Passive paddle changing wind power generator

A wind-driven generator, passive technology, applied in the direction of wind-driven engine, wind-driven motor combination, wind-driven engine control, etc., can solve problems such as high manufacturing cost, complex structure, wind-driven generator influence, etc., to improve safety and stability, The effect of pitch change is obvious and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

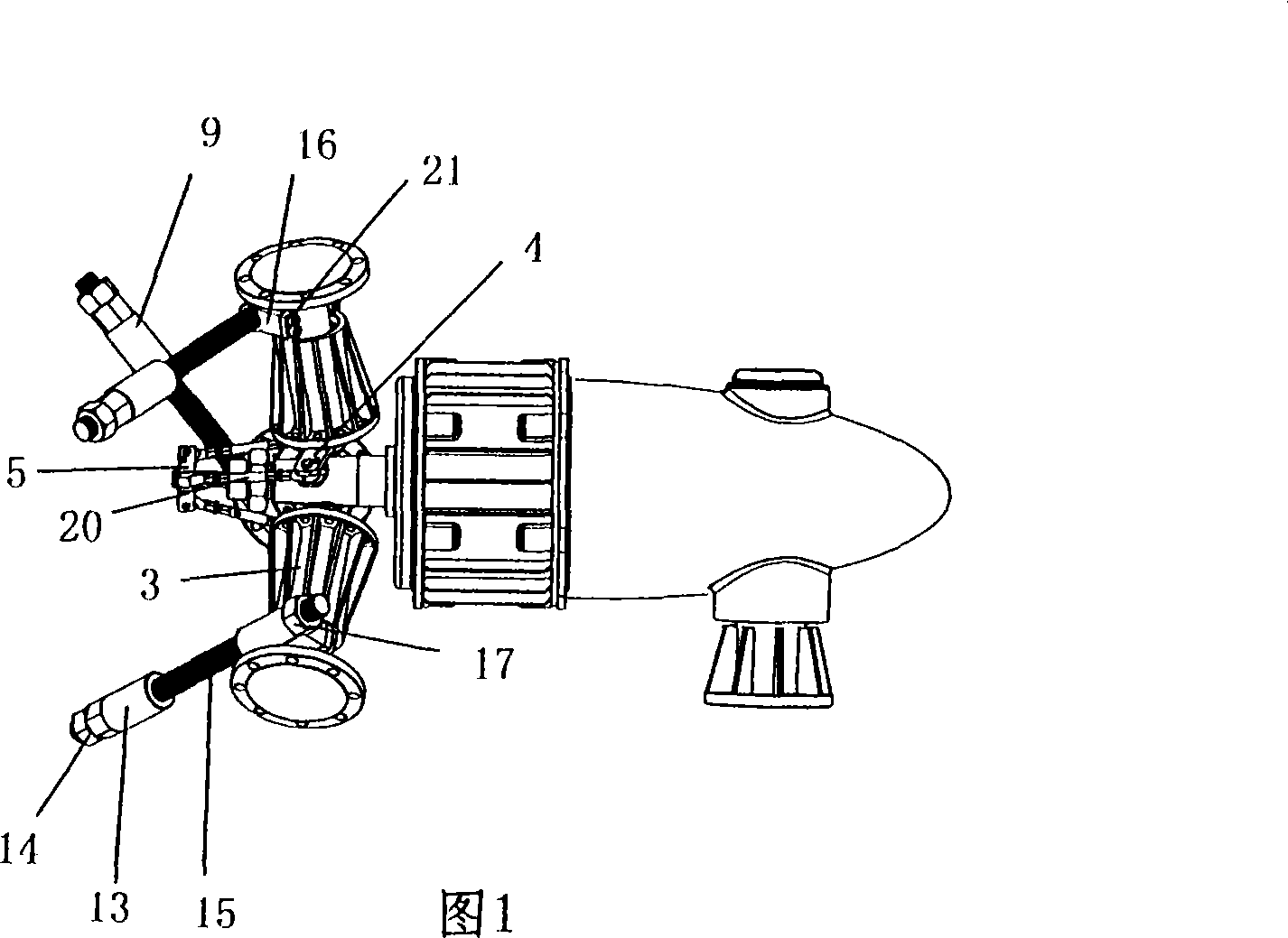

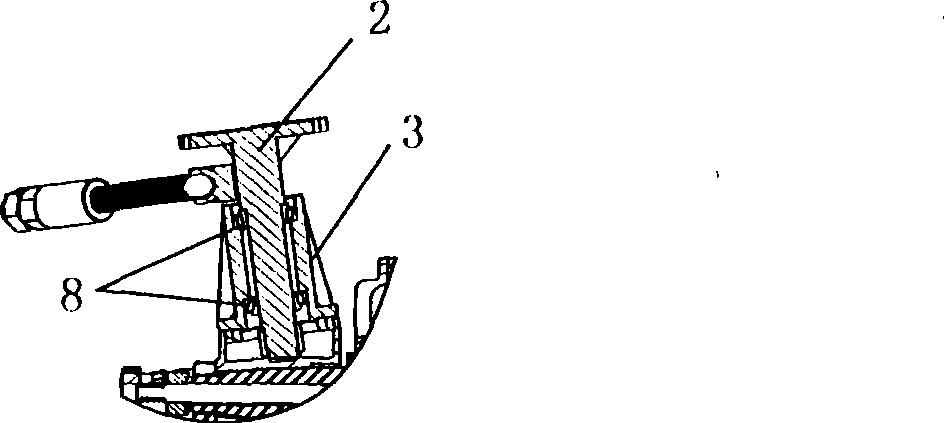

[0015] As shown in Figures 1 and 2, the passive pitch wind turbine described in this embodiment includes a fan blade 1, a blade connecting handle 2, a hub spoke tube 3, a crank 4, a synchronous disc 5, a motor shaft 6, a tie rod 7. The fan blade 1 is installed on the fan blade connecting handle 2, and the fan blade connecting handle 2 is connected with the hub spoke tube 3 through the bearing 8, and can rotate relatively. The root of the fan blade connecting handle 2 is connected with the crank 4 by a key, and the crank 4 is connected with the synchronizing plate 5 through the linkage structure composed of three connecting rods 20 and six joint bearings, so that the rotary motion of the fan connecting handle 2 is converted into synchronization. Reciprocating movement of the