Patents

Literature

262 results about "Blade handle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

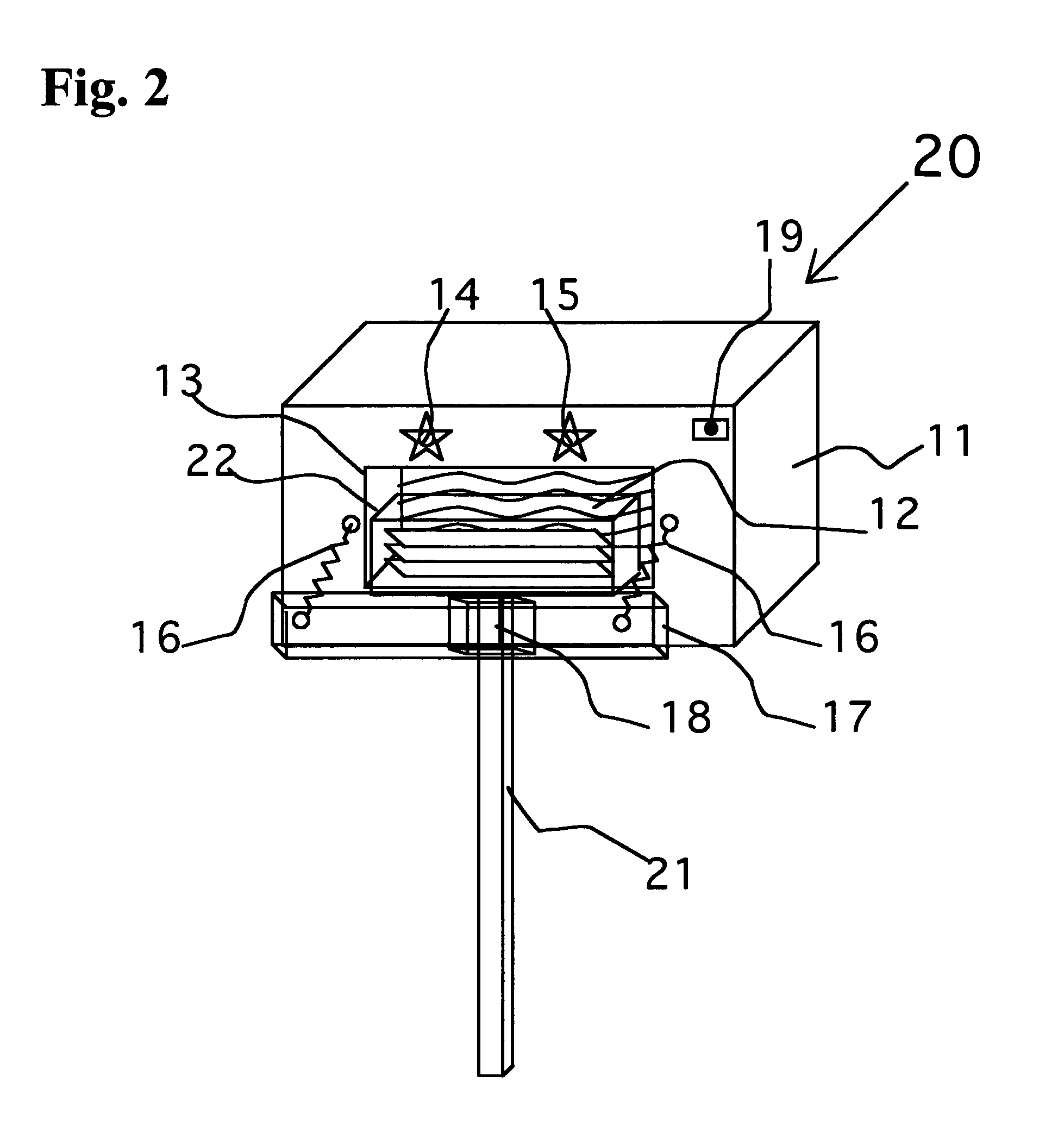

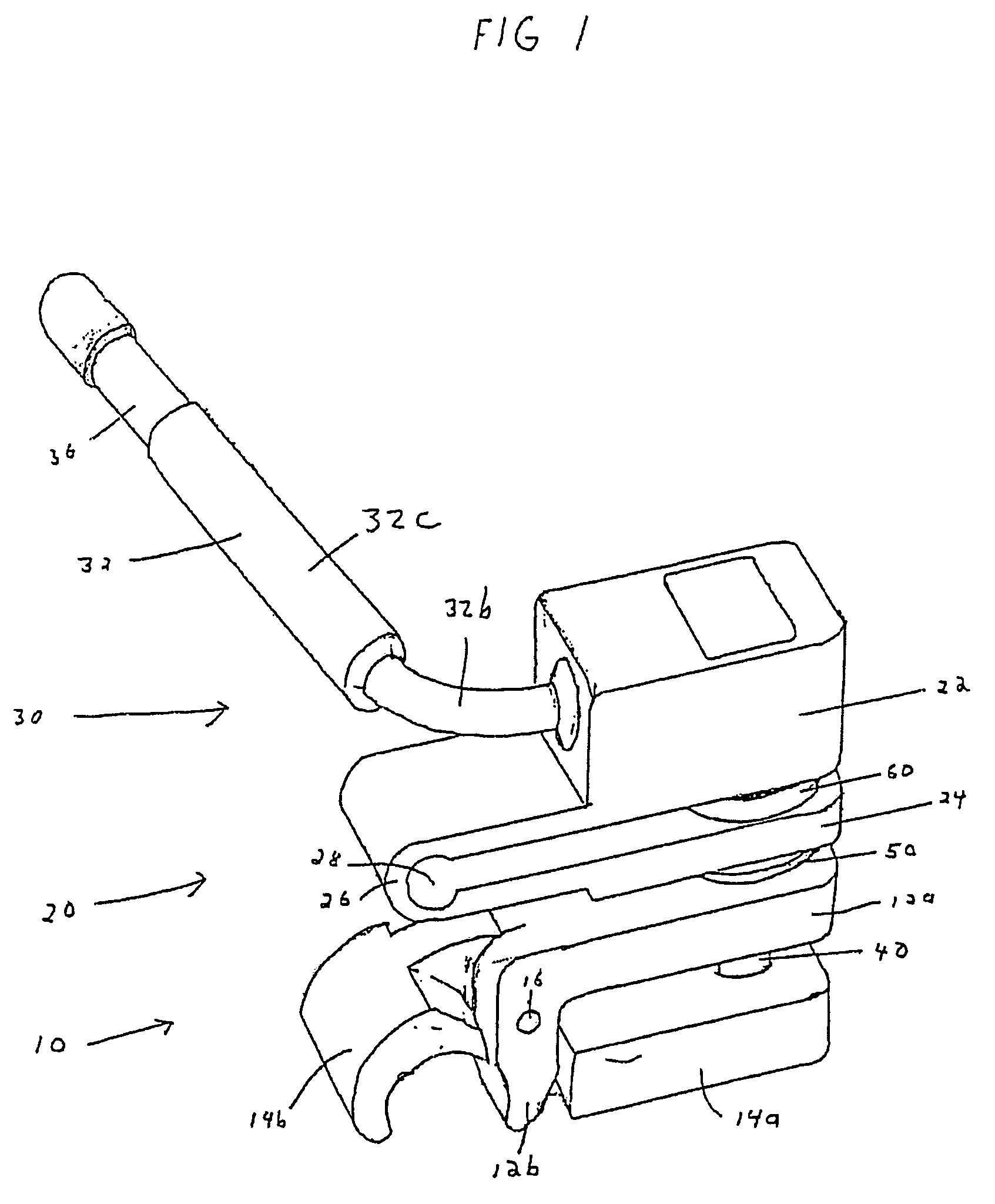

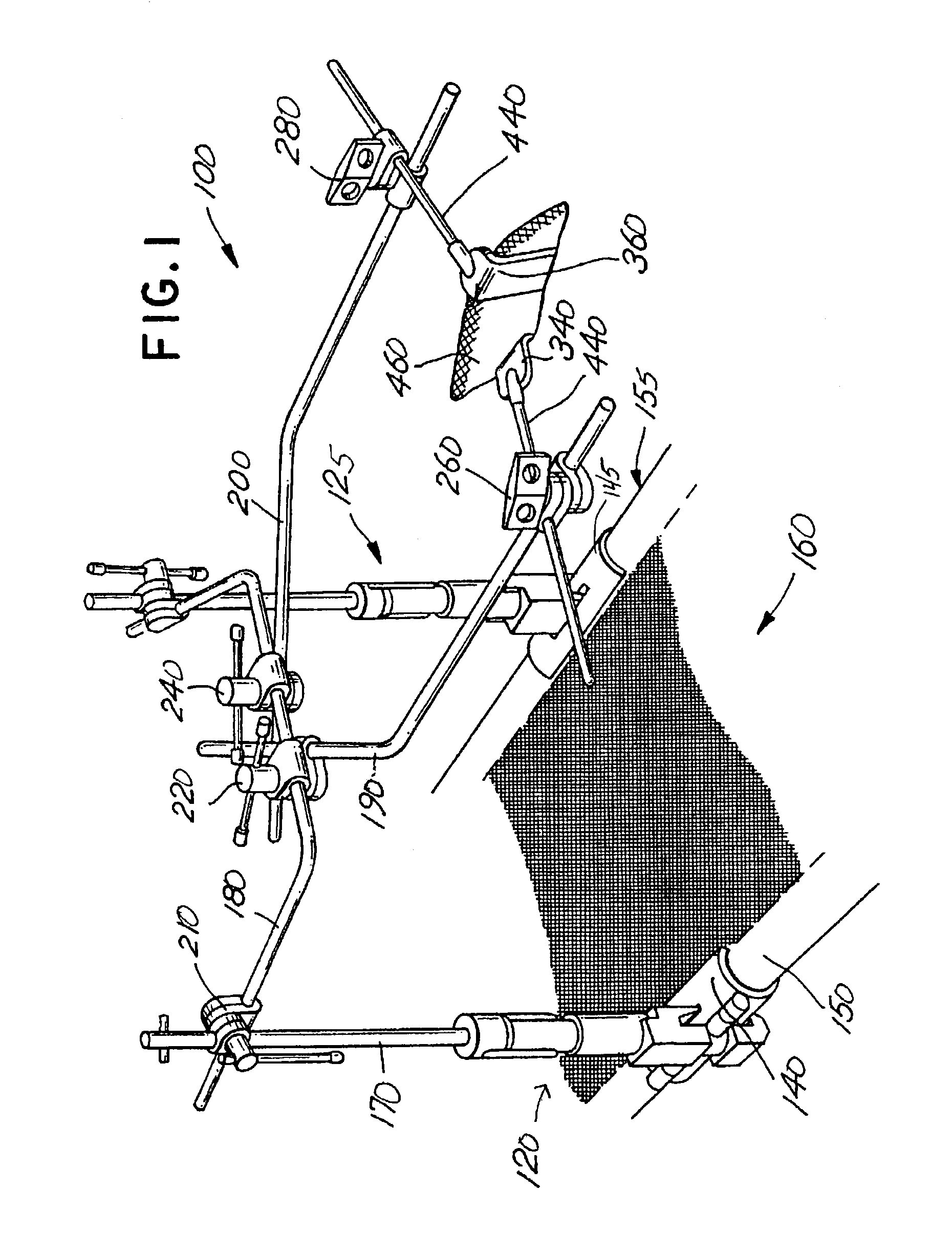

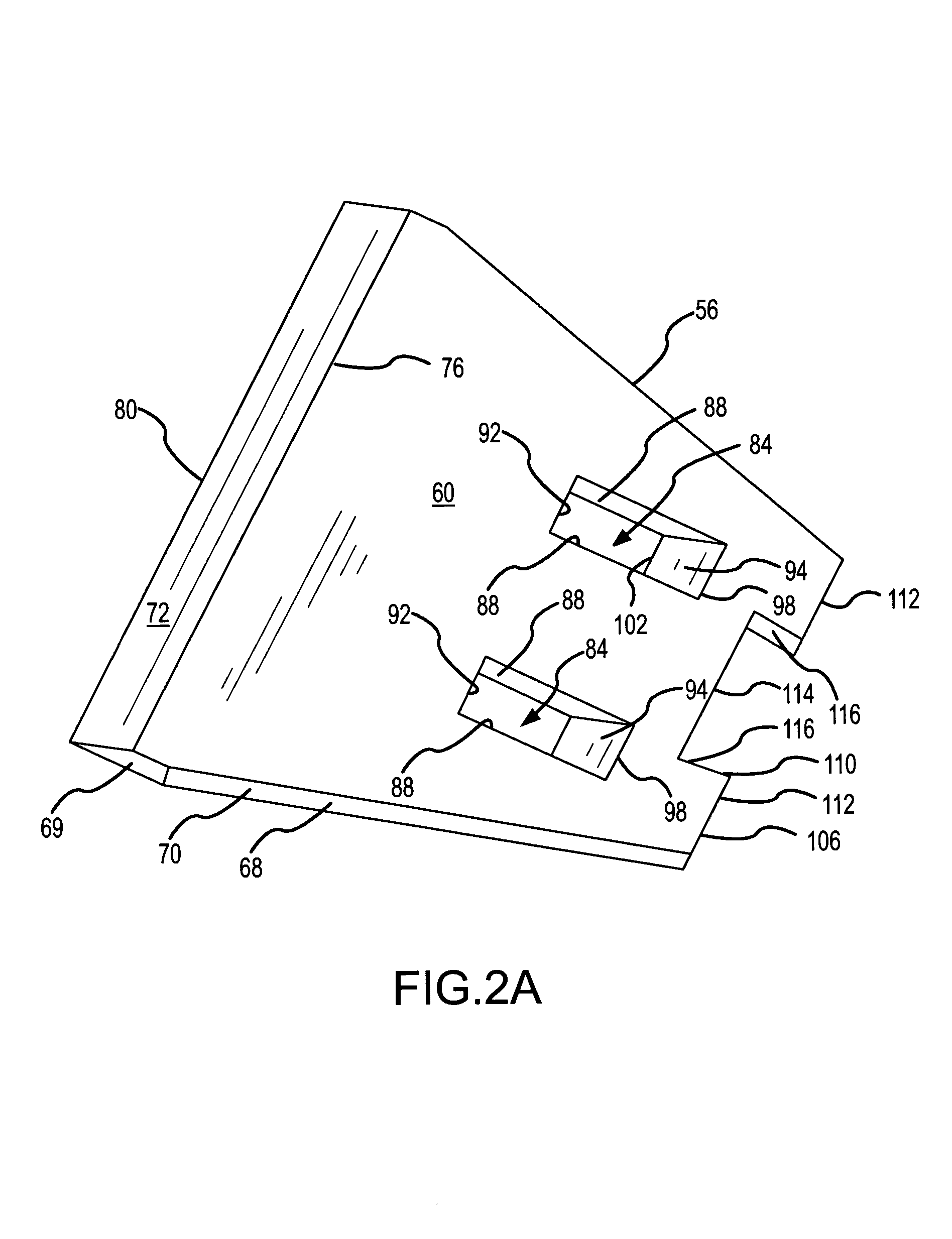

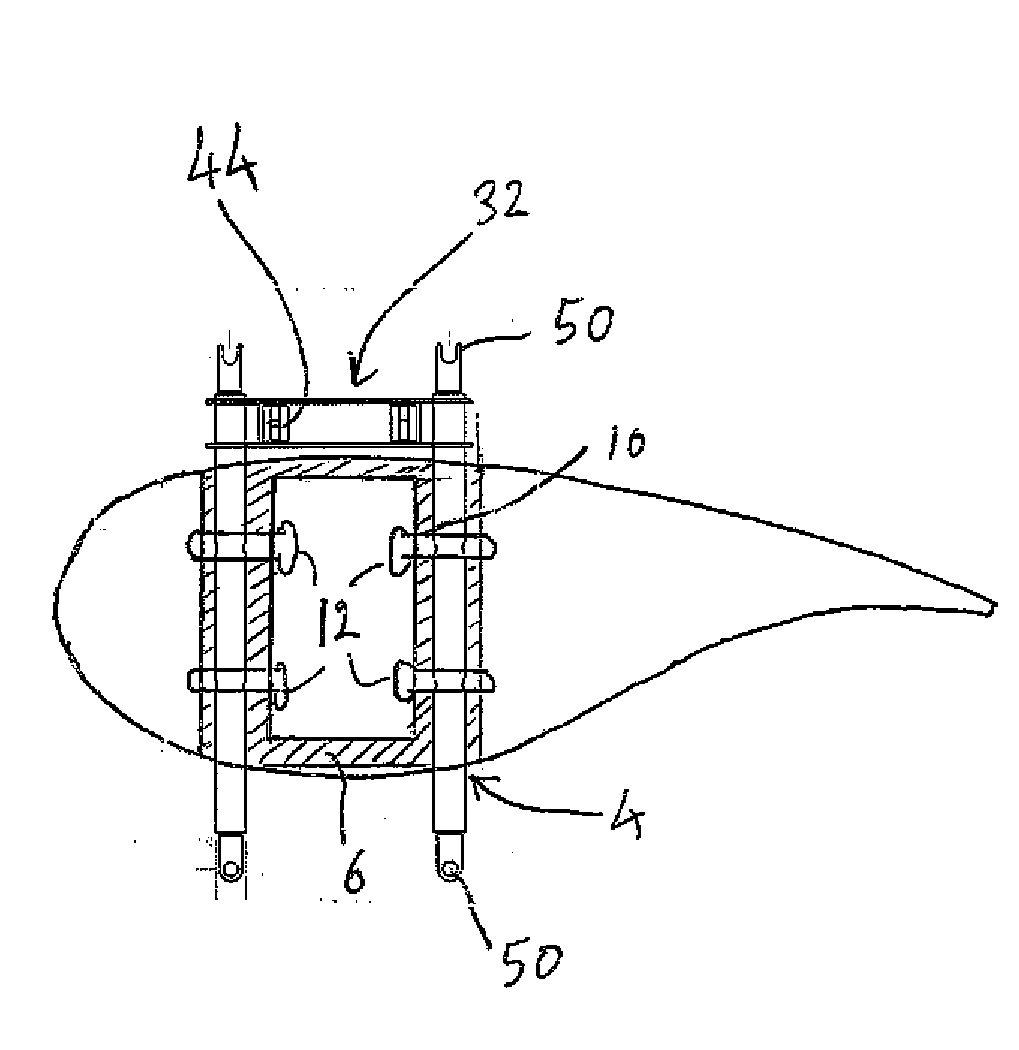

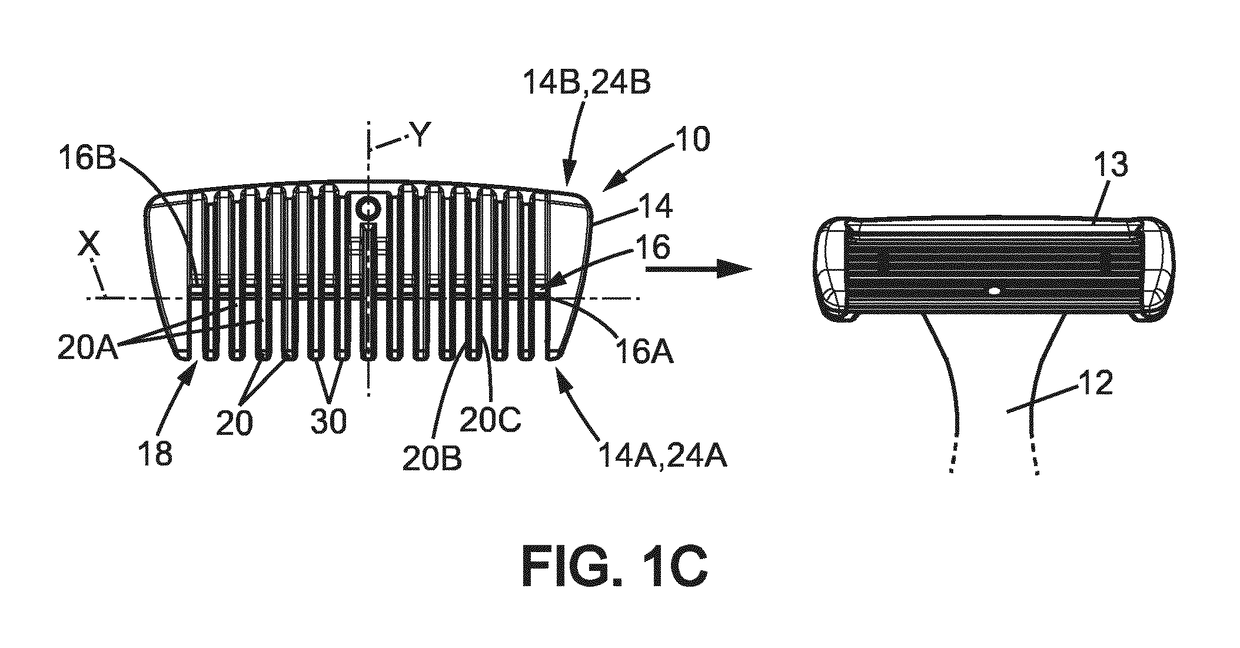

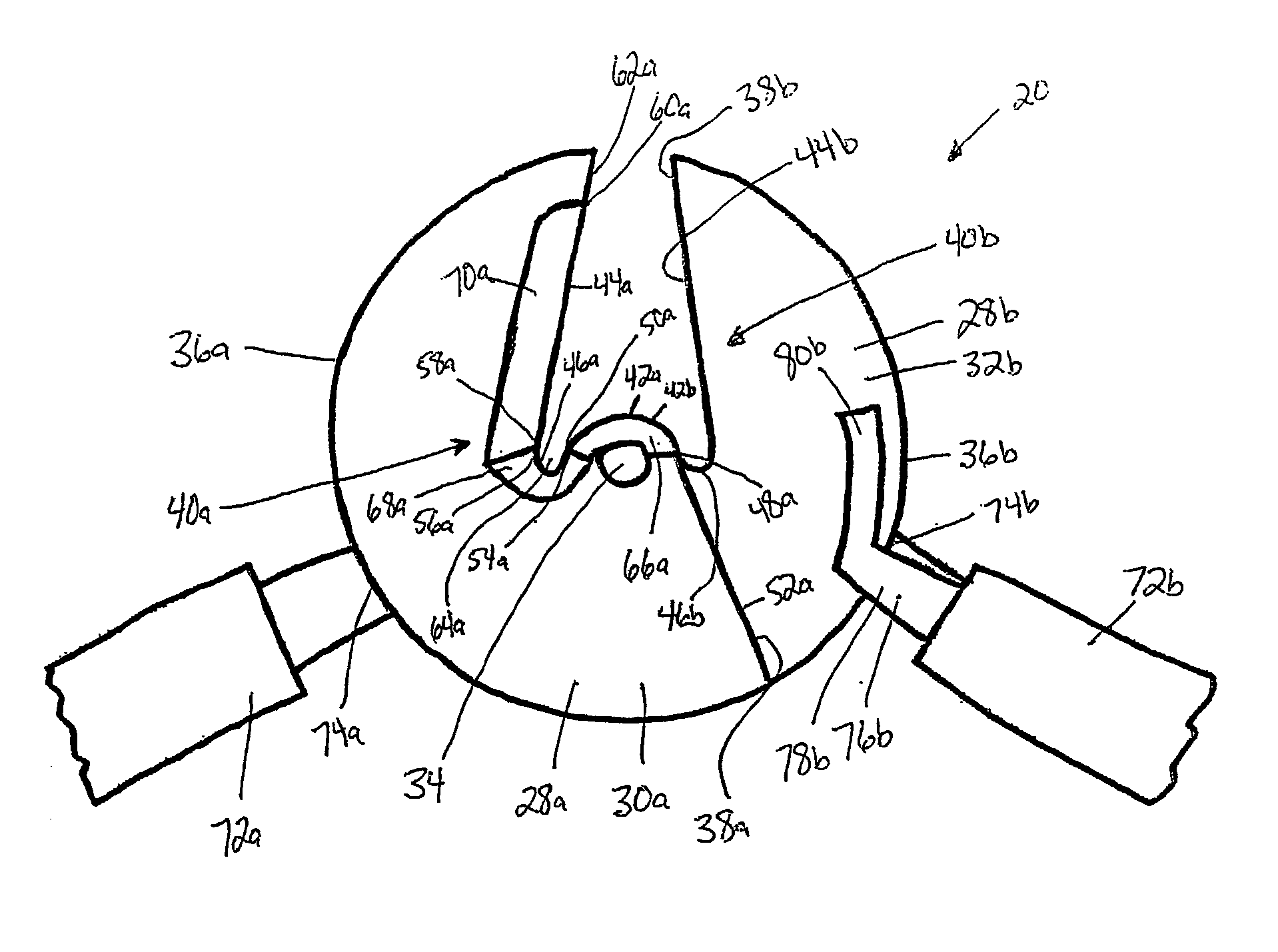

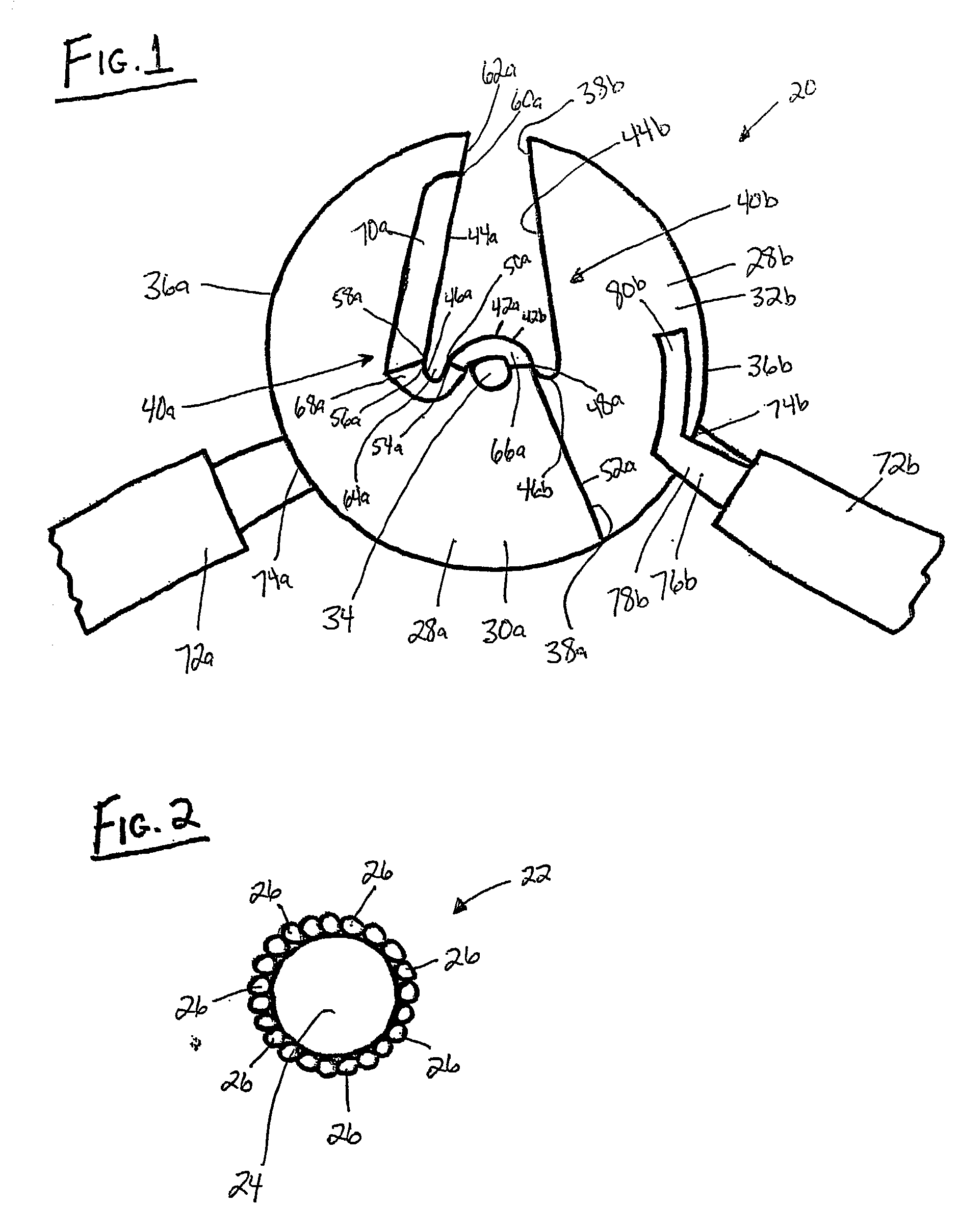

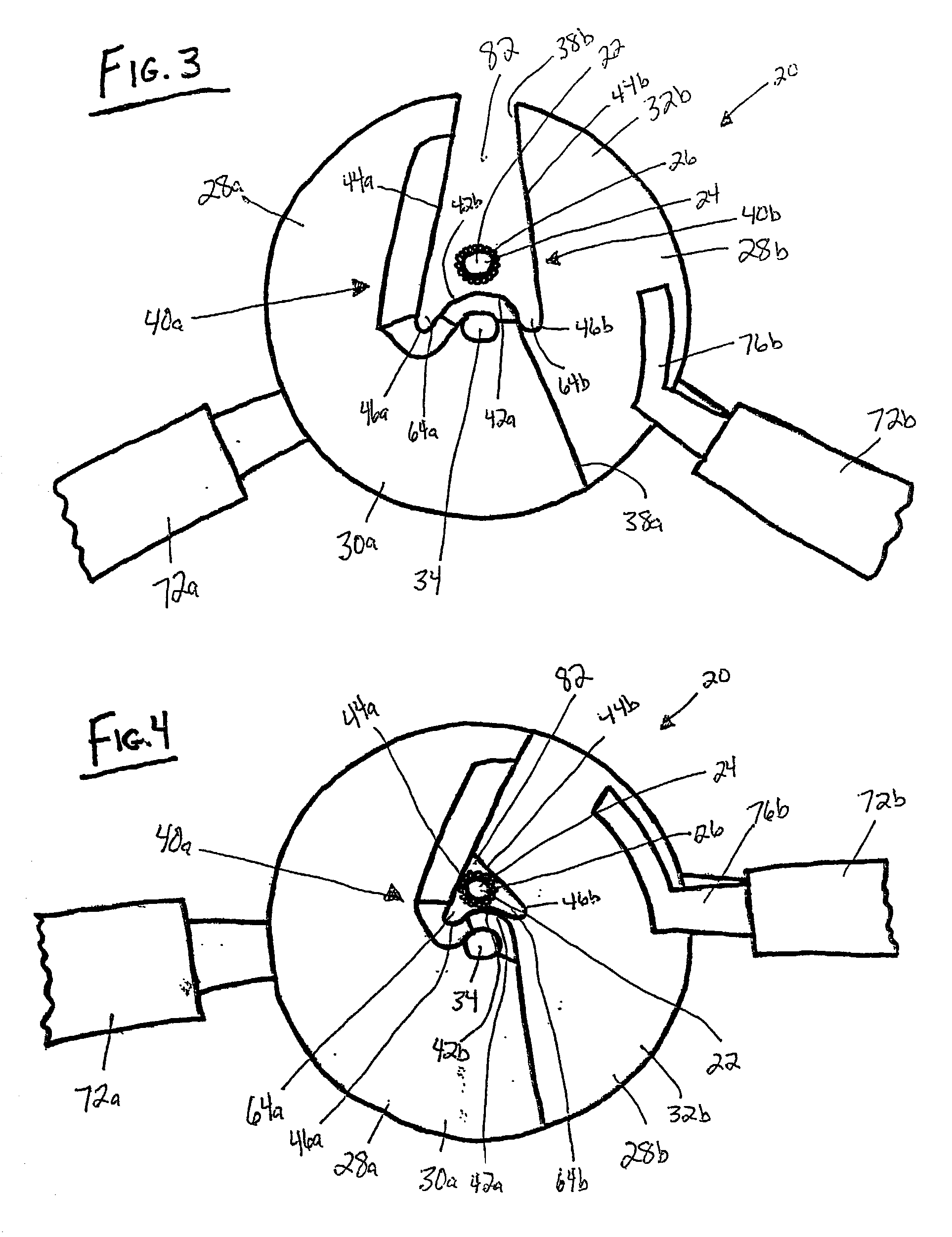

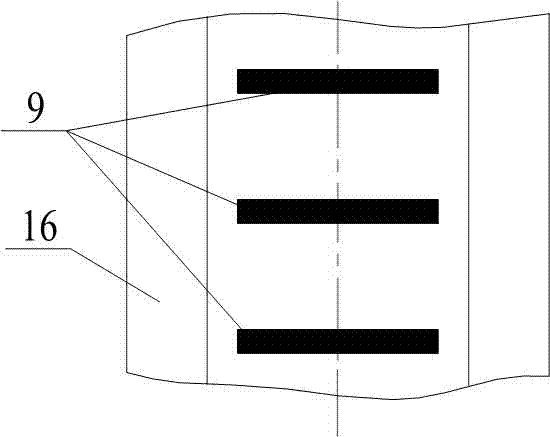

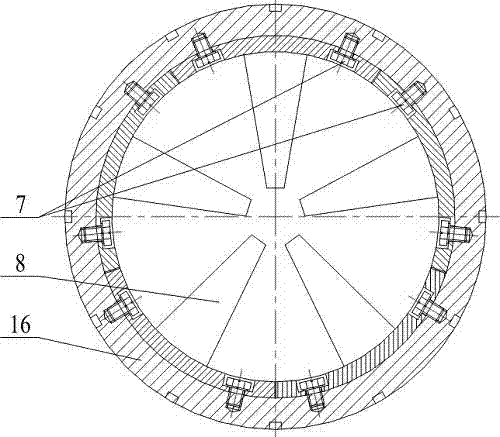

Surgical retractor

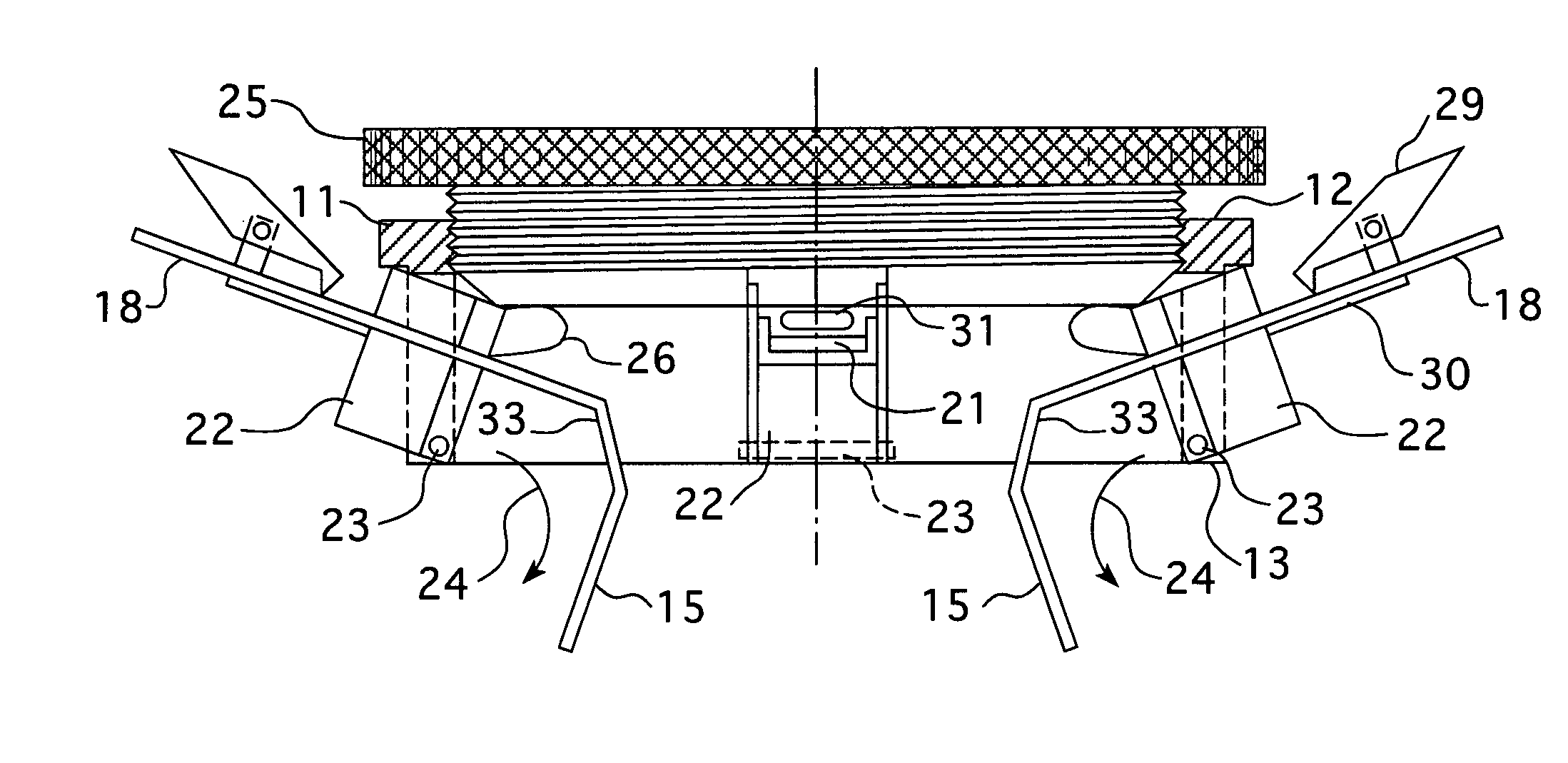

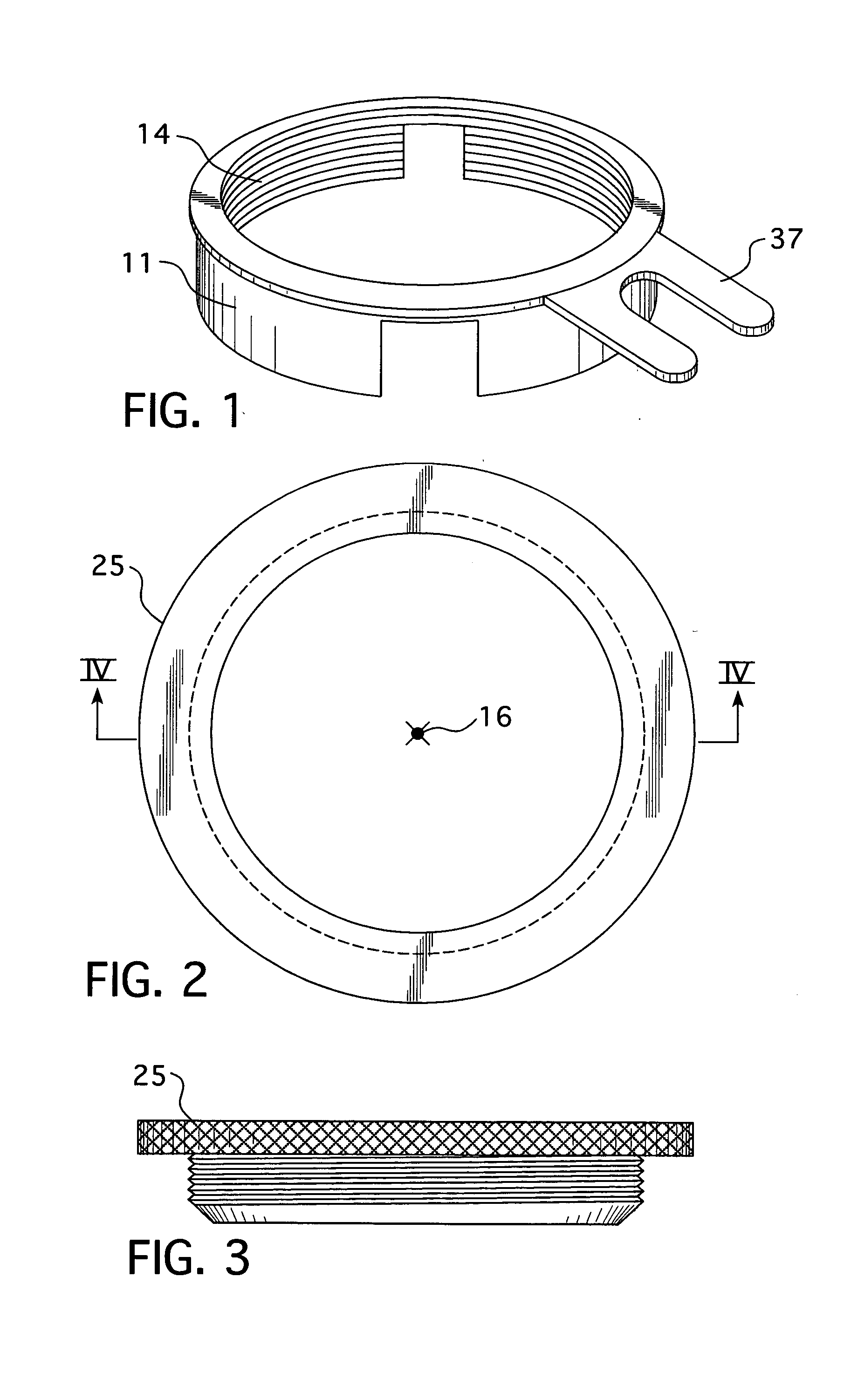

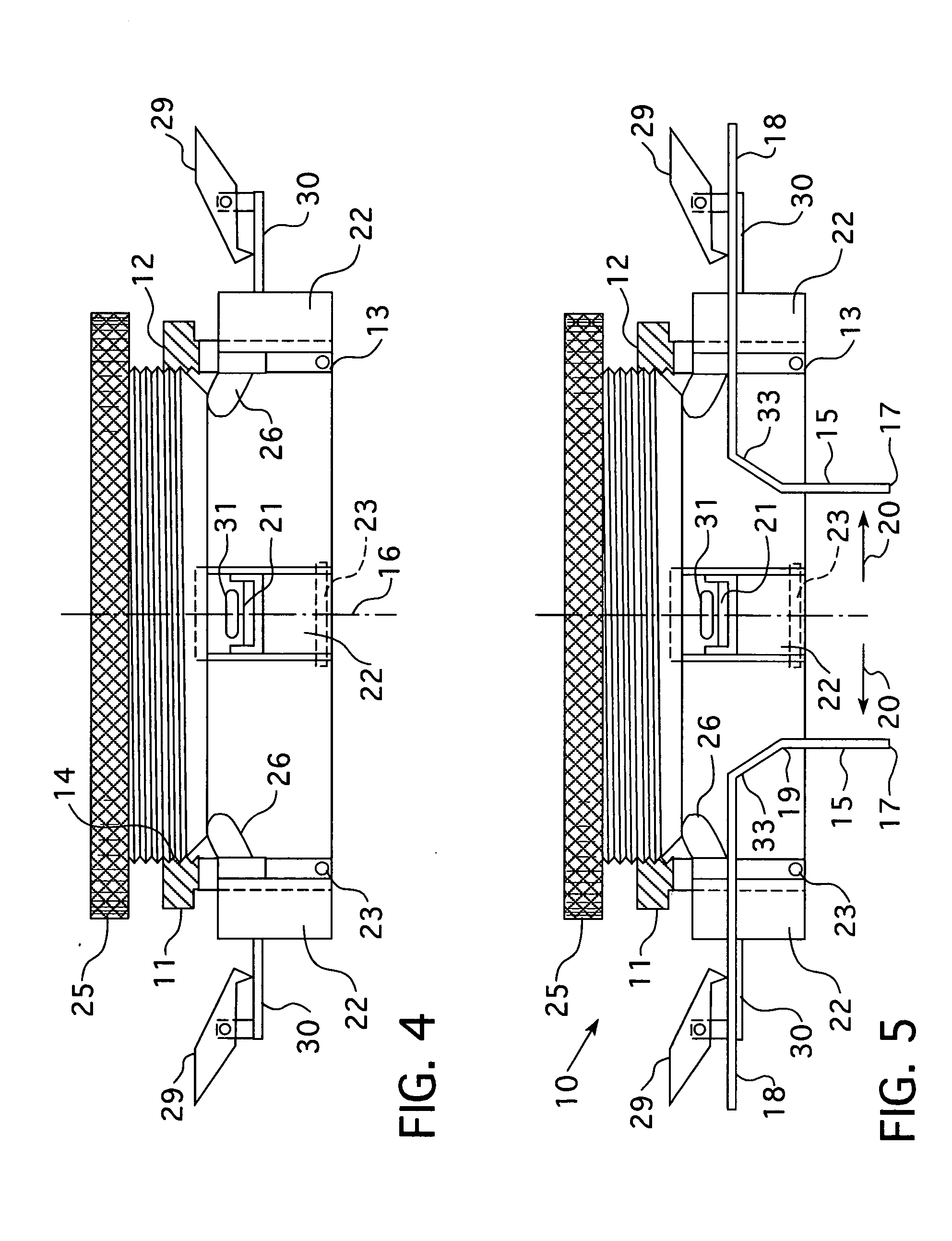

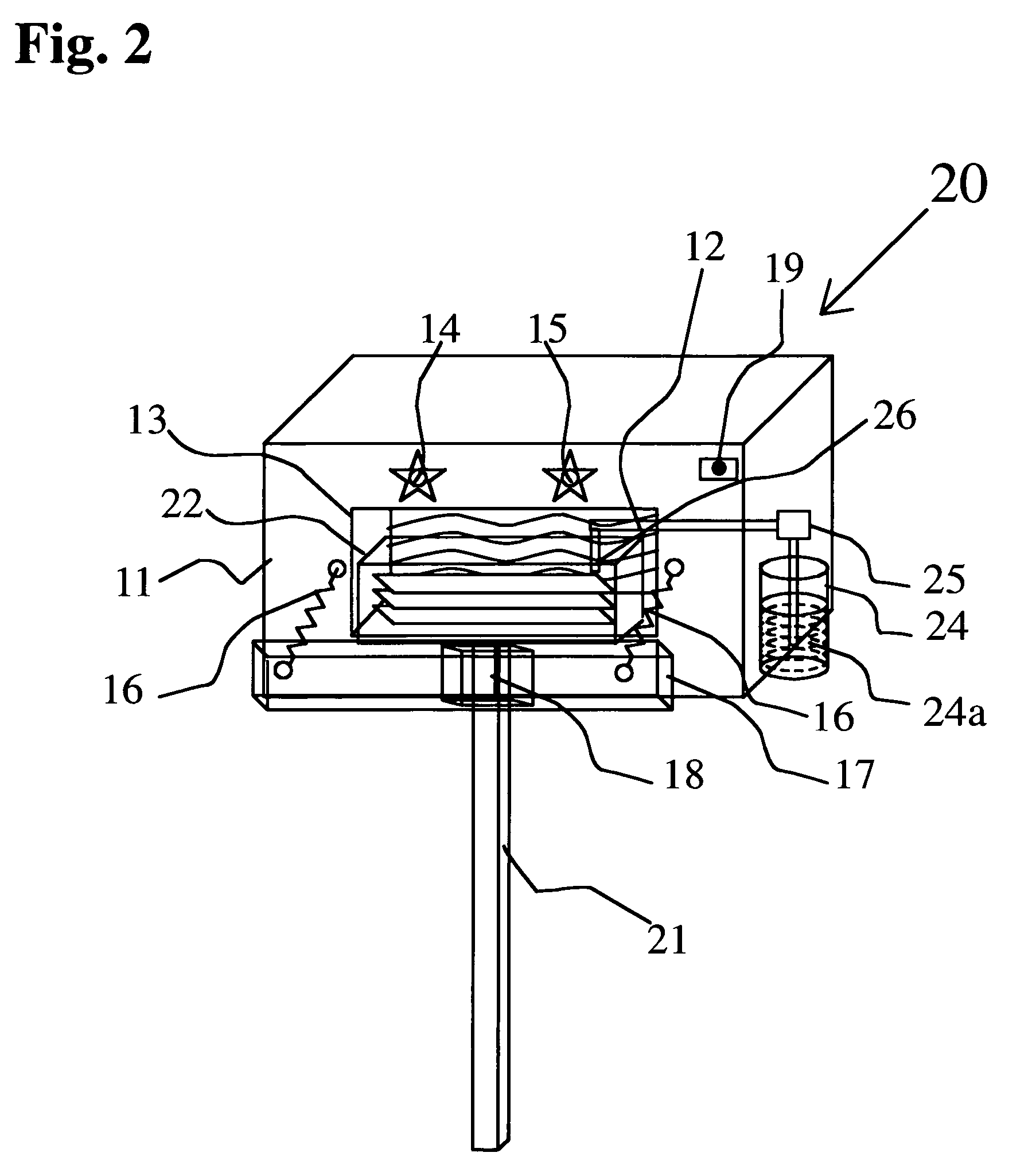

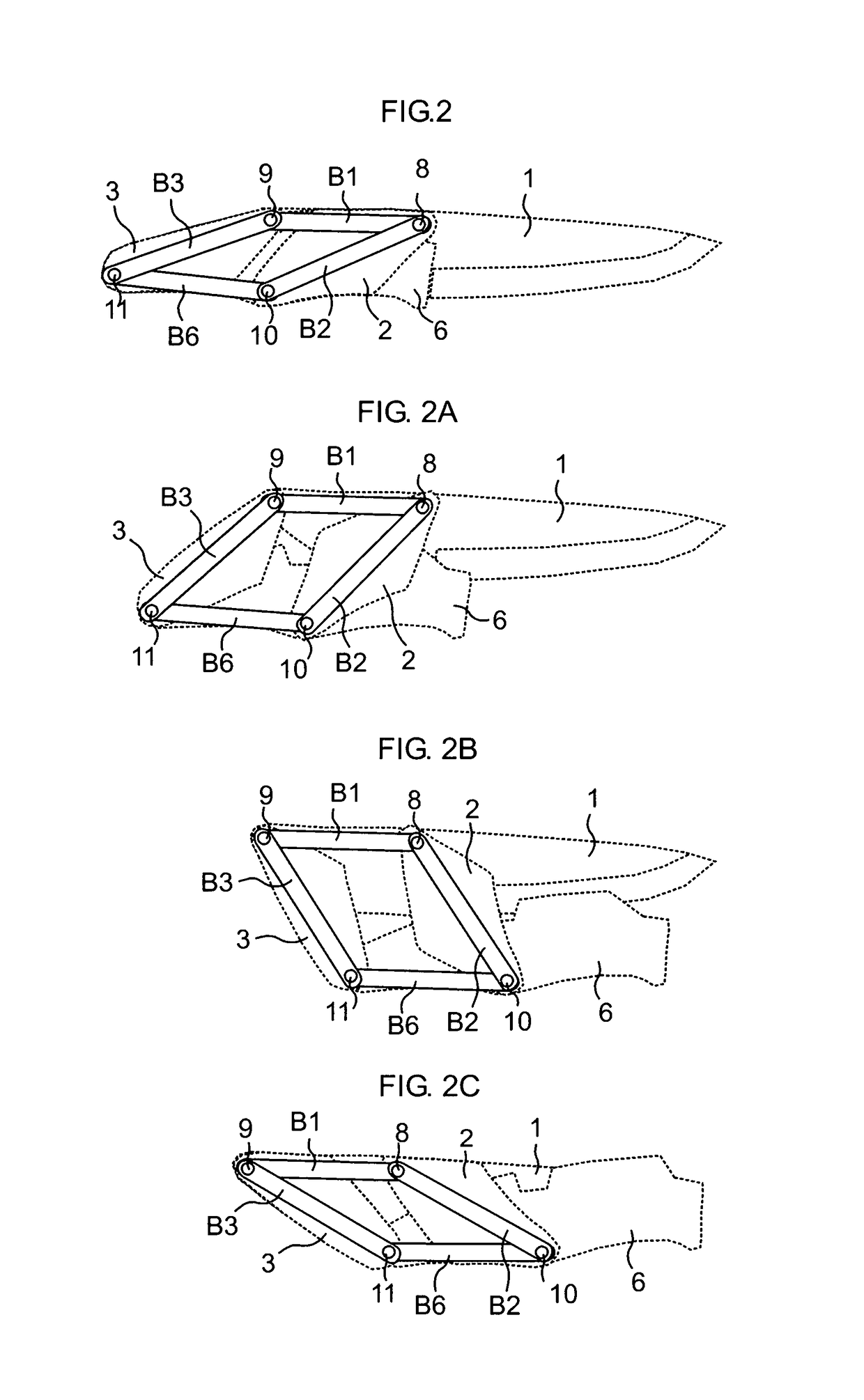

The surgical retractor of the present invention includes a proximal base frame having an opening for overlying an operative site on a patient. A plurality of tissue engaging retractor blades are arrayed and disposed about and extend downwardly from the frame about a central axis of the opening to distal blade ends. Each blade has an outwardly and generally horizontally extending blade handle at their proximal ends which handles are slidably mounted to the frame whereby the blades may be selectively retracted by the handles from the central axis for thereby retracting tissue. The blade handles pass through guide slots in the frame, and more particularly through guide slots provided in respective pivotal segments that are pivotally secured to the frame on respective horizontal axes thereby the blades may be thereby independently pivoted downwardly and outwardly from the central axis. An internally opened expansion collet is coaxially received in the top of the frame for adjustable coaxial advancement