Patents

Literature

740 results about "Dust collection system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dust collection system is an air quality improvement system used in industrial, commercial, and home production shops to improve breathable air quality and safety by removing particulate matter from the air and environment. Dust collection systems work on the basic formula of capture, convey and collect.

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

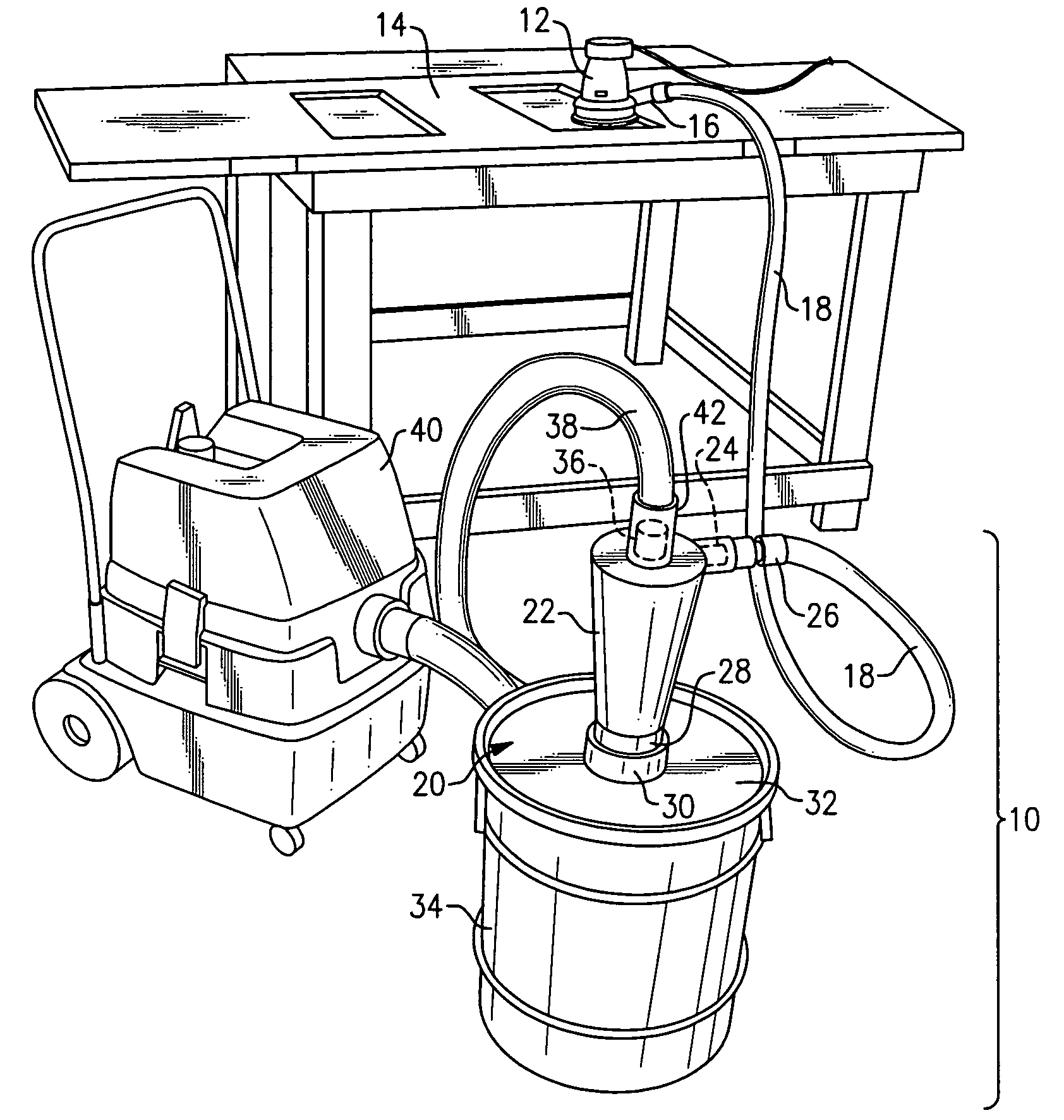

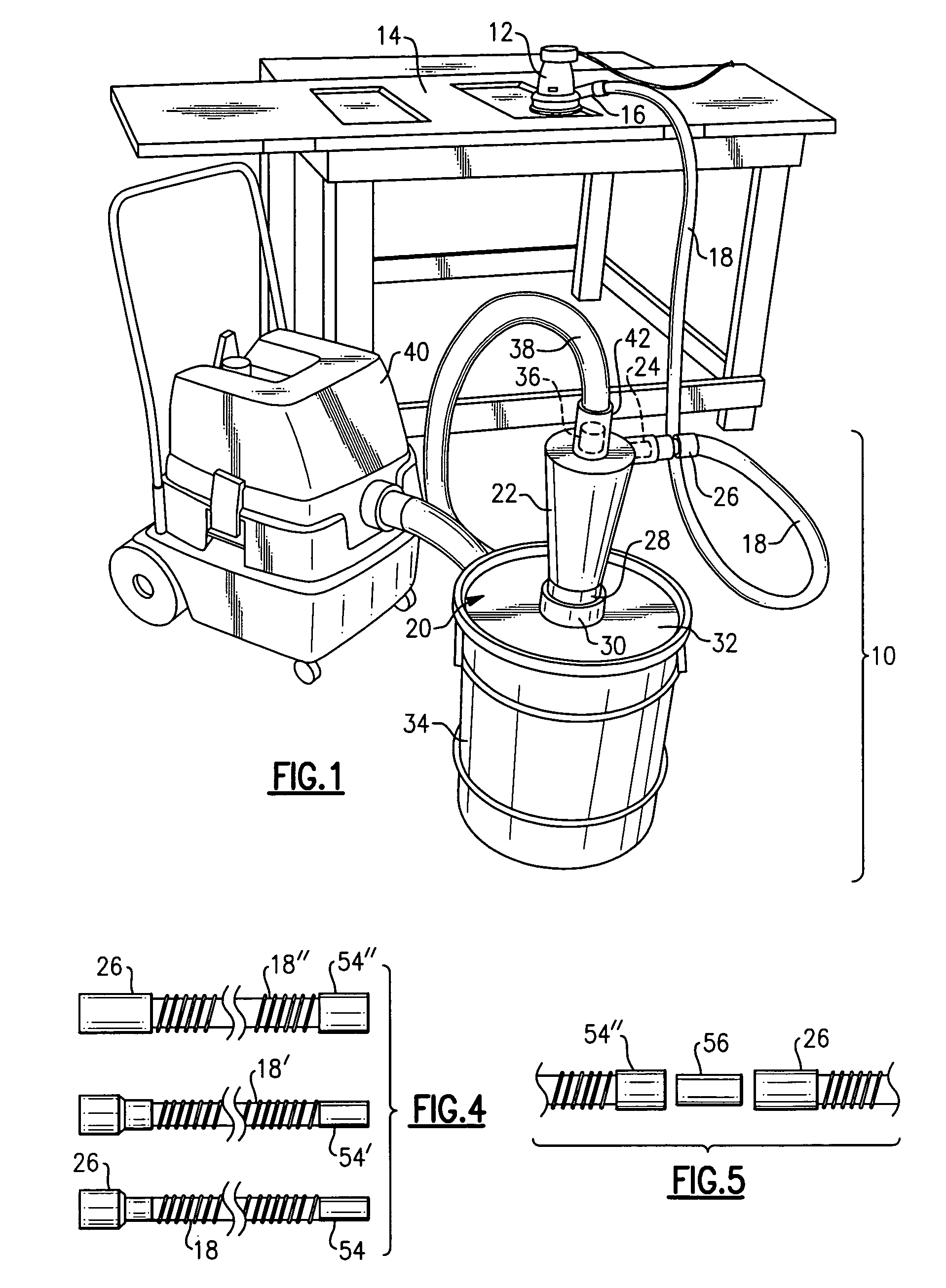

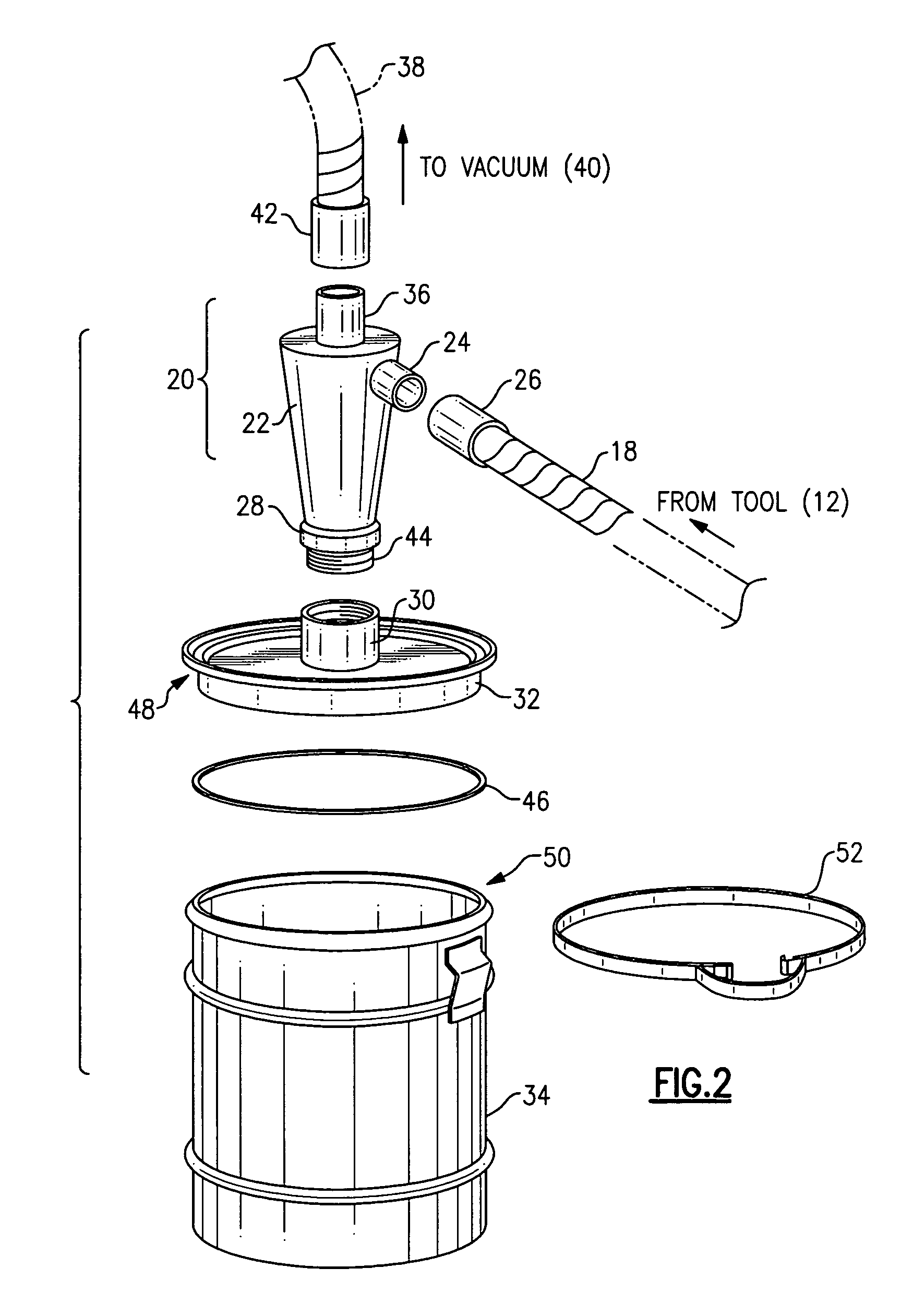

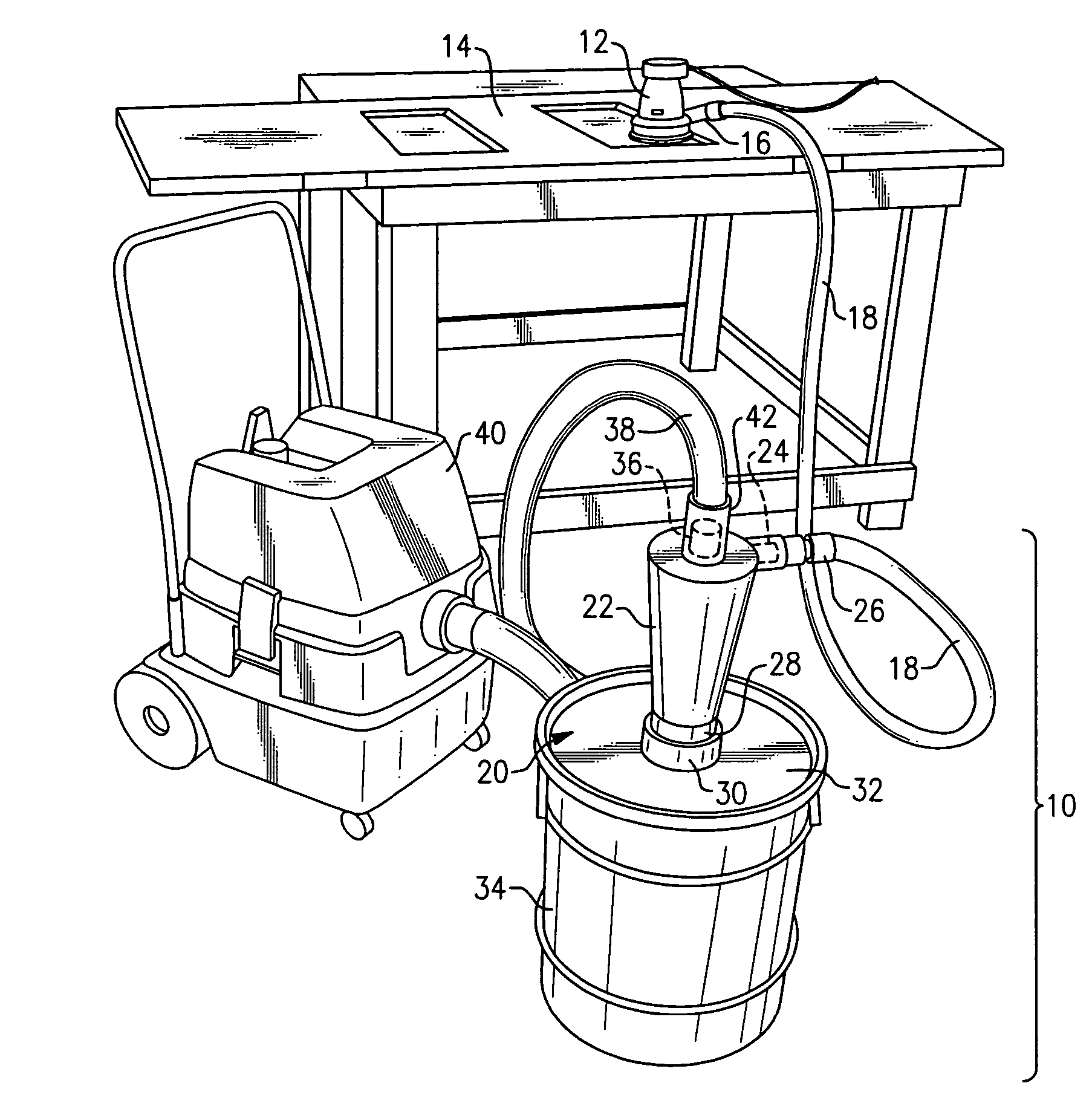

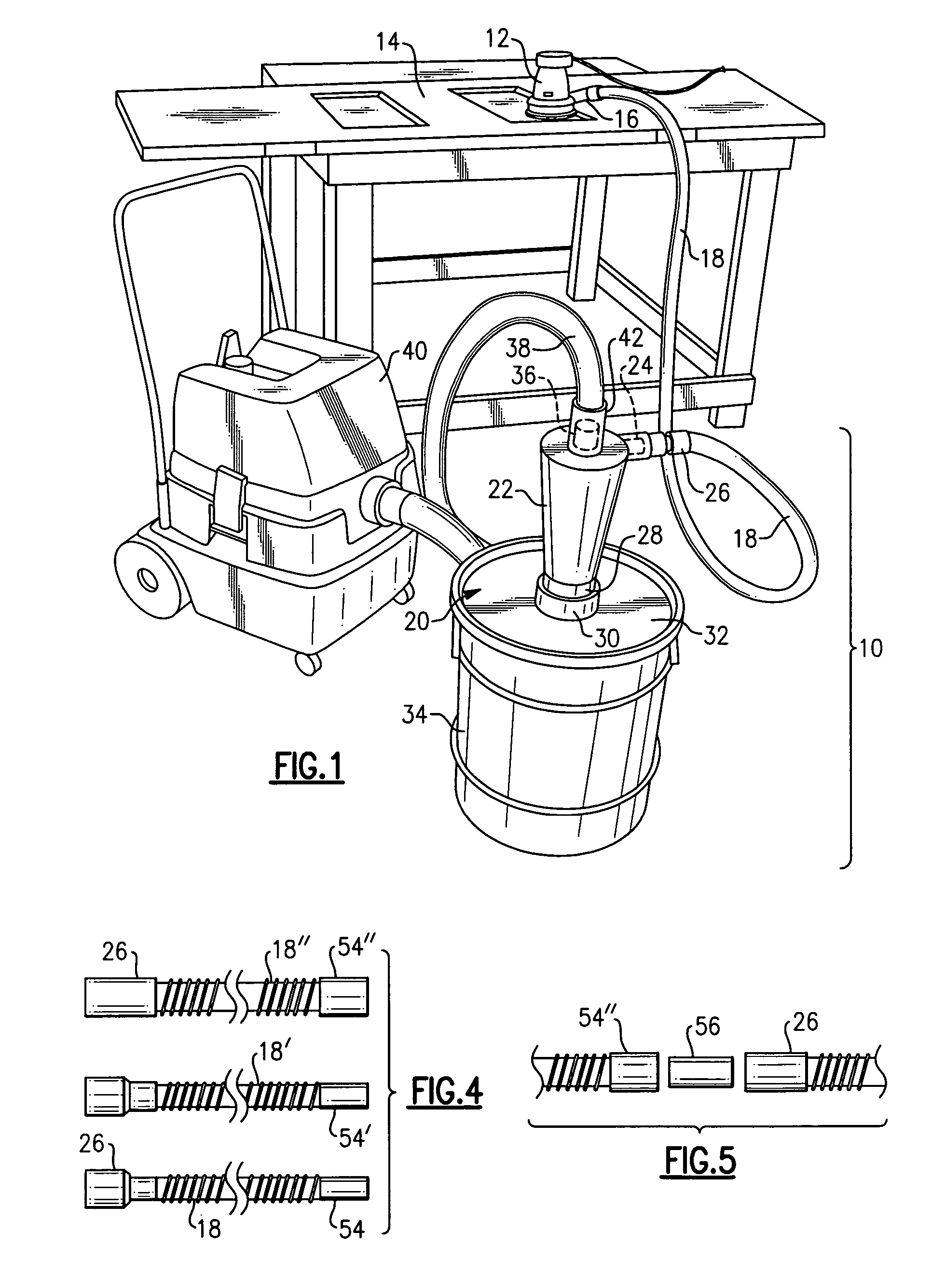

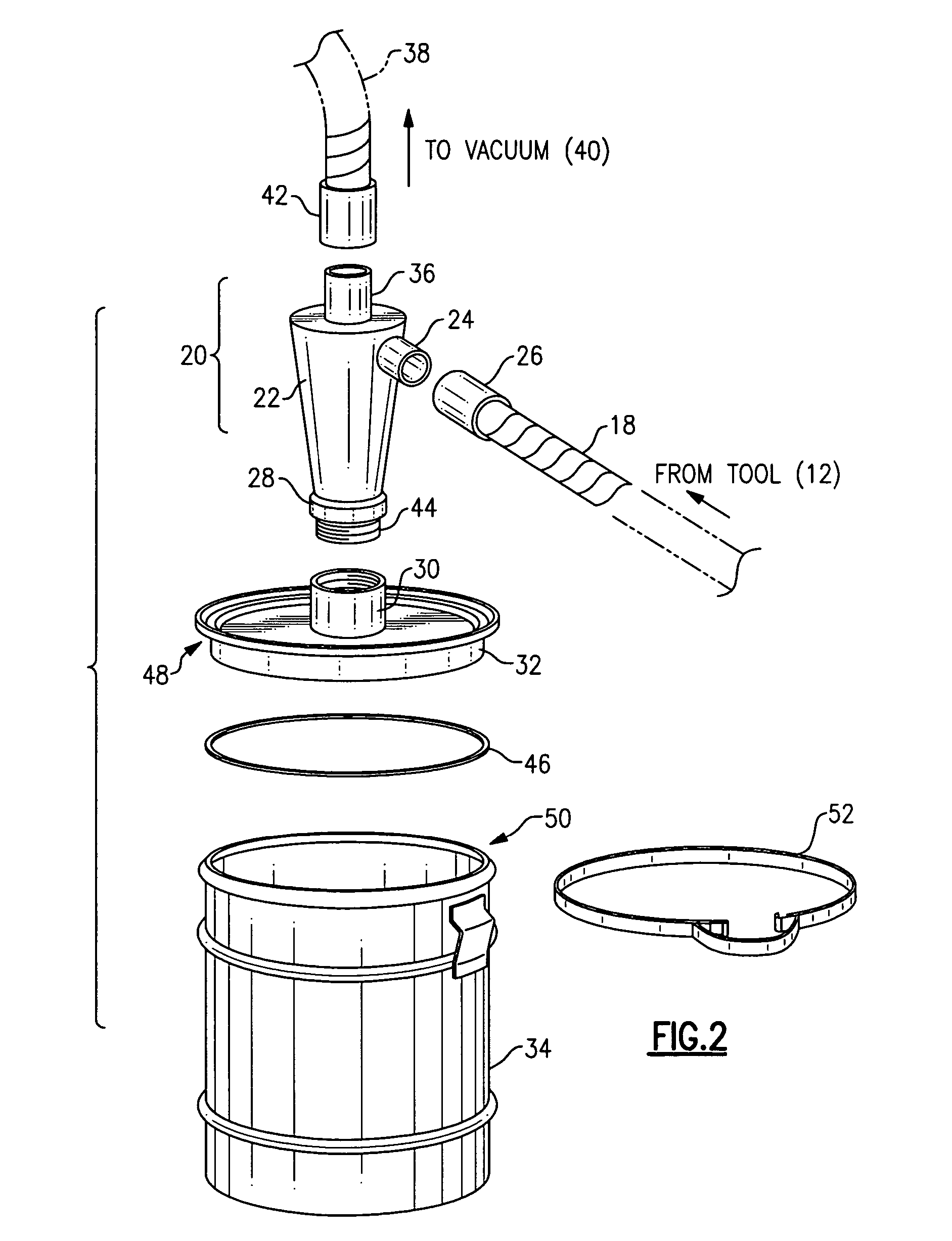

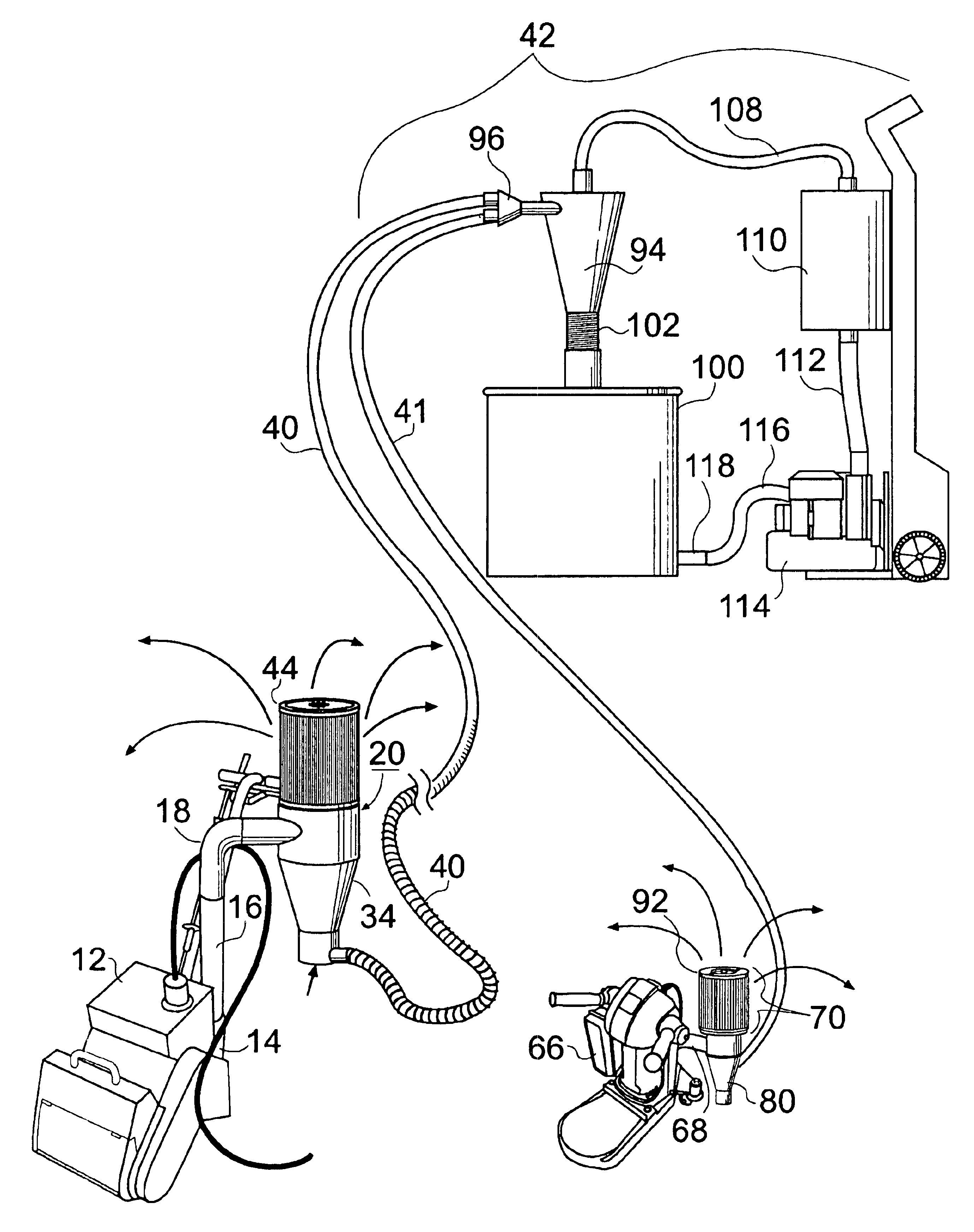

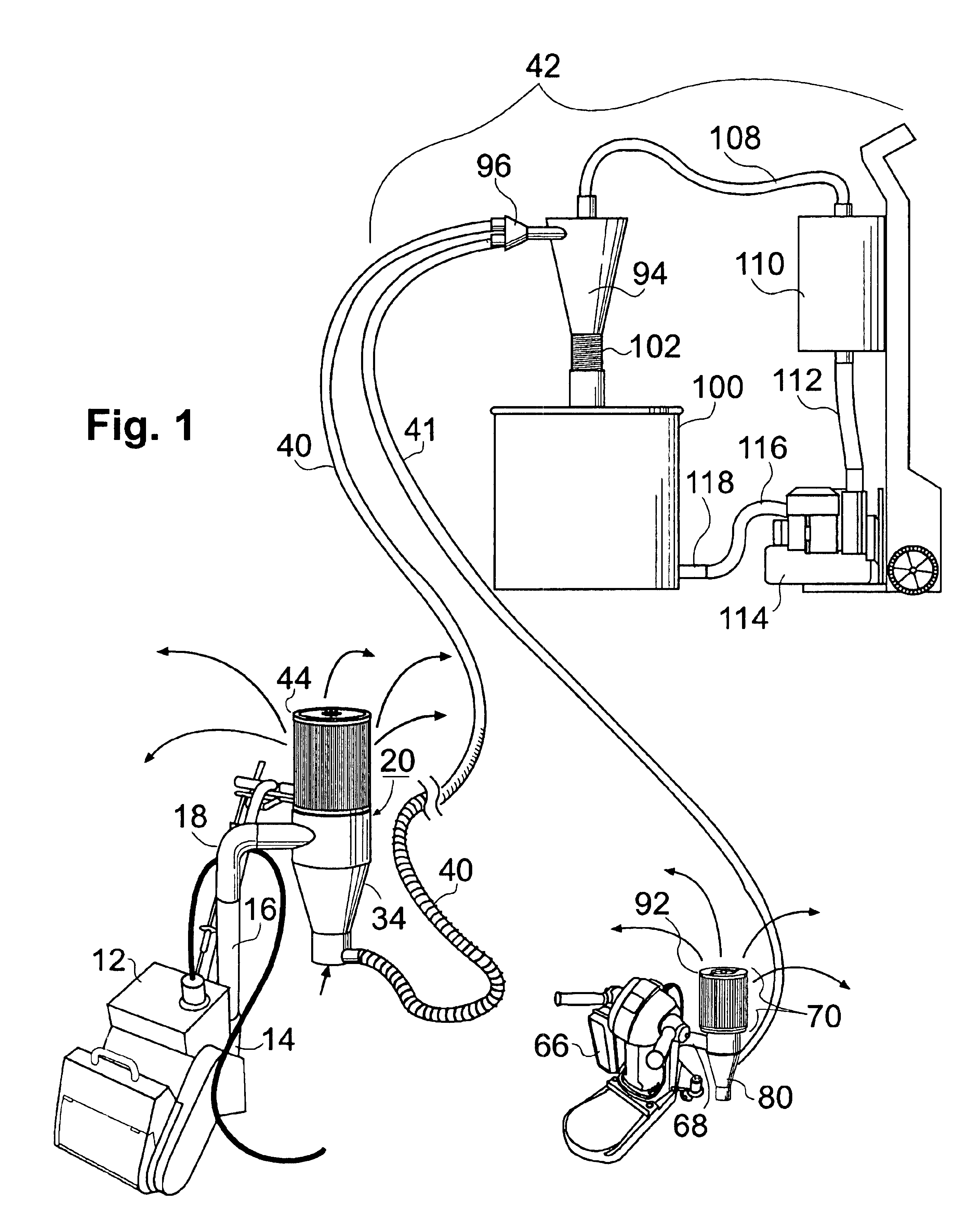

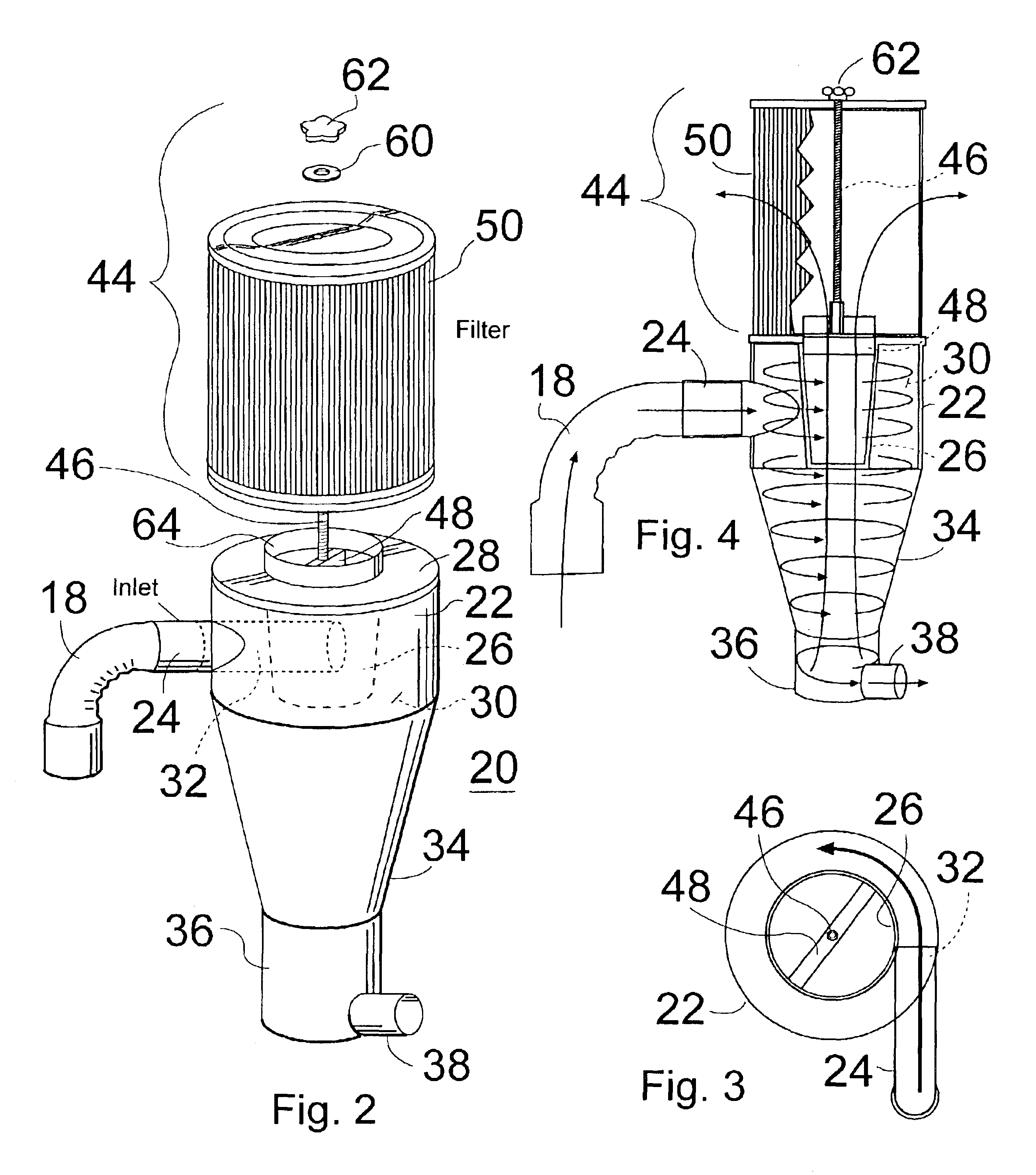

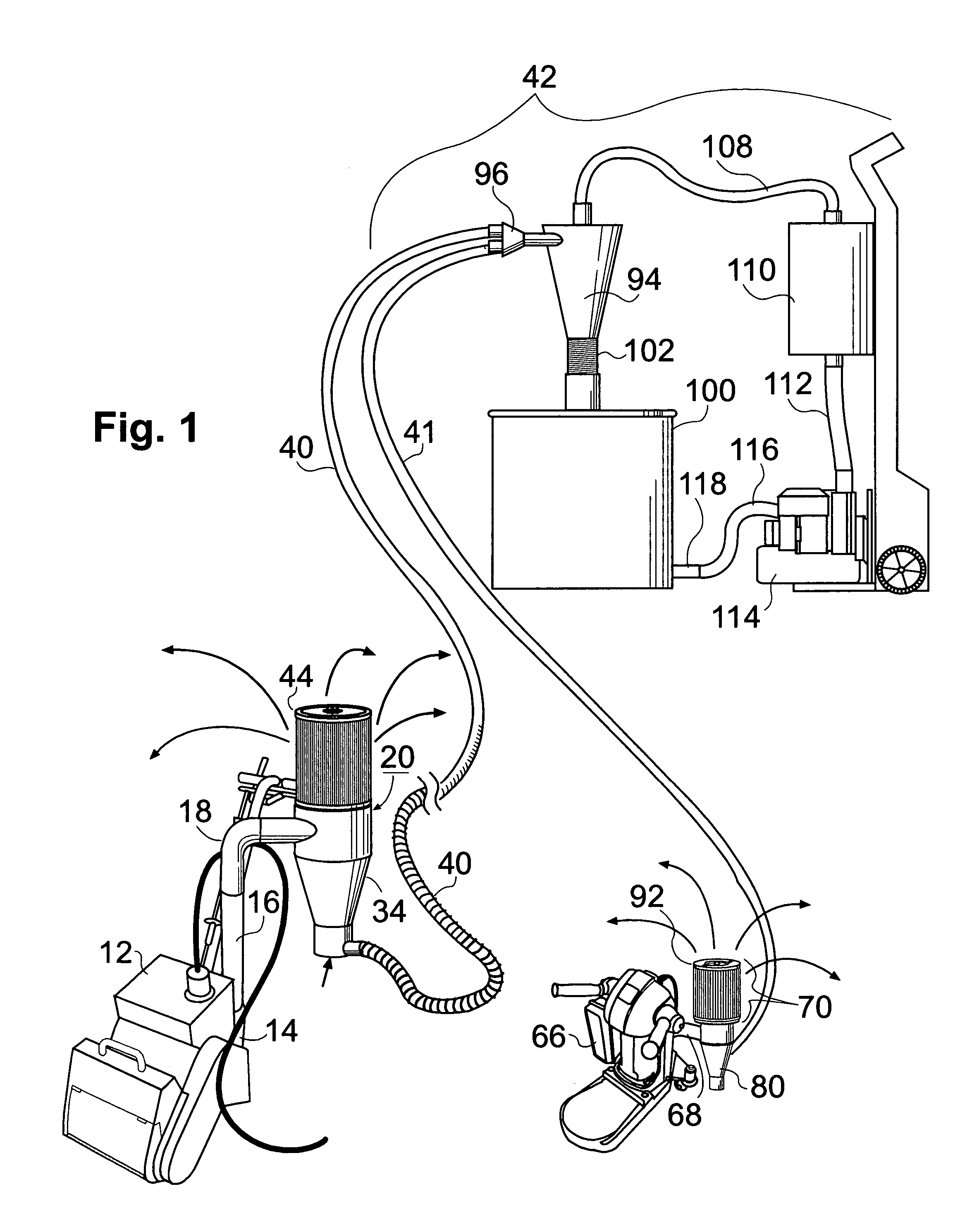

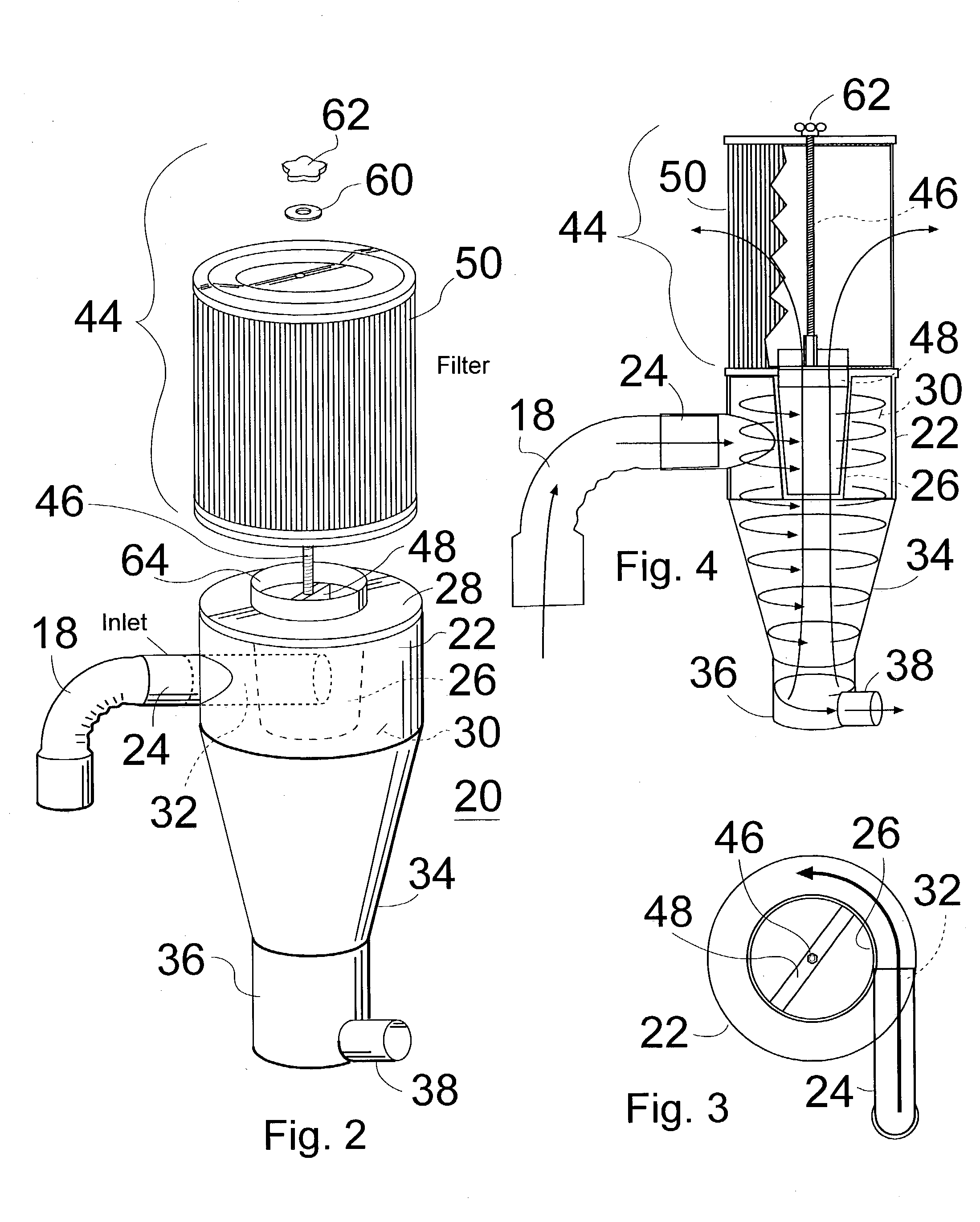

