Patents

Literature

46 results about "Change density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

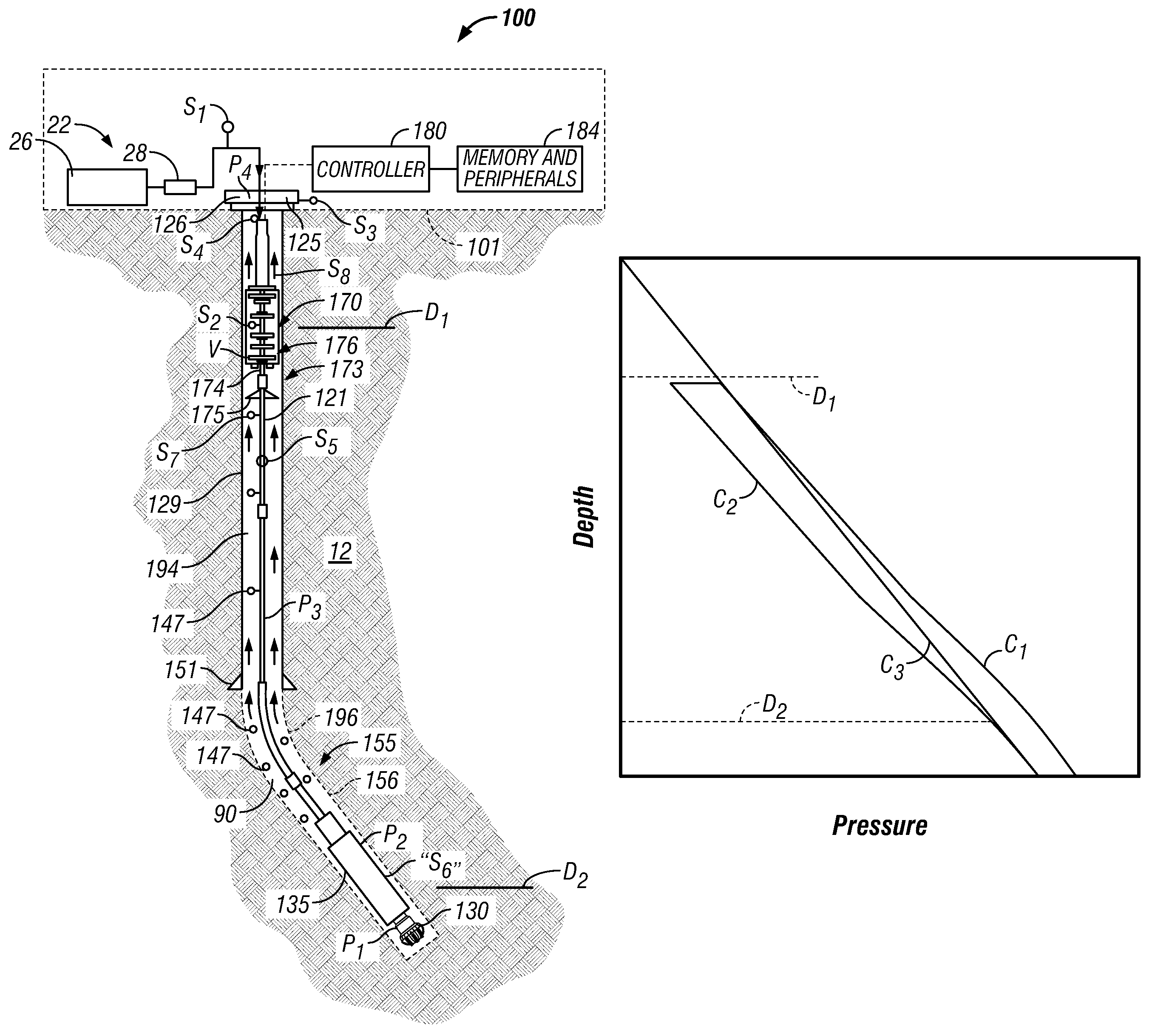

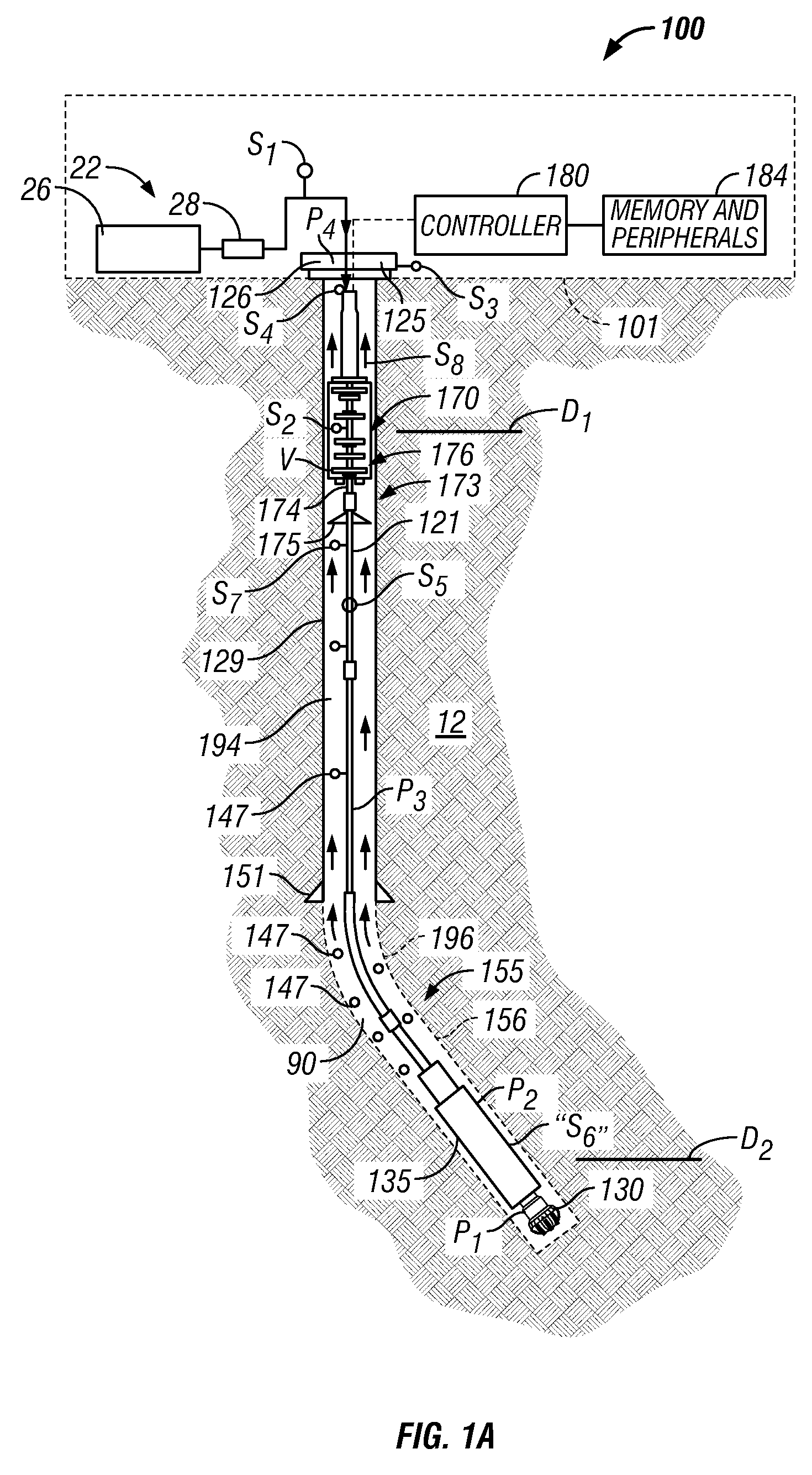

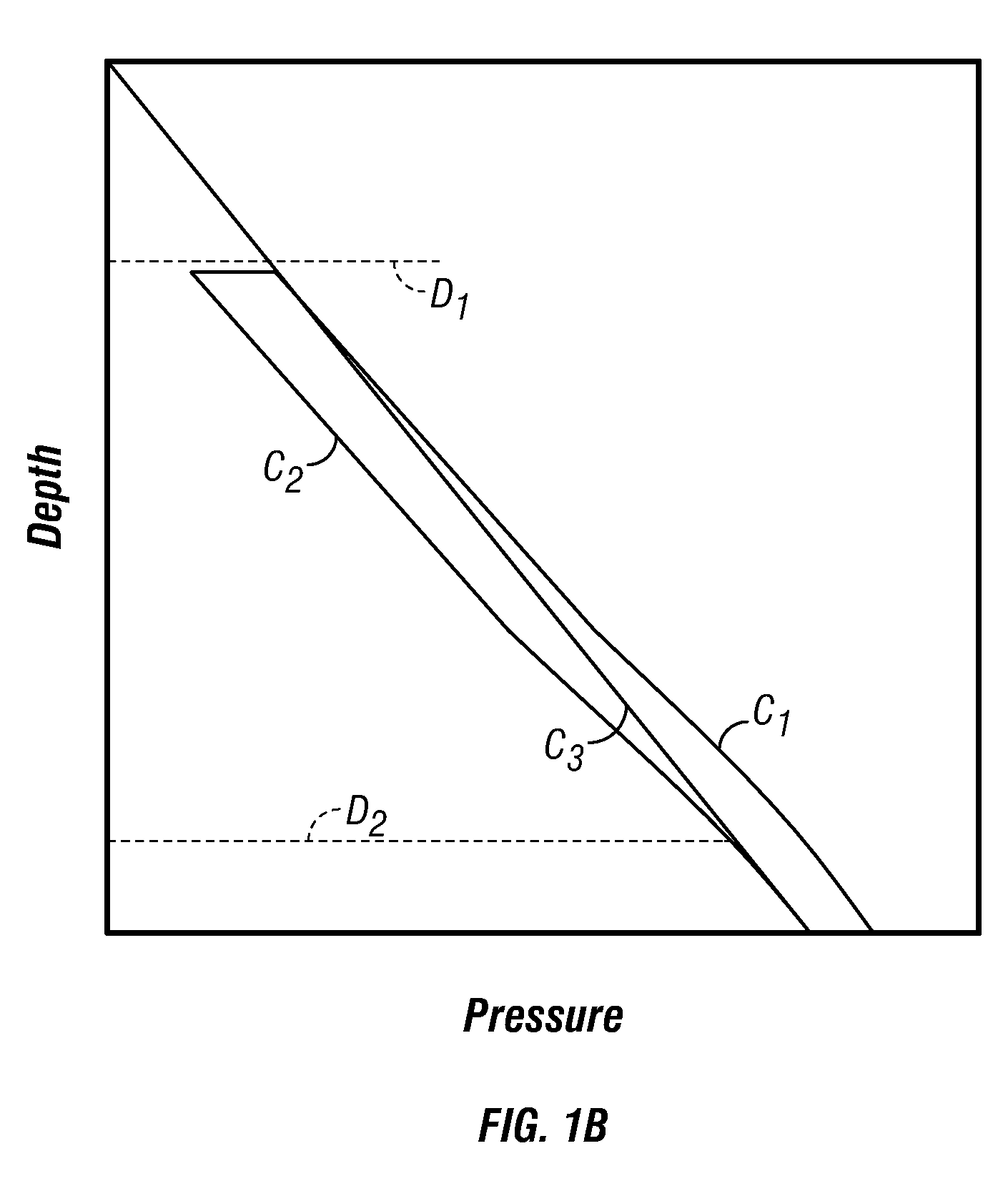

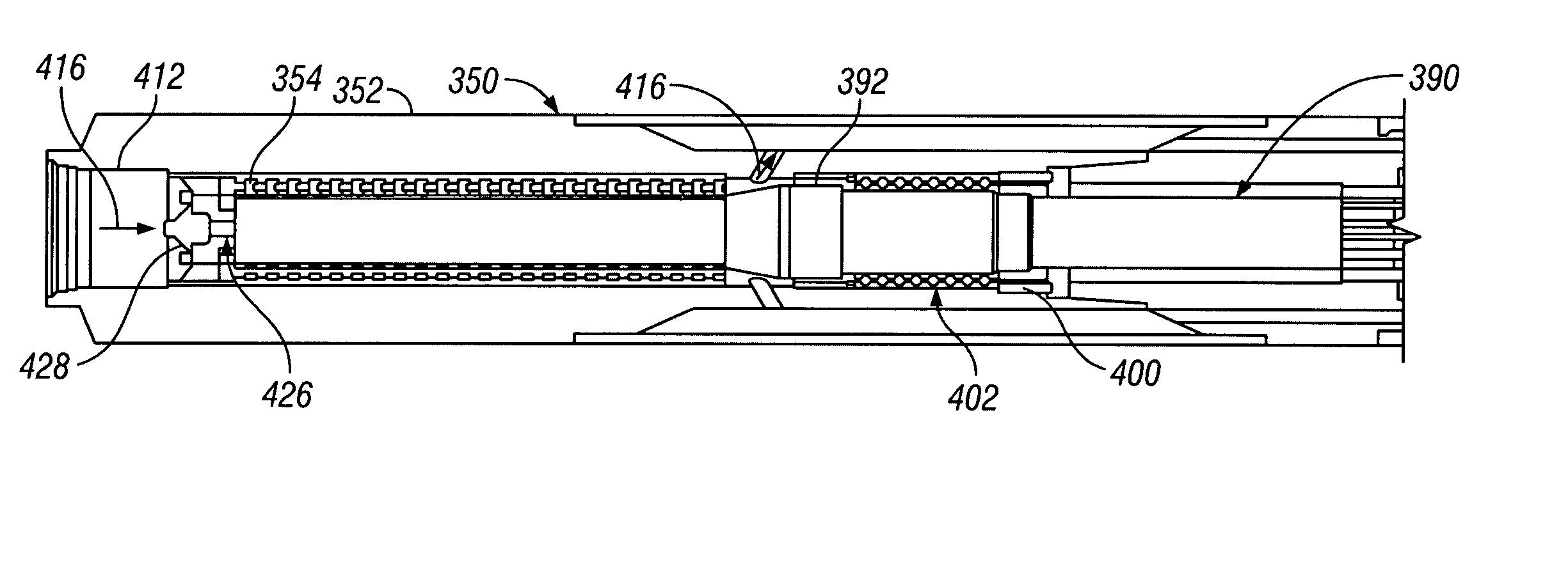

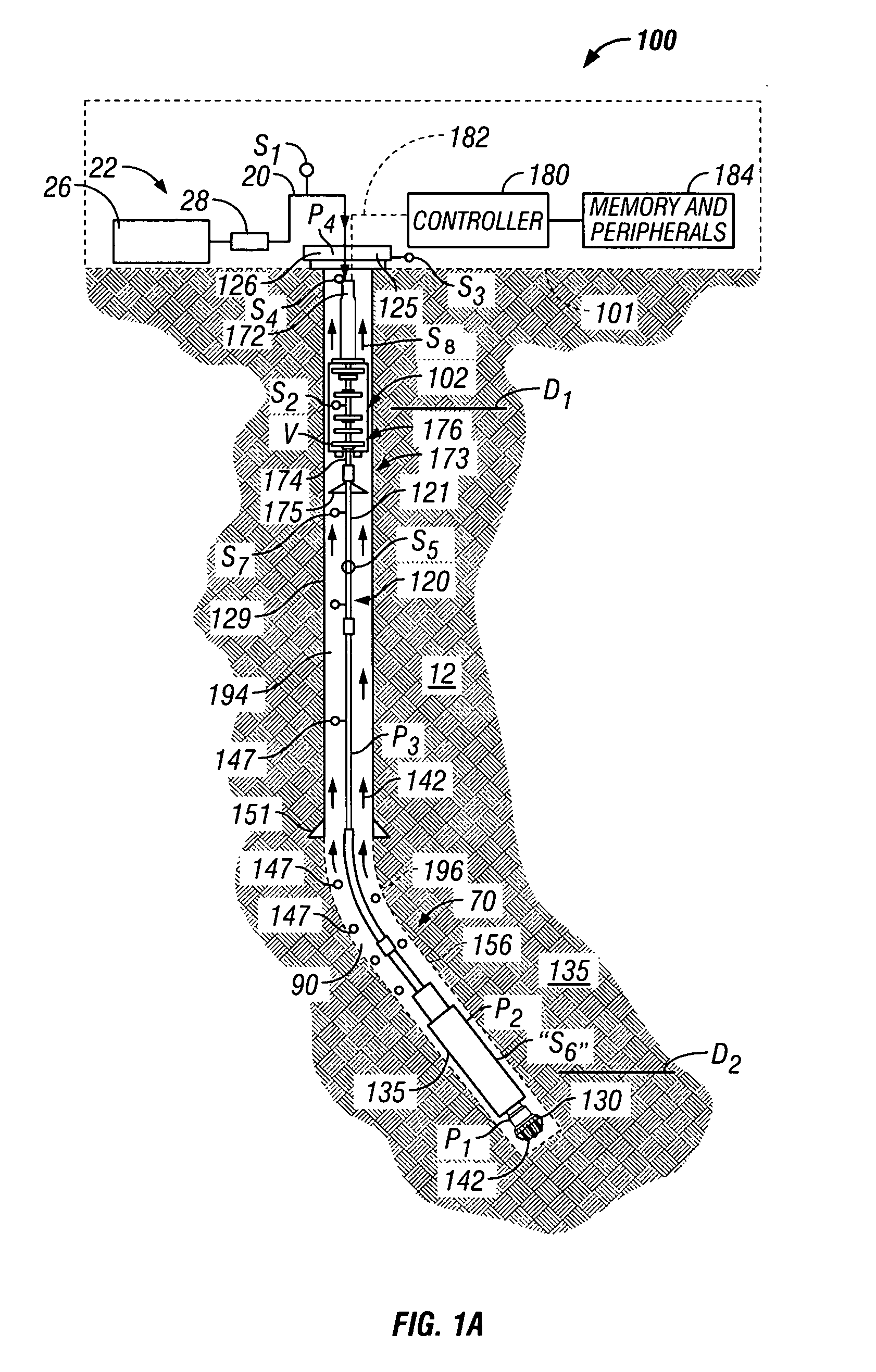

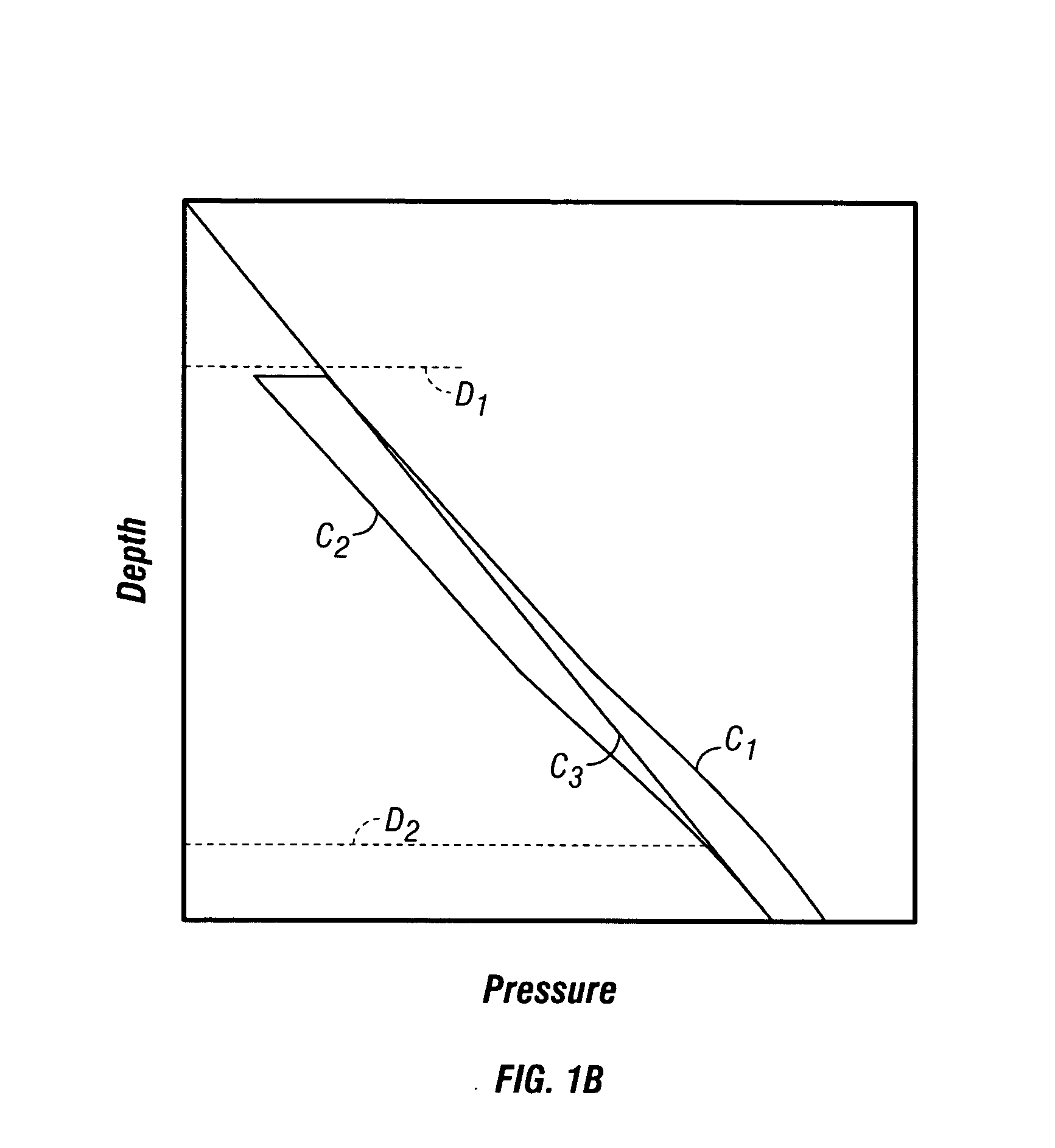

Active controlled bottomhole pressure system and method with continuous circulation system

An APD Device provides a pressure differential in a wellbore to control dynamic pressure loss while drilling fluid is continuously circulated in the wellbore. A continuous circulation system circulates fluid both during drilling of the wellbore and when the drilling is stopped. Operating the APD Device allows wellbore pressure control during continuous circulation without substantially changing density of the fluid. The APD Device can maintain wellbore pressure below the combined pressure caused by weight of the fluid and pressure losses created due to circulation of the fluid in the wellbore, maintain the wellbore at or near a balanced pressure condition, maintain the wellbore at an underbalanced condition, reduce the swab effect in the wellbore, and / or reduce the surge effect in the wellbore. A flow restriction device that creates a backpressure in the wellbore annulus provides surface control of wellbore pressure.

