Patents

Literature

16975results about "Dirt cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

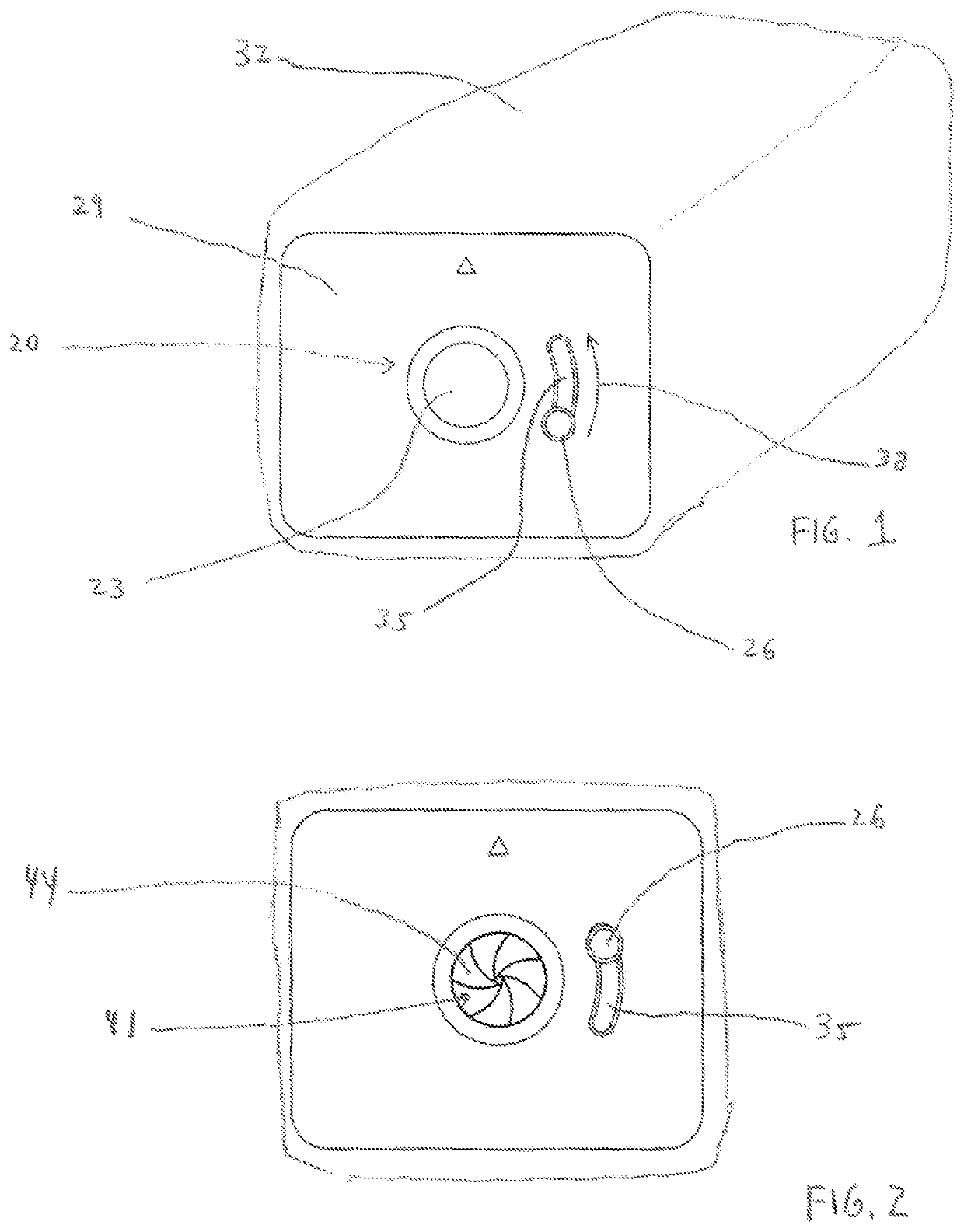

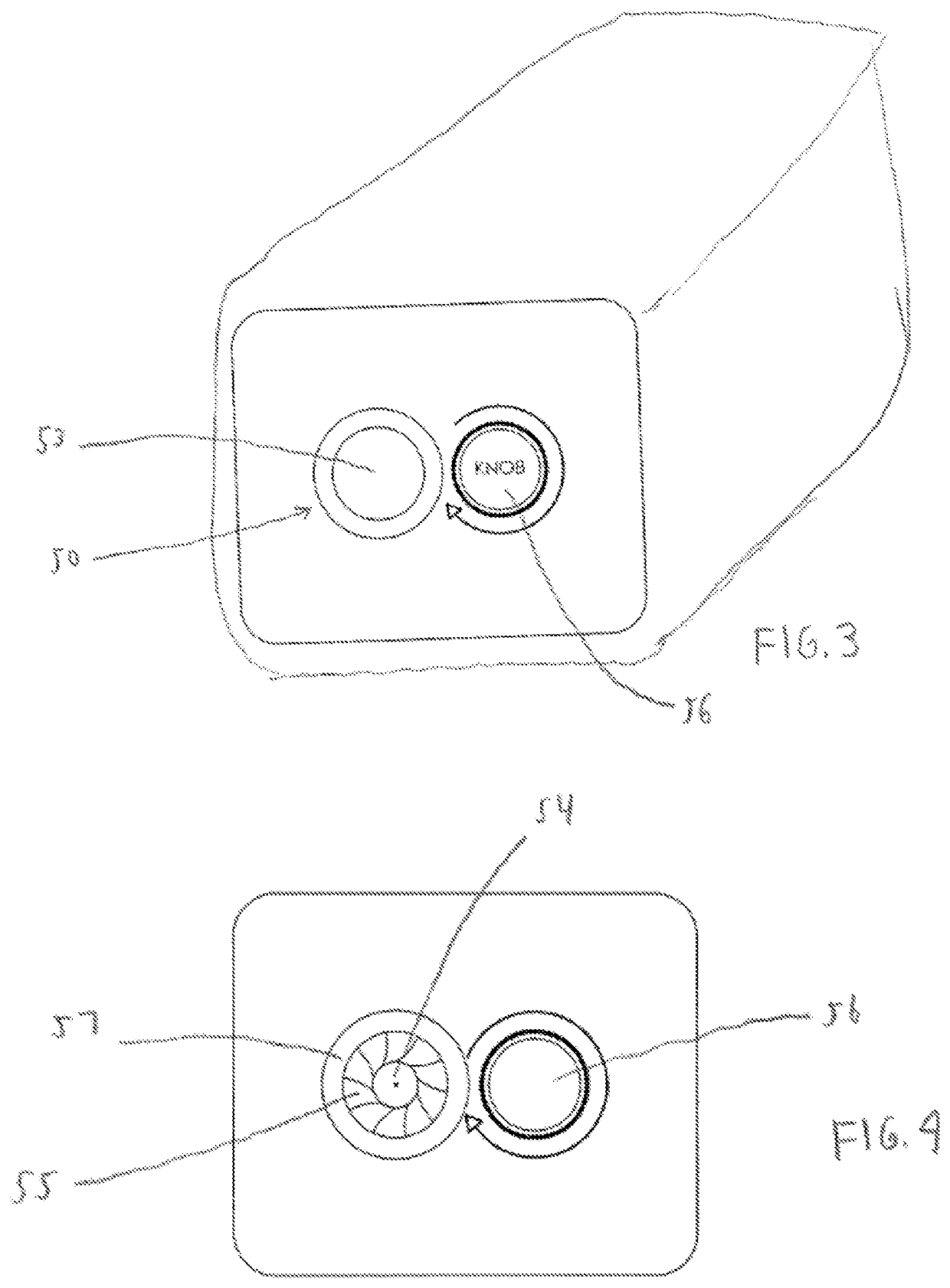

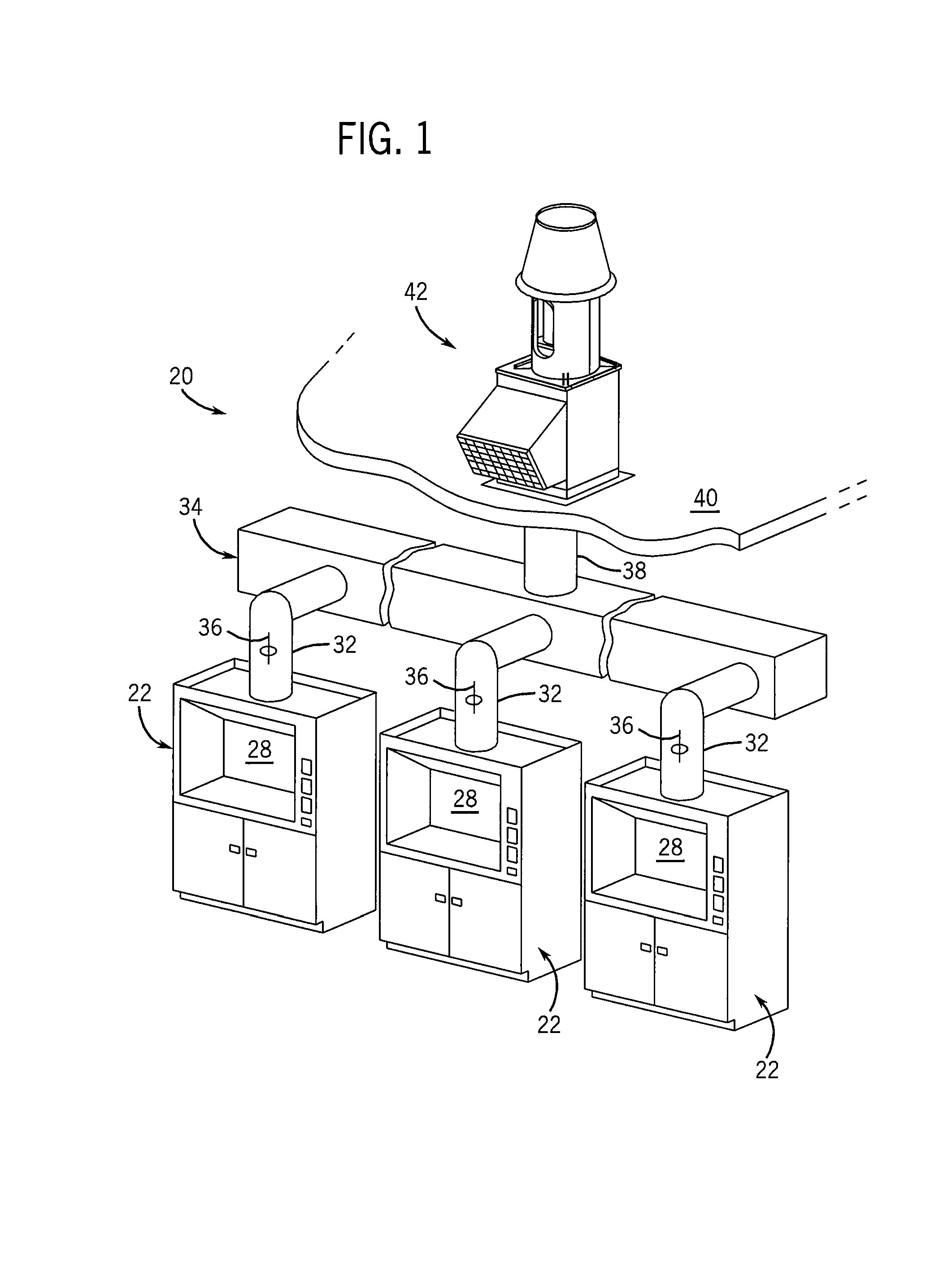

Range hood

ActiveUS20060278216A1Domestic stoves or rangesSpace heating and ventilation safety systemsElectronic controllerDisplay device

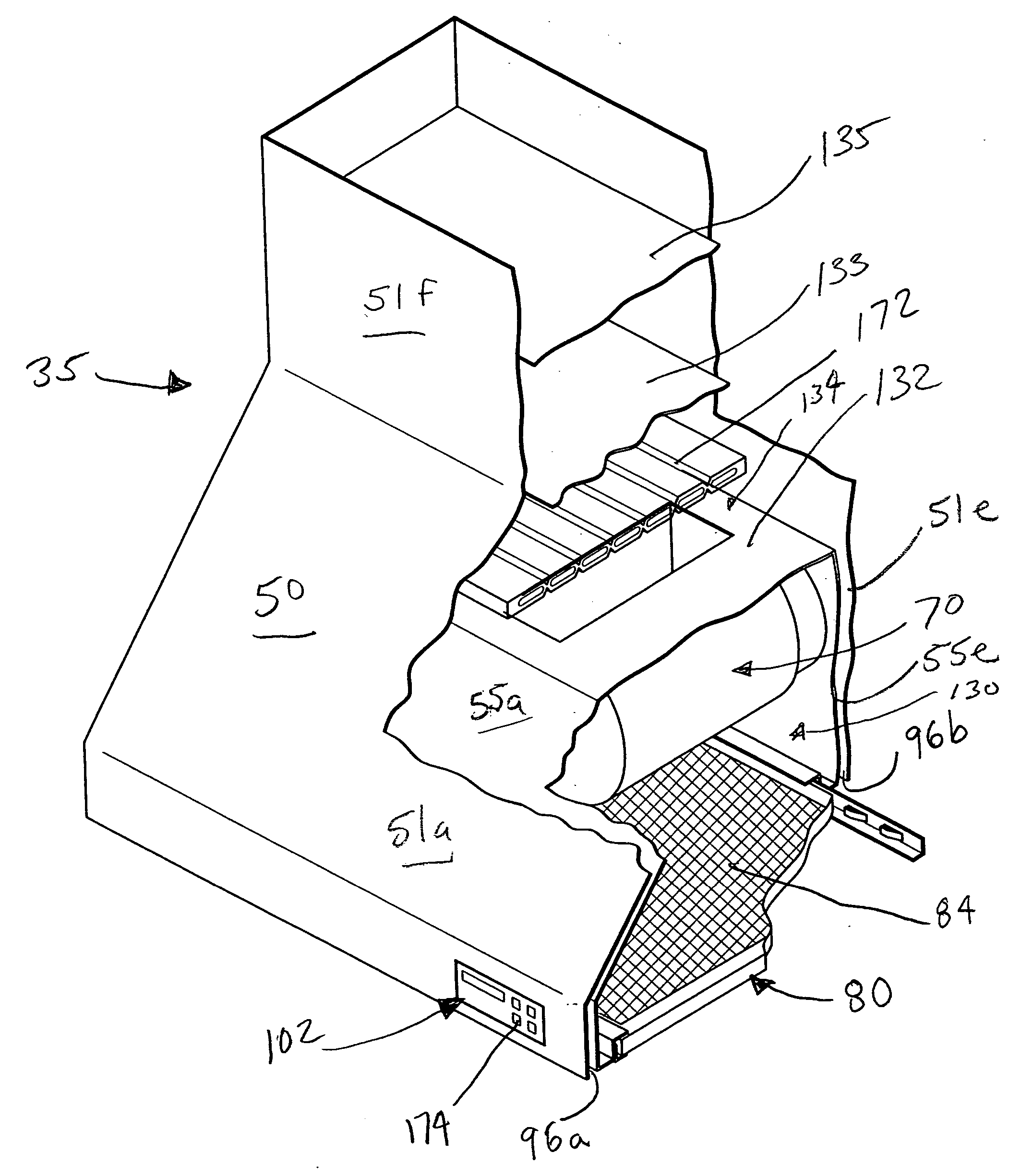

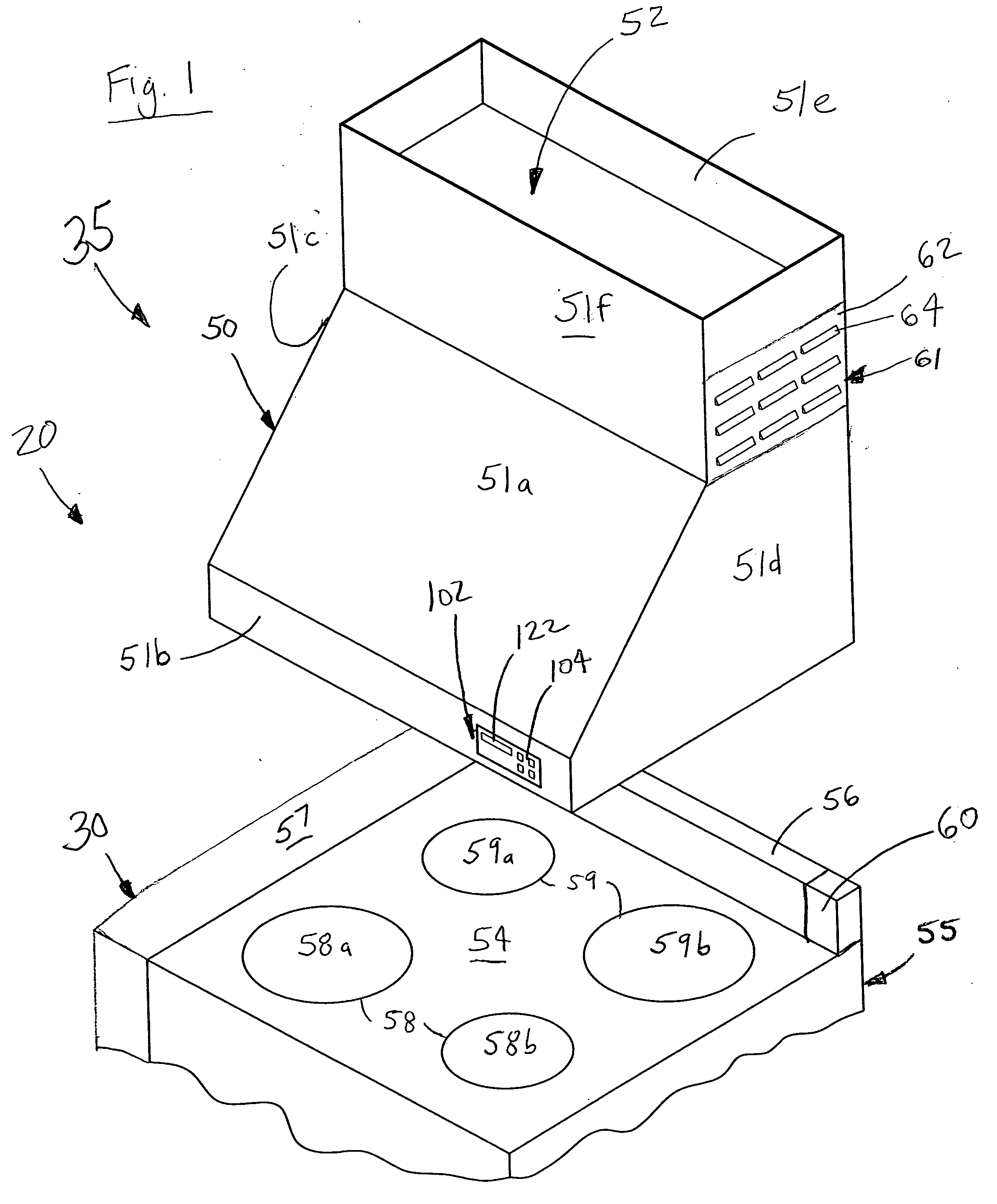

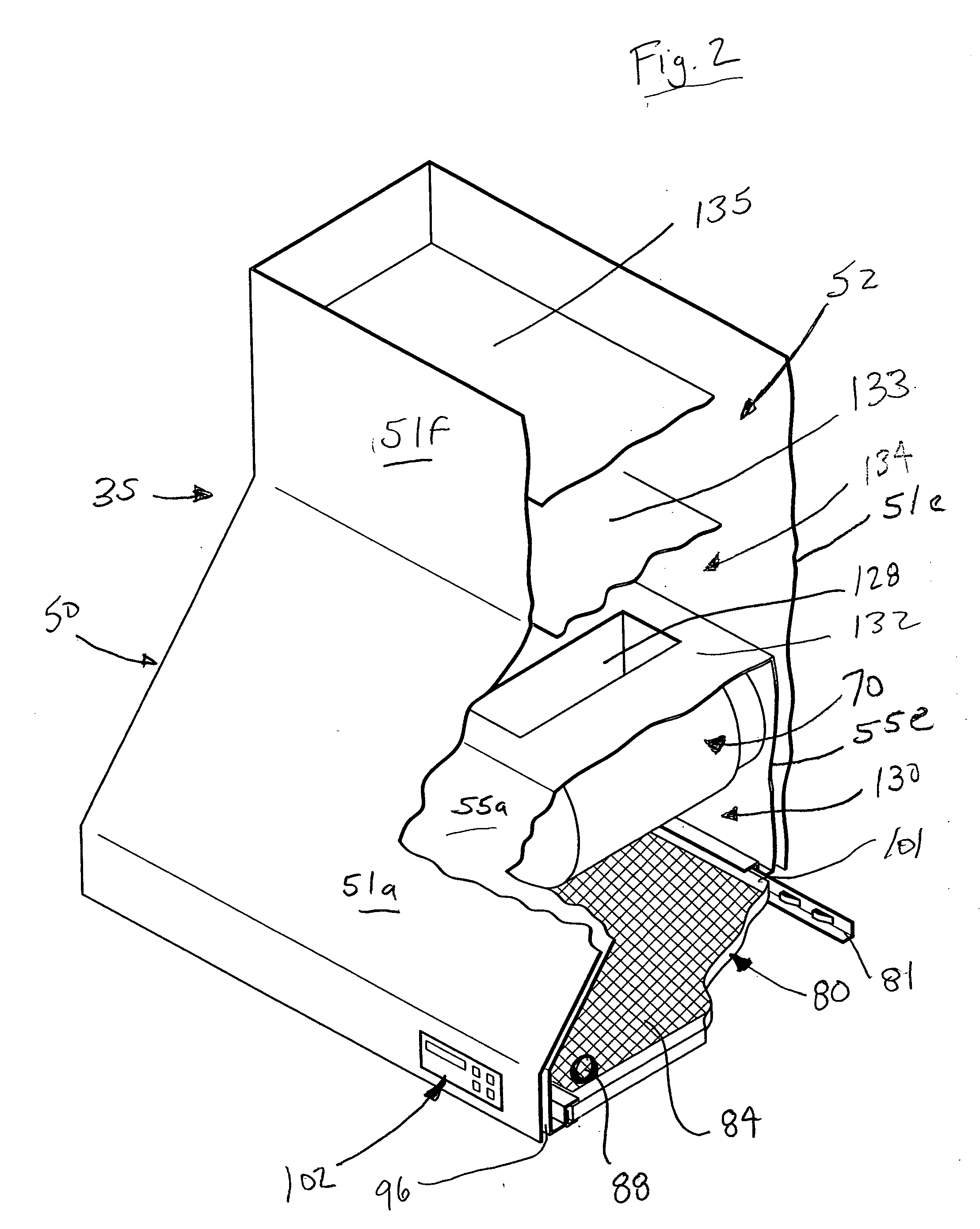

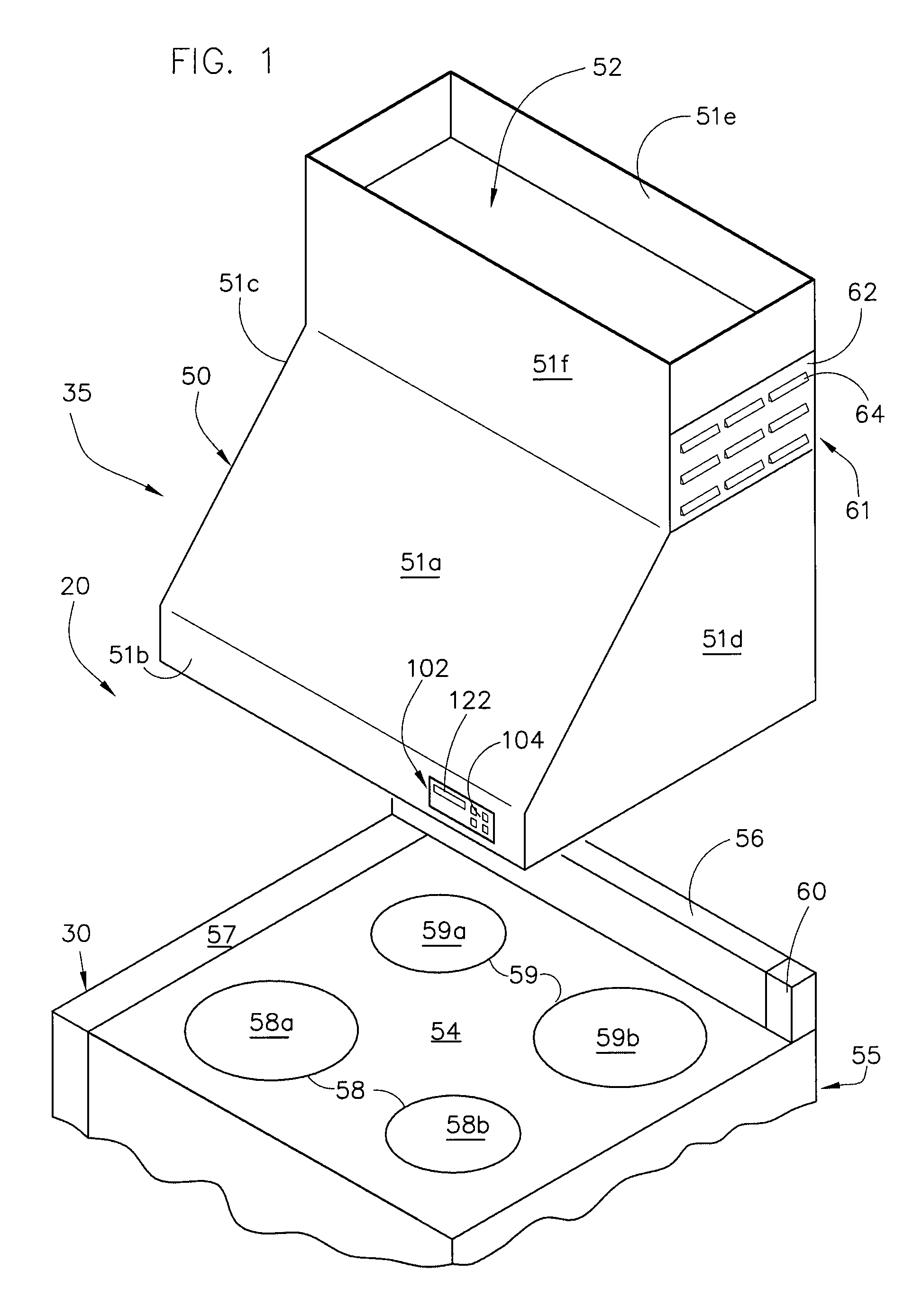

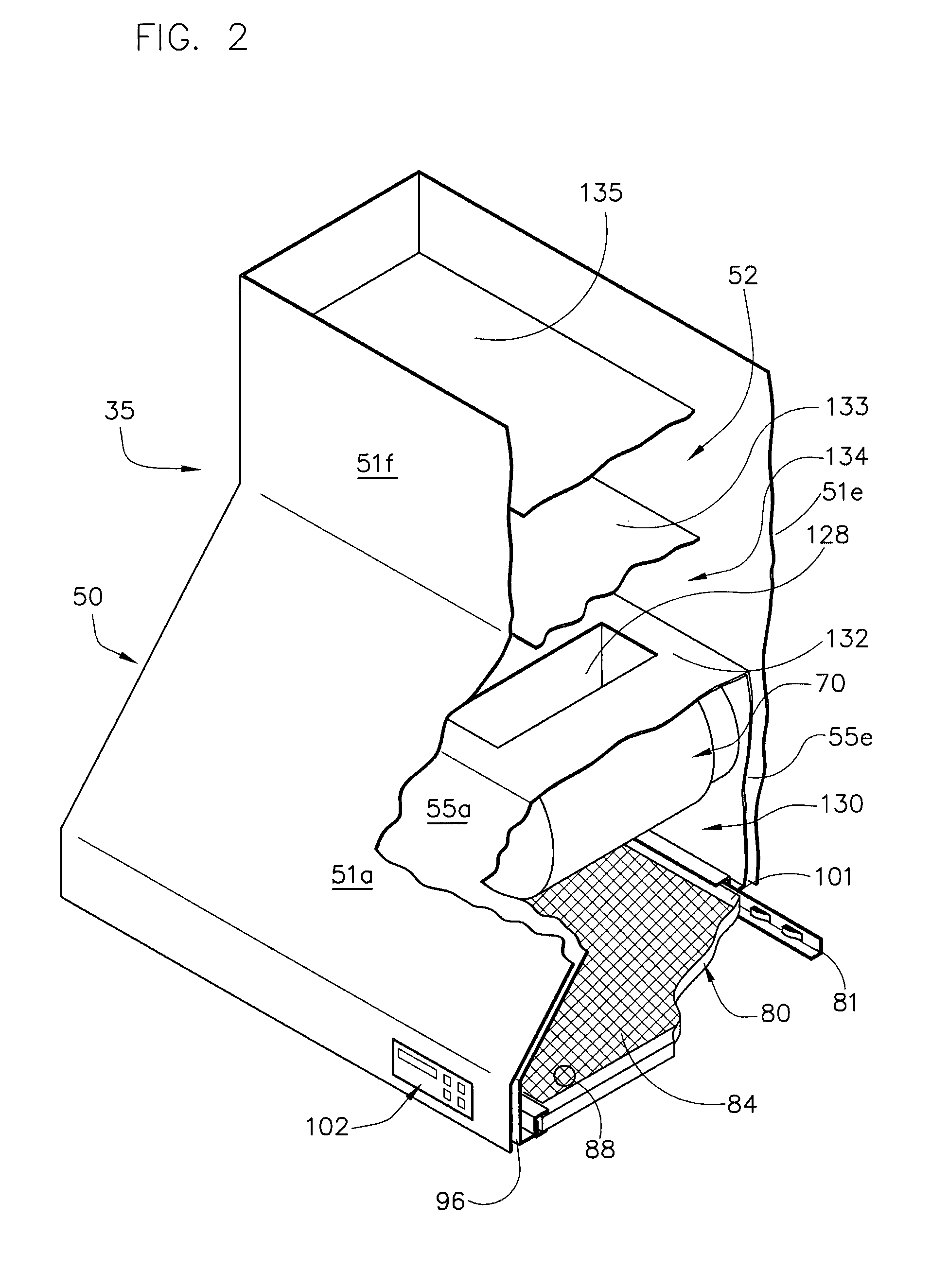

A hood for a cook top is controlled preferably by an electronic controller through a touch keypad. The hood has front and side walls and attaches to a back wall. It has an internal cavity and structure to restrict airflow out of the hood. The structure also creates an air curtain. The curtain traps and moves heated air and effluents upwardly off of the cook top. At least one blower is located near the cook top for moving the air and effluents. The hood may also have at least one: filter, sensor, duct, lighting fixture, vent, display, and circuit board.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