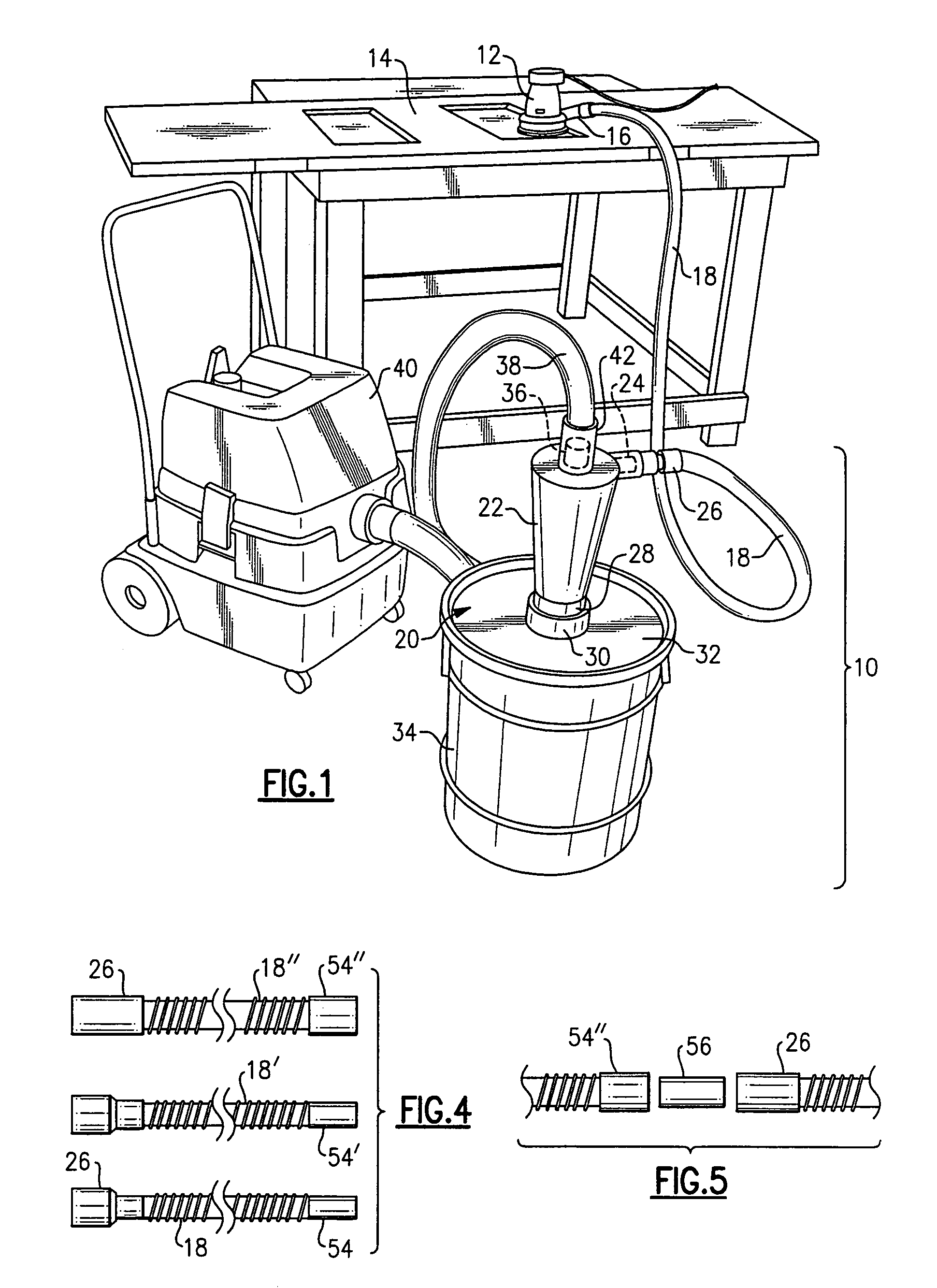

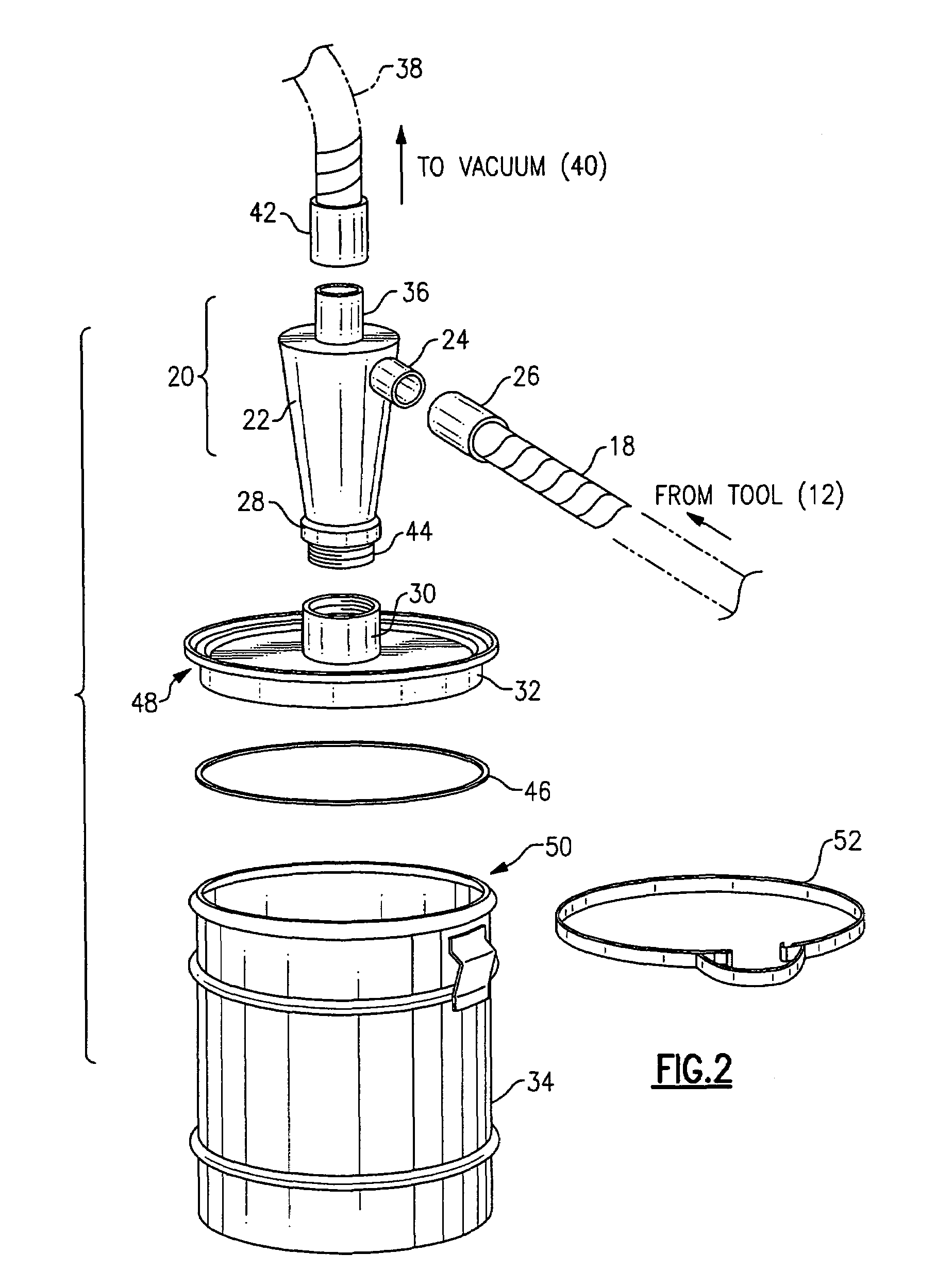

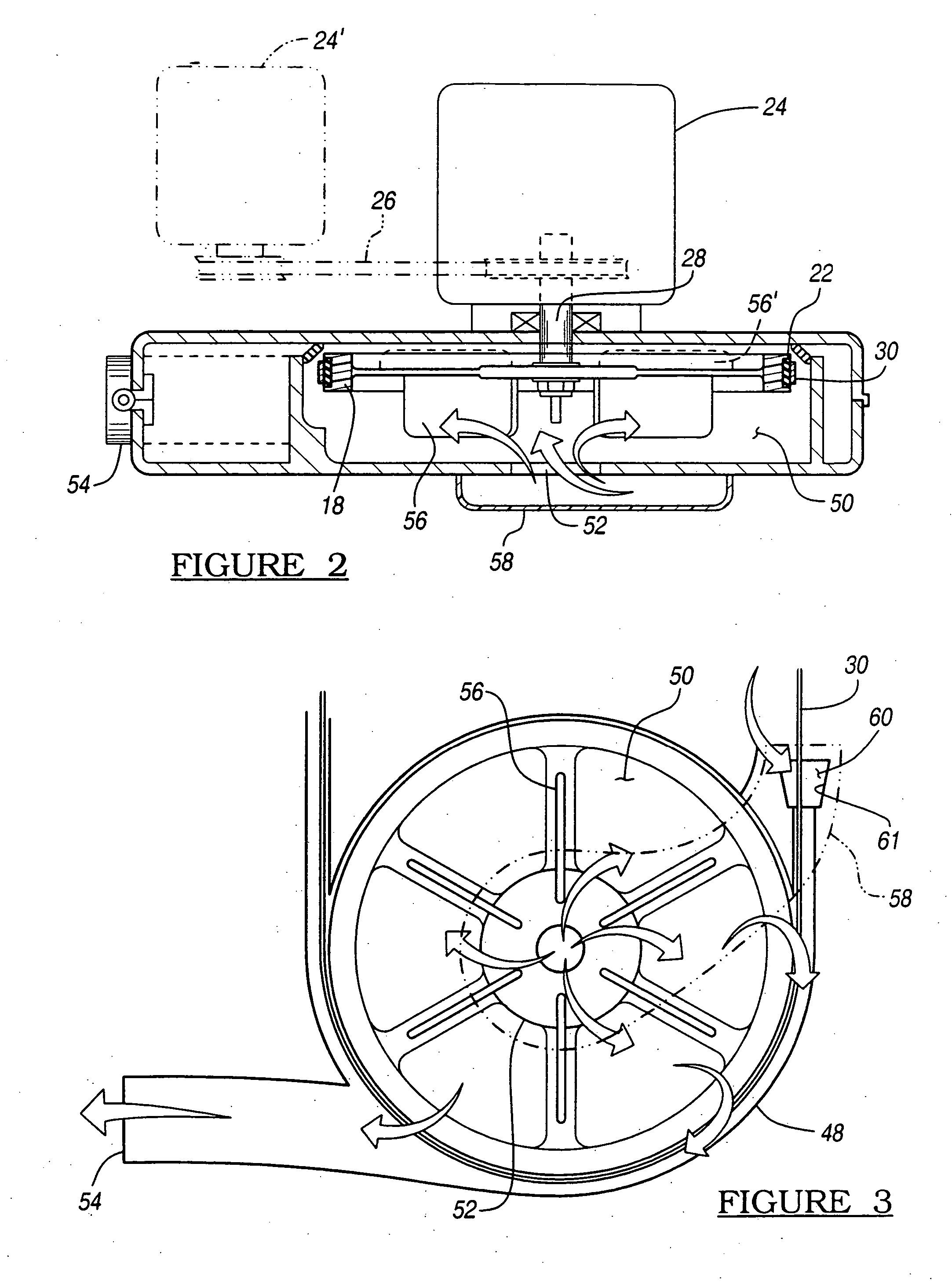

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

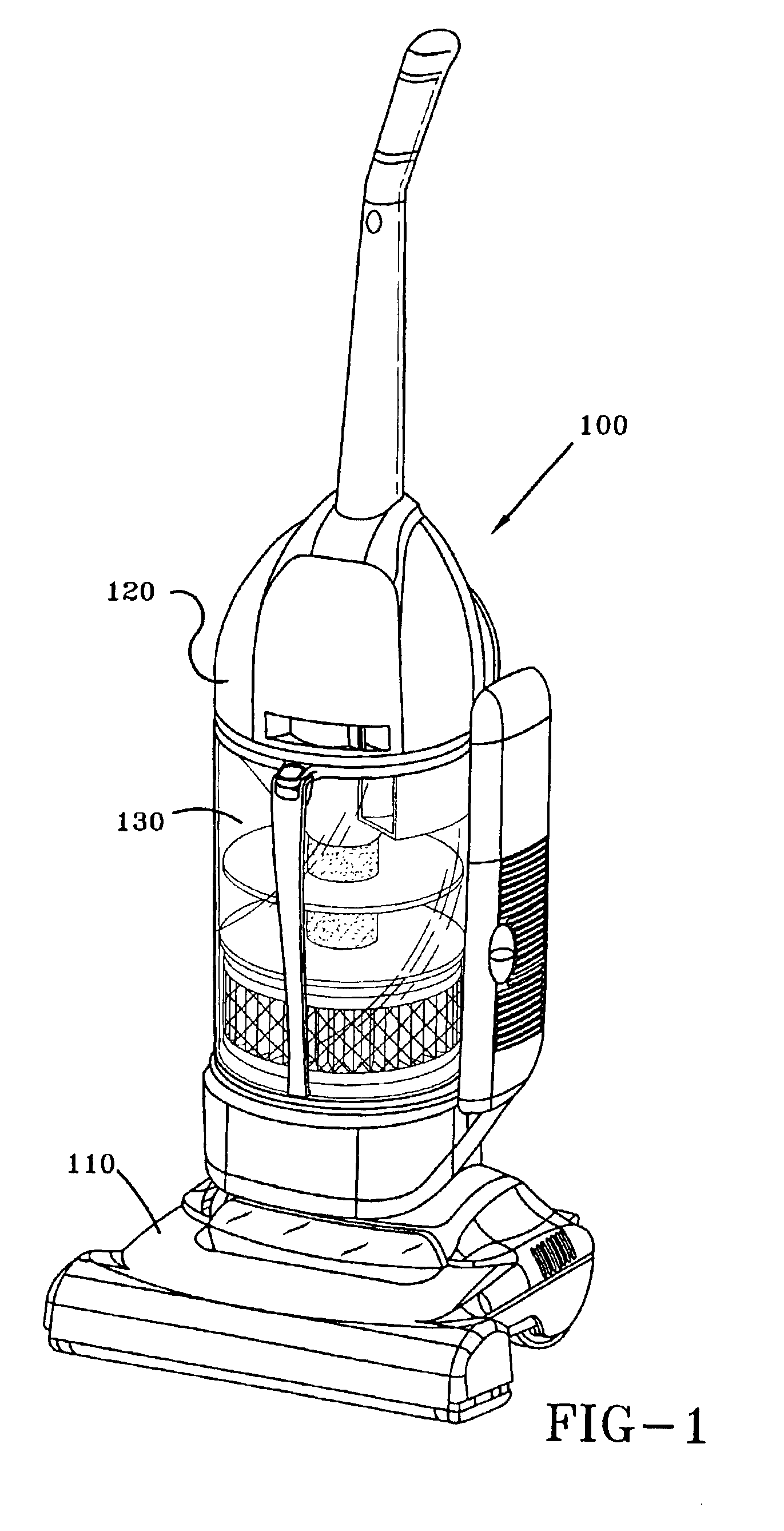

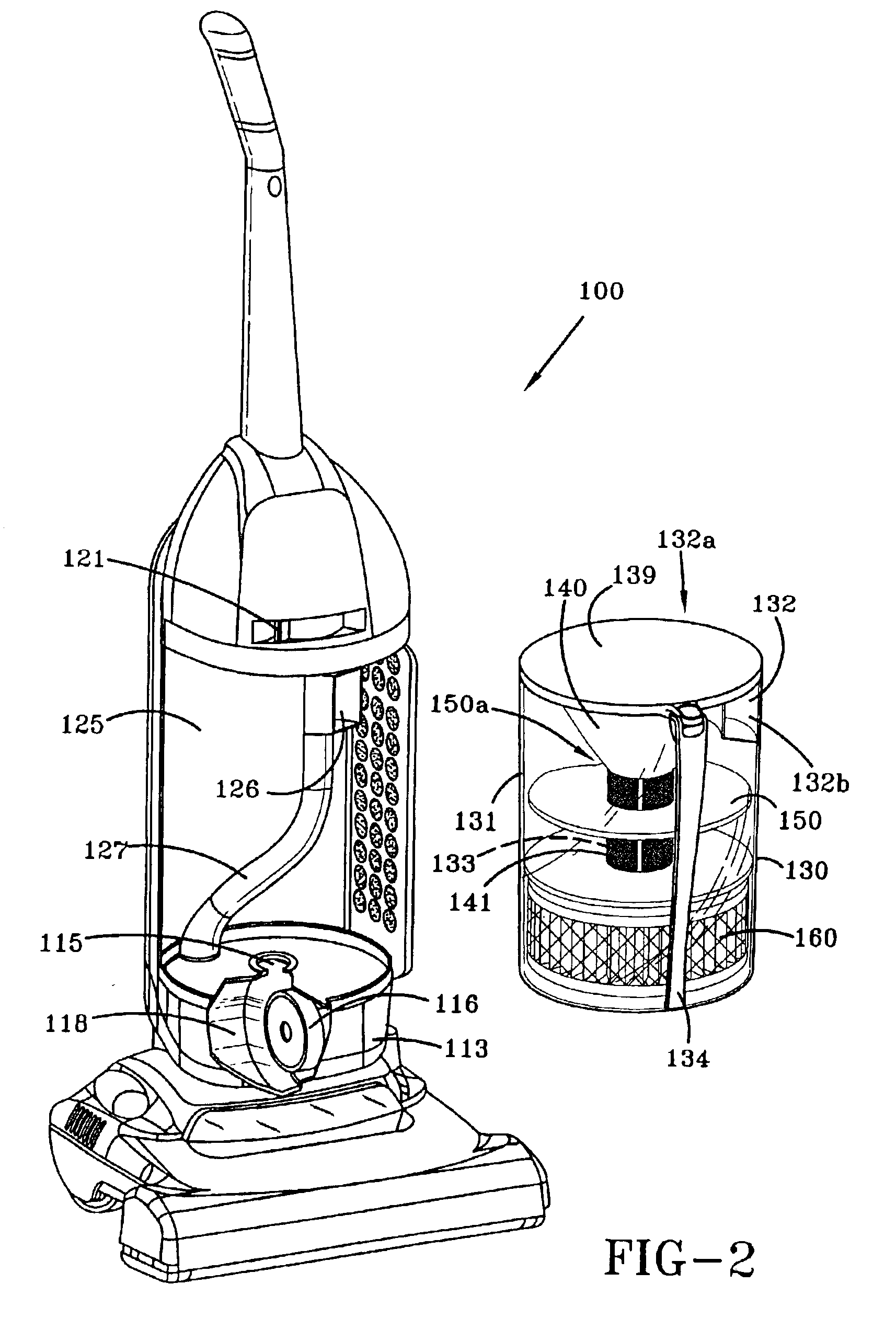

Dirt collecting system for a floor care appliance

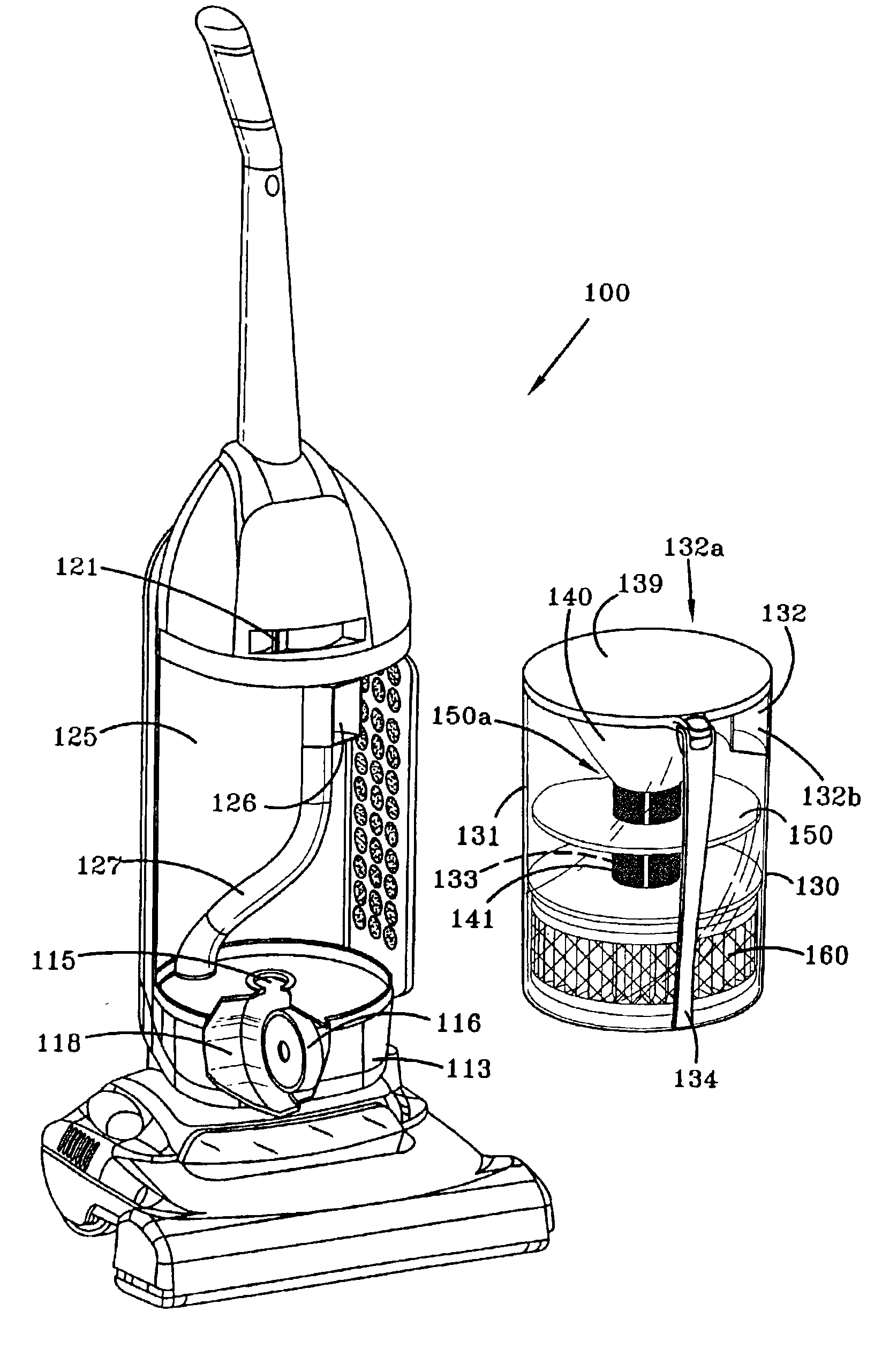

InactiveUS6896719B2Improve filtering effectEasy to emptyCleaning filter meansCombination devicesEngineeringGuide tube

Owner:HEALTHY GAIN INVESTMENTS

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

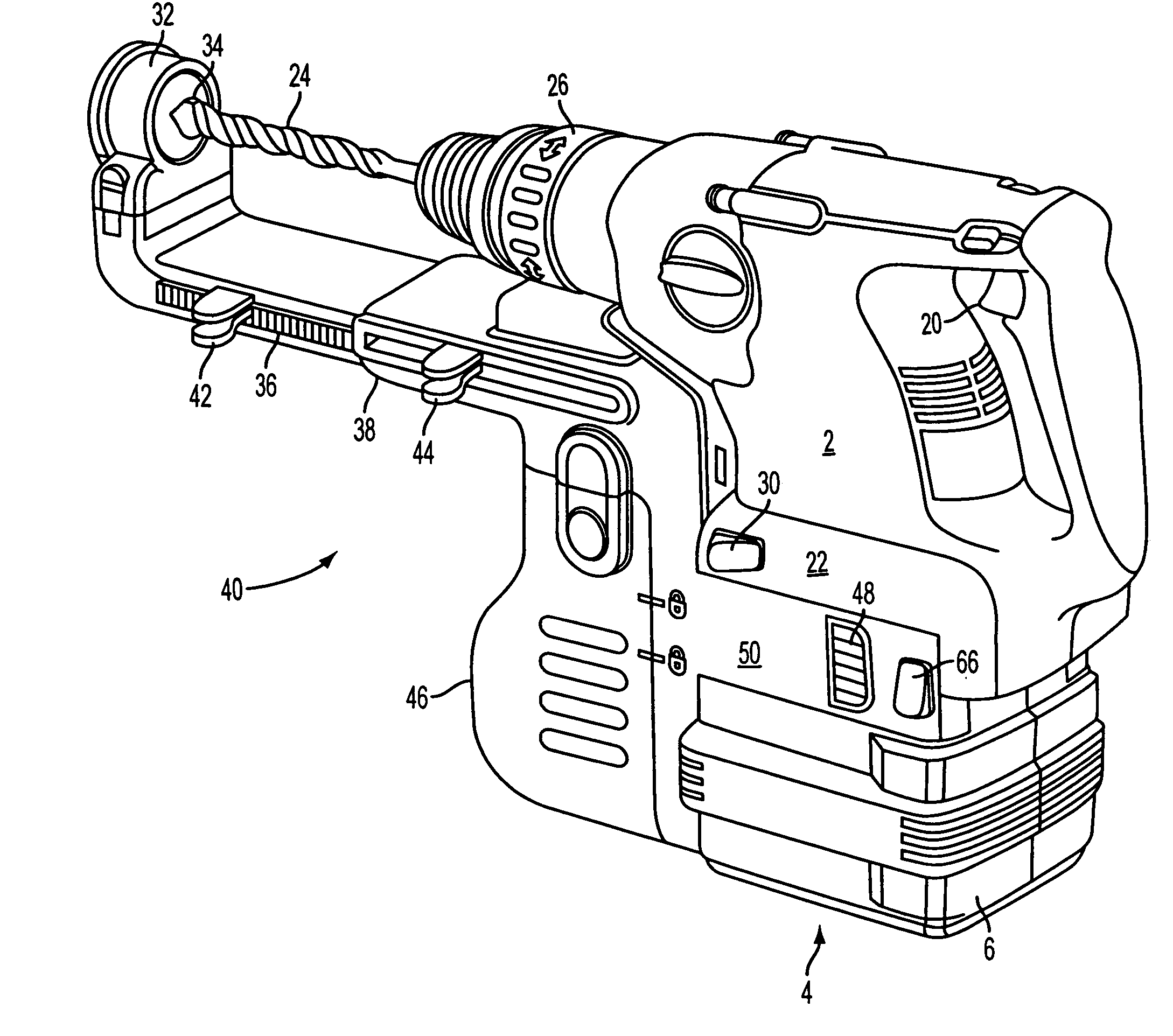

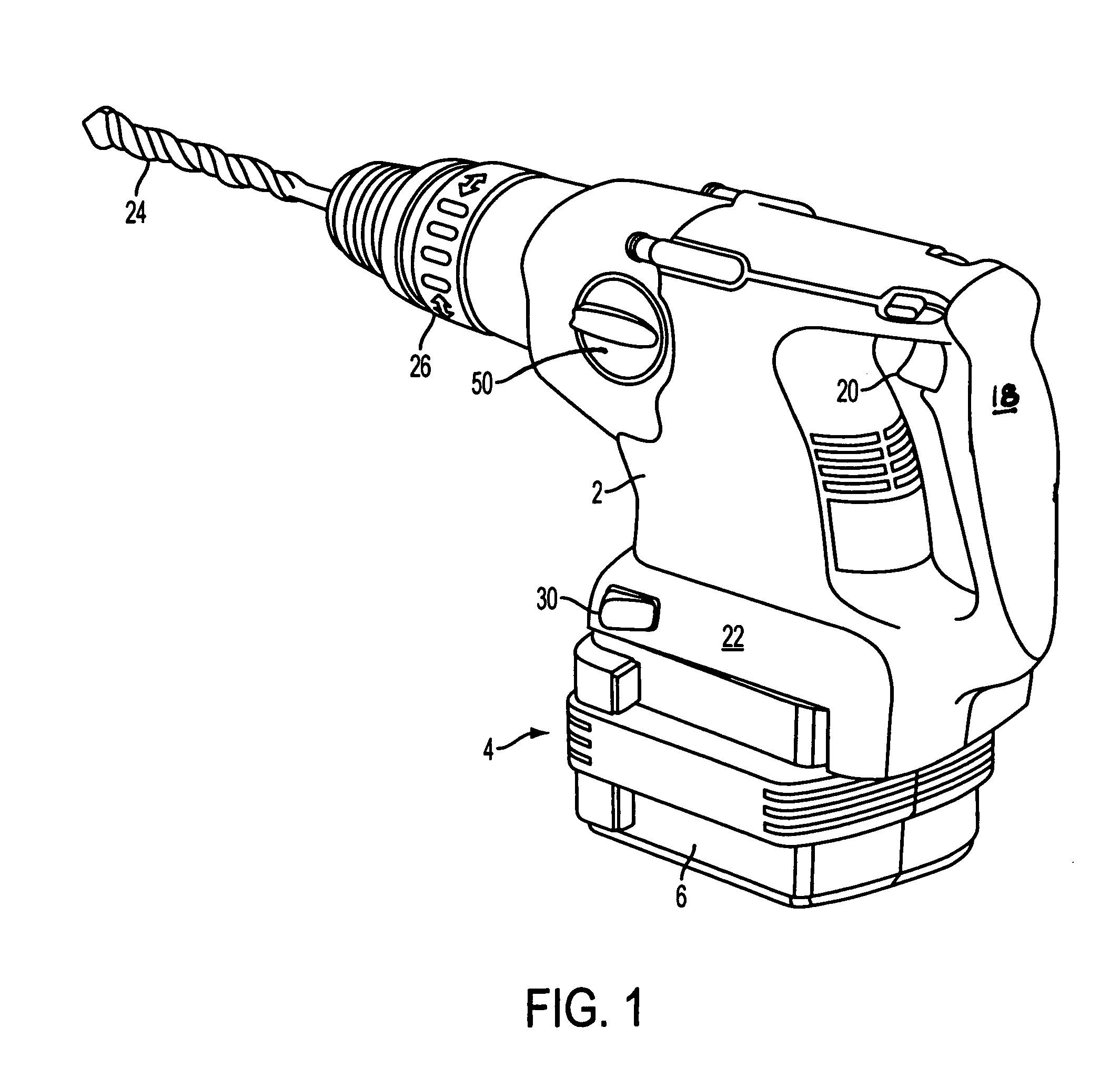

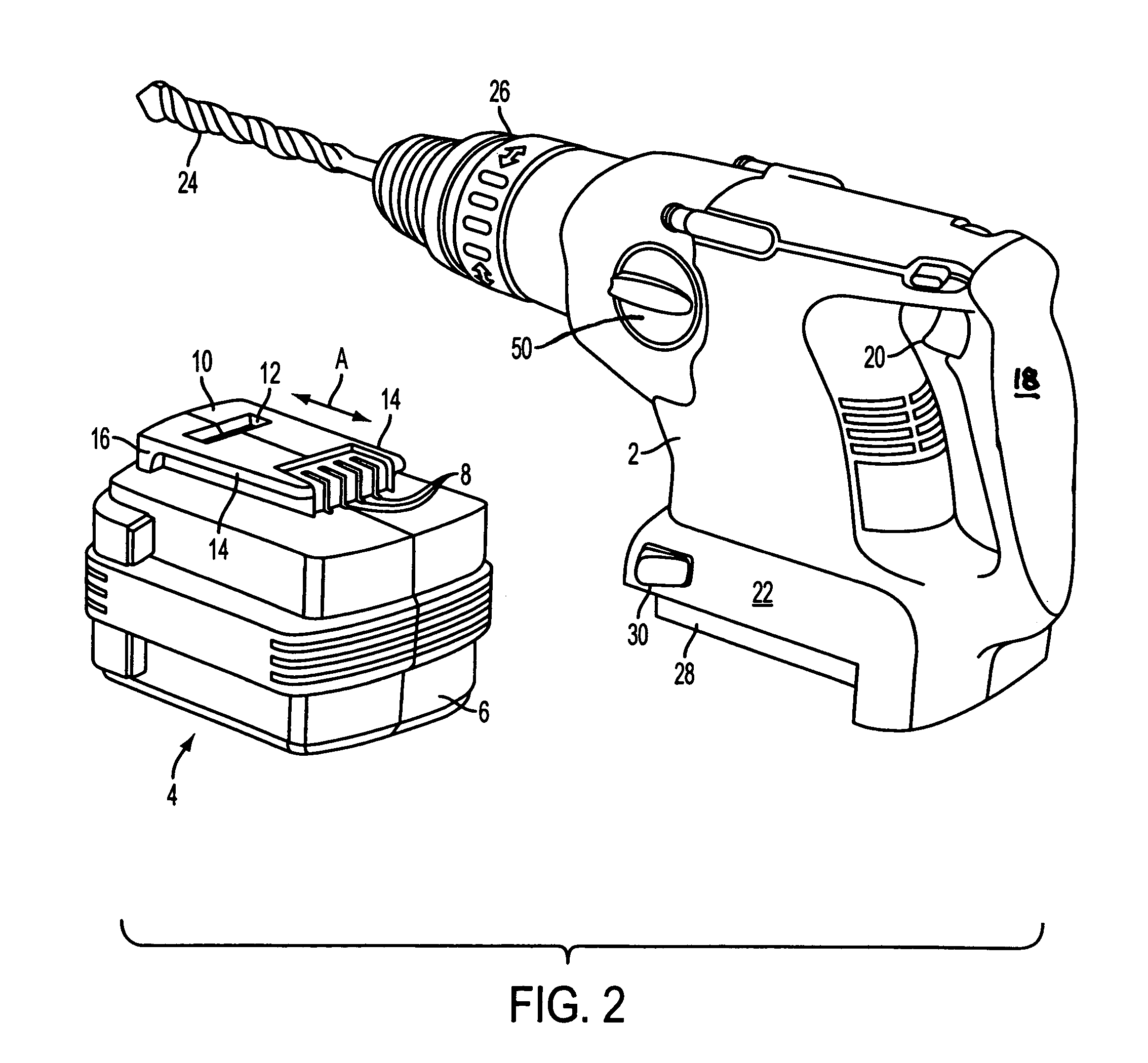

Cordless hand held power tool with powered accessory

Owner:BLACK & DECKER INC

Dust collection system

InactiveUS6833016B2Reduced Power RequirementsReduce the risk of explosionCombination devicesReversed direction vortexCycloneCollection system

