Patents

Literature

17015 results about "Centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In Newtonian mechanics, the centrifugal force is an inertial force (also called a "fictitious" or "pseudo" force) that appears to act on all objects when viewed in a rotating frame of reference. It is directed away from an axis passing through the coordinate system's origin and parallel to the axis of rotation. If the axis of rotation passes through the coordinate system's origin, the centrifugal force is directed radially outwards from that axis. The concept of centrifugal force can be applied in rotating devices, such as centrifuges, centrifugal pumps, centrifugal governors, and centrifugal clutches, and in centrifugal railways, planetary orbits and banked curves, when they are analyzed in a rotating coordinate system. The term has sometimes also been used for the reactive centrifugal force that may be viewed as a reaction to a centripetal force in some circumstances.

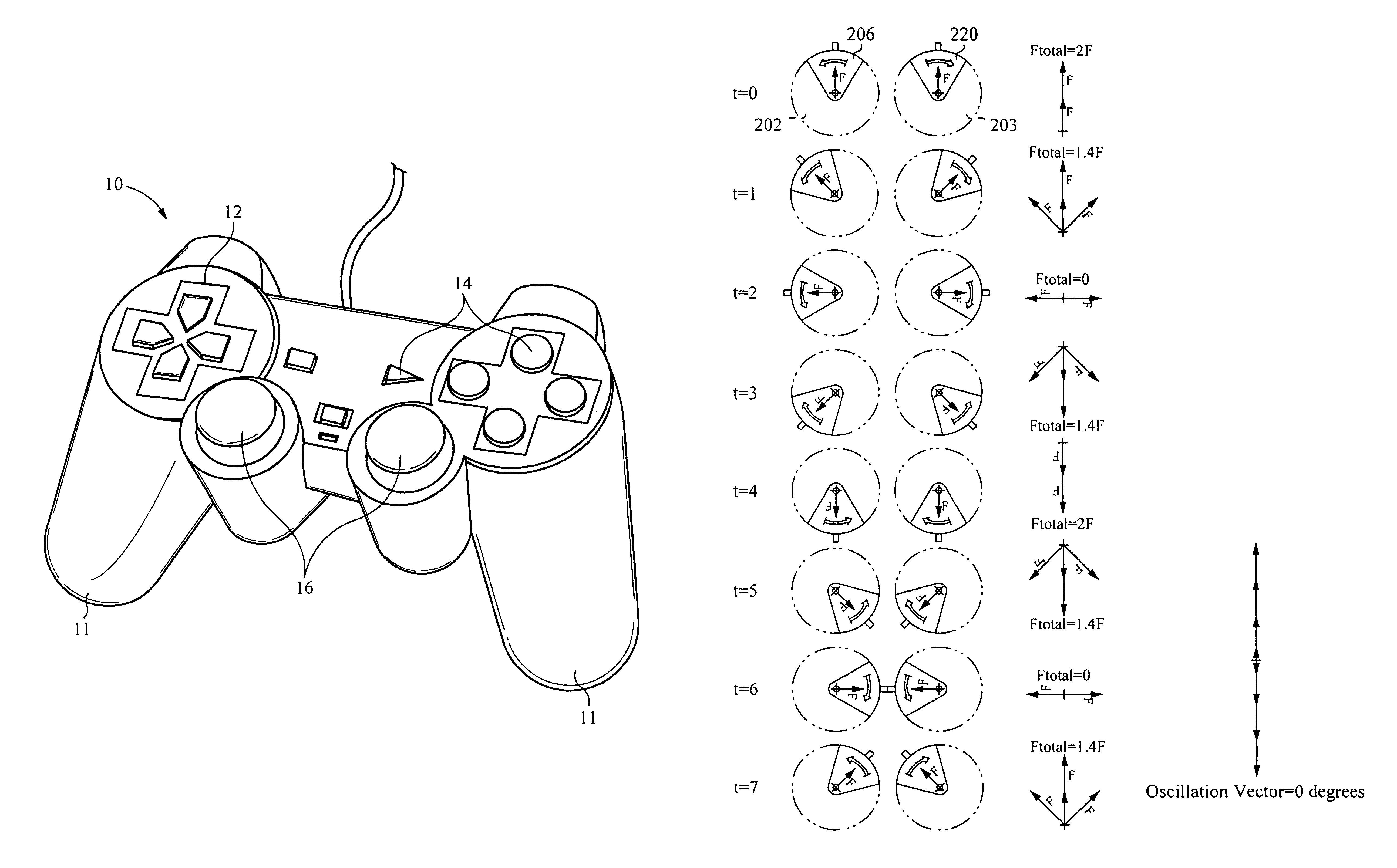

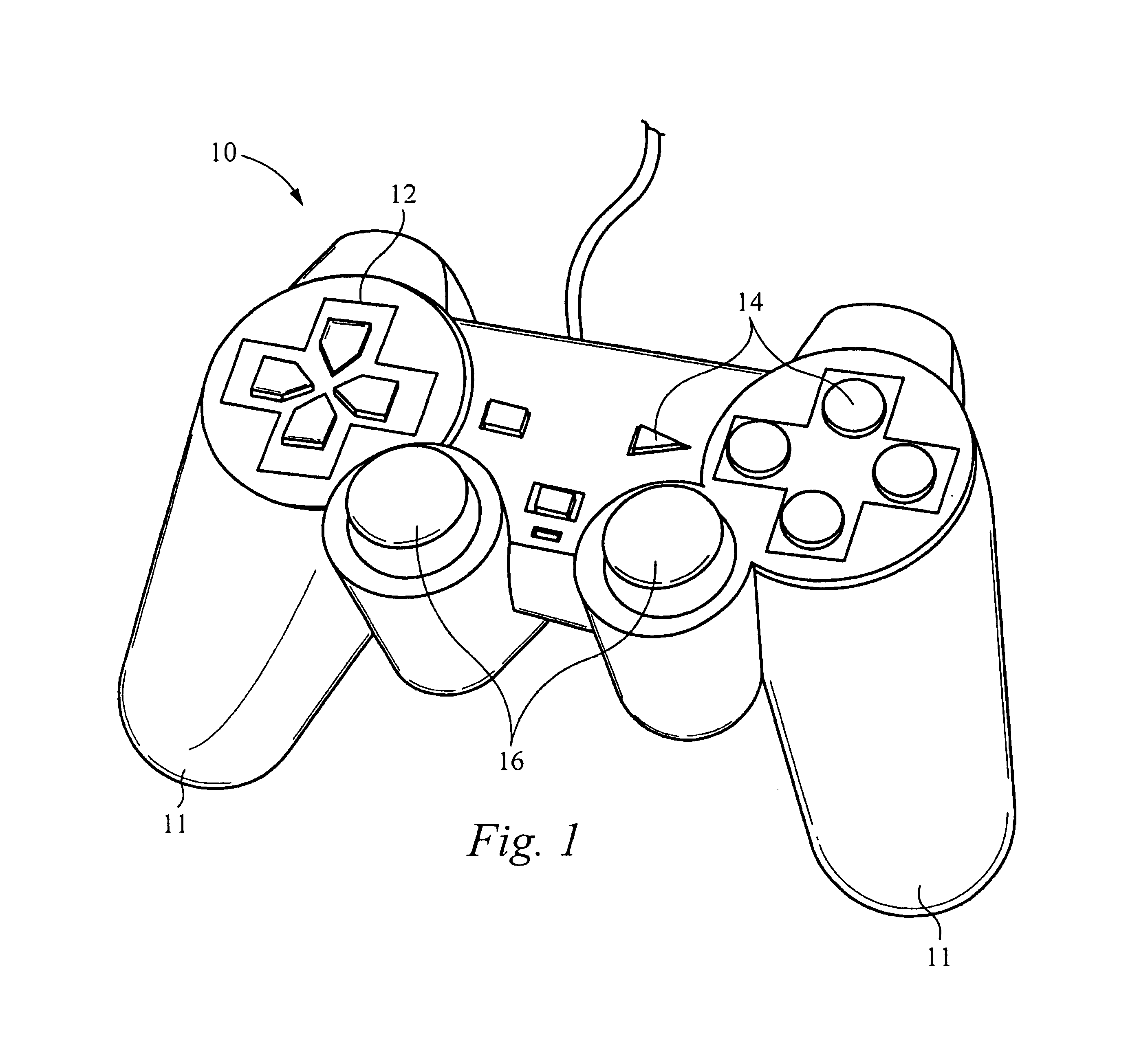

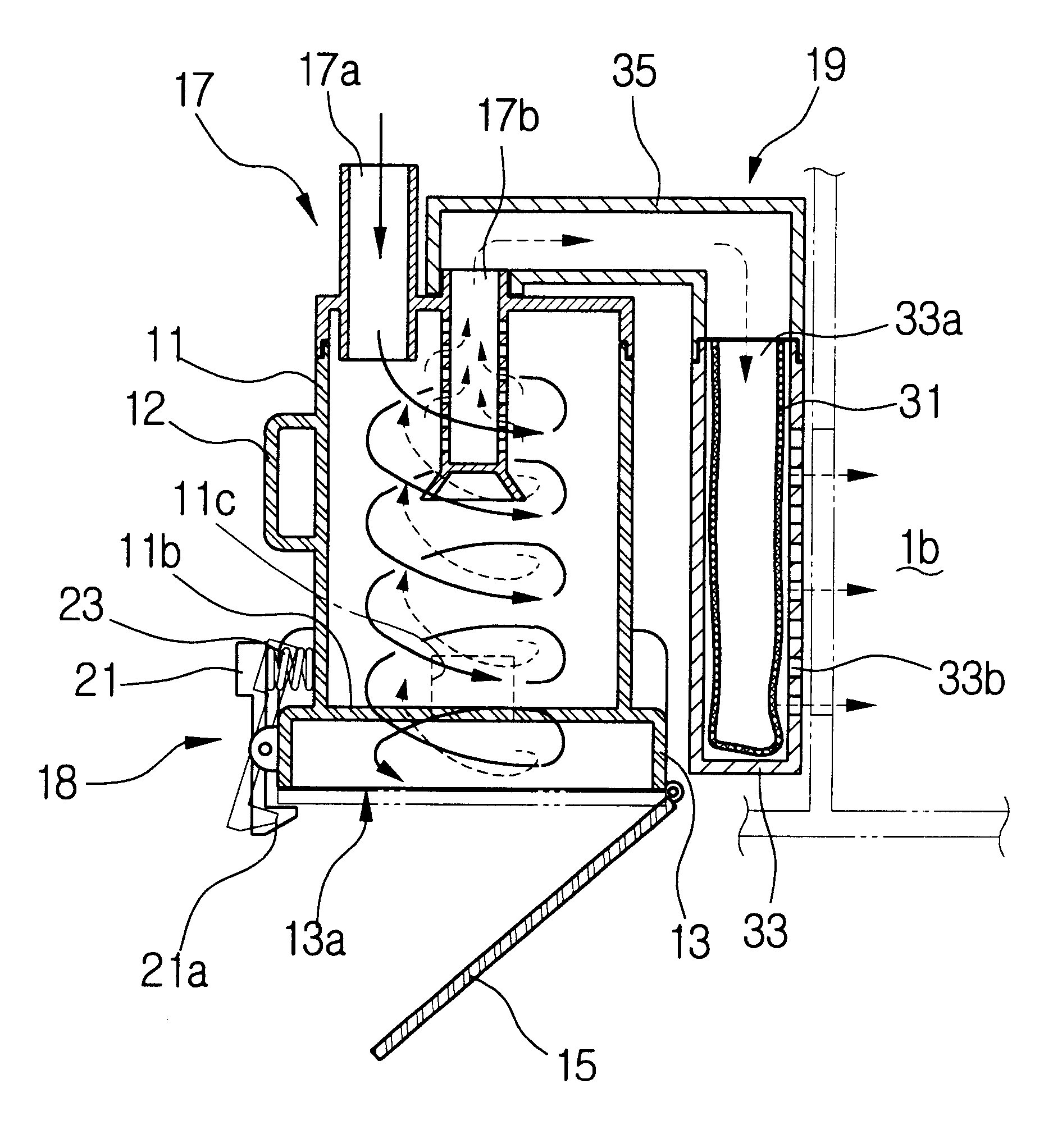

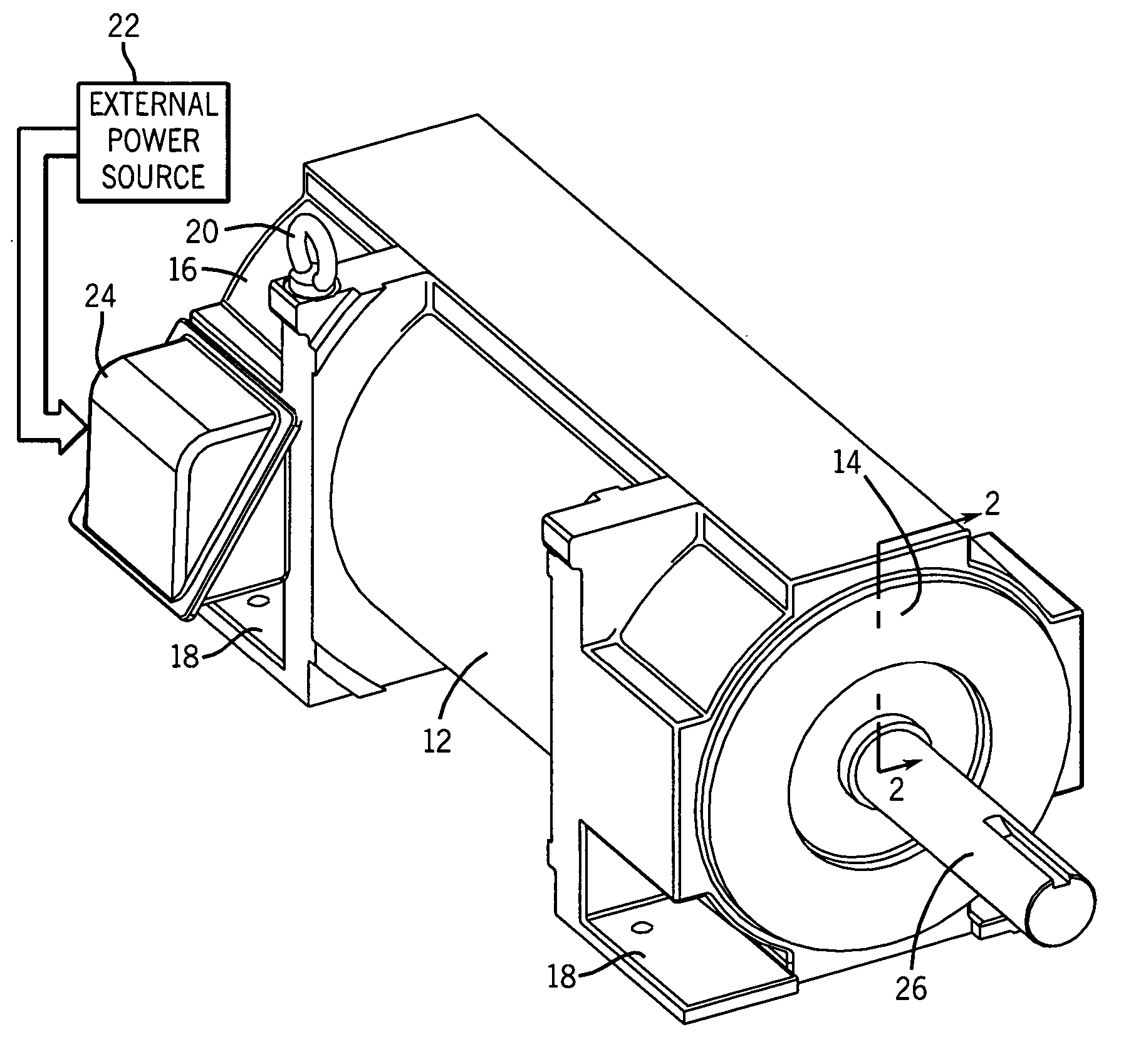

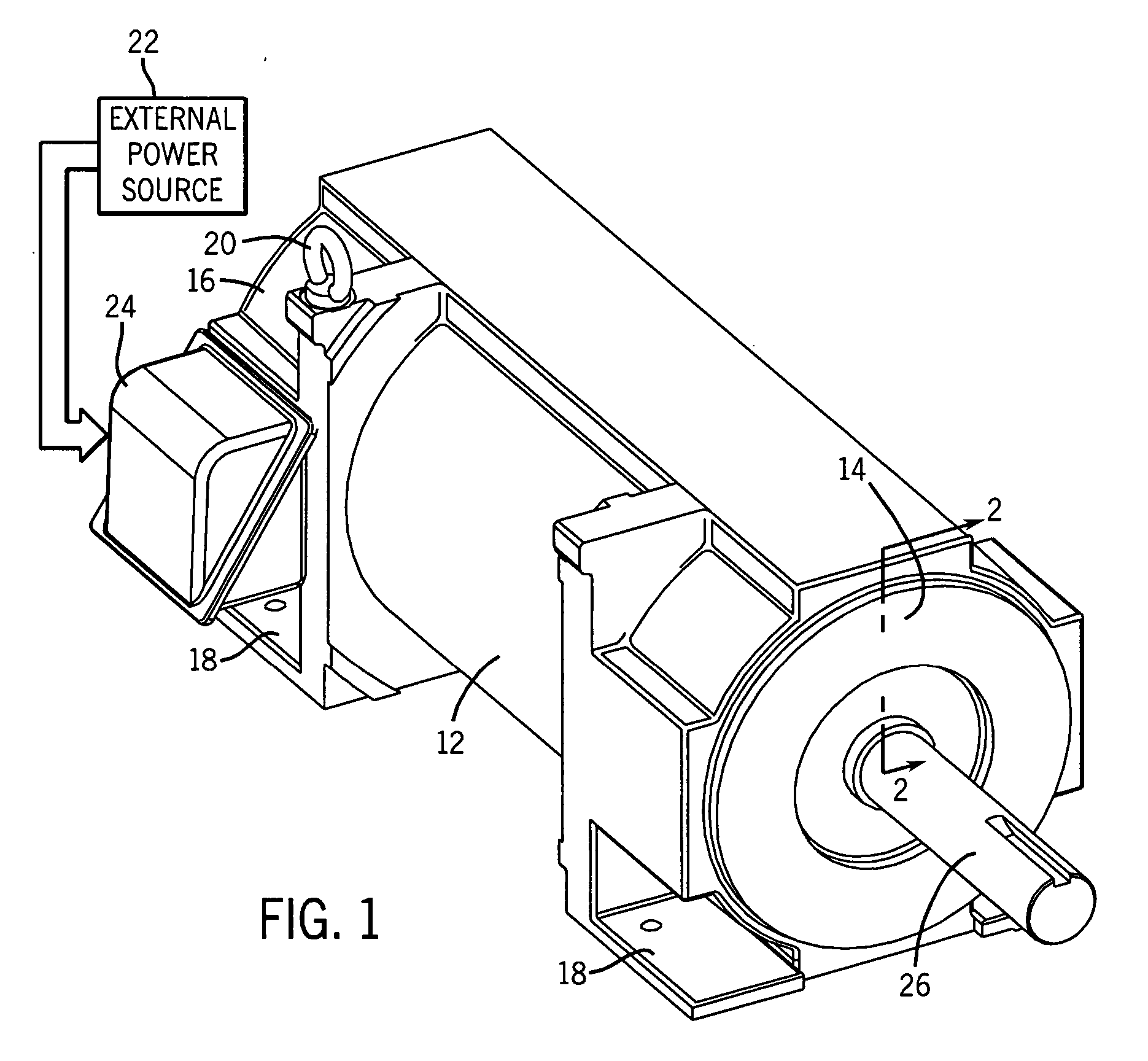

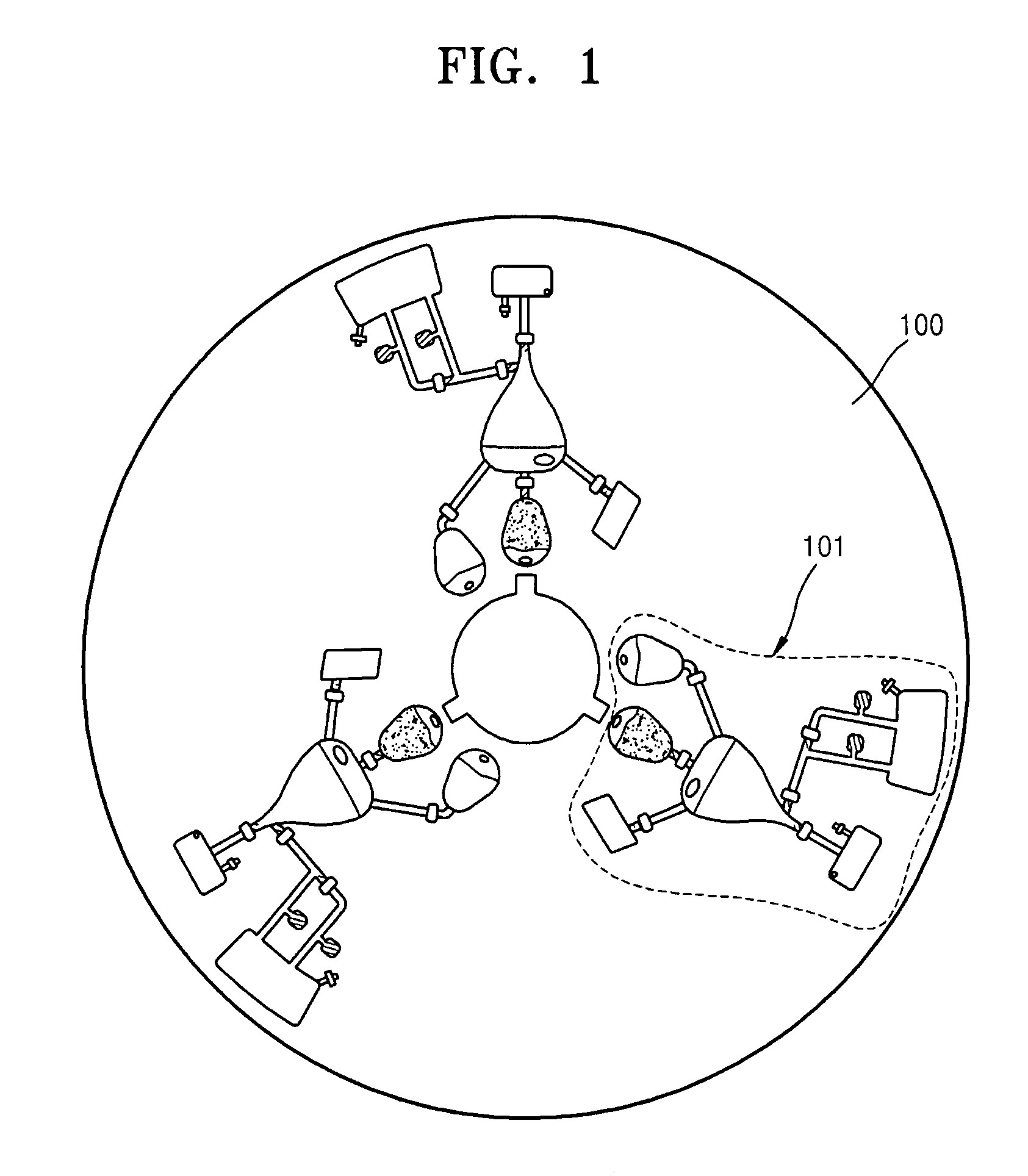

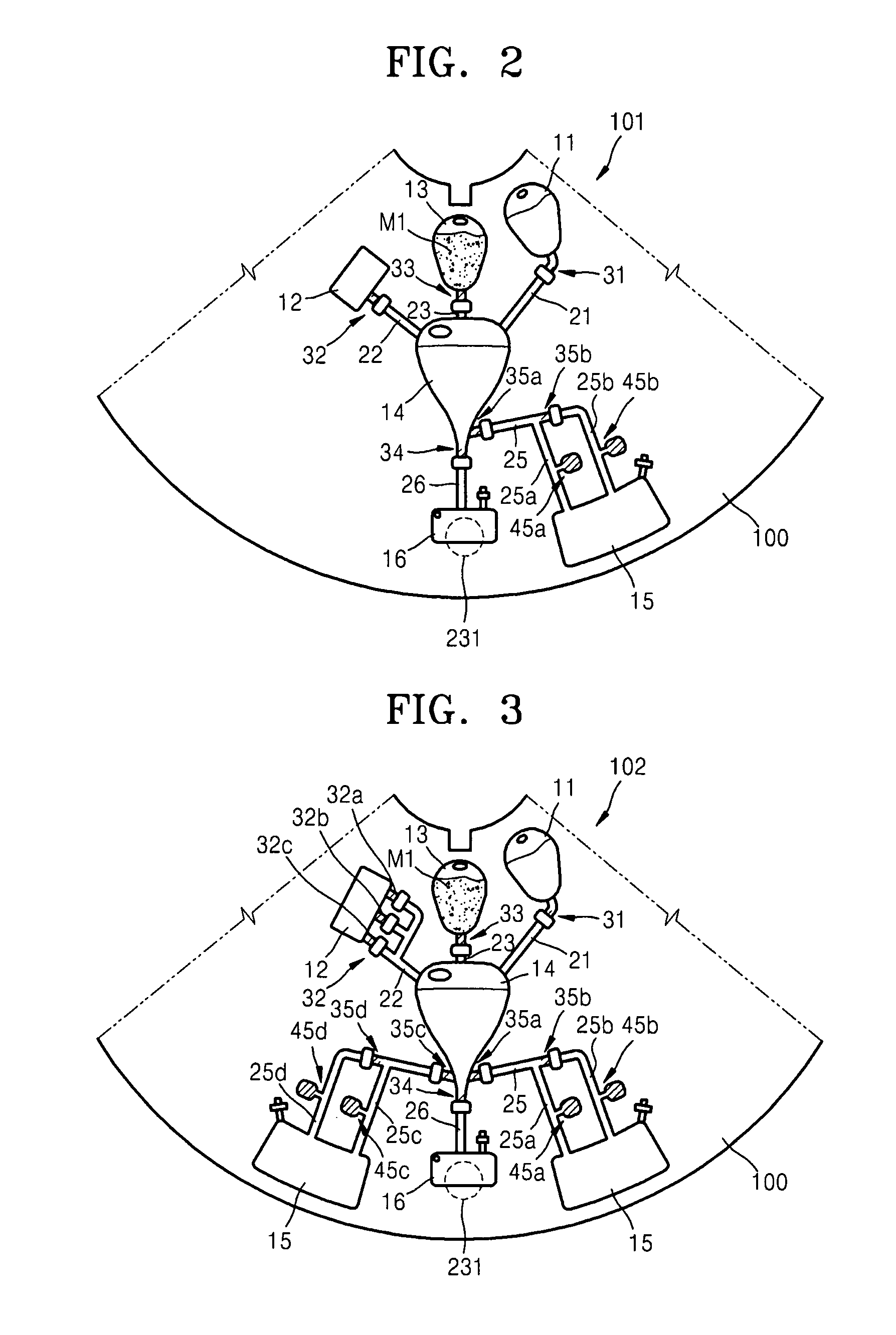

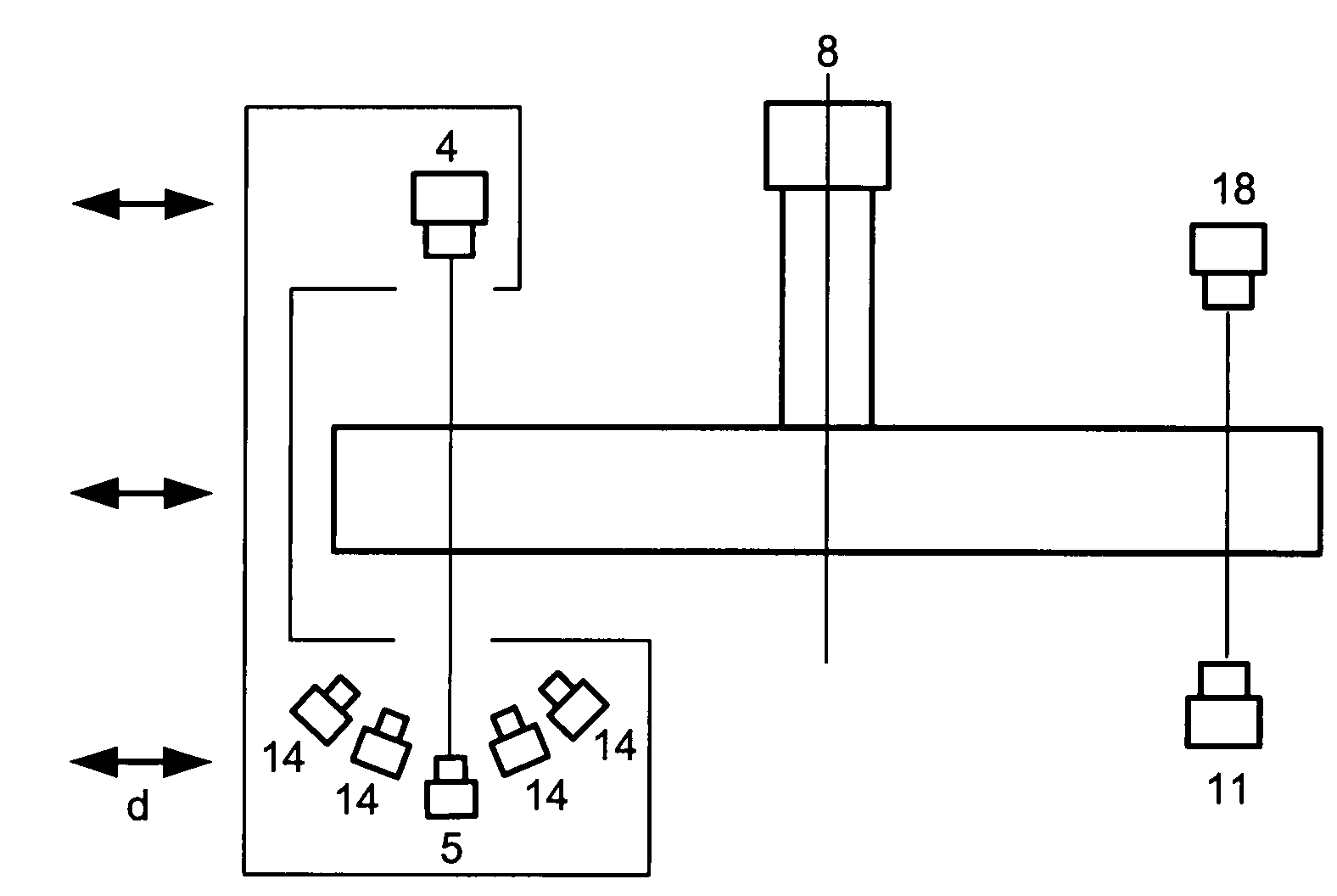

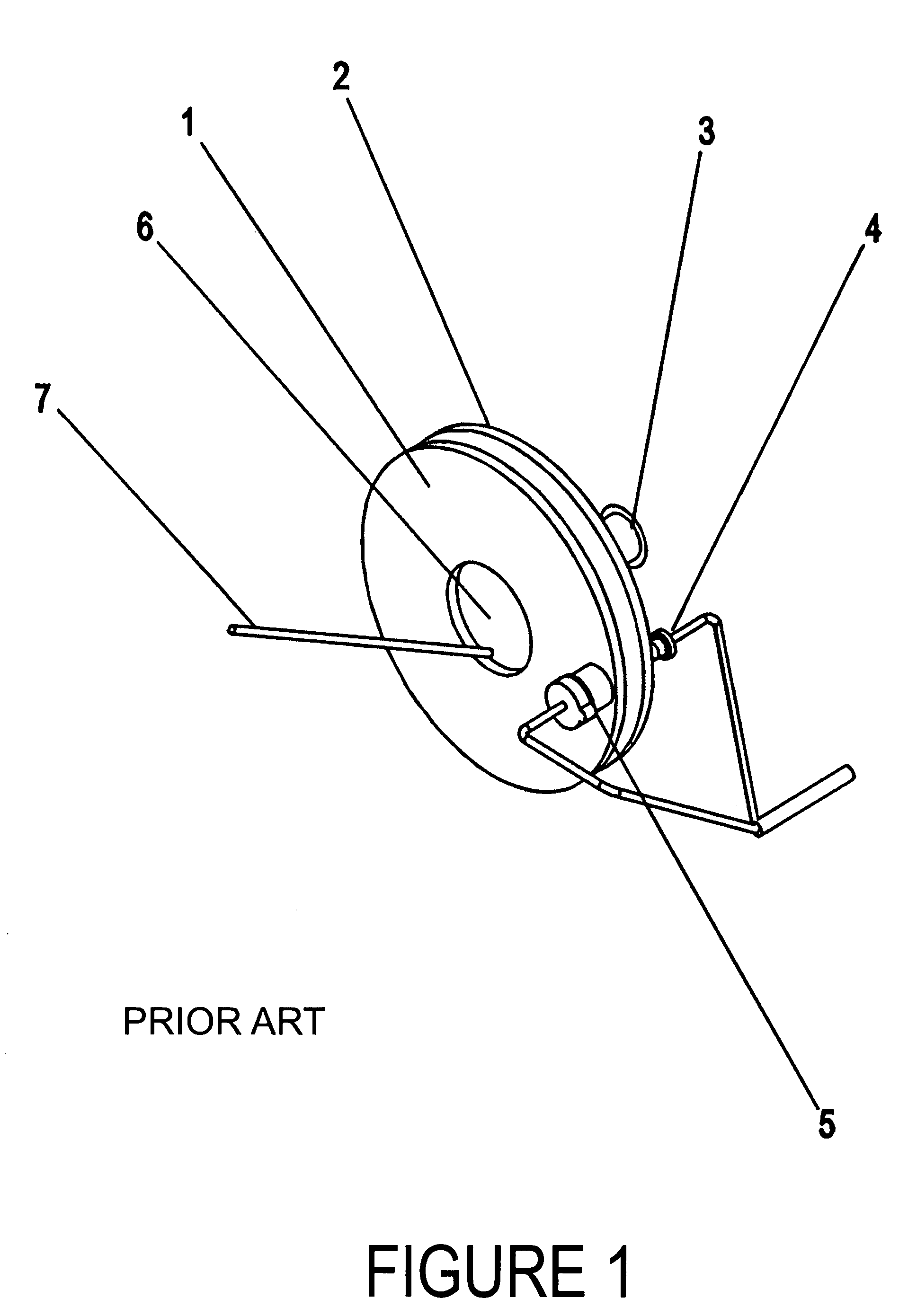

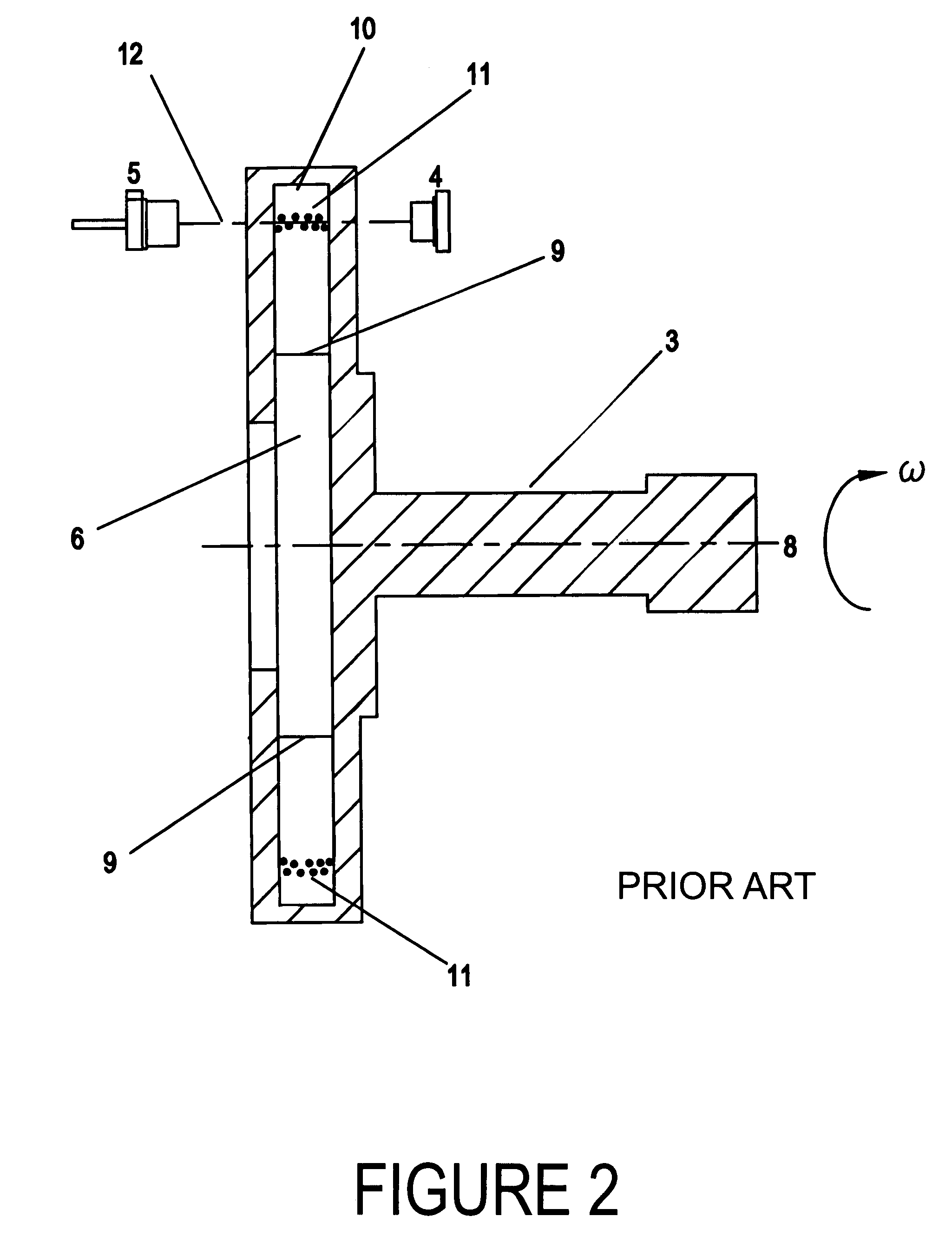

Directional inertial tactile feedback using rotating masses

InactiveUS7182691B1Low costIncrease varietyCathode-ray tube indicatorsVideo gamesControl signalEngineering

Directional haptic feedback for a haptic feedback interface device. A haptic feedback interface device, in communication with a host computer, includes a housing physically contacted by a user operating the interface device, and a plurality of actuators producing inertial forces when the actuators are driven by control signals. Each of the actuators includes a rotatable eccentric mass positioned offset on a rotating shaft of the actuator, where the actuators are rotated simultaneously such that centrifugal forces from the rotation of masses combine to output the inertial forces substantially only along a single axis having a desired direction approximately in a plane of rotation of the masses.

