Patents

Literature

355 results about "Lead nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

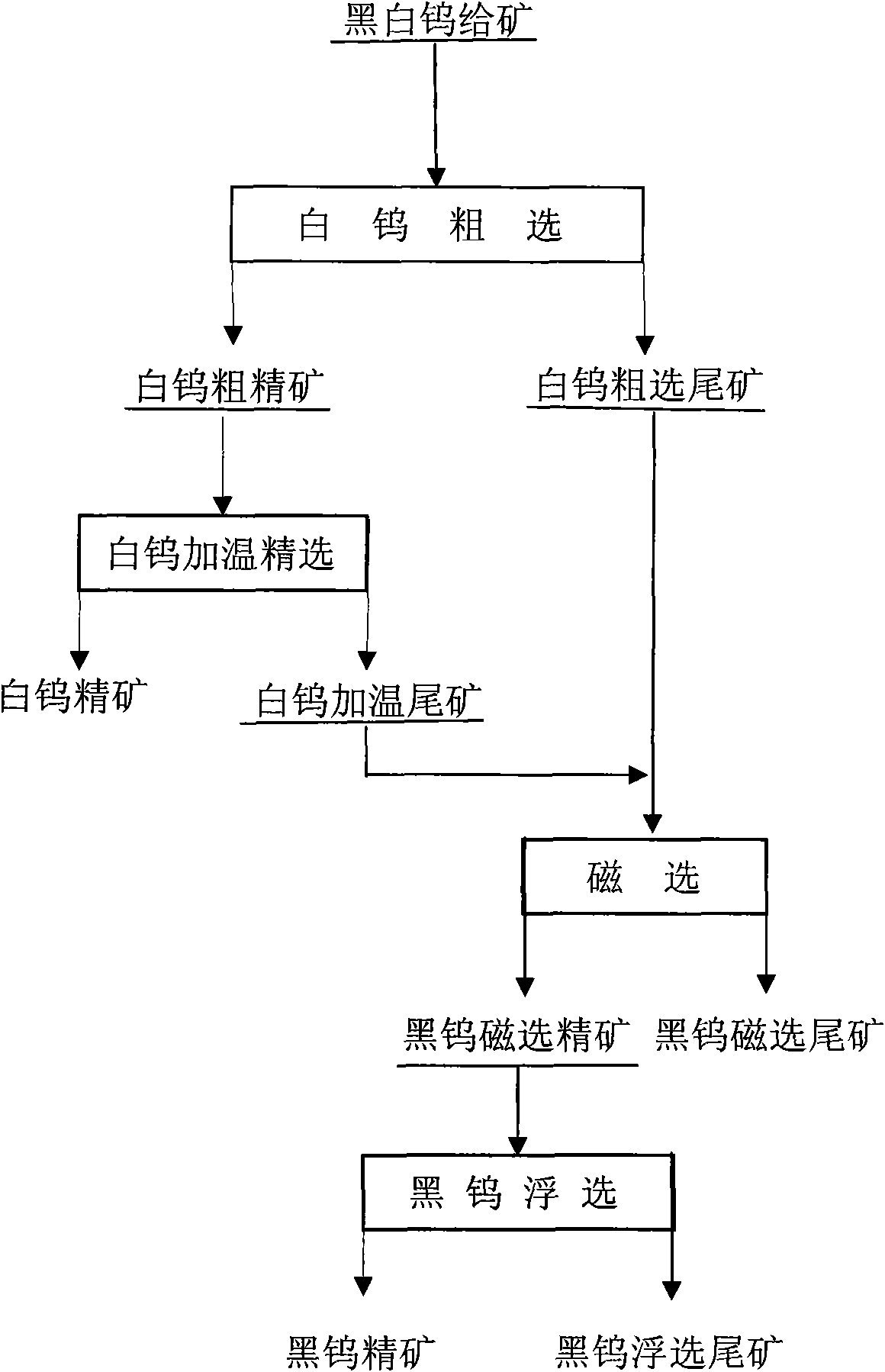

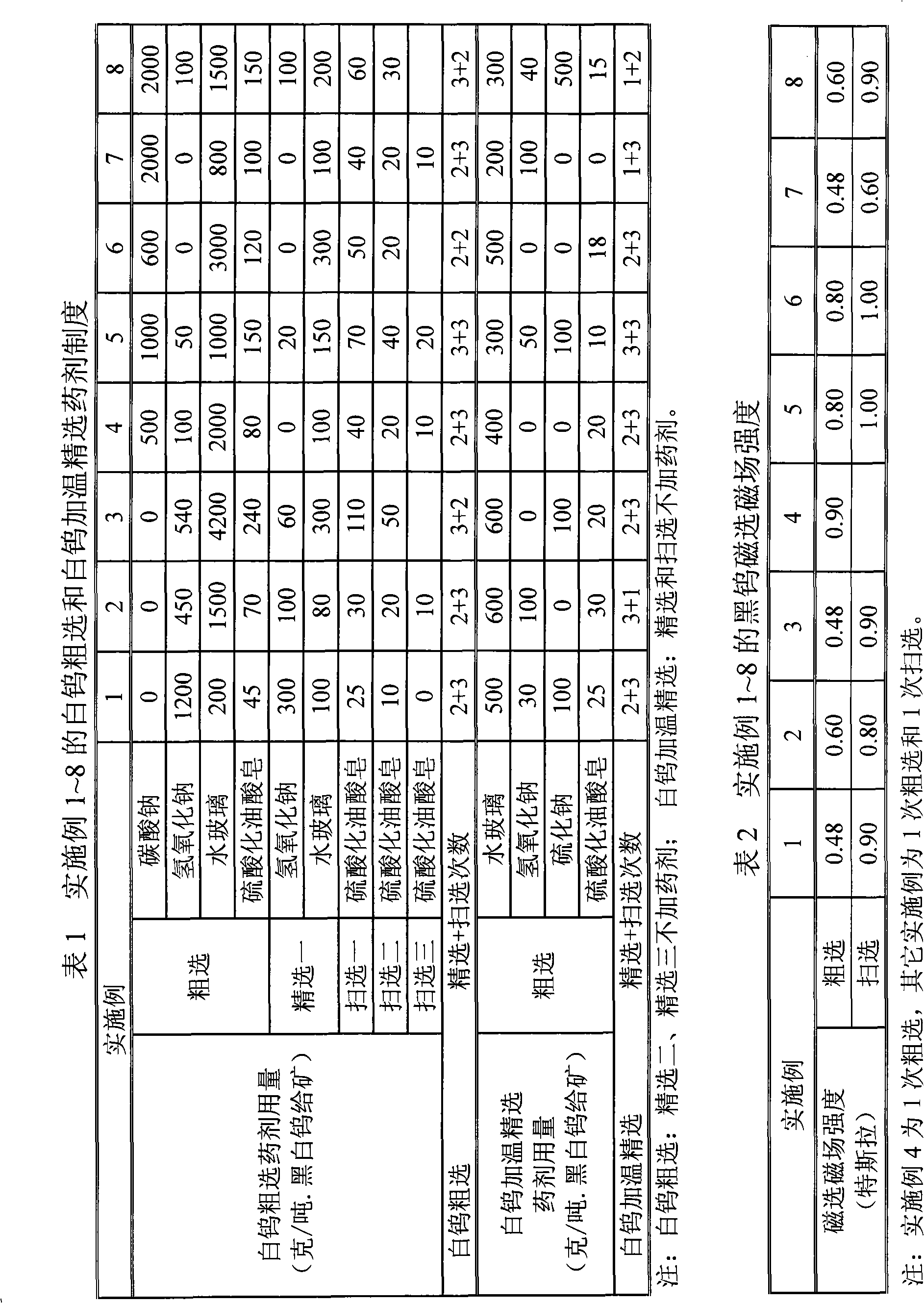

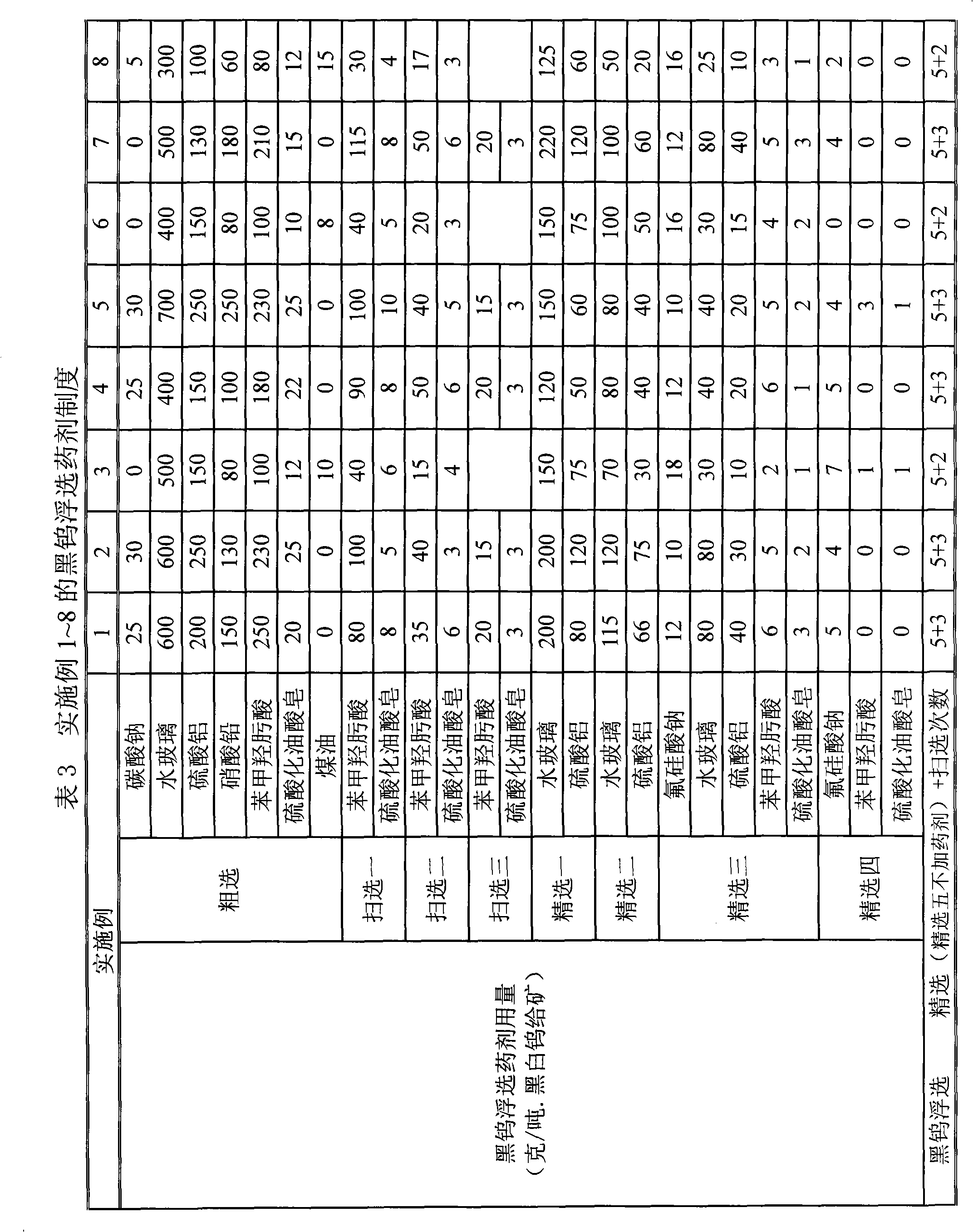

Beneficiation method of black and white tungsten mineral

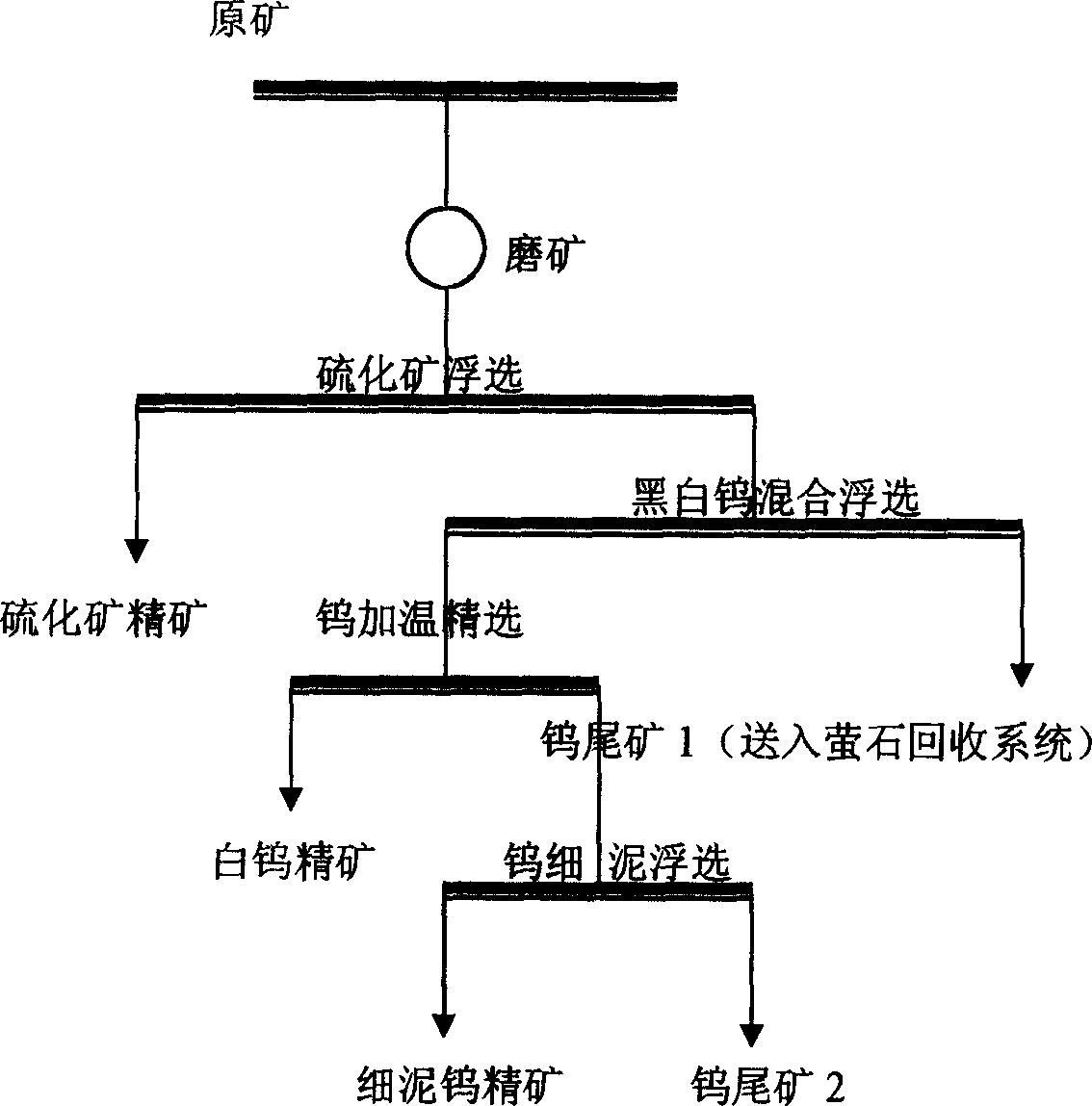

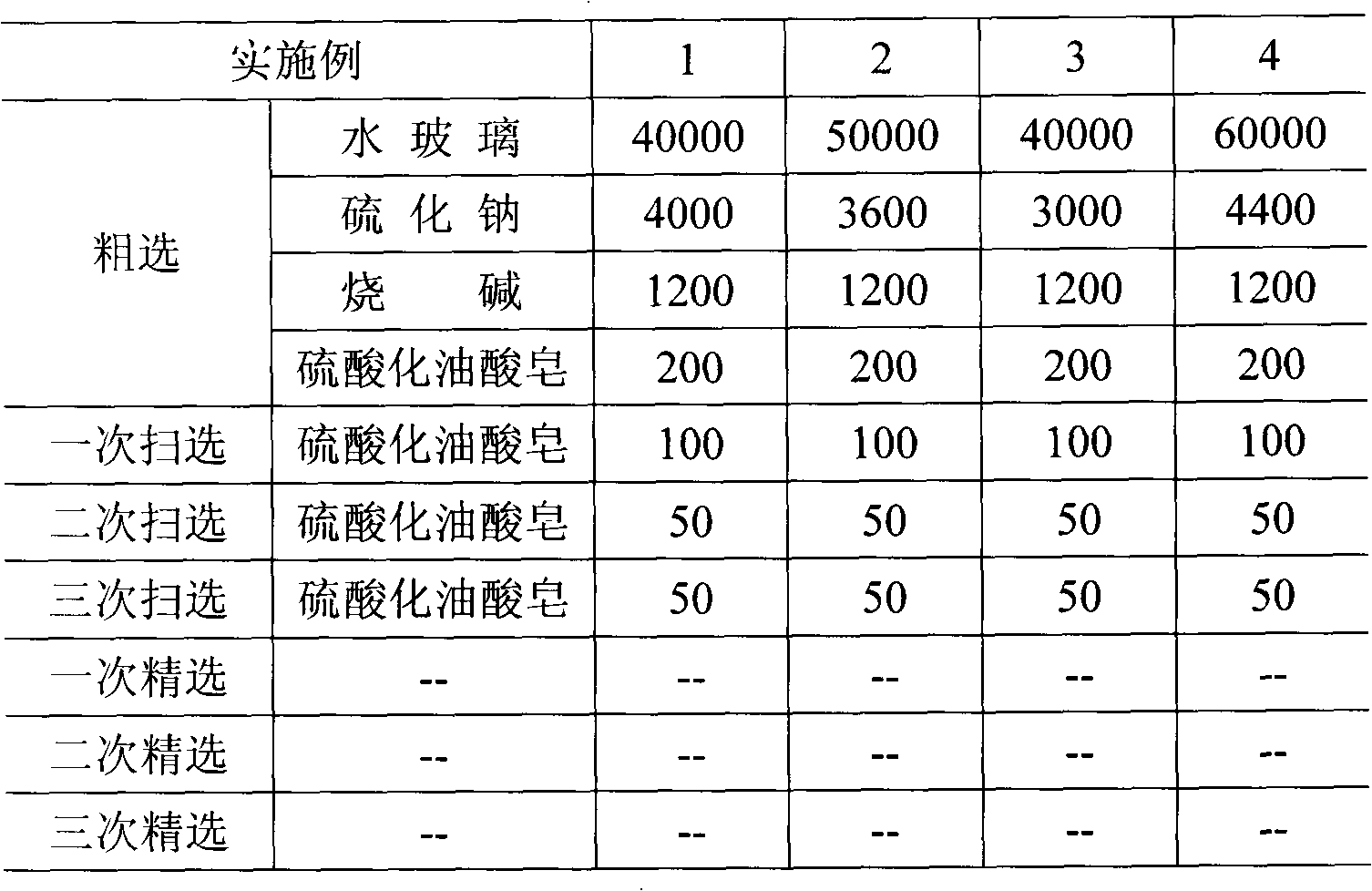

The invention relates to a beneficiation method of black and white tungsten mineral.The method is characterized in that: black and white tungsten mineral through sulfide floatation and magnetic separation deferrization is added with sodium hydroxide, sodium carbonate, sodium silicate and sulphated nascent soap for white tungsten roughing, so as to obtain white tungsten rough concentrate and white tungsten rougher tailings; the white tungsten rough concentrate is added with sodium silicate, sodium hydroxide, sodium sulfide and sulphated nascent soap for white tungsten warming cleaning, so as to obtain white tungsten concentrate and white tungsten warming tailings; the white tungsten rougher tailings and the white tungsten warming tailings are mixed for magnetic separation, so as to obtain black tungsten magnetic separation concentrate and black tungsten magnetic separation tailings; the black tungsten magnetic separation concentrate is added with sodium carbonate, sodium silicate, aluminum sulfate, lead nitrate, sodium fluosilicate, benzohydroxamic acid, sulphated nascent soap and karaffin oil for black tungsten flotation, so as to obtain black tungsten concentrate and black tungsten flotation tailings. The method of the invention is simple in recovery technology, steady in process, high in tungsten recovery rate and low in reagent cost, the used beneficiation reagent does not pollute the environment, and tailings water can meet emission requirement. The invention is applicable to black and white tungsten mineral with WO3 content of .15-2.0% and black and white tungsten proportion of 1:9 to 9:1.