Owner:WITTER ROBERT M

Process for transporting and quenching coke

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

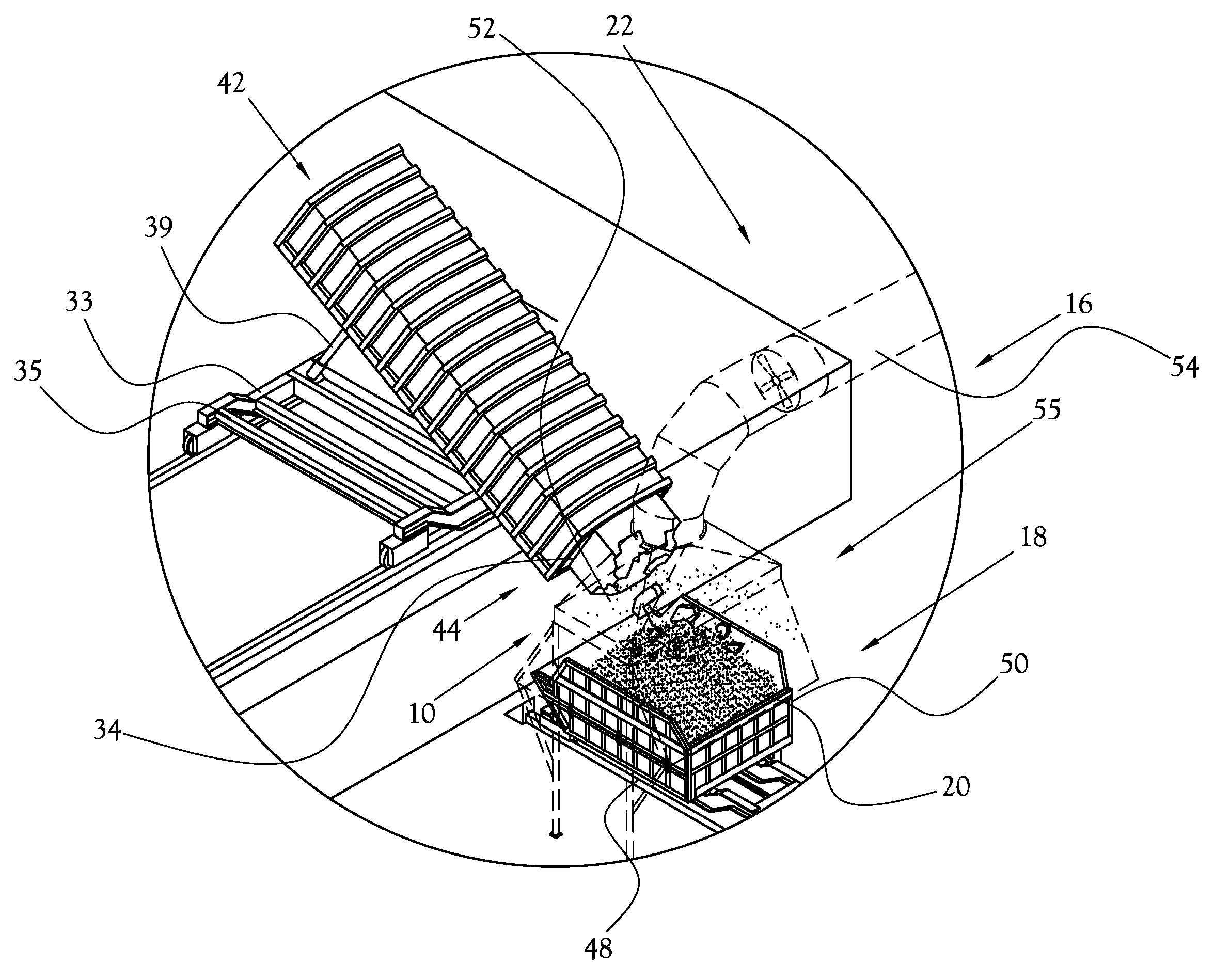

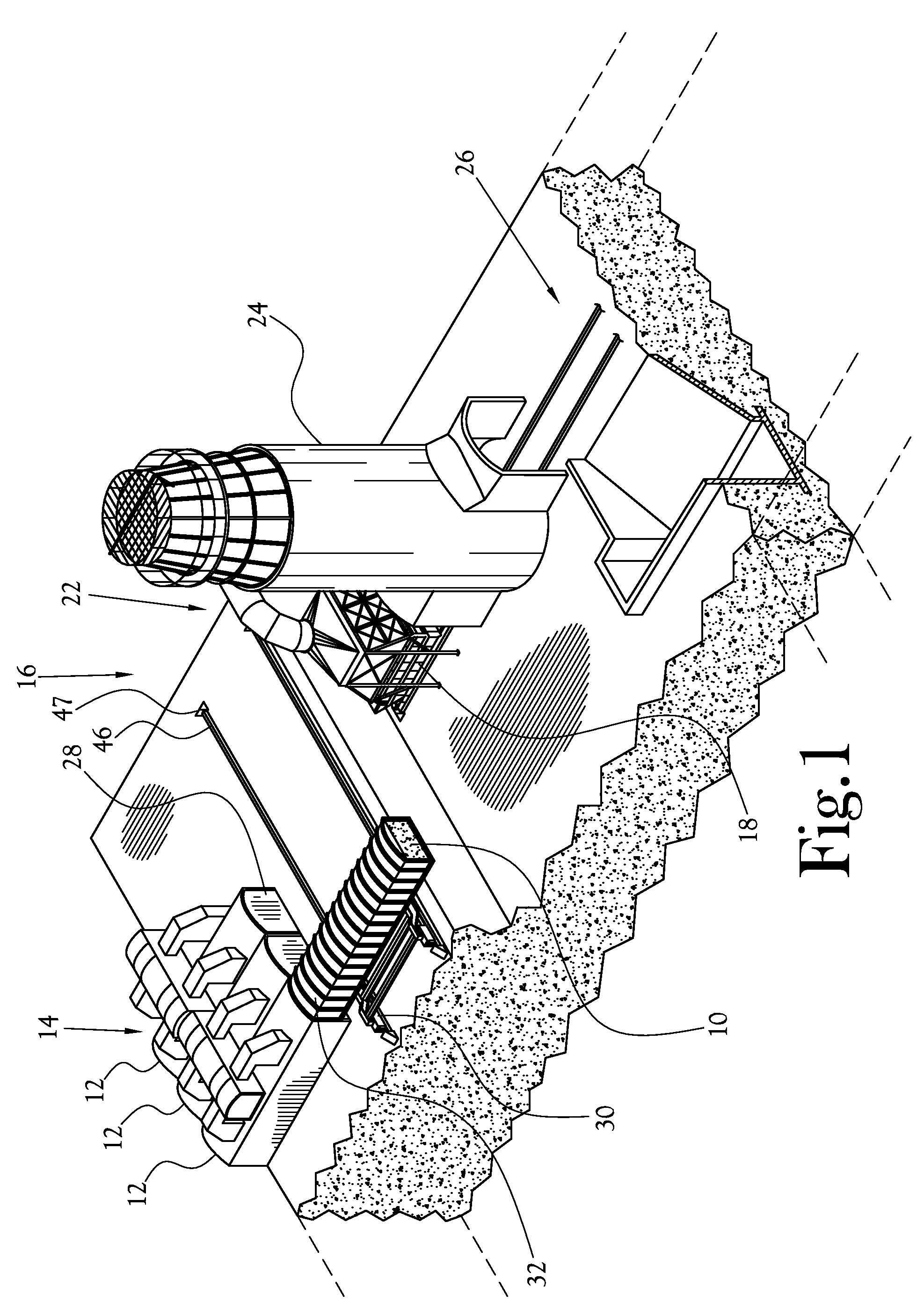

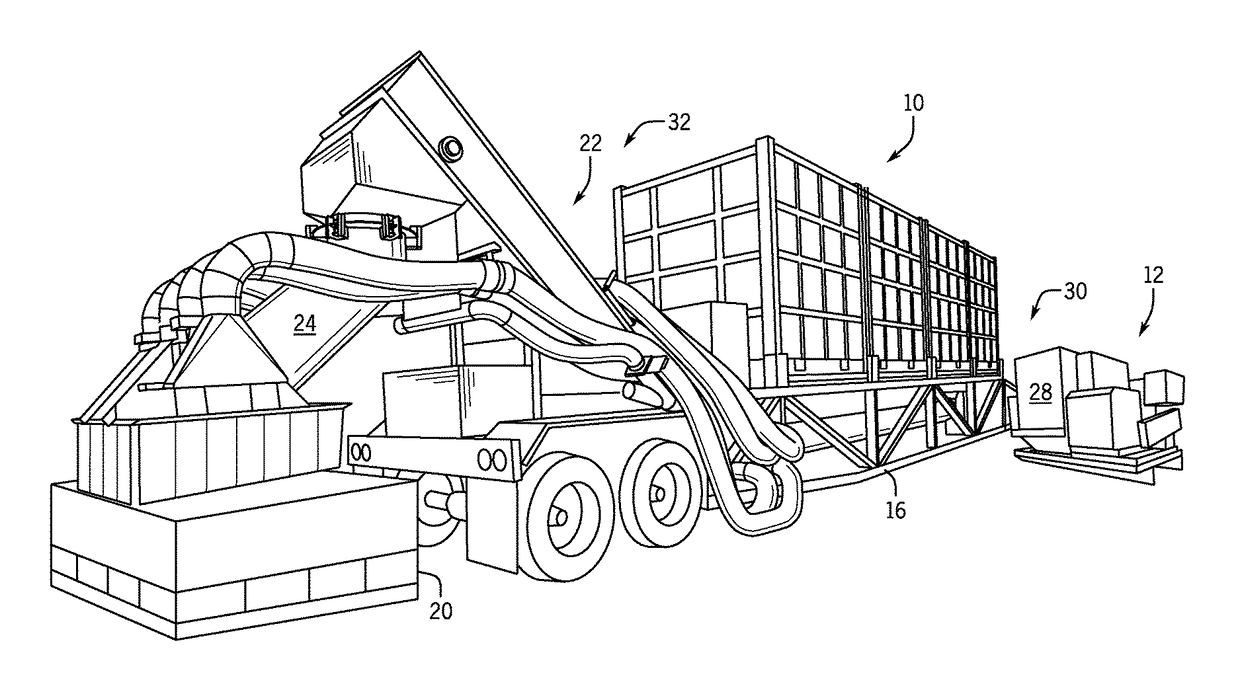

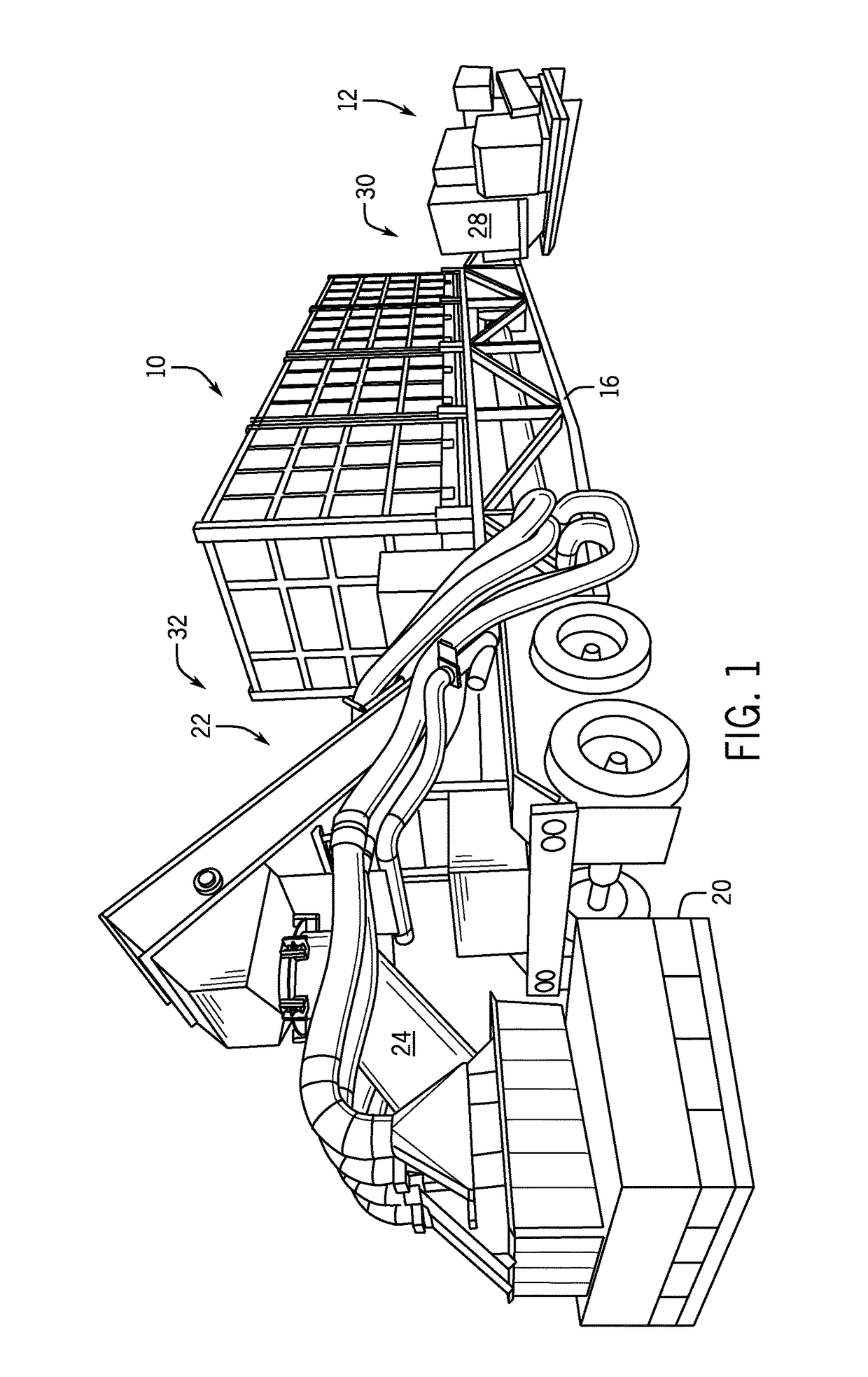

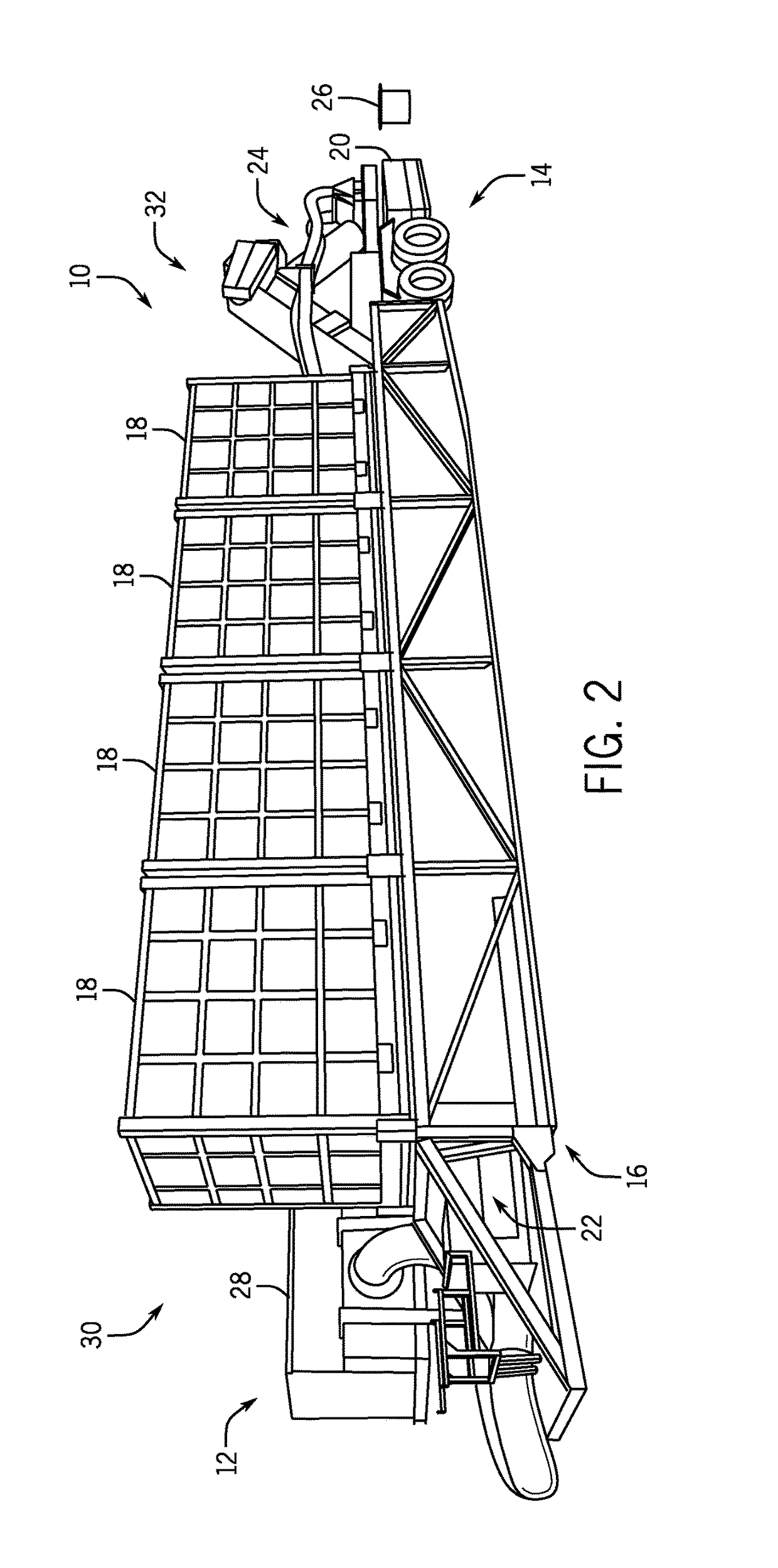

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

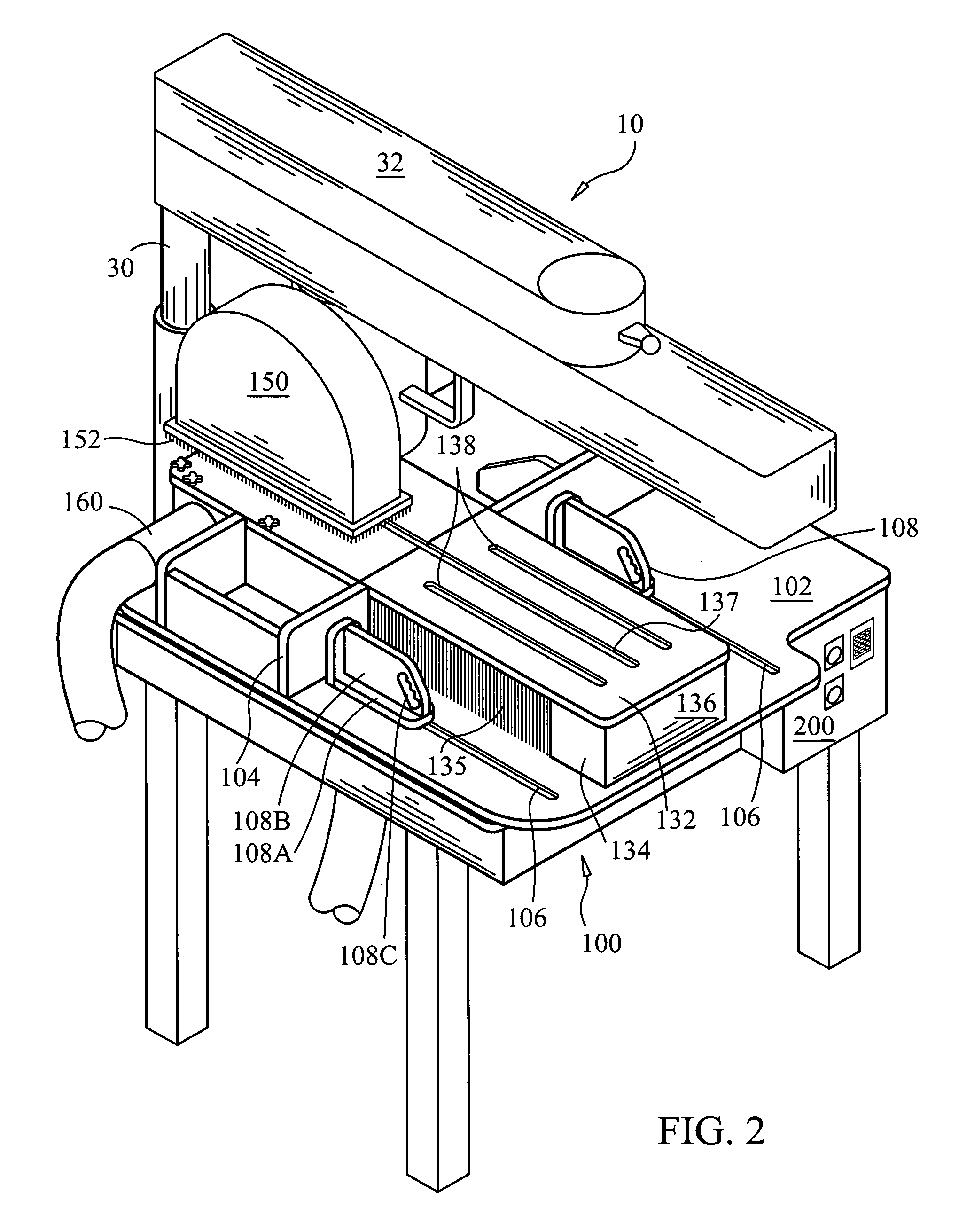

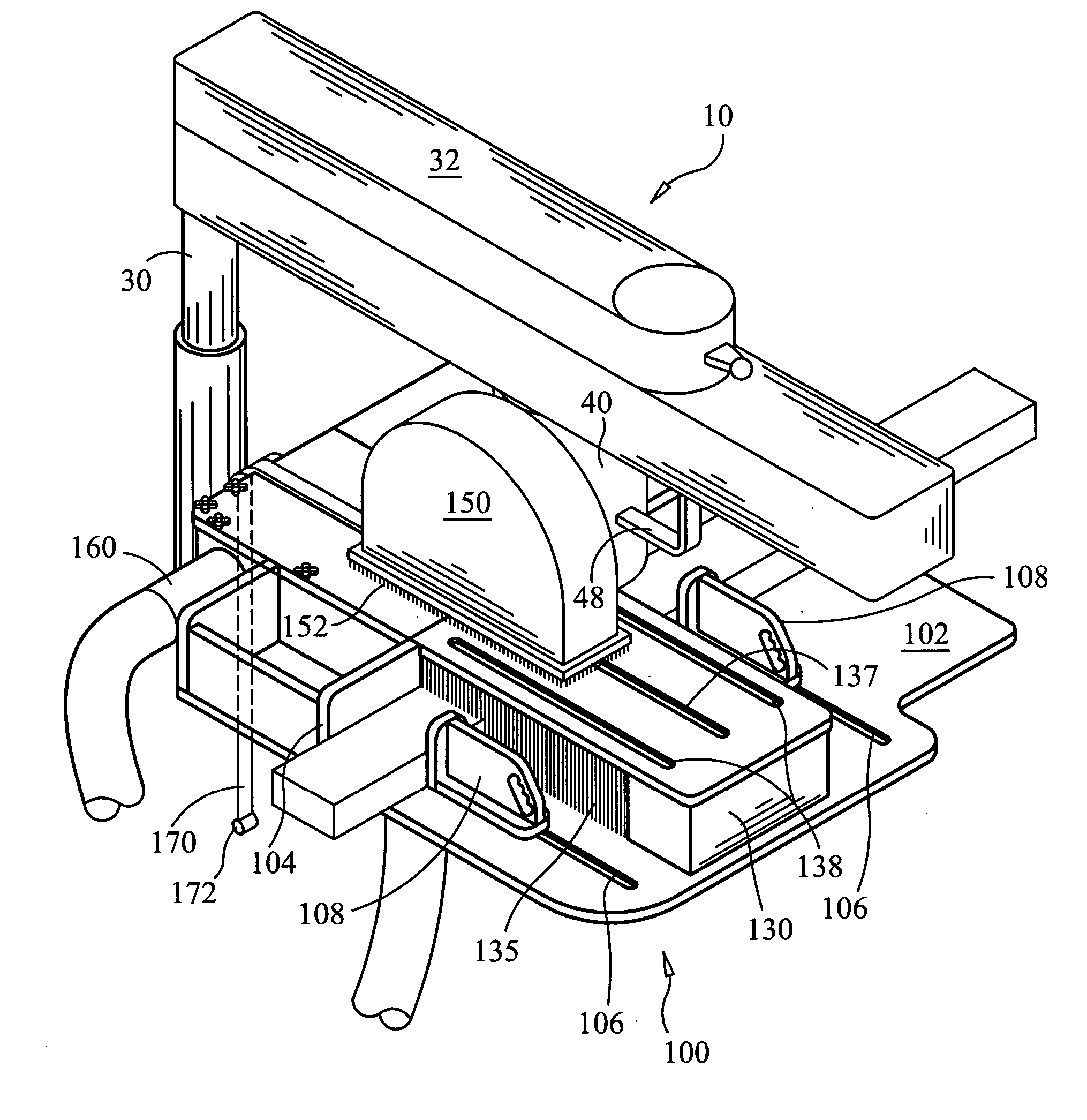

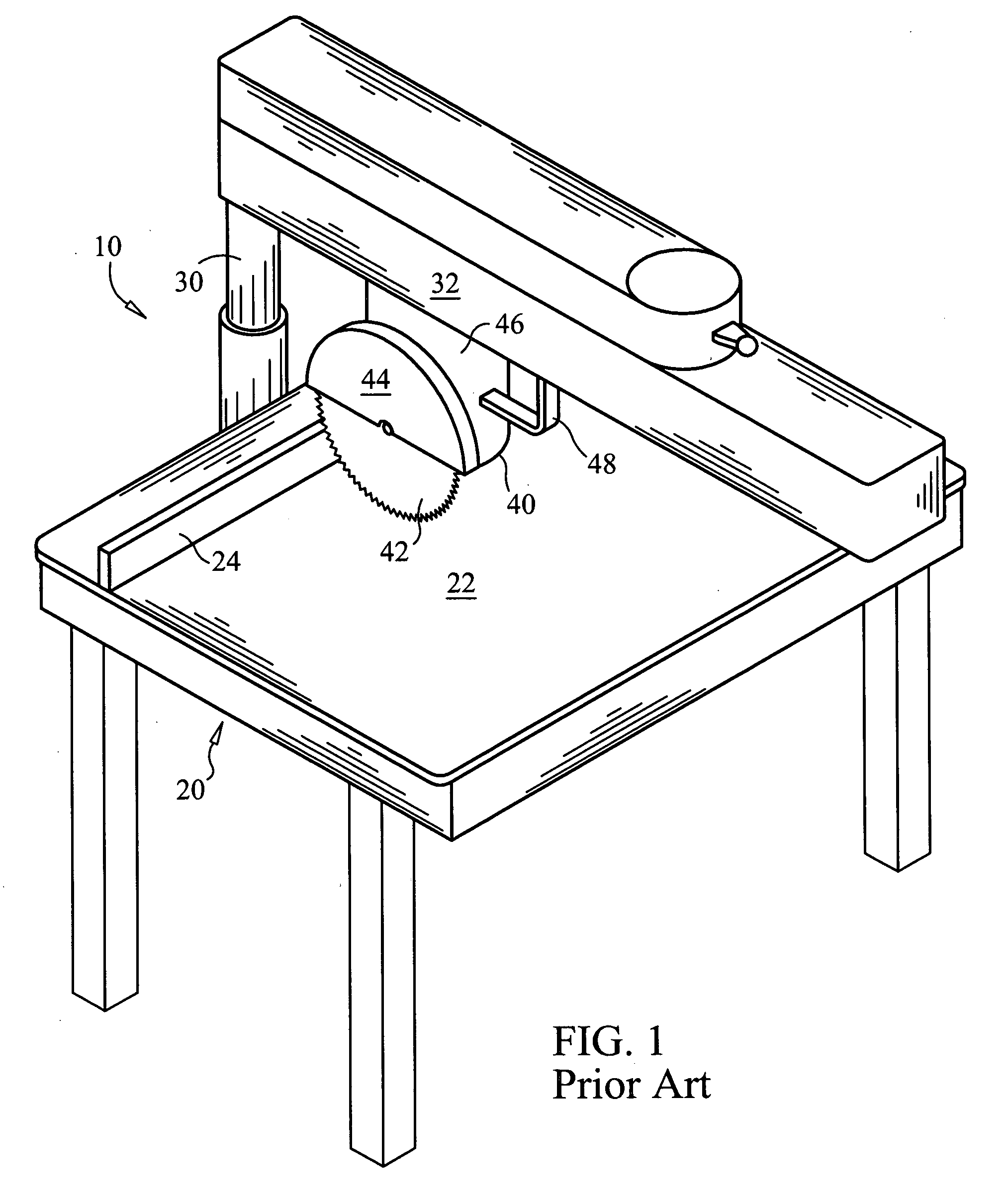

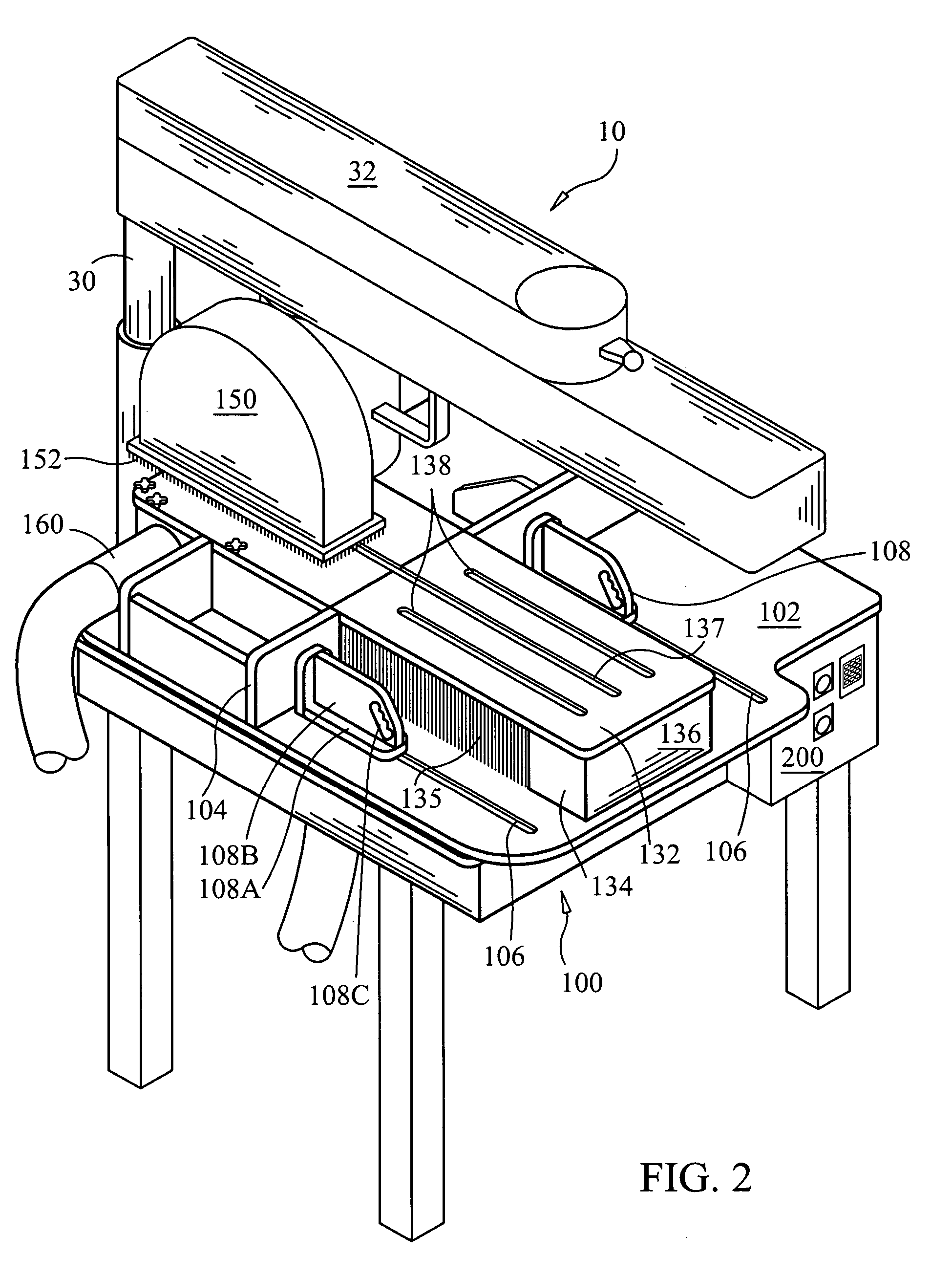

Radial arm saw safety top

InactiveUS7044039B2Overcome disadvantagesMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

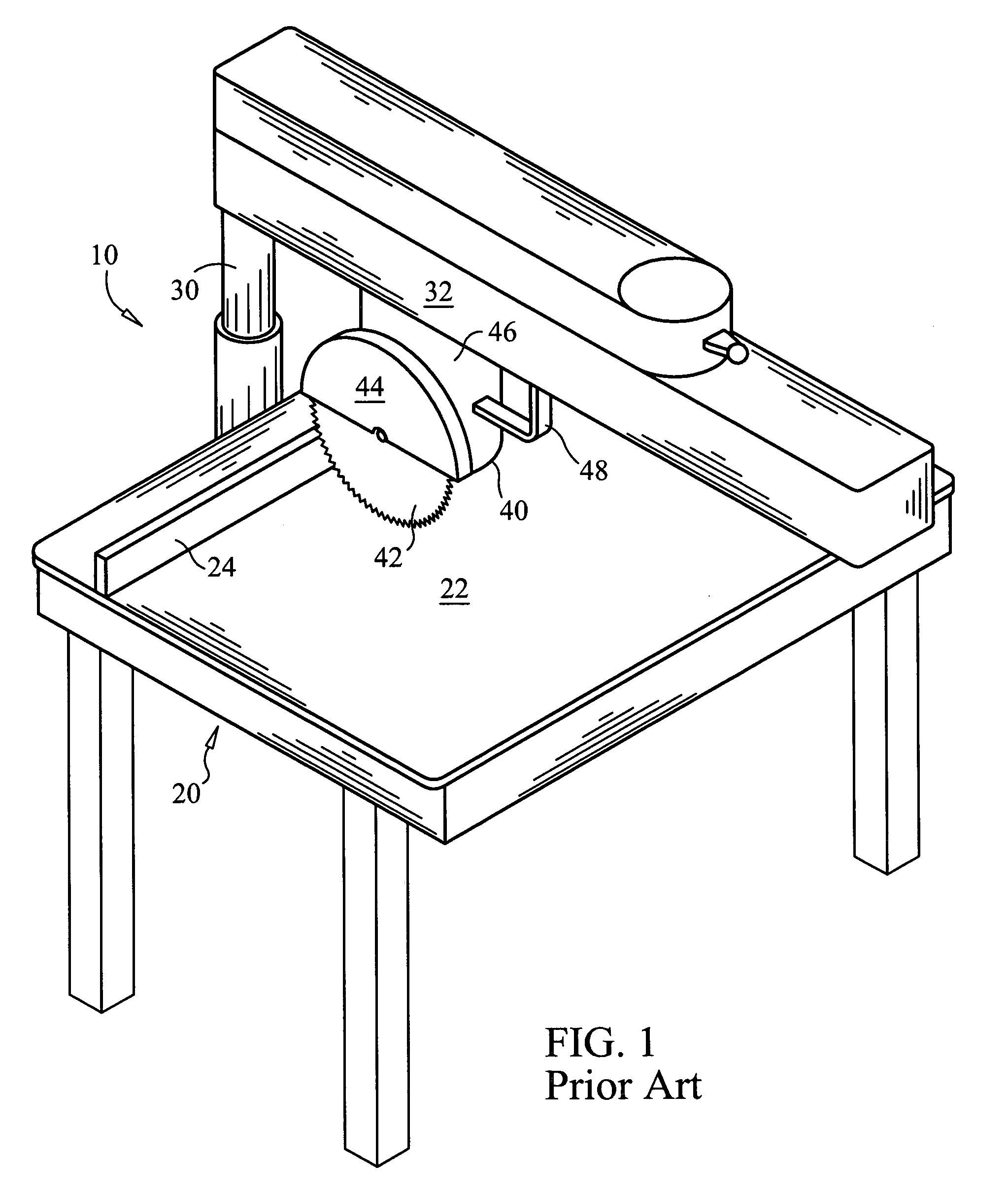

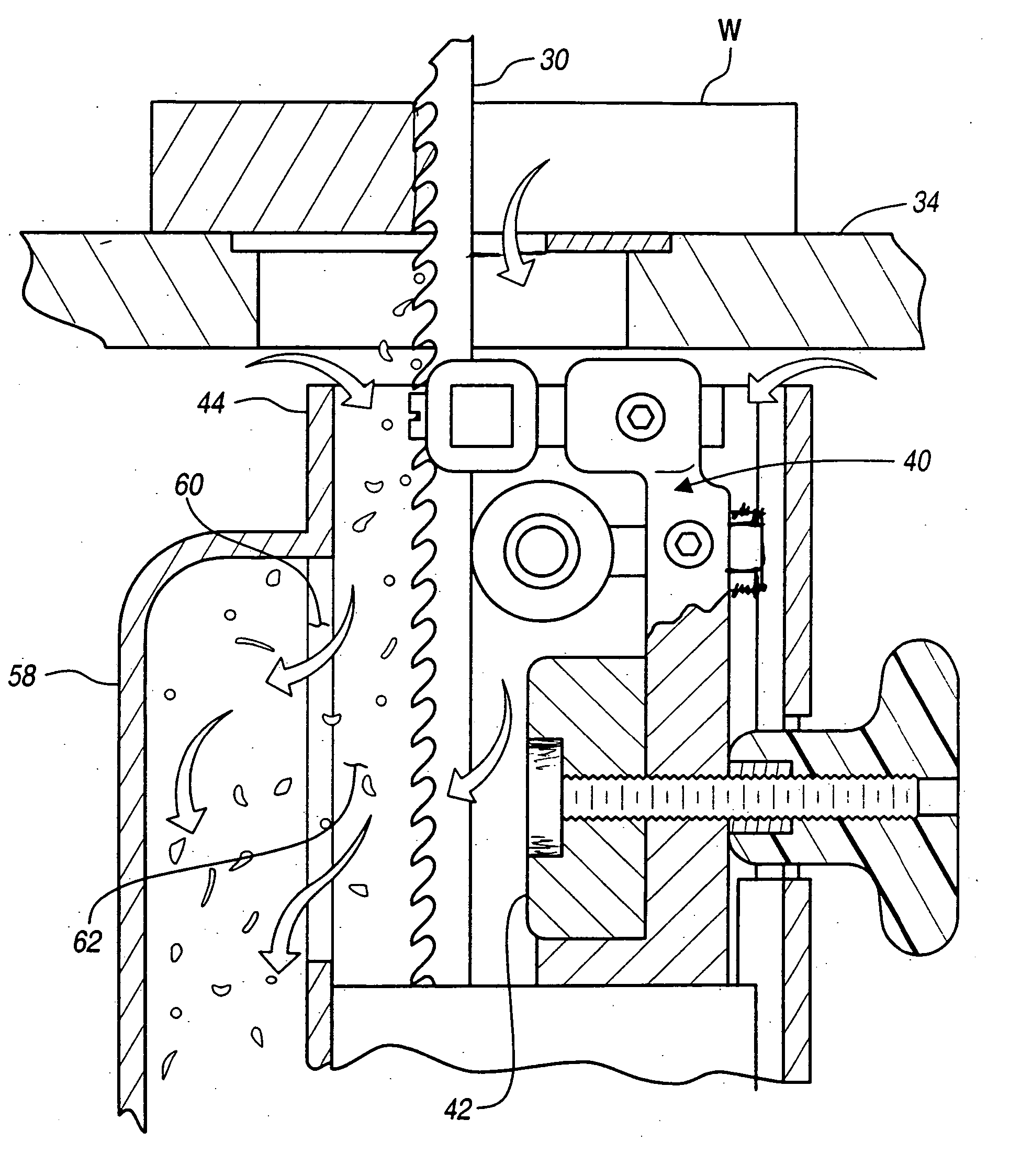

A radial arm saw is adapted with a safety top configured with cutting box enclosure that contains and collects substantially all of the sawdust generated during use. A dust collection system is in fluid communication with the cutting box for removing the sawdust contained therein. Spring biased push blocks function to hold the work piece in place during the sawing process while maintaining the user's hands safely away from the saw blade. A laser alignment device projects a beam within the cutting box along the cutting plane. A control panel is provided to allow use by authorized users upon entry of an authorization code.

