Patents

Literature

662 results about "SODIUM METAPHOSPHATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Metaphosphate, Sodium Trimetaphosphate and Sodium Hexametaphosphate are all sodium polyphosphates made of repeating units of NaPO3. Sodium Metaphosphate generally refers to a long chain of NaPO3 units that is not soluble in water, which is why it is sometimes called insoluble metaphosphate.

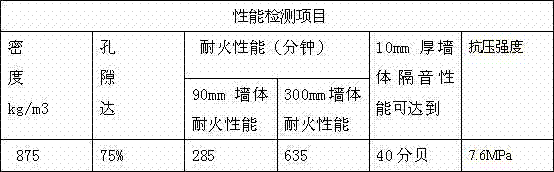

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

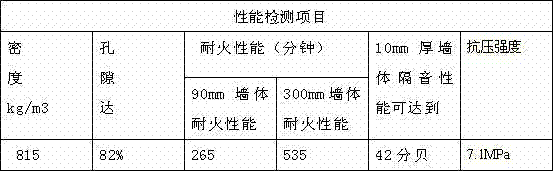

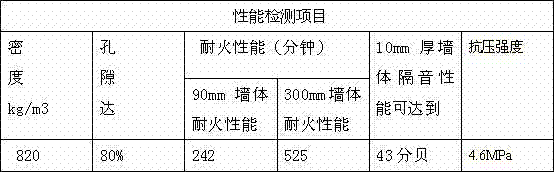

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Fluorite slag-containing aerated concrete block

The invention discloses a fluorite slag-containing aerated concrete block. The fluorite slag-containing aerated concrete block is prepared from the following raw materials by the conventional process for preparing the aerated concreted block: 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of volcanic rock powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.02 to 0.08 weight part of peregal, 0.03 to 0.08 weight part of oxyparaffin soap, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of bentonite, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium hexametaphosphate and an appropriate amount of water. Nano mineral powder is added, so that the volume weight of the brick, and the energy consumption are reduced; the aerated brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated concrete block, the fluorite slag-containing aerated concrete block has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:沛县铸本混凝土有限公司

Method for preparing aluminum alloy anodic oxide film sealant

InactiveCN101812713AImprove pass rateImprove protectionSurface reaction electrolytic coatingSODIUM METAPHOSPHATEPolyvinyl alcohol

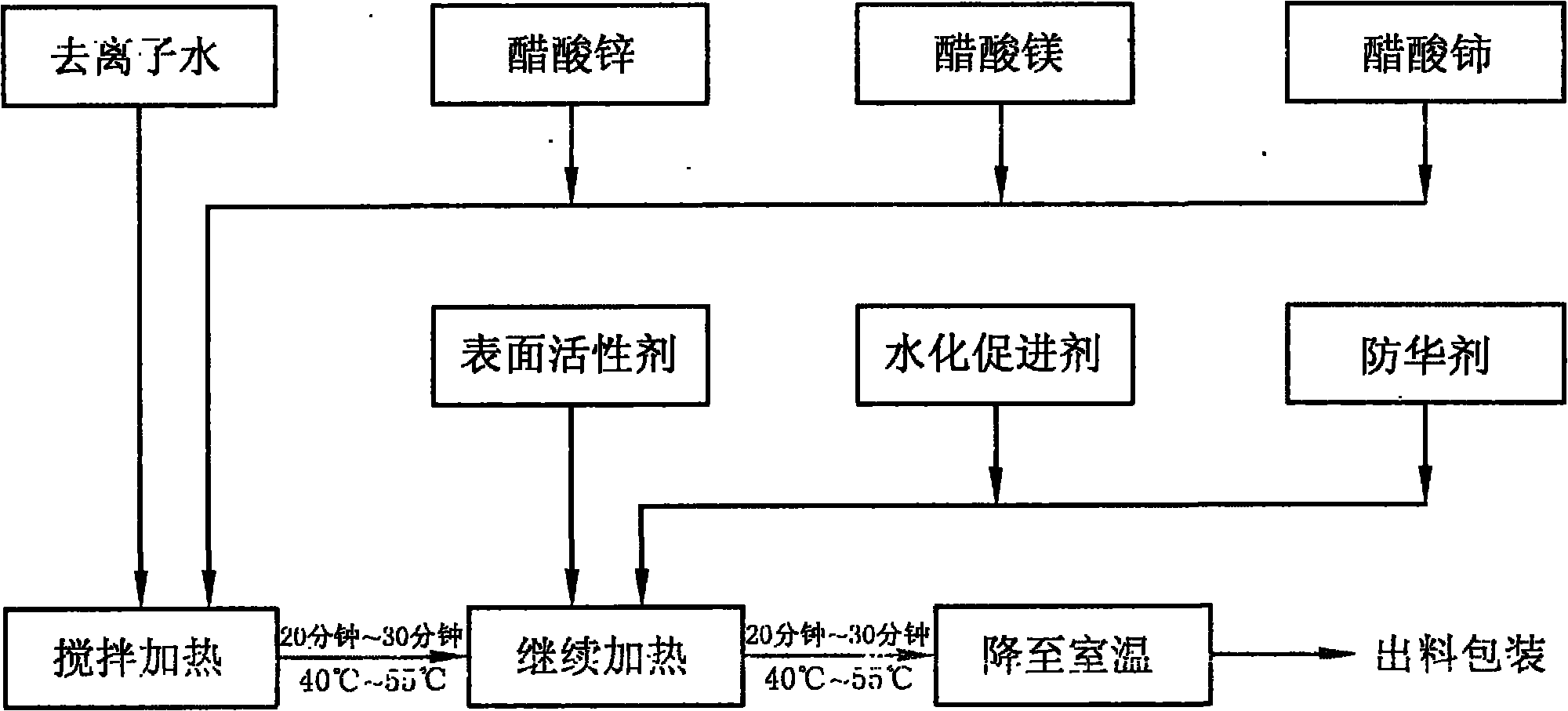

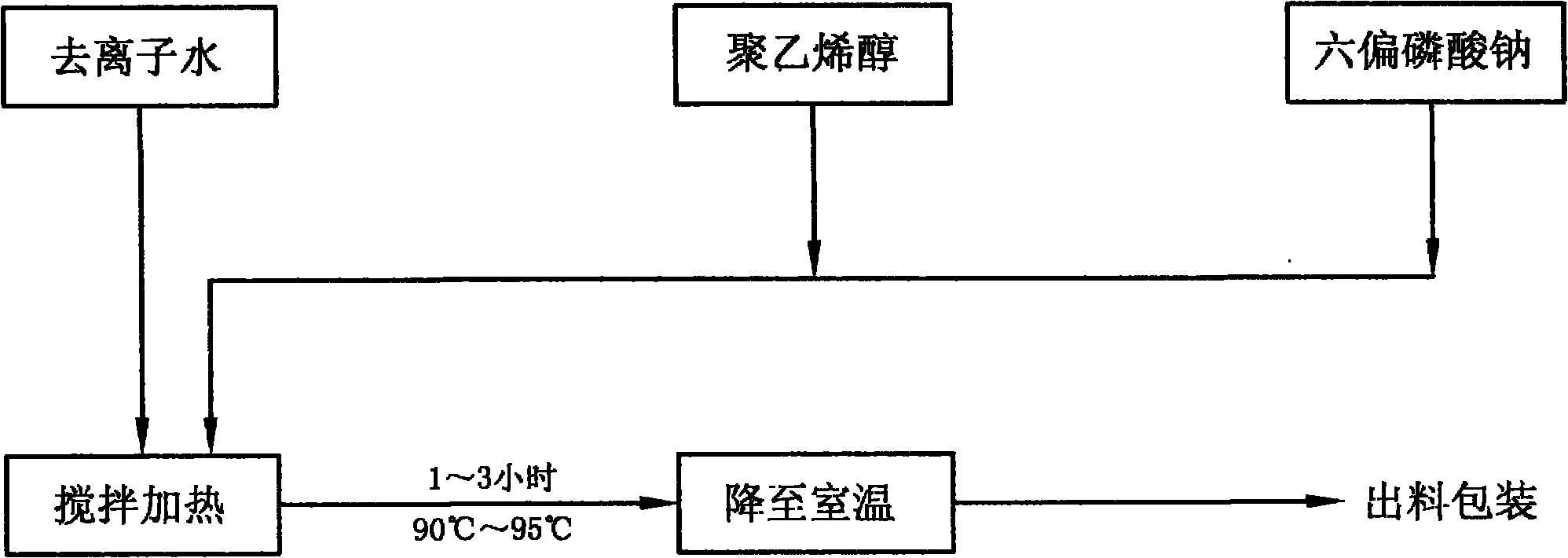

The invention discloses a method for preparing an aluminum alloy anodic oxide film sealant, which comprises the main processes of adding deionized water, zinc acetate, magnesium acetate, cerium acetate, surfactant, hydration promoter and sublimation preventing agent into a reaction kettle in turn, and mixing, stirring and heating the components to form the sealant. One of the important components of the sealant is sublimation preventing agent which is prepared by mixing the deionized water, polyvinyl alcohol and sodium hexametaphosphate together and then stirring and heating the mixture in the reaction kettle. The raw materials adopted by the preparation method do not contain nickel and fluorine elements, so the sealant is favorable for environmental protection; and the sealant reduces energy consumption during use, and improves the qualification rate of aluminum alloy products.

