Patents

Literature

3169 results about "Dynamic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

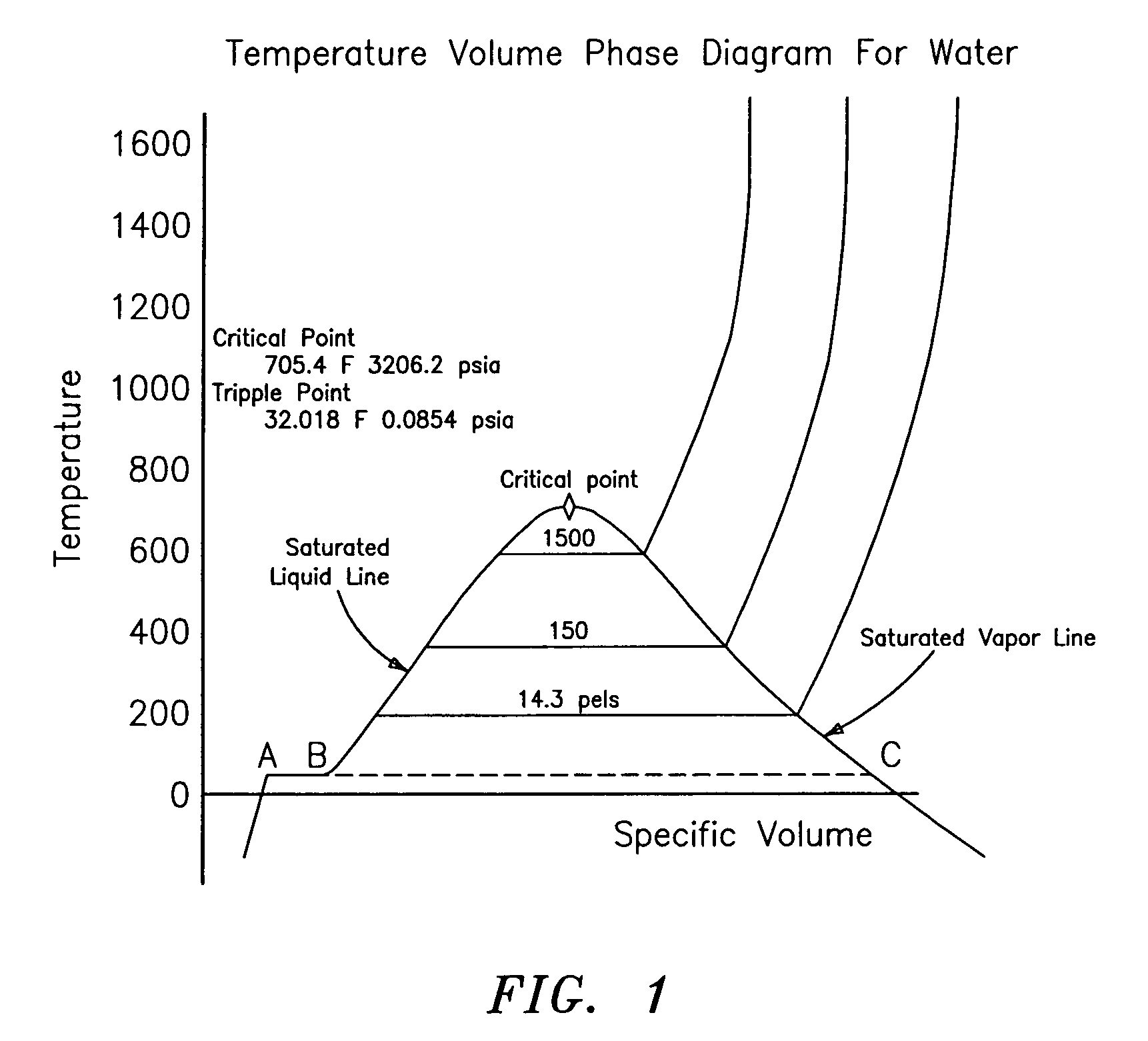

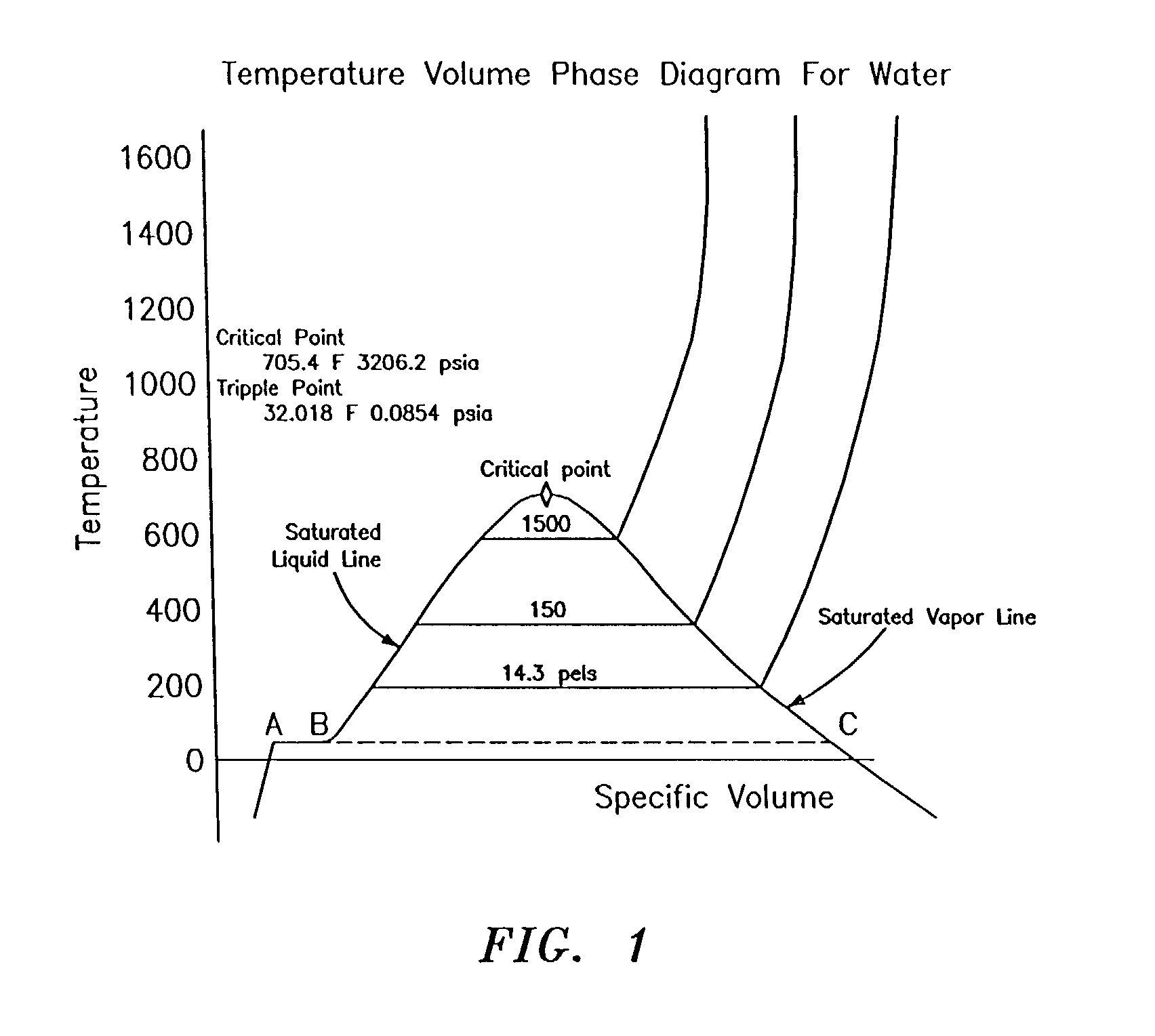

Dynamic pressure (sometimes called velocity pressure) is the increase in a moving fluid's pressure over its static value due to motion. In incompressible fluid dynamics, it is indicated as q, or Q, defined by: q=(ρ u²)/2 where (using SI units): q = dynamic pressure in pascals, ρ = fluid density in kg/m³ (e.g. density of water), u = flow speed in m/s.

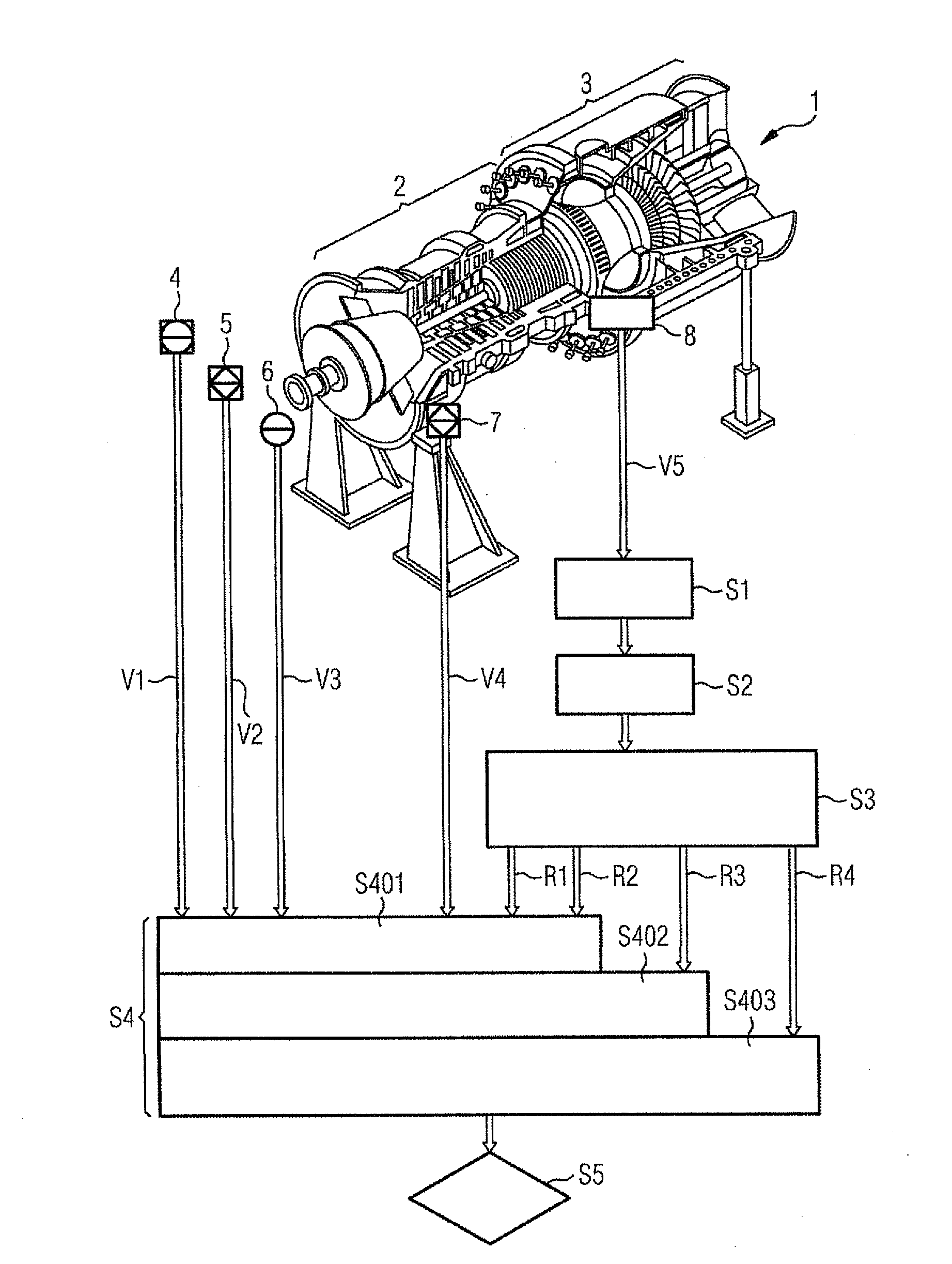

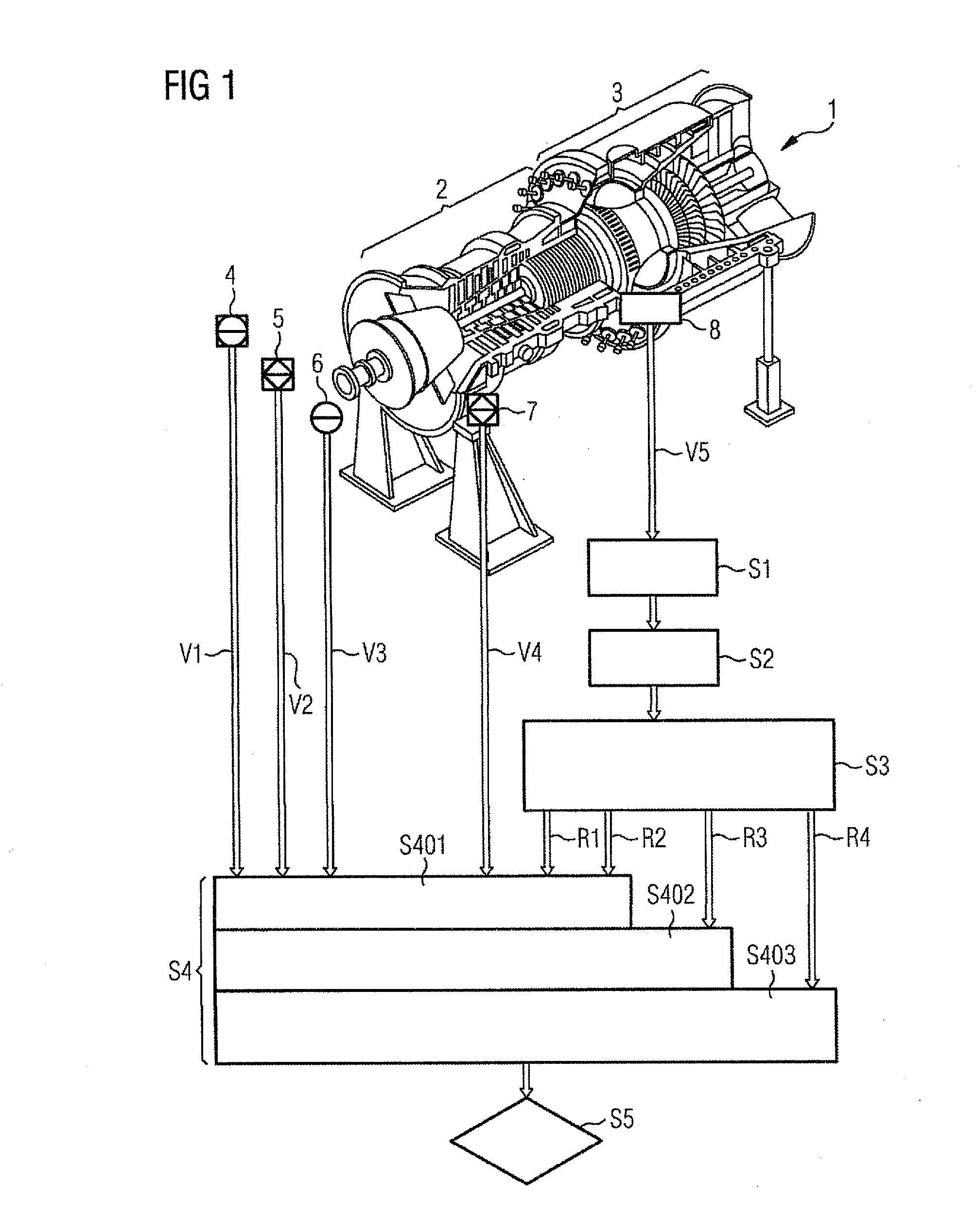

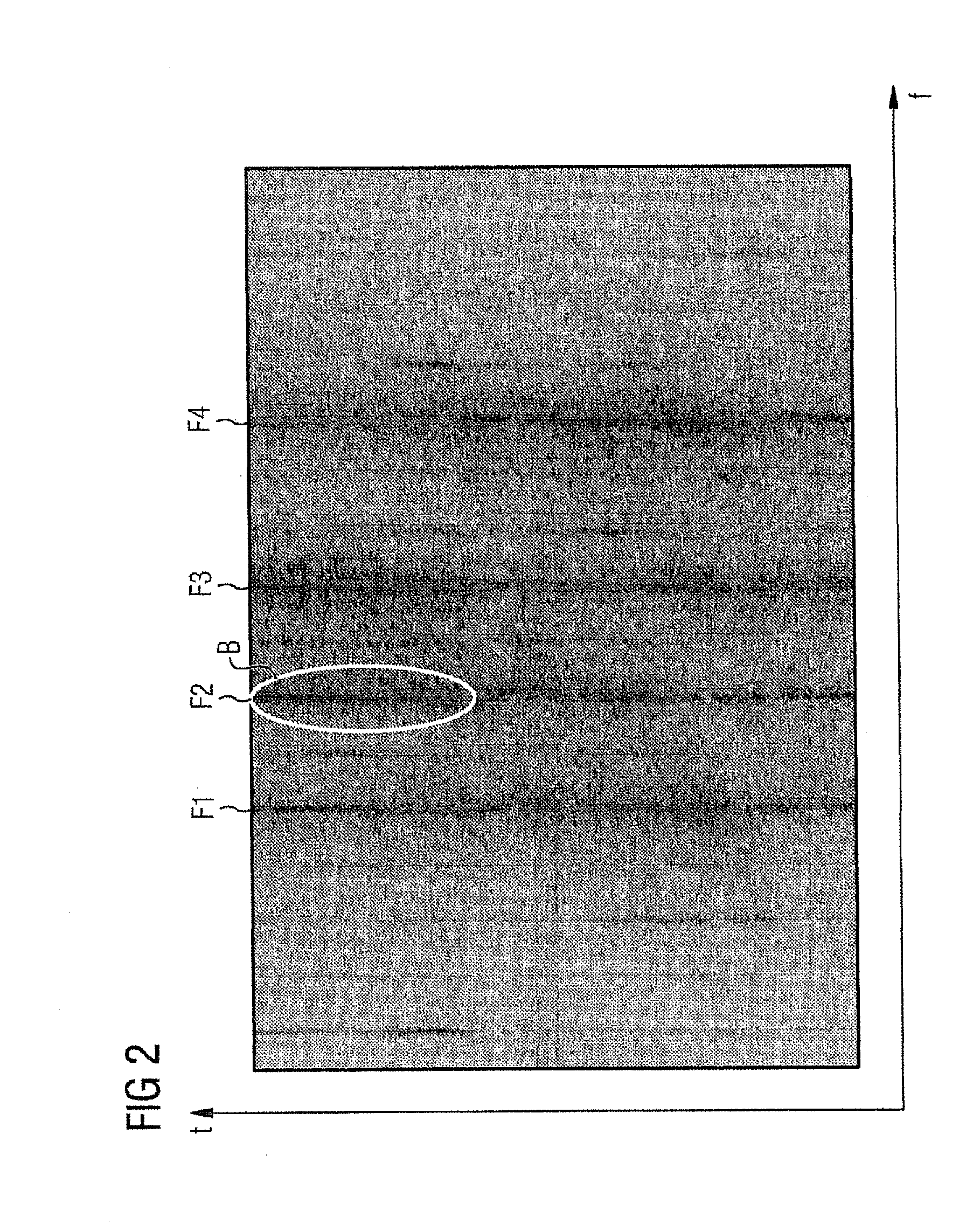

Method for analysis of the operation of a gas turbine

ActiveUS20100262401A1Accurate diagnosisLess sensorsGas-turbine engine testingEngine fuctionsFrequency spectrumEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

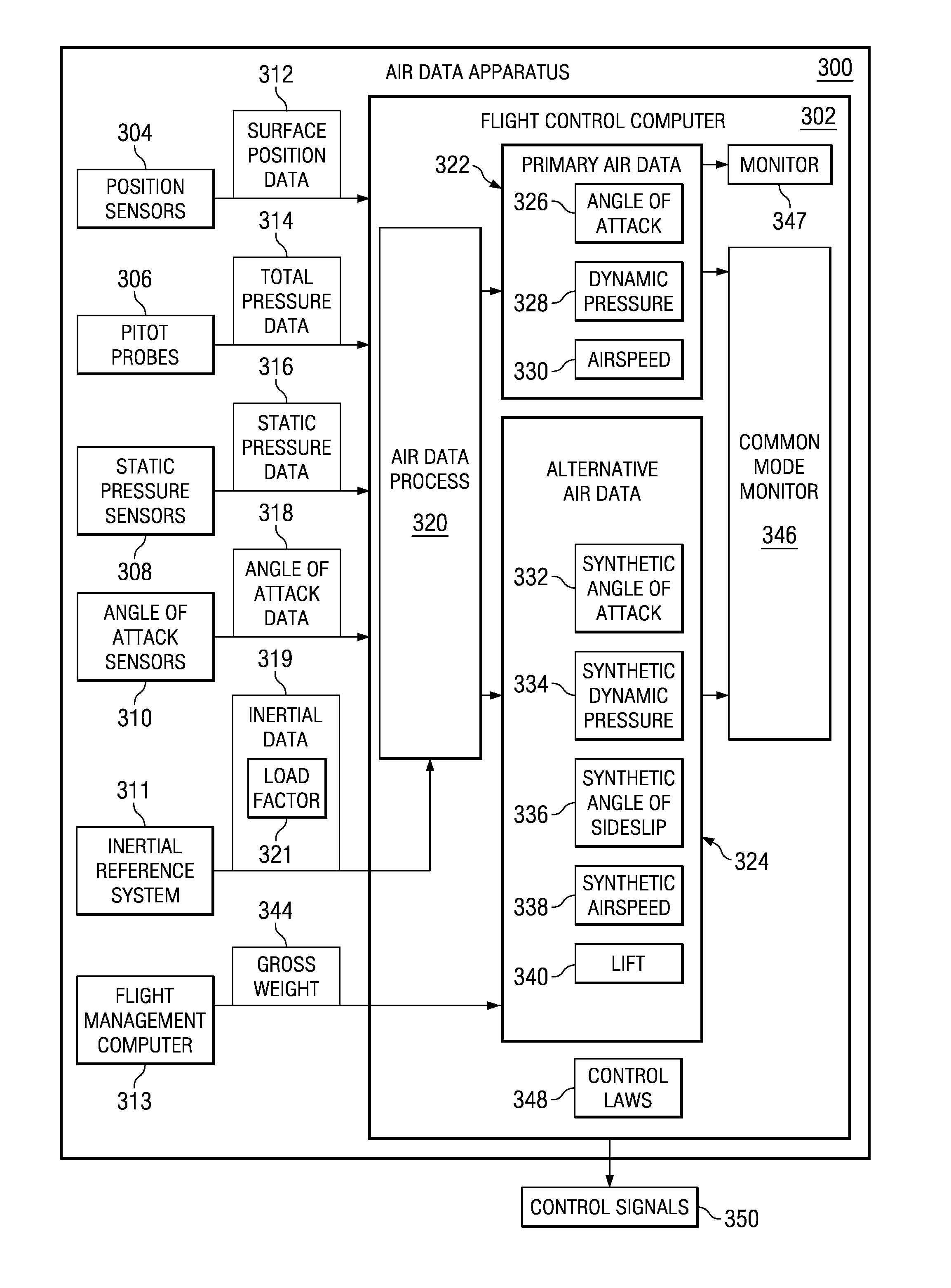

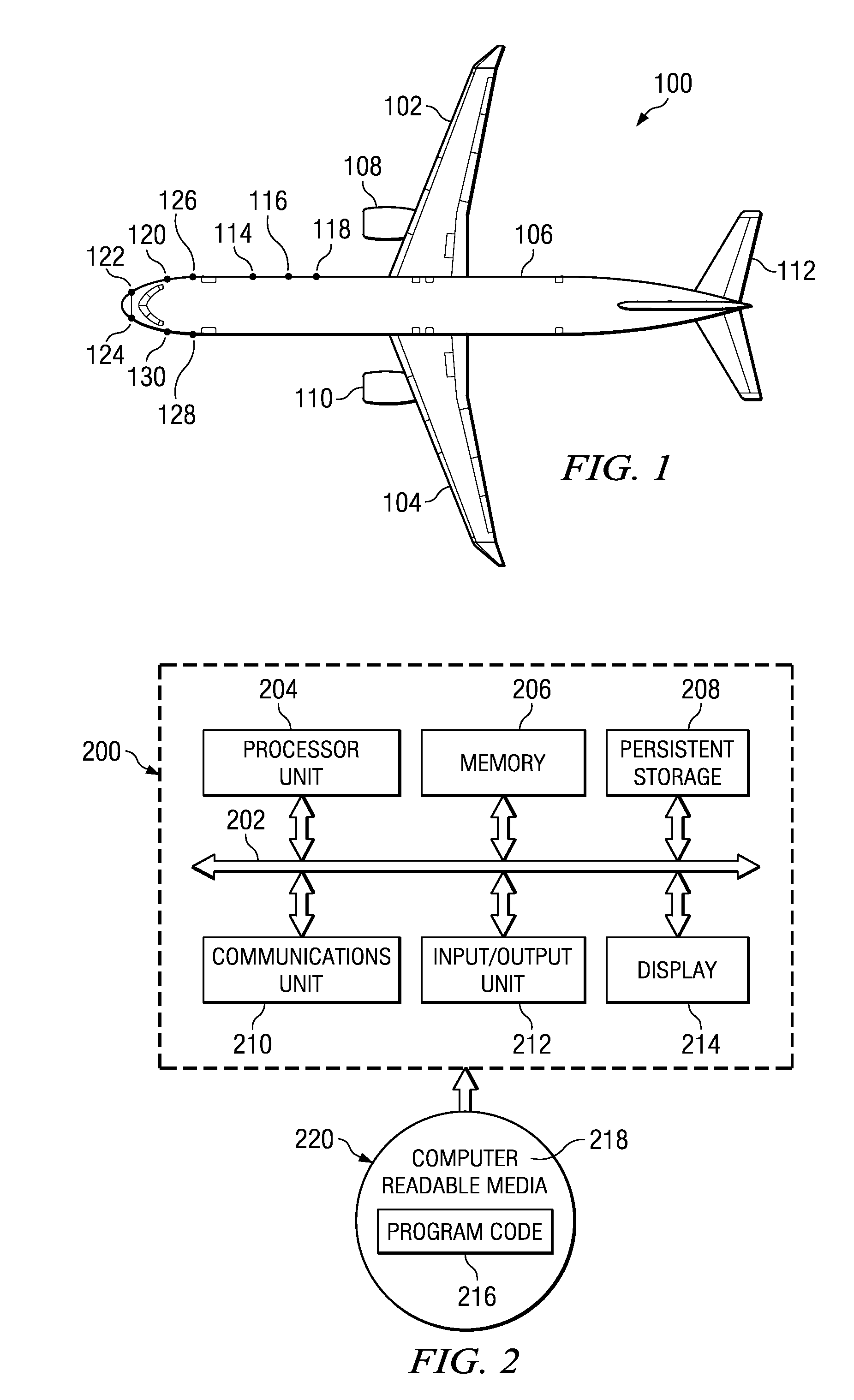

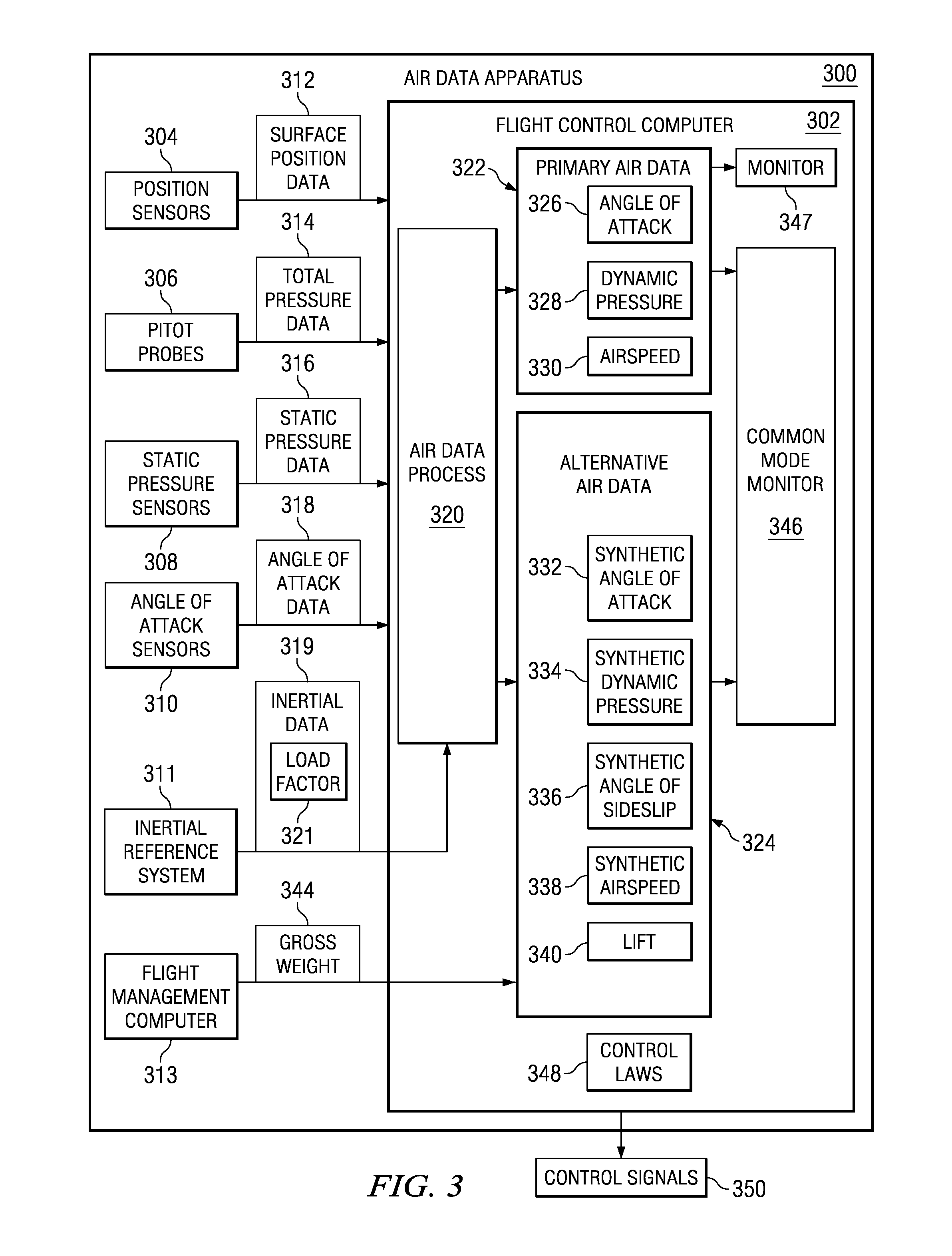

Alternative method to determine the air mass state of an aircraft and to validate and augment the primary method

ActiveUS20100100260A1Aircraft controlDigital data processing detailsFlight vehicleAlternative methods

A method, apparatus, and computer program product for identifying air data for an aircraft. The lift for the aircraft is identified. The number of surface positions for the aircraft is identified. The angle of attack during flight of the aircraft is identified. A synthetic dynamic pressure is computed from the lift, the number of surface positions, and the angle of attack.