Owner:BAKER HUGHES HLDG LLC

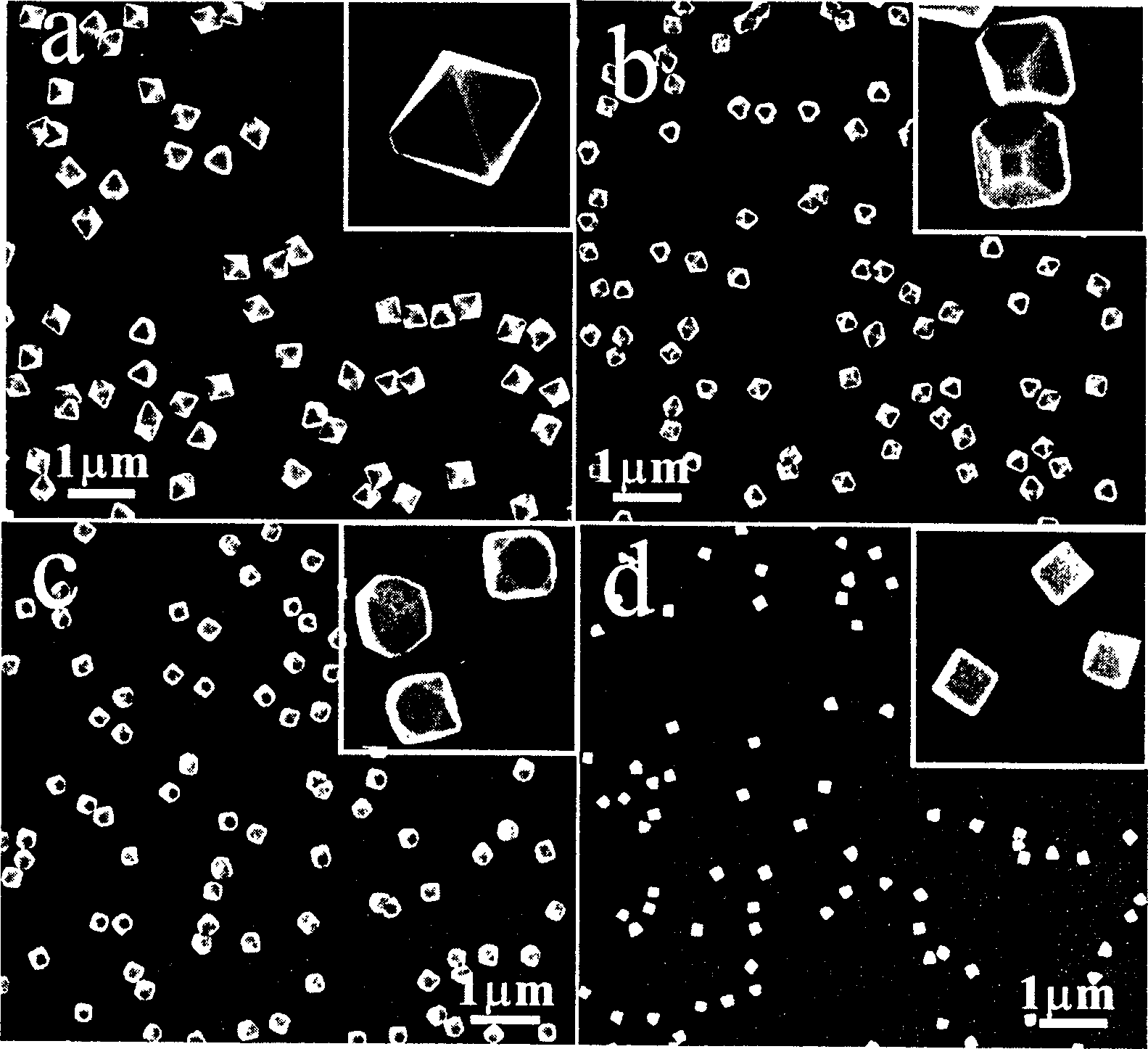

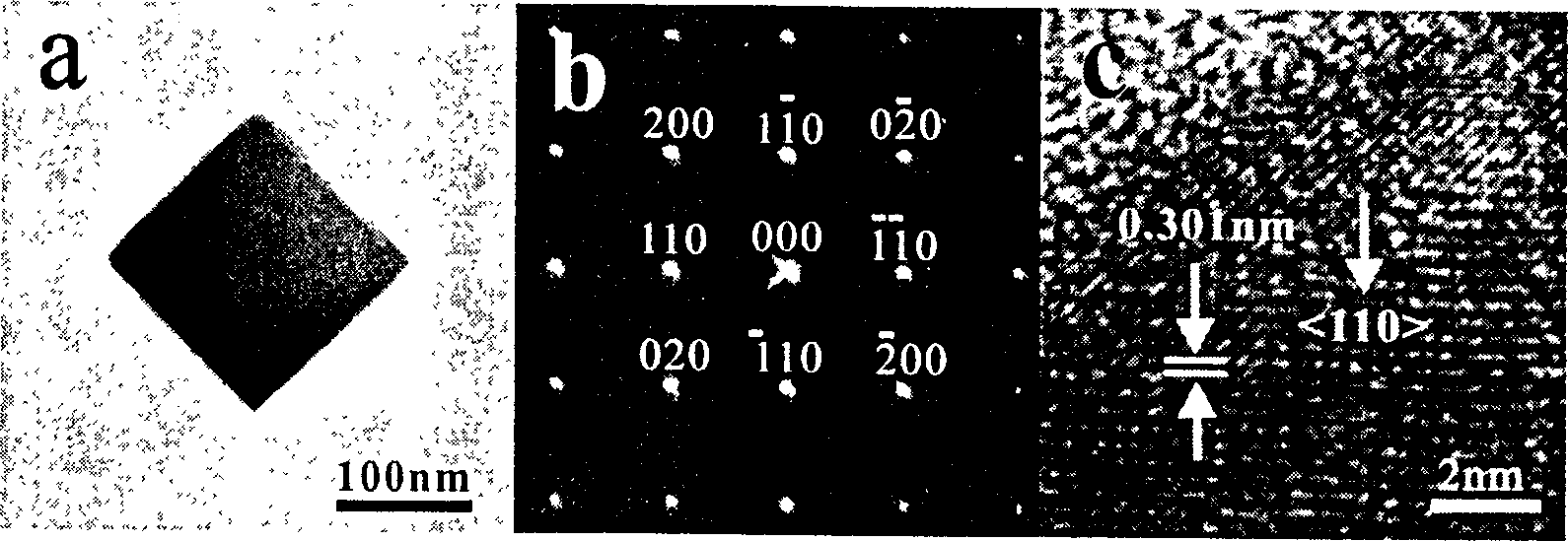

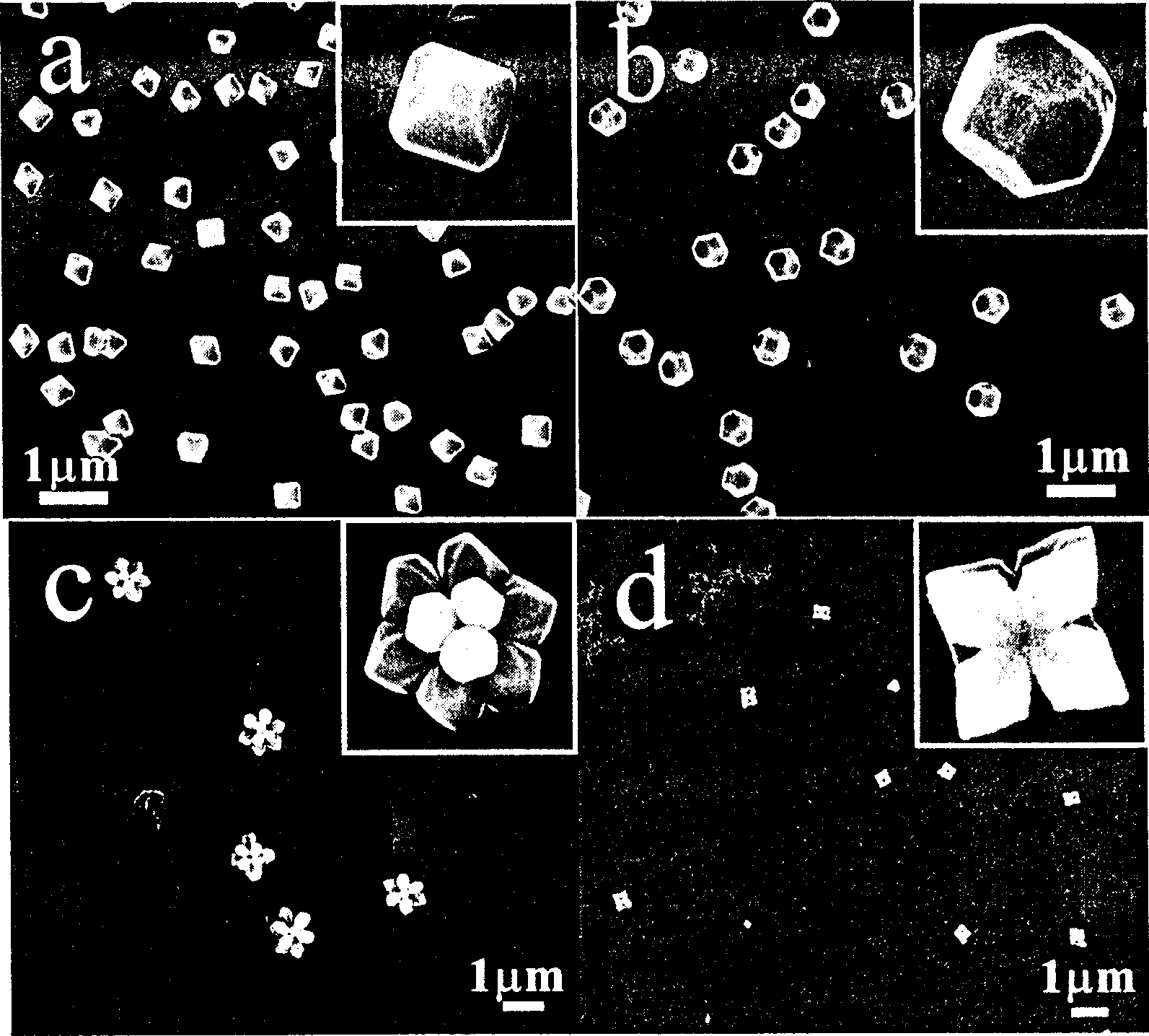

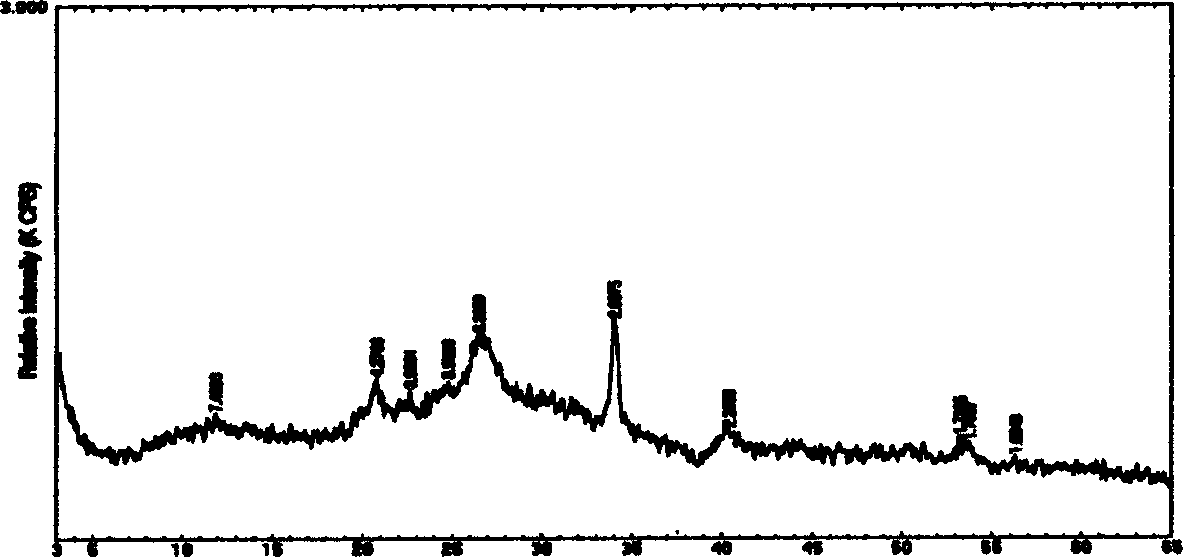

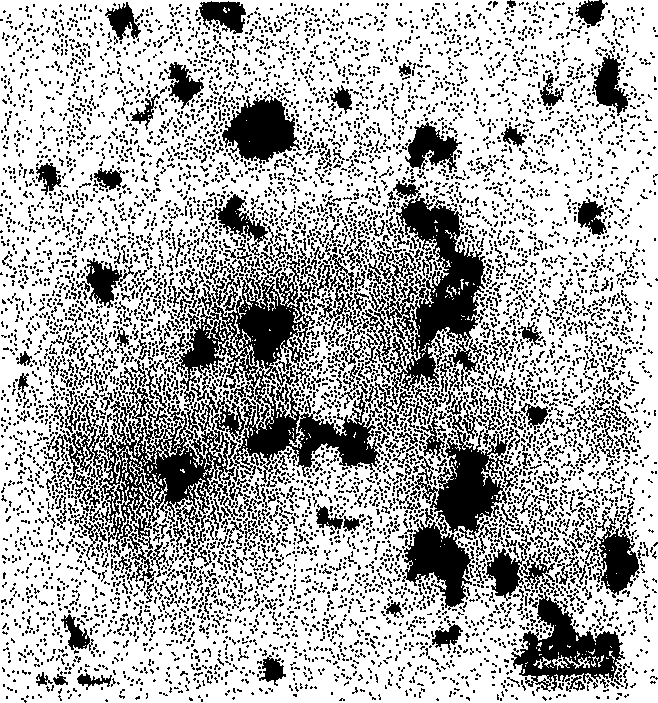

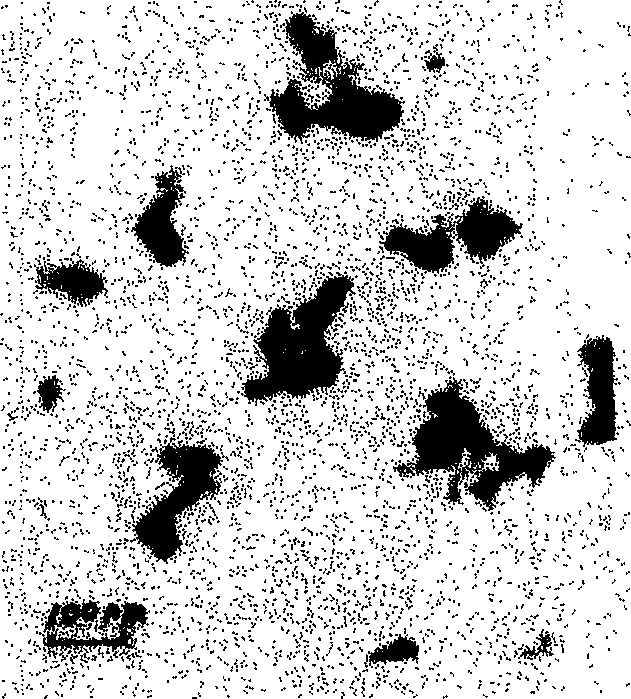

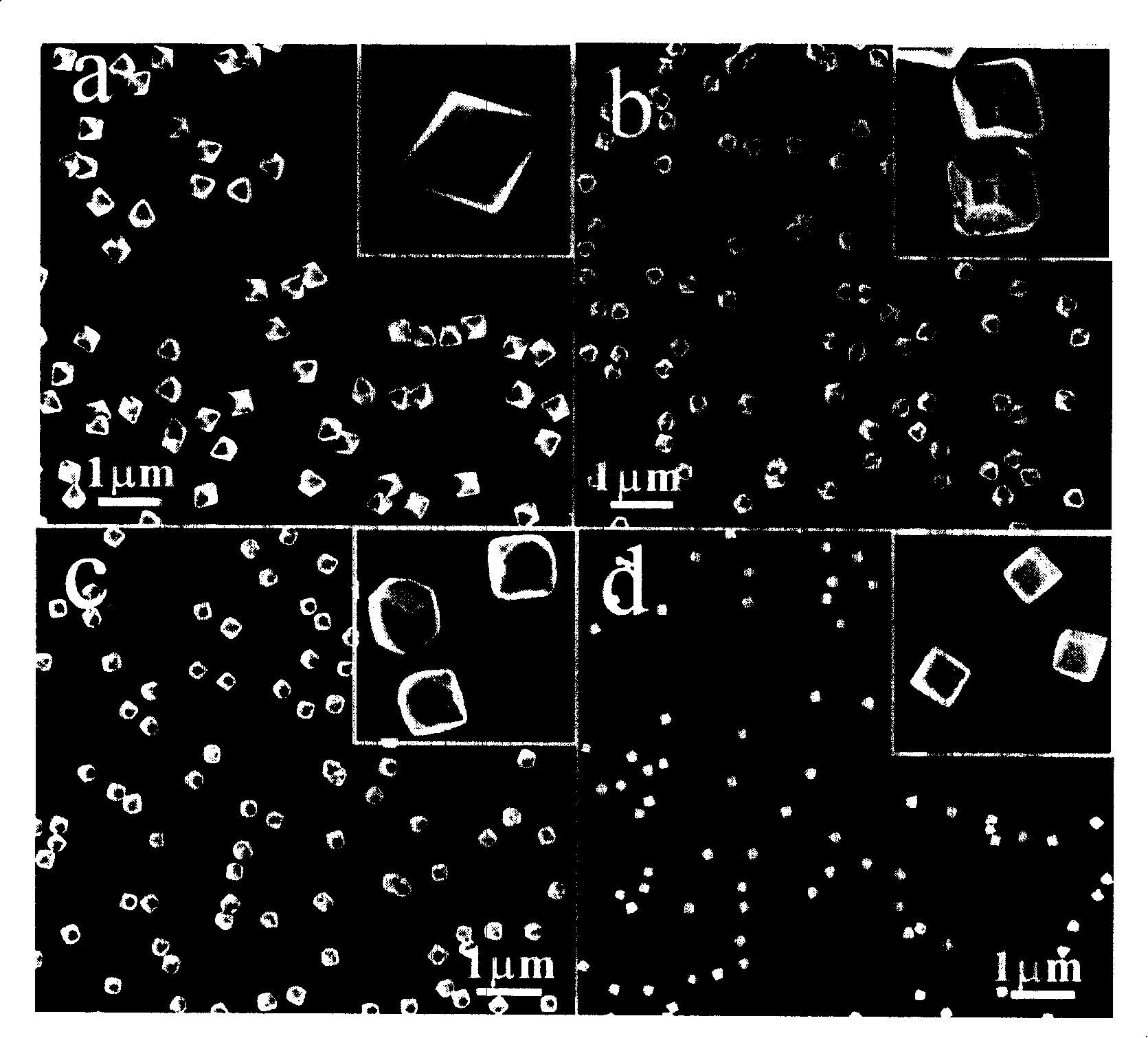

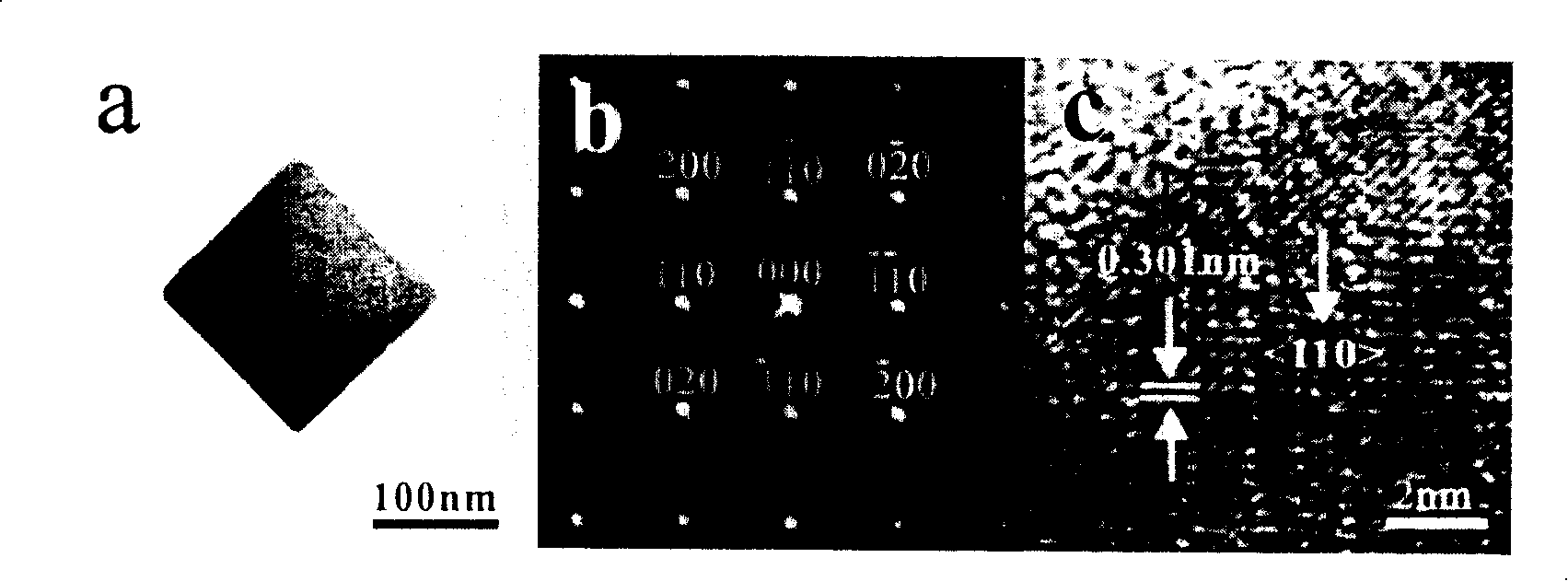

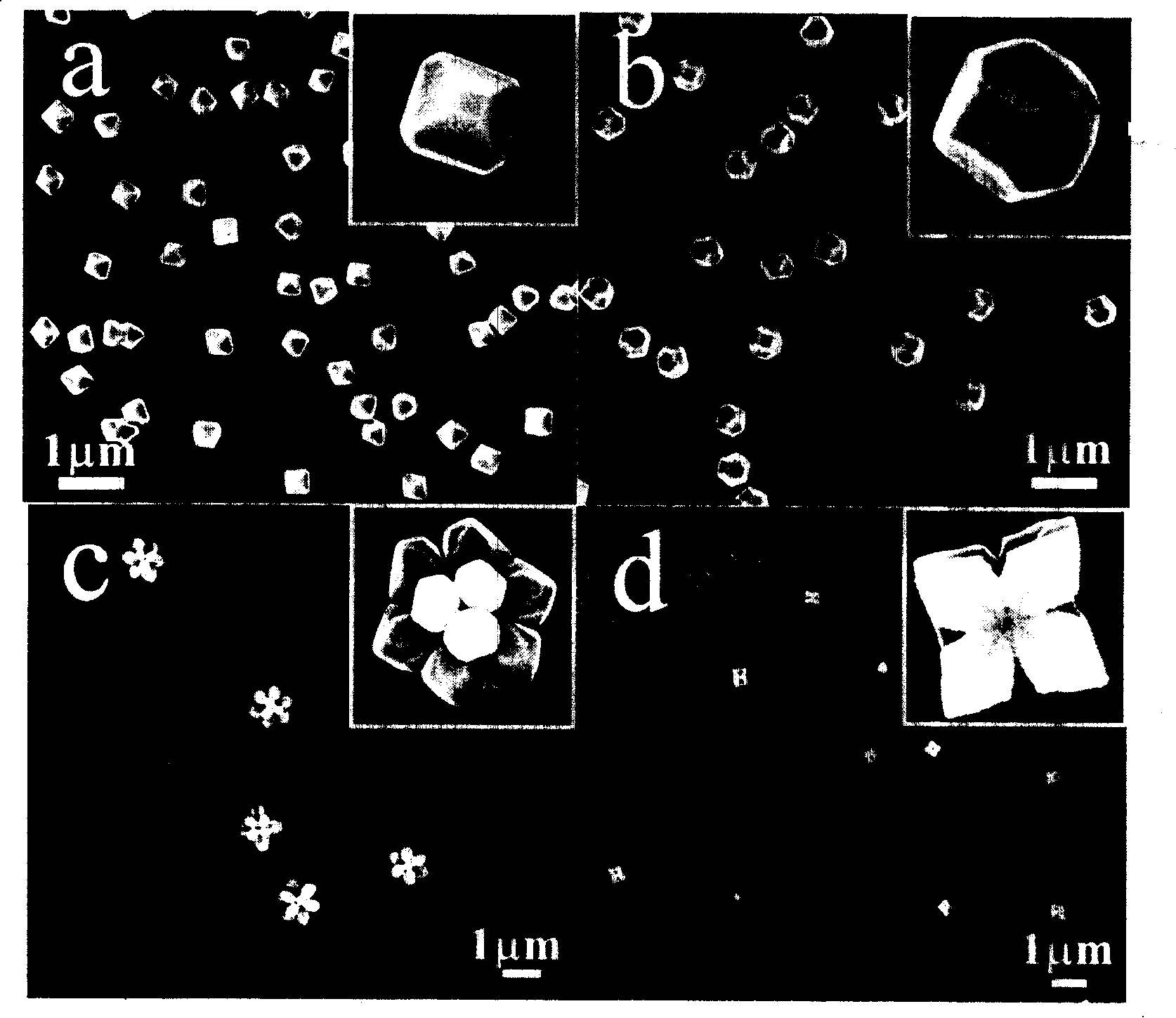

Process for preparing shape controllable cuprous oxide micro/nano crystal by electrochemical deposition

InactiveCN1807688AThe experimental equipment is simpleGood symmetryPolycrystalline material growthElectrolysis componentsSupporting electrolyteChange density

The invention discloses a shape-controlled cuprous oxide micron / nanometer crystal preparing method with electrochemical deposition, which comprises the following steps: pre-processing conductive basal body; formulating electrolyte solution; carrying on constant current electrochemical deposition; gaining Cu2O micron / nanometer crystal. The method is characterized by the following: the cuprous oxide micron / nanometer crystal is gained by changing density of electrolyte solution and electrochemical parameter by constant current electrodeposition method at room temperature, which needn't any supporting electrolytes and surface activators; the form is composed of octahedron, top rake octahedron, top rake cube and cube.

Owner:XIAMEN UNIV

Active controlled bottomhole pressure system and method with continuous circulation system

InactiveUS20070007041A1Reduce the impactKeep the pressureDrilling rodsBorehole drivesChange densityEngineering

An APD Device provides a pressure differential in a wellbore to control dynamic pressure loss while drilling fluid is continuously circulated in the wellbore. A continuous circulation system circulates fluid both during drilling of the wellbore and when the drilling is stopped. Operating the APD Device allows wellbore pressure control during continuous circulation without substantially changing density of the fluid. The APD Device can maintain wellbore pressure below the combined pressure caused by weight of the fluid and pressure losses created due to circulation of the fluid in the wellbore, maintain the wellbore at or near a balanced pressure condition, maintain the wellbore at an underbalanced condition, reduce the swab effect in the wellbore, and / or reduce the surge effect in the wellbore. A flow restriction device that creates a backpressure in the wellbore annulus provides surface control of wellbore pressure.

Owner:BAKER HUGHES INC

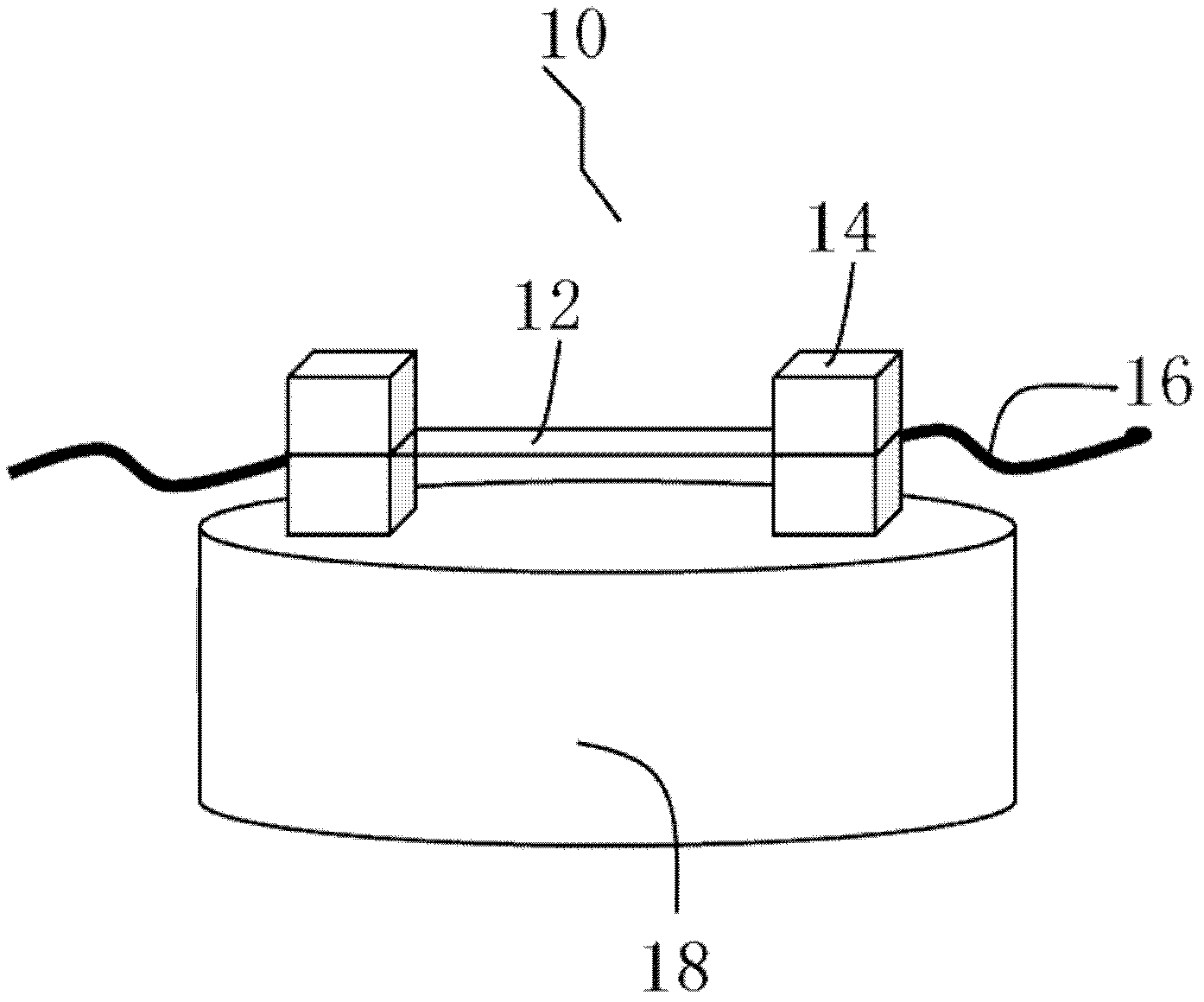

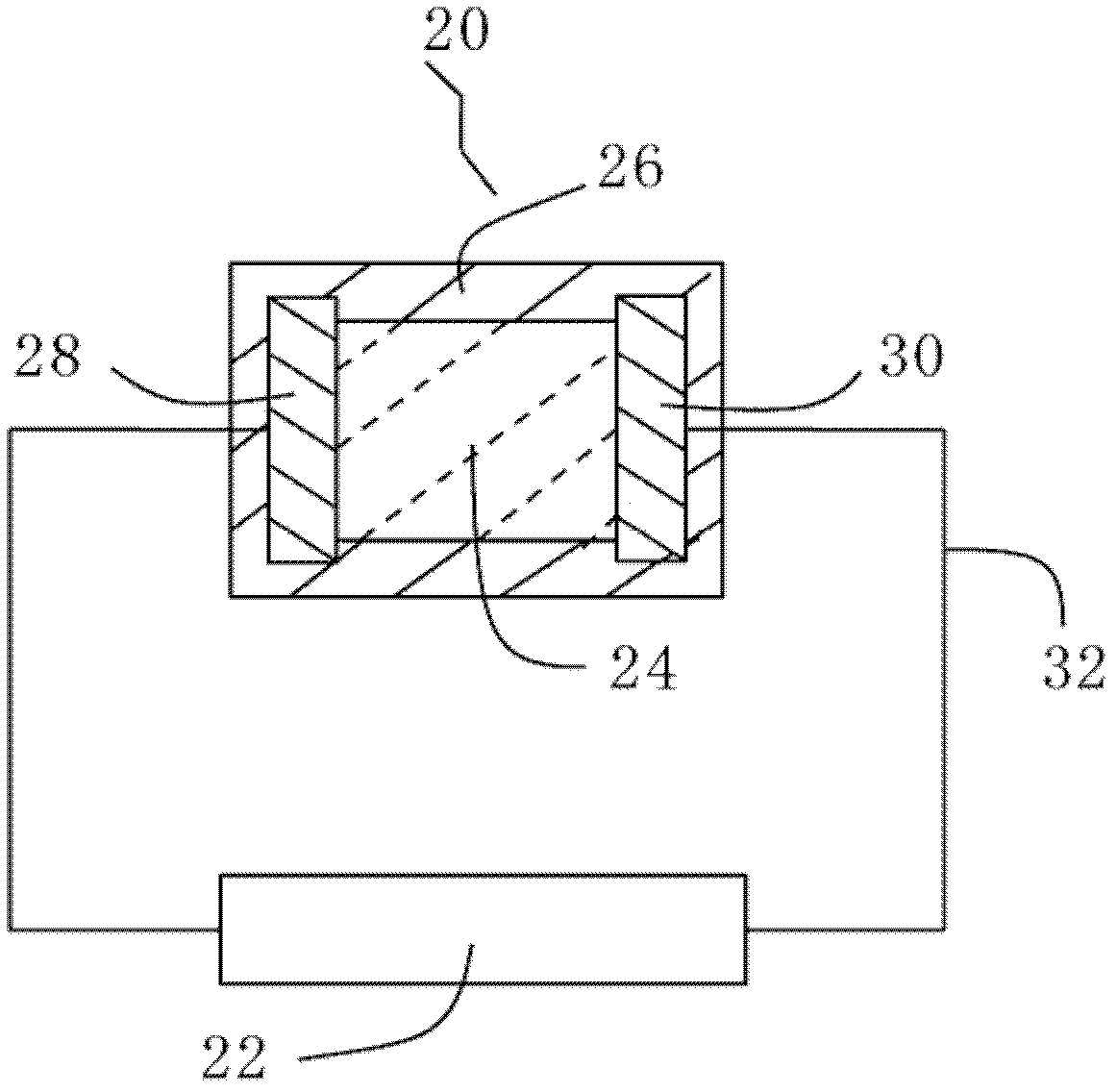

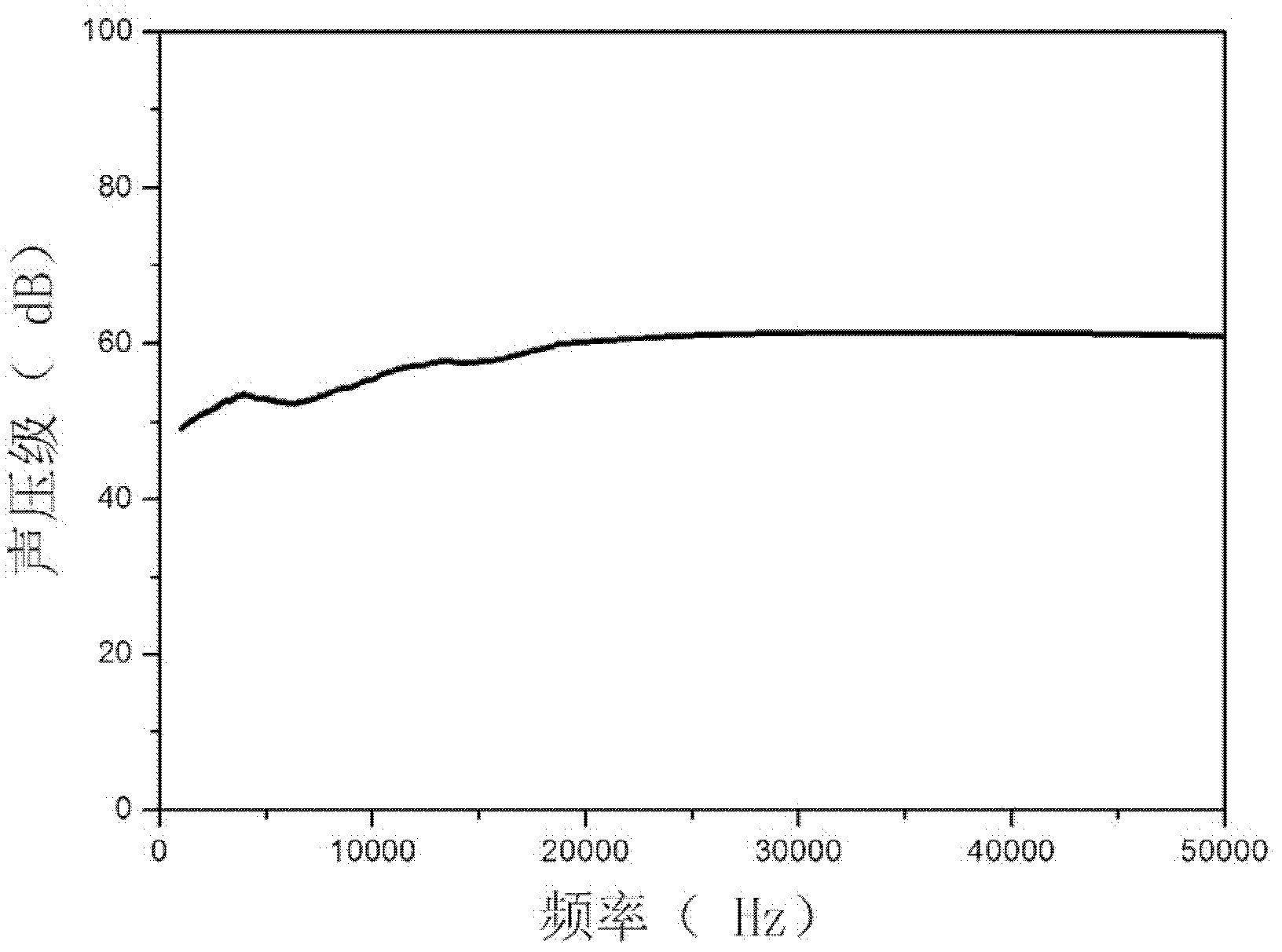

Flexible and transparent thermotropic sounding apparatus

InactiveCN102572667AHigh light transmittanceHigh mechanical strengthTransducer detailsChange densityEngineering

The invention, which belongs to the sounding apparatus technology field, relates to a flexible and transparent thermotropic sounding apparatus. The apparatus comprises a sound element and a signal input device connected with the sound element. The sound element includes a flexible and transparent substrate; and at least one conductive film structure and a pair of electrodes or multi-pair electrodes are arranged on the substrate, wherein one ends of the pair of electrodes or the multi-pair electrodes are connected at two sides of the conductive film structure. And an input terminal of the signal input device is connected with the other ends of the electrodes. Therefore, the conductive film structure changes density of surrounding mediums to emit sound waves. According to the invention, there is no mechanical oscillation on the sound element itself and the sound element is transparent and can be bent and stretched. The thermotropic sounding apparatus can generate high sound pressure output within a frequency range of from 101 kHz to 100 MHz as well as has advantages of high reliability, flexibility, transparency, low cost, and high performance; besides, the apparatus can be integrated with a display screen and simultaneously enables sounding and display functions to be realized. Therefore, the provided apparatus can be widely applied to electronic fields like a mobile phone, a MP3, a MP4, a television, a computer, ultrasonic imaging, and a range finding system and the like.