Owner:李继光

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Light refractory castable material for heat insulation lining of cast steel plate (CPS) furnace roller

The invention discloses a light refractory castable material for a heat insulation lining of a cast steel plate (CPS) furnace roller. The light refractory castable material comprises the following components by weight percent: 40-50% of light mullite bone material, 5-8% of flint clay with a particle size of 0.1-1mm, 5-7% of kyanite powder, 6-9% of first-class bauxite chamotte with a particle sizeof less than or equal to 180 meshes, 7-9% of silicon micro powder, 5-8% of alpha-Al2O3 micro powder, 10-18% of bauxite cement, 1-4% of refractory fiber, 1-1.5% of spodumene, 0.05-0.154% of sodium hexametaphosphate, 0.05-0.15% of organic water reducing agent, 0.04-0.07% of organic silane coupling agent and 0.013-0.06% of defoaming agent. The refractory castable material has the characteristics of light volume weight, strong high temperature resistance, good mechanical property, good heat insulation property and excellent thermal shock stability performance.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Electrolytic manganese residue curing/stabilizing treatment method

ActiveCN104307849AGuaranteed curing/stabilizing effectReduce processing costsSolid waste disposalSODIUM METAPHOSPHATESodium phosphates

The invention discloses an electrolytic manganese residue curing / stabilizing treatment method. The method comprises the following steps: (1) adding electrolytic manganese residue into a mixer to mix, and adding water to the manganese residue; (2) adding alkaline medicament in the mixing process for several times, adding sodium hexametaphosphate after adding the alkaline medicament for the first time; (3) placing the mixed electrolytic manganese residue into a rotary releaser to perform ammonia gas continuous treatment, and unloading to obtain cured / stabilized electrolytic manganese residue. On the premise of guaranteeing the curing / stabilizing effect of the manganese residue, the solid waste pH requirement after treatment is satisfied by adding the alkaline medicament for several times, the lime additive amount is obviously reduced, and the manganese curing / stabilizing treatment cost is reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Corrosion-release scale-proof wax-removal viscosity-reducing agent and preparation method thereof

ActiveCN101100601AMeet the requirements of wax removal and viscosity reductionMeet anti-corrosion and anti-fouling requirementsDrilling compositionSODIUM METAPHOSPHATESodium phosphates

A viscosity reducer with corrosion-inhibiting, scale-inhibiting and wax-cleaning functions consists of 2-alkyl-1-hydroxyethyl-3-hydroxypropyl-imidazoline sodium phosphate 5-10 wt%, lauryl dimethyl benzyl ammonium chloride 10-15 wt%, FC-NO1 fluorocarbon surface activator 0.05-0.2 wt%, alkylphenol ethoxylates(14) 3-8 wt%, methanal 3-7 wt%, hexamine 8-15 wt%, hexa-sodium metaphosphate 5-8 wt%, hydroxy-ethyl-crossing di-phosphoric acid 5-8 wt% and water residues. It has excellent coordination and corrosion protection and can be used in oil filed and oil well.

Owner:PETROCHINA CO LTD

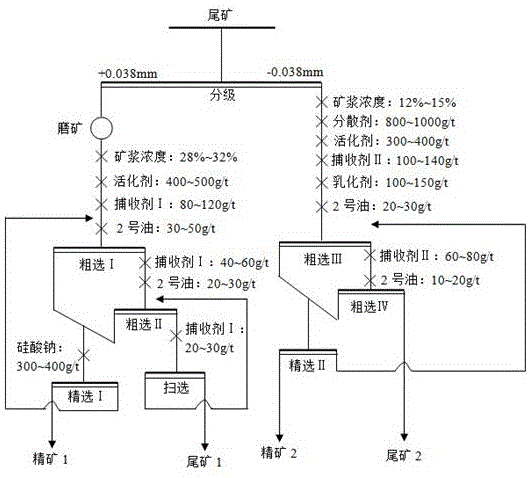

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

Inhibitor for preventing browning of cut vegetable

InactiveCN101664055APrevent browningPlay the role of anti-corrosion and fresh-keepingFruit and vegetables preservationSODIUM METAPHOSPHATECarrageenan

The invention relates to an inhibitor for preventing browning of a cut vegetable, comprising the following components: one of solvent water and ethanol or mixture thereof; one of sodium alginate, xanthan gum, carrageenan and chitosan, one or more of sodium tripolyphosphate, sodium pyrophosphate and 6-sodium metaphosphate, one or more of phytic acid, ascorbic acid, cinnamic acid, citric acid, kojicacid and edible acetic acid, and one or more of potassium sorbate, sodium dehydroacetate, sodium chloride and 4-hexylresorcinol. The inhibitor is used by soaking, and the soaking time varies with thetemperature and the air pressure of the processing environment. All the components used in the inhibitor are permitted in the GB2760-2007 (hygienic standards of food additives), and the inhibitor issulfite-free, safe and non-toxic, and can be used for fresh cut vegetables and can play the multiple roles of pH regulation, enzyme activity inhibition, oxygen removal and isolation and water retention to effectively prevent browning and play a role of anticorrosion and refreshment.

Owner:SHANGHAI ACAD OF AGRI SCI

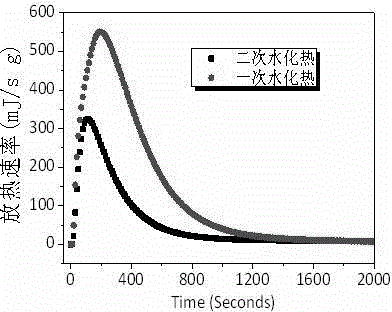

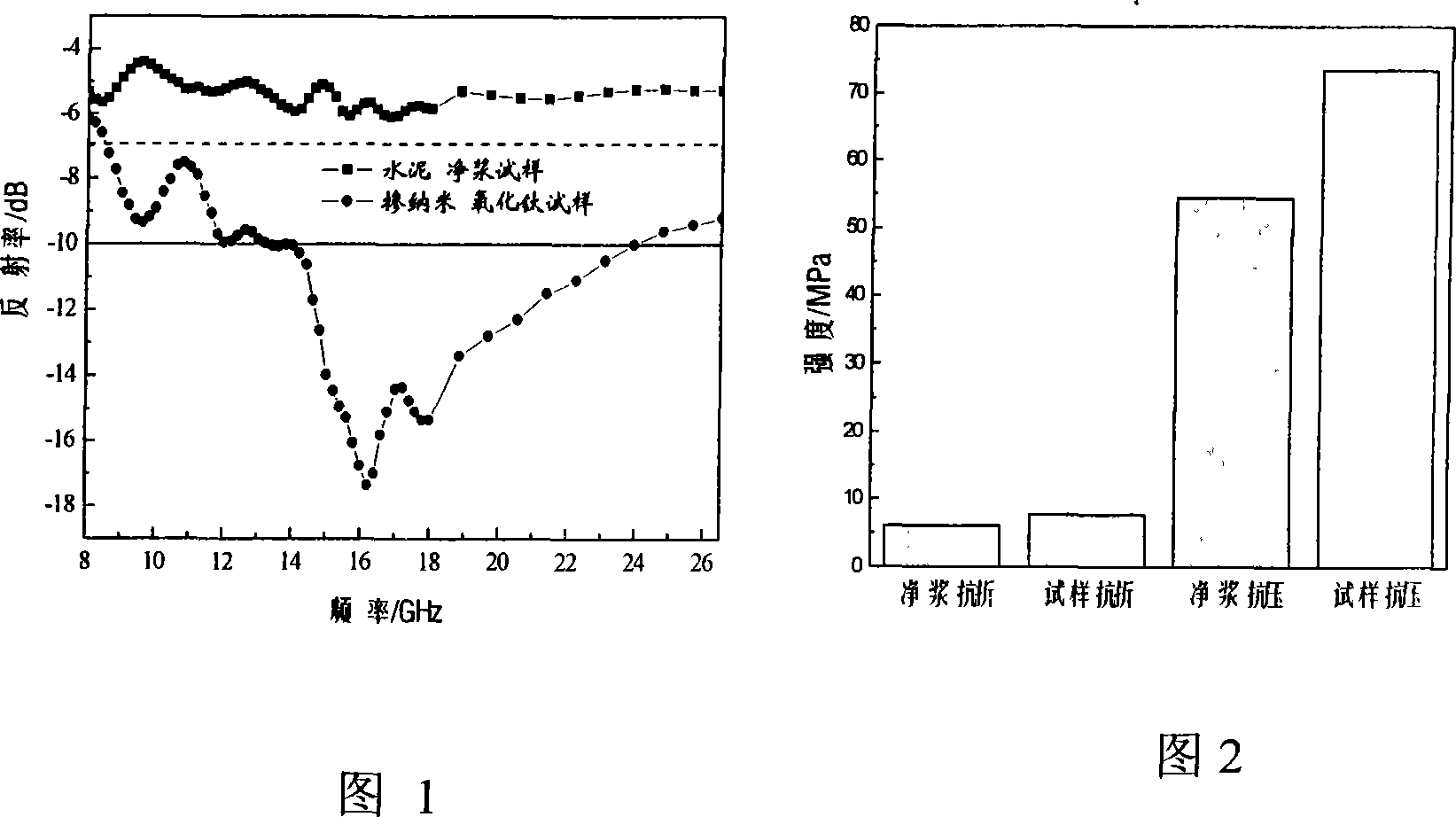

Nano titanium oxide doped cement-base composite wave-absorbing material and preparation method thereof

InactiveCN101186474AImprove absorbing performanceImprove mechanical propertiesCost (economic)Titanium oxide

The invention relates to a cement-based absorbing composite absorbing material mixed with nano-titania and a preparation method thereof. The composite absorbing material consists of nano titania, dispersant, portland cement and water; a dispersion system comprises dispersant sodium hexametaphosphate and water, wherein, the dispersant sodium hexametaphosphate accounts for 0.3 percent to 0.7 percent by mass ratio of the weight of the dispersion system and the ratio between the water and dry materials, namely the water-cement ratio is between 0.32 to 0.38. The preparing steps of the invention are: a. nano-titania suspension is prepared by ultrasonic; b. the method of preparing cement-based composite absorbing material mixed with nano-titania. The invention mixes a small quantity of nano-titania absorbent into traditional cement materials, so the cement-based composite absorbing material has relatively good absorbing property and mechanical property and does not have many increased economic costs and has feasible and simple preparation technique.