downwardly into the frame. The collet is dimensioned for simultaneous engagement of selected of the pivotal segments for thereby simultaneously urging them together with their respective blades downwardly and outwardly away from the central axis to further retract tissue.

Owner:DALTON BRIAN E

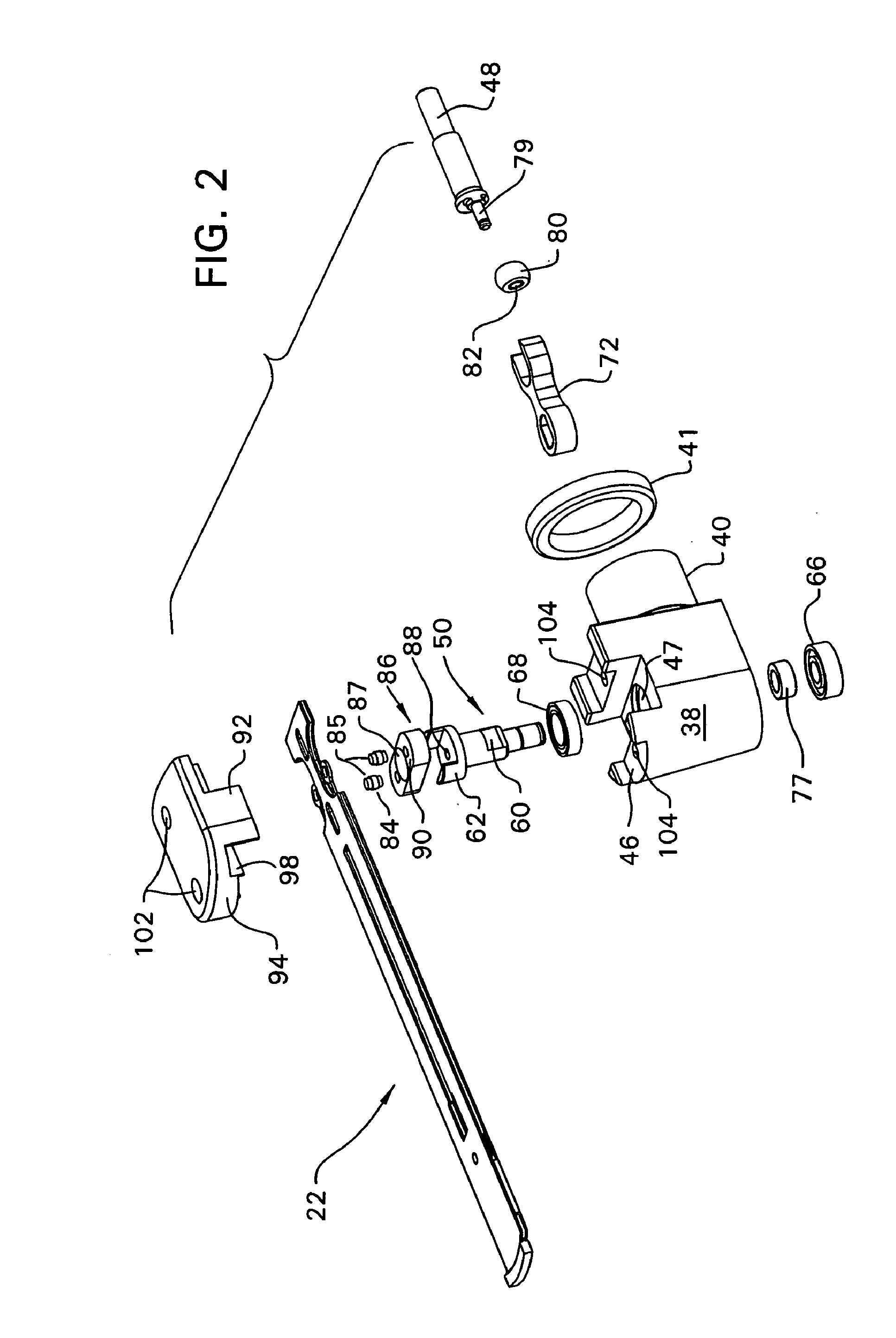

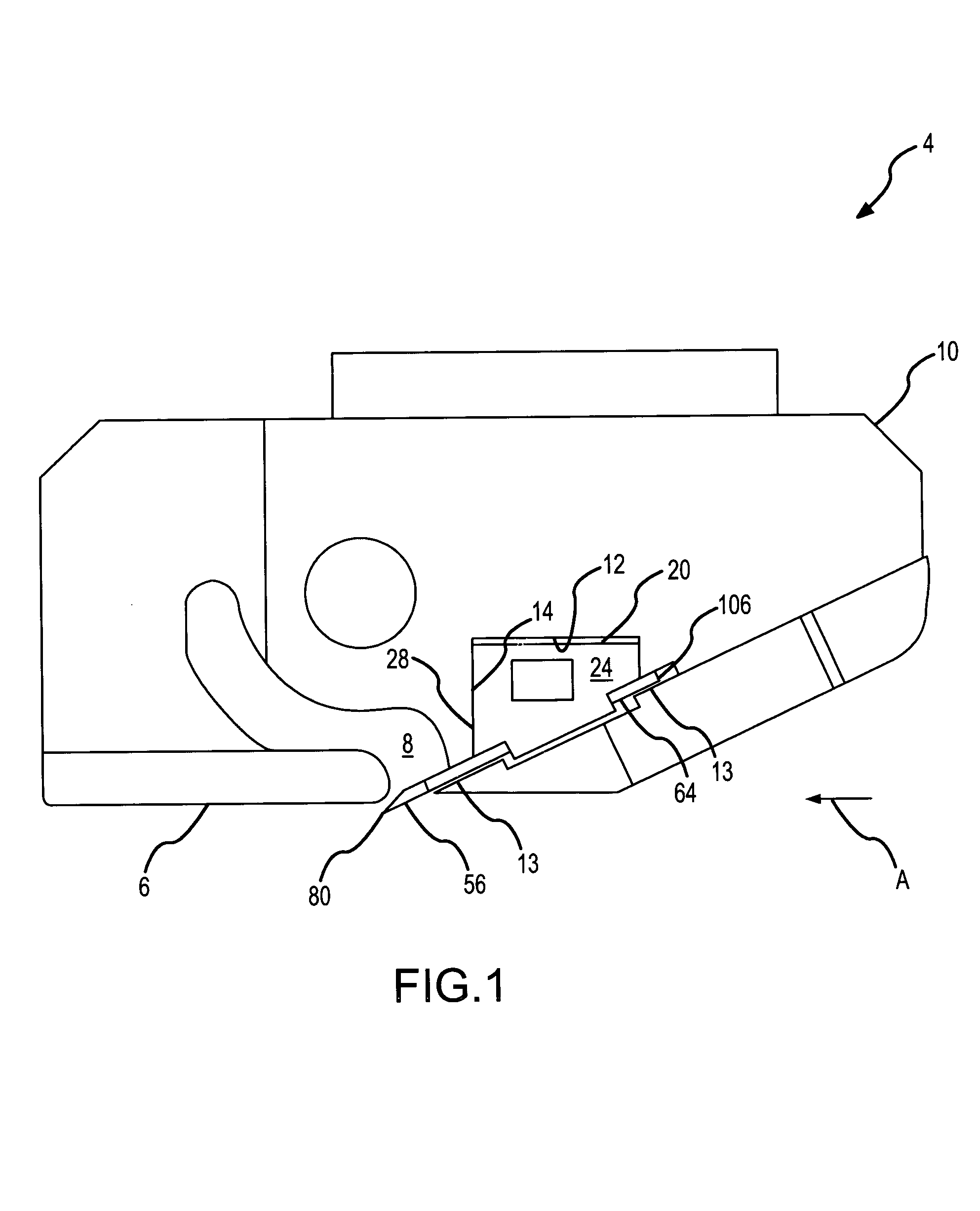

Surgical sagittal saw blade including a guide bar, a blade head and drive rods for pivoting the blade head

ActiveUS20090138017A1Less vibratory motionAvoid excessive wearPower driven reciprocating sawsSurgical sawsReciprocating motionEngineering

Owner:STRYKER CORP

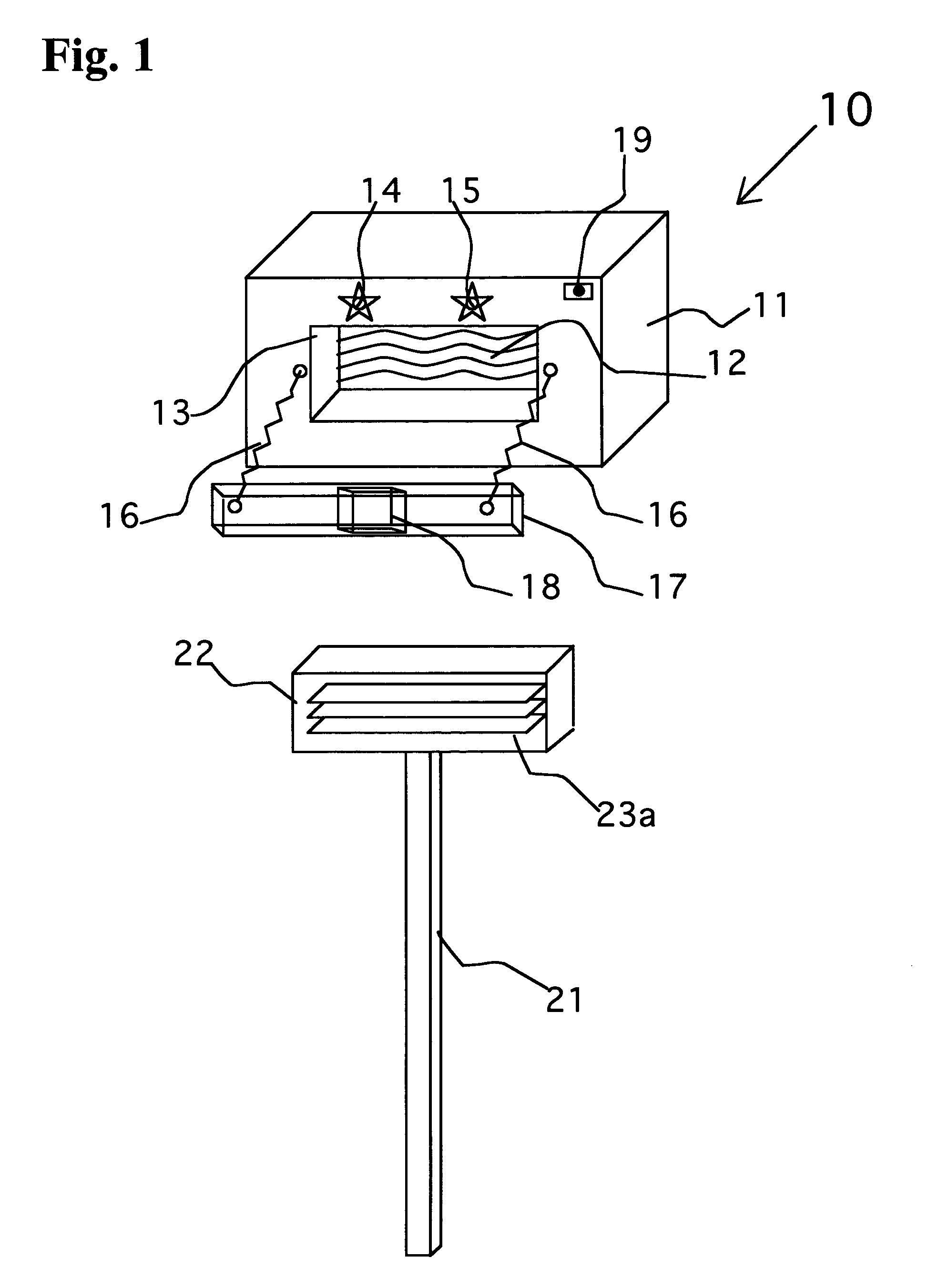

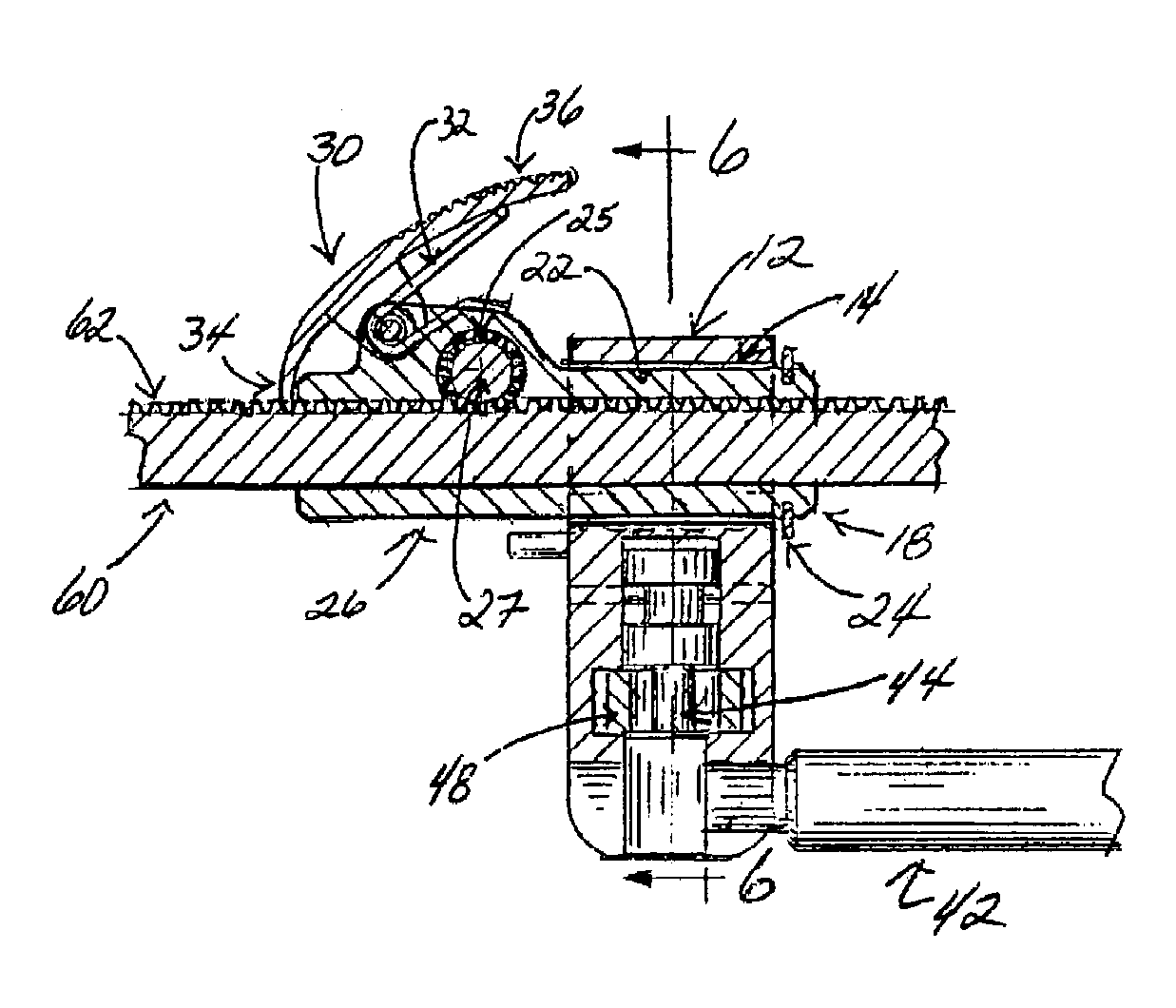

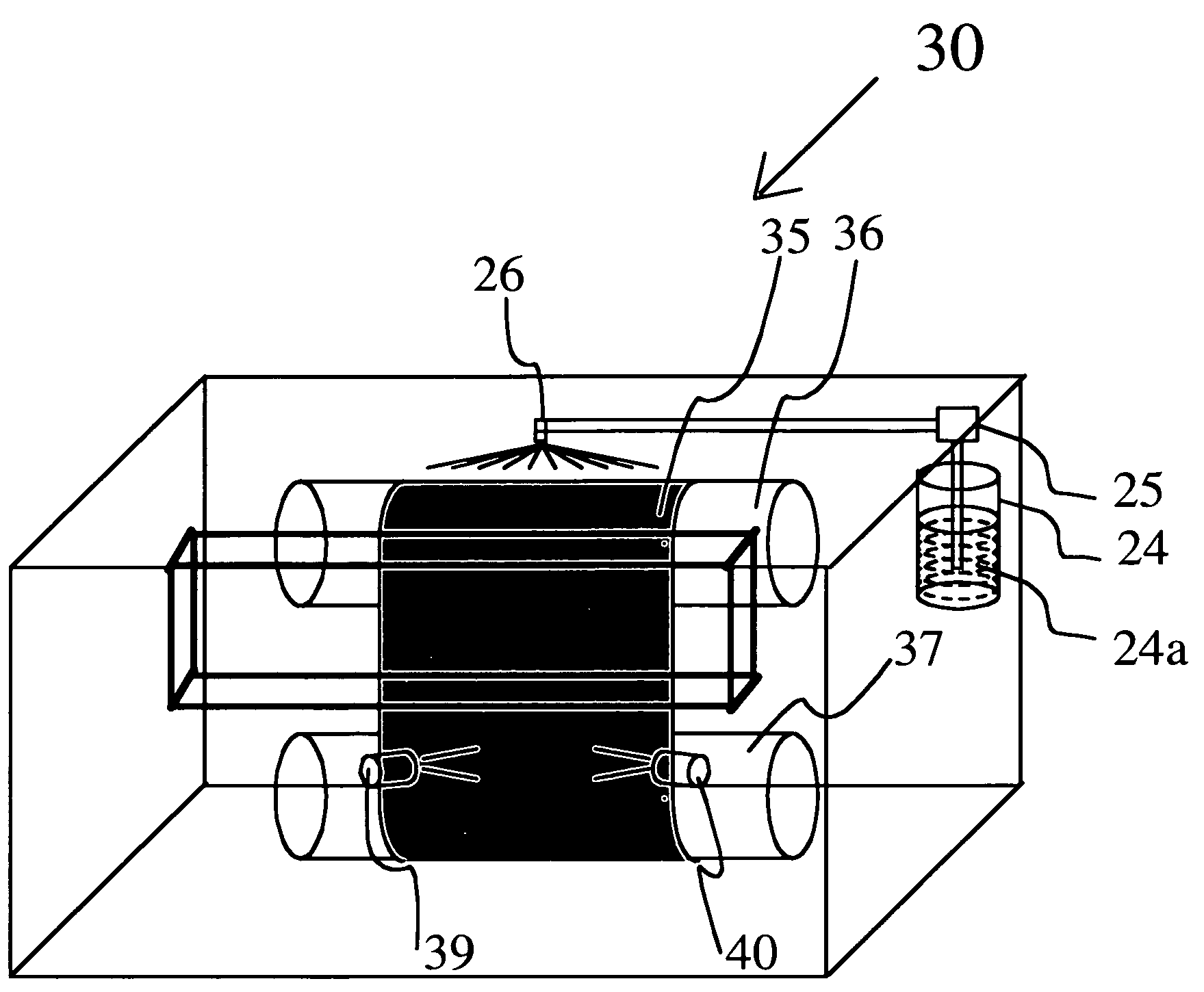

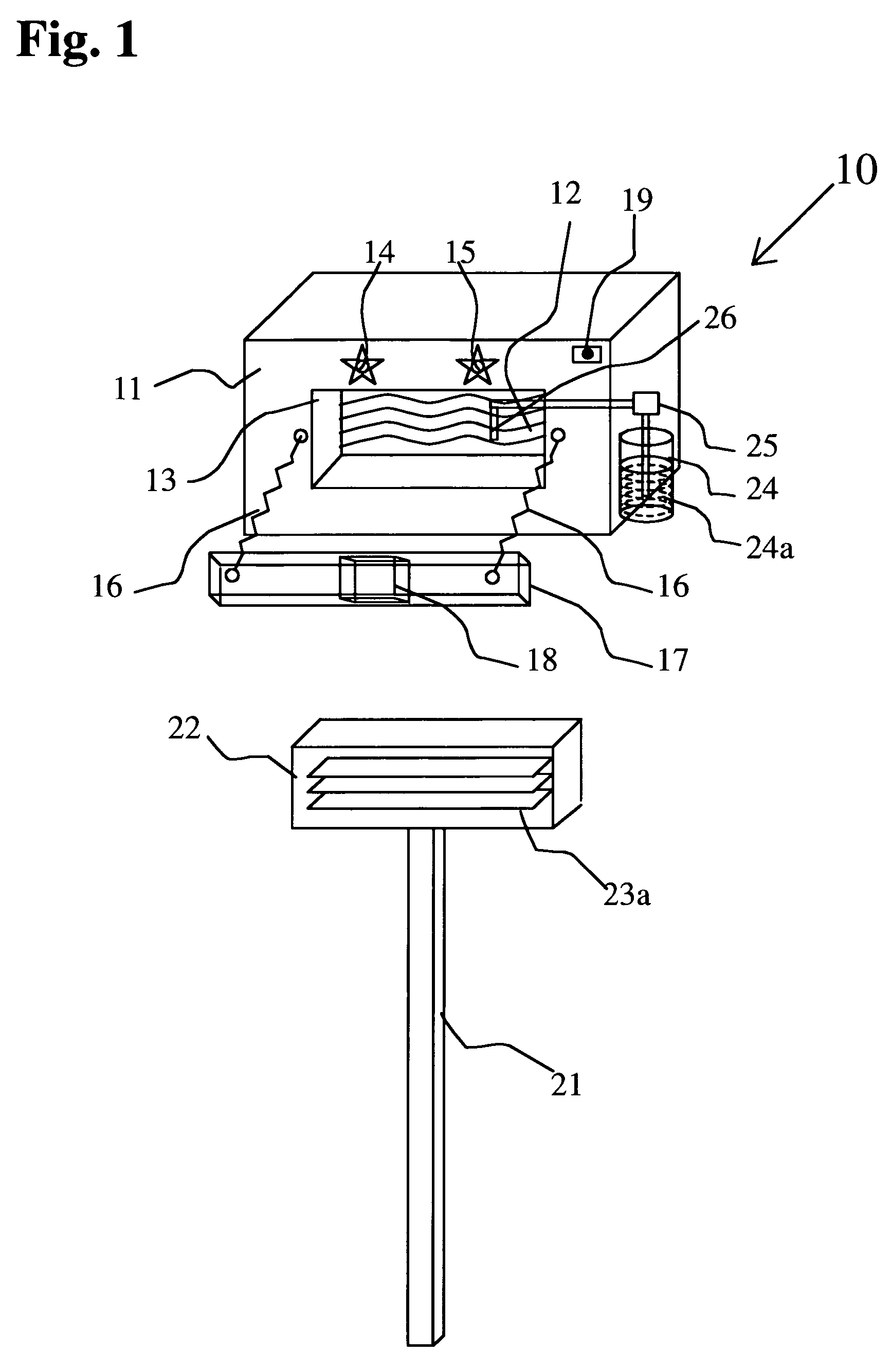

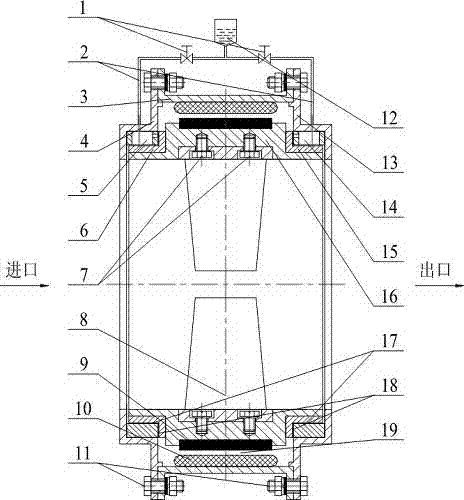

Razor blade sharpener

An automatic razor blade sharpener simultaneously sharpens multiple edges of a spring-loaded disposable razor blade cartridge by gently contacting the blade edges with a moving rubber or polymeric compliant belt that is motor driven. The disposable razor blade handle is set in a cradle aperture, which is spring loaded against the moving belt. A timer terminates the blade sharpening operation, indicated by a green LED. A liquid is dispersed on the moving belt forming a thin liquid layer on the belt surface, illuminated by transversely located light illumination and the reflected light is received by a transversely located sensor. When the blade contacts the thin liquid layer, deep grooves in the blade cutting edge reduce this reflection indicating that the blade is too worn to be sharpened and a red LED light is indicated. Absence of reflection indicates that the thin liquid film has evaporated or spilled out.

