Patents

Literature

78results about How to "Increase spray pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine

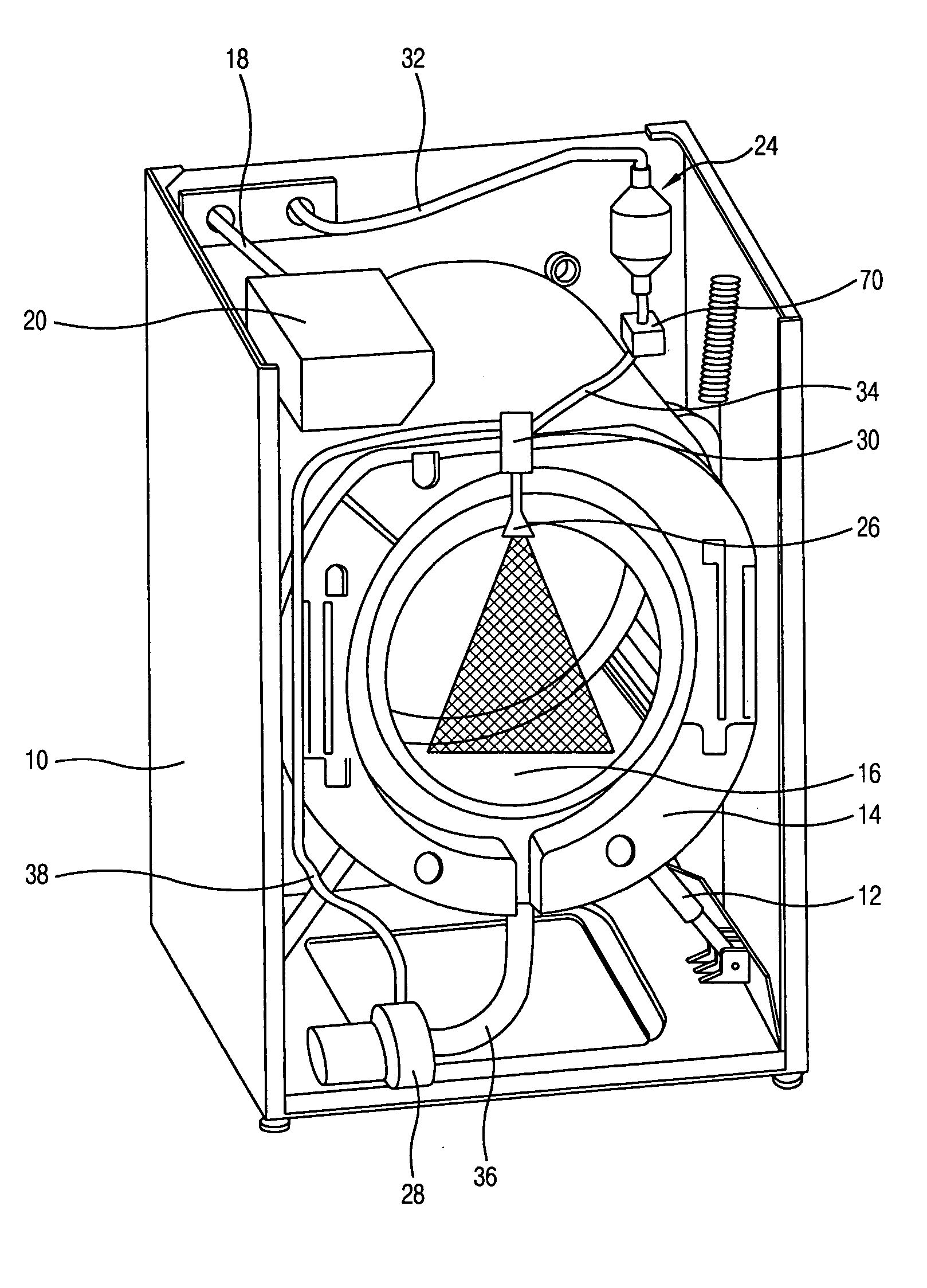

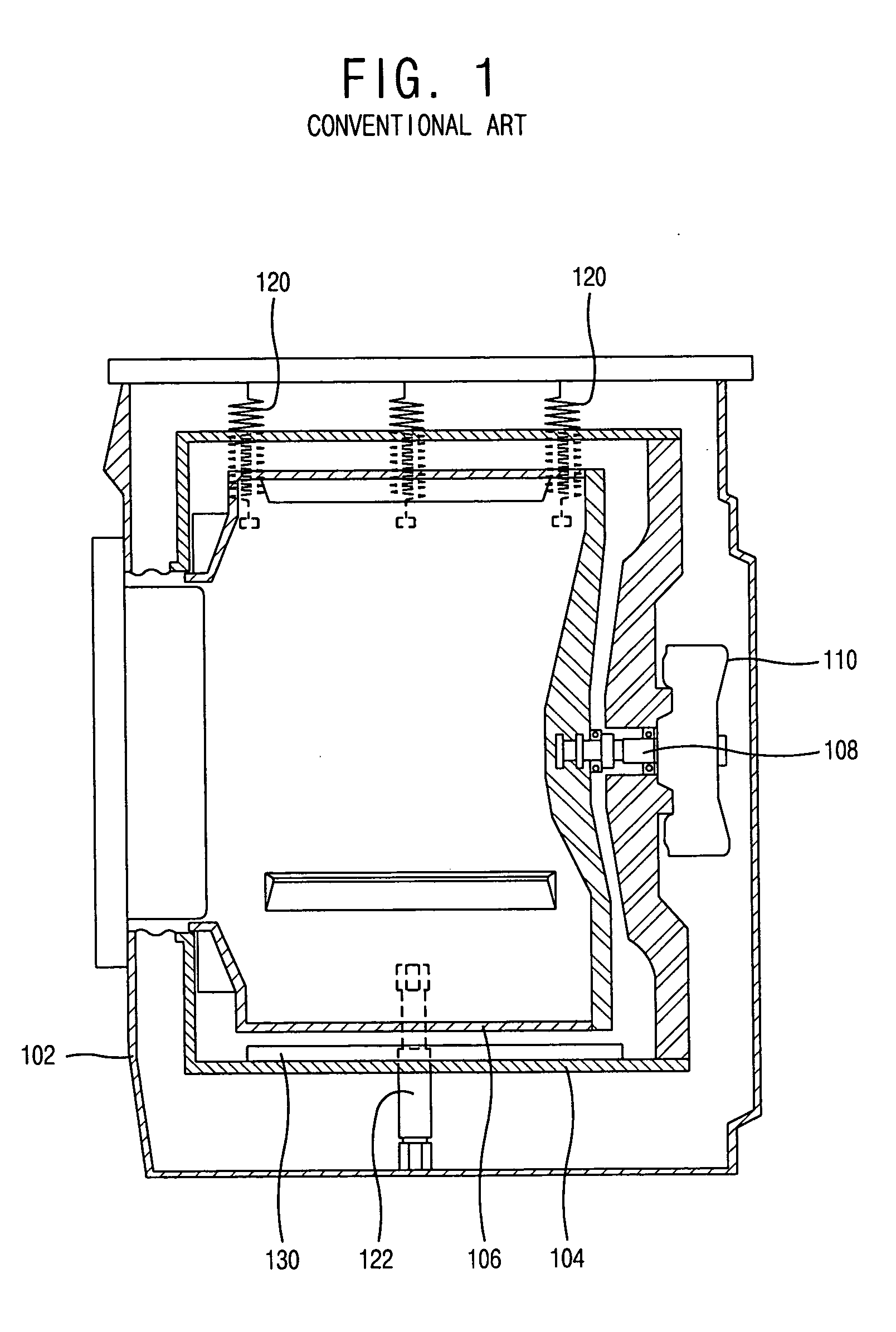

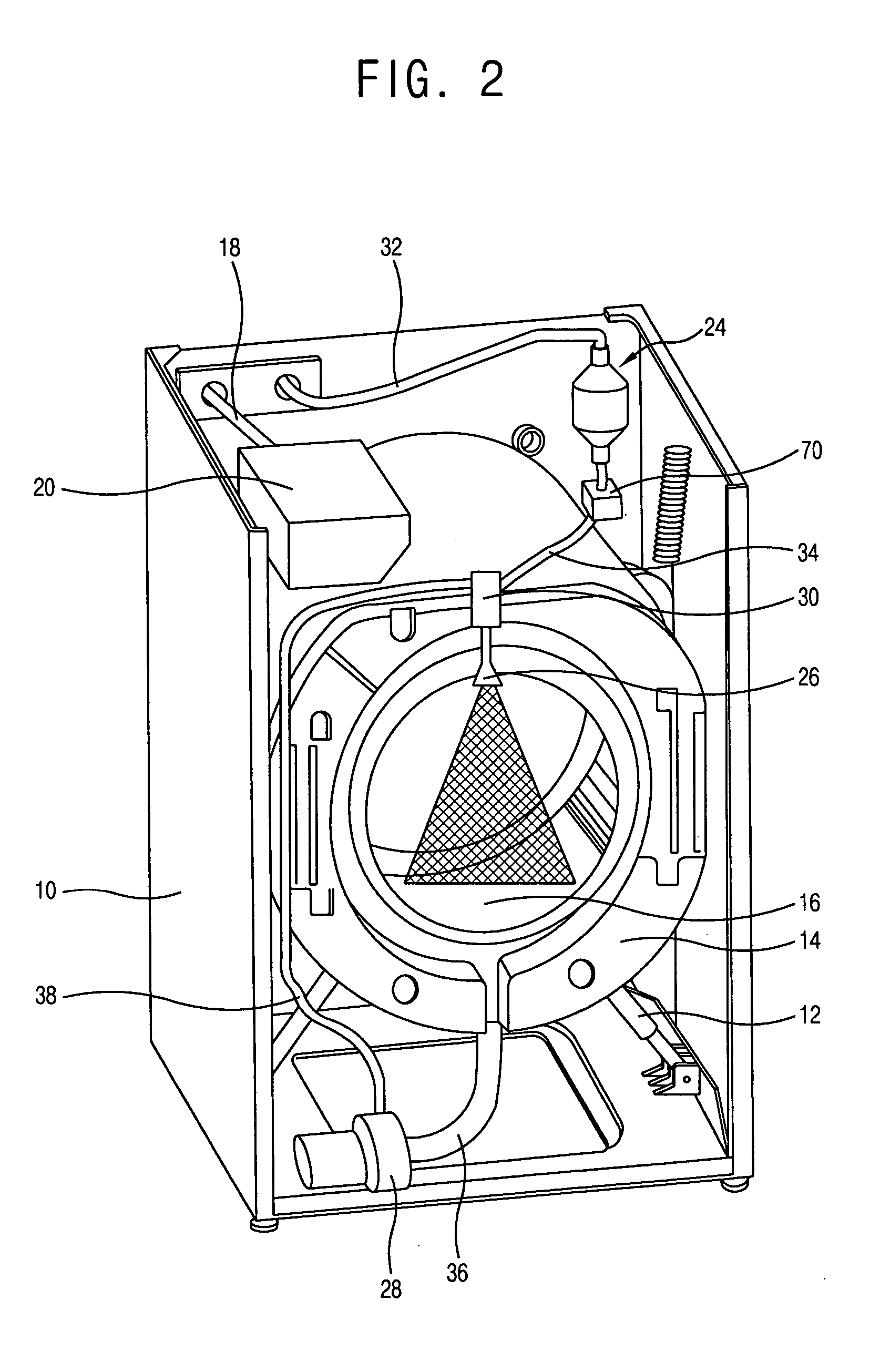

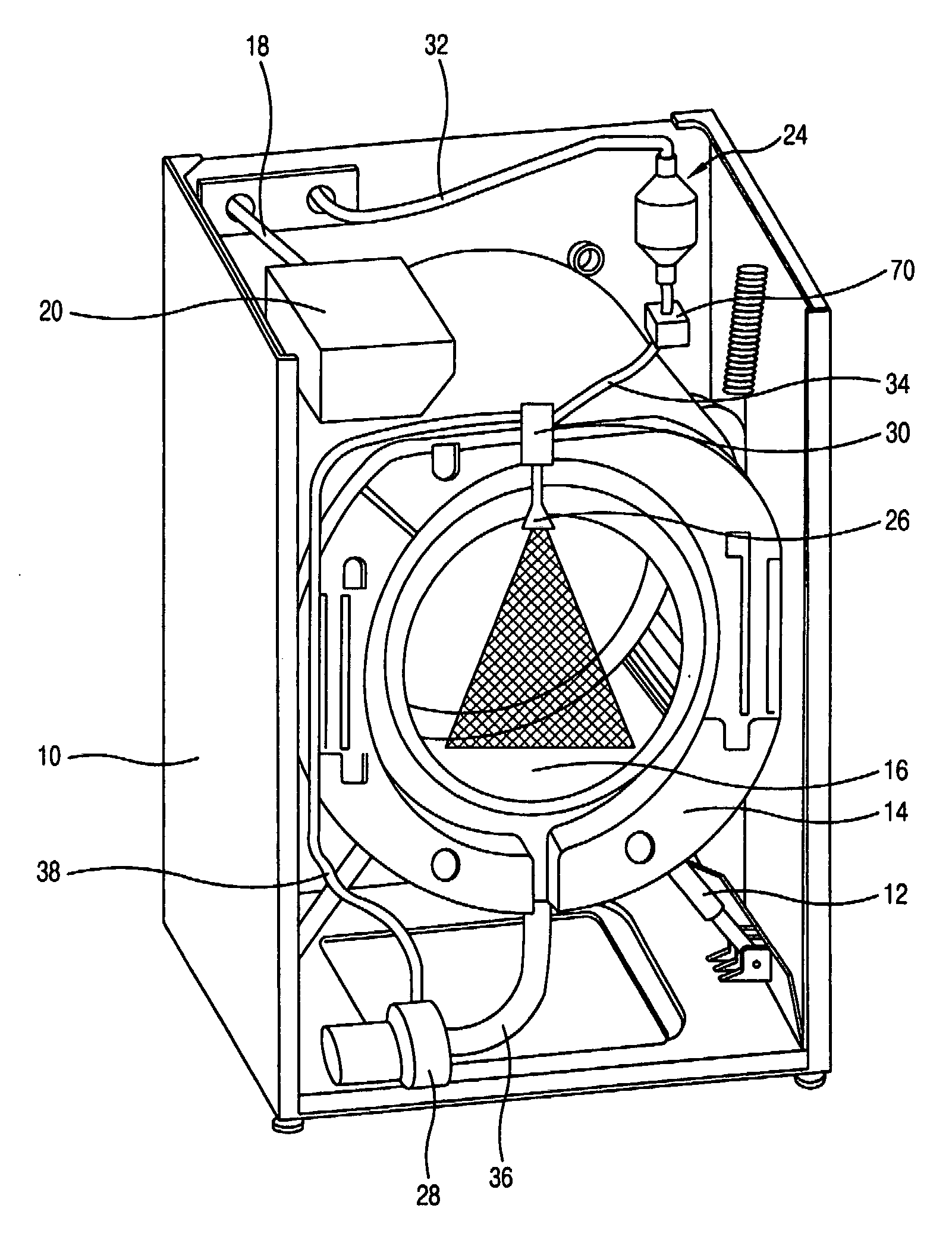

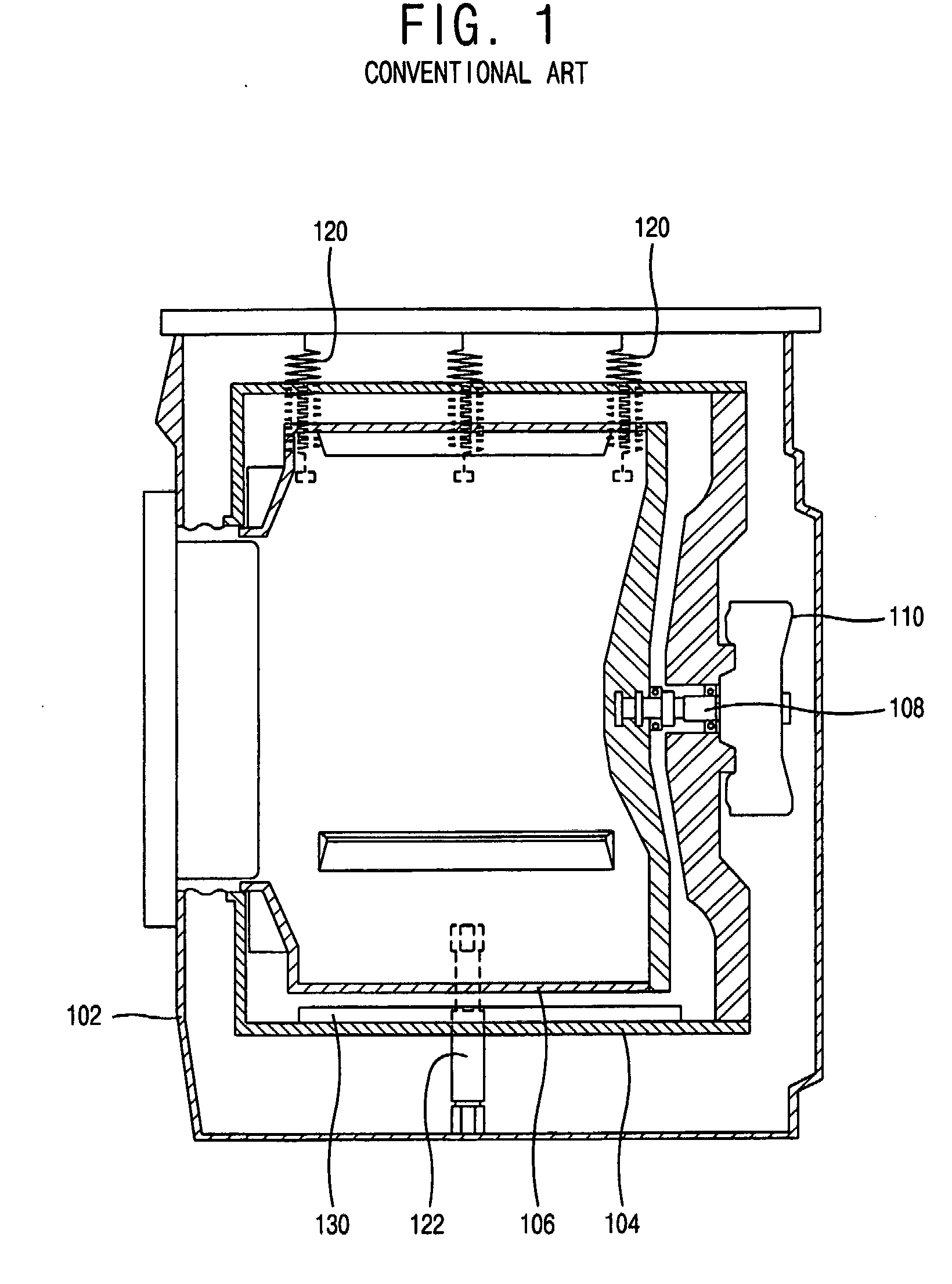

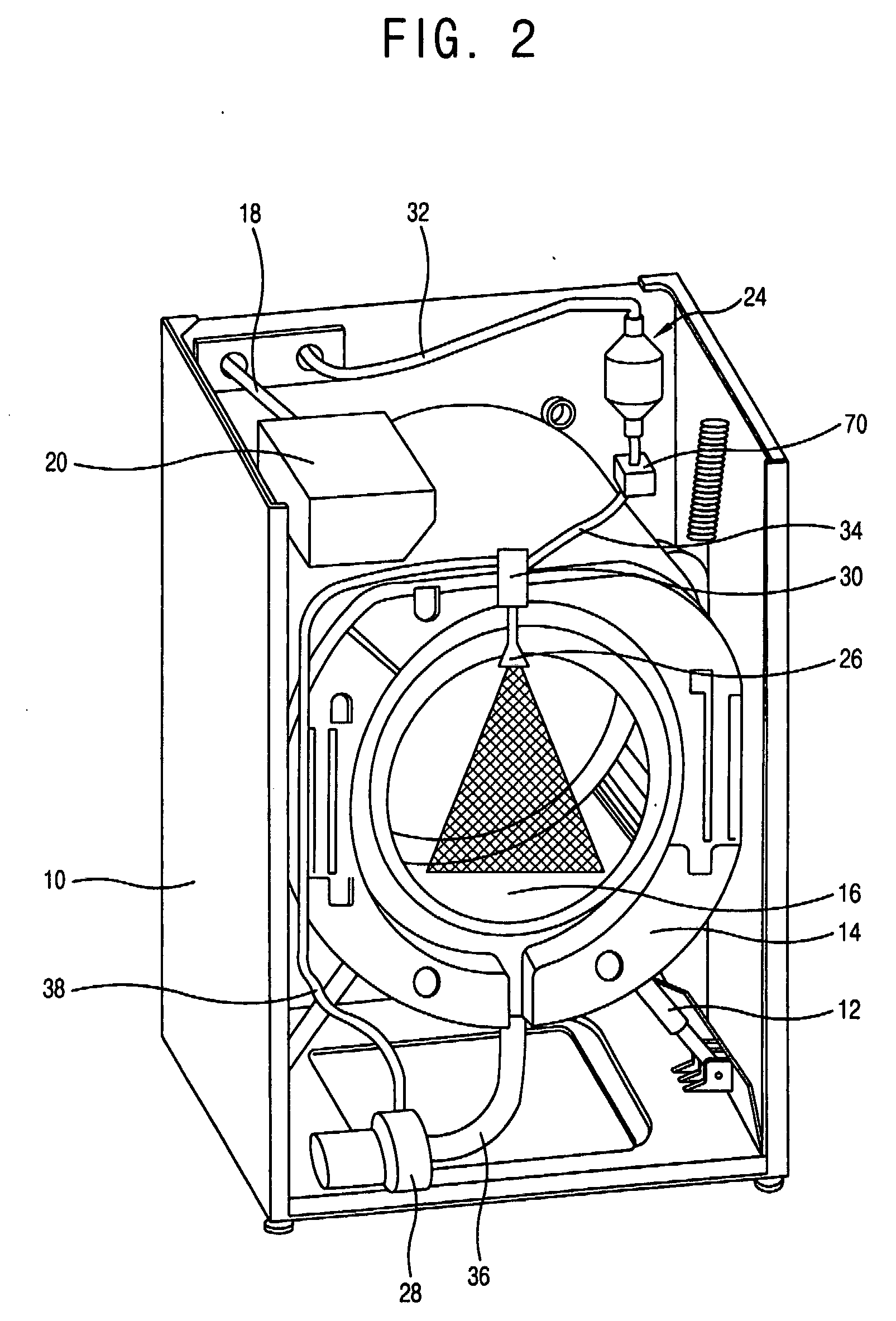

InactiveUS20050034490A1Small sizeReduce the amount of waterSteam generation heating methodsTextile treatment machine partsEngineeringLaundry

A washing machine includes a tub disposed inside a cabinet, for storing water; a drum rotatably disposed inside the tub, for washing laundry; and a steam generating apparatus disposed at the cabinet, for generating steam supplied to the inside of the drum, by using high-frequency induction heating. Accordingly, by generating steam using high-frequency induction heating, a structure of the steam generating apparatus can be simplified, and performance of generating steam can be improved.

Owner:LG ELECTRONICS INC

Washing machine

ActiveUS20070125133A1Reduce the amount requiredSmall sizeSteam generation heating methodsTextile treatment machine partsEngineeringLaundry

A washing machine includes a tub disposed inside a cabinet, for storing water; a drum rotatably disposed inside the tub, for washing laundry; and a steam generating apparatus disposed at the cabinet, for generating steam supplied to the inside of the drum, by using high-frequency induction heating. Accordingly, by generating steam using high-frequency induction heating, a structure of the steam generating apparatus can be simplified, and performance of generating steam can be improved.

Owner:LG ELECTRONICS INC

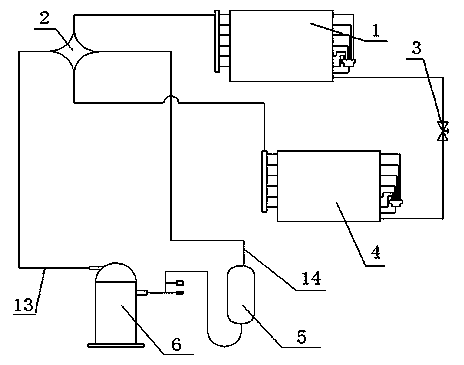

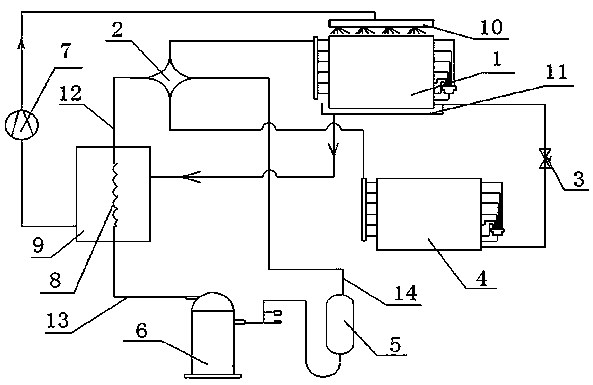

Air conditioner defrosting circulation system

InactiveCN103574860AImprove heating efficiencyIncrease water temperatureEnergy recovery in ventilation and heatingCorrosion preventionFour-way valveVapor–liquid separator

The invention provides an air conditioner defrosting circulation system comprising a compressor. A compressor exhaust pipe is connected with a four-way valve which is connected with an outdoor heat exchanger, an indoor heat exchanger and a gas-liquid separator, the gas-liquid separator is connected with a compressor intake pipe, a heat storage water tank is arranged on the compressor exhaust pipe, and a water spray port of the heat storage water tank is formed in the outdoor heat exchanger and matched with a return pipe of a water storage tank. The four-way valve is not switched, but the heat-preservation heat storage water tank is arranged on the compressor exhaust pipe to collect waste heat during circulation and fully utilize the waste heat, an outdoor unit is defrosted by a hot water spraying mode, normal heating of an indoor unit is guaranteed in the whole defrosting process, heating efficiency is improved effectively, and service life of the system is prolonged.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

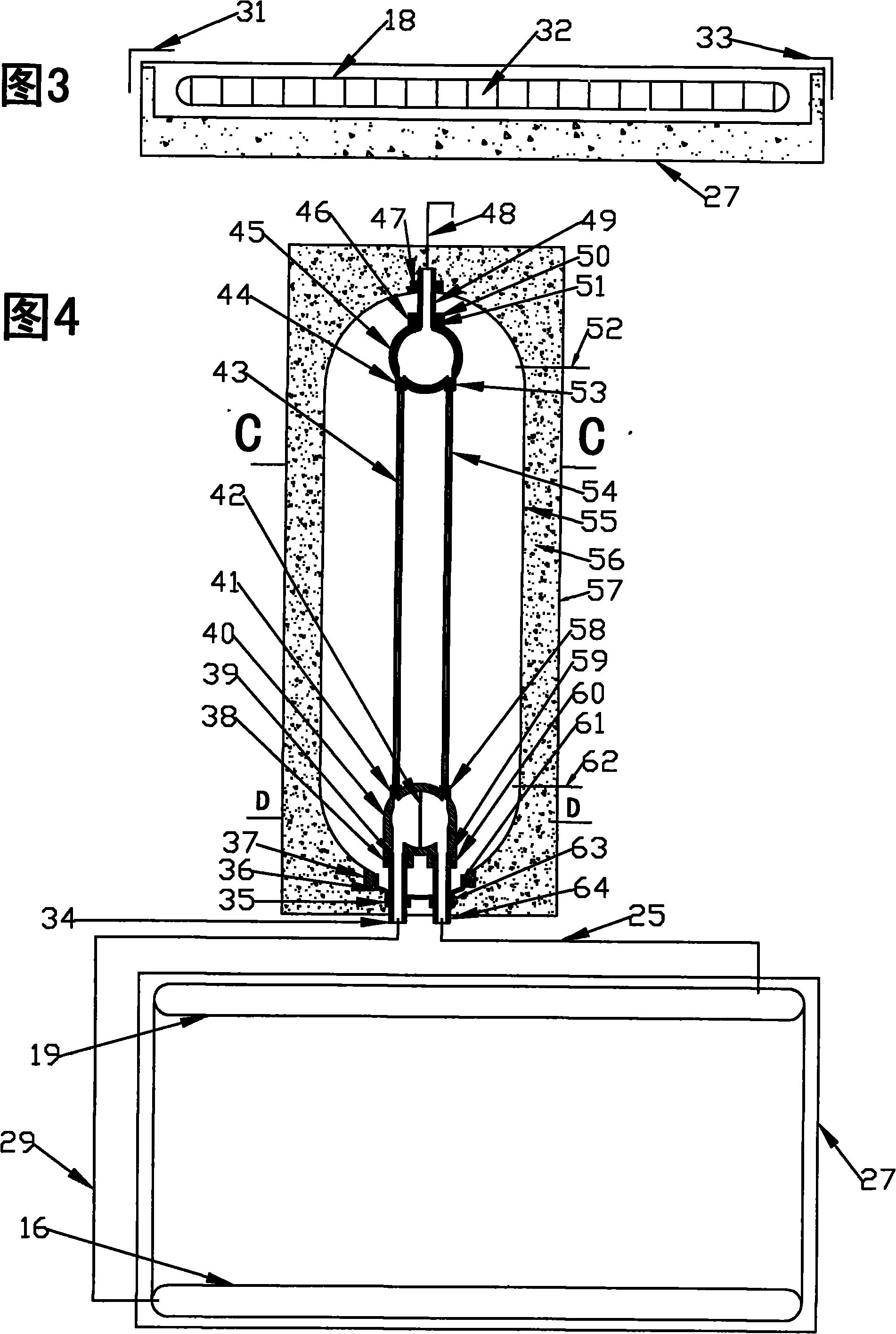

Pressure chamber nozzle assembly

InactiveUS20050236436A1Reduce morbidityInexpensive and economicalOpening closed containersBottle/container closureEngineeringNozzle

A nozzle assembly is disclosed which provides for increased atomization, a finer spray, and a reduced tendency of the apparatus to clog. The nozzle assembly includes a pressure chamber through which the spray material must pass prior to exiting the spray container through a discharge orifice. As material exiting the container passes through the pressure chamber, pressure is built up, resulting in increased shearing and atomization of the spray material.