Owner:EAST CHINA UNIV OF TECH +1

Fluorite slag aerated brick and preparation method thereof

ActiveCN102875186AGood heat insulationImprove sound insulationSolid waste managementCeramicwareParaffin waxCellulose

The invention provides a fluorite slag aerated brick which is prepared through processing raw materials in part by weight: 20 to 30 parts of fluorite slag, 25 to 30 parts of sand, 5 to 10 parts of cement, 4 to 6 parts of modified attapulgite, 5 to 10 parts of ceramsite, 5 to 10 parts of waste in ceramic factories, 5 to 10 parts of light calcium powder, 10 to 15 parts of lime, triethanolamine, 4 to 5 parts of gypsum, 0.02 to 0.08 part of aluminum powder, oxidized paraffin wax soap, 0.01 to 0.02 part of calcium bicarbonate, 2 to 3 parts of lava, 1 to 2 parts of lignocellulose, 0.3 to 0.5 part of sodium silicate, 0.03 to 0.05 part of borax, 1 to 2 parts of sodium hexametahposphate, 1 to 2 parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1 to 0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3 to 5 percent of that of the aluminum powder. Fluorite slag is added in the raw materials of the aerated brick, meanwhile, other conventional additives and modified nano additives are added, a proper process is adopted to manufacture the aerated brick, and the aerated brick is low in cost and good in performance, achieves the circular economy effect of turning waste into valuable, reduces the pollution, is light in weight, high in heat insulation property, good in sound-absorbing effect, and high in strength, and can be used as a non-bearing wall or a bearing wall.

Owner:山东未来城建筑工程有限公司

Starch hollow capsule and preparation method thereof

ActiveCN103070845ALow priceQuality improvementPharmaceutical non-active ingredientsCapsule deliverySODIUM METAPHOSPHATECross-link

The invention provides a starch hollow capsule and a preparation method thereof. The starch hollow capsule comprises components in parts by weight as follows: 60 parts to 90 parts of cross-linking high amylose, 3 parts to 15 parts of tributyl citrate, 5 parts to 15 parts of guar gum, 1 part to 5 parts of span-80 and 1 part to 5 parts of inulin. The cross-linking high amylose is prepared by cross-linking natural high direct connection starch through a cross-linking agent consisting of sodium metaphosphate and adipic acid. The starch hollow capsule has the advantages that the price is low, the quality is good, and the strength is high, standards of Chinese Pharmacopoeia are achieved, the friability is 5%, the disintegration time is five minutes, and obvious effects are achieved in practical application.

Owner:北京爱特康医疗科技有限公司

Preparation method of phosphorylated epimedium polysaccharide

ActiveCN105601760AImmunomodulatory in vitroAntiviralAntinoxious agentsAntiviralsEpimediumPhosphorylation

