Patents

Literature

606results about How to "Full color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

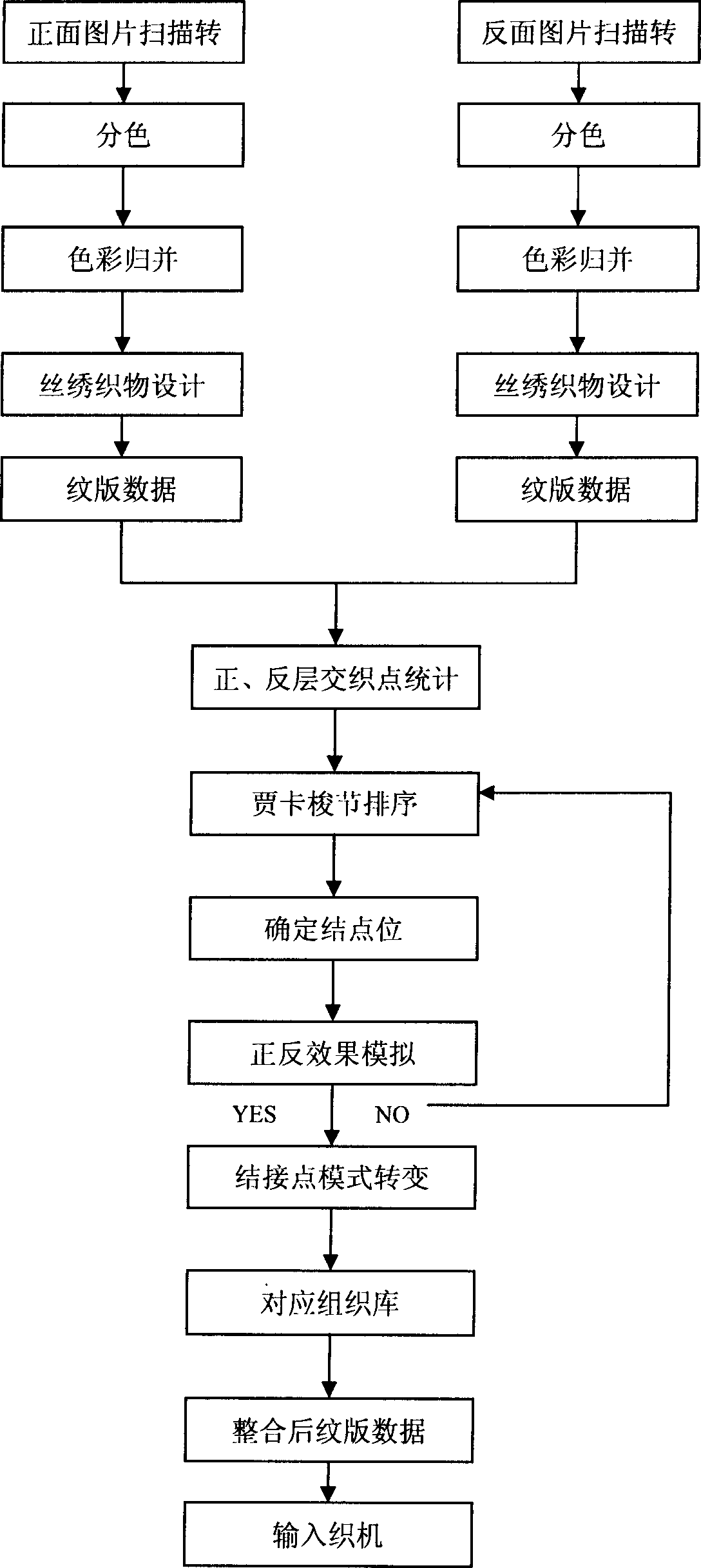

Digitel code manufacturing method jacquard weave double surface beautiful and glorious

InactiveCN1786308AMeet individual needsWide range of materialsPattern making devicesCard-punching apparatusTexture designPersonalization

The invention belongs to silk weaving picture-scenery technique development field, especially relates to a digital pattern two side beautiful brocade manufacturing method. The method includes the following steps: scanning, changing, color separating to set color bank; adding up crossing point according to electron lag; doing knitted texture design and confirming crunode position; inputting electron lag into loom control system. Materials drawing of the invention are very wide. And the product can satisfy consumerí»s individuation demand.

Owner:韩容

Method for preparing environment-friendly natural fiber printing paste

The invention discloses a method for preparing an environment-friendly natural fiber printing paste, comprising the following steps of: 1) selecting fine diatomaceous earth having a grain size less than or equal to 2 microns; 2) preparing raw printing paste, wherein the raw printing paste is composed of the following components in terms of weight: 6-13% organic printing paste material, 1-8% fine diatomaceous earth and 0.2-0.6% sodium hexametaphosphate, and rest being water; and 3) preparing the printing paste, wherein the printing paste is composed of the following components in terms of weight: 1-4% dye, 1-7% urea, 1-7% urea replacing agent, 1.5-2.5% sodium bicarbonate, 0.2-1% reserve salt S and 50% raw printing paste, and rest being water. The printing paste obtained through the method of the invention is capable of ensuring the printing quality and also capable of greatly reducing the content of organic matters in sewage discharged after printing, thereby reducing pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

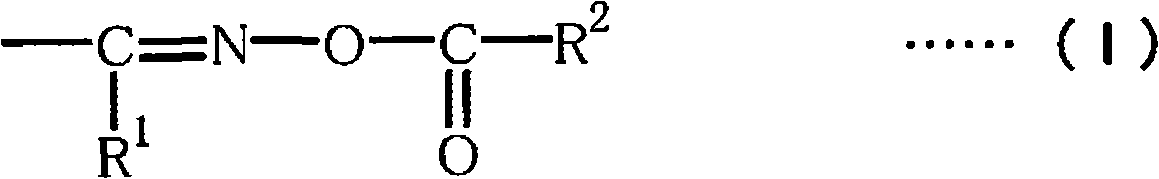

Photocuring resin composition, dry film, curing product and print circuit board

ActiveCN101303527AFull colorIncreased sensitivityOrganic chemistryPhotosensitive materials for photomechanical apparatusUltravioletCarboxylic acid

The invention provides a photocurable resin composition, dry film, cured substance and printed circuit board. The invention provides a photocurable resin composition which is fully coloured, has high photosensitivity under the exposure of ultraviolet ray and laser such that it has good curing depth, in the mean time, adjusting absorption in the ultraviolet region by using red or yellow colorant as well as oxime ester initiators. The photocurable resin composition which may develop through alkaline aqueous solution contains (A) carboxylic acid-containing resins, (B) red colorants, (C) oxime ester initiators and (D) compounds having more than two unsaturated alkene groups in the molecules.

Owner:TAIYO HLDG CO LTD

Slurry disperse dye and preparation method and appliance

The invention discloses a slurry disperse dye and a preparation method and an appliance, wherein the slurry disperse dye comprises liquid disperse dyes, functional prepolymers and synthetic thickeners, the synthetic thickeners and functional additives are added into the slurry disperse dye to prepare trace printing paste, and can complete printings of polyester fabrics on a common rotary screen printing machine or a screen printing machine, then printed polyester fabrics are prepared through a heat-setting stenter in 180 DEG C-210 DEG C for 45-120s. The slurry disperse dye has the advantages of short printing process when being used for polyester fabric printings, is soft in fabric handing, does not need post process, saves a lot of water and energy consumption, nearly does not have discharge amount of waste water, uses common equipment as process equipment, and is a green printing process technology.

Owner:SUZHOU UNIV

Sweetmuscat wine and brewing process thereof

The invention aims at providing sweet muscat wine which uses muscat grapes as a raw material, is rosy in appearance color, is clear and transparent, typical, rich, fresh and elegant in aroma, mellow and full in taste, smooth in wine body, balanced in taste, lasting in aftertaste and high in alcohol degree and a brewing process thereof, belonging to the technical fields of wines. The technical scheme is as follows: the brewing process of the sweet muscat wine adopts a segmented fermentation method,an impregnation process and a fermentation process are not fully synchronized, the impregnation is performed for a fixed time of 96h in an alcohol fermentation process I, peel and pomace are separated and then an alcohol fermentation process II is performed, and the impregnation time length is fixed and appropriate.

Owner:山西戎子酒庄有限公司

Picture-grade high-light water-proof colour ink-jet printing paper

InactiveCN1814913AHigh transparencyHigh whitenessSpecial visual effect coatingsMetal coatingsPulp and paper industrySilicon

Photo-stage high brightness water-proof color ink-jet printing paper includes a basic material and a coat coated on it characterizing that said coat contains nm modified Al2O modified by a strong anode ion dispersing agent and a bonder, since the coat contains modified Al2O with the diameter of 30-80nm and inorganic silicon sol with the diameter smaller than 20nm, the invented paper can either absorb water ink or make the ink not to disperse.

Owner:SHANTOU XINXIE SPECIAL PAPER TECH

Chafing dish bottom flavorings and preparation method

InactiveCN101209117APromote secretionPromote peristalsisEdible oils/fatsFood preparationFlavorAdditive ingredient

The invention relates to a bottom material of chafing dish and the preparation method, which is characterized in that the formula and the parts by weight of all the components of the bottom materials are: 220 to 260 parts of butter, 80 to 120 parts of glutinous rice cake hot pepper, 4 to 6 parts of wild pepper, 6 to 10 parts of bean paste, 8 to 12 parts of black bean sauce, 18 to 22 parts of mature ginger, 7 to 9 parts of garlic, 10 to 14 parts of fragrance, 0.8 to 1.5 parts of rock sugar and 2 to 4 parts of liquor. The bottom material of chafing dish which is fried by the applicant of the invention has special process. The usage of the bottom material of chafing dish of the invention can prepare the chafing dish with pure taste, maintain the characteristics of being numb, spicy, delicious, spiced and back sweet and have the advantages of being spicy but not dry and numb but not intense.