Owner:IMMERSION CORPORATION

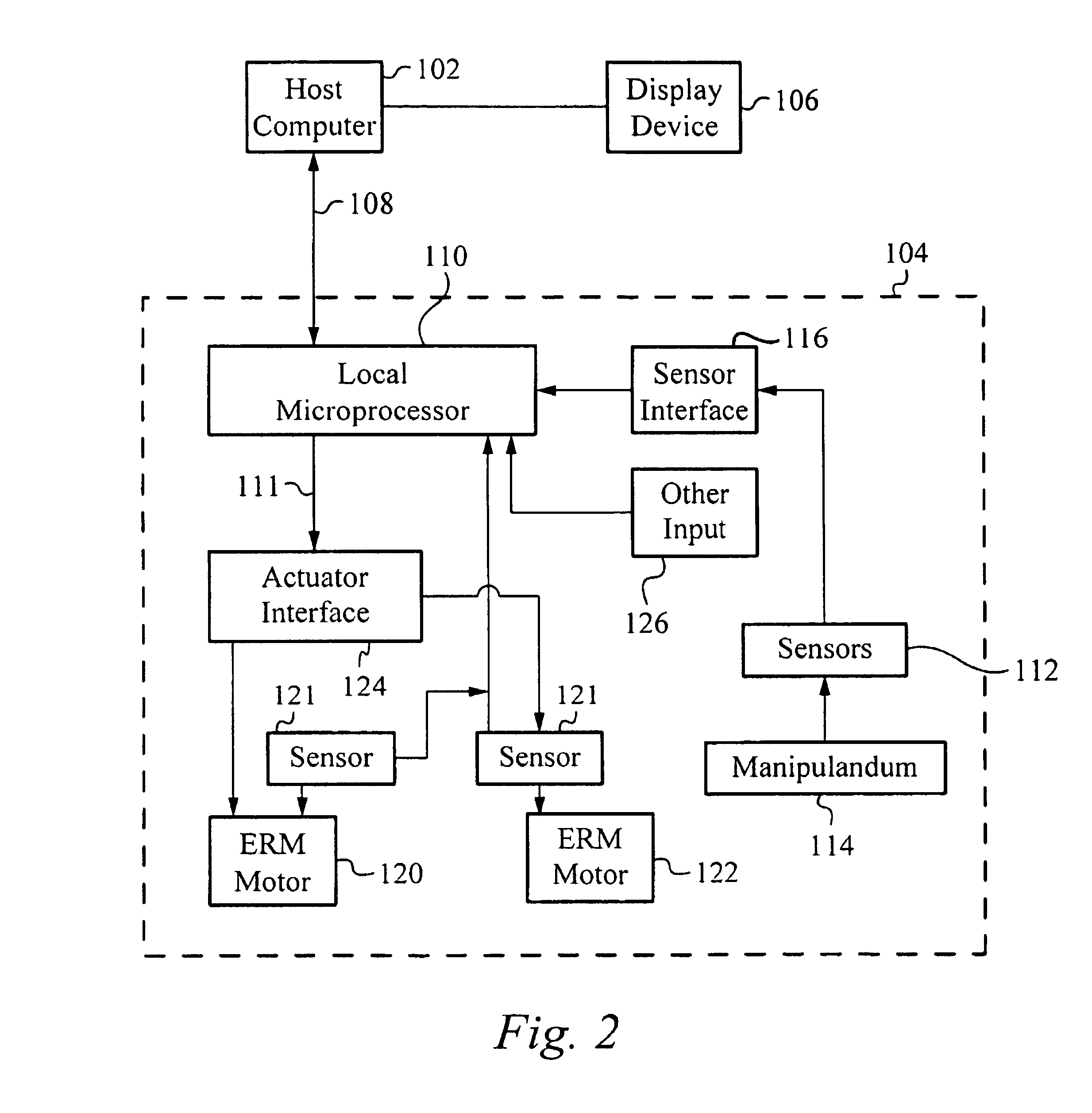

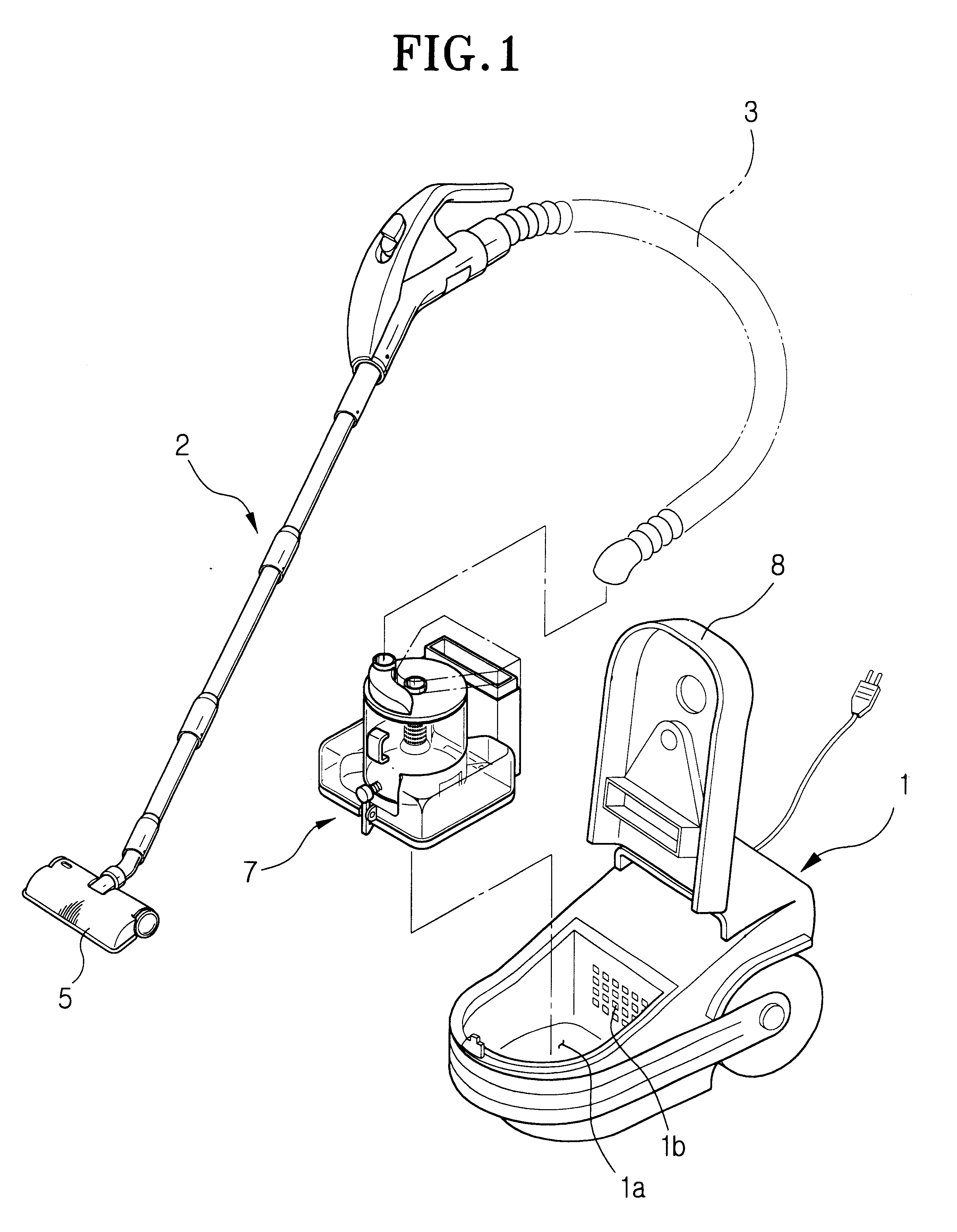

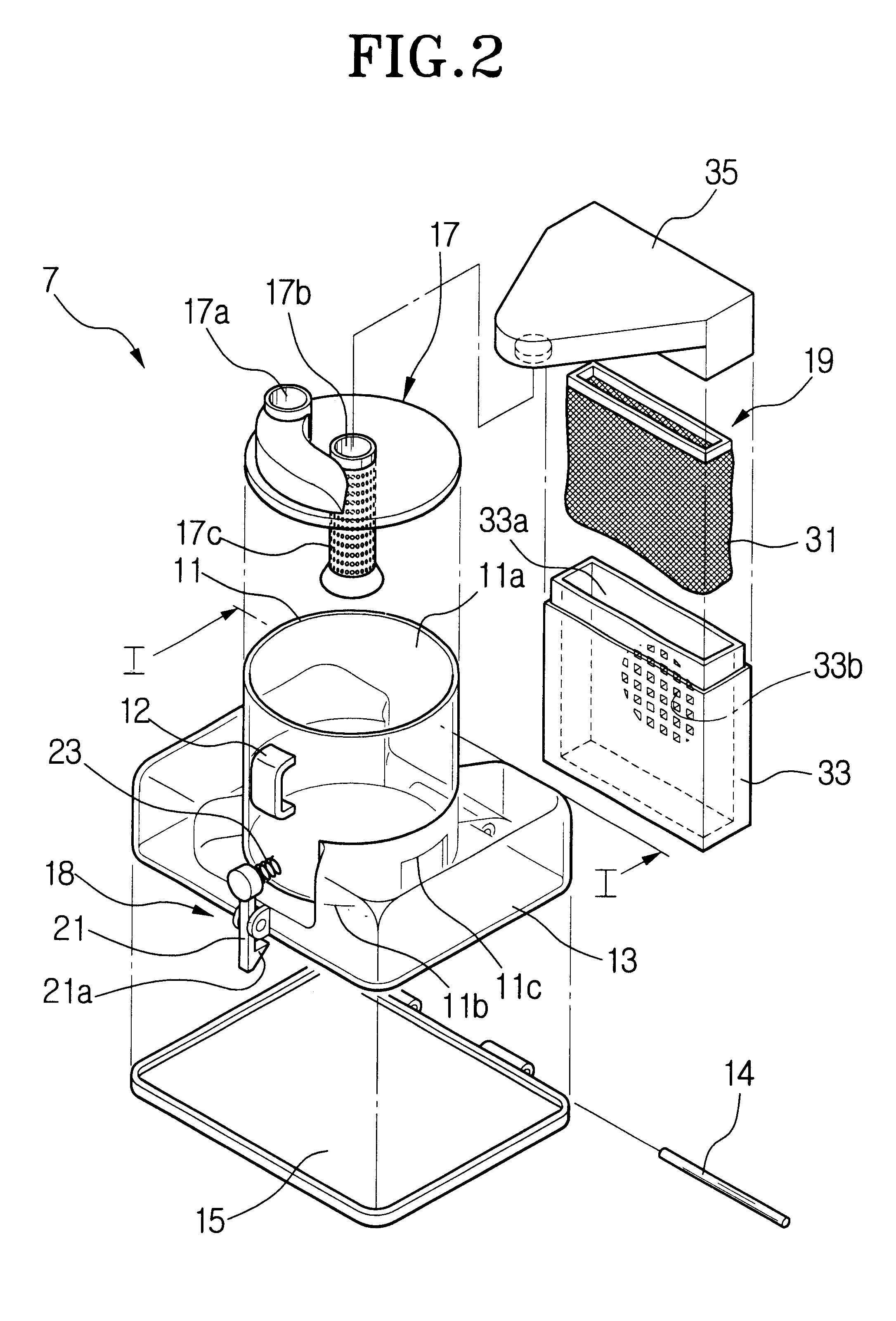

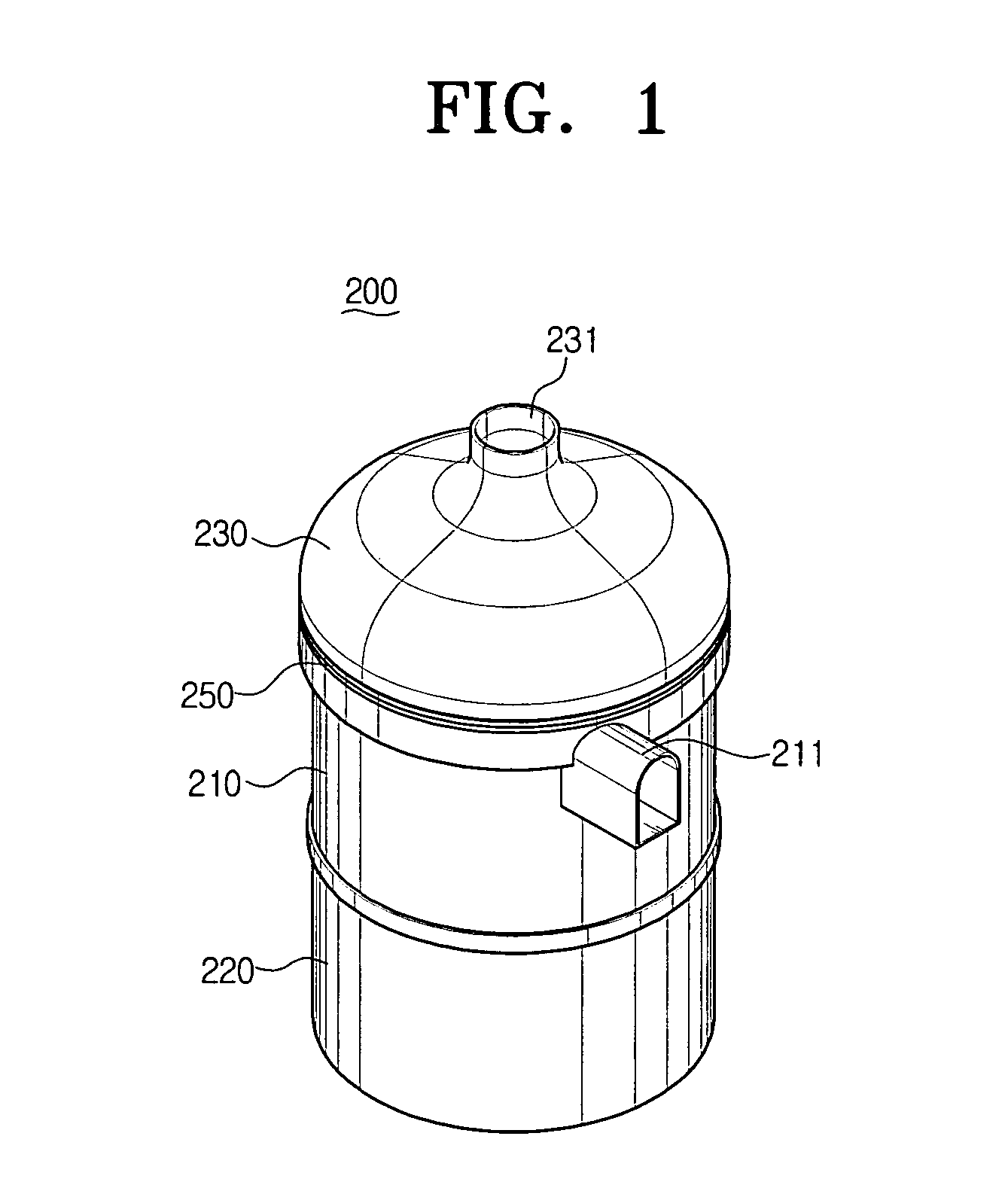

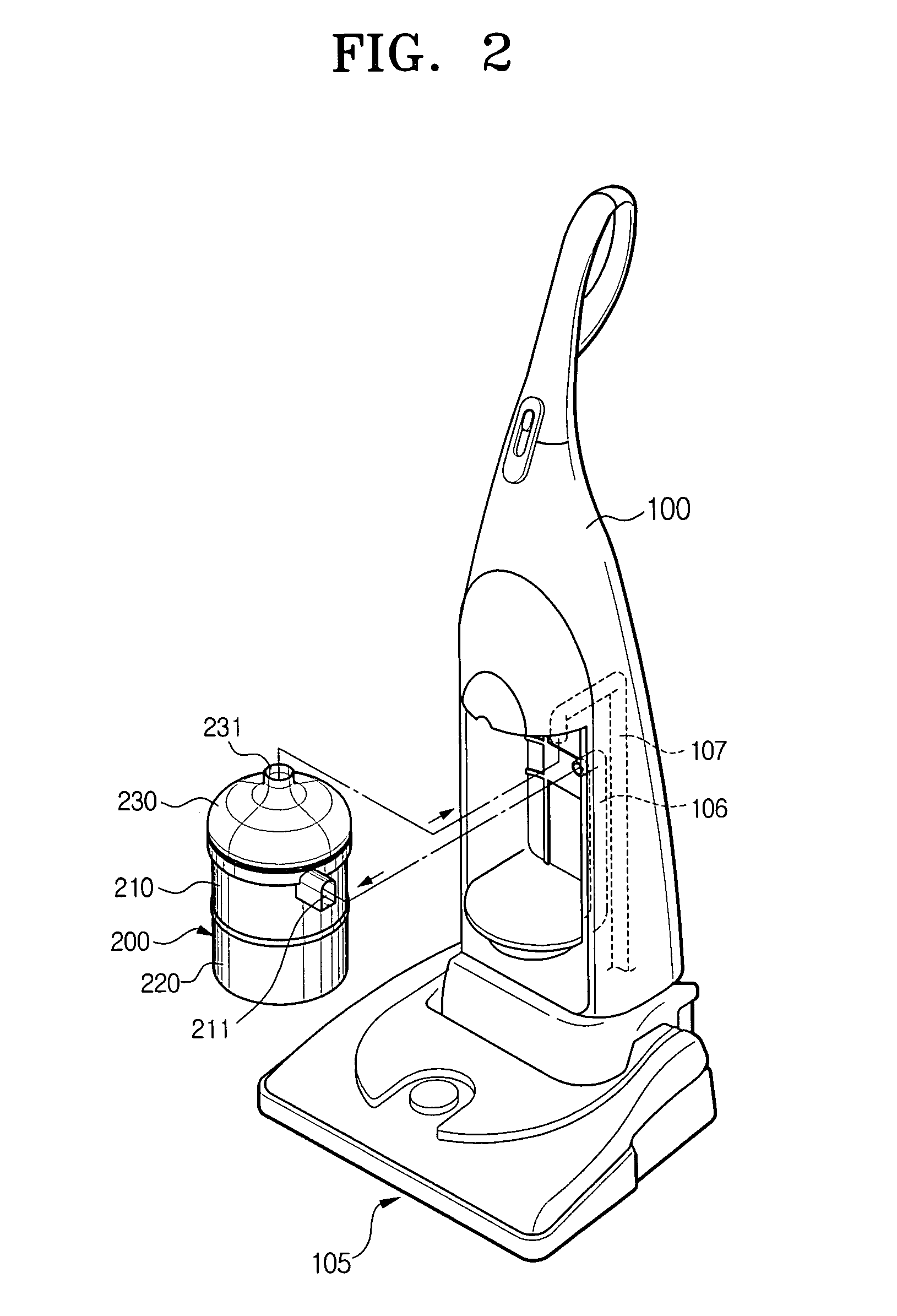

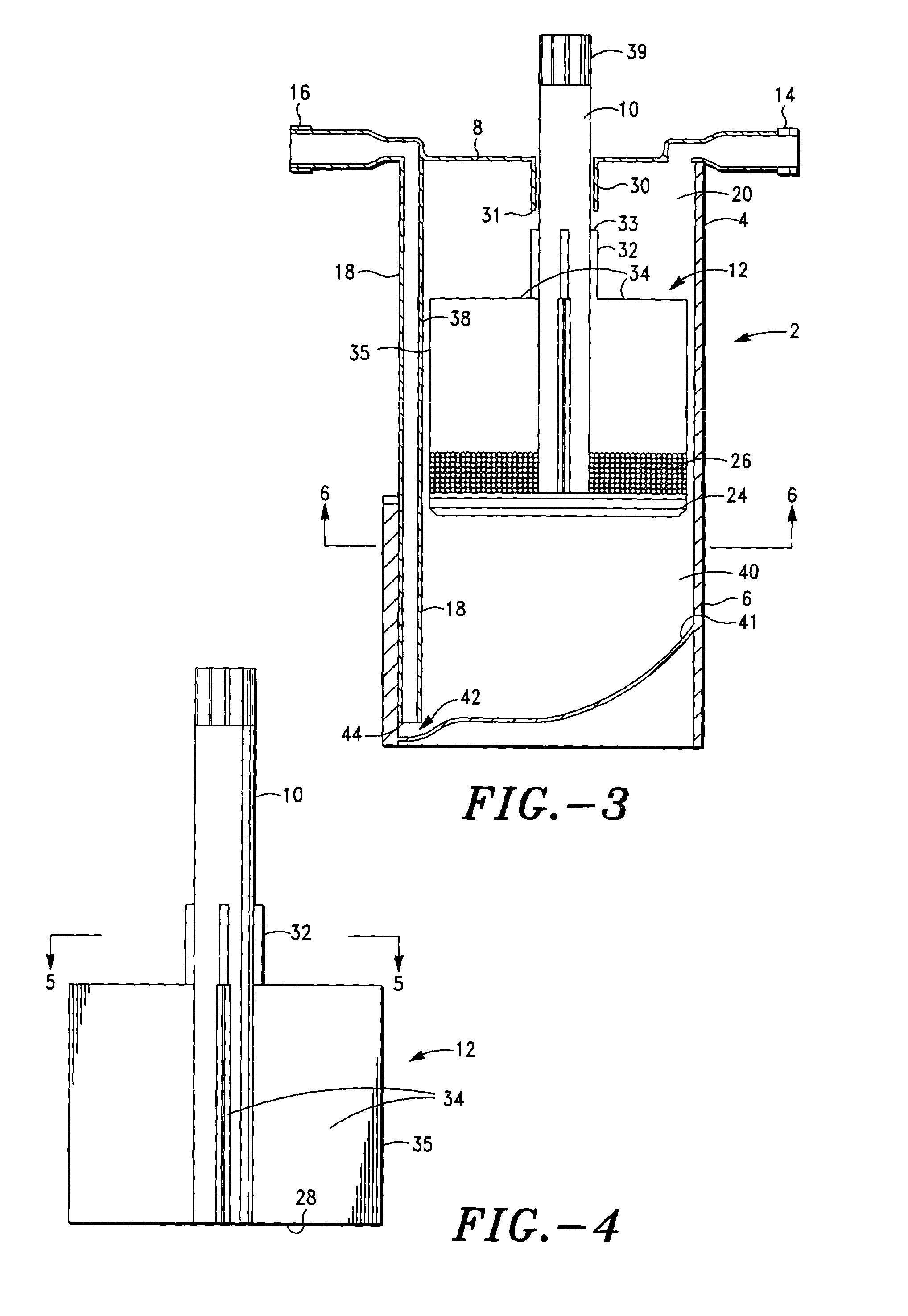

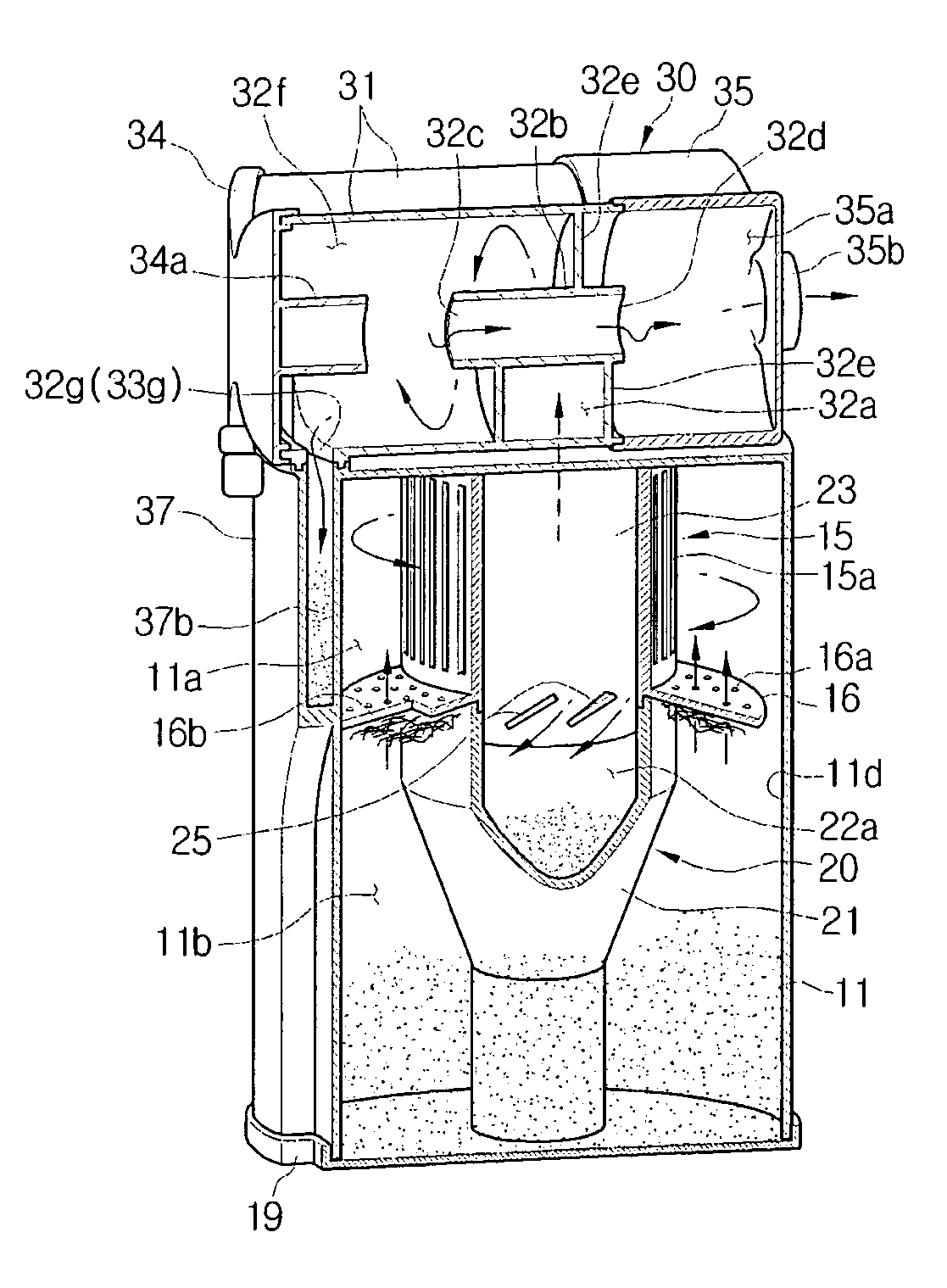

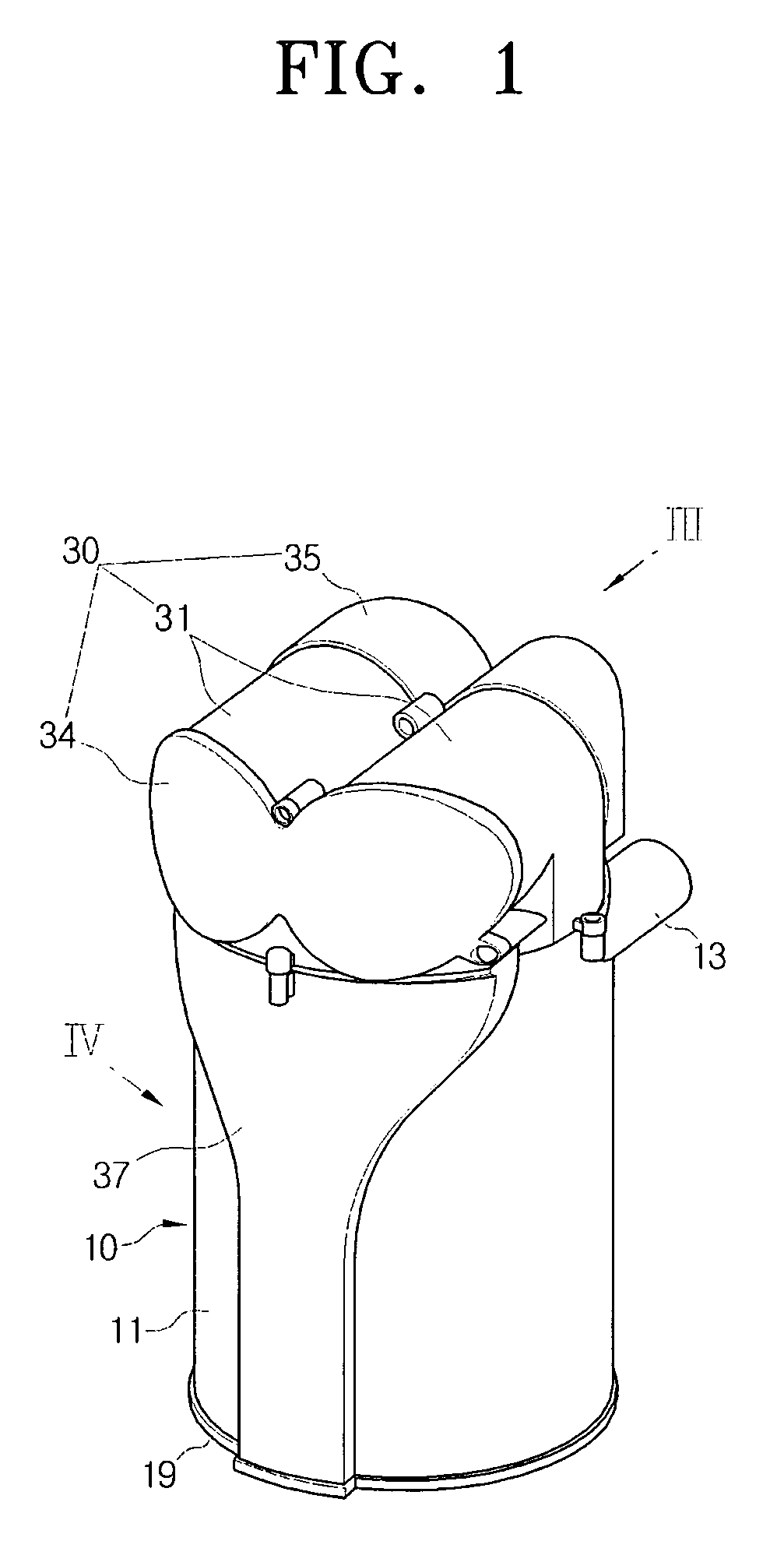

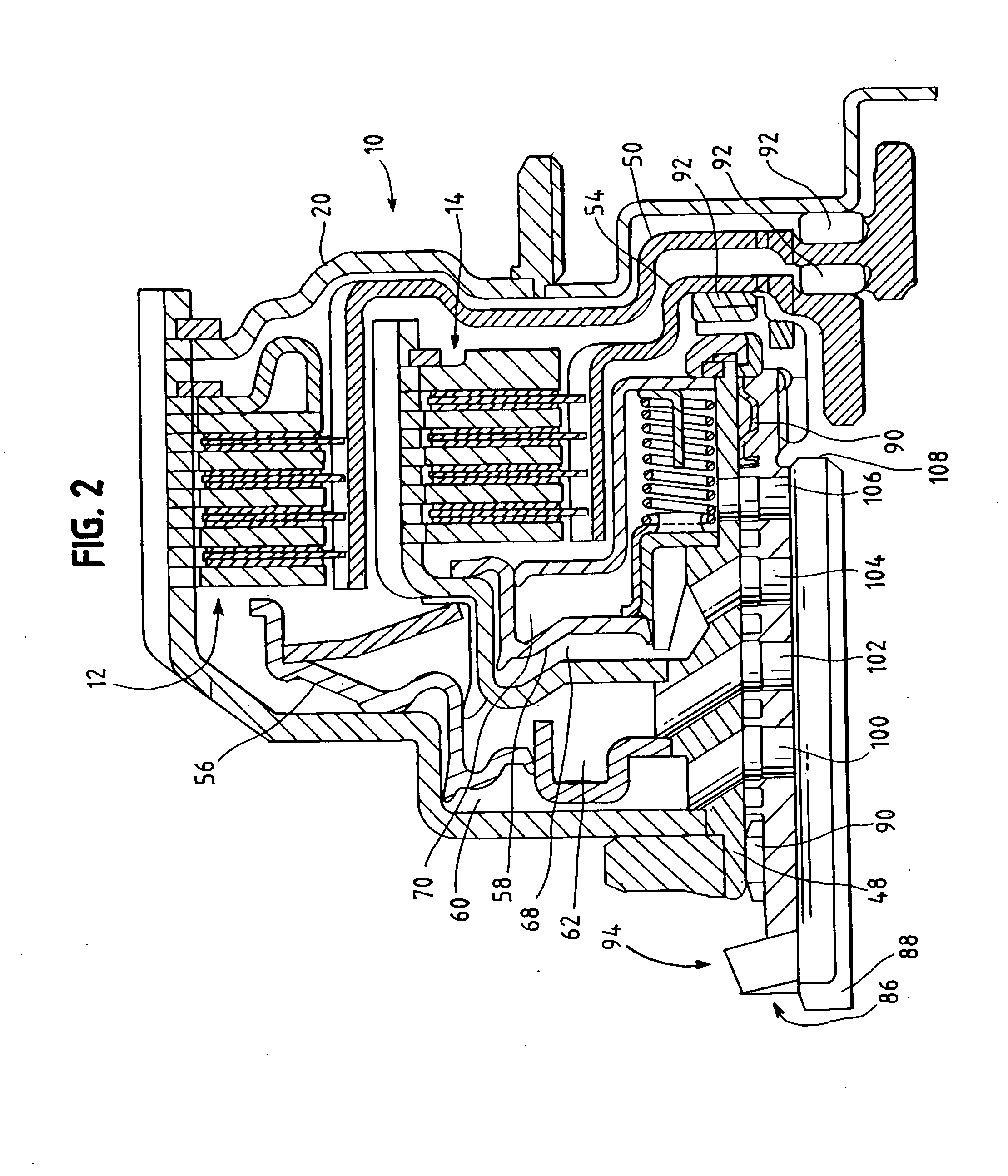

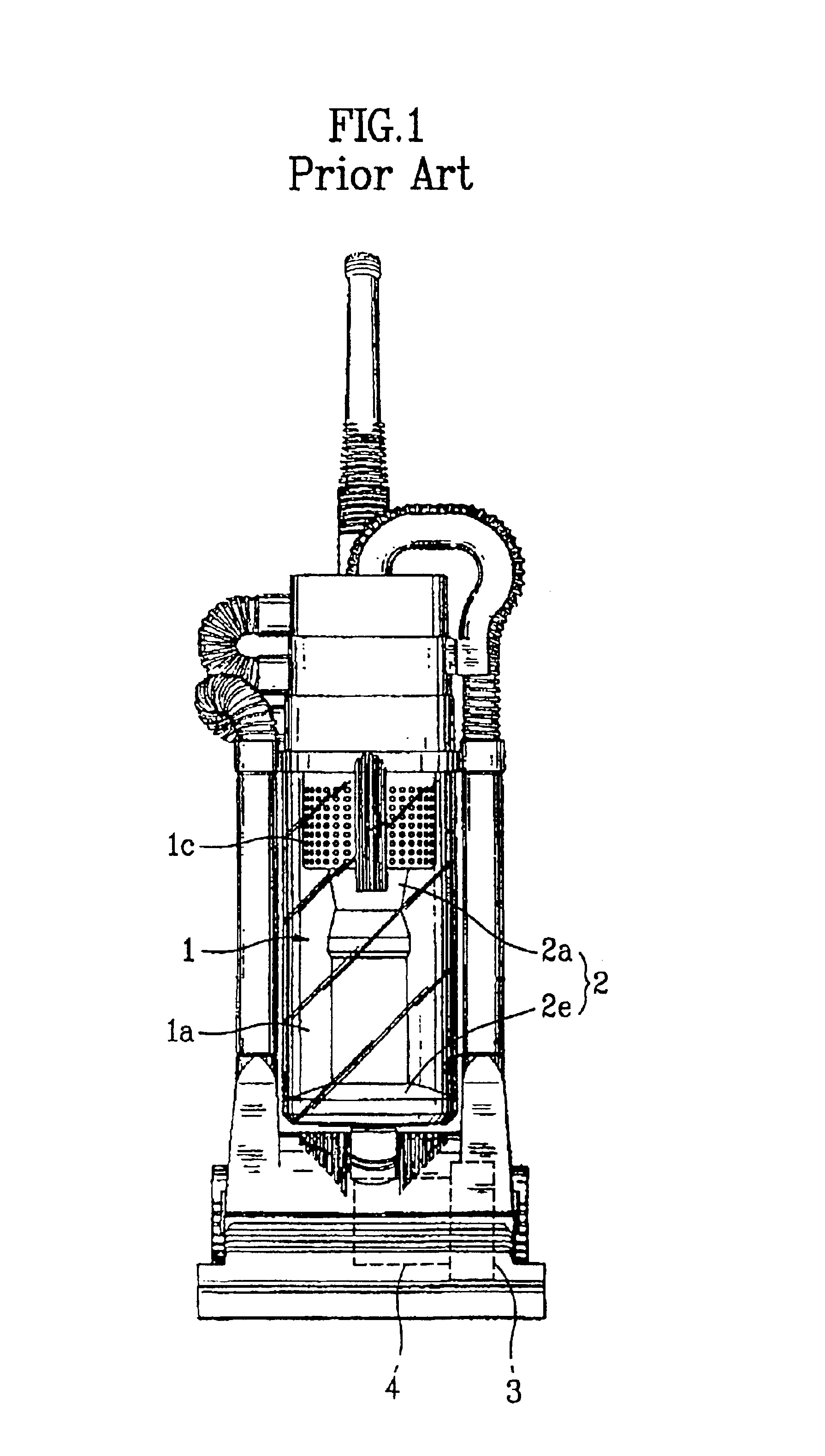

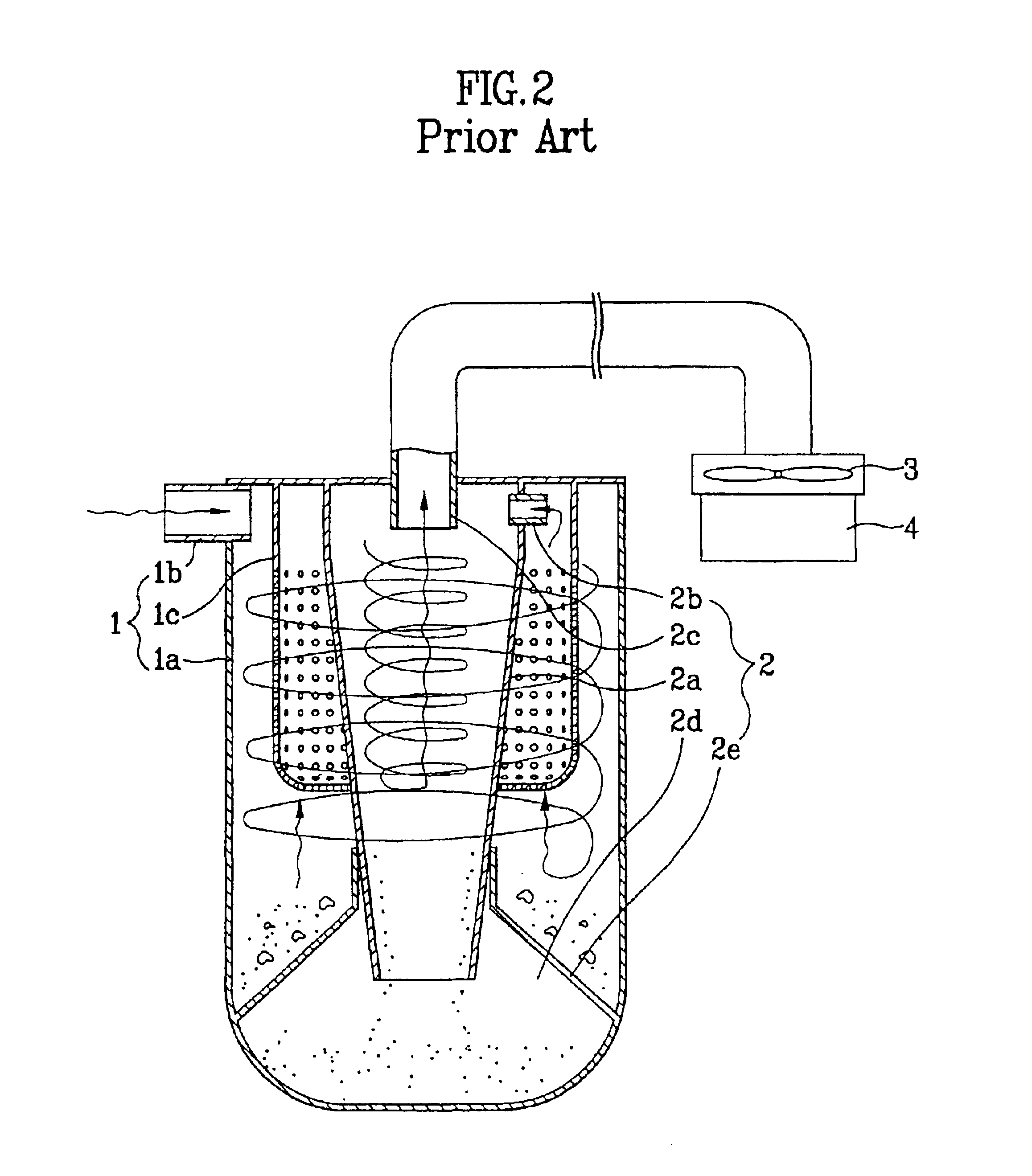

Vacuum cleaner having a cyclone type dust collecting apparatus

A vacuum cleaner includes a cleaner body, a suction brush, through which air and contaminants are drawn in, and a cyclone type dust collecting device. The cleaner body has a motor driving chamber and a dust collecting chamber in communication with the motor driving chamber. The cyclone type dust collecting device is mounted in the dust collecting chamber and separates by centrifugal force the contaminants from the air. The cyclone type dust collecting device includes a hollow cylindrical cyclone body having an open top, a closed bottom, and a contaminant outlet. The open top allows air and contaminants into the cyclone body, where the contaminants are separated from the air by centrifugation. The contaminants are then discharged from the cyclone body through the contaminant outlet. The cyclone type dust collecting device further includes a contaminant receptacle for collecting the contaminants discharged through the contaminant outlet, a base member hingedly connected to the contaminant receptacle, and a cover for covering the top of the cyclone body. The cover has an air inlet passage, through which air and contaminants drawn in through the suction brush enter into the cyclone body, an air outlet passage, through which the air is discharged from the cyclone body, and a contaminant separating grill. The grill extends downward from the air outlet passage into the cyclone body and has a plurality of fine holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

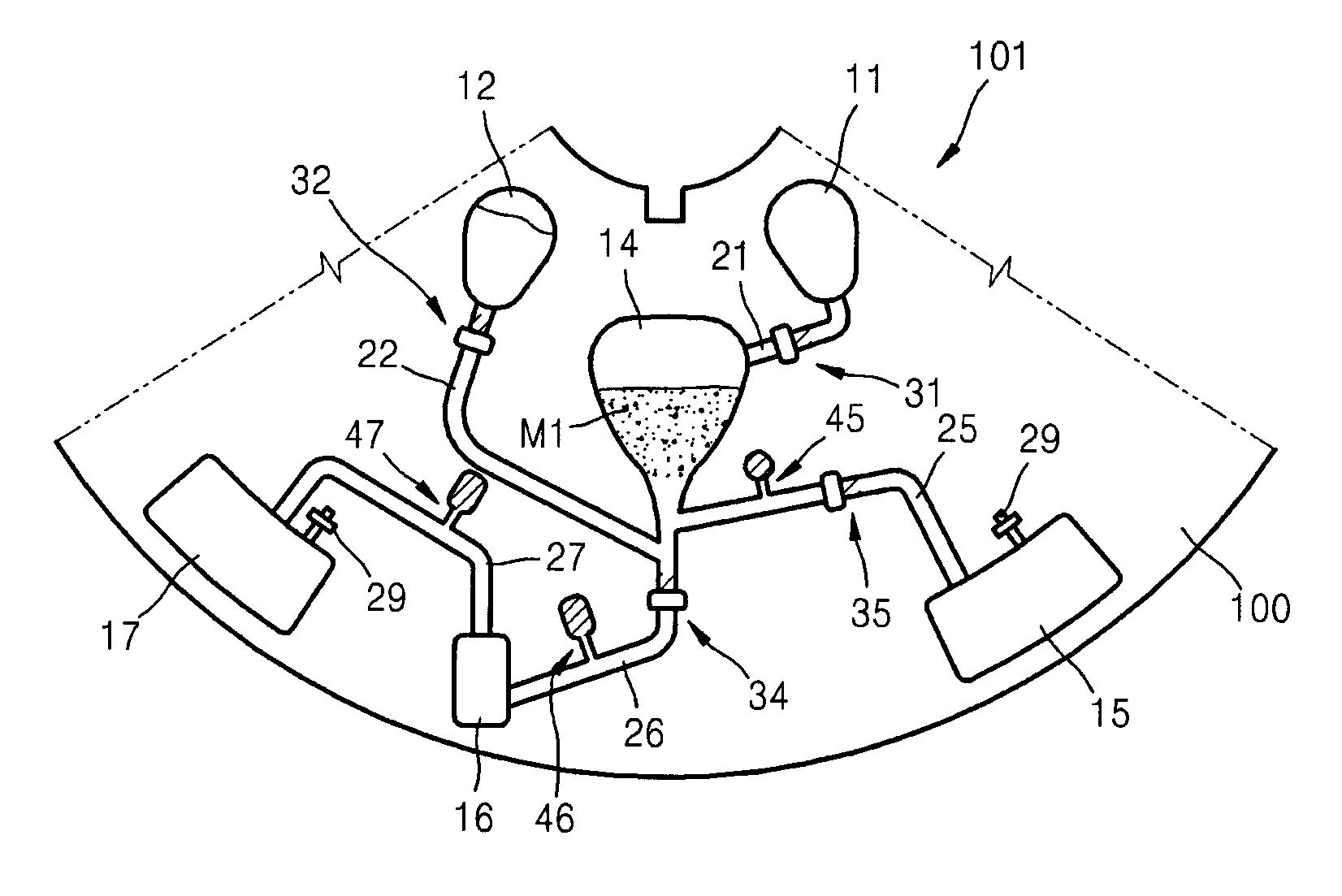

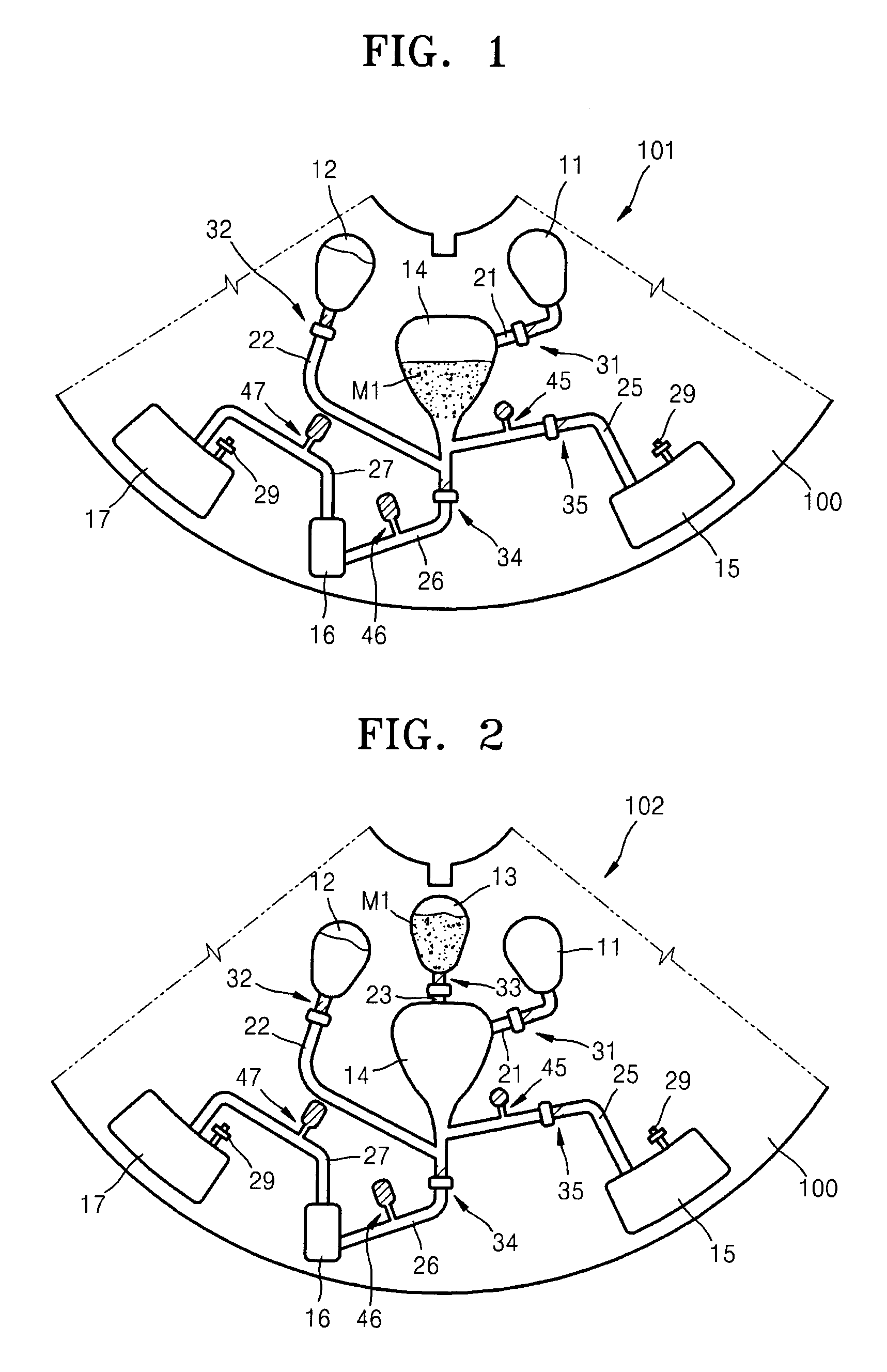

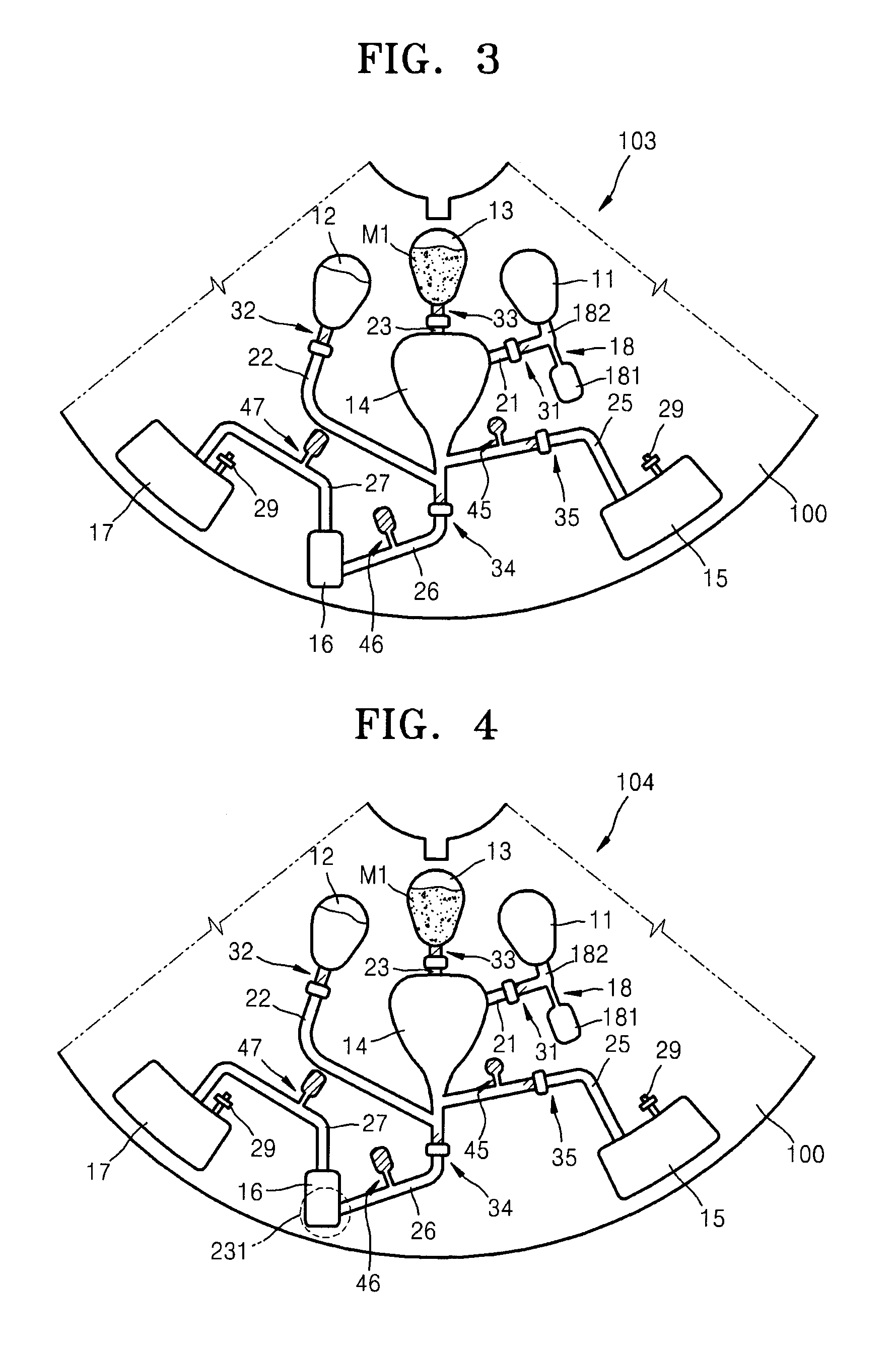

Spin head, apparatus for treating substrate, and method for treating substrate

ActiveUS20100126539A1Prevent excessive speedSemiconductor/solid-state device manufacturingCleaning using liquidsRotational axisCentrifugal force

Provided is a spin head supporting a substrate and rotating the substrate. The spin head includes a body, chuck pins installed on the body and moving between supporting positions where a substrate is supported and waiting positions providing space for loading / unloading of the substrate, and a chuck pin moving unit configured to move the chuck pins. The chuck pin moving unit includes a rotation rod coupled with each of the chuck pins, a pivot pin fixing the rotation rod to the body, and a driving member rotating the rotation rod about the pivot pin as a rotation shaft to move the chuck pin from the supporting position to the waiting position. When the body rotates, the rotation rod uses reverse centrifugal force to apply force to the chuck pin from the waiting position to the supporting position. The chuck pins include first pins and second pins that alternately chuck a substrate during a process.