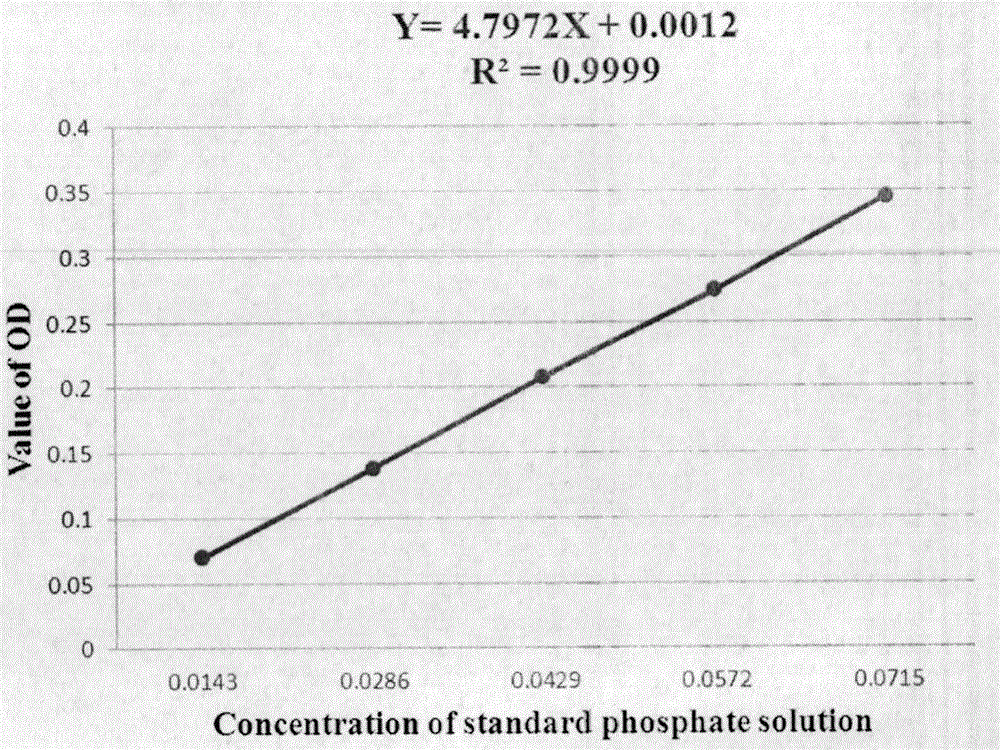

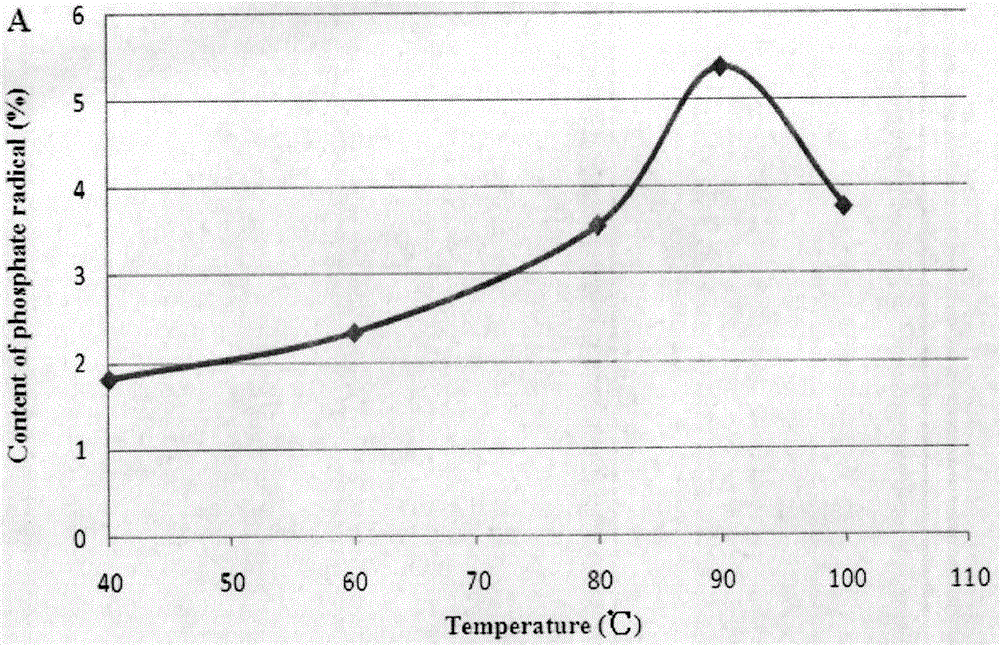

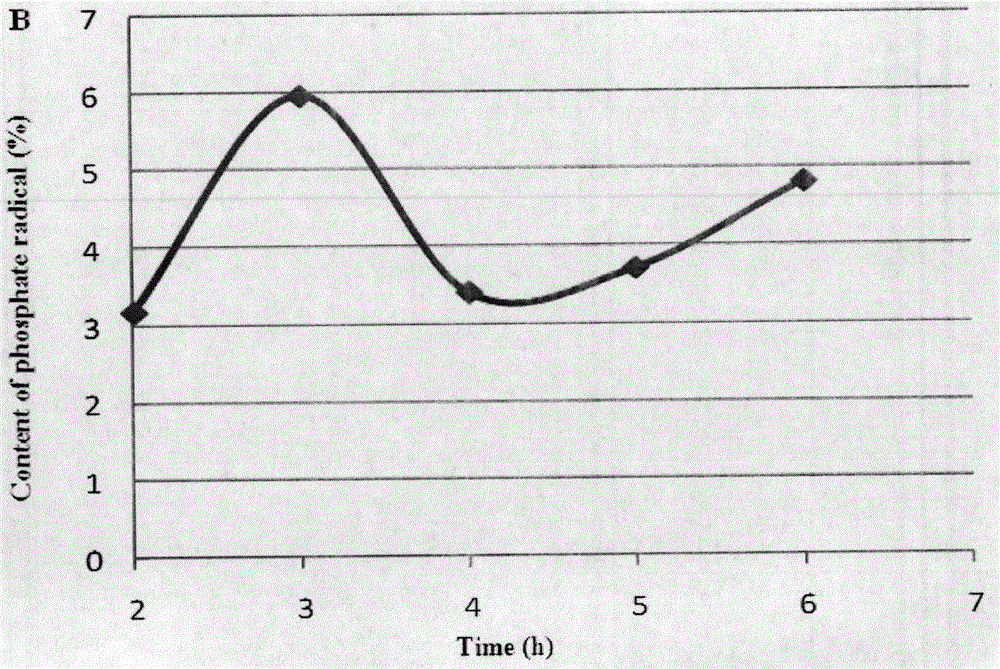

The invention belongs to the technical field of preparation and structural transformation of traditional Chinese medicine polysaccharide and relates to a preparation method of phosphorylated epimedium polysaccharide. The preparation method of the phosphorylated epimedium polysaccharide comprises the following steps: carrying out heating reaction on a phosphorylating reagent (sodium tripolyphosphate-sodium trimetaphosphate), epimedium polysaccharide and sodium sulfate for a period of time under alkaline condition, carrying out phosphorylation molecular modification, and selecting out optimal conditions for phosphorylation modification on the epimedium polysaccharide by carrying out a response surface experiment with content of phosphate radicals of products and reagent ratio, reaction temperature, reaction pH value and reaction time as factors. After the phosphorylated epimedium polysaccharide is prepared, in vitro activity of a modified product is studied, and results show that the phosphorylated epimedium polysaccharide has a certain immunoregulation, antiviral and antioxidant effects.

Owner:NANJING AGRICULTURAL UNIVERSITY

Reinforced concrete rust inhibitor

The invention discloses a reinforced concrete rust inhibitor, and relates to the technical field of building materials. The reinforced concrete rust inhibitor consists of the following components in percentage by weight: 10.0 to 15.0 percent of nitrite, 0.1 to 1.0 percent of sodium hexametaphosphate, 0.5 to 1.0 percent of diethylenetriamine, 0.8 to 1.5 percent of thiourea, 0.5 to 1.0 percent of sodium benzoate, 1.0 to 1.5 percent of naphthamine, 3.0 to 5.0 percent of triethanolamine, 5.0 to 1.0 percent of water reducing agent, 0.001 to 0.005 percent of air entraining agent, and the balance of water. The reinforced concrete rust inhibitor has the advantages of low consumption, capability of reducing the consumption of a single rust inhibitor and the like, and can be widely applied to fresh reinforced concrete structures of projects of harbors, railways, coastal buildings, civil buildings and the like. The durability and the comprehensive corrosion resistance of concrete can be promoted, the service life of a building is remarkably prolonged, and remarkable economic benefit and social benefit can be brought.

Owner:浙江五龙新材股份有限公司

Special coloring agent of diammonium phosphate compound fertilizer and preparation method thereof

InactiveCN101671209AGood colorSolve easy fadingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLiquid stateDiammonium phosphate

The invention discloses a special coloring agent of a diammonium phosphate compound fertilizer, comprising the following constituents: 40-50 parts of humic acid salt, 0.1-3 parts of carbon soot, 2-4 parts of acid black, 1-2 parts of acid brilliant scarlet, 0.2-1 part of sodium hexametaphosphate, and 40-56.7 parts of water by weight parts; the preparation process is that: the material is prepared by weight parts, water is added in a vertical round reaction tank, and then the humic acid salt, the carbon soot, the acid black and the acid brilliant scarlet are added and are stirred uniformly, andthen sodium hexametaphosphate is added, the mixture is stirred continuously and uniformly, so as to obtain the special coloring agent of the diammonium phosphate compound fertilizer; the invention solves the problems that the diammonium phosphate particles produced under an acid slurry condition are easy to decolorize and the chromaticity is unstable; the special coloring agent of the diammonium phosphate compound fertilizer is green and environmental-protection, has no pollution and is beneficial to the growth of crops; the product is in a liquid state and transported closely, and has convenient usage; the raw material is cheap and easy to obtain, the cost is low and the economic benefit is good.

Owner:中化重庆涪陵化工有限公司

Magnesite slag aerating brick and preparation method thereof

ActiveCN102875188ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATECellulose

The invention provides a magnesite slag aerating brick. The magnesite slag aerating brick is processed and manufactured by the following raw materials in parts by weight: 20 to 30 parts of magnesite slag, 25 to 30 parts of fly ash, 5 to 10 parts of cement, 4 to 6 parts of modified kaolin, 5 to 10 parts of sewage treatment sludge, 5 to 10 parts of caustic sludge, 5 to 10 parts of calcium carbonate powder, 10 to 15 parts of lime, 0.1 to 0.3% of triethanolamine based on weight of lime, 4 to 5 parts of gypsum, 0.02 to 0.08 part of aluminum powder, 3 to 5% of oxyparaffin soap based on weight of aluminum powder, 0.01 to 0.02 part of calcium bicarbonate, 2 to 3 parts of expanded vermiculite, 1 to 2 parts of lignocellulose, 0.3 to 0.5 part of water glass, 0.03 to 0.05 part of sodium borate, 1 to 2 parts of sodium hexametaphosphate, 1 to 2 parts of hydroxypropyl methyl cellulose sodium and 1 to 2 parts of superfine polyvinyl alcohol. According to the magnesite slag aerating brick and the preparation method provided by the invention, the magnesite slag is added to the raw material of the aerating brick, and other common assistants and modified nanometer additives are synchronously added; the aerating brick processed by a proper technology is low in cost and high in performance, the circulating economic benefit of turning waste into wealth is achieved, and the pollution is reduced; the processed aerating brick has the characteristics of being light in unit weight, high in heat insulating performance, high in effect of sound absorbing and high in strength; and the aerating brick can be used as the non-bearing wall or bearing wall.

