Patents

Literature

3564 results about "Ceramic glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic glaze is an impervious layer or coating of a vitreous substance which has been fused to a ceramic body through firing. Glaze can serve to color, decorate or waterproof an item. Glazing renders earthenware vessels suitable for holding liquids, sealing the inherent porosity of unglazed biscuit earthenware. It also gives a tougher surface. Glaze is also used on stoneware and porcelain. In addition to their functionality, glazes can form a variety of surface finishes, including degrees of glossy or matte finish and color. Glazes may also enhance the underlying design or texture either unmodified or inscribed, carved or painted.

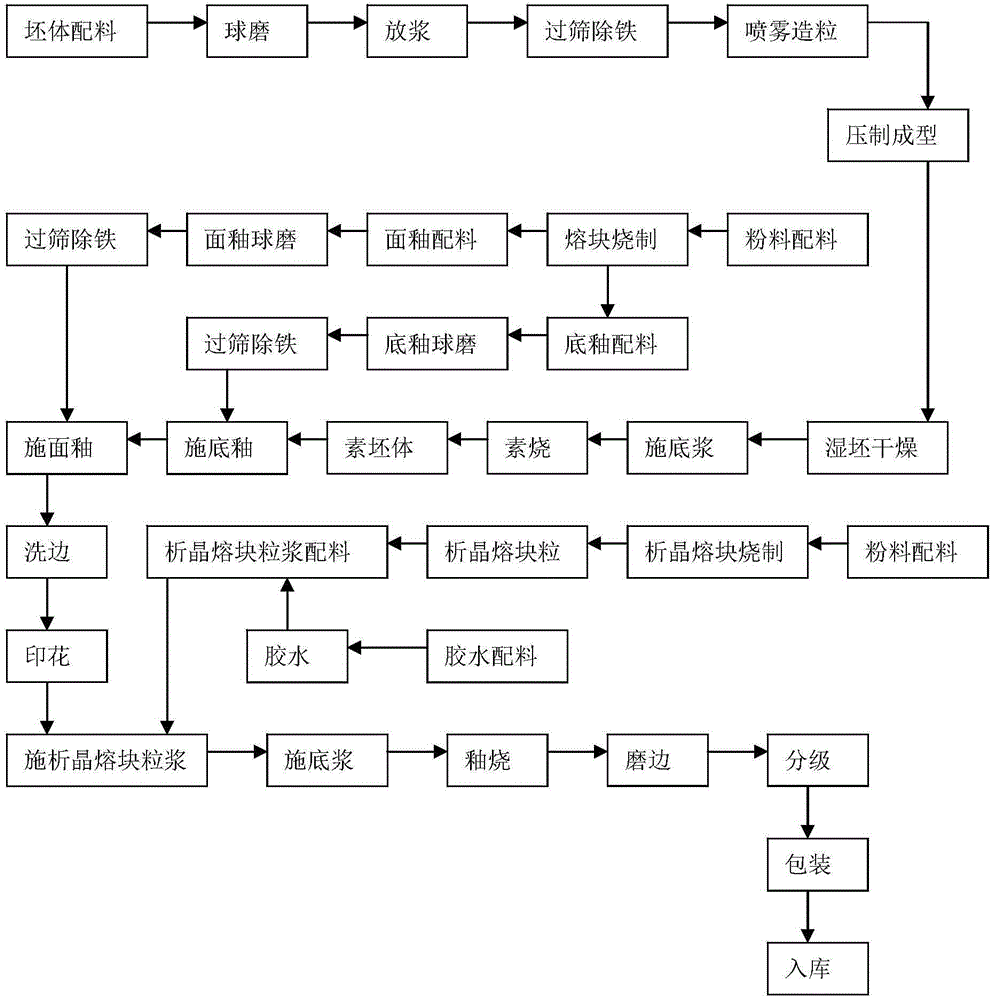

Formula and preparation method of national flag bright red glazed brick

The invention relates to a formula and preparation method of a national flag bright red glazed brick. On the basis of not changing the existing glazed brick production technique too much, the invention mainly adjusts and optimizes the composition of blank materials, the composition of base / cover coating fused blocks, the preference and proportion of the fused blocks having different properties in base / cover coating, the processing technique of the cover coating, the formula composition of the base coating, the water absorptivity of a biscuit, the firing temperature and the like, thereby ensuring that the fired national flag bright red glazed brick has a dazzlingly beautiful glaze color, is bright like a reflective mirror, and has a high decorative effect and an artistic aesthetic effect; and the color is as pure as the color of a national flag and is glossy and bright, so that the national flag bright red glazed brick can shine like the rising sun. Meanwhile, the technology has high universality, and is readily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +1

