Patents

Literature

395 results about "Product Recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

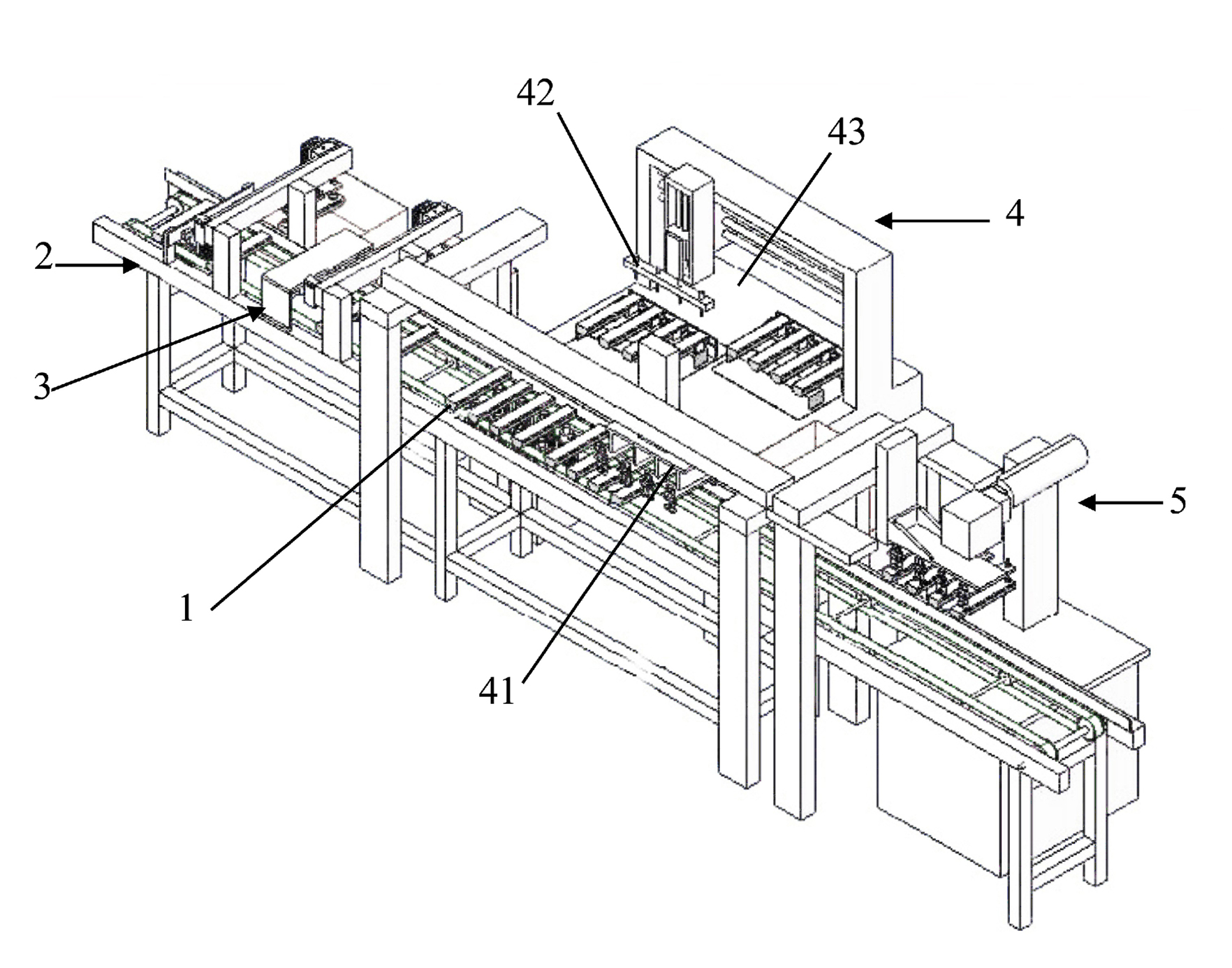

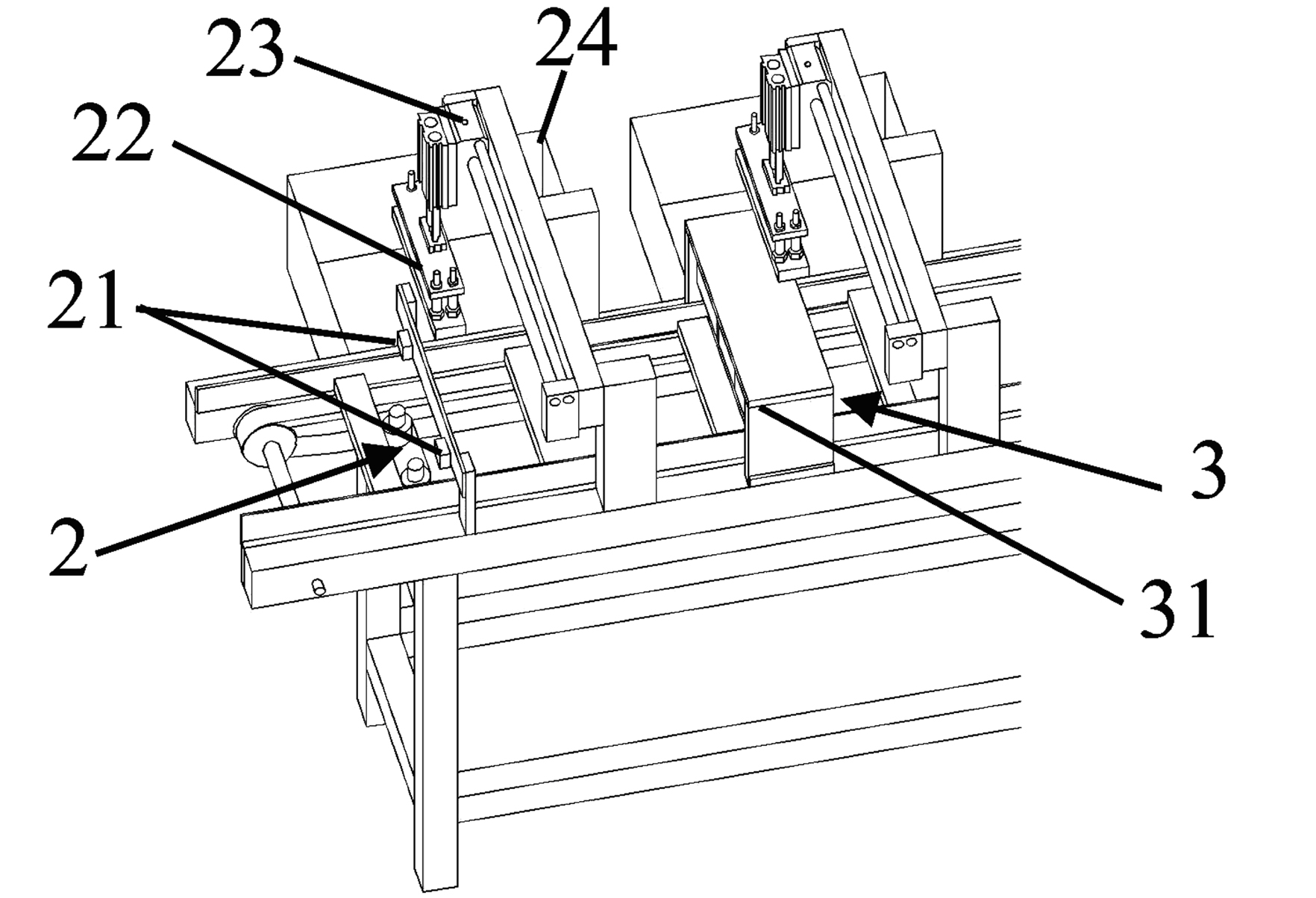

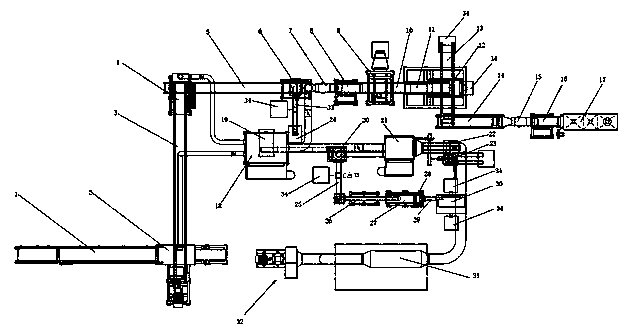

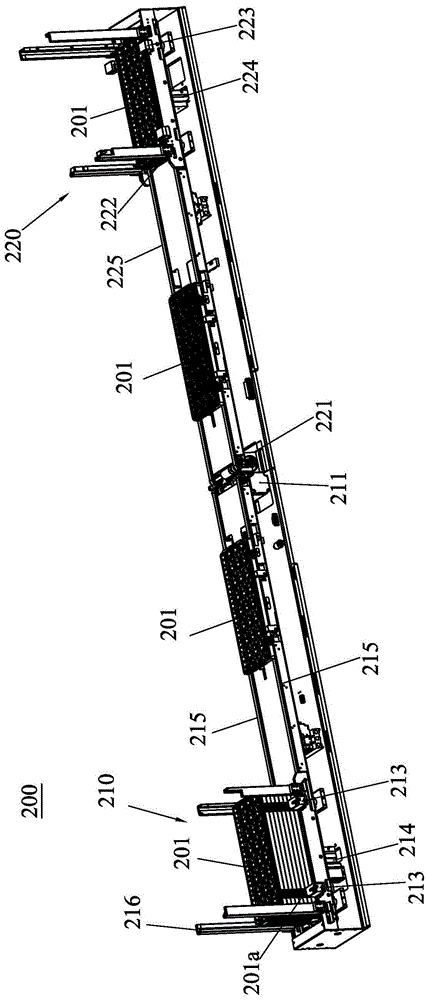

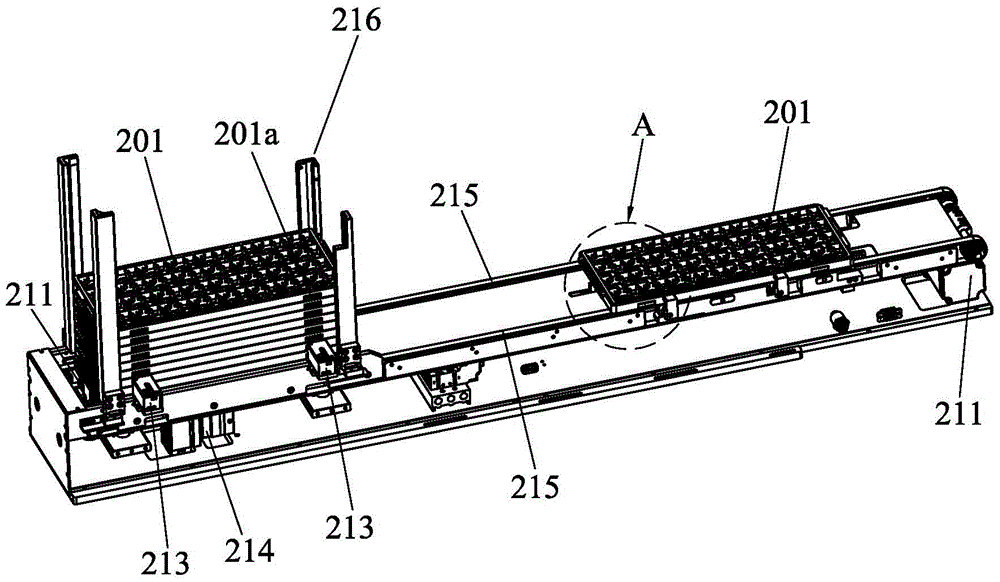

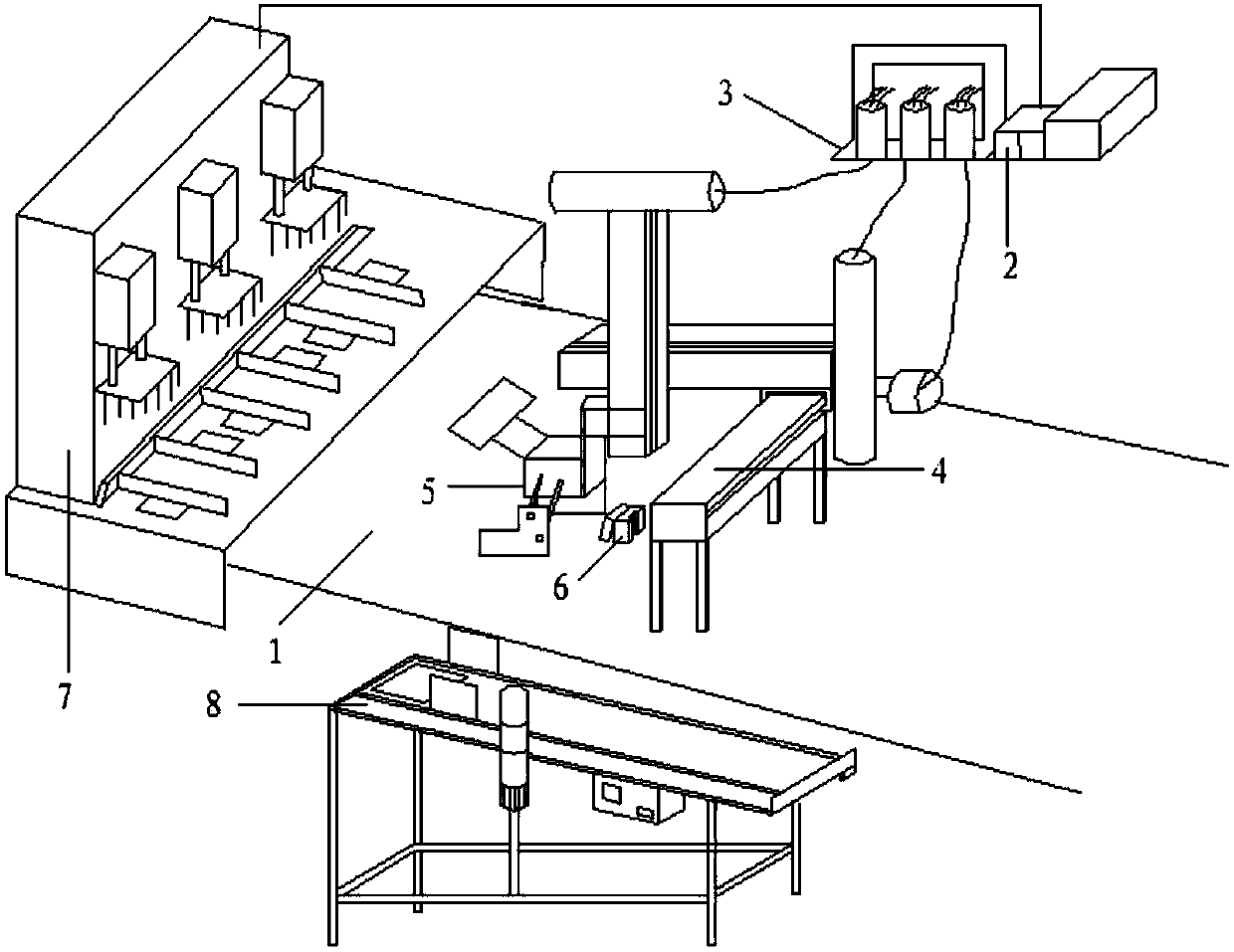

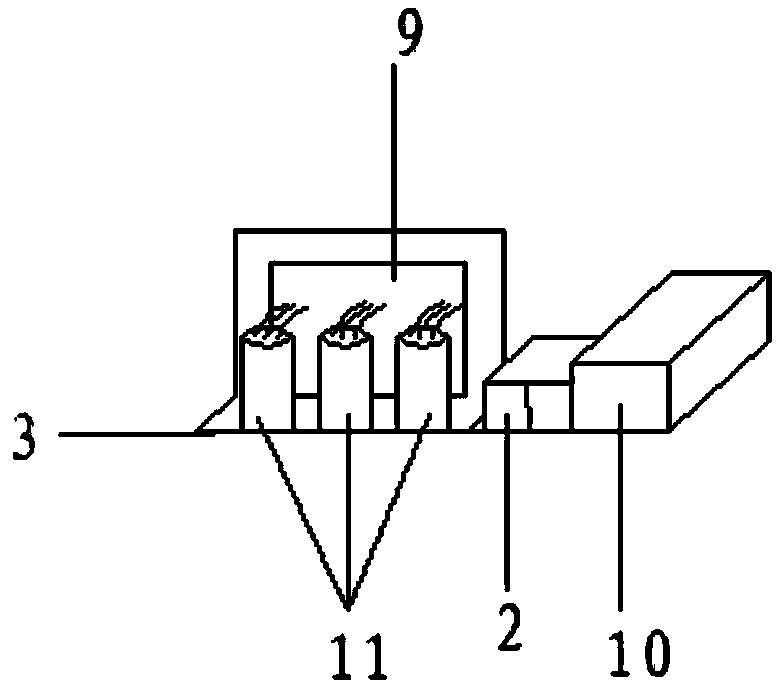

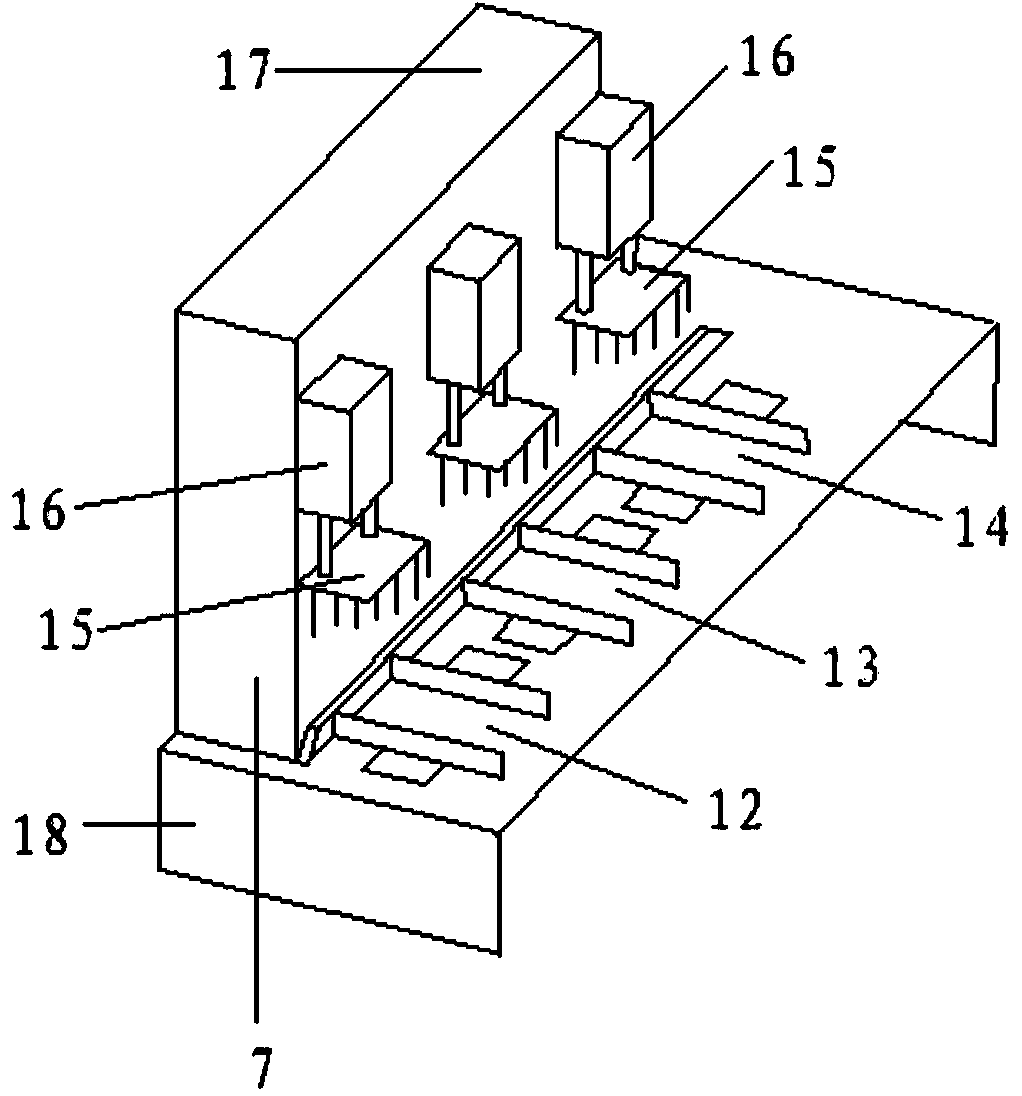

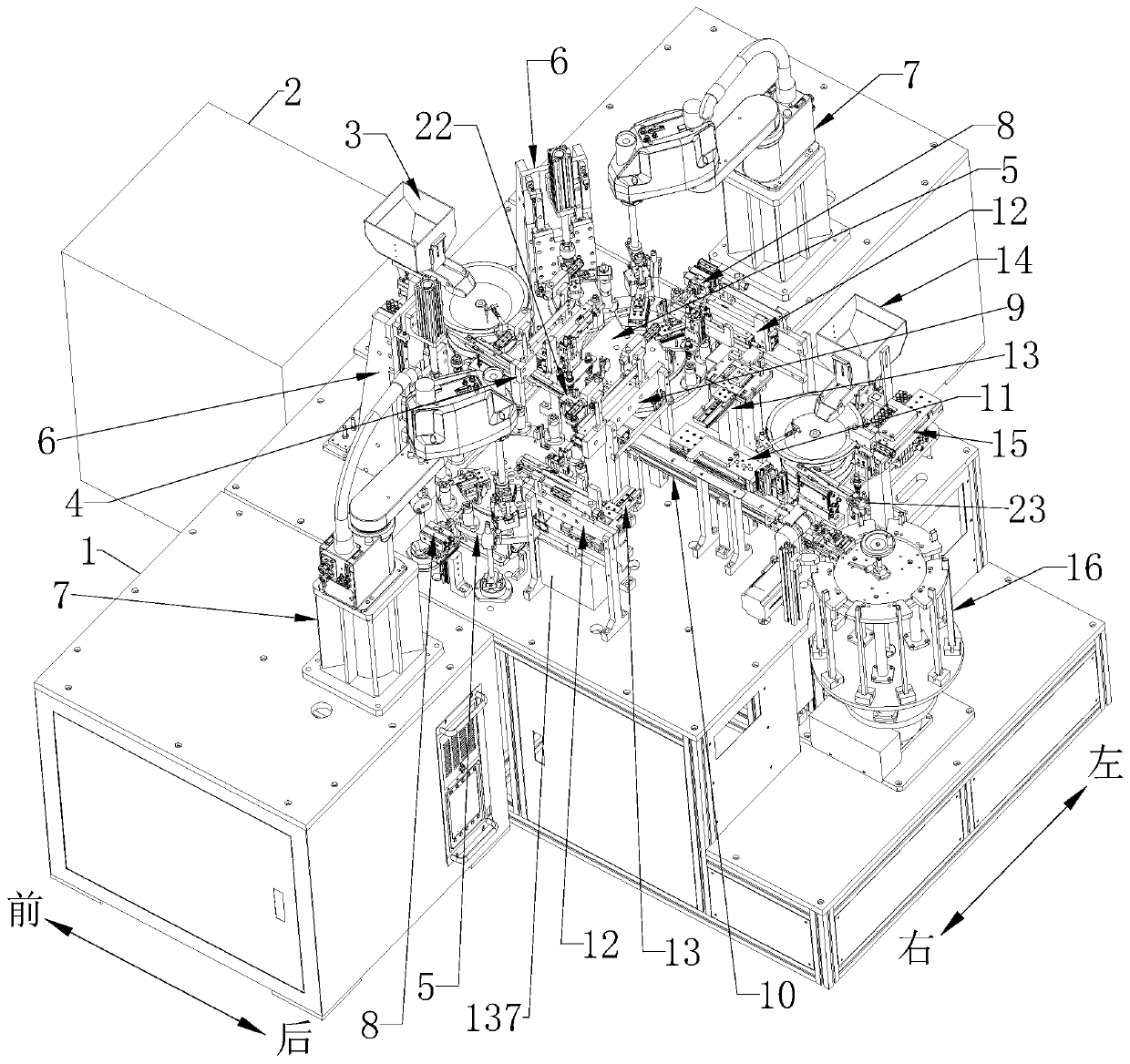

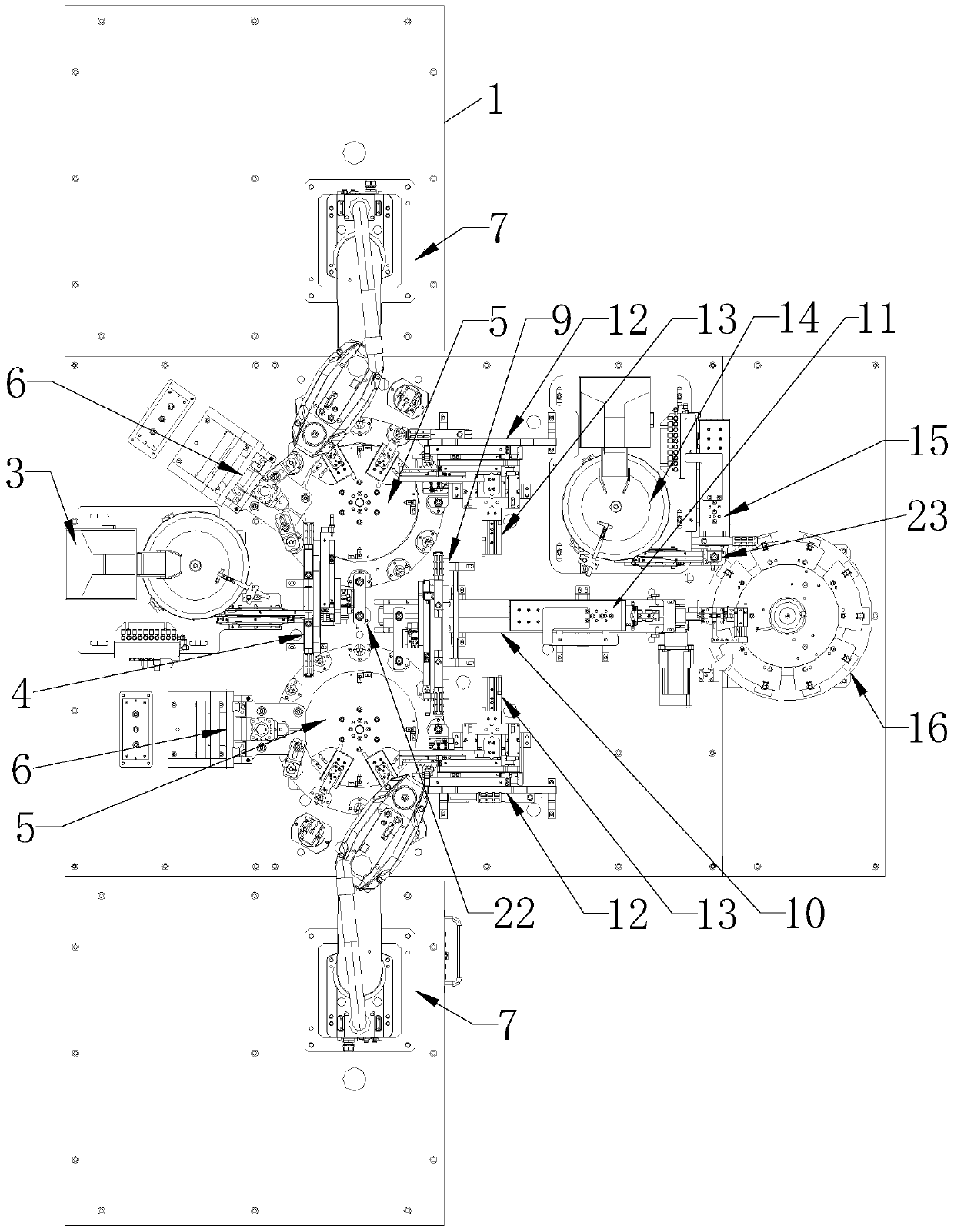

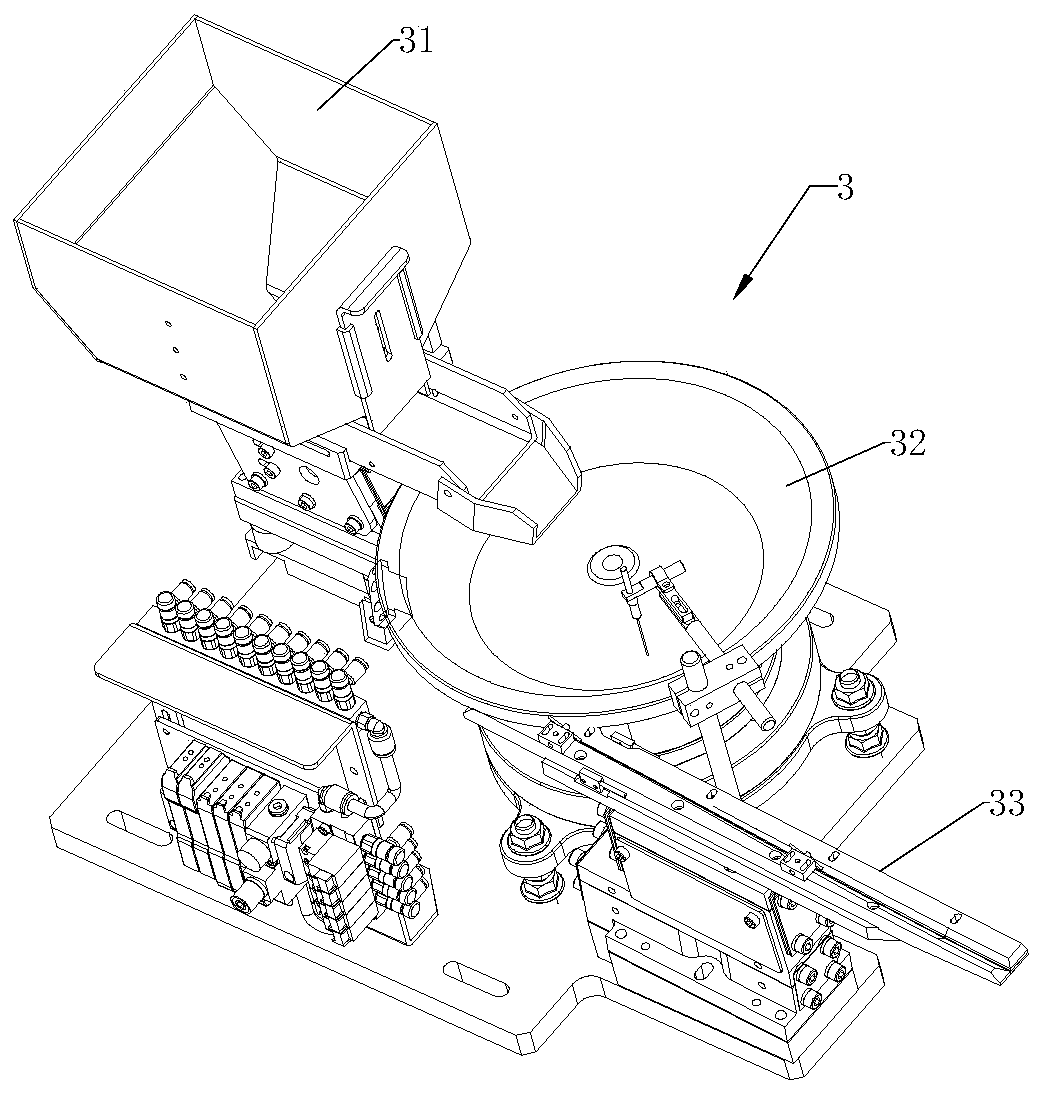

Remote controller automatic detection production line

InactiveCN102062584AAutomatic detection of realityImprove detection efficiencyElectrical testingOptically investigating flaws/contaminationProduction lineProcess engineering

The invention relates to a remote controller automatic detection production line, comprising a conveyor belt and also at least comprising an appearance detection working station and a function detection working station, wherein the appearance detection working station comprises an appearance detection device arranged on the conveyor belt and an unqualified-appearance product recycling device; the function detection device