Patents

Literature

779 results about "Heating cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

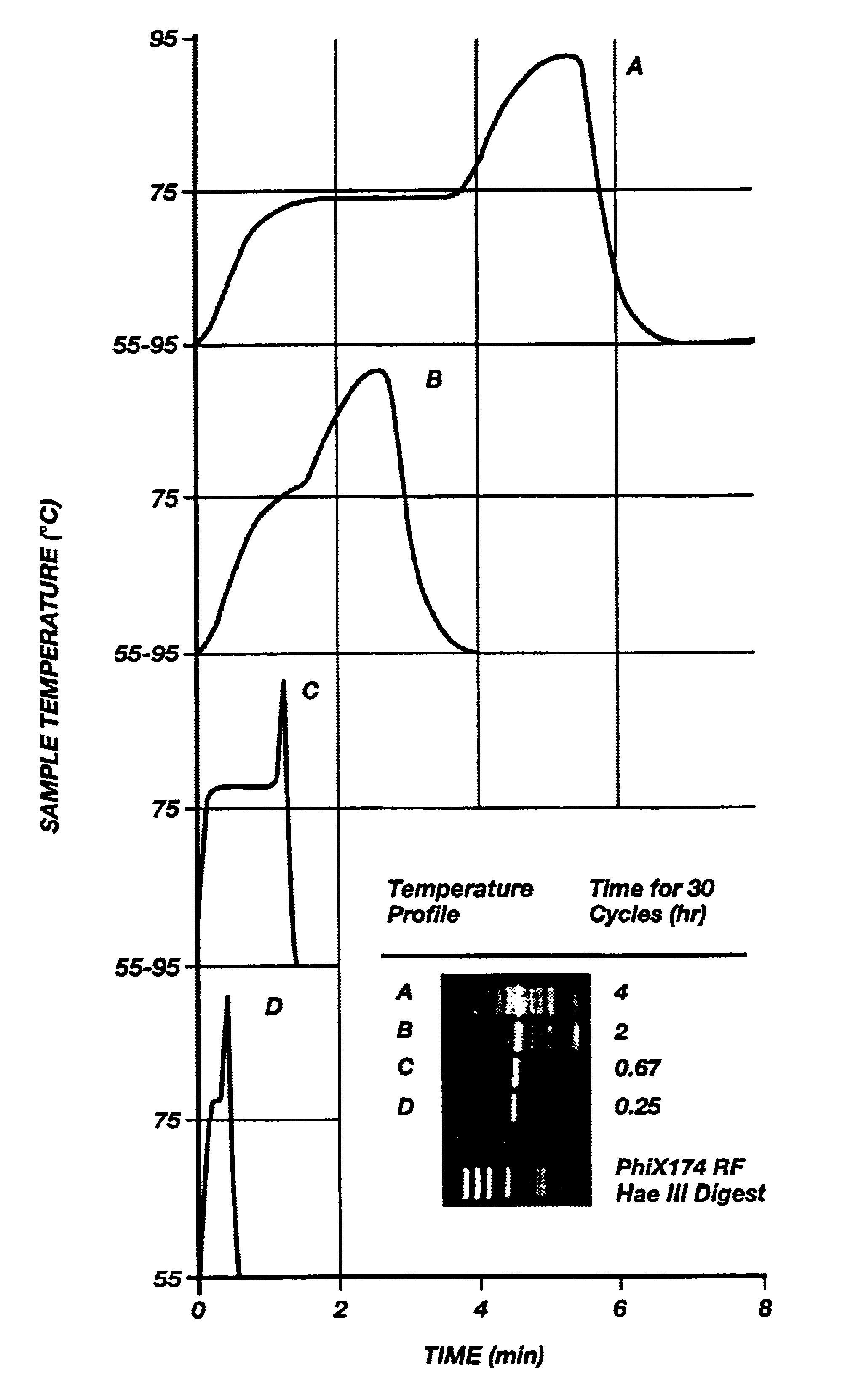

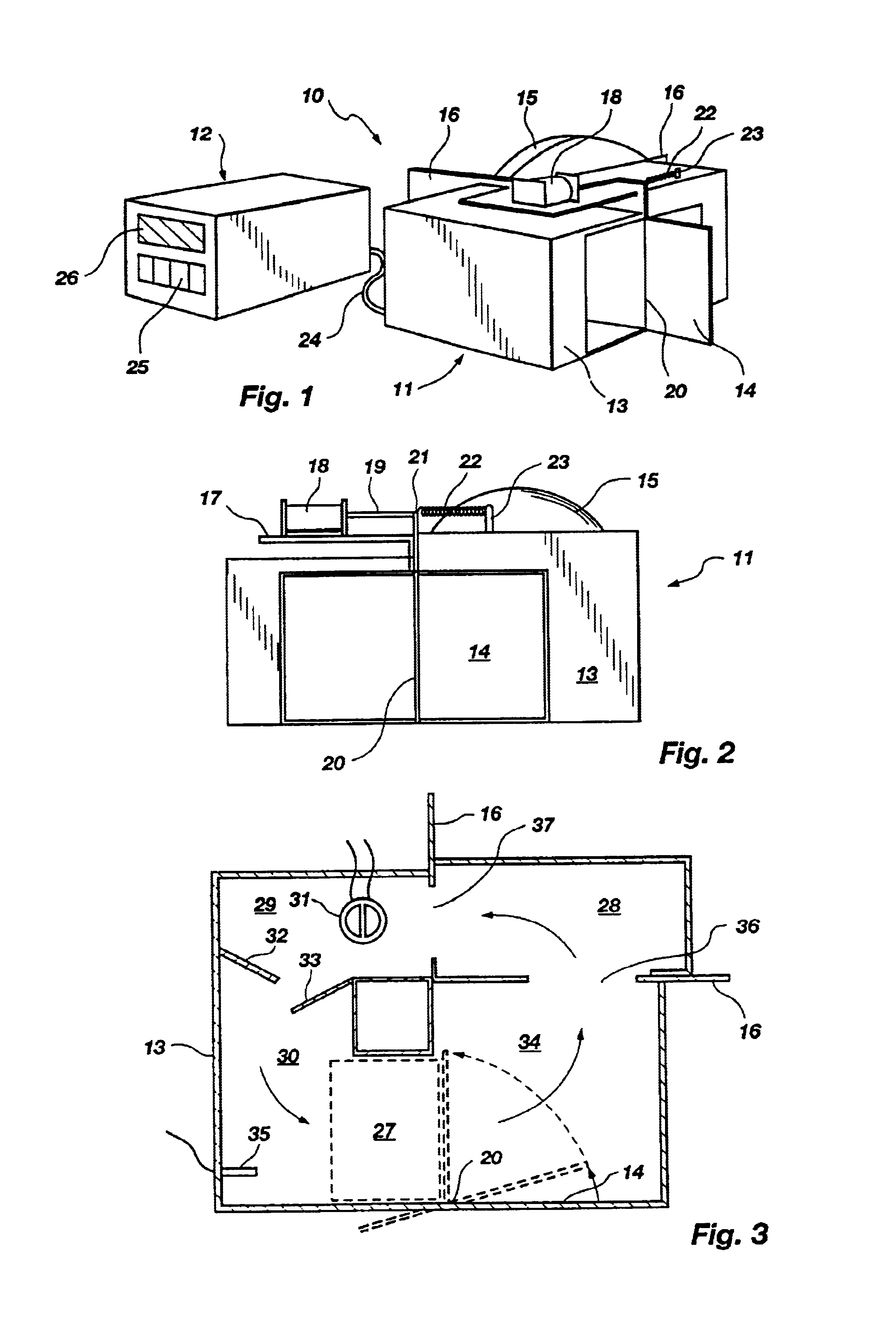

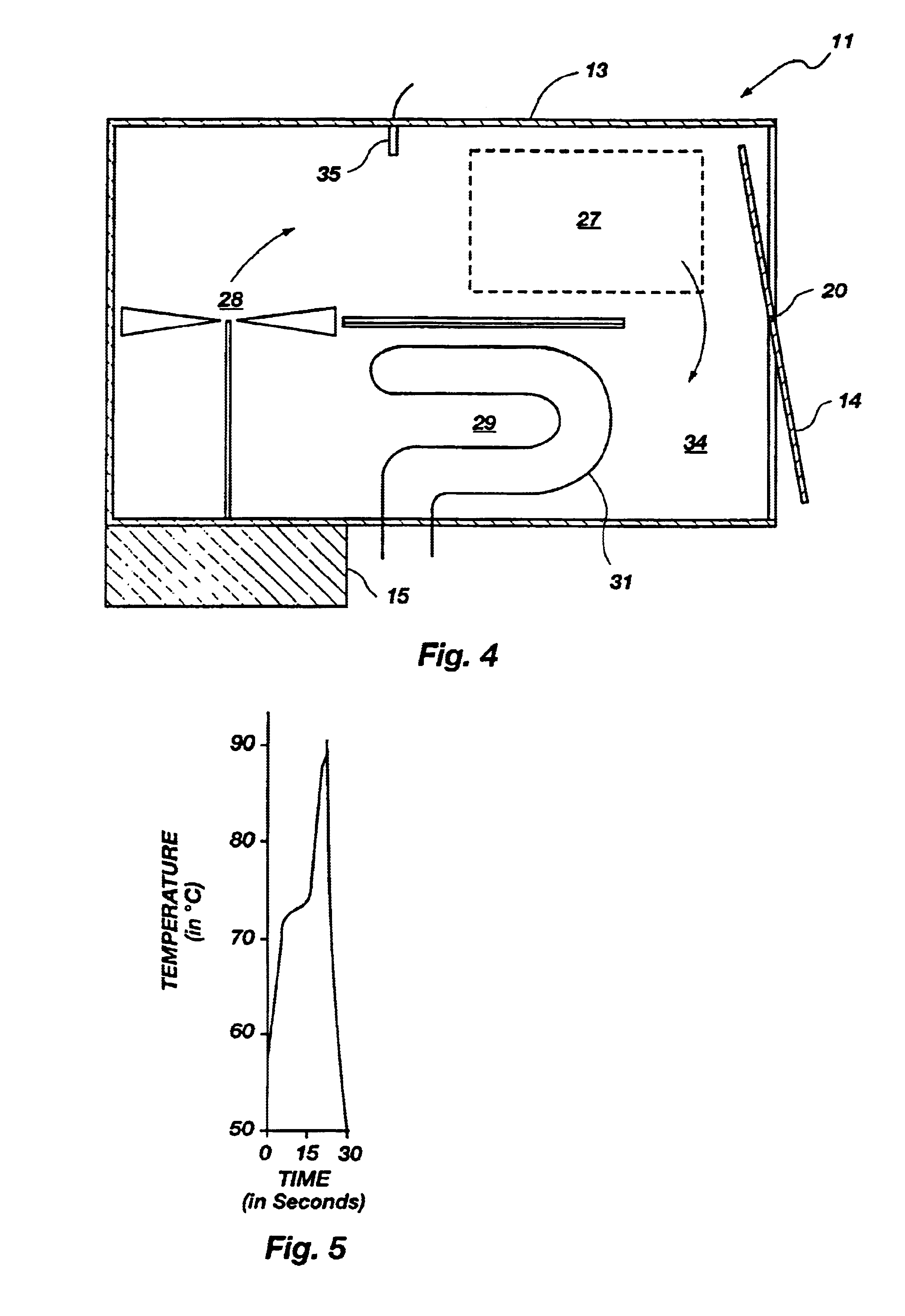

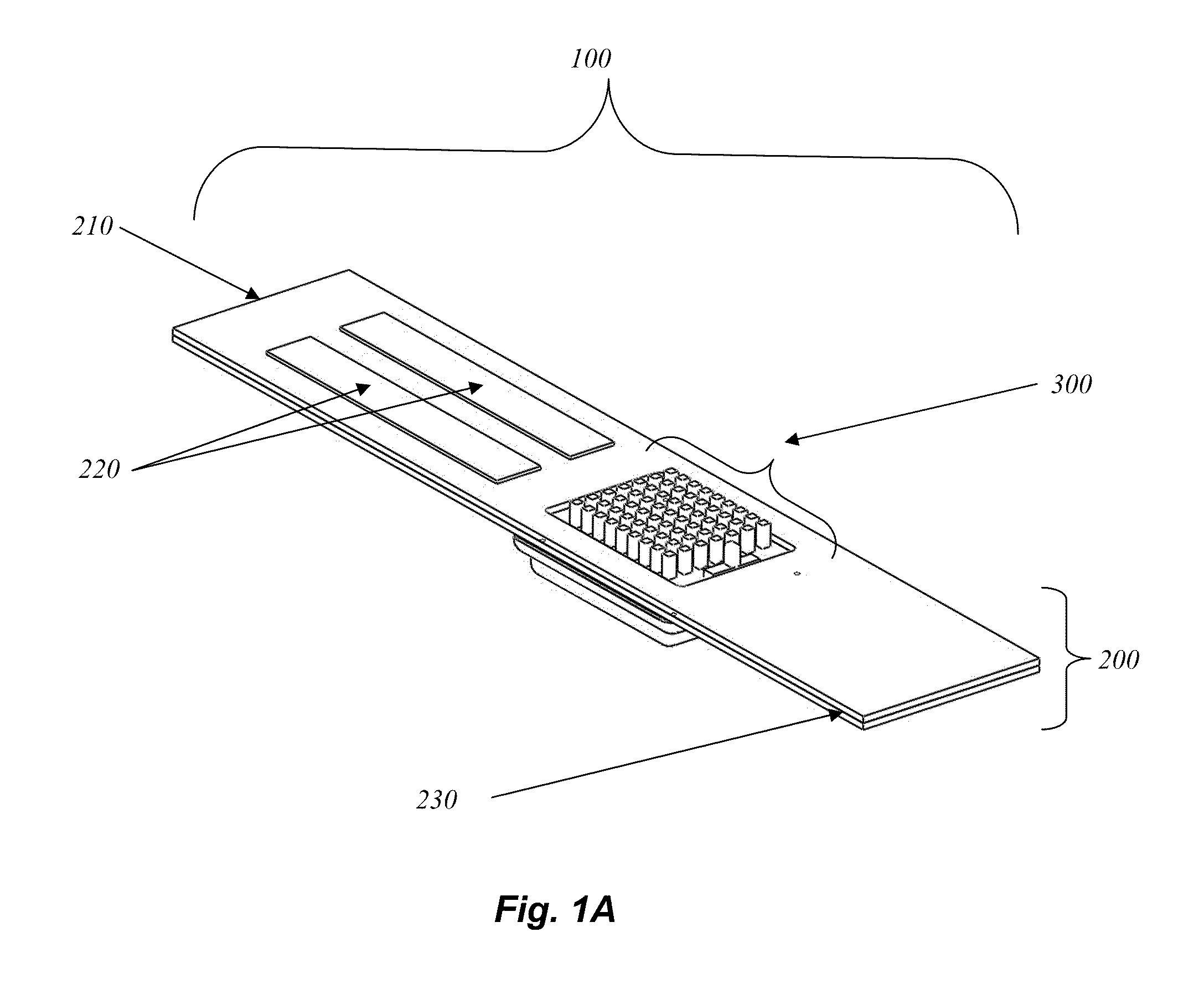

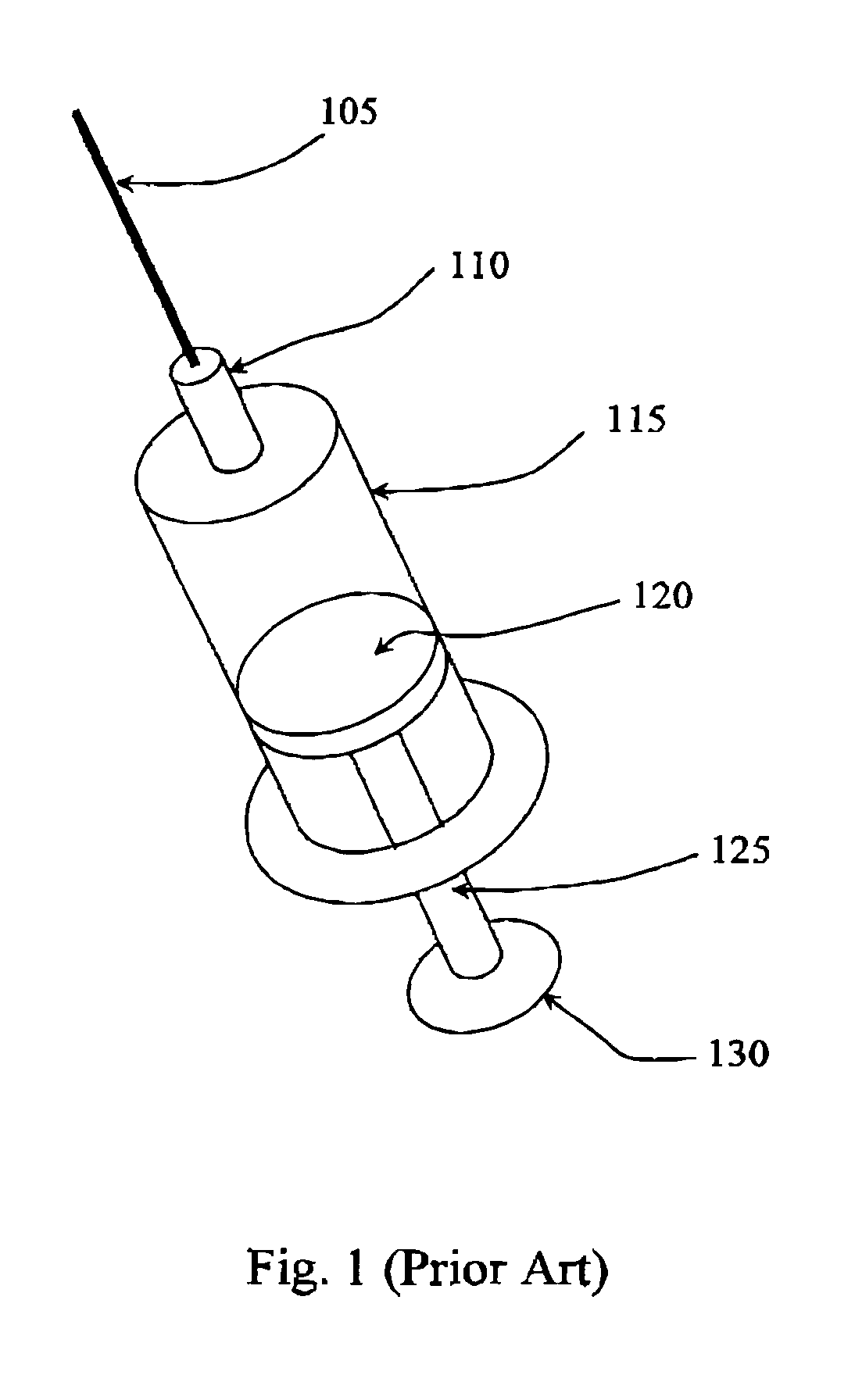

Method for rapid thermal cycling of biological samples

InactiveUS6787338B2Thermal massHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsTime profileAmplification dna