Owner:广东省资源综合利用研究所

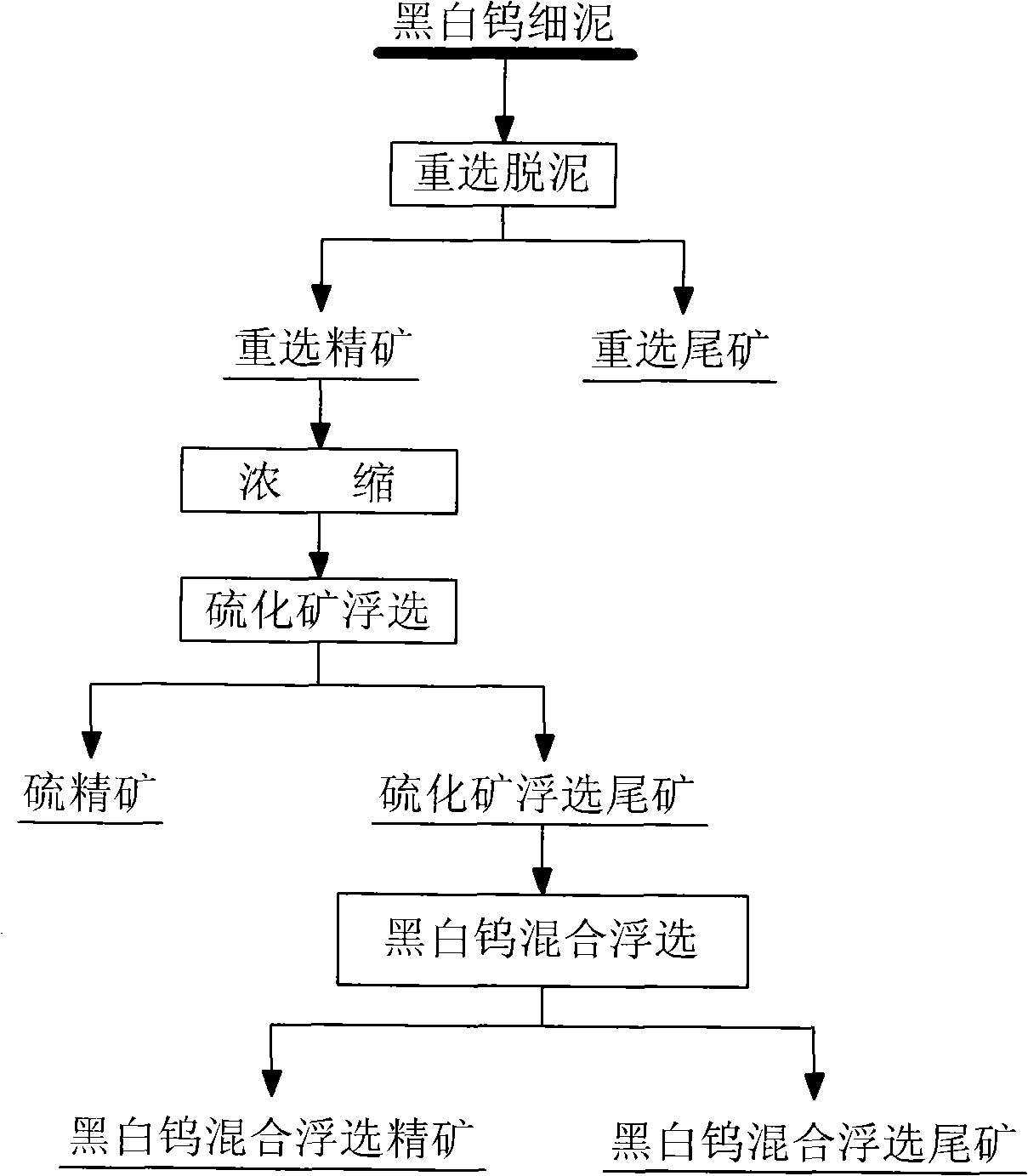

Beneficiation method for black and white tungsten fine deposit

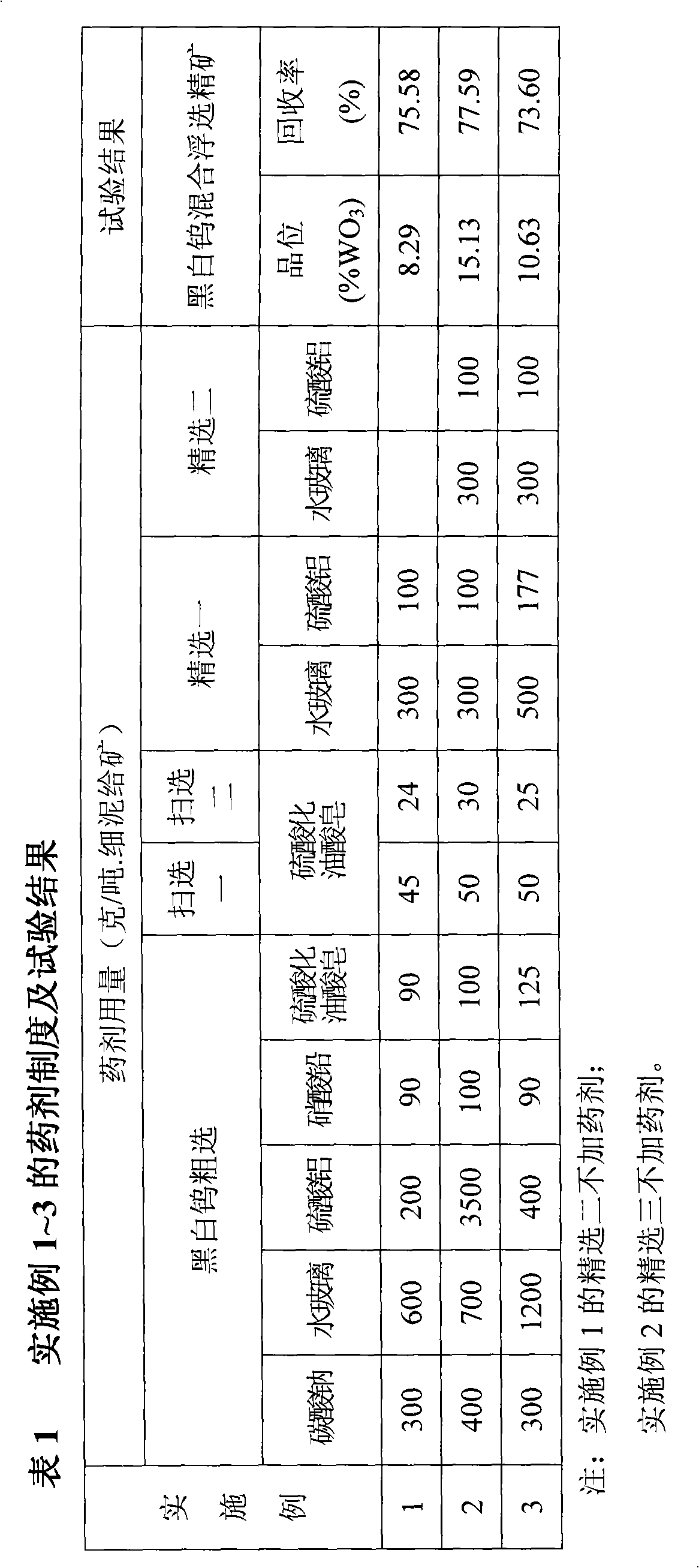

The invention relates to an ore dressing method for black-and-white tungsten fine deposit. The method is characterized in that: (1) gravity concentrate and gravity tailings are obtained by gravity desliming; (2) sulphide concentrate and sulphide ore flotation tailing are obtained by sulphide flotation; (3) the mixed flotation of black-and-white tungsten is performed, the sulphide ore flotation tailing is added with a regulator such as sodium carbonate, sodium silicate, aluminum sulfate, and lead nitrate, and is also added with a collector such as sulfating nascent soap; black-and-white tungsten mixed flotation concentrate and black-and-white mixed flotation tailing are obtained after one-time rough flotation, two or three times of fine flotation and two or three times of scavenging. The method provided by the invention is characterized in that the recovery process of the black-and-white tungsten fine deposit is simple, the flotation process of mixed black-and-white tungsten is stable, the recovery rate of tungsten is high and the cost of the dose is low. The method is suitable for the black-and-white tungsten fine deposit of which the content WO3 ranges from 0.10 to 0.50 percent, the WO3 is less than 30 micrometers and metals account for no less than 60 percent.

Owner:广东省资源综合利用研究所

Mineral dressing method for black and white tungsten minerals

A technology for dressing the mixture of wolframite and scheelite incldues magnetic separation to remove iron, floatation for removing sulfide ore, adding water glass, aluminium sulfate and lead nitrate for regulating sludge, adding benzhdroxyoximic acid, sulfated oleic soap and kerosene, and combined floatation.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