Owner:SEMES CO LTD

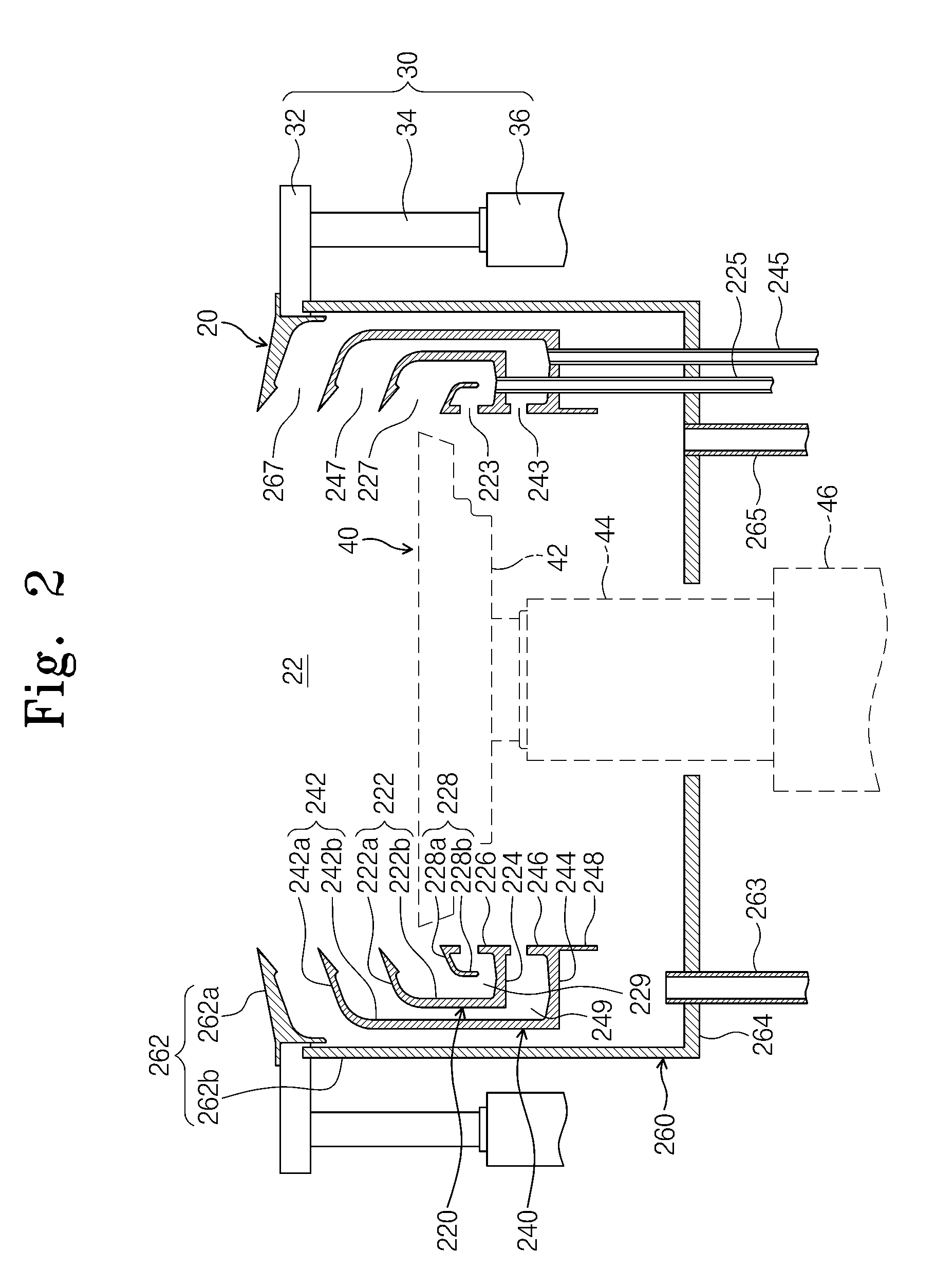

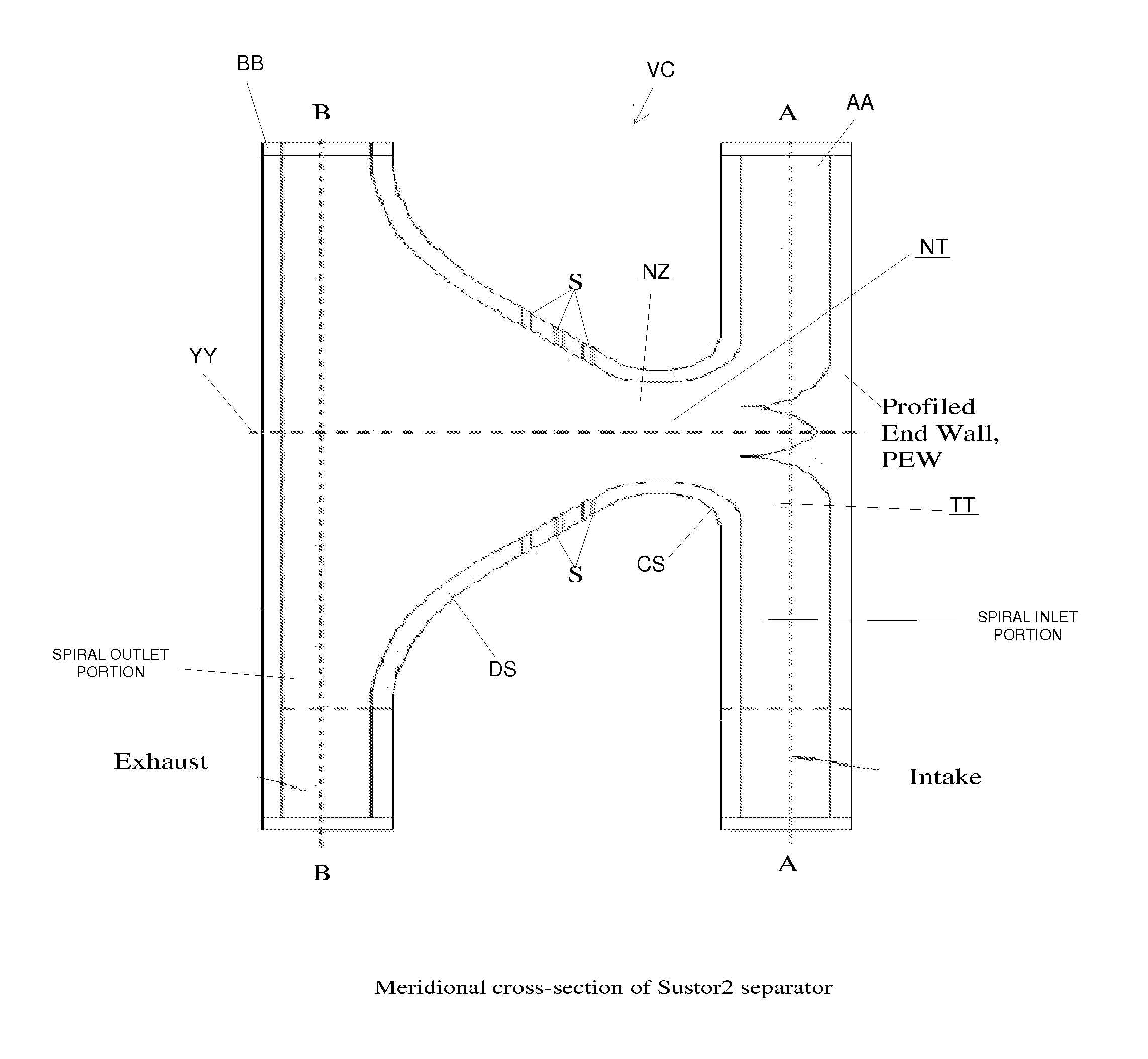

Supersonic swirling separator 2 (Sustor2)

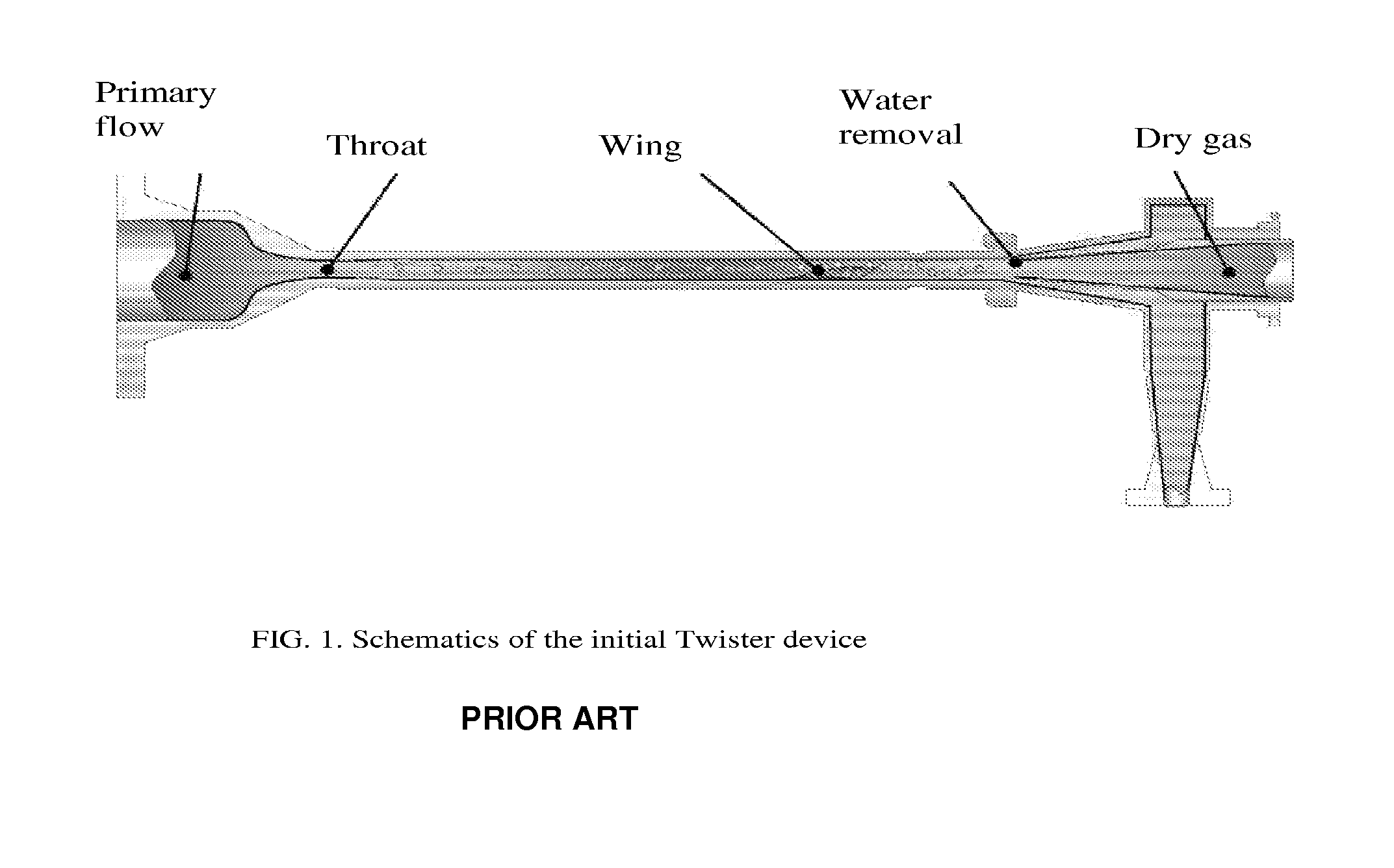

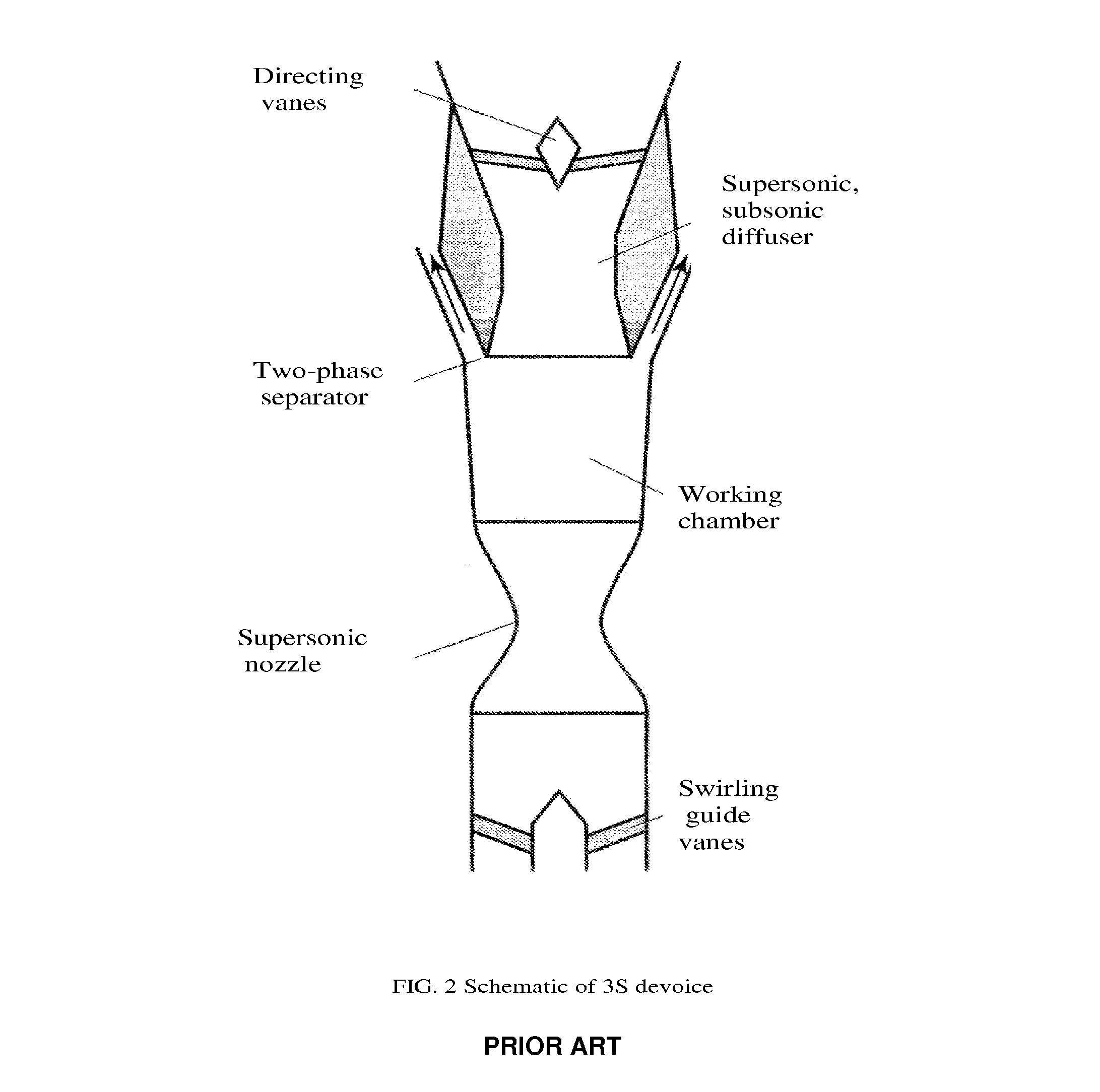

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

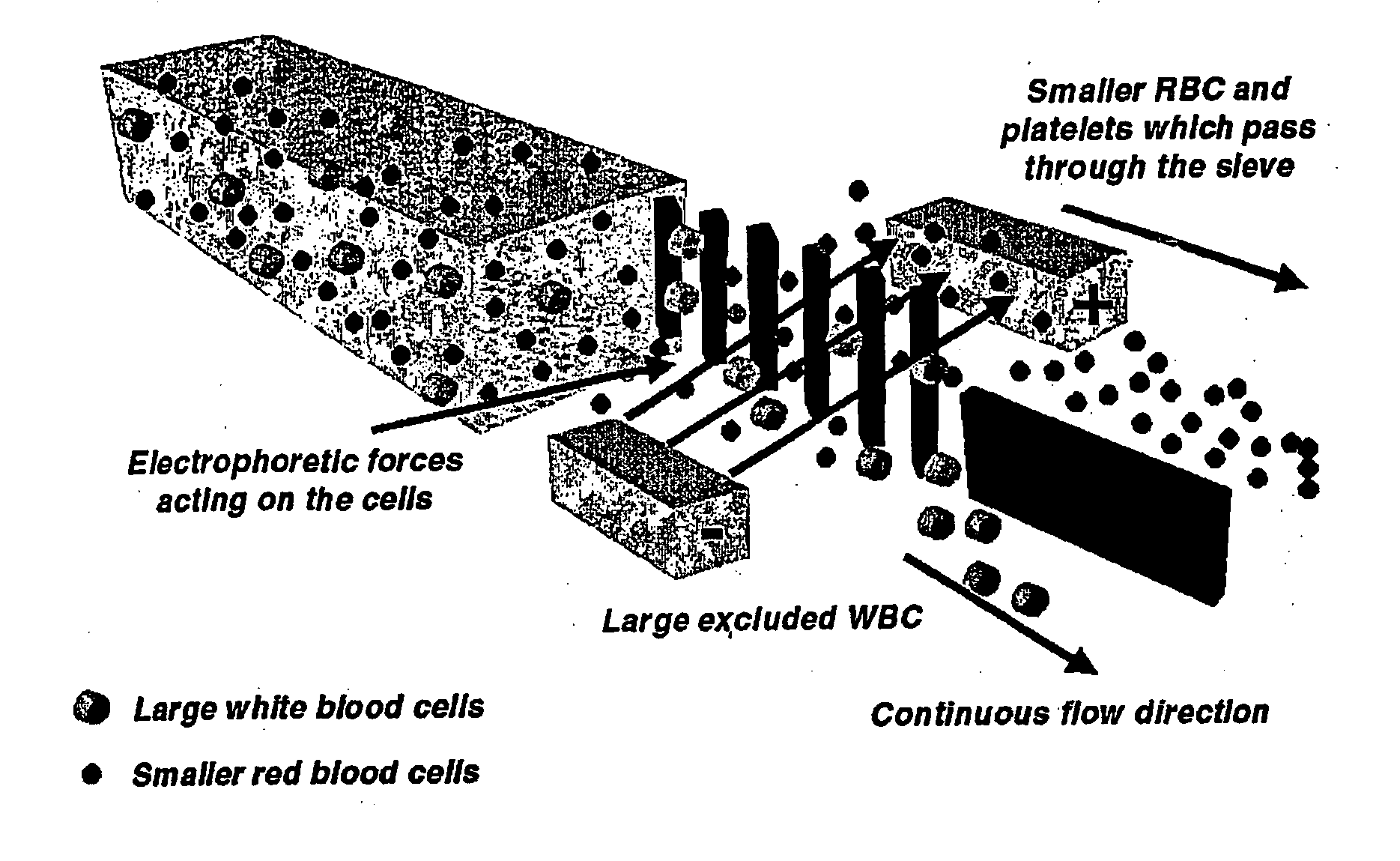

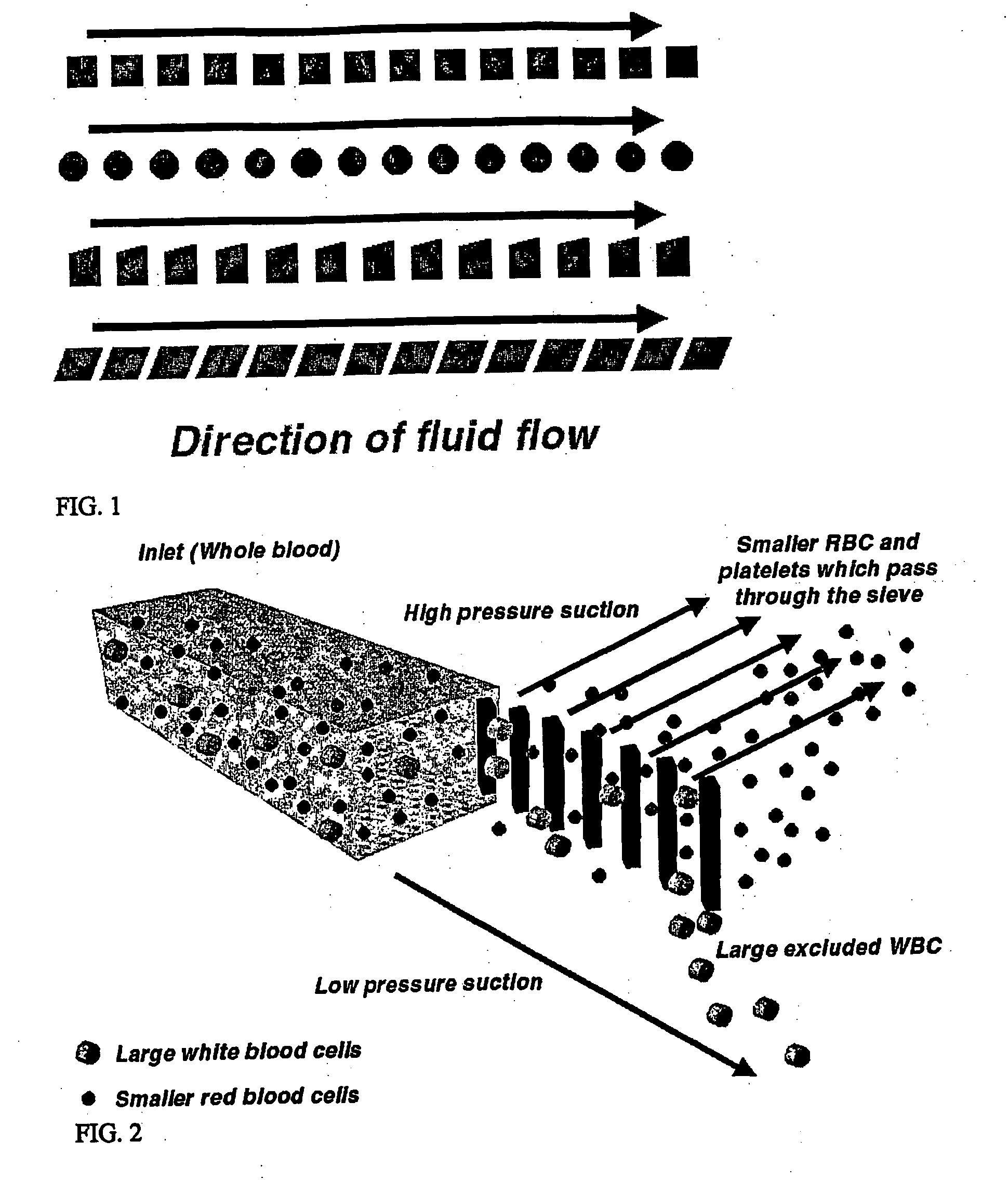

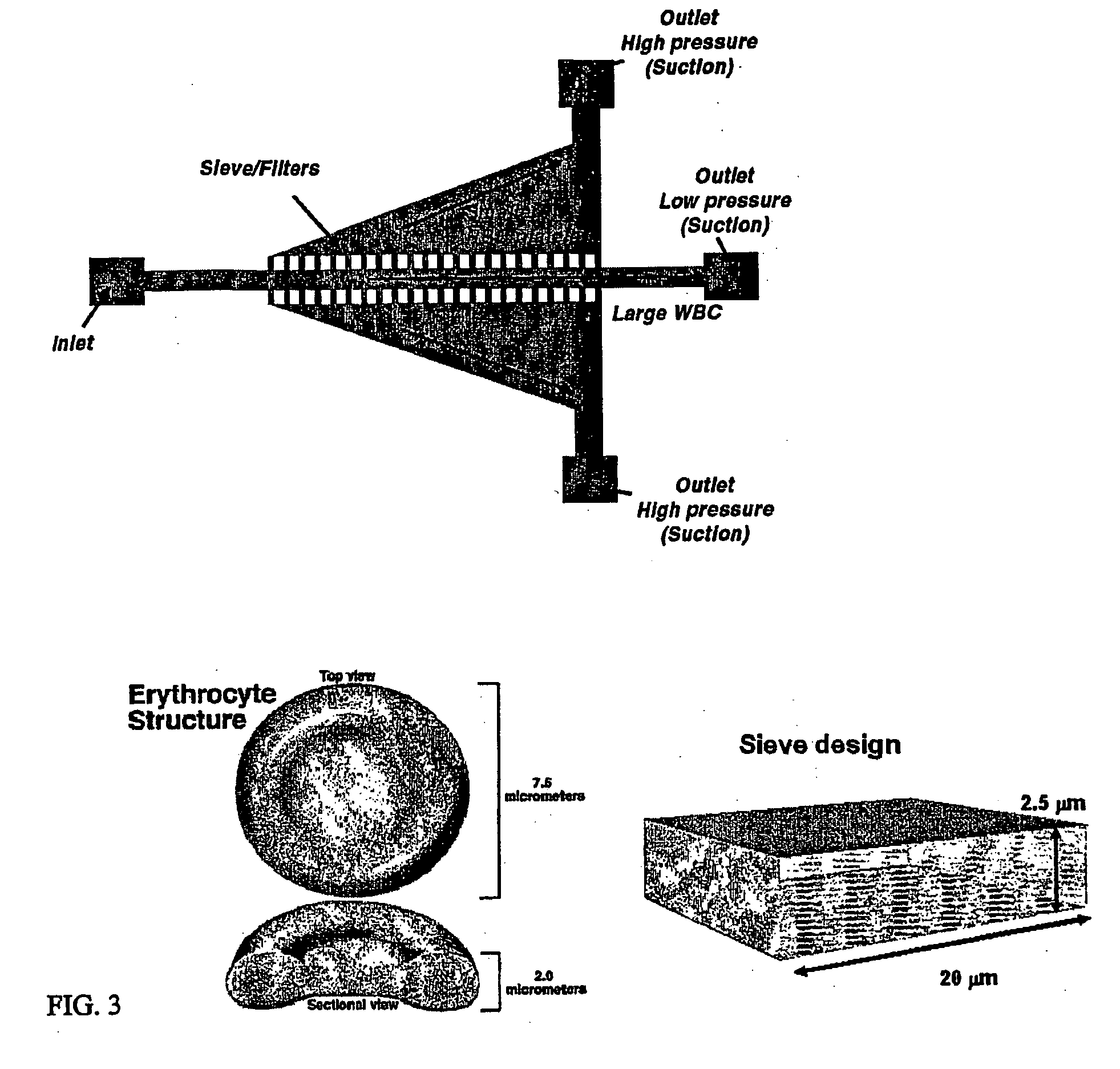

Microfluidic systems for size based removal of red blood cells and platelets from blood

The invention features devices and methods for enriching a sample in one or more desired particles. An exemplary use of these devices and methods is for the enrichment of cells, e.g., white blood cells in a blood sample. In general, the methods of the invention employ a device that contains at least one sieve through which particles of a given size, shape, or deformability can pass. Devices of the invention have at least two outlets, and the sieve is placed such that a continuous flow of fluid can pass through the device without passing through the sieve. The devices also include a force generator for directing selected particles through the sieve. Such force generators employ, for example, diffusion, electrophoresis, dielectrophoresis, centrifugal force, or pressure-driven flow.

Owner:THE GENERAL HOSPITAL CORP

Method for preparing a beverage or food liquid and system using brewing centrifugal force

A capsule, device, system and method for preparing a liquid food or beverage. The capsule comprises an enclosure containing one or more extractable or infusible ingredients and configured and dimensioned to have a perimeter and be radially symmetrical about a central axis to facilitate rotation; and an opening arrangement that allows liquid food to leave the capsule after passing through the ingredient(s), wherein the opening arrangement is configured and positioned near or upon the perimeter of the enclosure to allow the liquid food to leave the capsule radially due to the application of the centrifugal forces. The method and device introduce liquid into the capsule to form the liquid food while applying centrifugal forces to the capsule to urge the liquid to pass through the ingredient(s).