Owner:PAPETTI JULIA GRACE

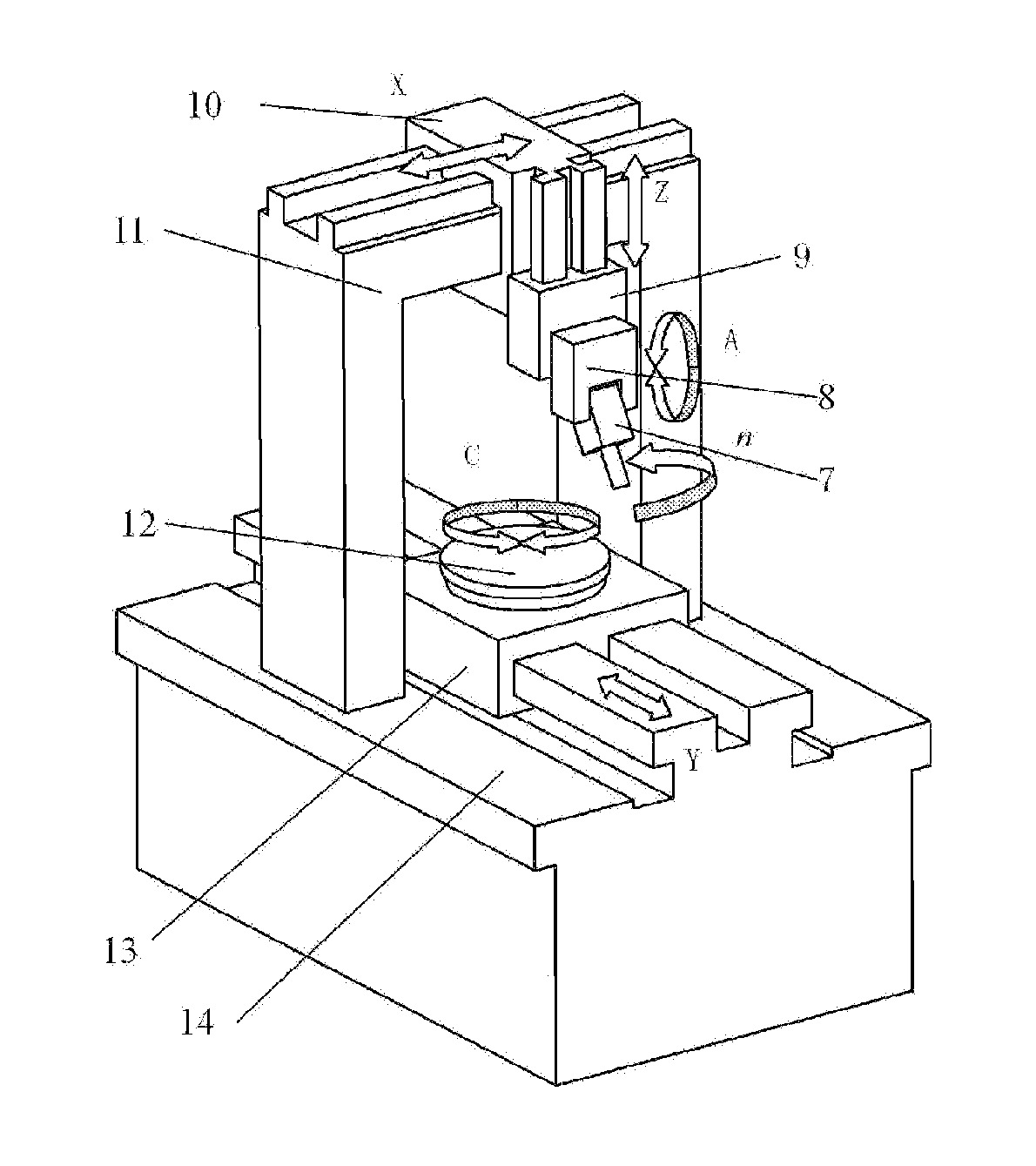

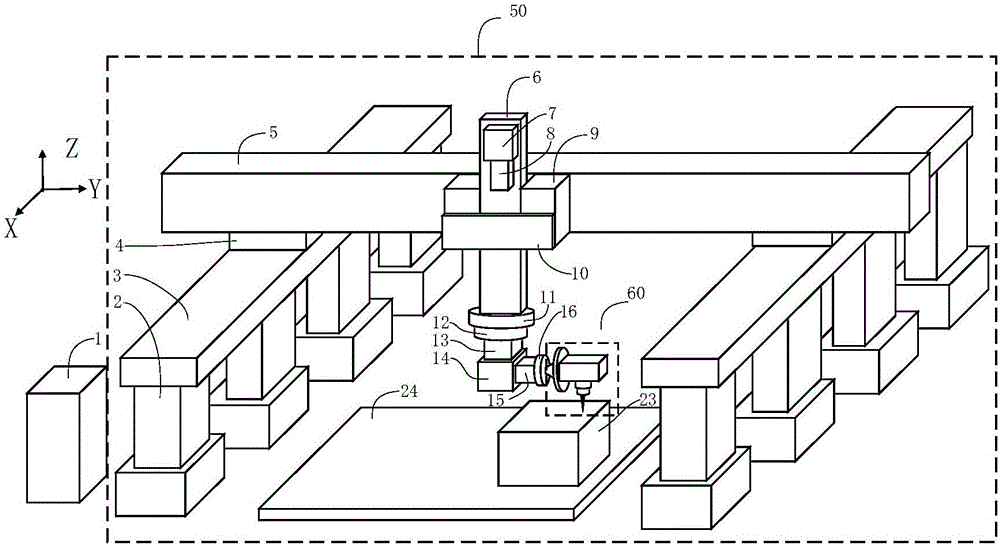

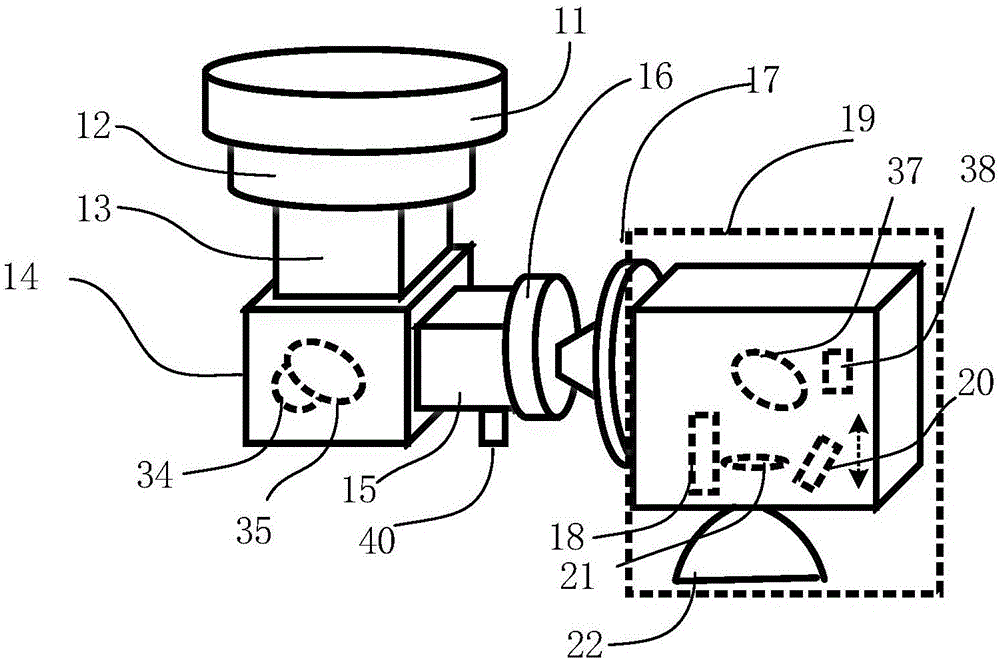

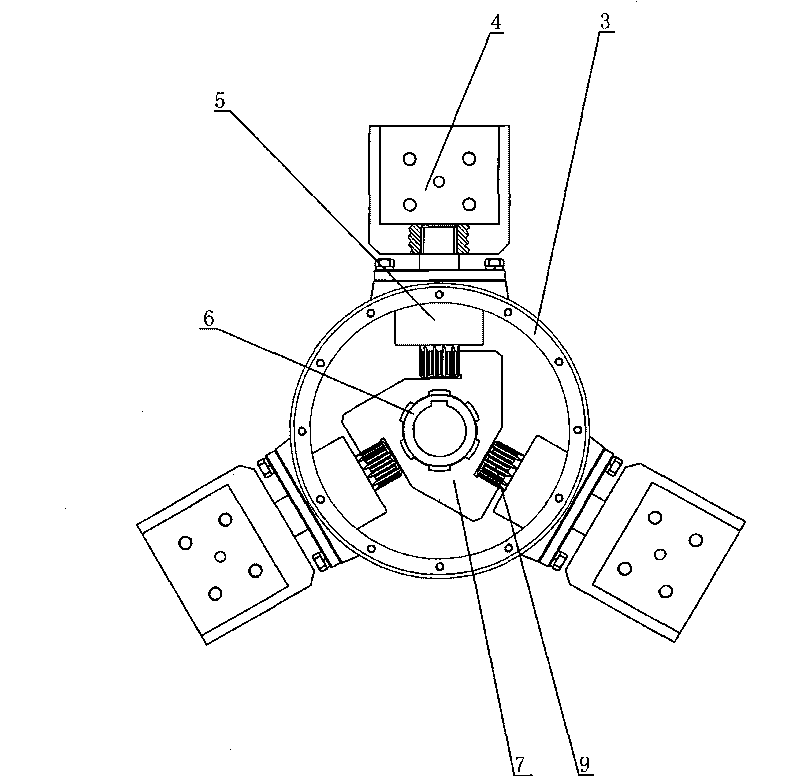

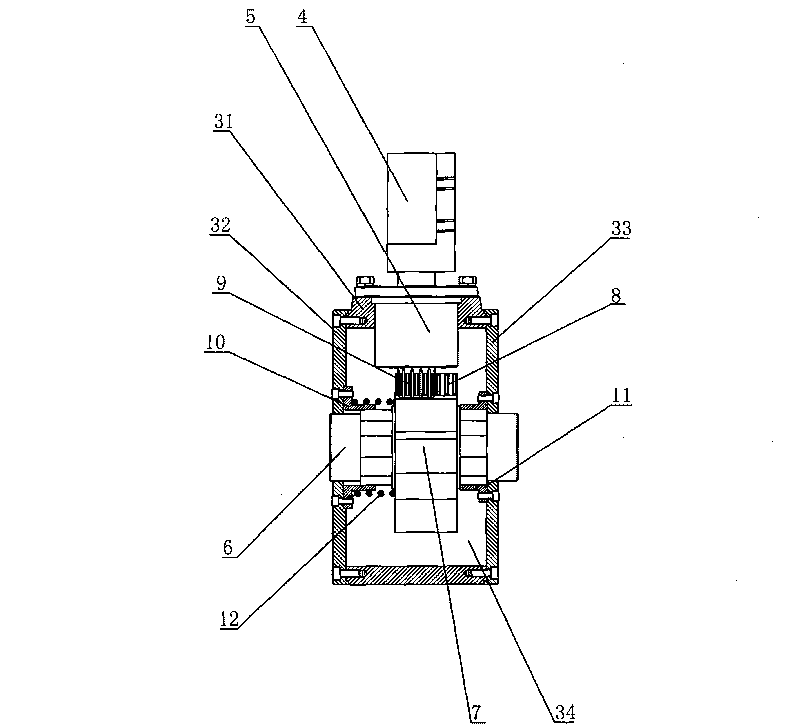

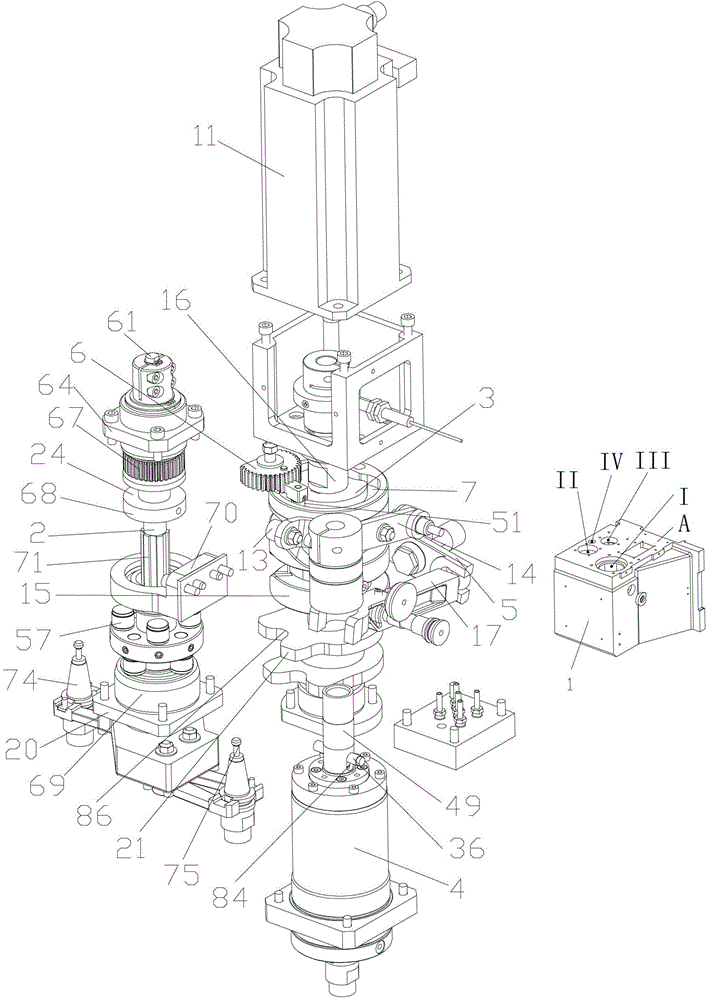

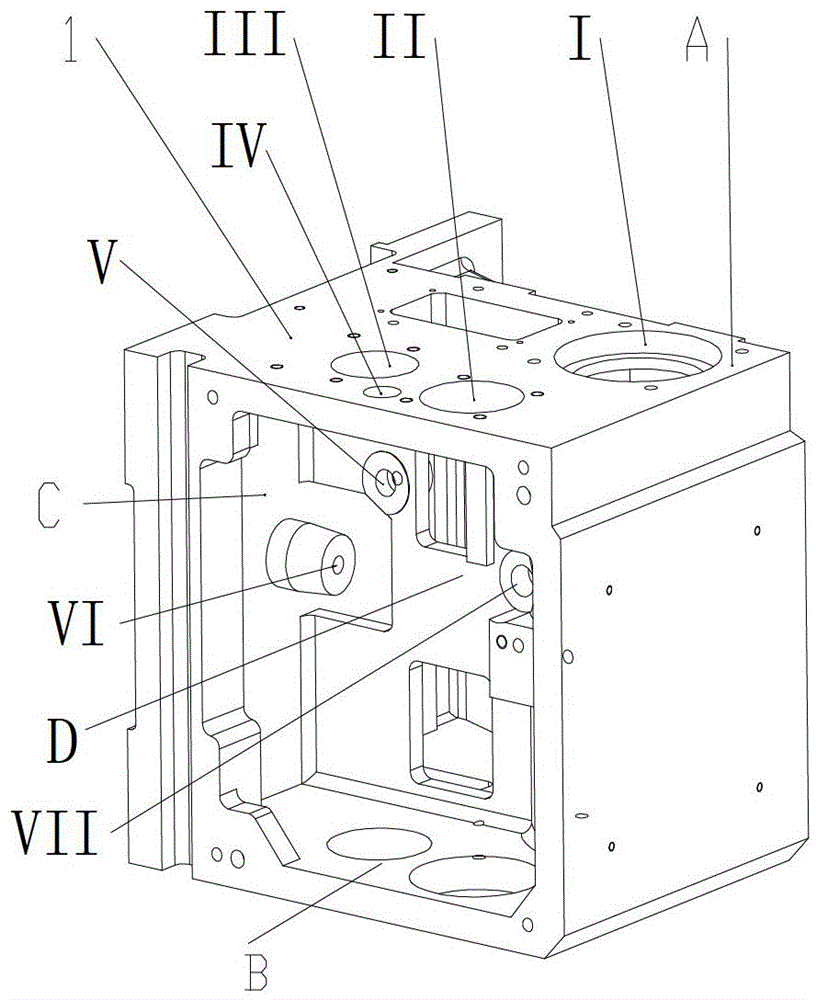

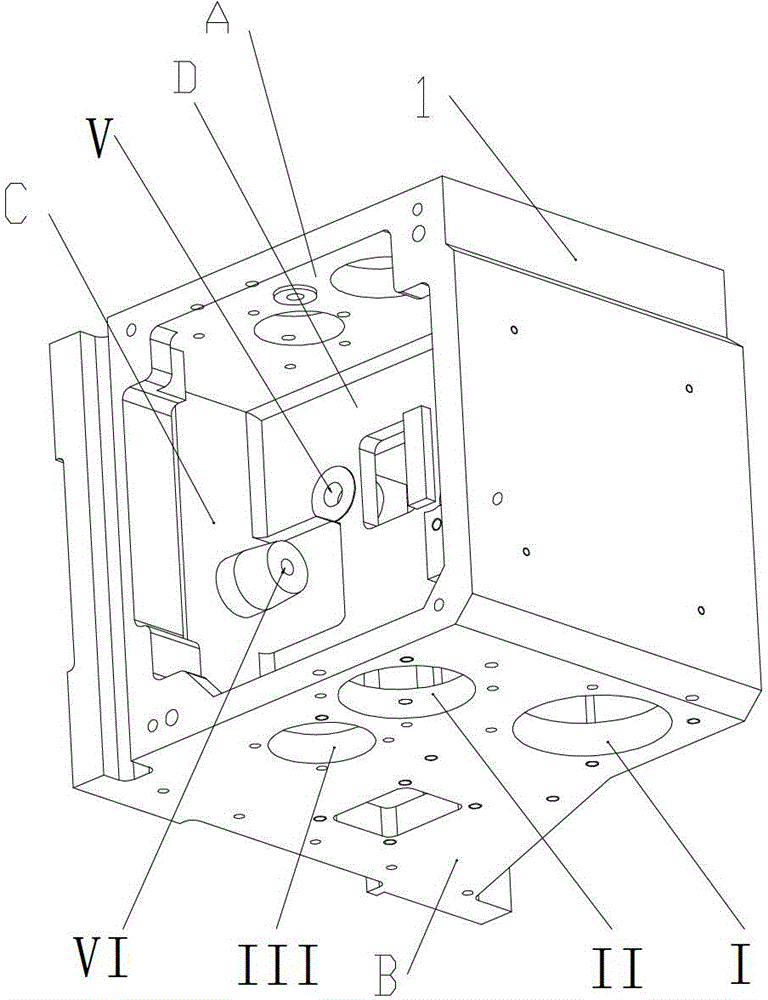

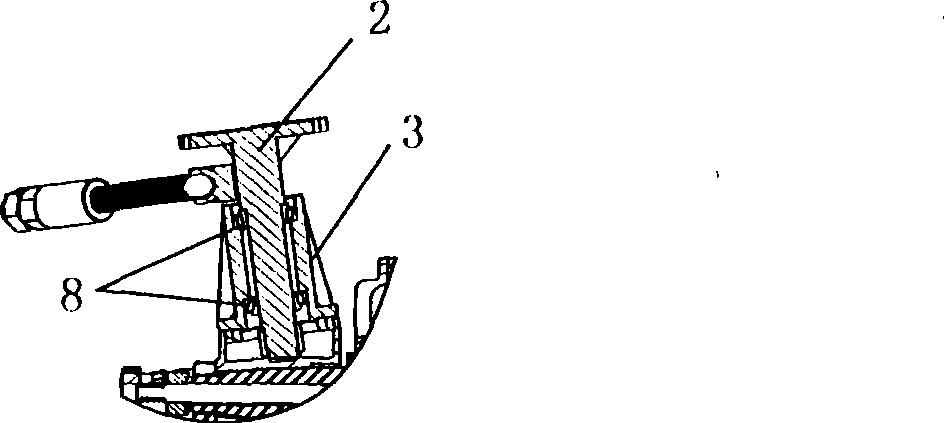

Multi-axle joint shifting loading apparatus for processing center and detection method for static stiffness distribution

ActiveUS20130111981A1Satisfies requirementMachine tool componentsMeasurement/indication equipmentsMultiaxial jointSteel ball

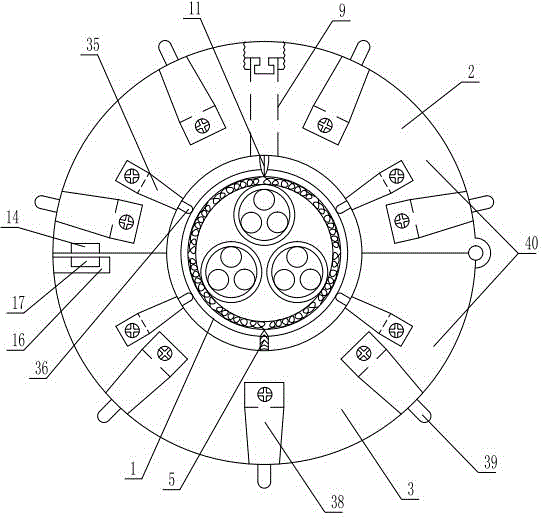

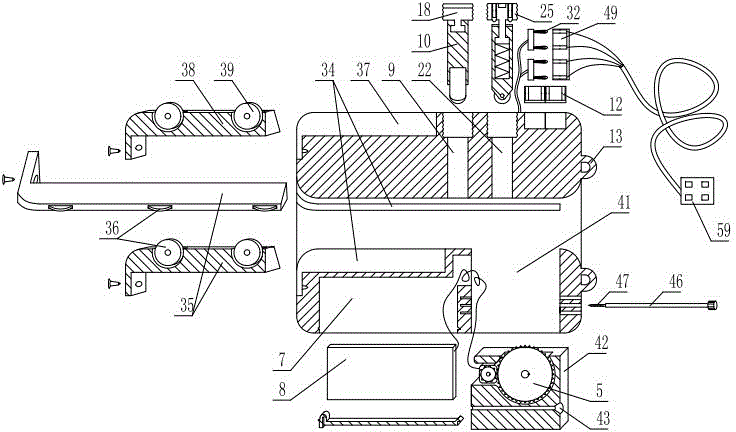

Disclosed is a processing center multi-axis joint deflection loading apparatus comprising a load-receiving test piece and a load-exerting component. The load-exerting component is constituted by a steel ball, a cap, a ball socket, a bent board, a force sensor, a connection component A, and a connection component B. The connection component A is fixedly connected to a blade handle of the processing center; the blade handle is pulled tight within a bored hole on a main axle; and the connection component A is connected to a main housing via the connection component B. In a method using the apparatus for an inspection of static stiffness distribution, by means of a multi-axle joint movement, moving the load-exerting component and the load-receiving test piece to a preset loading position, allowing the normal at a load-receiving point on a load-receiving face of the load-receiving piece to be aligned with the axis of the ball socket; with the amount of shift measured by position-shift sensors fitted on the main axle, the main axle housing, and a working platform, and the amount of simulated load measured by the force sensor of the loaded-exerting component, deriving a stiffness measurement of the load-exertion position under a simulated load; changing the load-exertion position by means of a multi-axle joint movement, repeating in sequence the previous steps, thus deriving a stiffness distribution under the simulated load.

Owner:XIAN UNIV OF TECH

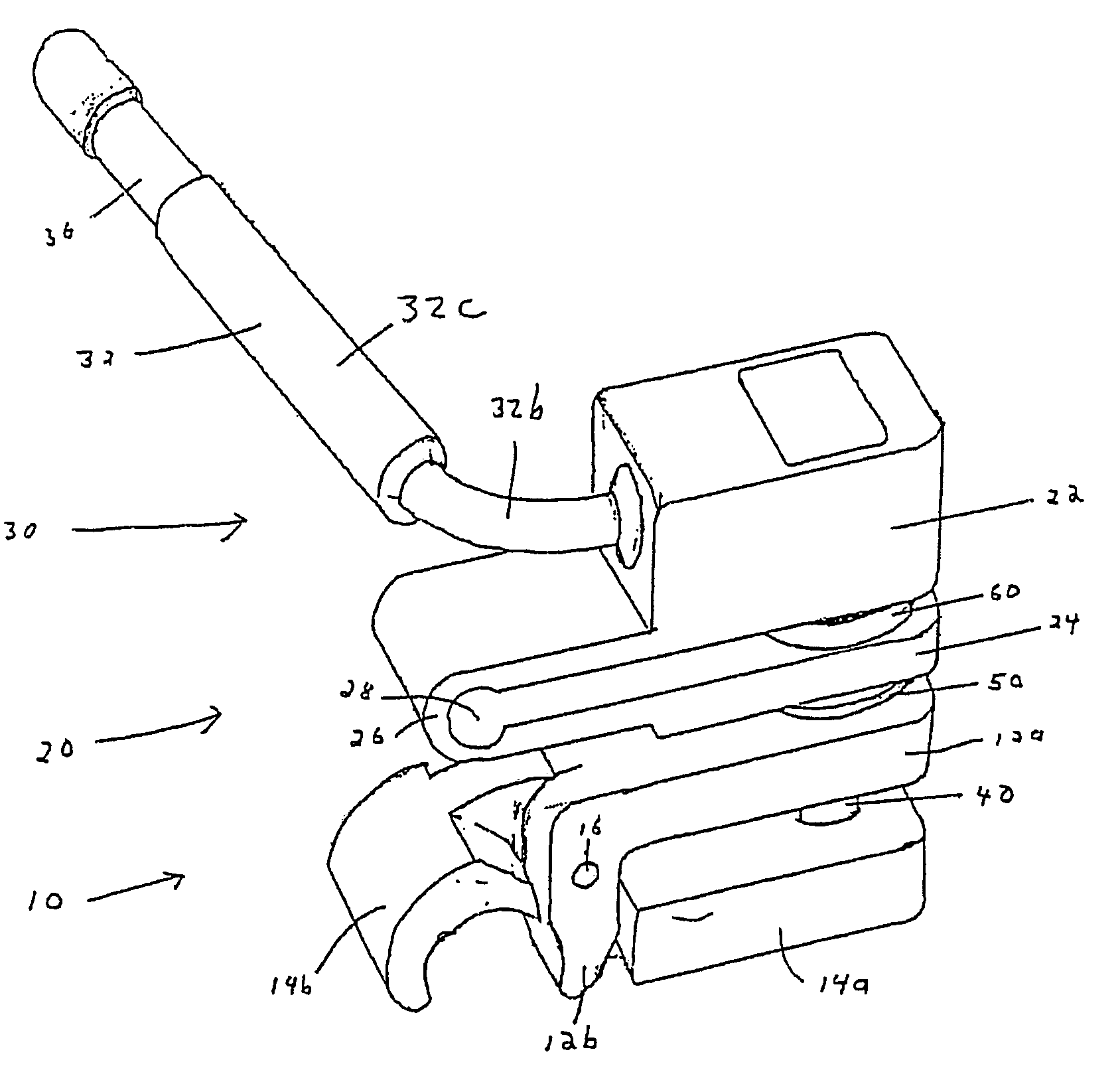

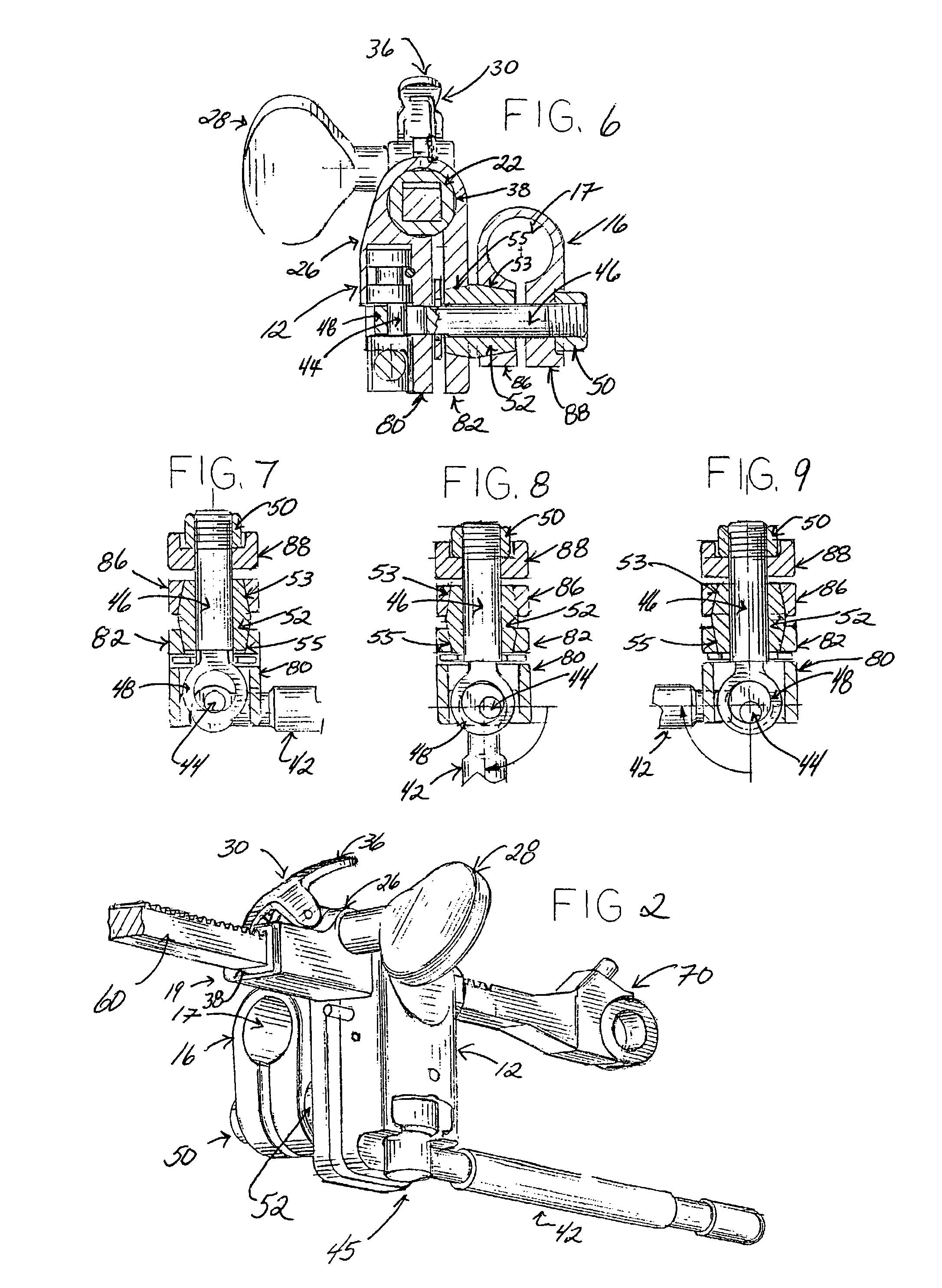

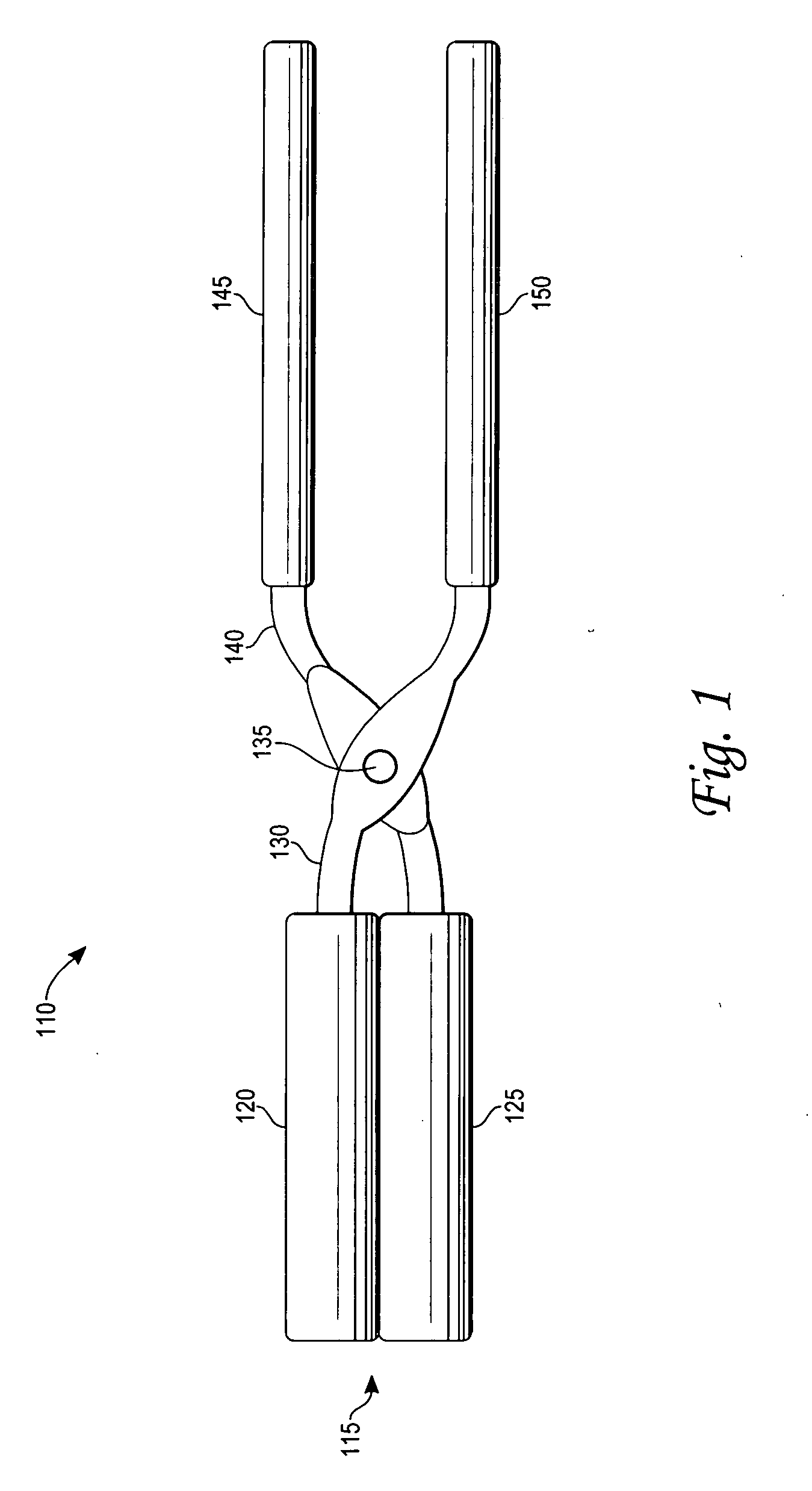

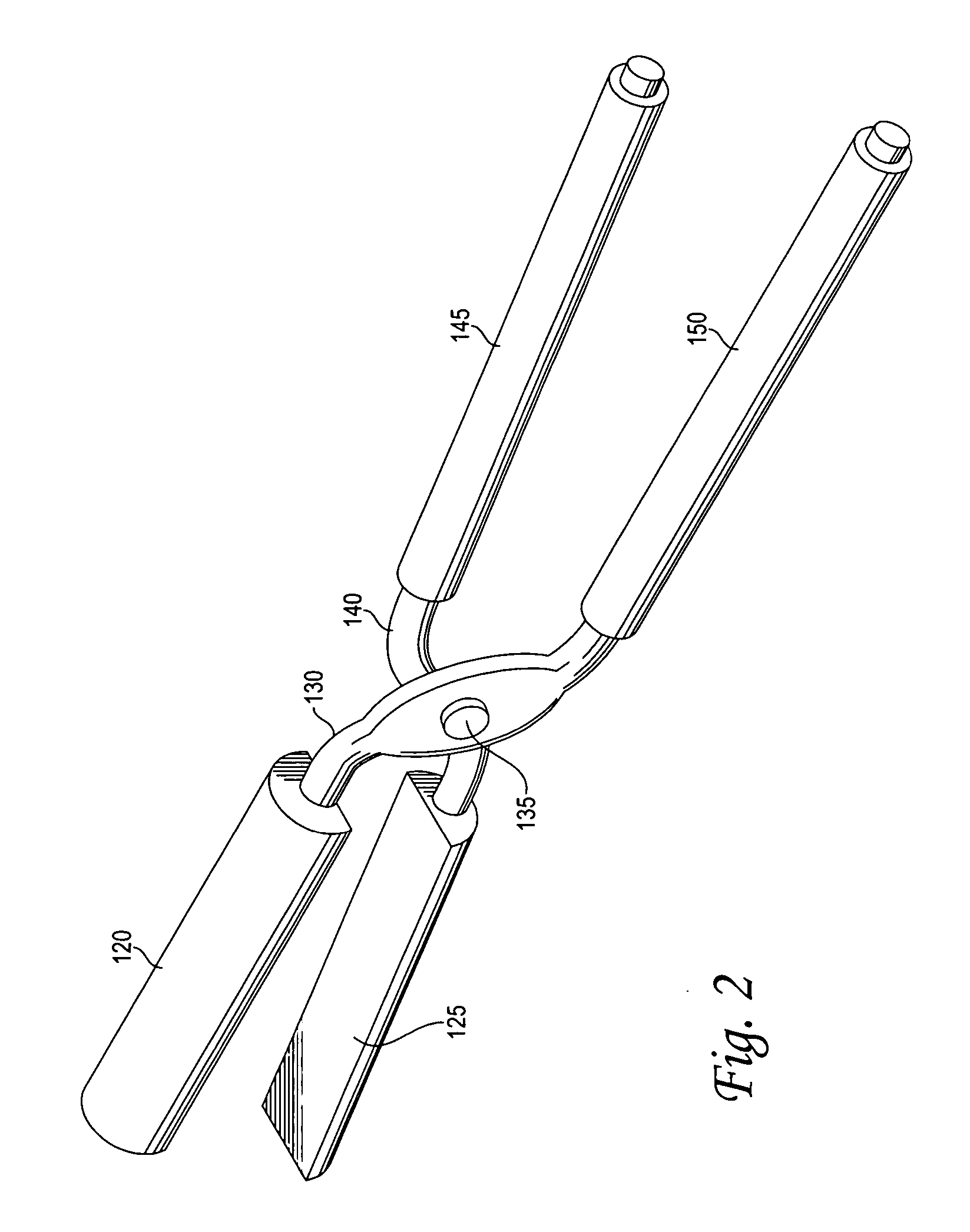

Universal scissors joint apparatus

ActiveUS7749163B2Rigid and stableEasy to useDiagnosticsSurgical instrument supportBraced frameUniversal joint

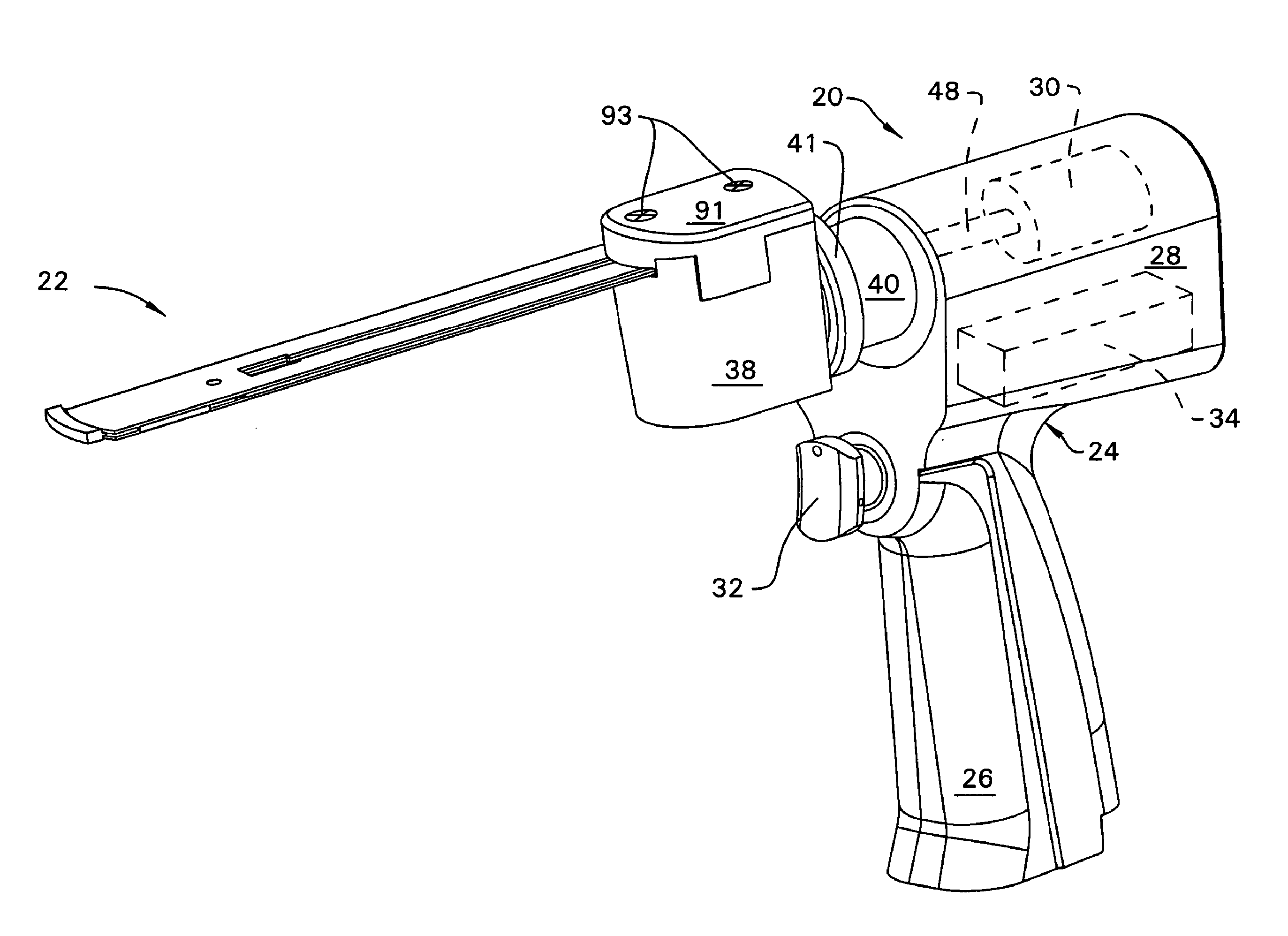

A universal joint apparatus comprises clamps, a locking mechanism, and a rod connecting the clamps and the locking mechanism. At least one clamp is a scissors clamp, i.e. a clamp comprising two segments fastened by a pivot. The scissors clamp generates extra compressive force on the object being held, providing a stable and rigid universal joint. Clamps are able to rotate with respect to each other, allowing for greater flexibility in usage. The universal joint apparatus is capable of being added to a support frame between other components. In one embodiment of the invention, the universal joint includes a dedicated retractor blade handle to ensure that the locked position of the cam handle is oriented substantially away from the operative site.