Owner:TSINGHUA UNIV

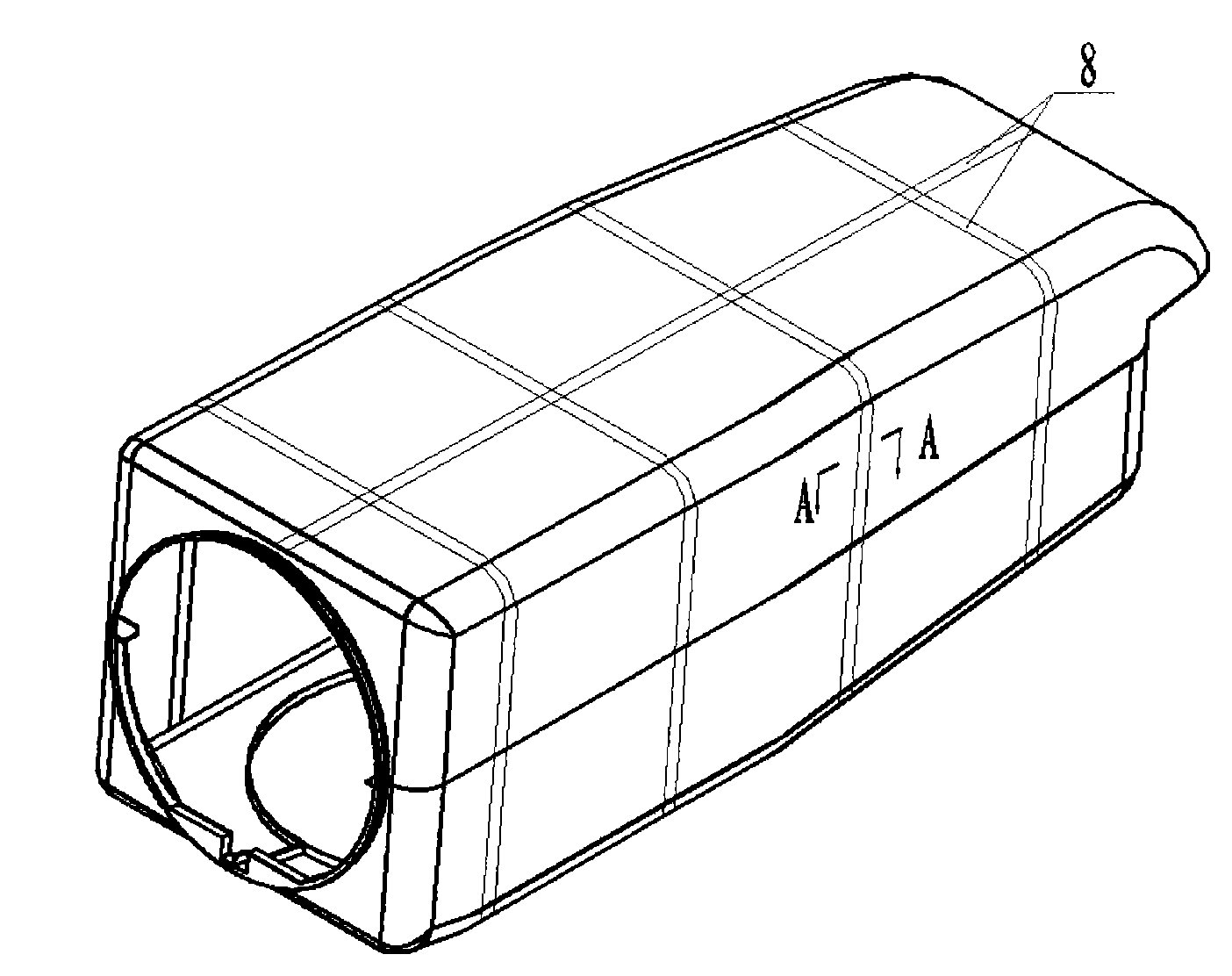

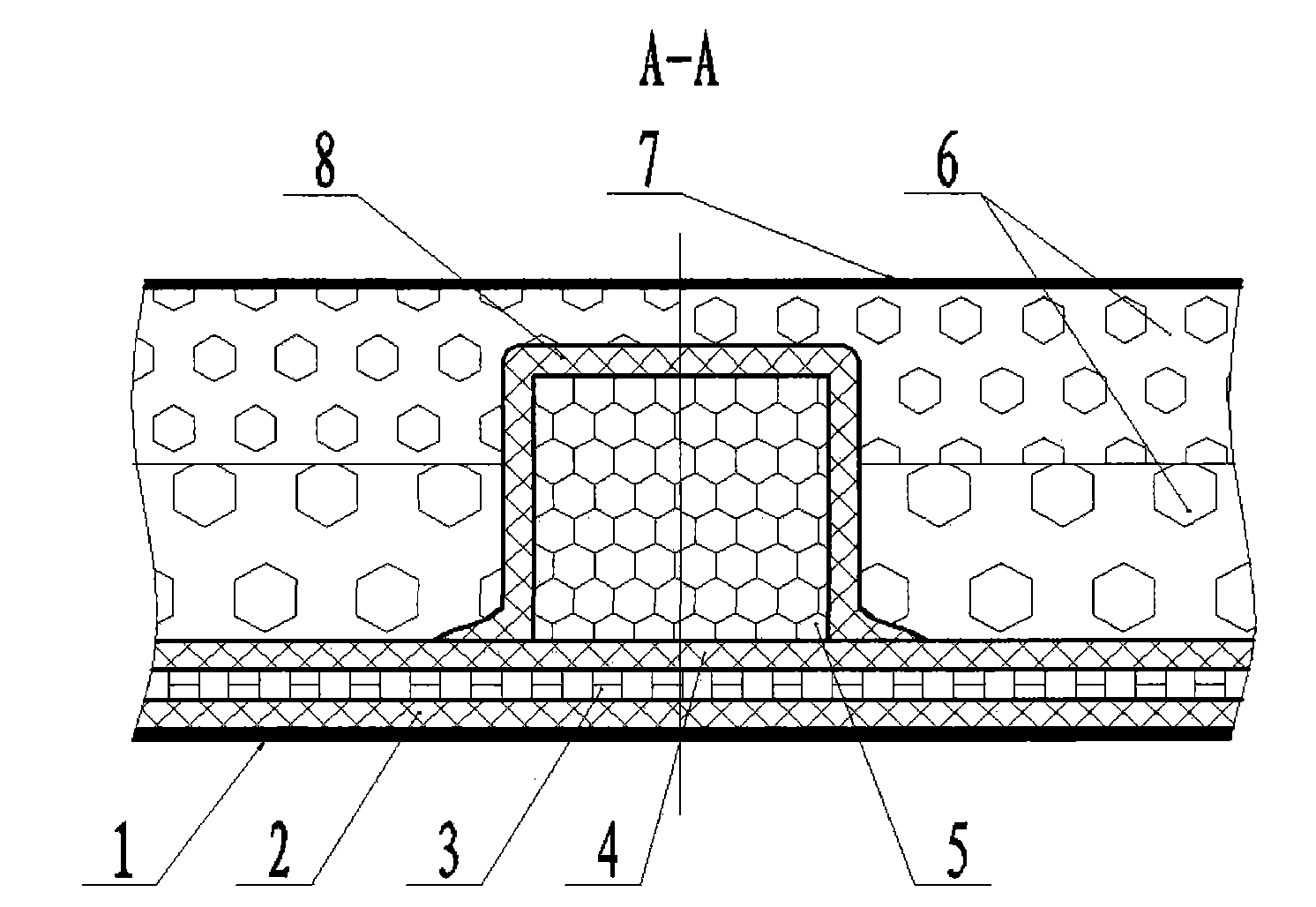

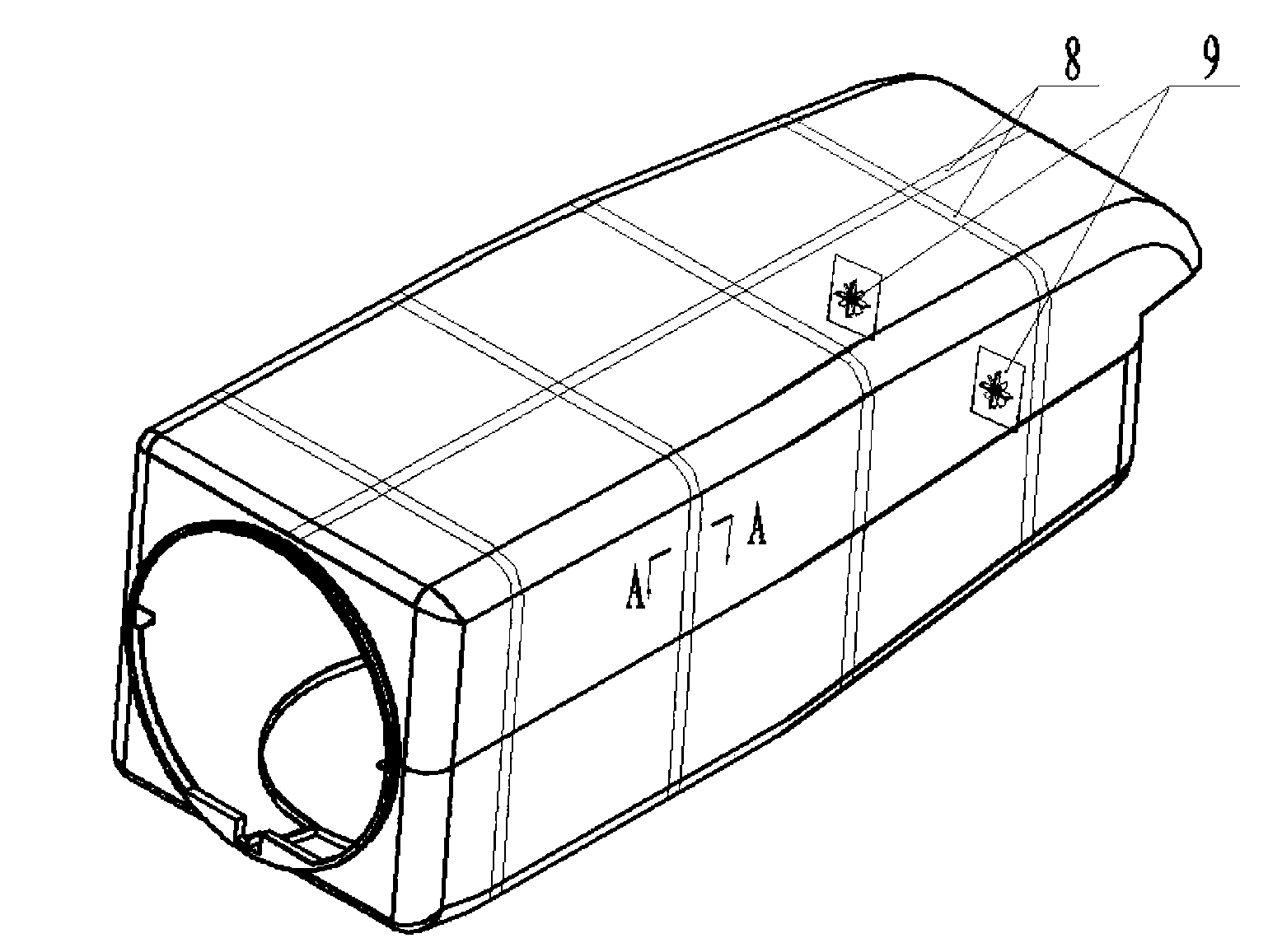

Sound insulation and noise reduction type cabin cover of wind power generator

InactiveCN101649818AIncrease stiffnessIncreasing the thicknessMachines/enginesWind energy generationChange densitySurface layer

The invention relates to a main component of large wind power generation equipment, in particular to a sound insulation and noise reduction type cabin cover of a wind power generator, comprising a decorative protecting surface layer, an FRP outer plate, a sandwich layer, an FRP inner plate, a hard foam plastic inner core, foam plastics with gradually changed density, a foam plastic skinning layerand a reinforcing frame, wherein the FRP outer plate, the sandwich layer, the FRP inner plate and the reinforcing frame form an integral frame by continuous formation, and the FRP outer plate, the sandwich layer, the FRP inner plate, the foam plastics with gradually changed density and the reinforcing frame form an integral structure. The invention provides the cabin cover of the wind power generator, which has good sound insulation and noise reduction functions, and heat insulation or temperature keeping and flame retardant performance and is suitable for high temperature and cold areas.

Owner:秦皇岛耀华装备集团股份有限公司

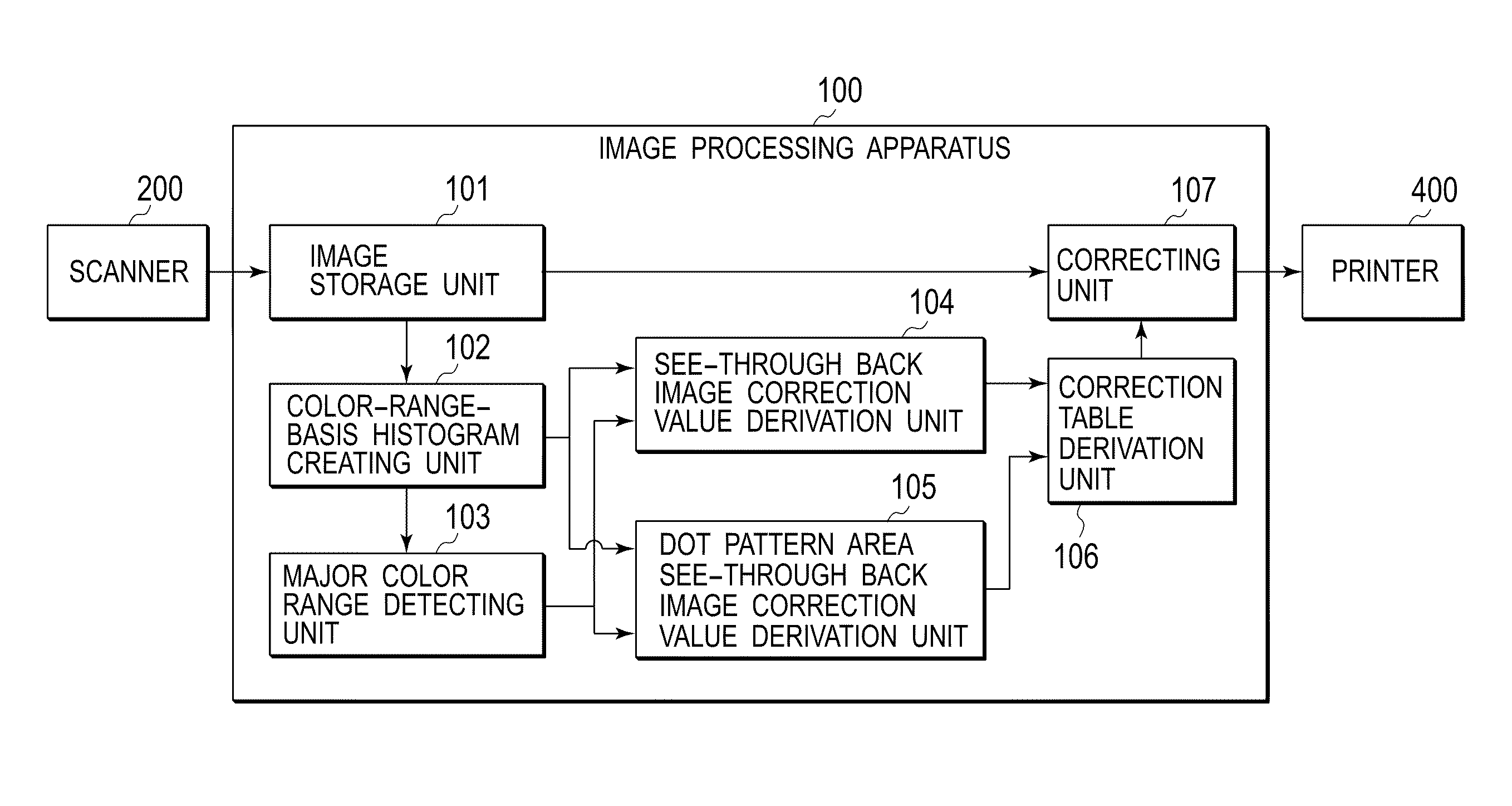

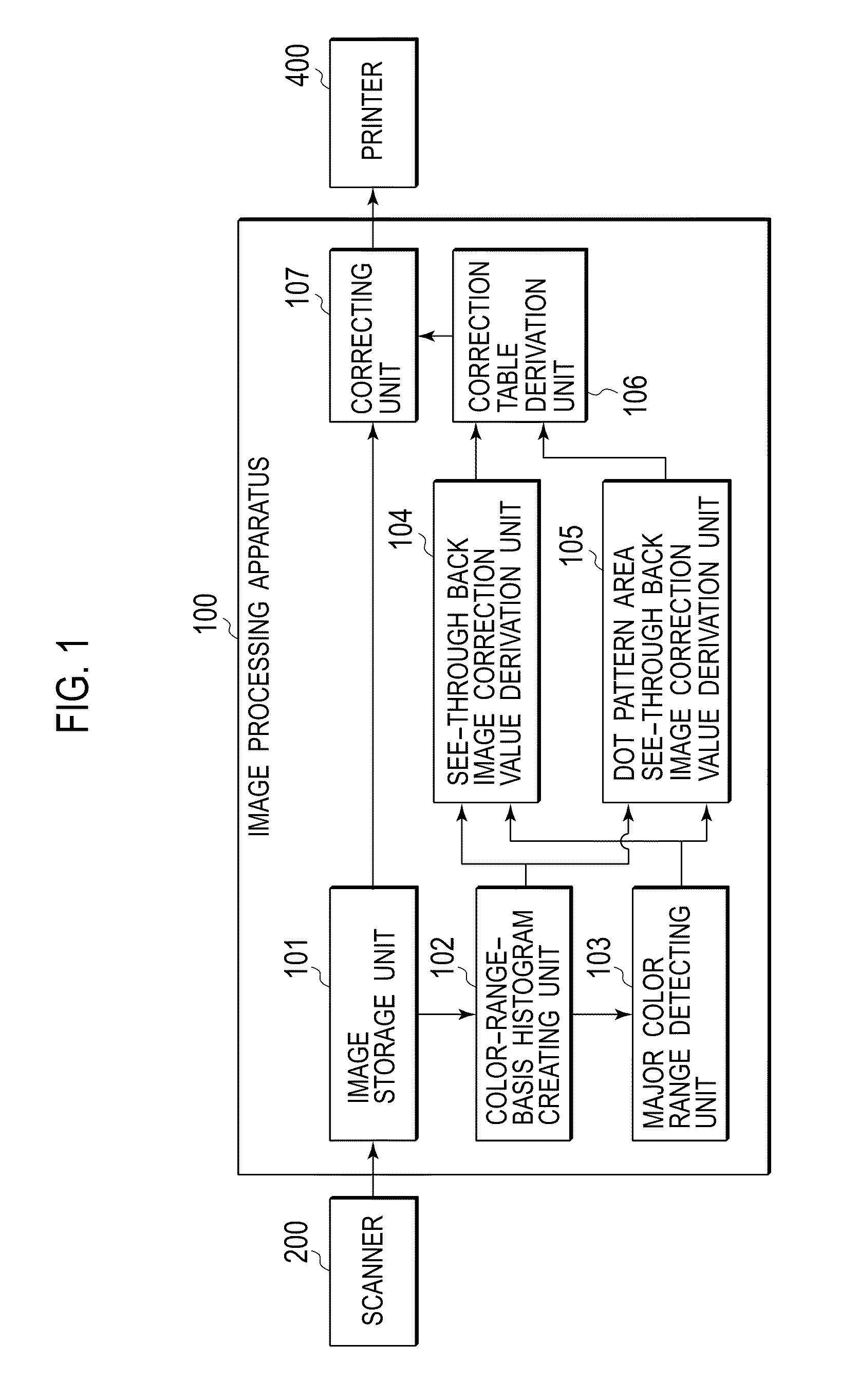

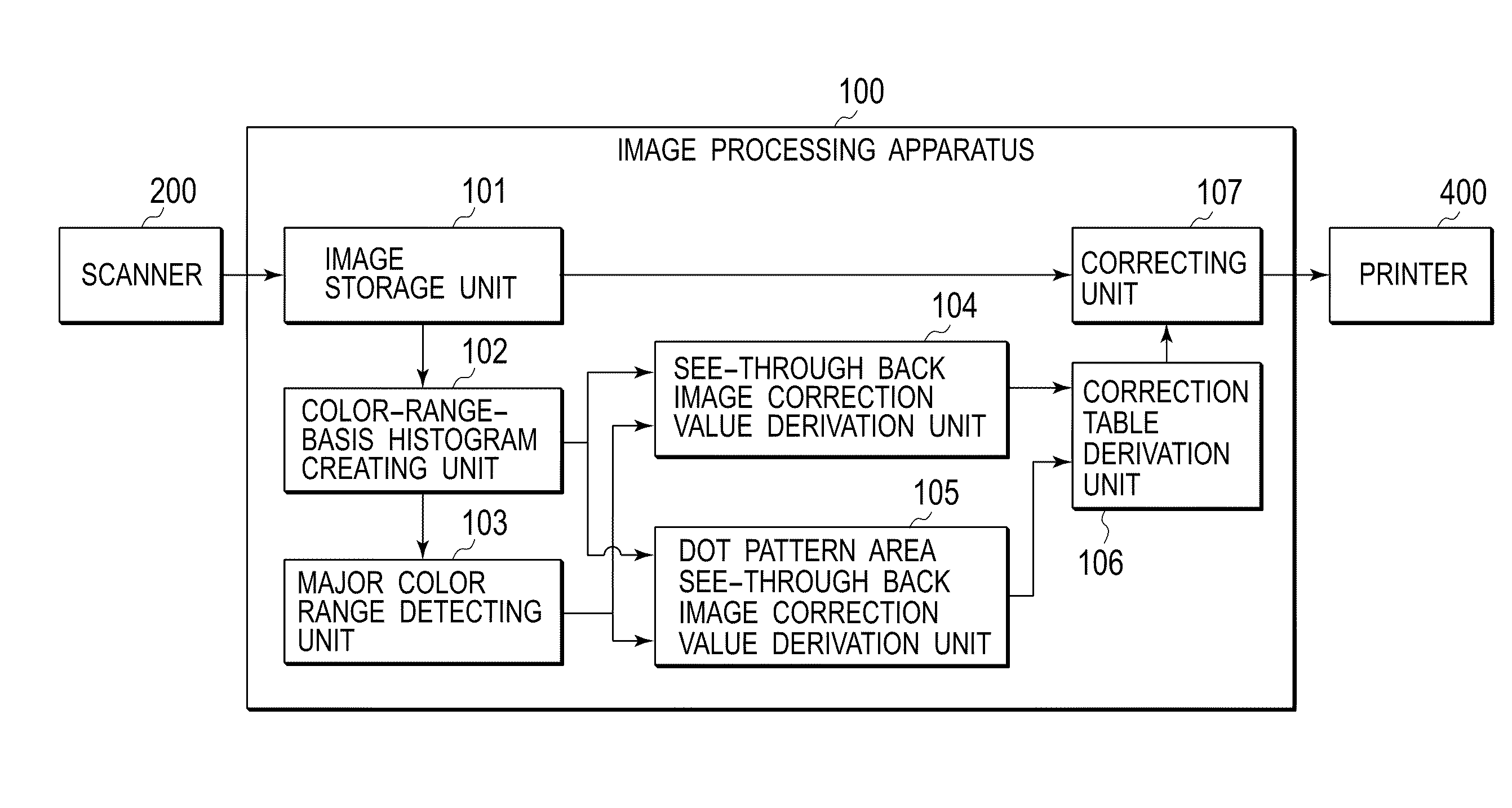

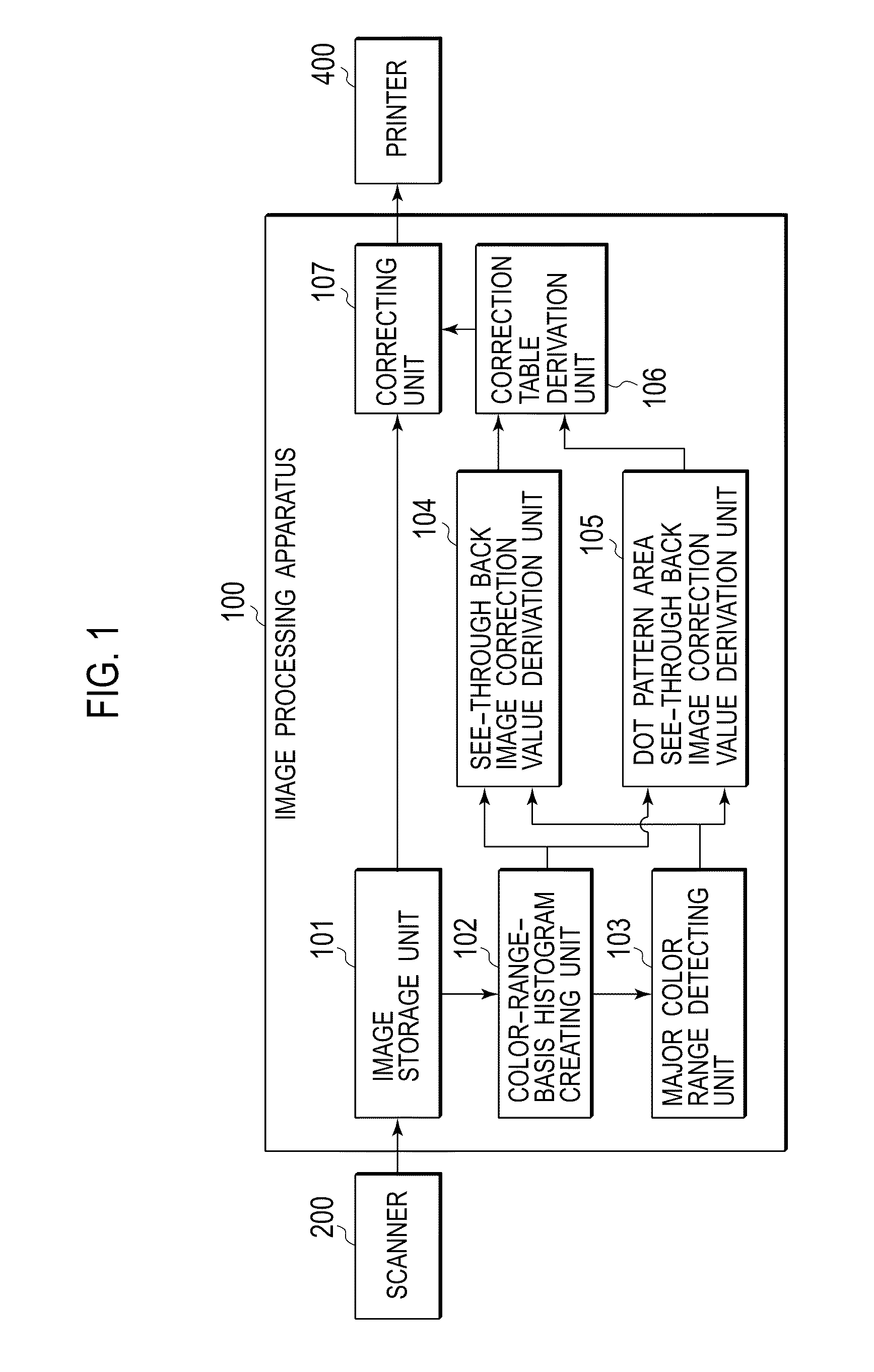

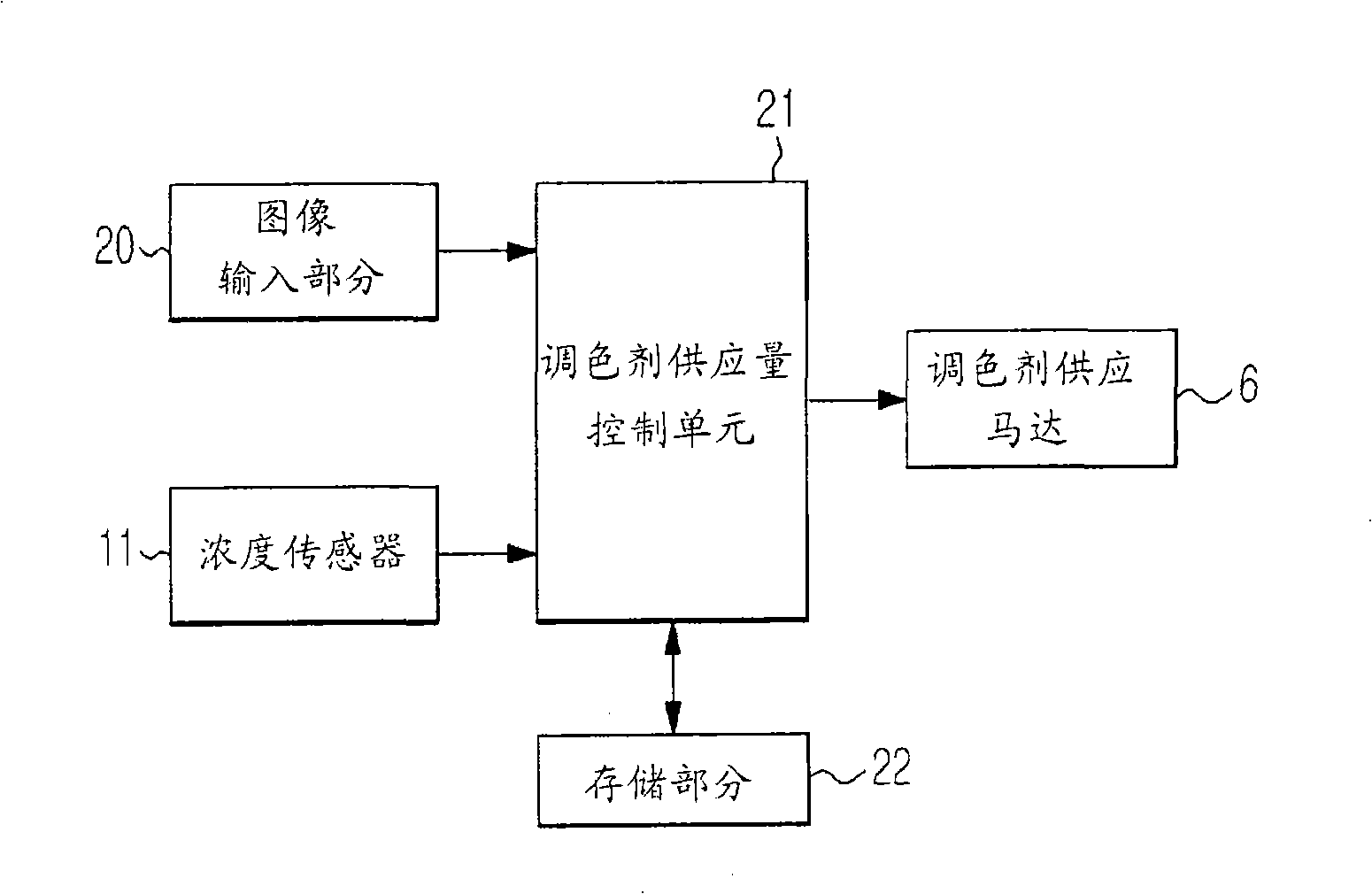

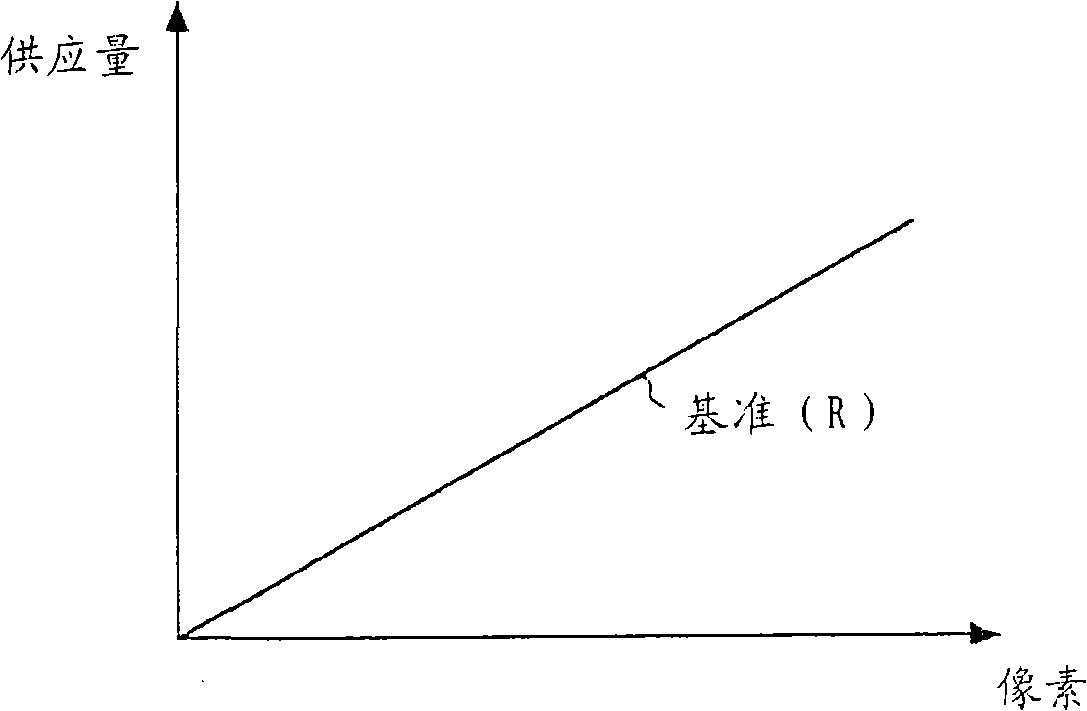

Image processing apparatus

InactiveUS8395832B2Preventing Image Quality DeteriorationMaintain continuityImage enhancementDigitally marking record carriersChange densityImaging processing

An image processing apparatus includes a major color range detector detecting the major color range from the image data; a criteria density setting unit determining a density value where the largest number of pixels exists in a density histogram of the major color range as a criteria density; a first correction value derivation unit deriving a first correction value to change density values in a predetermined range higher than the criteria density to be closer to the criteria density; a second correction value derivation unit deriving a second correction value to change density values in a predetermined range lower than the criteria density to be closer to the criteria density; a correction table derivation unit deriving a gradation correction table based on the first correction value and the second correction value; and a correcting unit correcting density of the scanned image data based on the gradation correction table.

