Fluid sensing in a drip tray

a drip tray and fluid sensing technology, applied in the direction of liquid handling, packaging, cap, etc., can solve the problems of cumbersome use, complex construction and/or construction, and high manufacturing cost of conventional commercial appliances and some consumer appliances, and achieve the effect of minimizing the amount of wasted bag material and improving the heat sealing operation of vacuum packaging appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

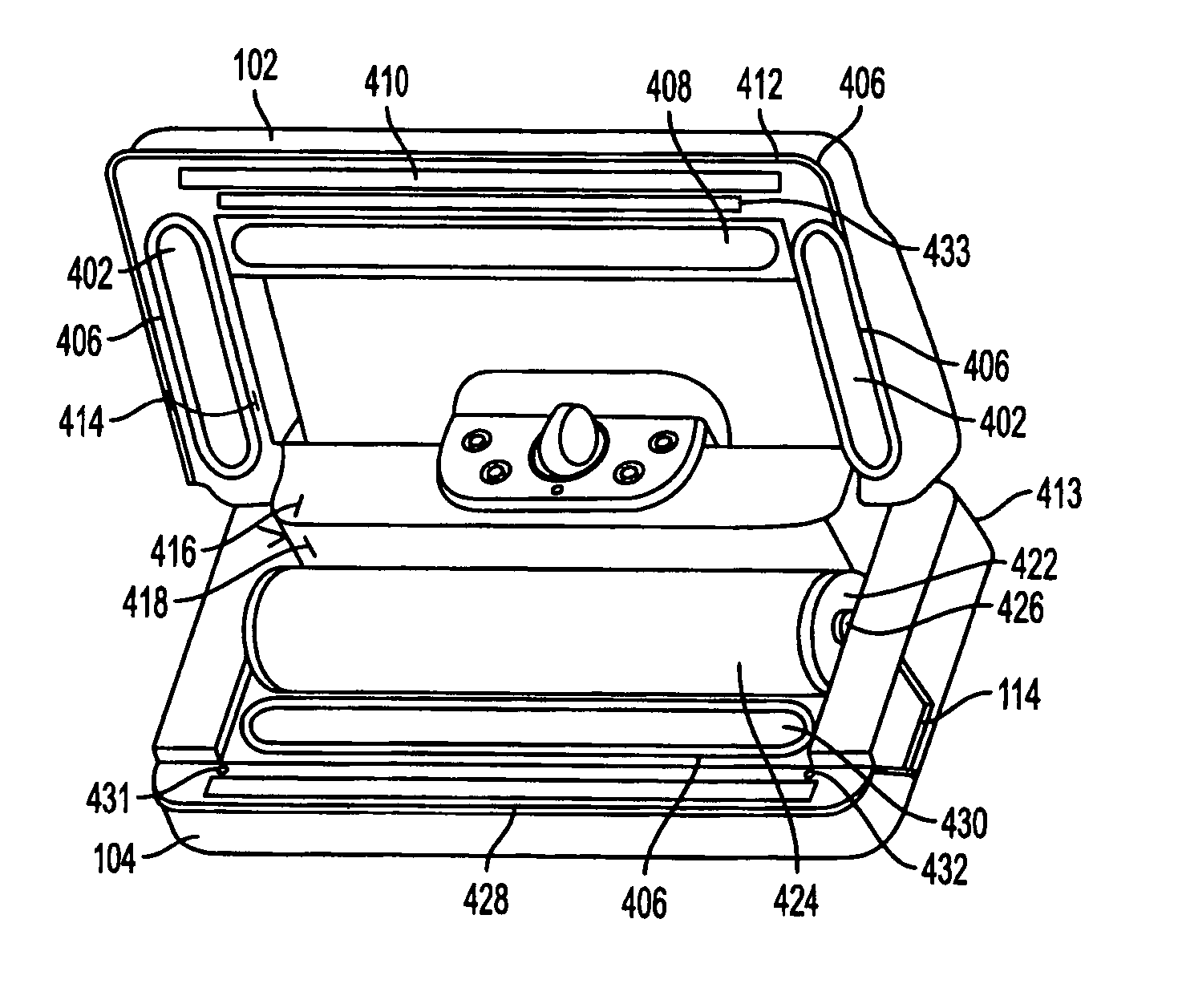