Owner:POWELL MICHAEL S

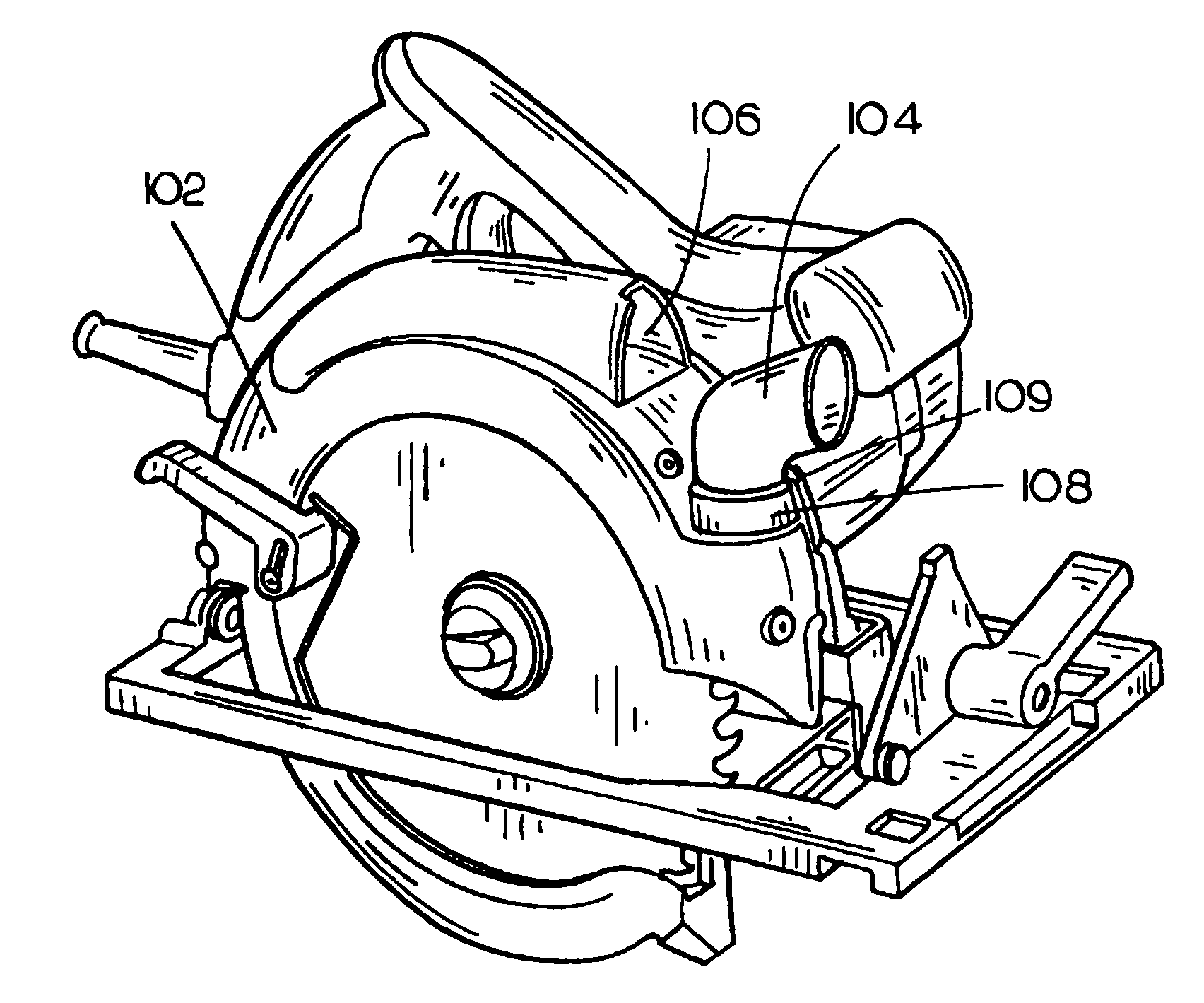

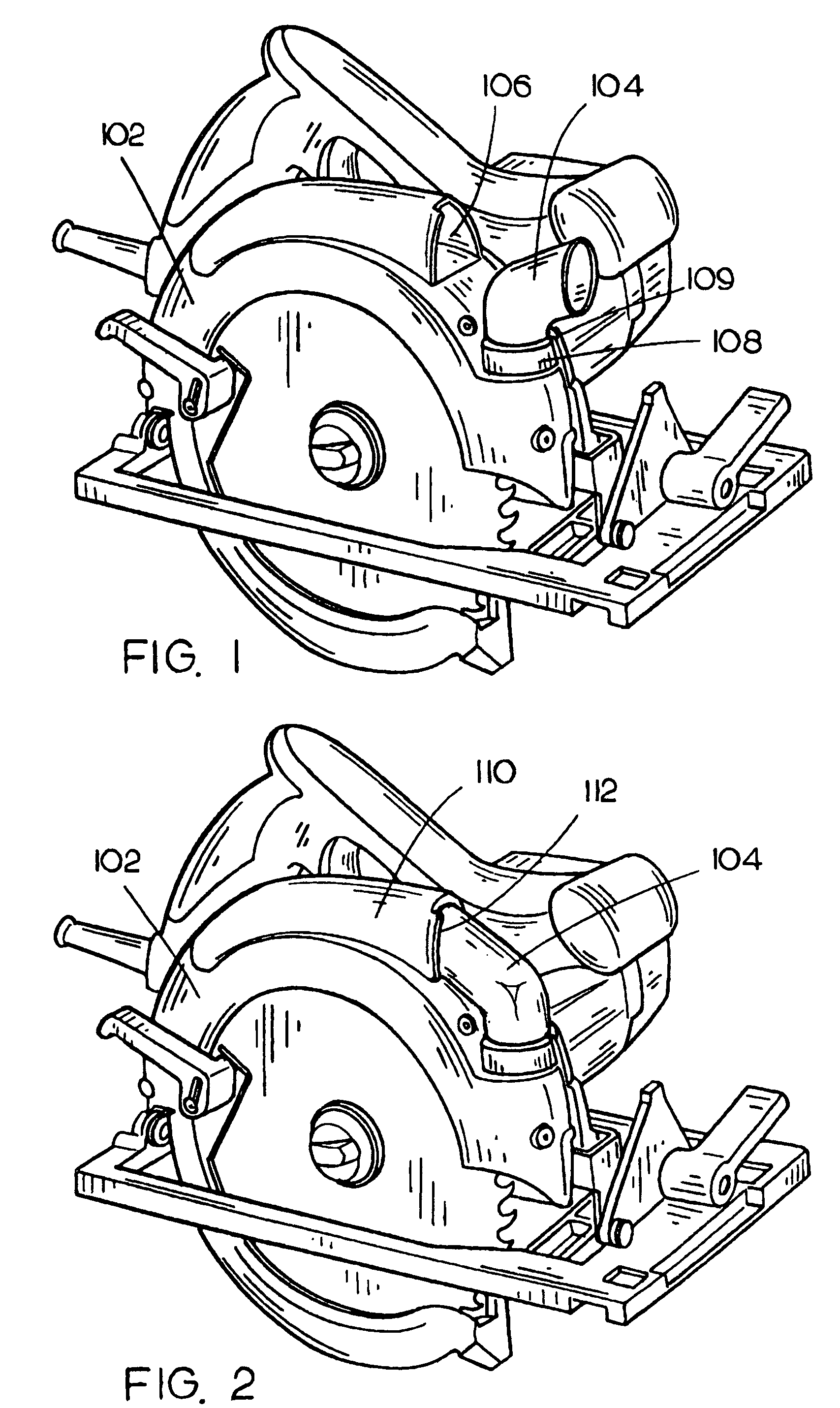

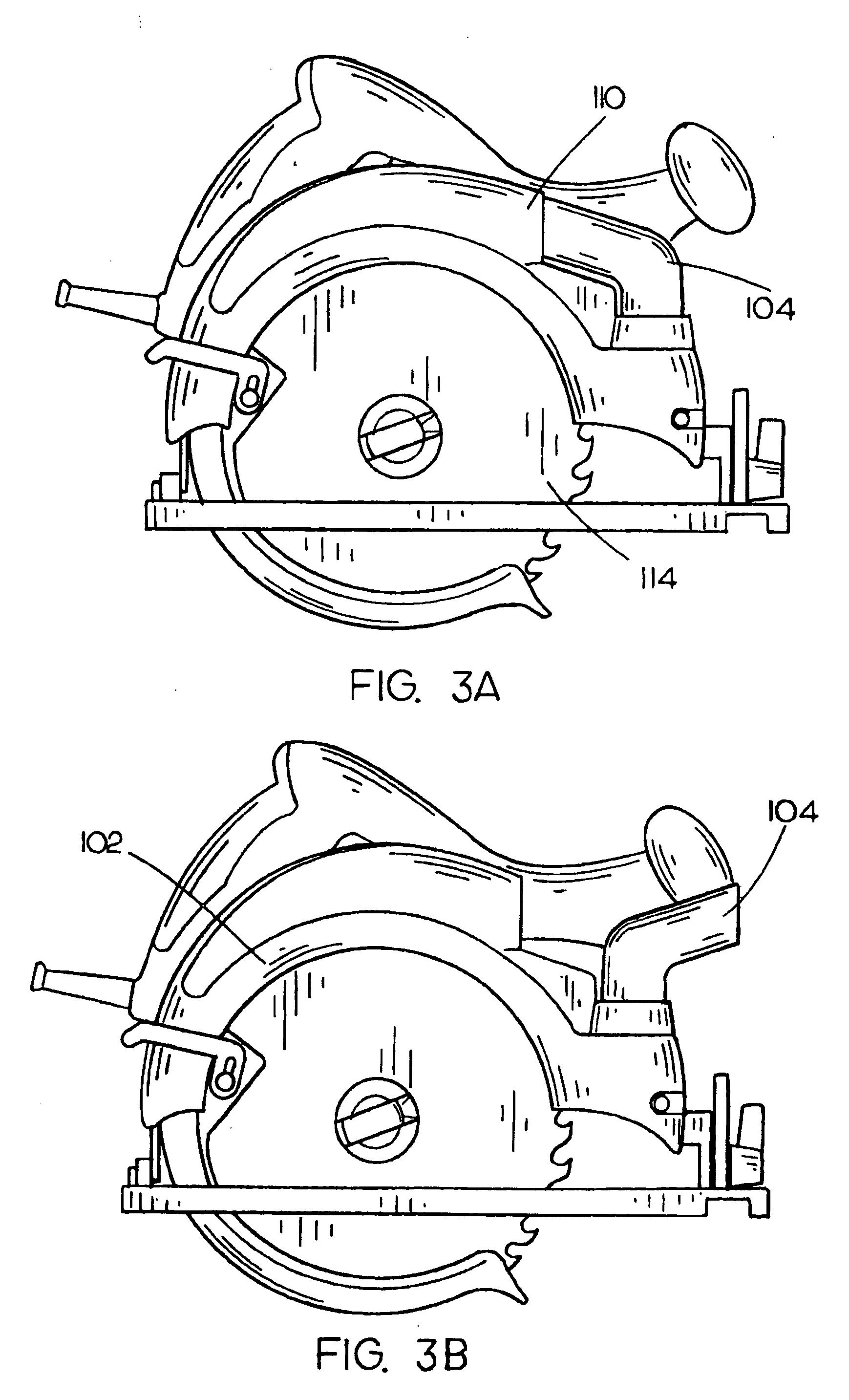

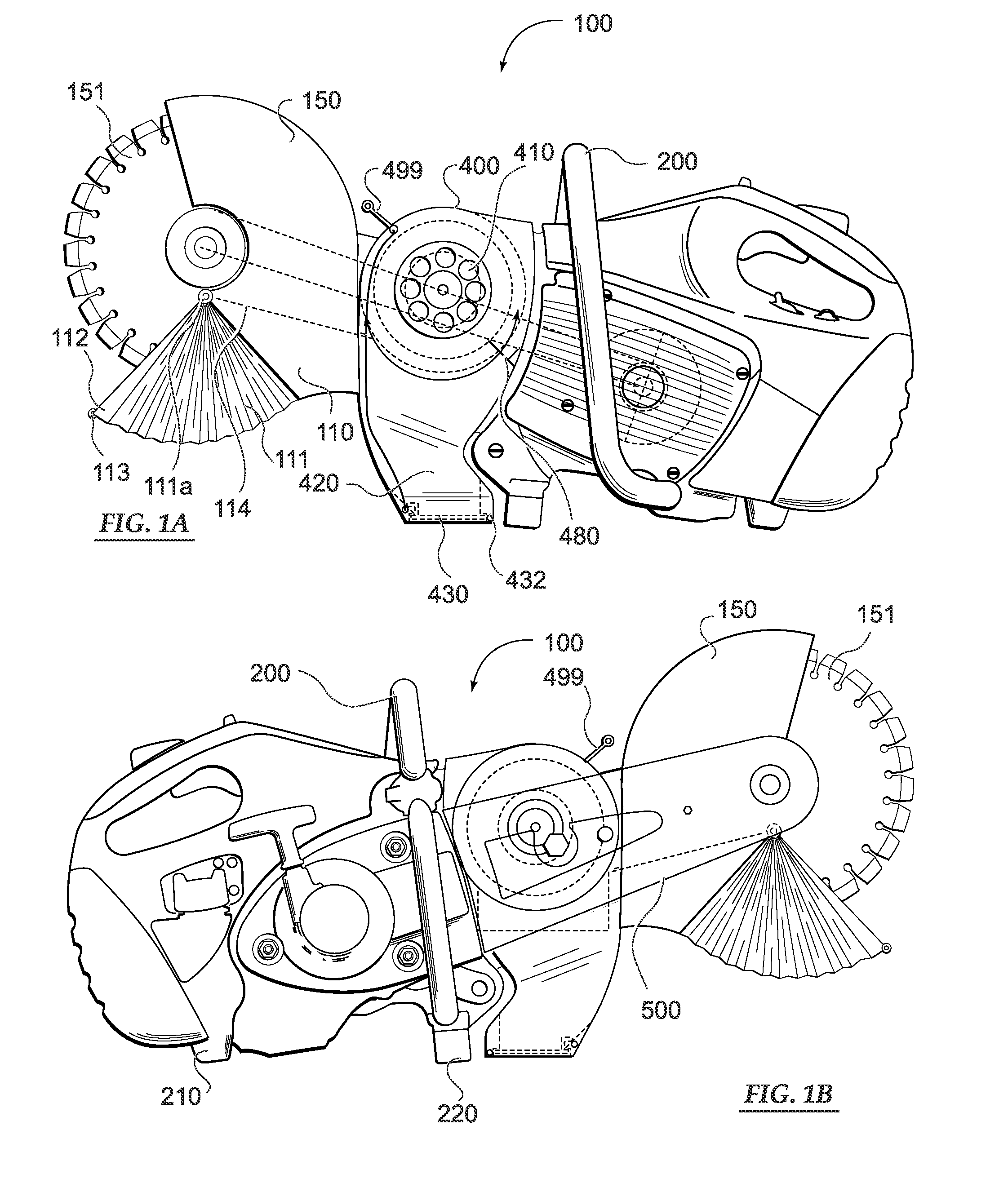

Variable dust chute for circular saws

The present invention is directed to a hand-held circular saw with an integrated dust collection system. Such saw may include an upper blade guard for protecting the user from a saw blade, the upper blade guard configured with a front region and a back region, the front region including a hollow channel to control the pathway of dust and debris and a dust collection system incorporated within the front region of the upper blade guard allowing dust and debris to be directed away from the user.

Owner:BLACK & DECKER INC

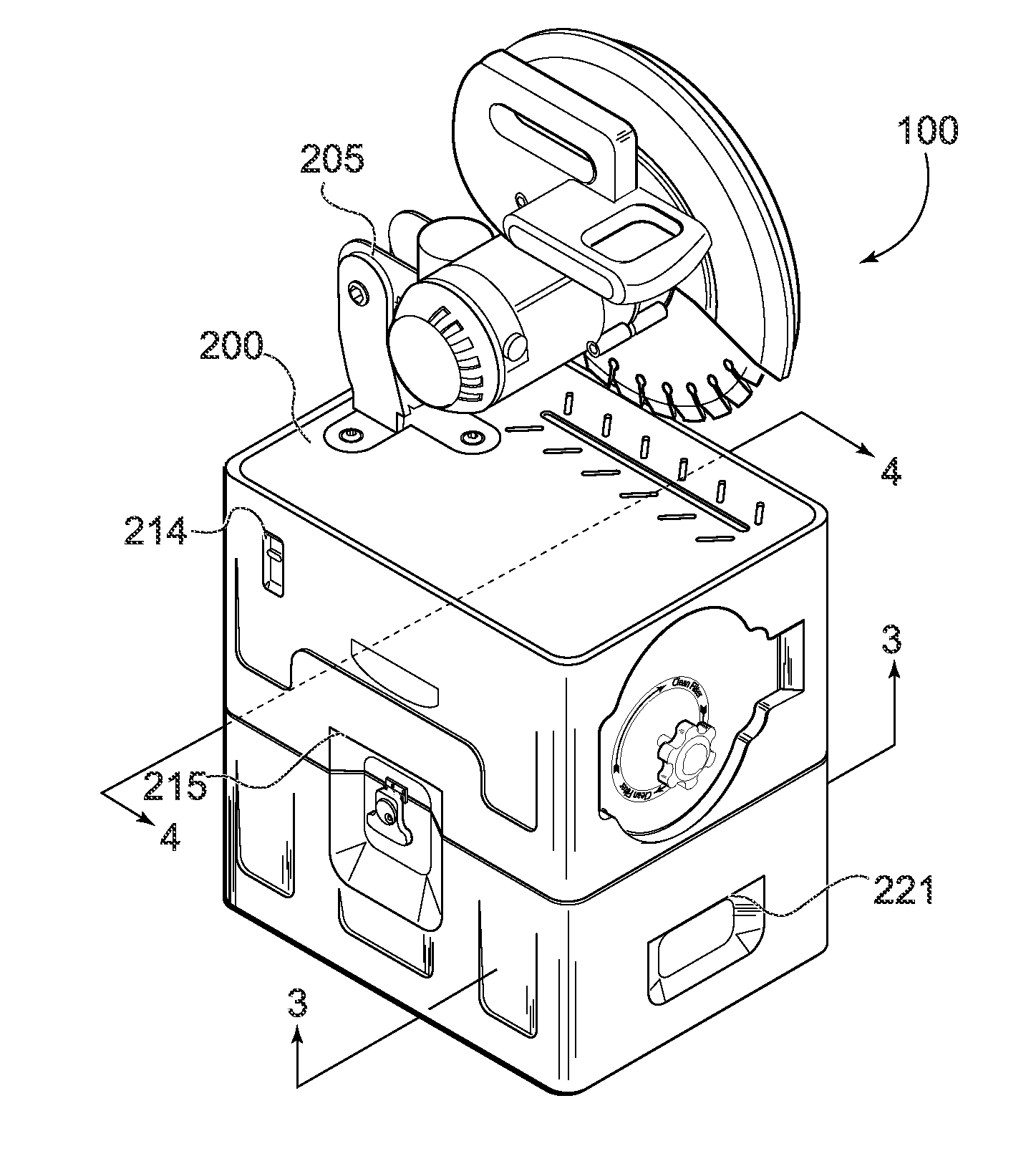

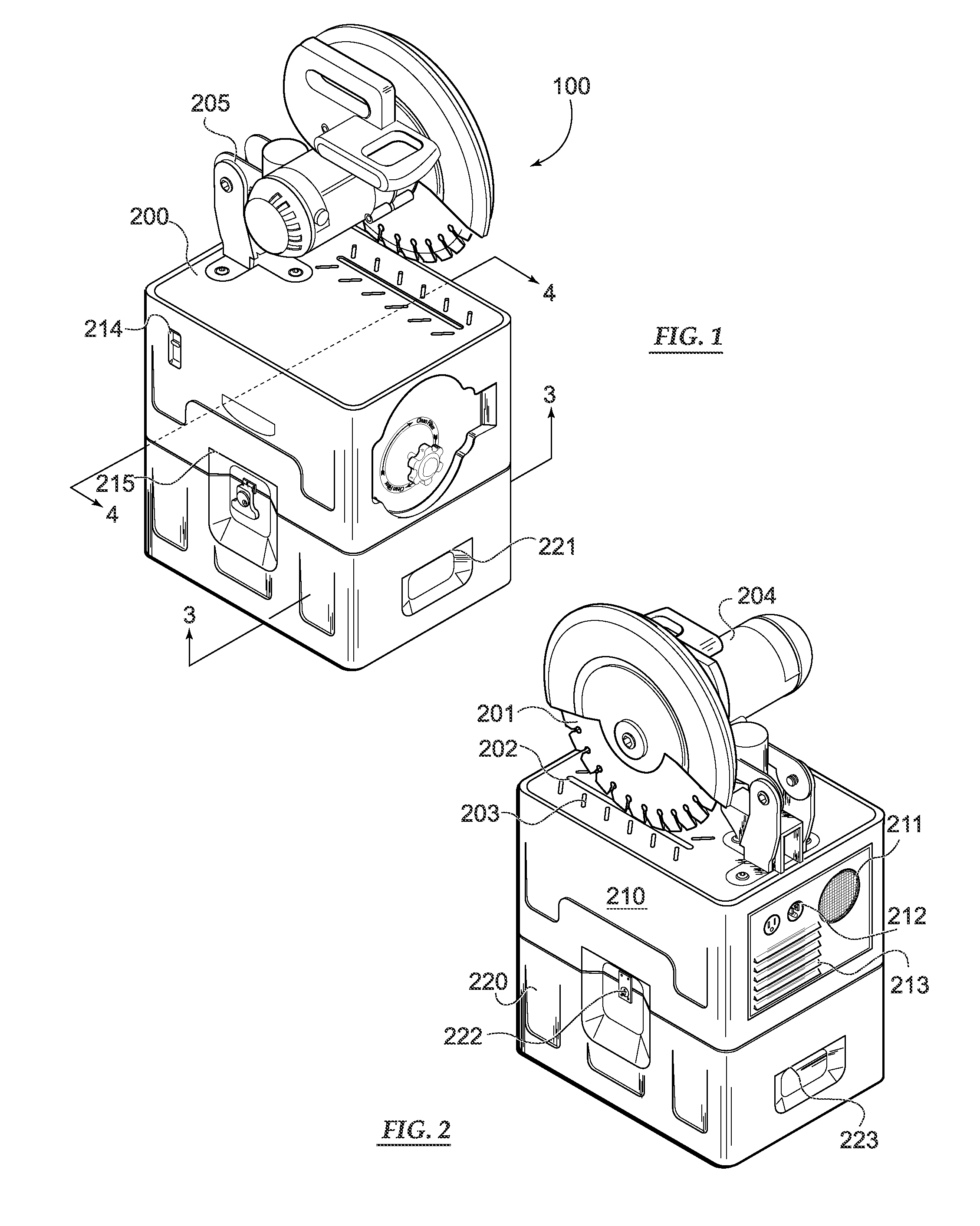

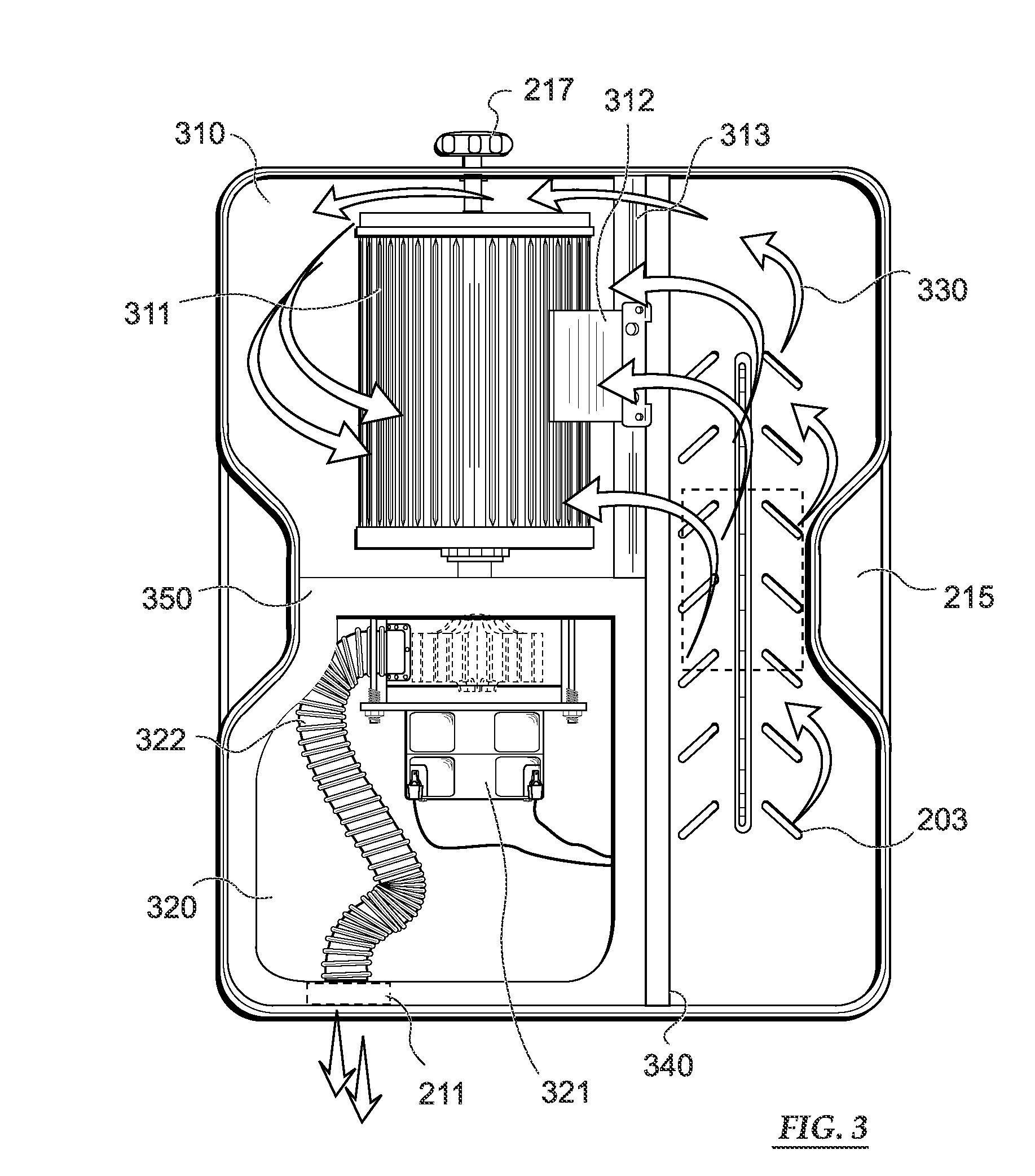

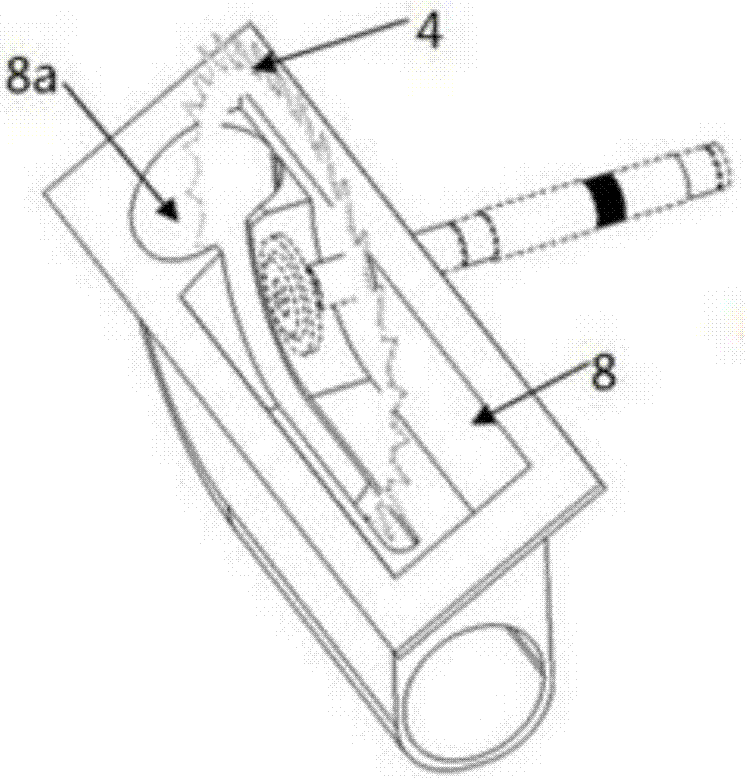

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

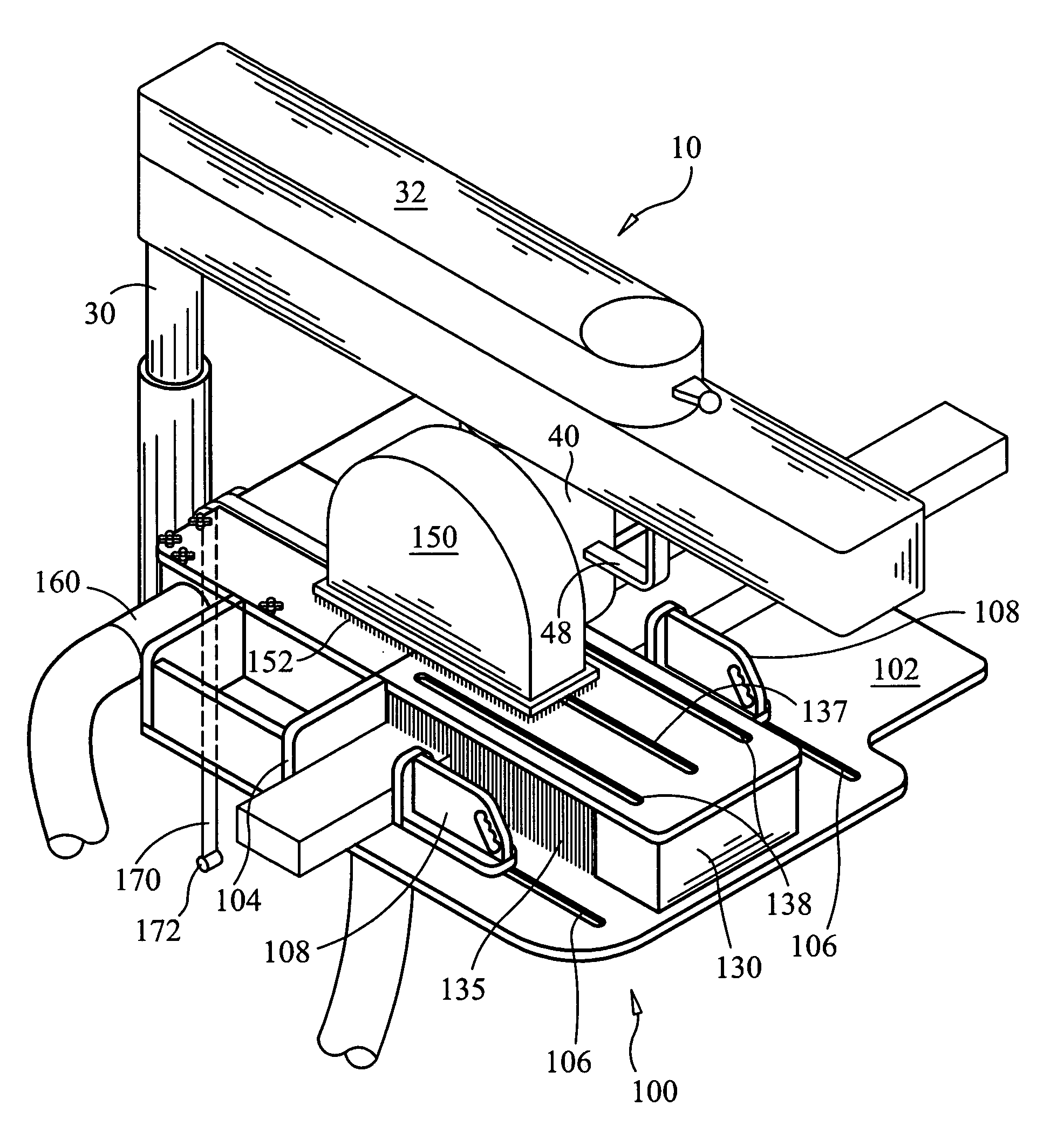

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

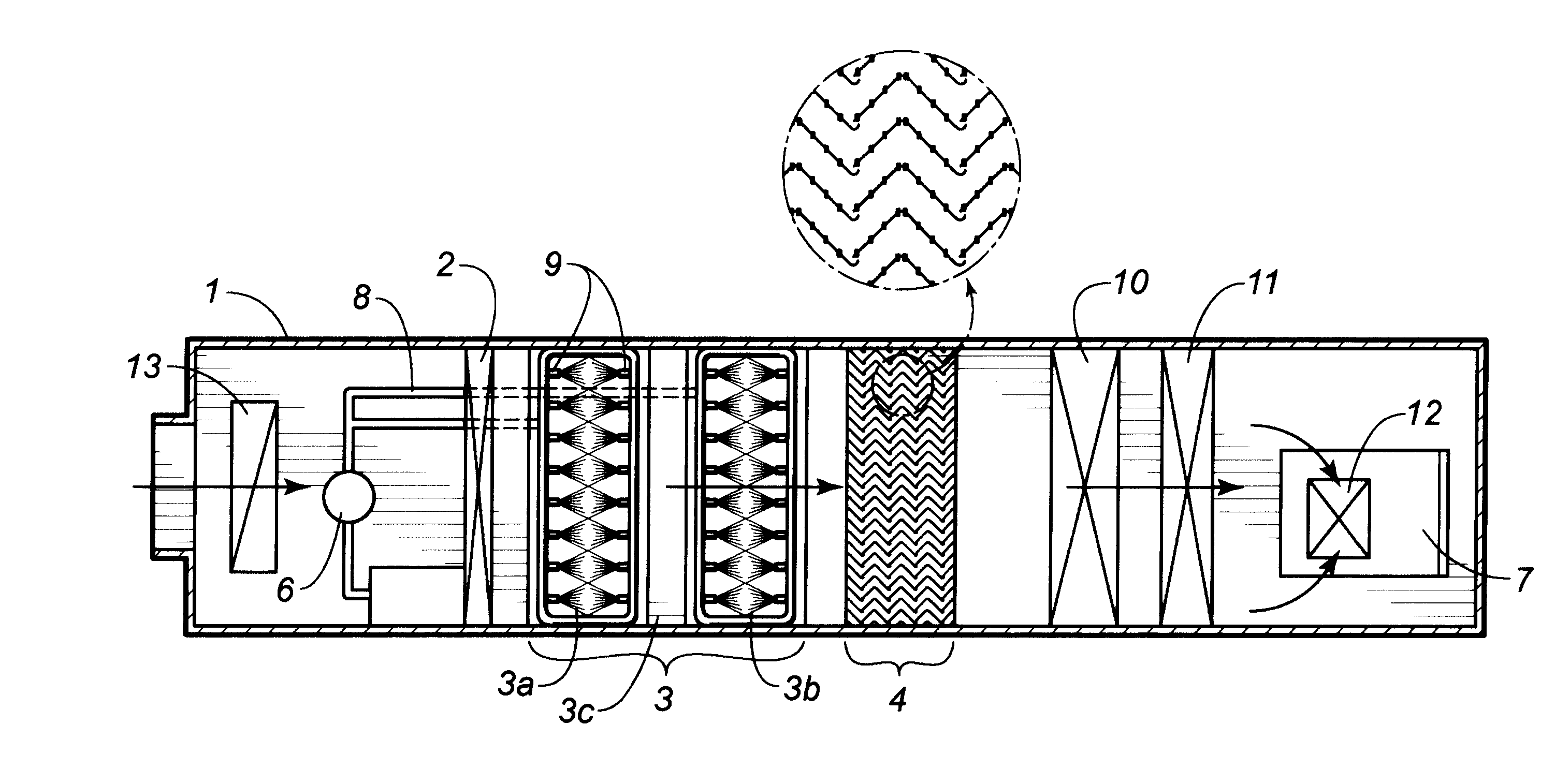

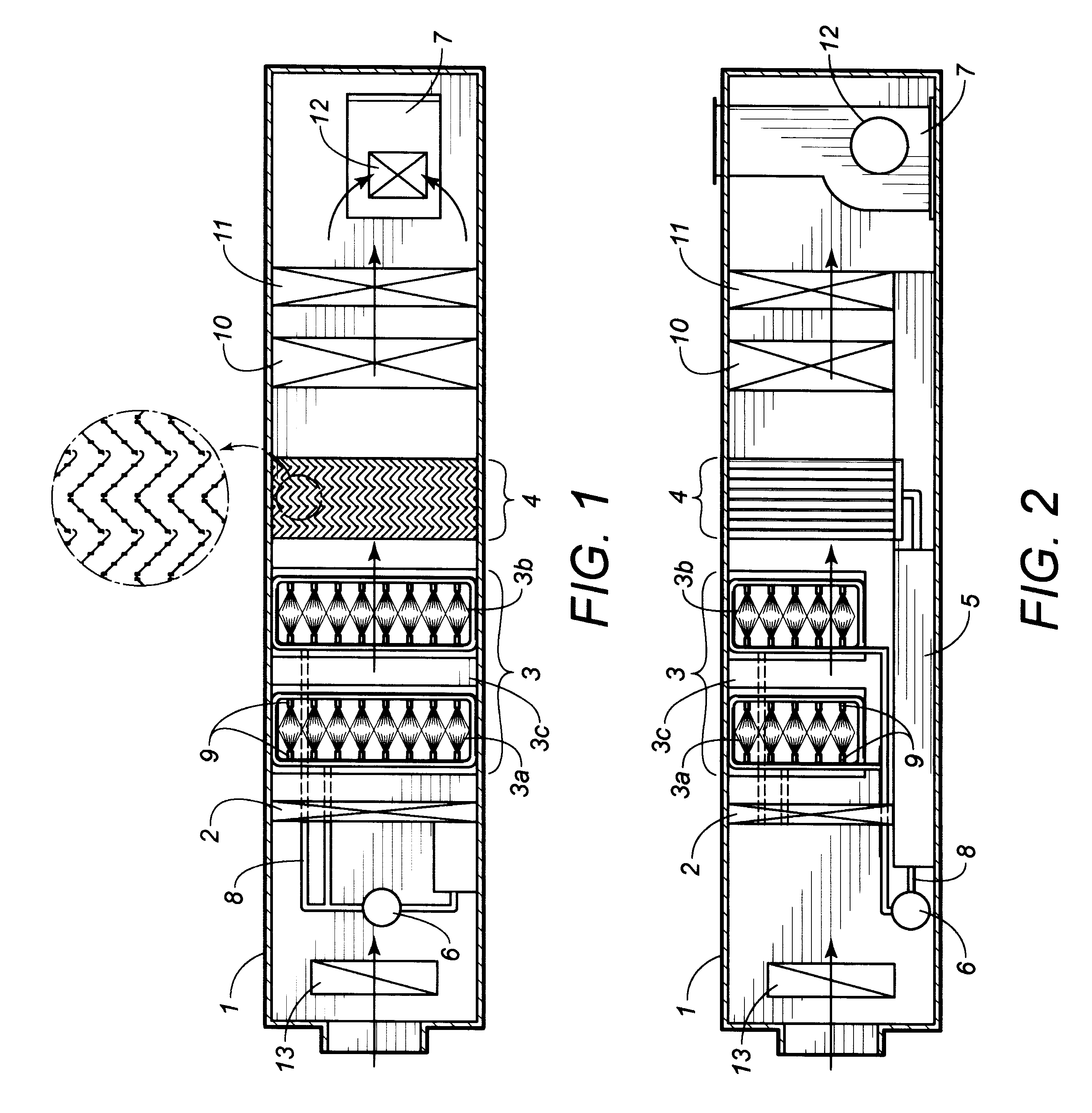

Air cleaner for removing air pollutants by water spray type of dust collecting system

InactiveUS6451096B1Reduce maintenance costsIncrease spray pressureCombination devicesUsing liquid separation agentForeign matterAerodynamic drag

An air cleaner for removing air pollutants by a water spray type of dust collecting system, which includes a dust collecting part and an air and water separating part in the interior of an air duct, the dust collecting part composed of primary and secondary dust collectors by water spraying, each of which having a plurality of spraying nozzles layeredly arranged by predetermined intervals to be opposed at an angle of 30° from the top to bottom thereof, and a space dust collector by water spraying disposed in a space between the primary and secondary dust collectors by water spraying, such that the three-step air and water contact causes foreign materials such as dust, gases and so on to be absorbed, dissolved and settled, and the air and water separating part formed of a groove-engaged type and layeredly curved by six-step folding at an angle of 90° in consideration of air resistance, for passing only the air flowing from the dust collecting part and collecting water drops.

Owner:KOREAN CLEAN AIR SYST +2

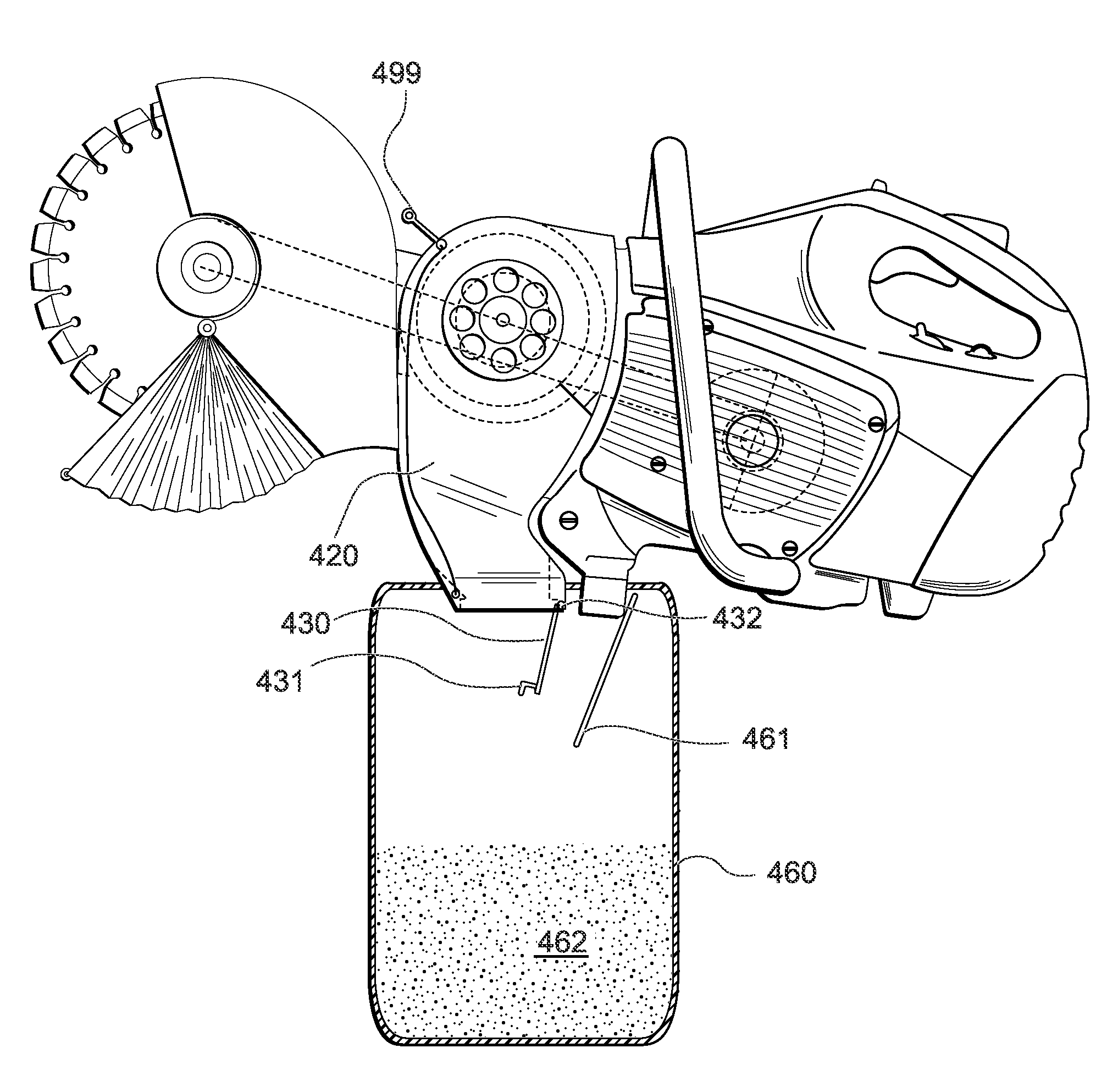

Power saw apparatus with integrated dust collector

ActiveUS20110079207A1Reduce frictionUseful surface areaMetal sawing devicesMetal sawing accessoriesParticulatesSpins

A power saw having a circular saw blade or, grinding wheel incorporated to a dust collection system that is easily portable is disclosed herein. In a preferred embodiment, negative pressure and resulting air flow is provided at a lower blade guard to capture particulate matter as a byproduct of cutting a work piece. A unique dust collection housing is additionally provided having a filter to remove dust from air and exhaust the filtered air at a lateral side of the saw. A spin handle is additionally disclosed to increase the usable surface of the filter and to work in conjunction with a filter cleaning flap. A drive belt according to a preferred embodiment, drives the circular saw and a vacuum fan. Among the beneficial aspects of the power saw is its portability by obviating a need for a dust collection bag and / or a separate vacuum unit.