Owner:重庆刘一手餐饮管理有限公司

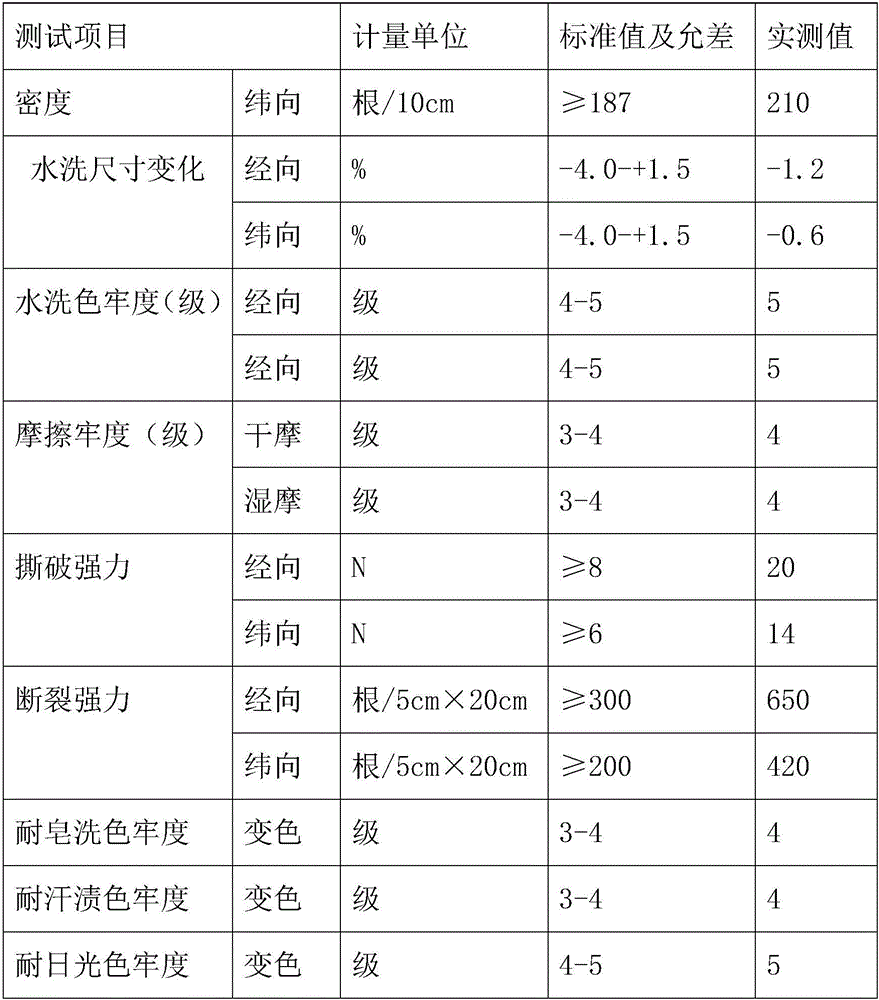

Anti-infrared military camouflage fabric and printing and dyeing process thereof

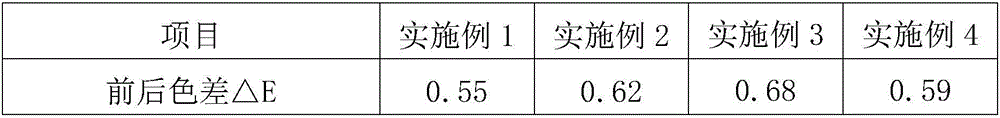

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

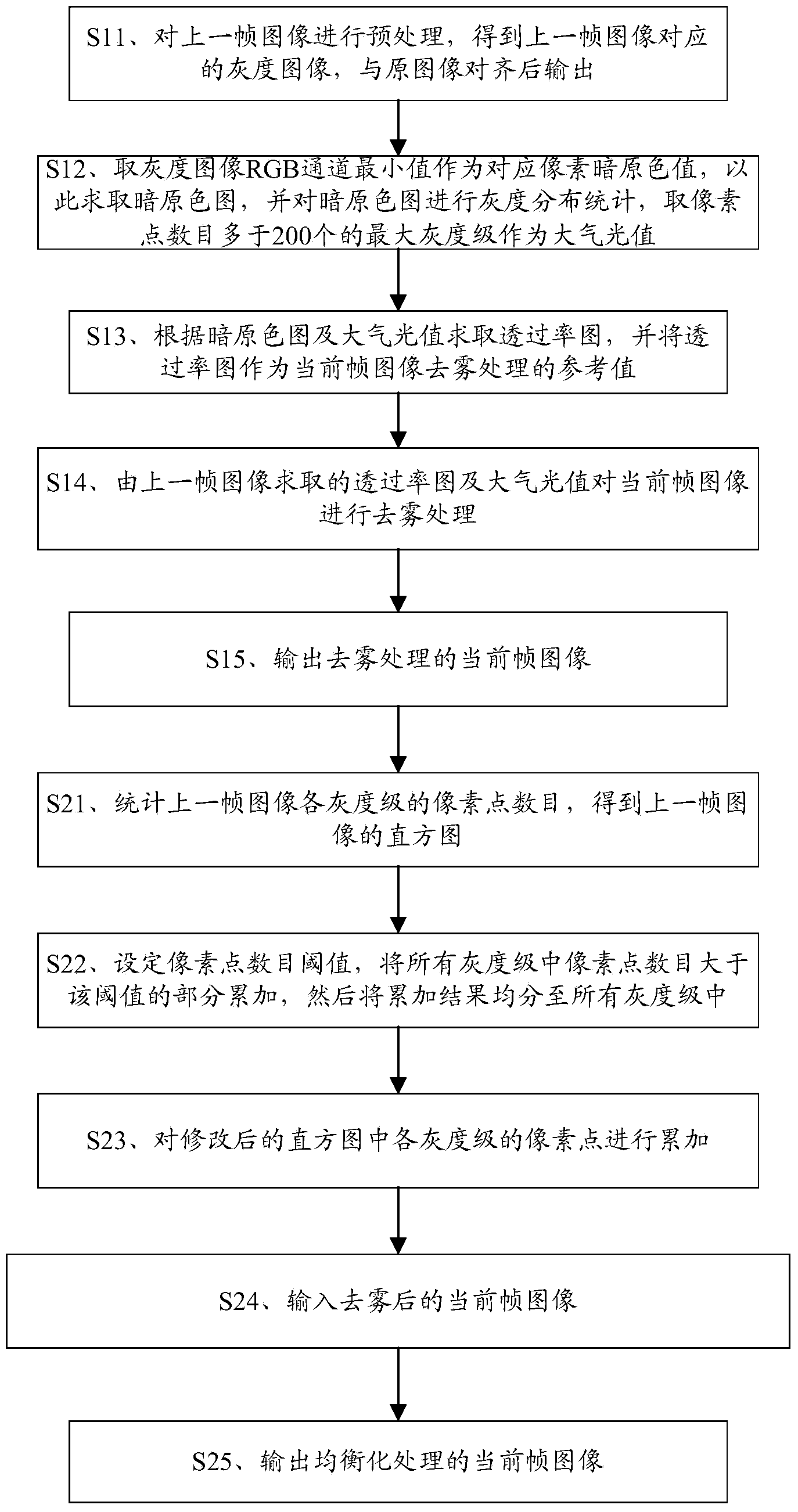

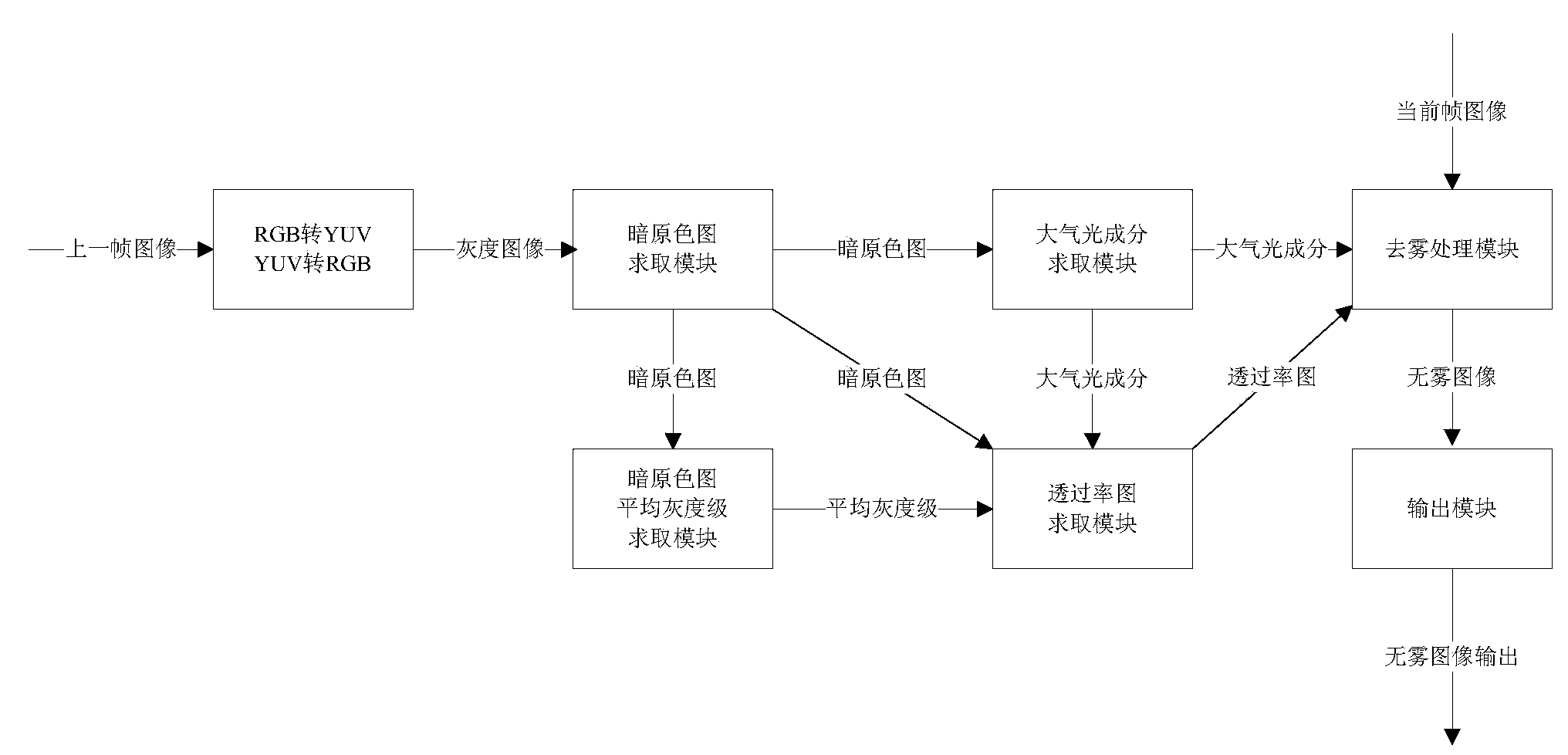

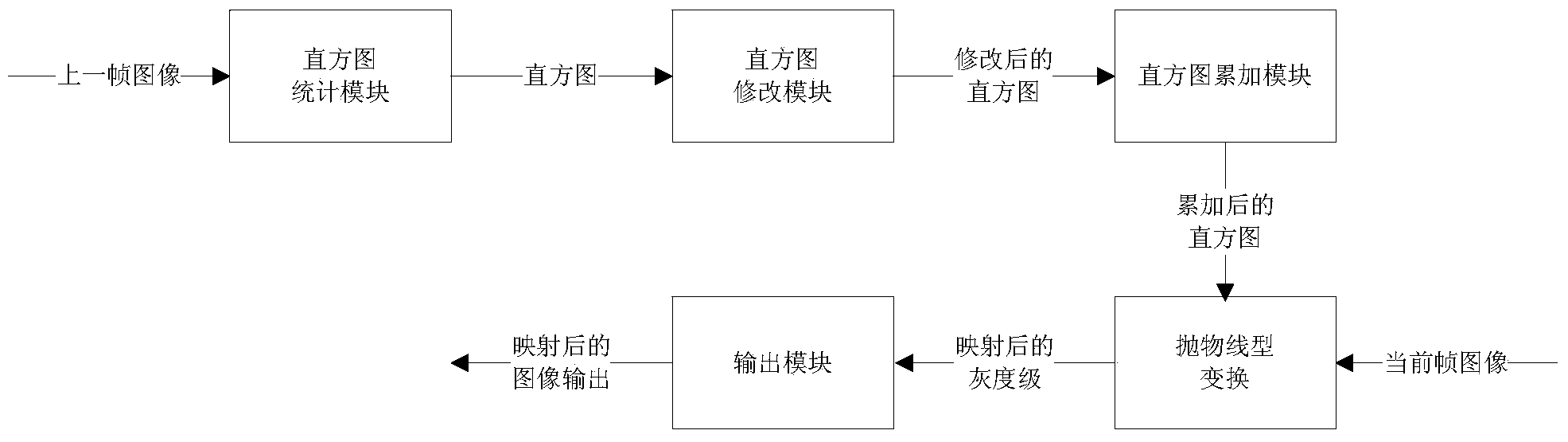

Digital video image enhancement achieving system and method based on FPGA

ActiveCN103714520AIncrease brightnessIncrease contrastImage enhancementDigital videoFpga implementations

The invention discloses a digital video image enhancement achieving system and method based on an FPGA. The digital video image enhancement achieving method based on the FPGA mainly comprises the steps of dehazing processing on a current frame image and anti-reflection processing on the current frame image, wherein the step of dehazing processing on the video image is achieved through a dark channel prior dehazing algorithm, and a good dehazing effect can be achieved; the step of anti-reflection processing on the current frame image is achieved through an image histogram equalization algorithm, and the effect of converting a low-illumination-level gray image into a clear image can be achieved. By the adoption of the image dehazing process and the image anti-reflection process, the brightness, contrast ratio and color saturation of the image can be improved, and the image can be clearer, transparent and saturated in color.

Owner:SHENZHEN INFINOVA

Preparing composite of modifing glass fiber reinforced plastics pultrusion section bar and preparation method thereof

The invention is a combination for preparing modified glass fibre reinforced plastic pull-extrude (GFRP) sectionbar including unsaturated polyester resin 92.6-64 (wt.%), nano silicon dioxide 0.5-4, calcium carbonate 5-20, benzoyl peroxide 0.2-2, methyl ketone peroxide 0.2-2, demoulding agent 0.5-2 and mill base 1-6. Batching in the above weight percents, selecting a ultrasonic wave dispersive apparatus to fully disperse the nano silicon dioxide in 2Kg resin; dispersing and blending, where the glue soluting temperature is controlled at 30 plus or minus 2 deg.C and the fully blending and dispersing time is 1 hour; adding in other additives in proportion in turn, fully blending until the mixture is uniform and meets the preset viscosity number; prepring structural sections: pouring the well-prepared glue soluting in a presoaking glue tank and keep constant temperature at 25 plus or minus 2 deg.C; placing the glass yarn felts ccording to a sectionbar perform guiding device to enter in the glue tank for fully soaking with the glue; making the yarn felts soaked with resin glue soluting enter in a well-heated mould for solidification moulding, and pulling into products by a hydraulic drag device, and at last cutting for fixed size.

Owner:天津市金锚科技发展有限公司

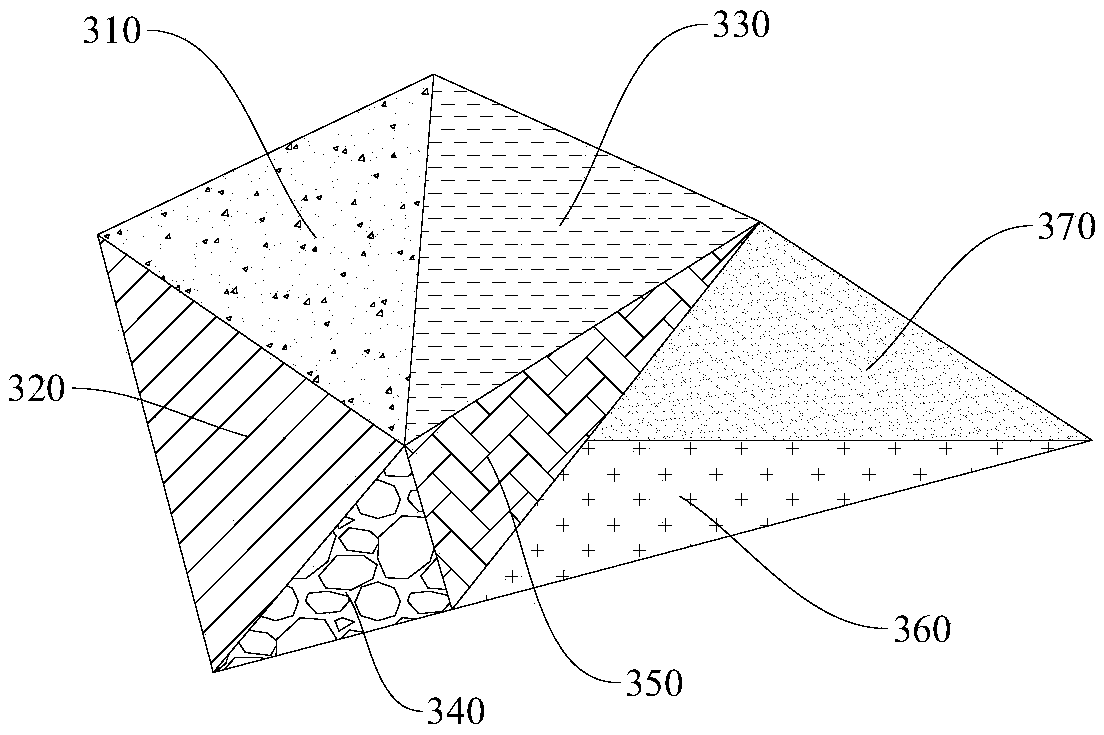

Color ceramic, casing, preparation methods thereof and electronic device

ActiveCN109640563AFull colorImprove personalizationCasings/cabinets/drawers detailsWhole bodyMetallurgy

