Patents

Literature

202 results about "Cassiterite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cassiterite is a tin oxide mineral, SnO₂. It is generally opaque, but it is translucent in thin crystals. Its luster and multiple crystal faces produce a desirable gem. Cassiterite has been the chief tin ore throughout ancient history and remains the most important source of tin today.

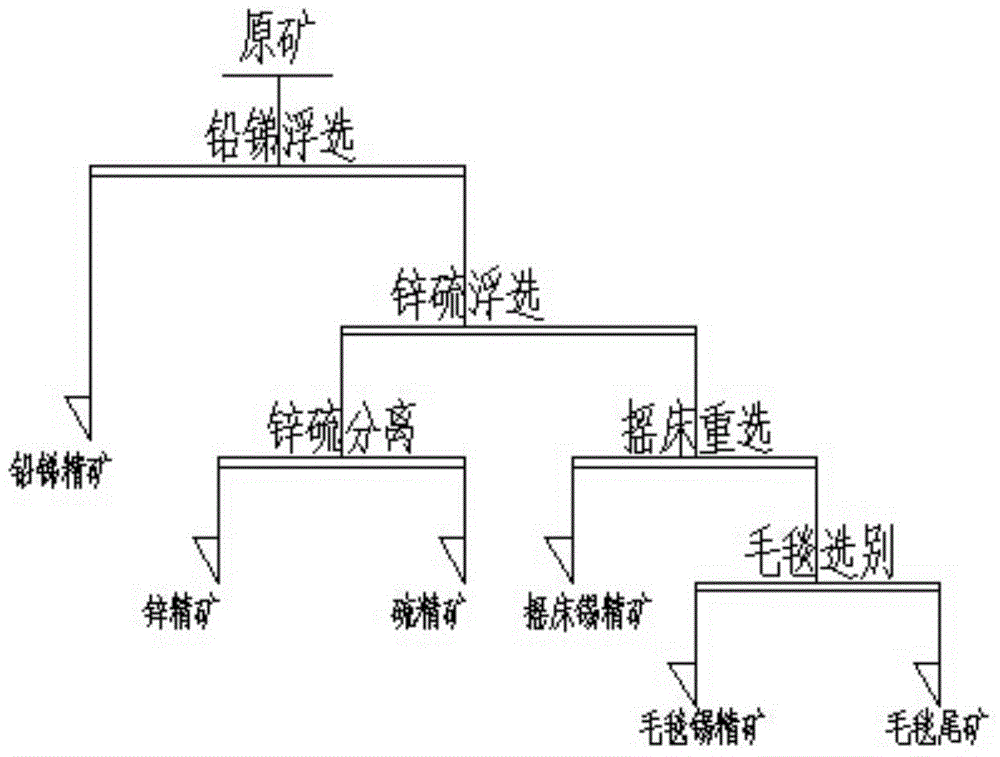

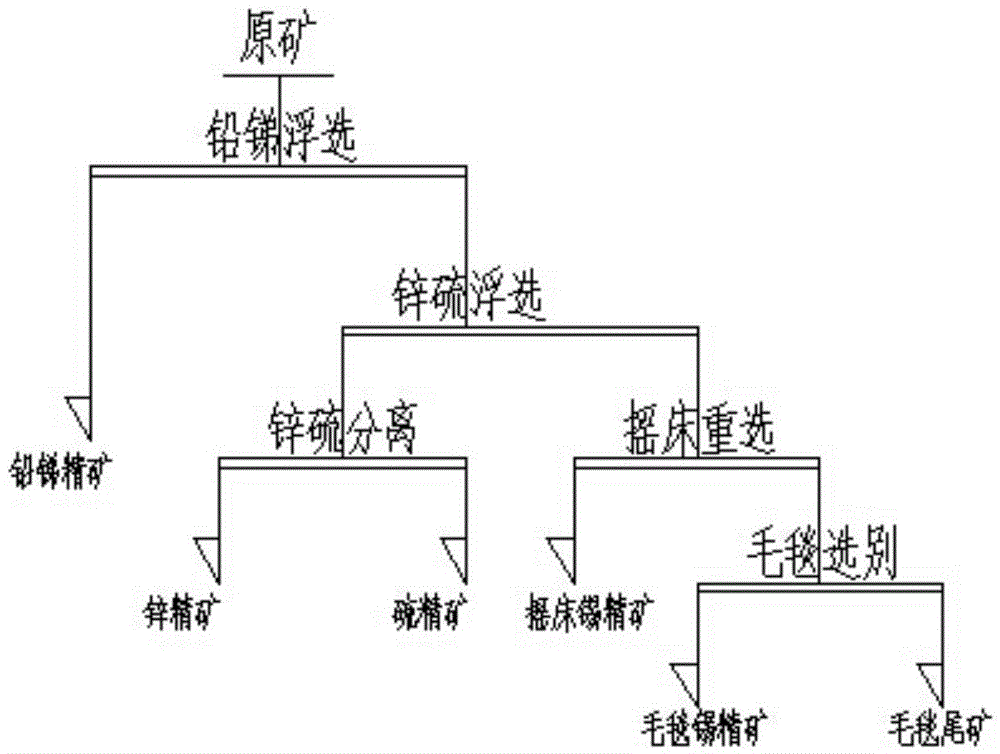

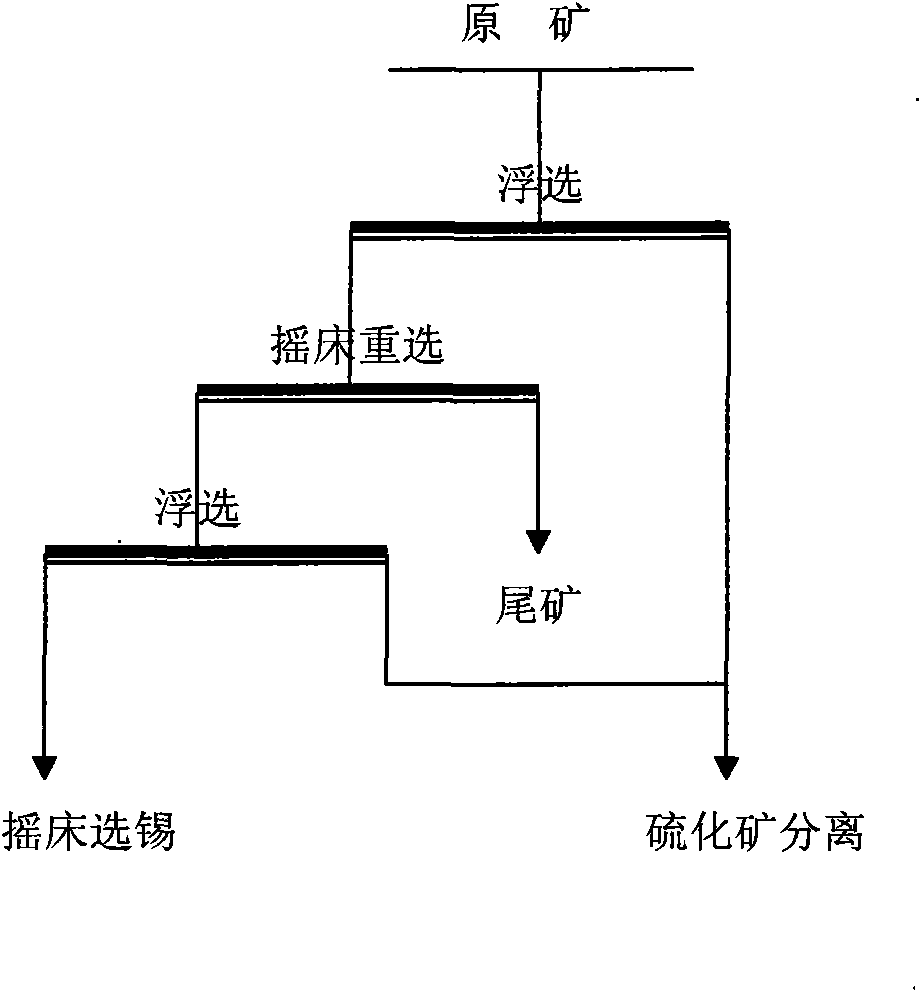

Combined mineral dressing technology of fine grain and micro grain cassiterite

ActiveCN101884951AAchieve separationAvoid interferenceFlotationWet separationNiobiumConcentration ratio

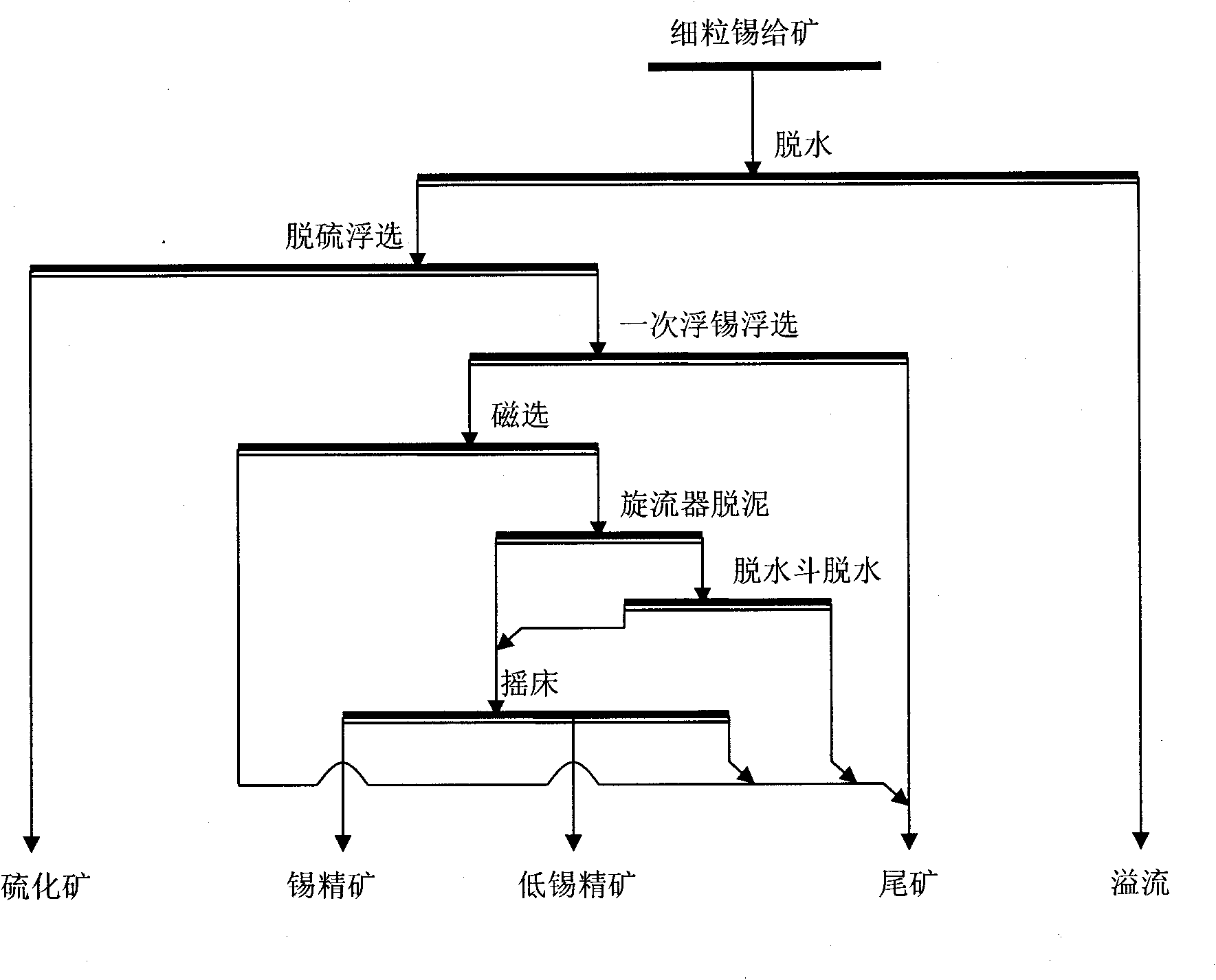

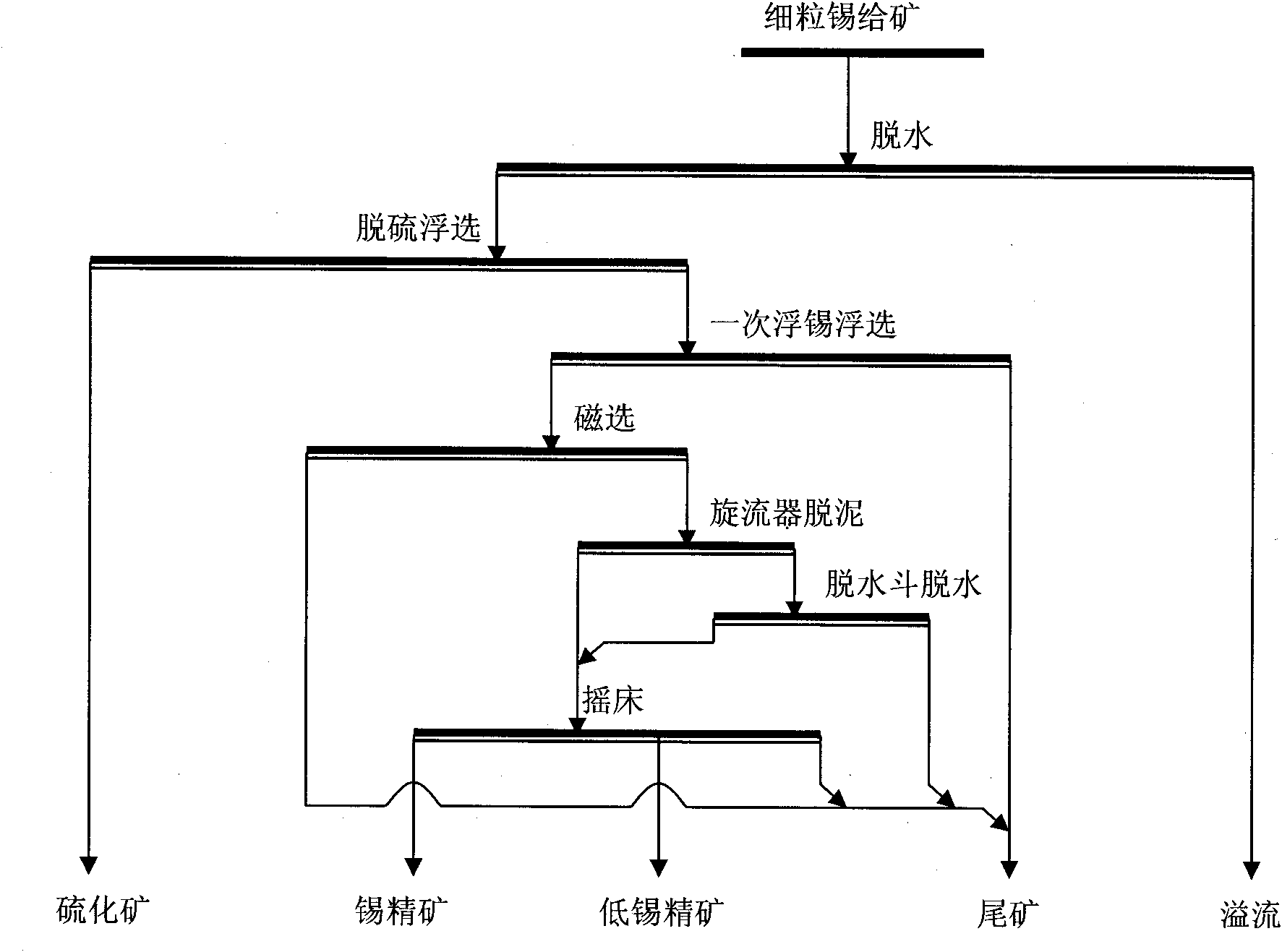

The invention relates to a combined mineral dressing method of fine grain and micro grain cassiterite, which gives up the single mineral dressing method of fine grain and micro grain cassiterite for years. The invention adopts the effective combination of two-time flotation operation, magnetic separation operation, desliming and dewatering operation and reselection operation, provides a new mineral dressing model for selecting grain and micro grain cassiterite which has the size of 10-37 micrometers and has complex mineral property, high impurity content and big mineral dressing difficulty, and improves the cassiterite concentration ratio and cassiterite operation recovery rate; cassiterite concentration ratio can reach 5-10, the cassiterite operation recovery rate can be above 70%, and the tin-containing grade of tin concentrate products can be above 50%. The method also can be used for the mineral dressing of fine grains and micro grains of non-ferrous metal, such as tungsten, molybdenum, tantalum, niobium and the like and has favorable economic benefit and social benefit.

Owner:广西华锡矿业有限公司铜坑矿业分公司

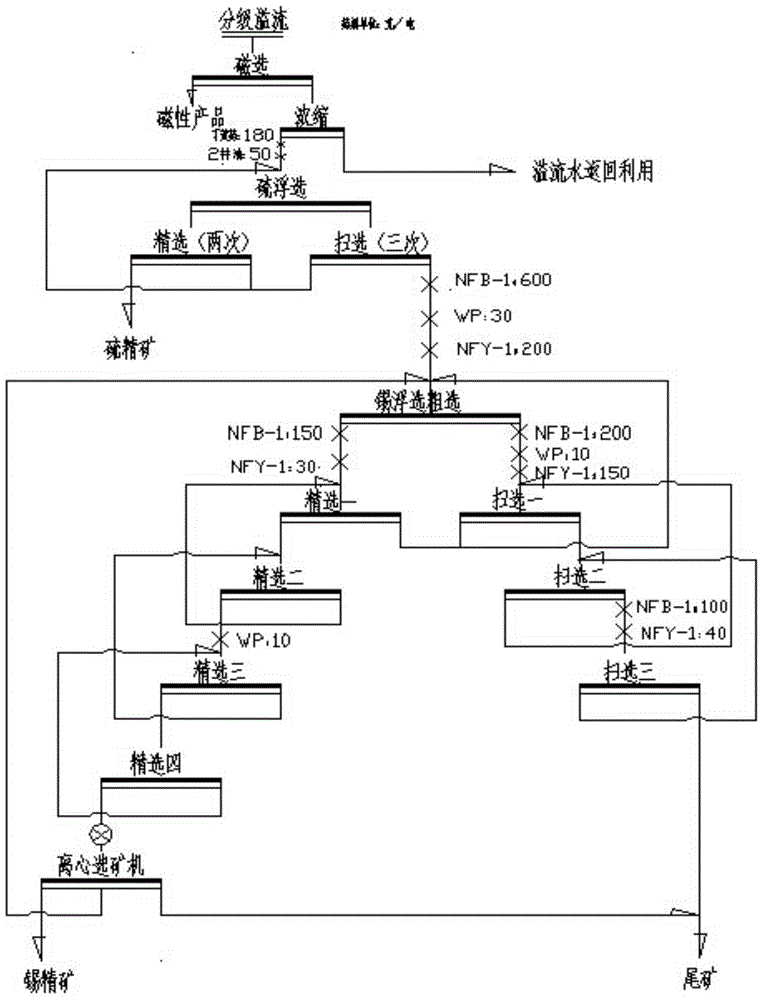

Beneficiation method for ultrafine fraction cassiterite

InactiveCN102631977AMineral processing method to solveEfficient recyclingFlotationWet separationCassiteriteMaterials science