Owner:JPL GLOBAL

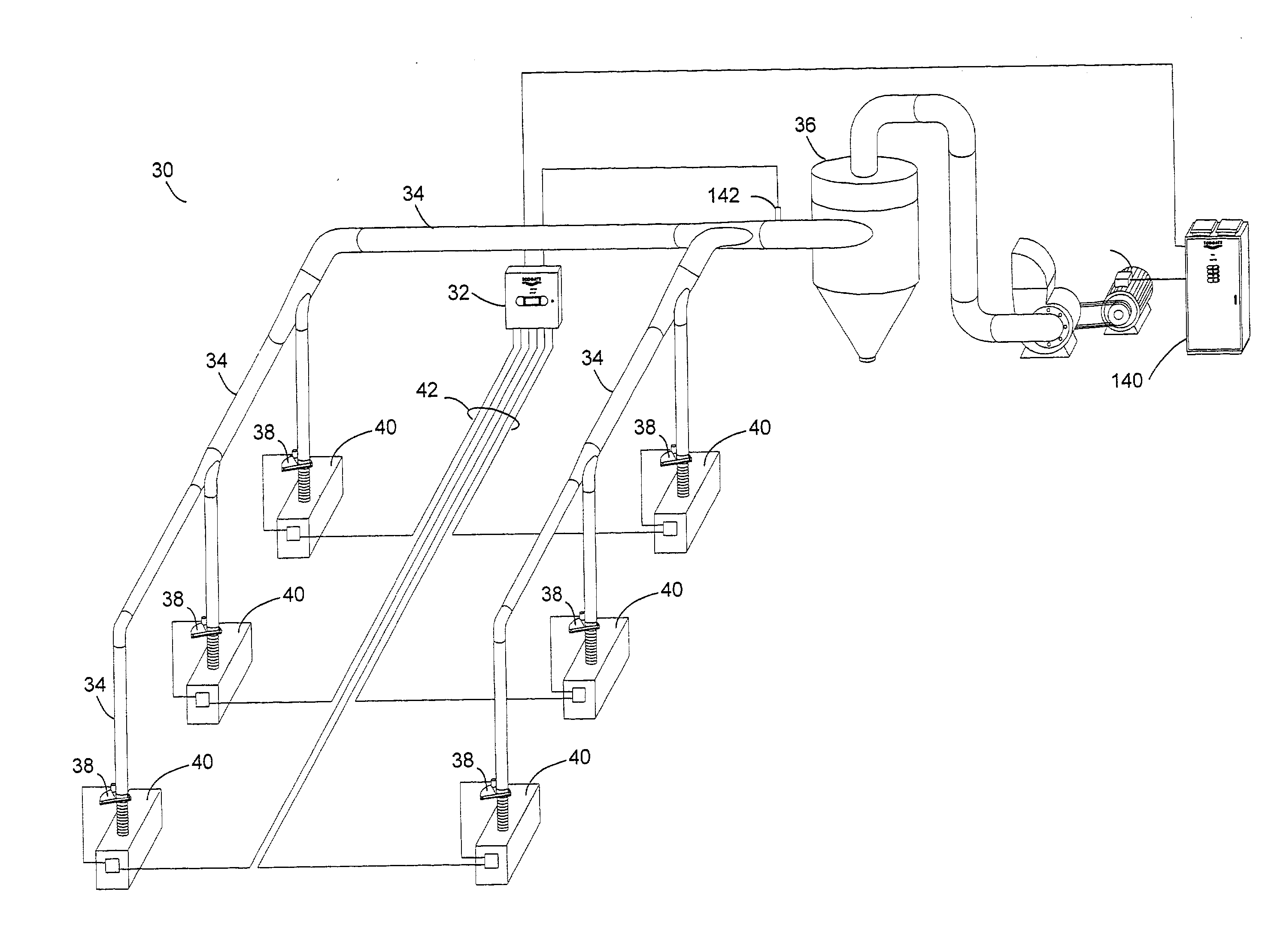

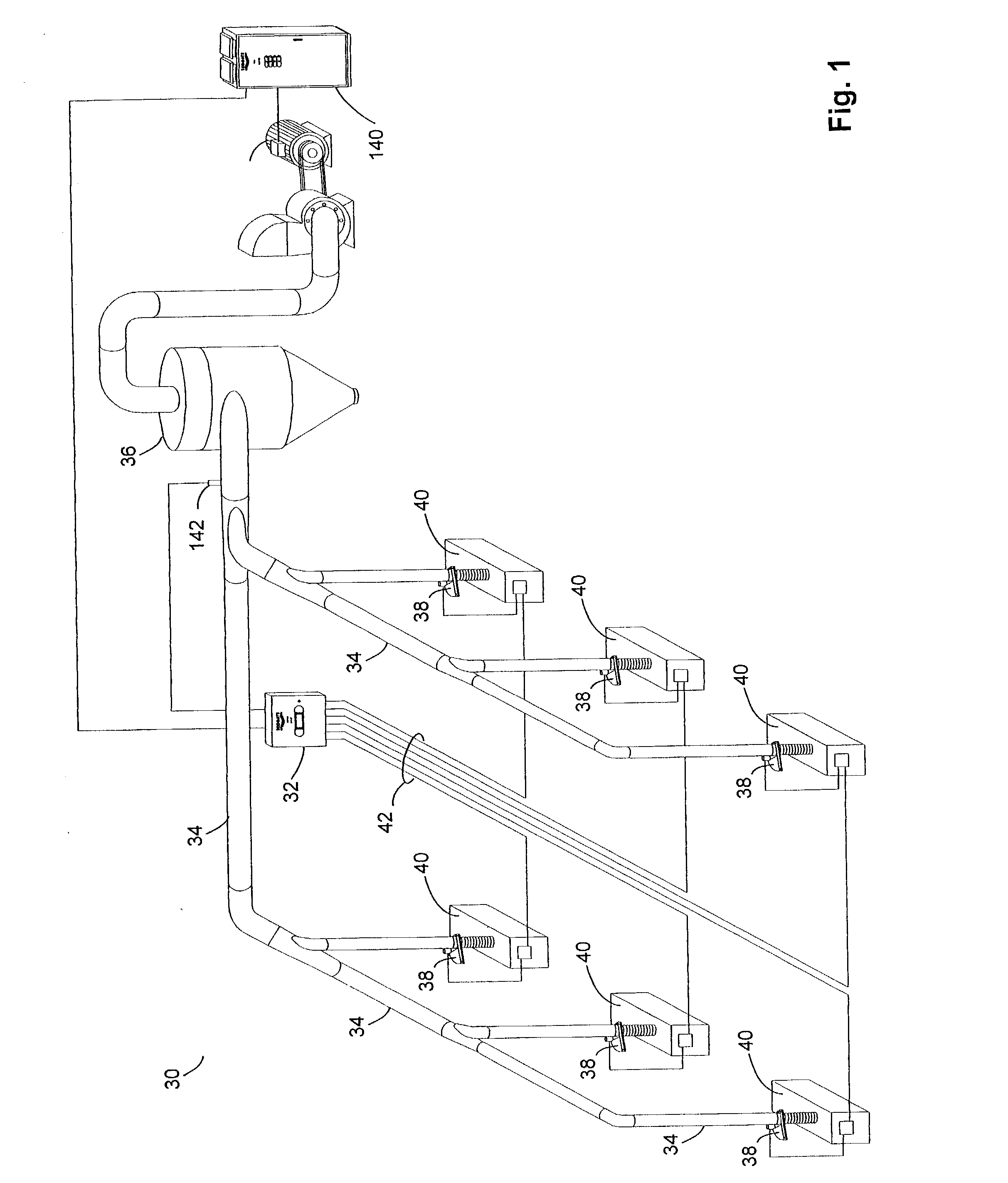

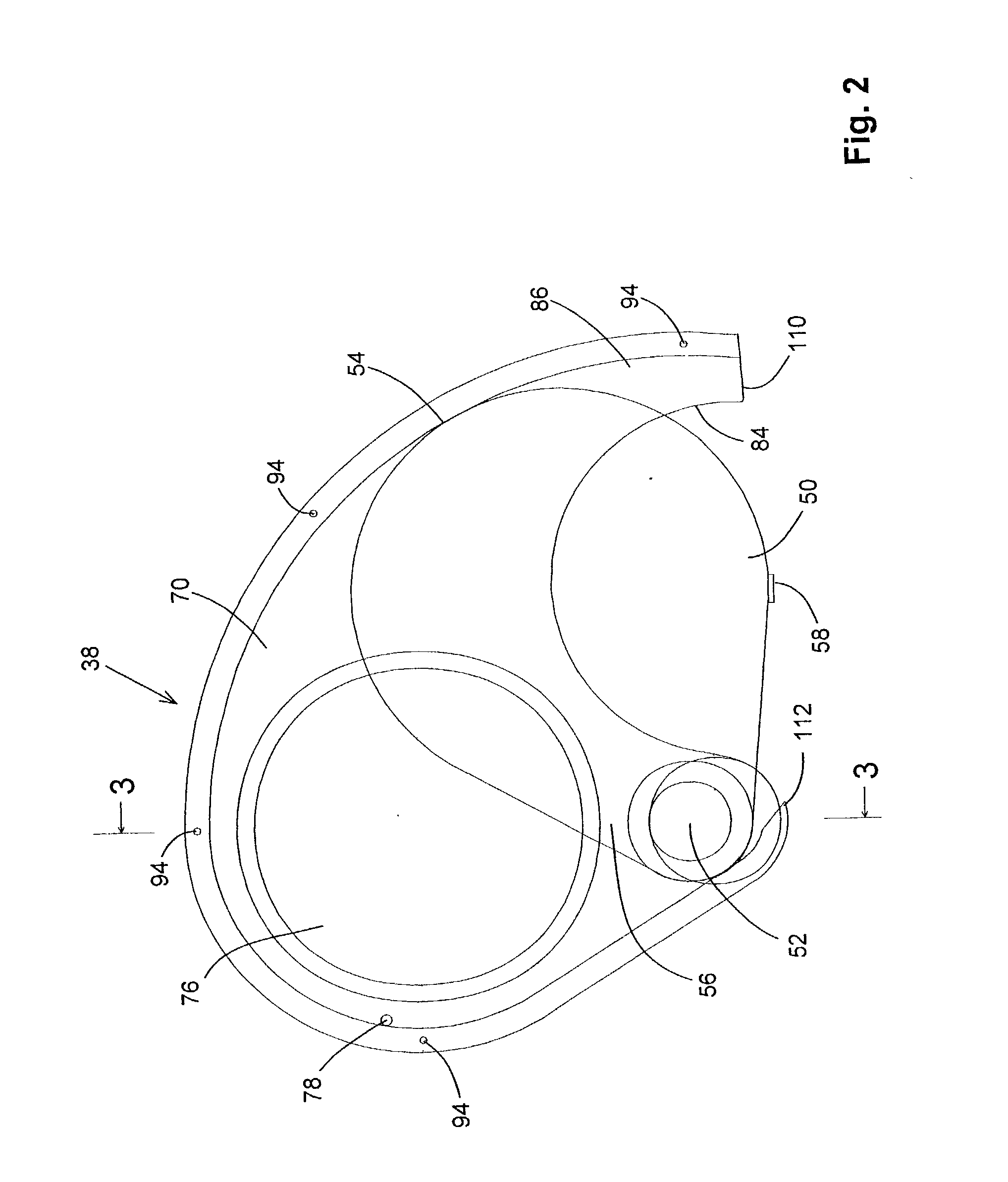

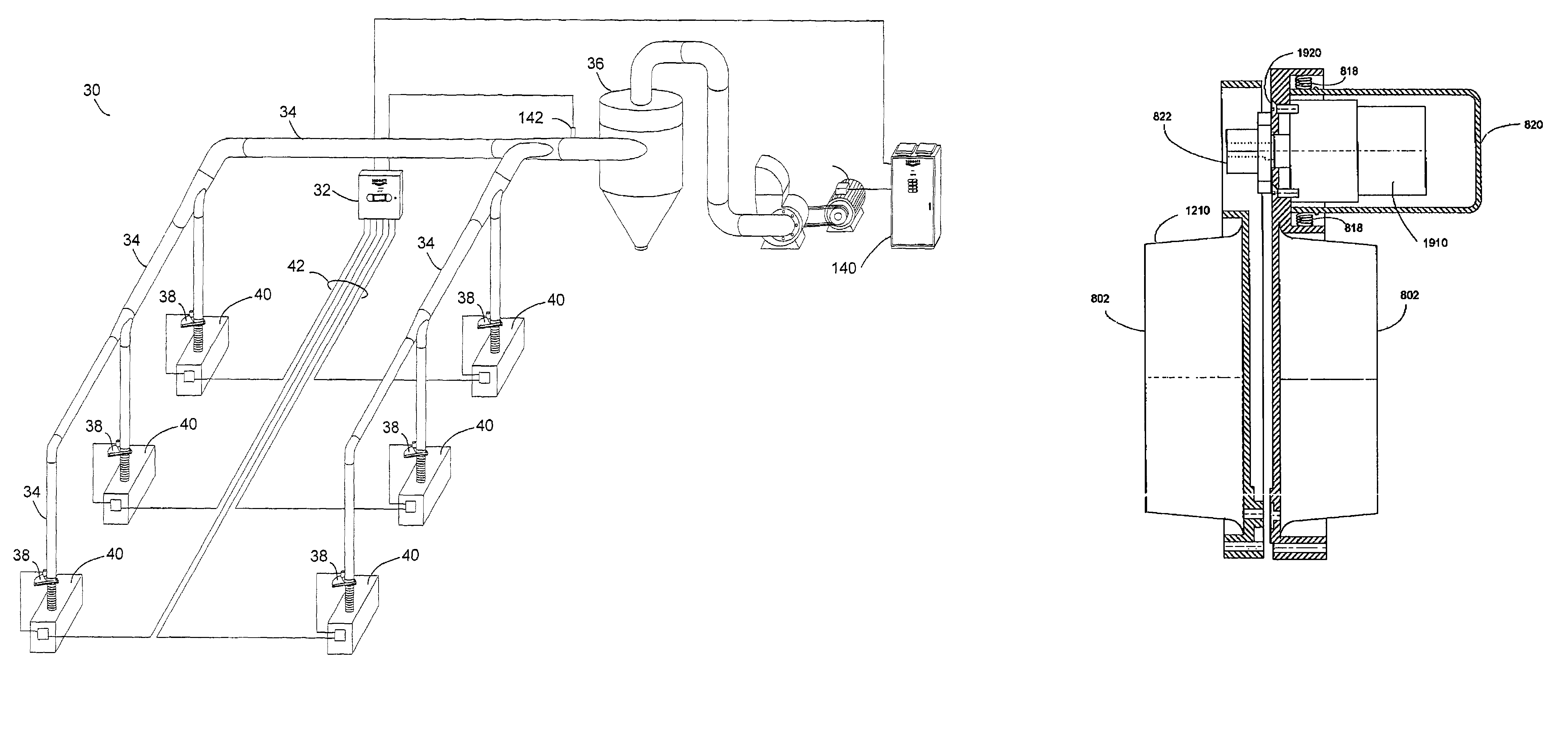

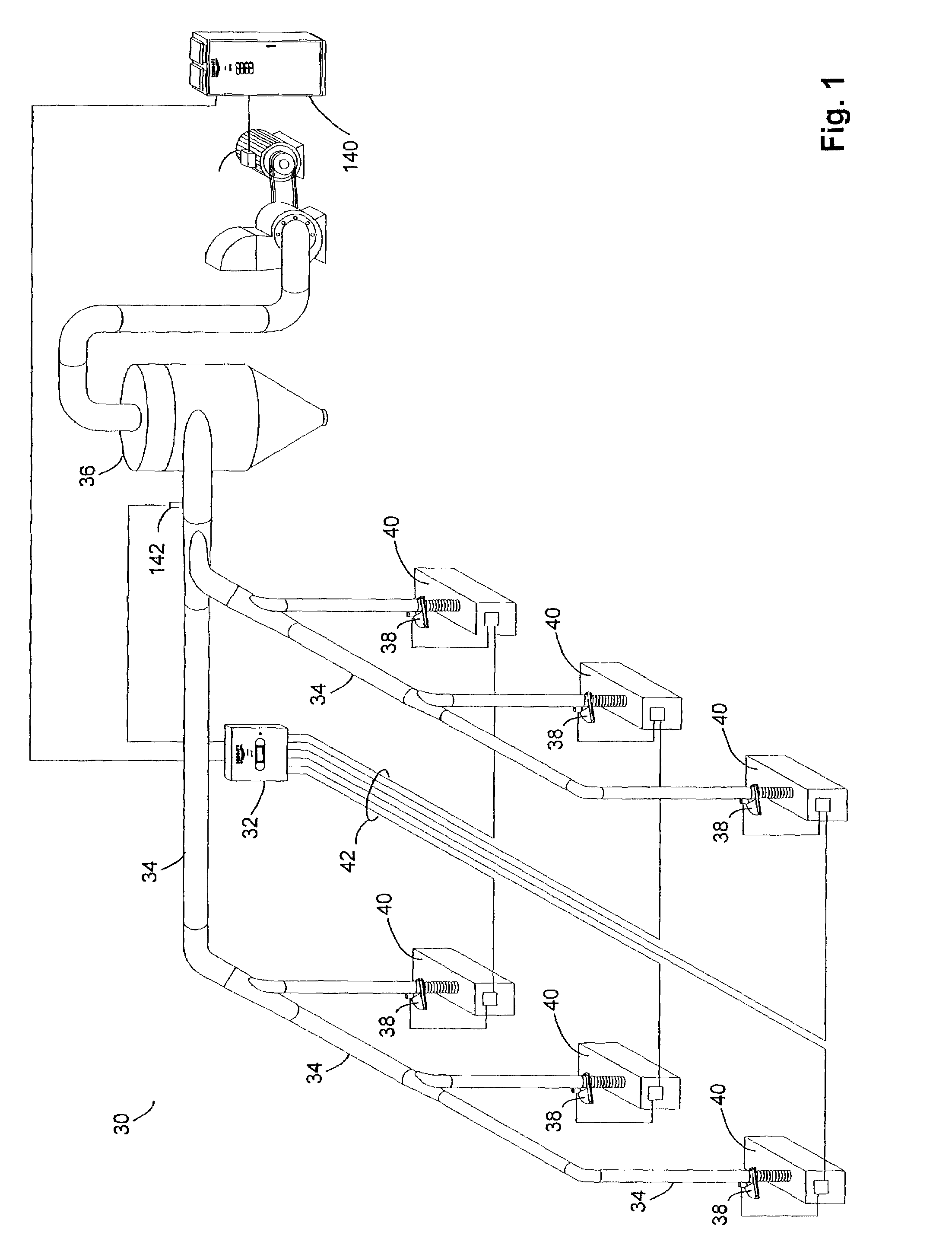

Energy saving vacuum system for particle, mist, and fume collection

ActiveUS20040093682A1High ratio leverageGuaranteed uptimeMetal sawing accessoriesVehicle cleaningMachine shopCollection system

An improved energy-efficient vacuum system for machine shop dust, particulate matter, and the like. Blast gates, including large-diameter blast gates, control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch, an increased current feedback system, a biasing-spring assembly or otherwise to limit the rotation driving of the rotating blade. In one embodiment, the blast gate blade bears teeth about its perimeter. The DC motor engages the perimeter blade teeth with a gear. Greater mechanical advantage is achieved over the blast gate blade and less torque arises in contrast to a driving system located at the blade's central pivot point. Additionally, sensing apparatus or system calculation allow the dust collecting vacuum system to operate in an energy-efficient manner. By supplying only the vacuum needed to collect present dust, energy is saved in comparison with a dust collection system operating continuously at full capacity.