Owner:SPRAYTEX

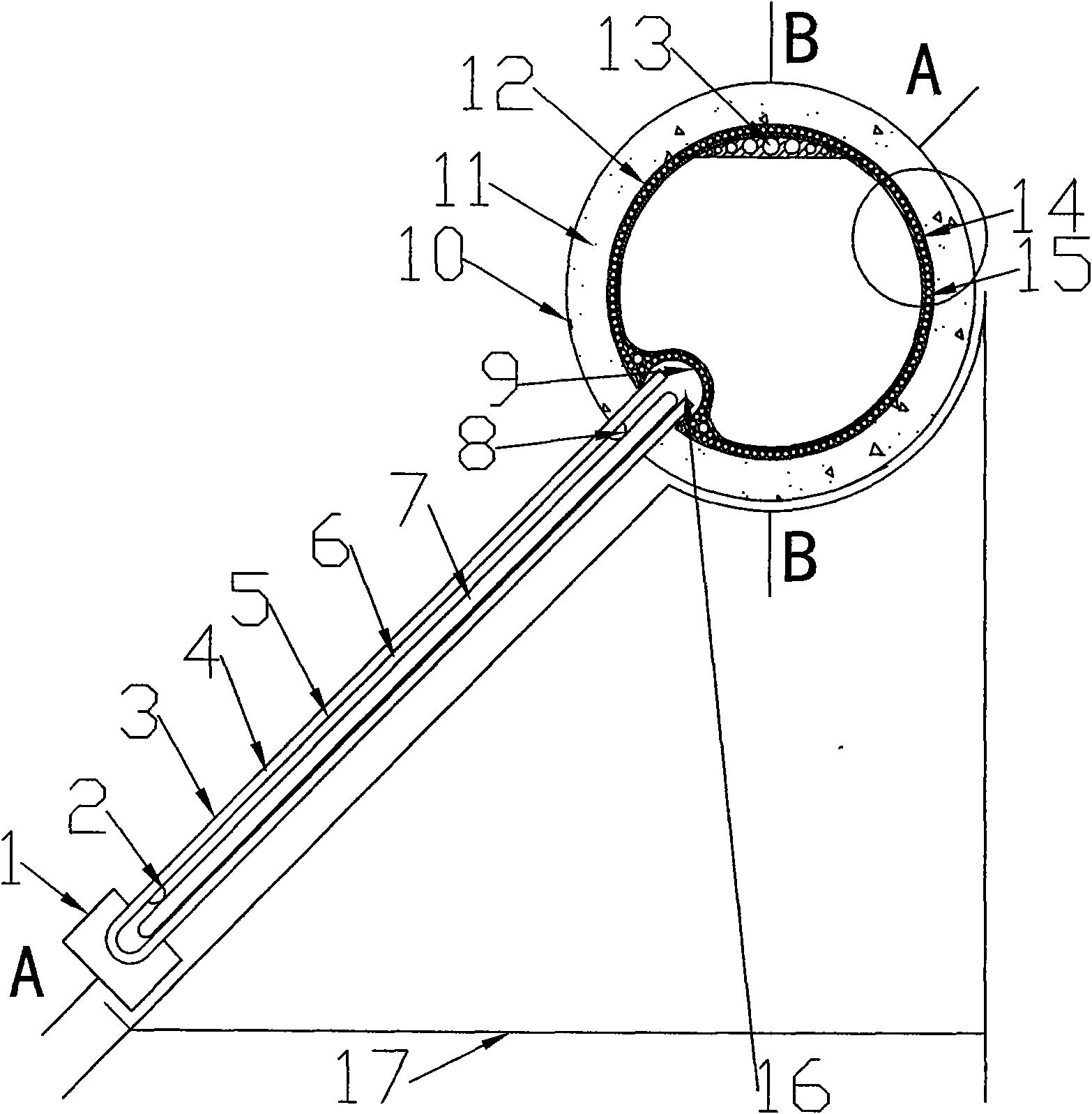

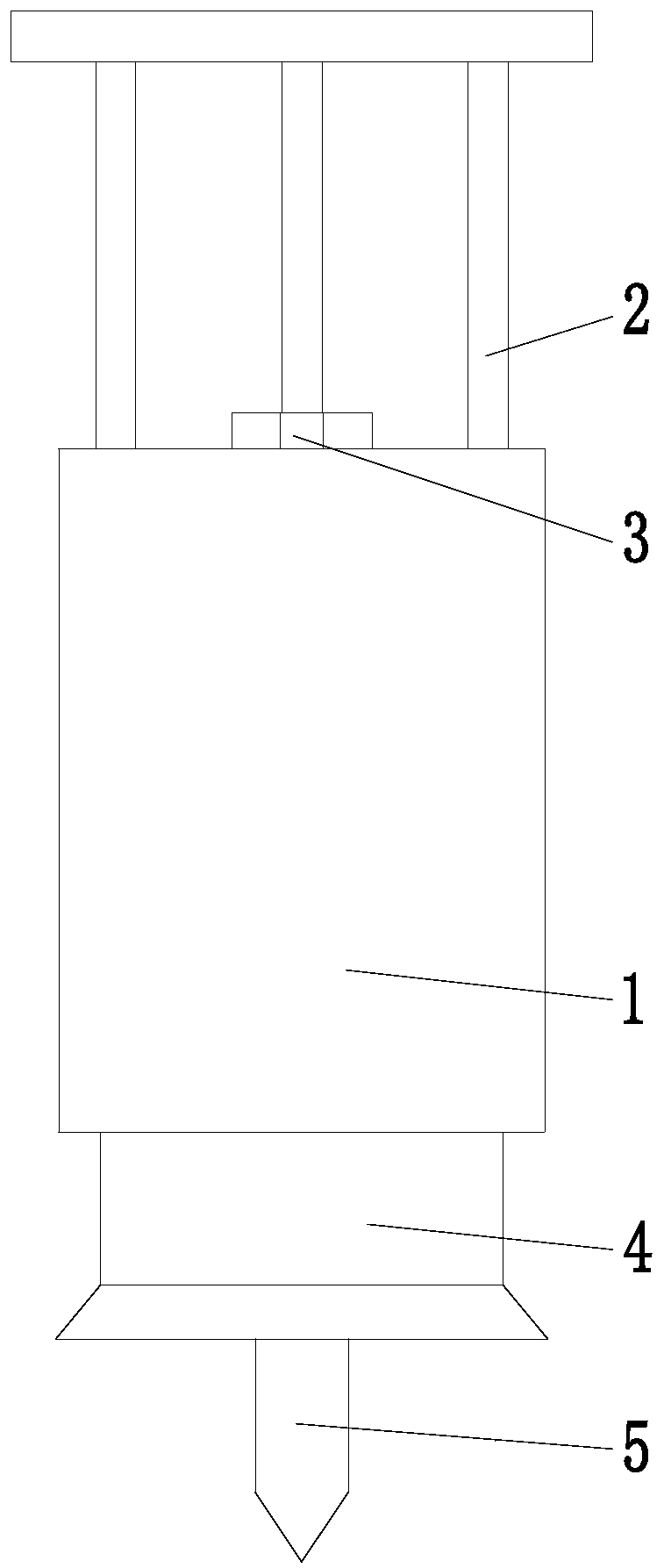

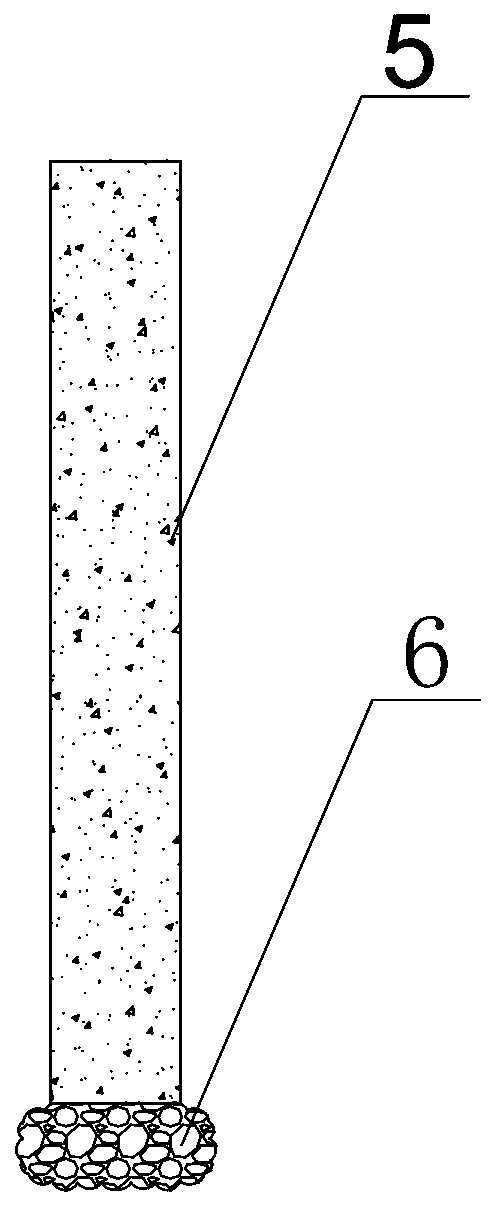

Reducing swing-injected agitating pile

The invention relates to a reducing swing-injected agitating pile. Stirred cement paste is pressed into a cement paste tube through a slurry pump. The cement paste enters a faucet through a cement paste pipe connector, then enters a grouting steel tube and is sprayed out through a high-pressure slurry sprayer, and a soil body is cut at high pressure. While the soil body is cut through high-pressure cement paste, reducing stirring blades arranged on an outer drill pipe and an inner drill pipe can synchronously achieve stirring of the soil body. While the soil body is cut through a high-pressure grouting mode and the stirring blades of the inner and outer drill pipes rotate to stir the soil body, under the action of a lifting system, the whole high-pressure grouting and stirring system carries out grouting, stirring and sinking at the same time or stirring and uplifting at the same time according to design requirements. By means of a series of motions, the cement cylindrical agitating pile with a certain diameter can be obtained. On the basis that the advantages that a construction machine is simple and speed is high in a deep layer stirring method are inherited, the comprehensive advantages that a high-pressure swing-injection method is large in guniting pressure, wide in applicable stratum range and large in three-axis agitating pile power are combined, and the agitating pile has the characteristic of being wide in application range.