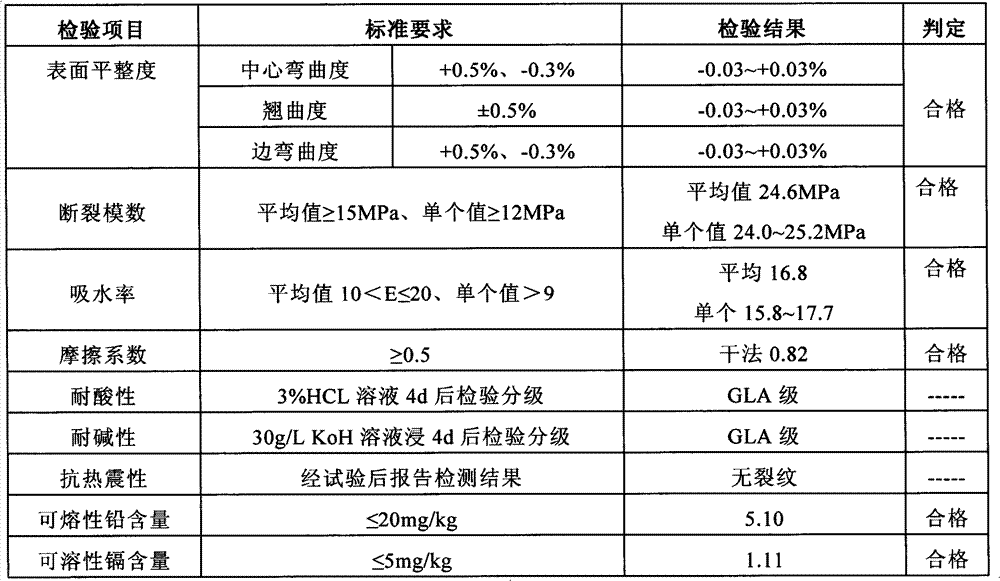

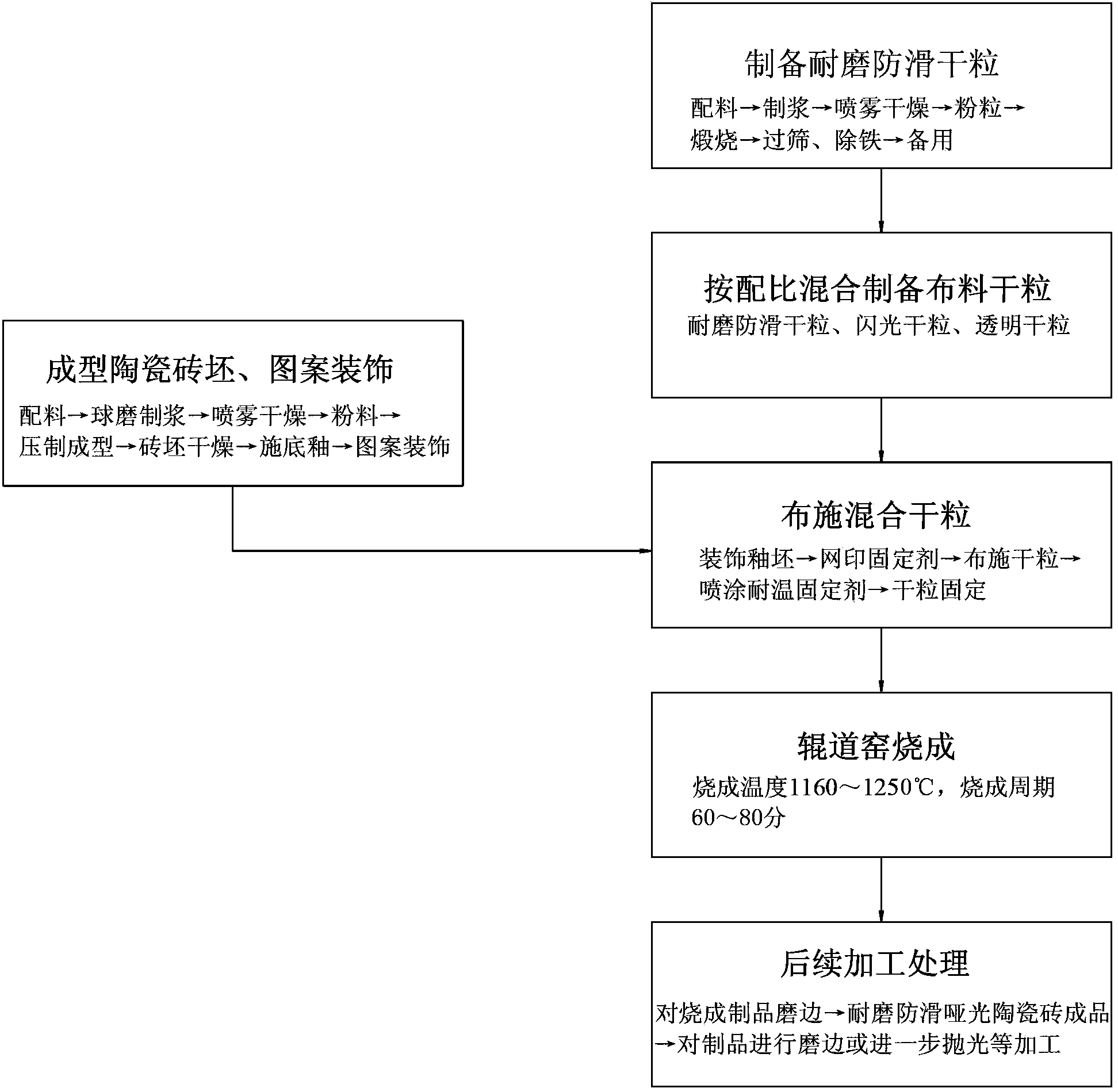

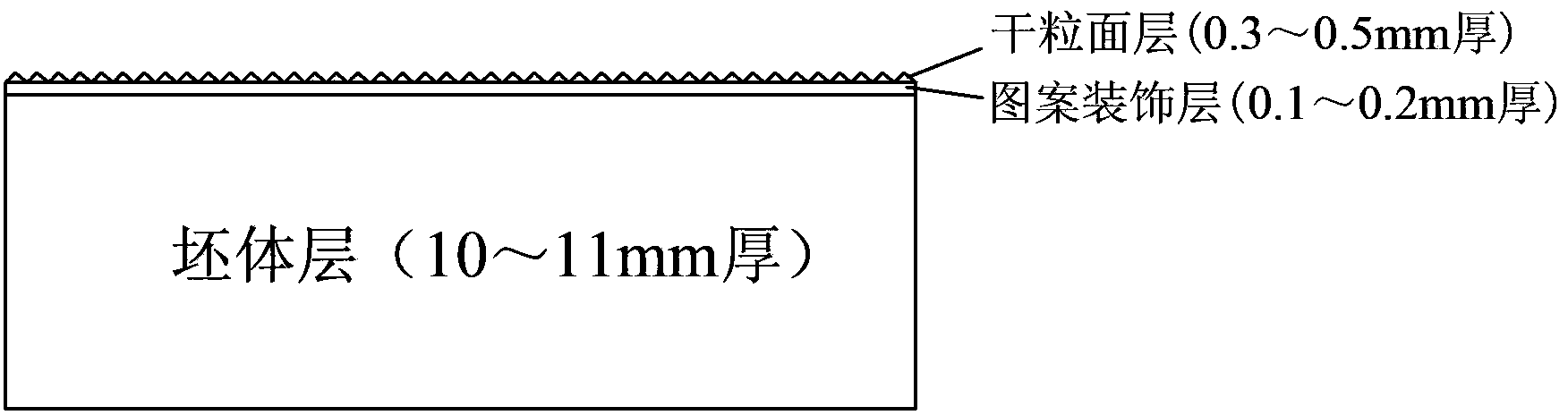

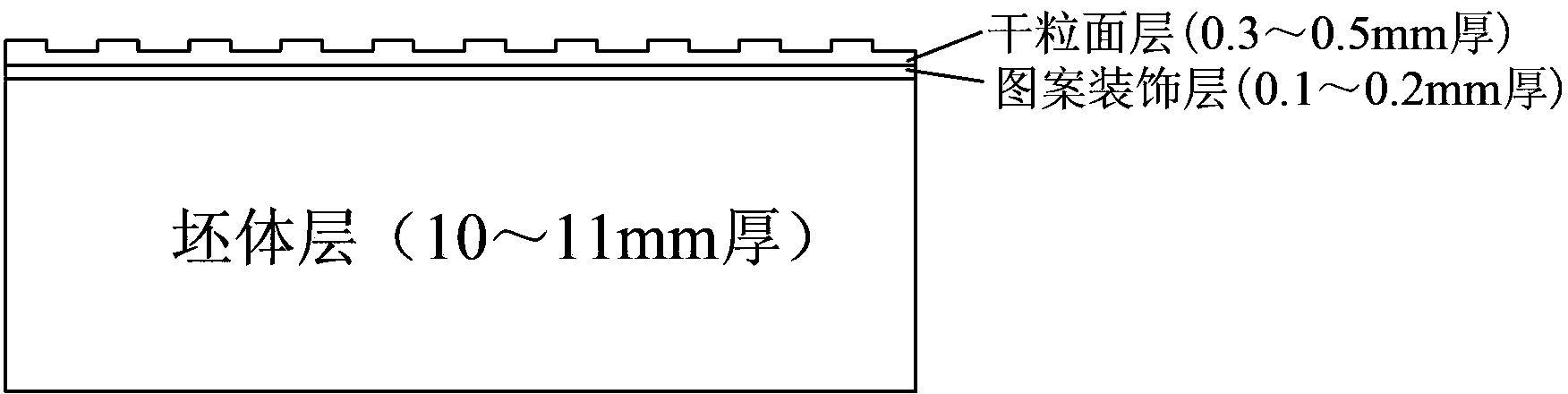

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

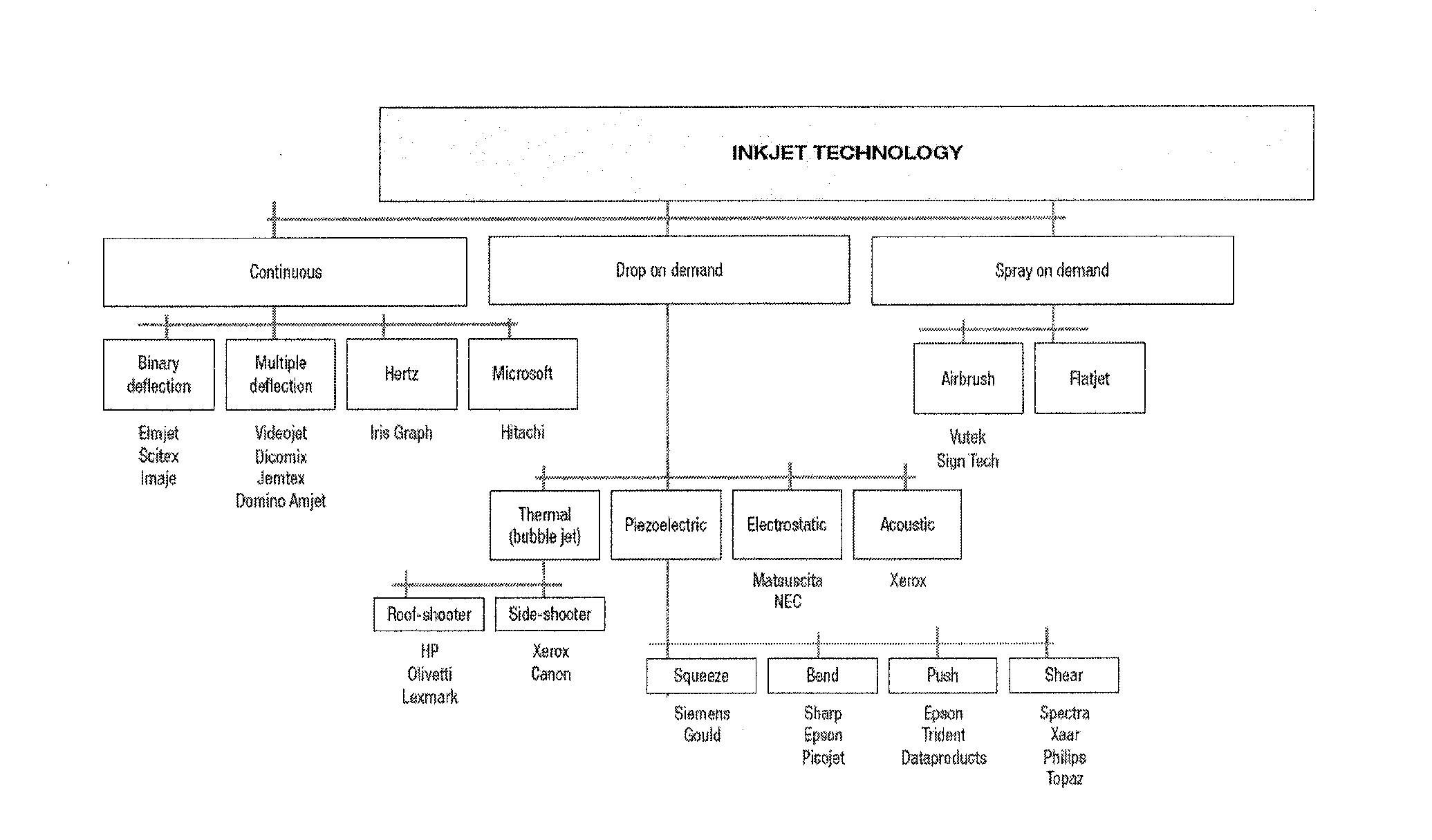

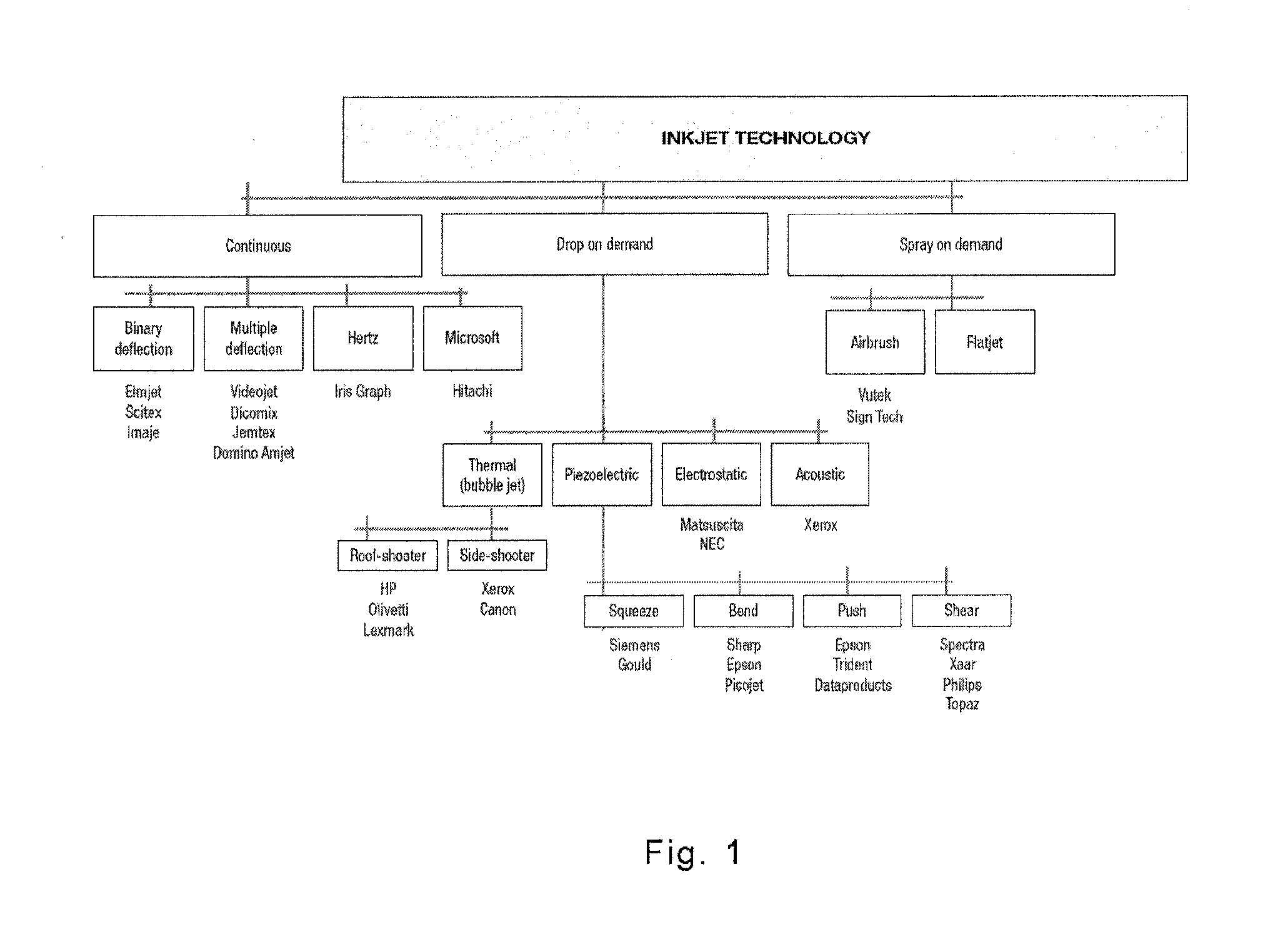

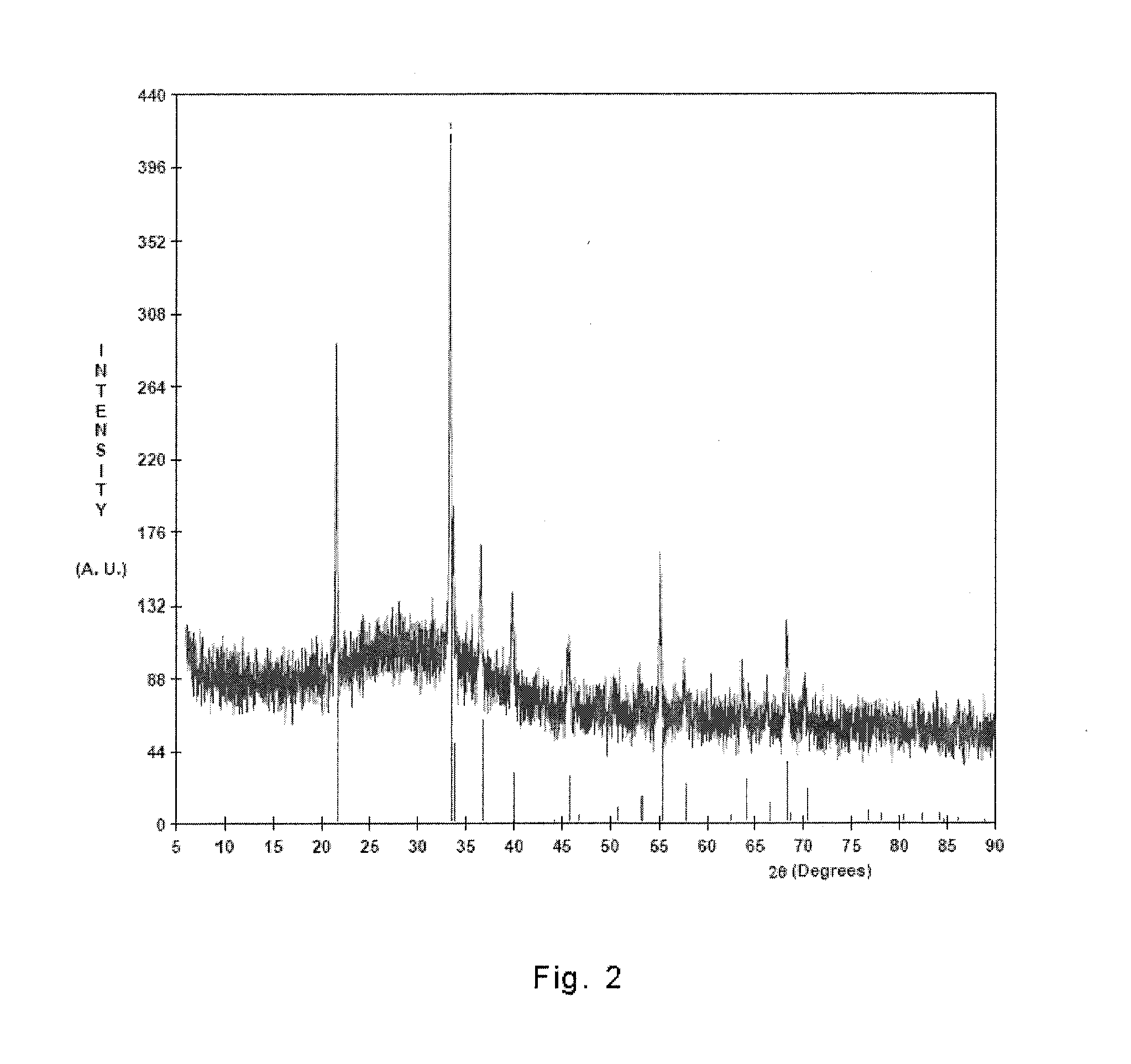

Inkjet Compositions For Forming Functional Glaze Coatings

Inkjet compositions that can be applied to glass and / or ceramic substrates to impart various effect to the substrate after firing, including: gloss, matt, contrast gloss (luster), specular reflection (metallic appearance), relief and slipperiness. The inkjet compositions include solvents, additives for dispersion, and inorganic substances, but preferably do not include any color-producing ceramic pigments. The inorganic substances contained in the inkjet compositions are the responsible for the above mentioned effects on the surface of the ceramic article. Depending on the type of effect desired, the inorganic substance may be a specific frit, a crystalline oxide, or a combination of frits and crystalline oxides.

Owner:FERRO CORP

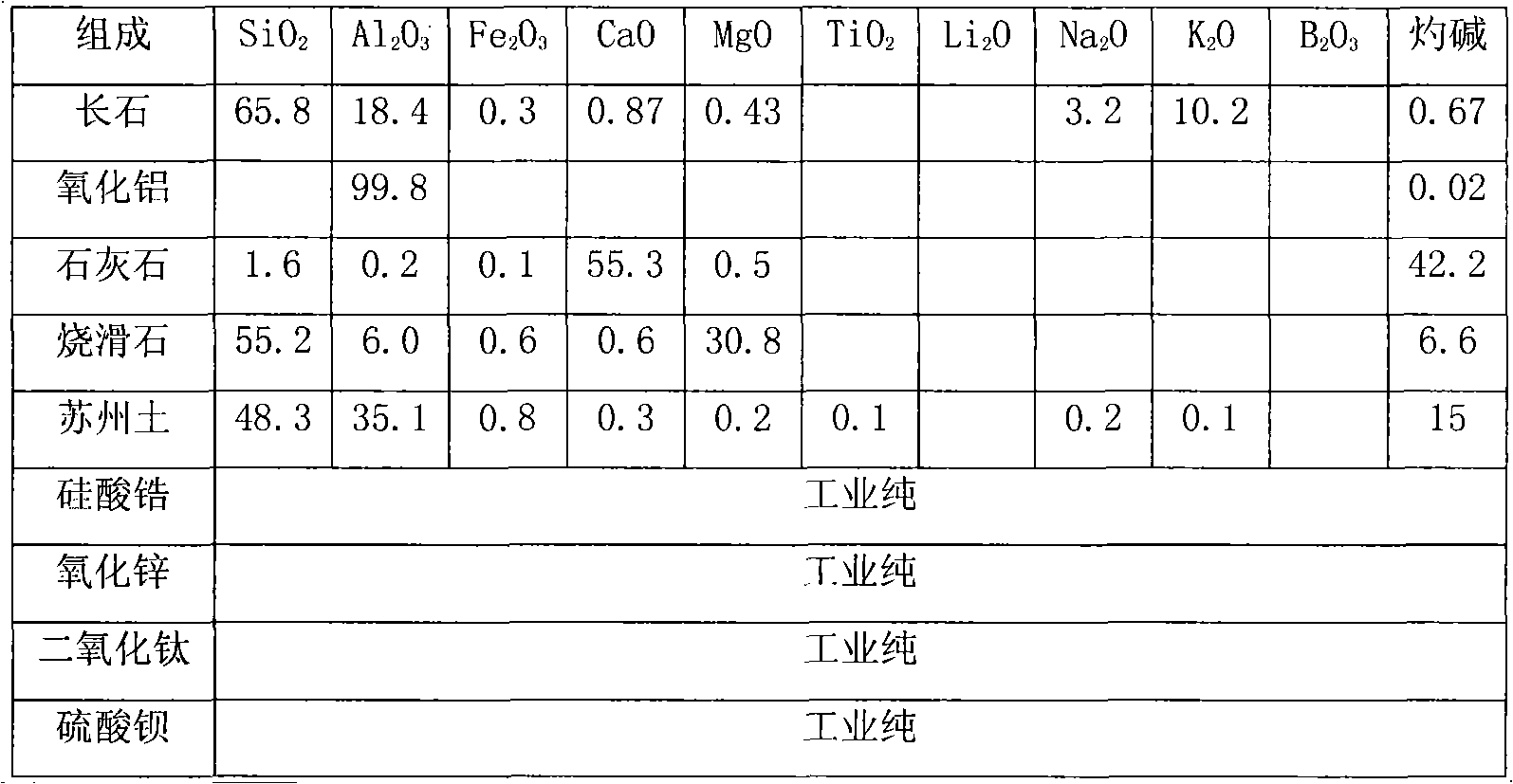

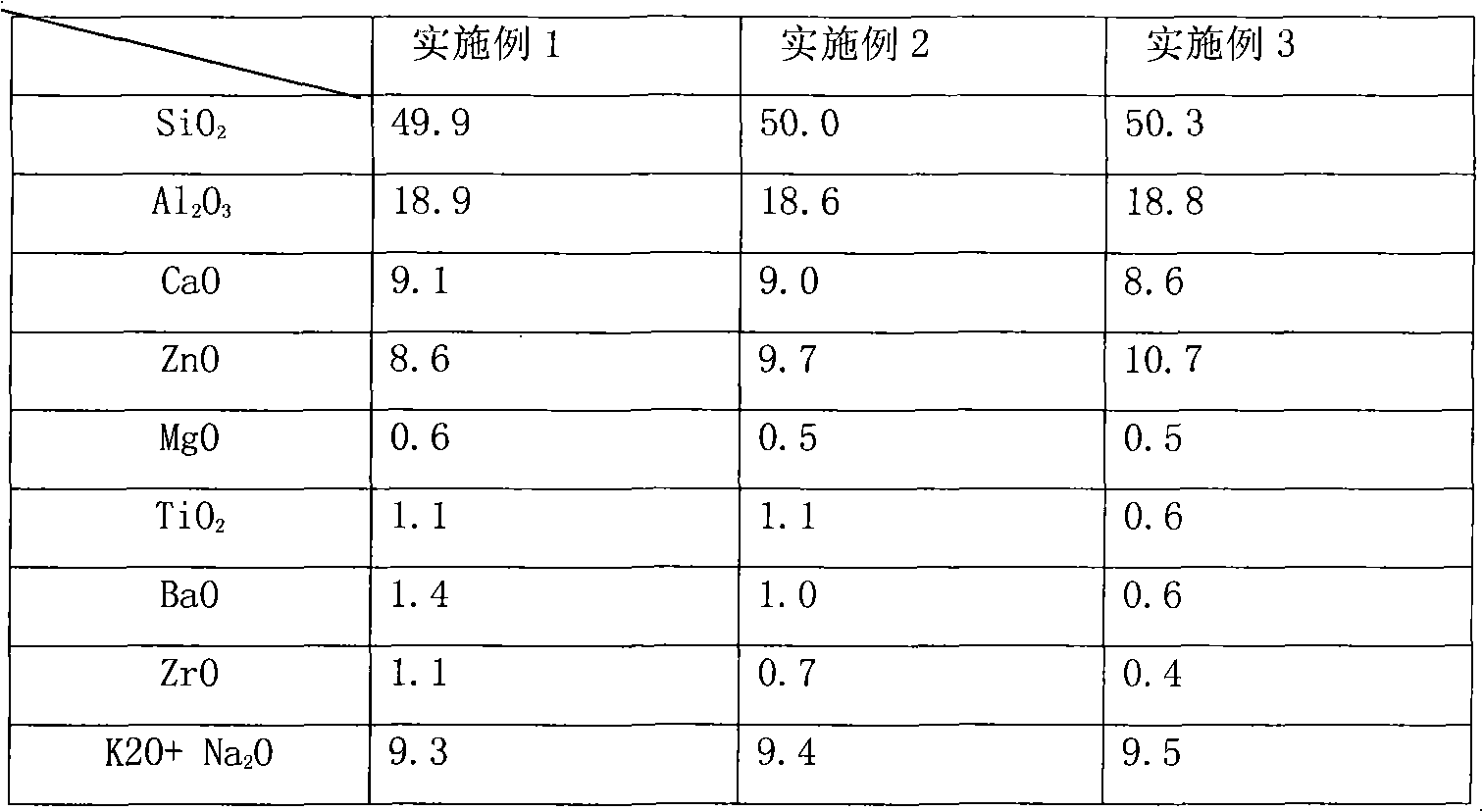

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

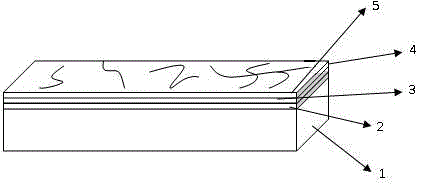

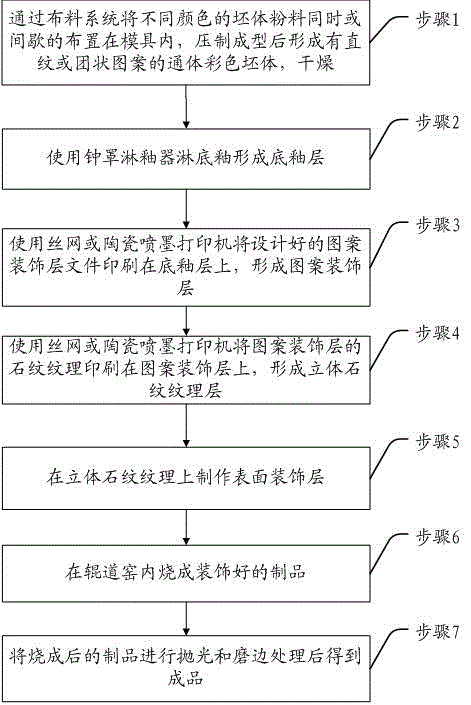

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Preparation method of glazed ceramic brink with stone imitation pattern based on fused block wrapping pigment