Owner:THE UNIV OF UTAH

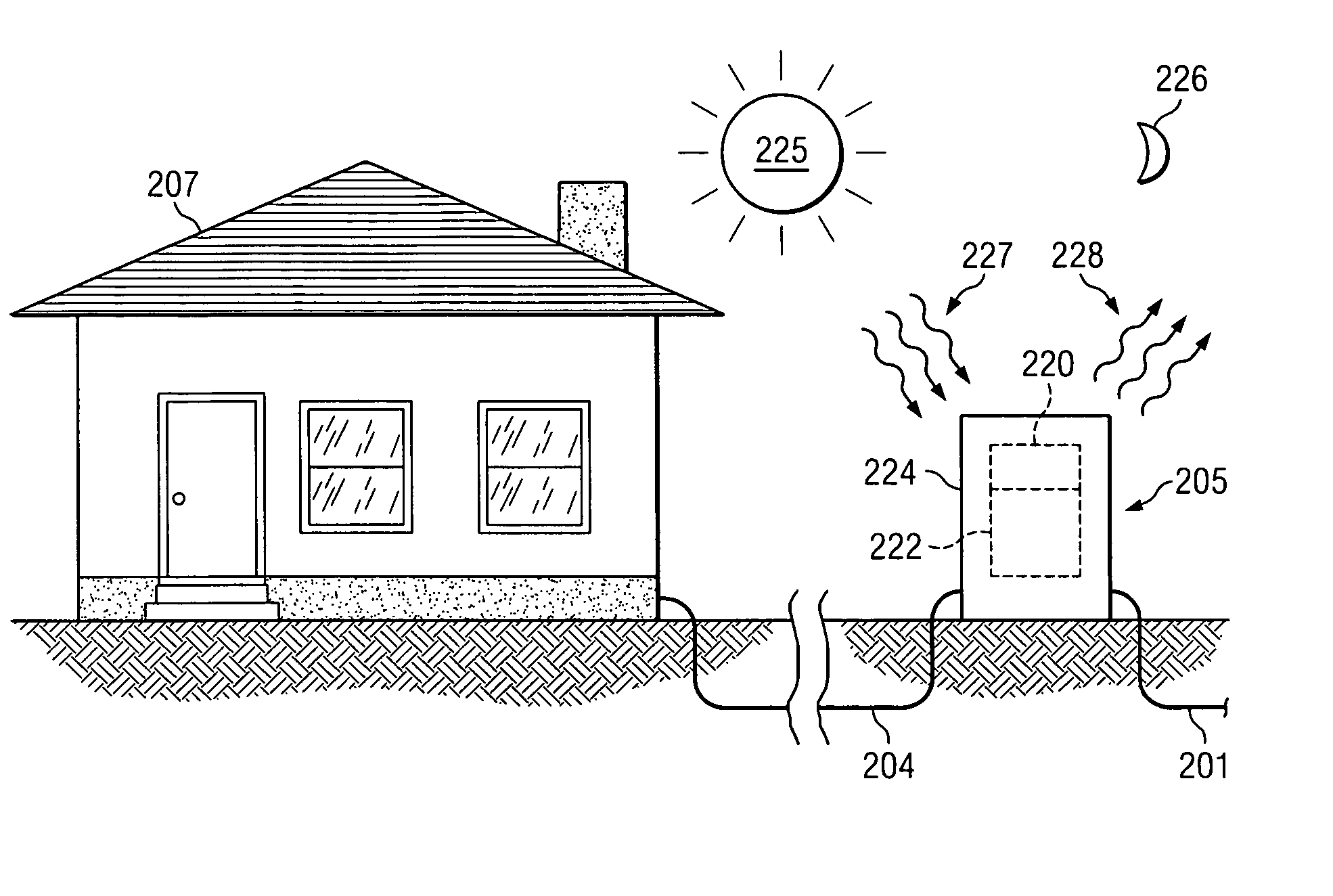

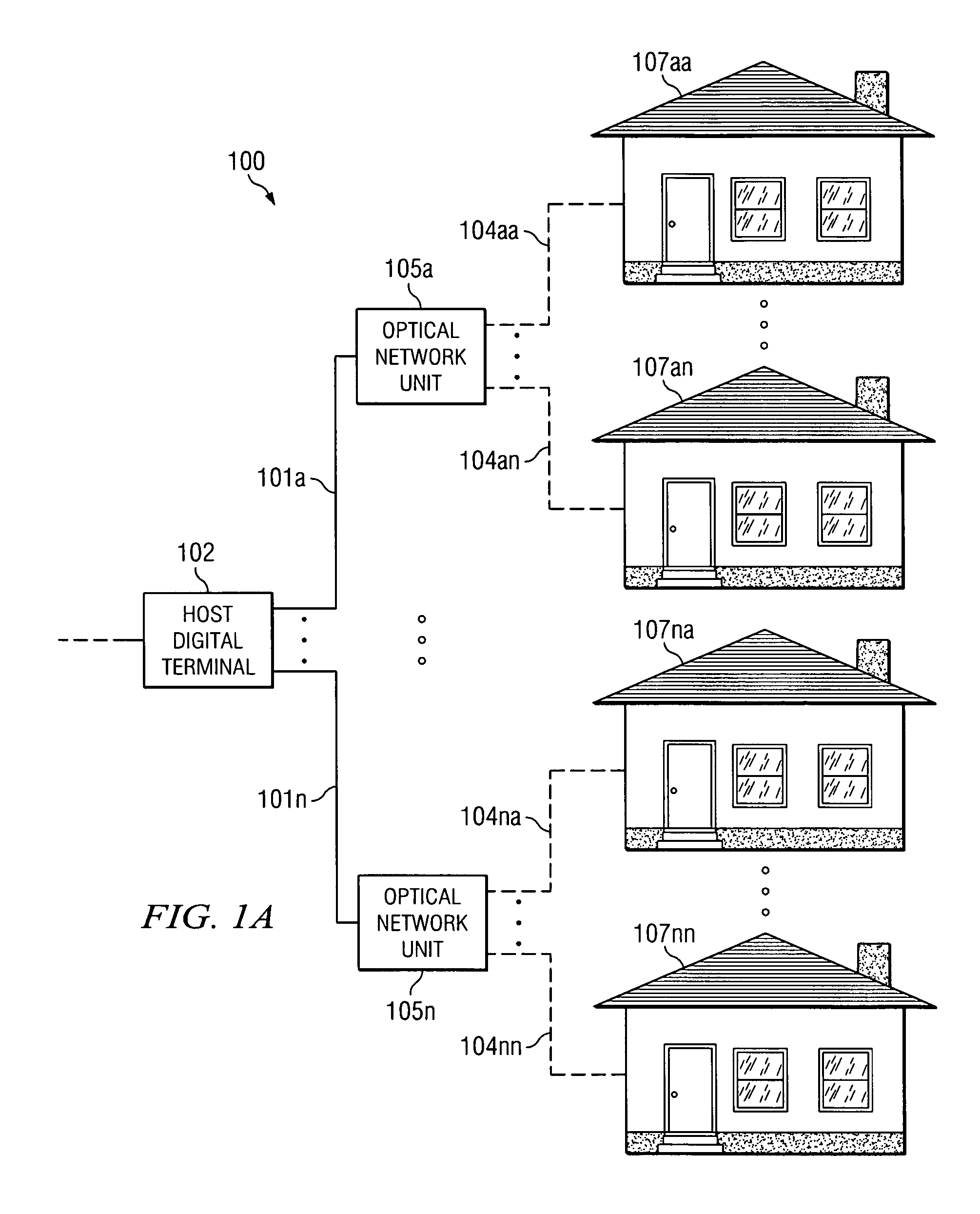

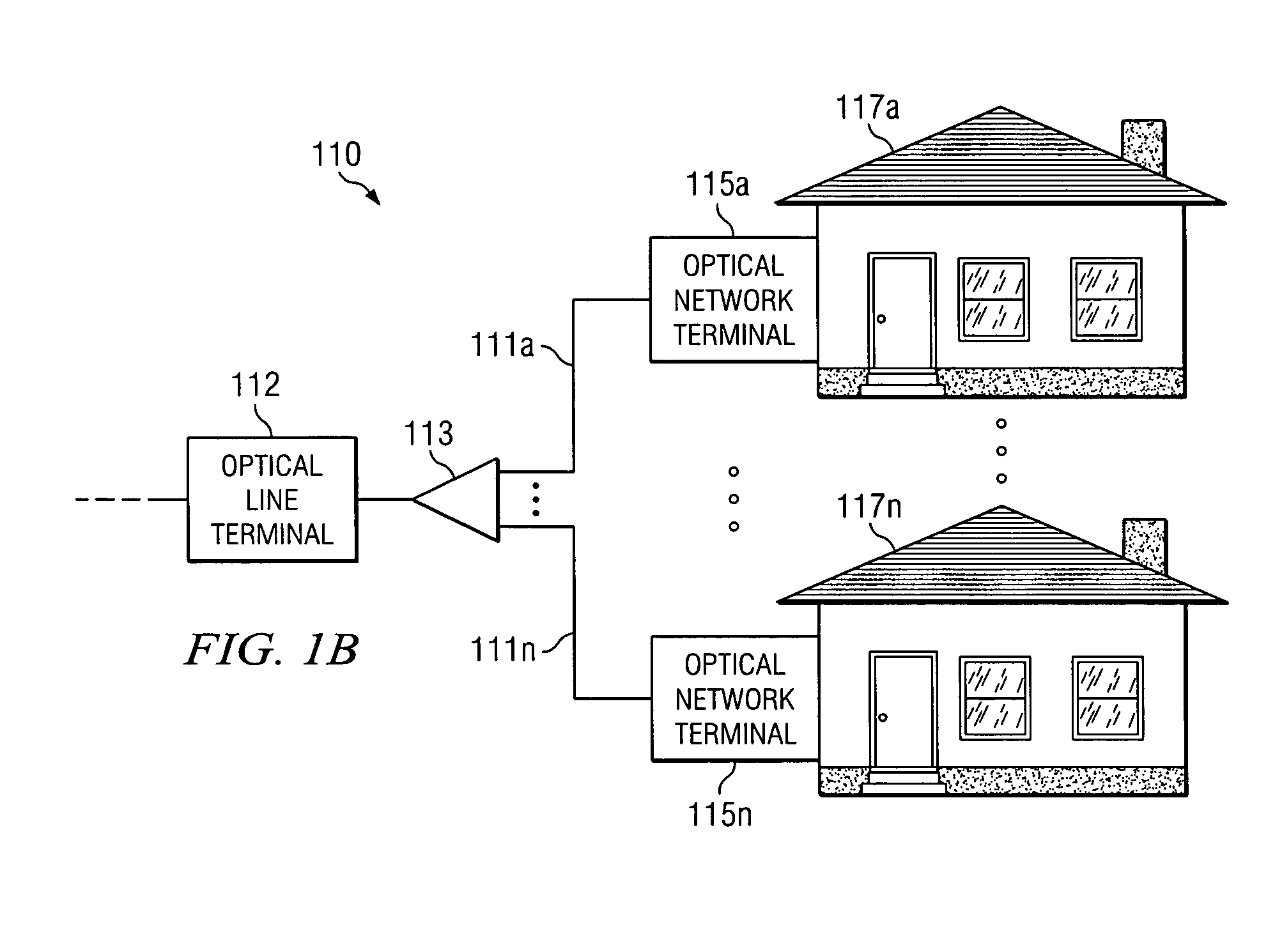

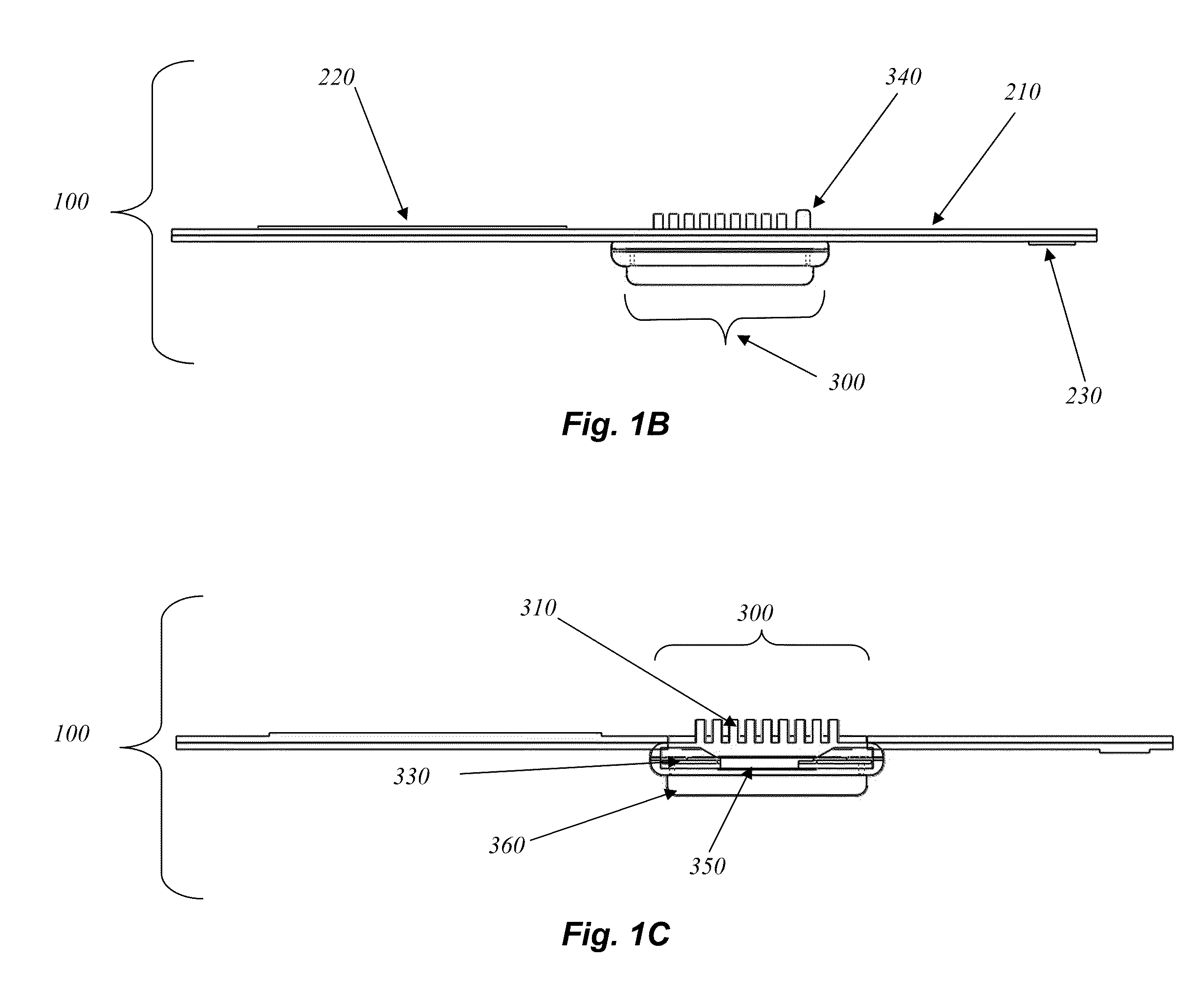

Passive cooling for fiber to the premise (FTTP) electronics

InactiveUS20070115635A1Indirect heat exchangersCooling/ventilation/heating modificationsFiberEngineering

A phase change material, including multiple phase change materials of different formulations, is placed in heat transfer association with an electronics enclosure (e.g., a sealed enclosure) deployed in an environment that causes the electronics and the phase change material to experience periods of heating and periods of cooling. During the periods of heating, the phase change material absorbs heat and changes at least partially from a first state to a second state to maintain the temperature of the electronics at a desirable level. During the periods of cooling, the phase change material reverts at least partially back to the first state for future heat absorption. The phase change material is cooled by a thermally cooler body such as the night sky. The electronics enclosure and phase change material may be placed in a second enclosure covered with a paint having a paint additive that reflects solar radiation.