Owner:THE BOEING CO

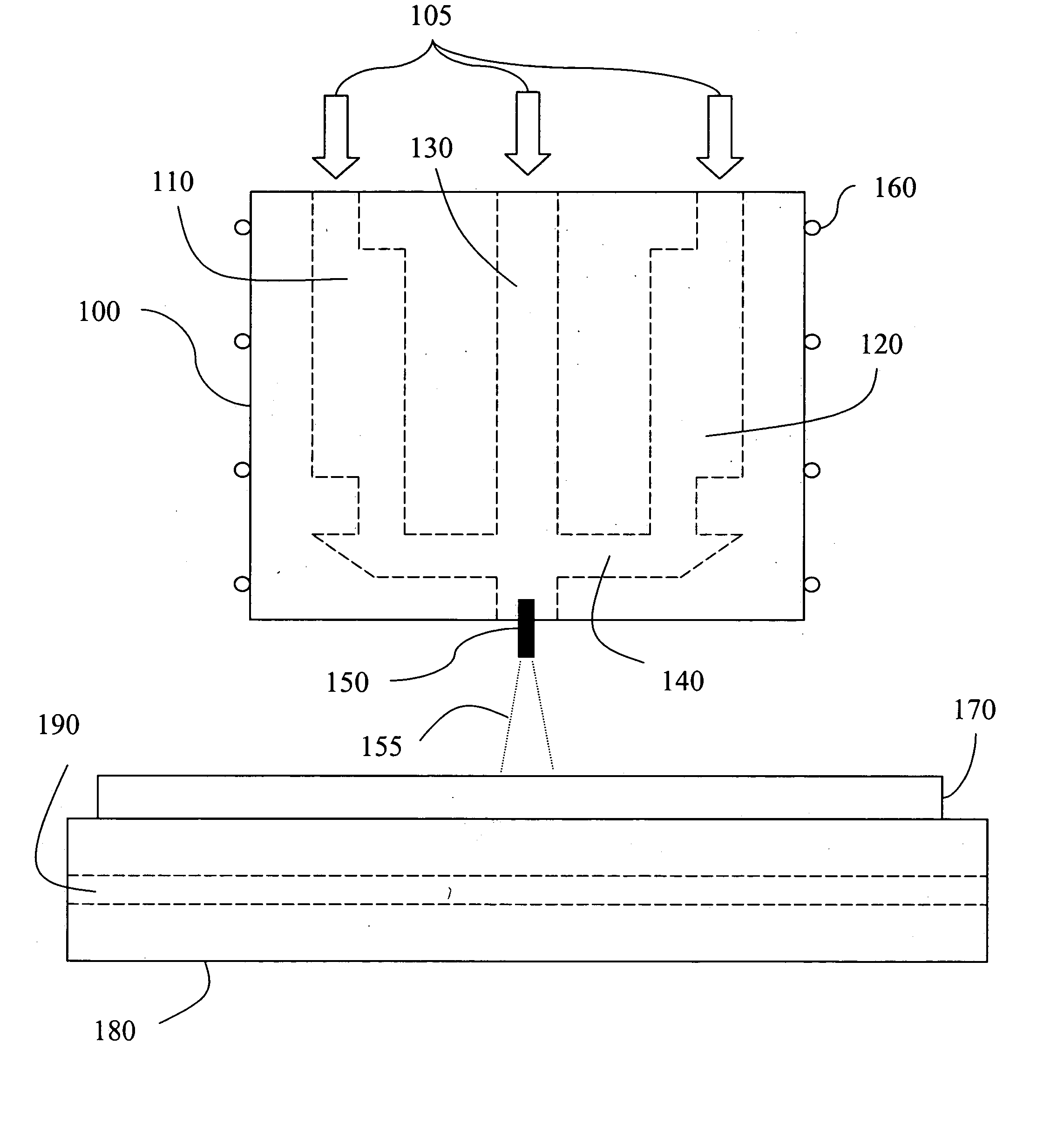

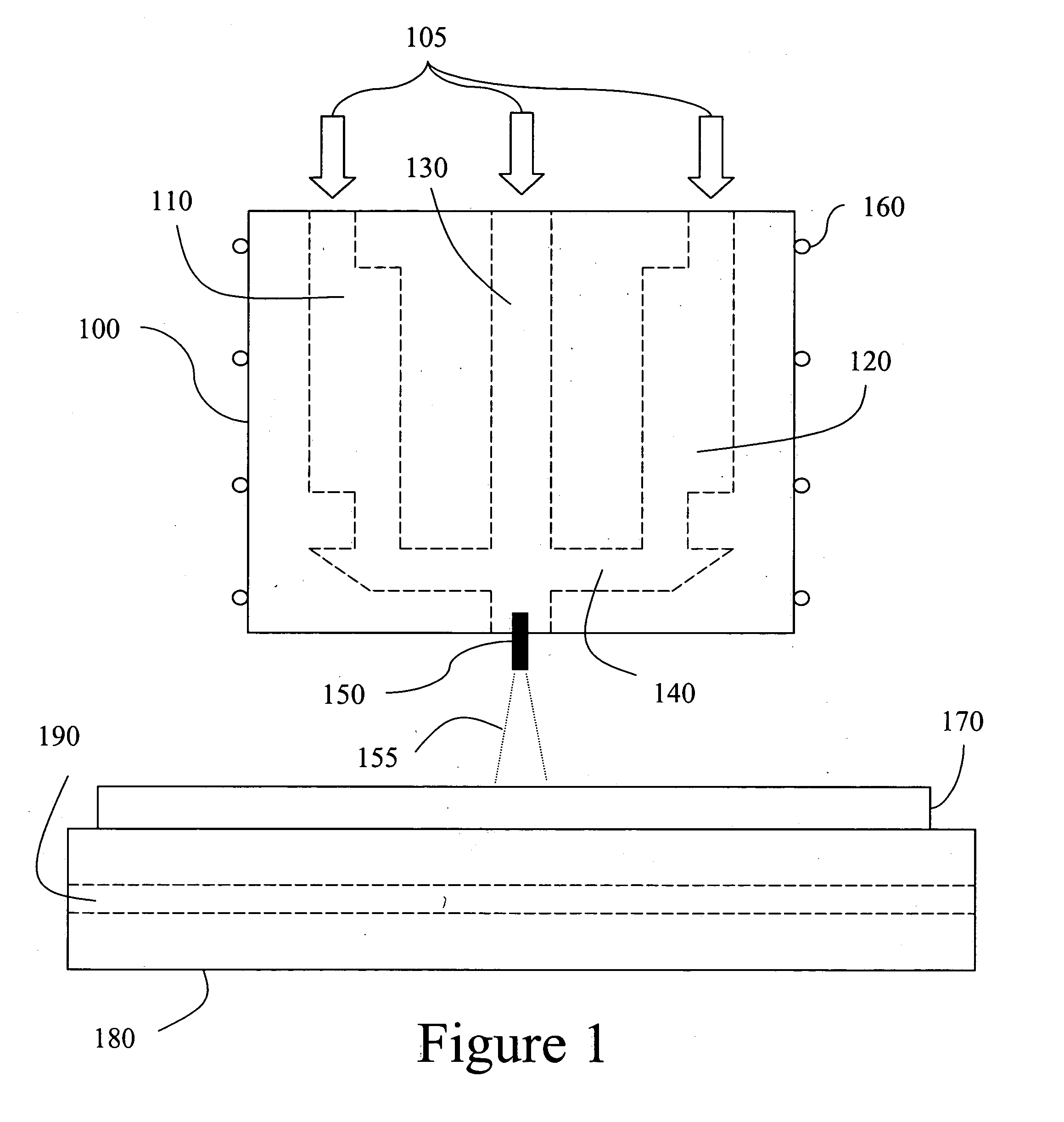

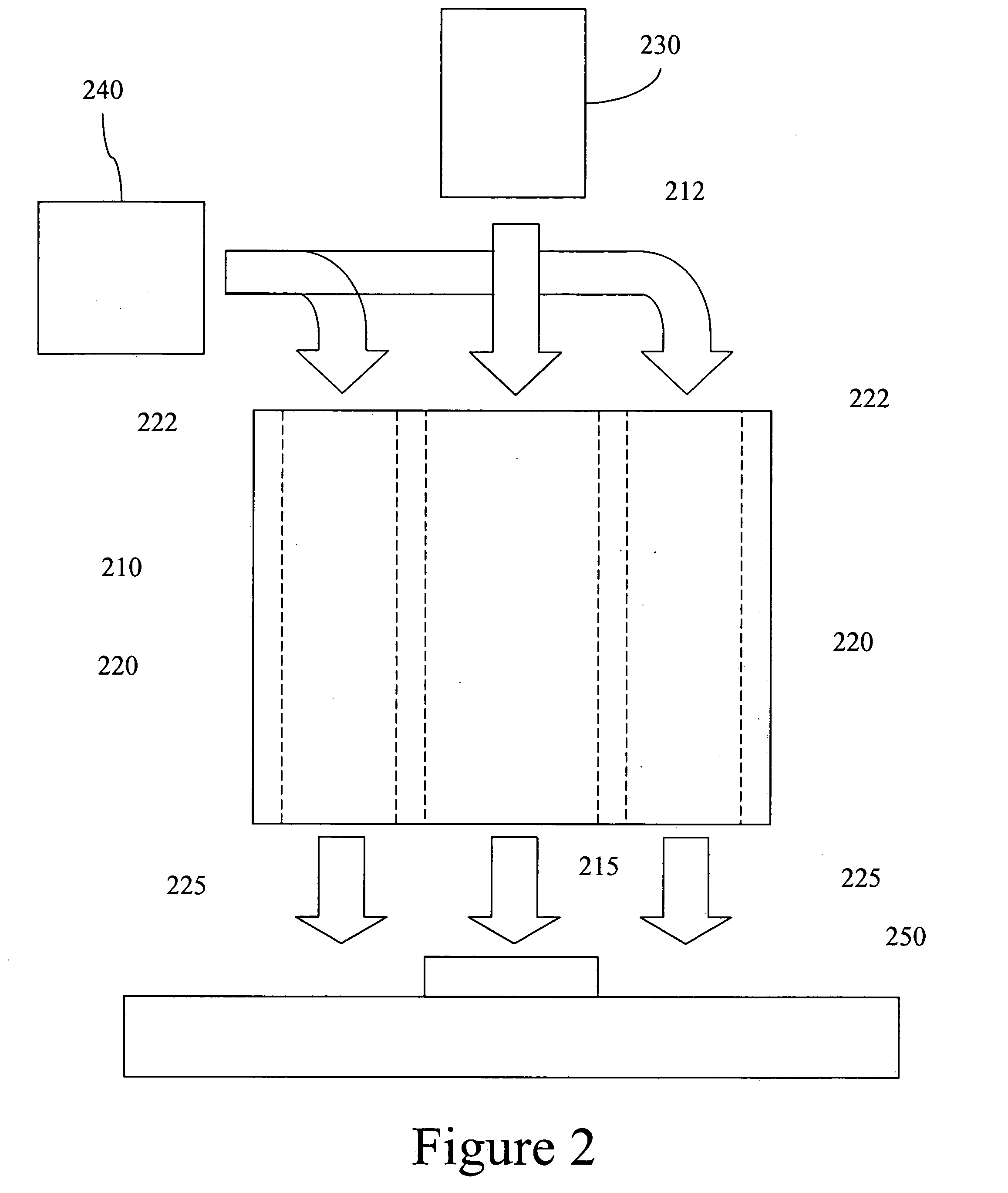

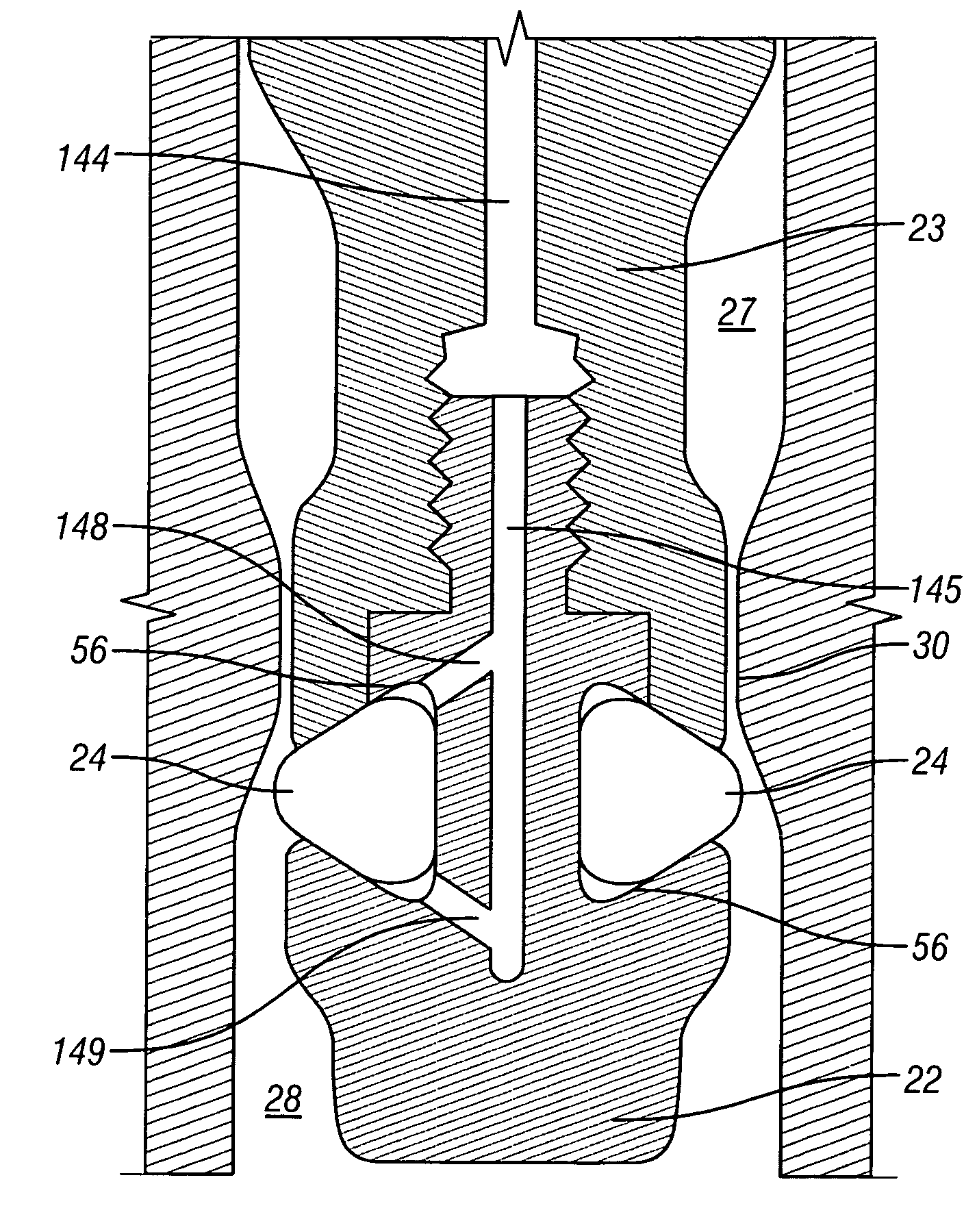

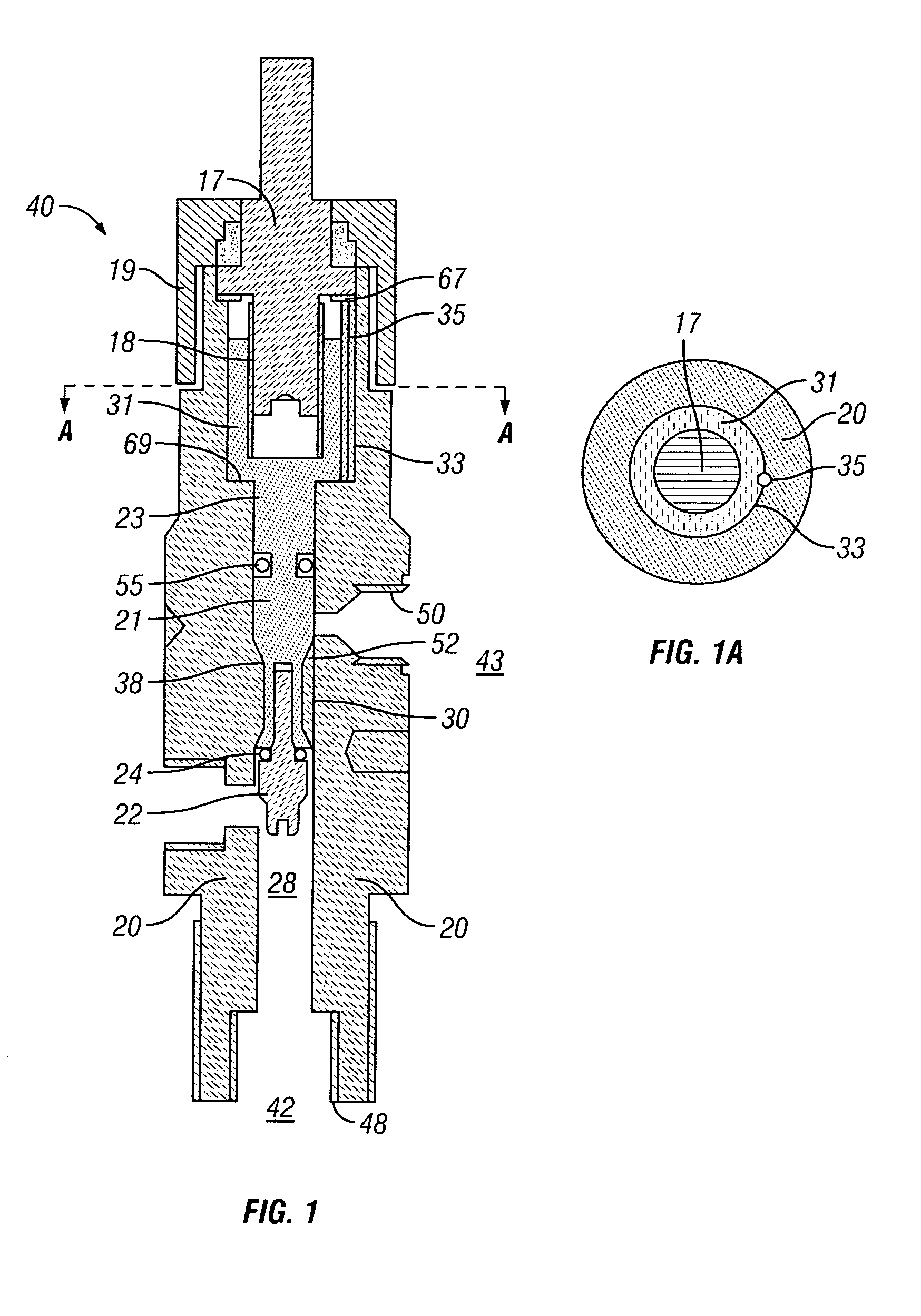

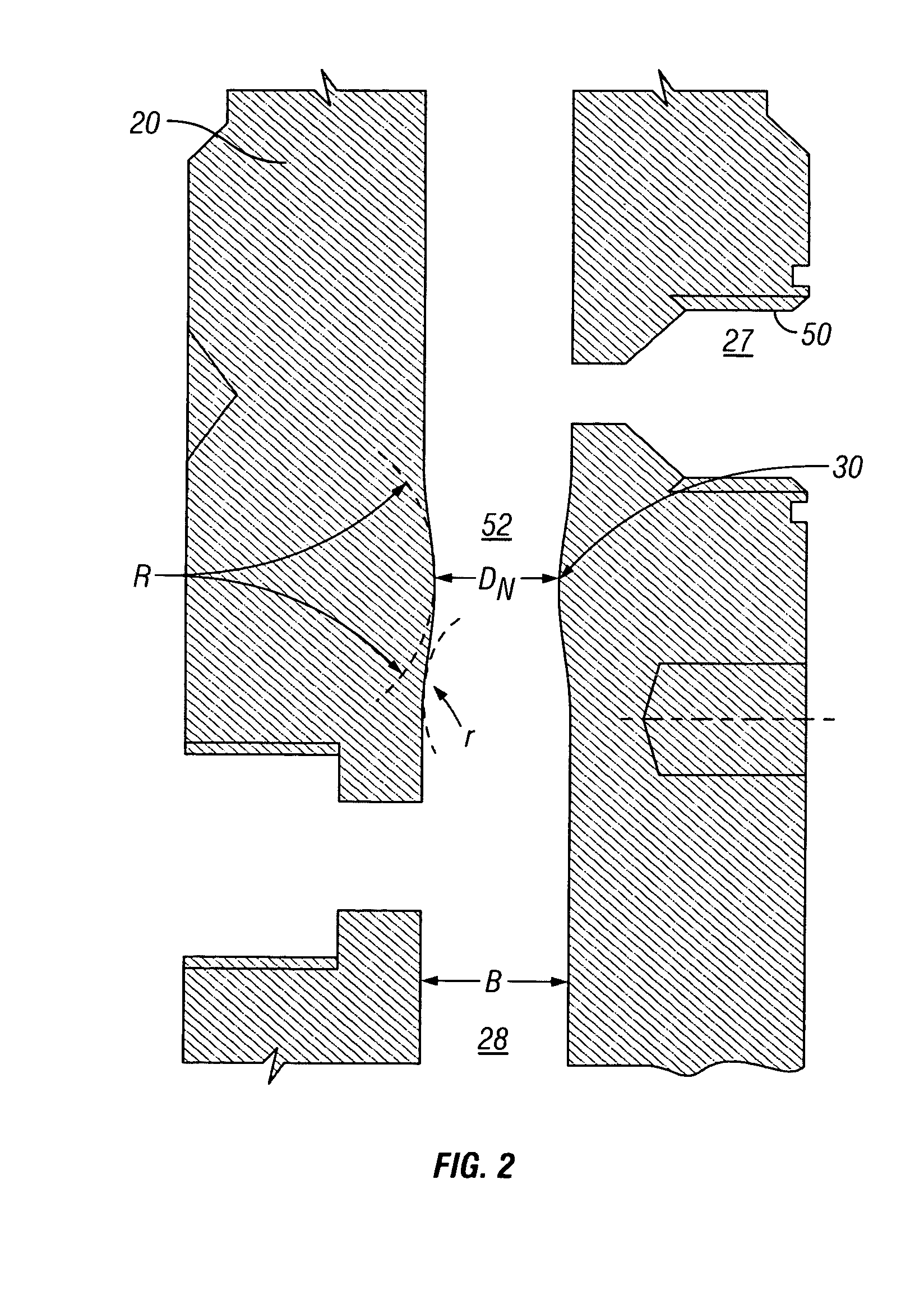

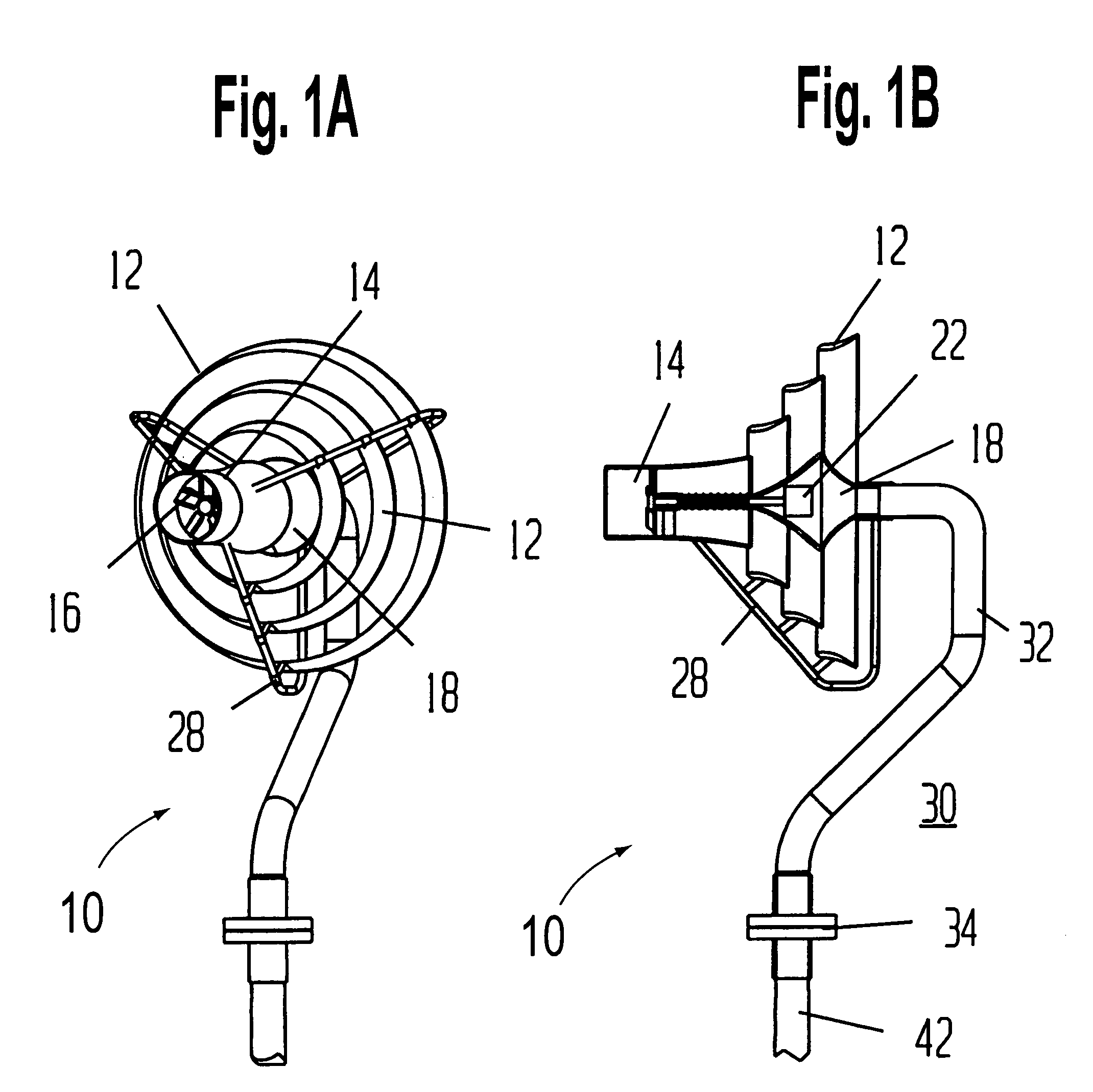

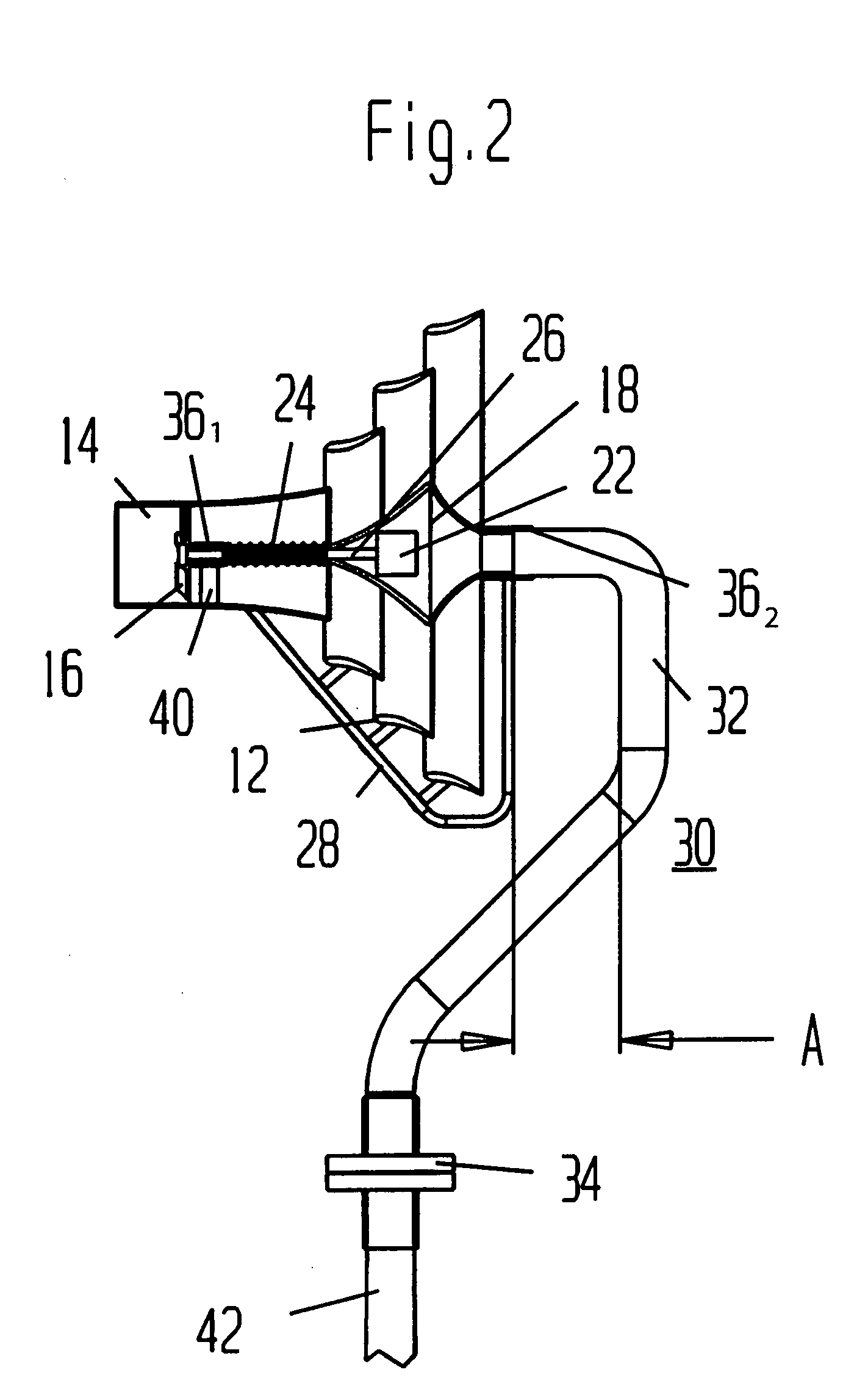

Method and apparatus for depositing material

A method of depositing organic material is provided. A carrier gas carrying an organic material is ejected from a nozzle at a flow velocity that is at least 10% of the thermal velocity of the carrier gas, such that the organic material is deposited onto a substrate. In some embodiments, the dynamic pressure in a region between the nozzle and the substrate surrounding the carrier gas is at least 1 Torr, and more preferably 10 Torr, during the ejection. In some embodiments, a guard flow is provided around the carrier gas. In some embodiments, the background pressure is at least about 10e-3 Torr, more preferably about 0.1 Torr, more preferably about 1 Torr, more preferably about 10 Torr, more preferably about 100 Torr, and most preferably about 760 Torr. A device is also provided. The device includes a nozzle, which further includes a nozzle tube having a first exhaust aperture and a first gas inlet; and a jacket surrounding the nozzle tube, the jacket having a second exhaust aperture and a second gas inlet. The second exhaust aperture completely surrounds the first tube aperture. A carrier gas source and an organic source vessel may be connected to the first gas inlet. A guard flow gas source may be connected to the second gas inlet. The device may include an array of such nozzles.

Owner:THE TRUSTEES FOR PRINCETON UNIV

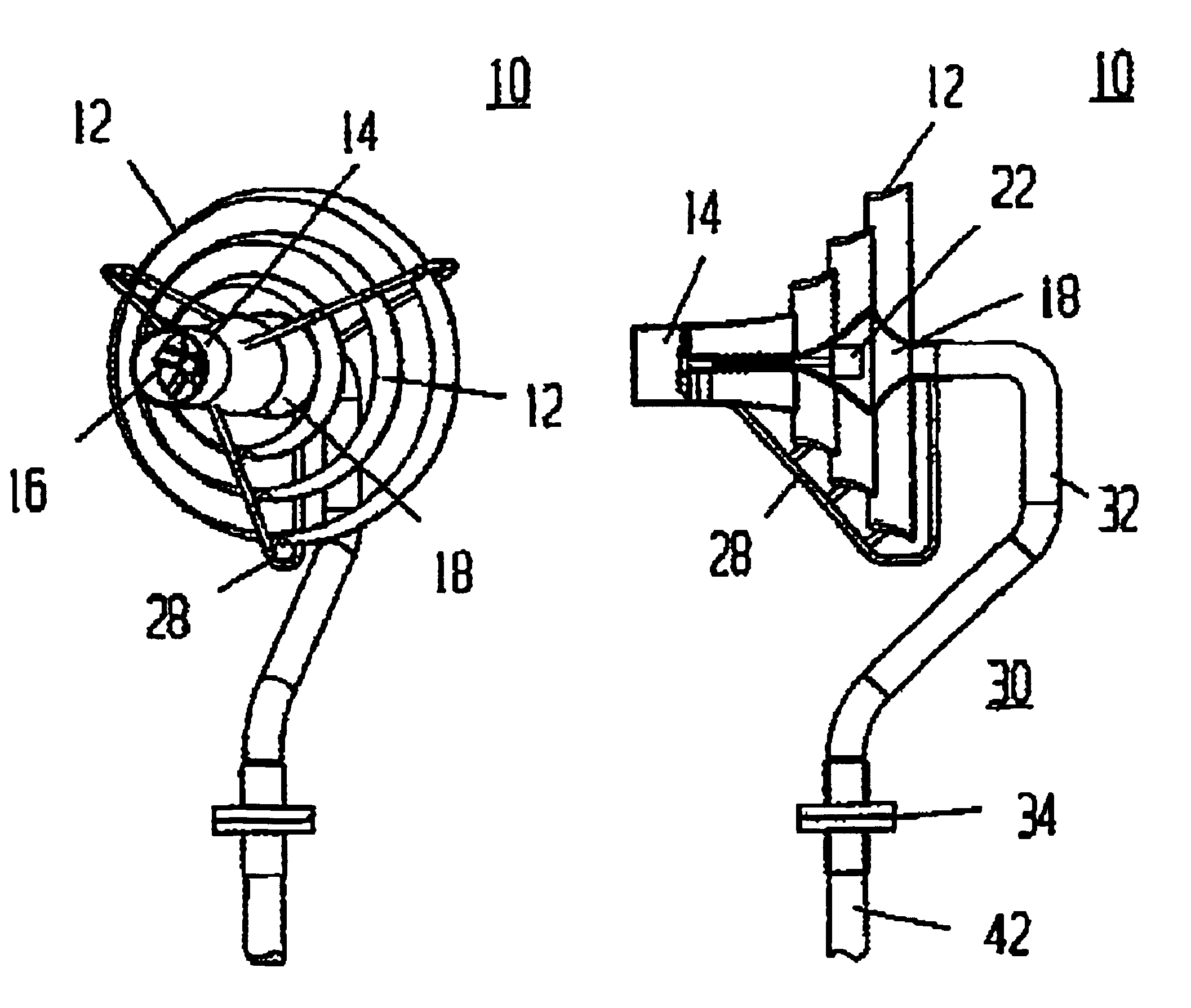

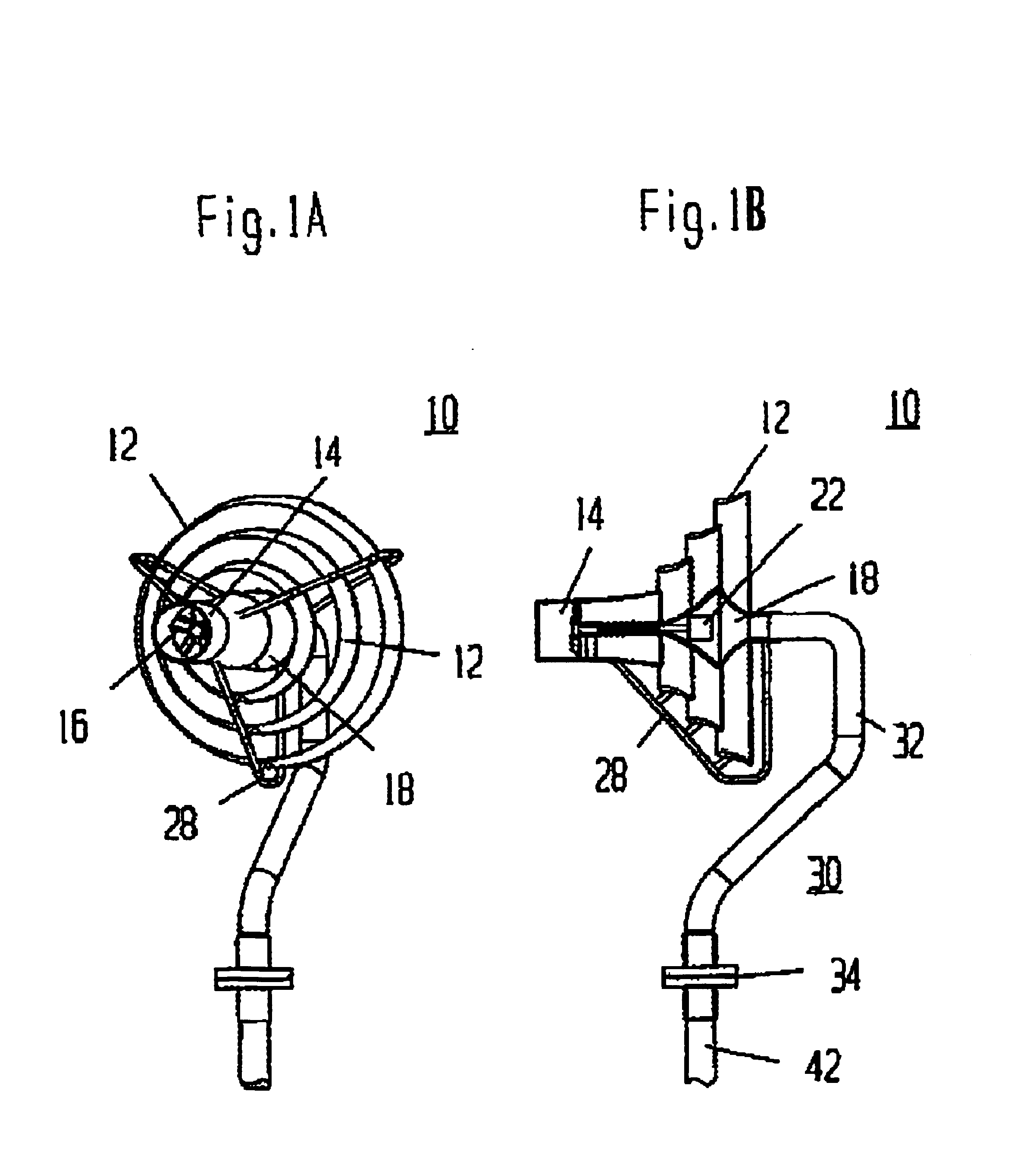

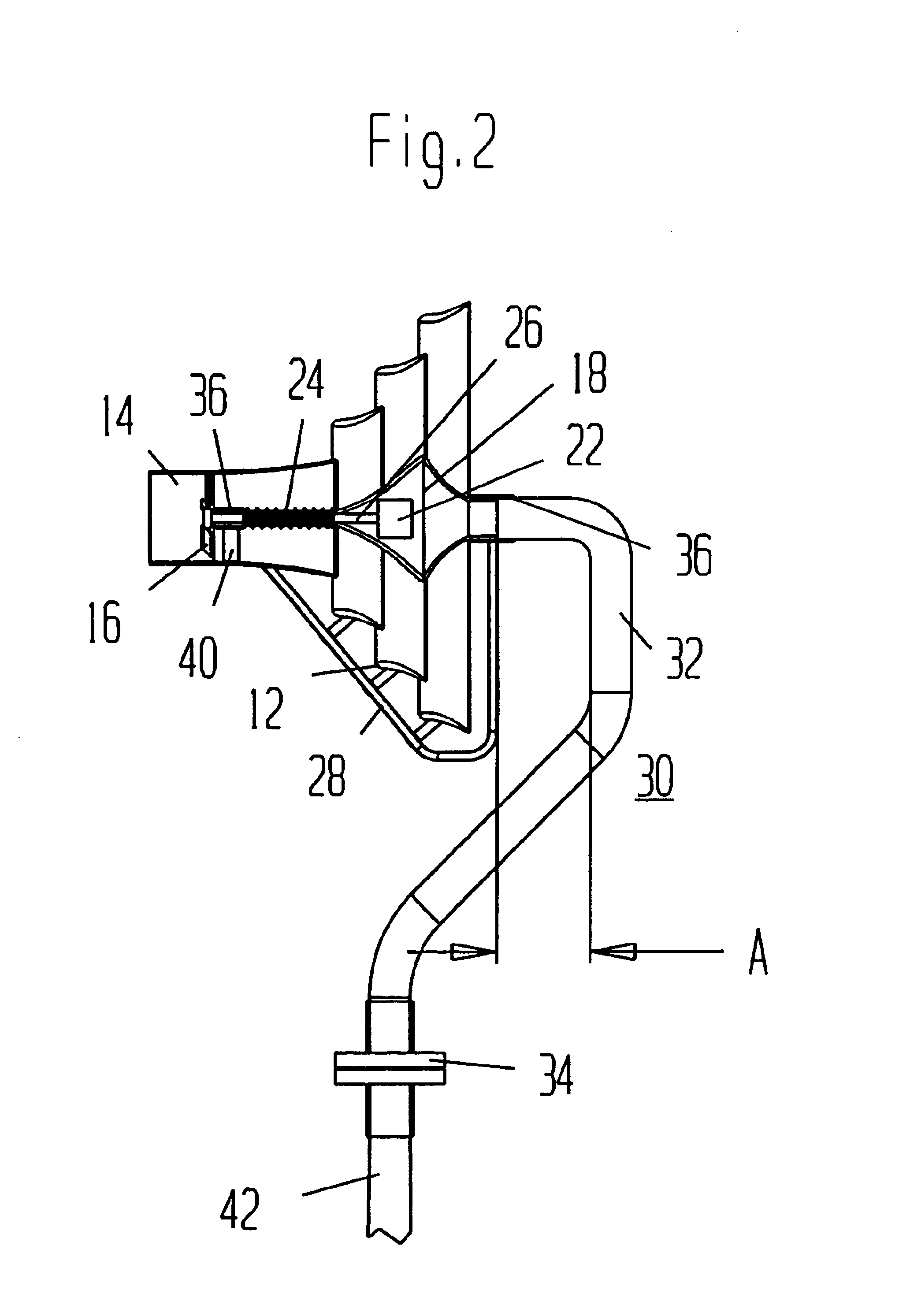

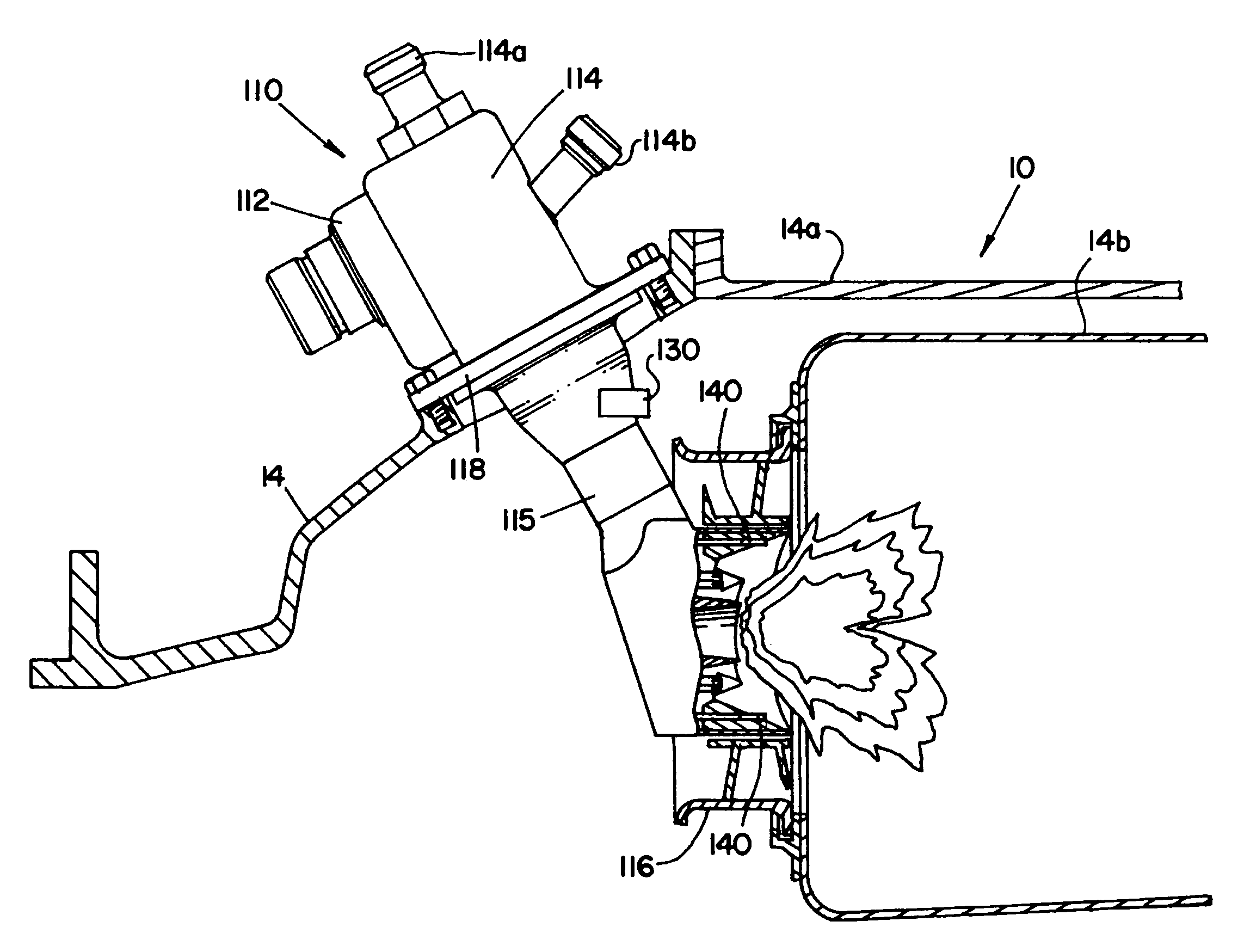

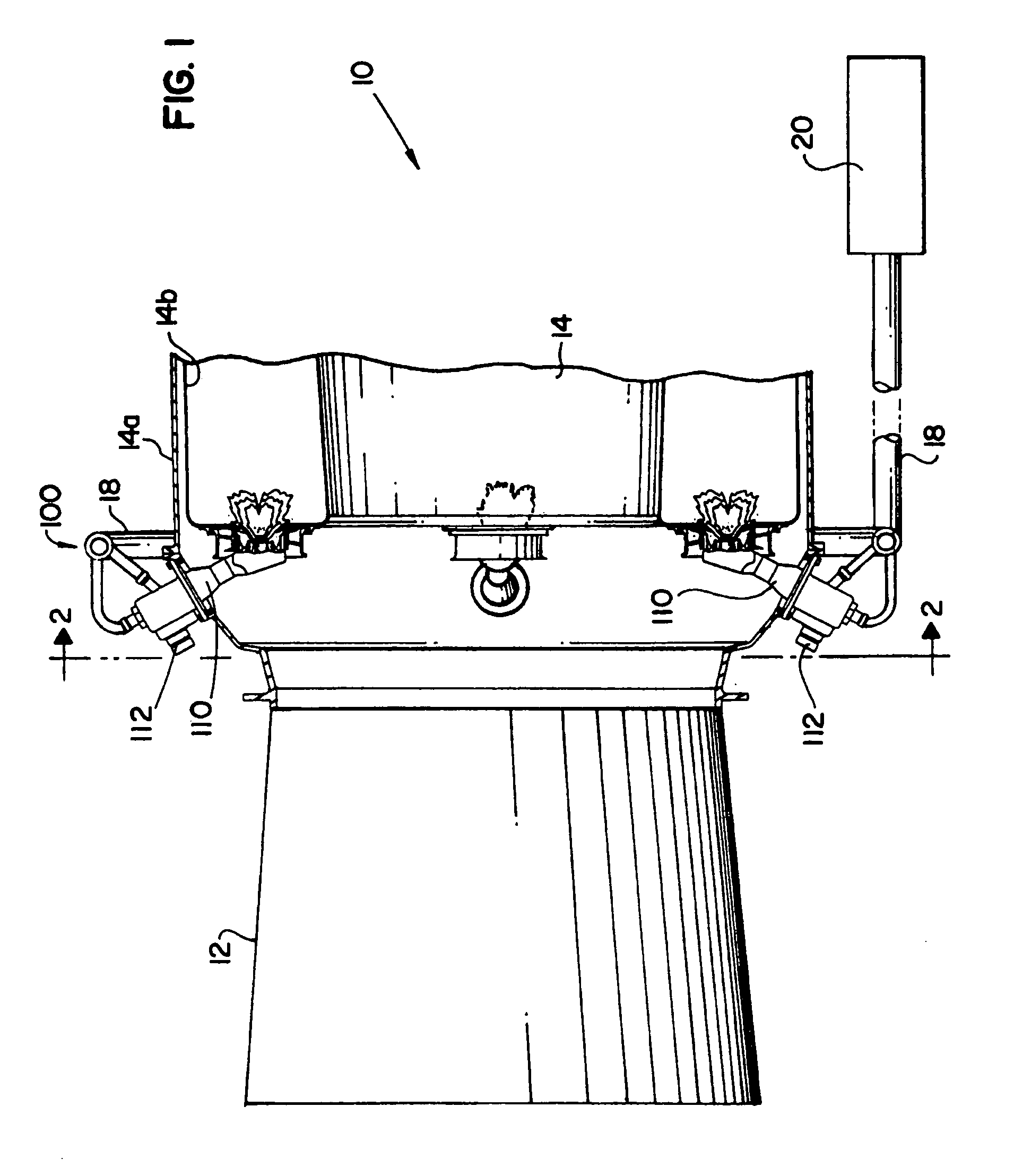

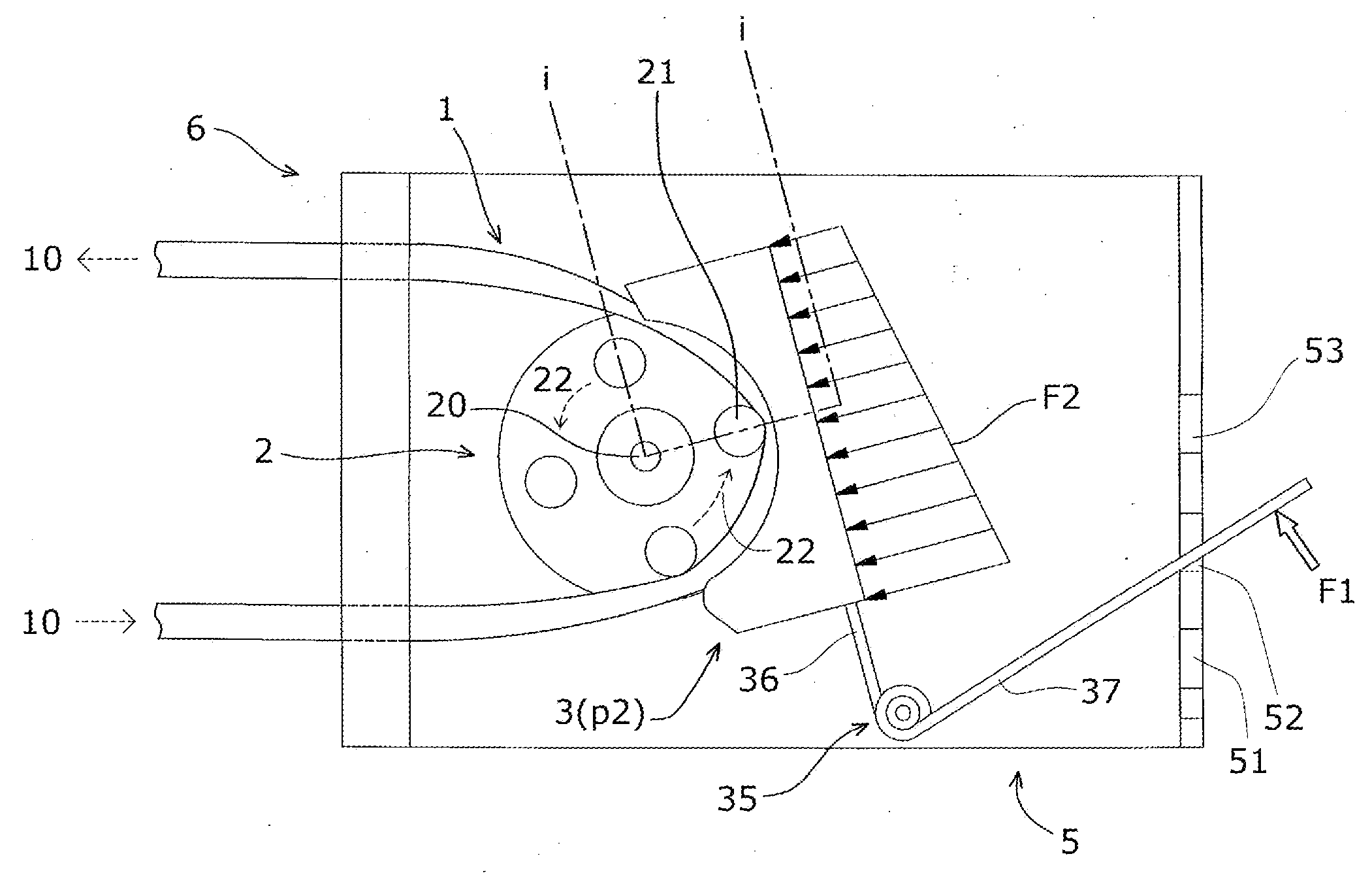

Habitat friendly, pressure conversion, wind energy extraction

ActiveUS6887031B1Spin easilyQuick responseWind motor controlOther chemical processesGlobal wind patternsDynamic pressure

A habitat friendly, pressure conversion, wind energy extraction system is disclosed for safely extracting usable energy from wind. The system includes one or more shrouds or concentrator wings that convert the dynamic pressure of wind into relatively lower static pressure and thereby induces a vacuum that draws wind into a turbine centralized within the shrouds or concentrator wings. As such, the turbine impellor blades may be significantly smaller than the large diameter rotor blades of current popular designs and may be enclosed within the shrouds or concentrator wings that present themselves as highly visible objects and as such are easily avoided by birds in flight. The novel system in particular includes a device and method of airflow regulation than minimizes or prevents the stalling, or the generation of a turbulent flow of wind over or between the shrouds or concentrator wings. This stalling has been shown to occur when airflow is quickly accelerated by force of vacuum and drawn out of the turbine shroud which then mixes with and disturbs the otherwise smooth flow of wind over or between the shrouds or concentrator wings. The system may also include an aerobrake that responds quickly to protect the impellor blades or associated mechanisms from overspeeding or exceeding other design limitations under gusting or violent wind conditions. The system may also include a method of guiding elements of the system to orient appropriately into prevailing winds, and a method to support elements of the system, without unduly impeding the free flow of wind. Other advantages and objects are as well disclosed that increase safety and efficiency, increase installation potential, reduce costs and expenses, and minimize negative environmental impact.