disc 5. The synchronizing plate 5 is matched with the pull rod 7 passing through the hollow motor shaft 6 by a flat key, and the pull rod 7 is provided with bolts to fix the pull rod 7 and the synchronizing...

Embodiment 2

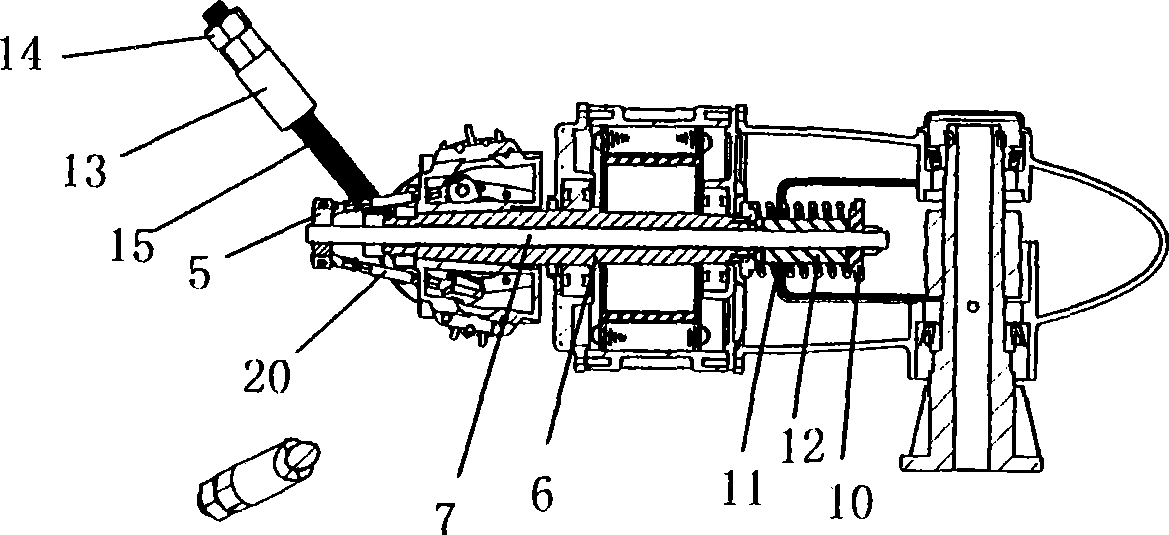

[0017] like image 3 As shown, the passive pitch wind turbine described in this embodiment is based on Embodiment 1, and a spring cover 10 is provided at one end of the pull rod 7, and a spring 11 is provided between the motor shaft 6 and the spring cover 10. , the spring 11 is provided with a damper 12, and the elastic force generated by the deformation of the spring 11 forms a pair of balance forces through the centrifugal force of the pull rod 7, the concentric disc 5, the crank 4, the blade connecting handle 2 and the centrifugal hammer 9. When the rotation speed of the blade 1 is slowed down and the centrifugal force of the centrifugal hammer 9 is reduced, the angle of the fan blade 1 is automatically reset by the elastic force of the spring 11, and the compression and reset of the spring 11 are restricted by the damper 12, which can eliminate the frequent change of the wind speed. The vibration caused by the pitch, so as to achieve the purpose of more stable passive pitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com