Owner:LITOMISKY IVAN +2

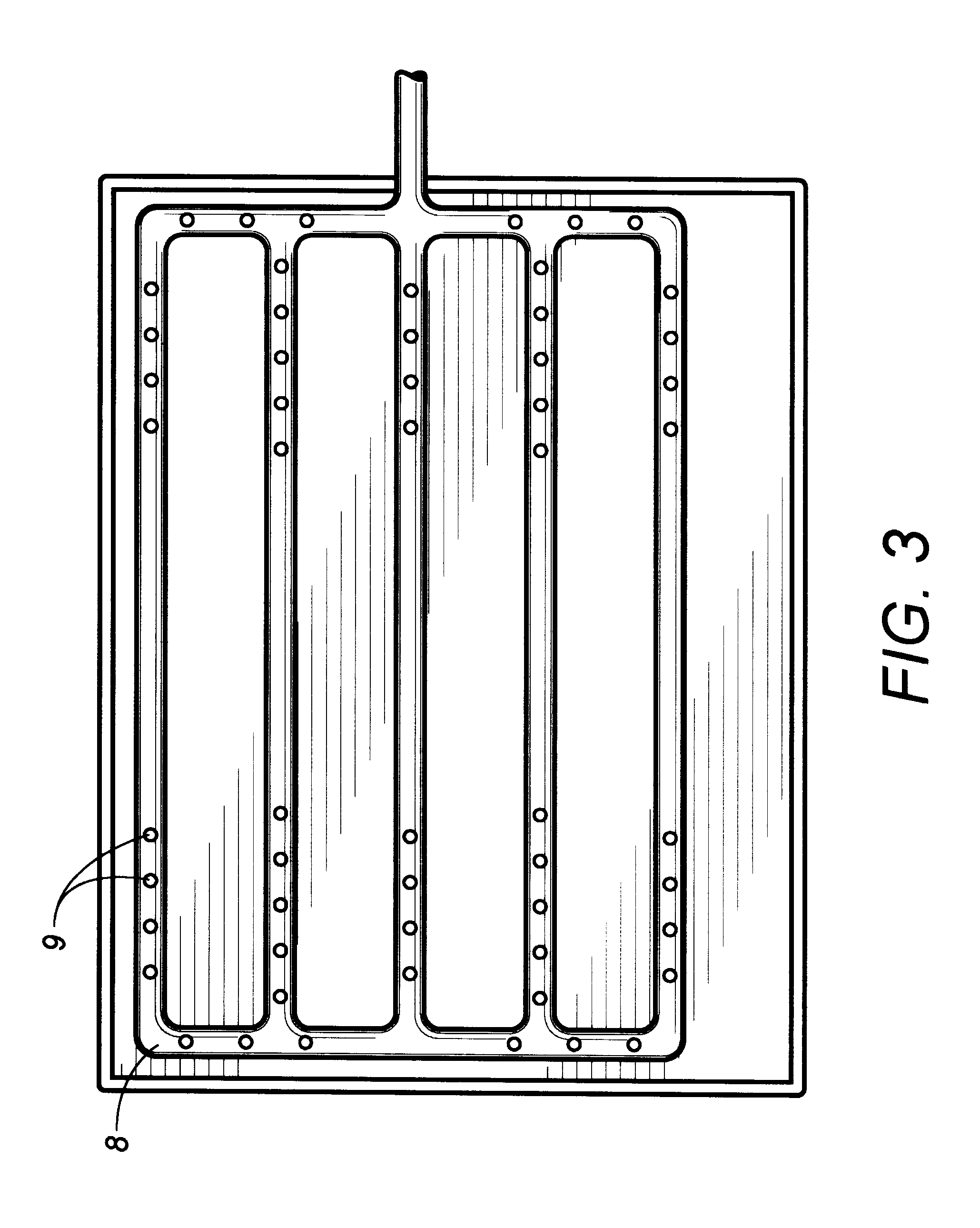

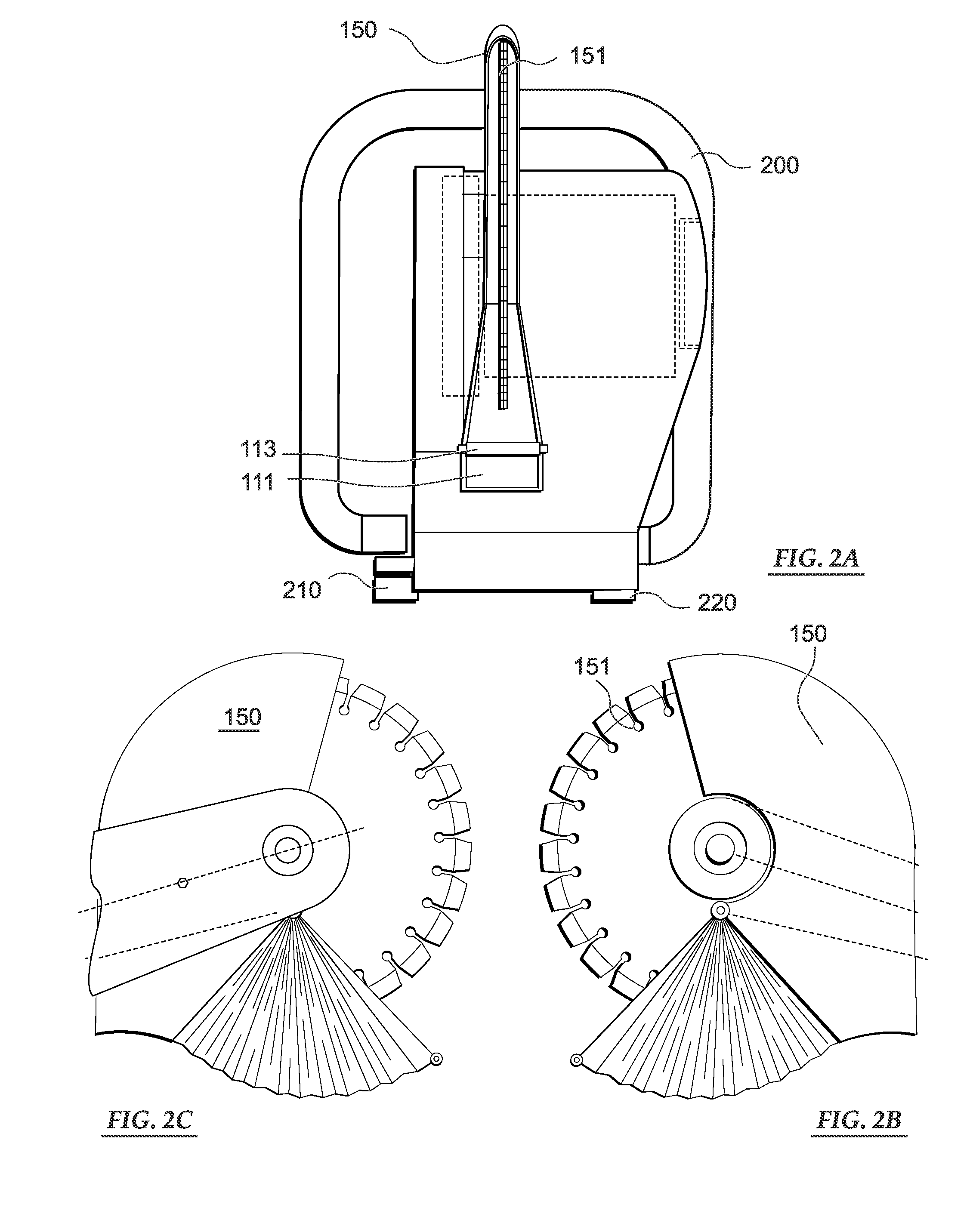

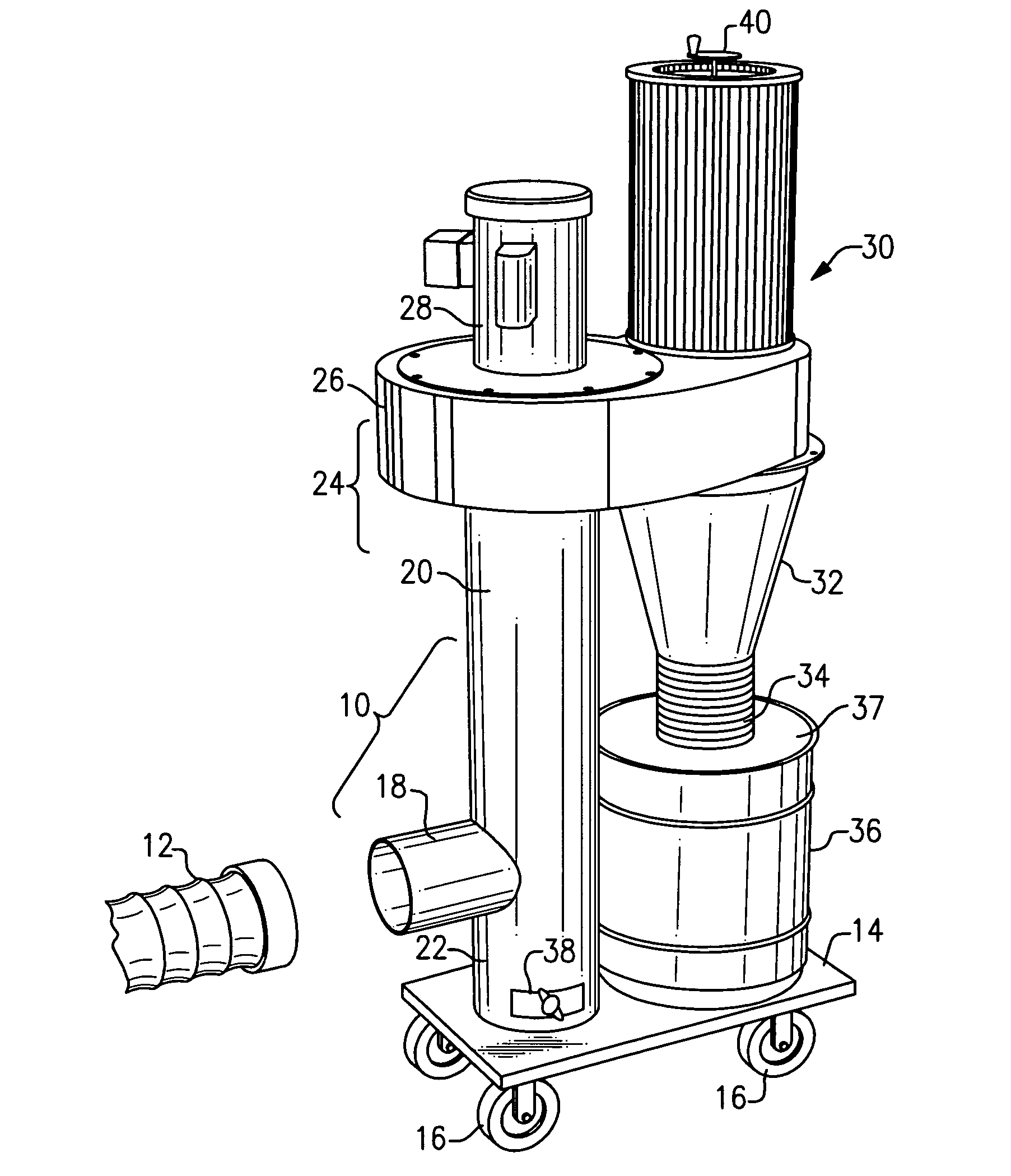

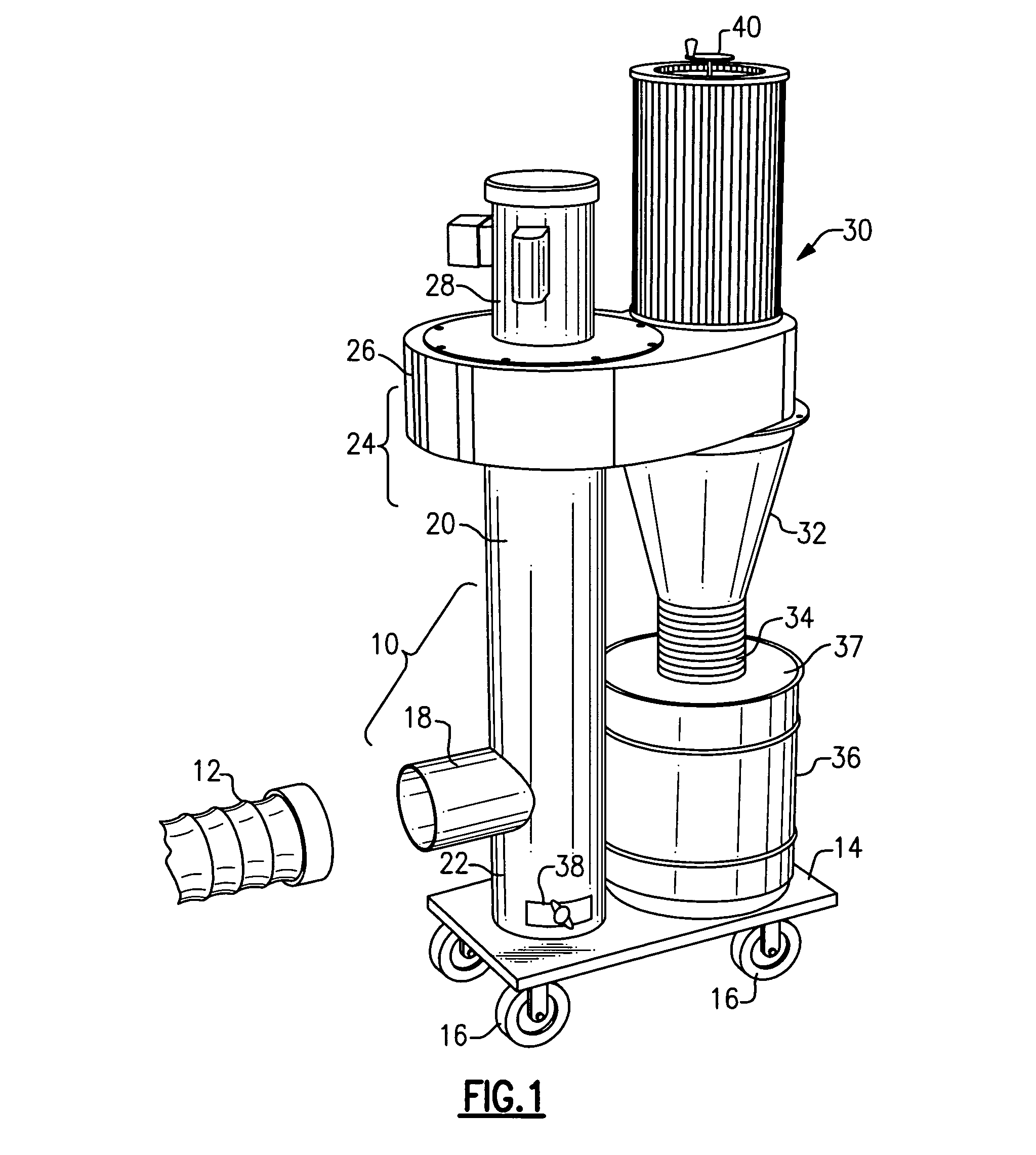

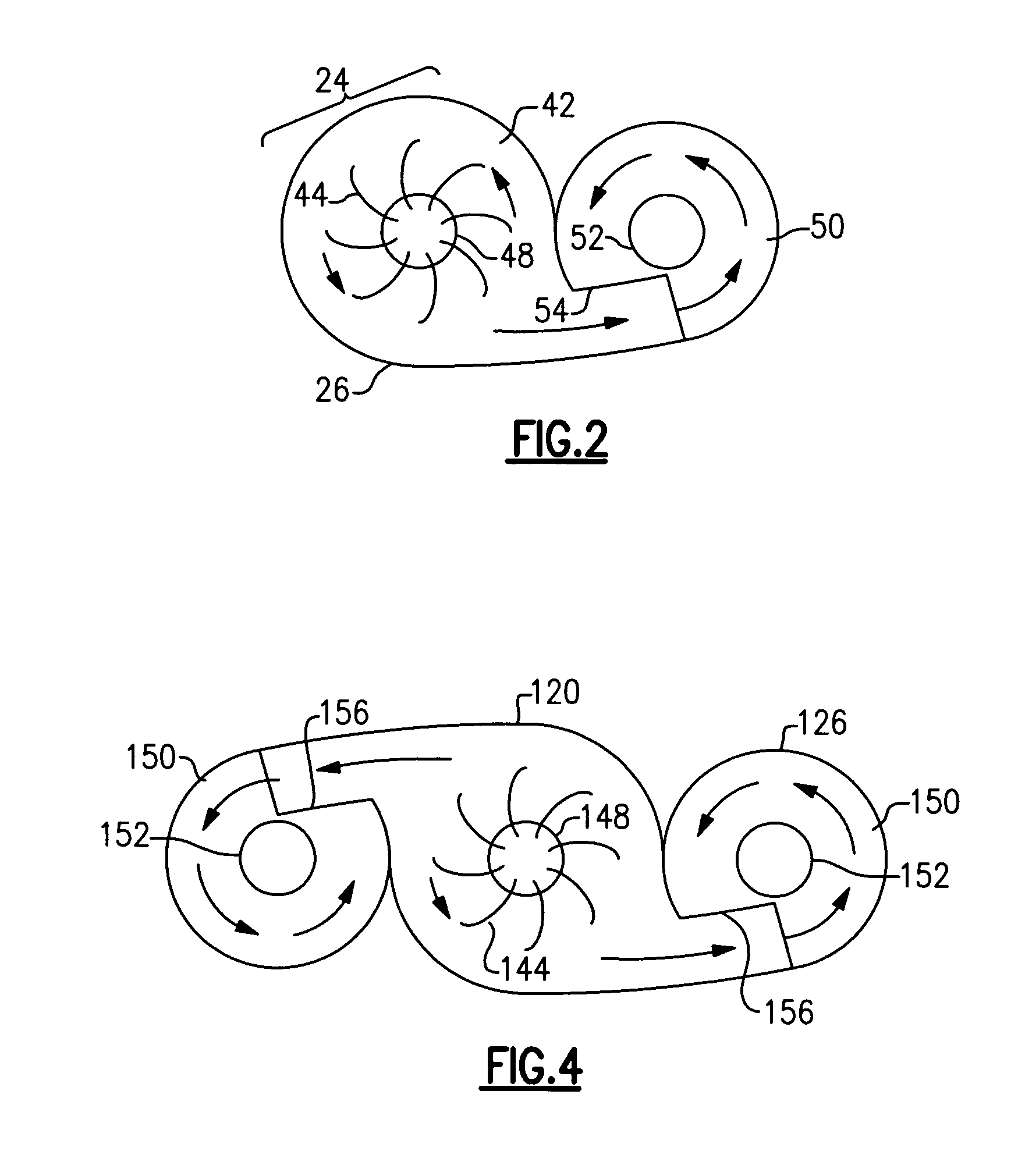

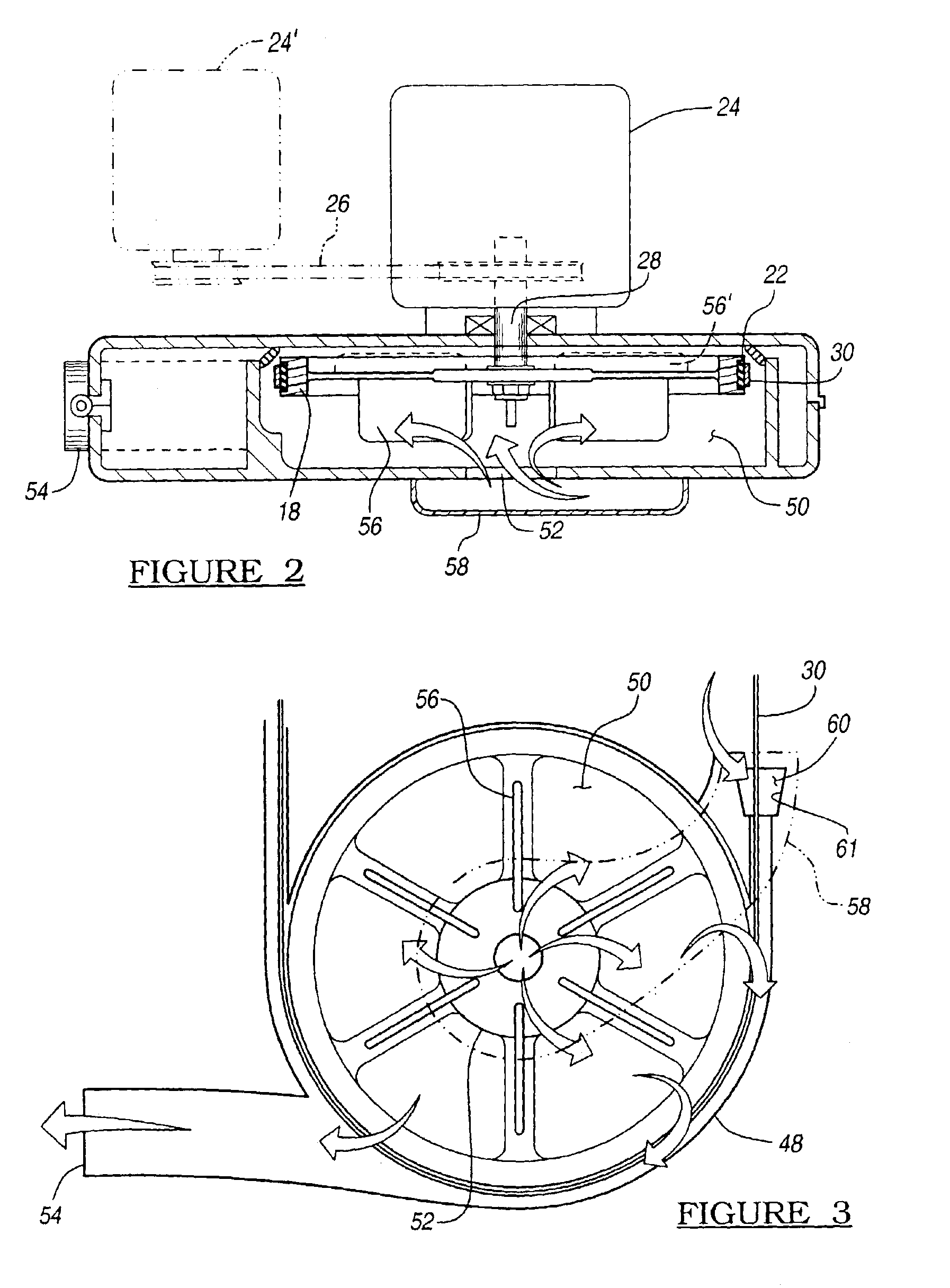

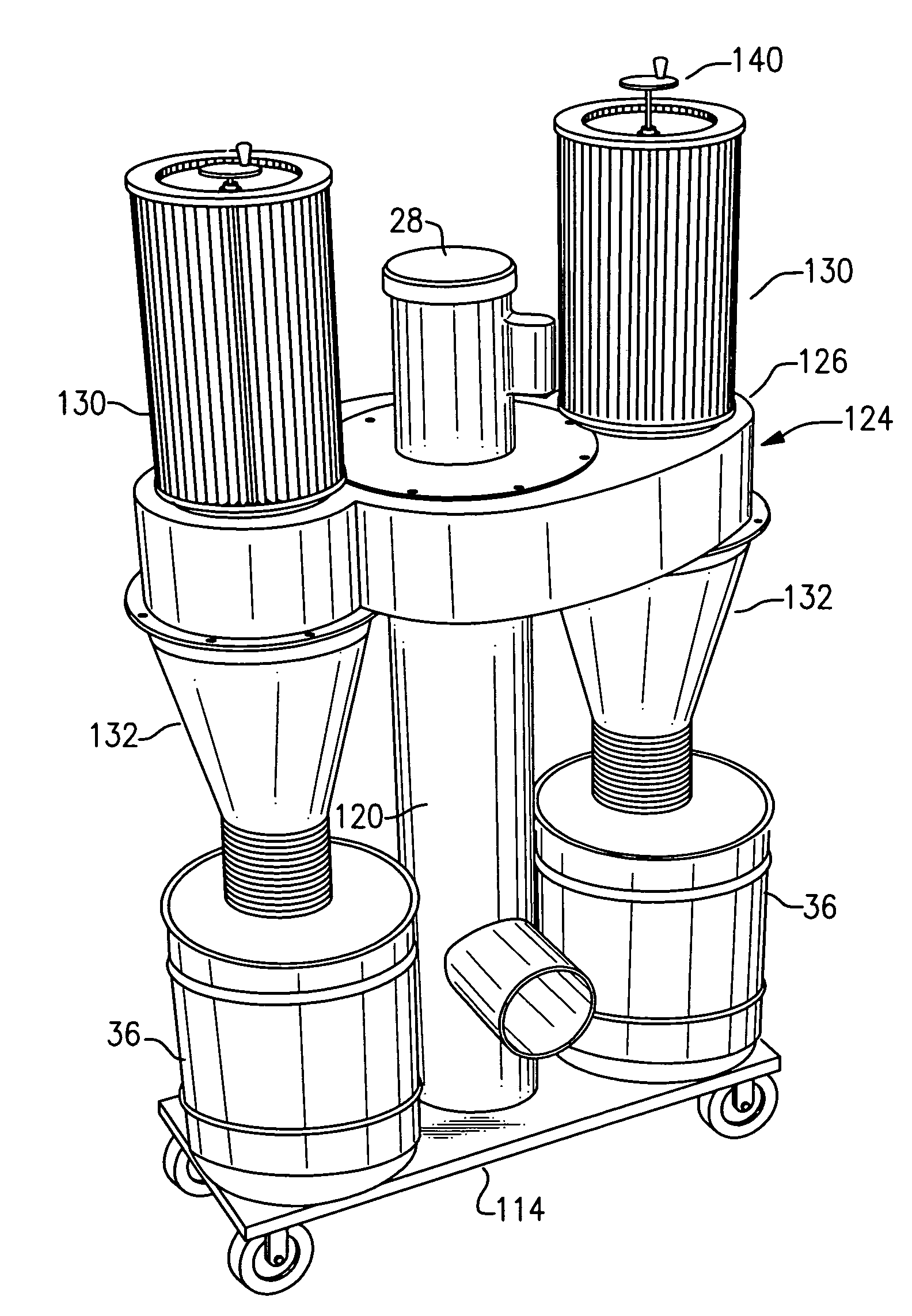

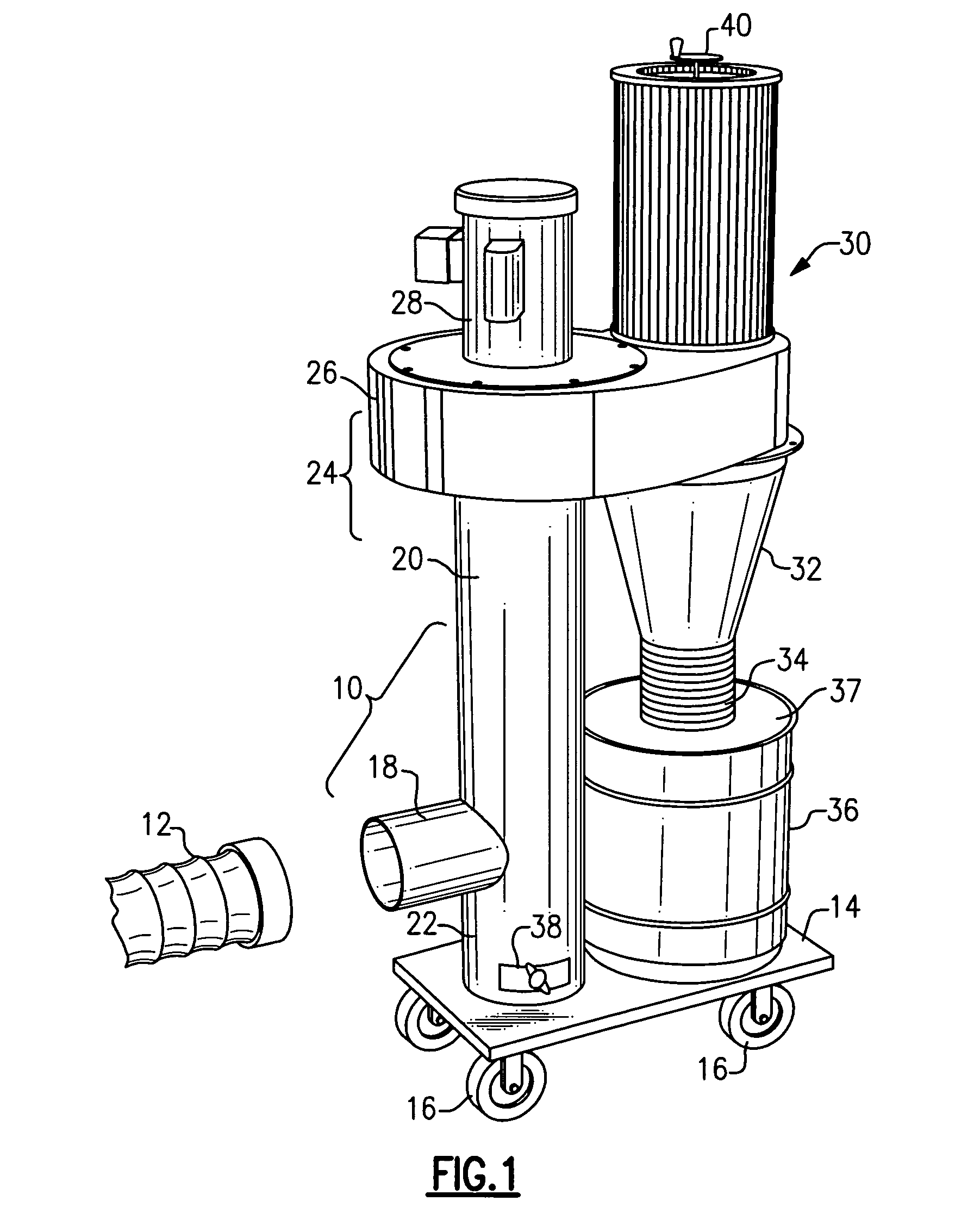

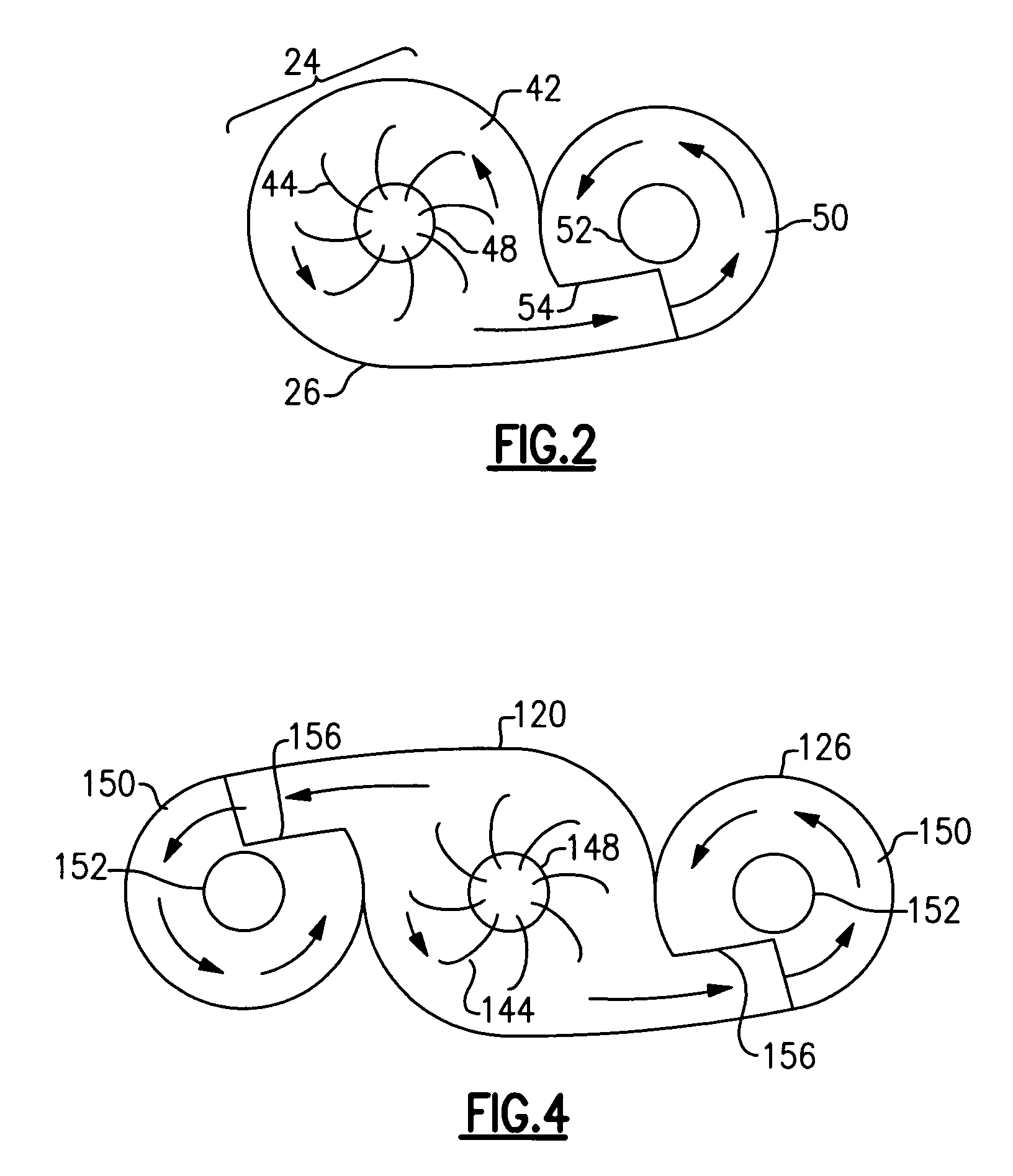

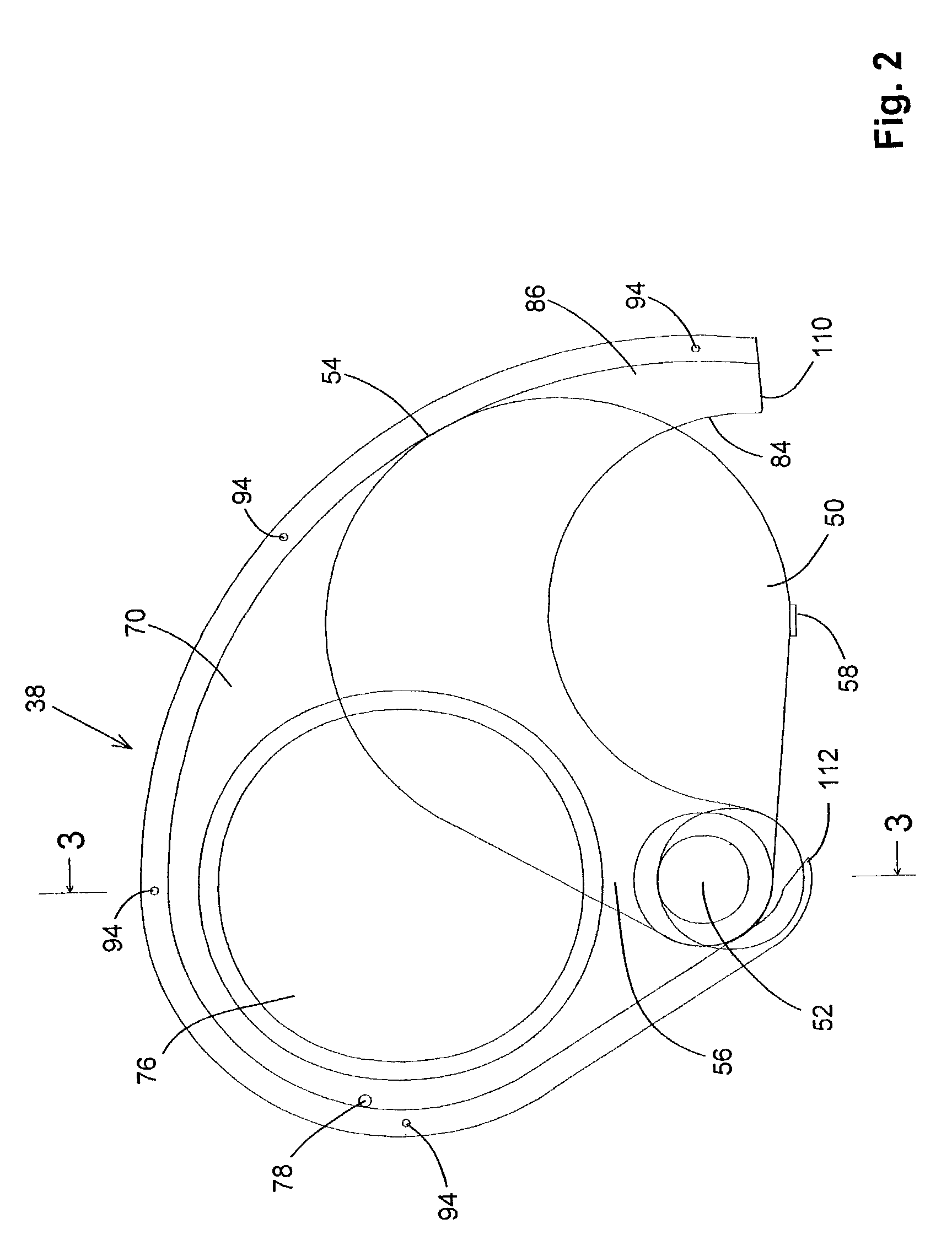

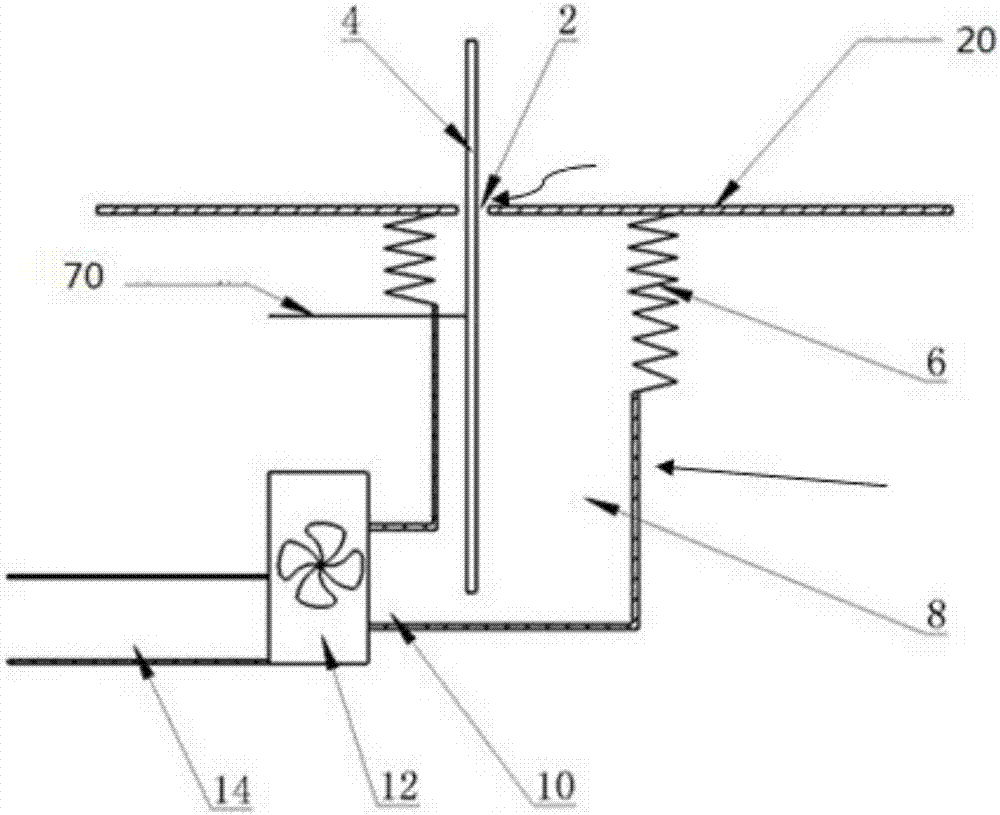

Portable cyclonic dust collection system

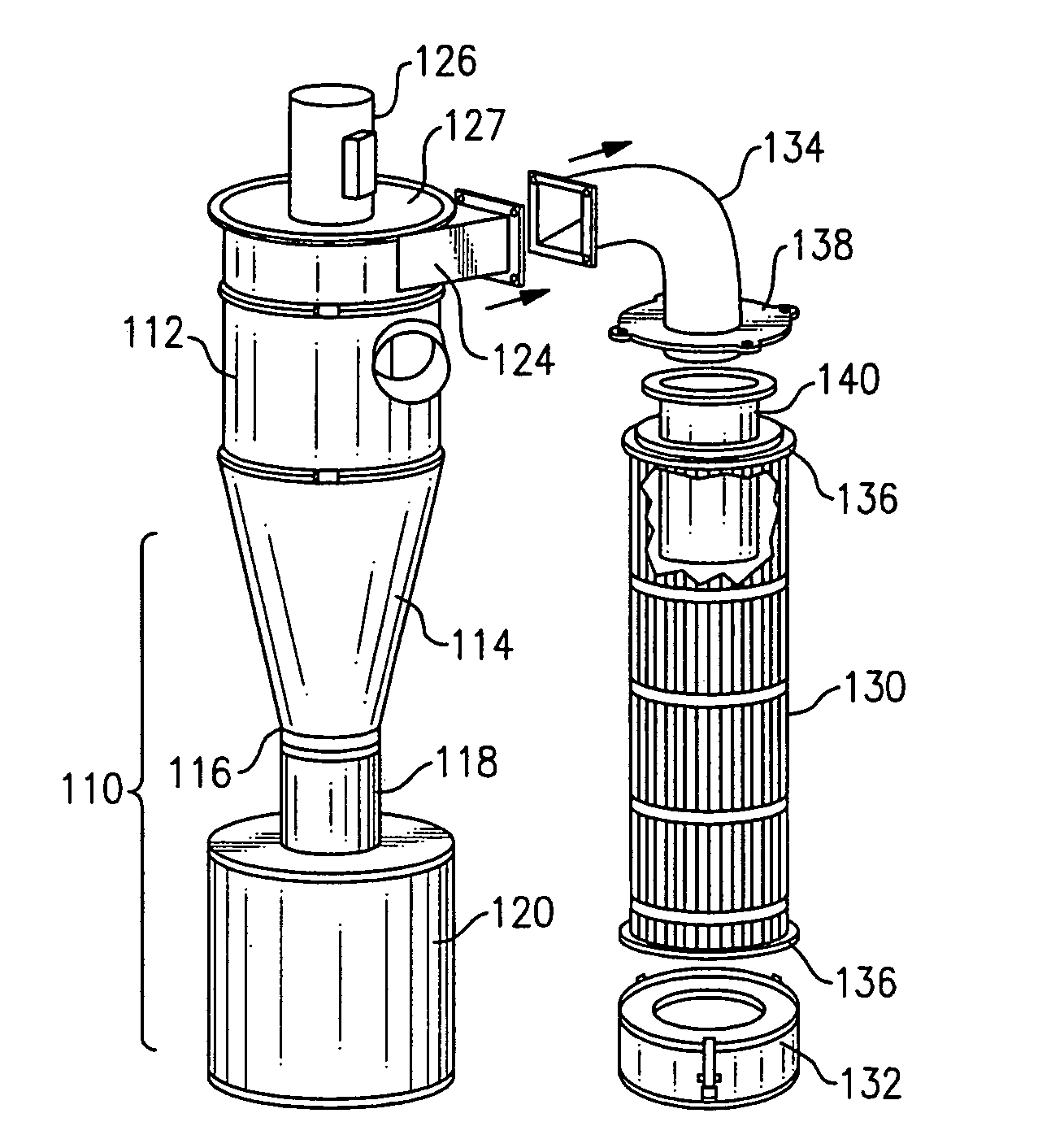

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

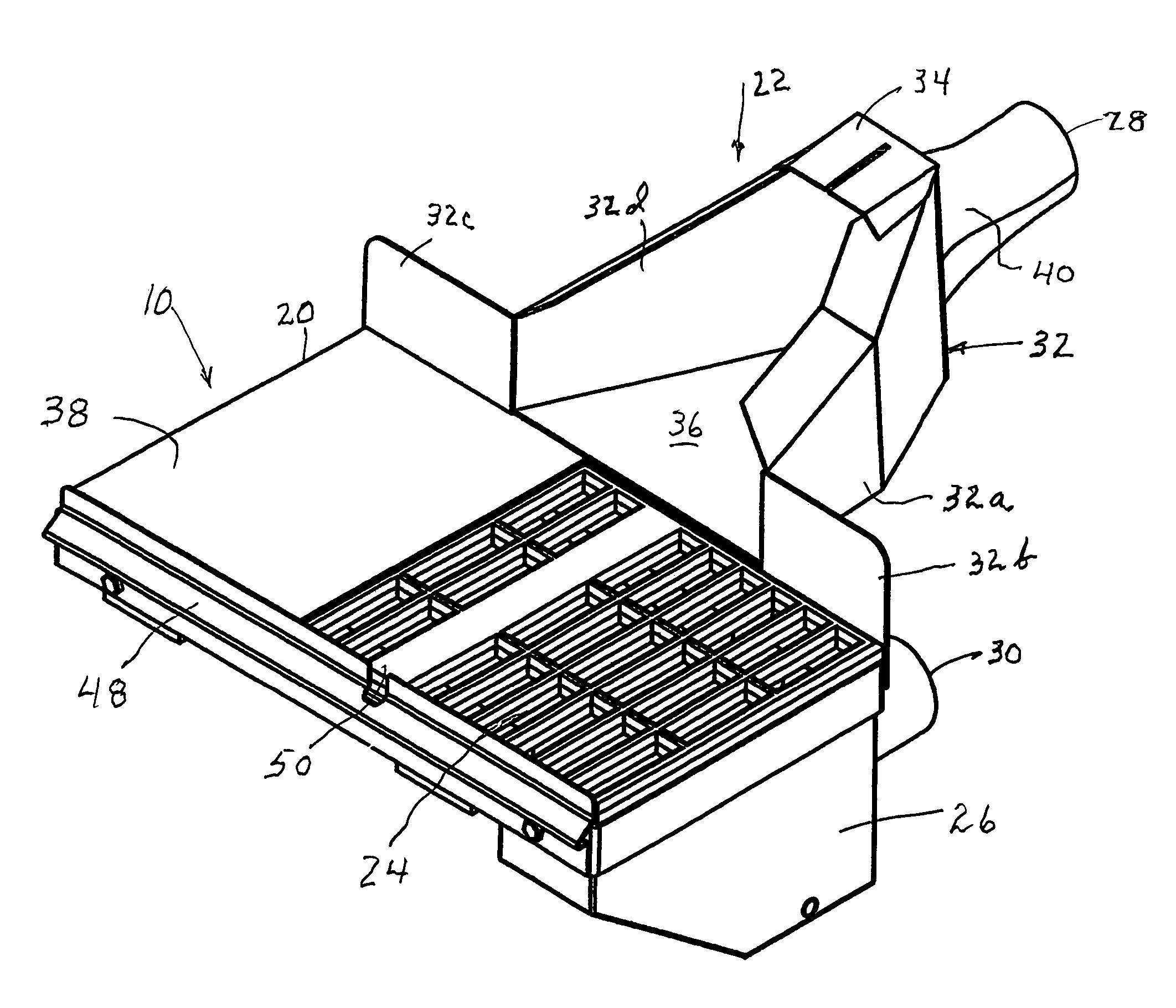

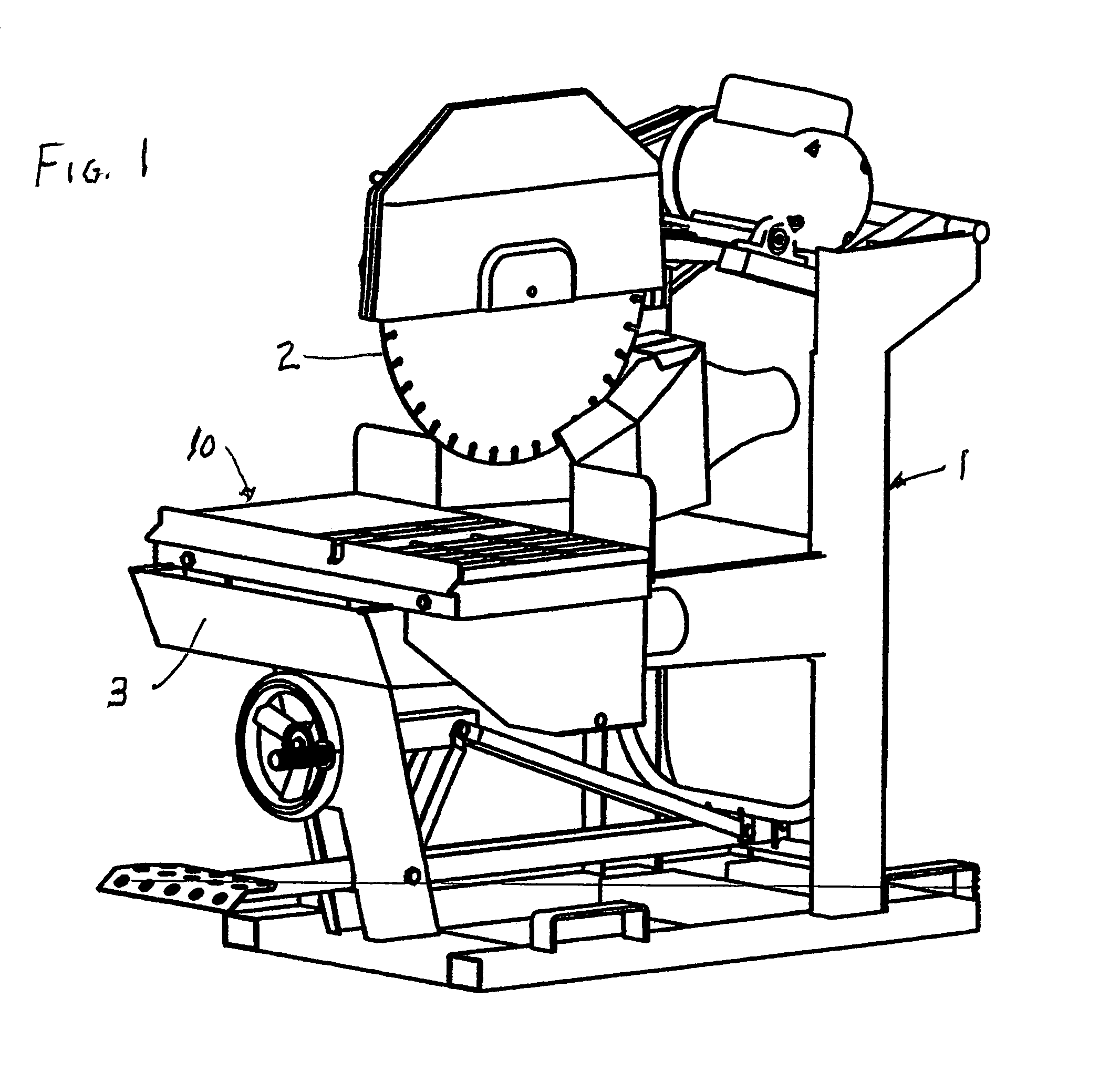

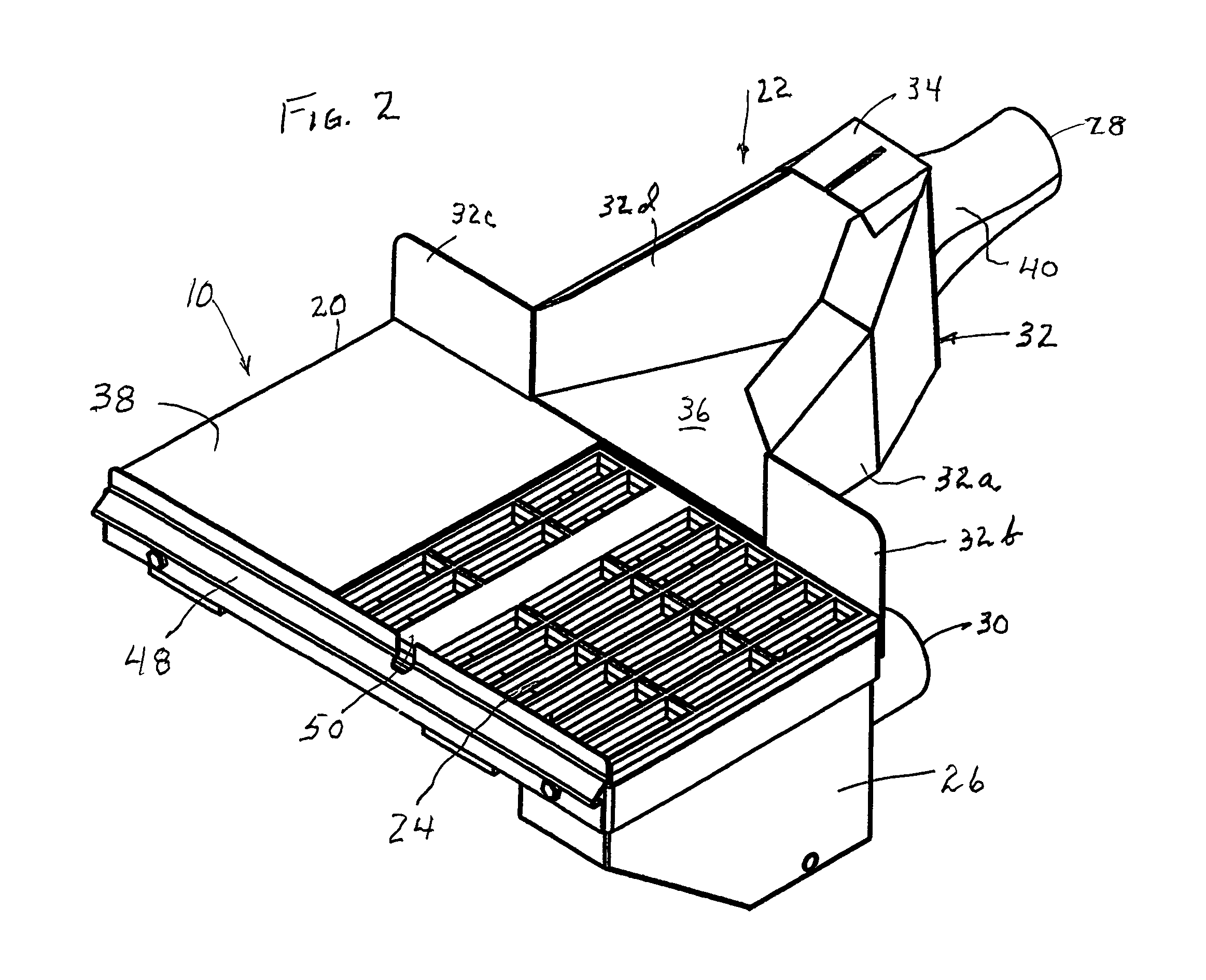

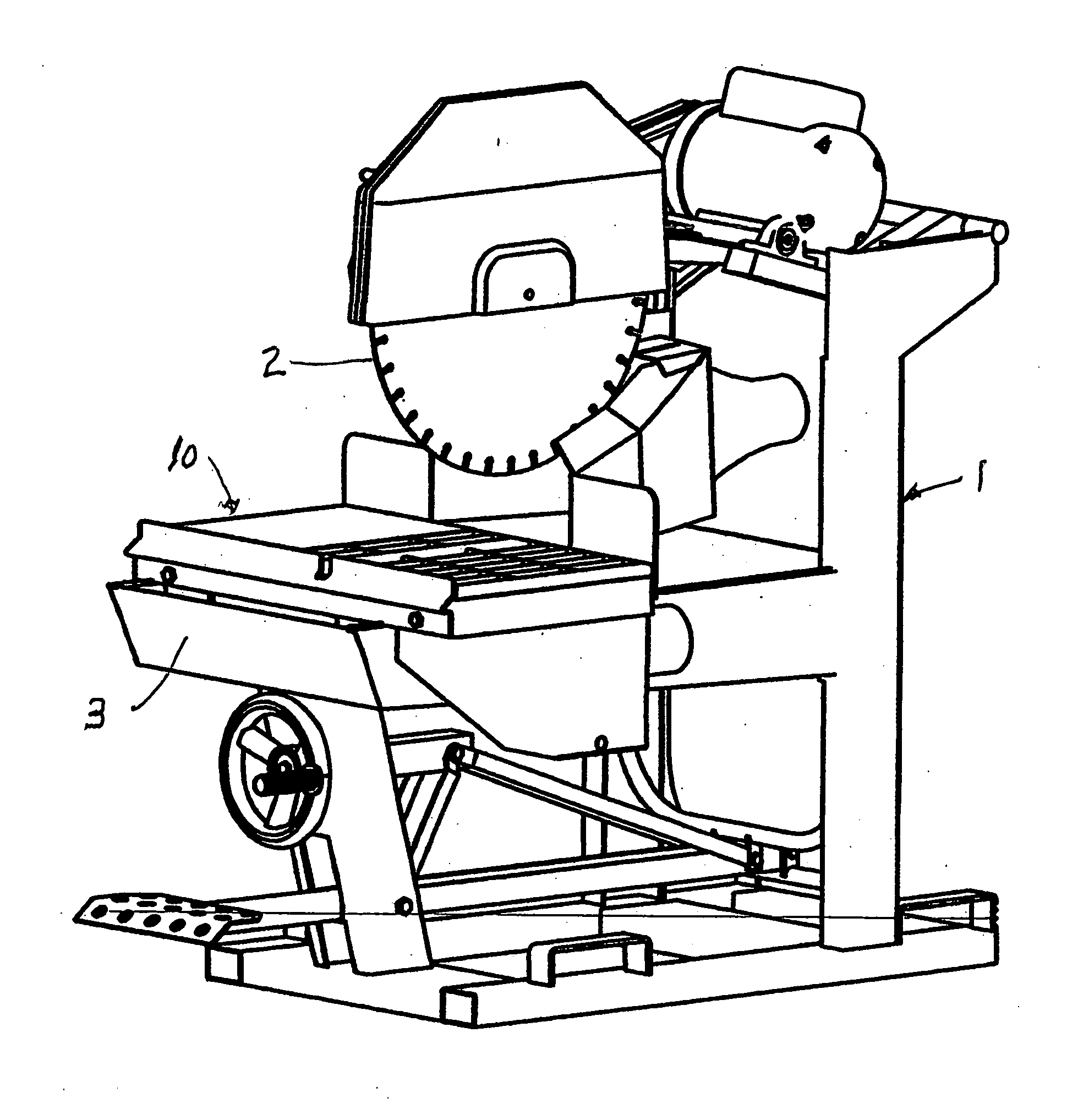

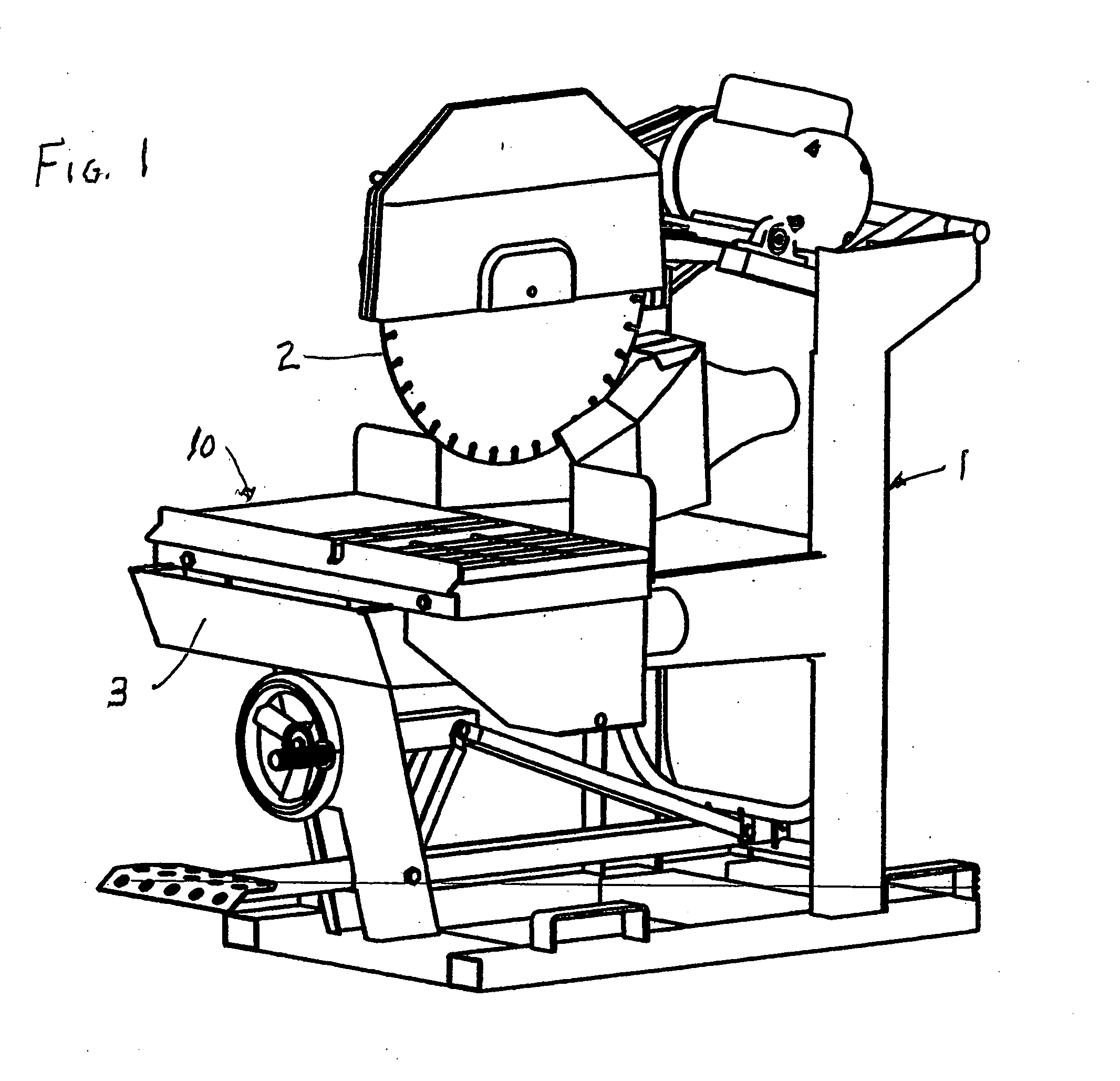

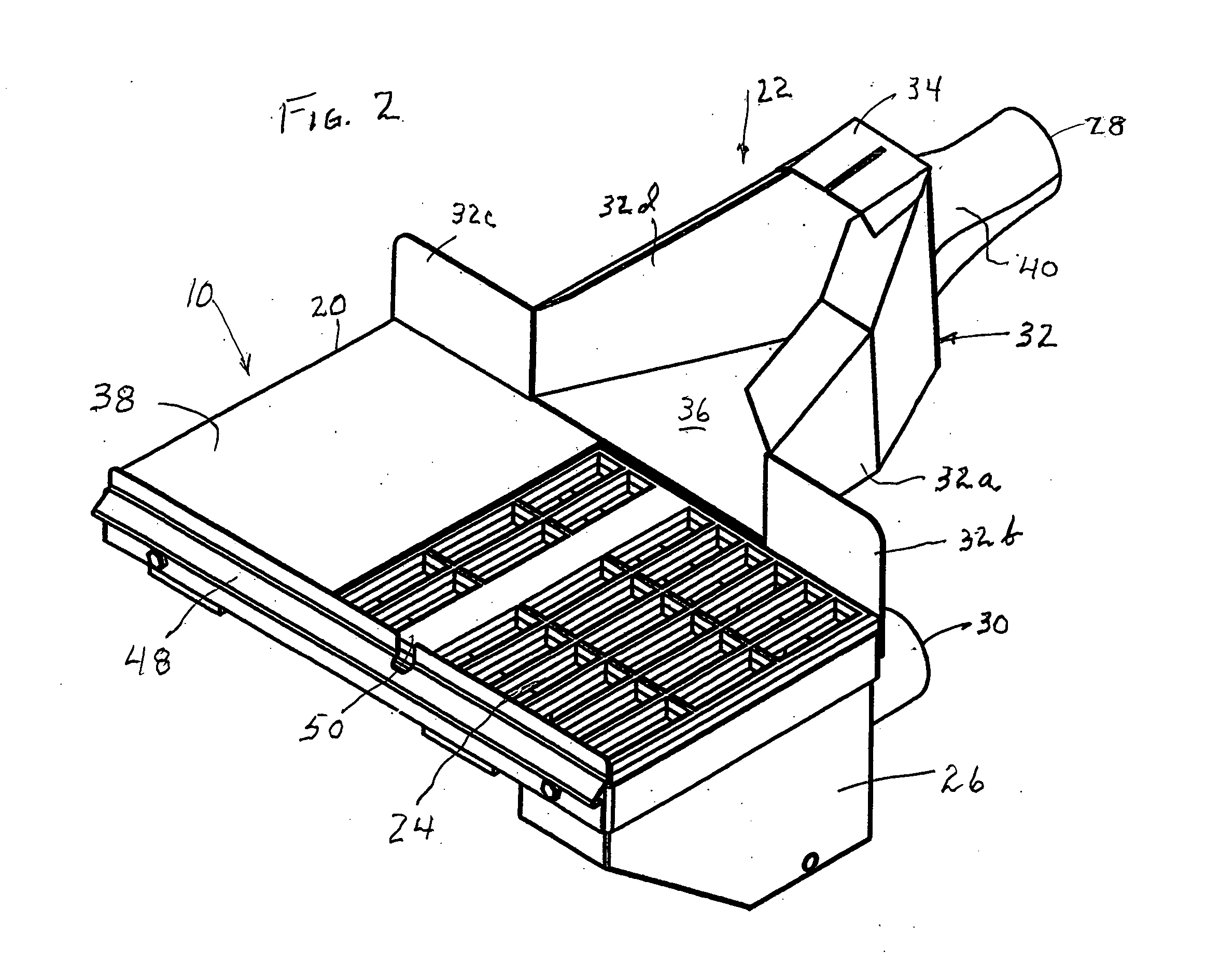

Dust collection system for a masonry saw

ActiveUS7013884B2Quantity minimizationIncrease the areaWorking accessoriesGrinding work supportsBrickCollection system

Dust and debris resulting from the sawing or cutting of concrete masonry units, blocks, bricks, tiles and other masonry products is collected via a three point dust and debris collection system. A movable work supporting table for cooperation with a masonry saw has a grated surface, a vacuum chamber below the grated surface acting as one collection point or area, a heavy debris collection chamber below and in communication with the table vacuum chamber acting as another collection point or area, and a shroud or hood assembly extending rearwardly from the table adapted to extend about the sides and rear of the saw blade and including a vacuum chamber acting as a primary collection point or area. The system is highly effective in achieving dust capture.

Owner:JPL GLOBAL

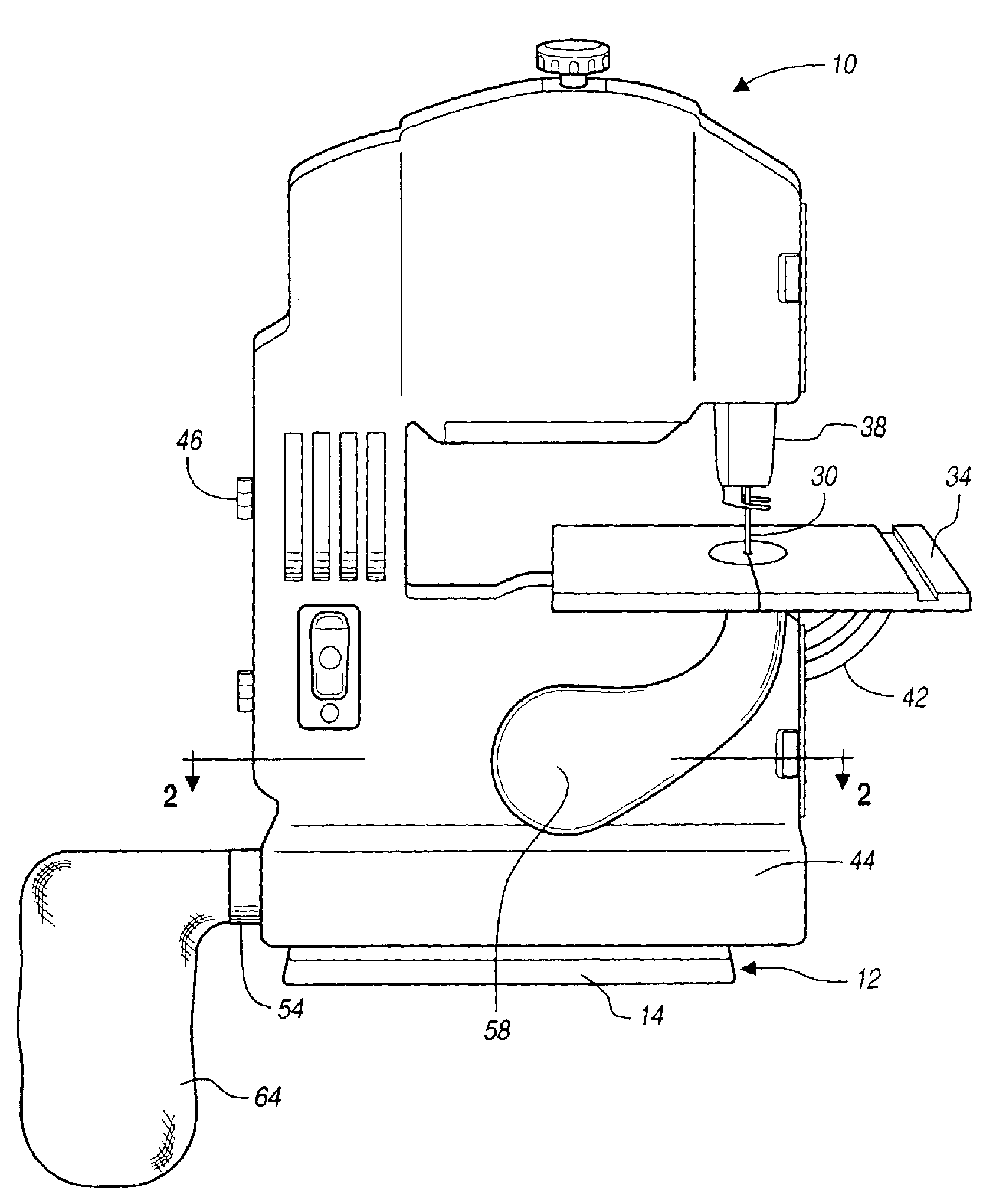

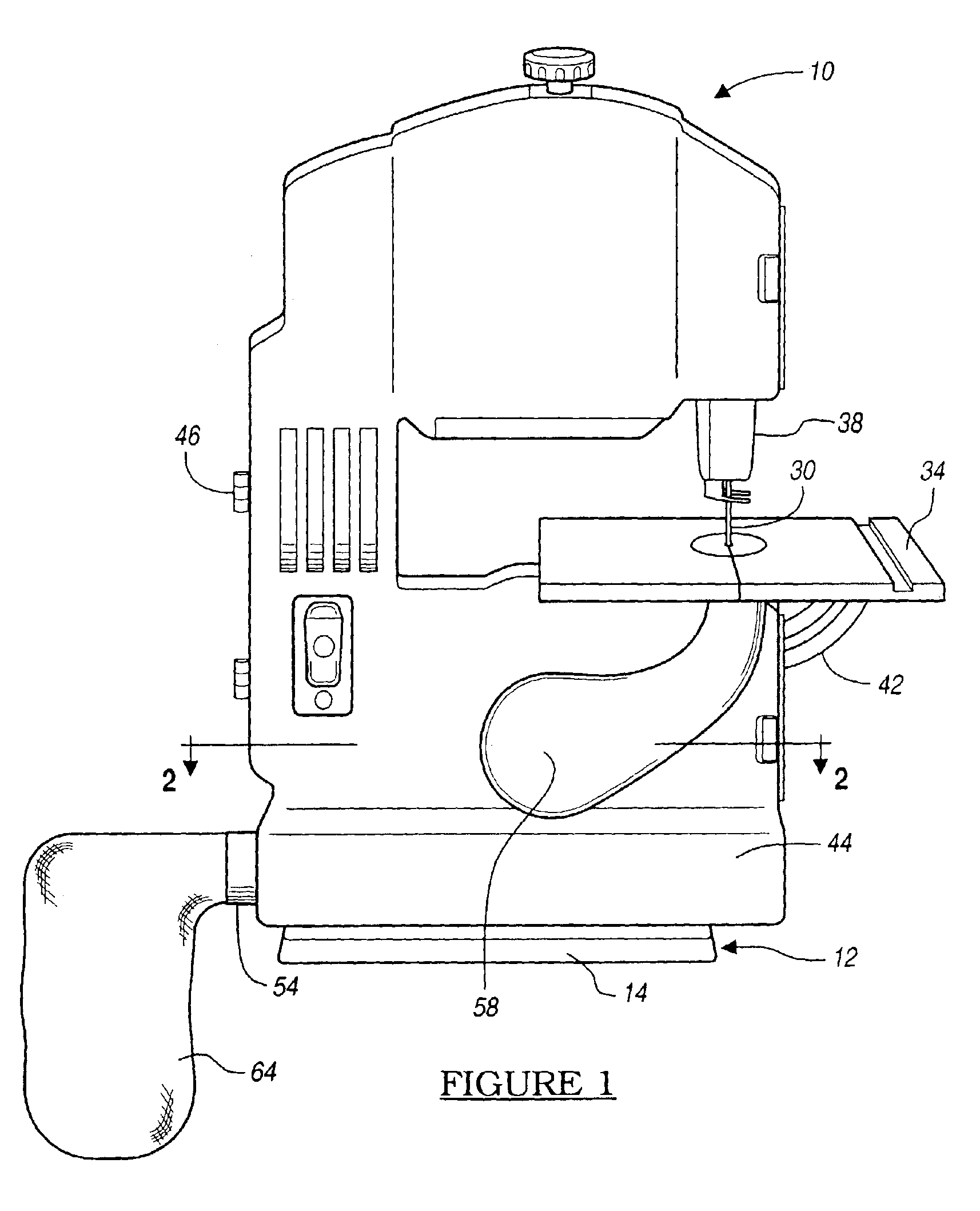

Motor driven wood working tool with vacuum feature

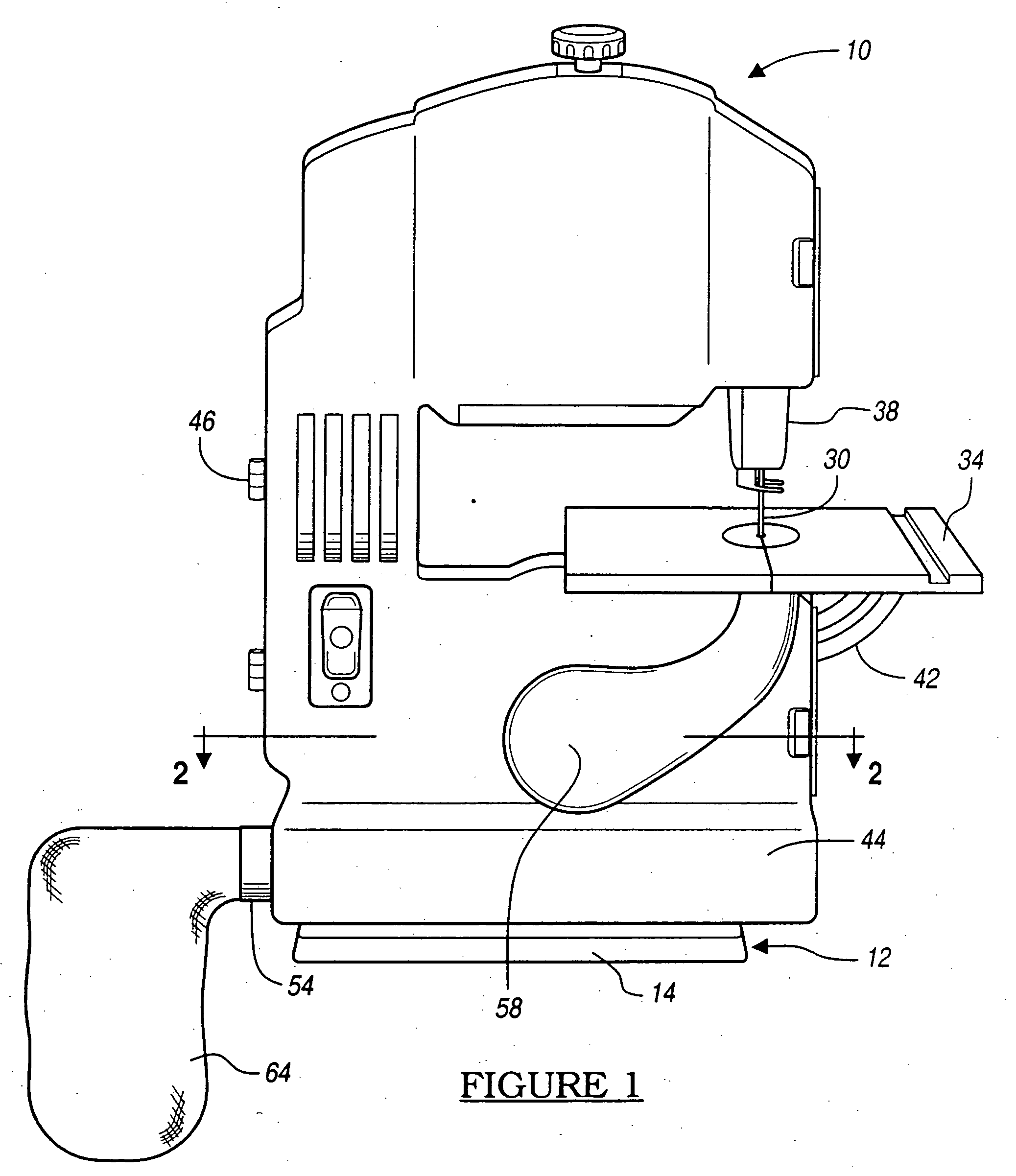

InactiveUS6948412B2Efficient collectionMetal sawing devicesMetal sawing accessoriesSanderMotor drive

A motor driven power tool is provided having an internal dust collection system. A single electric motor drives the working member such as a saw or sander and simultaneously drives an air pump which acts as a collector vacuum for debris created when the power tool is in use. A dust collector shroud surrounds a portion of the cutting member and forms an outlet connected to the air pump inlet.

Owner:ONE WORLD TECH

Portable cyclonic dust collection system

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

Dust collection system

InactiveUS20040187449A1Reduced Power RequirementsReduce the risk of explosionCombination devicesReversed direction vortexCycloneAir filter

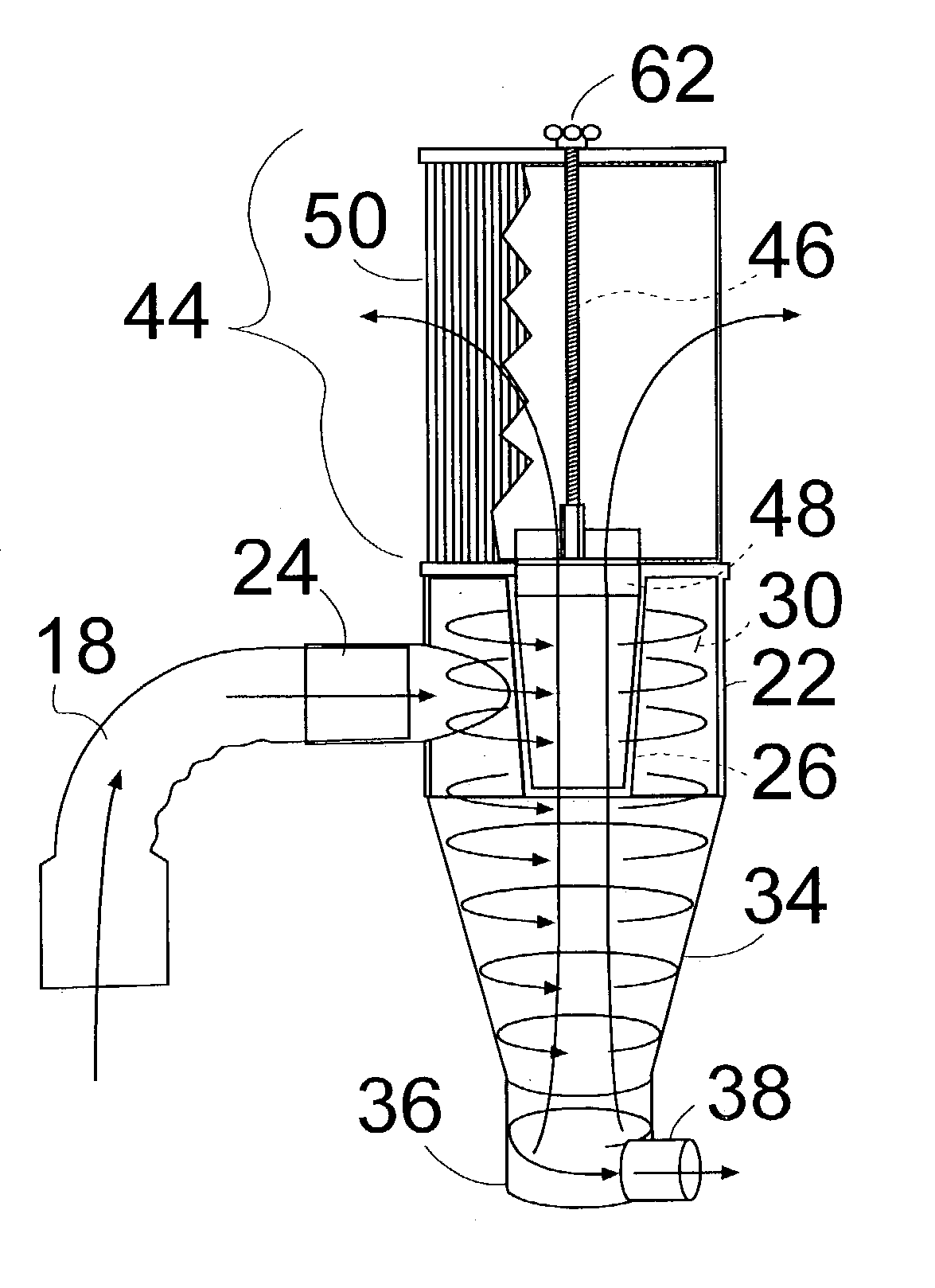

A dust collection system for portable sanding or grinding equipment employs a cyclone separator mounted directly on the tool or machine, with a dust outlet duct at the narrow lower end of the cyclone, and a cartridge air filter mounted on the top of the cyclone. The filter returns the air flow from the machine to the ambient air in the vicinity of the tool. The dust is concentrated in the cyclone, and a small volume air flow then moves the dust through an elongated flexible hose or duct to a remote dust collection station. An air pump at the remote dust collection station provides sufficient air flow to draw the small volume of air plus entrained dust from the tool-mounted cyclonic separator. A cyclonic separator at the remote station separates this dust from the air flow and deposits it in a collection tank or drum.

Owner:WITTER ROBERT M

Silencer for dust collection system