Owner:OKI DATA CORP

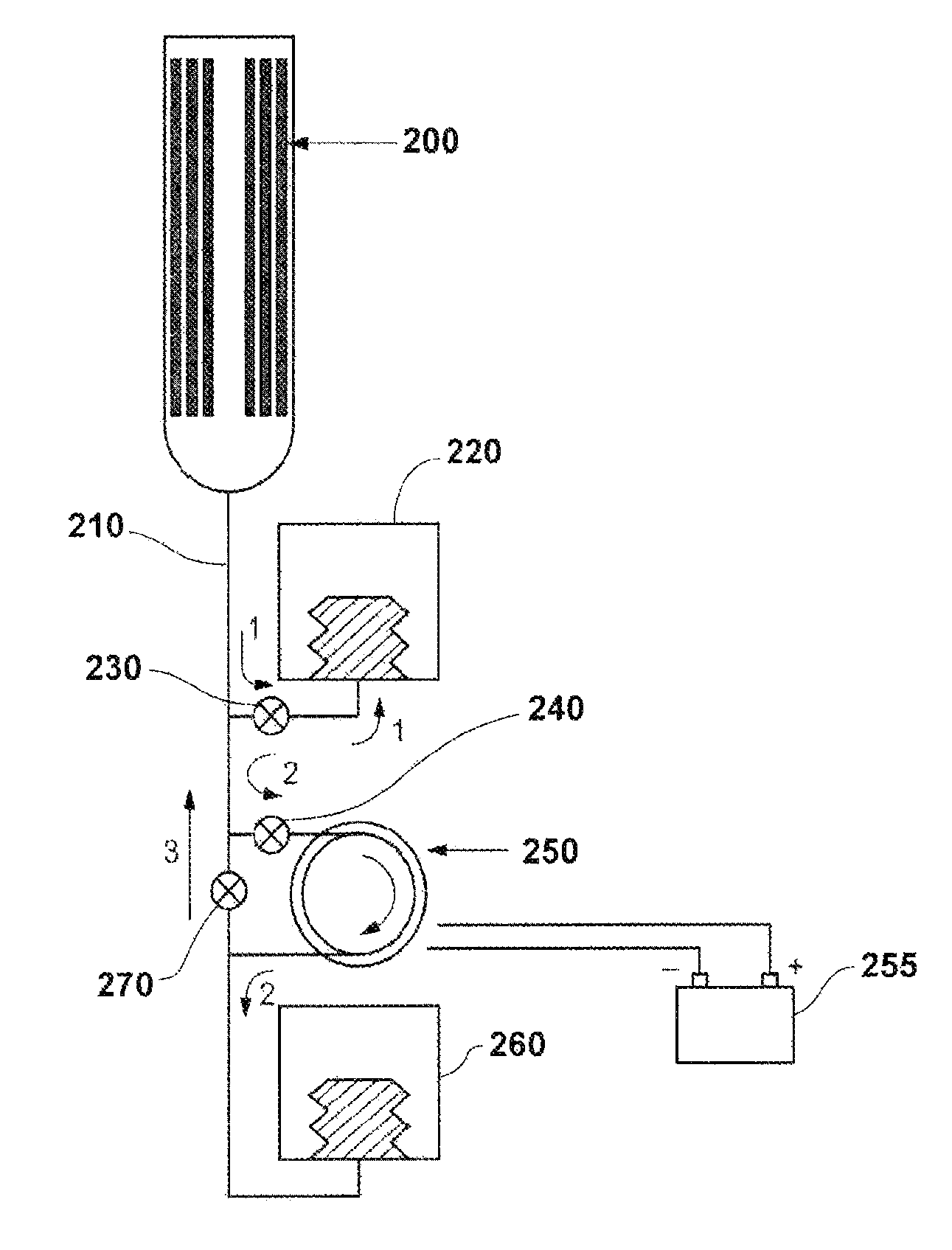

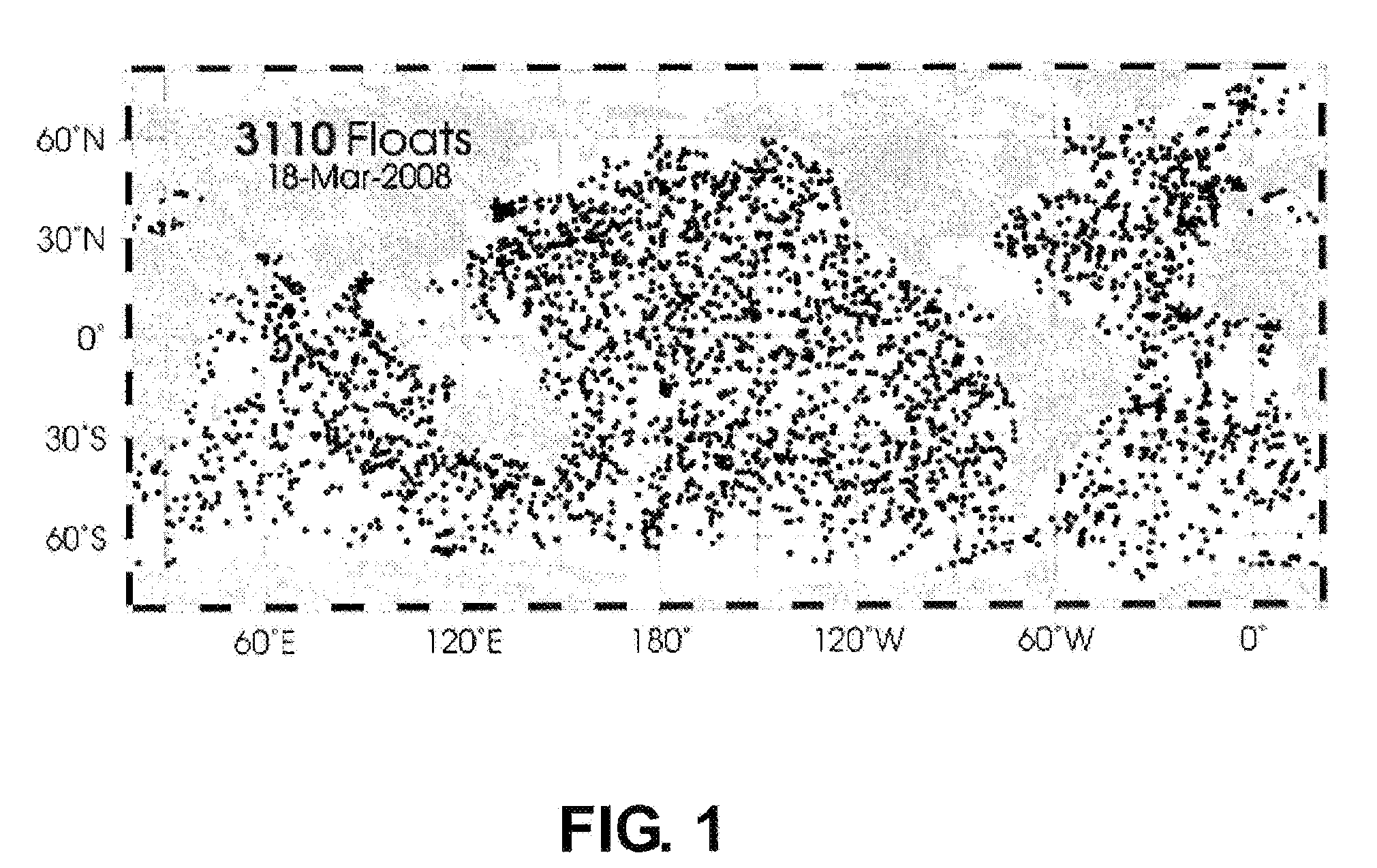

Phase change material thermal power generator

An energy producing device, for example a submersible vehicle for descending or ascending to different depths within water or ocean, is disclosed. The vehicle comprises a temperature-responsive material to which a hydraulic fluid is associated. A pressurized storage compartment stores the fluid as soon as the temperature-responsive material changes density. The storage compartment is connected with a hydraulic motor, and a valve allows fluid passage from the storage compartment to the hydraulic motor. An energy storage component, e.g. a battery, is connected with the hydraulic motor and is charged by the hydraulic motor when the hydraulic fluid passes through the hydraulic motor. Upon passage in the hydraulic motor, the fluid is stored in a further storage compartment and is then sent back to the area of the temperature-responsive material.

Owner:CALIFORNIA INST OF TECH

Microwave coprecipitation method for preparing nano glaze of lead metaborate

The invention relates to prepn. method of nanometre borate. The processing steps are: (1) taking Boratex and lead nitrate with mole ratio 1:1 to prepare 20 percent of aqueous solution; (2) taking 2-ethyl sulfo group sodium succinate to added into said lead nitrate aqueous solution to change density to 2 perent; (3) slowly pouring said sodium succinate into mixed solution to be fully stirred to create precipitation, constant temp. 35-45 deg.C, reaction time 1.5-2 hours, then to be batch processed by 500 W microwave illuminating 4-6 minutes, temp of solution is 80-100 deg.C; (4) said product is centrifugated to generate precipitant which is washed by distilled water two times and by absolute ethyl alcohol three times to produce nanometre lead metaborate; (5) drying said nanometre lead metaborate 10 hours in 60 deg.C vacuum to produce nanometre lead metaborate frit.

Owner:皮晓天

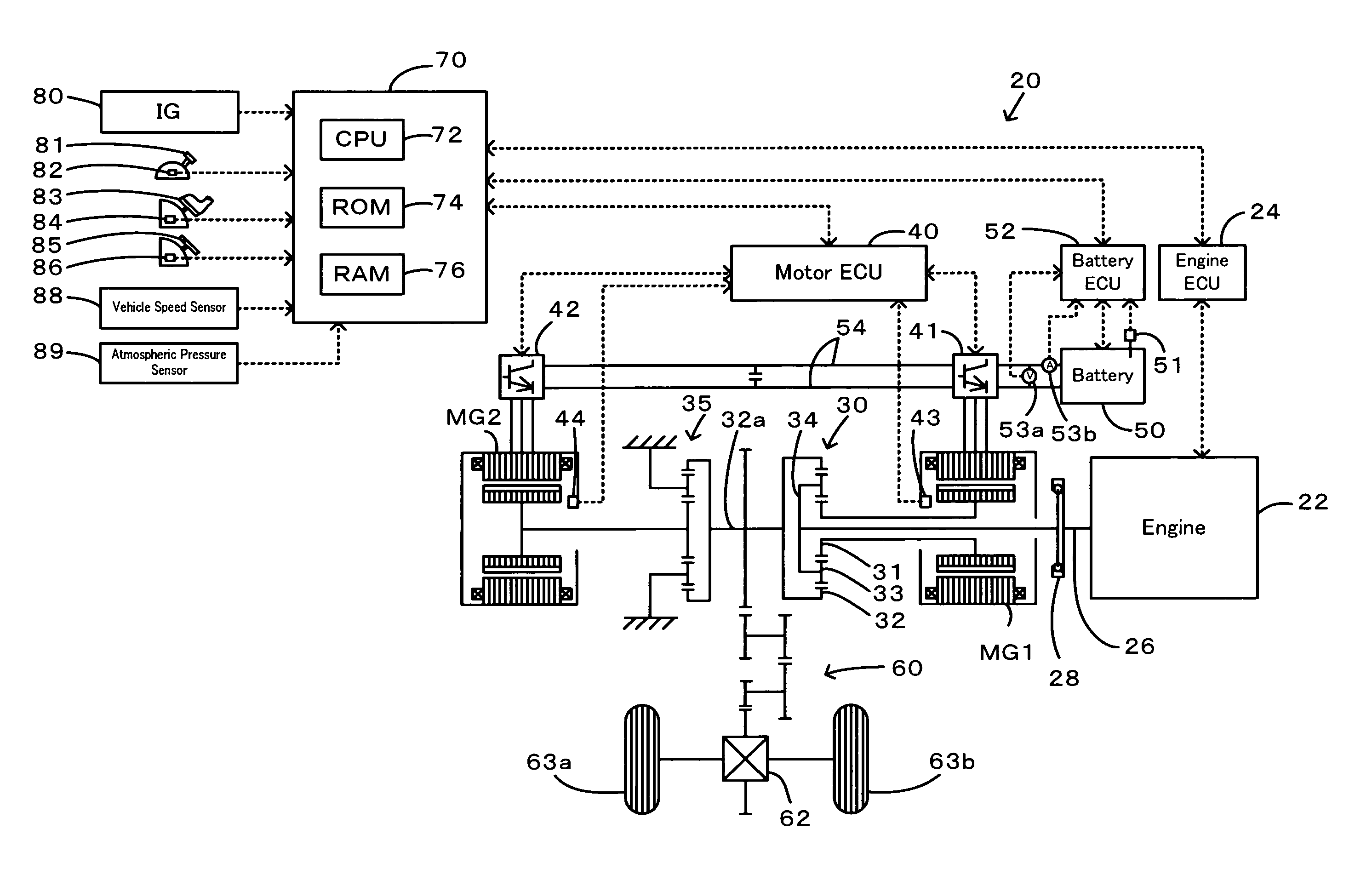

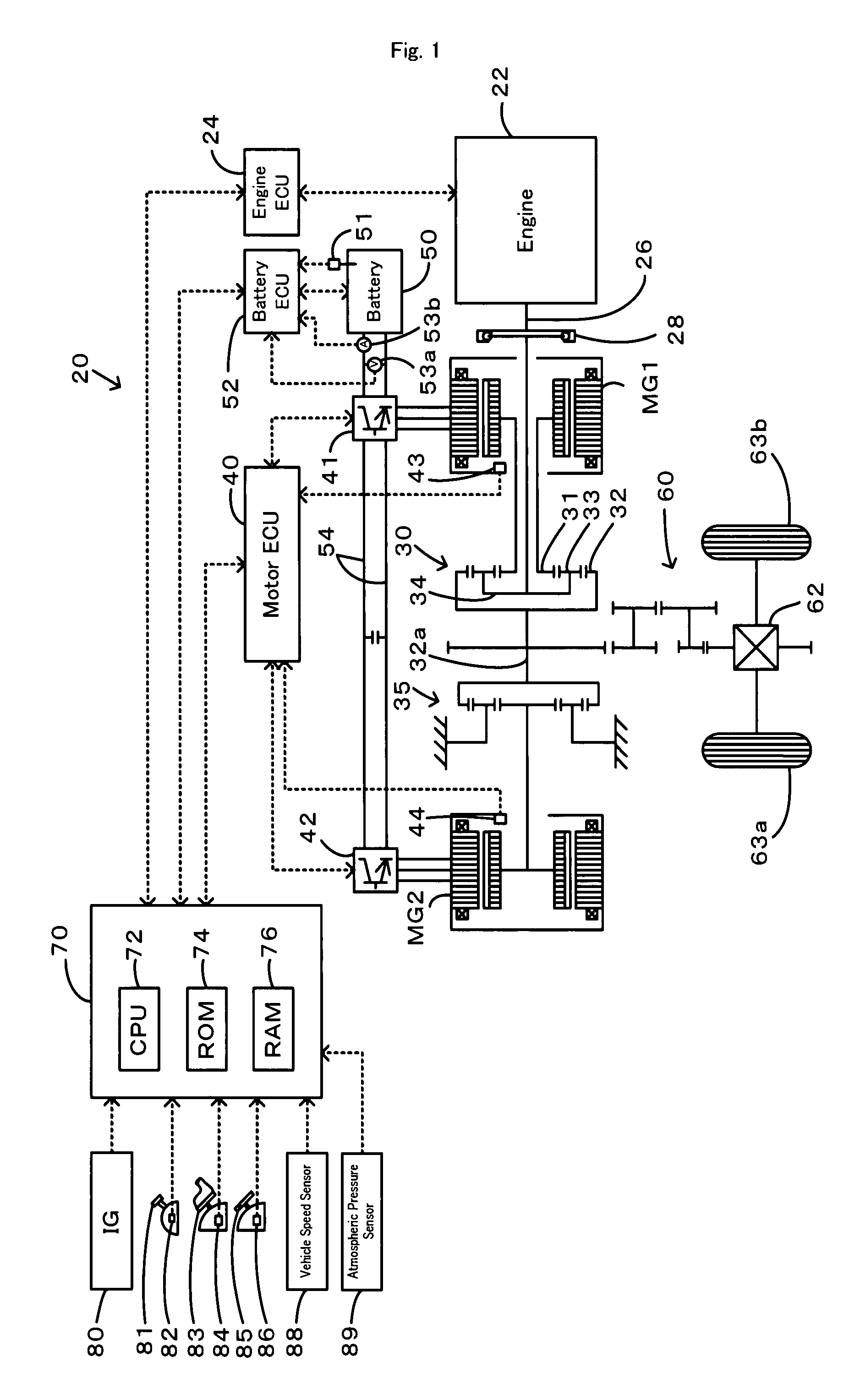

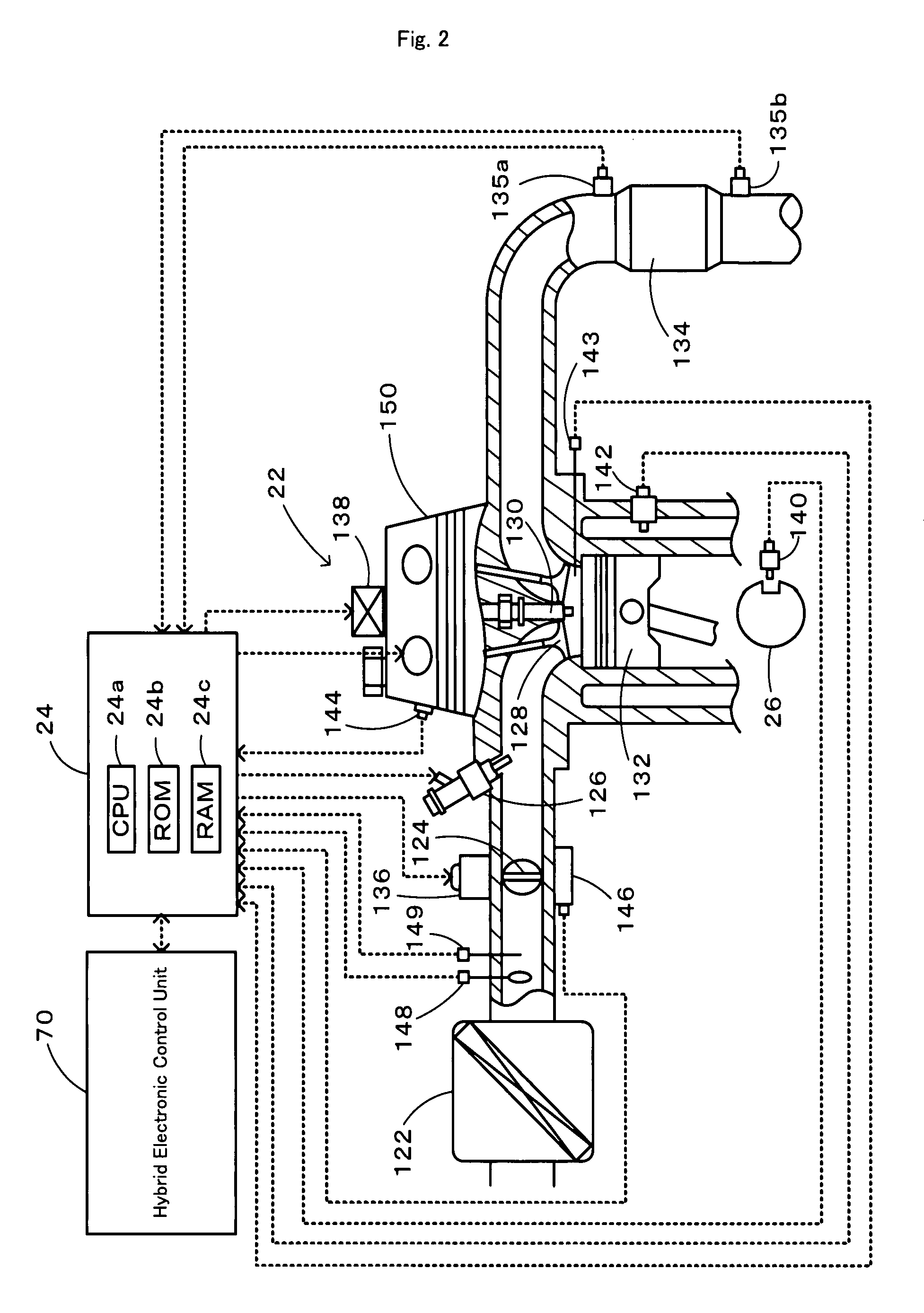

Power output apparatus, control method of power output apparatus, and vehicle equipped with power output apparatus

ActiveUS7918762B2Increase powerEasy to operateHybrid vehiclesElectrical controlChange densityVolumetric Mass Density

The drive control of the invention executed in a vehicle sets a correction coefficient keg, based on an intake air temperature and an atmospheric pressure reflecting the density of intake air supplied to an engine, and multiplies a power demand required for the vehicle by the set correction coefficient keg to specify a target engine power, which is to be output from the engine. The engine and two motors are then controlled to ensure output of the specified target engine power from the engine and output of a torque demand, which depends upon an accelerator opening. The varying density of the intake air may cause output of excessive power from the engine or output of insufficient power from the engine. A battery is charged or discharged to compensate for the excessive power output from the engine or for the insufficient power output from the engine. The drive control of the invention effectively deals with the environmental change and prevents the battery from being excessively charged with an unexpectedly high electric power or from being excessively discharged to supply an unexpectedly high electric power.

Owner:TOYOTA JIDOSHA KK +1

Image processing apparatus

InactiveUS20100091348A1Preventing Image Quality DeteriorationMaintain continuityImage enhancementImage analysisChange densityImaging processing

An image processing apparatus includes a major color range detector detecting the major color range from the image data; a criteria density setting unit determining a density value where the largest number of pixels exists in a density histogram of the major color range as a criteria density; a first correction value derivation unit deriving a first correction value to change density values in a predetermined range higher than the criteria density to be closer to the criteria density; a second correction value derivation unit deriving a second correction value to change density values in a predetermined range lower than the criteria density to be closer to the criteria density; a correction table derivation unit deriving a gradation correction table based on the first correction value and the second correction value; and a correcting unit correcting density of the scanned image data based on the gradation correction table.

Owner:OKI DATA CORP

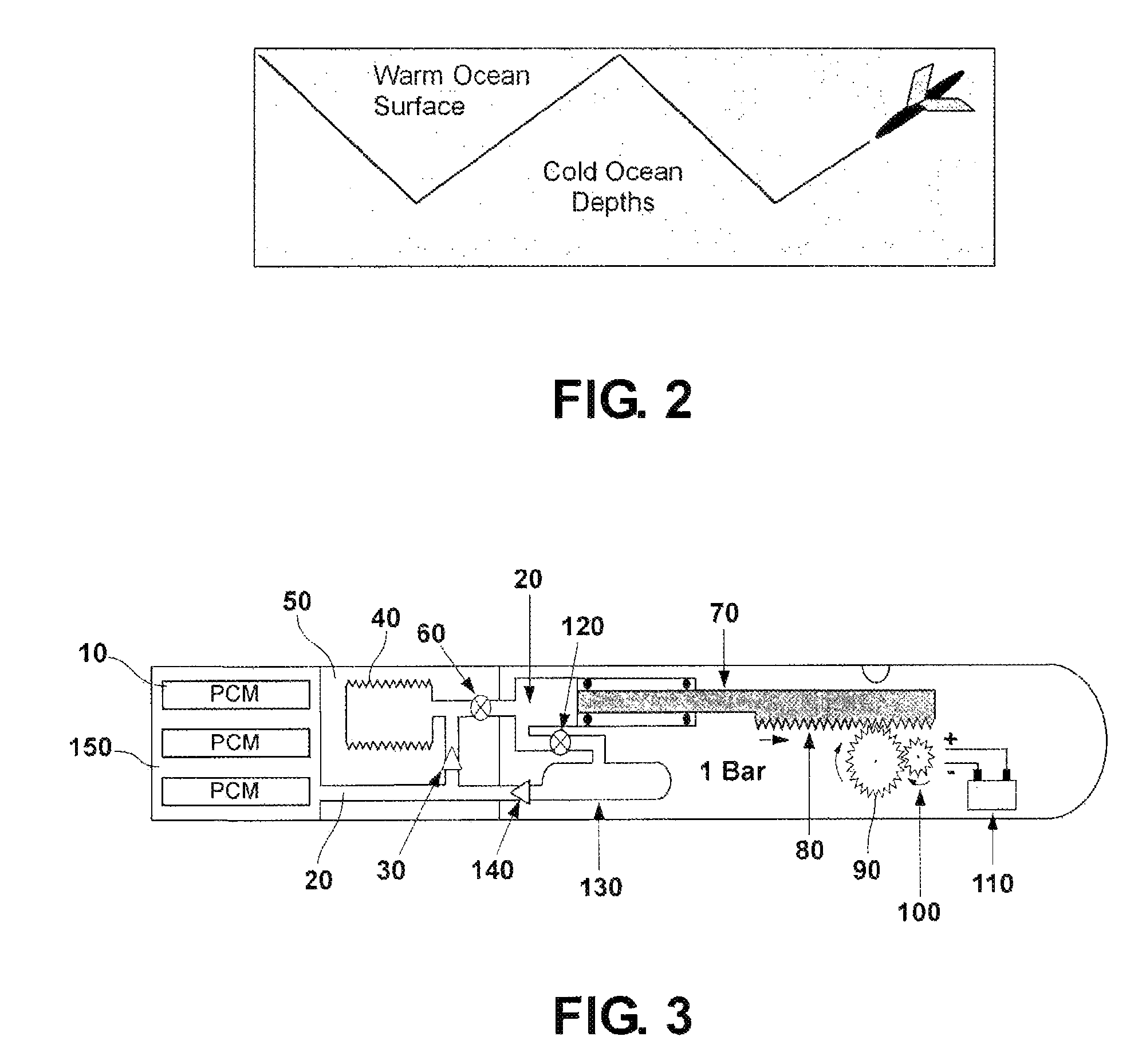

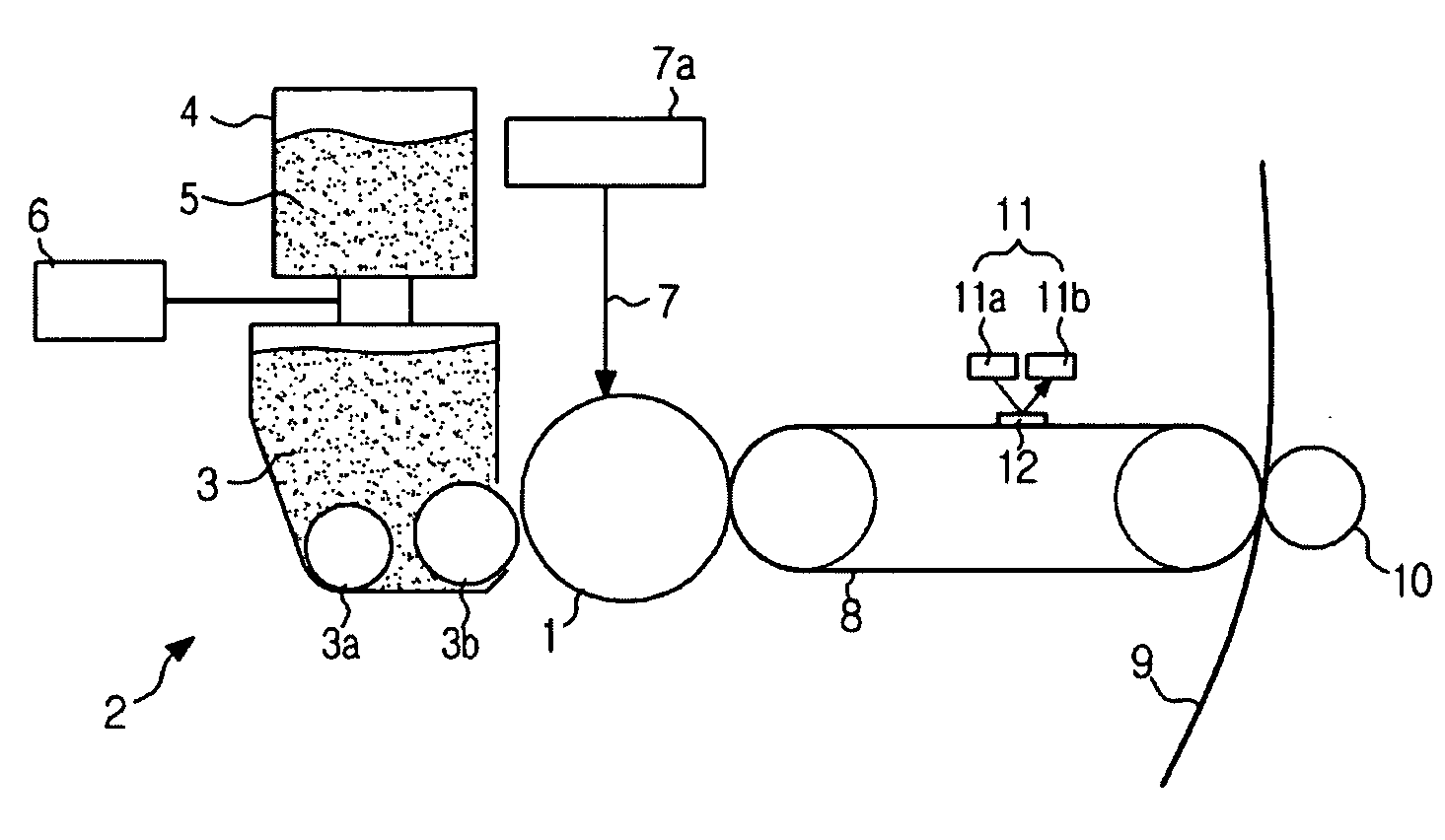

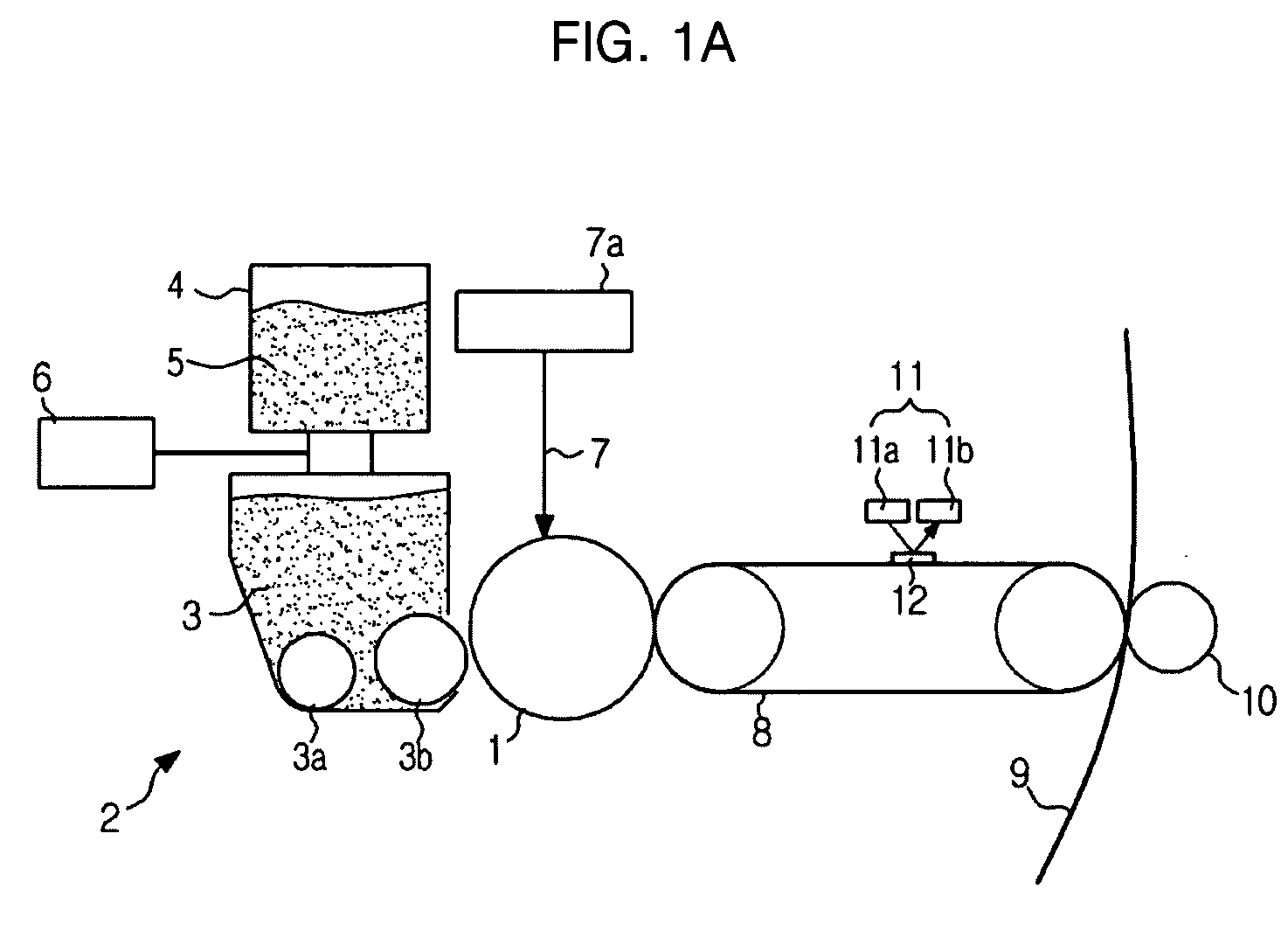

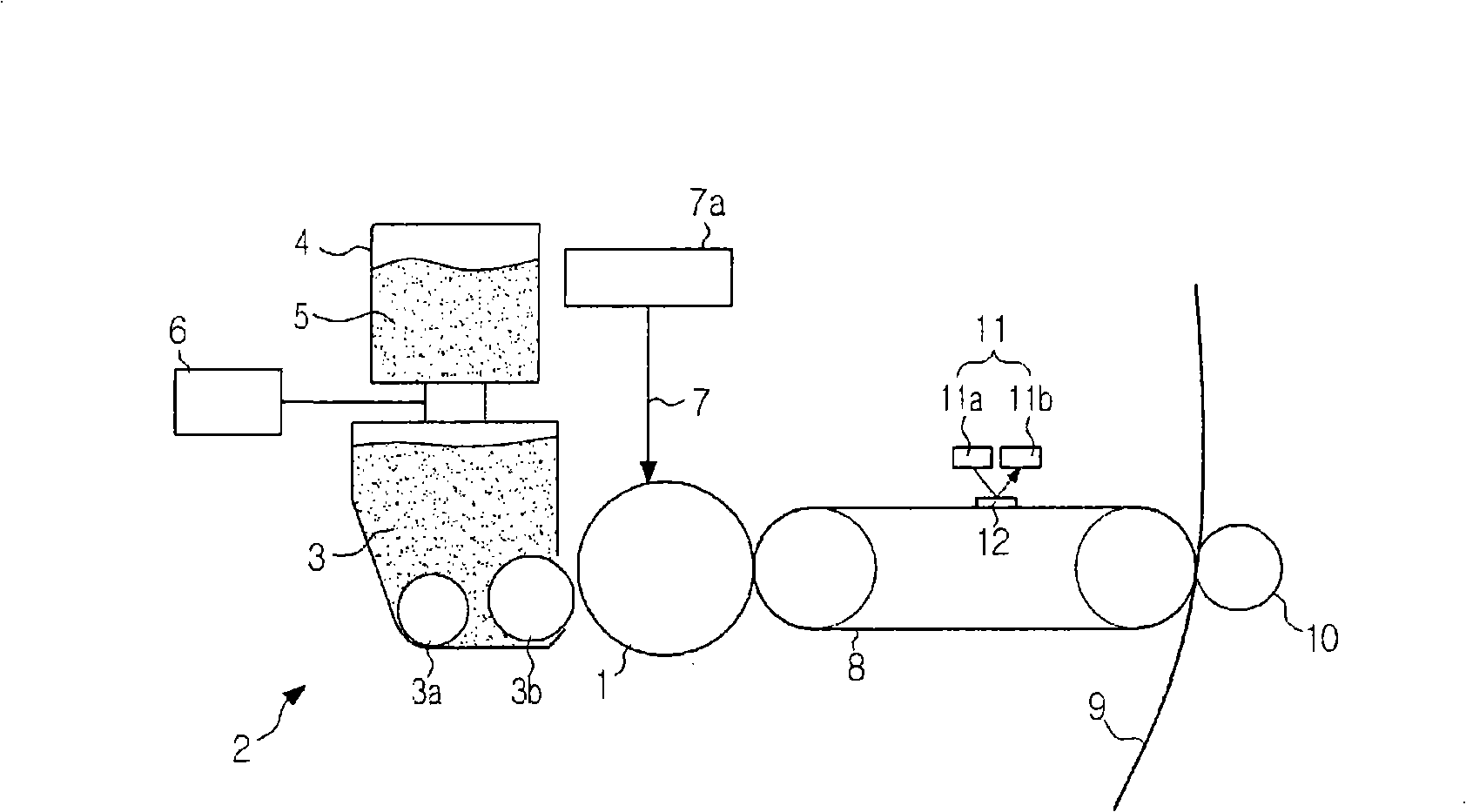

Image forming apparatus and control method thereof

InactiveUS20080219687A1Extending a cycle of detecting density of image quality longMaintain relatively stableElectrographic process apparatusChange densityImage formation

An image forming apparatus and a control method thereof. The image forming apparatus includes an image input part, a development unit which is supplied with a toner and forms a developer to develop an input image inputted from the image input part, a transfer member to form a patch image, a density sensor which detects density of the patch image, and a toner supply amount control unit which sets a toner supply amount of the development unit according to changed density of the patch image which is detected by the density sensor with a predetermined detecting cycle and applies the set toner supply amount to operation of printing the input image. Accordingly, a cycle of test printing the patch image can be extended to a longer period, unnecessary consumption of the toner is prevented, and the density of the printed image can be maintained stably.

