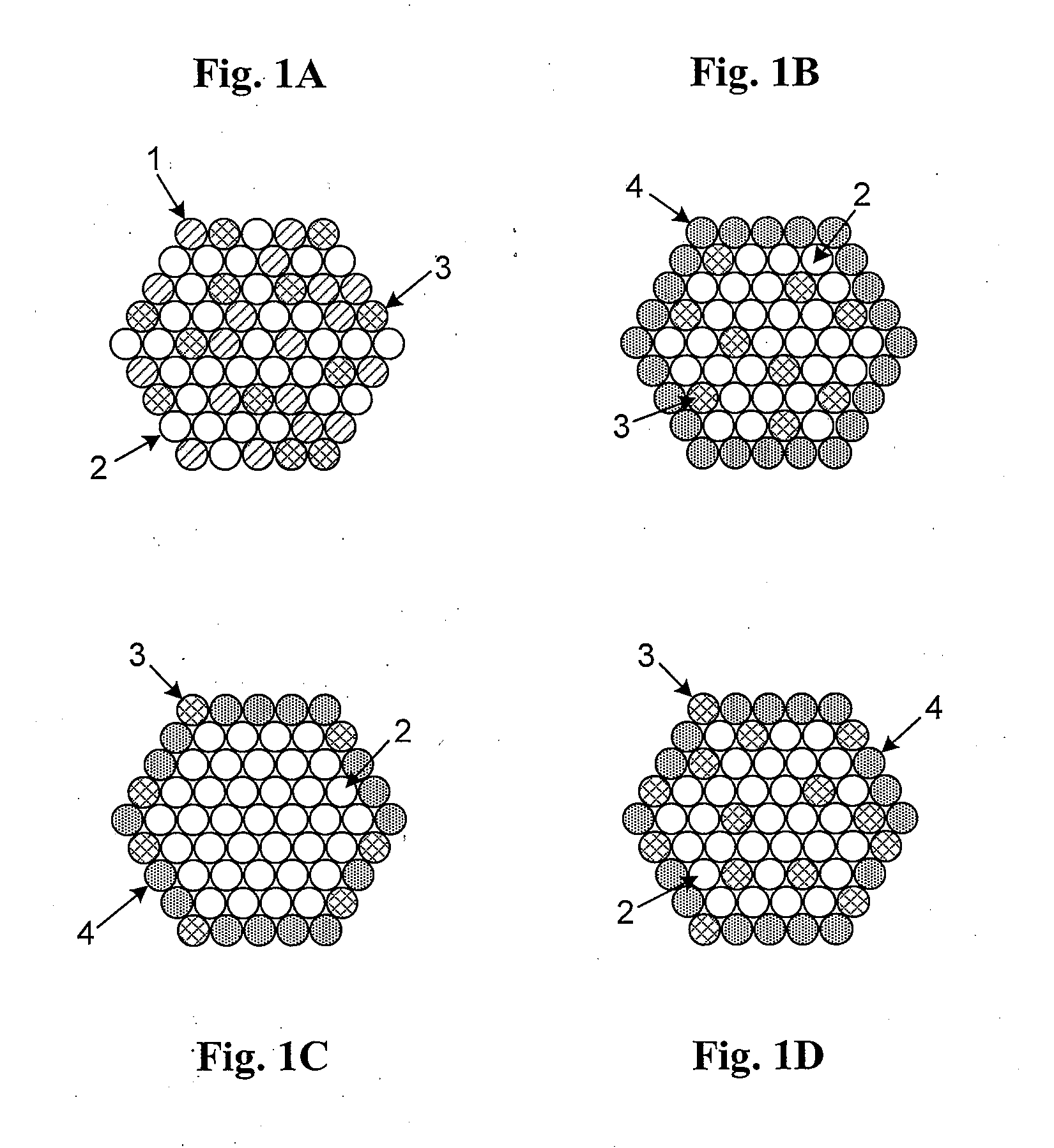

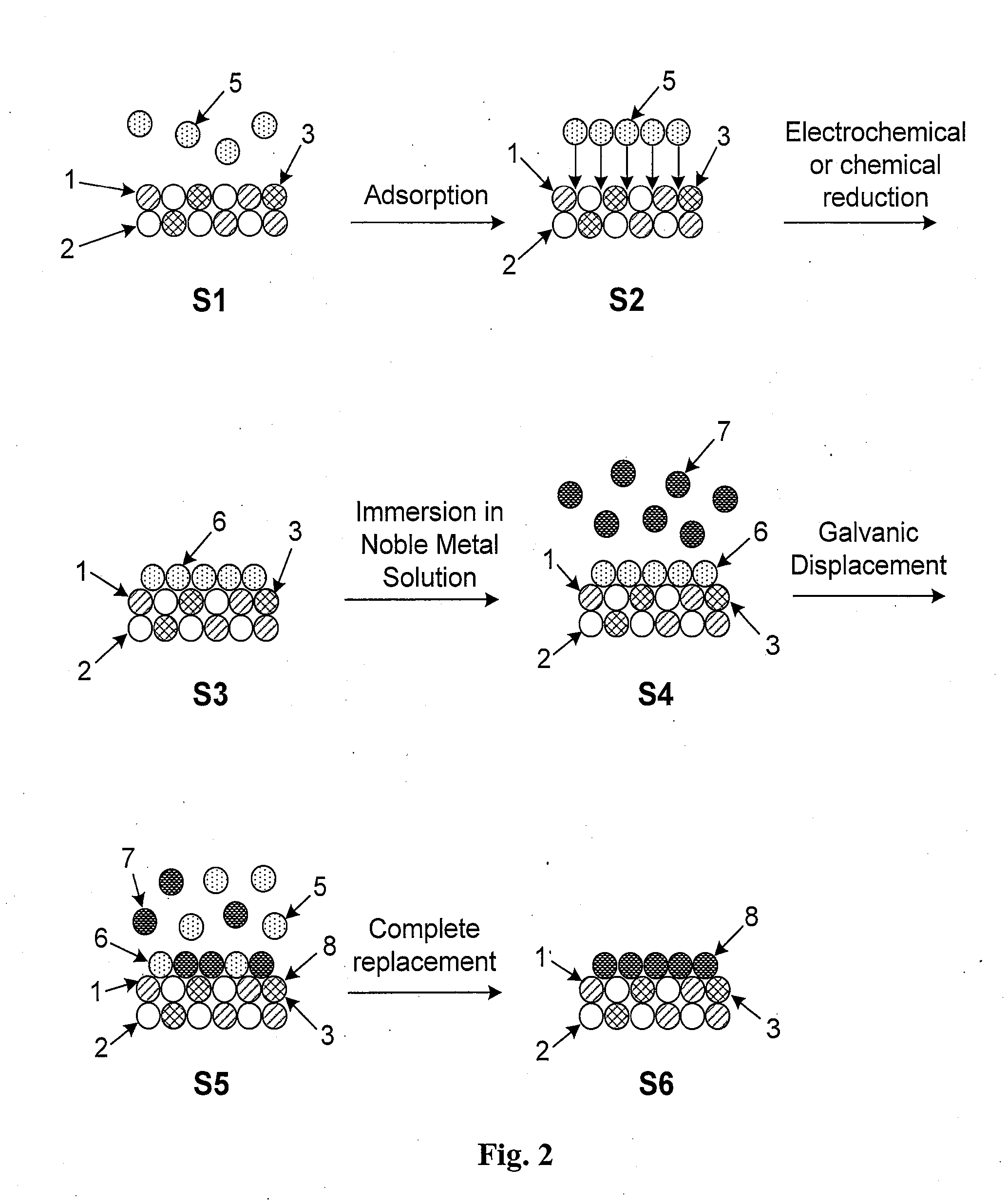

High Stability, Self-Protecting Electrocatalyst Particles

InactiveUS20100216632A1Avoid corrosionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCore shell nanoparticlesAlloy

High-stability, self-protecting particles encapsulated by a thin film of a catalytically active noble metal are described. The particles are preferably nanoparticles comprising a passivating element having at least one metal selected from the group consisting of columns IVB, VB, VIB, and VIIB of the periodic table. The nanoparticle is preferably encapsulated by a Pt shell and may be either a nanoparticle alloy or a core-shell nanoparticle. The nanoparticle alloys preferably have a core comprised of a passivating component alloyed with at least one other transition metal. The core-shell nanoparticles comprise a core of a non-noble metal surrounded by a shell of a noble metal. The material constituting the core, shell, or both the core and shell may be alloyed with one or more passivating elements. The self-protecting particles are ideal for use in corrosive environments where they exhibit improved stability compared to conventional electrocatalyst particles.