Owner:TELLABS BEDFORD

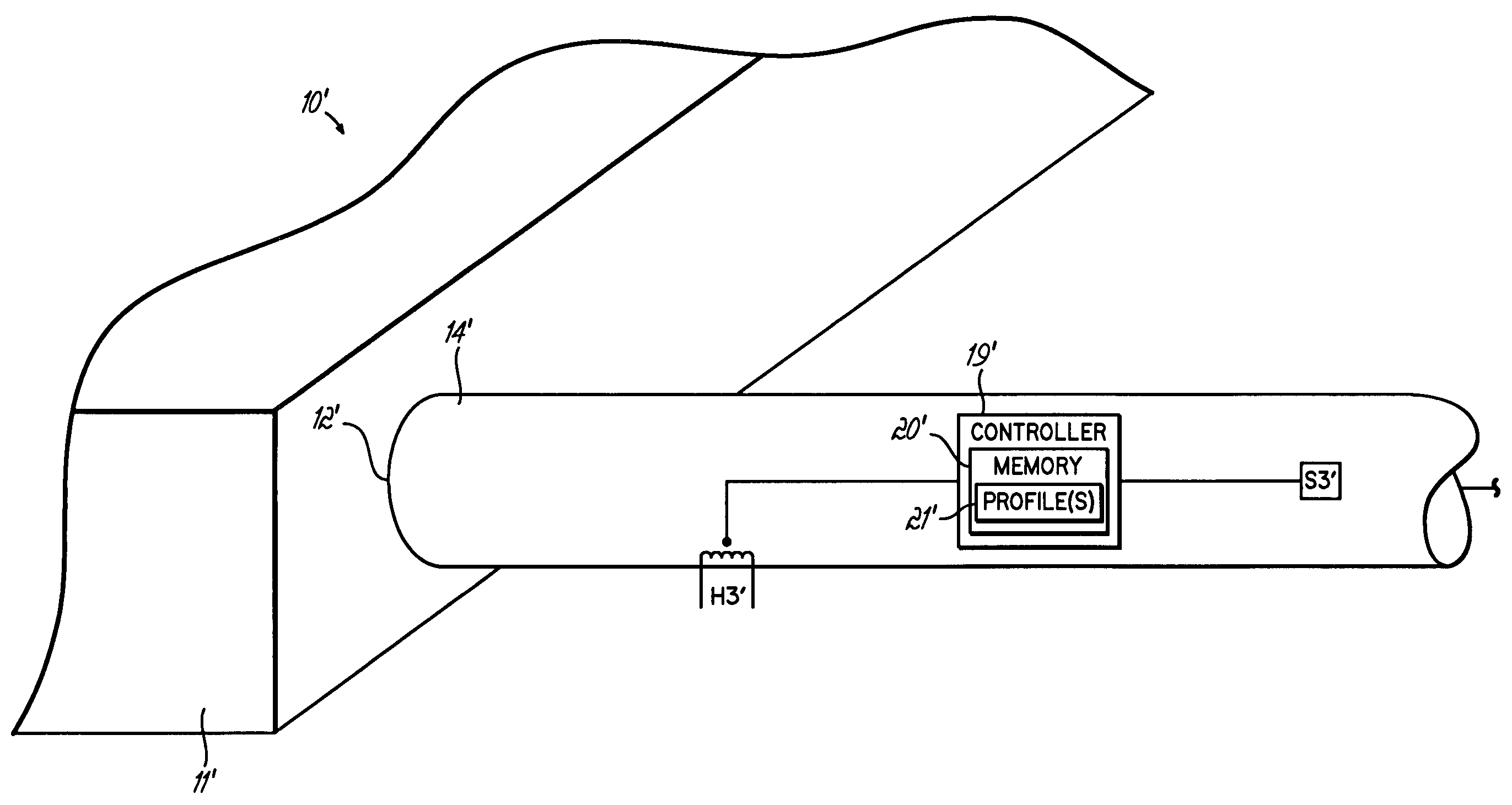

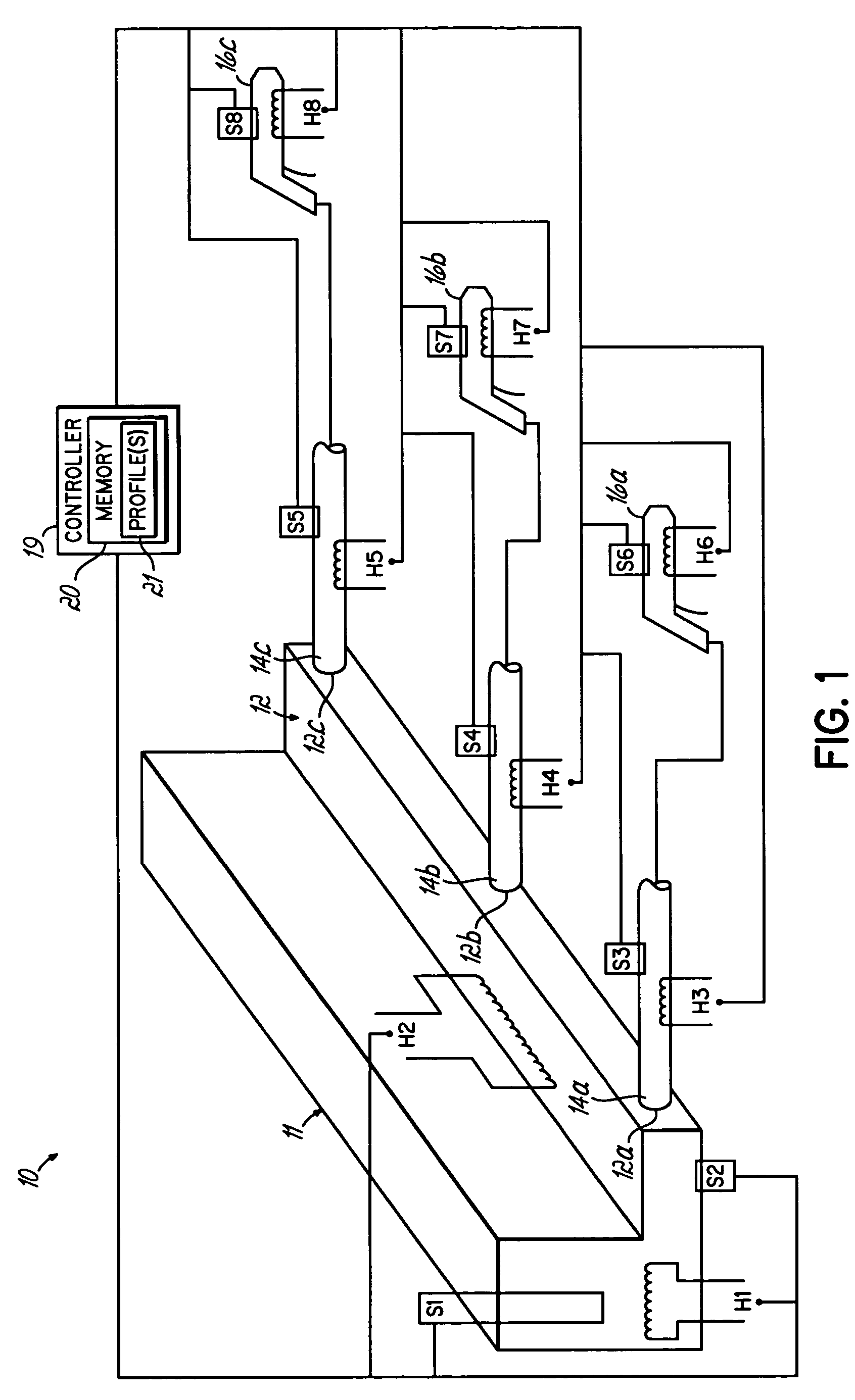

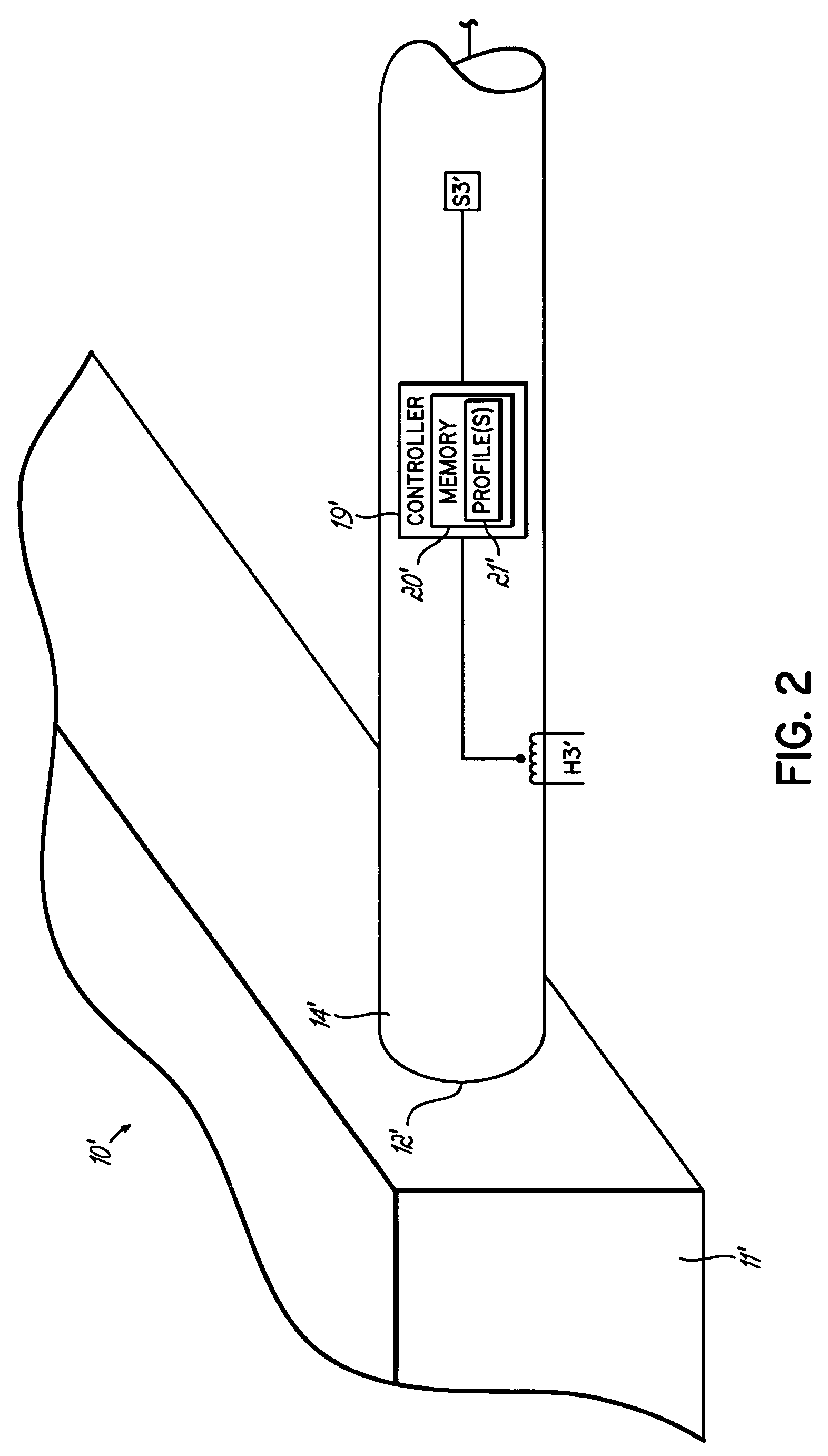

Inferential temperature control system

InactiveUS7510895B2Liquid surface applicatorsSemiconductor/solid-state device testing/measurementTemperature controlControl system

A system manages the temperature of thermoplastic material by initiating a default heating cycle in response to a sensor failure. The system may thus continue to heat the thermoplastic material according to the default heating cycle until the sensor can be repaired or replaced. A system controller implements the default heating cycle using a stored profile. That is, the controller causes a heating element to generate heat according to a default heating profile retrieved from a memory. The profile may be determined using historical heating data, user input and / or a factory setting.

Owner:NORDSON CORP

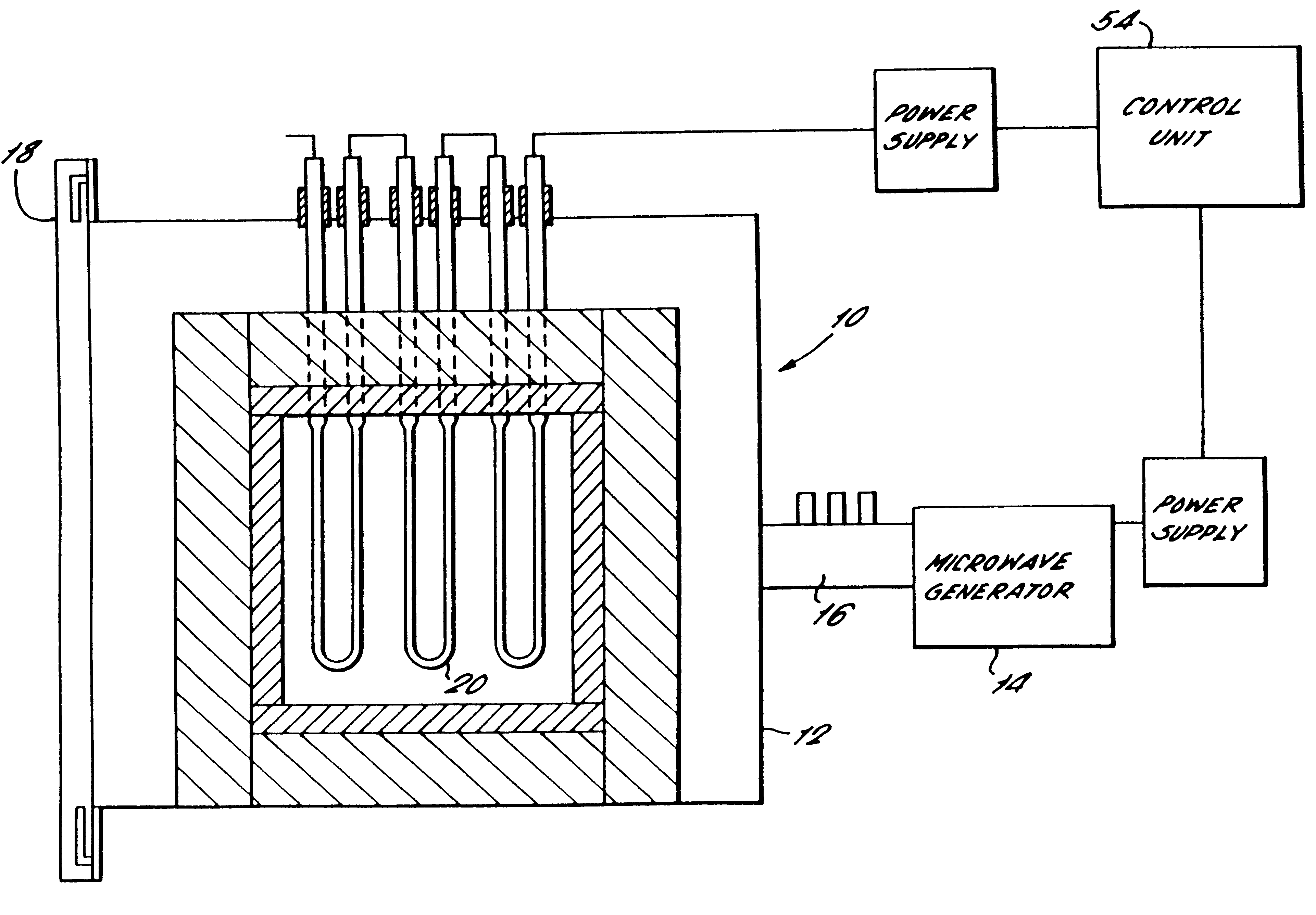

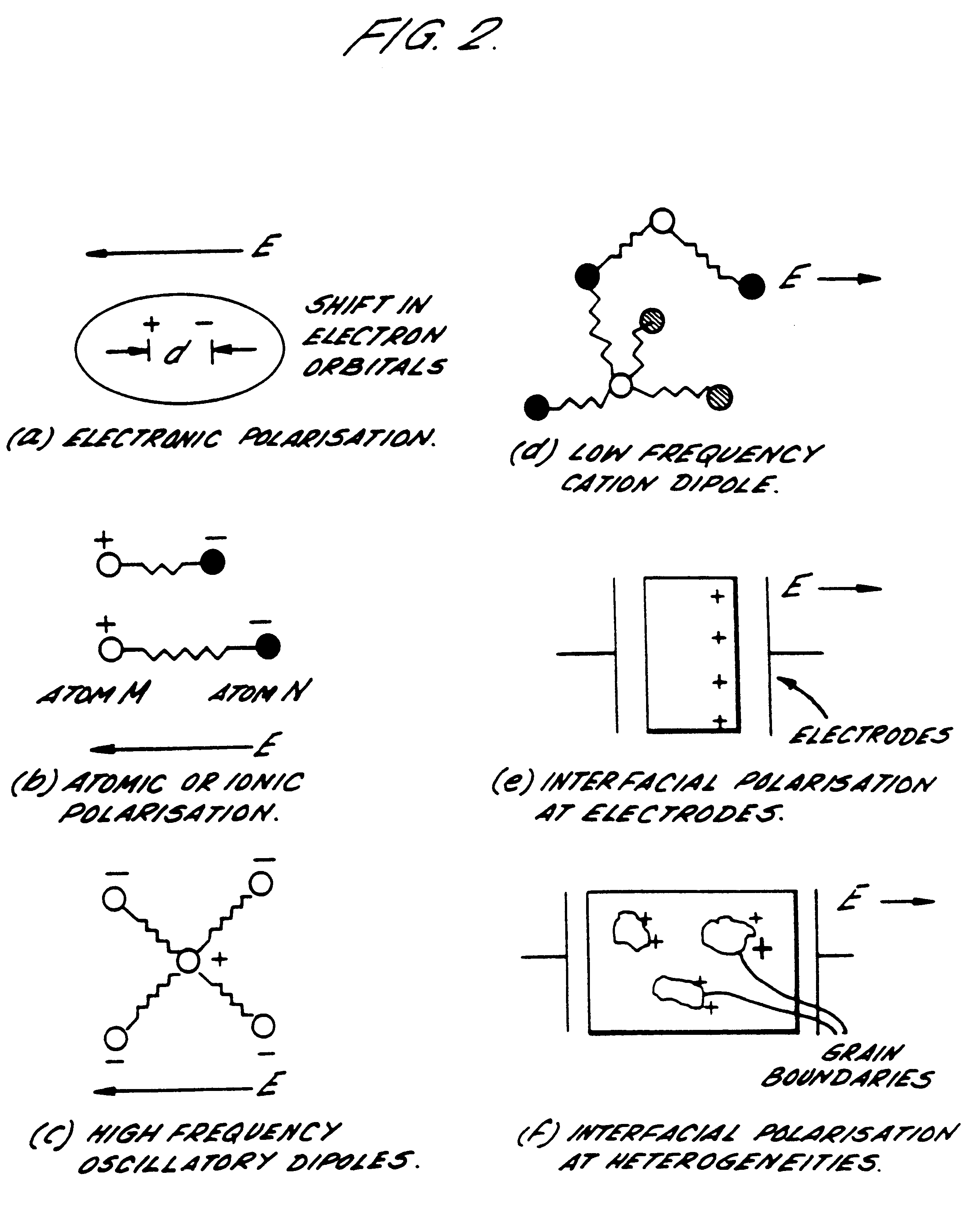

Method of processing ceramic materials and a microwave furnace therefore

InactiveUS6172346B1Less microwave energyIncrease ratingsOhmic-resistance heatingMicrowave heatingTemperature controlMicrowave oven

A microwave furnace (10) of the type comprising a microwave source (14), coupled to an enclosure for the confinement of microwaves and for containing an object to be heated (12). An independently controllable alternate heating (20) is disposed in relation to the enclosure (12) to provide at least one of radiant and convective heating within the enclosure. The method comprises the steps of energizing the alternate heater (20) so as to generate heat substantially throughout the heating cycle of the furnace (10) and controlling the quanity of heat generated in the object y one or both of the microwaves and the alternate heater so as to provide a desired thermal profile in the object. A temperature sensor to measure the ambient temperature within the enclosure (12) can be provided and control circuit (54) responsive to the sensed temperature controls the quanity of heat generated in the object by the microwaves and the alternate heat so as to provide a desired thermal profile within the object.