comprises an automatic function detection device arranged above or at one side of the conveyor belt and an unqualified-function product recycling device. The remote controller automatic detection production line realizes automatic online detection of remote controllers, not only improves the detecting efficiency, but also avoids influence from artificial subjective judgment and improves the detecting quality.

Owner:深圳市瑞摩特科技发展有限公司

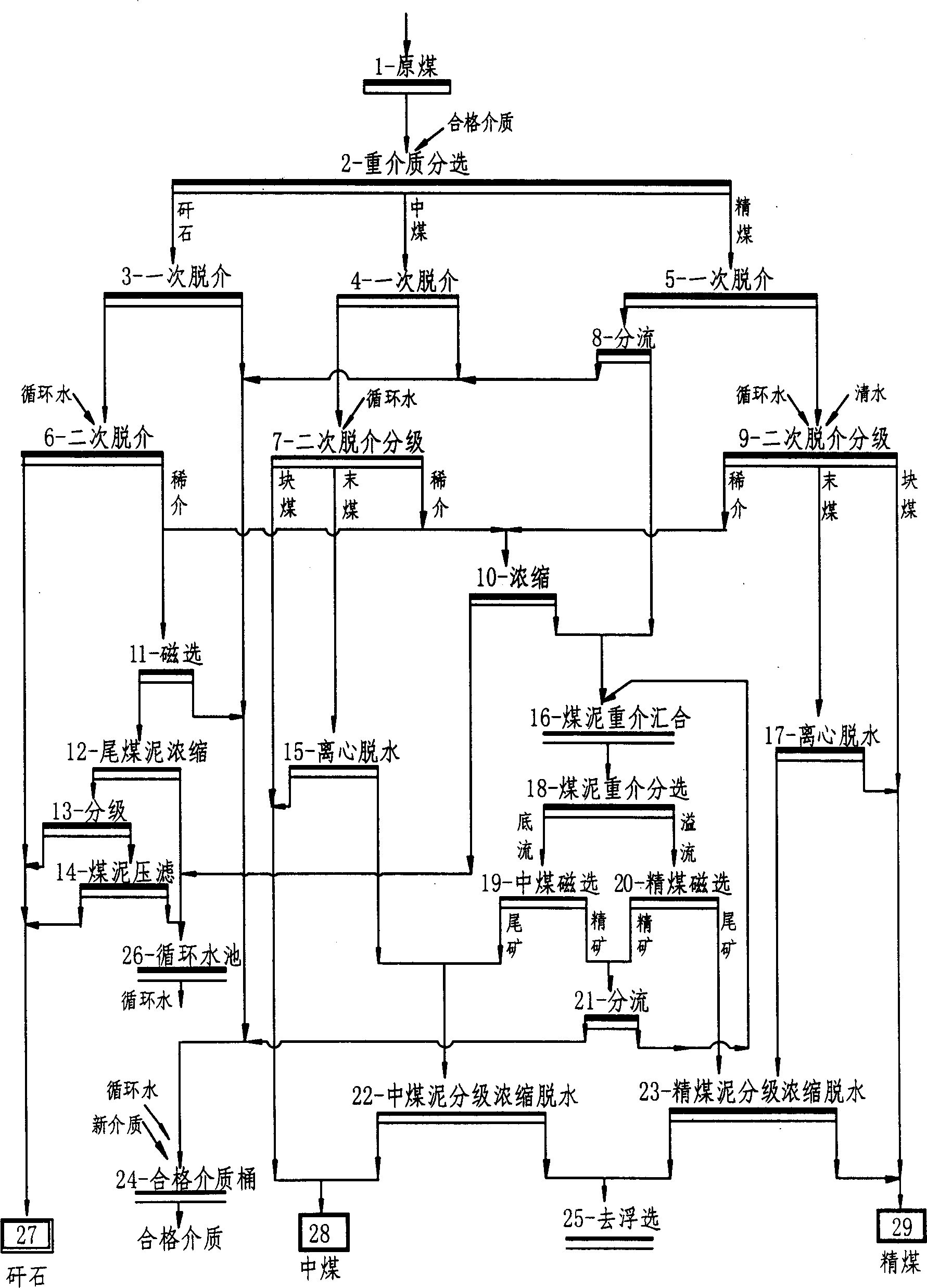

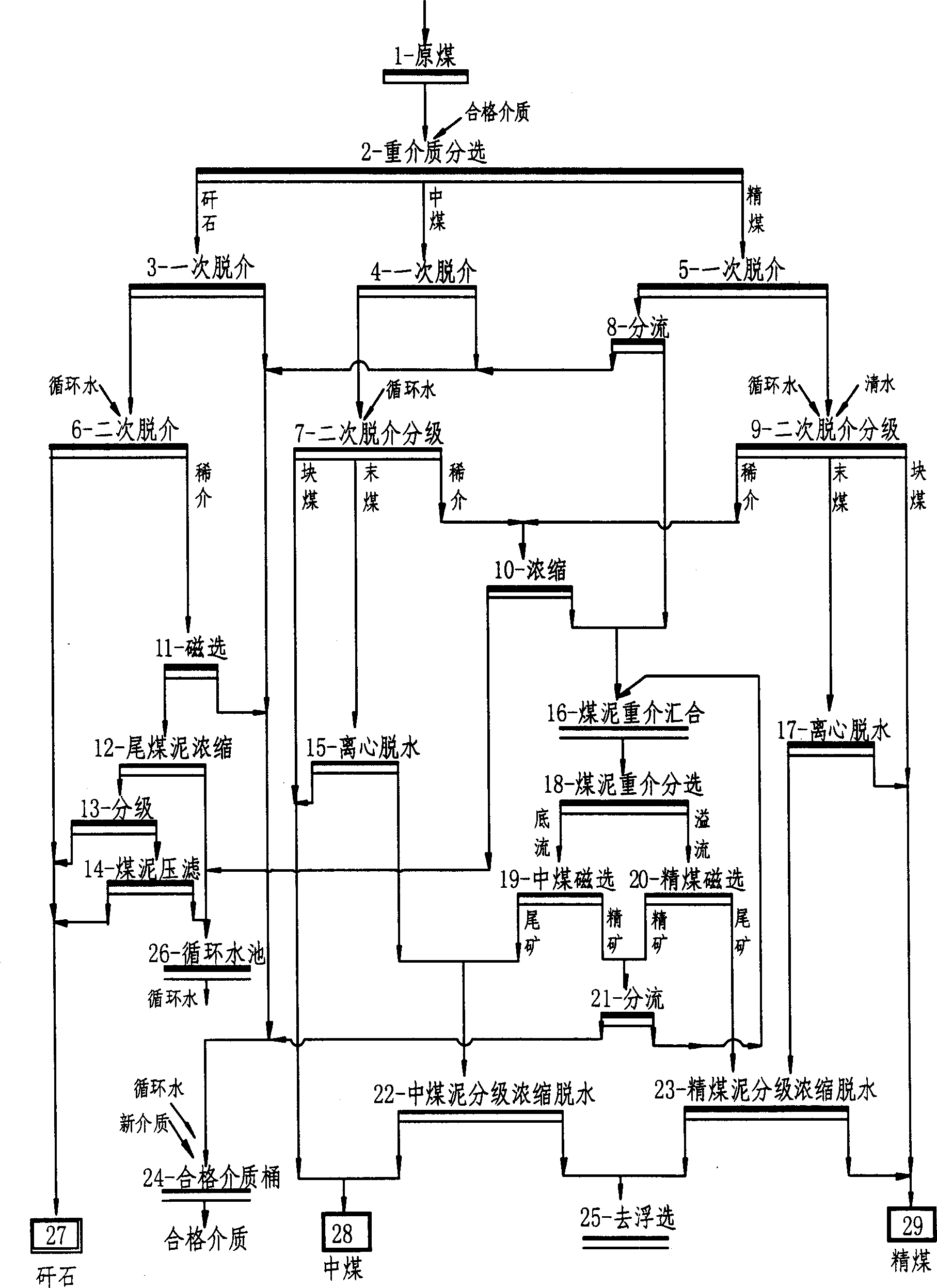

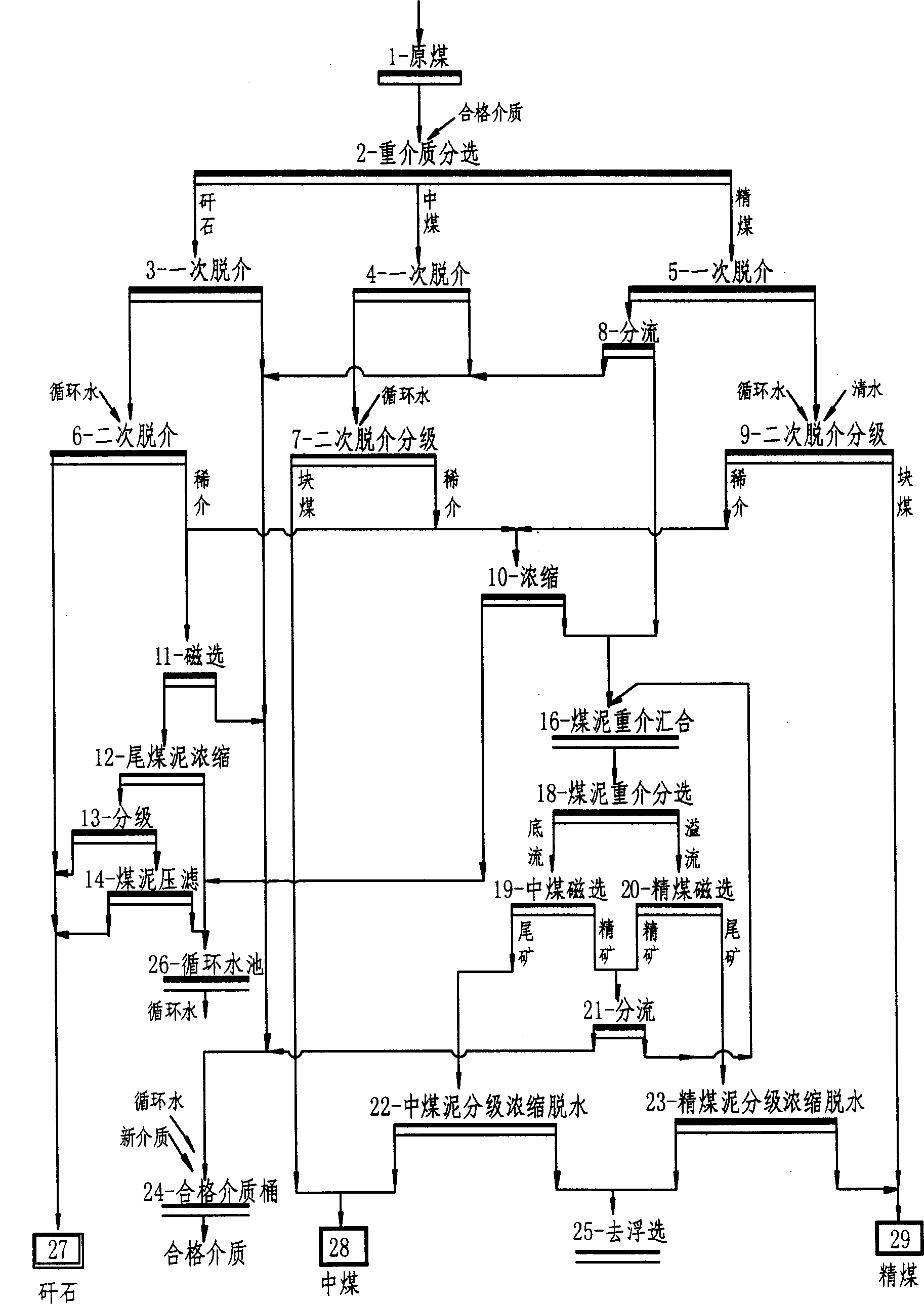

Process for heavy media separation of coarse coal slurry

InactiveCN1424151ALess investmentReduce the lower limit of heavy media sortingReversed direction vortexMagnetic separationCycloneRecovery method

A heavy medium coal-dressing process for recovering all the coarse slime is based on the simplifier JZJ technology and features its additional technological steps such as concentrating the suspension of diluted medium, mixing it with suspension of clean coal, regulating the dressing density, separating by small-diameter cyclone equipment, removing medium and recovering product. Its advnatages are simple system, high outupt rate of clean coal, and low cost.

