Spray printing method and device for color patterns on workpieces

A color pattern and workpiece technology, applied in printing devices, printing, etc., can solve the problems of reducing the yield of workpiece printing, difficulty in determining the measurement of adhesives, and position deviation of smearing, so as to improve productivity, reduce scrap rate, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0059] The inkjet printing method of the color pattern on the workpiece provided by this embodiment comprises the following steps:

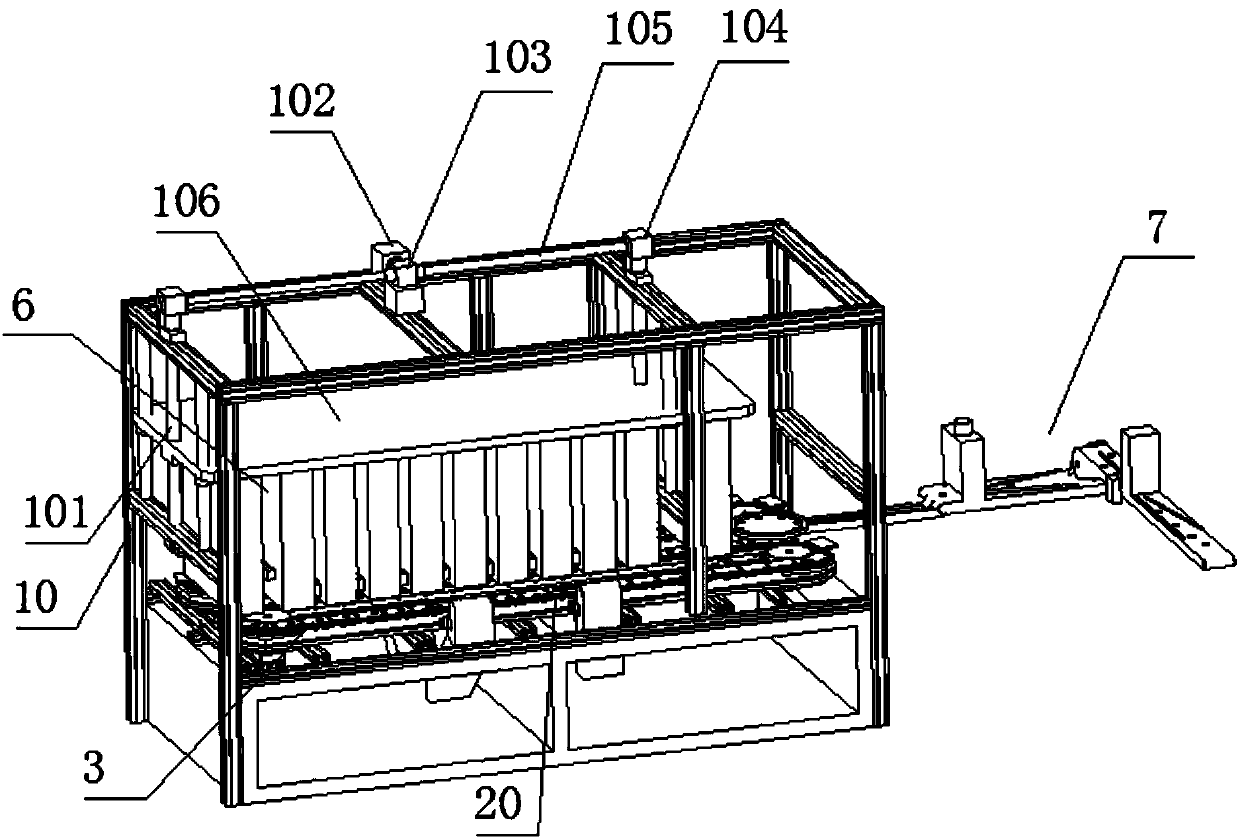

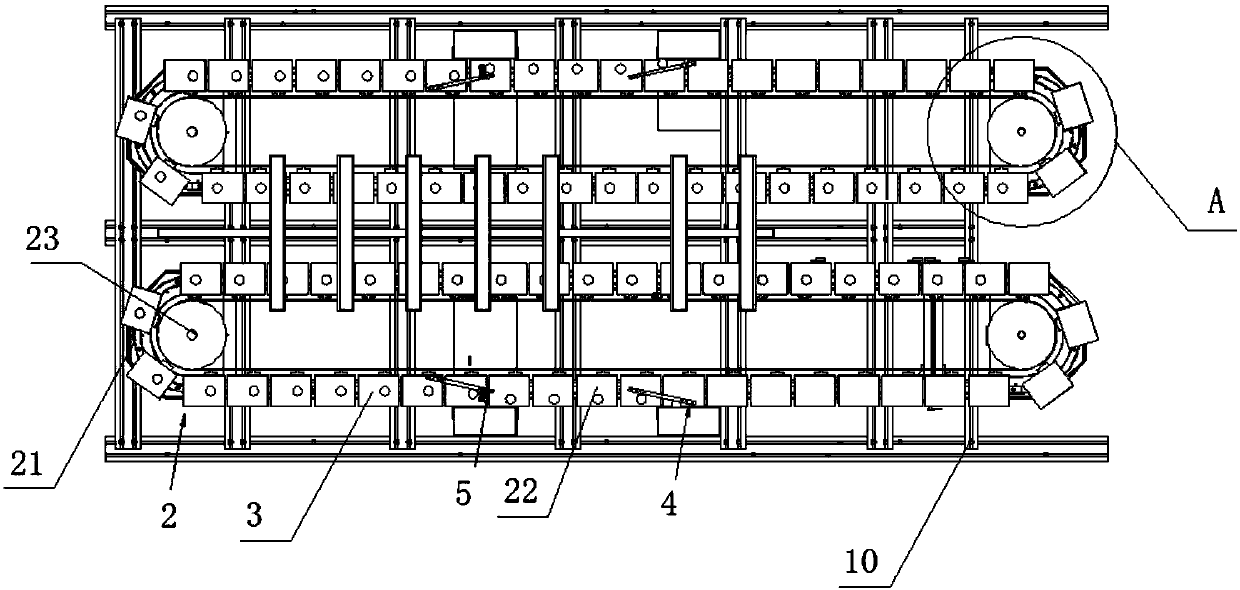

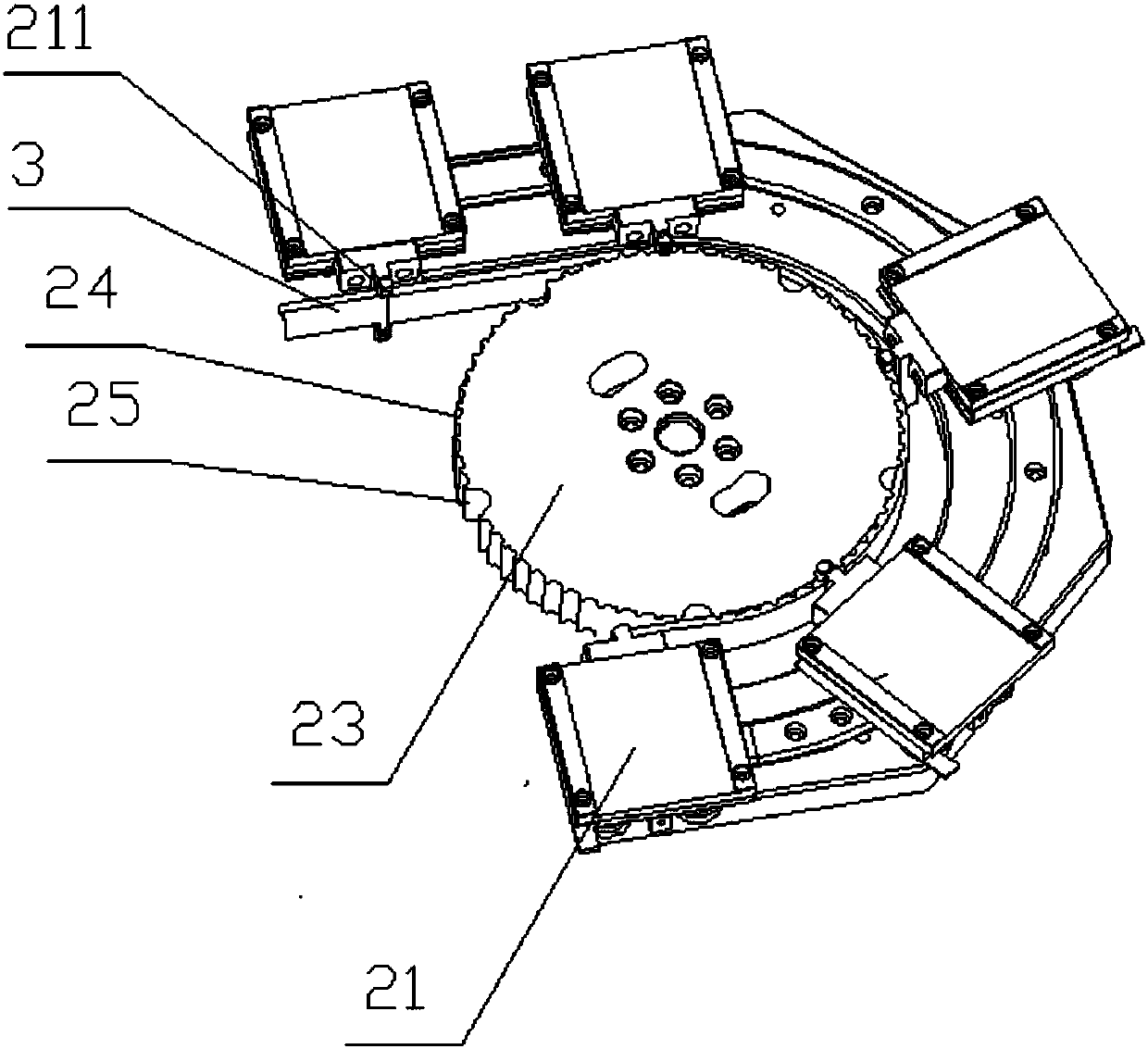

[0060] 1) Place the workpiece on the transmission carrier, and the transmission carrier drives the workpiece to move on the set trajectory. The transmission carrier of this embodiment is a conveyor belt, and moves along two circular motion tracks, see figure 1 , figure 2 . Of course, the present application is not limited to two circular motion trajectories, and may also be linear motion trajectories.

[0061] 2) The CCD camera collects the position information of the workpiece on the transmission carrier and the surface pattern of the workpiece, and combines the position information of the workpiece to obtain the printing parameters corresponding to each workpiece according to the set printing pattern.

[0062] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com