Owner:CAPENHURST TECH

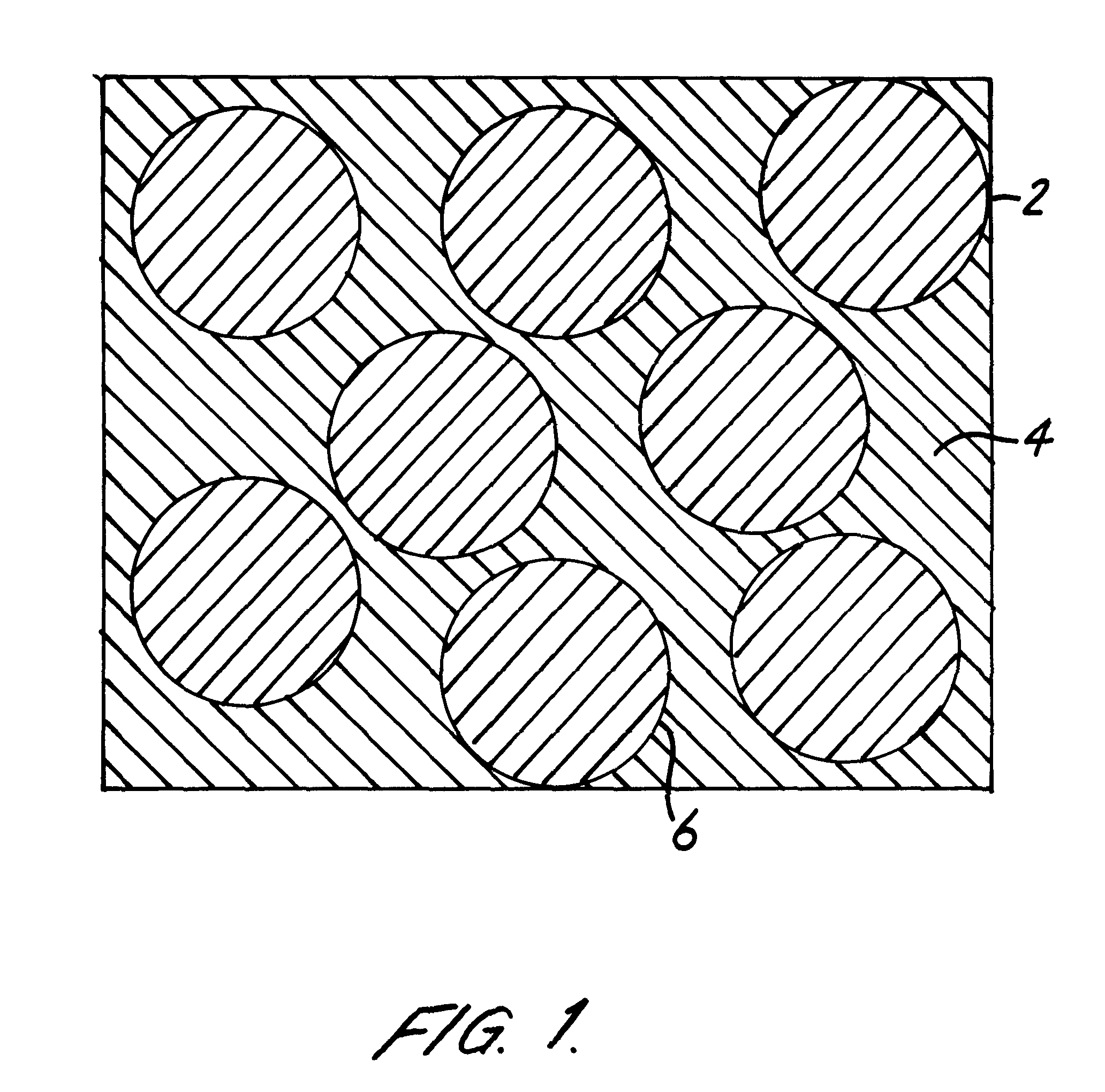

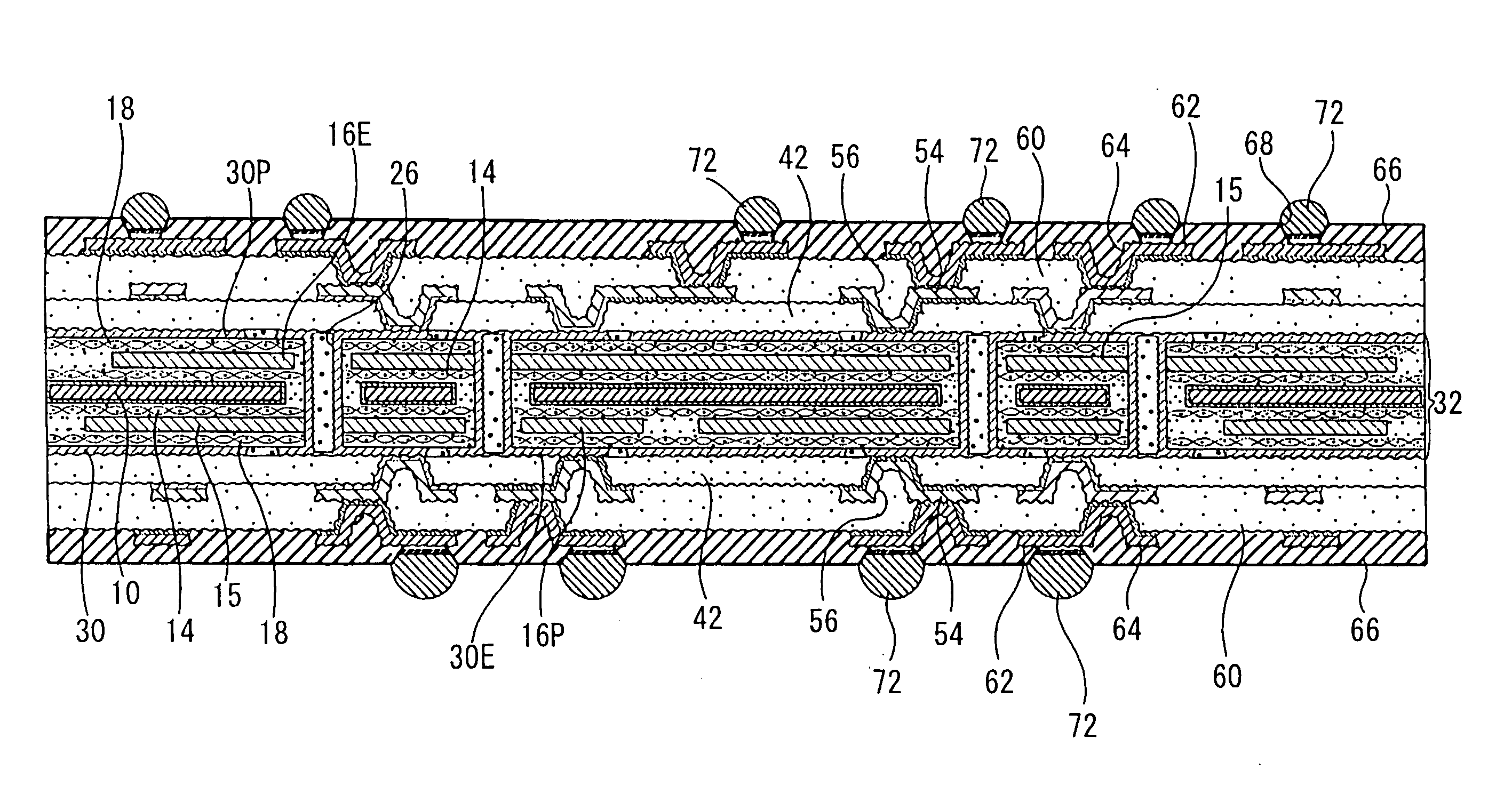

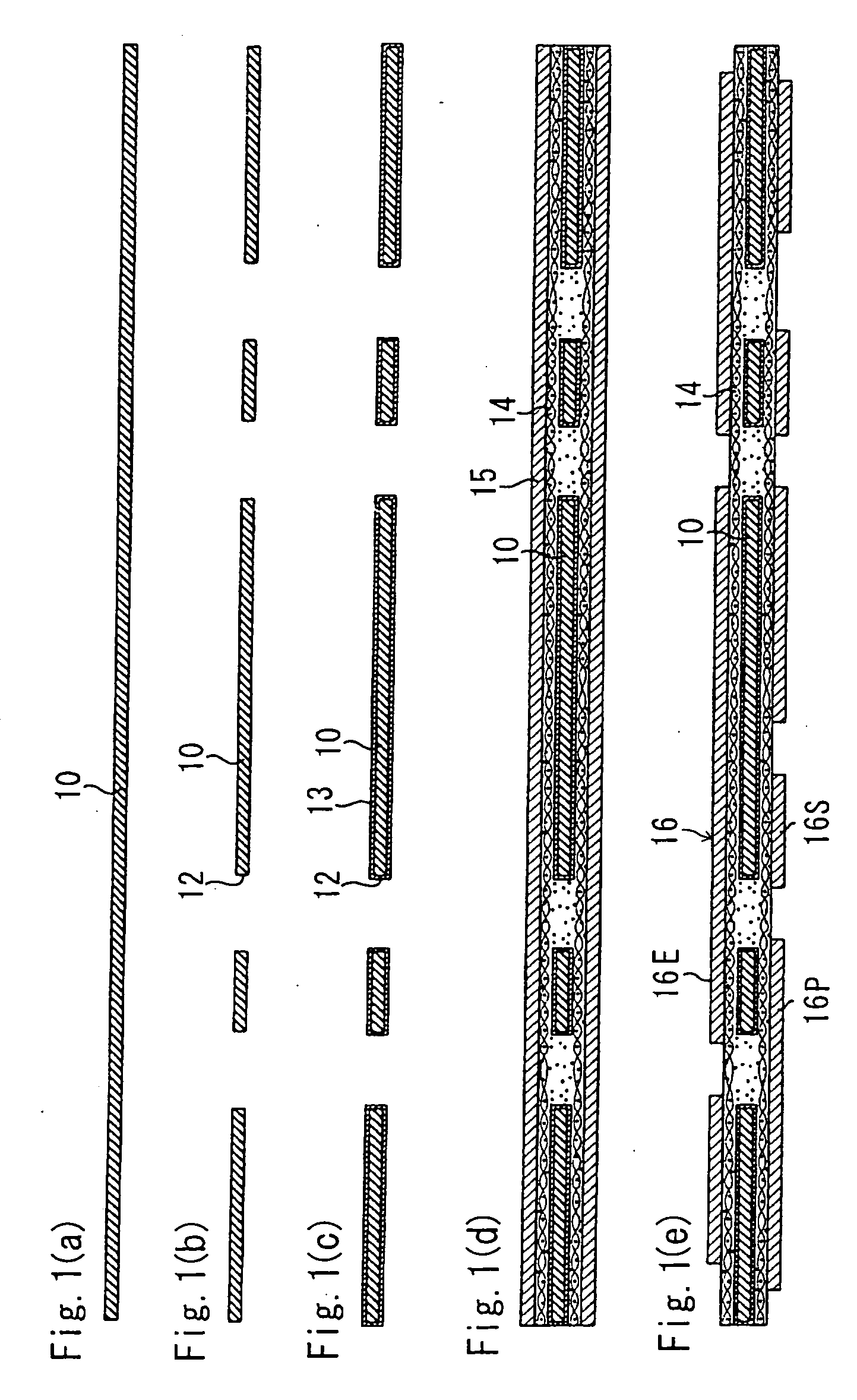

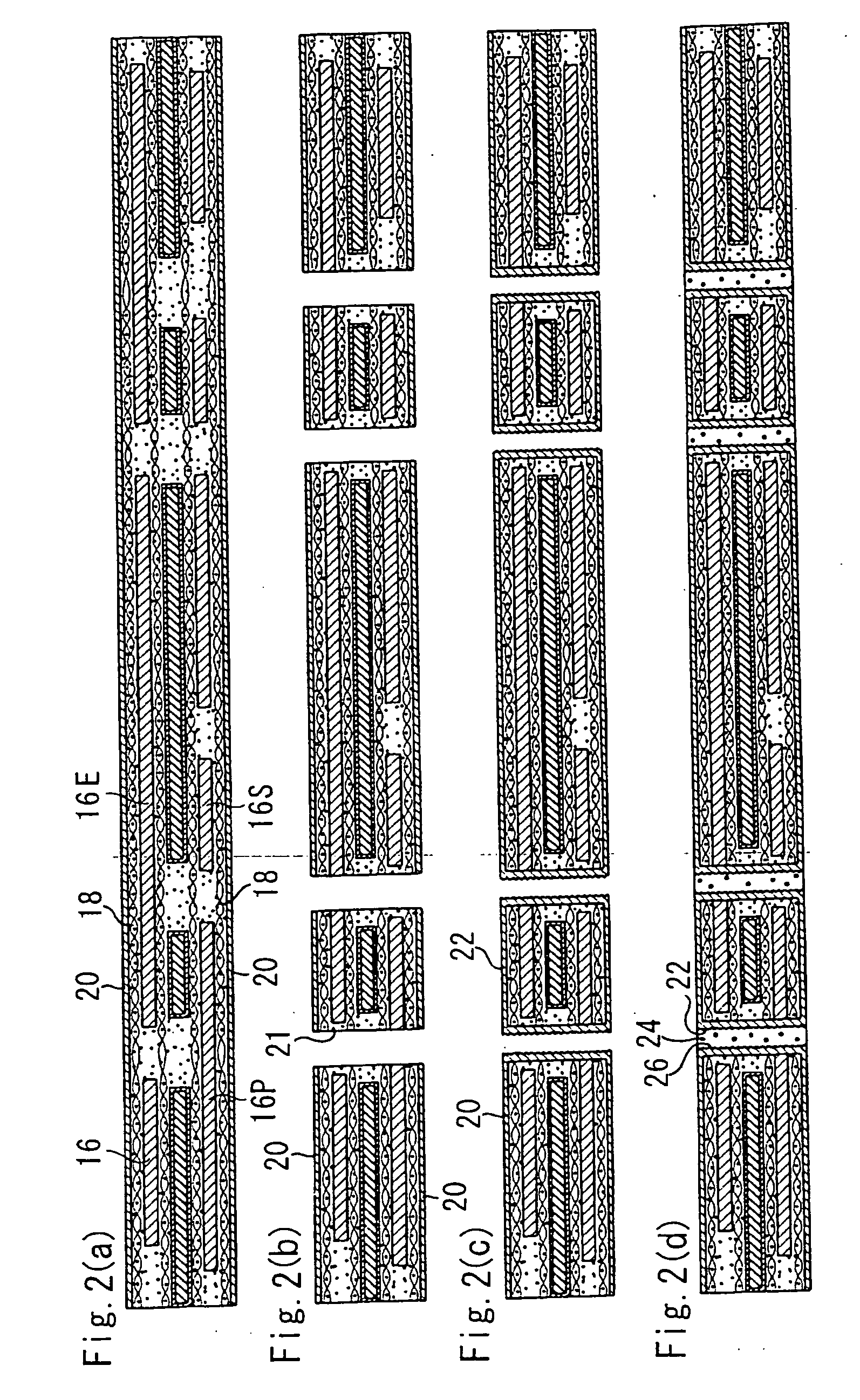

Interlayer insulating layer for printed wiring board, printed wiring board and method for manufacturing same

InactiveUS20070013049A1Small in expansibilitySmall in contractilityLayered productsSemiconductor/solid-state device detailsEtchingHeat resistance

A printed wiring board is provided which includes an interlayer dielectric layer formed on a substrate from a curable resin having flaky particles dispersed therein. The printed wiring board is excellent in cooling / heating cycle resistance and packaging reliability while maintaining a satisfactory heat resistance, electrical insulation, heat liberation, connection reliability and chemical stability. Also a method of producing a printed wiring board is proposed in which an imprint method using a mold having formed thereon convexities corresponding to wiring patterns and viaholes to be formed being buried in an interlayer dielectric layer is used to form the wiring patterns and viaholes by transcribing the concavities of the mold to the interlayer dielectric layer. The imprint method permits to form the wiring patterns and viaholes but assures an easy and accurate transcription without any optical transcription or complicated etching. Thus, a multilayer printed wiring board excellent in insulation reliability and interlayer connection and having fine wiring patterns formed therein can be mass-produced extremely easily and inexpensively.