Owner:TOCHER ANGUS J

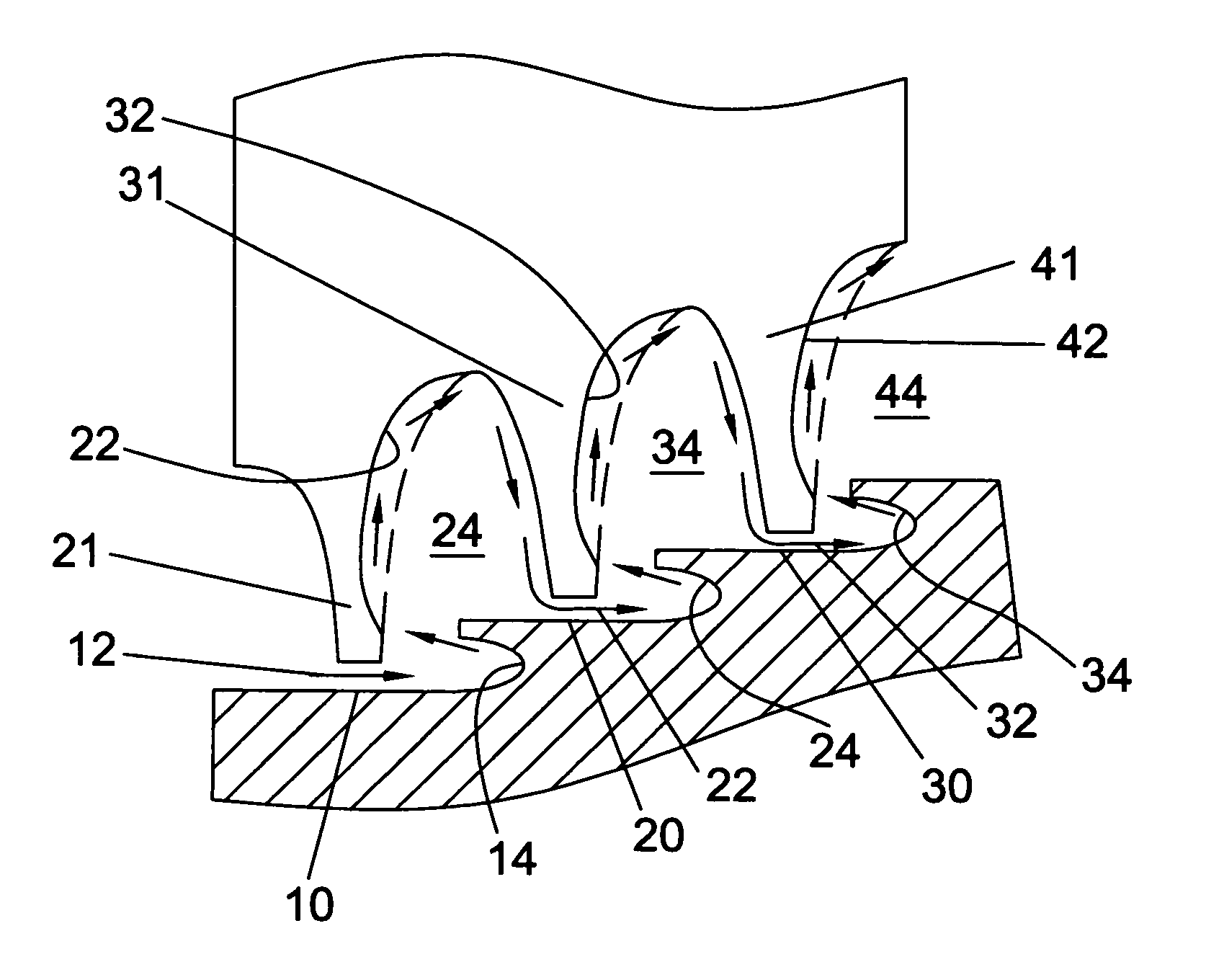

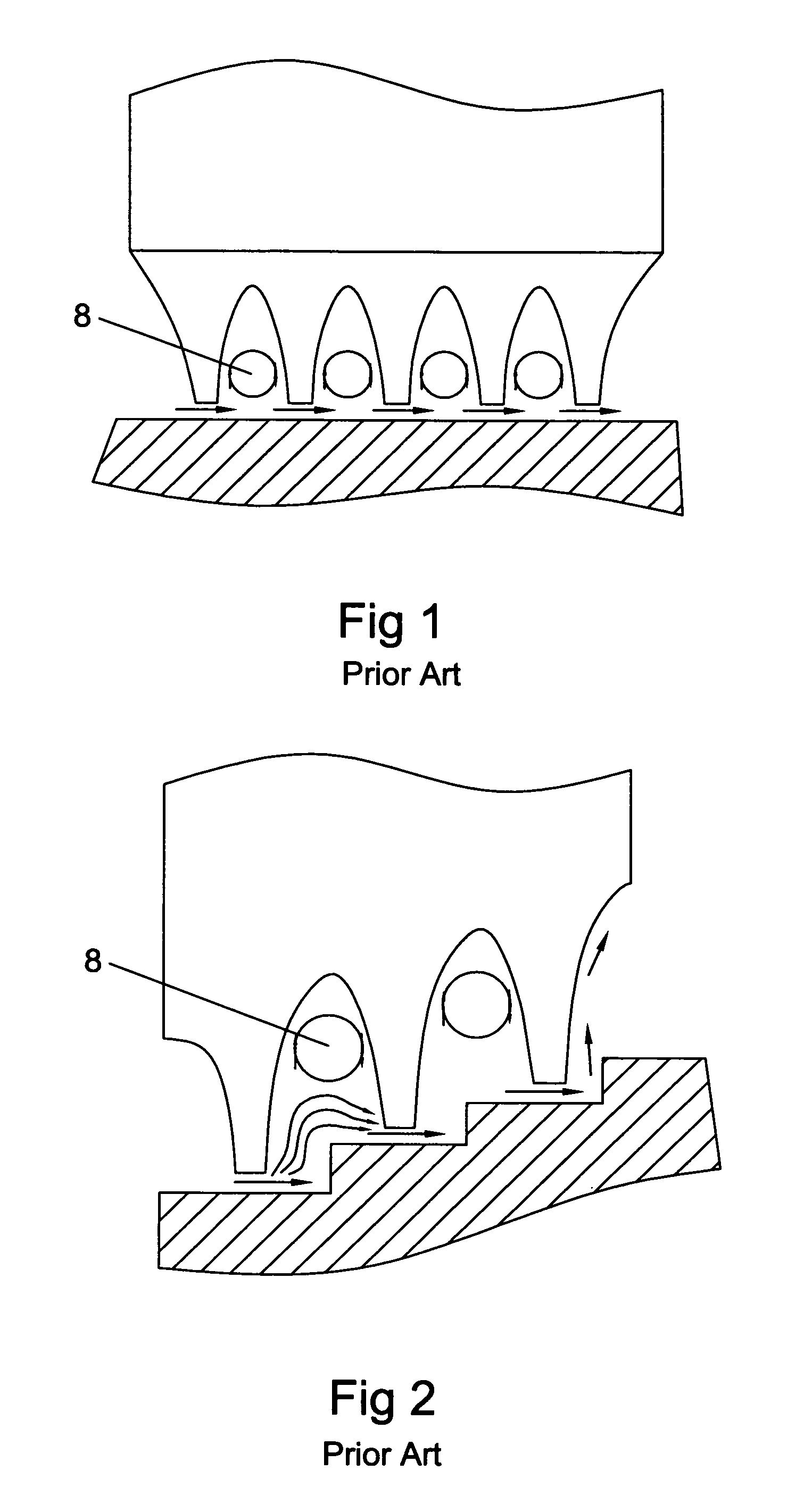

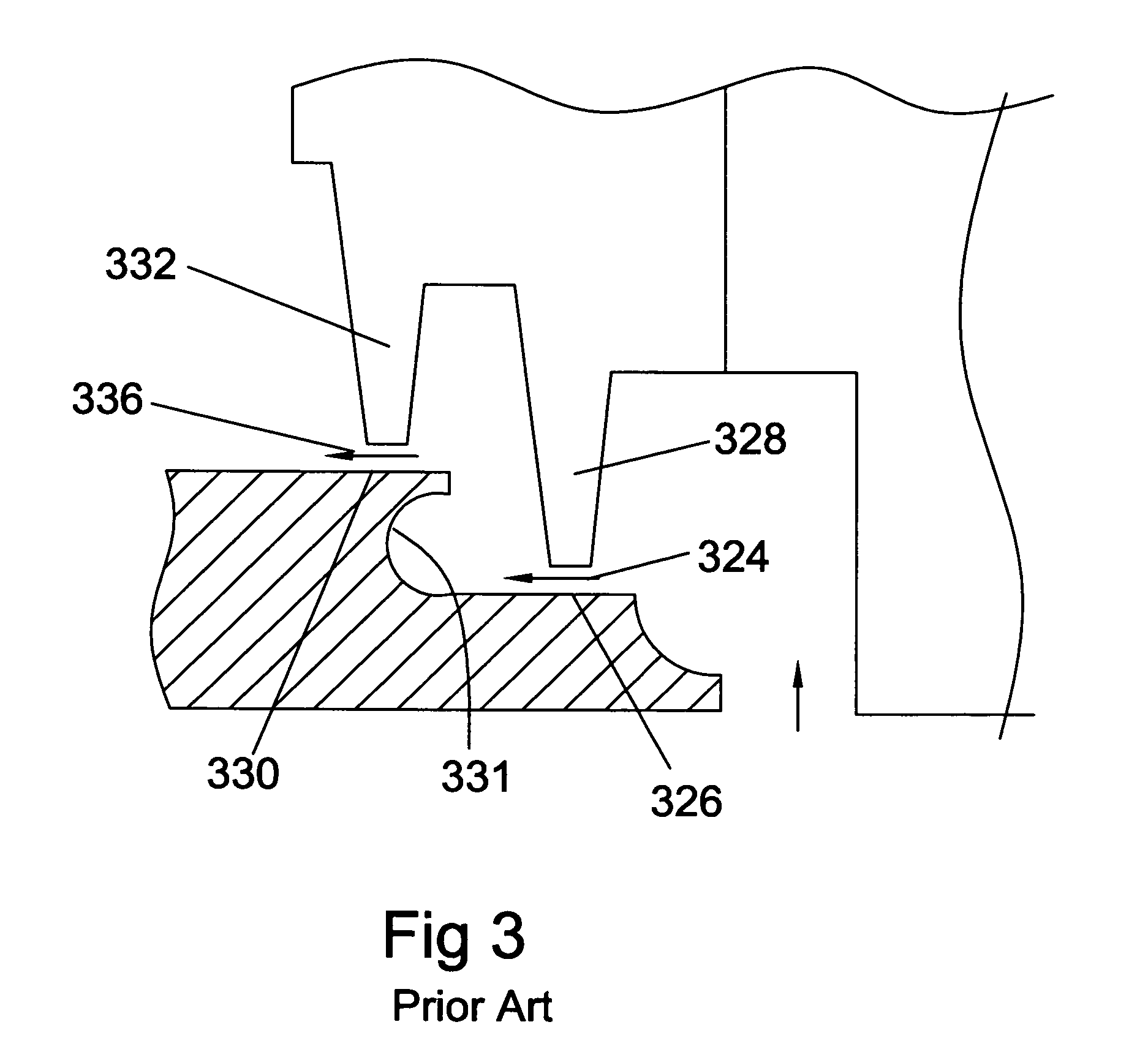

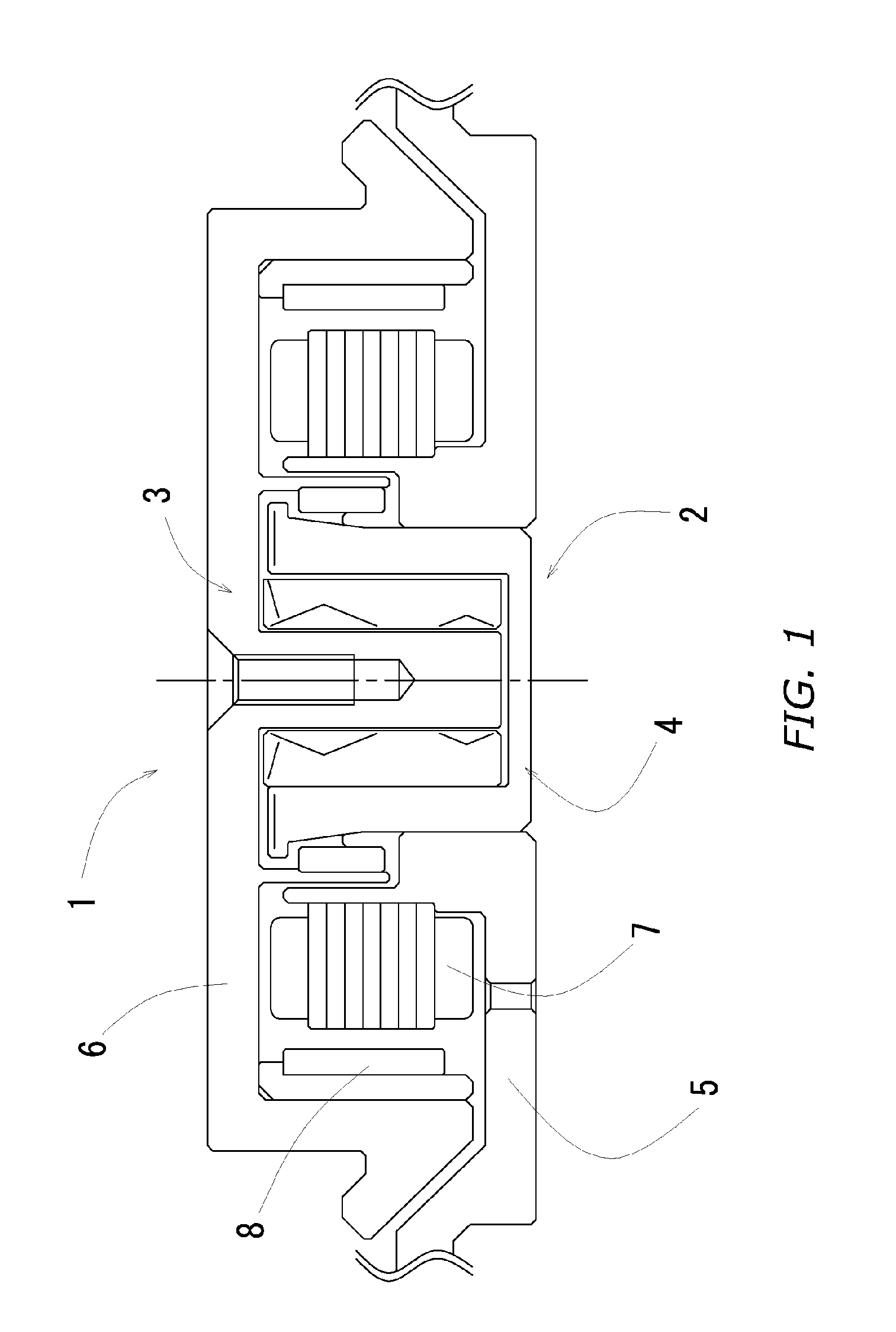

Stepped labyrinth seal

InactiveUS7445213B1Without slowing leakage flowReduce the impactEngine sealsEngine manufactureEngineeringLeakage flow

A stepped labyrinth seal for a turbomachine, the seal having a stepped portion with a redirecting groove formed thereon to redirect a leakage flow through the gap in substantially a reverse direction and onto a surface of the finger such that the dynamic pressure of the leakage flow is not substantially reduced and the static pressure increased. The cavity formed between adjacent fingers has a flow guiding surface that maintains the dynamic pressure of the flow, thereby keeping the flow at high velocity and low static pressure.

Owner:FLORIDA TURBINE TECH

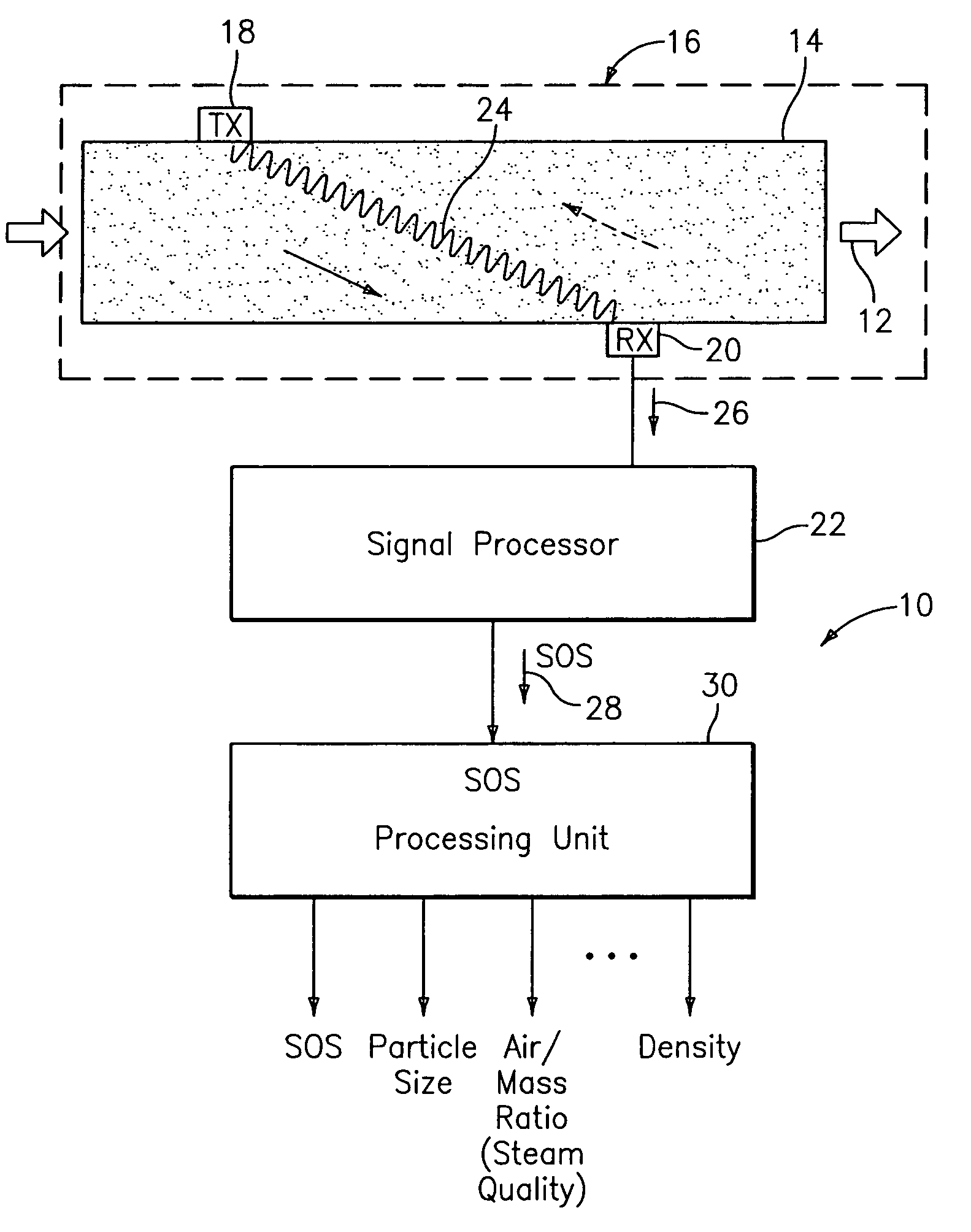

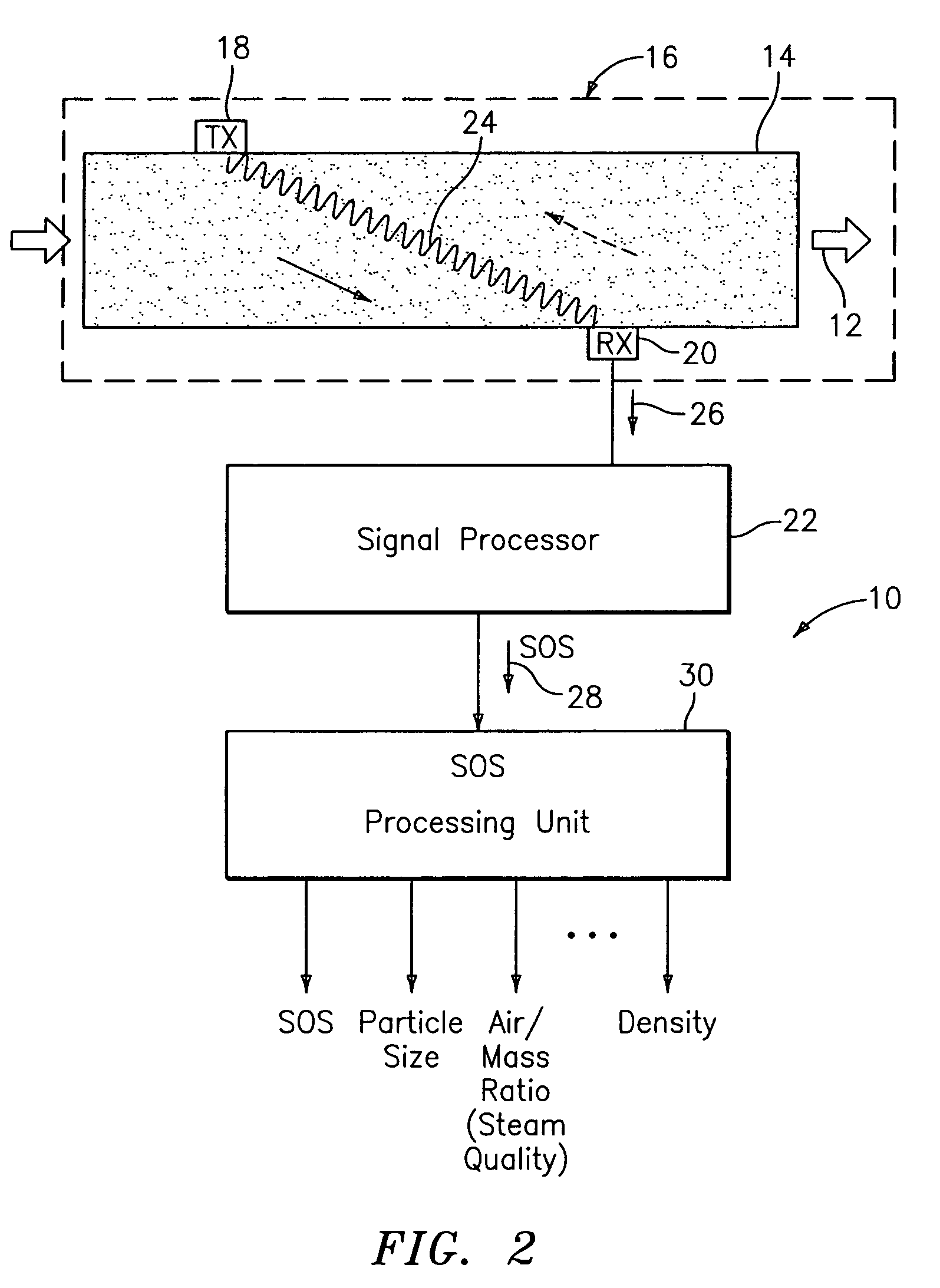

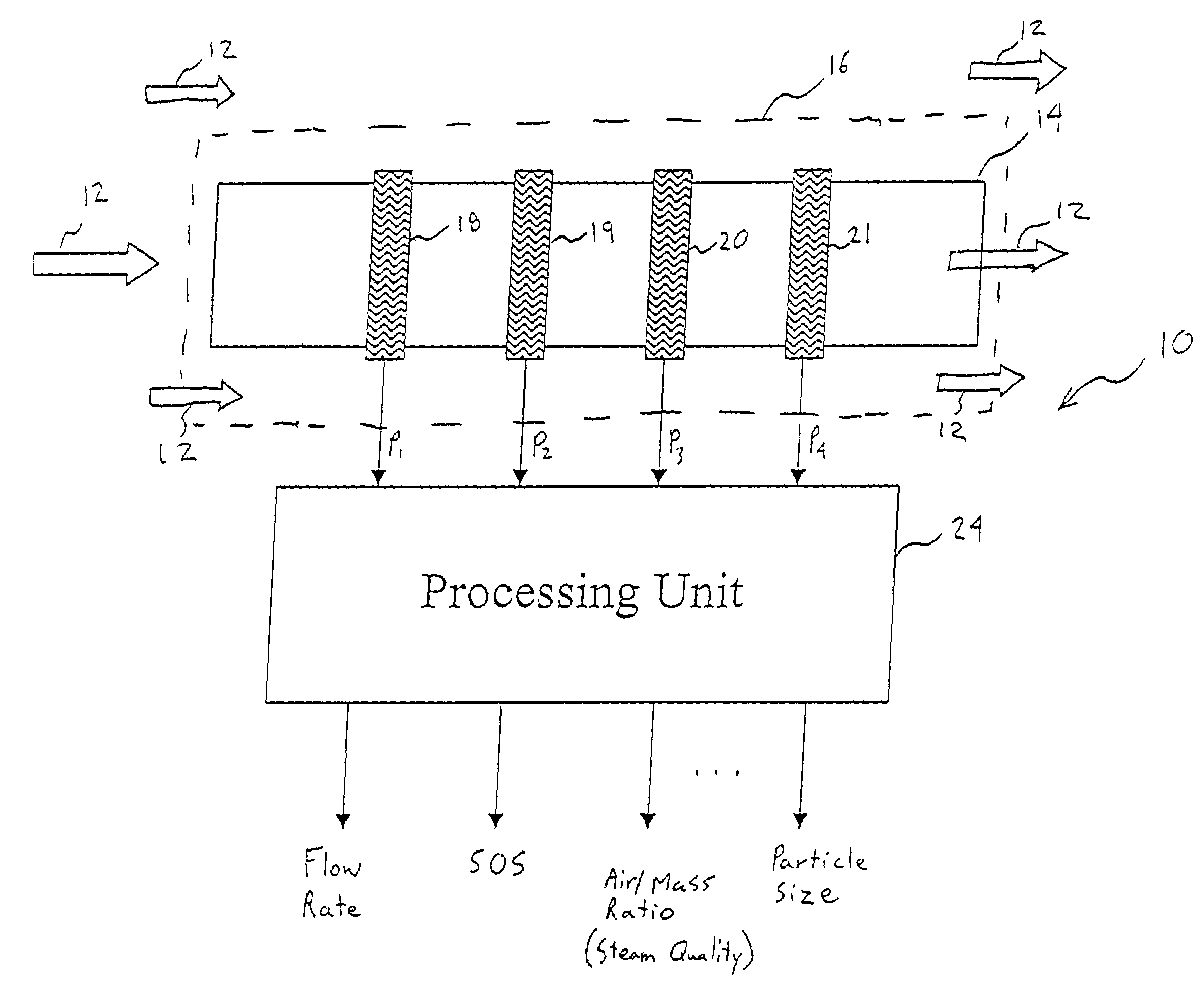

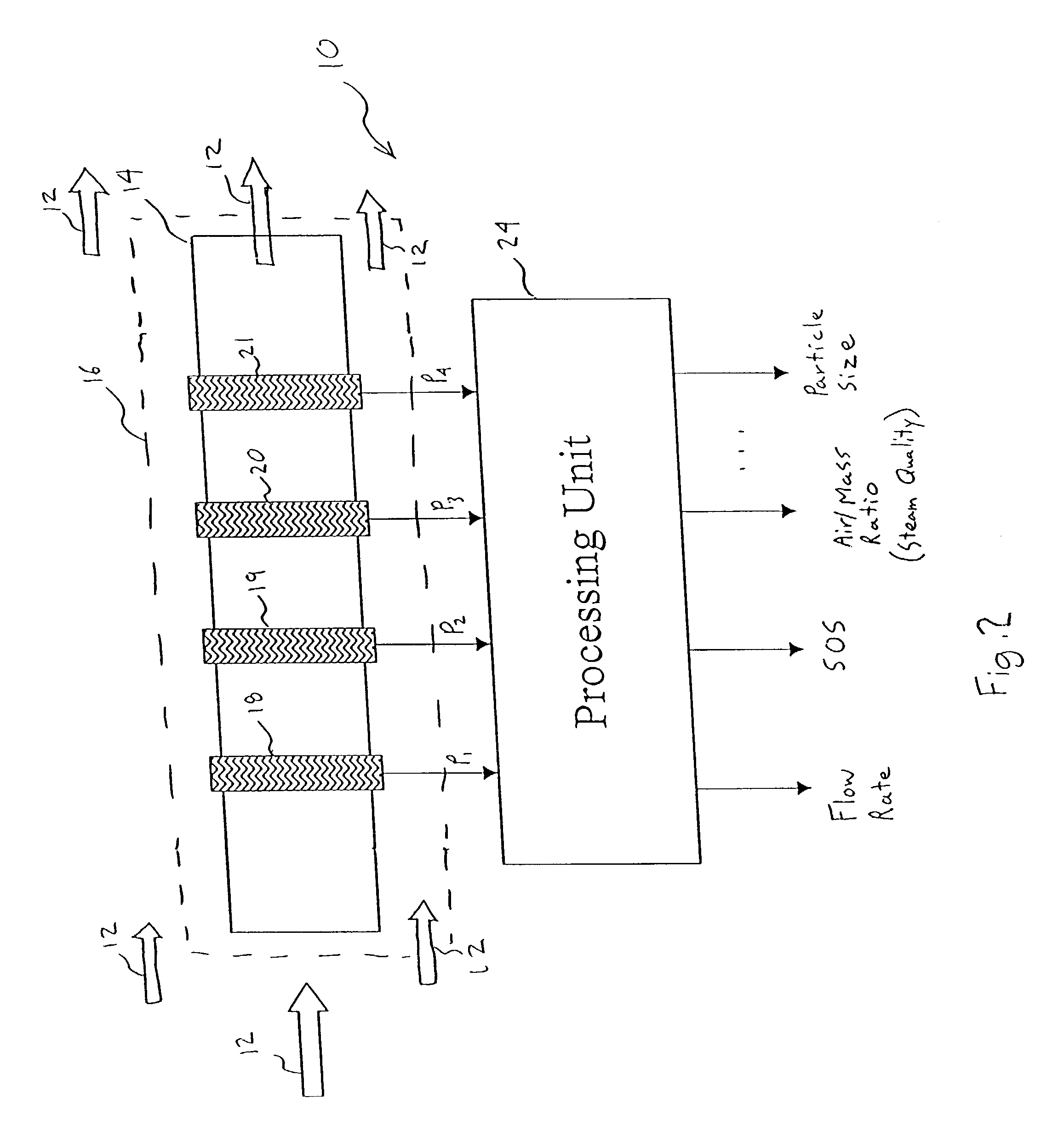

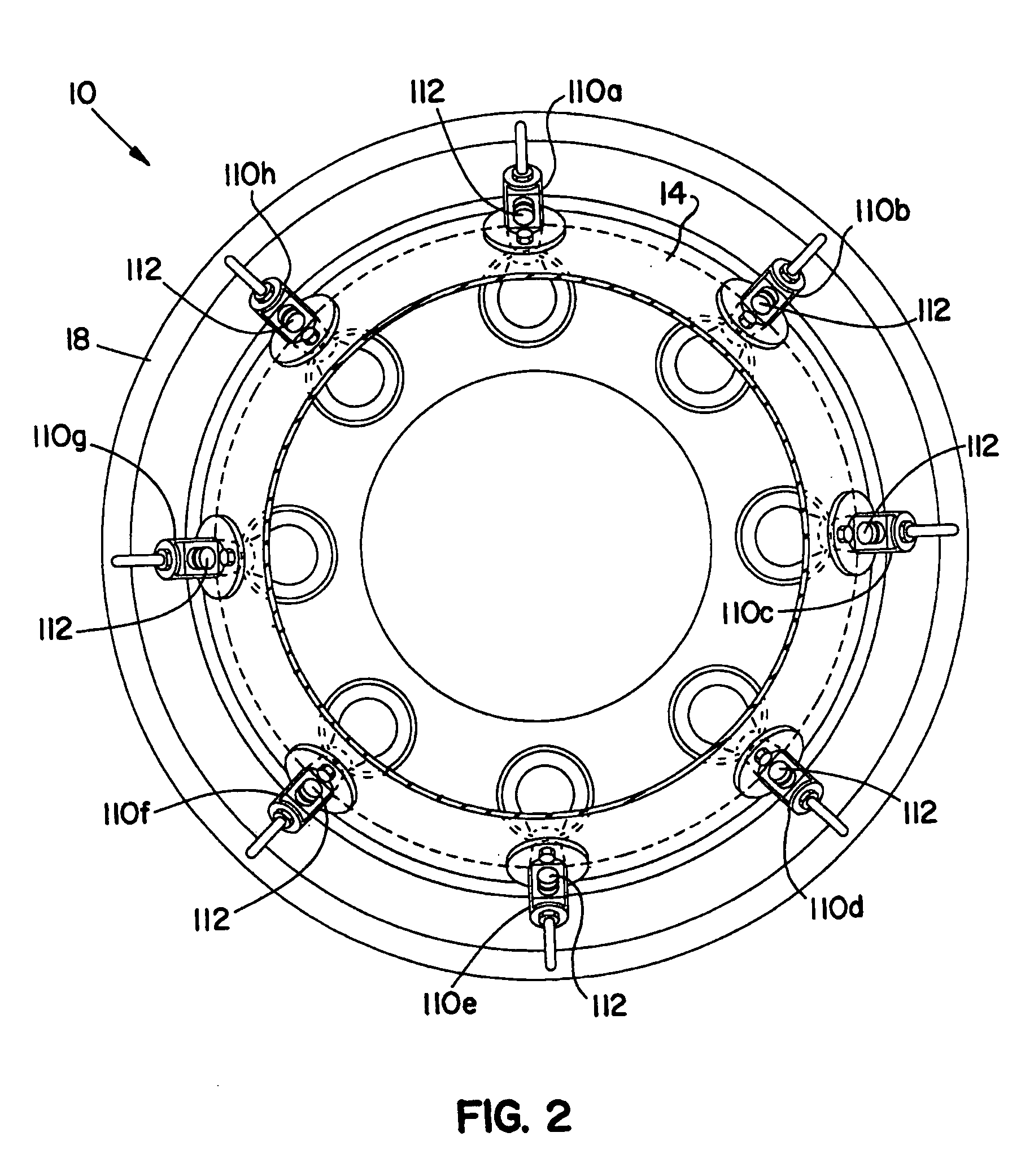

Apparatus for measuring parameters of a flowing multiphase mixture

ActiveUS7096719B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorMass ratio

An apparatus 10 is provided that measures the speed of sound propagating in a multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The apparatus includes a pair of ultrasonic transducers disposed axially along the pipe for measuring the transit time of an ultrasonic signal to propagate from one ultrasonic transducer to the other ultrasonic transducer. A signal process, responsive to said transit time signal, provides a signal representative of the speed of sound of the mixture. An SOS processing unit then provides an output signal indicative of at least one parameter of the mixture flowing through the pipe. The frequency of the ultrasonic signal is sufficiently low to minimize scatter from particle / liquid within the mixture. The frequency based sound speed is determined utilizing a dispersion model to determine the at least one parameter of the fluid flow and / or mixture.

Owner:CIDRA CORP SERVICES

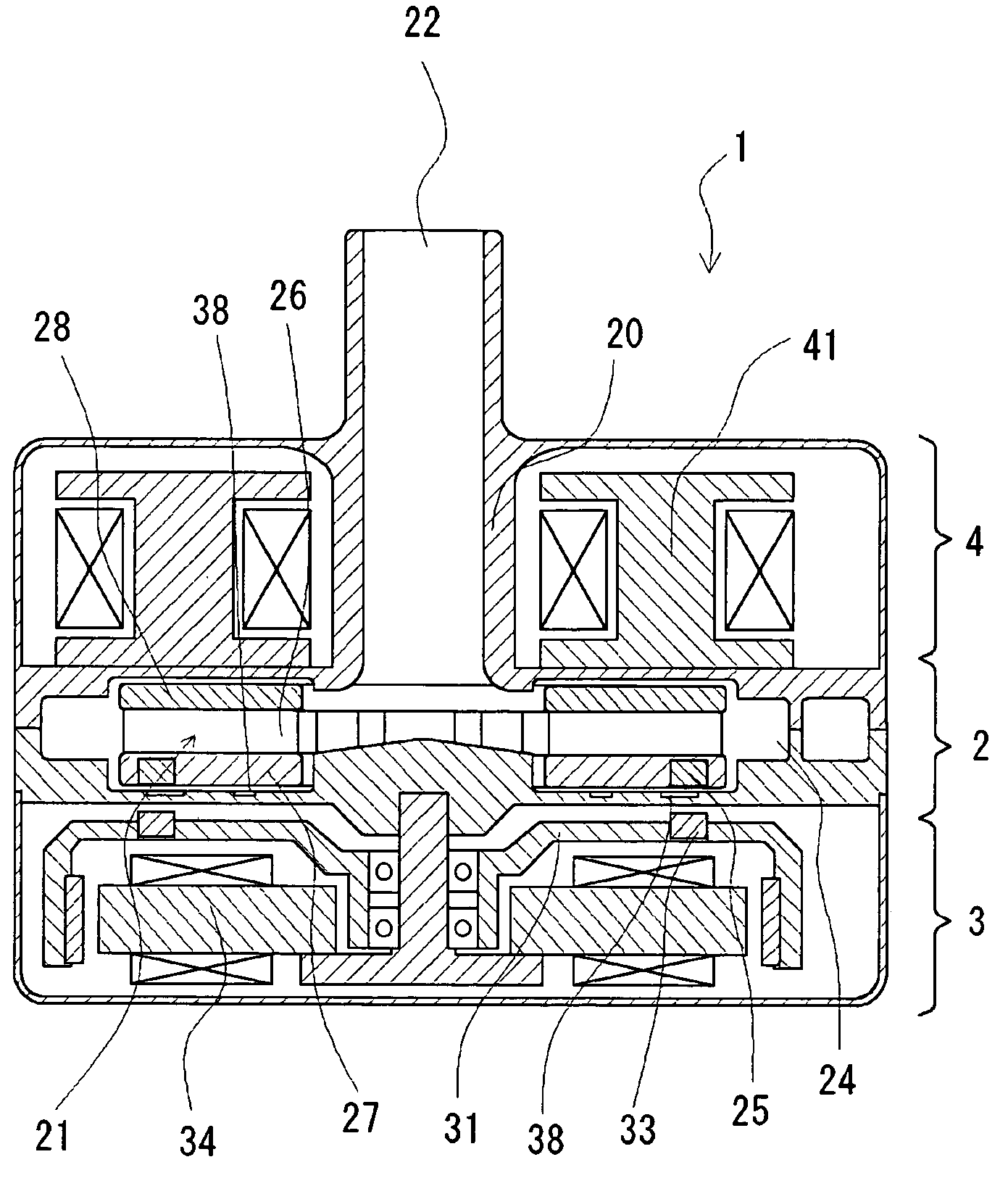

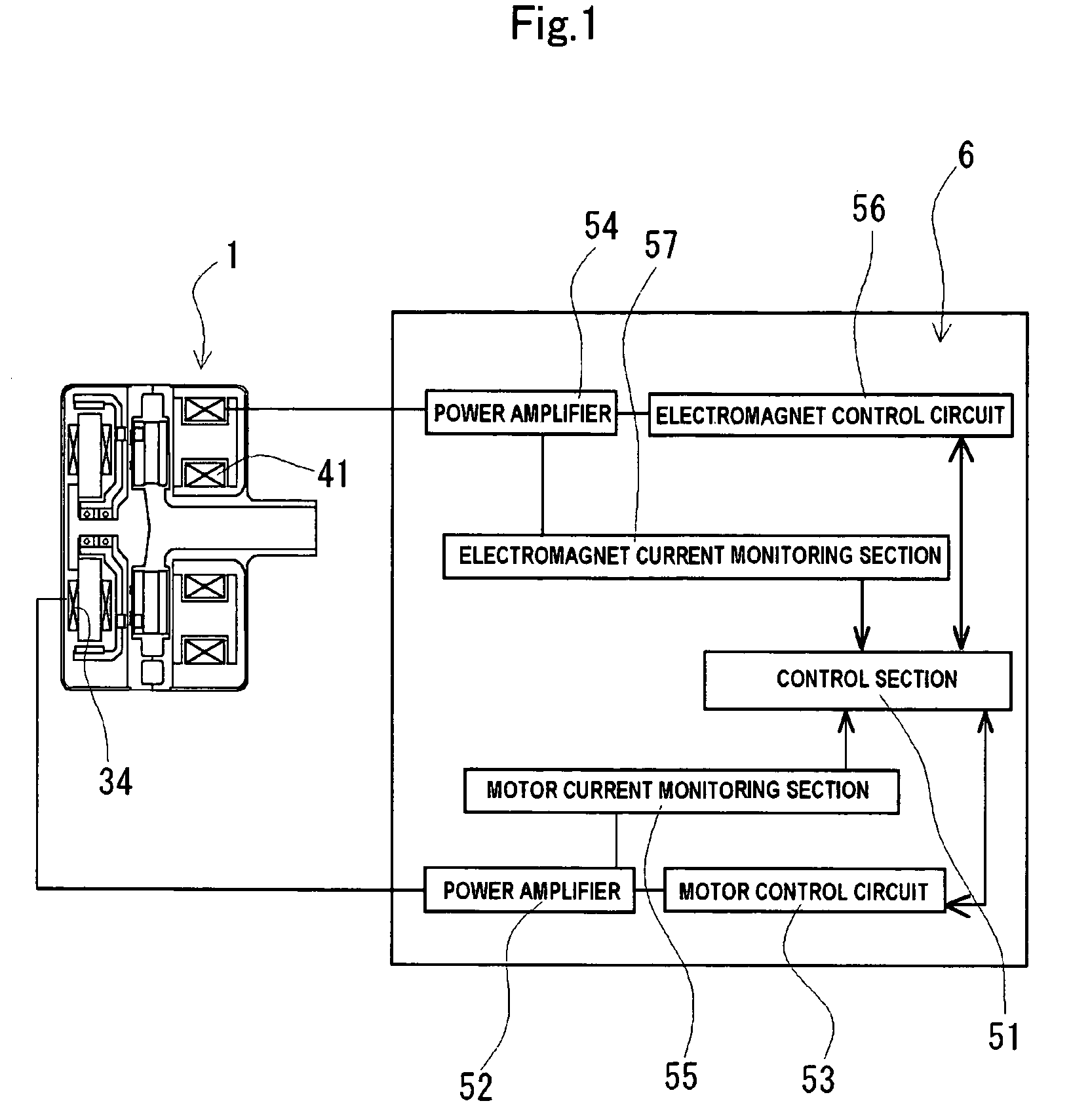

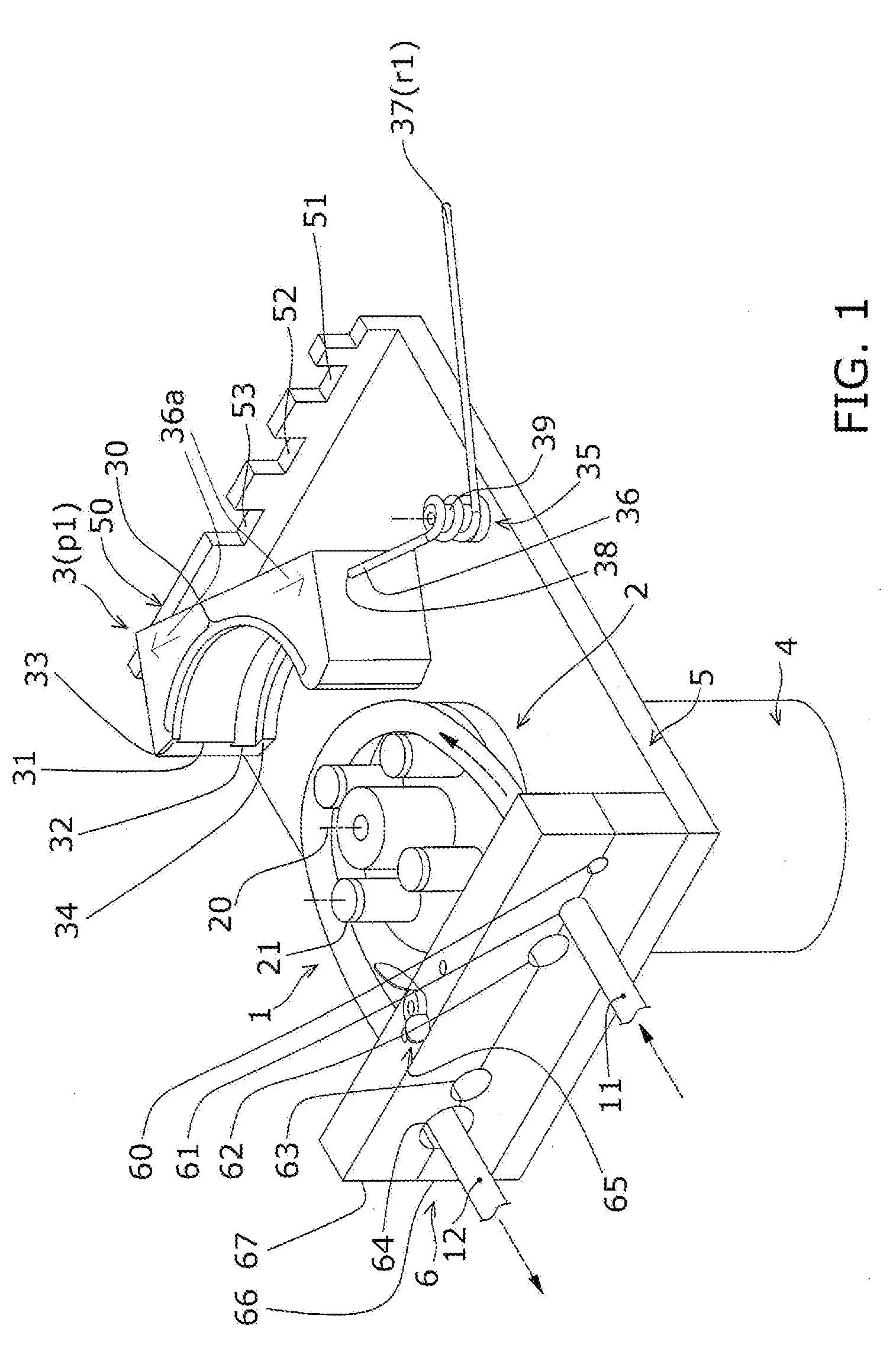

Centrifugal blood pump apparatus

A centrifugal blood pump apparatus has a centrifugal pump section including an impeller having a first magnetic material therein and rotating inside the housing to feed a fluid by a centrifugal force generated during a rotation thereof; an impeller rotational torque generation section having a rotor having a magnet for attracting the first magnetic material of the impeller thereto, and a motor for rotating the rotor; and a dynamic pressure groove formed at a portion, of an inner surface of the housing, located at a rotor-disposed side thereof. The centrifugal blood pump apparatus further includes an electromagnet for attracting the impeller in a direction opposite to a direction in which the magnet of the rotor attracts the impeller and helping the impeller levitate.