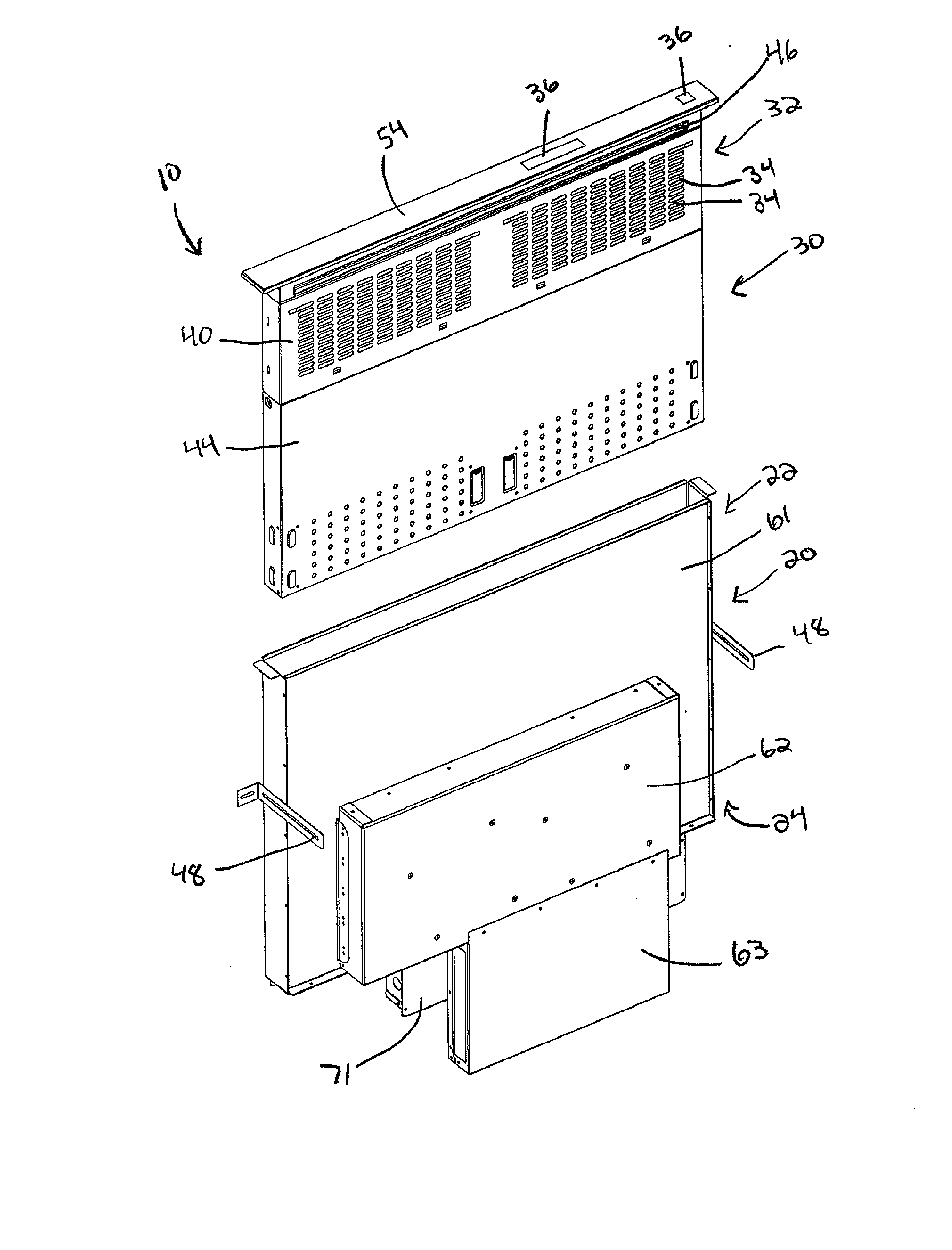

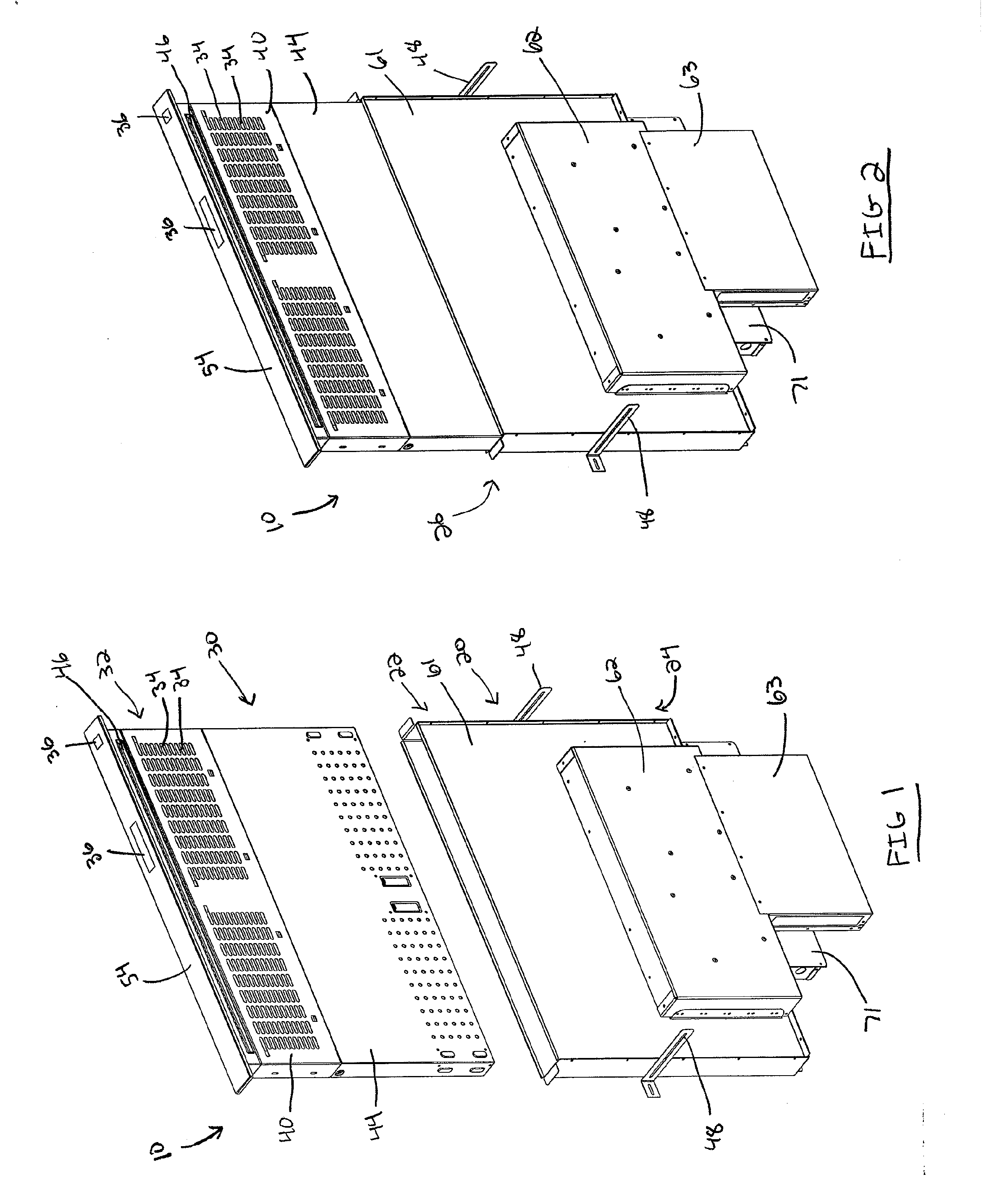

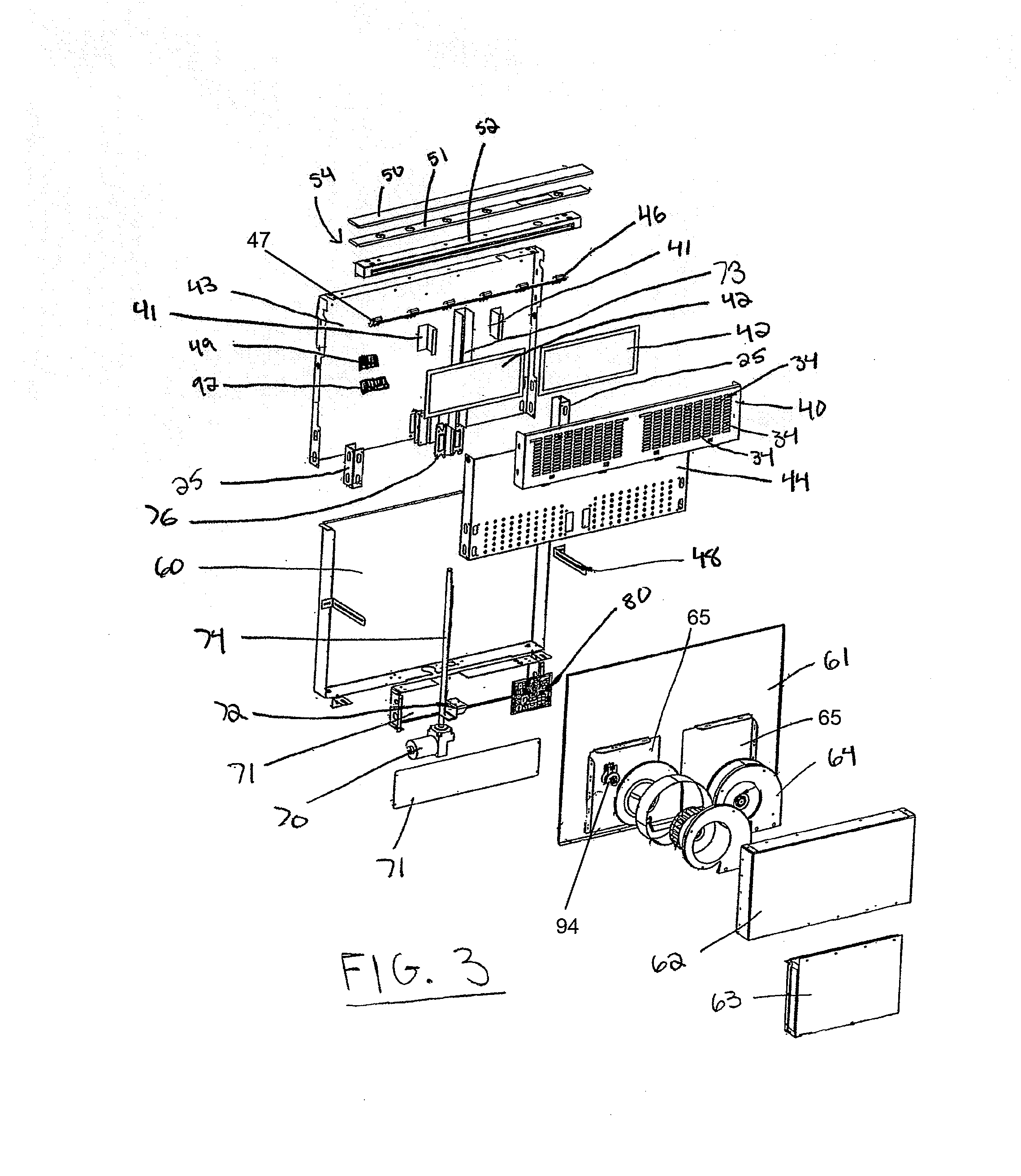

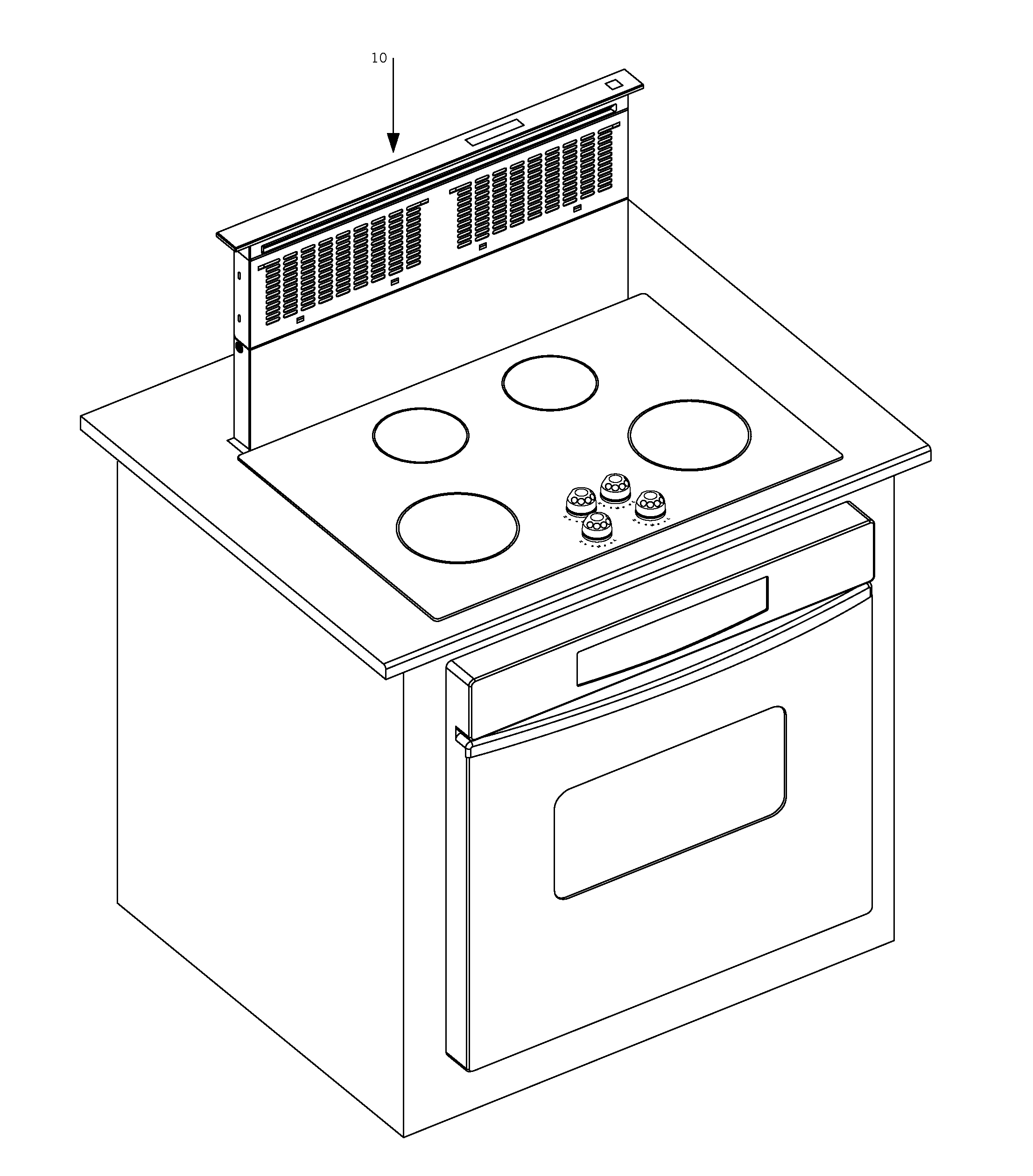

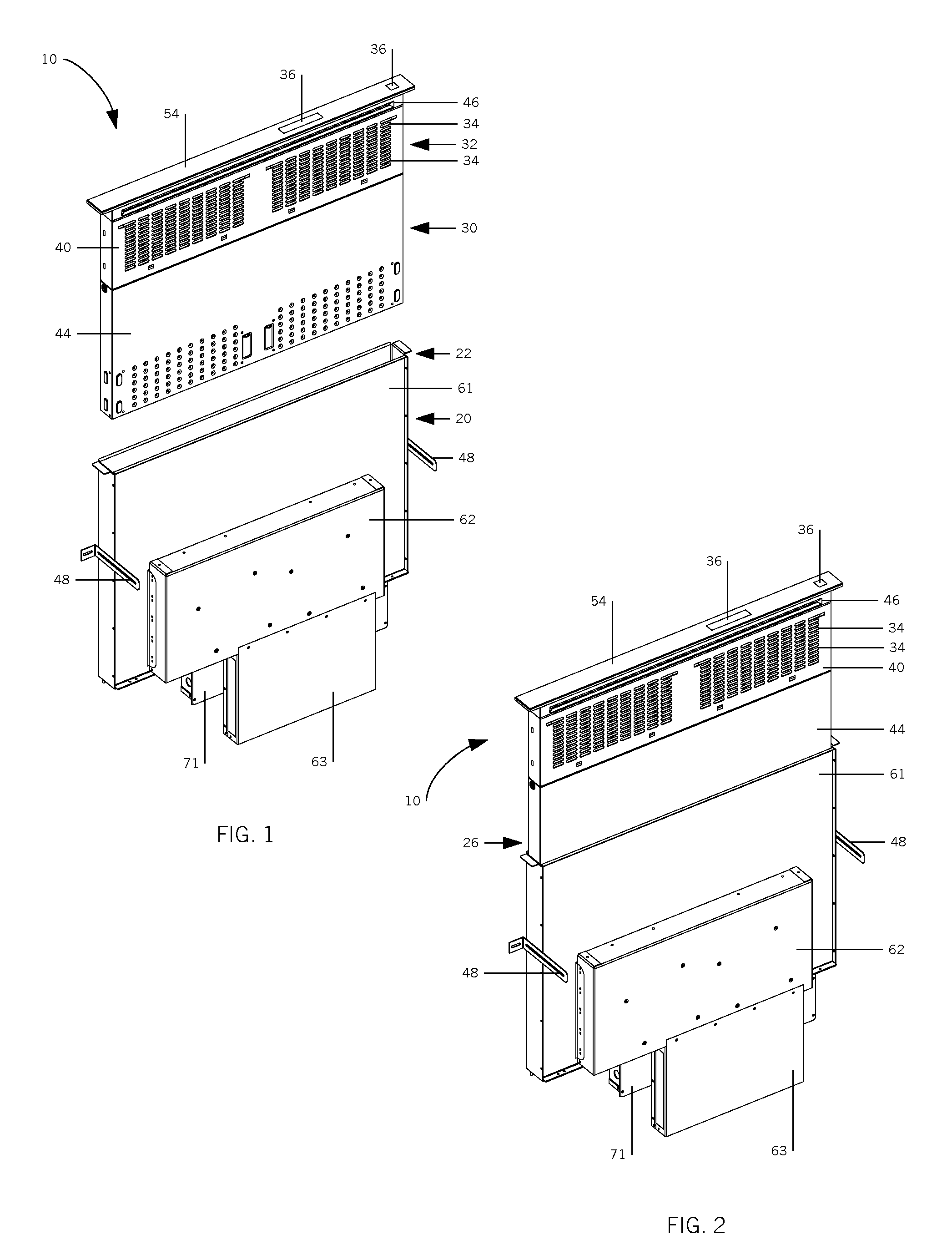

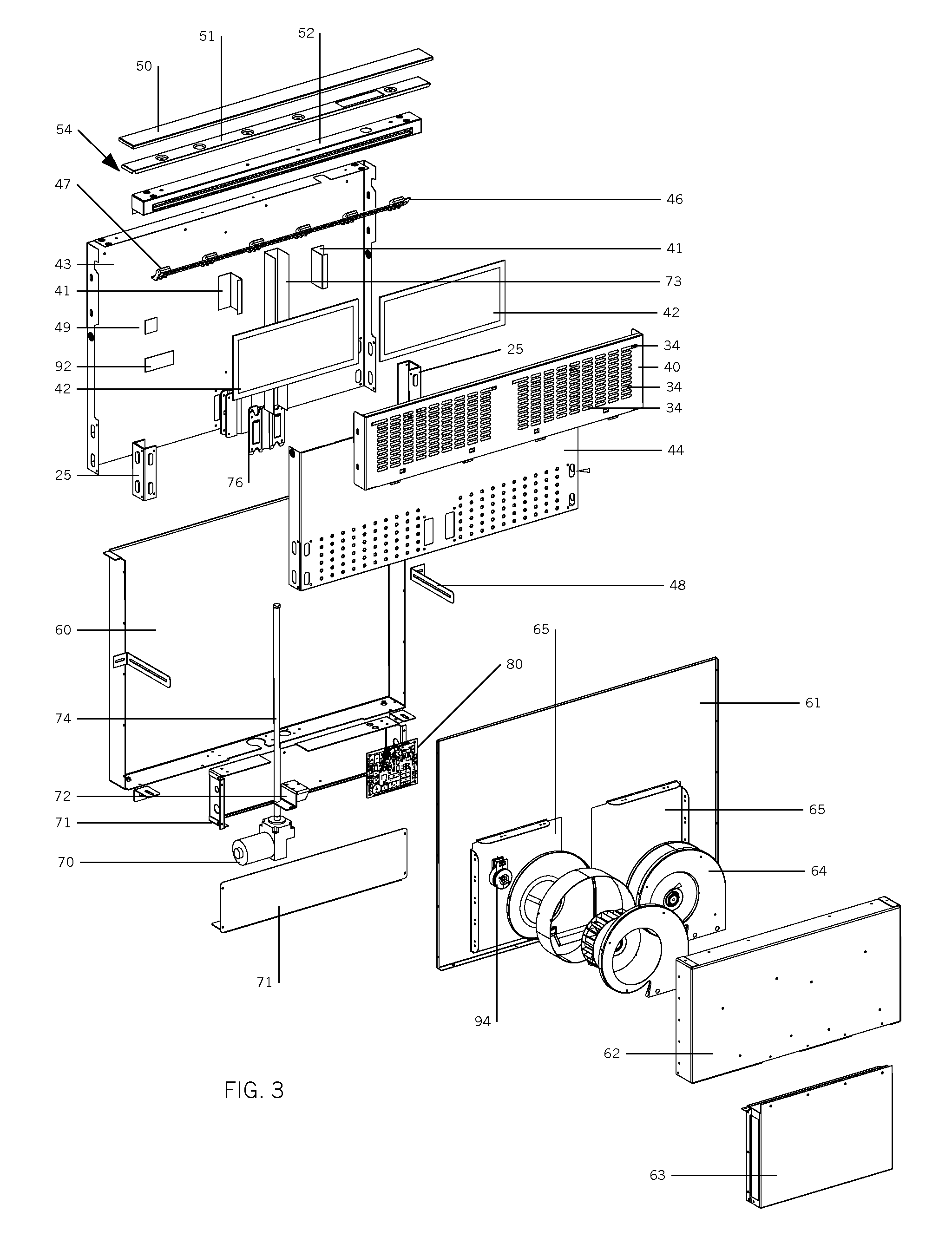

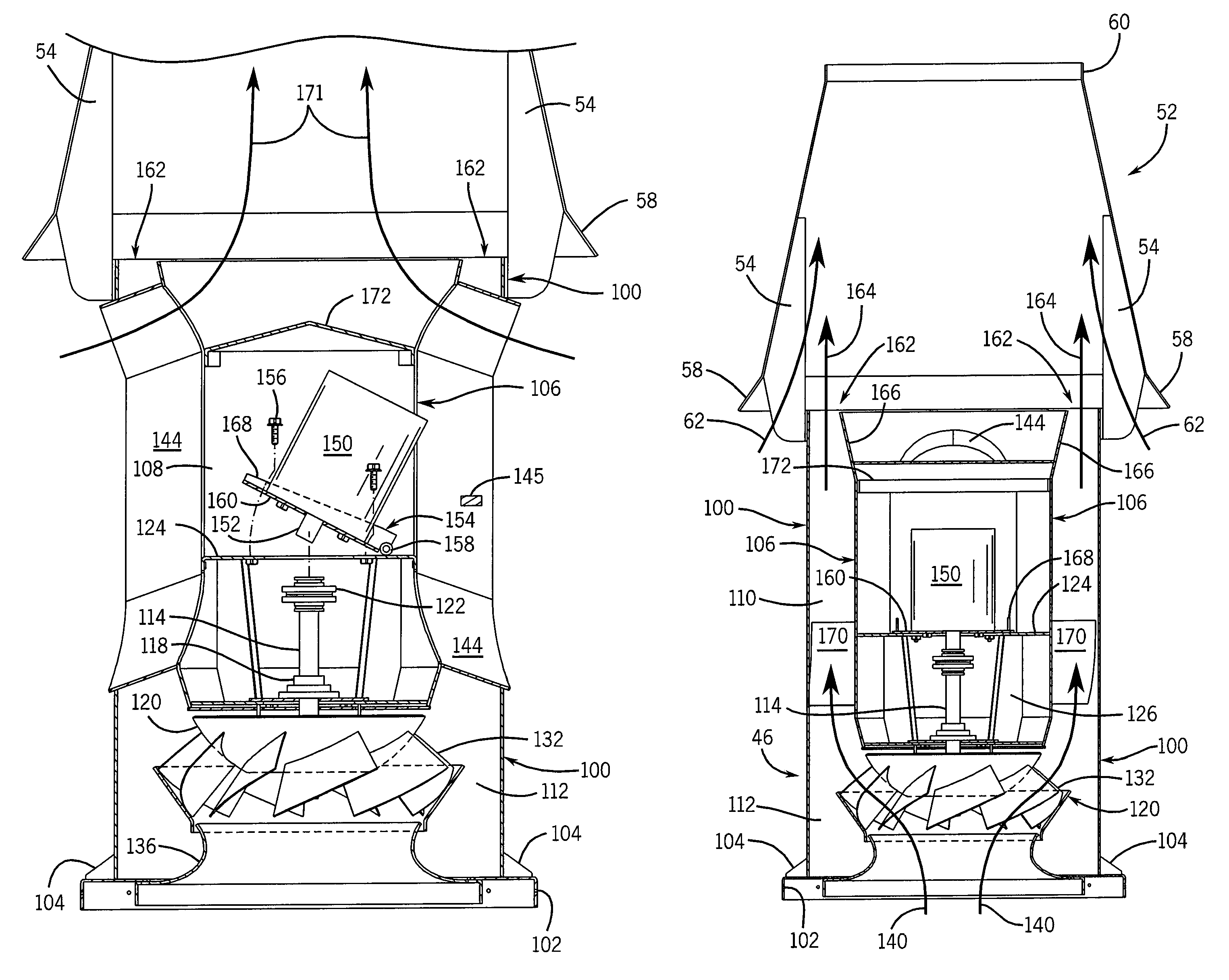

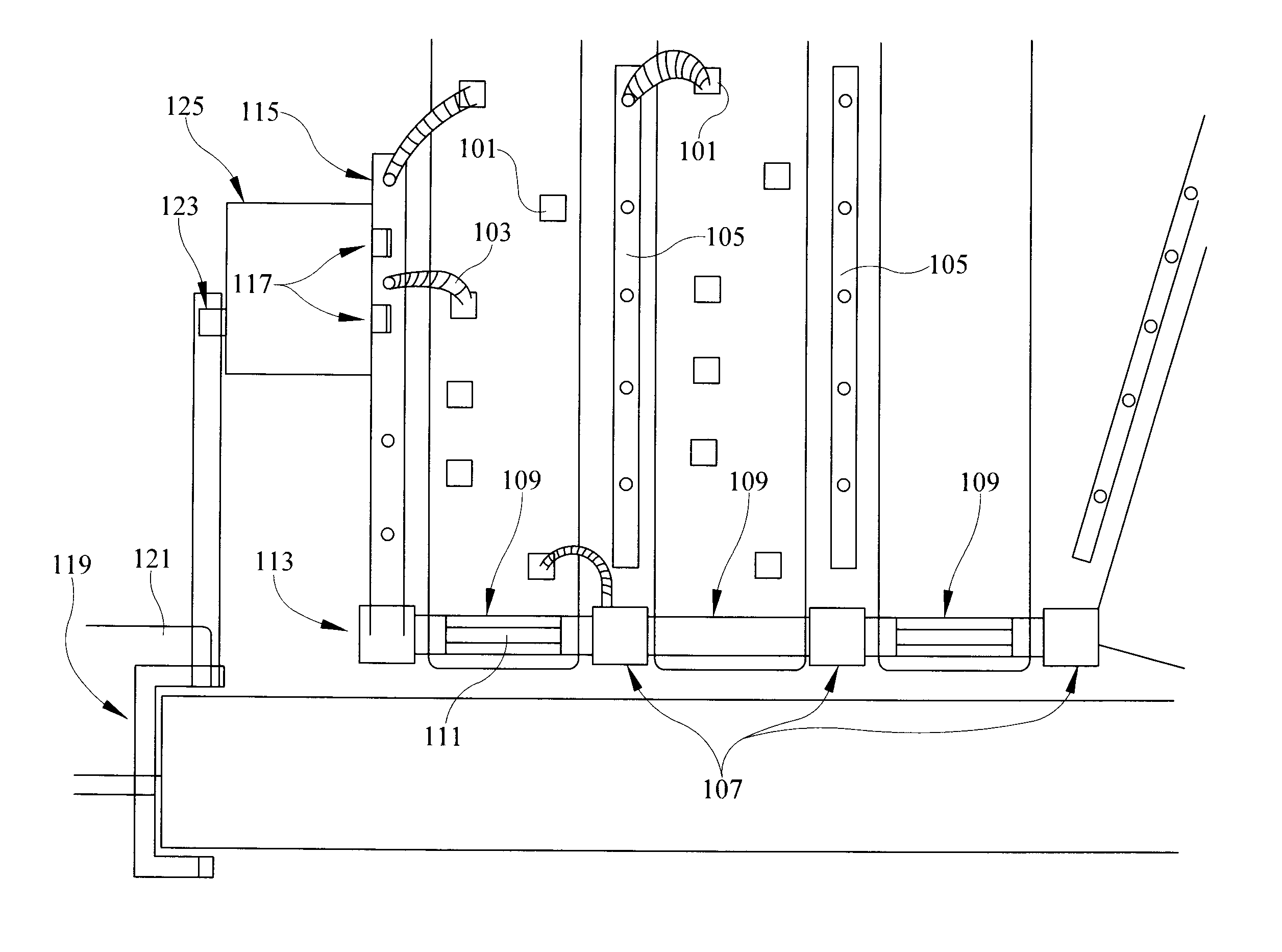

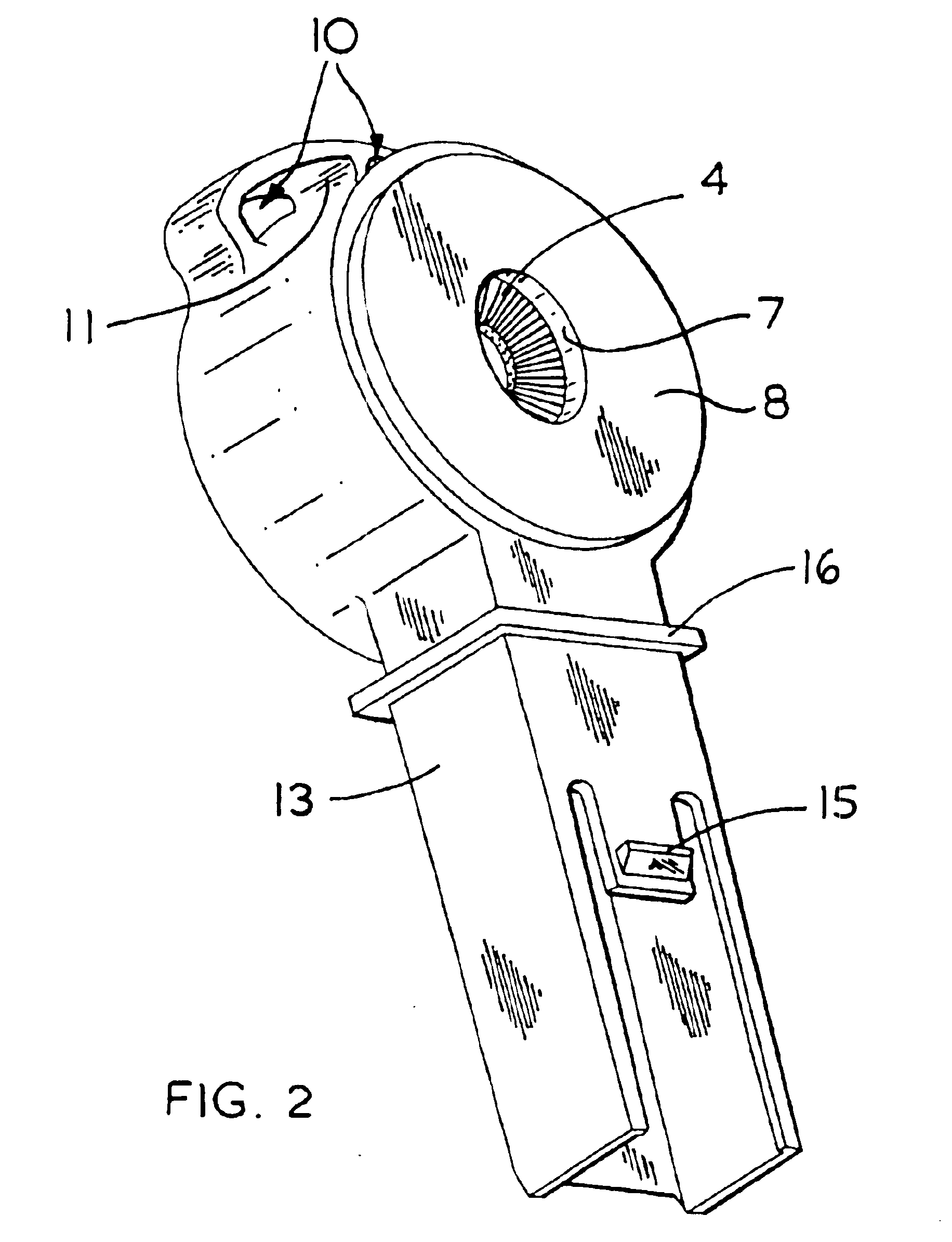

Low Depth Telescoping Downdraft Ventilator

ActiveUS20080029081A1Accuracy in removalEasy to controlCombination devicesLiquid degasificationElectrical resistance and conductanceElectronic controller

A low depth telescoping downdraft ventilator controlled by an electronic controller providing a precisely controlled and efficient way of removing gases and fumes is disclosed. The low depth telescoping downdraft ventilator has the ability to fit behind a built-in oven placed below a cook top unit. The telescoping downdraft ventilator has an almost infinitely selectable range of heights above a cook top with a built in oven. The ventilator collects and draws in exhaust fumes and smoke, filters it and re-circulates or expels it either outdoors or indoors. The inner member of the telescoping ventilator may house the exhaust fans and may move up or down without the use of mechanical switches for elevation detection and stopping. The ventilator may have sensors to detect temperatures, filter change need, fan speeds, telescoping stop points, energy consumption, resistance and voltage, enabling programmable set point operation.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

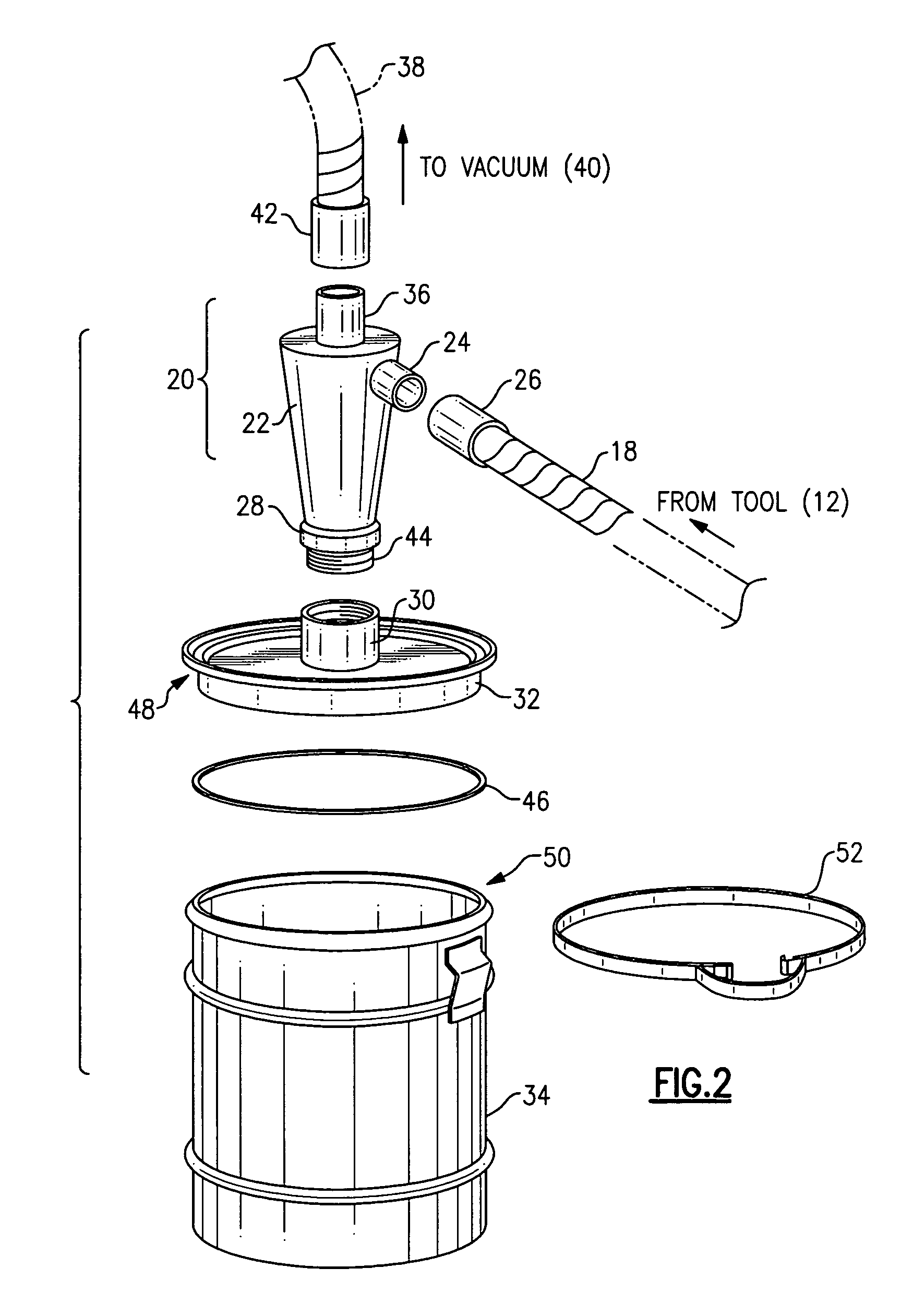

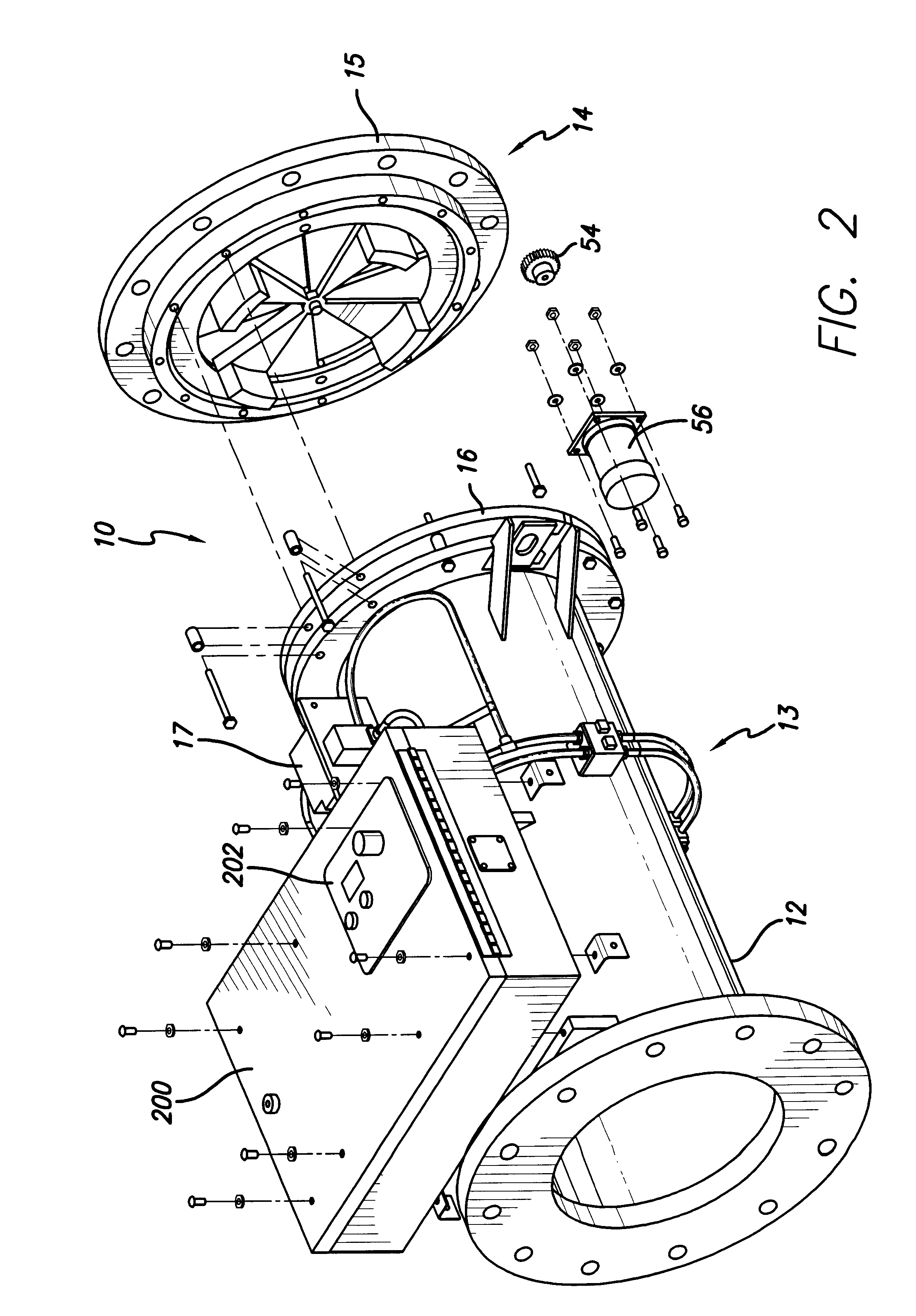

Method and apparatus for attachment and evacuation

ActiveUS10751768B2Two pole connectionsDispersed particle filtrationPhysical medicine and rehabilitationEngineering