Owner:天地科技股份有限公司唐山分公司

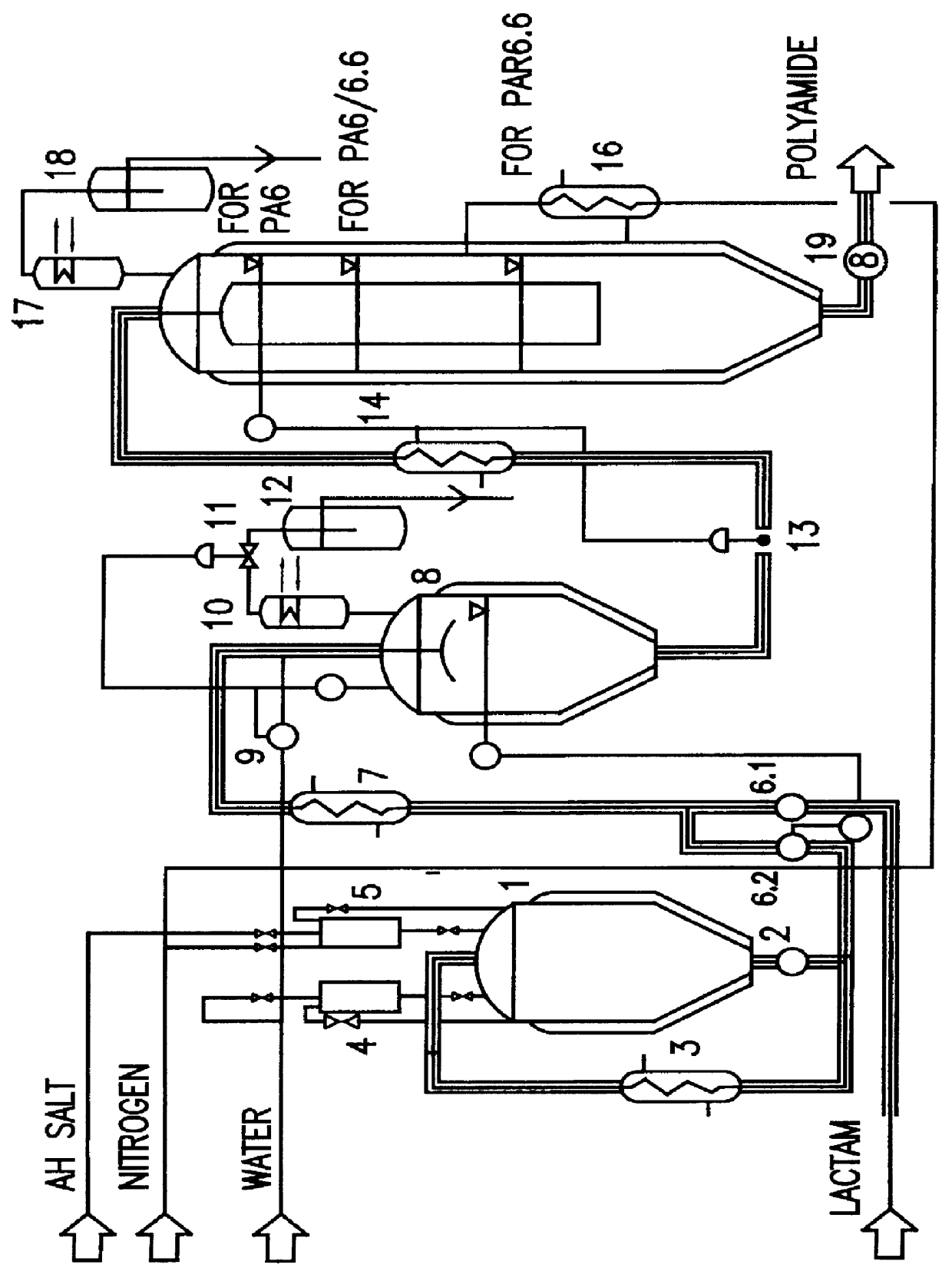

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

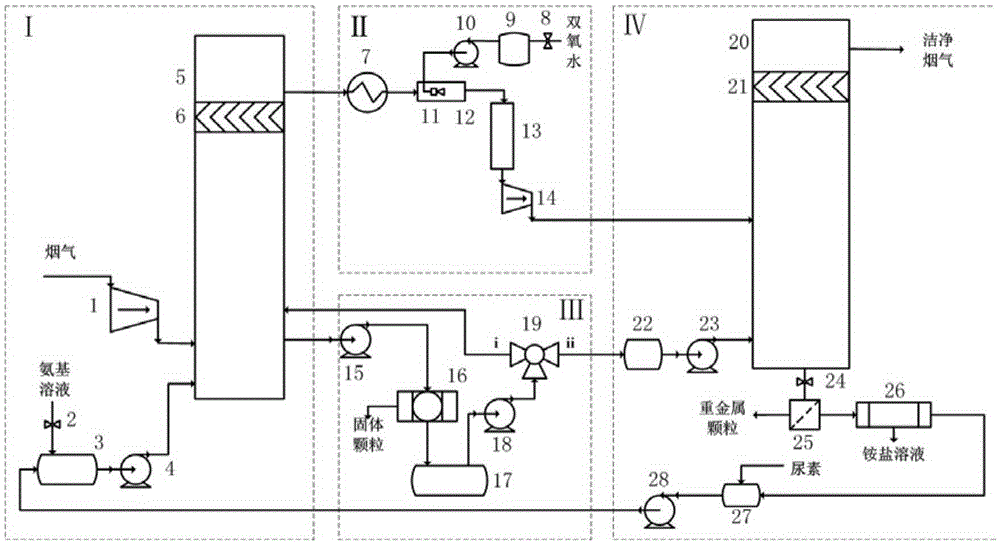

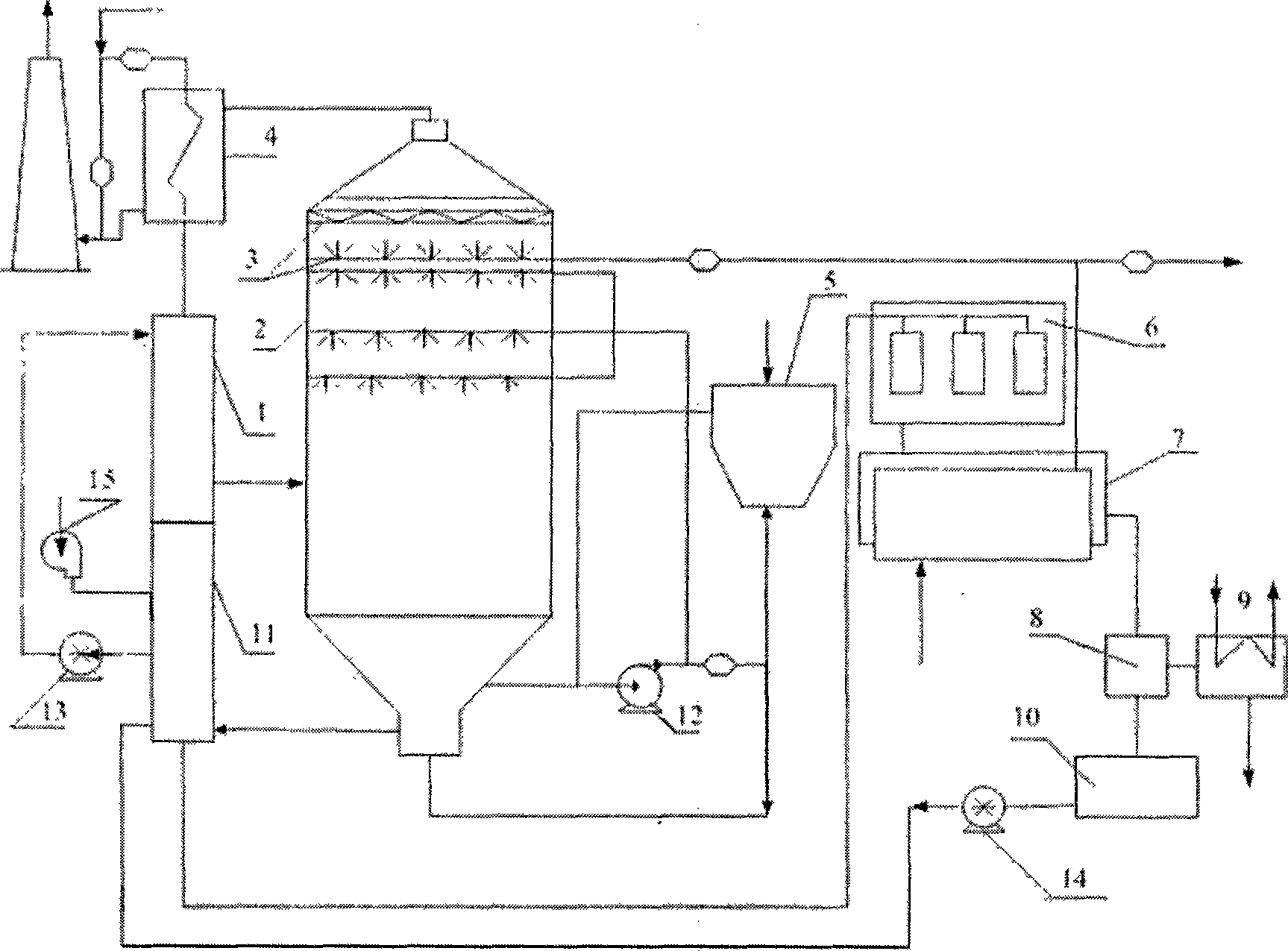

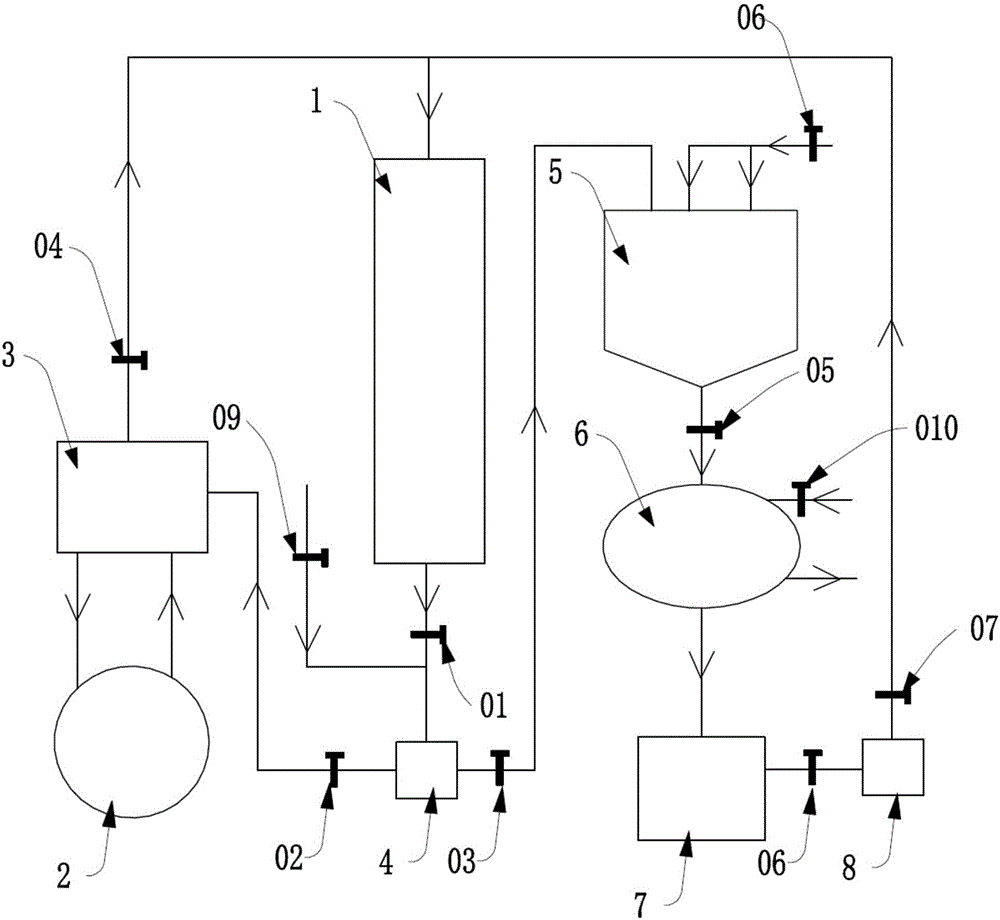

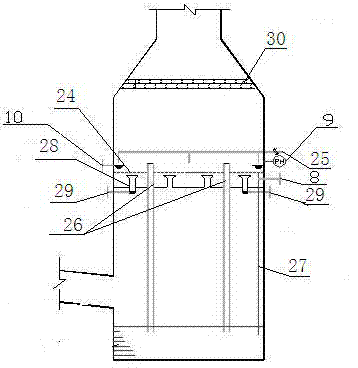

Hydrogen peroxide oxidation combined amino wet desulphurization and denitration method and device

ActiveCN105381699AEffective absorptionReduce consumptionGas treatmentDispersed particle separationNitric oxideNitrogen gas

The invention provides a hydrogen peroxide oxidation combined amino wet desulphurization and denitration method and device. Firstly, an amino solution is used for removing sulfur dioxide with high efficiency to obtain a sulfite solution having reductibility; secondly, hydrogen peroxide is decomposed on the surface of a catalyst to obtain nitric oxide in high-activity free radical high-efficiency oxidation desulphurization gas; and finally, sulfite solution and nitric oxides are mixed and react to realize an aim of highly effectively absorbing the nitric oxides, so that a competitive relation formed by reaction of sulfur dioxide and nitric oxide with high-activity free radicals is avoided, the consumption quality of an oxidizing agent is saved, and the reductibility of the sulfite solution can be used for reducing part of the nitric oxides to obtain nitrogen. The method and the device can be used for solving the technical problems that the denitration efficiency is low, the oxidation efficiency is low, the running cost is high and the like in a traditional pollutant removing process, a liquid-phase high-efficiency removal smoke products and product recycling type desulphurization and denitration mode is built, and the classification conversion of pollutants in a two-stage tower can be realized.

Owner:SOUTHEAST UNIV

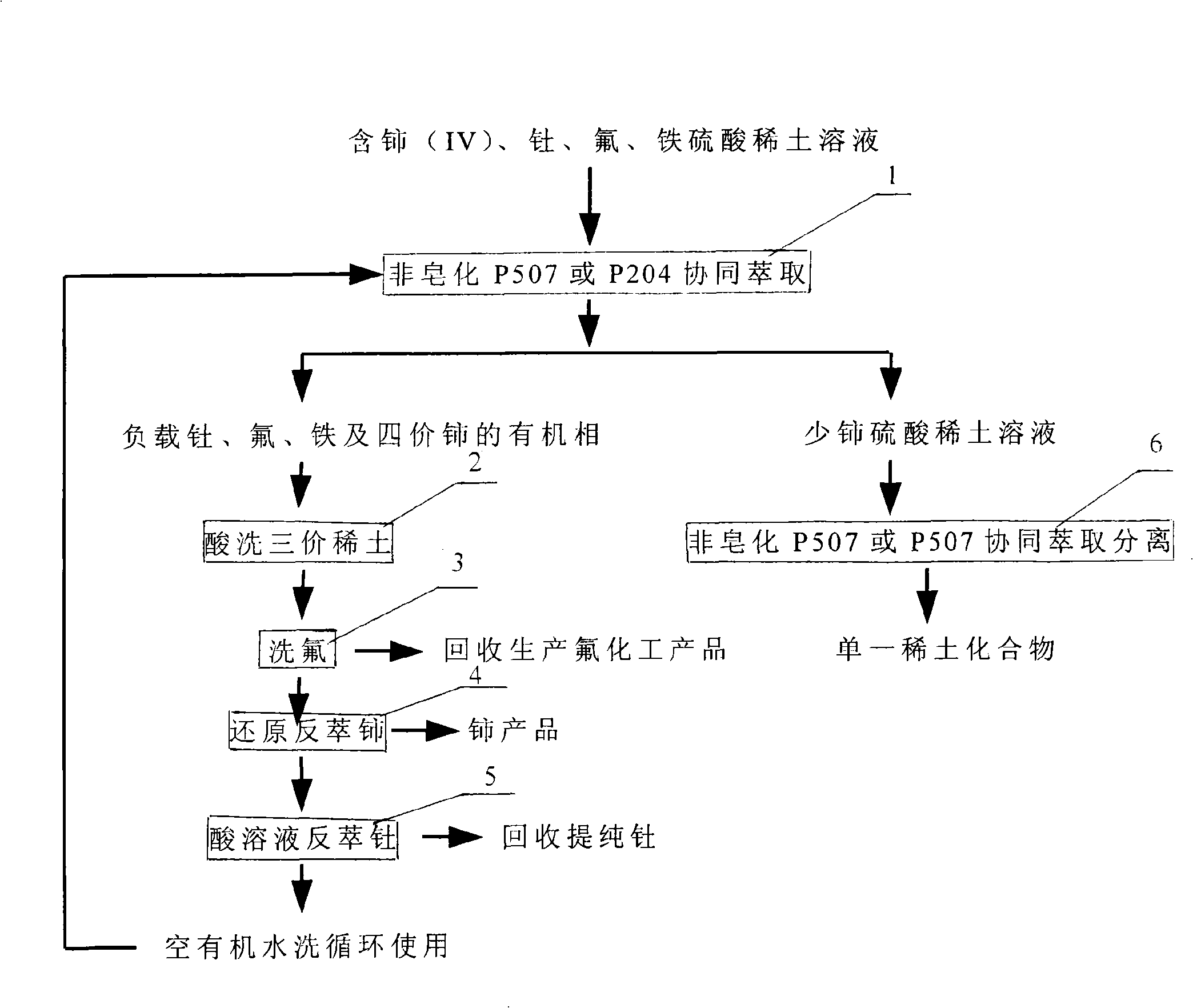

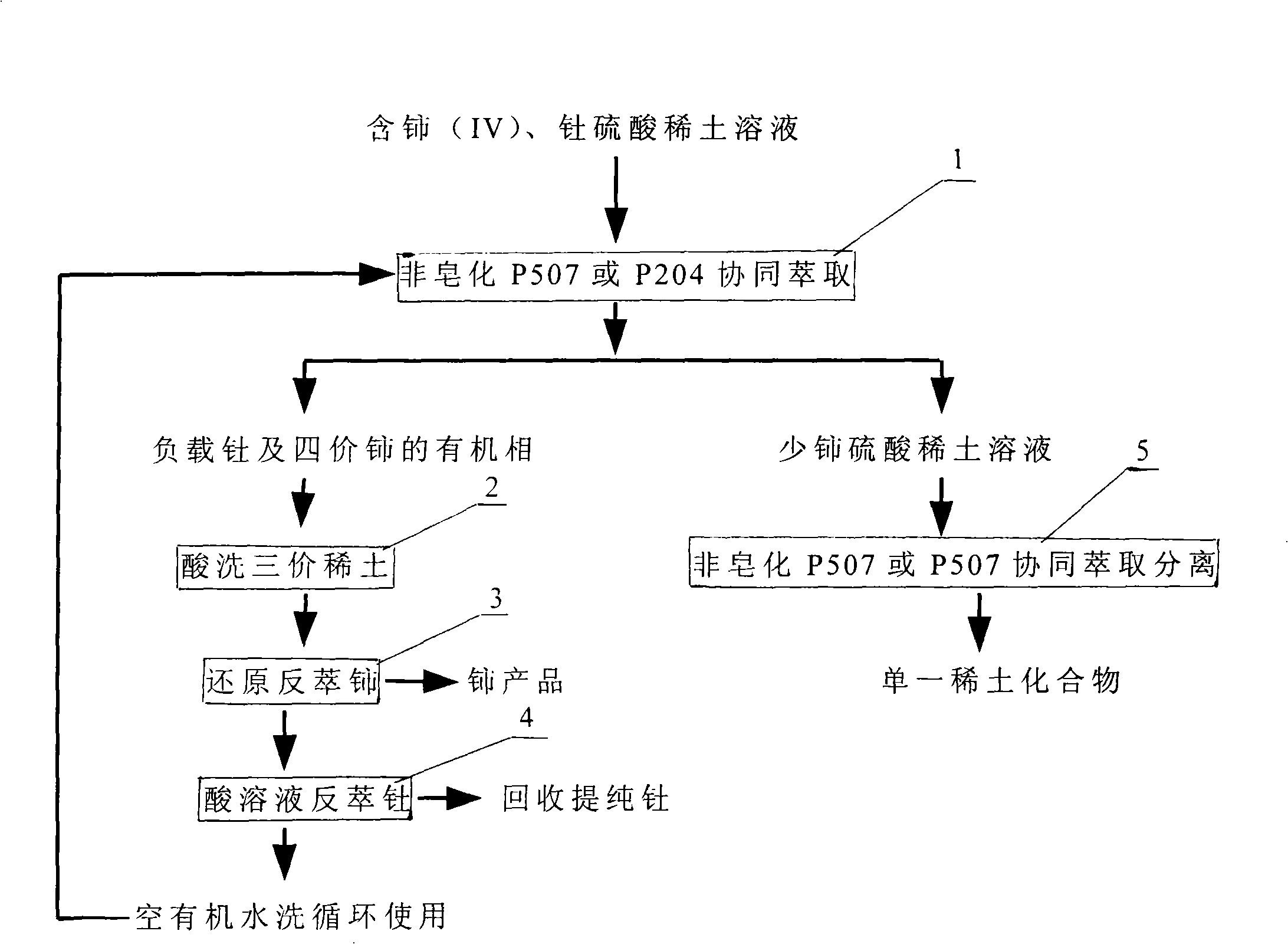

Technique for extraction separation of quadravalence cerium, thorium, fluorine and cerium less tervalence rare earth from sulphuric acid rare earth solution

ActiveCN101294244ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, fluorine and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains high-valence cerium, the fluorine, the thorium and ferrum, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (1V), the thorium, the fluorine, and the ferrum are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain three products that are the cerium, the fluorine, and the thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements. The technological method has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (1V), the thorium, the fluorine, the ferrum and the trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium and the fluorine are recovered as products, and the pollutions caused by thorium-containing waste residue, fluoride-containing wastewater and the ammonia-nitrogen wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

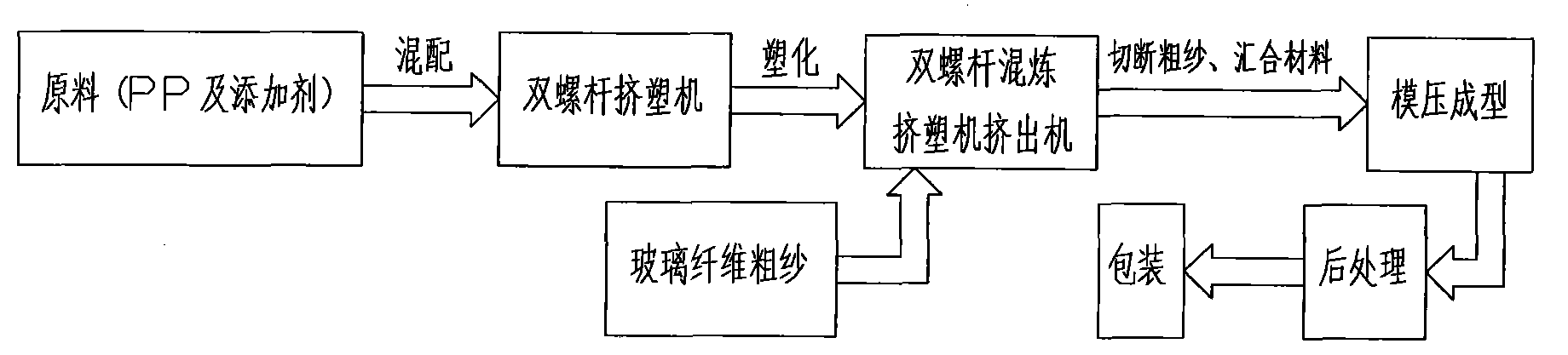

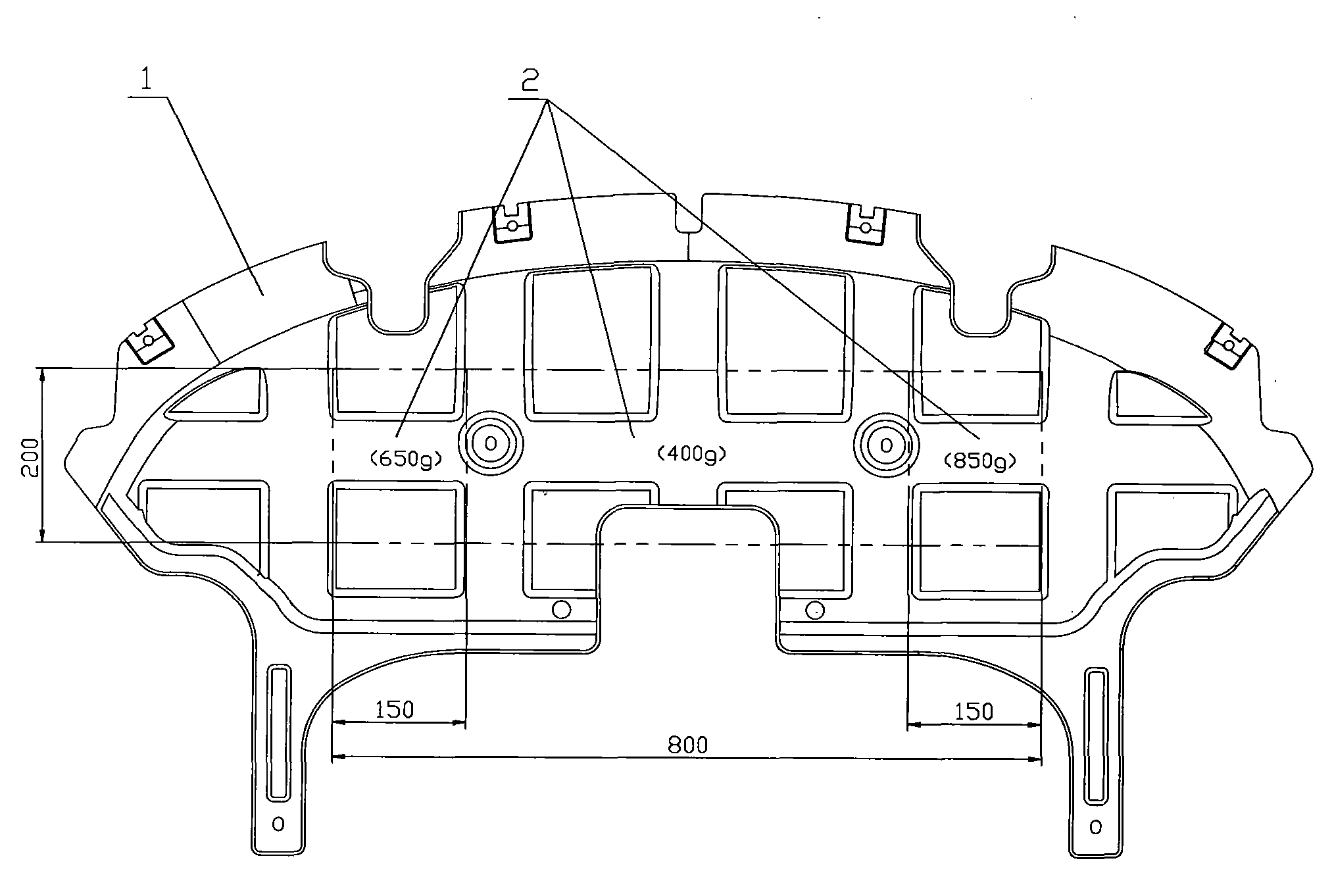

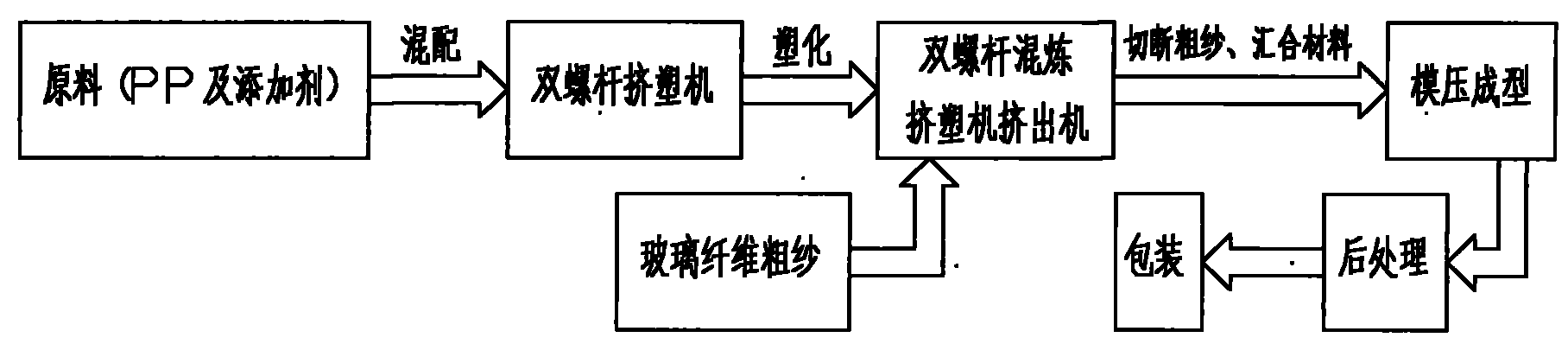

Automobile bottom deflector made of LFT-D (Fiber Reinforce Thermoplastic-Direct) material and manufacture method thereof

InactiveCN101935420AFlexible choiceImprove impact resistanceComponent optimizationVehicle body streamliningGlass fiberWork in process

The invention relates to an automobile bottom deflector made of an LFT-D (Fiber Reinforce Thermoplastic-Direct) material and a manufacture method thereof. The automobile bottom deflector made of the LFT-D material is directly produced by a raw material jointly comprising glass fibers, PP (Polypropylene) and necessary additives, wherein the formula of the LFT-D raw material can be correspondingly adjusted according to the requirements of products; the average length of the glass fibers in the automobile bottom deflector made of the LFT-D material reaches 25mm; and the density thereof is 2 / 3 of the density of an SMC (Sheet Molding Compound) material. The LFT-D production process has the advantage of flexible material selection and can be used for adjusting different additives, fiber contents and the fiber length on line so as to meet the requirement of a final product; an LFT-D material product has good mechanical properties and heat resistant properties such as shock resistance, creep resistance, and the like and has light weight; the LFT-D material can be used for producing products with more complicated structures; and semi-finished products in the LFT-D on-line production process are removed, thus the process has the advantages of low raw material and production cost, product recycling and short production period.