Owner:IBIDEN CO LTD

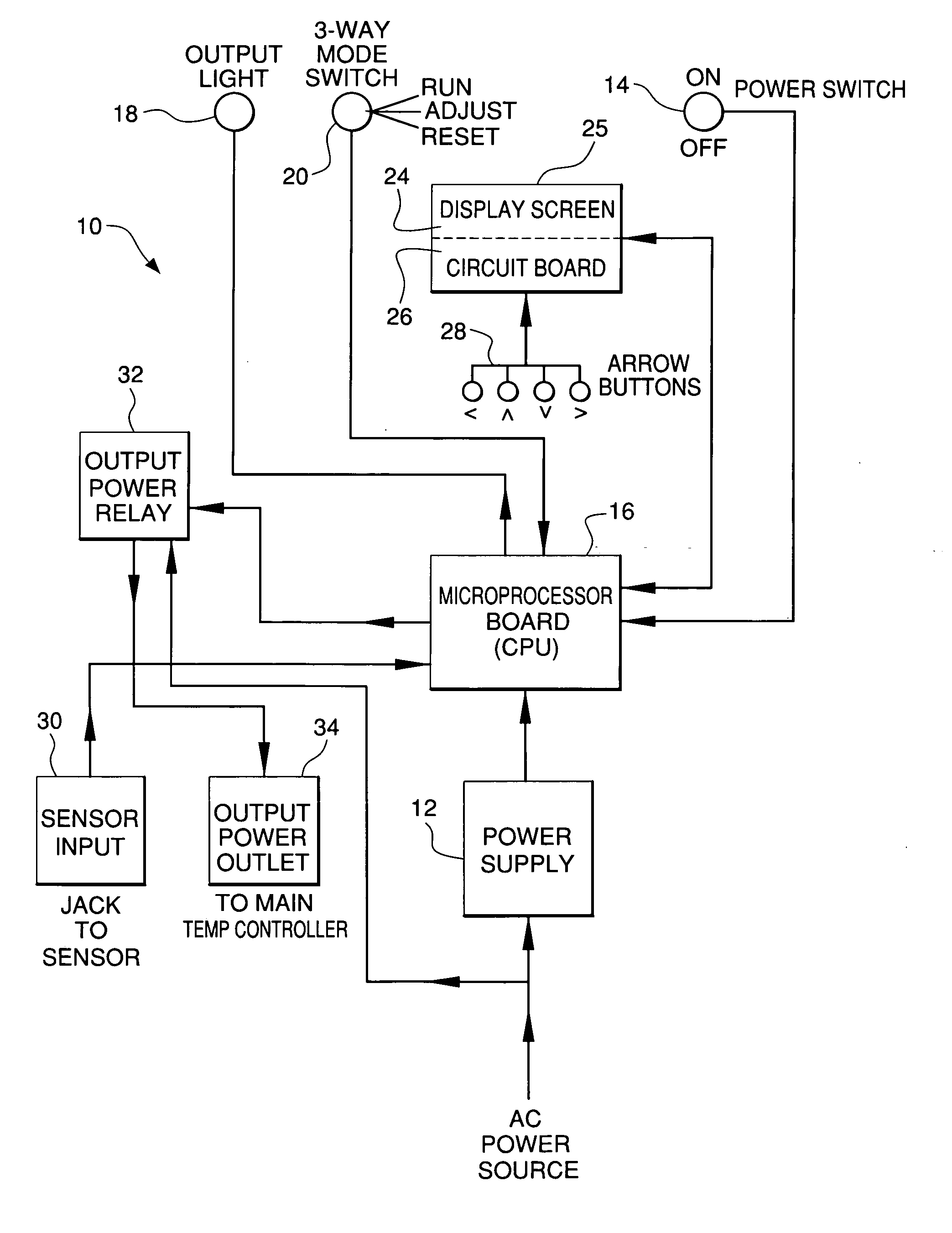

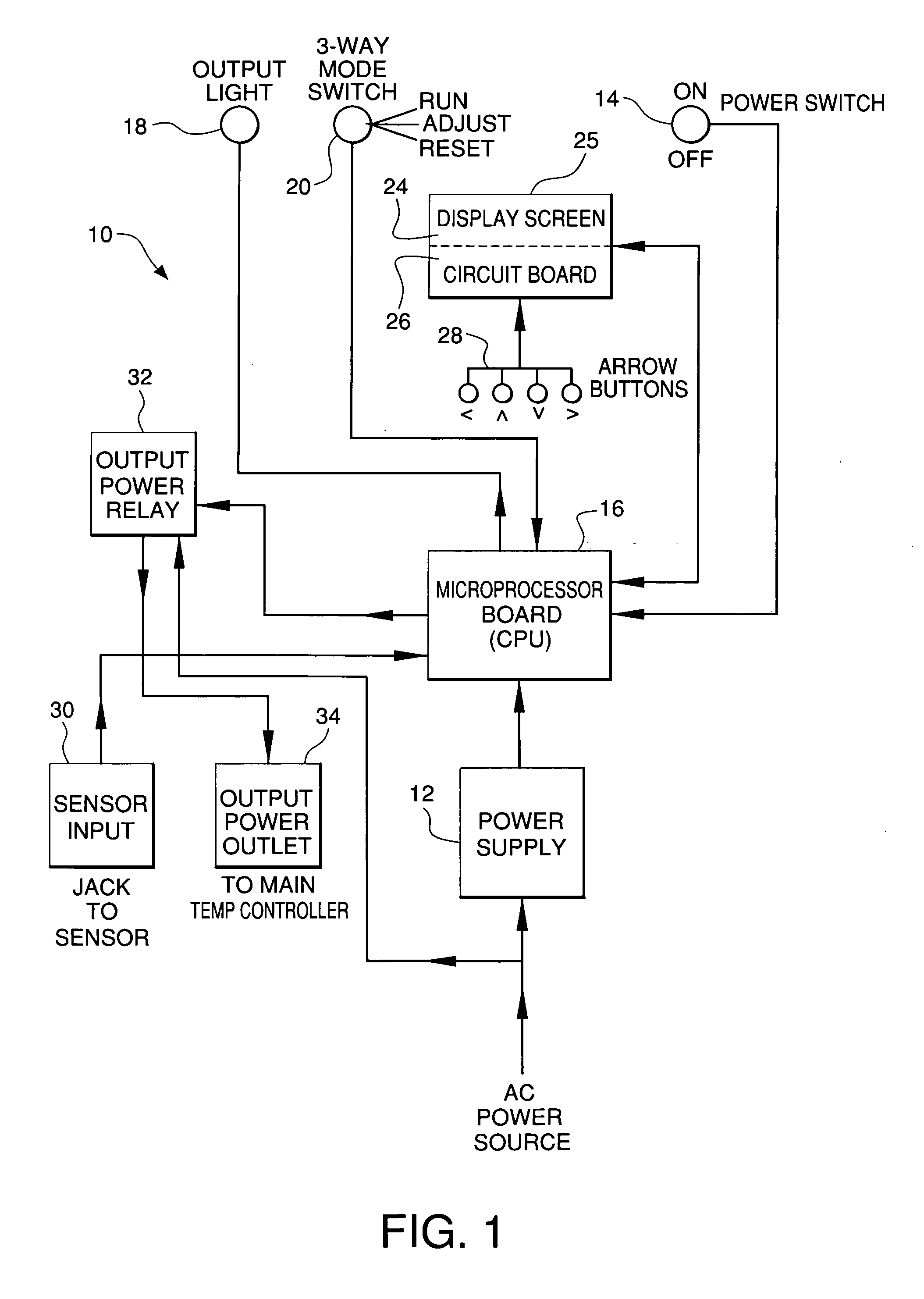

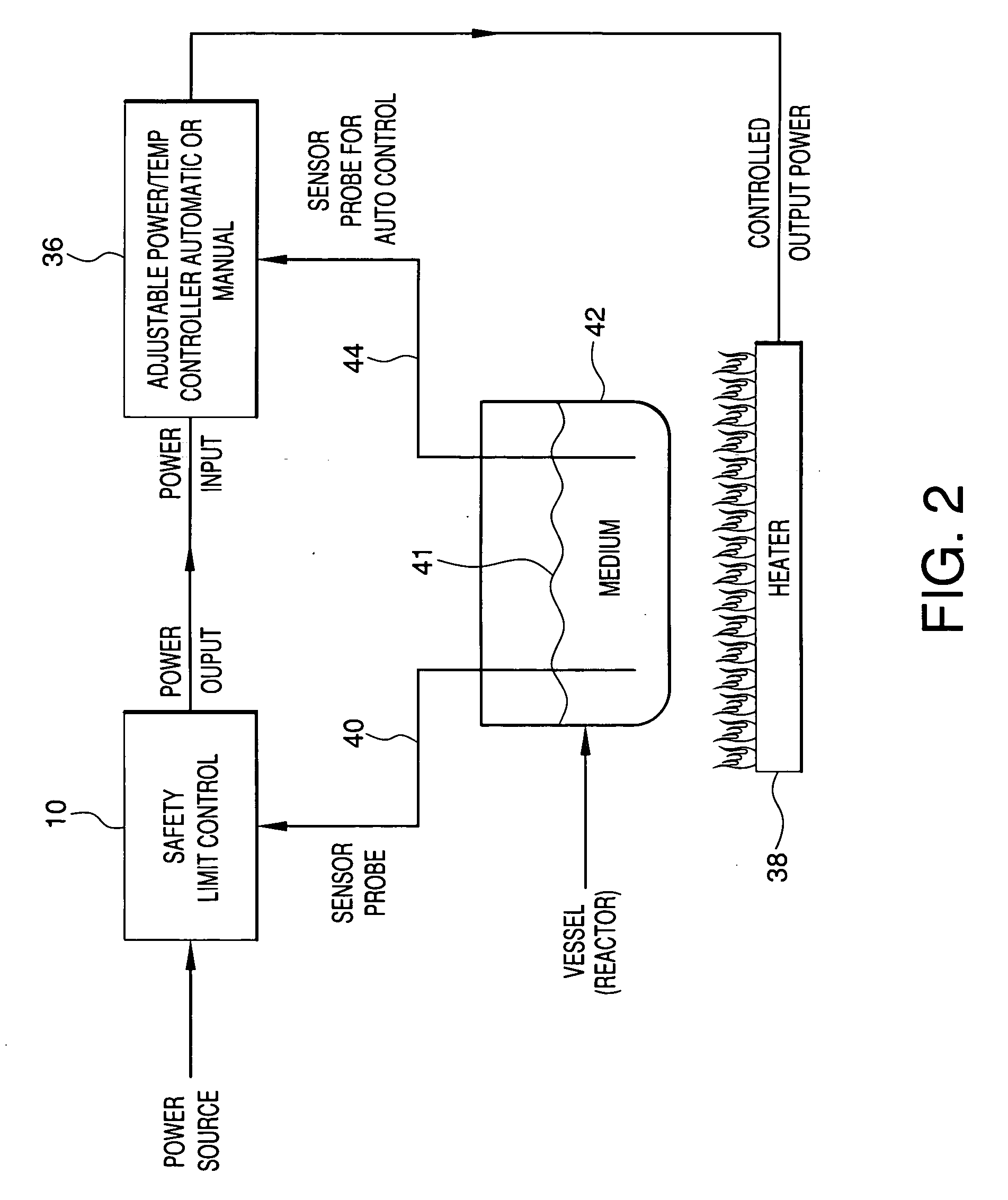

Temperature controller backup device

InactiveUS20070080235A1Reduce processTemperature control without auxillary powerFuel supply regulationTemperature controlHeating cycle

A temperature controller device including informative display screens, predeterminable heating cycles, automated system checks and other utilities that reduces human involvement in a monitoring process. The device may be incorporated into a temperature controller or may be a separate “stand alone” unit.

Owner:ACE GLASS

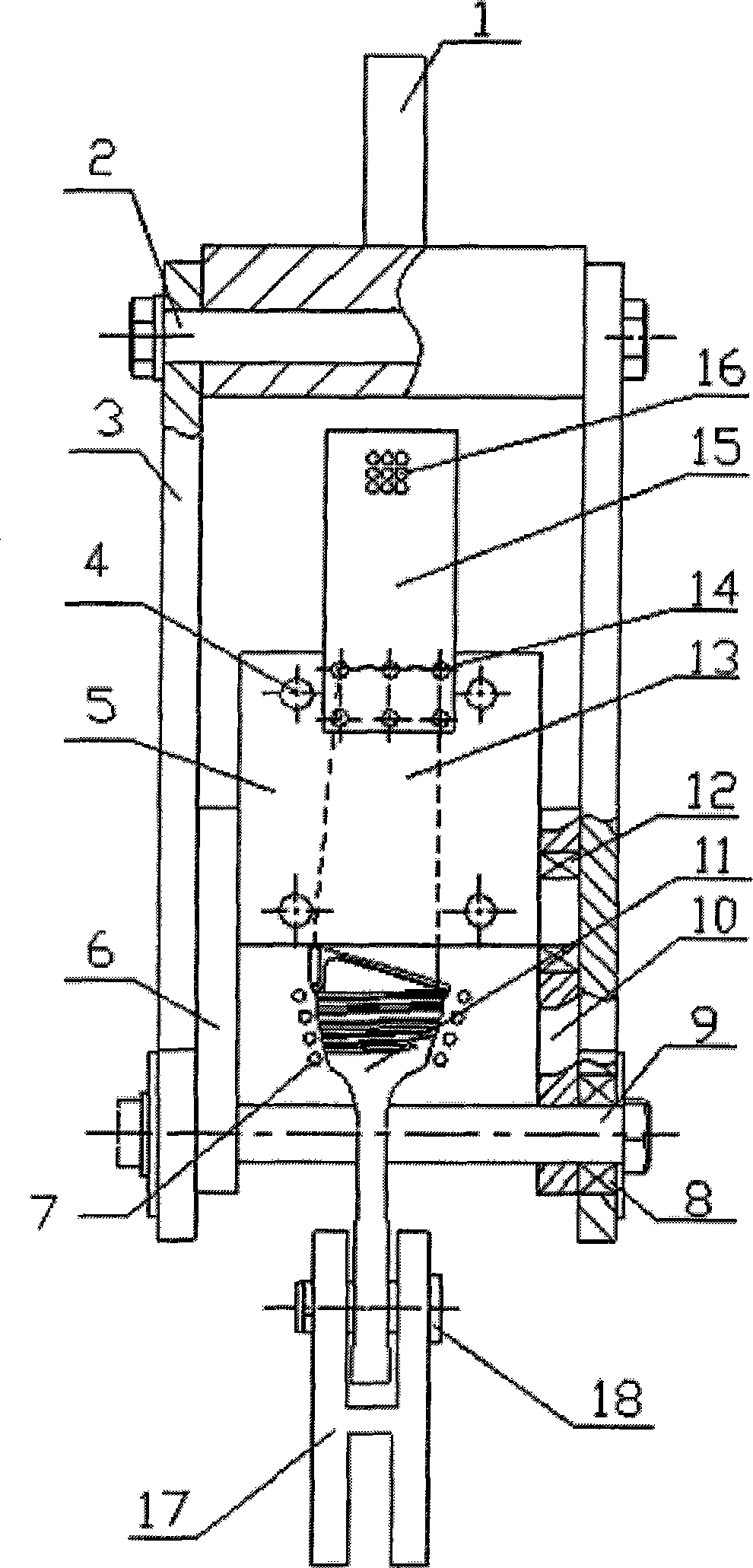

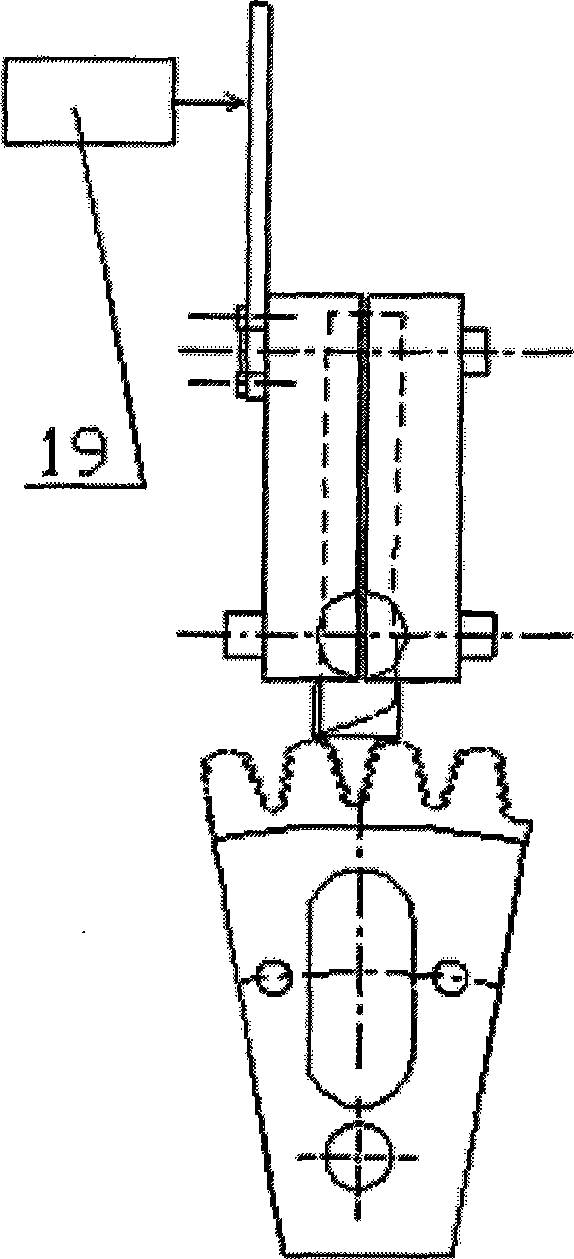

High temperature composite fatigue loading method and apparatus for turbine disc/blade joggled joint

InactiveCN101464240AResolve mutual interferenceReduce resistanceMaterial strength using repeated/pulsating forcesStress distributionFatigue loading

A turbine disc / blade tenon connection high-temperature combined fatigue loading device comprises a low cycle load stress application mechanism, a force transmission pin, a force transmission main tension plate, a force transmission crown plate, a force transmission round bar, a blade clamp, a rolling bearing, a hold-down bolt, a high cycle transmission plate, a high-frequency heating cycle, and a vibration generator, wherein, the low cycle load stress application mechanism is connected with the force transmission main tension plate through the force transmission pin; the force transmission main tension plate is connected with the force transmission round bar through the rolling bearing; the lower end of the force transmission crown plate is sleeved on the force transmission round bar, and the upper end is connected with the load bearing dummy club of the blade clamp through the rolling bearing; the blade clamp is connected with the blade of a turbine through the hold-down bolt; the turbine disc is connected with the low cycle load stress application mechanism through the force transmission pin; the high cycle transmission plate is connected with the blade clamp through the hold-down bolt; and the vibration generator is positioned on one side above a high cycle load transmission plate. The loading method is characterized in that the force application point of low cycle loads is moved backwards, thereby enabling small high cycle loads to be smoothly transferred to the tenon connection position, ensuring the stress distribution along the tenon tooth is reasonable, and preventing combined loads from interfering with each other.