Owner:BUFFALO FILTER

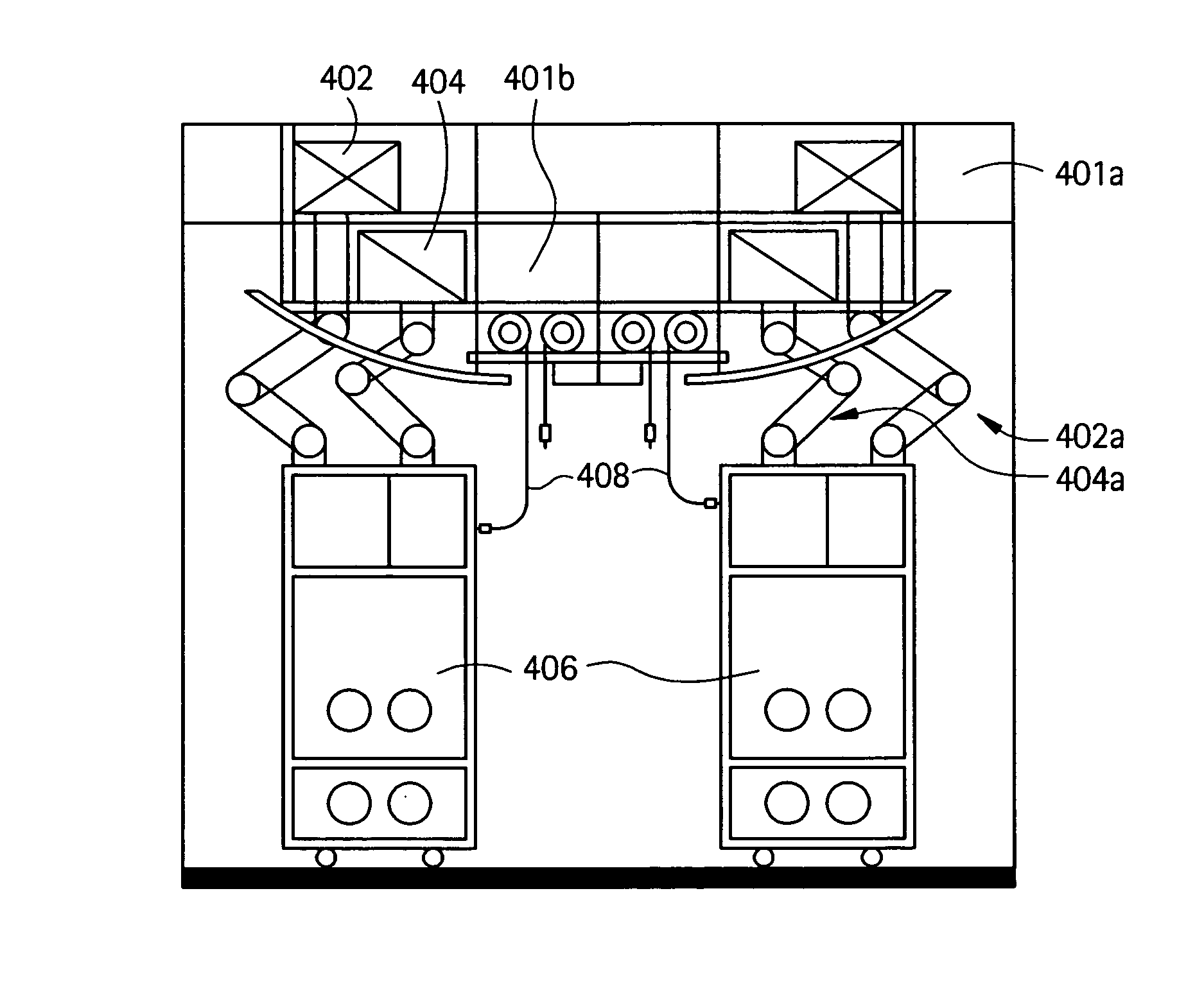

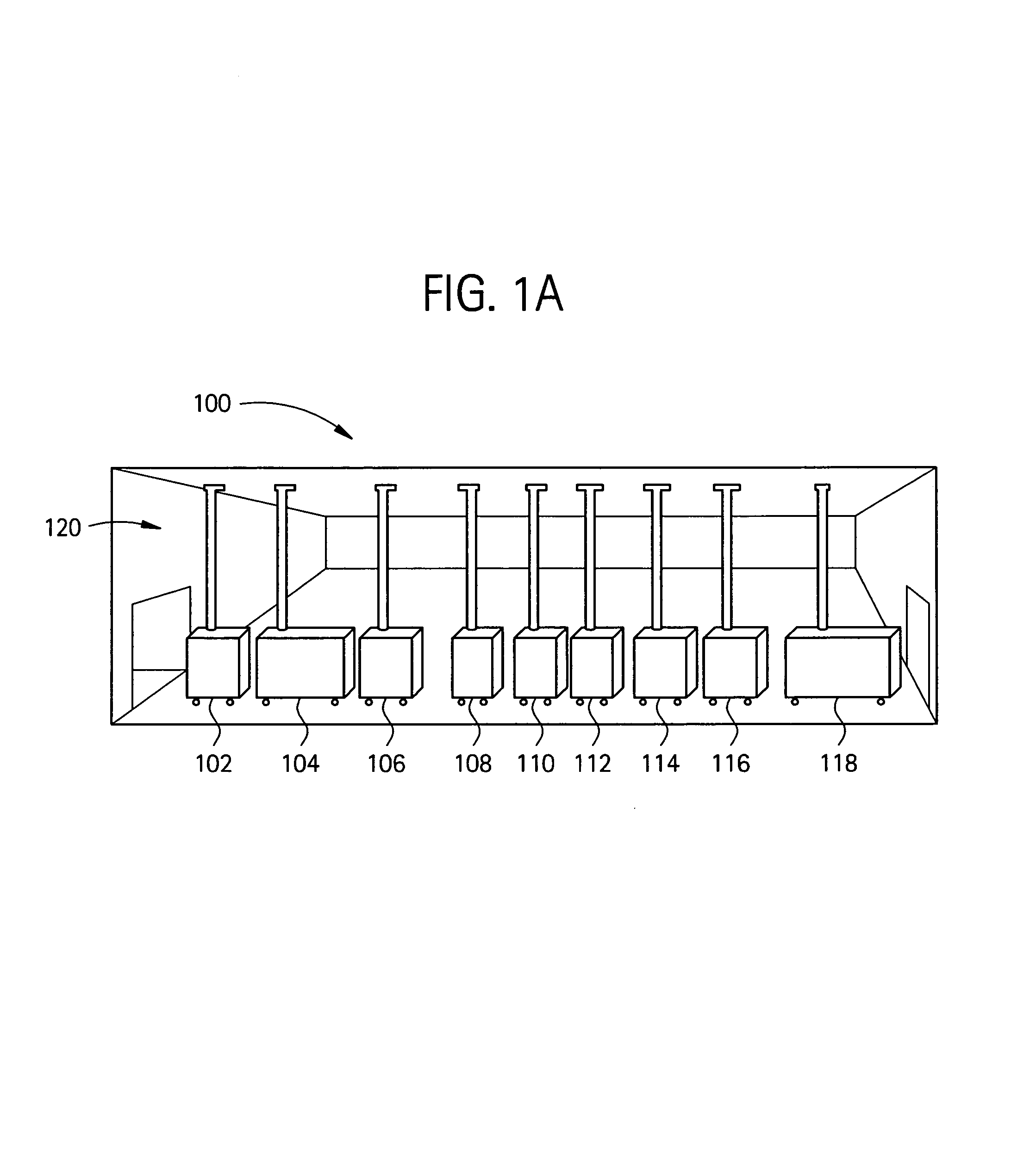

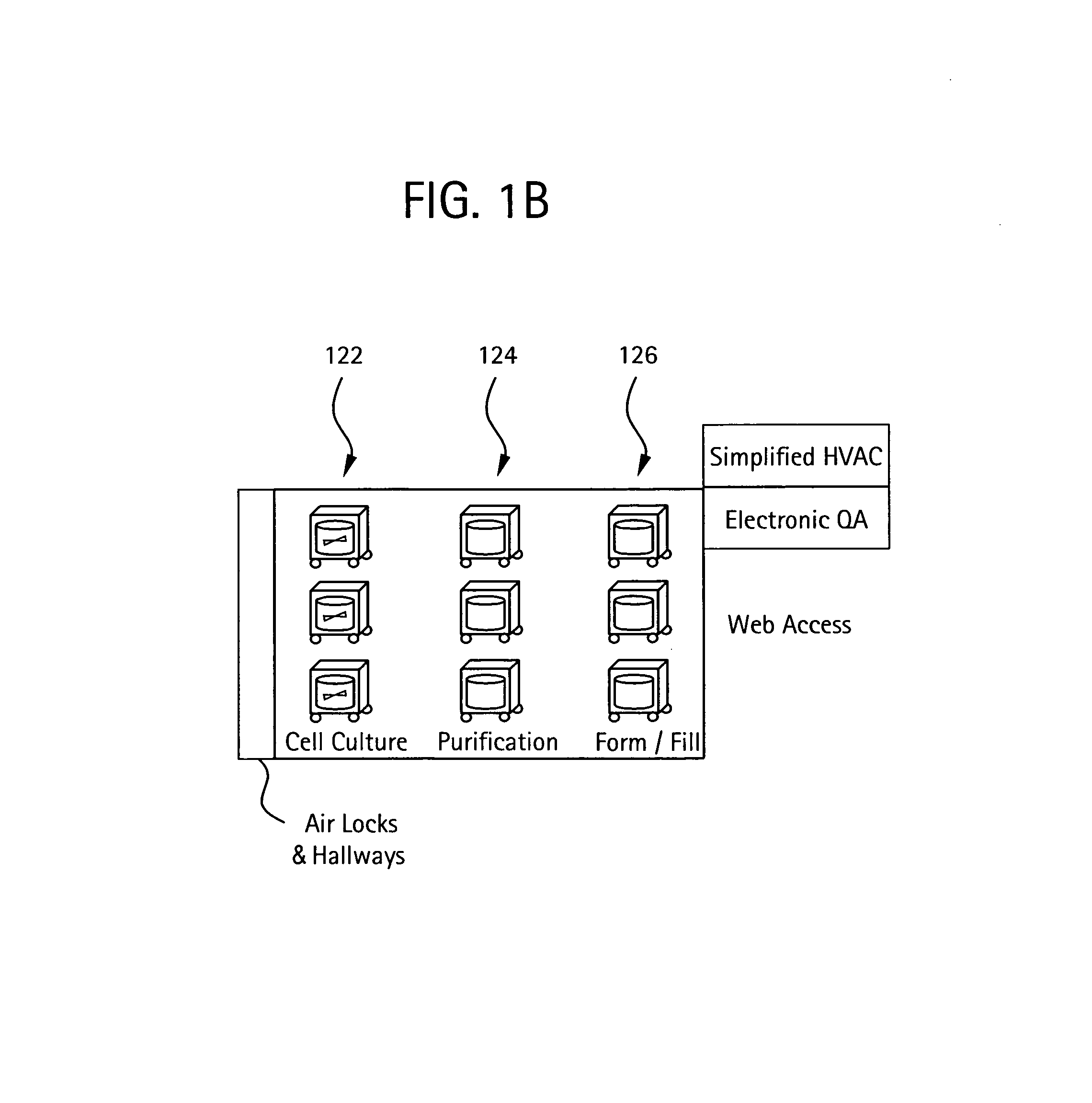

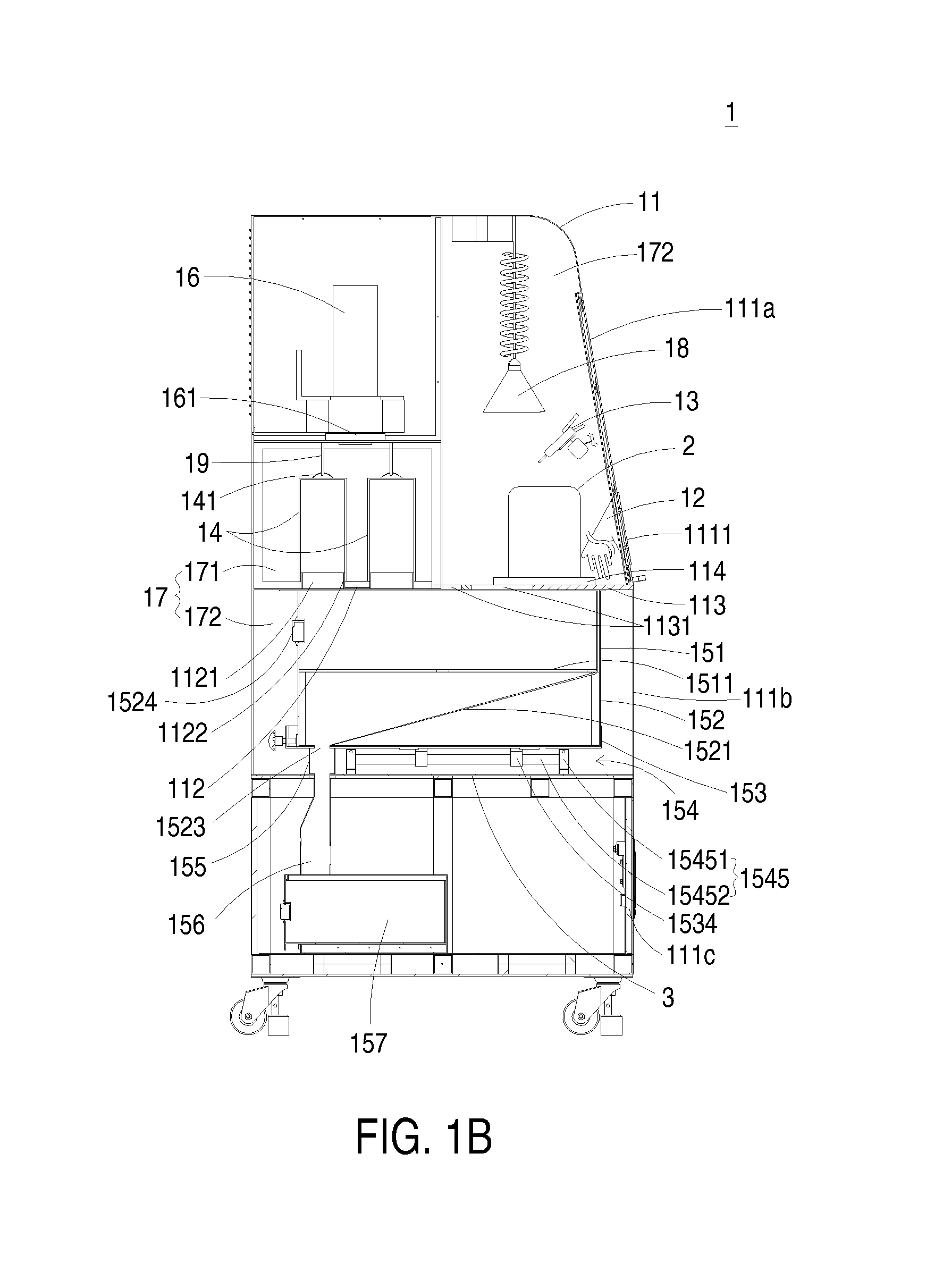

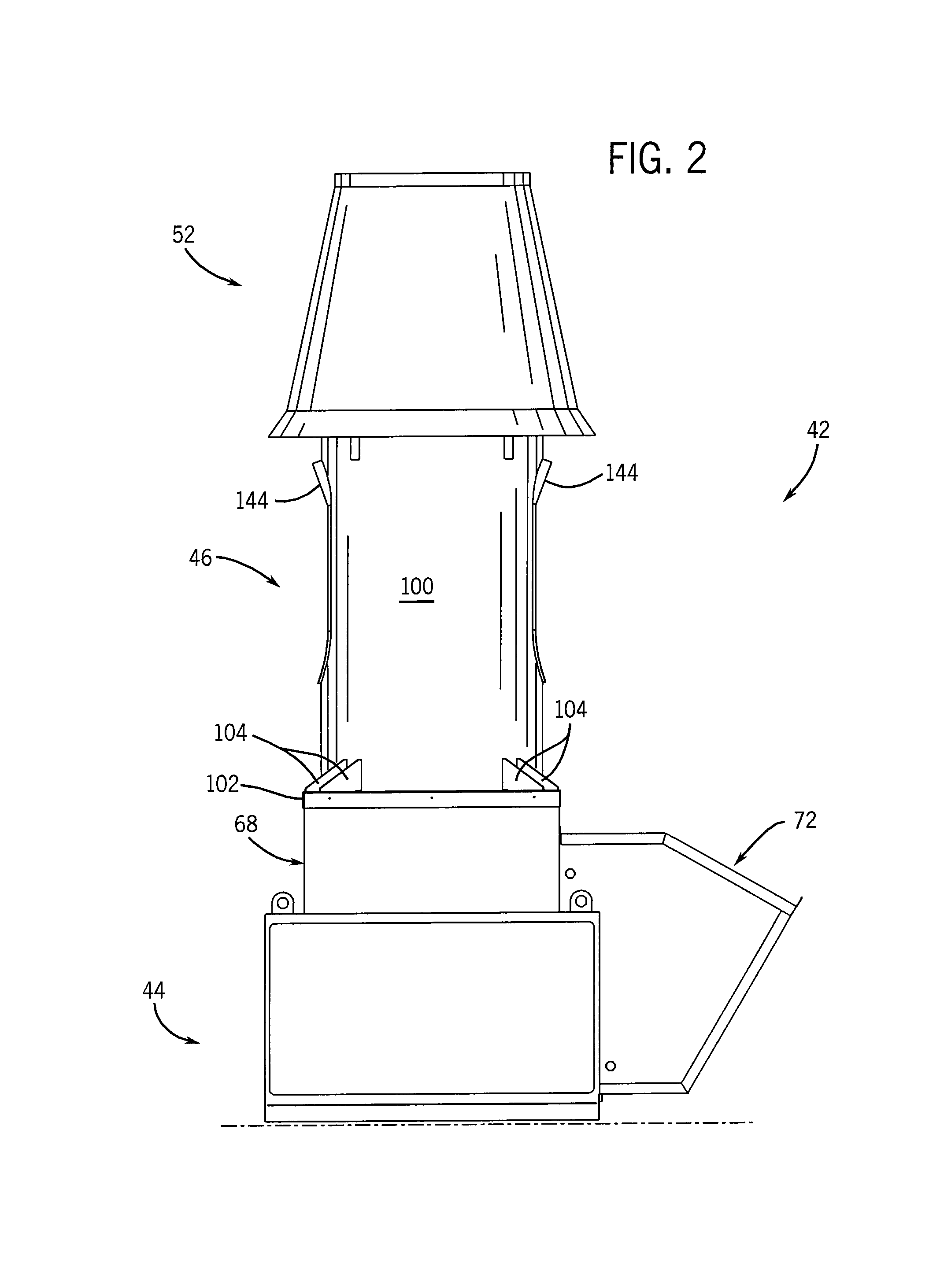

System and method for manufacturing

ActiveUS8298054B2Increase capacityLess expensiveDomestic stoves or rangesSpace heating and ventilationFir systemOn board

Embodiments of the present invention are directed to a customizable bio-manufacturing system which includes a manufacturing space having a first air handling system for providing supply air and a second air handling system for handling exhaust air, the supply air system being optionally provided with at least one of filtration, heating, cooling and or humidity control and a plurality of portable modules provided within the manufacturing space. At least one module having an interior capable of being interconnected with another module interior and each module's interior includes one or more components to perform at least one specific task of a biological, chemical, and / or pharmaceutical manufacturing process. At least one module includes an on-board environmental control system for controlling an environment within the module and a connection means for interconnecting the module interior with another module interior. The system also includes a central controller operating to at least perform one or more of operation and information collection for the operation of at least one of the system and one or more modules.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

Apparatus and method for welding

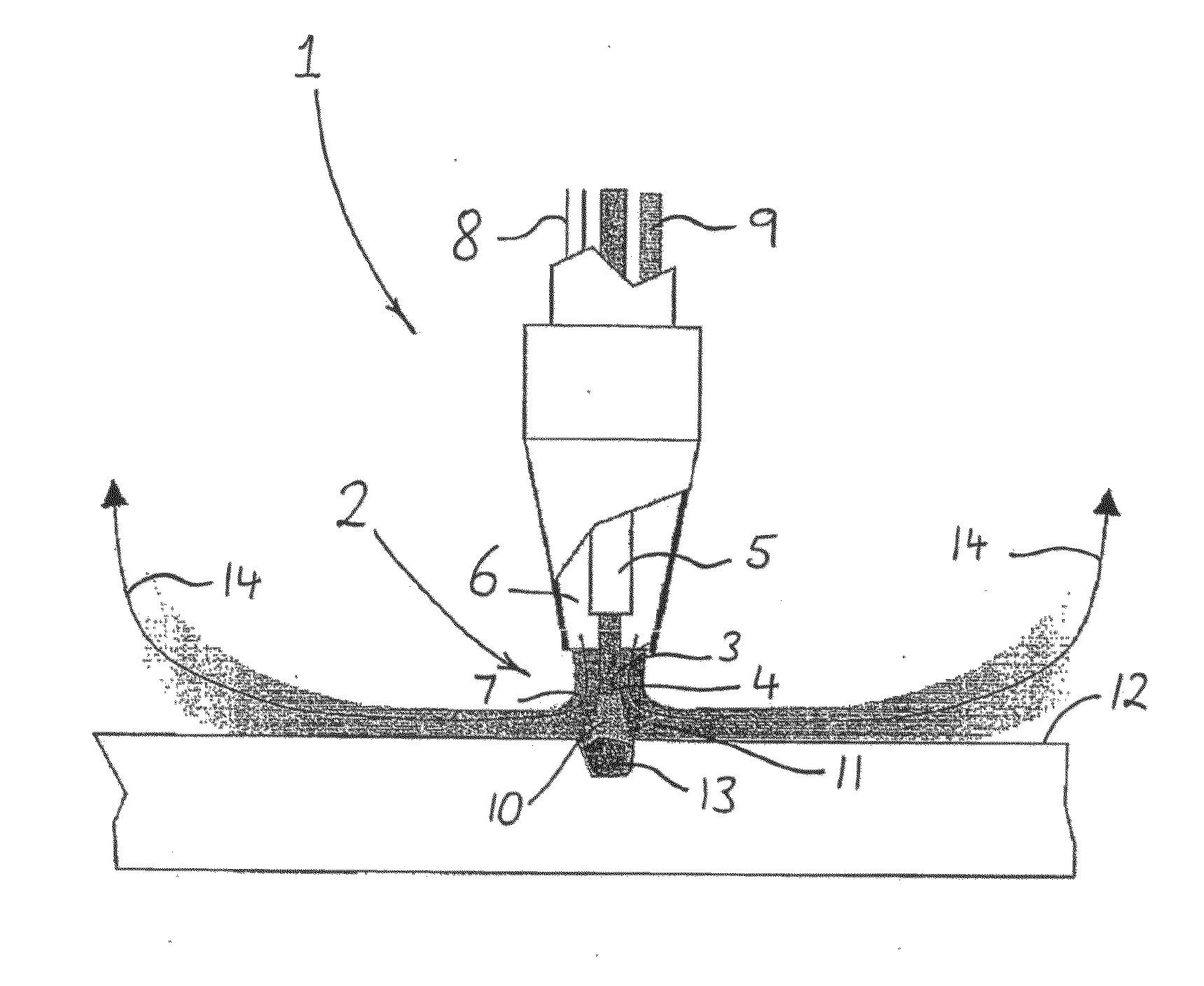

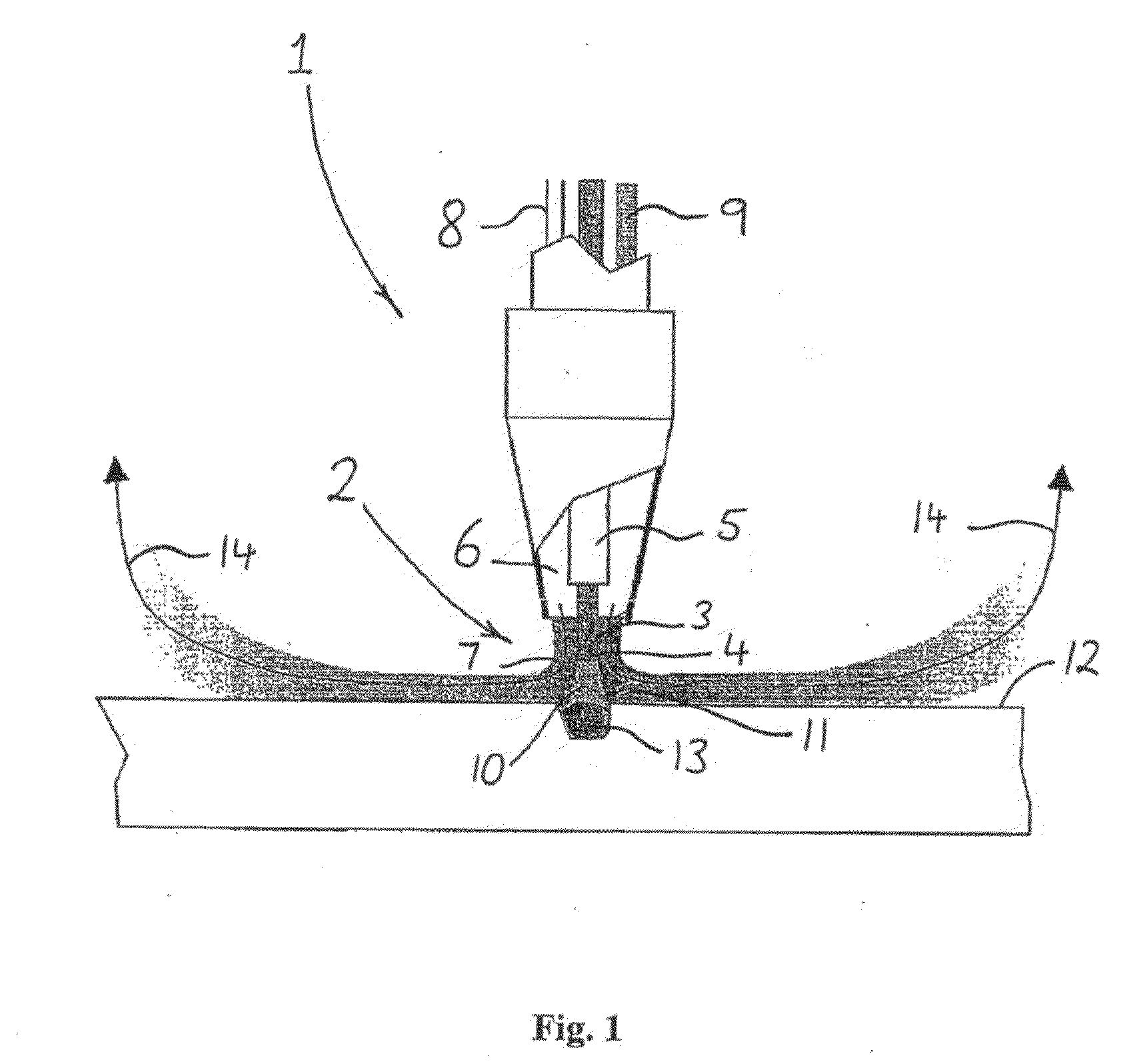

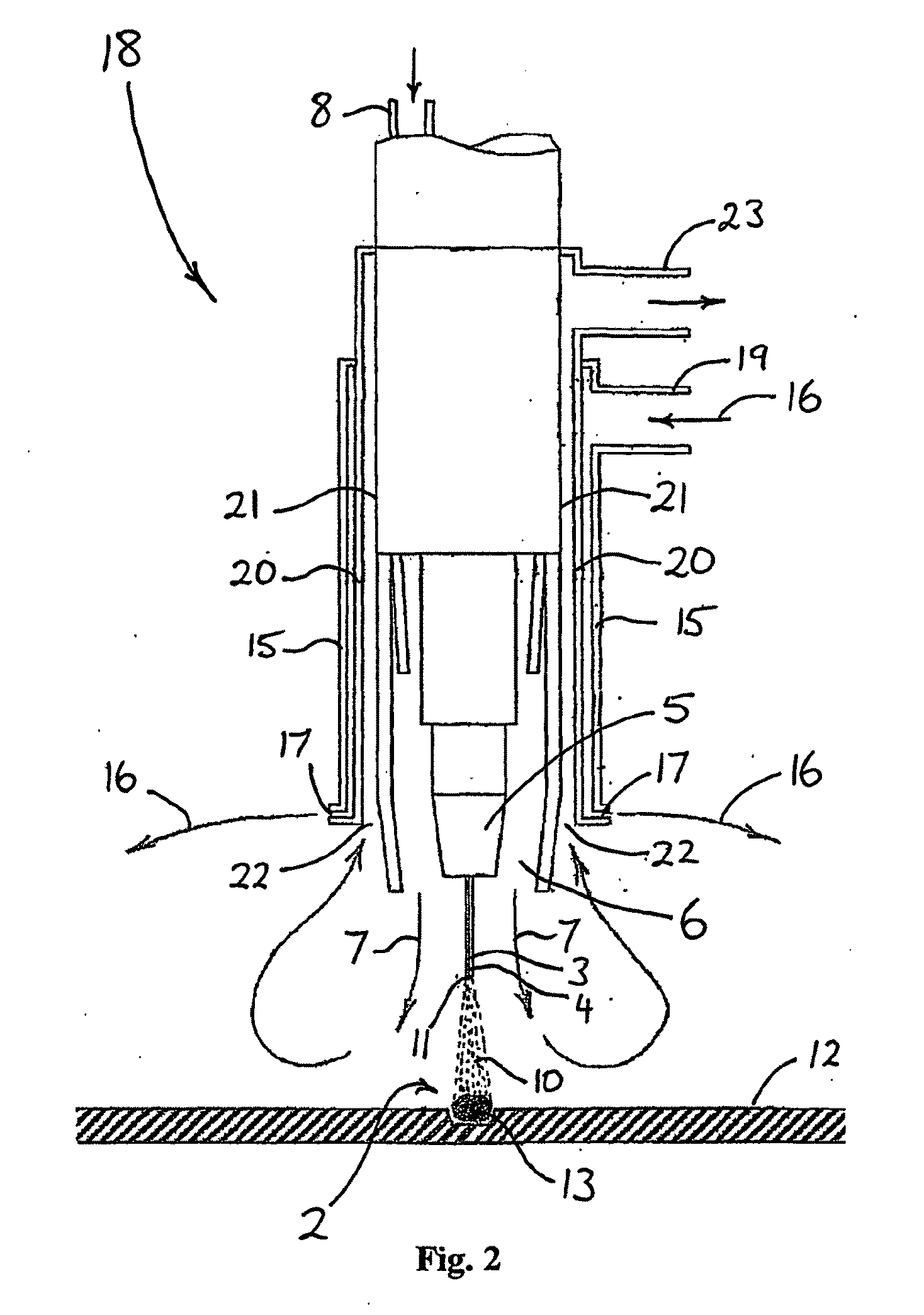

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

Variable-volume exhaust system

ActiveUS10029289B2Reduce energy consumptionReduce flow ratePump componentsSpace heating and ventilation safety systemsControl systemShock absorber

Owner:GREENHECK FAN

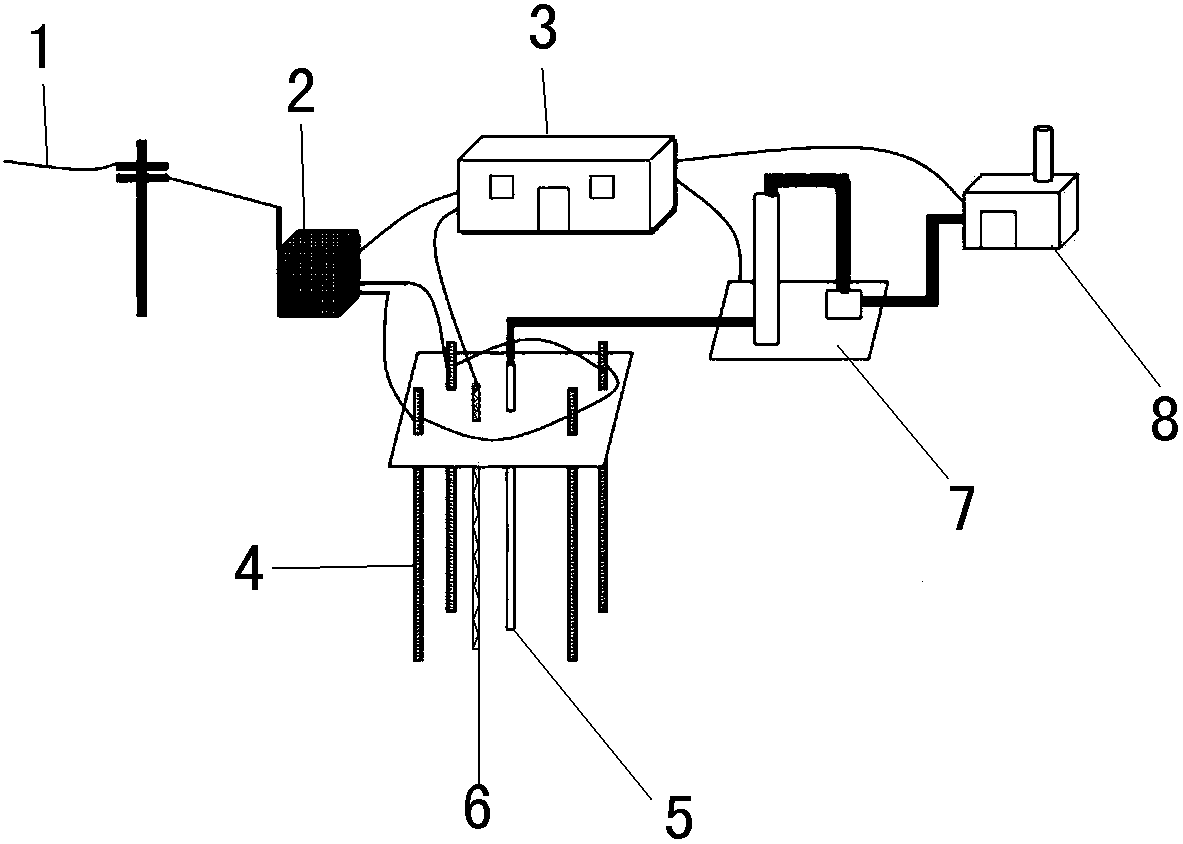

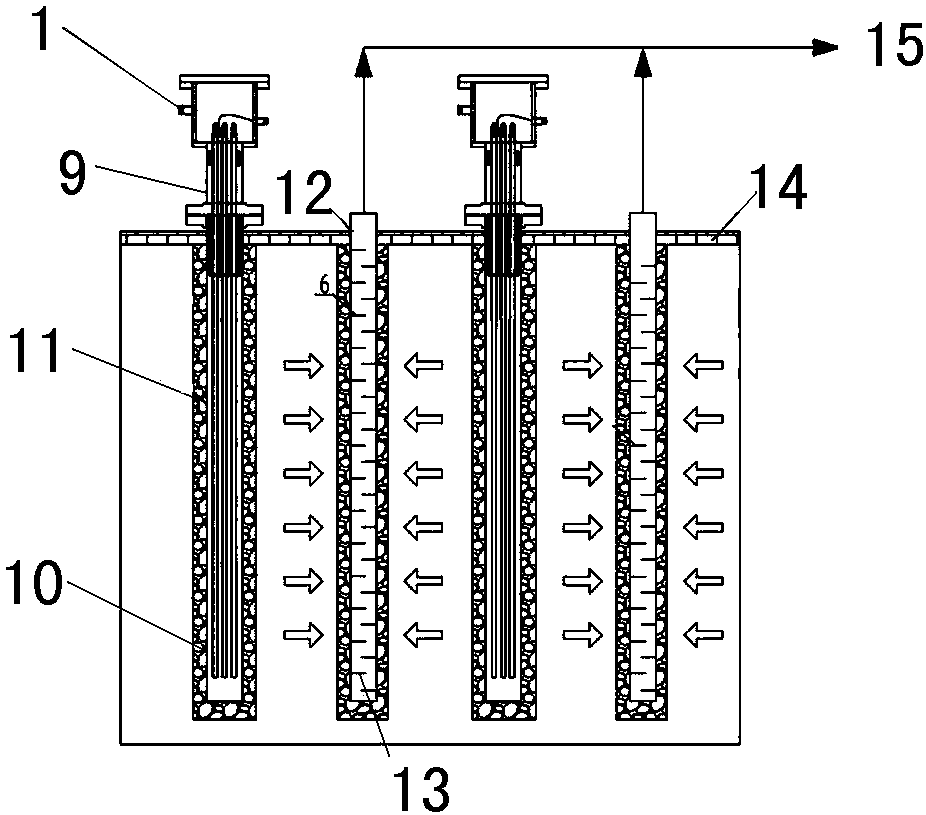

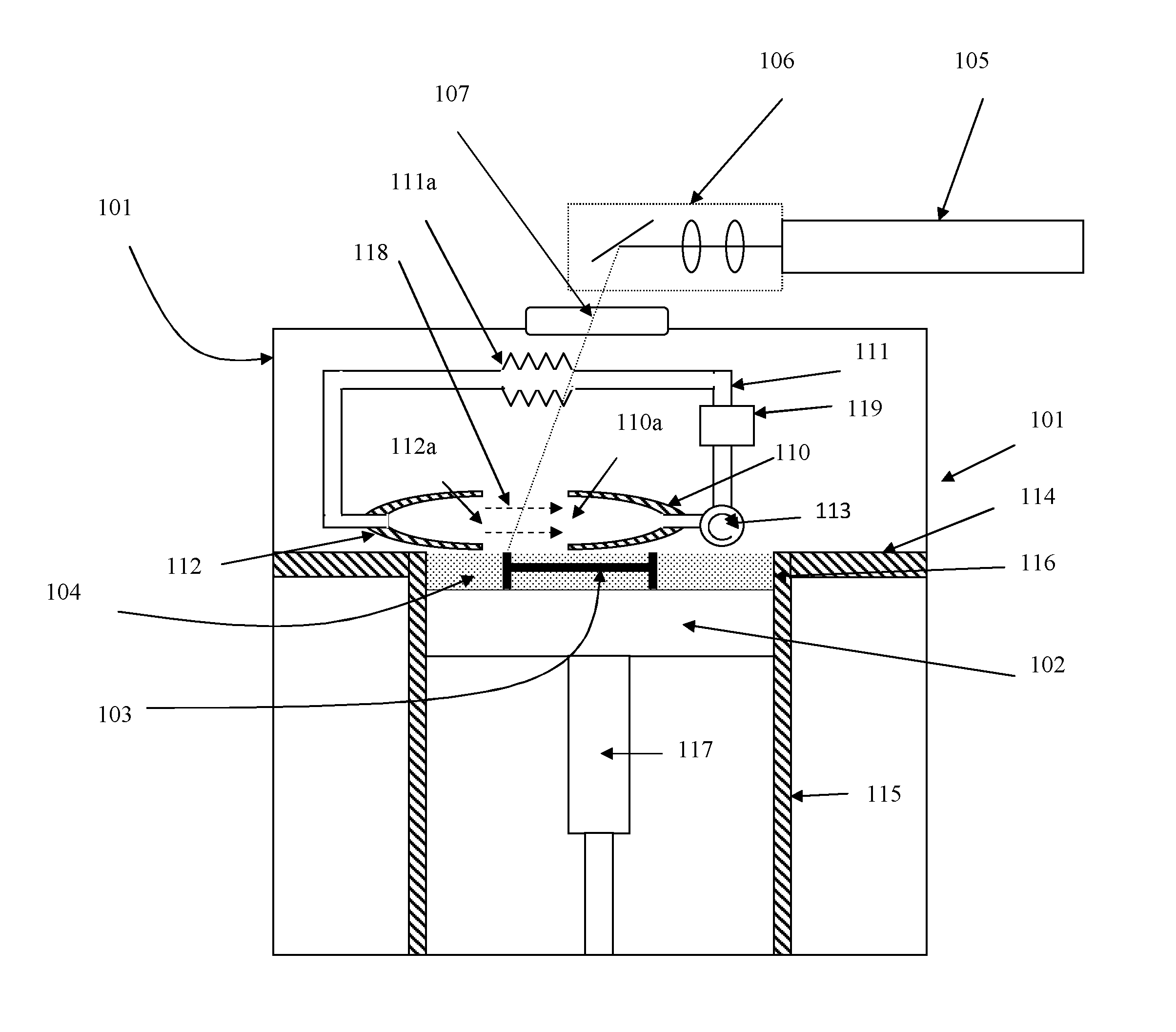

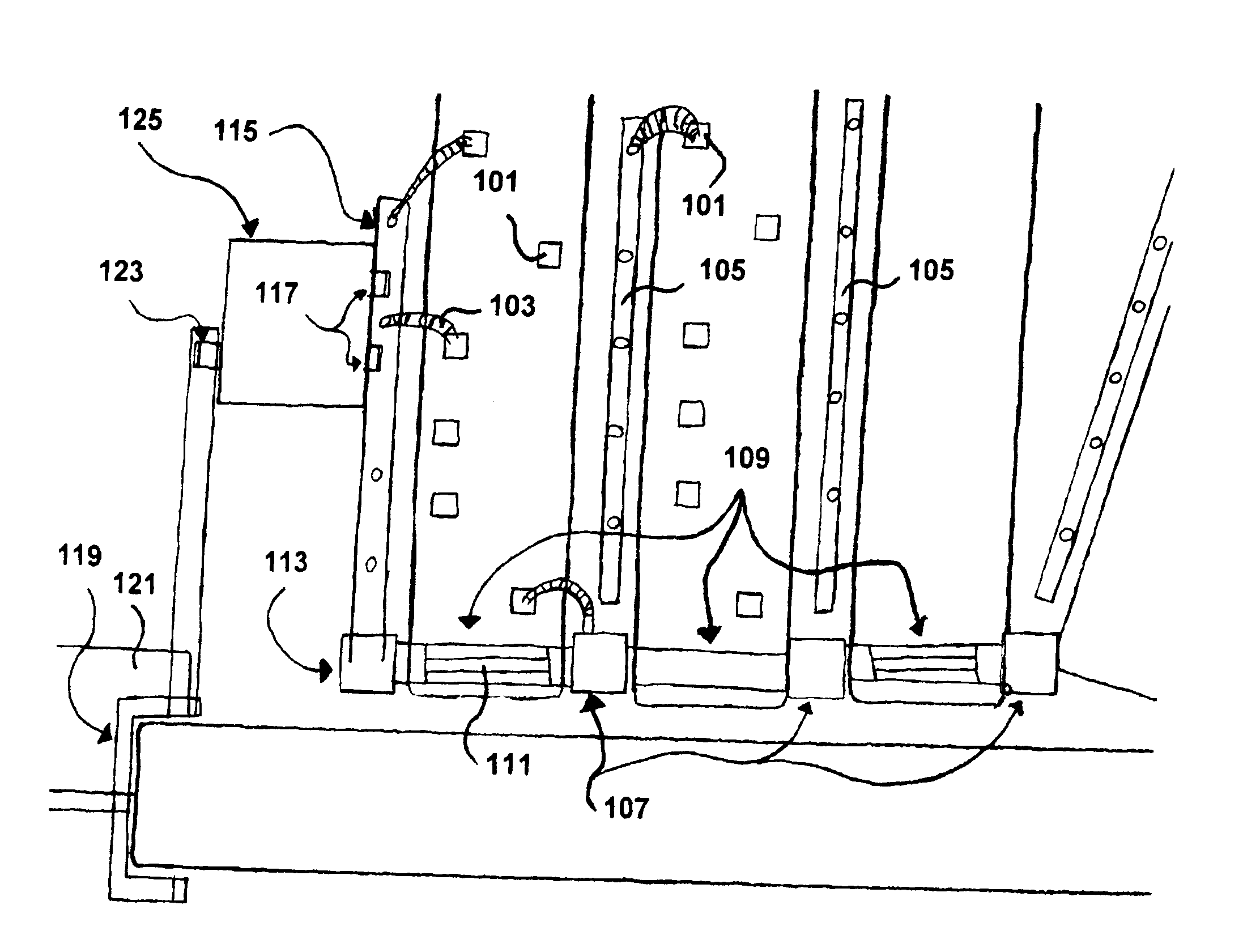

System for restoring organic contaminated soil through in-situ electrical heating and treatment method