Owner:SOC DES PROD NESTLE SA

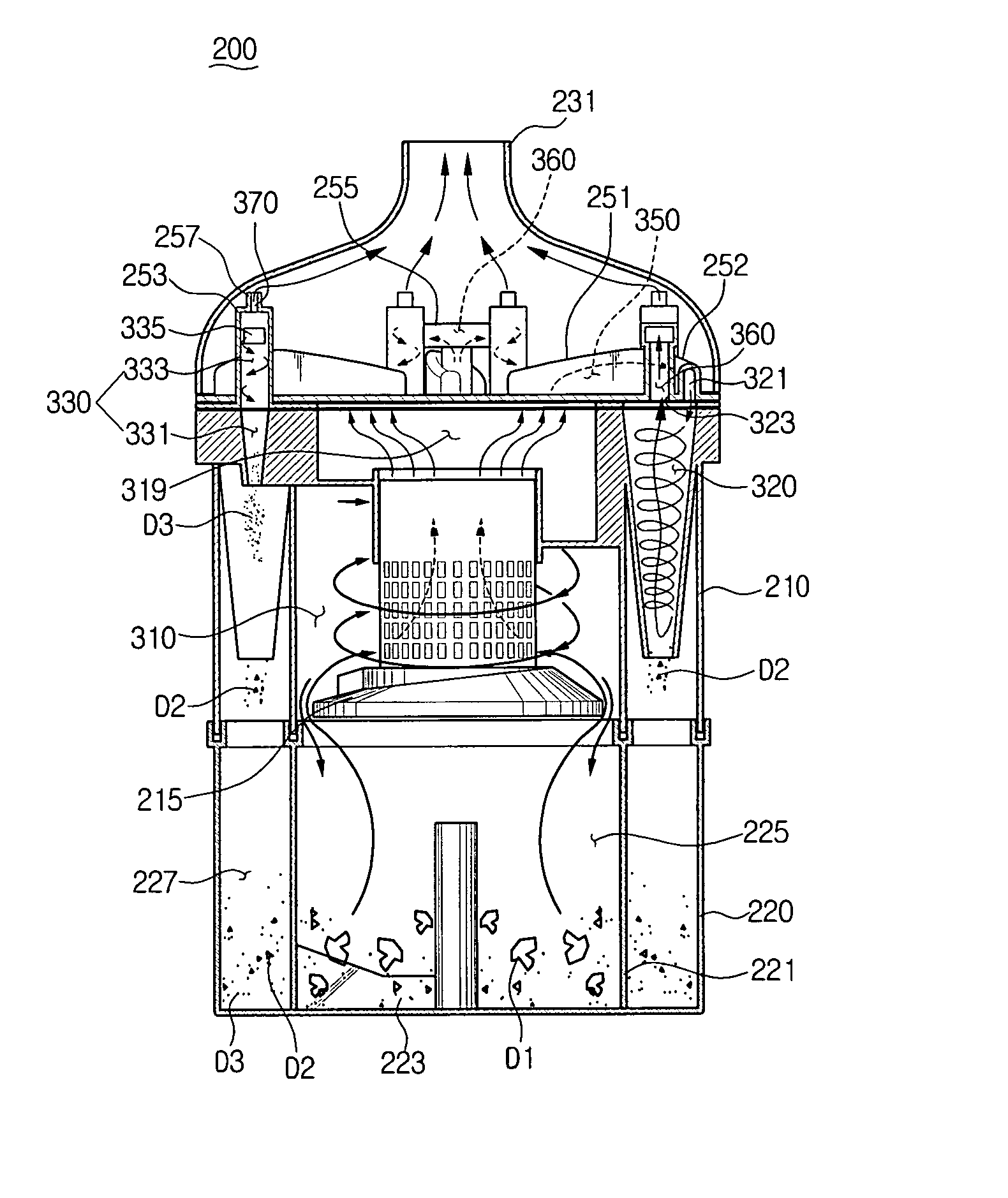

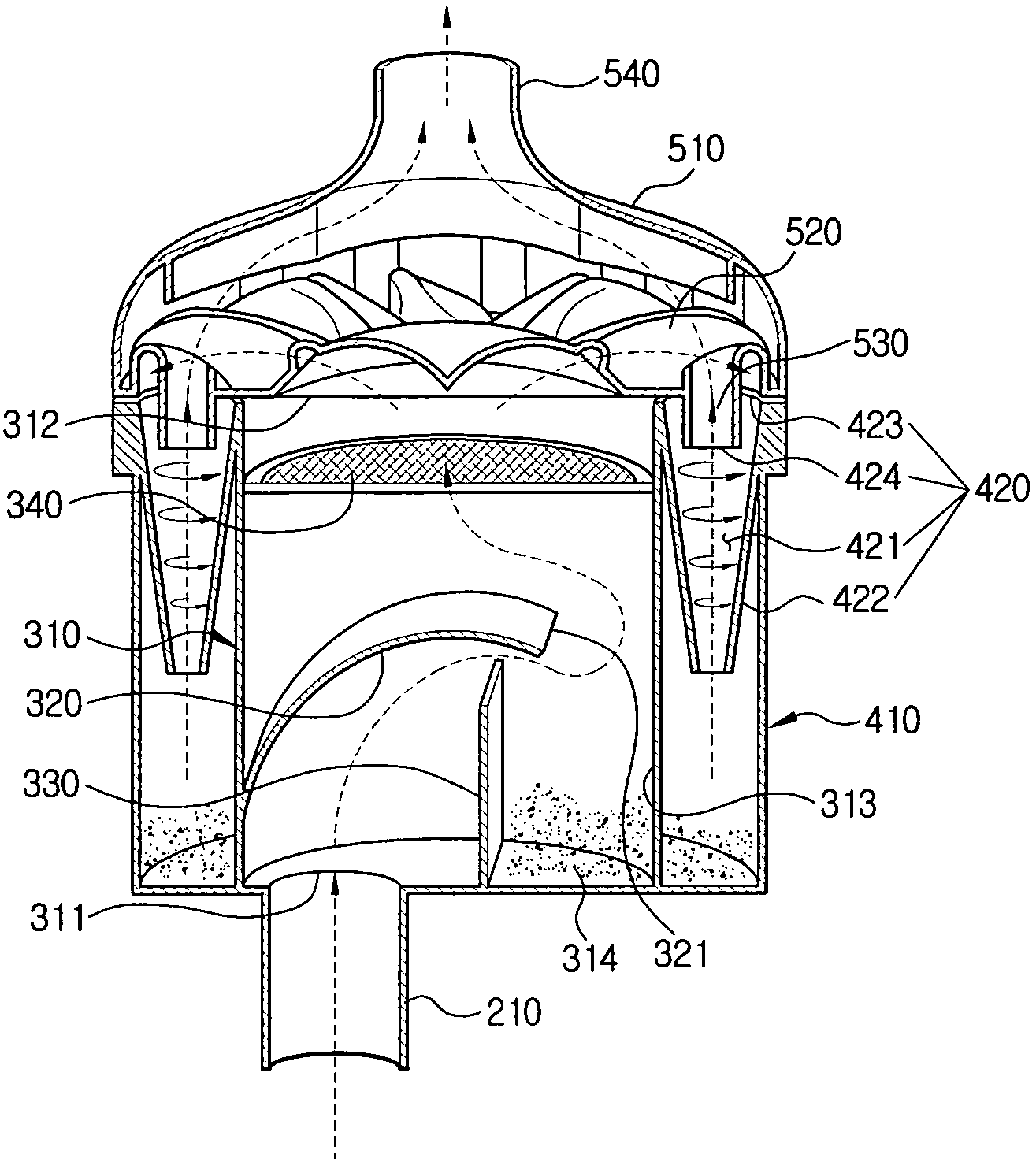

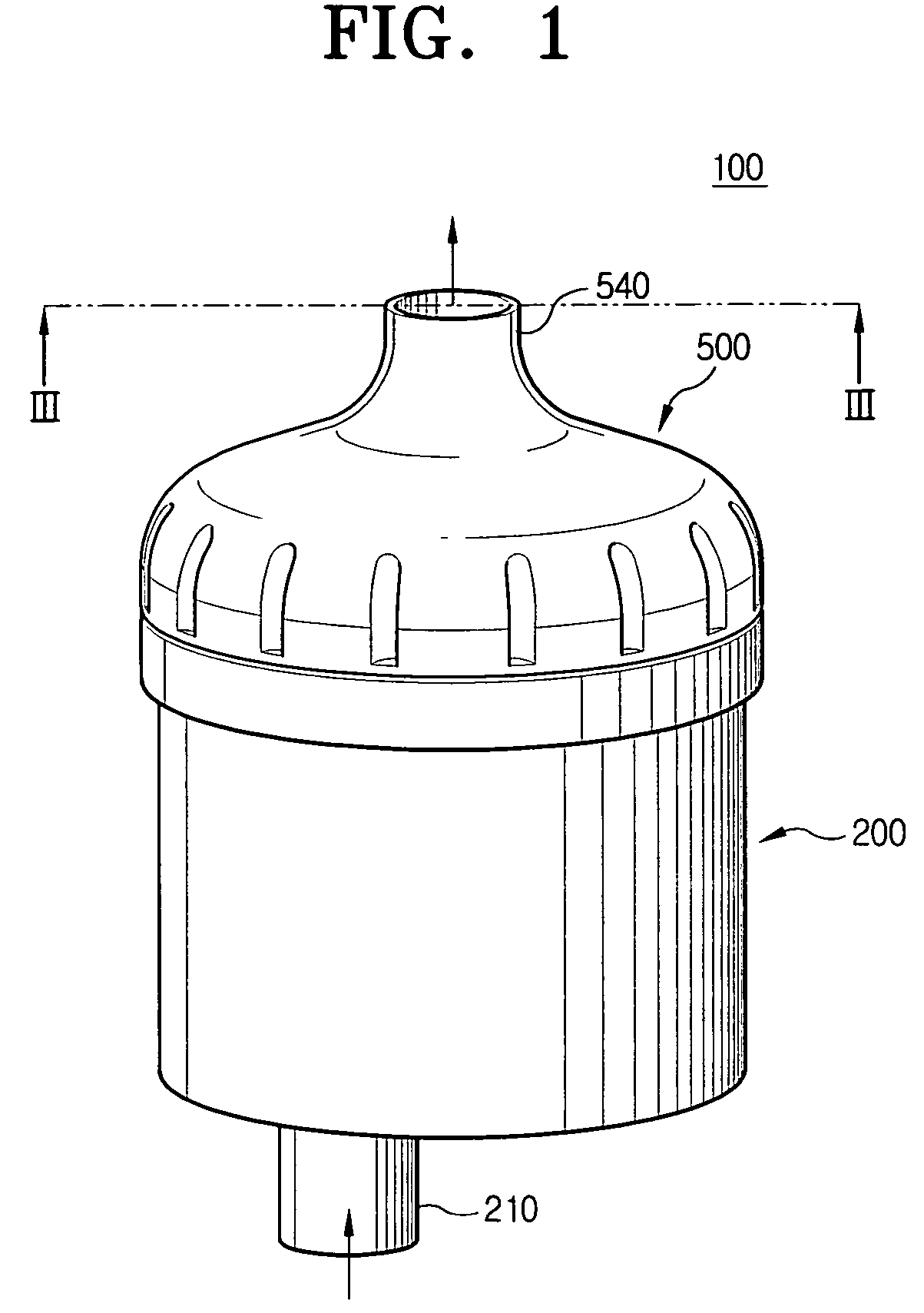

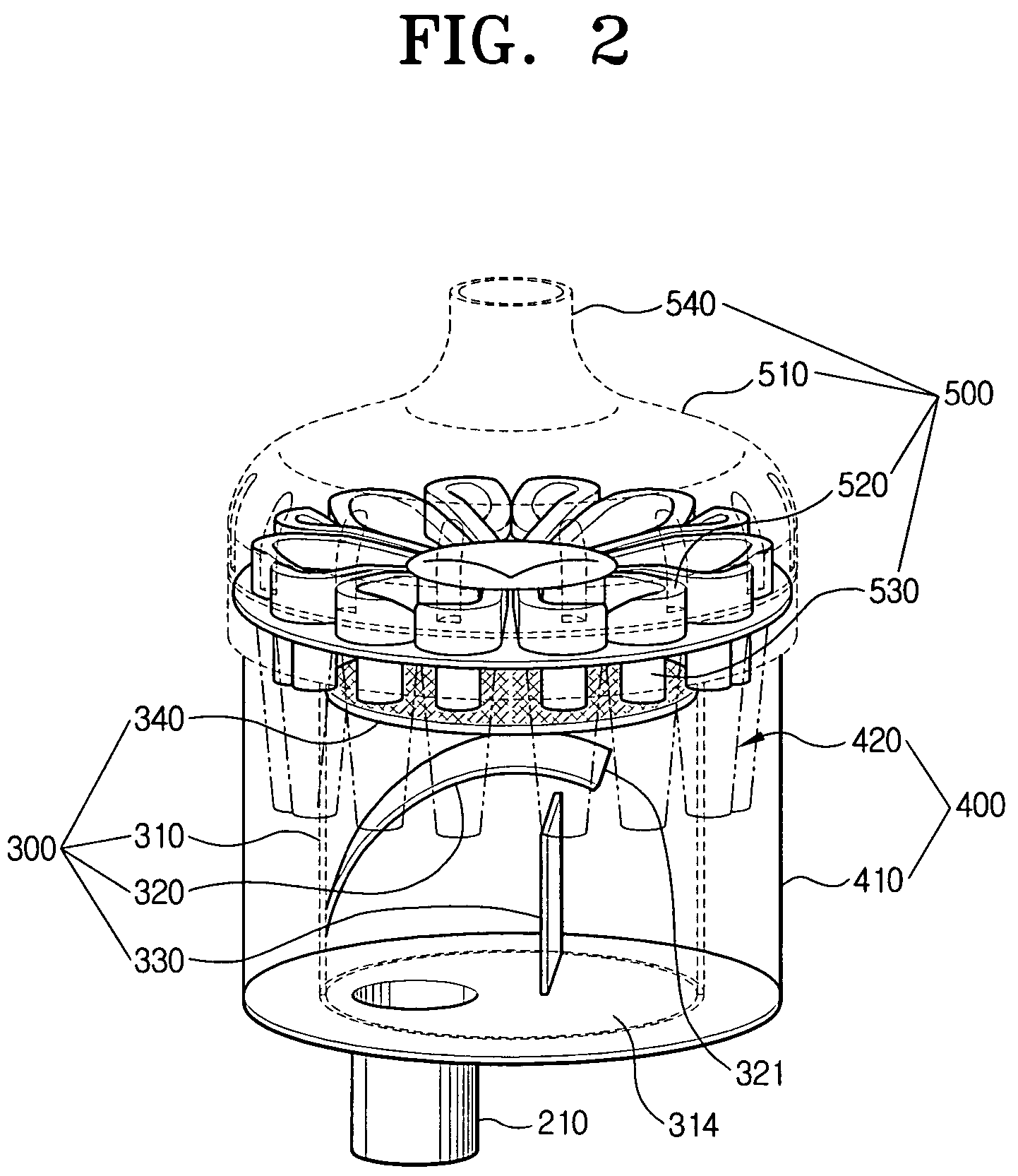

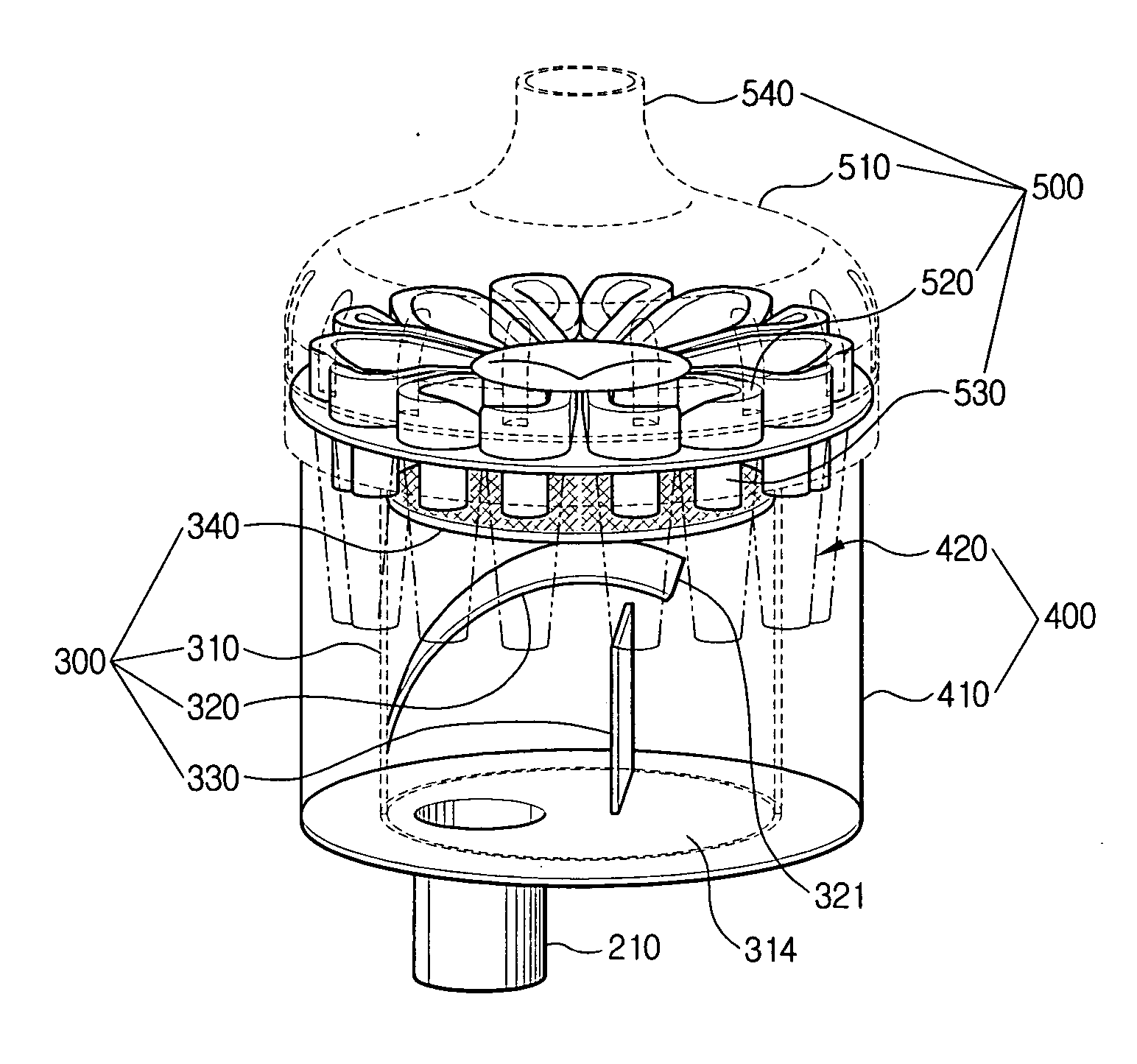

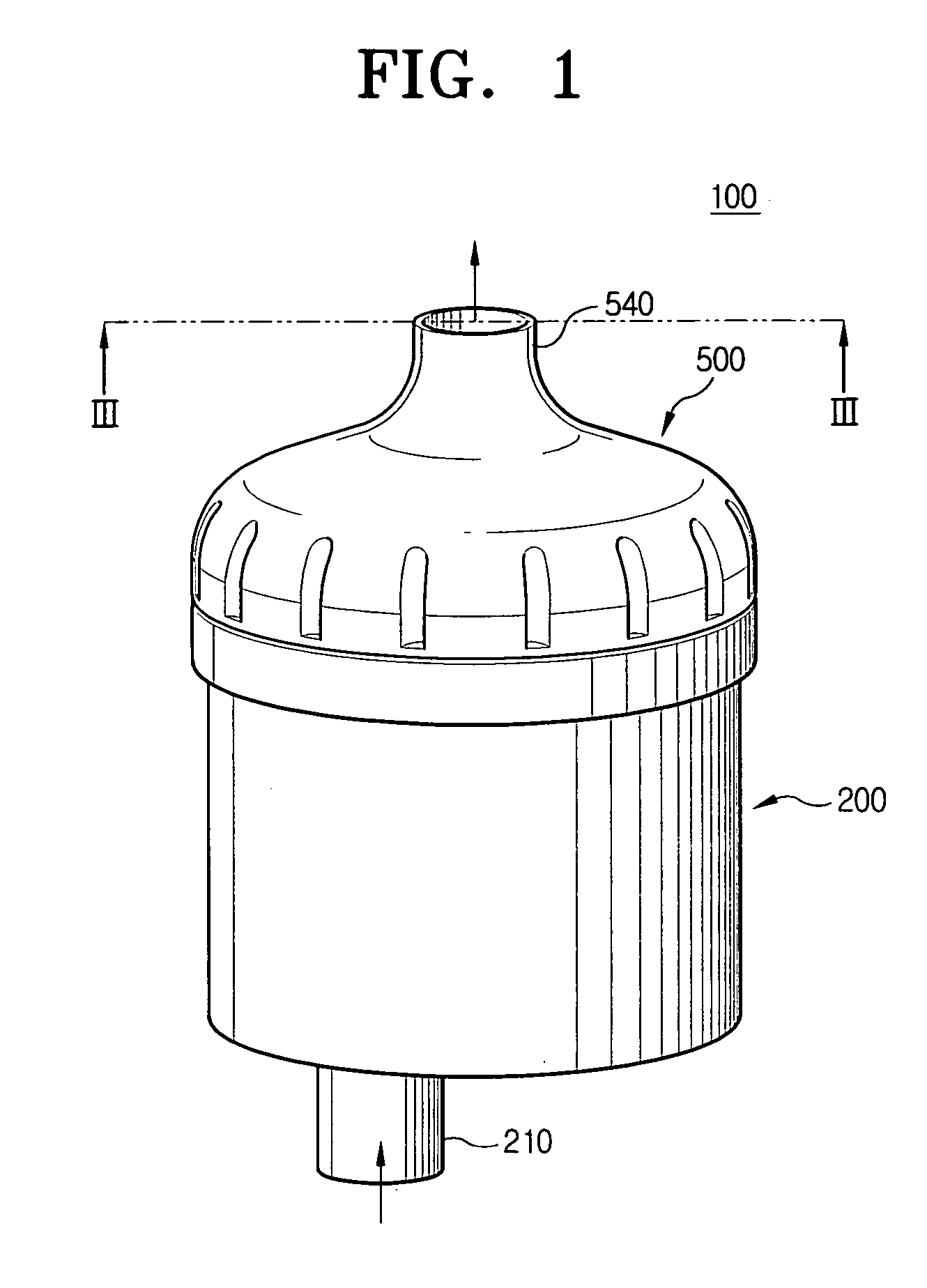

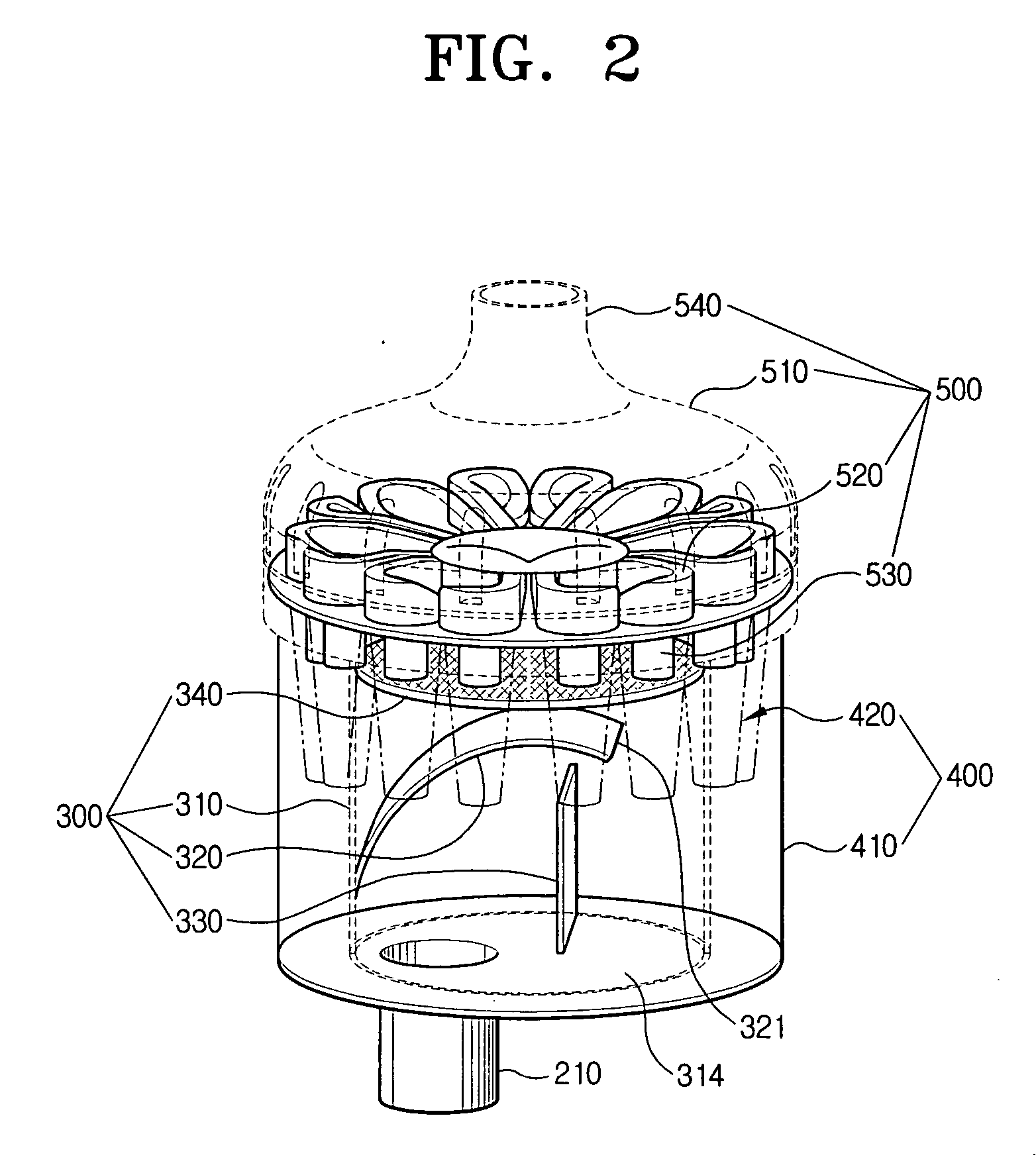

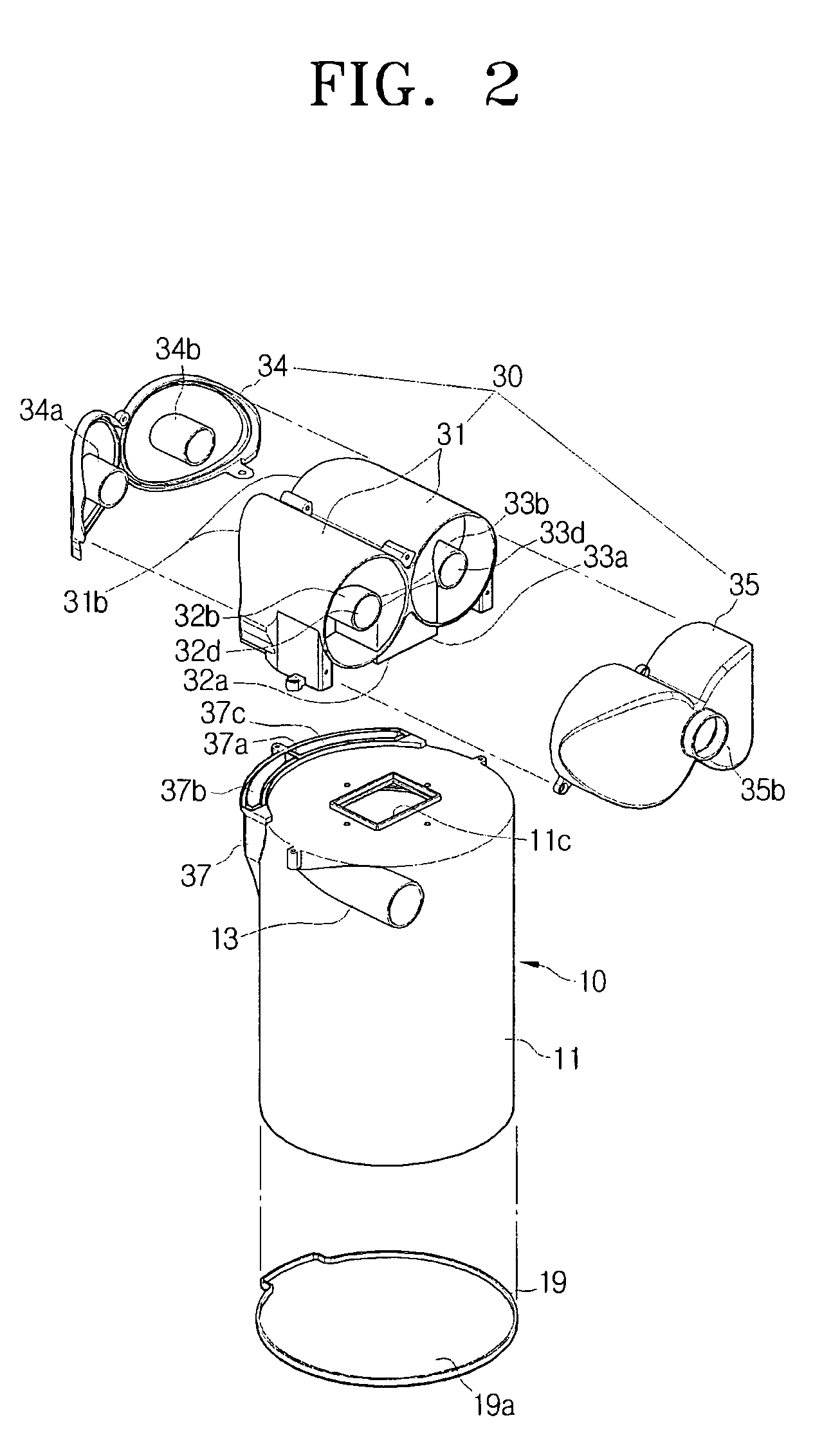

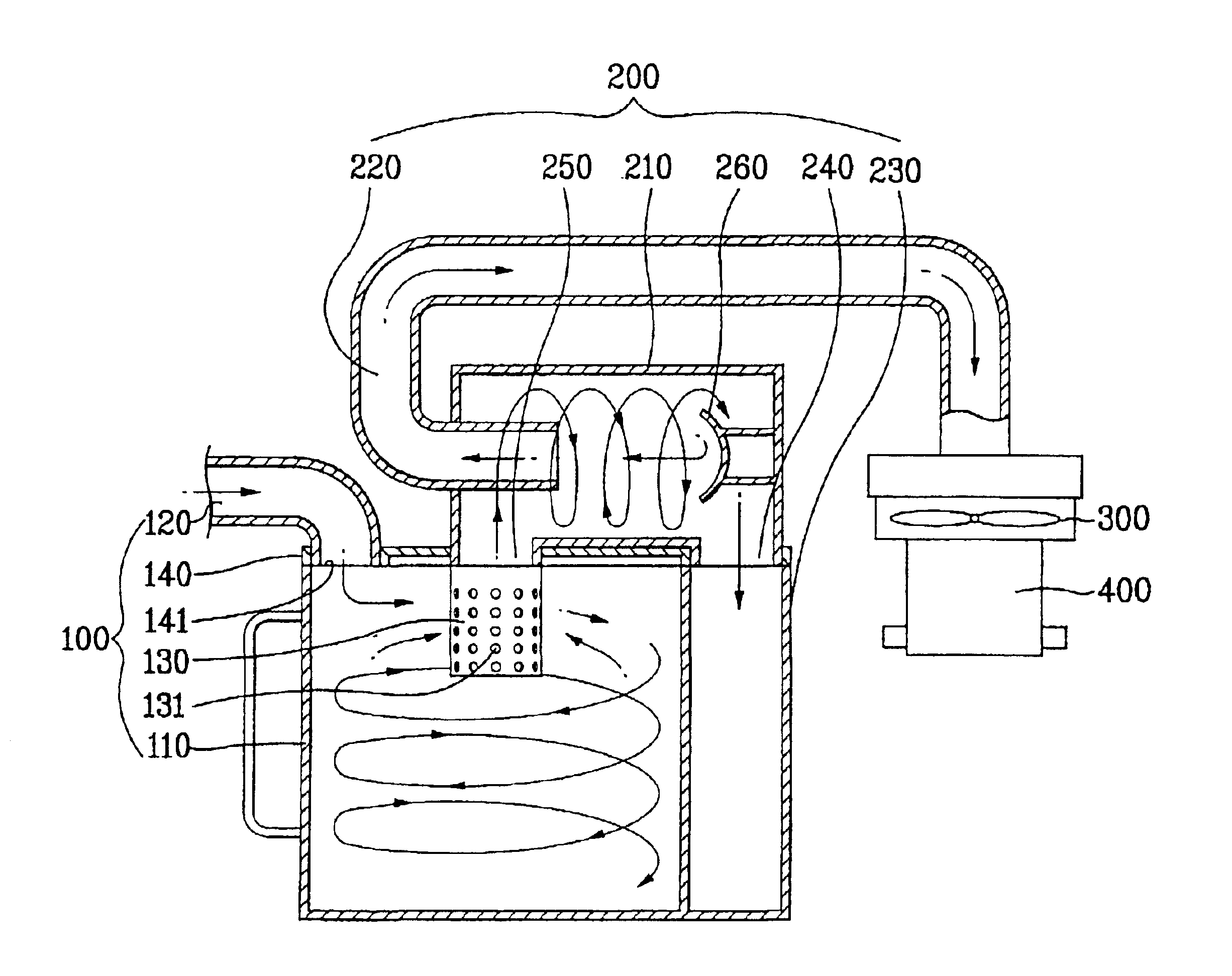

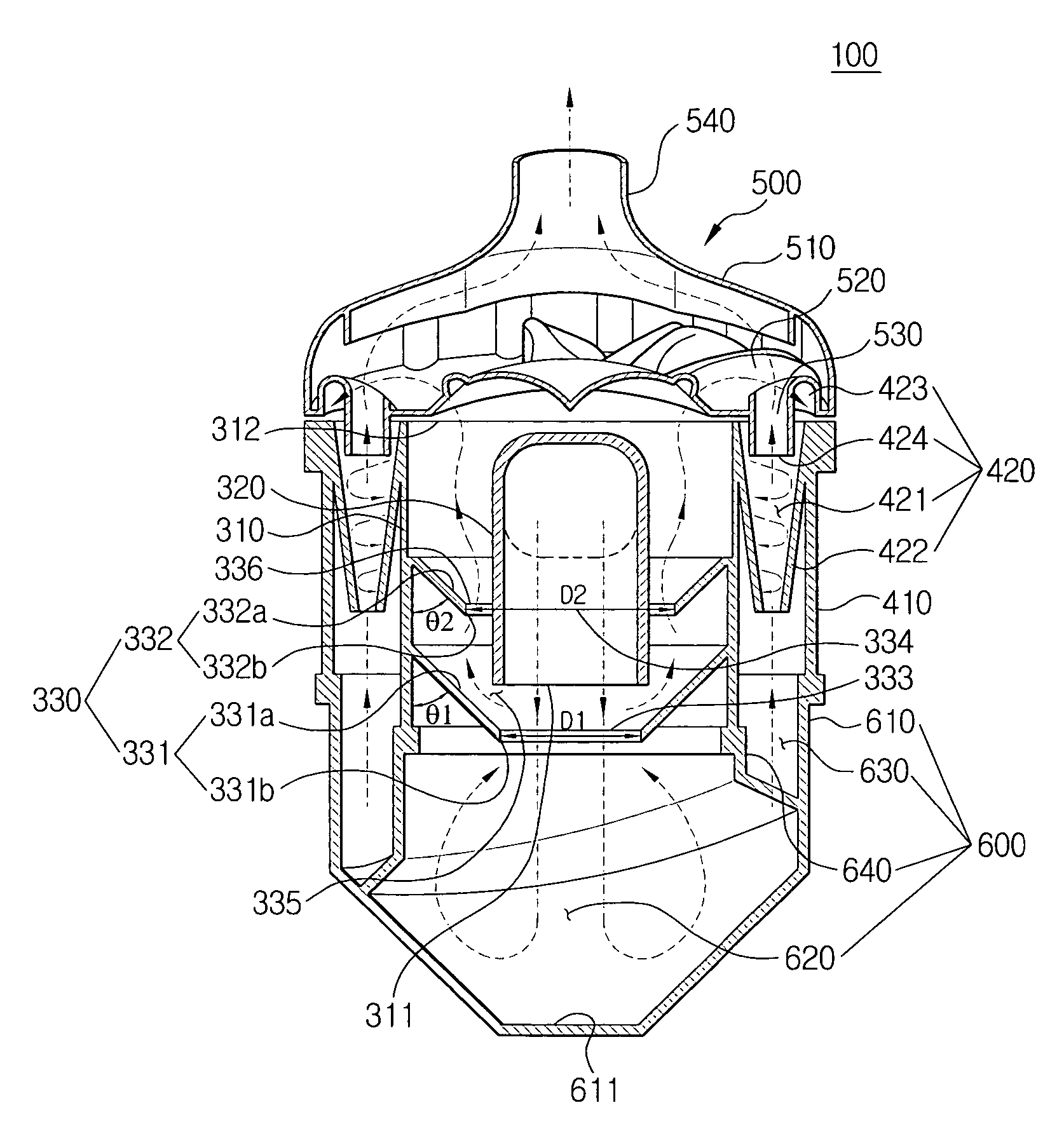

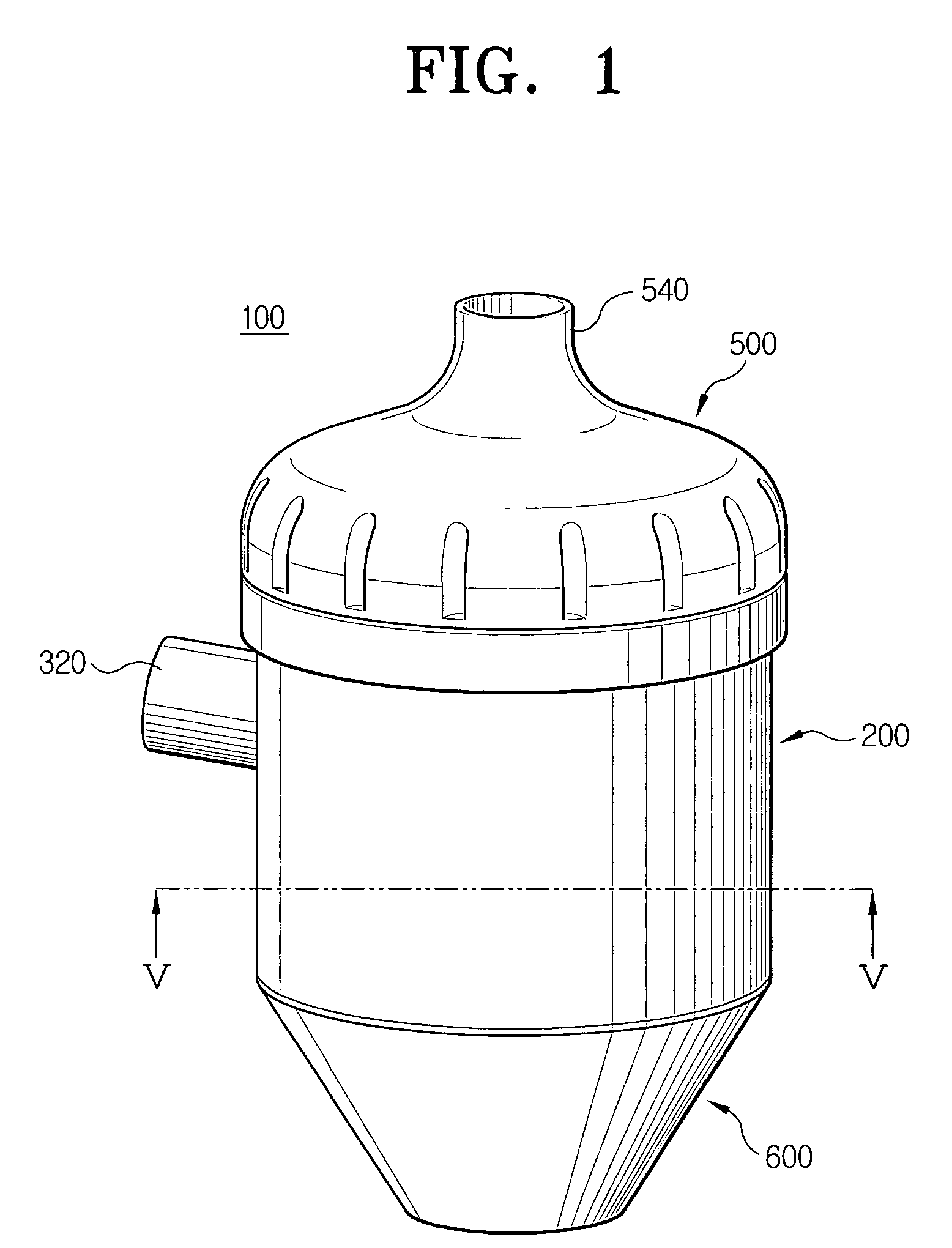

Cyclone dust separating apparatus for vacuum cleaner and vacuum cleaner having the same

ActiveUS20060230724A1Improved contaminant separation efficiencySmall sizeSuction filtersReversed direction vortexCycloneEngineering

A cyclone dust separating apparatus has a first cyclone chamber for separating particles from the externally-drawn fluid by centrifugal force, one or more second cyclone chambers for separating particles from the fluid discharged from the first cyclone chamber by centrifugal force, and one or more third cyclone chambers for separating particles from the fluid discharged from the second cyclone chambers, and causing the fluid to be discharged out via a discharge passage. The second and the third cyclone chambers are arranged in radial relation with respect to the first cyclone chamber, and thus, surround the first cyclone chamber. Therefore, the cyclone dust separating apparatus provides multi-stage centrifugal cleaning process and improved cleaning efficiency, while remaining compact-sized.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Motor rotor cooling with rotation heat pipes

InactiveUS20060066156A1Promote formationSmall sizeMagnetic circuit rotating partsCooling/ventillation arrangementInner loopEngineering

A heat pipe is partially-filled with a liquid, such as water, and is used to transfer heat from a rotating element, such as a rotor, via phase change and internal recycle of the liquid. Several heat pipes may be disposed radially around the rotating axis of the rotating element. The heat pipes may have a curved inner surface with a curvature not corresponding to the central axis of the heat pipe and positioned opposite the rotating axis so to experience greater centrifugal forces, to advance formation of a liquid film to improve heat transfer. For a rotor, the heat pipes, though individually placed as revolving heat pipes, in total exhibit behavior that approximates the favorable heat-transfer behavior of a single larger rotating heat pipe, but with heat-transfer surface area dispersed throughout the rotor, and without compromising structural integrity of the rotor shaft.

Owner:BALDOR ELECTRIC COMPANY

Multi dust-collecting apparatus

InactiveUS7547338B2Improve efficiencyConstant forceCombination devicesAuxillary pretreatmentCycloneEngineering

A multi dust-collecting apparatus for a vacuum cleaner is provided. The apparatus includes a dust-collecting unit having an air guide member to separate dirt particles from drawn-in air by using a gravity and an inertia and a filter member to remove dirt particles from the discharged air. The apparatus also includes a plurality of cyclones to swirl the air discharged from the dust-collecting unit and separate minute dirt particles from the air by using a centrifugal force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