Owner:上海耀华大中新材料有限公司

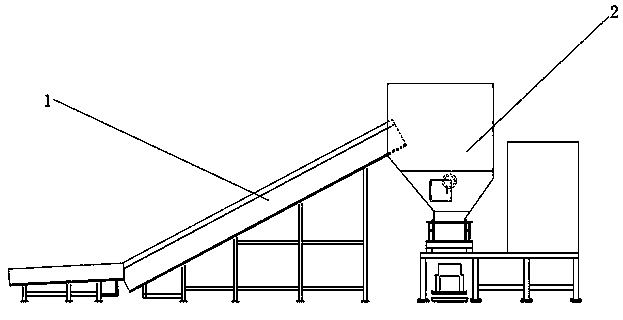

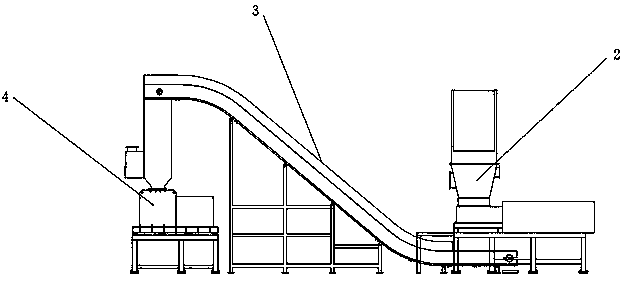

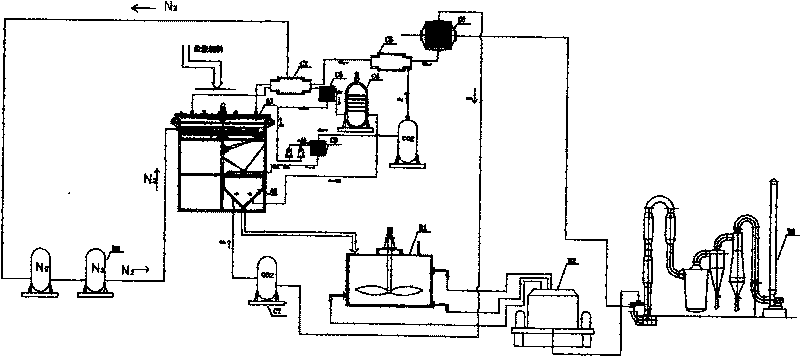

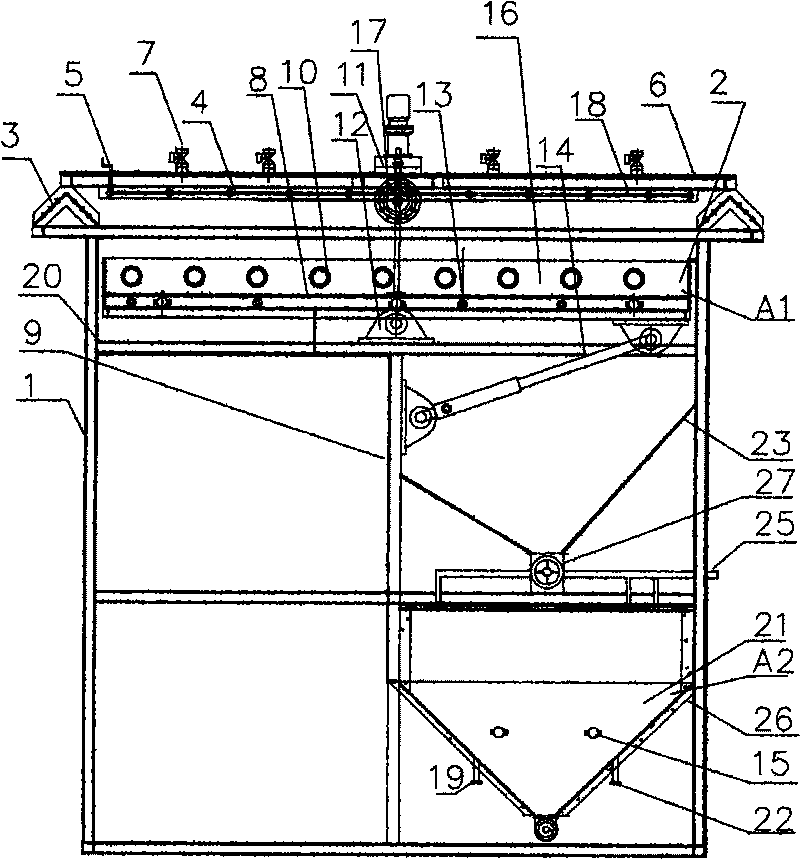

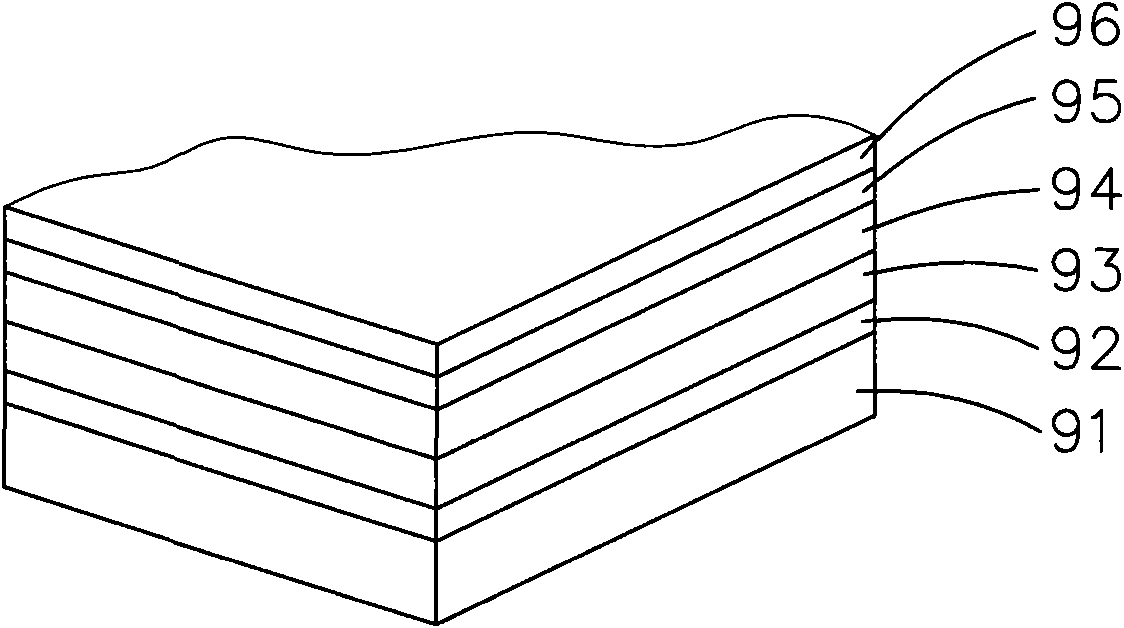

Recycling system for waste electrical and electronic products

InactiveCN103722003AReduce vacancy rateImprove efficiencySolid waste disposalGrain treatmentsProduction lineCollection system

The invention discloses a recycling system for waste electrical and electronic products. The recycling system is characterized by comprising a control system as well as a crushing system, a separation system, a dust collection system, a waste gas collection system and a draught fan which are controlled by the control system, wherein the crushing system comprises a knocking crusher, the separation system comprises a winnower and a plastic and metal separation device, and the knocking crusher, the winnower and the plastic and metal separation device are connected through conveyer devices sequentially to form a plastic and metal separation production line; the knocking crusher and an air outlet of the winnower are connected with the dust collection system respectively for collecting light materials and dust of the whole recycling system; an air outlet of the dust collecting system is connected with the waste gas collection system; and the draught fan is connected with the waste gas collection system, so that the knocking crusher, the winnower, the dust collection system and the waste gas collection system are in negative pressure states. The system can be applied to crushing and separation treatment of various waste electrical appliances such as a refrigerator, a circuit board and the like respectively.

Owner:CHINA NAT ELECTRIC APP RES INST +1

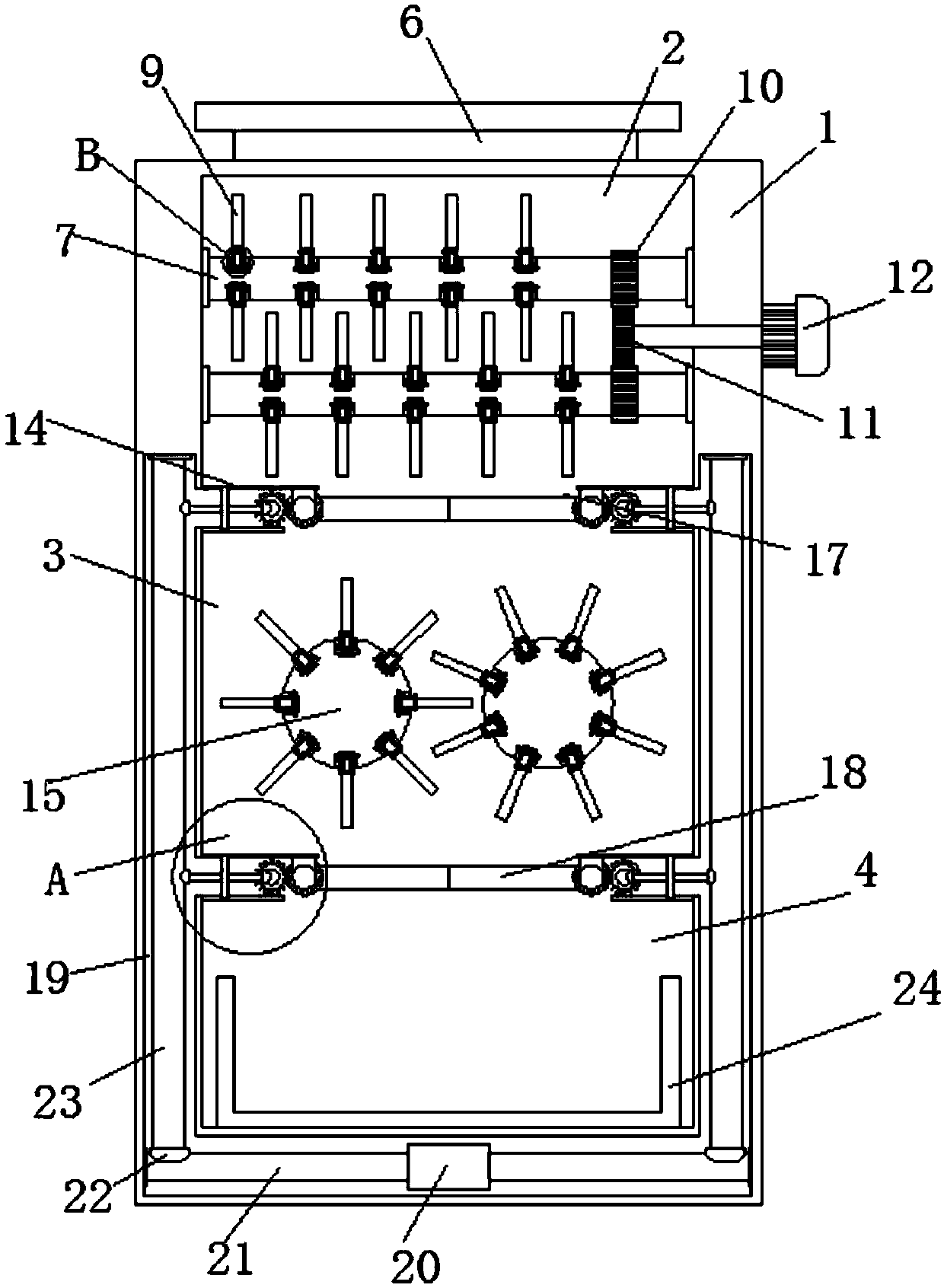

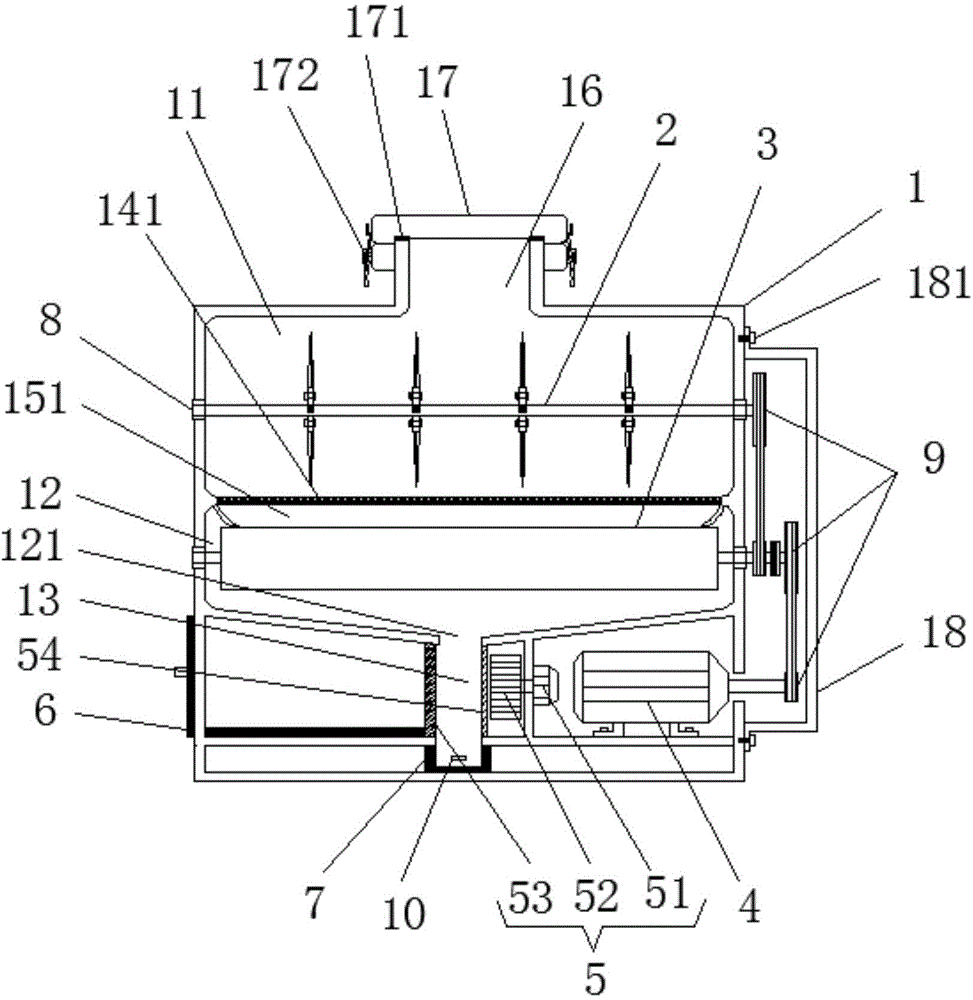

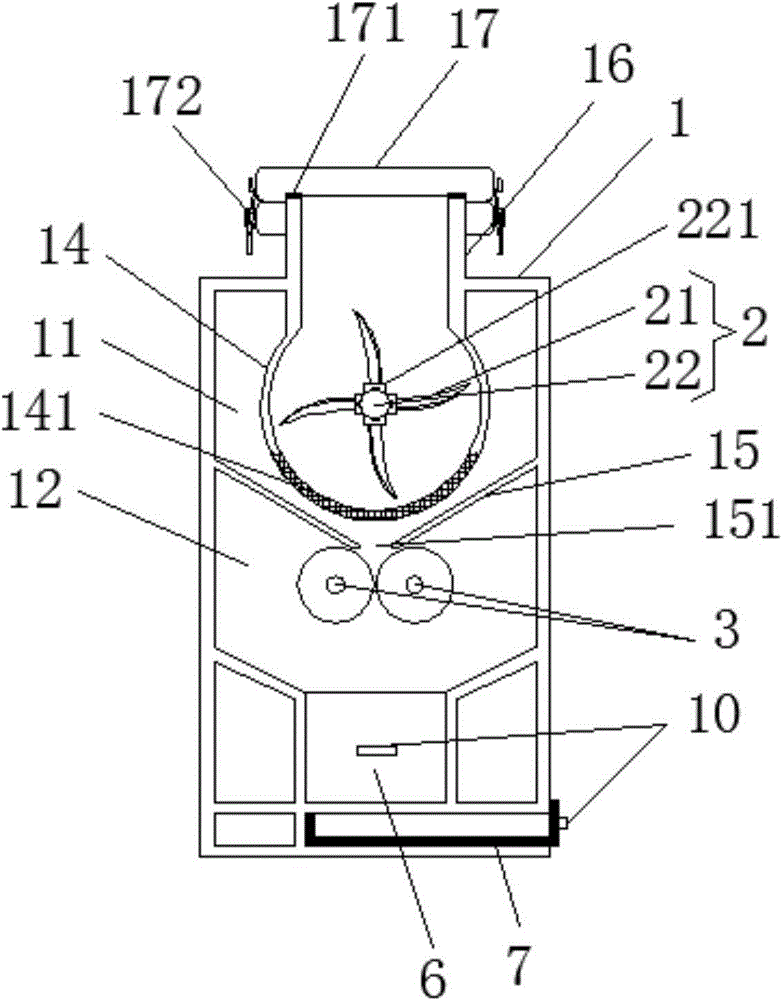

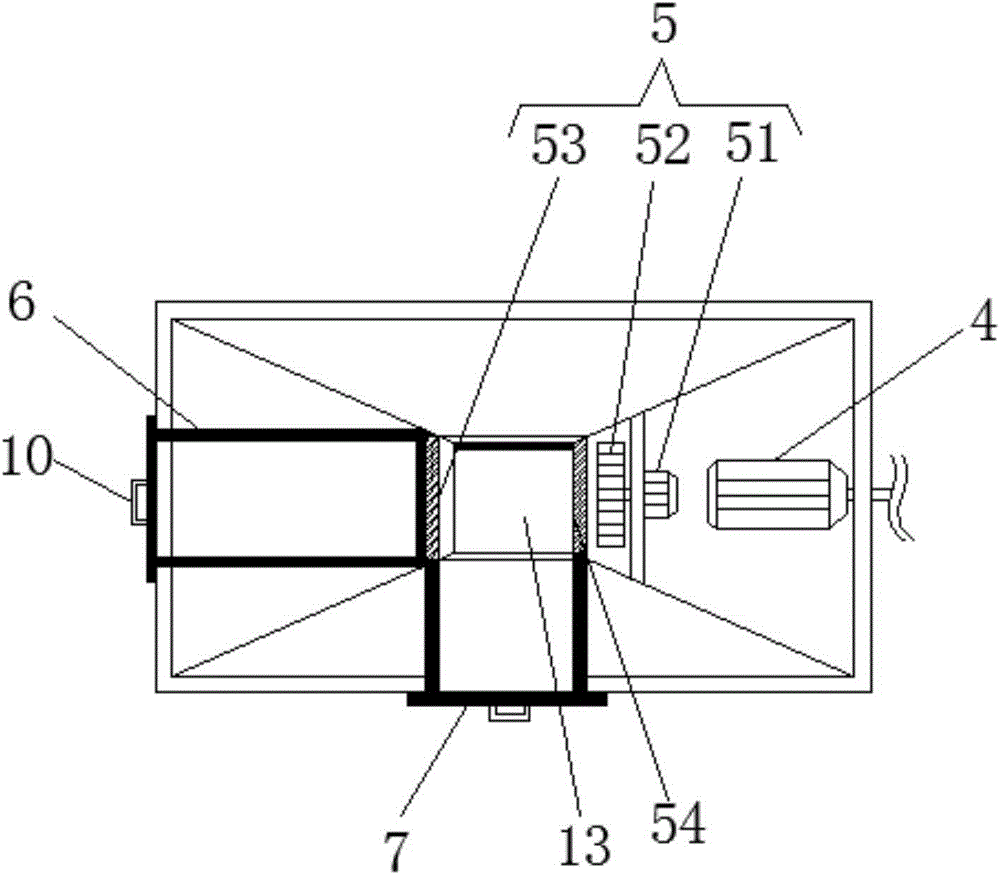

Plastic product recycling machine

InactiveCN108015927ACompletely brokenReduce recycling efficiencyPlastic recyclingGrain treatmentsEngineeringPlastic recycling

The invention discloses a plastic product recycling machine. The plastic product recycling machine comprises a shell, wherein the shell is of a hollow structure; the interior of the shell is divided into a first crushing cavity, a second crushing cavity and a collecting cavity through two partition plates which are arranged in parallel; discharge ports are formed in the partition plates; the firstcrushing cavity, the second crushing cavity and the collecting cavity communicate with one another through the discharge ports; two first rotating rollers which are arranged in parallel are connectedin the first crushing cavity in a rotating mode; and a plurality of cutting blades are arranged on the two first rotating rollers and are arranged in a staggered mode. According to the plastic product recycling machine, waste plastic can be fully crushed so that the plastic can be crushed more thoroughly, the space, occupied by the plastic, of a collecting box can be decreased, and the phenomenonthat the collecting box is frequently replaced can be avoided; and meanwhile, the cutting blades on the rotating rollers can be conveniently replaced, and the phenomenon that the plastic recycling efficiency is reduced due to the fact that the crushing efficiency is influenced by blade passivation can be avoided.