Owner:TC1 LLC

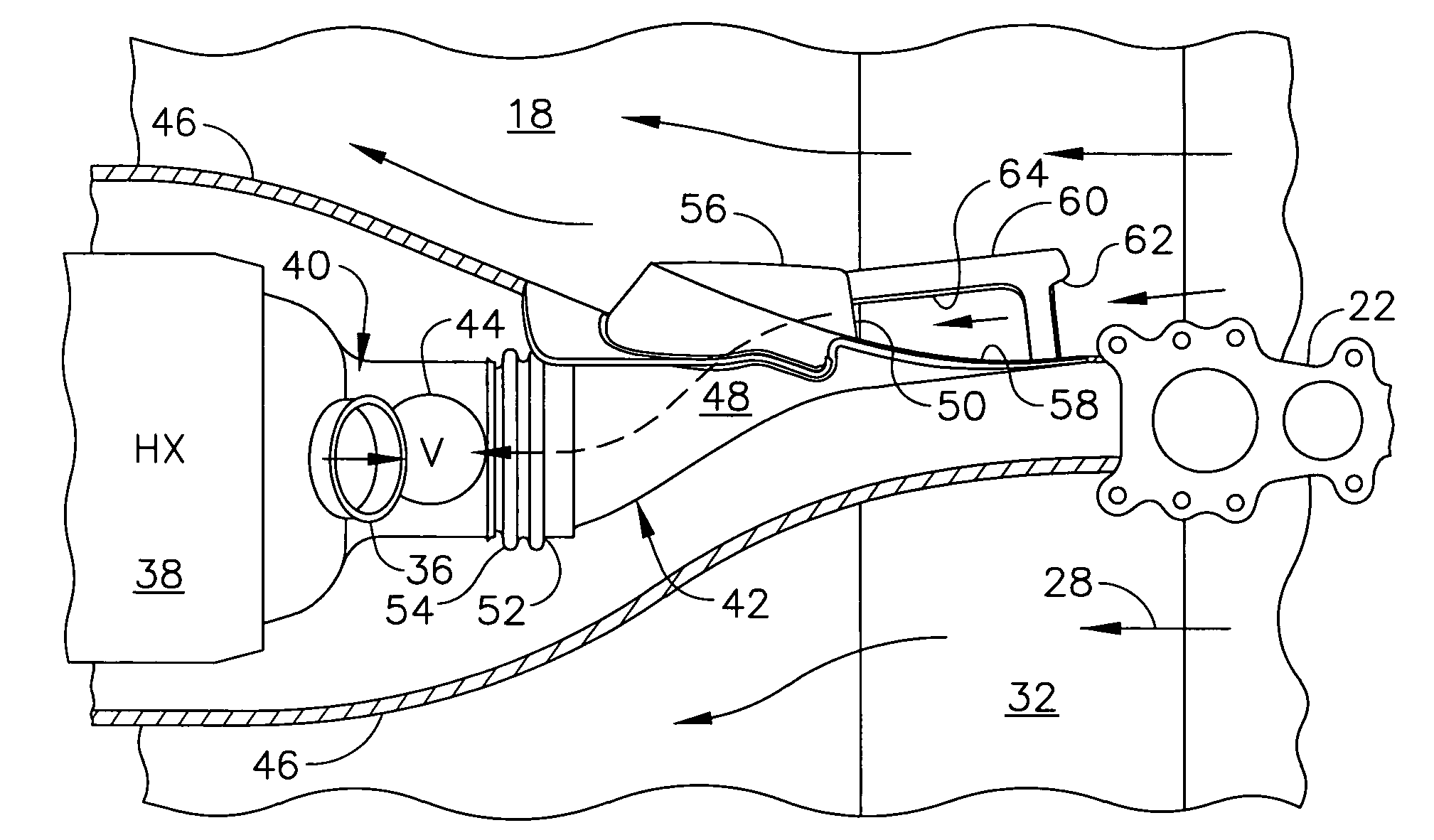

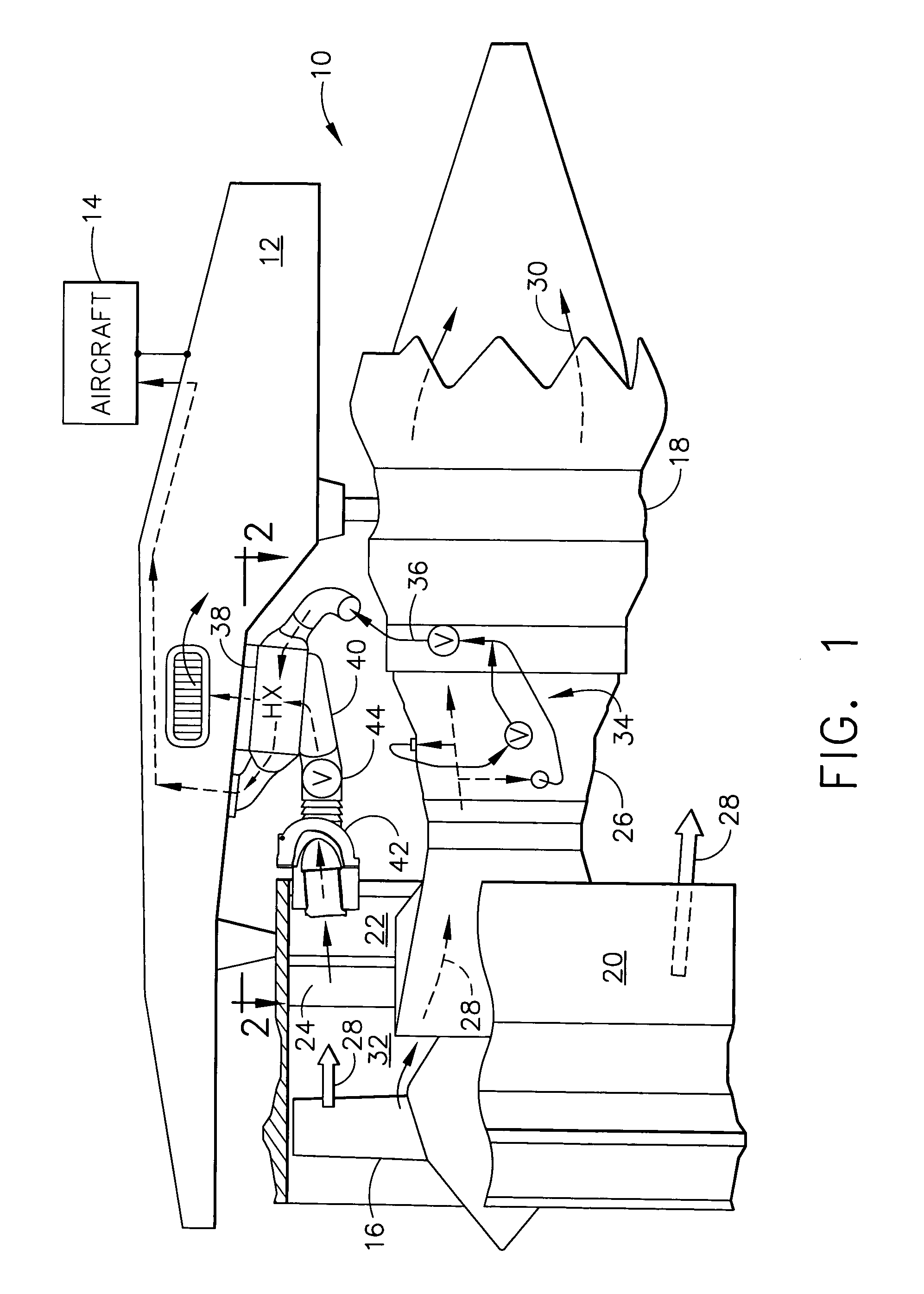

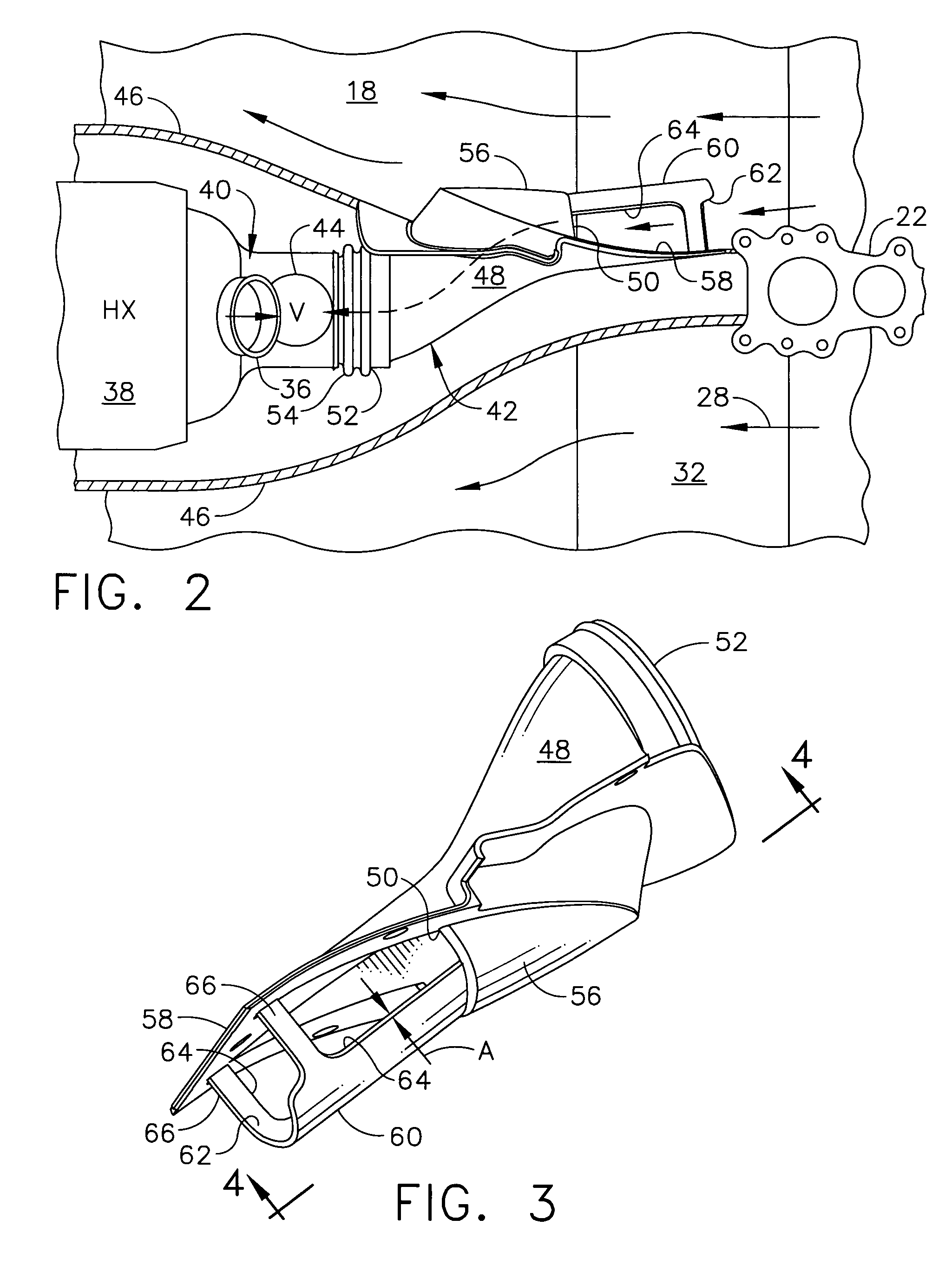

Shrouded turbofan bleed duct

A bleed duct is configured for bleeding fan air from the fan bypass duct in a turbofan aircraft engine. The bleed duct includes a tubular conduit having an inlet and outlet at opposite ends. The conduit is configured in flow area for recovering pressure from speeding fan air bled therethrough. A shroud extends forwardly from the duct inlet for suppressing dynamic pressure oscillations inside the conduit without degrading the pressure recovery.

Owner:GENERAL ELECTRIC CO

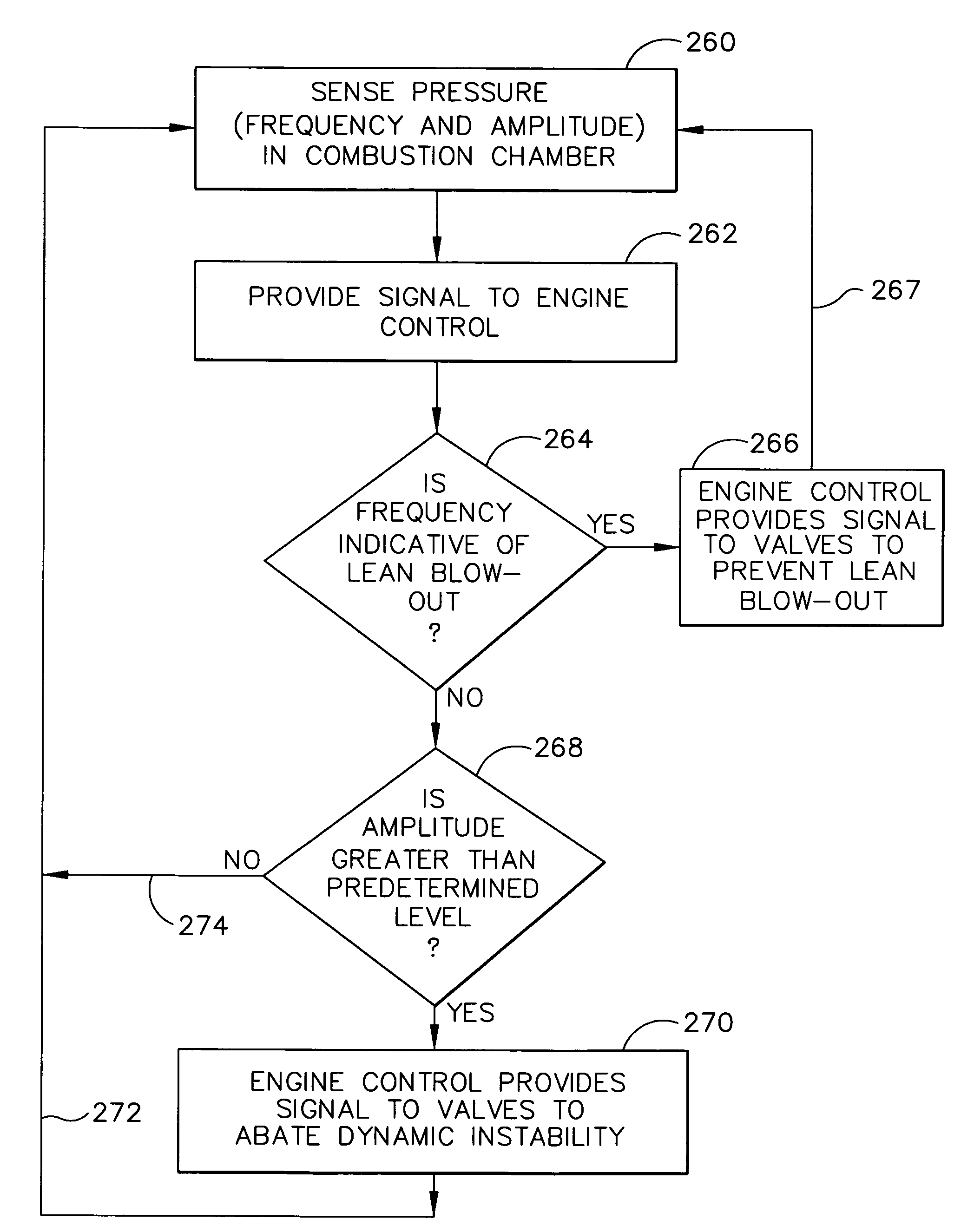

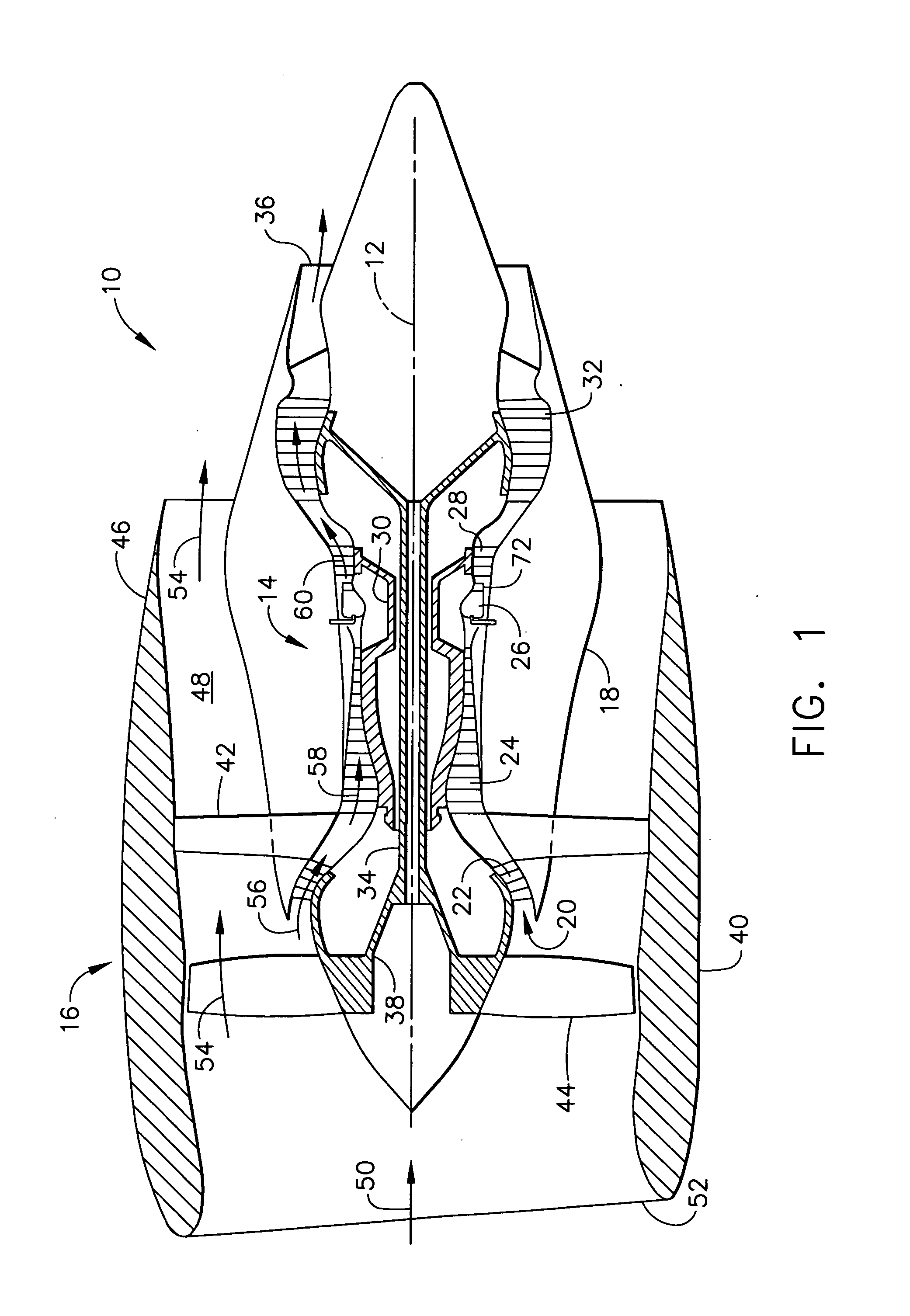

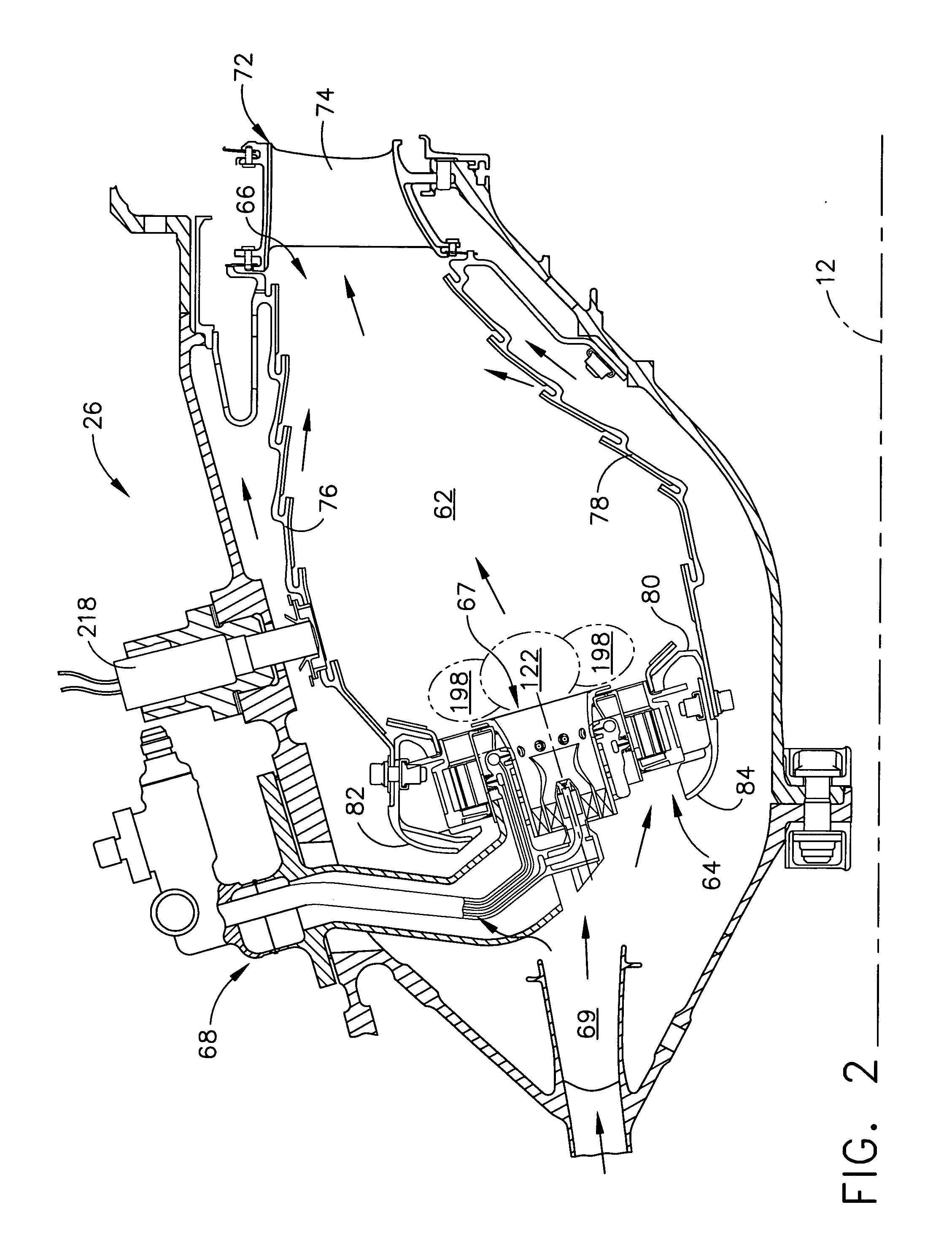

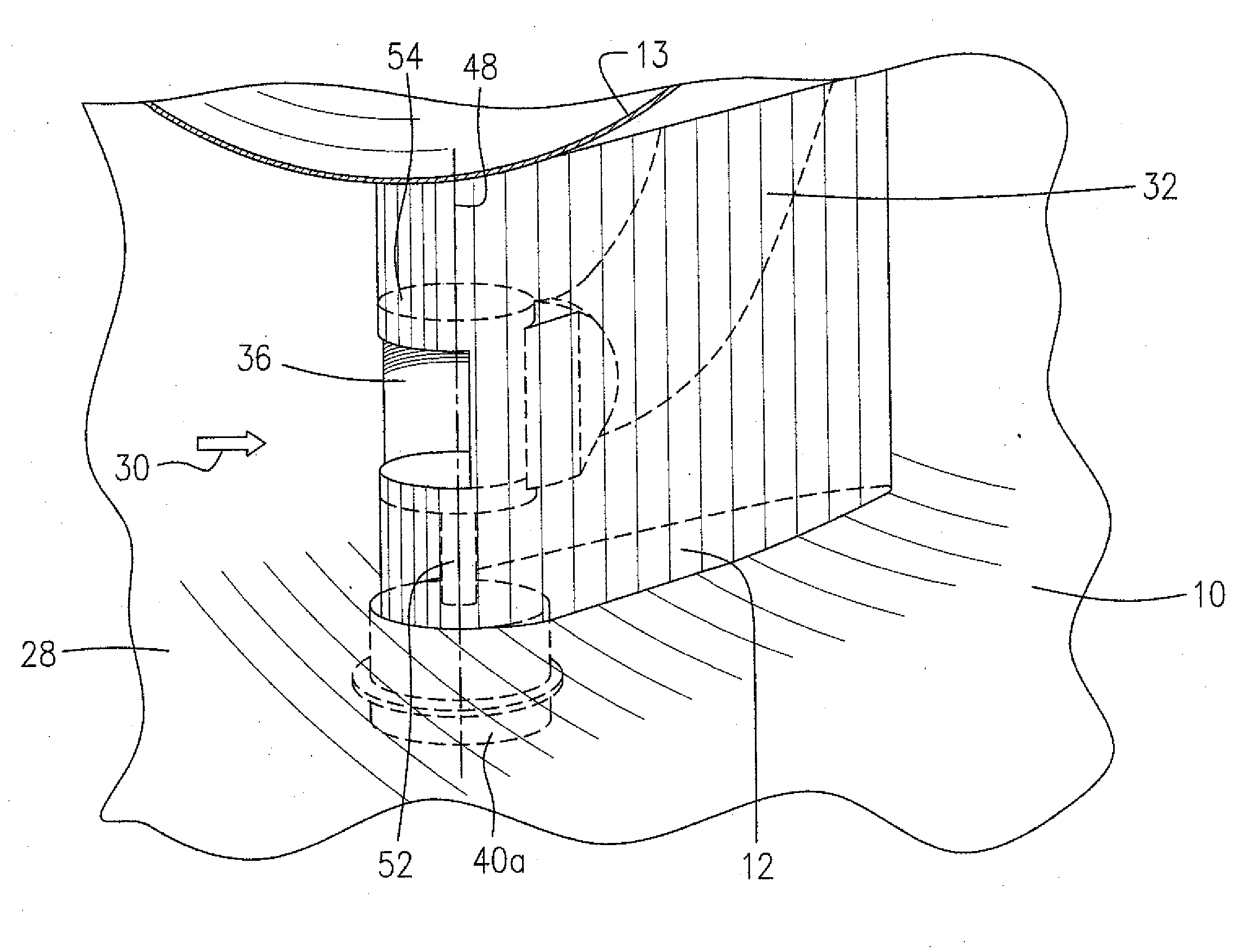

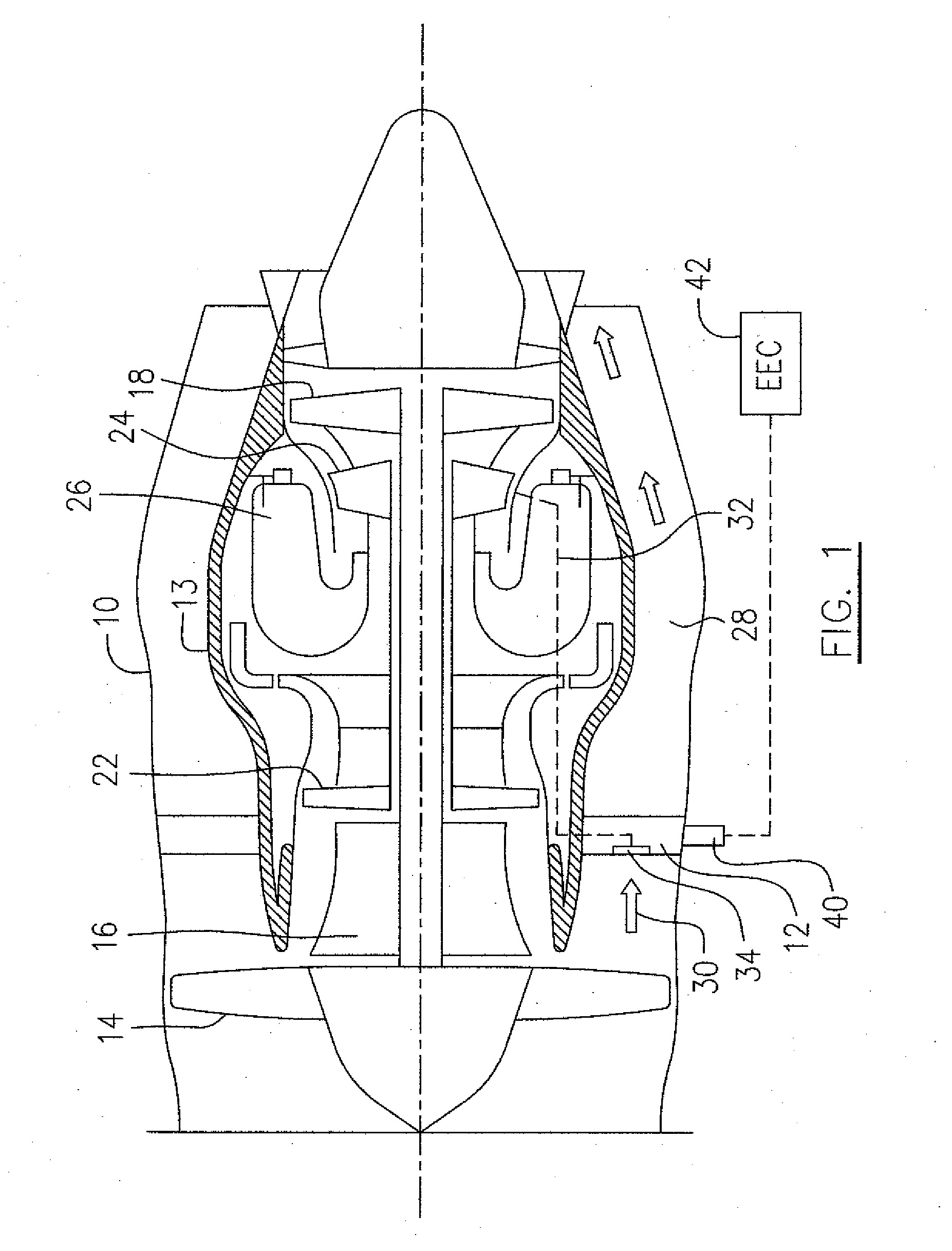

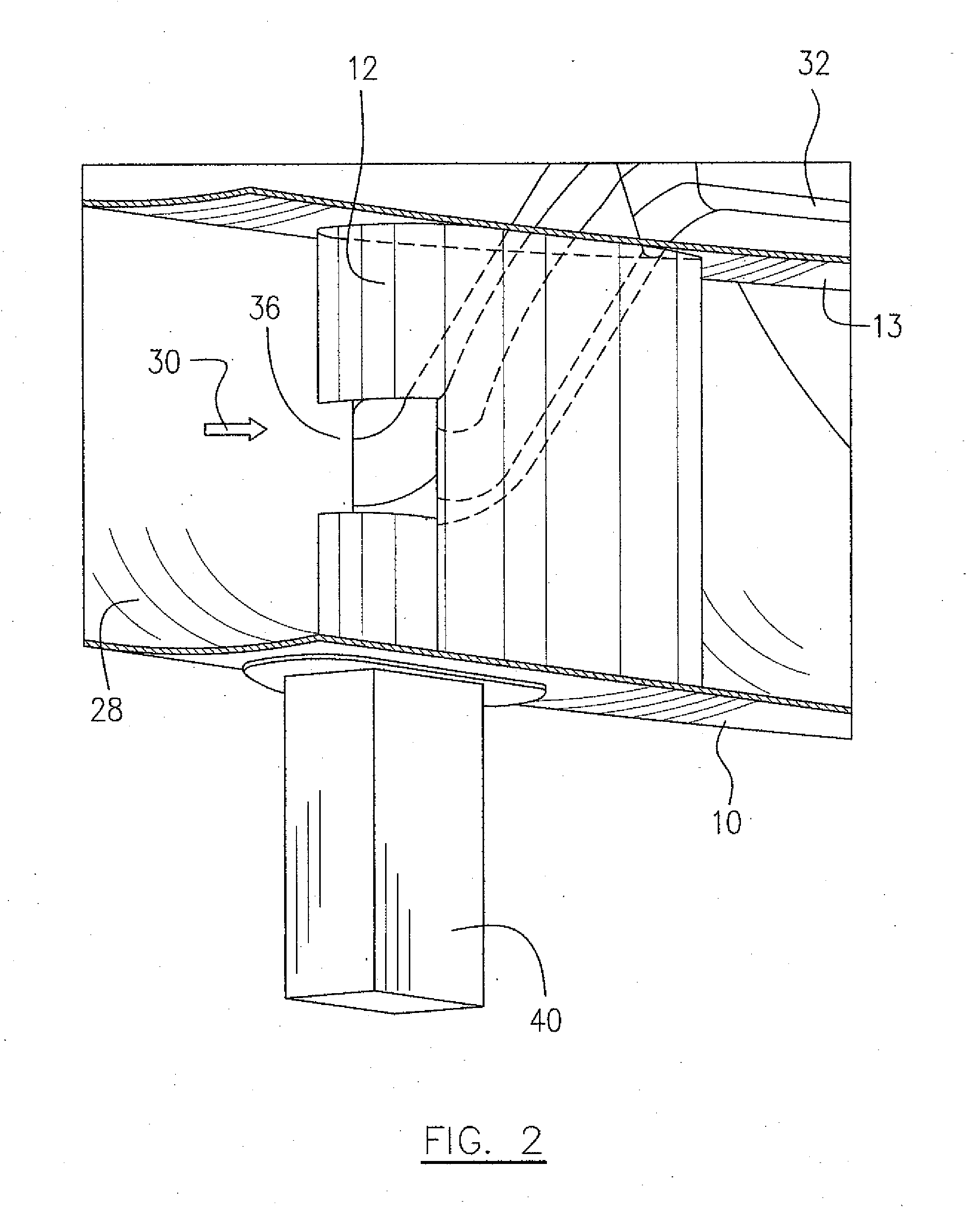

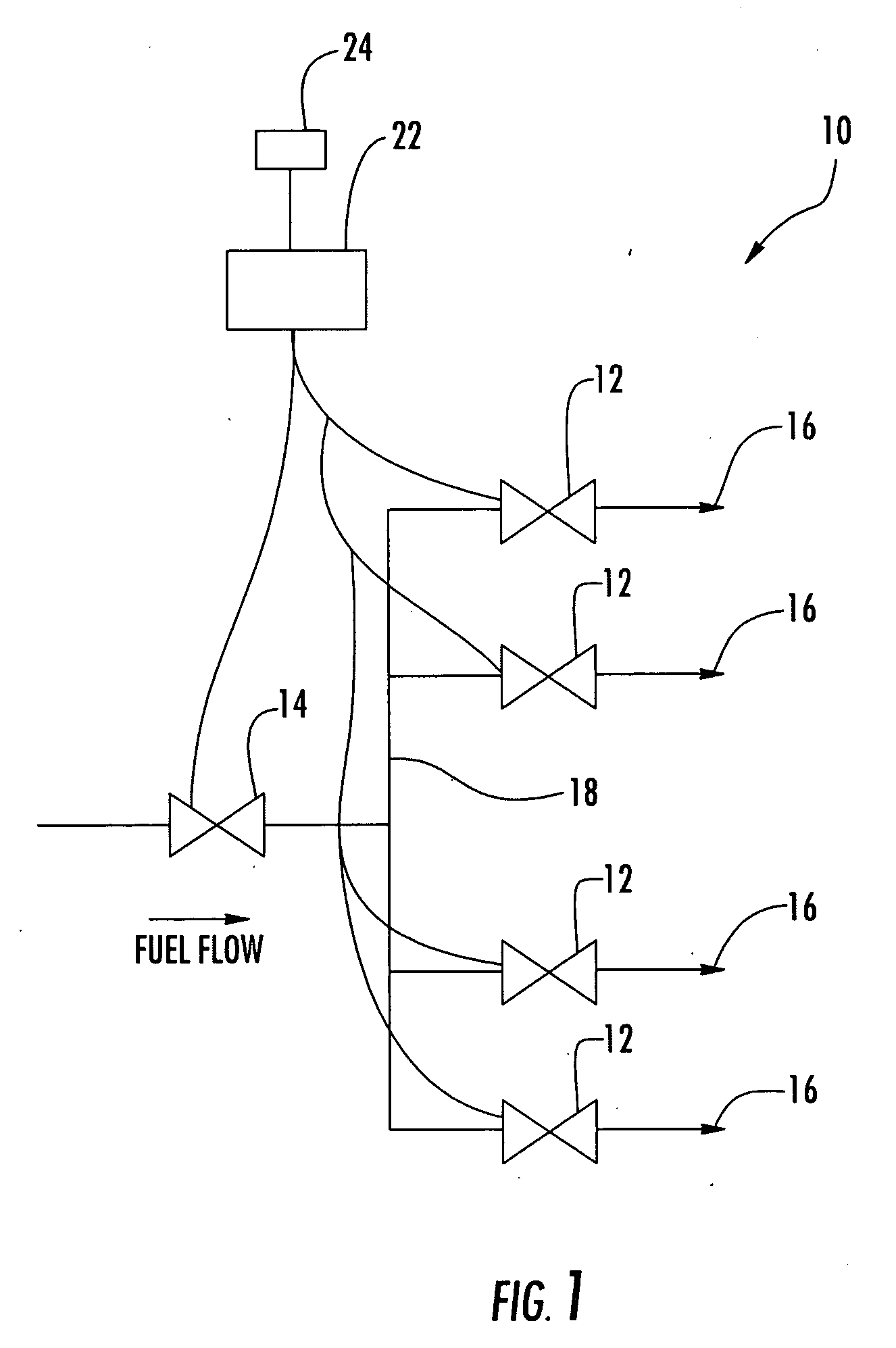

Method and apparatus for actively controlling fuel flow to a mixer assembly of a gas turbine engine combustor

ActiveUS20070271927A1Continuous combustion chamberTurbine/propulsion engine ignitionCombustorStream flow

An apparatus for actively controlling fuel flow from a fuel pump to a mixer assembly of a gas turbine engine combustor, where the mixer assembly includes a pilot mixer and a main mixer. The pilot mixer further includes an annular pilot housing having a hollow interior, a primary fuel injector mounted in the pilot housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing, a plurality of axial swirlers positioned upstream from the primary fuel injector. The fuel flow control apparatus further includes: at least one sensor for detecting dynamic pressure in the combustor; a fuel nozzle; and, a system for controlling fuel flow supplied by the fuel nozzle through the valves. The fuel nozzle includes: a feed strip with a plurality of circuits for providing fuel to the pilot mixer and the main mixer; and, a plurality of valves associated with the fuel nozzle and in flow communication with the feed strip thereof. The control system activates the valves in accordance with signals received from the pressure sensor.