Owner:广东高微晶科技有限公司

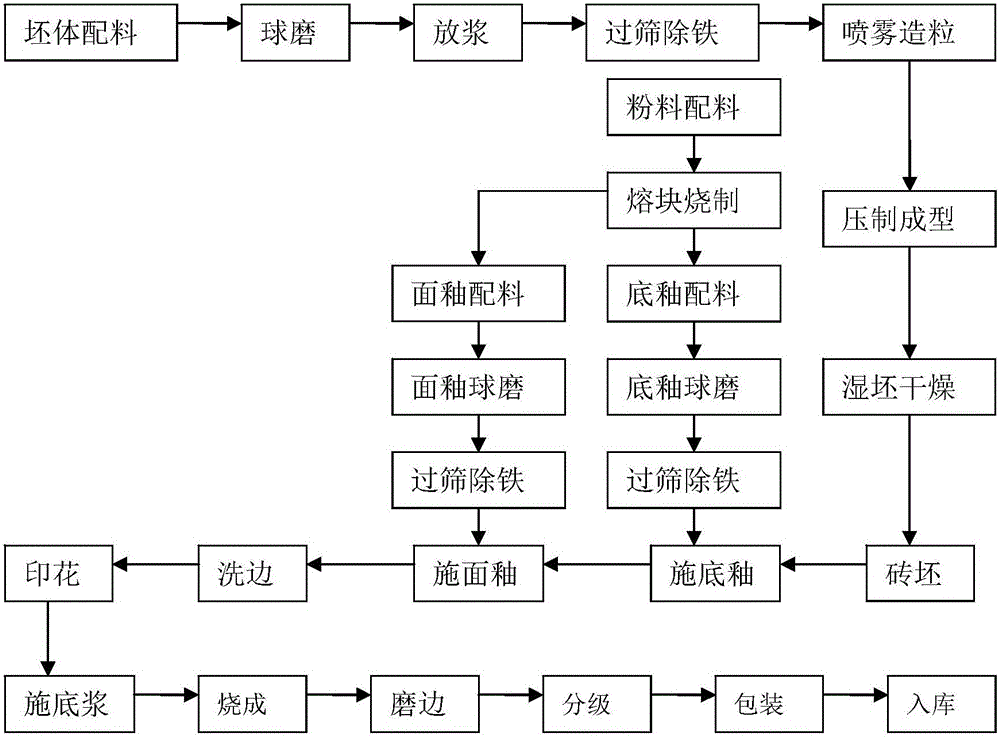

Ceramic glaze pattern-glazed brick and production method thereof

The invention discloses a ceramic glaze pattern-glazed brick and a production method thereof. The ceramic glaze pattern-glazed brick is prepared by performing decorations of printing, colors and patterns in a ceramic brick glaze, burning the ceramic brick glaze at a high temperature of between 1,220 and 1,260 DEG C, and adopting a soft surface polishing process. The production method comprises the following steps: preparing a formulation of a combined blank; performing press forming on the blank; drying the blank; spraying a ground glaze on the surface of the dried blank; using a fancy glaze to perform printing on the ground glaze; spraying a cover glaze on the surface of the blank after the printing; burning the blank sprayed with the cover glaze at a temperature of between 1,220 and 1,260 DEG C for 50 to 60 minutes; and finally edging and polishing the burnt blank to obtain the ceramic glaze pattern-glazed brick. The ceramic glaze pattern-glazed brick has the advantages of abrasion resistance, no dirt absorption, good texture, high glossiness and transparency, good decorative effect and wide decorative varieties.

Owner:郑水泉

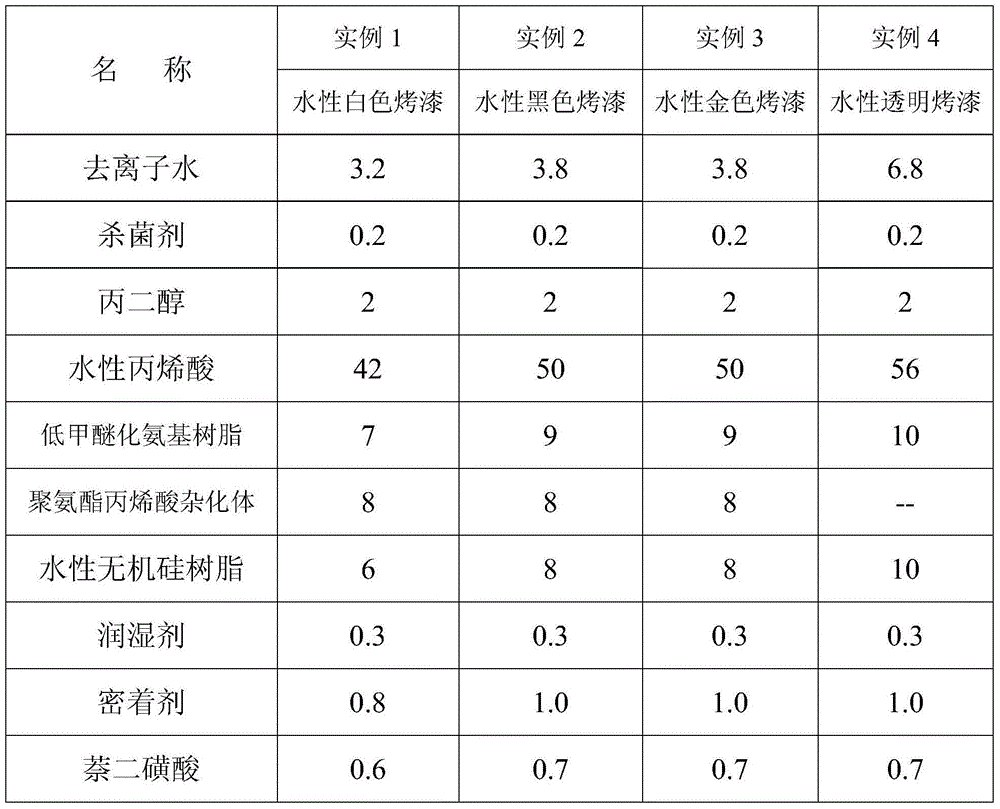

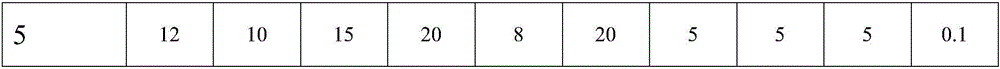

Preparation method for high-hardness water-based glass baking paint

ActiveCN103937354AHigh hardnessNo pollution in the processPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention relates to a preparation method for a high-hardness water-based glass baking paint composed of nano water-based acrylic resin, low-methoxylation amino resin, a water-based polyurethane acrylic hybrid, hardening resin, a colorant, a substrate wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage. A prepared paint film has the hardness reaching 5 H or more, and has anti-scratch and wear-resistance properties of a ceramic glaze film; a prepared glass product achieves effects of blue and white porcelain, enamel colored glaze porcelain, and white glazed porcelain; and the water-based glass baking paint is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

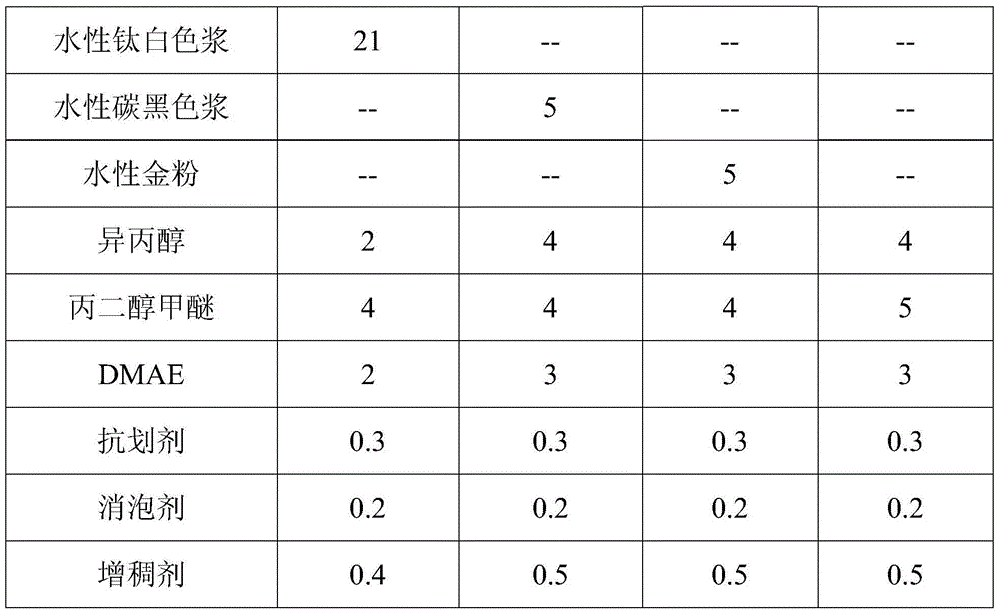

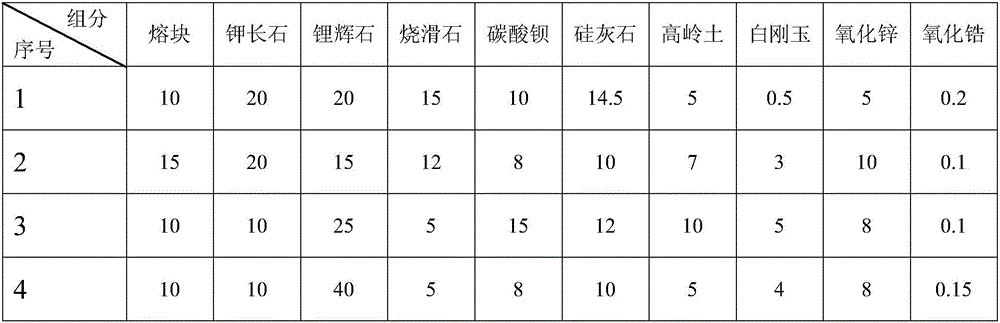

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

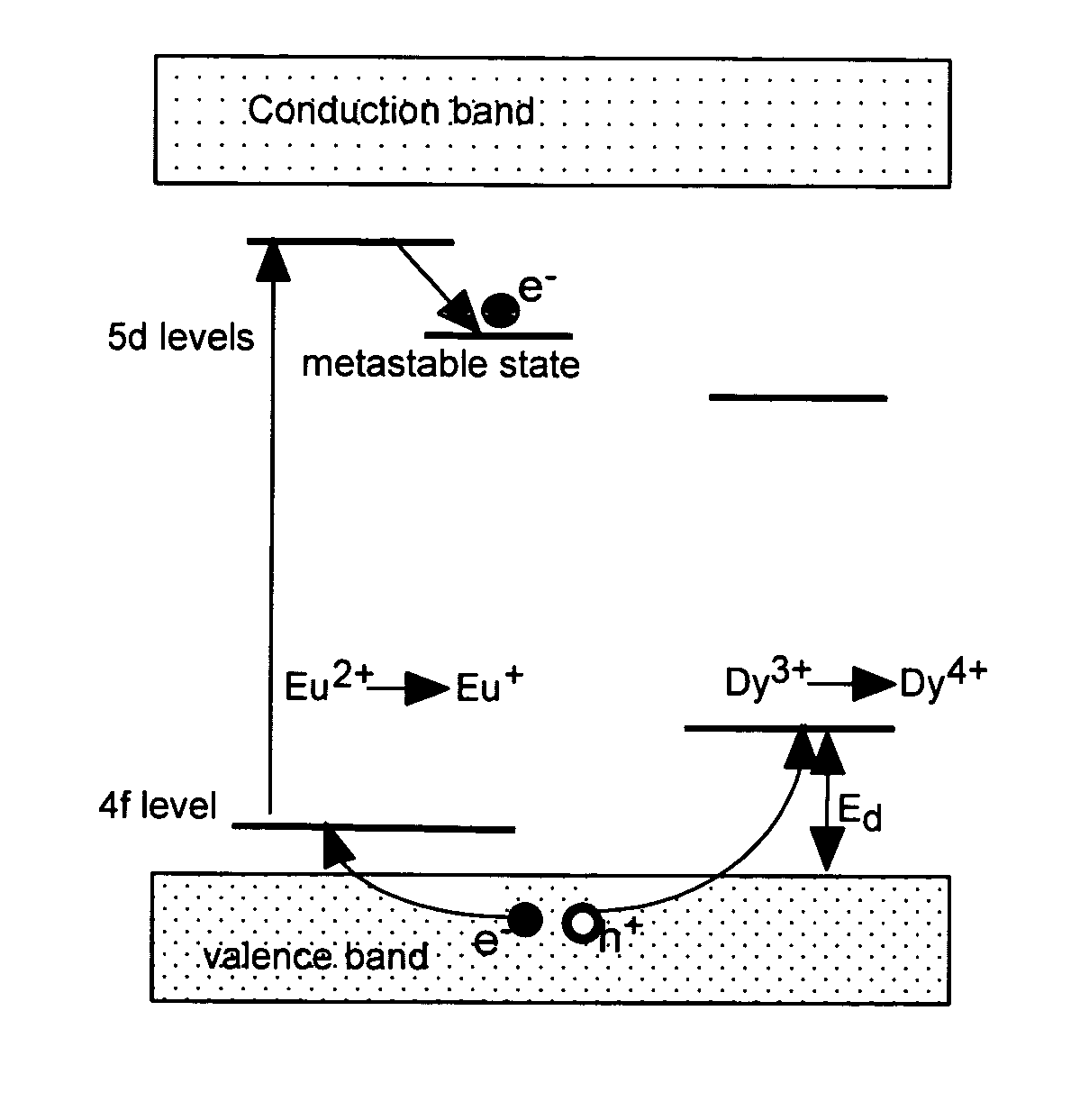

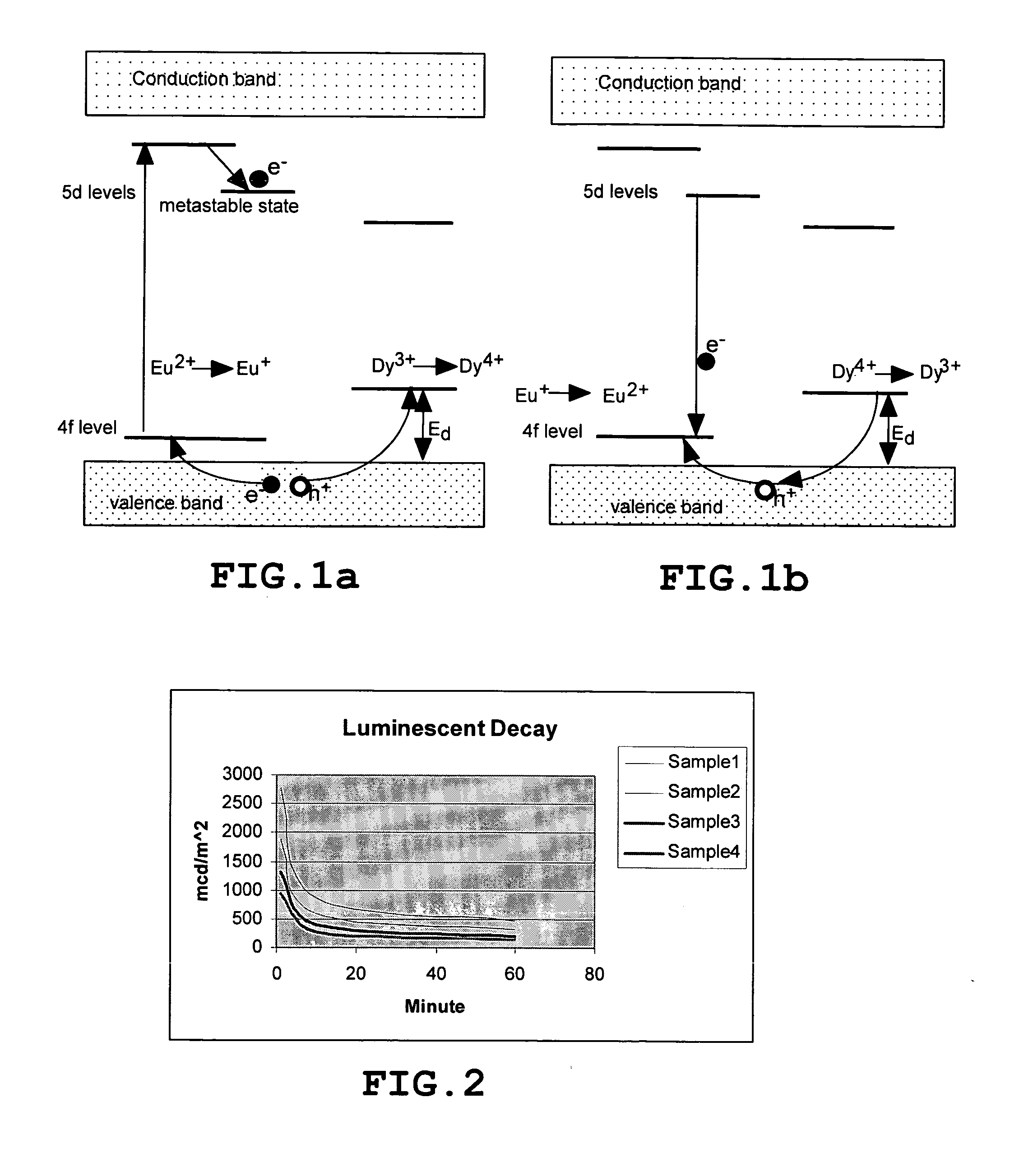

Phosphorescent blends

InactiveUS20050035331A1Avoid safety hazardsFilm/foil adhesivesLuminescent compositionsPhosphatePreventing injury