The invention provides a color ceramic, a casing, preparation methods thereof and an electronic device. The preparation method of the color ceramic comprises the steps of placing a plurality of ceramic modules in a coordinated manner, and sintering an obtained product, wherein the two ceramic modules placed adjacent to each other are different in color. Therefore, the preparation method is simpleand easy to operate, the process is mature, and the industrial production is easy. According to the above preparation method, the ceramic modules of different colors are directly spliced together, the color of the obtained color ceramic is more full, the boundaries between the different colors are clear and distinct, a strong color contrast effect between different colors can be realized, and therefore, the individualization of the color ceramic is improved. By sintering, the two adjacent ceramic modules can be tightly combined to allow a plurality of ceramic modules to form a whole body, and the color ceramic with a color contrast pattern is achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

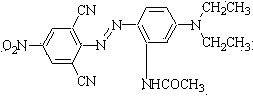

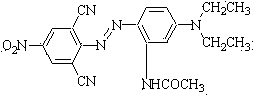

Blue disperse dye mixture

The invention discloses a blue disperse dye mixture. The dye mixture is prepared from the following ingredients of a dye monomer A, represented by a chemical formula (1) shown in a drawing, with the weight percent of 10-80%, a dye monomer B, represented by a chemical formula (2) shown in a drawing, with the weight percent of 0-20%, a dye monomer C, represented by a chemical formula (3) shown in a drawing, with the weight percent of 0-20%, a dye monomer D, represented by a chemical formula (4) shown in a drawing, with the weight percent of 0-10% and the balance of adjuvants. The dye mixture disclosed by the invention meets the environmental-friendly and ecological requirements of European Community Oeko-Tex Standard 100; on the premise that the condition that color light of the dye mixture is consistent with that of C.I. disperse blue 60 is guaranteed, the dye mixture is plump in color and luster, high in coloring rate, insensitive to metal ions, good in upgrading power and good in even dyeing performance, and the washing fastness, sublimation fastness and rubbing fastness are improved greatly; and the dye mixture has the advantages of good compatibility, low dyeing cost, and the like.

Owner:JIANGSU YABANG DYE

Fertilizer special for soybean

InactiveCN1508097AMeet nutritional needsNitrogen fixationHorticultureFertilizer mixturesSulfate radicalsPlant nodule

The present invention relates to a special-purpose fertilizer for soyabean. It is characterized by that it comprises nitrogen, phosphorus and potassium, also includes additive with slow-releasing action and special-purpose microfertilizer. The weight percentage of nitrogen, phosphorus and potassium is 0.4-1:0.1-0.3:0.2-0.4. Said invention is complete in nutrients and reasonable in formula, can fully meet nutrient requirement for soyabean growth and development process, also contains the nutrient components of nitrate nitrogen, sulfate radical, boron and molybdenum, so that it is favorable for soyabean nitrogen-fixing root nodule.

