Patents

Literature

36892 results about "Conveyor belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

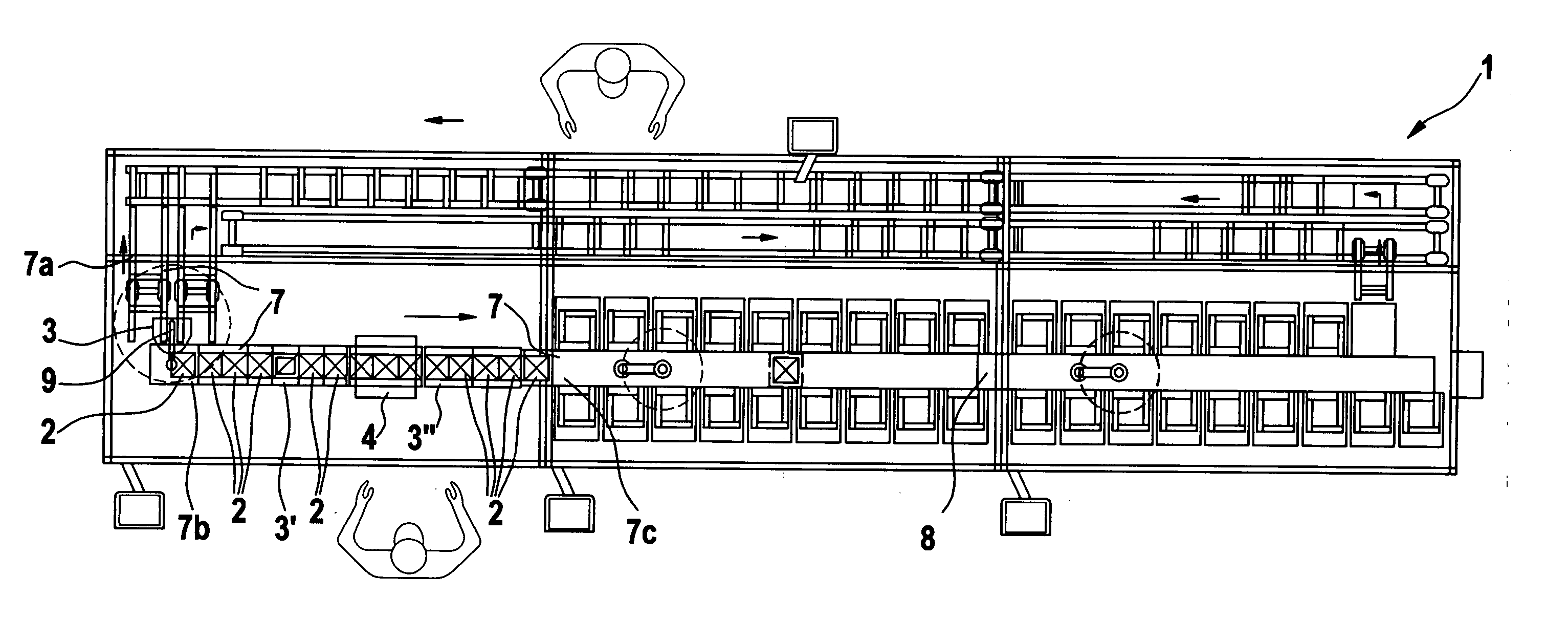

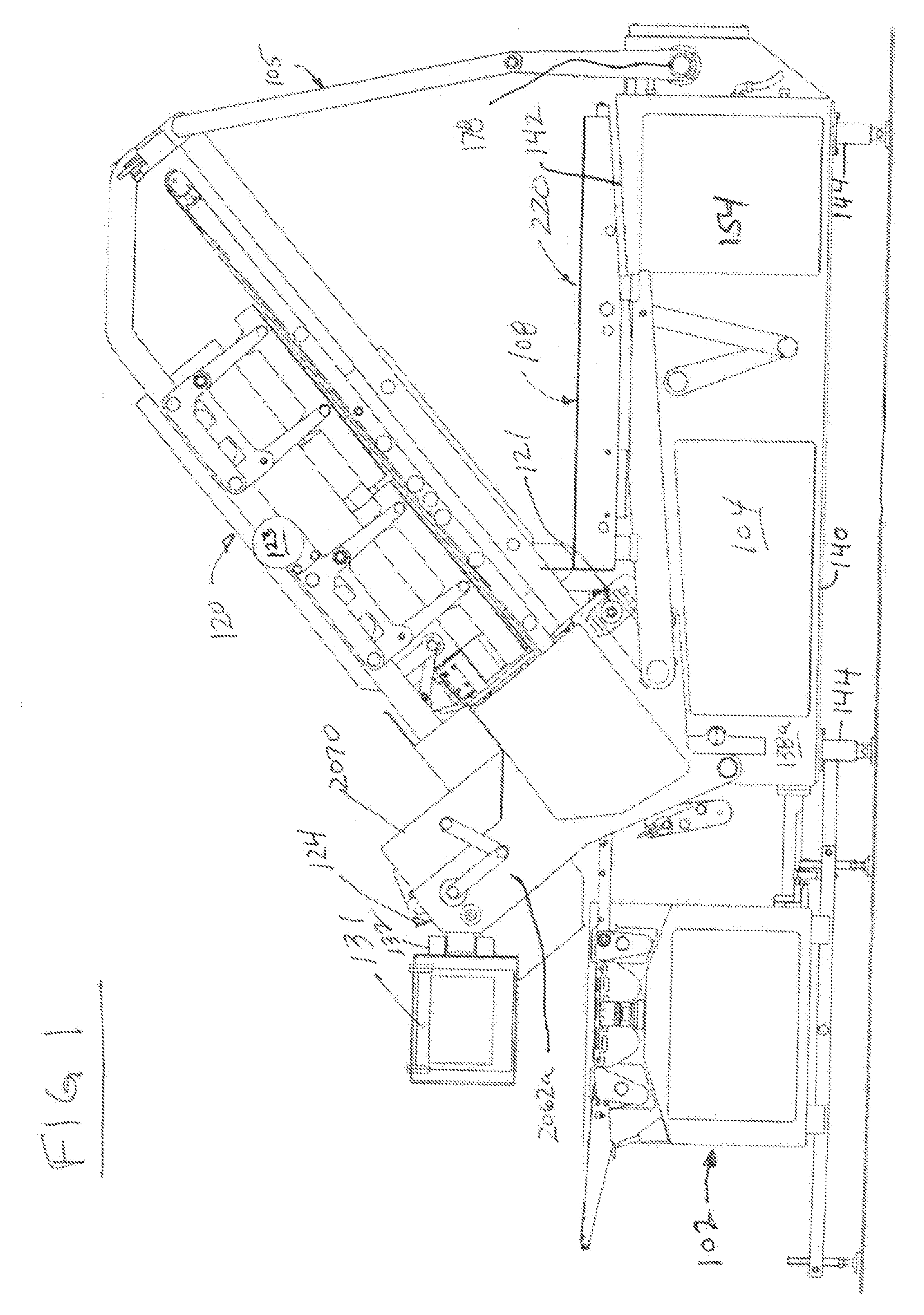

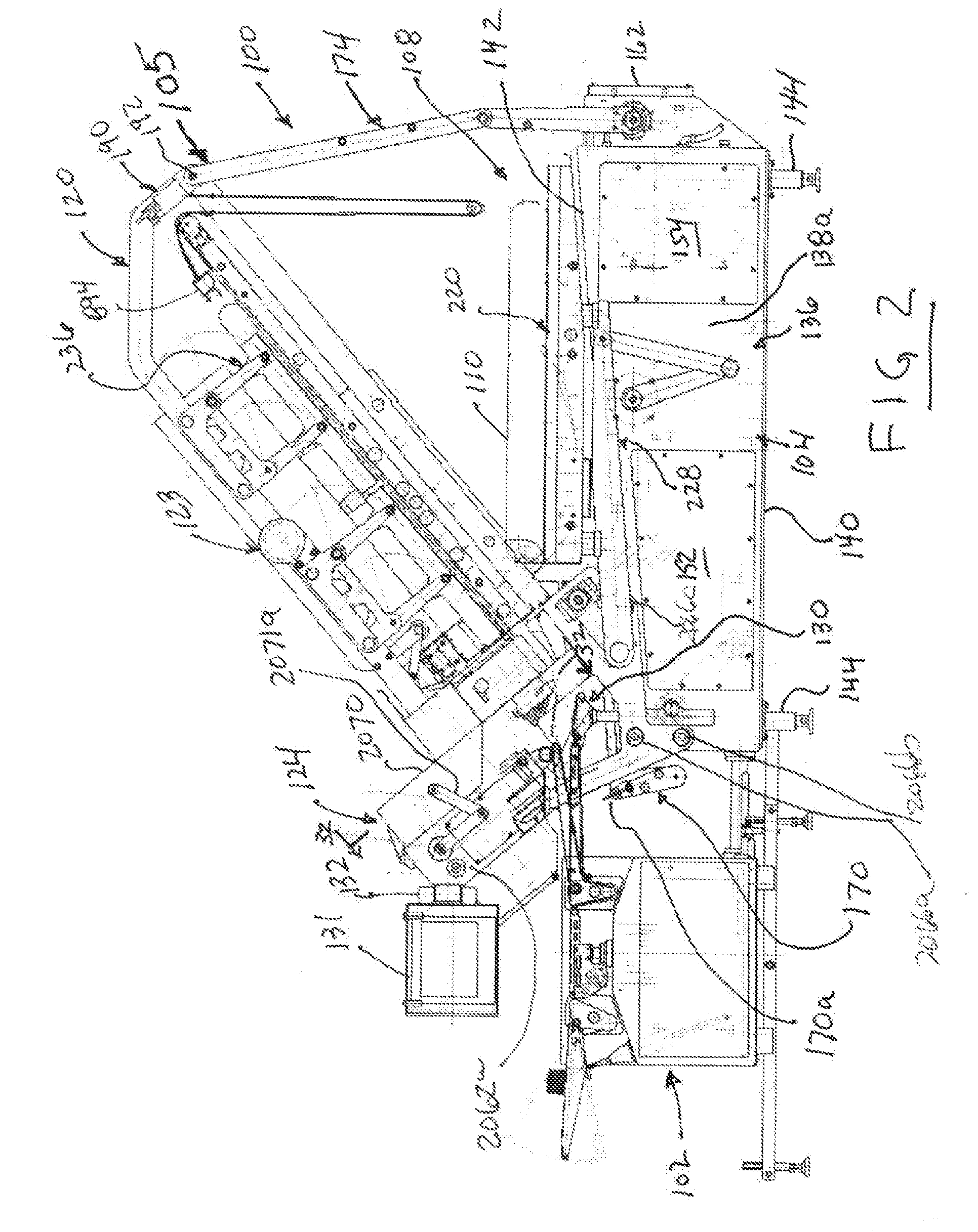

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

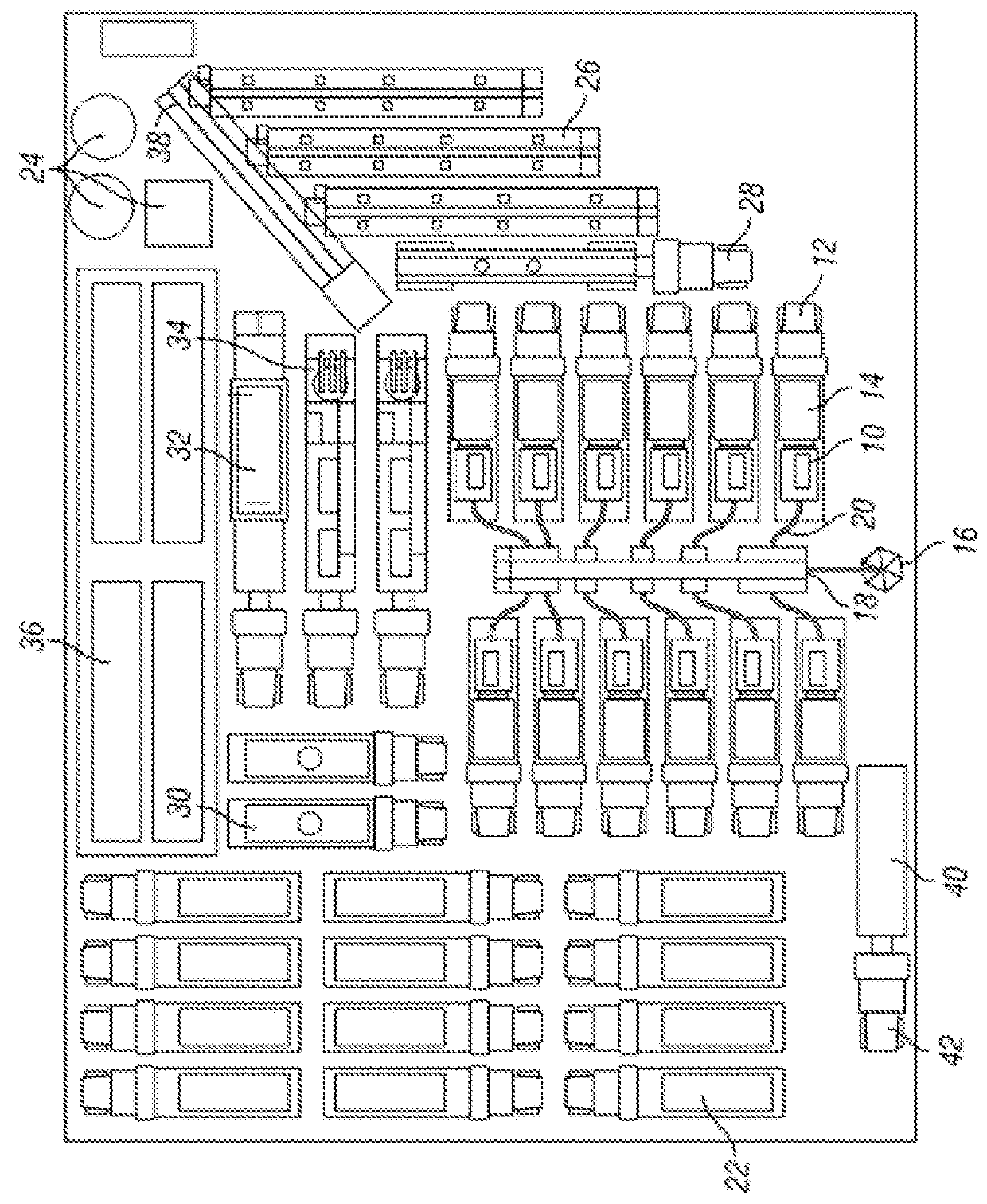

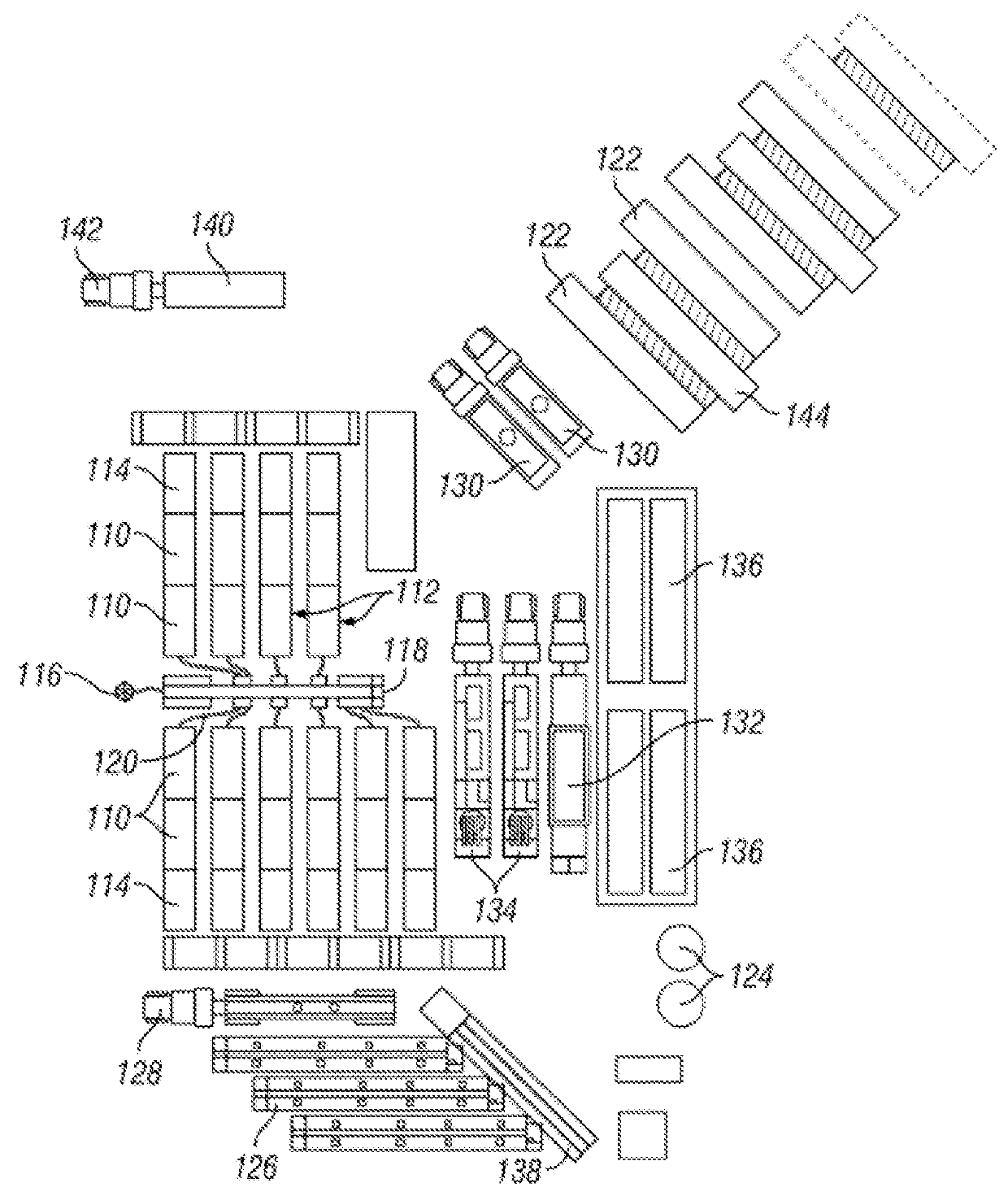

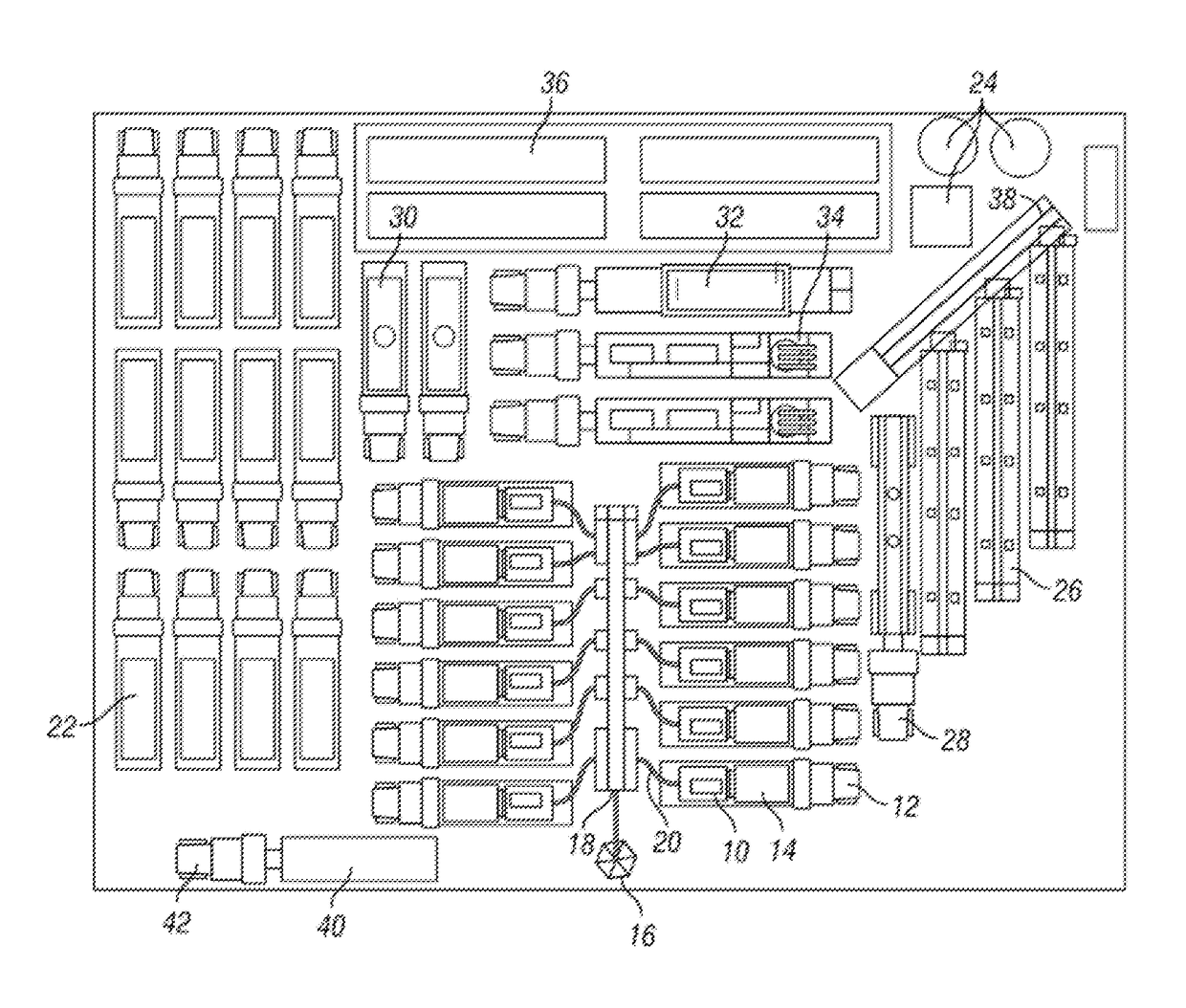

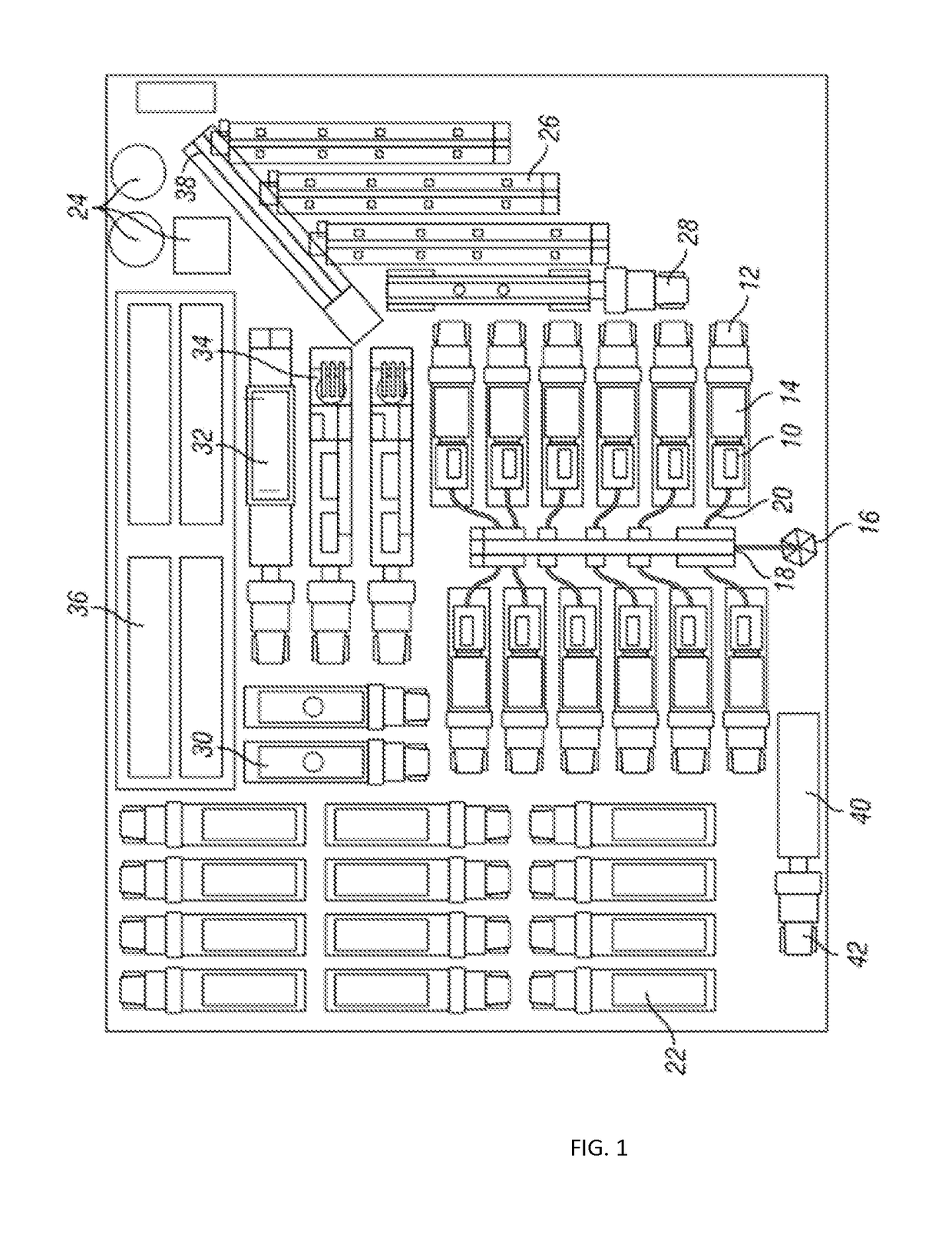

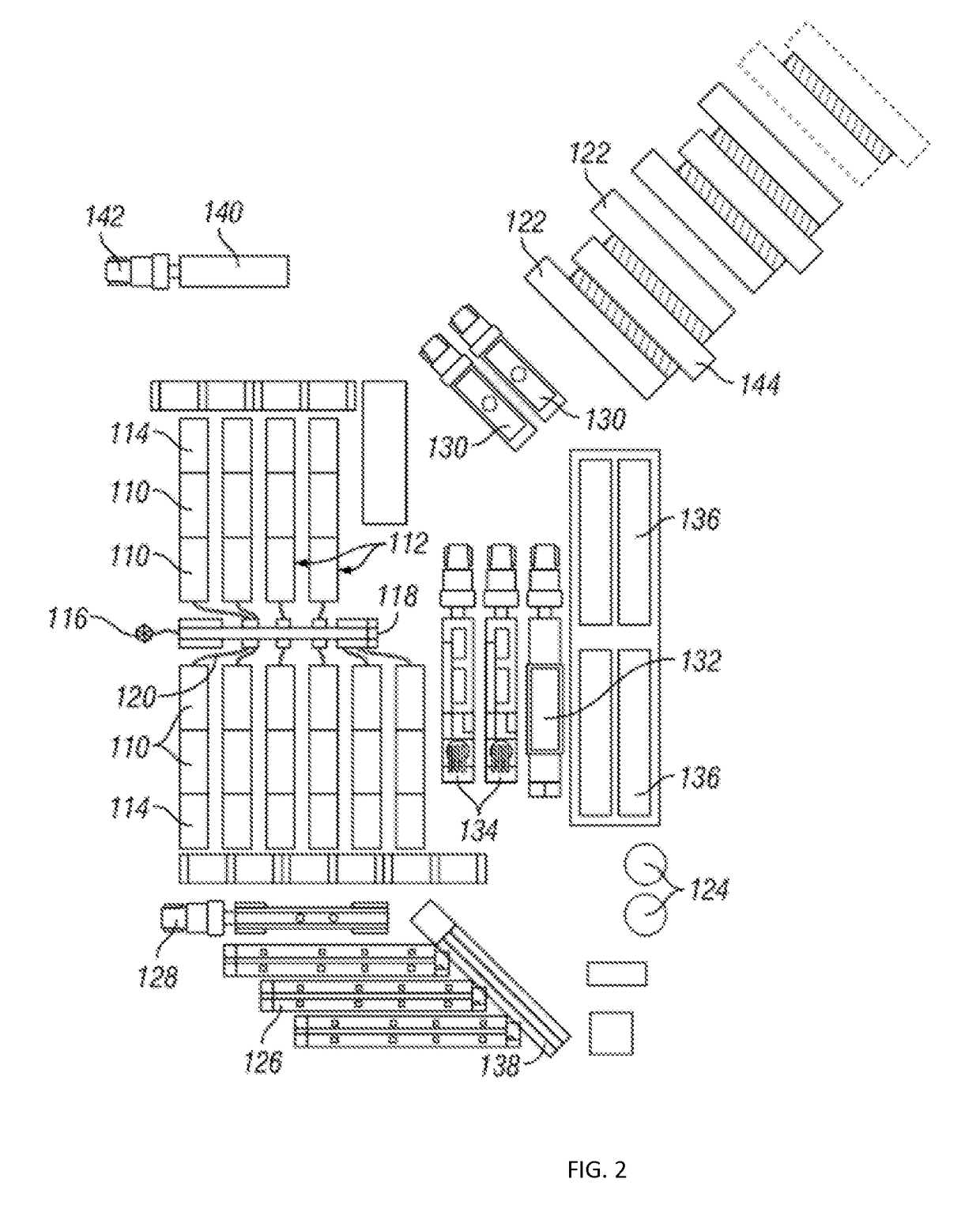

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

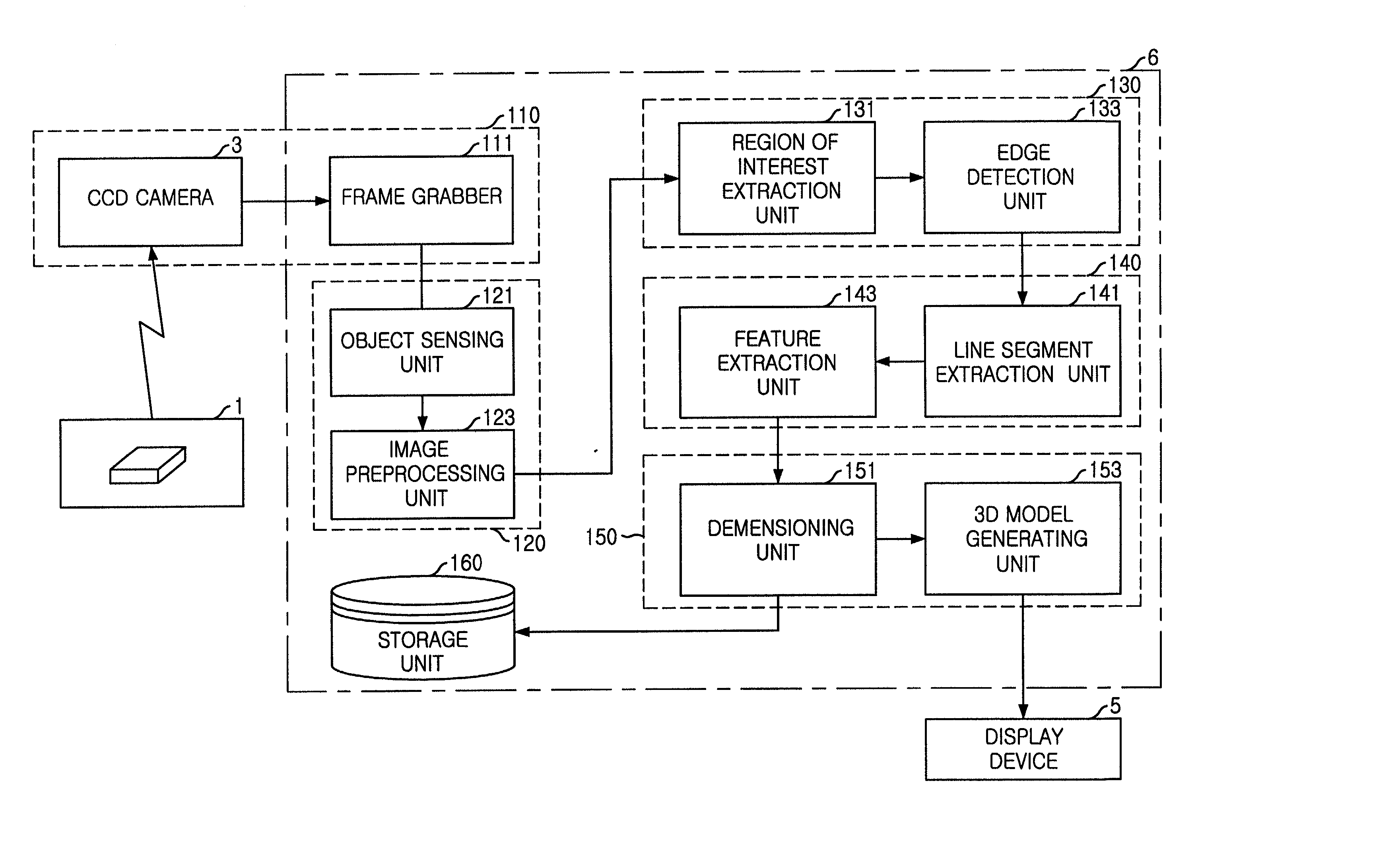

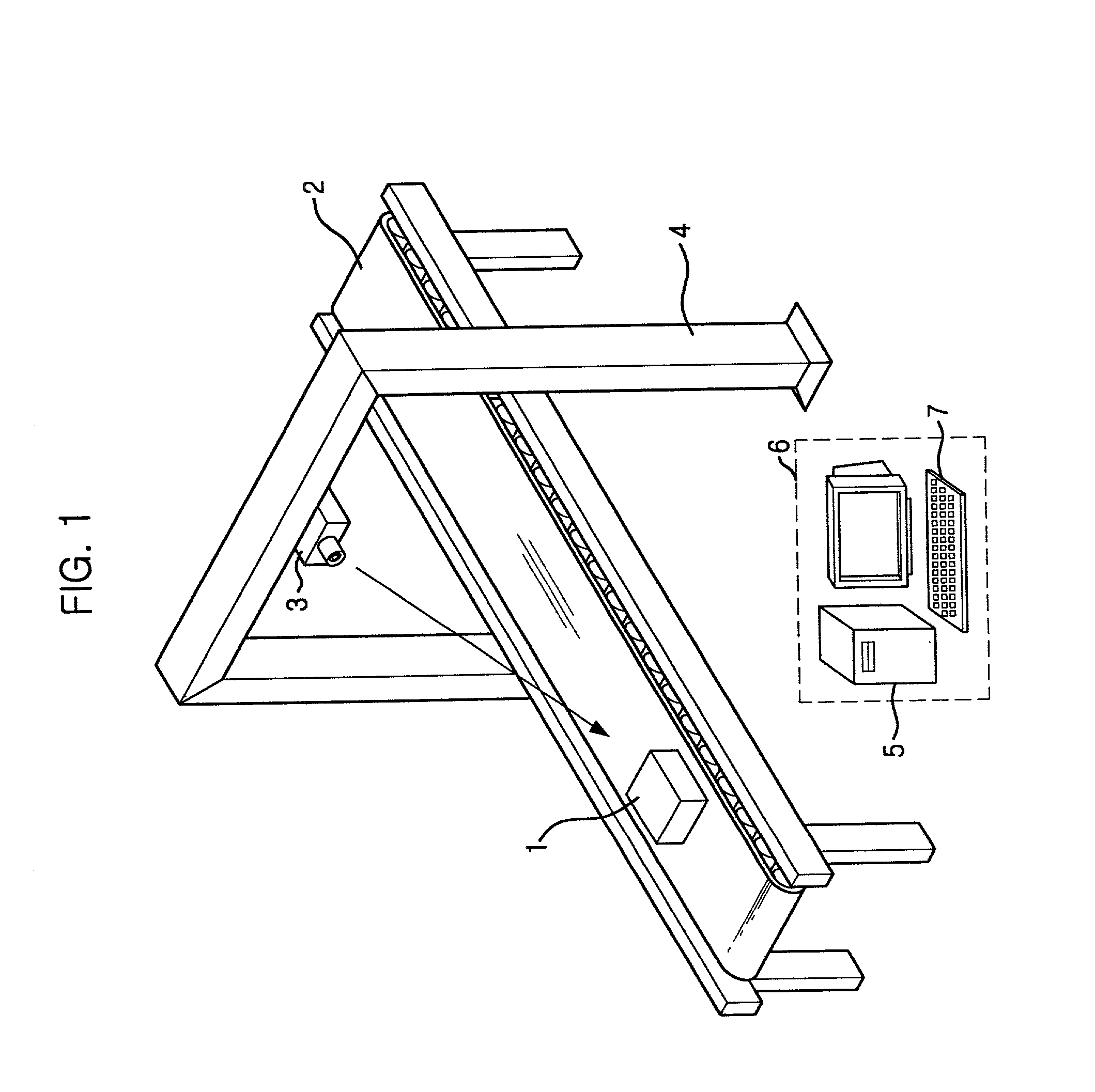

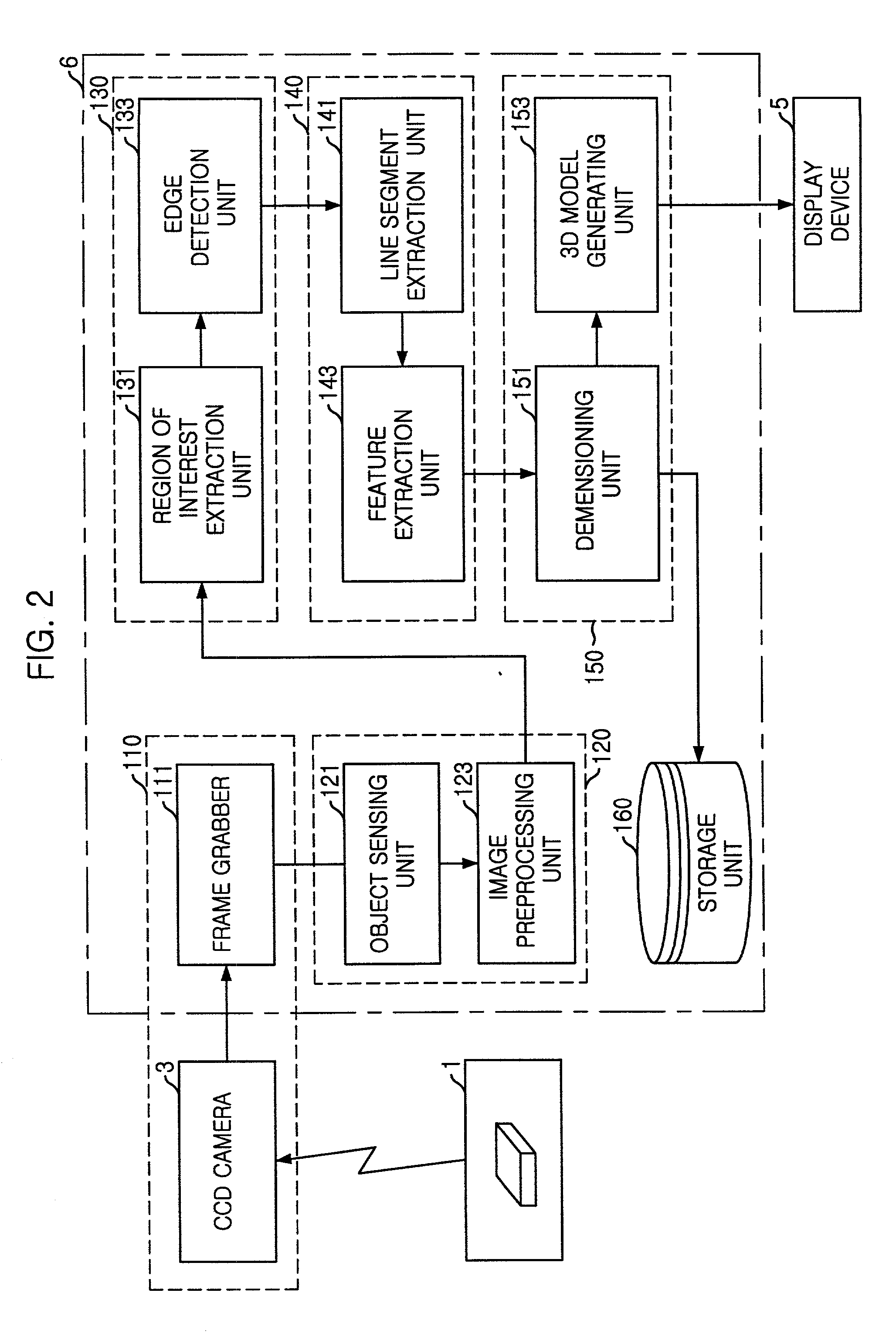

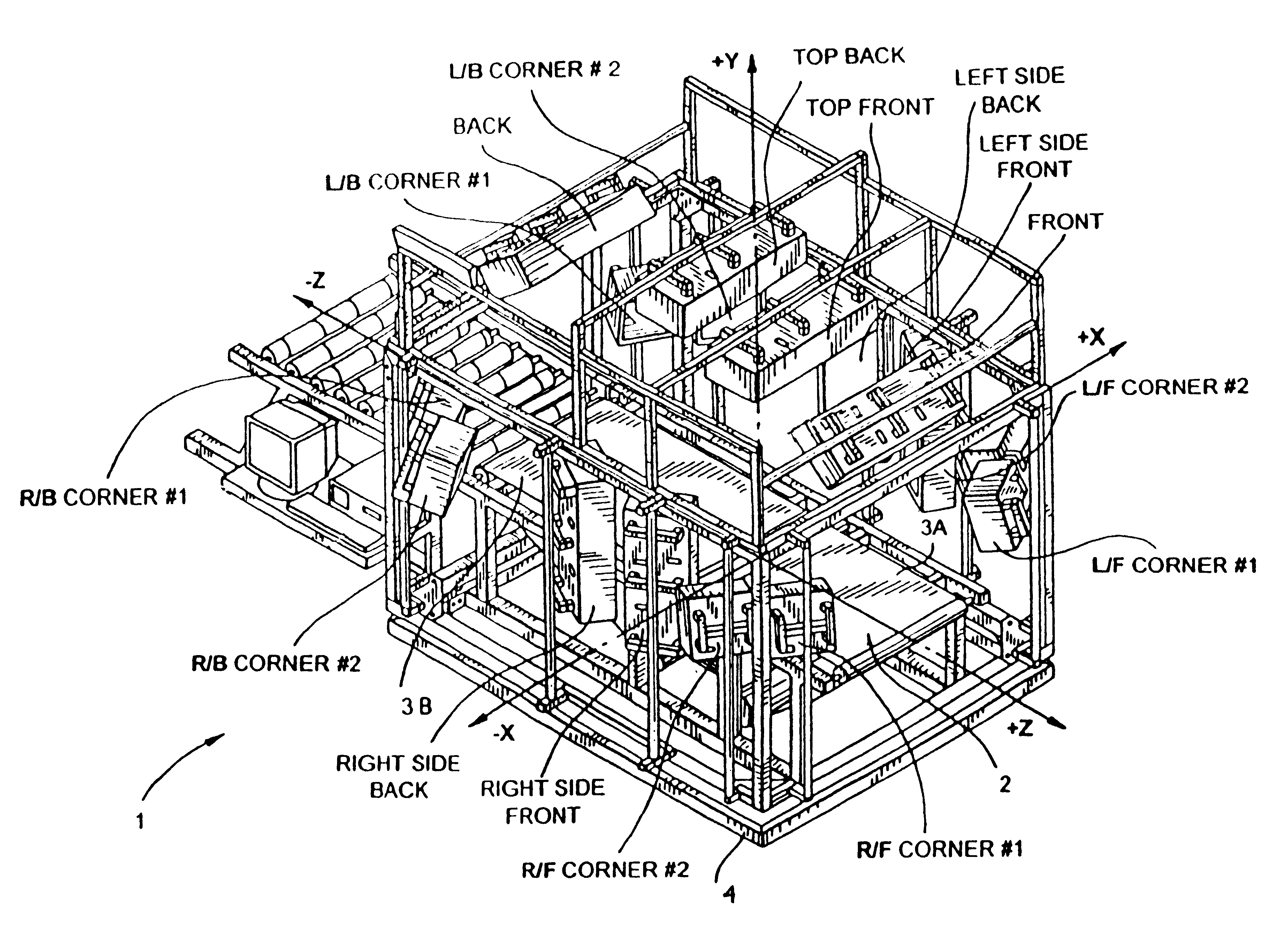

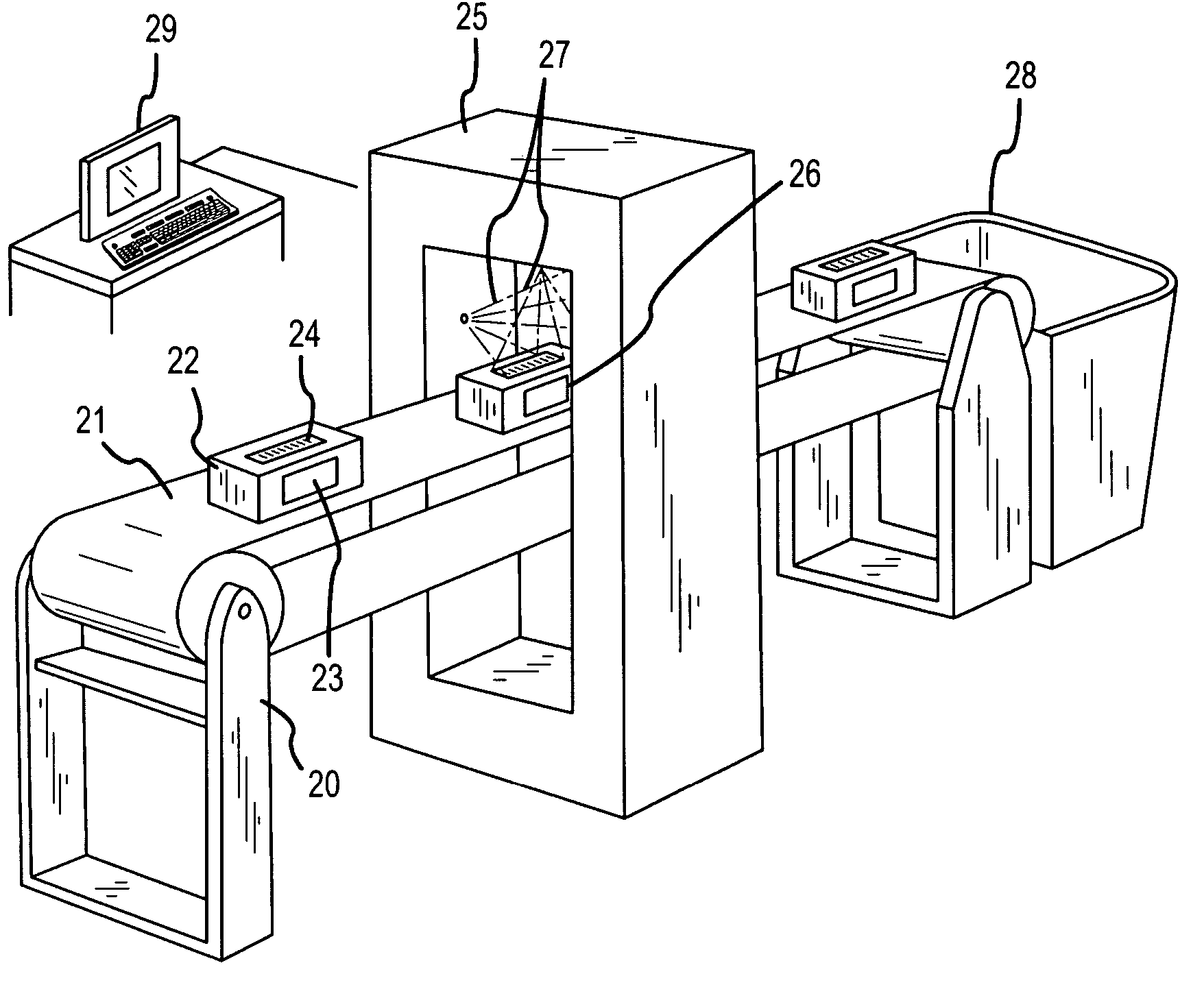

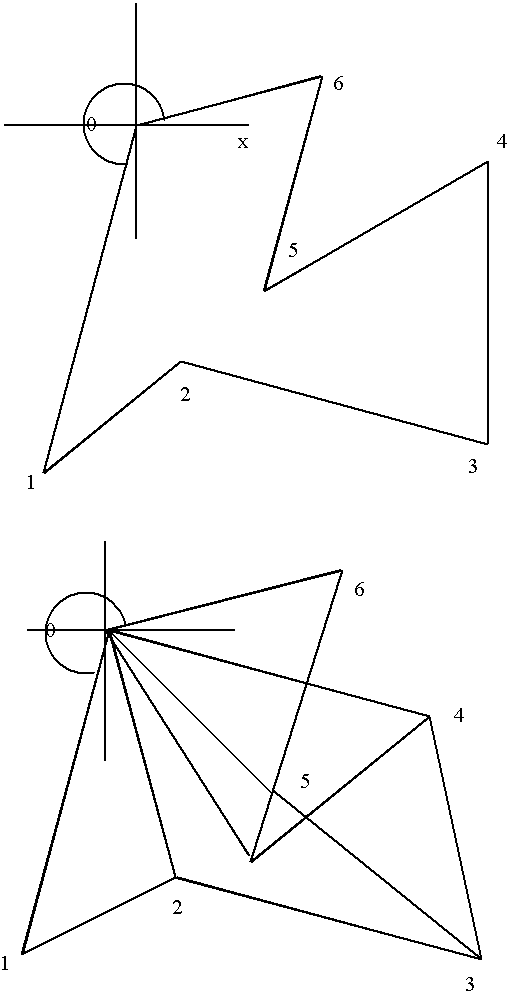

Apparatus and method for taking dimensions of 3D object

The present invention relates to an apparatus and method for real-time automatically taking the length, width and height of a rectangular object that is moved on a conveyor belt. The method of taking the dimensions of a 3D object, the method comprising the steps of: a) obtaining an object image having the 3D object; b) detecting all edges within a region of interest of the 3D object; c) extracting line segments from the edges of the 3D object and then extracting features of the 3D object from the line segments; and d) generating 3D models based on the features of the 3D object and taking the dimensions of the 3D object from the 3D models.

Owner:ELECTRONICS & TELECOMM RES INST

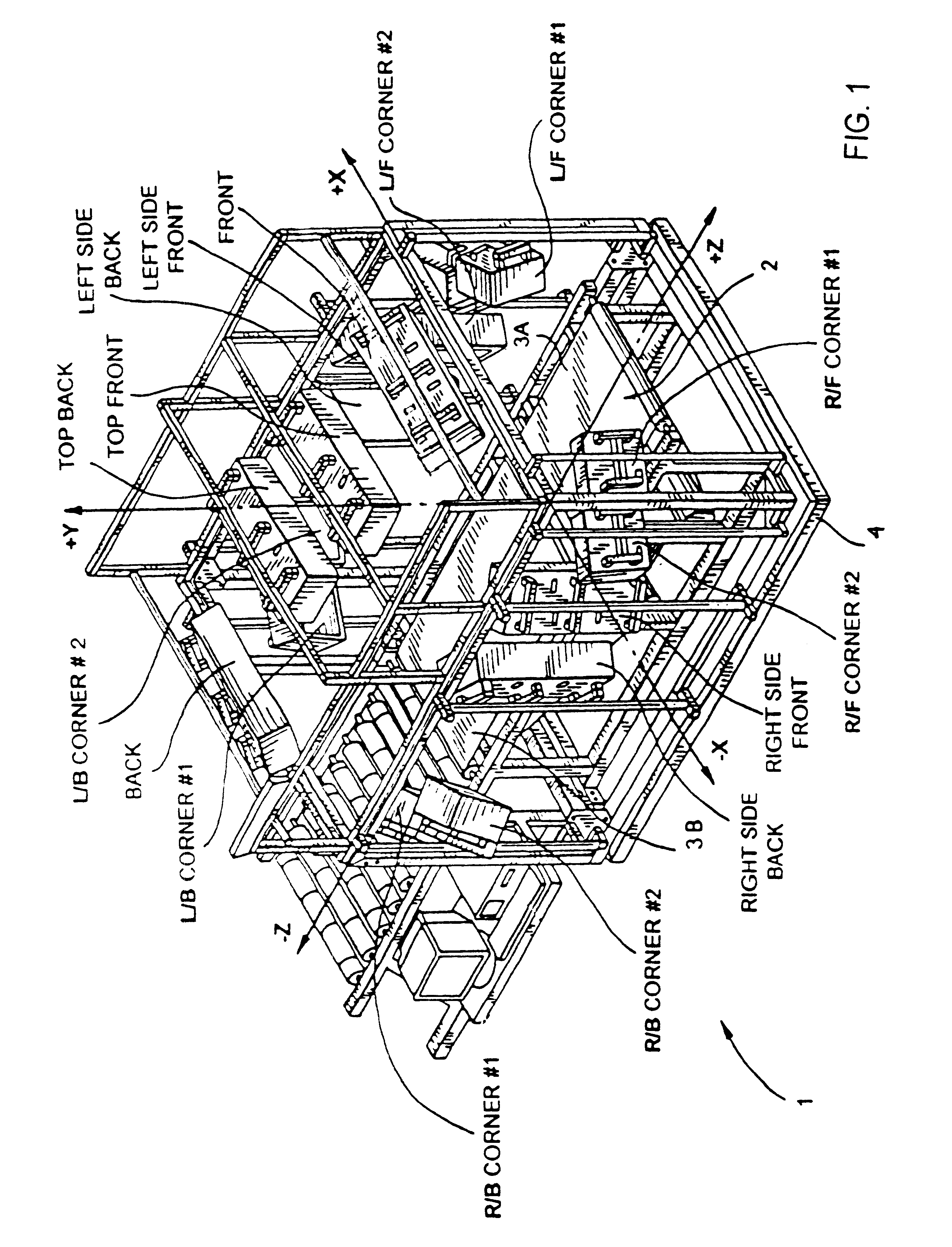

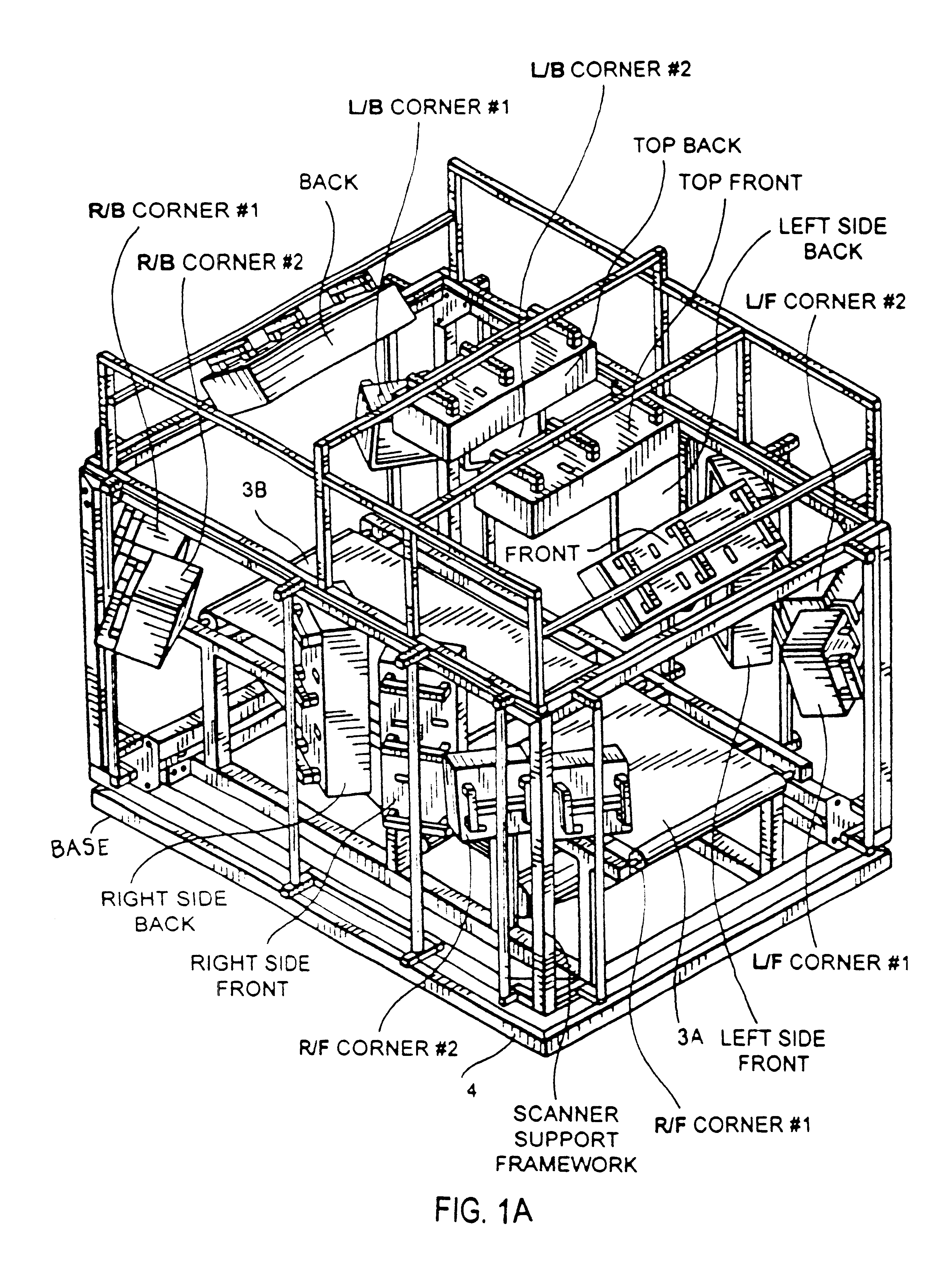

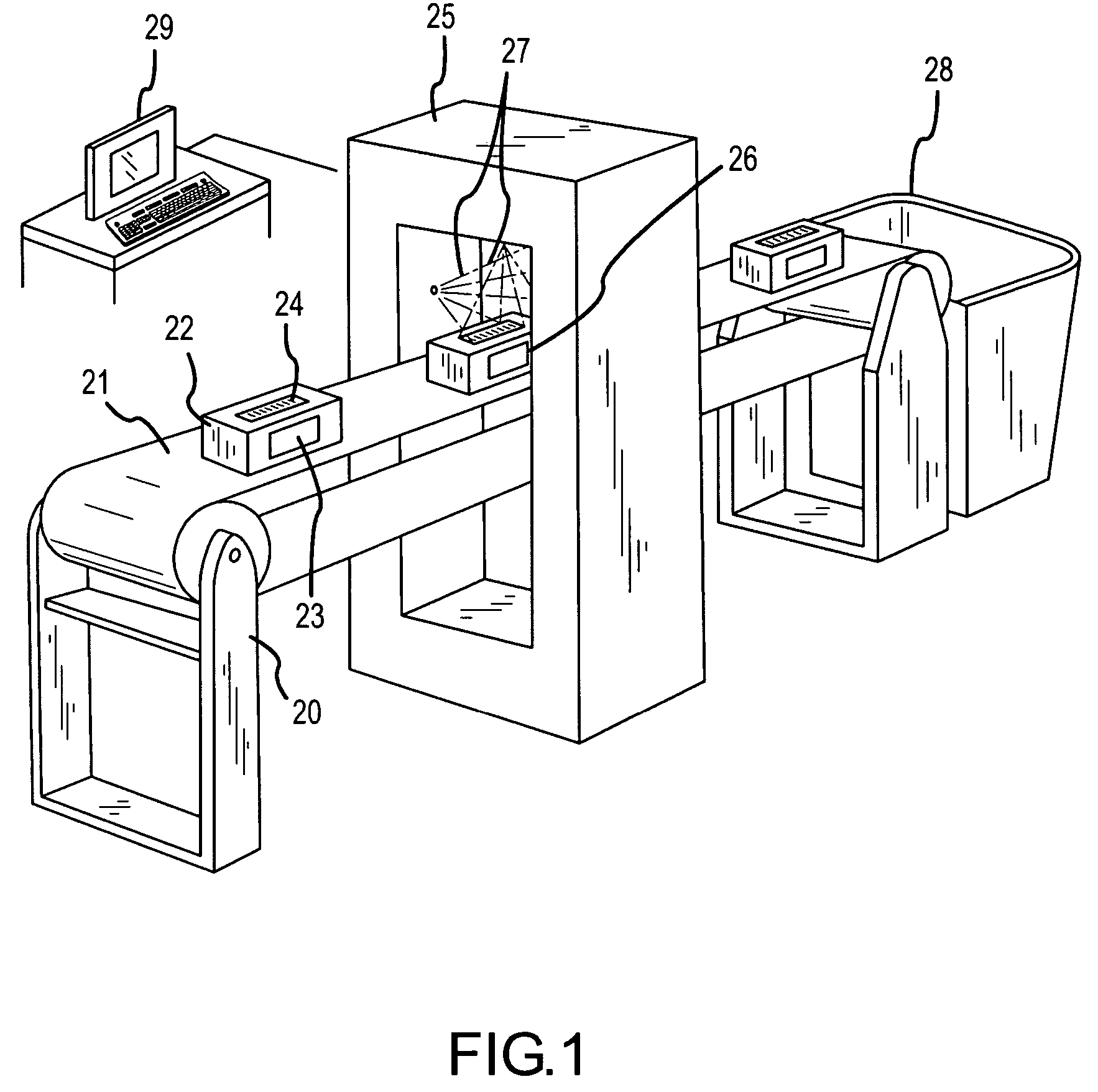

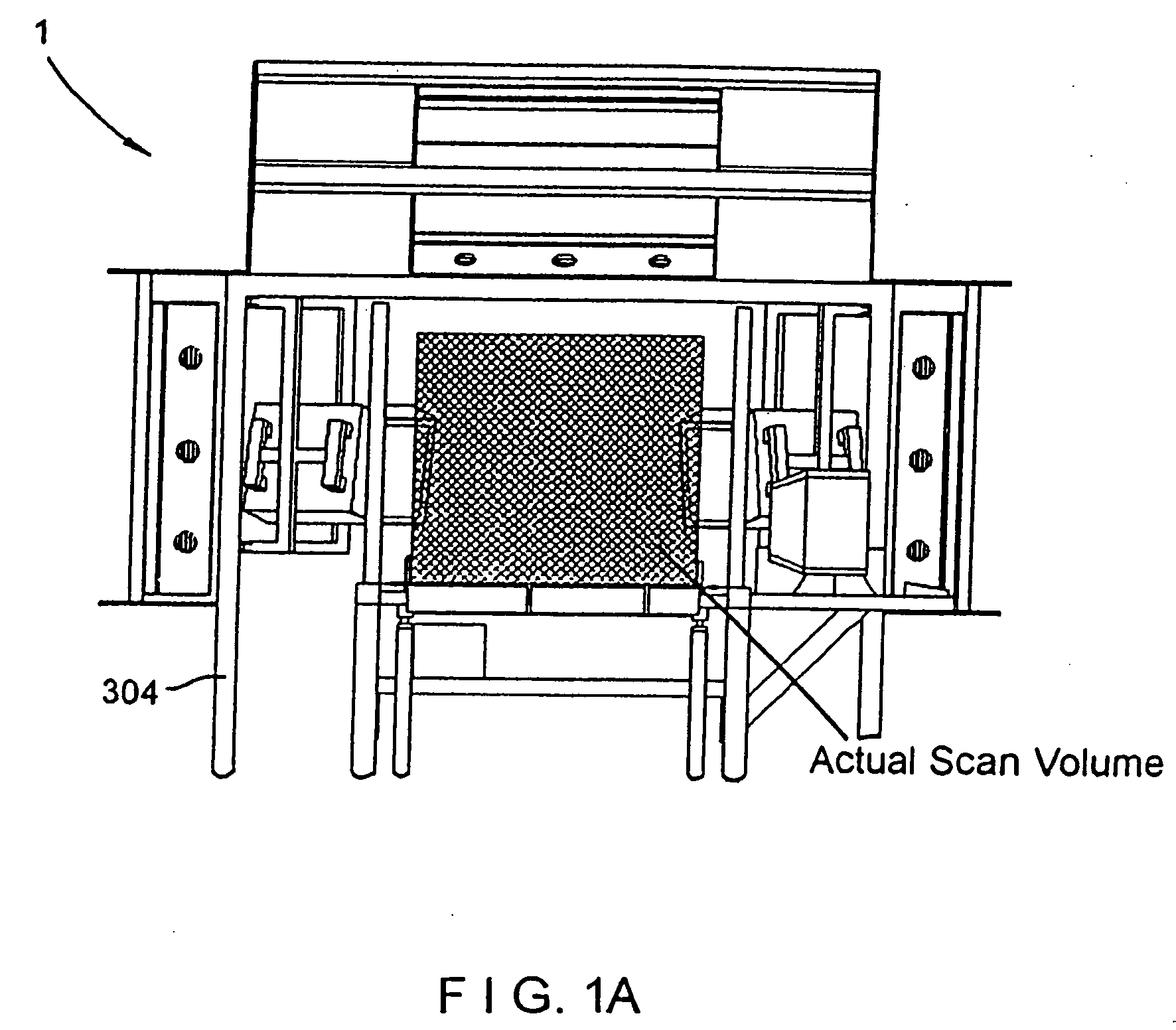

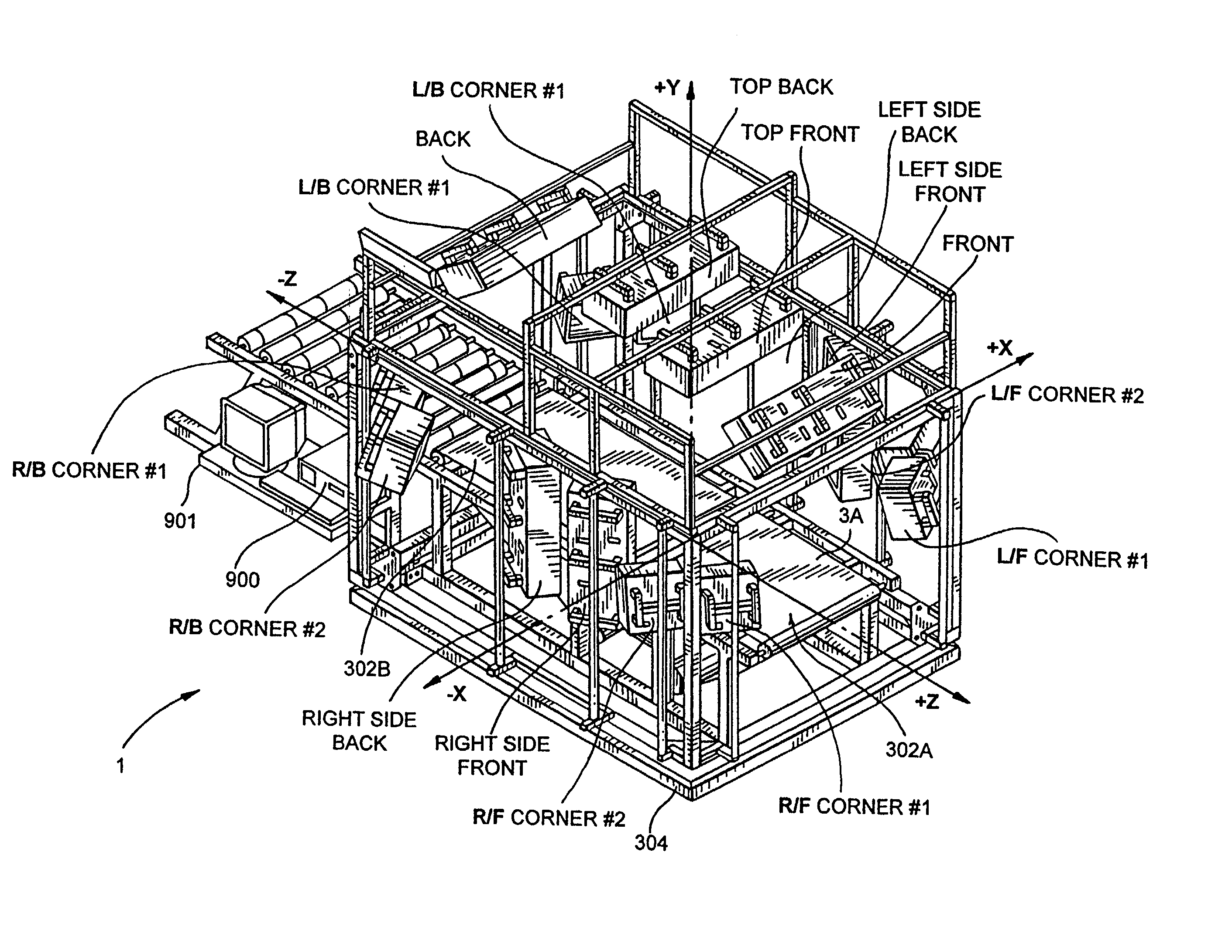

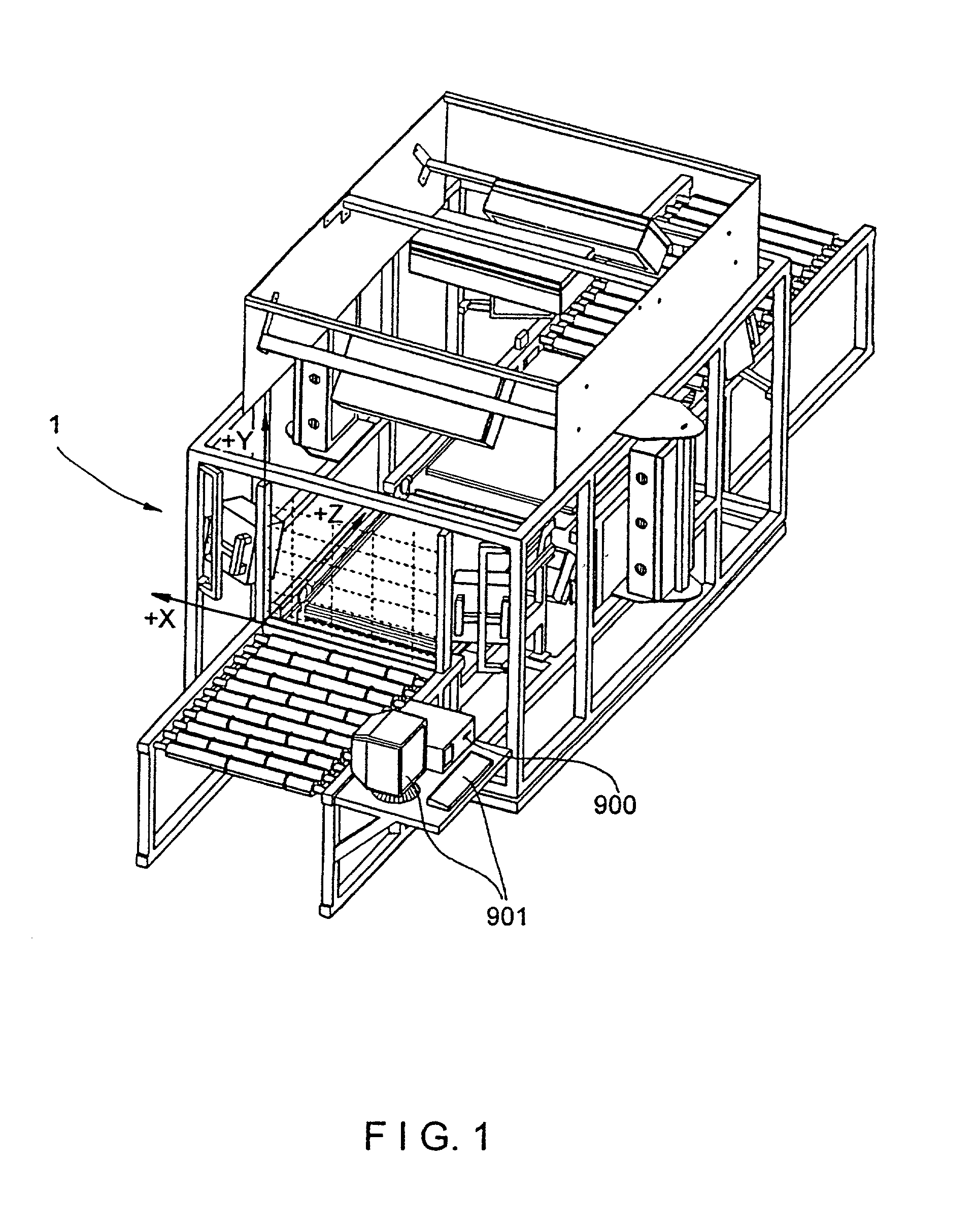