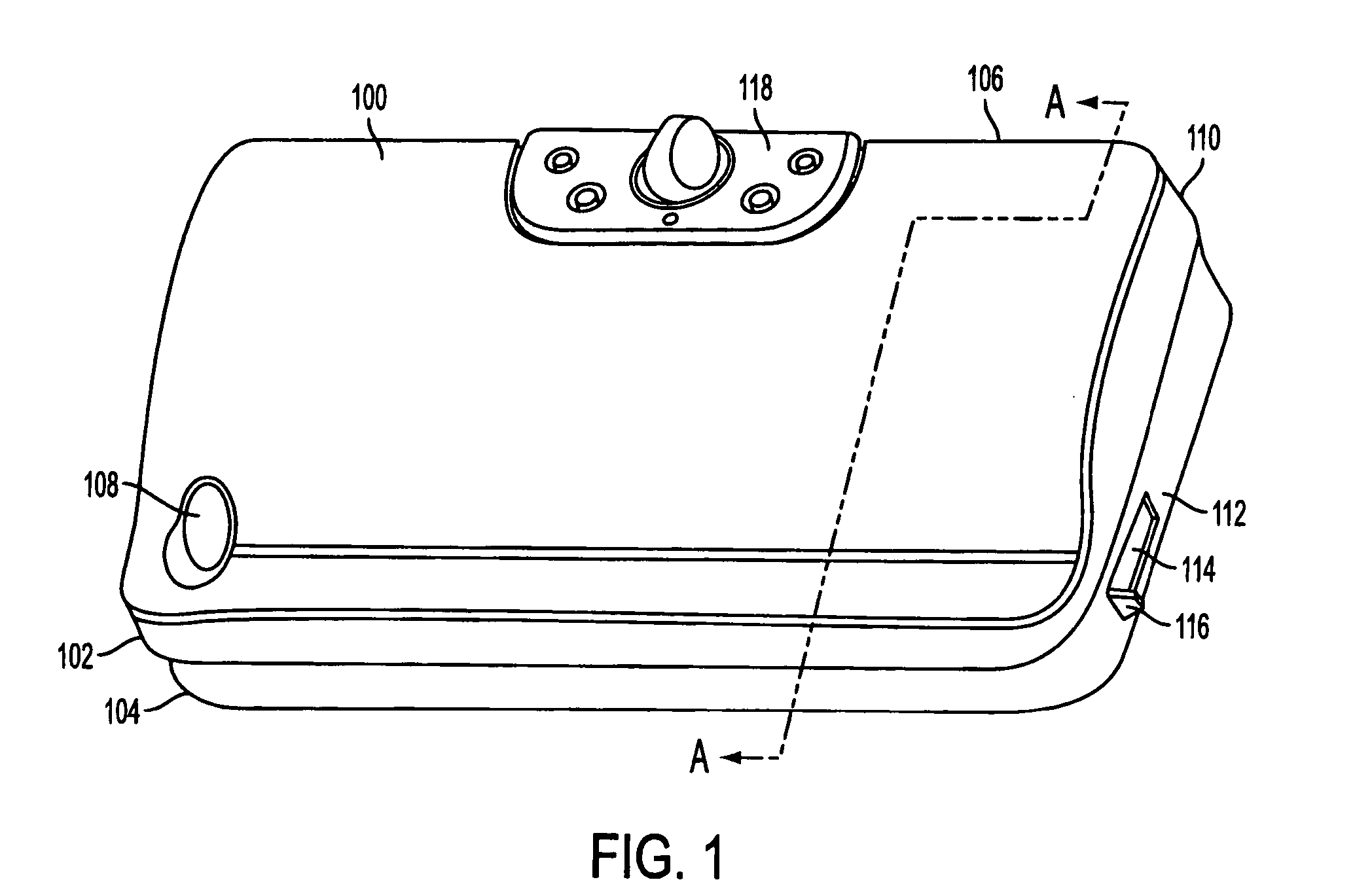

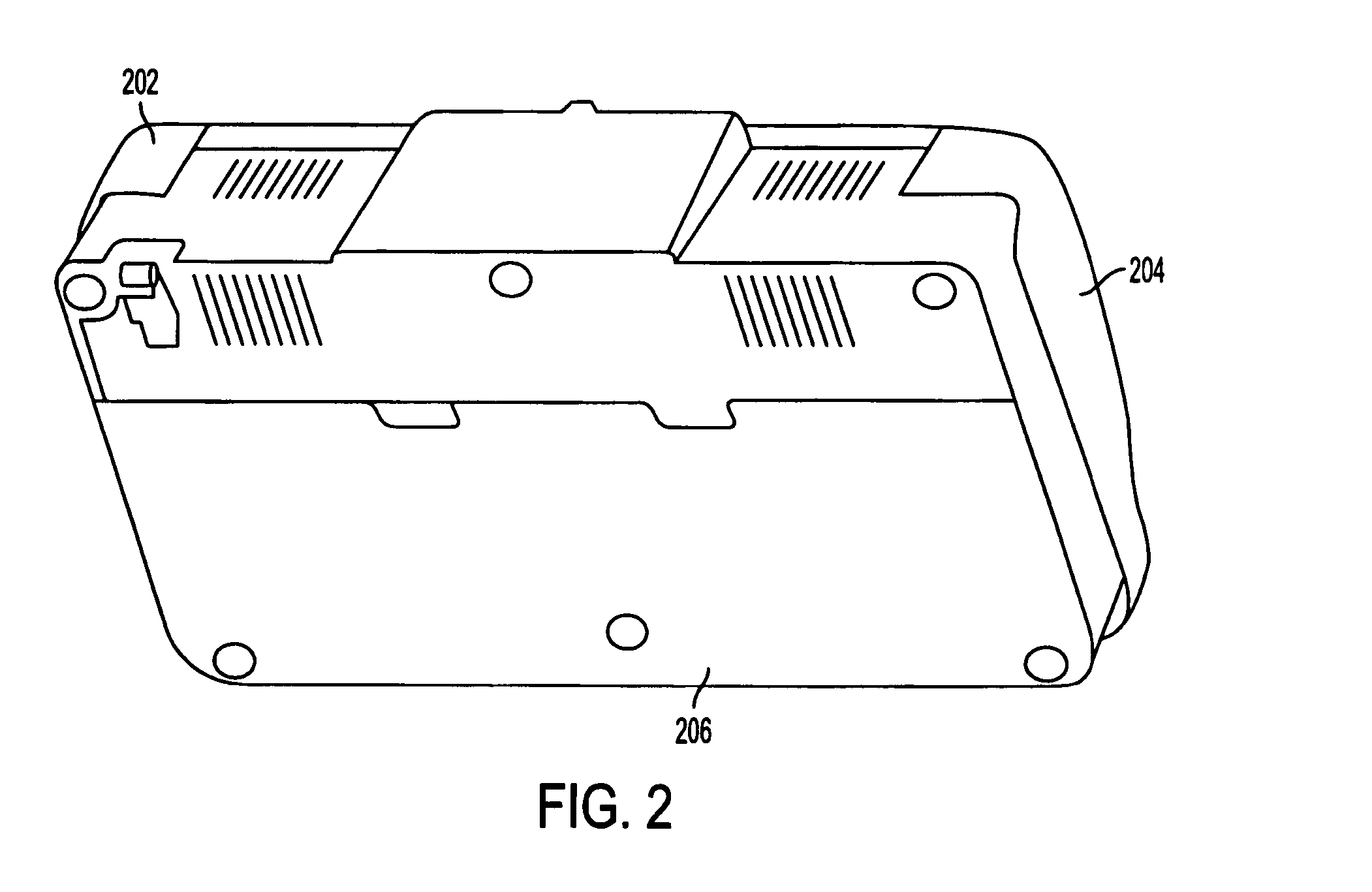

[0029] For clarity of presentation, the FIGS. are grouped and discussed as follows. FIGS. 1-4 describe general features and structures of the present invention relating to a vacuum packaging appliance. FIGS. 5-9 focus on the liquid sensing and controlling structures of the appliance and their interaction with the structures described in FIGS. 1-4. FIGS. 10-12 show flowcharts of methods enacted by the present invention.

[0030]FIG. 1 shows a vacuum packaging appliance 100 for vacuum packaging articles in a container that includes a liquid sensing capability. The vacuum packaging appliance 100 has a lid 102 and a base 104 that are pivotally connected at a back side 106 of the appliance 100. However, in alternate embodiments the lid and base maybe connected in any other convenient manner or they may be independent parts.

[0031] The lid includes a blade handle 108 that is associated with a blade (not shown) on the inside of the lid 102 of the vacuum packaging appliance 100. The blade han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com