Owner:BROOKHAVEN SCI ASSOCS

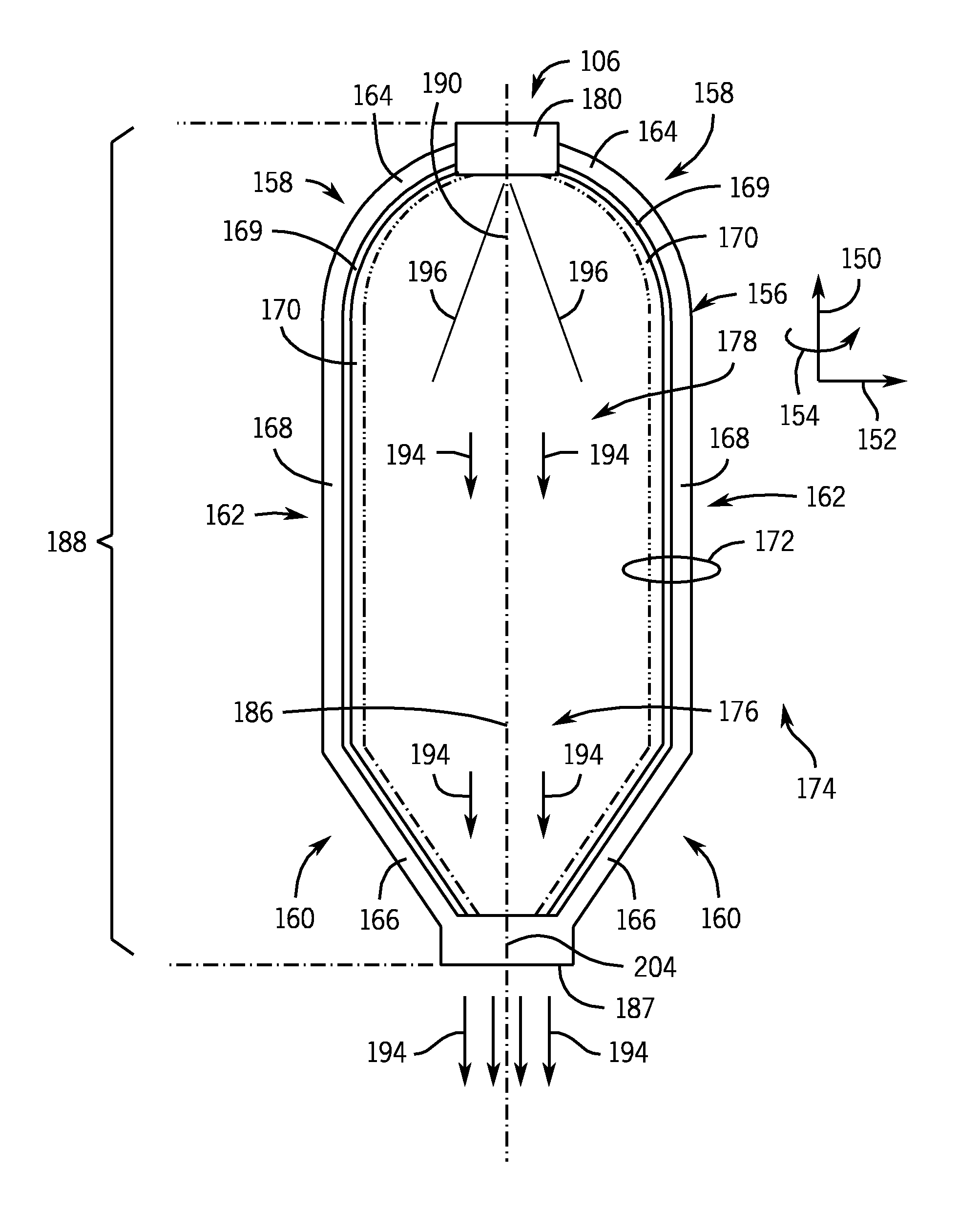

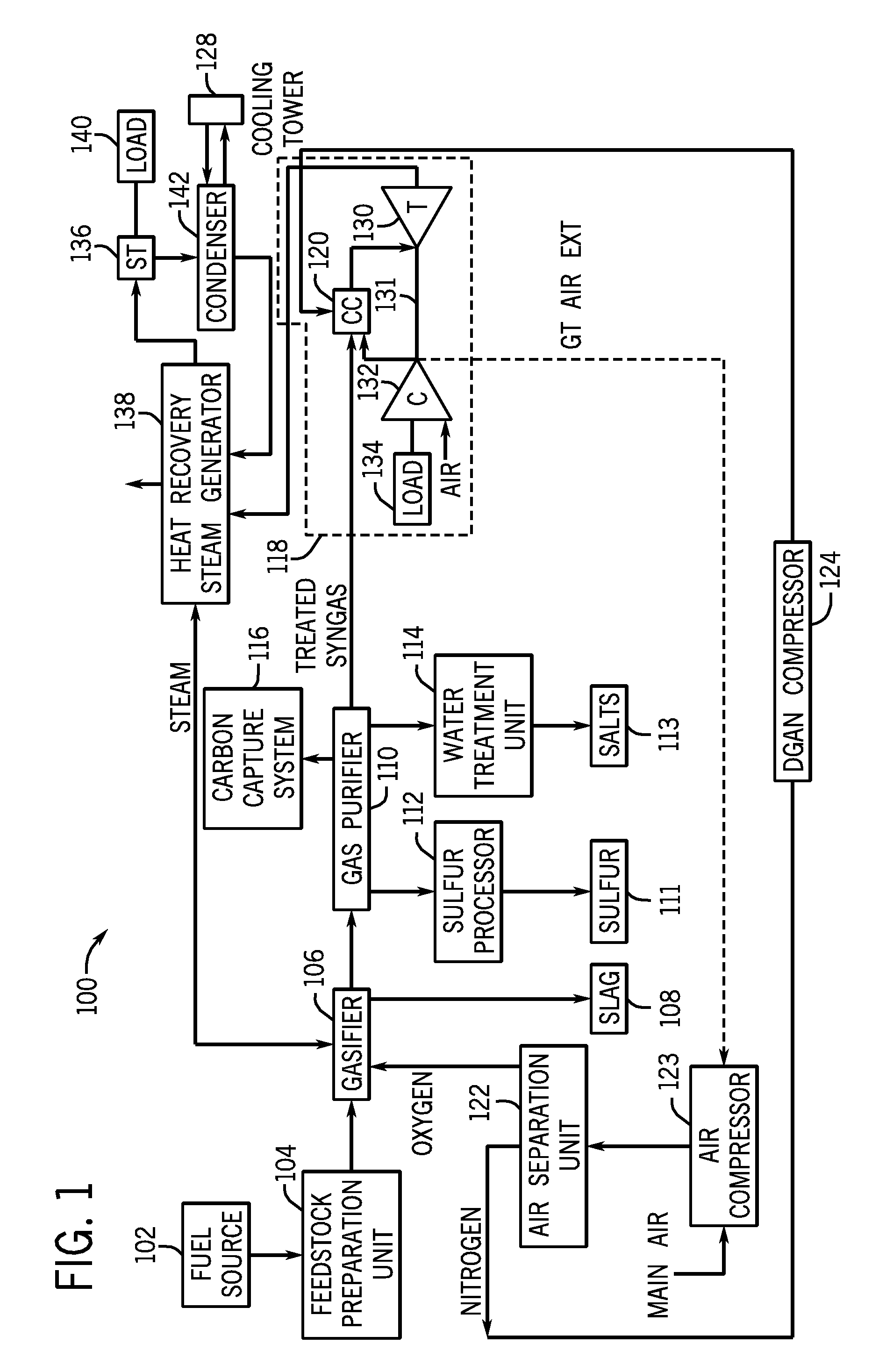

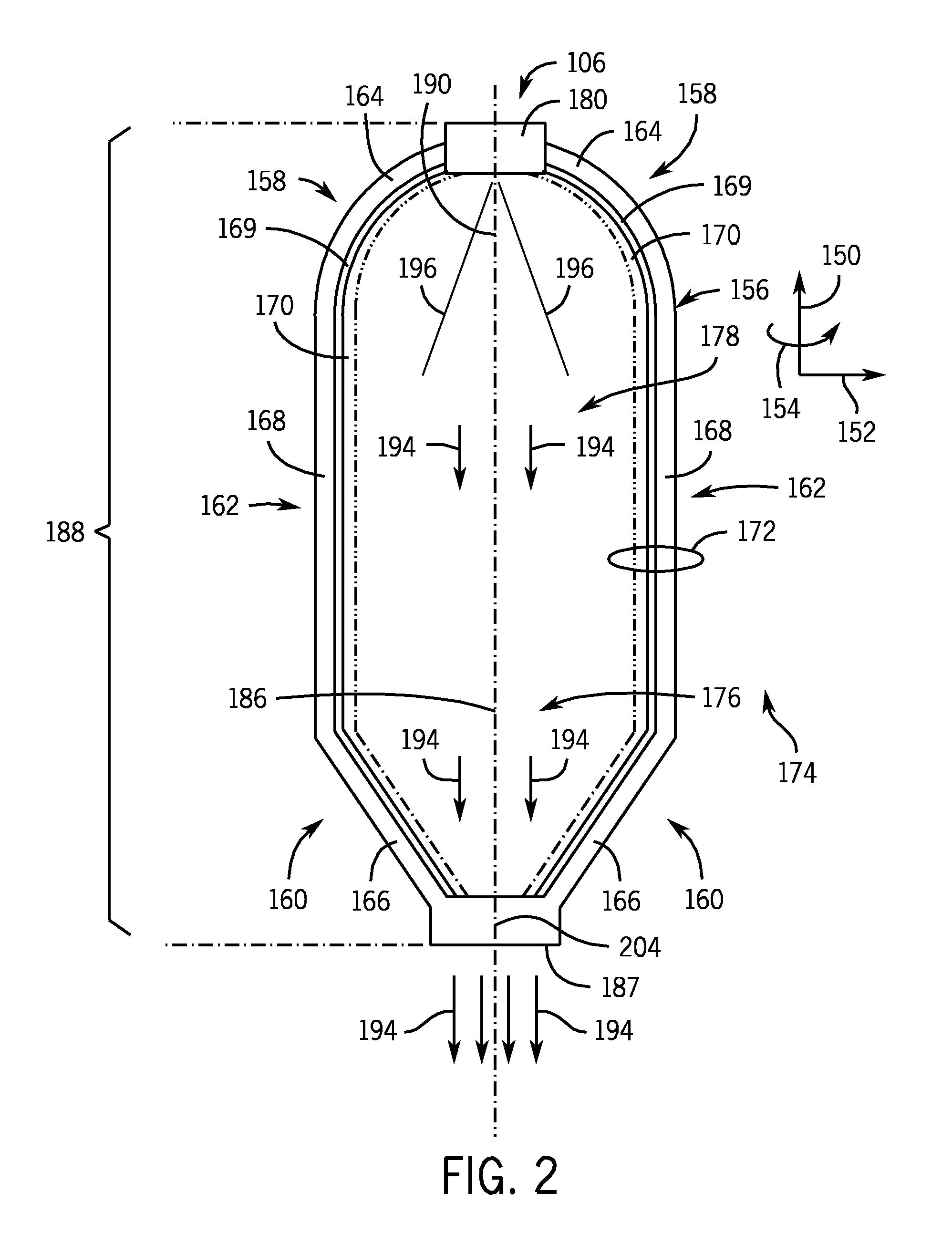

System for protecting gasifier surfaces from corrosion

ActiveUS8372251B2Avoid corrosionGasification processes detailsCombined combustion mitigationMaterials scienceCorrosion

According to various embodiments, a system includes a gasifier that includes a shell made of a first material exposed to a gasification region inside the gasifier and a patterned anode layer coupled to the shell inside the gasifier. The patterned anode layer is made of a second material, and the patterned anode layer is configured to protect the shell from corrosion by condensing hot gas in the gasification region.