Automated holographic-based tunnel-type laser scanning system for omni-directional scanning of bar code symbols on package surfaces facing any direction or orientation within a three-dimensional scanning volume disposed above a conveyor belt

InactiveUS6360947B1OptimizationCo-operative working arrangementsCharacter and pattern recognitionMobile laser scanningMathematical model

A fully automated package identification and measuring system, in which an omni-directional laser scanning system are used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

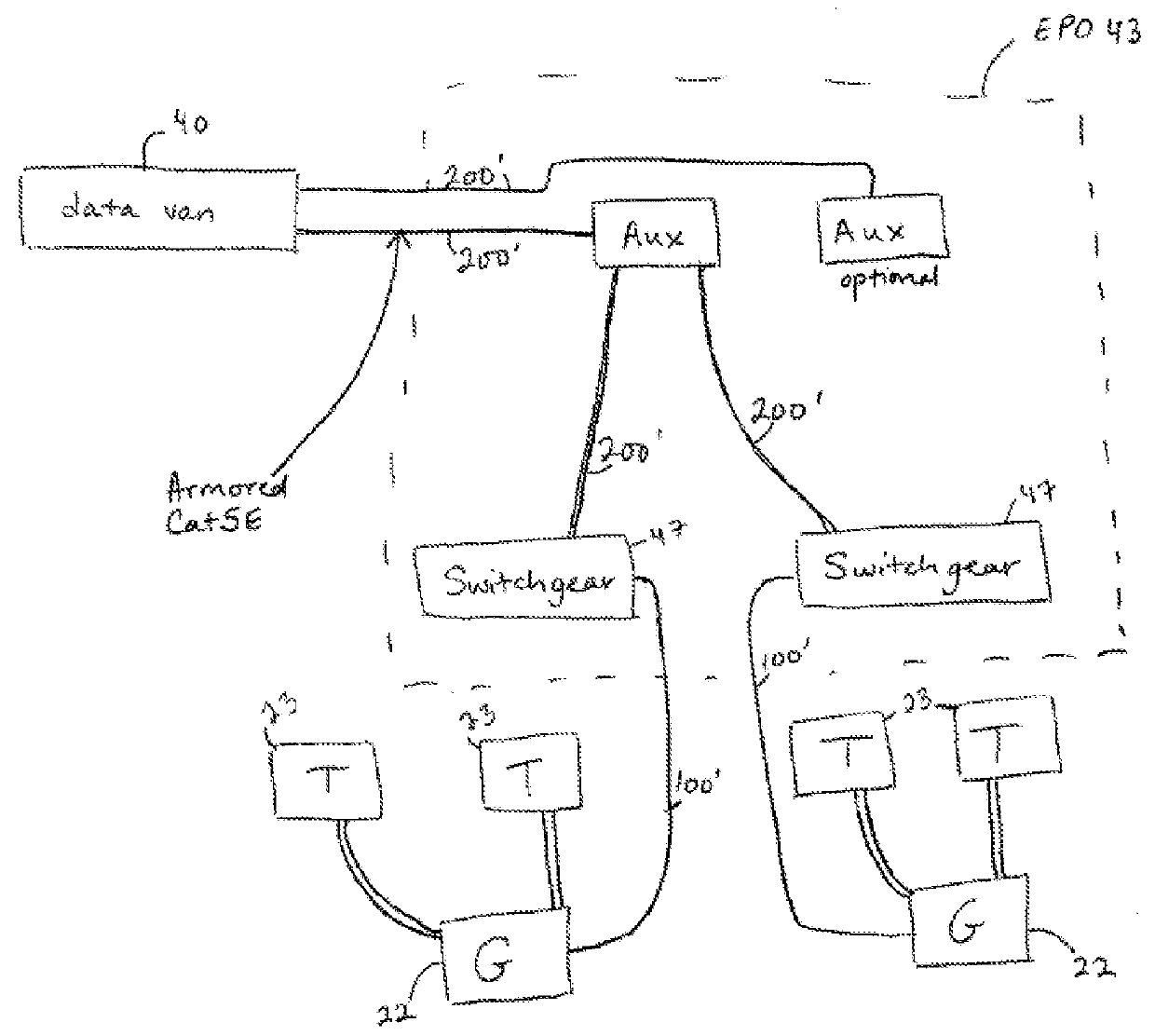

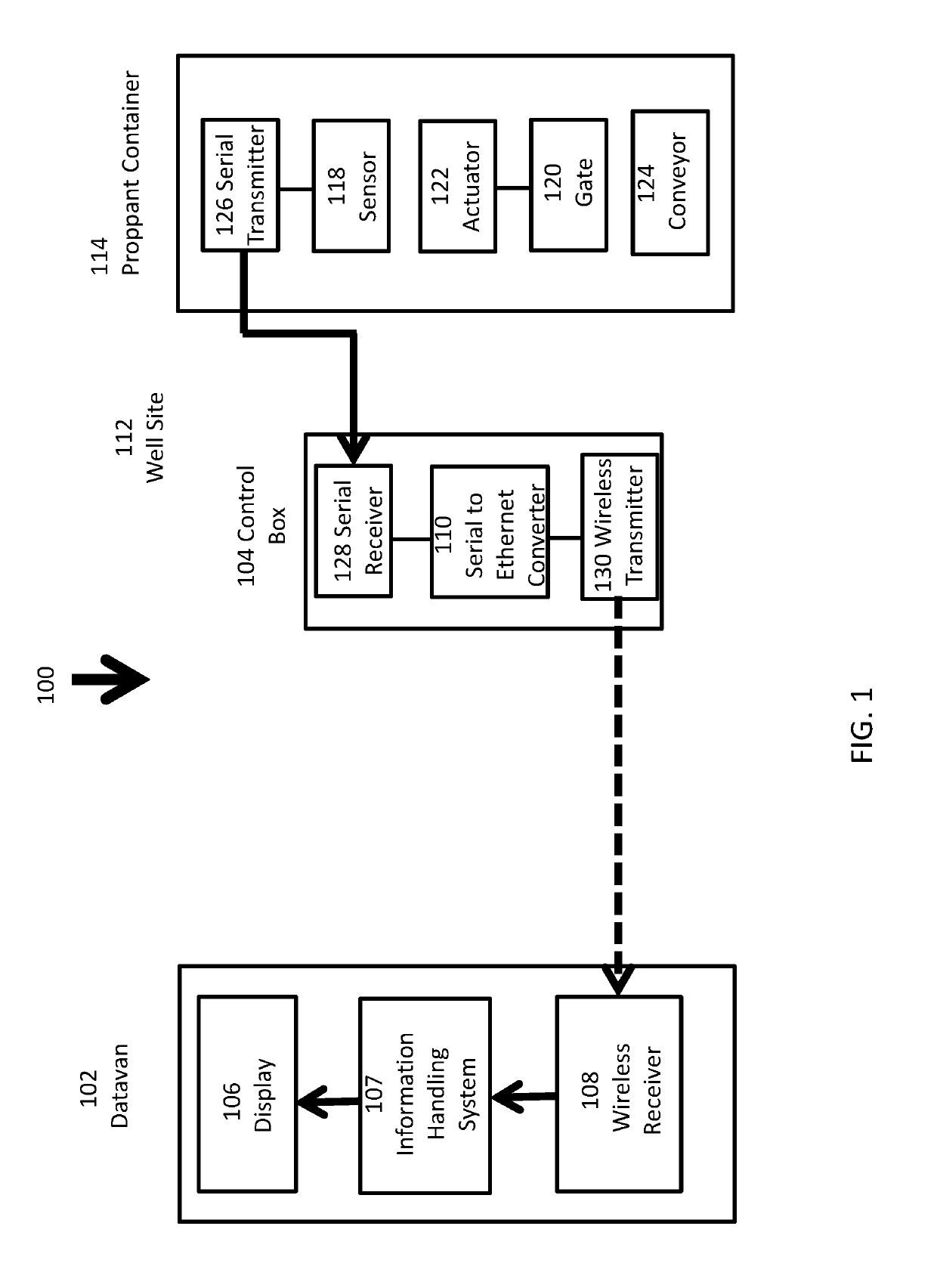

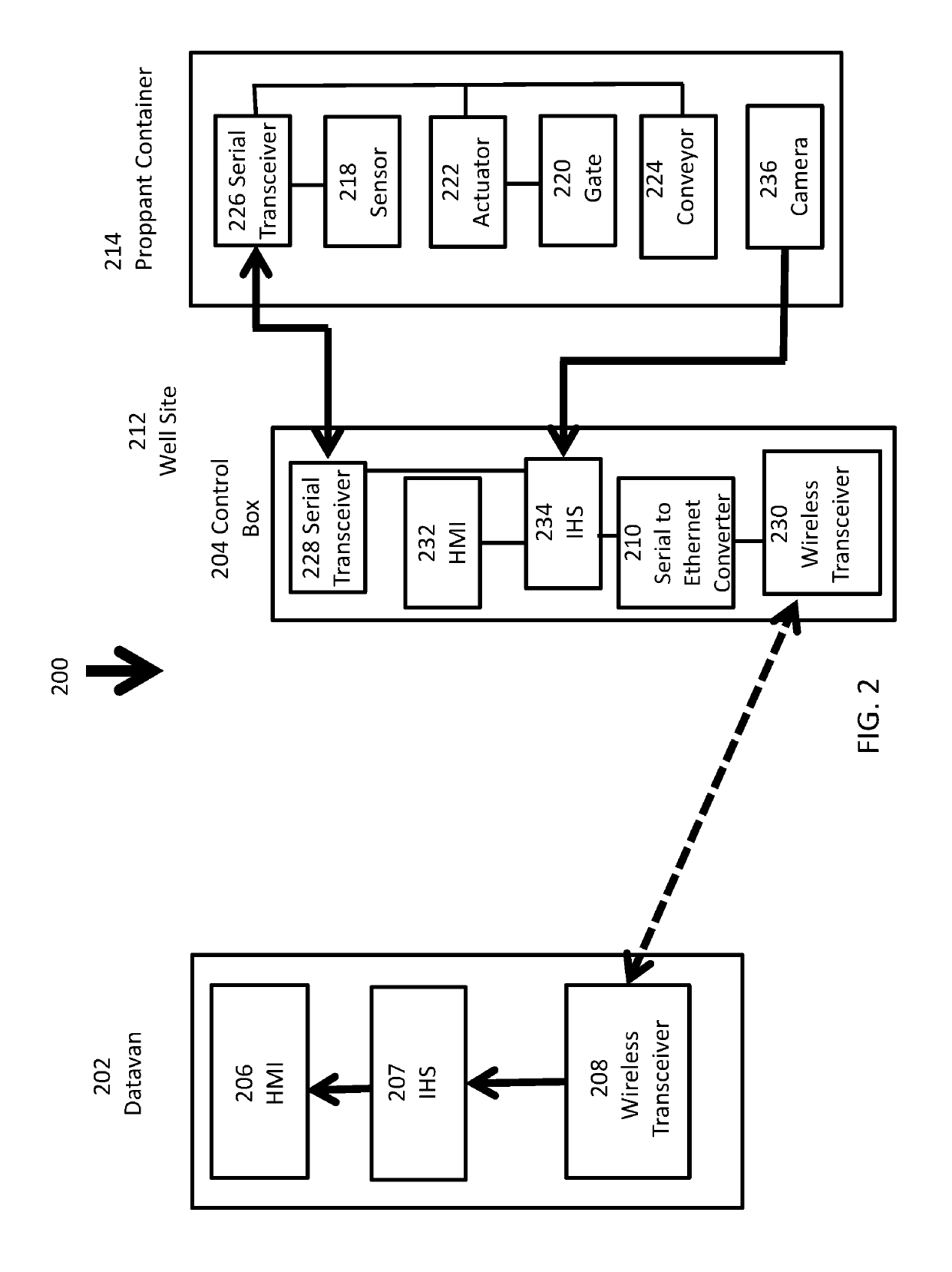

Monitoring and control of proppant storage from a datavan

ActiveUS10254732B2Automate processingHydraulic programme controlComputer controlTime informationDisplay device

A system and method that remotely monitors and controls proppant usage in a fracturing operation. The system and method allow operators to wirelessly monitor and control proppant storage units from inside a datavan through sensors and control mechanisms that interface with fracturing software to schedule the flow of the proppant. A sensor monitors the weight, container level, or volume of the proppant being used to keep the induced hydraulic fracture open. A serial to Ethernet converter converts this information and sends it wirelessly to a datavan. A user at the datavan controls the proppant usage through a display in the datavan of the storage units with the appropriate weight. The container monitoring software links with the fracturing software, providing real-time information about proppant usage so that the user can properly schedule proppant flow to the well through valves, conveyor belts, and other control mechanisms.