Owner:BEIHANG UNIV

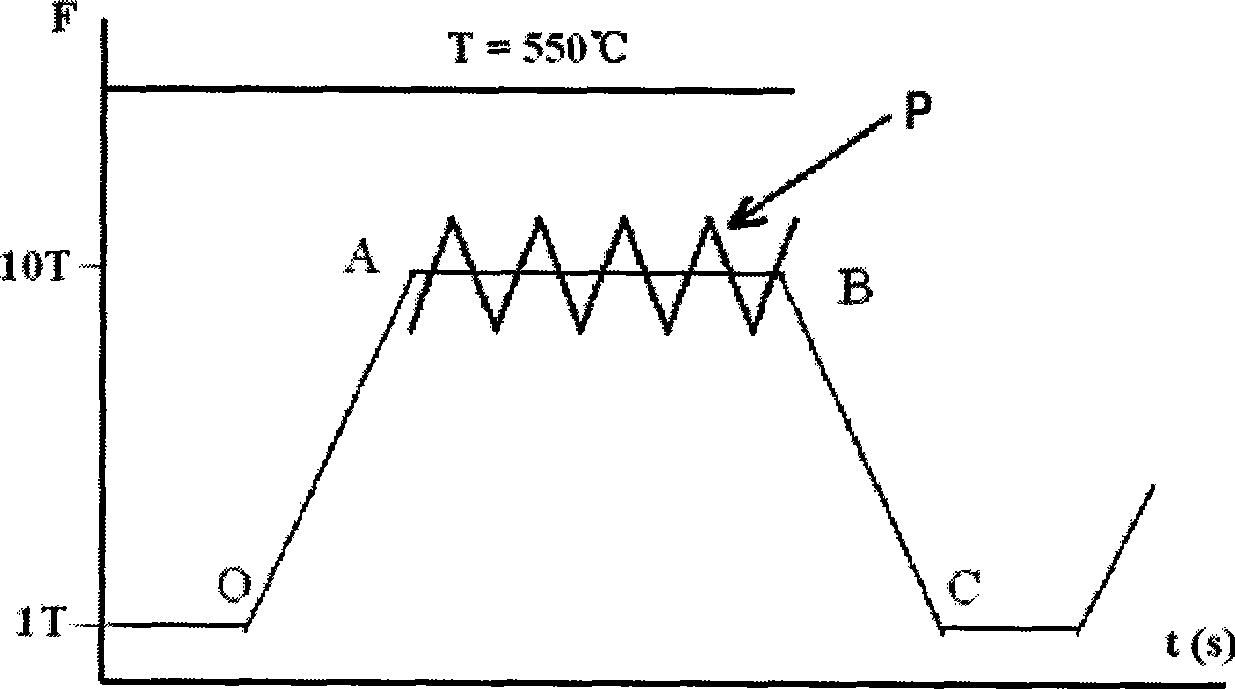

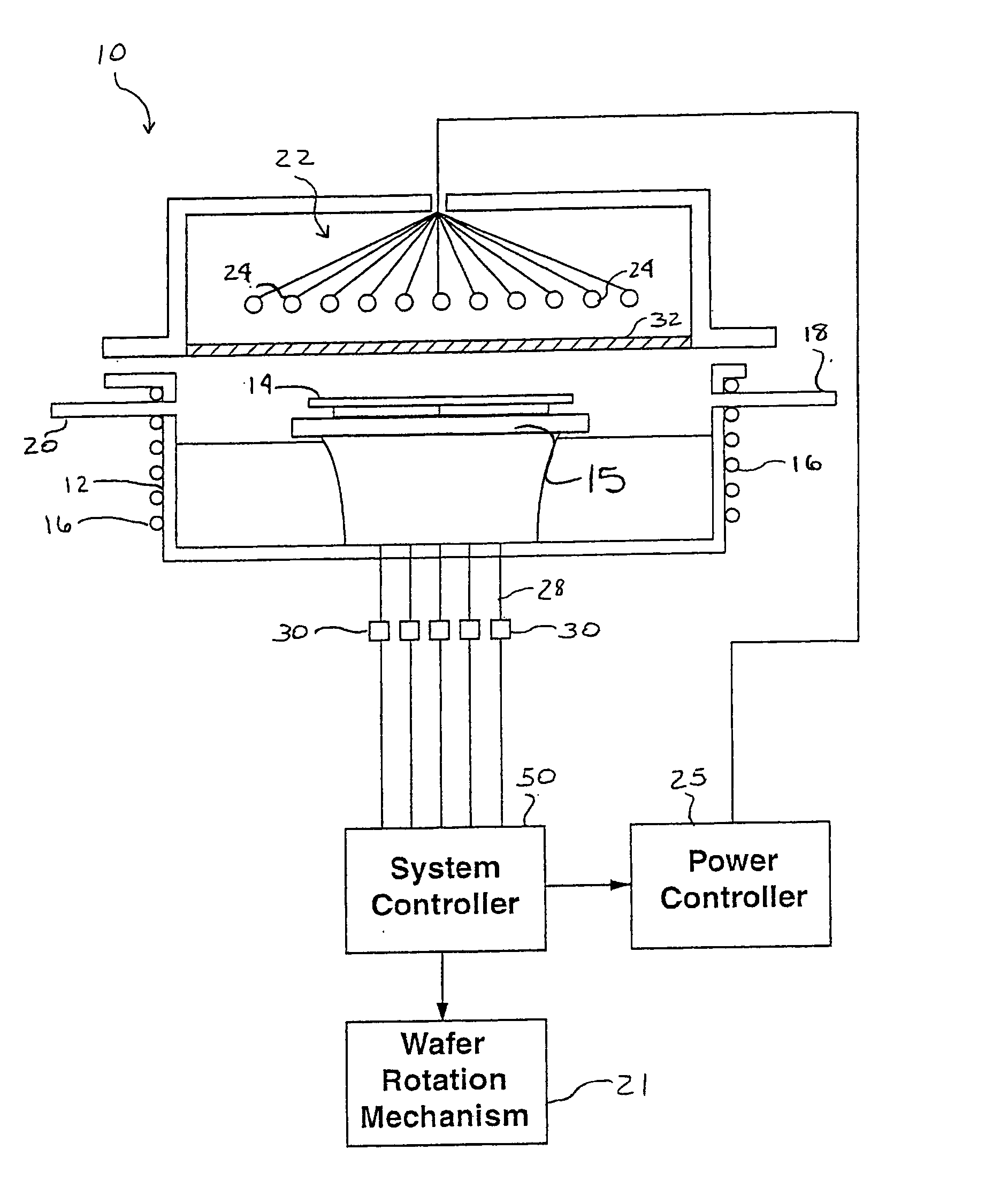

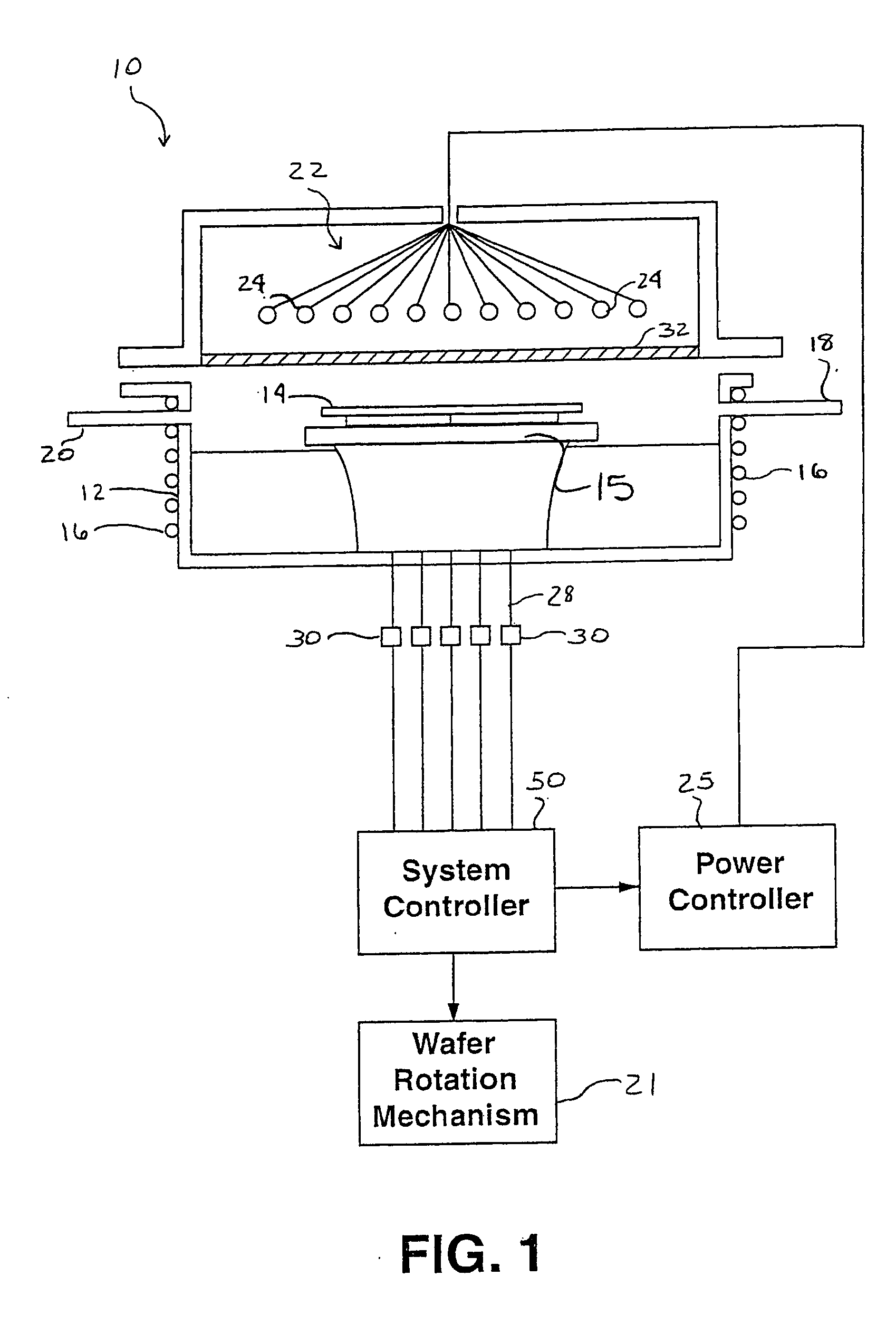

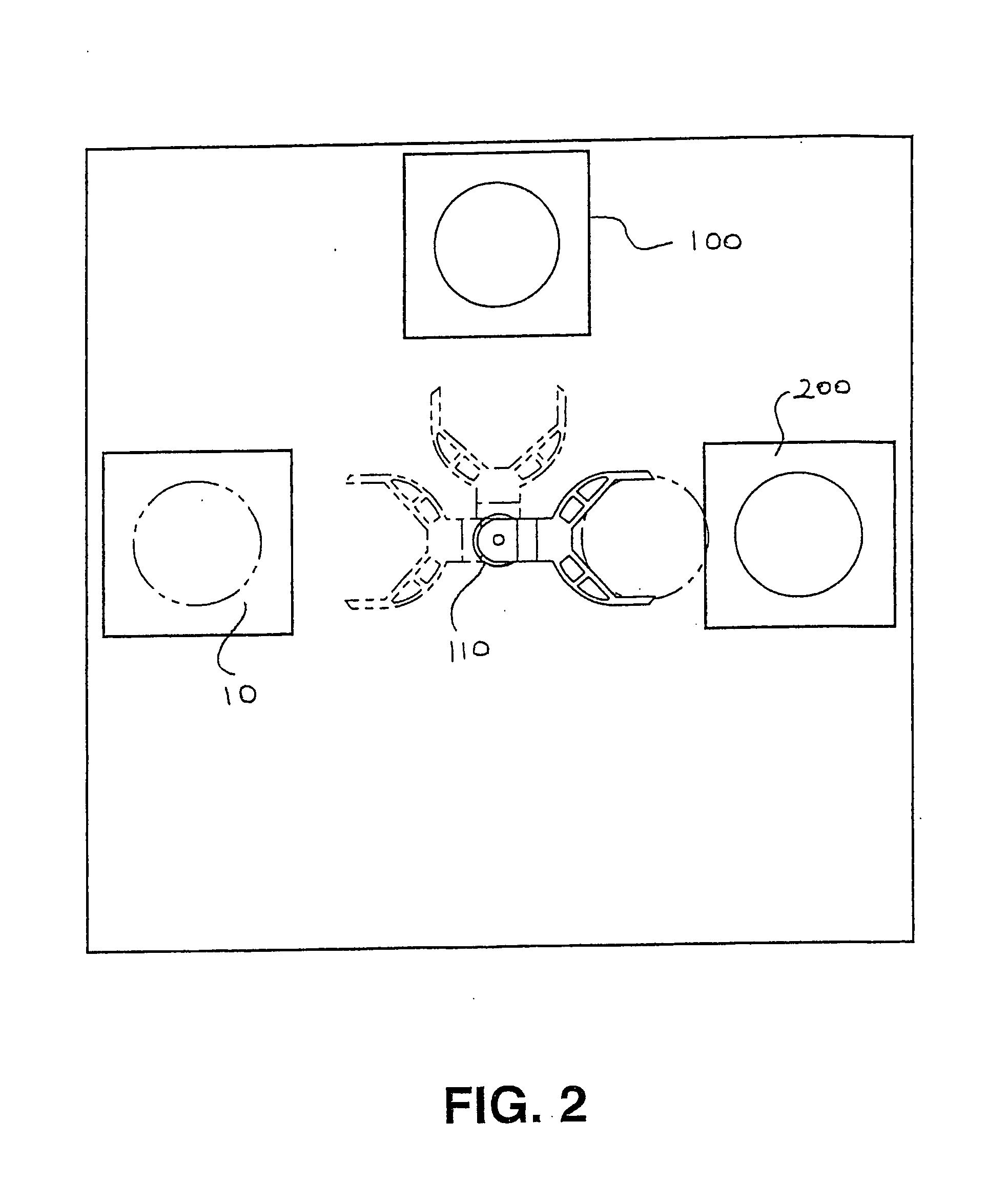

Method and system for determining optical properties of semiconductor wafers

ActiveUS20070020784A1Precise heatingImprove accuracyRadiation pyrometrySemiconductor/solid-state device testing/measurementOptical propertyEmissivity

A method and system are disclosed for determining at least one optical characteristic of a substrate, such as a semiconductor wafer. Once the optical characteristic is determined, at least one parameter in a processing chamber may be controlled for improving the process. For example, in one embodiment, the reflectivity of one surface of the substrate may first be determined at or near ambient temperature. From this information, the reflectance and / or emittance of the wafer during high temperature processing may be accurately estimated. The emittance can be used to correct temperature measurements using a pyrometer during wafer processing. In addition to making more accurate temperature measurements, the optical characteristics of the substrate can also be used to better optimize the heating cycle.