Owner:S PRINTING SOLUTION CO LTD

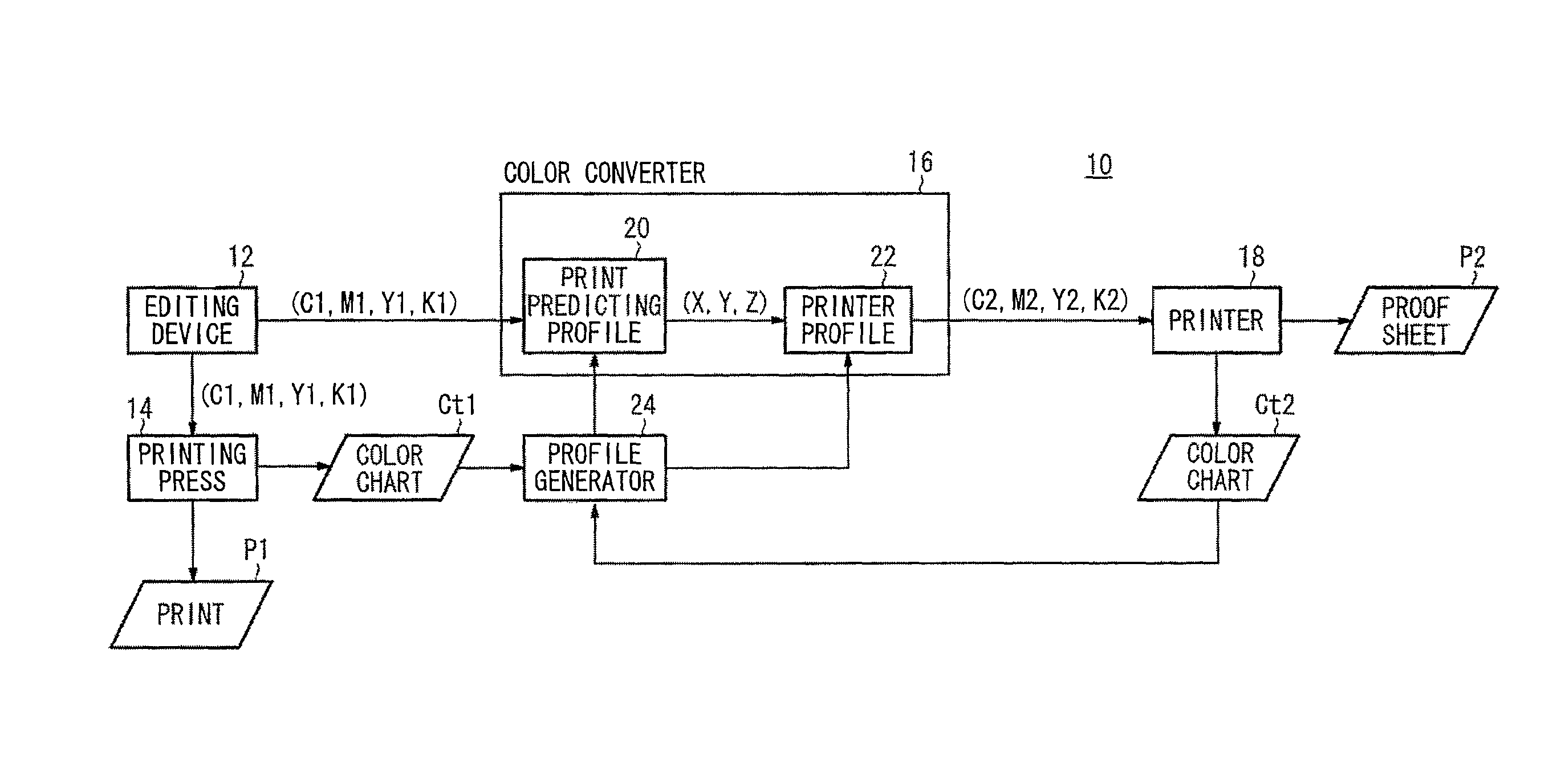

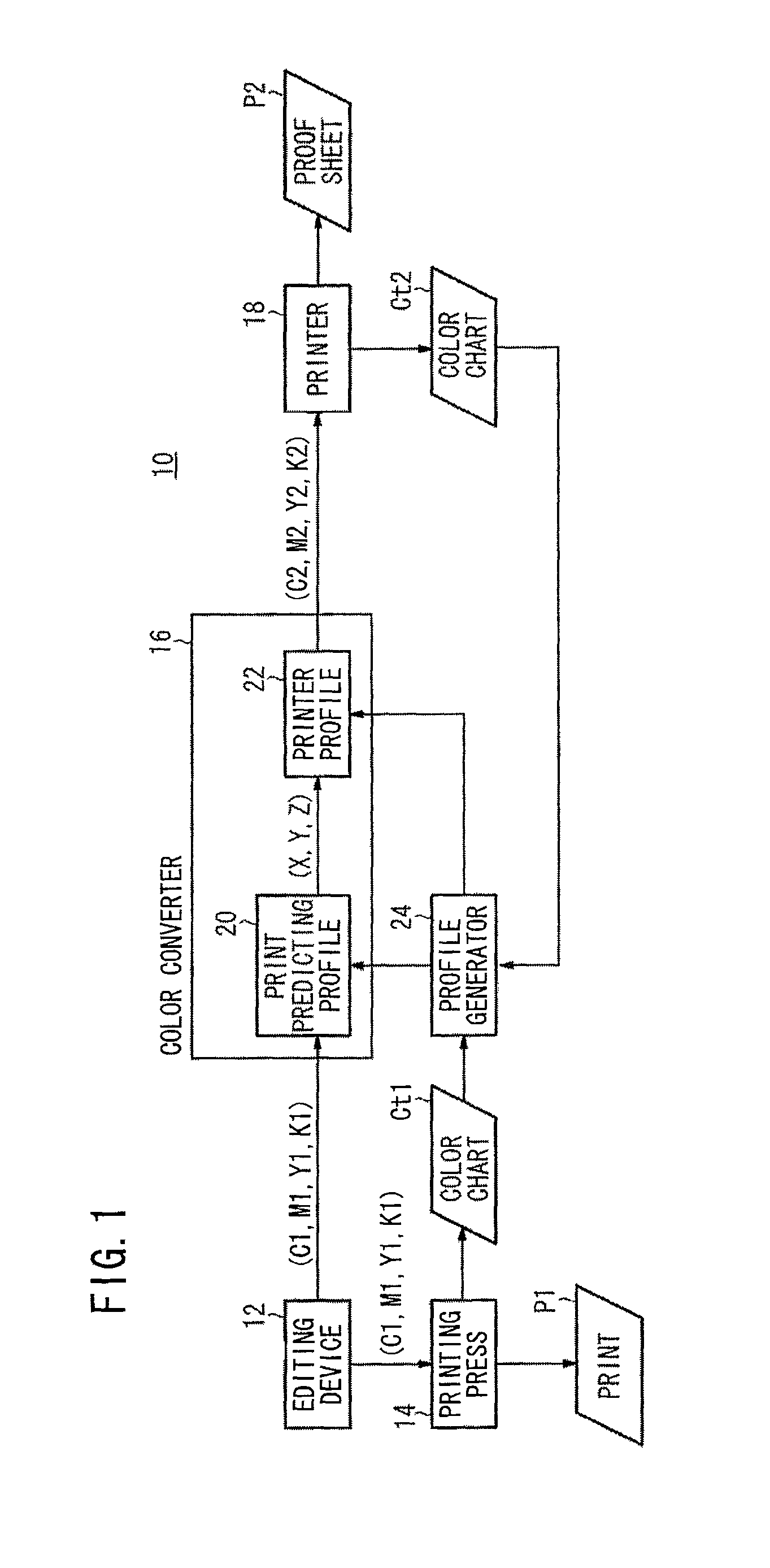

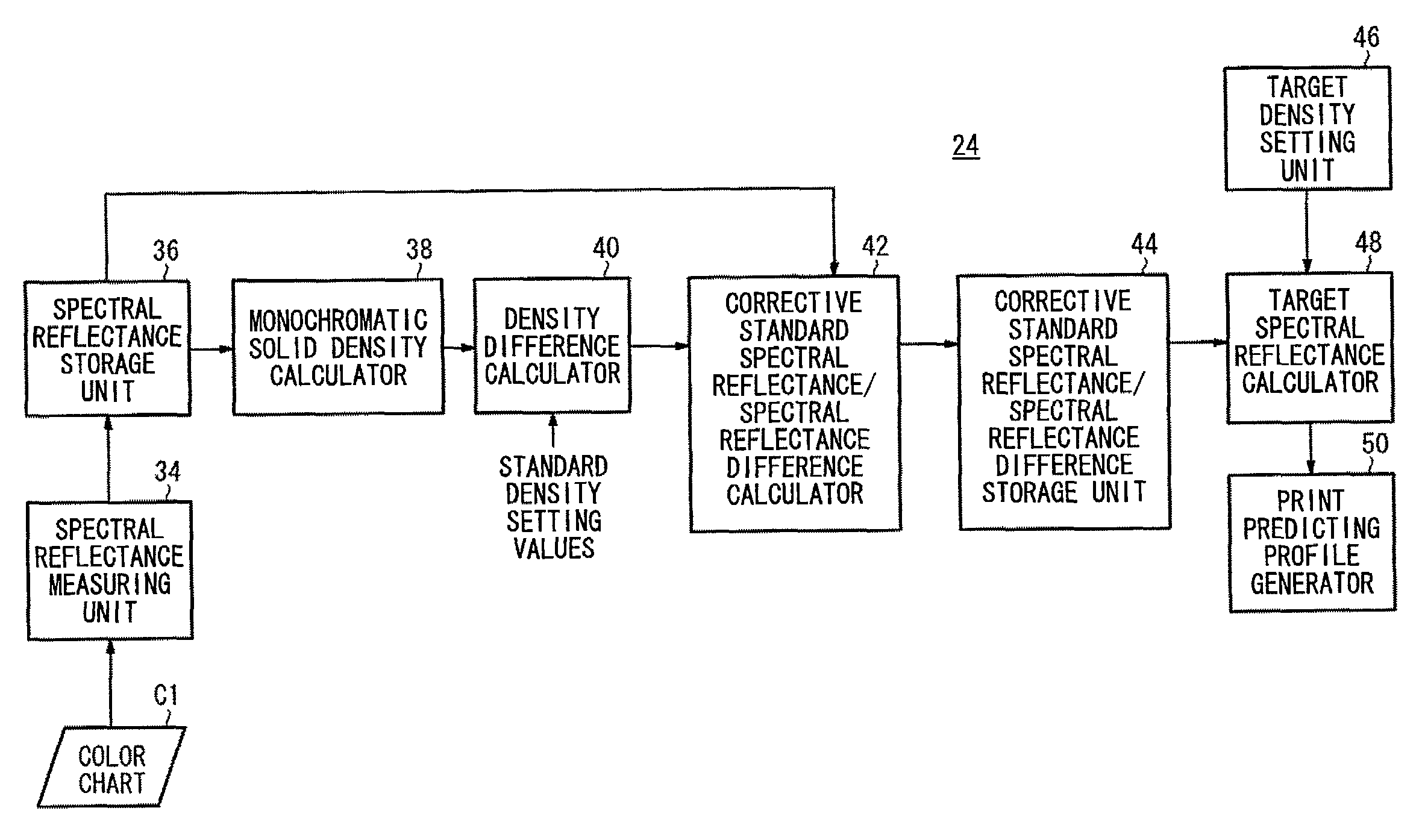

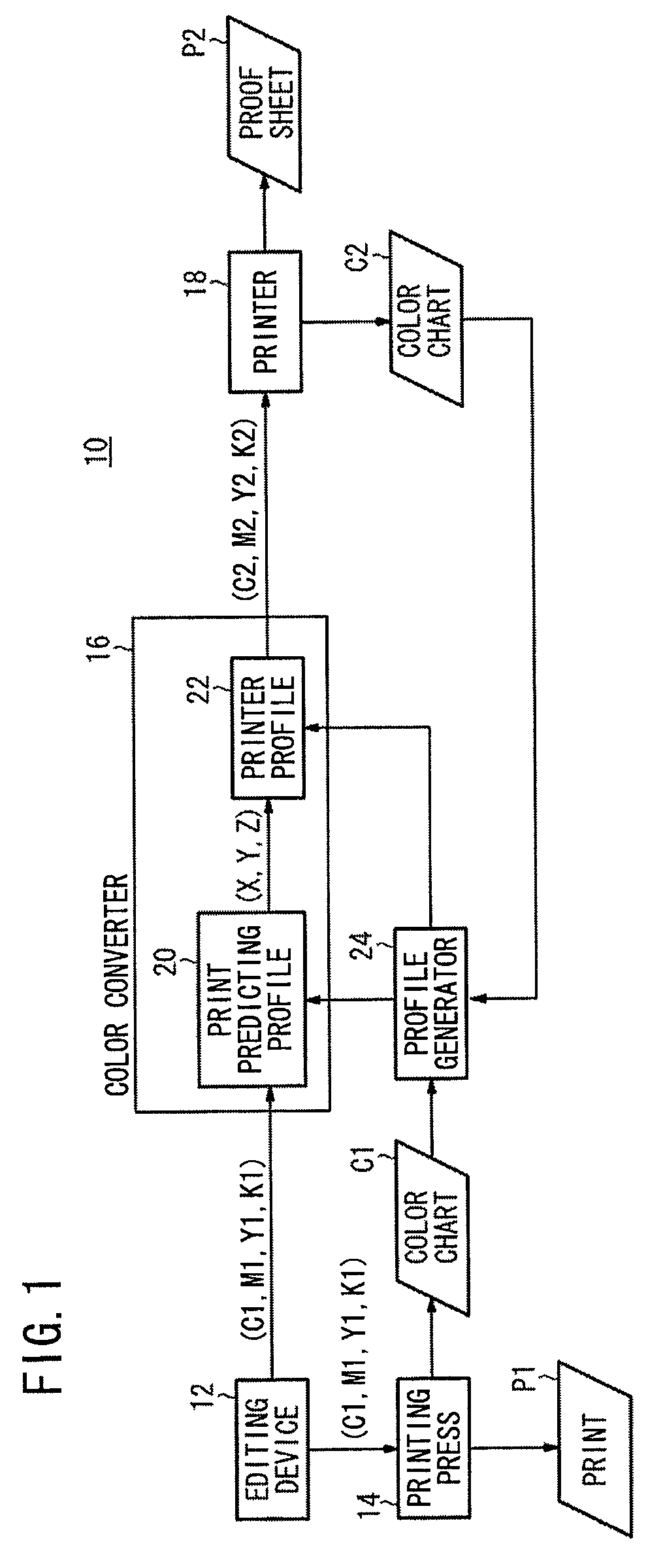

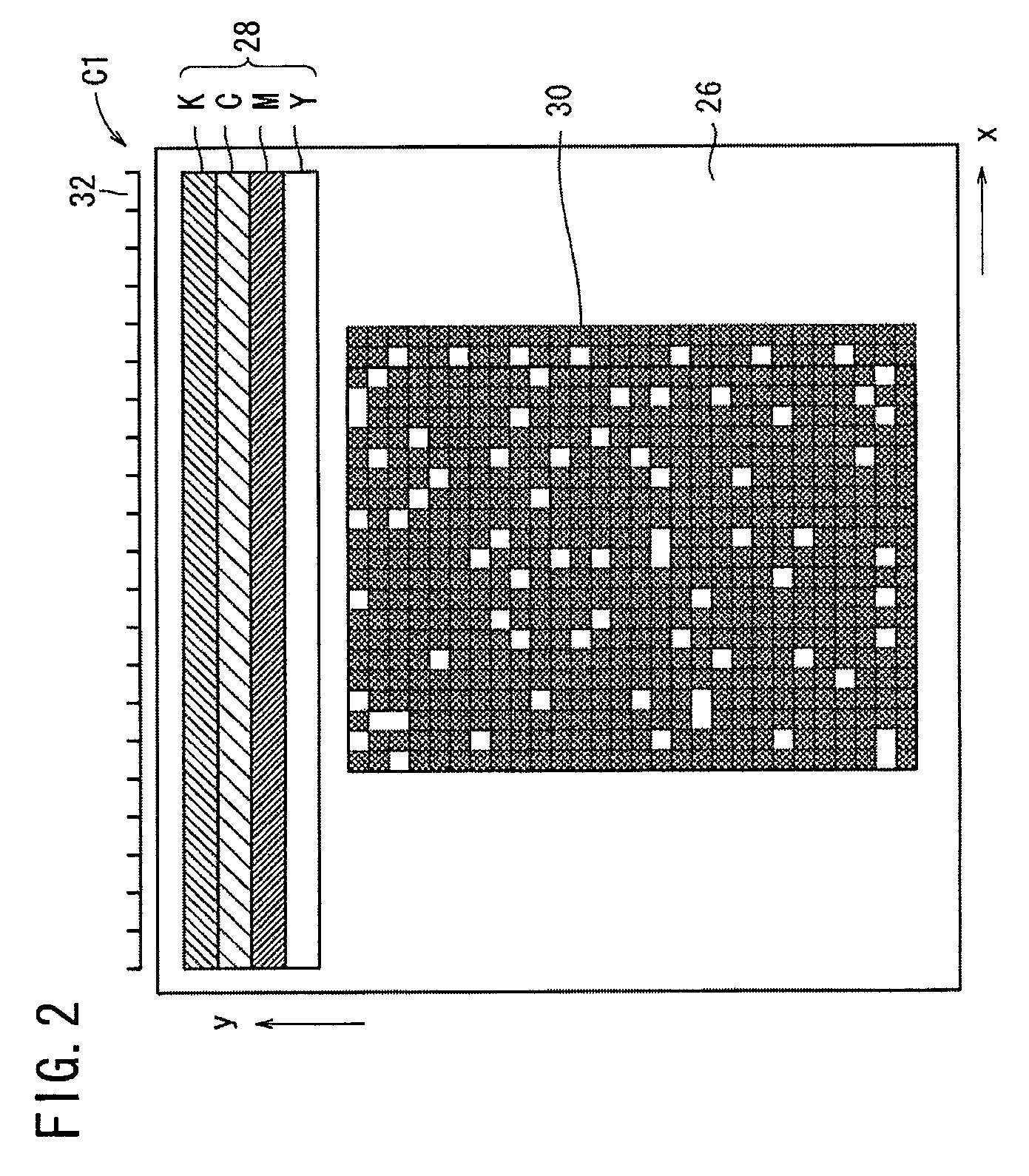

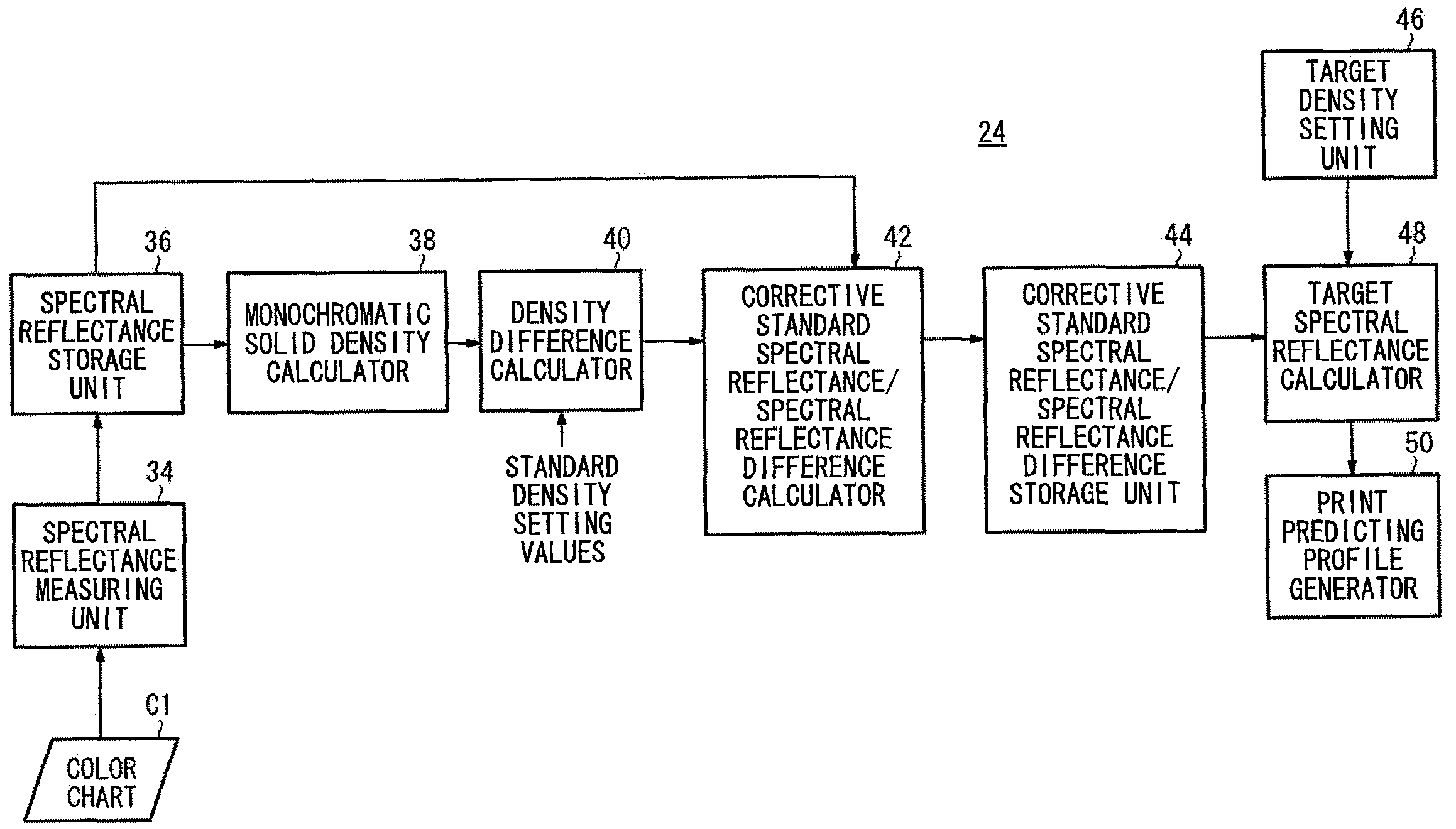

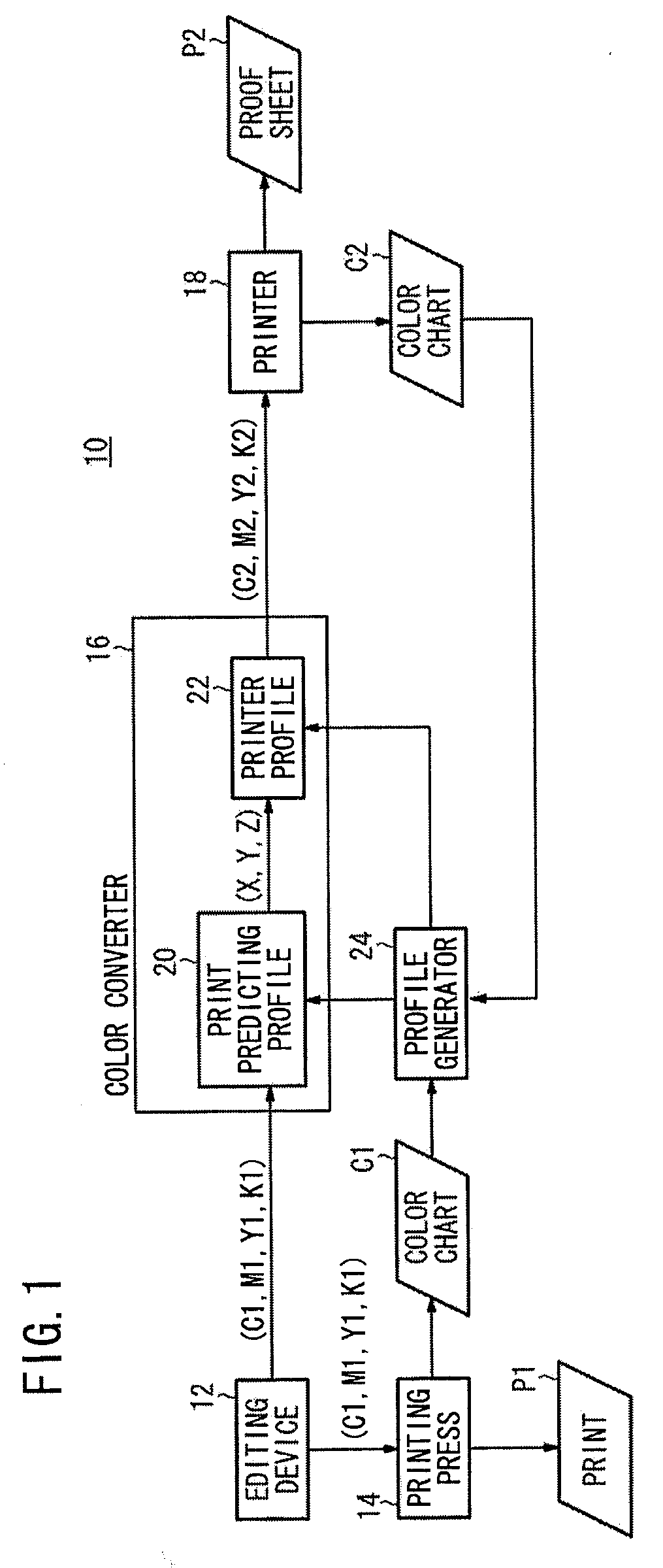

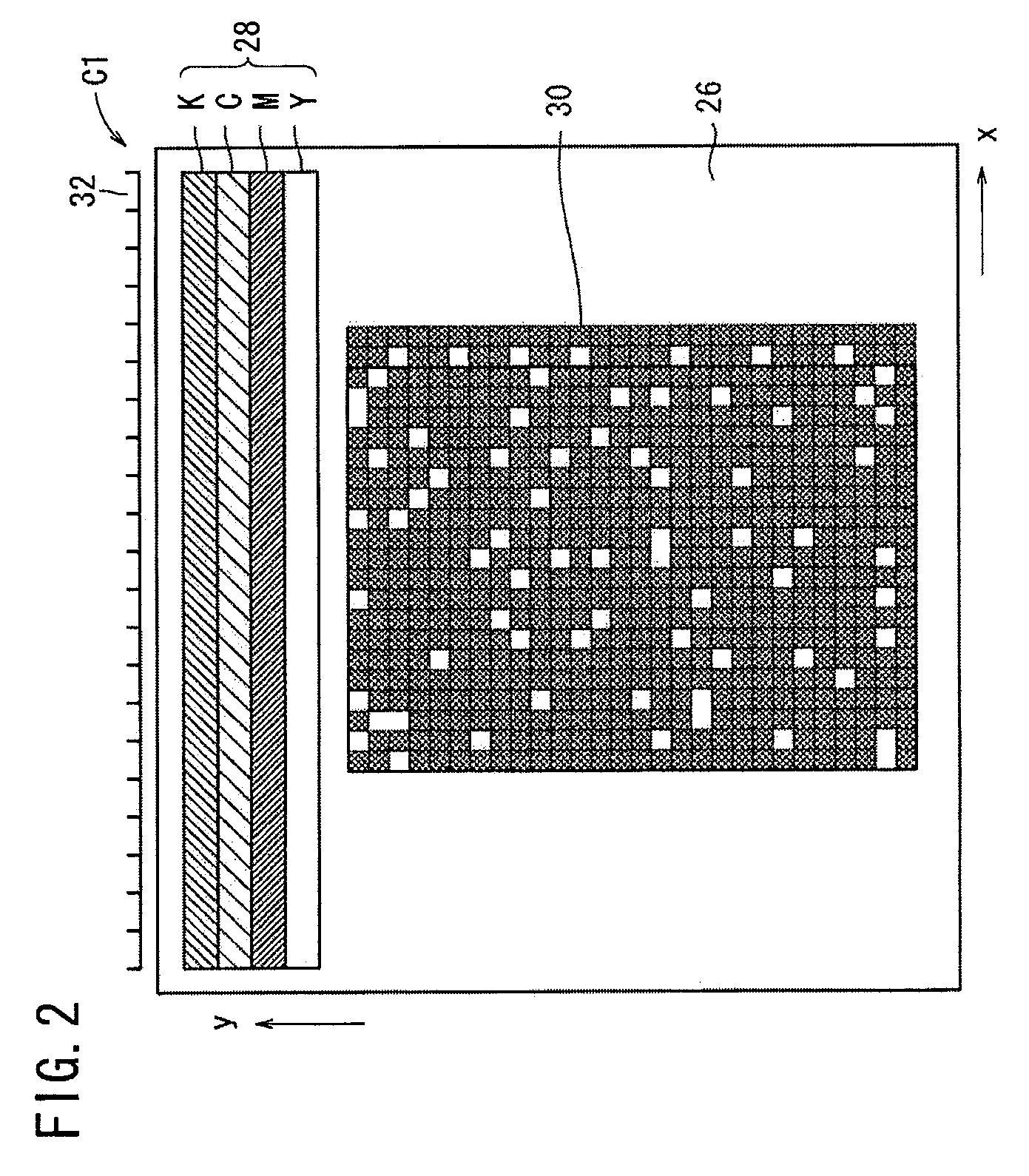

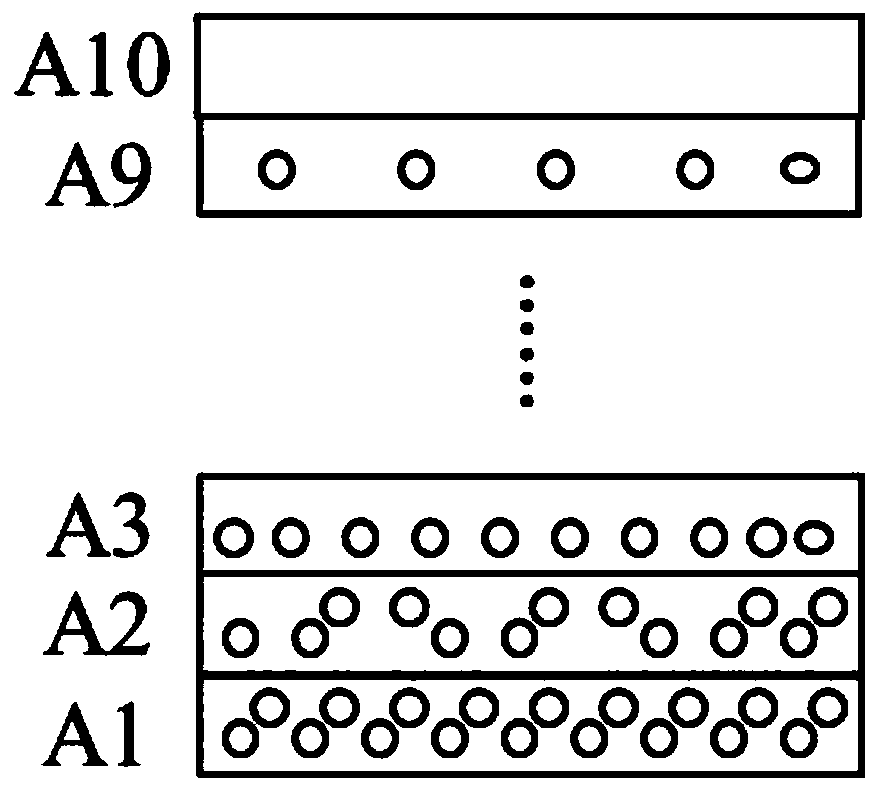

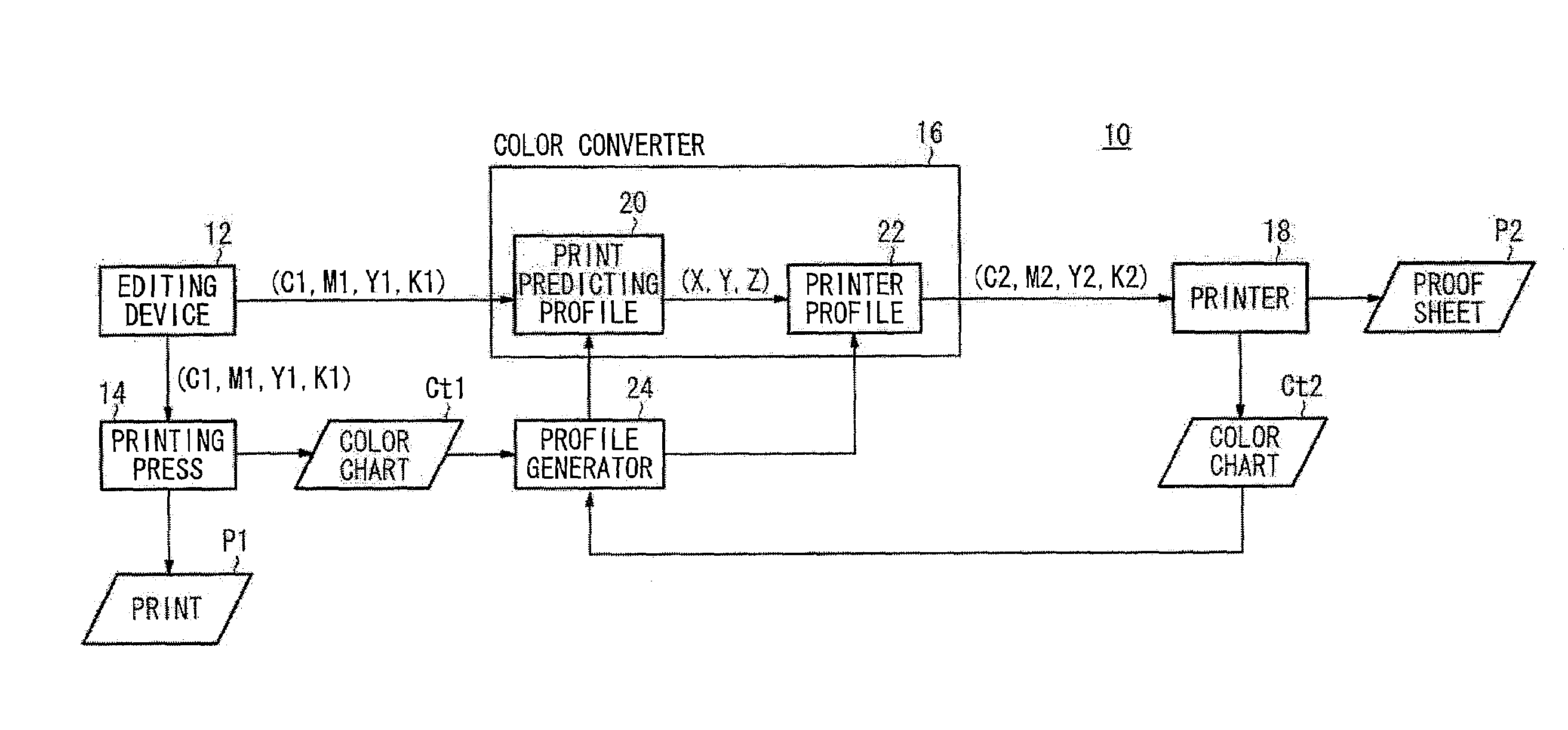

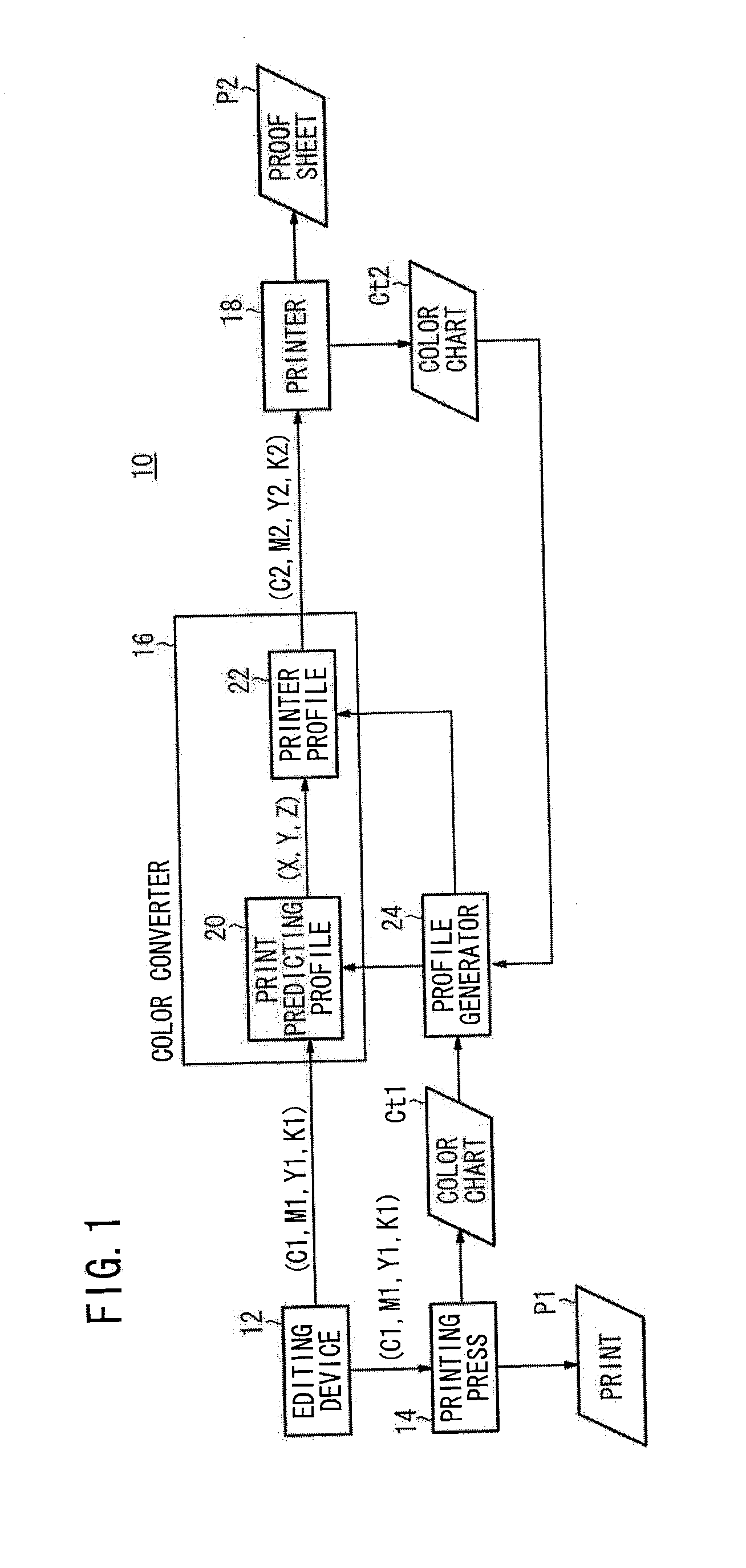

Method of and system for predicting print colors

InactiveUS8373897B2Easy and quick responseTrue colorDigitally marking record carriersDigital computer detailsChange densityComputer science

A method and a system for predicting print colors are provided. A profile generator determines standard density spectral reflectances of a color chart printed under standard density conditions, first changed density spectral reflectances of a color chart printed with only the density of one of colors C, M, Y, K being changed by a given amount, and second changed density spectral reflectances of a color chart printed with the densities of the colors C, M, Y, K being changed by the same amount. The profile generator generates a print predicting profile for obtaining desired target densities, using the standard density spectral reflectances, the differences between the standard density spectral reflectances and the first changed density spectral reflectances, and corrective coefficients for obtaining the second changed density spectral reflectances, and predicts highly accurately colors of the print where the density of a desired color is changed, using the print predicting profile.

Owner:FUJIFILM CORP

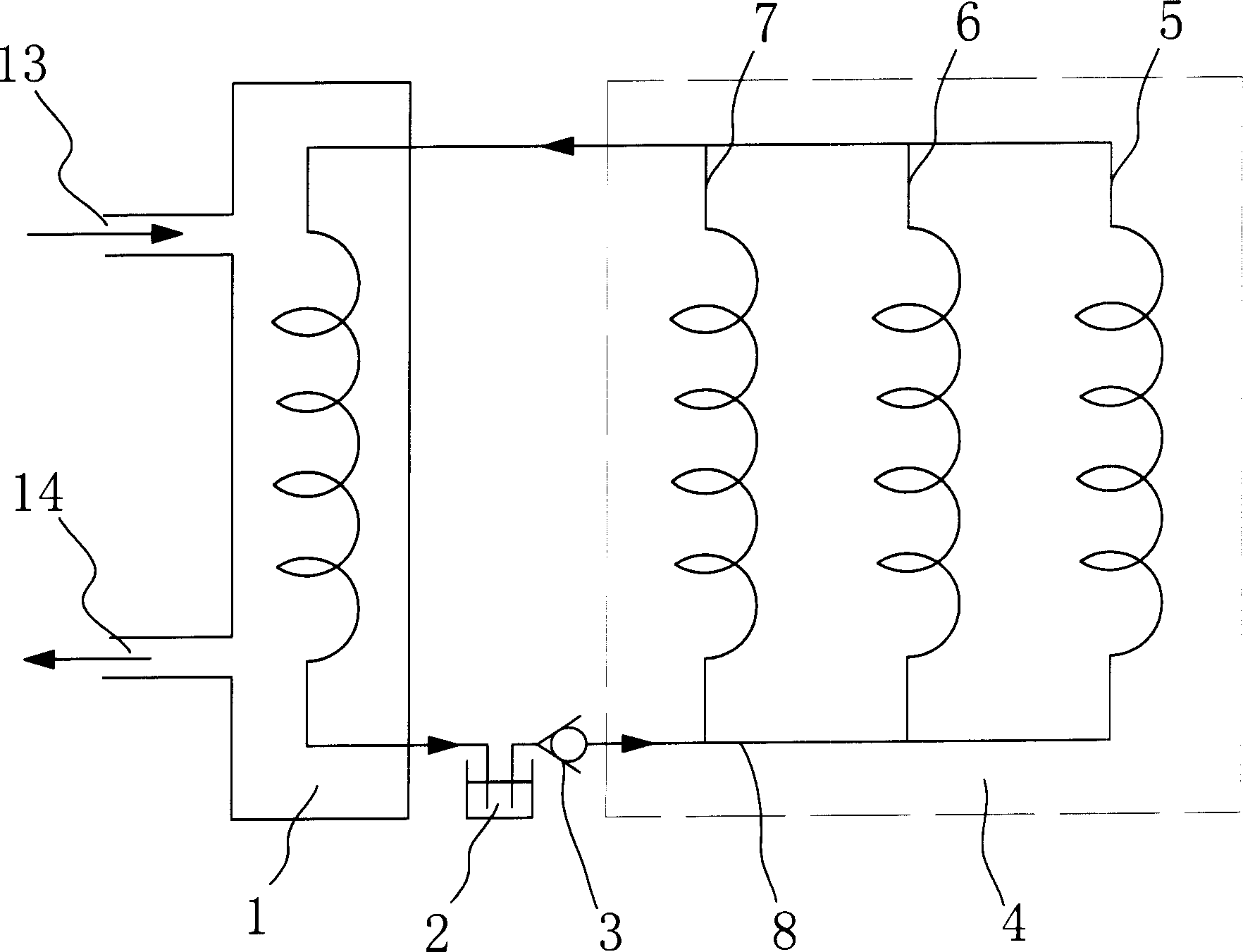

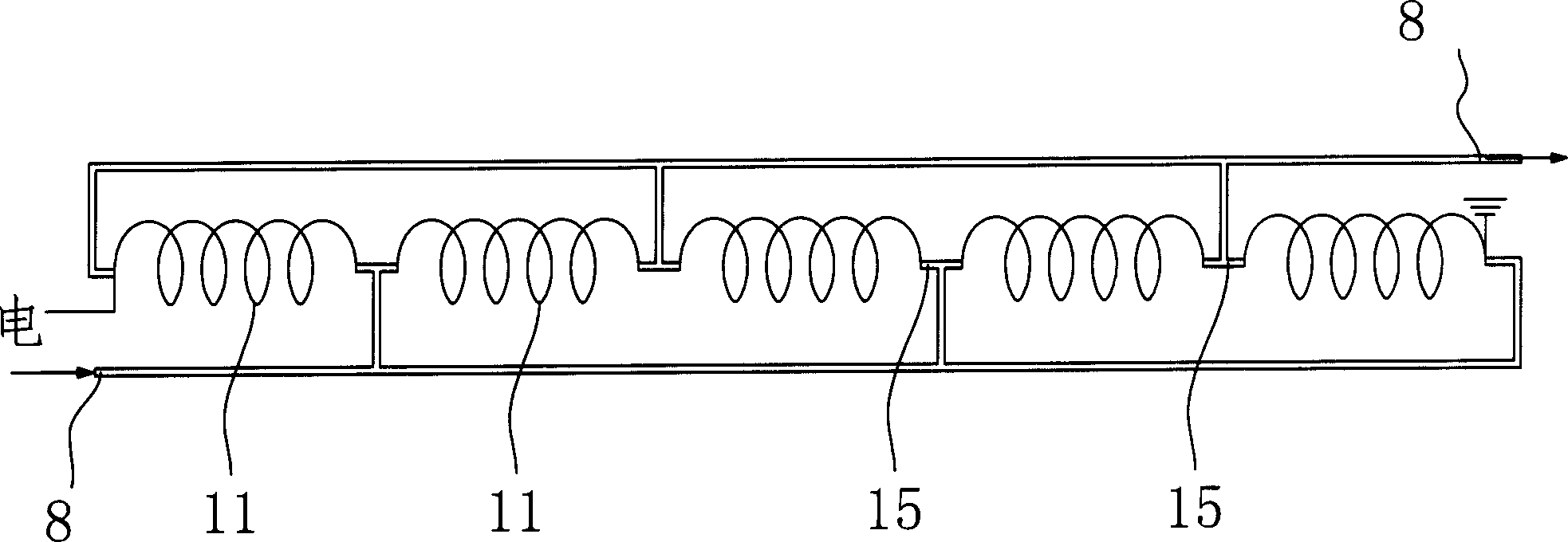

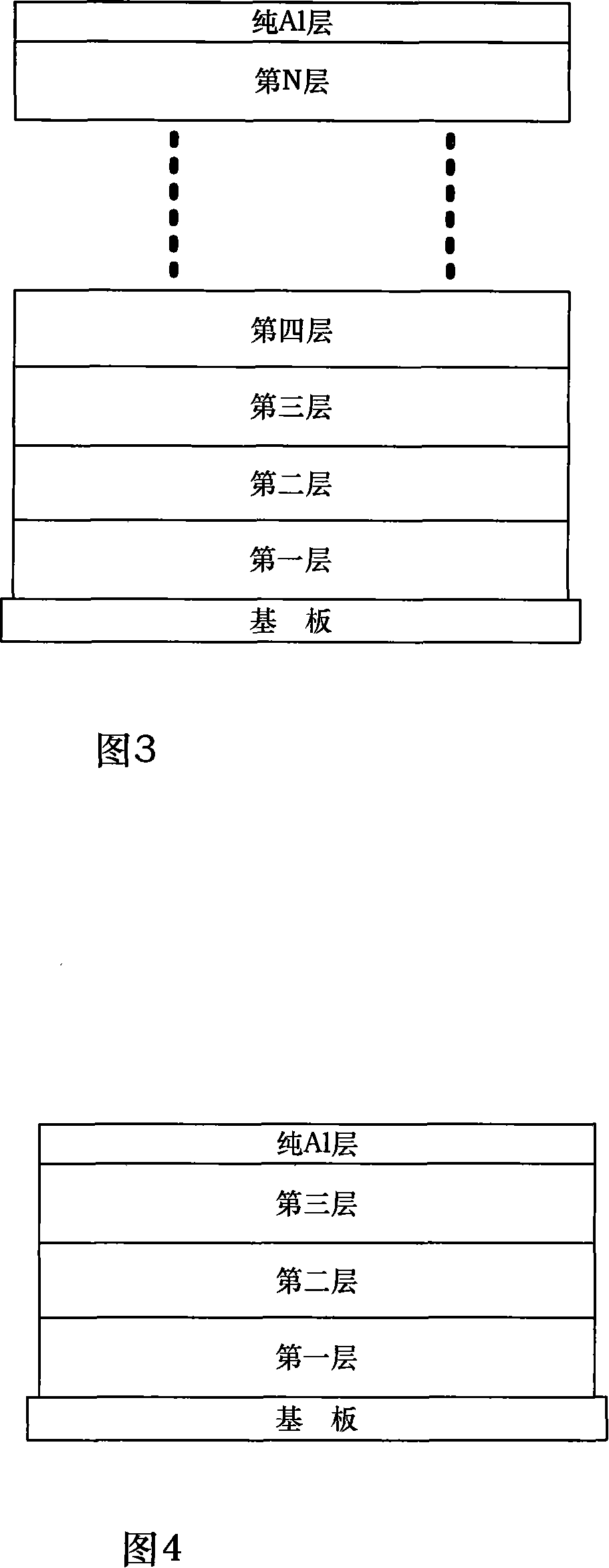

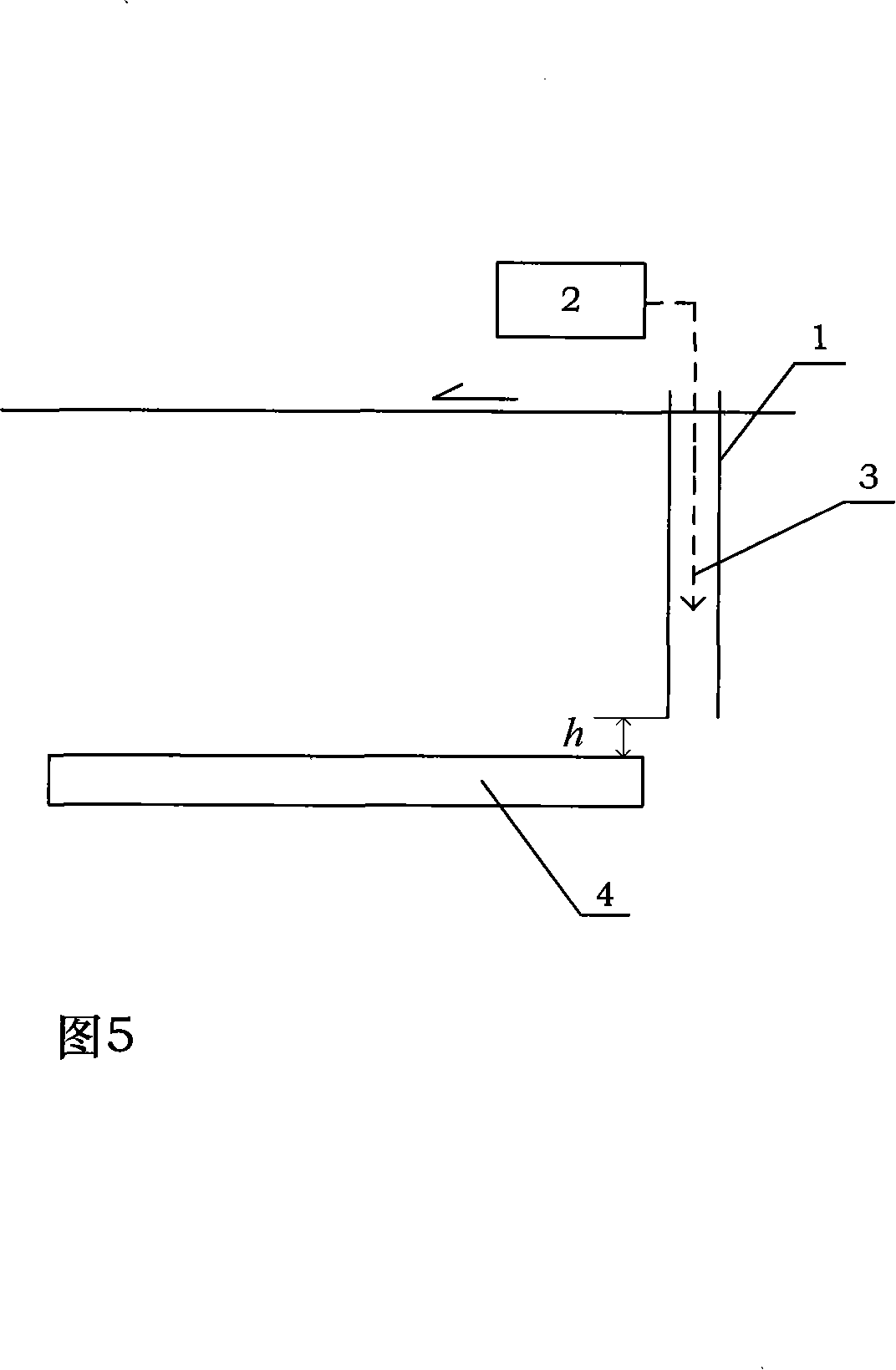

Evaporating and cooling system of electric vibration testing bench

ActiveCN1885001ARealize self-circulation evaporative coolingSolve the driving coilInstrumental cooling apparatusStrength propertiesChange densityBoiling point