Owner:南京路鼎搅拌桩特种技术有限公司 +1

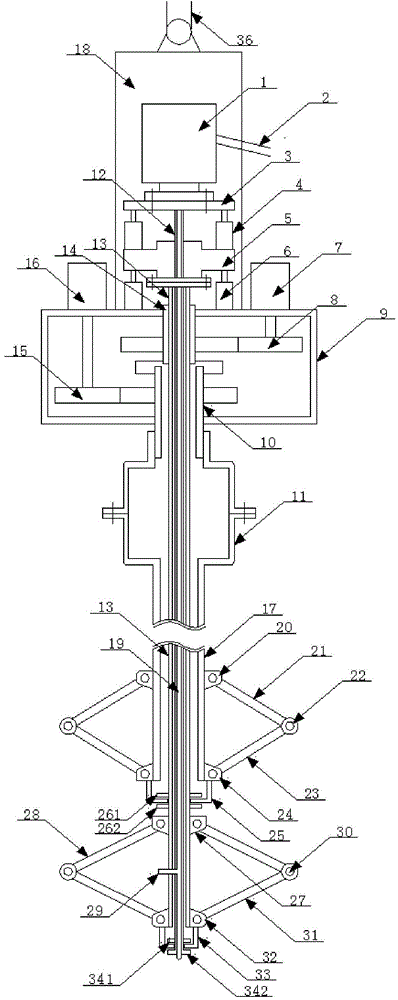

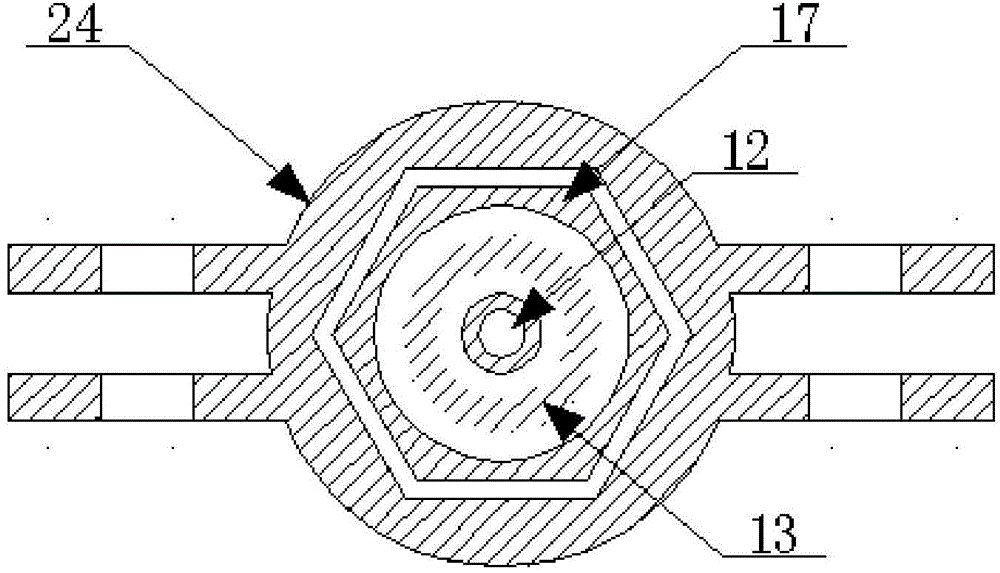

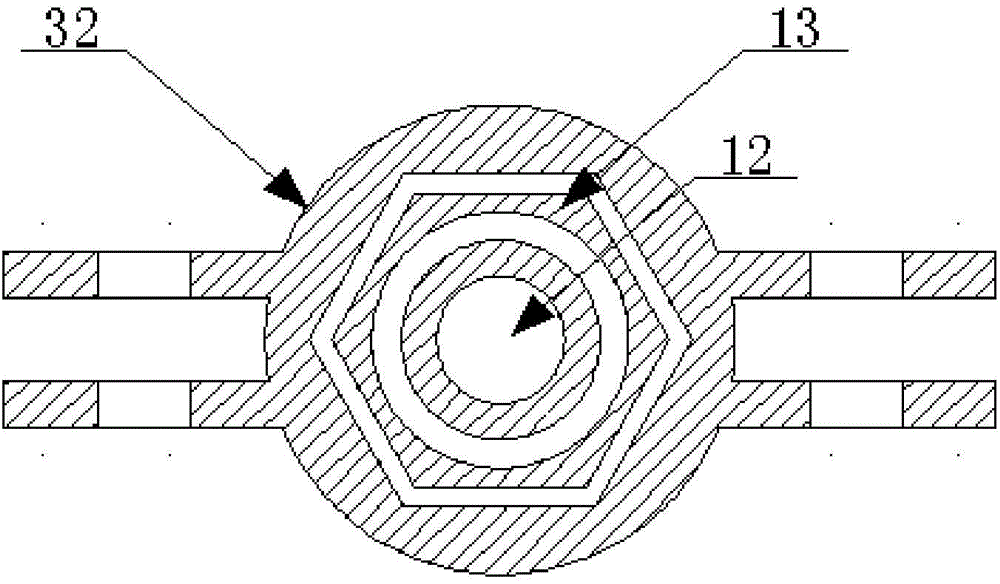

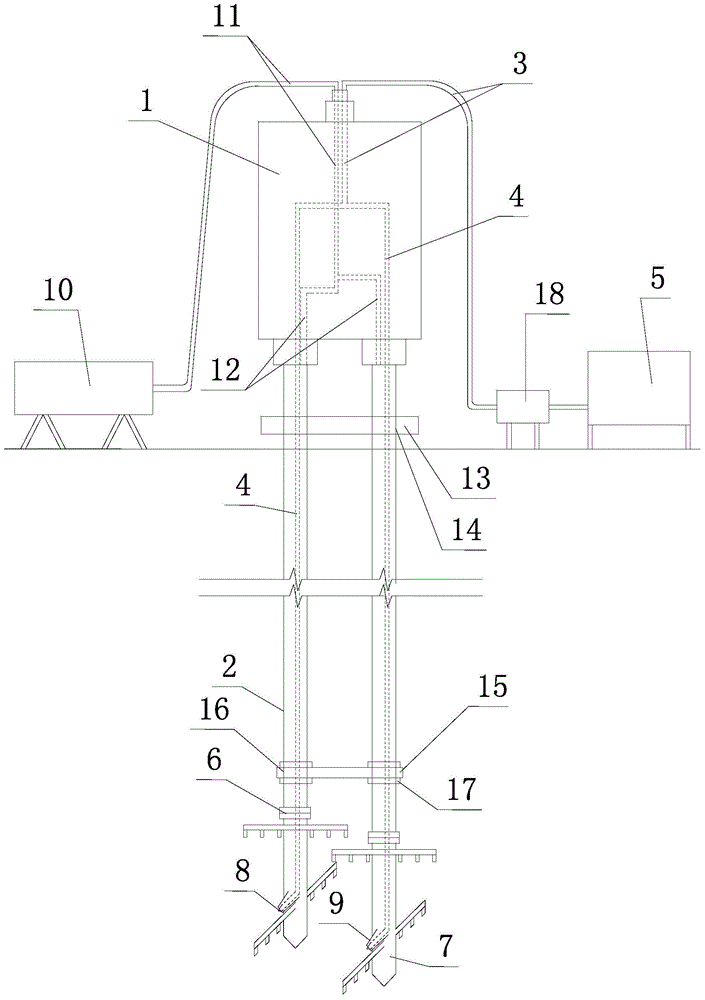

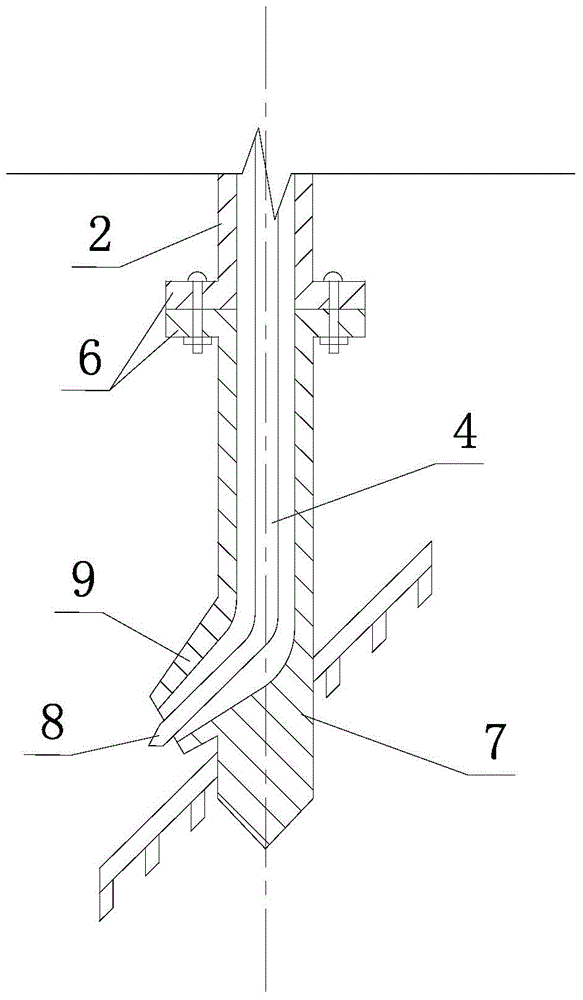

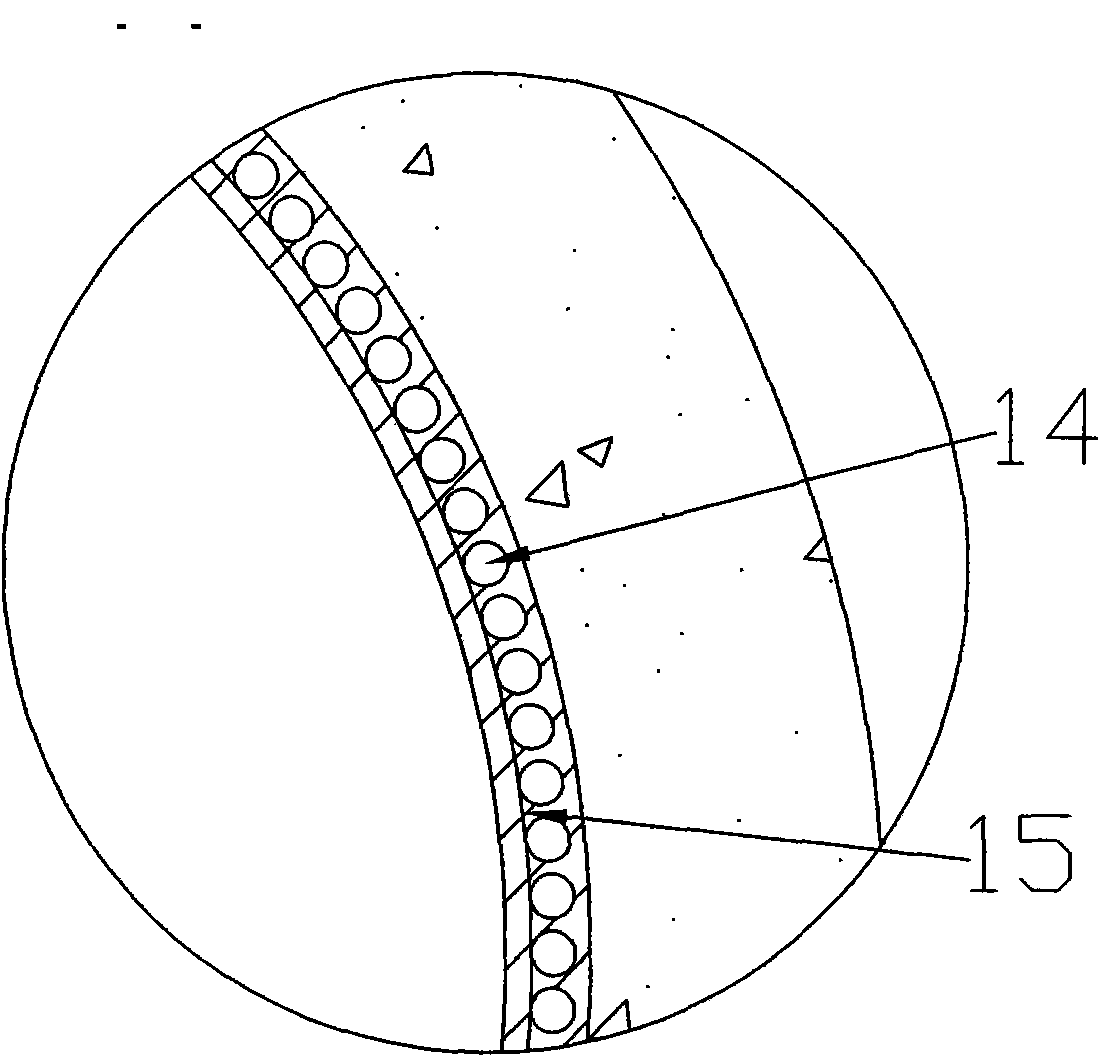

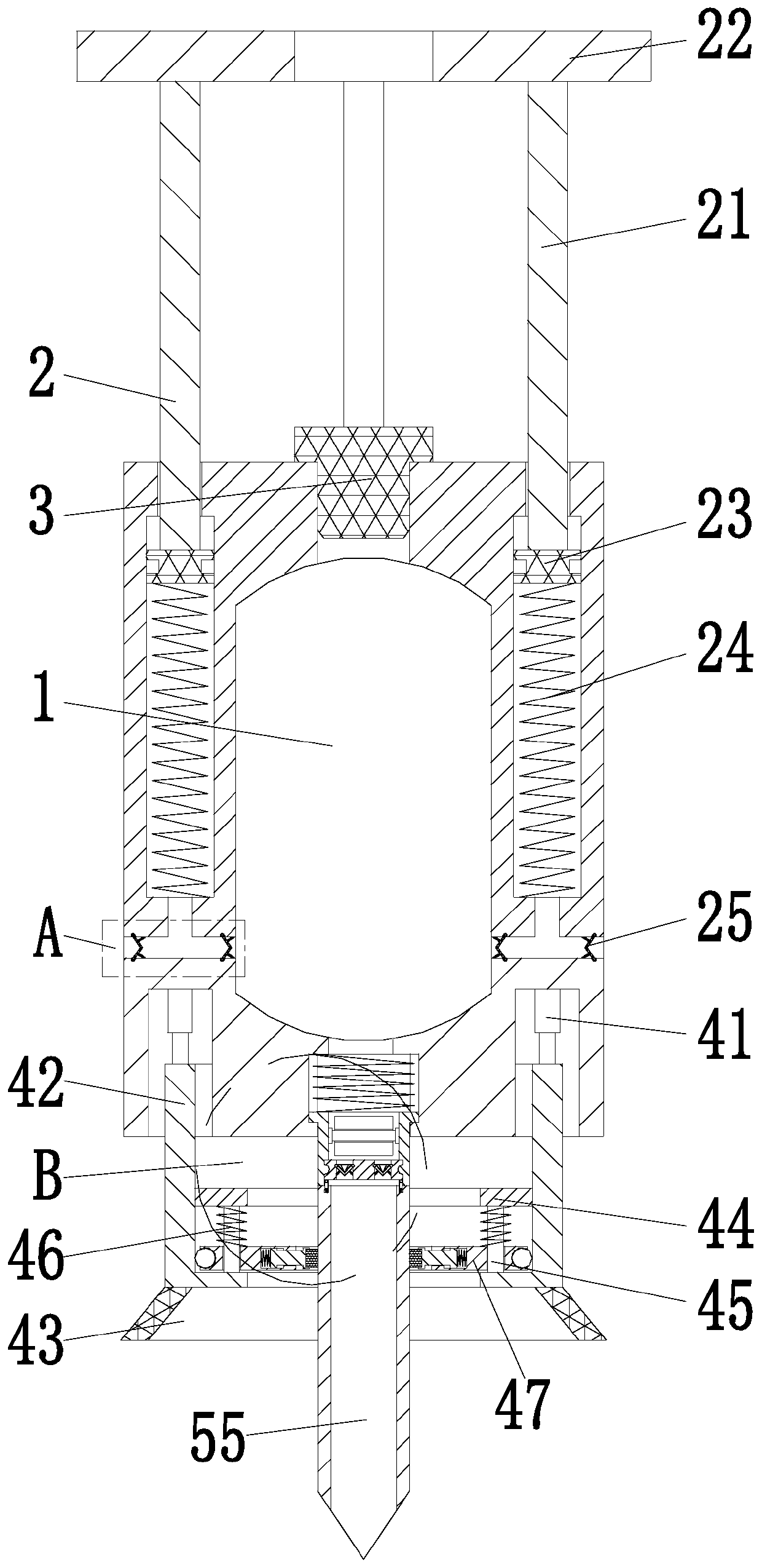

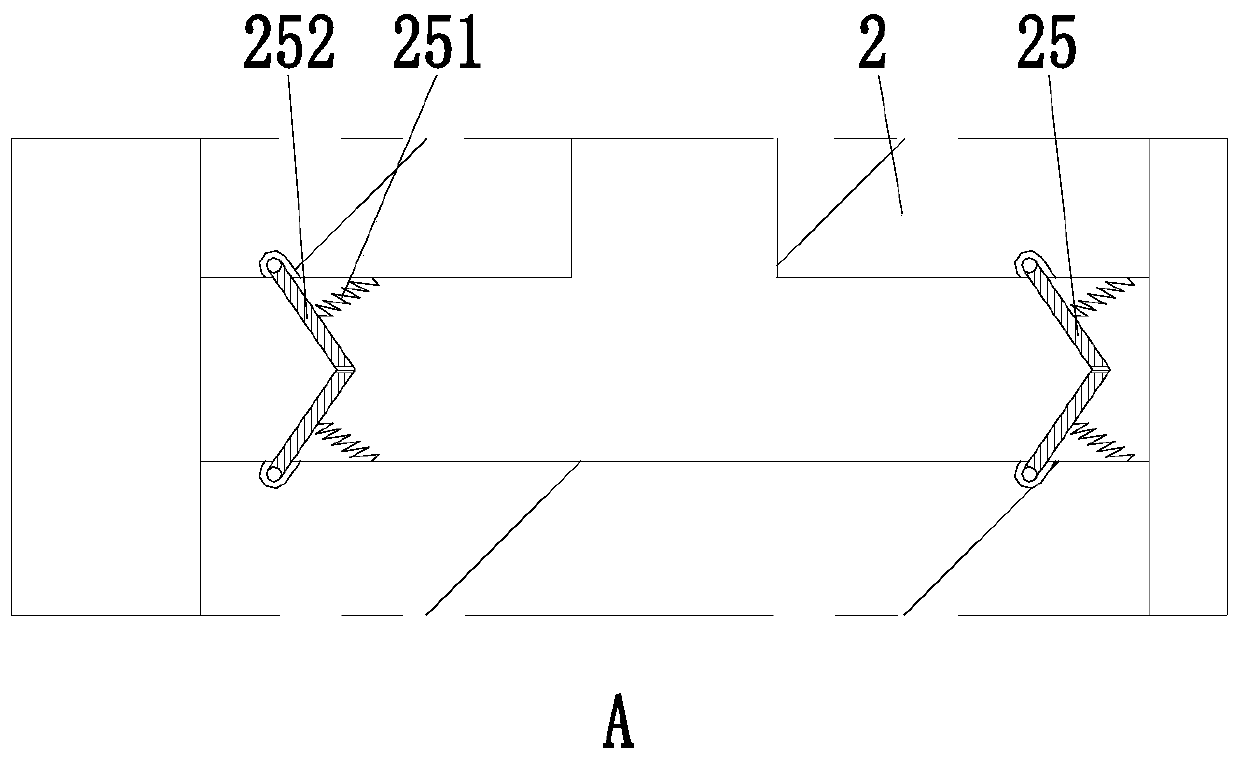

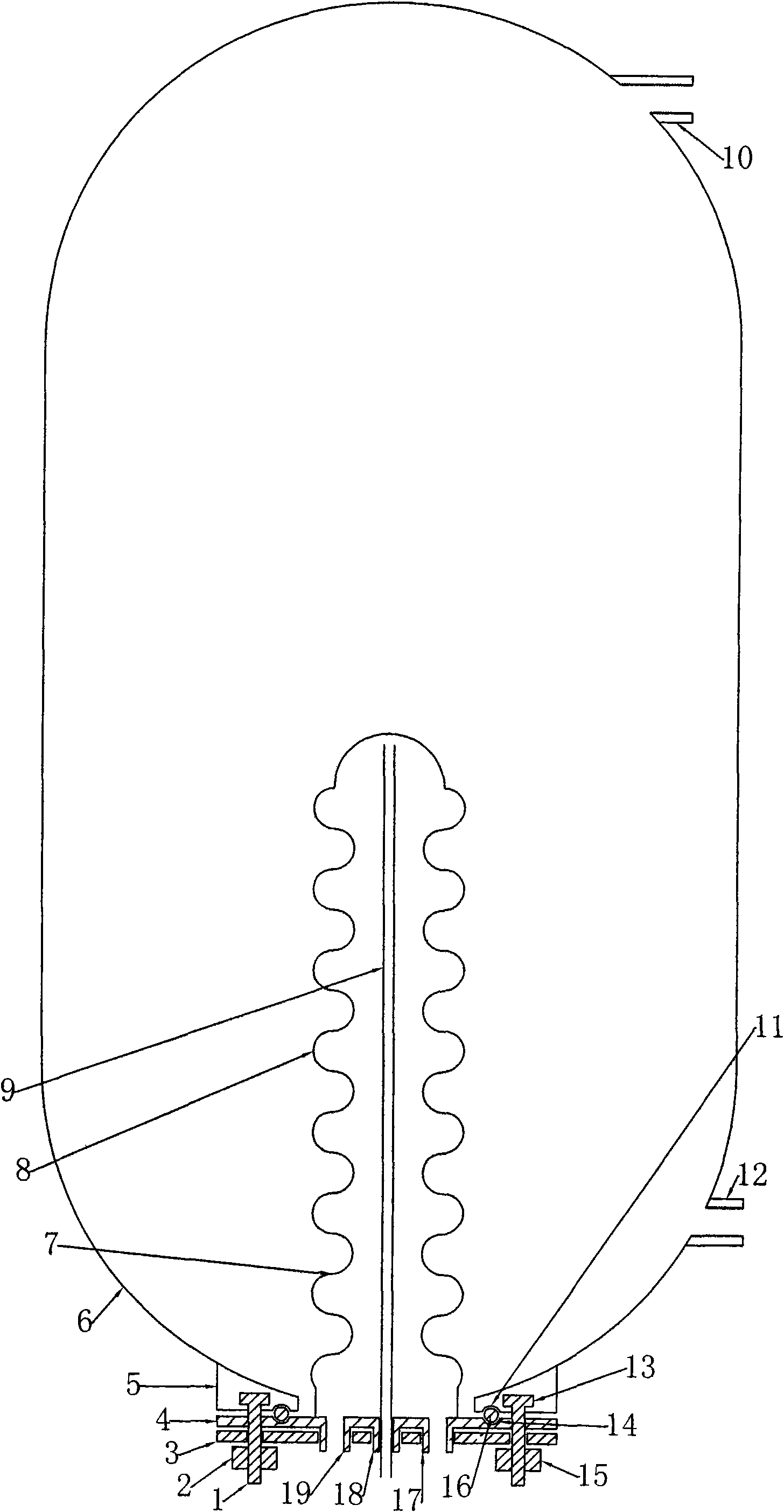

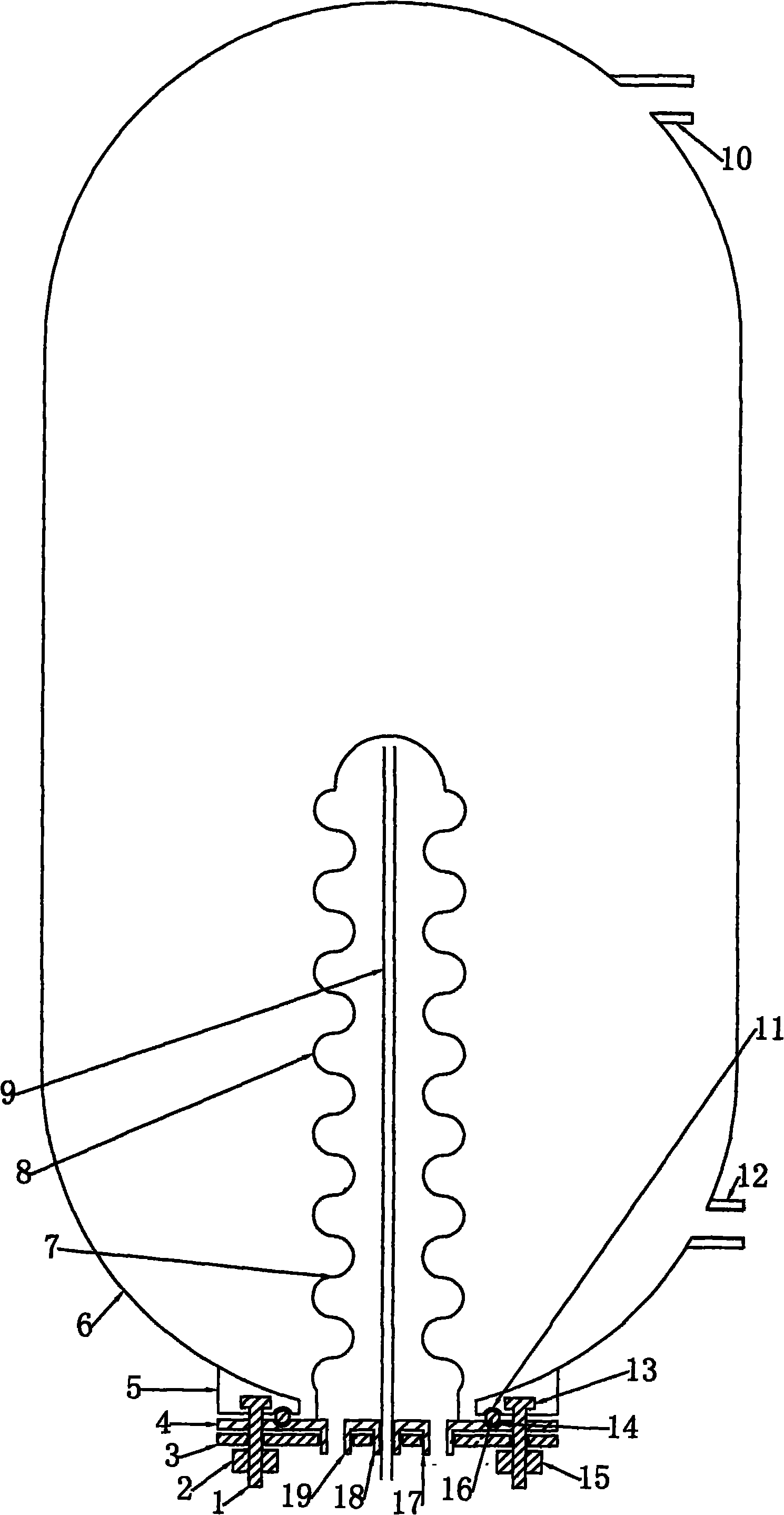

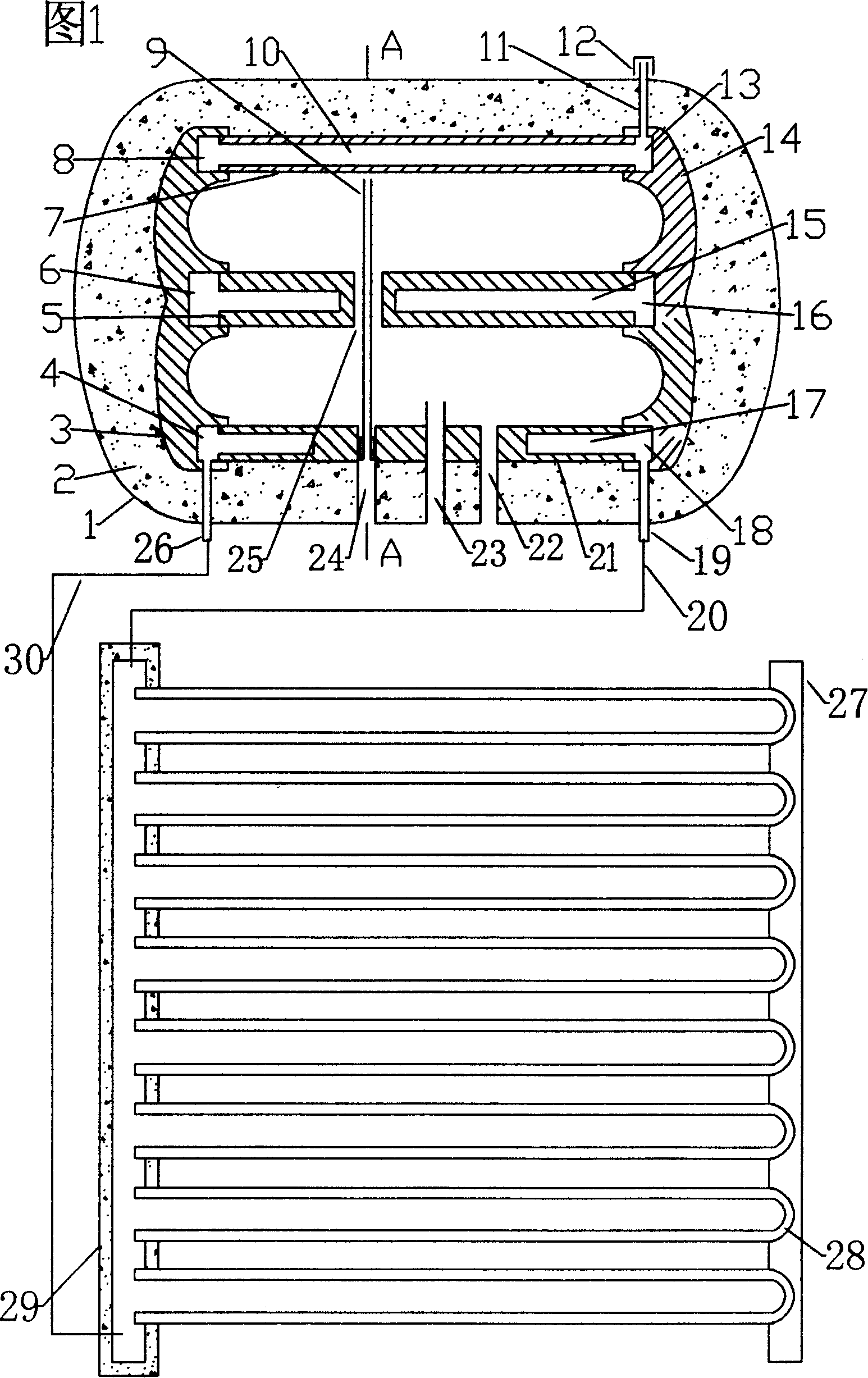

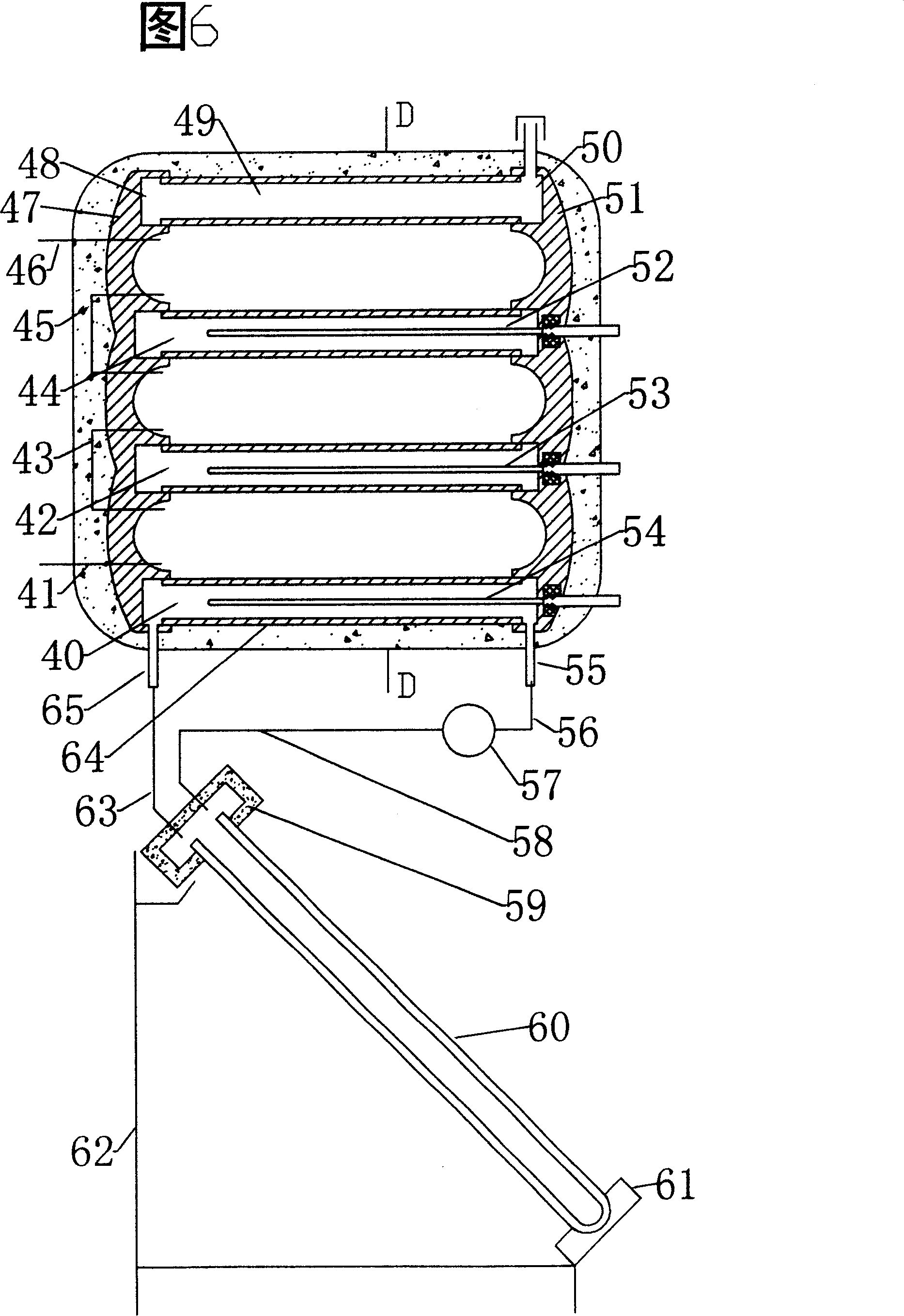

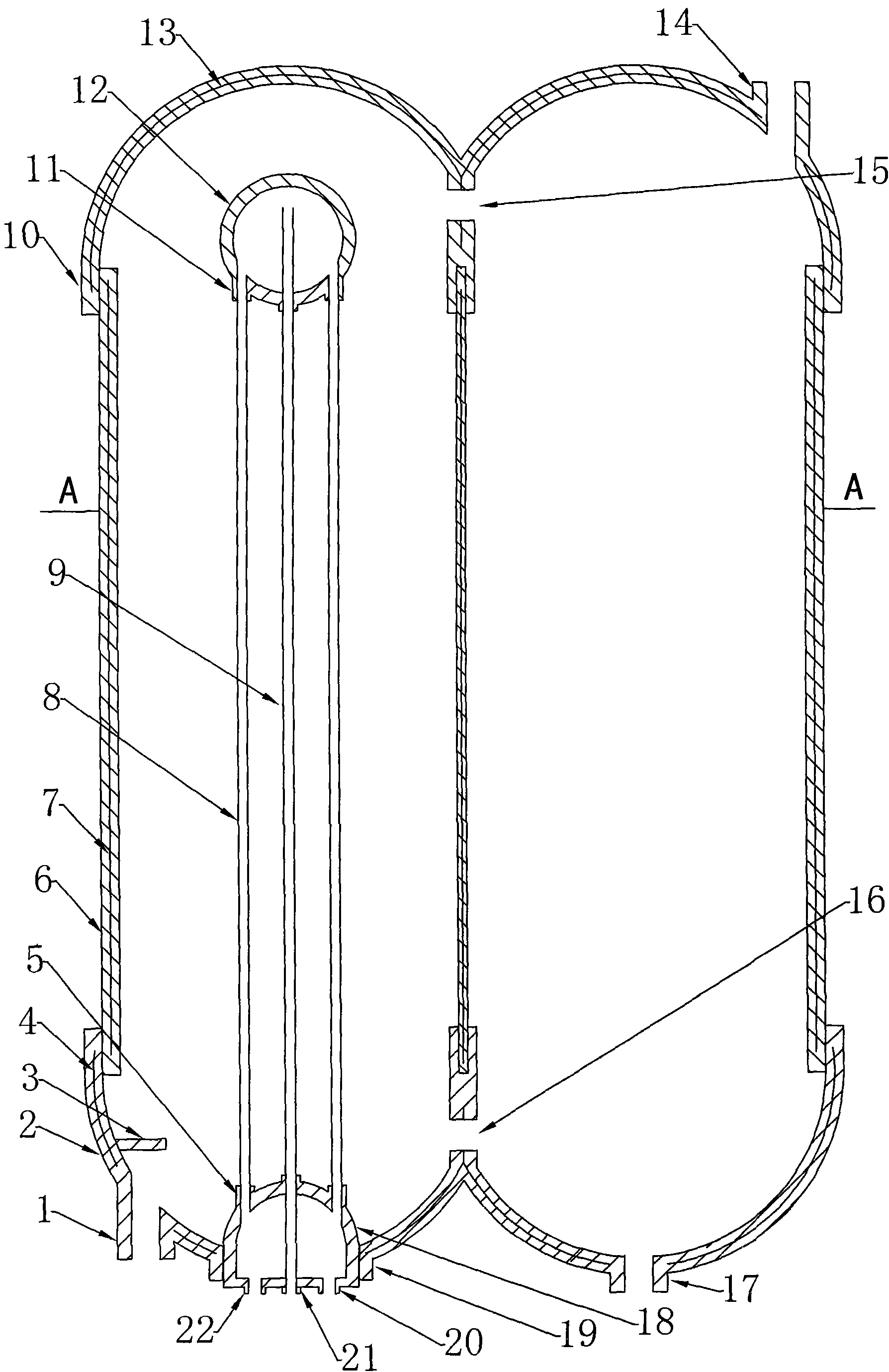

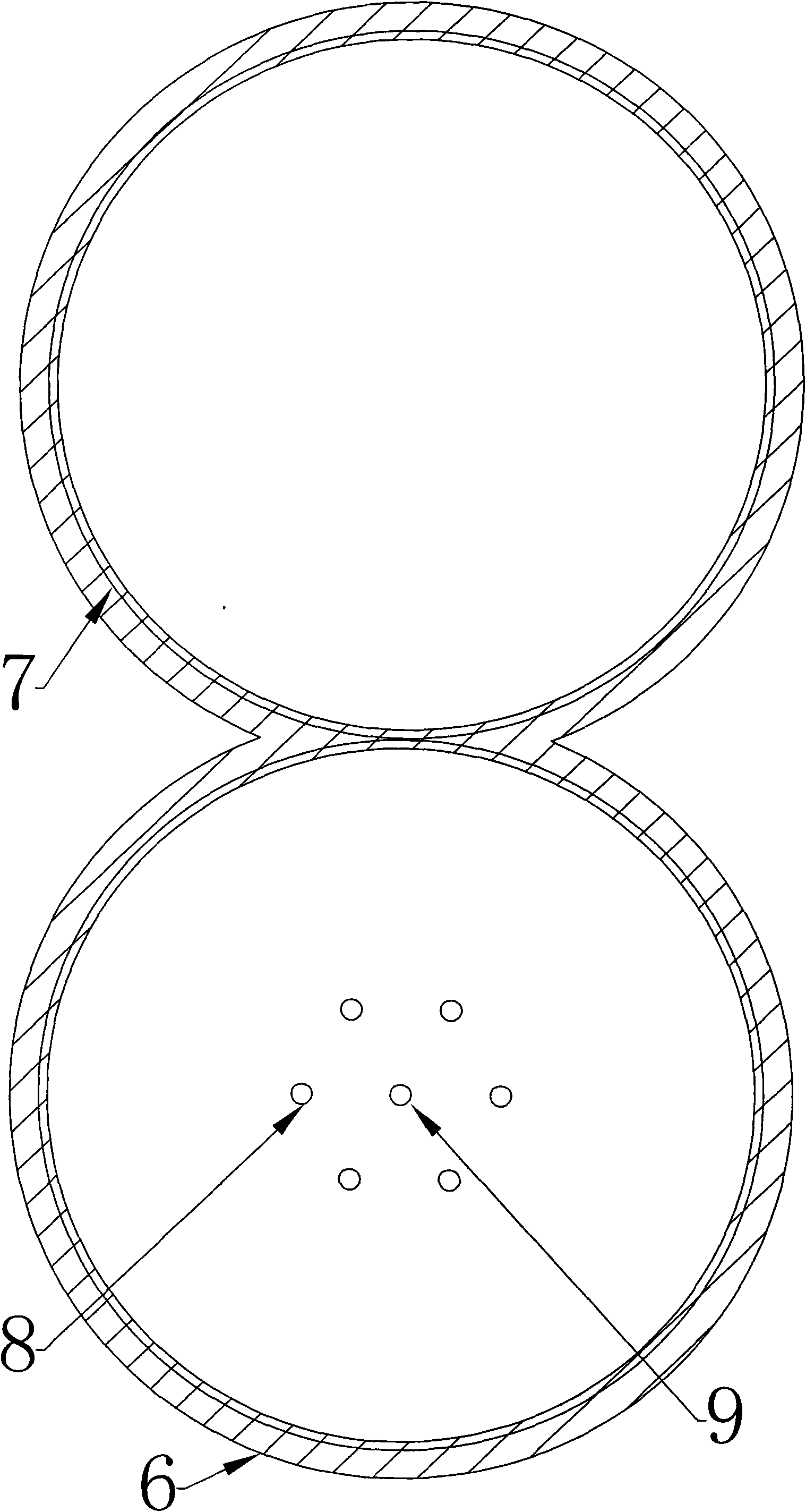

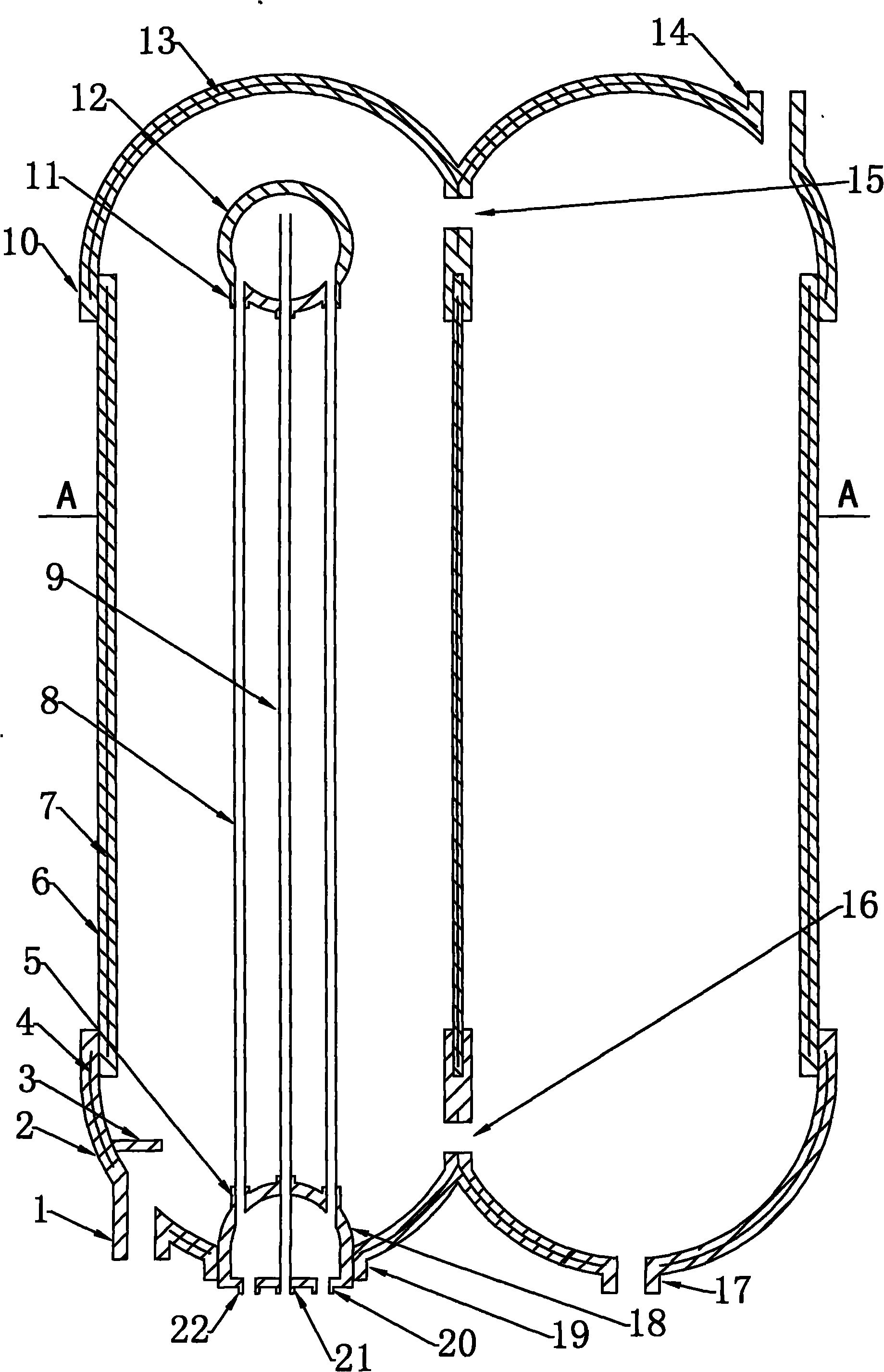

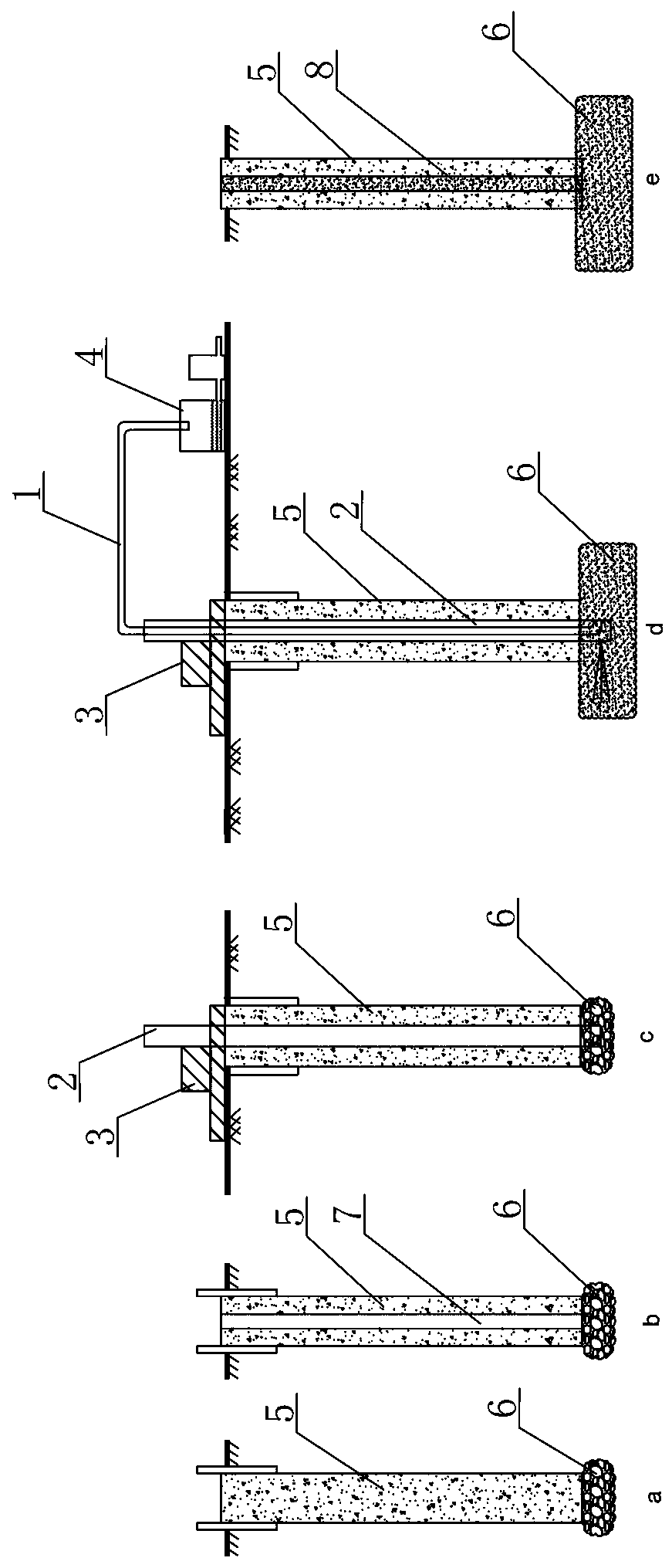

Double-shaft air-injection rotary jet type stirring pile machine and method for forming pile by using pile machine

The invention discloses a double-shaft air-injection rotary jet type stirring pile machine and a method for forming a pile by using the pile machine. The pile machine disclosed by the invention comprises a pile frame, a power head (1), a stirring shaft (2), an air nozzle (9), an air compressor (10), an air transmission header pipe (11) and an air transmission branched pipe (12); a slurry nozzle (8) and the air nozzle (9) are fixed on a stirring head (7); the air nozzle (9) is arranged outside the slurry nozzle (8) in a sleeving manner; the air nozzle (9) is communicated with the air transmission branched pipe (12); the air transmission branched pipe (12) is communicated with the air transmission header pipe (11) and the air compressor (10). The construction method provided by the invention comprise the key step of spraying slurry under coercing of high-pressure air while drilling through a stirring shaft (2) or lifting upwardly and stirring a soil body. Due to the pile machine and the method for forming the pile by utilizing the pile machine, which are disclosed by the invention, piled cemented soil is uniform in density and good in pile-forming quality; the pile-forming depth can be increased; furthermore, a pile can be formed in a soil body with relatively high hardness; in addition, the construction efficiency is improved; the time limit for a project is shortened; the machine-shift cost and the labour cost are saved.