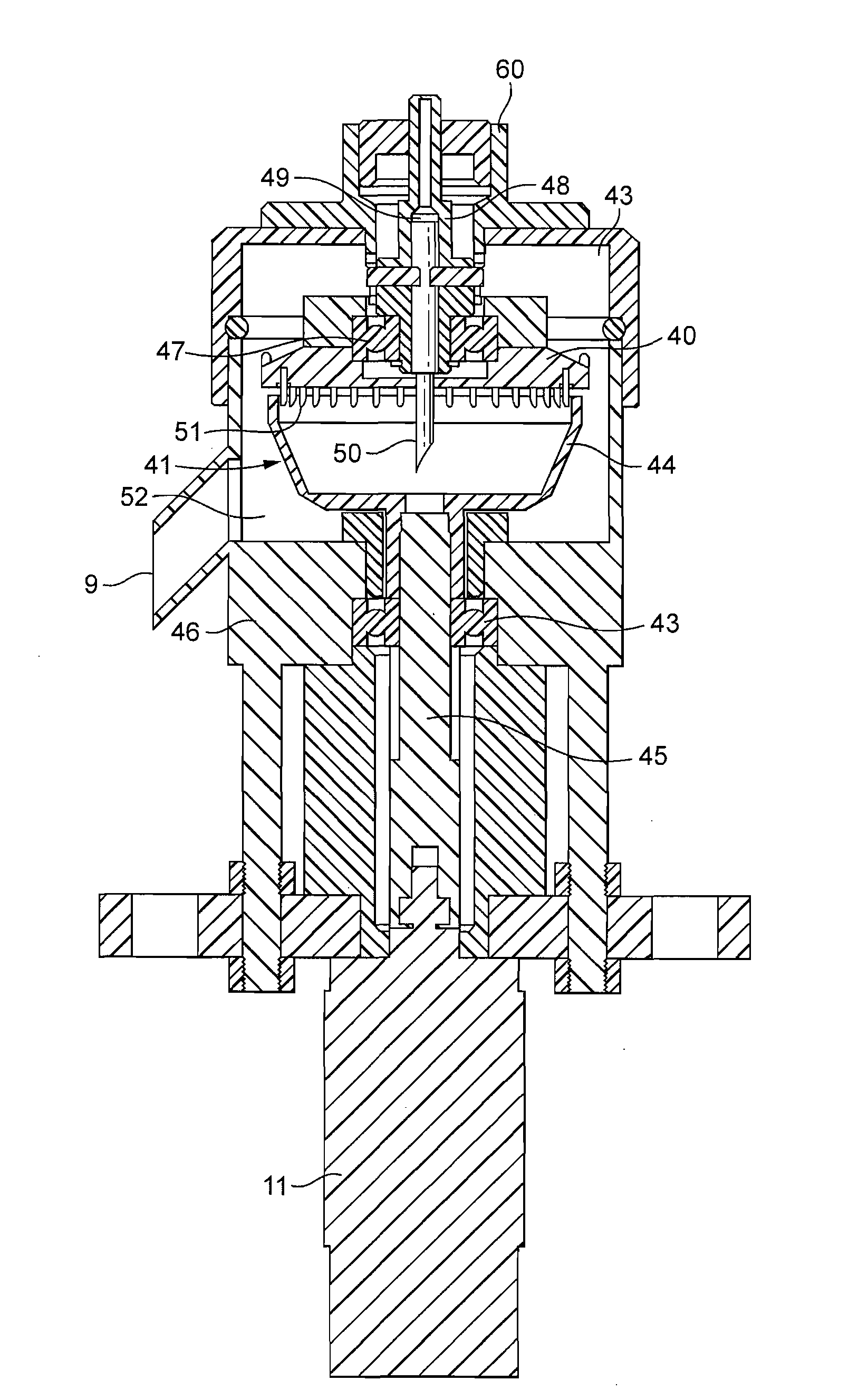

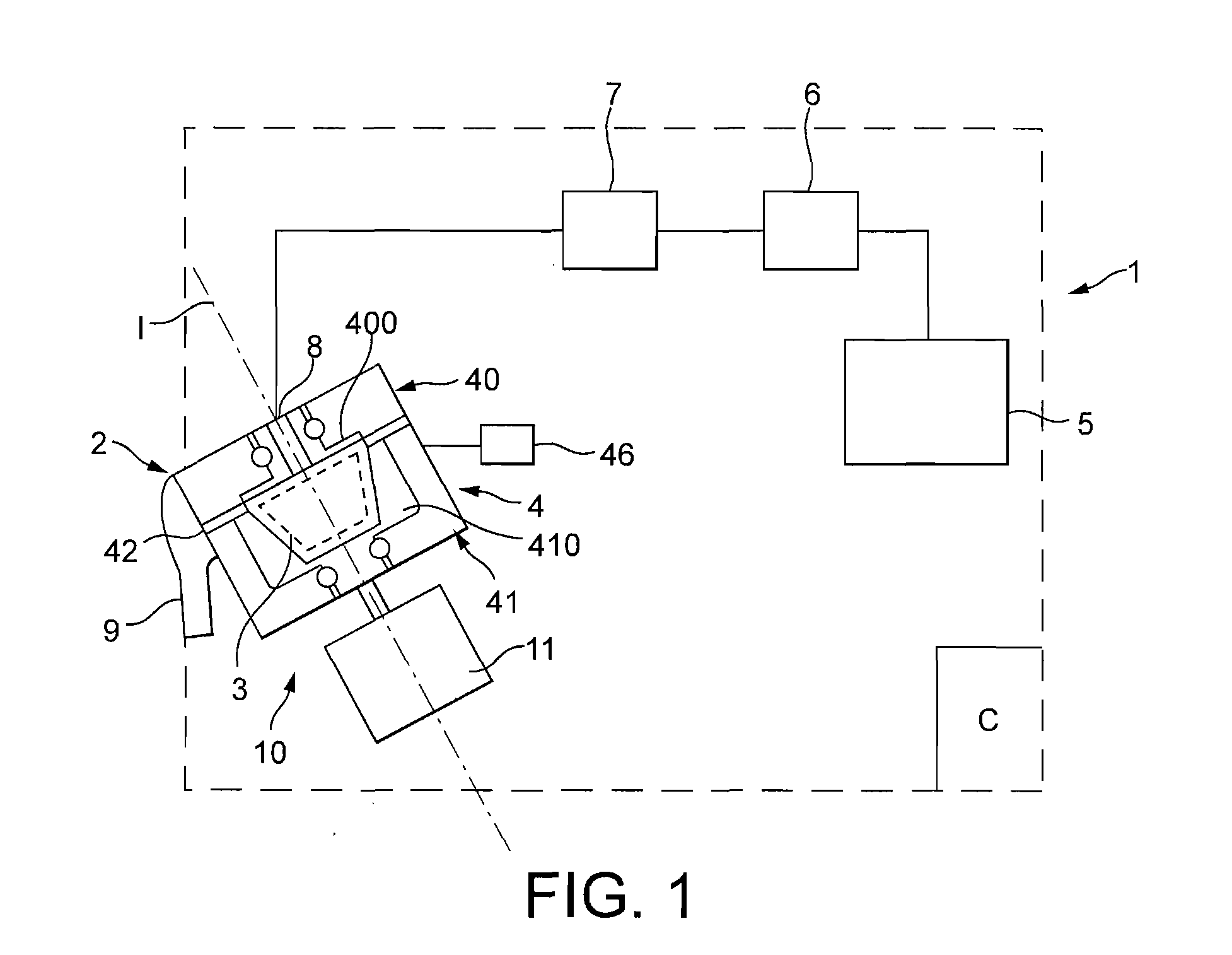

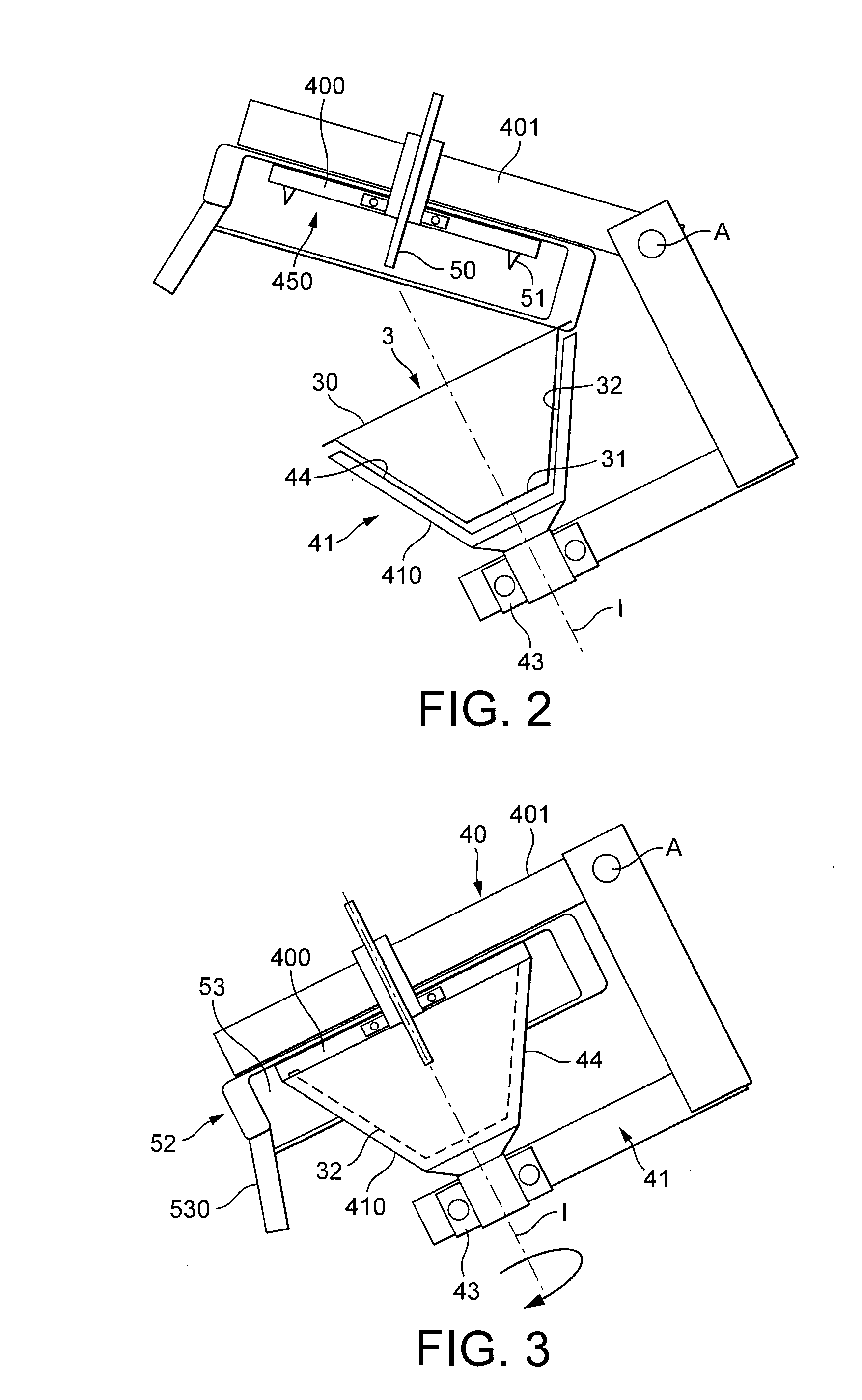

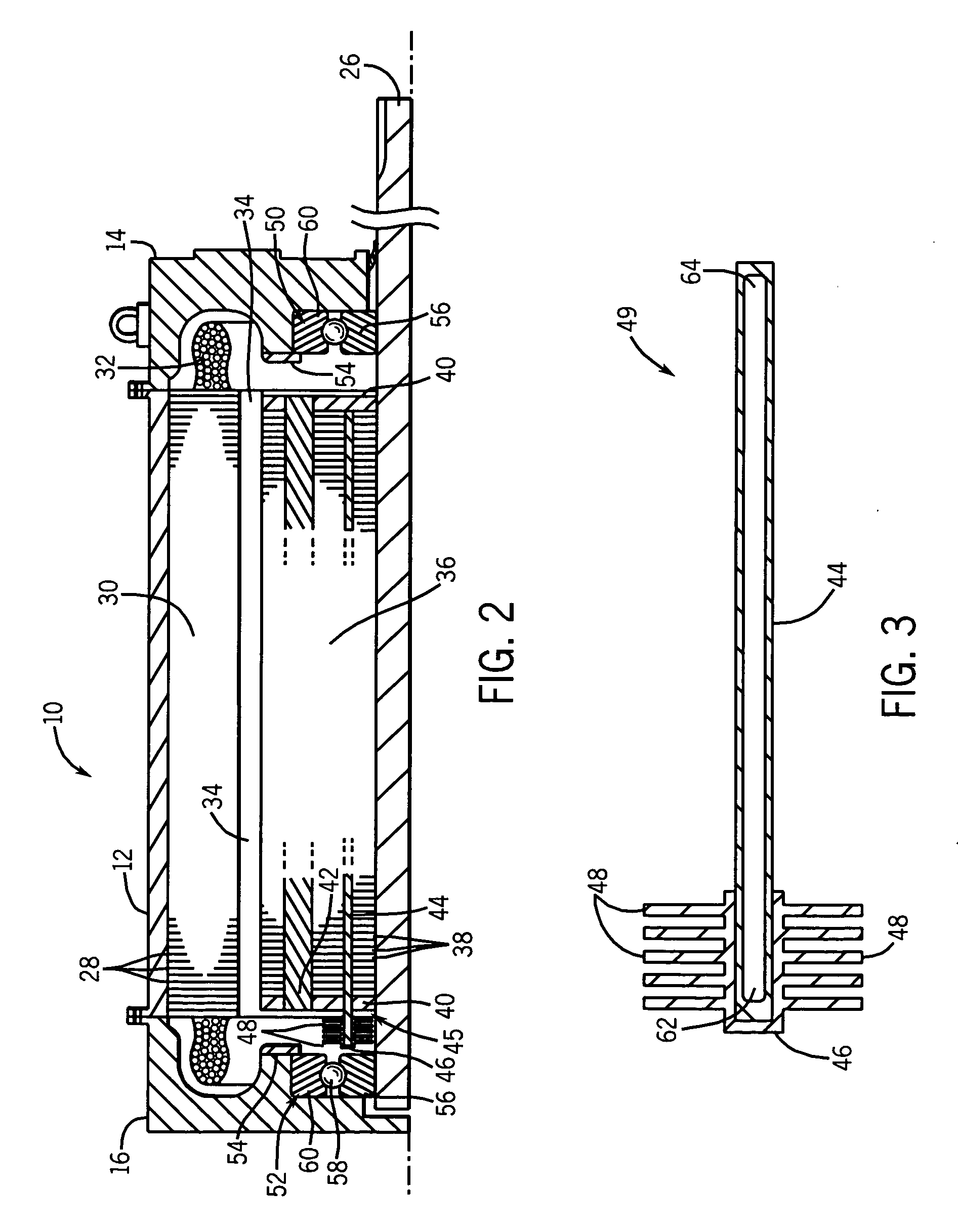

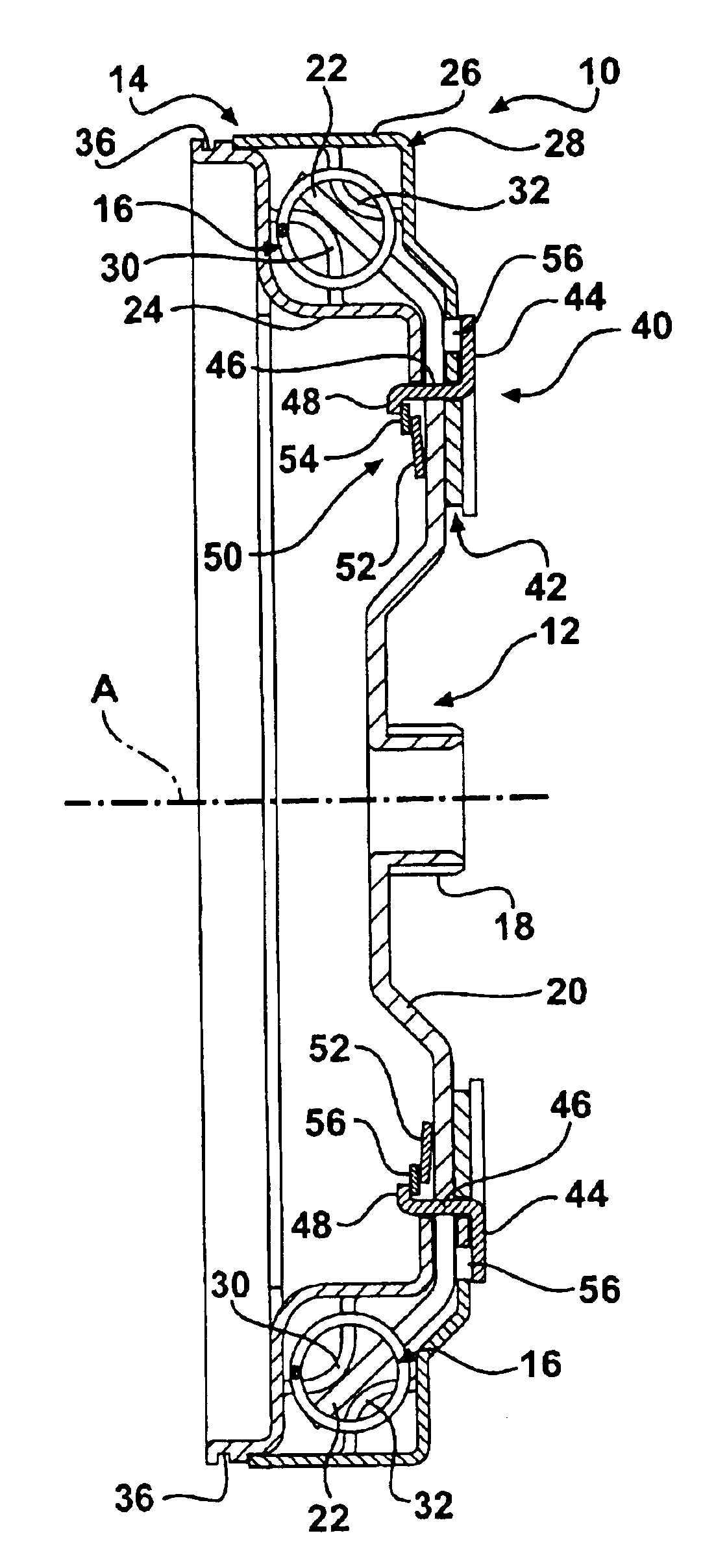

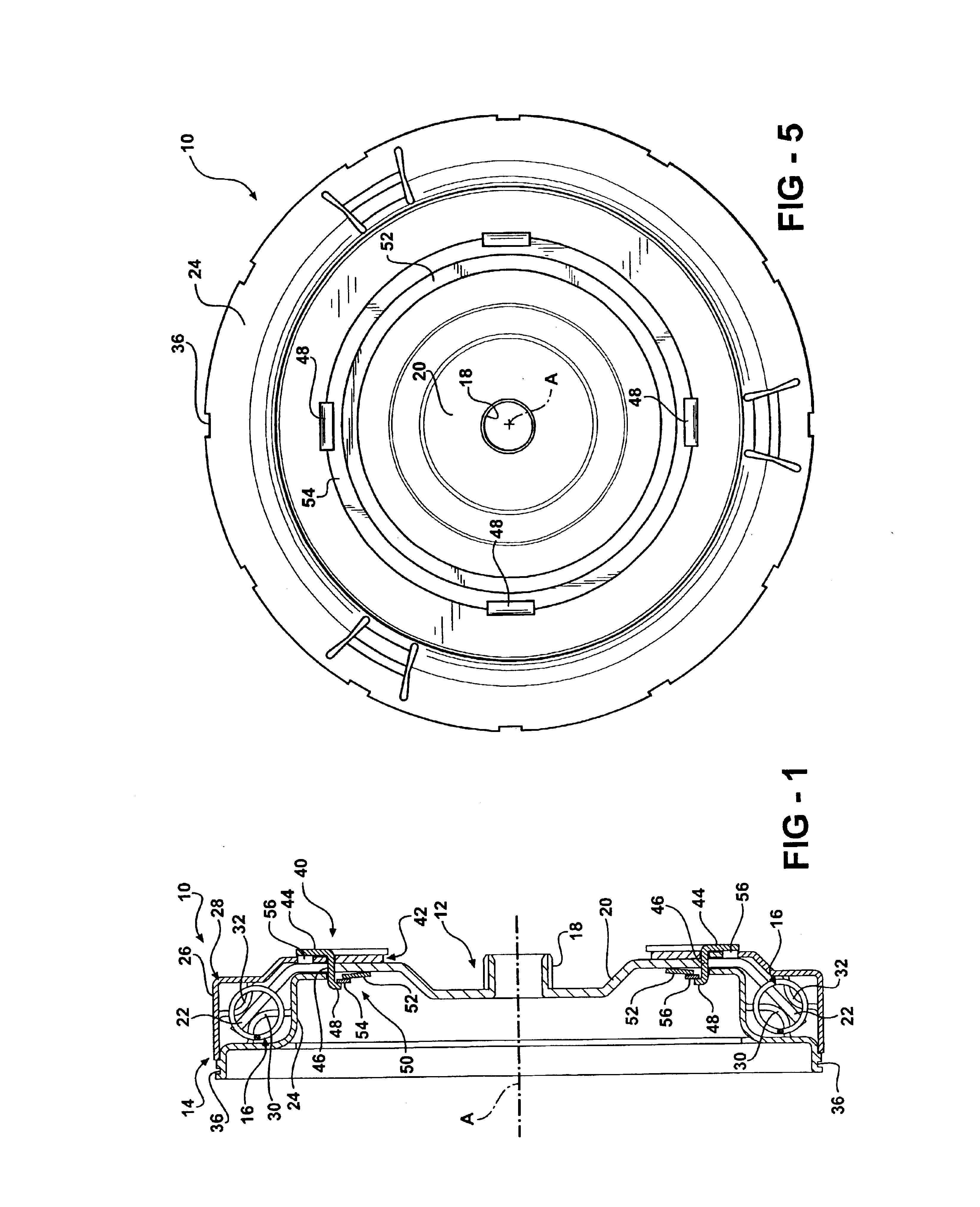

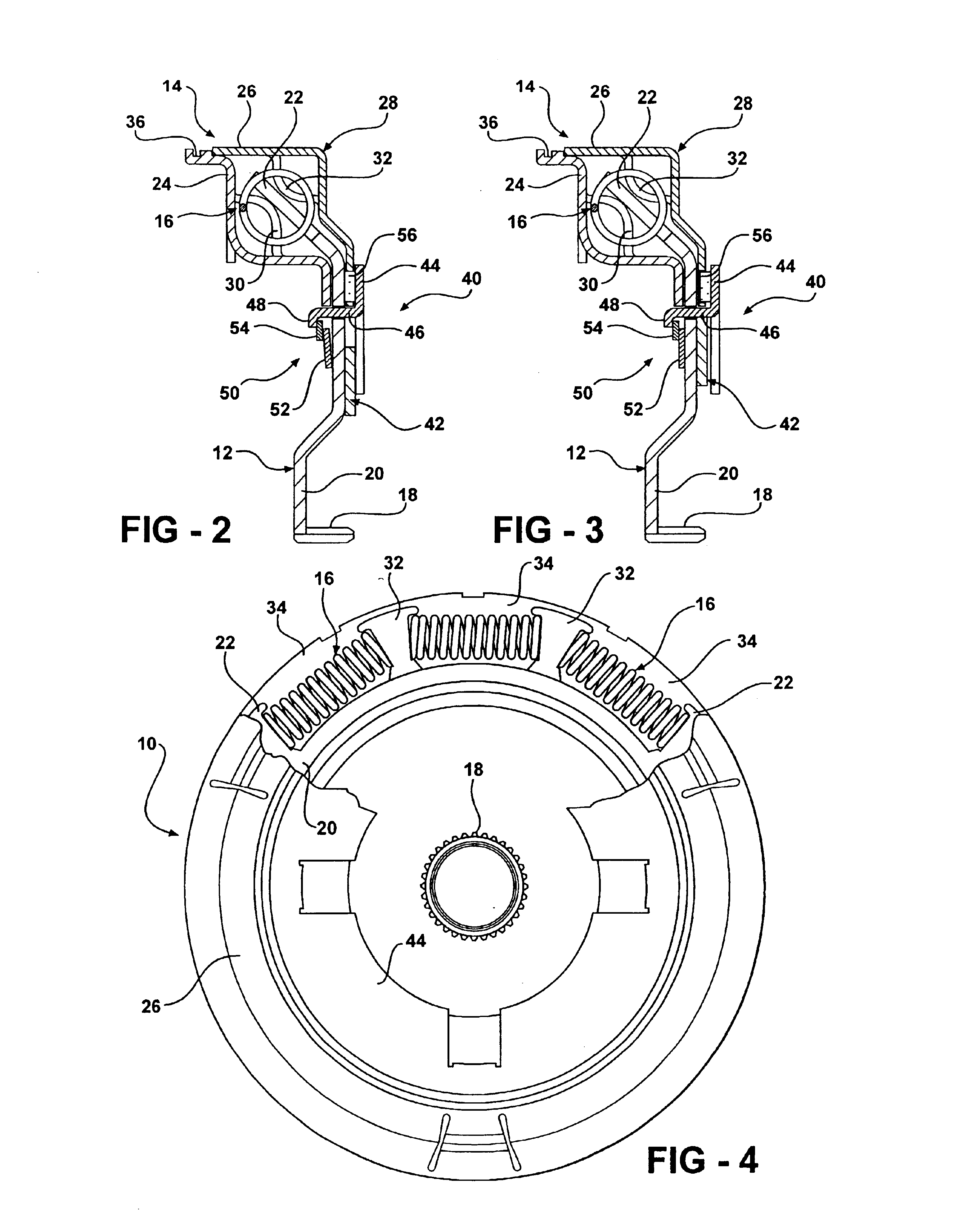

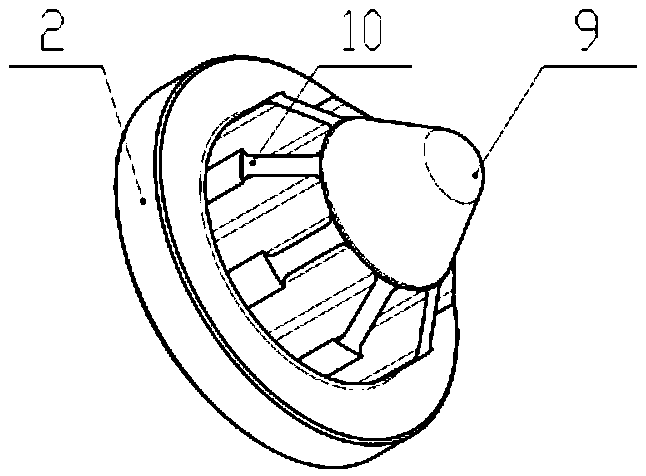

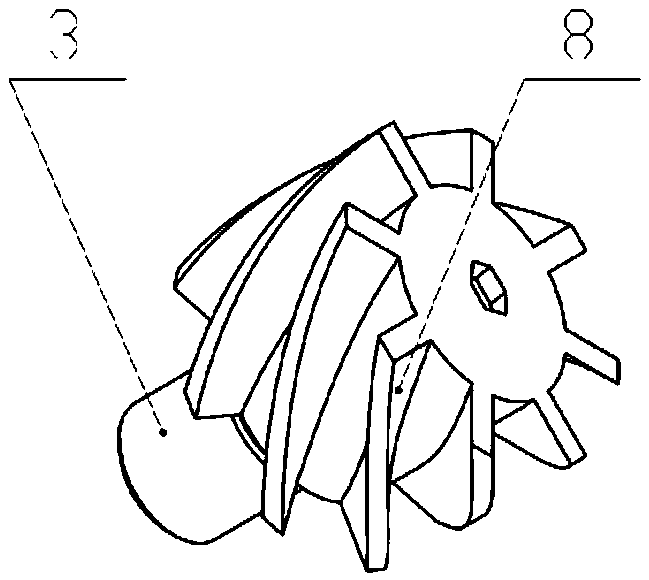

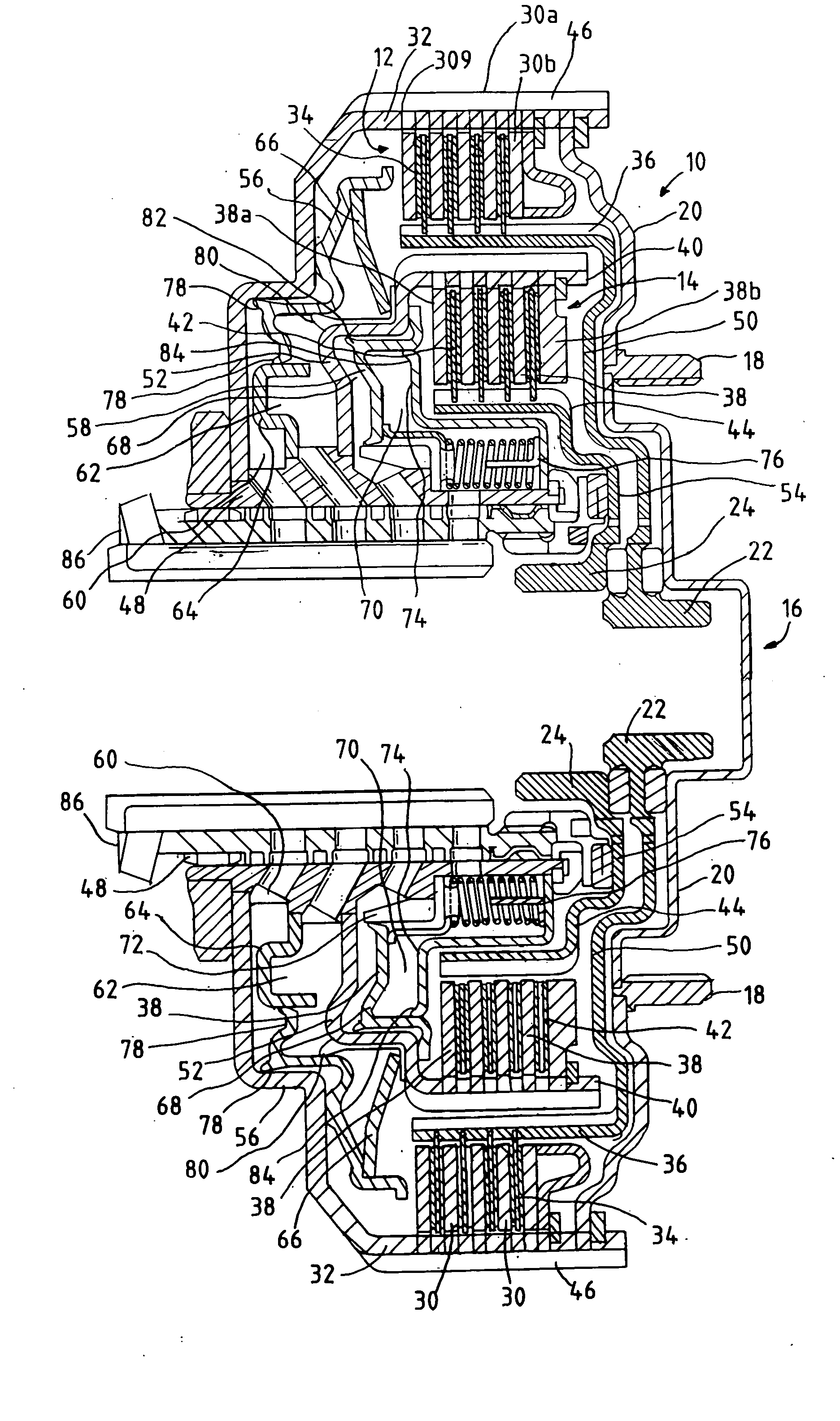

Torsional damper having variable bypass clutch with centrifugal release mechanism

InactiveUS6854580B2Restraint torsionReduce torqueYielding couplingRotary clutchesCentrifugal forceControl theory

A torsional damper (10) rotatably supported for translating torque between a prime mover and the input of a transmission including a torque input member (12) that is operatively connected for rotation with the power take-off of a prime mover, an output member (14) operatively connected for rotation with the input to a transmission and a plurality of damping elements (16) interposed between the input member and the output member. The damping members (16) act to translate torque between the input and output members and to dampen torsional forces generated between the prime mover and the transmission. A bypass clutch (40) acts to translate torque directly between the input and output members thereby providing a path for partial torque translation that bypasses the damping elements at low rotational speeds of the input and output members. In addition, the torsional damper (10) includes a clutch release mechanism (42) that is responsive to centrifugal forces acting on the torsional damper to disengage the bypass clutch (40) to reduce the torque translated directly between the input and output members at high rotational speeds.

Owner:BORGWARNER INC

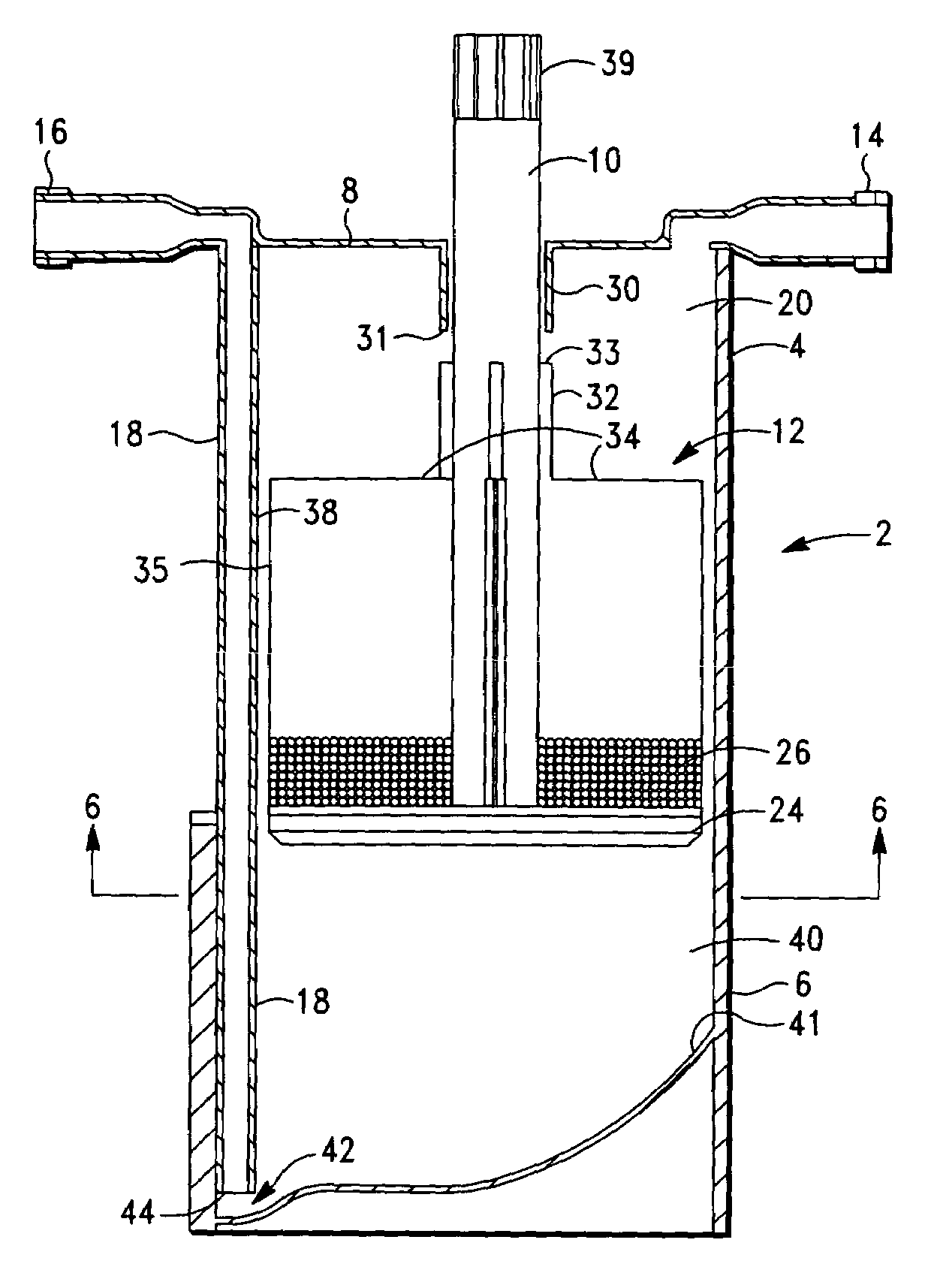

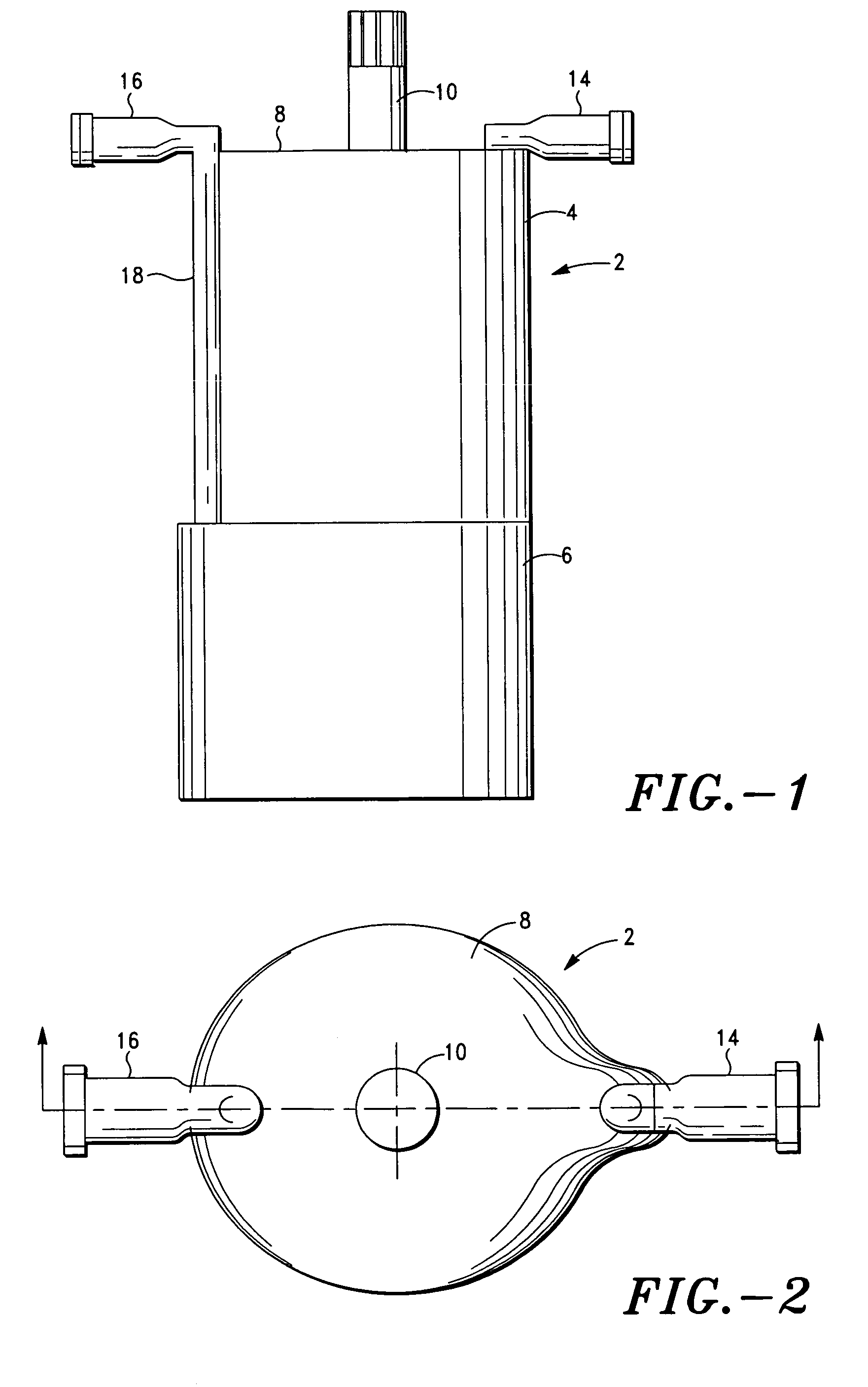

Plasma concentrator device

Owner:HANUMAN +1

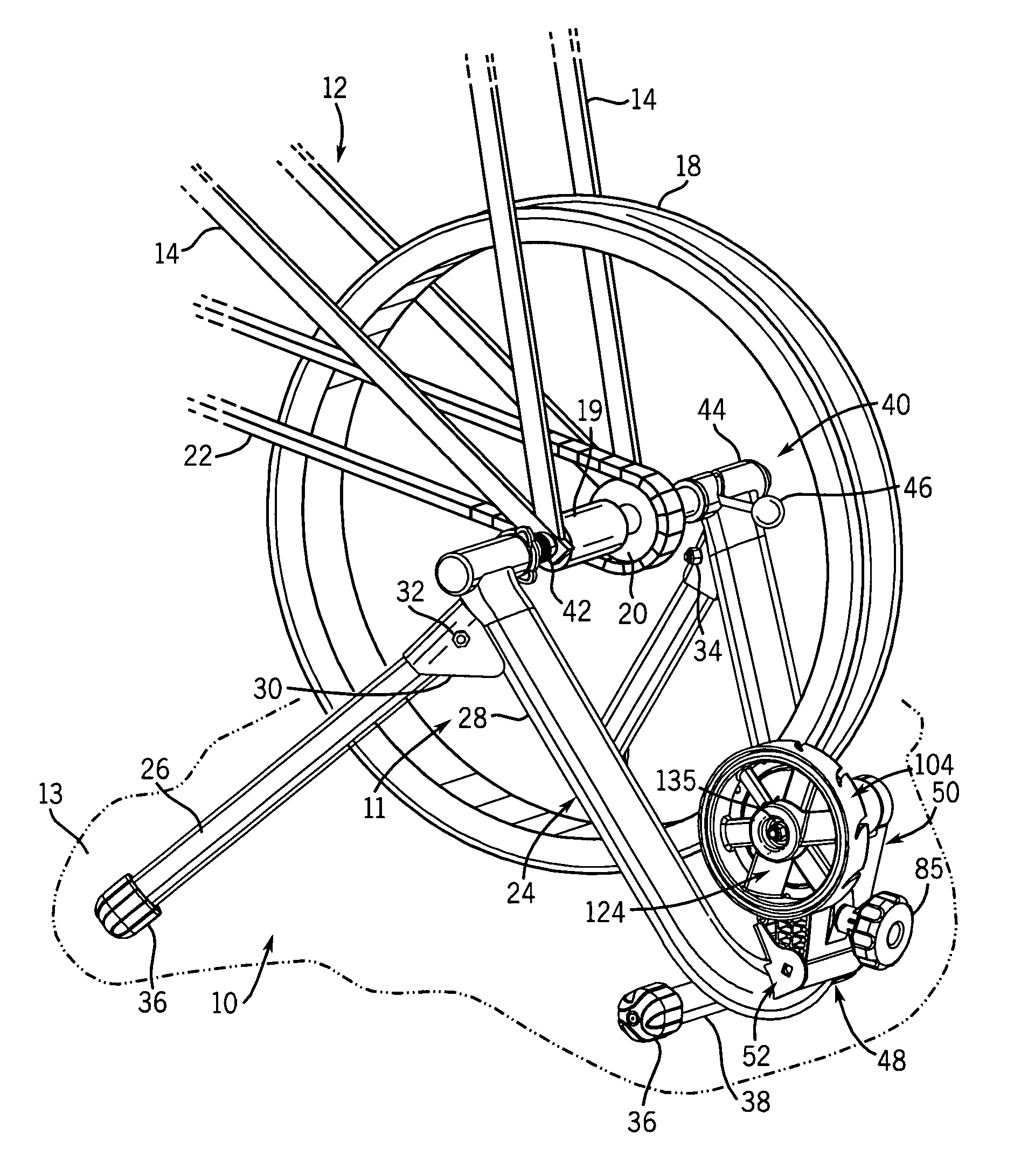

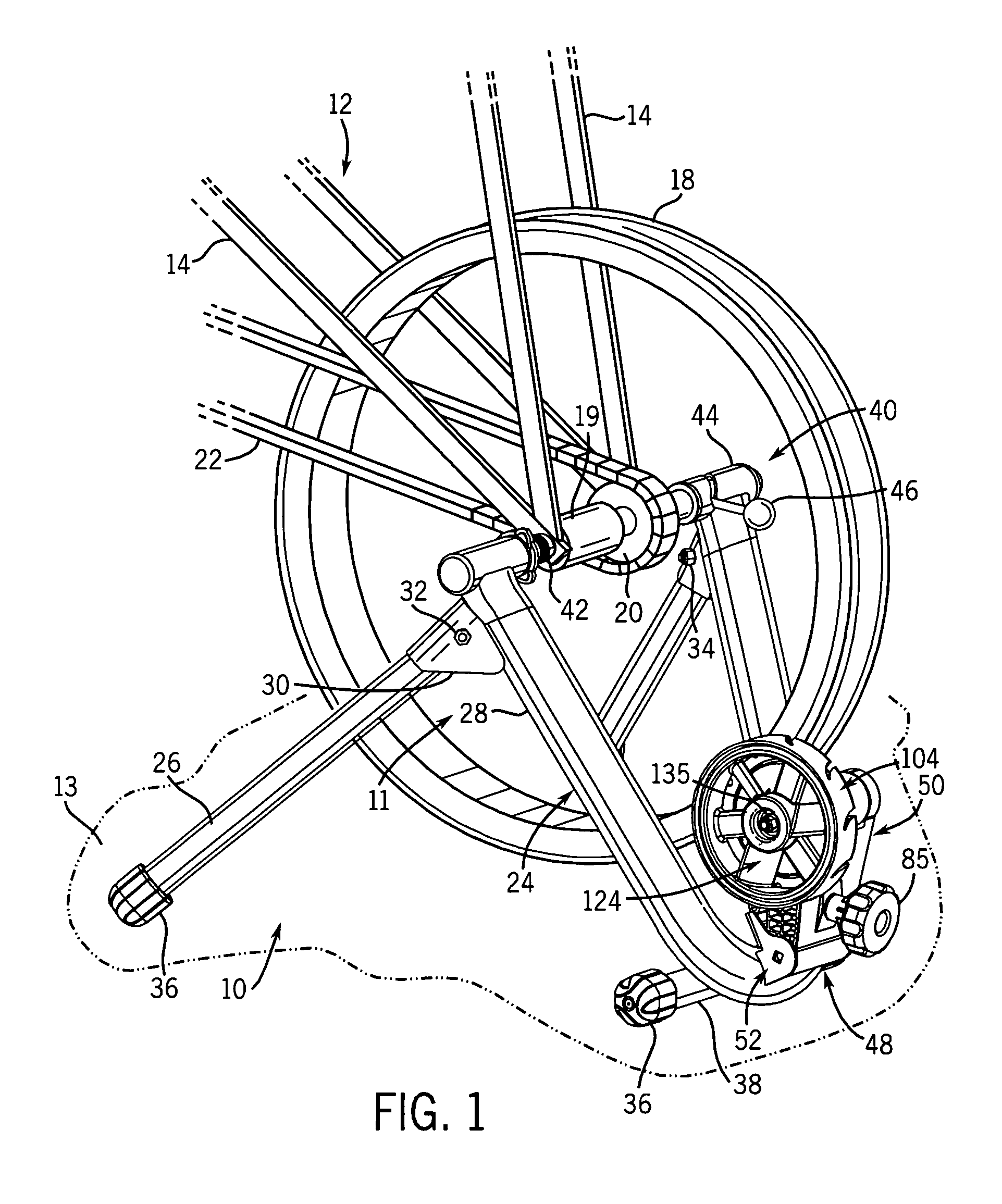

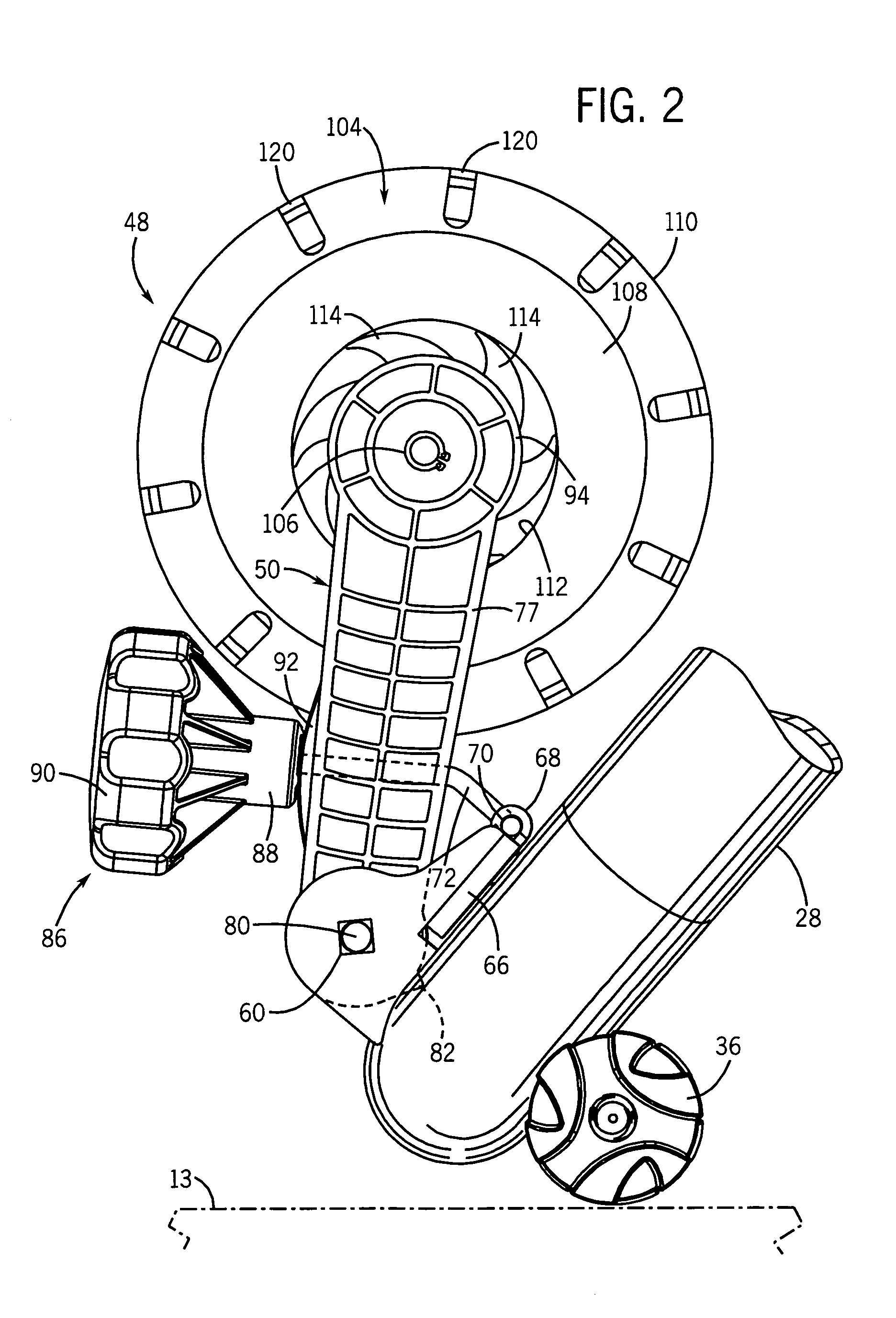

Variable magnetic resistance unit for an exercise device

InactiveUS7011607B2Realize automatic adjustmentRegulation stabilityMuscle exercising devicesMovement coordination devicesFreewheelRotation velocity

An automatically adjusting magnetic resistance unit for an exercise device such as a bicycle trainer, in which the degree of resistance is automatically and non-linearly adjusted in relation to the rotational speed of a rotating member caused by the input of a user. The rotating member may be in the form of a flywheel having a number of supports extending between a hub and a rim. The supports define longitudinal grooves which slidably retain magnets that are biased inwardly toward the hub by biasing members. An electrically conductive member is located adjacent the flywheel. As the flywheel rotates in response to rotation of the bicycle wheel, the magnets interact with the conductive member to establish eddy currents that provide resistance to the rotation of the flywheel. The speed of rotation of the flywheel increases as the speed of rotation of the bicycle wheel increases, and centrifugal forces act on the magnets to cause the magnets to slide outwardly along the grooves in opposition to the bias of the biasing members. The outward movement of the magnets causes outward movement of the eddy current forces, to increase the resistance provided to rotation of the flywheel and the bicycle wheel. The variable resistance due to the increased or decreased rotational speed of the flywheel is smooth, based on the constant interaction of the counteracting forces of the biasing members and the centrifugal forces acting on the magnets.