Owner:中山市中南机电安装工程有限公司

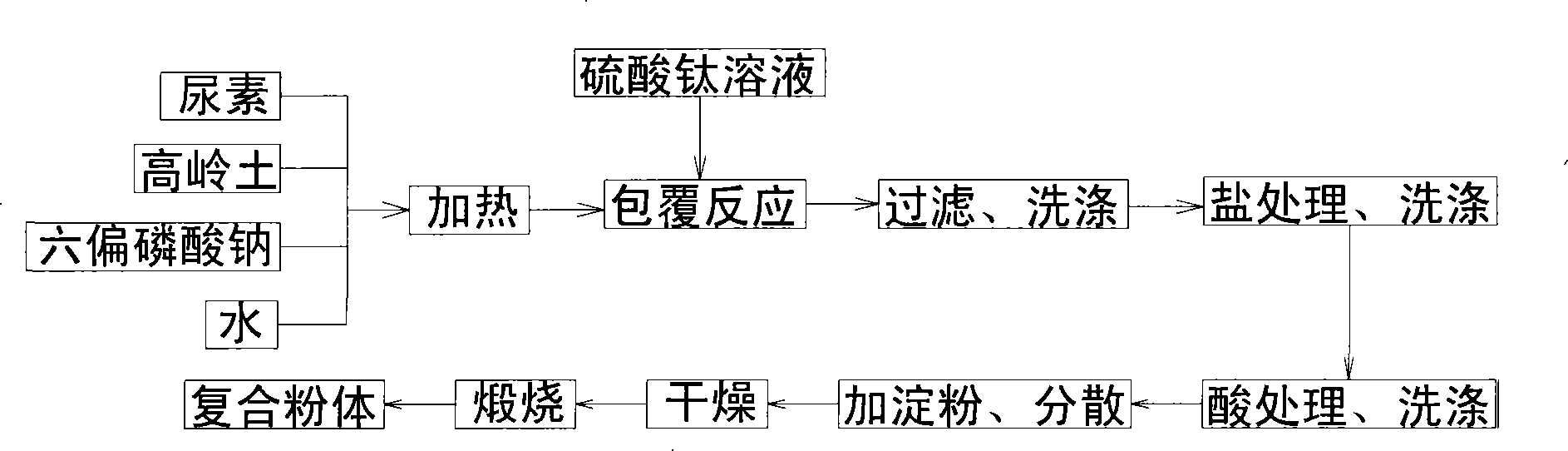

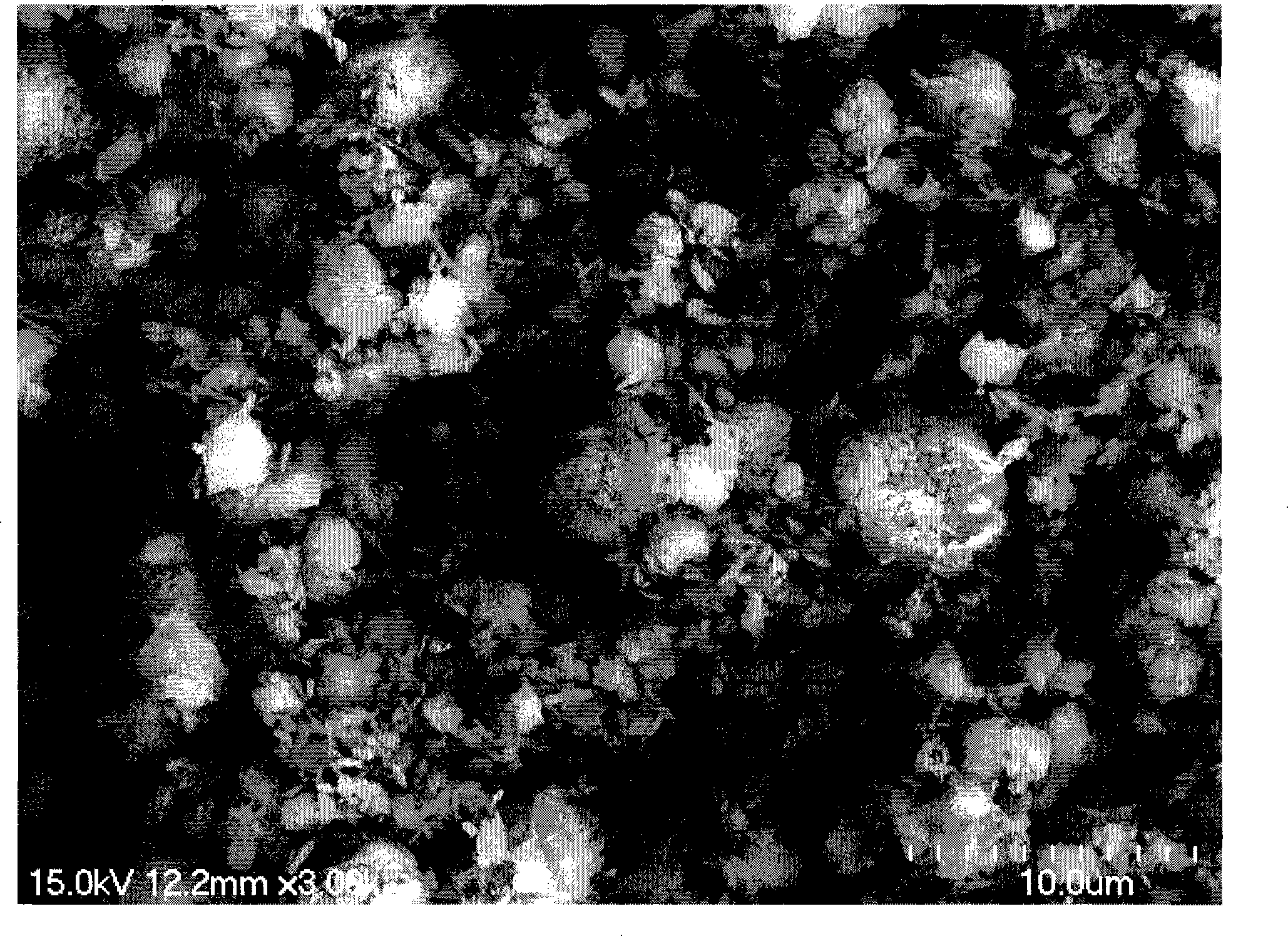

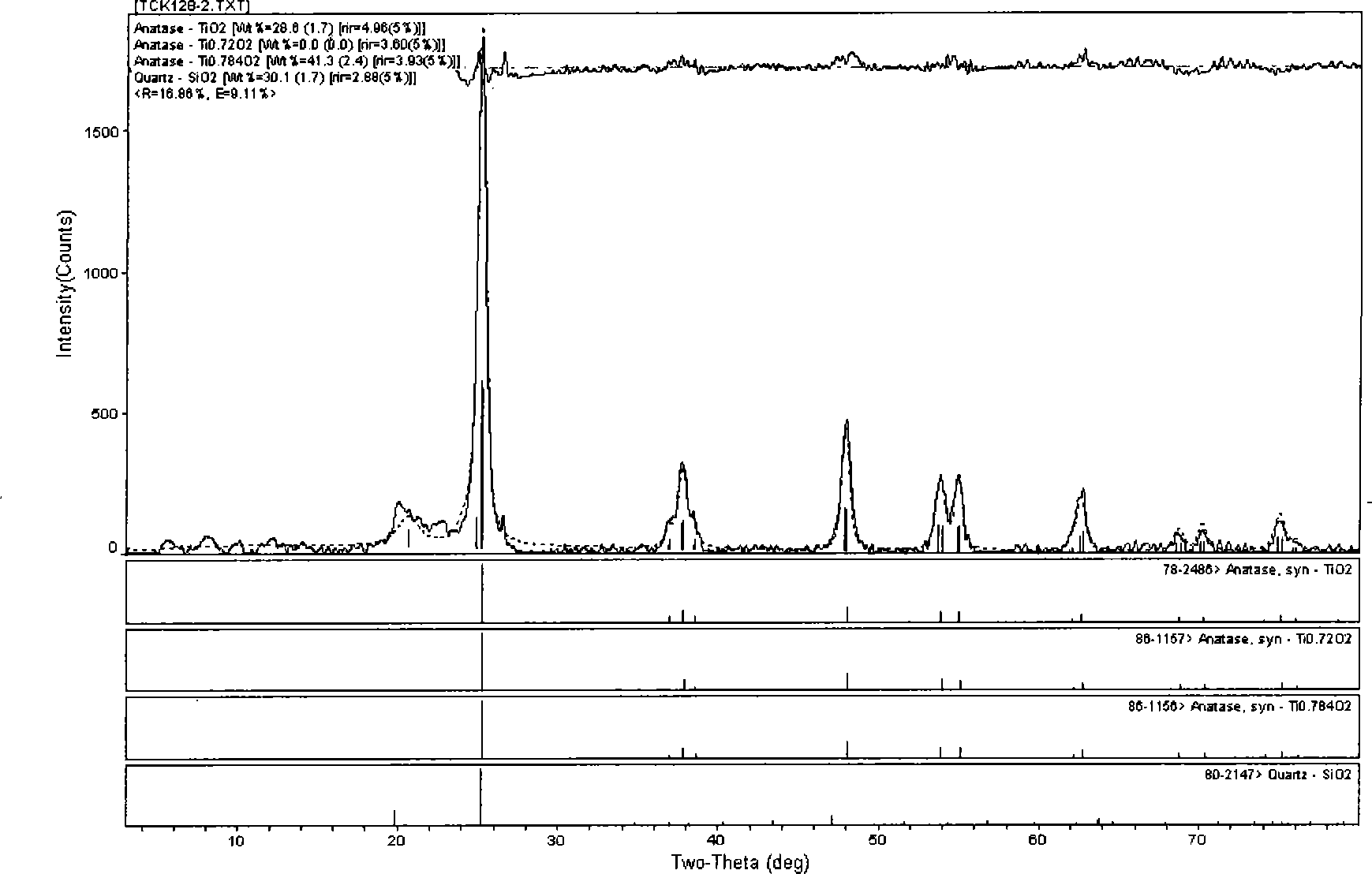

Titania coating kaolinite compound powder and method for preparing same

InactiveCN101250337AUniform whitenessSmall particle size distribution rangeInorganic pigment treatmentSODIUM METAPHOSPHATESodium phosphates

Titanium oxide coating kaolin composite powder belongs to a process for producing composite white pigment powder through the inorganic treatment method. The raw material formulation is formed by following components with percentage by weight: 12%-18% titanium sulfate, 6%-9% kaolin, 10%-19% carbamide, 0.15%-0.30% sodium hexametaphosphate, 0.5%-1.2% starch, 0.04%-0.08% water-soluble carbonate, 0.01%-0.05% phosphorus acid and rest amount of water. The preparation process comprises the steps of coating reacting, water scouring, salt treatment, acid treatment, dispersion, drying and calcination. The titanium oxide coating kaolin composite powder which is prepared through adopting the homogenous precipitation method has the advantages of even whiteness and small particle size distribution range, and each index all approximates to the index of titanium white powder.

Owner:中国高岭土有限公司

A retarding water reducer for bored occlusal piles in subway

InactiveCN102276184AImprove adaptabilityGood water reduction effectSODIUM METAPHOSPHATESodium phosphates

The invention provides a retarding and water reducing agent for an occlusal pile of subway drilling, belonging to the field of retarding and water reducing agents. The retarding and water reducing agent mainly comprises the following components in percentage by mass: 15% to 25% of naphthalene series water reducing agent, 20% to 30% of fatty acid series water reducing agent, 2% to 6% of sodium hexametaphosphate, 3% to 5.5% of sorbitol, 4.5% to 6.0% of citric acid, 2% to 4.5% of maltodextrin, 0.2% of bleed air component and the balance of water. According to the invention, the coagulation time can be controlled freely to reach more than 72 hours through regulation of addition quantity and superposition action of various materials; and simultaneously, the steady increase of concrete intensity can be ensured and the product has good adaptability to various concrete materials.