Owner:SUN XIAO DONG

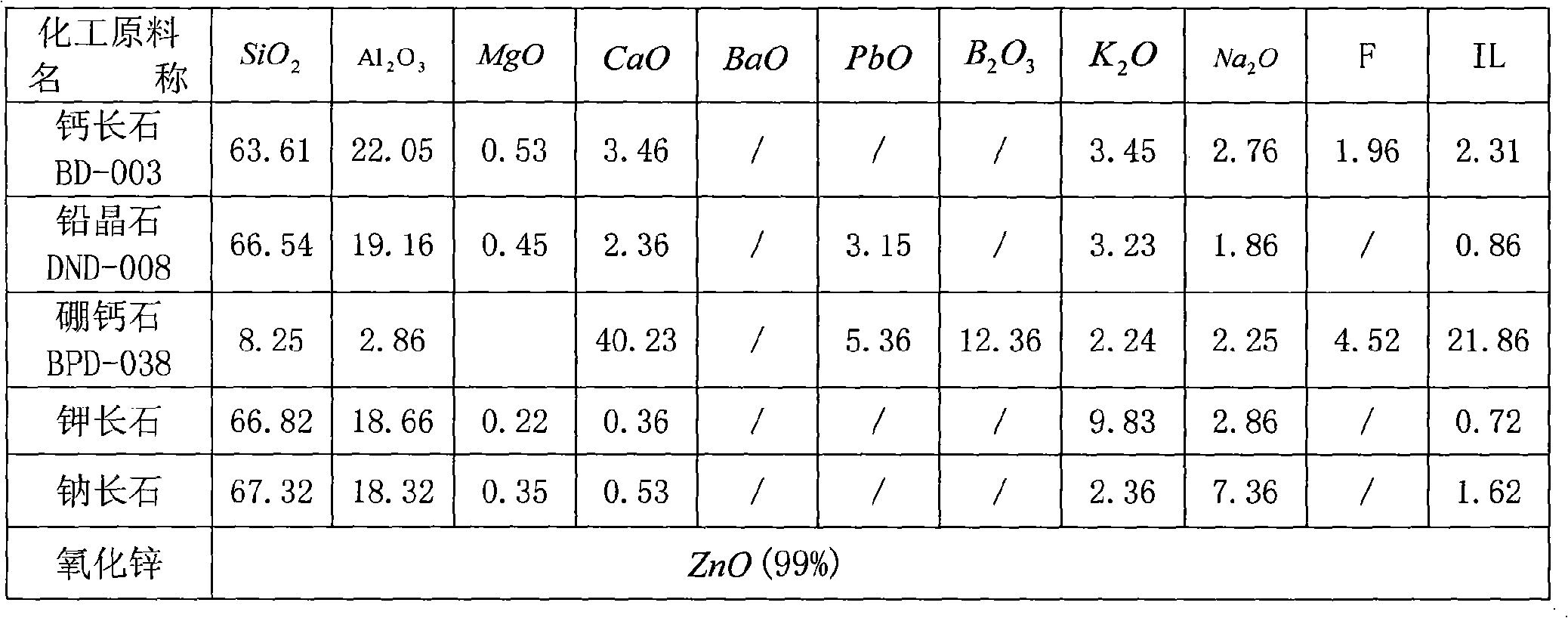

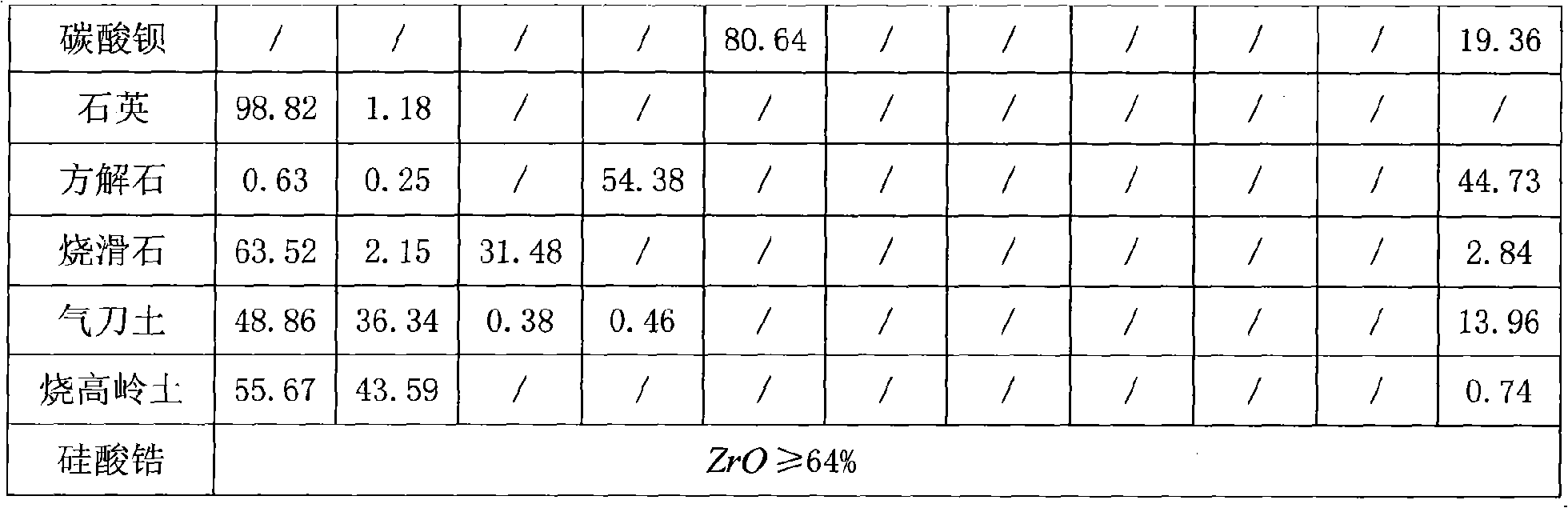

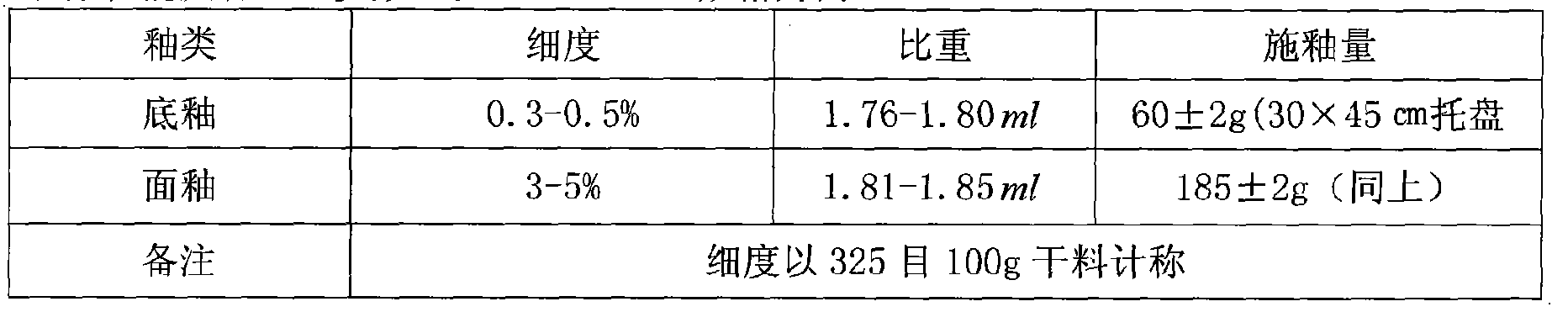

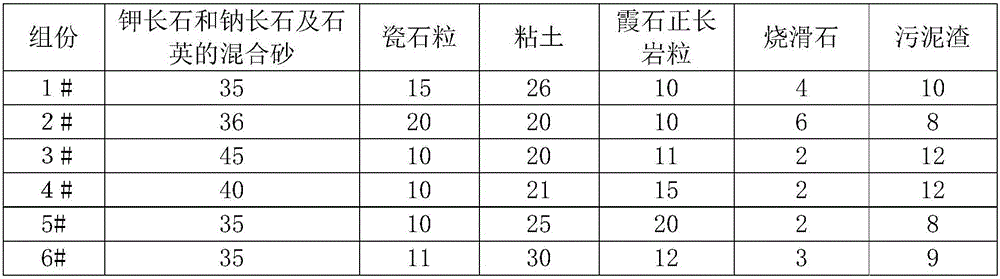

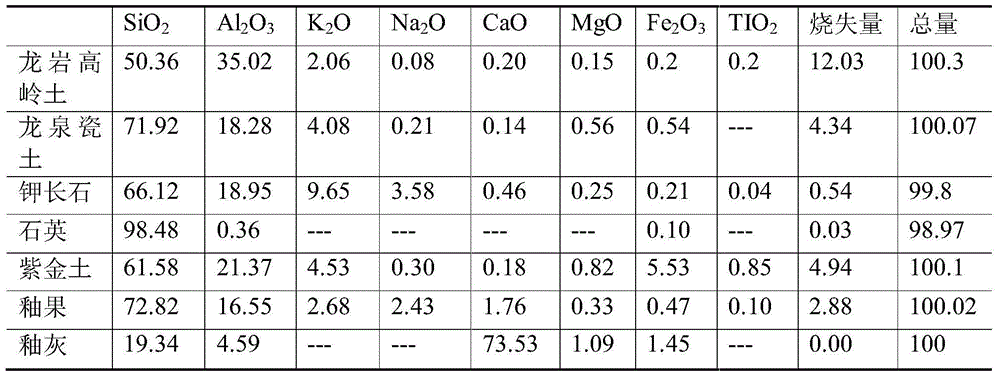

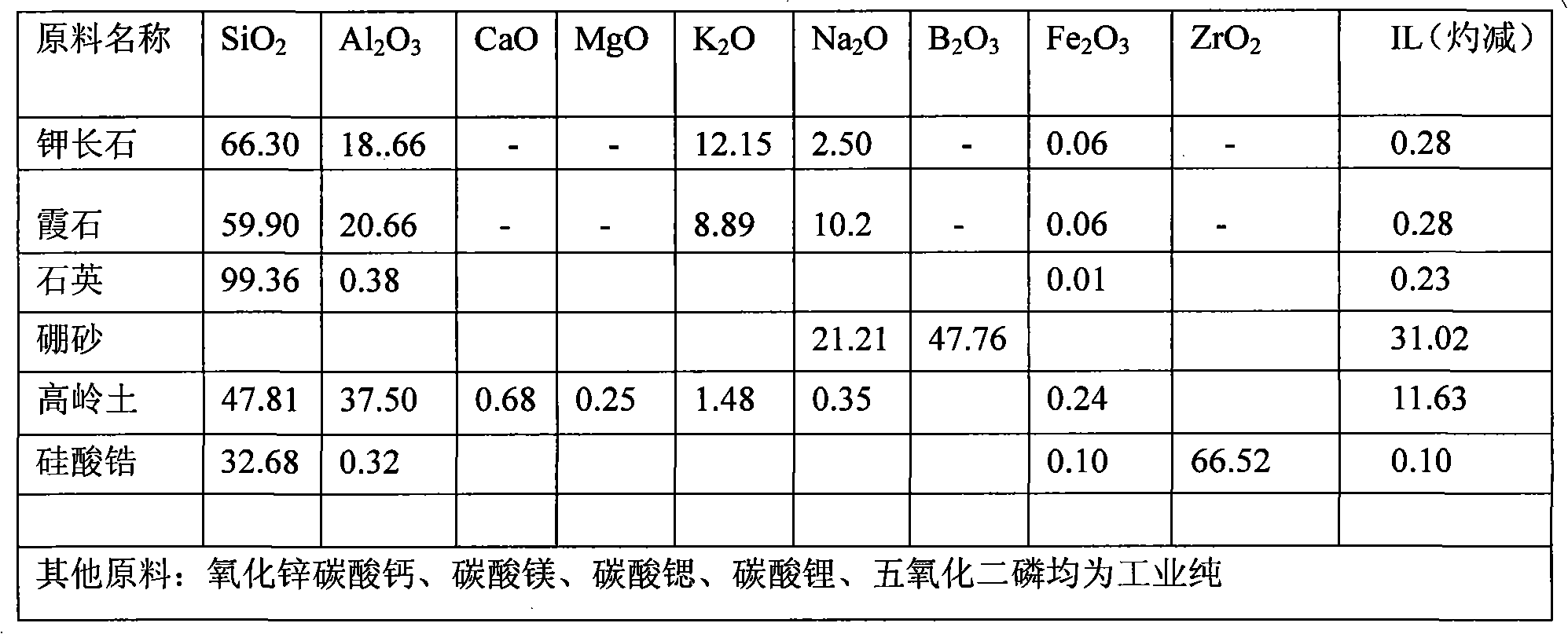

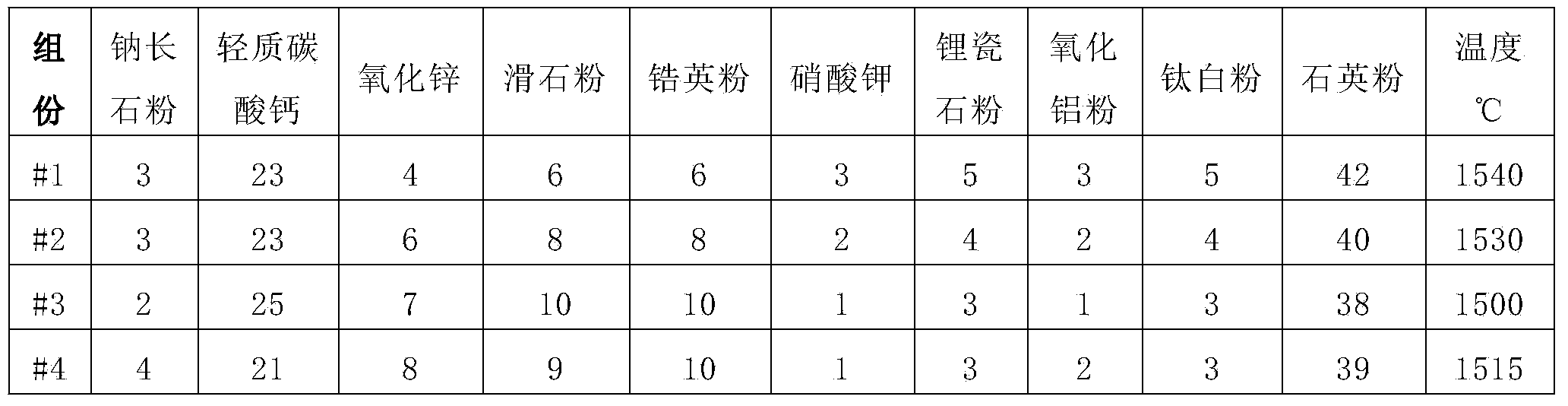

Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

ActiveCN105837172AAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

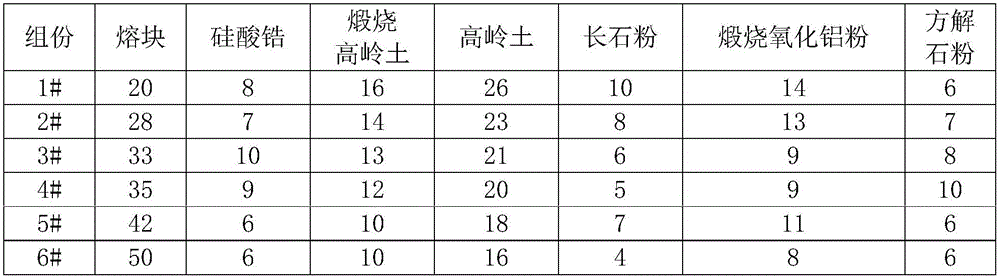

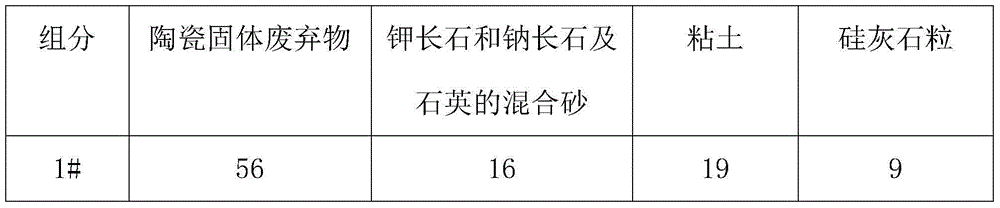

Glazed tile manufactured by using ceramic waste and having broken diamond sand flashing starlight on surface, and preparation method thereof