The invention relates to an electric vibration test table vaporize cooling system, wherein it uses fluorocarbon whose boiling point is 50-60Deg. C as cooling medium; uses exciting coil and driving coil cooling channel to be filled into the exciting coil and driving coil of electric vibration table; via boiling medium, absorbs the hidden heat to cool the electric vibration table; the cooling medium is heated and vaporized at the exciting and driving coils to be condensed by heat exchanger (condenser) without compression; uses the secondary cooling water to emit the heat in normal temperature; the boiled medium will change density, to utilize the changes of absorbed heat and medium density to generate pressure difference, to form self-circulated power; therefore, the invention can avoid additional power, to circulate the medium in cooling system, to realize self-circulated vaporization cooling. The invention has high efficiency and high reliability.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

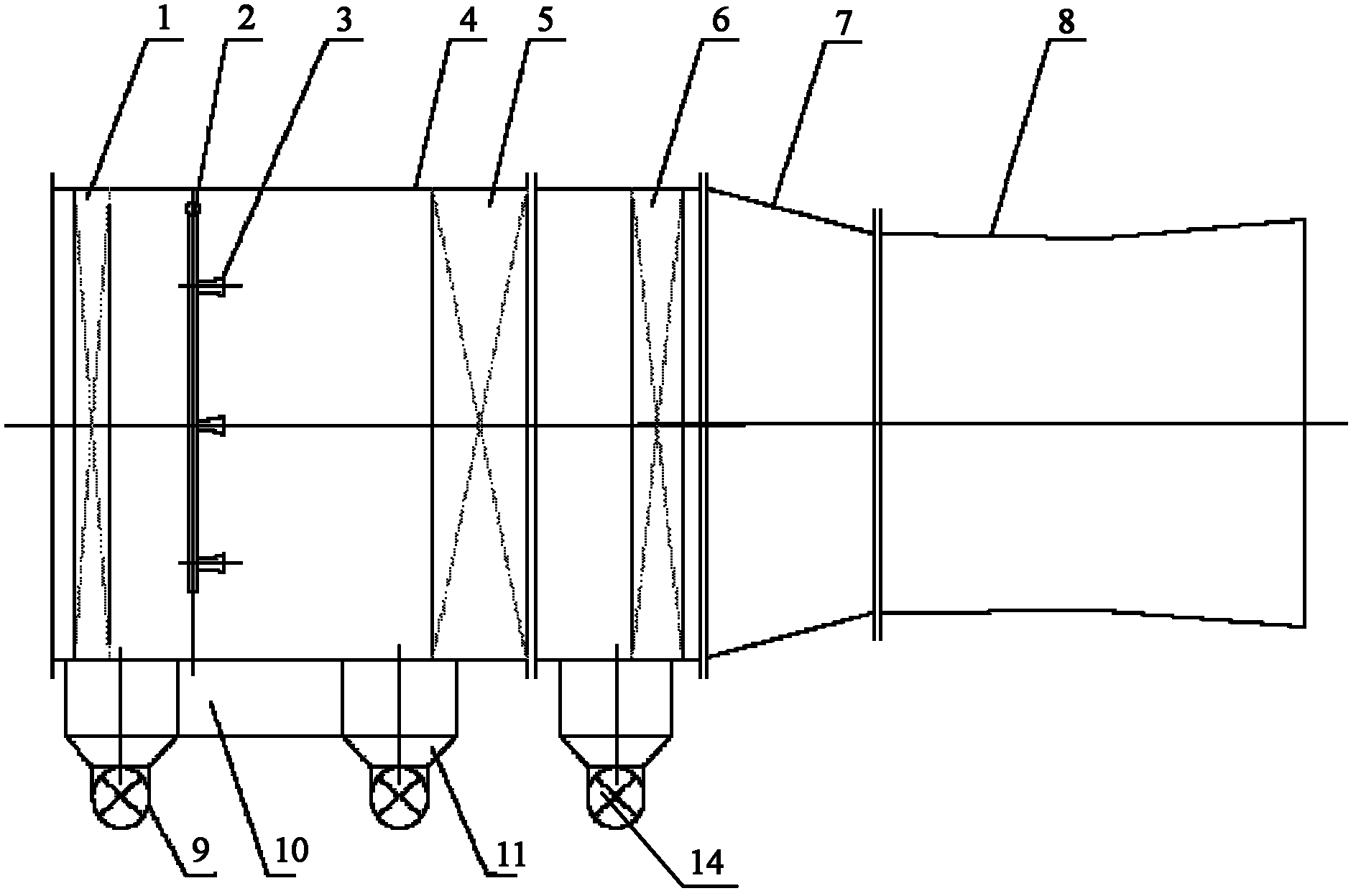

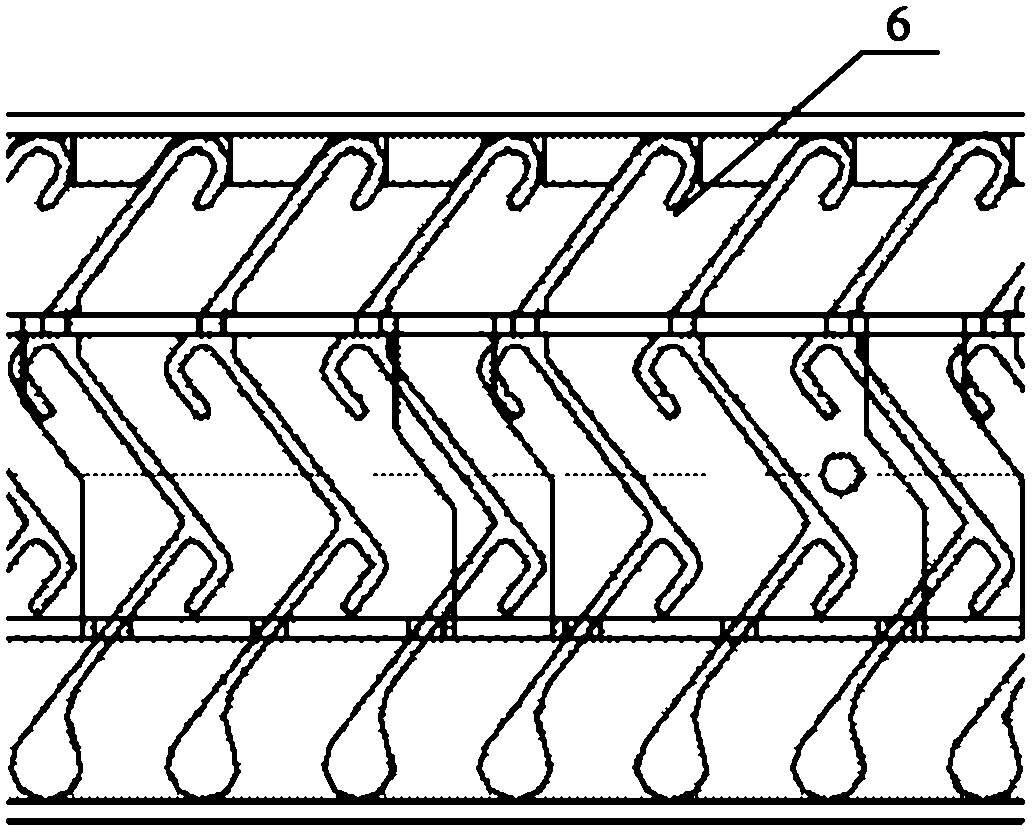

Tube curtain-wet type gradually-changed-density fiber grid composite dust remover for development machine

The invention discloses a tube curtain-wet type gradually-changed-density fiber grid composite dust remover for a development machine, and belongs to the technical field of dust removers. The tube curtain-wet type gradually-changed-density fiber grid composite dust remover comprises a box body, wherein a tube curtain, a gradually-changed-density fiber grid and a maze are arranged in the box body, wherein a spray pipe provided with a water-fog spray head is arranged between the tube curtain and the gradually-changed-density fiber grid; the other end of the gradually-changed-density fiber grid is connected with one end of the maze, and the other end of the maze is connected with a blower through a reducing pipe; a dry ash bin, a sludge bin of the gradually-changed-density fiber grid, a sludge bin of the maze and a circulating water tank are arranged at the lower end of the box body; the dry ash bin is connected with the bottom of the tube curtain; the sludge bins are connected with the bottom of the gradually-changed-density fiber grid; a filter is arranged in the circulating water tank; the circulating water tank is connected with the spray pipe through a water pump; and the density of each layer of fence-shaped textile of the gradually-changed-density fiber grid is gradually changed from sparseness to compactness.