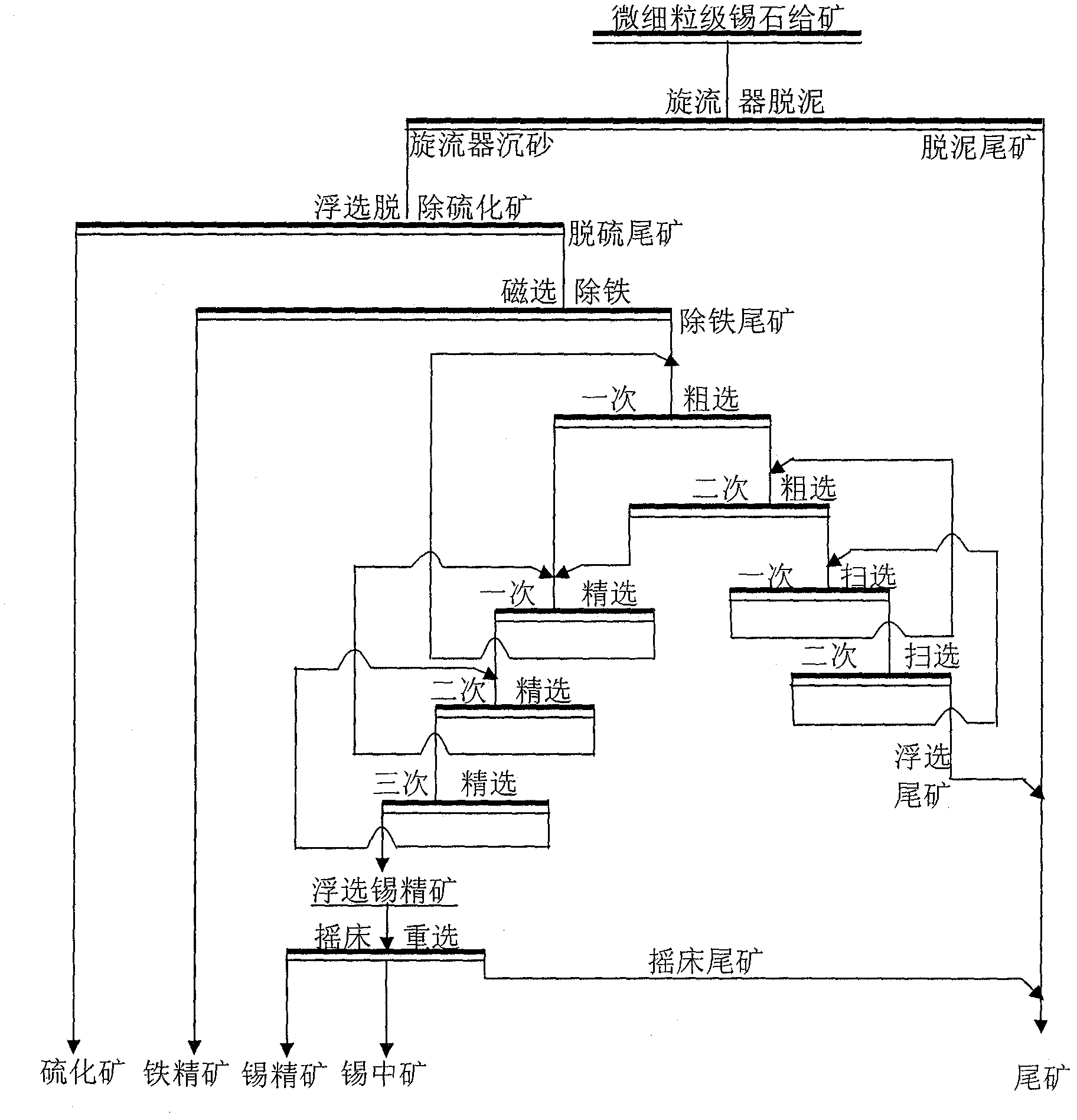

A beneficiation method for ultrafine fraction cassiterite is characterized in that a swirler is used for desliming to obtain swirler settled sand and deslimed tailings; sulfide ores are separated from the swirler settled sand so that the sulfide ores and desulfurized tailings are obtained; iron is removed from the desulfurized tailings by means of magnetic separation to obtain iron ore concentrate and deironed tailings; flotation tin concentrate and flotation tailings are obtained after secondary roughing flotation, secondary scavenging flotation and tertiary blank concentration flotation for the deironed tailings; and a table concentrator is used for performing gravity concentration for the flotation tin concentrate to obtain tin concentrate, tin middlings and table concentration tailings. The grade of the tin concentrate is higher than 40%, the tin recovery rate of the tin concentrate is higher than 50%, the grade of the tin middlings ranges from 1% to 3%, the tin recovery rate of the tin middlings is higher than 15%, and the overall tin recovery rate of the tin concentrate and the tin middlings is higher than 65%. The beneficiation method for the ultrafine fraction cassiterite is high in recovery rate, low in production cost, high in tin grade and applicable to recovery of the ultrafine fraction cassiterite with the silt content ranging from 10% to 30%.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Method for separating fine cassiterite

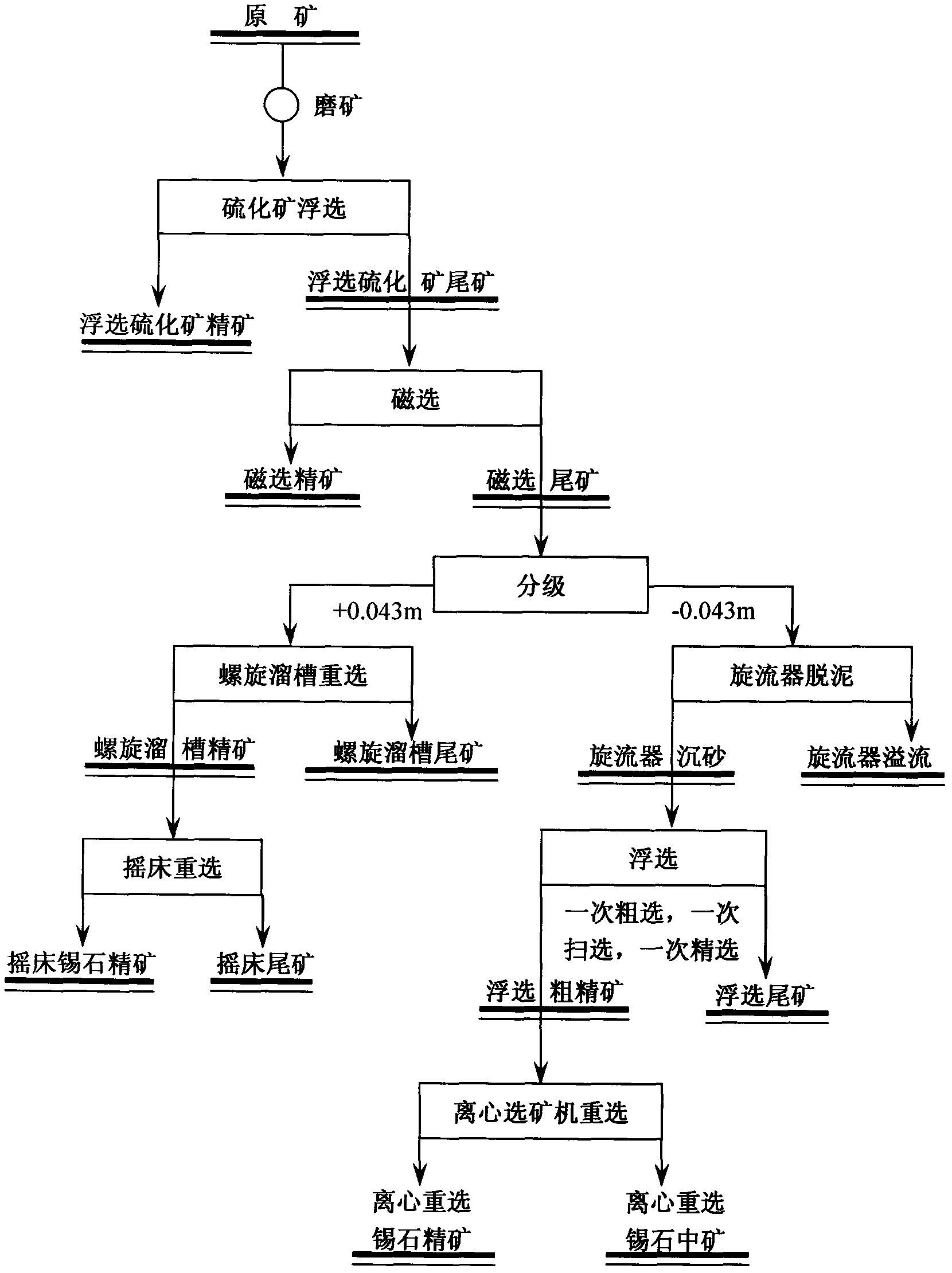

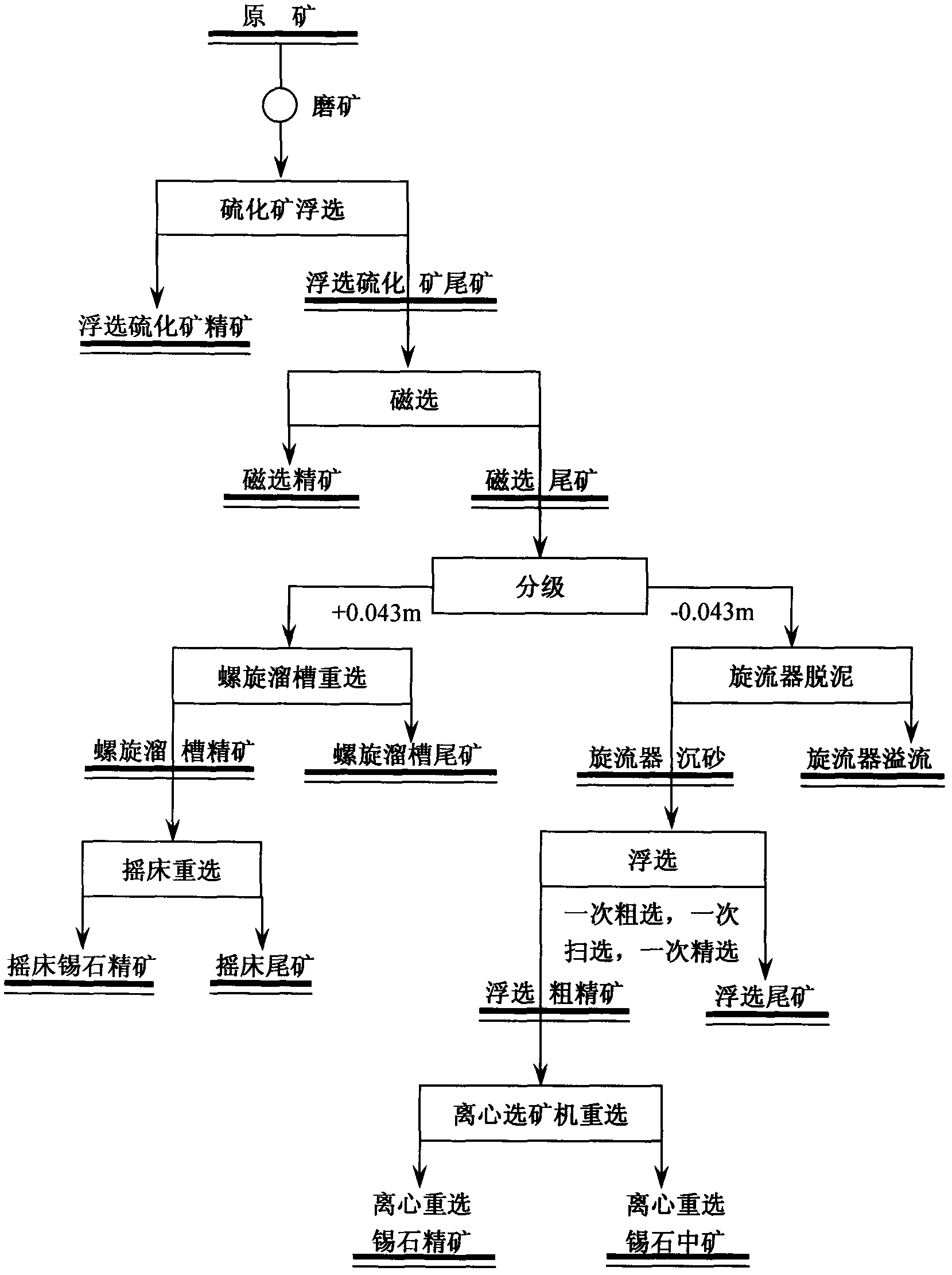

The invention relates to a method for separating fine cassiterite, which is characterized by comprising the following steps of: grinding a raw ore, performing size mixing, and performing flotation on a sulfide ore; performing magnetic separation on tailings of the sulfide ore subjected to flotation, and grading the tailings subjected to magnetic separation into particles of +0.043mm and particlesof -0.043mm; performing gravity separation on the particles of +0.043mm by using a spiral chute and a shaker to obtain a shaker cassiterite concentrate; desliming the particles of -0.043mm by using acyclone to obtain cyclone settled sand; performing size mixing, primary flotation roughing, primary flotation scavenging and primary flotation cleaning on the cyclone settled sand to obtain a flotation coarse concentrate; performing gravity separation on the flotation coarse concentrate by using a centrifugal ore separator to obtain a centrifugal gravity separation cassiterite concentrate; and mixing the shaker cassiterite concentrate and the centrifugal gravity separation cassiterite concentrate to obtain a total cassiterite concentrate. Roughing is performed by the spiral chute, so that theprocessing capacity in a unit area is greatly improved, the occupied area is saved, and separation efficiency is high; and flotation roughing and gravity separation cleaning are combined, so that theconsumption of a flotation agent is low, cost is low, the ore separation enrichment ratio is 5 to 10, and the recovery rate of the cassiterite is high.

Owner:西乌珠穆沁旗银漫矿业有限责任公司

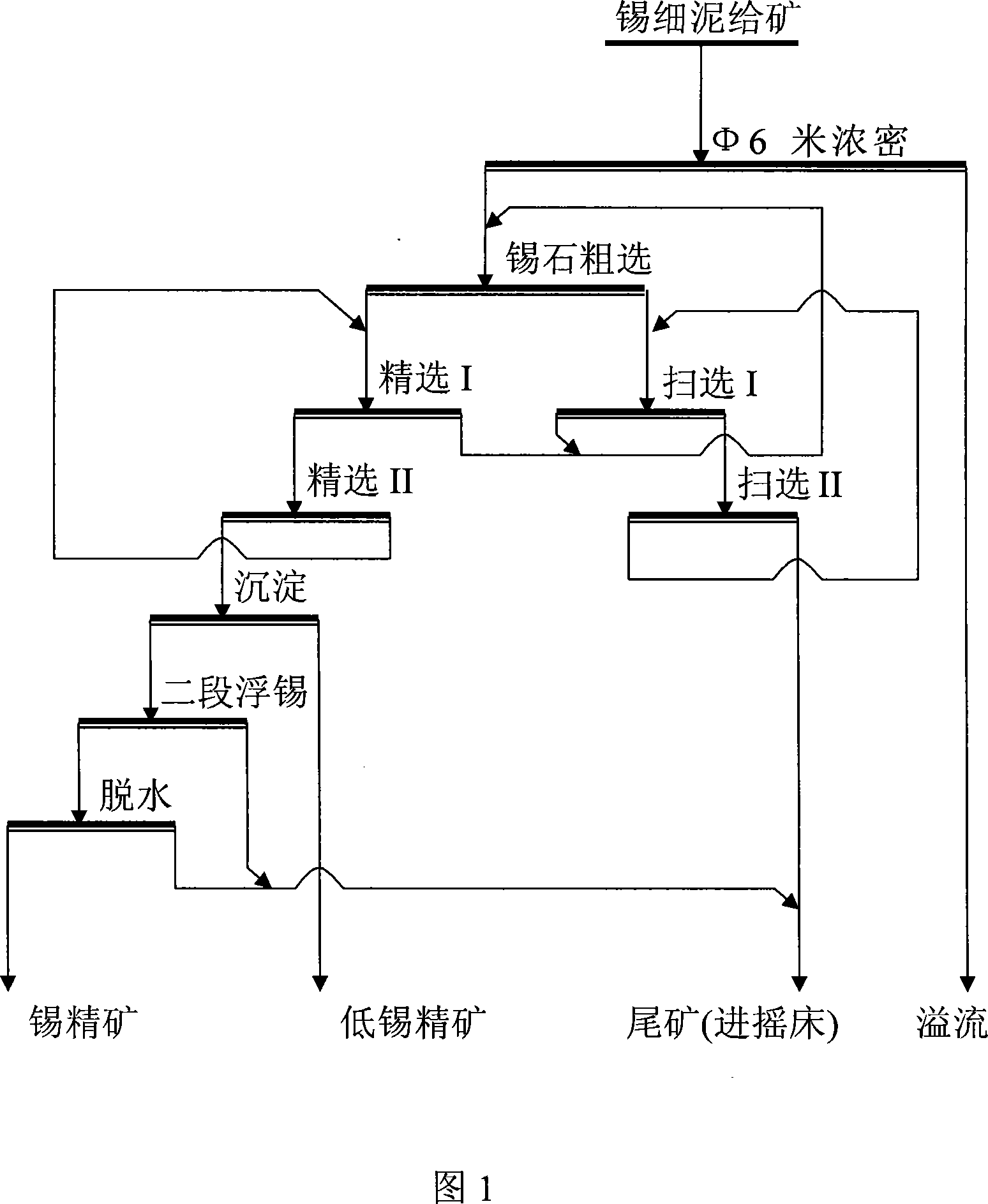

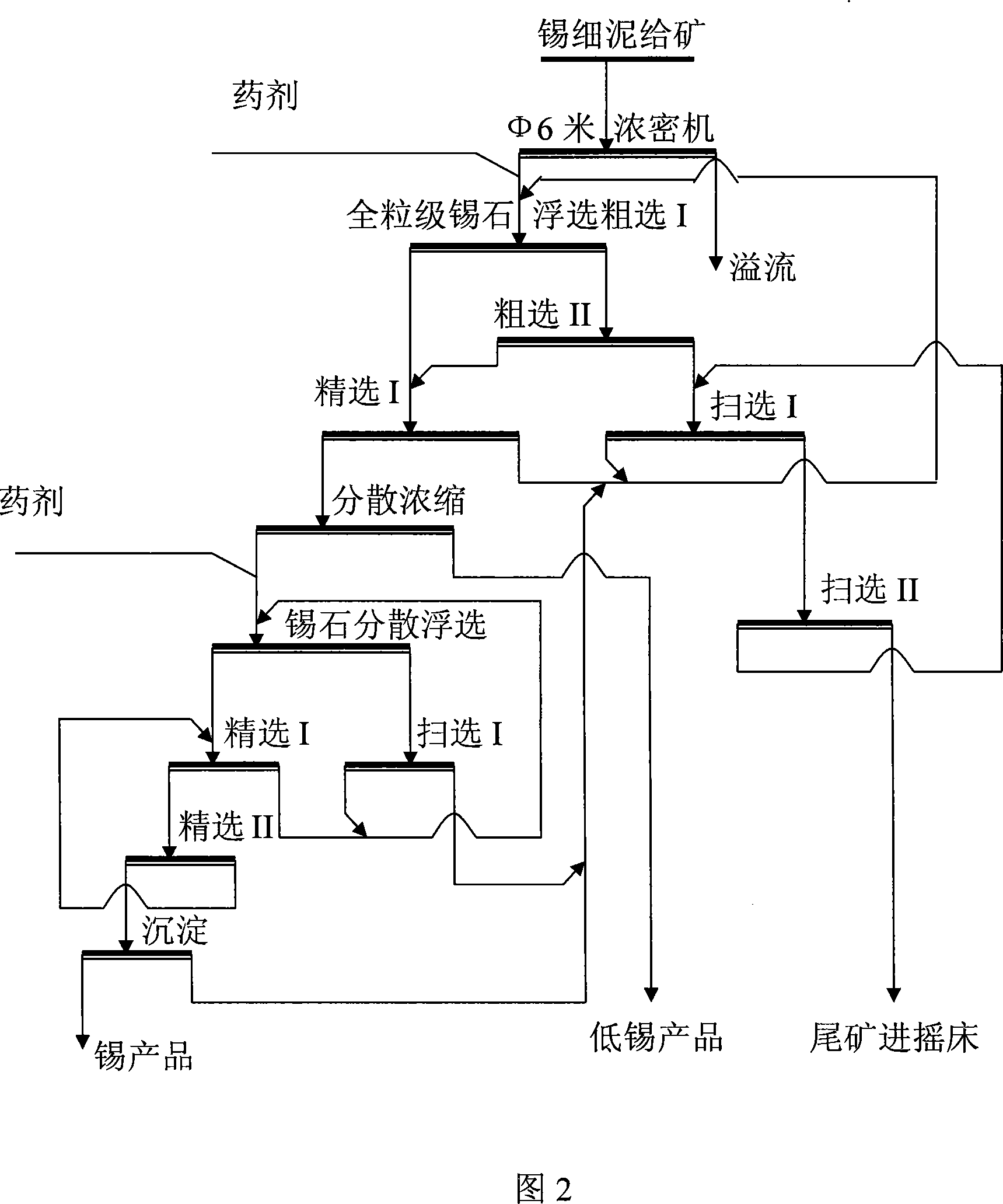

Novel technics of cassiterite clay flotation

ActiveCN101081377AConsistent structure principleImprove beneficiation indexFlotationCassiteriteSlurry