Owner:NINGBO HONGCHEN CONSTR +1

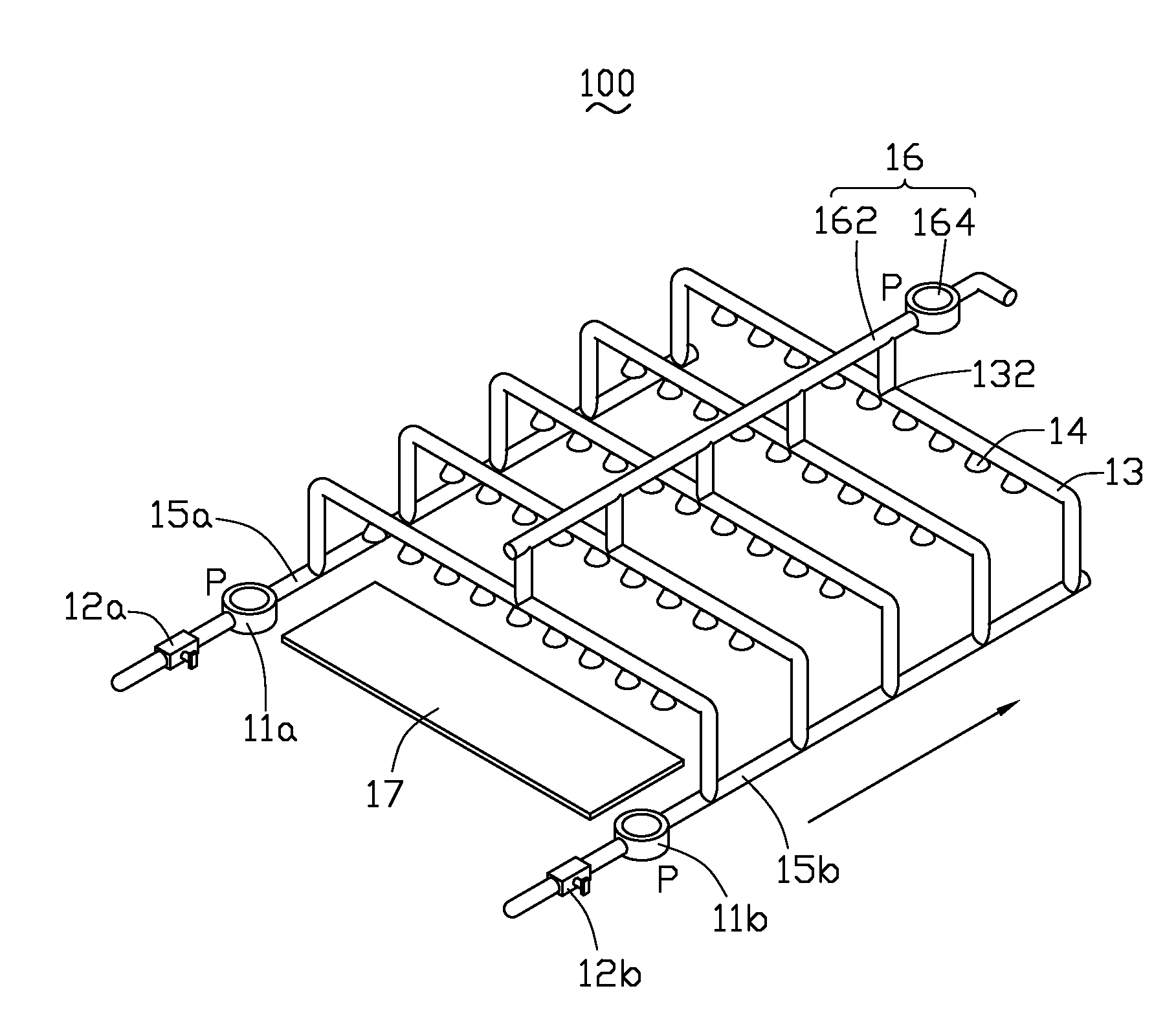

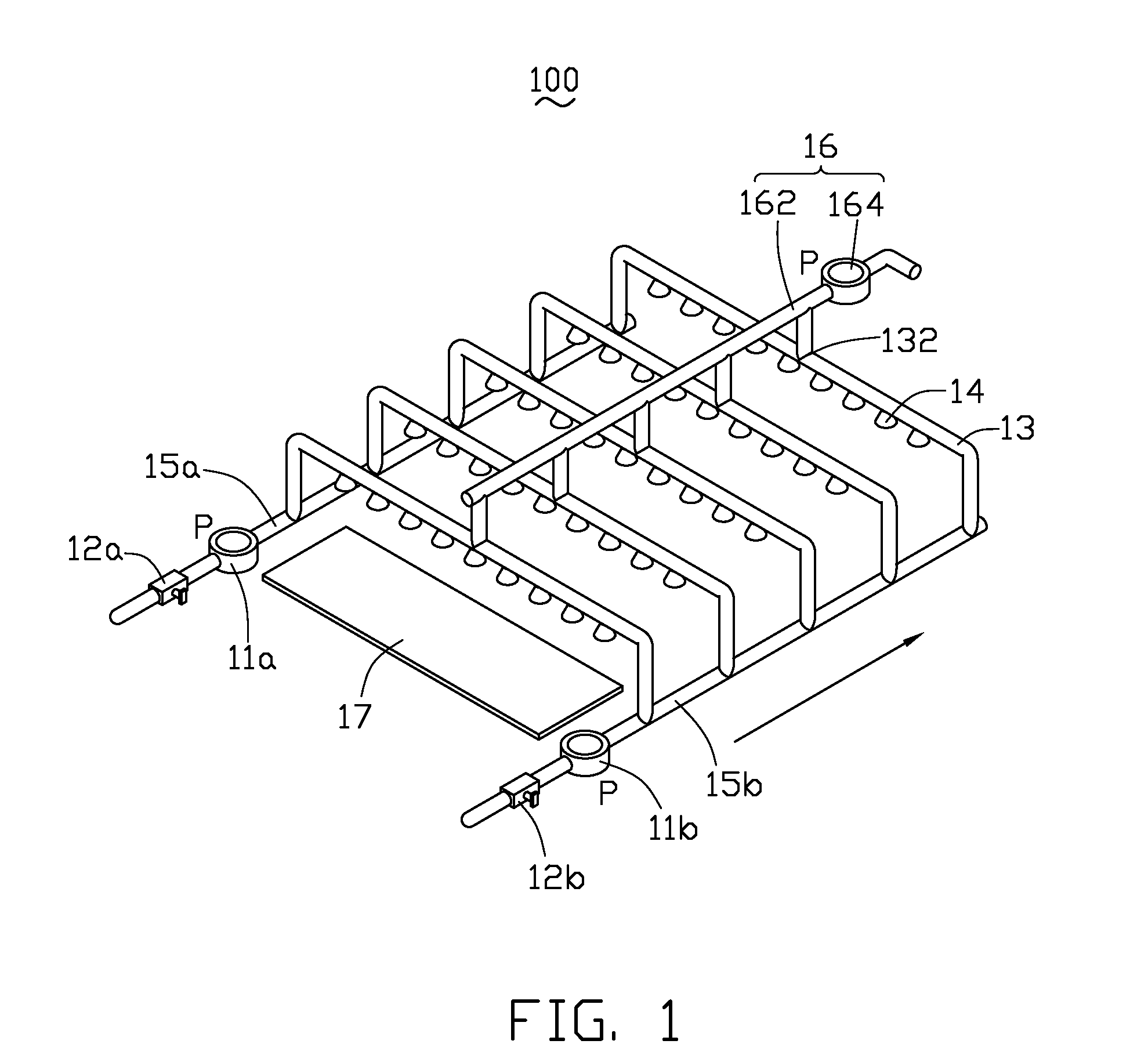

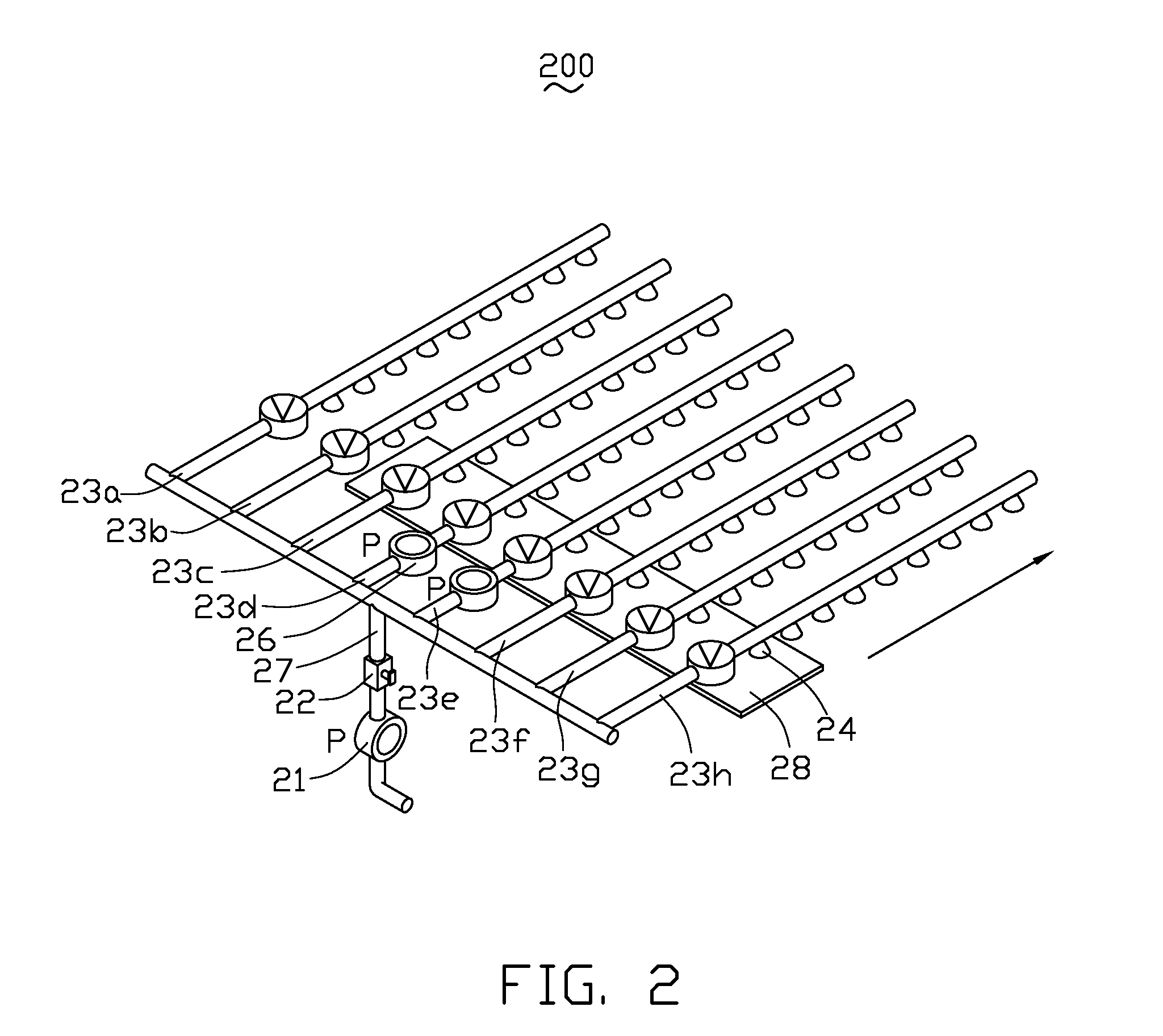

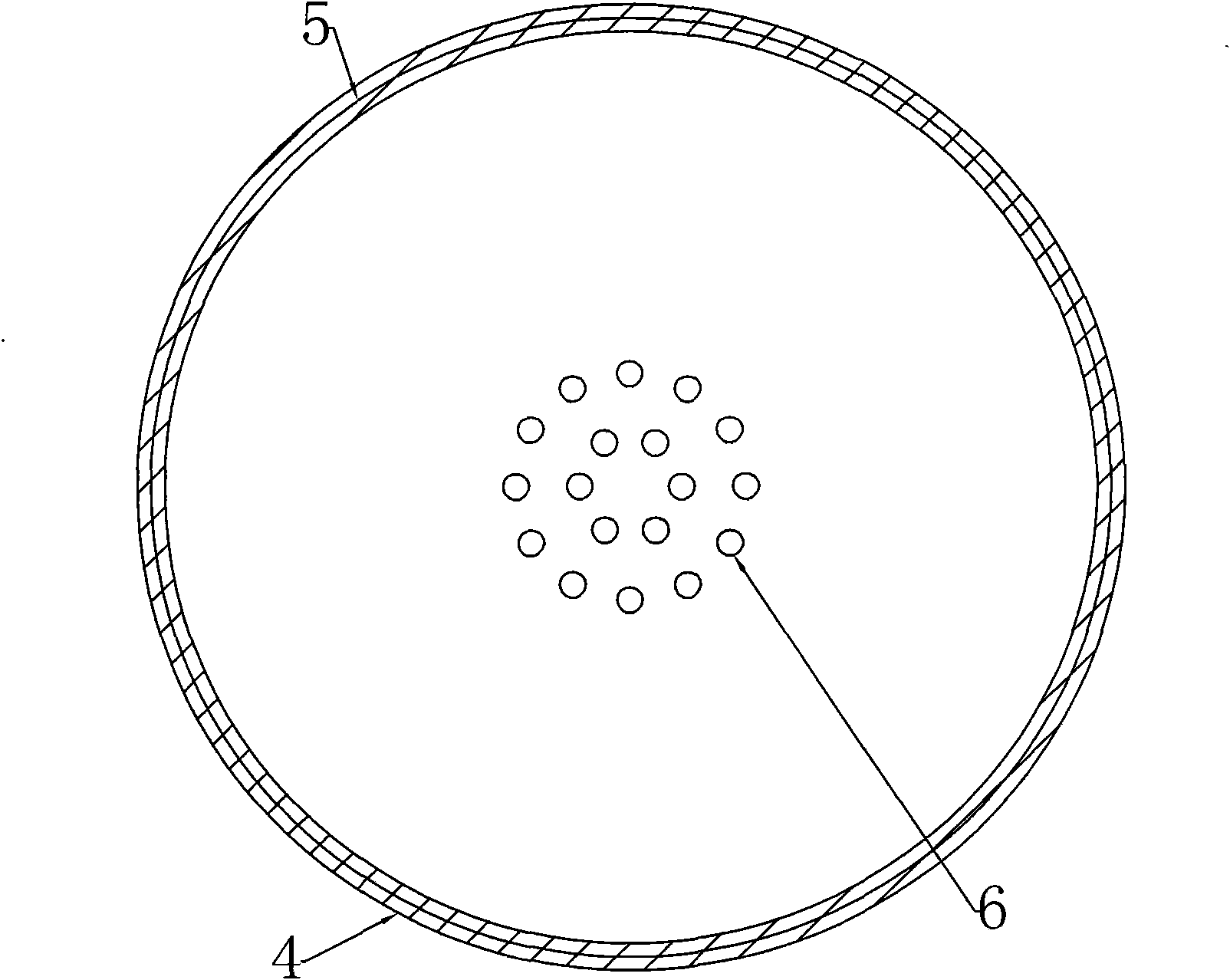

Apparatus for spraying etchant and use method thereof

ActiveUS20080035603A1Increase spray pressureDecorative surface effectsSemiconductor/solid-state device manufacturingSpray nozzleEngineering

The present invention relates to an apparatus for spraying an etchant and a method for manufacturing a printed circuit board. In one exemplary embodiment the apparatus includes a manifold, a plurality of feed pipes in fluid communication with the manifold, each of the feed pipes having a plurality of spray nozzles mounted thereon, the feed pipes cooperatively constitute a spray region, and a pressure-boosting device configured for increasing a spray pressure of the spray nozzles which are located at a central area of the spray region. The apparatus can overcome “the puddle effect” on an upper surface of the printed circuit board.

Owner:GARUDA TECH CO LTD

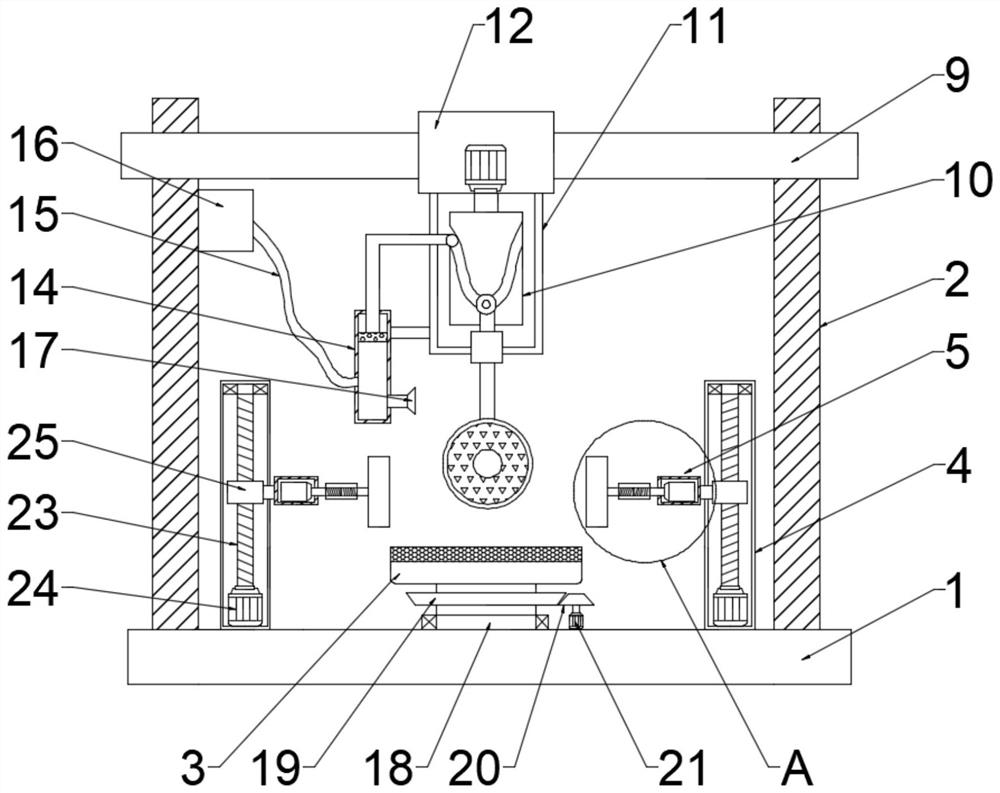

Hardware part end face grinding clamp

InactiveCN112222975AEasy to processEasy to polishGrinding drivesGrinding work supportsEngineeringWorkbench

The invention relates to the technical field of hardware machining, in particular to a hardware part end face grinding clamp which comprises a base. Supporting columns are symmetrically arranged on the two sides of the upper portion of the base, a workbench is arranged in the center of the base, mounting columns are arranged on the two sides of the workbench, and mounting cavities are connected tothe sides, close to the workbench, of the mounting columns. Air cylinders are installed in the installation cavities and connected with telescopic rods, and one end of each telescopic rod is connected with a fixing plate. A supporting plate is transversely and fixedly installed at the upper portions of the supporting columns, an electric sliding base is arranged in the middle of the supporting plate, a transmission bin is arranged at the lower portion of the electric sliding base, and a lifting device is arranged in the transmission bin. According to the hardware part end face grinding clamp,a good fixing effect can be provided for hardware parts, a grinding plate can be cooled when the parts are ground, the service life of the grinding plate is prolonged, and the grinding effect of thegrinding plate on the end faces of the hardware parts is improved.

Owner:江门市新会区司前贸易中心有限公司

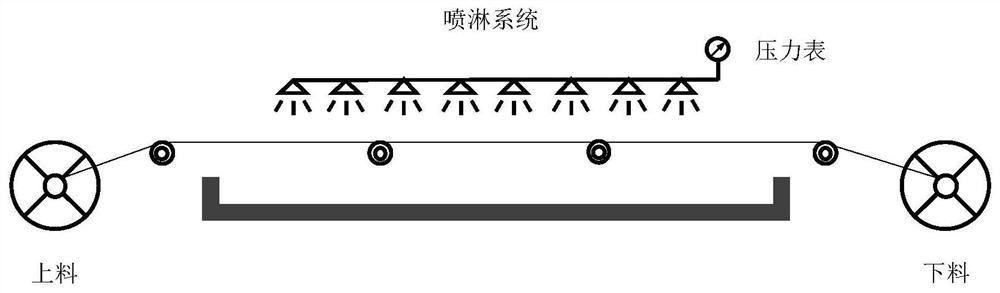

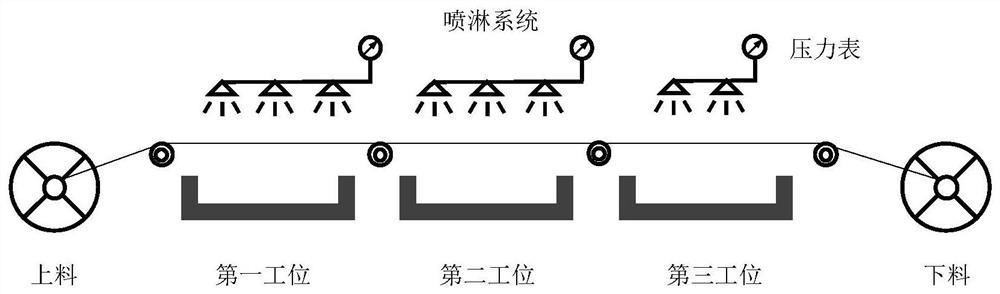

High-precision etching production system and method for flexible PCB

InactiveCN112399723AReduce concentrationReduce the impact of side erosionFlexible printed circuitsProcessing steps orderEtchingPhysical chemistry

The invention discloses a high-precision etching production system and method for a flexible PCB. The system comprises a PCB substrate feeding device, a line body conveying device and a finished product discharging device, the line body conveying device is provided with a plurality of etching stations in the line body conveying direction, and a spraying system for independently controlling parameters is disposed above each etching station. The PCB substrate feeding device is used for feeding exposed and developed PCB substrates to the line body conveying device, the PCB substrates pass throughthe three etching stations in sequence through line body conveying, the spraying pressure of the three etching stations is gradually increased, the concentration of etching liquid is gradually reduced, a large amount of etching of metal etching layers on the PCB substrates is completed through different parameters, and basic forming etching and high-precision forming etching are carried out, so that high-precision etching production of the flexible PCB is completed. The system and the method are simple in structure, high in production efficiency, high in etching precision and suitable for mass production of high-precision miniature circuit boards, and the efficiency of an existing production line can be greatly improved by modifying the prior art.

Owner:WUHAN UNIV

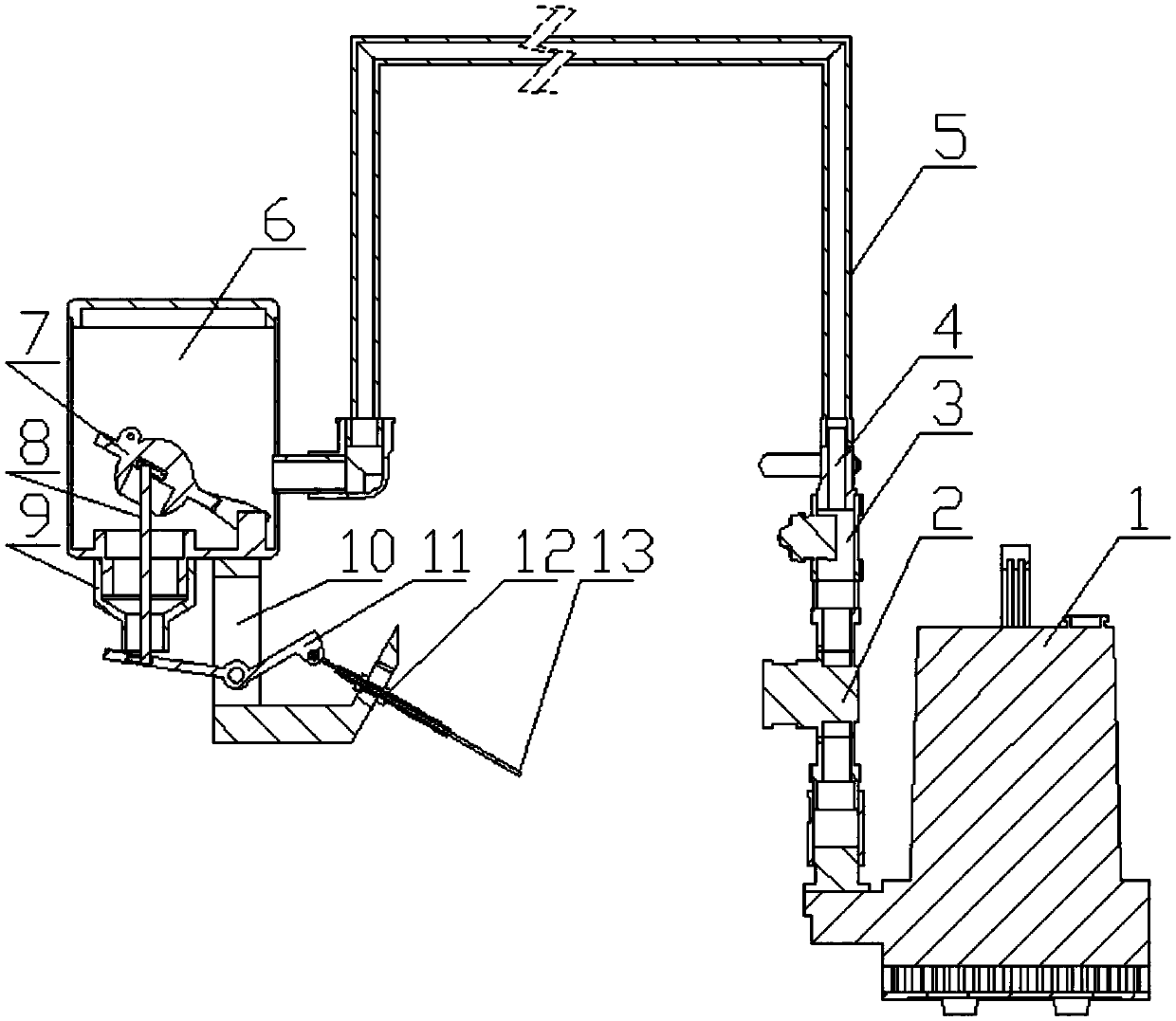

Root water spraying system and implementing method thereof

ActiveCN105494039AReduce the watering timeIncrease spray pressureWatering devicesCultivating equipmentsAutomatic controlWater discharge

The invention discloses a root water spraying system. The root water spraying system is characterized by comprising a transplanter, a water tank, a fixing frame, a water supply mechanism, a water storage tank and a spraying mechanism, wherein the water tank is arranged on the transplanter, the water storage tank is mounted on the transplanter through the fixing frame, the spraying mechanism is connected with the water storage tank, and the water supply mechanism is connected with the water storage tank. The water storage tank simultaneously stores water and pressure, the water discharge time is shortened and the water spraying pressure is increased by means of high pressure in the water storage tank; meanwhile, the water spraying amount can be controlled by regulating the pressure in the water storage tank. A water control switch is mounted, a submerged pump is automatically controlled by use of water flow, and energy conservation and environmental protection are realized. The working efficiency is improved, the labor intensity is reduced, and water resources are saved. The system is simple in structure, can realize automation to a certain extent and has high popularization applicability.