Owner:MAANSHAN CHINASEA NEW MATERIAL

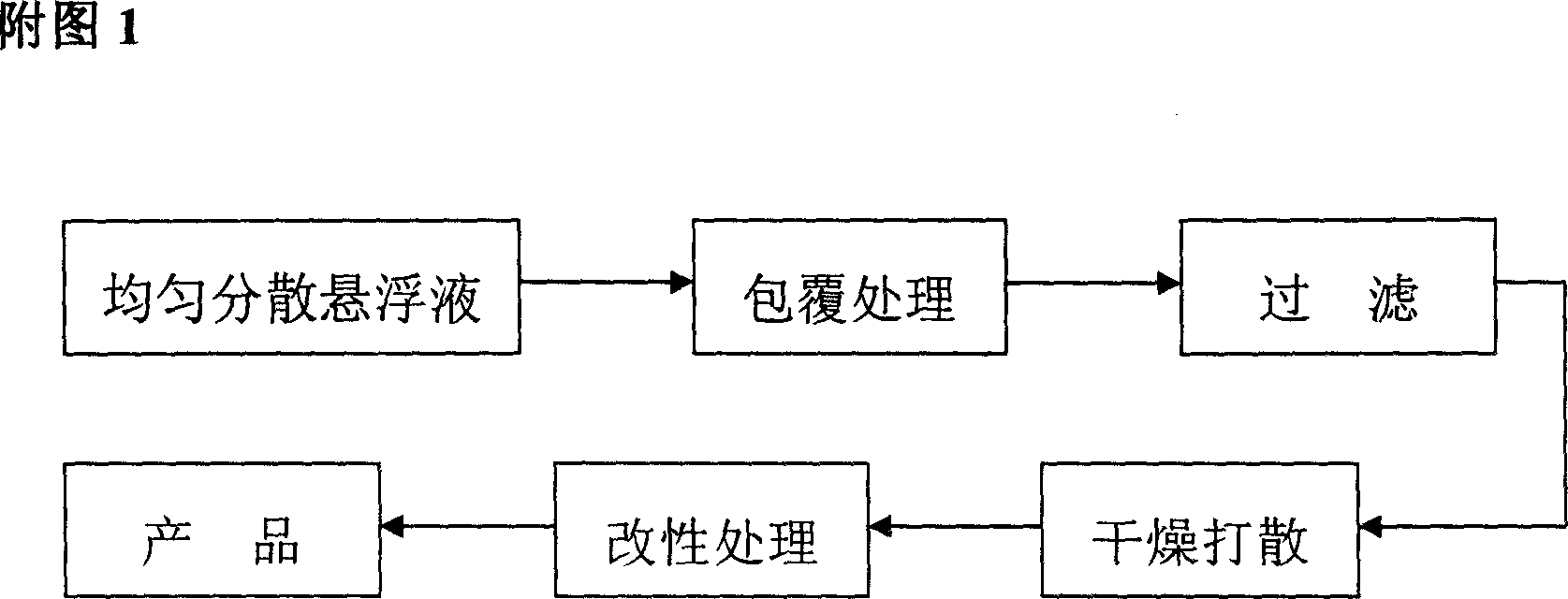

Preparation method of surface cladding type composite inorganic fire retardant

InactiveCN1948430AImprove mechanical propertiesOvercoming whiteness lossFireproof paintsSODIUM METAPHOSPHATEAluminium hydroxide

This invention relates to a hydration zinc oxide coated magnesium hydroxide or hydration zinc oxide coated aluminium hydroxide compounding fire - retardant agent. Superfine aluminium hydroxide or magnesium hydroxide is scattered in to water with hexa- sodium metaphosphate for making suspension, and then zinc saline solution and alky solution are added into suspension simultaneously for coating reaction, at last, the reaction product of coating reaction is filtered, washed, dried, deploymerized and conducted surface reshaping treatment with couplant. This compounding inorganic fire-retardant agent make the chemical combination of aluminium hydroxide and hydration zinc oxide, magnesium hydroxide and hydration zinc oxide into truth, so the coordinated fire-retardant effect of aluminium hydroxide, magnesium hydroxide and hydration zinc oxide can be played at greatest extend to improve the fire-retardant efficiency of compounding inorganic fire-retardant agent obviously.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

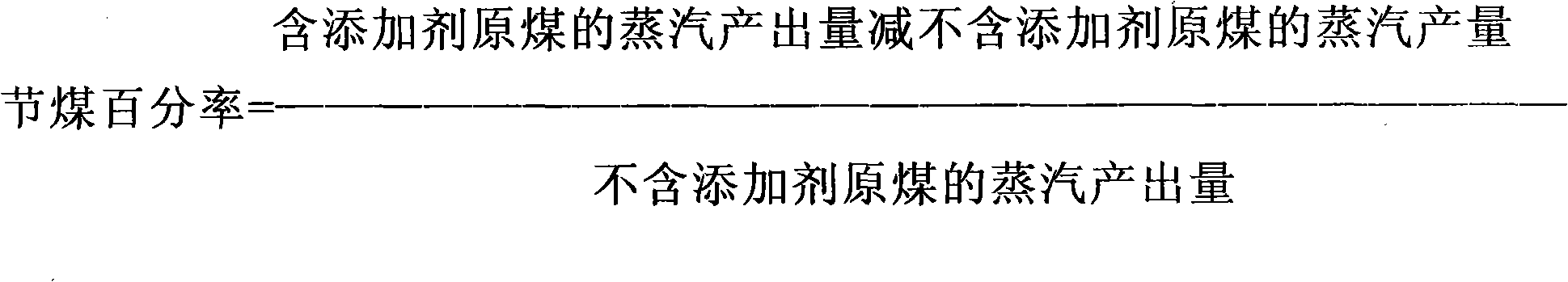

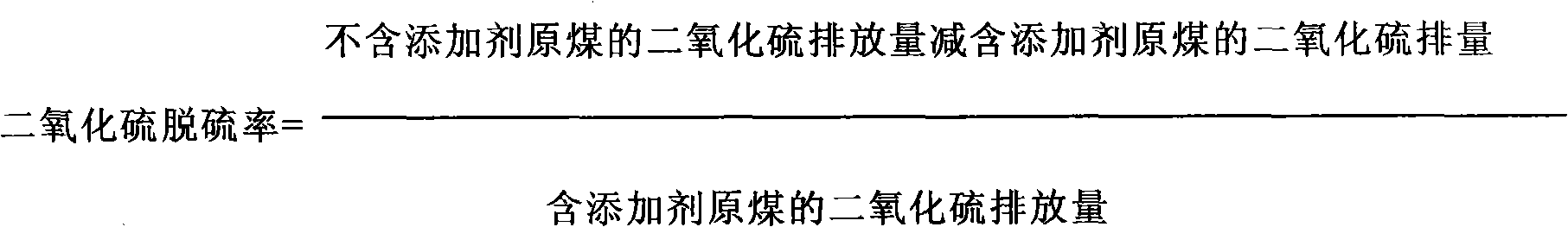

Fire coal energy-saving additive

InactiveCN101265429ALower ignition pointSpeed up the burning processSolid fuelsFurnace temperatureChemical reaction

The invention relates to a coal-fired energy-saving additive, which comprises the following components and contents (weight percentage): 6 to 16 percent of phthalocyanine blue; 5 to 20 percent of porphyrin; 12 to 19 percent of tween 60; 3 to 9 percent of iron oxide; 3 to 12 percent of magnesium oxide; 2 to 18 percent of manganese carbonate; 2 to 10 percent of calcium oxide; 6 to 12 percent of sodium chloride; 2 to 11 percent of potassium nitrate; 2 to 8 percent of sodium nitrate; 5 to 13 percent of potassium permanganate; 1 to 16 percent of sodium hydrate; 3 to 10 percent of sodium dodecyl benzene sulfonate; 8 to 11 percent of sodium heametaphosphate; 3 to 9 percent of trisodium phosphate; 3 to 13 percent of vermiculite; 7 to 16 percent of terrae rare. The additive solves the quick ignition of the coal during the combustion process, has the effect of the cracking gasification strong combustion supporting, improves the flame to heighten and enlarge the flame, and enables the radiation to be intensified; the adding of the coal-fired energy-saving additive can increase the furnace temperature to be more than 200 DEG C; the utilization of the coal-fired energy-saving additive can ensure the accumulative carbon on a boiler tank and a tube wall in a boiler to automatically drop off through chemical reactions and physical reactions, thereby improving the thermal efficiency, saving the energy and reducing the pollution.