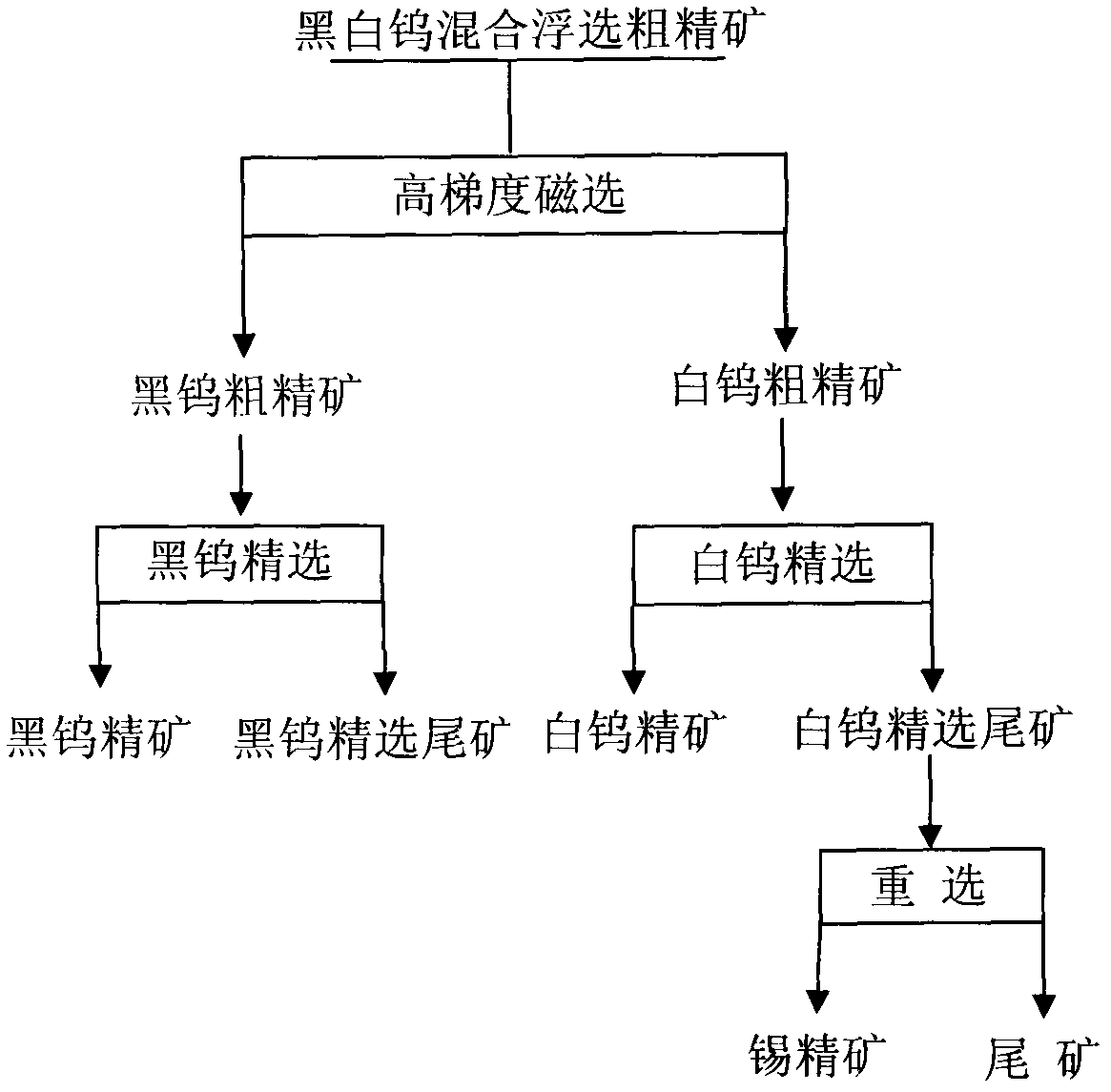

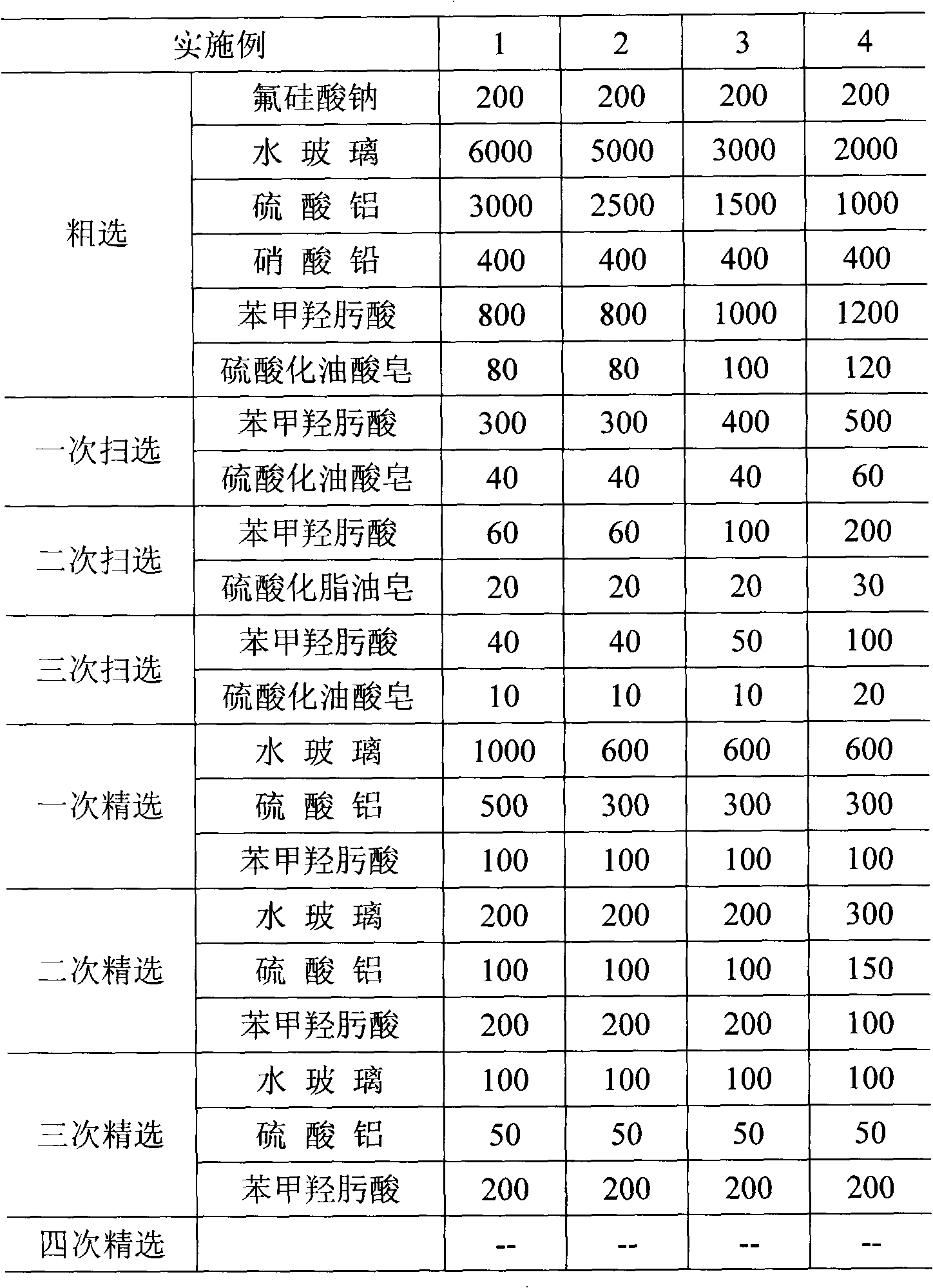

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

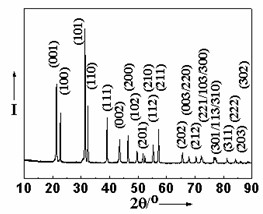

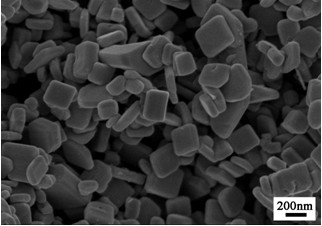

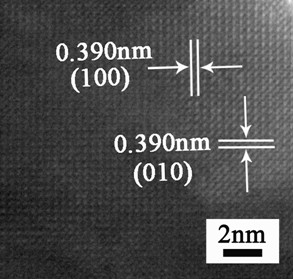

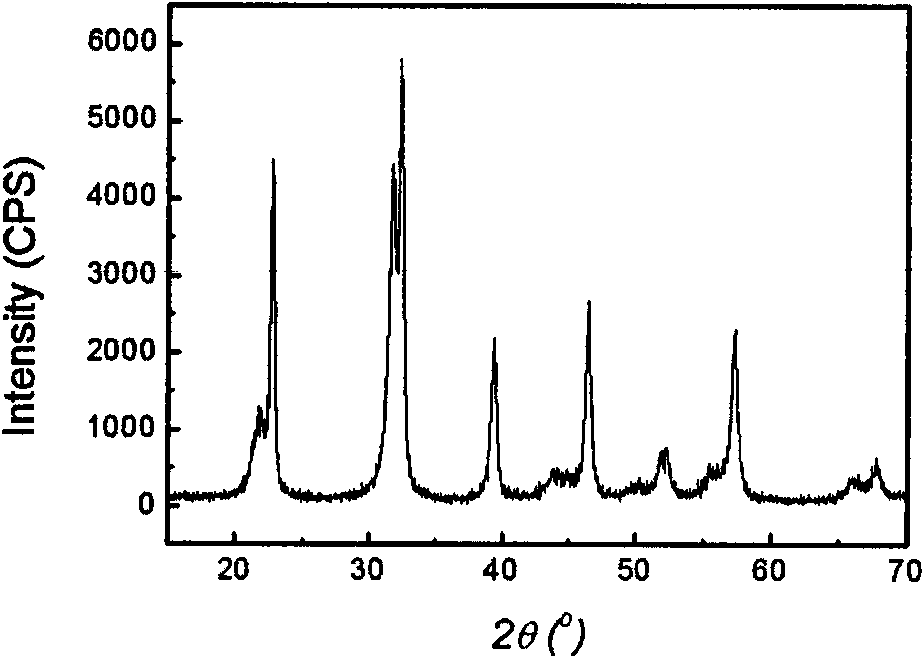

Preparation method for perovskite lead titanate single-crystal nanometer sheet

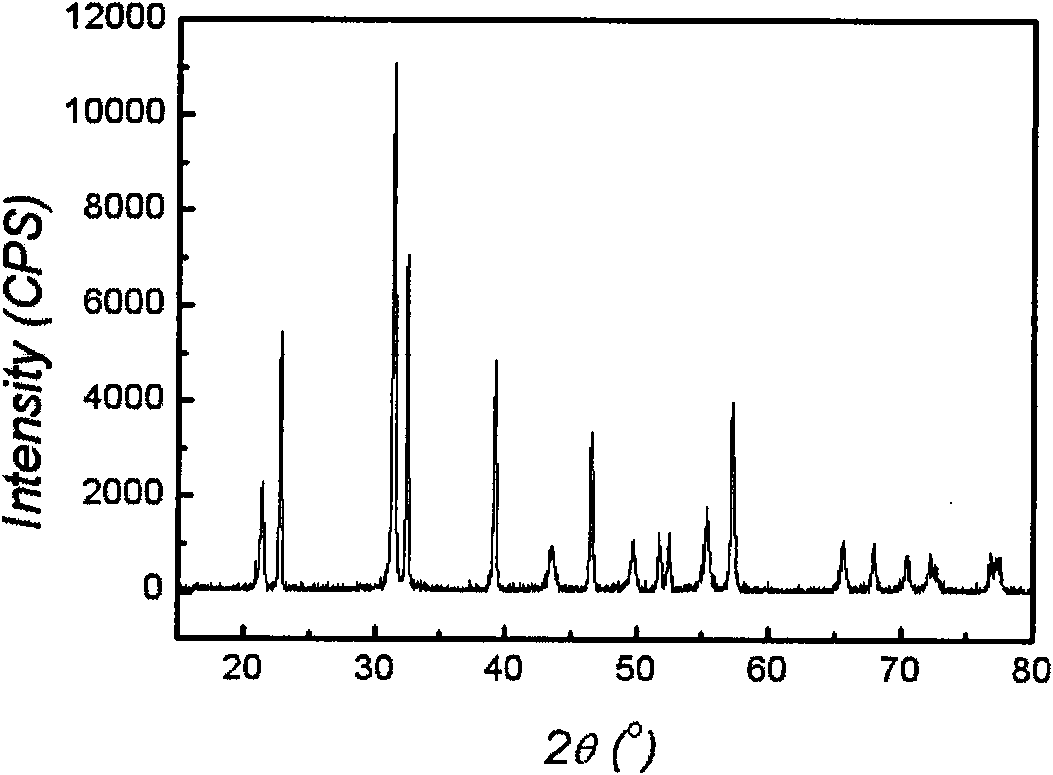

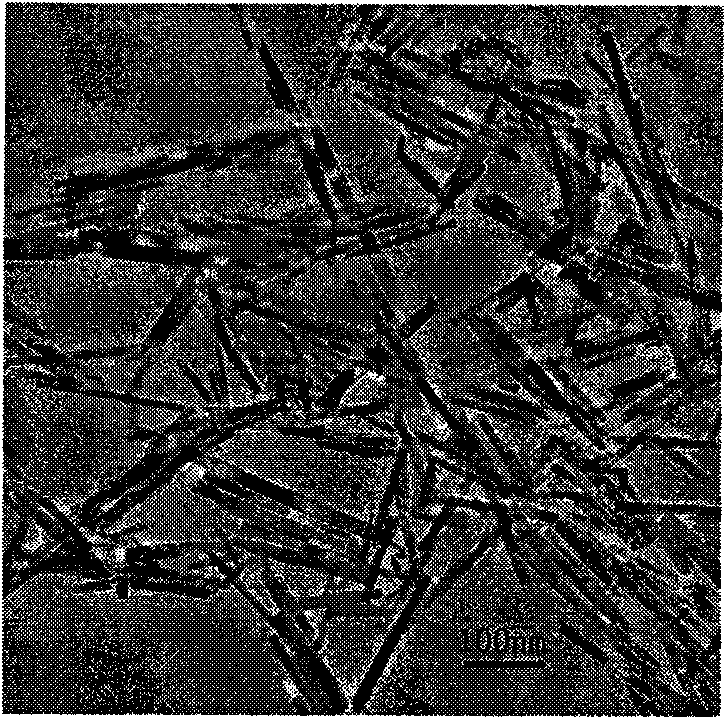

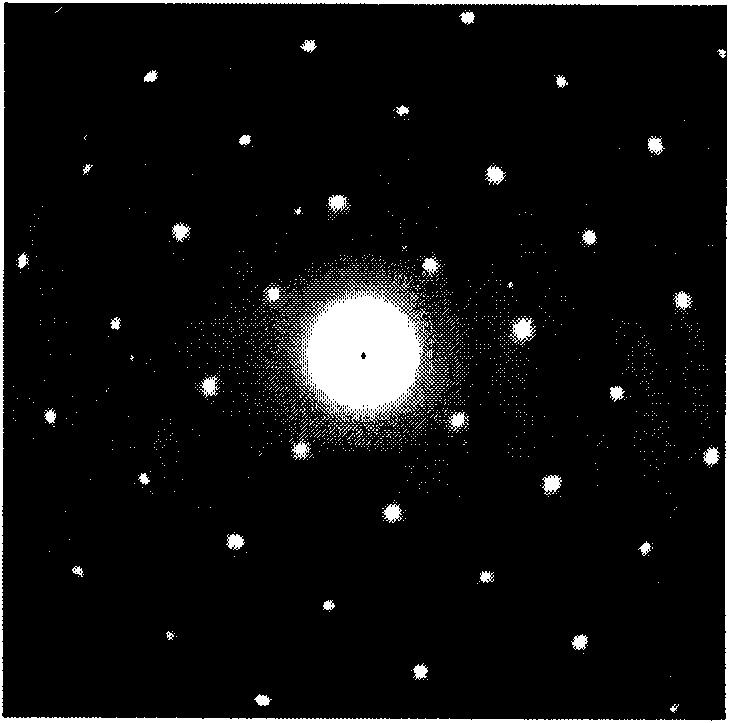

ActiveCN102534794AAchieve synthesisHigh purityPolycrystalline material growthFrom normal temperature solutionsLead nitratePotassium hydroxide

The invention relates to a preparation method for a perovskite lead titanate single-crystal nanometer sheet. A hydro-thermal reaction method is adopted according to the preparation method. The preparation method comprises the following steps: taking titanium dioxide as a raw material; taking a potassium hydroxide aqueous solution as a hydro-thermal medium and dropwise adding a lead nitrate aqueous solution; and stirring, and then performing thermal treatment at high temperature, thereby obtaining the perovskite lead titanate single-crystal nanometer sheet with a two-dimensional laminated structure. The technical process of the preparation method has the advantages of simpleness, easiness in control, zero pollution, low cost and easiness in mass production. The prepared perovskite lead titanate single-crystal nanometer sheet with the two-dimensional laminated structure is high in purity and excellent in dispersibility.

Owner:ZHEJIANG UNIV

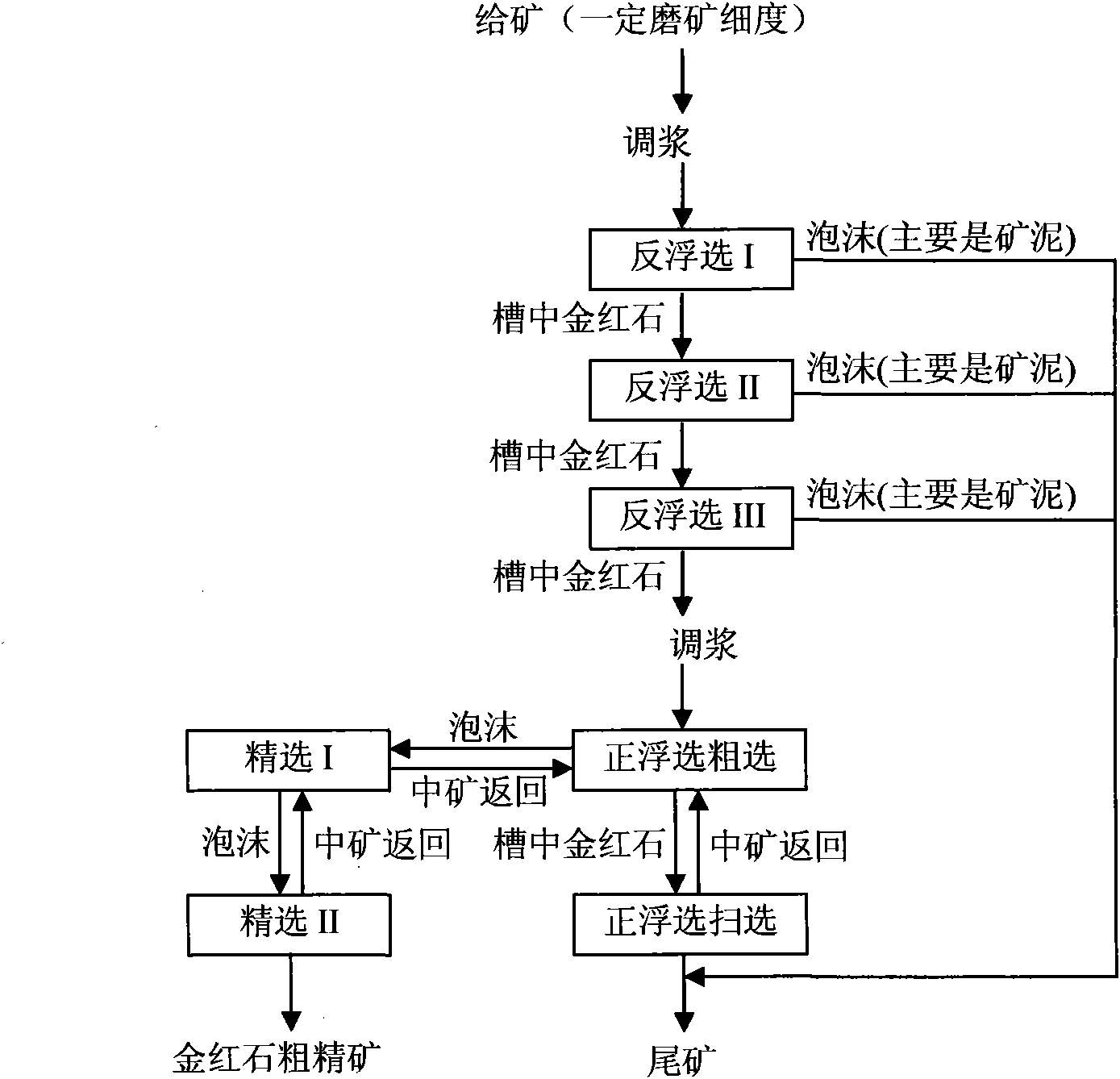

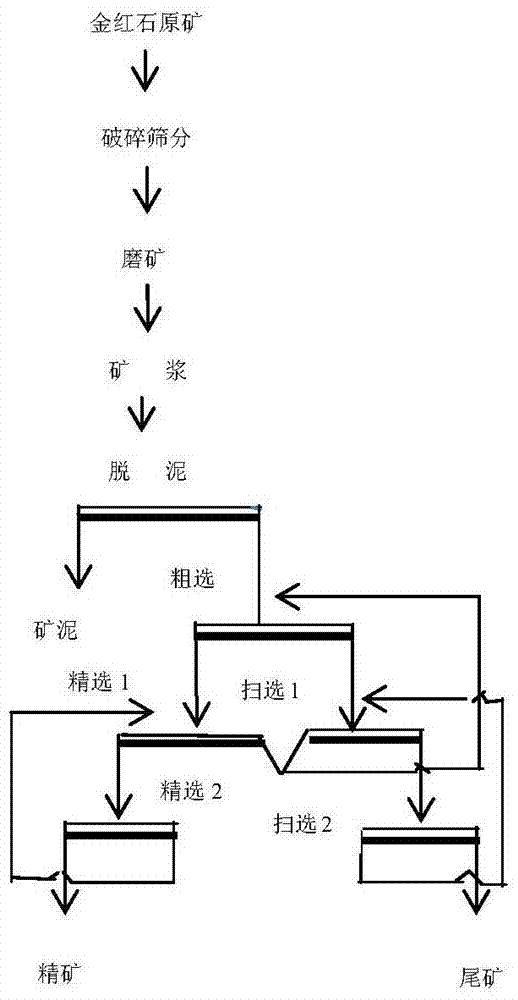

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

The invention provides a method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation, relating to the technique for roughing and tailings-discarding of fine rutile ore by multi-stage floatation and belonging to the technical field of mineral processing engineering. The method of the invention comprises the following steps: firstly, conducting the reverse floatation of rutile by using sodium oleate as a collector according to the characteristics that aluminum sulfate can inhibit the rutile and activate silicate minerals in varying degrees, so as to effectively deslime in the process of reverse floatation; and then, conducting the forward floatation of rutile by using lead nitrate (or lead acetate) as an activator of rutile and using sodium alkyl hydroxamate and benzyl arsonic acid (or styryl phosphonic acid) as a combined collector according to the characteristic that gangue minerals can be inhibited on a combined basis under the synergistic action of sodium fluorosilicate, carboxymethylcellulose and the residual aluminum sulfate in the ore pulp, briefly, the method of the invention can realize the roughing and tailings-discarding of fine rutile by the multi-stage floatation comprising the following steps: firstly, conducting the reverse floatation by inhibiting the rutile; and then, conducting the forward floatation by activating the rutile. The method of the invention has the advantages that the enrichment ratio and recovery rate of rutile are high, the tailings of rutile ore can be discarded thoroughly and the mineral processing cost of rutile can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

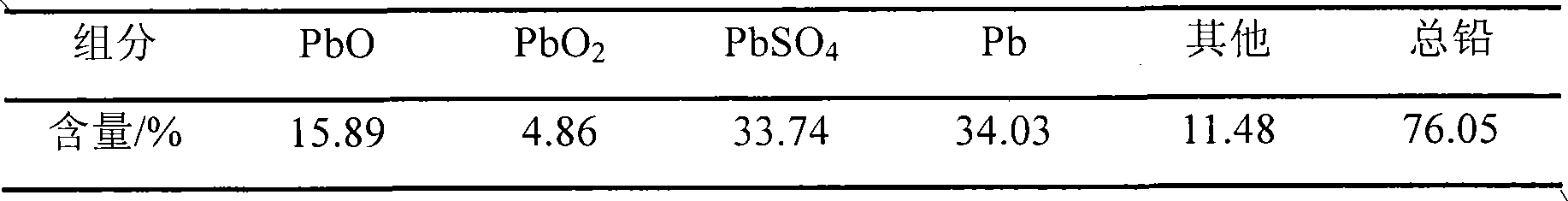

Method for preparing lead nitrate and lead oxide by using lead plaster of waste lead accumulator

InactiveCN101857919ASimple processNo waste dischargeProcess efficiency improvementGranularityLead nitrate

The invention discloses a method for preparing lead nitrate and lead oxide by using lead plaster of a waste lead accumulator, which comprises the following steps of: mixing the lead plaster with the granularity of less than 100 microns and 4.5 to 6.5 percent ammonium carbonate solution in a weight ratio of 1: 10-12, then reacting the mixture for 2 to 3 hours at the temperature of between 60 and 100 DEG C with stirring, separating and washing the reaction product, and collecting filter cakes; then mixing the filter cakes, 6 to 12 percent diluted nitric acid and 28 to 30 percent hydrogen peroxide in turn in a weight ratio of 1: 8-10 and 1: 0.05-0.2 respectively, reacting the mixture for 1 to 1.5 hours at the temperature of between 40 and 60 DEG C with stirring, separating and washing the reaction product, and collecting filtrate; concentrating the filtrate till the density of the solution is 1.30 to 1.45 g / cm<3>, adding 65 to 70 percent nitric acid into the solution in a volume ratio of 1: 8-10 and mixing the solution, reacting the solution for 1 to 2 hours with stirring, separating and washing the reaction product, and drying and dehydrating the filter cakes to obtain a lead nitrate product; and performing reaction conversion on the lead nitrate and sodium hydroxide solution, and calcining the reaction product to obtain a lead oxide product. The purities of both the lead nitrate and the lead oxide are more than or equal to 99 percent. The process adopts closed cycle and has no three-waste emission.