Owner:US WELL SERVICS LLC

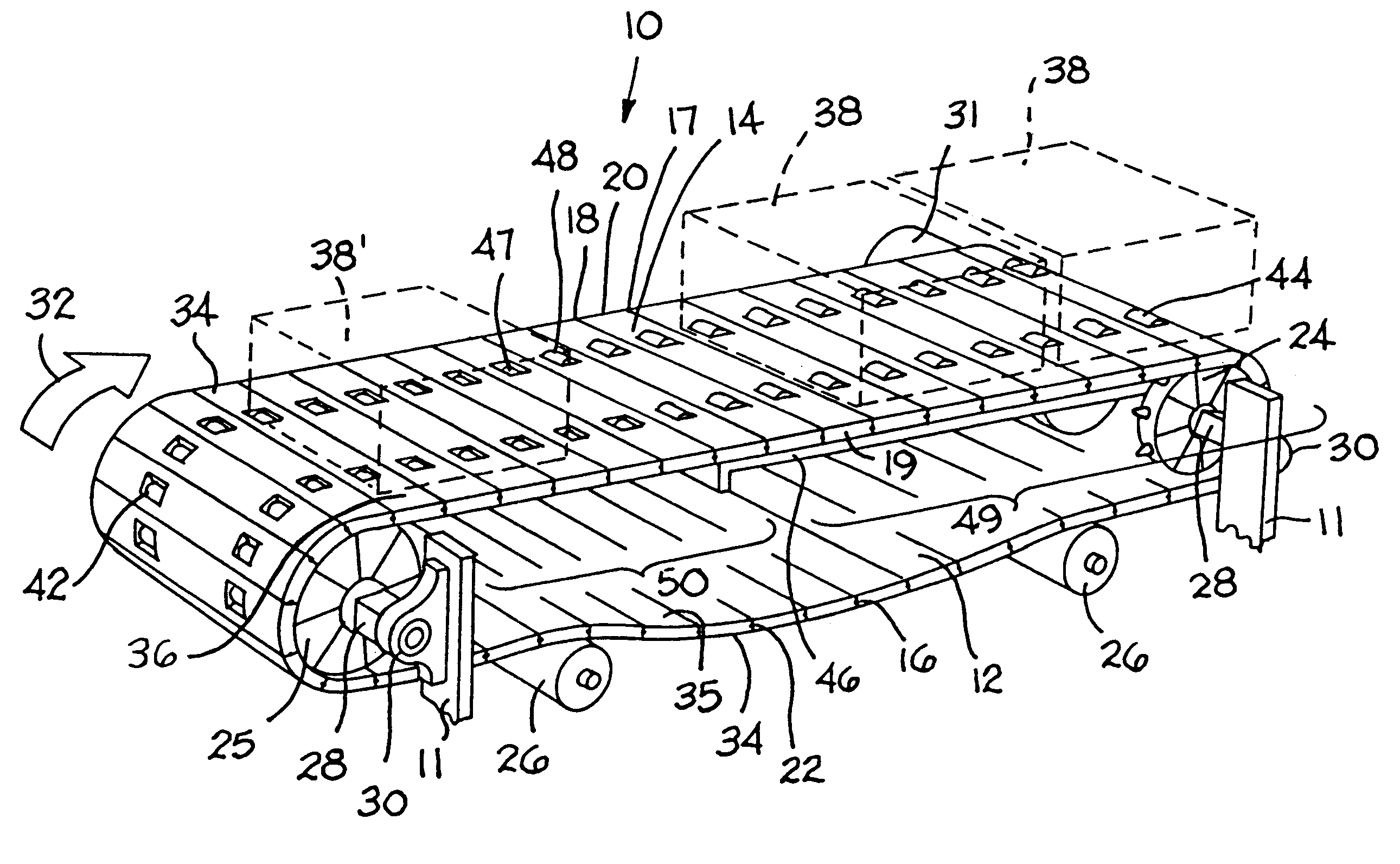

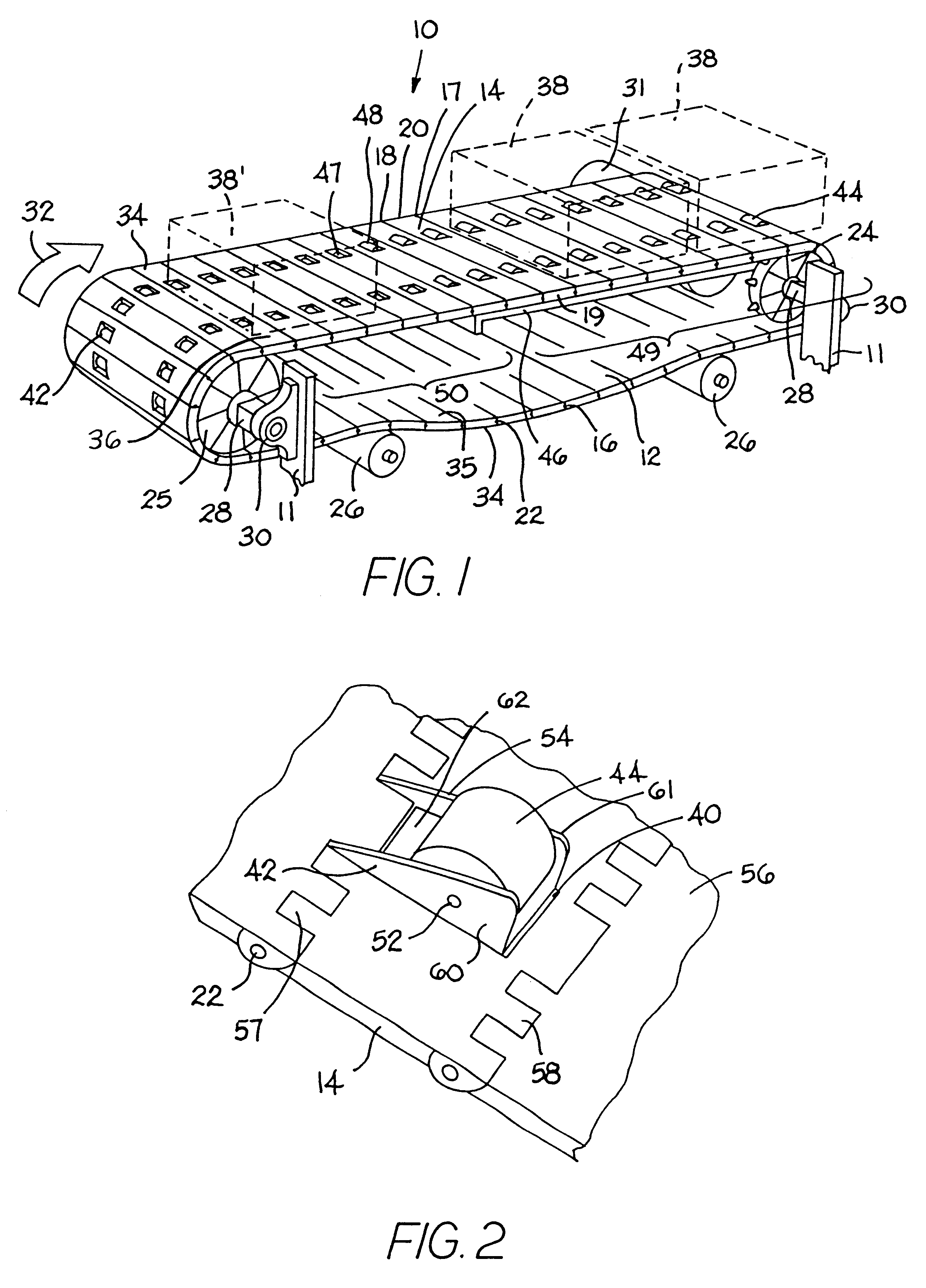

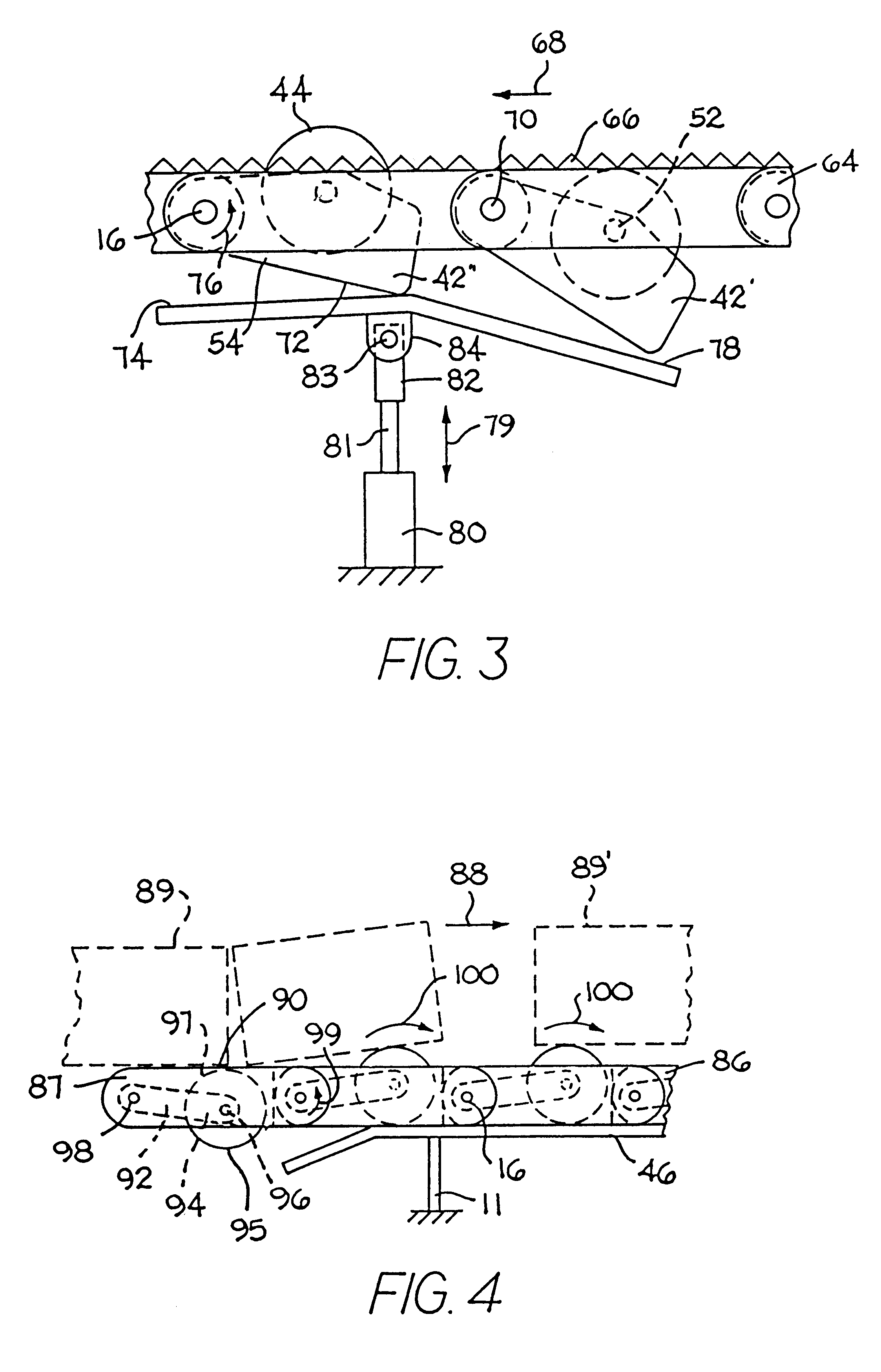

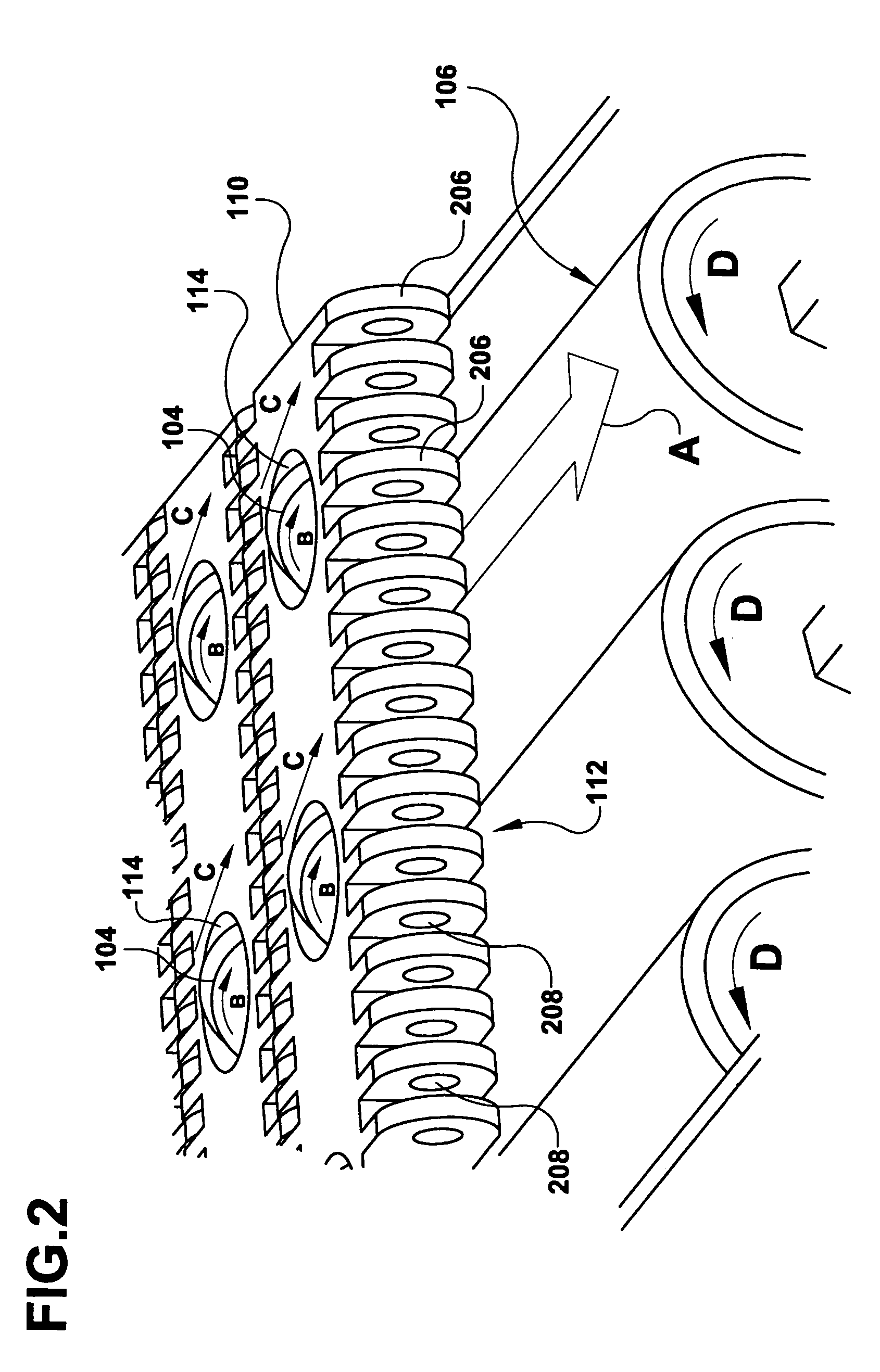

Changing the characteristics of an article-conveying belt surface on a running conveyor

A belt conveyor whose article-conveying characteristics can be changed as the belt is running. The conveyor belt includes a plurality of movable assemblies supporting an article-supporting element and an adjustable element. The adjustable element coacts with an adjustment control element supported in the conveyor frame as the belt is running. The coaction causes the adjustable element to move the article-supporting element to provide a different article-conveying characteristic to articles supported at the conveying surface of the belt in zones defined by the adjustment control elements.

Owner:THE LAITRAM CORP

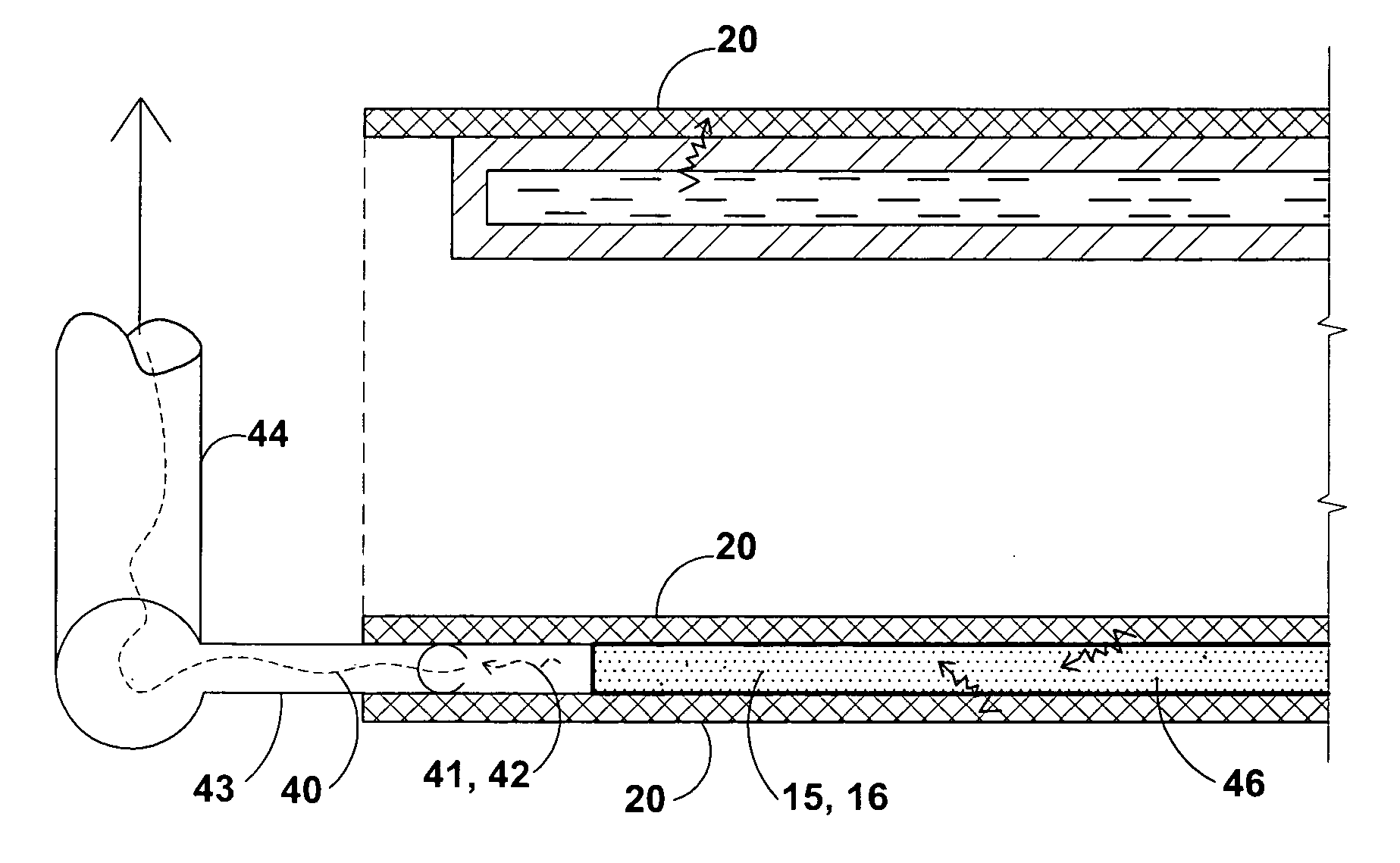

Method and apparatus for biomass torrefaction using conduction heating

InactiveUS20080223269A1Reduce air pollutionEasy to storeDrying solid materials with heatBiofuelsThermal contactConveyor belt

A method for torrefaction of wood which includes providing a first endless conveyor belt; heating the first endless belt; and positioning a planar wood product on the first belt to heat the wood product by conduction to achieve torrefaction. Other forms provide a second endless belt that disposed in sandwich relation to wood to be torrefied. Some embodiments of the method provide a metal chamber having opposed planar sides dimensioned and configured for receiving a wood sheet with the respective opposed sides of the wood sheet in intimate thermal contact with respective opposed sides of the metal chamber. Other embodiments include the apparatus for torrefaction of an associated wood sheet.

Owner:PAOLUCCIO JOHN A

Method and apparatus for preparing an item with an RFID tag

ActiveUS7218231B2Control devices for conveyorsCo-operative working arrangementsComputer hardwareBarcode

An automated reading system for associating an RFID tag and product information includes a conveyor belt for moving a product having an RFID tag and a bar code. The system also includes an RFID scanner and a bar code scanner for reading information on the product as it travels down the conveyor belt. A collecting device is used for receiving the product, and a computer having a database is used for recording the association between the RFID tag and the product information.

Owner:OMNICELL

Automated method of and system for dimensioning objects over a conveyor belt structure by applying contouring tracing, vertice detection, corner point detection, and corner point reduction methods to two-dimensional range data maps of the space above the conveyor belt captured by an amplitude modulated laser scanning beam

A fully automated package identification and measuring system, in which an omni-directional holographic scanning tunnel is used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

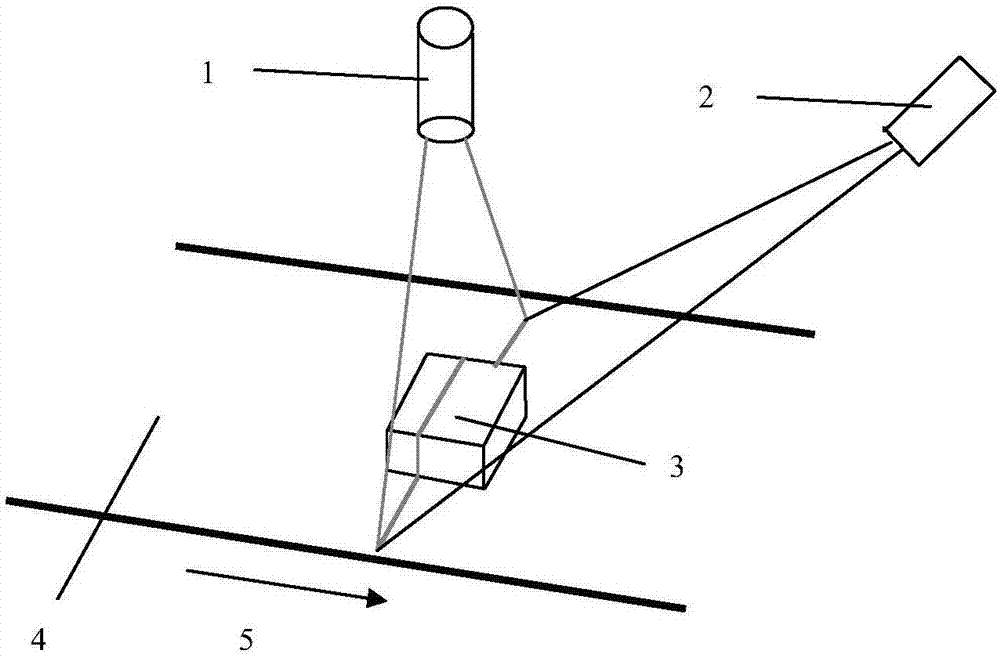

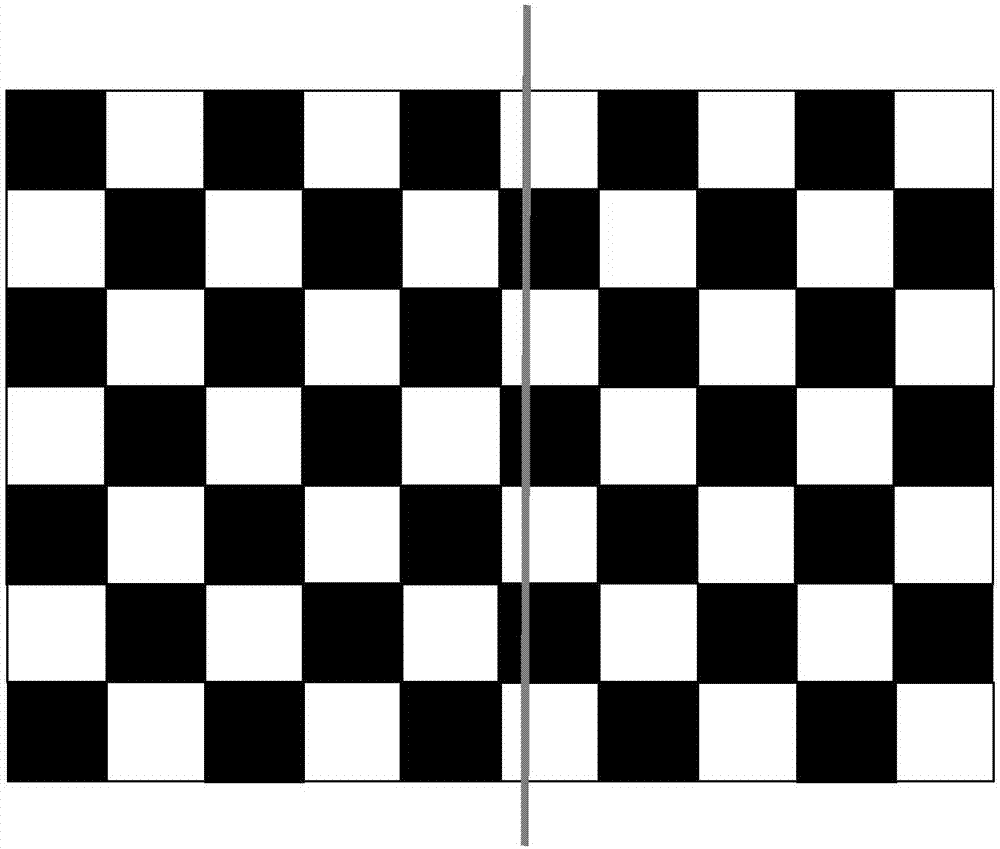

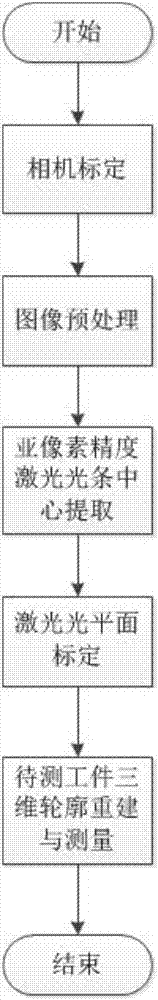

A method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning

ActiveCN107578464AHigh measurement accuracyAccurate measurementImage analysisUsing optical meansMobile laser scanningLaser light

The invention discloses a method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning. The method comprises the following steps of obtaining camera internal and external parameters through camera calibration, carrying out filtering and laser light strip center position initial extraction through an image preprocessing step, carrying out sub-pixel precision refinement on the center coordinates of a light bar, obtaining a light plane equation through the laser light plane calibration and finally carrying out reconstruction and measurement of the three-dimensional contour information of a workpiece to be measured. The workpiece 3D contour measurement brought forward by the invention has the following advantages: a high measurement precision which means thethree-dimensional contour information of the workpiece to be measured can be accurately obtained through the laser light bar extraction with sub-pixel precision and 3D reconstruction; a fast measurement speed which means real-time measurement of 3D contour information of the workpiece to be tested can be realized to improve the efficiency of industrial production site operations; and low hardwarecosts which is realized in a hardware implementation mode in which laser is combined with a monocular camera. Accordingly, the technical method of the application has advantages such as being in a non-contact mode, high in measurement precision, fast in speed and low in cost, and can be applied to an industrial automation production process to realize accurate measurement of the 3D contour information of the workpiece on the conveyor belt.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

Automated method of and system for dimensioning objects over a conveyor belt structure by applying contouring tracing, vertice detection, corner point detection, and corner point reduction methods to two-dimensional range data maps of the space above the conveyor belt captured by an amplitude modulated laser scanning beam

InactiveUS20020179708A1Coin-freed apparatus detailsSemiconductor/solid-state device manufacturingData graphAlgorithm

A fully automated package identification and measuring system, in which an omni-directional holographic scanning tunnel is used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