Owner:NORTHEASTERN UNIV

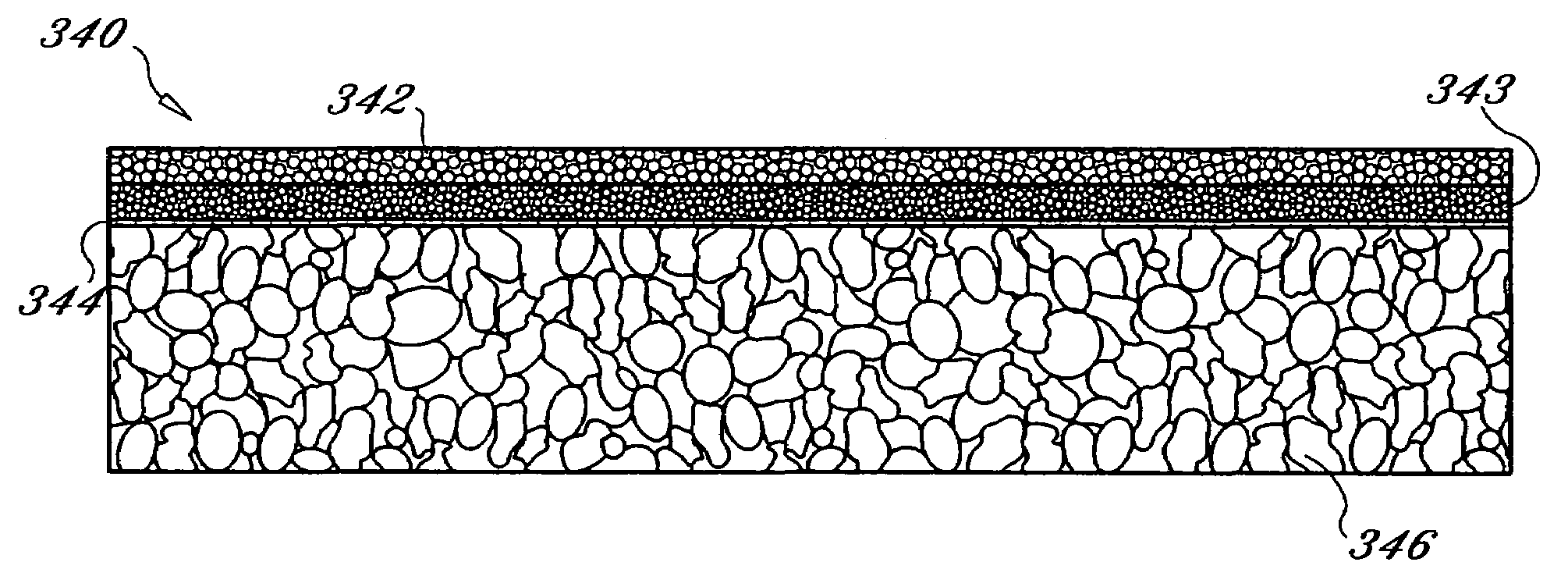

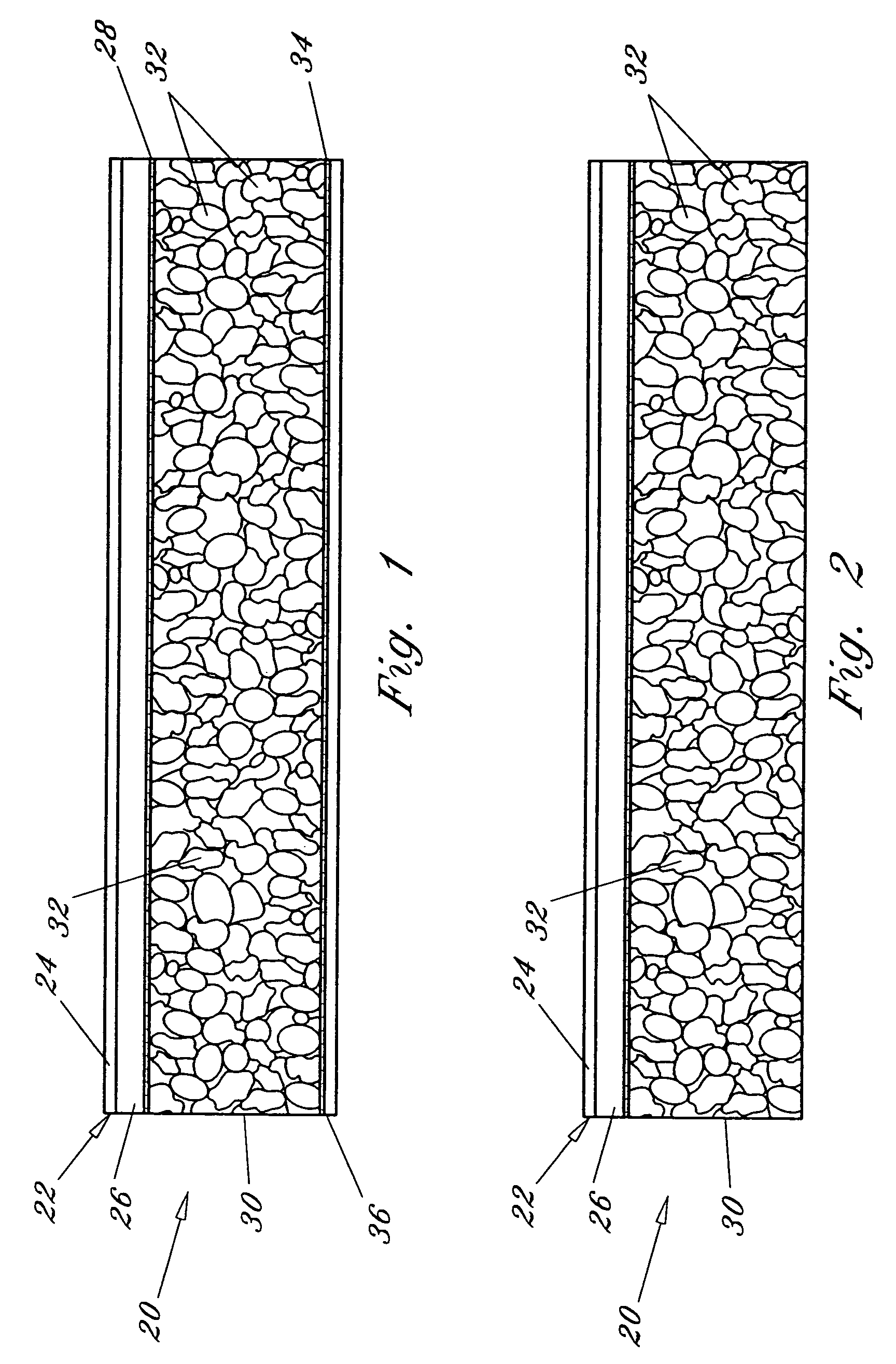

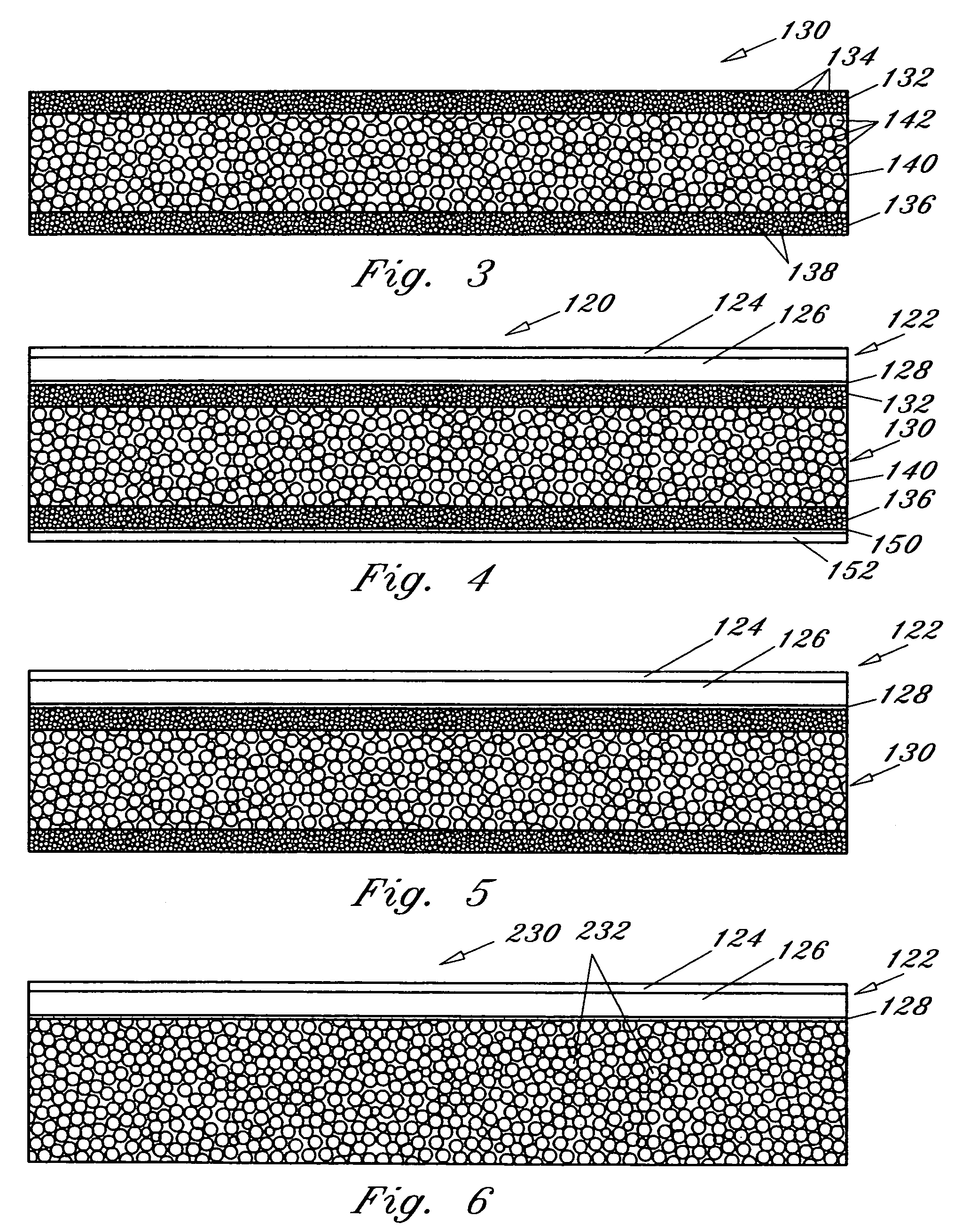

Thermoplastic multi-layer composite structure

InactiveUS7105073B2Hard surfaceAchieve recyclabilityLamination ancillary operationsSynthetic resin layered productsChange densityAdhesive

A thermoplastic multi-layer composite structure is disclosed and consist in a first embodiment of a co-extruded acrylic polypropylene outer skin and high melt strength polypropylene substrate which is attached to a first surface of a polypropylene foam core. An inner polypropylene skin can be provided and is attached to a second surface of the foam core. The foam core can either be constructed from an expanded polypropylene or an extruded polypropylene. Where an expanded polypropylene foam core is provided, the foam core is attached to the outer and inner skin through the use of a polypropylene adhesive. Where the extruded polypropylene foam core is provided, the skins can be attached to the foam core through a welding or bonding process in lieu of adhesives. The polypropylene adhesives can also be utilized for attaching the skins to the extruded foam core. Additionally, the extruded foam core can vary in density to provide a composite foam core. Preferably, the various densities of the composite foam core are arranged such that the lowest density foam is provided at the center of the core and the varying densities of the foam core extend outward from the center in numerical order. In an alternative embodiment, an all acrylic composite multi-layered structure is provided.

Owner:BRUNSWICK CORPORATION

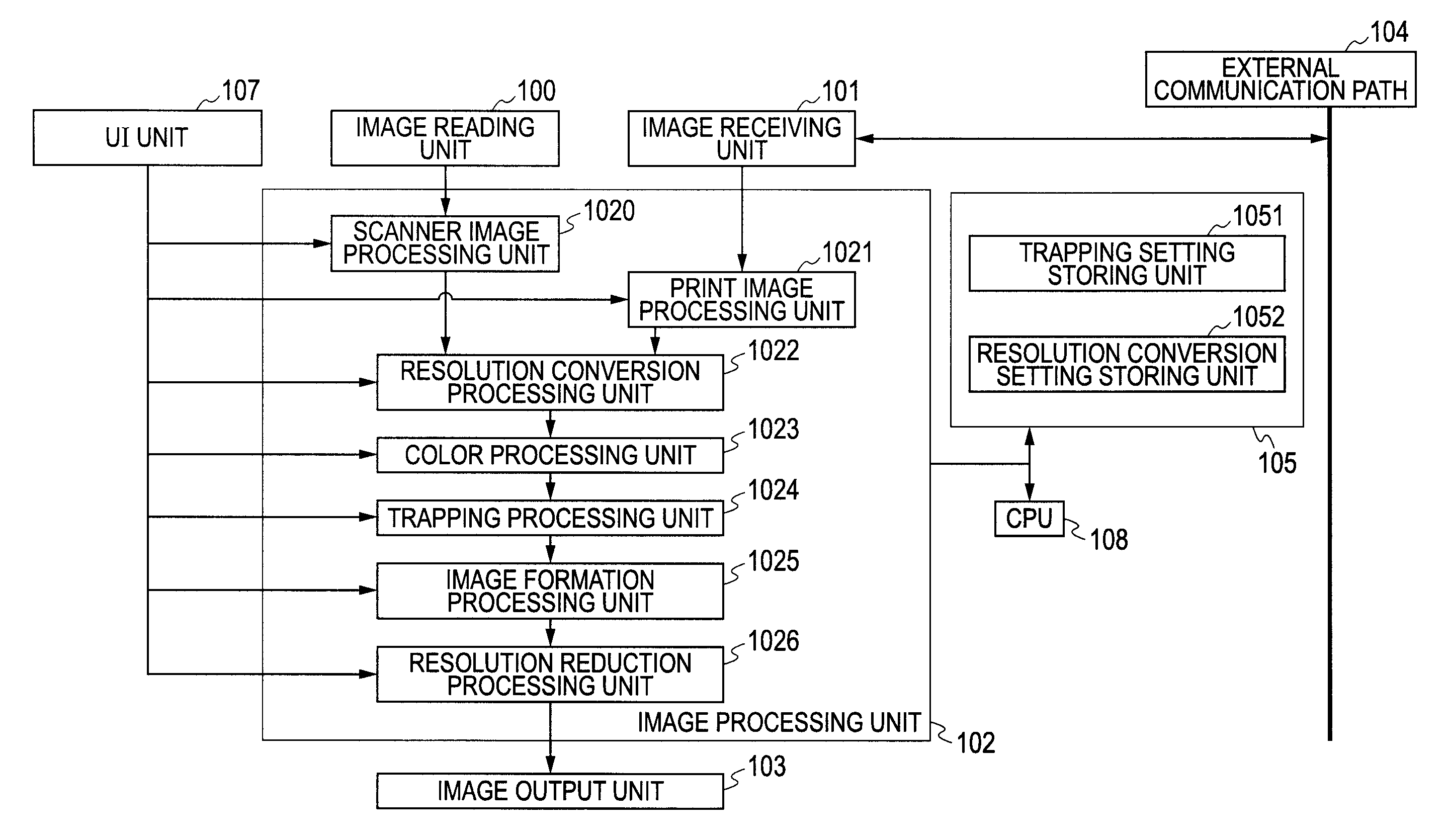

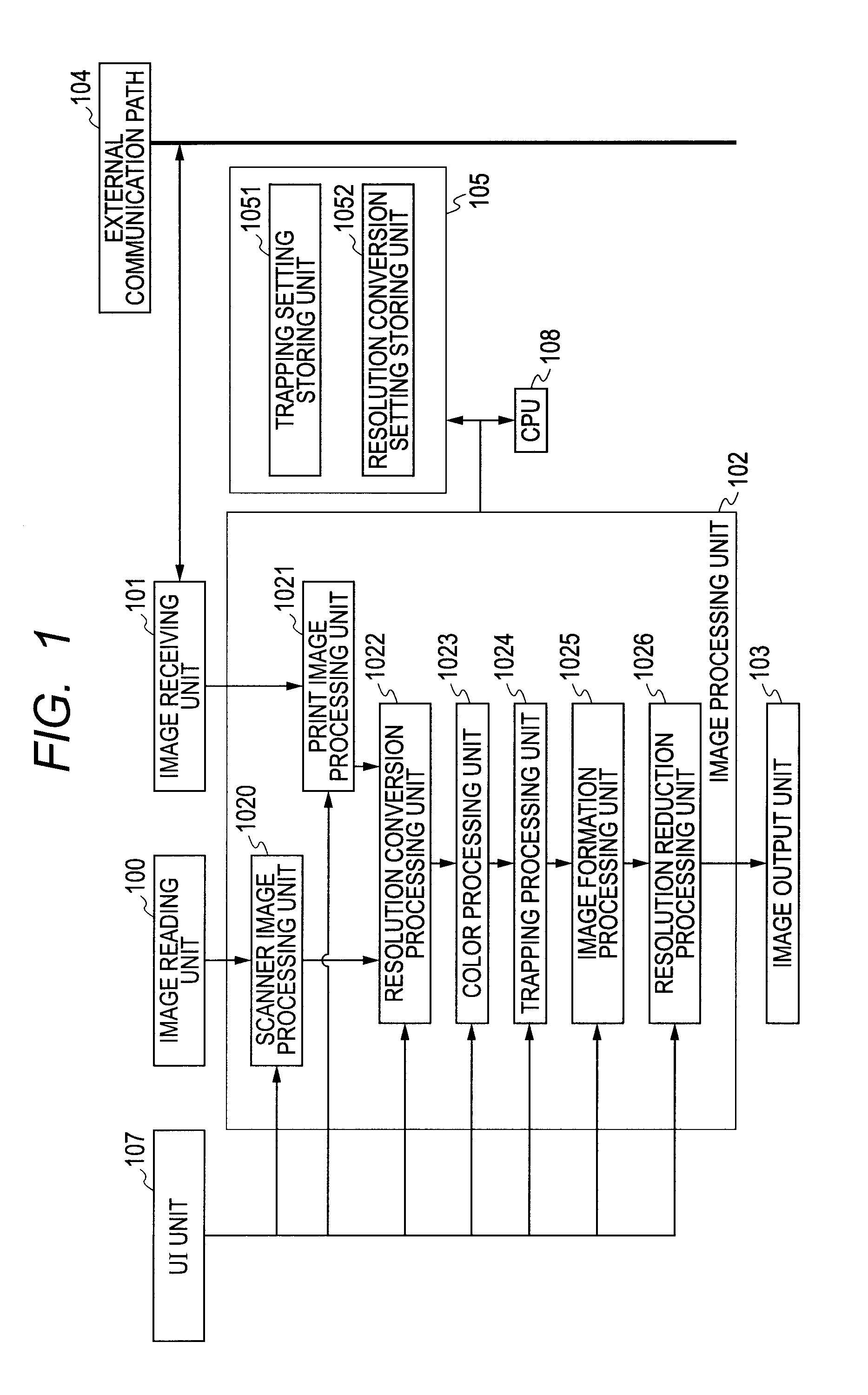

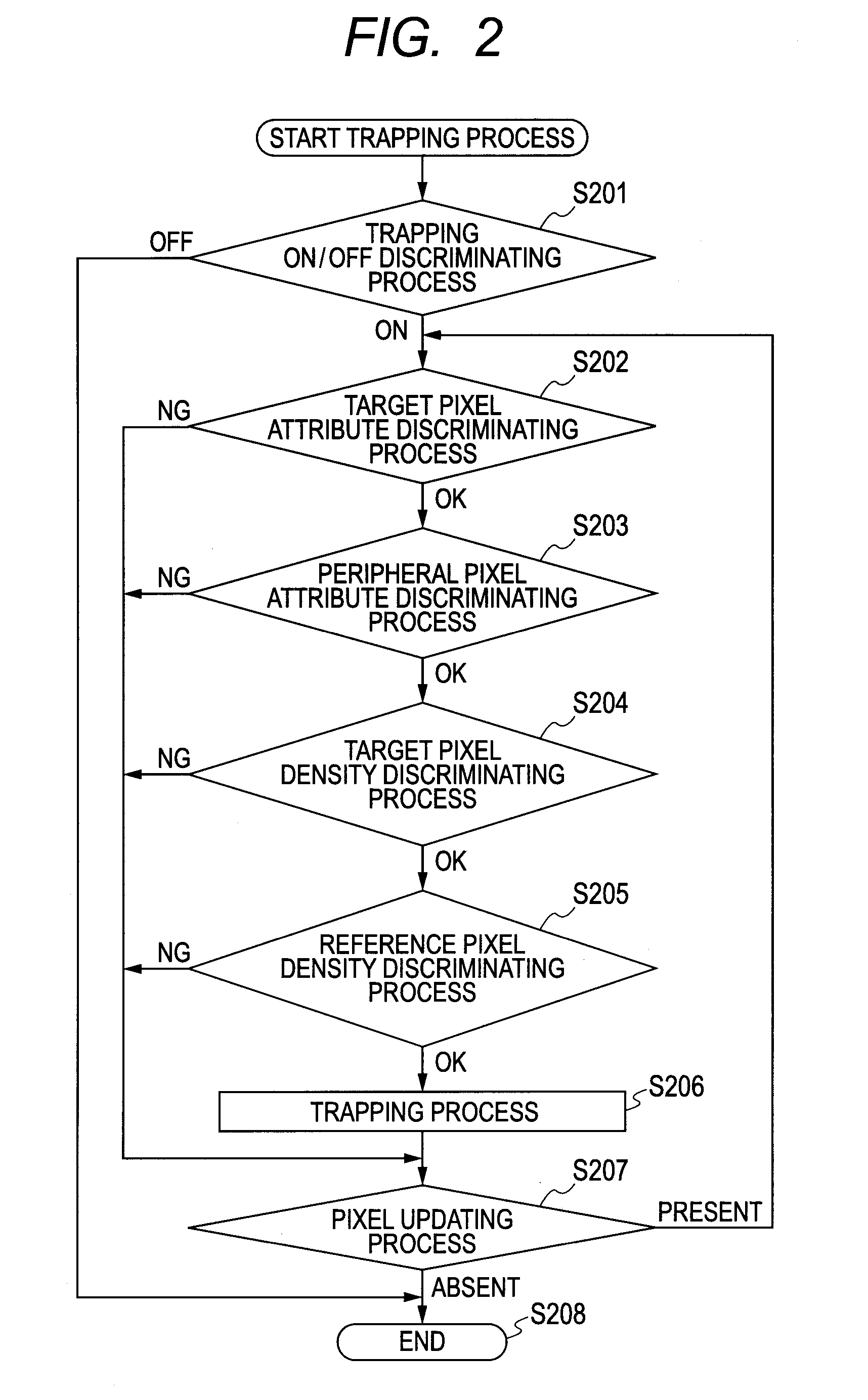

Image forming apparatus and image processing method

InactiveUS20110128556A1Inhibit deteriorationDigitally marking record carriersGeometric image transformationChange densityImaging processing

When both of a trapping and a resolution converting process are executed, a deterioration in picture quality occurs. In order to solve this problem, an image forming apparatus is provided which performs a trapping process to expand outlines of objects whose boundaries are in contact with each other, performs a resolution conversion process to change density of edges of an image, and restricts processing so that the trapping process and the resolution conversion process are not executed to a same pixel.

Owner:CANON KK

Method of and system for predicting print colors

InactiveUS8311321B2Exact matchEasily and quickly colorDigitally marking record carriersDigital computer detailsChange densitySolid density

Owner:FUJIFILM CORP

Packaging devices and methods of producing same

InactiveUS20080217464A1High strengthBoxes/cartons making machineryPaper-makingChange densityBiomedical engineering

Owner:RIDGEWAY LAWRENCE M +1

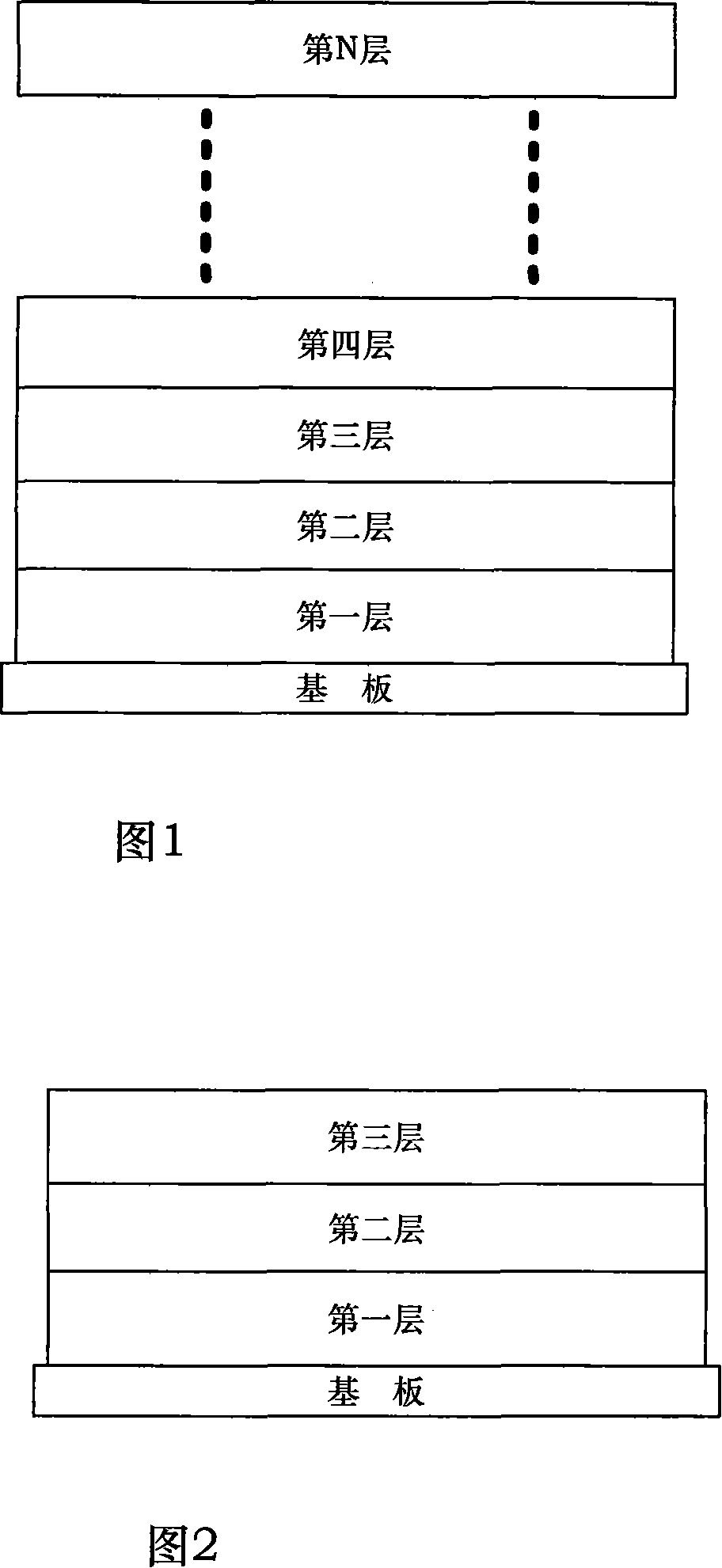

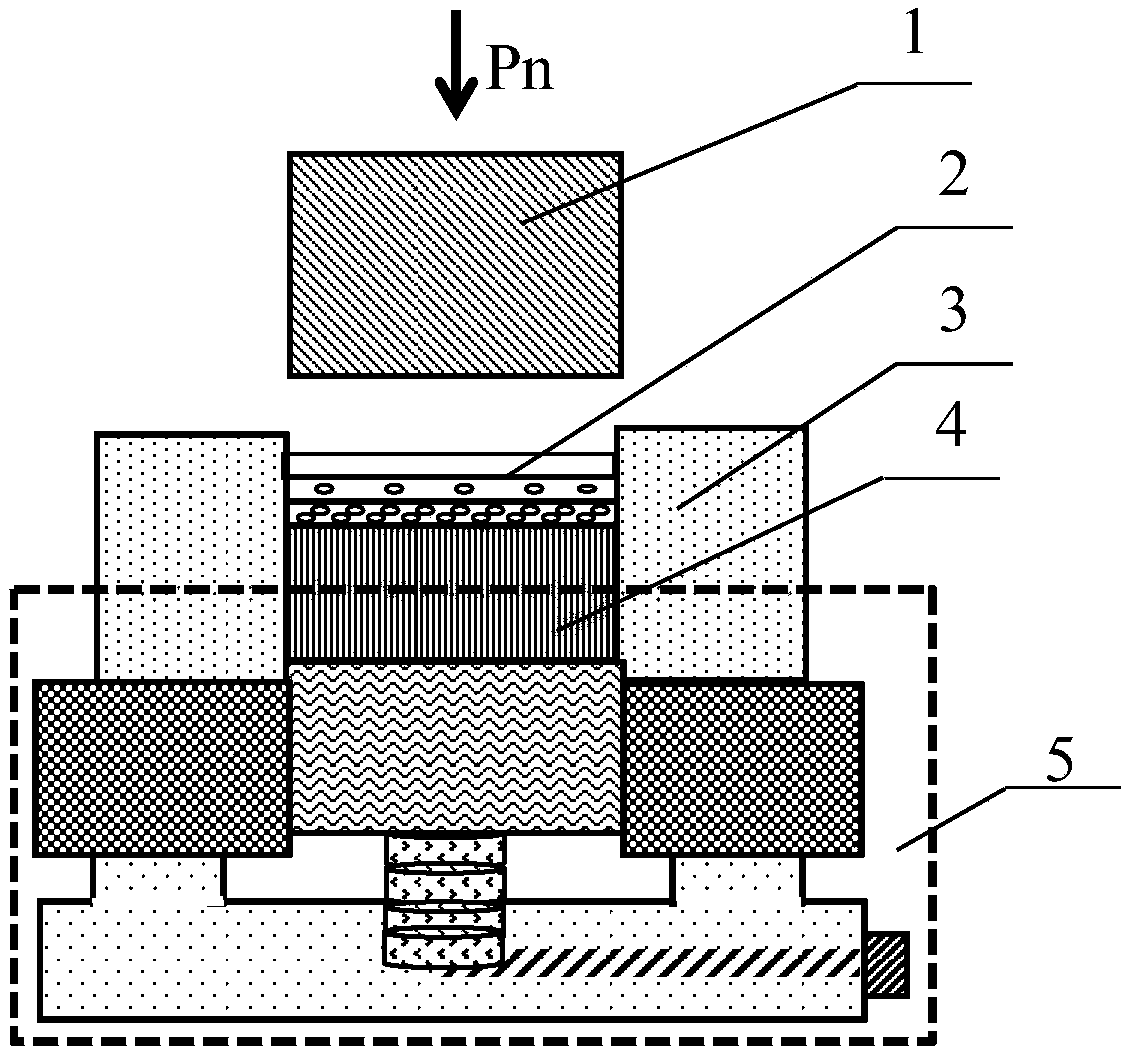

Al-W composite material with gradient changing density and its preparation method

InactiveCN101148101AEvenly distributedDensity controllableMetal layered productsHeat inorganic powder coatingChange densityMetallurgy

The multilayer composite Al-W material with gradient density consists of N layers in densities of 12.0-13.9 g / cu cm, 10.0-12.0g / cu cm, 8.0-10.0g / cu cm, 5.5-8.0g / cu cm ... 2.9-5.5g / cu cm separately. It is prepared through spraying of mixture powder in different W contents, and the spraying process has no oxidation of Al and W, no generation of other phase, and controllability of the composite material density and thickness.