Owner:SARIS EQUIP LLC

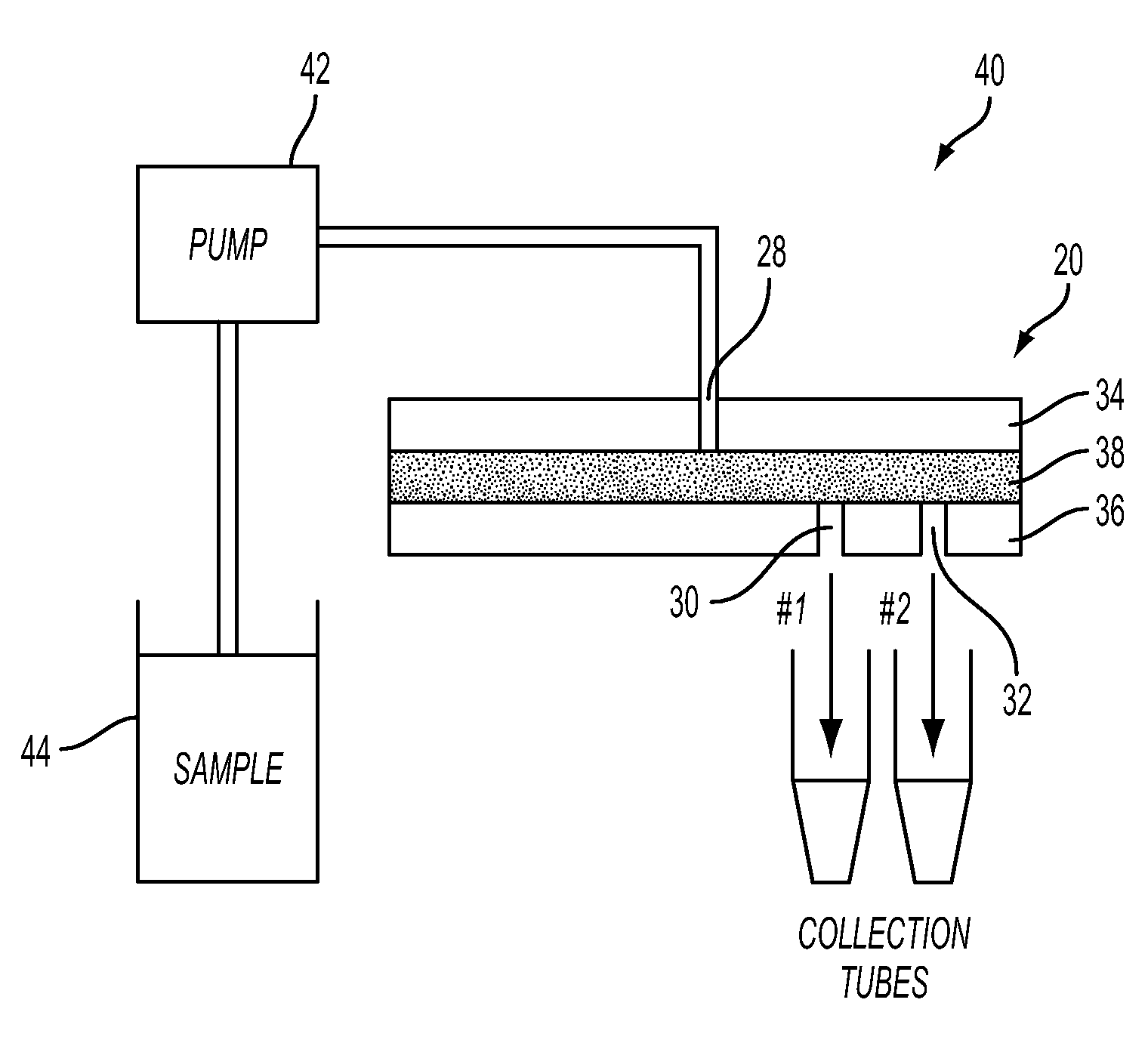

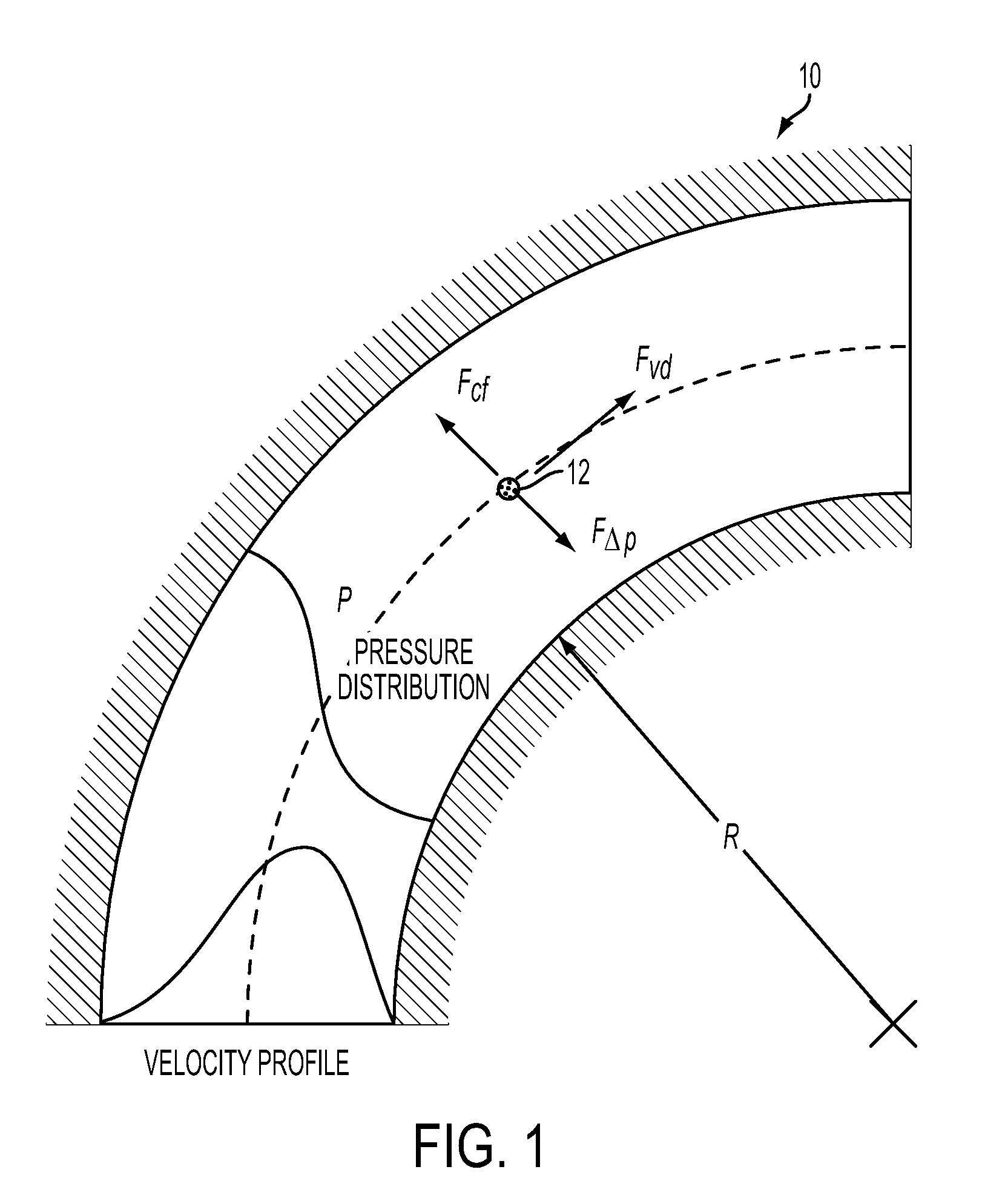

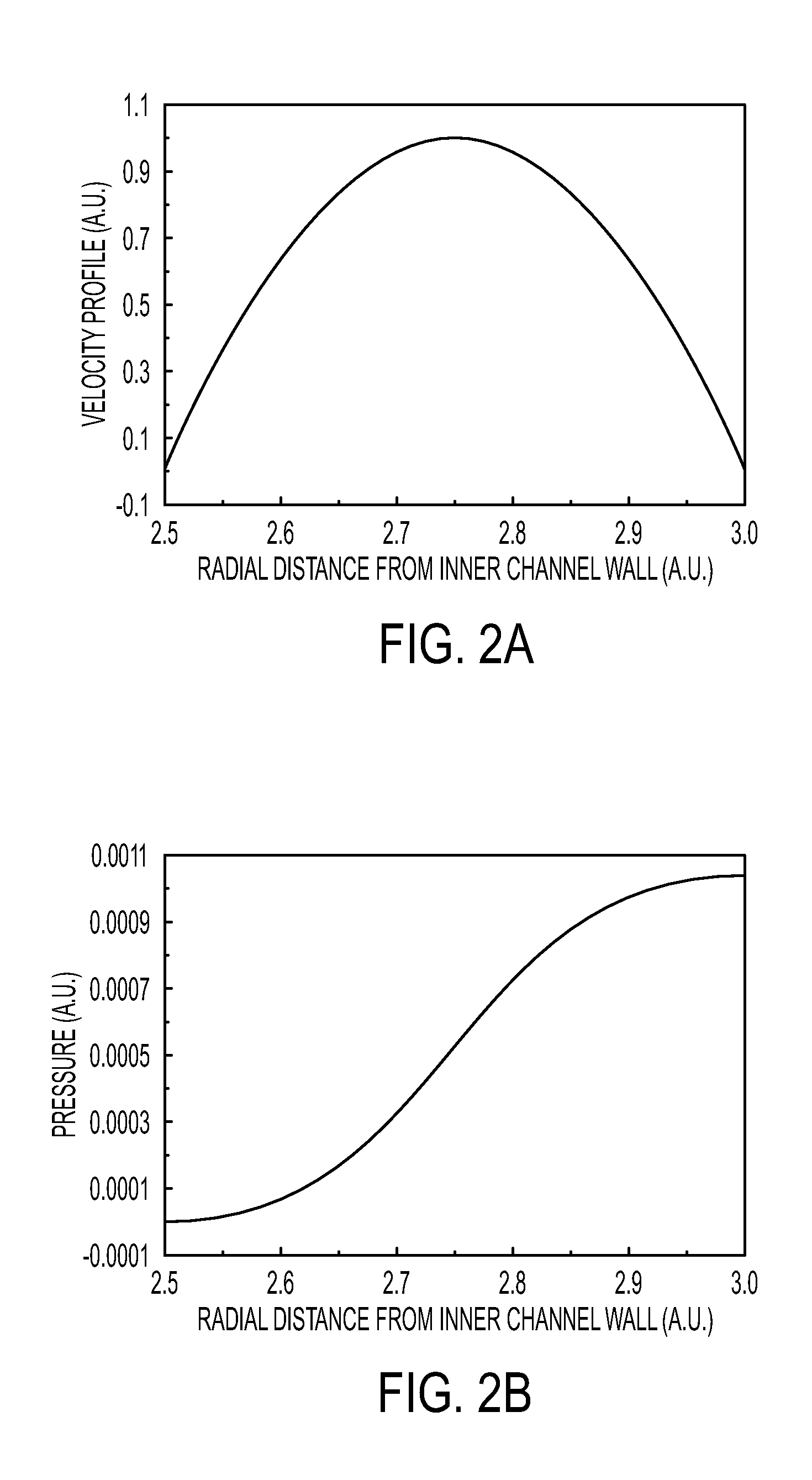

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

Multi dust-collecting apparatus

InactiveUS20060230723A1Improve dust collection efficiencyConstant suction forceCombination devicesAuxillary pretreatmentCycloneEngineering

A multi dust-collecting apparatus for a vacuum cleaner is provided. The apparatus includes a dust-collecting unit having an air guide member to separate dirt particles from drawn-in air by using a gravity and an inertia and a filter member to remove dirt particles from the discharged air. The apparatus also includes a plurality of cyclones to swirl the air discharged from the dust-collecting unit and separate minute dirt particles from the air by using a centrifugal force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust-collecting apparatus

InactiveUS7691161B2High dust collecting efficiencyLow pressure lossCleaning filter meansCombination devicesCycloneCentrifugal force

A cyclone dust-collecting apparatus to separate dust from air drawn in through a suction port body of a vacuum cleaner using a centrifugal force and to collect the separated dust is provided. The cyclone dust-collecting apparatus includes a primary cyclone unit to separate dust from air drawn in through the suction port body; a secondary cyclone unit disposed inside the primary cyclone unit to separate dust from air discharged from the primary cyclone unit; and a tertiary cyclone unit disposed above the primary cyclone unit at an angle different from the primary and secondary cyclone units.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

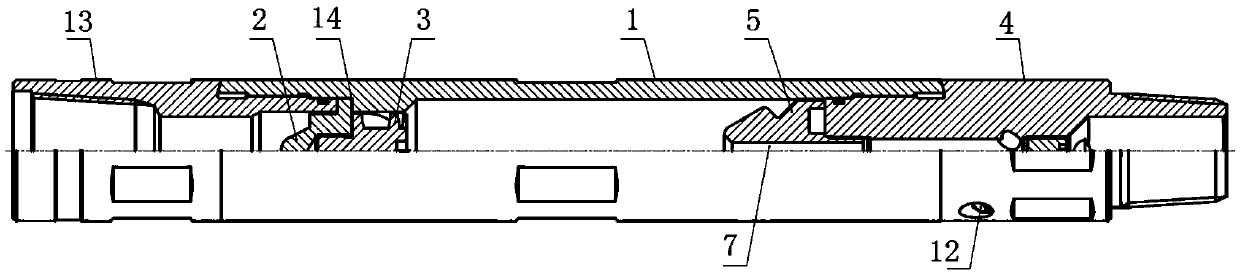

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

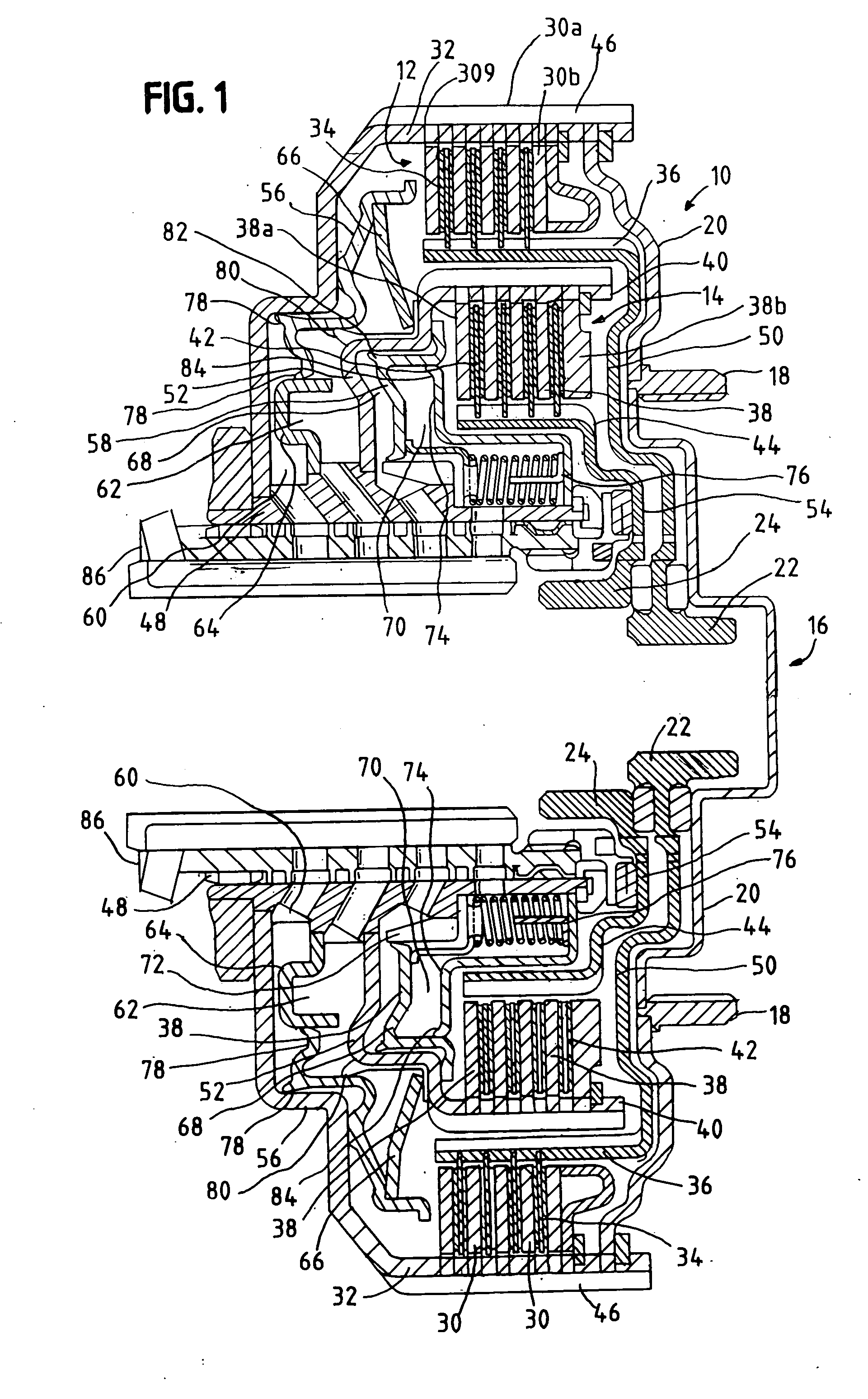

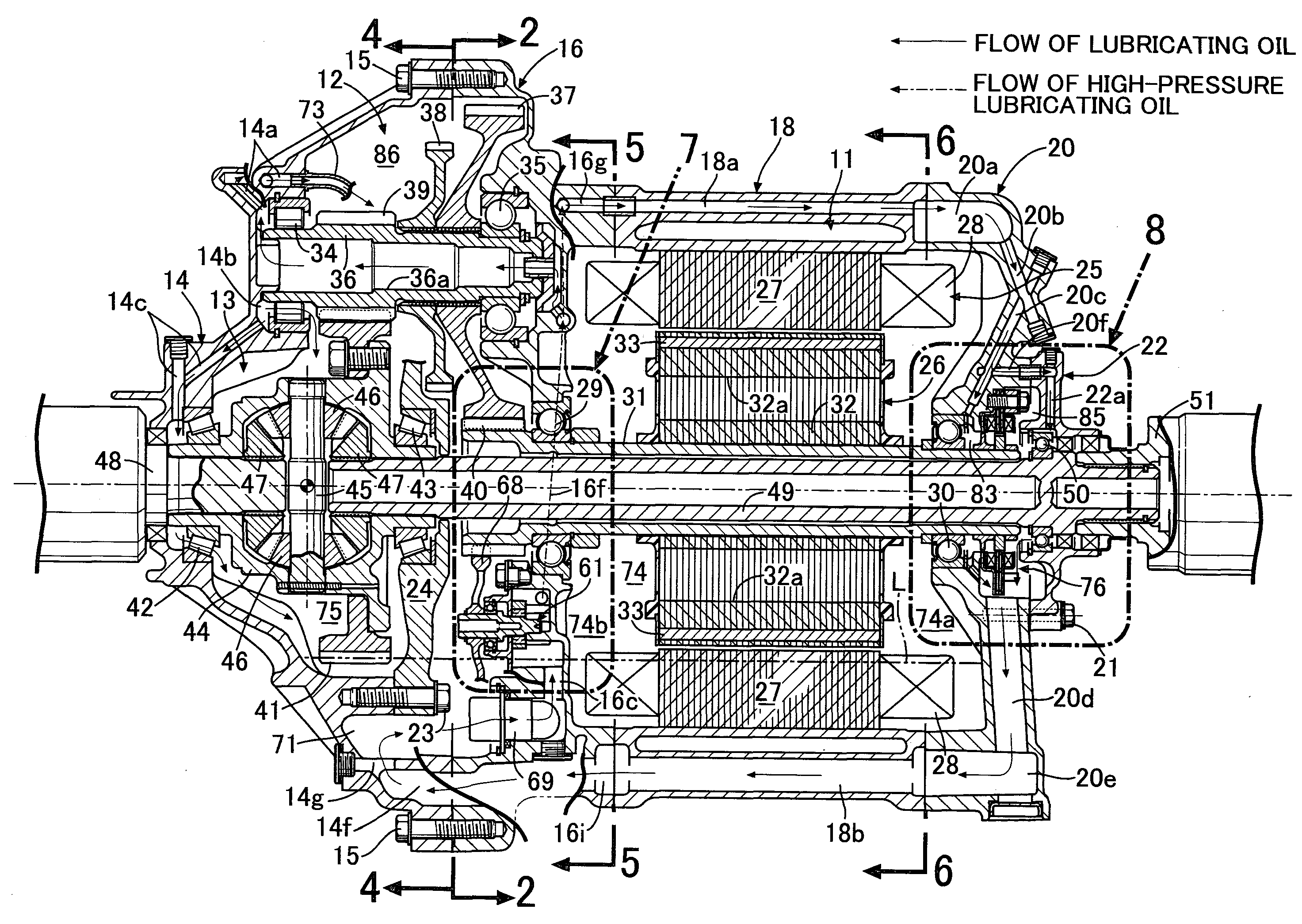

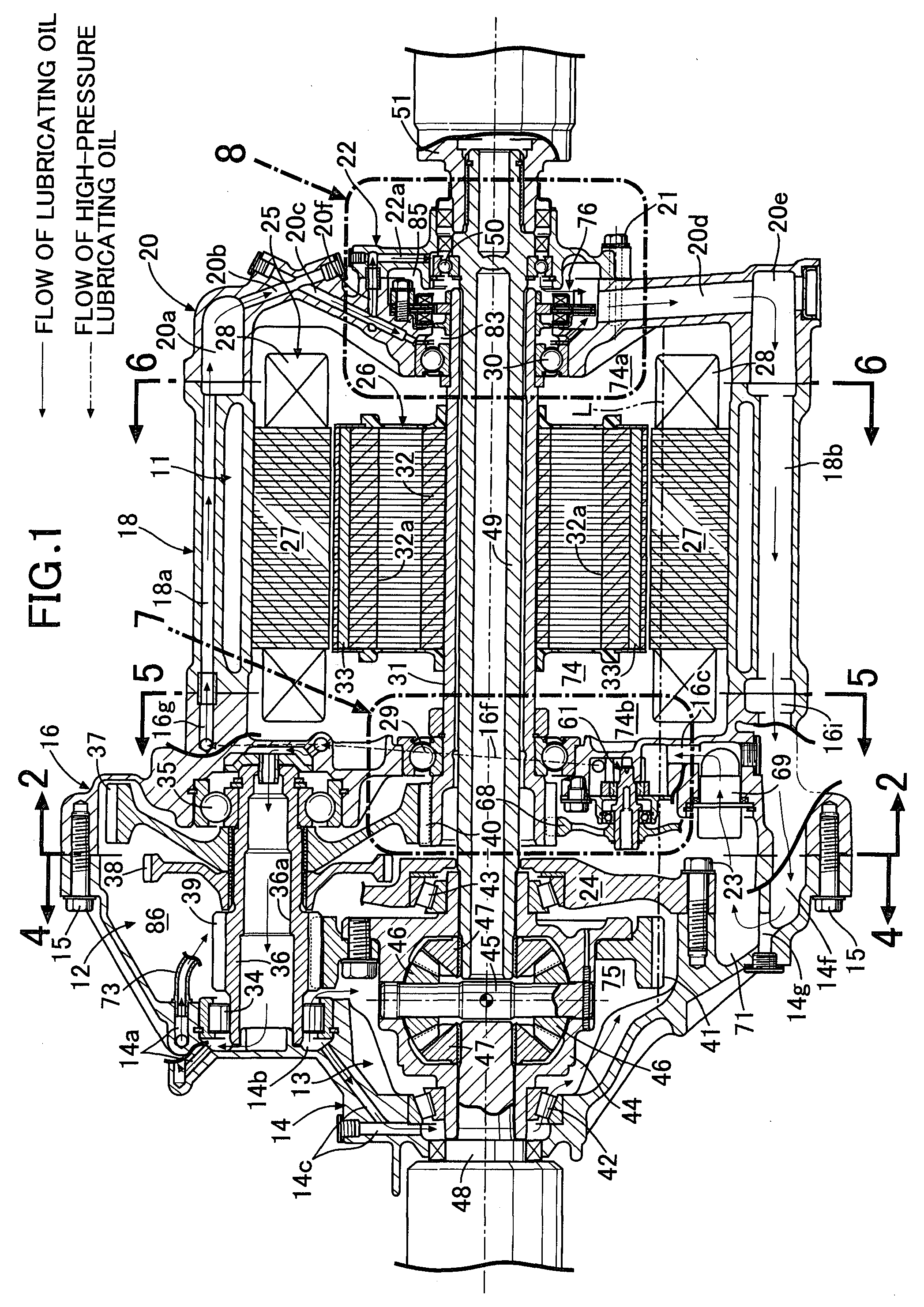

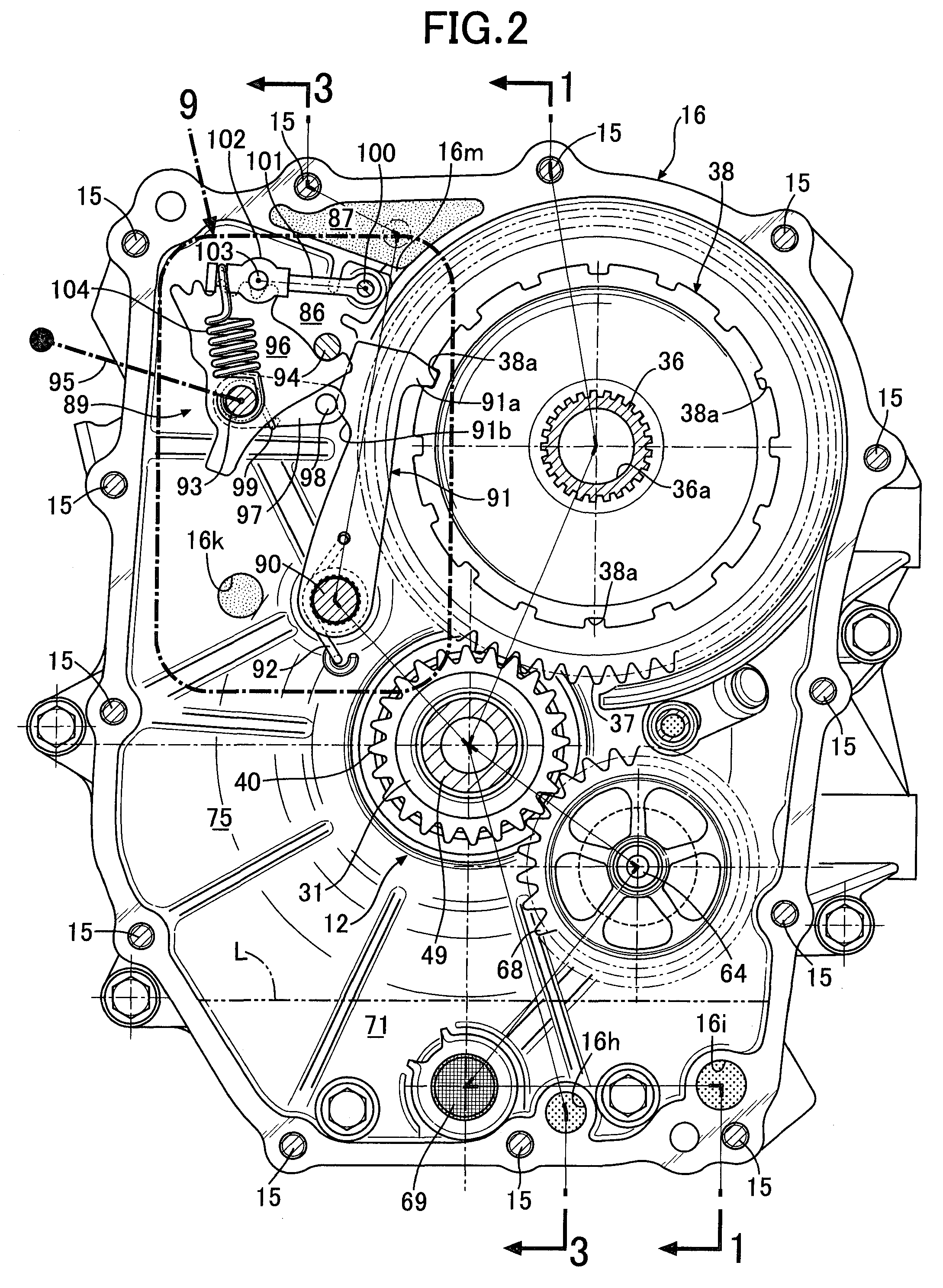

Oil management system for dual clutch transmissions

InactiveUS20050067251A1Solve the lack of balanceReduce flow of fluidFluid actuated clutchesGear lubrication/coolingEngineeringCentrifugal force

The present invention provides an improved fluid management system for dual and other multiple clutch assemblies having fluid-operated pistons and fluid operated balance chambers offsetting the undesired pressures exerted by fluids within the piston chamber induced by centrifugal forces. Among other improvements, the system provides an effective and cost efficient arrangement of fluid supply channels and supply openings capable of maintaining desired fluid levels in the balance chambers under low, otherwise insufficient, flow rate conditions. In another aspect, the system provides a reservoir for the balance chambers under conditions where the fluid flow is stopped or interrupted.

Owner:BORGWARNER INC

Multi cyclone vacuum cleaner

InactiveUS6840972B1Maximize capacityEasy to discardCombination devicesAuxillary pretreatmentCycloneForeign matter

The disclosure is directed to a cyclone dust collector for separating air from dusts by way of a centrifugal force and, more particularly, to a novel canister type vacuum cleaner capable of using a dual cyclone dust collector with maximized allowable dust capacity. The entire structure of the vacuum cleaner as suggested herein is configured for the user's simple manipulation in discarding various foreign matters collected in the vacuum cleaner, thereby improving reliability to the user.

Owner:LG ELECTRONICS INC

Multi dust-collecting apparatus

InactiveUS7547337B2Improve efficiencyMaintain suctionCleaning filter meansCombination devicesCycloneEngineering

A multi dust-collecting apparatus for a vacuum cleaner separating dirt particles from air by taking two steps. The multi dust-collecting apparatus includes a dust-collecting unit to separate dirt particles from the air by using gravity and inertia, and a plurality of cyclones to swirl the air discharged from the dust-collecting unit and separate the dirt particles from the air by using centrifugal force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

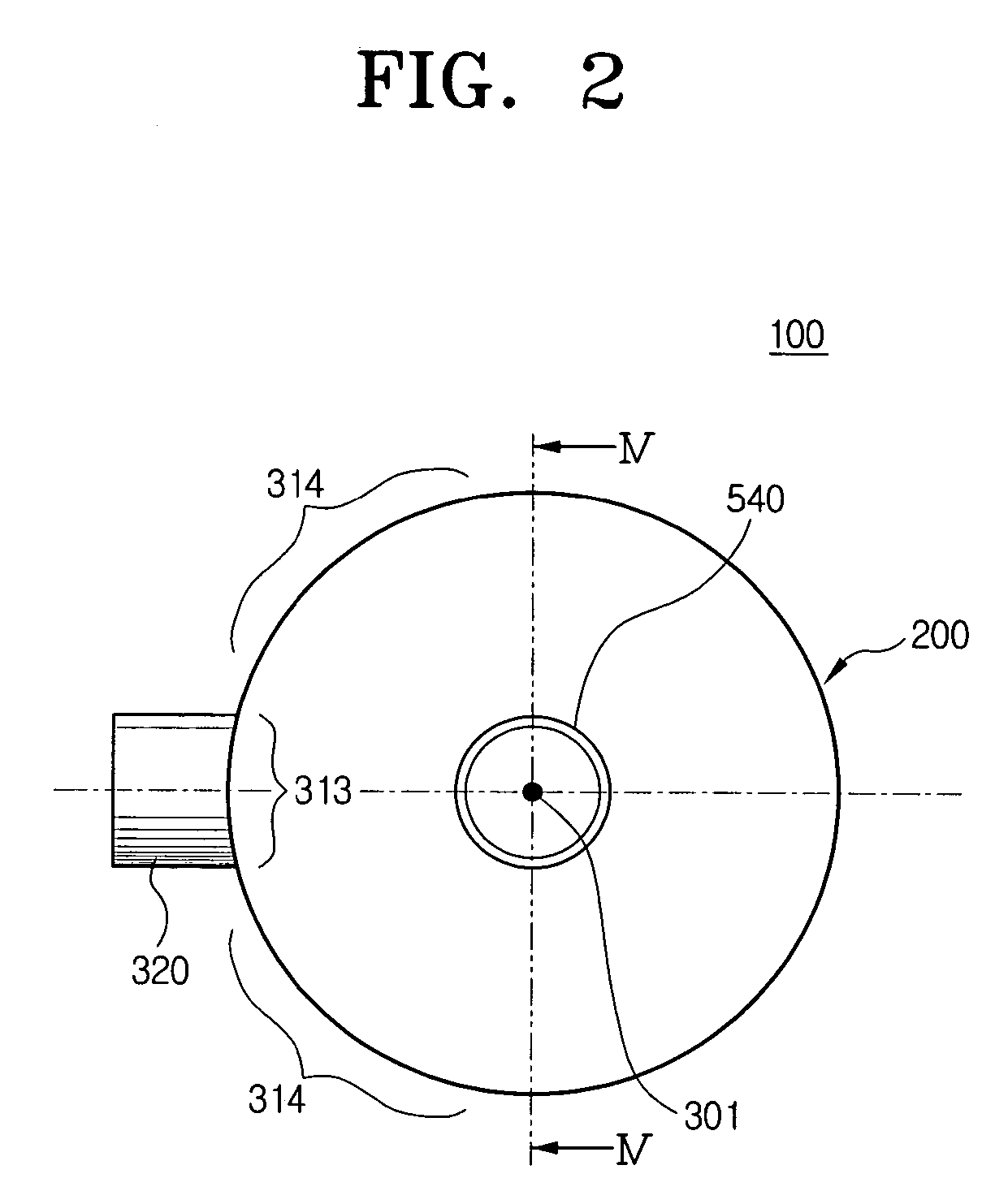

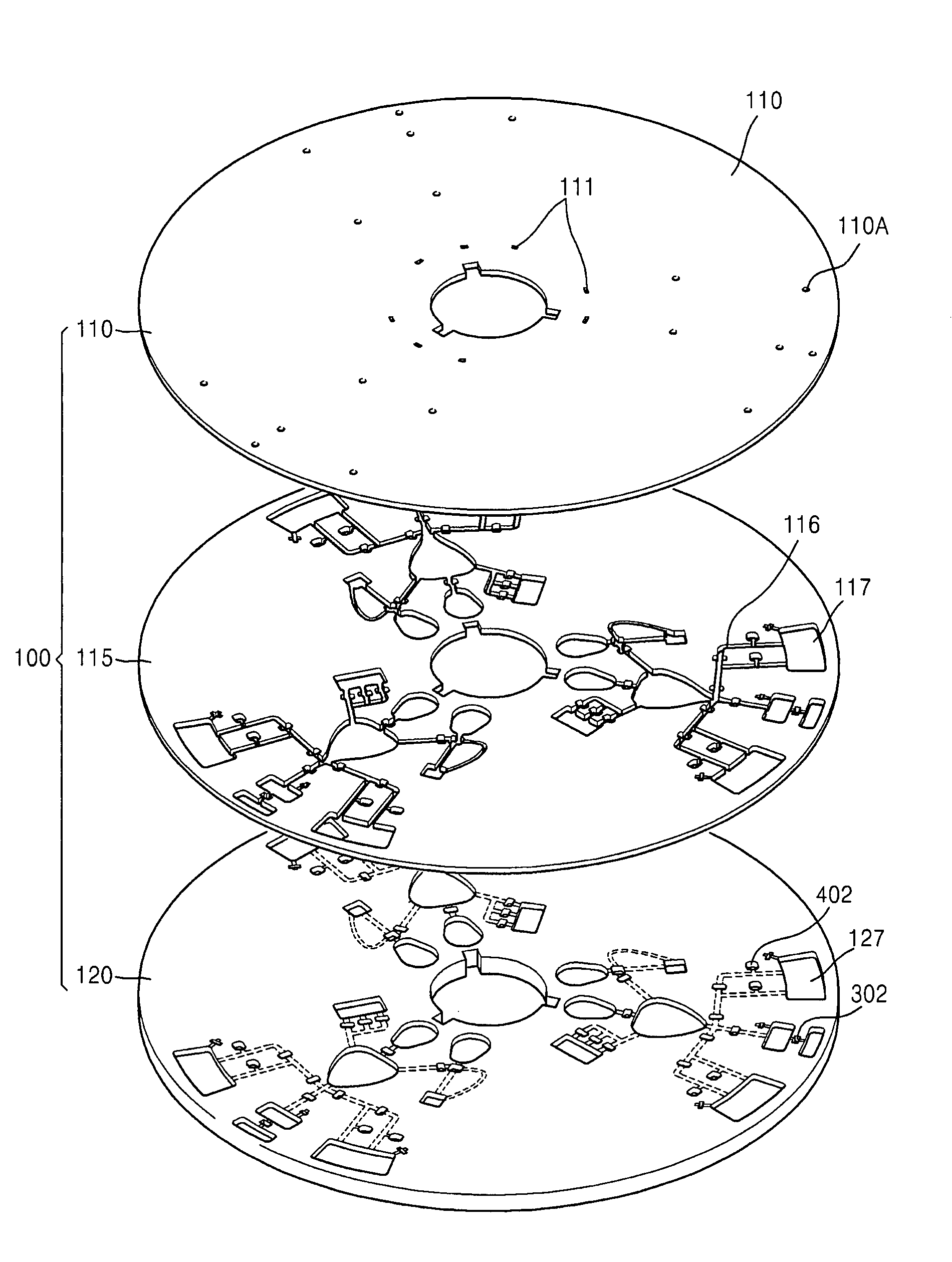

Centrifugal force-based microfluidic device for protein detection and microfluidic system including the same

ActiveUS20080056949A1Bioreactor/fermenter combinationsBiological substance pretreatmentsProtein detectionProtein target

A centrifugal force-based microfluidic device for the detection of a target biomolecule and a microfluidic system including the same are provided. The device includes a body of revolution; a microfluidic structure disposed in the body of revolution including chambers, channels connecting the chambers, and valves disposed in the channels to control fluid flow, the microfluidic structures transmitting fluid using centrifugal force due to rotation of the body of revolution; and beads disposed in the microfluidic structures, the beads having capture probes on the surfaces thereof which are selectively bonded with target protein; and a detection probe disposed in the microfluidic structures and selectively bonded to the target protein, and which includes a material required to express an optical signal, wherein the microfluidic structure mixes the beads, biological samples, and the detection probe to react and washes and separates the beads after the reaction.

Owner:PRECISIONBIOSENSOR INC

Centrifugal force-based microfluidic device for nucleic acid extraction and microfluidic system including the microfluidic device

ActiveUS20080108120A1Bioreactor/fermenter combinationsValve arrangementsExternal energyMicrofluidics

A centrifugal force-based microfluidic device for nucleic acid extraction and a microfluidic system are provided. The microfluidic device includes a body of revolution; a microfluidic structure disposed in the body of revolution, the microfluidic structure including a plurality of chambers, channels connecting the chambers, and valves disposed in the channels to control fluid flow, the microfluidic structure transmitting the fluid using centrifugal force due to rotation of the body of revolution; and magnetic beads contained in one of the chambers which collect a target material from a biomaterial sample flowing into the chamber, wherein the microfluidic structure washes the magnetic beads which collect the target material, and separates nucleic acid by electromagnetic wave irradiation from an external energy source to the magnetic beads. The microfluidic system includes the microfluidic device; a rotation operating unit which rotates the body of revolution; and an external energy source which irradiates electromagnetic waves.