Owner:YINGSHANG LONGYUYANG IND & TRADE

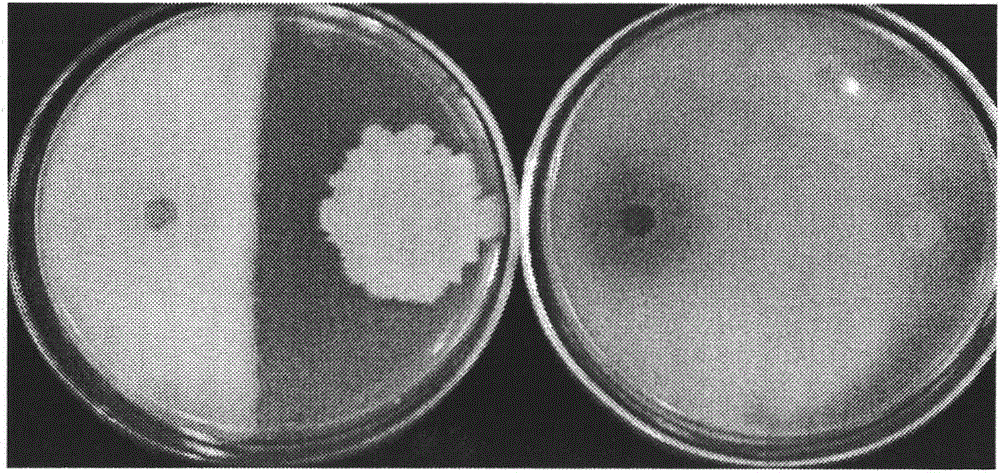

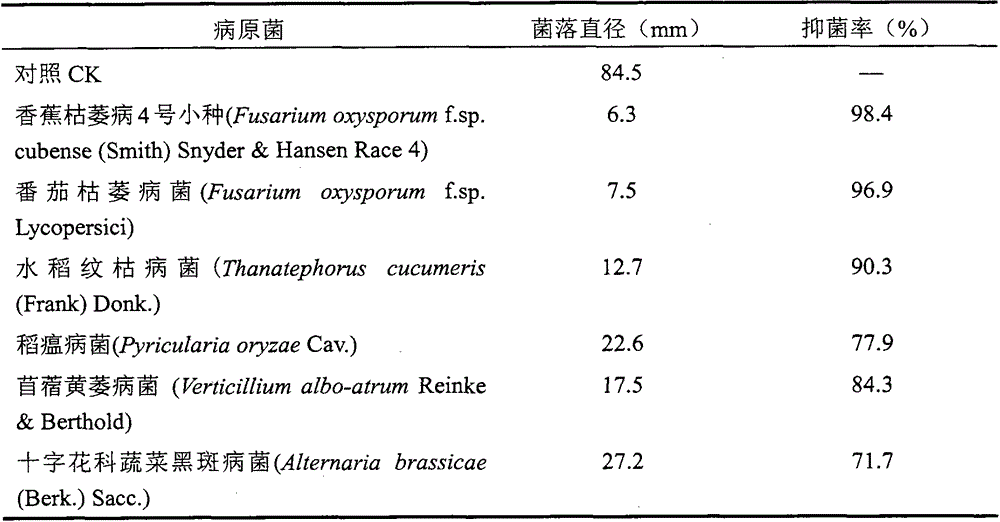

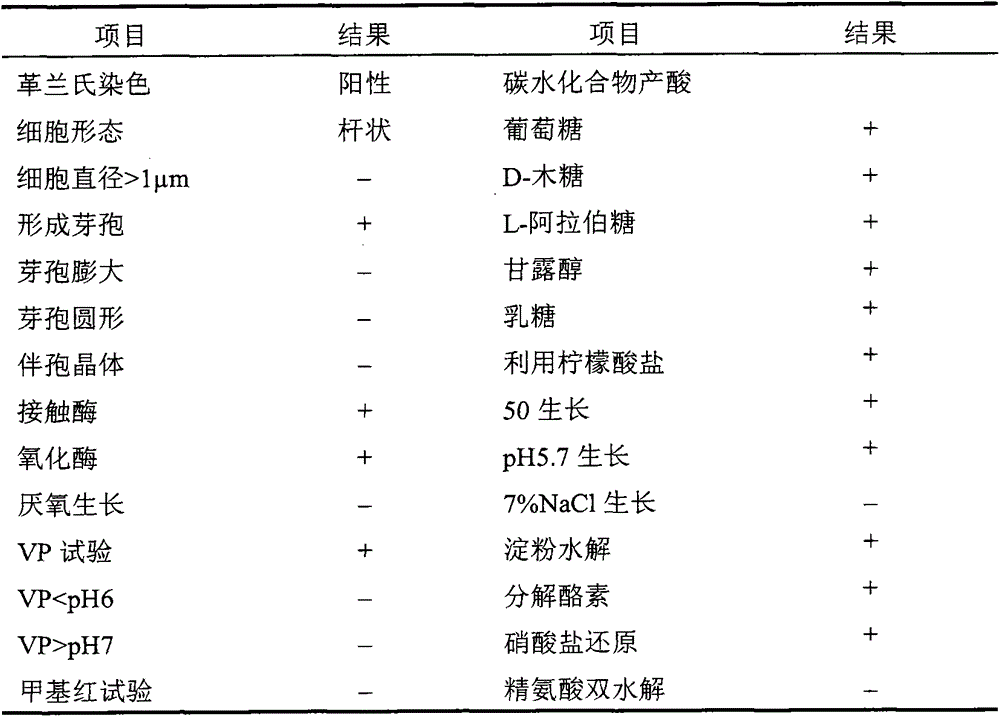

Bacillus amyloliquefaciens HN-11 and microbial inoculums thereof

The present invention relates to bacillus amyloliquefaciens and a preparation method of a microbial inoculum of the bacillus amyloliquefaciens, and belongs to the field of bio-pesticides and plant protection. The bacillus amyloliquefaciens HN-11 is isolated from azadirachta indica tree rhizosphere soil, azadirachta indica residue is used as a medium raw material and a microbial inoculum adsorption carrier for secondary solid state fermentation composting to prepare the microbial inoculums, the microbial inoculums comprises an arbitrary content of the bacillus amyloliquefaciens, 0 to 30% of the azadirachta indica residue, 4 to 12% of the soybean powder, 5 to 25% of wheat bran, 30-50% of peat, 1-5% of KCl, 0.5 to 2% of urea and 1 to 8% of a surfactant. Tests show that the microbial inoculum can overcome the problem of seedling injury caused by direct use of the azadirachta indica residue, can expand the control spectrum, has obvious integral control effect on banana wilt and Radopholus similes Thorne, can also promote plant growth, and the field control effect on the banana wilt can reach 96.2%. The microbial inoculum has great significance to the promotion of integral pest control and agricultural and sideline product recycling, and has broad application prospects in the production practice.

Owner:深圳华农中绿生物科技研究有限公司

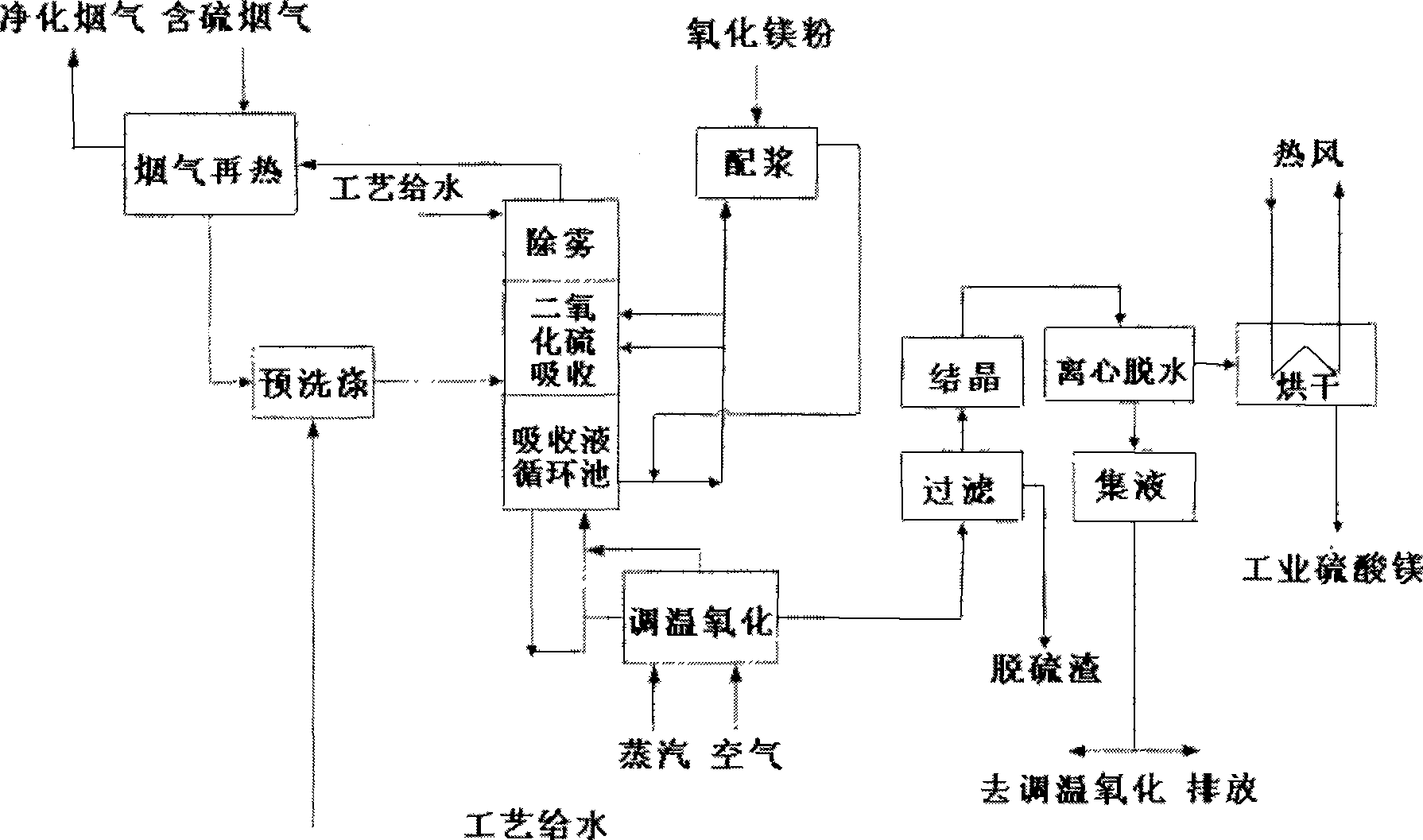

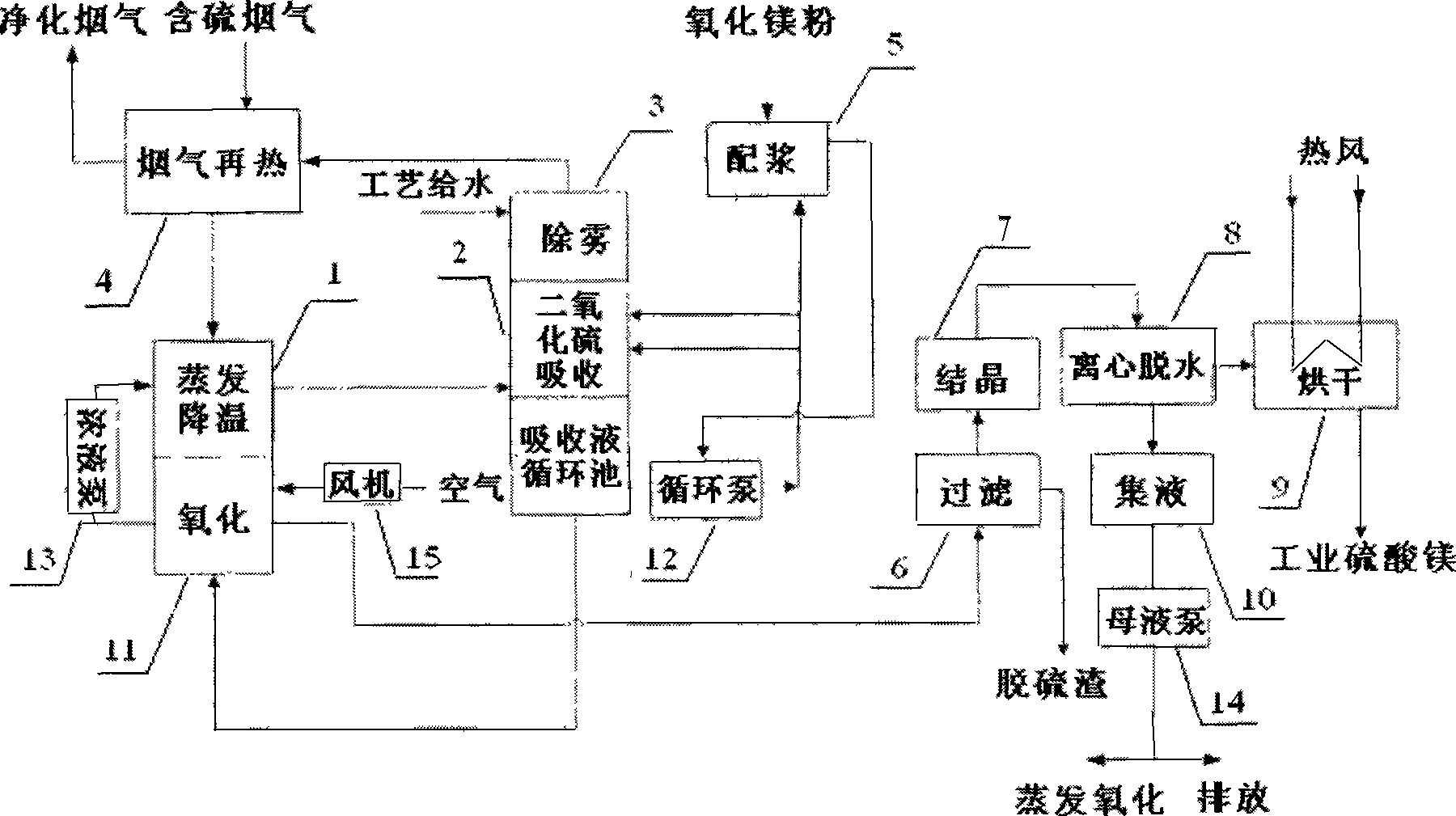

Flue gas desulfurization by magnesia wet method and recovering process of automatic concentration of product

ActiveCN101530725AAvoid intensive external energy consumptionAvoid external energy consumptionDispersed particle separationMagnesium sulfatesFiltrationSlurry

Flue gas desulfurization by the magnesia wet method and a recovering process of automatic concentration of the product relates to the improvement of the existing flue gas desulfurization by the magnesia wet method and product recovering process by the thick slurry process, belonging to the technical field of flue gas desulfurization and product recycling. The process is technically characterized in that the thick slurry is shunted in the process of recyclable absorption and desulfurization; spray cooling is carried out to cool flue gas; inspissation liquid is oxidized to generate MgSO4; then filtration, crystallize and the like are carried out to generate mm level MgSO4. 7H2O or MgSO4. H2O crystal grain. The invention not only features in low cost, but also has low spray flow rate and power consumption as well as outstanding water conservation effect; what is more, the invention avoids external power consumption of the concentration of the desulfurized product, can remarkably improve stability and economical efficiency of recovery. All steps of automatic concentration are linked with one and another, as a result, the application range of the invention is expanded to high-sulphur coal and technical support is provided for more economical, effective and direct recovery of magnesium sulfate monohydrate.

