Tungsten tin mineral beneficiation method

A beneficiation method and tungsten-tin technology, which can be applied in flotation, solid separation and other directions, can solve the problems of inability to achieve effective recovery of cassiterite, unrecoverable cassiterite, and low cassiterite content, and achieve the effect of improving comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

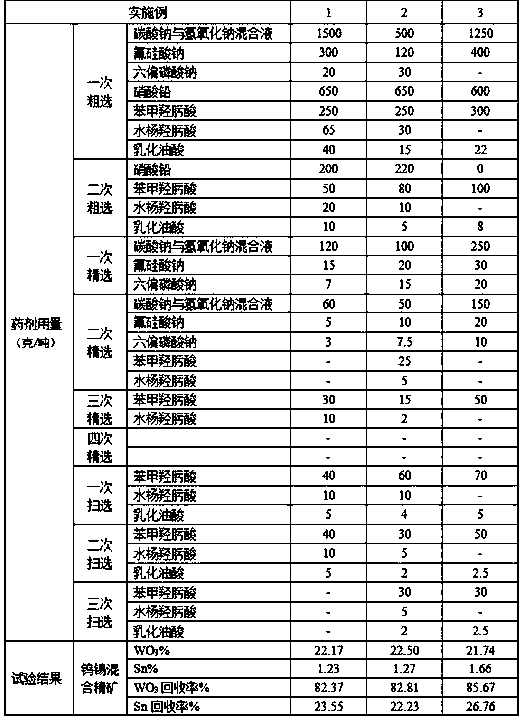

[0015] Example 1: tungsten-tin ore feed WO3 0.43%, Sn 0.09%, CaF2 24.67%, CaCO3 4.53%, fineness -0.074mm content 85%, scheelite monomer dissociation degree 90%, wolframite monomer dissociation The dissociation degree is 92%, the cassiterite monomer dissociation degree is 95%, the ratio of scheelite to wolframite is about 8:2, and the tungsten-tin mixed flotation is carried out according to the following steps (the amount of reagents is based on the quality of tungsten-tin ore feed):

[0016] 2 times of rough selection: According to the pharmaceutical system in Table 1, 1st rough selection: add 1500 g / ton of mixed solution with a mass ratio of sodium carbonate to sodium hydroxide of 3:1 and a total mass content of 10%, 300 g / ton of sodium fluorosilicate, Sodium hexametaphosphate 20 g / ton and lead nitrate 650 g / ton, stir for 8 minutes, add 250 g / ton benzyl hydroxamic acid, 65 g / ton salicylic hydroxamic acid and 40 g / ton emulsified oleic acid, stir for 10 minutes Secondary rough ...

Embodiment 2

[0019] Example 2: Tungsten-tin ore feed WO30.25%, Sn0.074%, CaF214.87%, CaCO26.03%, fineness -0.074mm content 71.04%, scheelite monomer dissociation degree 90%, black tungsten The dissociation degree of ore monomer is 90%, the dissociation degree of cassiterite monomer is 92%, the ratio of scheelite to wolframite is about 2:8, and the mixed flotation of tungsten and tin is carried out according to the following steps (the amount of medicament is based on the quality of tungsten and tin ore count):

[0020] 2nd rough selection: According to the pharmaceutical system in Table 1, 1st rough selection: add 500 g / ton of sodium carbonate and sodium hydroxide mixed solution with a mass ratio of sodium carbonate and sodium hydroxide of 1:3 and a total mass content of 1%, fluorosilicone 120 g / ton of sodium hexametaphosphate, 30 g / ton of sodium hexametaphosphate, 650 g / ton of lead nitrate, and stir for 10 minutes. Add 250 g / ton of benzohydroxamic acid, 30 g / ton of salicylic hydroxamic a...

Embodiment 3

[0023]Example 3: Tungsten-tin ore feed WO30.50%, Sn0.15%, CaF216.77%, CaCO39.18%, fineness -0.074mm content 78.98%, scheelite monomer dissociation degree 90%, black tungsten The dissociation degree of ore monomer is 90%, the dissociation degree of cassiterite monomer is 92%, the ratio of scheelite to wolframite is about 6:4, and the mixed flotation of tungsten and tin is carried out according to the following steps (the amount of medicament is based on the quality of tungsten and tin ore count):

[0024] 2 times of rough selection: According to the pharmaceutical system in Table 1, 1st rough selection: add 1250 g / ton of sodium carbonate and sodium hydroxide mixed solution with a mass ratio of sodium carbonate and sodium hydroxide of 3:2 and a total mass content of 5%, fluorosilicone 400 g / ton of sodium nitrate, 600 g / ton of lead nitrate, stirring for 10 minutes. Add 300 g / ton of benzohydroxamic acid, 22 g / ton of emulsified oleic acid, and stir for 8 minutes; second rough sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com