Owner:PRECISIONBIOSENSOR INC

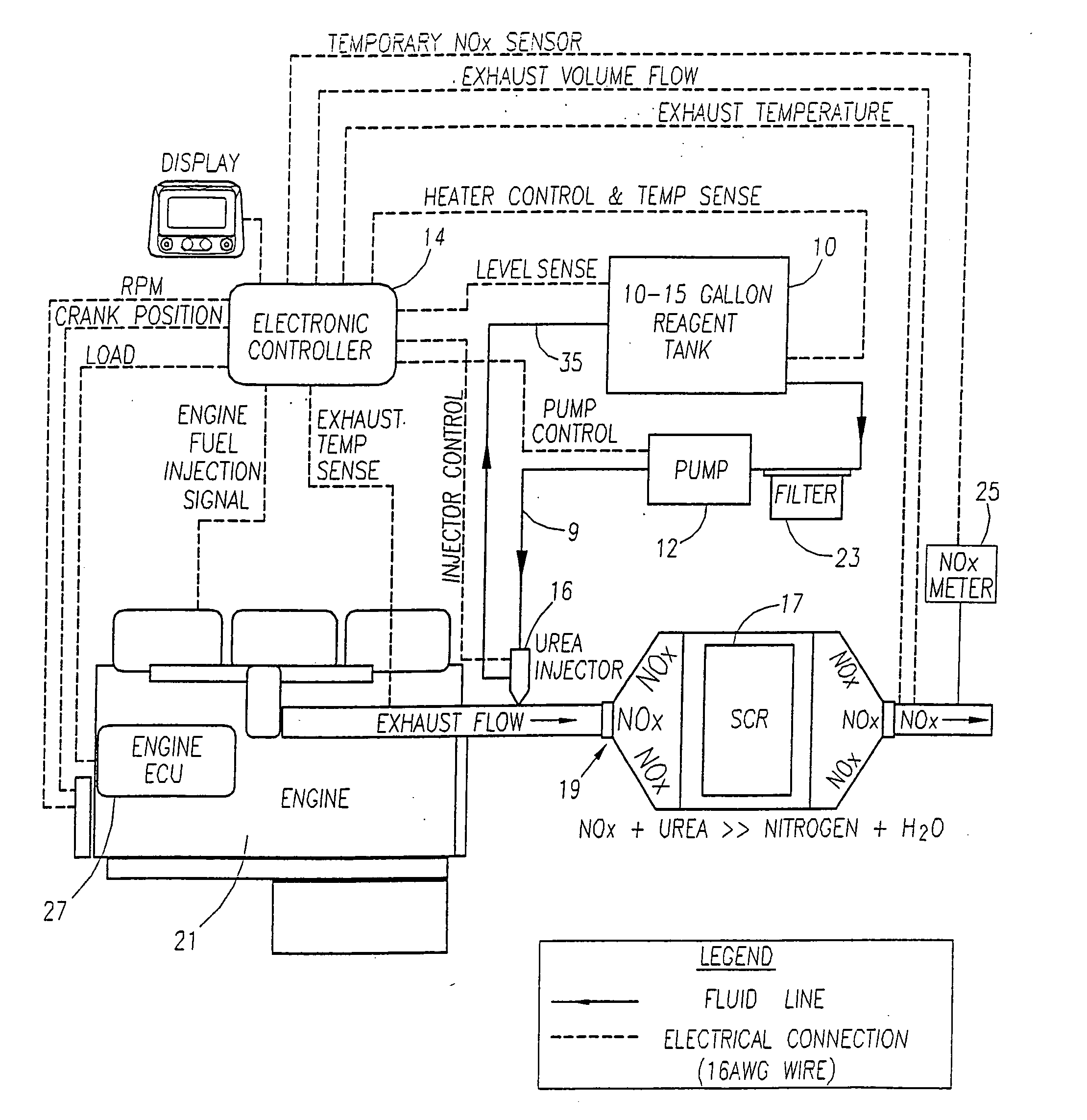

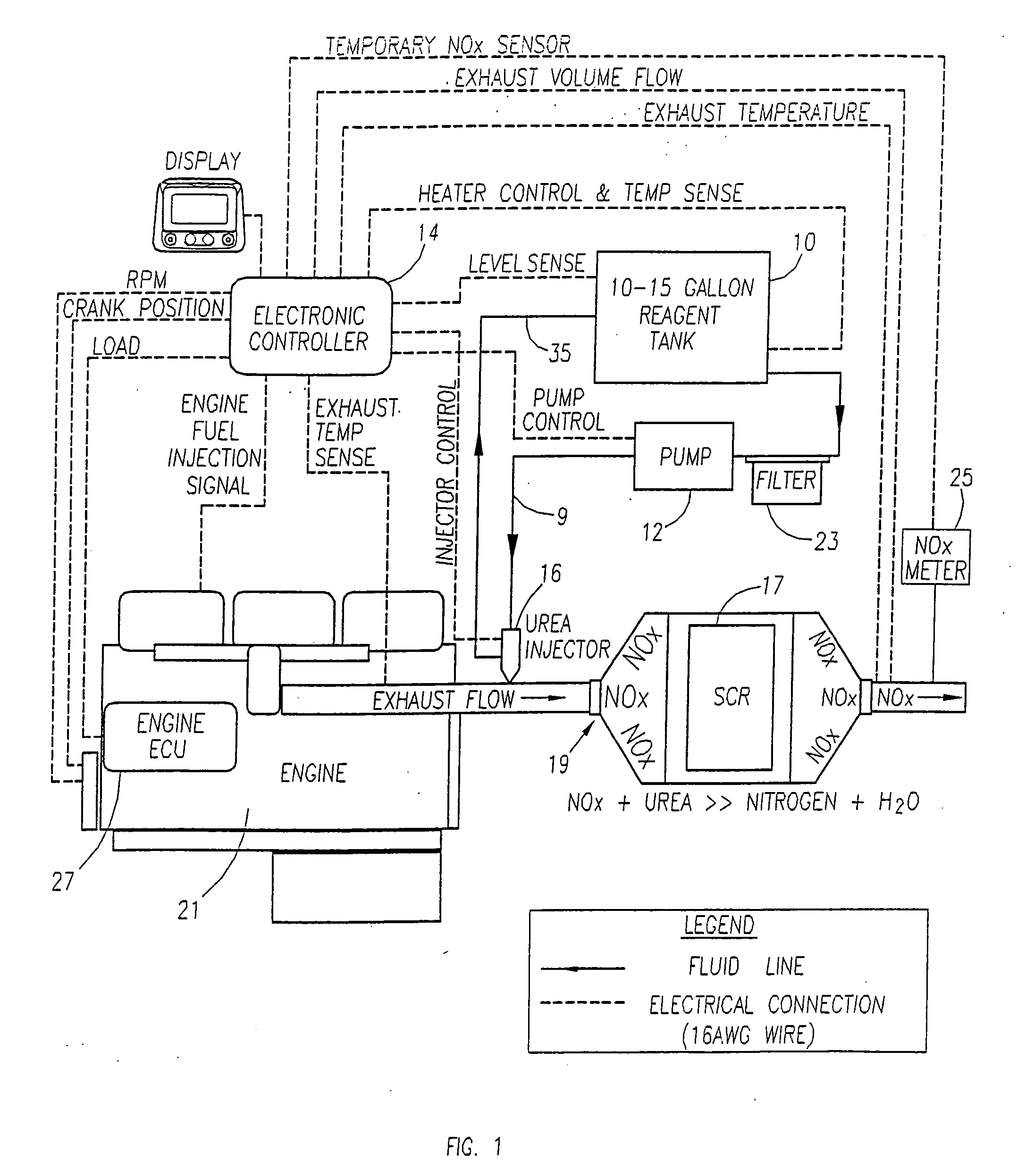

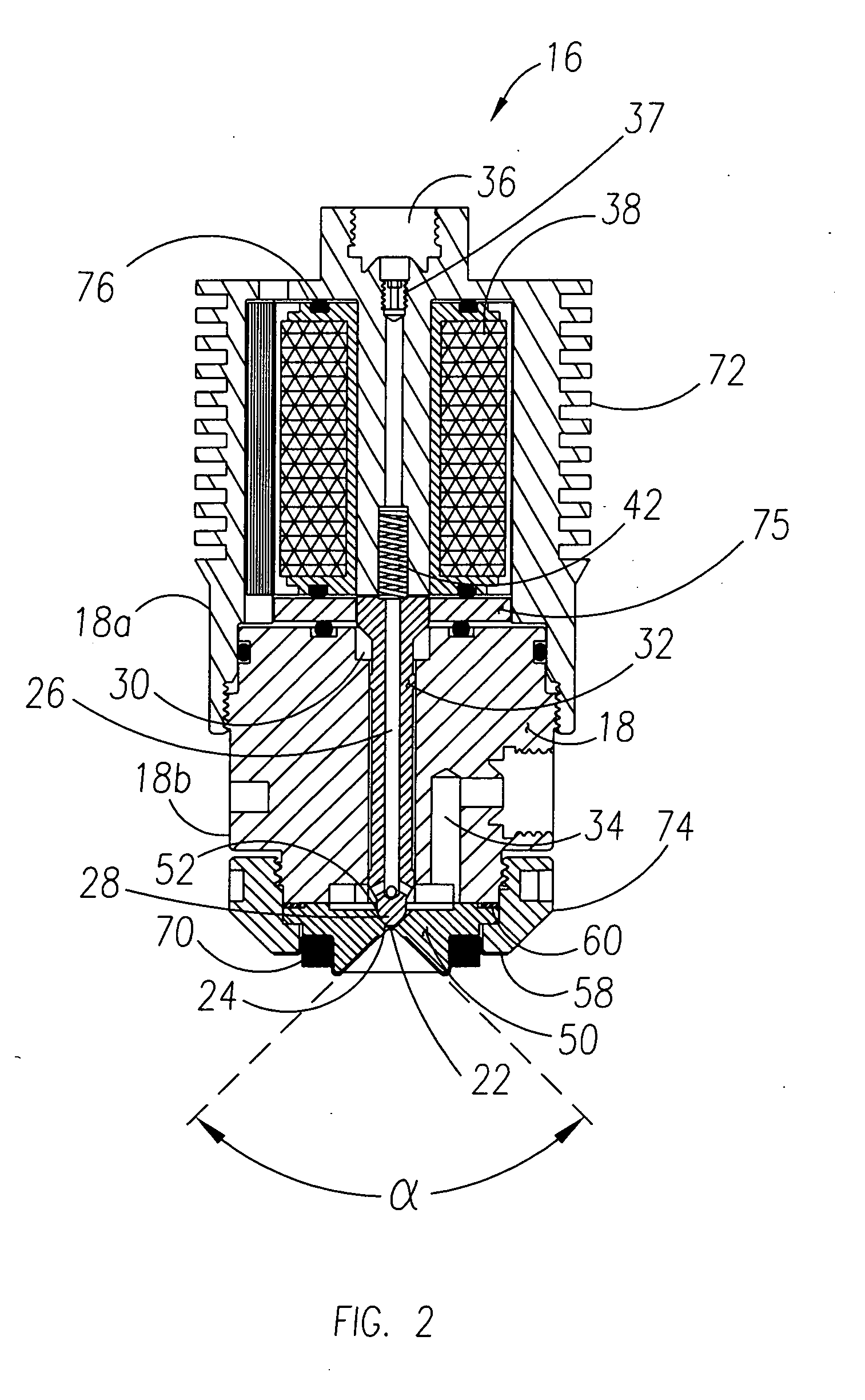

Methods and apparatus for injecting atomized fluid

ActiveUS20050235632A1Reduce oxide of nitrogen (NOx) emissionImprove performanceInternal combustion piston enginesExhaust apparatusDiesel engineNOx

The present invention provides methods and apparatus for injecting fluid, such as an aqueous urea solution, into an exhaust stream in order to reduce oxides of nitrogen (NOx) emissions from diesel engine exhaust The present invention uses mechanical spill return atomization techniques to produce droplets approximately 50 μm SMD (Sauter mean diameter) or smaller. This size range is appropriate to allow urea to react into ammonia within the residence time associated with an on-road diesel engine. This effect is achieved through the use of a whirl plate having a plurality of whirl slots surrounding an exit orifice of the injector, which produce a high velocity rotating flow in the whirl chamber. When the rotating flow of fluid is passed through the exit orifice into an exhaust stream, atomization occurs from a combination of centrifugal force and shearing of the fluid by air as it jets into the exhaust stream.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

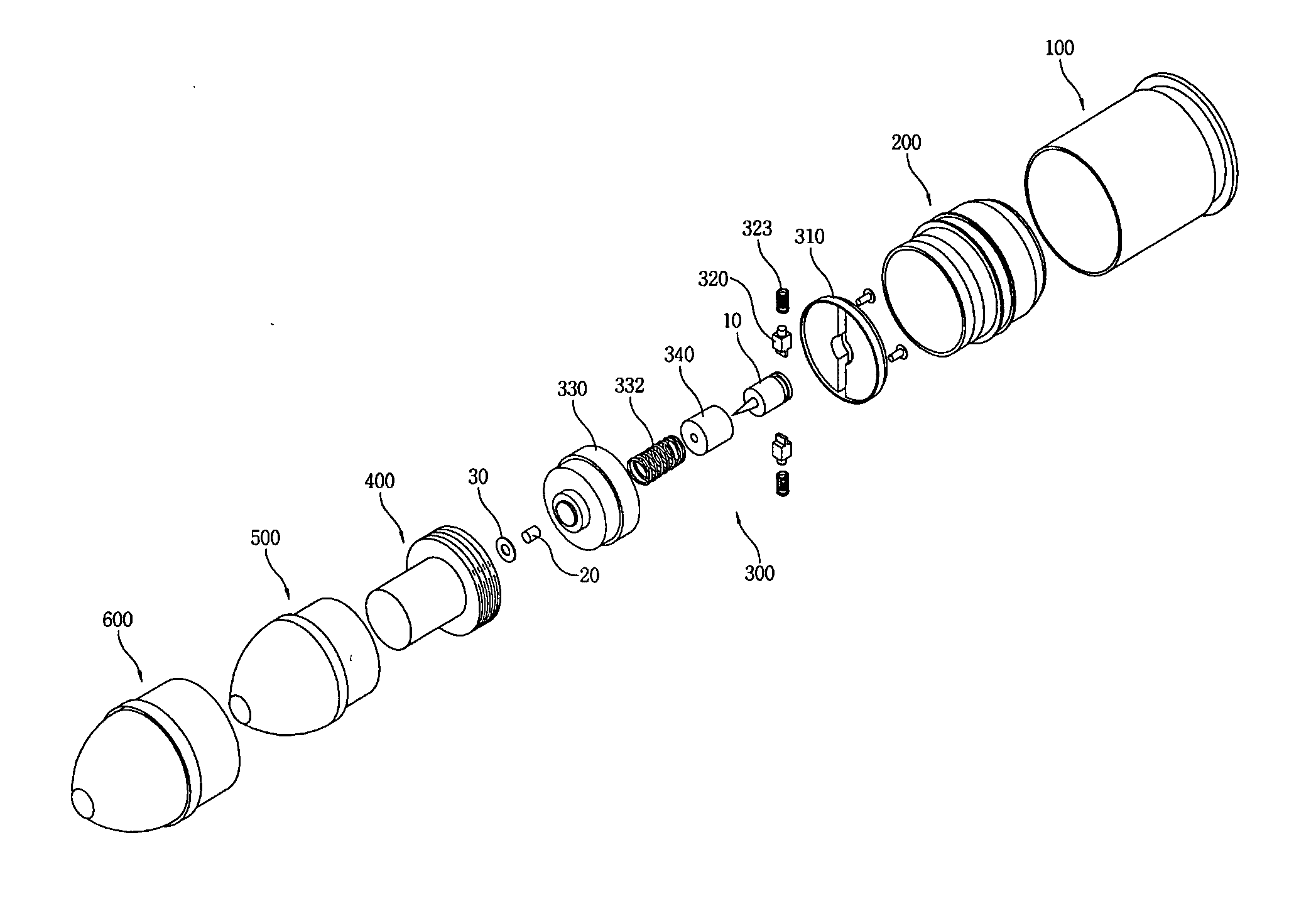

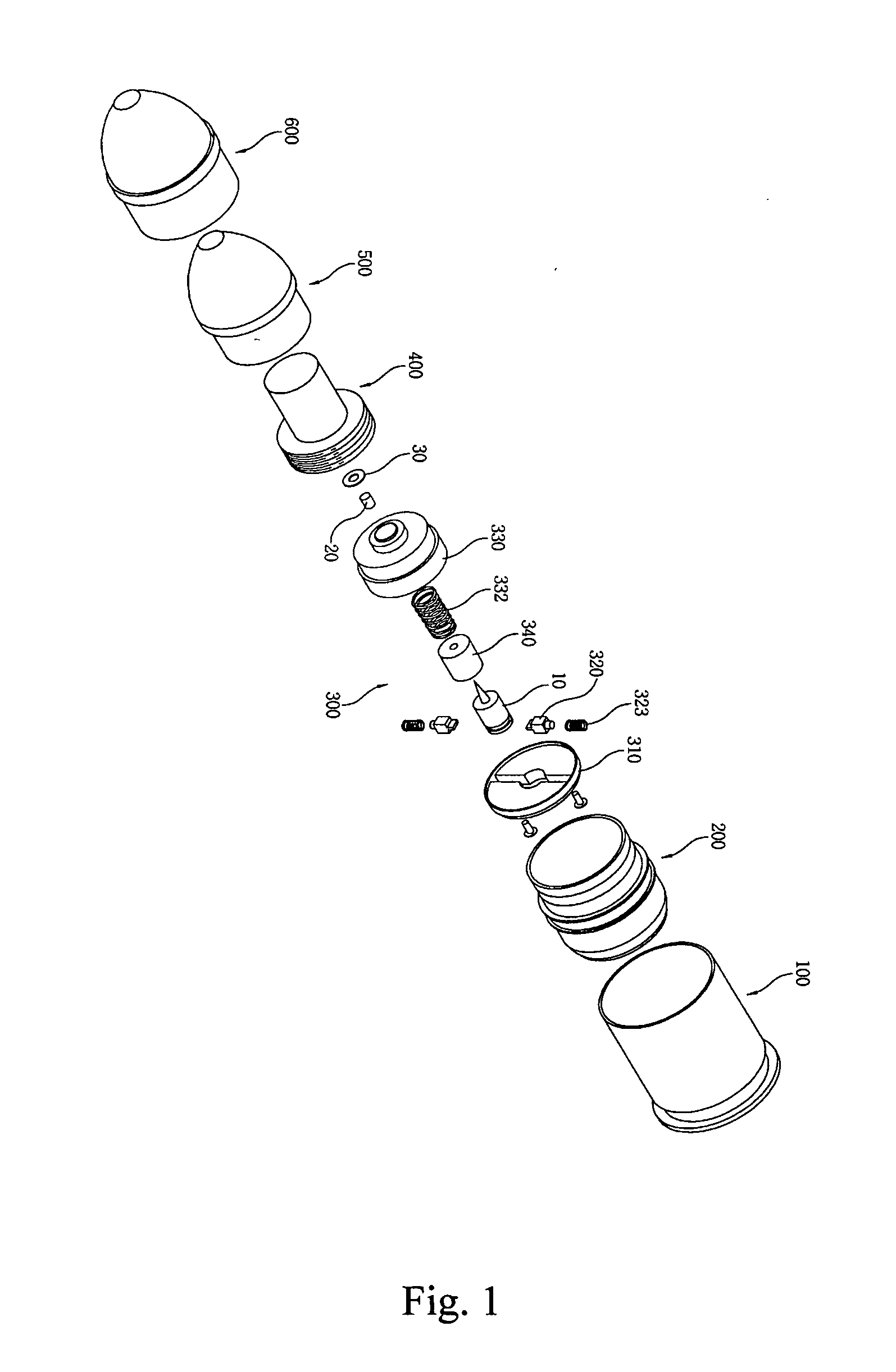

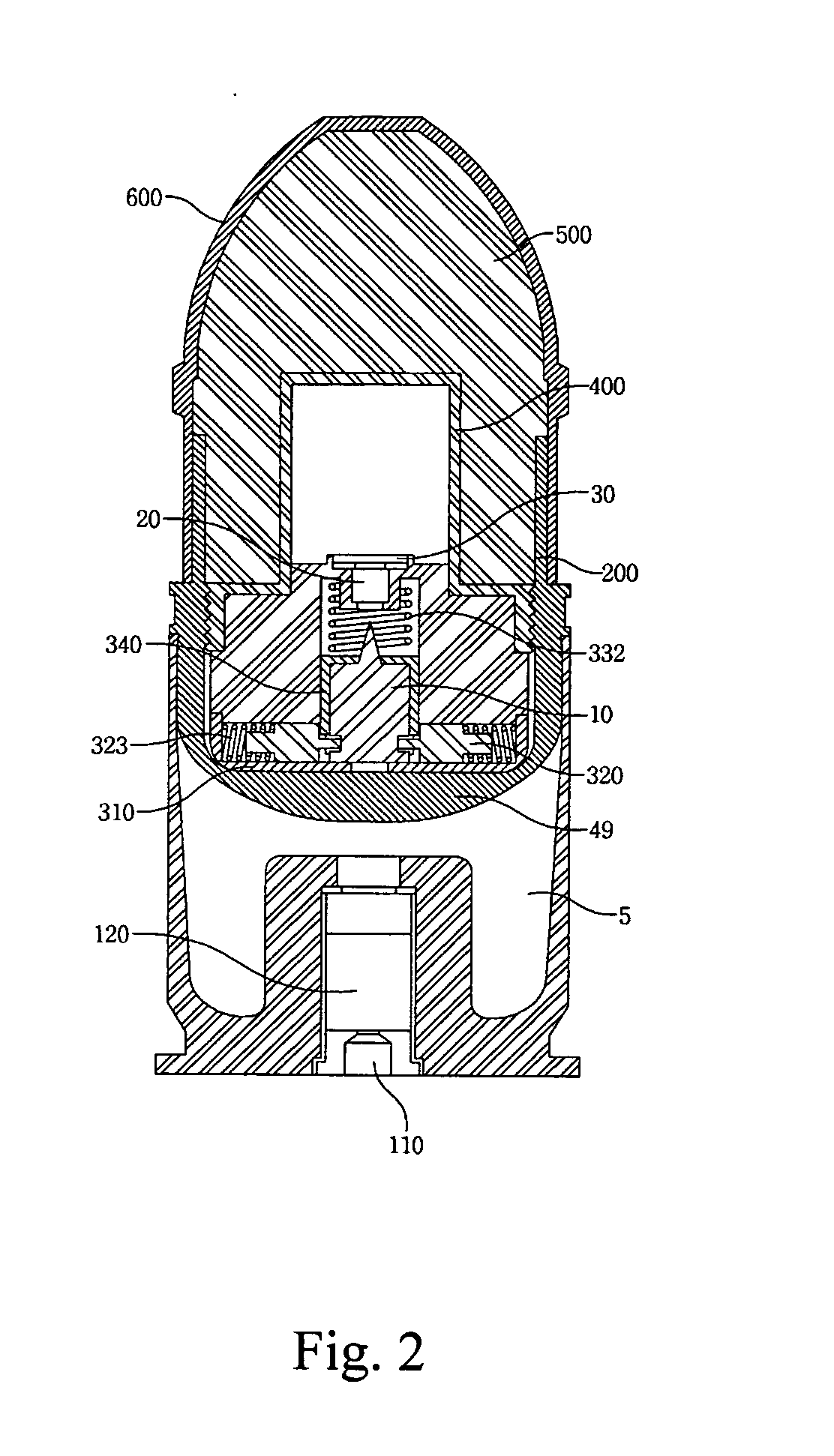

Forty millimeter caliber exercise bullet

ActiveUS20120180685A1Safely securedAvoid failureAmmunition projectilesTraining ammunitionDetonatorCentrifugal force

A forty millimeter caliber exercise bullet has improved for properly exploding on a target, and securely maintaining the unloaded status during ordinary time. The improved exercise bullet comprising that; a skirt (200), a striking pin (10), a safety device assembly (300) consisting a detent cover (310) with a central mounting groove (311) and a pair of mounting grooves (312), a detent (320) for retaining the striking pin (10) by engaging or disengaging into the circumferential groove (11) by springs (323), a detonator cap (330) forming a hollow pocket (331) to insert a detonator trigger (20), a washer (30), and a press-spring (332) for pressing a guiding cap (340), an explosion pipe (400), a smoke shell (500), and an ogive (600). When the bullet is fired, the rotation of bullet generates centrifugal force to slide the retainer outward for disengaging the circumferential groove, then the striking pin moves upward to impact the detonator trigger when it hit on the target.

Owner:C N O TECH KOREA

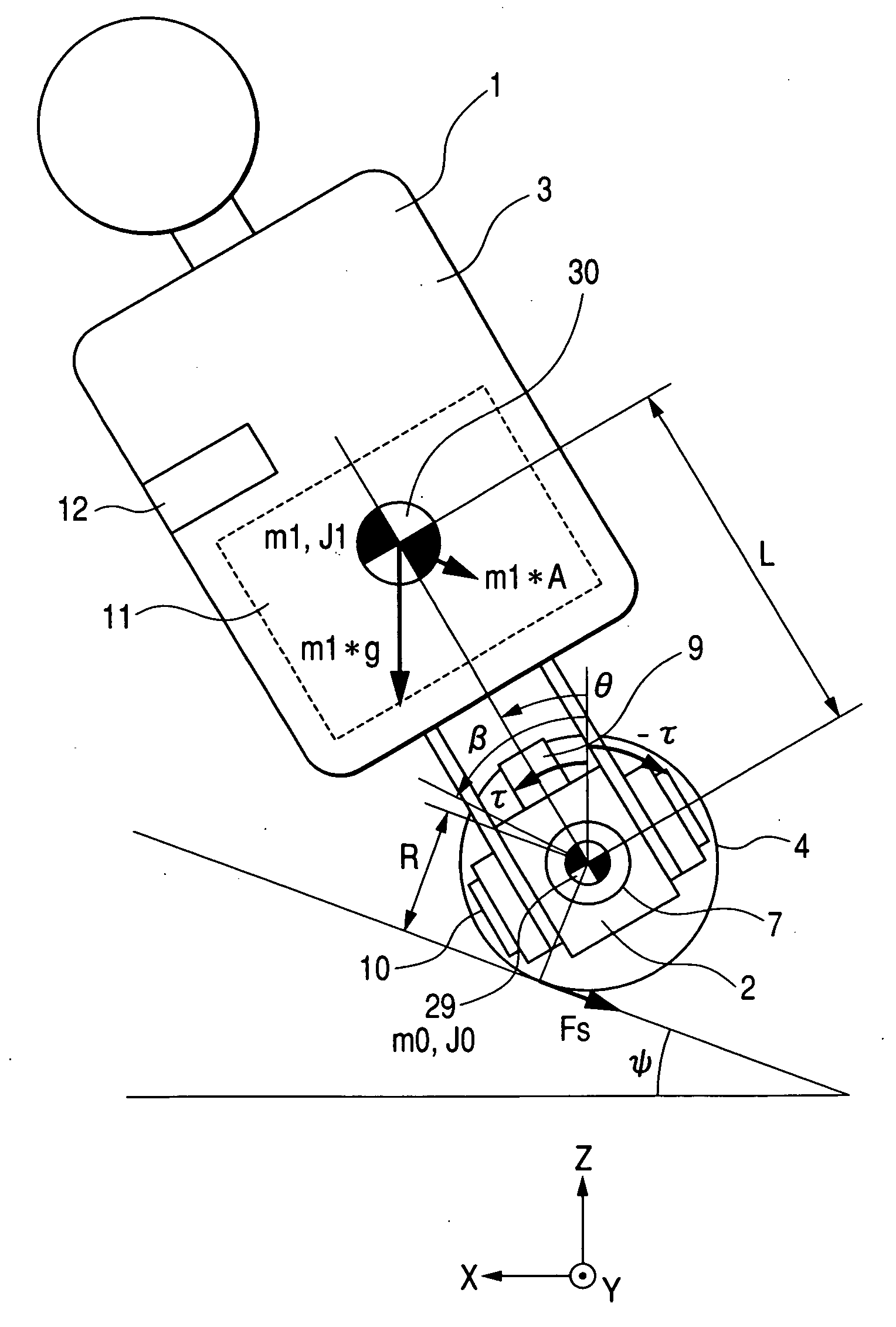

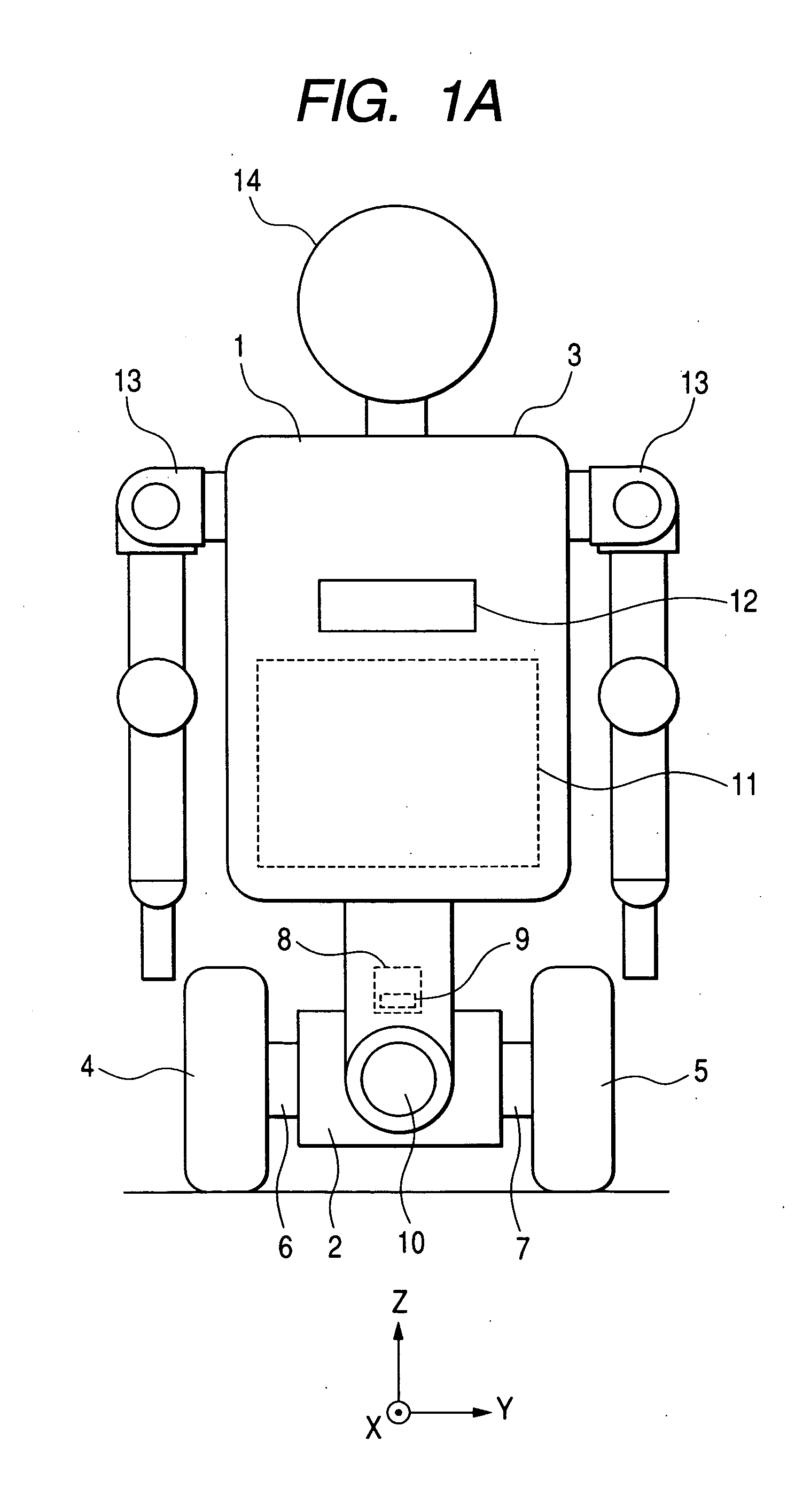

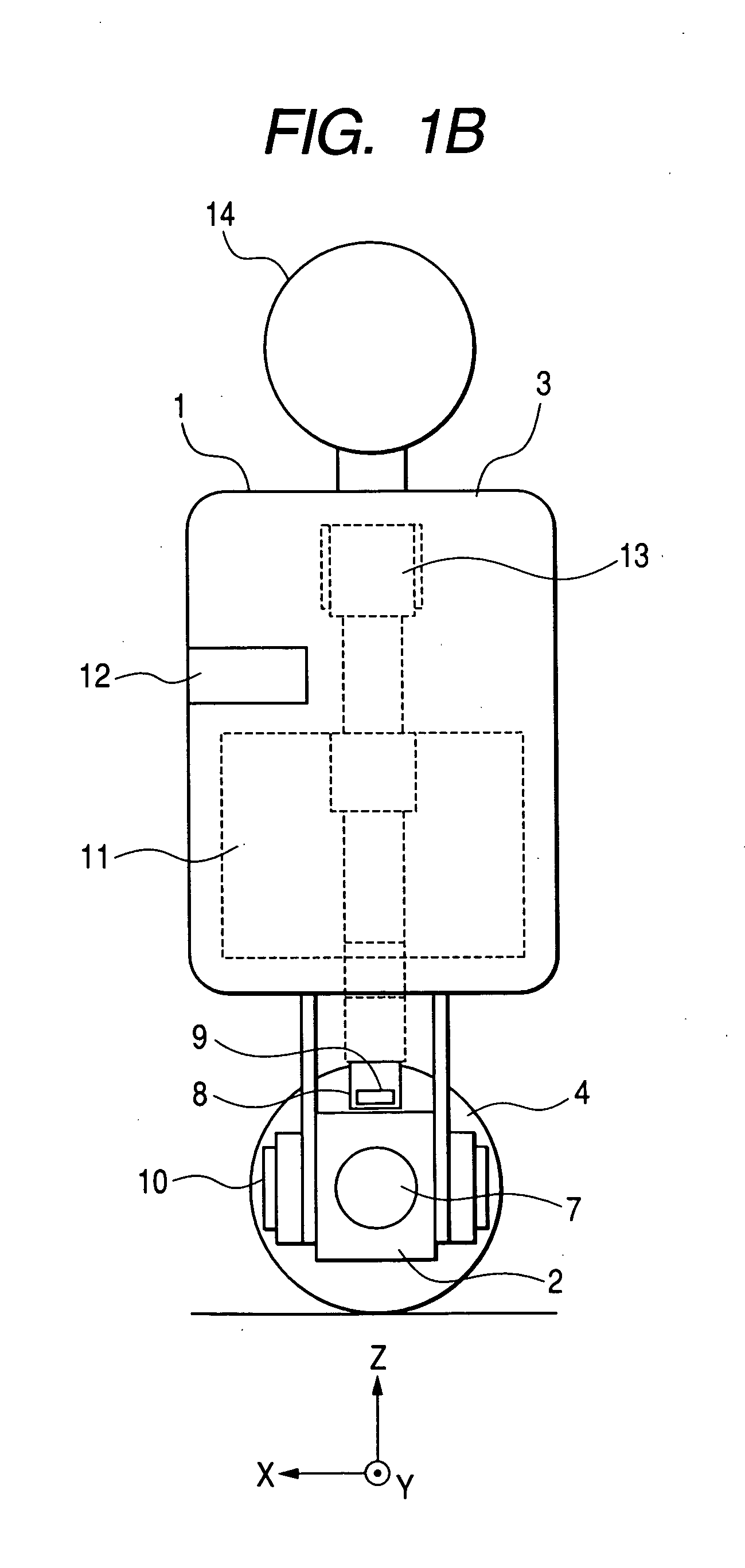

Mobile robot

InactiveUS20060097683A1Travel fastSmall footprintRobotVehicle position/course/altitude controlEngineeringGround plane

A mobile robot has a mobile mechanism, a swing mechanism and a control unit. The mobile mechanism is of a coaxial two-wheeled type and controls a forward thrust using inverted pendulum control. The swing mechanism actively swings an upper body laterally with respect to the mobile mechanism. A centrifugal force and a gravitational force act on a center of gravity of the mobile robot. A swing attitude is controlled such that a location of intersection of an extension of a composite vector of the forces acting on the center of gravity of the mobile robot and a ground plane of wheels is kept between left and right wheels.

Owner:HITACHI LTD

Method and apparatus for characterizing solutions of small particles

A method and apparatus is described by which means molecules in suspension may be characterized in terms of the size and mass distributions present. As a sample solution is separated by centrifugal means, it is illuminated at a particular radial distance from the axis of rotation by a fine, preferably monochromatic, light beam. Despite the high resolution of such devices, a key problem associated with most separators based upon use of centrifugal forces is the difficulty in deriving the absolute size and / or molar mass of the separating molecules. By integrating means to detect light scattered, over a range of scattering angles, from samples undergoing centrifugal separation, molecular sizes in the sub-micrometer range may be derived, even in the presence of diffusion. Adding a second light beam at a displaced rotational angle, preferably of an ultraviolet wavelength, that intersects the sample at the same radial region as the first beam permits determination of the molecular concentration at that region. Combining the light scattering data with the associated concentration permits the determination of the associated molar mass. In a preferred embodiment, the light beam and detectors may be controlled to scan synchronously the sample radially during separation.

Owner:WYATT TECH

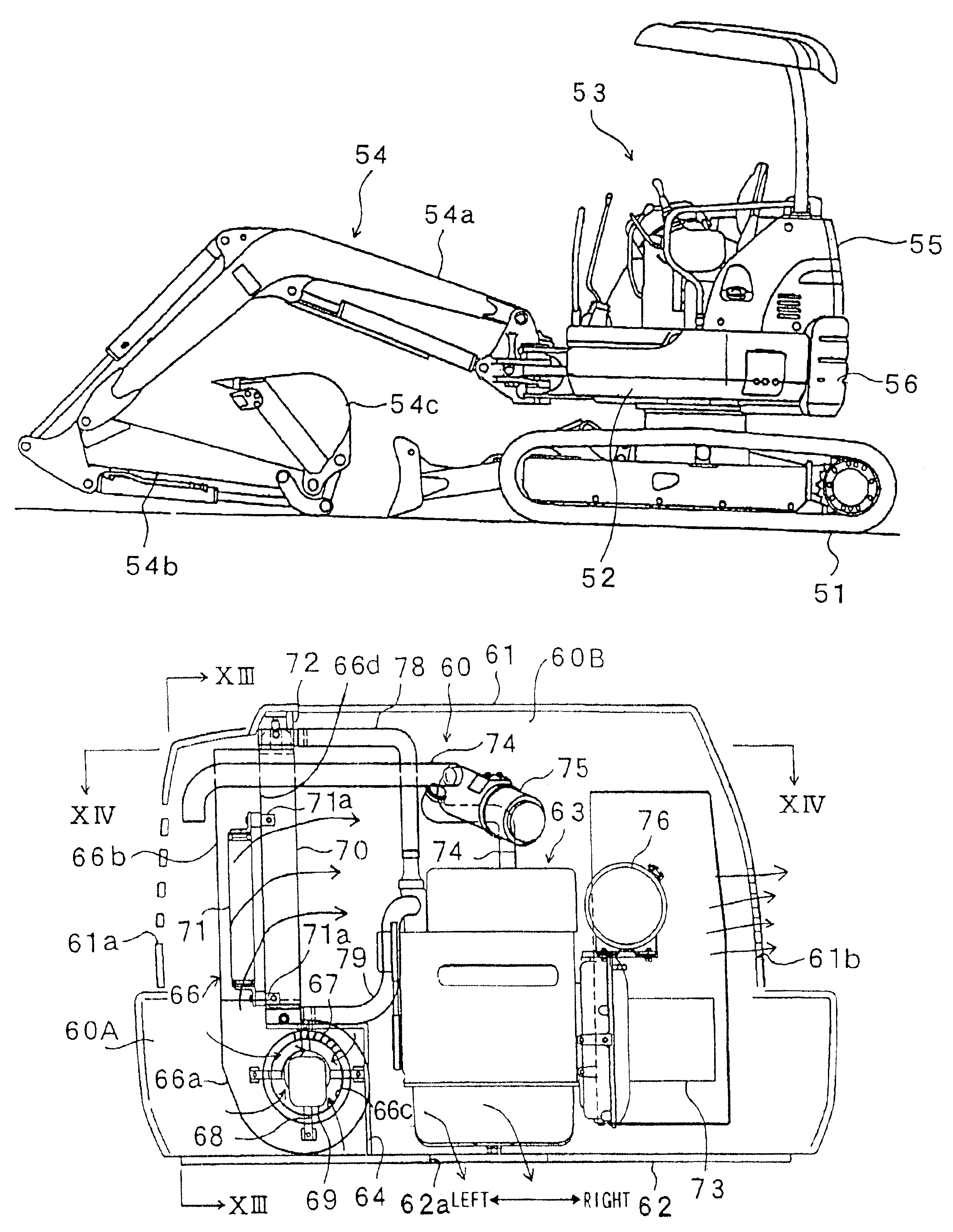

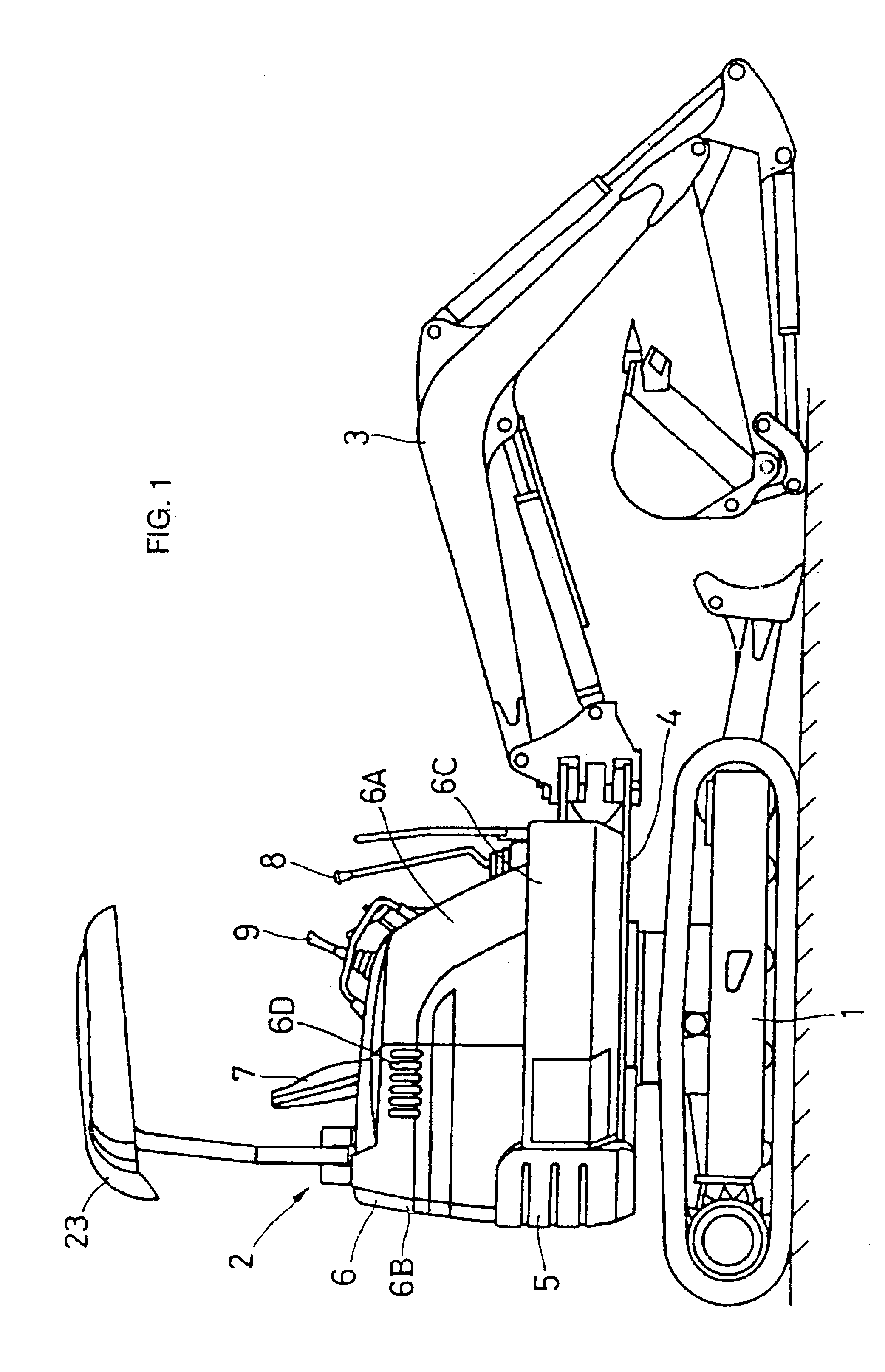

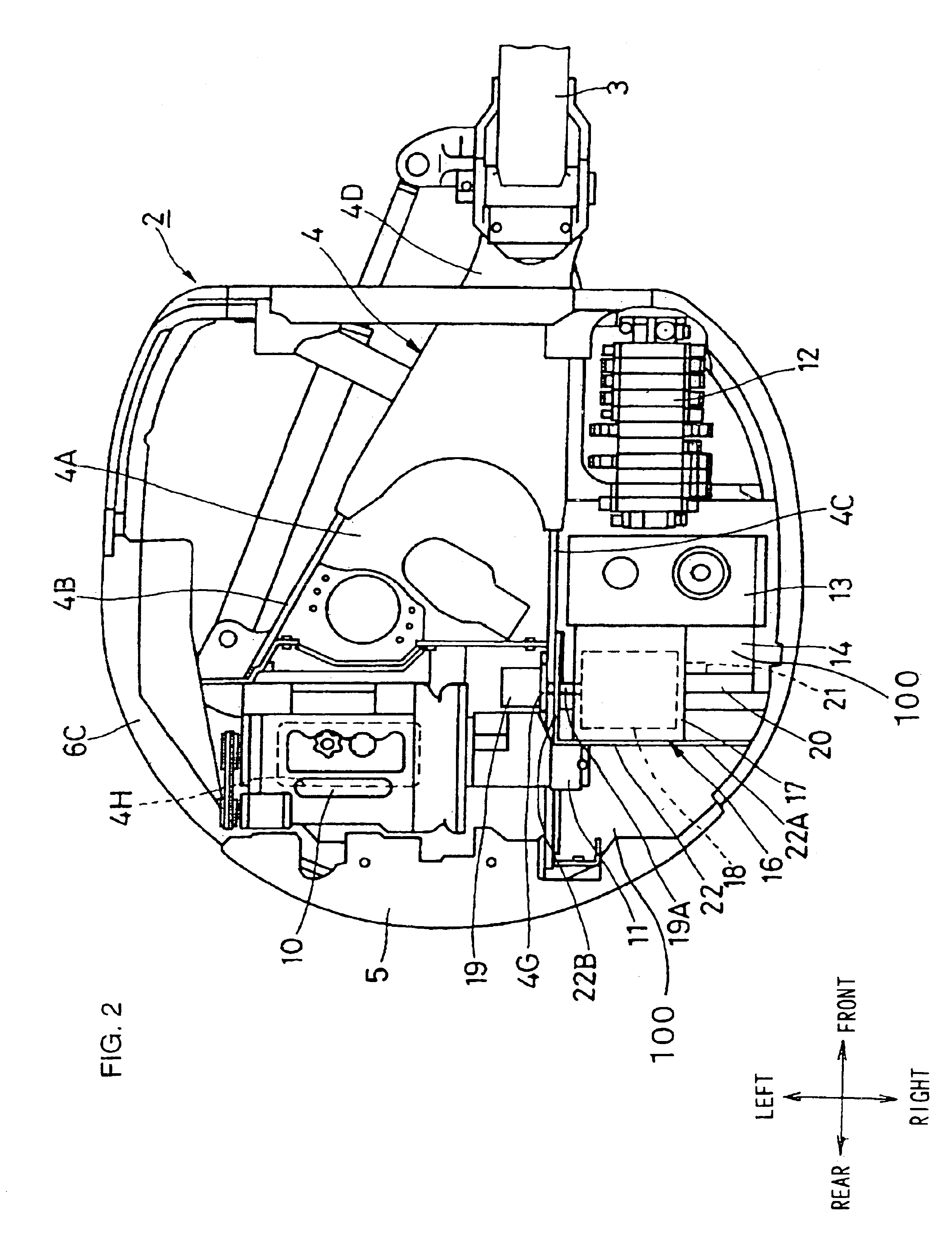

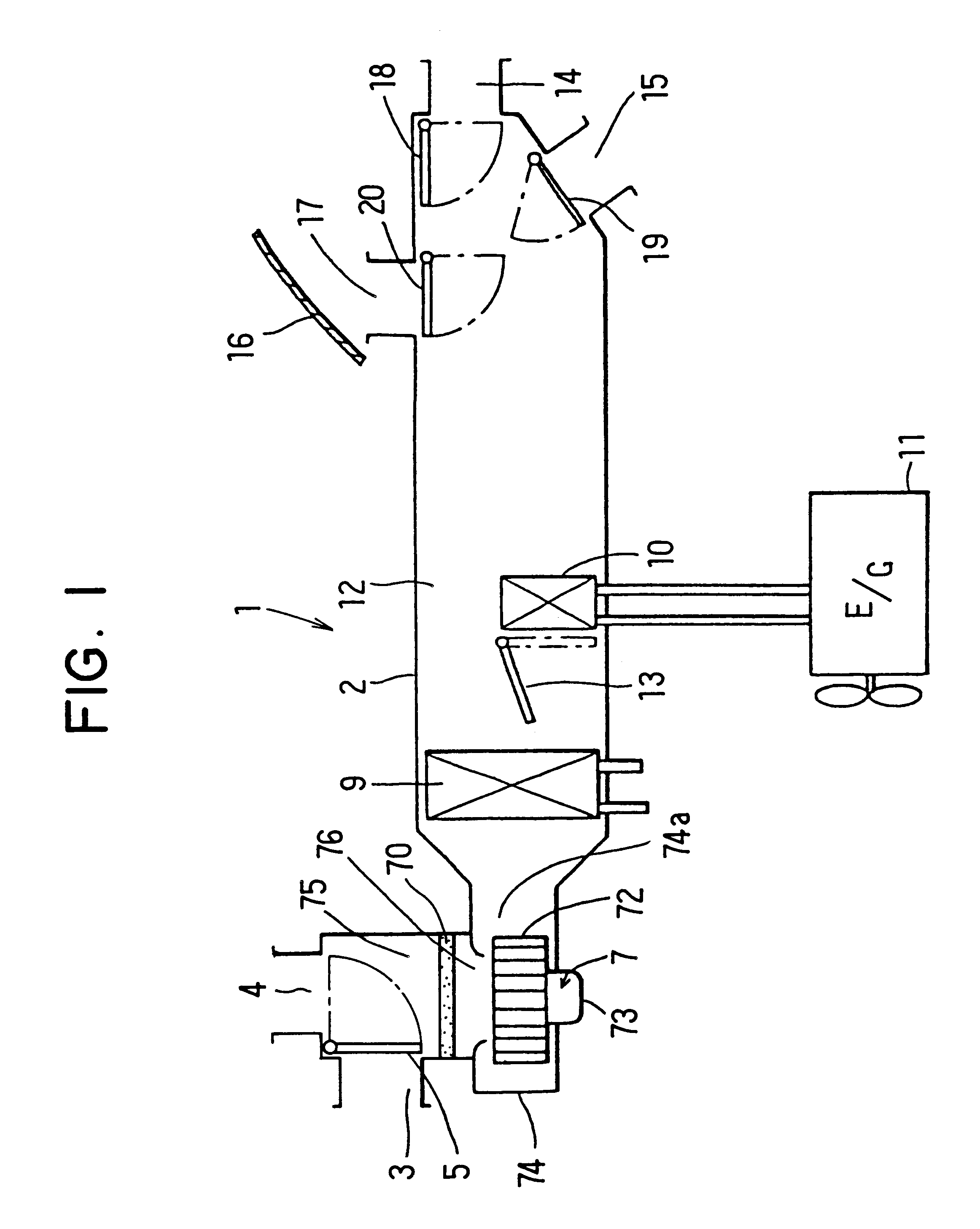

Construction machine

InactiveUS6922925B2Improve cooling efficiencyReduce noiseCoolant flow controlAir coolingEngineeringCentrifugal force

A construction machine of the present invention is provided, in a compartment formed by a cover, with an engine, a centrifugal fan, and a heat exchanger for exchanging heat between cooling air blown by the centrifugal fan and a specified medium, wherein the centrifugal fan and the heat exchanger are arranged further upstream than the engine with respect to flow of cooling air, so that cooling air sucked in by the centrifugal fan is led to the engine after passing through the heat exchanger.