Owner:GENERAL ELECTRIC CO

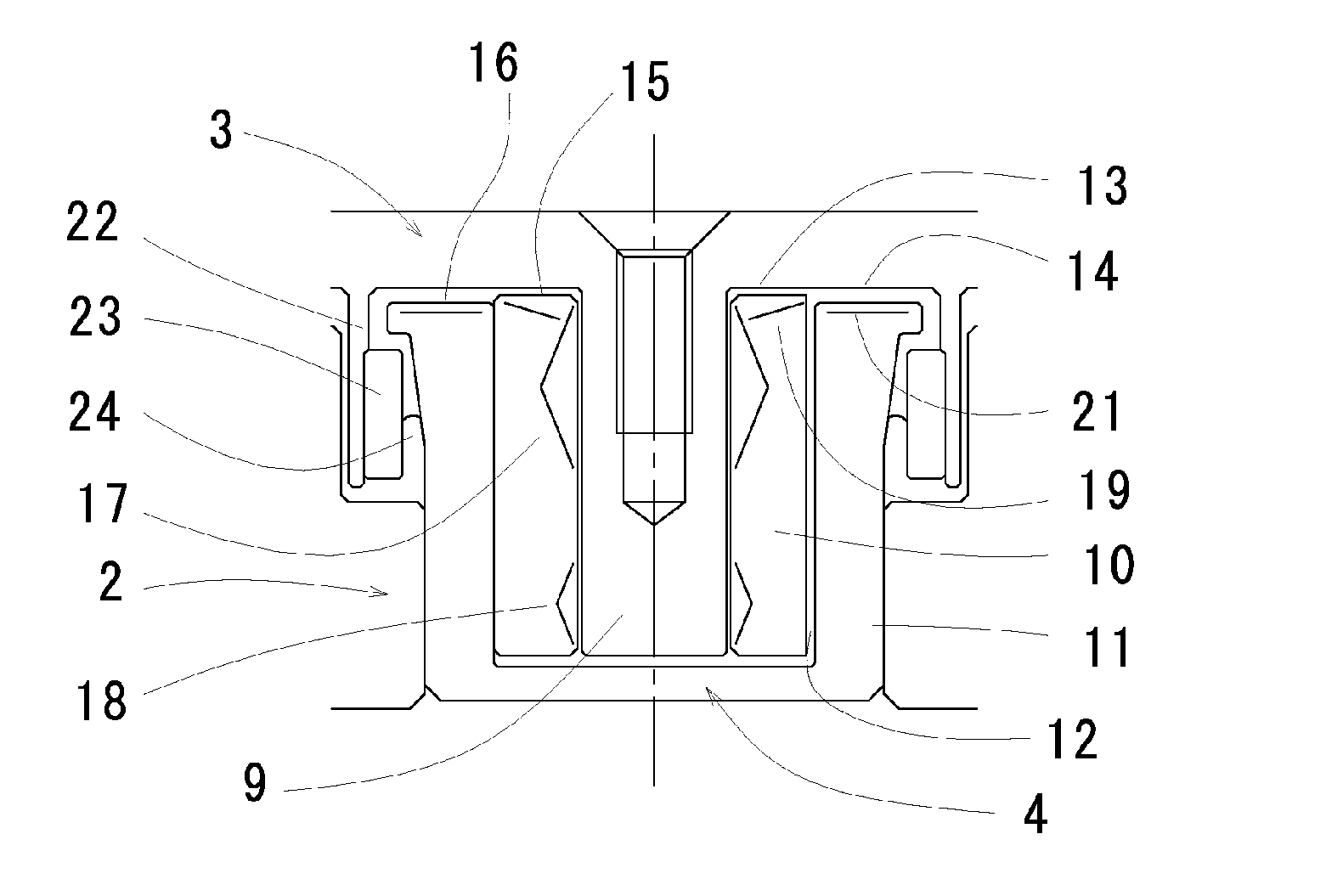

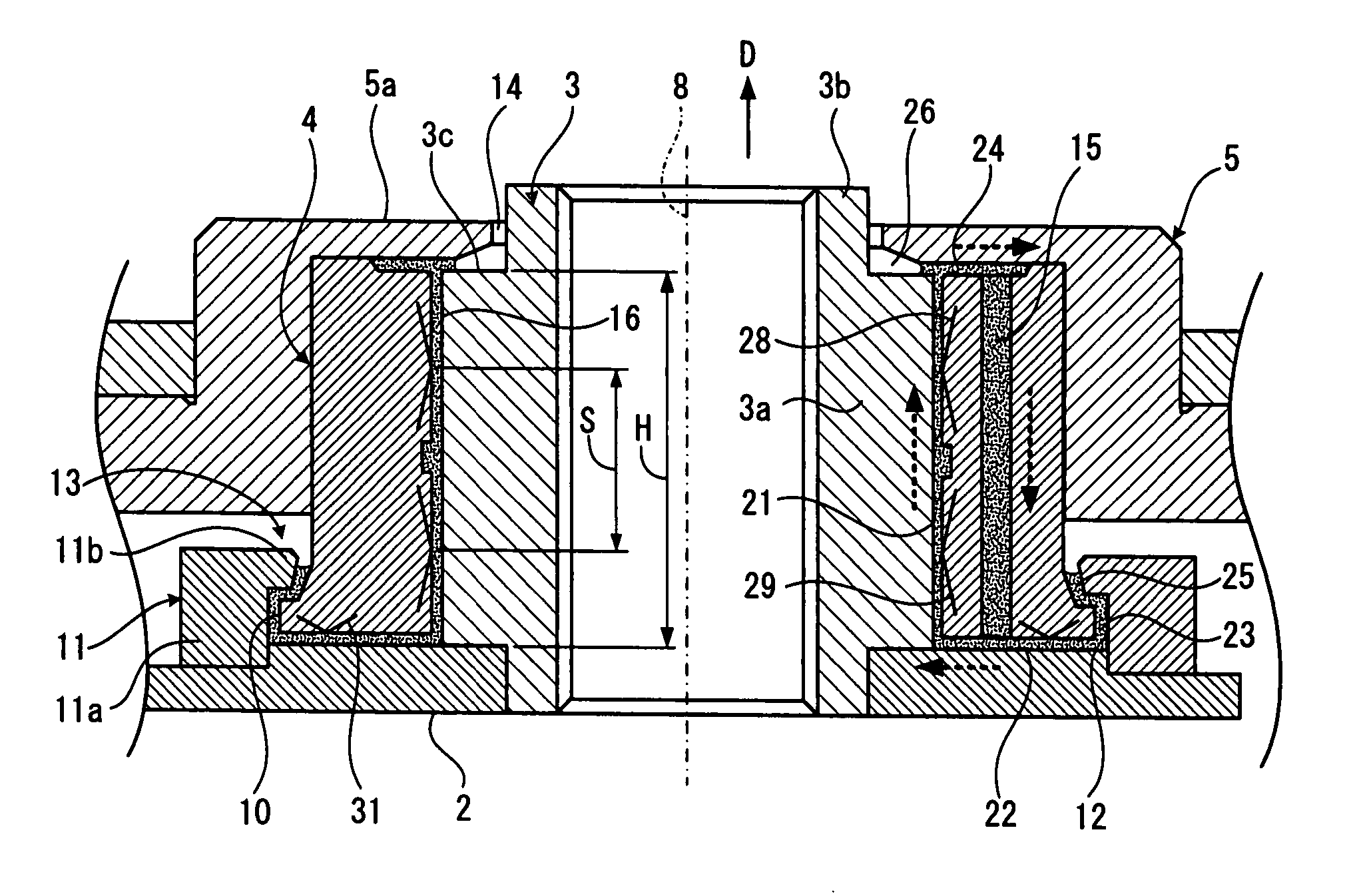

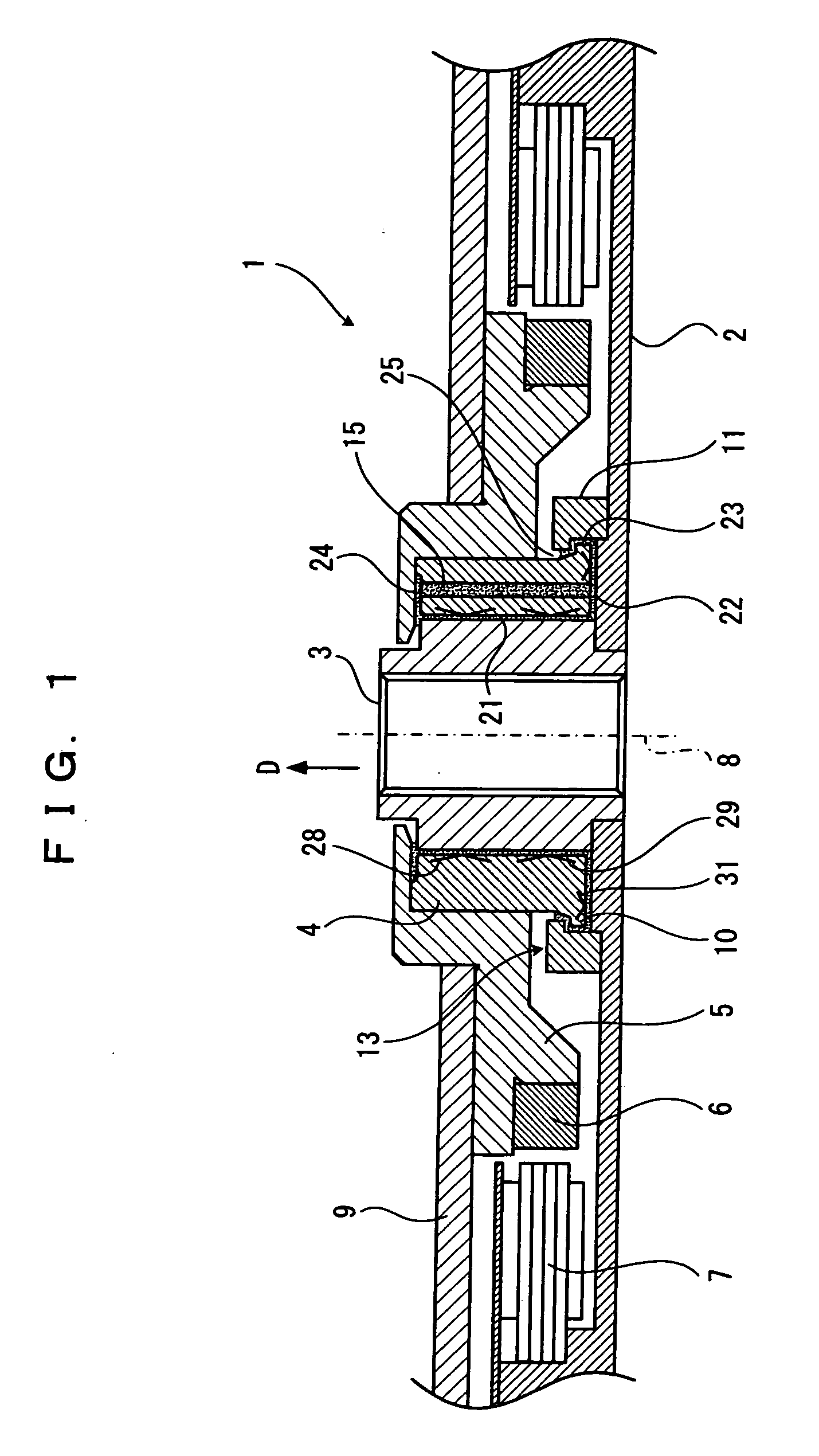

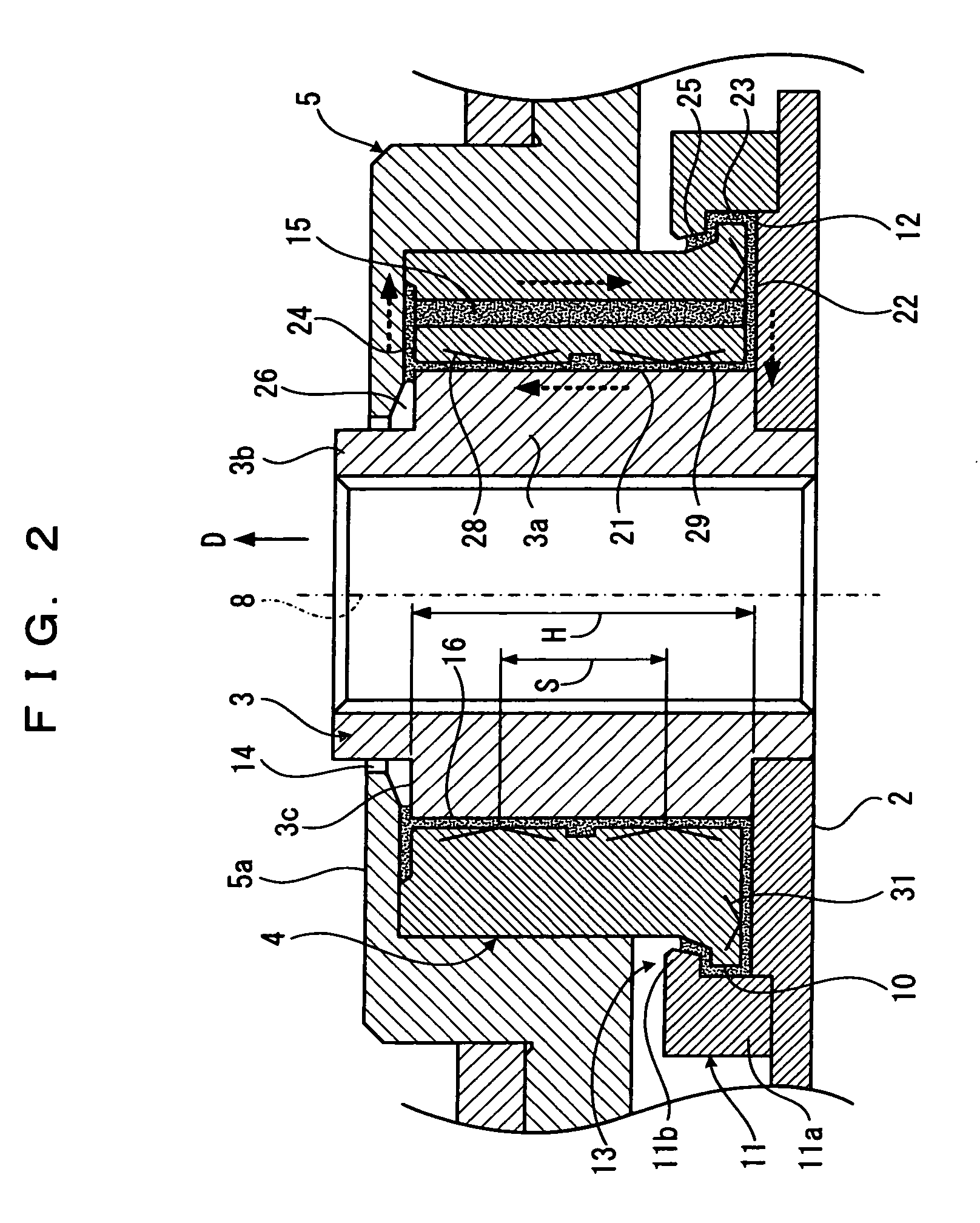

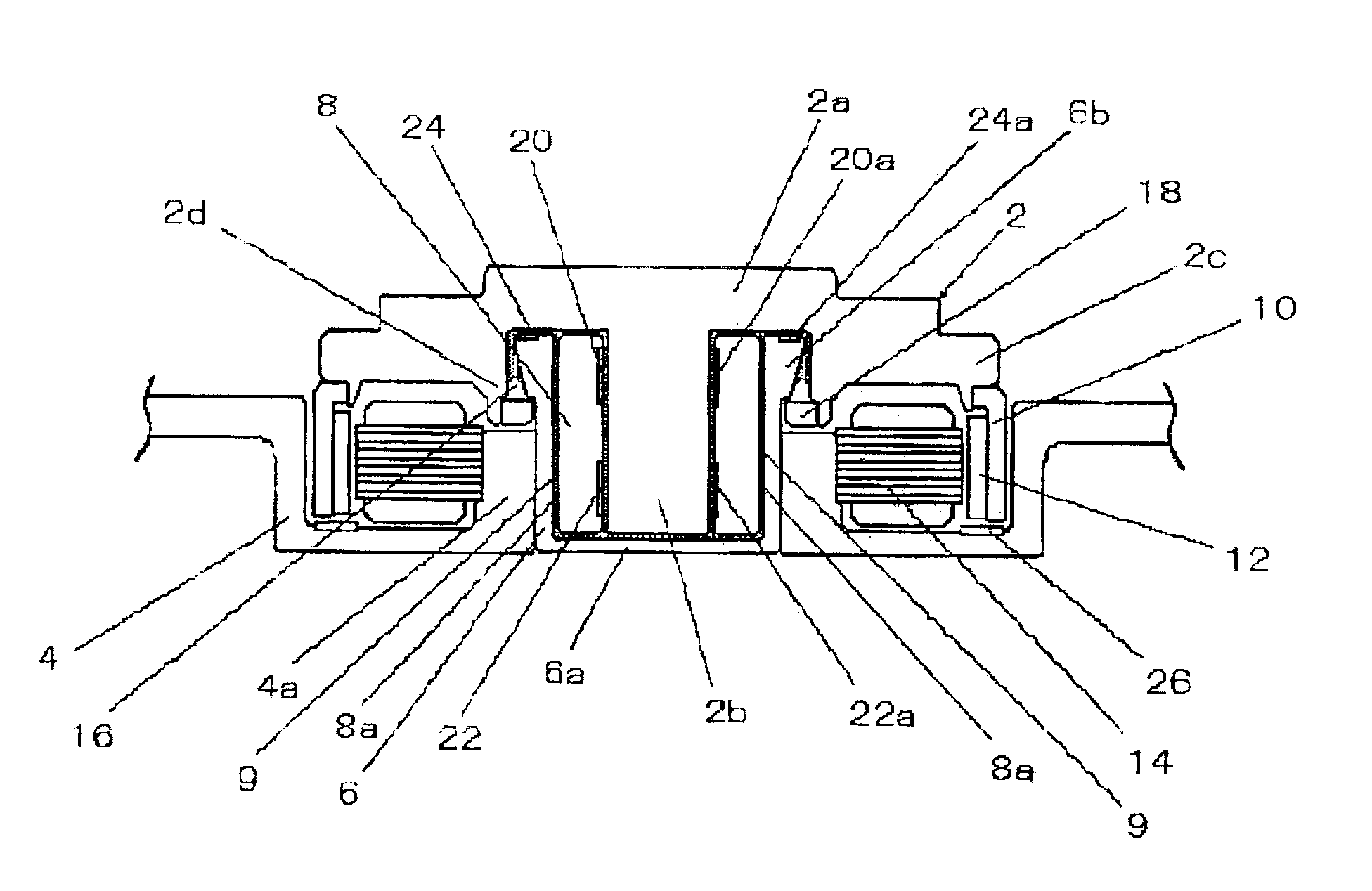

Fluid Dynamic-Pressure Bearing Device and Spindle Motor

ActiveUS20060051001A1Easy maintenanceReduce the overall heightBearing assemblyShaftsEngineeringDynamic pressure

Owner:NIDEC CORP

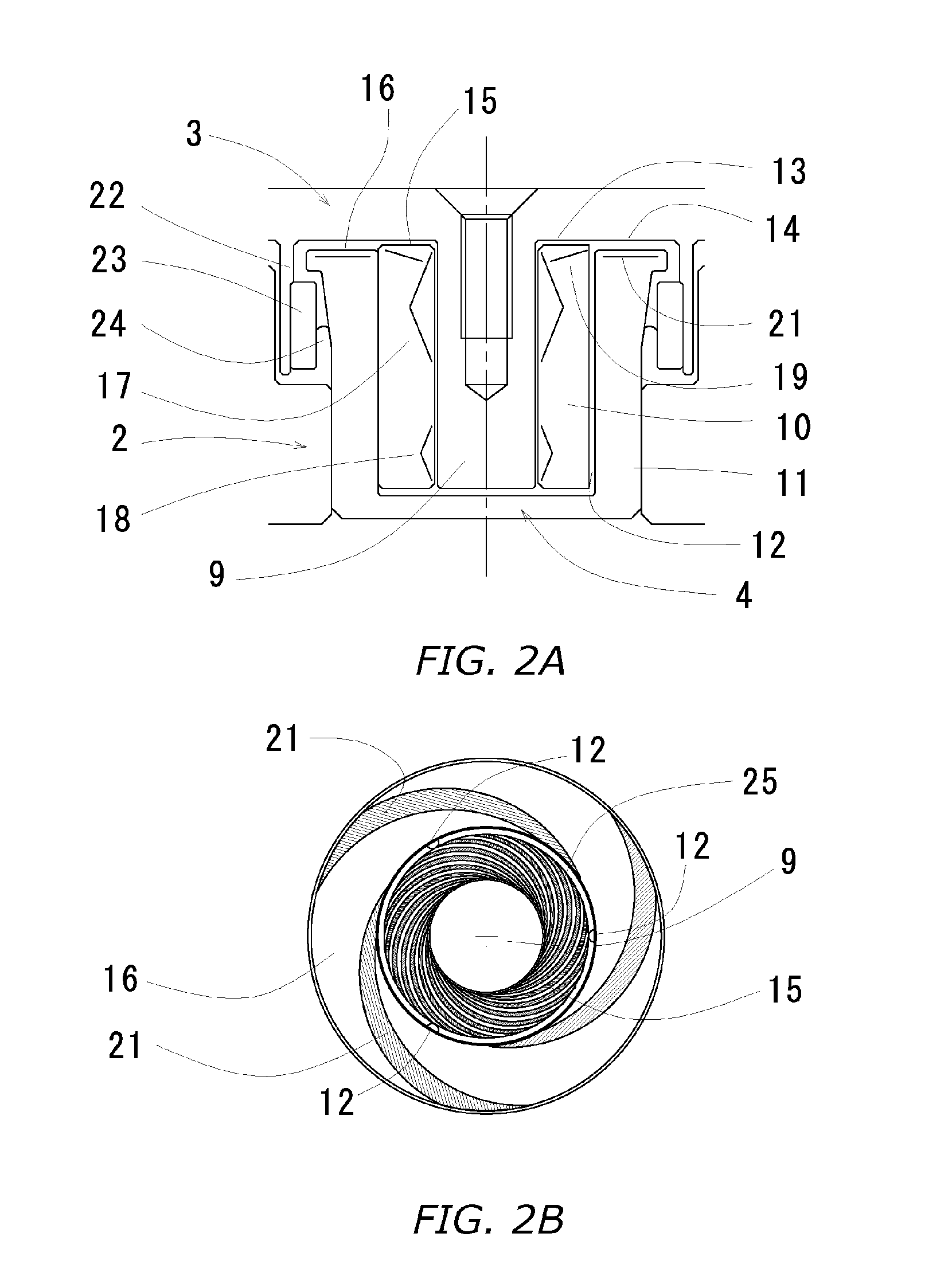

Probe for measuring parameters of a flowing fluid and/or multiphase mixture

A probe 10,170 is provided that measures the speed of sound and / or vortical disturbances propagating in a single phase fluid flow and / or multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The probe includes a spatial array of unsteady pressure sensors 15-18 placed at predetermined axial locations x1-xN disposed axially along a tube 14. For measuring at least one parameter of a saturated vapor / liquid mixture 12, such as steam, flowing in the tube 14. The pressure sensors 15-18 provide acoustic pressure signals P1(t)-PN(t) to a signal processing unit 30 which determines the speed of sound amix propagating through of the saturated vapor / liquid mixture 12 in the tube 14 using acoustic spatial array signal processing techniques. Frequency based sound speed is determined utilizing a dispersion model to determine the parameters of interest.

Owner:EXPRO METERS

Combination valve and regulator with vented seat for use with pressurized gas cylinders, particularly oxygen cylinders

Owner:LUXFER INC

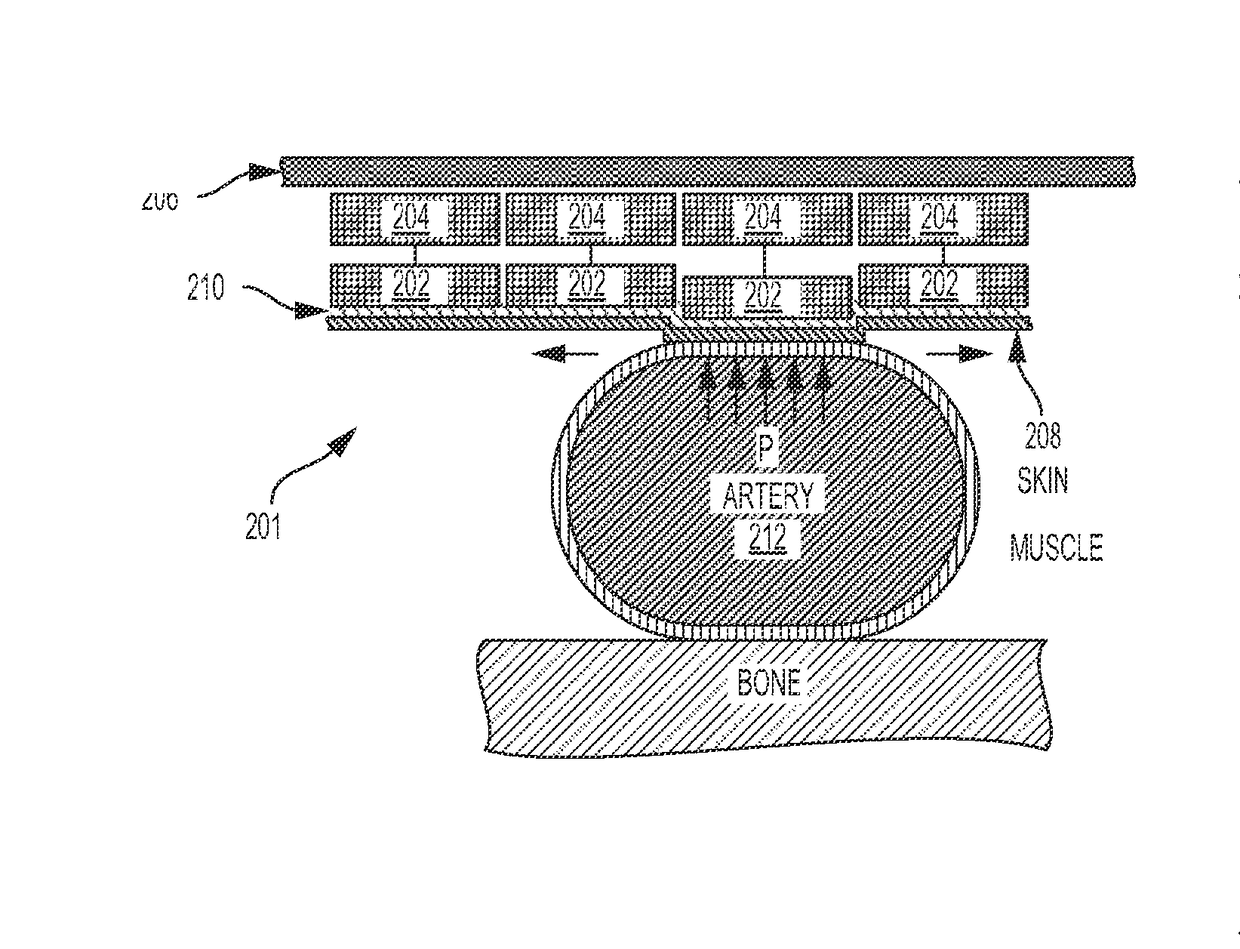

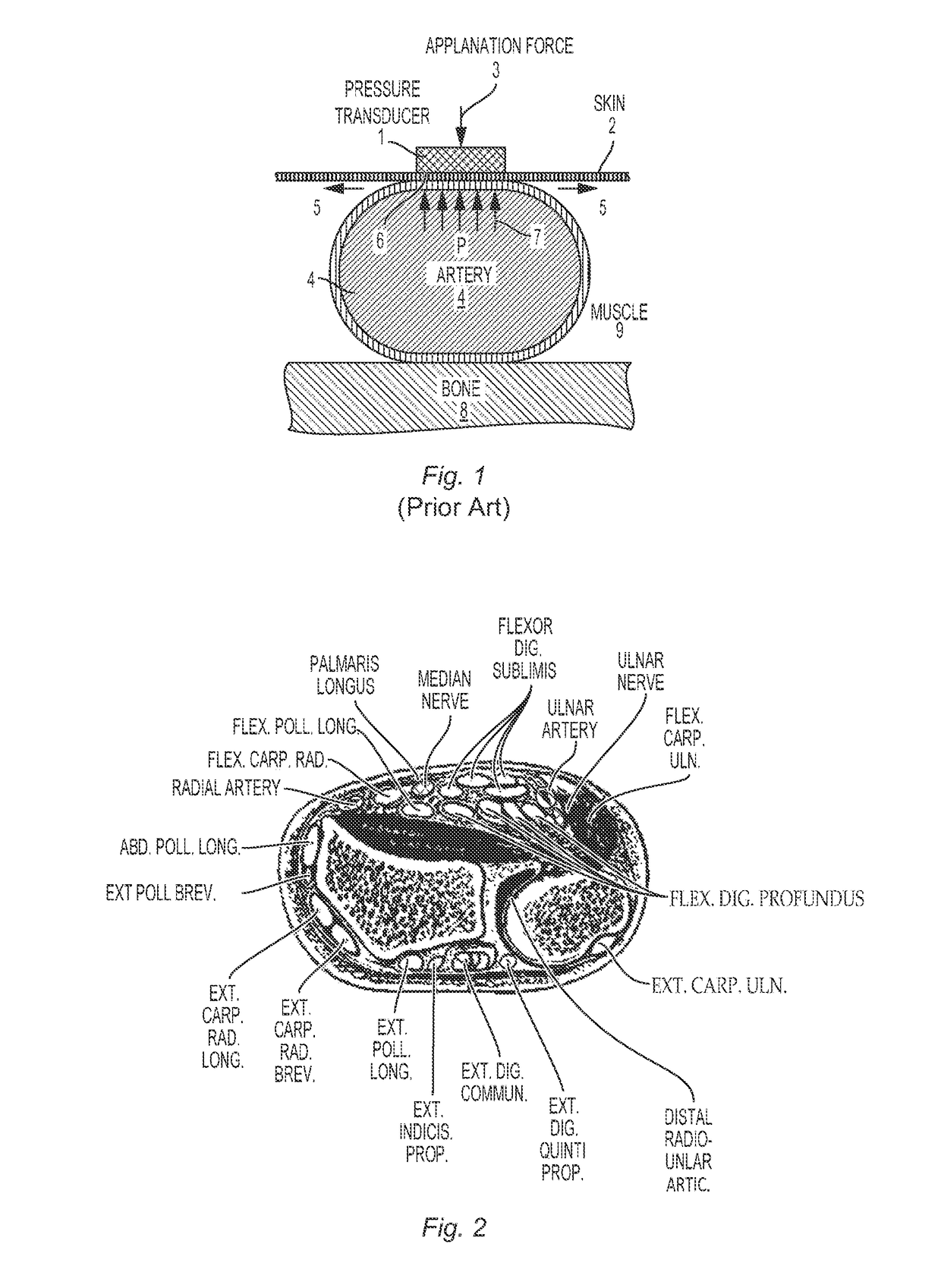

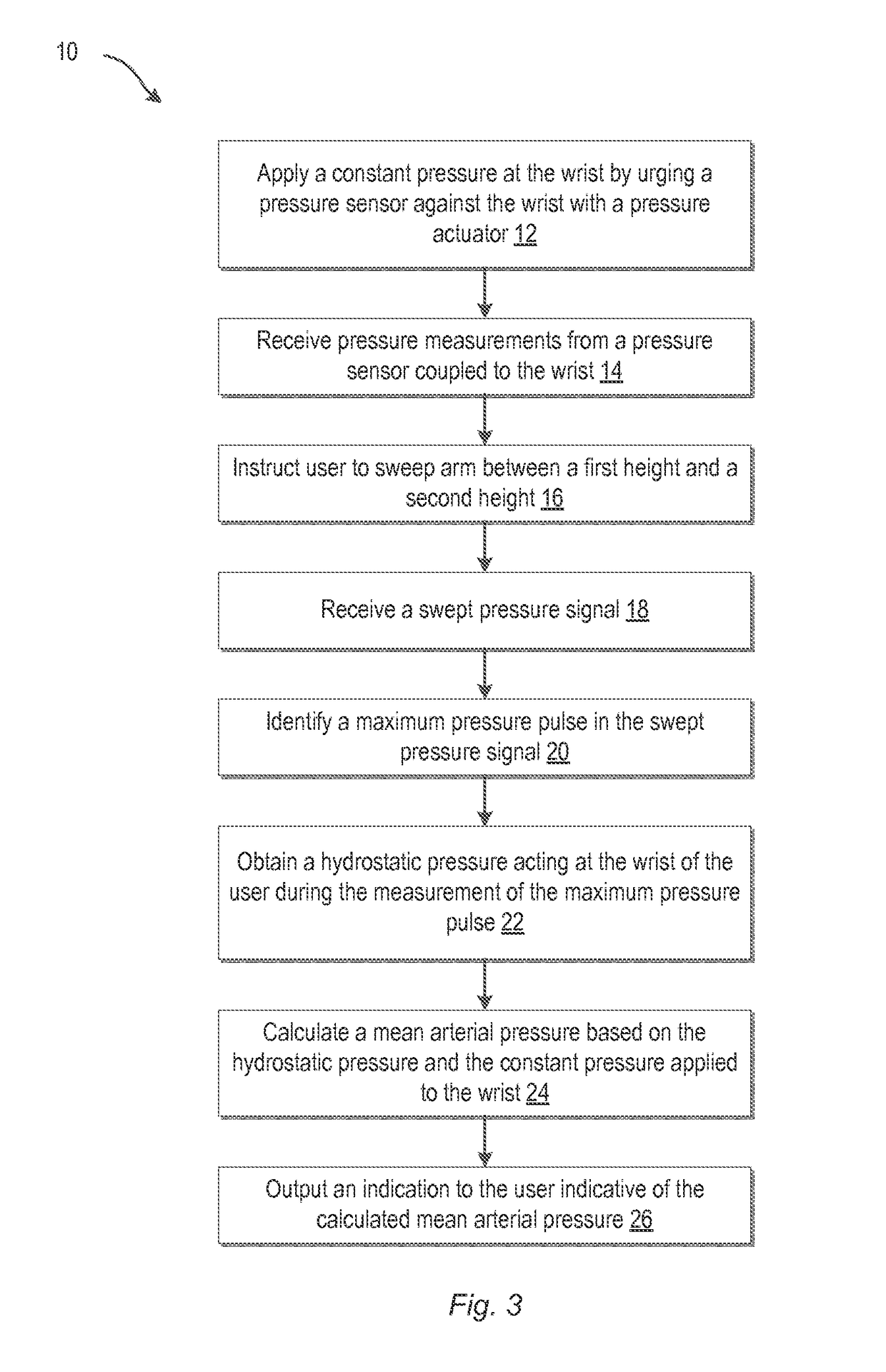

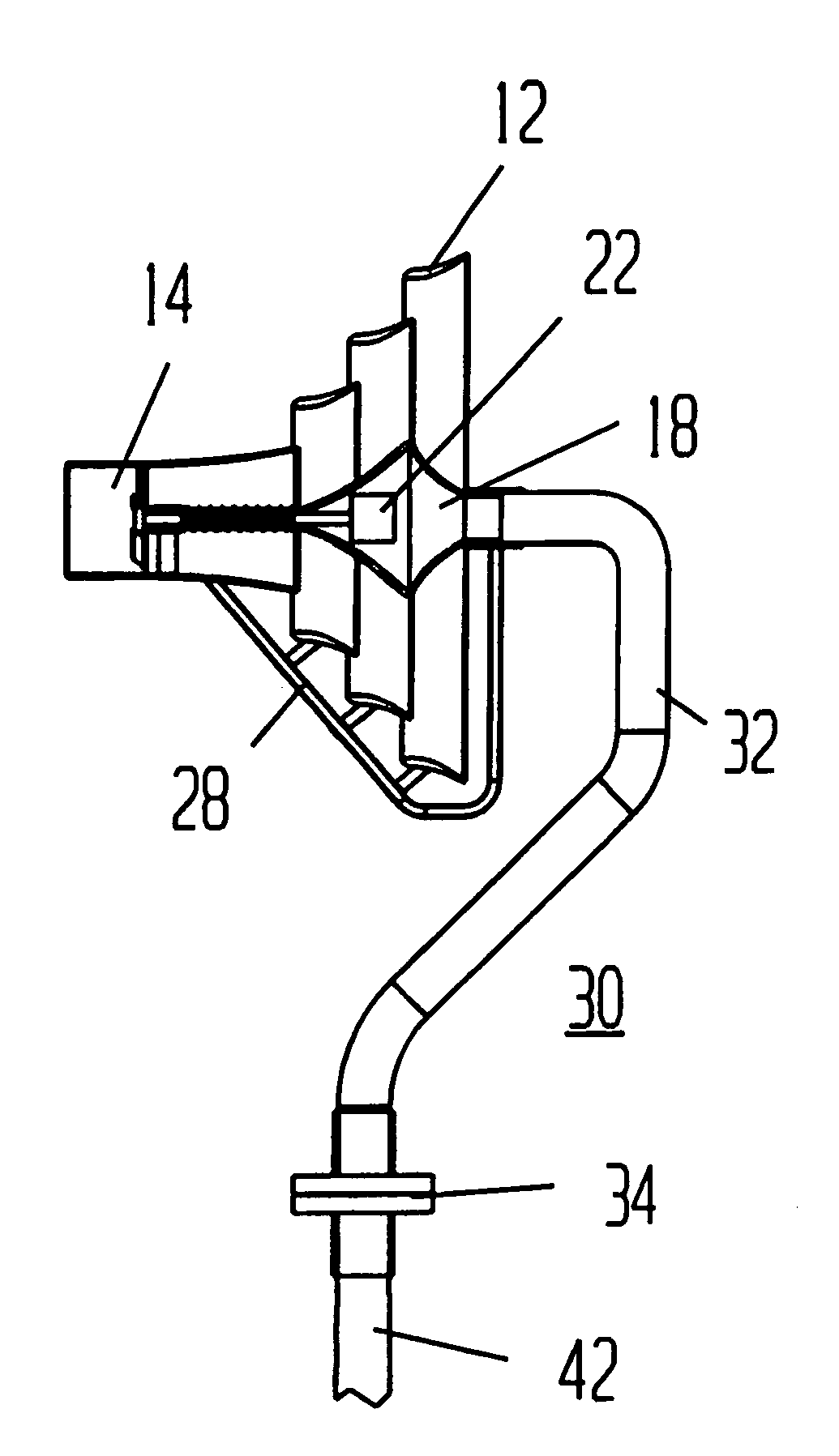

Systems, devices, and methods for measuring blood pressure of a user

ActiveUS20170360306A1Diagnostics using pressureEvaluation of blood vesselsElectricityMonitor blood pressure

The present invention generally relates to blood pressure monitoring. In some embodiments, methods and devices of measuring a mean arterial pressure are provided and / or monitoring blood pressure changes. A wrist-worn device may include a plurality of sensors backed by a plurality of actuators. Subsets of the plurality of sensors may be selectively actuateable against a wrist of a user using one or more of the plurality of actuators. A preferred sensor and location may be identified based on pressure signals received from each of the sensors. In some embodiments, devices may use a fluid bladder coupled with piezoelectric film sensors. A fluid bladder pressure sensor may be used to calibrate the piezoelectric film signal to provide a static and dynamic pressure reading. In yet another embodiment, a mean arterial pressure may be calculated by processing a swept pressure signal obtained as a sensor is swept through different heights.

Owner:APPLE INC

Habitat friendly, multiple impellor, wind energy extraction

A habitat friendly, wind energy system is disclosed for safely extracting usable energy from wind. Included are one or more concentrator wings that convert the dynamic pressure of wind into relatively lower static pressure and thereby induces a vacuum that draws wind into an area defined by the concentrator wings. The airflow regulation minimizes or prevents the stalling of, or the generation of a turbulent flow of wind over or between concentrator wings. Further included are multiple impellors, at least one power converter, a riser supporting these component pieces, all positioned within the area defined by the concentrator wings. Accordingly, one or more flow regulators are positioned to assist in promoting laminar flow across or between the concentrator wings and to reduce the dynamic pressure of wind on the riser to thereby increase efficiency of the system.