Owner:HEFEI UNIV OF TECH +1

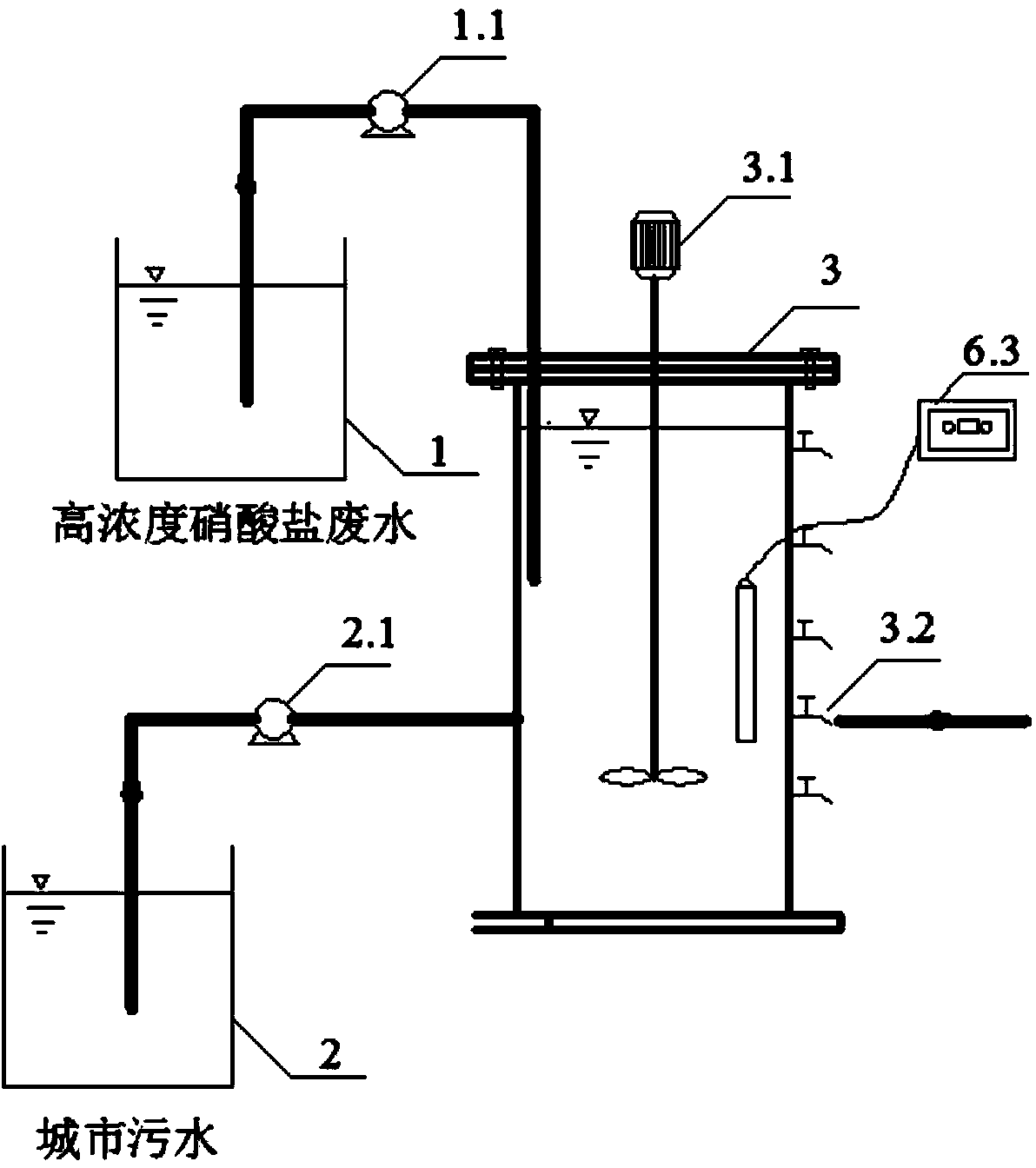

Method for treating high-concentration nitrate waste water and municipal sewage through denitrification anaerobic ammonium oxidation SBR

ActiveCN104276656AStable reaction matrixImprove nitrogen removal efficiencyWater contaminantsBiological treatment apparatusHigh concentrationLead nitrate

The invention provides a method for treating high-concentration nitrate waste water and municipal sewage through denitrification anaerobic ammonium oxidation SBR, belonging to the field of sewage biotreatment. The method comprises the following steps: firstly, culturing and acclimating denitrifying bacteria population and anaerobic ammonium oxidation bacteria population which have inadequate denitrification characteristic, then inoculating anaerobic ammonium oxidation sludge and denitrifying sludge with high nitrite accumulation rate in the same reactor, leading nitrate waste water and municipal sewage to flow in denitrification anaerobic ammonium oxidation SBR reactor at a certain ratio, performing anaerobic ammonium oxidation to nitrite accumulated during reduction of nitrite and ammonium nitrogen in the municipal sewage to generate nitrogen gas and synchronously removing. According to the method, nitrate generated during anaerobic ammonium oxidation can be reduced through denitrifying bacteria without the condition of adding a carbon source, the nitrogen removal efficiency of a system can be improved, and the effective route for realizing sewage nitrogen removal with high efficiency and low energy consumption can be provided.

Owner:BEIJING UNIV OF TECH

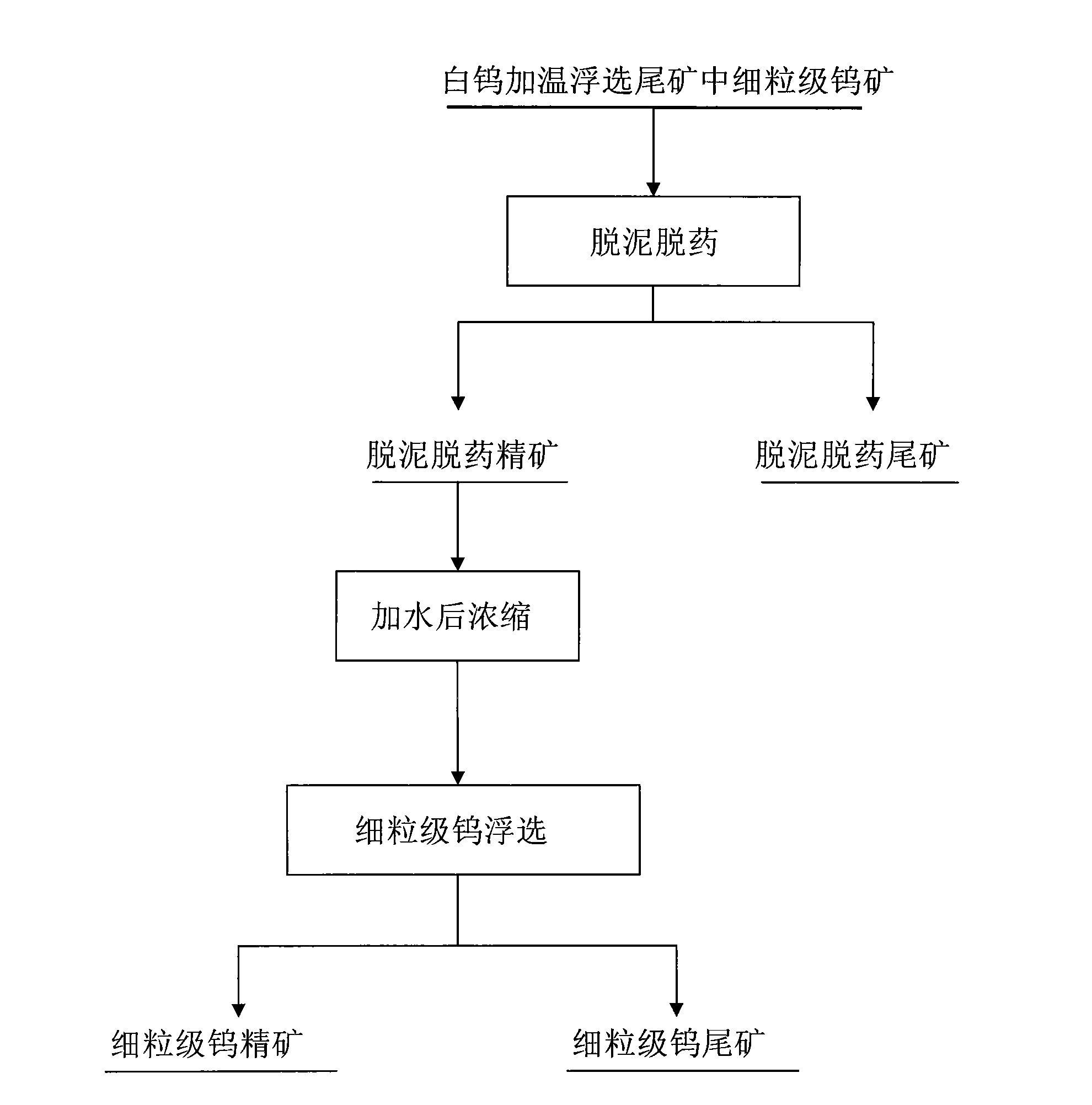

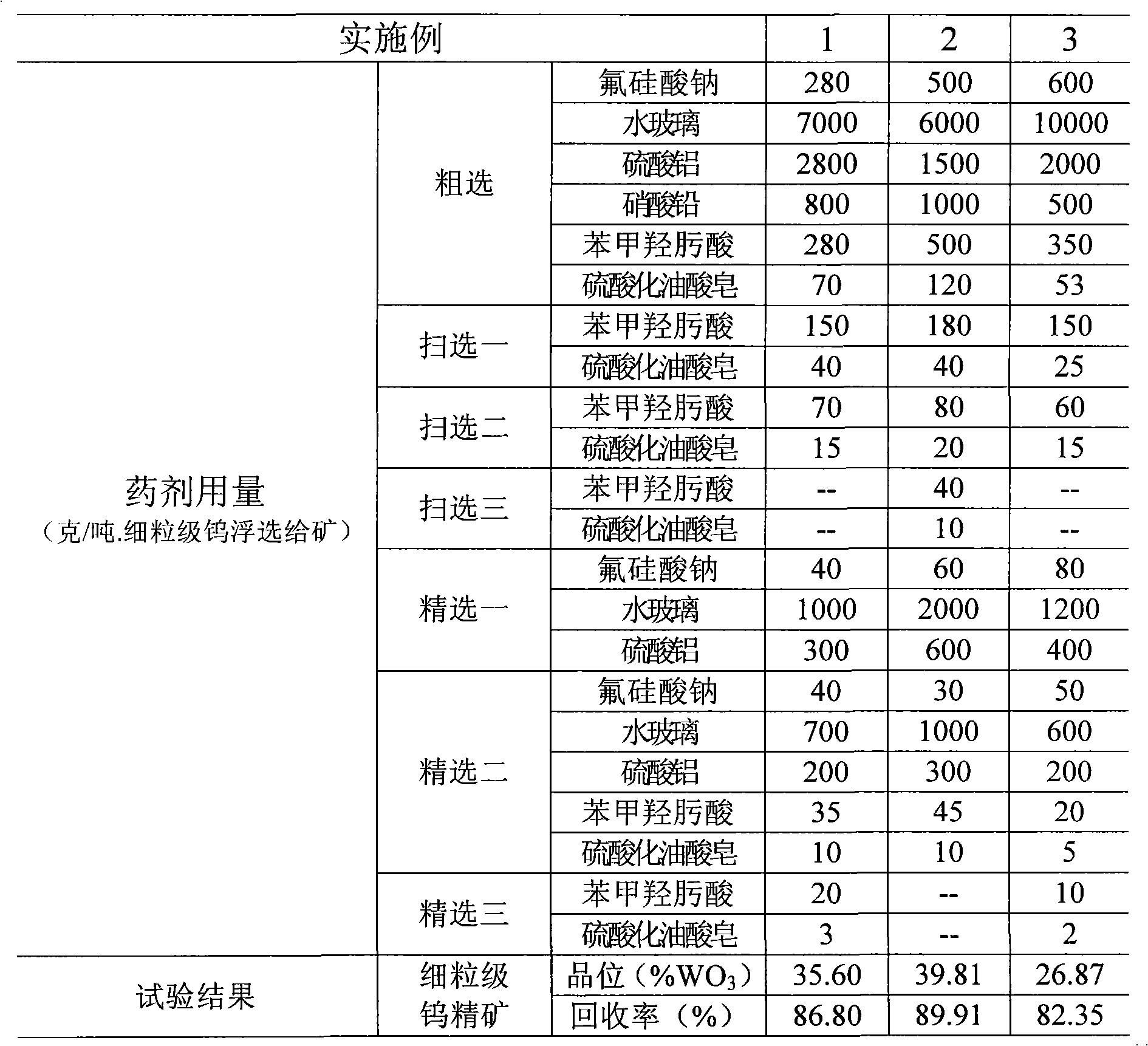

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

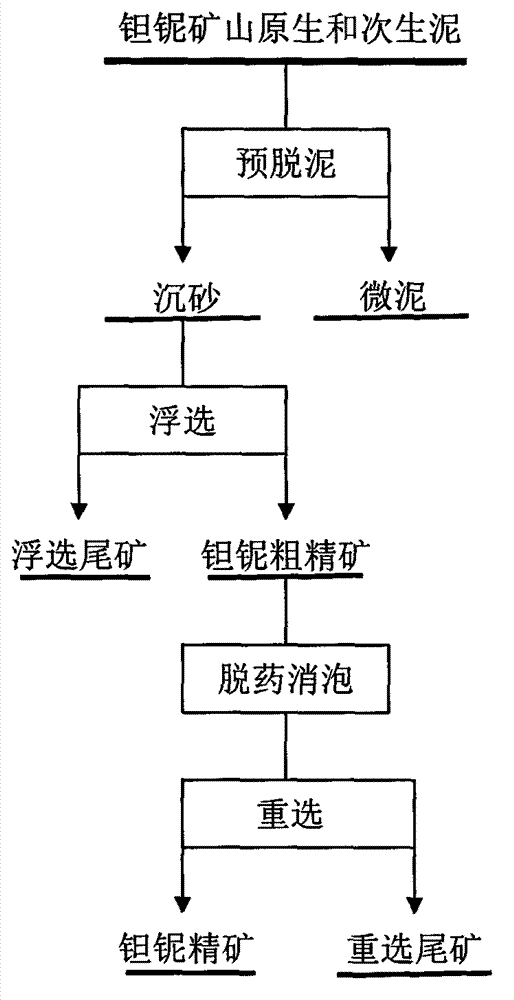

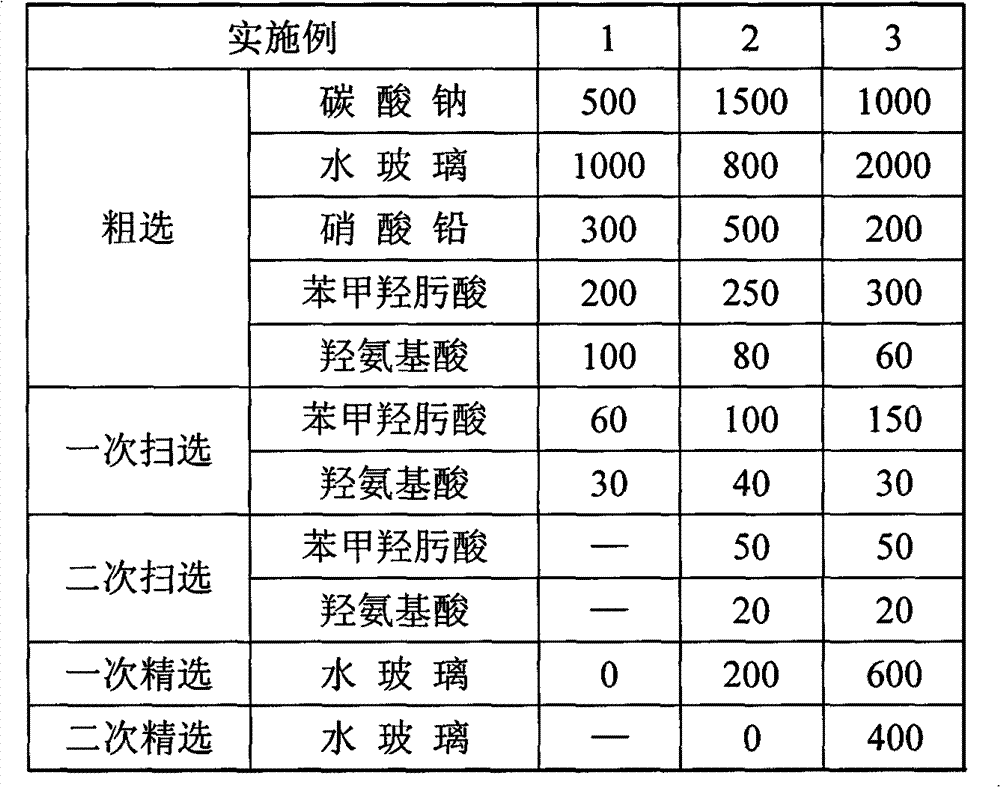

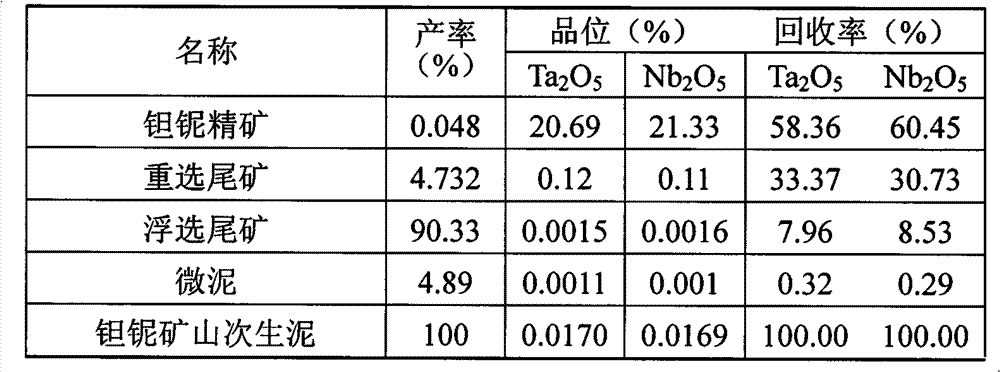

Ore dressing method of micro-fine particle tantalum-niobium ores

InactiveCN102861662AEliminate selection noiseImprove flotation recoveryPlaning/slotting machinesWet separationBenzohydroxamic acidLead nitrate