Owner:TSINGHUA UNIV

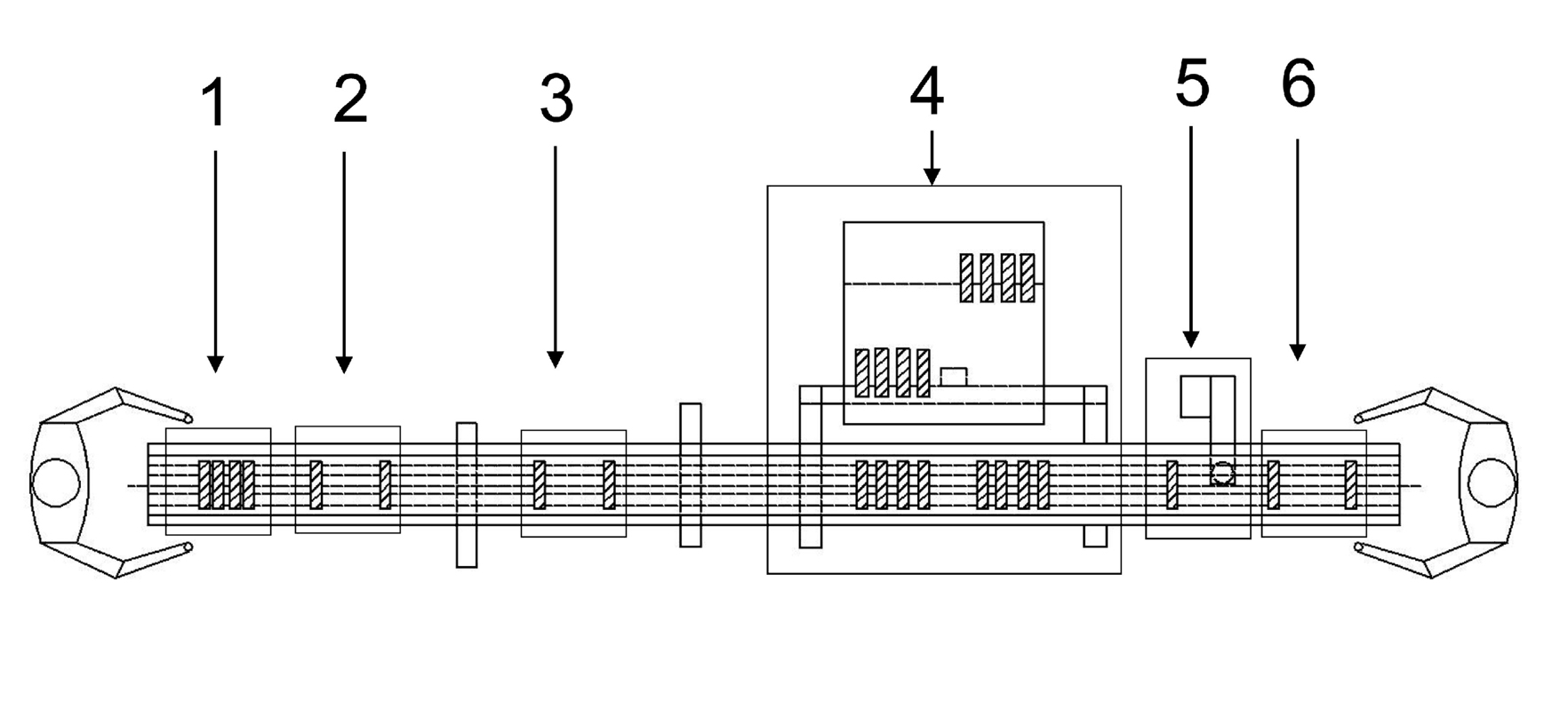

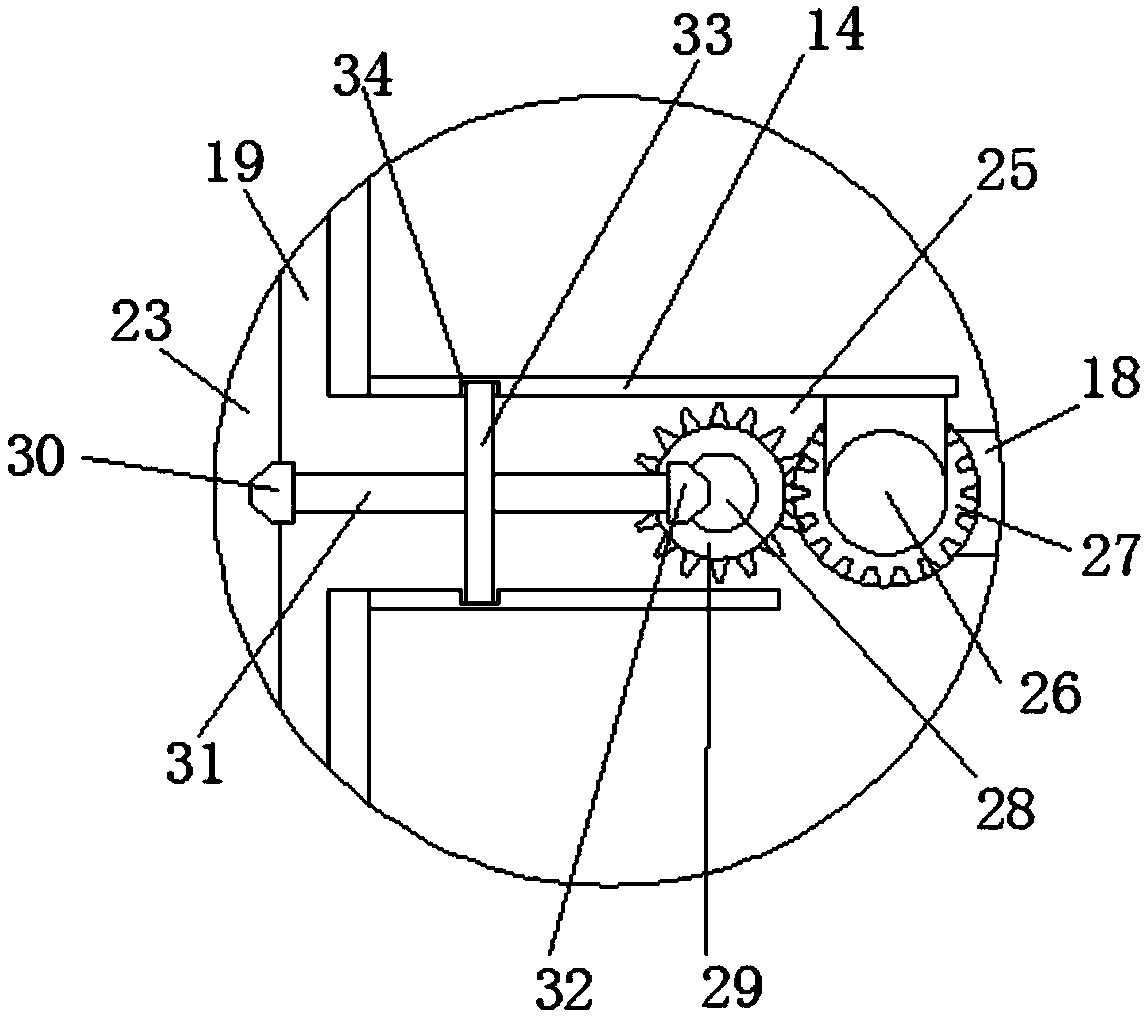

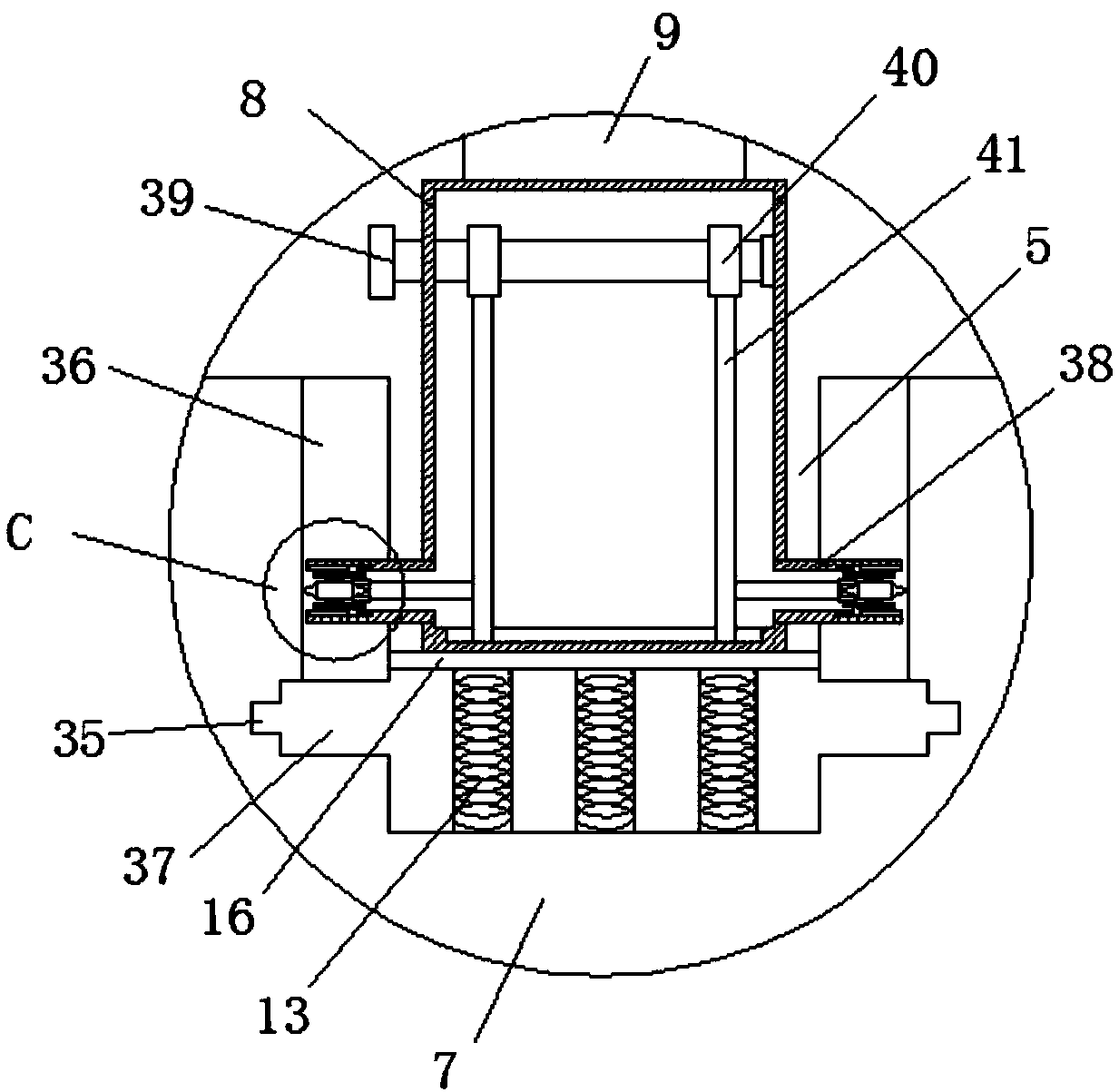

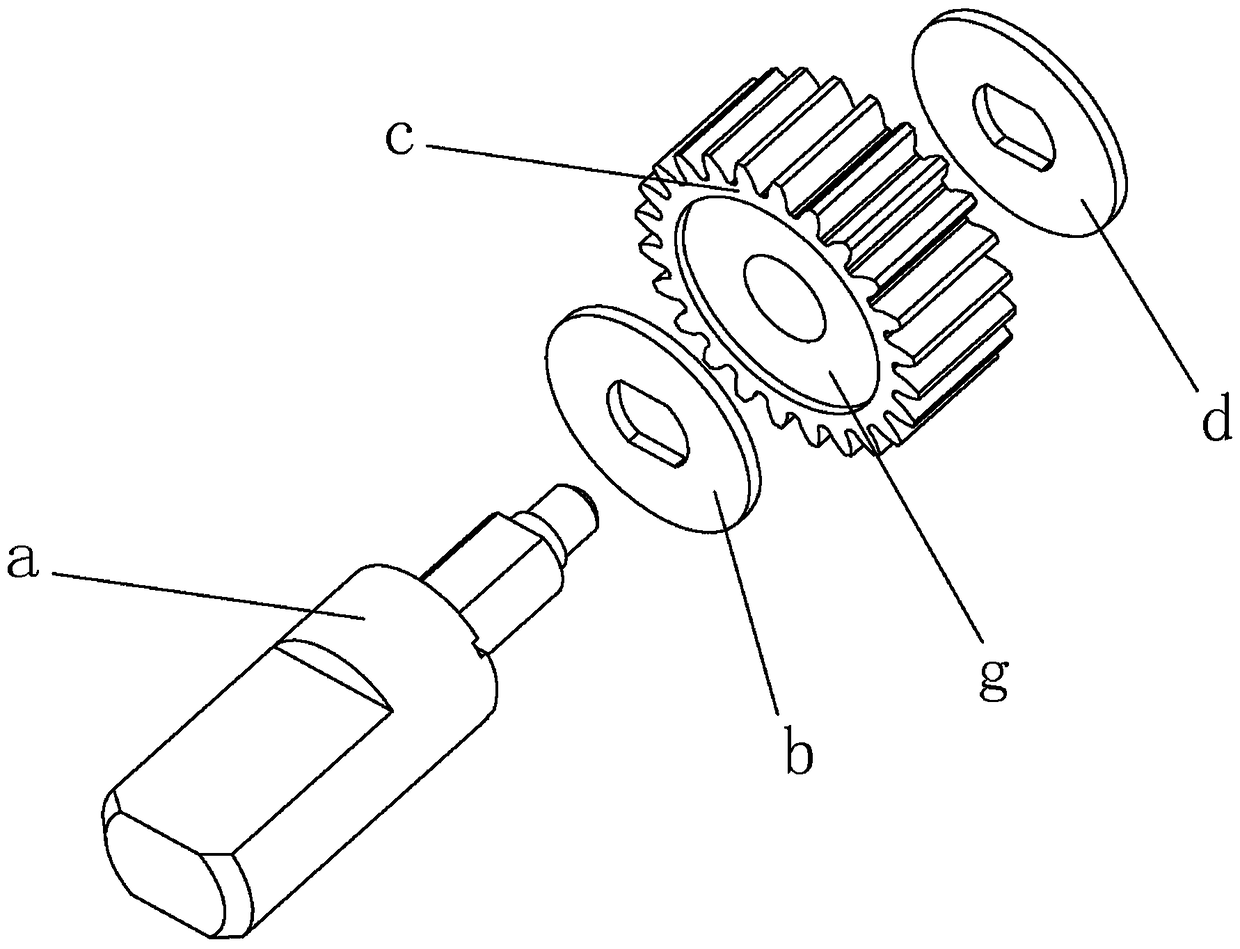

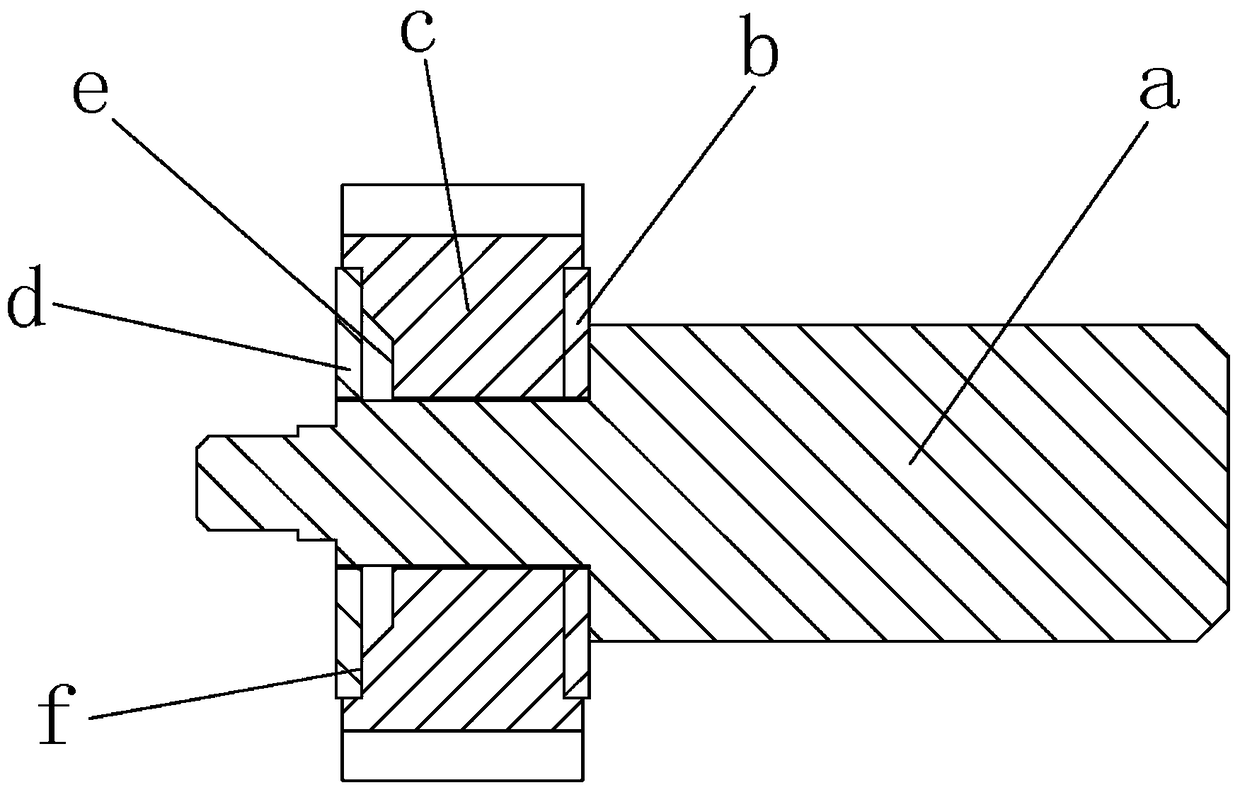

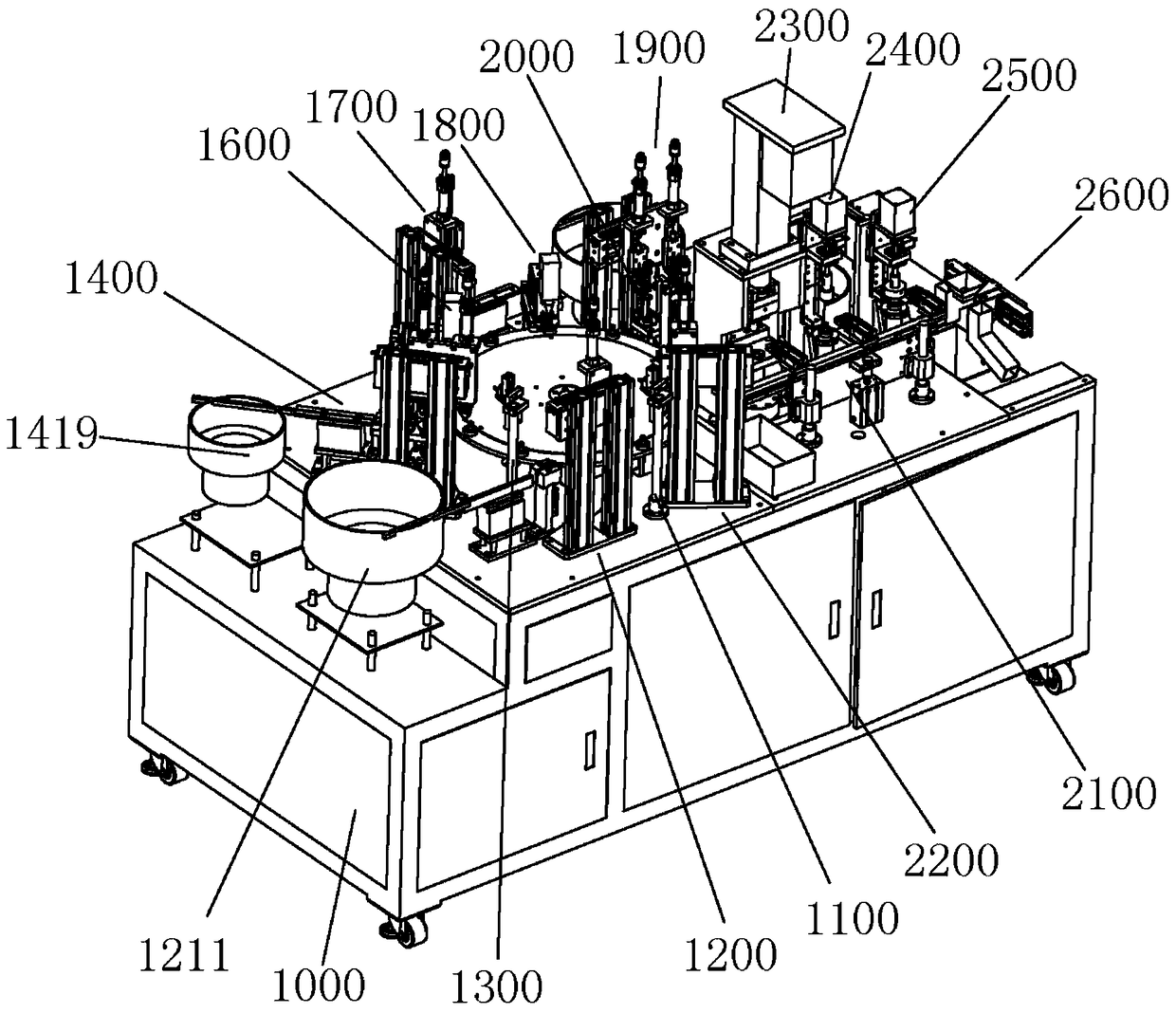

Motor rotation shaft assembly method and assembly machine implementing same

PendingCN108768110AEasy to analyzeHigh degree of automationAssembly machinesManufacturing dynamo-electric machinesGear wheelControl system

The invention discloses a motor rotation shaft assembly method comprising the steps as follows: a rotary disc is arranged on a machine stand, and an axis rod fixed seat detection device, an axis rod transportation and installation device, an axis rod detection device, a lower pressing ring transportation and installation device, a lower pressing ring detection device, a first oil injection device,a gear transportation and installation device, a second oil injection device, an upper pressing ring transportation and installation device, an upper pressing ring detection device, a finished product moving device and a defective product recycling device are arranged around the rotary disc; a riveting device, a running-in device, a friction force detection device and a sorting device are installed on one side of the rotary disc; and a PLC control system for controlling the device is also installed on the machine stand. Five processes such as automatic assembling, riveting, detecting slippingfriction force and sorting are combined together. The invention also discloses equipment for implementing the method. According to the equipment and the method, the product friction force is controlled in a closed loop, the degree of automation is high, the production cycle of products is effectively shortened, the production cost is reduced; during a production process, detection can be performed according to user demands and product characteristics, the production status can be conveniently better analyzed, an alarm can be given for the abnormal condition during the production process; theproduction abnormity can be eliminated in time, and the product qualification ratio is ensured.

Owner:广东英达思迅智能制造有限公司

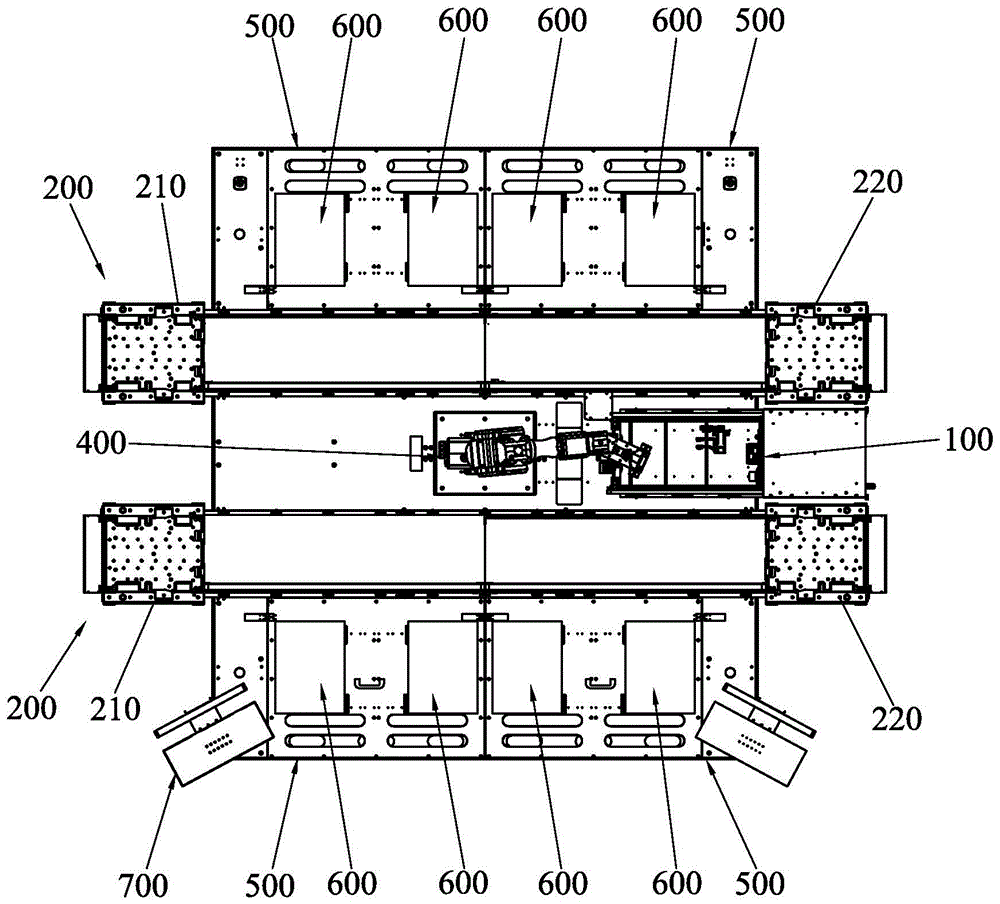

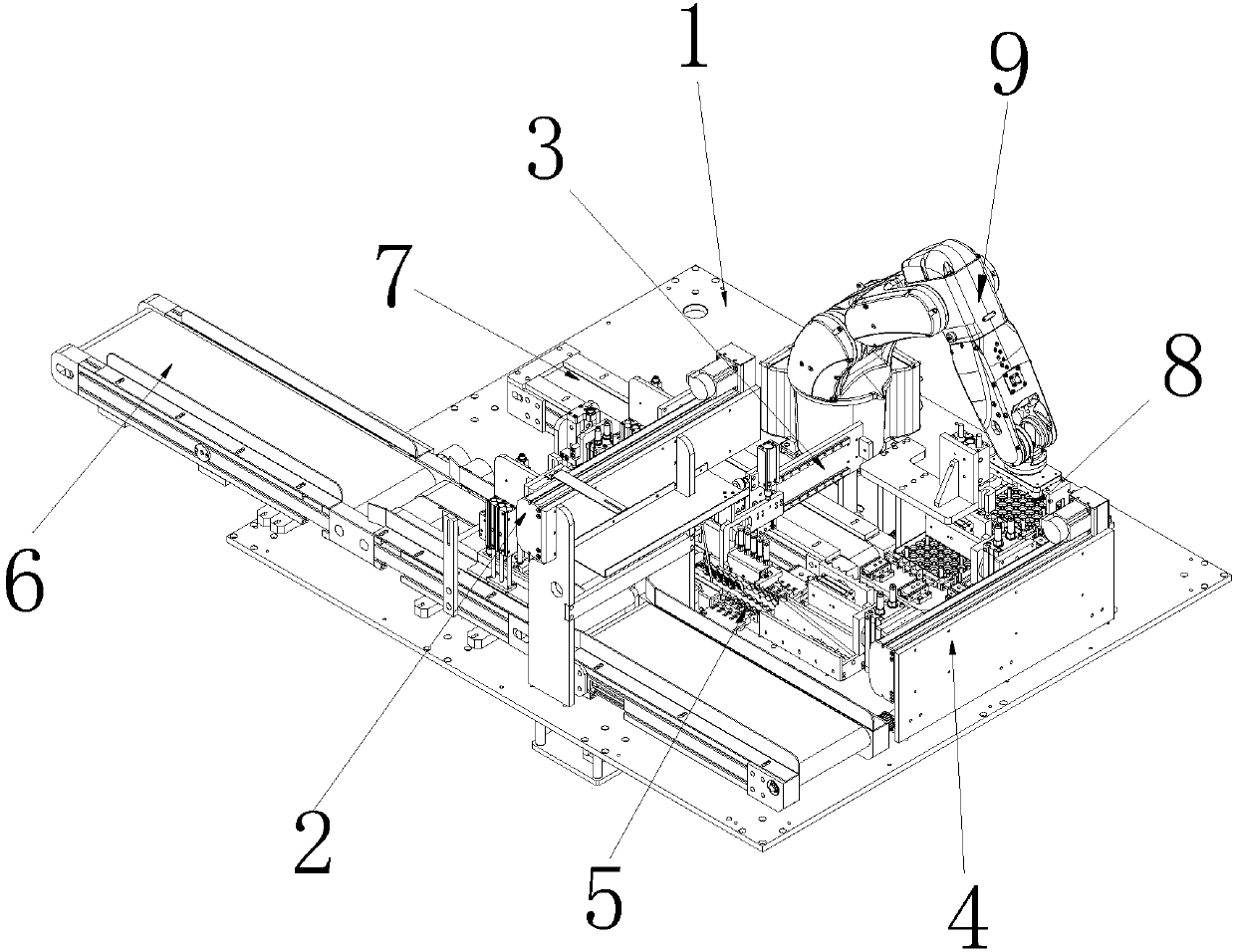

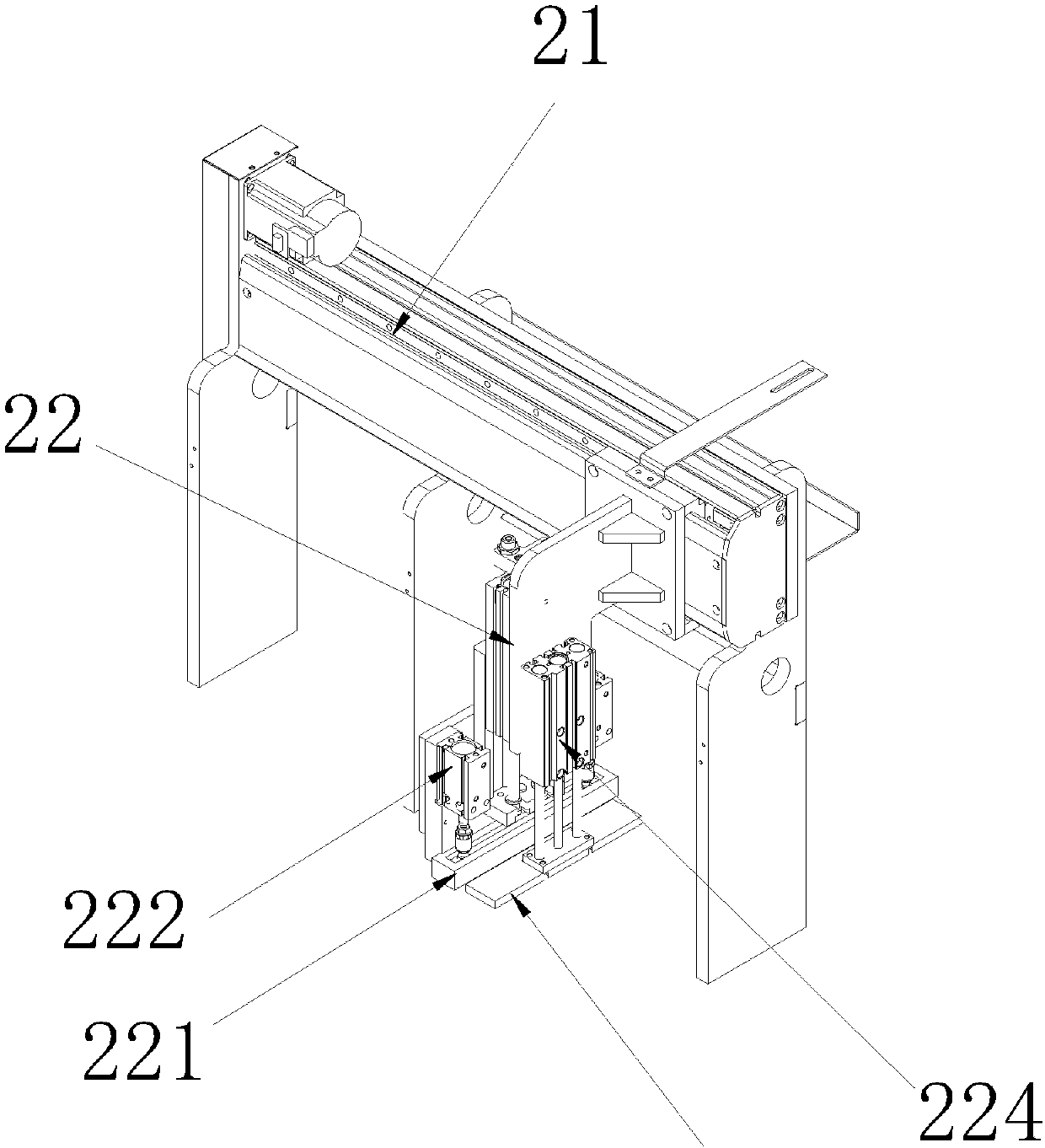

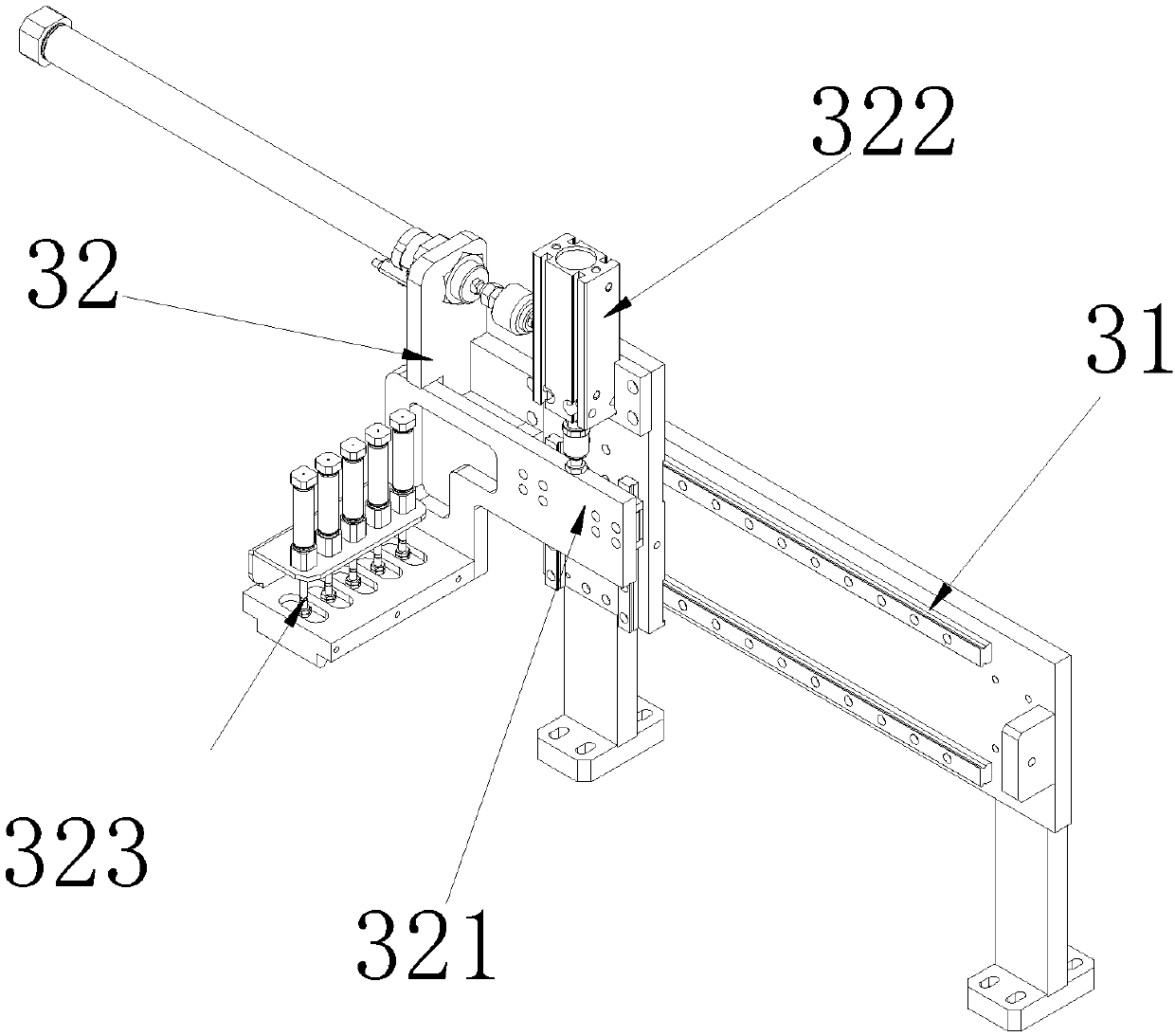

Automatic testing machine

ActiveCN105731088ARealize automated productionIncrease productivityStacking articlesDe-stacking articlesControl systemEngineering

The invention discloses an automatic testing machine. The automatic testing machine comprises a six-axis mechanical arm arranged in the center, at least two material disc conveyors arranged on the two sides of the six-axis mechanical arm, at least one testing platform arranged on the outer side of each material disc conveyor, at least one testing device arranged on each testing platform, a defective product recycling device arranged at one end of the six-axis mechanical arm, and a control system controlling the above devices. Tested products are arranged in material discs of the material disc conveyors, the material disc conveyors output or recycle the material discs, the six-axis mechanical arm transfers the tested products to the testing devices from the material discs for testing, and the six-axis mechanical arm transfers the tested products to the original position after testing is finished. The automatic testing machine has the beneficial effects of being fully automatic and high in production efficiency.