ActiveUS7247180B1Simple and straightforward in constructionImprove reliabilityCombination devicesAuxillary pretreatmentProcess noiseSander

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. A cyclonic separator is connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise. The acoustic foam can have a textured surface on the sound-facing side.

Owner:ONEIDA AIR SYST

Motor driven wood working tool with vacuum feature

InactiveUS20070044609A1Efficient collectionMetal sawing devicesMetal sawing accessoriesSanderMotor drive

A motor driven power tool is provided having an internal dust collection system. A single electric motor drives the working member such as a saw or sander and simultaneously drives an air pump which acts as a collector vacuum for debris created when the power tool is in use. A dust collector shroud surrounds a portion of the cutting member and forms an outlet connected to the air pump inlet.

Owner:BRAZELL KENNETH M +1

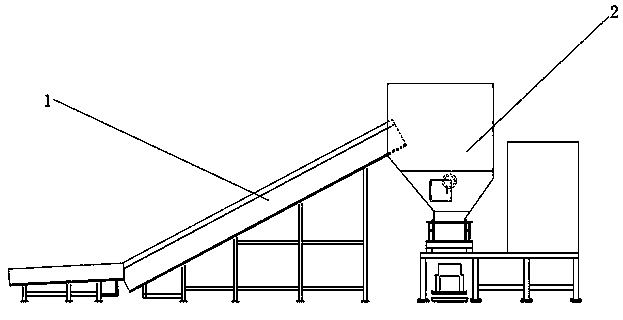

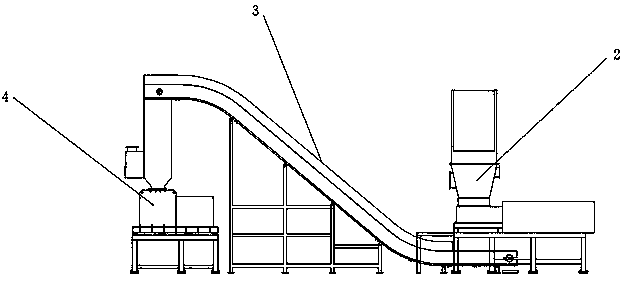

Conveyor with integrated dust collector system

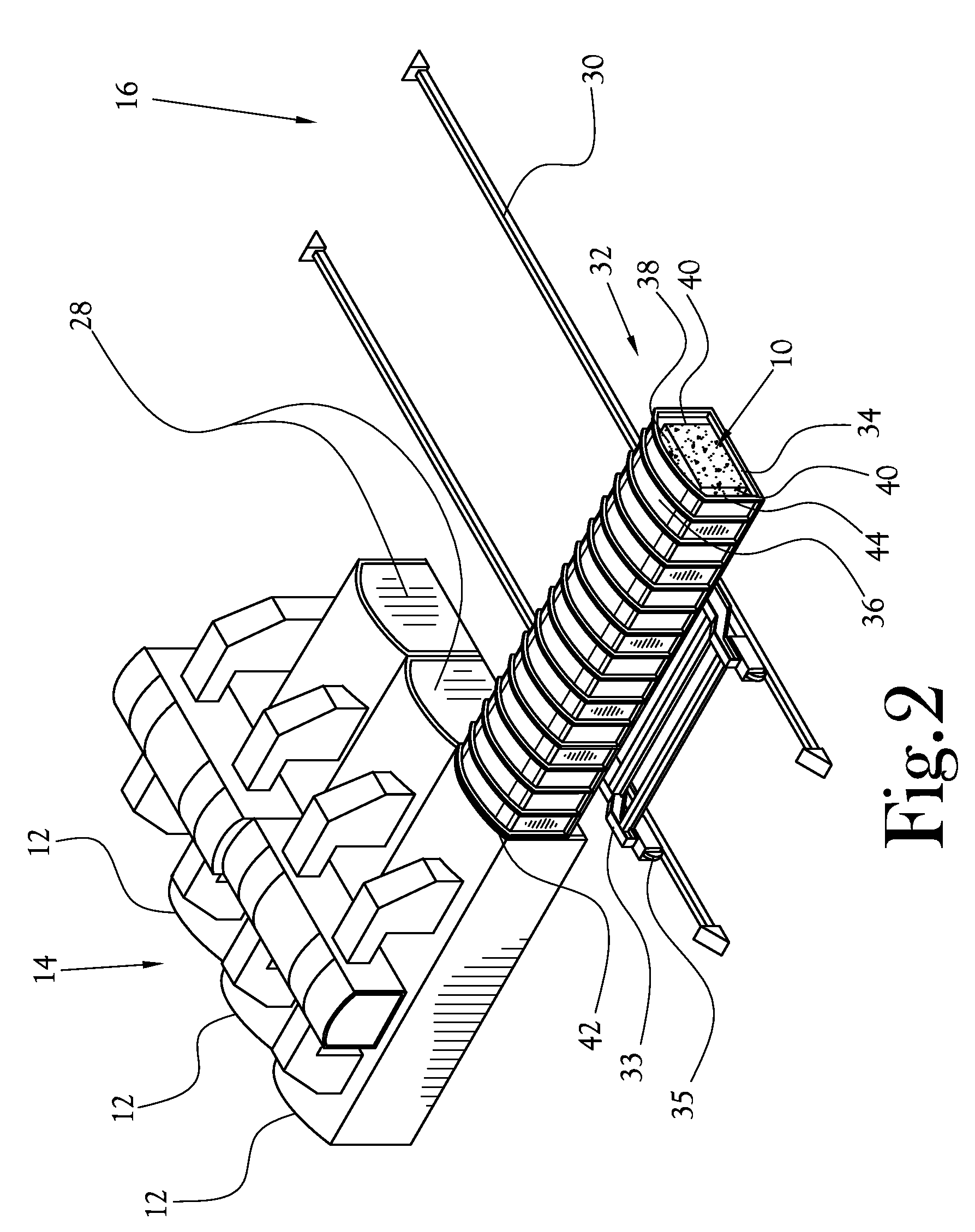

Embodiments of the present disclosure a system for capturing proppant dust particles when positioned at a fracking operation site including a proppant delivery assembly to receive one or more containers having proppant stored therein. The system dispenses the proppant from the one or more containers and delivers the proppant to other fracking operation equipment. Moreover, the system includes a dust collection assembly positioned proximate and associated with the proppant delivery assembly to capture dust particles released by movement and settling of the proppant when being dispensed and delivered by the proppant delivery assembly. The dust collection assembly is positioned to direct an air flow in a flow path overlying the dust particles to capture the dust particles and move the dust particles away from the proppant thereby reducing risk of dust exposure to fracking operation site personnel.

Owner:SANDBOX ENTERPRISES LLC

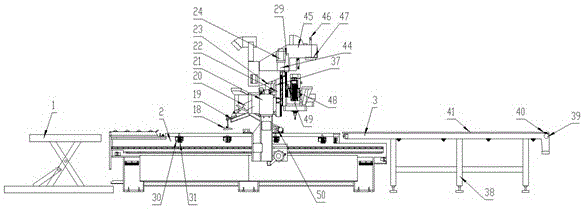

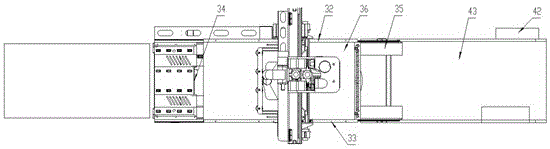

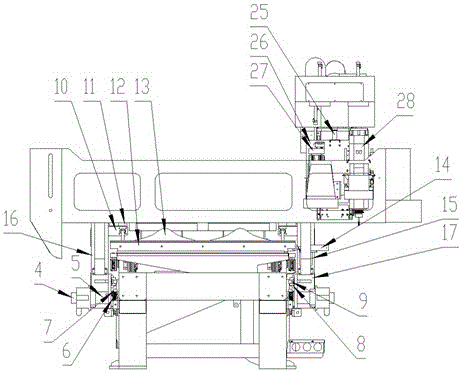

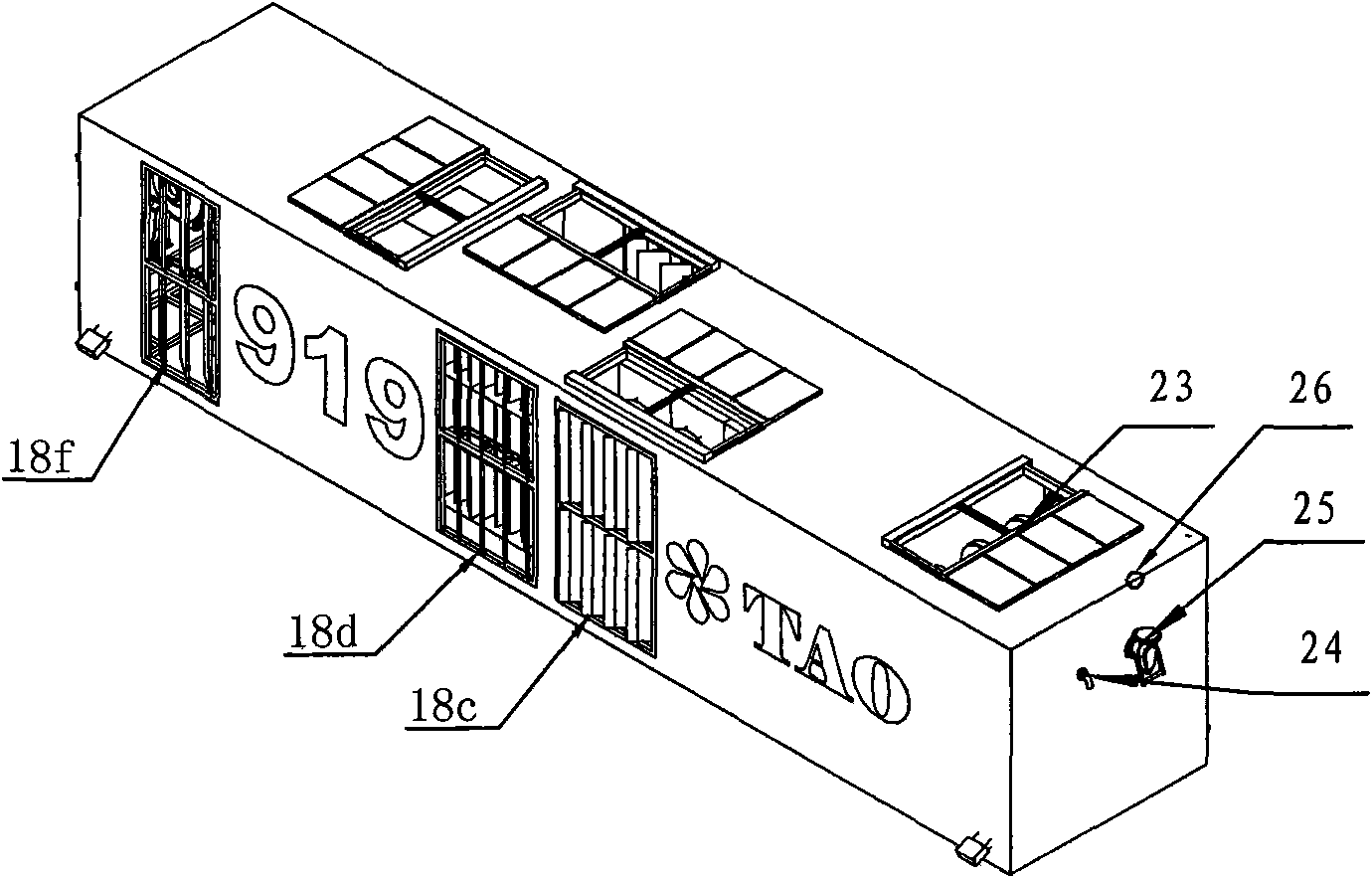

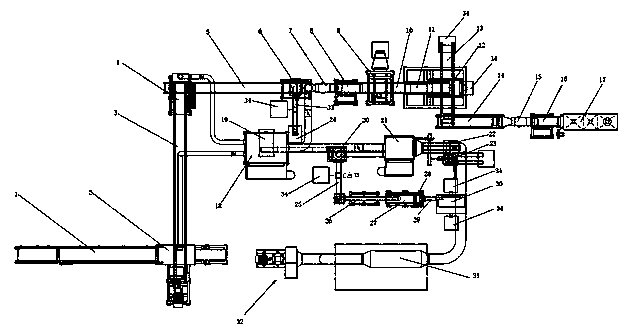

Plate type production line capable of automatically charging and discharging

InactiveCN105058142AHigh positioning accuracyIncrease profitMetal working apparatusMaintainance and safety accessoriesElectricityProduction line

The invention discloses a plate type production line capable of automatically charging and discharging. The plate type production line comprises a charging platform, a machine body and a discharging platform; the charging platform comprises a lifting platform which is arranged on a base, a shear shank is arranged at the lower part of the lifting platform, and one end of a hydraulic cylinder is connected to the base; the discharging platform consists of a motor, a reduction box, a belt, a stopping bakelite plate, a section frame, an optoelectronic switch and a rolling shaft; the machine body consists of a bed body assembly, a gantry assembly, a charging assembly, a rear locator, a lateral locating system, an X sliding plate assembly, a Z shaft assembly, a dust collection system and a pushing system. The plate type production line provided by the invention has the beneficial effects that manual labor can be reduced greatly, the plate locating precision is higher, the use ratio of plates can be improved, and the production cost can be reduced; furthermore, plates can be pushed to the discharging platform timely after the completion of plate processing, so that time that plates occupy the machine main body, after the completion of processing, can be reduced, and the production efficiency can be greatly improved.