Owner:SOUTH CHINA AGRI UNIV

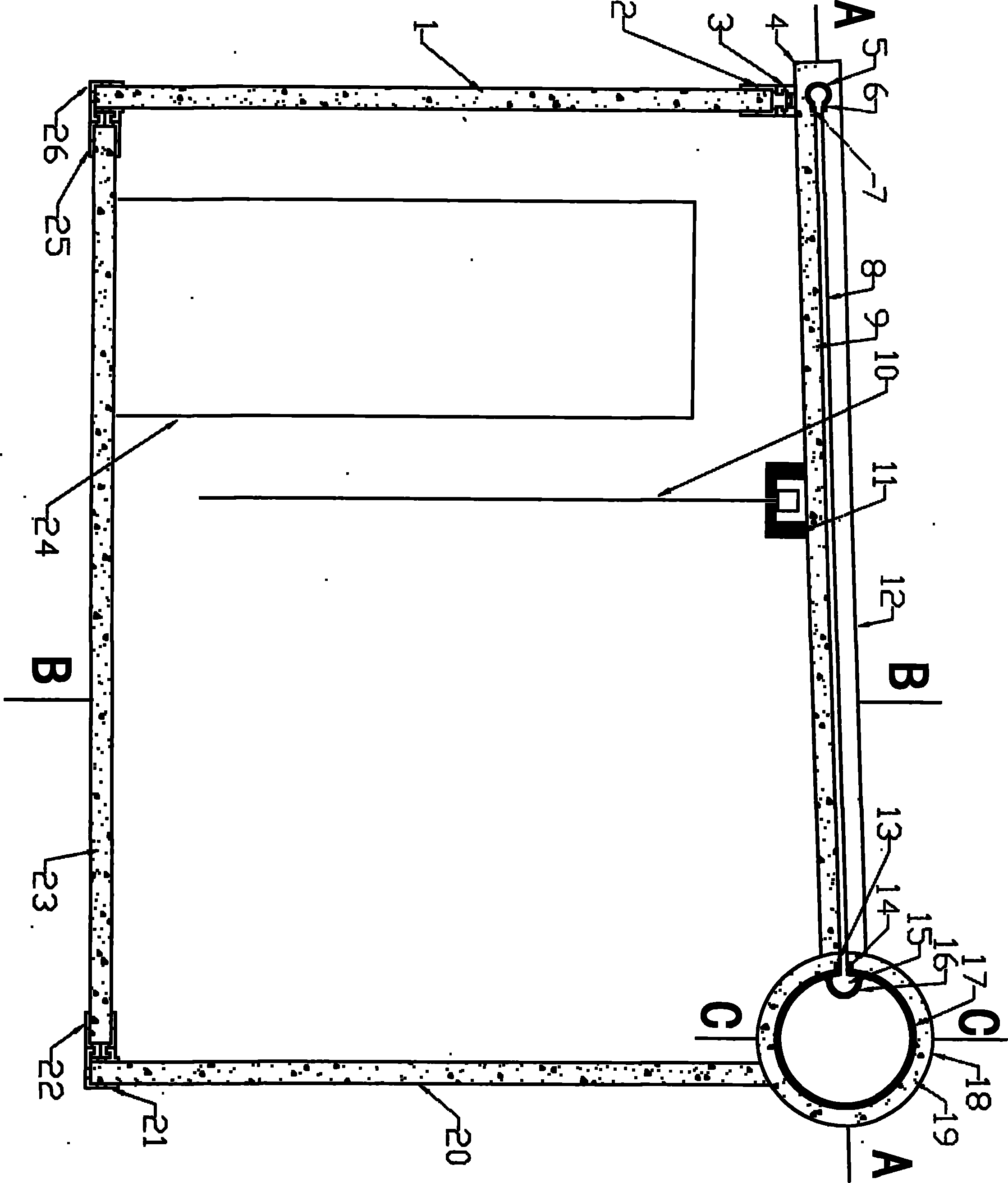

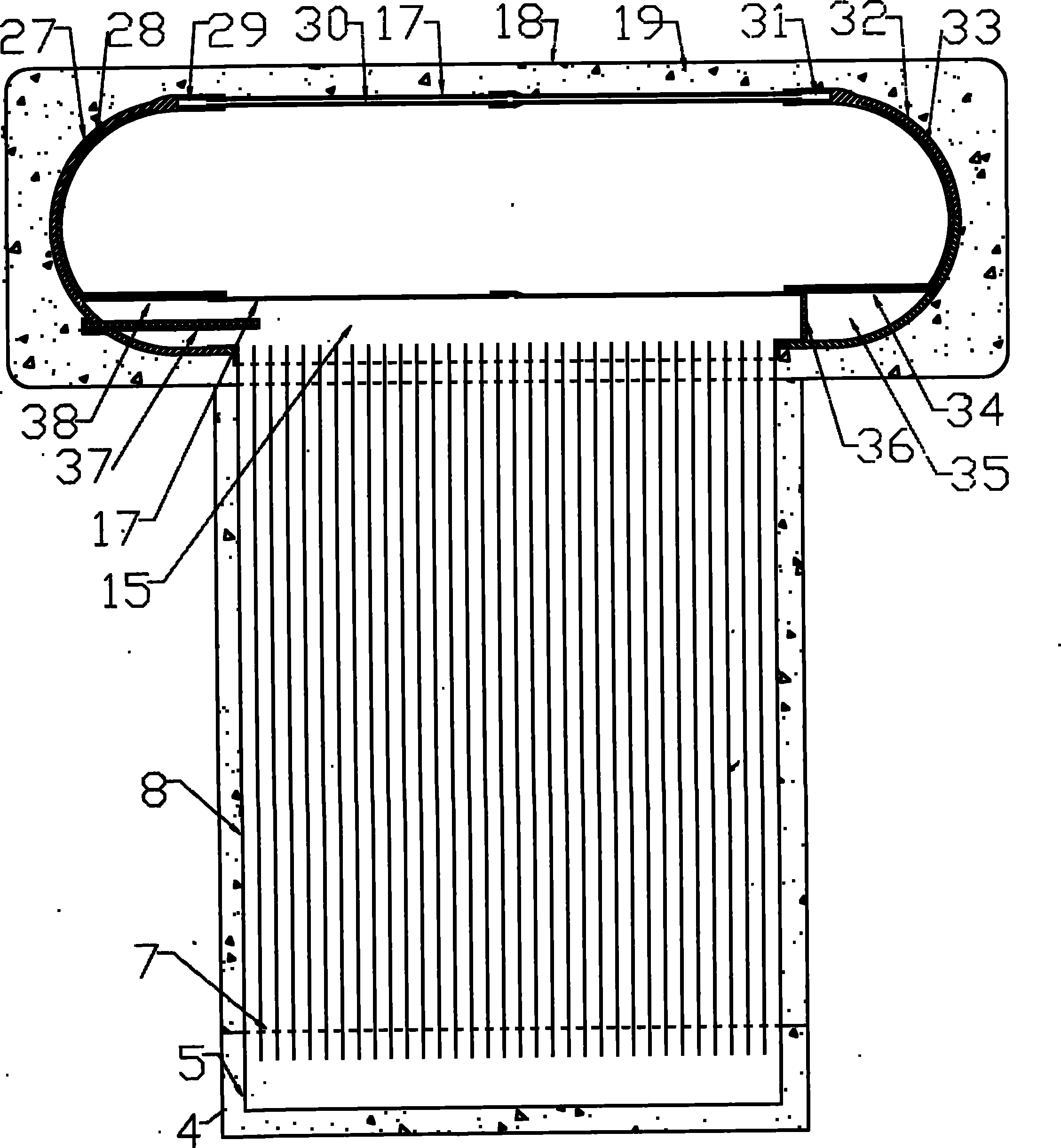

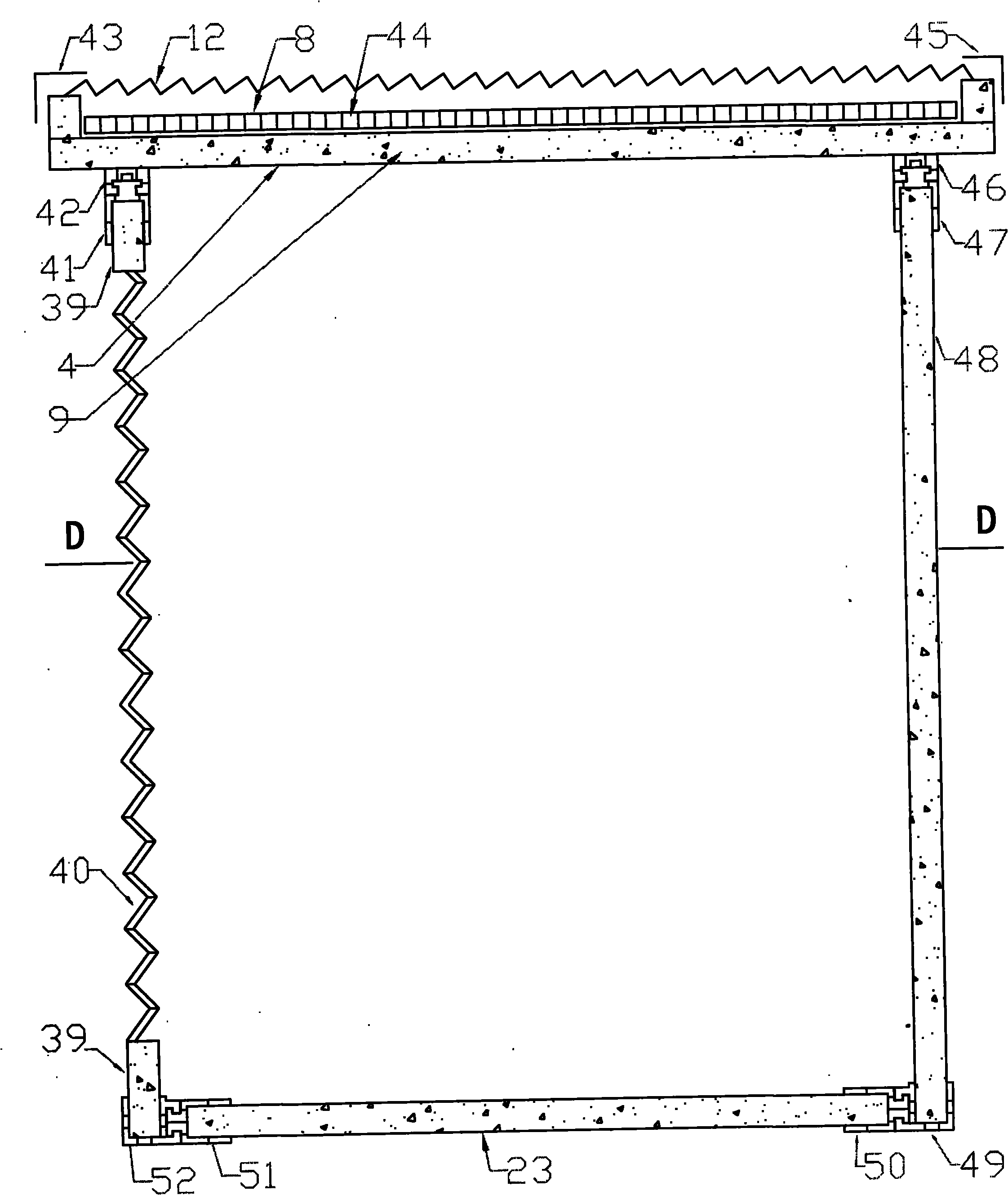

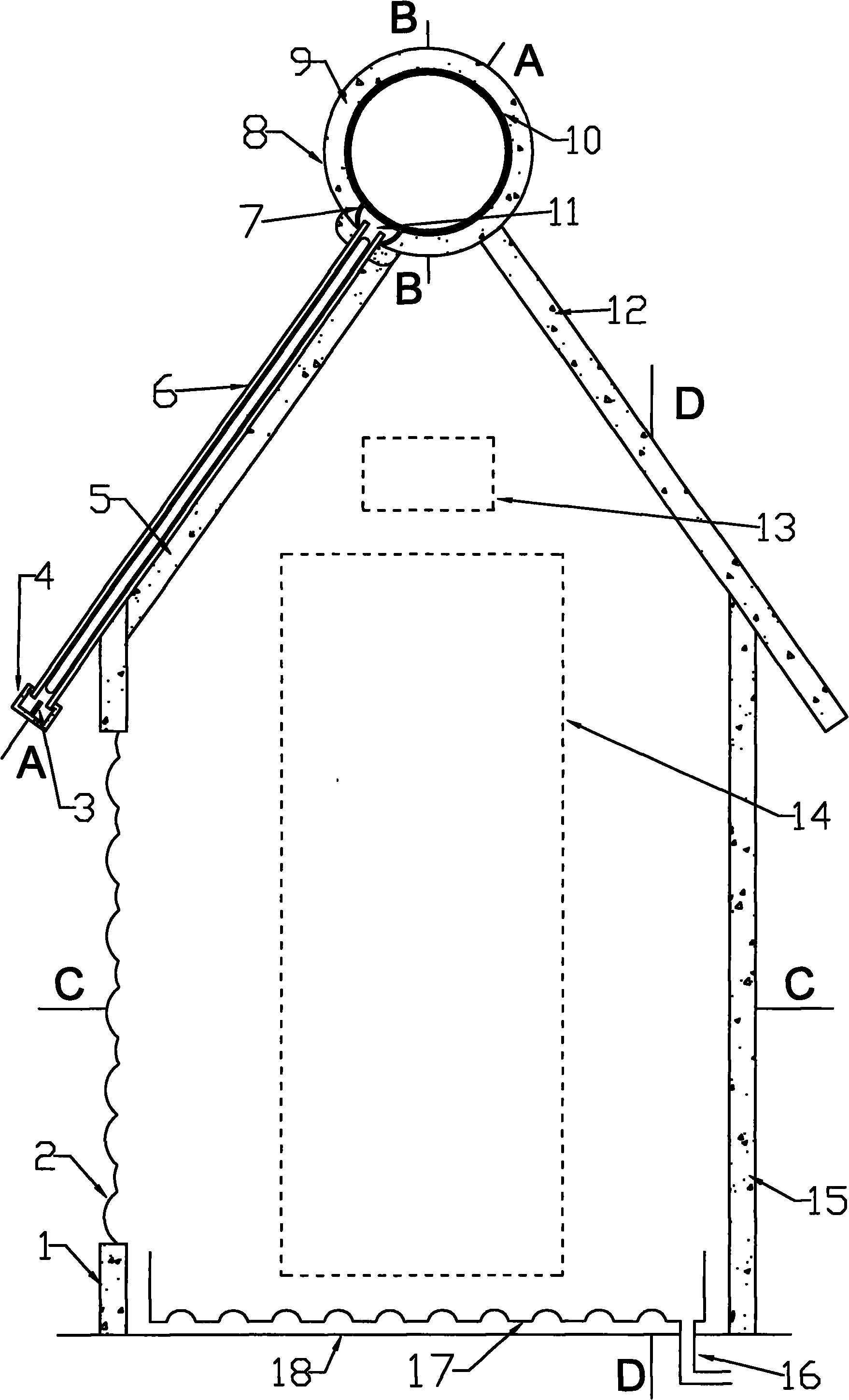

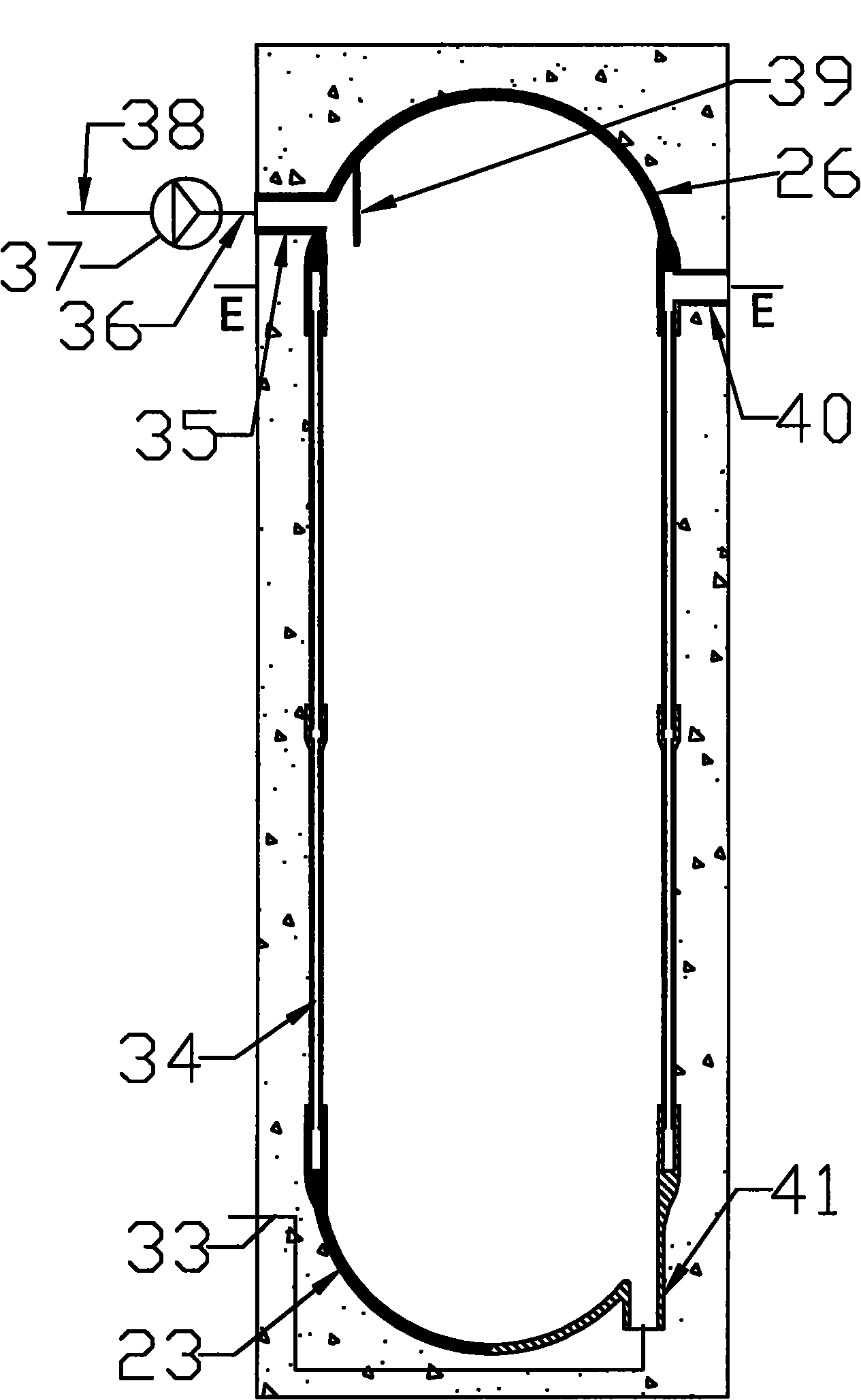

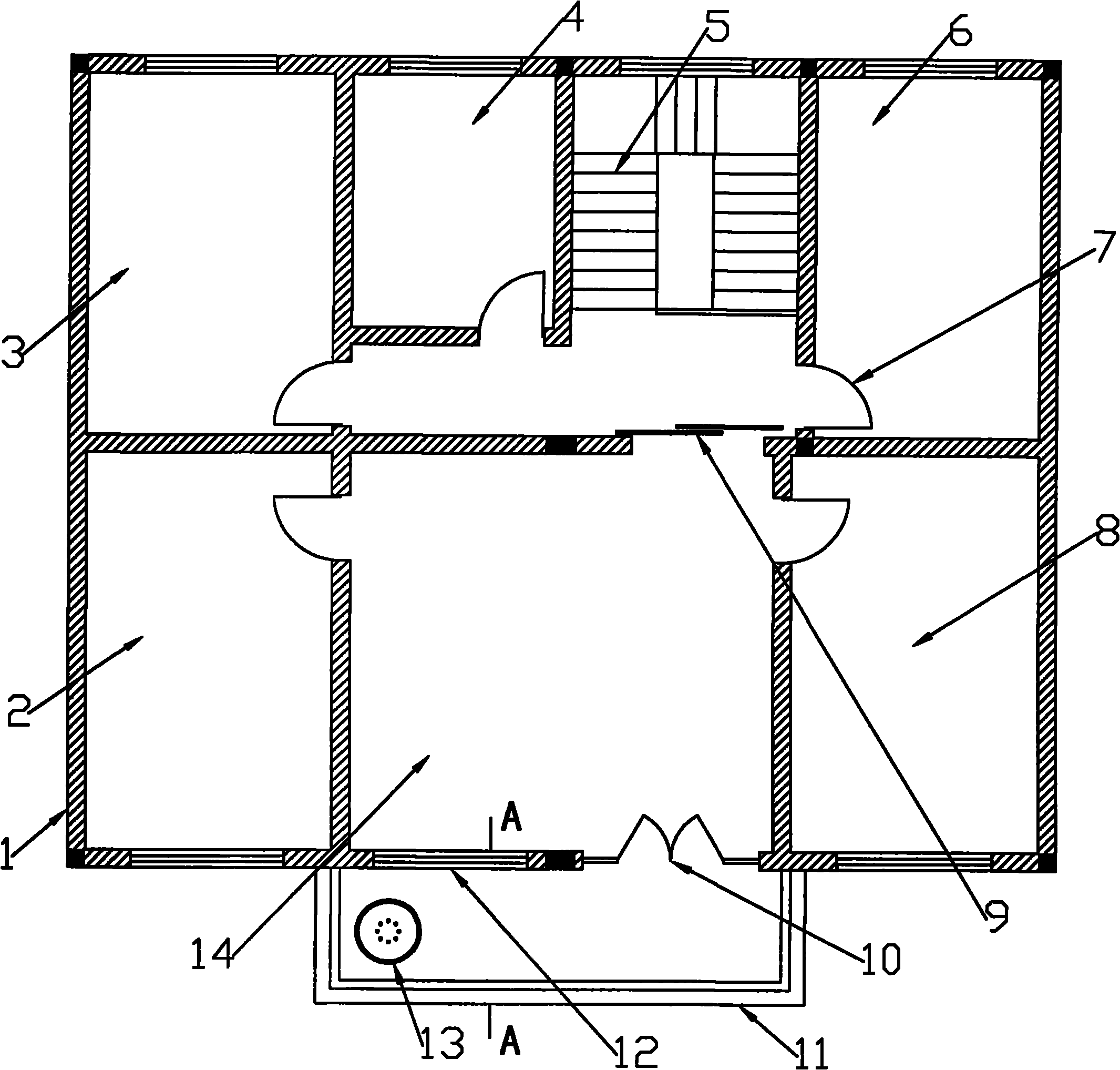

Flat-plate type roofed solar bathroom

InactiveCN101988337ASave raw materialsImprove heat transfer efficiencySolar heating energyWallsCold winterSolar water

The invention discloses a flat-plate type roofed solar bathroom, which is composed of a solar greenhouse, a pressure-bearing double-cycle solar water heater and connecting pipes thereof. The space jointly enclosed by heat insulation wallboards, a concentrator, a heat insulation water tank, a bilayer toothed transparent plate, a door, windows and the ground is the solar greenhouse. In the invention, one part of the water tank wall also serves as one part of a collector pipe, and the water tank wall is a heat exchanger, thus saving the raw materials and improving the heat transfer efficiency. In the invention, the pressure-bearing double-cycle solar water heater and the solar greenhouse are integrally designed, thus being capable of providing a great quantity of domestic hot water as well as a bathing space with the room temperature of 25-45 DEG C, therefore, a bathroom can be rapidly heated and is maintained at a constant temperature by adopting hot water in the water tank even in a cold winter night. The balcony of the bathroom not only serves as a balcony with all intrinsic functions, but also can be used as a bathroom or a toilet as well as a ventilation channel between adjacent rooms.

Owner:侯国山

Method for preventing circuit board solder mask ink from blocking hole

InactiveCN102548232ALow costNo cloggingInsulating layers/substrates workingNon-metallic protective coating applicationSolder maskPrinting ink

The invention discloses a method for preventing circuit board solder mask ink from blocking a hole, which comprises the steps of utilizing a white net to perform silk-screen printing to one surface of a circuit board, spraying the other surface of the circuit board and flushing off the ink in a circuit board through hole. The method utilizes a screen printing plate with no blocking points to perform silk-screen printing ink to the board surface of the circuit board, and increases spraying pressure to the other surface of the circuit board when pre-baking, exposure and developing are performed to the board surface, flushes out the ink entering the through hole due to the silk-screen printing, and then repeats the steps to the other surface of the circuit board to achieve the whole silk-screen printing process. Compared with the prior art, the silk-screen printing ink on the surfaces of the whole circuit board is comprehensive, the phenomenon that no ink exists on the outer side of the through hole is not caused, and the situation that the hole is blocked does not exist. In addition, the screen printing plate with no blocking points is not required to be manufactured, and the method for preventing the circuit board solder mask ink from blocking the hole has the advantage of being low in cost.

Owner:DALIAN CHONGDA CIRCUIT

Rapid-washing automobile dry cleaning agent

InactiveCN103160384AIncrease spray pressurePromote gasificationNon-ionic surface-active compoundsDetergent compounding agentsCarnuba waxWater resources

The invention provides a rapid-washing automobile dry cleaning agent which consists of carnauba wax, OP-10 emulgator, sun-screening agent, aminoethylisothiourea (AET)-1 conditioning agent, AET-2 conditioning agent and emulsifying carnauba wax. The dry cleaning agent includes by mass 70% carnauba wax, 10% OP-10 emulgator, 5% sun-screening agent, 5% aminoethylisothiourea (AET)-1 conditioning agent, 5% AET-2 conditioning agent and 5 % emulsifying carnauba wax. The invention further provides a cleaning method of the rapid-washing automobile dry cleaning agent and a packing method of the rapid-washing automobile dry cleaning agent. Technical problems that in the existing car-washing technology, water resources are wasted, the environment is polluted and the paint surface is damaged are solved and the car-washing efficiency is improved.

Owner:ZHEJIANG TIANTAI SUNSHINE IND & TRADE

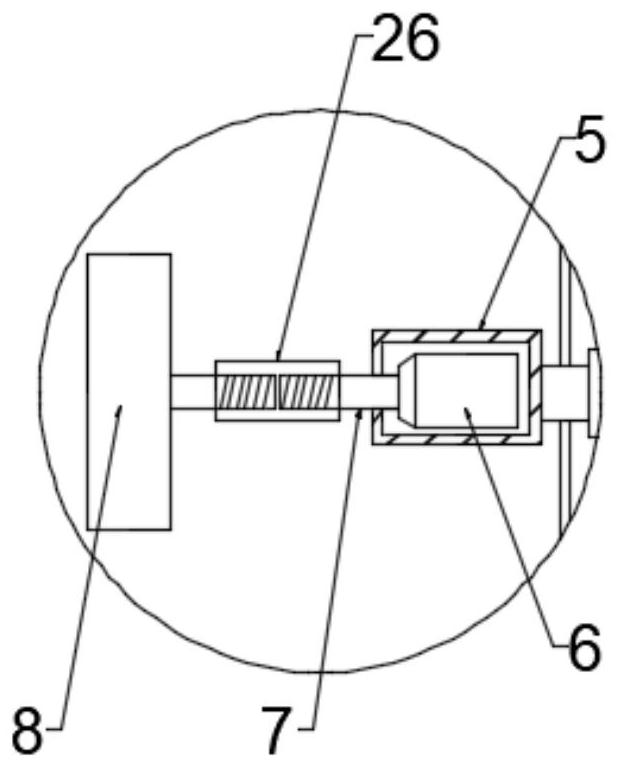

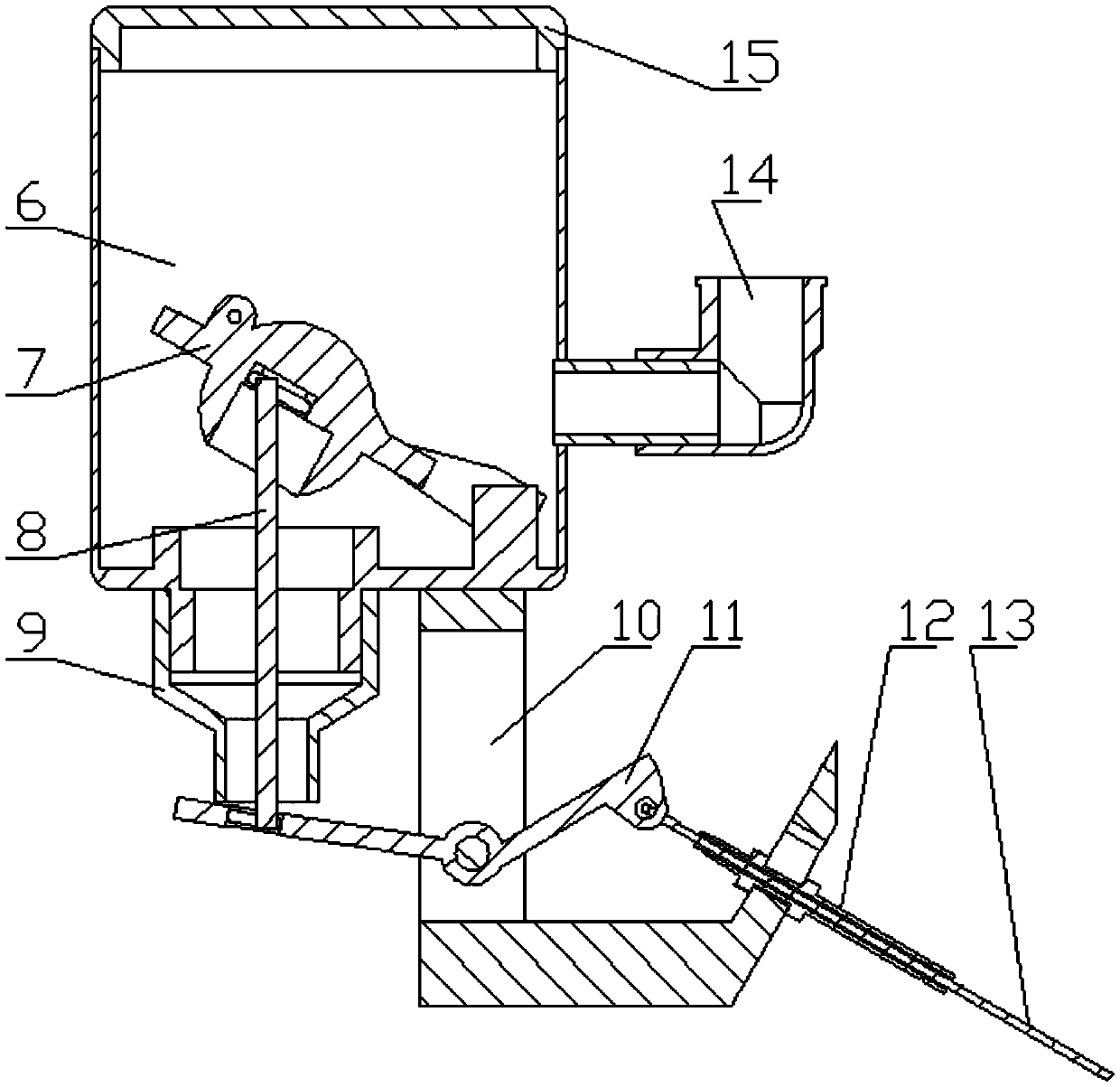

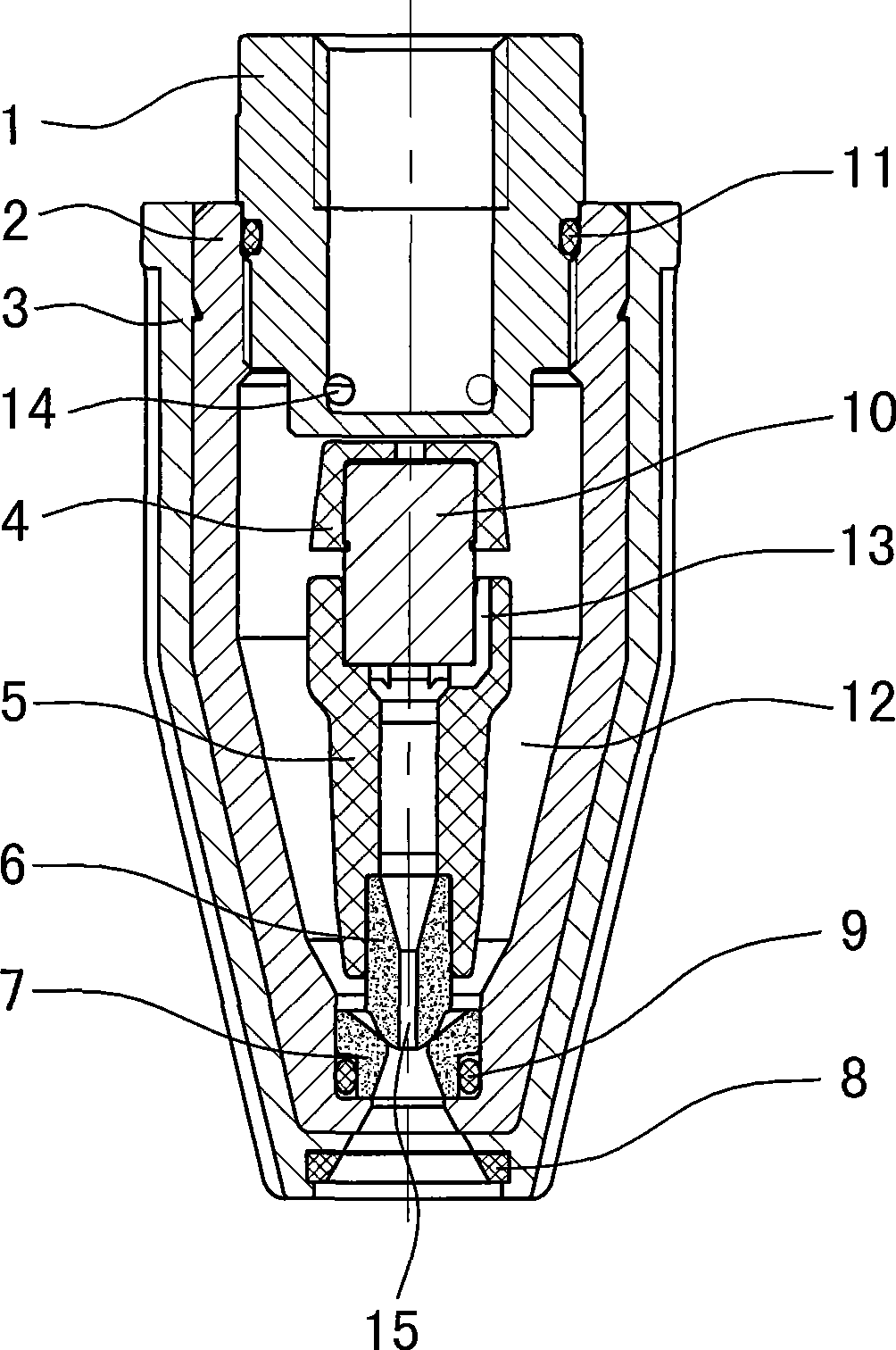

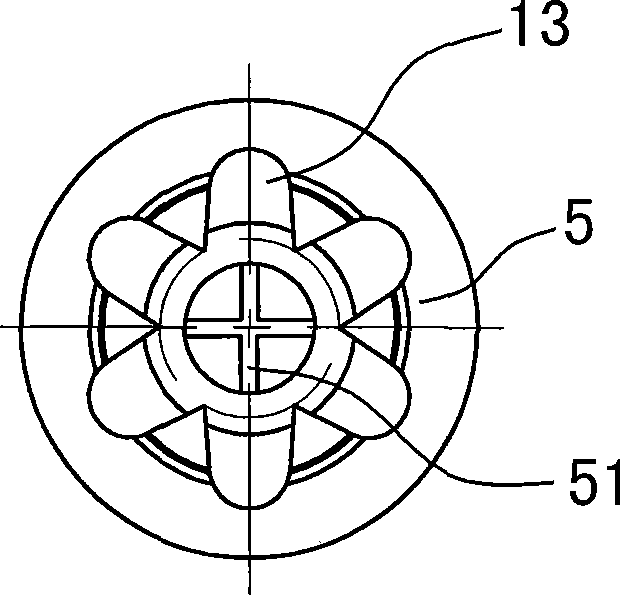

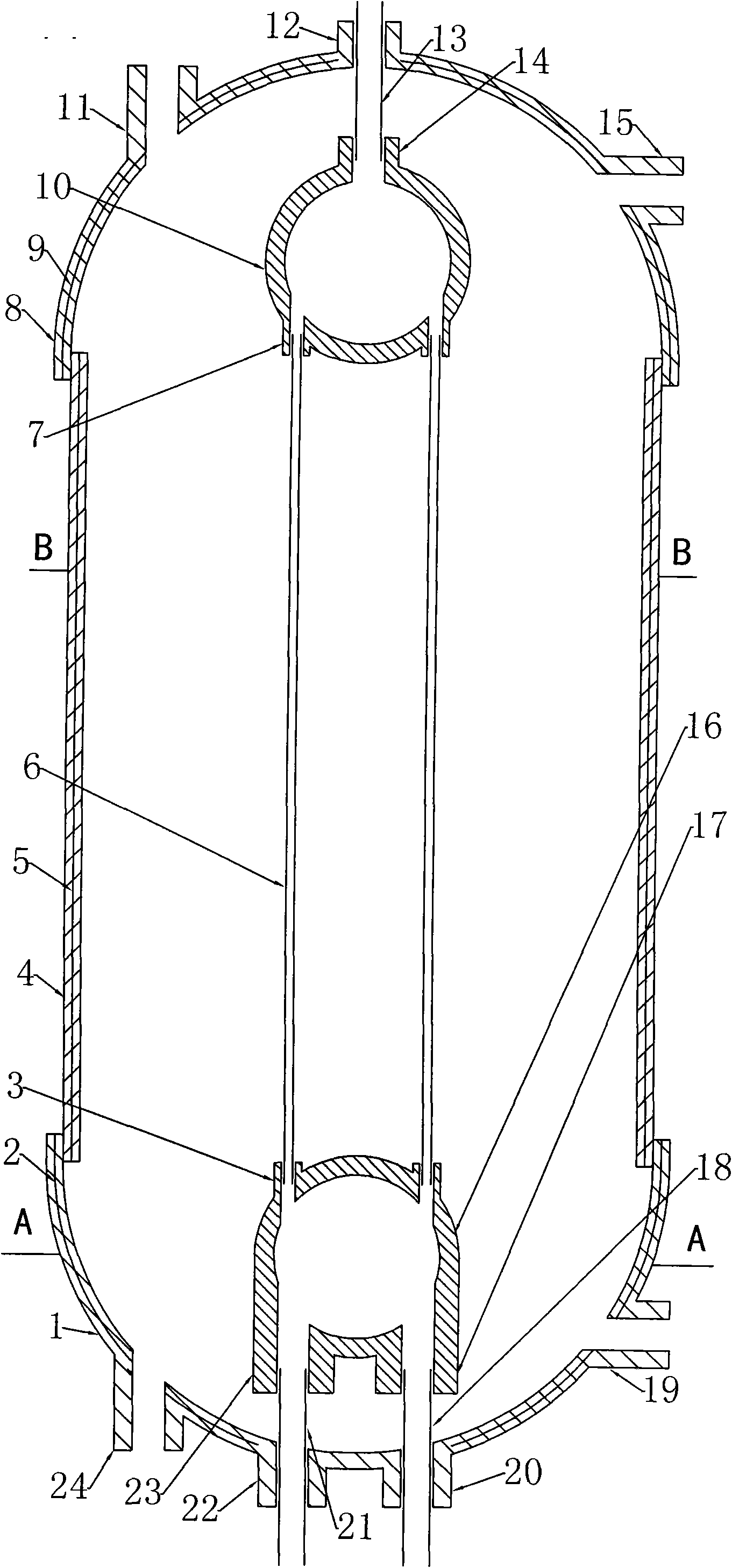

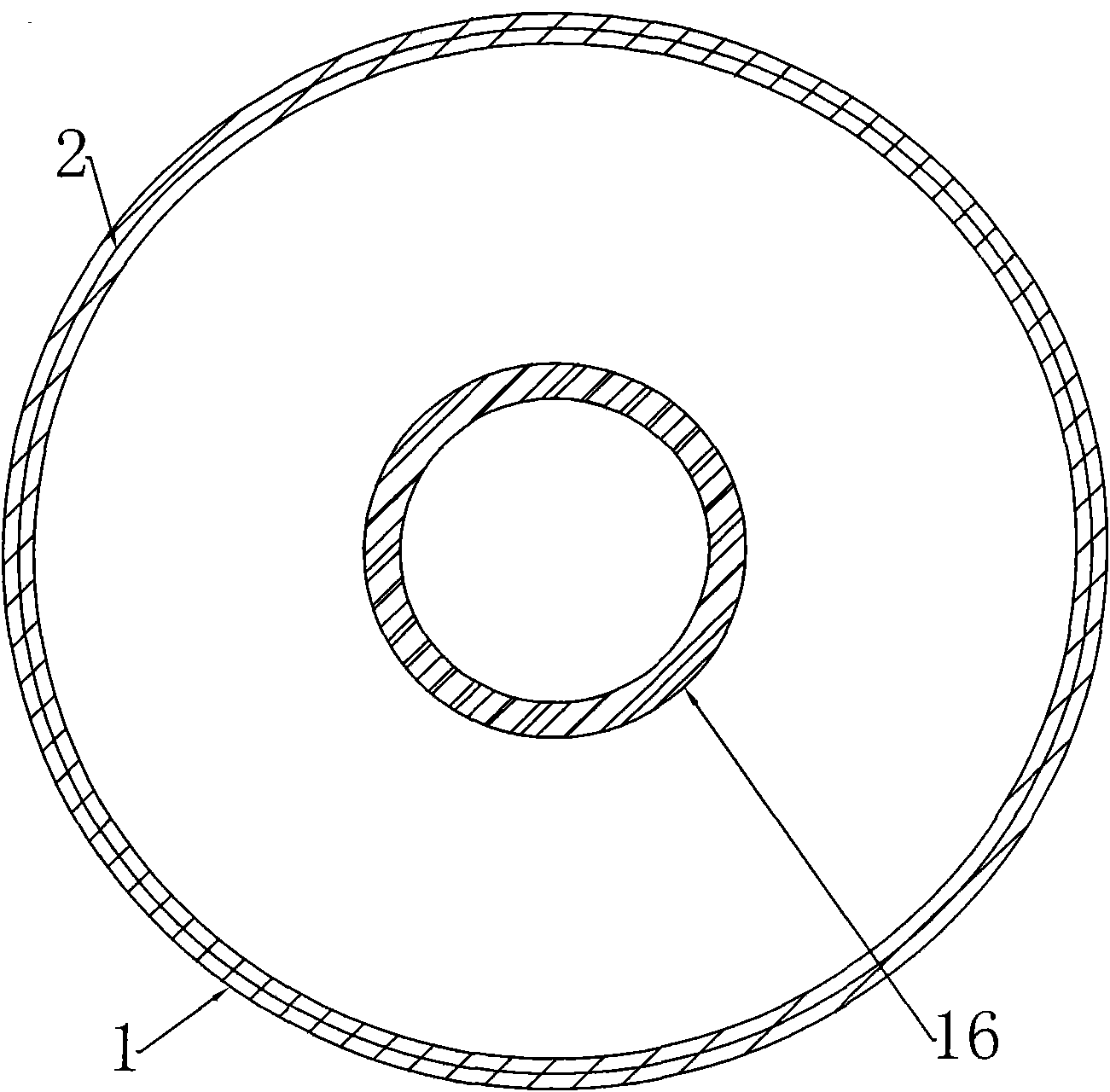

Rotary nozzle of washer

InactiveCN101428260AIncrease spray pressureImprove washing effectMovable spraying apparatusCleaning using liquidsNozzleEngineering

A rotating nozzle of a cleaning machine comprises a nozzle holder connected with a spray boom; a nozzle cage is connected with the nozzle holder; the nozzle cage is sleeved with a nozzle sheath; a nozzle core is arranged in the nozzle cage; and a spray hole is formed on the nozzle core. The rotating nozzle is characterized in that a nozzle rotating seat is installed in the head of the nozzle cage; the nozzle core is in movable fit with the nozzle rotating seat; a nozzle core sleeve is connected with the nozzle core; the nozzle core sleeve is connected with a fixed pin; a pin cap is arranged on the fixed pin; a spraying channel is arranged between the fixed pin and the nozzle core sleeve; a spraying cavity is formed between the nozzle core sleeve and the nozzle sleeve; and two water inlets at an angle of 180 degrees are formed in the nozzle holder and introduced into the spraying cavity. When the nozzle core adopts a 0 degree spraying hole, the spraying pressure is high and the flushing effect is good; and when the nozzle core is swung and rotated, the spraying degree of the spraying hole is constantly changed and the spraying area is enlarged, thereby being equivalent to the effect caused by a 40 degree spraying hole. The invention has the advantages that the cleaning speed is high, the time is saved and the resource is saved.