The present invention relates to a glazed tile manufactured by using ceramic waste and having broken diamond sand flashing starlight on the surface, and a preparation method thereof. According to the present invention, on the base of no major change on the existing glazed tile production process, the green body formula composition, the bottom glaze clinker composition, the surface glaze clinker composition, the bottom glaze formula composition, the surface glaze formula composition, the crystallization clinker composition, the particle size optimizing, the glue formula composition, the crystallization clinker particle slurry formula composition, and process parameters for applying bottom glaze, applying surface glaze and applying crystallization clinker particle slurry are importantly adjusted and optimized, such that the glaze surface of the prepared the glazed tile product likes the matte state through being viewed under the natural light, the slight concave-convex feeling is provided when touching through finger, the glaze surface is smooth and likes jade, the glaze surface crystal such as small quartz grains, pyroxene particles, fine mica sheets and the like in the granulated sugar-like aplite can emit broken diamond sand flashing starlight under side light or light irradiation so as to provide the poetry and painting feeling, the printing pattern texture is delicate, the stimulated stone is vivid, the visual effect is unique, and the whole art sense is strong; and the technology has strong universal property, and is easy to spread in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

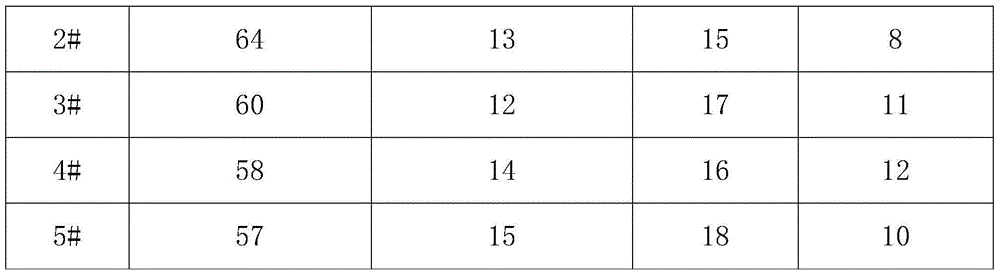

Longquan celadon crackle glaze wine bottle and preparation method thereof

ActiveCN104150873ANovel preparation methodSatisfy the wine storage functionClaywaresPotassiumWine bottle

The invention relates to a longquan celadon crackle glaze wine bottle and a preparation method thereof. Raw material proportions of a blank material, an internal glaze and an external glaze of the bottle are respectively described as follows: the blank material comprises: 40-55% of Longyan kaolin, 15-25% of Longquan china clay, 8-20% of potassium feldspar, 7-15% of quartz and 5-10% of zijin clay; the internal glaze comprises: 65-70% of glaze fruit, 12-25% of glaze ash and 5-10% of zijin clay; and the external glaze comprises: 60-70% of potassium feldspar, 8-15% of quartz, 8-13% of Longyan kaolin, 8-15% of glaze ash, 5-13% of zijin clay and 0.2-0.4% of Fe2O3. On the basis of above raw materials, the longquan celadon crackle glaze wine bottle is prepared by following steps: preparing slurry, performing an injection moulding process to obtain a wet blank; performing a drying process, a trimming process and a biscuiting process to complete a blank manufacturing process; and finally applying the internal glaze and the external glaze and performing a glazing firing process to obtain a finished product of the longquan celadon crackle glaze wine bottle. The bottle is free of stripes on the internal glaze. The external glaze is decorated through crackles. The bottle is good in quality and is free of internal leakage of wine. The method is low in cost and good in effect.

Owner:龙泉市尚唐瓷艺发展有限公司 +1

Enamel glaze and preparation process thereof

The invention discloses an enamel glaze which belongs to the technical field of ceramic materials, and the enamel glaze comprises a colored glaze basic glaze, an enamel glaze basic glaze and coloring pigments. The invention further discloses a preparation process of the enamel glaze and an application of the enamel glaze. The preparation process can improve the firing temperature of the enamel colored glaze, expand the firing range of the glaze, improve the viscosity of the enamel colored glaze and ensure that coloring metal oxides can not be diffused or the color can not be dimmed due to the flowing of the glaze by optimizing the formula of the enamel colored glaze, adopting an appropriate amount of zinc oxide for replacing heavy metal flux materials, such as lead oxide and the like, integrating the applicable color development performances of a variety of coloring materials and introducing a rare earth compound of yttrium oxide. The preparation process can further ensure that the coloring metal oxides in the enamel glaze can not be oxidized by oxygen or water vapor in the air through the way of underglaze color, thereby further ensuring that a product can not change the color or fade forever, closing heavy metals contained in the coloring oxides for avoiding solventing-out and solving the problem of heavy metal pollution.

Owner:SHENZHEN YONG FENG YUAN IND

Core glaze for matte sand streak enamel glaze and production method thereof

The invention discloses a core glaze for a matte sand streak enamel glaze, belonging to the technical field of enamel glazes. The core glaze comprises, by weight, 20 to 35% of quartz sand, 20 to 30% of magnesium oxide, 18 to 28% of soda ash, 8 to 15% of potash feldspar, 2 to 5% of borax, 1 to 2% of fluorite, 1 to 3% of calcium carbonate, 2 to 5% of trisodium phosphate and 0.02 to 0.1% of cobalt oxide. Through cooperative usage of the core glaze with commercially available bright glazes, colorants and the like, matte sand streak glaze products of different colors and different texture can be conveniently and rapidly at a low temperature in a small scale.

Owner:娄底湘信新材料科技有限公司

Ceramic glaze having antimicrobial property

An antimicrobial ceramic glazing composition contains one or more antimicrobial agents disposed therein. Methods for making and using the glazing composition are disclosed, as well as substrates having a fired antimicrobial glaze thereon. The antimicrobial agents comprise metallic oxides, with a subset of the disclosed combinations exhibiting synergistic effect in fired glazes.

Owner:MICROBAN PROD CO INC

Colorful ceramic and preparation method thereof

The invention provides colored ceramics and a preparation method thereof. Ceramic mud for the colored ceramics at least comprises the following compositions in weight percentage: 20 to 35 percent of kaoline, 60 to 70 percent of at least two of pottery stones, lithium pottery stones, feldspar and quartz, 0.2 to 6 percent of coloring matter, and 1 to 5 percent of nanometer quartz. The method for preparing the colored ceramics comprises the following: a step of pulp injection molding, in which part of colored mud cake or colored mud strip is mixed with liquefacient with 0.3 to 0.8 percent of total amount for pulping, and the mud which is screened from a screen of between 80 and 120 meshes is injected into a mold to produce a hollow or solid briquette; and a step of glazing and maturing, in which the briquette which is manufactured by pulp injection molding or plastic molding is cemented and dried according to creativities, and are directly applied with clear glaze, and the glazed briquette body is placed in an oxydizing flame roller kiln or an electrical kiln for 1 to 4 hours at a temperature of between 1,150 and 1,200 DEG C for maturing. The method can not only reduce clinkering cost, but also improve the moisture retention, bonding performance and corrosion resistance of strong ceramic mud, and further show energy conservation and environmental protection.

Owner:JINGDEZHEN HAHANI CERAMIC CULTURE DEV

Golden yellow metal lustre glaze and preparation thereof

The invention discloses a golden metallic luster glaze which is made by mixing a ceramic glaze material and a golden pearlescent pigment. The glaze is made from 40-90% of the ceramic glaze material and 10-60% of the golden pearlescent pigment by weight. The golden pearlescent pigment is added to the ceramic glaze material to ensure that the thermal stability of mica pearl essence in the golden pearlescent pigment increases to over 1100 DEG C, therefore, products which can be made by burning at high temperature of 1000-1200 DEG C can show beautiful golden color.

Owner:GUANGDONG DOWSTONE TECH

Self-cleaning antibacterial ceramic glaze and preparation method and ceramic product thereof

The invention discloses a self-cleaning antibacterial ceramic glaze and a preparation method and a ceramic product thereof. The key of the self-cleaning antibacterial ceramic glaze provided by the invention is that the ceramic glaze contains Ti element and Ag element. The ceramic glaze comprises the following components in percentage: 52-72% of SiO2, 5-9% of Al2O3, 6-10% of CaO, 2-6% of K2O, 0.5-1.5% of Na2O, 0.5-3% of ZnO, 1-3% of Li2O, 4-8% of Ti2O, 1-3% of V2O5 and 1-5% of Ag2O3. The ceramic product of the invention comprises a ceramic noumenon, which is characterized by containing a self-cleaning antibacterial ceramic glaze layer on the surface of the ceramic noumenon. The composition of the invention is suitable to be adopted in primary glazing process, and the surface of the ceramic glaze has high flatness, fined and delicate crystalloid, good smooth finish, no needle pole, extremely soft and good glass like and smooth in touch and reaches the self-cleaning antibacterial effect of ultra smooth glaze layer enamel.

Owner:广东澳丽泰陶瓷实业有限公司

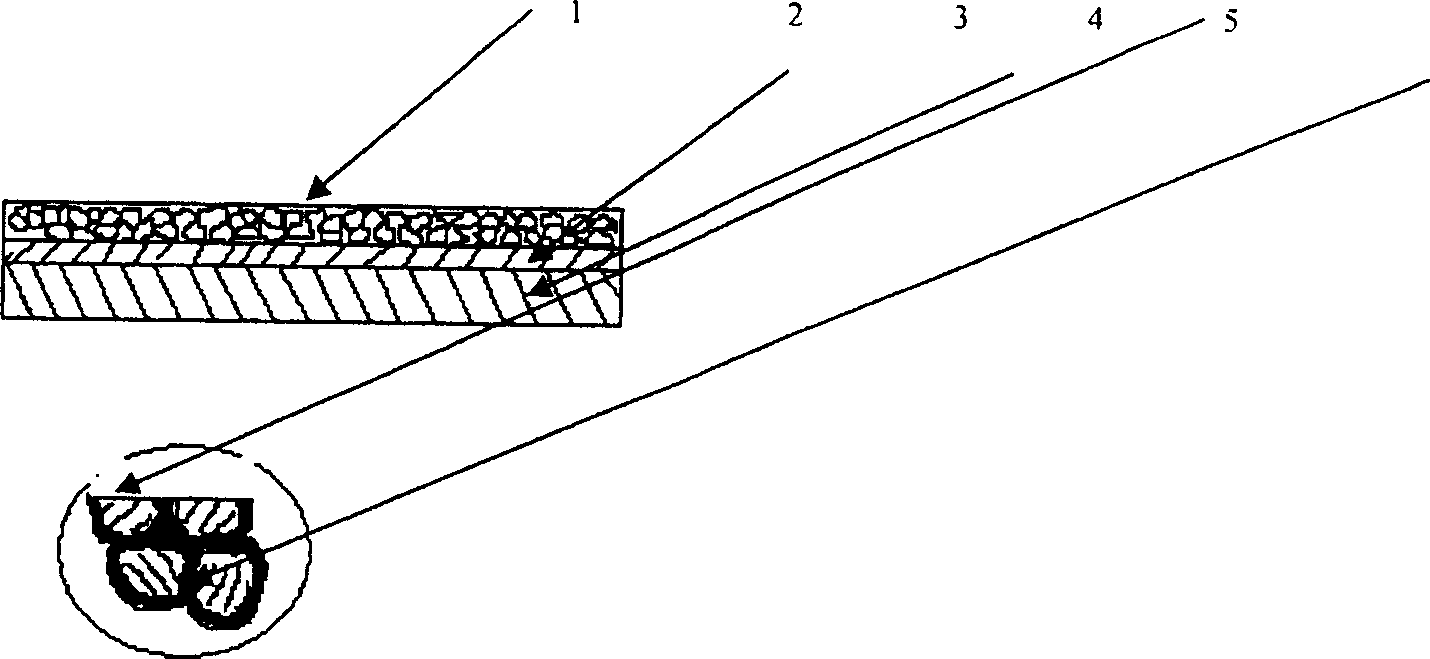

Ceramic tile having antiskid effect and manufacturing method thereof

The invention discloses a ceramic tile having an antiskid effect and a manufacturing method thereof. The ceramic tile is composed of a base body layer, a base glaze layer and a cover glaze layer from bottom to top; as improved, the ceramic tile further comprises an antiskid glaze layer which is located above the cover glaze layer. The manufacturing method of the ceramic tile is to form the antiskid glaze layer by printing an antiskid glaze slip by use of a flat silk screen, wherein the antiskid glaze layer is sprayed on the cover glaze layer of the ceramic tile and fused with the cover glaze layer by virtue of high-temperature calcination, and consequently, the ceramic tile is enabled to have a wet antiskid effect, and therefore, the usability of a ceramic glazed floor tile can be remarkably improved and the market application range of the ceramic glazed floor tile can be expanded. The manufacturing method of the ceramic tile is carried out according to a traditional production and manufacturing flow and does not need to be greatly modified in the basic process flow; besides, the manufacturing method is wide in application range, and capable of simultaneously adapting to ceramic products such as once-fired stoneware floor tiles, once-fired porcelain floor tiles and twice-fired ceramic glazed floor tiles.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +2

Ru agate glaze and processing method and application thereof

The invention discloses a Ru agate glaze, which contains the following components by weight parts: 6 to 26 parts of agate, 40 to 65 parts of feldspar, 10 to 23 parts of calcite, 13 to 28 parts of black limestone, 3 to 8 parts of limonite, 2 to 4 parts of talcum and 5 to 10 parts of chestnut ash. The invention also discloses a processing method for the Ru agate glaze and the application of the Ru agate glaze on Ru porcelains, and also discloses a Ru porcelain. The basic tones of the glaze of the Ru porcelain fired with the Ru agate glaze are green and blue, and therefore the glaze can present the deep colors of azure, cyan and bluish white as well as the bright, transparent colors of pea green, light green and light greenish blue; the texture of the porcelain body is fine and dense, the porcelainizing degree is high, the water absorption does not exceed 1.2 percent, and the sound is silvery when the product is knocked; the thermostability is good, and defects, such as through cracks and leakage, do not exist.