Owner:JINAN SINGHUI CNC TECH

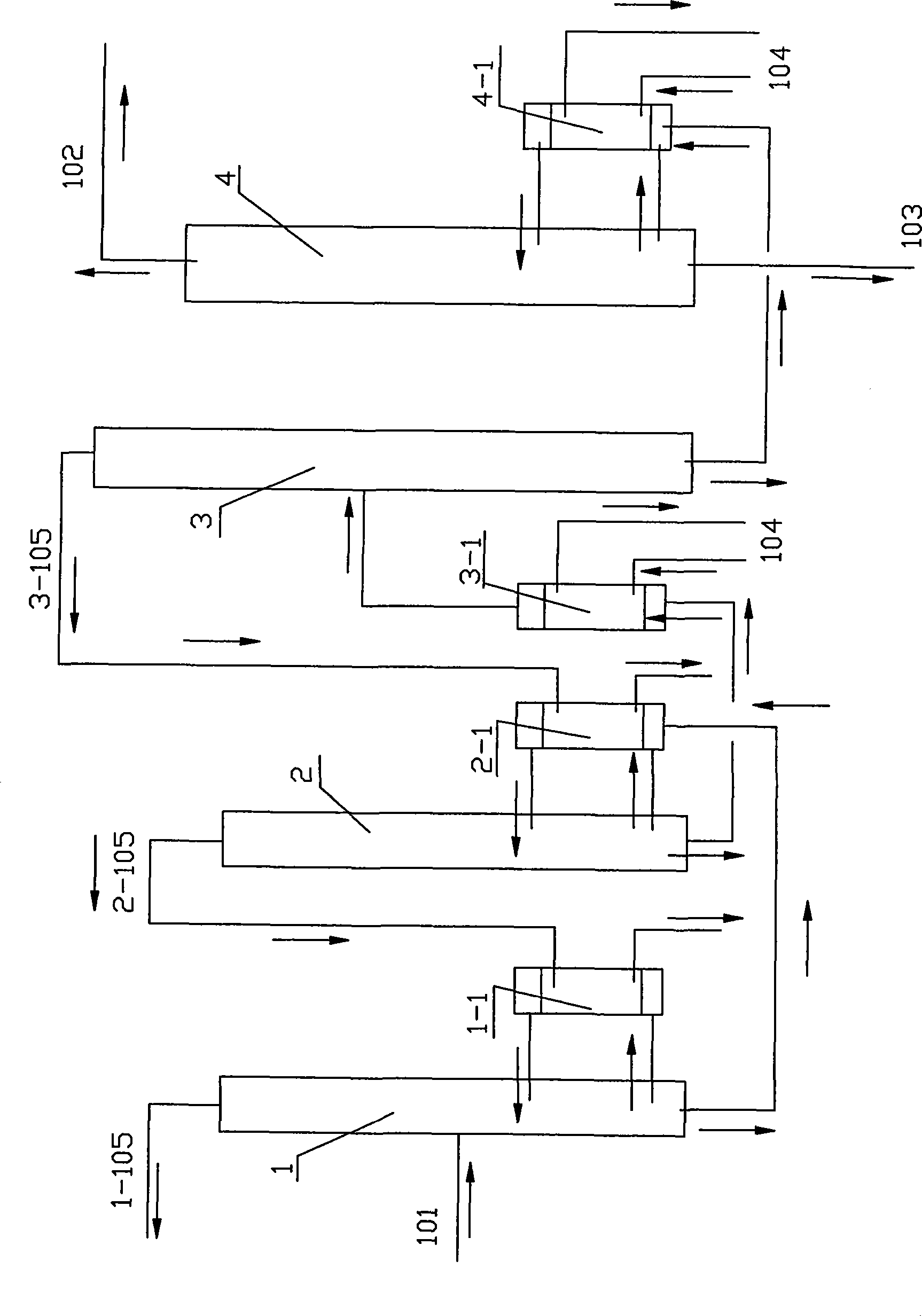

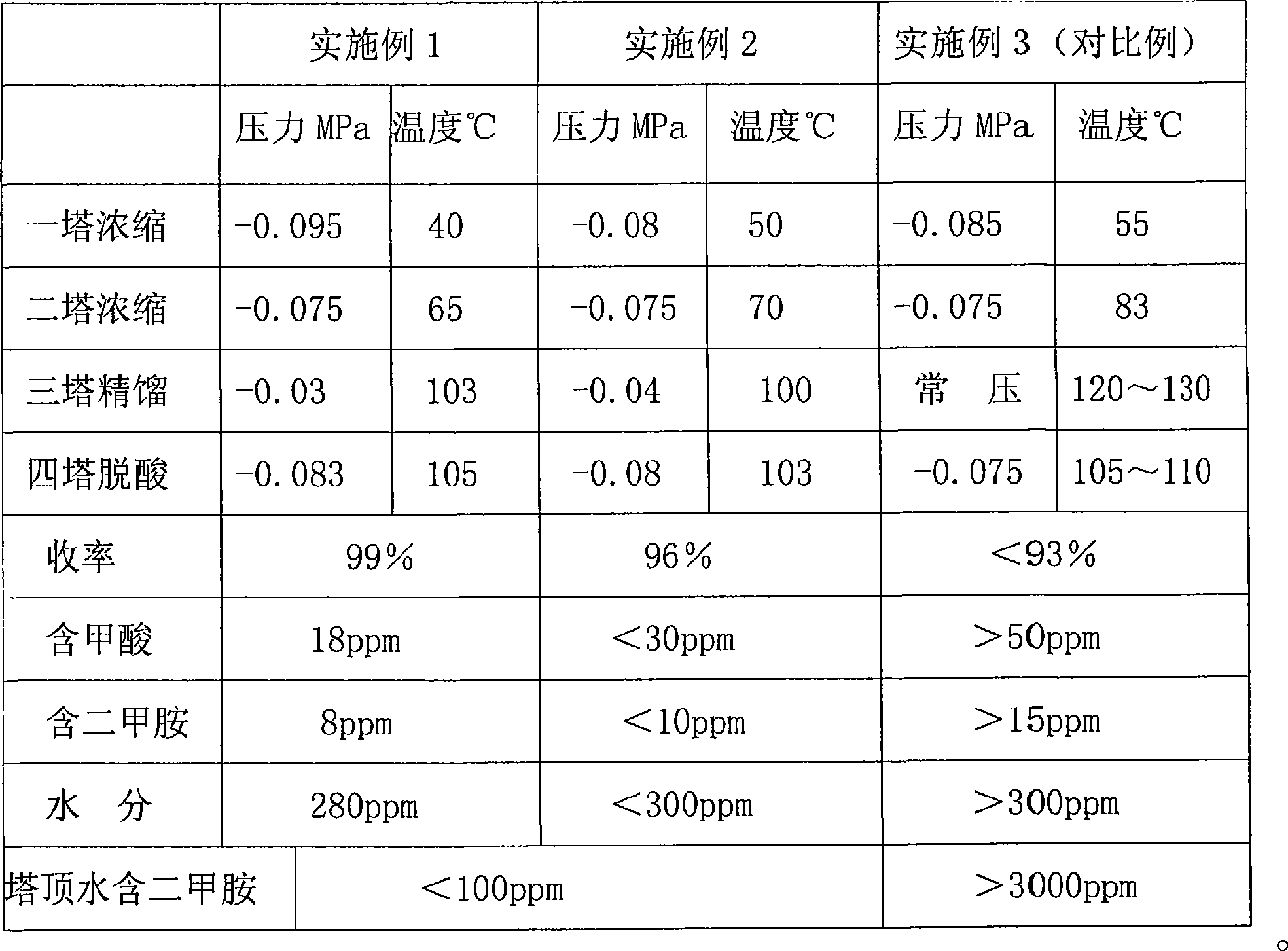

Method for recovering dimethyl formamide

ActiveCN101519362AReduce decomposition rateReduce return steam rateCarboxylic acid amide separation/purificationMultistage water/sewage treatmentDecompositionWastewater

A method for recycling dimethyl formamide relates to a method for recovering dimethyl formamide from waste water by an all-subpressure operation method. The method includes the steps of utilizing conduction oil or low-pressure steam as a heat source, sequentially leading the waste water containing DMF to four subpressure operation towers, and performing subpressure concentration in the first tower and the second tower, subpressure fractionating in the third tower and deacidification in the fourth tower, thereby obtaining finished DMF and methanoic acid. Due to the great decrease of stable operating temperature, the recovery rate of the DMF can reach over 99 percent, and the rate of purity reaches 99.99 percent; the resolution ratio of the DMF and the back evaporation rate of the peracid DMF are obviously reduced, a methanoic acid decomposition tower is cancelled, almost no DMF contains peracid, repeated rectification is not needed, and energy sources are saved by over 10 percent; and meanwhile, the dimethylamine quantity generated by decomposition is little and is completely absorbed by a boiler screen dust collection system without emission.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

Radial arm saw safety top

InactiveUS20060042439A1Overcome disadvantagesOvercomes shortcomingMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A radial arm saw is adapted with a safety top configured with cutting box enclosure that contains and collects substantially all of the sawdust generated during use. A dust collection system is in fluid communication with the cutting box for removing the sawdust contained therein. Spring biased push blocks function to hold the work piece in place during the sawing process while maintaining the user's hands safely away from the saw blade. A laser alignment device projects a beam within the cutting box along the cutting plane. A control panel is provided to allow use by authorized users upon entry of an authorization code.

Owner:POWELL MICHAEL S

Energy saving vacuum system for particle, mist, and fume collection

ActiveUS7146677B2Cost effectiveEnergy efficiencyMetal sawing accessoriesLighting and heating apparatusMachine shopCollection system

An improved energy-efficient vacuum system for machine shop dust, particulate matter, and the like. Blast gates, including large-diameter blast gates, control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch, an increased current feedback system, a biasing-spring assembly or otherwise to limit the rotation driving of the rotating blade. In one embodiment, the blast gate blade bears teeth about its perimeter. The DC motor engages the perimeter blade teeth with a gear. Greater mechanical advantage is achieved over the blast gate blade and less torque arises in contrast to a driving system located at the blade's central pivot point. Additionally, sensing apparatus or system calculation allow the dust collecting vacuum system to operate in an energy-efficient manner. By supplying only the vacuum needed to collect present dust, energy is saved in comparison with a dust collection system operating continuously at full capacity.

Owner:LITOMISKY IVAN +2

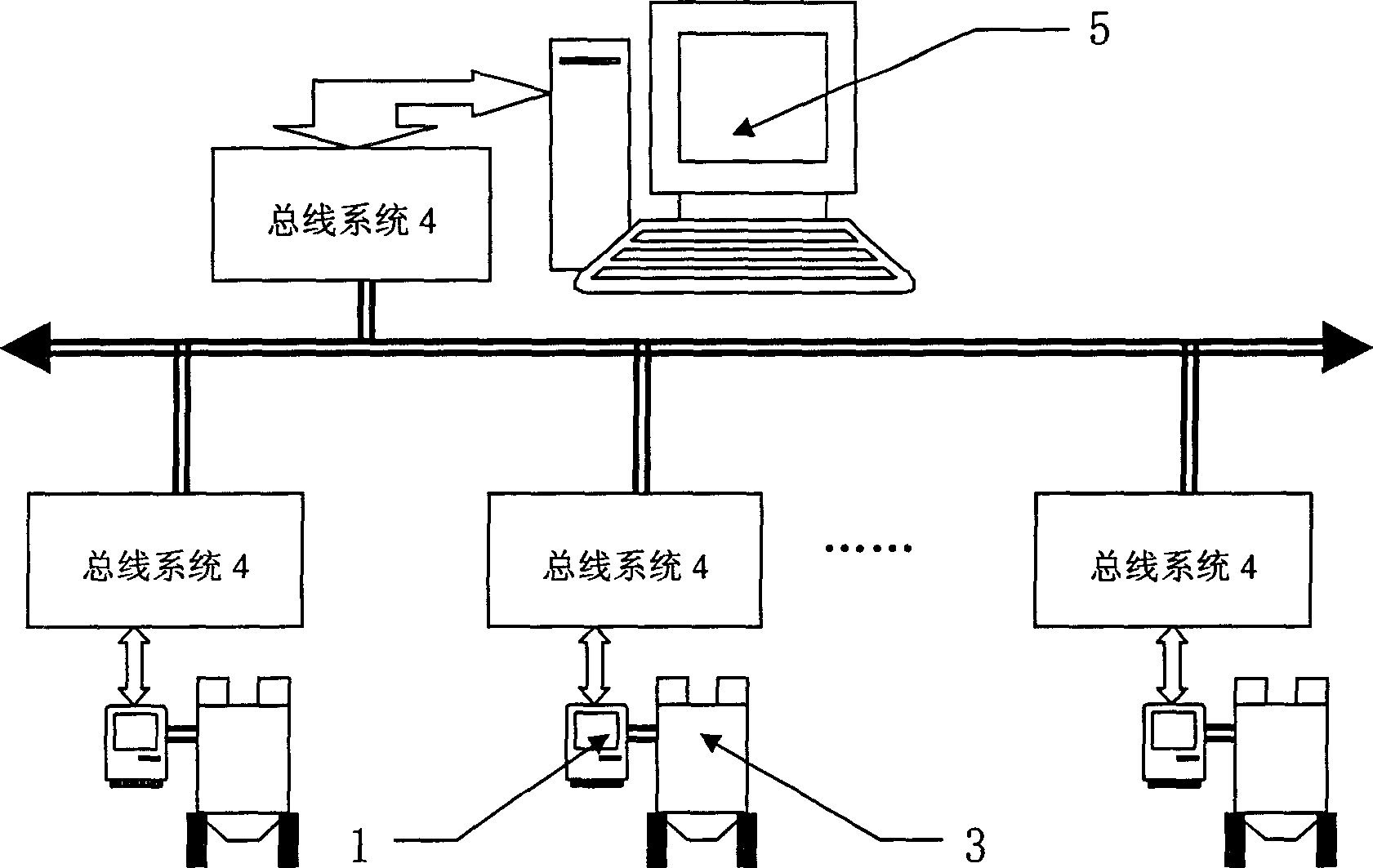

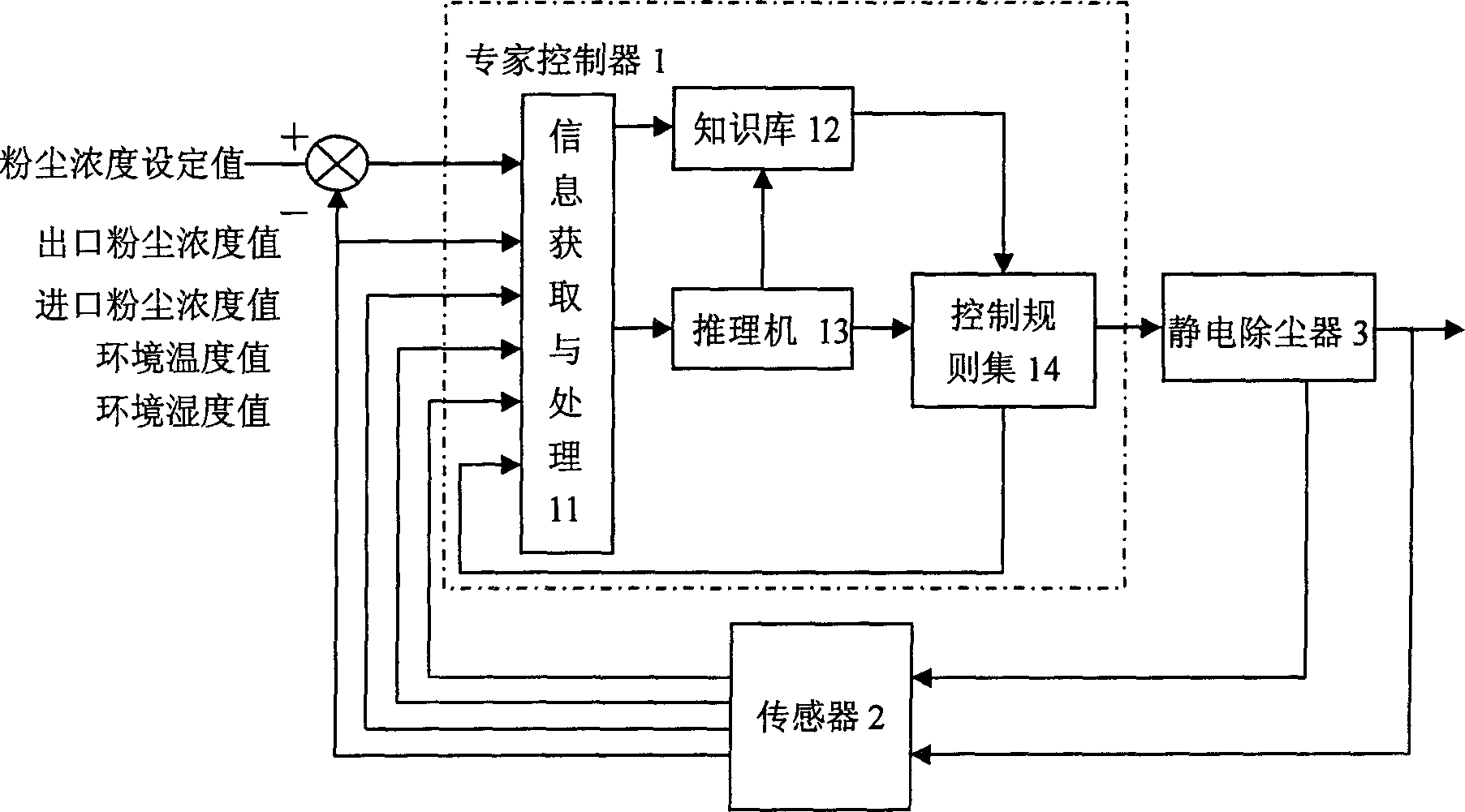

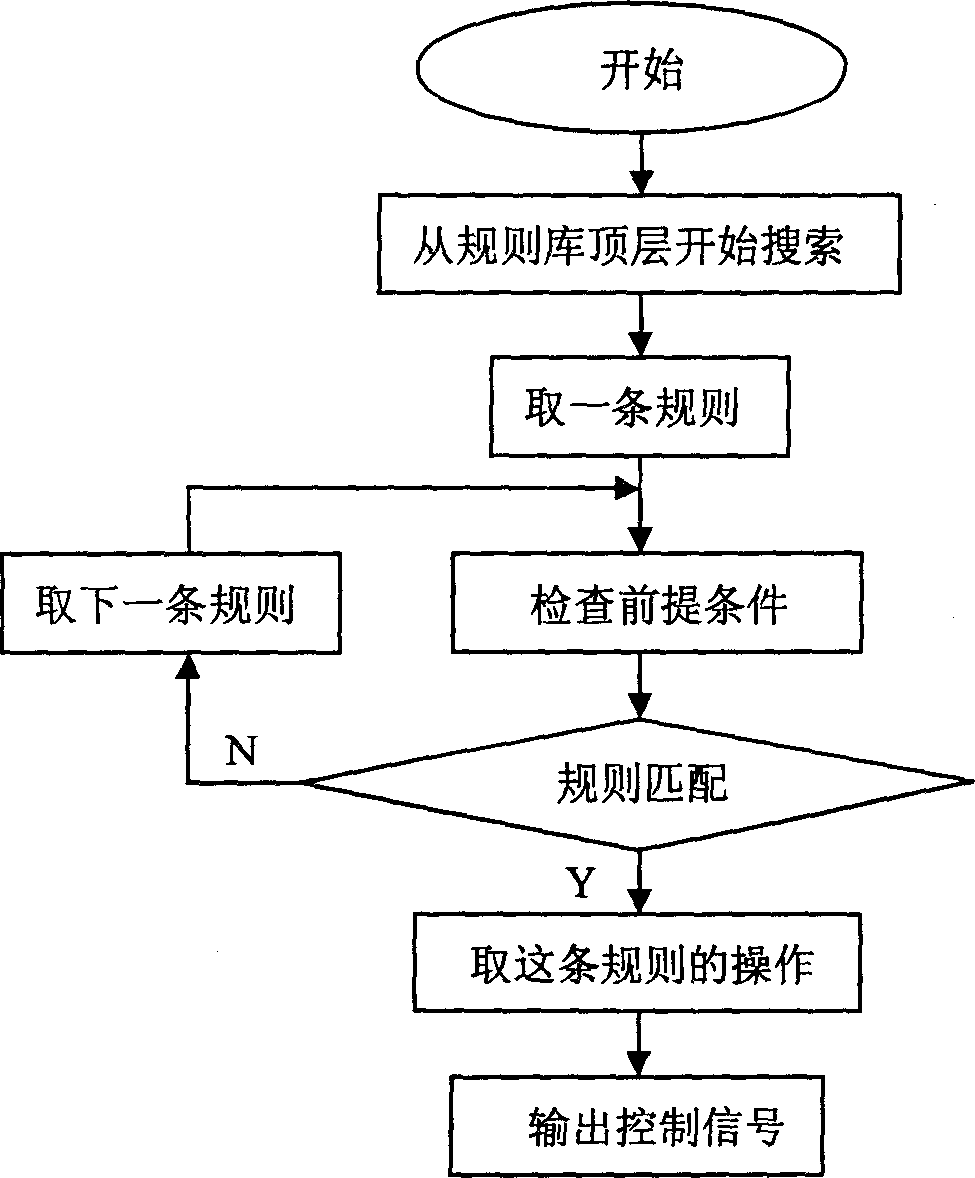

Static dust collection system

InactiveCN1843632ASolve concentrationIncrease the level of automationElectric supply techniquesControl signalControl system

Owner:WUYI UNIV

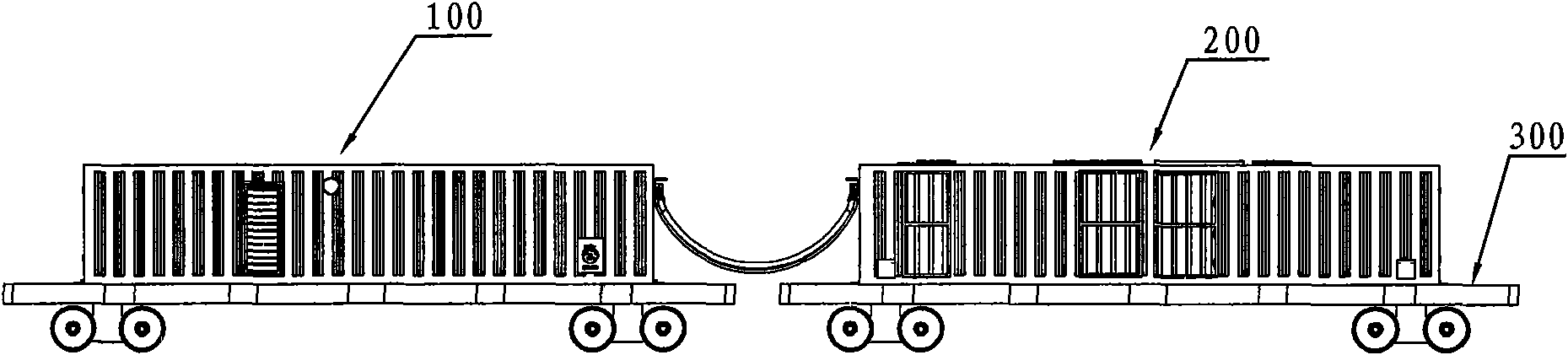

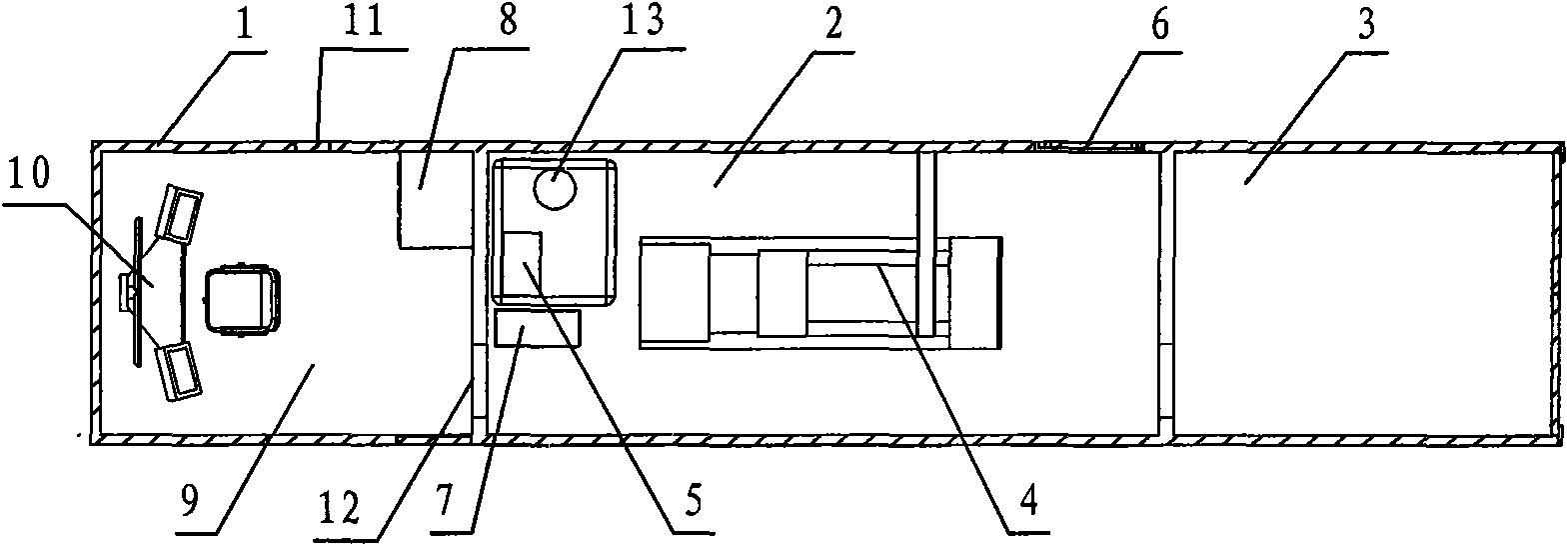

Large tunnel dust removal plant and dust removal method thereof

ActiveCN101581228AImprove efficiencyEasy to transportDust removalFire preventionModular designElectric control

The invention discloses a large tunnel dust removal plant and a dust removal method thereof. The dust removal plant comprises a dust removal electric control group and a dust removal operation group; wherein, the dust removal electric control group comprises an equipped distribution and control chamber and an equipped electric power chamber; the dust removal operation group comprises a 1# operation room, a 2# operation room, a 3# operation room and a 4# operation room. The method of the invention comprises the following steps: an operation car adopts a high-pressure dust blower to blow dust toward the bottom surface and the sides; dust collection ports are respectively arranged in the upper, lower, left and right directions, so as to form spatially closed dust collection; the direction of air flow is adjusted by opening a pneumatically reversible air door; the dust collection ports are combined with air outlets so as to form an air curtain to block leakage of dust, after the dust is filtered, clean air is exhausted through a dust collection blower, thus completing dust removal operation. The air doors can be combined in different directions to complete forward or backward dust removal operation. The invention adopts modular design, is convenient for transport, has the advantages of high efficiency, low cleaning cost, good use effect, safety, reliability and the like, and is suitable for tunnel dust removal of railways and highways.

Owner:北京京铁世安机械安全技术研究所

Dust collection system for a masonry saw

ActiveUS20050205075A1Quantity minimizationIncrease the areaWorking accessoriesGrinding work supportsBrickCollection system

Dust and debris resulting from the sawing or cutting of concrete masonry units, blocks, bricks, tiles and other masonry products is collected via a three point dust and debris collection system. A movable work supporting table for cooperation with a masonry saw has a grated surface, a vacuum chamber below the grated surface acting as one collection point or area, a heavy debris collection chamber below and in communication with the table vacuum chamber acting as another collection point or area, and a shroud or hood assembly extending rearwardly from the table adapted to extend about the sides and rear of the saw blade and including a vacuum chamber acting as a primary collection point or area. The system is highly effective in achieving dust capture.

Owner:JPL GLOBAL

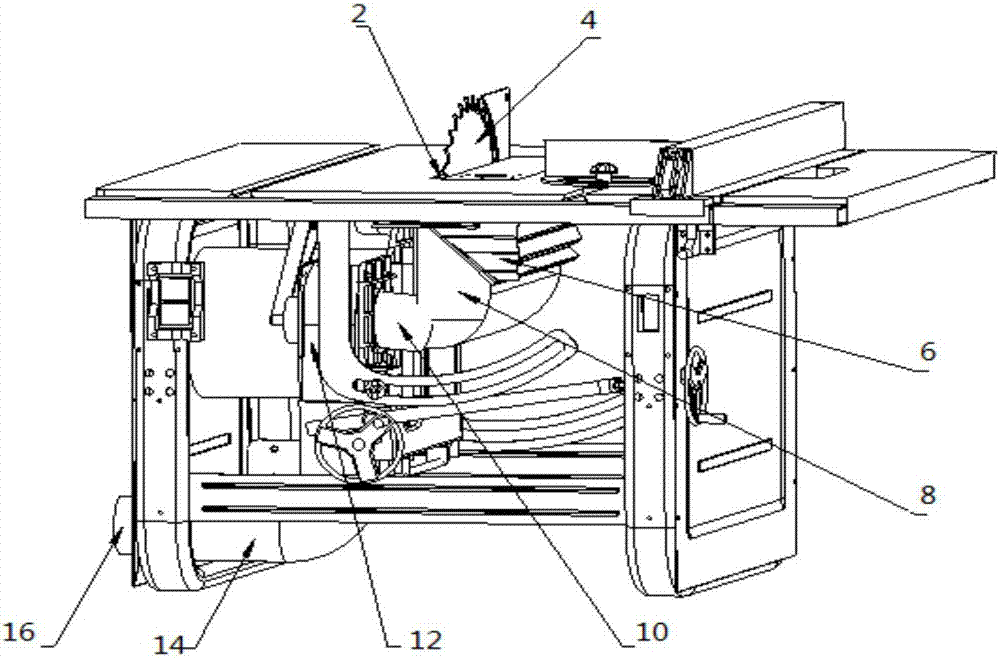

Dustless Table Saw

ActiveCN107150378AMetal sawing devicesMetal sawing accessoriesMechanical engineeringDust collection system

A dustless table saw with a built-in dust collection system is disclosed. The table saw uses a soft foldable seal to seal the gap between the blade slot and the blade housing, the blade housing has an internal extraction channel to maximize the dust collection. Another variation of the table saw utilizes a U-shaped blade housing with a divider. The table saw has a built-in raising / lowering mechanism to raise / lower the blade, and a built-in tilting mechanism to tile the blade. The table saw also utilizes an anti-dust blade guard to optimize the dust extraction.

Owner:SIROCCO DUSTLESS LLC

Recycling system for waste electrical and electronic products

InactiveCN103722003AReduce vacancy rateImprove efficiencySolid waste disposalGrain treatmentsProduction lineCollection system

The invention discloses a recycling system for waste electrical and electronic products. The recycling system is characterized by comprising a control system as well as a crushing system, a separation system, a dust collection system, a waste gas collection system and a draught fan which are controlled by the control system, wherein the crushing system comprises a knocking crusher, the separation system comprises a winnower and a plastic and metal separation device, and the knocking crusher, the winnower and the plastic and metal separation device are connected through conveyer devices sequentially to form a plastic and metal separation production line; the knocking crusher and an air outlet of the winnower are connected with the dust collection system respectively for collecting light materials and dust of the whole recycling system; an air outlet of the dust collecting system is connected with the waste gas collection system; and the draught fan is connected with the waste gas collection system, so that the knocking crusher, the winnower, the dust collection system and the waste gas collection system are in negative pressure states. The system can be applied to crushing and separation treatment of various waste electrical appliances such as a refrigerator, a circuit board and the like respectively.

Owner:CHINA NAT ELECTRIC APP RES INST +1

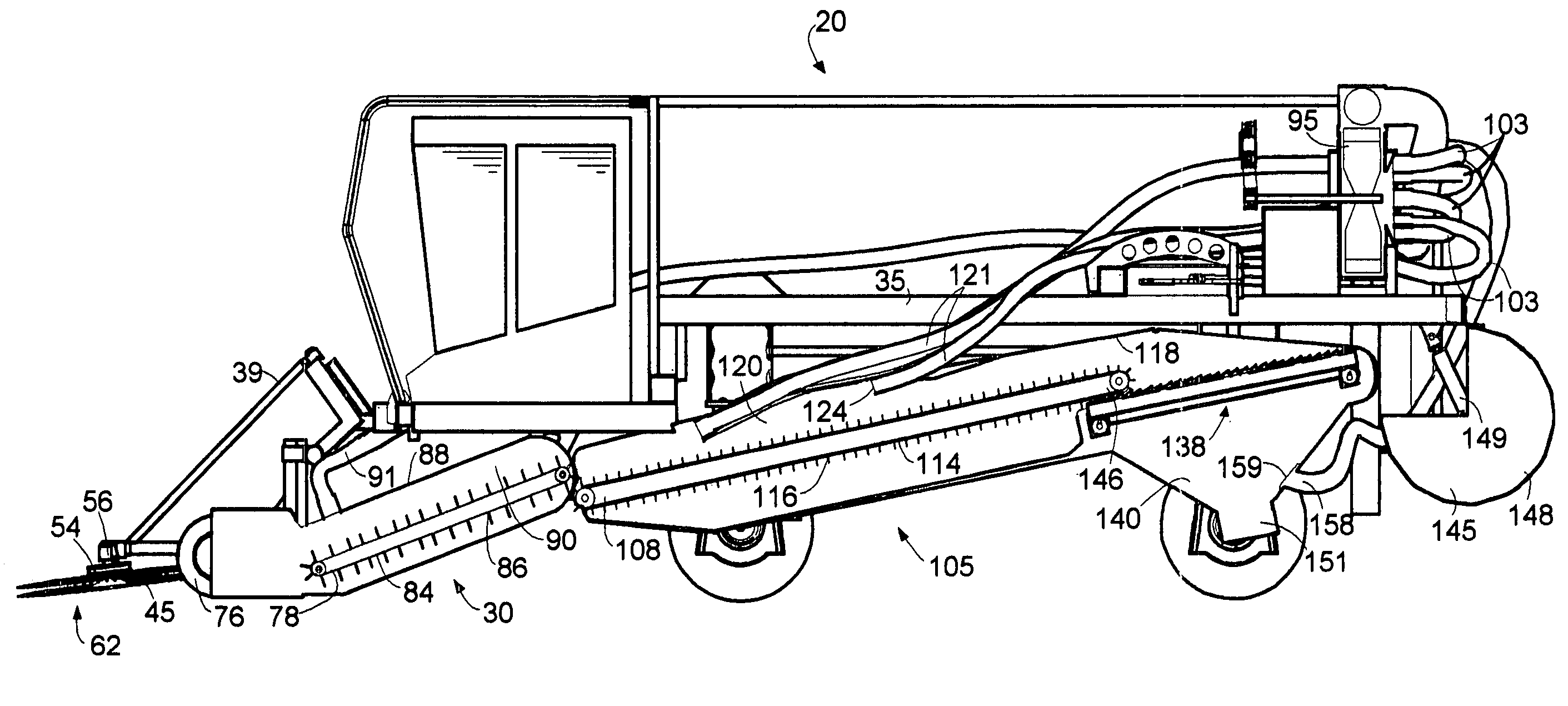

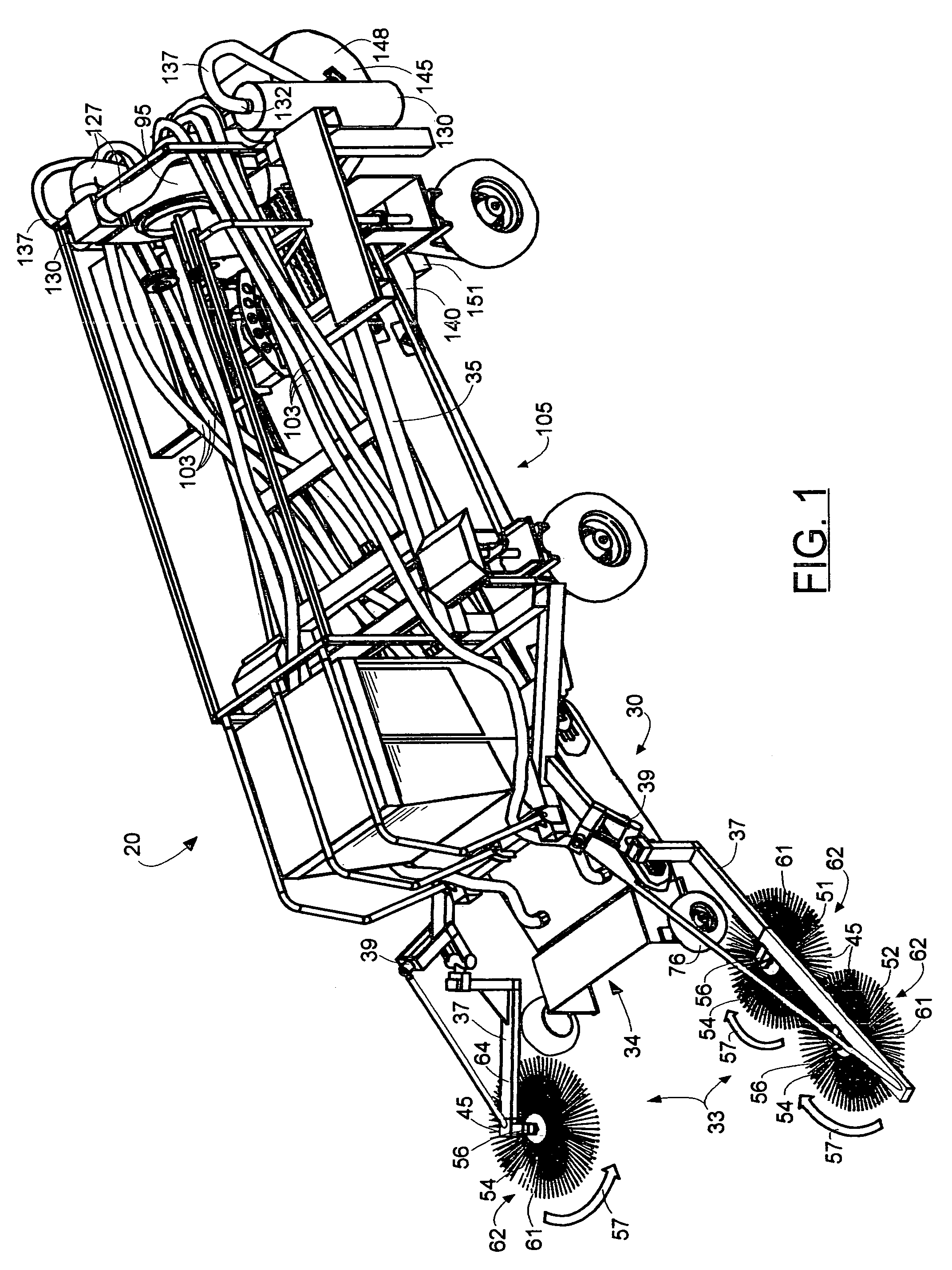

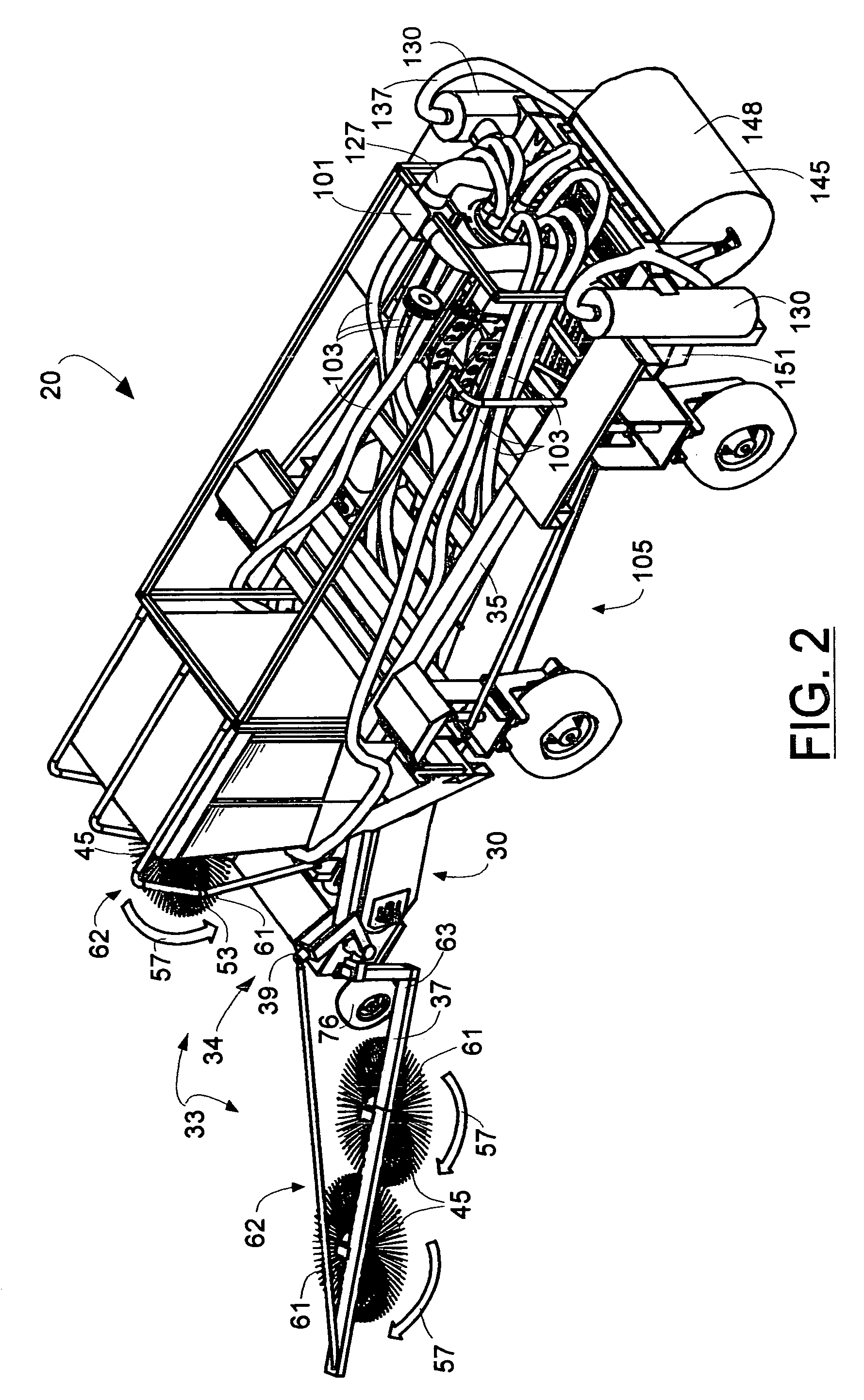

Method for retrieving and processing bulk harvested nuts and fruits

An apparatus for processing nuts and fruits, and more specifically, to a mobile apparatus that picks-up fruits and nuts, and similar products from the ground and conditions them, in bulk. The mobile apparatus conditions the fruits and nuts by removing debris with a combination of a belted conveyor and a high volume fan. The plenum of the apparatus is sized to achieve a constant velocity of air throughout the portions of the plenum in contact with the product, providing a constant suction to prevent the entrainment of product into the dust collection system. The processing apparatus can be utilized in a conditioner that picks-up and processes the product and then returns the cleaned and conditioned product to the floor of the orchard or grove. The processing apparatus can also be utilized in a harvester that picks-up and processes the product and then stores the product temporarily in a bin.

Owner:FLORA JONATHAN J +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com