Owner:中国石油化工股份有限公司巴陵分公司

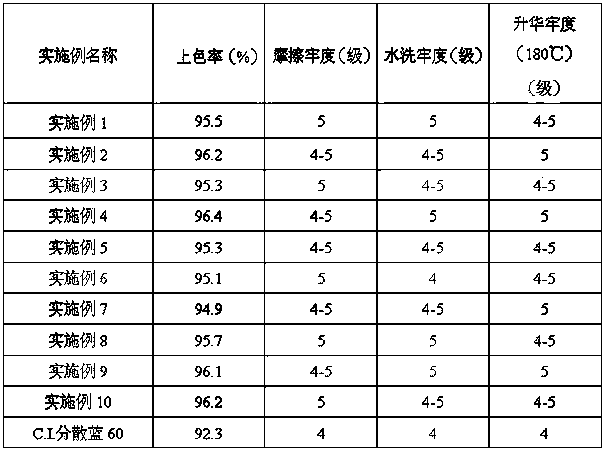

Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

ActiveCN101660190AThe preparation process steps are simpleEasy to operateSurface reaction electrolytic coatingProsthesisTectorial membranePlasma electrolytic oxidation

The invention discloses a preparation method of a titanium and titanium alloy surface black protective film for surgical implantation, comprising the following steps: step 1: carrying out micro-arc oxidation coloring processing on titanium and titanium alloy surface to be processed, in the process, firstly, preparing a micro-arc oxidation electrolysing solution, and then carrying out the micro-arcoxidation coloring processing; and step 2: carrying out subsequent processing on the micro-arc oxidation film, wherein the subsequent processing comprises the following steps: firstly, preparing a mixed solution for hydro-thermal processing, completely dipping the titanium and titanium alloy after micro-arc oxidation shading processing in the mixed solution, carrying out the hydro-thermal processing on the surface by adopting a hydro-thermal method, drying the titanium and titanium alloy under the condition of low temperature when the hydro-thermal processing is completed, and generating a layer of pure black micro-arc oxidation film with uniform and plump surface on the titanium and titanium alloy surface. The invention has simple and convenient operation, economy, high production efficiency, and high bonding strength between a generated ceramic film, i.e. the micro-arc oxidation film and a substrate, and the invention can effectively overcome various defects and deficiencies which exist in the prior coating processing techniques.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

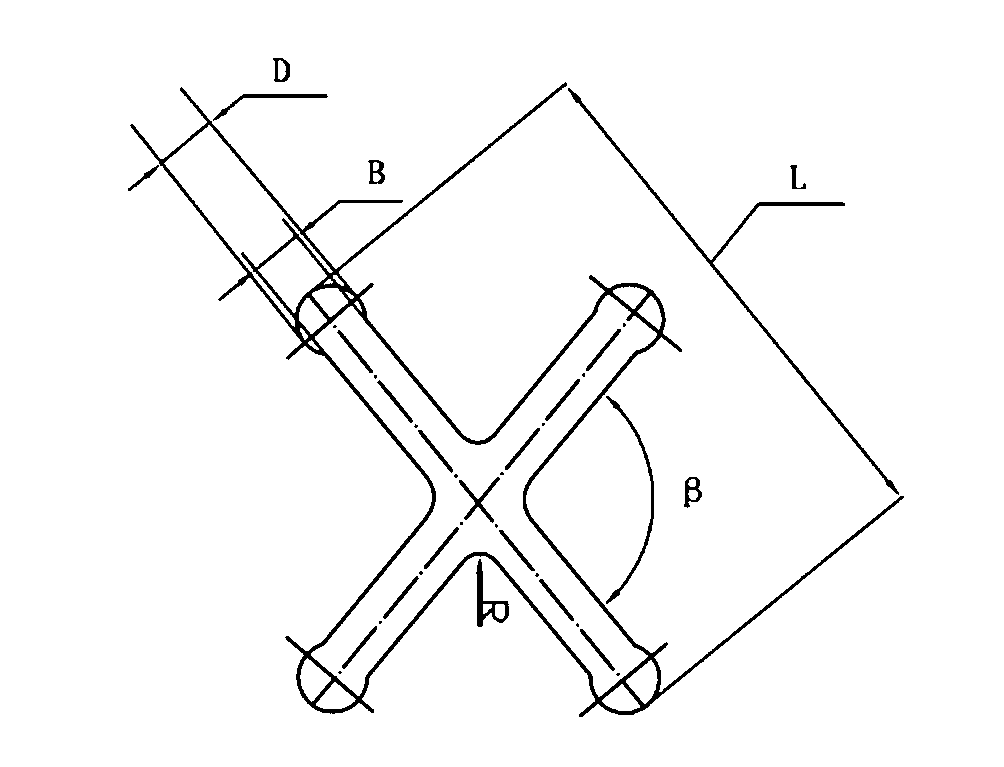

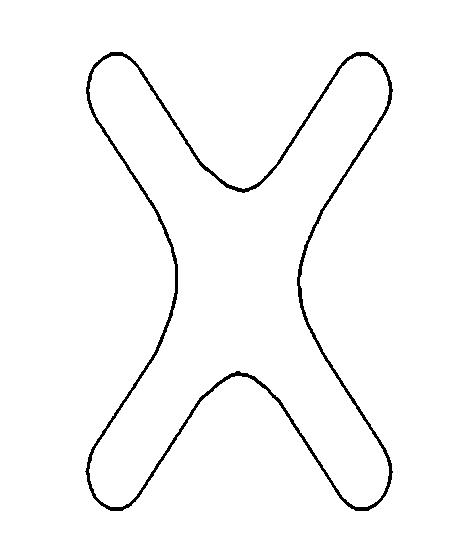

Porous ultrafine X-shaped polyester fiber and preparation method thereof

InactiveCN102851762AHigh porosityHigh degree of abnormalityFilament/thread formingMonocomponent polyesters artificial filamentPolyesterHeat setting

The invention discloses a porous ultrafine X-shaped polyester fiber and a preparation method of the porous ultrafine X-shaped polyester fiber. According to the porous ultrafine X-shaped polyester fiber, a spinning micropore structure of a spinning jet is in a shape of symmetric X blades; an obtuse angle ranges from100 to 110 degrees, and the length-width ratio of the blade is 5 to 8: 1; a cooling formation technology is the combination of annealing and cross air blow cooling; a first hot roll temperature under a thermal forming technology is at 88 to 92 DEG C, and a second hot roll temperature is at 125 to 130 DEG C, and the coiling is carried out at a speed of 3800 to 4200m / min. The fiber prepared by the preparation method provided by the invention is high in profile degree, and different fine groove capillary shapes are formed on the section; high porosity among the fibers is ensured, and the fibers are light in weight; the humidity conductivity and humidity absorbing performance of the fibers are effectively improved, and the water retaining performance and air permeability are effectively improved as well; and meanwhile, the fiber and fabric manufactured by the fiber have good effect of dyeing, and are easily dyed, and have the characteristics of being full in color and bright in gloss; and the fabric touches fluffy and elastic.