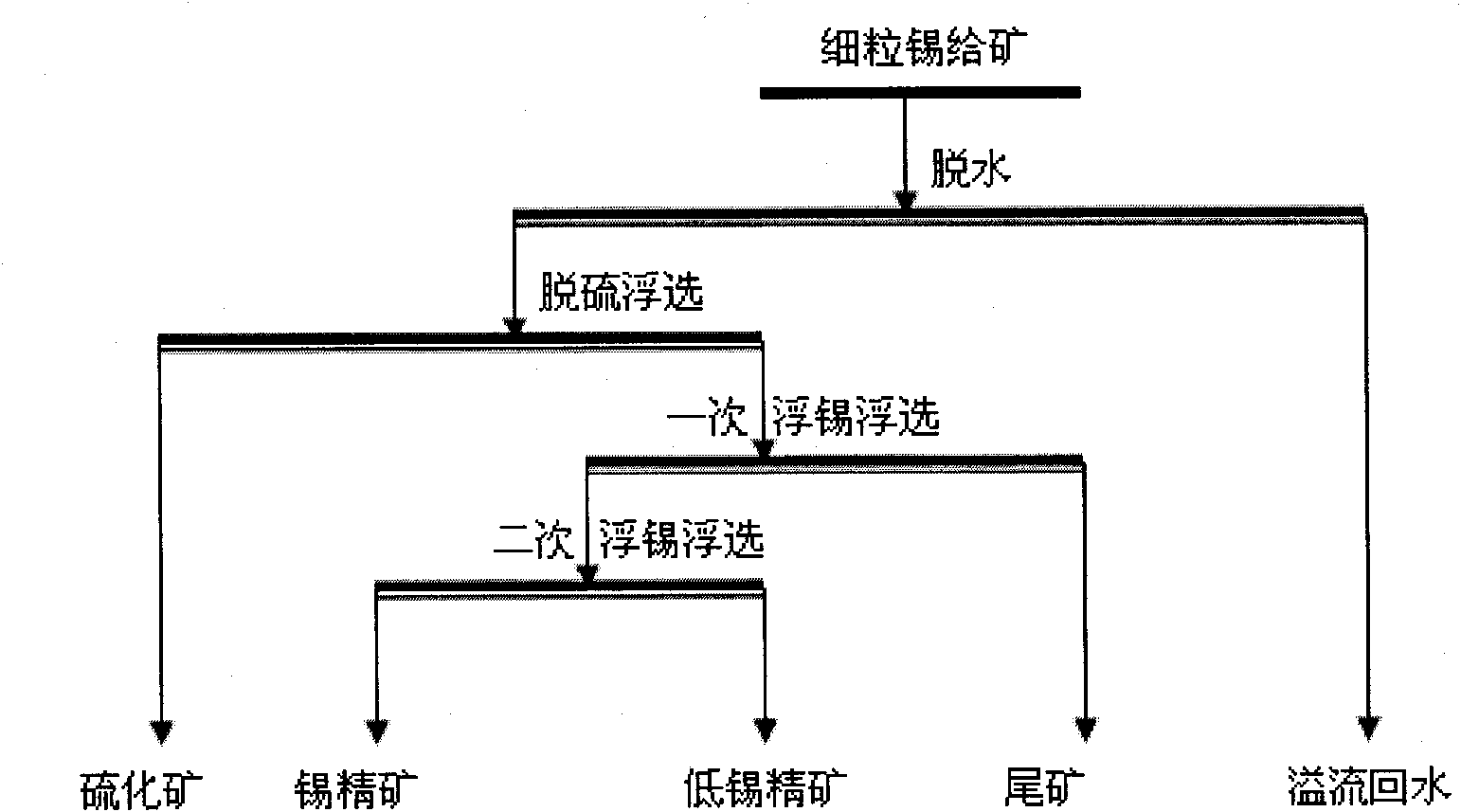

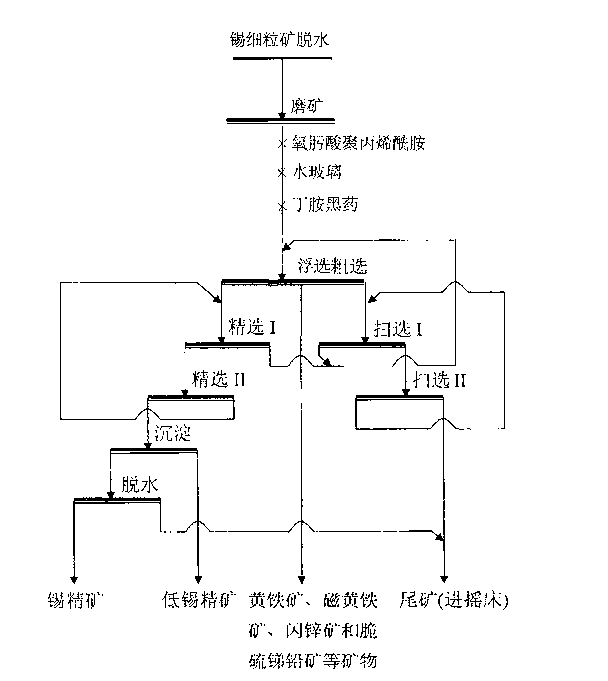

The present invention relates to fine and superfine cassiterite recovering technology. The whole production process of recovering cassiterite includes the following steps: collecting the fine grain ore slurry, dewatering to stabilize, floating all cassiterite of different sizes by means of proper amount of floating agent, dispersion dewatering, shaking table recovering large cassiterite, dispersion floating the desilting from dispersion dewatering, and depositing and dewatering the ultimate tin concentrate.

Owner:广西华锡矿业有限公司铜坑矿业分公司

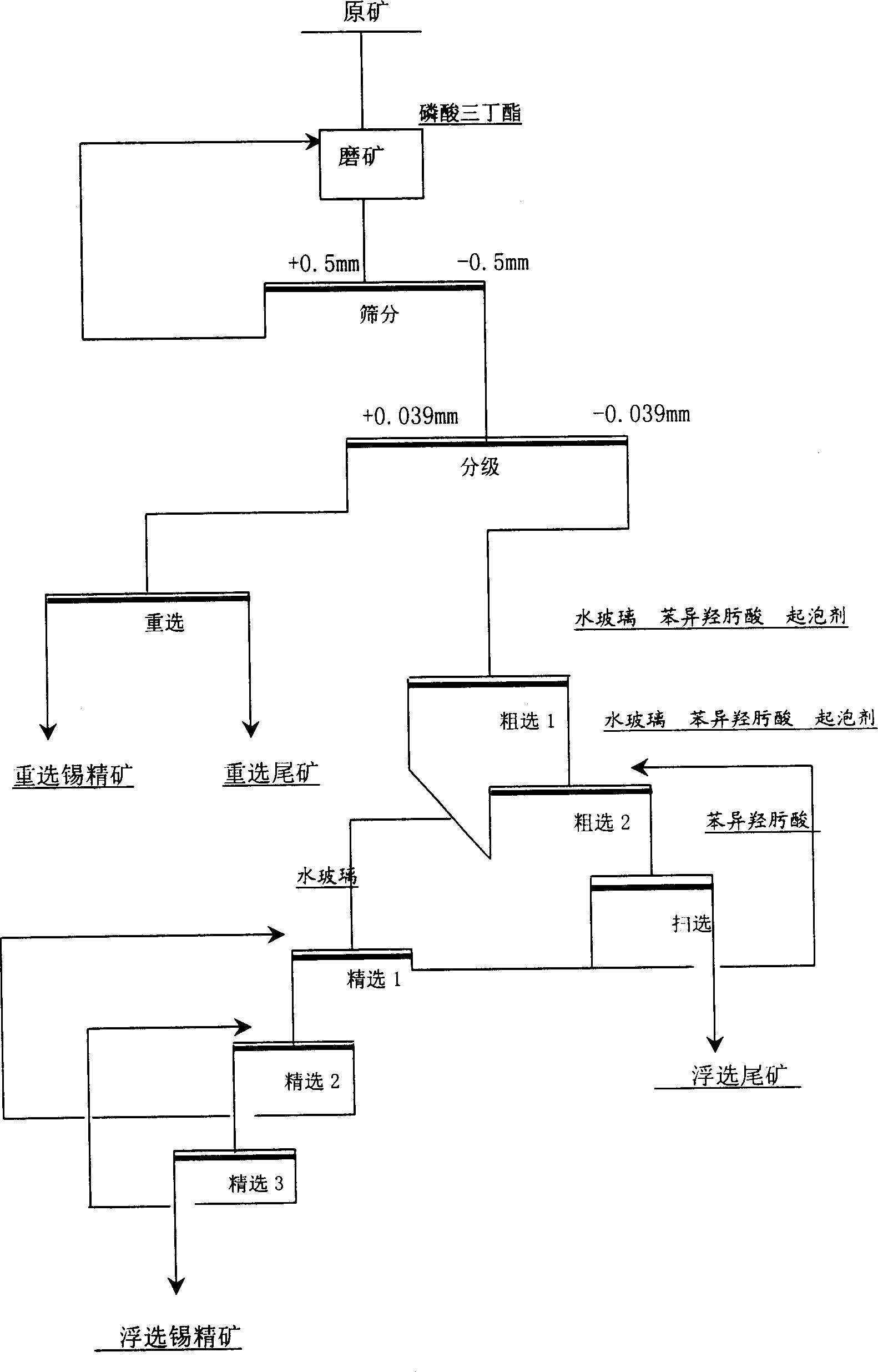

Cassiterite ore separation method

InactiveCN1721080AAvoid over crushingReduce contentFlotationCassiteritePhosphoric acid tributyl ester

Mineral separation for cassiterite ore comprises break, grinding, classification and the floatation for classified fine fraction less than 0.039mm. The floatation takes process of roughing for two times, scavenging for one time and refining for three times. It avoids over breaking, decreases fine ore greatly; as adding TBP, the ore needs not pre-desliming to recovery with floatation for the fine ore of less than 0.039mm. With this invention, for the cassiterite-quartz ore or tin placer with Sn content 0.6~2.0%, the flotation concentrate contains Sn more than 26%, the floatation recovery rate is more than 80%, and compared with traditional technique, the total recovery rate is increased more than 10%.