Owner:罗昌国

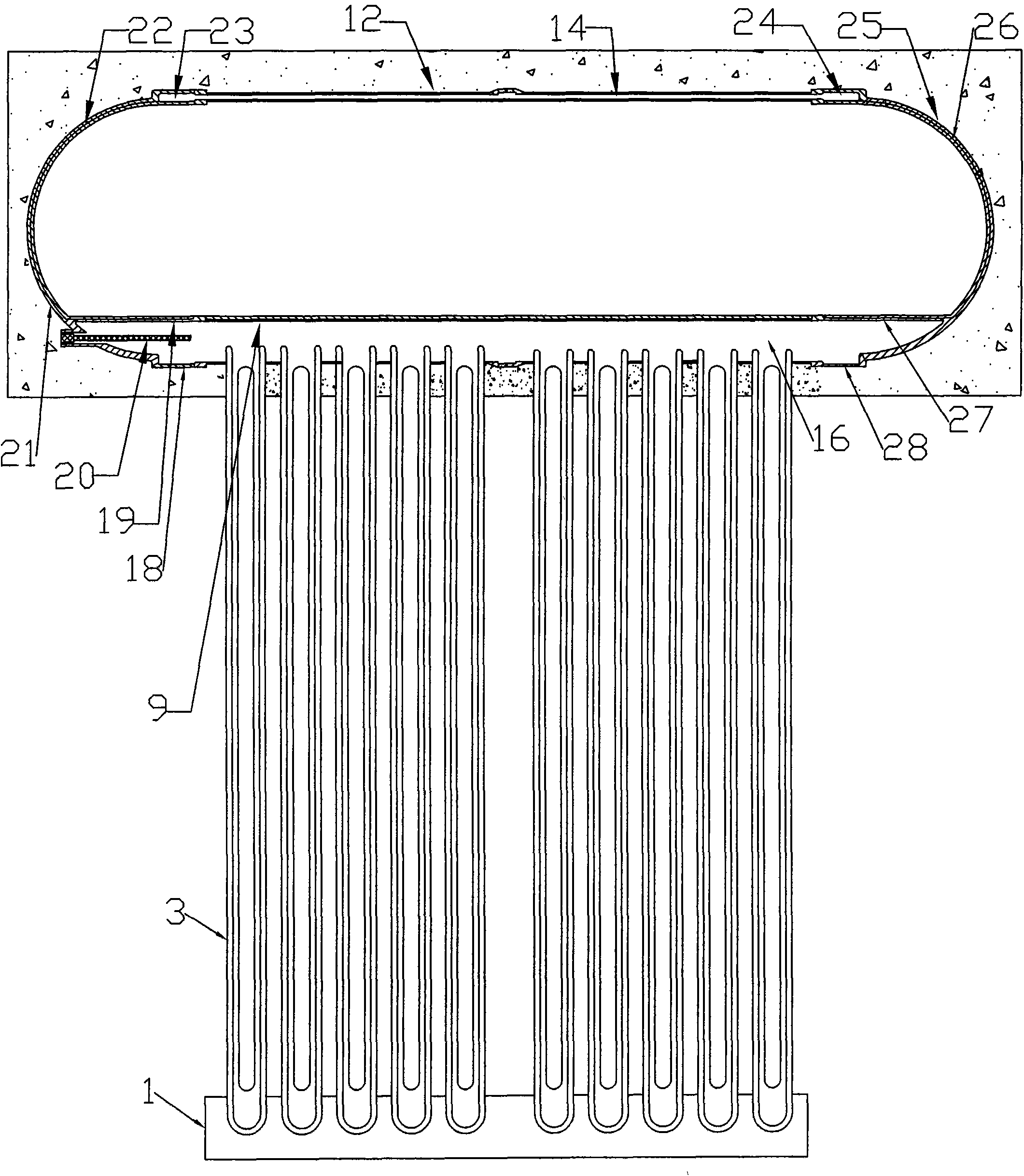

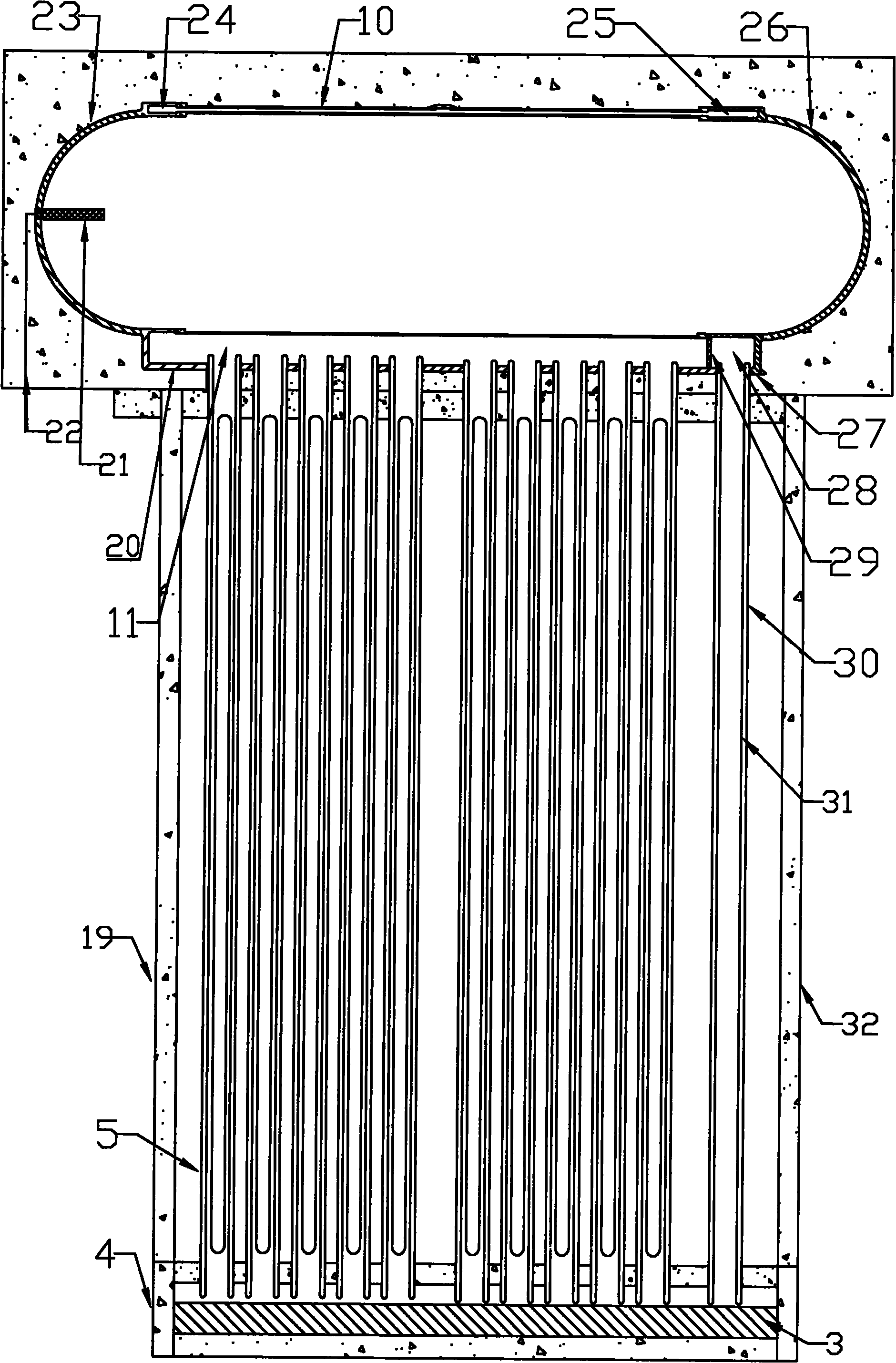

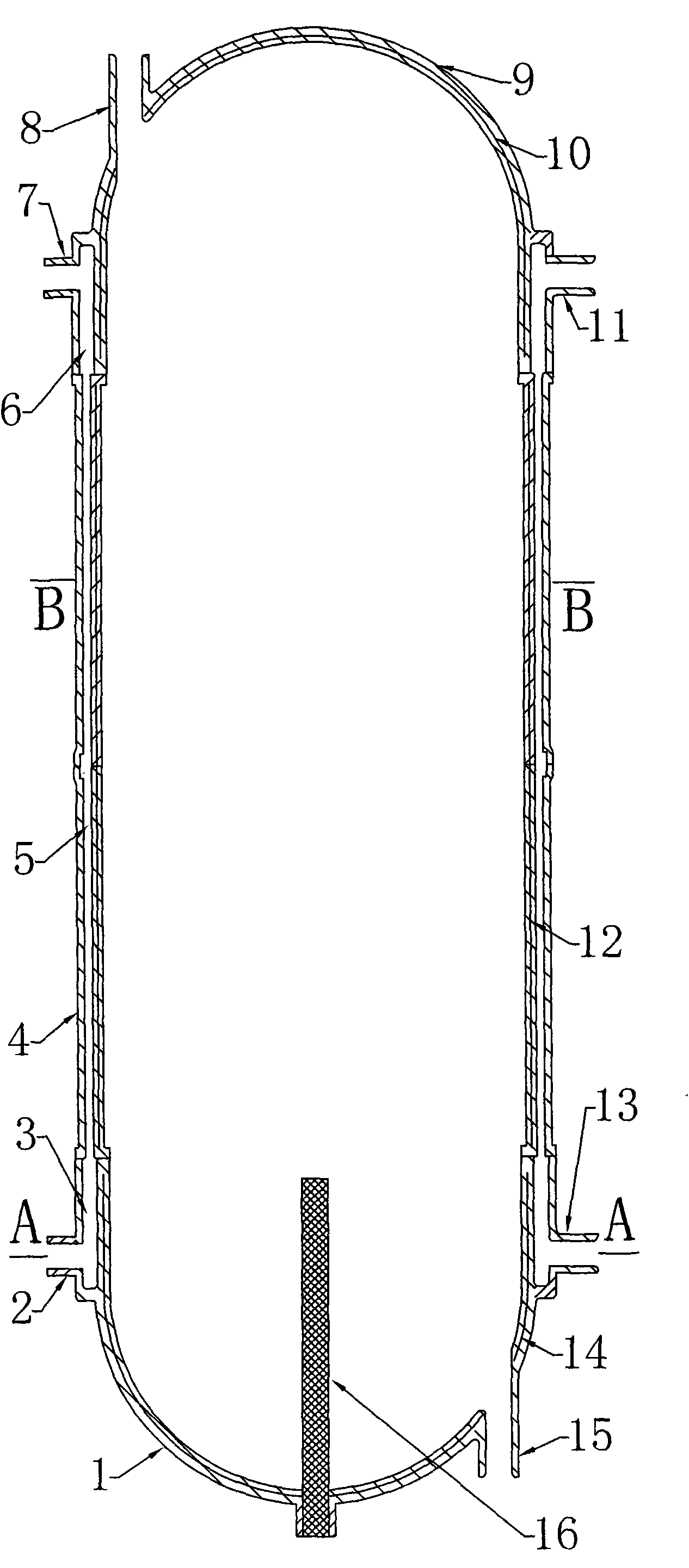

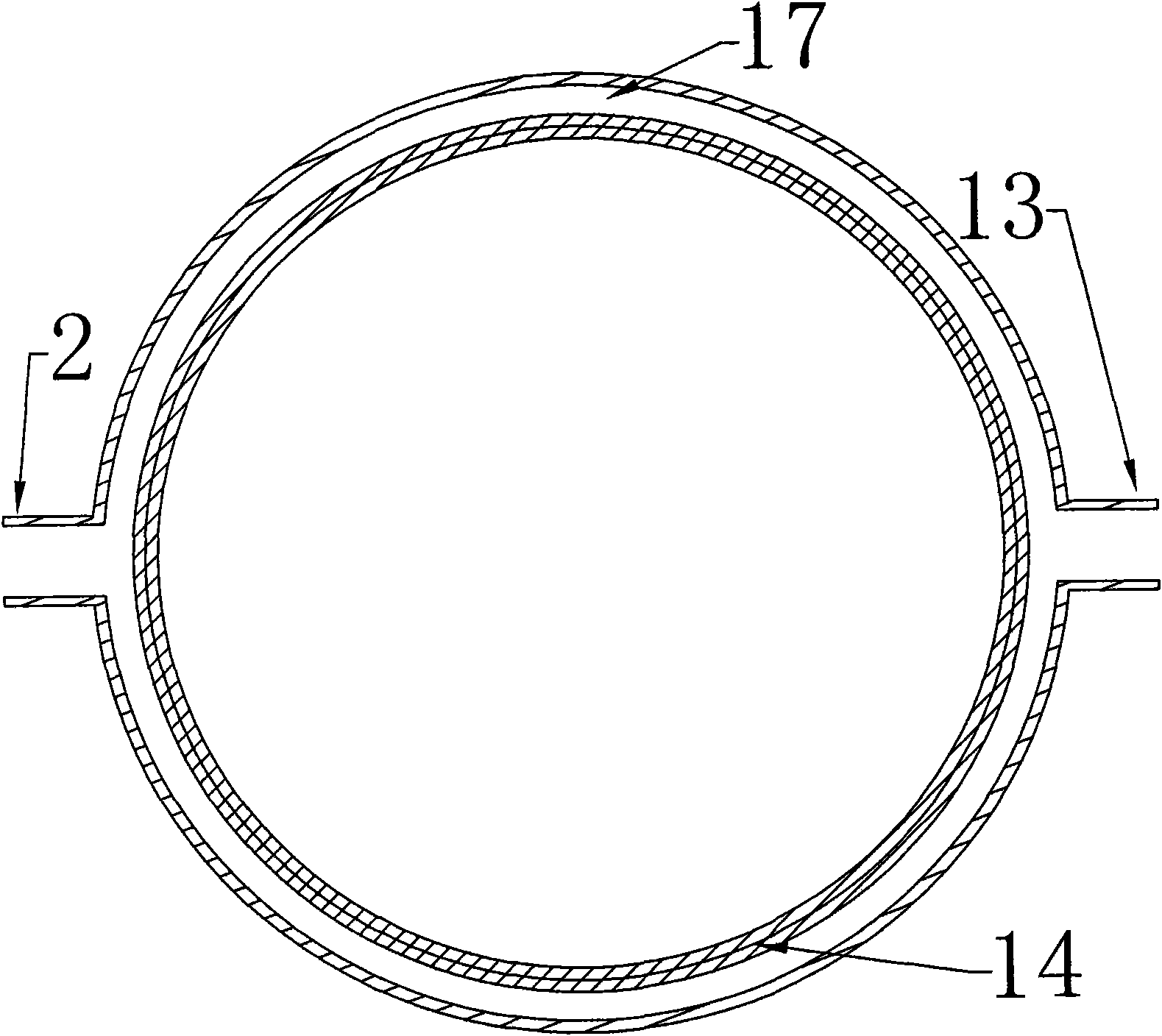

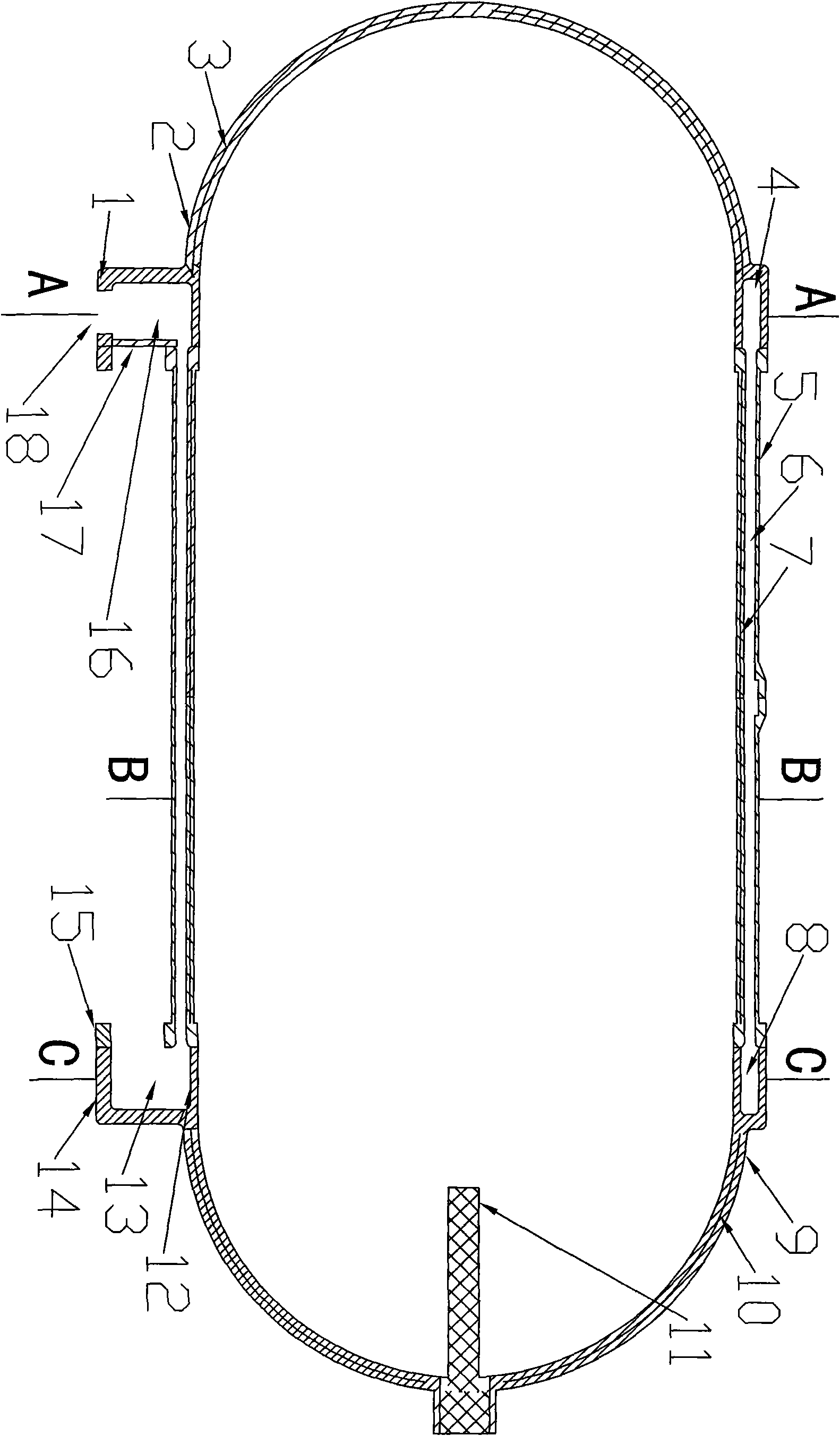

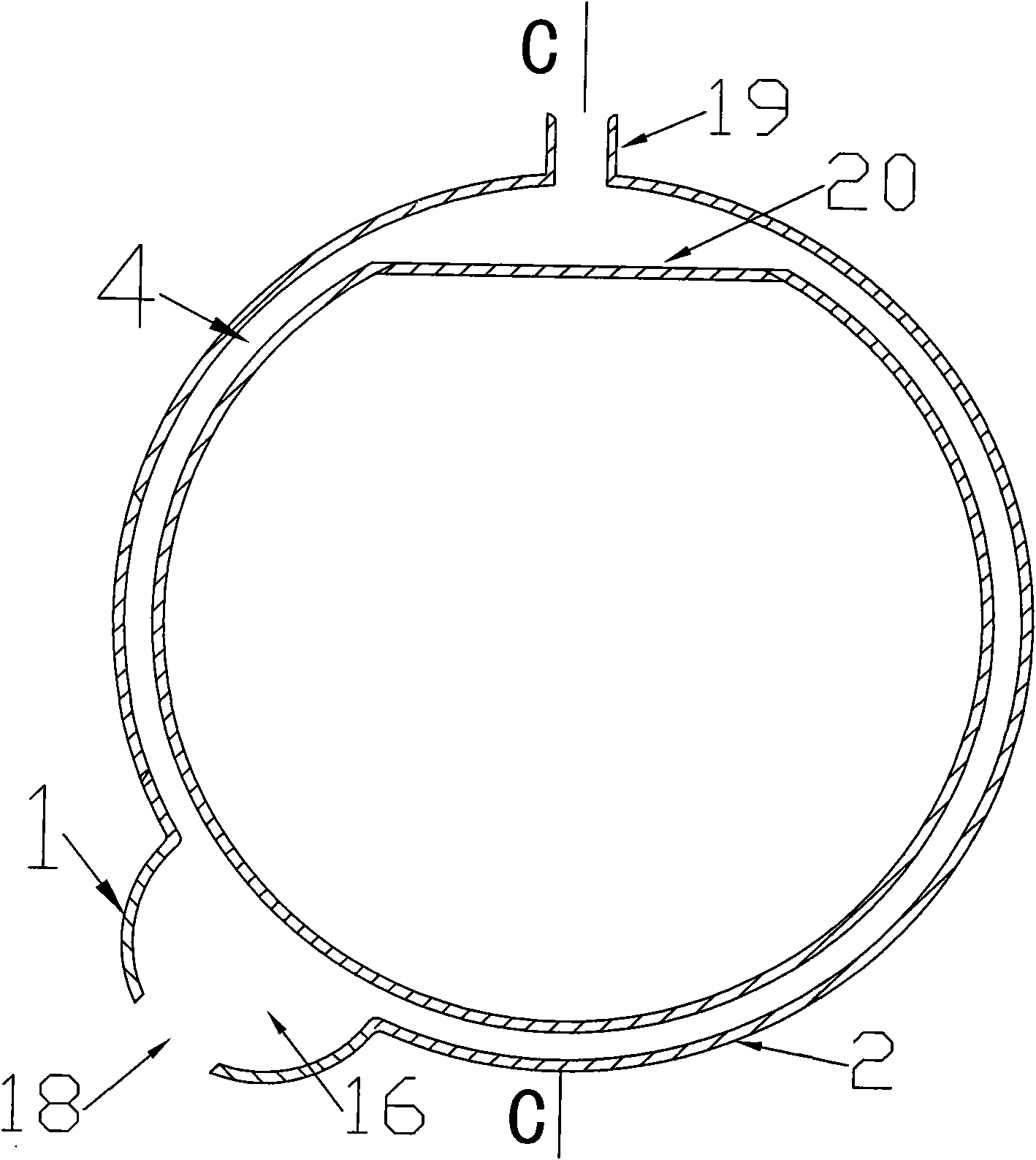

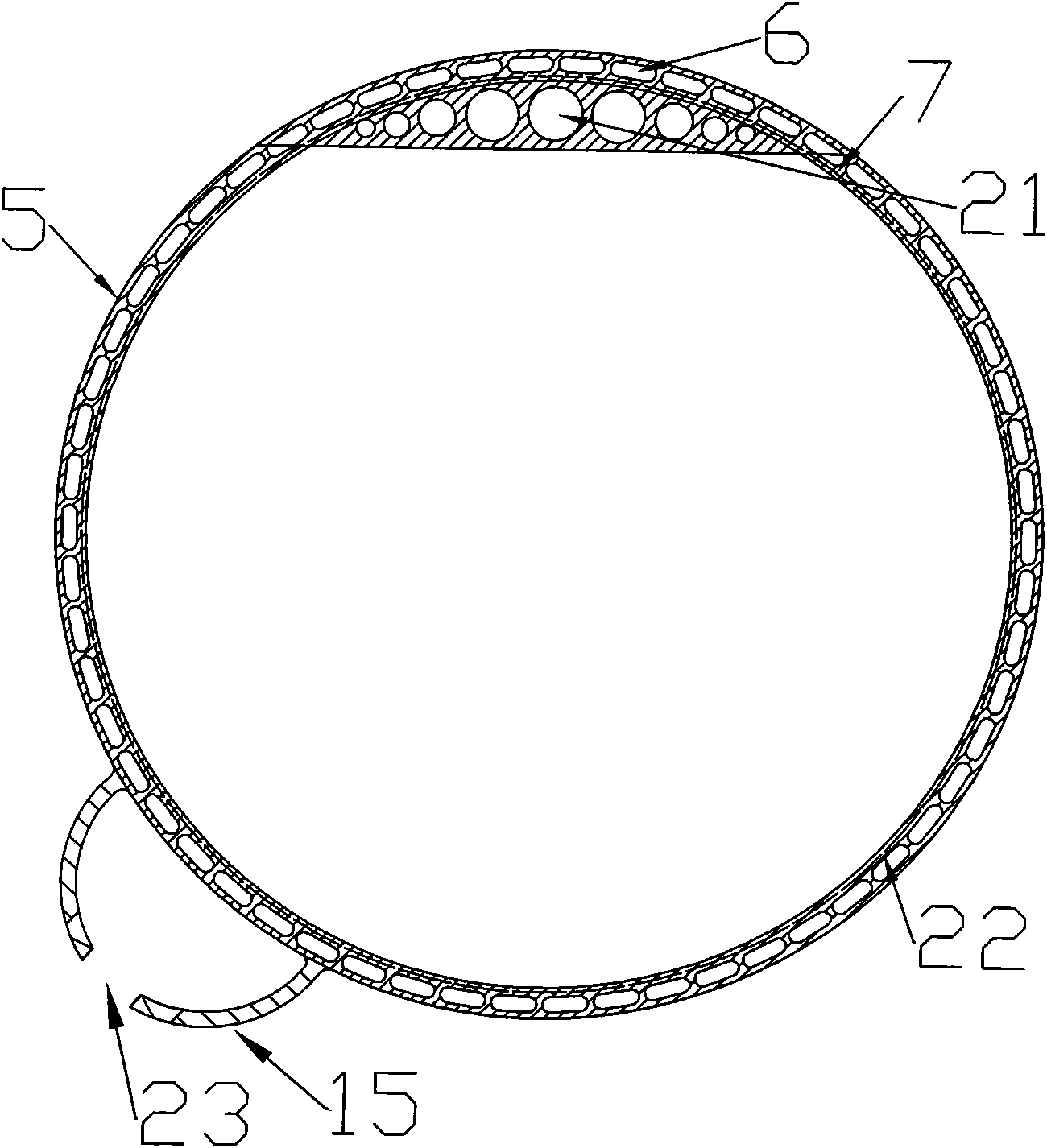

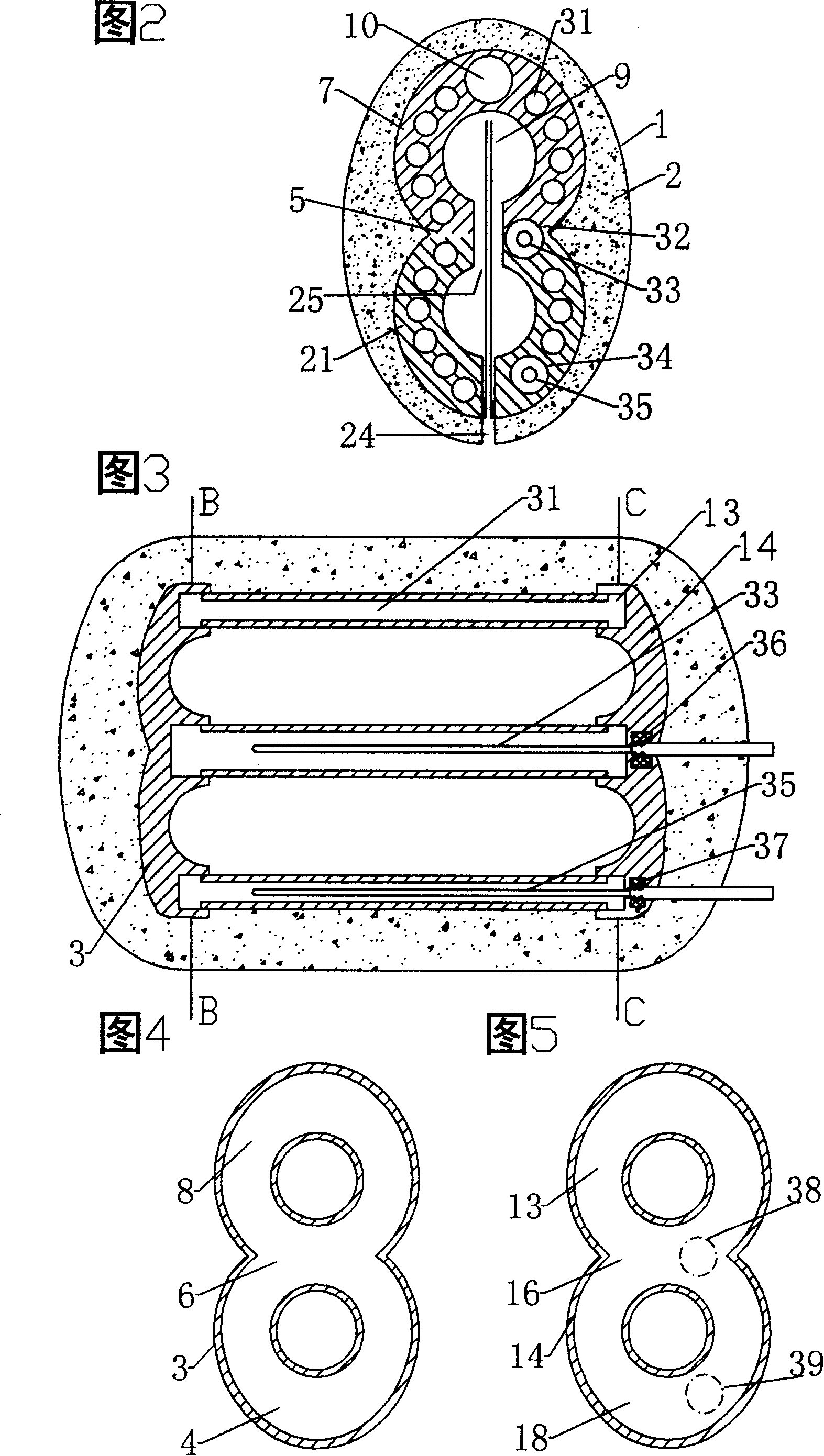

All-plastic straight pressure-bearing double-cycle solar water heater

InactiveCN101988749ASave raw materialsImprove heat transfer efficiencySolar heating energySolar heat devicesHeat resistanceSolar water

The invention discloses an all-plastic straight pressure-bearing double-cycle solar water heater, comprising a heat insulation water tank, a full-glass tri-cavity vacuum solar collector tube, a tail box and a bracket. An annular groove on the end cover is connected with the water tank to form an annular hole, and the annular hole is communicated with the holes in the water tank wall and is communicated with a collection pipe. In the invention, one part of the water tank also serves as one part of a water collecting tube, multiple holes in the water tank wall provide a circular channel for heating cycle, and the water tank wall is a heat exchanger, thus saving the raw materials and improving the heat transfer efficiency. In the invention, the heat exchange surface is big enough, thus the heat resistance is small, the heat exchange temperature is low, the heat exchange surface is prevented from scaling, and higher heat transfer efficiency can be maintained forever. The liner in the invention is mainly made from a polymer material and has the advantages of long service life, high reliability, simple production process, capability of large-scale industrialized production and wide market prospect, a great quantity of metal raw materials are saved, and the system manufacturing cost is greatly lowered.

Owner:侯国山

Direct insertion pressure bearing double-circulation solar bathroom

InactiveCN101988330ASave raw materialsImprove heat transfer efficiencySolar heating energyWallsGreenhouseSolar water

The invention relates to a direct insertion pressure bearing double-circulation solar bathroom which consists of a solar green house, a pressure bearing double-circulation solar water heater and a connecting pipe of the pressure bearing double-circulation solar water heater, wherein a space jointly circulated by a heat insulation wall plate, a heat insulation water tank, a light transmission plate, a door, a window and a heating floor is the solar green house, a part of the water tank wall of the invention is a part of a collecting pipe, and the water tank wall per se is a heat exchanger, so raw materials are saved, and heat transfer efficiency is also improved. After being matched with a support frame, the direct insertion pressure bearing double-circulation solar water heater of the invention can be used as an independent solar water heating device for use. Through the integral design of the pressure bearing double-circulation solar water heater and the solar green house of the invention, the invention can provide a large amount of hot water for living and can also provide a bath space with the room temperature capable of achieving 25 to 45 DEG C at the same time, hot water in the water tank can also be used at night in winter with cold north wind, so the temperature of the bathroom can be quick raised and can maintain the constant state.