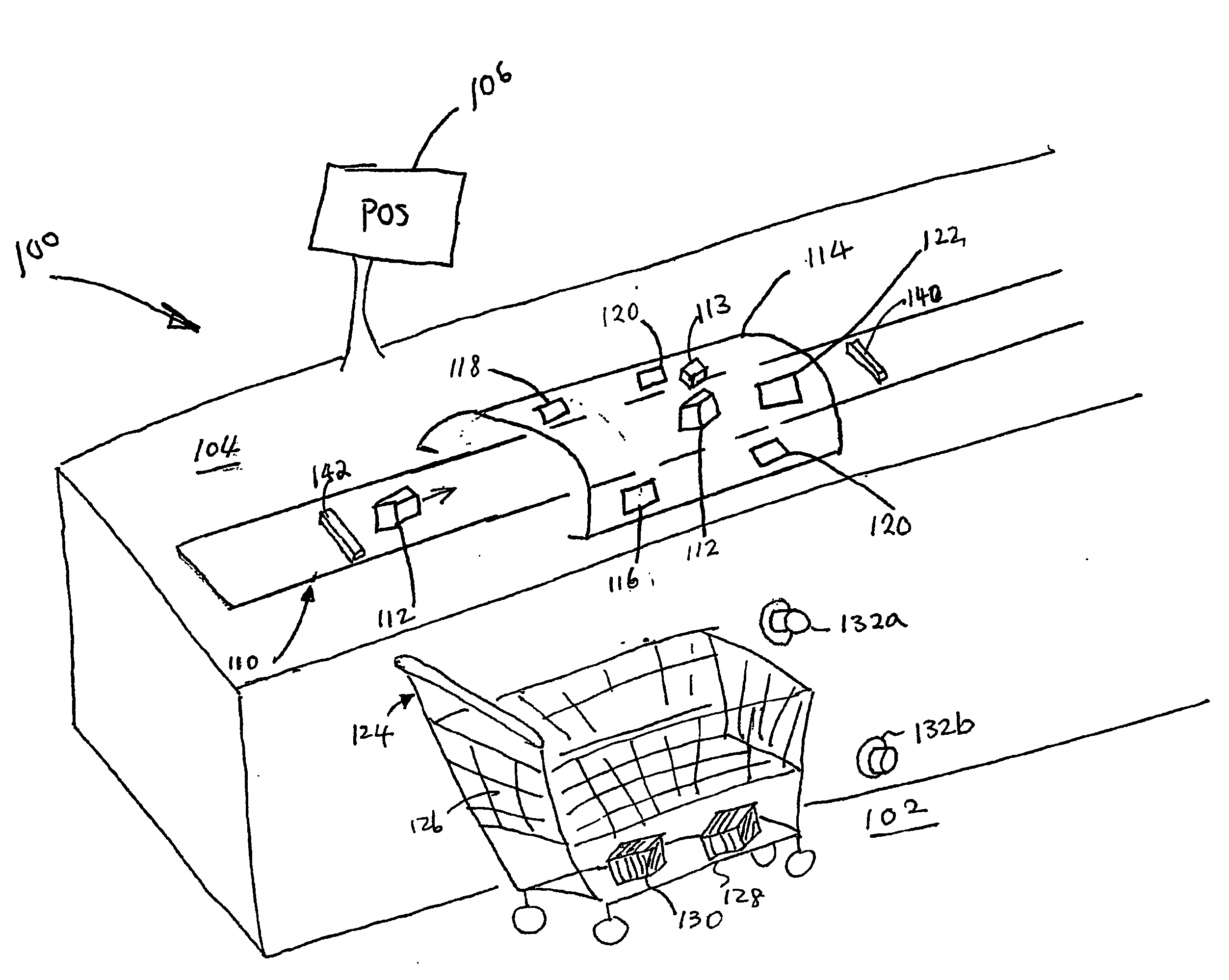

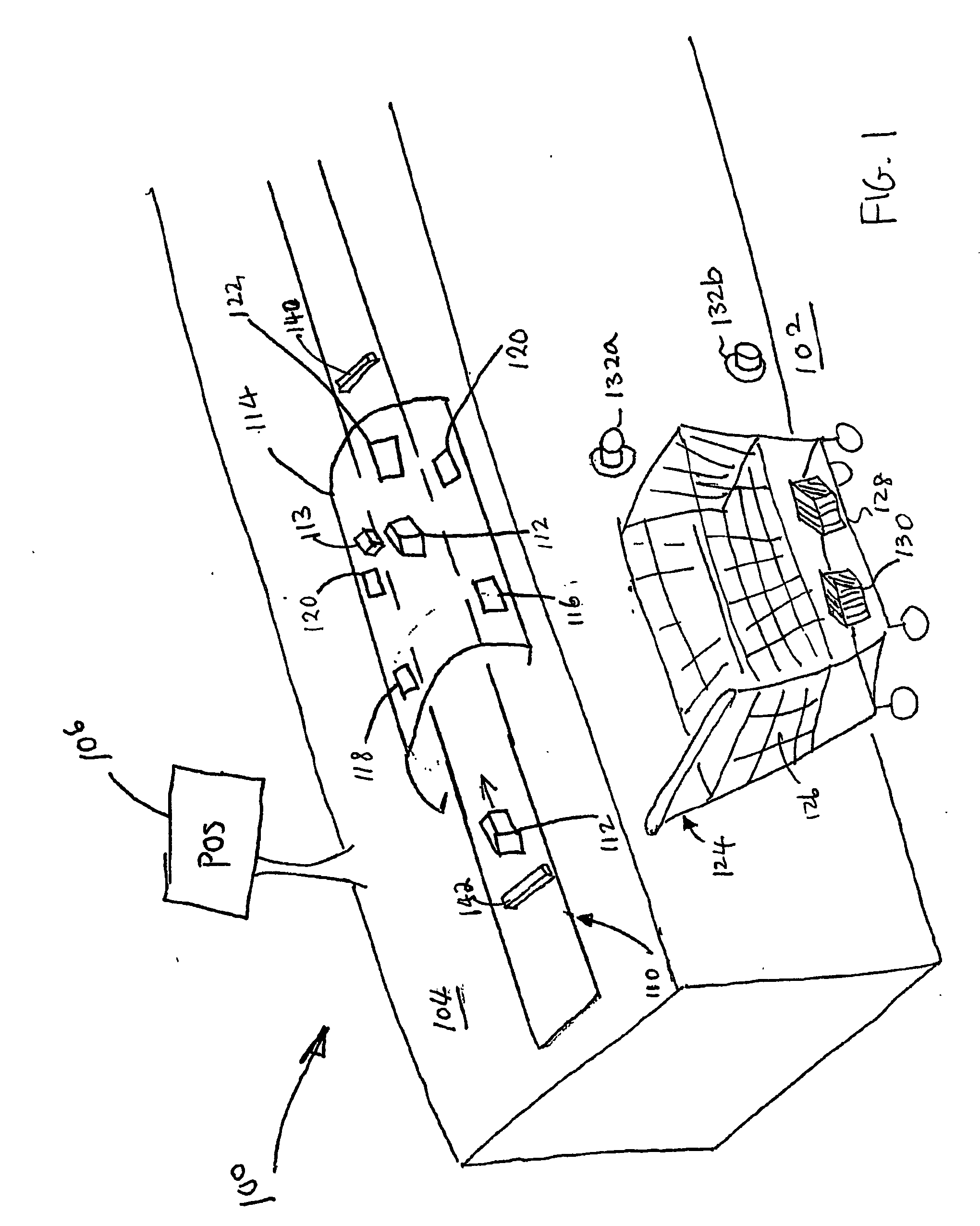

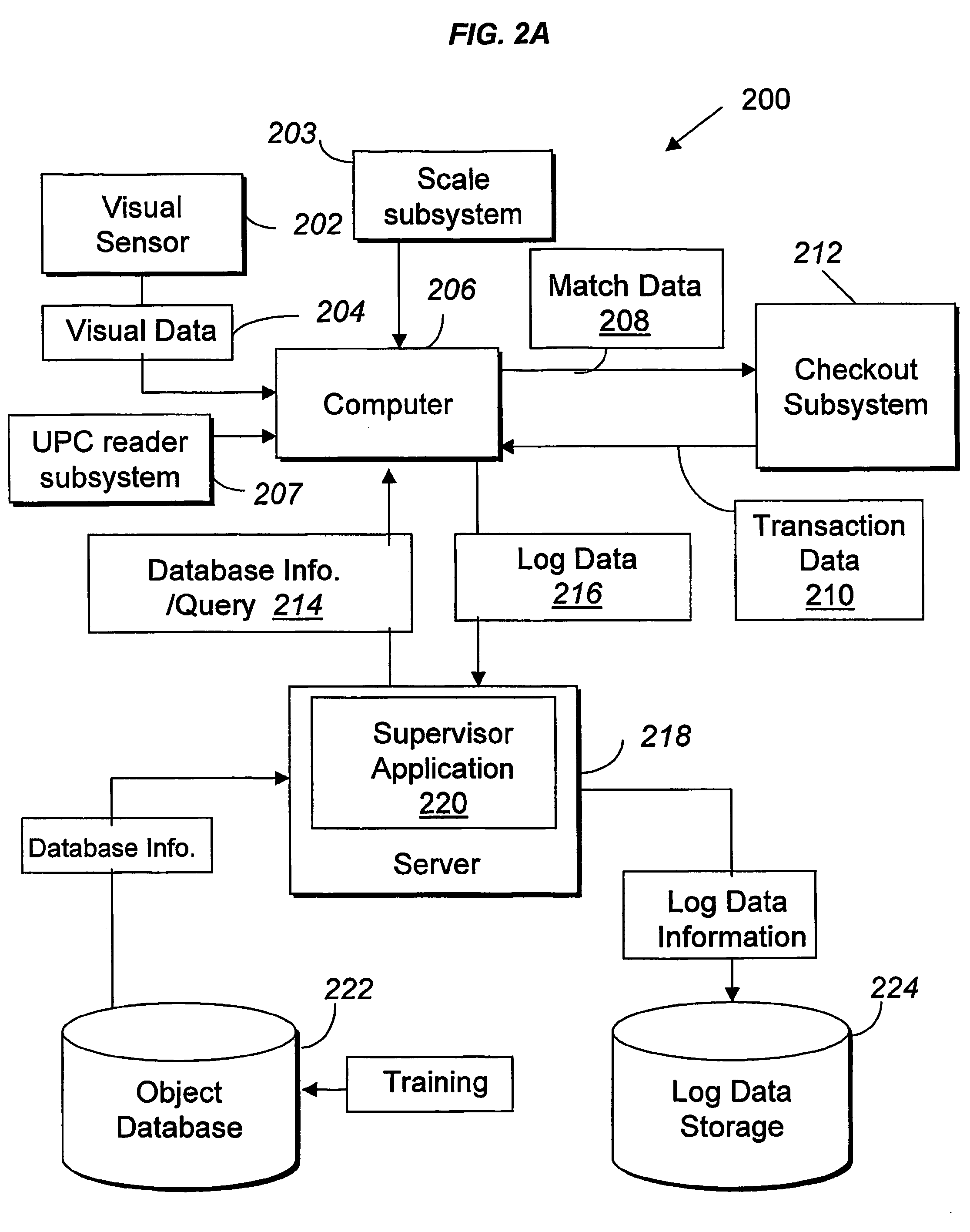

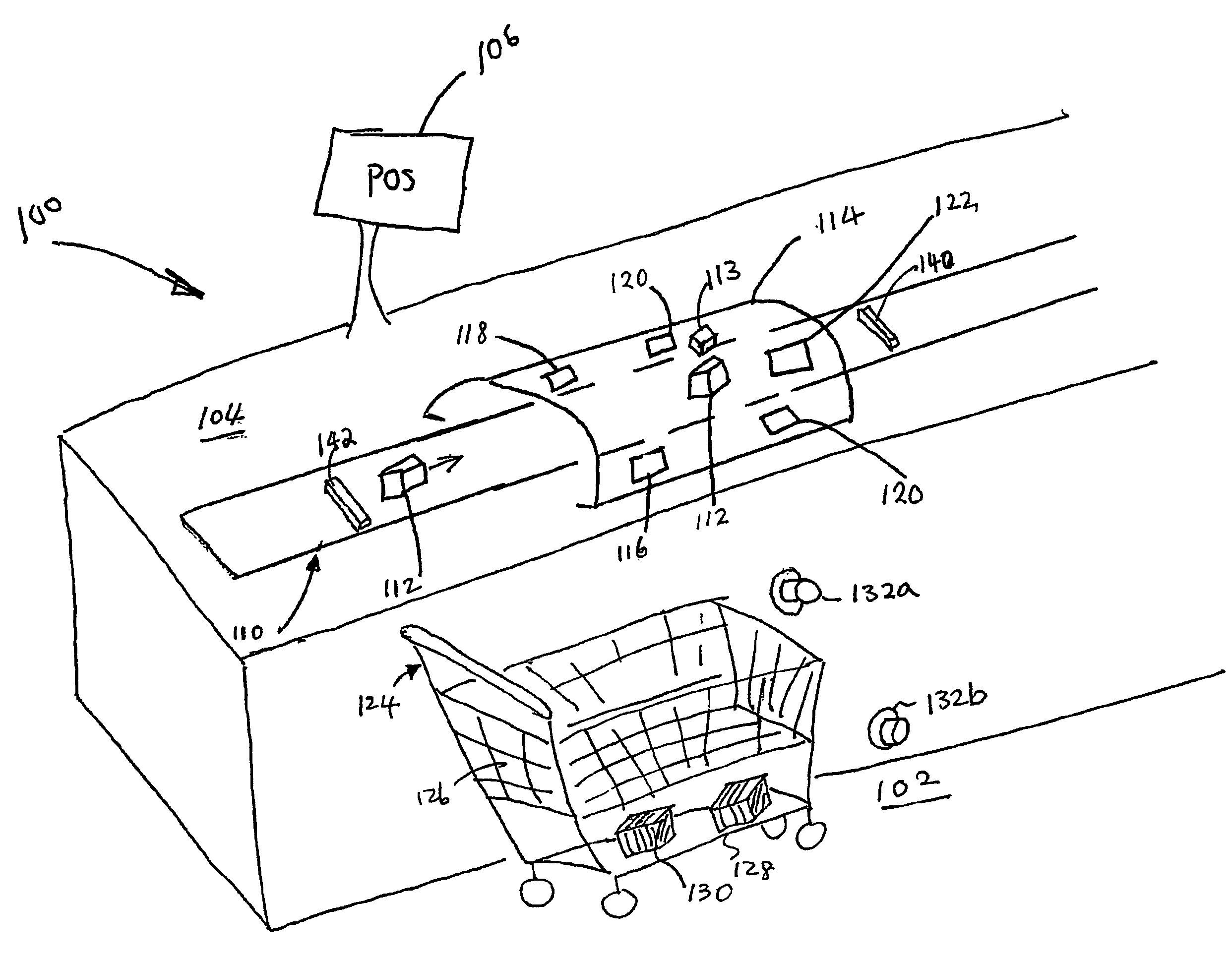

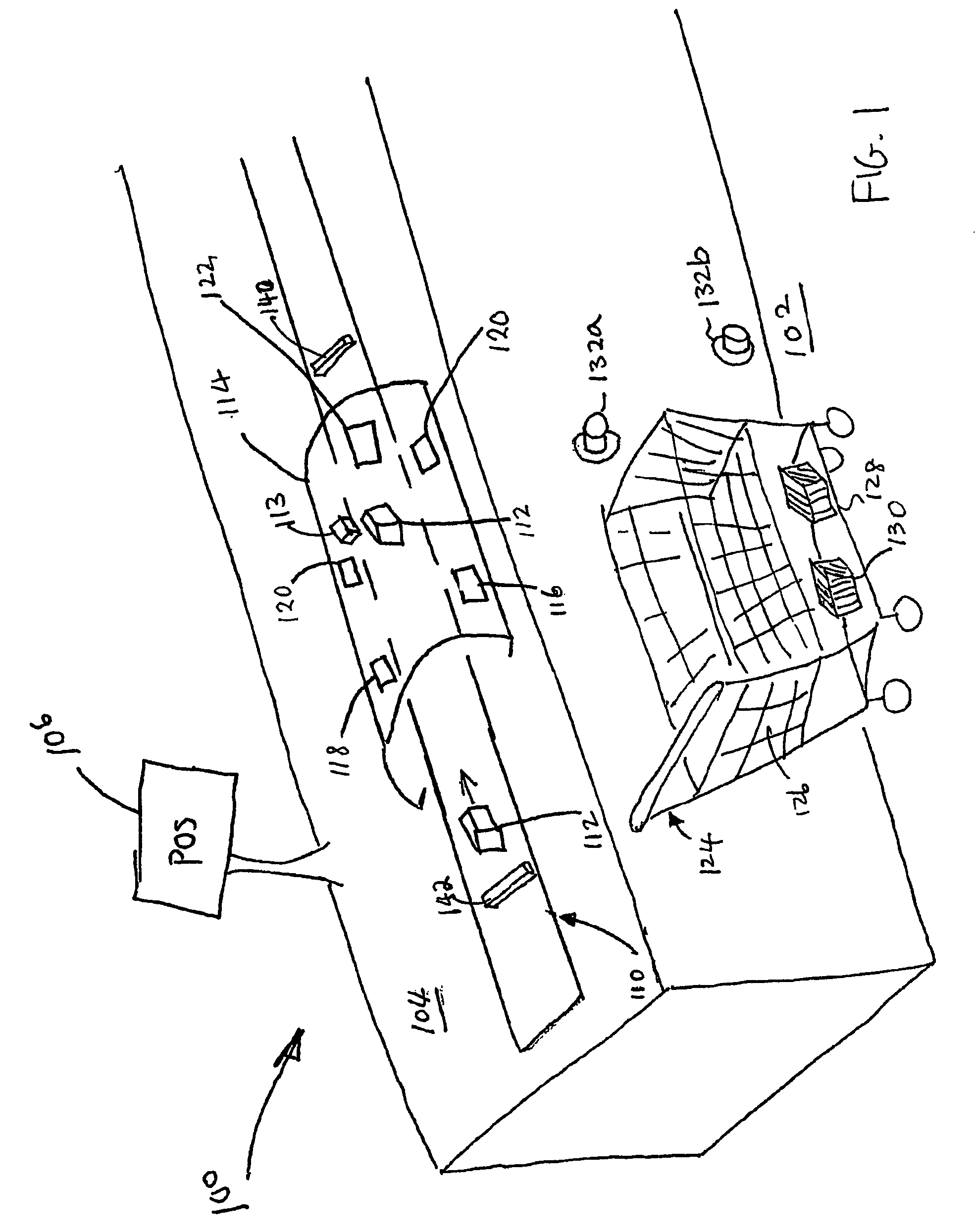

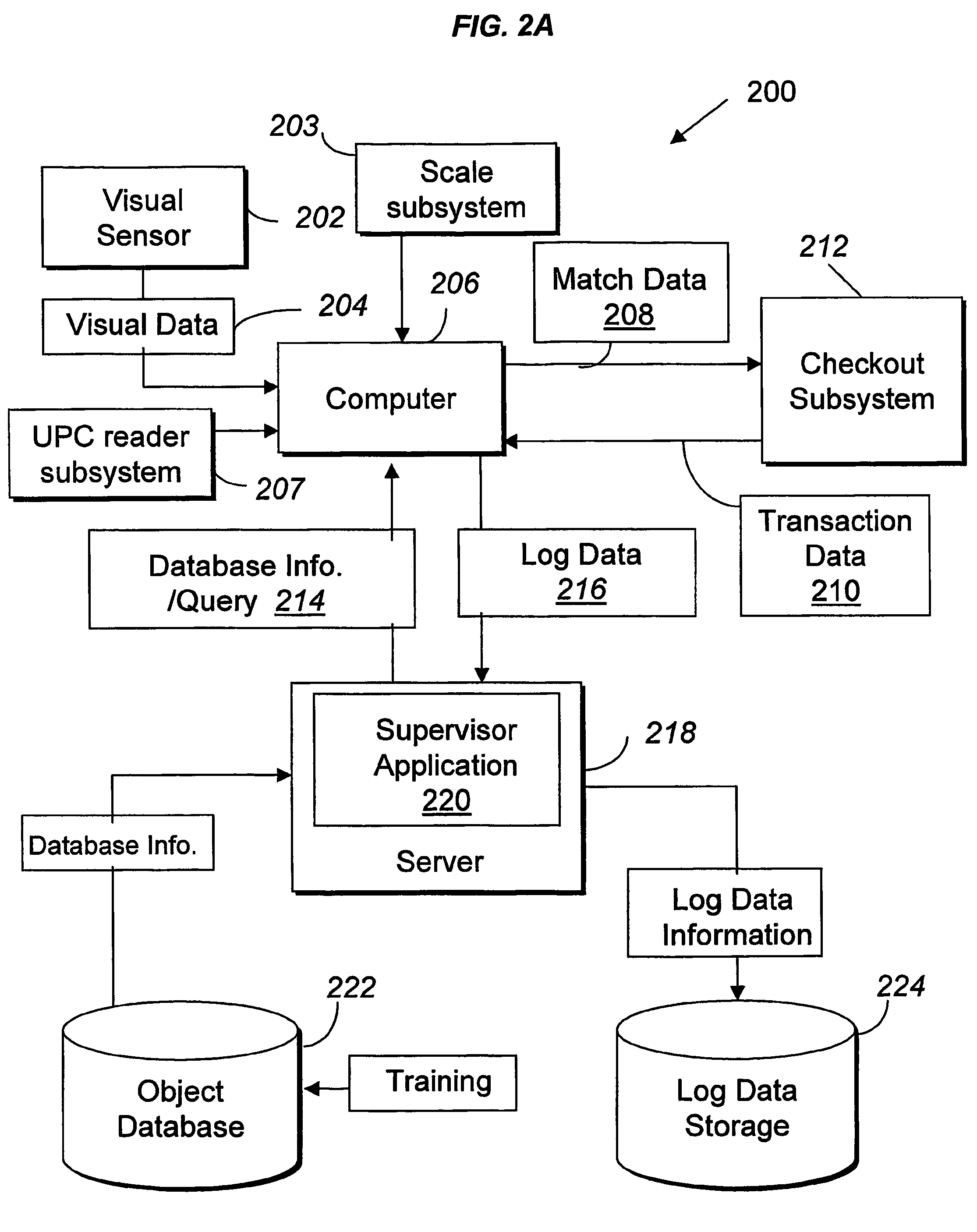

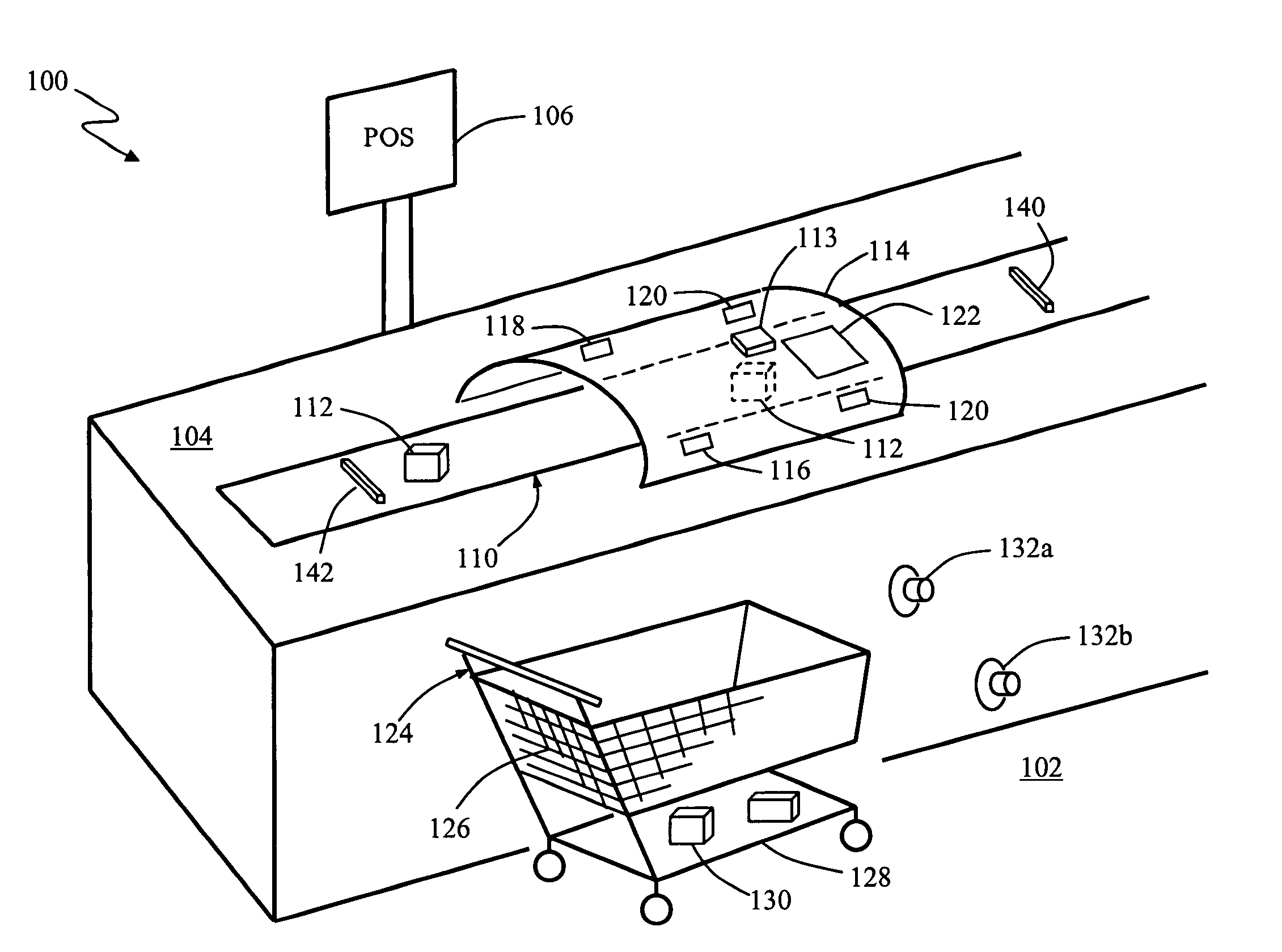

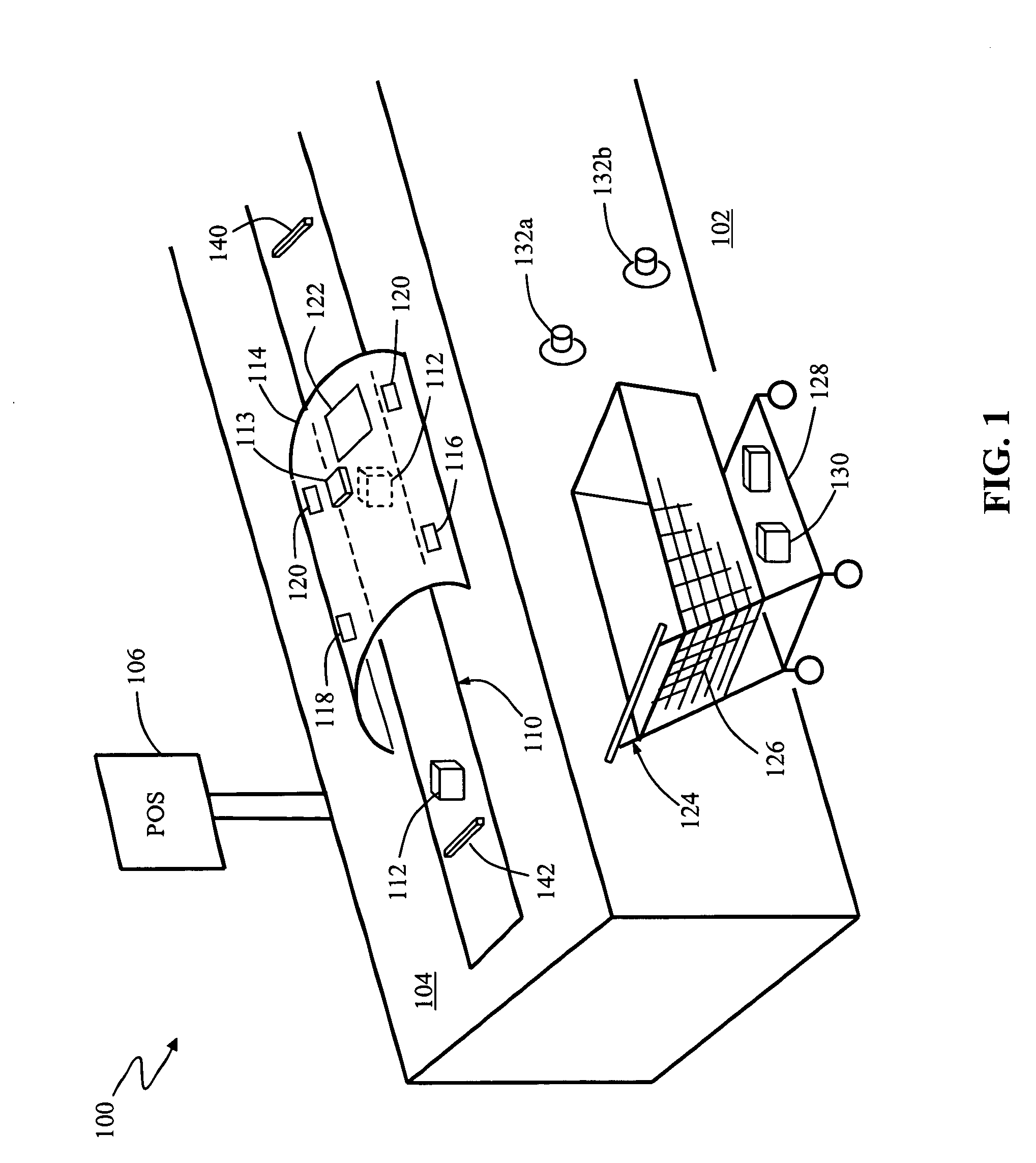

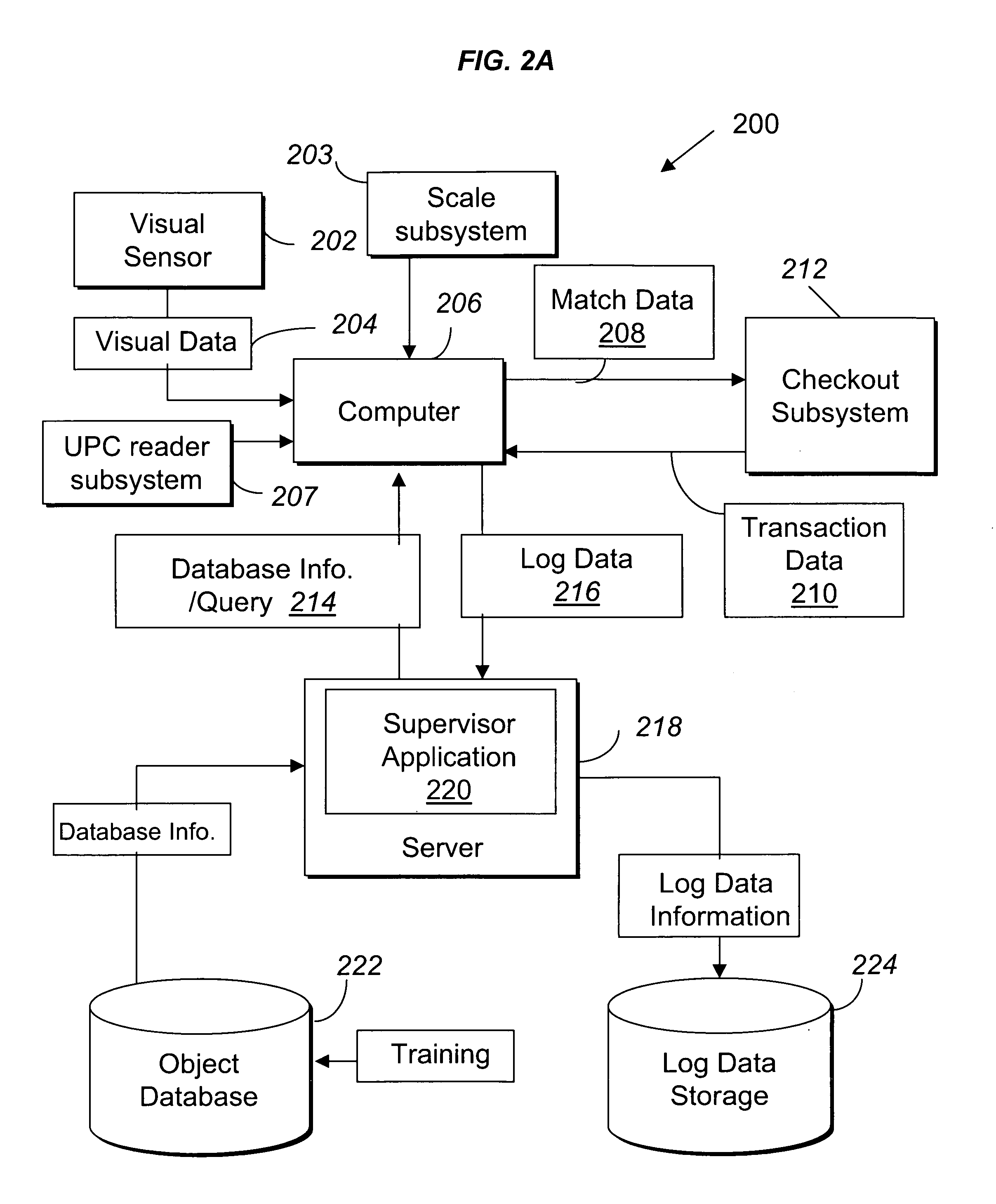

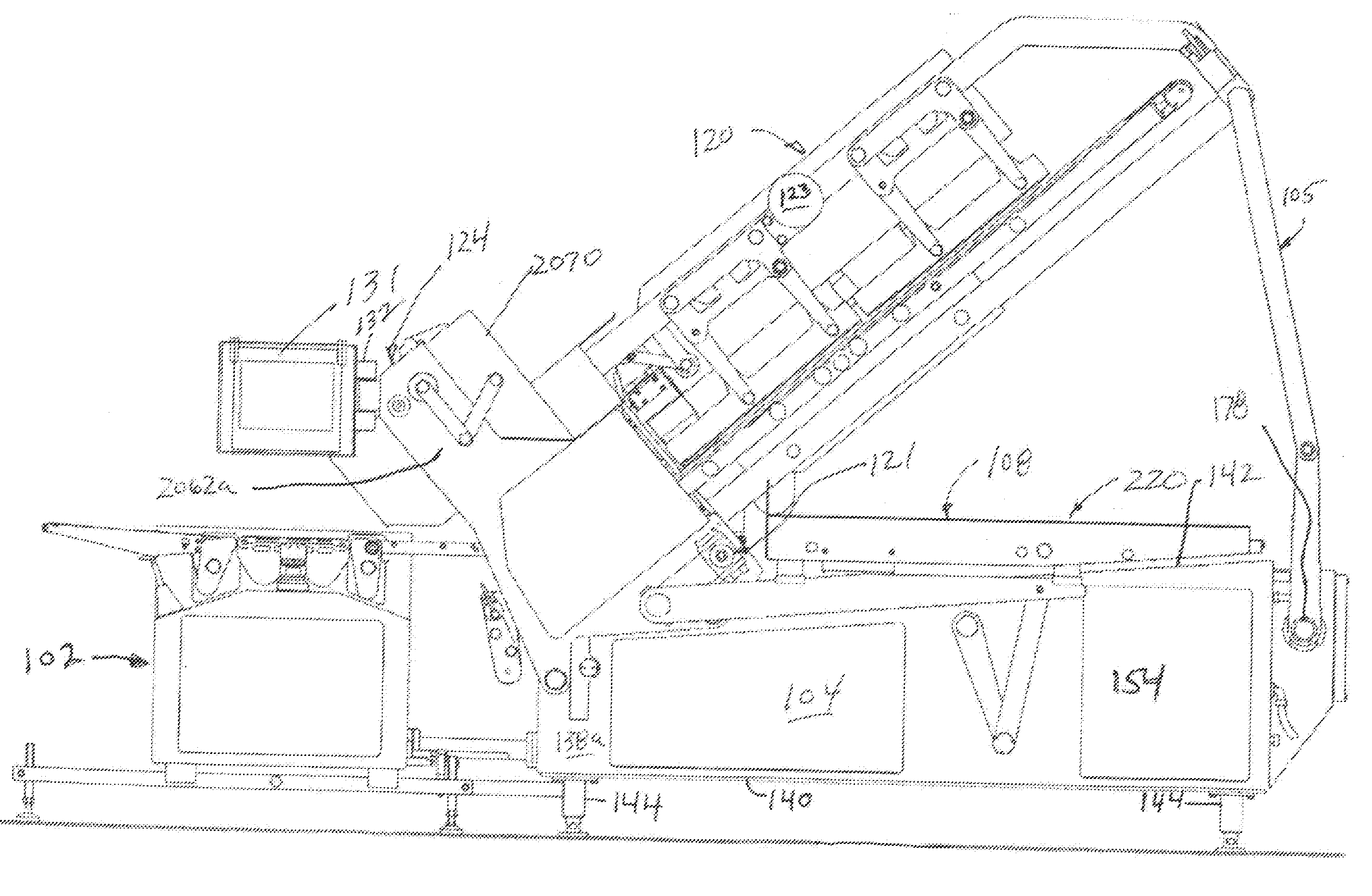

Systems and methods for merchandise automatic checkout

Systems and methods for automatically checking out items located on a moving conveyor belt for the purpose of increasing the efficiency of a checkout process and revenue at a point-of-sale. The system includes a conveyor subsystem for moving the items, a housing that enclosed a portion of the conveyor subsystem, a lighting subsystem that illuminates an area within the housing, visual sensors that can take images of the items including UPCs, and a checkout system that receives the images from the visual sensors and automatically identifies the items. The system may include a scale subsystem located under the conveyor subsystem to measure the weights of the items, where the weight of each item is used to check if the corresponding item is identified correctly. The system relies on matching visual features from images stored in a database to match against features extracted from images taken by the visual sensors.

Owner:DATALOGIC ADC

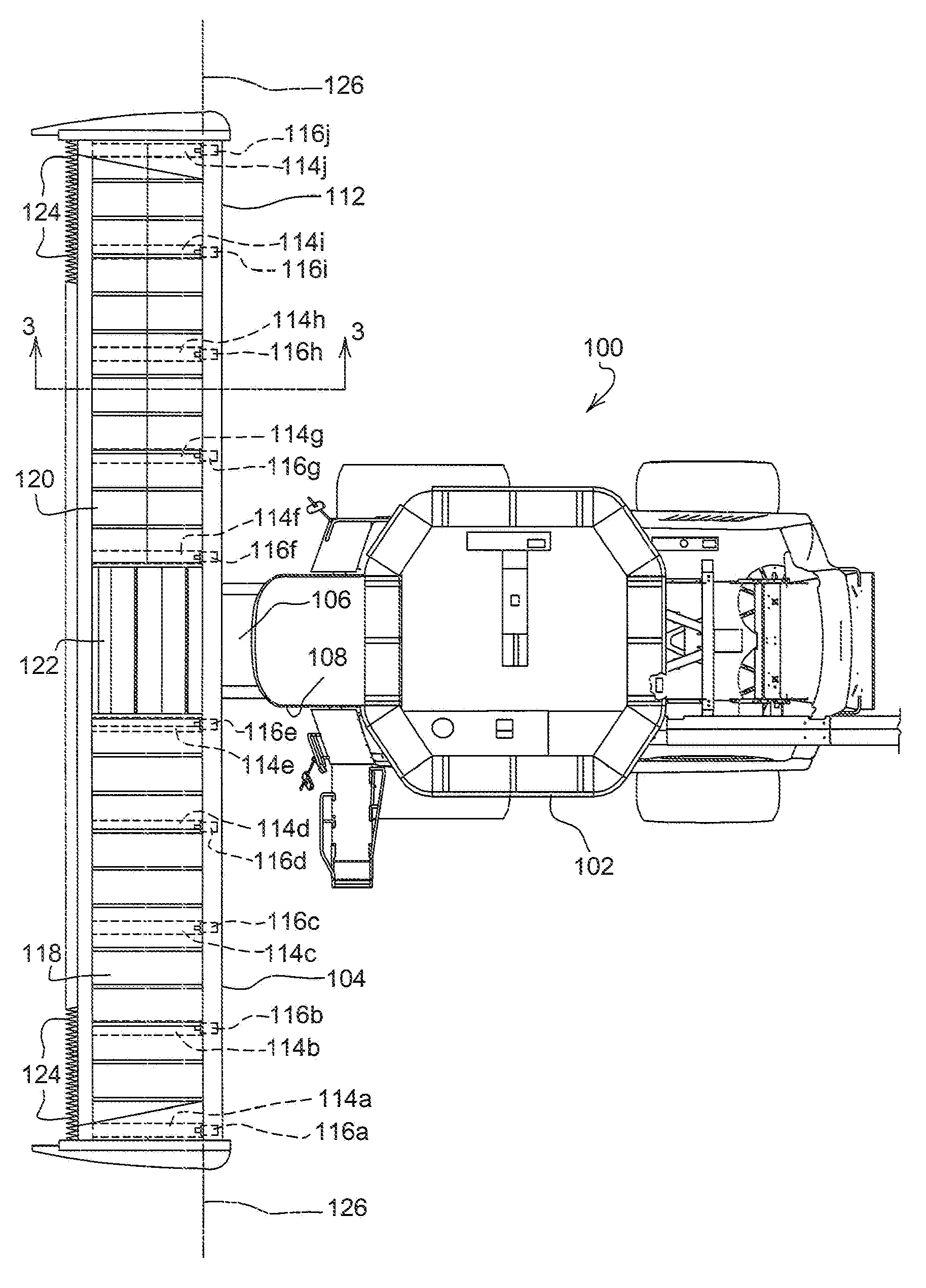

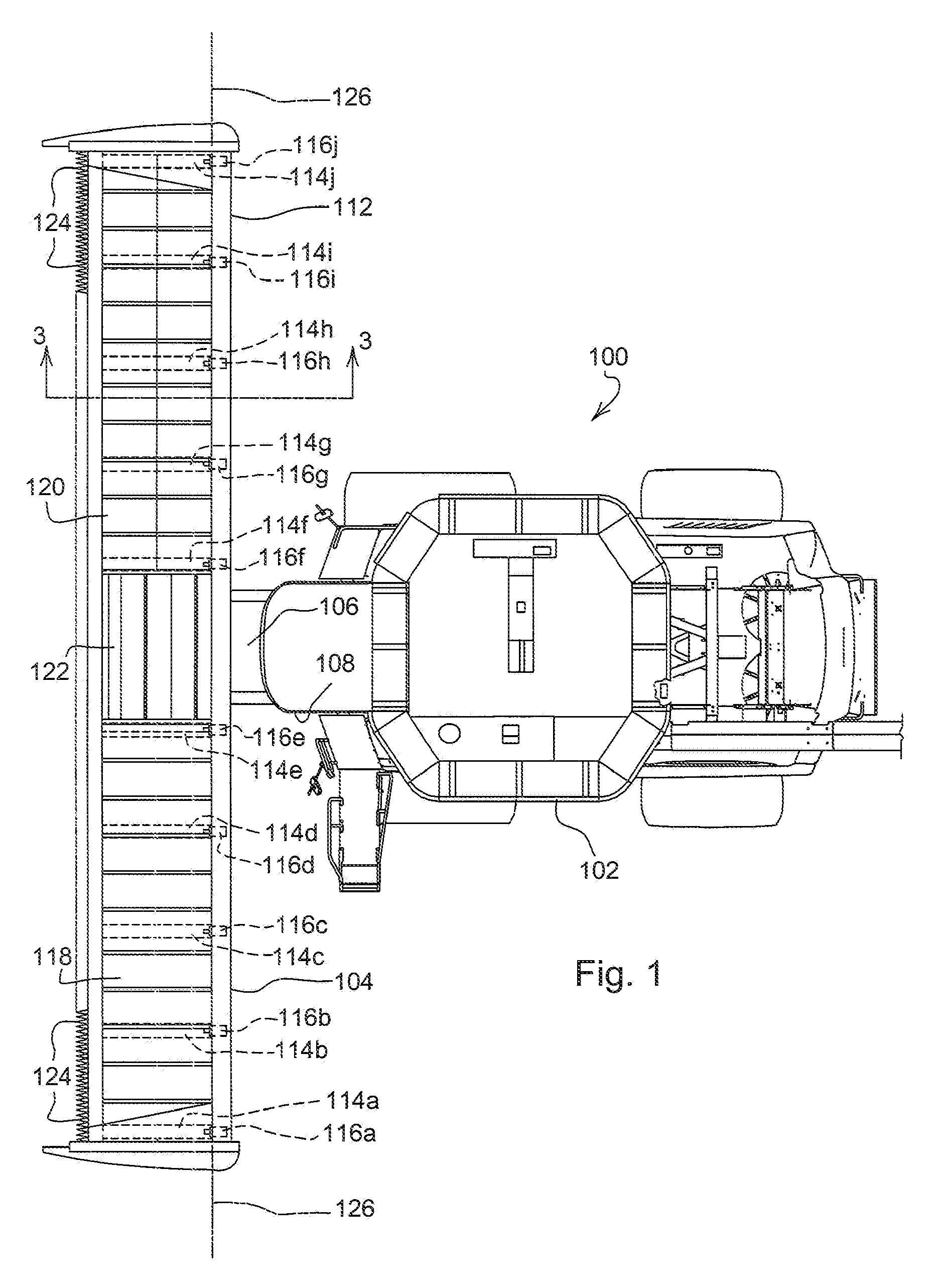

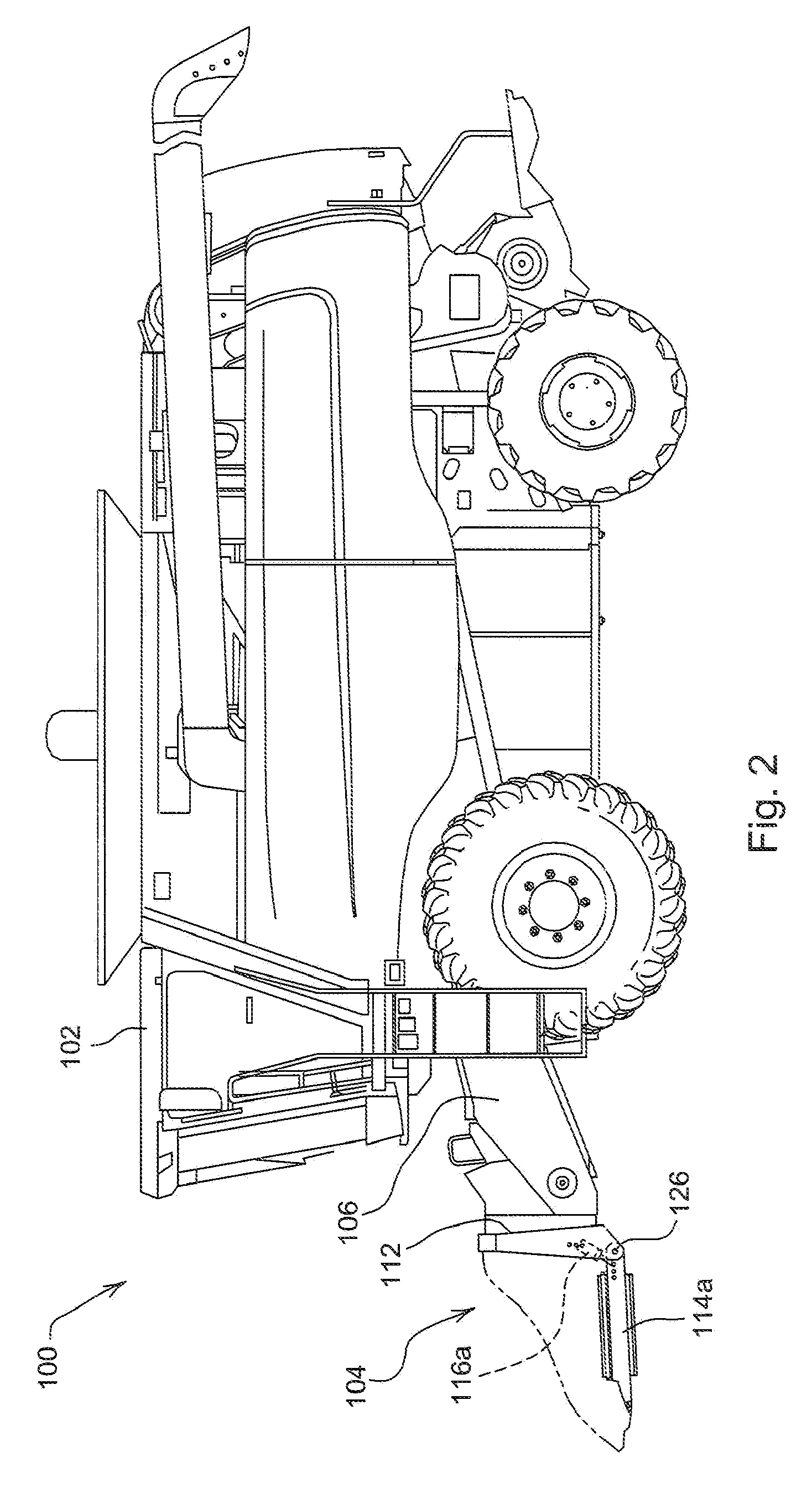

Header float arm load compensation

A float arm load compensation system for a header of an agricultural harvester includes a header frame; a plurality of header float arms pivotally coupled to the header frame; a cutter bar fixed to forward ends of the plurality of header float arms; at least one conveyor belt supported on the plurality of header float arms and configured to traverse the header perpendicular to the direction of travel of the header, wherein the conveyor belt is further configured to receive crop material cut by the cutter bar; and a plurality of springs, wherein each spring is coupled to an associated header float arm of the plurality of header float arms to exert a force on the associated header float arm compensating for the weight of cut crop material supported by the associated header float arm.