Owner:黎东明

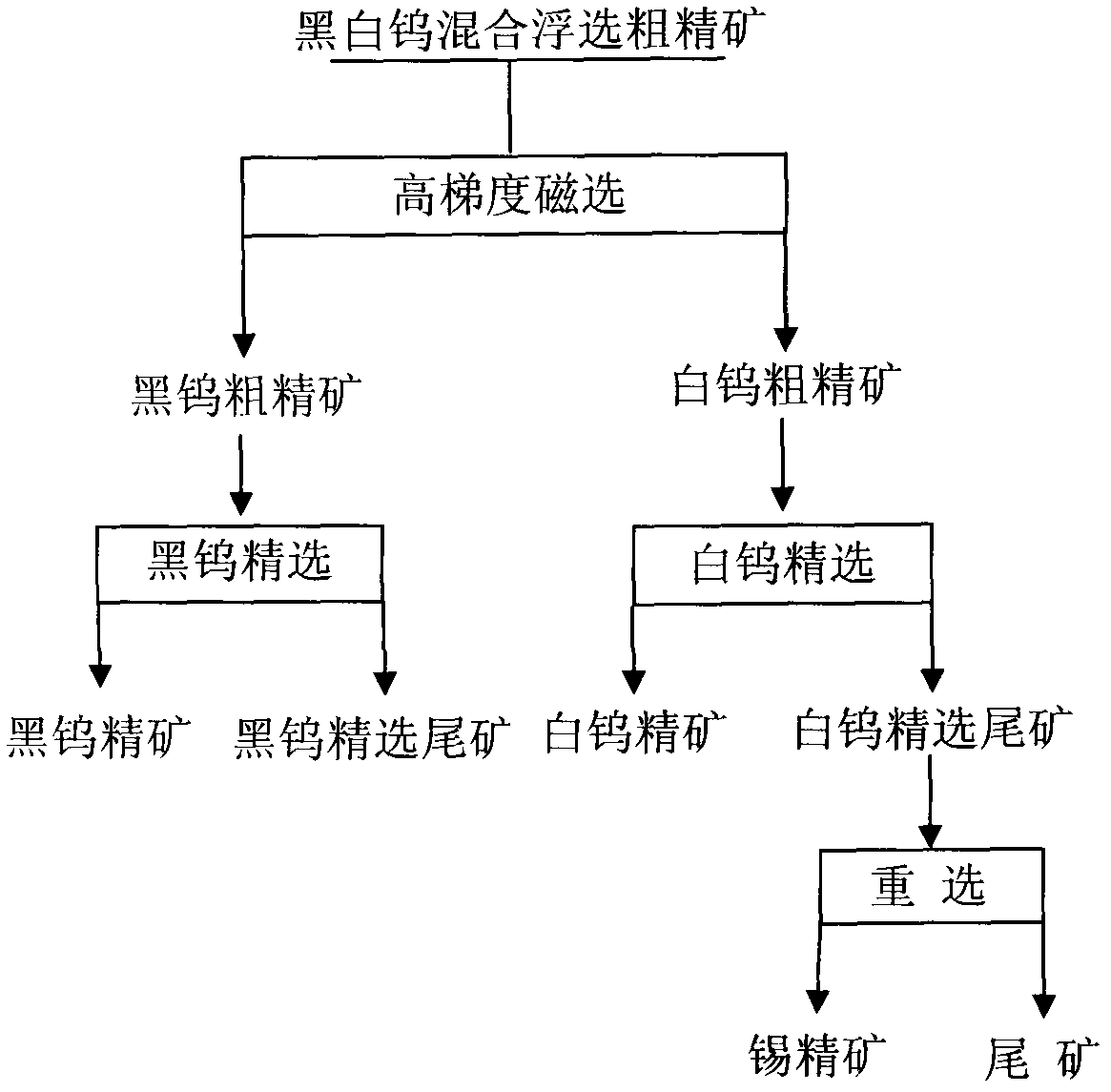

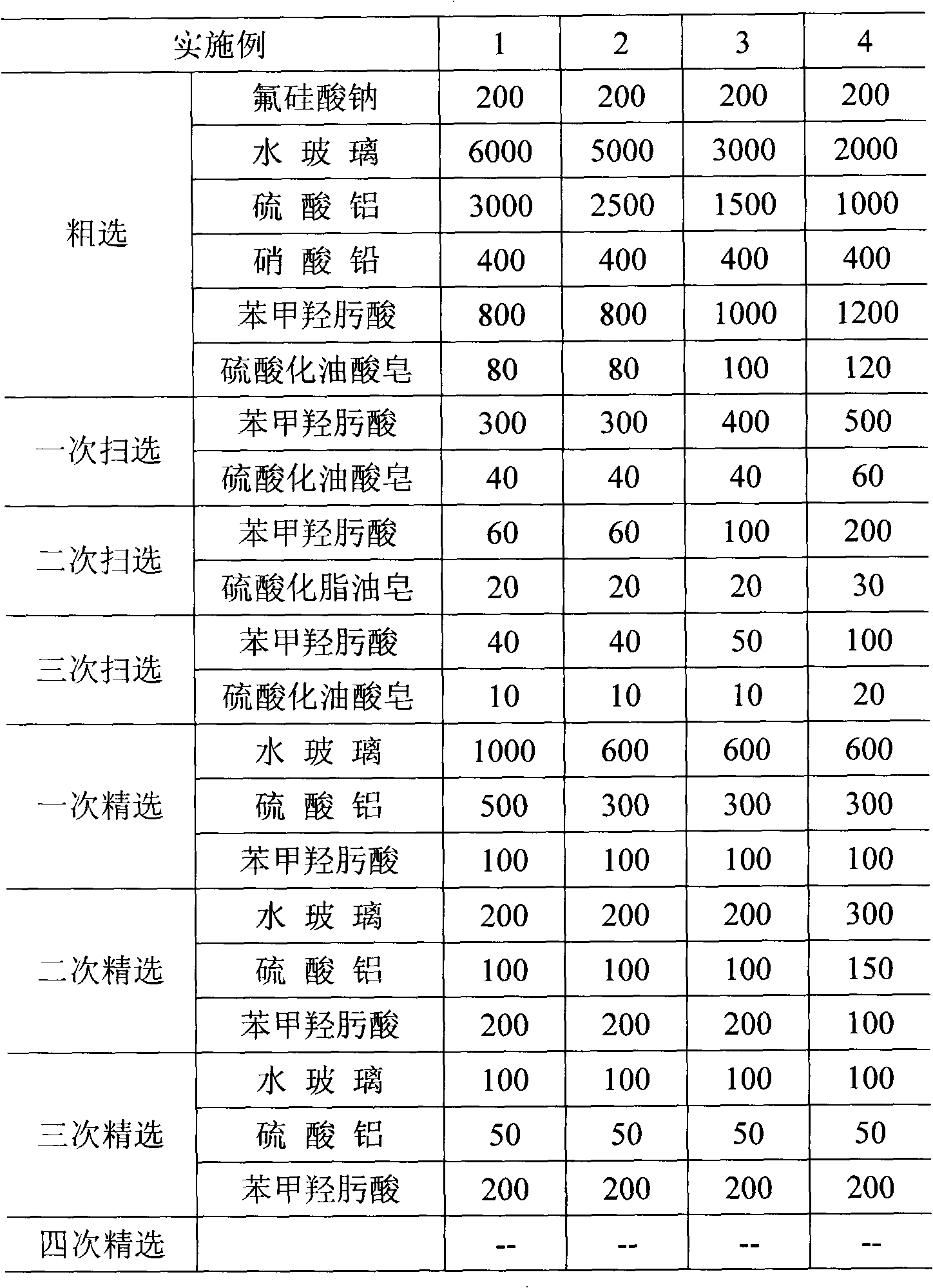

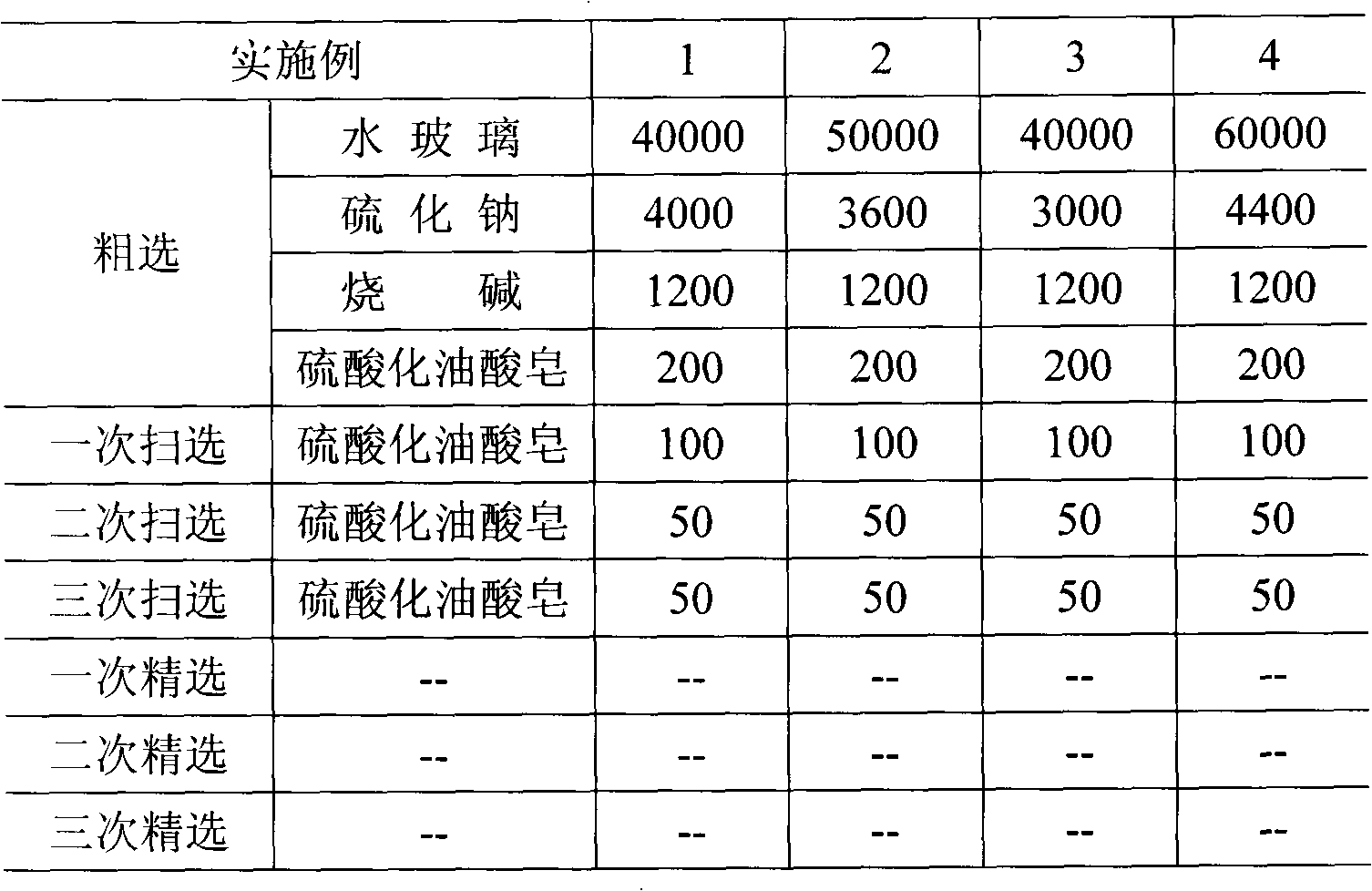

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

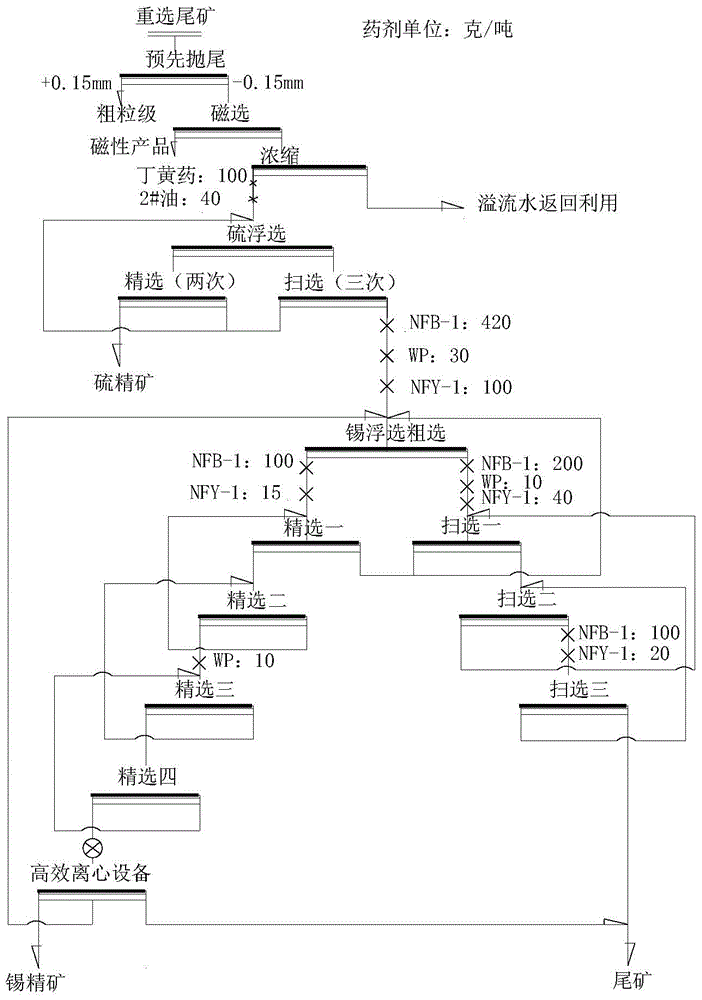

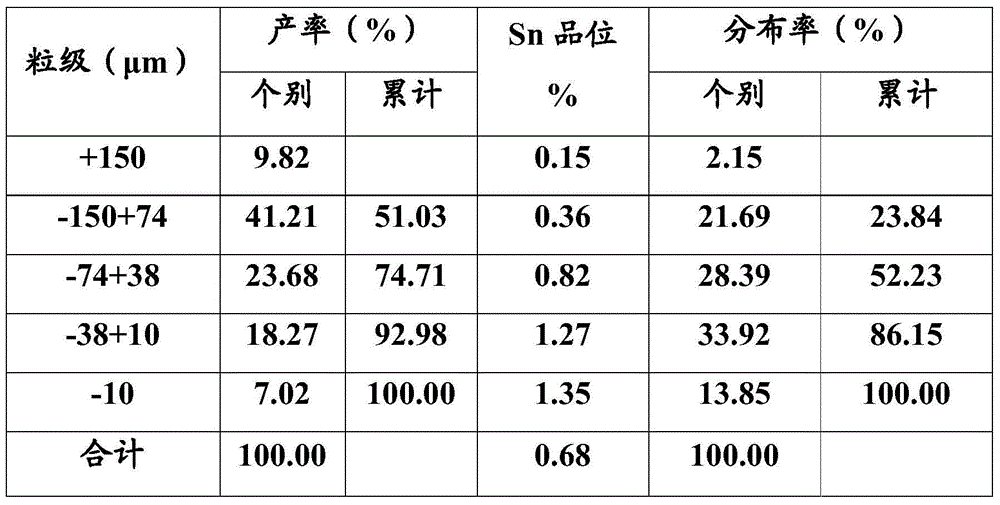

Gravitation separation tailing cassiterite flotation method

The invention provides a technological method for recovering cassiterite in gravitation separation tailings. The method is characterized by comprising the step that the gravitation separation tailings are subjected to pretreatment to remove tailings, wherein a vibrating screen is adopted to remove the tailings at the level of +150 microns in the gravitation separation tailings in advance. According to the method, through the processes of pretreatment to remove tailings, magnetic separation to remove iron, concentration, desulfuration floatation and buoyant weight combination, the fine silt cassiterite in the gravitation separation tailings can be effectively recovered; meanwhile, since the vibrating screen is used for removing the tailings at the level of +150 microns in advance, the feed grade selected in the process can be increased, the concentrate grade and the recovery rate can also be increased, and the reagent cost can be lowered; besides, by the adoption of an independently developed floatation reagent, tin concentrate with the concentrate grade of 7.36% and the recovery rate of 60.34% can be obtained by means of flotation when the tin grade of the gravitation separation tailings is 0.66%; qualified tin concentrate with the tin grade of 40.21%, the process feed recovery rate of 46.05% and the concentration plant raw ore recovery rate of 17.45% can be obtained by sorting tin flotation concentrate through efficient centrifugal equipment.

Owner:临武县南方矿业有限责任公司

Method for recovering fine mud cassiterite

The invention discloses a method for recovering fine mud cassiterite. The method comprises the following steps of dispersing a fine mud cassiterite mineral in an agitator by using sodium hexametaphosphate as a dispersing agent, grading the fine mud cassiterite mineral by using a high frequency fine screen, recovering the graded fine mud cassiterite mineral through gravity separation by using a fine mud cassiterite table concentrator to obtain fine mud rough concentrates in different particle sizes, and combining the fine mud rough concentrates in different particle sizes and performing floatation recovery on the fine mud cassiterite to obtain a cassiterite concentrate. By the method, the fine mud cassiterite can be effectively recovered, and the fine mud cassiterite concentrate of which the cassiterite grade is 45.87-46.21 percent and the recovery rate is 52.51-56.75 percent can be obtained under the condition that the fed mineral has the cassiterite grade of 0.37-0.45 percent.

Owner:广西华锡集团股份有限公司

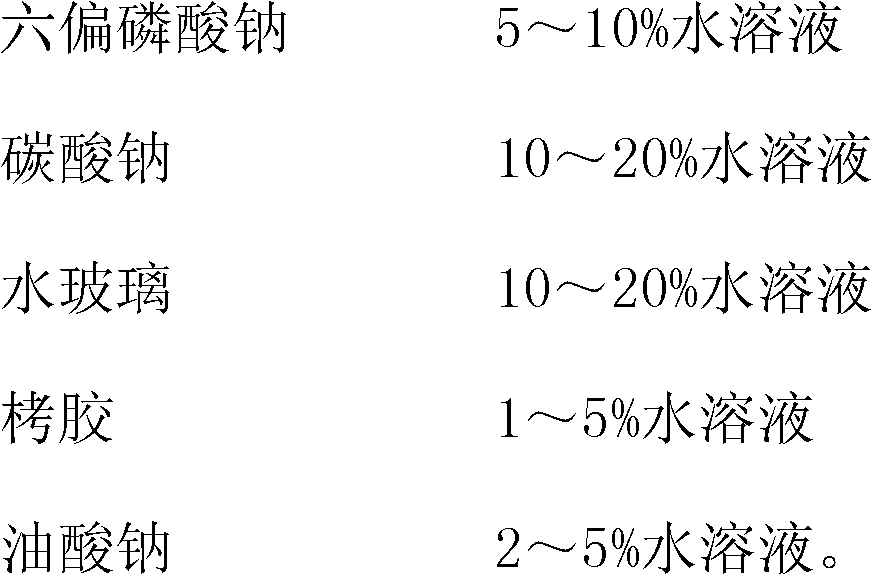

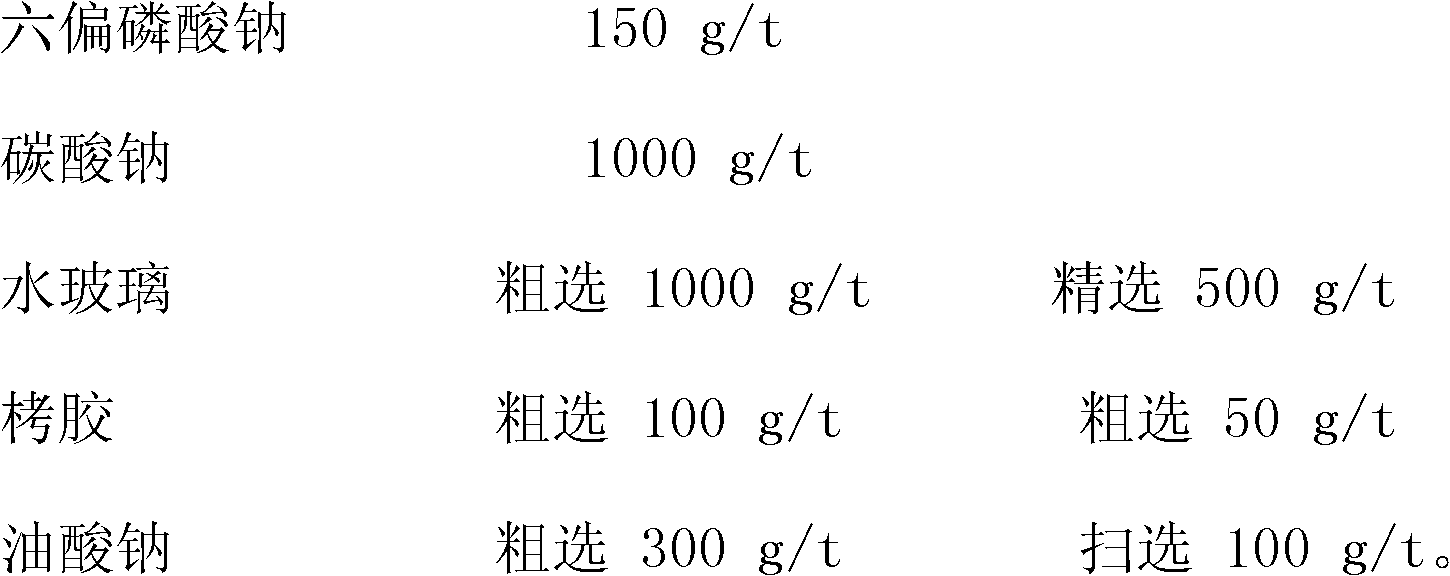

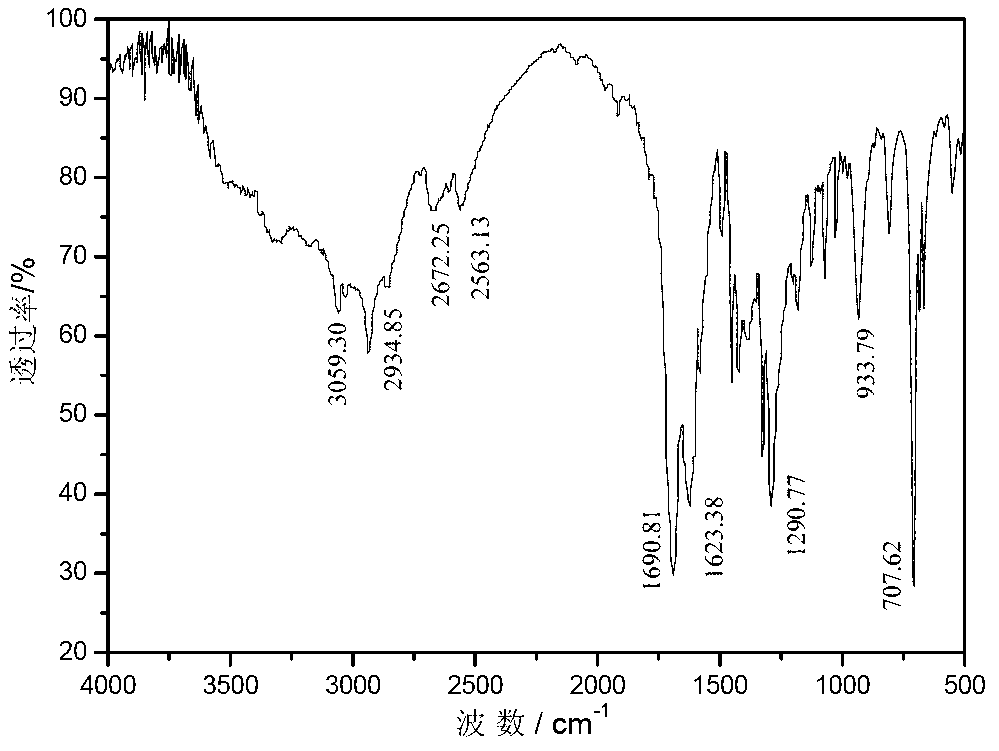

Cassiterite flotation agent composition

The invention provides cassiterite flotation agent composition. The cassiterite flotation agent composition comprises a collecting agent, a combined inhibitor and an optical auxiliary collecting agent, wherein the collecting agent comprises the following ingredients in percentage by weight: 30wt%-50wt% of styryl phosphoric acid, 20wt%-30wt% of aliphatic phosphoric acid (preferably selecting C6-C8 aliphatic series), 10wt%-20wt% of alkyl sulfonated succinic acid and 10wt%-20wt% of alkyl hydroximic acid. The cassiterite flotation agent composition provided by the invention is soluble under normal temperature, non-toxic and tasteless, good in dispersibility, efficient and environment-friendly and good in return water utilizability; mineral processing index of cassiterite flotation can be increased, the agent consumption can be reduced, the agent cost is reduced, and particularly for mineral processing on fine particle cassiterite, a unique effect is obtained; the loss of intermediate products during a tin rough concentrate recycling process is avoided; the industrial application processing capacity can be up to 50-60 tonnage / day, and more preferably, the industrial application processing capacity can be up to 80 tonnage / day; when the flotation ore feeding tin grade is 0.70%-0.80%, good technical indexes of 6%-10% of tin flotation concentrate grade and 60%-70% of operation recovery rate is obtained by agents; the dosage of the agents is greatly reduced.