ActiveCN108311535AUniversalPull out in timeCombination devicesContaminated soil reclamationTreatment effectSoil properties

The invention provides a system for restoring organic contaminated soil through in-situ electrical heating. The system comprises an infrastructure technology, an electronic control system, a gas treatment system, a monitoring and data acquisition system and a repairing effect comprehensive assessment system. The infrastructure technology comprises heating well and extraction well construction, ground compaction and insulating layer construction technologies; heating wells are distributed on a contaminated site according to a triangle arrangement principle and a proximity principle, and the extraction well is arranged in the geometric center of the layout of the heating well; the gas treatment system is composed of a pre-cooling adsorption sledge, an extraction sledge and a treatment sledge, and is used for completing gas extraction and treatment and achieving the tail gas discharging requirement; and the repairing effect comprehensive assessment system evaluates the temperature risingeffect of the contaminated soil in the restoring process and the treatment effect of the contaminated soil. According to the system, the technological route is complete, the soil property applicability is wide, the heating temperature can reach 500 DEG C or above, and volatile and difficult-to-volatilize organic contaminant can be treated at the same time.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION +1

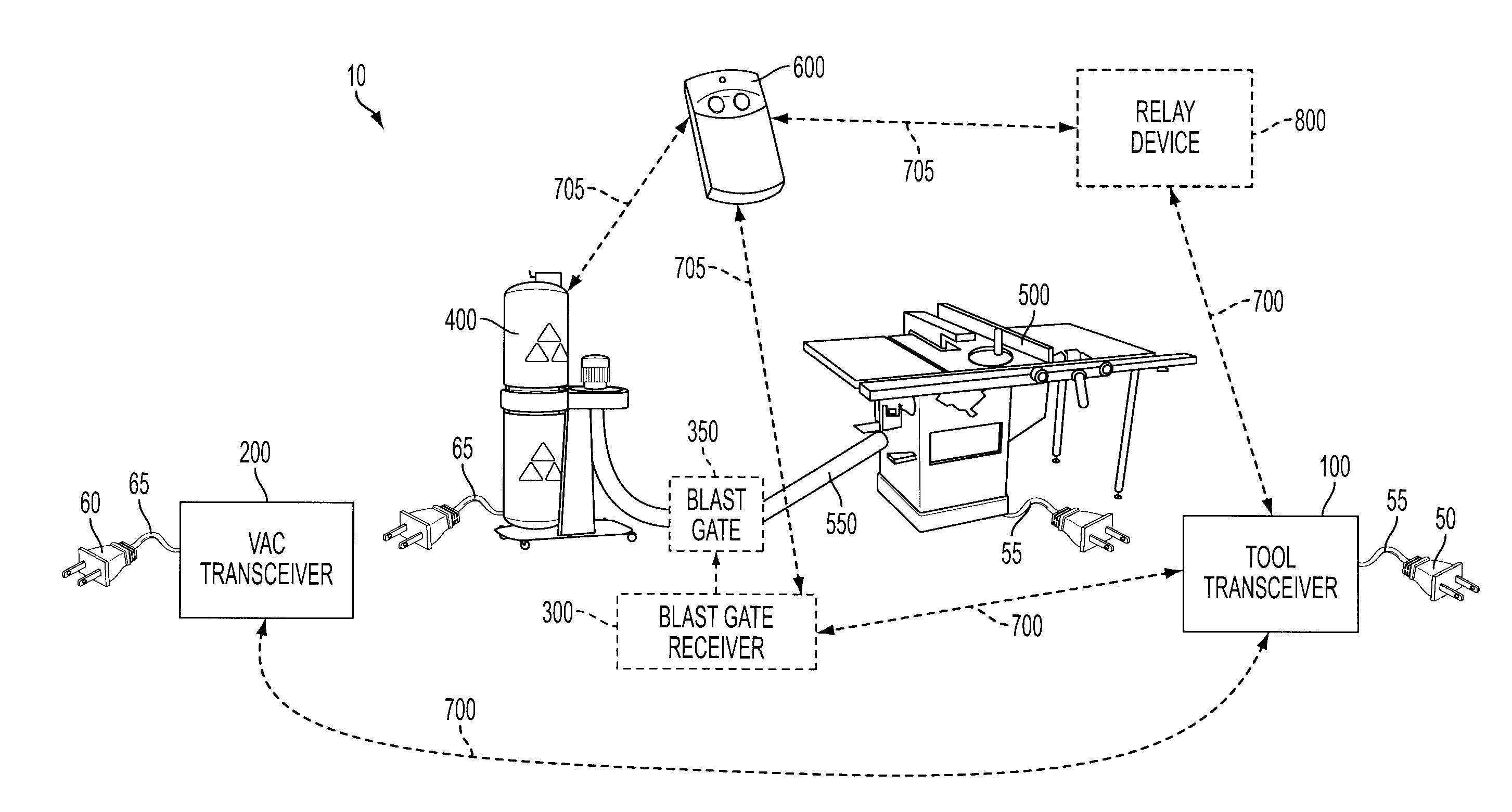

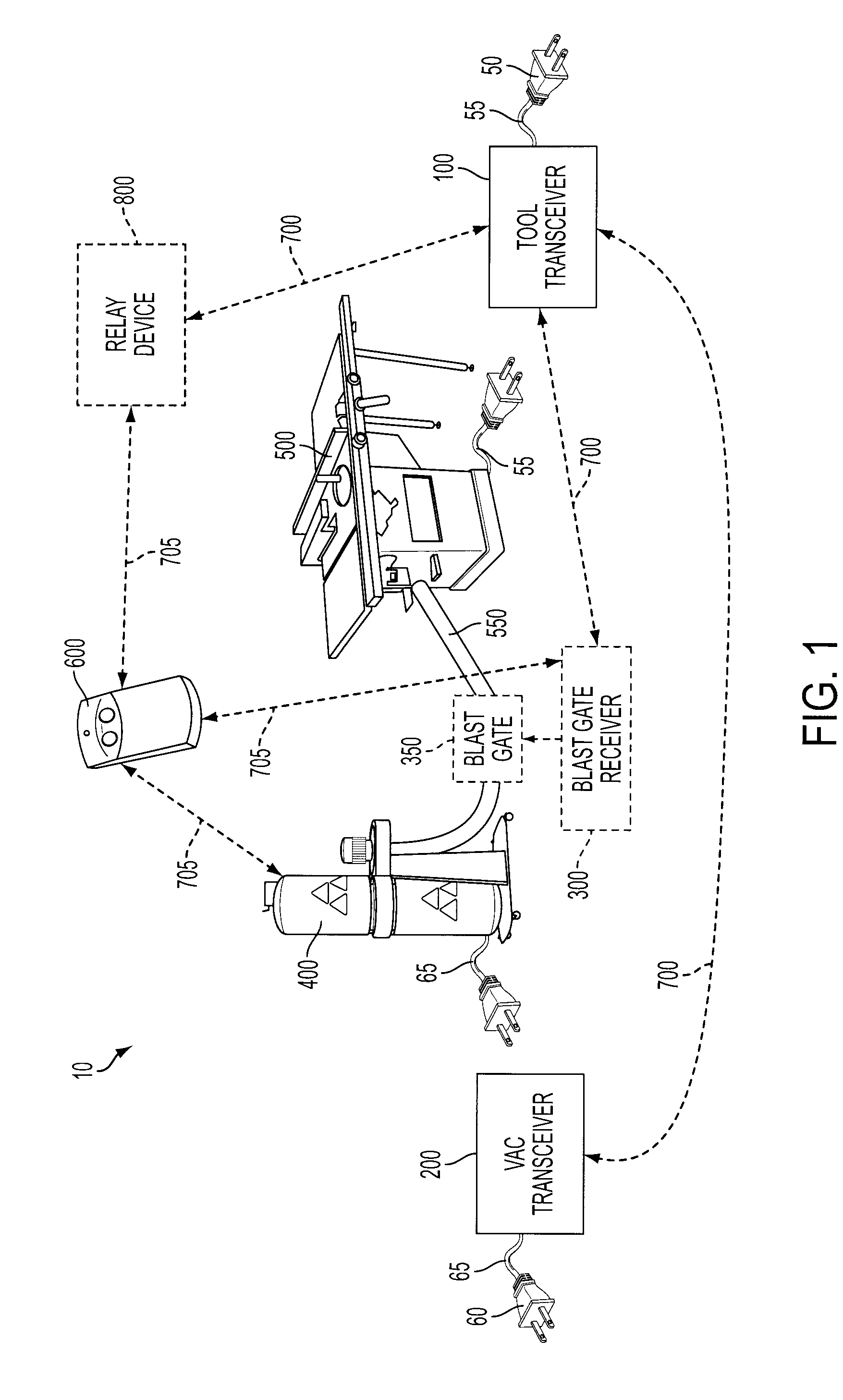

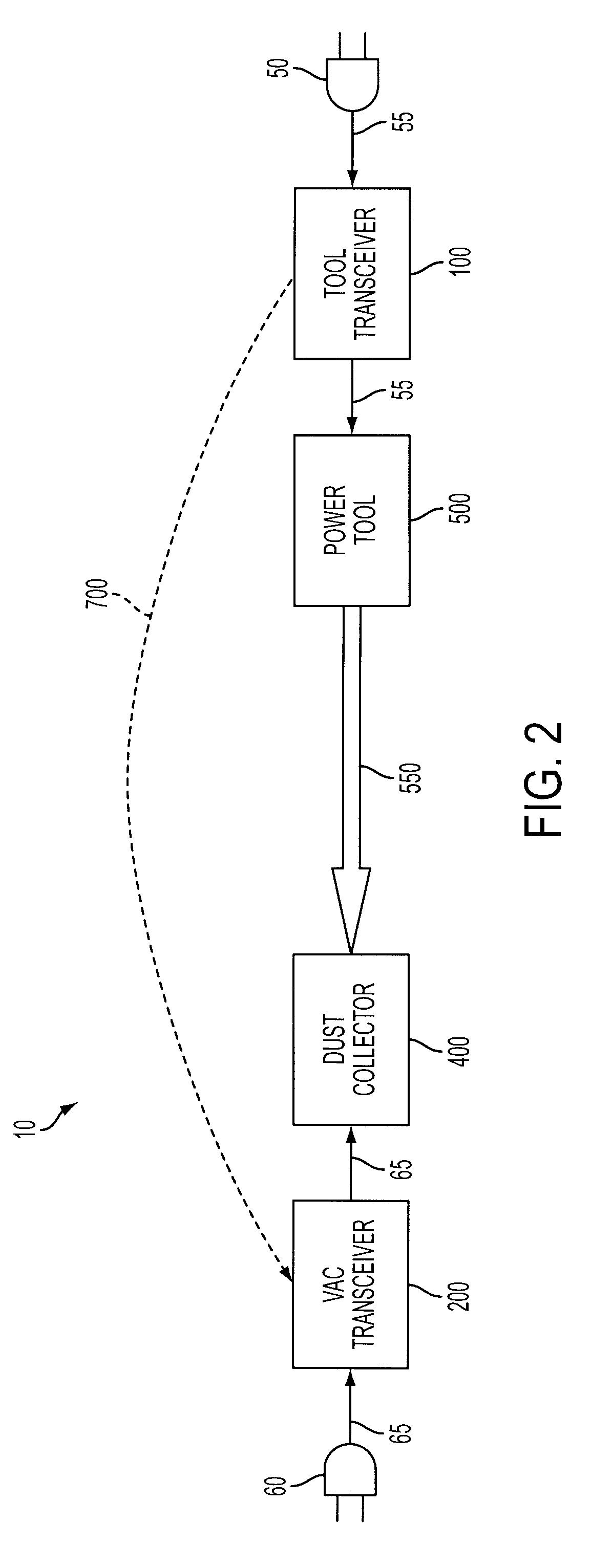

Wireless particle collection system

InactiveUS20100199453A1Metal sawing accessoriesDispersed particle filtrationCollection systemUnique identifier

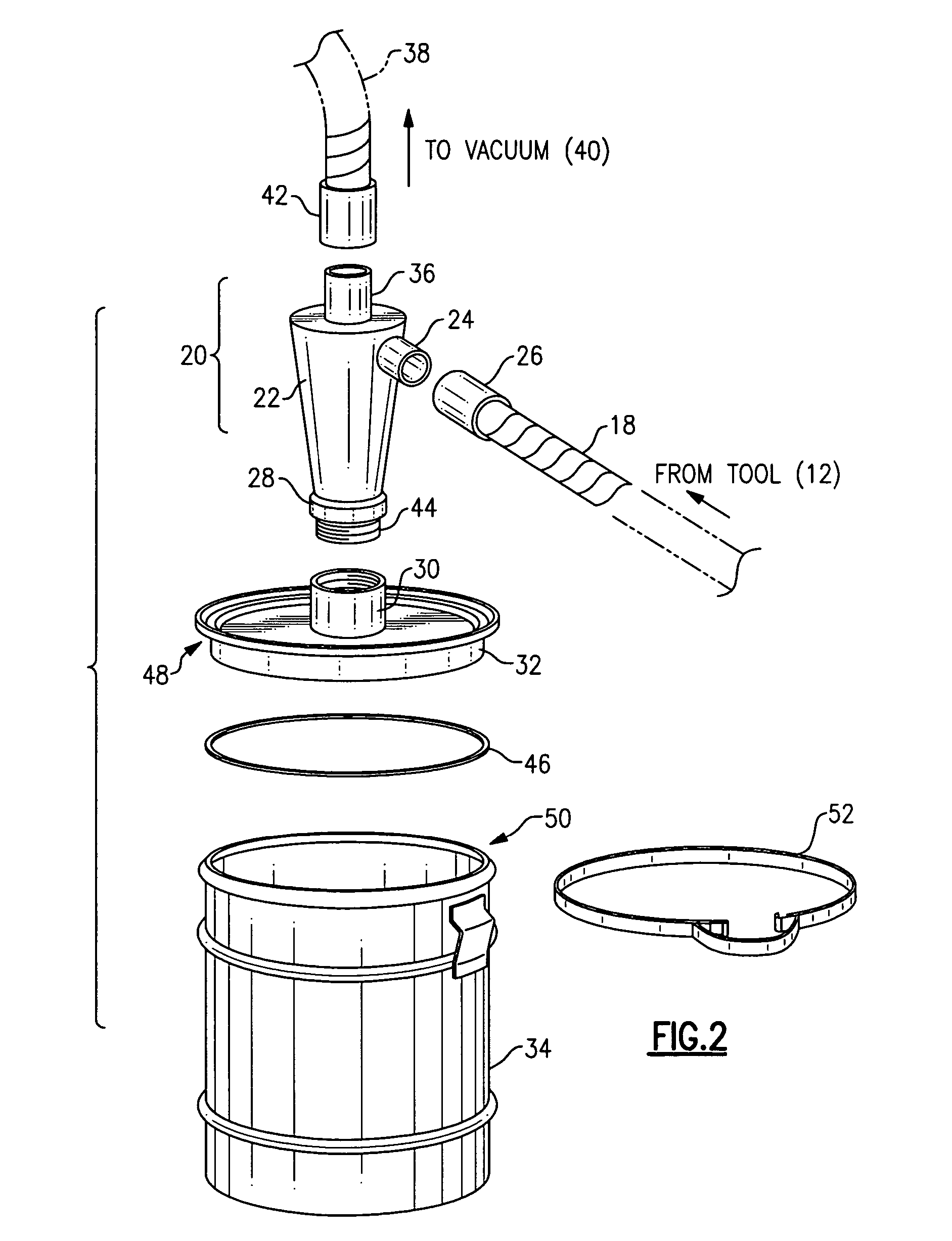

A wireless particle collection system includes a dust collector and at least one power tool coupled to the dust collector. The power tool is associated with a unique identifier contained in a wireless signal transmitted from the power tool upon an activation event of the tool. The unique identifier is recognized by the dust collector, and the dust collector activates or de-activates upon receipt of the wireless signal.

Owner:CHANG TYPE INDAL

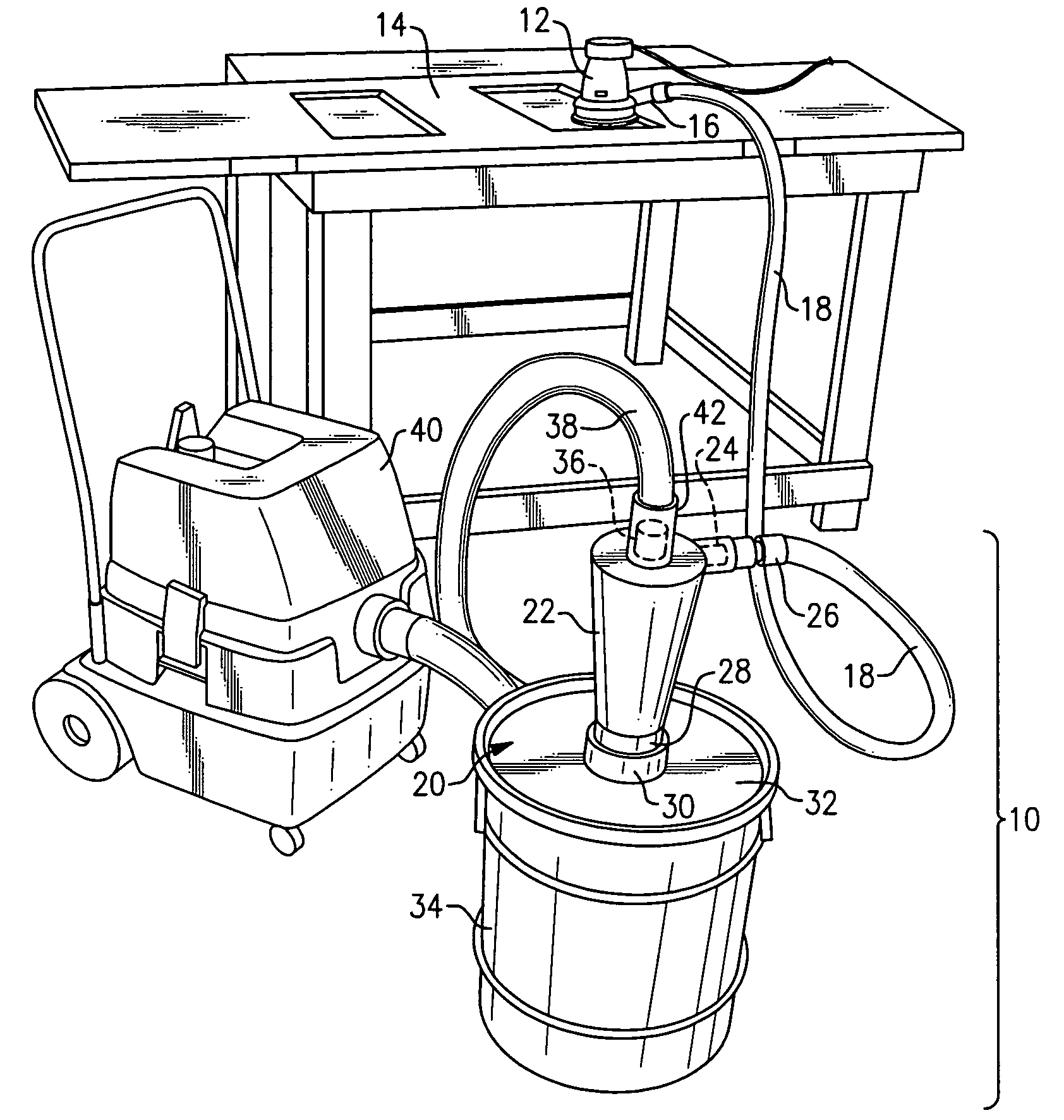

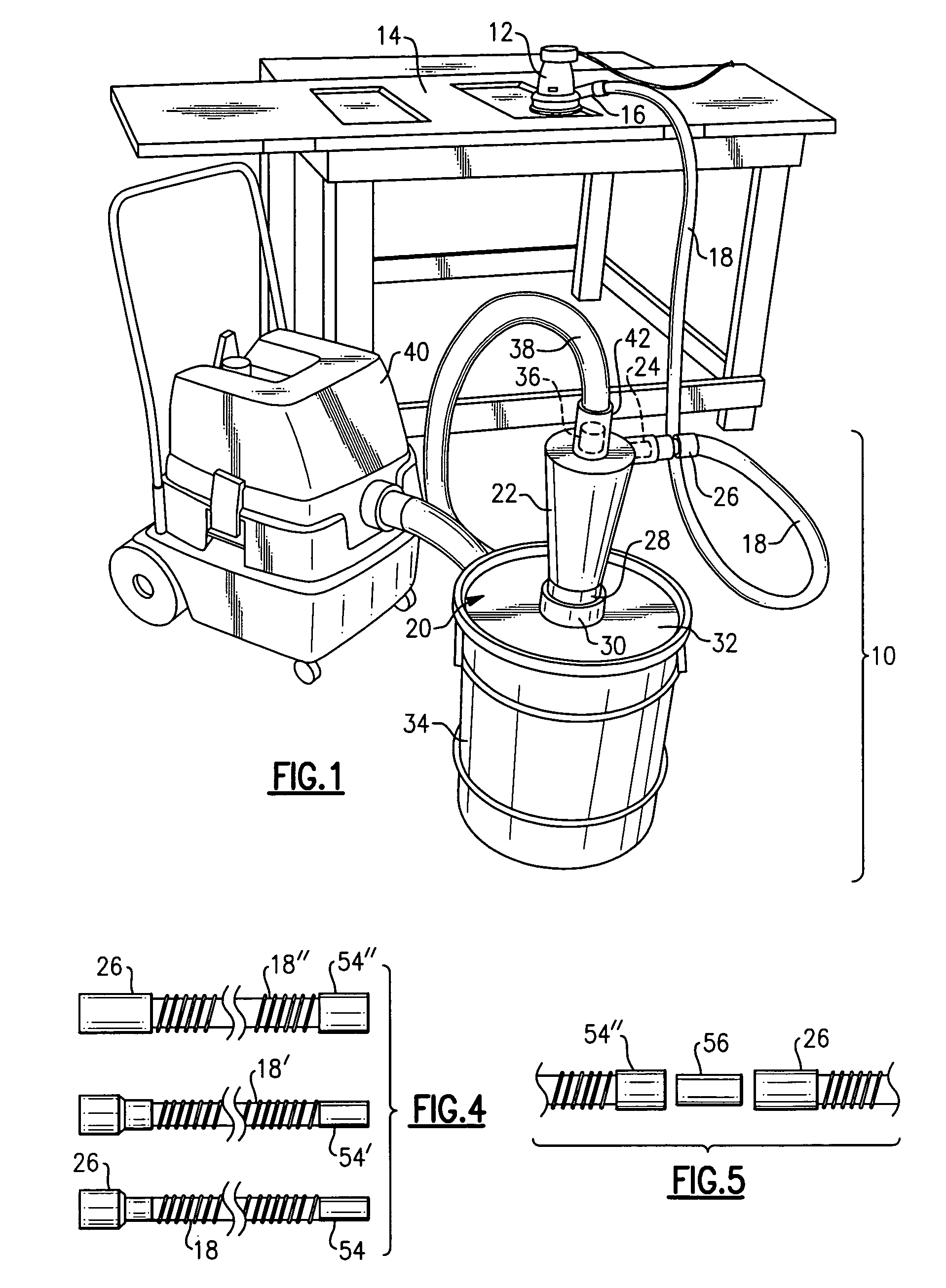

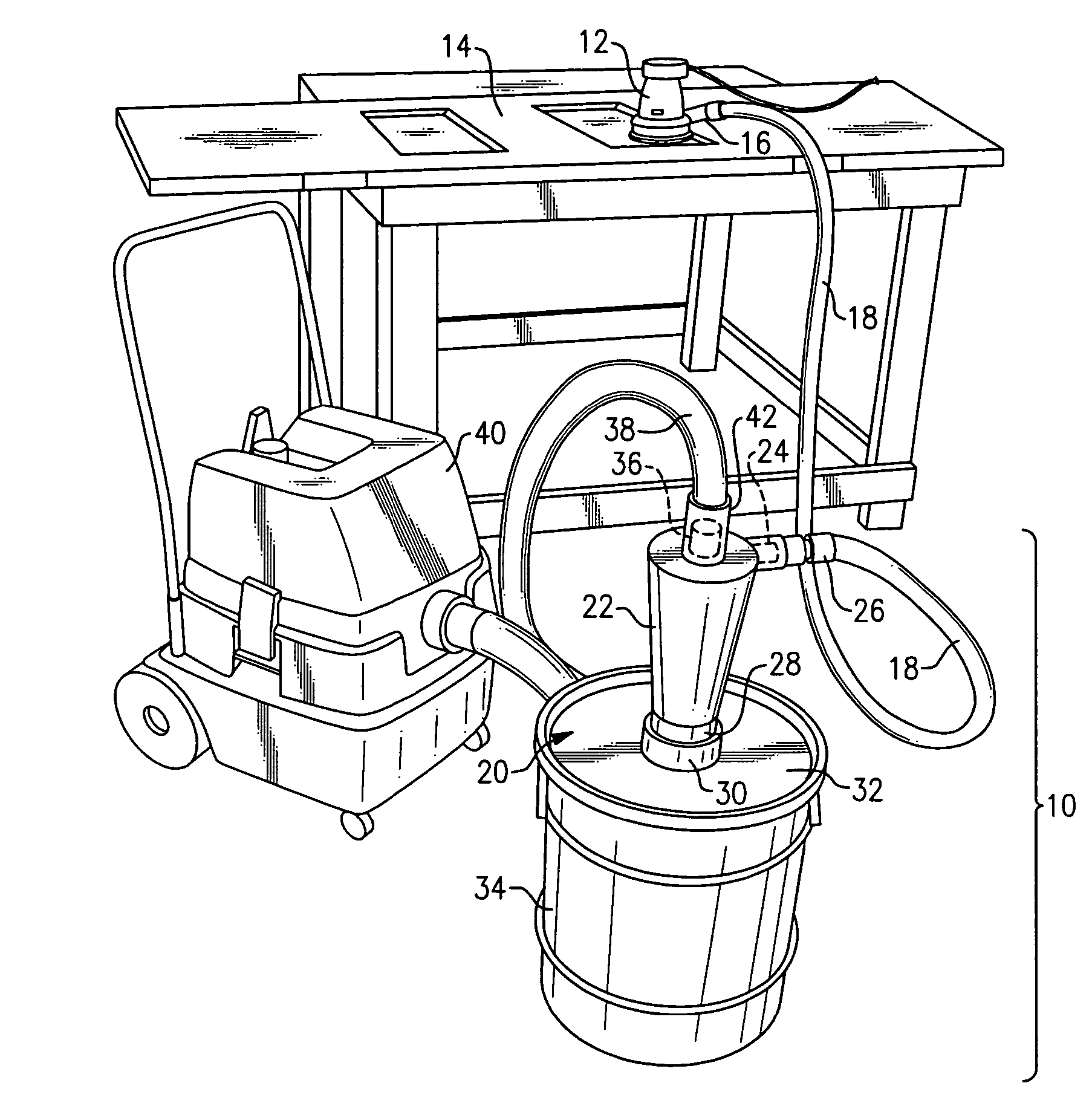

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

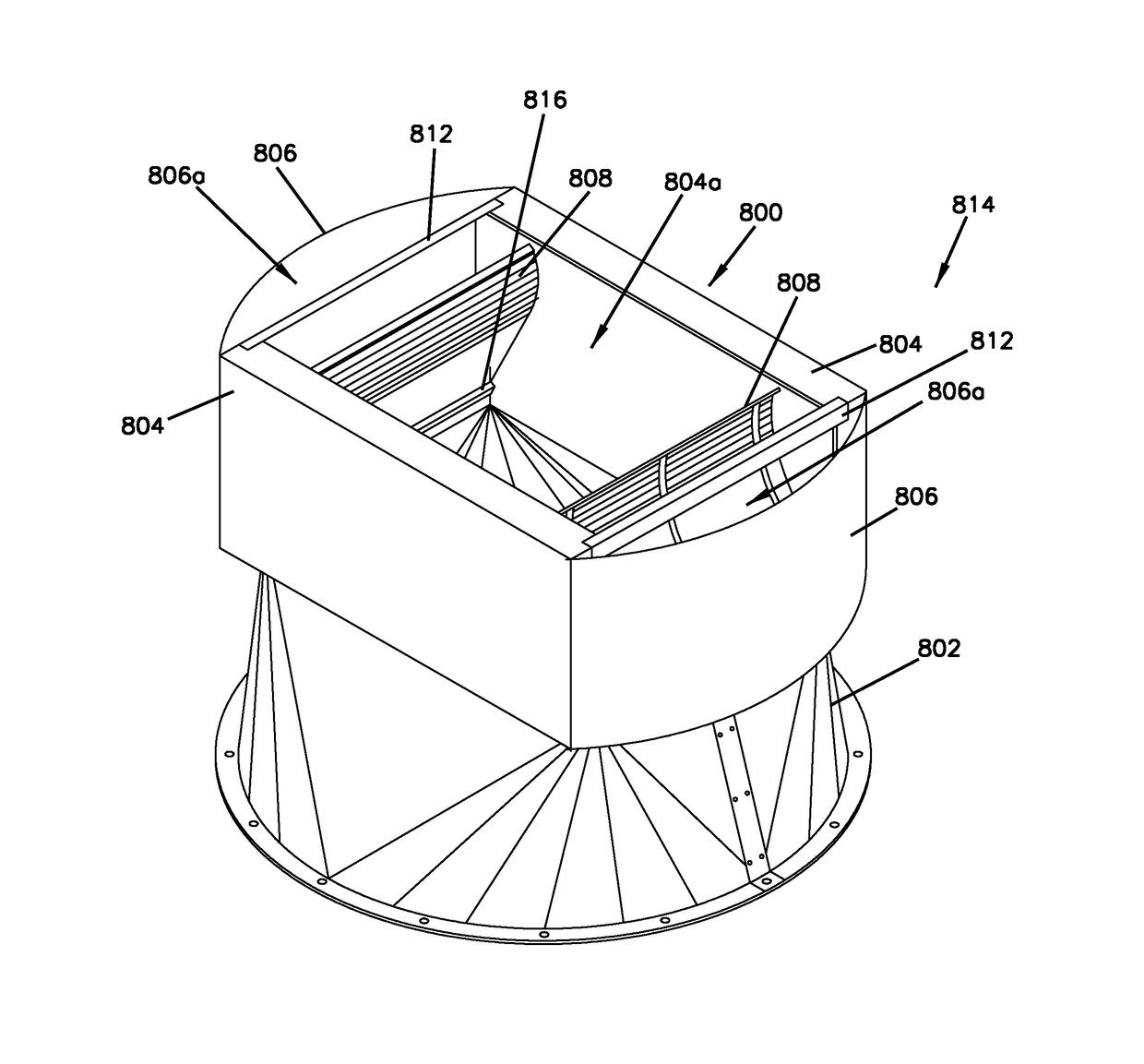

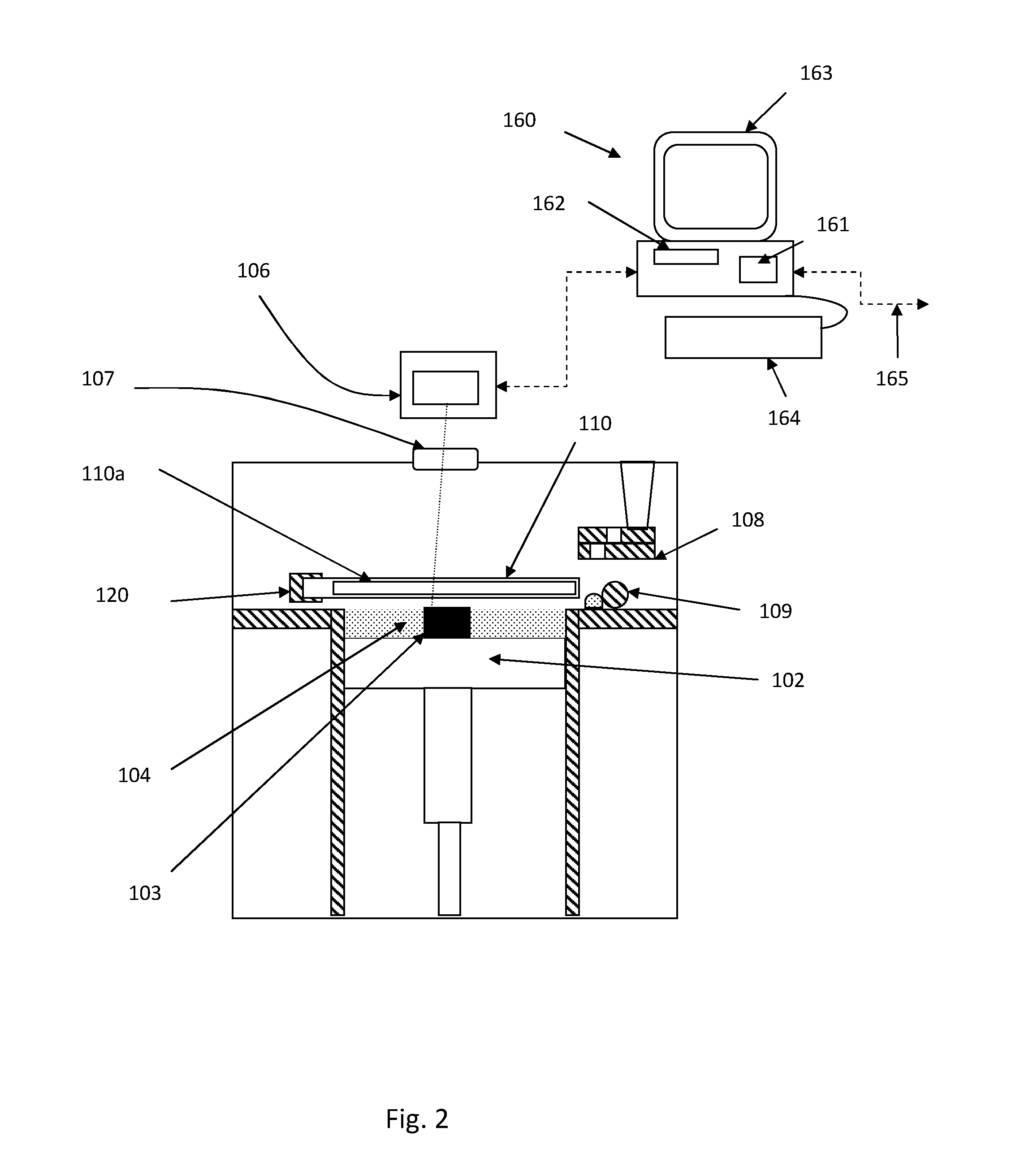

Additive manufacturing apparatus and method

ActiveUS20160136731A1Additive manufacturing apparatusDirt cleaningManufactured apparatusProcess engineering

An additive manufacturing apparatus for building objects by layerwise consolidation of material. The apparatus includes a build chamber containing a working area, a high energy beam for consolidating material deposited in the working area in layers and a flow device for generating a gas flow across at least a part of the working area from a gas inlet to a gas outlet. The gas inlet and gas outlet are arranged to be movable within the build chamber.