Owner:东莞市善易机械科技有限公司

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN101294245ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains the thorium and high-valence cerium, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (4) and the thorium are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain the products including pure cerium and pure thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements after impurity removal. The technological methodn has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (4), the thorium and trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium is recovered as products, and the pollutions caused by thorium-containing waste residue and the ammonia-nitrogen containing wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste

InactiveCN108525843AValue cost enhancementGreat benefitWet separationMechanical material recoveryNiobiumSlag

The invention discloses a method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste. The method is characterized in that the difficult-to-treat mine solid waste is taken as a raw material, wherein the difficult-to-treat mine solid waste is a valuable component material containing a trace of (Ta, Nb)2O5, lepidolite and feldspar, and themethod comprises the step of recovering the tantalum-niobium concentrate, the feldspar powder and the lepidolite, recovering of the tantalum-niobium concentrate is achieved though the following steps,the series-connection technology of weak magnetism, medium magnetism and strong magnetism is carried out on the difficult-to-treat mine solid waste raw material for separation of iron slag, magneticminerals and non-magnetic mineral so that the influence of iron minerals on the reselection of the tantalum-niobium ore can be eliminated, a tantalum-niobium ore waste stone raw material is obtained,the tantalum-niobium ore waste stone raw material undergoes classification by adopting a stage grinding-stage separation process method, coarse grains enter a ball mill for ore grinding, a high-frequency vibration fine sieve is adopted for carrying out intensifying classification on the fine fraction, and then the tantalum-niobium concentrate and the feldspar-lepidolite mixture with tailings beingiron-tantalum-niobium contained weak-magnetic impurities are prepared. The method has the advantages that the technology is simple, the efficiency is high, the economic and technical benefits are obvious, and the recovery rate of the tantalum-niobium and other mineral resource products is high.

Owner:江西金辉再生资源股份有限公司

Titanium tetrachloride purification system and method

InactiveCN103011268APlay the role of heat exchangeReduce energy consumptionTitanium halidesTetrachloridePurification methods

The invention relates to a titanium tetrachloride purification system and a titanium tetrachloride purification method, wherein raw titanium tetrachloride material liquid treated by a vanadium removal process is subjected to heat exchange by a preheater and then flows into the middle of a de-light rectifying tower to remove impure light components such as SiCl4 and lose a little amount of titanium tetrachloride; the material flow at the tower bottom contains rather pure titanium tetrachloride and flows into the middle of a de-heavy rectifying tower to remove heavy components such as AlCl3 and FeCl3 and lose a little amount of the titanium tetrachloride; and highly pure titanium tetrachloride is obtained at the top of the tower. The operation pressure at the top of the de-light rectifying tower is the normal pressure, the reflux ratio is 60.0-80.0, and the theoretical stage number is 16-22 in total; and the operation pressure at the top of the de-heavy rectifying tower is the normal pressure, the reflux ratio is 1.0-1.2, and the theoretical stage number is 16-22 in total. The purity of the highly pure titanium tetrachloride is at least 99.99%, and the product recycling rate in the process is higher than 97.0%.

Owner:TIANJIN UNIV

Automatic multi-electricity-meter-position parameter setting and detecting method

ActiveCN103760515ALive View SettingsReal-time display of detection statusElectrical measurementsProduction lineMachine control

The invention belongs to the technical field of automatic setting and detecting and relates to an automatic multi-electricity-meter-position parameter setting and detecting method. As a multi-electricity-meter-position testing device, a mechanical arm, a main machine control unit, an in-place identifier, a mechanical arm controller, a mechanical arm claw and the like are mutually connected for communication on an electricity meter production line, full-automatic parameter setting and detecting such as electricity meter in-place judgment, grasping, barcode identifcation, parameter setting, result judging and flow-out after classification are achieved. The method can support all projects of the existing FA function test, wherein the projects comprise setting of parameters, reading and verification, switching-off and switching-on detection and the like. The mode of one-multiple parallel operation is adopted, operation electricity meter positions can be intelligently distributed, qualified products and disqualified products can be distinguished, and multi-electricity-meter parallel asynchronous operation is achieved. A setting and detection state can be displayed in real time as a display screen is arranged. A specific disqualified product recycling device can perform sound and light alarming after a groove is full of the collected disqualified products. The design principle is reliable, the automation degree is high, the application range is wide and the automatic multi-electricity-meter-position parameter setting and detecting method is friendly to environment.

Owner:QINGDAO ITECHENE TECH CO LTD

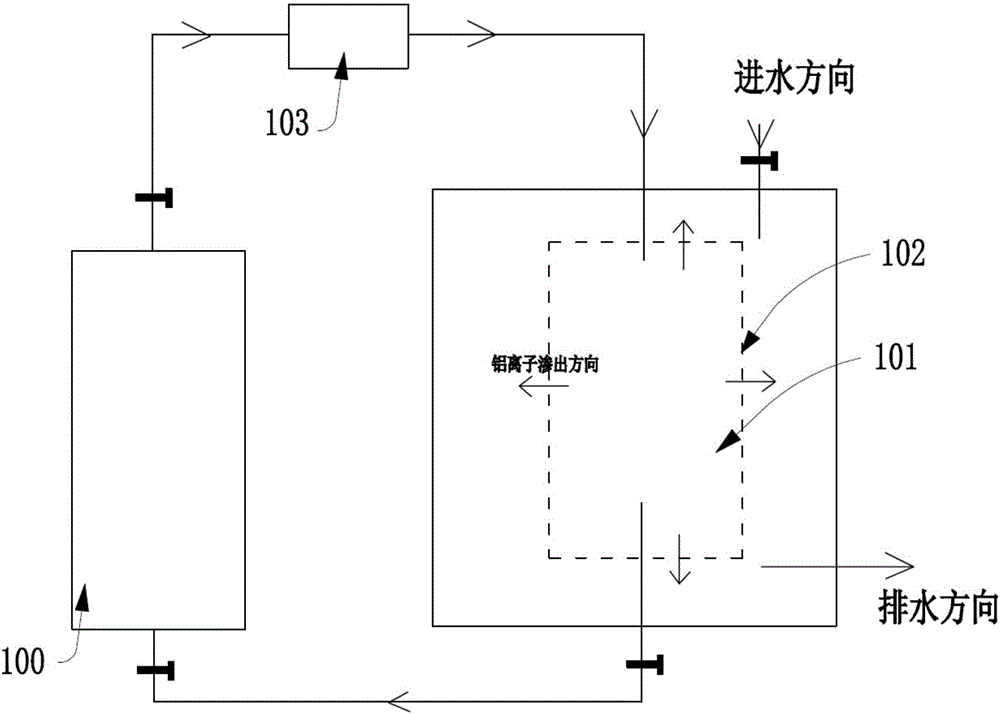

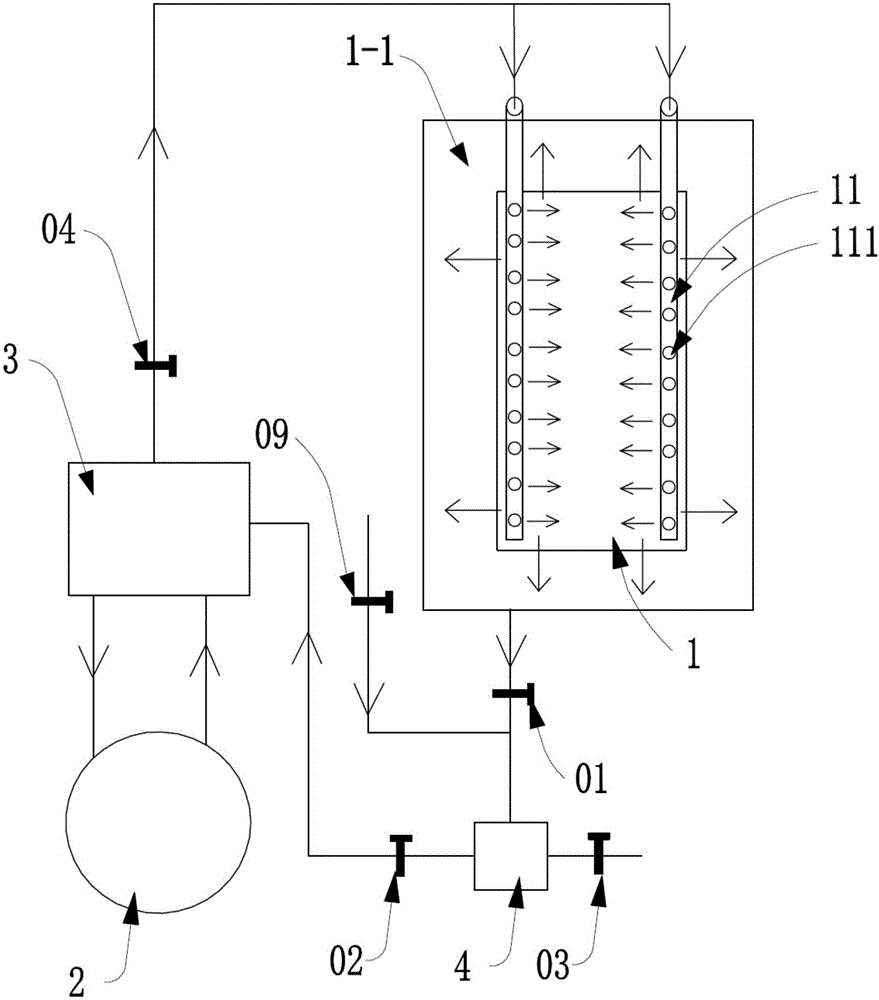

Oxidation energy-saving method for recycling aluminium ions and sulphuric acid of oxidation tank and improving current density

ActiveCN106757255AReduce the amount of dissolutionHigh densityCellsAnodisationHigh current densityEvery Hour

The invention discloses an oxidation energy-saving method for recycling aluminium ions and sulphuric acid of an oxidation tank and improving current density. The method comprises an oxidation solution circulating cooling step, an aluminium ion crystal product recycling step, a sulphuric acid oxidation solution recycling step, a gas stirring step, a defrosting step and a current density adjusting step; the current density adjusting step comprises the following steps: adjusting the flow of a variable frequency pump to be that the oxidation solution is circulated not more than six times every hour; adjusting the current density in an anodic oxidation tank. The invention provides an oxidation energy-saving method for recycling the aluminium ions and the sulphuric acid of the oxidation tank and improving the current density, the oxidation current density is improved, the oxidation time is shortened, the dissolving amount of oxidation films is reduced, and the oxidation energy consumption is reduced for the first time on the premise of blowing cold an oxidation film interface by fully utilizing a cathode cooling pipe.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

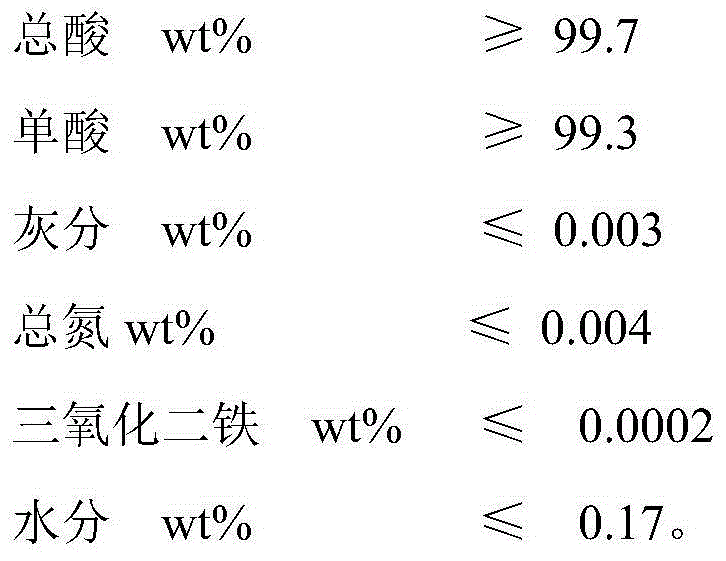

Recycling method of long carbon chain binary acid purification and refining crystallization mother liquor

ActiveCN104447274AImprove solubilityHigh recovery rateOrganic compound preparationHydroxy compound preparationSolventChemistry

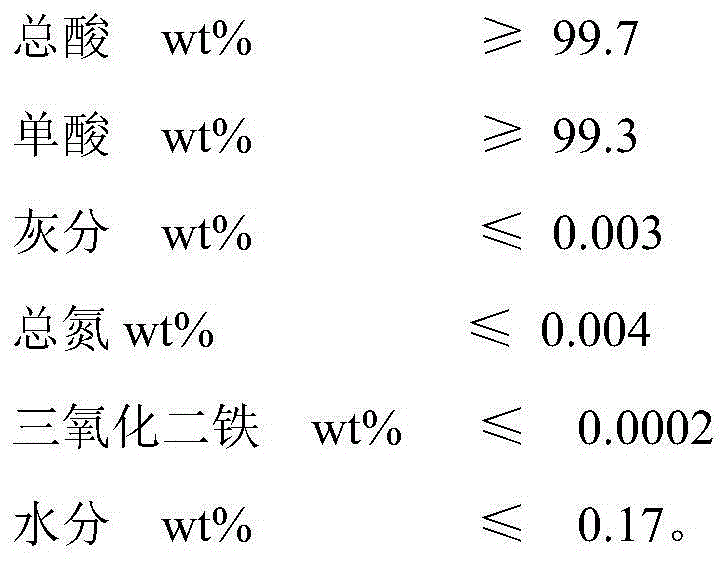

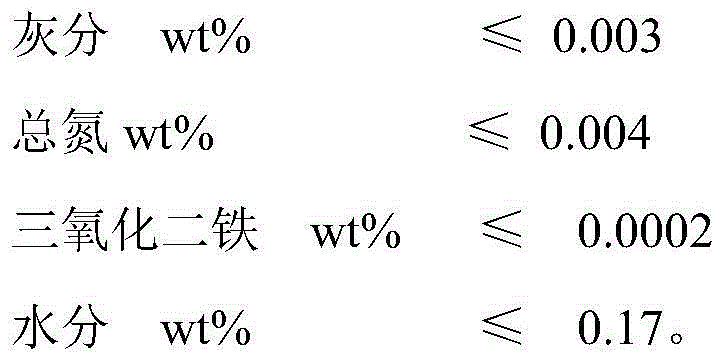

The invention discloses a recycling method of long carbon chain binary acid purification and refining crystallization mother liquor, and belongs to a separation treatment method of acyclic dicarboxylic acid with 12 carbon atoms. The method comprises the following operation steps: (1) recovering solvent methanol; (2) dissolving and diluting a residual material at the bottom of a distillation kettle; (3) performing high-temperature acid-out crystallization; (4) drying. The recycling method of the long carbon chain binary acid purification and refining crystallization mother liquor has the advantages that the recovered long carbon chain binary acid product has good color, high purification and high recovery yield, equipment investment is saved, the operation is easy and convenient, the resource is saved, and environment protection is facilitated. By using the method, the long carbon chain binary acid recovery rate is greater than or equal to 97.0 percent. The product quality reaches the following technical indexes that the total acid is greater than or equal to 99.7 percent by weight, the single acid is greater than or equal to 99.3 percent by weight, the ash content is smaller than or equal to 0.003 percent by weight, the total nitrogen is smaller than or equal to 0.004 percent by weight, the ferric oxide is smaller than or equal to 0.0002 percent by weight, and the moisture is smaller than or equal to 0.17 percent by weight.

Owner:山东广通新材料有限公司

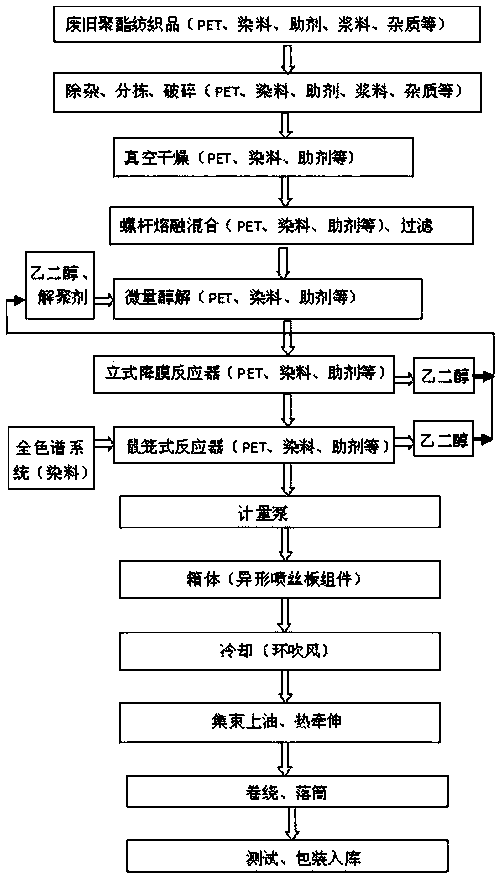

Method for producing high-performance regenerated polyester colored special-shaped filaments on basis of waste polyester textile products

InactiveCN108396392AEfficient removal of impuritiesSimple processDrying solid materials without heatMelt spinning methodsDepolymerizationHigh energy

The invention relates to a method for producing high-performance regenerated polyester colored special-shaped filaments on the basis of waste polyester textile products. By the aid of the method, theproblems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in existing waste textile product recycling procedures can be solved. The method includes steps of 1), pretreating the waste regenerated polyester textile products; 2), carrying out vacuum drying; 3), carrying out screw melting extrusion, micro-depolymerization, conditioning viscosity increasing, full-color-spectrum color matching and toning, spinning manifold treatment, circular air blowing cooling, bundling oiling and winding doffing on dried polyester textile products to obtain the high-performance regenerated polyester colored special-shaped filaments. The method has the advantages that the problems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in the waste textile product recycling procedures can be solved by the aid of the method; the monofilament denier of fibers obtained by the aid of the method ranges from 1.0 dtex to 3.0 dtex; the yarn evenness of the fibers is lower than or equal to 2.2%; the breaking strength of the fibers is higher than or equal to 4.0 cN / dtex; the elongation at break ranges from 15% to 25%.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

Preparation method of chicken bone meal and chicken essence containing same

InactiveCN104305271AIncrease profitImprove efficiencyFood preparationProtein food ingredientsFood additiveInitial treatment

The invention discloses a preparation method of chicken bone meal and a chicken essence containing the same. The preparation method comprises the steps of initial treatment of chicken skeletons, grinding, enzymolysis, enzyme deactivation, finish grinding and high-pressure spray drying, wherein a raw material adopted in the method is commercially available low-price fresh chicken bones, a lot of protein and minerals of calcium, phosphorus and the like are extracted from the chicken bones, and meanwhile, chicken bone marrows are fully extracted, so that the comprehensive utilization value of the chicken skeletons is developed; by using the preparation method, the product yield of the chicken bones can reach up to 98%; the preparation method is simple, has low technical requirements, and is low in equipment cost and high in efficiency; moreover, protease and flavor enzyme adopted in the step of enzymolysis can be flexibly added according to required tastes of customers, so that the chicken bone meal has an extremely wide application range, and not only can be used for preparing the chicken essence but also can be applied to other seasonings or food additive materials.

Owner:安阳市兴厨调味品有限责任公司

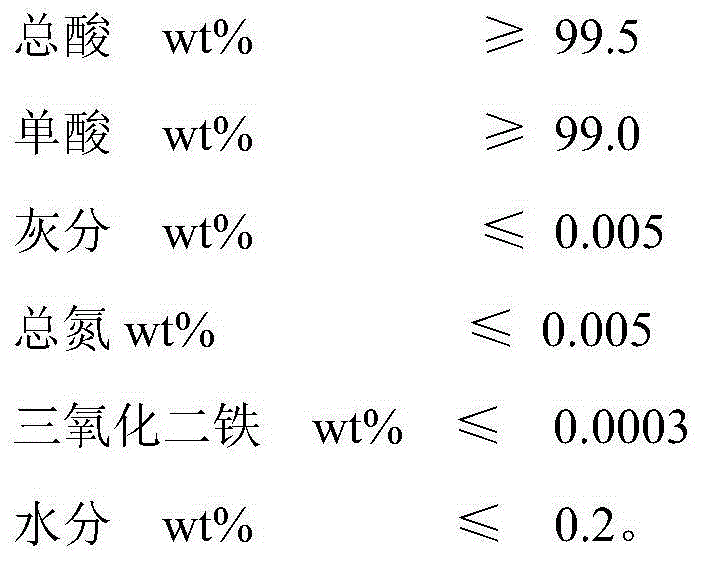

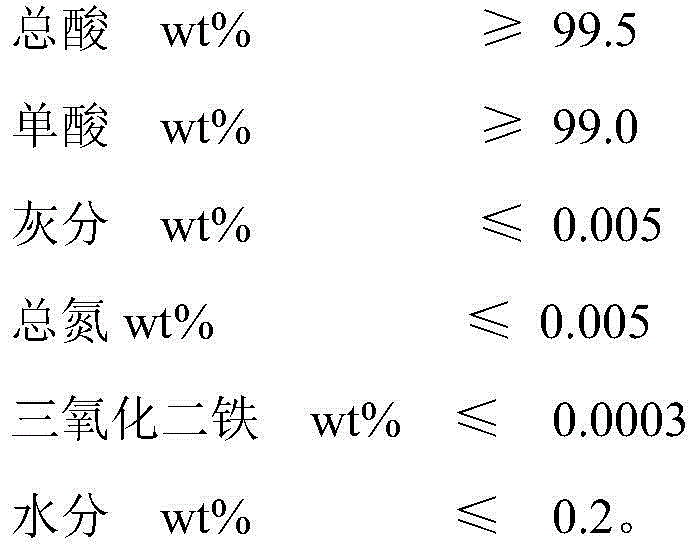

Recycling method of purifying, refining and crystallizing mother liquor of dodecanedioic acid

ActiveCN104447280AInhibition of esterificationSolve complexityOrganic compound preparationHydroxy compound preparationTotal nitrogenSolvent

The invention provides a recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid, and belongs to the separation treatment method of non-acyclic dicarboxylic acid containing 12 carbon atoms. The recycling method comprises the steps of (1) recovering a solvent which is methanol; (2) distilling to dissolve and dilute materials residual at the bottom of a kettle; (3) performing acidification under a high temperature, and crystallizing; (4) drying. The recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid has the advantages that the recovered dodecanedioic acid product has a good color and luster and is of high purity, and moreover, the recovery yield is raised, the device investment is saved, the operation is simple and convenient, the resource can be saved, and the environment is protected; the recovery yield of the dodecanedioic acid product is not less than 97.0%; the product quality meets the technical indexes that the total acid is not less than 99.7wt% (percentage by weight), single acid is not less than 99.3wt%, ash content is not greater than 0.003wt%, the total nitrogen is not greater than 0.004wt%, ferric oxide is not greater than 0.0002wt%, and water content is not greater than 0.17wt%.