Owner:吴江赴东扬程化纤有限公司

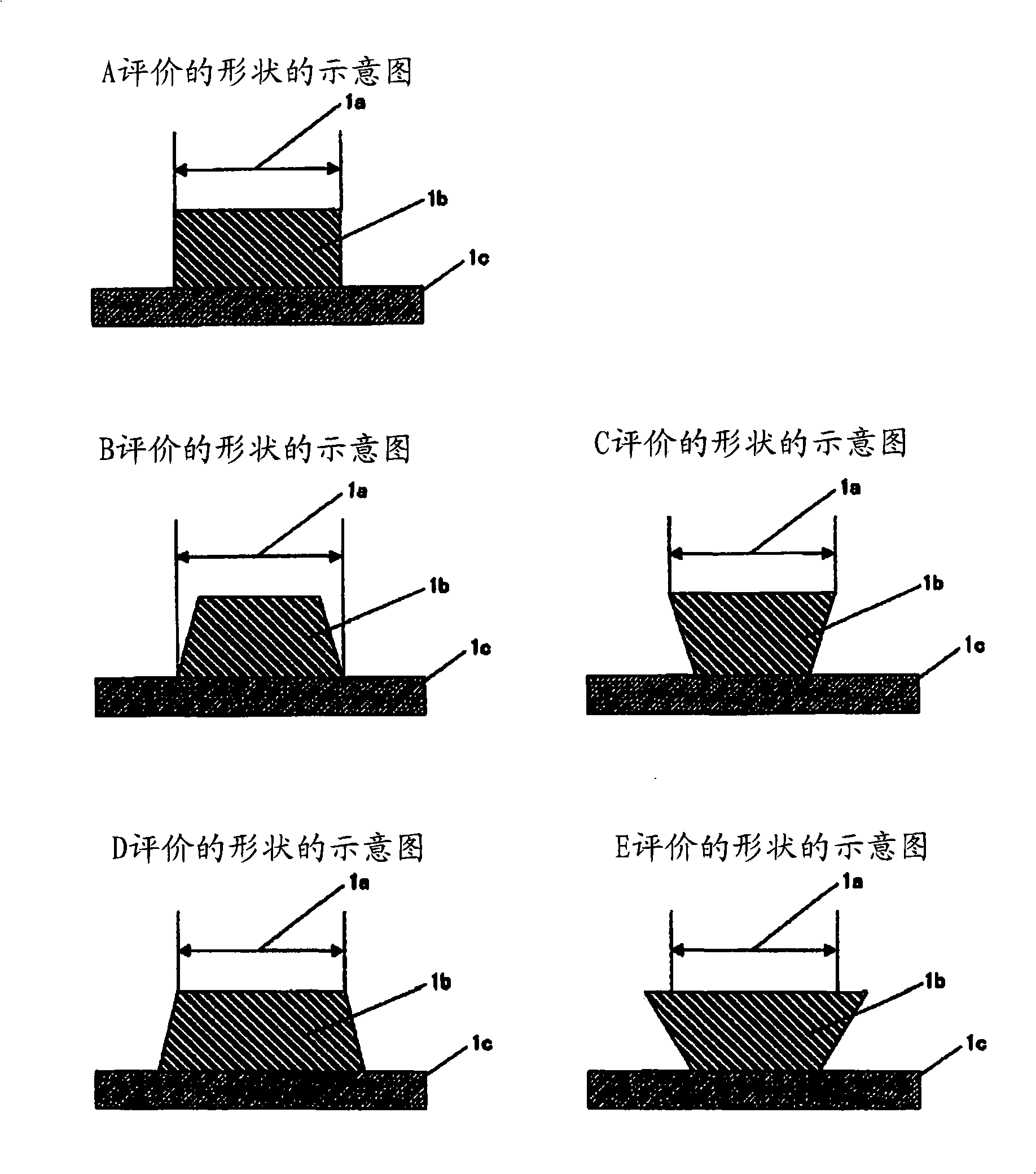

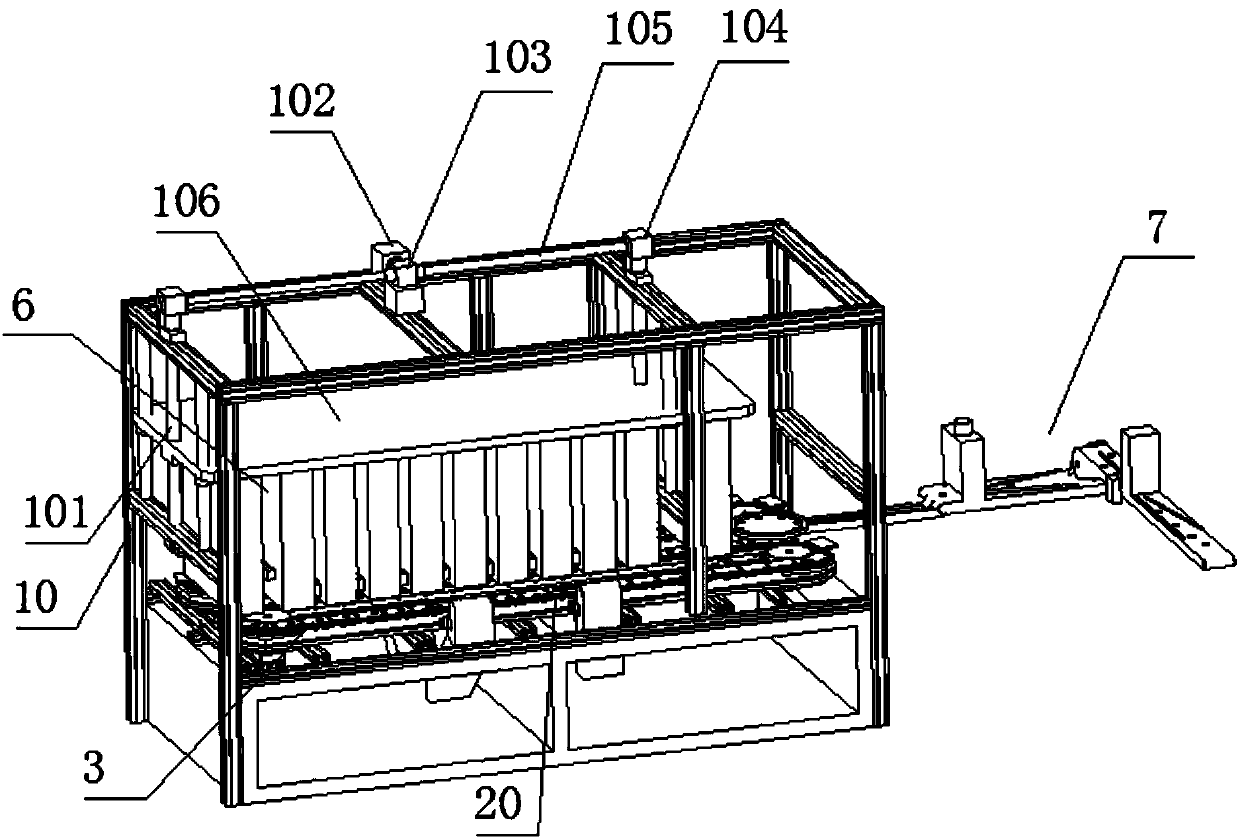

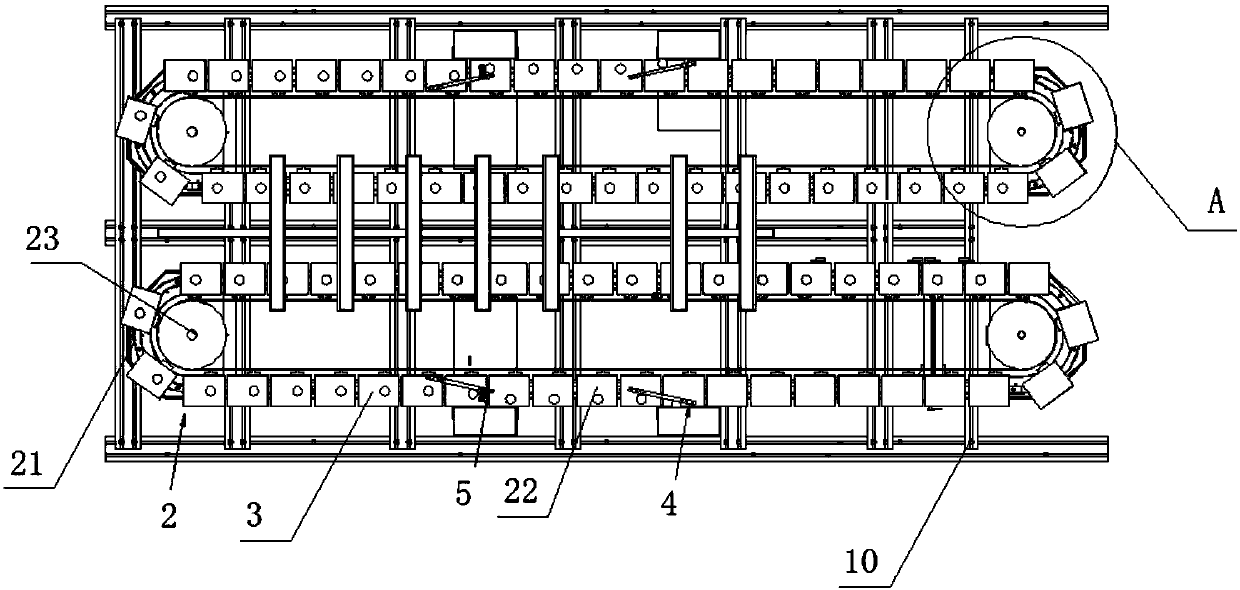

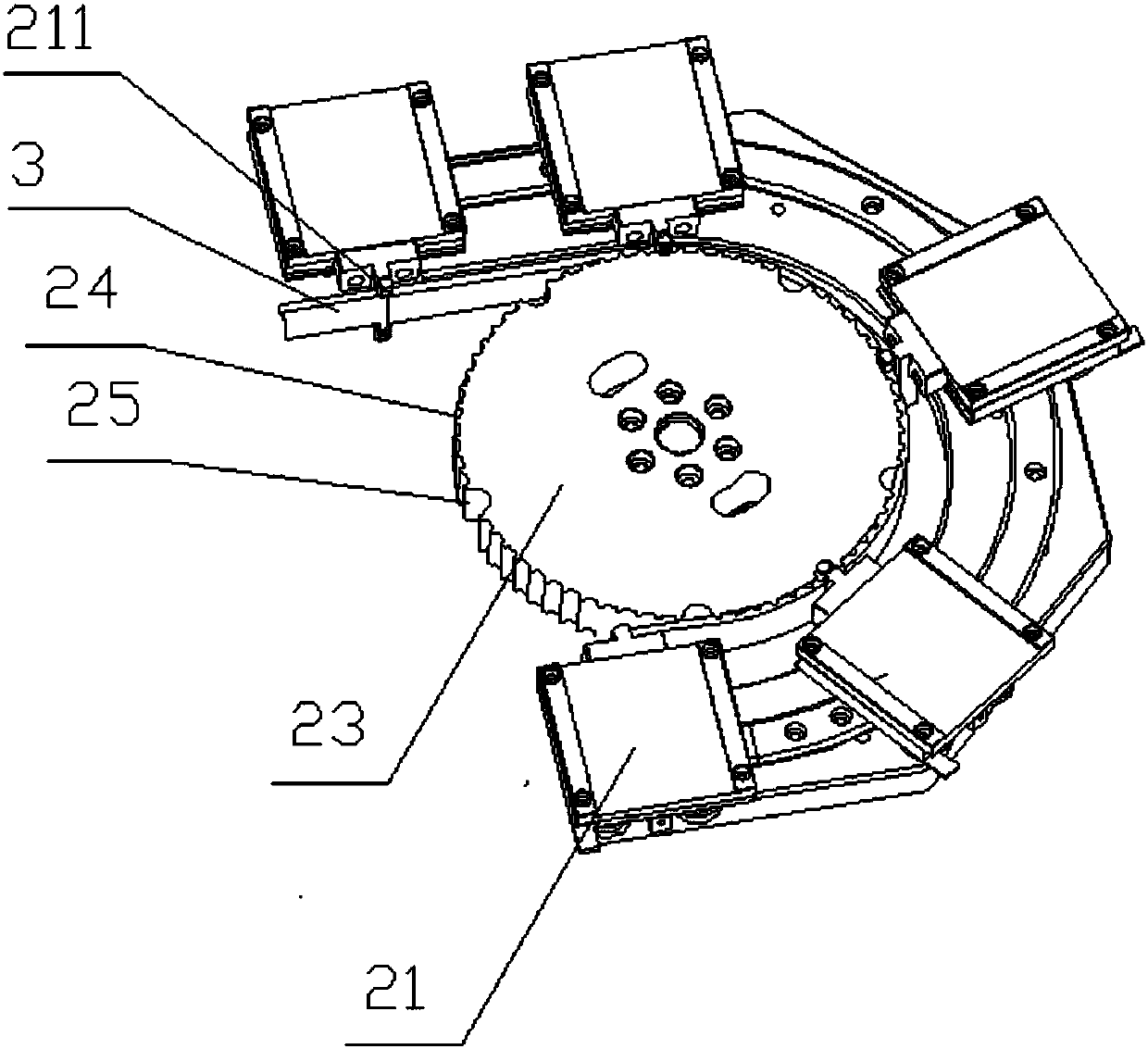

Spray printing method and device for color patterns on workpieces

ActiveCN107696707APrecise positioningImprove yieldOther printing apparatusSurface patternProcess engineering

The invention relates to a spray printing method for color patterns on workpieces. The spray printing method includes the following steps that the workpieces are placed on a conveying carrier, and theconveying carrier drives the workpieces to move according to the set track; position information of the workpieces on the conveying carrier and the patterns on the surfaces of the workpieces are collected through a camera, and printing parameters corresponding to the workpieces are obtained with the combination of the position information of the workpieces and the set printing patterns; and an ink jet printing module conducts spray printing and curing operation on the workpieces in sequence according to the printing parameters, and finally the patterns which are completely the same are formedon the workpieces. The spray printing method has the beneficial effects that the workpieces do not need to be rotated, a special clamp body does not need to be used for achieving accurate positioning, the yield is greatly increased, and any spray printing pattern can be designed according to needs; in addition, coating can be conducted more accurately according to the shapes of the patterns whena bottom layer is coated, metering can also be better controlled to avoid waste, and the rejection rate is reduced; and the overall process is compact, and efficient spray printing is achieved due tothe assembly line design.

Owner:江苏科思机电工程有限公司

High-whiteness pure cotton fabric processing technology

ActiveCN105297392AContinuityRealize continuous productionBleaching apparatusTextile printerPulp and paper industry

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a high-whiteness pure cotton fabric processing technology which comprises a whitening process. The whitening process comprises the following steps: conducting padding on a pure cotton fabric by use of a whitening liquid, carrying out steaming in a steaming box fully filled with saturated steam, and then carrying out water washing, neutralization and drying, wherein the pH value of the dried pure cotton fabric is controlled to be 6-7.5. According to the processing technology, padding by the whitening liquid, steaming, water washing, drying are conducted on the pure cotton fabric which is subjected to singeing, desizing, scouring, oxygen bleaching and mercerization, and then tentering and pre-shrinking are carried out; in the oxygen bleaching process, H2O2 is utilized for bleaching, and meanwhile organic peracid is added; a brightening agent with a medium or relatively high affinity is selected as the whitening liquid; after the pure cotton fabric is subjected to padding by the whitening liquid, the pure cotton fabric subjected to padding enters the guide roller type steaming box fully filled with the saturated steam for steaming, and then water washing, neutralization and drying are carried out; after the pure cotton fabric is treated according to the processing technology, the whiteness of the pure cotton fabric is improved to 155 or above, and the whitened pure cotton fabric is bright in color and has the soaping fastness of four-level or above.