Owner:陈汉明

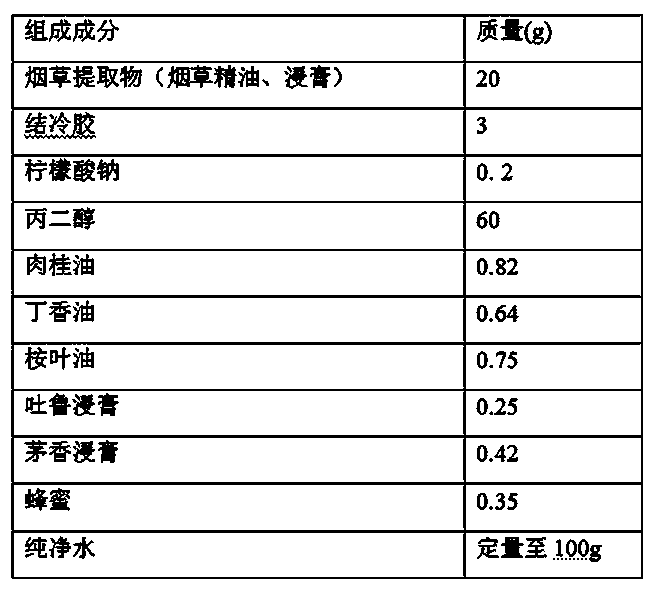

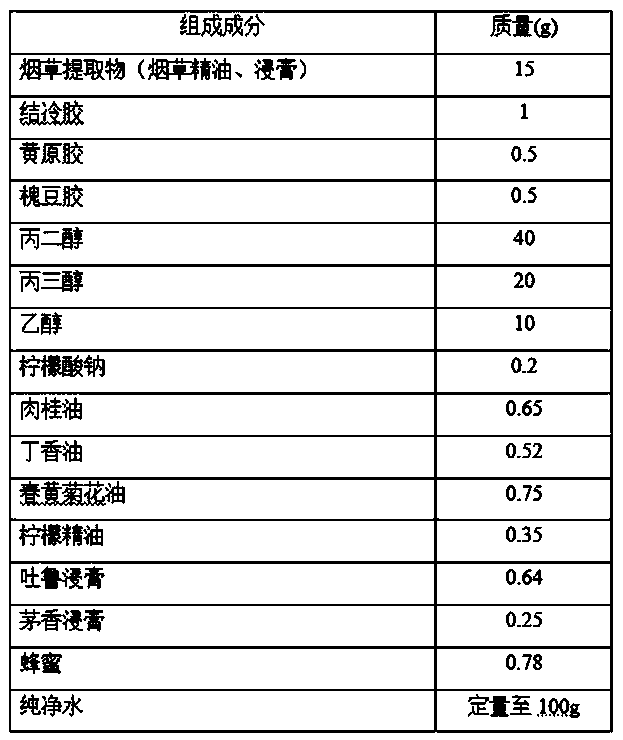

Gel state tobacco cartridge of electronic cigarette and preparation method thereof

InactiveCN104382236APrevent volatilizationImprove heat resistanceTobacco treatmentTobacco devicesBiotechnologySODIUM METAPHOSPHATE

The invention relates to a gel state tobacco cartridge of an electronic cigarette. The gel state tobacco cartridge mainly consists of a combination of tobacco extract, food gum, integrating agent, humectant, essence spice and purified water by mixing, wherein the tobacco extract is one or a combination of tobacco essential oil and extract; the food gum is one or a combination of gellan gum mixed xanthan gum and locust bean gum; the integrating agent is one or a combination of sodium citrate and sodium hexametaphosphate; the essence spice is one or a combination of cinnamon oil, clove oil, chamomile oil, eucalyptus oil, lemon essential oil, Tolu extract, Senega extract and honey. The gel state tobacco cartridge of the electronic cigarette has the advantages that the taste is improved, the stability of products is improved and potential safety hazards caused by leakage of tobacco liquid of liquid electronic cigarettes are further avoided.

Owner:CHINA TOBACCO ZHEJIANG IND

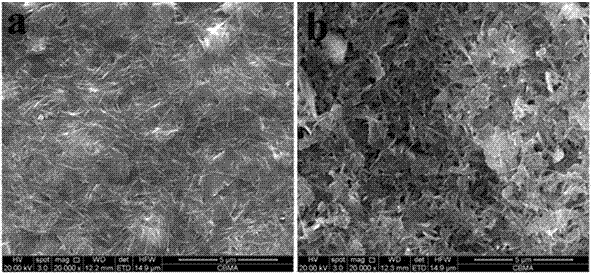

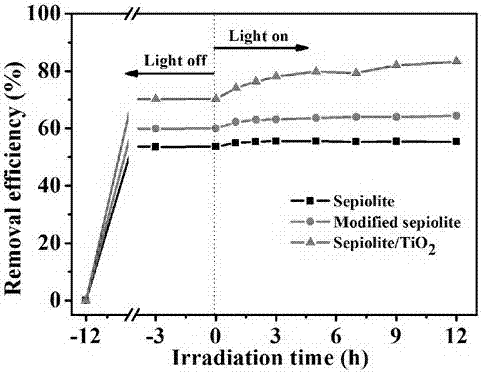

Multi-passage-structure and high-adsorption-performance sepiolite/TiO2 composite material and preparation method thereof

InactiveCN107344093AThe method is simple and energy-savingExtensive sources of raw materialsGas treatmentPhysical/chemical process catalystsFiberPyrophosphate

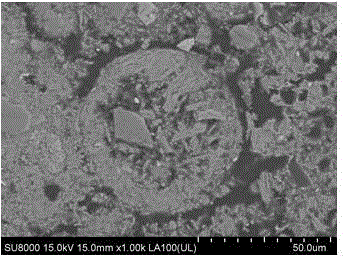

The invention discloses a preparation method of a multi-passage-structure and high-adsorption-performance sepiolite / TiO2 composite material. The preparation method comprises the following steps of firstly, carrying out acid modification on sepiolite to obtain modified sepiolite; afterwards, carrying out debundling dispersion on the sepiolite through adding a dispersant; finally, synthesizing the sepiolite / TiO2 composite material under the assistance of ammonia sulfate by adopting an ammonia water precipitation method and using TiCl4 as a titanium source. The morphology of the composite material prepared by the method is that TiO2 nano particles are highly uniformly dispersed on the surface of the fiber-plate-shaped sepiolite; TiO2 particles are combined with the sepiolite to form a loose whole; the composite material shows a multi-passage stricture. According to the preparation method, the sepiolite / TiO2 composite material is prepared under the action of the dispersant of sodium polymetaphosphate, sodium ortho-metaphosphate or sodium pyrophosphate and the like and by using the modified sepiolite as a raw material and the TiCl4 as the titanium source and adopting the ammonia water precipitation method; the TiO2 nano particles are uniformly loaded on a fiber plate of the sepiolite; moreover, the obvious aggregation does not exist; the compound is of the multi-passage structure, high in adsorption performance and is time-saving and environment-friendly in synthesis condition.

Owner:湘潭海泡石科技有限公司 +2

Flour improver for instant frozen dumplings, method for manufacturing flour improver and application thereof

InactiveCN104663763AGood lookingGreat tasteDough treatmentDough preparationBiotechnologySODIUM METAPHOSPHATE

The invention discloses a flour improver for instant frozen dumplings, a method for manufacturing the flour improver and application thereof. The flour improver for the instant frozen dumplings comprises, by weight, 2-5 parts of xanthan gum, 2-4 parts of guar gum, 2-4 parts of monostearin, 5-9 parts of stearic calcium and sodium lactate, 1-4 parts of composite phosphate, 1-3 parts of glutamine transaminase and 2-6 parts of sodium chloride. The composite phosphate comprises tetrasodium pyrophosphate, sodium tripolyphosphate and sodium hexametaphosphate. The method includes respectively sieving the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride by the aid of Number-CB36 sieves; mixing the xanthan gum, the guar gum, the monostearin, the stearic calcium and sodium lactate, the tetrasodium pyrophosphate, the sodium tripolyphosphate, the sodium hexametaphosphate, the glutamine transaminase and the sodium chloride with one another to obtain the improver for the instant frozen dumplings. The flour improver, the method and the application have the advantages that problems of frost cracking and the like of dumpling wrappers of existing instant frozen dumplings during instant freezing, mechanical packaging and low-temperature storing can be solved by the aid of the improver for the instant frozen dumplings, the smoothness, the boiling fastness and the freeze-thaw stability of the instant frozen dumplings can be enhanced, and the taste and the appearance of the instant frozen dumplings can be obviously improved.

Owner:SHANGHAI INST OF TECH

Compound disinfection powder for disinfecting hospital and aquaculture wastewater

InactiveCN104585232AImprove the bactericidal effectReduce dosageBiocideDisinfectantsSODIUM METAPHOSPHATESodium phosphates

The invention discloses disinfection powder for disinfecting hospital and aquaculture wastewater. The powder is prepared from the following components in percentage by mass: 20%-30% of potassium monopersulfate, 15%-20% of sodium dichloro isocyanurate, 25%-45% of dodecyl dimethyl benzyl ammonium chloride, 10%-15% of protochloride and 2%-5% of sodium hexametaphosphate. The compound disinfection powder has the advantages that (1) the compound disinfection powder is an oxidizing and non-oxidizing fungicide complex, and is good in sterilization effect; (2) the compound disinfection powder contains a dispersant component, is capable of stripping biological slime and is free of a dead angle in sterilization and disinfection; (3) the compound disinfection powder is low in consumption and does not generate secondary pollution; and (4) residual chlorine in discharged water does not exceed the standard.