Owner:郭秀贞

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

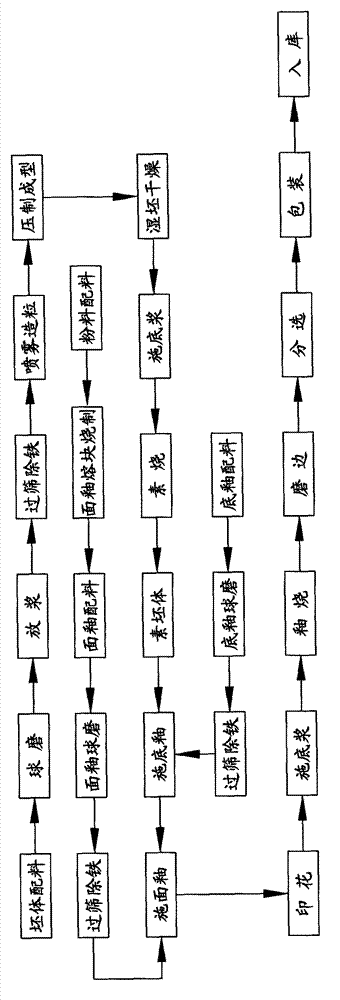

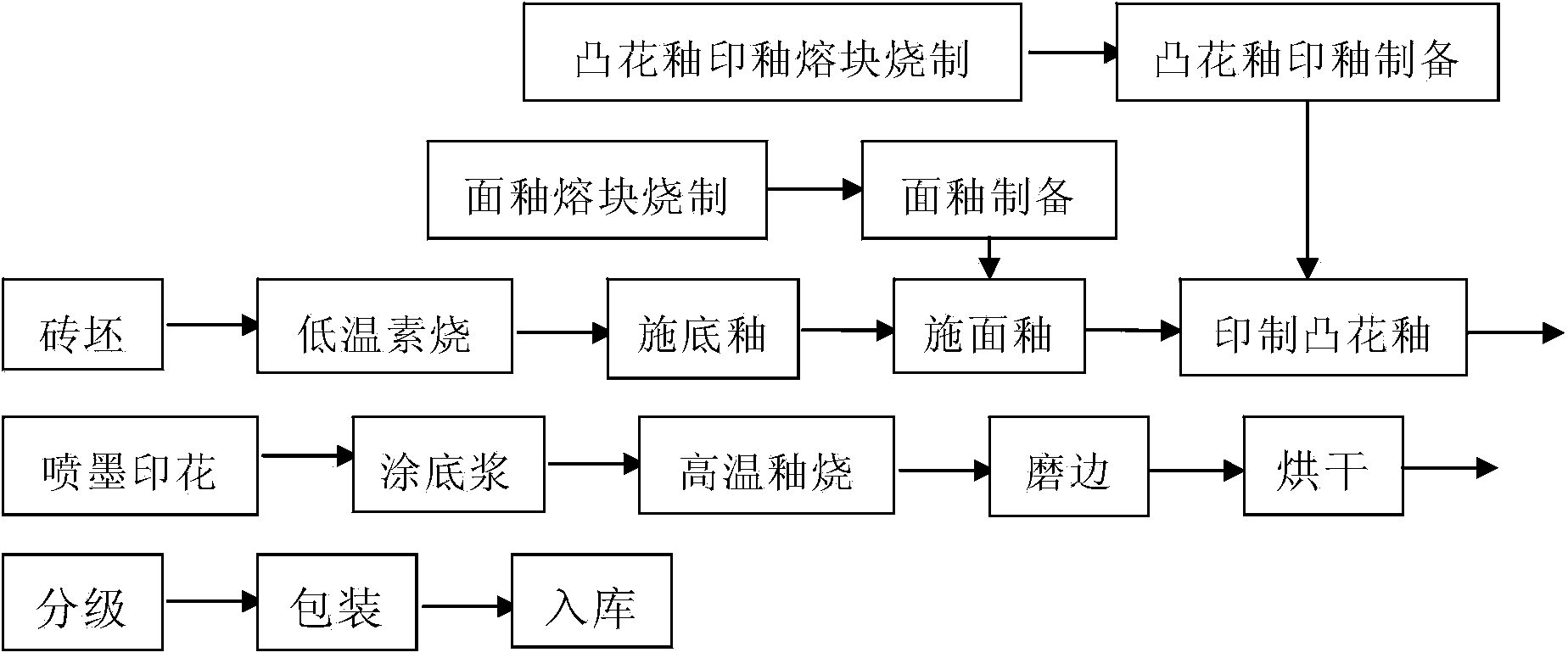

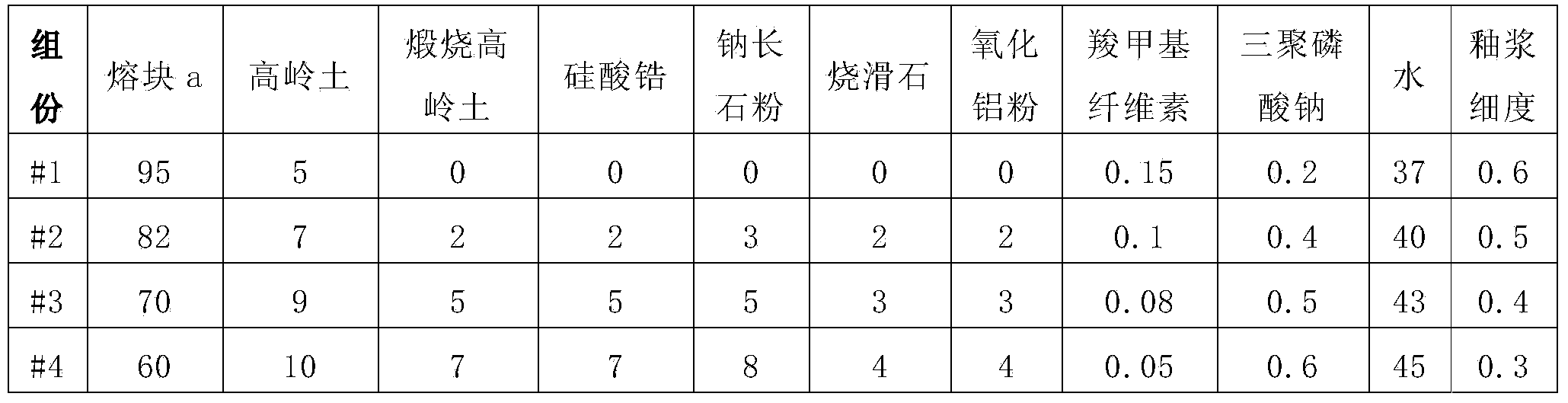

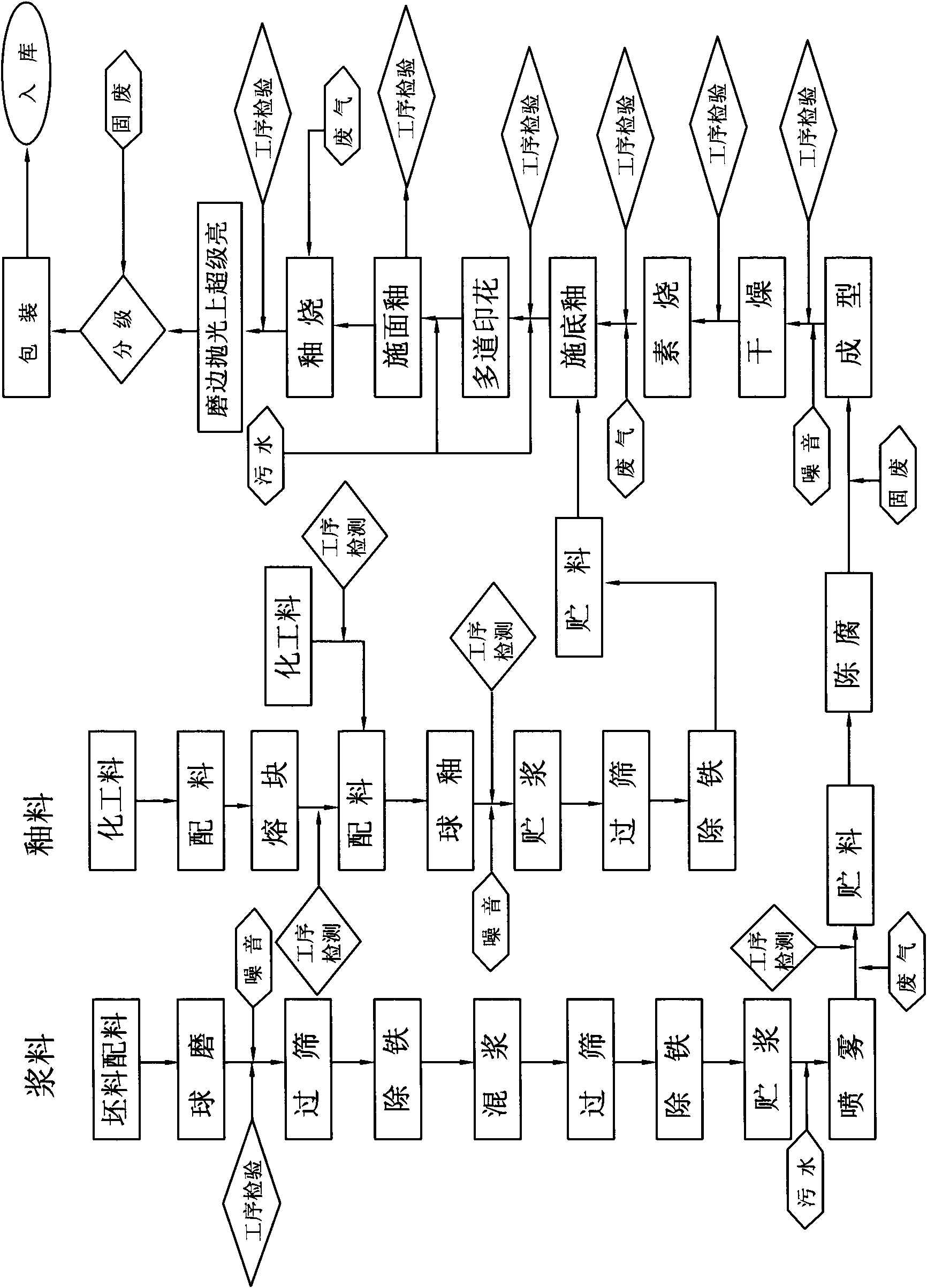

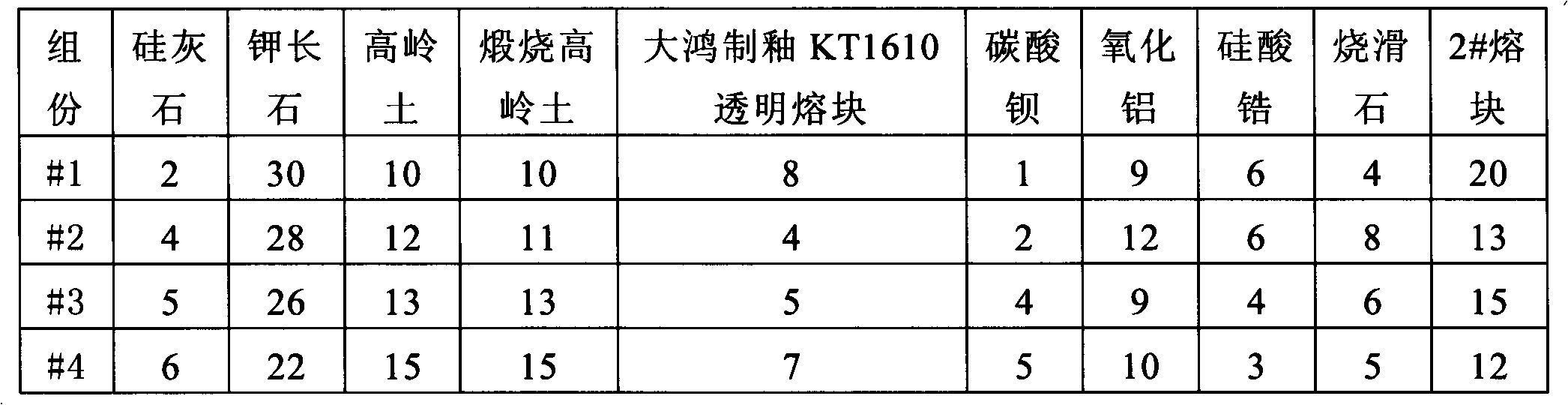

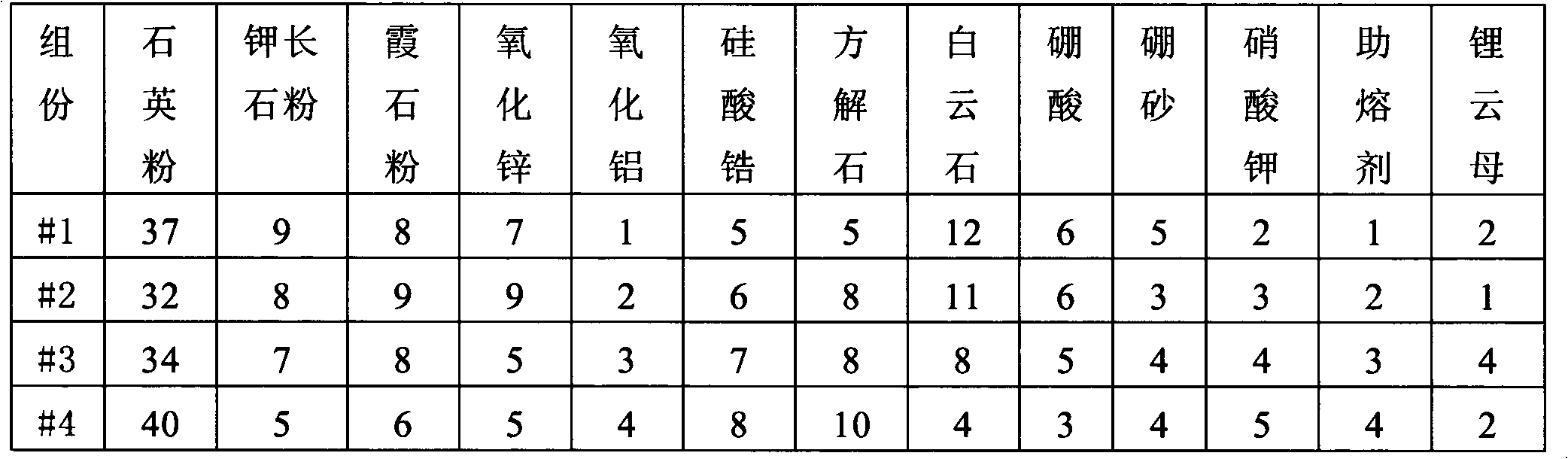

Production technology of super-flat high-crystal stone tile

The invention relates to a production technology of super-flat high-crystal stone tiles. The technology comprises steps that: blank materials are prepared; a glaze is prepared; the blank materials are molded by pressing; the blank materials are subject to low-temperature biscuit-firing; a ground glaze is applied on dry blanks; patterns are printed; a surface glaze is applied; high-temperature glaze firing is carried out; rims are burnished; and ultra-bright polishing is carried out. According to the invention, a special blank material formula and a special glaze formula are adopted; with the effects of low-temperature biscuit-firing and high-temperature glaze firing, the glazes and the blank body are sufficiently bonded, such that the glaze surfaces of the tiles provided by the invention are smoother than those of common glazed tiles, and the glaze surfaces are super-flat. The glaze surfaces are as transparent as those of common micro-crystal stones, and have hardness higher than thatof common micro-crystal stones.