Owner:鲁丰织染有限公司

Nylon camouflage fabric preparation process

ActiveCN103541232AGood color consistencyHigh color fastnessDyeing processTextile printerCooking & baking

The invention relates to a textile printing and dyeing process, and especially relates to a nylon camouflage fabric preparation process. The process comprises the steps of original cloth stitching, pretreatment, styling, bottom dyeing, printing, baking, steaming, post-finish tentering, and inspecting. The formula of the printing material is that: every 100kg of a colorant comprises 0.6-1.8kg of a dispersing material, 0.01-5.0kg of an acidic material, and 0.02-0.5kg of paint. In the baking step, a moving speed is 35+ / 1m / min, and a temperature is 165-170 DEG C. in the steaming step, the moving speed is 10+ / 1m / min, the temperature is 101-105 DEG C, and the time is 30min. In the post-finish step, different auxiliary agents are used, such that waterproof, air-permeating, oil-repelling, and antistatic functions are made compatible. The process has the advantages of short production process, good color phase consistency, good color fastness, bright color, and low cost. The method mainly adopts environment-friendly dyes, and is especially suitable for high-grade products in anti-infrared camouflage product fabrics.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

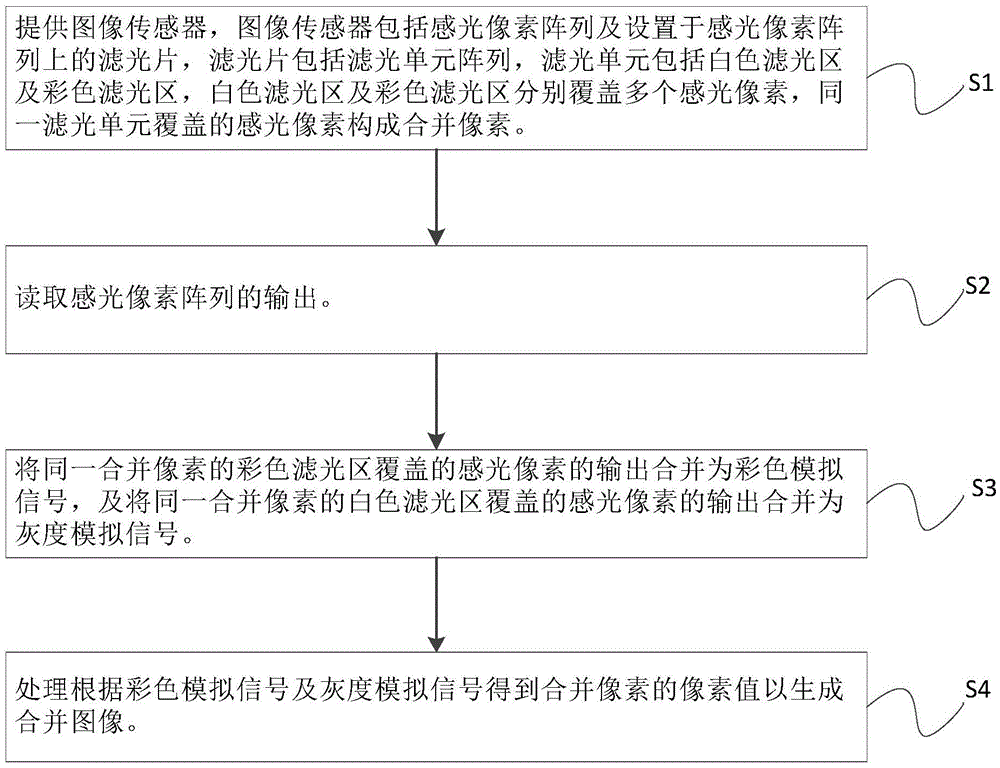

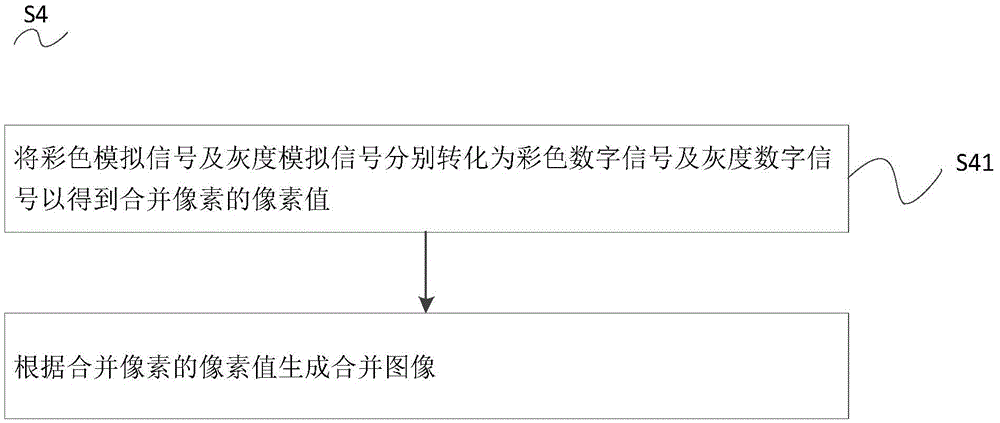

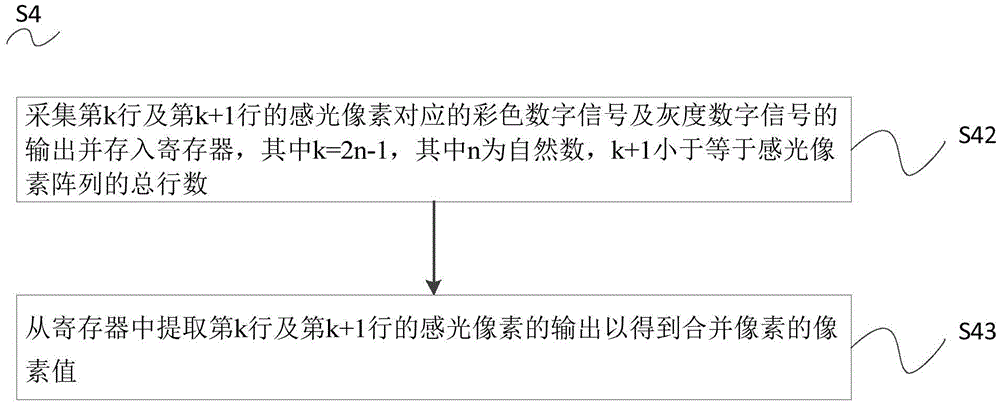

Imaging method, imaging device, and electronic device

ActiveCN105592303AFull colorGood brightness and clarityPicture signal generatorsLight filterPixel array

The invention discloses an imaging method comprising steps of: providing an image sensor including a light-sensing pixel array and a light filter disposed thereon, wherein the light filter comprises a light filtering unit array and each light filtering unit comprises a white light filtering region and a color light filtering region each of which covers multiple light-sensing pixels; reading an output of the light-sensing pixel array in order to combine the outputs of the light-sensing pixels covered by the color light filtering region of a combined pixel into a color analog signal and to combine the outputs of the white light filtering region into a gray analog signal; processing the color analog signal and the gray analog signal to obtain a pixel value of the combined pixel to generate a combined image. The combined image involves complete color information and has high brightness and sharpness and few noise points. The invention also discloses an imaging device capable of implementing the imaging method and an electronic device using the imaging device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