Owner:临武县南方矿业有限责任公司

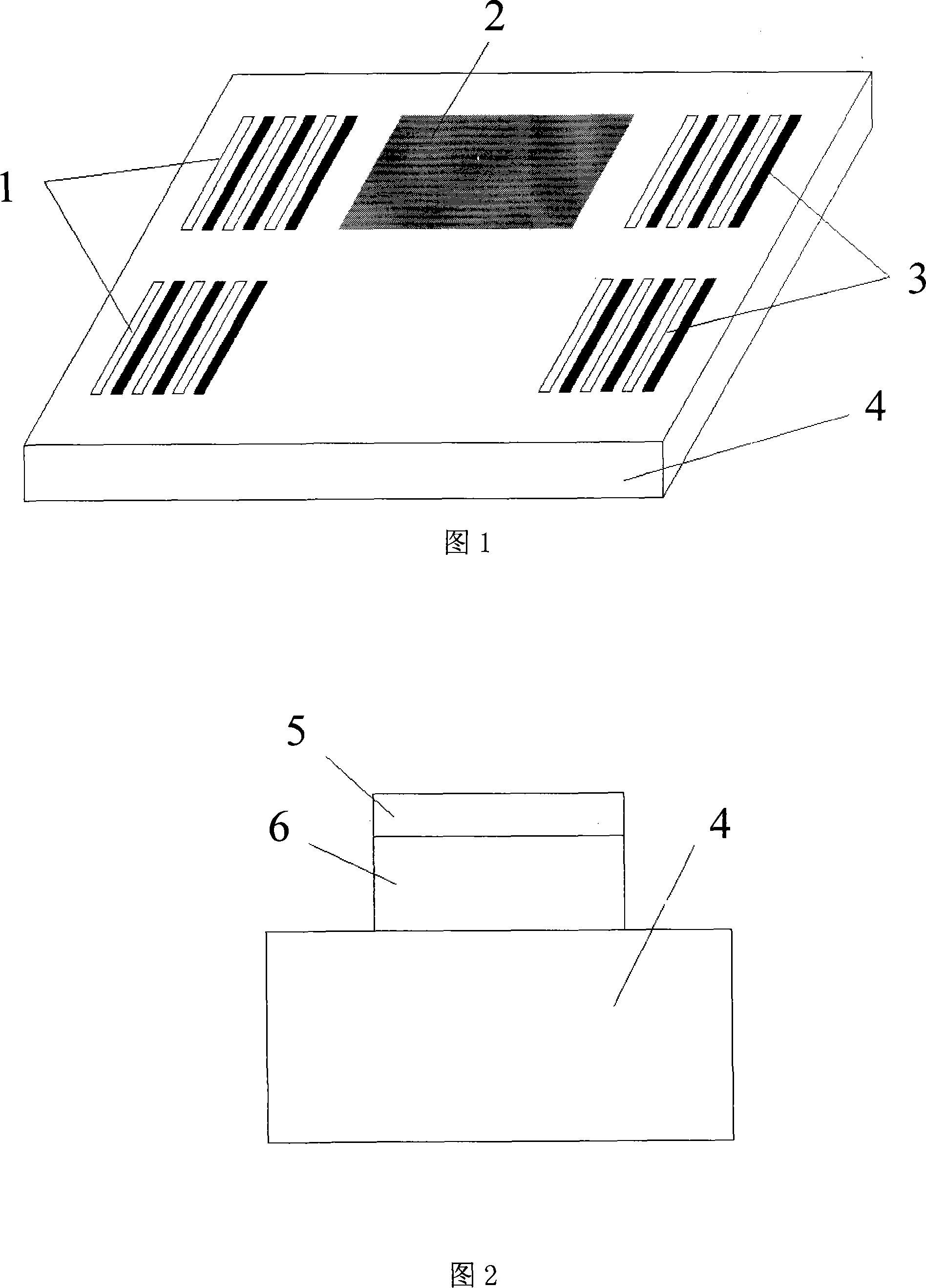

Acoustic surface wave microhydrogen sensor and its production process

InactiveCN101101278AHigh sensitivityEasy CalibrationAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityHydrogen

The invention discloses a acoustic surface wave tiny hydrogen transducer and its preparation artwork, it mainly uses the field of hydro safety detection technology in the process of hydrogen of production, repertory, transportation and distribution. The transducer not only has the characteristic of monolayer palladium film transducer under the normal temperature, but also improves the sensitivity of hydrogen transducer greatly, at the same time, because of the excellence of using EMES artwork tiny hydrogen transducer which is compactness, response fast, easy integration, good steady, low cost and easy volume production etc. The acoustic surface tiny hydrogen transducer mainly includes: piezoelectricity floor, input forked transducer, output forked transducer and hydrogen agile film which is made up of palladium silver alloys film and cassiterite film, cassiterite film is on the piezoelectricity floor, palladium silver alloys film is on the cassiterite, and it makes two-double sensitive film.

Owner:NANJING UNIV OF TECH

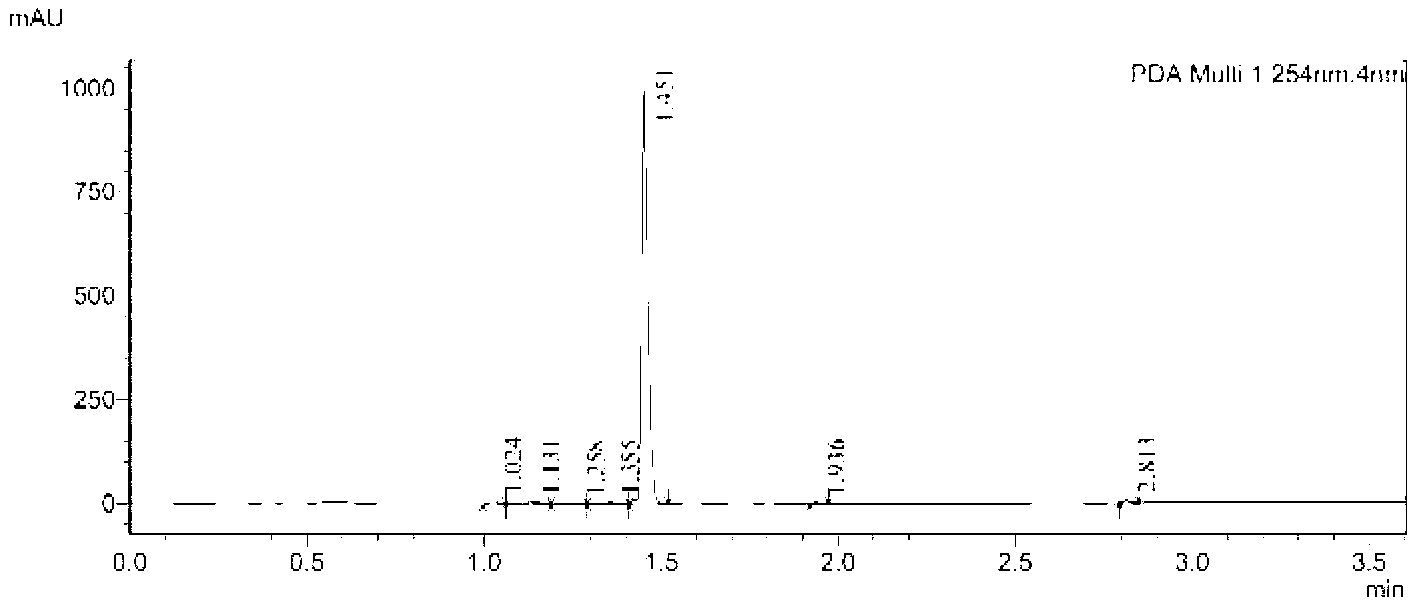

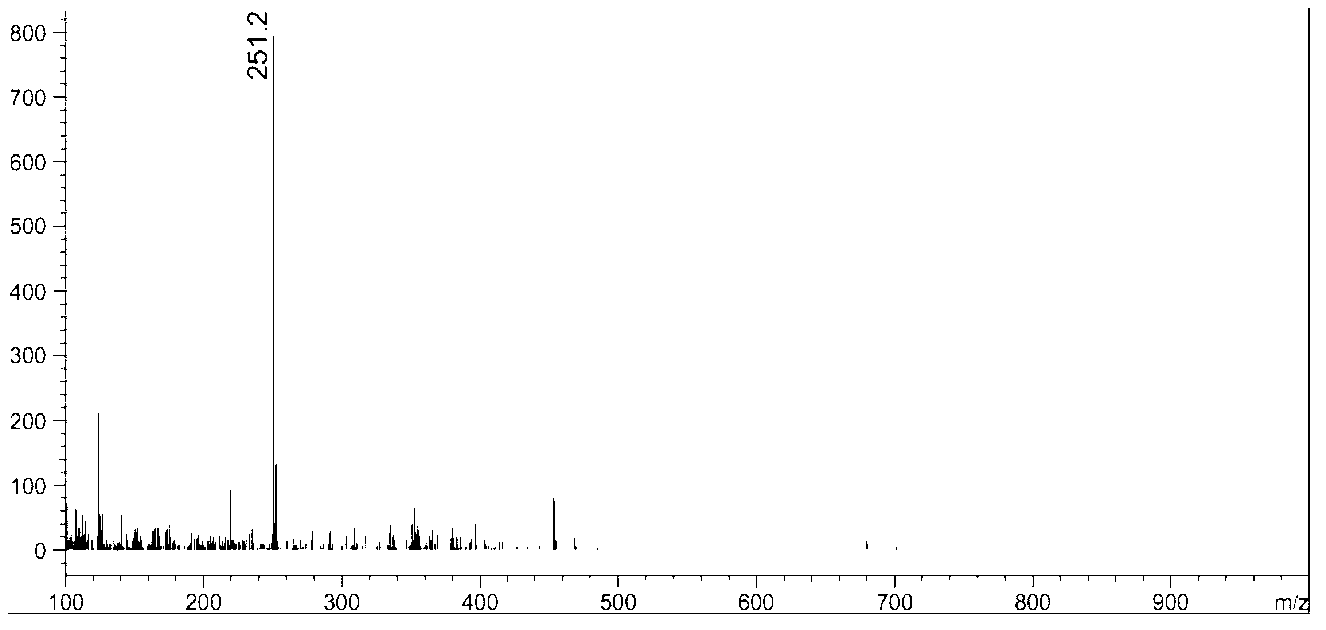

6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301953AStrong harvesting abilityImprove flotation recoveryFlotationPotassium hydroxideSodium hydroxide

The invention discloses a 6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof. 6-aryl amido hexyl hydroximic acid represented by a formula (I) is taken as a collecting agent and utilized in flotation of tungsten ore, tombarthite ore, tin ore or bauxite, wherein R represents H or C1-8 alkyl. 6-aryl amido hexyl hydroximic acid and sodium hydroxide, potassium hydroxide or ammonium hydroxide are put into water to prepare an aqueous solution of 6-aryl amido hexyl hydroxyoximate; a flotation reagent is added for size mixing during an ore grinding and / or flotation process, the added reagent at least contains the aqueous solution of 6-aryl amido hexyl hydroxyoximate, and the dosage of 6-aryl amido hexyl hydroximic acid ranges from 100g / t to 3,500g / t; and useful metallic minerals are floated out through a froth flotation method, and the flotation recovery rate can be increased by 2%-5%.

Owner:CENT SOUTH UNIV

Composite sodium salt for producing sodium stannate from cassiterite concentrate and application of composite sodium salt

The invention discloses a composite sodium salt for producing sodium stannate from cassiterite concentrate and an application of the composite sodium salt. The composite sodium salt consists of 70%-90% of sodium carbonate, 5%-20% of sodium bicarbonate, 2.5%-5% of sodium borate and 2.5%-5% of sodium humate by mass. When the composite sodium salt is used, the composite sodium salt is ground to the particles with the size fraction of minus 0.1mm being no less than 90% by mass, the cassiterite concentrate of the fine fraction and the composite sodium salt are mixed according to the mass ratio of 1:(0.5-2), pelletized and dried, coke powder or anthracite is taken as a reducing agent, the mixture is calcined for 30 minutes-90minutes at the temperature of 800 DEG C-950 DEG C, and the cooled calcined product is ground, leached, filtered, purified, concentrated and crystallized, so that the sodium stannate product is obtained. The adopted composite sodium salt is reasonable in component, can be widely obtained, is low in price, is easy to obtain and does not cause pollution to the environment. With the composite sodium salt, the stable crystal structure of the cassiterite concentrate can be obviously damaged, and the composite sodium salt can be widely applied to various cassiterite concentrates so as to directly produce sodium stannate.

Owner:CENT SOUTH UNIV

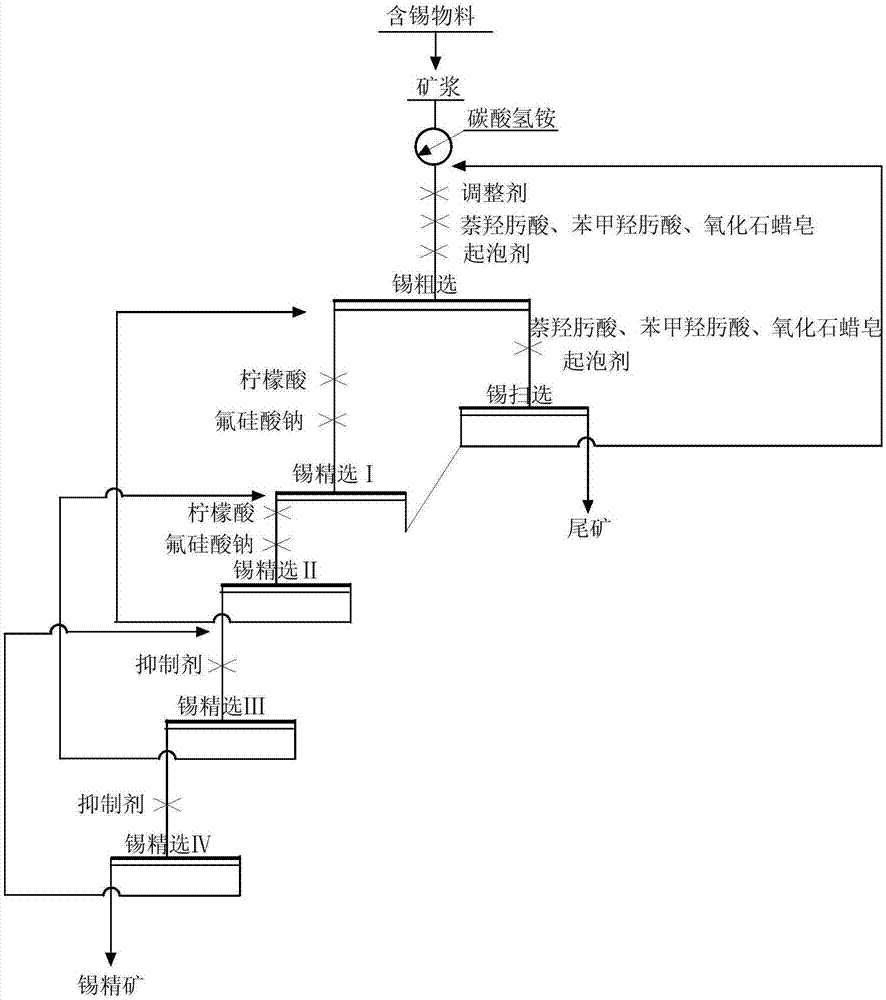

Micro-fine particle cassiterite flotation method

The invention relates to a micro-fine particle cassiterite flotation method. The micro-fine particle cassiterite flotation method comprises the steps that tin-containing materials are prepared into pulp, and ammonium bicarbonate is added in the pulp; then an adjusting agent, collecting agents and a foaming agent are added, wherein the collecting agents comprise naphthalene hydroximic acid, benzohydroxamic acid and oxidized paraffin wax soap; and the pulp is subjected to roughing, and then citric acid and sodium fluosilicate are added into tin rough concentrate for choiceness to obtain cassiterite concentrate. The problems that the micro-fine particle cassiterite flotation recovery rate is low, the concentrate grade is unsatisfactory, and the impurity content is high are solved, and the tin concentrate with the Sn content being larger than or equal to 35% and the recovery rate being larger than or equal to 90% can be obtained; and compared with the prior art, the thin concentrate recovery rate is increased by 15-20%, and the tin concentrate grade is improved by 10-15%. The low-carbon, environment-friendly, economical and efficient method for micro-fine particle cassiterite recovery through flotation is simple in technique, has the advantages that the material adaptability is high, using is safe and stable, the reagent dosage is few, and pollution is little, and has good application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

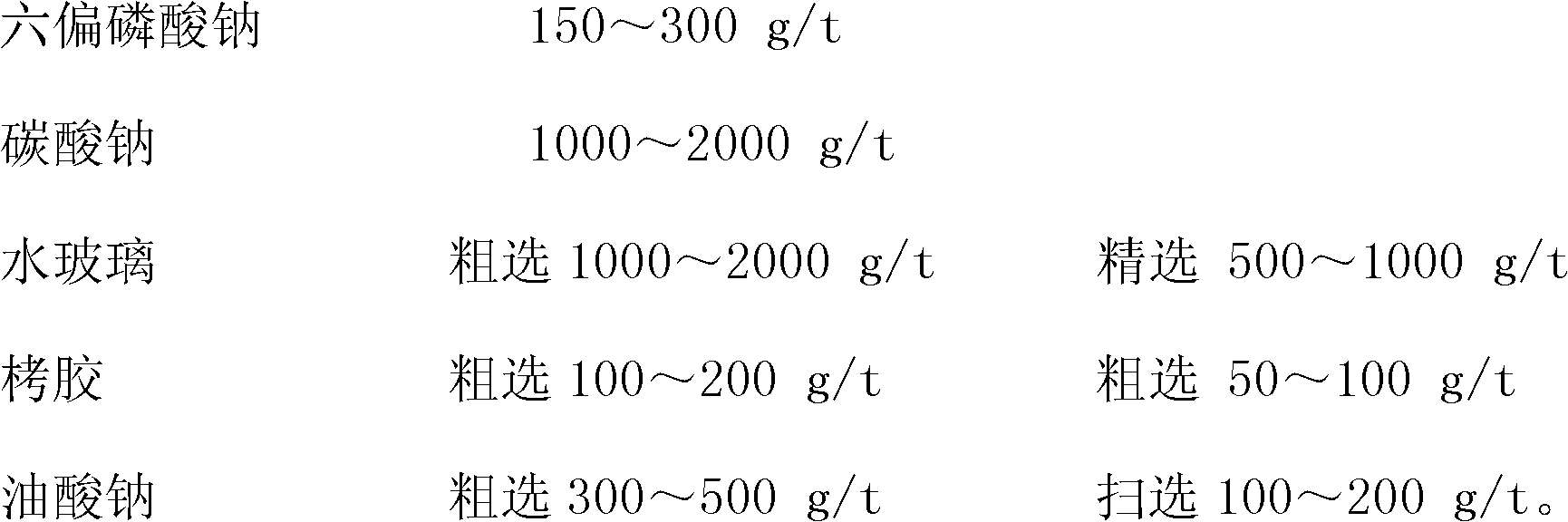

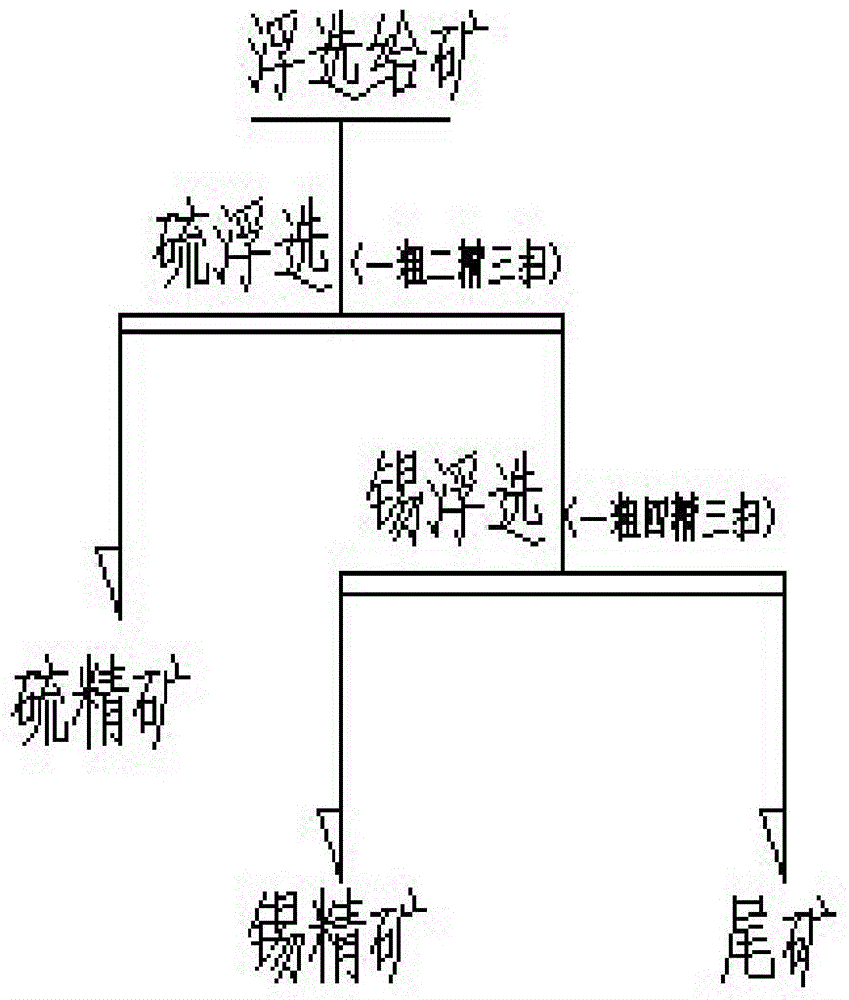

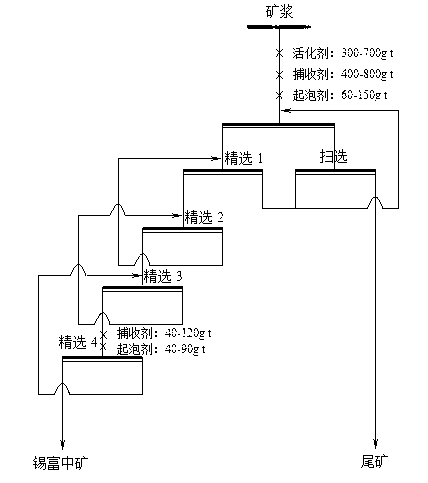

Method for recycling fine and superfine cassiterites from oxidized lode tin mud tailings

The invention relates to a method for recycling fine and superfine cassiterites from oxidized lode tin mud tailings and belongs to the technical field of mineral process engineering. The method comprises the following steps: adding water to the oxidized lode tin mud tailings and mixing slurry; during a roughing process, respectively adding activating agents, collecting agents and foaming agents in turn; roughing, thereby obtaining a foam product as a roughing concentrate and obtaining an in-slot product as a roughing middling; without adding any drug, scavenging the roughing middling, thereby obtaining the foam product as the scavenging middling and the in-slot product as the final tailing; returning the scavenging middling to the roughing operation for roughing again; and during a finely separating process, finely separating the roughing concentrate for four times, respectively returning the fine separating middling obtained from the finely separating operation at each time to the last operation for separating again, only adding the collecting agents and the foaming agents after finishing the fine separating for the third time, and separating and finally obtaining the tin-rich middling. According to the method, the process is simple, the flow structure is reasonable, the adaptability to raw materials is wider and the industrial implementation is easily performed.