Owner:THOMPSON SURGICAL INSTR

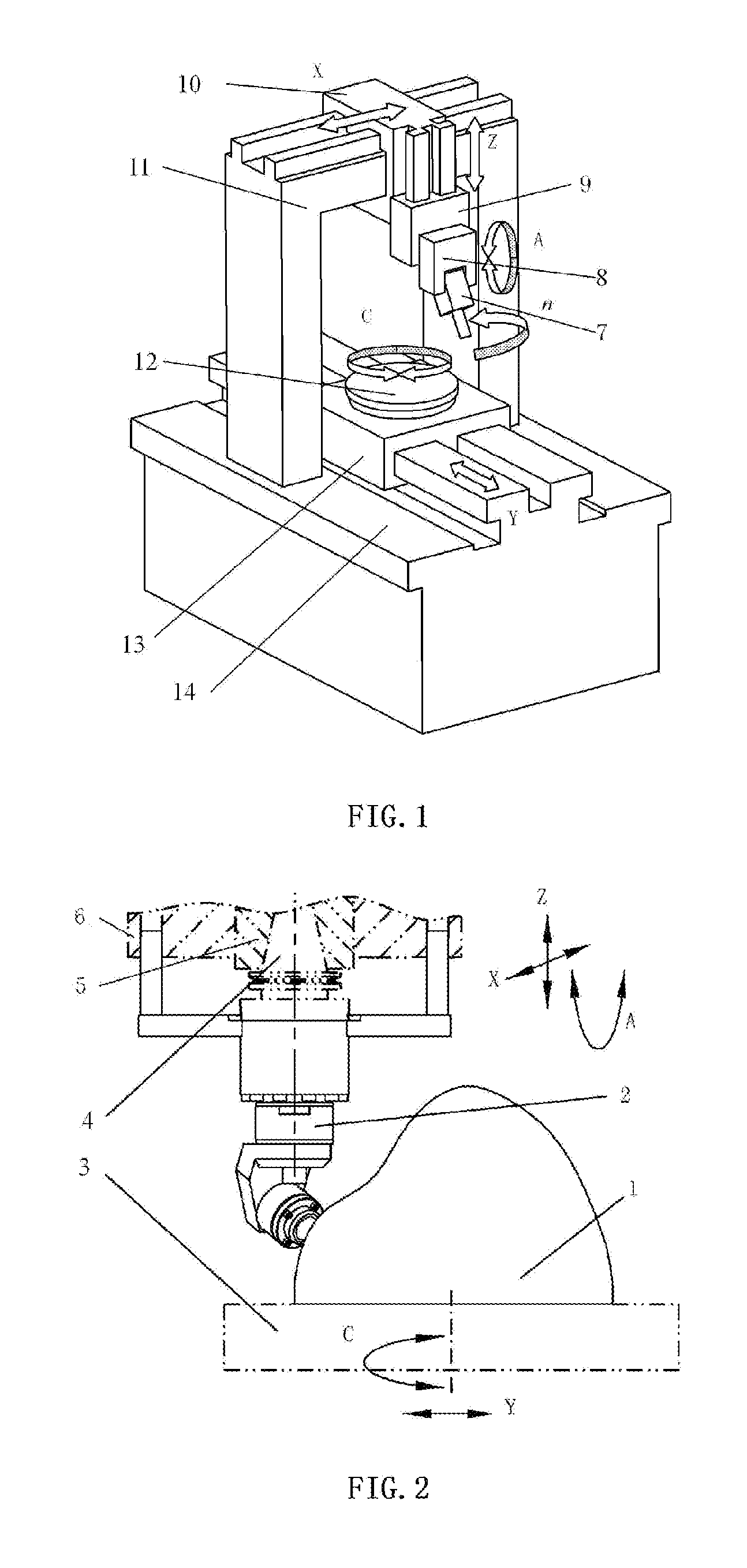

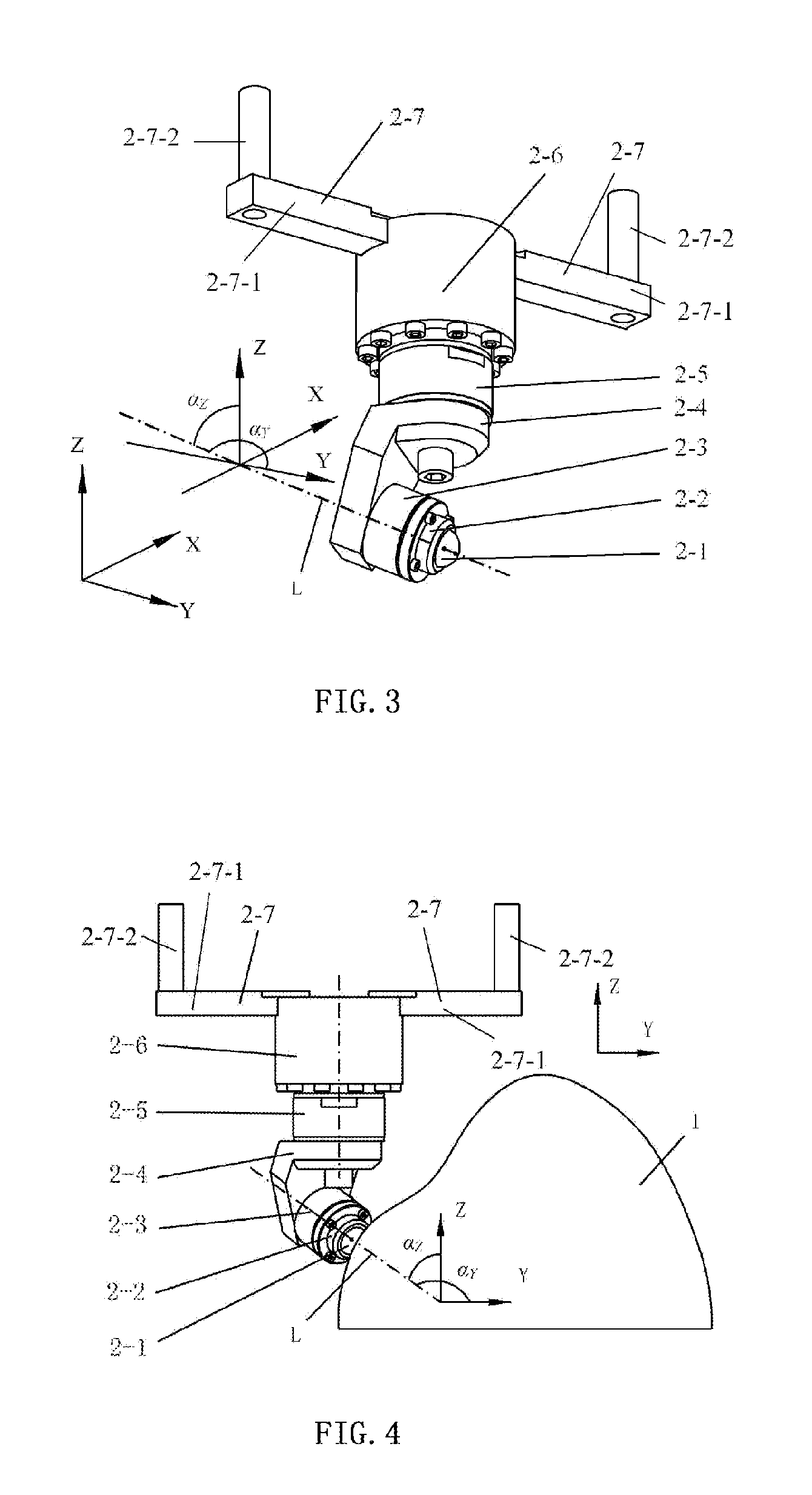

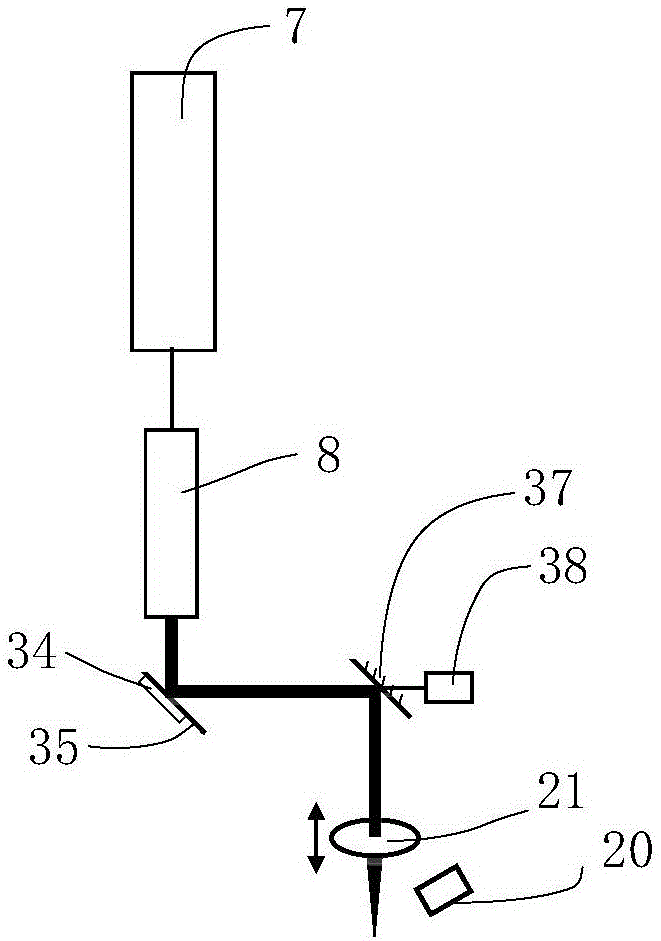

Multi-light source, multi-function and multi-axis laser processing head and apparatus

ActiveCN106563880AAchieve laser fine etchingRealize cutting processLaser beam welding apparatusNumerical controlEngineering

The present invention discloses a laser processing head and a multi-light source, multi-function and multi-axis processing apparatus comprising the same. The laser processing head includes a shell, an optical path system, a locating conical disk-shaped connecting mechanism, a laser range finder, a motor driving mechanism and a dust collection protection cover. The laser processing head has the advantages of a plurality of processing modes, flexibility in laser selection and easiness in replacement. The multi-light source, multi-function and multi-axis processing apparatus includes an apparatus control and operation system platform, a multi-axis linkage numerically-controlled machine tool and the laser processing head; the laser processing head is fixed on a high-precision multi-axis linkage machine tool through a blade handle type positioning cone device; and large-breadth and cross-scale laser fine processing only requires the switching of a laser light source, a laser optical path and the laser processing head, so that at least three kinds of large complex component fine surface processing application can be realized. The multi-light source, multi-function and multi-axis processing apparatus is especially for the aerospace field. The laser processing head and the multi-light source, multi-function and multi-axis processing apparatus comprising the same of the invention have the advantages of low manufacturing cost, wide application range, convenience in mass production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

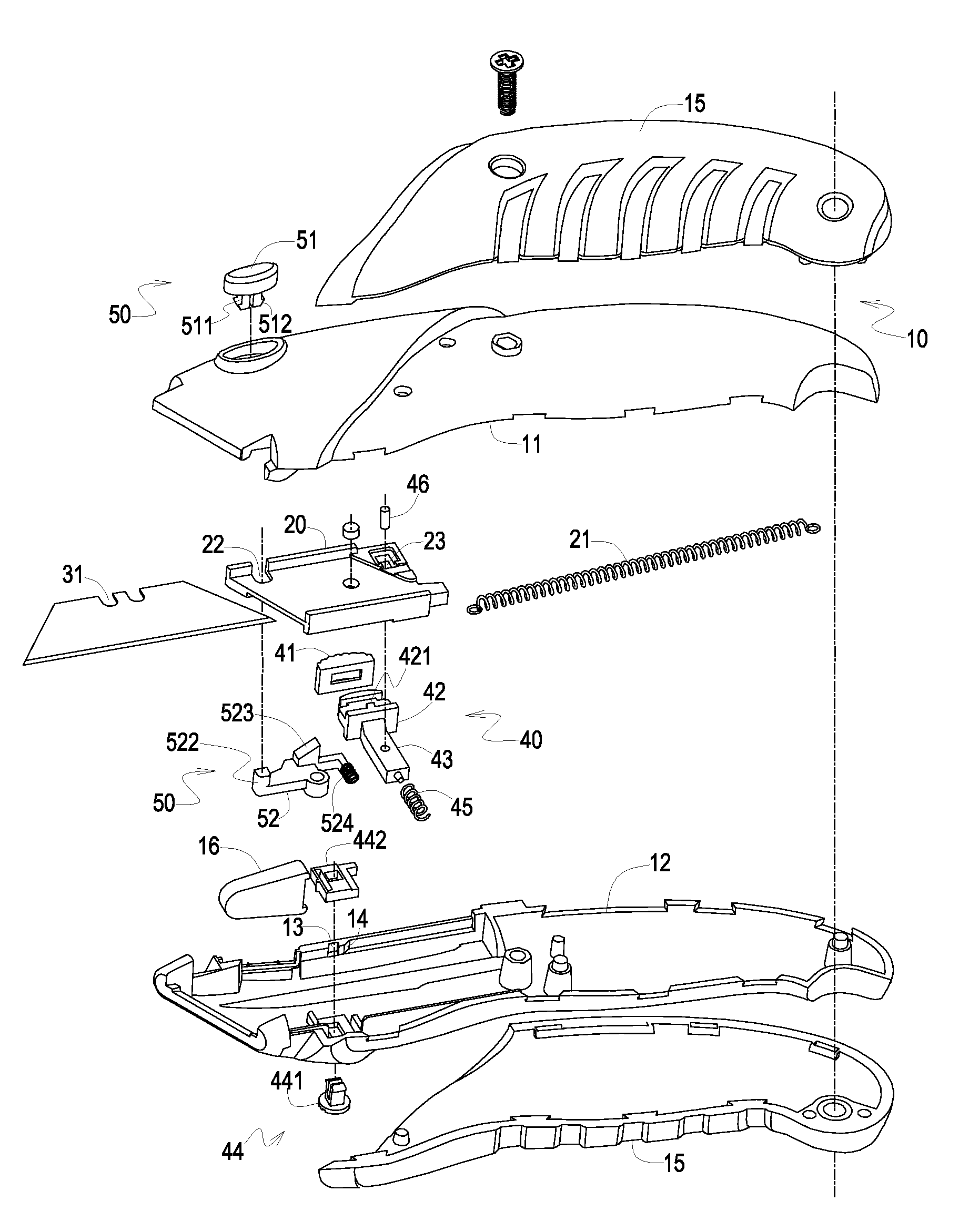

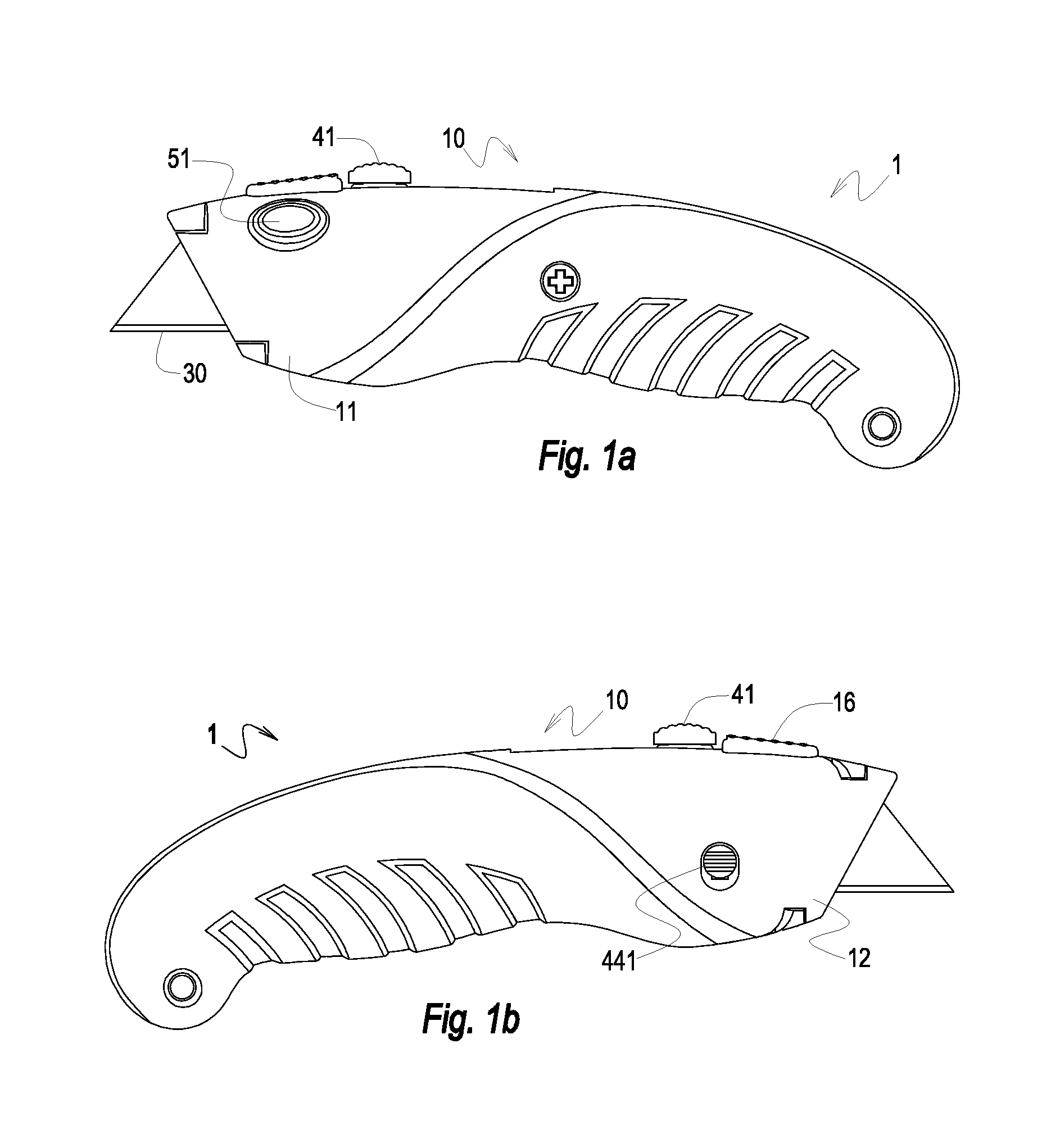

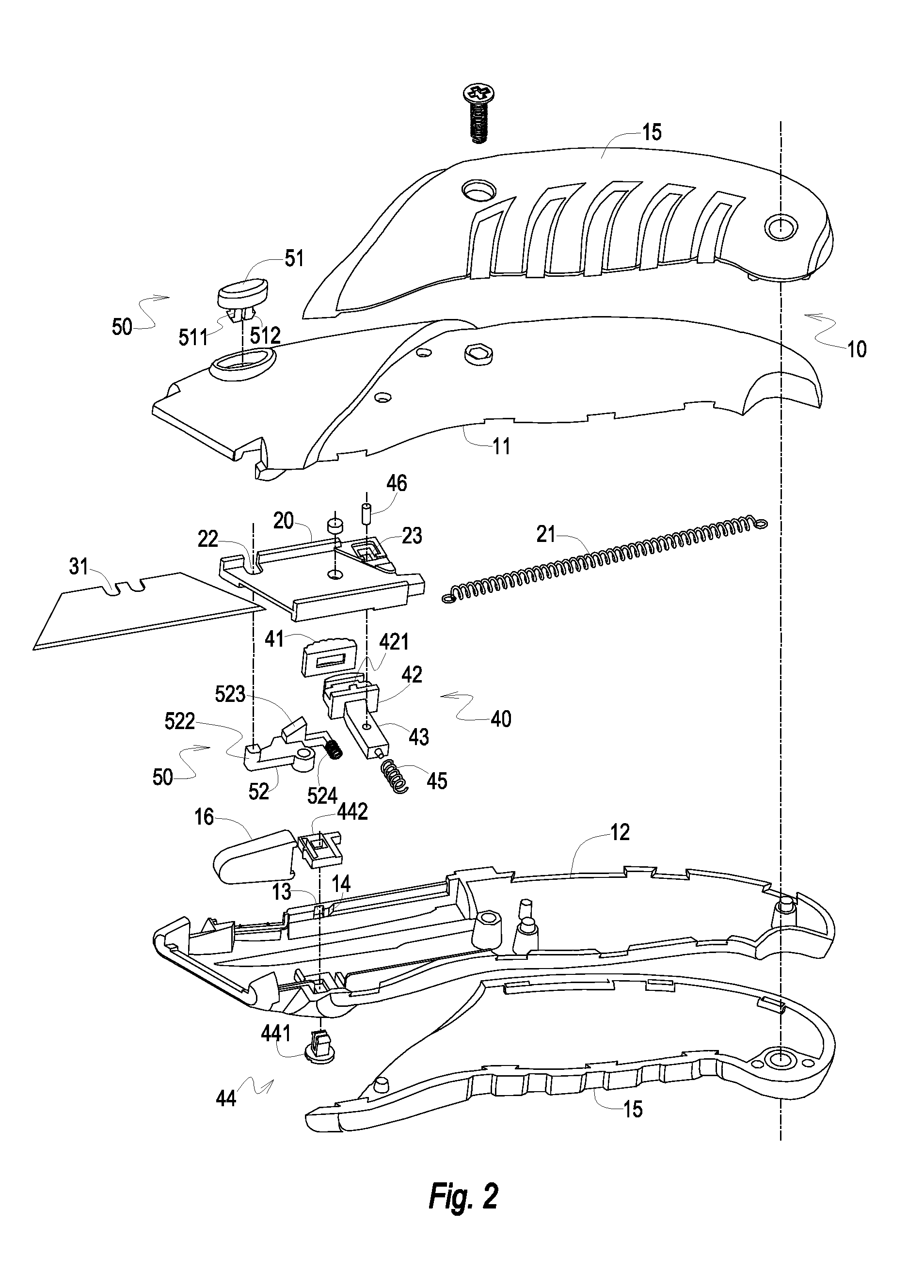

Retractable Utility Knife

A retractable utility knife has a housing, a blade seat forward slidably received in the housing, a blade fixed to the blade seat, a driving unit having an actuator protruding out from the housing and an actuator seat reciprocally slidable along the housing, a blade seat return spring linking the blade seat and the housing, and a blade change means. The blade of the retractable utility knife is also able to be locked when fully extended to avoid painstaking thumb pushing when works for mass workloads.

Owner:WU YUEWEI

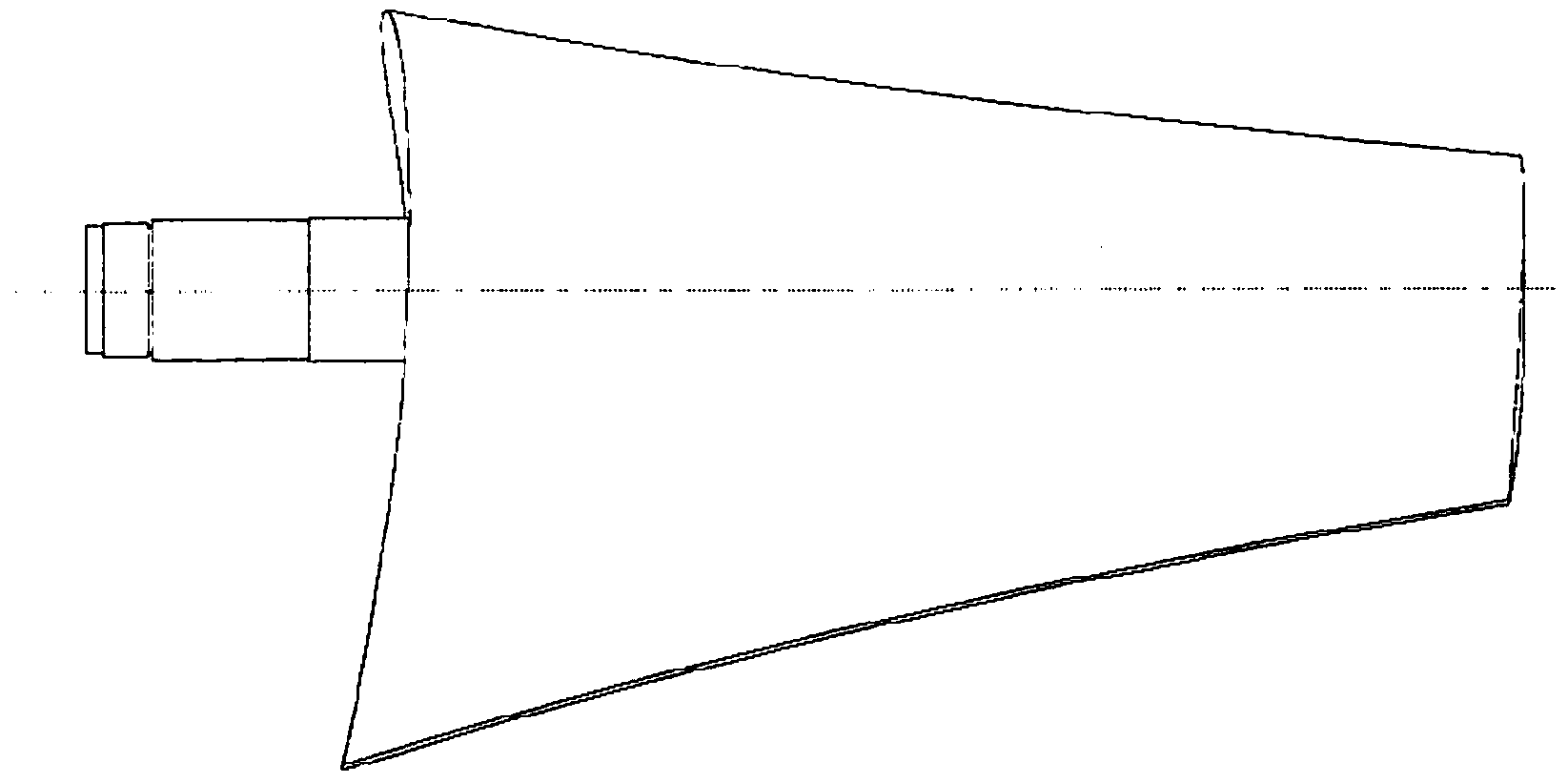

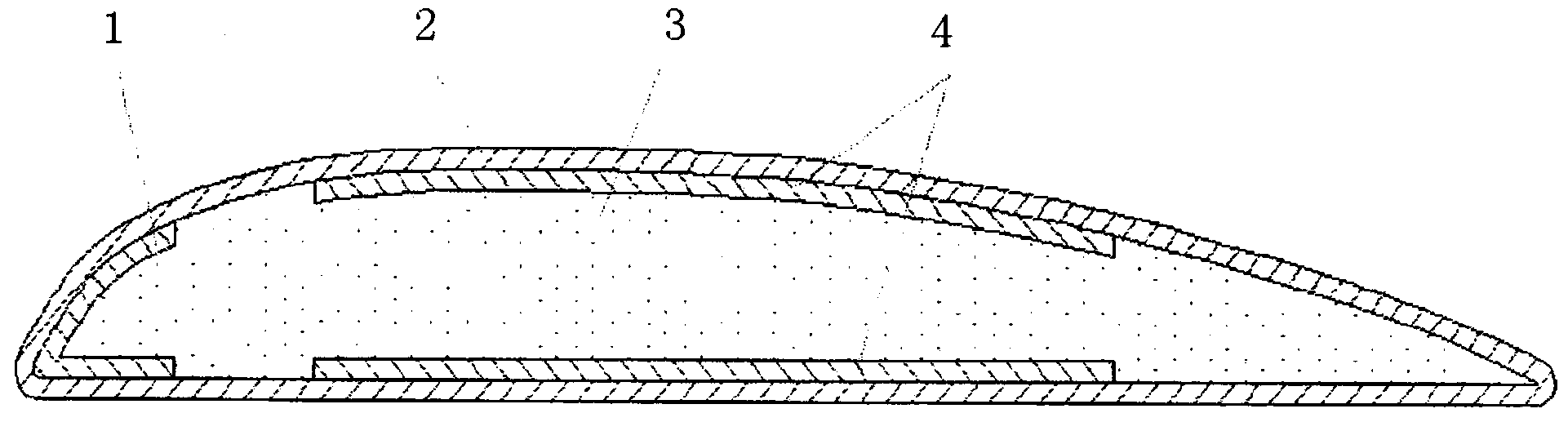

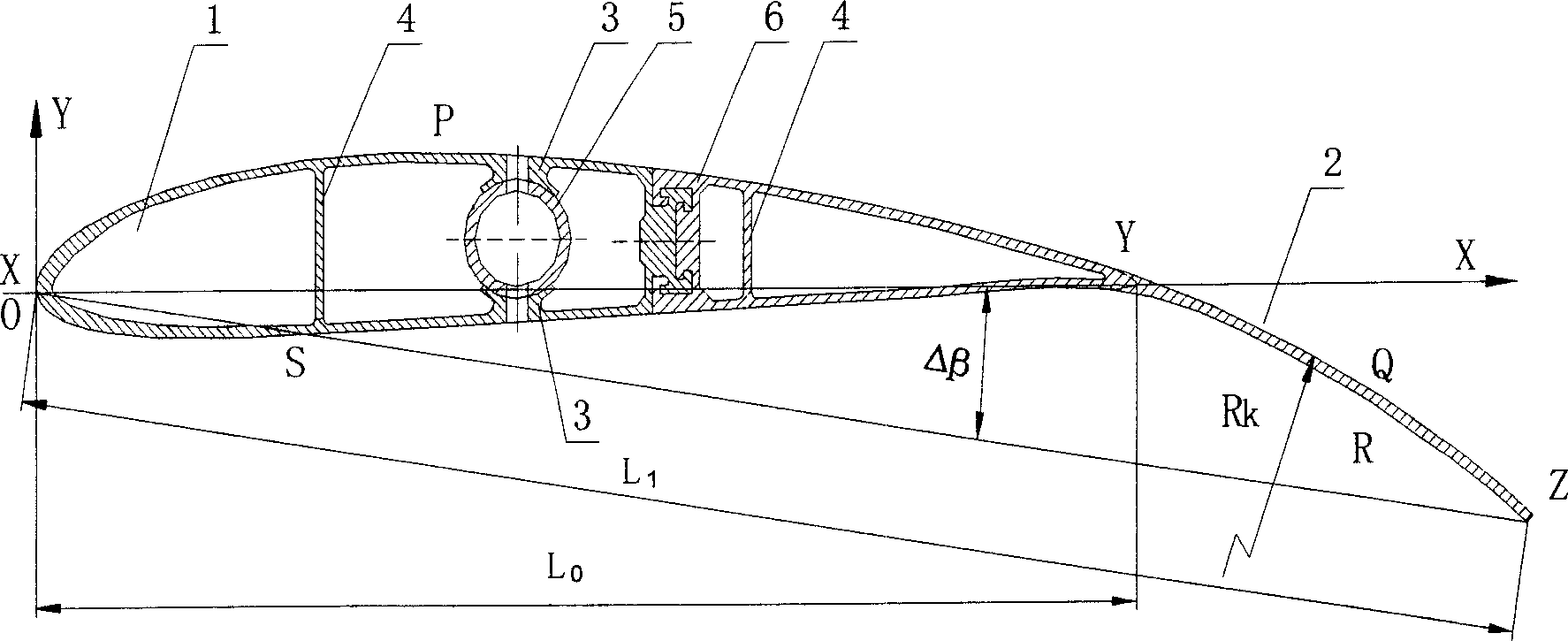

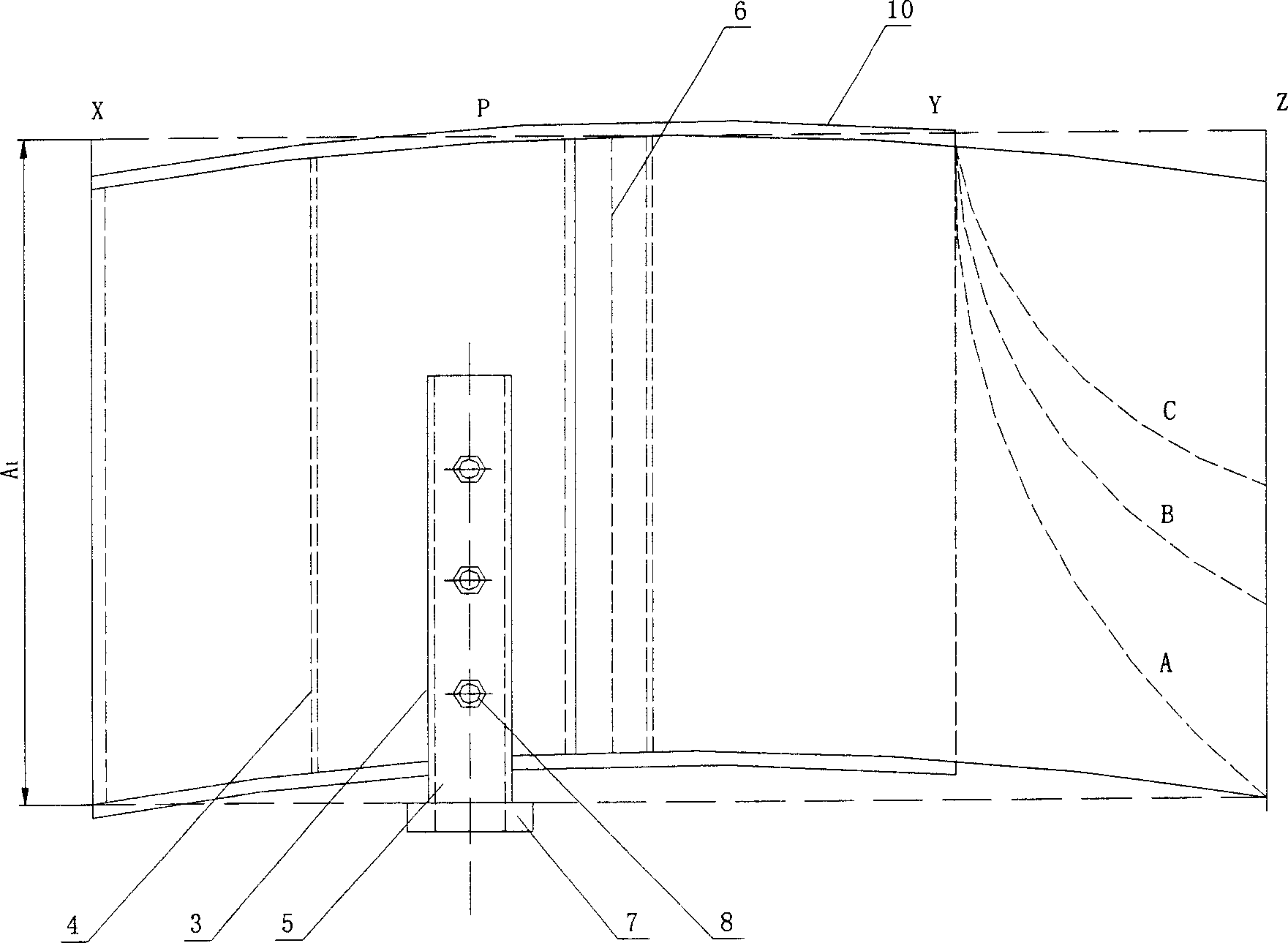

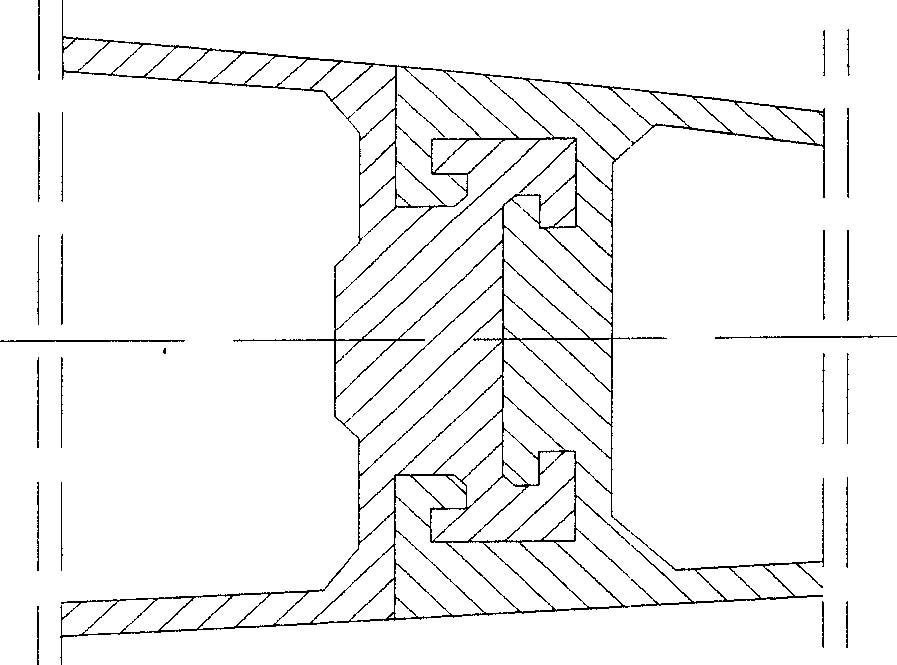

Carbon fiber composite foam core sandwich structure wind tunnel fan blade and molding method