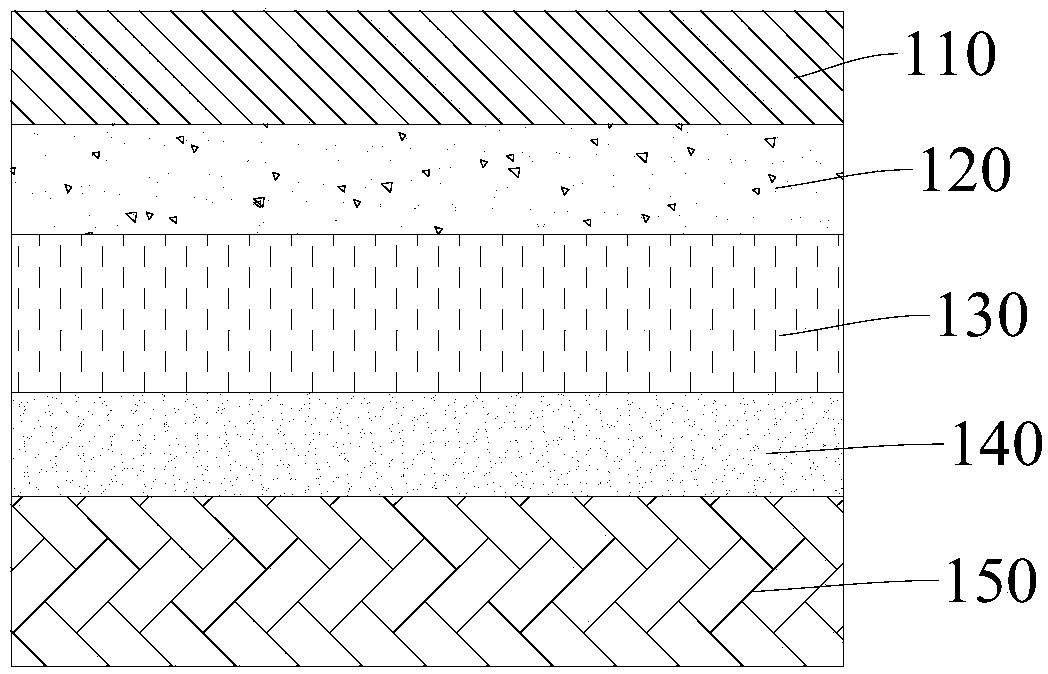

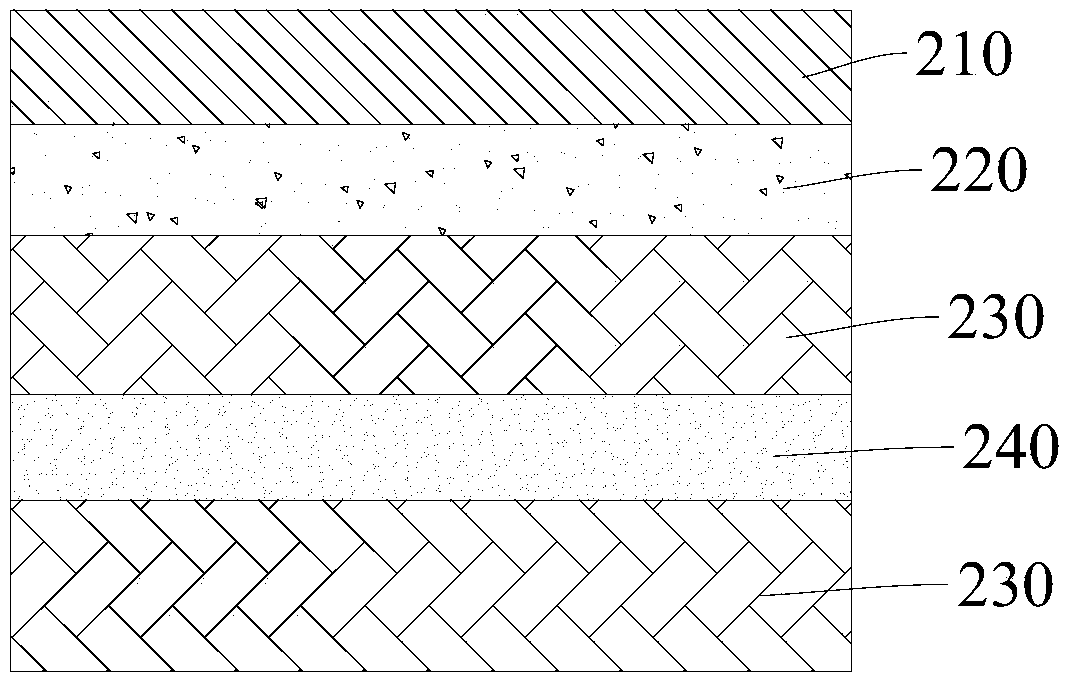

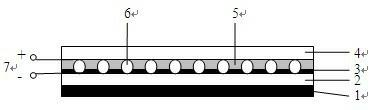

Flexible liquid crystal thin film and preparation method thereof

InactiveCN102615894AFull colorSimple preparation processSynthetic resin layered productsNon-linear opticsLiquid crystallineCrystallography

The invention discloses a flexible liquid crystal thin film and a preparation method thereof and belongs to the technical field of liquid crystal. The flexible liquid crystal thin film is divided into five layers, wherein the lowest layer is a black light absorption coating; and a lower transparent electrode layer, an interface layer, a liquid crystal layer and an upper transparent electrode layer are arranged on the black light absorption coating in turn. The preparation method comprises the following steps of: preparing the upper transparent electrode layer with display patterns, preparing the interface layer, preparing a liquid crystal box, filling liquid crystal and preparing the liquid crystal thin film. The invention has the advantages that: the preparation process is simple and is suitable for large-area display application; by the prepared flexible liquid crystal thin film, the bistable control of cholesteric liquid crystal is realized by utilizing an interface stabilization mode, the control voltage is reduced, and the film has rich colors; and moreover, a conductive electrode is treated by an etching technology, and a flexible pattern liquid crystal thin film is prepared.

Owner:TIANJIN UNIV

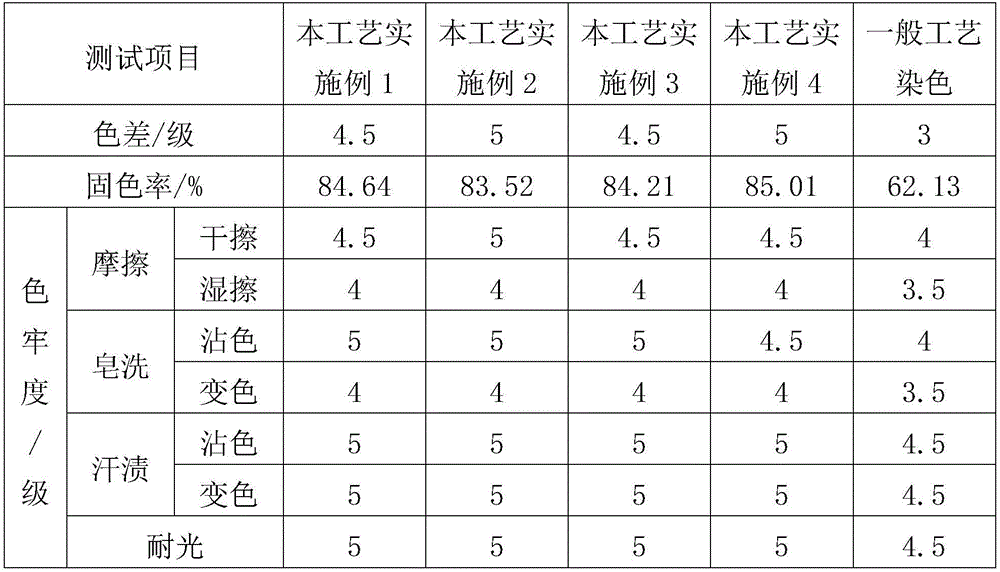

Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

ActiveCN106245368AHigh color fixing rateAvoid hydrolysisDry-cleaning apparatus for textilesDyeing processDisperse dyePh buffering

The invention discloses a polyester-cotton disperse dye, and a reactive dye one-bath process dyeing method. The reactive dye one-bath process dyeing method comprise following steps: a dyeing solution is prepared at normal temperature; pH value of the dyeing solution is adjusted to 4 to 6; polyester-cotton fabric is immersed; the temperature is increased to 95 to 105 DEG C at a rate of 2 to 3 DEG C / min, and then is increased to 130 to 150 DEG C at a rate of 1 to 2 DEG C / min; suction filtration of the dyeing solution and isolation of disperse dye microcapsules are carried out, and continuous dyeing is carried out for 15 to 25min; the temperature is reduced to 85 to 95 DEG C at a rate of 1.5 to 2.5 DEG C / min; and primary water washing, soaping, afterwashing, and drying are carried out. The dyeing solution comprise, 0.5 to 1.5%owf of a reactive dye, 30 to 40g / L of anhydrous sodium sulfate, 1.5 to 3.5g / L of a pH buffering agent, 0.5 to 5%owf of disperse dye microcapsule, and 0.1 to 3g / L of a dyeing auxiliary. The reactive dye one-bath process dyeing method is simple; period is short; fixation rate is high; and levelling properties are excellent.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dedicated fertilizer for ornamental pineapple

ActiveCN1884225AIn line with the law of fertilizer requirementsMeet high NMagnesium fertilisersAlkali orthophosphate fertiliserSodium molybdatePotassium nitrate

The invention discloses a specific fertilizer of ornamental pineapple in the floral fertilizer technological domain, which comprises the following parts: 0-30% calcium ammonium nitrate, 0-60% potassium nitrate, 0-30% monobasic potassium phosphate, 0-8.2% monoammonium phosphate, 2-47% potassium sulfate, 4.3-23% magnesium sulfate, 0-17% aquacare, 0.422-0.823% EDTA-Fe, 0.048-0.096% zinc sulfate, 0.007-0.013%copper sulfate, 0.013- 0.024%sodium molybdate and 0.055-0.110% manganese sulfate.

Owner:浙江传化生物技术有限公司

Fluorescent wool-like elastic gabardine spinning yarns, lining prepared thereby and preparation method thereof

ActiveCN101397704AHigh strengthImprove color brightnessDyeing processWoven fabricsFluorescenceEngineering

The invention relates to a fluorescent wool-like elastic gabardine spinning yarn which is characterized in that the spinning yarn is formed by the steps of adopting 100D cationic polyester low stretch yarns and 32S R / triangular polyester to carry out air cladding to 40D urethane elastic fibers by a networking threading machine; in addition, the R / triangular polyester comprises the following raw materials according to weight ratio: 77 percent to 83 percent of viscose staple fibers and 17 percent to 23 percent of bright triangular polyester. The invention also discloses a fluorescent wool-like elastic gabardine fabric and a preparation method thereof. Compared with the prior art, the invention has the advantages of making full use of the respective features of filament yarns and the staple fibers so as to greatly improve the color light, the strength and the curly and fluffy feeling and the like of the yarn, thereby causing the obtained fabric to have a remarkably full and smooth style; by the coloring difference after post treatment and the dyeing contrast of the white color of bright polyester, the fabric has the light effect of peekaboo fluorescence.