Owner:TOCHER ANGUS J

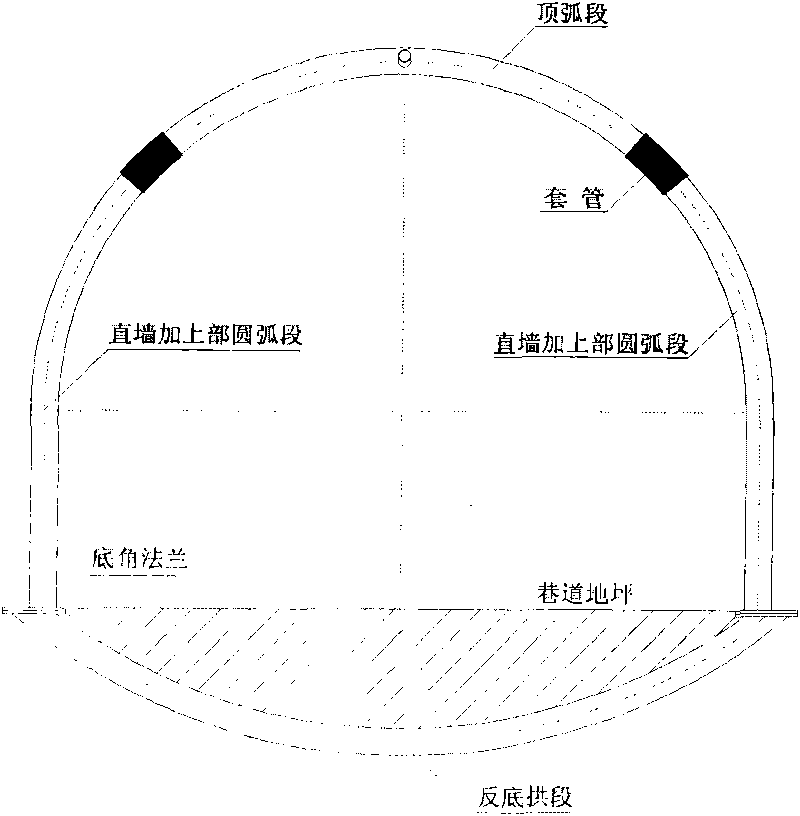

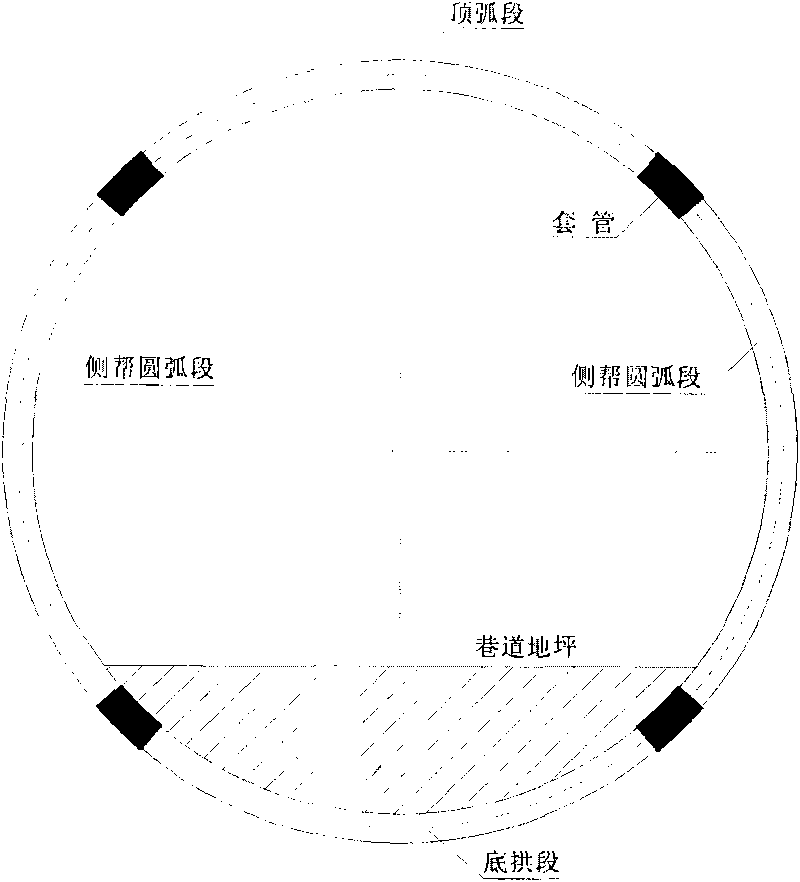

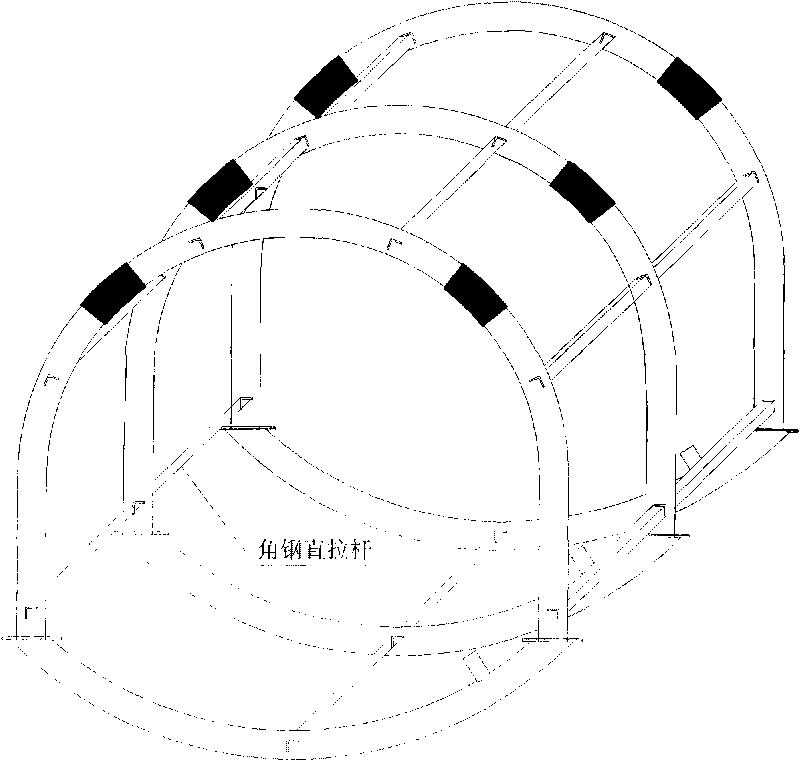

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

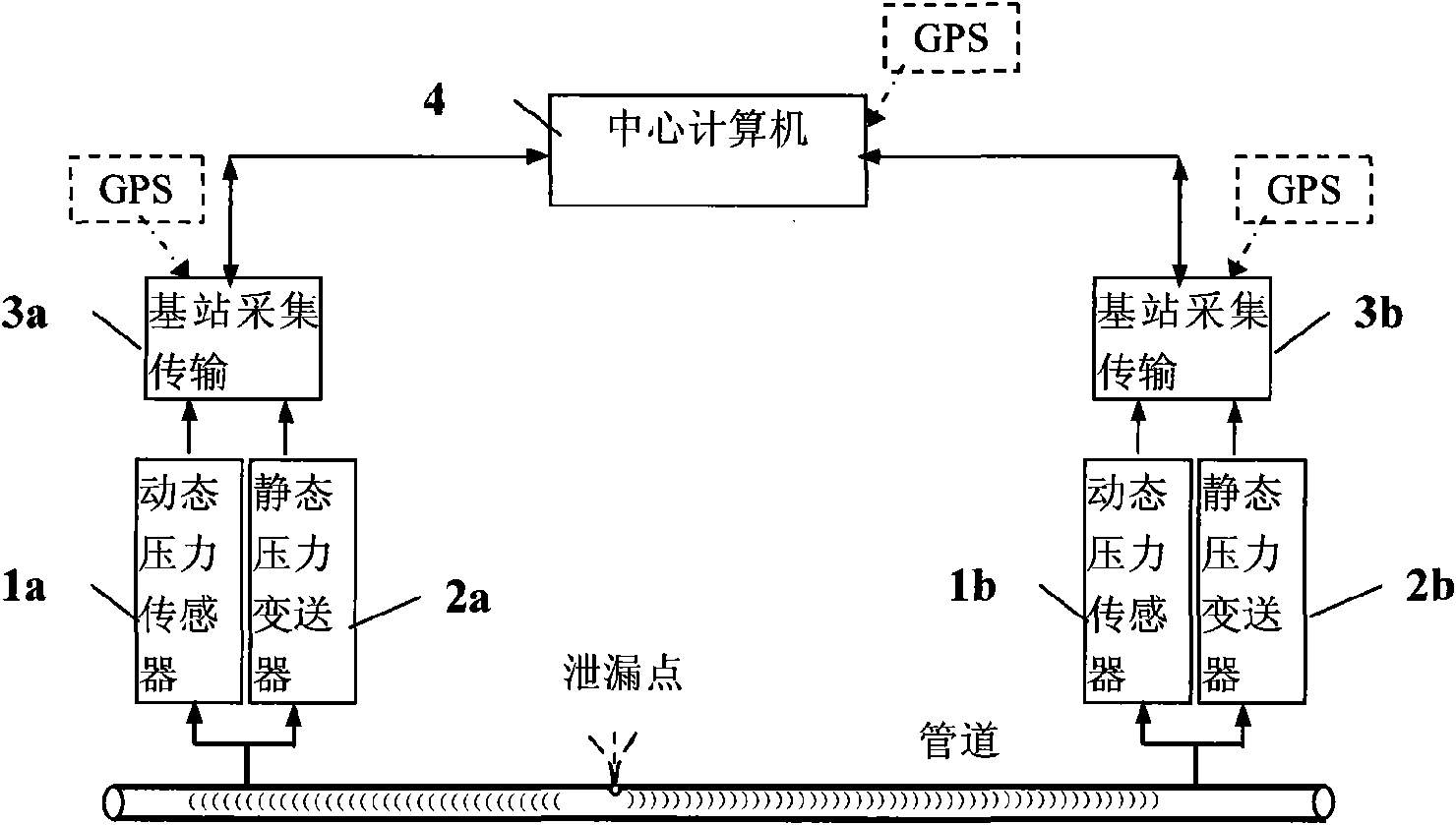

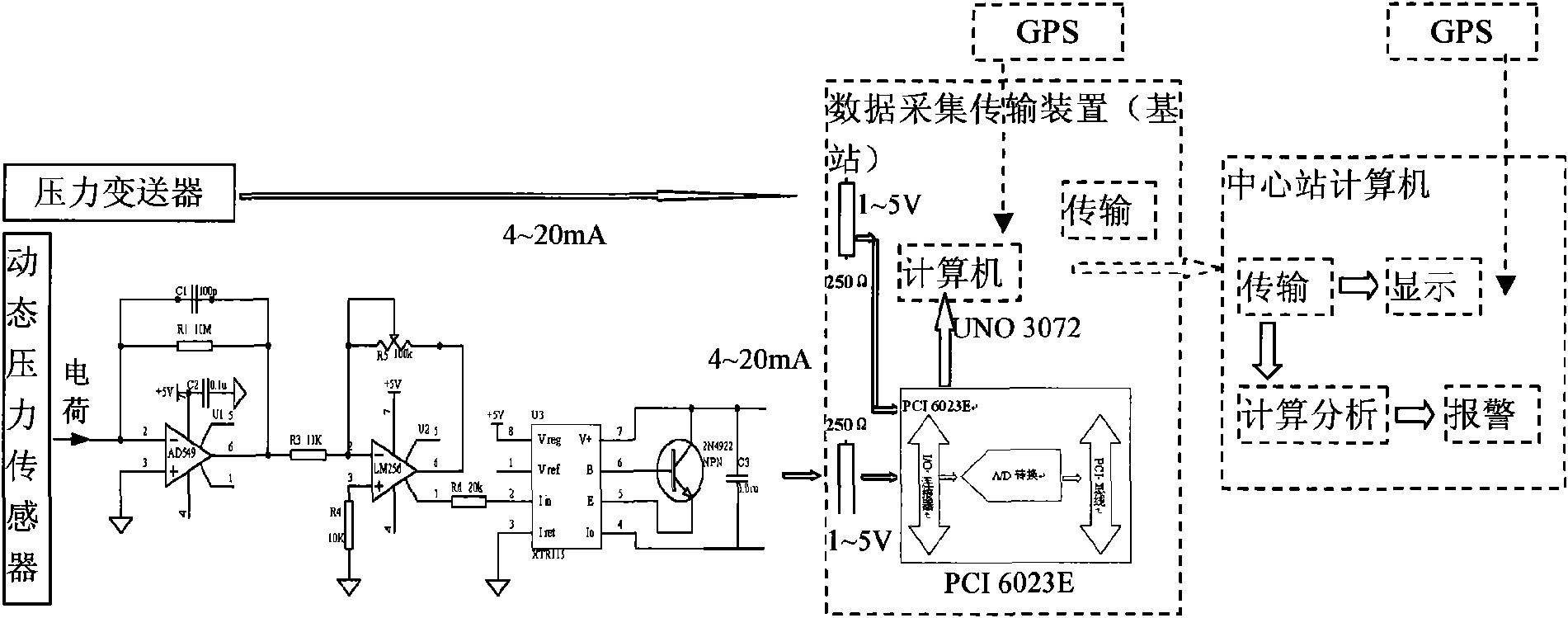

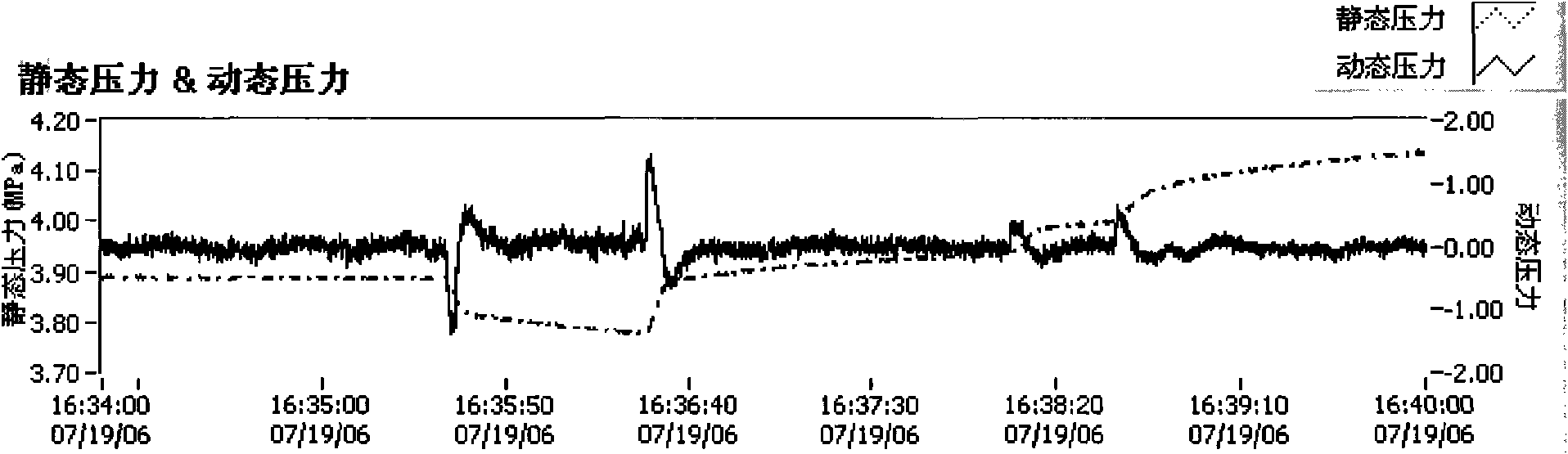

Method and device for monitoring pipeline leakage

The invention provides a method and a device for monitoring pipeline leakage, and relates to the technical field of acoustic wave measurement, flow pressure measurement and pipeline systems. A set ofdynamic pressure sensors (1a) and (1b) and a set of static pressure sensors (2a) and (2b) are respectively arranged at the head end and the tail end of a pipeline respectively; acoustic wave signals measured by the dynamic pressure sensor (1a) and (1b) and the static pressure sensor (2a) and (2b) are processed by data acquisition devices (3a) and (3b) respectively so as to take leakage signals out; a global position system GPS is adopted to determine the time that the leakage acoustic wave signals are transmitted to two ends of a monitored pipeline section; and leakage points can be positionedby adding and subtracting the sampled time and then multiplying the propagation velocity of the acoustic waves in a medium. The method and the device can reliably and accurately judge the leakage happened in the pipeline, improve the monitoring sensitivity, and have high response speed and high positioning precision.

Owner:PIPECHINA SOUTH CHINA CO

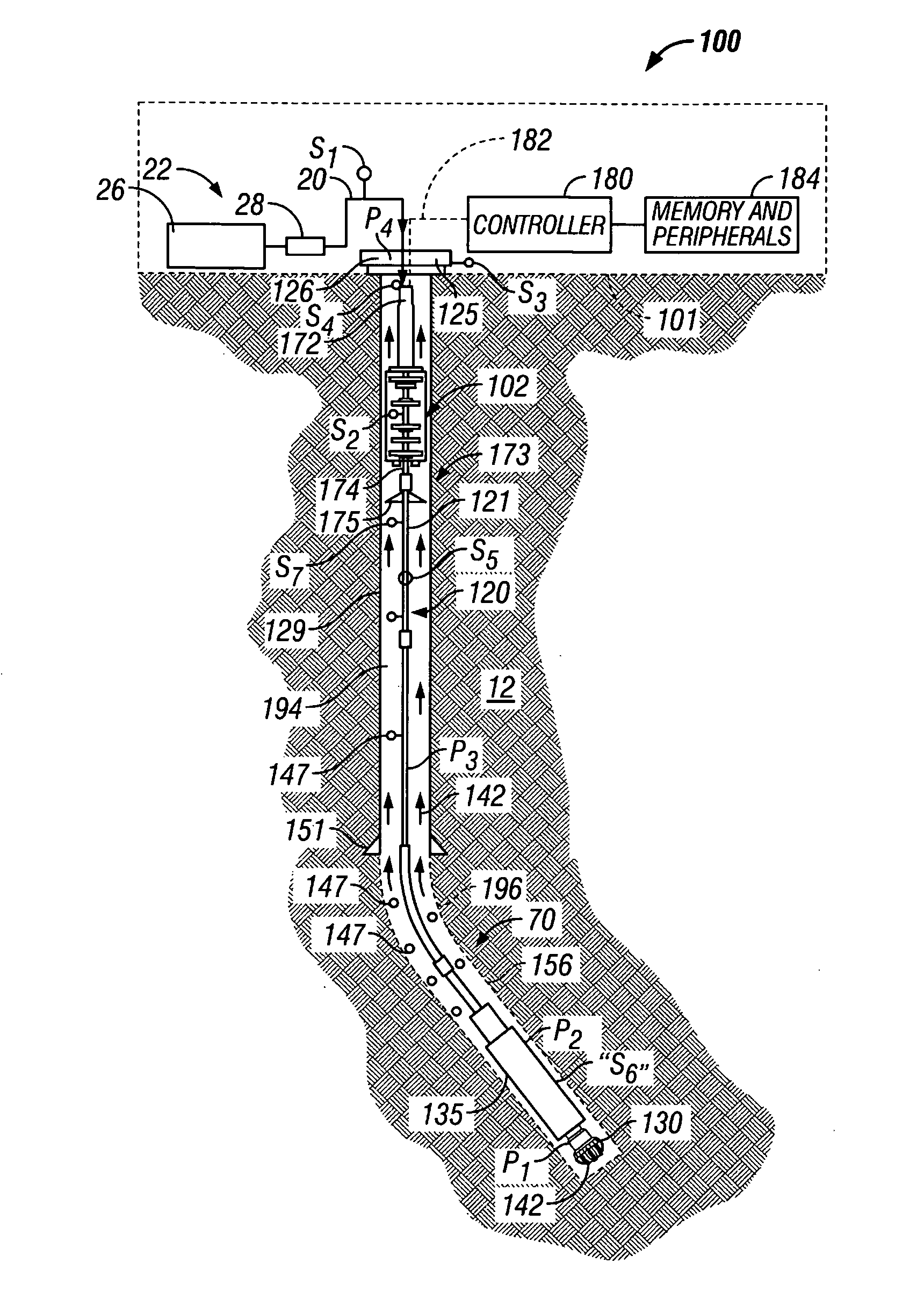

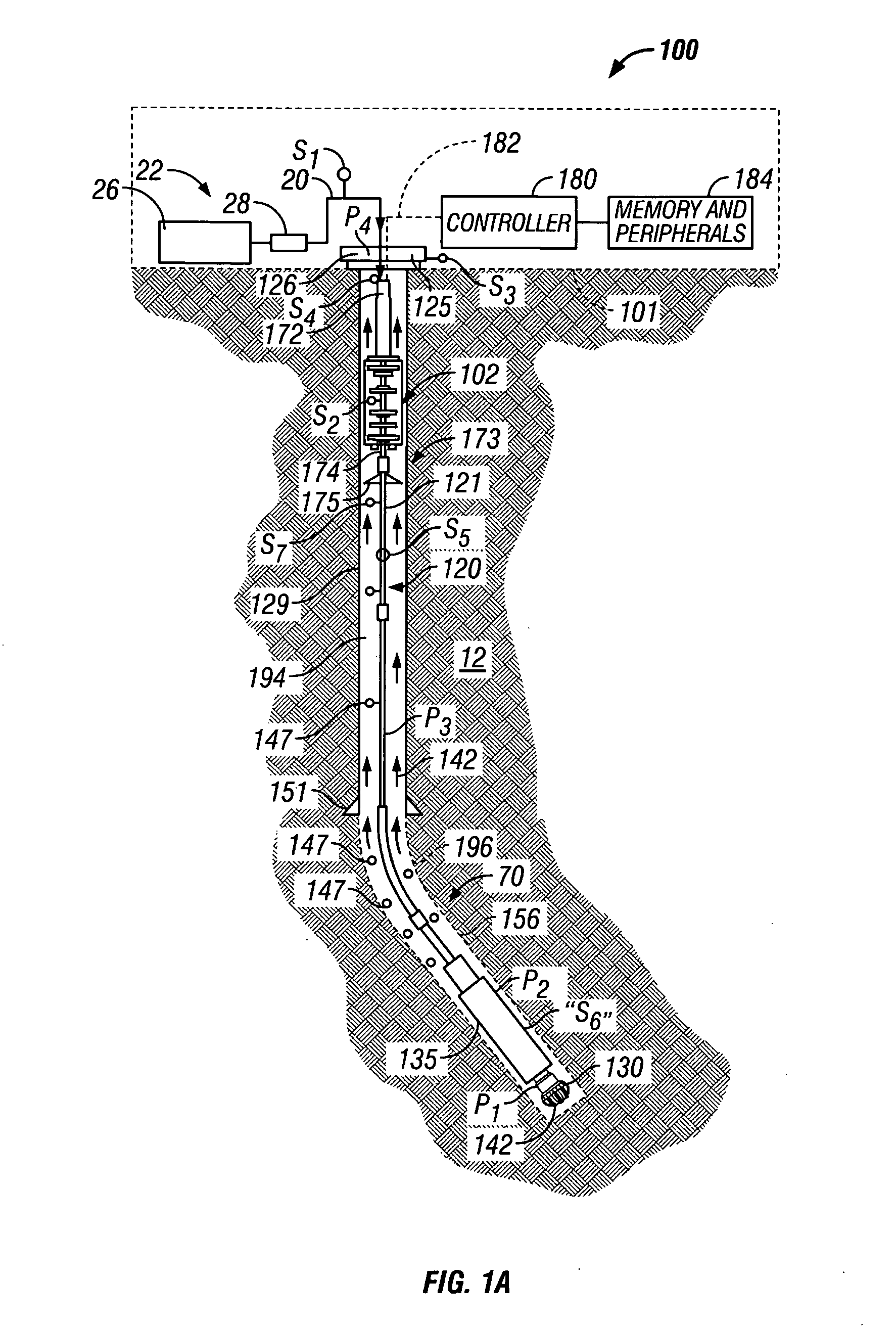

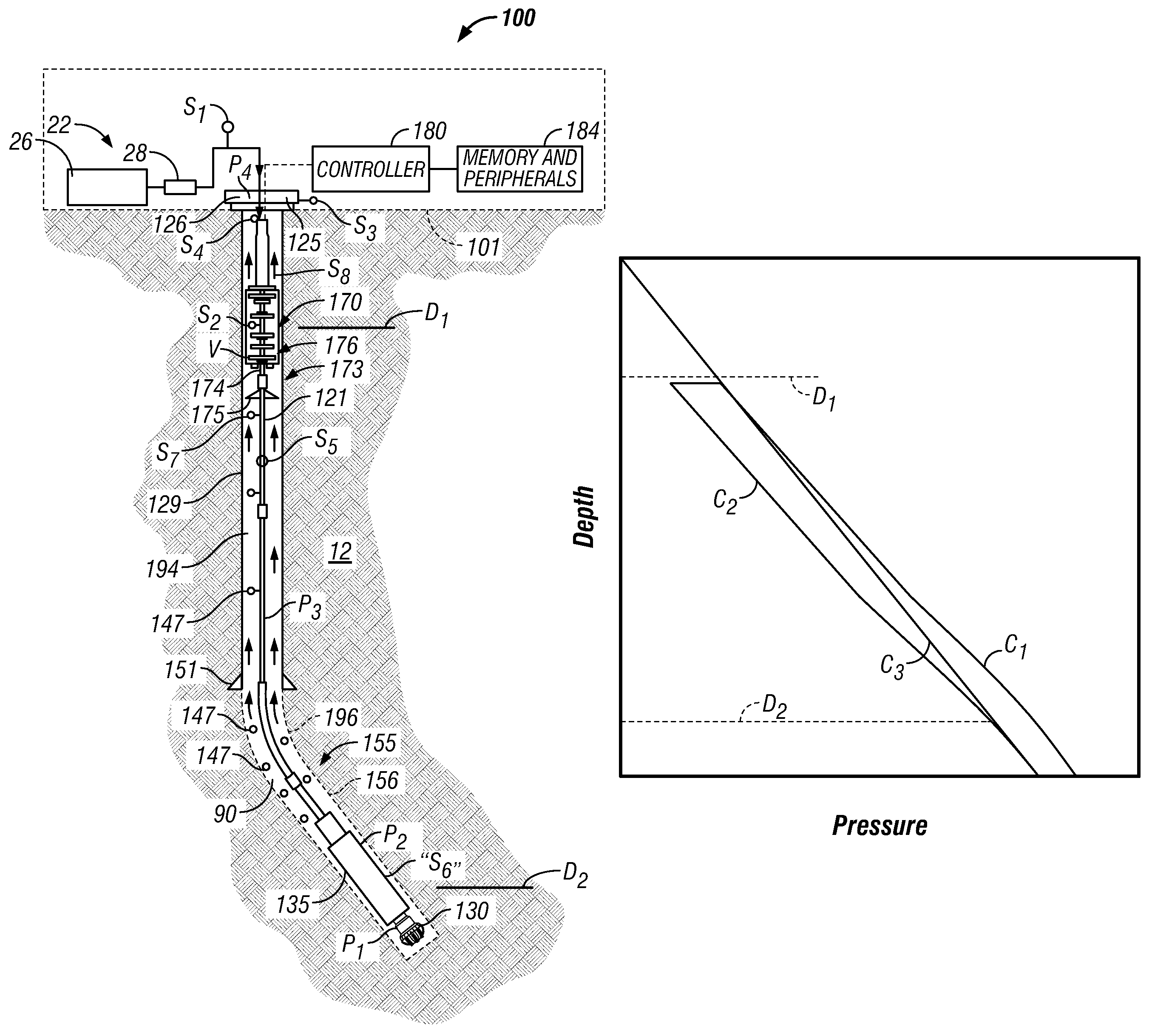

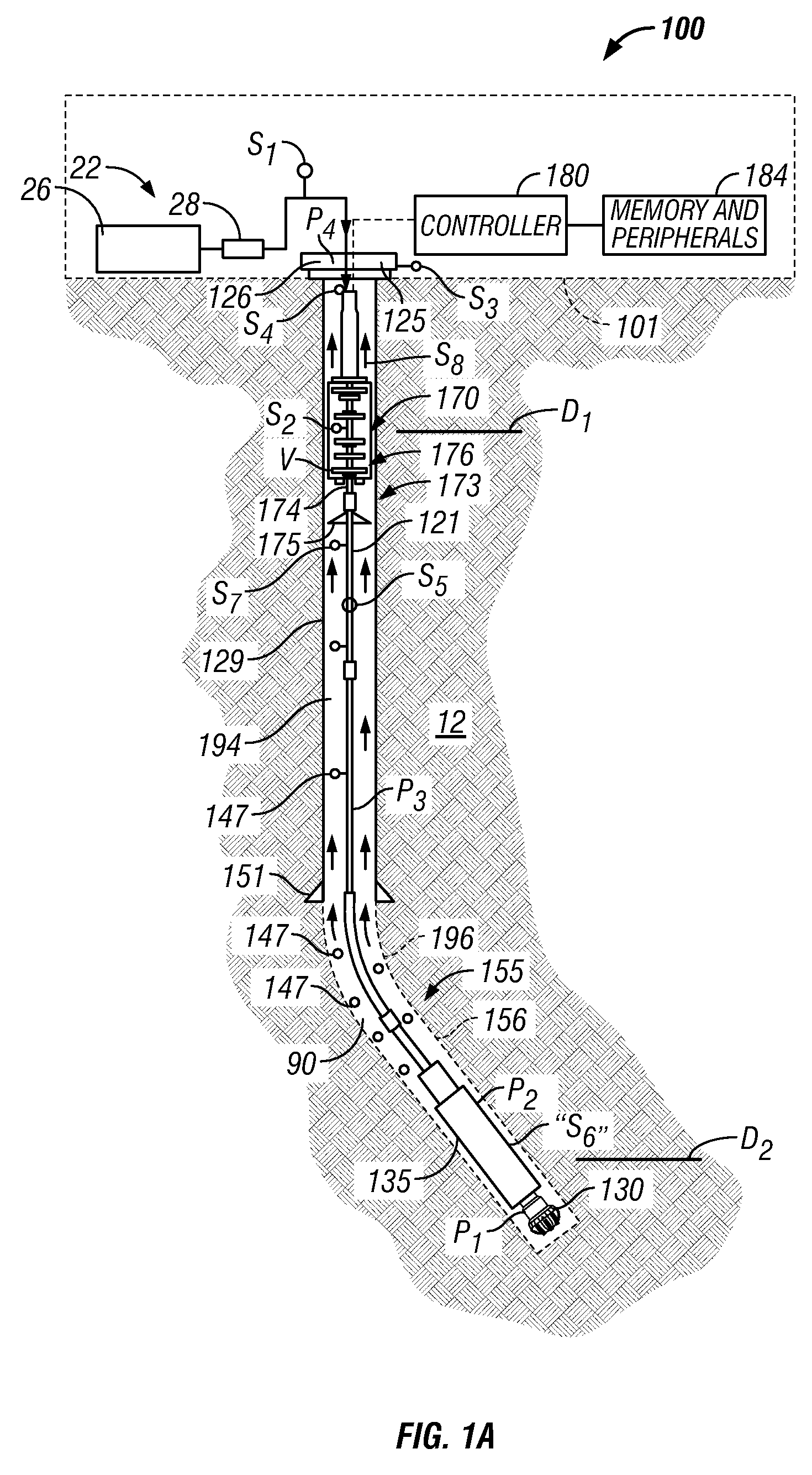

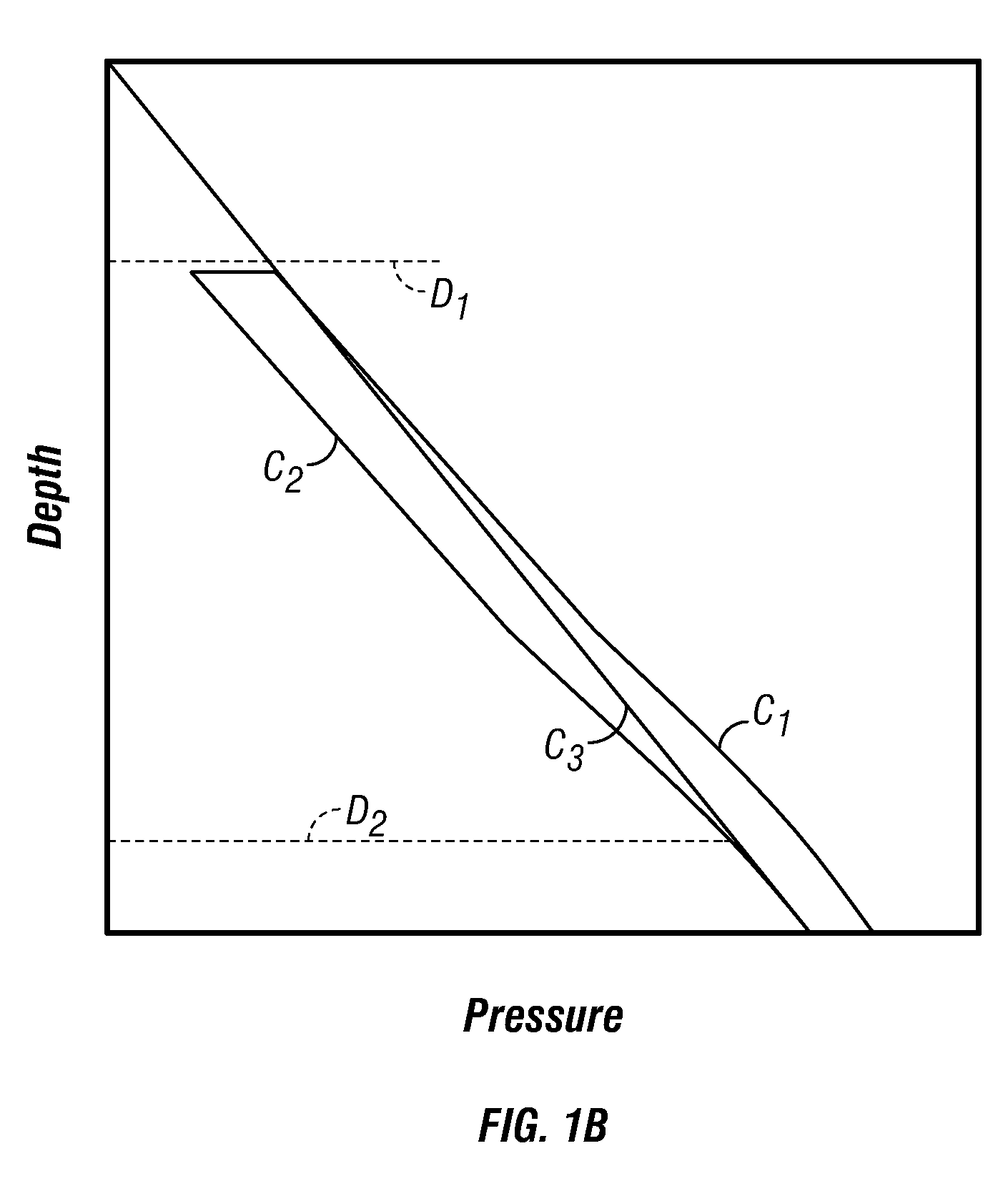

Active buttonhole pressure control with liner drilling and completion systems

InactiveUS20070068704A1Increase pressureEliminate needDrilling rodsBorehole drivesWell drillingEngineering

One exemplary APD Device is used with a liner drilling assembly to control wellbore pressure. The APD Device reduces a dynamic pressure loss associated with the drilling fluid returning via a wellbore annulus. Another exemplary APD Device is used to control pressure in a wellbore when deploying wellbore equipment, including running, installing and / or operating wellbore tools. The APD Device is set to reduce a dynamic pressure loss associated with a circulating fluid. The APD Device can also be configured to reduce a surge effect associated with the running of the wellbore equipment. Still another APD Device is used to control pressure in a wellbore when completing or working over a well. Exemplary completion activity can include circulating fluid other than a drilling fluid, such as a gravel slurry. The APD Device can reduce the dynamic pressure loss associated with circulation of both drilling fluid and non-drilling fluid.

Owner:BAKER HUGHES INC

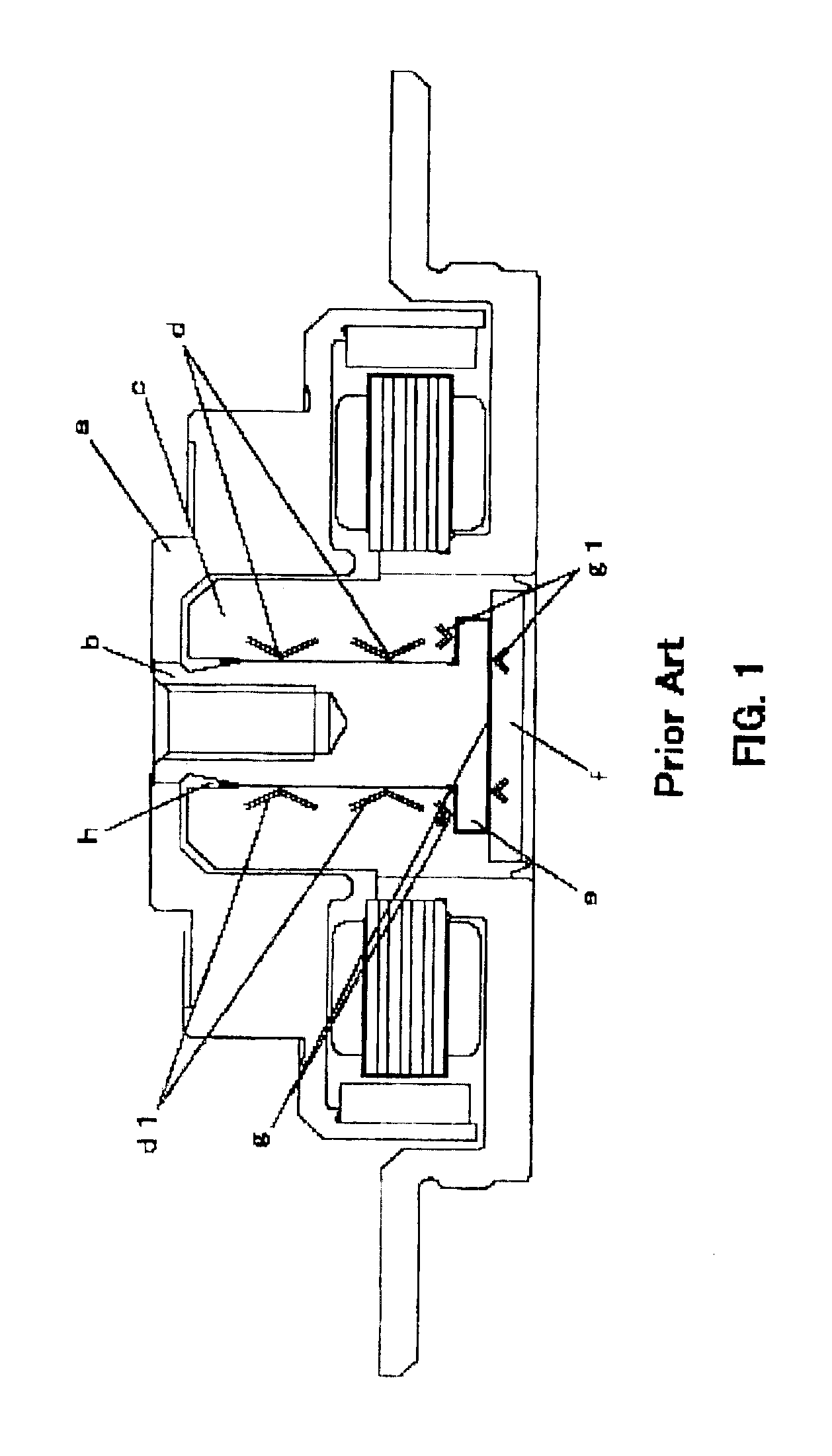

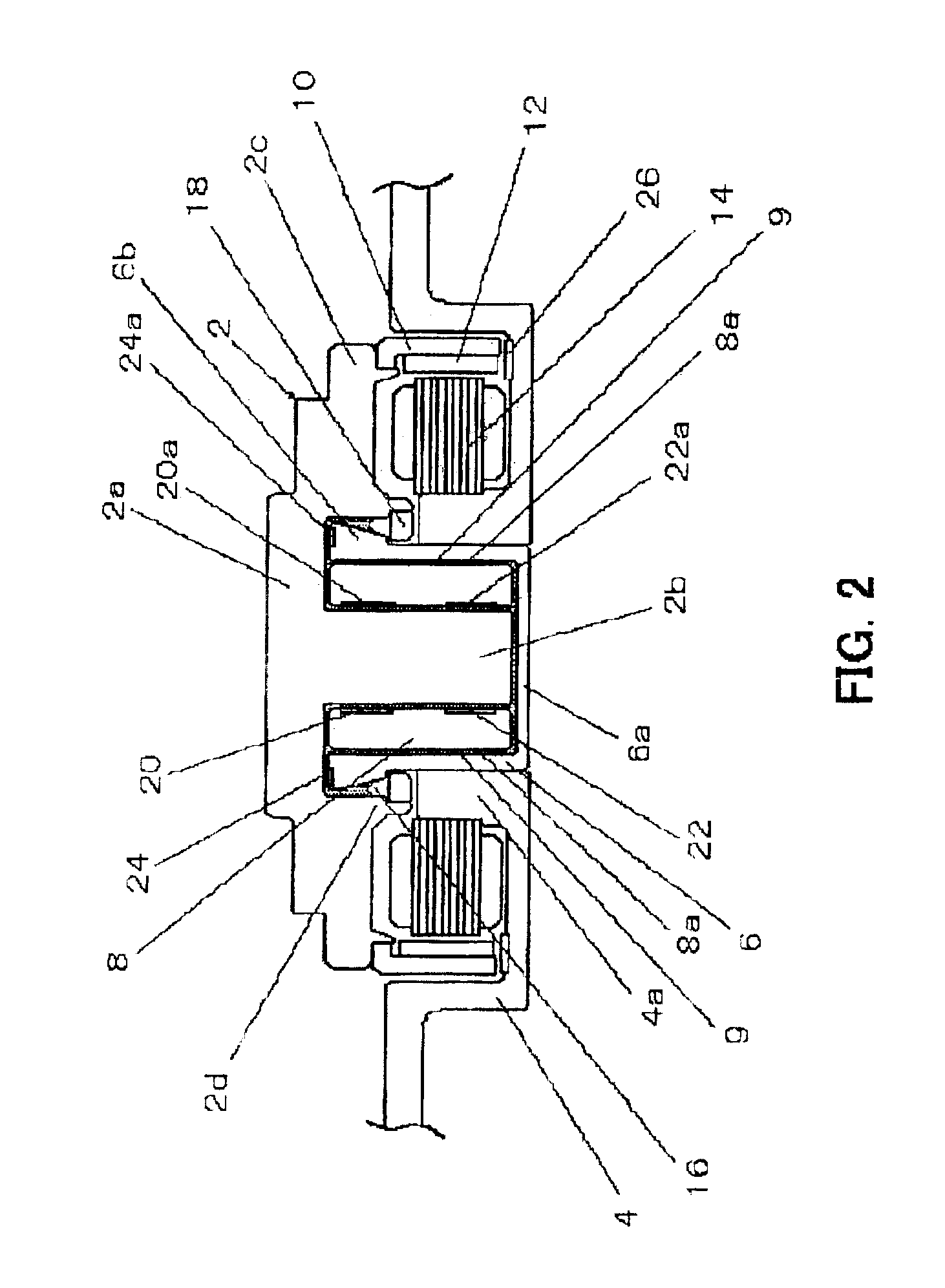

Hydrodynamic bearing device, spindle motor including the same, and recording and reproducing apparatus

A cylindrical sleeve is rotatably fitted over a fixed shaft erected on a base, the sleeve including an outer collar part at an outer periphery of the lower end portion thereof, a slip-out preventing member for preventing the slip-out from the fixed shaft while allowing the sleeve to rotate is provided on the base, the slip-out preventing member including an inner collar part that engages with the outer collar part in the slip-out direction. A hub is provided on the upper end portion of the sleeve, a pair of upper and lower radial bearings formed with a dynamic pressure generating groove are provided on the inner peripheral surface of the sleeve, and a thrust bearing formed with a dynamic pressure generating groove is provided at the lower end face of the sleeve.