Owner:威海百克环保工程有限公司

Water-based paint for pipeline and preparing method of water-based paint

InactiveCN105255332ACorrosionStrong adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEMelamine phosphate

The invention relates to water-based paint for a pipeline. The water-based paint for the pipeline is prepared from modified phenolic resin, pitch, alcohol acid emulsion, chromium oxide green, an anti-rusting agent, low polymer polyhydric alcohols, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylated fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine phosphate, pentaerythritol, aluminum silicate fibers, silicon dioxide, antibacterial preservative, titanium dioxide, Ni, Zn, water and other raw materials. Due to the fact that the ingredients such as Ni and Zn are contained in the water-based paint for the pipeline, the water-based paint for the pipeline has the high-temperature resisting and corrosion resisting performance, is suitable for coating demands of various occasions, does not contain toxic organic solvents, is free of pollution and has the advantages that a paint surface cannot crack, and the paint is resistant to aging, high in adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Rare earth added antibacterial ceramic glaze and preparation method thereof

InactiveCN106348787AGood antibacterial and bactericidal effectLong antibacterial timeSODIUM METAPHOSPHATEPolyethylene glycol

The invention provides rare earth added antibacterial ceramic glaze and a preparation method thereof and relates to the field of ceramic preparation. The ceramic glaze mainly comprises the following raw materials in parts by weight: 25-45 parts of silicon dioxide, 5-13 parts of aluminum oxide, 3-5 parts of deep sea mineral mud, 3-6 parts of magnesium oxide, 2-6 parts of copper oxide, 1-5 parts of zinc oxide, 4-8 parts of zirconium silicate, 1-3 parts of titanium dioxide, 3-9 parts of opal shale, 0.2-0.5 part of polyethylene glycol, 2-7 parts of sodium metaphosphate, 2-12 parts of rare-earth metal oxide and 67-95 parts of organic solvents; and the raw materials also comprise 2-6 parts of silver nitrate. The rare earth added antibacterial ceramic glaze provided by the invention is lasting in antibacterial time and high in efficiency, and other performances of ceramic products are not influenced.

Owner:FOSHAN LANTU TECH CO LTD

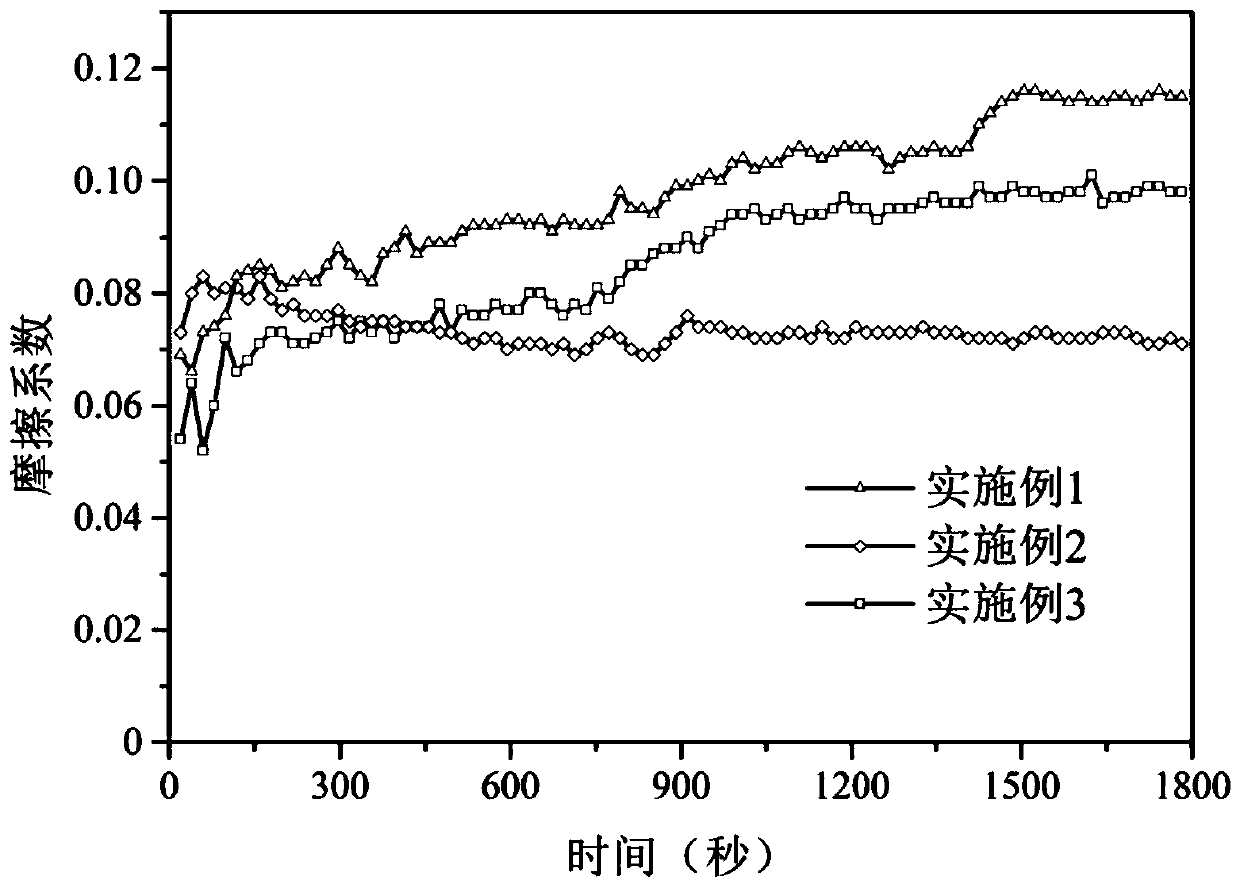

Method for preparing nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization

ActiveCN111117746AMeet friendly requestEasy to save energyLubricant compositionSodium acetateSODIUM METAPHOSPHATE

A method for preparing a nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization belongs to the technical field of lubrication. The method comprises the following steps: auto-polymerizing dopamine to form polydopamine, modifying the surface of a molybdenum disulfide nanosheet with the polydopamine to obtain a polydopamine-modified molybdenum disulfide nanosheet; then adding aluminum chloride hexahydrate, polyethylene glycol 200 and sodium acetate, centrifuging the obtained obtained solution, and washing and drying the obtained material to obtain nano-MoS2-Al2O3 composite powder; and finally, dispersing the prepared composite nano-powder into deionized water, and adding glycerol, triethanolamine, sodium hexametaphosphate, sodium dodecyl benzene sulfonate, water-based borate and a trace amount of a defoaming agent to obtain the required composite rolling lubricant. The composite lubricating oil is simple in preparation process, good in reproducibility, low in cost, high in efficiency and beneficial to batch production, can replace traditional rolling lubricating oil severely polluting the environment to a certain extent, is used for technological lubricationin the plate and strip steel hot rolling process, and promotes energy conservation, emission reduction and environment-friendly production in the plate and strip steel rolling process.

Owner:UNIV OF SCI & TECH BEIJING

Flavored soybean milk powder prepared by adopting wet method and method of flavored soybean milk powder

ActiveCN103947759ALower pH valueMeet the needs of tasteMilk substitutesBiotechnologySODIUM METAPHOSPHATE

The embodiment of the invention discloses flavored soybean milk powder which comprises the following components in percent by weight: 30-60 percent of soybeans, 1-15 percent of whole milk powder, 20-50 percent of malt syrup, 10-40 percent of white granulated sugar, 1-10 percent of a fruity material, 1-5 percent of soybean oil, 0.5-3 percent of soyabean lecithin, 0.1-0.5 percent of sodium tripolyphosphate and 0.1-0.5 percent of sodium hexametaphosphate. The embodiment of the invention further discloses a method for preparing the flavored soybean milk powder by adopting a wet method. By adopting the method, the problem of schlammbildung caused by reduction of a soybean milk PH value when a fruity material is added is avoided so that the flavored soybean milk powder is relatively stable; by adding fruit juice or jam, the prepared flavored soybean milk powder is rich in vitamins, accords with the demands of a consumer on the flavor and the nutrient of the flavored soybean milk powder, and is low in equipment input, high in benefit, and easy to popularize.

Owner:广州市拿森生物科技有限公司

Nanometer photocatalytic air purifying spraying technology

InactiveCN101053767AEasy to synthesizeTo achieve the purpose of purifying the airLighting and heating apparatusDispersed particle separationSODIUM METAPHOSPHATEIndoor air quality

The invention relates to nano-photocatalysis air rectification spray technology. At present, the environment in the car and room commonly has serious problems that is the longterm existence of the harmful gas such as formaldehyde, benzene, toluene, xylene and so on, harmful to the health of human. The purpose of the invention is to develop a nano-catalysis air rectification spray technology. The technical proposal of the invention is to: quantificationally withdraw deionized water, fill into the reaction kettle to react, put in triethanolamine and sodium metaphosphate at the same time, mix round and melt, raise the stirring rate of the reaction kettle to the maximum, add nano-powder, keeping stir for 3-5 hours to get the white suspended etching solution. The use is to contact the nano-zinc oxide with the air under natural light to produce much of anion like supperoxide anion and hydroxyl free radical, which can rapidly and fully degrade the harmful gas like formaldehyde, raise the air quality indoor rapidly, and raise the security indoor and the human health all the better.

Owner:陕西太和科技股份有限公司

Willow weaving paint

The invention discloses a willow weaving paint, which is prepared from the following components: waterborne acrylic resin, water, a water-soluble alkyd paint, manganese dioxide, calcium stearate, tristearin, acrylic emulsion, sodium dodecyl sulfate, sodium metaphosphate, pentaerythritol and an auxiliary, wherein the auxiliary comprises 30 weight percent of attapulgite, 30 weight percent of epoxy resin and 40 weight percent of starch. The willow weaving paint is a waterborne coating, and is free of volatile substances such as benzene, so that side effects on a user are eliminated; the special auxiliary is added, so that the coating is higher in adhesive power and high in leveling property, is unlikely to come off, and can be dried faster when being used, and a willow weaving product can be stored for more than 3 years without paint drop.

Owner:阜南县猛发工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com