ActiveCN104358708AEasy to controlGuarantee molding qualityPump componentsPumpsInterior spaceHigh humidity

The invention provides a carbon fiber composite foam core sandwich structure wind tunnel fan blade. The wind tunnel fan blade is characterized in that a skin is arranged at the outer part; the internal front end of the skin is connected to a front edge reinforcing area; the internal middle part of the skin is connected with a main bearing beam; an internal space defined by the skin, the front edge reinforcing area and the main bearing beam is filled with a foam core material; the skin comprises an inner skin and an outer skin; the outer skin is laid and adhered to the surface of the inner skin; the thickness of the main bearing beam is changed from 8-10 mm at the root part of the blade to 2-4 mm at the tip of the blade; the thickness of the front edge reinforcing area is 2-5 mm, the thickness of the inner skin is 2-5 mm, and the thickness of the outer skin is 1-3 mm. A molding method comprises the following steps: (a), pasting a blade handle with the foam core material; (b), feeding prepreg; (c), performing paving and glue suction compaction on the front edge reinforcing area and the main bearing beam; (d), performing paving and glue suction compaction on the inner skin; (e), solidifying; (f), molding the outer skin. According to the invention, the high-performance wind tunnel fan blade can be produced, and the use requirements under low-temperature, high-pressure, high-humidity and normal-temperature vacuum simulated climate environments can be met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

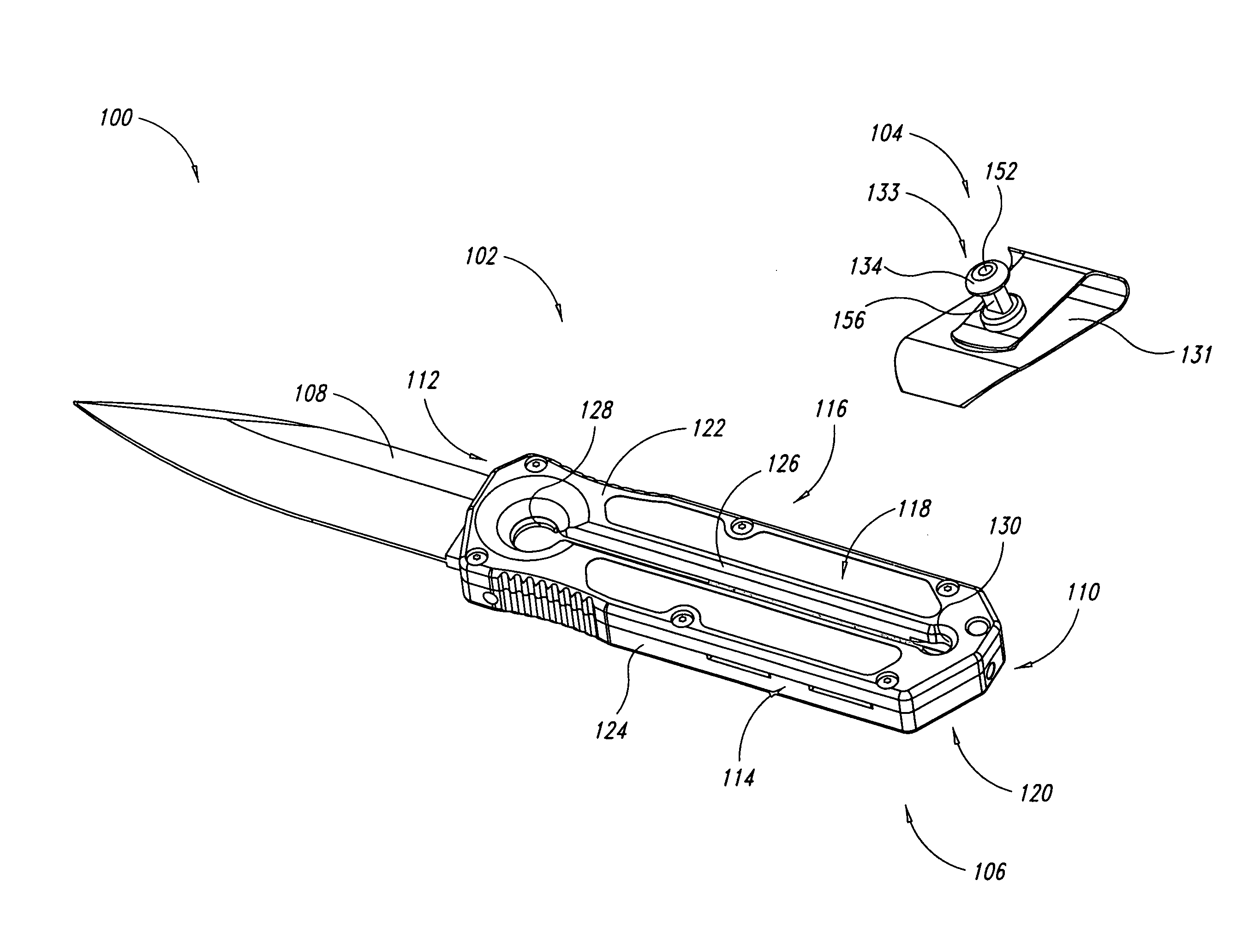

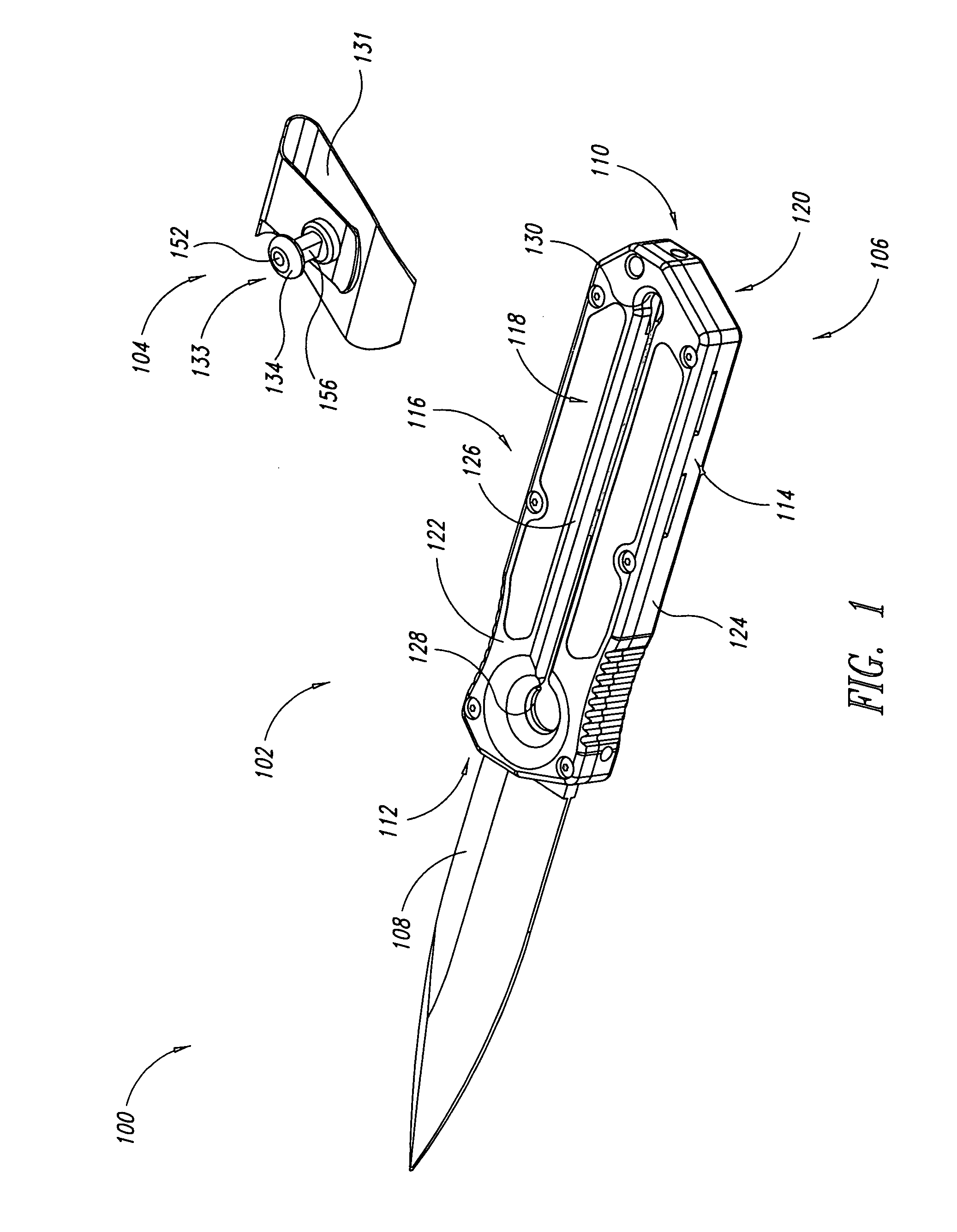

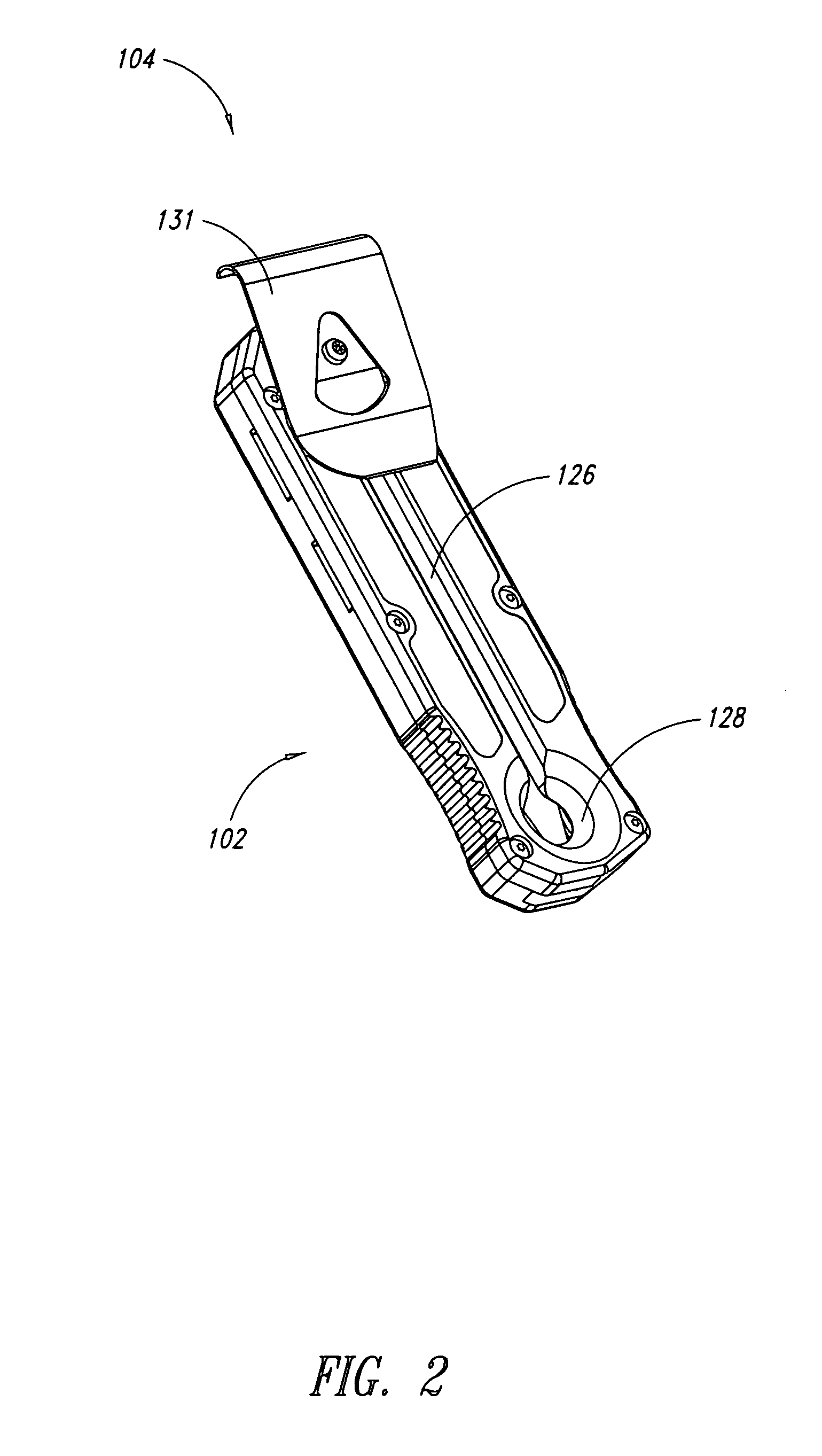

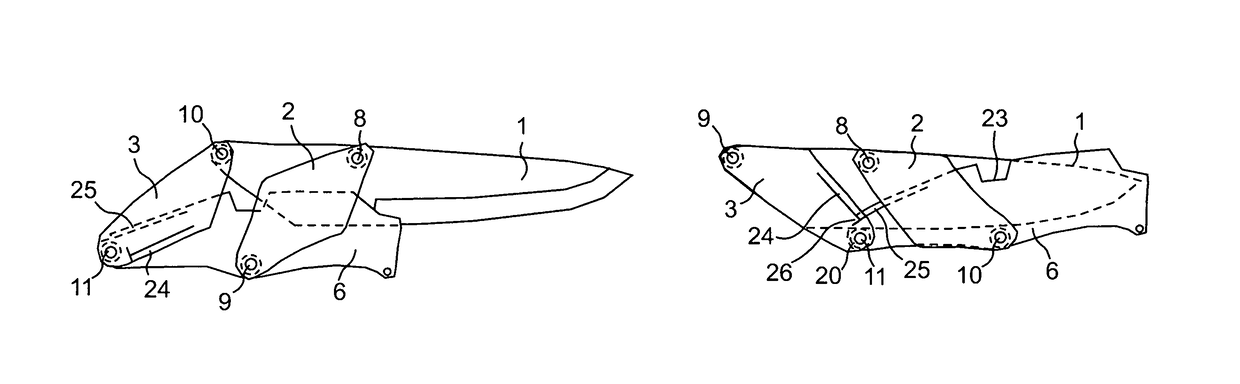

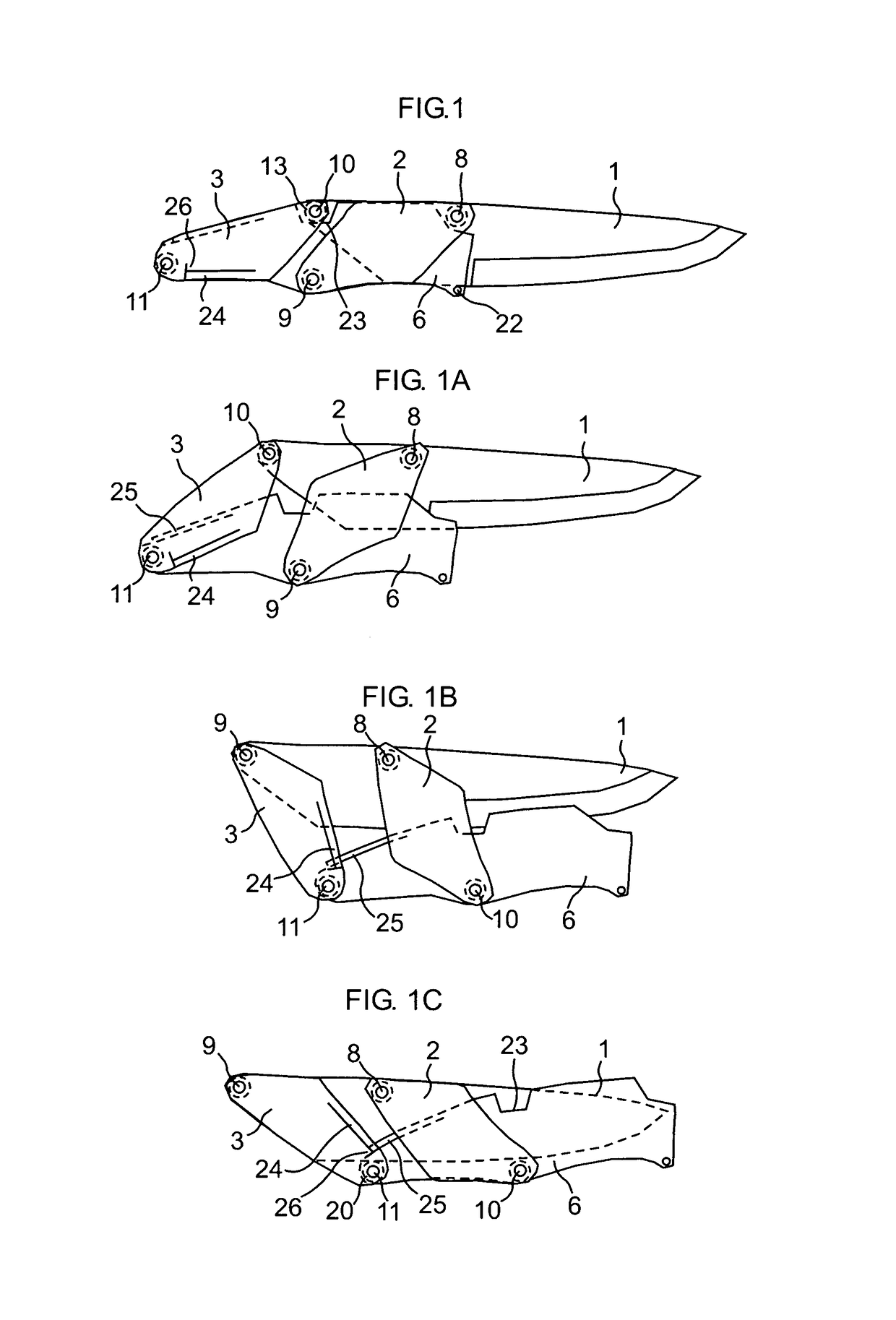

Knife with sliding blade and disengageable deployment mechanism

A knife assembly includes a handle having a blade cavity and a deployment slot extending longitudinally in the handle. A blade is slidably positioned within the blade cavity, and is slidable between a retracted position, in which the blade is wholly enclosed within the handle, and an extended position, in which a portion of the blade extends from a first end of the handle. A clip assembly includes a pin configured to releasably engage a tang portion of the blade in the blade cavity via the deployment slot. While the pin engages the blade, it can traverse the deployment slot from a first end to a second end to move the blade between the extended and retracted positions. The handle is configured to hang from the pin at the second end of the deployment slot while the blade is in the retracted position.

Owner:KAI US

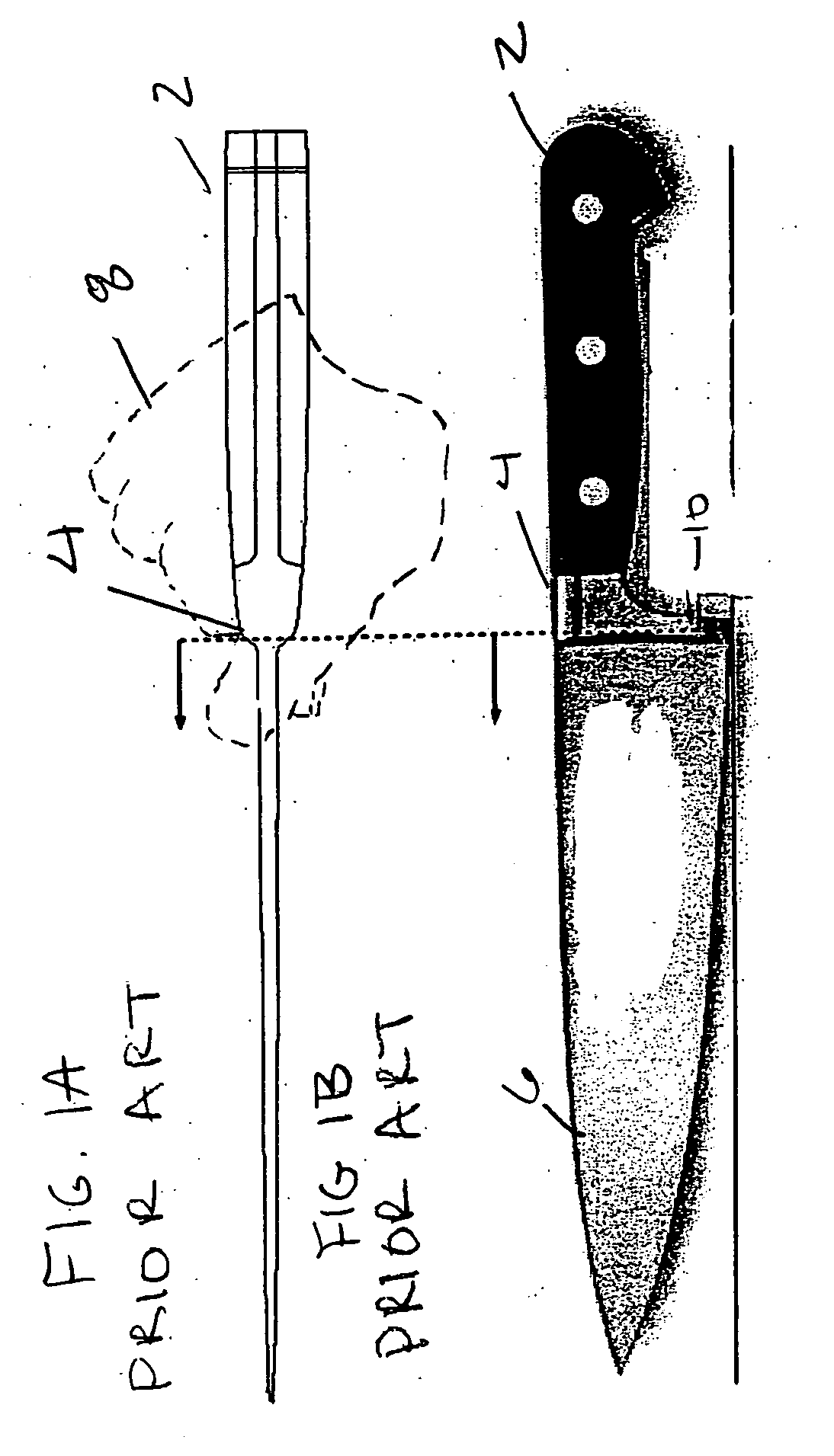

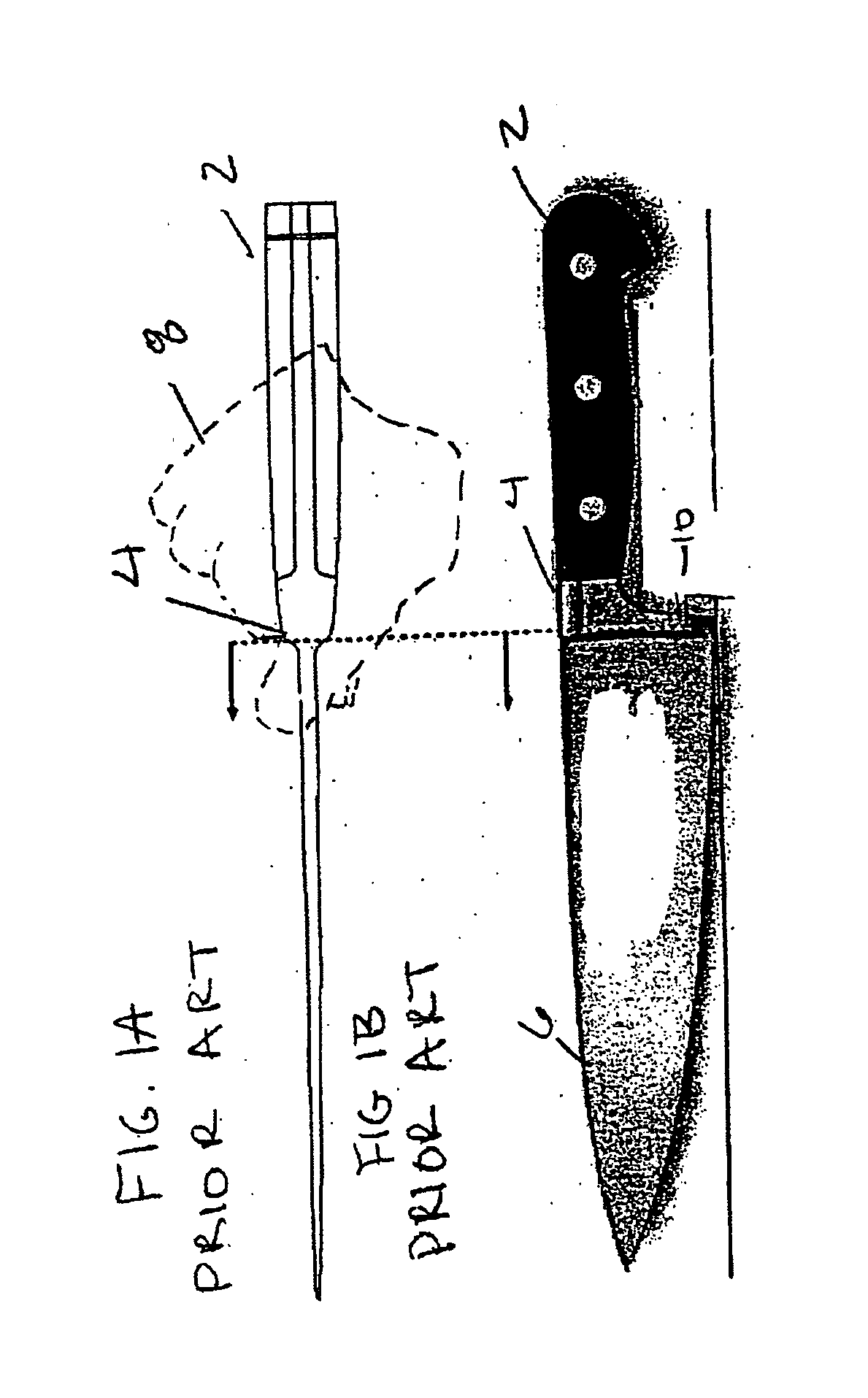

Cutlery implement

InactiveUS20060117576A1Reduce the cross-sectional areaMetal working apparatusMetal-working hand toolsCutleryEngineering

A cutlery implement includes a blade, a handle and a bolster. The bolster is positioned at a balance point, in front of the back edge of the blade. The bolster has a tapered thickness to create a smooth transition from the blade to the handle. The bolster provides a more comfortable gripping portion, such that user may safely grip the cutlery implement at its balance point.