Owner:KUNMING UNIV OF SCI & TECH

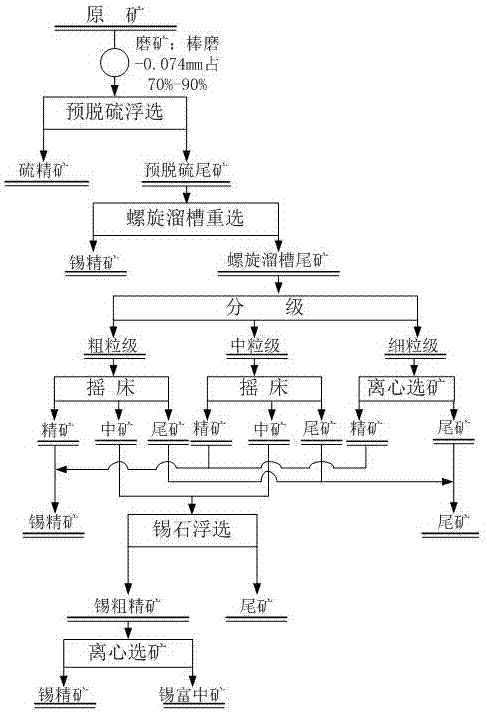

Fine particle embedded cassiterite beneficiation method

The invention relates to a fine particle embedded cassiterite beneficiation method, and belongs to the technical field of mineral processing. Fine particle embedded cassiterite ores are grinded by a rod grinding machine for primary advanced desulfurization flotation to obtain sulfur concentrates and predesulfurized tailings; the predesulfurized tailings are fed in a spiral chute for reselection to roughly select tin to obtain qualified tin concentrates and spiral chute tailings; the spiral chute tailings are classified to obtain three products of +0.053 mm thick particle grade, 0.053-0.038 mm medium particle grade and -0.038 mm fine particle grade; the shaker reselection is performed on the products of+0.053 mm thick particle grade and 0.053-0.038 mm medium particle grade to obtain shaker concentrates, middlings and tailings; the products of -0.038 mm fine particle grade are reselected by a centrifugal beneficiation machine to obtain tin concentrates and tailings; the shaker concentrates are merged with the tin concentrates reselected by the centrifugal beneficiation machine as qualified tin concentrates; the tailings are merged as final tailings; the shaker middlings are merged for cassiterite beneficiation to obtain tin thick concentrates; and the tin thick concentrates are reselected and finely selected by the centrifugal beneficiation machine to obtain qualified tin concentrates and tin-rich middlings. The method is lower in production cost and higher in recovery rate.

Owner:KUNMING UNIV OF SCI & TECH

Method for selectively milling cassiterite multi-metal sulfides ores

The invention discloses a method for selectively milling cassiterite multi-metal sulfides ores. In the method, by utilizing the hydrophily / hydrophobicity difference between the surface of cassiterite and the surfaces of sulfides ores such as pyrite, pyrrhotite, blende and jamesonite, and by adding a floating agent in a milling process, floatation separation of cassiterite and the sulfides ores in ores can be realized under a condition of larger milling granularity by using a floatation method. The method disclosed by the invention can be adopted for treating the cassiterite multi-metal sulfides ore which contains 0.5 to 1 percent of Sn and 12 to 17 percent of S; and by adopting the method, the ore milling granularity required in floatation can be decreased, the content of fine-grained cassiterite (with the granularity of minus 0.039 millimeter) is reduced by 20 percent, and over-crushing phenomena of cassiterite are greatly reduced.

Owner:CENT SOUTH UNIV +1

Selective milling-flotation method for cassiterite multi-metal sulfide ore

The invention discloses a selective milling-floatation method for cassiterite multi-metal sulfide ore. In the method, cassiterite multi-metal sulfide ore is selectively milled, so that the surface hydrophilic / hydrophobic properties of cassiterite and sulfide minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like in ore are changed, the surface of cassiterite does not react with a flotation collector but reacts with hydroxamic acid polyacrylamide, and selective flocculation is performed on the surfaces of cassiterite minerals; and surfaces of minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like do not adsorb hydrophilic substances, and a fresh surface which is obtained by milling ore and dissociating reacts with a flotation collector which is added into an ore mill, so that floatability is realized for the surface hydrophilic property, the problems of low cassiterite floatation efficiency, high tin loss rate and severe environmental pollution caused by excessive smashing of cassiterite with the conventional floatation method in the ore dressing process of cassiterite multi-metal sulfide ore are solved, and the recovery of cassiterite with a subsequent gravity separation technology is facilitated.

Owner:GUANGXI GAOFENG MINE IND

Process for preparing polyphenylethylene/tin dioxide nucleic shell microball

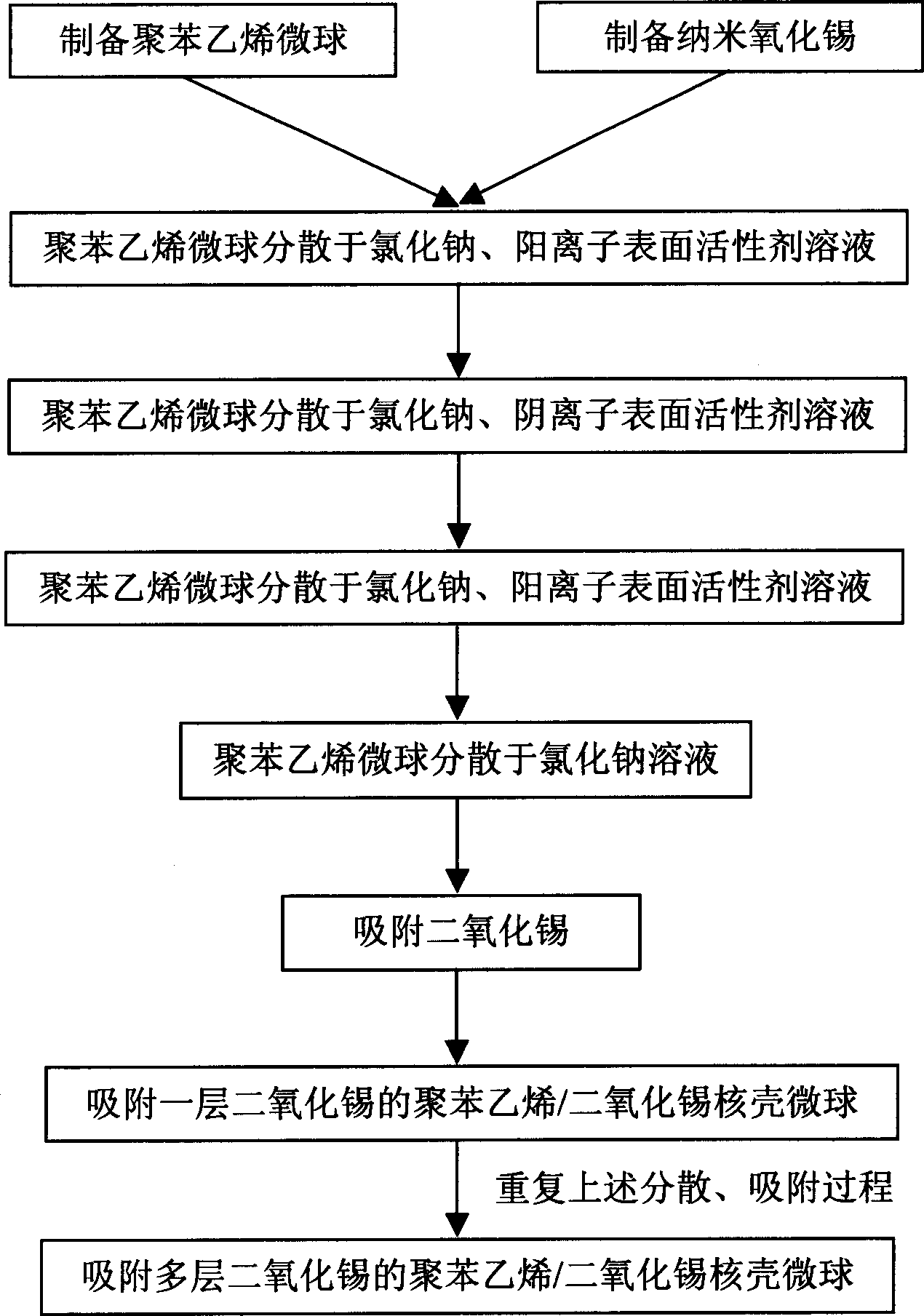

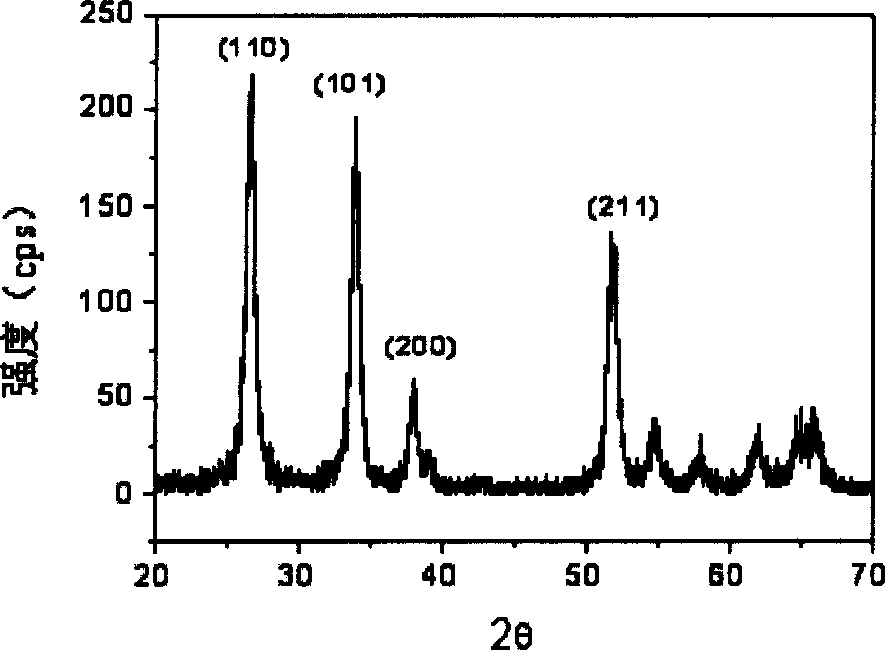

The invention discloses a manufacture method for polystyrene / cassiterite nucleocapsid microsphere that adopts self-assembly method in solution to make nucleocapsid microshere, uses micro-emulsion polymerization to make polystyrene microsphere and sol gel method to make nm cassiterite, uses self-assembly method in solution to made polystyrene / cassiterite nucleocapsid microsphere. It disperses polystyrene microsphere in the NaCl water solution, cationic surface active agent, anionic surface active agent, and cationic surface active agent water solution. The polystyrene microsphere is dispersed in NaCl water solution adding nm cassiterite, taking centrifugal separation, washing, drying to gain polystyrene / cassiterite nucleocapsid microsphere. The process is easy to control. The invention has the advantages of low consumption, common material, equal cassiterite layer.

Owner:SHANGHAI JIAO TONG UNIV

Beneficiation method for cassiterite-polymetallic sulfide ores

InactiveCN105618273ASolve the low selection efficiencyLow water utilizationFlotationFoaming agentCassiterite

The invention relates to a beneficiation method for cassiterite-polymetallic sulfide ores, and belongs to the technical field of beneficiation. The beneficiation method comprises the following steps: putting the cassiterite-polymetallic sulfide ores into an ore mill, and milling the cores until ore materials with grain size being (-)200 meshes account for 85%; carrying out primary flotation on the ore materials to obtain sulfide ores and residual ore pulp, wherein use of a floating reagent added in a floating process is that one ton of cassiterite-polymetallic sulfide ores contain 500g of butyl-xanthate, and use of a foaming agent is that one ton of cassiterite-polymetallic sulfide ores contain 20g of terpenic oil; and carrying out primary rough concentration, primary scavenging and secondary concentration and flotation on the residual ore pulp to obtain tin concentrates and tailings. According to the method, useful minerals are effectively recycled through a selective ore milling-floatation method, so that a tin beneficiation process is greatly simplified, and therefore, the beneficiation method has good economic benefits.

Owner:KUNMING UNIV OF SCI & TECH

Flotation activating agent for fine-grain cassiterite and preparing method of flotation activating agent

The invention discloses a flotation activating agent for fine-grain cassiterite and a preparing method of the flotation activating agent. The flotation activating agent is a coordination compound of lead and ammonia, and the molecular formula of the coordination compound is [Pb(NH3)x]2+, wherein X in the molecular formula ranges from one to eight. The preparing method of the flotation activating agent mainly comprises the steps that, lead nitrate, lead acetate hydrate and lead acetate are dissolved in ethyl alcohol or methyl alcohol or water through ammonium hydroxide dissolving, then, sodium hydroxide and sodium carbonate are added, mixing is conducted for the reaction, and the flotation activating agent is obtained through drying. The flotation activating agent is used for activating the fine-grain cassiterite in ore, the surface hydrophobicity of the fine-grain cassiterite is improved, the proportion of lead and ammonia in the flotation coordination compound of the cassiterite is increased, adjustment can be conducted according to the specific beneficiation raw material condition, flexibility and changeability are achieved, adaptability is high, and the application range is wide. The flotation tin concentrate grade and recycling rate of the fine-grain cassiterite are increased, economic benefits are increased, raw materials are cheap and easy to obtain, and the production cost is low.

Owner:YUNNAN YUANKUANG TECH DEV CO LTD

Mineral flotation collector as well as preparation method and application thereof

ActiveCN109590115ASolve difficult problems that are not easy to separateHigh selectivityFlotationMass ratioMineral flotation

The invention discloses a mineral flotation collector as well as a preparation method and application thereof. The mineral flotation collector contains soluble metal salt, a chelating type medicamentand fatty acid or a derivative thereof, wherein the mass ratio of the soluble metal salt to the chelating type medicament to the fatty acid or the derivative thereof is (0.5 to 1) to (1 to 3) to (0.05to 0.5). According to the mineral flotation collector, metal coordination ions in the soluble metal salt, a chelating agent and a fatty acid type collector are pre-assembled according to a specific ratio to obtain a multi-ligand collector with high selectivity and collection capability, and a traditional thinking that sediment is generated when the soluble metal salt, the chelating type medicament and a fatty acid type medicament are mixed and the acting effect of the medicament is reduced is broken through; and the difficulty that tungsten ore and cassiterite are not easily separated from gangue minerals, especially calcium-containing gangue minerals, is solved.