Owner:DEERE & CO

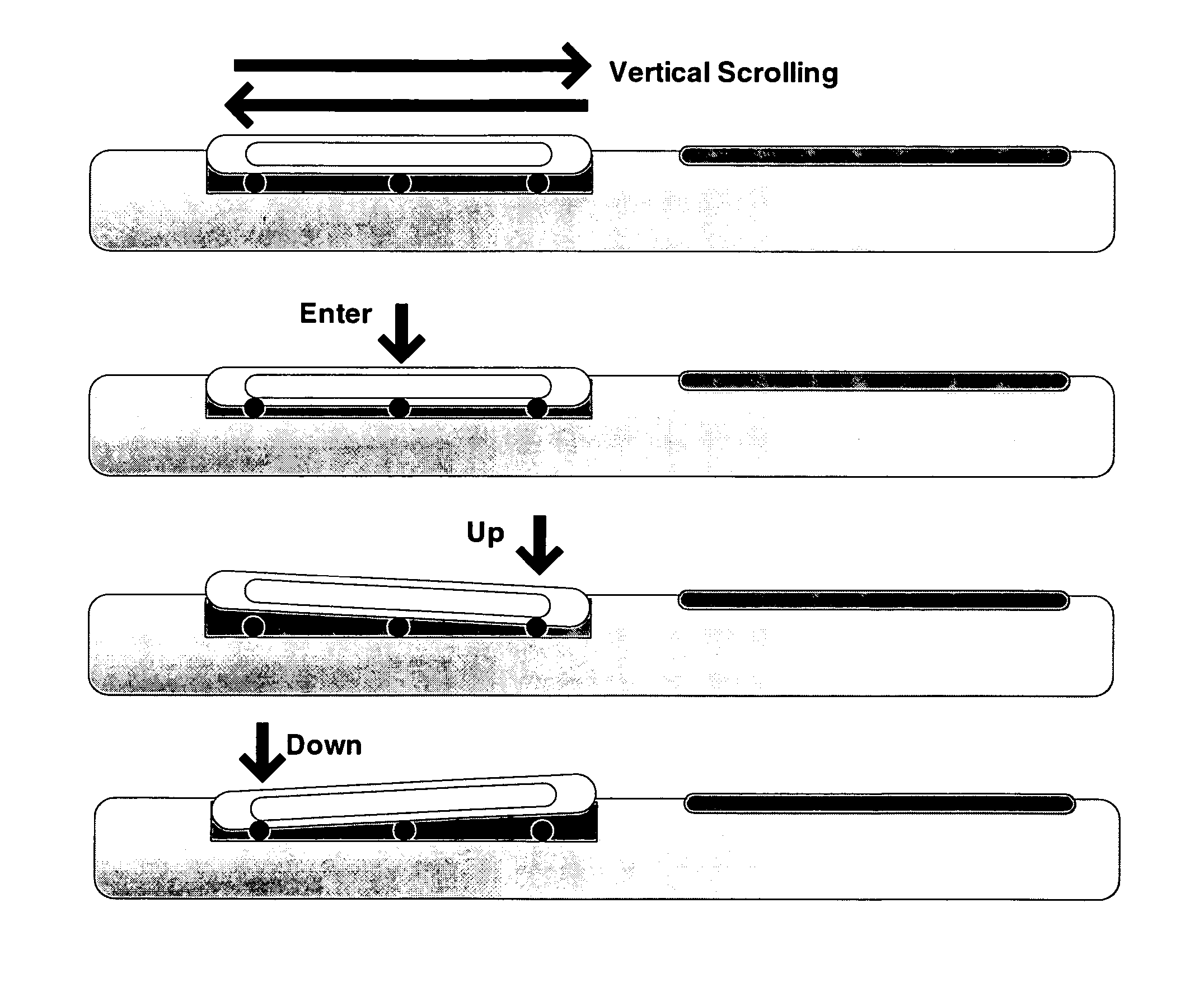

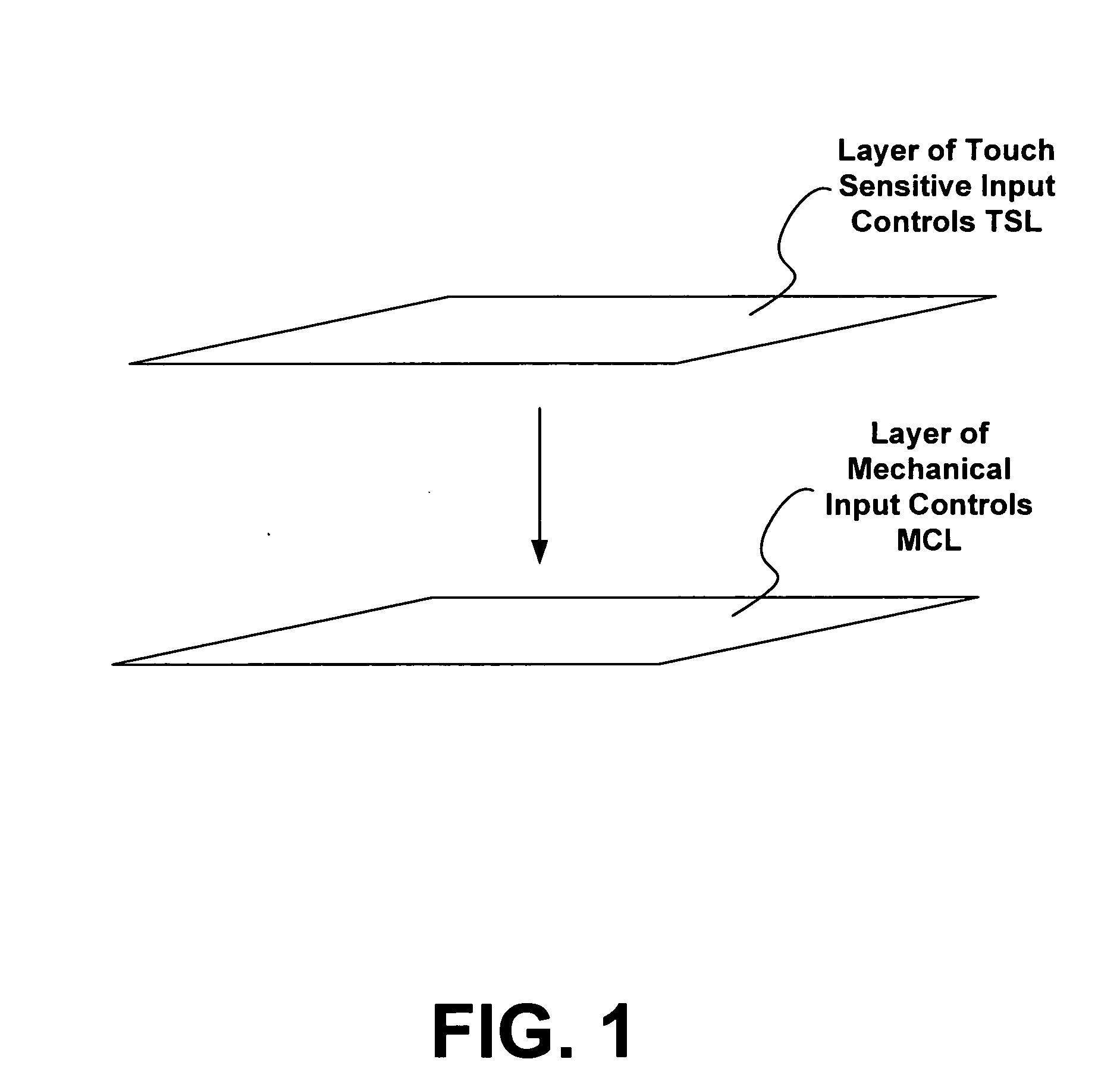

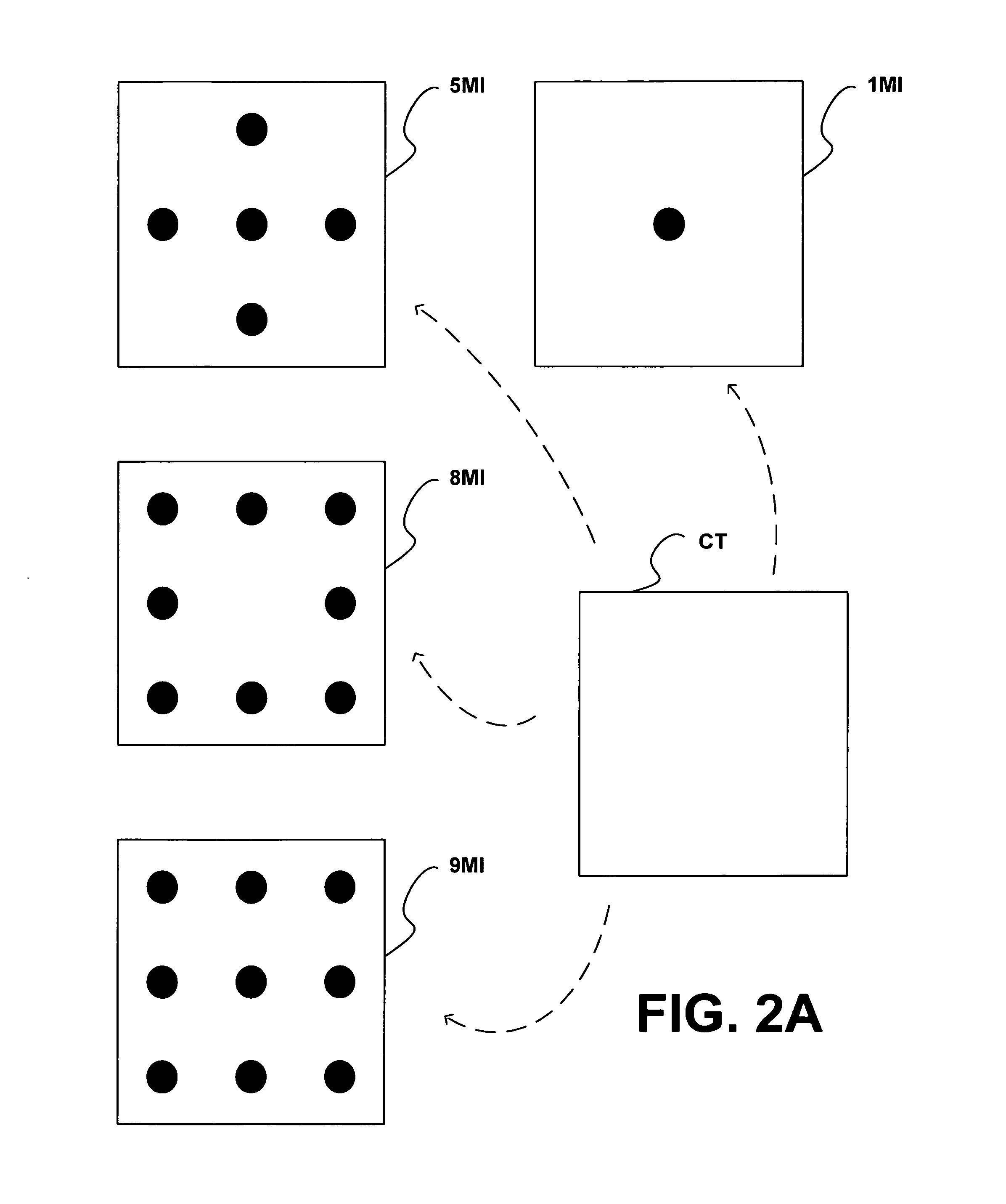

Touch sensitive and mechanical user input device

InactiveUS20070236470A1Improve versatilityImprove input characteristicsCathode-ray tube indicatorsInput/output processes for data processingCapacitanceUser input

User interfaces or input devices are provided with both touch-sensitive (e.g., capacitive) and mechanical hardware input portions. Mechanical switches are overlaid with a touch sensitive pad, providing improved versatility of input. An application programming interface (API) enables different modes of input operation for the mechanical and touch sensitive input portions, whereby various combinations and / or permutations of touch sensitive input portions and / or mechanical input portions are enabled or disabled to provide optimal input characteristics for a set of tasks at hand. Visual or audio indicators may be utilized to reveal the mode of operation to the user. The touch sensitive pad may be a capacitive touchpad, a touch sensitive display screen, a conveyor belt or a push pad. Up to 9 mechanical switches may be placed underneath the touch sensitive input portions.

Owner:MICROSOFT TECH LICENSING LLC

Systems and methods for merchandise automatic checkout

Systems and methods for automatically checking out items located on a moving conveyor belt for the purpose of increasing the efficiency of a checkout process and revenue at a point-of-sale. The system includes a conveyor subsystem for moving the items, a housing that enclosed a portion of the conveyor subsystem, a lighting subsystem that illuminates an area within the housing, visual sensors that can take images of the items including UPCs, and a checkout system that receives the images from the visual sensors and automatically identifies the items. The system may include a scale subsystem located under the conveyor subsystem to measure the weights of the items, where the weight of each item is used to check if the corresponding item is identified correctly. The system relies on matching visual features from images stored in a database to match against features extracted from images taken by the visual sensors.

Owner:DATALOGIC ADC

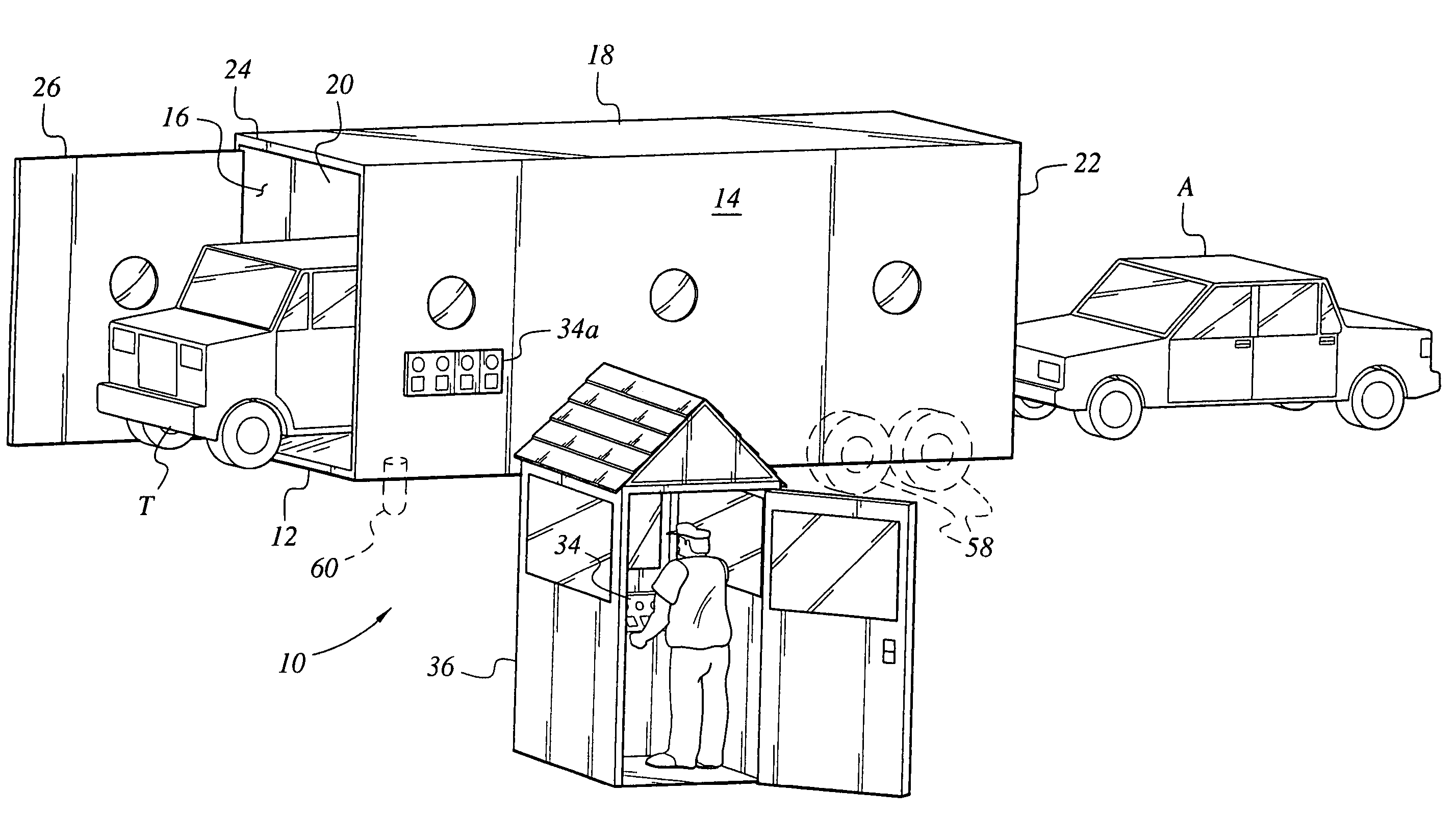

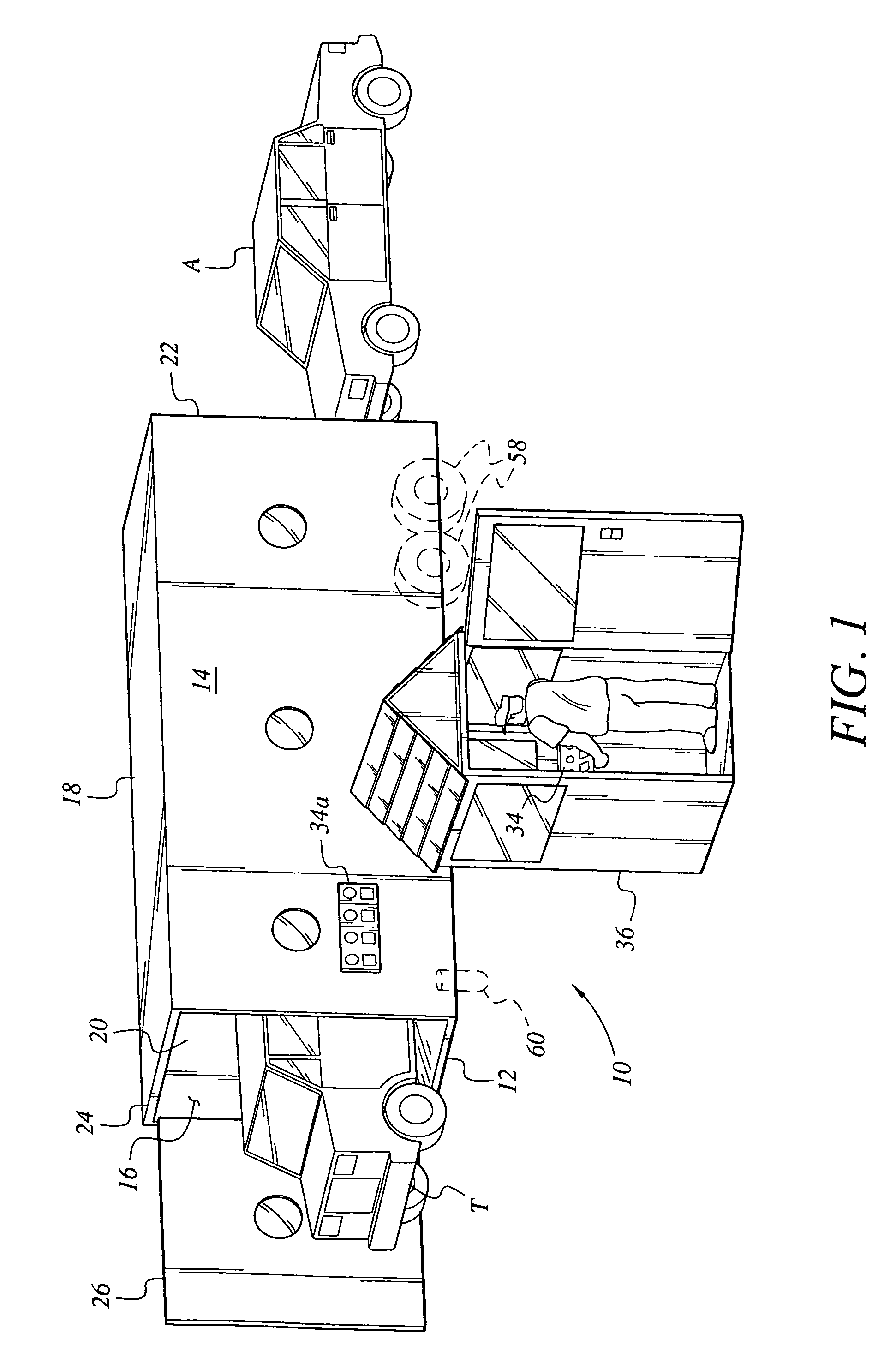

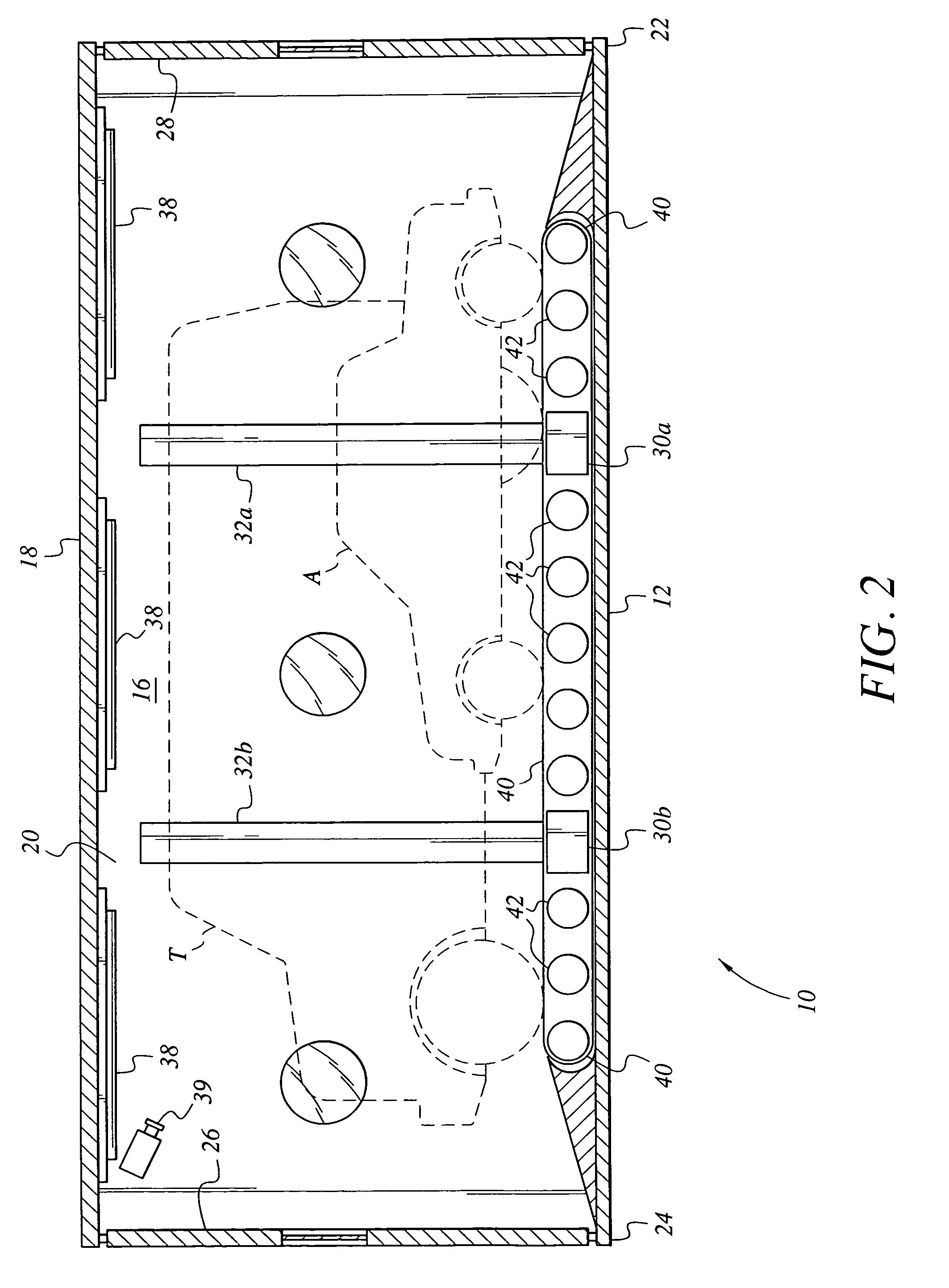

Vehicle security inspection system

ActiveUS6972693B2For quick inspectionRoad vehicles traffic controlError detection/correctionMobile vehicleSurveillance camera

The vehicle security inspection system may include multiple automated detection devices for detecting explosives, weapons, contraband, etc. which may be contained on or within a motor vehicle. The system includes a tunnel or enclosure with a moving conveyor therein. A motor vehicle is driven into the entrance to the enclosure, and conveyed past the series of sensors by the conveyor belt. One or more surveillance cameras may be installed in the enclosure, as well. The various sensors incorporated therein check the vehicle for illegal articles, and the vehicle is released from the enclosure. A control gate may be provided as a door at the exit of the enclosure, and / or as a gate guiding vehicles along their intended route or to a detention area, as appropriate. The system may be provided either as a portable device or as a permanent installation, and / or may be configured as a multiple lane inspection system.

Owner:BROWN BETTY J +1

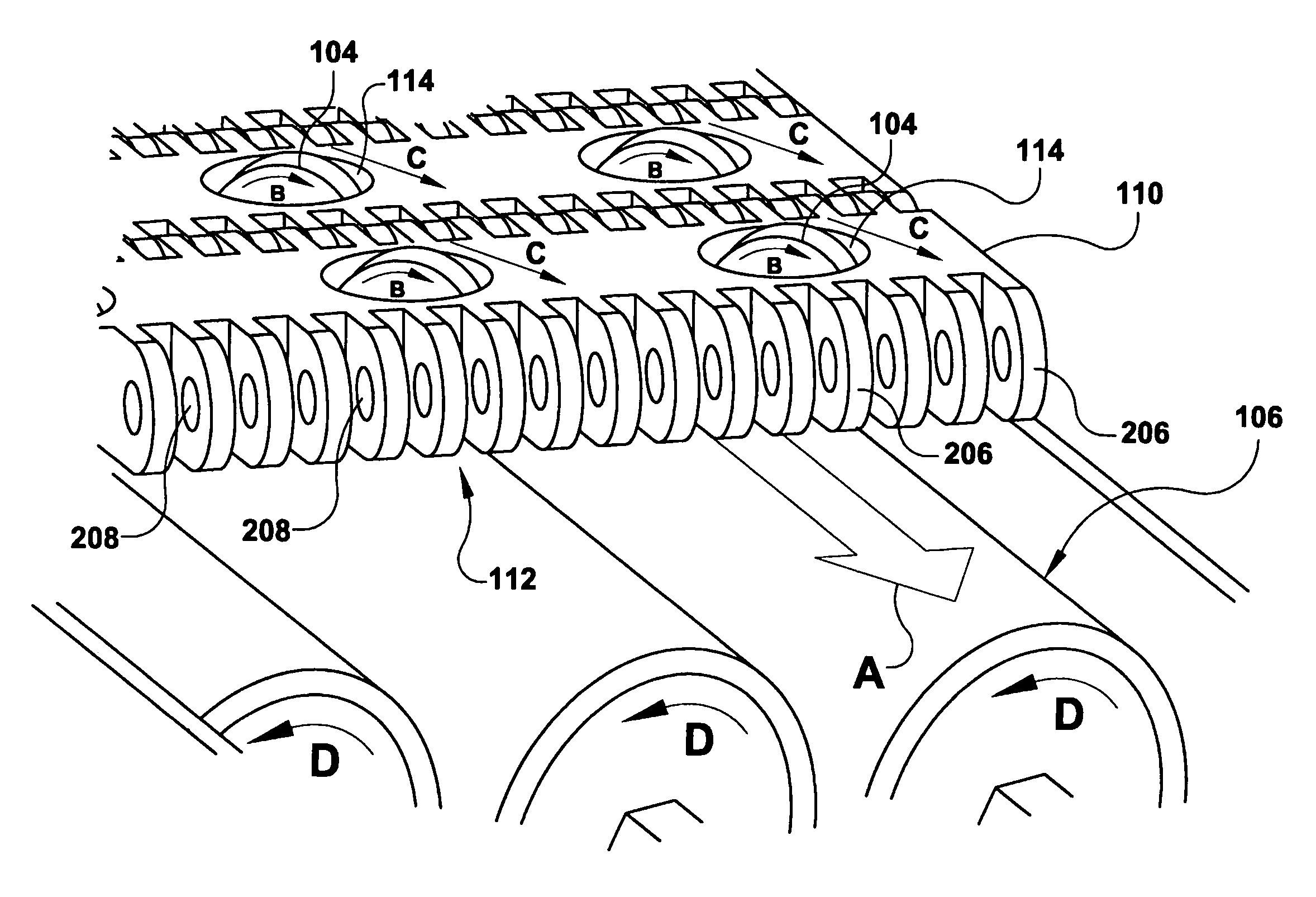

Apparatus and methods for conveying objects

InactiveUS6968941B2Slippage of the first rollers is reducedReduce slippageConveyor partsRotary conveyorsEngineeringConveyor belt

Disclosed are conveyors and methods for making the conveyors. In one embodiment, a conveyor comprises a modular conveyor belt that includes a plurality of mat-top chains having a plurality of cavities and a plurality of first rollers disposed in the cavities of the mat-top chains. The conveyor further includes at least one second roller that operatively couples to the first rollers such that the first rollers rotate as the conveyor belt travels along the second roller. The invention can also be construed as providing the method for conveying objects. The method can comprise the steps of driving a modular conveyor belt in a direction of belt travel; rotating a plurality of first rollers disposed into the modular conveyor belt in a manner in which slippage of the first rollers is reduced; and conveying objects on the modular conveyor belt using the rotating first rollers.

Owner:LAITRAM LLC

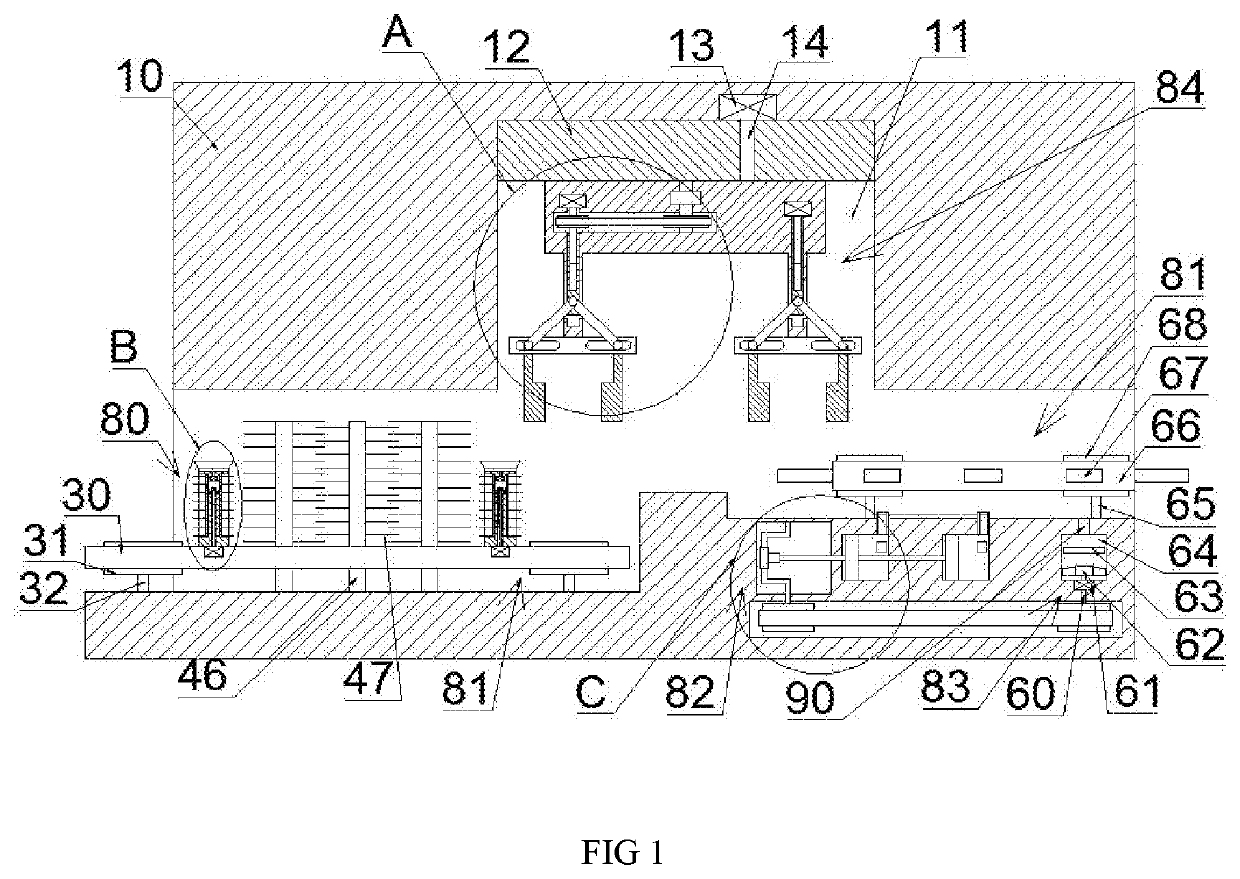

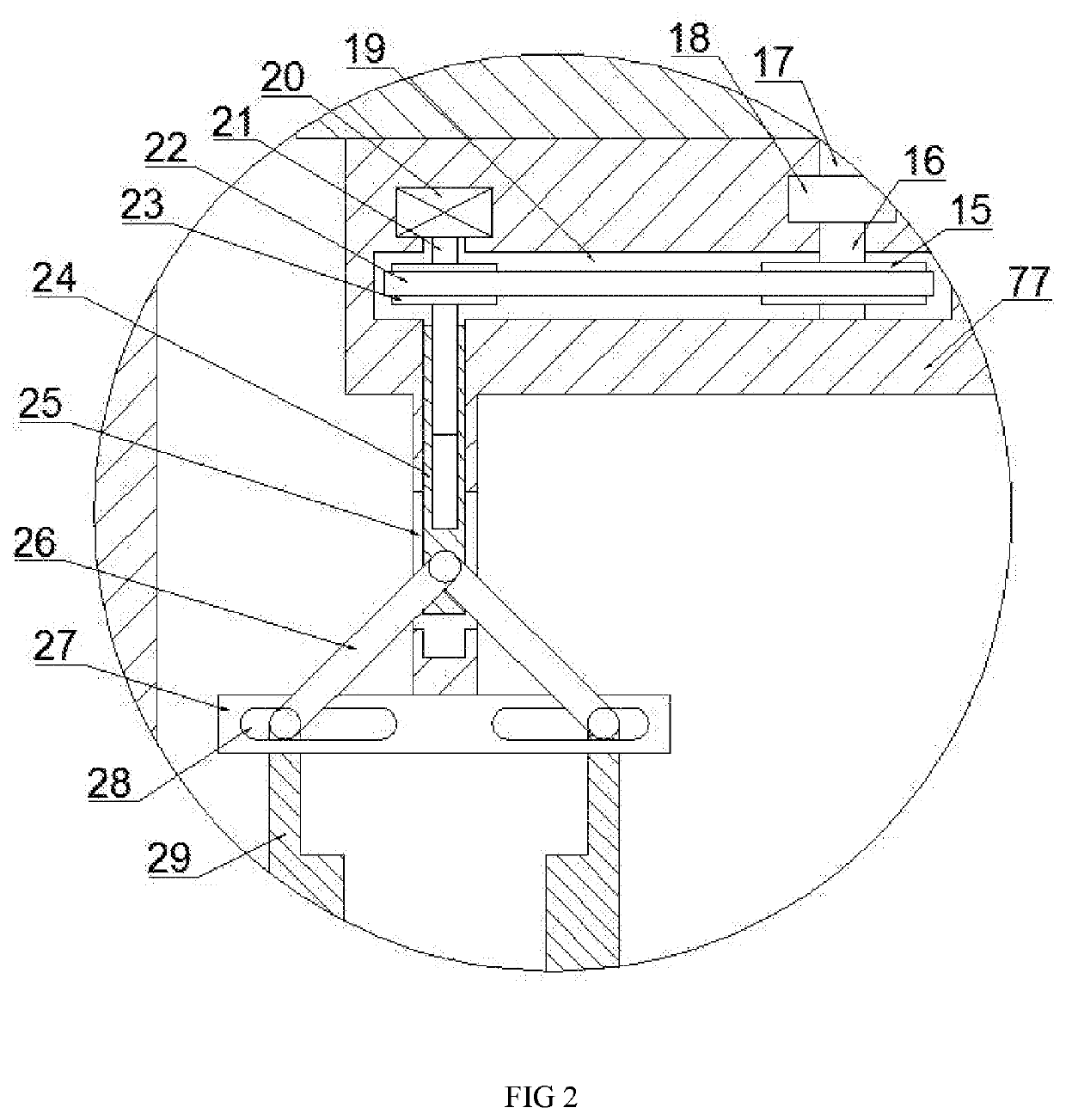

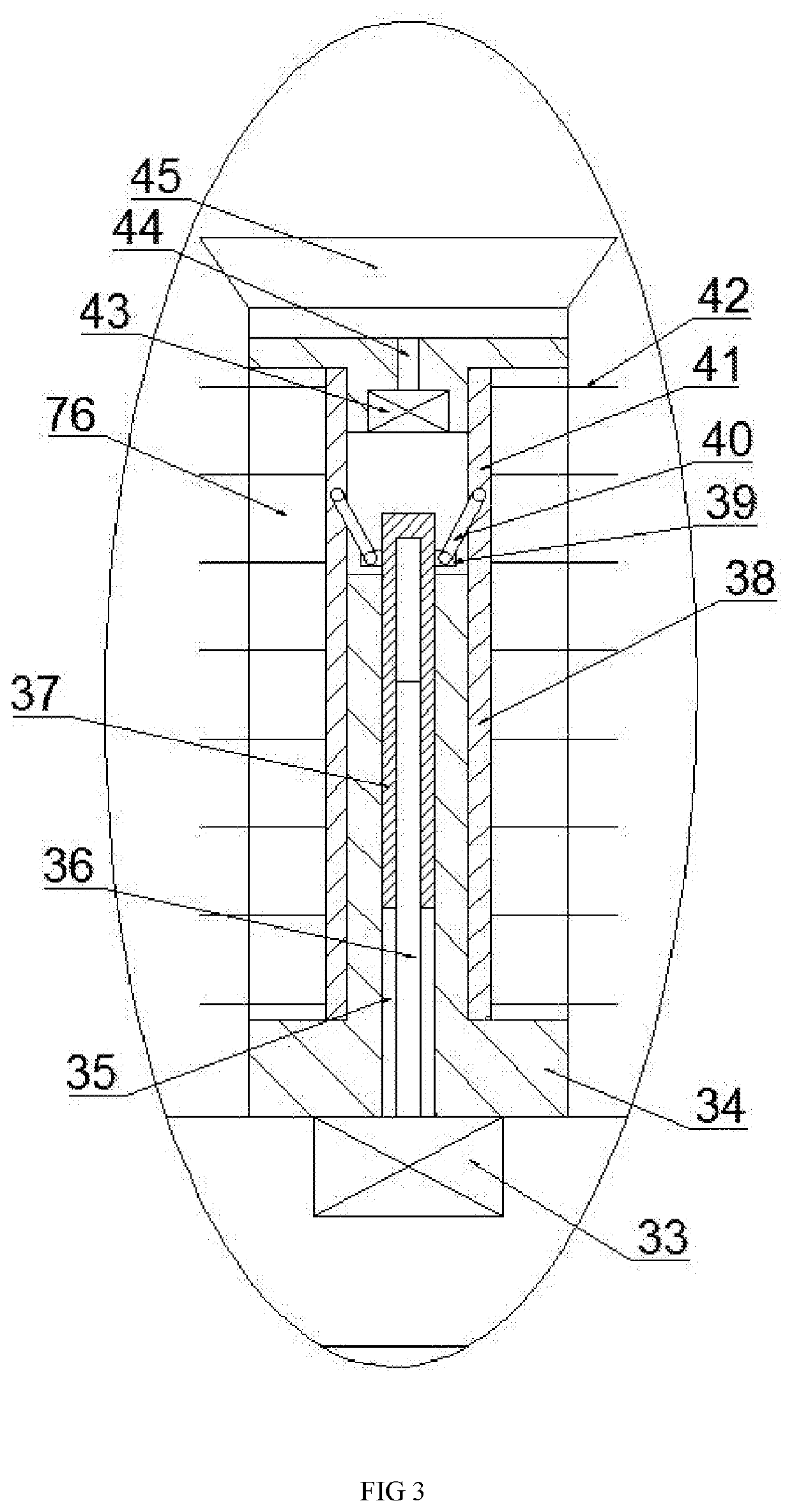

Automatic cleaning and recycling device for glass bottles

InactiveUS20200130032A1Low costReduce inputSolid waste disposalHollow article cleaningProcess engineeringBottle

The invention discloses an automatic cleaning and recycling device for glass bottles, which includes a fuselage. A central cavity is opened in the fuselage. A first conveyor belt is provided near the bottom of the central cavity on the left side of the first conveyor belt. A cleaning mechanism is provided. The storage chamber is provided with a first slider, a right side of the storage chamber is provided with a fan chamber, the fan chamber is provided with a drying mechanism. The device is fixed by a cleaning mechanism and The inner wall of the glass bottle is cleaned, the outer wall of the glass bottle is cleaned by a first brush, the glass bottle is conveyed by a conveyor mechanism, the inner wall of the glass bottle is rinsed by squeezing the disinfectant and water through the first slider, and the glass bottle is quickly dried by the drying mechanism.