Disclosed is an ore dressing method of micro-fine particle tantalum-niobium ores. The ore dressing method is characterized by including steps of firstly, performing desliming pre-treatment to obtain set sand and micro-mud; secondly, adding an adjusting agent of sodium carbonate, an inhibiting agent of water glass, an activating agent of lead nitrate and collectors of benzohydroxamic acid and hydroxyamino acid to the set sand for once roughing; adding the benzohydroxamic acid and the hydroxyamino acid for once or twice scavenging; adding the water glass for once or twice concentration or blank concentration to obtain tantalum-niobium rough concentrates and flotation tailings; thirdly, performing de-reagent and de-foaming: adding sulfuric acid to the tantalum-niobium rough concentrates, and stirring the mixture until foams are disappeared; and fourthly, performing gravity concentration: subjecting the tantalum-niobium rough concentrates to de-reagent and de-foaming, and subjecting the tantalum-niobium rough concentrates to gravity concentration to obtain tantalum-niobium concentrates and gravity concentration tailings. According to the ore dressing method of the micro-fine particle tantalum-niobium ores, the recovery rate of the micro-fine particle tantalum-niobium ores is increased by over 30%, and the ore dressing method is applicable to primary mud and secondary mud with sizes of -0.037mm in tantalum-niobium ores.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

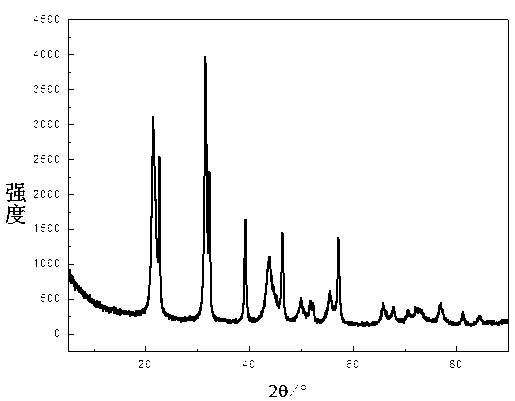

Method for preparing perovskite structure lead titanate monocrystal nano rod

InactiveCN101619494ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsLead nitratePotassium hydroxide

The invention relates to a method for preparing a perovskite structure lead titanate monocrystal nano rod. A titanium and lead oxyhydroxide mixed sediment for hydrothermal reaction is prepared by a two-step precipitation method. The method comprises the following steps: taking titanium sulfate as a raw material for precipitating titanium, taking lead nitrate as a raw material for precipitating lead and taking potassium hydroxide as a precipitating agent; precipitating titanium ions; precipitating lead ions; after the product is filtered and washed, obtaining the mixed sediment containing the titanium ions and the lead ions; mixing and dispersing the mixed sediment and the potassium hydroxide in deionized water; sealing the mixture in a reaction kettle; and carrying out hydro-thermal treatment at 160-240 DEG C for 5-48 hours to obtain the perovskite structure lead titanate monocrystal nano rod. The invention has simple technology process, no pollution and low cost and is easy to control and carry out mass production.

Owner:ZHEJIANG UNIV

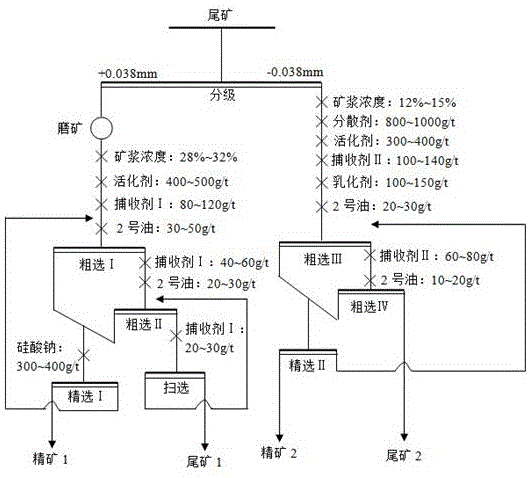

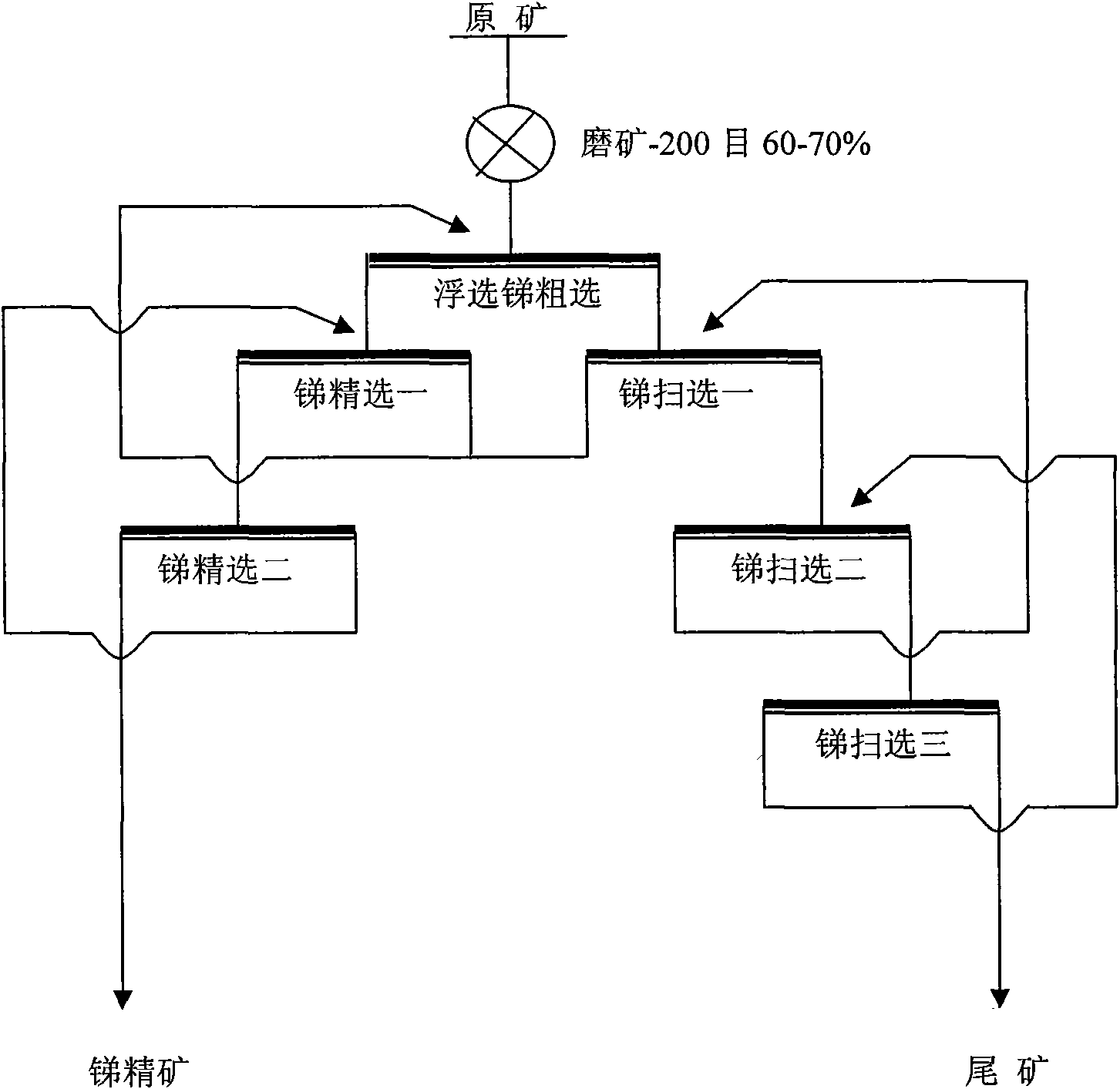

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

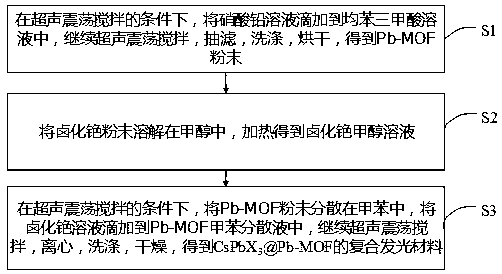

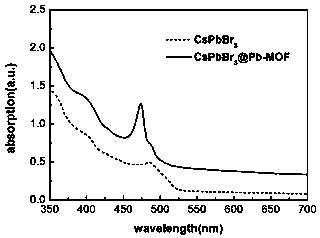

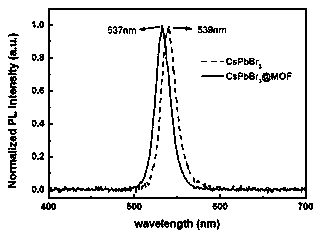

Preparation method of perovskite quantum dot and metal-organic framework (MOF) composite luminescent material

InactiveCN110041915AOutstanding FeaturesHighlight significant progressLuminescent compositionsPorosityLead nitrate

The invention discloses a preparation method of a perovskite quantum dot and metal-organic framework (MOF) composite luminescent material. The preparation method comprises the following steps: dropwise adding a lead nitrate solution into a trimesic acid solution to obtain Pb-MOF powder under the conditions of ultrasonic oscillation and stirring; dissolving cesium halide powder in methanol, and heating to obtain a cesium halide methanol solution; dispersing the Pb-MOF powder in toluene, and dropwise adding the cesium halide solution into the toluene dispersion of Pb-MOF to obtain the compositeluminescent material of CsPbX3@Pb-MOF under the condition of ultrasonic oscillation. According to the preparation method disclosed by the invention, the porosity of the Pb-MOF is utilized to nucleatea perovskite quantum dot in the mesopores of the Pb-MOF by an in-situ growth method under the condition of room temperature and ultrasonic oscillation, and the formed CsPbX3@Pb-MOF composite luminescent material improves the stability of the perovskite quantum dot and enhances the optical properties of the perovskite quantum dot.

Owner:SHENZHEN UNIV

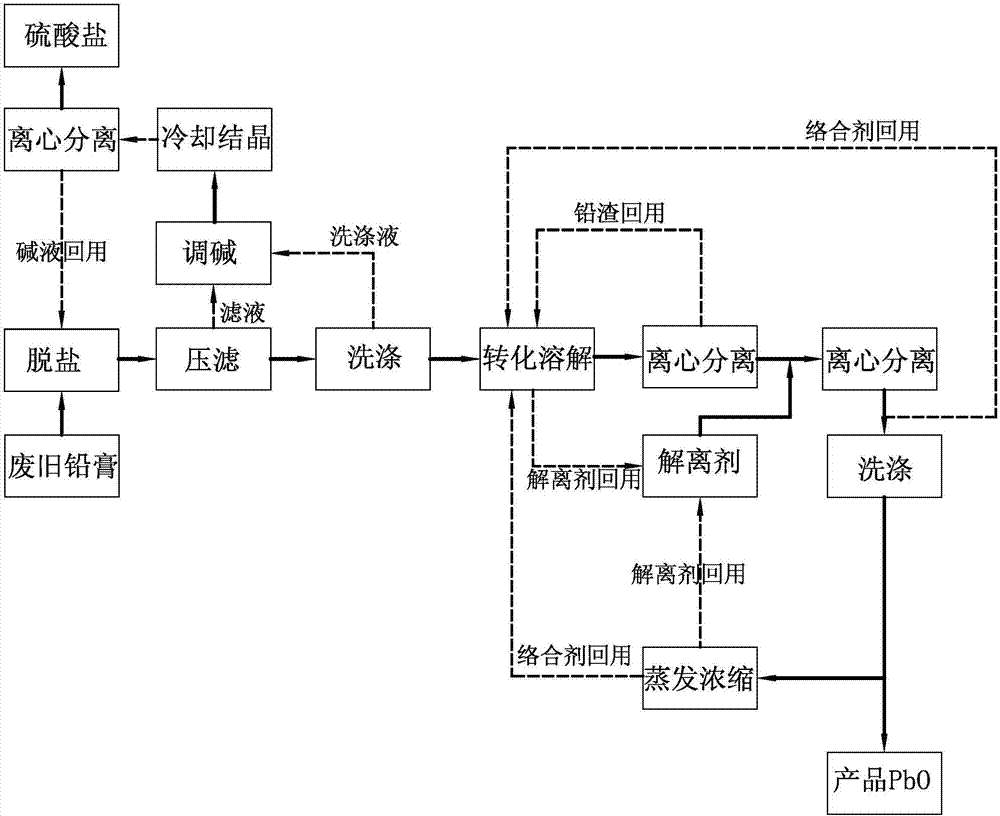

Method for recycling lead oxide from lead plaster of waste lead-acid storage battery

ActiveCN107460339AImprove economyAchieve a reversible cycleLead monoxideWaste accumulators reclaimingEnvironmental resistanceLead dioxide

The invention relates to the technical field of clean recycling of waste batteries and discloses a method for recycling lead oxide from lead plaster of a waste lead-acid storage battery. The method comprises the following steps that (1) pre-desalination is conducted, specifically, the lead plaster of the waste lead-acid storage battery is added with alkali liquor to be subjected to pre-desalination, so that lead acid, lead acetate, lead nitrate, lead perchlorate or lead carbonate in the lead plaster is removed; (2) dissolution is conducted, specifically, a complexing agent solution is added into the lead plaster subjected to pre-desalination, all PbO in the lead plaster reacts with a complexing agent to generate lead complex ions, and a lead-bearing solution and filter residues are obtained; (3) dissociation is conducted, specifically, the pH value of the lead-bearing solution is adjusted by adding a dissociation agent solution, so that the lead complex ions are dissociated, and the PbO and a mixed solution containing the complexing agent and a dissociation agent are obtained; and (4) separating is conducted, specifically, a lead oxide product is obtained after solid-liquid separation and washing. According to the method, the technological condition is mild, the technological process is environmentally friendly, the technological procedure is simple, energy consumption is small, the cost is low, the lead oxide recycling rate is high, the purity is high, and the method has very high industrial application value.

Owner:CHAOWEI POWER CO LTD

Method for recovering rutile

The invention relates to a method for recovering rutile. According to the method for recovering the rutile, desliming is conducted after raw ore is subjected to ore grinding, lead nitrate serves as an activator, sodium fluosilicate and water glass serve as inhibitors, styrene phosphoric acid and 1-capryl alcohol serve as collecting agents, second oil serves as a foaming agent, flotation separation is conducted, and rutile concentrate is obtained. The technical scheme of the method for recovering the rutile has the following technical effects that (1) the flotation index of the rutile is greatly increased to enable the grade of the rutile to be improved by over 80% and the recovering rate to be about 60% in roughing, then one-time medicating concentration, one-time blank concentration and two-time scavenging are conducted, finally, the TiO2 content in the concentrate reaches 92%, the concentration ratio is over 20, the recovering rate is between 80% and 85%, the TiO2 content in tailings is reduced to 0.5-0.7%; and (2) the pH of ore pulp does not need to be adjusted, operation is easy, a flotation foam layer is thick, control is easy, and the flotation velocity is high.

