Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

A process method and technology of rare earth sulfate, applied in the field of extraction and separation, extraction and separation of thorium and cerium-less trivalent rare earth, and extraction and separation of cerium, can solve the problems of complex impurity ion behavior, low extraction capacity, low purity, etc., to avoid acid-base crossover, Simple process flow, green process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

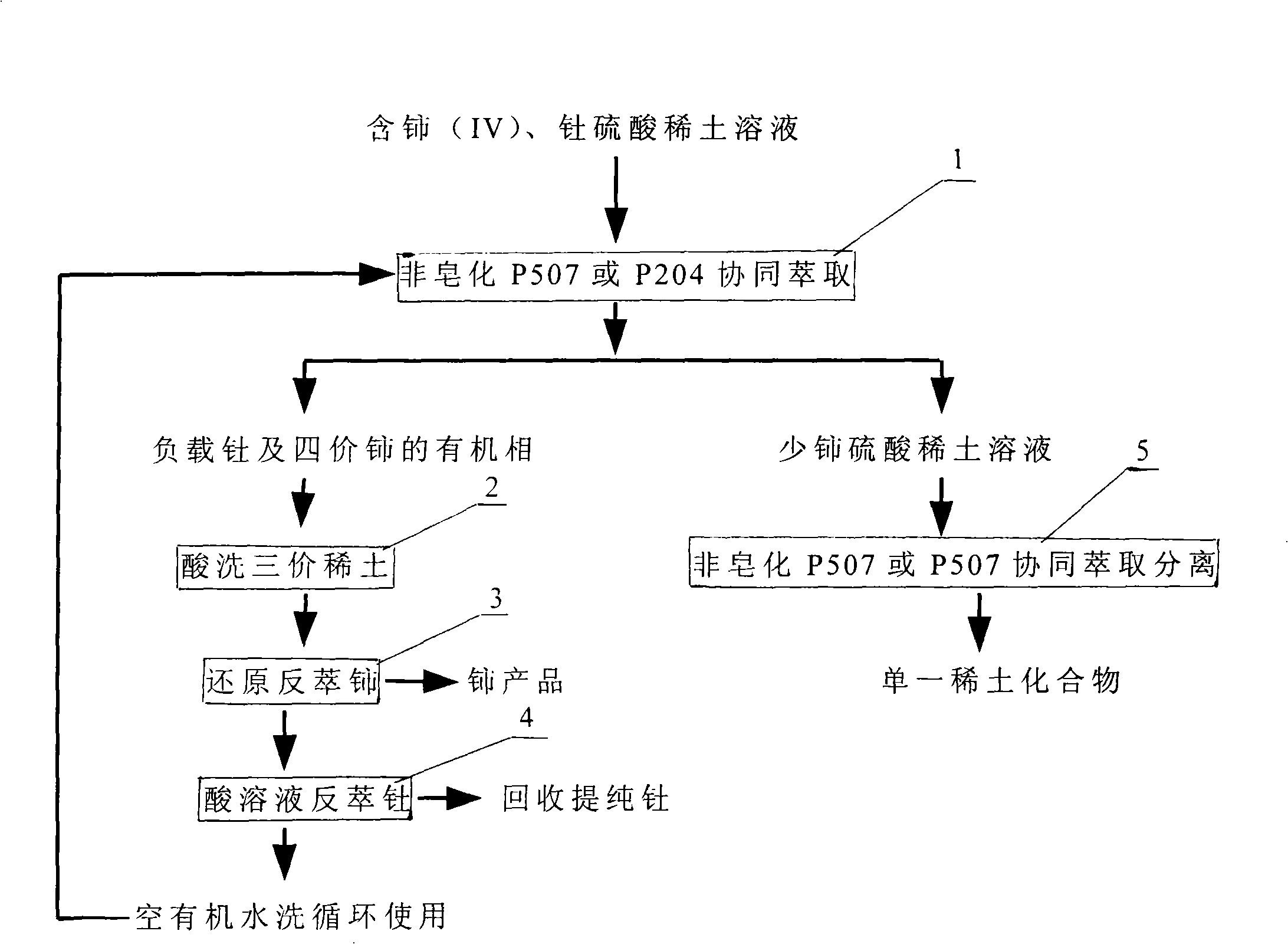

Image

Examples

Embodiment 1

[0031]The rare earth sulfate solution obtained by roasting bastnaesite with sodium carbonate - washing with fluorine - leaching with dilute sulfuric acid is used as the raw material solution, and the raw material solution contains Ce 4+ / ∑Ce is 93% (weight percent), the rare earth concentration REO is 0.3 mol / liter, H + At a concentration of 0.50 mol / L, ThO 2 The concentration is 0.1 g / L. The extractant is a mixed extractant of 95% P507 and 5% TBP, the concentration is 1.0 mol / liter, the diluent is sulfonated kerosene, and the flow ratio used is organic phase: solid liquid=2:1. After three stages of countercurrent extraction, the raffinate containing cerium (IV), thorium organic phase and trivalent rare earth containing less cerium is obtained.

[0032] The loaded organic phase after extraction is washed with 1 mol / L sulfuric acid through three stages of countercurrent washing, and the trivalent rare earth extracted into the organic phase is washed into the water phase.

[...

Embodiment 2

[0037] A rare earth sulfuric acid solution is used as the raw material solution, and the raw material solution contains Ce 4+ / ∑Ce is 97%, rare earth concentration REO is 0.6 mol / L, H + At a concentration of 1.2 mol / L, ThO 2 The concentration is 0.50 g / L. The extractant is a mixed extractant of 90% P507 and 10% TRPO, the concentration is 1.5 mol / liter, the diluent is sulfonated kerosene, and the flow ratio used is organic phase: solid liquid=6:1. After 6 stages of countercurrent extraction, a raffinate containing cerium (IV), thorium organic phase and trivalent rare earth is obtained.

[0038] The loaded organic phase after extraction is washed with 7 stages of countercurrent with 4 mol / L sulfuric acid, and the trivalent rare earth extracted into the organic phase is washed into the water phase.

[0039] The loaded organic phase after washing is used to contain 5% hydrogen peroxide and 5 mol / liter of nitric acid, and the organic phase is back-extracted with 7 grades of ceri...

Embodiment 3

[0043] A rare earth sulfuric acid solution is used as the raw material solution, and the raw material solution contains Ce 4+ / ∑Ce is 95%, rare earth concentration REO is 0.8 mol / L, H + At a concentration of 1.5 mol / L, ThO 2 The concentration is 0.30 g / L. The extractant is a mixed extractant of 85% P204 and 15% TRPO, the concentration is 1.25 mol / liter, the diluent is sulfonated kerosene, and the flow ratio used is organic phase: solid liquid=4:1. After five stages of countercurrent extraction, a raffinate containing cerium (IV), thorium organic phase and trivalent rare earth is obtained.

[0044] The loaded organic phase after extraction is washed with 3.0 mol / L sulfuric acid through 5 stages of countercurrent washing, and the trivalent rare earth extracted into the organic phase is washed into the water phase, and the purity of cerium in the organic phase is CeO 2 / REO reached 99.99%. The loaded organic phase after washing was back-extracted with 4% hydrogen peroxide and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com