Owner:侯国山

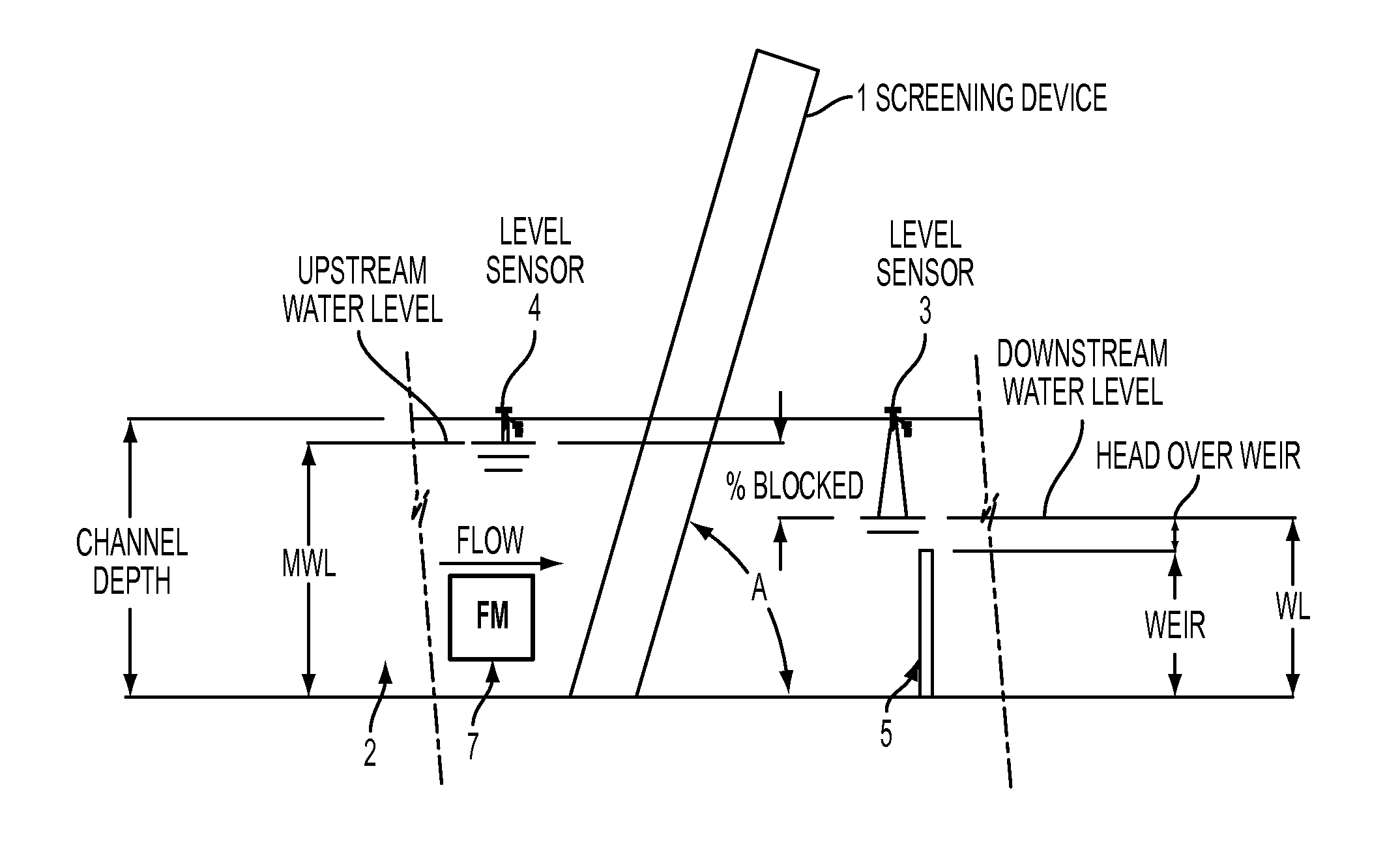

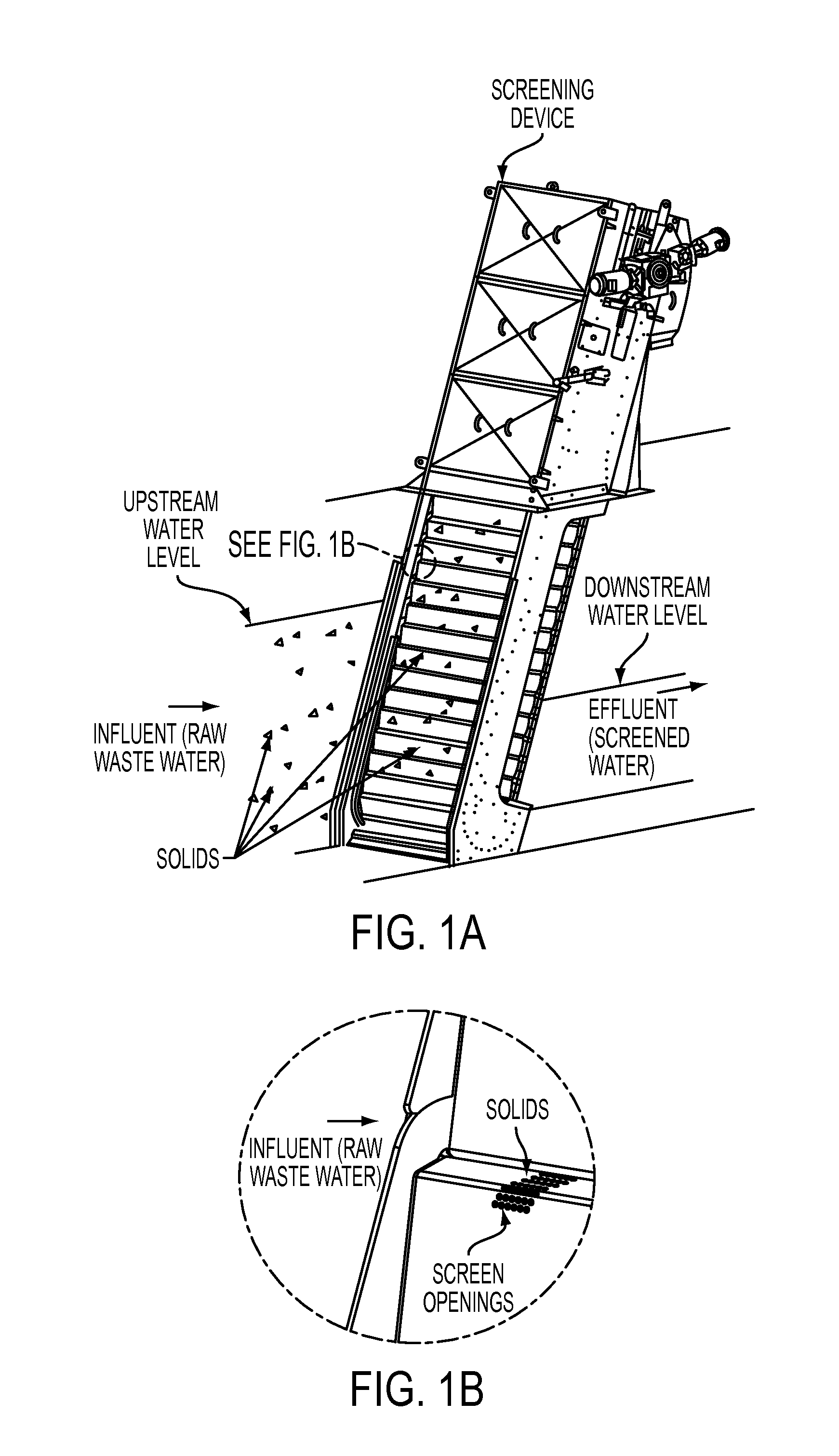

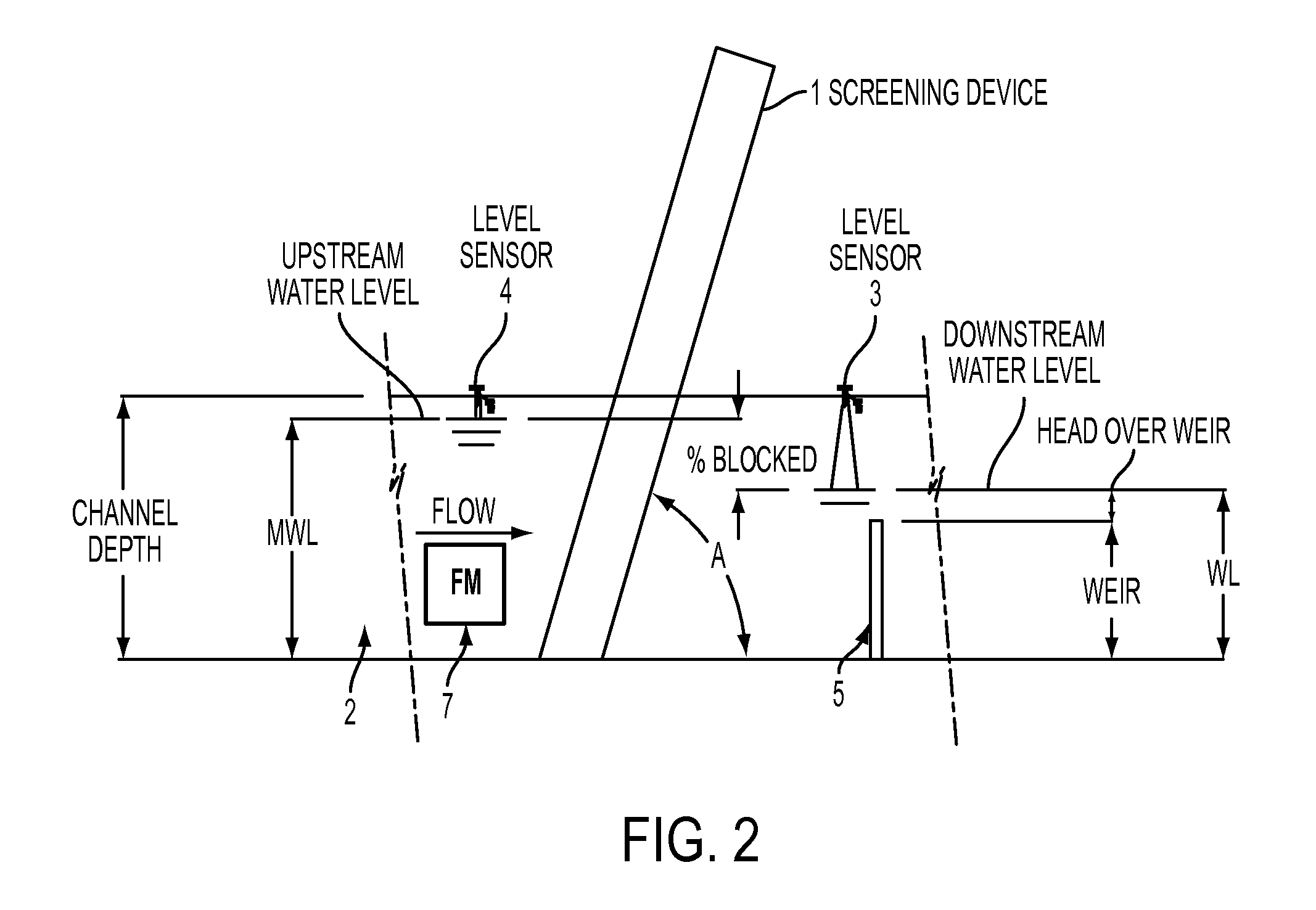

Screen blockage measurement and flow performance optimization system

ActiveUS20110315638A1Increase spray pressureIncrease flow rateWater/sewage treatmentSedimentation separationEngineeringStreamflow

An apparatus and method are provided that enable the control of a screening operation based on a calculated screen blockage percentage and the velocity throughput of the screen. The apparatus includes an upstream level detector, a downstream level detector and flume or weir placed downstream of the screen. The apparatus may further include a blockage determination unit which determines the percent screen blockage based on the flow level upstream of the screen and the flow level downstream of the screen.

Owner:SULZER MANAGEMENT AG

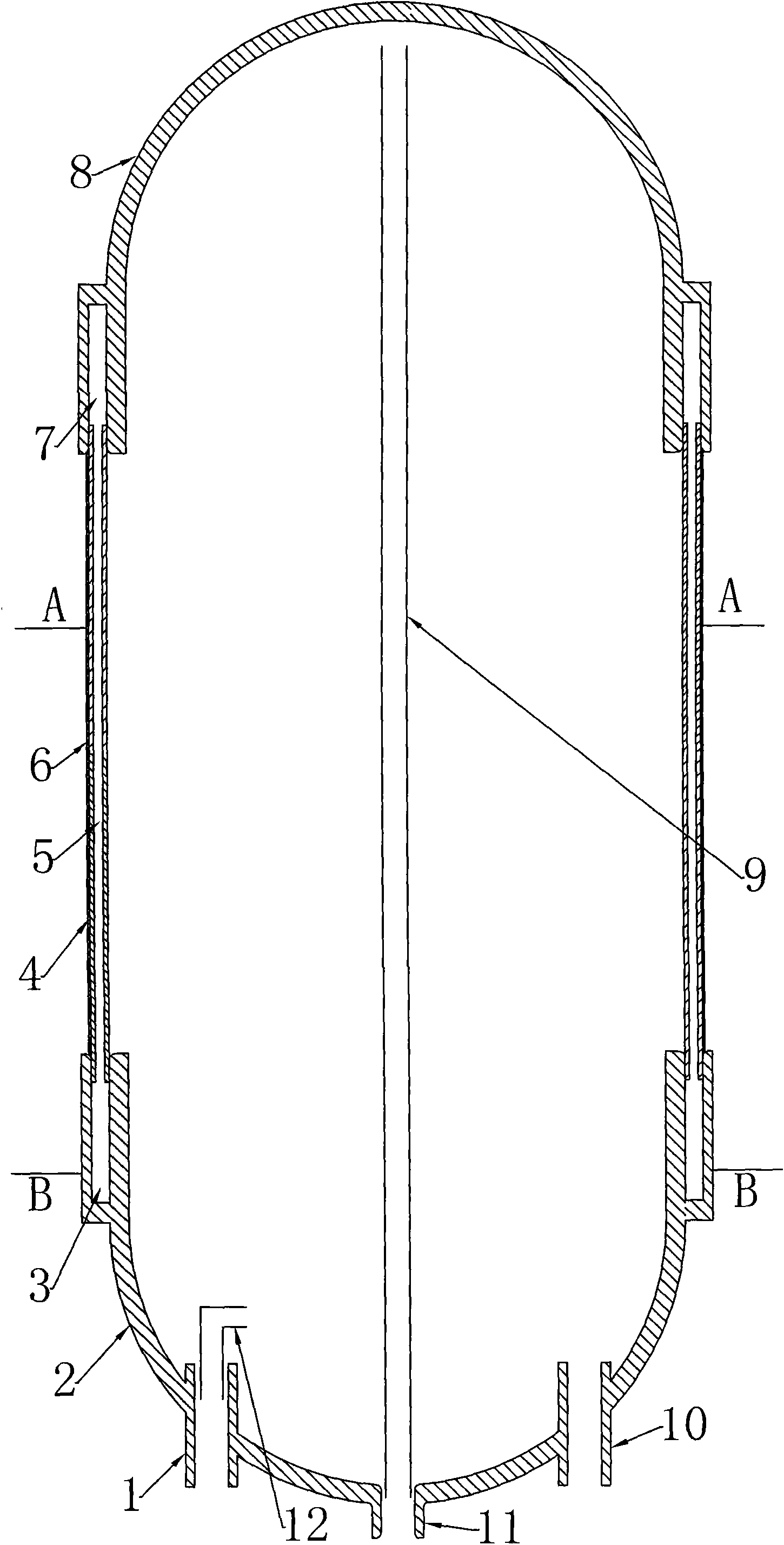

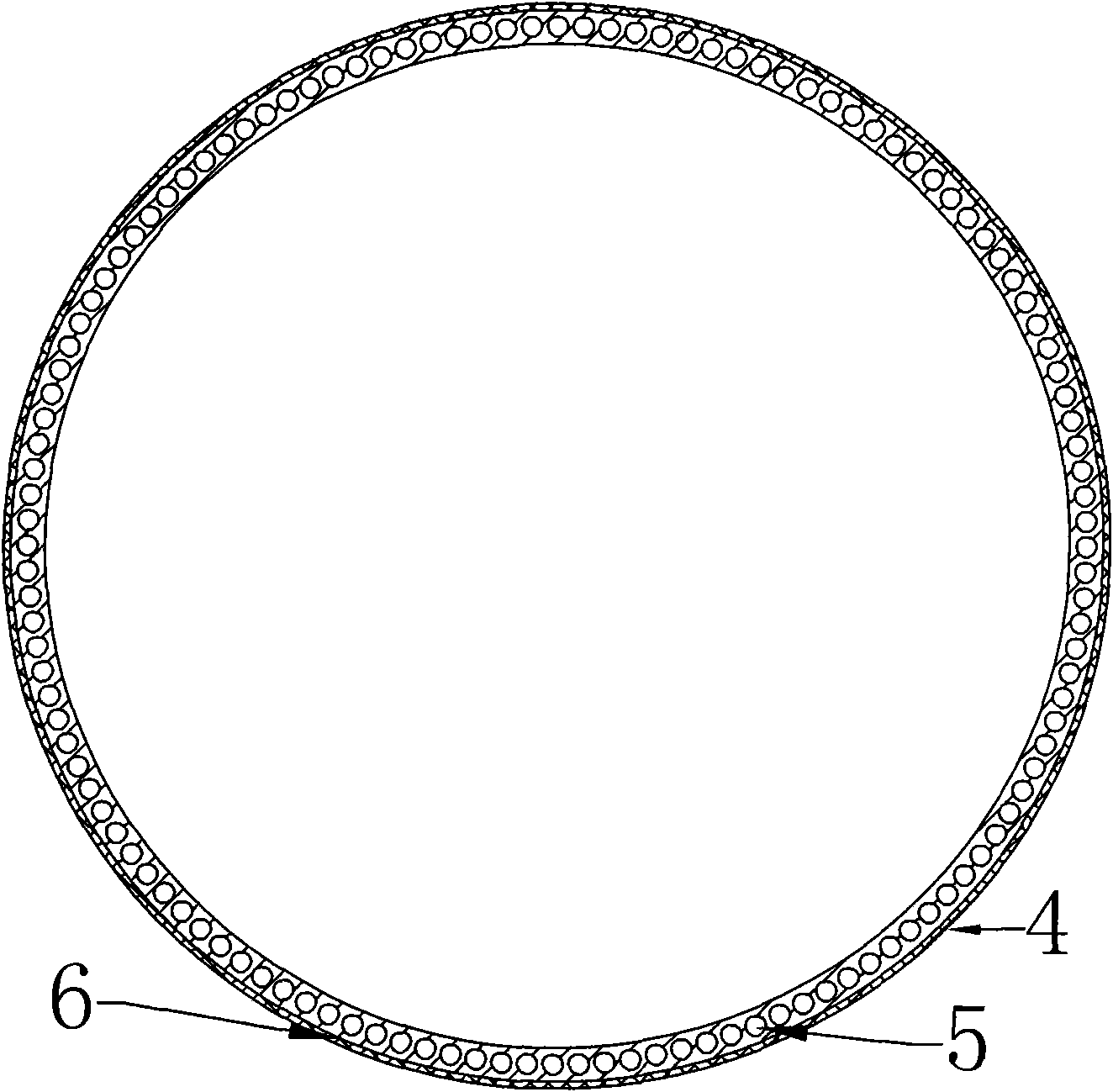

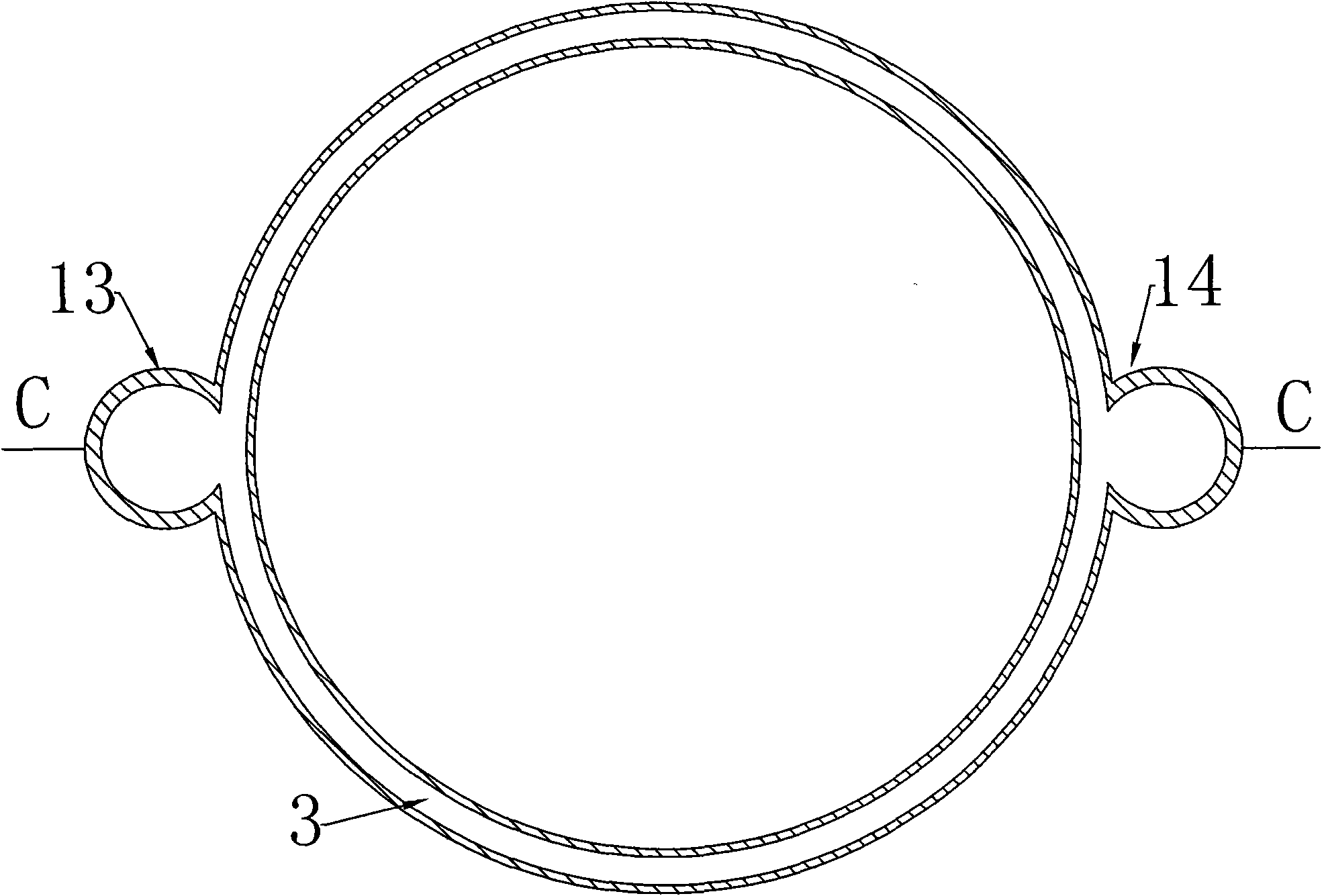

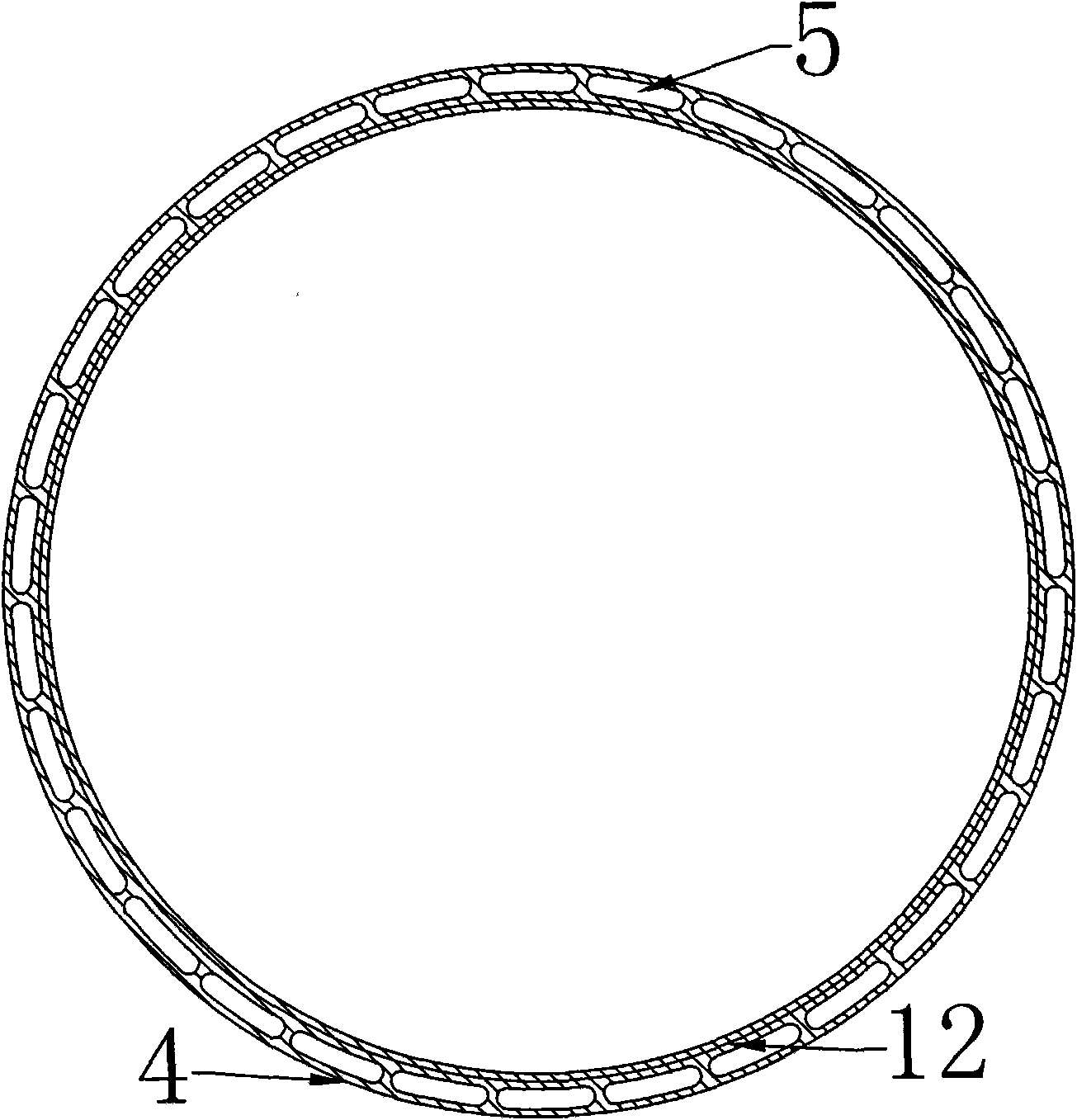

Vertical pressure-bearing double-cycle all-plastic water tank liner

InactiveCN101988758ASave raw materialsImprove heat transfer efficiencyFluid heatersSolar heat devicesHeat resistanceEngineering

The invention discloses a vertical pressure-bearing double-cycle all-plastic water tank liner, comprising an end cover and a water tank. An annular groove on the end cover is connected with the water tank to form an annular hole, and the annular hole is communicated with the holes in the water tank wall and is communicated with the outside via a pipe of the annular groove. Multiple holes in the water tank wall are connected in parallel to form a circular channel, the circular channel has a large total cross section, and the circular medium has very low flow resistance, thus laying a foundation for realizing the working state of heating by natural circulation. In the invention, the heat exchange surface is big enough, thus the heat resistance is small, the heat exchange temperature is low, the heat exchange surface is prevented from scaling, and higher heat transfer efficiency can be maintained forever. The liner in the invention is mainly made from a polymer material and has the advantages of long service life, high reliability, simple production process, capability of large-scale industrialized production and wide market prospect, a great quantity of metal raw materials are saved, and the system manufacturing cost is greatly lowered.

Owner:侯国山

Pressure-bearing double-cycle all-plastic water tank liner

InactiveCN101988768ASave raw materialsImprove heat transfer efficiencyFluid heatersSolar heat devicesHeat resistanceHeat transfer efficiency

The invention provides a pressure-bearing double-cycle all-plastic water tank liner, which is composed of an end cover, a liner pipe and an auxiliary electric heater. An annular groove on the end cover is connected with the water tank to form an annular hole, and the annular hole is communicated with the holes in the liner pipe wall and is communicated with the outside via a pipe of the annular groove. Multiple holes in the liner pipe wall are connected in parallel to form a circular channel, the circular channel has a large total cross section, and the circular medium has very low flow resistance, thus laying a foundation for realizing the working state of heating by natural circulation. In the invention, the heat exchange surface is big enough, thus the heat resistance is small, the heat exchange temperature is low, the heat exchange surface is prevented from scaling, and higher heat transfer efficiency can be maintained forever. The liner in the invention is mainly made from a polymer material and has the advantages of long service life, high reliability, simple production process, capability of large-scale industrialized production and wide market prospect, a great quantity of metal raw materials are saved, and the system manufacturing cost is greatly lowered.

Owner:侯国山

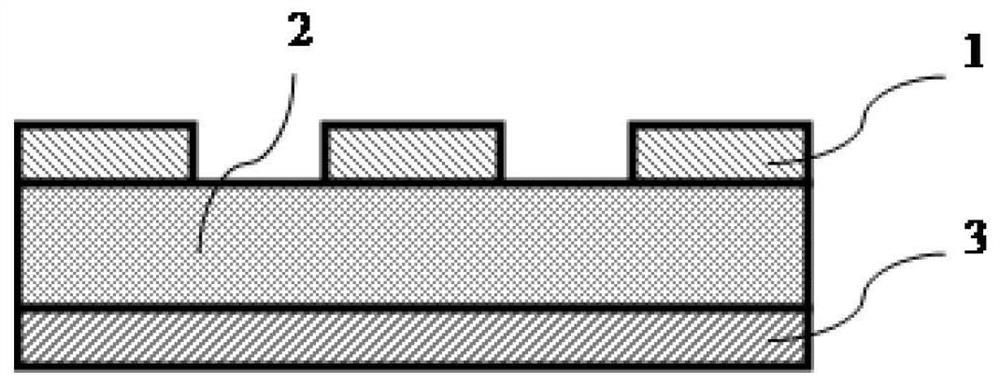

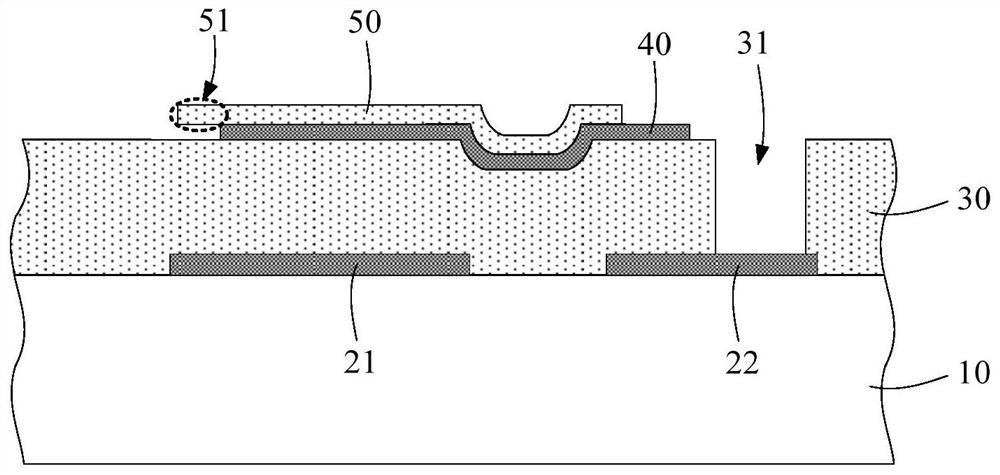

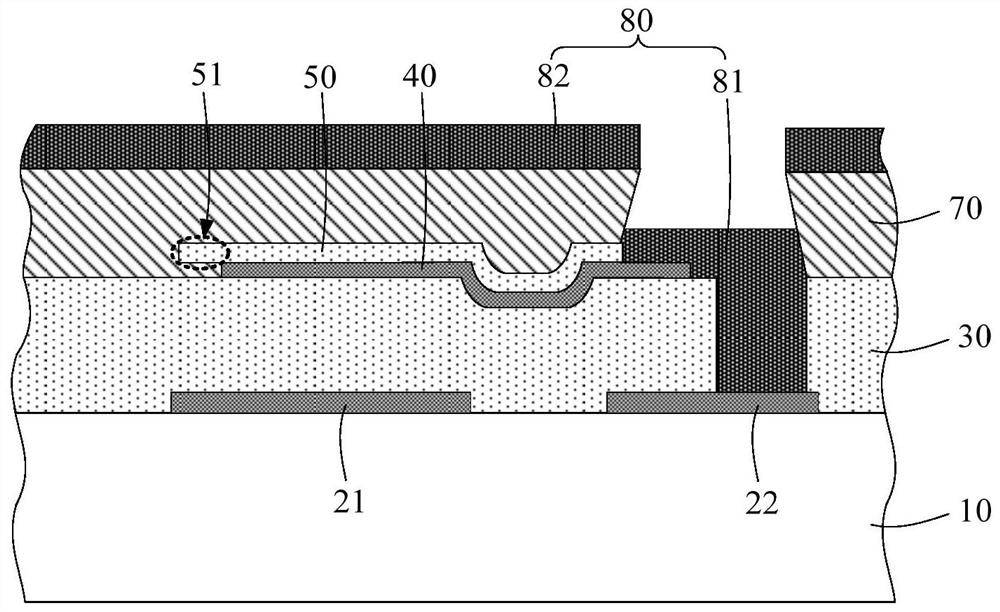

Semiconductor device and forming method thereof

ActiveCN111740001AImprove stripping efficiencyImprove the problem of removing impuritiesPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksDevice materialEngineering

The invention provides a semiconductor device and a forming method thereof. A protective layer is formed between a photoresist layer and a passivation layer, so that a film layer below the protectivelayer can be prevented from being damaged under the interval protection of the protective layer. Specifically, the passivation layer can be prevented from being exposed when the photoresist layer is stripped, so that a suspension part in the passivation layer can be prevented from being damaged, on one hand, the size of the suspension part in the passivation layer can be further increased to improve the performance of the device, and on the other hand, the spraying pressure of the stripping liquid can be further increased when the photoresist layer is removed to improve the stripping efficiency of the photoresist layer and improve the problem that the photoresist layer cannot be removed completely.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

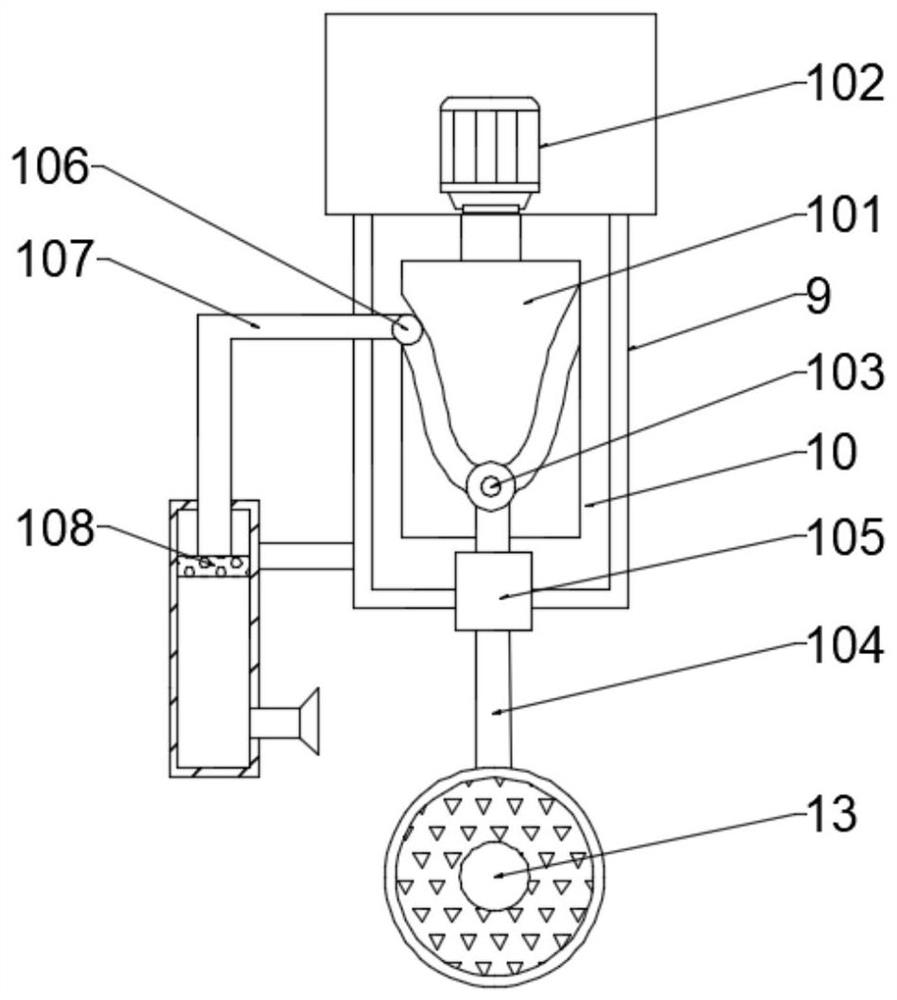

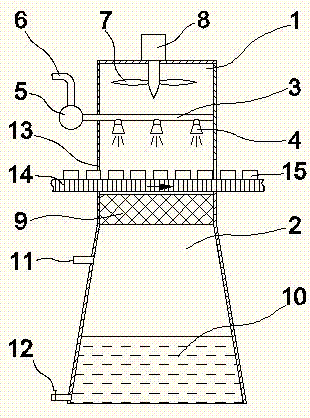

Powerful spray dedusting device

InactiveCN107413722AIncrease spray pressureImprove dust removal efficiencyCleaning using gasesCleaning using liquidsAgricultural engineeringWater spray

The invention discloses a powerful spray dust removal device, which comprises an upper chamber and a lower chamber. The water main pipe is connected to the booster pump outside the upper chamber, and the booster pump is connected to the water inlet main pipe; the bottom of the lower chamber is provided with a sump, and the top of the spray pipe is also provided with a fan. Driven by a fan motor set on the top of the upper chamber. A powerful spray dust removal device of the present invention can automatically carry out powerful spray dust removal treatment on finished products, saving time and labor. High efficiency and other advantages.