Owner:MATTSON TECHNOLOGY +1

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

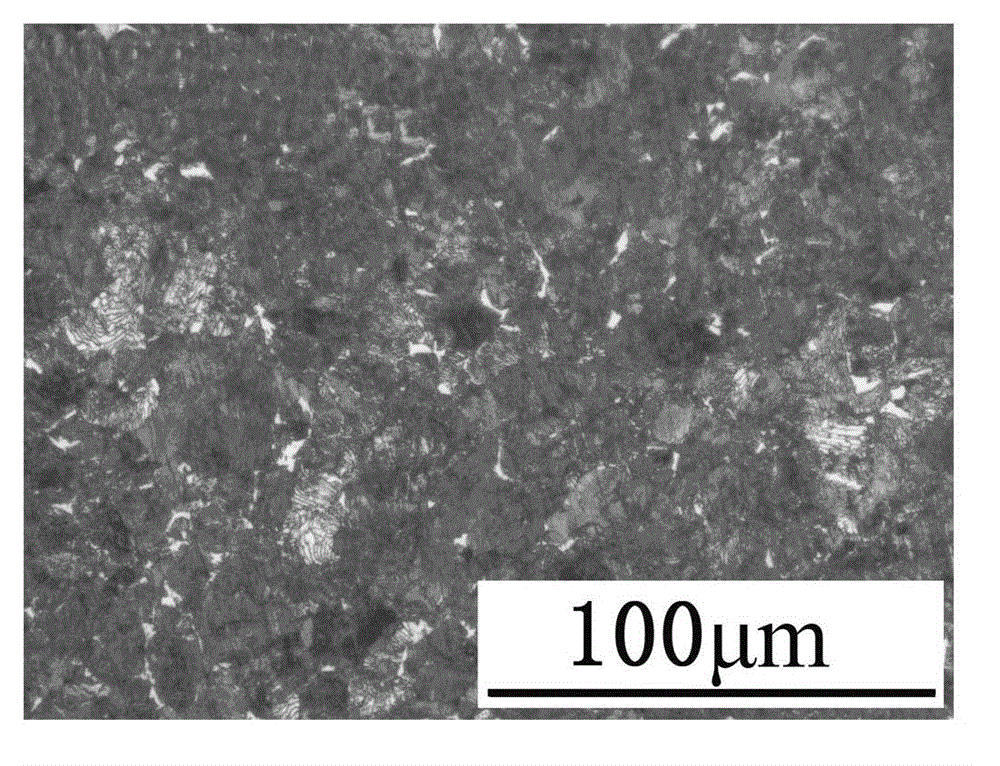

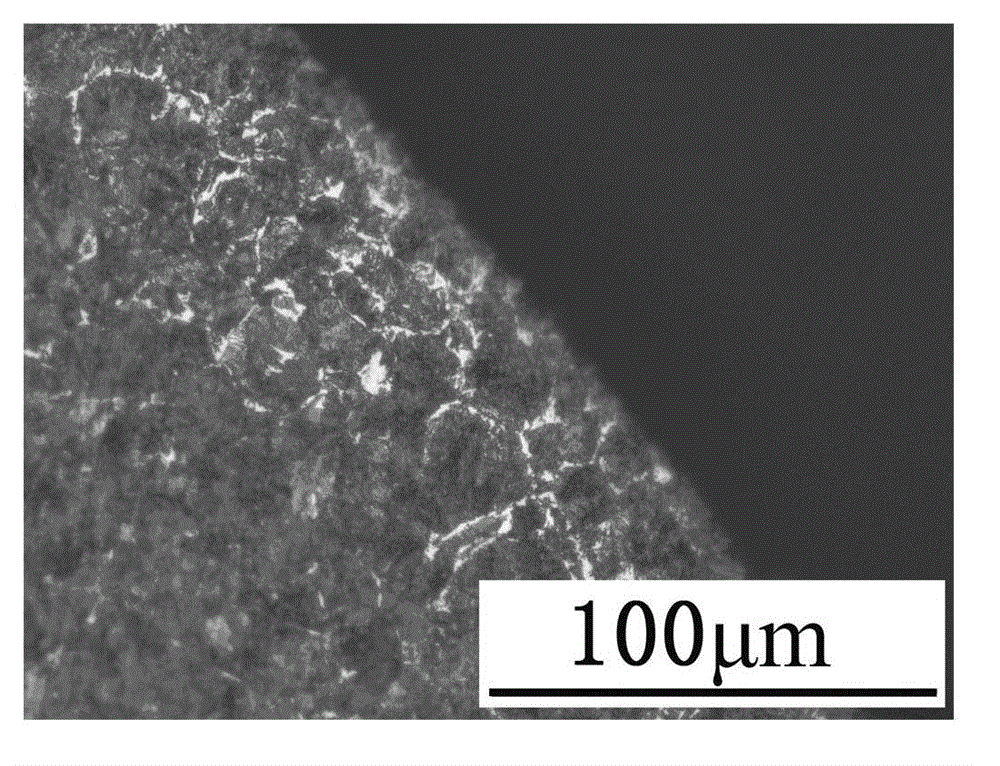

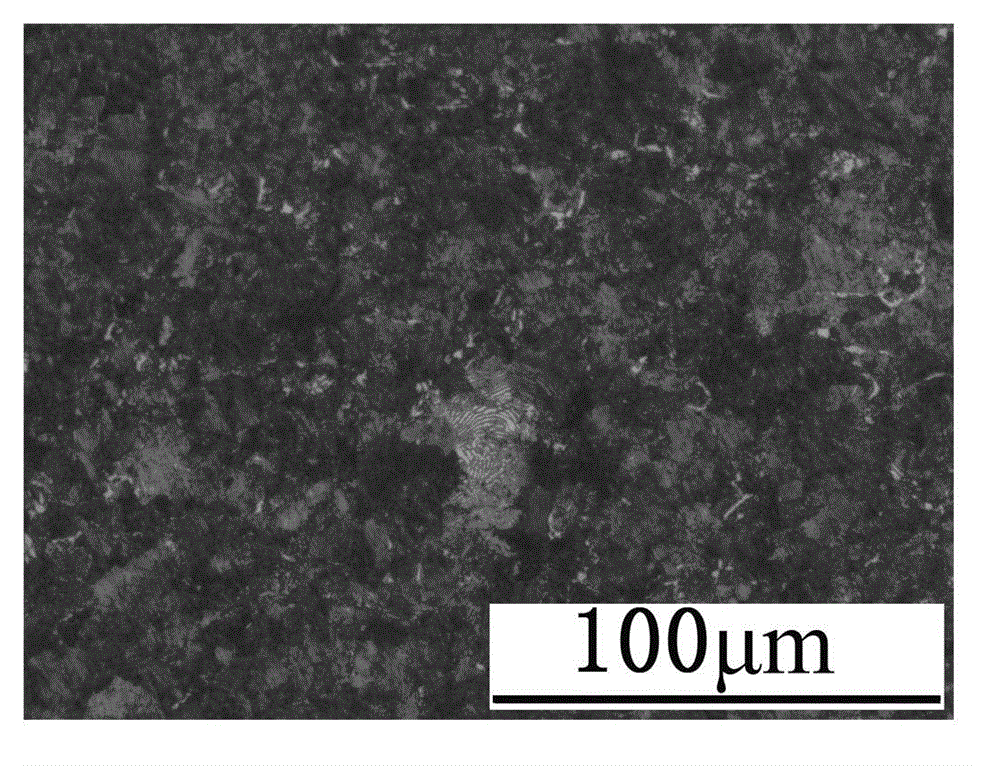

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

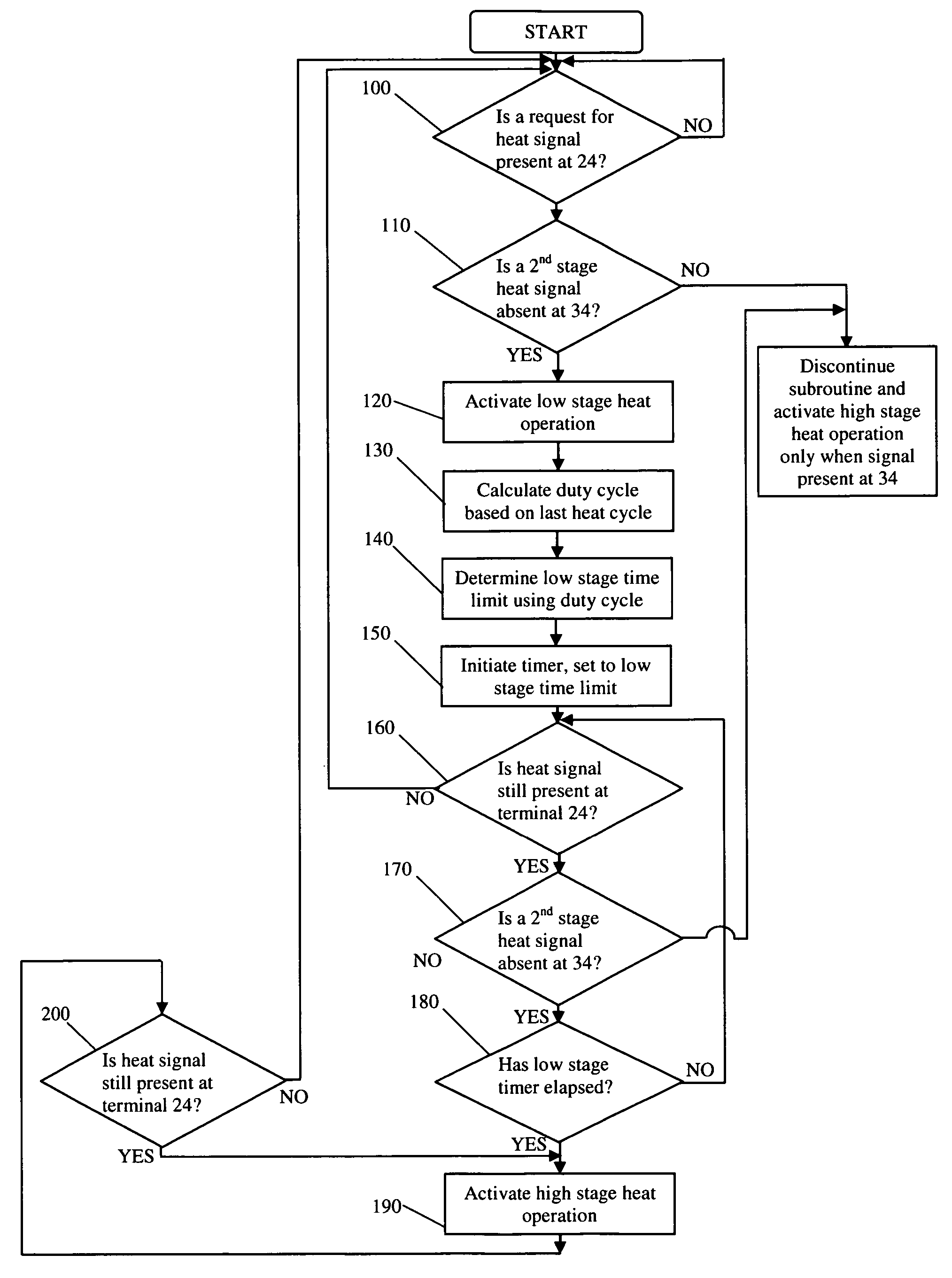

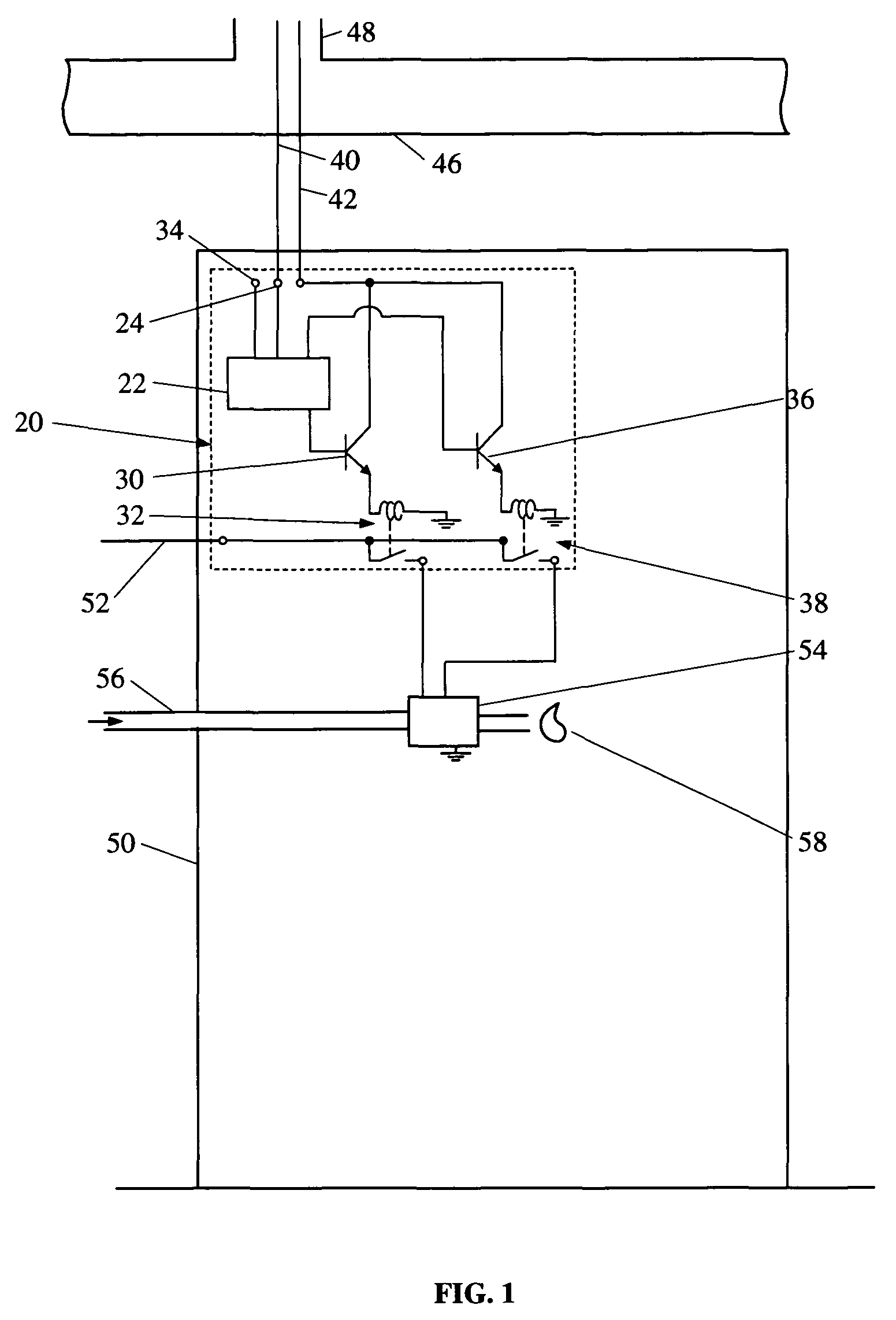

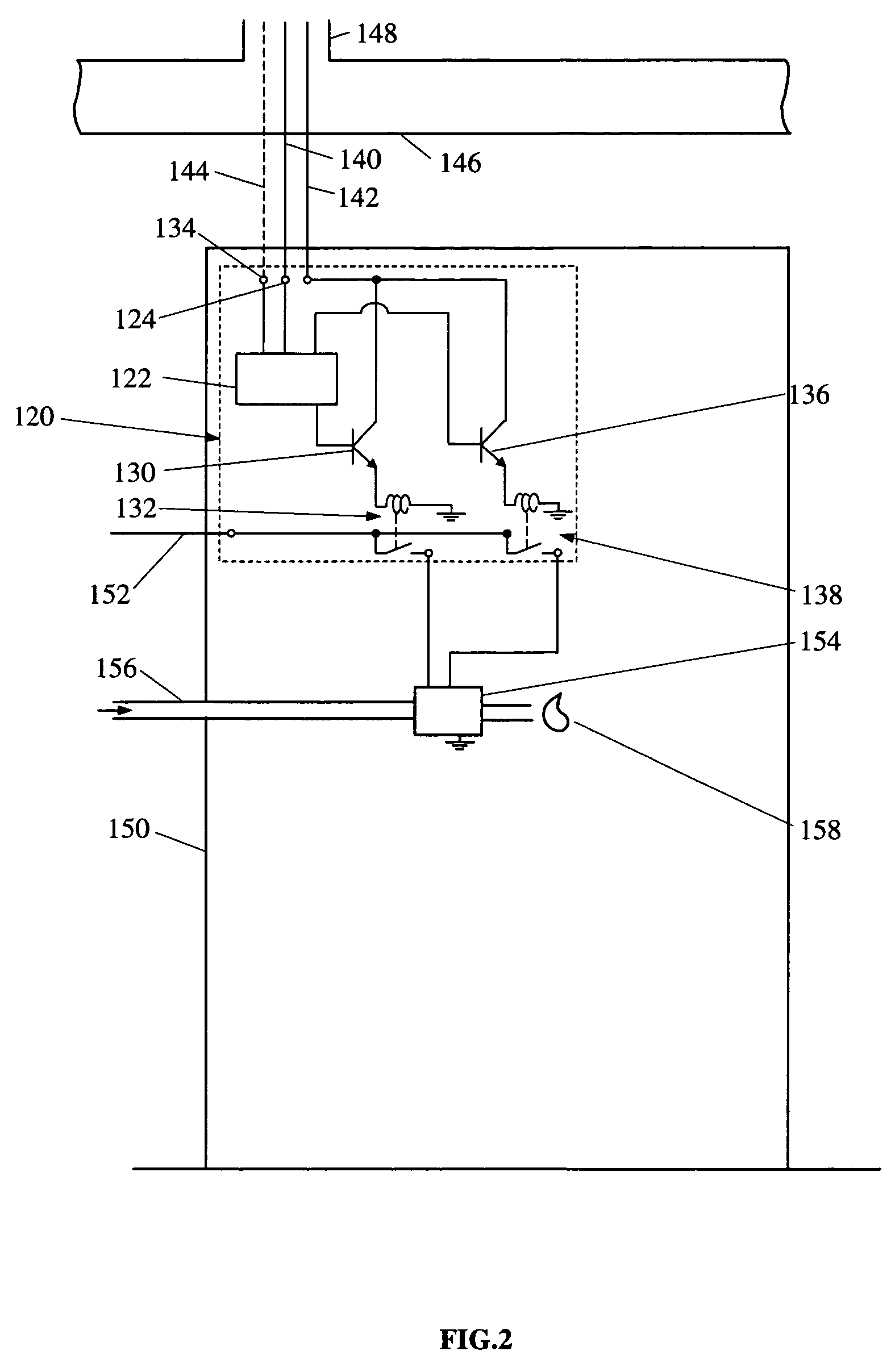

Controller for two-stage heat source usable with single and two stage thermostats

ActiveUS7731096B2Fluid heatersTemperature control without auxillary powerMicrocontrollerSingle stage