Owner:PANASONIC CORP

Active combustion control system for gas turbine engines

InactiveUS7775052B2Fuel supply regulationContinuous combustion chamberCombustion chamberElectronic controller

Owner:ROSEMOUNT AEROSPACE

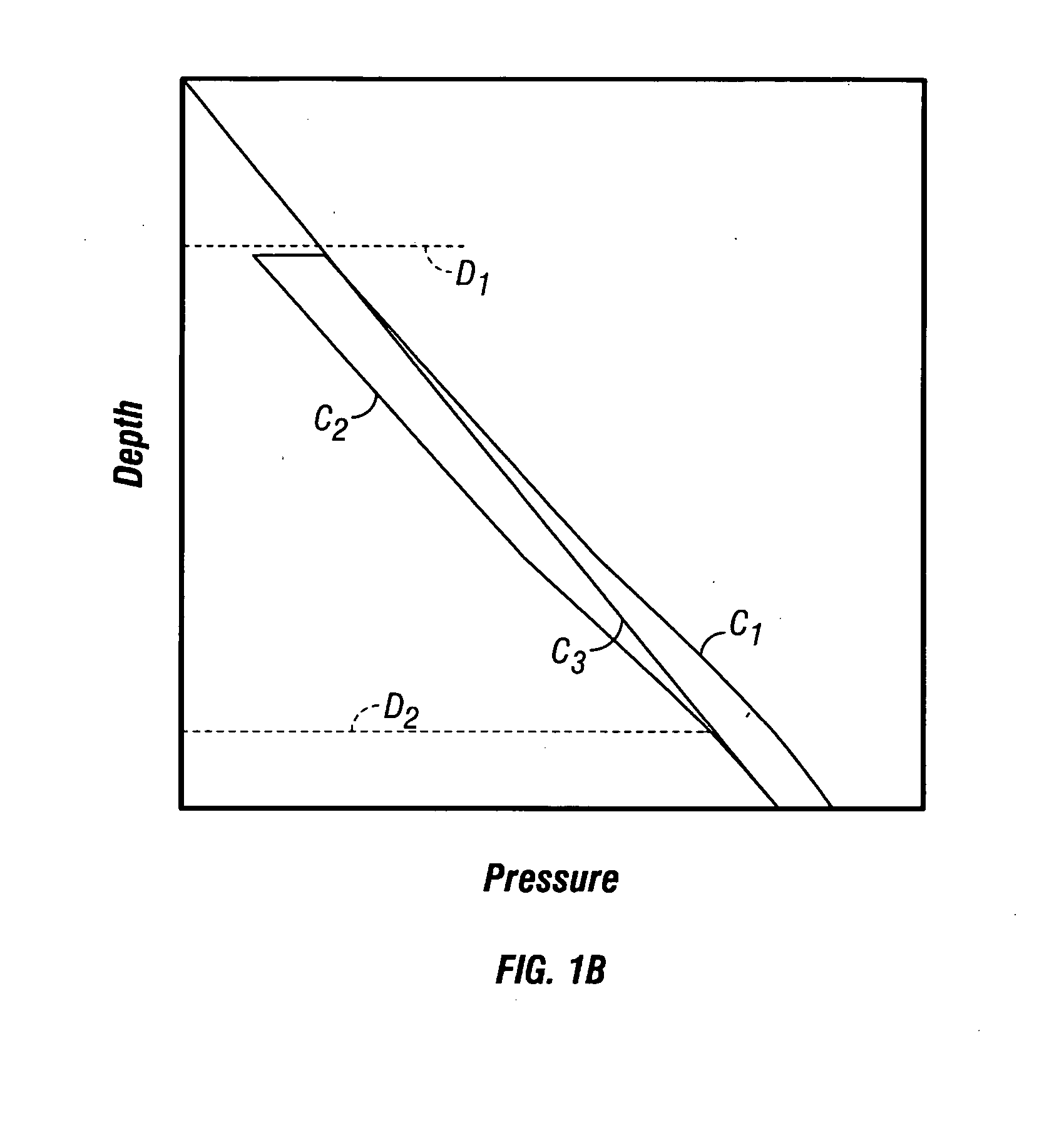

Active controlled bottomhole pressure system and method with continuous circulation system

An APD Device provides a pressure differential in a wellbore to control dynamic pressure loss while drilling fluid is continuously circulated in the wellbore. A continuous circulation system circulates fluid both during drilling of the wellbore and when the drilling is stopped. Operating the APD Device allows wellbore pressure control during continuous circulation without substantially changing density of the fluid. The APD Device can maintain wellbore pressure below the combined pressure caused by weight of the fluid and pressure losses created due to circulation of the fluid in the wellbore, maintain the wellbore at or near a balanced pressure condition, maintain the wellbore at an underbalanced condition, reduce the swab effect in the wellbore, and / or reduce the surge effect in the wellbore. A flow restriction device that creates a backpressure in the wellbore annulus provides surface control of wellbore pressure.

Owner:BAKER HUGHES HLDG LLC

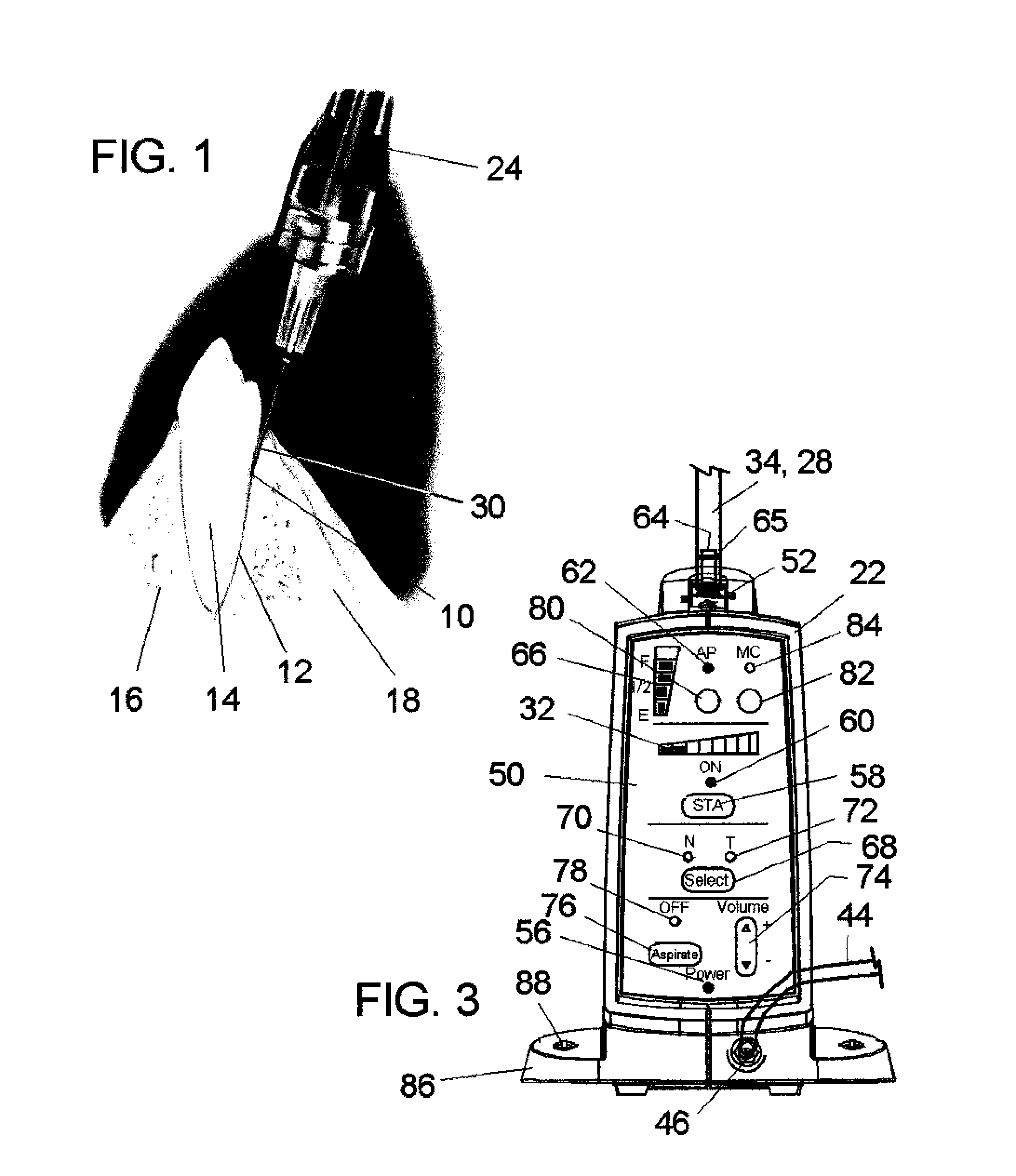

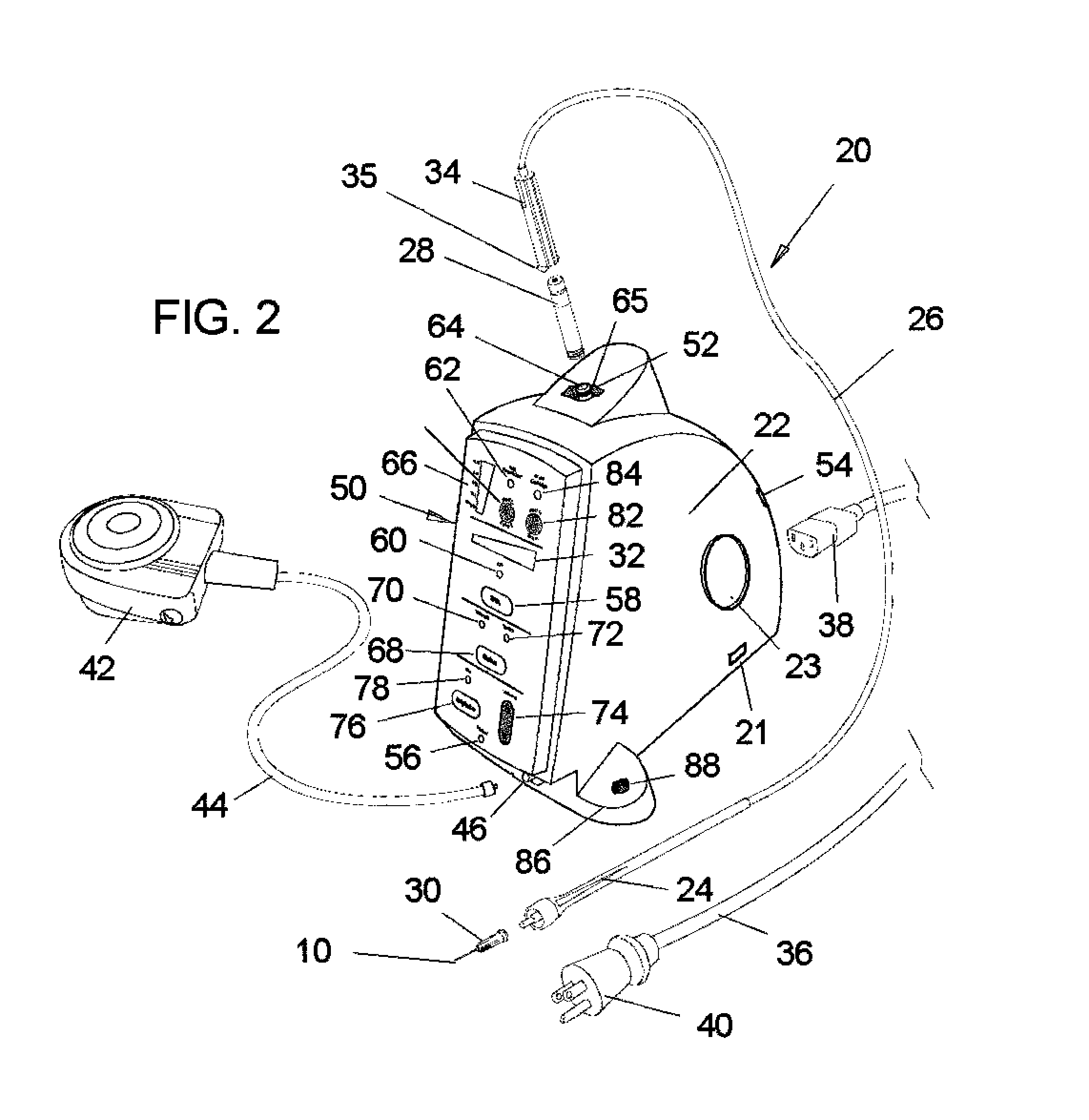

Computer controlled drug delivery system with dynamic pressure sensing

ActiveUS20080154188A1Reliably perform single tooth anesthesiaHigh pressureAmpoule syringesMedical devicesSurgeryVisual perception

An apparatus and method for a controlled injection of a drug into a selected tissue of a subject by a practitioner, uses a drive unit for supplying the drug and a handpiece to be held and guided by the practitioner, connected to the drive unit for receiving the drug. The handpiece holds an injection needle to be inserted into the selected tissue by the practitioner for passing the drug to the selected tissue at an instantaneous and absolute pressure that varies as a function of the type of tissue and the placement of the needle. A pressure sensor senses this instantaneous pressure and a feedback mechanism supplies a perceptible audible, visual or other signal to the practitioner that indicates when the instantaneous pressure has reached a minimum desired pressure, the practitioner thus being informed that the correct placement and dosage has been attained.

Owner:MILESTONE SCIENTIFIC INC

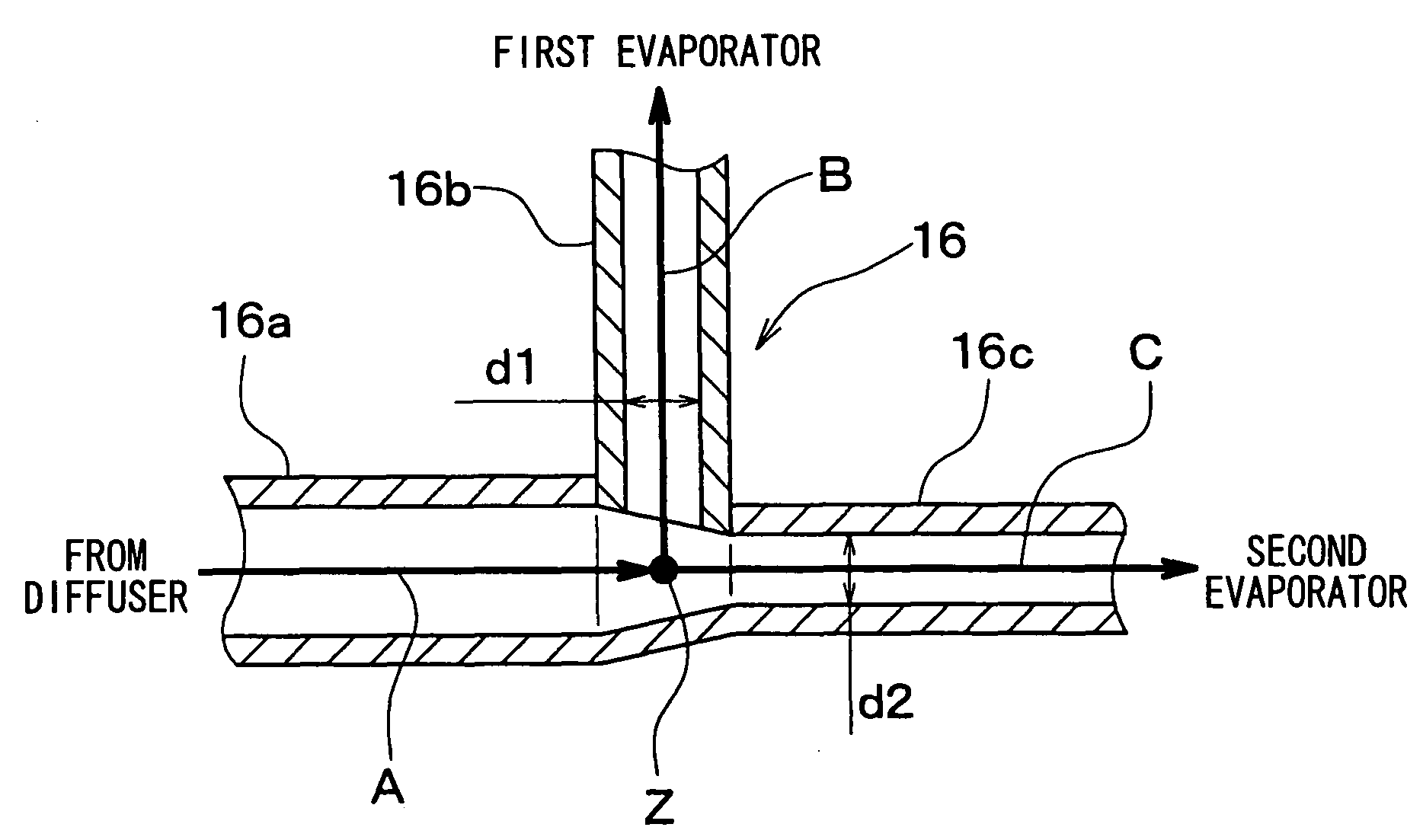

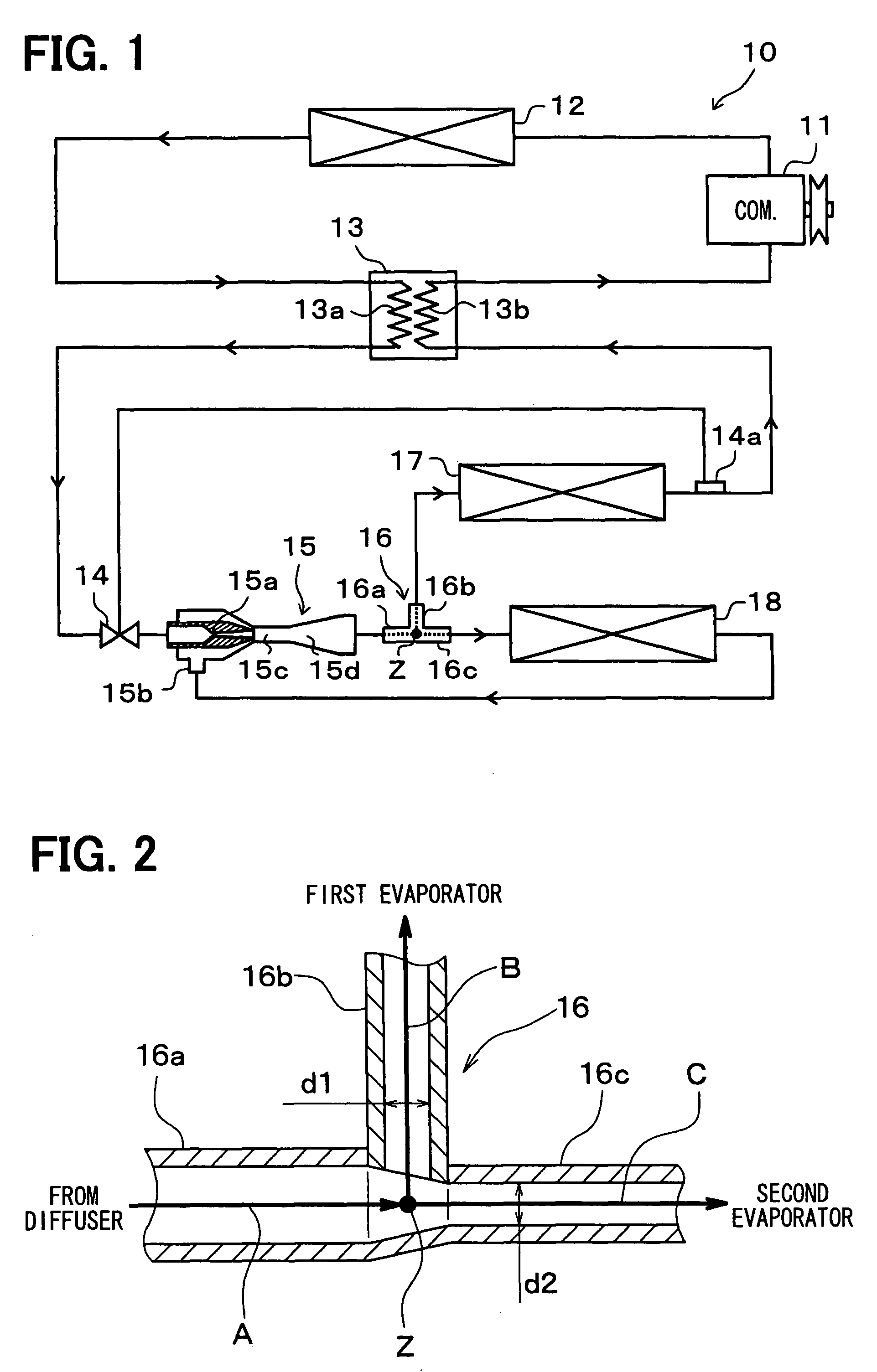

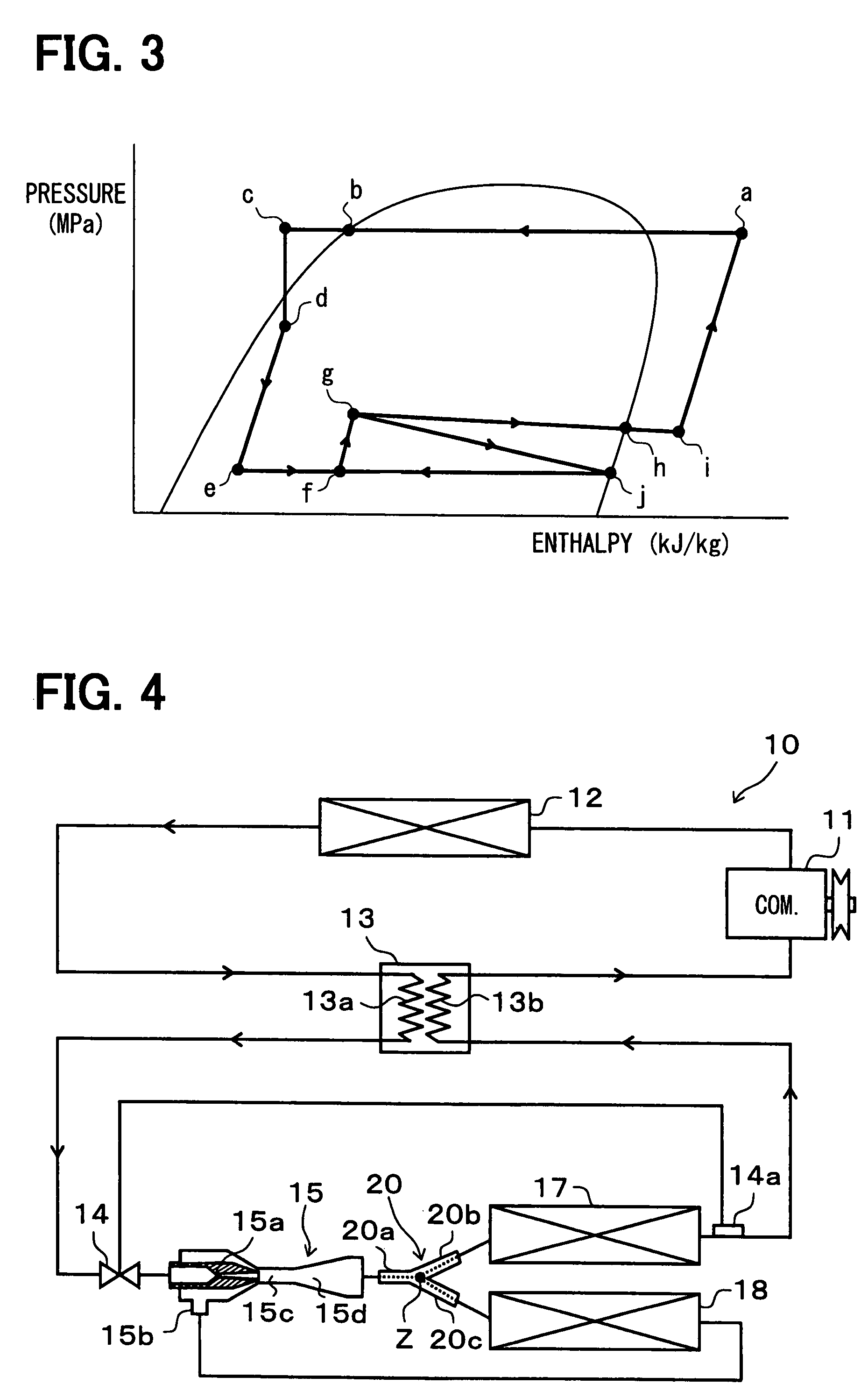

Refrigerant cycle device

InactiveUS7823401B2Improve cooling effectEfficient use ofCompression machines with non-reversible cycleEvaporators/condensersRefrigerantDynamic pressure

In a refrigerant cycle device having an ejector, a branch portion for branching a flow of refrigerant flowing out of the ejector into at least a first refrigerant stream and a second refrigerant stream is located. A first evaporator for evaporating the refrigerant of the first refrigerant stream is located to allow the refrigerant to flow to a suction side of the compressor, and a second evaporator for evaporating the refrigerant of the second refrigerant stream is located to allow the refrigerant to flow to an upstream side of a refrigerant suction port of the ejector. In addition, the branch portion is located to maintain a dynamic pressure of the refrigerant flowing out of the ejector, and the second evaporator is connected to the branch portion in a range where the dynamic pressure can be applied to an inside of the second evaporator.

Owner:DENSO CORP

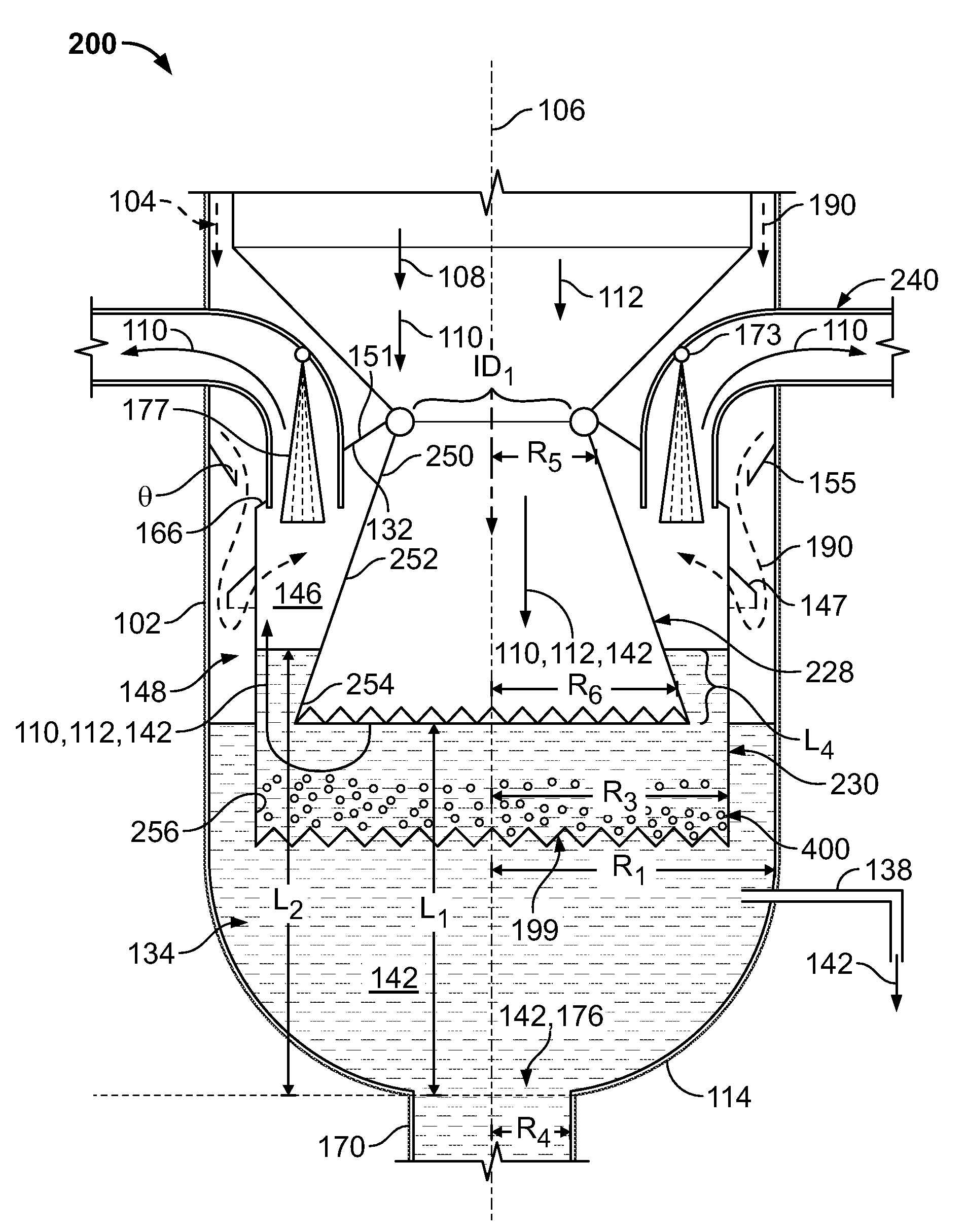

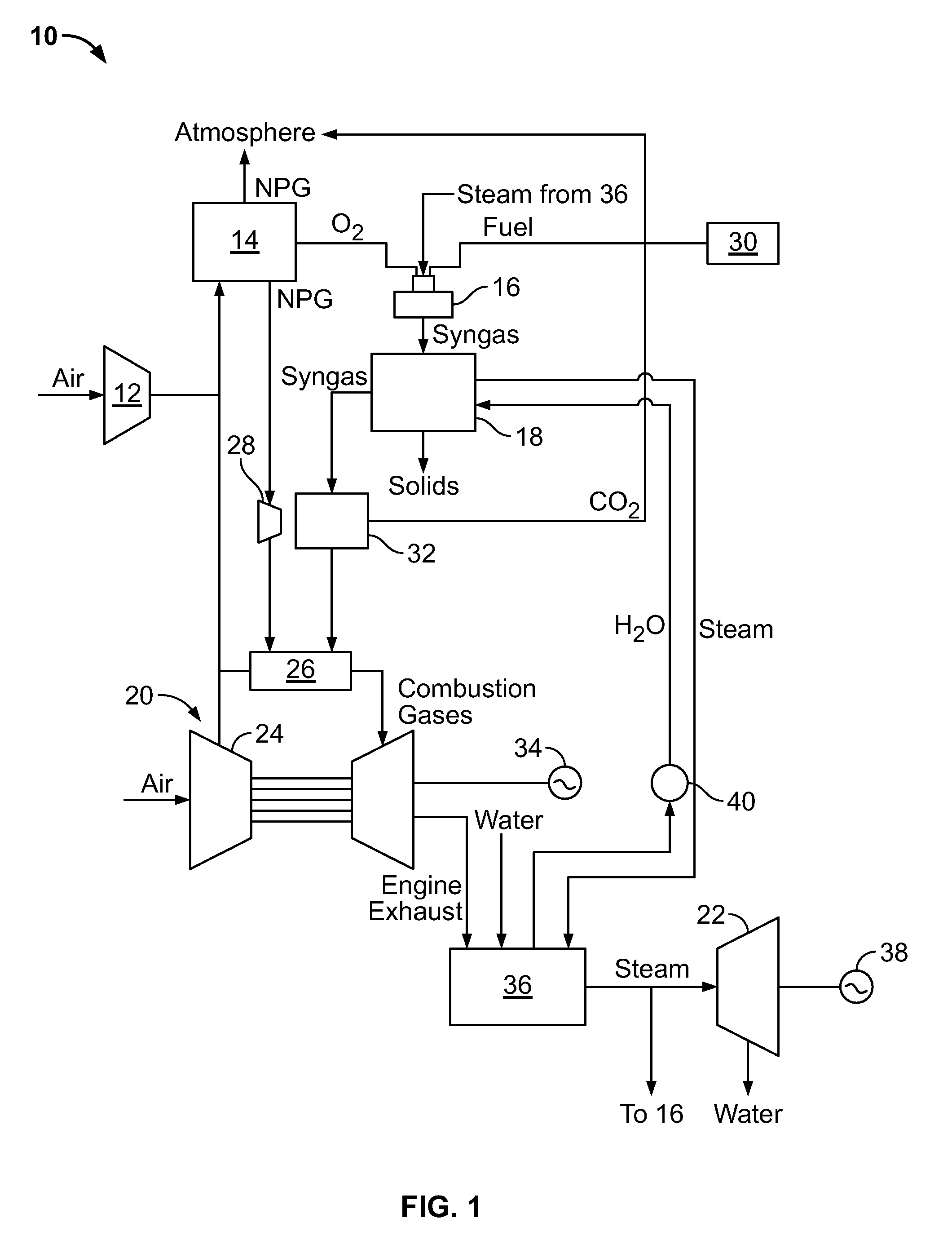

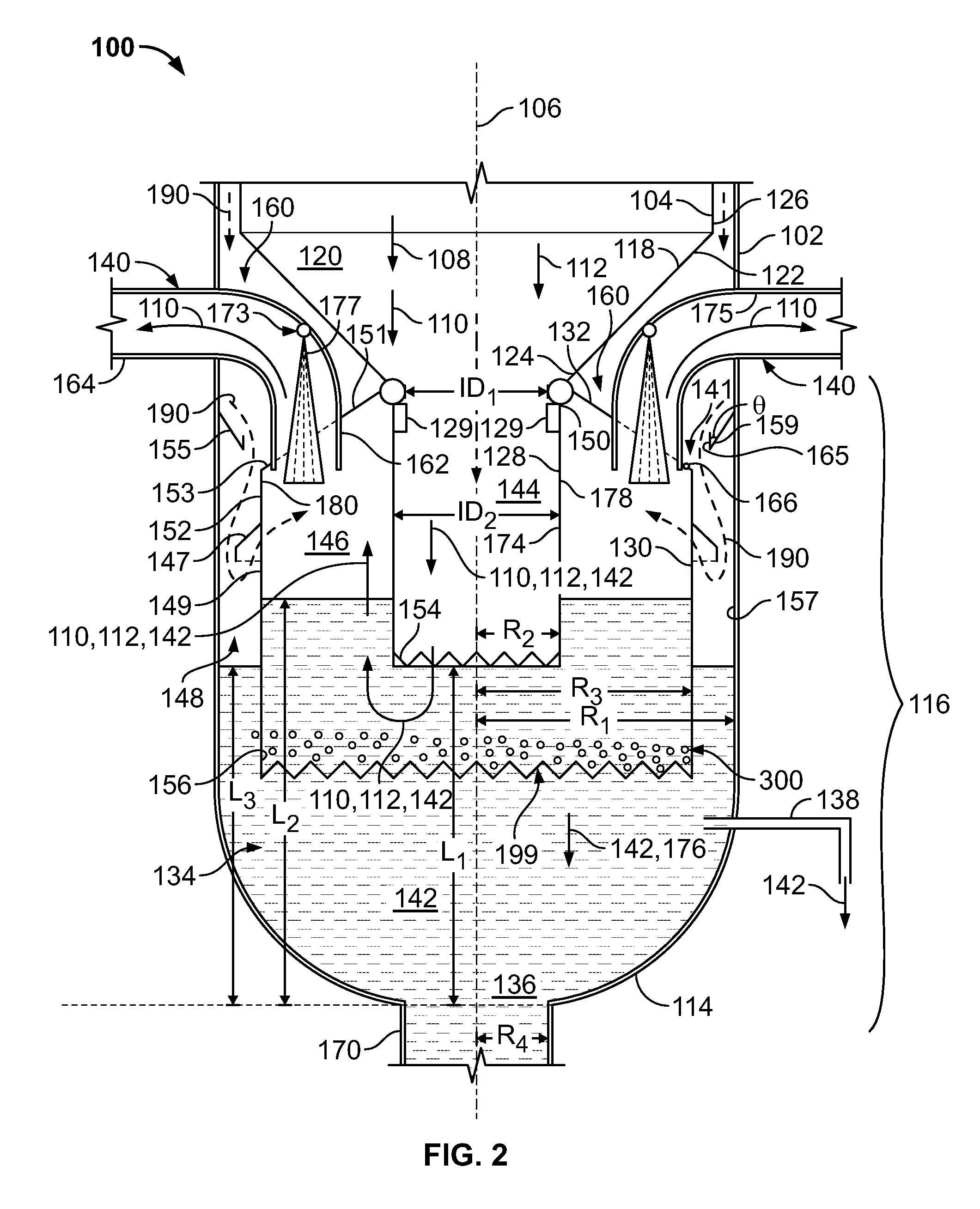

Method and apparatus for cooling syngas within a gasifier system

A method of assembling a synthesis gas (syngas) cooler for a gasification system includes positioning a dip tube within a shell of the syngas cooler. The dip tube is configured to quench the syngas flowing through the shell and / or at least partially channel the syngas through the dip tube. The method also includes coupling an isolation tube to the dip tube such that the isolation tube is substantially concentrically aligned with, and radially outward of, the dip tube. The isolation tube is coupled in flow communication with a purge gas source and is configured to at least partially form a dynamic pressure seal. The method further includes coupling at least one of the isolation tube and the dip tube in fluid communication with a fluid retention chamber. The method also include at least partially filling the fluid retention chamber with fluid, thereby further forming the dynamic pressure seal.

Owner:AIR PROD & CHEM INC

Spindle motor and disk drive furnished therewith

ActiveUS6914358B2Avoid Bubble ProblemsShaftsRecord information storageInternal pressureAtmospheric air

In a spindle motor utilizing dynamic-pressure bearings having a full-fill structure, a bearing configuration that balances and sustains at or above atmospheric pressure the internal pressure of the bearing oil. Thrust and radial bearing sections are configured within oil-filled bearing clearances in between the rotor, the shaft, and a shaft-encompassing hollow bearing member. A communicating passage one end of which opens on, radially inwardly along, the thrust bearing section is formed in the bearing member. Either axial ends of the bearing clearance in between the bearing member and shaft communicate through the passage. The communicating passage enables the oil to redistribute itself within the bearing clearances. Pressure difference between the axial upper and lower ends of the oil retained in between the bearing member and the shaft is compensated through the communicating passage, preventing incidents of negative pressure within the oil and of over-lift on the rotor.