Owner:RENISHAW PLC

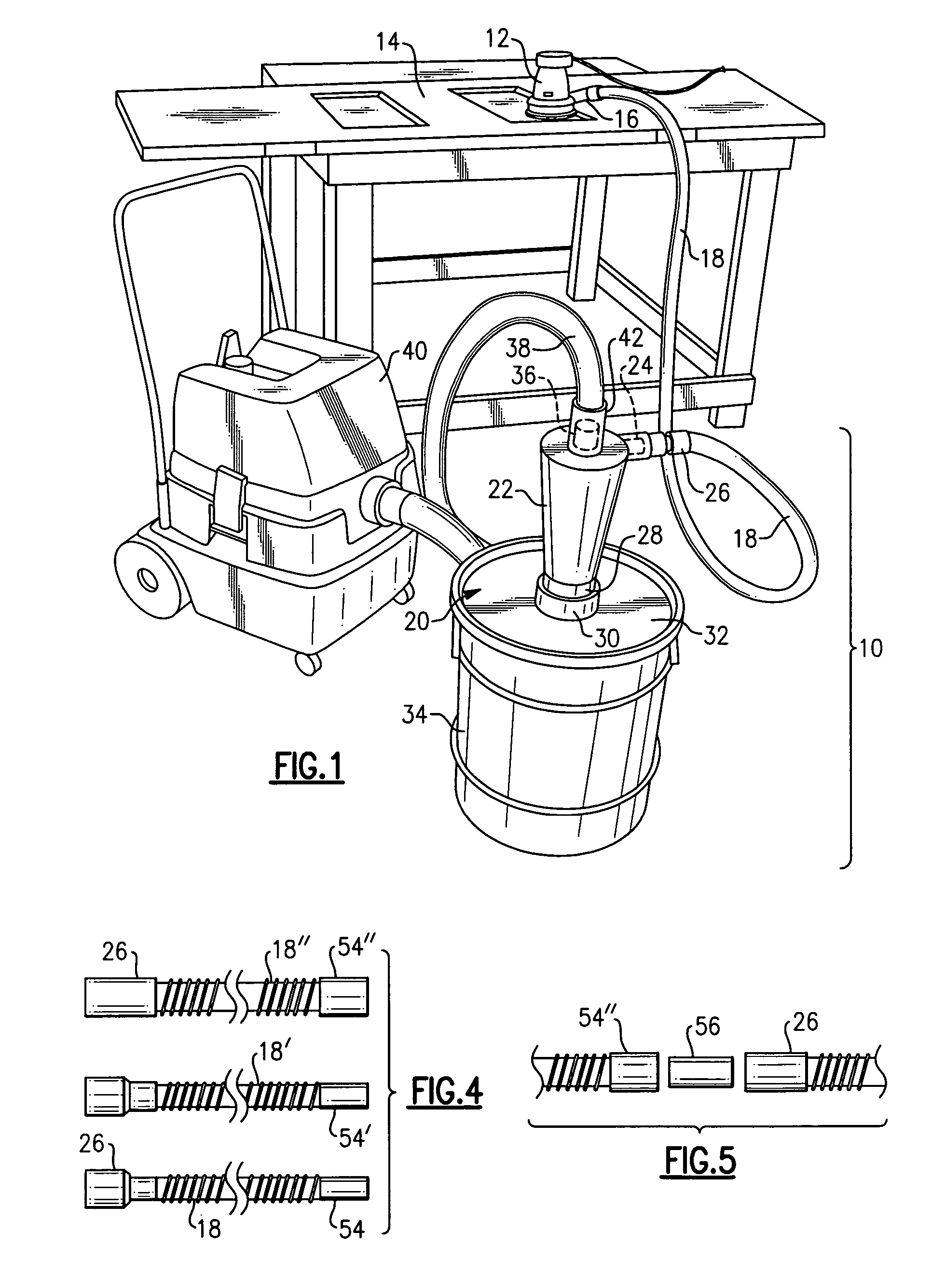

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

Range hood

ActiveUS7699051B2Domestic stoves or rangesSpace heating and ventilation safety systemsElectronic controllerEngineering

A hood for a cook top is controlled preferably by an electronic controller through a touch keypad. The hood has front and side walls and attaches to a back wall. It has an internal cavity and structure to restrict airflow out of the hood. The structure also creates an air curtain. The curtain traps and moves heated air and effluents upwardly off of the cook top. At least one blower is located near the cook top for moving the air and effluents. The hood may also have at least one: filter, sensor, duct, lighting fixture, vent, display, and circuit board.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

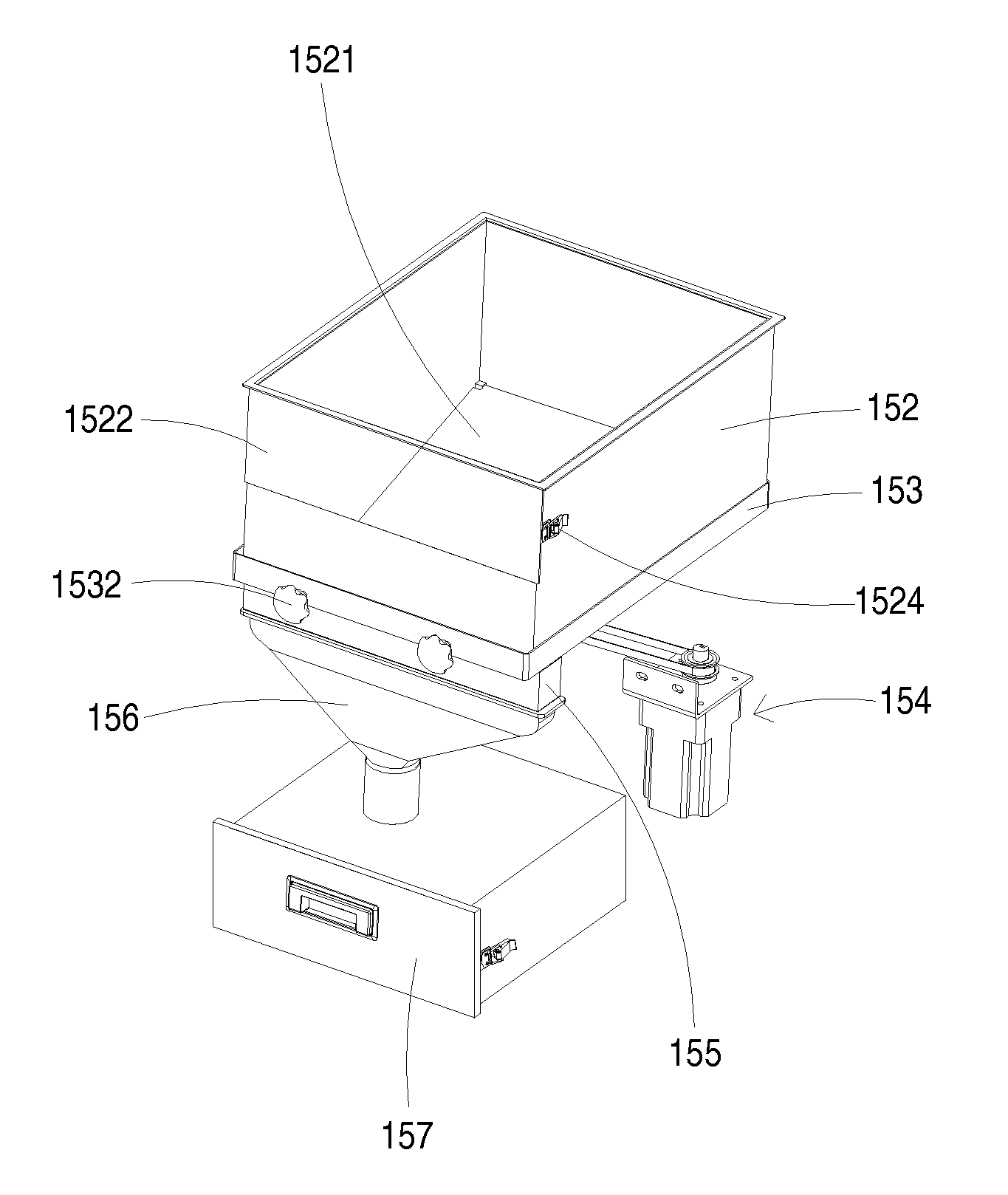

Automatic powder recycling apparatus

InactiveUS20120052145A1Avoid pollutionFunction increaseAdditive manufacturing apparatusConfectioneryBiomedical engineering

An automatic powder recycling apparatus includes a housing, a plurality of isolation elements, an air-blowing device, a powder filtering member, a recycling member and an air-inhaling device. A sealed space is defined within the housing. The air-blowing device is disposed within the sealed space for removing the powder attached on the surface of the finished product. The air-inhaling device is in communication with the first receptacle for allowing the first receptacle to be in a negative pressure state. When the powder on the finished product is removed by the air-blowing device and directed to the powder filtering member by the air-inhaling device, the powder is filtered and blocked by the powder filtering member. When the air-inhaling device is disabled, the powder blocked by the powder filtering member naturally falls down to the recycling member.

Owner:MICROJET TECH

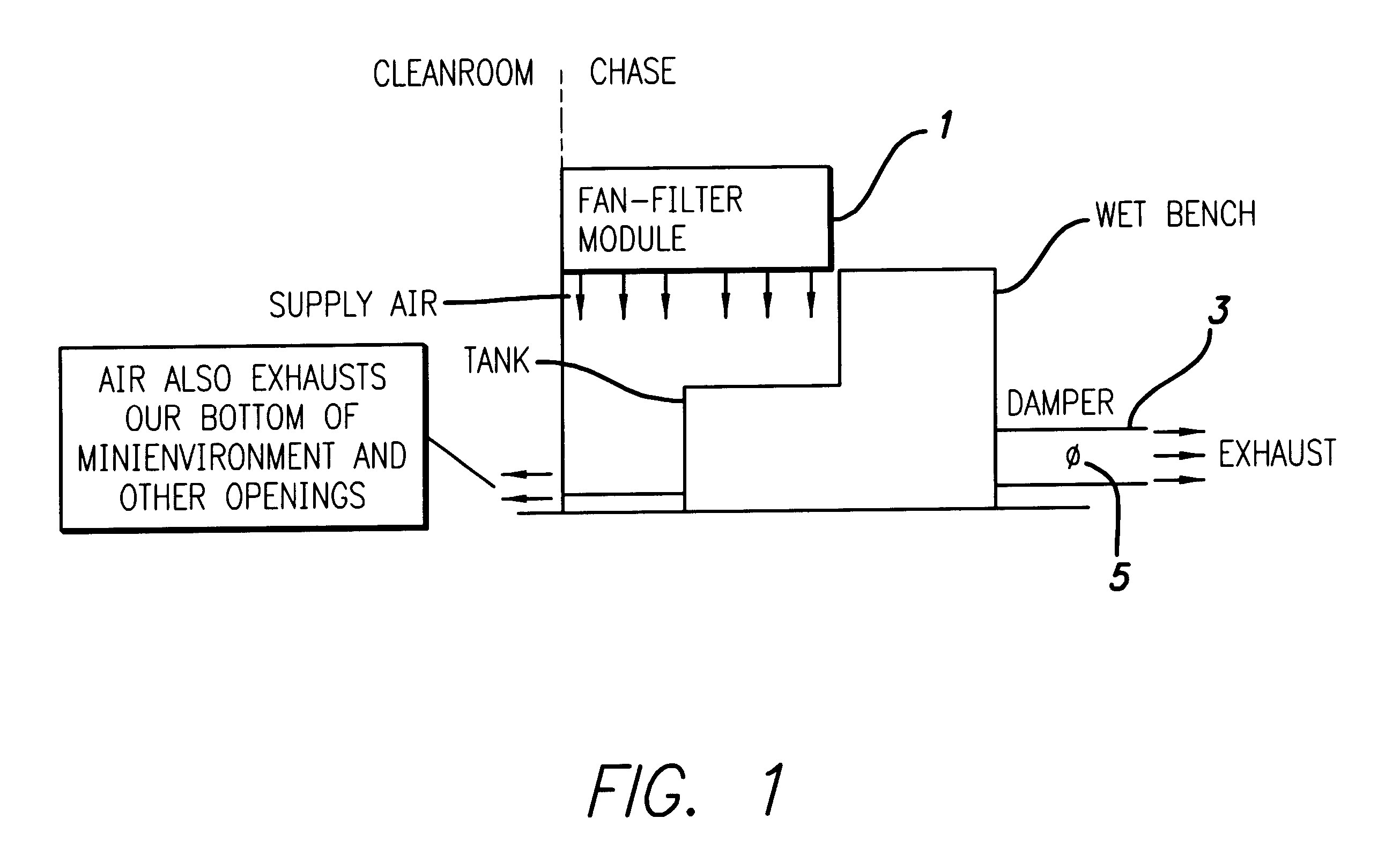

Airflow control valve for a clean room

An airflow control valve for a clean room having a duct section with a damper positioned within the duct. The damper being capable of an adjustment from an open position to a closed position. The opening and closing of the duct is accomplished through a magnetic coupling such that the duct can remain sealed during operation. The airflow control valve includes a sensor for measuring the airflow rate, so that the duct can be adjusted to maintain one or more predetermined flow rate set-points.

Owner:SYNETICS SOLUTIONS +2

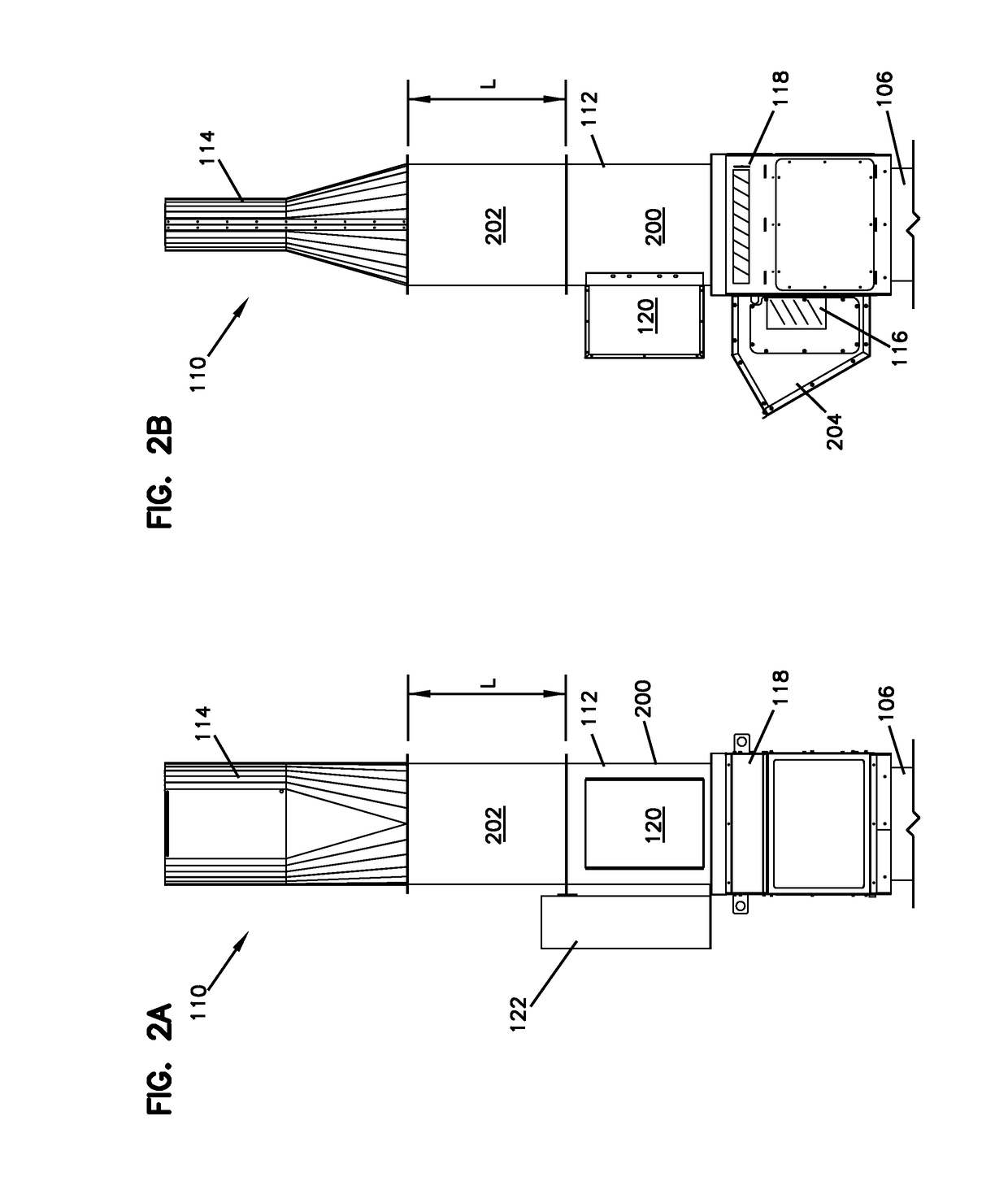

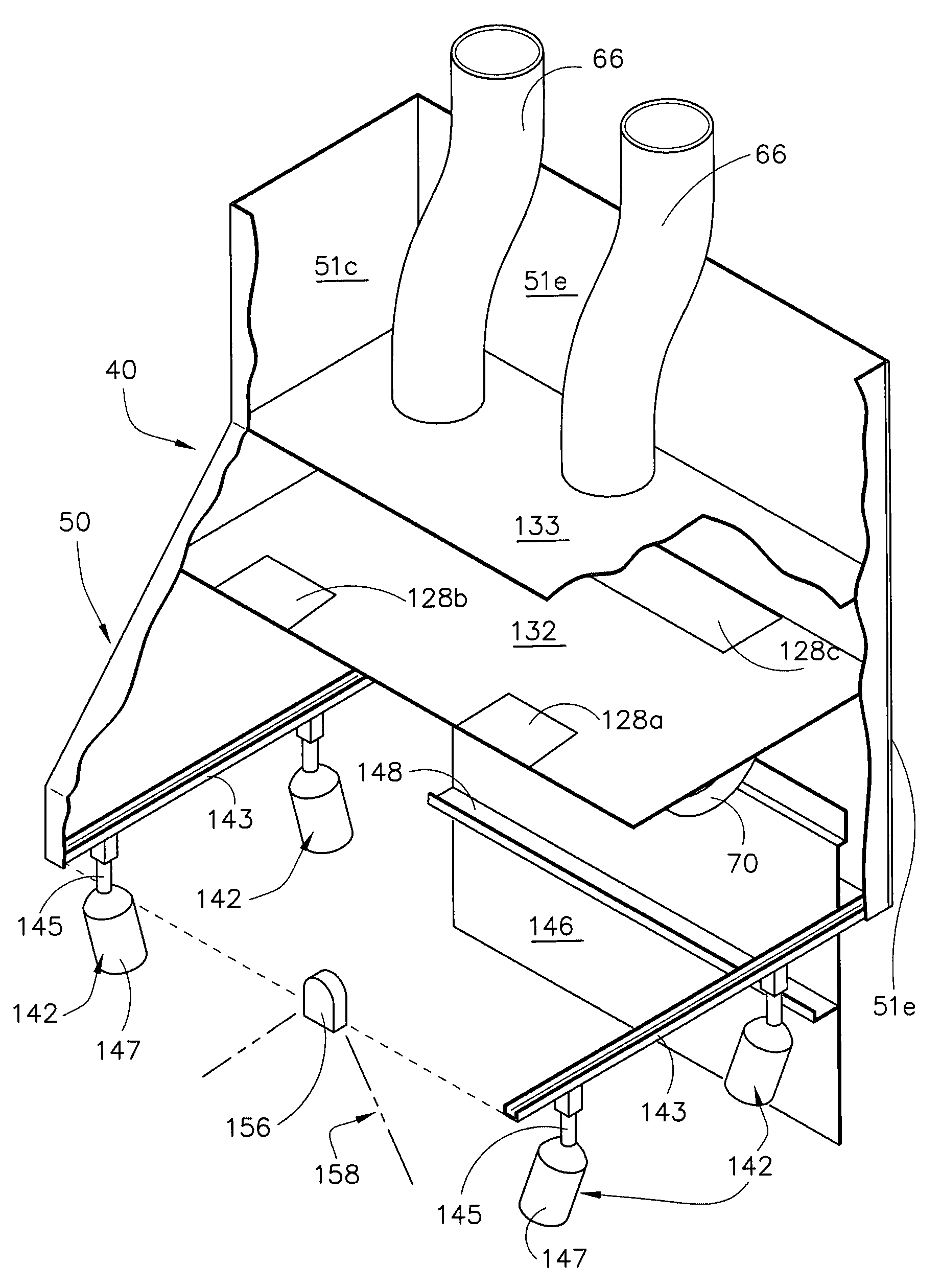

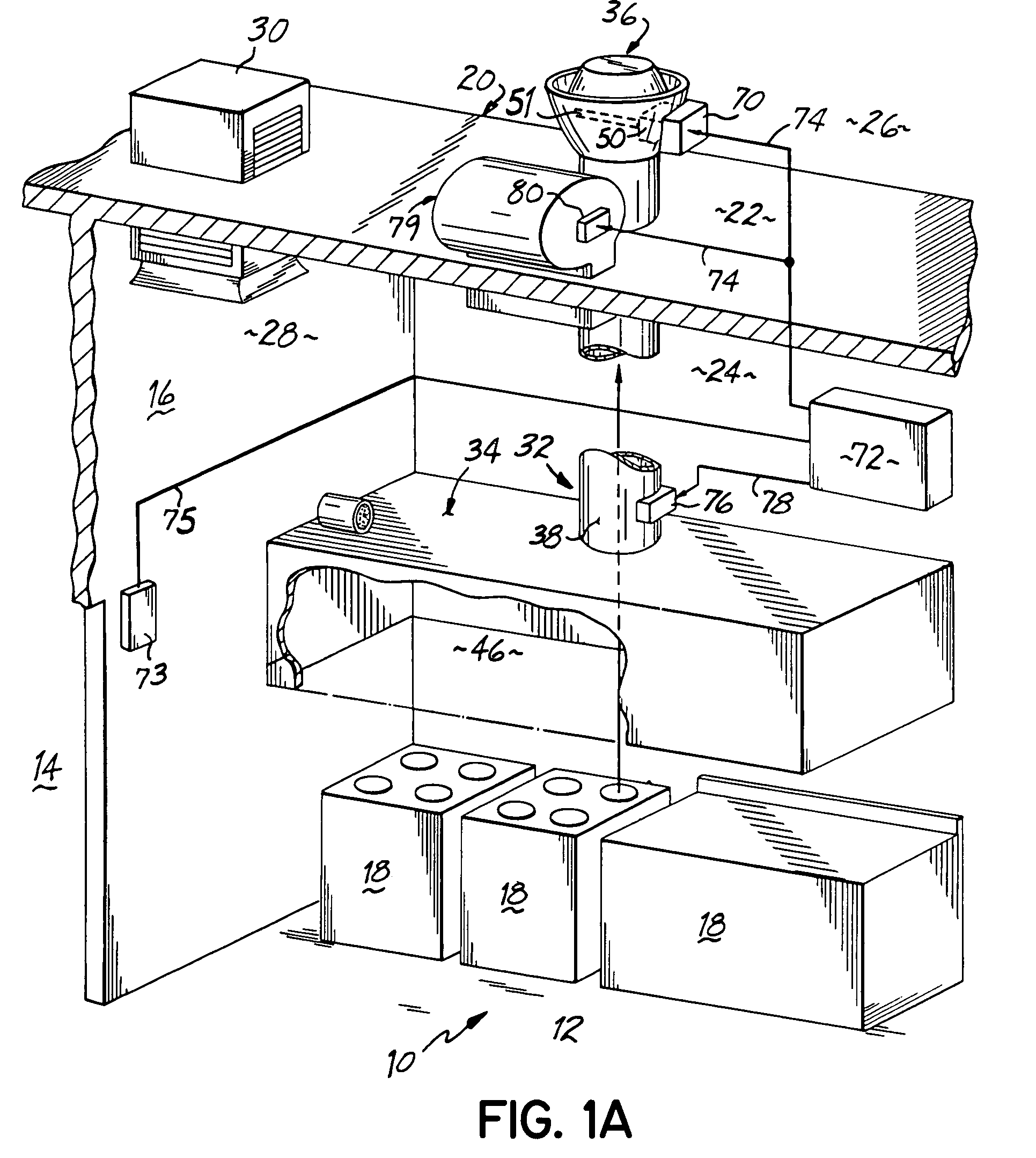

Low depth telescoping downdraft ventilator

ActiveUS8312873B2Accuracy in removalIncrease awarenessCombination devicesLiquid degasificationElectronic controllerExhaust fumes

A low depth telescoping downdraft ventilator controlled by an electronic controller providing a precisely controlled and efficient way of removing gases and fumes is disclosed. The low depth telescoping downdraft ventilator has the ability to fit behind a built-in oven placed below a cook top unit. The telescoping downdraft ventilator has an almost infinitely selectable range of heights above a cook top with a built in oven. The ventilator collects and draws in exhaust fumes and smoke, filters it and re-circulates or expels it either outdoors or indoors. The inner member of the telescoping ventilator may house the exhaust fans and may move up or down without the use of mechanical switches for elevation detection and stopping. The ventilator may have sensors to detect temperatures, filter change need, fan speeds, telescoping stop points, energy consumption, resistance and voltage, enabling programmable set point operation.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

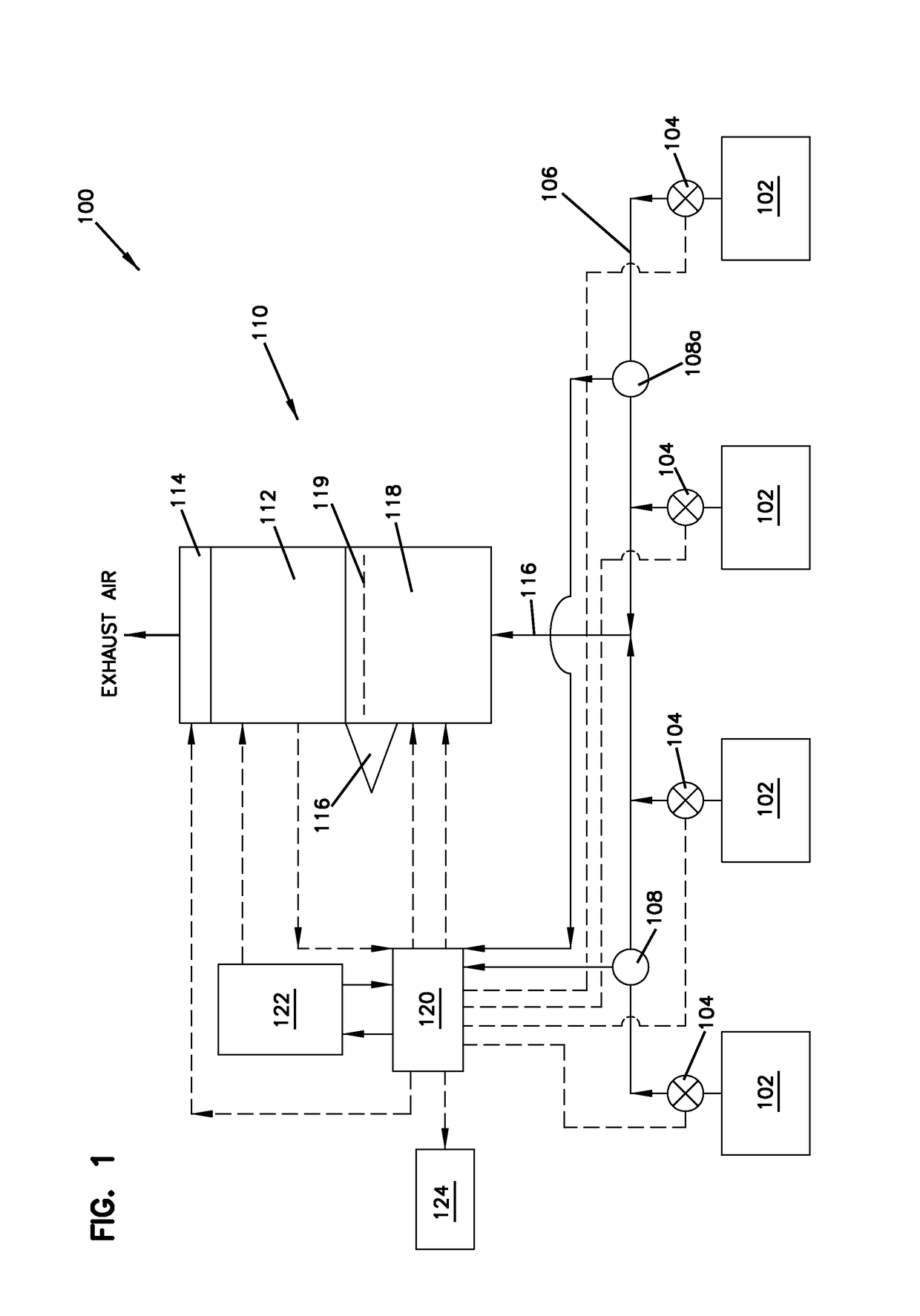

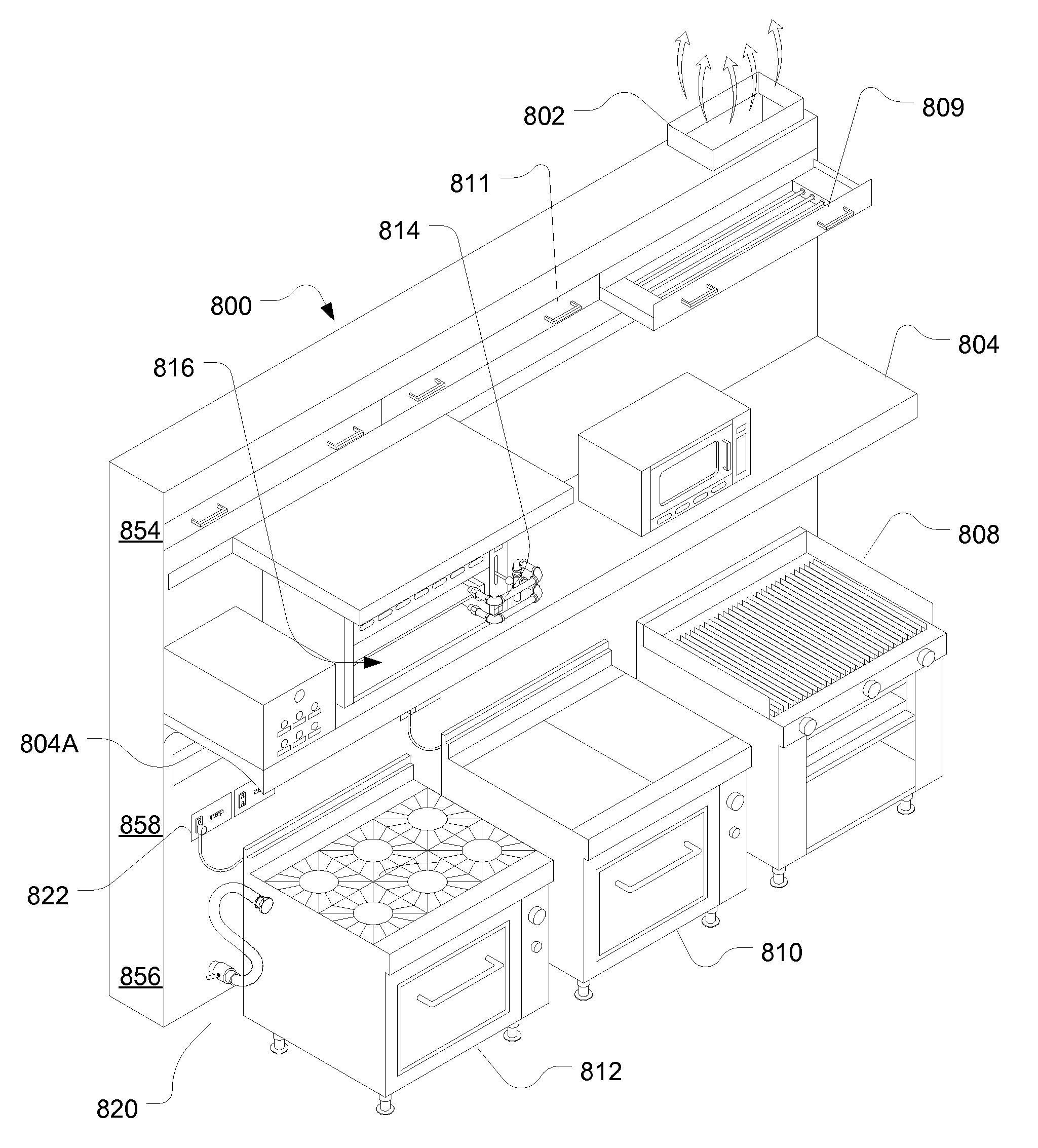

Recirculating exhaust system

ActiveUS20090264060A1Reduce net energy lossDomestic stoves or rangesRecuperative heat exchangersModularityEngineering

Systems, devices and methods provide energy recover, modular systems to build and revise commercial kitchen services, closed circuit exhaust, and high efficiency capture and containment of fumes from cooking processes.