Owner:AIR PROD & CHEM INC

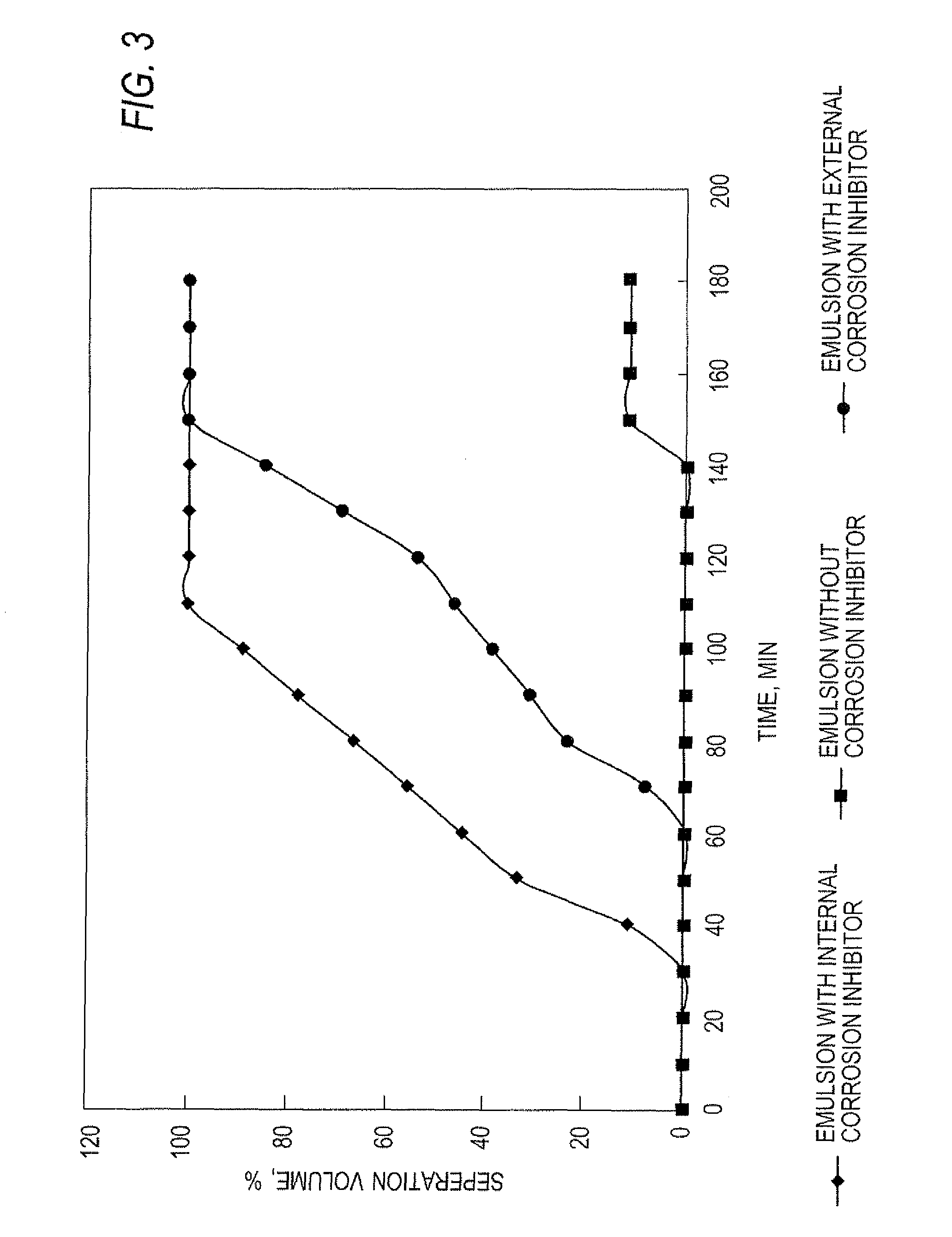

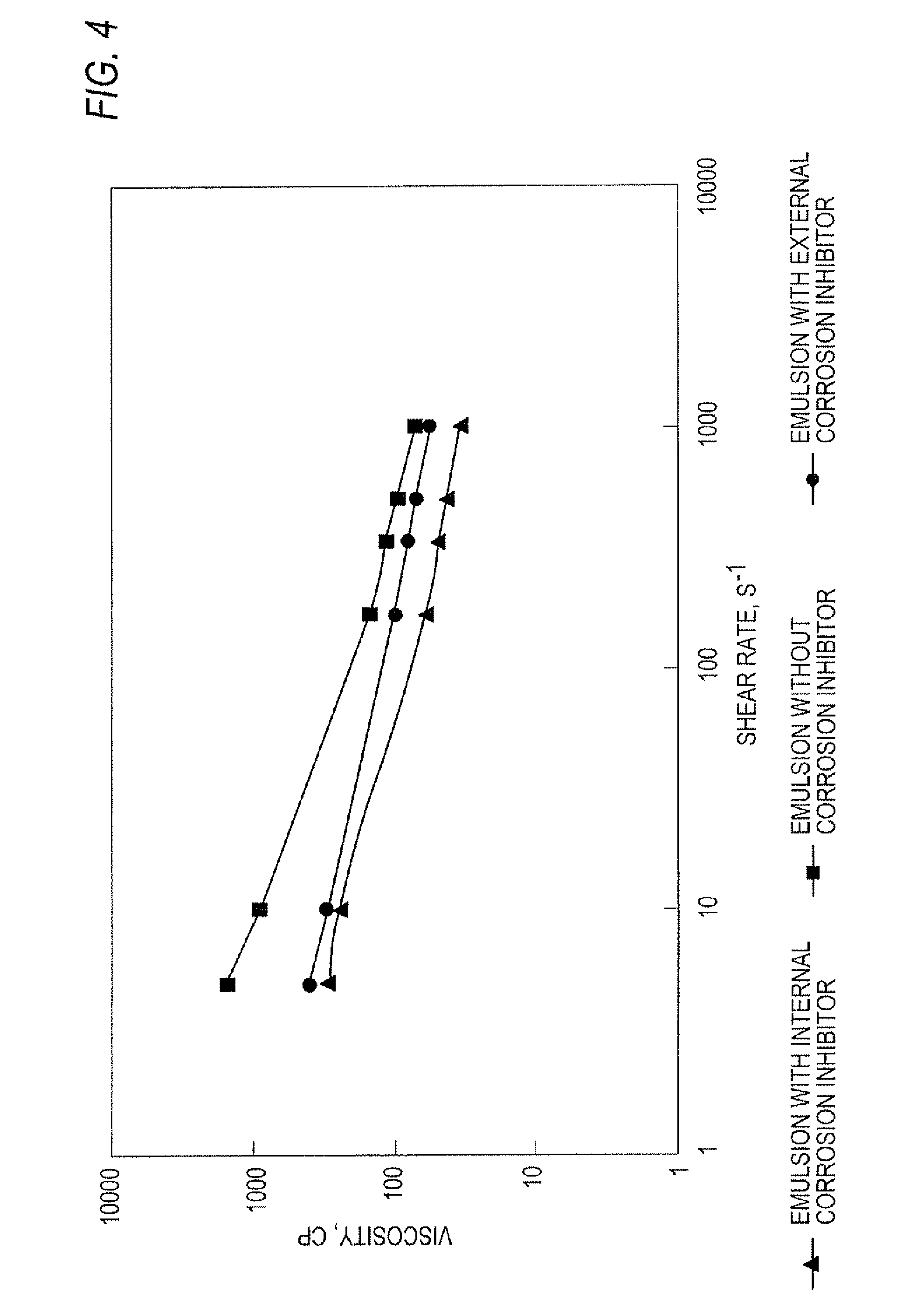

Method of mixing a corrosion inhibitor in an acid-in-oil emulsion

ActiveUS8039422B1Avoid corrosionPromote recoveryOther chemical processesMixing methodsOil emulsionWater in oil emulsion

An acid-in-oil emulsion having a corrosion inhibitor as the external phase has been found to prevent downhole corrosion when acidizing carbonate formations to enhance hydrocarbon recovery.

Owner:SAUDI ARABIAN OIL CO

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

Photoresist residue removing liquid composition

InactiveUS6864044B2Changing dielectric constantEfficient removalSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsPhotoresistLiquid composition

The object of the present invention is to provide, in the production of semiconductor circuit elements, a photoresist residue removing liquid composition which is excellent for removing photoresist residues after dry etching without attacking the wiring material or the interlayer insulating film etc.This is made possible by a photoresist residue removing liquid composition containing one or more members selected from the group consisting of reducing compounds and their salts and one or more members selected from the group consisting of aliphatic polycarboxylic acids and their salts.