Owner:CENT SOUTH UNIV

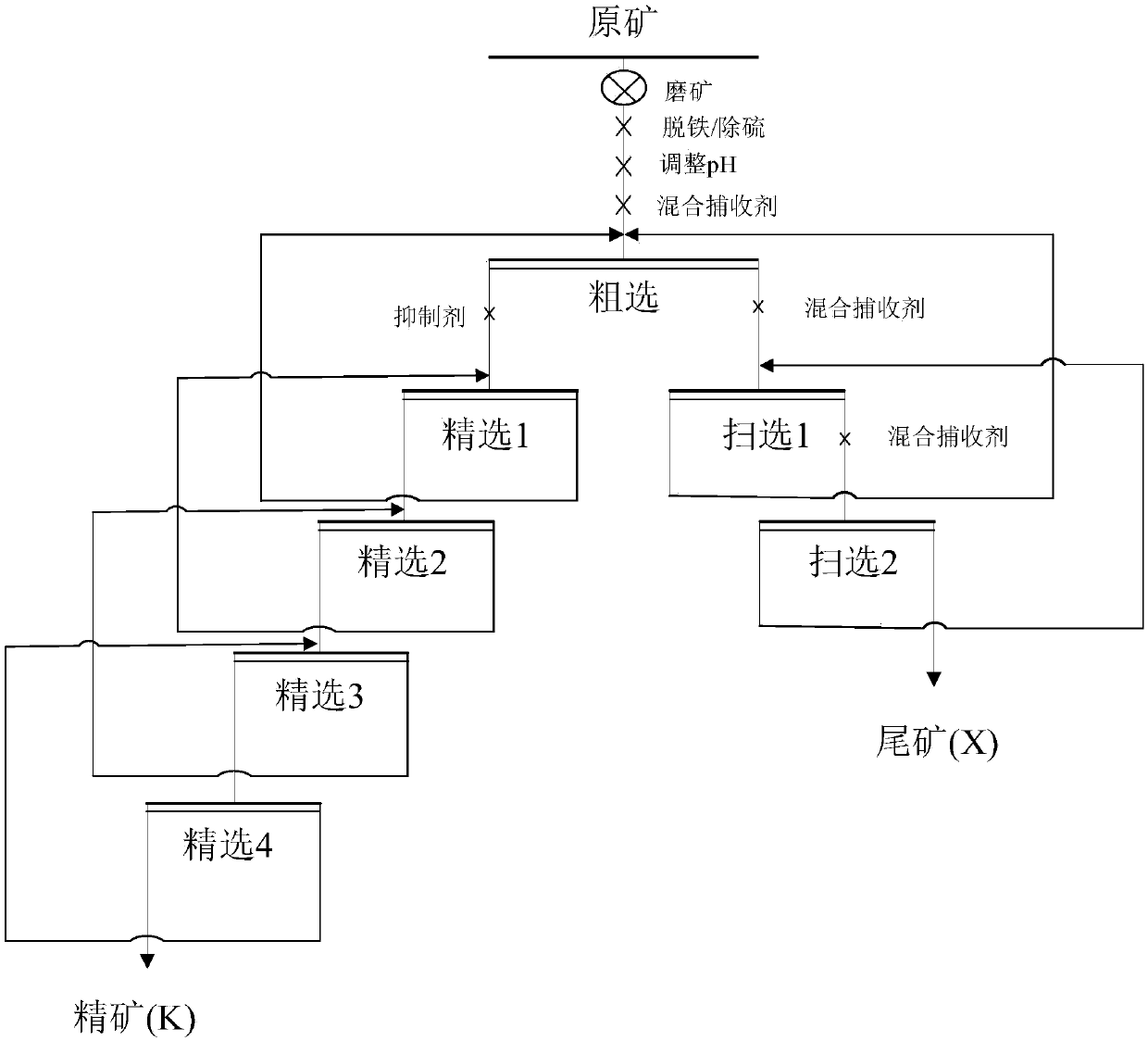

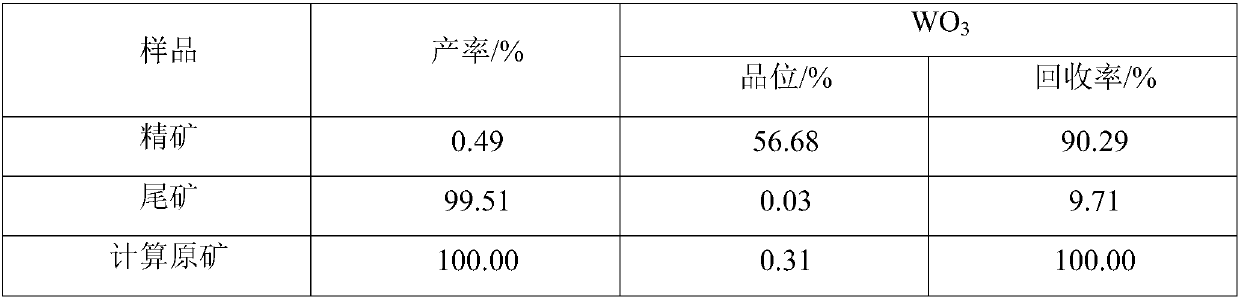

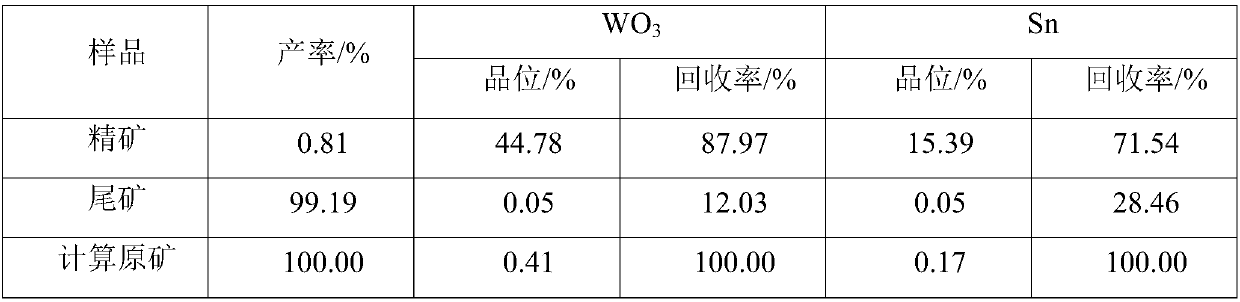

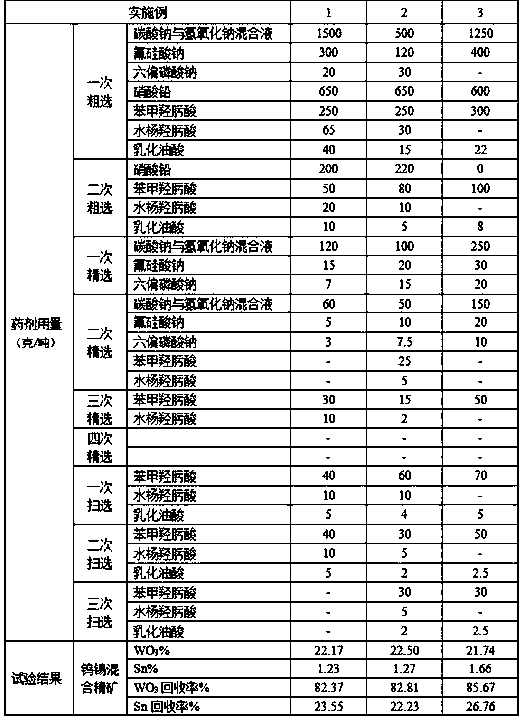

Tungsten tin mineral beneficiation method

ActiveCN109127120ASolve the problem of high mineral processing costIncrease profitFlotationLead nitrateHydroxamic acid

The invention discloses a tungsten tin mineral beneficiation method; and tungsten tin minerals are tungsten tin fed ores as sulfide ores flotation tailings obtained after grinding of multimetal ores of tungsten associated cassiterite, removal of magnetite by magnetic separation and removal of sulfur concentrates by sulfide ore flotation. Mixed liquid of sodium carbonate and sodium hydroxide, sodium fluosilicate, sodium hexametaphosphate and lead nitrate are added in the tungsten tin fed ores for pulping; then, collecting agents-benzohydroxamic acid, hydroxamic acid and emulsified oleic acid are added for tungsten tin mixed flotation; and tungsten tin mixed concentrates with WO3 of not less than 20% and Sn of not less than 1% are obtained by 2 times of roughing, 3-4 times of selection and 2-3 times of scavenging. The method has the following characteristics: the beneficiation method of tungsten tin mixed flotation is used for the tungsten tin fed ores; and when tungsten minerals are recovered by floatation, tin minerals are enriched in tungsten concentrates to achieve the purpose of synchronously recovering the tin minerals. The method is simple in recovery process flow, stable in beneficiation process and suitable for beneficiation of the tungsten tin fed ores with WO3 of 0.2-0.5%, Sn of not more than 0.2%, CaF2 of not more than 25%, CaCO3 of not more than 10% and the black andwhite tungsten ratio of 2: 8-8: 2.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Metal ion complex collecting agent and preparation method and application of metal ion complex collecting agent

ActiveCN105618272AAchieve selective separationResolve separation difficultiesFlotationCassiteriteRare earth

The invention discloses a metal ion complex collecting agent and a preparation method and application of the metal ion complex collecting agent. The metal ion complex collecting agent is formed by a ligand and metal ions in a coordination manner. The preparation method of the metal ion complex collecting agent comprises the step that soluble metal salt is added into a solution with the ligand for a reaction, and the metal ion complex collecting agent is obtained. The method is simple and low in cost. The prepared metal ion complex collecting agent has extremely high selective collecting capacity on tungsten-containing minerals, rare earth, cassiterite and the like, the tungsten-containing minerals, the cassiterite, the rear earth and the like can be selectively separated from calcic gangue minerals in the absence of a calcic mineral inhibitor, and the problem that calcic minerals are hard to separate is fundamentally solved. The metal ion complex collecting agent is good in selective collecting effect, stable in performance, low in use level, low in cost and capable of being widely applied to the floatation and separation process of the tungsten-containing minerals, the cassiterite and the rear earth, and the quality of concentrates is effectively improved.

Owner:CENT SOUTH UNIV +1

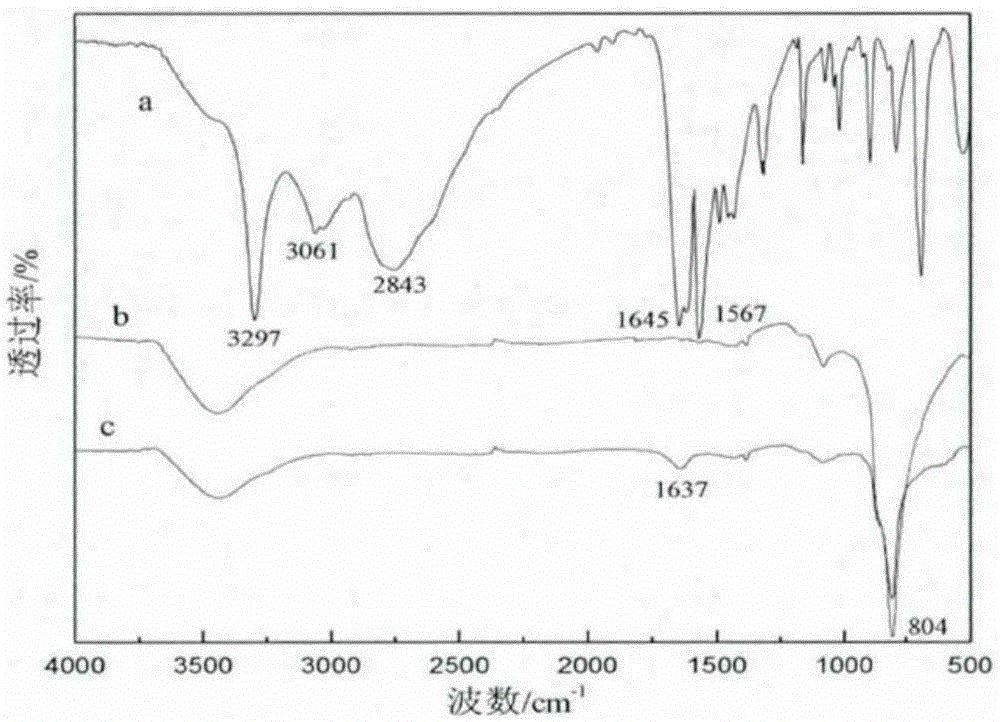

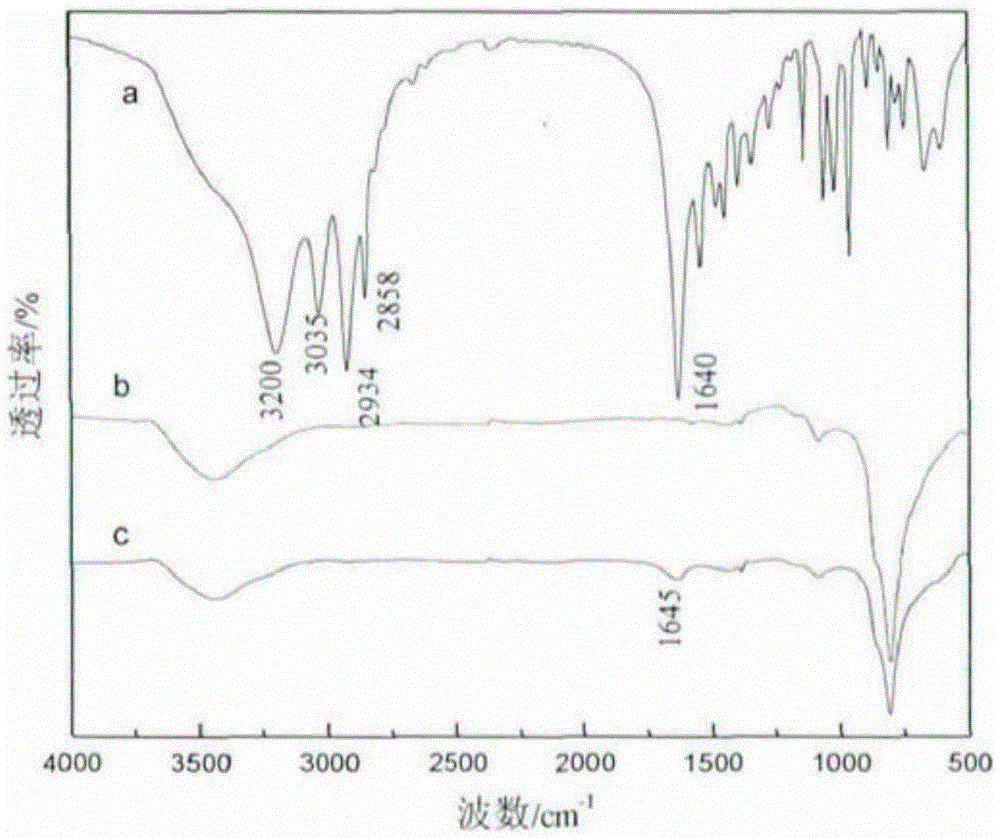

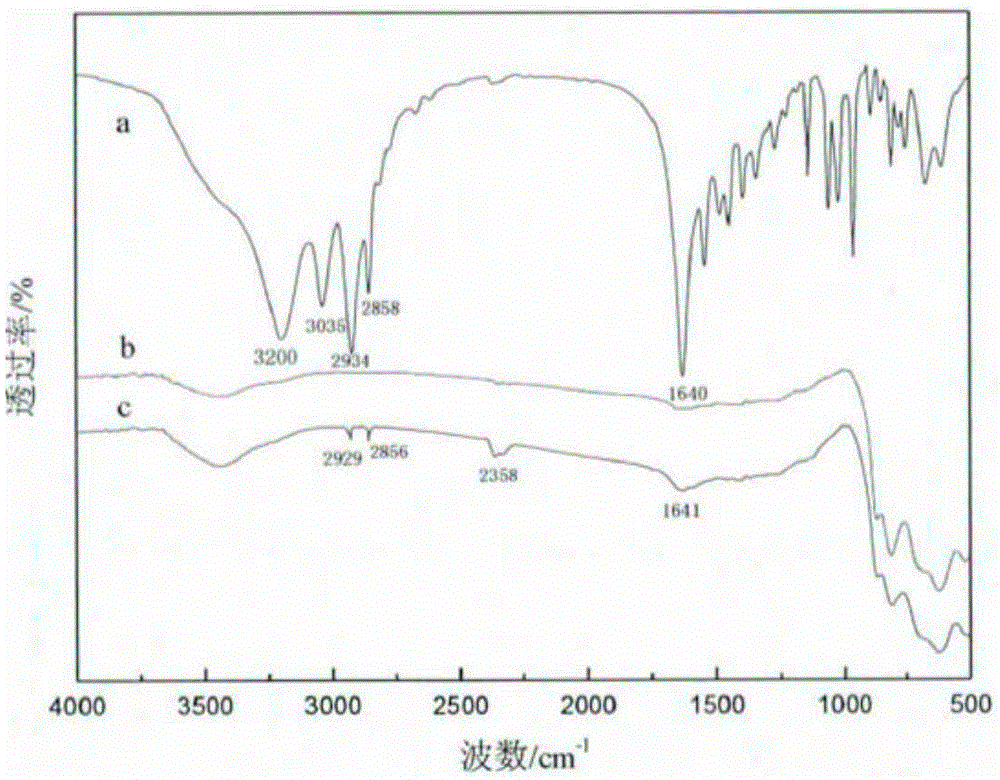

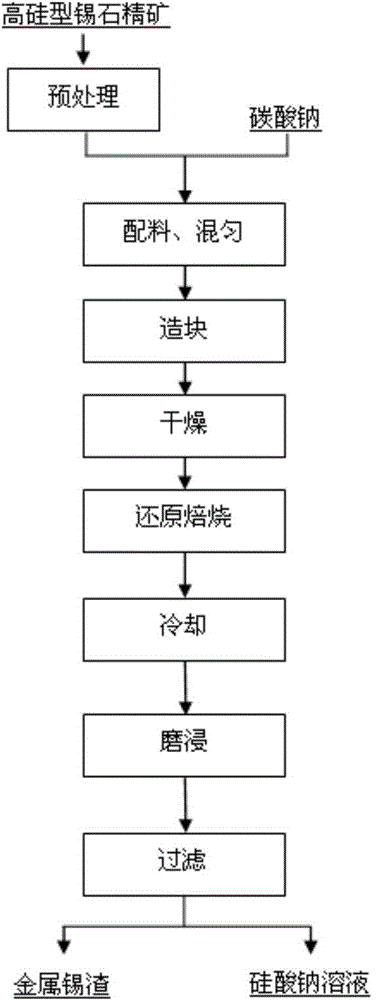

Method for preparing metallic tin and sodium silicate by utilizing high-silicon type cassiterite concentrate

The invention discloses a method for preparing metallic tin and sodium silicate by utilizing high-silicon type cassiterite concentrate. The method comprises the following steps: mixing the cassiterite concentrate pretreated by oxidizing roasting-acid leaching with sodium carbonate in a certain proportion, and then pressing the mixture into block mass; carrying out reduction roasting at a proper temperature in a reducing atmosphere, then carrying out ball-milling and leaching, and carrying out filtering separation so as to obtain metallic tin residue and a sodium silicate solution. The method is simple in process flow, gentle in process condition, low in cost and environmentally friendly, and can be used for realizing efficient separation of tin and silicon in the high-silicon type cassiterite concentrate. And moreover, a byproduct sodium silicate is obtained, so that the comprehensive utilization of the high-silicon type cassiterite concentrate resource is realized.

Owner:CENT SOUTH UNIV

Preparation method of micro-fine particle cassiterite mineral inhibitor and application of preparation method

InactiveCN103706484AEnhanced inhibitory effectReduce cassiterite contentFlotationWater bathsMass ratio

The invention discloses a preparation method of micro-fine particle cassiterite mineral inhibitor and an application of the preparation method. The preparation method includes steps of utilizing pericarps, leaves or barks as raw materials, drying by low temperature after cleaning, smashing and screening to obtain powder by an 80-mesh screen; taking mixed powder, sodium sulphide, sodium hydroxide and water according to the mass ratio 5-8:3-5:2-7:8-20, heating to 65-75 DEG C, stirring and reacting for 8-10 hours, filtering twice to three times, subjecting filtrate to centrifugally separating twice to three times, collecting supernatant liquid into a round-bottom flask to be decompressed and distilled, obtaining deep yellow concentrated solution, heating in a water bath, drying solvent at the temperature of 50-70 DEG C to obtain sticky liquid, and after drying in vacuum at the temperature 75 DEG C, obtaining yellow powder, namely micro-fine particle cassiterite mineral inhibitor. The inhibitor can suppress micro-fine particle cassiterite, and cassiterite content in floatation froth of sulphide ores can be reduced.