Owner:HALTON GROUP LTD

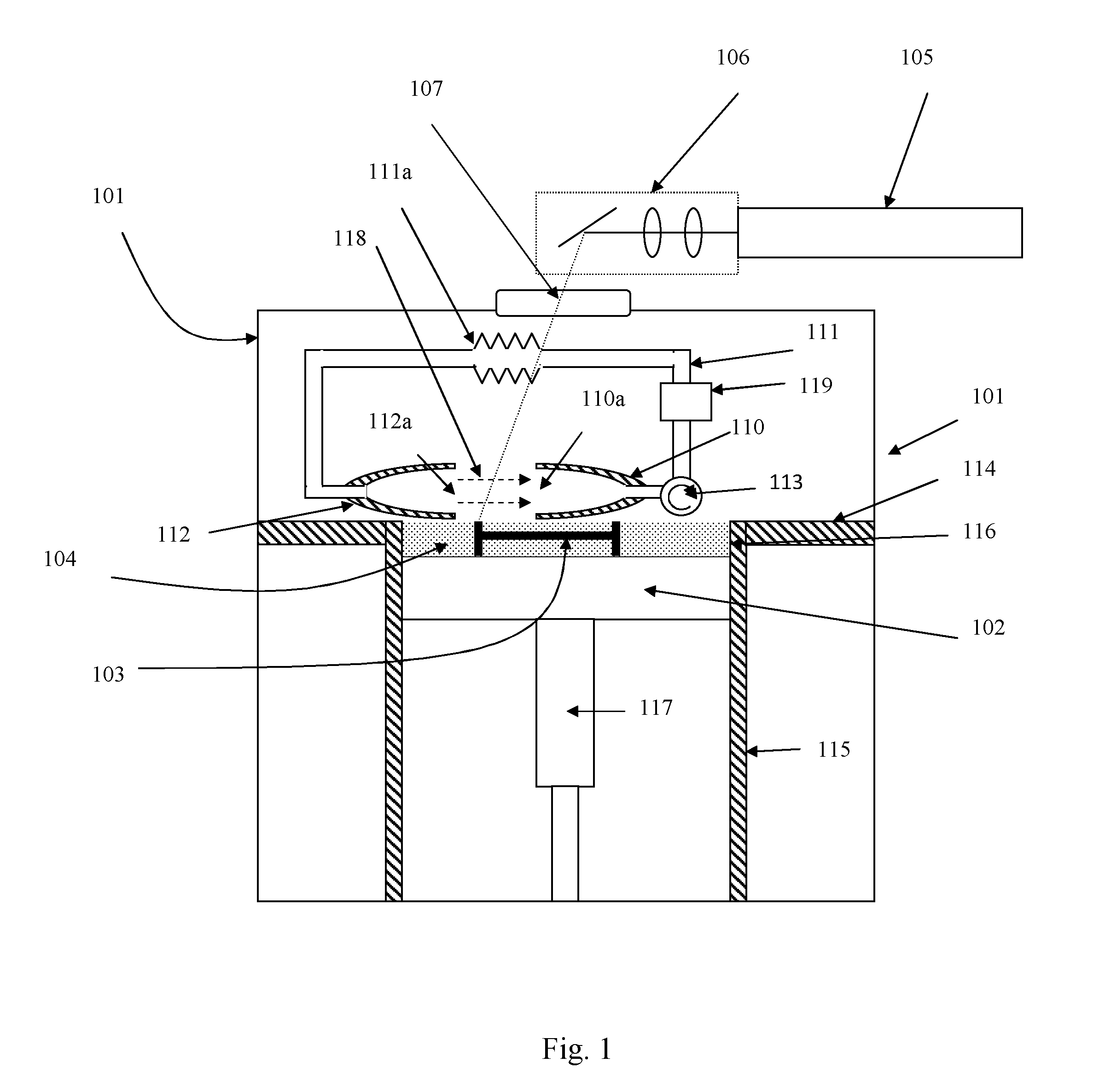

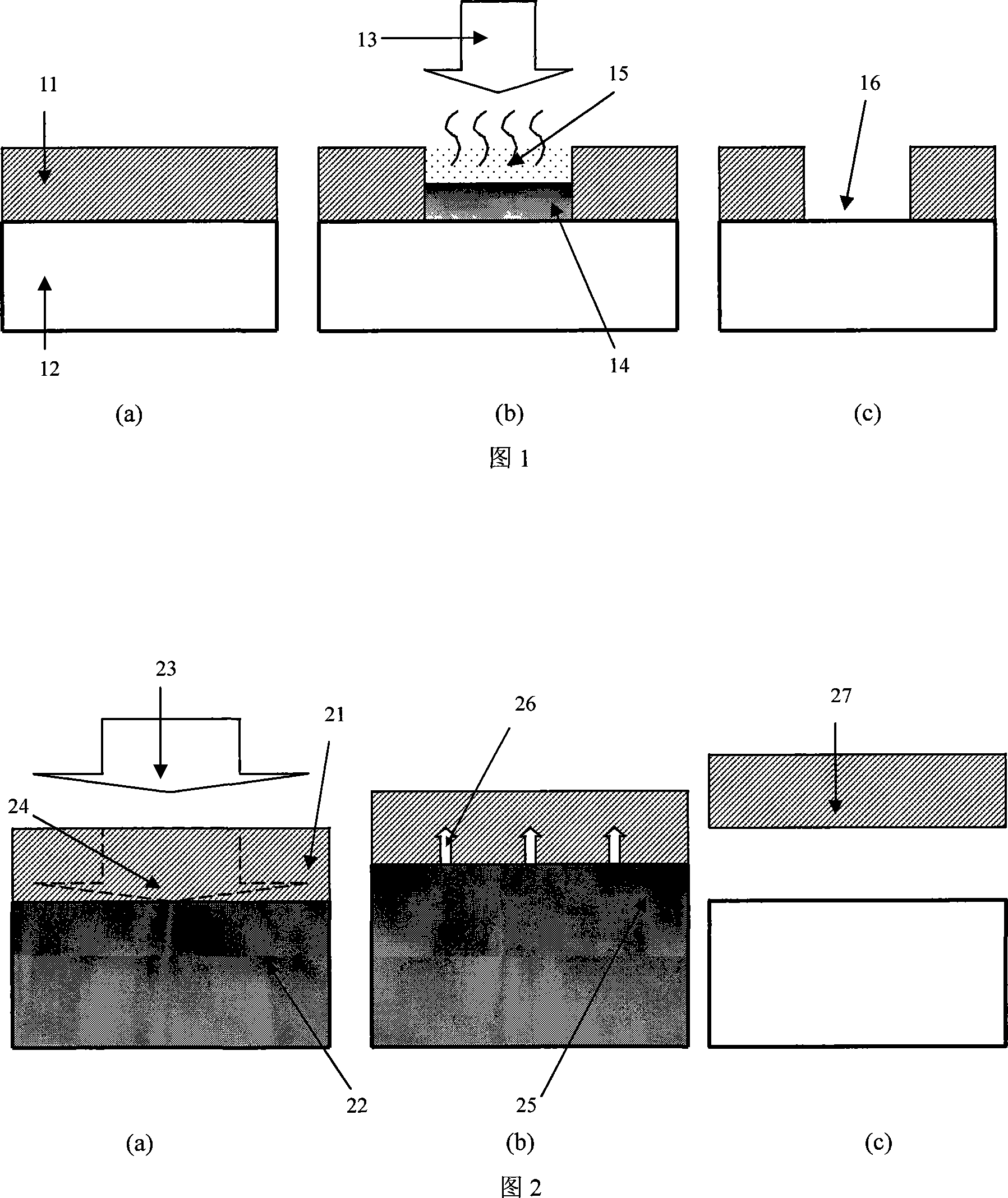

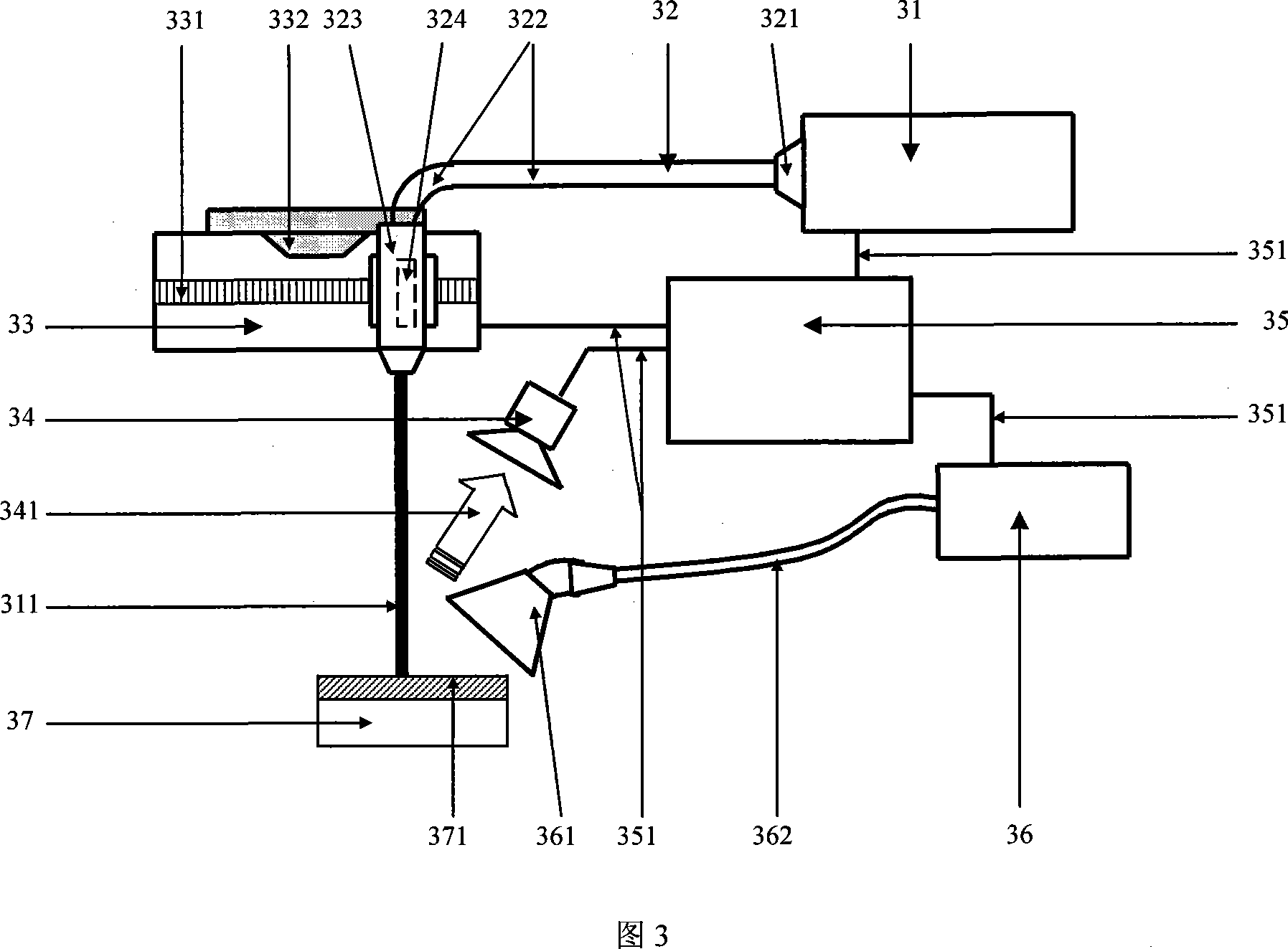

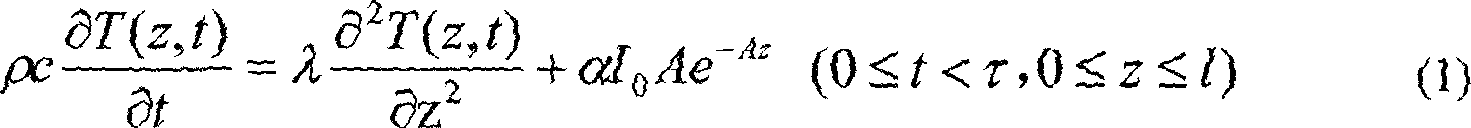

Ultrasonic detection narrow pulsewidth laser sludge remover and its sludge removing method

InactiveCN101143364AWon't happenGood decontamination effectAnalysing solids using sonic/ultrasonic/infrasonic wavesDirt cleaningShock waveAutomatic control

An ultrasonic detection narrow pulse wide laser cleaner includes a narrow pulse wide laser device (1), a beam adjustment transmission device (2), a moving platform device (3), an ultrasonic detection device (4), an automatic control device (5), a dust absorption recovery device (6) and an ultrasonic detection narrow pulse wide laser filth clearing method. A cleaned object surface is irradiated with narrow pulse wide lasers. And a strong vibration shock wave is produced in short time to remove filths from the medium surface. At the same time, an instrument device is used to monitor and analyze ultrasonic waves caused by the vibration during the cleaning process to ensure the good medium surface and realize the automatic cleaning process. The cleaner is used to remove various filths of oxides, corrosion matters, paint, grease marks, residues, etc. of the media surfaces of metals, semiconductors, buildings, etc. The cleaner has the advantages of good effect, non-damages, high efficiency, automation, etc.

Owner:NANKAI UNIV

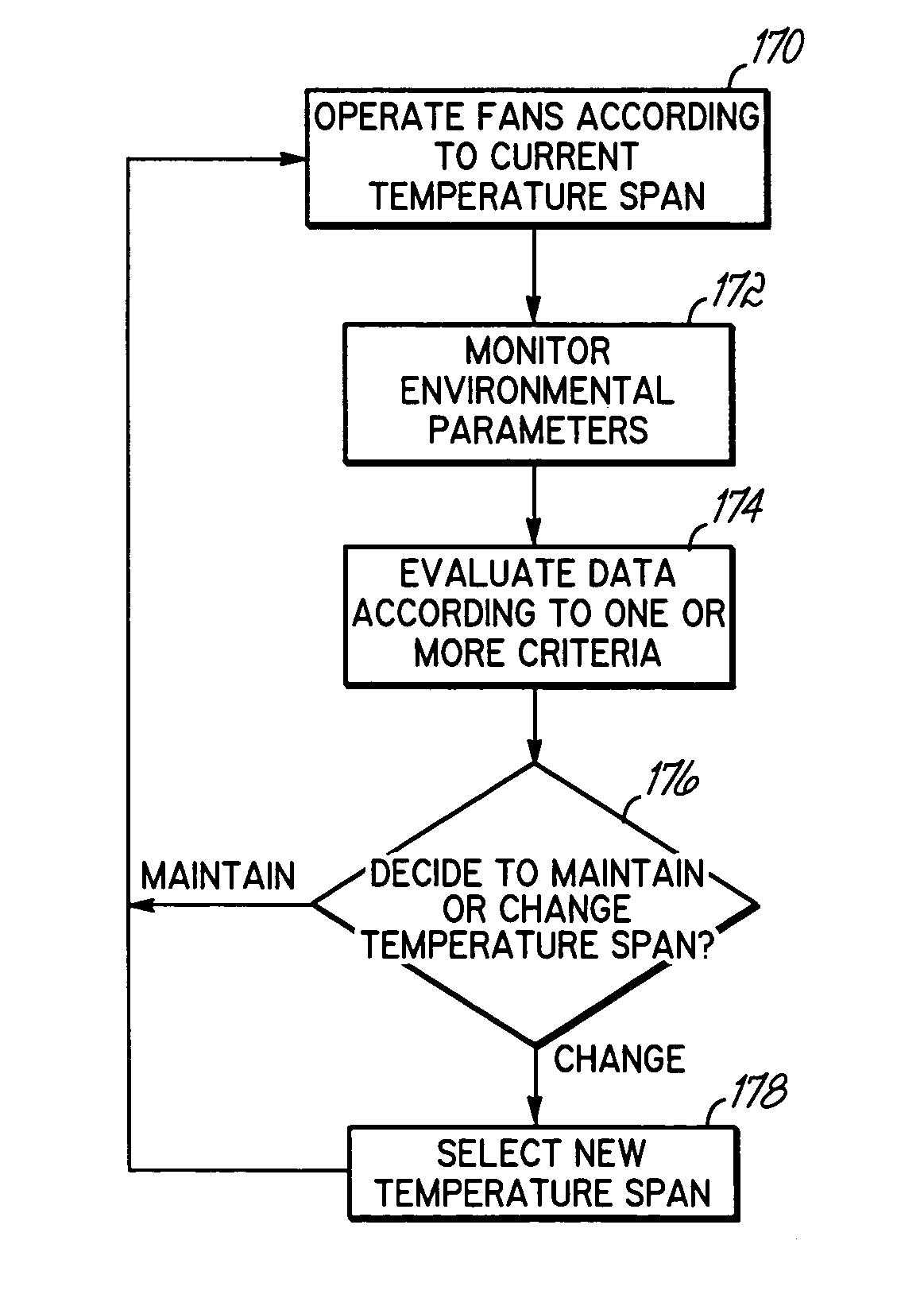

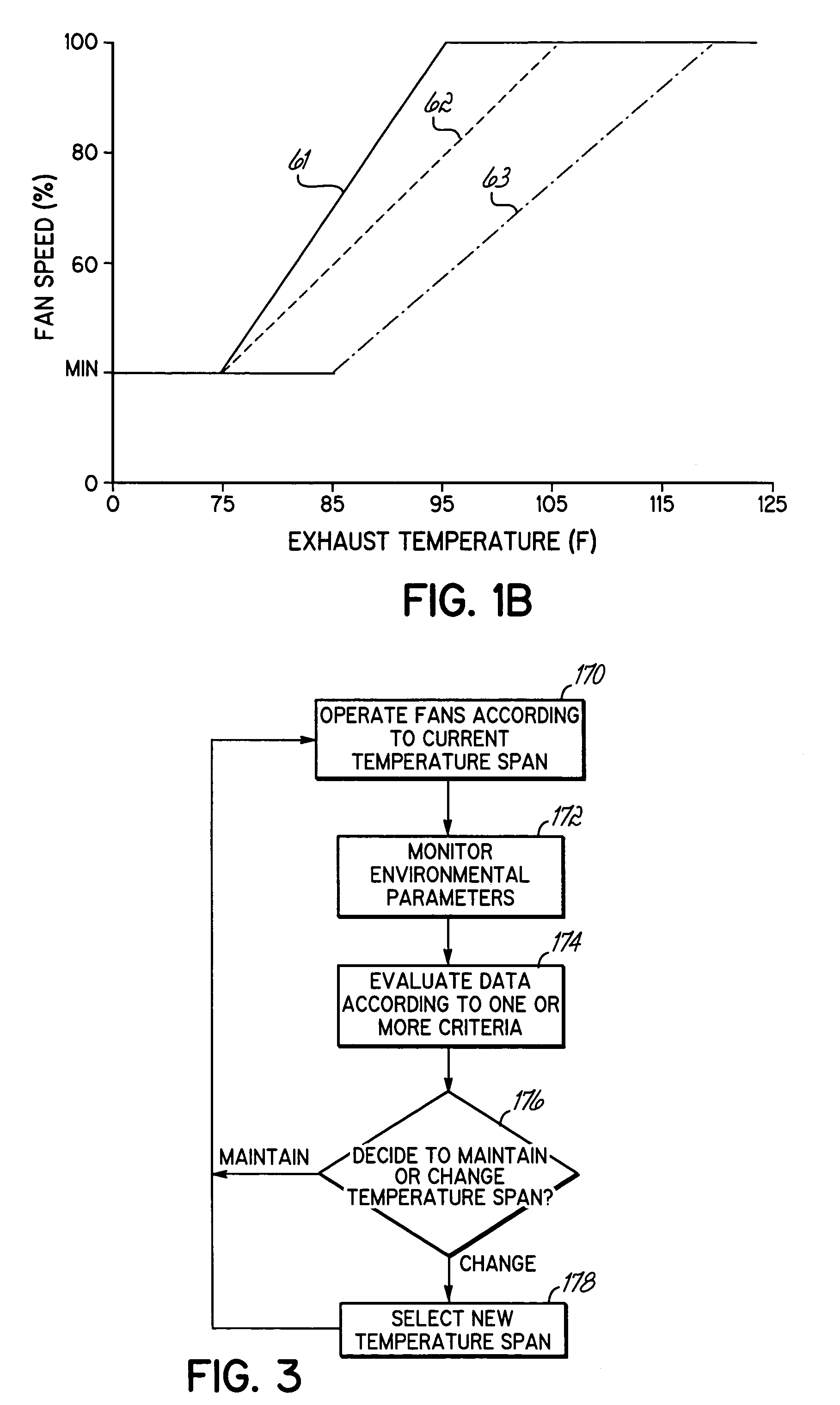

Kitchen exhaust optimal temperature span system and method

ActiveUS7048199B2Optimal exhausting conditionMechanical apparatusDomestic stoves or rangesControl systemProcess engineering

An exhaust control system (72) for a commercial or institutional kitchen exhaust system (32) is disclosed in which the exhaust fan speed is optimized for the amount of cooking heat and cooking by-product generated by the cooking units, as well as for comfort in the kitchen (12). Kitchen comfort is determined by sensing temperature, humidity, noxious gases, smoke, odor, or some combination thereof. In particular, exhaust air temperature can be used by the control system (72) to modulate fan speed from a minimum value to a maximum value based on the minimum and maximum temperatures that define a particular temperature span. During operation, the control system (72) continues to monitor environmental parameters of the kitchen (12) to determine if the current temperature span provides optimal performance. Upon determining that the current temperature span is no longer the optimal one, the control system (72) operates the exhaust system (32) according to a different temperature span.

Owner:MELINK CORP

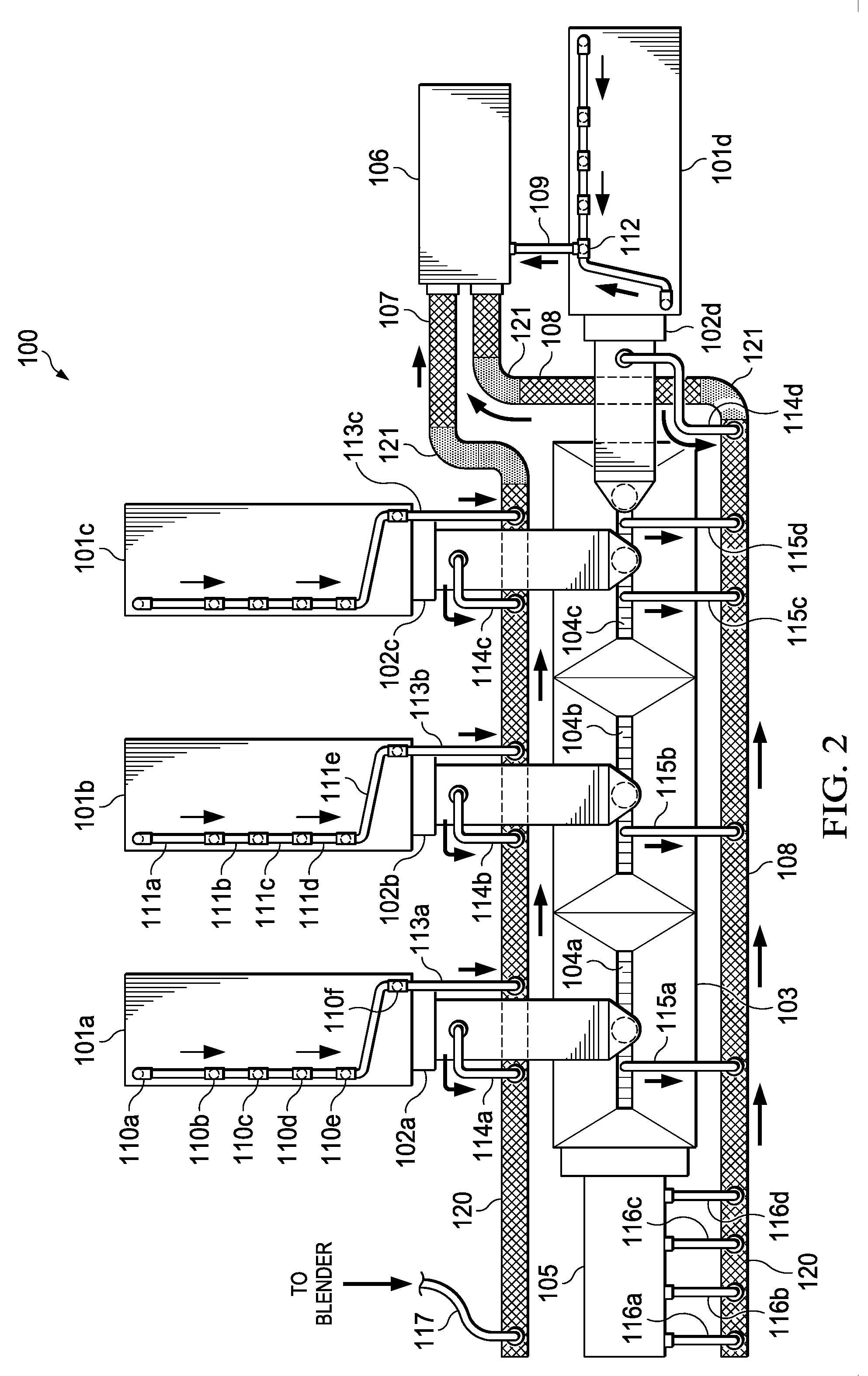

Systems and methods for controlling silica dust during hydraulic fracturing operations using an improved manifold

ActiveUS20160280480A1Simple apertureImprove efficiencyFouling preventionFluid removalHydraulic fracturingSilicon dioxide

A system for controlling dust during hydraulic fracturing operations includes a manifold having a plurality of ports for capturing dust when negative air pressure is applied to the manifold. A support frame positions the manifold above a piece of hydraulic fracturing equipment receiving sand from a sand source.

Owner:SIERRA DUST CONTROL

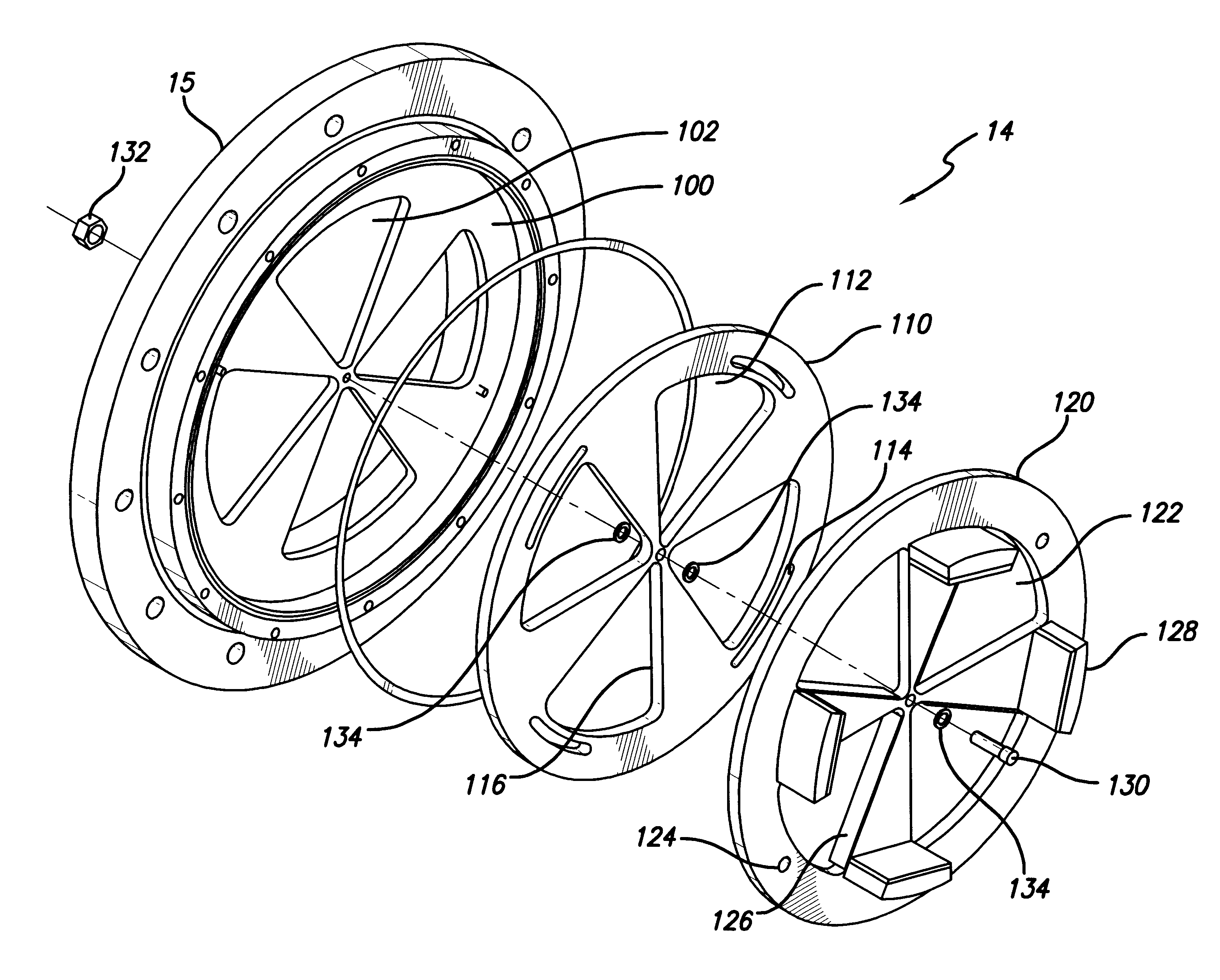

Exhaust fan assembly having flexible coupling

An exhaust assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a drive chamber and surrounding annular space. A fan driven by a motor whose shaft extends downward from the drive chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly. The motor is pivotally mounted inside the assembly to provide access to the motor components when it is desired to perform inspection and maintenance.

Owner:GREENHECK FAN

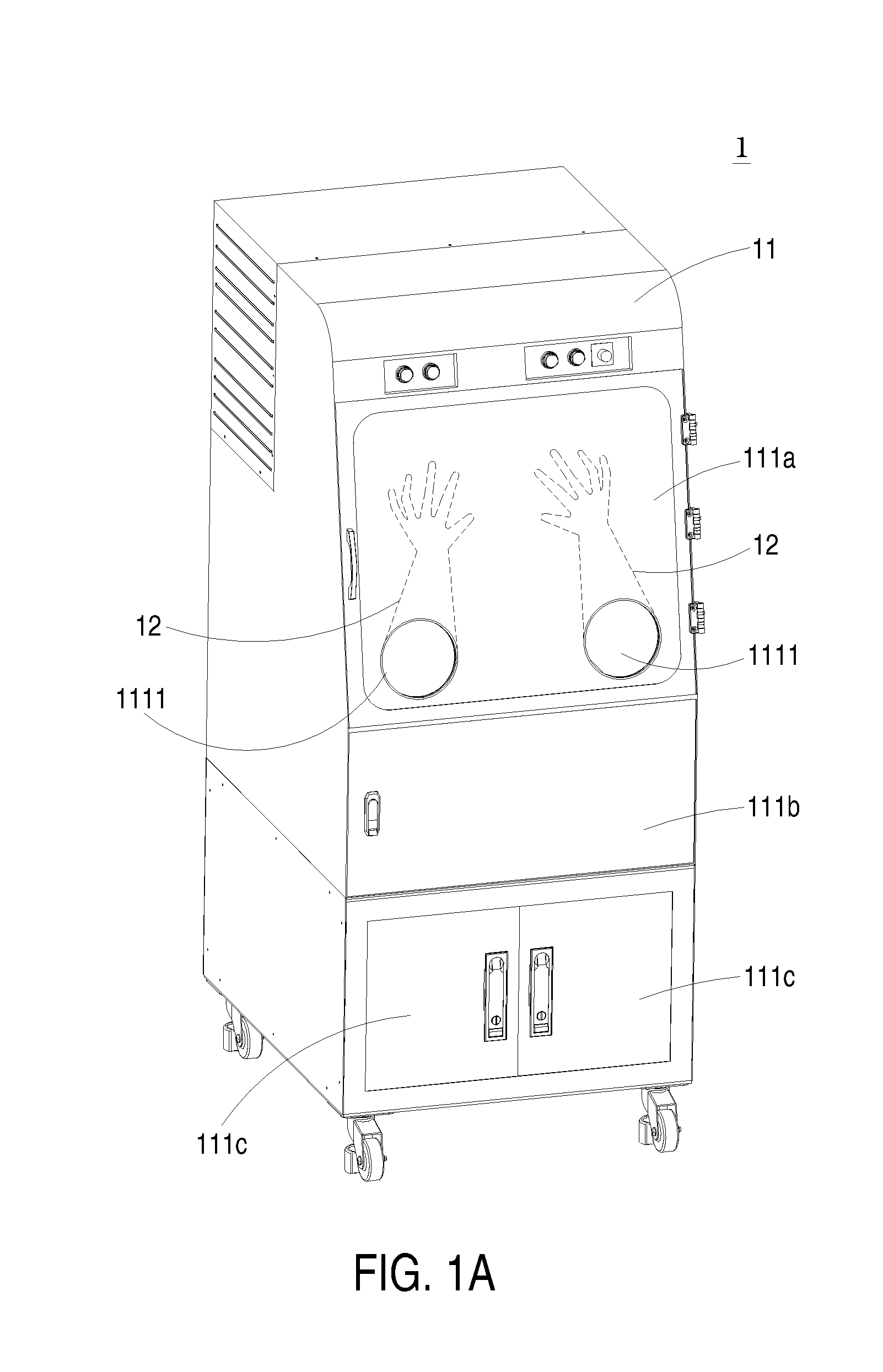

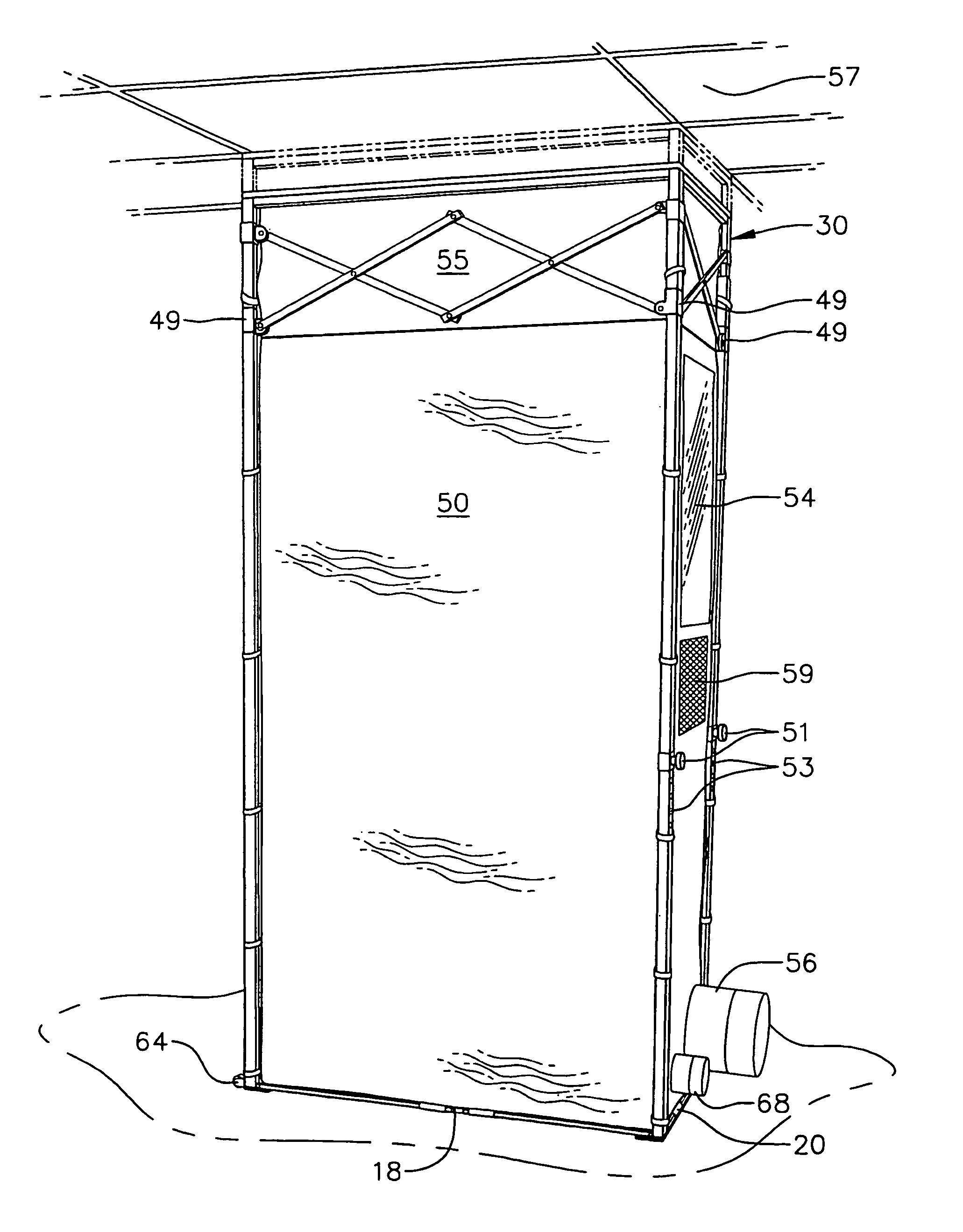

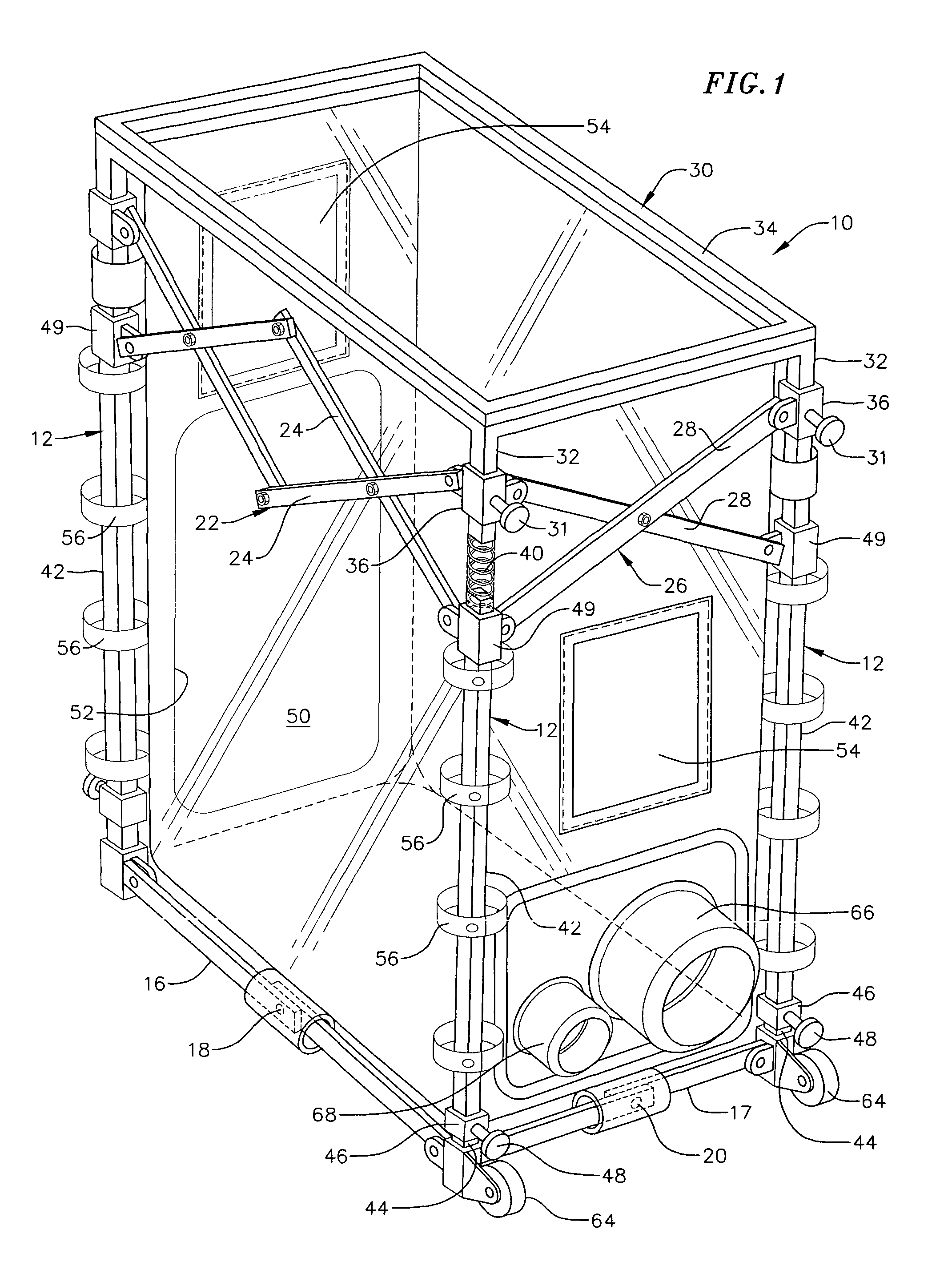

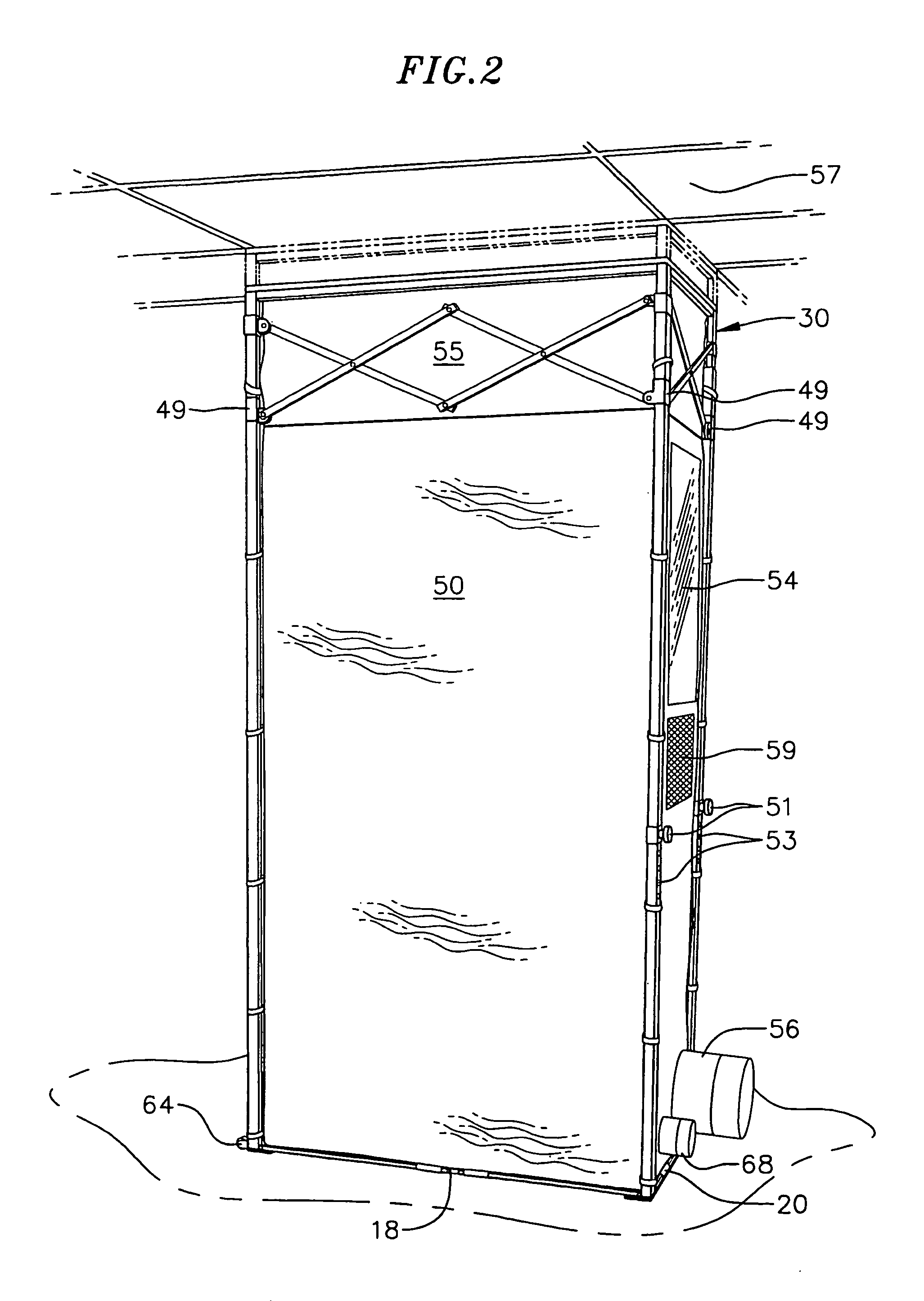

Environmental containment unit

ActiveUS7134444B2Eliminate and minimize incidenceAvoid spreadingCombination devicesDomestic stoves or rangesEngineeringGolf Ball

A portable enclosure, easily erectable and collapsible, to provide environment control and prevent contaminants from being released from the enclosure. The enclosure provides a flexible envelope attached to the interior of the space defined by vertical and horizontal supports which can be erected and collapsed. When erected the enclosure functions as an anteroom and has removable panels in the sides and top. In use, the enclosure is sealed against a vertical or horizontal surface to be worked on and a panel from the side of the enclosure is opened and closed to provide access to the surface by the user. When collapsed the enclosure is a package approximately the size of an average golf club bag which is easily portable to another location. Ducting is provided to which negative pressure pumps are connected to maintain negative pressure within the enclosure and draw contaminants into the pump and then into a closed container. In one embodiment, a four-sided flange extends from the rear side of the enclosure to allow sealing of the flange around the doorway and thereby provide a mechanism for isolating the room located interiorly of the doorway.