Owner:WUHAN UNIV OF TECH

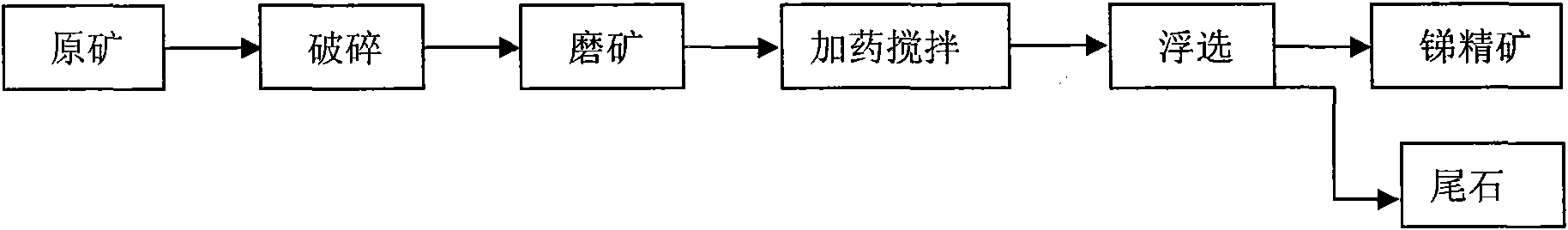

Beneficiation method of antimonyore

The invention provides an environment-friendly beneficiation method of antimonyore, which takes H2SO4 as ore pulp pH value conditioning agent and Al2(SO4)3 as antimonyore activator; the flotation effect which is the same as taking lead nitrate as the antimonyore activator can be obtained; the new medicament combination of butyl ammonium aerofloat, diethyldithiocarbamate and No. 25 black powder can be adopted, and the auxiliary agent is saved. The technical method is simple and free from pollution, can improve the surrounding environment of the place where antimonyore enterprises are positioned, and the beneficiation cost is greatly reduced. Antimony concentrate prepared by the beneficiation method has low lead content and high recovery rate, thus being a new way of environment-friendly antimony beneficiation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

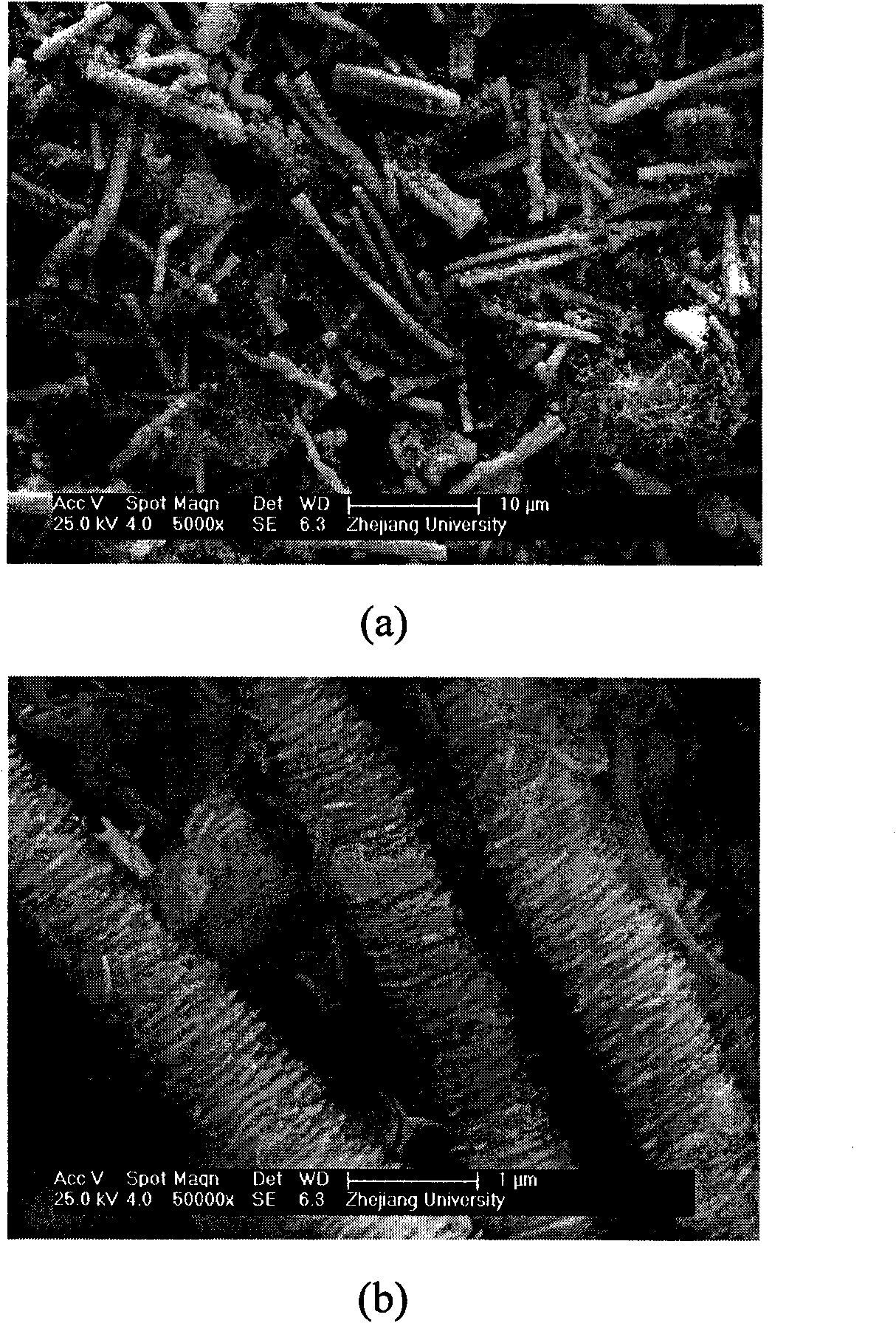

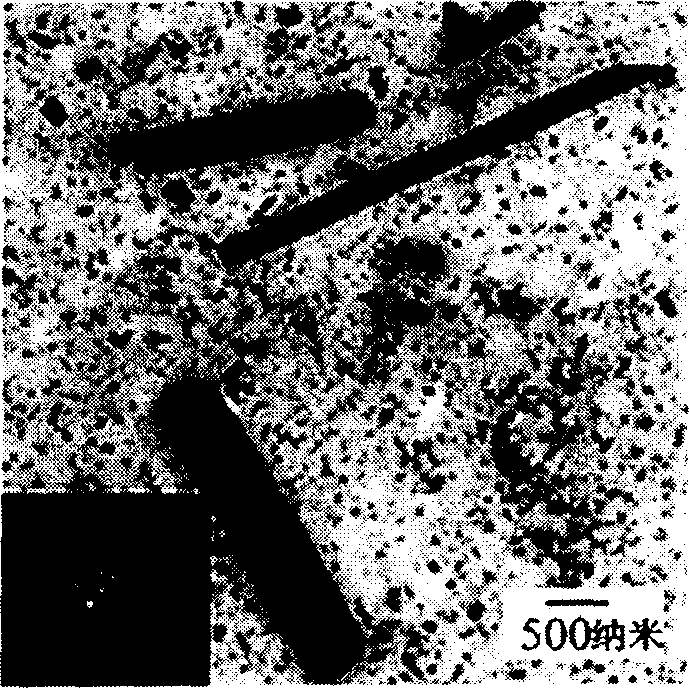

Method for preparing lead titanate nano column automatically assembled by perovskite structure nano pieces

InactiveCN101618889ASimple preparation processEasy to controlTitanium compoundsLead nitrateTitanium ion

The invention relates to a method for preparing a lead titanate nano column automatically assembled by perovskite structure nano pieces. A titanium and lead oxyhydroxide mixed sediment for hydrothermal reaction is prepared by a two-step precipitation method. The method comprises the following steps: hydrolyzing tetrabutyl titanate by ammonia solution to precipitate titanium ions; introducing lead nitrate in the ammonia solution suspended with a titanium oxyhydroxide sediment to precipitate lead ions; after the mixed sediment is filtered and washed, mixing the mixed sediment, potassium hydroxide and deionized water; and carrying out hydro-thermal treatment in a sealed reaction kettle at 160-240 DEG C for 5-48 hours to obtain the lead titanate nano column automatically assembled by the perovskite structure lead titanate nano pieces. The lead titanate nano column is 5-20 microns in length and 0.4-1 micron in diameter, and the perovskite structure lead titanate nano pieces of the lead titanate nano column are 2-10 microns in thickness. The invention has simple technology process, no pollution as well as low cost and is easy to control and carry out mass production.

Owner:ZHEJIANG UNIV

Modified lime sulphur and application thereof in gold leaching technology

ActiveCN103243222AReduce dosageImprove stabilityProcess efficiency improvementLead nitrateCalcium peroxide

The invention discloses a modified lime sulphur and an application thereof in a gold leaching technology. The modified lime sulphur comprises a stabilizer sodium-hexametaphosphate, oxidants-calcium peroxide and potassium cyanate, and additives-lead nitrate and soluble bromides (such as sodium bromide, potassium bromide, calcium bromide and the like). The modified lime sulphur is used as a gold leaching agent so as to effectively recover gold from gold-containing ores, gold concentrate powder and gold-containing wastes. The modified lime sulphur has the characteristics that the modified lime sulphur is easy to synthesize; the preparation cost is low; the preparation process is environment-friendly and toxic-free; and when the prepared modified lime sulphur is used for gold leaching, the gold leaching technology is simple, and the gold leaching velocity is high; and moreover, the modified lime sulphur is suitable for more ores than cyaniding gold leaching.

Owner:CENT SOUTH UNIV

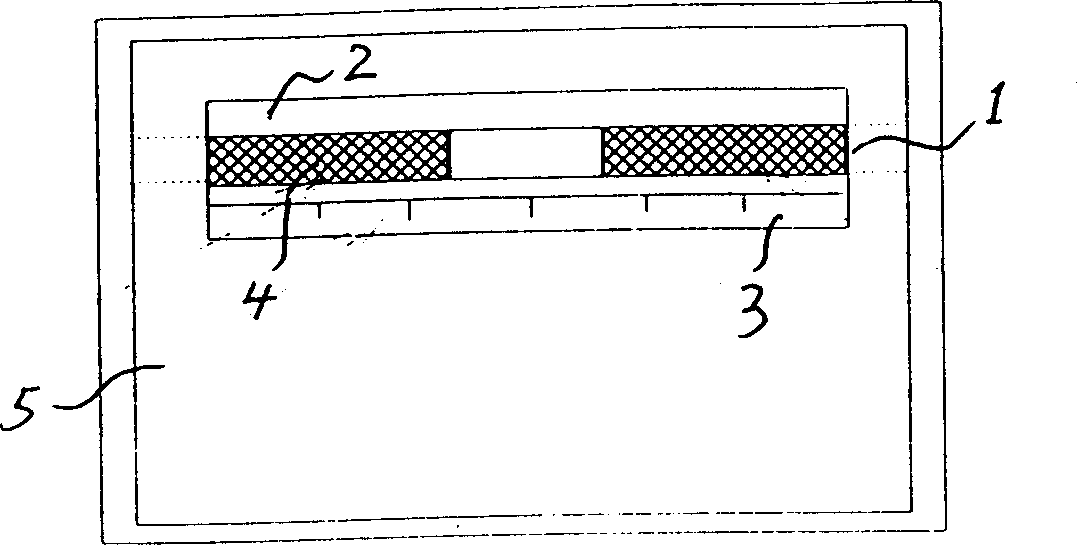

Portable direct-reading type power-free hydrogen-sulfide gas detector and preparation of indicating matter

InactiveCN1438480ANo power requiredHigh sensitivityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorDiffusionLead nitrate

The testing assembly comprises the glass tube, the indicating material in the glass tube and the diffusion control film on two ends of the glass tube. The indication scale for measuring value constitutes the indication window. The testing assembly and the scale are fixed on the carrier with badge shape. The indicating material comprises main agent, the inter surface modifying addition and ceramics powder in 80-120 mesh. One or several of lead acetate, lead nitrate and silver nitrate constitute the main agent. The intersurface modifying addition is soluble barium salt. The weight of the main agent is 1%-10% of the weight of the admixture. The invention provides the features of powerless, high sensitivity, good accuracy, low cost and convenience.

Owner:王宝辉 +1

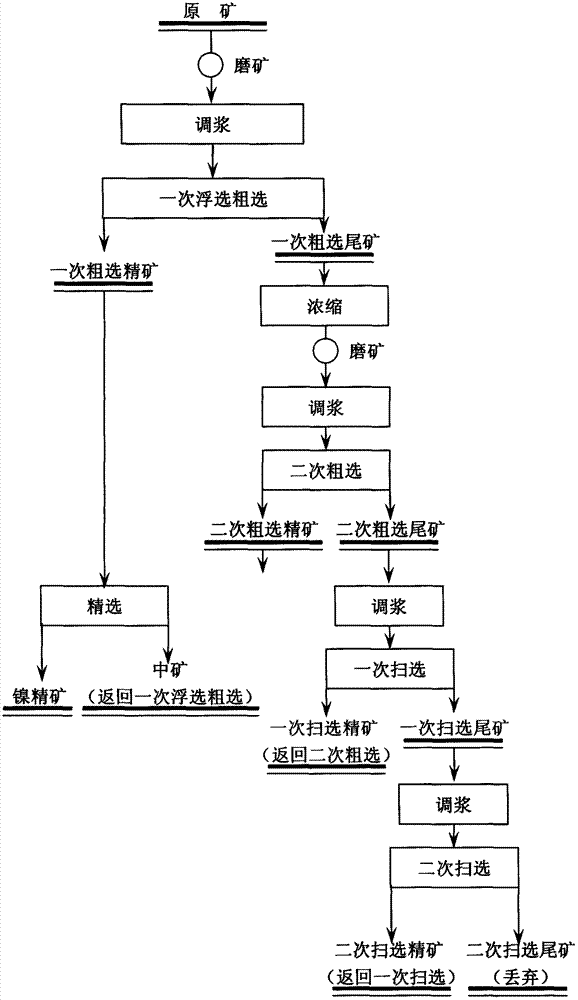

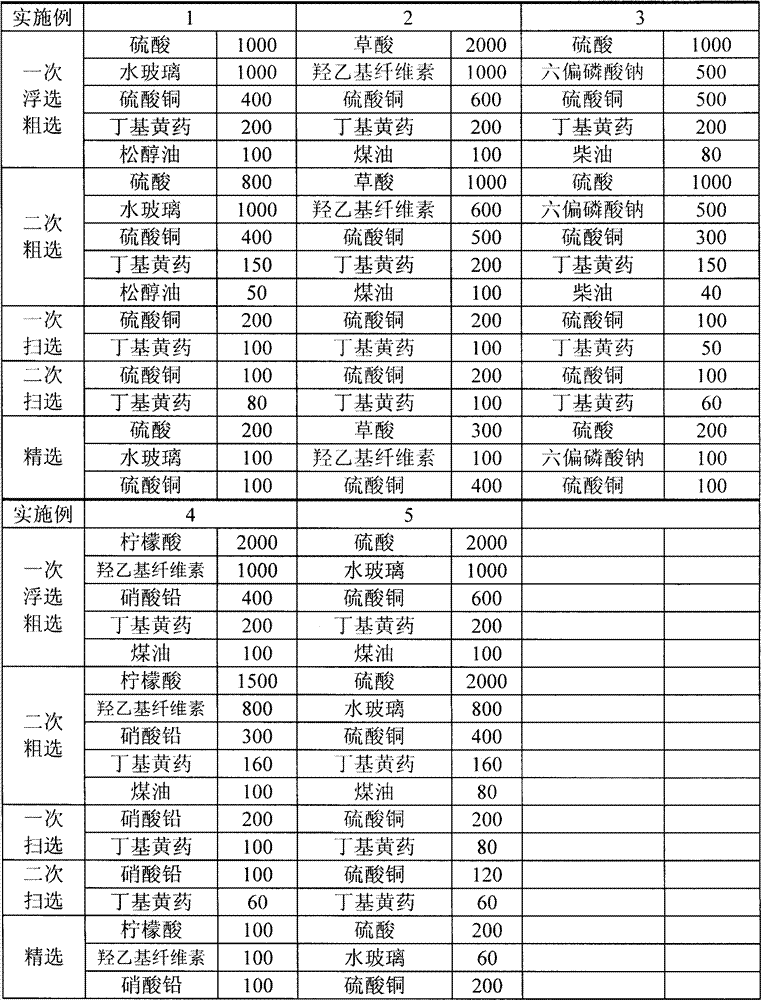

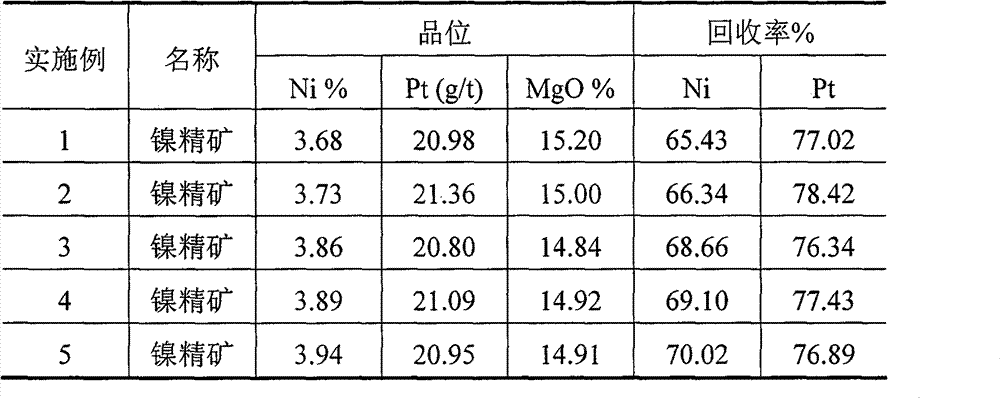

Flotation method for platinum-mineral-containing violarite

ActiveCN102886311AImprove ion compositionHigh selective adsorptionFlotationCelluloseOXALIC ACID DIHYDRATE

A flotation method for platinum-mineral-containing violarite is characterized in that sulfuric acid, oxalic acid or citric acid is taken as a regulator and added into a palatinum-containing nickel mineral, water glass, sodium hexametaphosphate or hydroxyethyl cellulose is taken as gangue inhibitor, copper sulfate or lead nitrate is taken as an activator, butyl xanthate is taken as a collenting agent, terpenic oil, kerosene or diesel oil is taken as a foaming agent, and the effective enrichment of the platinum-mineral-containing violarite is realized by performing stage grinding, stage screening, rougher flotation, scavenging flotation and essential selection. The medicaments are reasonably added, ion composition in pulp and surface characteristic of the mineral are improved, preferential absorption of a target platinum mineral and the violarite is improved by the collecting agent, the recovery rate of the nickel is improved by 5 to 10 percent, and the content of a magnesium oxide deleterious impurity in nickel concentrate is reduced. The method is simple in process and easy to operate.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Molten gold resisting high-temp sinter and its preparing process

A gold solution resisting high-temp sinter for ceramic decoration contains Au (10-15 wt.%), Th (2.2-3.0), Rh (0.1-0.3), Sb (0.1-0.8), Pb (0.3-0.4), Bi (1.0-1.4) and mixed solvent. It is prepared through preparing resinates of thorium nitrate, RhO3 and SbCl3, mixing them together; preparing gold ammonium percloride from AuCl3, reaction on balsam sulfide to obtain gold resinate; preparing resinatesof lead nitrate and bismuth nitrate, mixing them together; mixing said three components together, and diluting with mixed solvent.