Owner:CALPHALON

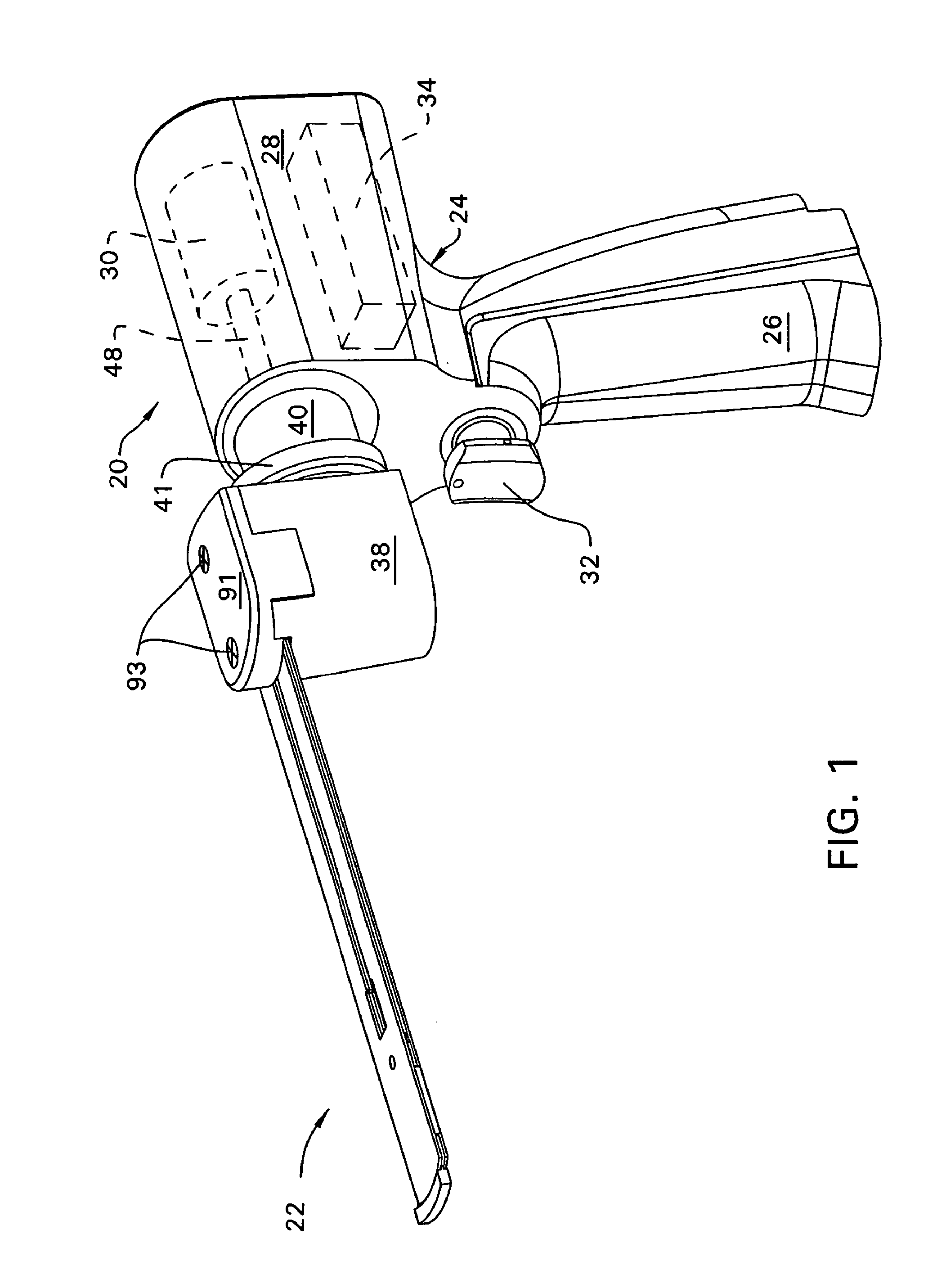

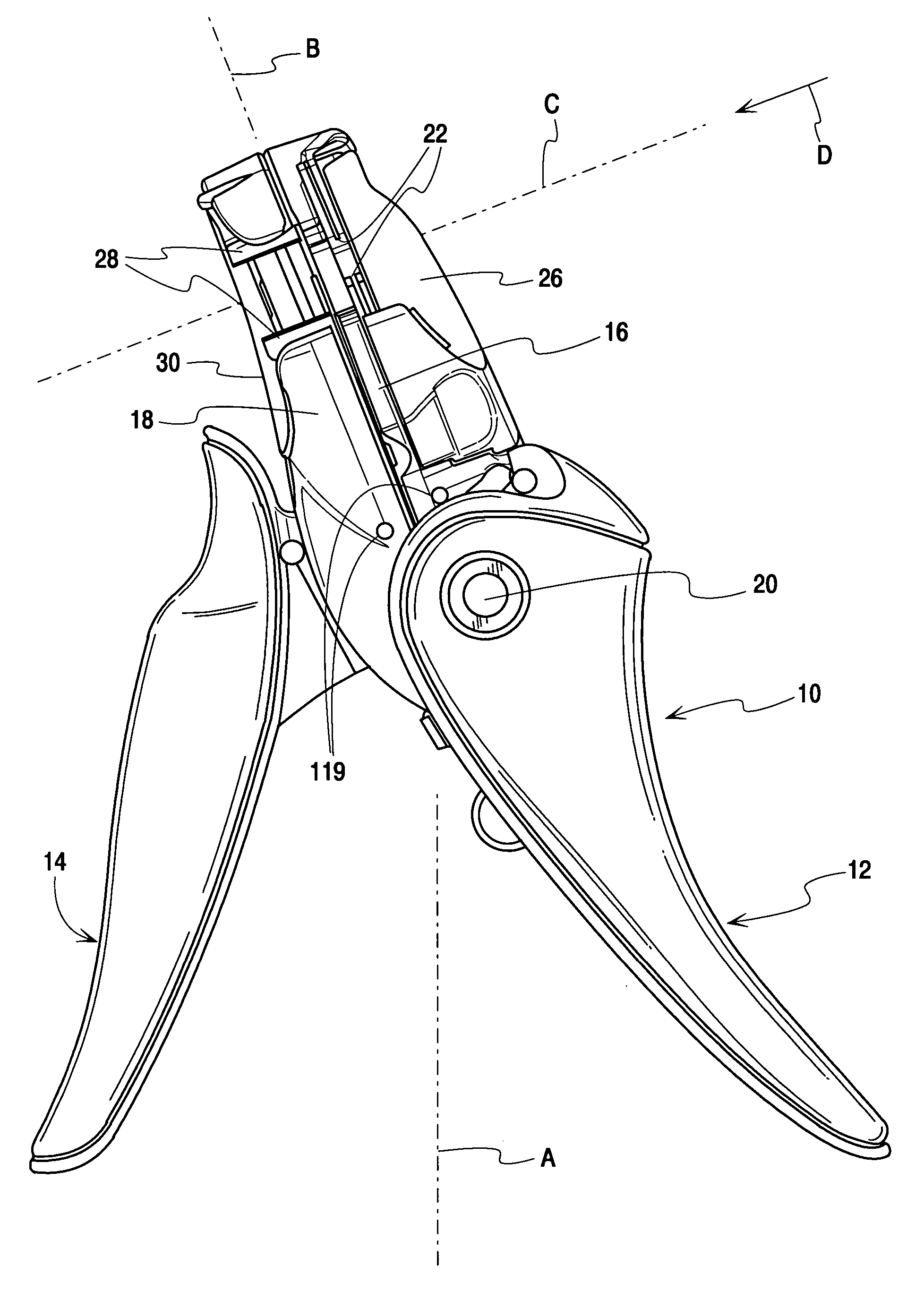

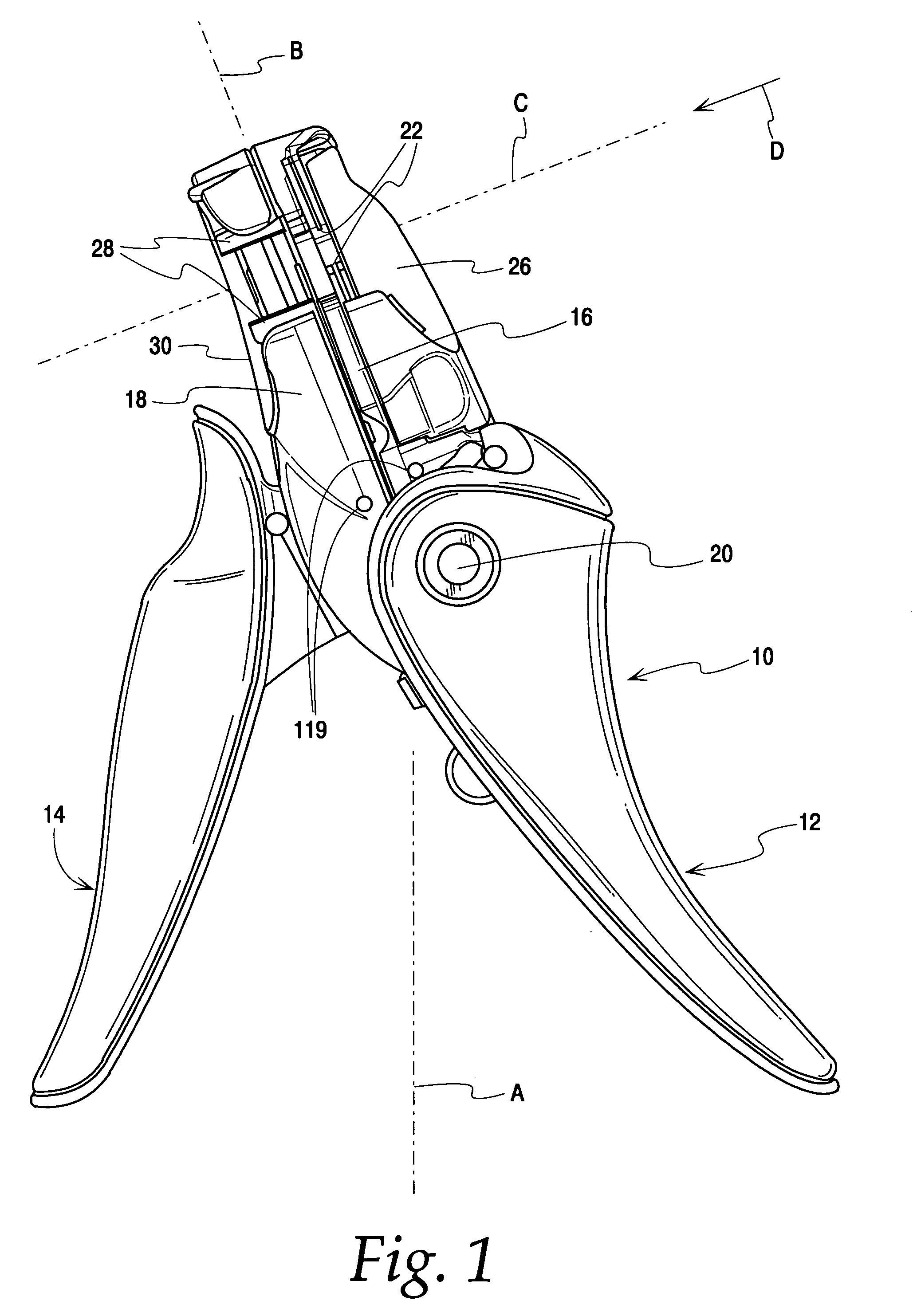

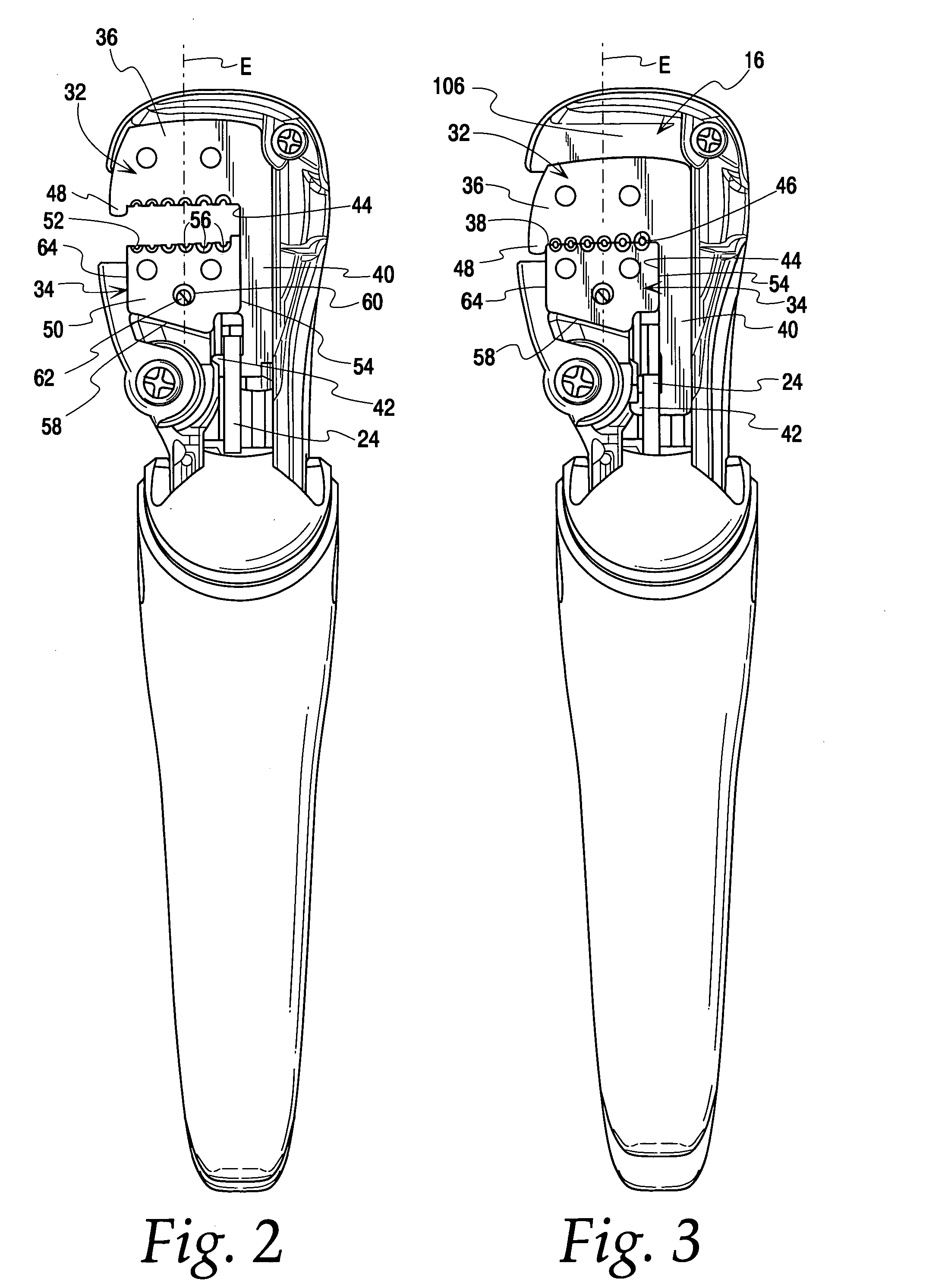

Crank retractor handle

ActiveUS7338442B2Prevent rotationEffective positioningDiagnosticsSurgical instrument supportUniversal jointSurgical site

The present invention relates to an apparatus for adapting a non-cylindrical serrated surgical retractor blade handle to the cylindrical bore of a universal joint. The apparatus includes an adaptor housing having a retractor handle passageway, at least a portion of the retractor handle passageway being configured to receive the slideable insertion of a non-cylindrical retractor blade handle. The adaptor housing is configured for rotational insertion into the cylindrical bore of a clamping member, thereby allowing the adaptor housing, the non-cylindrical retractor blade handle, and an attached retractor blade, to rotate about the longitudinal axis of the non-cylindrical retractor blade handle. In the illustrated embodiment, a pawl mechanism is connected to the adaptor housing and configured for automatic engagement with at least one of a plurality of serrations that are located on the non-cylindrical retractor blade handle, thereby allowing for the efficient adjustment and automatic locking of the linear position of the non-cylindrical retractor blade handle relative to the operative site.

Owner:THOMPSON SURGICAL INSTR

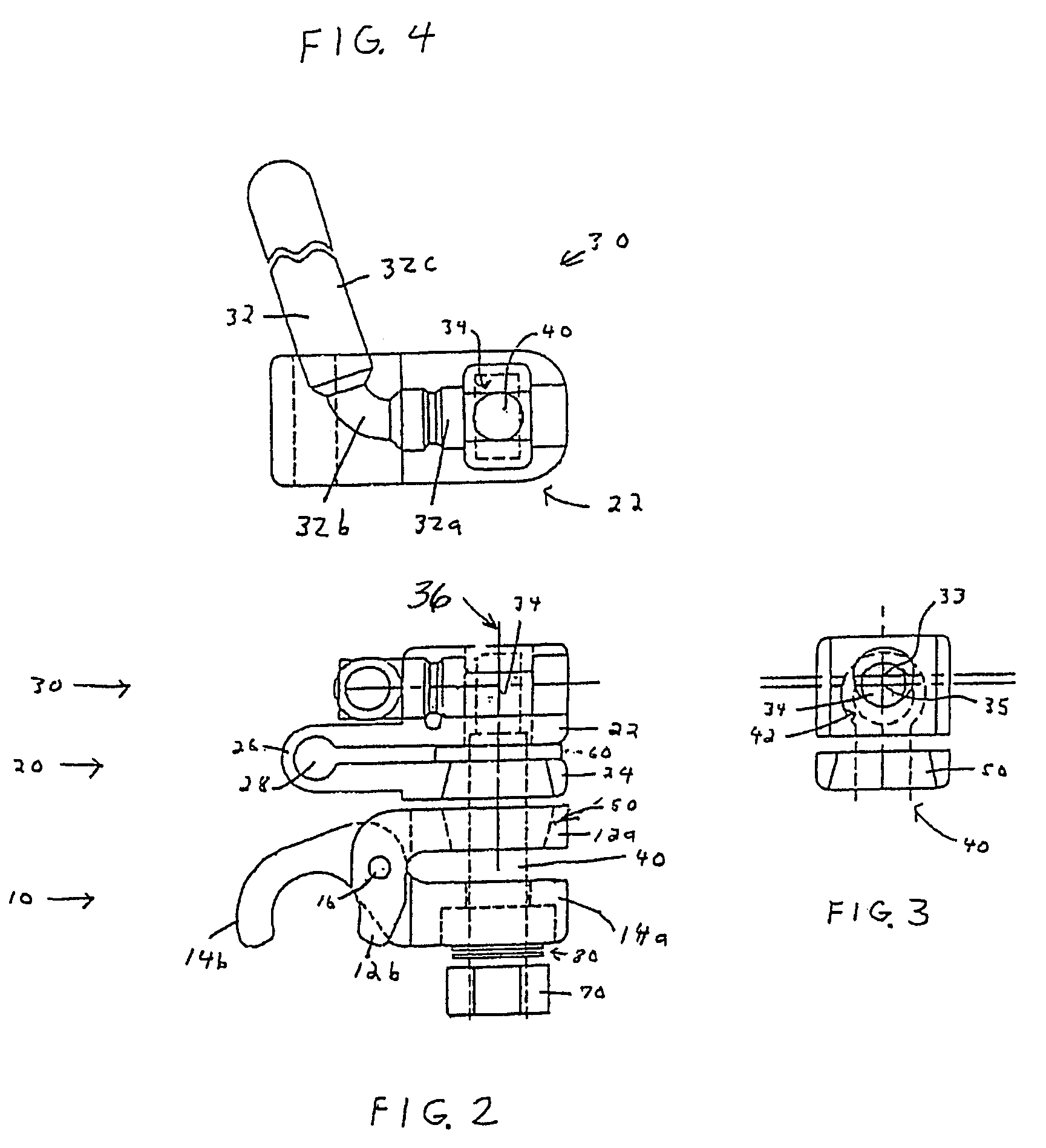

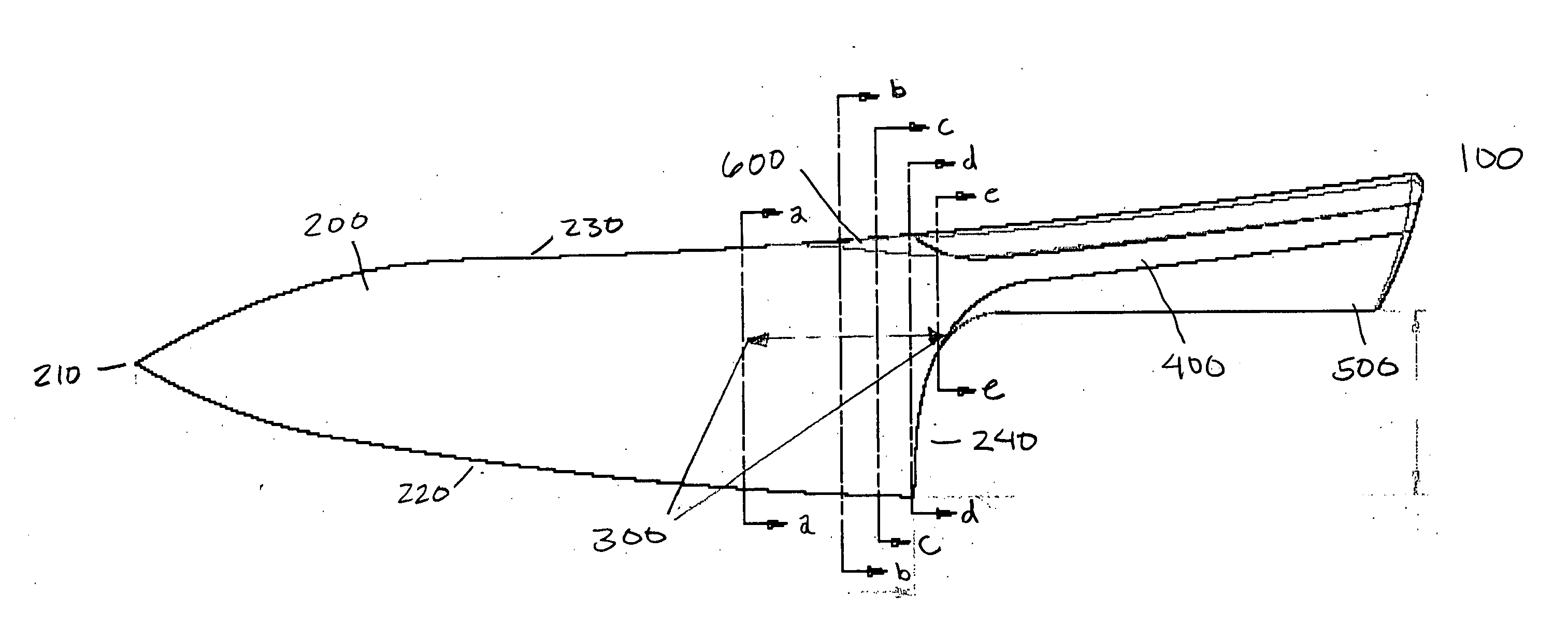

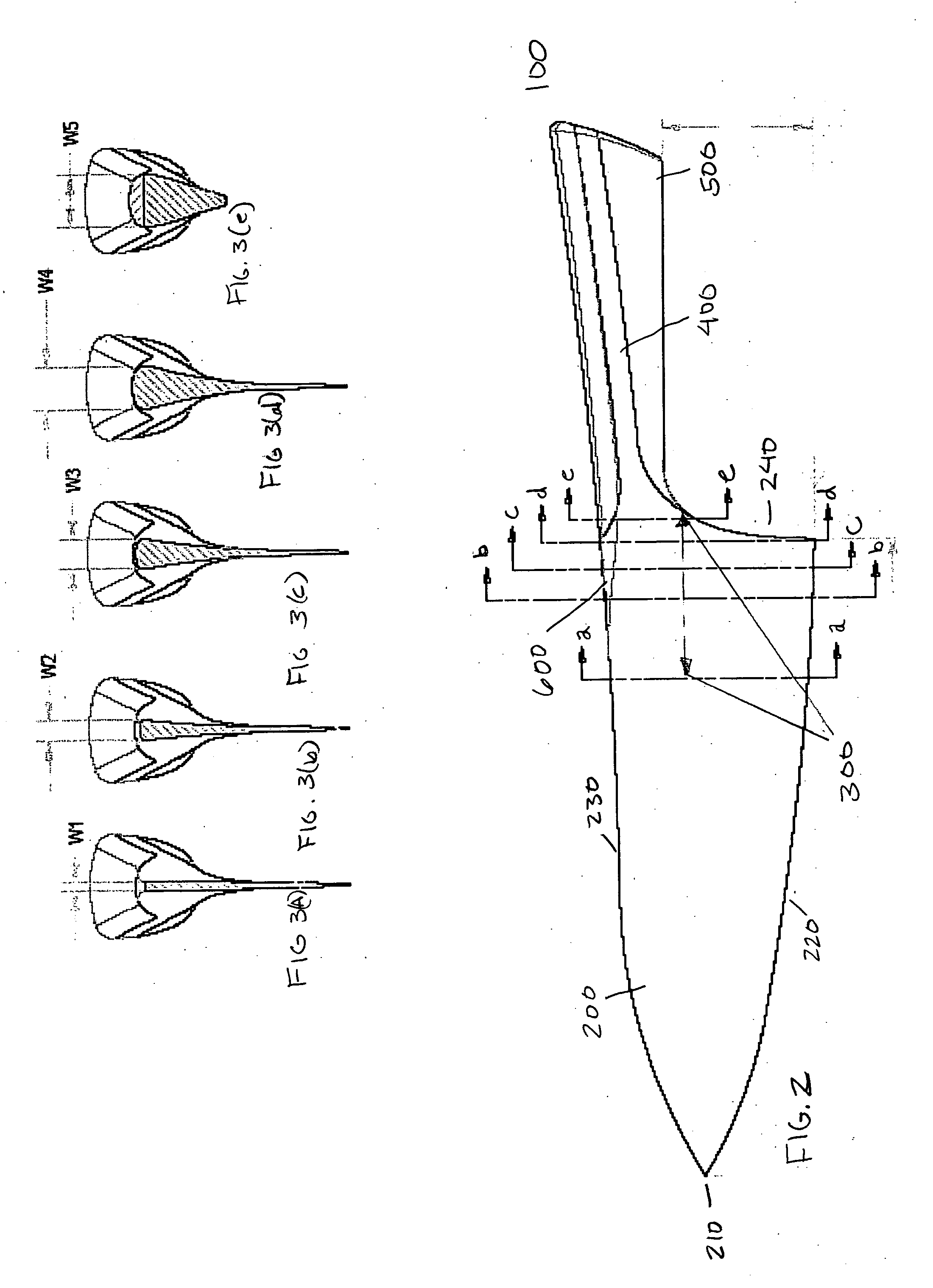

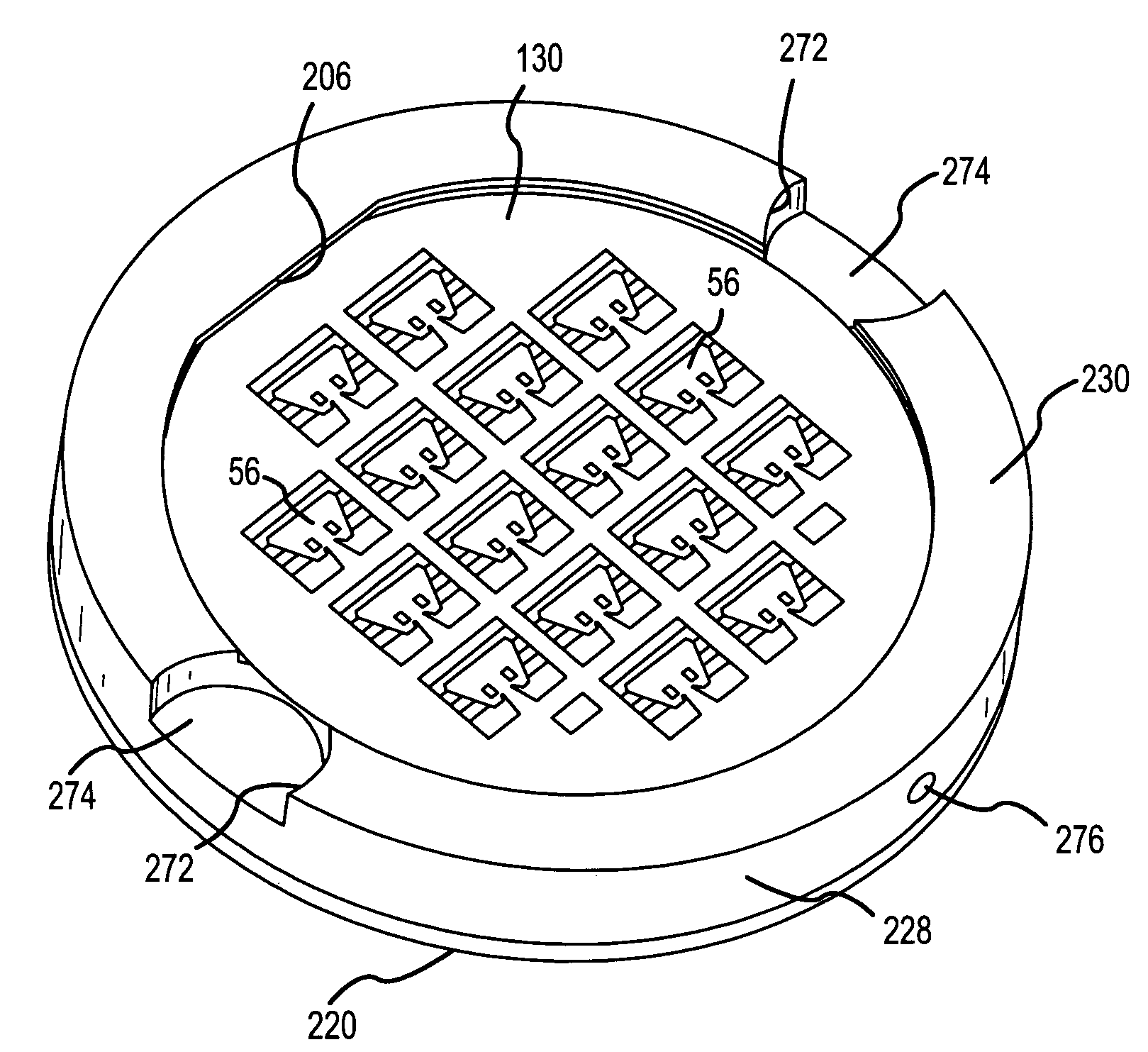

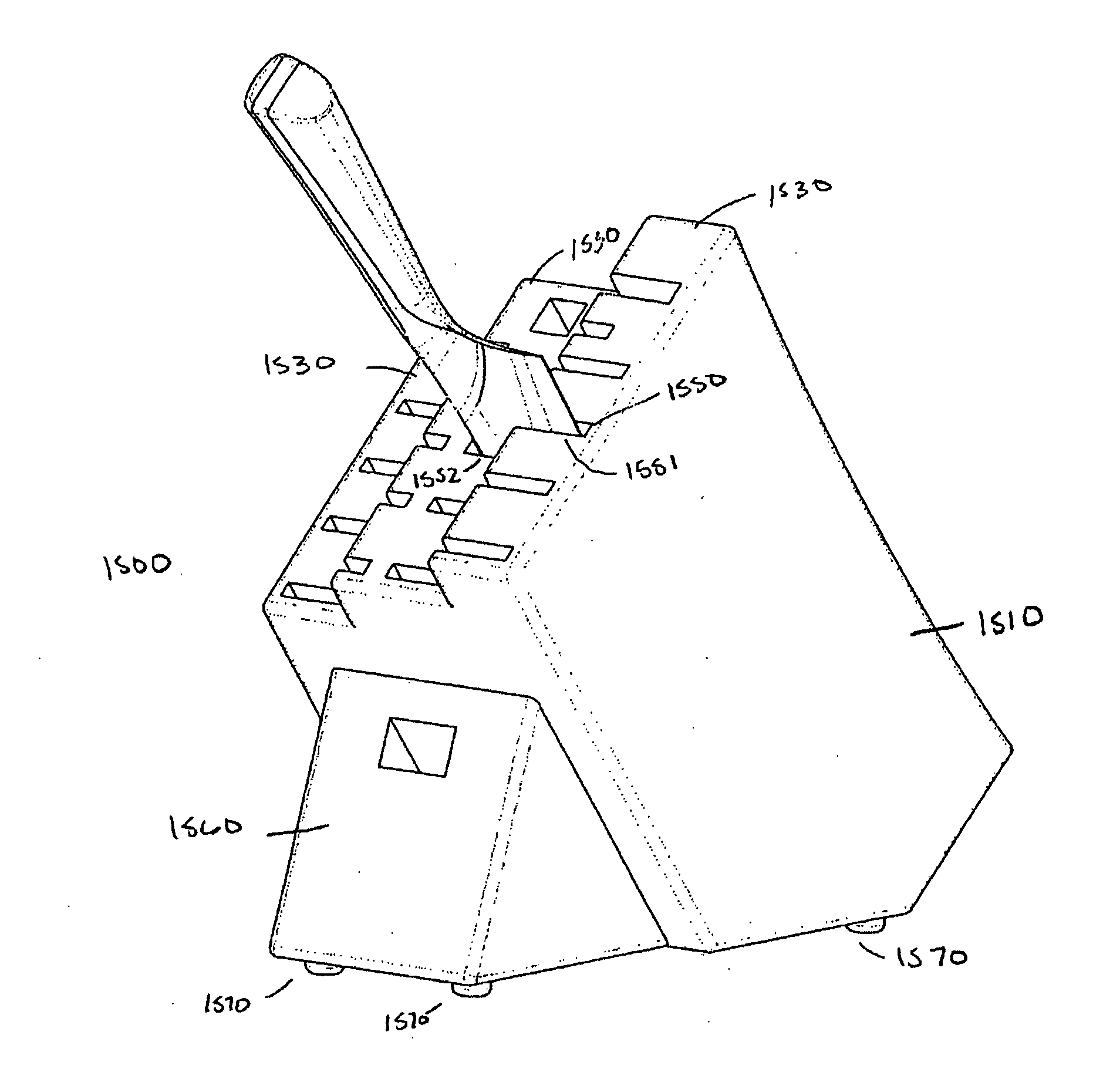

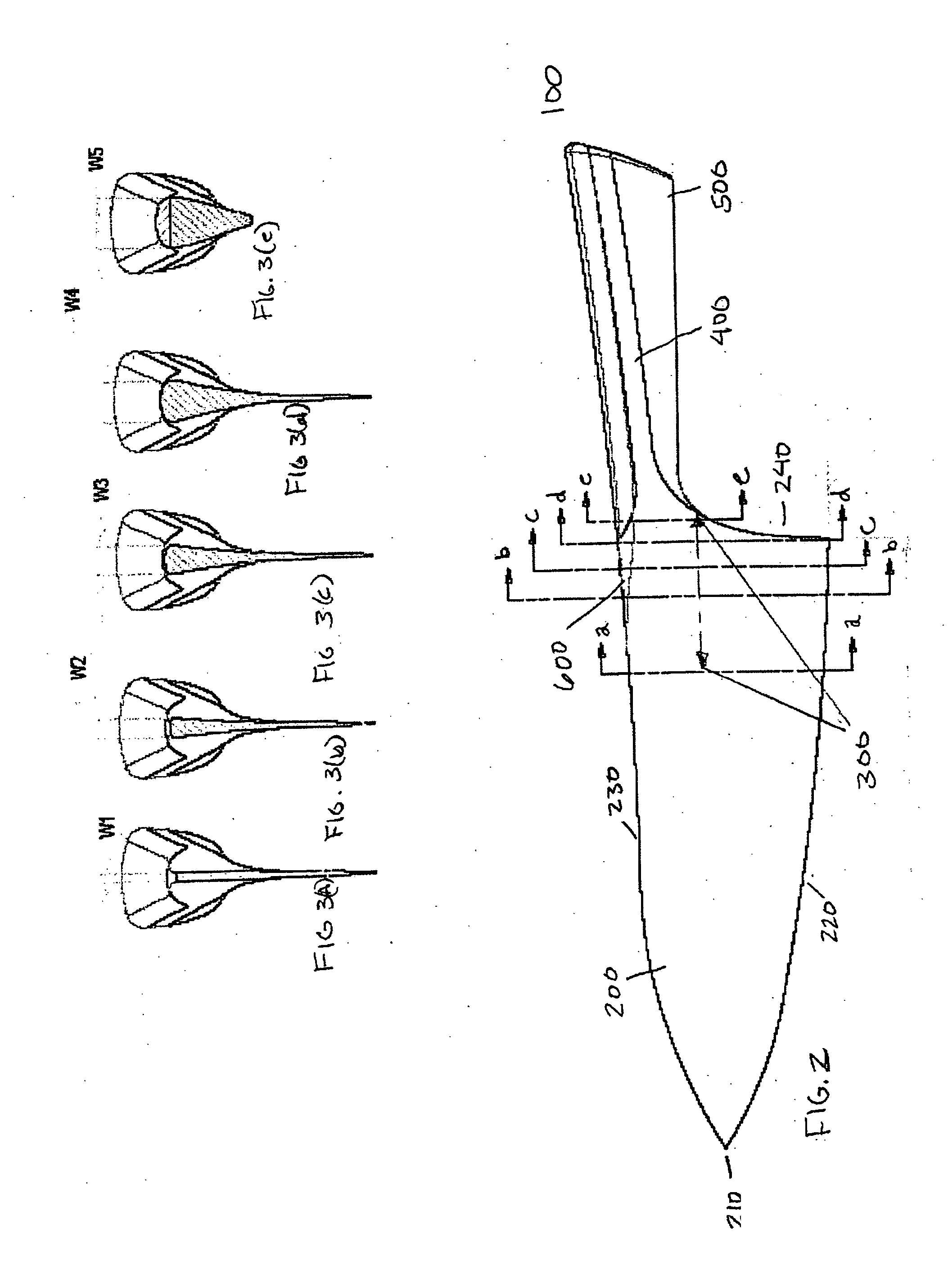

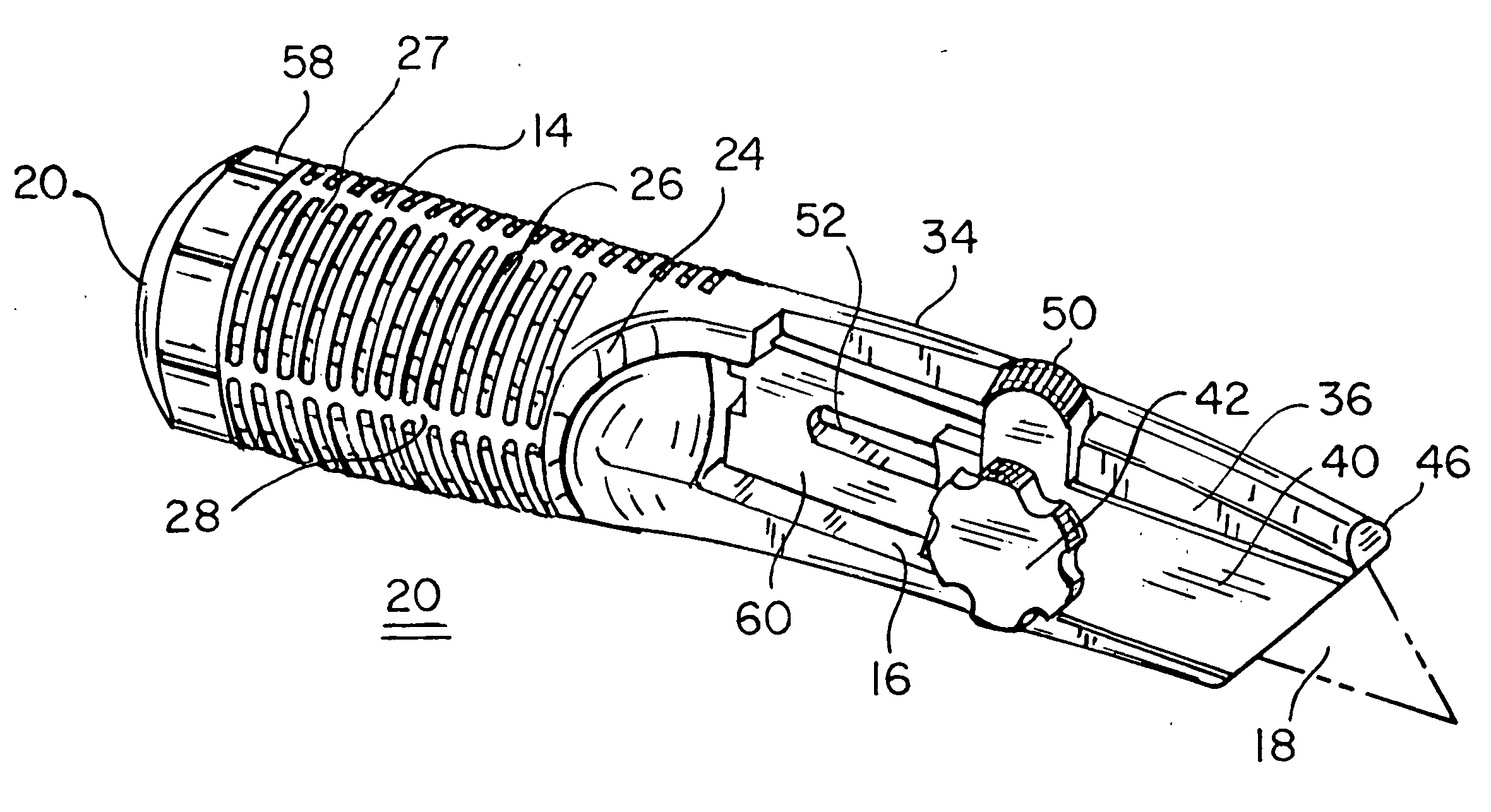

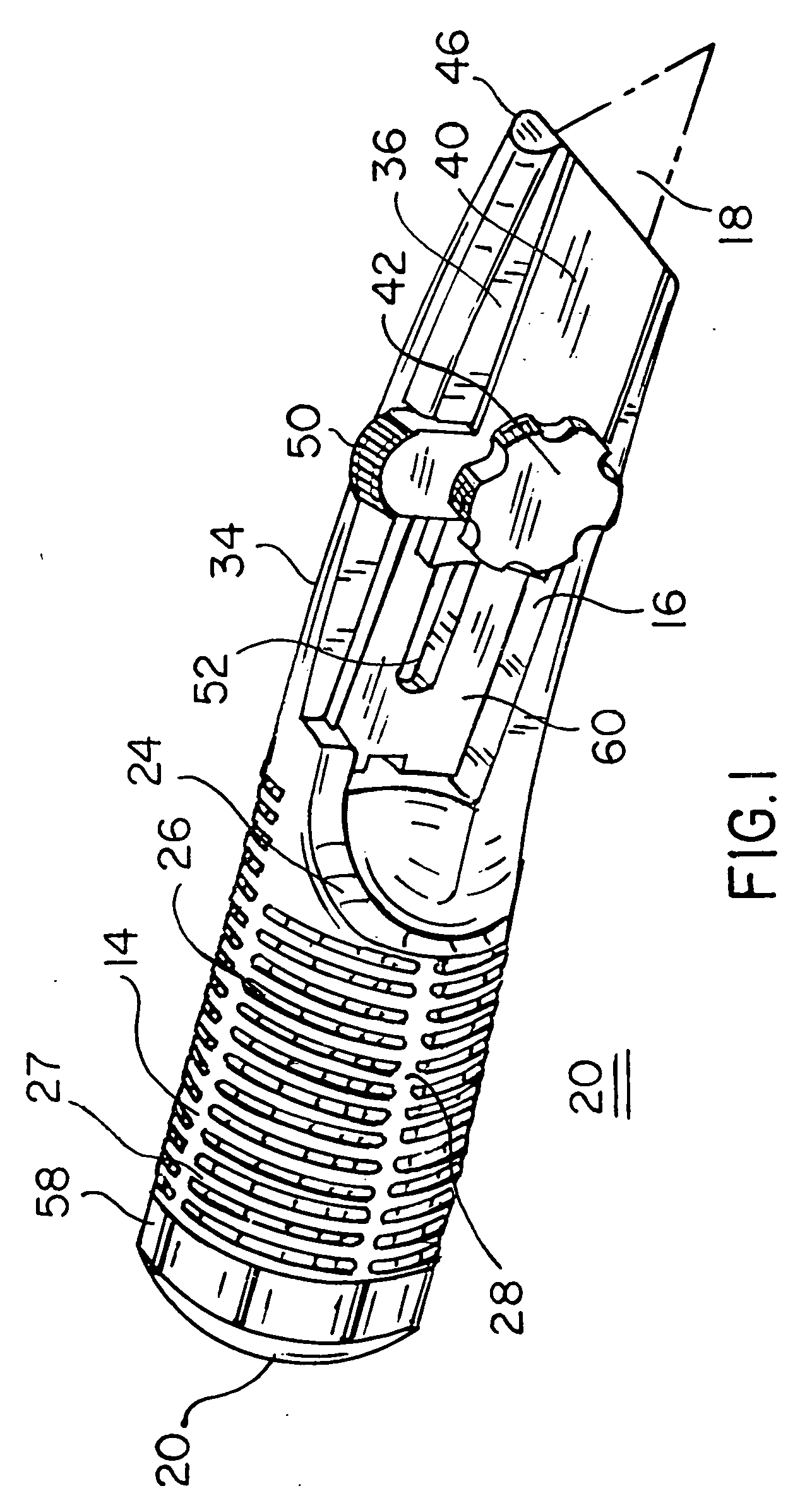

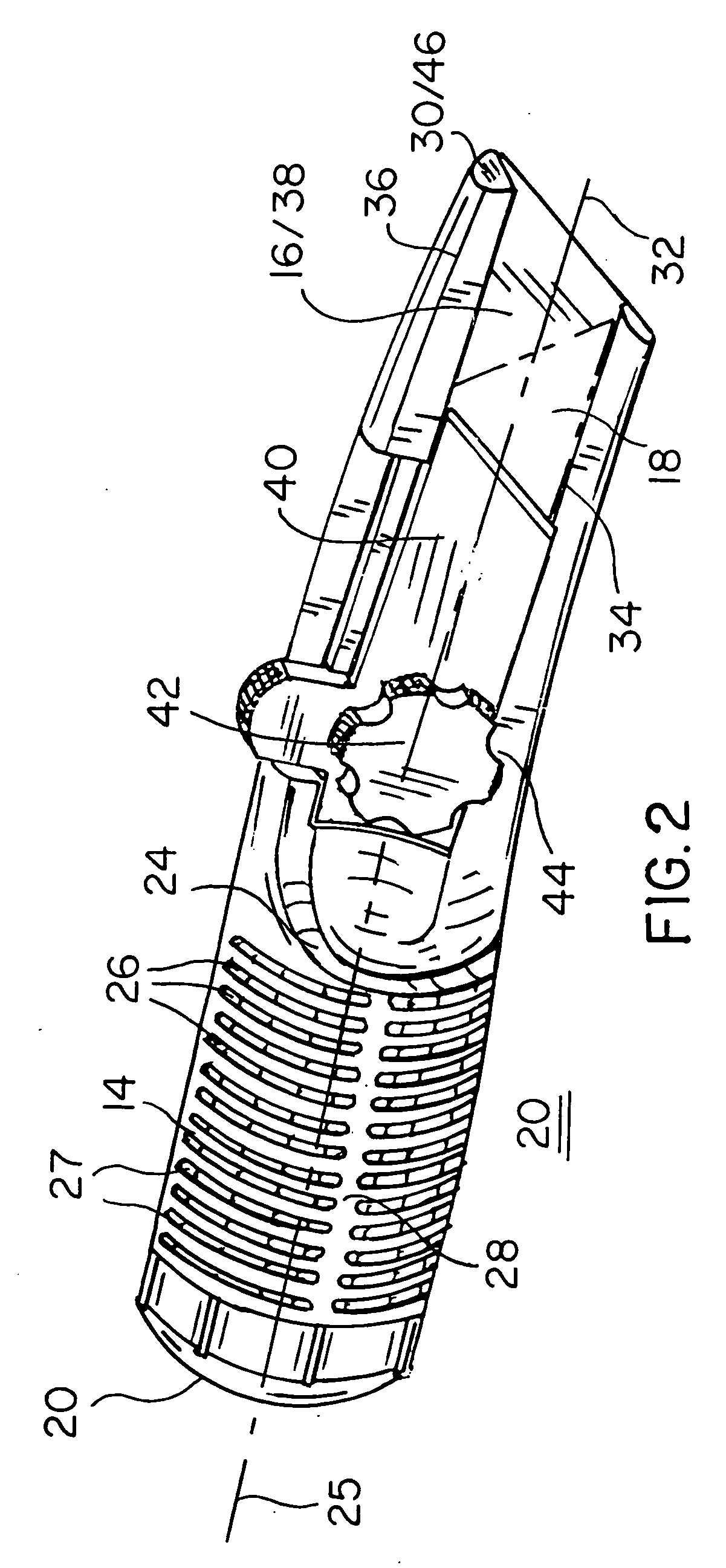

Multi-fixture assembly of cutting tools

InactiveUS6993818B2Easy to separateReduces potential for movementIncision instrumentsEye surgeryEngineeringBlade handle

Multiple cutting blades (56) are fabricated from a wafer (130). This wafer (130) is disposed on a blade handle mounting fixture (224) such that a blade handle (24) maybe mounted on each of the individual blades (56). A cutting edge (80) of each blade (56) is maintained in spaced relation to the fixture (224) as these blade handles (24) are being mounted. Thereafter, the wafer (130) is transferred to a blade separation fixture (300). Each blade 56 is suspended above the fixture (300). An appropriate force is transmitted to the individual blades (56) to separate the same from the wafer (130). Separation preferably occurs before the blade (56) contacts the fixture (300). Thereafter, the blade (56) in effect pivots into an inclined position where its cutting edge (80) projects at least generally upwardly. Preferably, at no time does the cutting edge (80) of any blade (56) contact either the blade handle mounting fixture (224) or the blade separation fixture (300).