Owner:MINTIE LLC

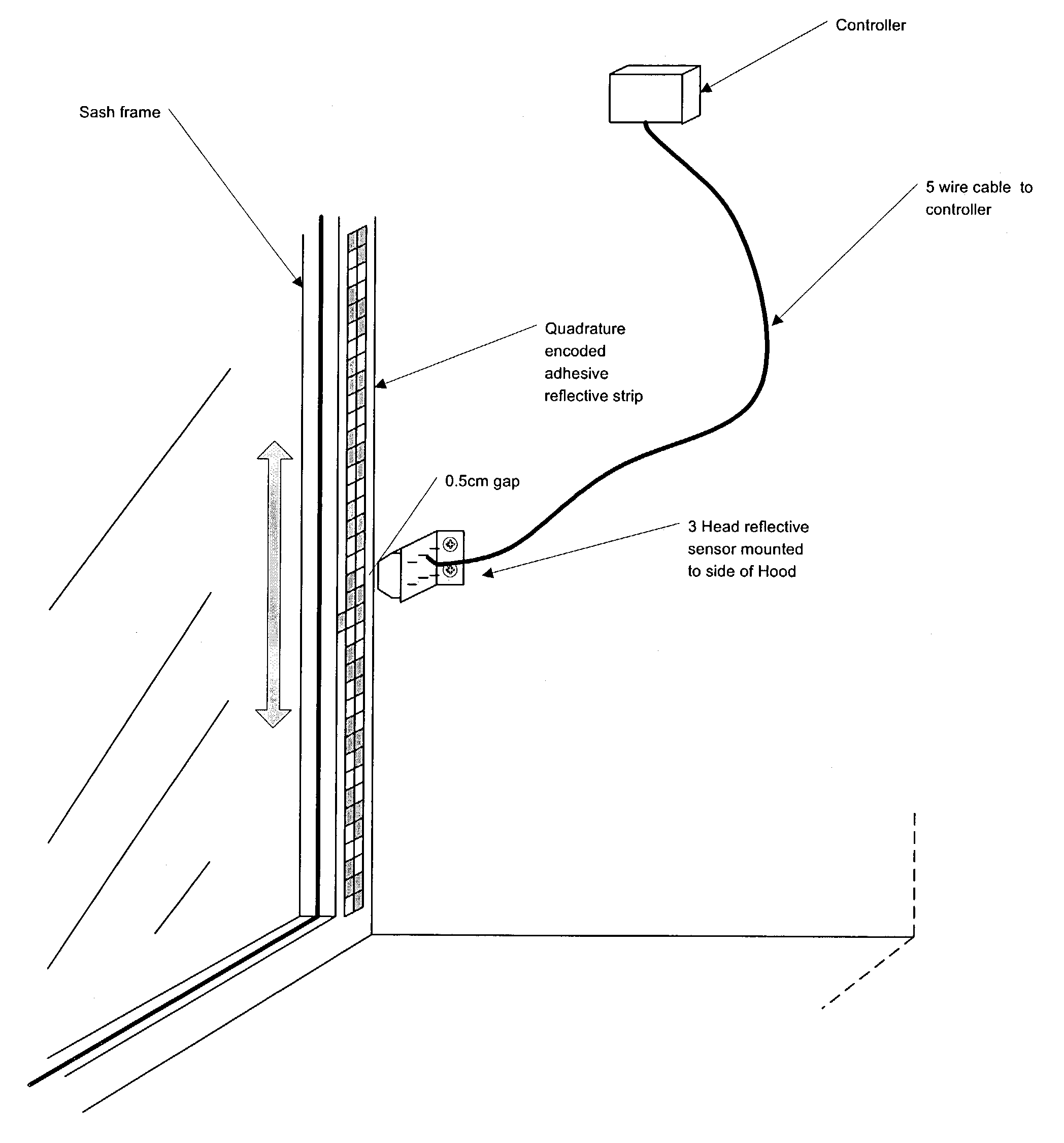

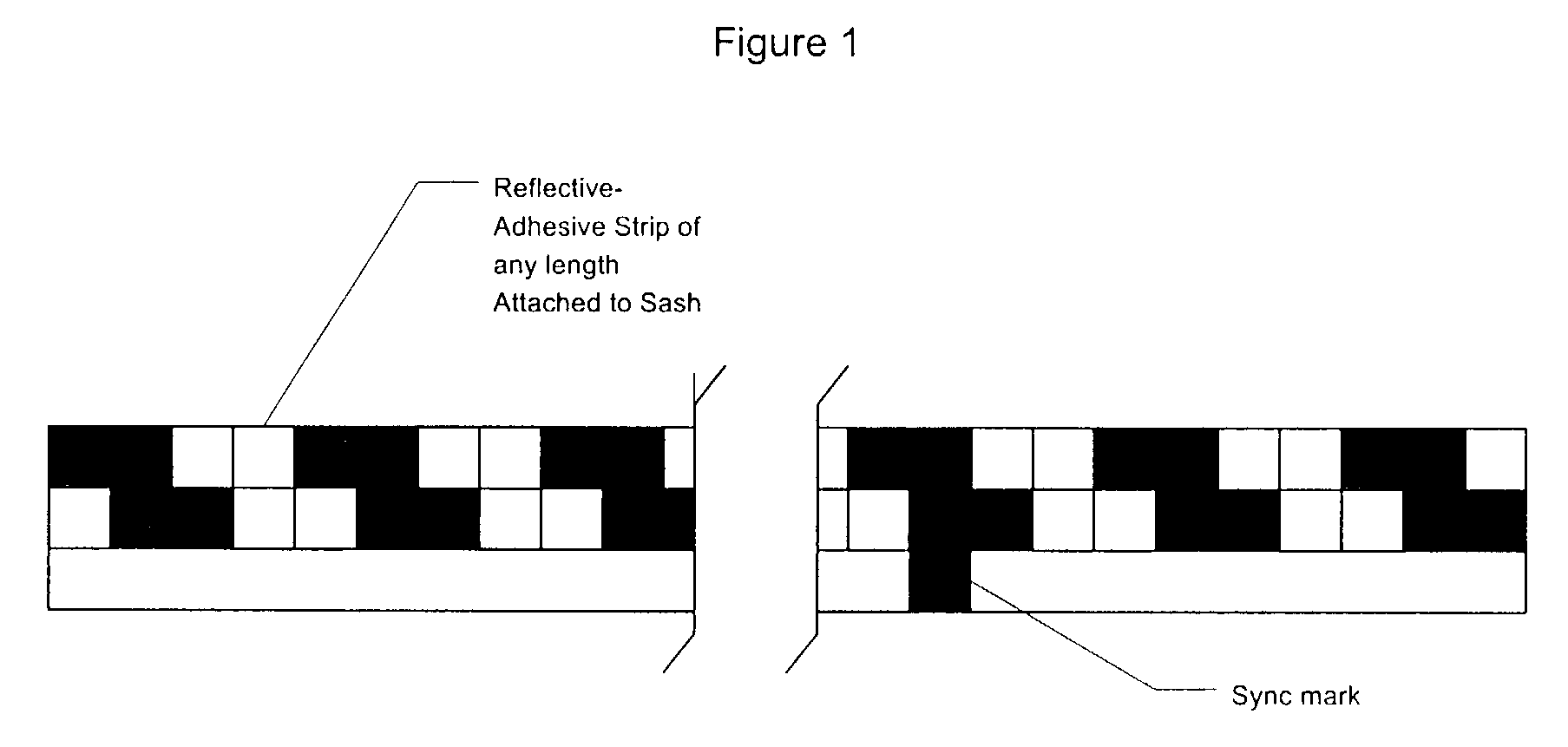

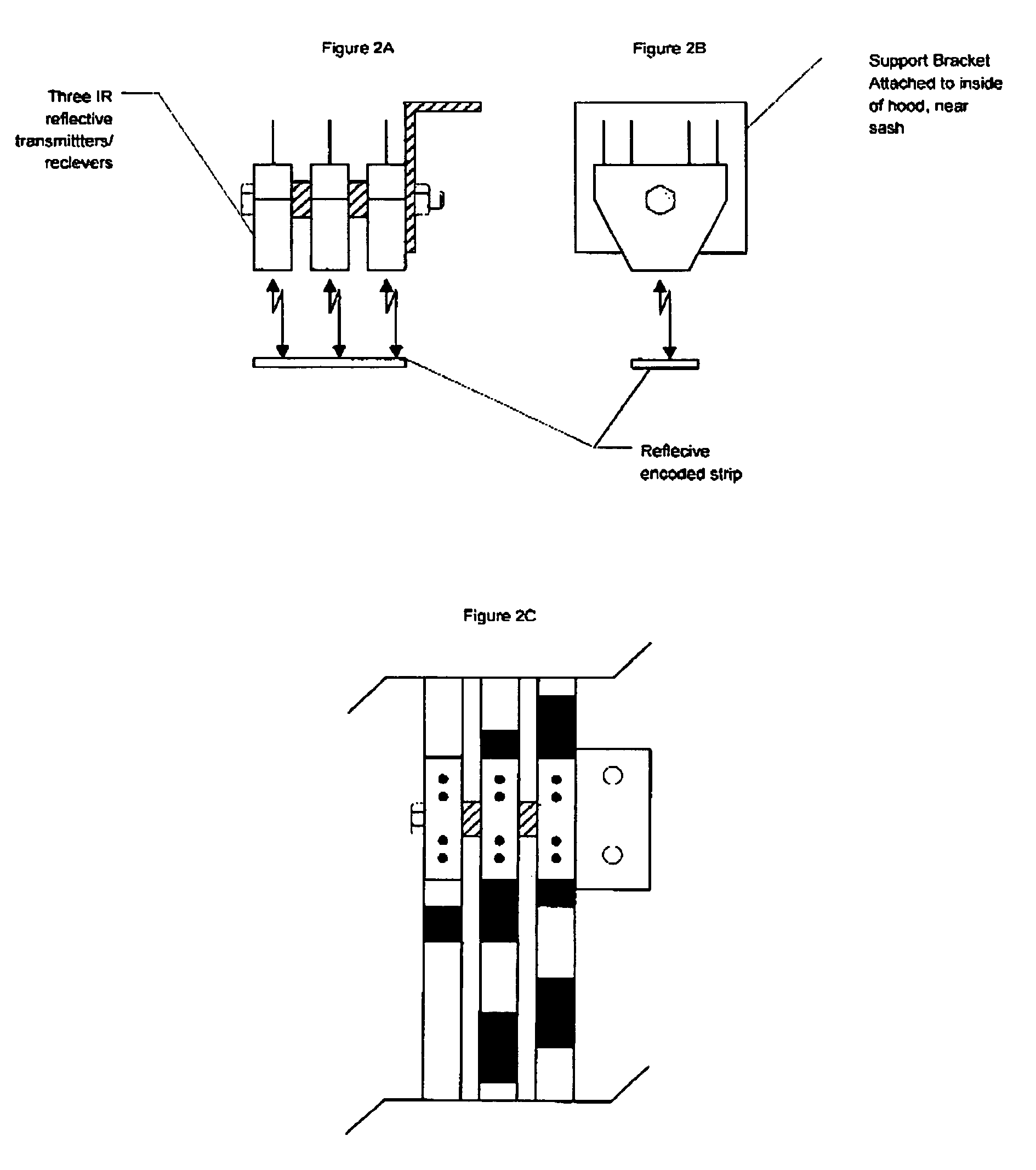

Optical sash sensing system for fume hoods

InactiveUS6994619B2Domestic stoves or rangesSpace heating and ventilation safety systemsSash windowControl signal

A fume hood optical sash sensing system for controlling the flow of air into a fume hood to maintain a constant face velocity by utilizing an optical sensing device mounted inside the fume hood that can sense the movement of a sash based on repeatable reflexive tape to produce an output control signal that corresponds to sash movement to produce desired airflow into the fume hood. The system includes an optical sensing device with a light source, reflexive tape with a repetitive, quadrature encoded pattern, a smart controller device that receives output control signals from the optical sensing device, and an actuation device capable of receiving the output signal from the controlling device to control the damper device that will result in constant face velocity across the face of the sash.

Owner:TRIATEK HLDG

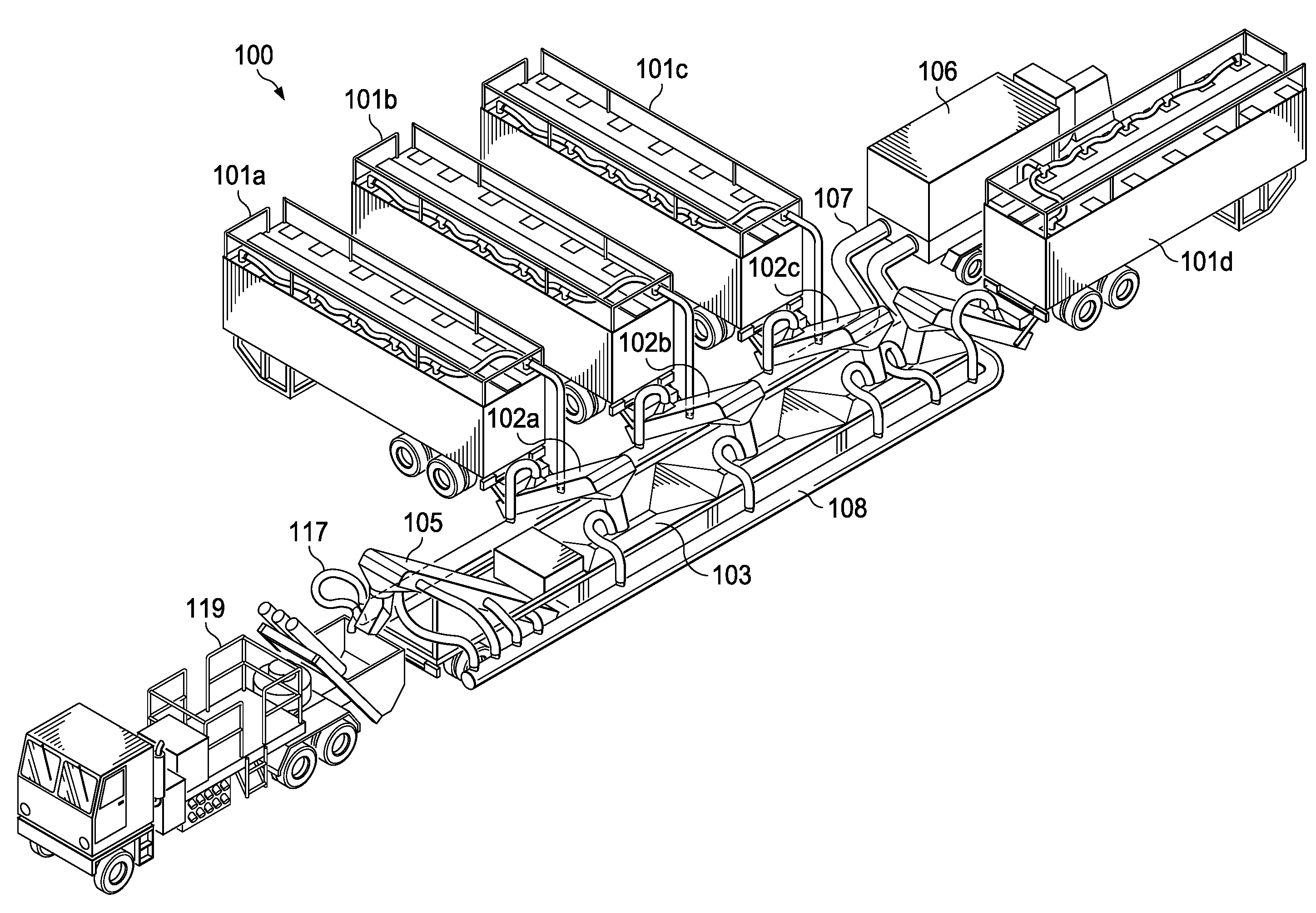

Method of reducing silicosis caused by inhalation of silica-containing proppant, such as silica sand and resin-coated silica sand, and apparatus therefor

InactiveUS8636832B2Reduce exposureMinimizing chanceCombination devicesAuxillary pretreatmentTrademarkSilicosis

A method of reducing silicosis caused by inhalation of silica-containing proppant, such as silica sand and resin-coated silica sand, and apparatus therefor. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KSW ENVIRONMENTAL LLC D B A AIRIS WELLSITE SERVICES

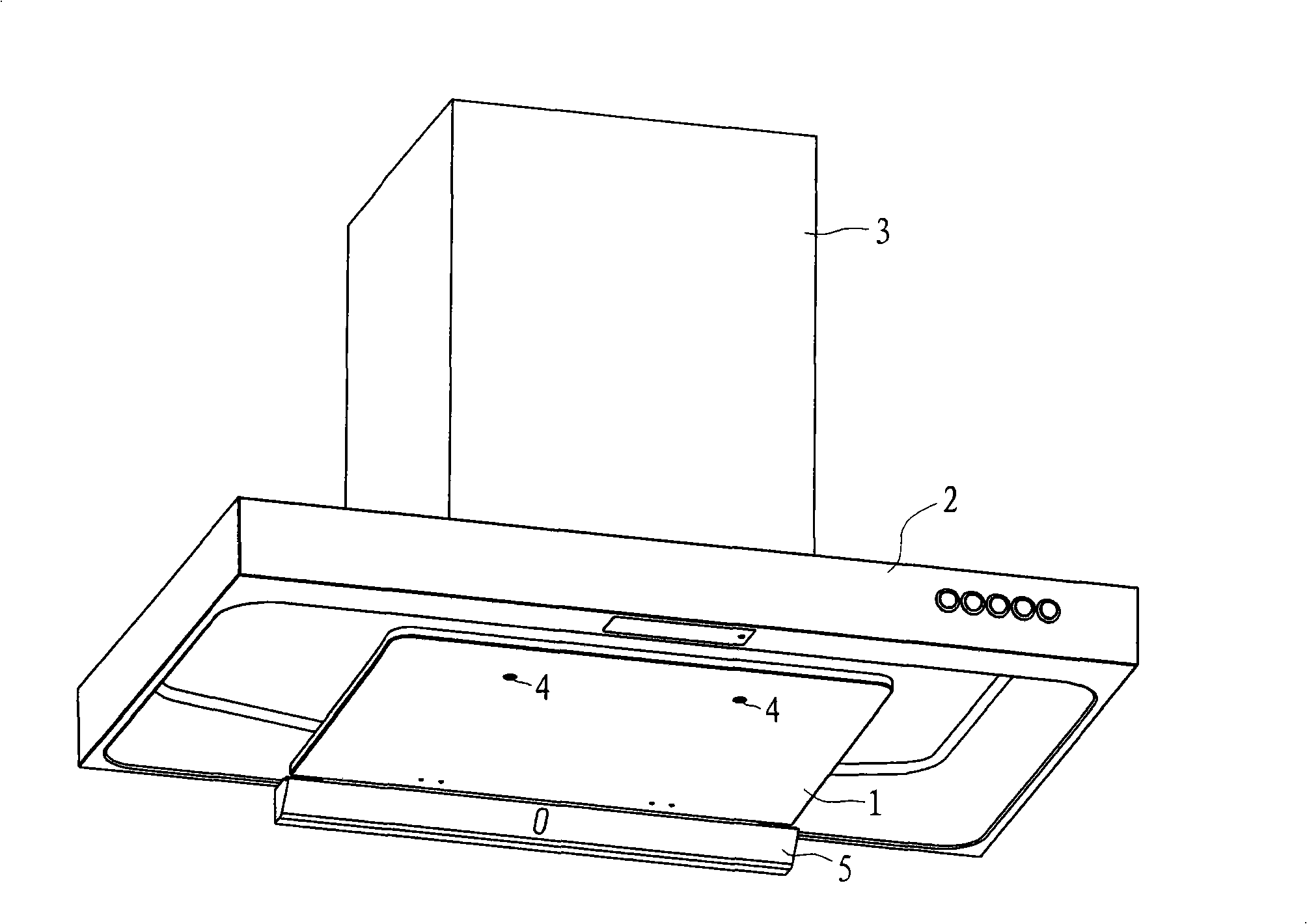

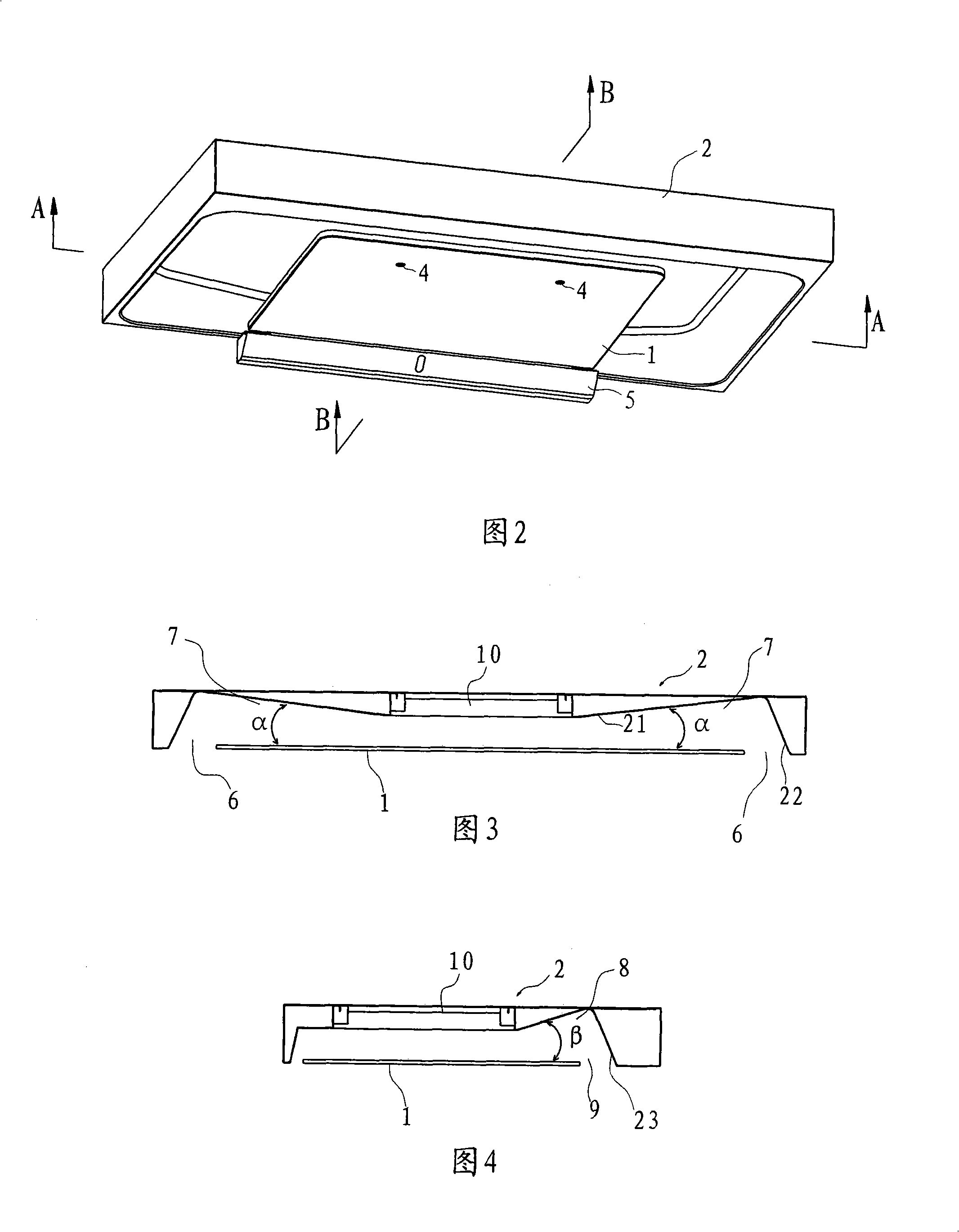

Range hood with smoke deflector

ActiveCN101514823ASpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturi effect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

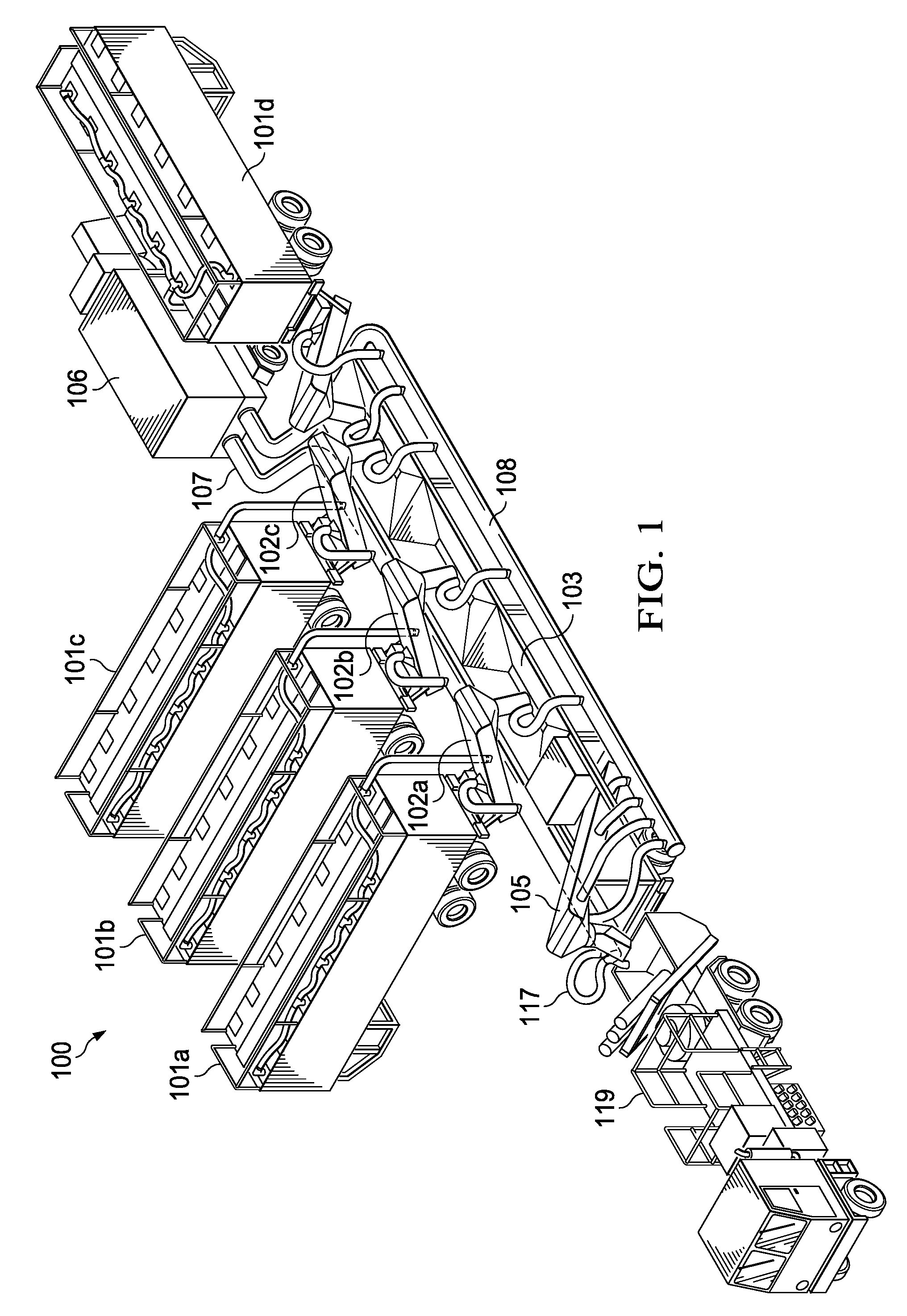

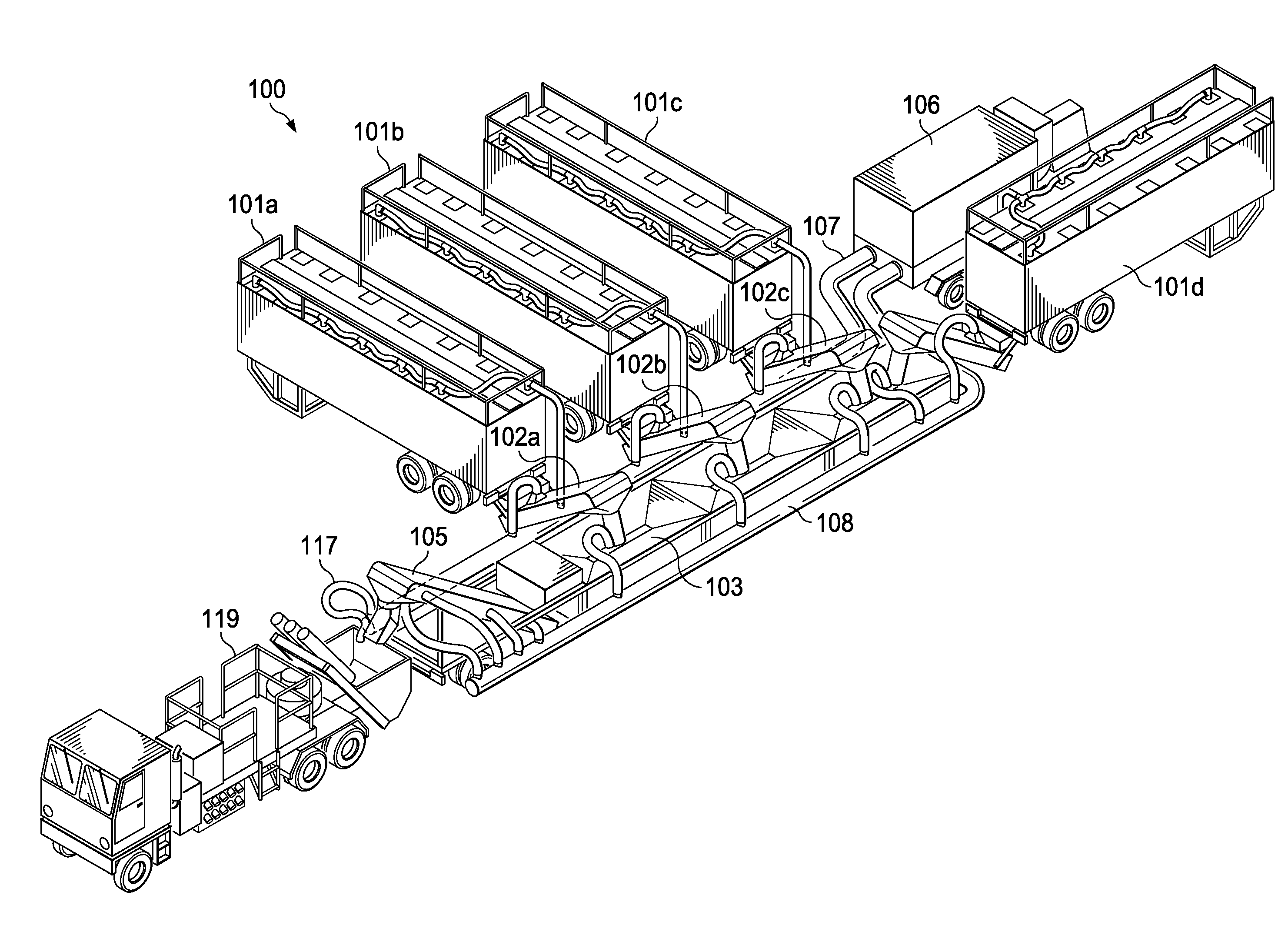

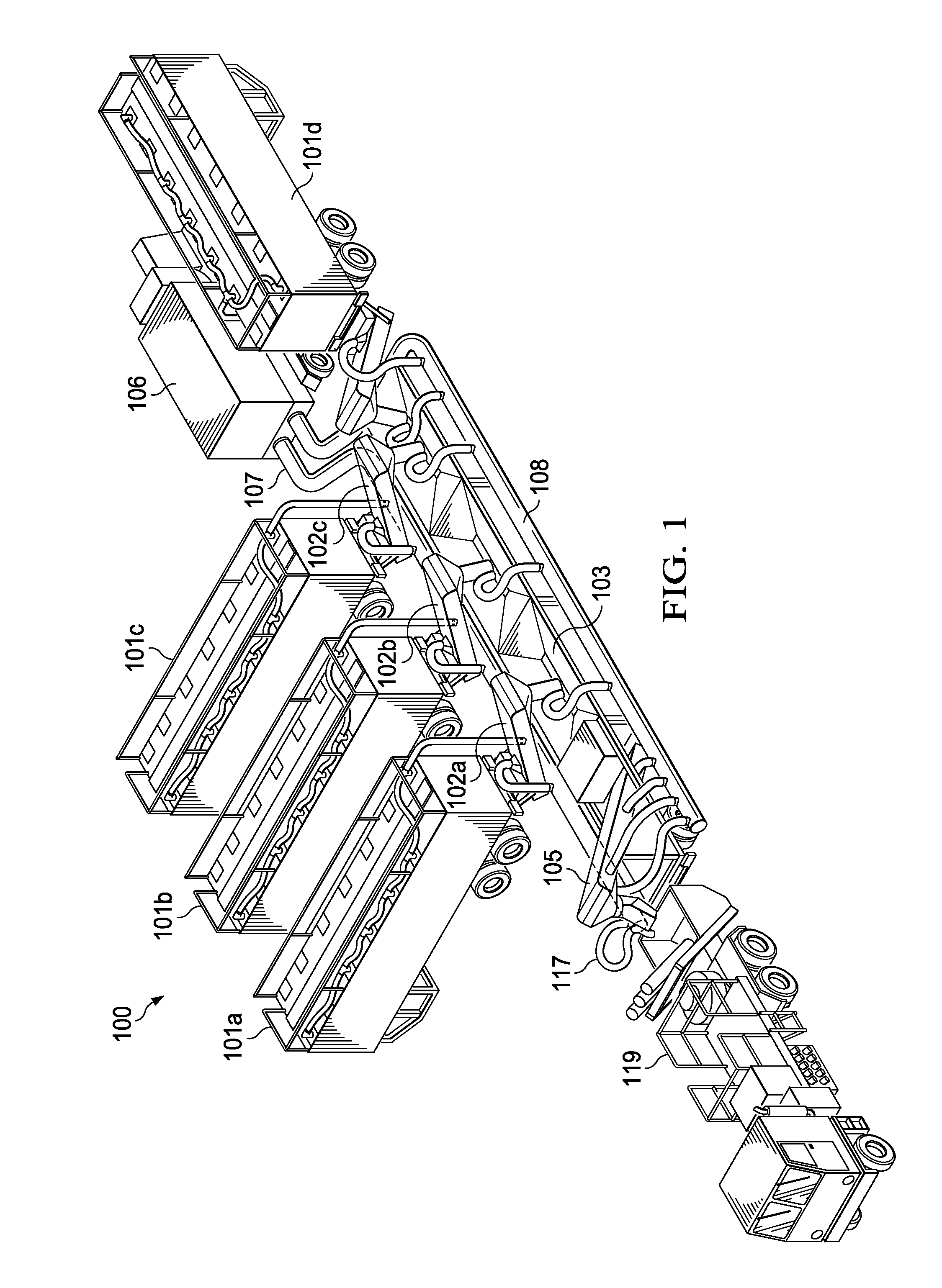

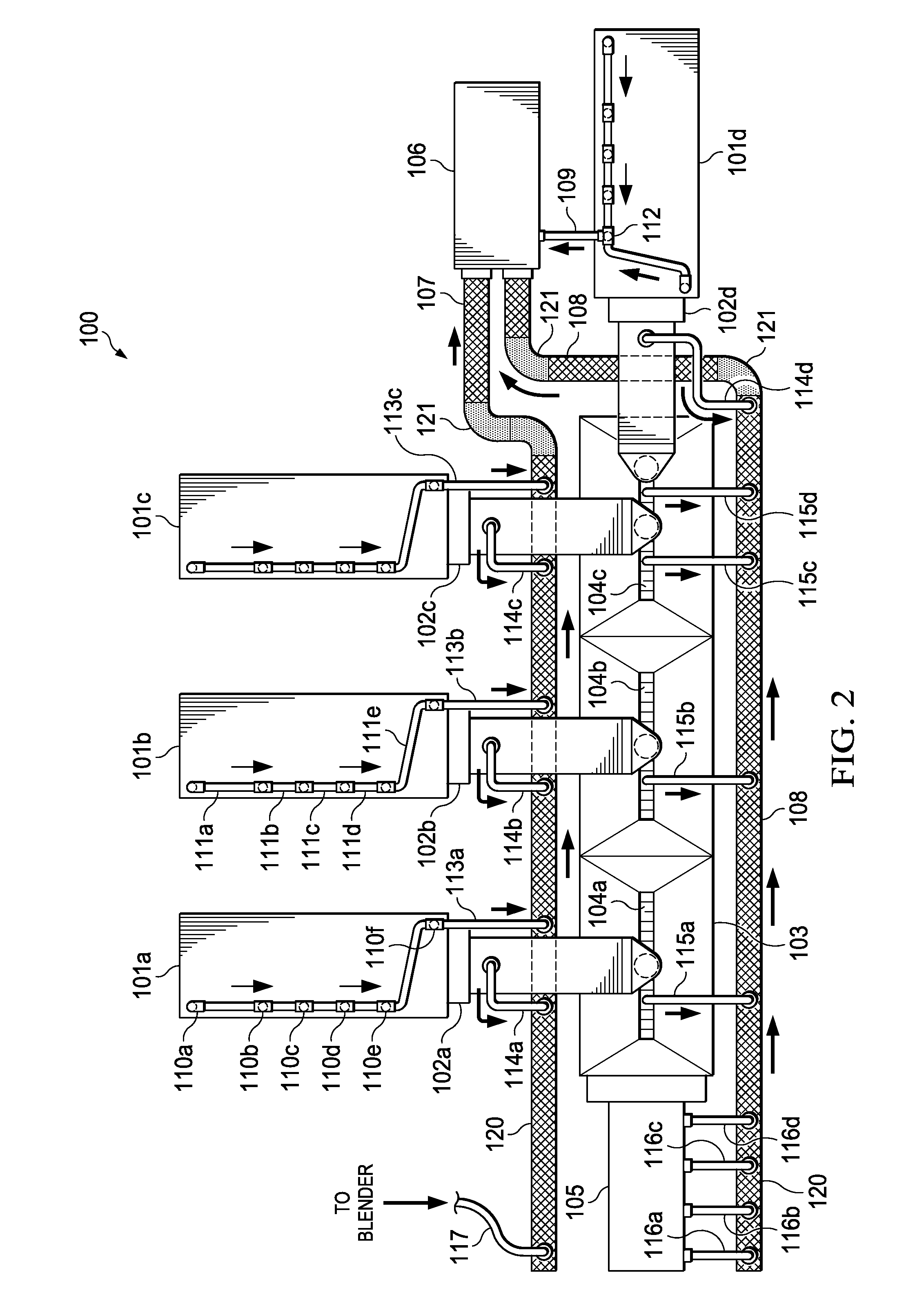

Systems and methods for controlling silica dust during hydraulic fracturing operations

ActiveUS8881749B1Improve flexibility and efficiencyEfficient and flexible systemMechanical cleaningPressure cleaningEngineeringHydraulic fracturing

A system for controlling silica dust generated during the transfer of frac sand from a storage container through a conveyor system includes a system of conduits having a plurality of inlets for collecting silica dust generated at selected points along the conveyor system. An air system pneumatically coupled to the system of conduits generates a negative pressure at each of the inlets to induce the collection of silica dust at the selected points along the conveyor.