Owner:KANTO CHEM CO INC

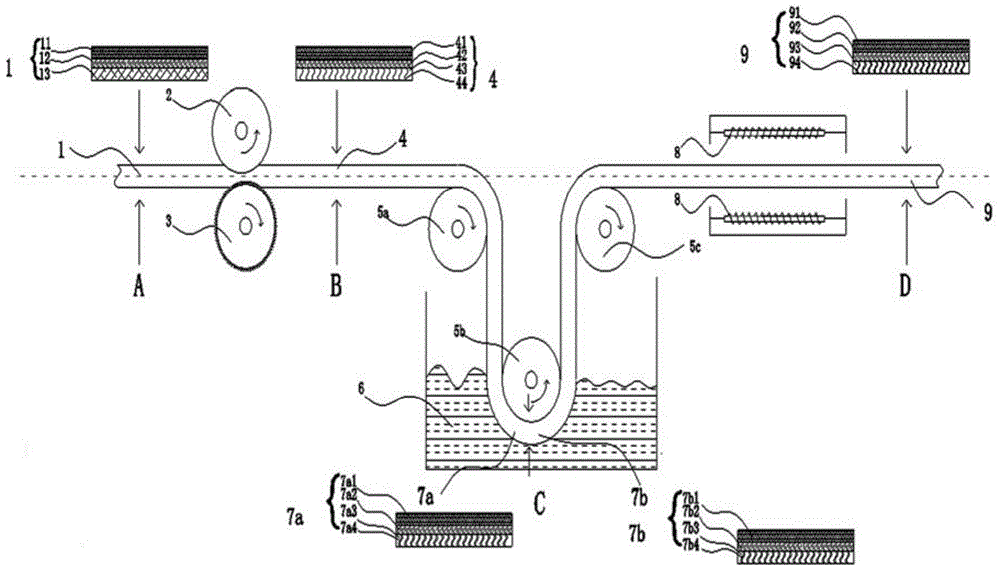

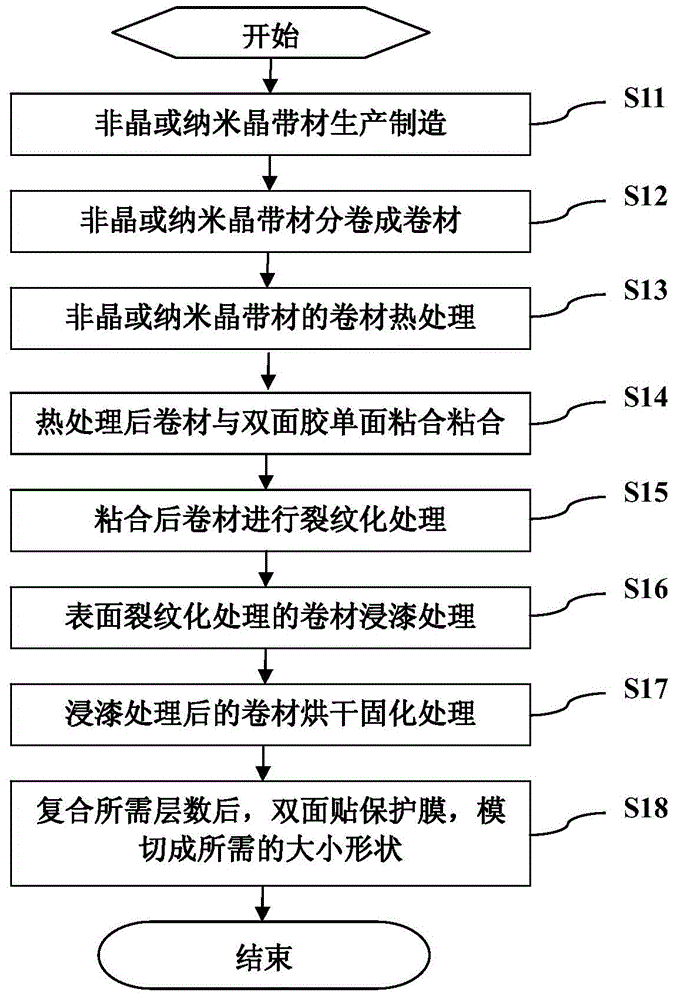

Single/multi-layer magnetic conductive sheet for wireless charging and preparation method thereof

ActiveCN104900383AImprove permeabilityIncrease contact resistanceBatteries circuit arrangementsElectromagnetic wave systemCrazingEngineering

The invention discloses a single / multi-layer magnetic conductive sheet for wireless charging and a preparation method thereof. The single-layer magnetic conductive sheet comprises a layer of magnetic slice. Multiple strips of cracks are uniformly distributed on the slice and divide the slice into multiple fragment units. Gaps of the cracks are filled with insulation medium, so fragment units on two sides of the cracks are mutually insulated. The single-layer magnetic conductive sheet also comprises a double-faced adhesive tape which is adhered to one face of the magnetic slice. A protection film formed by the insulation medium is formed on the other face of the magnetic slice. The preparation method comprises steps of heat treatment, adhesion of the double-faced adhesive tape, crack processing, gum dipping processing and drying and curing processing. According to the invention, inductance value and quality factor of a charging coil are increased, charging efficiency is increased and loss is reduced. The continuously prepared magnetic conductive sheet is characterized by controllable magnetic conductivity, continuous production, convenient operation and simple insulation processing.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