Owner:NIHON KENKI CO LTD

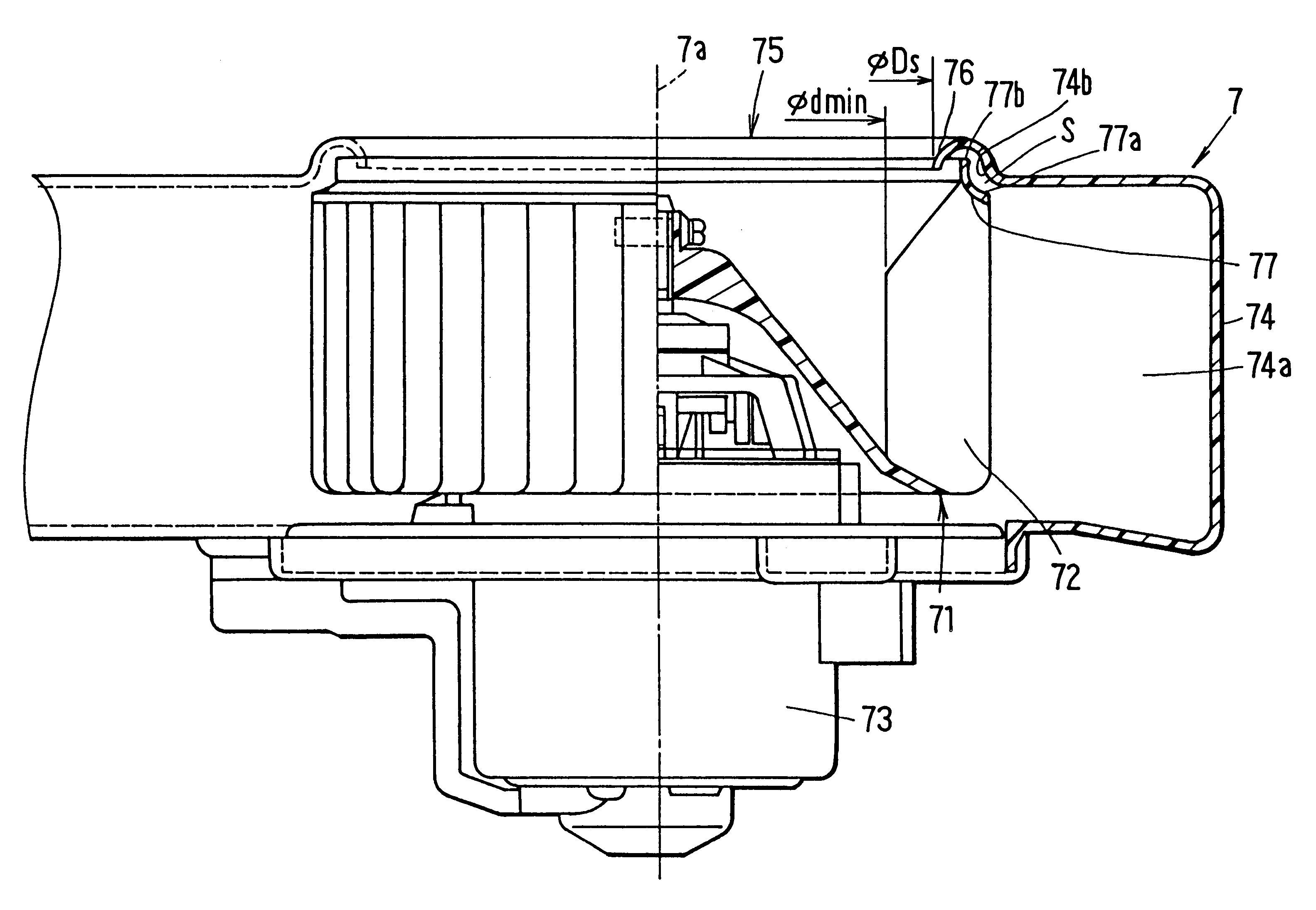

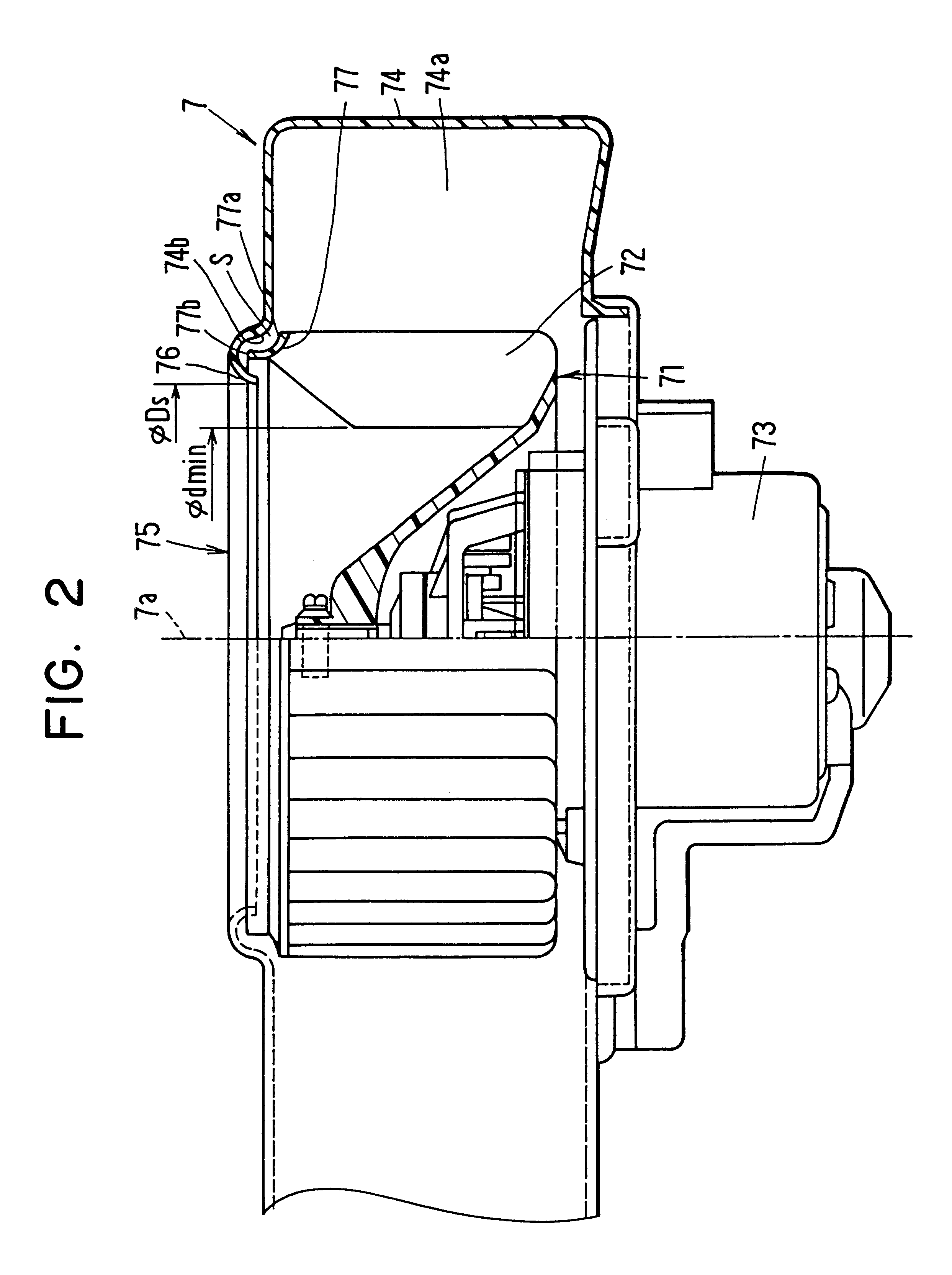

Centrifugal type blower unit

In a centrifugal type blower unit, a diameter of an air suction port is set to be larger than a minimum inner diameter of a centrifugal fan, and a slanting portion is formed in each blade of the centrifugal fan at a side of the air suction port so that an inner radius dimension of the centrifugal fan is increased toward the air suction port. Therefore, it can prevent sub-flow air which is sucked into the centrifugal fan from an end side of the blades in an axial direction from interfering with main-flow air which is sucked into the centrifugal fan from an inner radius side of the blades. Thus, the blower unit can reduce second noise generated therefrom without greatly reducing air-blowing capacity.

Owner:DENSO CORP

Motor-type power device

ActiveUS20090127954A1Suppress stirring resistance of oilEnsure performanceGearboxesGear lubrication/coolingEngineeringCentrifugal force

Due to a centrifugal force in a vehicle width direction due to turning of an automobile, oil in an electric motor housing chamber housing an electric motor and oil in a transmission housing chamber housing a reduction gear and a differential gear flows to-and-fro via oil communication passages that penetrate a partitioning wall. An opening on the transmission housing chamber side of the oil communication passages is spaced from the partitioning wall. Hence, when oil moves from the transmission housing chamber side to the electric motor housing chamber side, it is possible to prevent the oil quantity on the electric motor housing chamber side from increasing excessively and suppress an increase in resistance to oil stirring by a rotor of the electric motor while retaining a constant oil amount on the transmission housing chamber side to ensure lubricating performance for the reduction gear and the differential gear.

Owner:HONDA MOTOR CO LTD

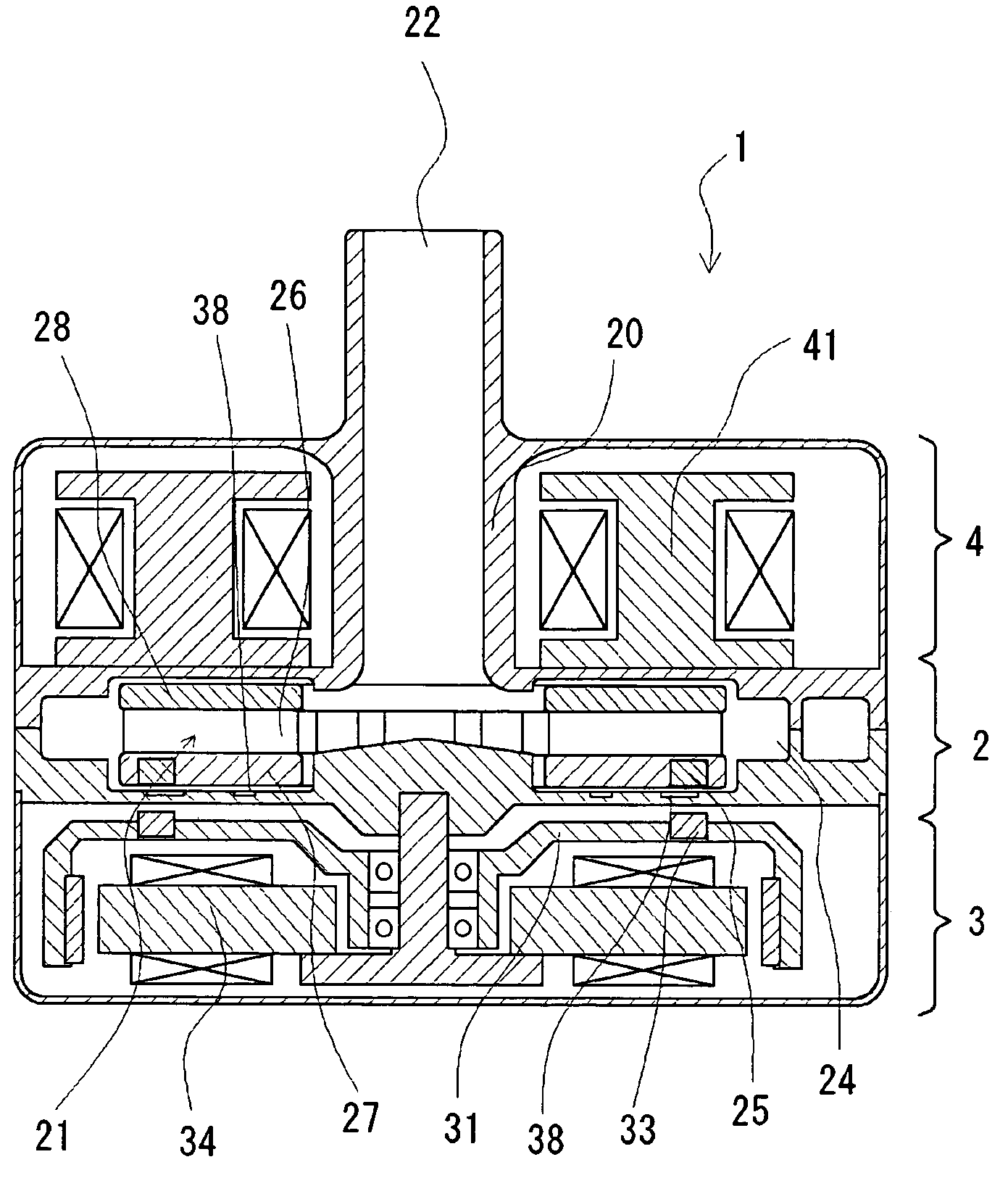

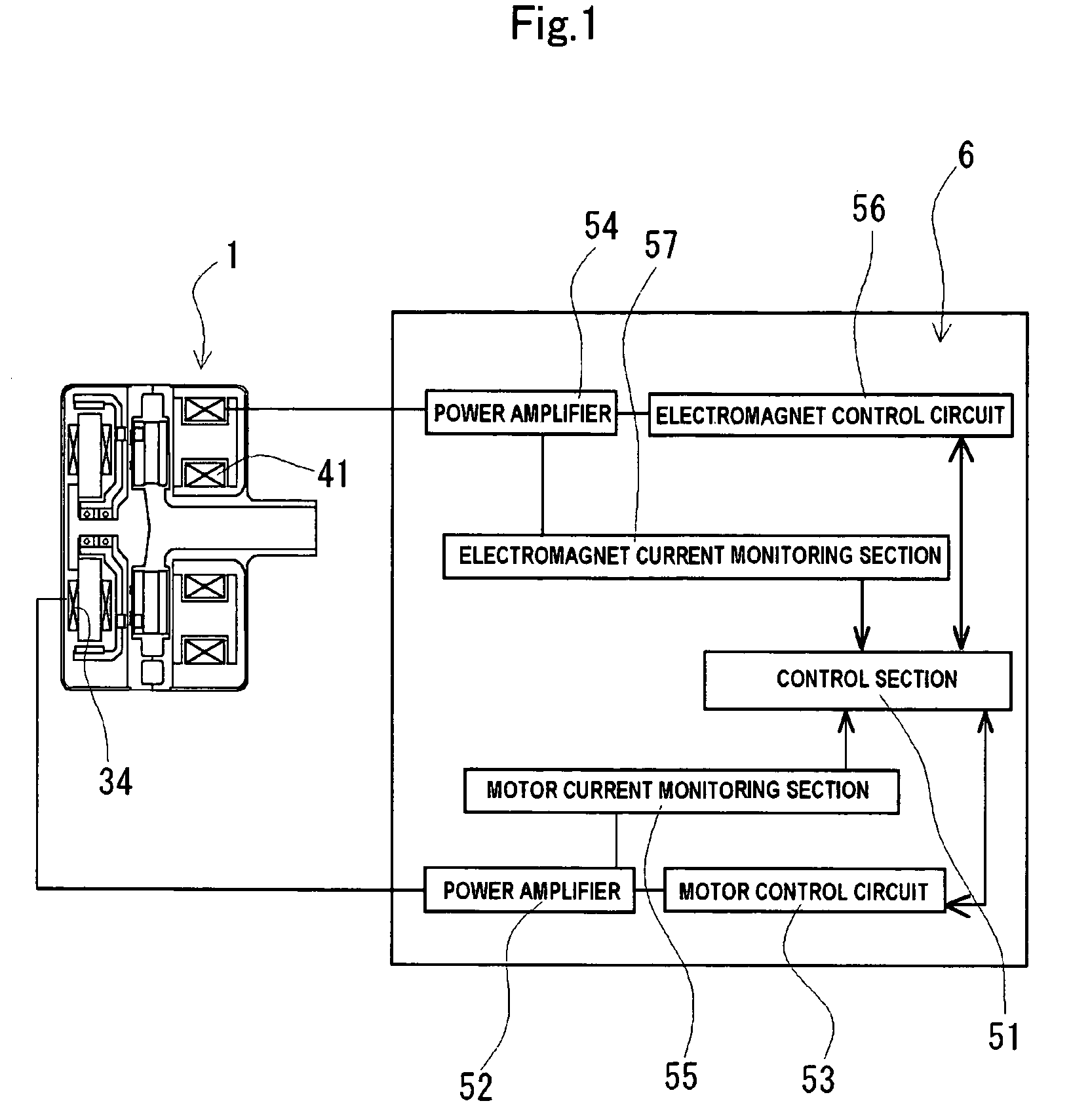

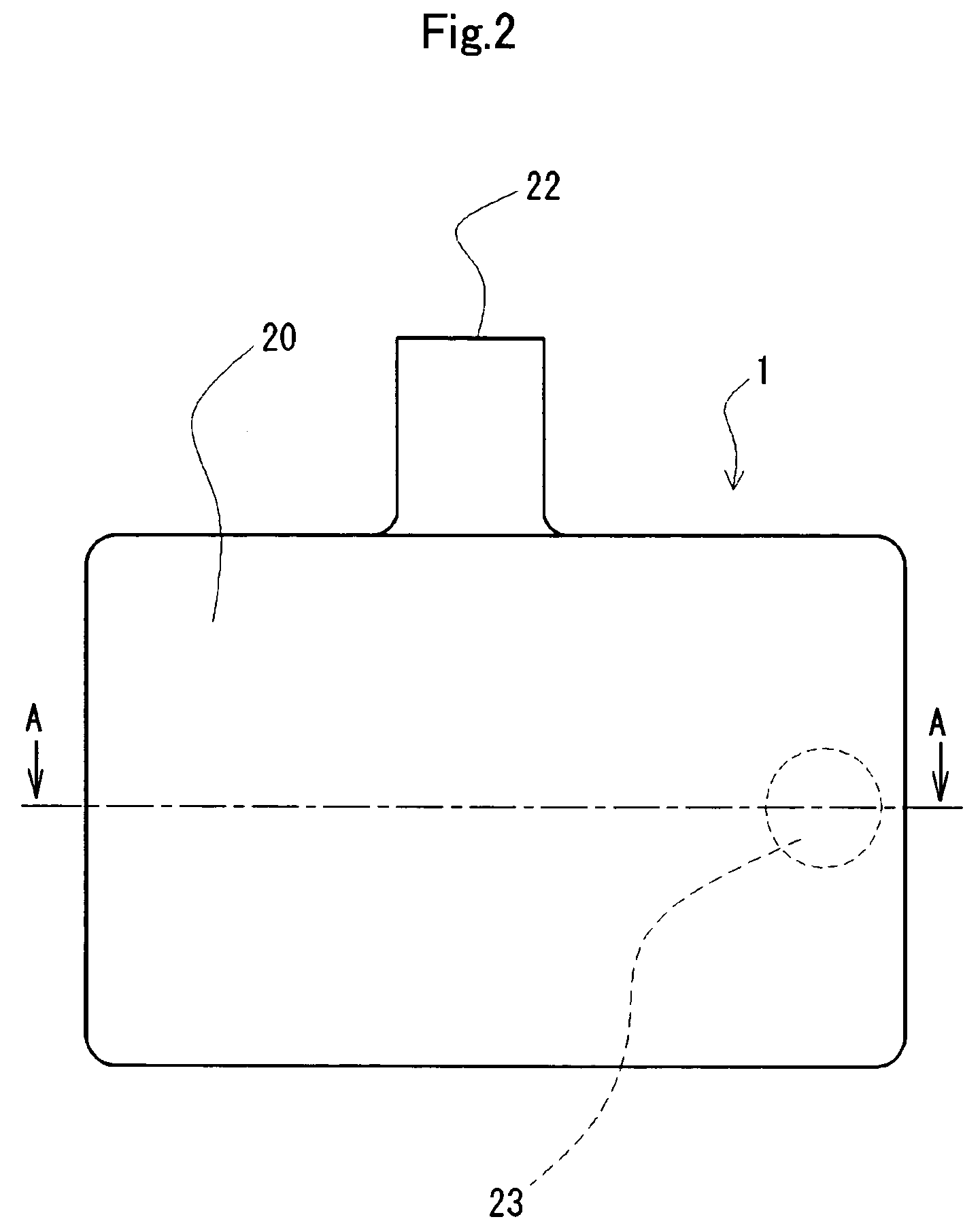

Centrifugal blood pump apparatus

A centrifugal blood pump apparatus has a centrifugal pump section including an impeller having a first magnetic material therein and rotating inside the housing to feed a fluid by a centrifugal force generated during a rotation thereof; an impeller rotational torque generation section having a rotor having a magnet for attracting the first magnetic material of the impeller thereto, and a motor for rotating the rotor; and a dynamic pressure groove formed at a portion, of an inner surface of the housing, located at a rotor-disposed side thereof. The centrifugal blood pump apparatus further includes an electromagnet for attracting the impeller in a direction opposite to a direction in which the magnet of the rotor attracts the impeller and helping the impeller levitate.

Owner:TC1 LLC

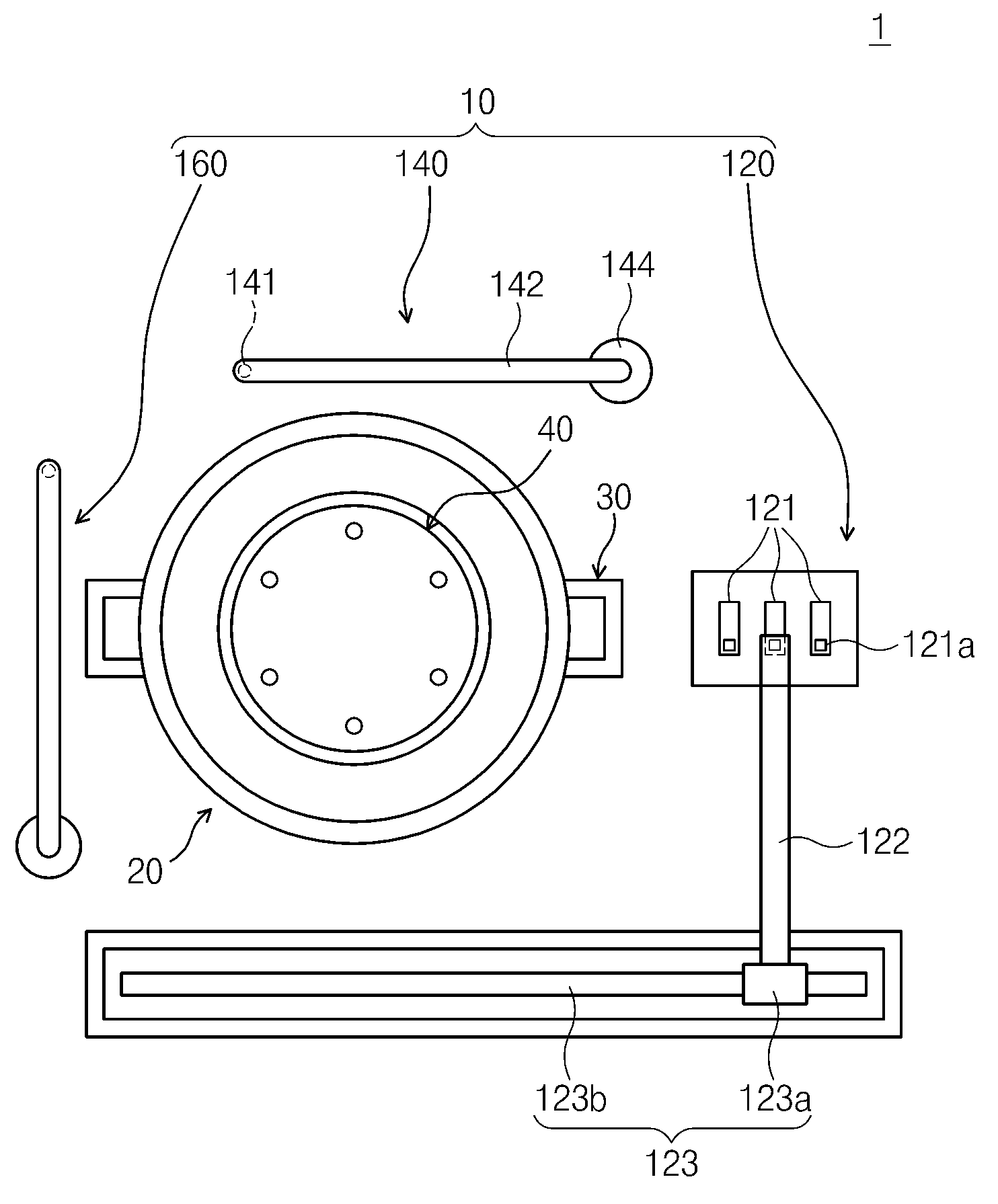

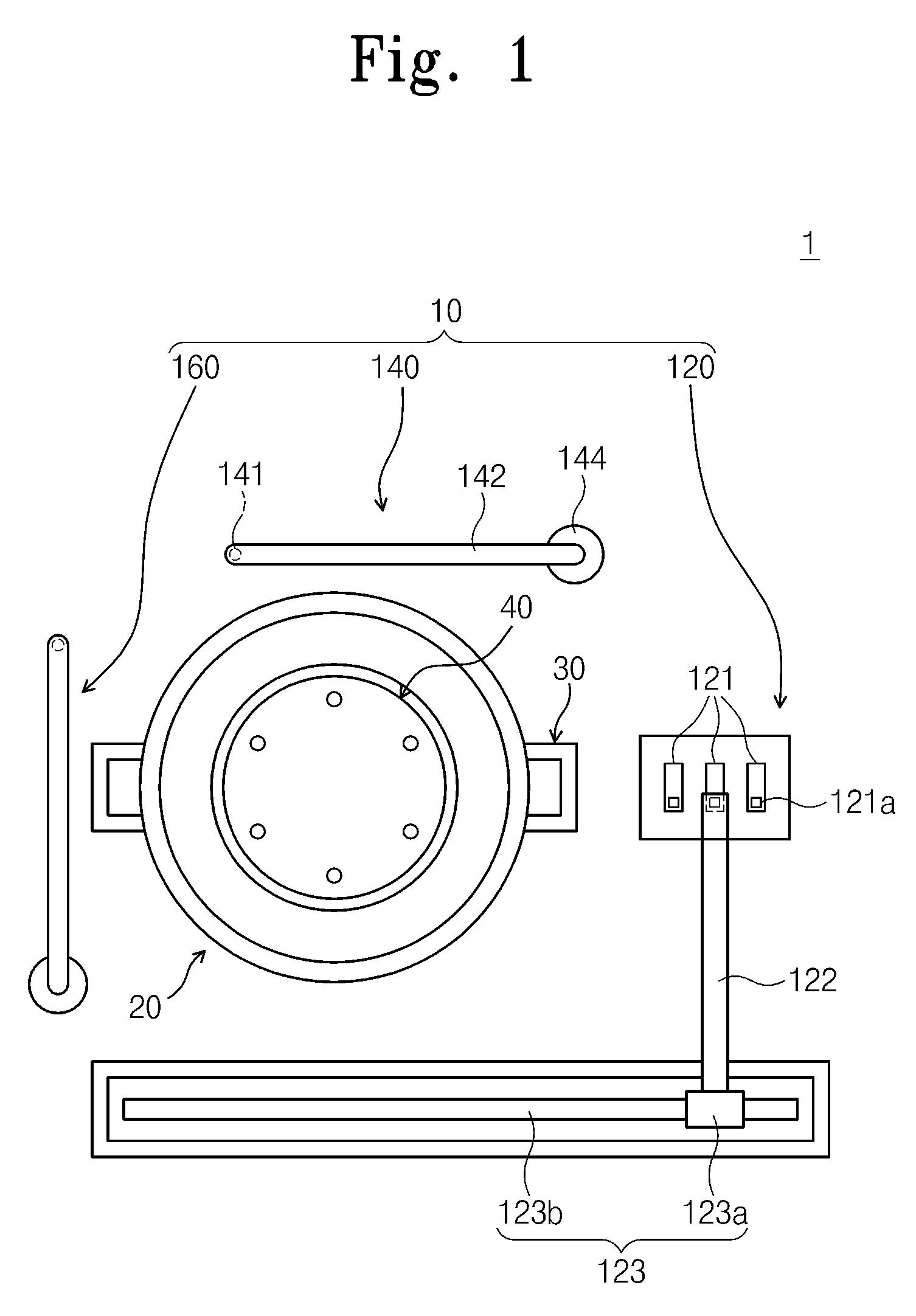

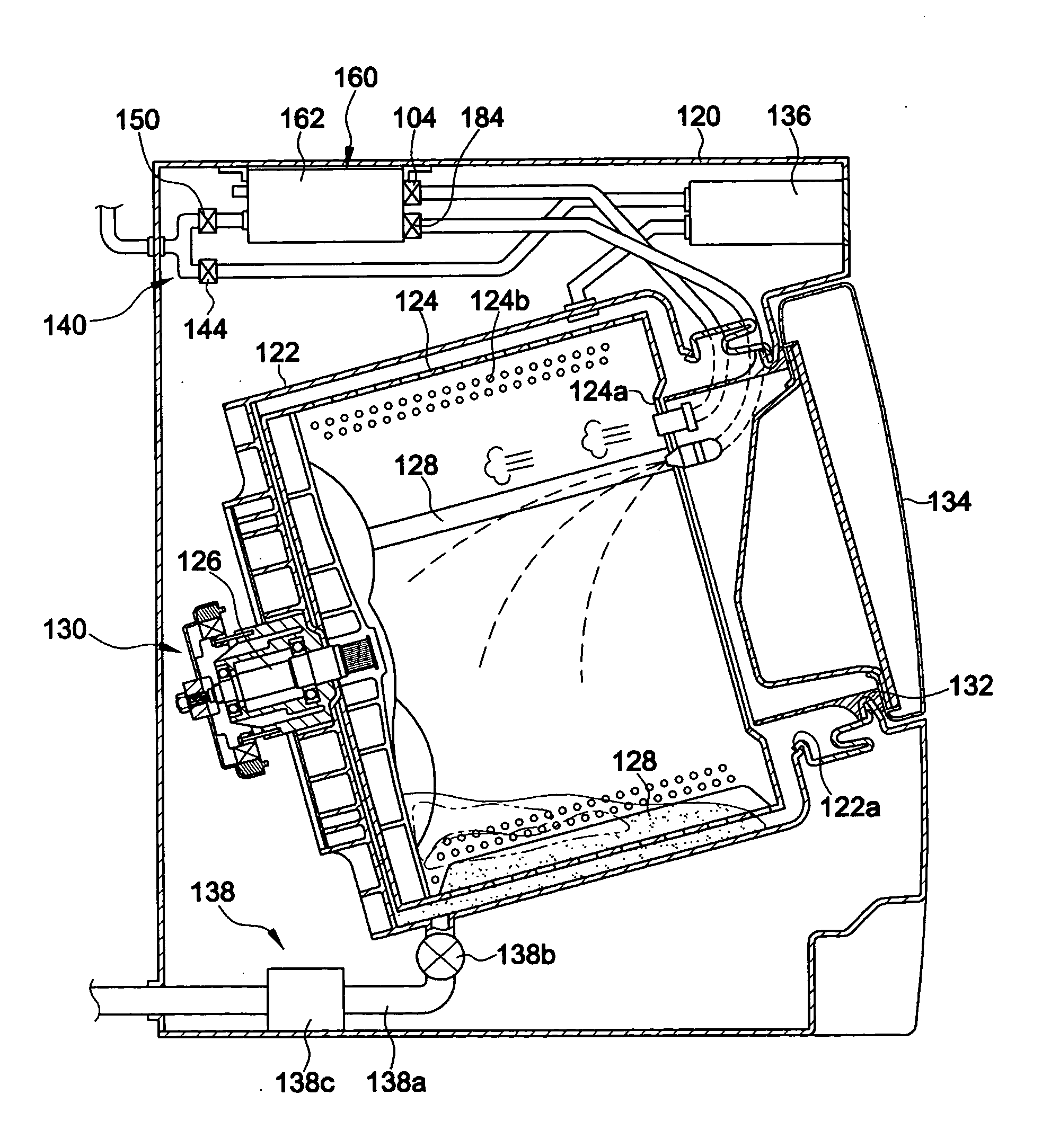

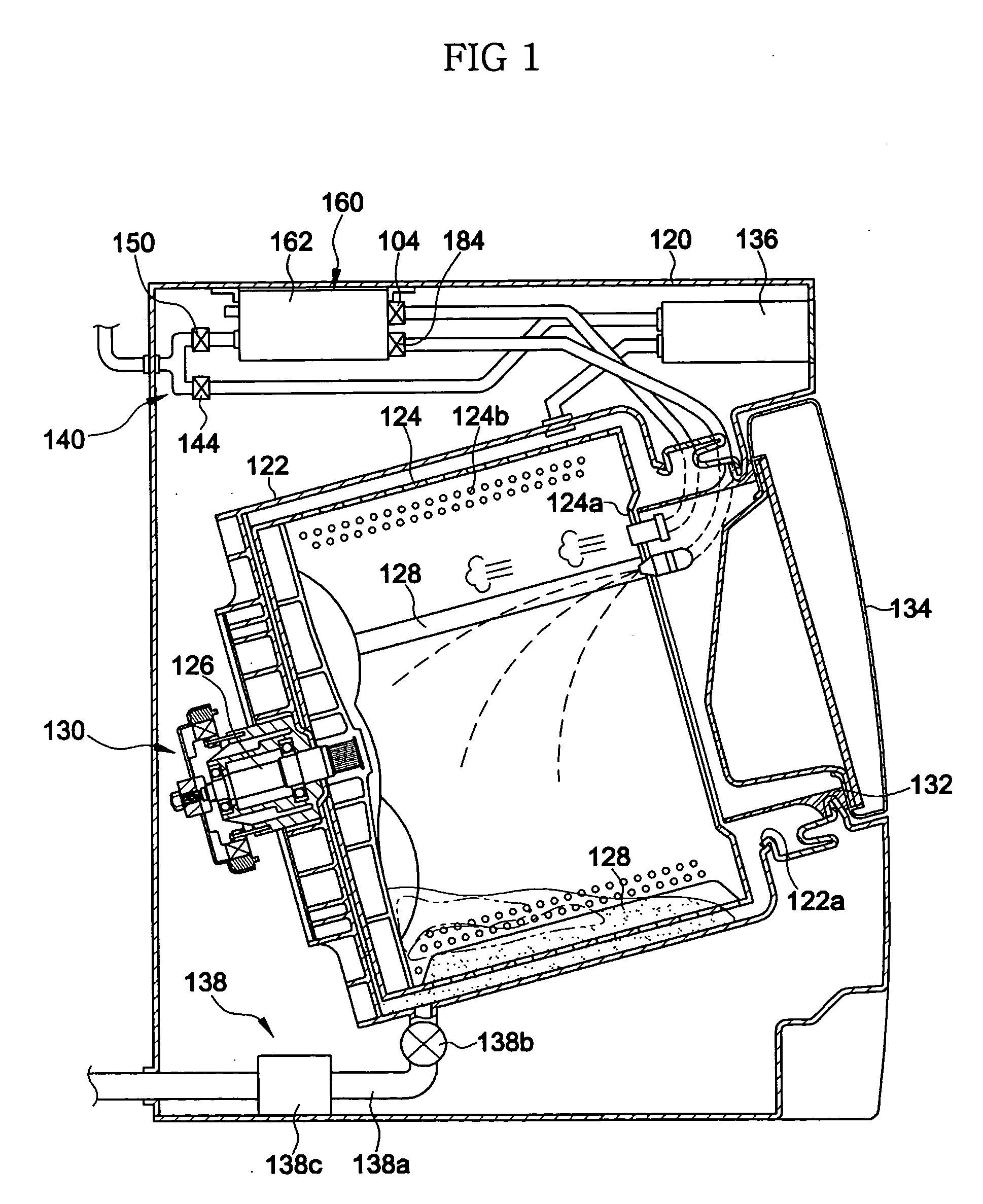

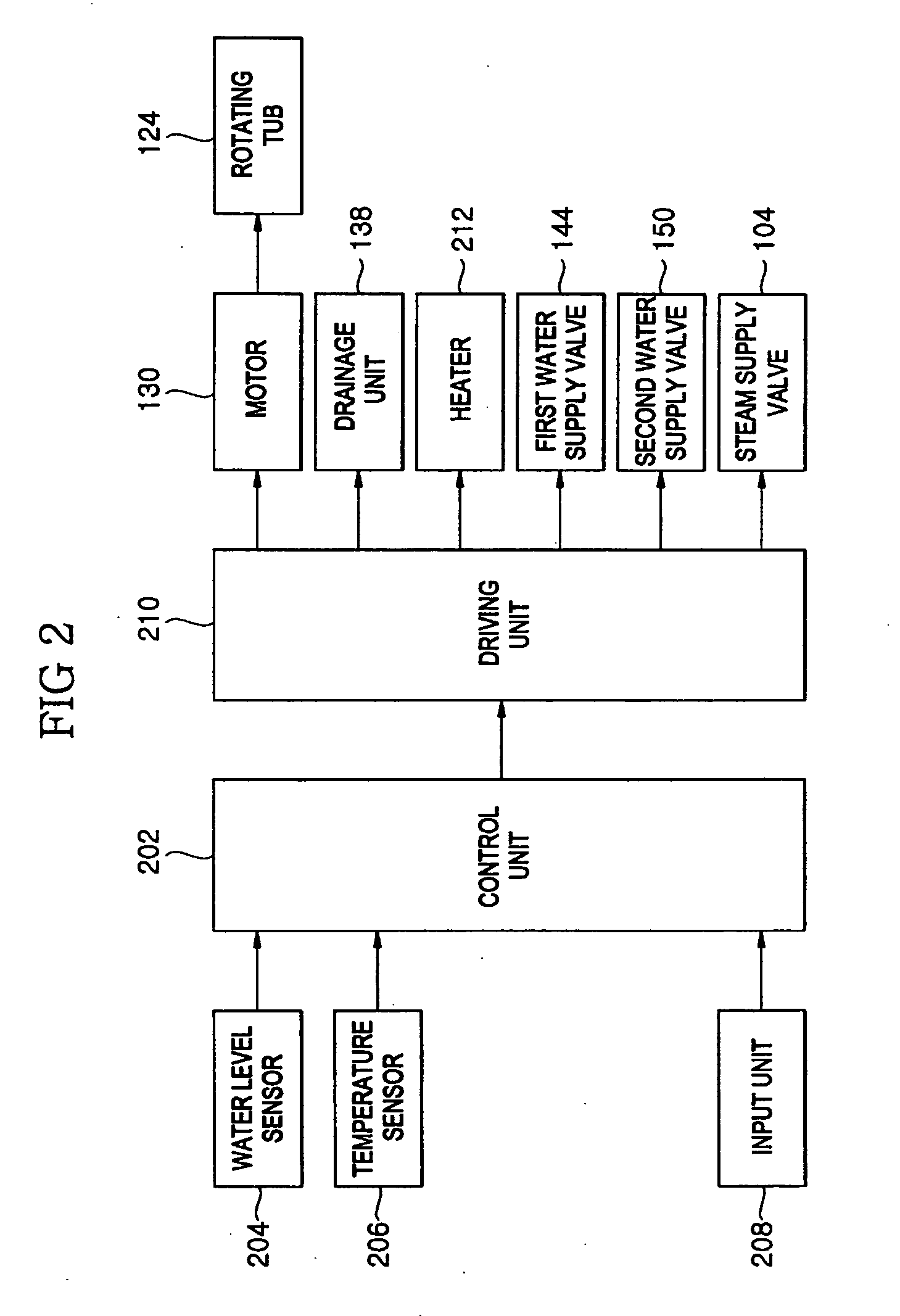

Washing machine and control method thereof

InactiveUS20050132503A1Grow fastShorten washing timeOther washing machinesControl devices for washing apparatusWash waterEngineering

A drum type washing machine in which wash water and laundry contained in a rotating tub are heated by steam supplied into the rotating tub, so as to rapidly increase the temperature of the wash water and laundry, thereby being capable of reducing the total wash time while reducing the amount of wash water to be used, and reducing the consumption of energy caused by heating of the wash water. The washing machine includes a steam generating unit for heating water supplied thereto, thereby generating steam, and a control unit for rotating the rotating tub at a high speed to cause the laundry contained in the rotating tub to be in constant contact with an inner peripheral surface of the rotating tub without falling down, by virtue of a centrifugal force generated during the rotation of the rotating tub, the control unit supplying the steam from the steam generating unit into the rotating tub during the high-speed rotation of the rotating tub, to increase the internal temperature of the rotating tub and the temperature of the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com