Owner:山东正凯新材料股份有限公司

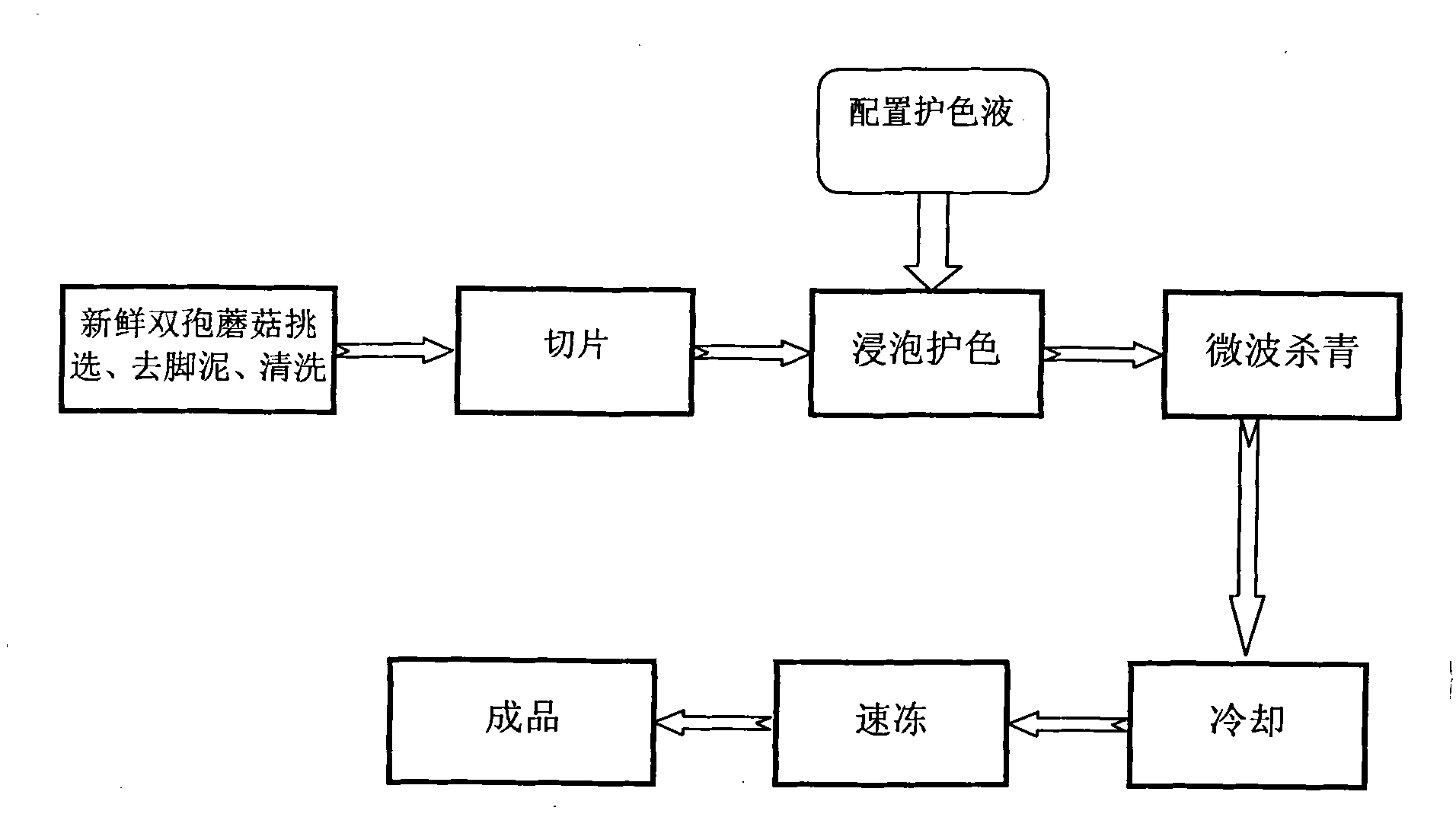

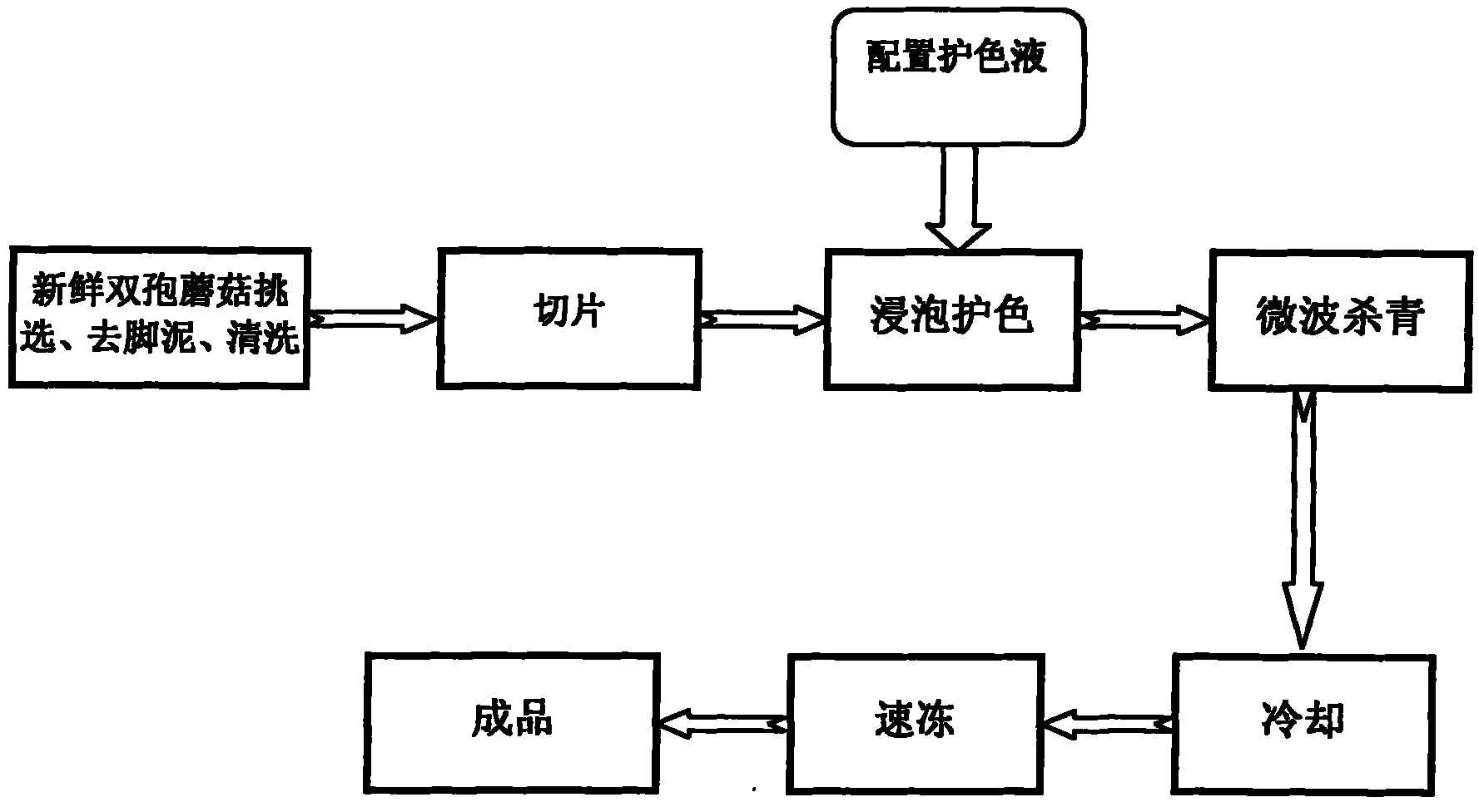

Method for preparing white mushroom slices

InactiveCN101961045AReduce churnLess nutrient lossFruits/vegetable preservation by heatingMicrowaveMoisture

The invention belongs to the technical field of edible fungus processing and relates to a preparation method of white mushroom slices. In the method, fresh white mushroom is used as a raw material; and the white mushroom slices are prepared by pretreatment, slicing, soaking, preserving color, killing green in microwaves, cooling, quickly freezing and refrigerating. The white mushroom slice products prepared by the method have natural color, full structure, less moisture loss, less nutrient loss, cooking effect similar to that of fresh white mushroom.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

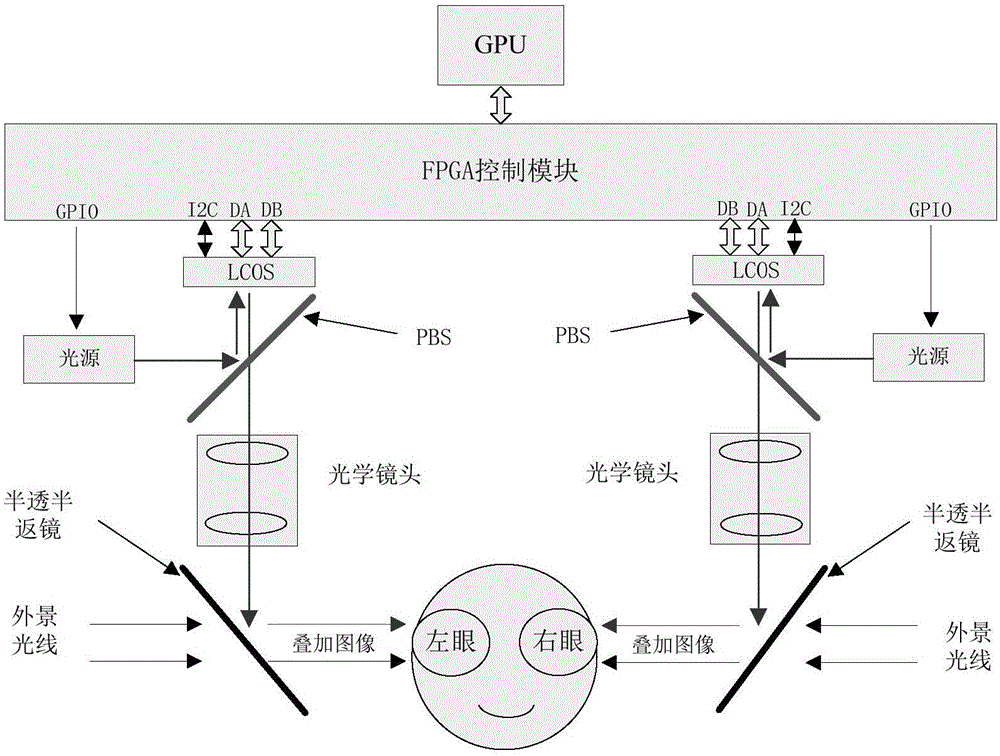

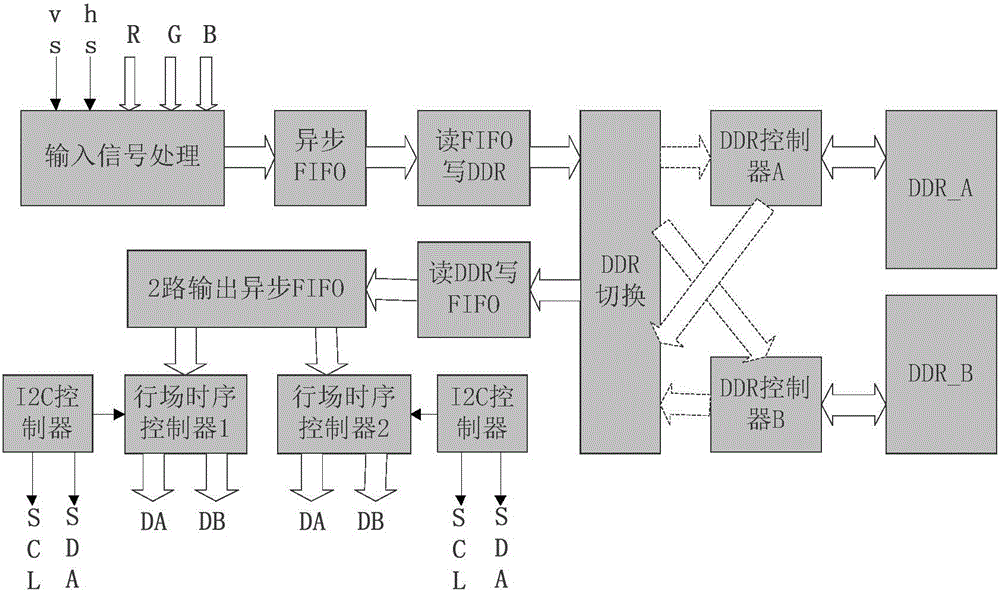

Intelligent helmet binocular display system for electric power inspection and realization method of intelligent helmet binocular display system

PendingCN106154553AStrengthen information exchangeImprove perceptionPicture reproducers using projection devicesOptical elementsSingle chipField-programmable gate array

The invention provides an intelligent helmet binocular display system for electric power inspection and a realization method thereof, which are used for assisting power grid power transformation, power distribution and power transmission inspection. According to the method, a binocular imaging optical subsystem and a sequential logical circuit based on an FPGA (Field Programmable Gate Array) are designed; an invented intelligent helmet binocular enhanced reality display system comprises image acquisition, data conversion, caching, storage, protocol conversion and an interface; intelligent helmet binocular imaging enhanced reality display for the electric power inspection is realized. The intelligent helmet binocular display system is high in hardware integration degree, good in system flexibility, low in power consumption and stable in display stability, and the reliability of the whole system is improved. According to an imaging system provided by the invention, the utilization rate of light source light in an imaging process can reach about one time of that of a single chip type imaging system. An image projected into eyes has more saturated and full colors, and a rainbow picture problem, which disturbs a single chip DLP imaging system, does not occur.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com