Owner:BEIHANG UNIV

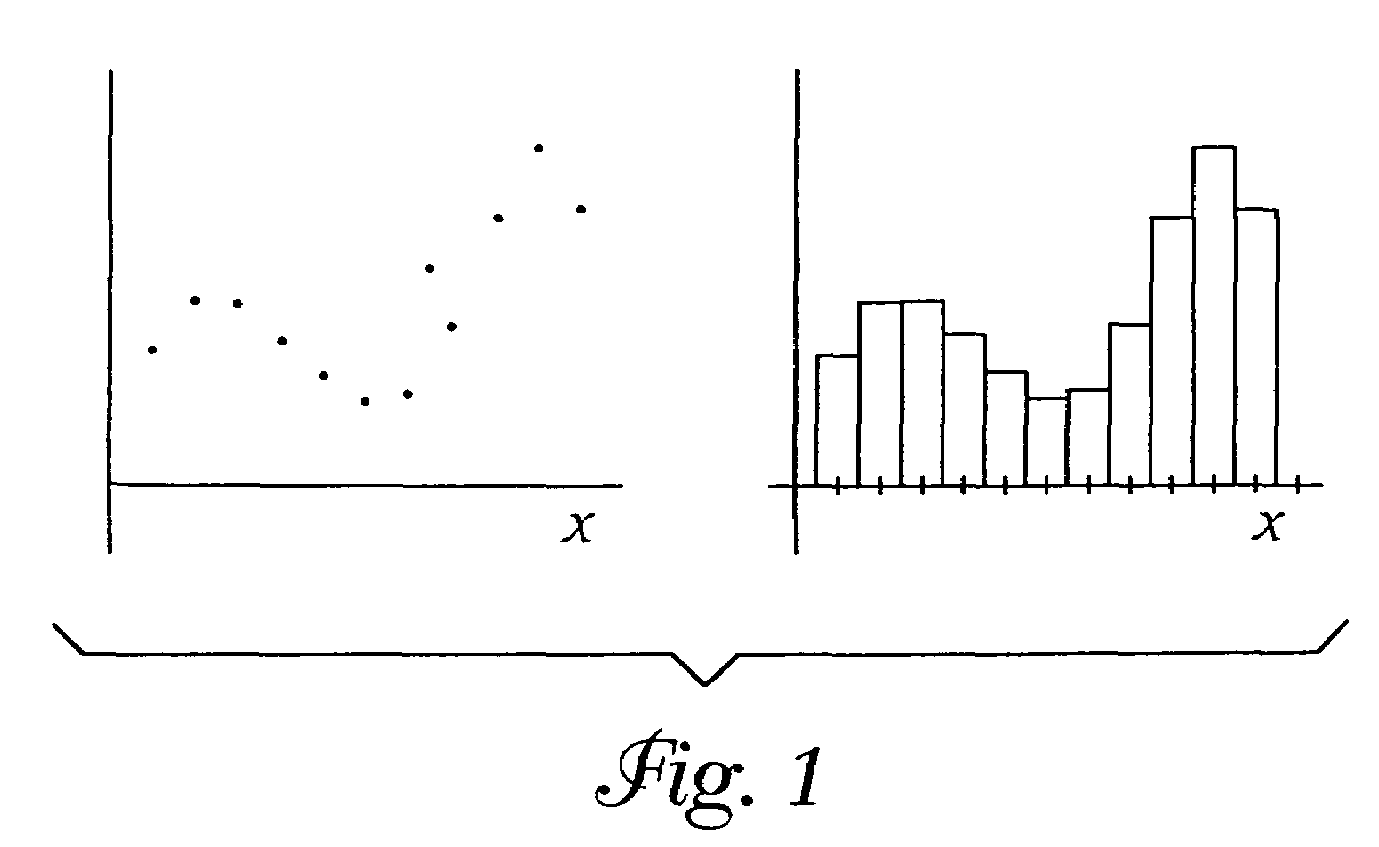

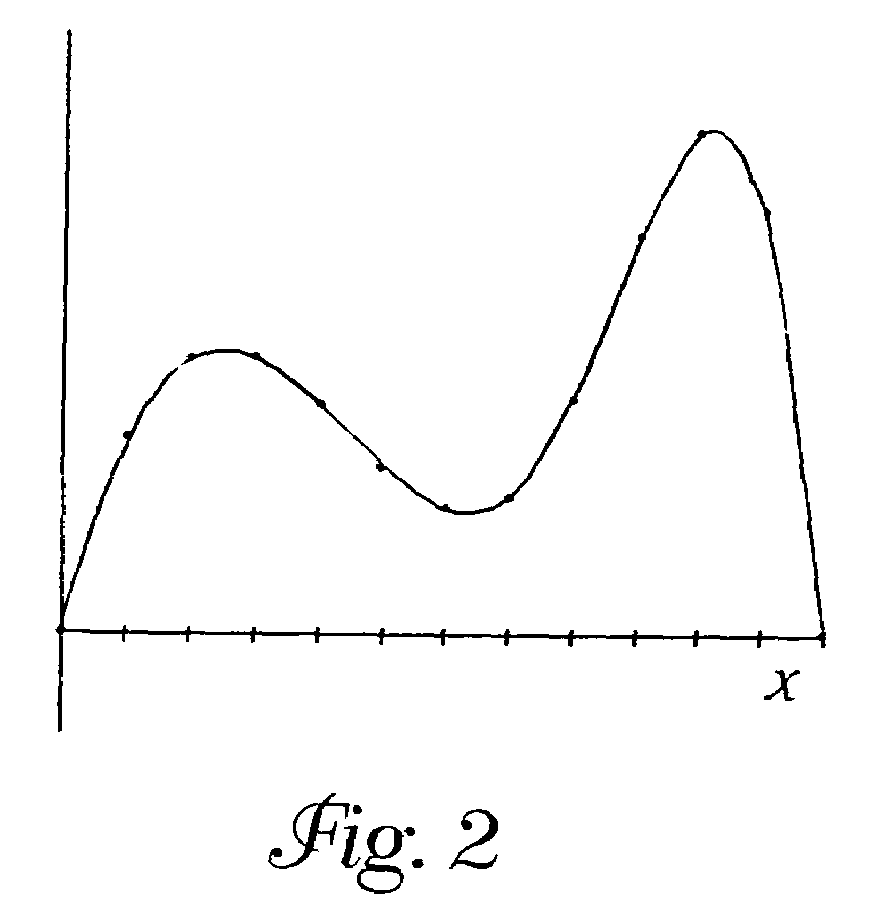

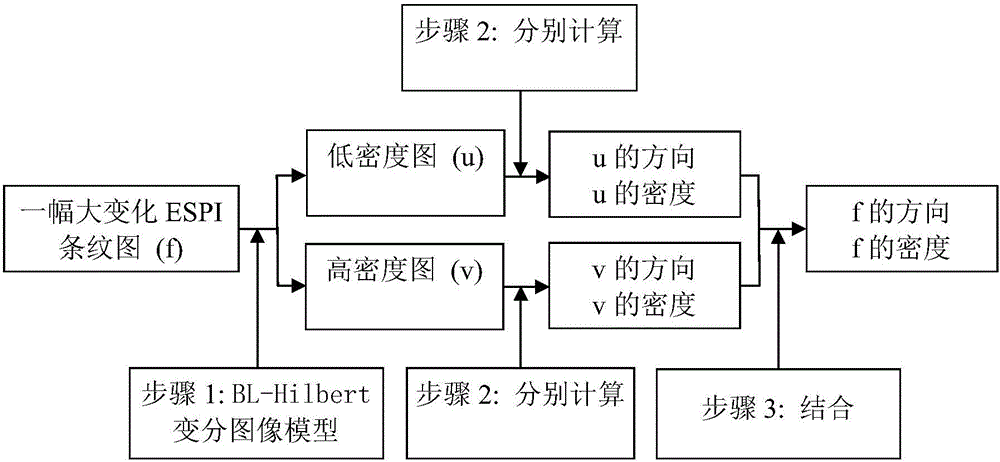

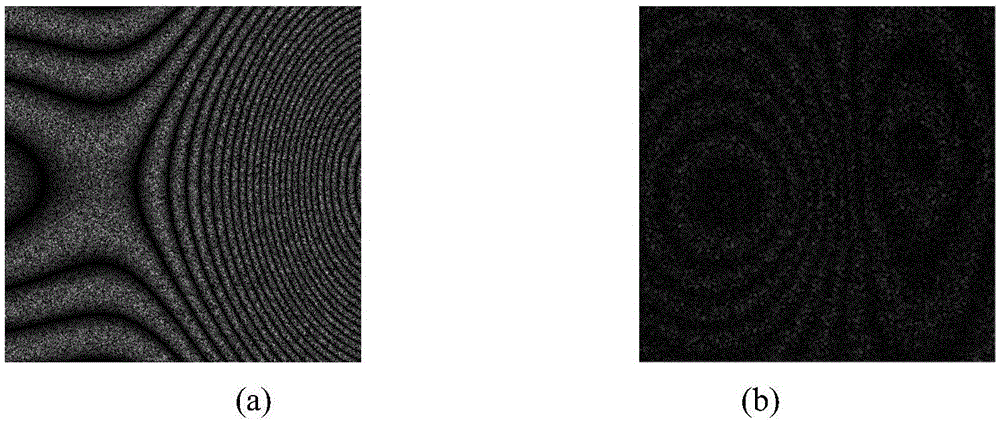

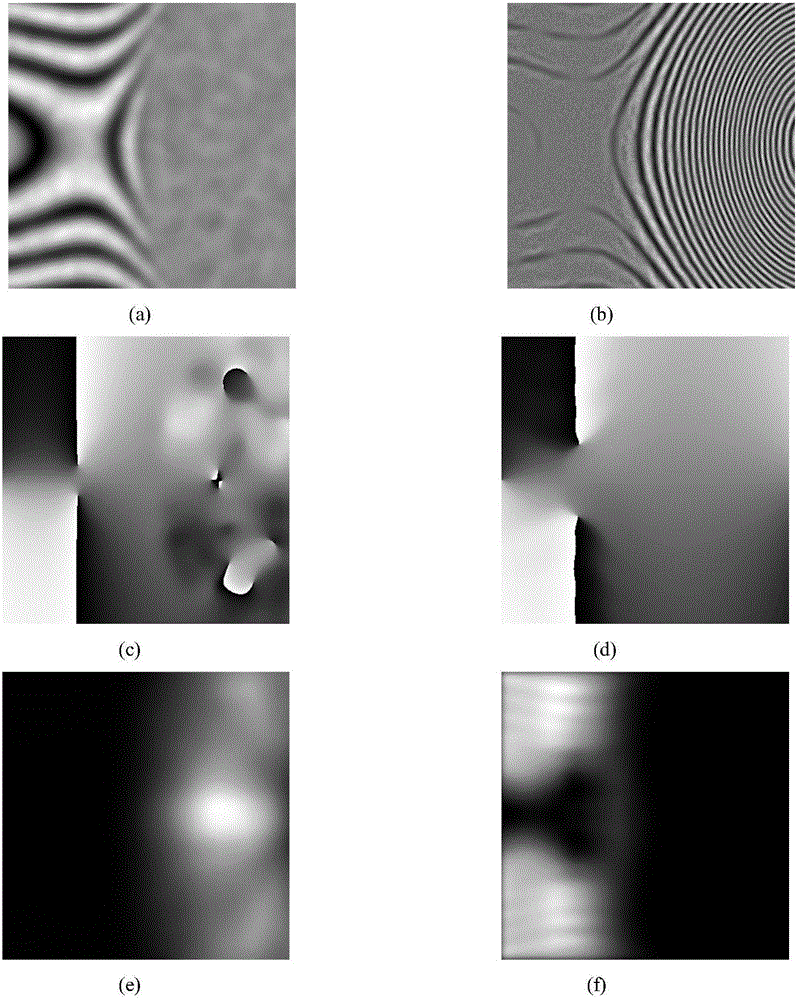

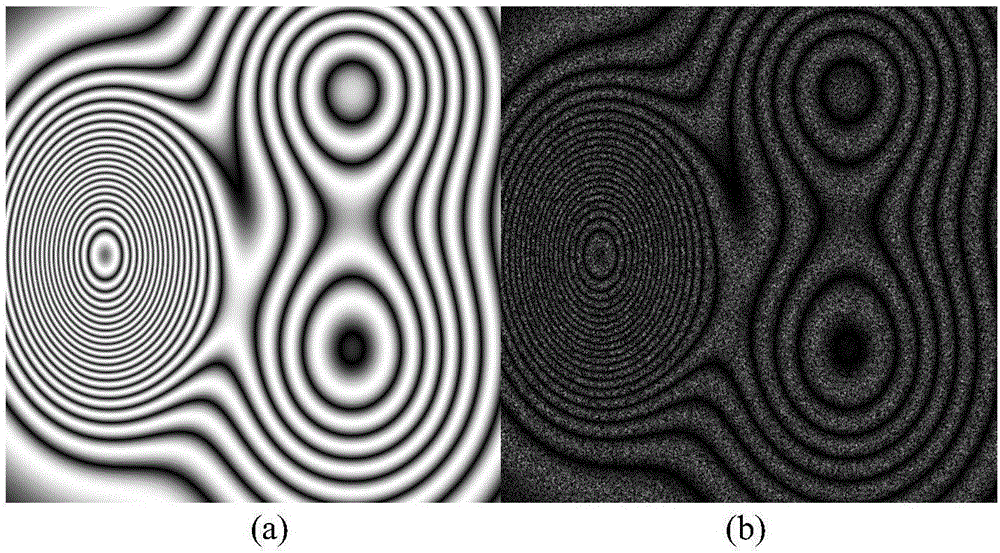

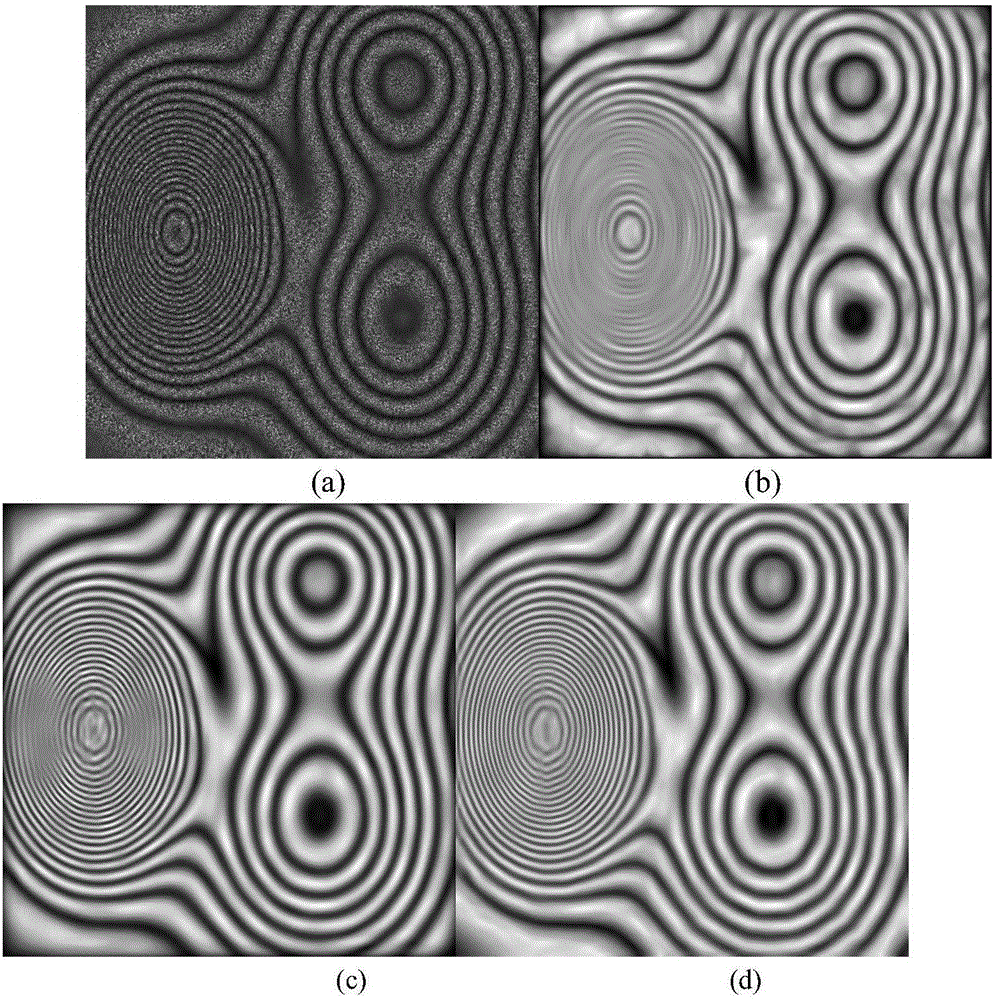

Large-change density electronic speckle interference fringe graph direction and density processing method

The invention belongs to the optical detection and optical information processing technology field and aims to acquire the direction and a density value of a large-change density electronic speckle interference fringe pattern. The method comprises steps that step 1, a large-change electronic speckle interference measurement ESPI fringe pattern f is inputted; step 2, a variation image decomposition BL-Hilbert model is utilized to divide the large-change ESPI fringe pattern f into two ESPI fringe patterns with uniformly-distributed densities; step 3, fringe directions and densities of a low-density ESPI fringe pattern u and a high-density ESPI fringe pattern v are respectively calculated; and step 4, the fringe direction and the density of the integral pattern can be acquired through comprehensively selecting the fringe directions and the densities of the low-density ESPI fringe pattern u and the high-density ESPI fringe pattern v. The method is mainly applicable to optical detection and optical information processing occasions.

Owner:TIANJIN UNIV

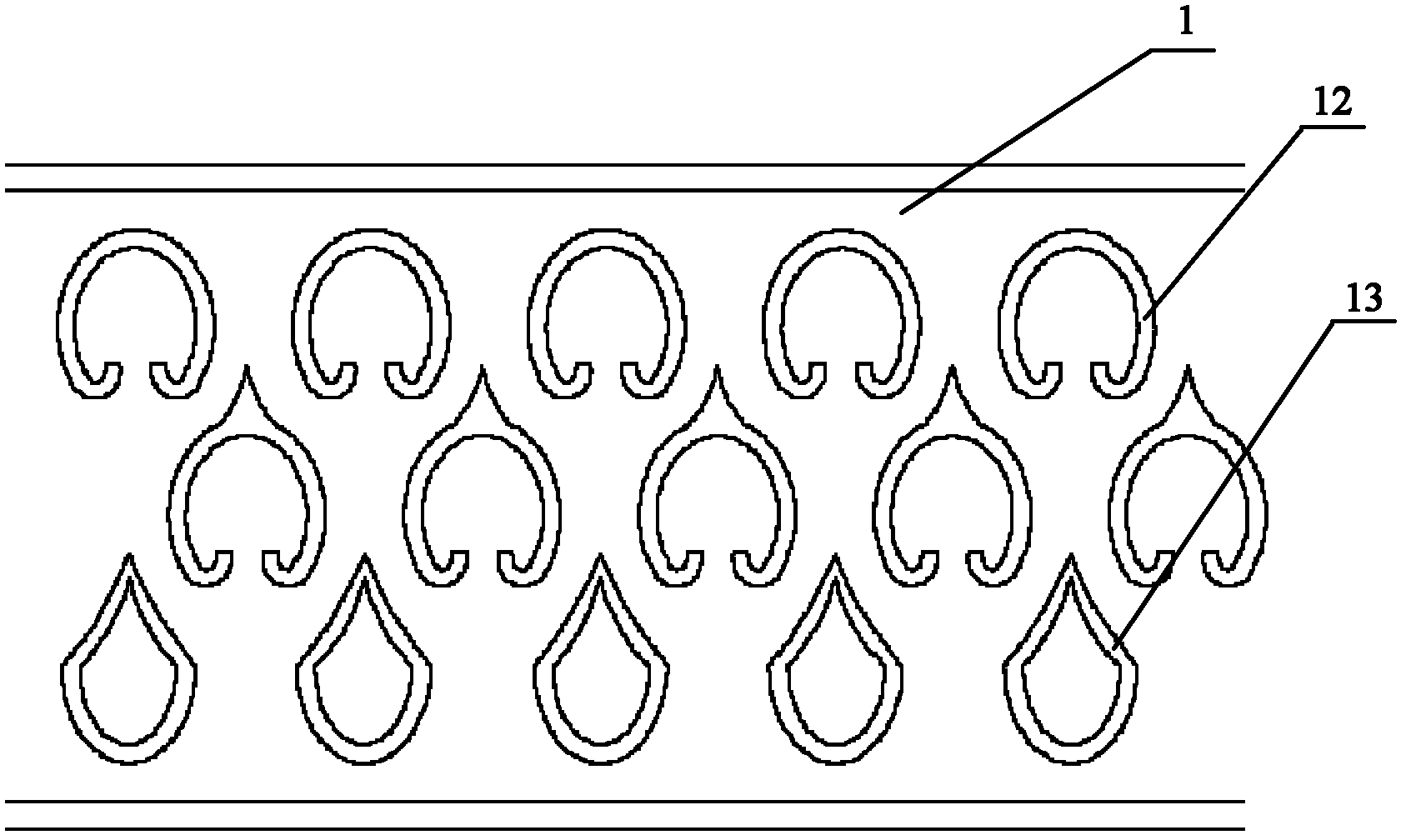

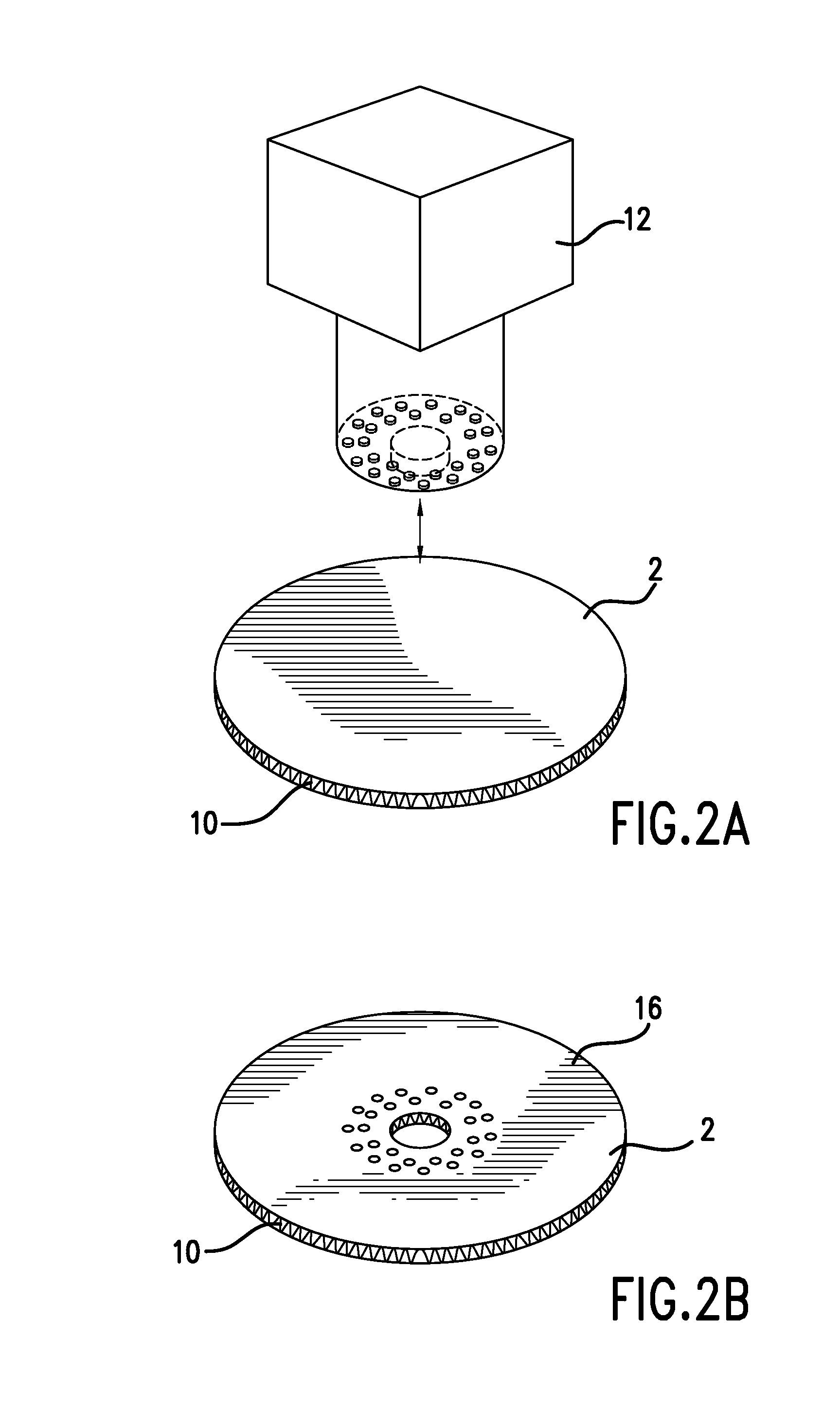

Ultrasonic velvet making method of solar cell slice

InactiveCN101599513AAccelerated corrosionImprove the preparation effectFinal product manufactureSemiconductor devicesChange densityMegasonic cleaning

The invention provides an ultrasonic velvet making method of a solar cell slice. A mixed solution of sodium hydroxide and isopropyl alcohol is put in a cleaning barrel of an ultrasonic cleaning machine; a group of silicon slices are put in the solution; and the ultrasonic cleaning machine is started to make velvets. The ultrasonic velvet making method of a solar cell slice utilizes the high-frequency mechanical vibration of the ultrasonic cleaning machine, and then the high-frequency mechanical vibration is transmitted to liquid trough a vibration plate. The energy of ultrasonic waves in the solution is forwards radiated with regularly-changed densities so as to continuously impact attachments on the surface of an object to ensure that bubbles are quickly stripped off, thus the sodium hydroxide solution can better corrode the surfaces of the silicon slices, thereby greatly improving the making effect of a velvet surface.

Owner:SHANGHAI SOLAR ENERGY S&T

Method of and system for predicting print colors

InactiveUS20100067783A1Exact matchEasily and quickly colorDigitally marking record carriersDigital computer detailsChange densitySolid density

In a method of and a system for predicting print colors, a profile generator corrects the standard spectral reflectances of a color chart printed under standard density conditions and the differences between the spectral reflectances of color charts for the respective colors in which the density of one of the colors C, M, Y, K is changed to a changed density setting value and the densities of the other colors are fixed to standard density setting values, using density differences with the standard density setting values which are calculated by a monochromatic solid density calculator. The profile generator then generates a print predicting profile for desired target densities based on the corrected corrective standard spectral reflectances and the spectral reflectance differences, and highly accurately predicts the colors of a print using the print predicting profile when the densities of desired ones of the colors are changed.

Owner:FUJIFILM CORP

Large-size ultrathin metal matrix density gradient material, and preparation method and application thereof

The invention relates to a large-size ultrathin metal matrix density gradient material, and a preparation method and application thereof. A designed product has an area with the gradient density and / or an area with the continuous changing density. The thickness of the designed product is less than or equal to 3 mm, the size of at least one dimension of the other two dimensions exceeds 50 mm. The forming method comprises the steps of prepressing raw material powder containing the maximum pore-foaming agent first to obtain a first preformed compact; laying set powder on the first preformed compact and then conducts prepressing to obtain a second preformed compact; repeating the steps until prepressing is completed, and conducting sintering and pore-foaming agent removal treatment to obtain afinished product. When an aluminum base serves as a matrix, the density of a sample is in gradient distribution within 1.3-2.7 g / cm3, and the number of gradient layers can be 10 at most on the premise of the total thickness not exceeding 2 mm. The metal matrix density gradient material prepared through the method has excellent properties and can be extensively applied to the fields of aerospace and national defense and military industry.

Owner:CENT SOUTH UNIV

Epothilone B purification method

The invention relates to an improved method for epothilone B extraction and purification, and belongs to the technical field of biological separation. According to the method, most of impurities are removed by a low-temperature refrigeration method, solid-liquid separation is achieved by changing density, the purity of finished products is further improved by a two-time crystal method, rate-limiting steps such as silica-gel column chromatography are decreased, an epothilone B extraction process is simplified, operation cost is reduced, and the method has a wider application prospect.

Owner:LUNAN PHARMA GROUP CORPORATION

Method of and system for predicting print colors

InactiveUS20100067026A1Easy and quick responseTrue colorDigitally marking record carriersDigital computer detailsChange densityComputer science

A method and a system for predicting print colors are provided. A profile generator determines standard density spectral reflectances of a color chart printed under standard density conditions, first changed density spectral reflectances of a color chart printed with only the density of one of colors C, M, Y, K being changed by a given amount, and second changed density spectral reflectances of a color chart printed with the densities of the colors C, M, Y, K being changed by the same amount. The profile generator generates a print predicting profile for obtaining desired target densities, using the standard density spectral reflectances, the differences between the standard density spectral reflectances and the first changed density spectral reflectances, and corrective coefficients for obtaining the second changed density spectral reflectances, and predicts highly accurately colors of the print where the density of a desired color is changed, using the print predicting profile.

Owner:FUJIFILM CORP

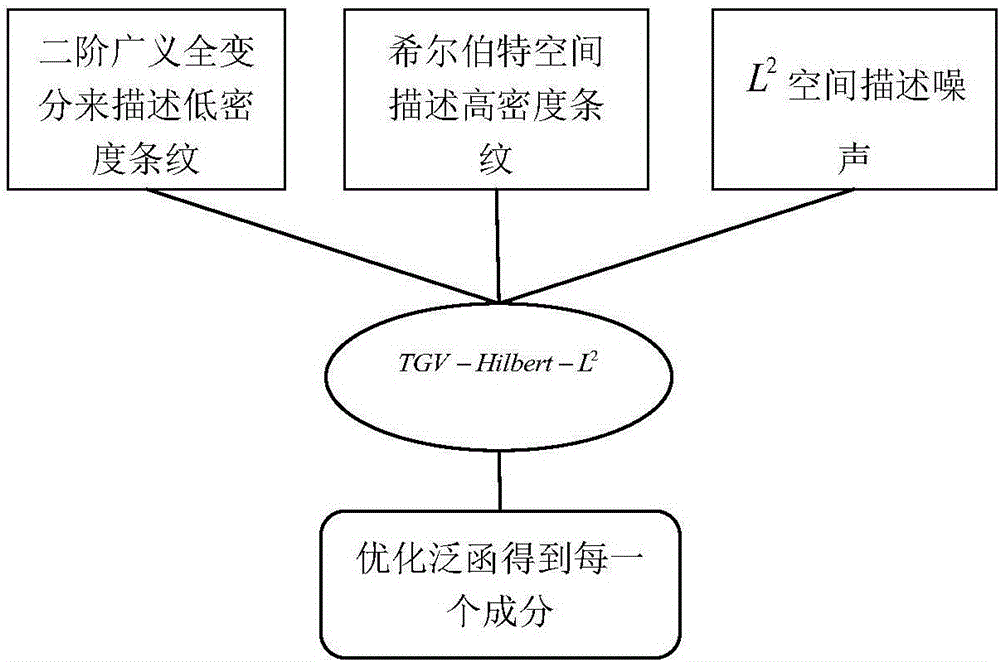

Large change density fringe pattern filtering method based on generalized total variation

InactiveCN106447619AGuaranteed smoothSatisfactory effectImage enhancementImage analysisChange densityInformation processing

The invention belongs to the optical detection and optical information processing technology field, and relates to a large change density fringe pattern filtering method based on generalized total variation. A new variation image decomposition model is provided, and is used in optical fringe pattern processing, and then a thick fringe part and a thin fringe part are separately processed, and in addition, the smoothness of the thick fringe part is guaranteed, and at the same time, the thin fringe part is not dimmed, and therefore a good large change density fringe filtering effect is provided. By adopting the technical scheme provided by the invention, the large change density fringe pattern filtering method based on the generalized total variation is characterized in that a second-order generalized total variation is used to describe the low density part, and Hilbert space is used to describe the high density fringe, and simple L2 space is used to describe a noise part, and then by optimizing a functional formula, every component u,v,w is finally acquired. The large change density fringe pattern filtering method is mainly used for optical detection and optical information processing occasions.

Owner:TIANJIN UNIV

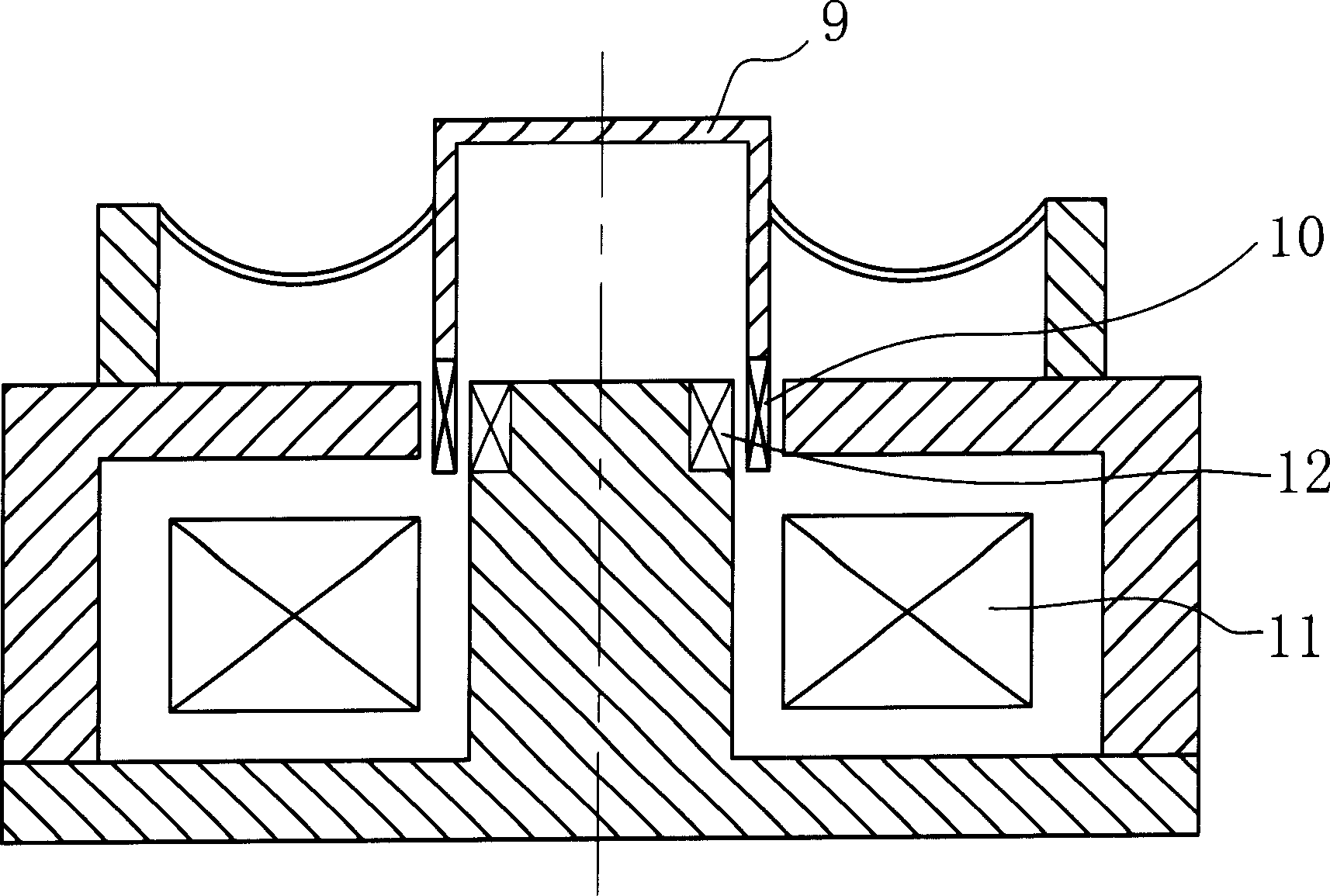

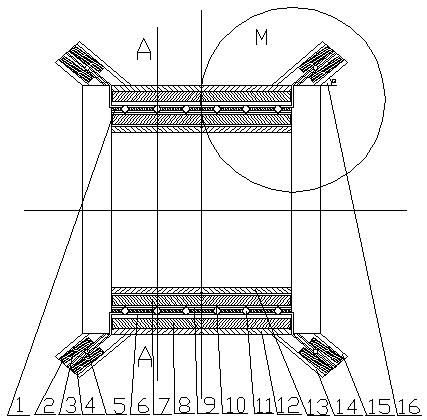

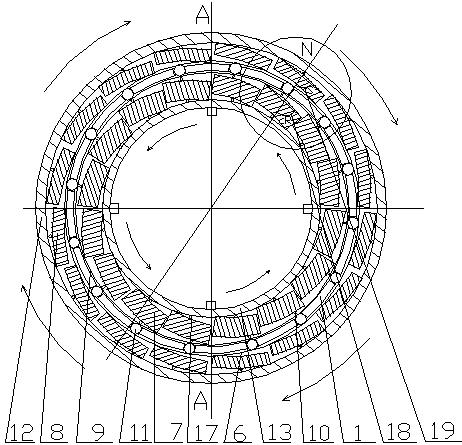

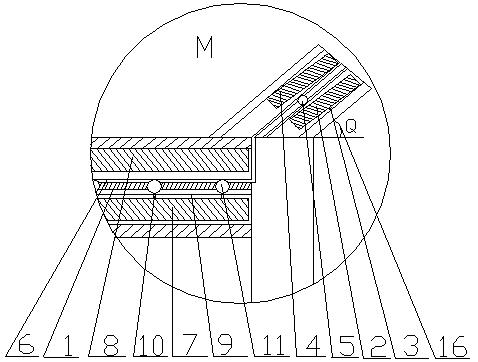

Self-aligning permanent magnet magnetic bearing

InactiveCN102518666AAuto SpacingIncrease the magnetic line densityBearingsChange densityMagnetic bearing

A self-aligning permanent magnet magnetic bearing comprises an inner ring, an outer ring, a plurality of elongated tile-shaped or rectangular permanent magnets, bearing balls, drive bars and drive rollers, wherein magnetic lines of force of the permanent magnets in sequential arrangement and a radial line of the bearing form small angles, the permanent magnets are mounted in interlayers of the inner ring and the outer ring, the bearing balls capable of rotating and moving radially are arranged between the inner ring and the outer ring, and the drive bars and the drive rollers push the inner ring or outer ring permanent magnets to rotate by certain small angles when the bearing balls move. The self-aligning permanent magnet magnetic bearing is characterized in that like poles of the bearing inner ring permanent magnets are opposite to those of the bearing outer ring permanent magnets, the included angles between the bearing inner ring or outer ring permanent magnets and the radial lineare different, a rotary bearing shaft is arranged at the center of inside of the inner ring permanent magnets, another rotary bearing shaft is arranged at the center of outside of the outer ring permanent magnets, and the permanent magnets can rotate around the rotary bearing shafts to adjust the included angles between the magnetic lines of force of the permanent magnets and the radial line so as to change density of the magnetic lines force in the radial direction, so that magnetic repulsive force of the magnets is changed.

Owner:魏伯卿

Process for preparing shape controllable cuprous oxide micro/nano crystal by electrochemical deposition

InactiveCN100389230CGood symmetryImprove controllabilityPolycrystalline material growthElectrolysis componentsSupporting electrolyteChange density

The invention discloses a shape-controlled cuprous oxide micron / nanometer crystal preparing method with electrochemical deposition, which comprises the following steps: pre-processing conductive basal body; formulating electrolyte solution; carrying on constant current electrochemical deposition; gaining Cu2O micron / nanometer crystal. The method is characterized by the following: the cuprous oxide micron / nanometer crystal is gained by changing density of electrolyte solution and electrochemical parameter by constant current electrodeposition method at room temperature, which needn't any supporting electrolytes and surface activators; the form is composed of octahedron, top rake octahedron, top rake cube and cube.

Owner:XIAMEN UNIV

Image forming apparatus and control method thereof

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com