Owner:NANJING UNIV

Process for preparing high-performance Ni-P alloy solution for chemical plating

InactiveCN1396304AImprove stabilityImprove corrosion resistanceLiquid/solution decomposition chemical coatingComplexonsSodium acetate

A high-performance soloution for chemical plating of Ni-P alloy contains primary salt (nickel sulfate and sodium hypophosphite), composite complexing agent (complexon, citric acid, lactic acid, sterculic acid and butanedioic acid), composite buffer (boric acid and sodium acetate), and composite stabilizer (sodium thiocyanate, ammonium mobybdenate and lead nitrate). Its advantages are high stability and high anticorrosion performance of its plated layer; and the plated layer can be applied with secondary plating.

Owner:郭福春 +1

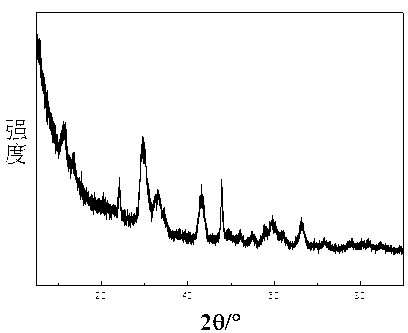

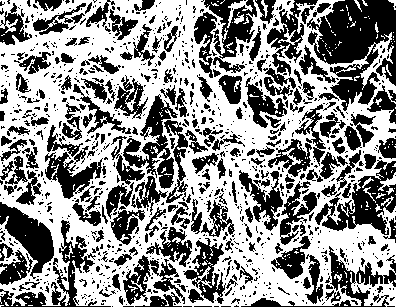

Perovskite structure lead titanate single crystal nano-sheet preparation method

InactiveCN103276448ASimple preparation processEasy to controlPolycrystalline material growthFrom normal temperature solutionsHigh concentrationLead nitrate

The invention relates to a perovskite structure lead titanate single crystal nano-sheet preparation method, which is mainly characterized by comprising: adopting a two-step hydrothermal method, adopting tetrabutyl titanate as a precursor to dissolve in anhydrous ethanol, adding deionized water in a dropwise manner to prepare titanium oxyhydroxide precipitate, washing, mixing with KOH, carrying out a hydrothermal treatment to prepare K2Ti6O13 nano-wire powder, adopting the K2Ti6O13 nano-wire powder as a titanium source, adopting lead nitrate as a lead source, adopting high concentration KOH as a mineralizer, and carrying out a secondary hydrothermal treatment to obtain tetragonal phase perovskite lead titanate single crystal nano-sheet with a thickness of 5-50 nm. The preparation method has characteristics of simple process, easy control, no pollution, low cost, and easy large-scale production achievement.

Owner:ZHEJIANG UNIV

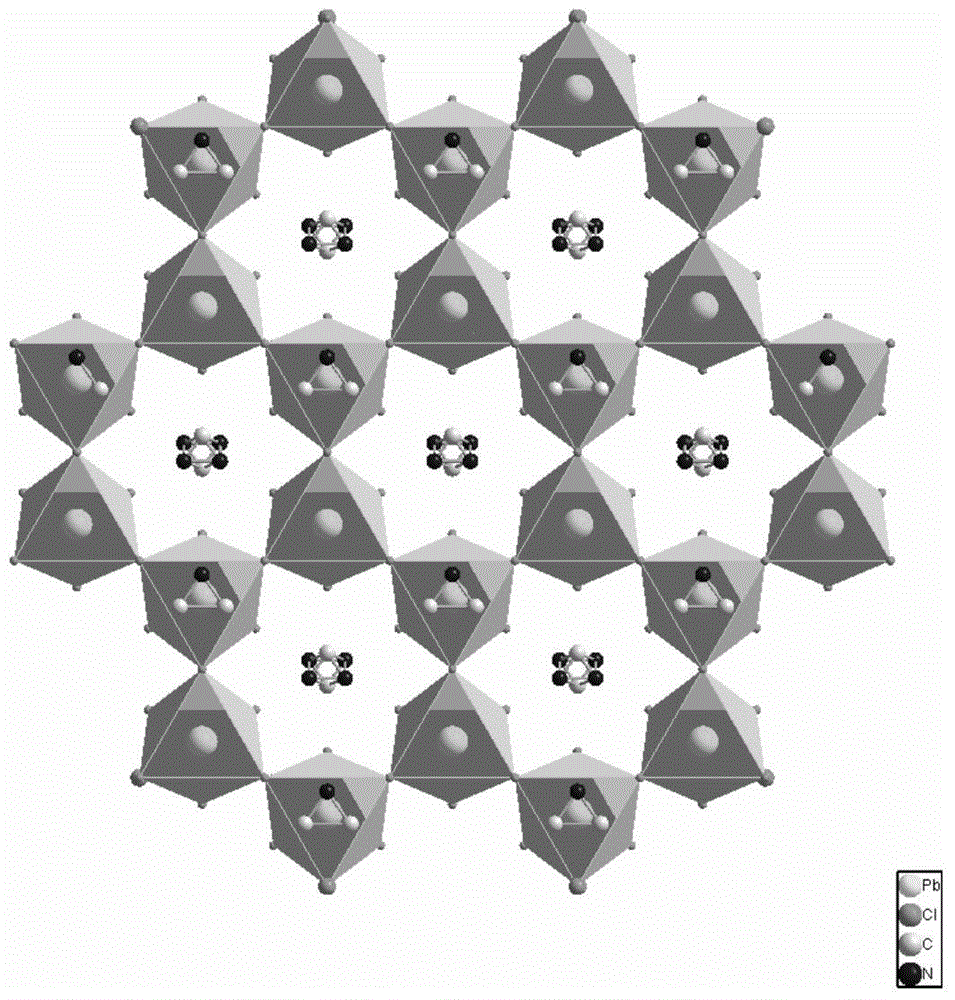

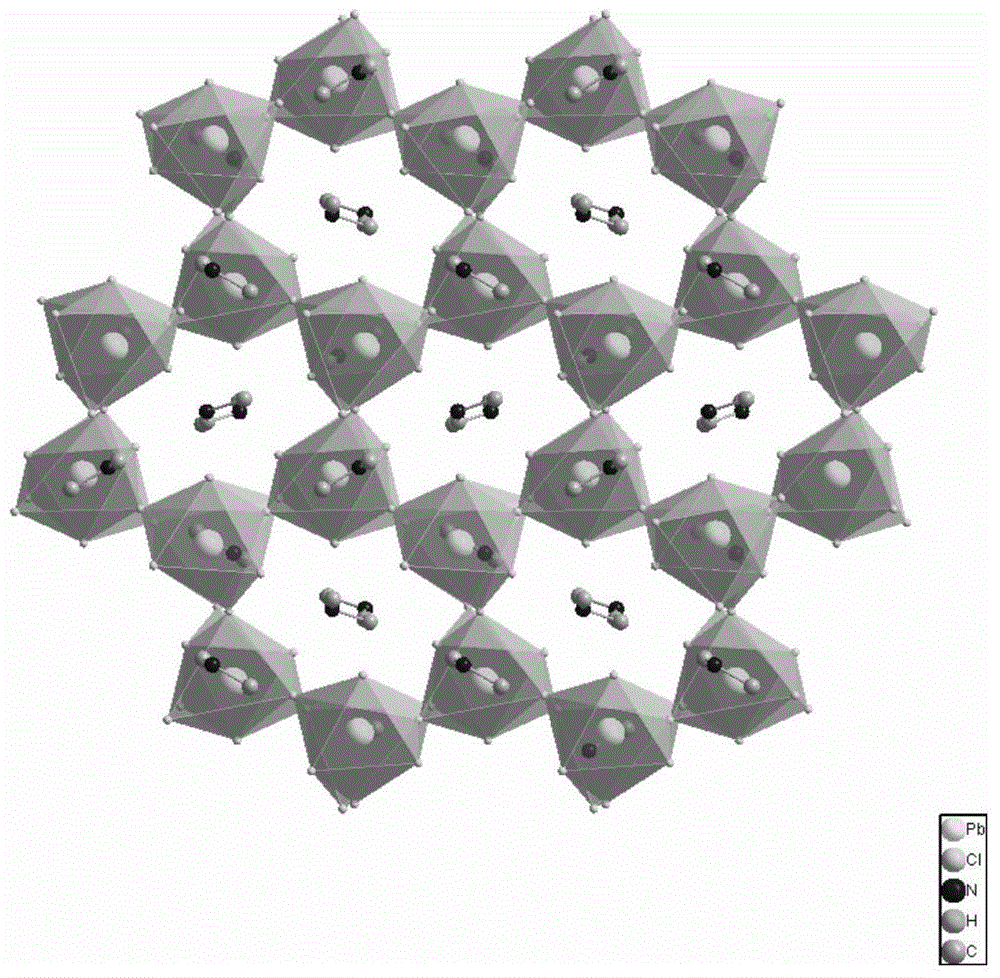

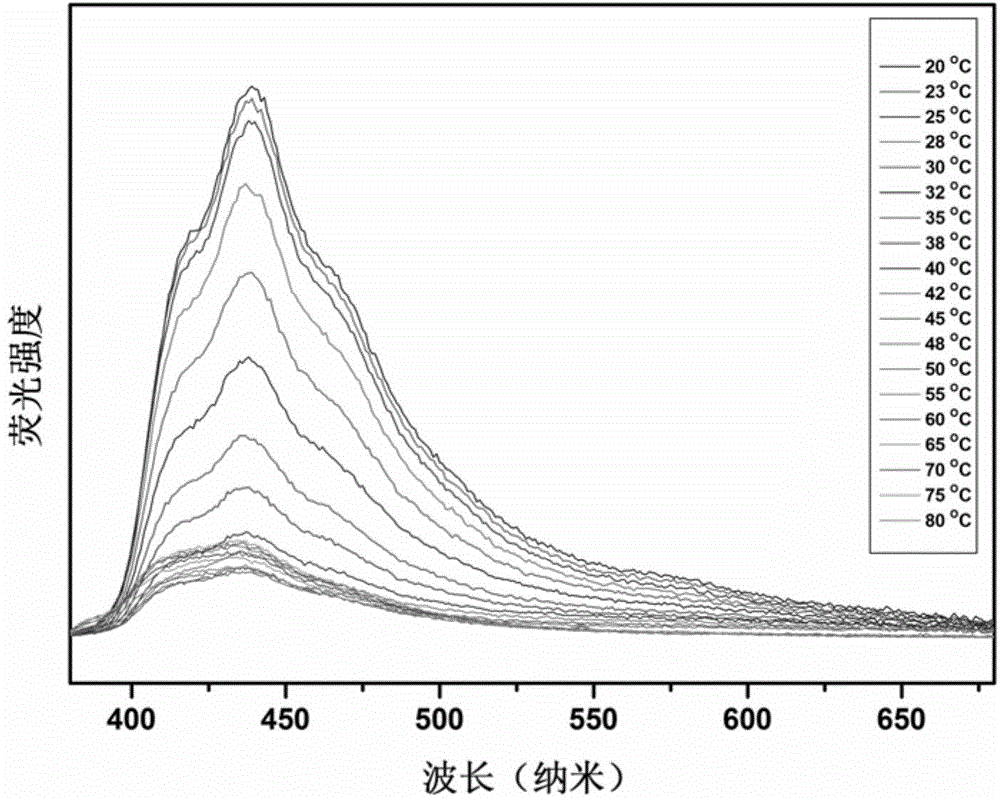

Organic-inorganic hybrid perovskite phase-change material with adjustable emitted light, and preparation method

ActiveCN104927840AHigh fluorescence intensityThermometers using physical/chemical changesLuminescent compositionsTriboluminescenceLead nitrate

The invention discloses an organic-inorganic hybrid perovskite phase-change material with adjustable emitted light, and a preparation method. The preparation method comprises the following steps: putting lead nitrate and sodium chloride into a reaction still according to a certain proportion; adding a mixed solvent of formic acid and DMF according to a certain proportion; carrying out a reaction at the temperature of 130 to 150 DEG C; cooling to room temperature through programmed cooling, so as to obtain colorless and transparent hexagonal flat crystals; collecting and washing the hexagonal flat crystals; carrying out vacuum drying to obtain the target product. The phase-change material has the advantages that the phase-change temperature of the phase-change material is about the room temperature; the fluorescence radiation color of the phase-change material can be changed through temperature adjustment, and is very sensitive to temperature when the environment temperature is about the room temperature, so that the organic-inorganic hybrid perovskite phase-change material can be used for qualitative temperature detection.

Owner:NANKAI UNIV

Analysis method of heavy metals in textiles

InactiveCN103389317AThe detection process is fastHarm reductionMaterial analysis using wave/particle radiationPreparing sample for investigationPolyesterLead nitrate

The invention discloses an analysis method of heavy metals in textiles. The method comprises the following steps: firstly, uniformly mixing cadmium nitrate, nickel nitrate, lead nitrate and lithium borate, and grinding to prepare a plurality of standard reserve substances in different mass concentrations; secondly, mixing the standard reverse substances with standard polyester-accompanied fragments to prepare a plurality of standard products in different mass concentrations; thirdly, measuring the fluorescence intensity of each element in the standard products, drawing a scatter diagram by taking the concentration as an X axis and the fluorescence intensity of the element as a Y axis to obtain a standard curve of each element and calculating a linear regression equation of each standard curve; and finally, measuring the X ray fluorescence intensities of cadmium, nickel and lead in a textile sample to be detected, checking the corresponding concentrations on the standard curve, or calculating the concentrations of the cadmium, the nickel and the lead in the sample to be detected according to the linear regression equations. The analysis method disclosed by the invention can be used for directly testing an original sample without damaging the sample and high in detection speed; the dosages of strong acid and a strong oxidant for digestion are reduced, and the damages to environments and testers are reduced.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