Owner:SICHUAN NEW ZHONGYUAN CERAMICS

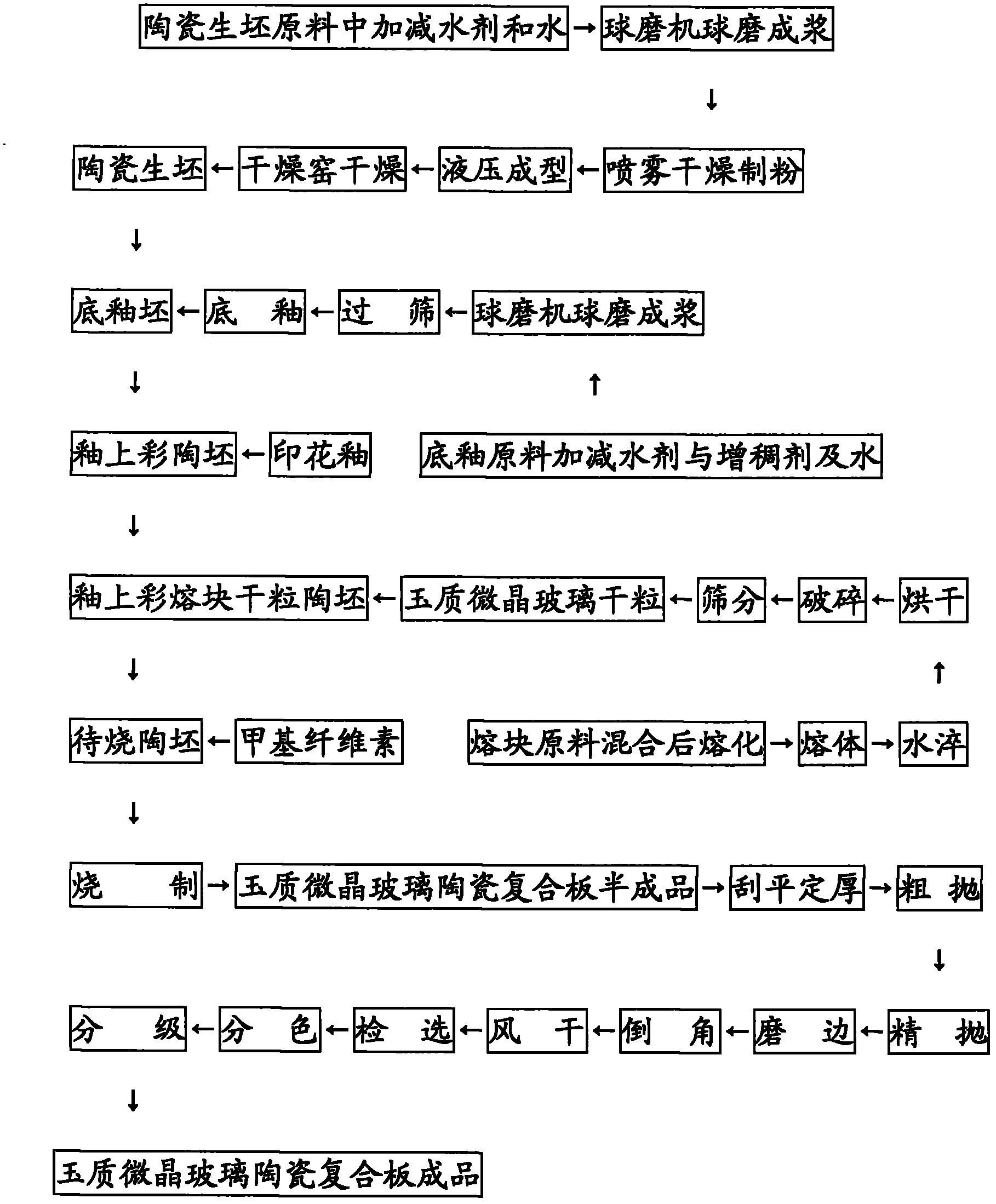

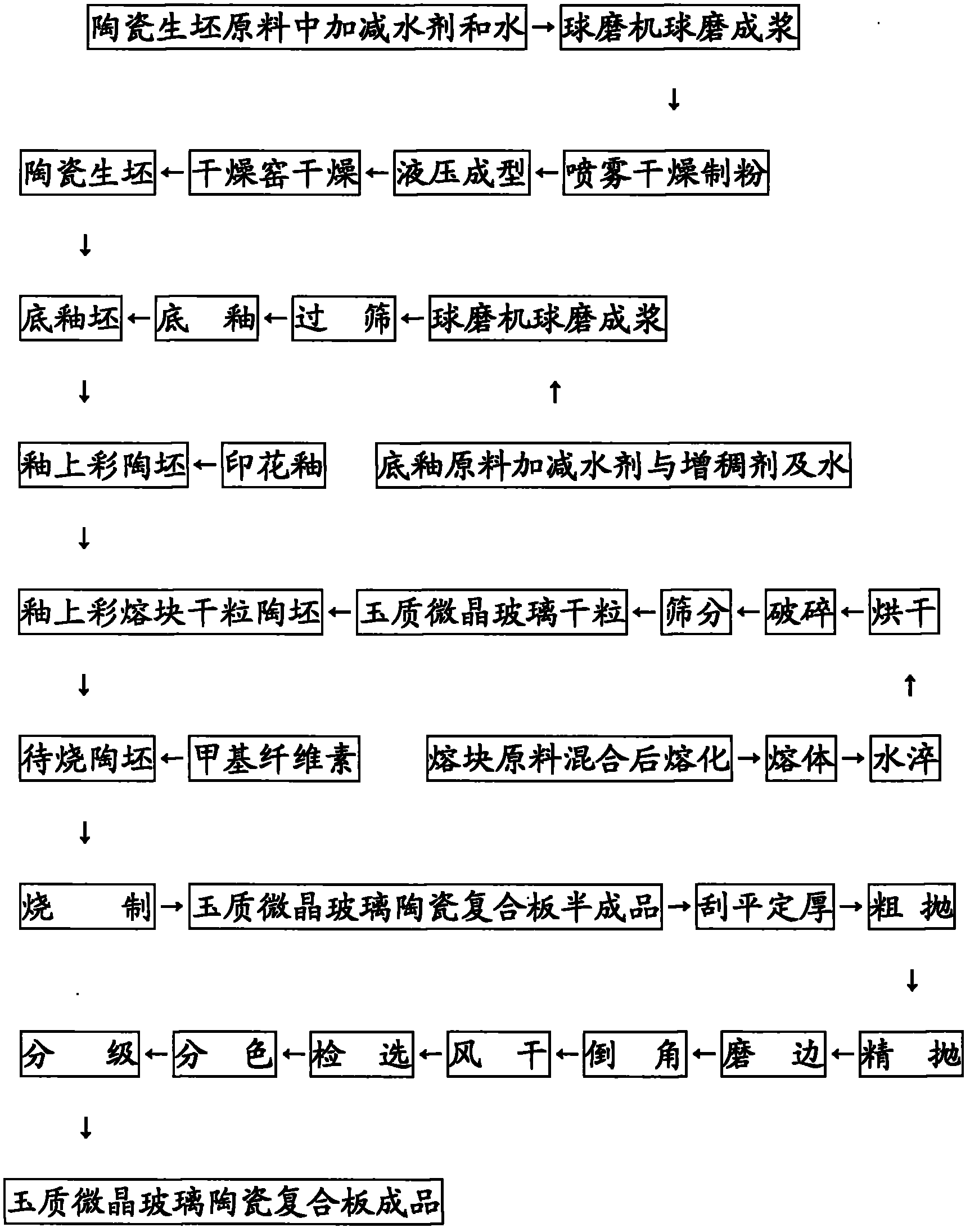

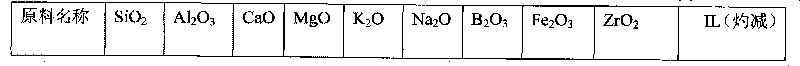

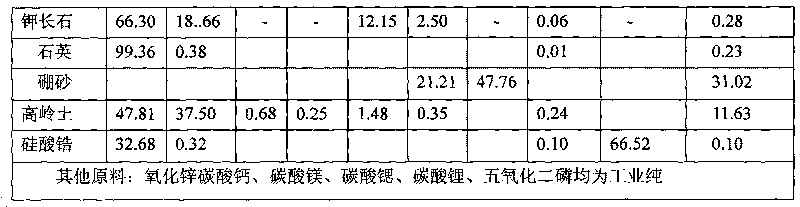

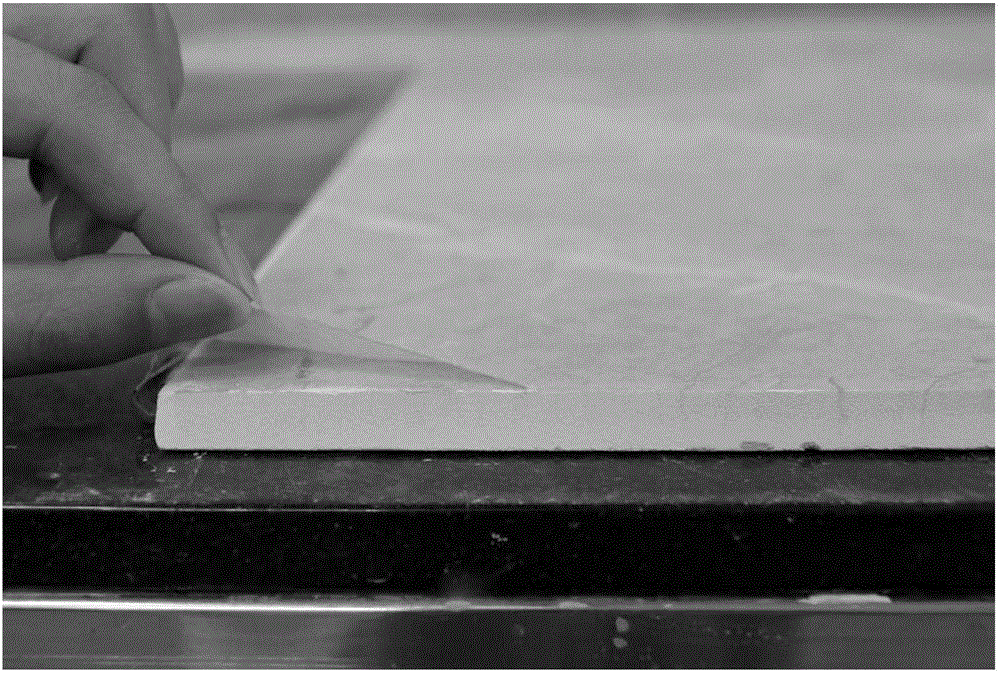

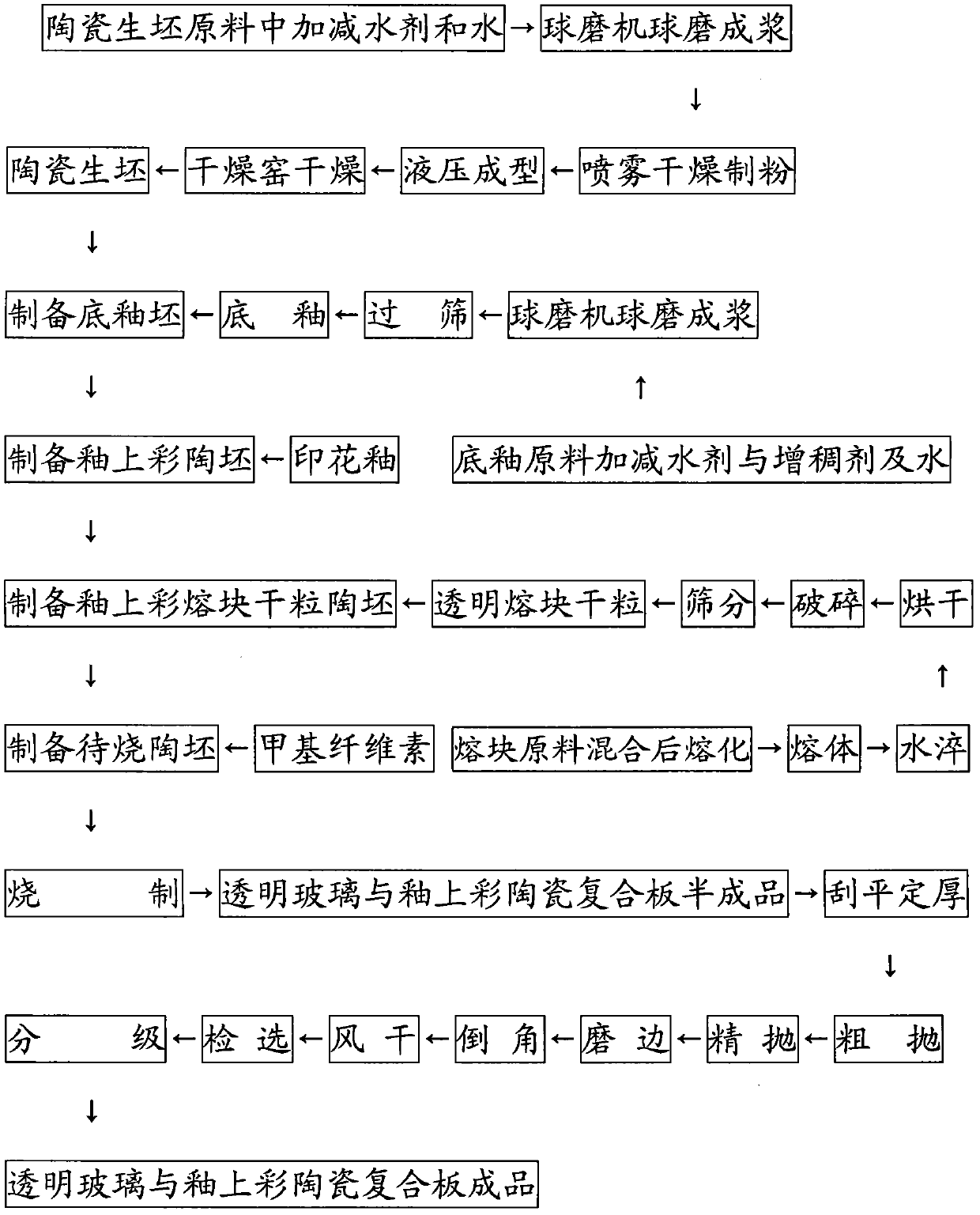

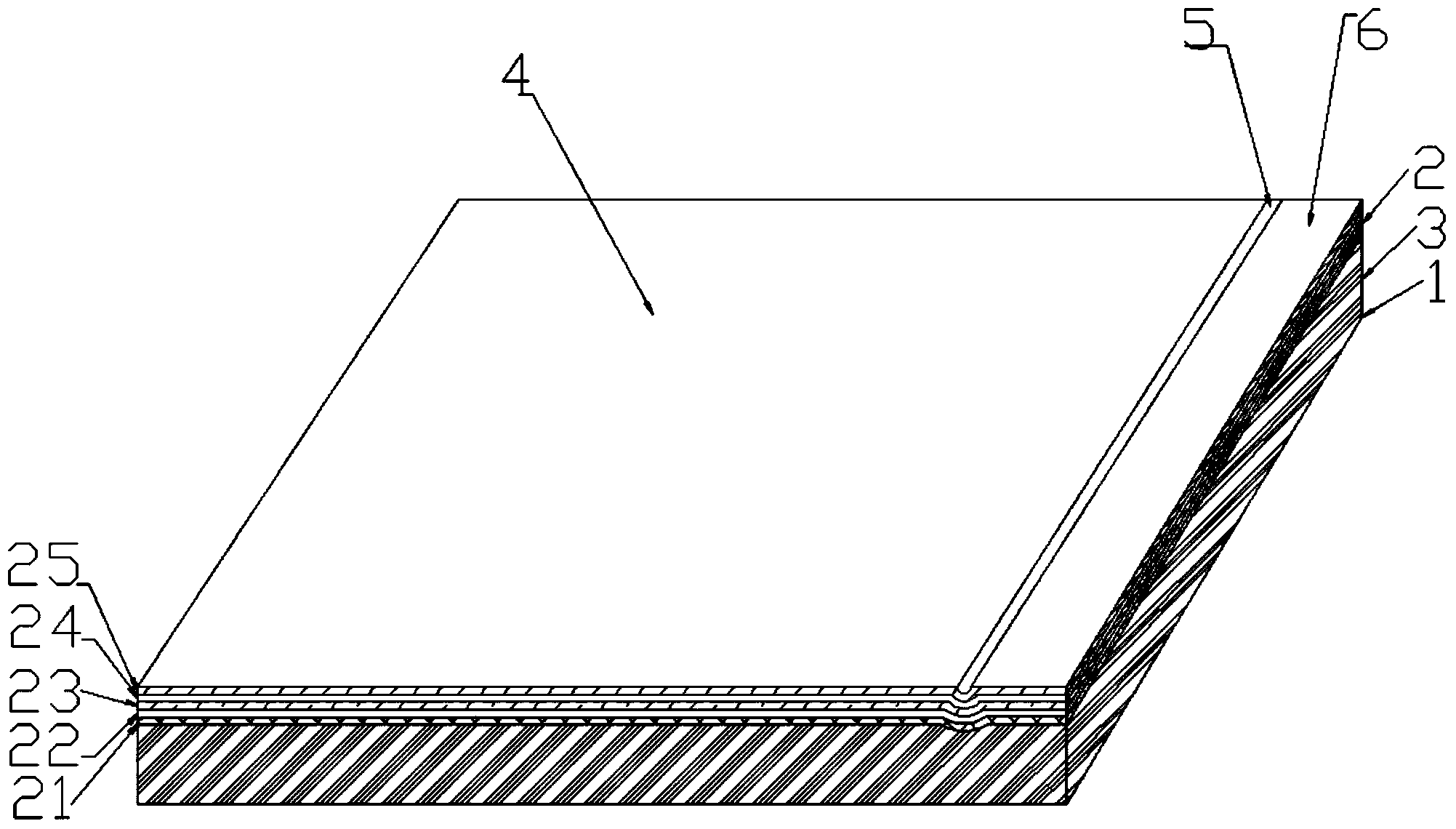

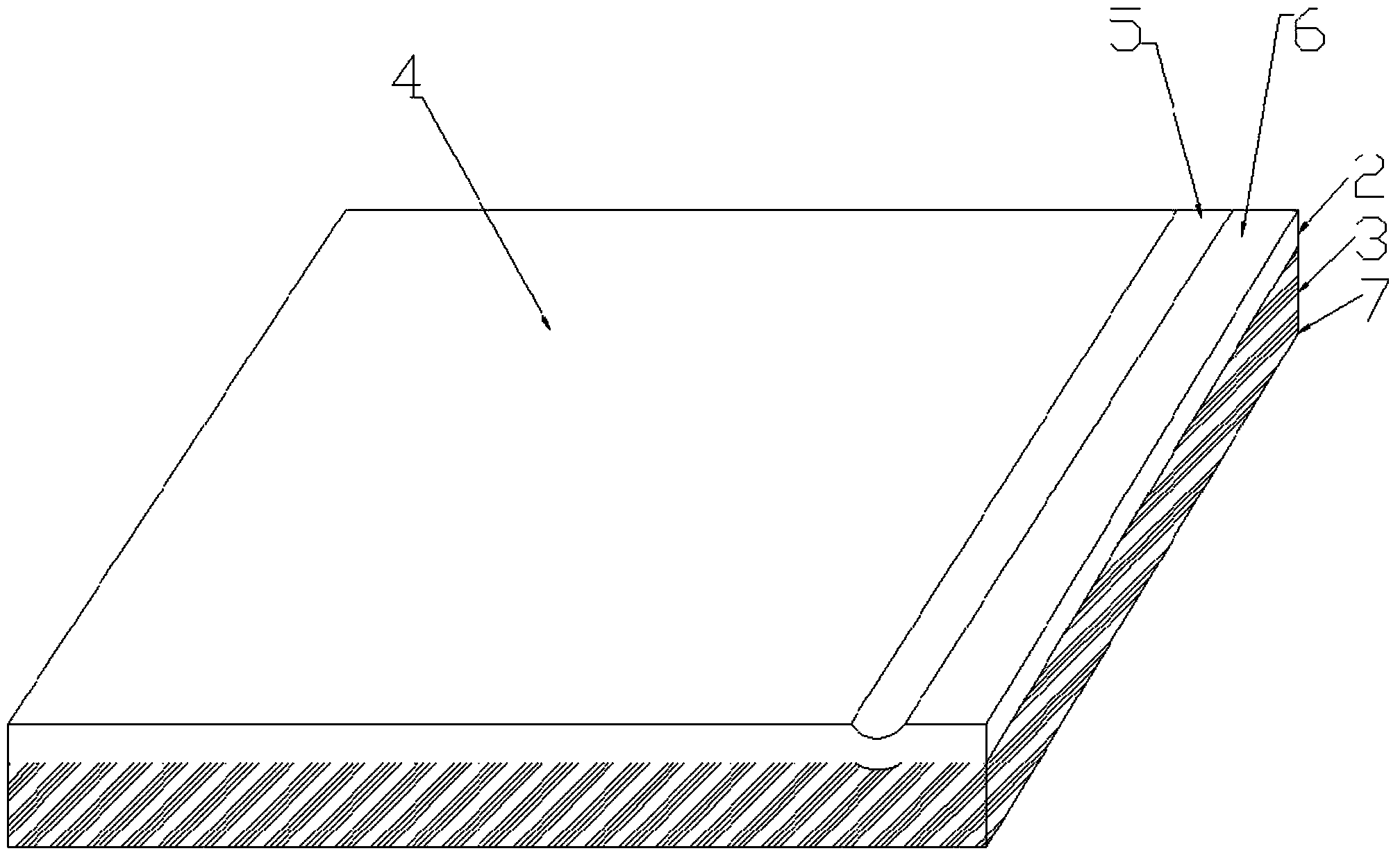

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Ceramic glaze and preparation process thereof

The invention discloses ceramic glaze, belonging to the technical field of ceramic materials and comprising basic glaze and coloring pigments, wherein the basic glaze comprises the following components by weight percent (wt%): 45% to 60% of SiO2, 7% to 12% of Al2O3, 5% to 12% of CaO, 0% to 5% of MgO, 0% to 5% of P2O5, 0.5% to 5% of SrO, 2% to 8% of ZnO, 1% to 7% of K2O, 1% to 5% of Na2O, 0.5% to 5% of Li2O, 1% to 8% of B2O3 and 0% to 4% of ZrO2. By separating the coloring pigments in colored glaze from the basic glaze and baking the coloring pigments at different temperatures for twice, the invention solves the problems that the product of colored ceramic glaze has poor color difference and color development and leads to pollution caused by heavy metals, such as lead, cadmium and the like, and the problem that the colored pigments or metal oxides are dependent on the basic glaze at the same time; and the invention lessens the difficulty in producing the colored ceramic glaze.