Owner:MEMX

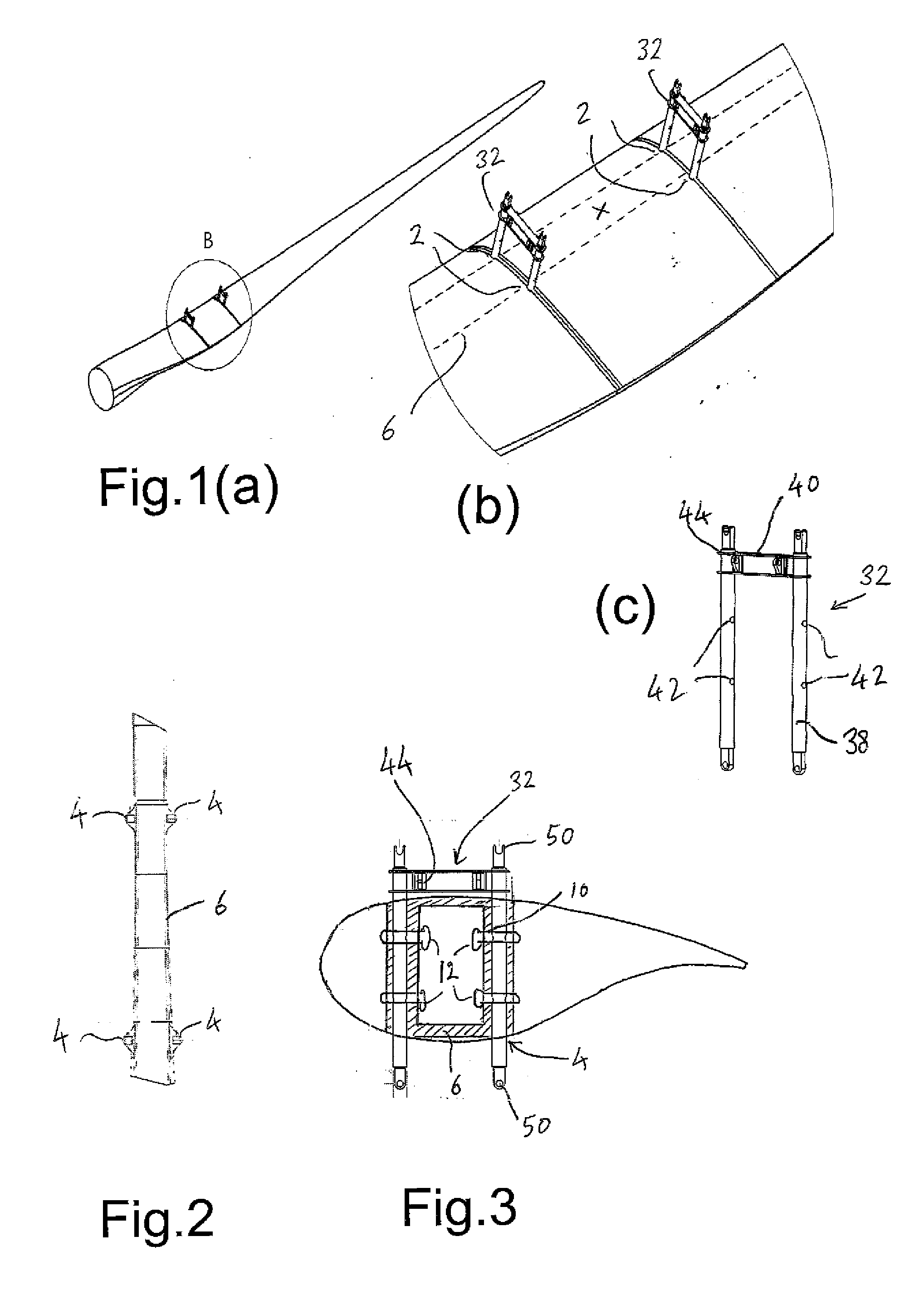

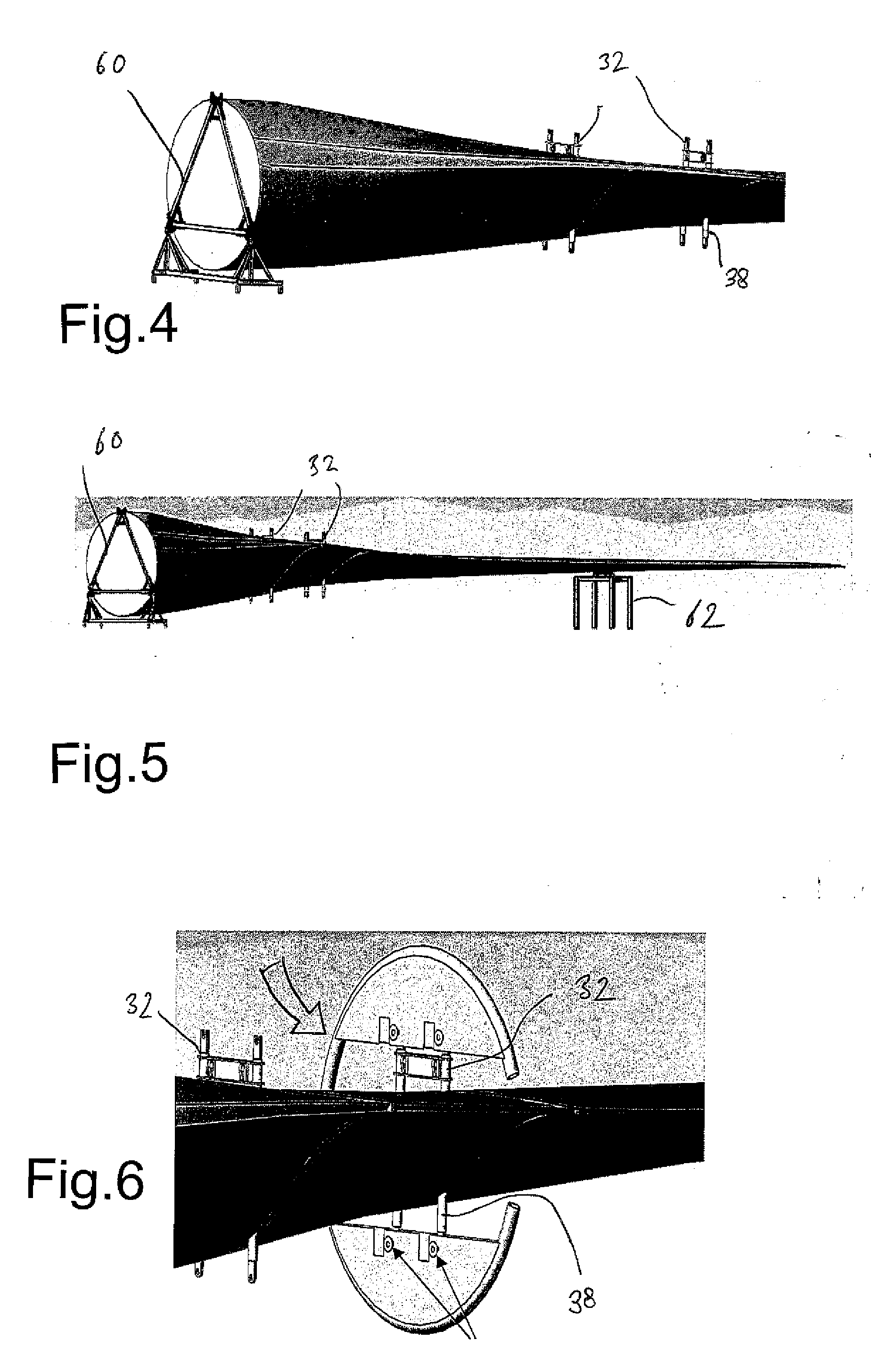

Apparatus for Manipulating a Wind Turbine Blade and Method of Blade Handling

Apparatus for manipulating a wind turbine blade and method of blade handling An apparatus for manipulating a wind turbine blade having fixed lifting points (2) on the blade has a blade turner base (36,62,82,100), a frame like support structure (34,64,84,112) carried on the base and connecting structures such as brackets (32,138) which engage in the lifting points (2) on the blade extending into openings in the blade, the support structure (34,64,84,112) having a part-circular portion or periphery at which it connects to the base, being movably supported on the base so as to rotate relative thereto about a substantially horizontal axis in order to vary the orientation of a blade supported thereon.

Owner:VESTAS WIND SYST AS

Cutlery implement and block

A cutlery implement includes a blade, a handle and a bolster. The bolster is positioned at a balance point, in front of the back edge of the blade. The bolster has a tapered thickness to create a smooth transition from the blade to the handle. The bolster provides a more comfortable gripping portion, such that user may safely grip the cutlery implement at its balance point. A cutlery block is configured to store a cutlery implement having a bolster with a tapered thickness such that the blade is safely concealed.

Owner:SUNBEAN PROD INC

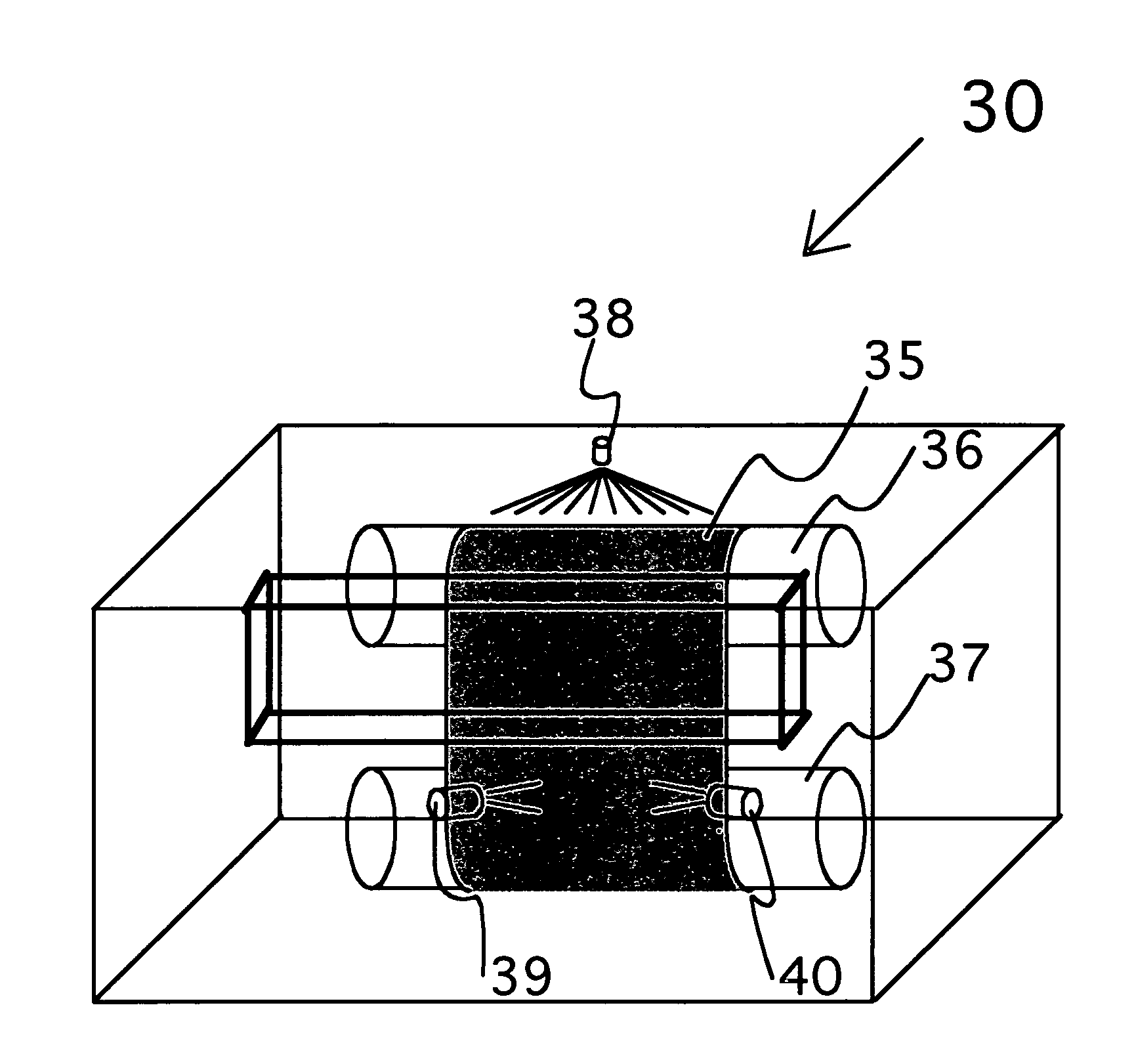

Lubricated razor blade edge sanitizer and sharpener

InactiveUS7134935B1Limit temperature risePreventing of cutting propertyBelt grinding machinesGrinding feed controlLiquid layerMultiple edges

An automatic razor blade sharpener simultaneously sharpens and sanitizes multiple edges of a spring-loaded disposable razor blade cartridge without edge overheating by lubricated gentle contact of the blade edges with a moving rubber or polymeric compliant belt that is motor driven. The disposable razor blade handle is set in a cradle aperture, which is spring loaded against the moving belt. A sanitizing and lubricating liquid is dispersed from a container between the razor blade edges and the moving belt forms a thin liquid layer on the belt surface. The liquid layer is illuminated by transversely located light illuminator and the reflected light is received by a transversely located sensor. Deep grooves in the blade cutting edge reduce this reflection, indicating an overly worn blade. The absence of reflection actuates an LED, informing the user that the thin liquid film has evaporated or spilled out, or that the container lacks a sufficient quantity of sanitizing and lubricating liquid.

Owner:PAPETTI JULIA GRACE

Cable stripper

InactiveCN105281258ASmooth peelingQuick peelApparatus for removing/armouring cablesEngineeringBlade handle

The invention discloses a cable stripper. The cable stripper includes a main half tube and an auxiliary half tube which are locked together through a locking device so as to form a sleeve; a power gear which is in press fit with the outer sheath of a cable and a motor for driving the power gear to rotate are arranged in a power cavity of the sleeve; the outer wall of the sleeve is provided with a switch for controlling the on-off of the power source of the motor; the cross section of a blade cavity of the sleeve is a regular polygon; the edges of the polygon are an positive integer times of four; a blade handle is slidingly inserted in the blade cavity; a blade which can longitudinally cut the cable is fixedly arranged in the inner end of the blade handle; the outer section of the blade cavity is in threaded connection with a positioning device for axially positioning the blade handle; and an end portion of the sleeve is fixedly provided with a connecting ring. With the cable stripper adopted, axial longitudinally-cutting stripping and transverse annularly-cutting stripping can be both realized, and stripping can be initially performed on any portion of the cable, and cable stripping can be performed in a pipeline, and stripping depth can be adjusted. The cable stripper has the advantages of automatic stripping and time-saving and labor-saving operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

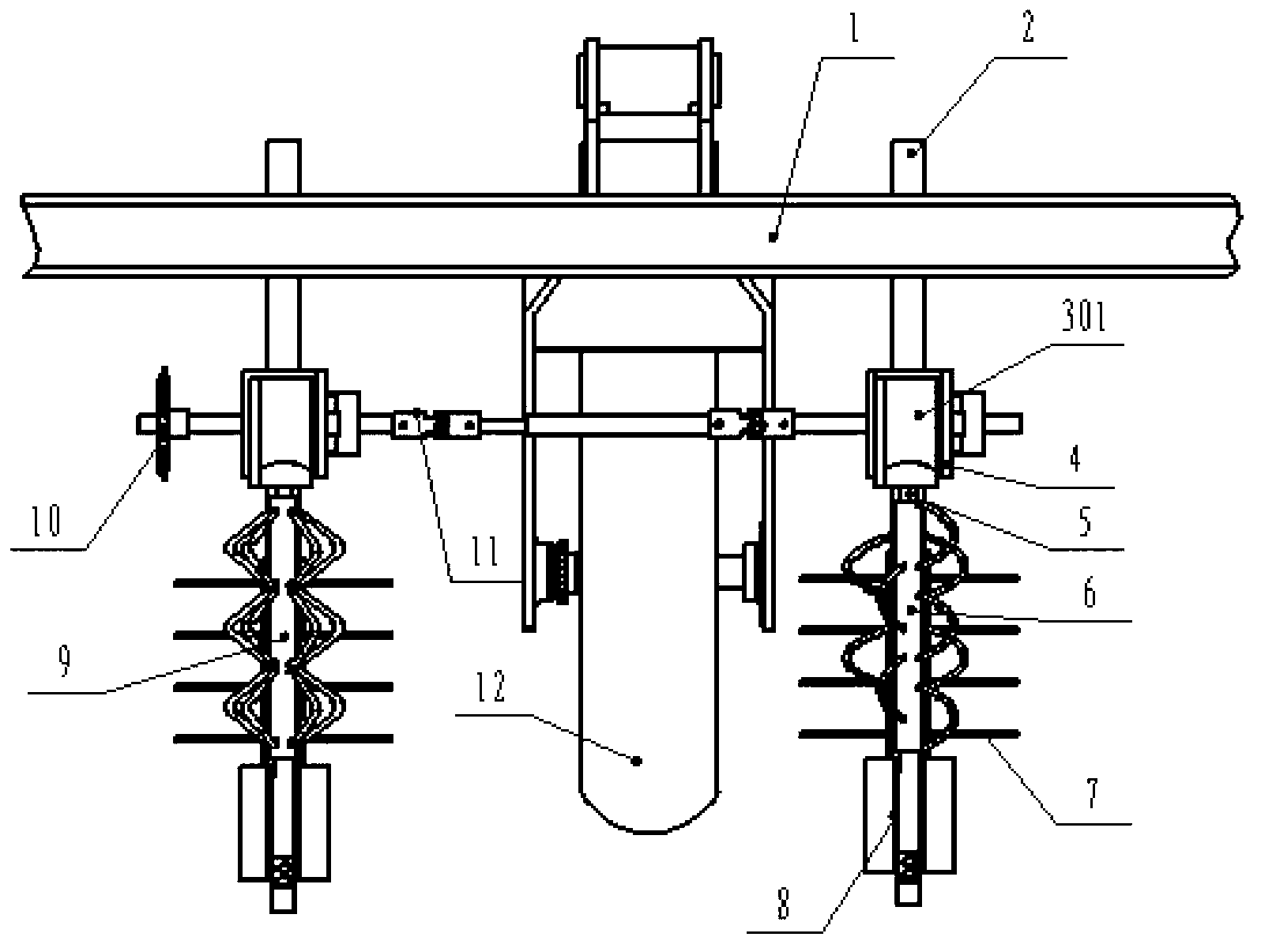

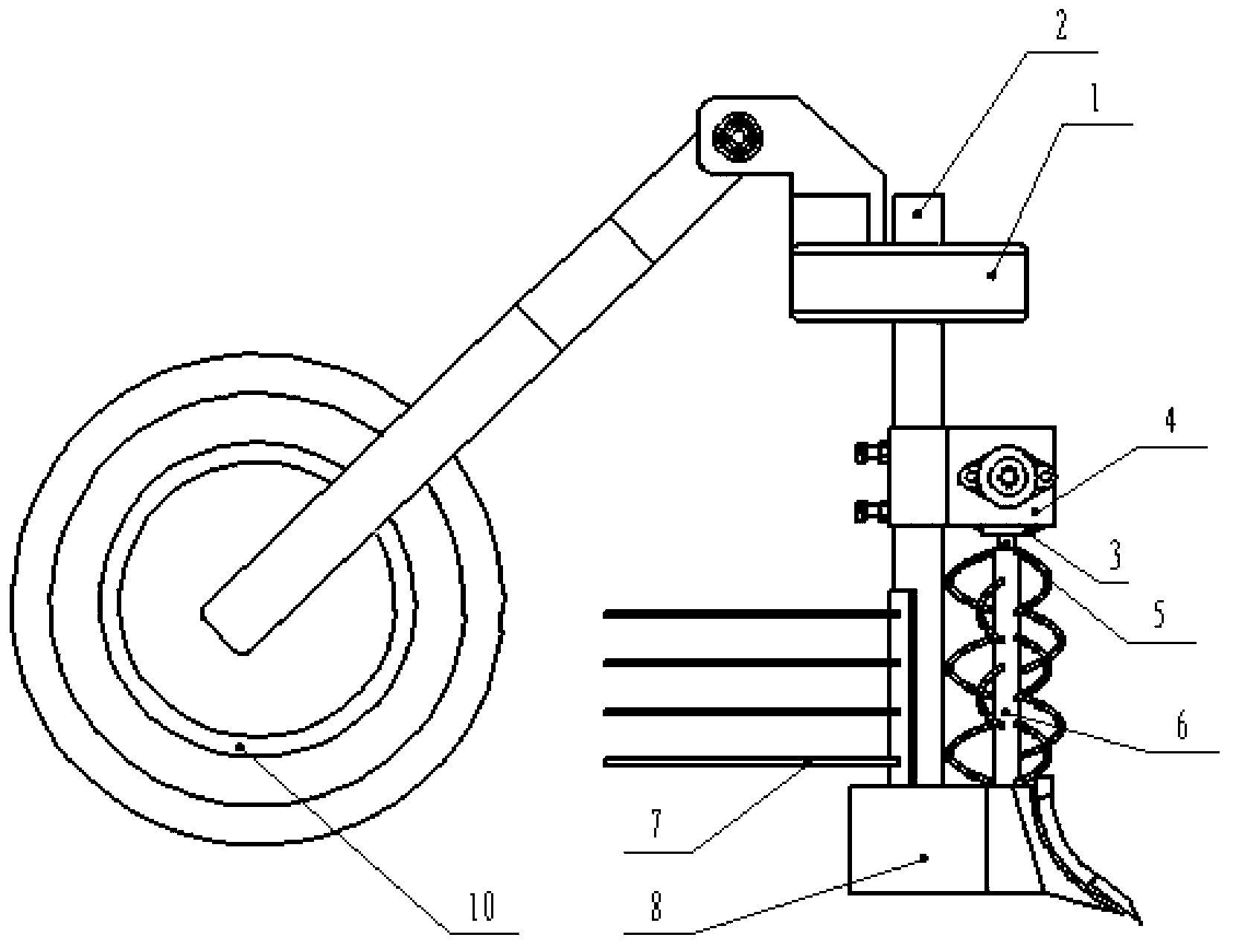

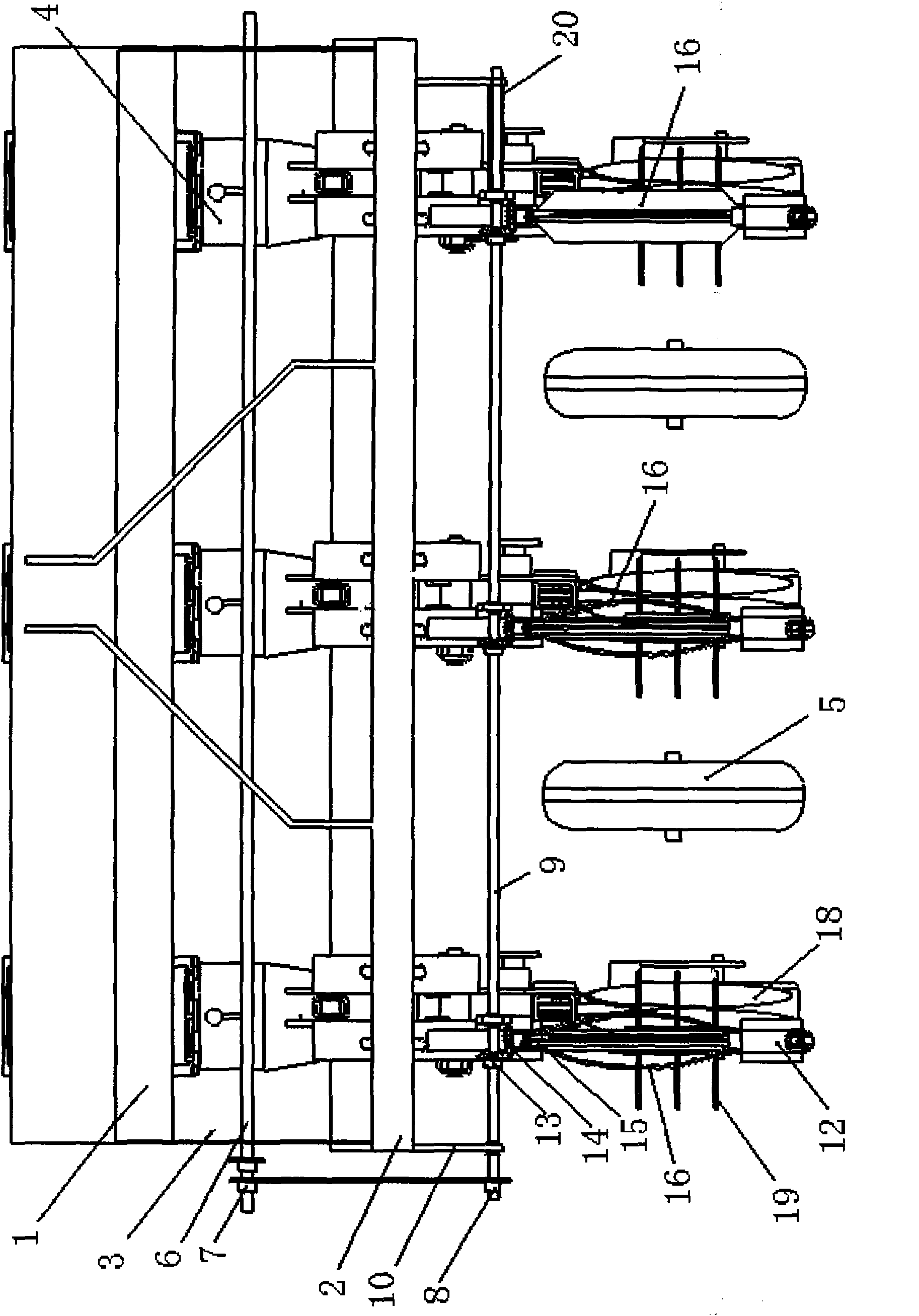

Novel driving drum anti-blocking device of no-tillage sower

The invention relates to a novel anti-blocking mechanism of a no-tillage sower. The novel anti-blocking mechanism comprises a rack, furrowing blade handles, furrow openers, drums, drum shaftings, division grid plates, a land wheel, universal couplings, driving chain wheels, gearboxes and gearbox fixing components, wherein each furrowing blade handle is fixed on the rack; each furrow opener is arranged at the bottom of each furrowing blade handle; a counter bore is formed in the top end of each furrow opener; each furrow opener and one gearbox fixing component determine the positions of each drum and each gearbox relative to the rack; the land wheel supplies power to each power input shaft through chain transmission; the adjacent power input shafts are connected by the universal couplings, so that one land wheel drives two or more anti-blocking devices; a pair of engaged bevel gears in each gearbox transfers the power to each drum; when the sower operates, the drums rotate to push front straws aside; the division grid plates behind the furrowing blade handles divide the straws thrown out by the drums by utilizing the convex arc shape characteristic so as to prevent the straws from falling into seed furrows opened by the furrow openers; the seed airing is avoided. The mechanism is applicable to a corn sower.

Owner:CHINA AGRI UNIV

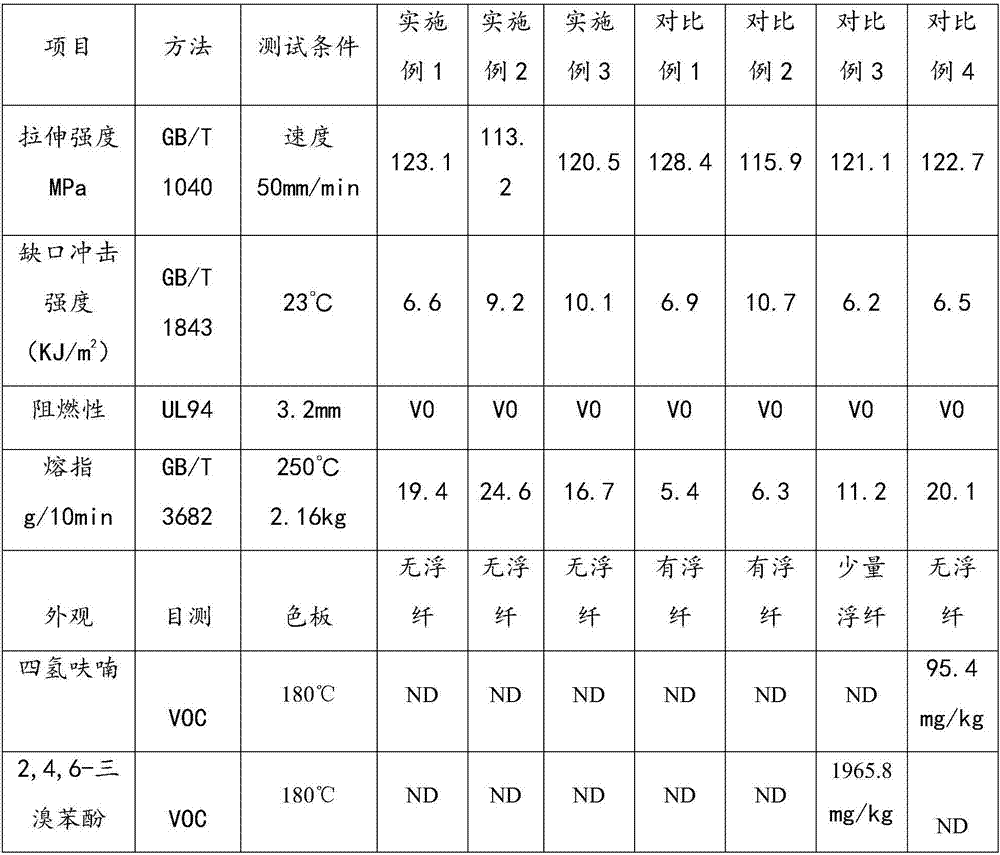

High-fluidity and reinforced-flame-retardant PBT material and preparation method thereof

The invention relates to a high-fluidity and reinforced-flame-retardant PBT material. The PBT material is composed of the following raw materials, in percent by weight: 49-68% of PBT resin, 11.5-13.5% of a flame retardant, 0-3% of a toughening agent, 20-33% of glass fibers, 0.2-0.5% of hyperbranched resin and 0.3-1% of other auxiliary agents. A preparation method of the high-fluidity and reinforced-flame-retardant PBT material is simple, firstly, the PBT resin is dried, and the dried PBT resin and the flame retardant are mixed and stirred, secondly, the toughening agent, the hyperbranched resin and the other auxiliary agents are added, and uniform stirring is performed, and finally, the uniformly mixed raw materials and the glass fibers are added to a melt extruder for extrusion, so that the high-fluidity and reinforced-flame-retardant PBT material is obtained. Compared with the prior art, the high-fluidity and reinforced-flame-retardant PBT material has the beneficial effects that the high-fluidity and reinforced-flame-retardant PBT material has good thermal stability, no white stripes precipitate during injection molding at 300 DEG C, besides, pungent smells cannot be emitted under high-temperature heating, the surface of a product is smooth, and the high-fluidity and reinforced-flame-retardant PBT material can be used for electronic appliance appearance parts such as blade handles, air discharging grilles and hot-runner one-module-multiple-output products which need high fluidity.

Owner:武汉顺威赛特工程塑料有限公司

Precision hand-held wire stripper

ActiveUS20050235778A1Highly precise insulation cuttingAvoids nickingApparatus for removing/armouring cablesResistHand held

A wire stripper has a blade handle, a gripper handle, a blade jaw and a gripper jaw all pivotally connected at a main pivot pin that is offset from the mating faces of the jaws. Movable and floating cutting blades mounted on the blade jaw are self-aligning due to a floating connection of the blades that allows them to move respective gauge surfaces into engagement during closing. A blade hold down spring urges the blades into alignment. The jaws are angled with respect to the handle axis so the throat of the cutting blades aligns with a user's line of sight. Individual handle springs have differential springs rates and are arranged so that the handles springs do no resist opening of the jaws.

Owner:IDEAL IND INC

Hair Iron

InactiveUS20050150511A1Retain heatEvenly and predictably distributedCurling-ironsCurling-tongsFree rotationEngineering

Owner:PARK KEITH

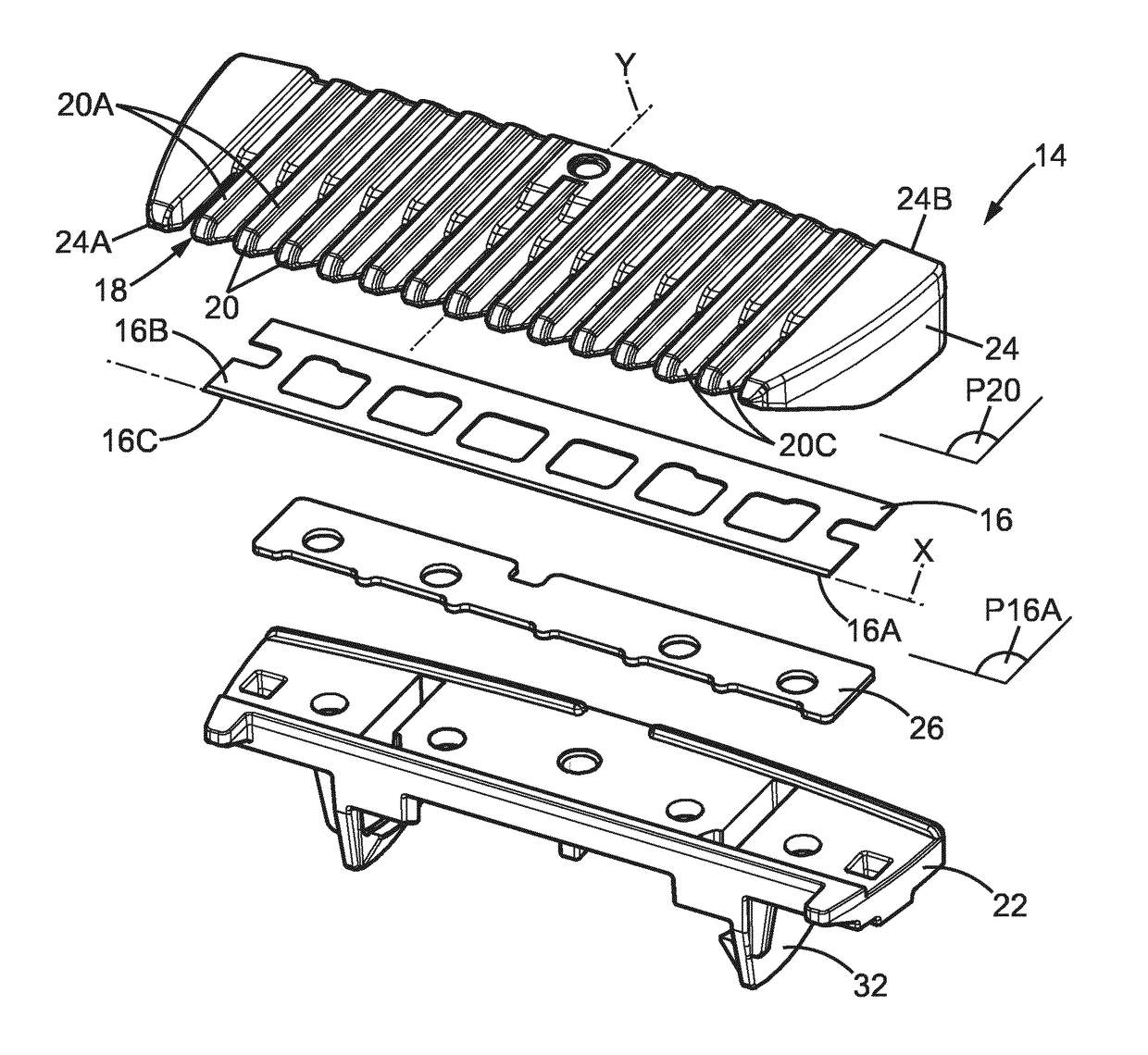

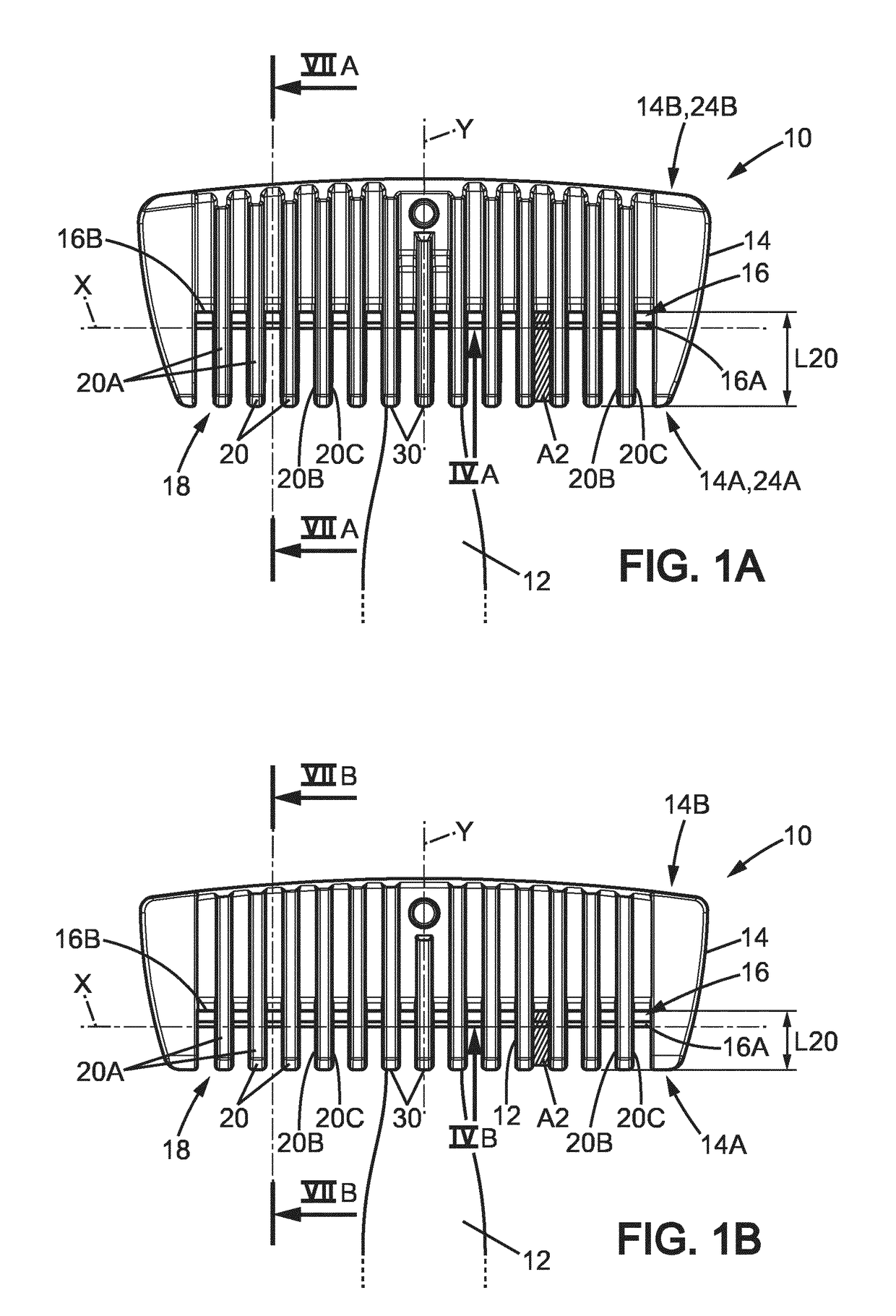

A trimming blade head and a razor comprising a razor handle and such a trimming blade head

ActiveUS20170210020A1Good and precise trimmingIncrease the lengthMetal working apparatusEngineeringLower face

A trimming blade system has a front and includes a supporting plate, a blade, and a cover plate. The blade has a cutting edge facing forwardly toward the front of the trimming blade system. The trimming blade system has a comb provided with teeth which project forwardly toward the front of the trimming blade system and which overlap the cutting edge. Each of the teeth has an upper face, two lateral faces, and a lower face. The lower face of each of the teeth is joined to the lateral faces by opposite chamfered faces.