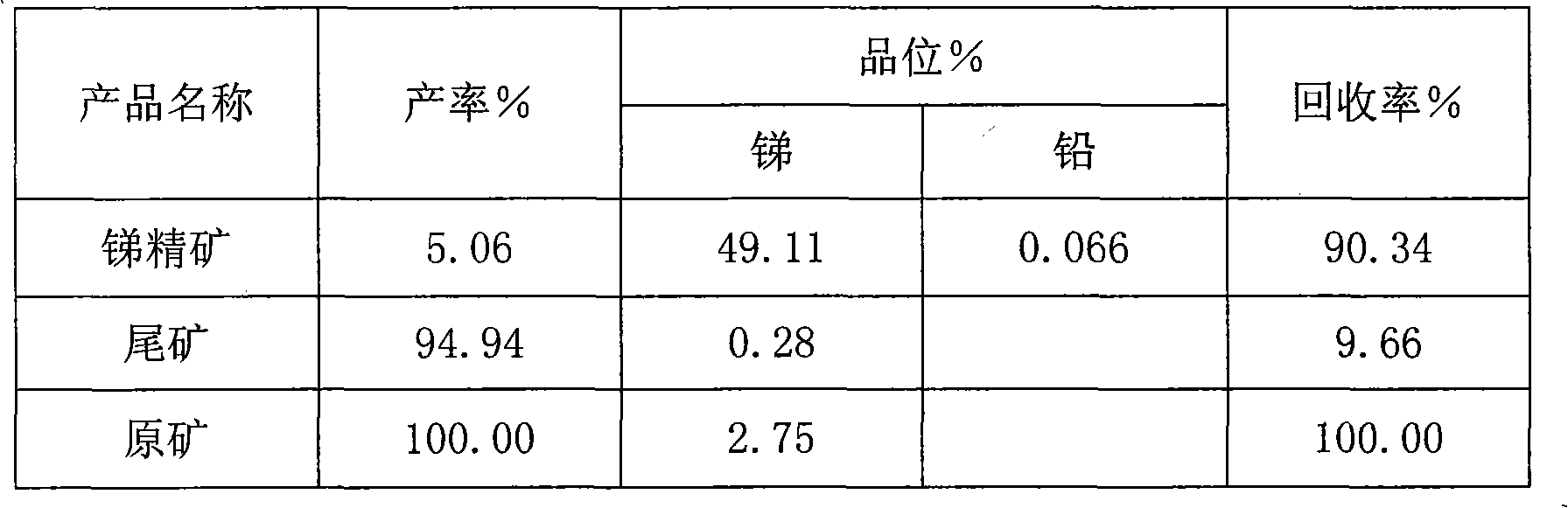

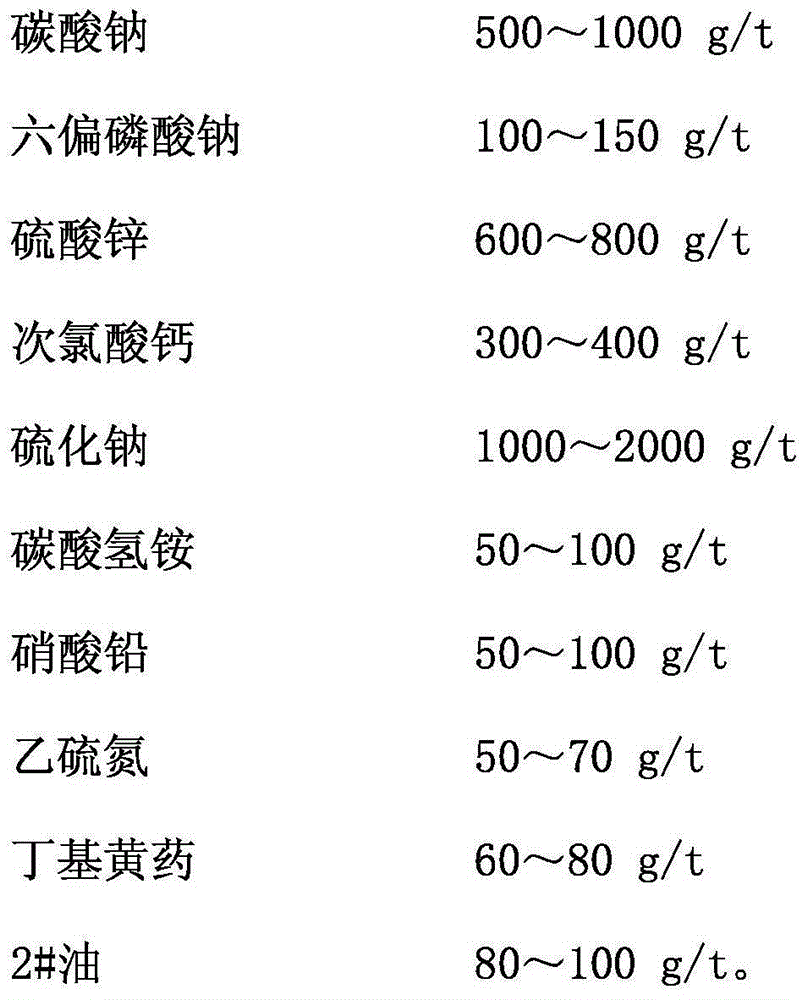

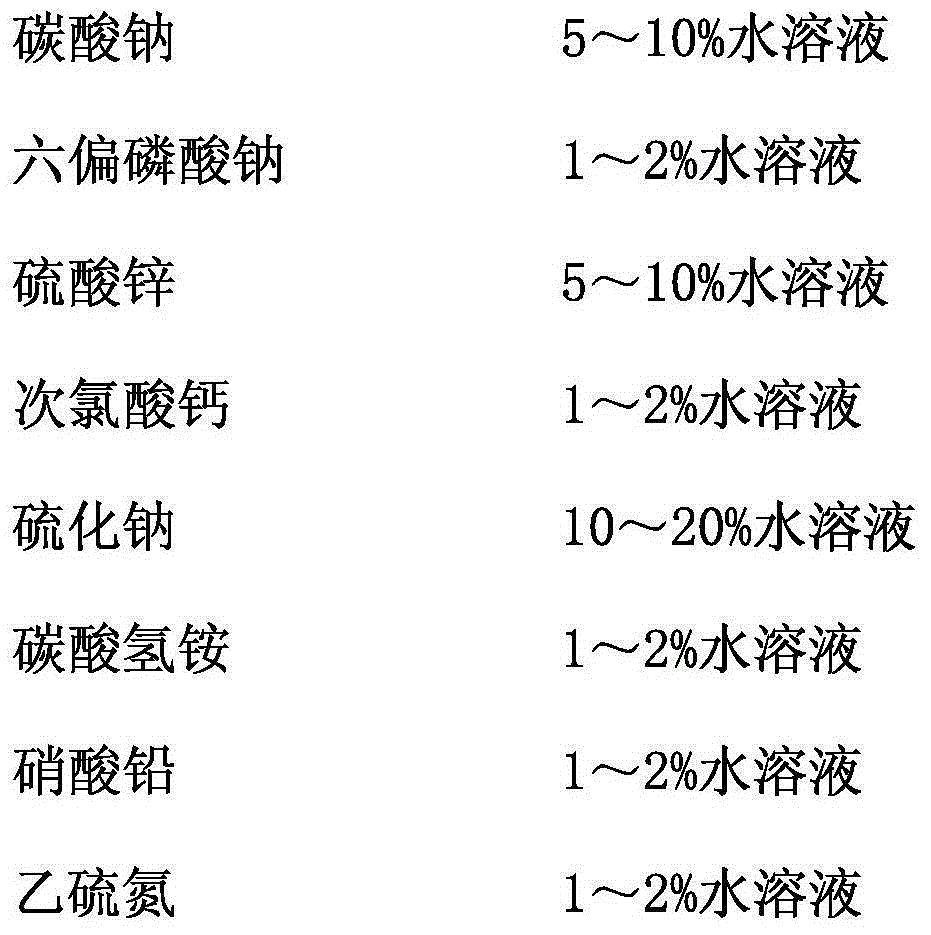

Floatation method of sulfur-oxygen mixed lead antimony ore

The invention relates to a floatation method of sulfur-oxygen mixed lead antimony ore. Sodium carbonate is used as a pH regulator, sodium hexametaphosphate is used as a fine sludge mineral dispersing agent, zinc sulfate and calcium hypochlorite are used as a gangue mineral inhibitor, sodium sulfide, ammonium bicarbonate and lead nitrate are used as a lead antimony ore activator, diethyl dithiocarbamate and butyl xanthate are used as a lead antimony ore collector, and 2# oil is used as a foaming agent, thereby performing floatation on the sulfur-oxygen mixed lead antimony ore to obtain the lead antimony mixed concentrate. The method can effectively recover the sulfur-oxygen mixed lead antimony ore. Under the conditions that the lead grade of the feed ore is 0.28-1.07% and the antimony grade is 0.24-0.83%, the lead antimony mixed concentrate, of which the lead grade is 20.87-34.55% and the antimony grade is 17.53-28.40%, can be obtained. The lead recovery rate is 75.21-82.77%, and the antimony recovery rate is 73.60-80.75%.

Owner:GUANGXI UNIV

Flotation activating agent for fine-grain cassiterite and preparing method of flotation activating agent

The invention discloses a flotation activating agent for fine-grain cassiterite and a preparing method of the flotation activating agent. The flotation activating agent is a coordination compound of lead and ammonia, and the molecular formula of the coordination compound is [Pb(NH3)x]2+, wherein X in the molecular formula ranges from one to eight. The preparing method of the flotation activating agent mainly comprises the steps that, lead nitrate, lead acetate hydrate and lead acetate are dissolved in ethyl alcohol or methyl alcohol or water through ammonium hydroxide dissolving, then, sodium hydroxide and sodium carbonate are added, mixing is conducted for the reaction, and the flotation activating agent is obtained through drying. The flotation activating agent is used for activating the fine-grain cassiterite in ore, the surface hydrophobicity of the fine-grain cassiterite is improved, the proportion of lead and ammonia in the flotation coordination compound of the cassiterite is increased, adjustment can be conducted according to the specific beneficiation raw material condition, flexibility and changeability are achieved, adaptability is high, and the application range is wide. The flotation tin concentrate grade and recycling rate of the fine-grain cassiterite are increased, economic benefits are increased, raw materials are cheap and easy to obtain, and the production cost is low.

Owner:YUNNAN YUANKUANG TECH DEV CO LTD

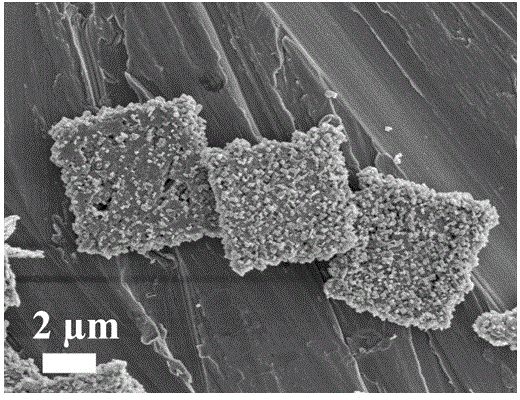

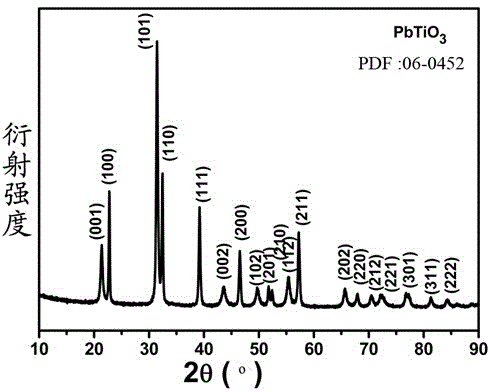

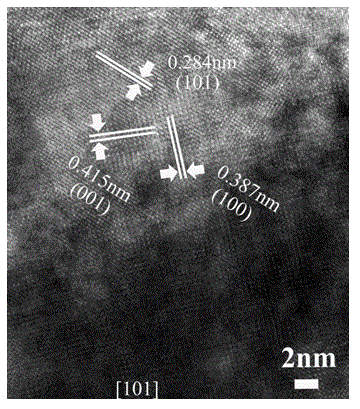

Method for preparing nano-particle self-assembled square perovskite phase PbTiO3 micron piece

ActiveCN104018226AMorphological rules and stabilityHigh crystallinityPolycrystalline material growthFrom normal temperature solutionsDispersityLead nitrate

The invention discloses a method for preparing a nano-particle self-assembled square perovskite phase PbTiO3 micron piece. According to the method, a hydrothermal reaction method is adopted, titanium dioxide, potassium hydroxide, lead nitrate, deionized water and absolute ethyl alcohol are used as reaction materials, and hydrothermal reaction is performed in a reaction kettle at 120-200 DEG C, thereby obtaining the nano-particle self-assembled square perovskite phase PbTiO3 micron piece. The square perovskite phase PbTiO3 micron piece is high in crystallization property, high in purity and good in dispersity. The method is simple in process, regular and stable in product morphology, easy to control the product morphology, low in cost, free of pollution and easy to produce in large scale.

Owner:ZHEJIANG UNIV

Method of preparing sulfide nano material of lead with calixarene adjusting solvent thermal system

InactiveCN1907863ARealize chemical reactionParticle size increases or decreasesNanostructure manufactureLead sulfidesLead nitrateThiourea

The invention belongs to the field of inorganic nanomaterials, and involves a preparation method for sulfur compounds of lead nanomaterial by calixarene in a specific thermal control system solvent. Said method comprises placing lead salt and calixarene in a container, using toluene as solvent, stirring at 70-90DEG C for 0.8-1.5 hours to obtain a mixture, transferring the mixture into a reactor and adding sulfur source, adding toluene to 3 / 5-4 / 5 of the reactor volume and sealing, reacting at 150-200DEG C for 18-30 hours and cooling to room temperature, washing, separating, and drying to obtain the final product. The molar ratio of sulfur source to lead salt is 1 : 1, wherein the lead salt is one of lead nitrate and lead acetate and sulfur source is one of thiourea, sulfur powders, and selenium powders. The raw materials of this invention are easy to get and cheap. This invention also has the advantages of simple operation and equipment, high purity, convenient treatment, and being easy for industrialization. This invention provides a new method for preparing nanomaterials by controlled synthesis.

Owner:TONGJI UNIV

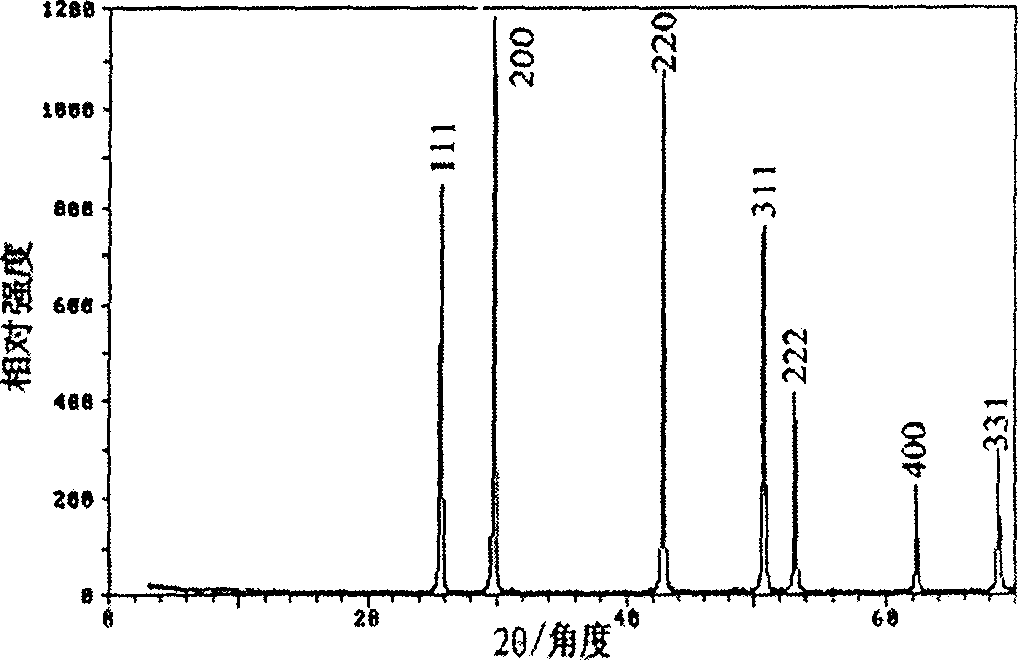

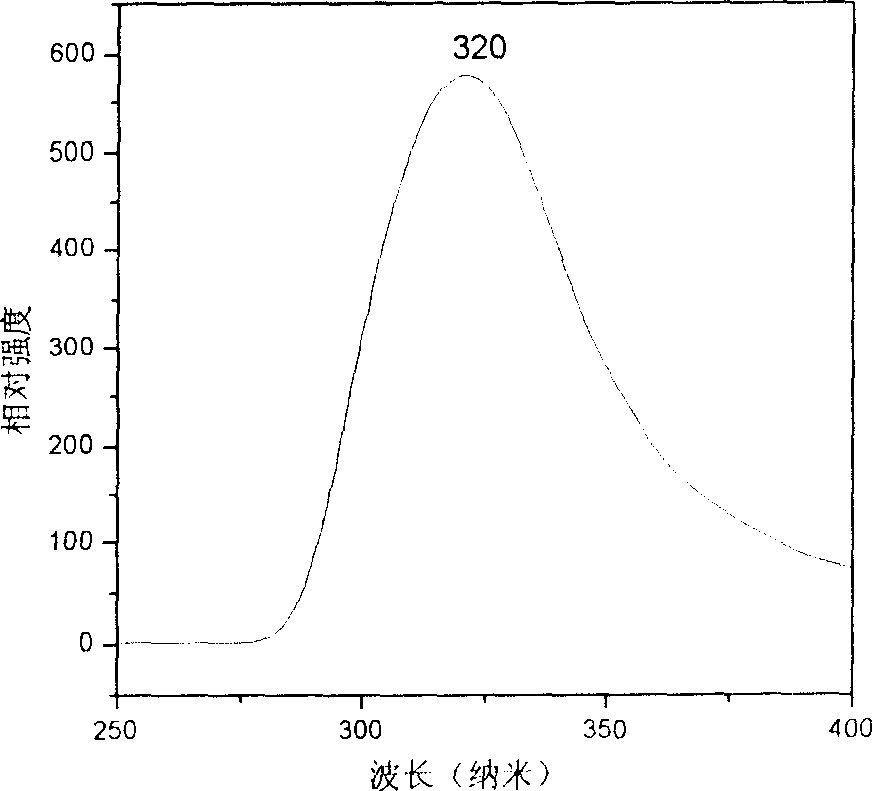

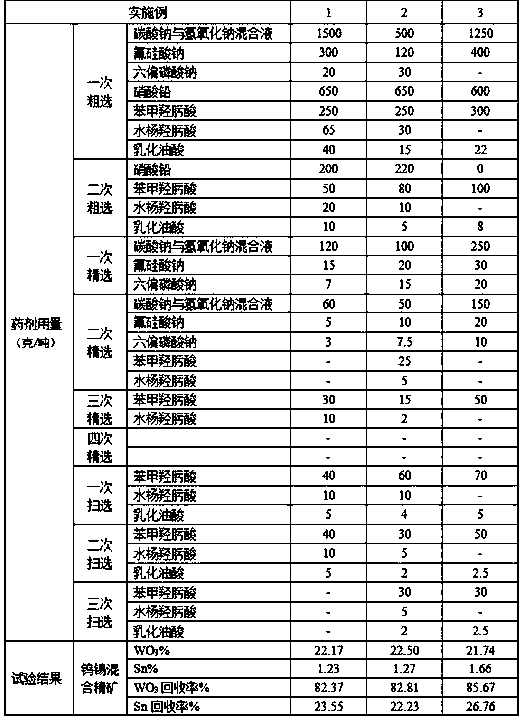

Tungsten tin mineral beneficiation method

ActiveCN109127120ASolve the problem of high mineral processing costIncrease profitFlotationLead nitrateHydroxamic acid

The invention discloses a tungsten tin mineral beneficiation method; and tungsten tin minerals are tungsten tin fed ores as sulfide ores flotation tailings obtained after grinding of multimetal ores of tungsten associated cassiterite, removal of magnetite by magnetic separation and removal of sulfur concentrates by sulfide ore flotation. Mixed liquid of sodium carbonate and sodium hydroxide, sodium fluosilicate, sodium hexametaphosphate and lead nitrate are added in the tungsten tin fed ores for pulping; then, collecting agents-benzohydroxamic acid, hydroxamic acid and emulsified oleic acid are added for tungsten tin mixed flotation; and tungsten tin mixed concentrates with WO3 of not less than 20% and Sn of not less than 1% are obtained by 2 times of roughing, 3-4 times of selection and 2-3 times of scavenging. The method has the following characteristics: the beneficiation method of tungsten tin mixed flotation is used for the tungsten tin fed ores; and when tungsten minerals are recovered by floatation, tin minerals are enriched in tungsten concentrates to achieve the purpose of synchronously recovering the tin minerals. The method is simple in recovery process flow, stable in beneficiation process and suitable for beneficiation of the tungsten tin fed ores with WO3 of 0.2-0.5%, Sn of not more than 0.2%, CaF2 of not more than 25%, CaCO3 of not more than 10% and the black andwhite tungsten ratio of 2: 8-8: 2.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com