Owner:山东广通新材料有限公司

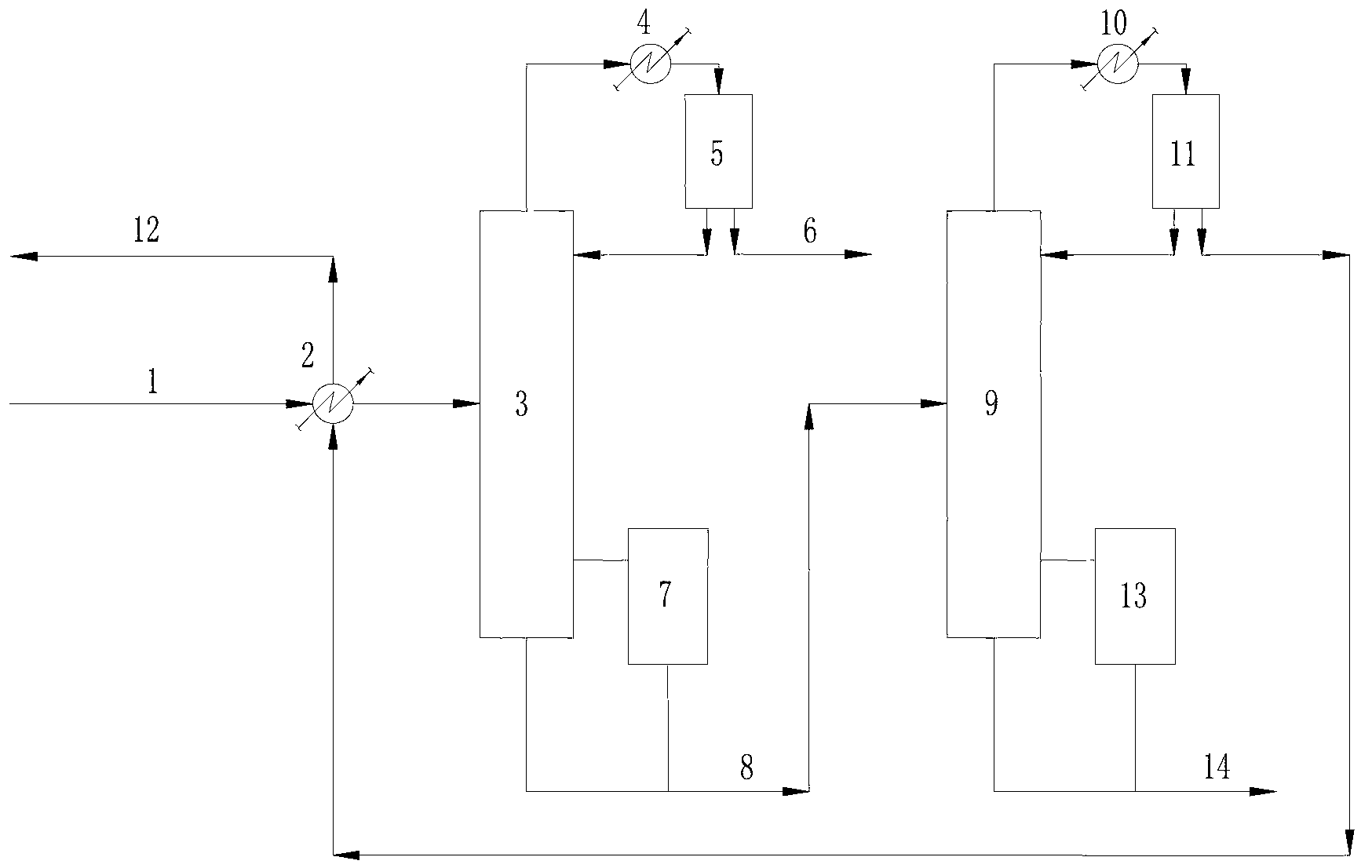

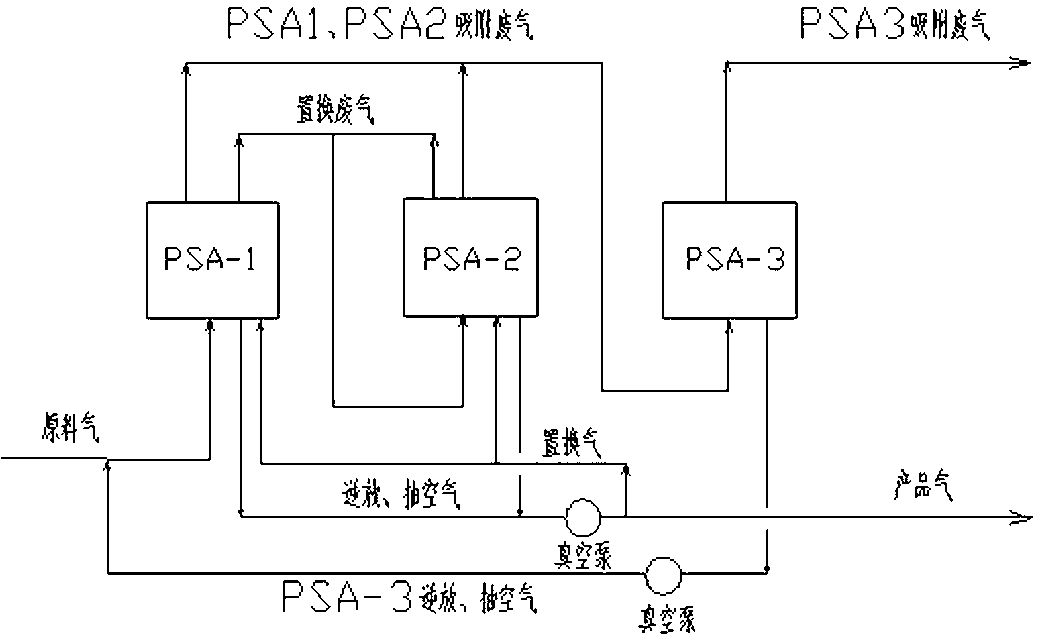

Variable pressure absorption method for increasing absorption phase product yield

The present invention discloses a variable pressure absorption method for increasing absorption phase product yield, wherein a variable pressure absorption system comprises a variable pressure absorption segment 1, a variable pressure absorption segment 2 and a variable pressure absorption segment 3, every variable pressure absorption segment respectively comprises at least two absorption towers filled with an absorption agent, every absorption tower of the variable pressure absorption segment 1 and the variable pressure absorption segment 2 is at least sequentially and circularly subjected to steps of absorption, displacement, evacuation and pressure increasing, displaced waste gas from the variable pressure absorption segment 1 and the variable pressure absorption segment 2 is adopted as raw material gas and enters the variable pressure absorption segment 2, every absorption tower of the variable pressure absorption segment 3 is at least sequentially and circularly subjected to steps of absorption, reverse releasing or evacuation, and pressure increasing, absorbed waste gas from the variable pressure absorption segment 1 and the variable pressure absorption segment 2 is adopted as raw material gas of the variable pressure absorption segment 3 and enters the variable pressure absorption segment 3, and reverse releasing gas or evacuation gas of the variable pressure absorption segment 3 returns to the variable pressure absorption segment 1, and is adopted as raw material gas of the variable pressure absorption segment 1.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Catalytic oxidation oil product desulfurization method based on phosphotungstic acid ionic liquid

ActiveCN104312621AReduce dosageImprove desulfurization efficiencyOrganic chemistryRefining with oxygen compoundsAfter treatmentReaction temperature

The invention belongs to the technical field of oxidative desulfurization of ionic liquid and particularly relates to a catalytic oxidation oil product desulfurization method based on phosphotungstic acid ionic liquid. The method is characterized in that the phosphotungstic acid ionic liquid is taken as a catalyst and is mixed with 30% of hydrogen peroxide and an oil product, a reaction is carried out at reaction temperature ranging from 25 DEG C to 70 DEG C under a stirring condition for 0.5-3.0 hours, and an upper oil phase separated after the reaction is finished is an oil product subjected to desulfurization. The method has the advantages that the use amount of the catalyst is low, and the desulfurization efficiency of the catalyst is as high as 97.23%; the reaction condition is mild, the reaction can be performed under normal pressure, and the reaction time is short; the product separation is easy, pollution is avoided, and the oil product recycling rate is high; the catalyst is stable in performance and is reusable, and the method is low in after-treatment cost, is environmentally friendly, and is expected to form a clean process route with high competitiveness.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Car lithium battery voltage inner resistance automatic detection sorting device

The invention discloses a car lithium battery voltage inner resistance automatic detection sorting device. The car lithium battery voltage inner resistance automatic detection sorting device comprisesa base, a battery taking mechanical arm, a defective product taking mechanical arm, a good product boxing mechanical arm, a loading box, a feeding assembly line, a code scanning detection mechanism and a defective product recycling assembly line, wherein the battery taking mechanical arm, the defective product taking mechanical arm, the good product boxing mechanical arm and the loading box are arranged on the base, the feeding assembly line, the code scanning detection mechanism and the defective product recycling assembly line are sequentially arranged on the base side by side, the batterytaking mechanical arm stretches over the feeding assembly line and the code scanning detection mechanism, the defective product taking mechanical arm stretches over the defective product recycling assembly line and the code scanning detection mechanism, the good product boxing mechanical arm stretches over the loading box and the code scanning detection mechanism, the battery taking mechanical armputs a battery on the feeding assembly line to the code scanning detection mechanism for code scanning detection, the good product boxing mechanical arm puts good batteries to the loading box for boxing, and the defective product taking mechanism puts defective batteries to the defective product recycling assembly line for recycling. Lithium battery code scanning, internal resistance and open-circuit voltage can be automatically detected, and good lithium batteries can be automatically boxed.

Owner:深圳蓬博精密机械有限公司

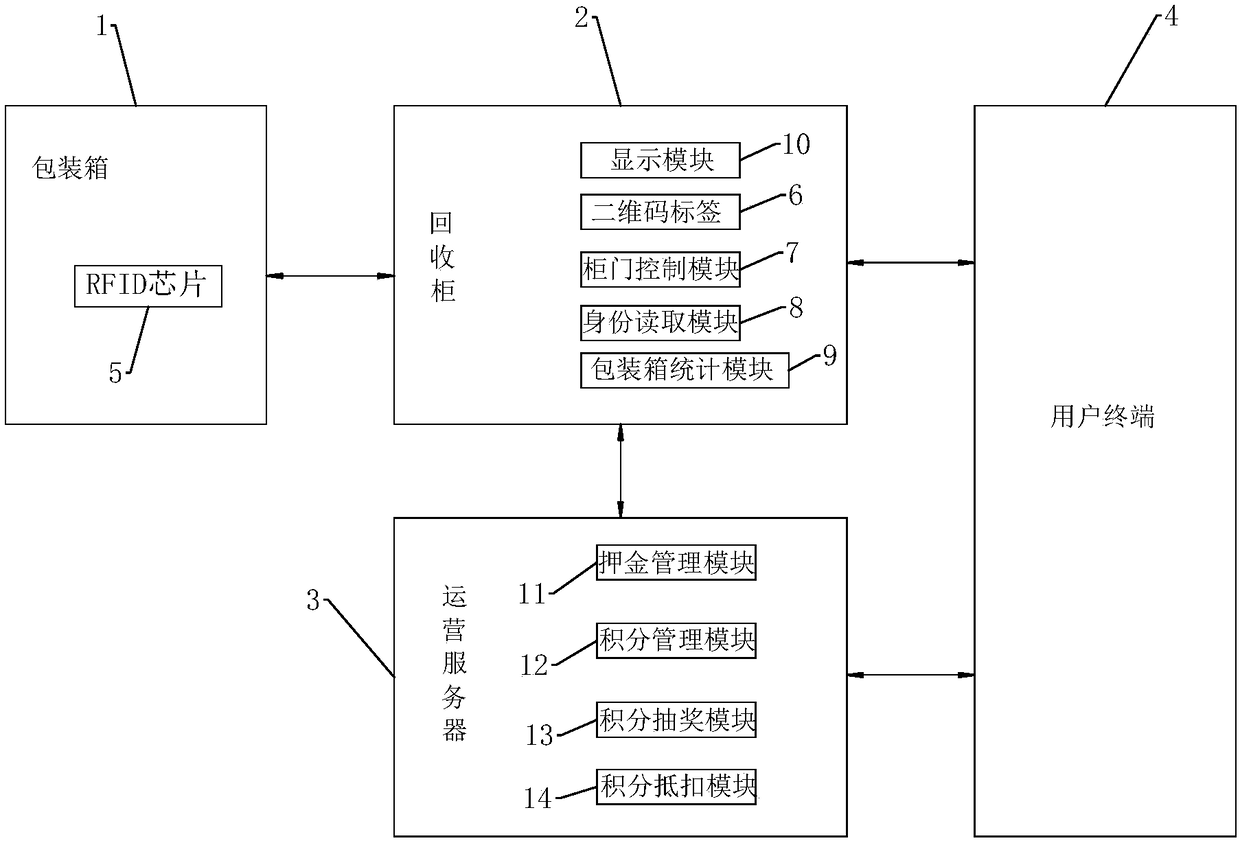

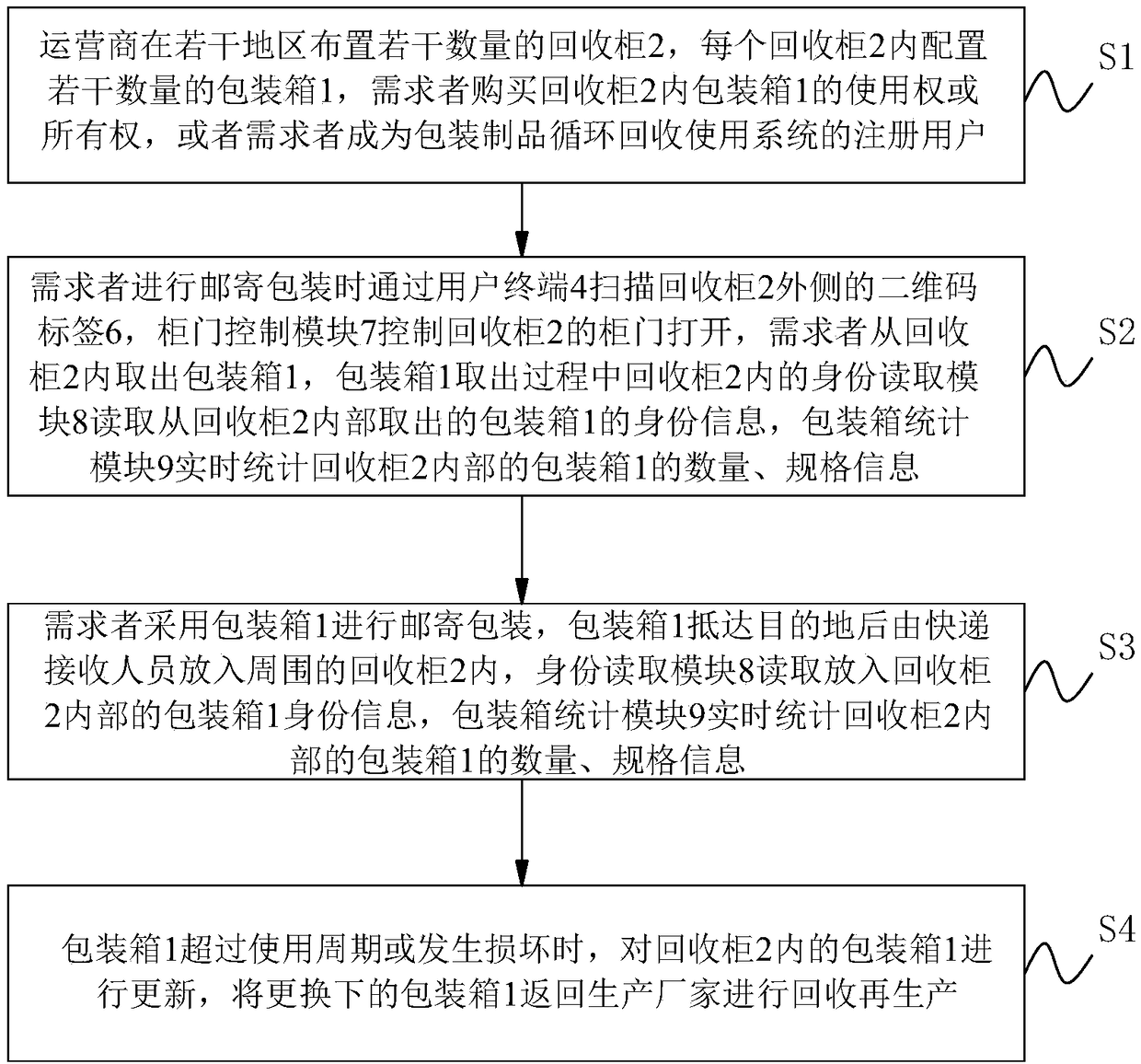

Packaging product recycling system and method

InactiveCN108597096AReduce wasteAchieve the purpose of protectionCo-operative working arrangementsLogisticsLogistics managementComputer module

The invention discloses a packaging product recycling system and method. A packaging box is provided with an RFID (radio frequency identification) chip configured with identity information and used for a logistic mailing business of a user; the packaging box is put in a recovery cabinet when in a standby state and taken out of the recovery cabinet by a user when used; the user scans a QR code tagthrough a user terminal to open a cabinet door of the recovery cabinet; a cabinet door control module controls opening or closing of the cabinet door of the recovery cabinet; an identity reading module reads identity information of the packaging box put in or taken out of the recovery cabinet; a packaging box counting module counts the number and specification information of the packaging box in the recovery cabinet; an operation server is managed and controlled by an operation manager; the user terminal establishes a connection relation with the recovery cabinet or the operation server, and the user terminal communicates with the recovery cabinet or the operation server. Repeated recycling of packaging products is realized, resource waste is reduced, life of people is facilitated, and theenvironmental protection purpose is really realized.

Owner:上海筌芳新材料科技有限公司

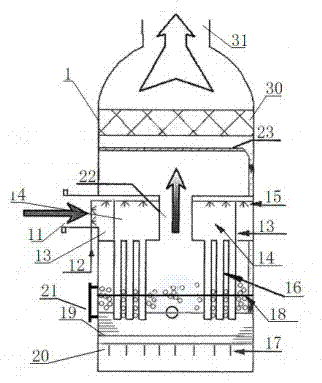

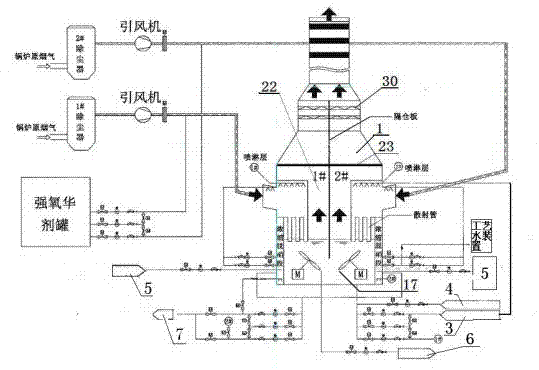

Desulfuration, denitration and dust removal (PM2.5 removal) three-in-one technical system for boiler exhaust gas by adopting ammonia method

ActiveCN104258719ALow powerAchieve desulfurization effectUsing liquid separation agentControl systemDust control

The invention discloses a desulfuration, denitration and dust removal (PM2.5 removal) three-in-one technical system for boiler exhaust gas by adopting an ammonia method, and relates to the technical field of boiler exhaust gas treatment. The system comprises an absorption system, a circulation system, an automatic ammonia injection system, a smoke dust pressing and filtering deslagging system, an oxidization system, a by-product recycling system and a self-control system. According to the technical system, the problems that ammonia and aerosol escape badly after desulfuration is executed by an air tower spraying ammonia method desulfuration device, the desulfuration efficiency is difficult to adjust and the investment is increased by the necessary extra arrangement of a dust removal device because the smoke dust emission amount cannot meet the standard are solved, the construction land use area is saved, and the repeated construction dust removal facility cost is lowered, and the disposable investment and running cost is greatly lowered; energy-saving, environment-friendly, economic, stable and standard running can be really realized, and the environment treatment concept of treating waste by waste and turning waste into treasures is achieved.

Owner:山东清能创新环保科技有限公司

Medicinal material pulverizer

ActiveCN104801406AIncrease the number ofImprove finenessGas current separationGrain treatmentsElectric machineryEngineering

The invention discloses a medicinal material pulverizer which comprises a cabin body, a smashing mechanism, grinding rollers, a primary motor, an air classification system, a finished product recycling box and an inferior-quality product recycling box, wherein the cabin body is sequentially separated into a smashing cabin, a grinding cabin and an air classification cabin from top to bottom; a cylindrical smashing drum is mounted in the smashing cabin; a smashing main shaft is mounted on the side wall of the smashing cabin of the cabin body through bearings at two ends; the grinding rollers are mounted on the side wall of the grinding cabin of the cabin body through bearings at two ends; the air classification cabin is positioned at the lower part of a second material outlet. The medicinal material pulverizer adopts combination of two smashing ways to greatly improve the smashing efficiency; the cylindrical smashing drum is arranged in an outer cabin, the smashing space can be optimized; the grinding rollers can further process the smashed material to increase the fineness of the smashed material; the medicinal material pulverizer is applicable to the fields of hospitals, medical institutes and scientific research.

Owner:张家界锦华中药饮片有限责任公司

Automatic magnetizing, detecting and tubing all-in-one machine for magnetic materials

ActiveCN110444366AReduce participationReduce labor intensityMagnetic bodiesMagnetic property measurementsEngineeringElectrical and Electronics engineering

The invention discloses an automatic magnetizing, detecting and tubing all-in-one machine for magnetic materials. The machine comprises a frame, and a magnetic material feeding mechanism, a magnetic material moving mechanism, a turntable mechanism, a magnetizing mechanism, a detecting mechanism, a rotating mechanism, a qualified product sucking mechanism, a qualified product conveying mechanism, aqualified product moving mechanism, an unqualified product sucking mechanism, an unqualified product recycling mechanism, a gasket feeding mechanism, a gasket moving mechanism and a tubing mechanismare arranged on the frame. The machine can be used for replacing manpower to achieve tubing of magnetic materials, thereby reducing operators, relieving the labor intensity of the operators, and increasing the tubing speed. Moreover, the magnetic materials can be magnetized and detected in the tubing process, and the working efficiency is high.

Owner:宁波名众自动化科技有限公司

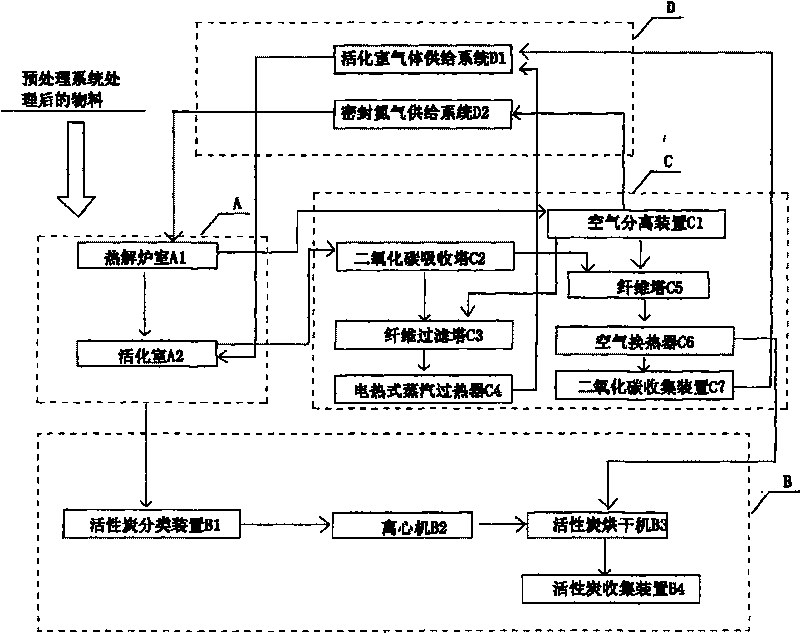

System, device and method for preparing active carbon

The invention relates to a system, a device and a method for preparing active carbon, which improve the recovery rate of the active carbon. The invention adopts the technical scheme that the system comprises a pyrolysis treatment subsystem for carrying out pyrolysis treatment on pretreated materials and an active carbon finishing system for further sorting and dewatering a primary active carbon product; in the system, a carbonization and activation integrated furnace of microwave heating and hermetic low-temperature pyrolysis processes is used as main equipment of the pyrolysis treatment subsystem; materials are cracked in a pyrolysis furnace chamber, and carbonized solid residues after cracking enter an activation chamber and processed into a primary active carbon product; and then the primary active carbon product is turned into an active carbon finishing subsystem, a carbonization and activation integrated furnace atmosphere guaranteeing system matched with the pyrolysis treatment subsystem and a gaseous product recycling system. The invention sufficiently utilizes products and energy in the process of production and has compact operation process and strong reliability.

Owner:深圳市兖能环保科技有限公司

Method for recycling transparent conducting glass substrate of solar cell

InactiveCN101562212ARecyclableReduce wasteWaste processingFinal product manufactureSolar cellEtching rate

The invention relates to a method for recycling a transparent conducting glass substrate of a solar cell, comprising the following steps of preparation, etching and finish. In the steps, a poor solar cell with a failed manufacture procedure is prepared and sequentially provided with a glass substrate, a transparent conducting glass layer and a failed manufacture procedure layer, and the poor solar cell with a failed manufacture procedure is selectively etched by an etching medium; the etching rate of the failed manufacture procedure layer by the etching medium is far larger than the etching rate of the transparent conducting glass layer and the glass substrate, the etching medium mainly etches and removes the failed manufacture procedure layer, and the left glass substrate and the transparent conducting glass layer are recycled, thus the invention has the advantages and effects of defective product recycling in the manufacture procedure, waste reduction, and the like.

Owner:CONTREL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com