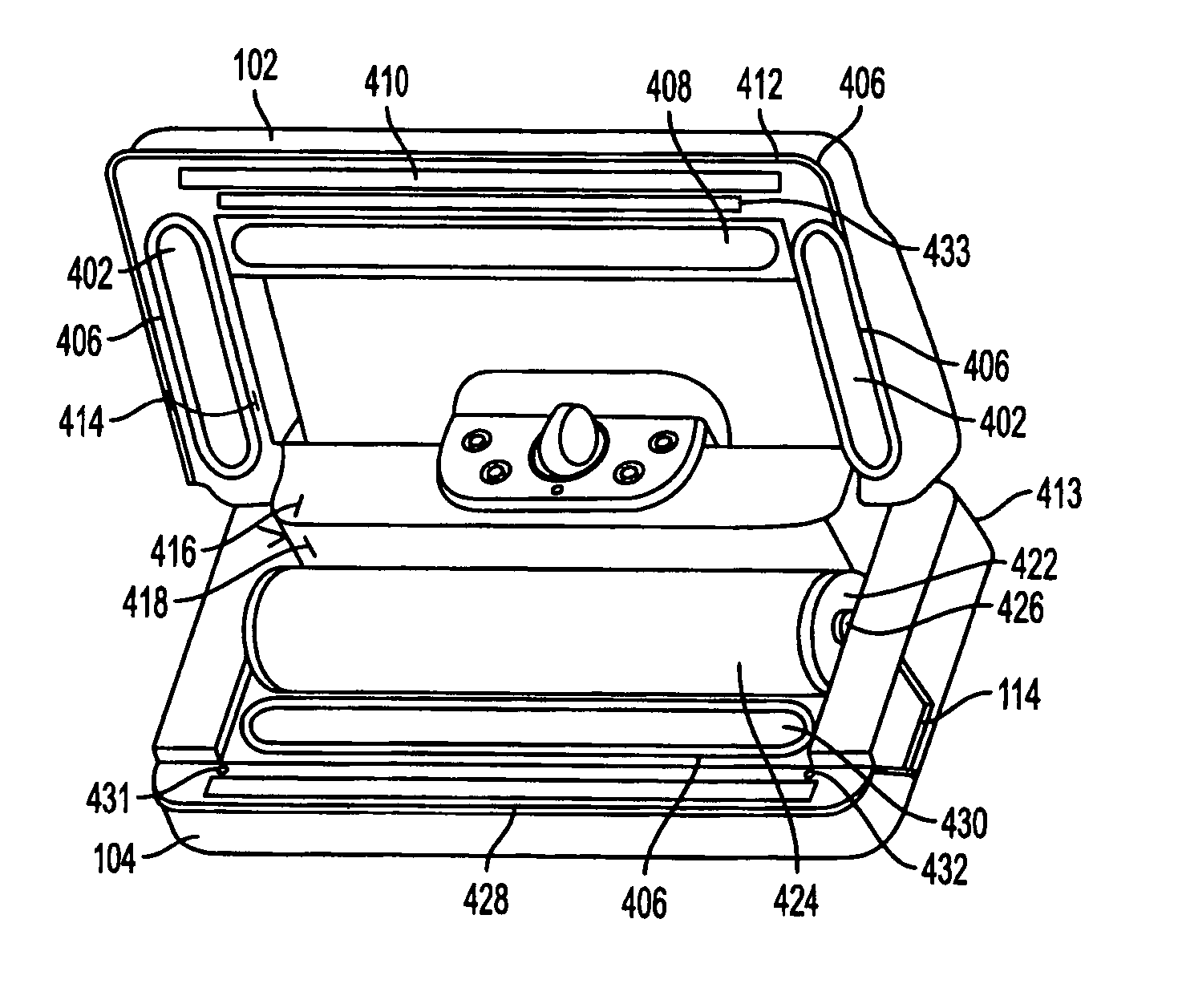

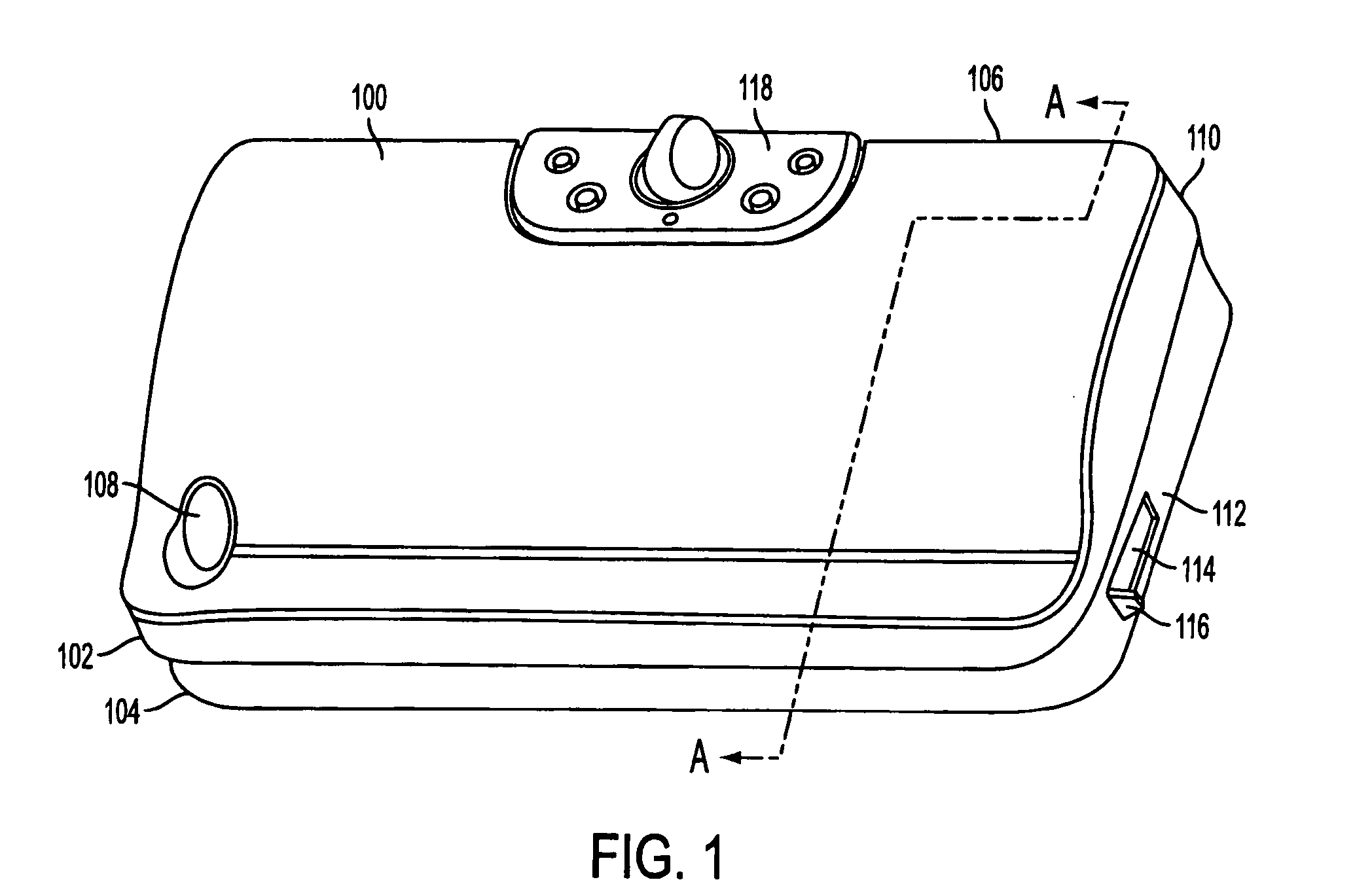

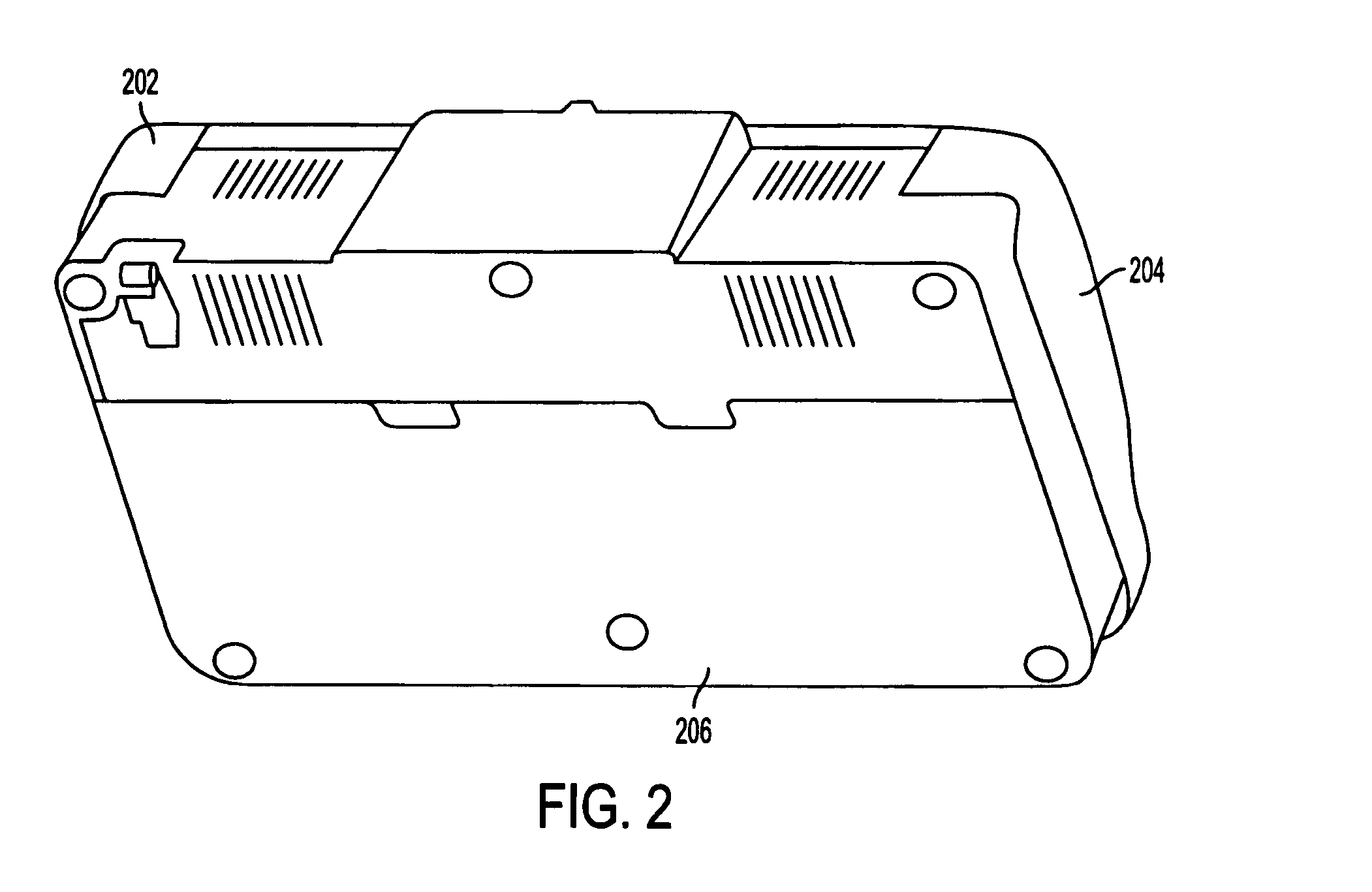

Fluid sensing in a drip tray

InactiveUS20050039420A1Enhances heat sealing operationQuantity minimizationCapsCapping machinery safety/controlCapacitanceElectrical resistance and conductance

A vacuum packaging appliance that detects the amount of liquid present while evacuating and sealing a container is disclosed. The appliance comprises a lid adapted to define a vacuum chamber when it is moved to a closed position relative to a trough in the base of the device. The trough in the lower portion of the device contains a heat-sealing element used to seal the contents of the bag once the vacuum packaging is complete. Disclosed are several embodiments relating to a liquid sensor molded into the walls of the trough. The liquid sensor comprises two electrodes that may be located on opposite sides of the trough or on the same side of the trough. When liquid is present in the trough, the capacitance and resistance between the electrodes changes, thereby sending a signal to a controller indicative of the amount of liquid within the trough while the container is being evacuated. The exact amount of liquid present is compared to a predetermined level of liquid. A vacuum pump controller may suspend operations if the amount of detected liquid exceeds a predetermined amount. The heat-sealing element is also controlled in accordance with the amount of liquid sensed in the trough. The amount of liquid sensed is also indicated to the operator.

Owner:TILIA INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com