Owner:LIN SHICHANG

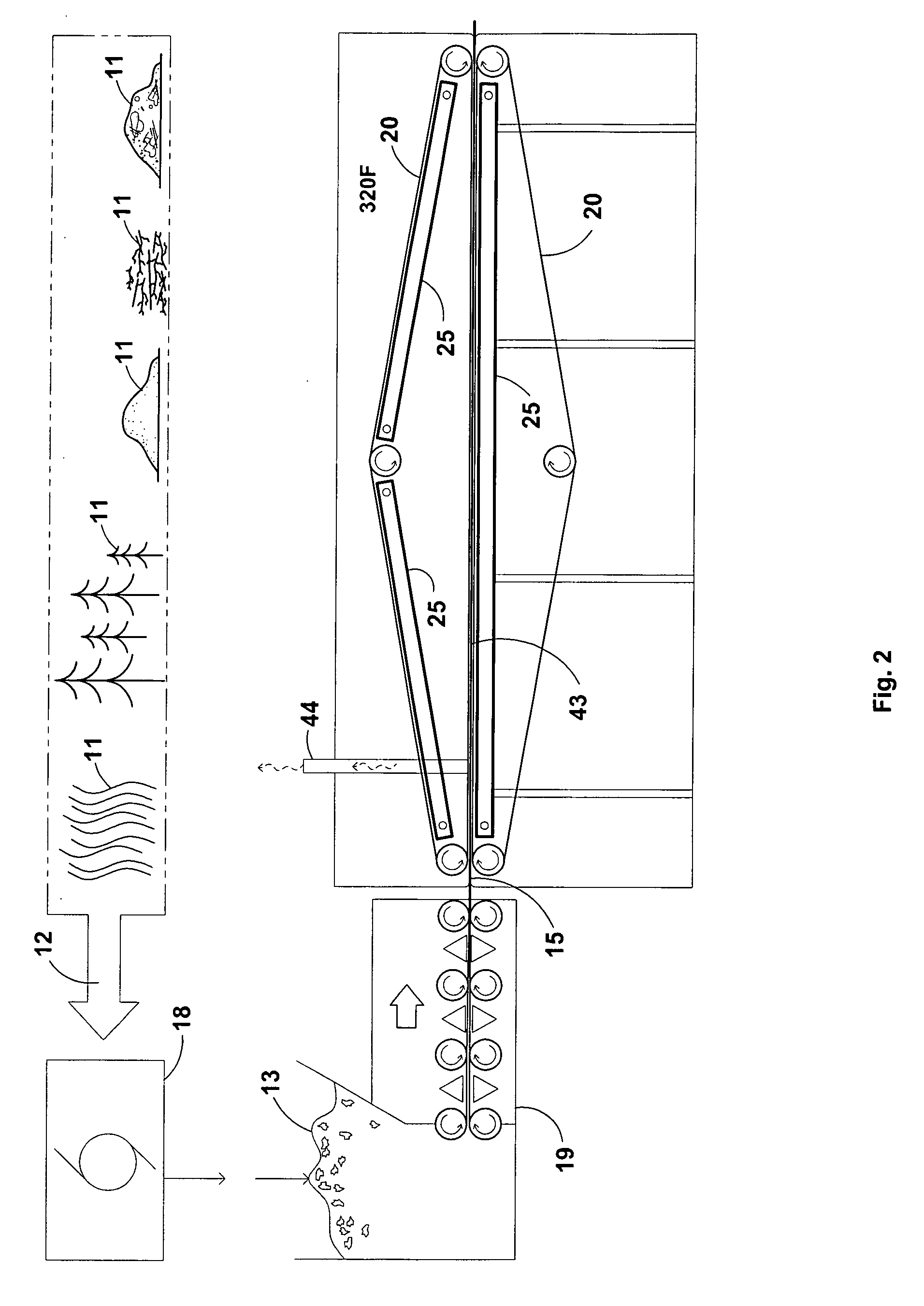

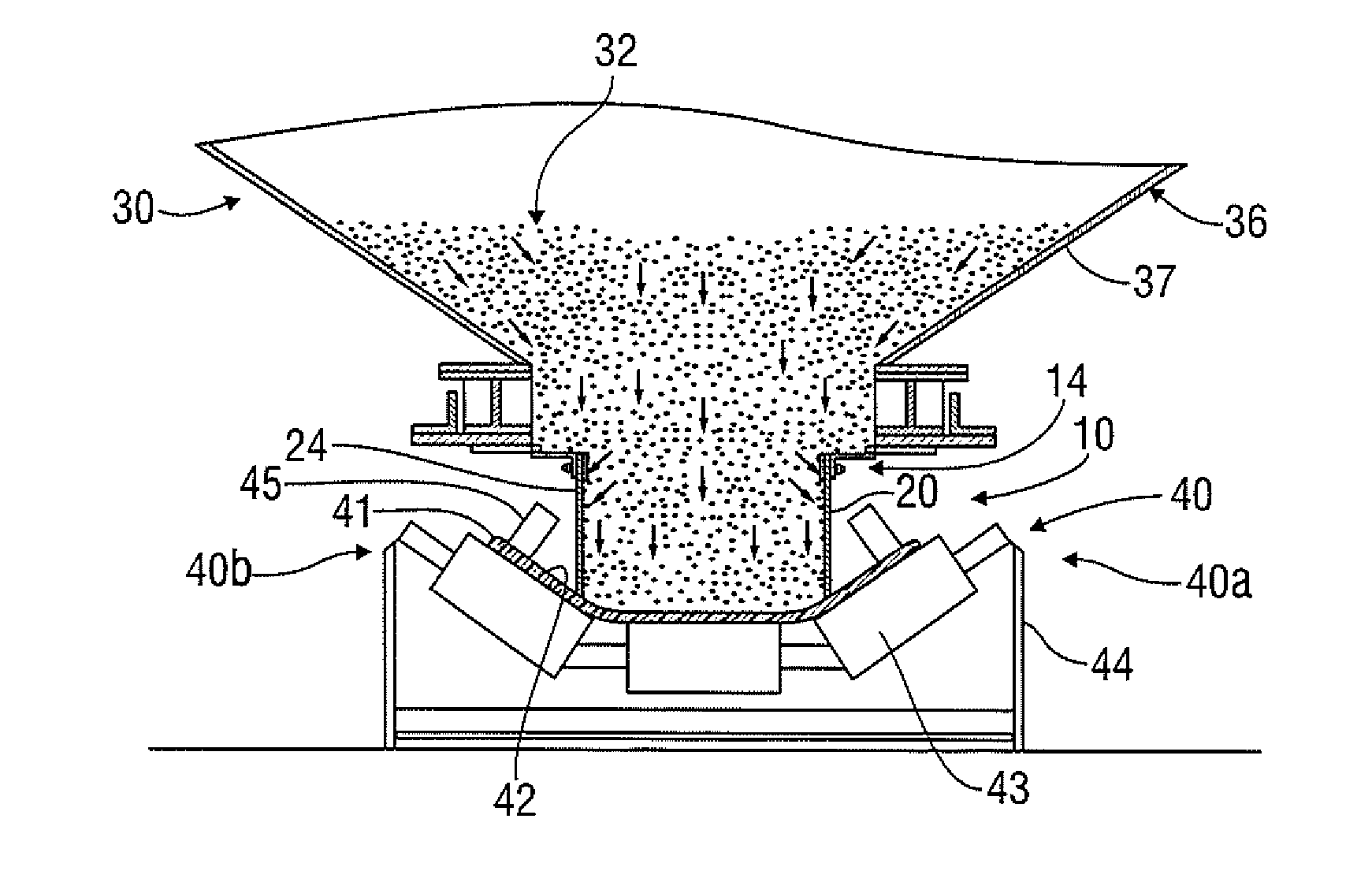

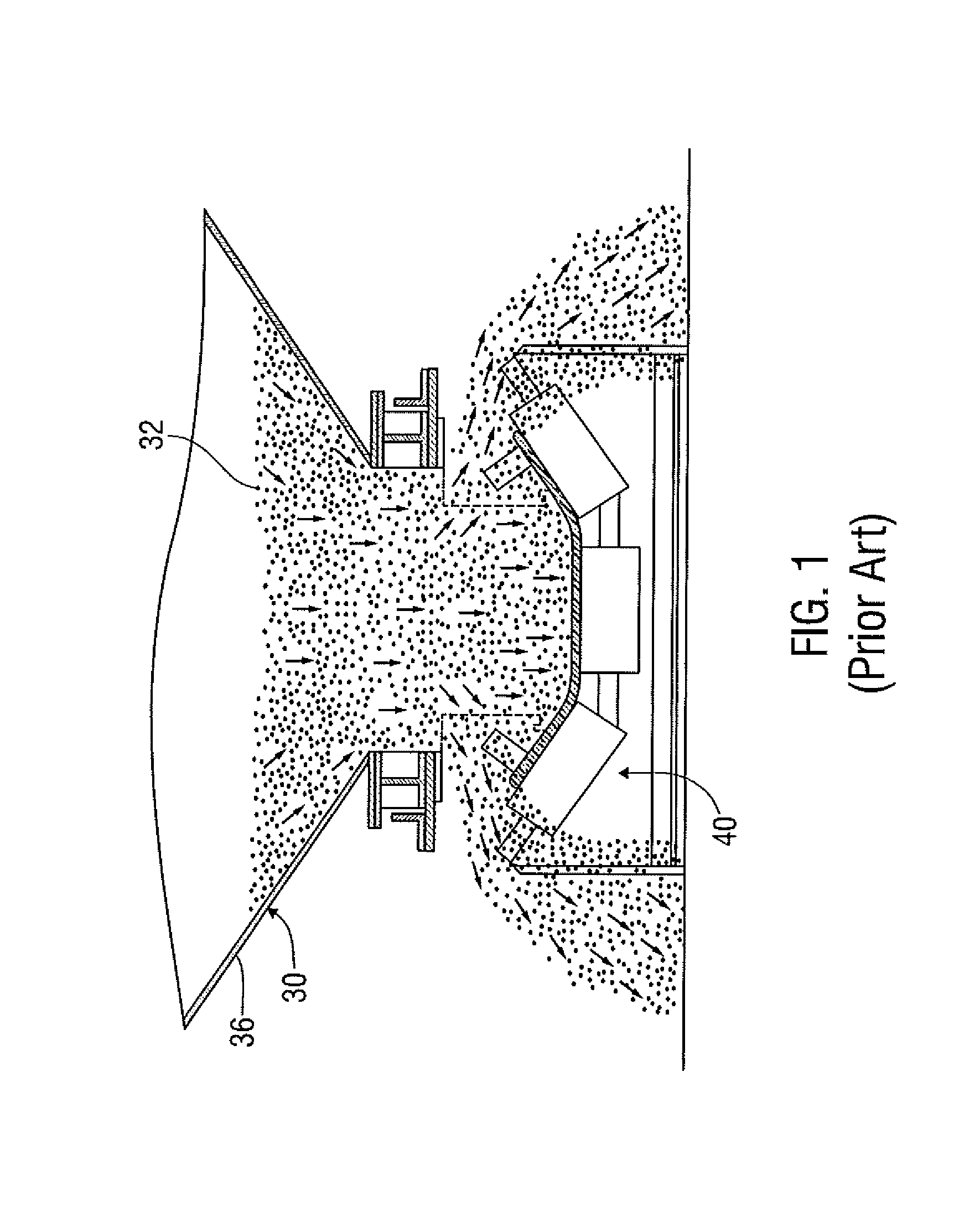

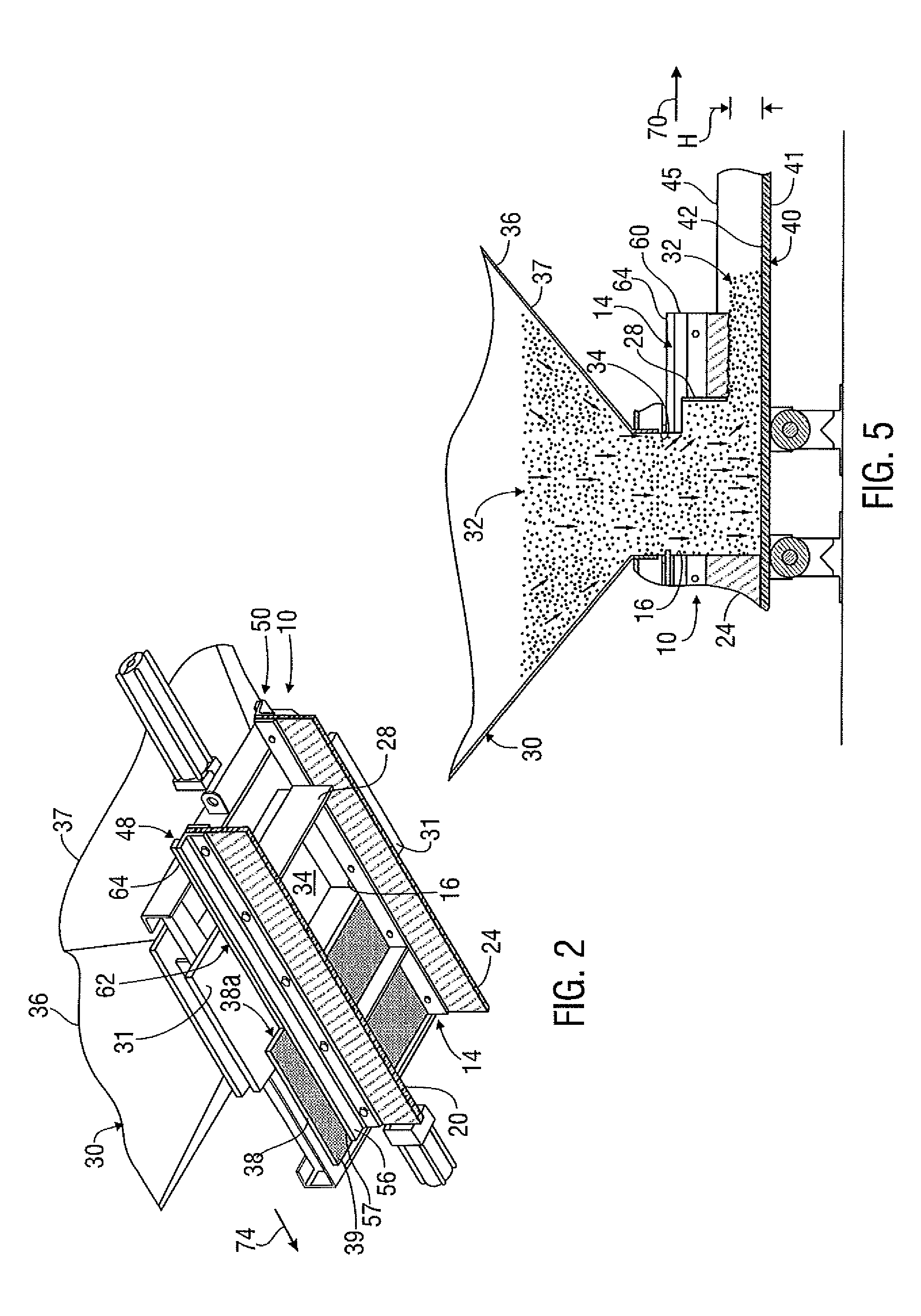

Apparatus and Methods for Assisting in Controlling Material Delivered on a Conveyor

ActiveUS20140044507A1Control devices for conveyorsWeighing apparatus for continuous material flowElectronic controllerConveyor belt

Method of controlling the amount of material delivered by conveyor belt includes measuring the speed of the conveyor belt or a drive pulley that drives the conveyor belt. A weighing device weighs material dispensed onto the conveyor belt from at least one material dispenser. Based at least in part upon such speed and weight measurements, an electronic controller maintains or changes the speed of the conveyor belt by dictating the output of at least one motor that drives the drive pulley.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

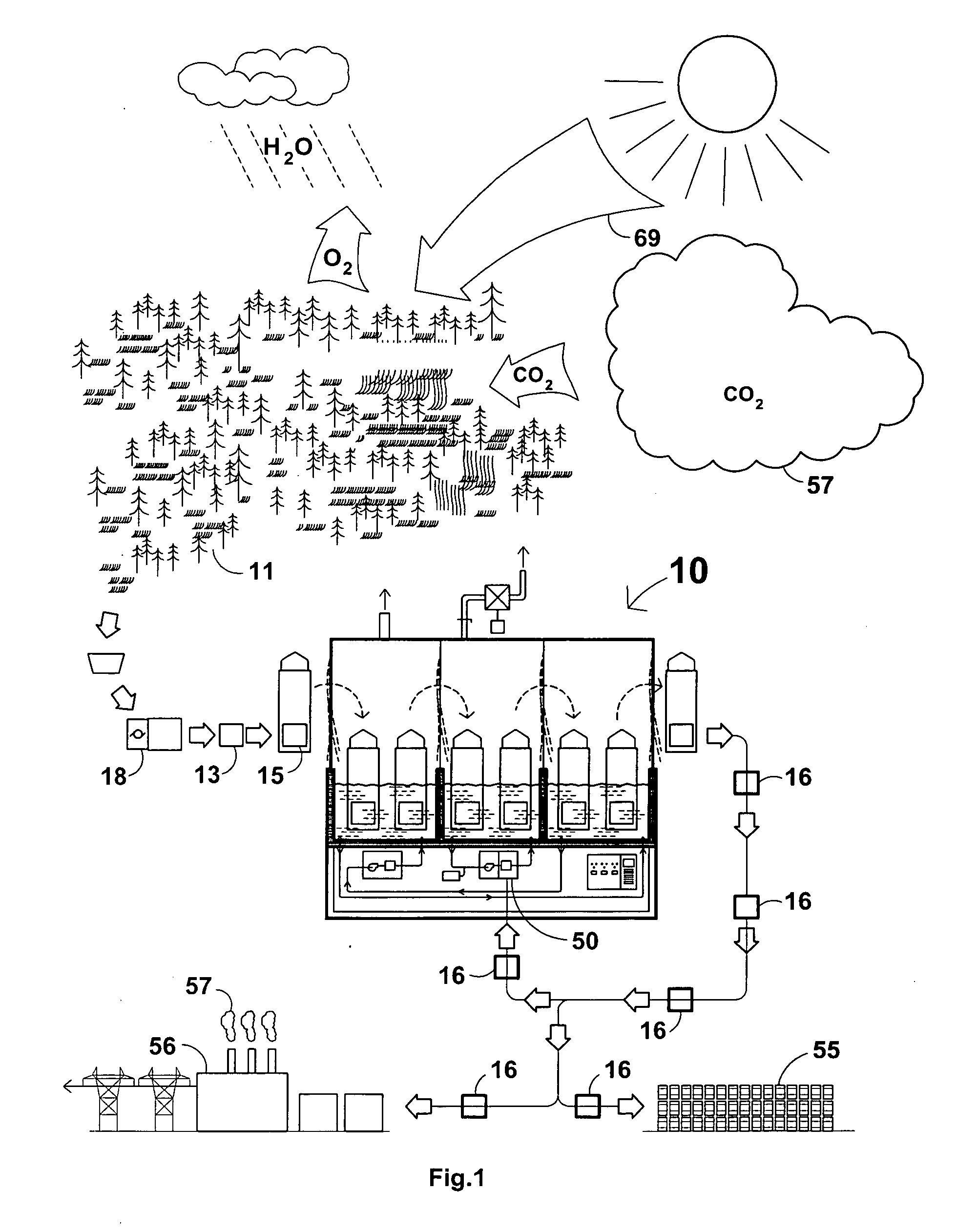

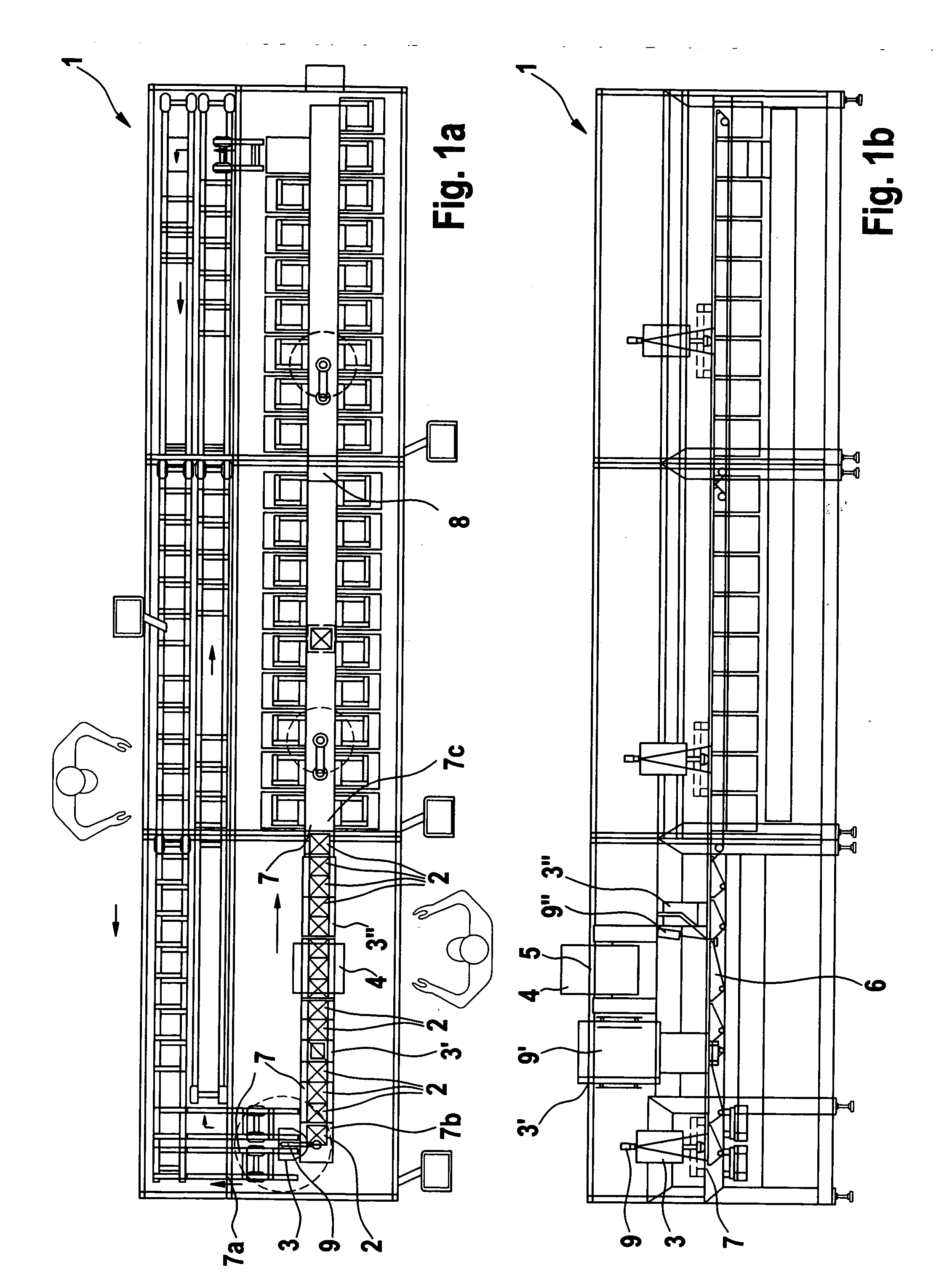

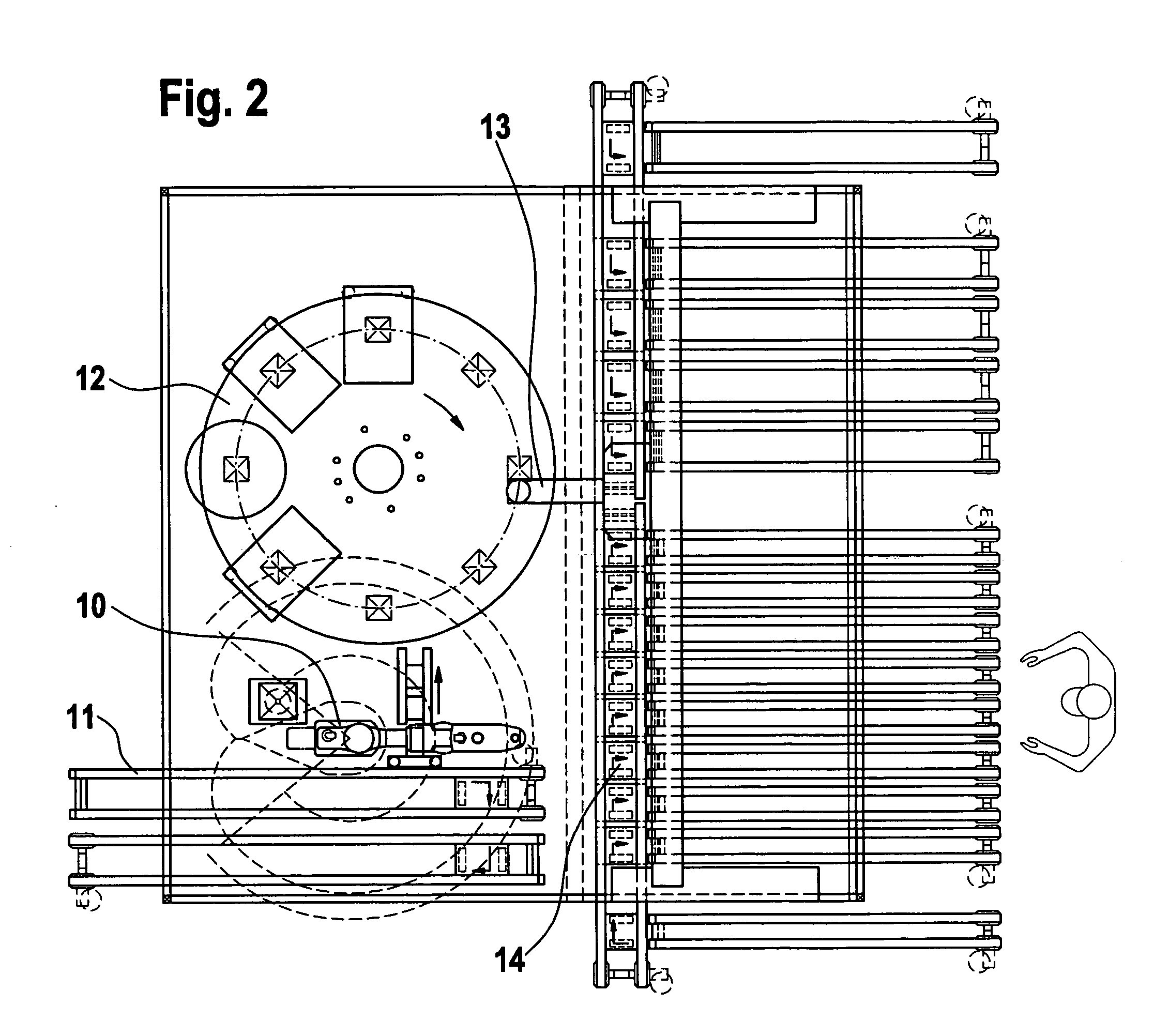

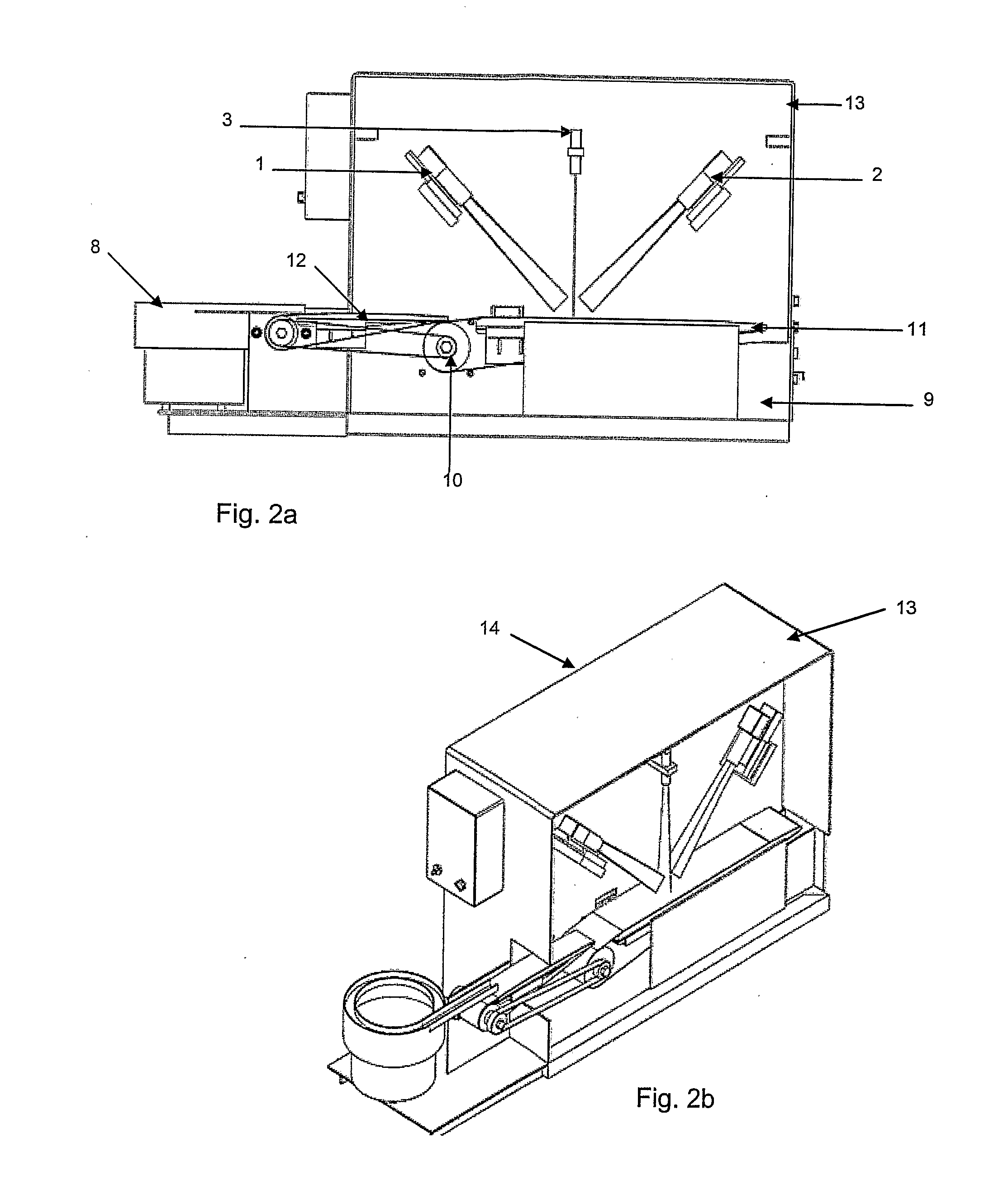

Testing system for solar cells

InactiveUS20060103371A1Improve refinementShorten cycle timePhotovoltaic monitoringElectronic circuit testingElectricityElectrical battery

A testing system for optical and electrical monitoring of a production quality and / or for determining optical and electrical properties of solar cells, comprising a first conveyor device for conveying the solar cells to a test region, a second conveyor device for moving the solar cells through the test region, a third conveyor device for conveying the solar cells out of the test region, an optical checking device located in the test region for visual checking of the solar, and an electrical checking device also located in the test region for checking electrical functions of the solar cells, the electrical checking device including an illumination device for shining light on light-sensitive surfaces of the solar cells and also including an electrical contacting device for picking up voltages and / or currents and electrical contacts of the solar cells, the first, second and third conveyor devices including a common, linear conveyor belt system which passes through the test region and has a vacuum suction device for holding the solar cells on a surface of a conveyor belt system.