Owner:NIPPON DENSAN CORP

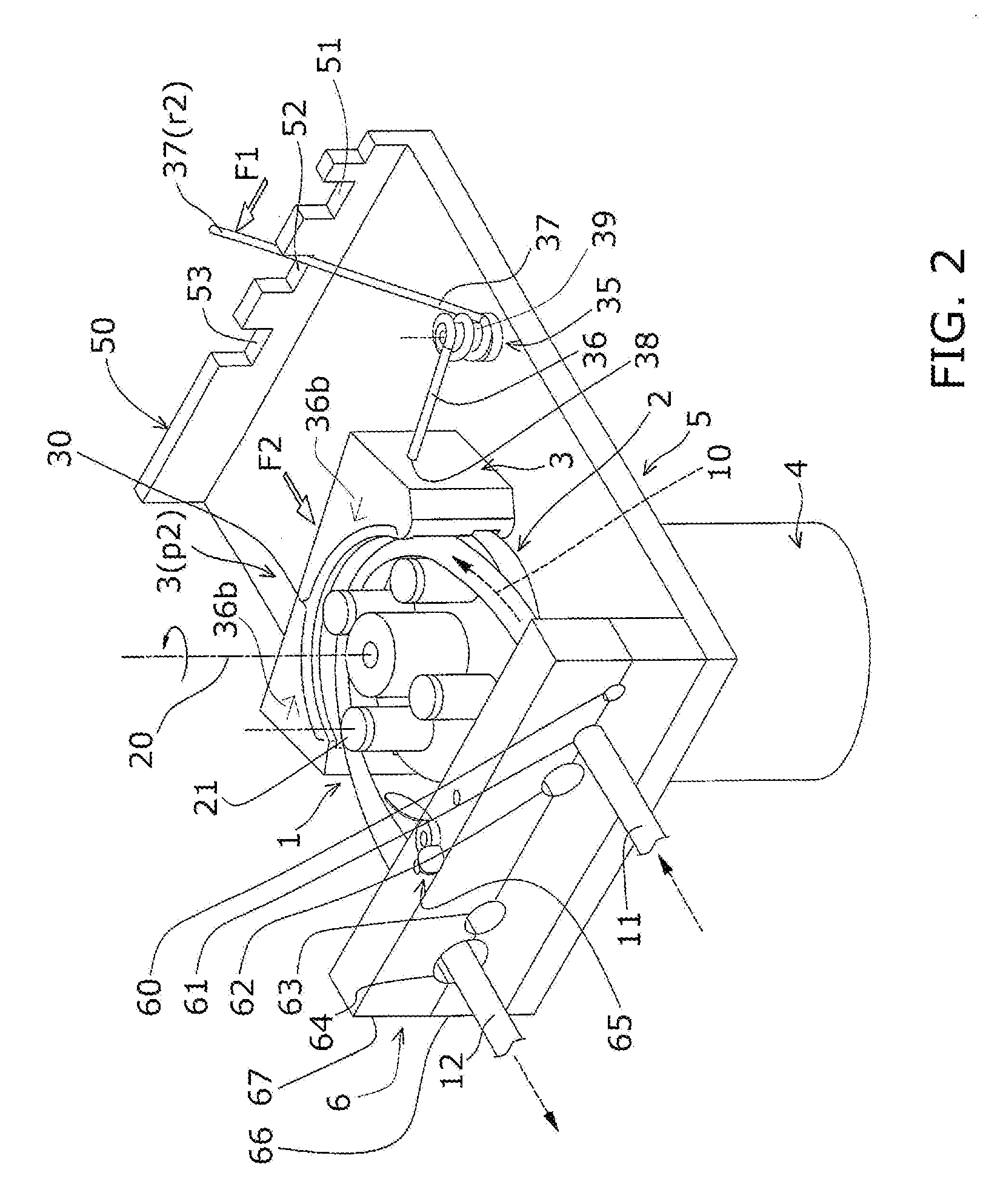

Tube loading assembly for peristaltic pump

ActiveUS20100129248A1Simplify mechanical designEasy to operateFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

Owner:MOU DUEN GANG

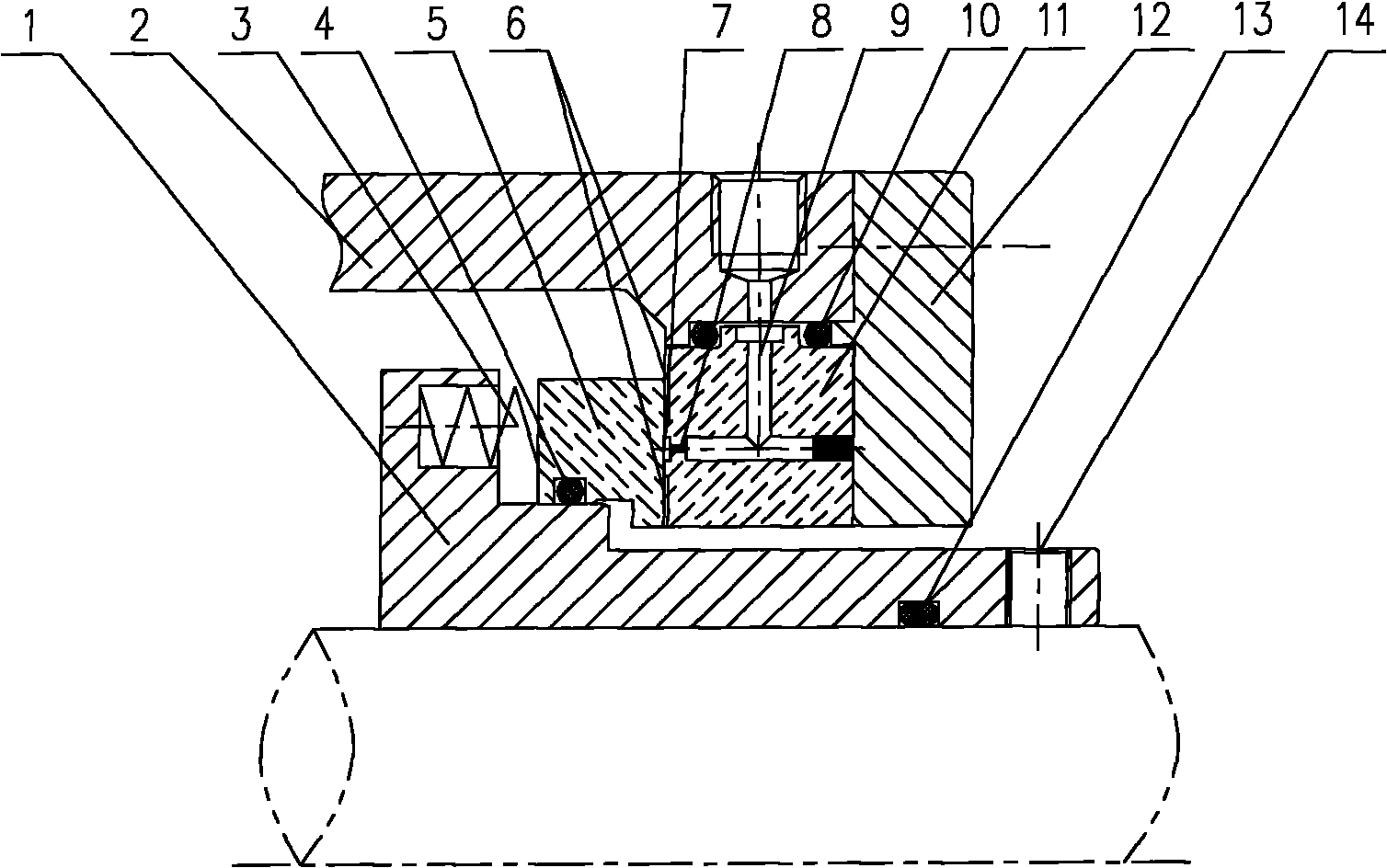

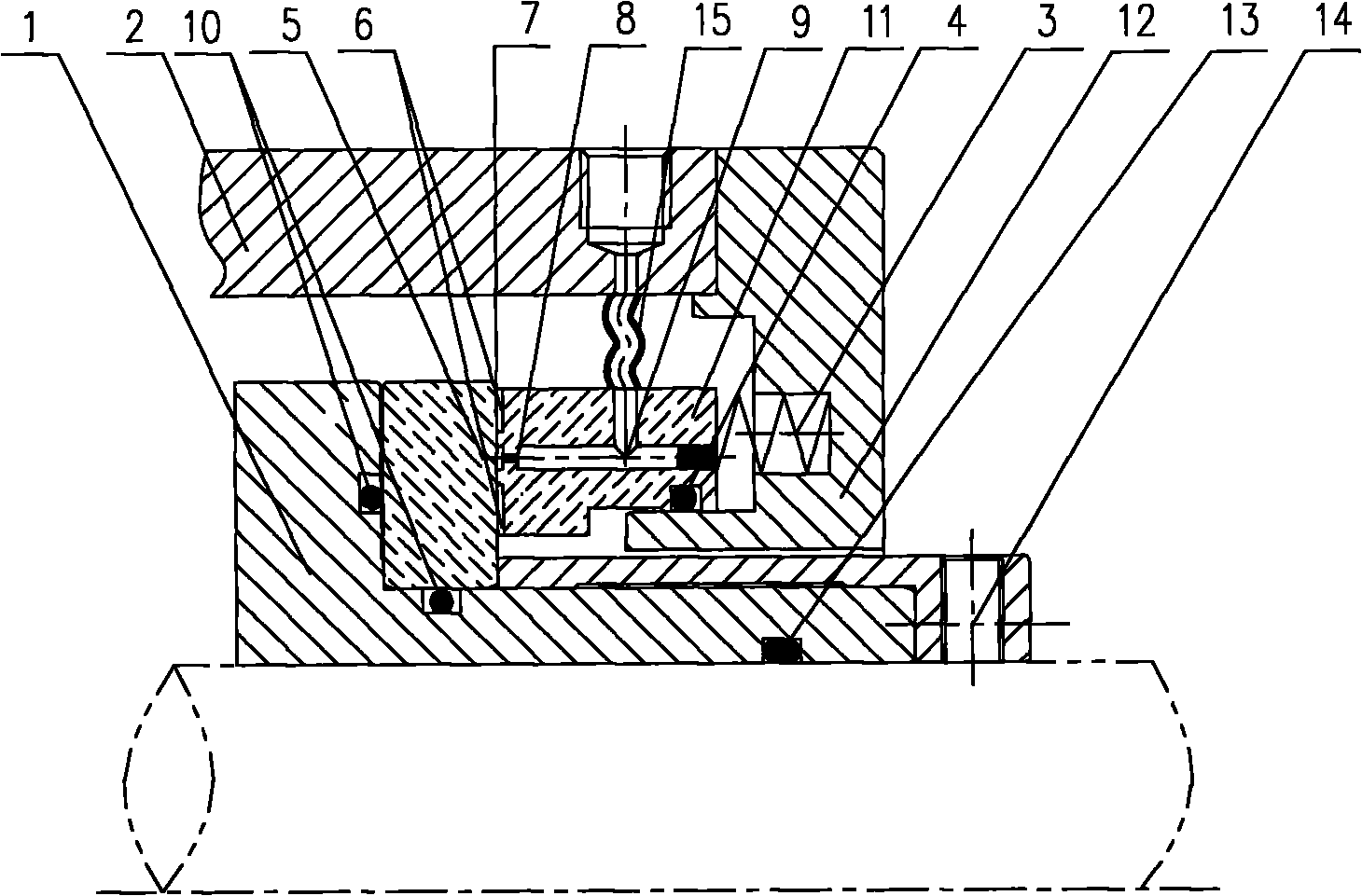

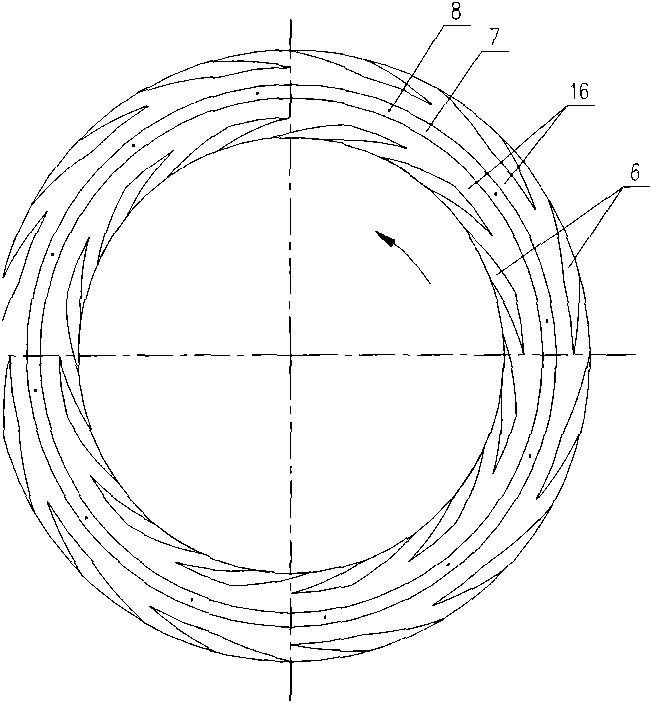

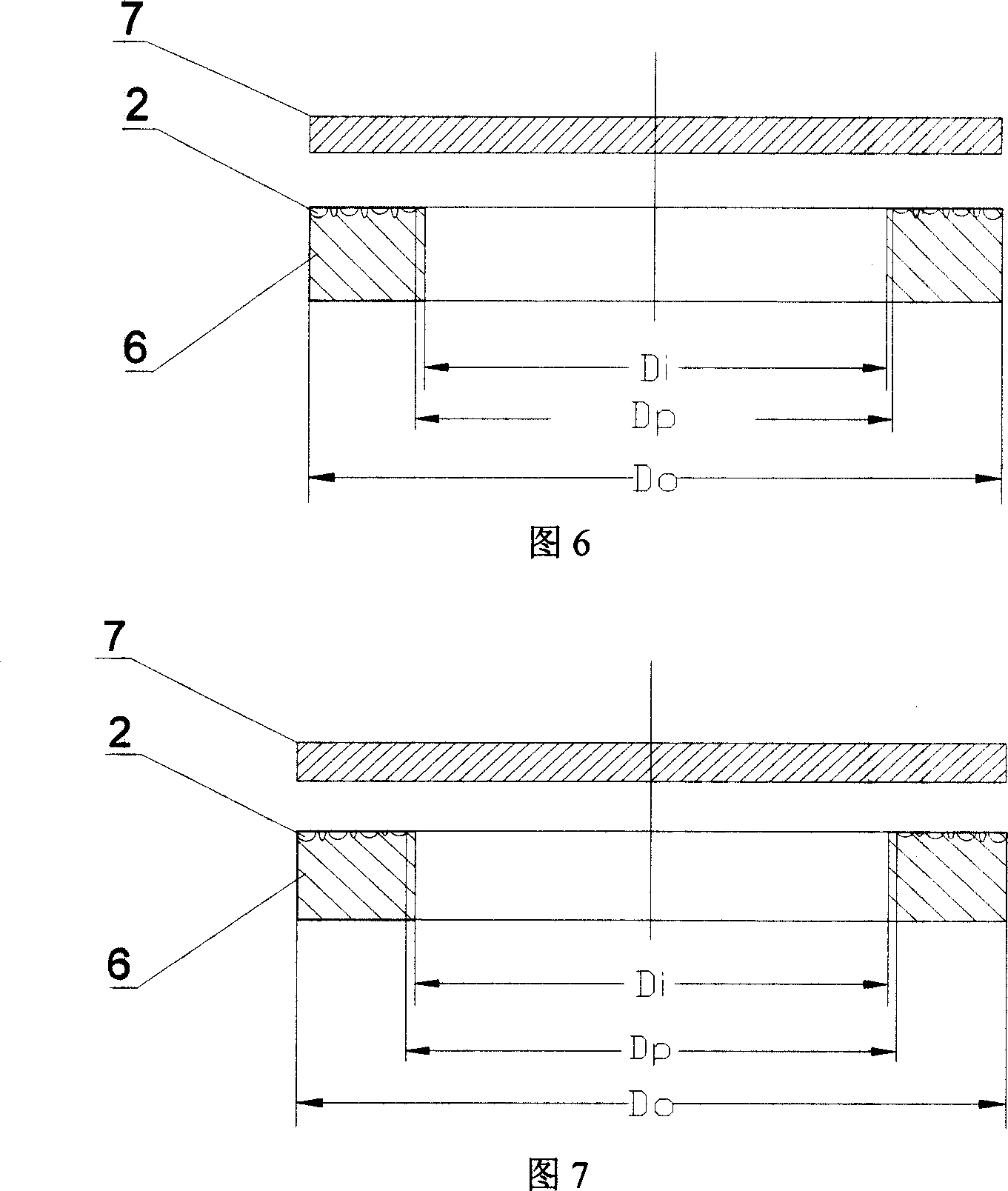

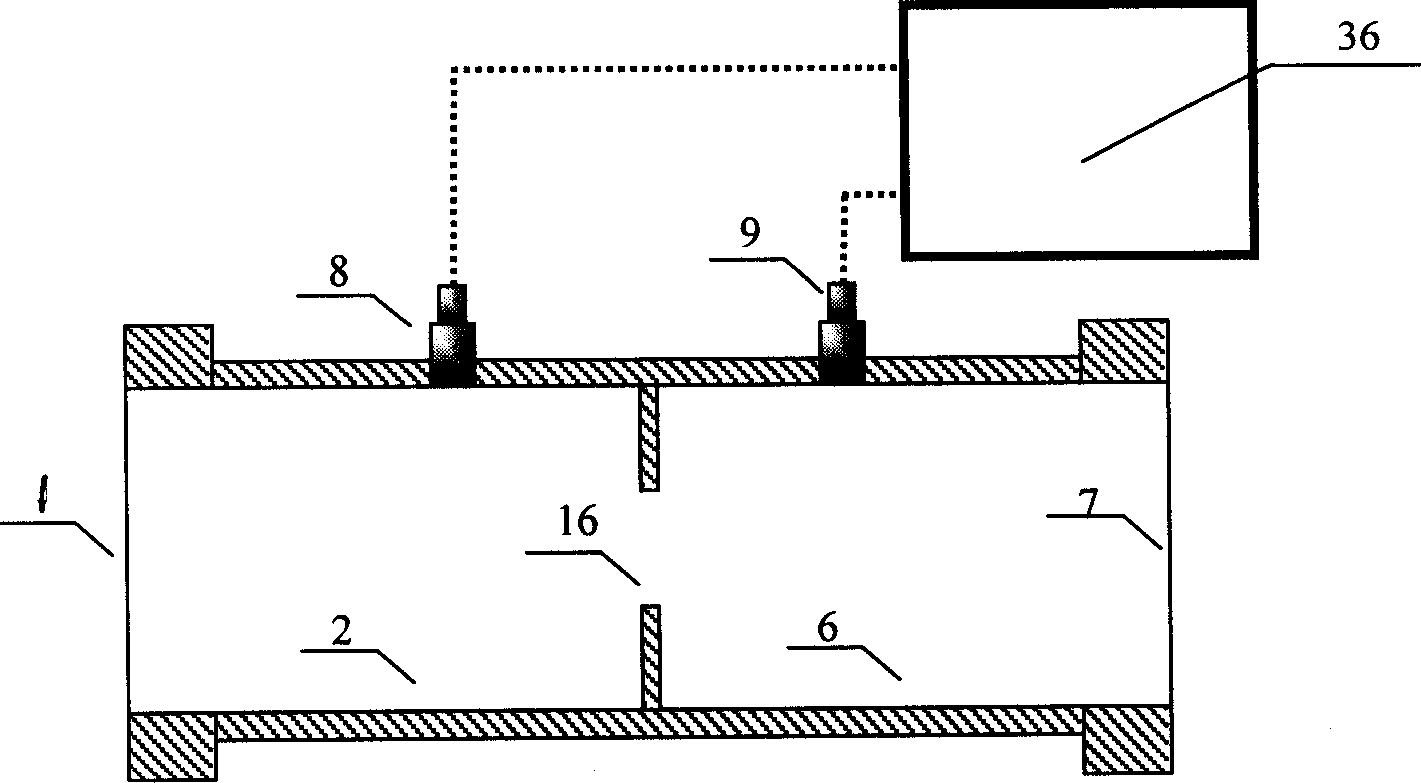

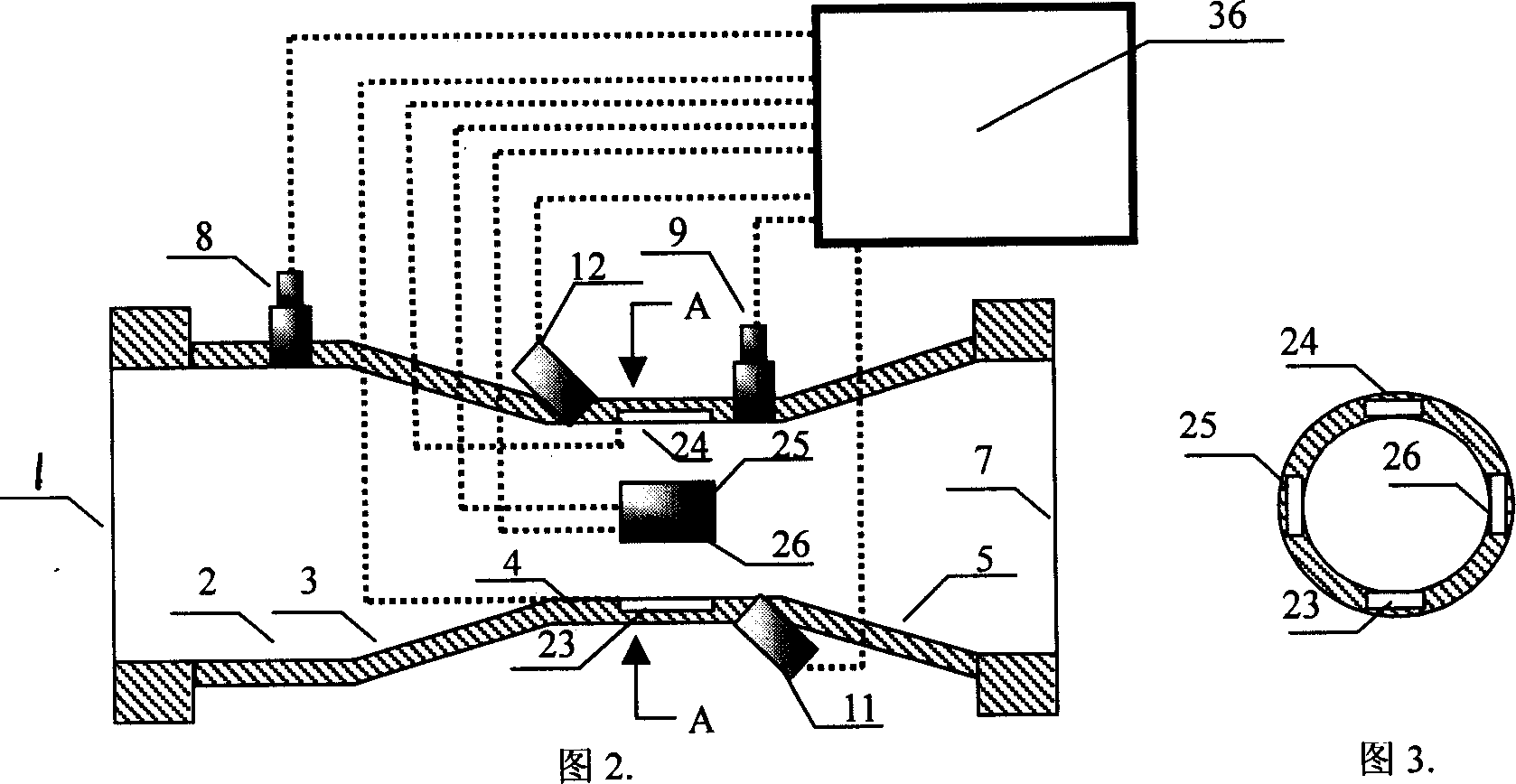

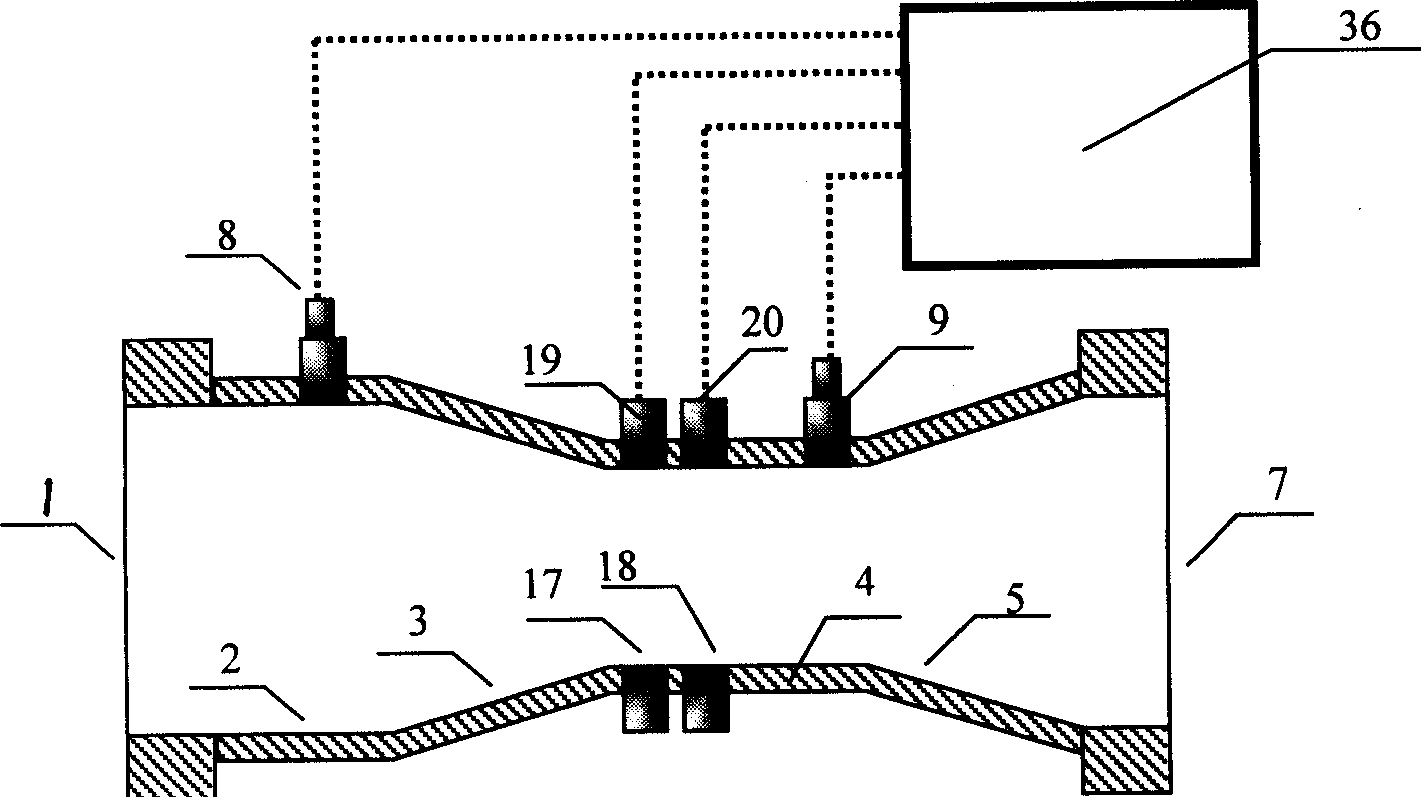

Outside pressurized type dynamic and static pressure gas lubricating and sealing device

The invention discloses an outside pressurized type dynamic and static pressure gas lubricating and sealing device, which comprises a moving ring (5) and a seal static ring (11), wherein the moving ring (5) is fixed on a moving ring seat (1) and rotates along with a spindle, and the seal static ring (11) is fixed on a seal cavity (2) and a seal end cover (12); channels (9) for introducing outsidepressurized gas from outside are arranged in the seal static ring (11), and the channels (9) of certain numbers are distributed in the seal static ring (11) along circumference; throttle devices (8) are arranged in the channels (9), and pressure equalizing troughs (7) of certain depth are arranged at the outlets of the channels (9); various dynamic pressure troughs (6) having dynamic pressure effects are formed on the end face of the moving ring (5) or the seal static ring (11), and the inside and outside of the pressure equalizing troughs (7) are provided with seal dams not communicated withthe pressure equalizing troughs; and on-line monitoring is realized by adjusting the pressure of the outside pressurized gas. The pressurized type dynamic and static pressure gas lubricating and sealing device greatly lowers resistance moment and power consumption and improves the phenomenon that the traditional end face seal abrasion is severe.

Owner:BEIJING UNIV OF CHEM TECH

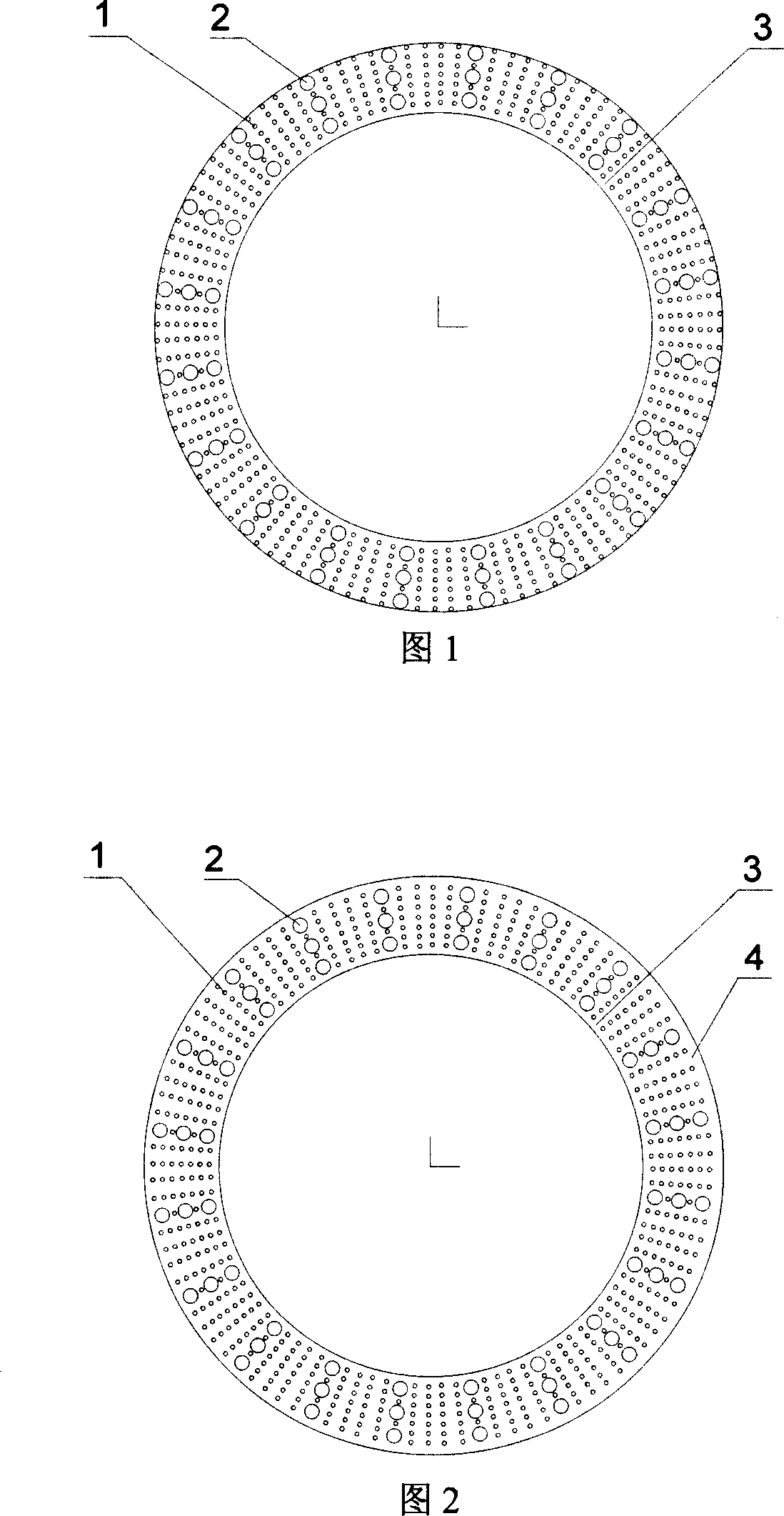

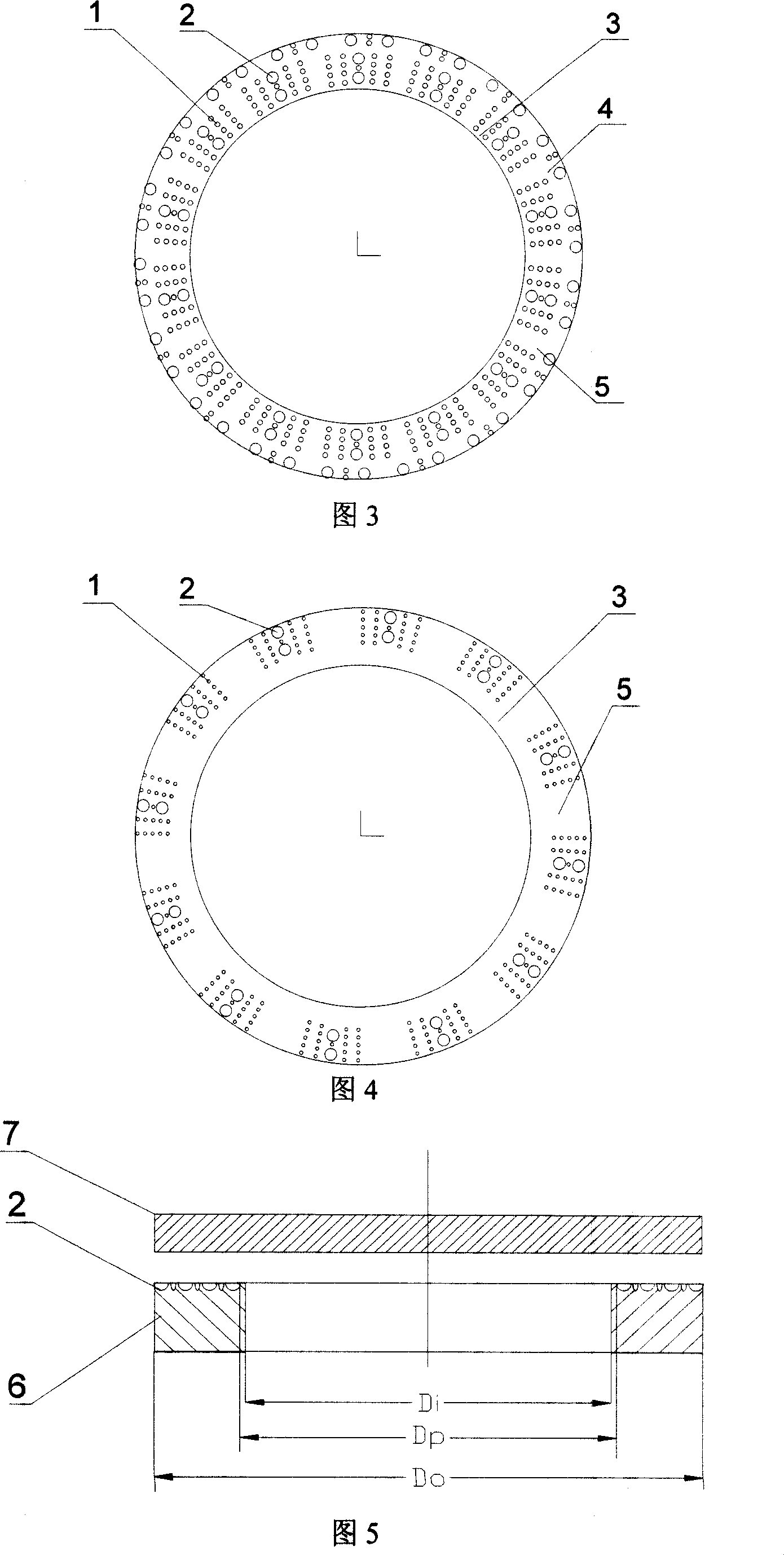

Variable distribution porous end face mechanical sealing structure

ActiveCN101016949AImprove wear resistanceImproved opening/stopping performanceEngine sealsHigh pressureWear resistance

The invention relates ton a variable-distribution porous end mechanical sealing structure, comprising a movable ring and a stable ring which are mechanically sealed, to form an annular sealing end. One side of the sealing end is high pressure side as ascending, while another end is low pressure side as descending, at least one sealing end is disposed with porous structure in different sizes symmetry distributed on the sealed end. Compared with present screw or groove mechanical sealing structure, the invention has better pressure resistance, abrasion resistance and better dynamic pressure effect on fluid membrane, to improve the carrier ability of fluid membrane.

Owner:ZHEJIANG UNIV OF TECH

Fluid flow rate detector

InactiveCN1731105AStable structureImprove performanceVolume/mass flow by differential pressureLine tubingStream flow

The invention relates to a flow measuring device of a stream, which fixes at least two dynamic pressure sensors on the measuring path of the changing cross-sectional area used to measure the undulating quantity value of restricting differential pressure which can measure the stream flow. The device overcomes the traditional shortages and can measure multiply two-phase flow. When adding a phase measuring device on the invention, it can measure two-phase flow with much accuracy and can be used to measure oil, gas and water three-phase flow.

Owner:陈宇

Bypass air scoop for gas turbine engine

A gas turbine engine has a plurality of radial struts in a bypass duct. At least one strut has a scoop incorporated with the fairing of the strut and in communication with an air passage of an engine secondary air system. The scoop faces a bypass air flow to scoop a portion of the bypass air flow using available dynamic pressure in the bypass duct. Scooped air may be provided, for example, to an active tip clearance control apparatus in a long duct turbofan engine.

Owner:PRATT & WHITNEY CANADA CORP

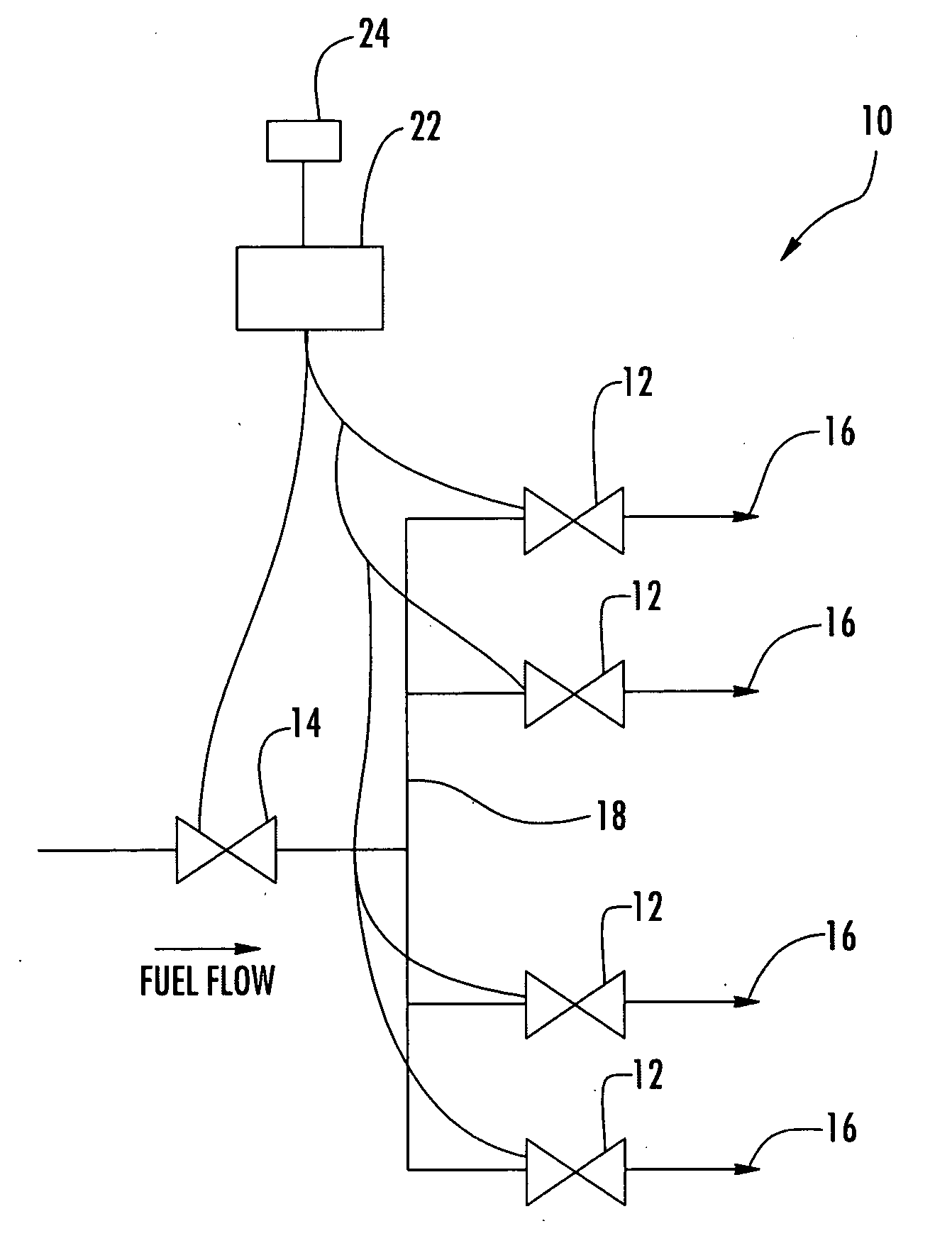

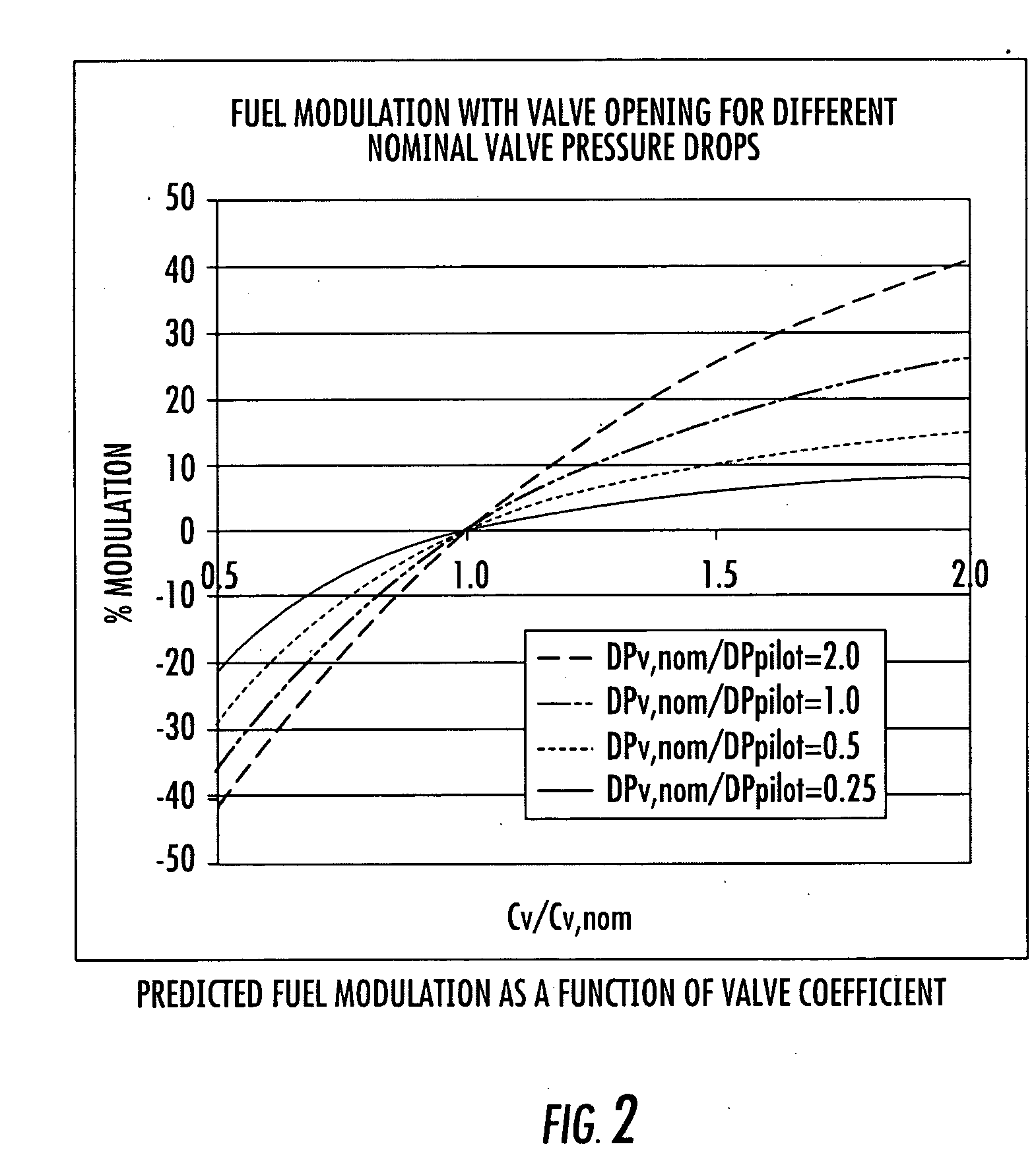

System for modulating fuel supply to individual fuel nozzles in a can-annular gas turbine

ActiveUS20080016875A1Ensure efficient flowReduce the amount of solutionFuel supply regulationContinuous combustion chamberCombustorEngineering

A fuel modulation system usable in can-annular combustor systems of turbine engines for more efficiently managing fuel flow to reduce the amount of NOx while maintaining appropriate combustor flame temperatures. The fuel modulation system controls individual inline modulation valves in cooperation with a overall stage control valve to bring a turbine engine through the startup phase and to maintain operating conditions at a load set point while reducing NOx variability between baskets by using individual combustor dynamic pressure measurements. The fuel modulation system may be managed such that individual inline modulation valves remain within a predetermined range of positions relative to a nominal position to reduce NOx variability.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com