Owner:SIERRA DUST CONTROL

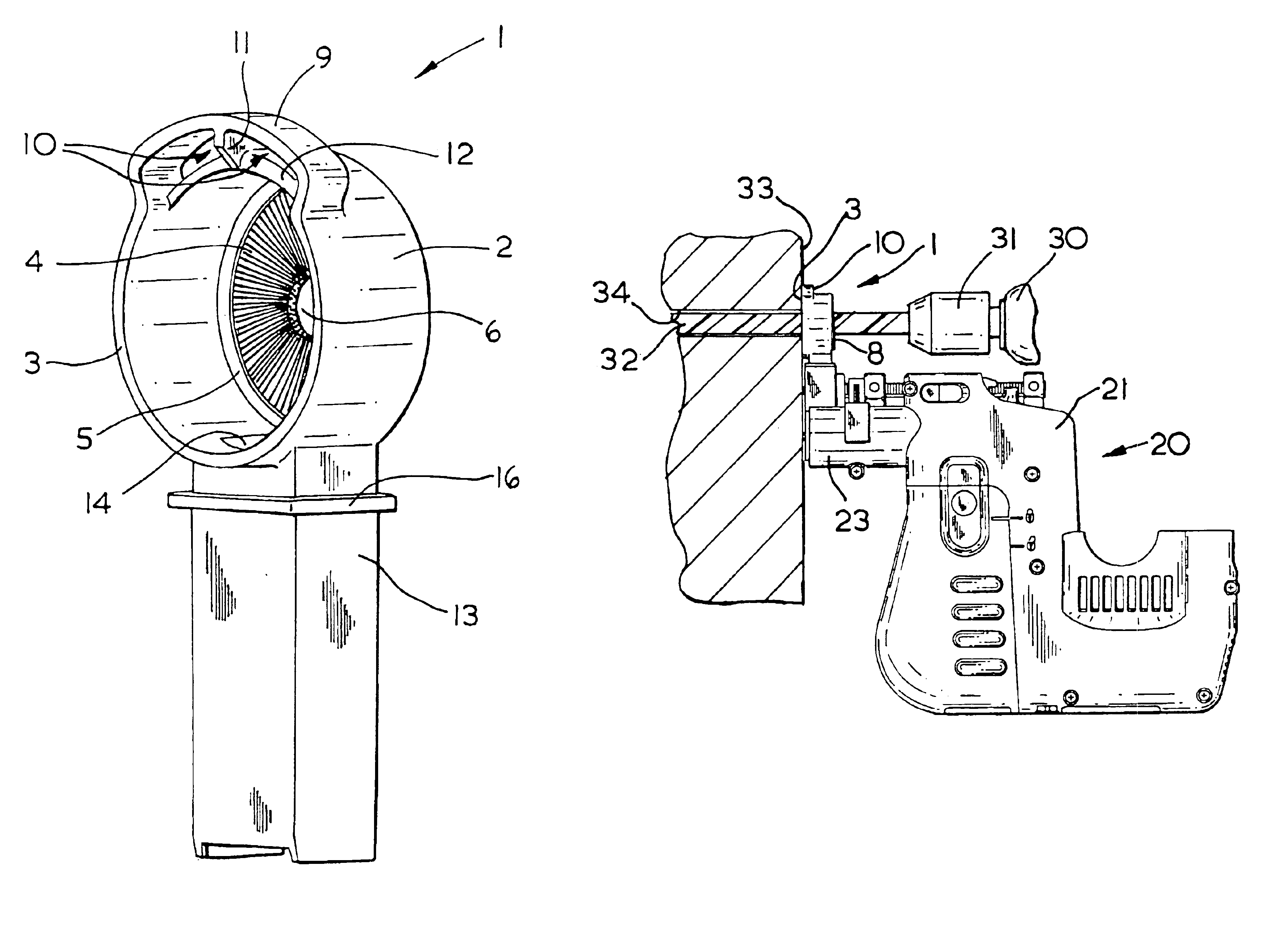

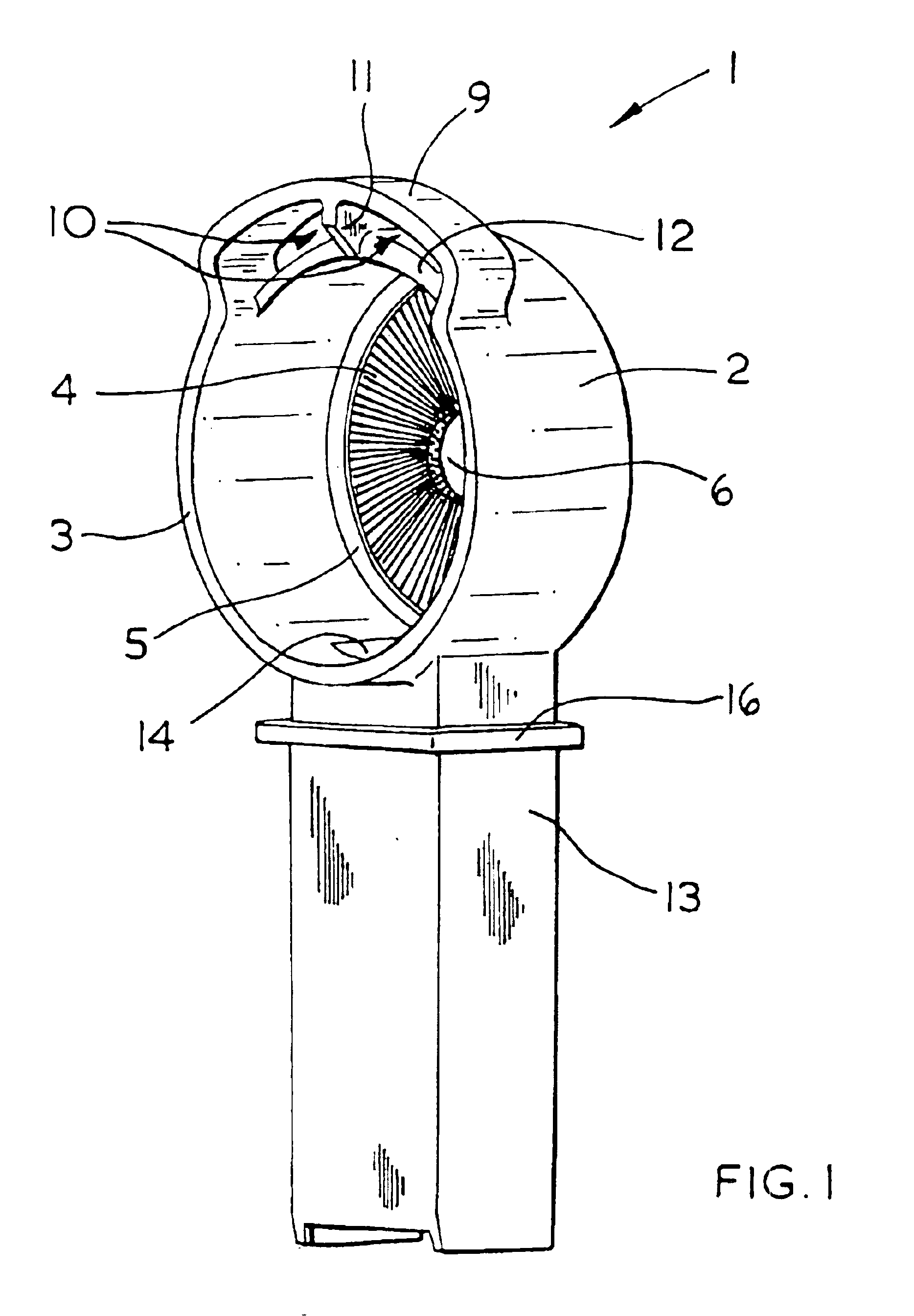

Dust extraction shroud for a power tool

A dust extraction shroud for a drill, which surrounds a drill bit and which lies adjacent the work surface, comprises a body portion defining a first inlet adapted to engage the work surface and to surround the location at which said bit penetrates the surface. The shroud body further defines a first outlet connected to a source of suction and a third inlet for allowing the bit to pass through said body portion. A first sealing means is arranged in said third inlet for surrounding said bit and resisting the flow of air. Wherein said body portion includes at least one protruding portion defining a second inlet between said protruding portion and an adjacent part of said body, and on a side of said protruding portion remote from the first inlet. The second inlet admits air to enter said body portion and travel to the first outlet.

Owner:BLACK & DECKER INC

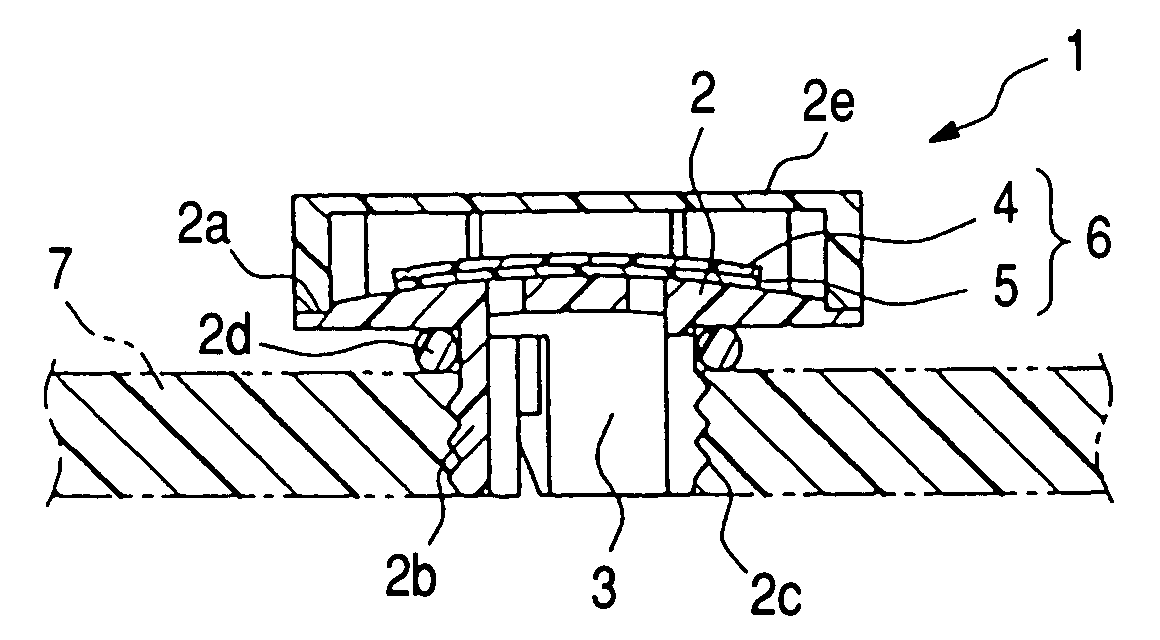

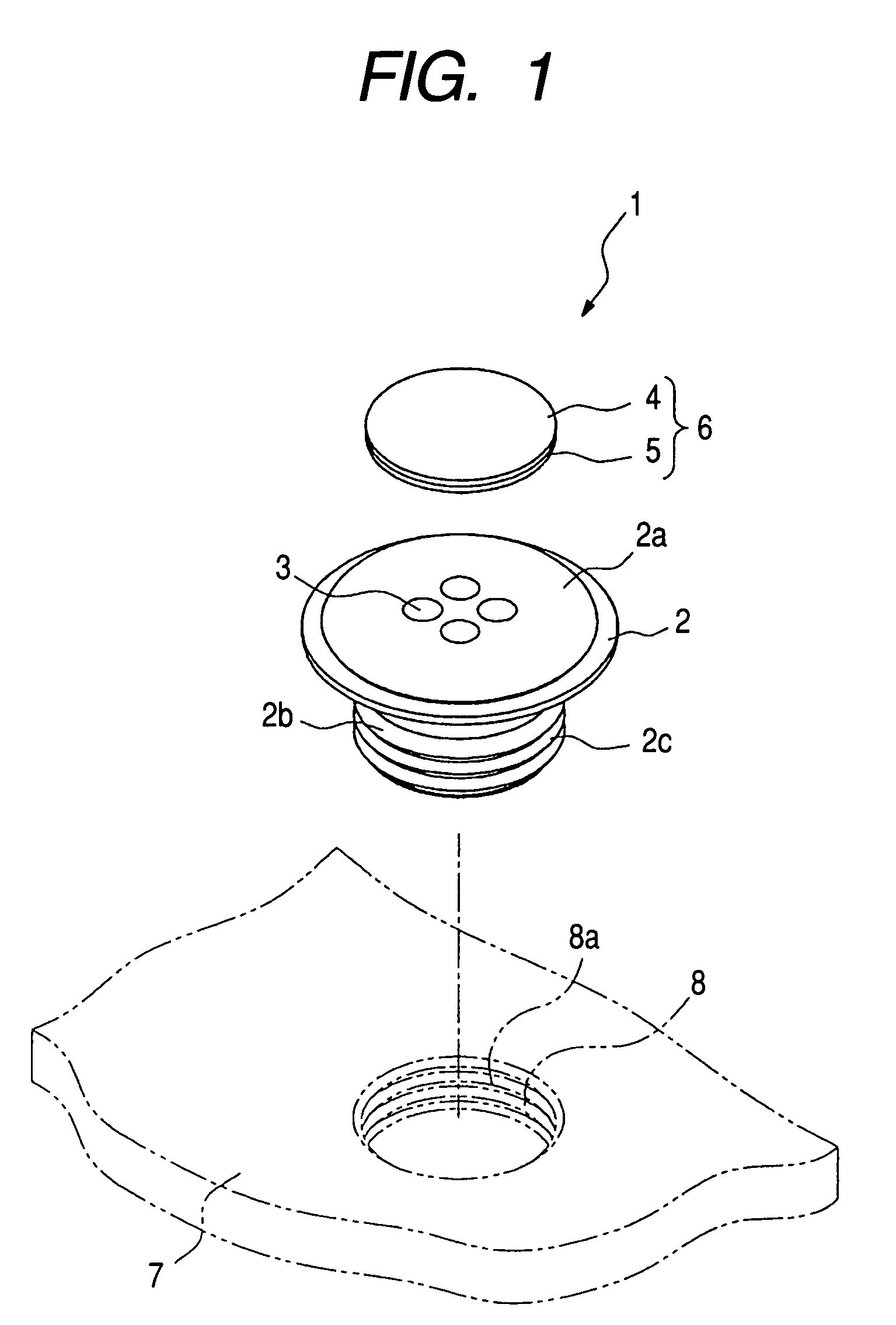

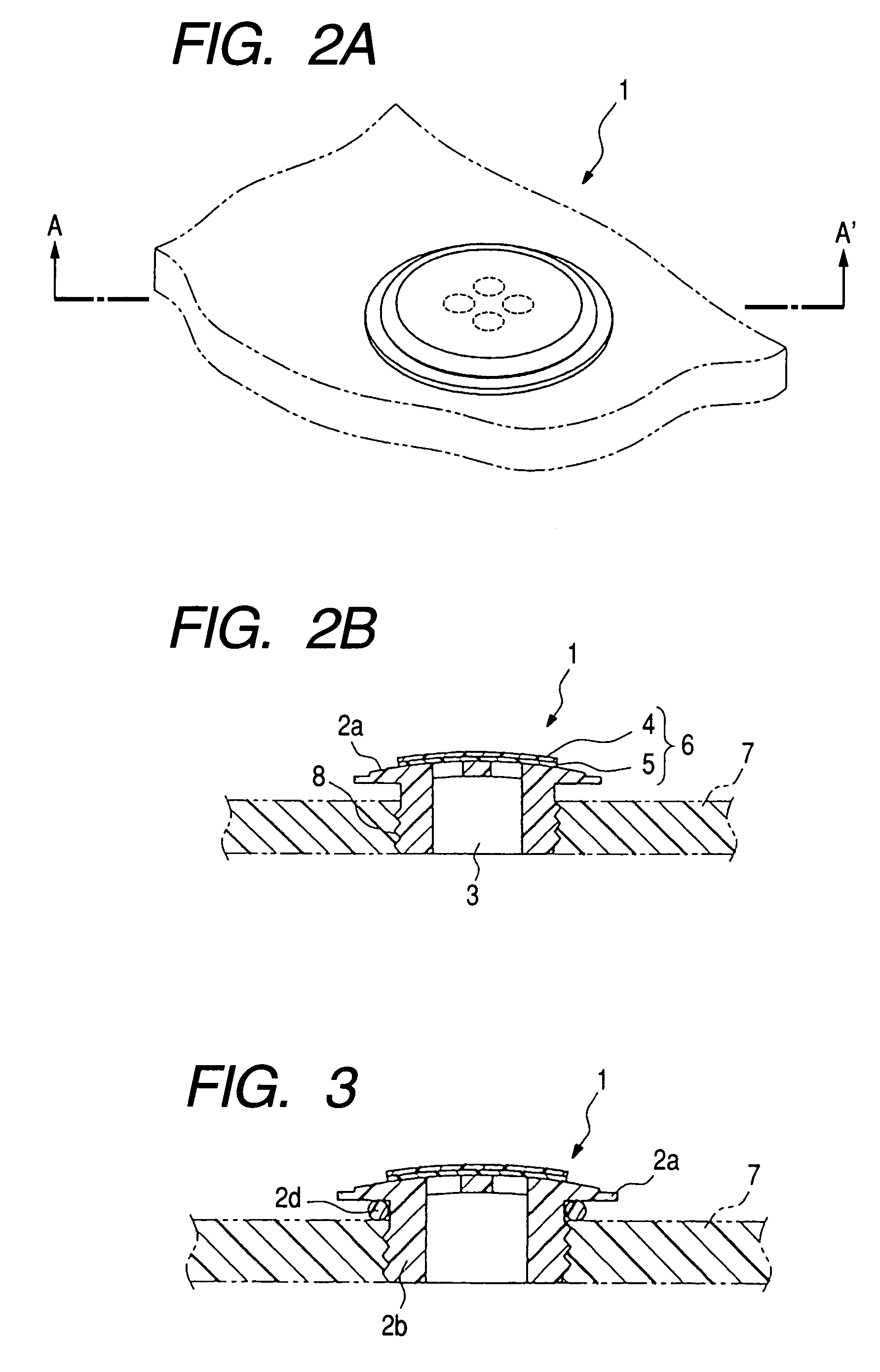

Ventilation member and vented housing using the same

InactiveUS7166024B2Reduce the possibilityCoupling device connectionsCombination devicesGas passingMechanical engineering

A ventilation member having: a breathable film transmitting gas passing through an opening portion of a housing in a state in which the breathable film is fixed to the opening portion; and a support including a supporting portion for supporting the breathable film and an insertion portion to be inserted into the opening portion of the housing; wherein a lock structure for locking the support in the housing by rotating the support around a central axis of the support is formed in the insertion portion.

Owner:NITTO DENKO CORP

Method of reducing silicosis caused by inhalation of silica-containing proppant, such as silica sand and resin-coated sand, and apparatus therefor

InactiveUS20120247335A1Reduce exposureMinimizing chanceDispersed particle separationDirt cleaningSilicosisInhalation

A method of reducing silicosis caused by inhalation of silica-containing proppant, such as silica sand and resin-coated silica sand, and apparatus therefor.

Owner:KSW ENVIRONMENTAL LLC D B A AIRIS WELLSITE SERVICES

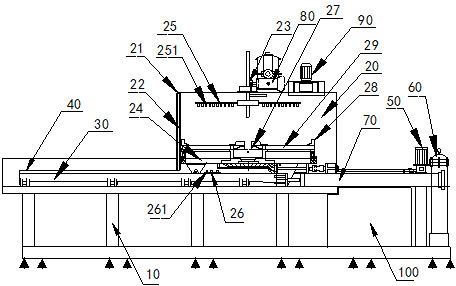

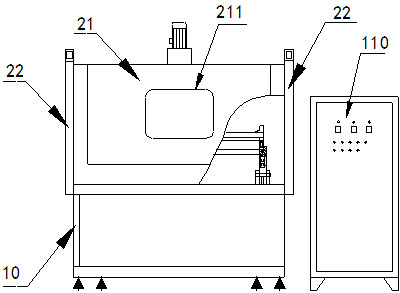

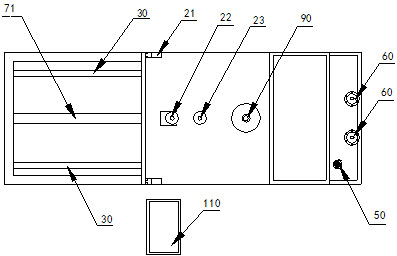

Bearing washer

InactiveCN101875046AEasy to operateFlexible operationDirt cleaningCleaning using liquidsControl engineeringElectric machinery

The invention discloses a bearing washer, which comprises a main body workbench, a washing chamber arranged on the main body workbench, a spraying pump and a drive motor, wherein the main body workbench is provided with an inlet-outlet path of the washing chamber; the inlet-outlet path is provided with a feed-discharge trolley; the inlet-outlet path is connected with an inlet-outlet cylinder; an upper spraying pipe is arranged at the top position in the washing chamber, and a lower spraying pipe is arranged at the bottom position in the washing chamber; the feed-discharge trolley is provided with an inner stationary fixture, an outer stationary fixture and an upper drive carriage, and the inner and outer stationary fixtures can adjust and clamp a large-size bearing; a rotary spindle, which can be jointed with the centre of the inner stationary fixture, is arranged at the top position in the washing chamber; and the rotary spindle is connected with the drive motor. The bearing washer has the advantages of reducing intermediate links, automatically completing the whole process of product washing, effectively washing dead corners in the products, greatly improving the cleanness of the product, along with high automation, high washing efficiency, low operation and labor intensity, quick, convenient and flexible clamping and fixing operation and complete washing.

Owner:宁波达克轴承有限公司

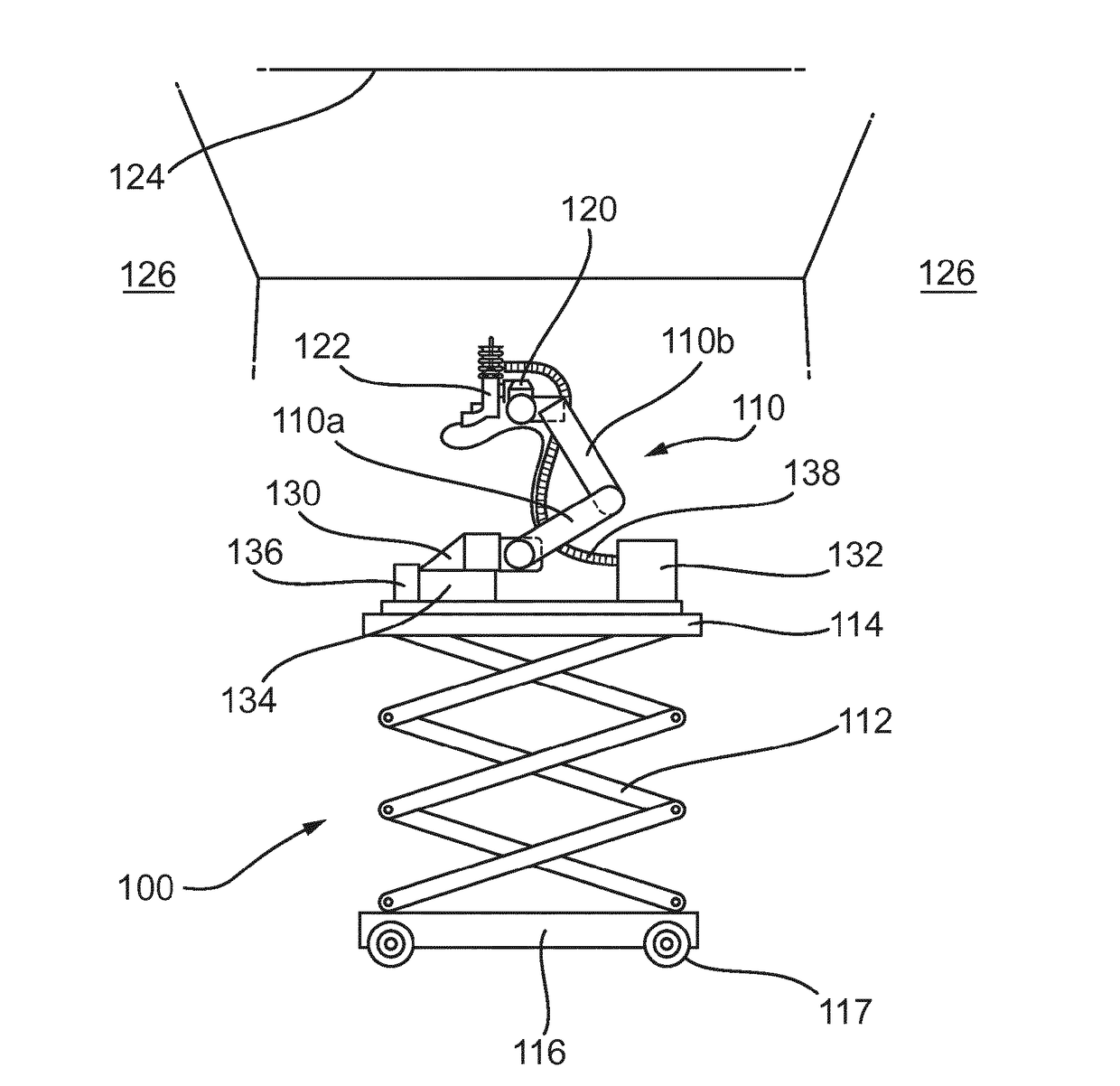

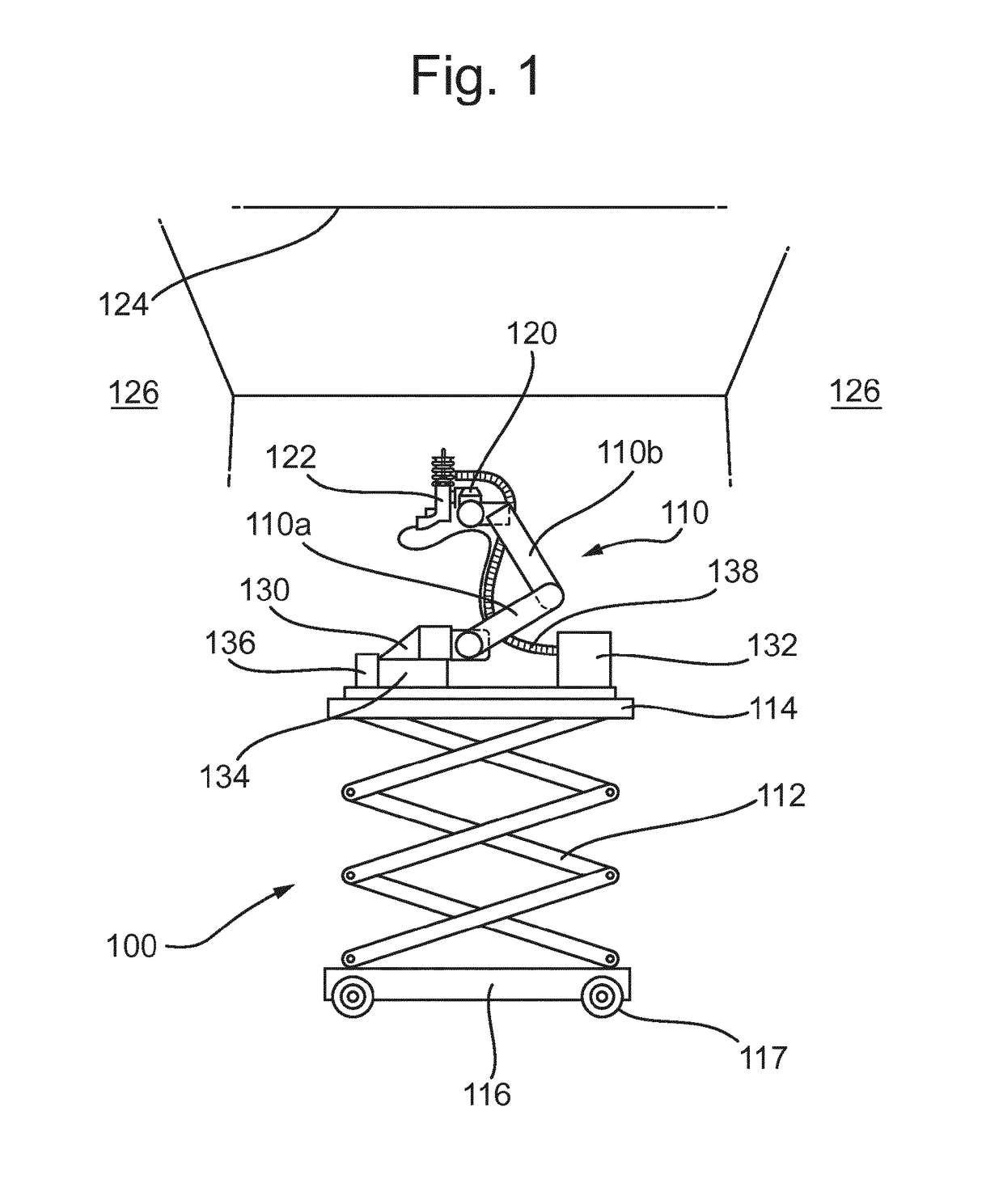

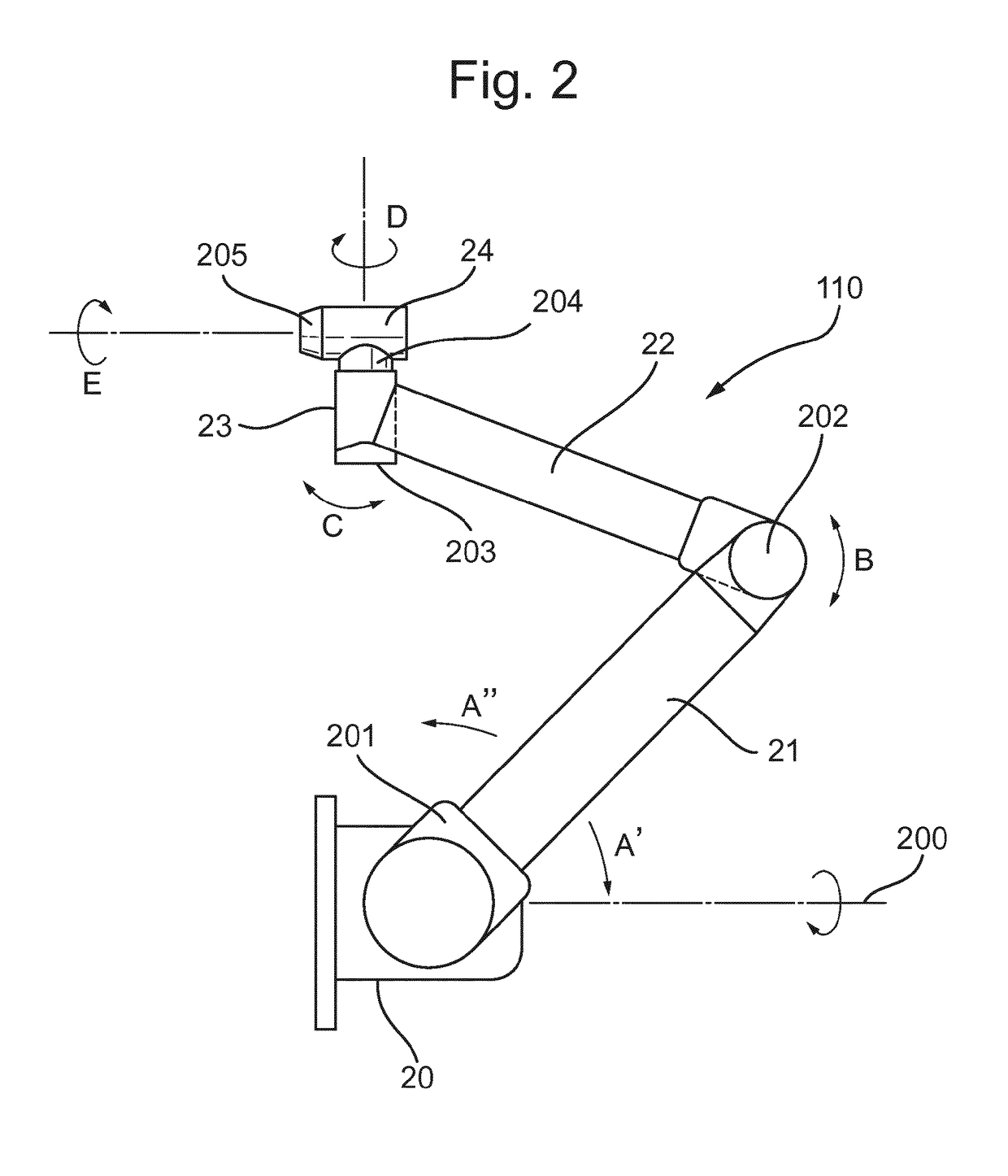

Mobile robotic drilling apparatus and method for drilling ceilings and walls

PendingUS20180326507A1Precise drillingDelay in reachingProgramme-controlled manipulatorWorkpiecesThree-dimensional spaceRobotic arm

A robotic drilling apparatus is described which has been adapted for drilling holes in ceilings and walls on a construction site. The apparatus (100) comprises a robotic arm (110) mounted to a substructure (112), the substructure comprising a lifting mechanism arranged to lift the robotic arm to a working position, wherein the robotic arm has a base end (110a) and a movable end (110b), the base end being mounted to an upper surface (114) of the lifting mechanism and the movable end being capable of movement with respect to the base end in a three dimensional space, wherein the robotic drilling apparatus further comprises a mount (120) provided on the movable end for holding a drilling device (122) and a control unit (134) for controlling the operation of the robotic arm. The lifting mechanism preferably comprises a scissor-jack lifting platform. The robotic arm (110) and any support structure (134) for the robotic arm weighs less than 43 kg, and preferably individually weigh less than 23 kg.

Owner:HILTI CORPOARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com