Owner:MANZ AUTOMATION

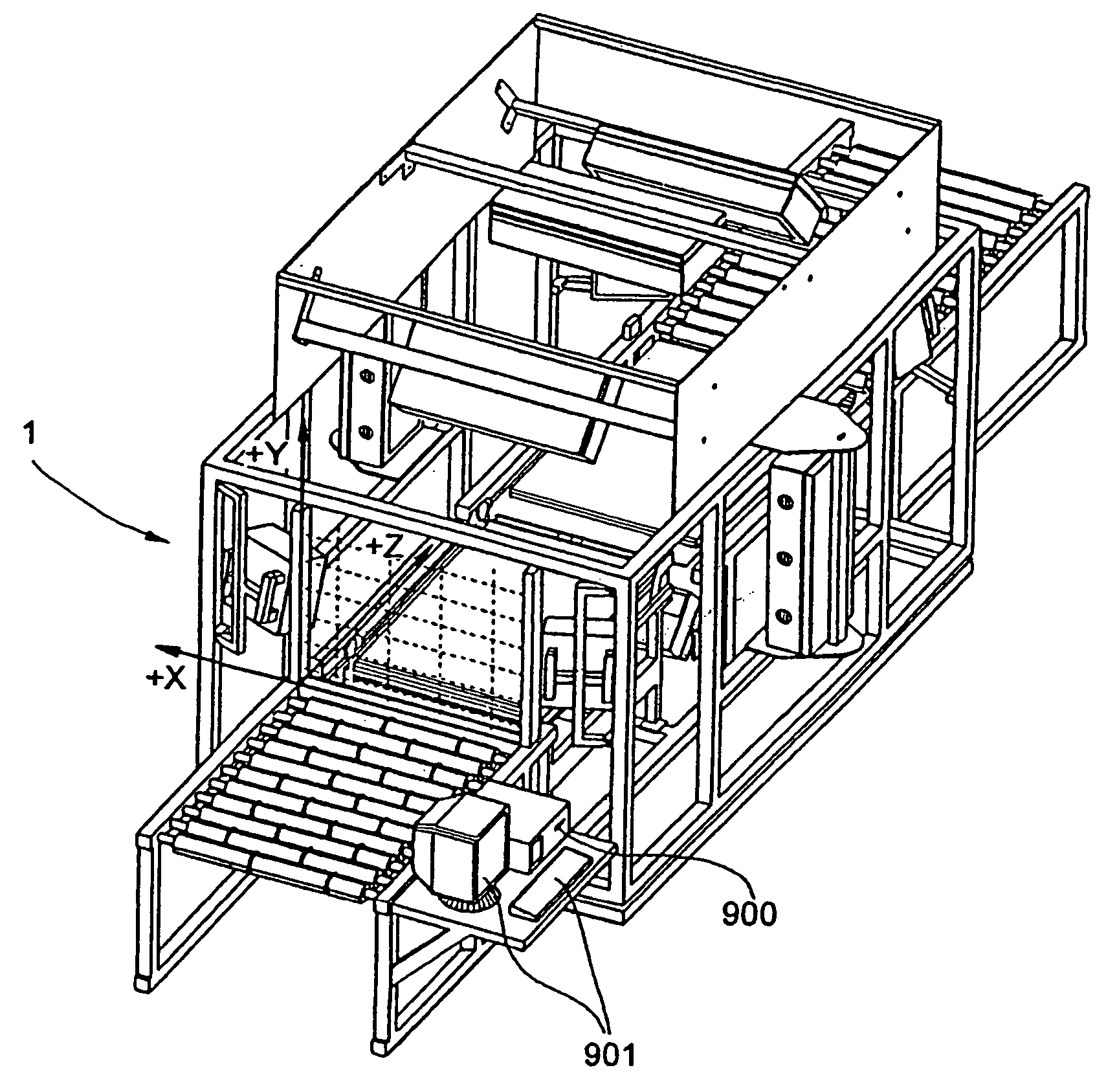

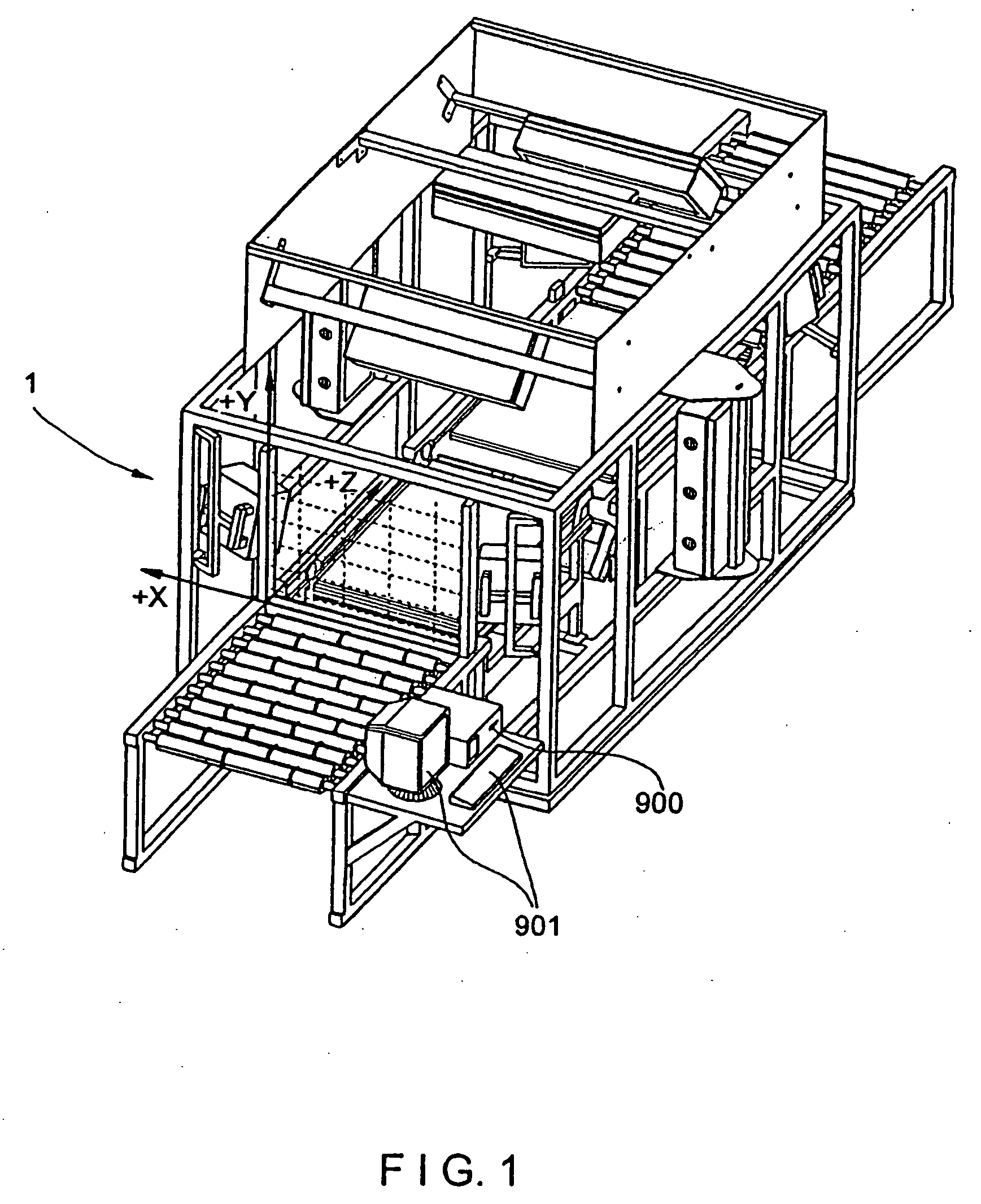

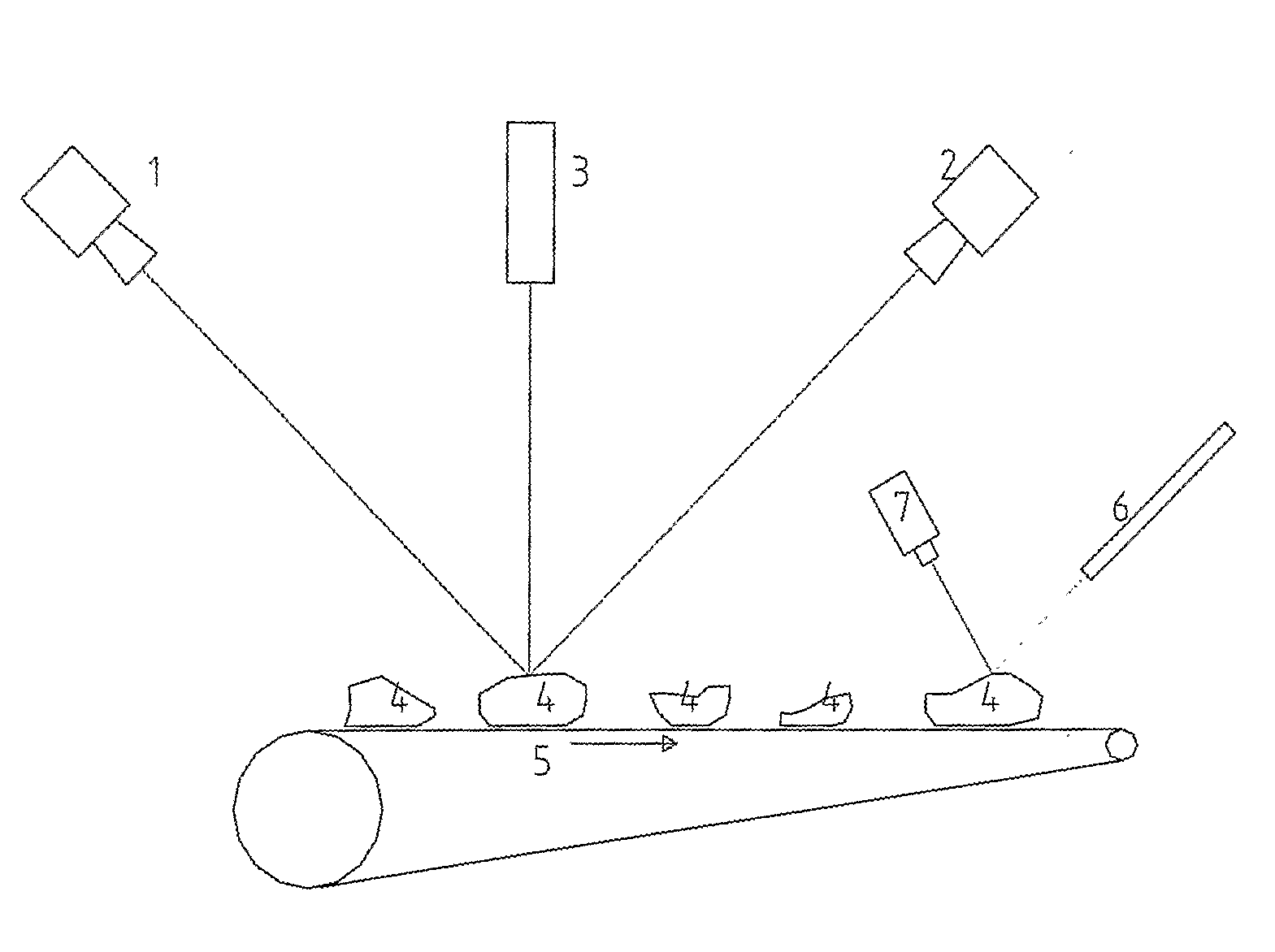

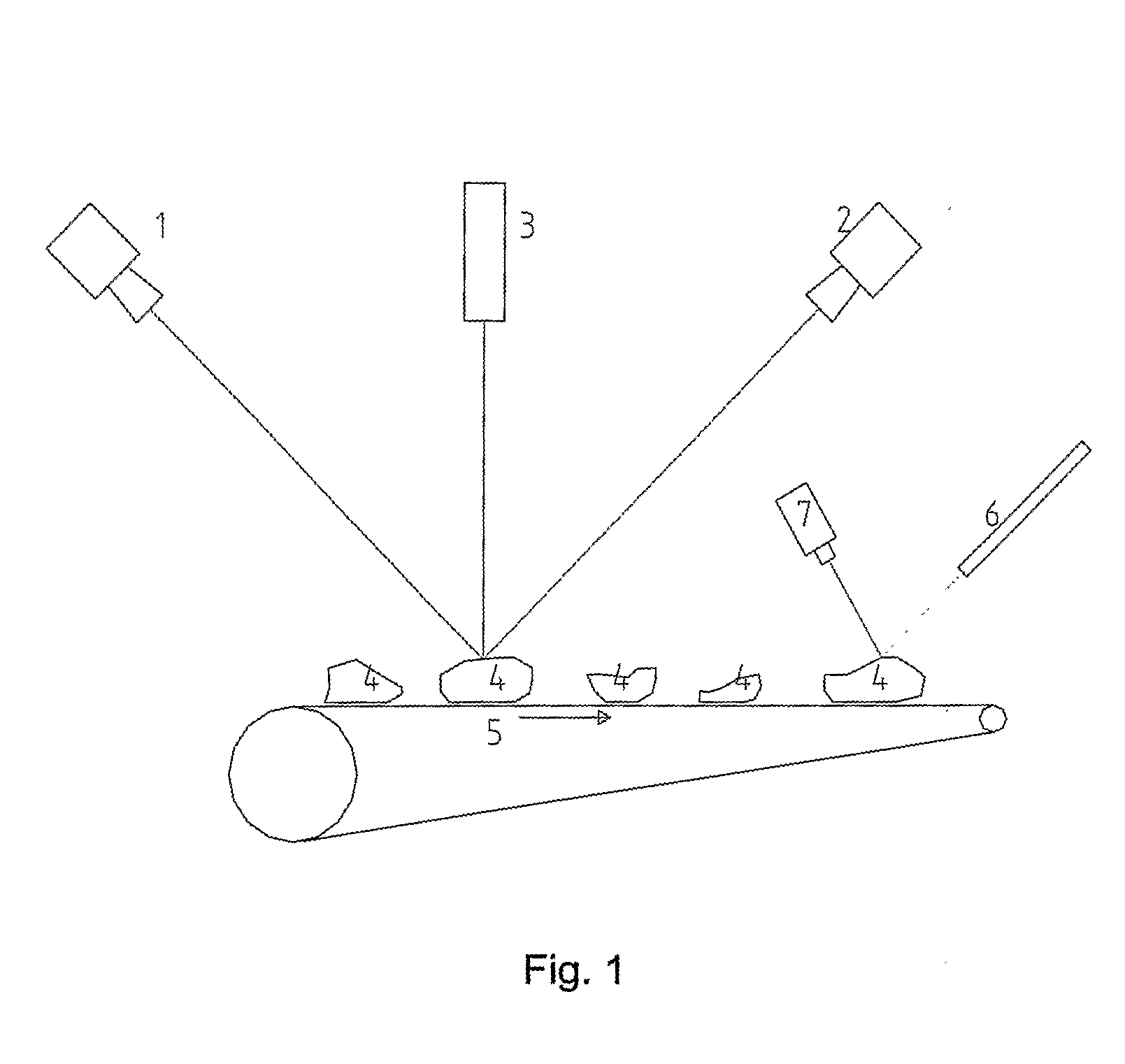

Apparatus and Method For Analysis of Size, Form and Angularity and For Compositional Analysis of Mineral and Rock Particles

ActiveUS20080192987A1Automatically and rapidly analyzeEarth material testingCharacter and pattern recognitionMachine visionThree dimensional measurement

Equipment and process for three-dimensional measurement of size and shape and for compositional analysis of mineral and rock particles and the like objects. A mixture of particles or objects of same or different sizes of minerals or rocks or the like are fed individually and automatically onto a conveyor belt for three-dimensional machine vision measurements using laser and two cameras and subsequently for spectroscopic measurements using visible and infrared light and are then collected at the end of the conveyor. Computer software is used to perform the measurement automatically and to calculate size, form, roundness, and preferably petrographic composition and other characteristics or properties of each individual object and the statistical distribution of relevant properties, either according to built-in measurement processes or user specific methods.

Owner:PETROMODEL EHF

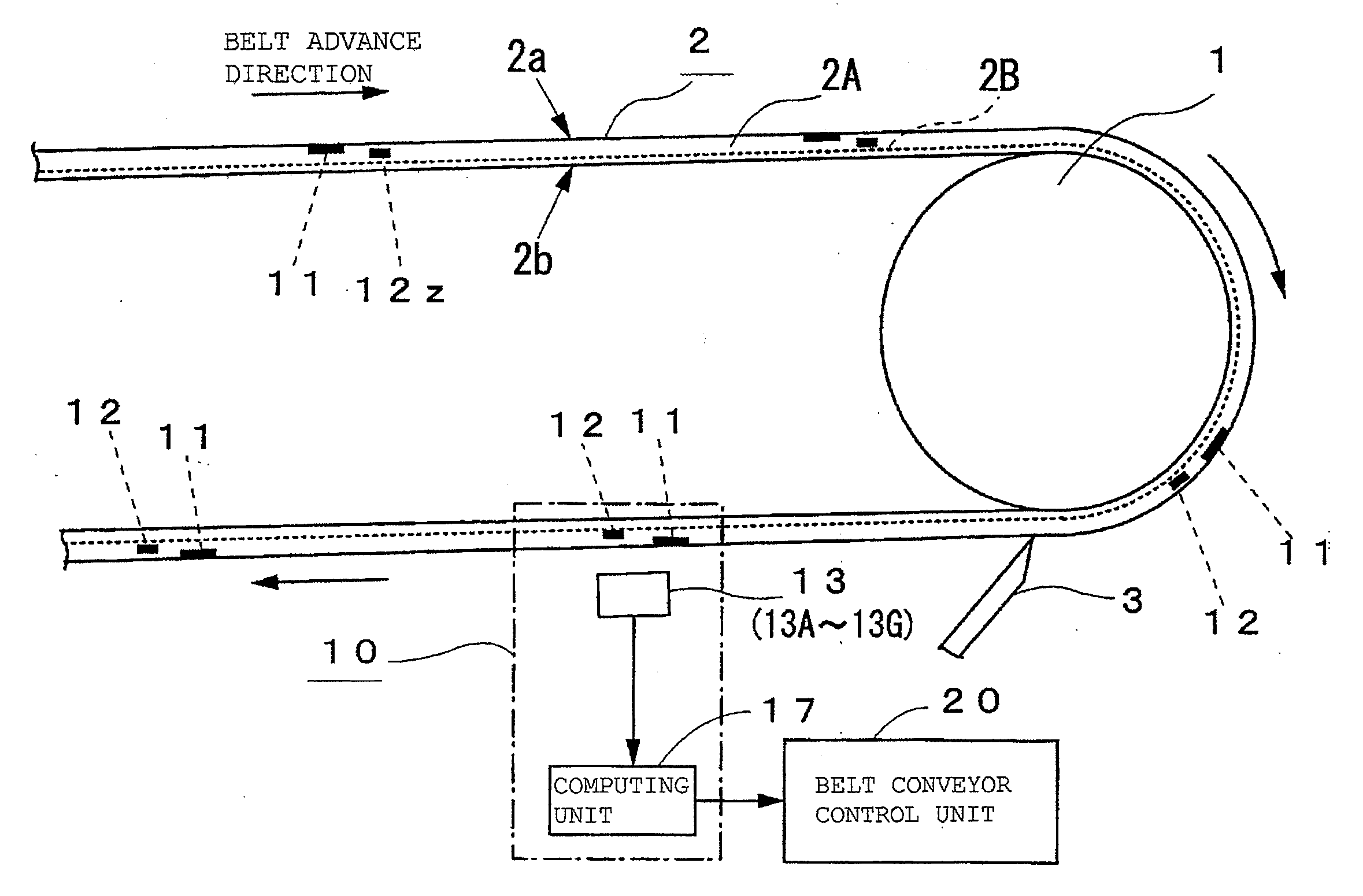

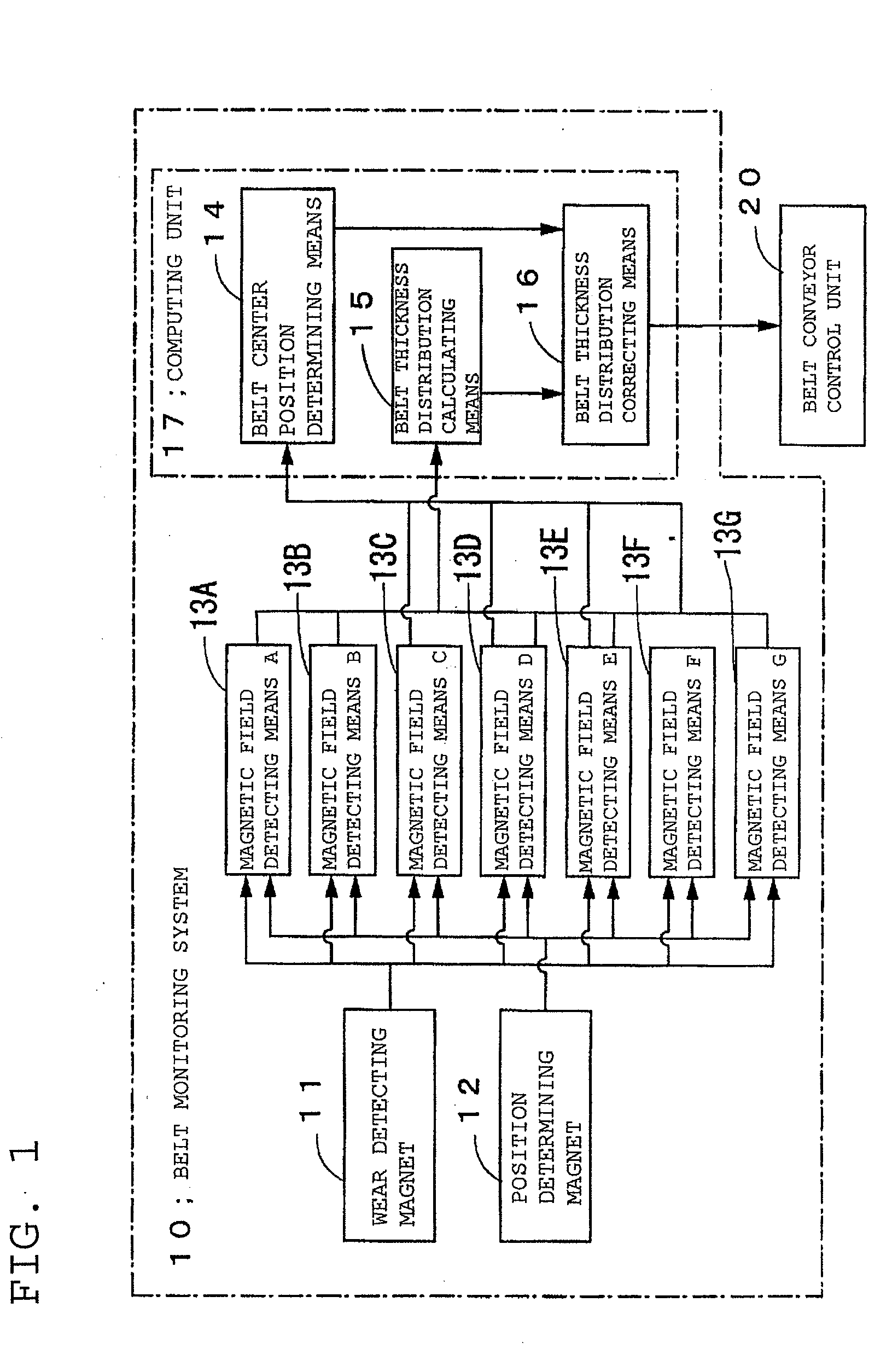

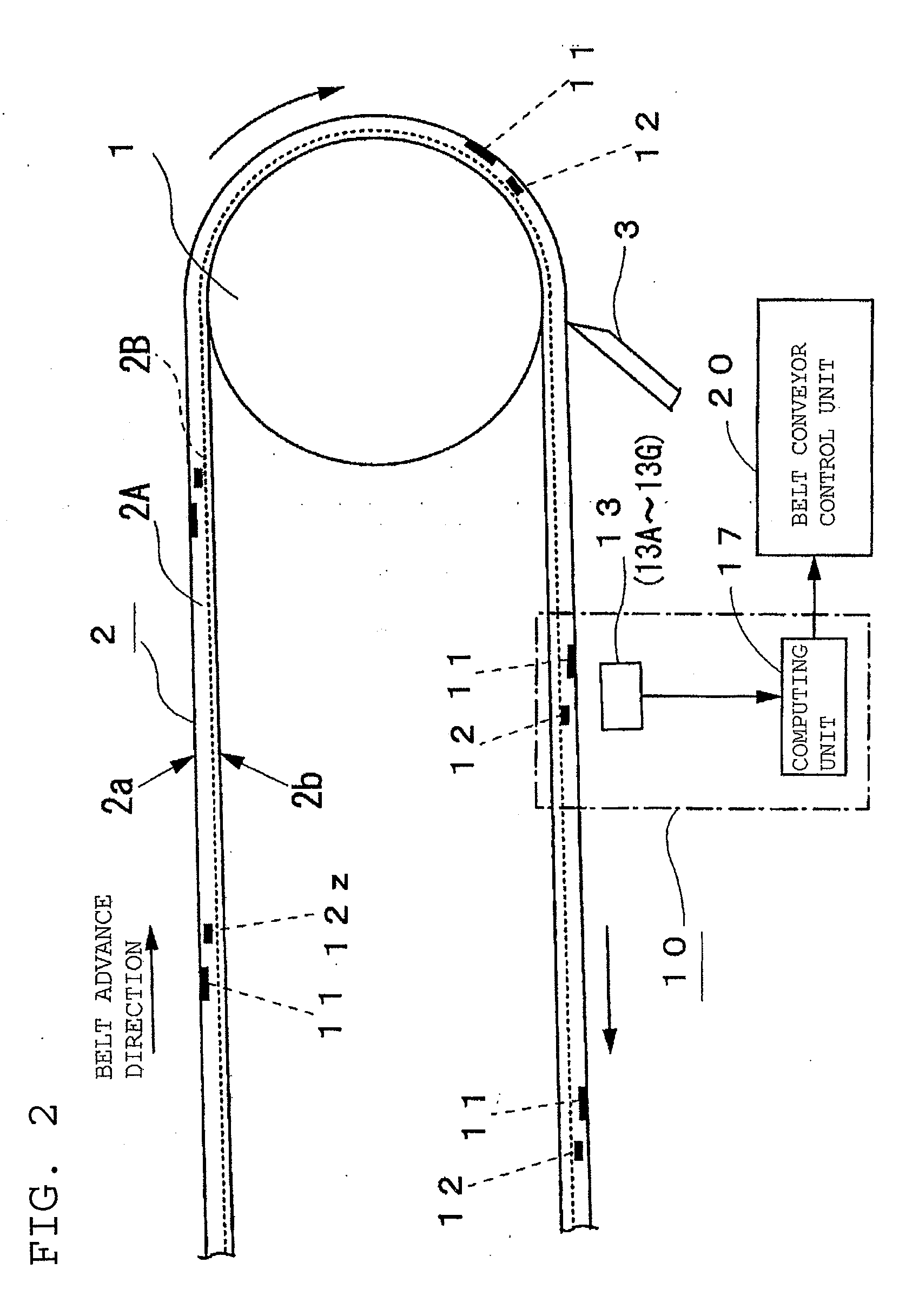

Belt monitoring system

ActiveUS20110050213A1Improve accuracyImprove monitoring accuracyControl devices for conveyorsMagnetic property measurementsMonitoring systemEngineering

A belt monitoring system which can accurately monitor the condition of a conveyor belt by correcting it for the effect of belt deviation. Wear detecting magnets (11), which are rubber magnets spanning the entire belt width, are embedded at intervals along the circumferential direction of the conveyor belt (2). Also, position determining magnets (12, 12z) are embedded in positions a predetermined distance apart from the wear detecting magnets (11). In addition, a plurality of magnetic field detecting means (13: 13A-13G) for detecting the magnetic fields from the magnets (11, 12, 12z), which are arranged at predetermined intervals in the width direction of the conveyor belt (2), are disposed in a position spaced apart from the surface of the conveyor belt (2). The state of deviation of the conveyor belt (2) is detected based on the output signals from the position determining magnets (12, 12z) detected by the magnetic field detection means (13), and then the belt thickness distribution of the conveyor belt (2) in the width direction is corrected based on the detected state of belt deviation.

Owner:BRIDGESTONE CORP

Systems and methods for merchandise automatic checkout

Systems and methods for automatically checking out items located on a moving conveyor belt for the purpose of increasing the efficiency of a checkout process and revenue at a point-of-sale. The system includes a conveyor subsystem for moving the items, a housing that enclosed a portion of the conveyor subsystem, a lighting subsystem that illuminates an area within the housing, visual sensors that can take images of the items including UPCs, and a checkout system that receives the images from the visual sensors and automatically identifies the items. The system may include a scale subsystem located under the conveyor subsystem to measure the weights of the items, where the weight of each item is used to check if the corresponding item is identified correctly. The system relies on matching visual features from images stored in a database to match against features extracted from images taken by the visual sensors.

Owner:DATALOGIC ADC

Food Article Feed Apparatus for a Food Article Slicing Machine

ActiveUS20090120256A1Easy to controlHigh yieldMeat packaging/handling/transportingEngineering safety devicesConveyor beltIngested food

A food article feed apparatus for a food article slicing machine. The apparatus has conveyor with a drive belt for connecting a drive source to a drive roller, and a conveyor belt. The drive roller is for driving the conveyor. The drive roller has an outer diameter and a recessed diameter where the drive belt is connected around the recessed diameter and the conveyor belt is connected around the outer diameter. The drive belt operates within an area defined by the first conveyor belt.

Owner:PROVISUR TECHNOLOGIES INC

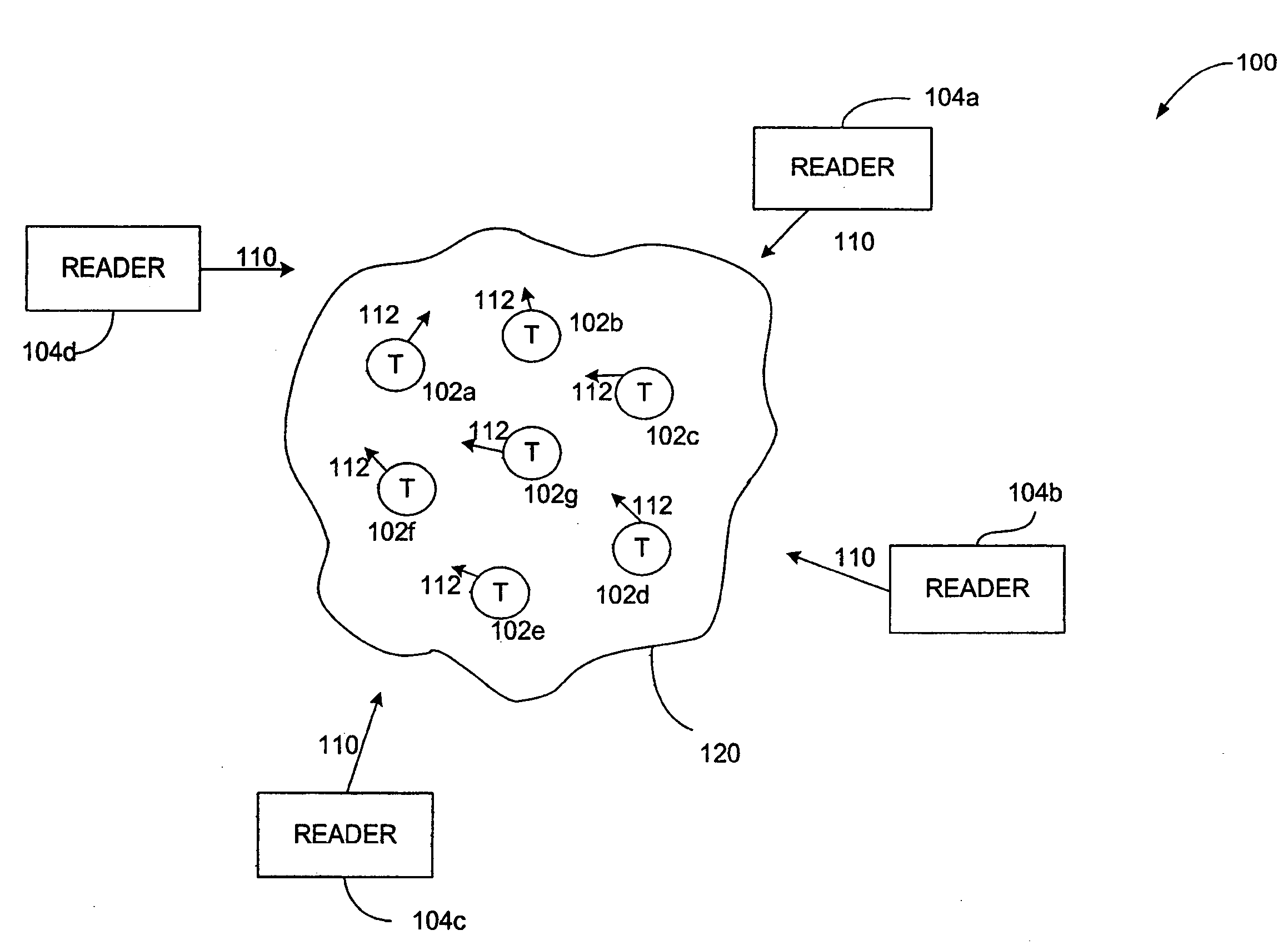

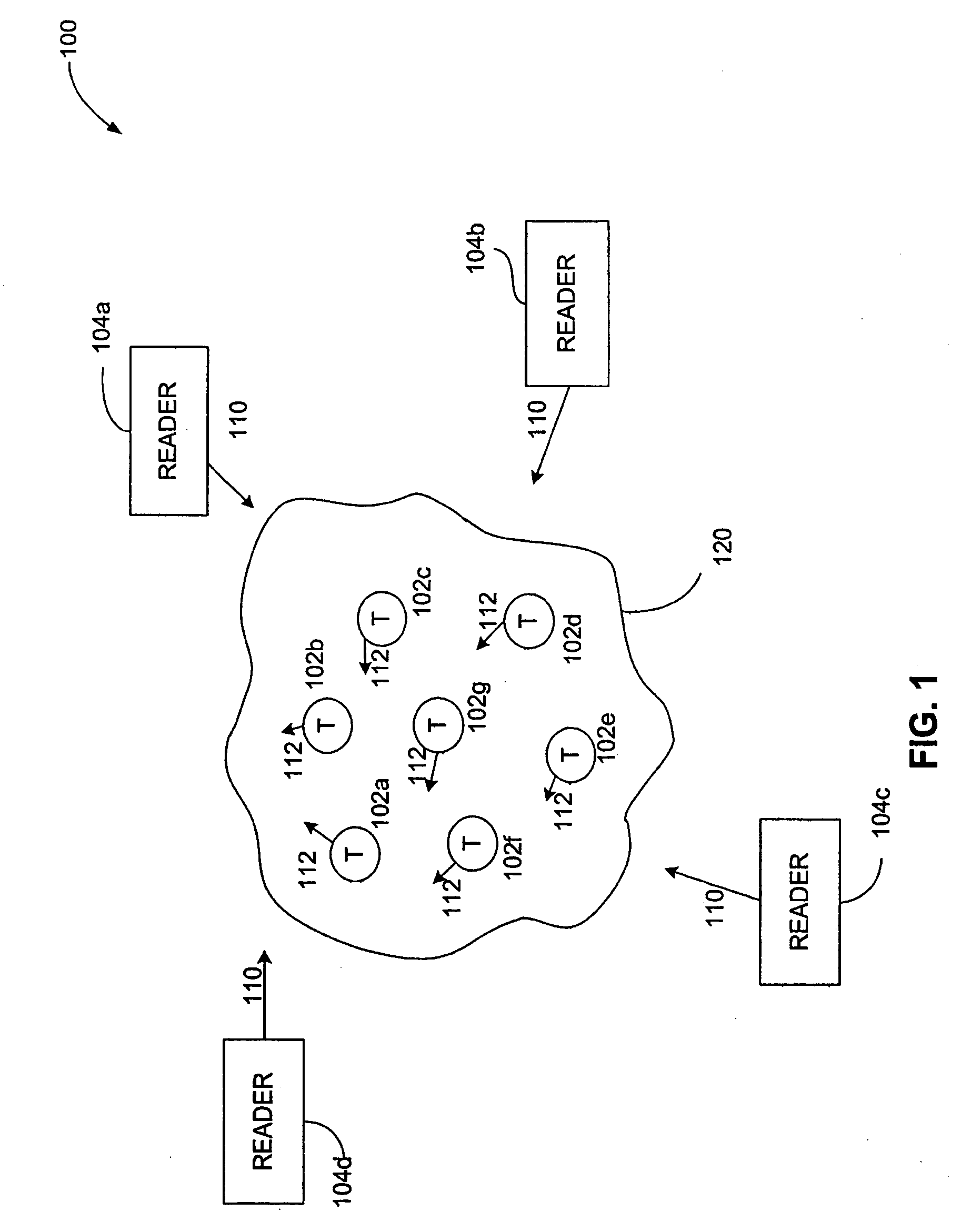

Frequency selective surface aids to the operation of RFID products

ActiveUS20080150691A1Electric signal transmission systemsDigital data processing detailsEngineeringSlide plate

The present invention is directed to systems that use frequency selective surfaces (FSS) to aid in the operation of radio frequency identification (RFID) devices and products. In one embodiment, a system for interrogating radio frequency identification (RFID) tags includes a conveyor belt and an RFID reader. The conveyor belt has a first surface and a second surface. The first surface is configured to receive an item to which an RFID tag is affixed and the second surface is configured to slide on a metal slide plate. The RFID reader is configured to transmit instructions embodied in a radio frequency (RF) signal to the RFID tag, wherein the metal slide plate is positioned between the RFID reader and the RFID tag and comprises a frequency selective surface that is substantially transparent to the RF signal.

Owner:SYMBOL TECH LLC

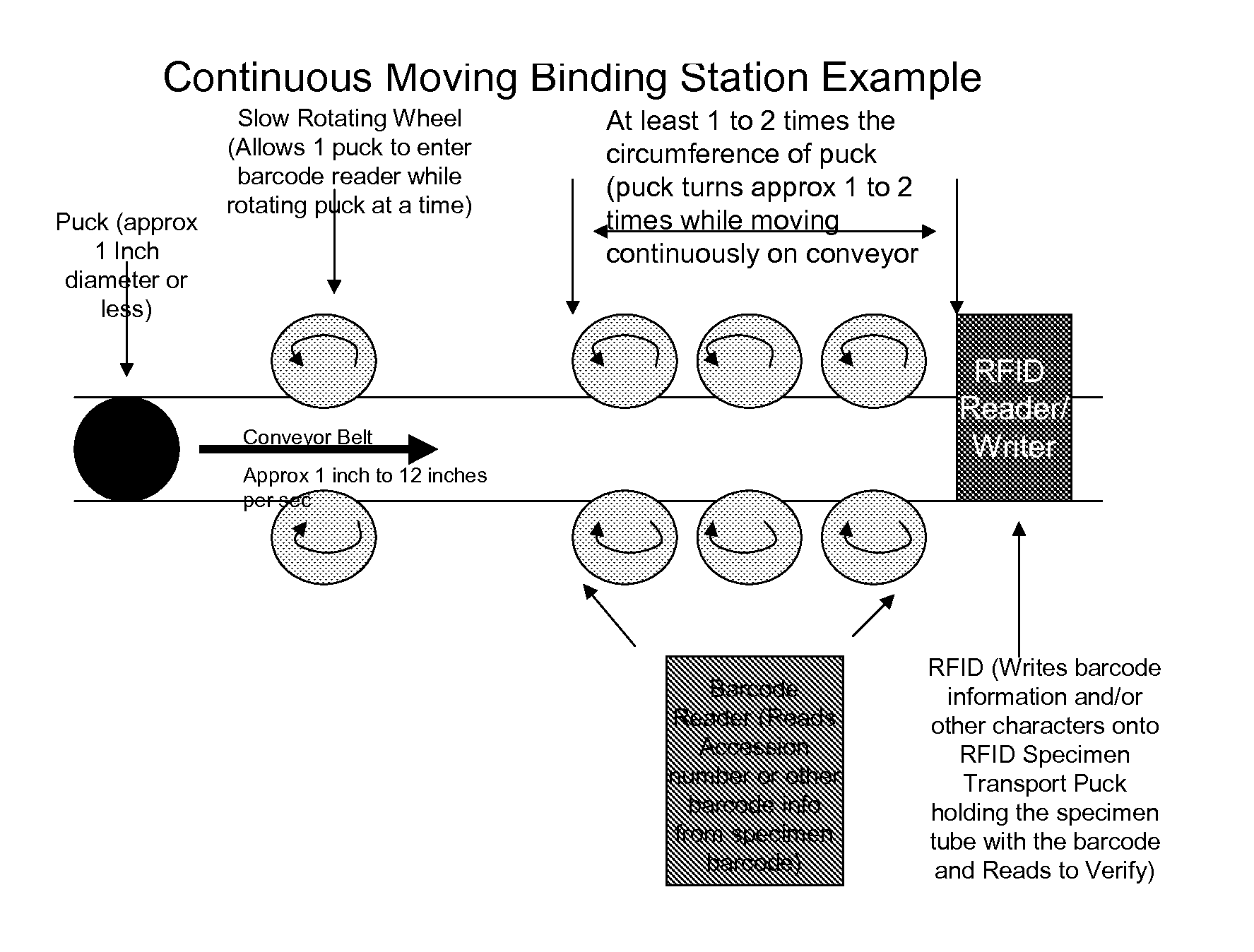

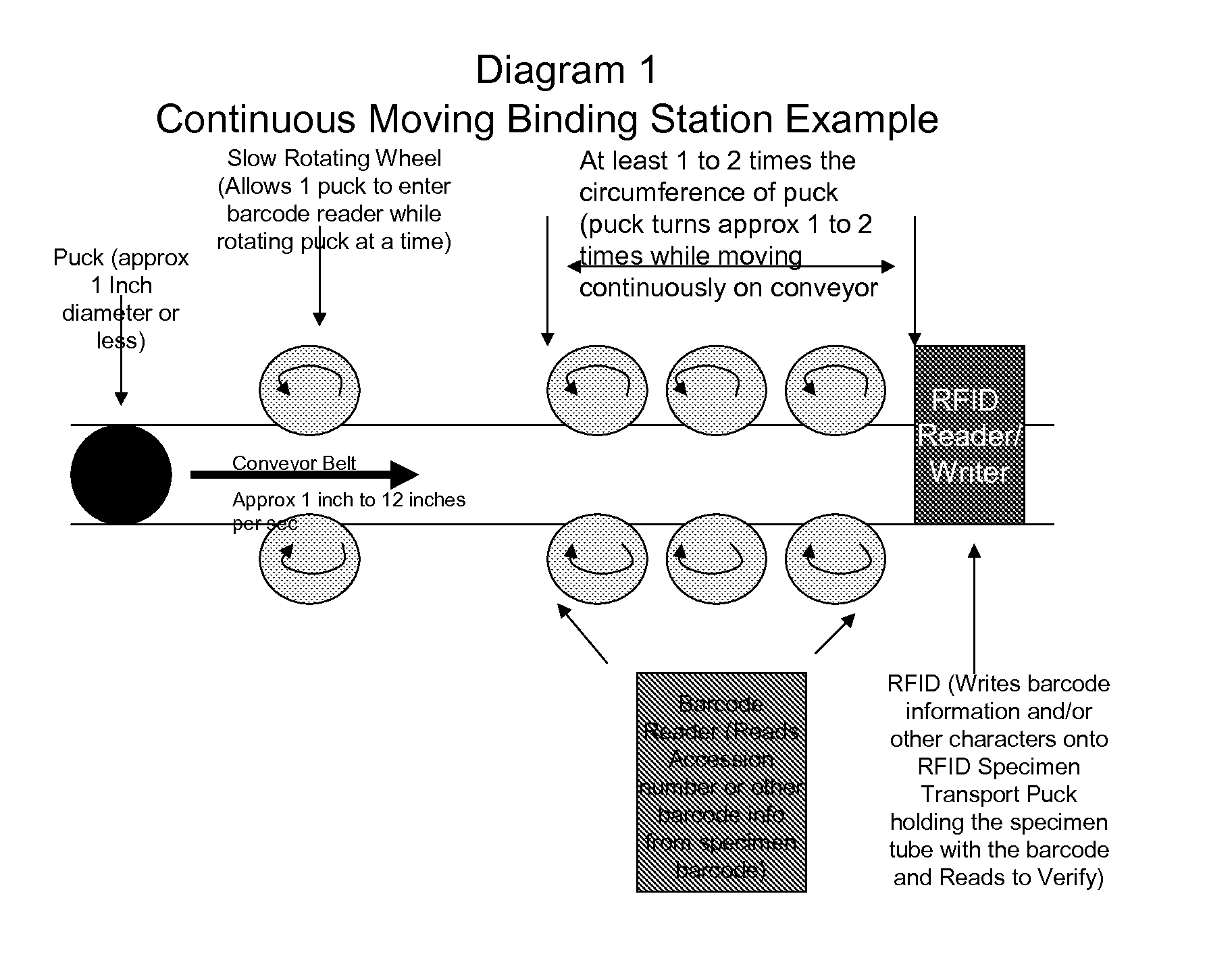

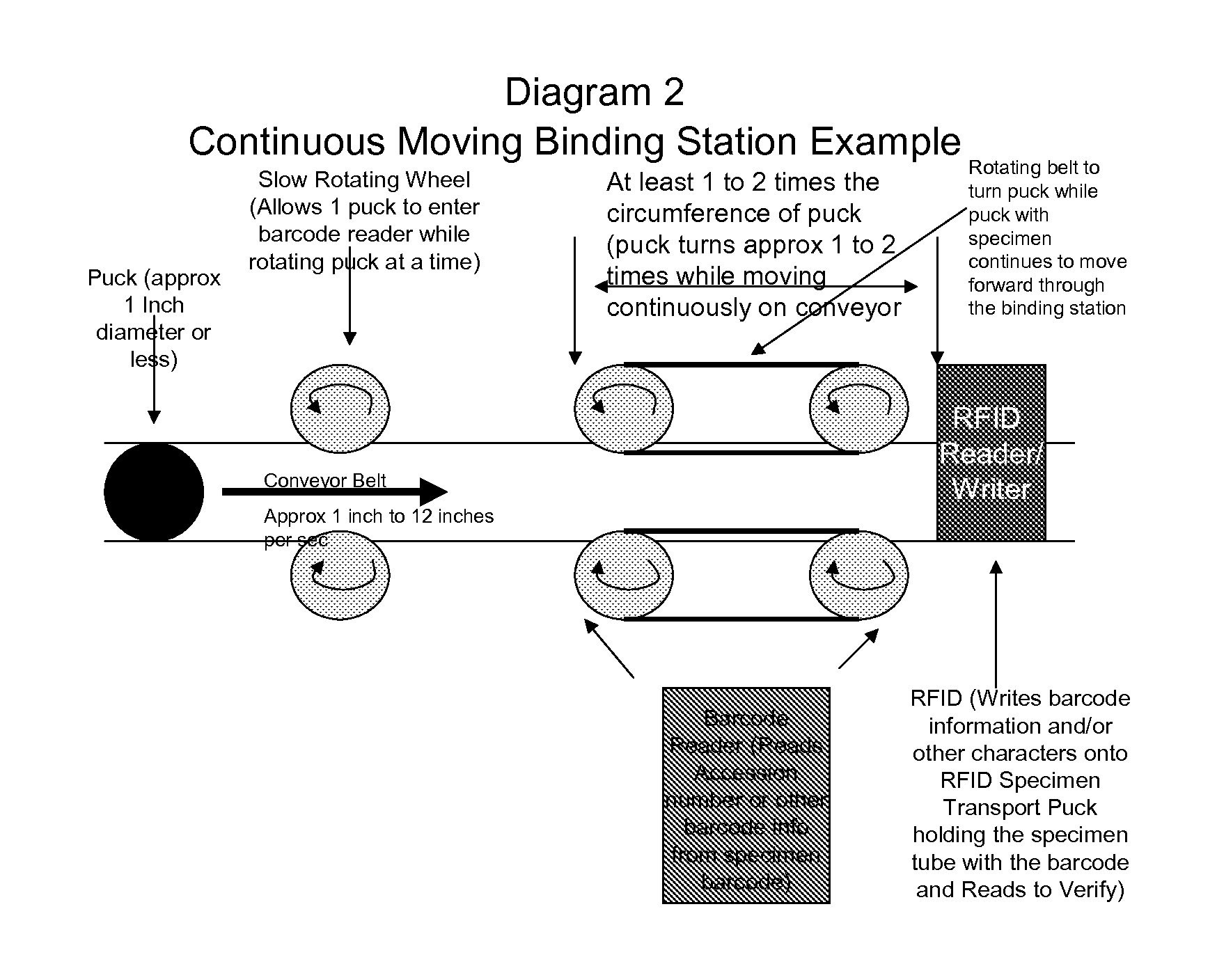

Transfer, Link, Bind, Specimen Tube Barcode Information To RFID Specimen Transport Puck In A Continuous Moving Binding Process Method

ActiveUS20120037696A1Maximize throughputFast and efficientCharacter and pattern recognitionRecord carriers used with machinesDatabase serverBarcode reader

The present invention relates generally to the process method of transferring / linking / binding specimen tube label barcode information (such as unique accession number along with other useful laboratory information such as test code information, testing department, specimen temperature) using an RFID Specimen Transport Puck moving continuously on a continuously moving conveyor belt and an RFID Reader / Writer that writes the information onto the RFID chip on the RFID Specimen Transport Puck. The process method is to space the specimen transport pucks on the conveyor, rotate the specimen transport puck that is holding the specimen tube with the barcode while the specimen is moving continuously forward using rotating wheels on the side of the conveyor belt and using a dispersed barcode reader to read the barcode information from the specimen tube label, and to transfer / link / bind the information from the specimen tube barcode label to the RFID chip on the specimen transport puck holding the specimen tube using an RFID reader / writer beneath the conveyor belt, a PLC and a database server.