Owner:WUXI AOYUTE NEW TECH DEV

Full-plastic plate pressure-bearing double-loop water tank liner

InactiveCN101988757ASave raw materialsHigh heat transfer efficiencyFluid heatersSolar heat devicesEngineeringWater tanks

The invention discloses a full-plastic plate pressure-bearing double-loop water tank liner. The full-plastic plate pressure-bearing double-loop water tank liner consists of an end cover and a water tank, wherein an annular groove on the end cover is connected with the water tank to form an annular hole; the annular hole is communicated with holes in the wall of the water tank; the annular hole is communicated with the external through a tube on the annular groove; a plurality of holes in the wall of the water tank are connected in parallel to form a circulation channel; the total cross section of the circular channel is very large; and the flow resistance of a circular medium is very low, which paves a way for a working condition of naturally circular heating. The plastic plate pressure-bearing double-loop water tank liner has an enough heat exchanger area, so that thermal resistance is low and a heat exchange temperature is low; a heat exchange surface does not scale; and higher heat exchange efficiency can be maintained forever. The liner of the invention is mainly made of a high molecular material, can save a large number of metal raw materials, greatly reduces the manufacturing cost of a system, is long in service life, high in reliability and simple in production process, is suitable for large-scale industrial production and has a wide market prospect.

Owner:侯国山

Flat-plate type solar balcony bathroom

InactiveCN101988335AImprove heating efficiencyImprove heat transfer efficiencySolar heating energySolar heat devicesSolar waterMature technology

A flat-plate type solar balcony bathroom consists of a passive solar house, a pressure-bearing dual-cycling solar water heater and a connecting pipe thereof. The passive solar house is enclosed by walls, a window, a door, a roof and a base of the balcony. A heat exchanger consists of a spherical shell, a pipe on the spherical shell, and a heat exchange tube. Both the heat exchanger and a solar collector have an all-plastic structure, and scale is never formed on the heat exchanger and a solar collector. Therefore, the heat exchanger and the solar collector can keep higher efficiency of heat collection and heat exchange. The flat-plate type solar balcony bathroom is in an internal thermal type heating mode, and the system has higher heating efficiency. The flat-plate type solar balcony bathroom is fully integrated with the building body into a whole, can supply a large quantity of hot water for living and provide a warm bathing space, is practical in living, is environmentally-friendly and has mature technology and wide market space.

Owner:侯国山

Self-cleaning type printing ink spraying gun head

ActiveCN111330762AGuaranteed normal functionIncrease spray pressureLiquid spraying apparatusPrinting inkMechanical engineering

The invention provides a self-cleaning type printing ink spraying gun head which comprises a gun barrel, a pressing unit, a rubber stopper, an auxiliary unit and a gun head unit. The self-cleaning type printing ink spraying gun head can solve the main problems in the use process of an existing printing oil spraying gun head. The problems include that a, the pressure of printing ink is not large enough when the printing ink in the printing ink gun is sprayed, consequently the printing ink is scattered on a workpiece, and the spraying quality of the workpiece is affected; b, the interior of theprinting ink gun is not cleaned for a long time, consequently, the printing ink precipitates, a gun head is blocked, and the uniformity of the printing ink at the spraying position of the printing inkgun is affected; and c, after spraying use of the gun head of the printing oil gun, a large amount of printing ink is left at the position of a gun opening of the printing ink gun, after the printingink gun is used each time, people need to conduct cleaning and wiping in time, or the gun opening is blocked.

Owner:山东蓝彩天下教育科技有限公司

Full-plastic heat exchanger water tank liner

InactiveCN101988810AImprove heat transfer efficiencyReduce heat lossFluid heatersSolar heat devicesMolecular materialsHeat transfer efficiency

The invention discloses a full-plastic heat exchanger water tank liner. The full-plastic water tank liner consists of a water tank and a heat exchanger, wherein a circular plate and a heat exchange column form the heat exchanger together; the heat exchange column is provided with annular waves; and the heat exchanger is arranged in a liner cavity, adopts an internal heating mode, and has higher heat exchange efficiency and low heat loss. The heat exchanger is made of a high molecular material; and because the coefficient of thermal expansion and cold shrinkage of the high molecular material is greatly different from that of water scale, the water scale cannot attach to the heat exchanger forever in a frequently cold and hot alternate environment; therefore, the heat exchanger can maintain higher heat transfer efficiency forever. The heat exchanger is made of the high molecular material, is long in service life, high in reliability and simple in production process, is suitable for large-scale industrial production and has a wide market prospect.

Owner:侯国山

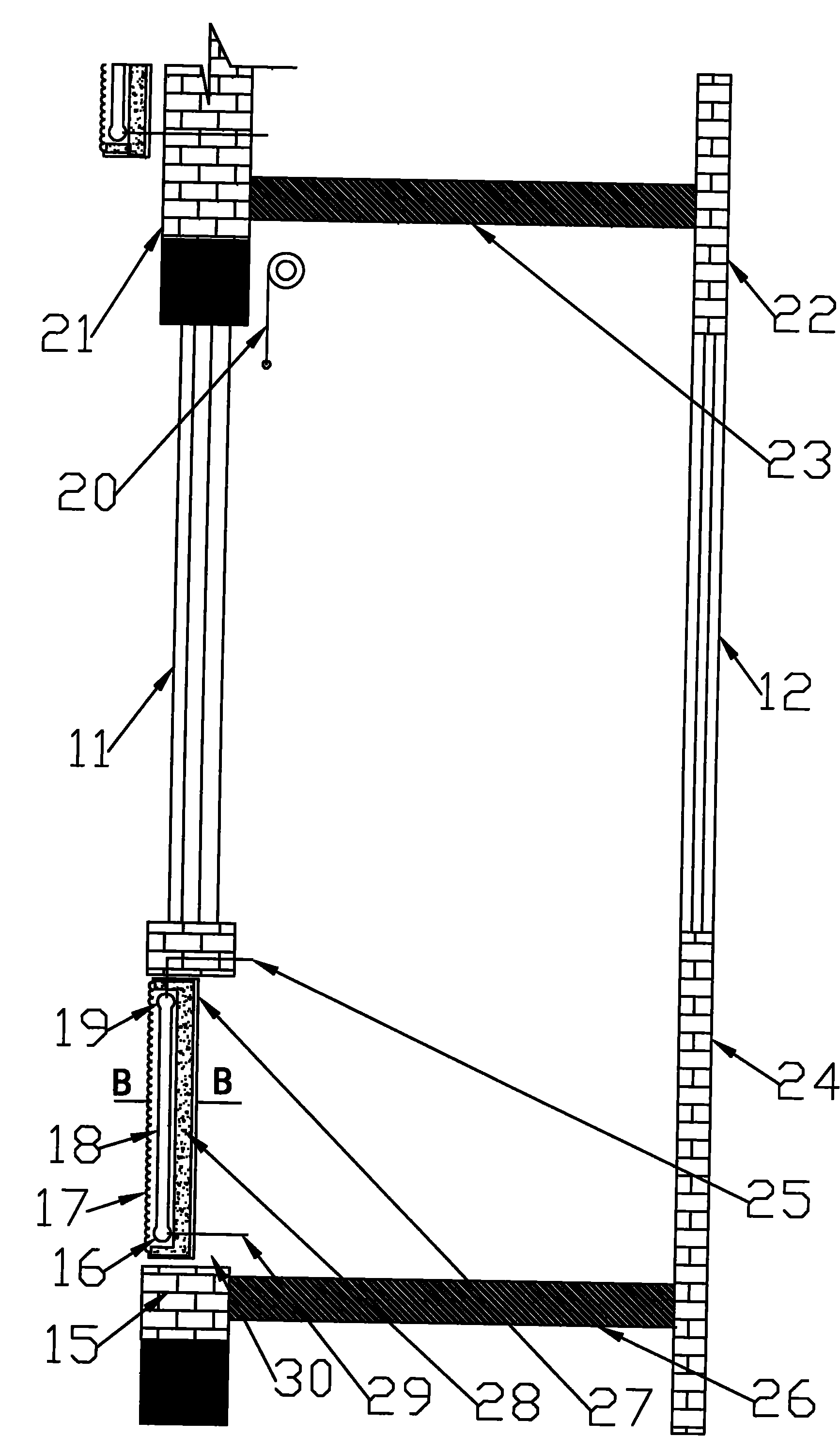

Split type solar energy water heater

InactiveCN101149187ASave raw materialsImprove heat transfer efficiencySolar heat devicesDomestic hot-water supply systemAutomatic controlControl system

This invention is a split type solar energy water heater. It includes heat preserving water tank, solar energy heat collector and assistant electric heater. It uses concave or convex shell shaped light transmitting plate, which has very high light transmitting rate and high heat collecting efficiency when arranged vertically or horizontally. The circulating system is filled with freeze proof circulating liquid. It avoids being frozen in very cold areas. This invention has high heat transferring area and high heat transferring efficiency. The heating circulating liquid and electric heater are insulated between each other. The heating circulating liquid and the water in water tank are insulated too. The water inlet and supplying system is under bearing double cycle working state. Thus, water level automatic control system can not be used. The operation is simple. It also has high spraying pressure. This invention uses multi-water tank structure. It saves space and energy.

Owner:侯国山

Pressure-bearing dual-cycle double-barrelled water tank liner

InactiveCN101988809AImprove heat transfer efficiencyReduce heat lossFluid heatersSolar heat devicesThermal expansionEngineering

The invention provides a pressure-bearing dual-cycle double-barrelled water tank liner, which is composed of an end cover, a liner pipe and an auxiliary electric heater. Two ends of multiple heat exchange tubes of a heat exchanger are communicated with two hollow spheres, and each hollow sphere is provided with an exhaust pipe and a circulating pipe which are communicated with the outside of the liner. In the invention, the heat exchanger is made from a high polymer material, and as the expansion and shrinkage coefficient of the high polymer material greatly differs from that of scale, scale is incapable of attaching on the heat exchange tubes and heat exchange spheres forever in a frequent cold heat exchange environment, thus higher heat transfer efficiency of the heat exchanger can be maintained. The multiple heat exchange tubes of the heat exchanger in the invention have big area surface, thus having small heat resistance, low heat exchange temperature, high heat transfer efficiency and small heat loss. In the invention, the liner is mainly made from the high polymer material and has the advantages of long service life, high reliability, simple production process, capability of realizing large-scale industrialized production and wide market prospect, a large quantity of metal raw materials can be saved, and the system production cost can be greatly reduced.

Owner:侯国山

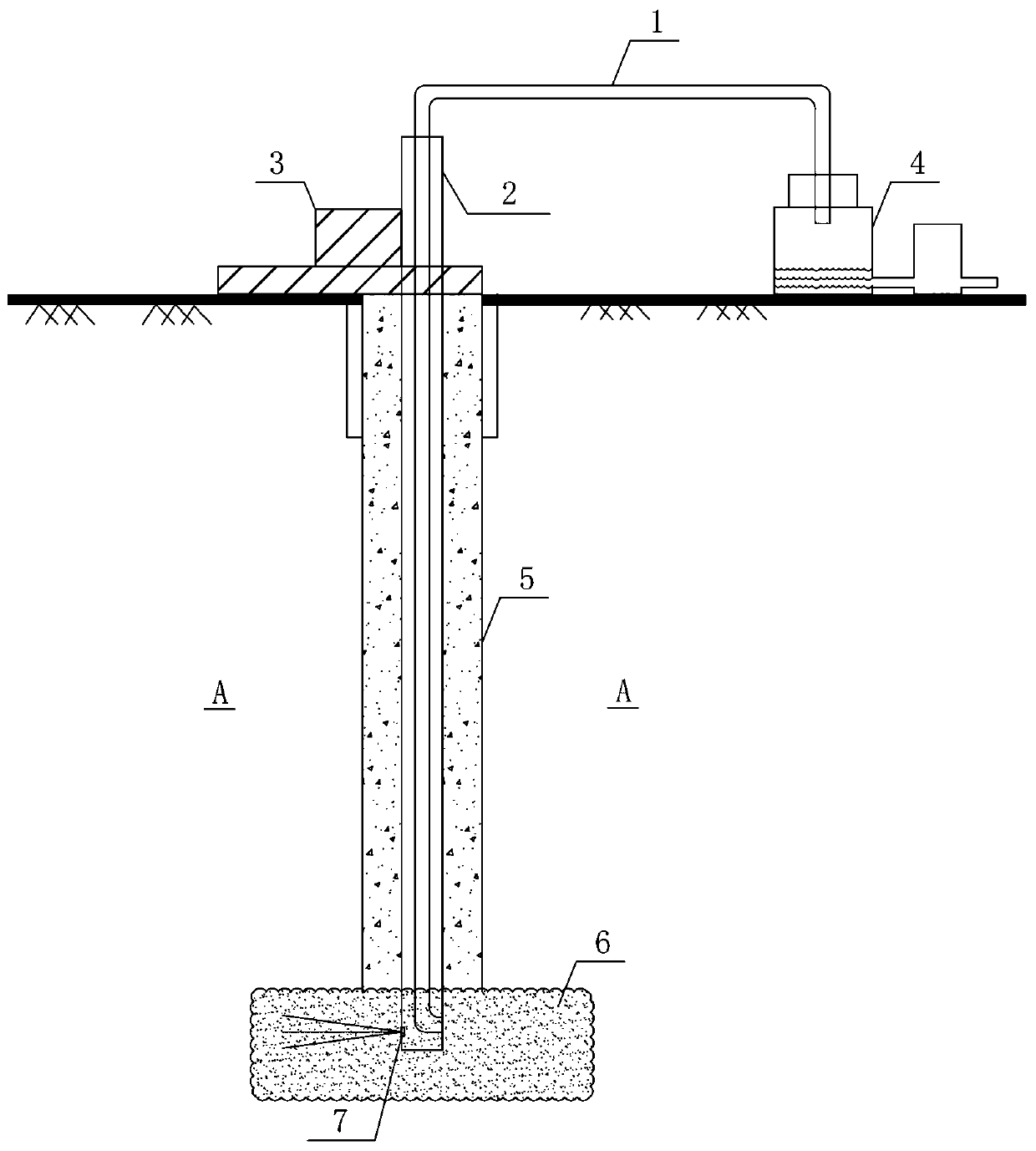

Pile bottom sediment ultra-high-pressure replacement slurry spraying structure and construction method thereof

The invention discloses a pile bottom sediment ultra-high-pressure replacement slurry spraying structure and a construction method thereof. The structure is characterized in that the bottom of a pouring pile is arranged on a cement soil swelling structure which is formed by slurry spraying and enhances the strength of pile side soil and pile end soil. The construction method of the structure comprises the steps of construction of the pouring pile, drilling and core taking, replacement slurry spraying, core taking grouting and the like. Compared with the prior art, the structure is simple, construction is convenient, the bearing force of the pile is effectively increased, the pouring pile is a rigid pile and is arranged in a flexible rotary stirring pile, no mud is generated in the construction process, the construction cost is further reduced, and the structure is green and environmentally friendly.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

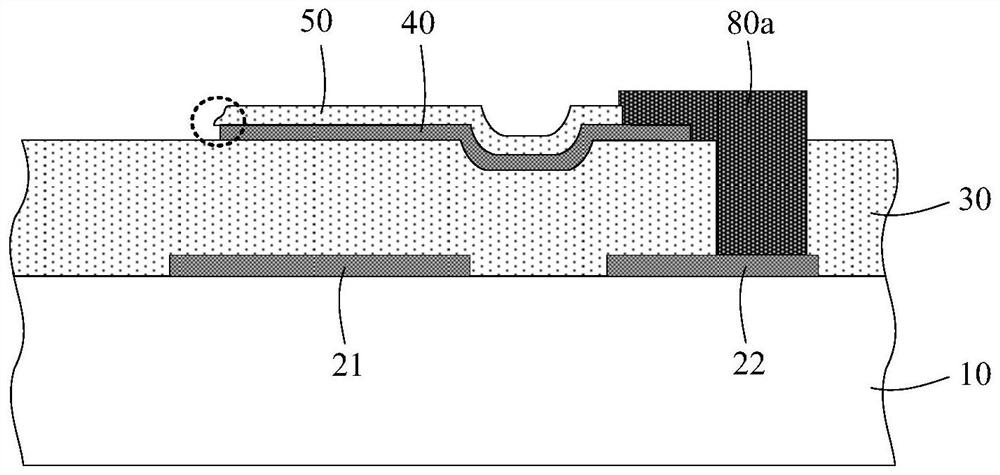

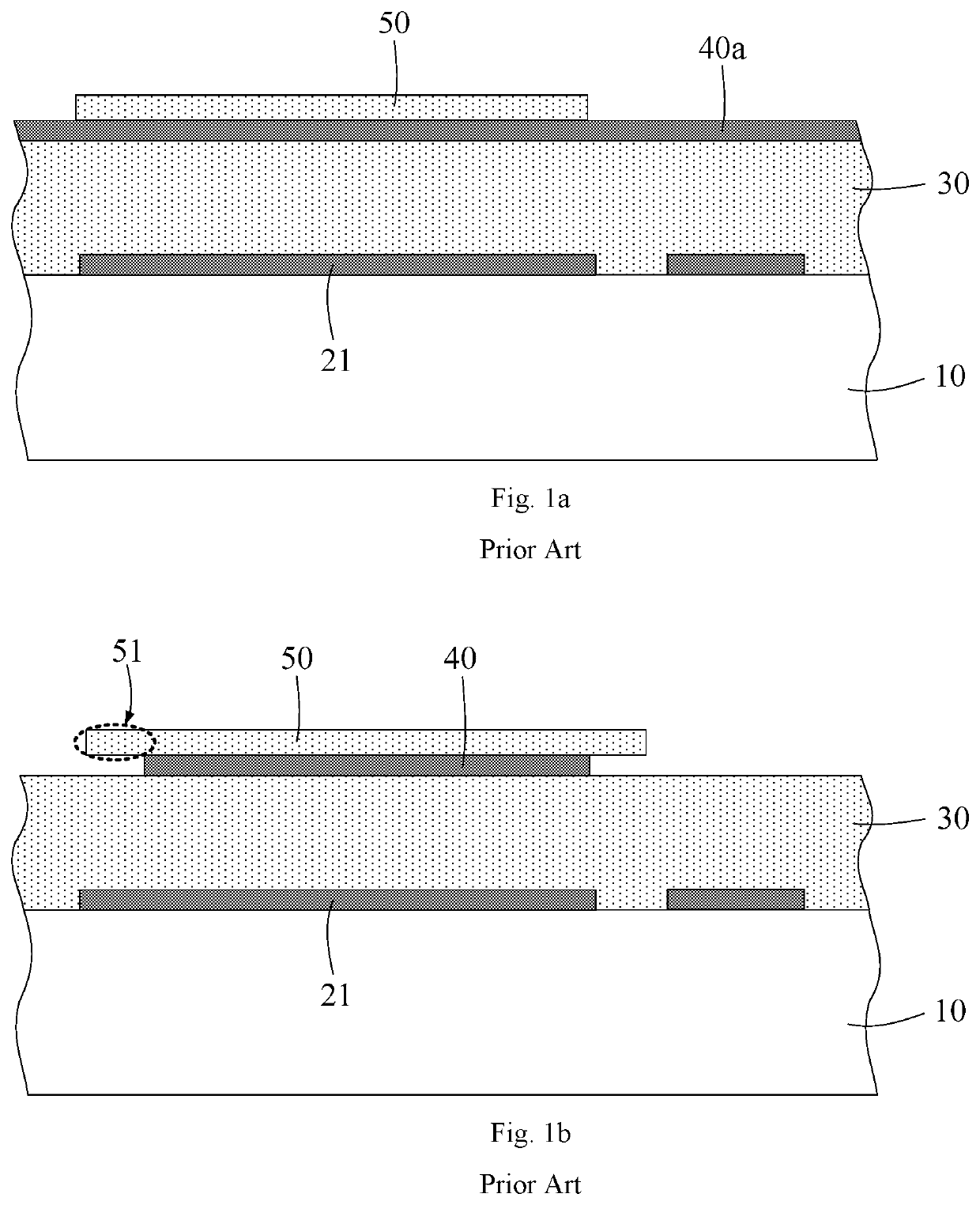

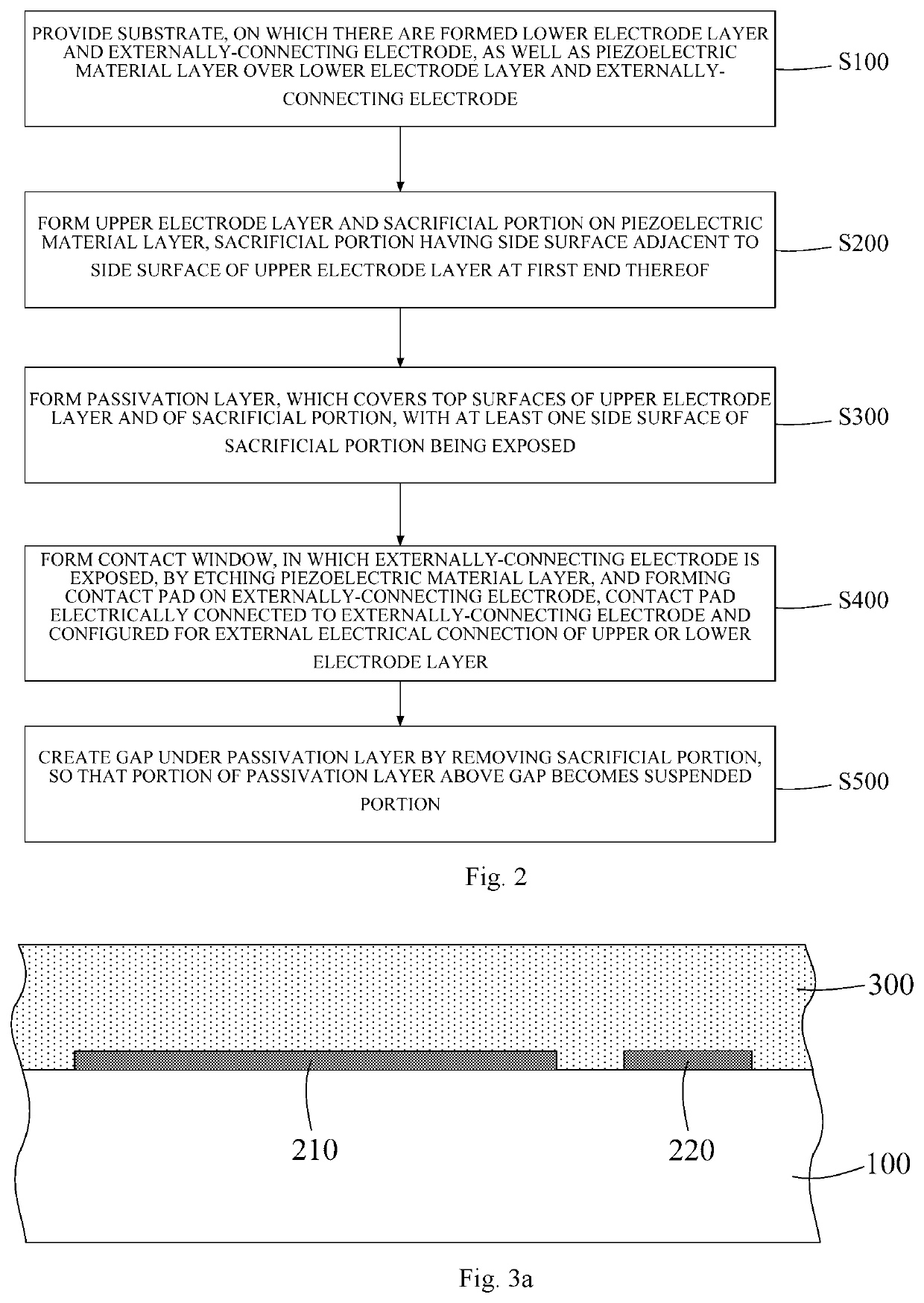

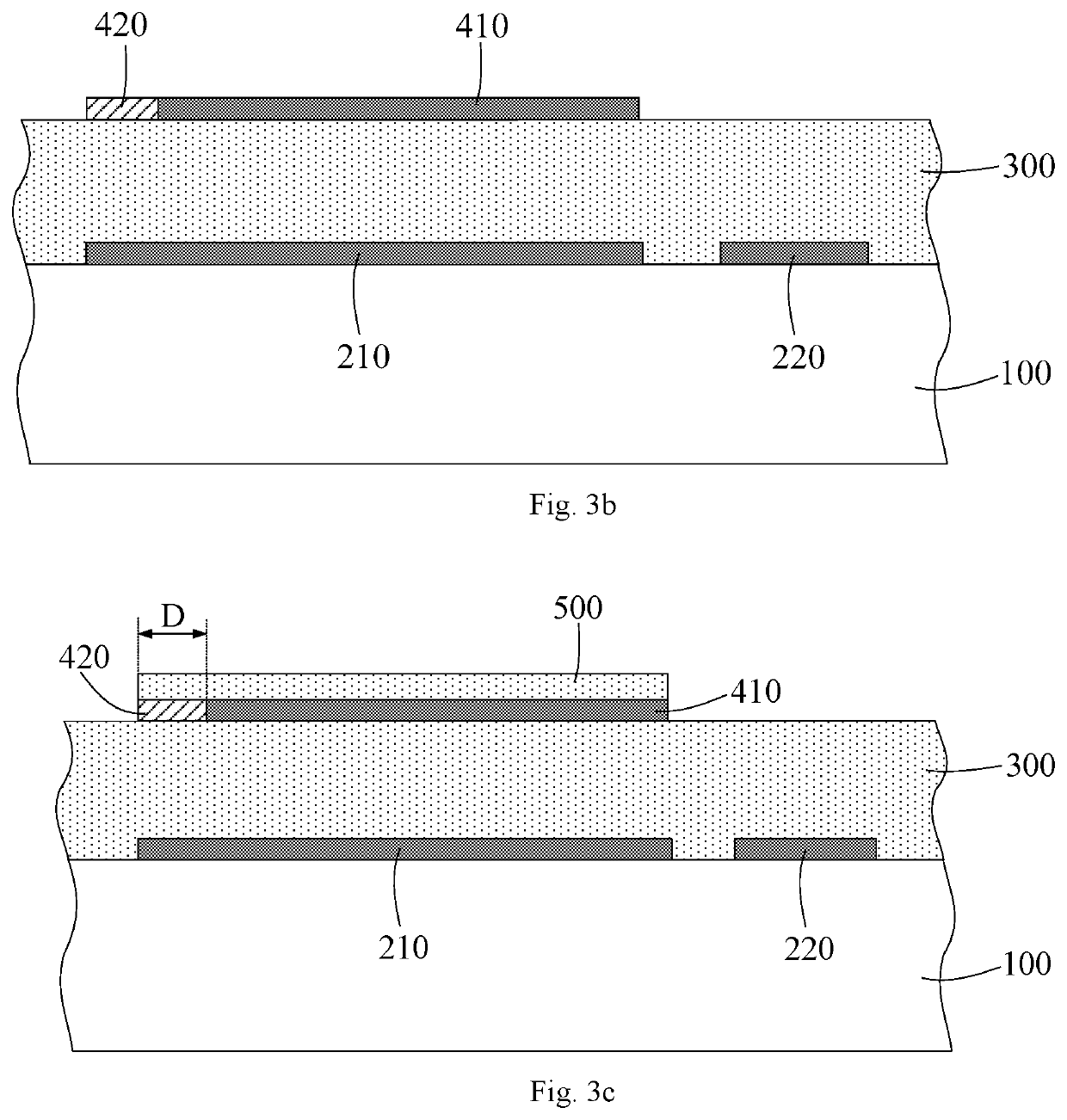

Method of fabricating a semiconductor device

ActiveUS10879450B1Easily damagedHigh pressurePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksContact padDevice material

A method of fabricating the semiconductor device includes the following steps. Forming a sacrificial portion at a first end of an upper electrode layer before a passivation layer is formed so that it supports a corresponding end portion of the passivation layer, making the passivation layer not suspended at all. In this way, the suspended portion of the passivation layer will not be damaged during the formation of a contact pad. In addition, subsequent to the formation of the contact pad, removing the sacrificial portion, freeing up a space under the end portion of the passivation layer so that the end portion itself becomes a suspended portion. This can ensure performance of the resulting semiconductor device.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

Pressure-bearing dual-cycle water tank liner

InactiveCN101988764AImprove heat transfer efficiencyReduce heat lossFluid heatersSolar heat devicesEngineeringThermal expansion

The invention provides a pressure-bearing dual-cycle water tank liner, which is composed of an end cover, a liner pipe and a heat exchanger. Two ends of multiple heat exchange tubes of the heat exchanger are communicated with two hollow spheres, and each hollow sphere is provided with an exhaust pipe and a circulating pipe which are communicated with the outside of the liner. In the invention, the heat exchanger is made from a high polymer material, and as the expansion and shrinkage coefficient of the high polymer material greatly differs from that of scale, scale is incapable of attaching on the heat exchange tubes and heat exchange spheres forever in a cold heat frequent alternation environment, thus higher heat transfer efficiency can be maintained by the heat exchanger. The multiple heat exchange tubes of the heat exchanger in the invention have big area surface, thus having small heat resistance, low heat exchange temperature, high heat exchange efficiency and small heat loss. In the invention, the liner is mainly made from a high polymer material and has the advantages of long service life, high reliability, simple production process, capability of large-scale industrialized production and wide market prospect, a large quantity of metal raw materials can be saved, and the system production cost can be greatly reduced.

Owner:侯国山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com