Owner:BIC VIOLEX SA

Utility knife with retractable blade

An improved utility knife has a blade housing, a handle region, and an end cap. The end cap is removably attached to the handle region. The handle region is cylindrical, with a slight taper and includes an interior storage chamber. The blade housing has a blade channel for permitting retraction and extension of the blade. Clench plates hold the blade securely within the blade channel and are slidable within it. An axis of the blade-holding portion of the knife is tilted relative to the axis of the gripping portion.

Owner:DELILLO DOMINICK

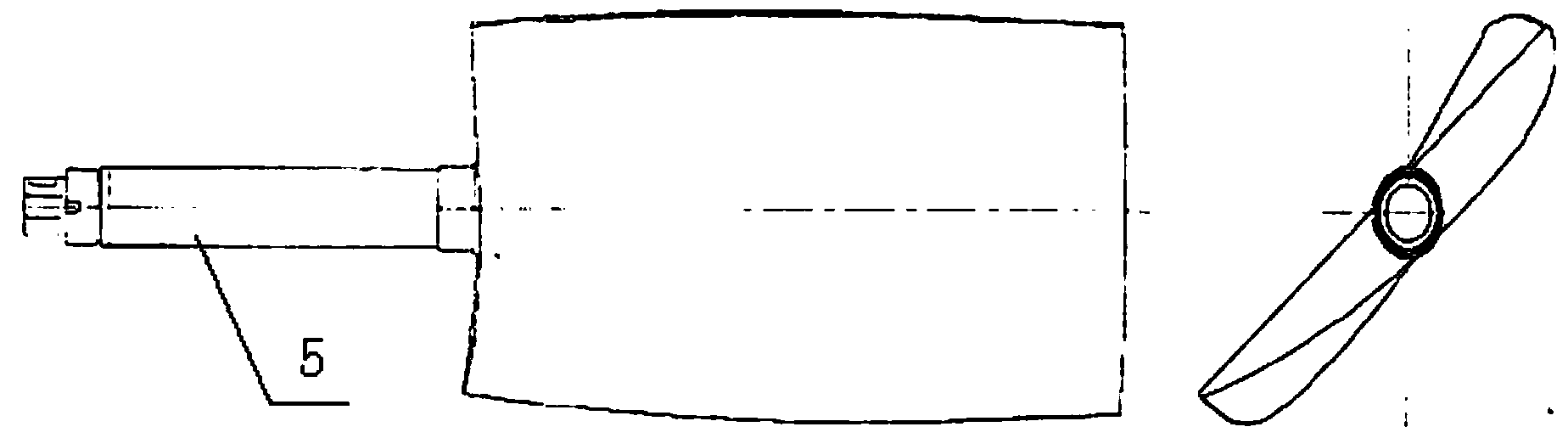

Axial type energy-saving fan blade for extrusion and cutting process

The invention relates to an axial flow energy-saving fan blade shaped by compression method, which is formed by hollow wing main body and solid tail edge, wherein the blade handle is inserted into the arc base of main chamber of wing to be fixed with the wing main body; another end of blade handle is fixed on the hub of blade wheel; the inner radius of blade is mounted with sealing plate, while the outer radius is mounted with end cover plate; the end cover plate has several water outlets; according to the size of the arc length of blade, several strengthen bars are arranged inside the chamber of main body to improve the blade rigidity; based on large fan, the main body can use segmented structure, while the segments are coupled by wedge grooves, without integrated mould and large compressor, to reduce the cost.

Owner:SHANGHAI JIAO TONG UNIV

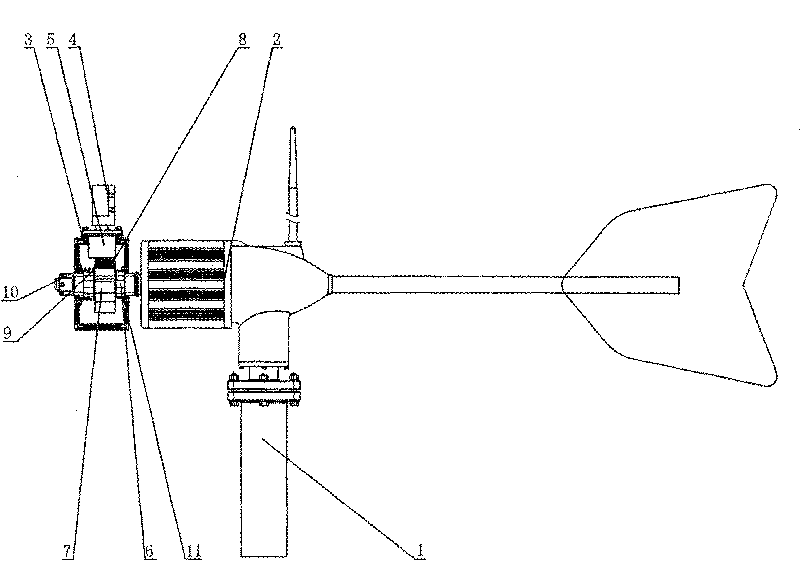

Assistance-free pitch-changing horizontal shaft wind driven generator

The invention relates to an assistance-free pitch-changing horizontal shaft wind driven generator, which comprises a generator set, a hub, a paddle blade and a paddle blade handle, wherein the hub is provided with more than two bearing blocks; the paddle blade handle is arranged on the bearing blocks through a bearing; the paddle blade is connected with one end part of the paddle blade handle; the hub can move axially on a spline shaft; the spline shaft is provided with a rack block, and the rack block is provided with a rack; one end of the paddle blade handle opposite to the mounted paddle blade is provided with a gear; the gear is meshed with the rack; and a spring is arranged between one lateral surface of the rack block and a cross section of the hub. In the structure, when the actual wind speed is larger than the set wind speed of the wind driven generator, the force acting on the paddle blade and the hub drives the paddle blade and the hub to overcome the elastic force of the spring and move along the axial direction of a spline, the paddle blade handle and the paddle blade are driven to rotate under the action of the rack and the gear, and the pitch angle of the paddle blade is changed, so the wind resistance of the wind driven generator is improved, the pitch-changing accuracy is high, and the structure is simple.

Owner:GUANG ZHOU HYENERGY TECH

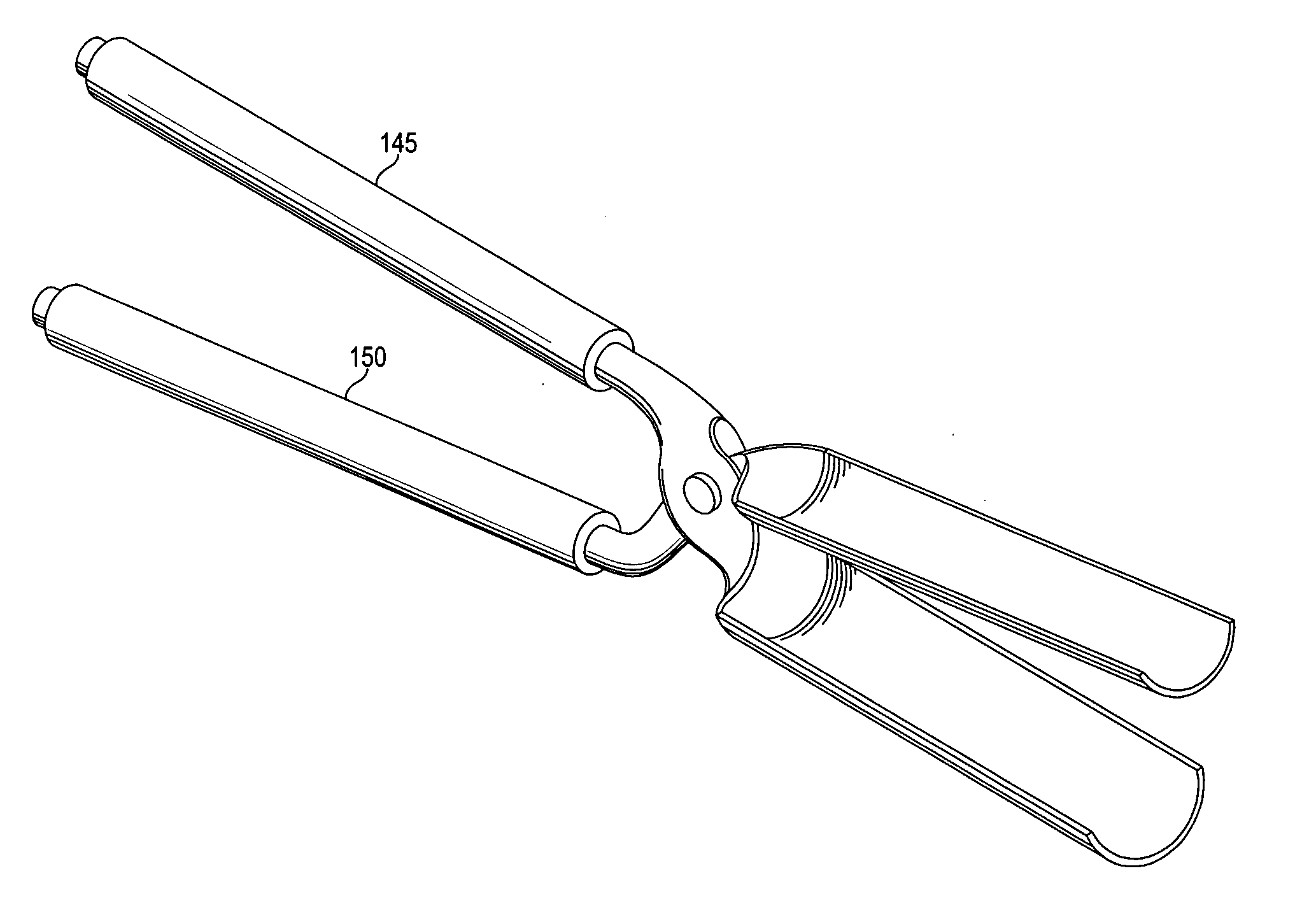

Cable cutter

InactiveUS20040040158A1Capable efficiently and effectively cutting ACSR cable usingEfficiently and effectively cuttingTube shearing machinesPortable handheld shearing machinesKnife bladesBlade handle

A tool for use in cutting cable, preferably ACSR cable, includes first and second blades having cutting configurations. The first and second blades are pivotally connected and a handle are attached to each blade. Movement of the handles rotates the blades about the pivot point. Cable positioned between the cutting configurations is systematically cut by the cutting configurations as the blades are rotated toward each other. Each cutting configuration includes first and second sharp edges and a blunt edge positioned therebetween which defines a concave recess. The first and second sharp edges are used to cut the aluminum strands surrounding the steel cable. During the cutting of the aluminum strands, the steel portion of the cable is urged into the concave recess defined by the blunt edges. The steel cable is then sheared using the blunt edges.

Owner:TEXTRON INNOVATIONS

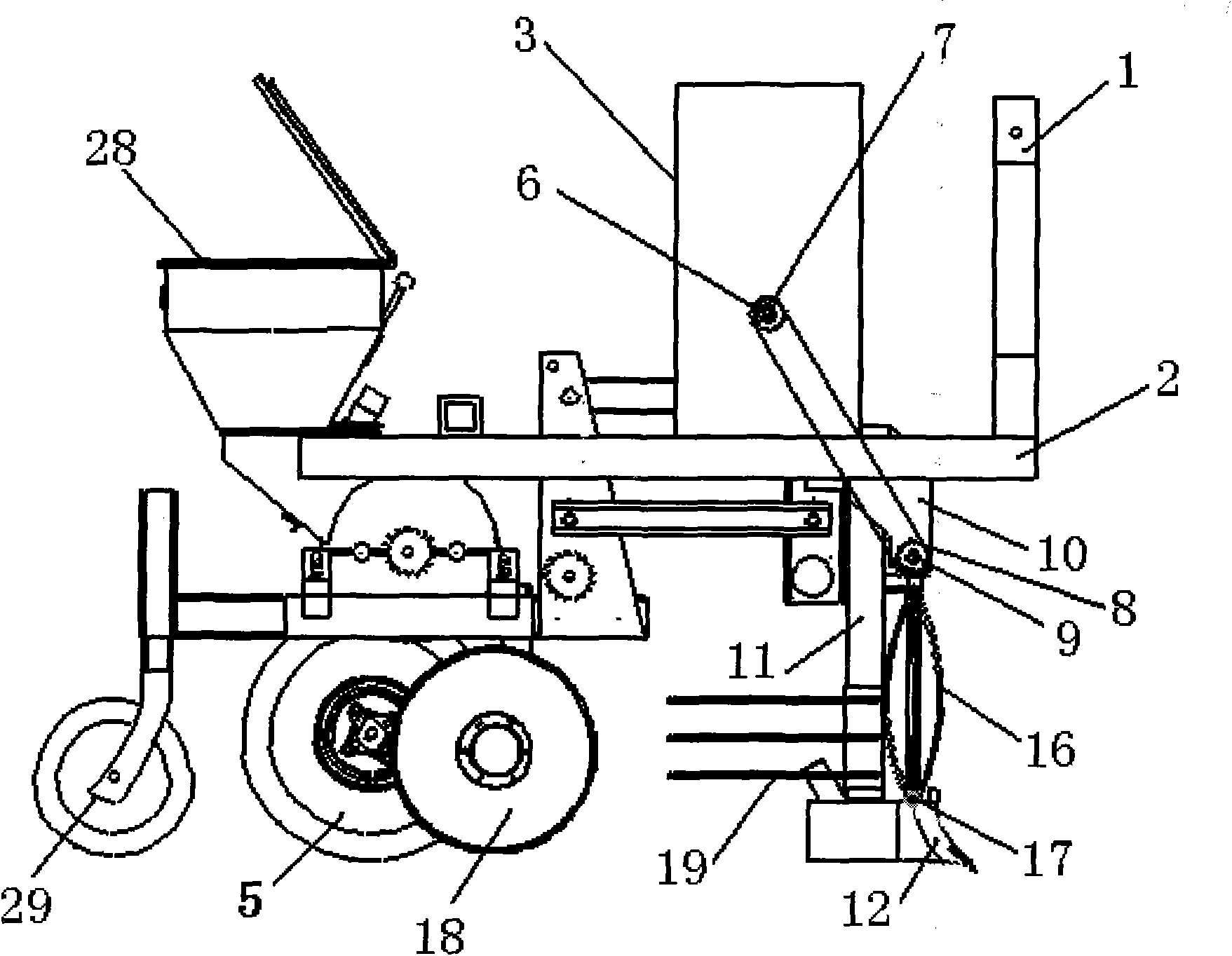

Anti-blockage corn no-tillage seeder

InactiveCN101965768AAvoid cloggingPrevent entanglement of strawPlantingAgriculture gas emission reductionDrive shaftAgricultural engineering

The invention relates to an anti-blockage corn no-tillage seeder, which comprises a machine frame, a fertilizer tank, a plurality of no-tillage seeder single bodies and ground wheels. The fertilizer tank and the plurality of no-tillage seeder single bodies are arranged on the machine frame. The fertilizer tank is provided with a fertilizing shaft which is connected with the ground wheels by chain transmission. Each no-tillage seeder single body comprises a seeding box and a furrowing blade handle, which are arranged on the machine frame, wherein the bottom of the furrowing blade handle is connected with a fertilizing furrower; and a seeding furrower and a press wheel are connected with the machine frame at the rear side of each fertilizing furrower. The anti-blockage corn no-tillage seeder is characterized in that: a driving shaft parallel to the fertilizing shaft is connected below the machine frame and in front of the furrowing blade handles by a plurality of supporting frames; one end of the driving shaft is connected with the fertilizing shaft through chain transmission; the driving shaft is provided with driving bevel gears corresponding to the no-tillage seeder single bodies; the centers of driven bevel gears meshed with the driving bevel gears are fixedly connected with roller shafts; each roller shaft is provided with a roller for pushing straw aside; and the lower ends of the roller shafts are connected with the fertilizing furrowers rotationally.

Owner:CHINA AGRI UNIV

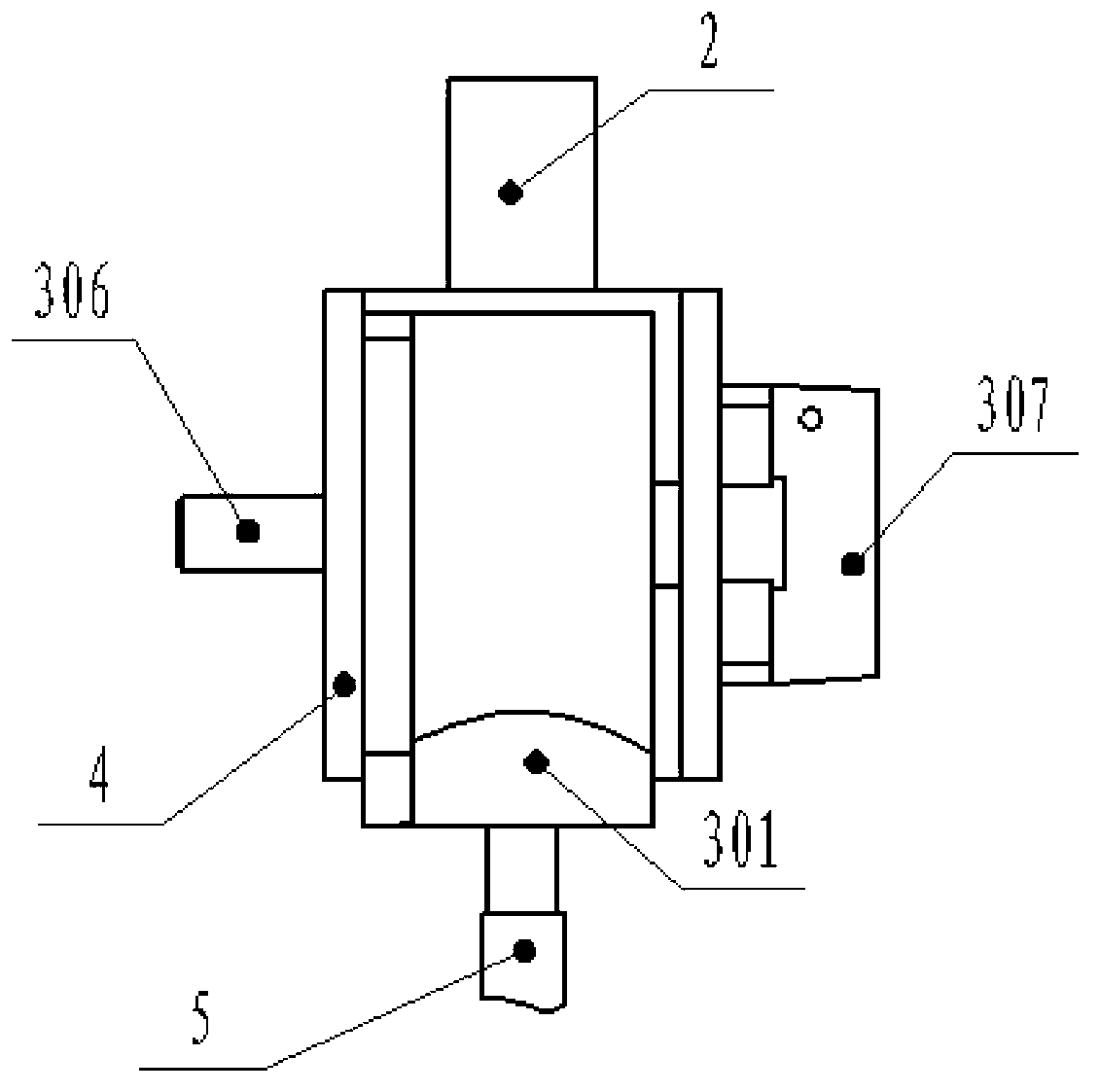

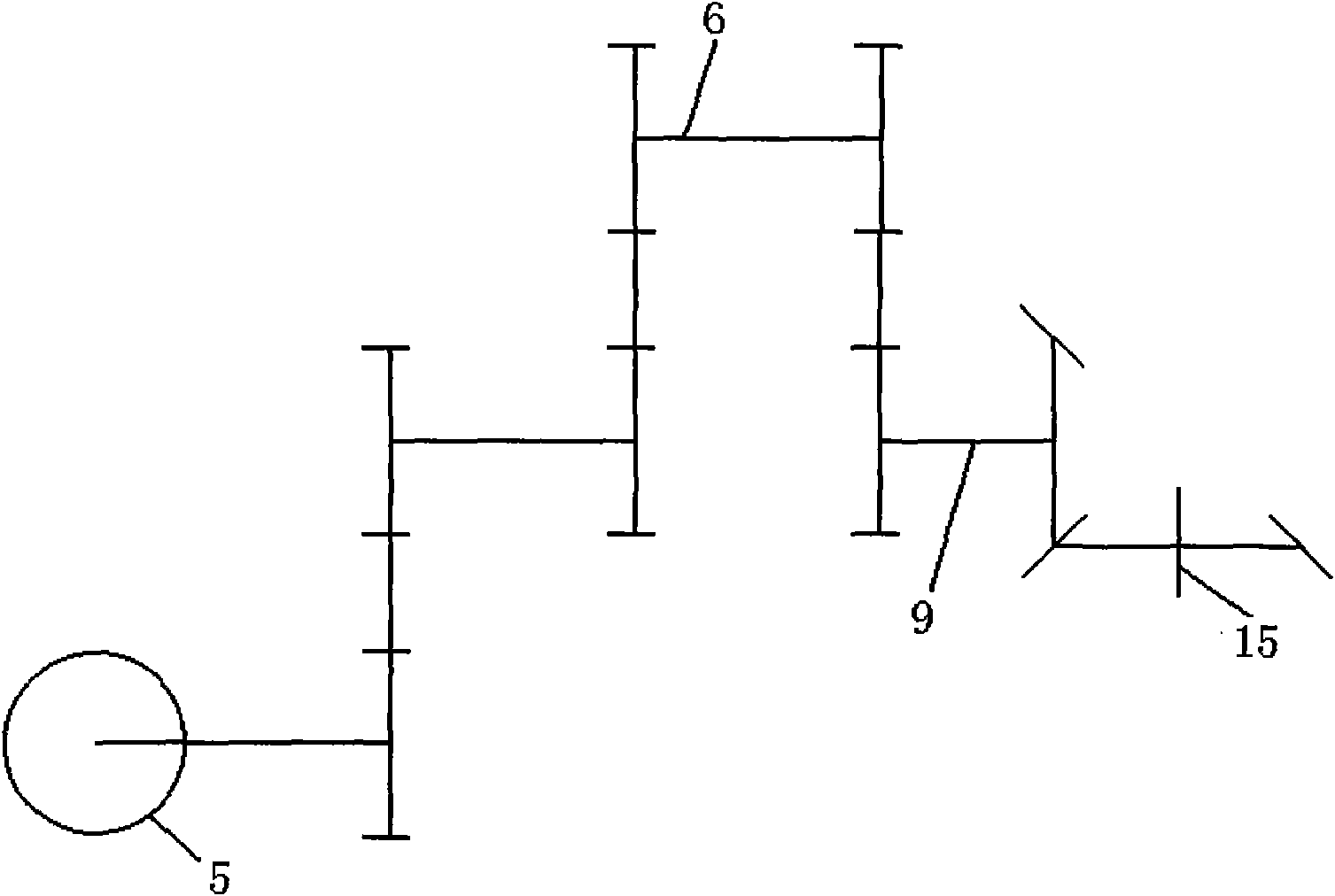

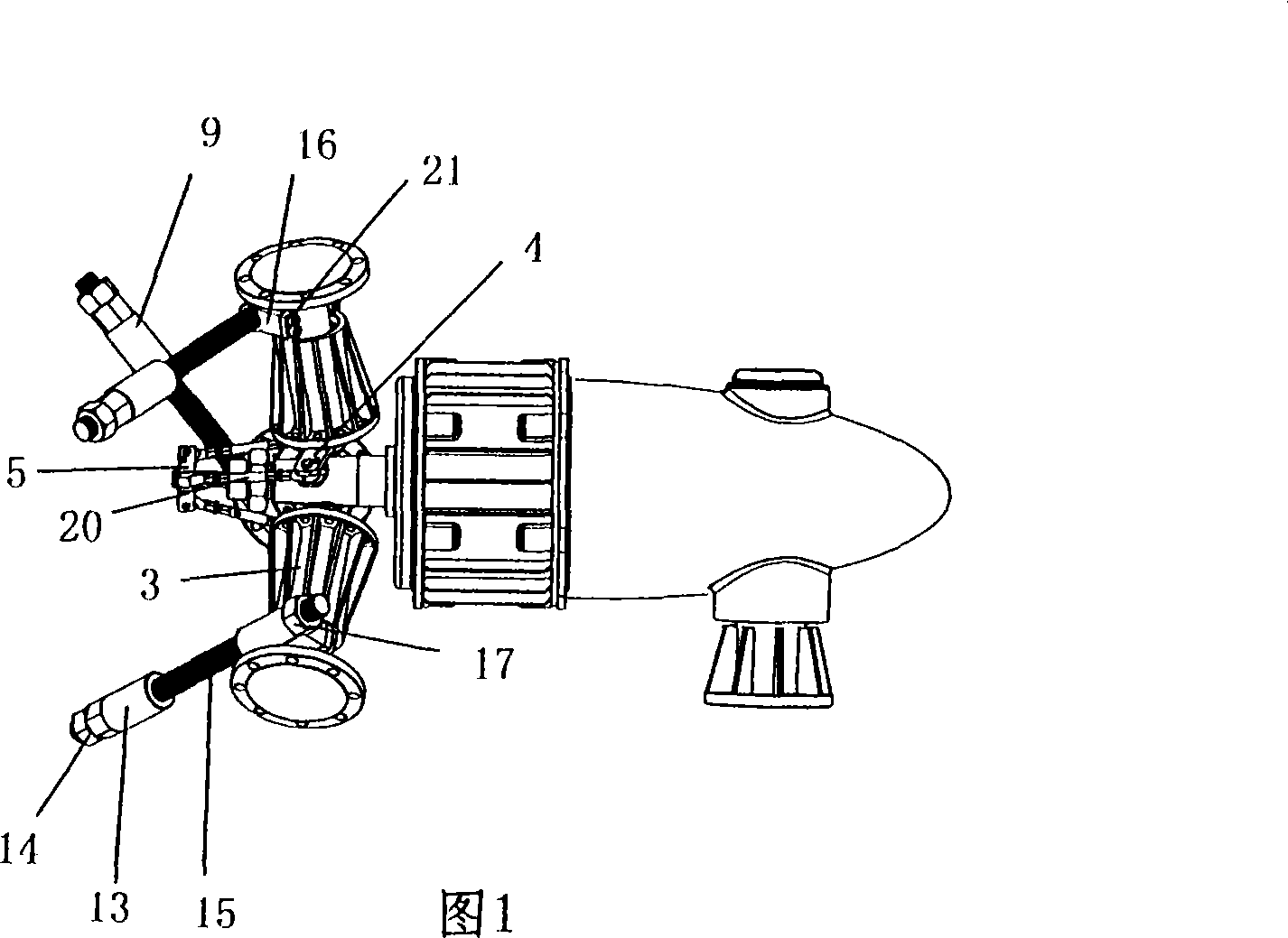

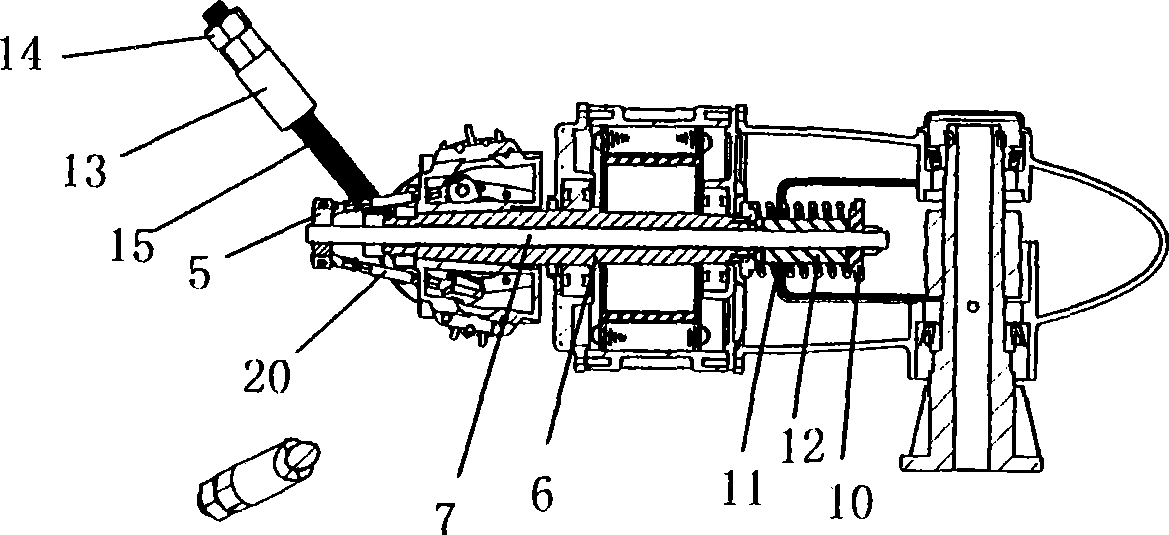

High-speed reblading mechanism for small drilling and milling center

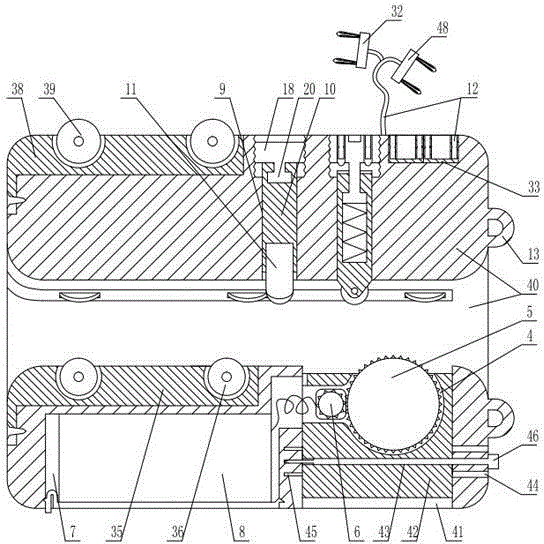

ActiveCN102717290ACompact structureReduce labor intensityPositioning apparatusMetal-working holdersGear wheelEngineering

A high-speed reblading mechanism for a small drilling and milling center comprises a spindle box body, a spindle, a cam shaft and a reblading and blade catching mechanism, wherein an end surface cylindrical cam and a planar cam are sleeved on the cam shaft of an axle, a lever mechanism is connected with a limit sleeve on the reblading and blade catching mechanism to achieve downward stretching and upward pulling of the reblading and blade catching mechanism during rotating of the end surface cylindrical cam, ends of the composite lever mechanism are pressed at two ends of a pin shaft on the spindle to achieve clamping or loosening of a blade handle, and the circumferential curved surface on the planar cam is connected with the reblading and blade catching mechanism to achieve 180-degree rotating of the reblading and blade catching mechanism. The end surface cylindrical cam rotates to drive a fan-shaped gear to swing, and the fan-shaped gear is simultaneously meshed with a gear shaft arranged at the upper end of the reblading and blade catching mechanism to achieve opening and closing actions of a blade claw. According to the high-speed reblading mechanism, a cam structure and a hollow spline shaft structure which are arranged in a spindle box are ingeniously used, so that the spindle box is compact in structure. The reblading mechanism is high in speed and reliable so that worker labor intensity is reduced and production efficiency is improved.

Owner:BAOJI XILI PRECISION MACHINERY

Wheel rim-driven shaftless fan

InactiveCN107461354ASave flow spaceSave materialPump componentsPump installationsInterference fitEngineering

The invention specifically relates to a wheel rim-driven shaftless fan. The wheel rim-driven shaftless fan comprises a stator component, a rotor component and a lubrication device, wherein the stator component comprises a front end cover 4, an inlet-side slide bearing 5, an air barrel 3, an armature 10, an outlet-side slide bearing 14 and a rear end cover 13, wherein the rotor component comprises an inlet-side shaft neck 6, a wheel hub 16, permanent magnets 9, blades 8 and an outlet-side shaft neck 15, the inlet-side shaft neck 6 and the outlet-side shaft neck 15 are both L-shaped and both installed on the wheel hub 16 in a manner of interference fit, a plurality of grooves are uniformly formed in the excircle surface of the wheel hub 16, and the permanent magnets 9 are inlaid in the grooves in the excircle surface of the wheel hub 16; a blade handle is arranged at the blade tip of each blade 8, each blade handle is an incurved tile, and all the tiles are spliced to just form the inner diameter of the wheel hub; and the lubrication device comprises an oil cup 12, a guide pipe 2 and an adjustment valve 1, one end of the guide pipe 2 is connected to the oil cup 12, and two outlets are formed in the other end of the guide pipe 2. According to the wheel rim-driven shaftless fan disclosed by the invention, a wheel hub needed for driving the central shaft of a traditional fan is avoided, the separation of secondary flow and a boundary layer at each blade root is reduced, and the flowing condition at each blade root is improved, so that the efficiency of the fan is increased; and moreover, a blade tip gap at each blade tip is avoided, so that detouring flow at each blade tip is avoided, a flow field structure is improved, energy conversion efficiency is increased, and a pneumatic noise is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Four bar knife

ActiveUS9908246B2Low structural requirementsImprove stabilityMetal working apparatusInherent safetyEngineering

A folding knife that uses a four bar linkage mechanism to open and close. The knife can include a means of one hand opening and closing as well as a means to become latched in, and released from, a fixed position. The four bar linkage knife includes a blade, a handle, and the motion of a four bar linkage to open and close the knife. The four bar knife provides inherent safety because the four bar linkage motion can not fold onto the users hand.

Owner:FRAUENGLASS ANDREW

Passive paddle changing wind power generator

InactiveCN101457744ALimit overloadImprove securityWind motor controlMachines/enginesPropellerCentrifugal force

The invention relates to a passive variable propellers aerogenerator, comprising fan blades, fan blade connection handles, hub radial canals, cranks, synchronous disks, a motor shaft and pull rods, wherein, the fan blades are installed on the fan blade connection handles connected with the hub radial canals by bearings, the fan blade connection handles and the hub radial canals can relatively rotate, the root parts of the fan blade connection handles are connected with a crank connected with the synchronous disks by linkage structures, the pull rods are connected on the synchronous disks, and centrifugal hammers are installed on the fan blade connection handles. In the aerogenerator, the variable propellers have simple structure, favorable stability and obvious effect, control and adjust the angle of each wind wheel blade handle by the centrifugal force to the centrifugal hammers by the rotation of the aerogenerator, and cause the wind wheel of the aerogenerator to be at an optimal start angle during low wind and to be at an optimal windward angle position at rated wind speed; during strong wind force, the rotate speed of the aerogenerator can be controlled with a rated rotate speed, thereby preventing the overload of the aerogenerator and improving the safety and the stability of the aerogenerator.

Owner:ZHEJIANG HUAYING WIND POWER GENERATOR

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com