Owner:宜春市洪州瓷业有限公司

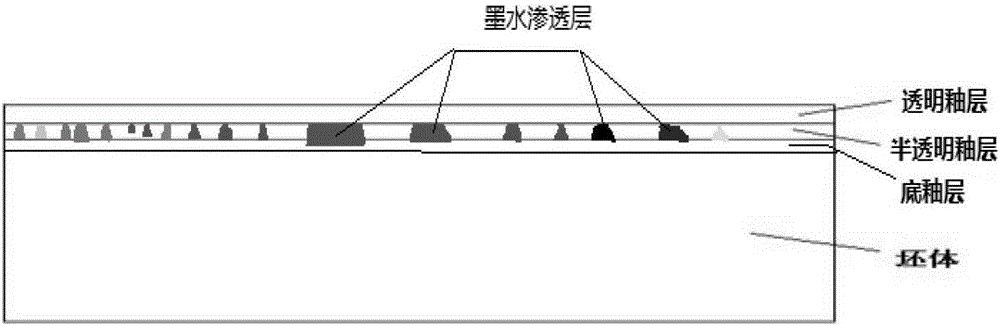

One-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and manufacturing method thereof

The invention relates to one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and a manufacturing method thereof. According to the manufacturing method, a bottom green brick layer, a priming glaze slurry, a semitransparent glaze slurry, and a transparent glaze slurry are prepared respectively; the bottom green brick layer is subjected to following treatment respectively: a priming glaze layer is formed via priming glaze slurry pouring, jet printing of decorative patterns is carried out, a semitransparent glaze layer is formed via semitransparent glaze slurry pouring, and drying is carried out; obtained green bricks are printed with decorative patterns with ink-jet of penetrating ink and jet printing of a permeation promoter, and are allowed to stand for more than 5min; the obtained green bricks are printed with isolation glaze with water isolating performance via silk-screen printing, and are dried and cooled; the green bricks are coated with the transparent glaze slurry via pouring; the green bricks are subjected to one time sintering so as to obtain one-time sintered ink-jet penetrating porcelain tile semi-finished products with three-dimensional decorative effects; the semi-finished products are subjected to polishing via inelastic module technology so as to obtain the one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects.

Owner:MONALISA GRP CO LTD

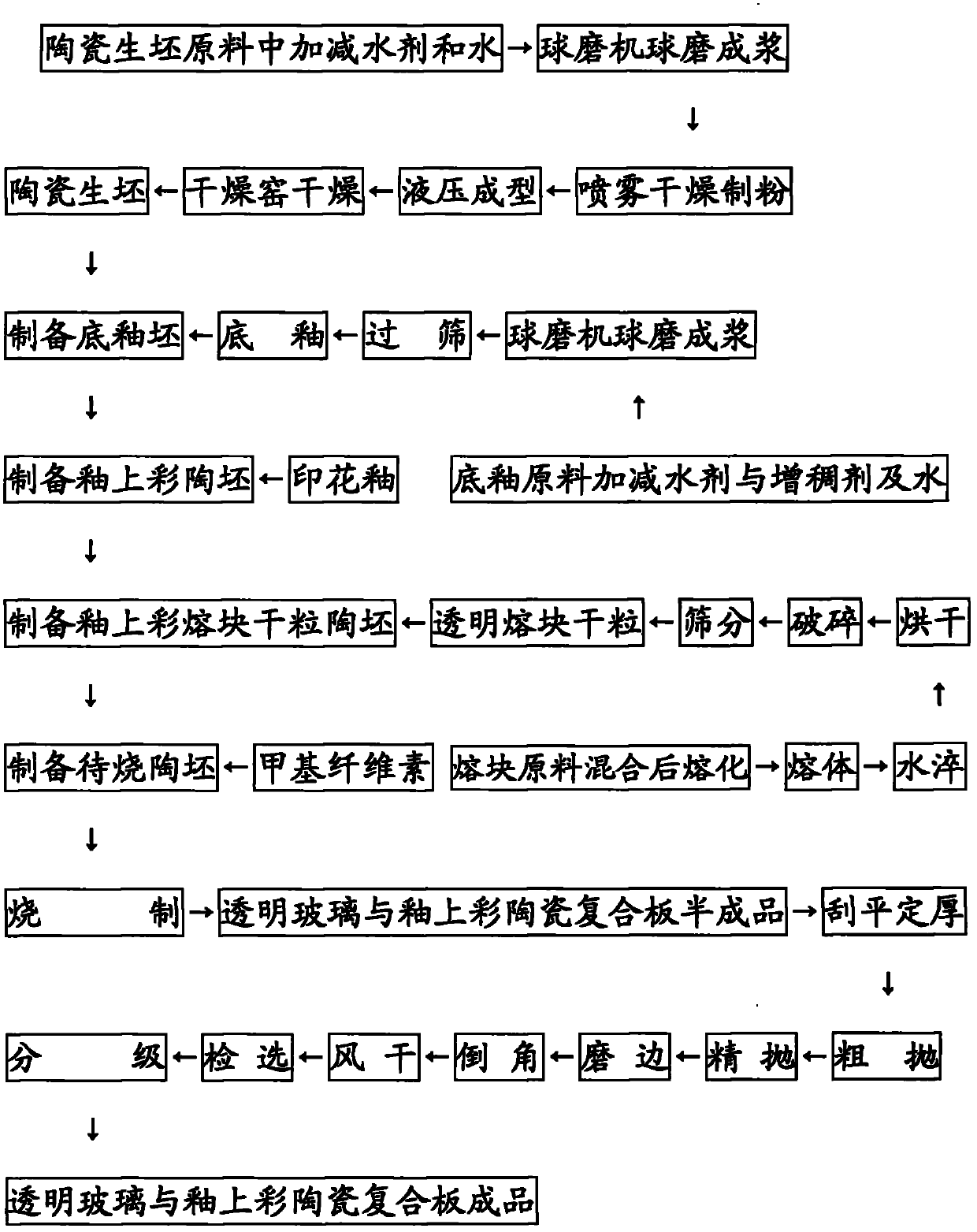

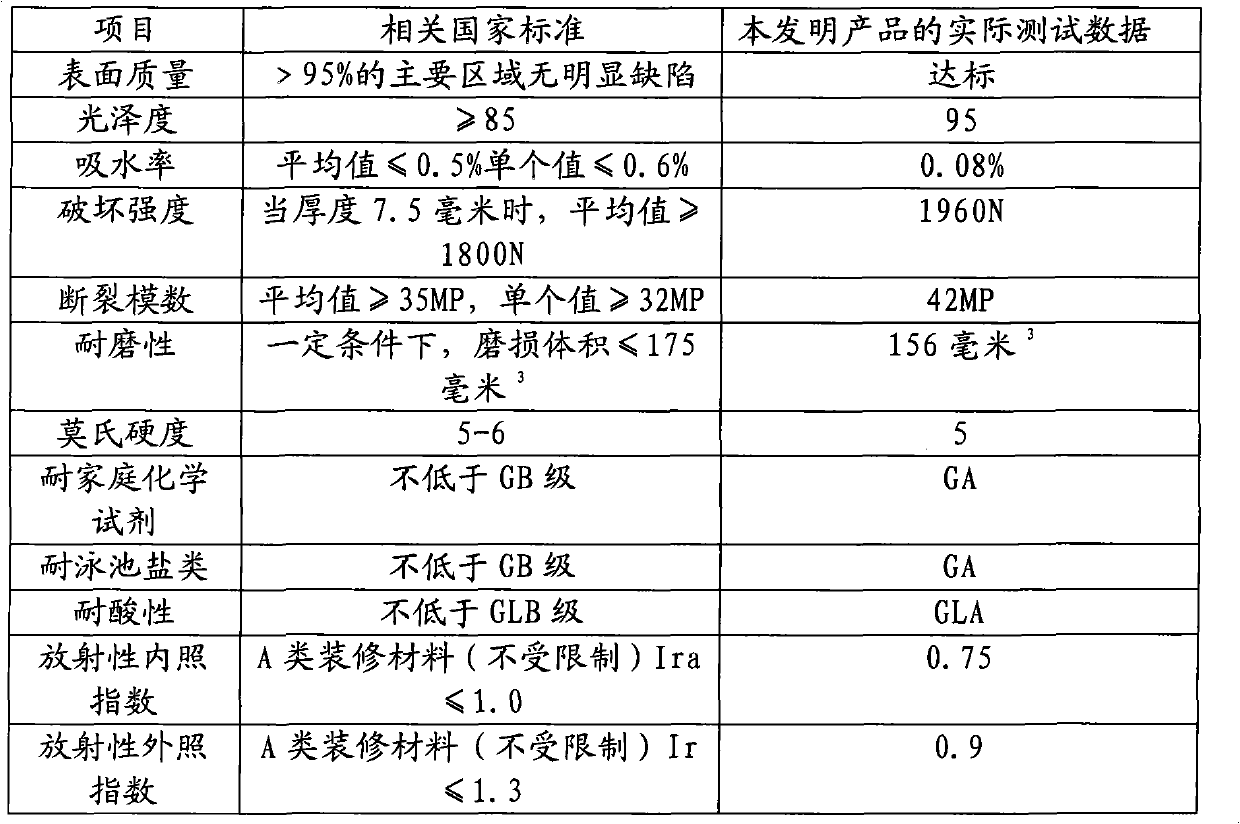

Method for producing transparent glass and overglazed color ceramic sandwich by single firing

A method for producing transparent glass and overglazed color ceramic sandwich by single firing in the invention relates to the technical field of building materials. By the adoption of ''a key single firing technology with material selection within the range of predetermined product components'', the method provided by the invention comprises the following steps of: applying ground-coat enamel on a ceramic green compact to prepare an enamel green body, printing gelatine-pad printed fancy glaze to prepare an overglazed color ceramic green body, applying transparent frit dry granules on the overglazed color ceramic green body to prepare overglazed color frit dry granular ceramic green body, spraying methyl cellulose for fixation to prepare a greenware to be sintered, sintering the greenware to be sintered to form a semi-finished product, followed by strickling for thickness determination, rough casting, fine casting, edging, chamfering, air drying, picking and grading to prepare the transparent glass and overglazed color ceramic sandwich finished product. The method is used for the production of transparent glass and overglazed color ceramic sandwiches and is the single firing technology with material selection within the range of predetermined product components.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Ceramic tile preparation method and product thereof

ActiveCN103833423ANo complicated color separationNo tedious workCovering/liningsBrickMaterials science

The invention discloses a ceramic tile preparation method, which comprises the following steps in order: performing mold design and molding, applying ground glaze to form a ground glaze layer, then performing ink-jet printing to form an ink-jet decorative layer; performing roller printing decoration on the ink-jet decorative layer to form a printing decorative layer; spraying a layer of transparent glaze on the printing decorative layer to form a transparent glaze layer; decorating the transparent glaze layer to form a decorated glaze layer, and performing high temperature sintering. With the method of the invention, prepared waistline and main tile parts are sintered integrally; the product has unified color, texture, and lines, has good decorative effect. When in use, not only is tedious work of tile alignment and tiling by colores and batches omitted, but also no customer complaint is generated, and the product has strong practicality; when compared with traditional methods in which waistlines and main tiles are produced and tiled respectively, the method of the invention can produce the integral product which omits tiling manpower, is simple in construction, and convenient for popularization.

Owner:FOSHAN DONGPENG CERAMIC +3

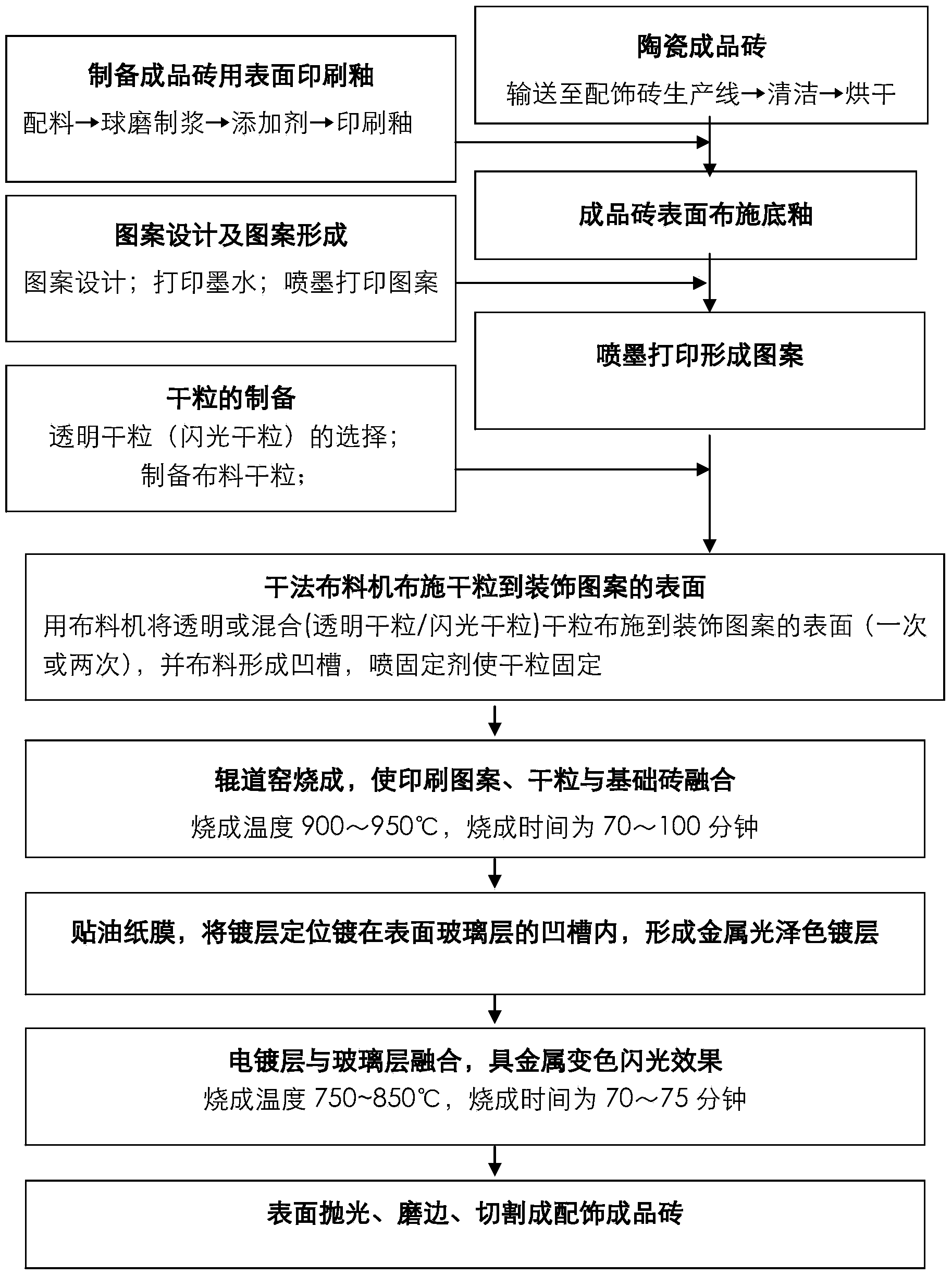

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

Superfine dry granular porcelain glazed tile

The invention discloses a superfine dry granular porcelain glazed tile which belongs to the field of preparation of porcelain glazed tiles. The superfine dry granular porcelain glazed tile comprises agreen body, ground glaze and surface glaze, wherein the surface glaze comprises the following raw materials in percent by weight: 22-25wt% of potassium feldspar, 6-8wt% of calcined talc, 17-20wt% ofbarium carbonate, 2-5wt% of calcined alumina, 3-5wt% of calcined zinc oxide, 3-5wt% of quartz, 5-8wt% of kaolin, 6-8wt% of dolomite and 26-30wt% of 10,139 # dry granules. The green body of the tile islow in water absorption and high in breaking strength; the green body, the bottom glaze and the surface glaze are good in combinability, and the tile in good in flatness; the superfine dry granules form a slightly rugged surface in the surface glaze, and the grain size of each of granular crystals protruding out of the glaze is 0.12-0.18mm, so that an anti-skidding and abrasion-proof effect can be achieved on the glaze, and the defect that dirt is hided and adsorbed in the glaze can be overcome.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com