Owner:LEAR SIROUS LAVI

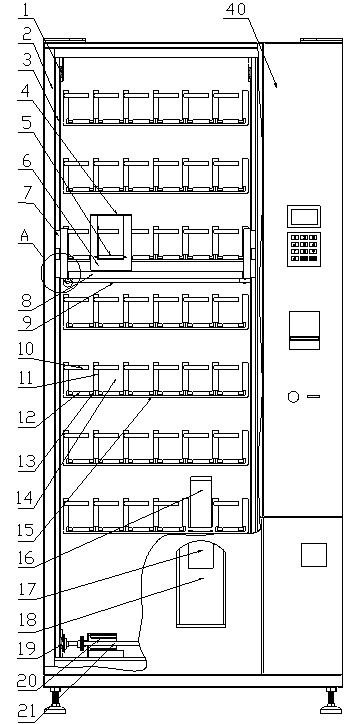

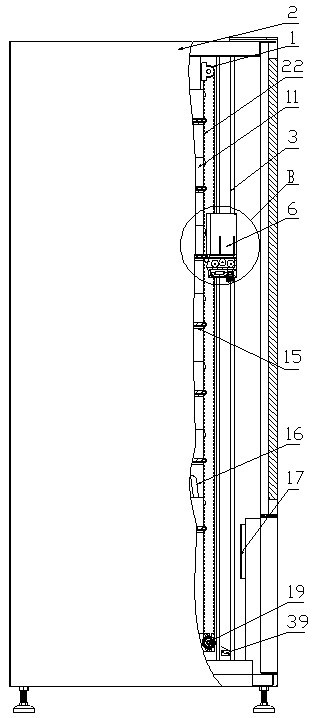

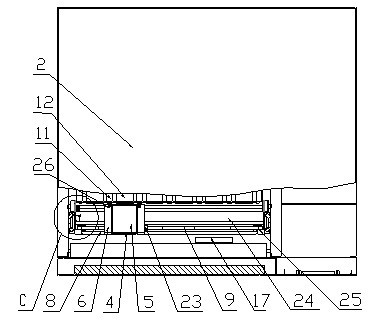

Vending machine shipment structure

InactiveCN102289881AAvoid potential damageAvoid complexityCoin-freed apparatus detailsApparatus for dispensing discrete articlesDrive wheelEngineering

The invention relates to a delivery structure of an automatic vending machine. Multiple rows of shelves are installed in the box body. The shelf partition divides the shelves into multiple cargo lanes. A baffle plate is installed on one cargo lane, the lifting platform installed horizontally in the box can move up and down along the guide rail (3) on the inner wall of the box body, and the pick-up rack installed on the lifting platform can move left and right along the guide rail (24) installed horizontally on the lifting platform Movement, a conveyor belt is installed at the bottom of the shelf, a baffle lever is installed on one side of the shelf, and a driving wheel is installed at the bottom of the shelf, the driving wheel drives the delivery device of the cargo lane, and the delivery device of the cargo lane will The goods are pushed onto the conveyor belt, and at the same time the conveyor belt rotates to transport the goods to the pick-up rack. According to the needs of buyers, the delivery structure can automatically run to the corresponding aisle to take out the goods, and then deliver the goods to the pick-up warehouse to ensure the normal sales of the goods.

Owner:HUNAN XINGYUAN TECH CO LTD

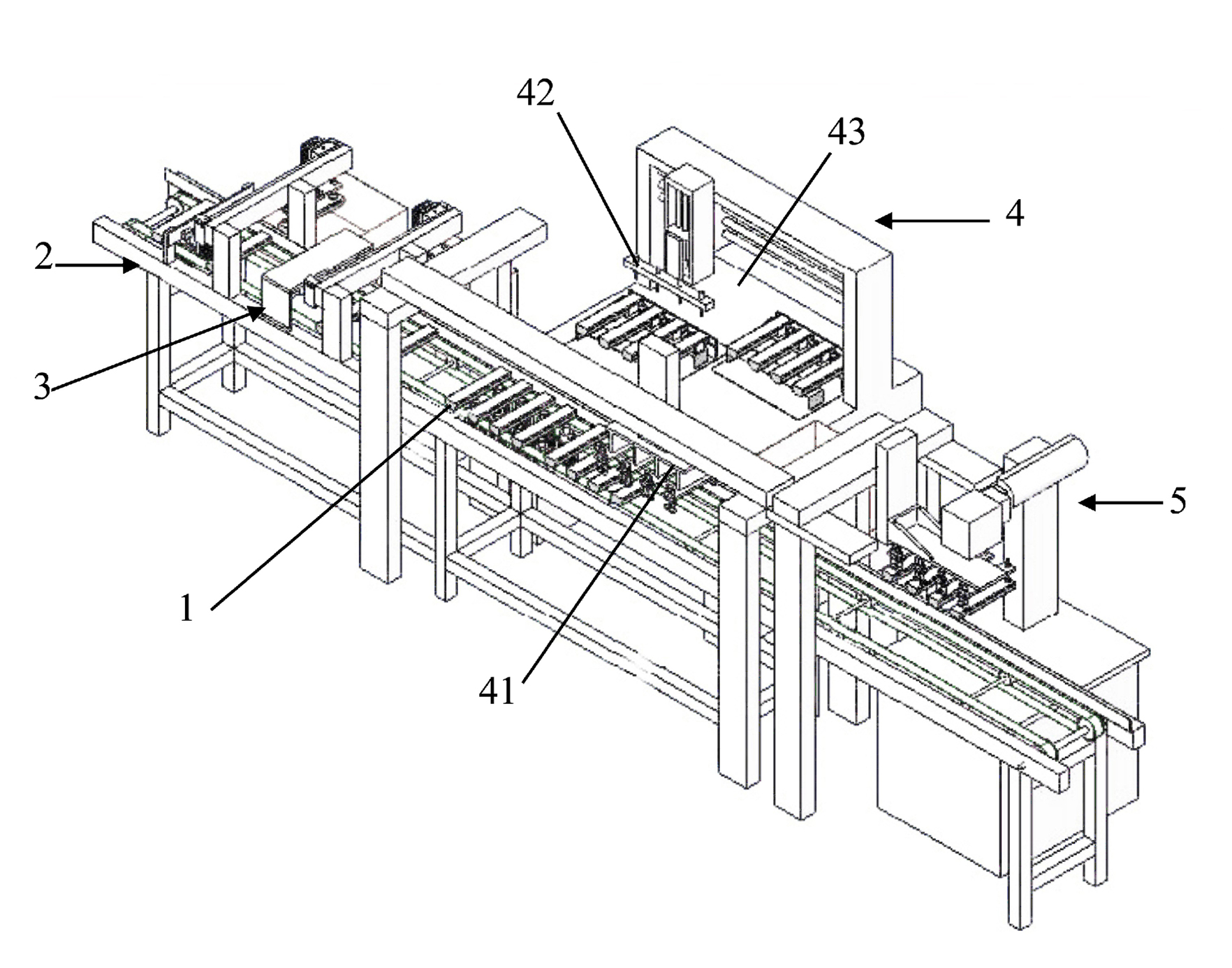

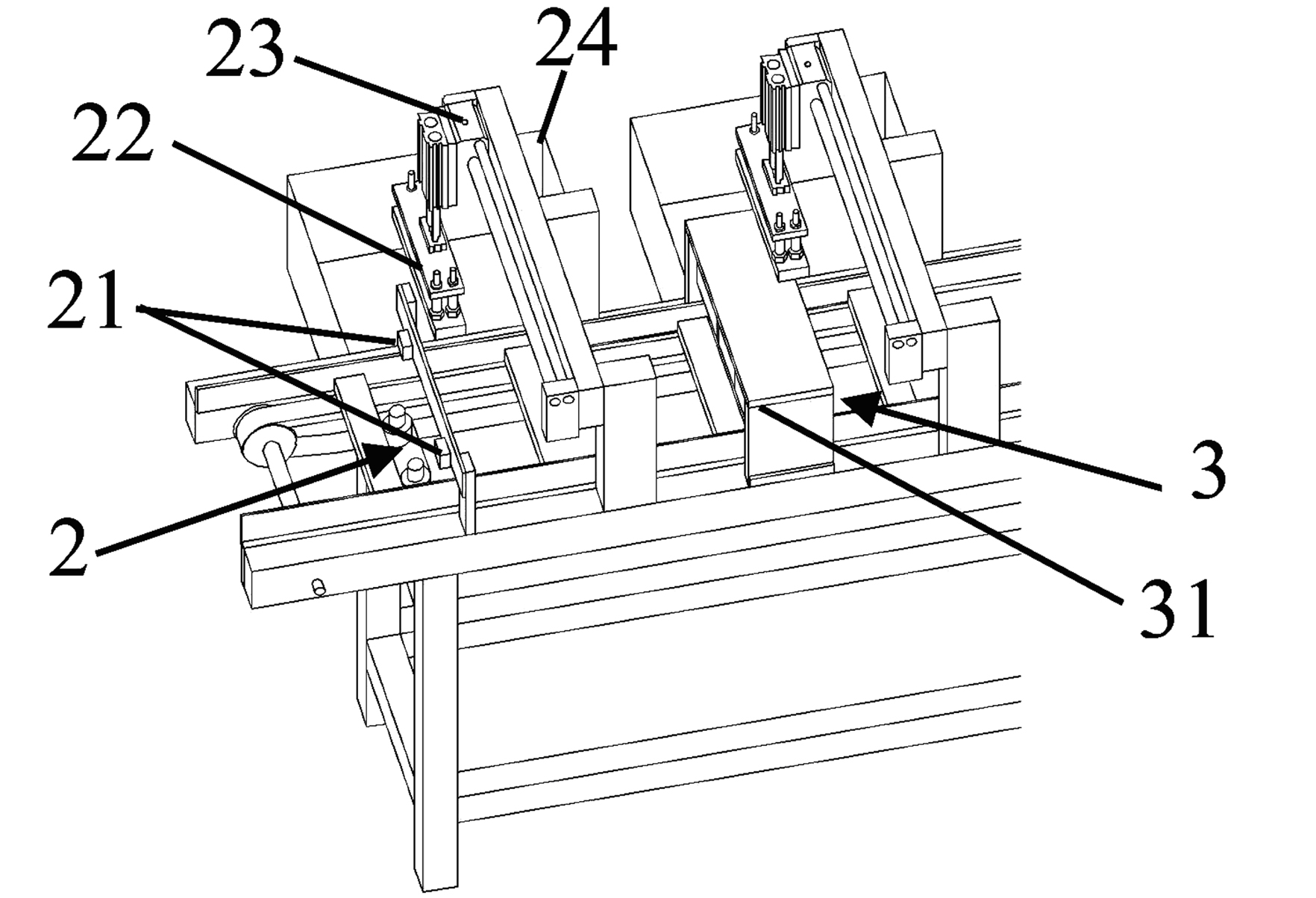

Remote controller automatic detection production line

InactiveCN102062584AAutomatic detection of realityImprove detection efficiencyElectrical testingOptically investigating flaws/contaminationProduction lineProcess engineering

The invention relates to a remote controller automatic detection production line, comprising a conveyor belt and also at least comprising an appearance detection working station and a function detection working station, wherein the appearance detection working station comprises an appearance detection device arranged on the conveyor belt and an unqualified-appearance product recycling device; the function detection device comprises an automatic function detection device arranged above or at one side of the conveyor belt and an unqualified-function product recycling device. The remote controller automatic detection production line realizes automatic online detection of remote controllers, not only improves the detecting efficiency, but also avoids influence from artificial subjective judgment and improves the detecting quality.

Owner:深圳市瑞摩特科技发展有限公司

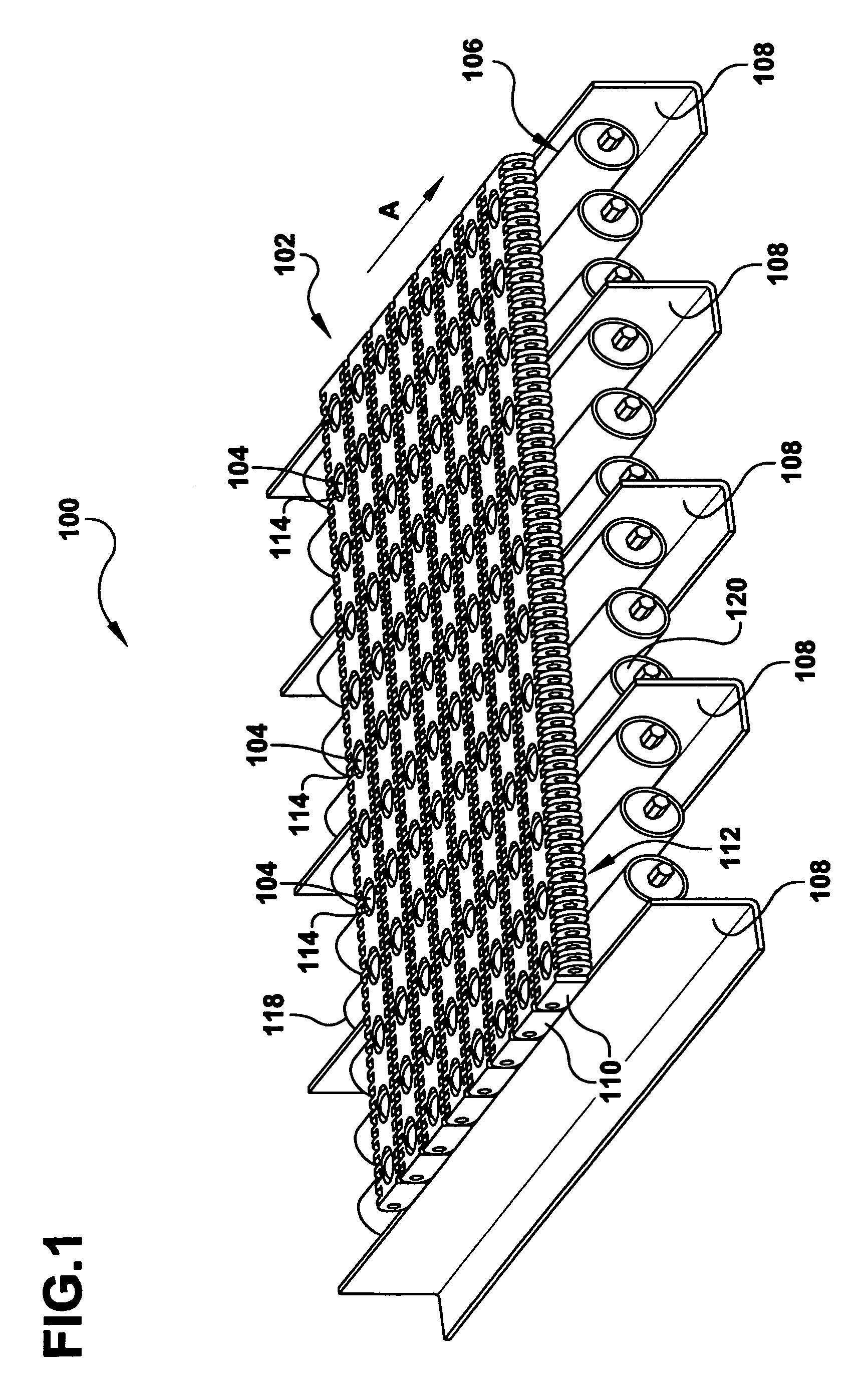

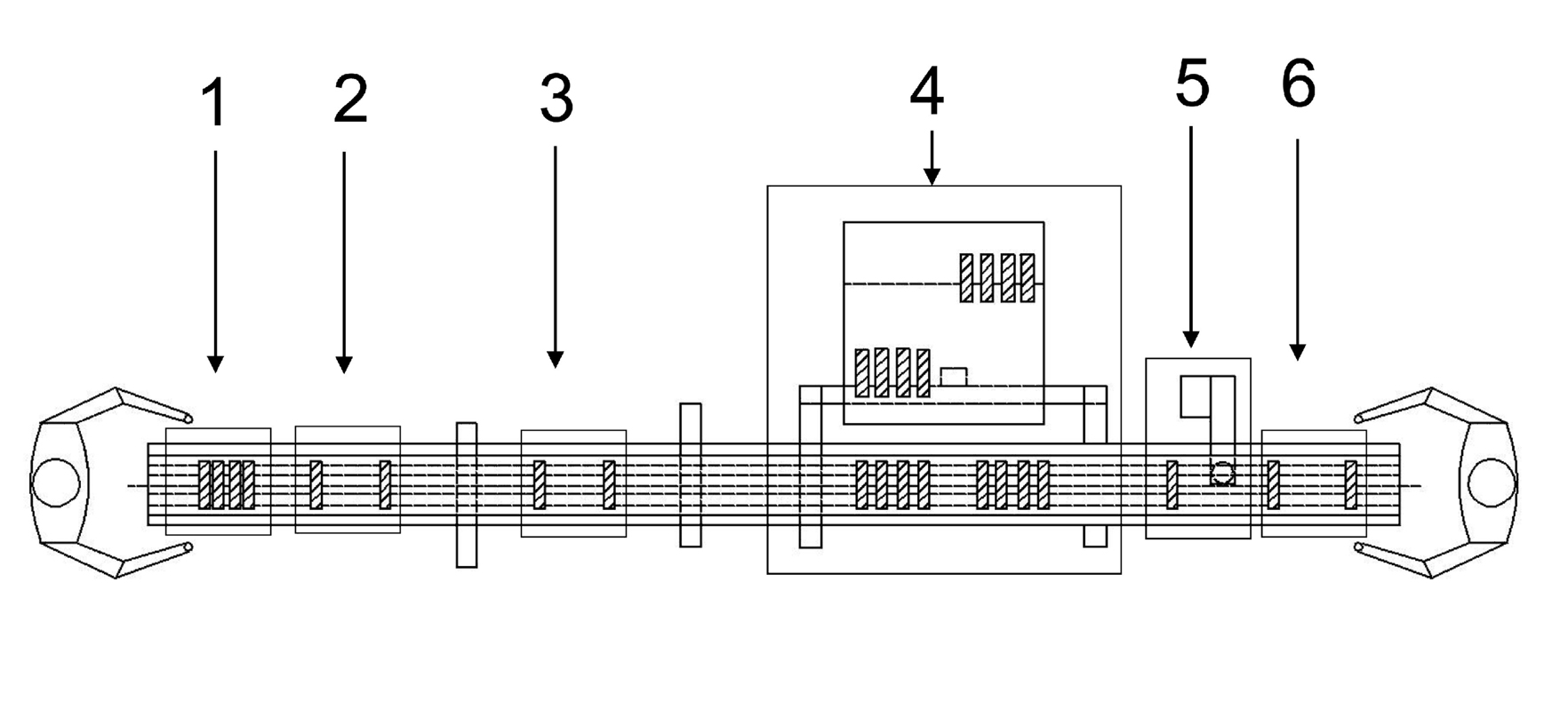

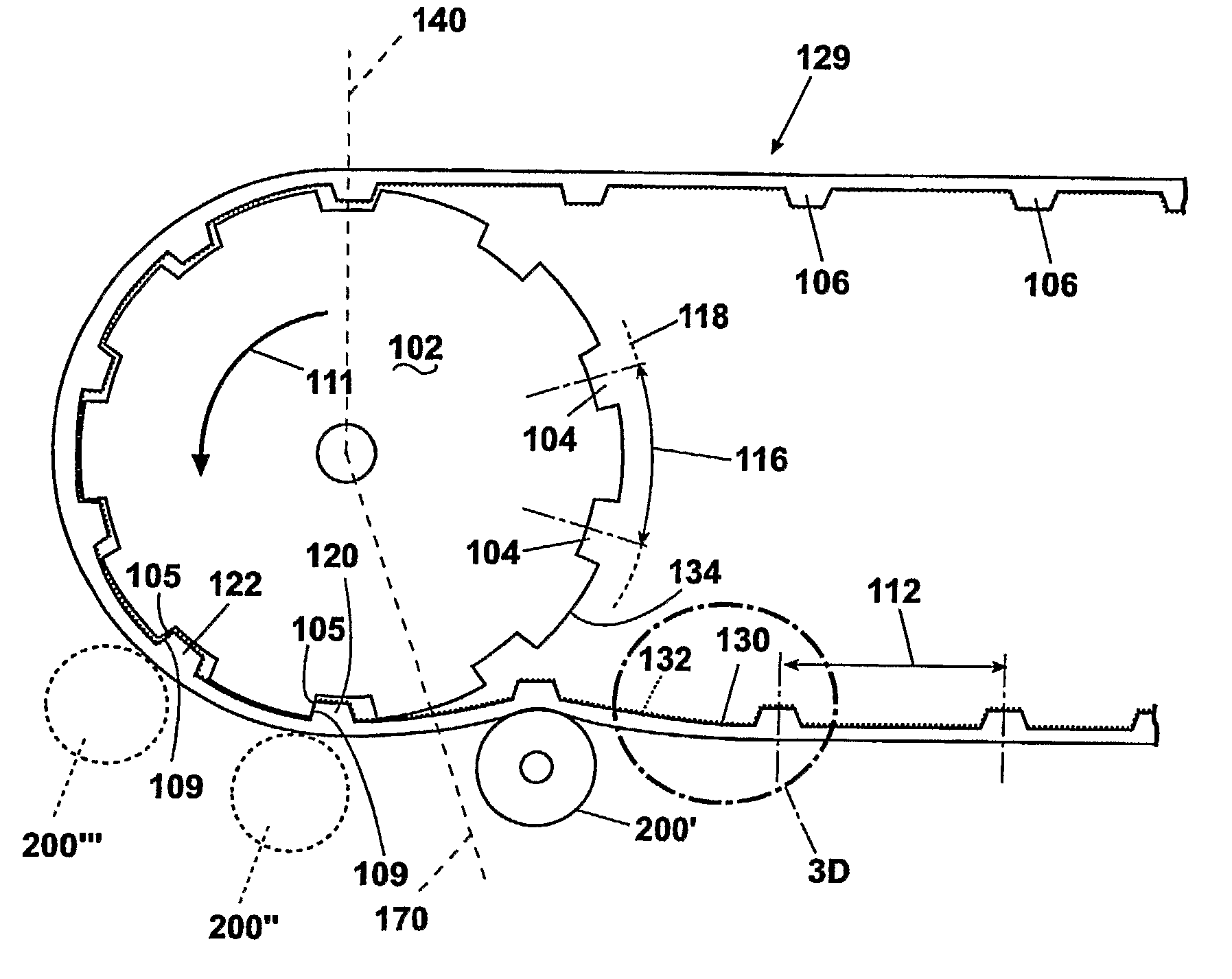

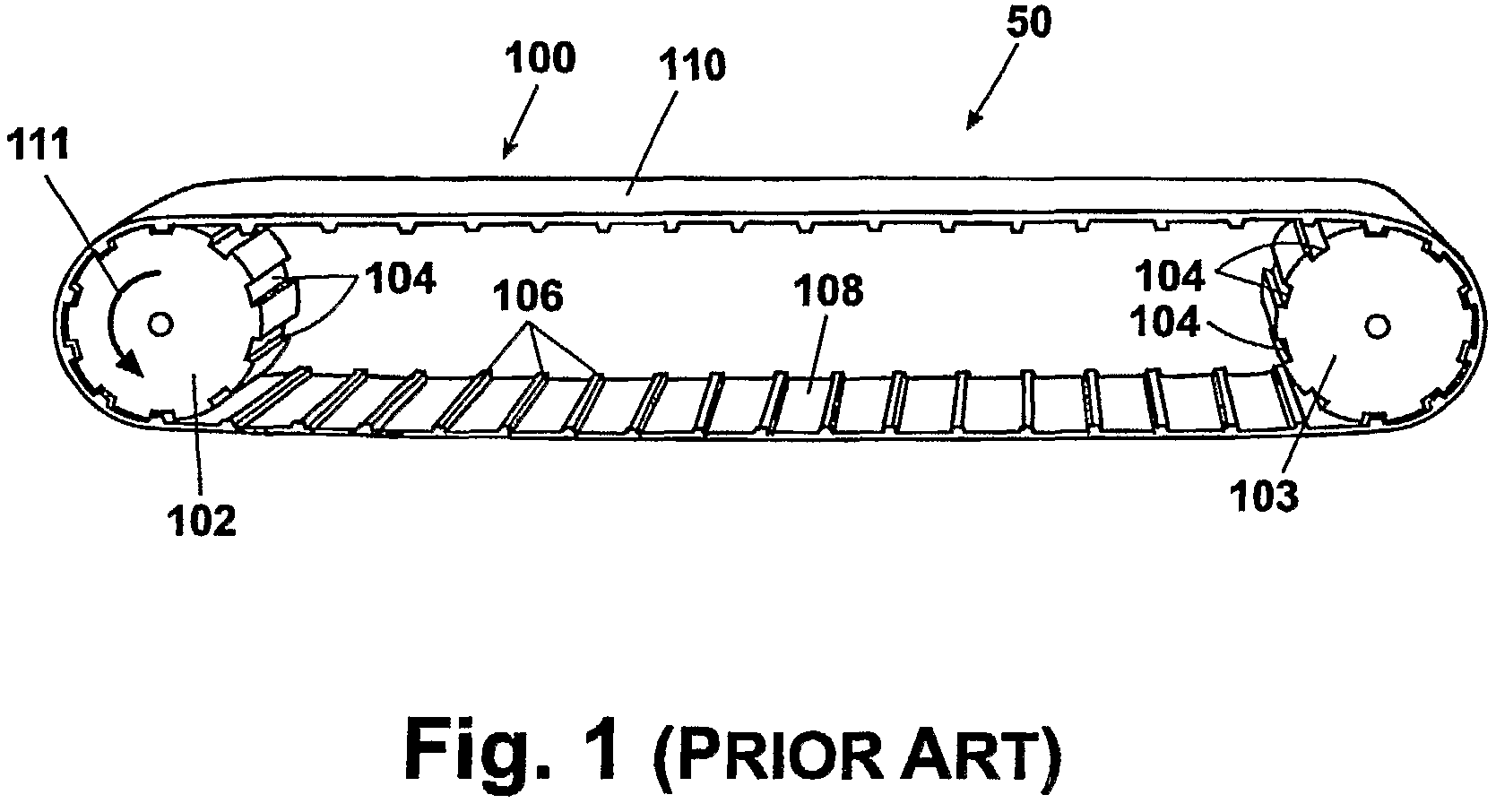

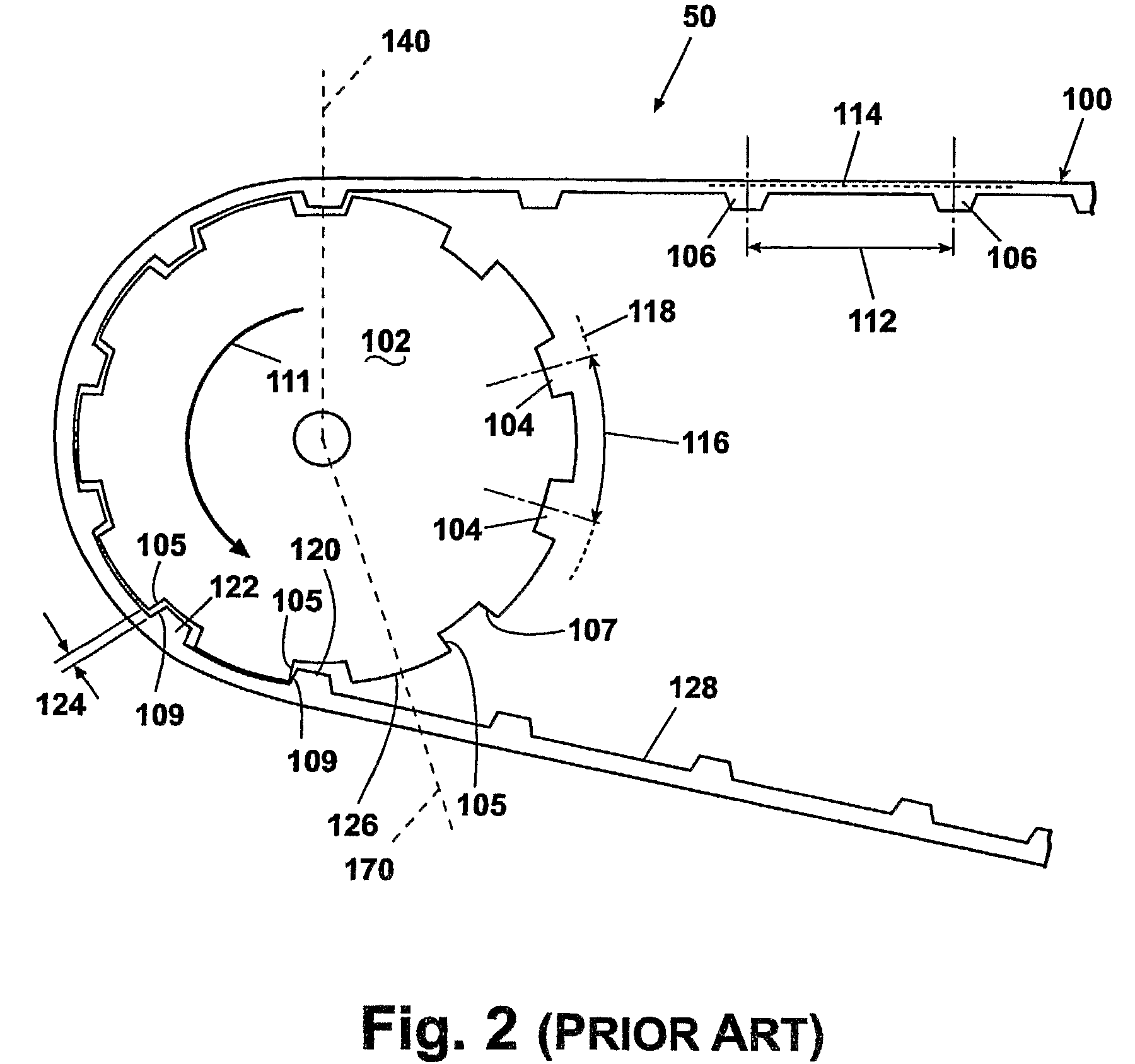

Low friction, direct drive conveyor belt

A thermoplastic endless belt (100) has a smooth outer surface substantially free of discontinuities and an inner surface with a plurality of teeth (106) at a given belt pitch. The teeth are adapted to engage a pulley (102) with circumferentially spaced sheaves (104) at a pulley pitch greater than the belt pitch. The belt is slightly stretchable so that the pulley can drive the endless belt when engaging the teeth within a range of load on the belt. Means (132, 136, 138) are provided to minimize friction between the belt and the drive pulley. Also, a position limiter (200) ensures that the driven tooth stays engaged optimally with the drive sheave.

Owner:LAITRAM LLC

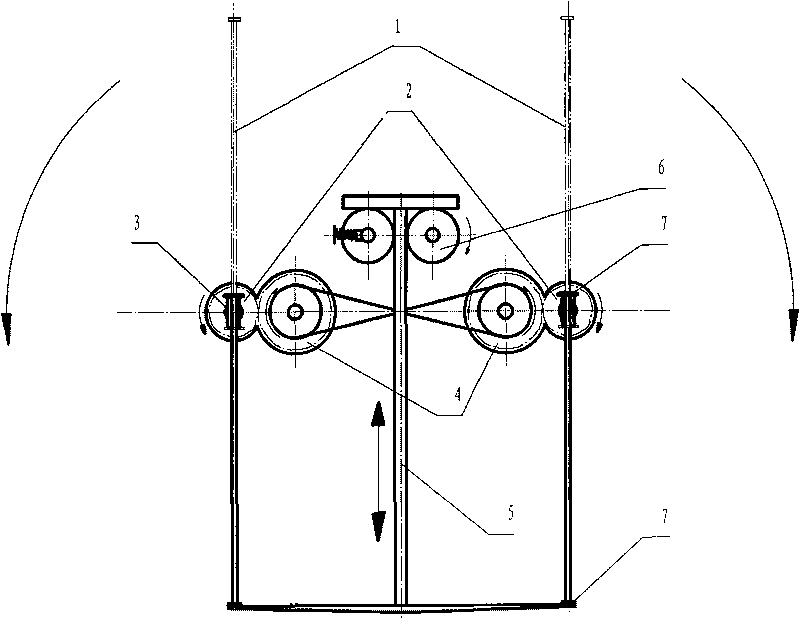

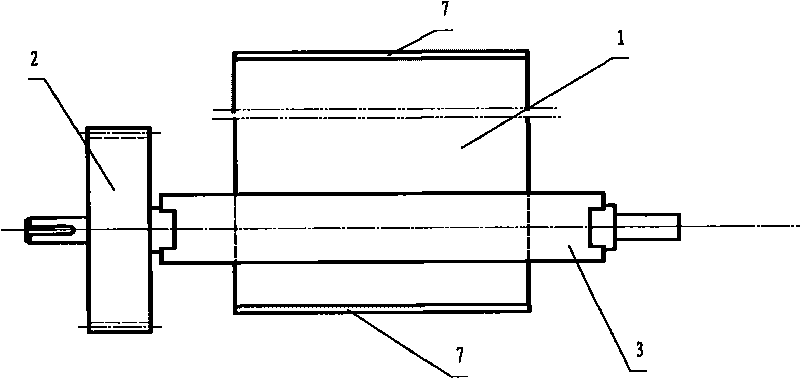

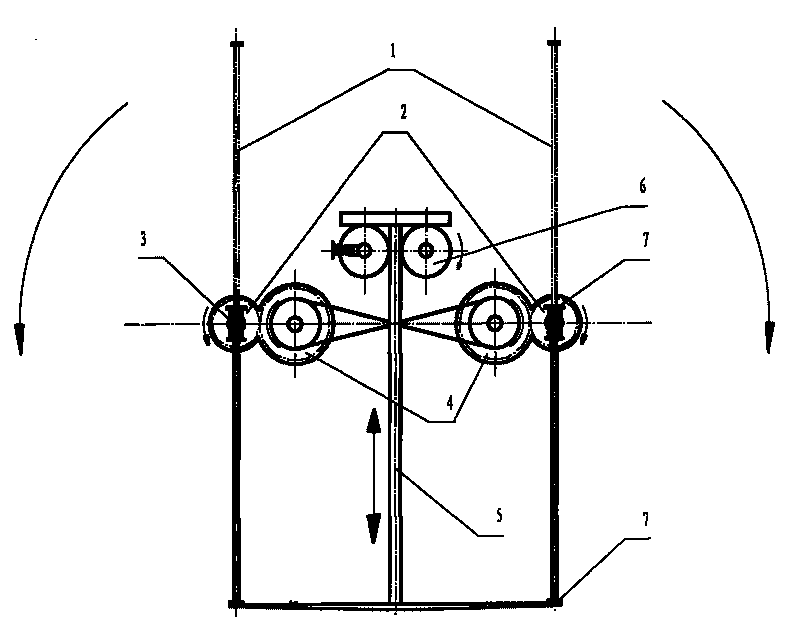

Flapping wing lift generating device

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com