Owner:GUANGXI UNIV

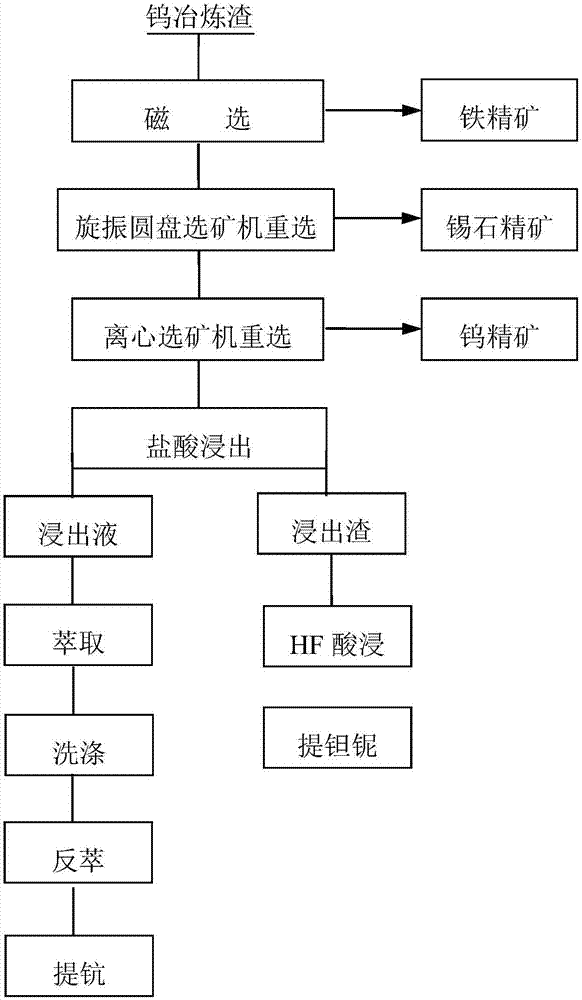

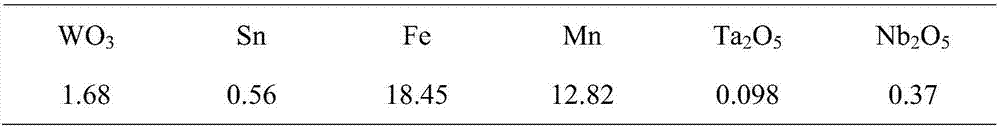

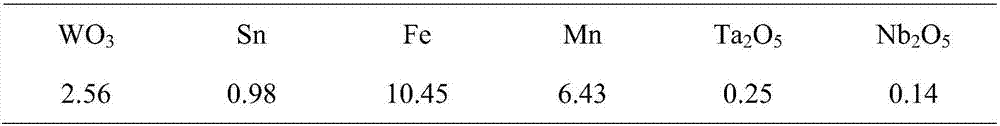

Method for comprehensively recovering useful metals from APT tungsten smelting slag

InactiveCN107999271ALow investment costEasy to realize industrial applicationSolid separationProcess efficiency improvementNiobiumManganese

The invention belongs to the metal recovery technology in the field of beneficiation and wet-process smelting, and particularly relates to a method for recovering tungsten, tin, iron, scandium, niobium and other metal elements from tungsten smelting slag. The specific technological process comprises the following steps of (1), screening and uniformly mixing the tungsten smelting slag; (2), recovering the iron by adopting a high-gradient magnetic separator magnetic separation process to obtain iron ore concentrate; (3), recovering cassiterite by using a rotary-vibration disc concentrator; (4),recovering the tungsten by adopting a centrifugal concentrator; and (5), recovering the three kinds of rare metals, namely the scandium, tantalum and the niobium from centrifugal tailings, wherein theprocess which comprises medium-temperature medium-pressure hydrochloric acid leaching, extraction, washing and back extraction is adopted to recover the scandium, and the tantalum and the niobium arerecovered by adopting a purification process after being leached in hydrofluoric acid. According to the method for comprehensively recovering the useful metals from the APT tungsten smelting slag, awhole set of process method for recovering the iron, manganese, the tungsten, the tin, the scandium, the tantalum and the niobium from the tungsten smelting slag is provided, the beneficiation and smelting combined technology is advanced, the process application range is wide, the investment cost is low, and the industrial application is easy to realize.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for mixed selection and re-purification of cassiterite and sulfide ores

ActiveCN101767056AEfficient recyclingReduce typesFlotationWet separationCassiteriteReverse flotation

The invention discloses a method for mixed selection and re-purification of cassiterite and sulfide ores, which comprises the following steps of: enriching fine-particle cassiterite and the sulfide ores into a mixed rough concentrate of the cassiterite sulfide ores by using a table concentrator; performing flotation on the sulfide ores in the mixed rough concentrate of the cassiterite sulfide ores by adopting a reverse flotation flow so as to obtain a cassiterite rough concentrate which does not contain the sulfide ores; and performing reselection on the cassiterite rough concentrate by usinga fine-particle table concentrator to obtain a cassiterite concentrate. The method can effectively recover the fine-particle cassiterite in tailings to obtain high-quality cassiterite concentrate of which the tin grade is 47.83 to 48.75 percent and the recovery rate is 63.51 to 64.37 percent under the condition that the feeding cassiterite content is 0.47 to 0.51 percent.

Owner:GUANGXI UNIV

Method for desulphurizing cassiterite polymetallic sulphide ore tailing by flotation step by step

The invention relates to a method for desulphurizing cassiterite polymetallic sulphide ore tailing by flotation step by step. In the method, sulphide ore is removed step by step by using the flotability difference of sulphide ore. The method comprises the following steps: firstly, performing flotation on the sulphide ore with high flotability; secondly, upgrading the flotation tailing into a cassiterite sulphide ore mixed rough concentrate by using a table; and adding depressor sodium silicate, activator sodium sulfide and collecting agent yellow catching agent into the cassiterite sulphide ore mixed rough concentrate for strengthening the flotation. By using the method, the sulphide ore in the cassiterite can be removed effectively, beneficiation reagent cost is reduced and beneficiationeconomic benefit is improved.

Owner:GUANGXI UNIV

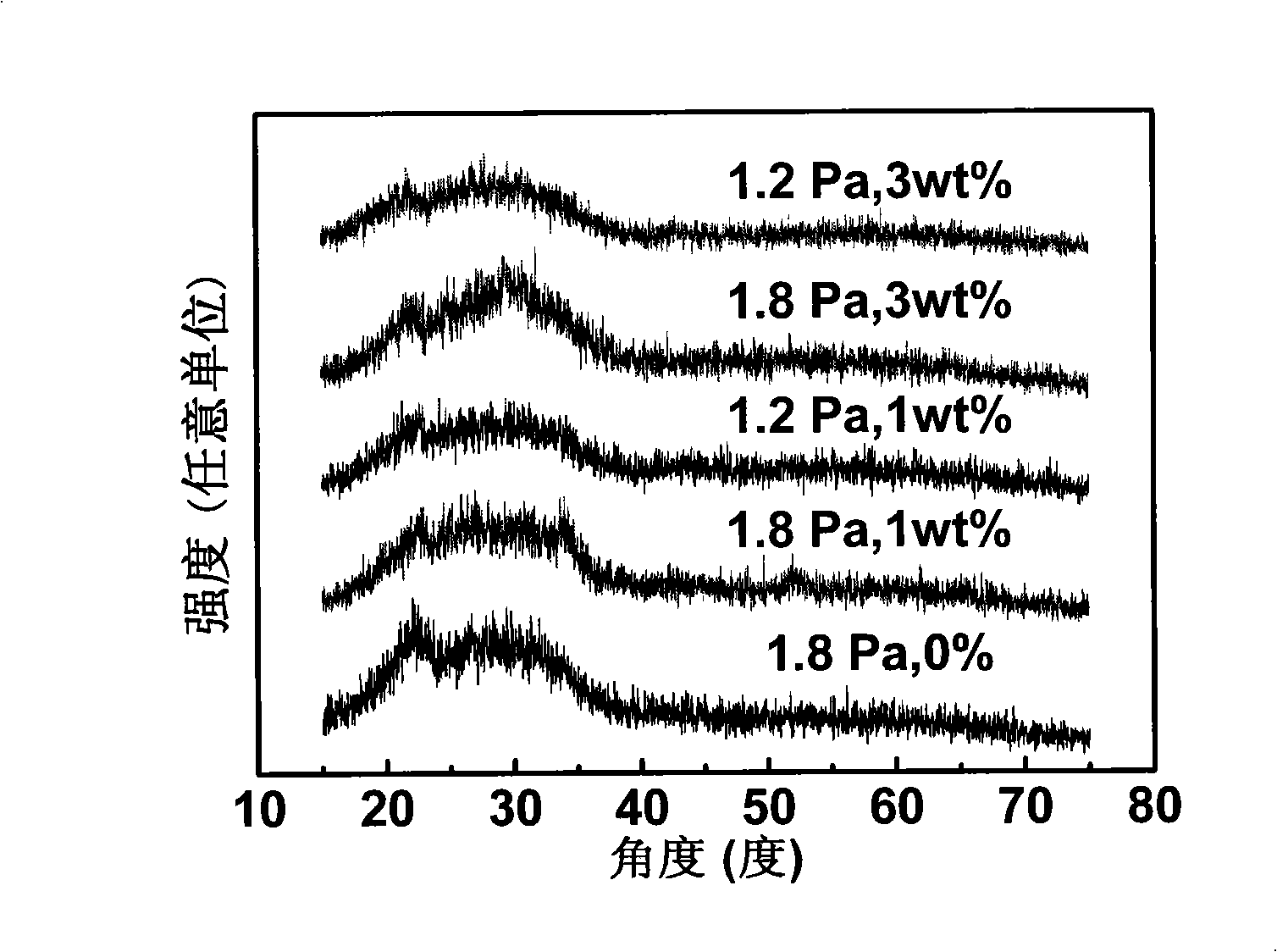

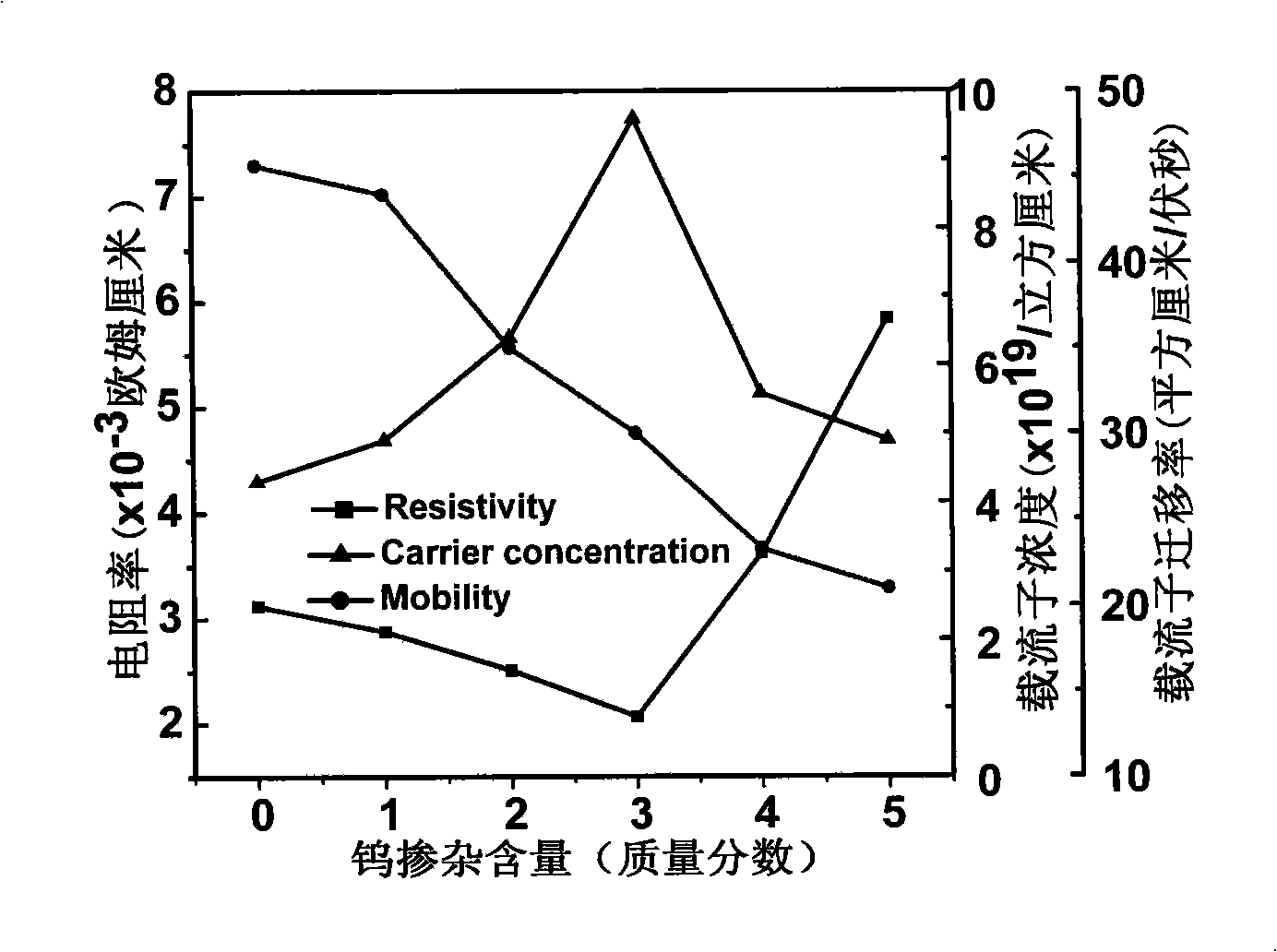

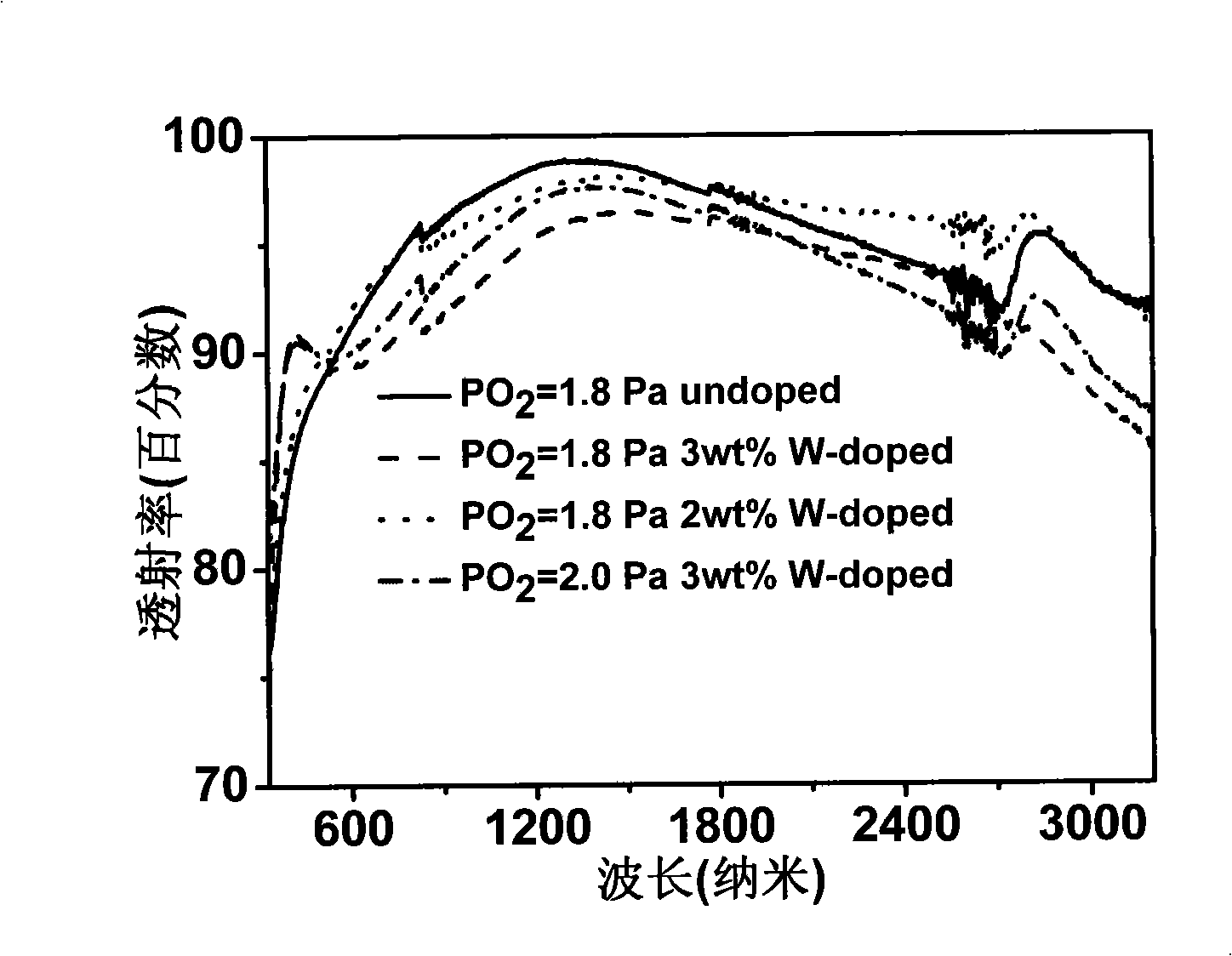

Amorphous tungsten-doped tin dioxide transparent conductive oxide thin film and preparation method thereof

InactiveCN101299423ALow resistivityIncrease deposition rateFinal product manufactureSemiconductor/solid-state device detailsTin dioxideCassiterite

The invention belongs to the technical field of the transparent conductive film, particularly to the amorphous W-doped cassiterite transparent conductive film and the preparation method. The invention uses the cassiterite and the metal tungsten powder through the grinding, mixing, tabletting and sintering to obtain the block material as the target materials.Through the pulse plasma deposit (PPD) technology on the common glass substrate, SnO2:W film with the amorphous structure is prepared, wherein the film has the excellent optical and electrical performance of low resistivity, high carrier mobility, high visible light range transmissivity and high near infrared range transmissivity. The film obtained by the method can be applied with good application foreground in the flat panel display, the photoelectric sensor and the solar cell.

Owner:FUDAN UNIV

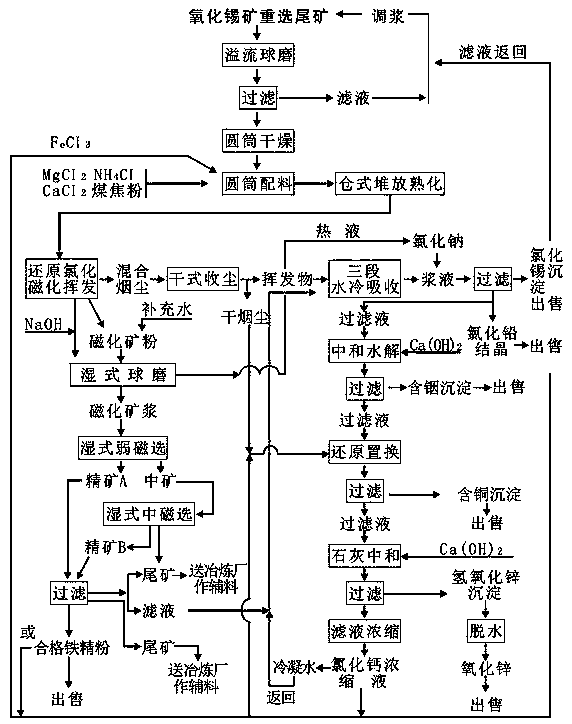

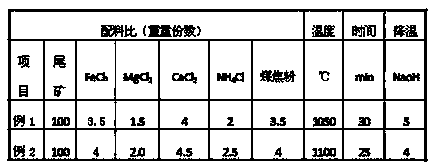

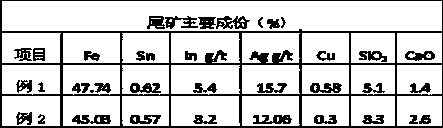

Comprehensive recovery method of gravity separation tailings of tin oxide ore

ActiveCN104294032ALow costAlleviating deprivationMagnetic separationProcess efficiency improvementIndiumWater chlorination

The invention relates to a comprehensive recovery method of gravity separation tailings of tin oxide. The comprehensive recovery method comprises the following steps: grinding tailings in a wet type, filtering, performing kiln type drying, mixing ferric chloride, magnesium chloride, calcium chloride, ammonium chloride and coking coal ash with the tailings by virtue of a cylinder, curing and performing high-temperature chlorination and reducing roasting in a kiln to produce magnetic iron ore powder and smoke, performing wet type magnetic separation for recovering iron ore powder containing 60% of iron and silicate tailings, performing water-cooling and absorption and separation on volatilized smoke to recover metal semi-finished product materials rich in tin, copper, silver, molybdenum, indium and the like, evaporating and concentrating circulating liquid to obtain calcium chloride, mixing and recovering. The grade of the iron ore concentrate is 62.08-64.3%, the recovery rate of ferrous and precious metals is 86.5%-96.6%, and the comprehensive recovery method has obvious practical significance.

Owner:云南锐洁鑫再生资源综合利用有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com