Owner:COPELAND COMFORT CONTROL LP

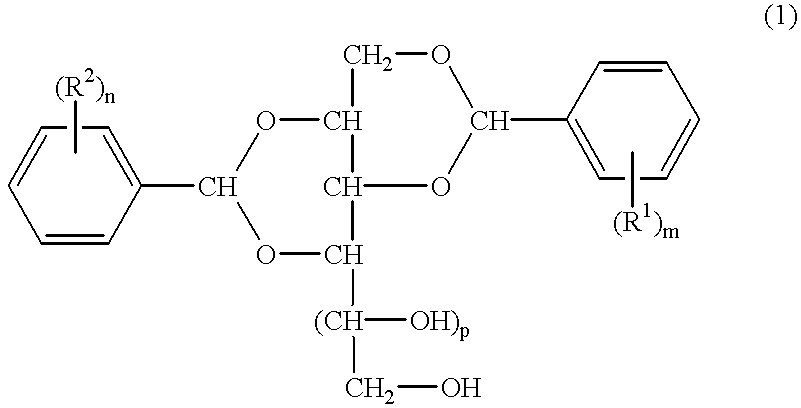

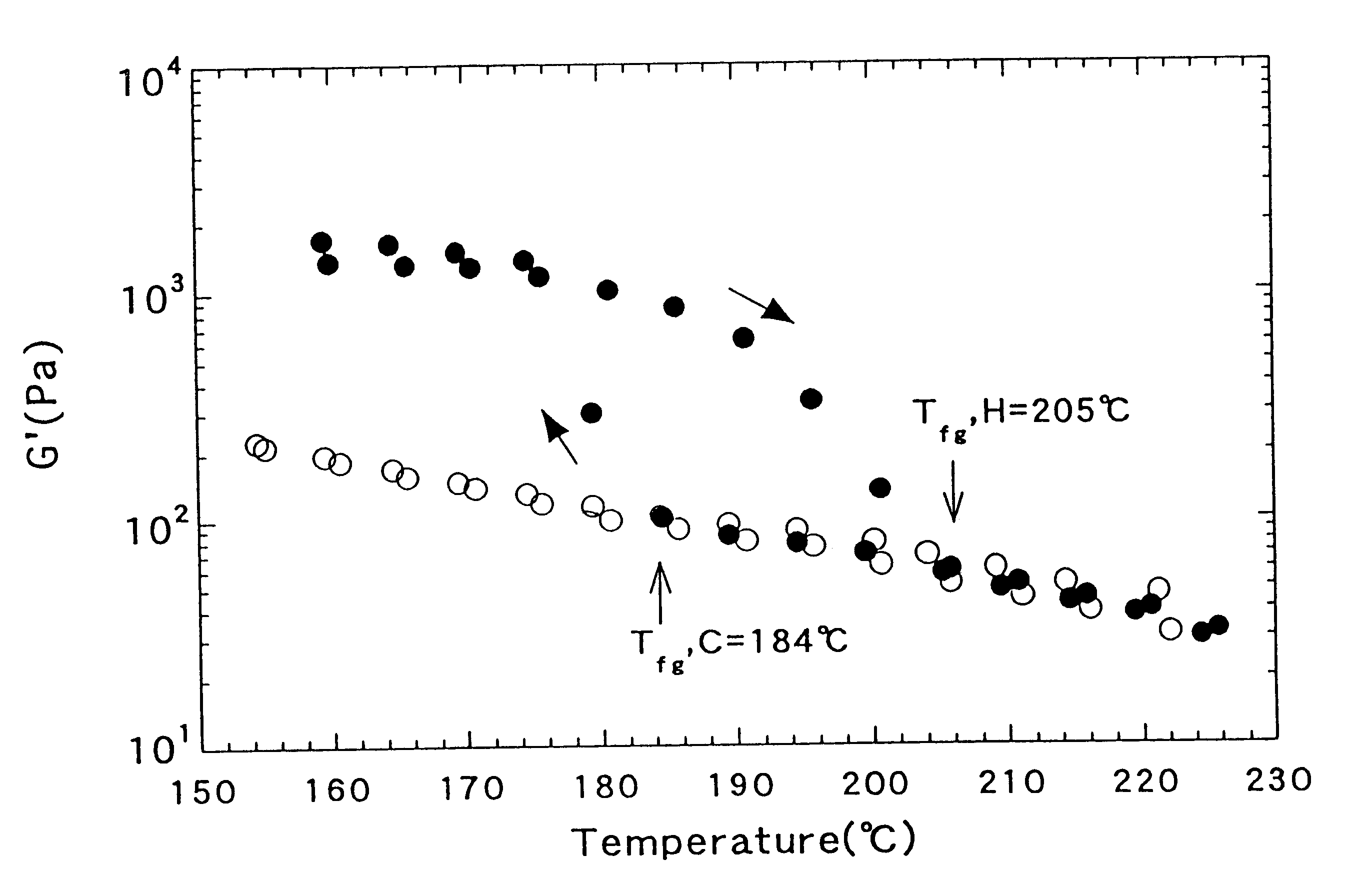

Orientated gel molding method of polyolefin based resin composition

InactiveUS6238615B1Organic detergent compounding agentsFilament/thread formingCyclic processPolyolefin

The present invention provides method of molding a polyolefin-based resin comprising the steps of dissolving at least one dibenzylidene sorbitol compound in a molten polyolefin resin, cooling the molten resin to a temperature not higher than the sol-gel transition temperature during the cooling cycle to form network-like crystals of the dibenzylidene sorbitol compound, and molding the resulting resin composition at a temperature not lower than the melting temperature of the polyolefin-based resin but not higher than the sol-gel transition temperature during the heating cycle; and a polyolefin resin molded article obtainable by this molding method.

Owner:NEW JAPAN CHEM CO

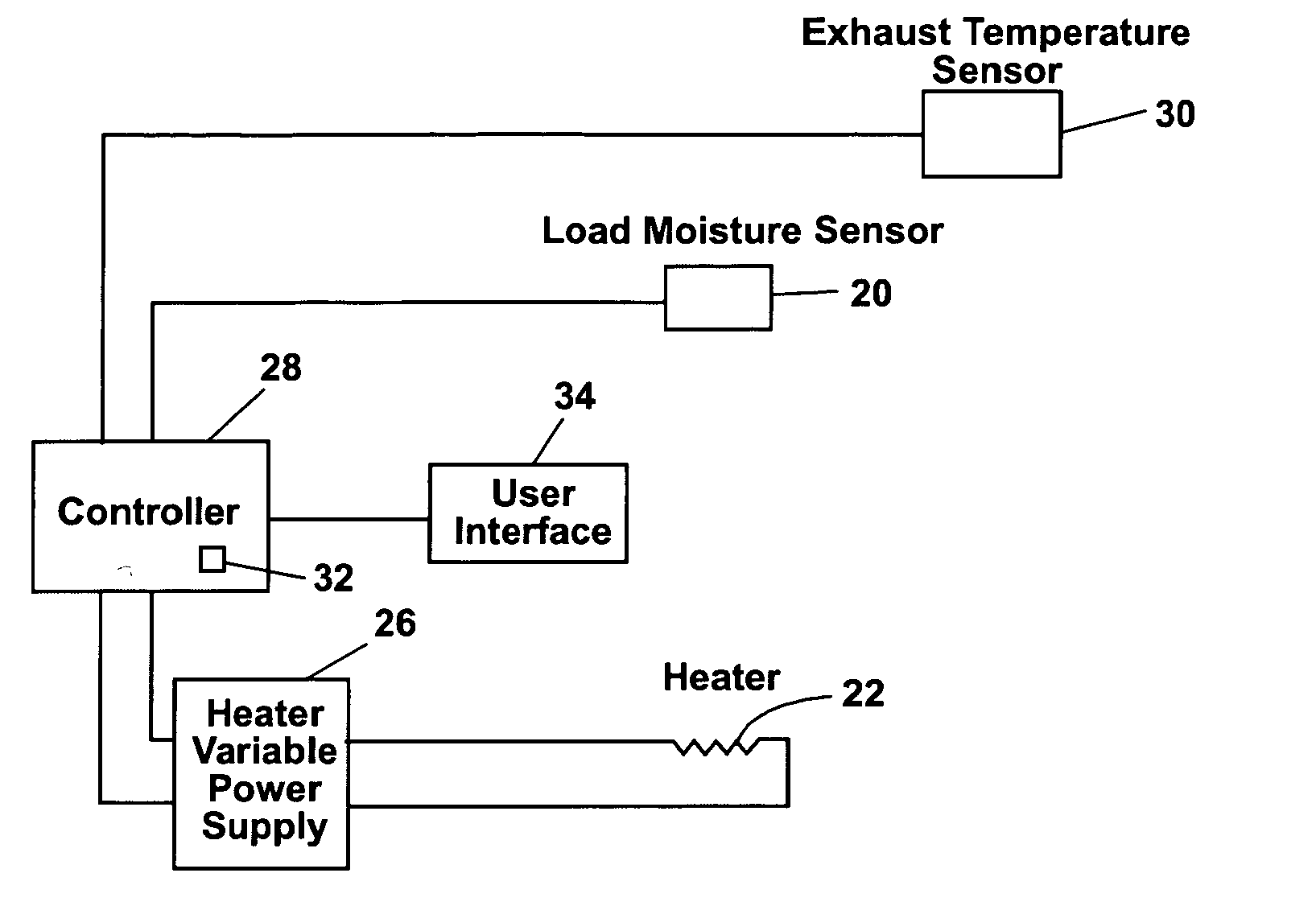

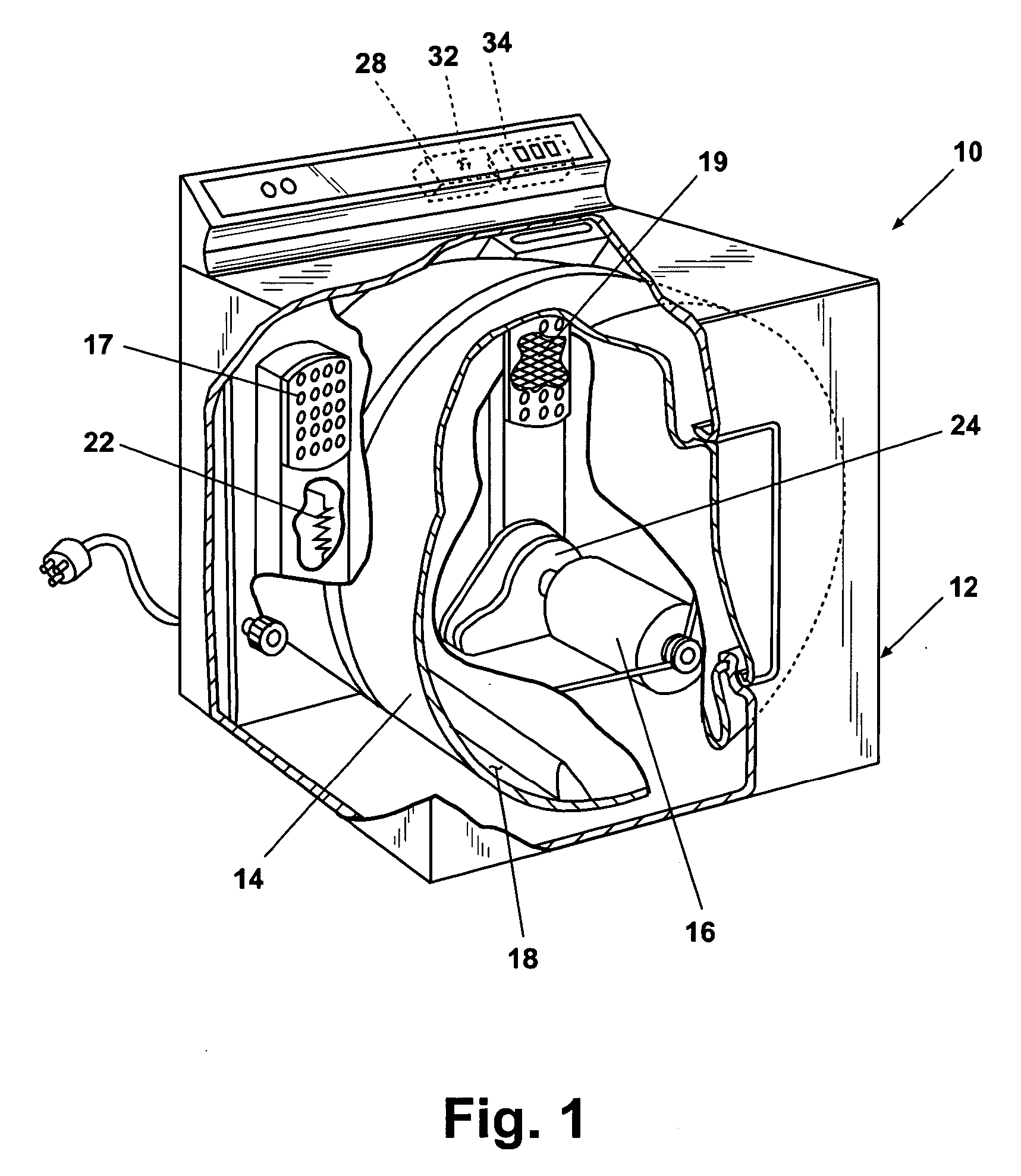

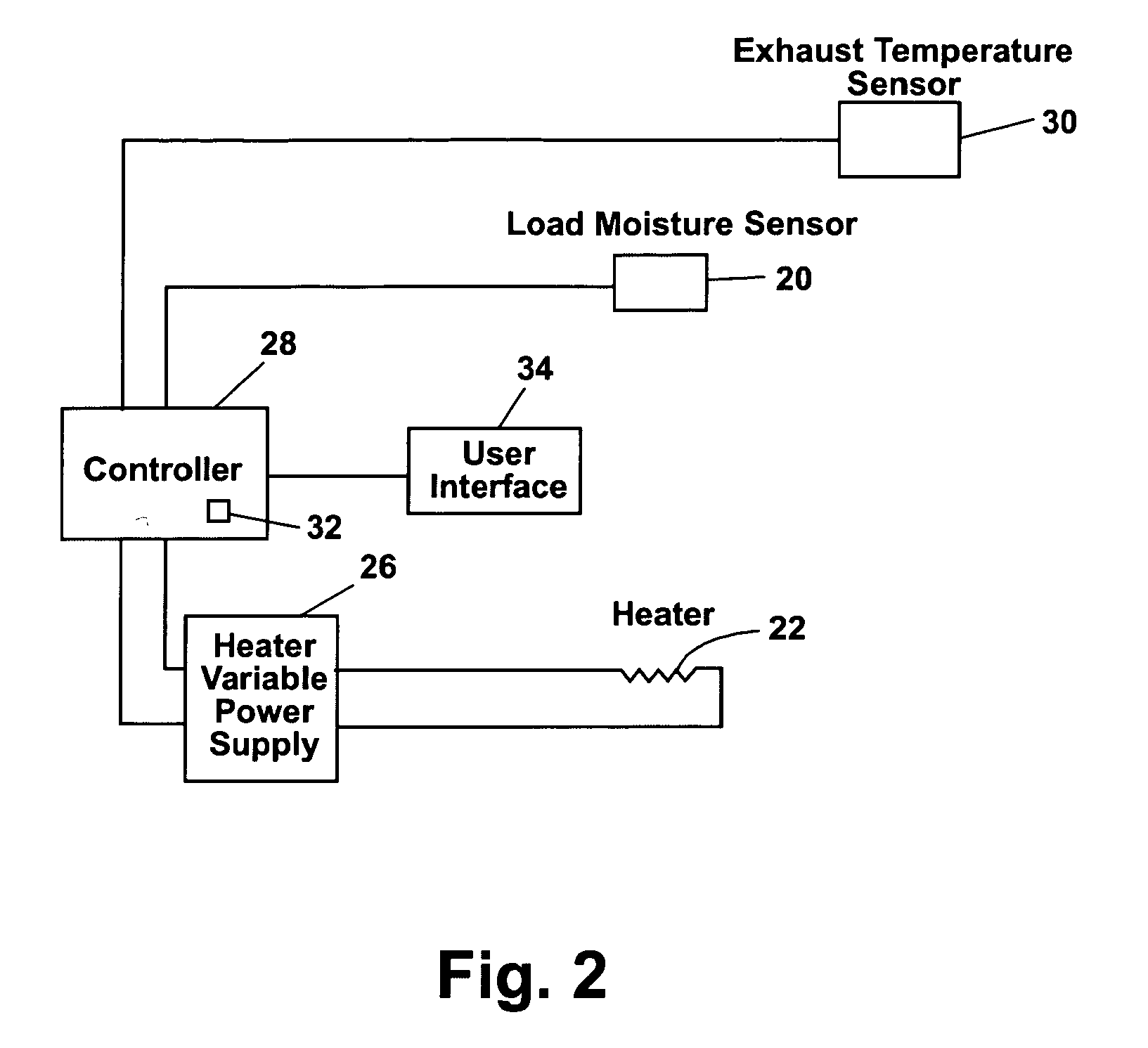

Detection of synthetic fabric loads in an automatic dryer

InactiveUS20060150437A1Drying solid materials with heatDrying gas arrangementsProcess engineeringHeating cycle

A method for detecting the presence of a synthetic fabric load during an automatic drying cycle in an automatic dryer avoids premature termination of the automatic drying cycle and ensures that the synthetic fabric items are dried according to a user's desired dryness level. The presence of the synthetic fabric load is detected by determining a duration of a first heating cycle, determining a duration of a second heating cycle, and determining the presence of the synthetic fabric load based on the durations of the first and the second heating cycles.

Owner:SEAGATE TECH LLC +1

SMA actuator with improved temperature control

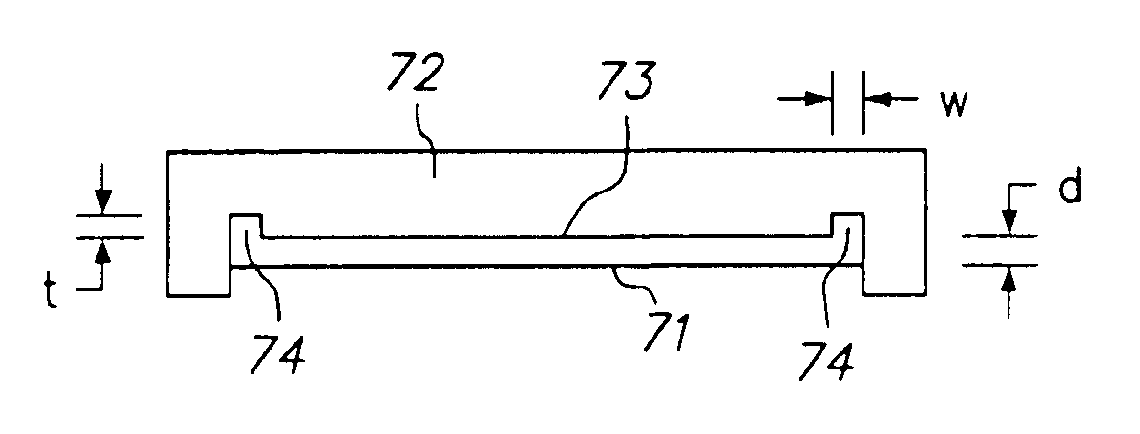

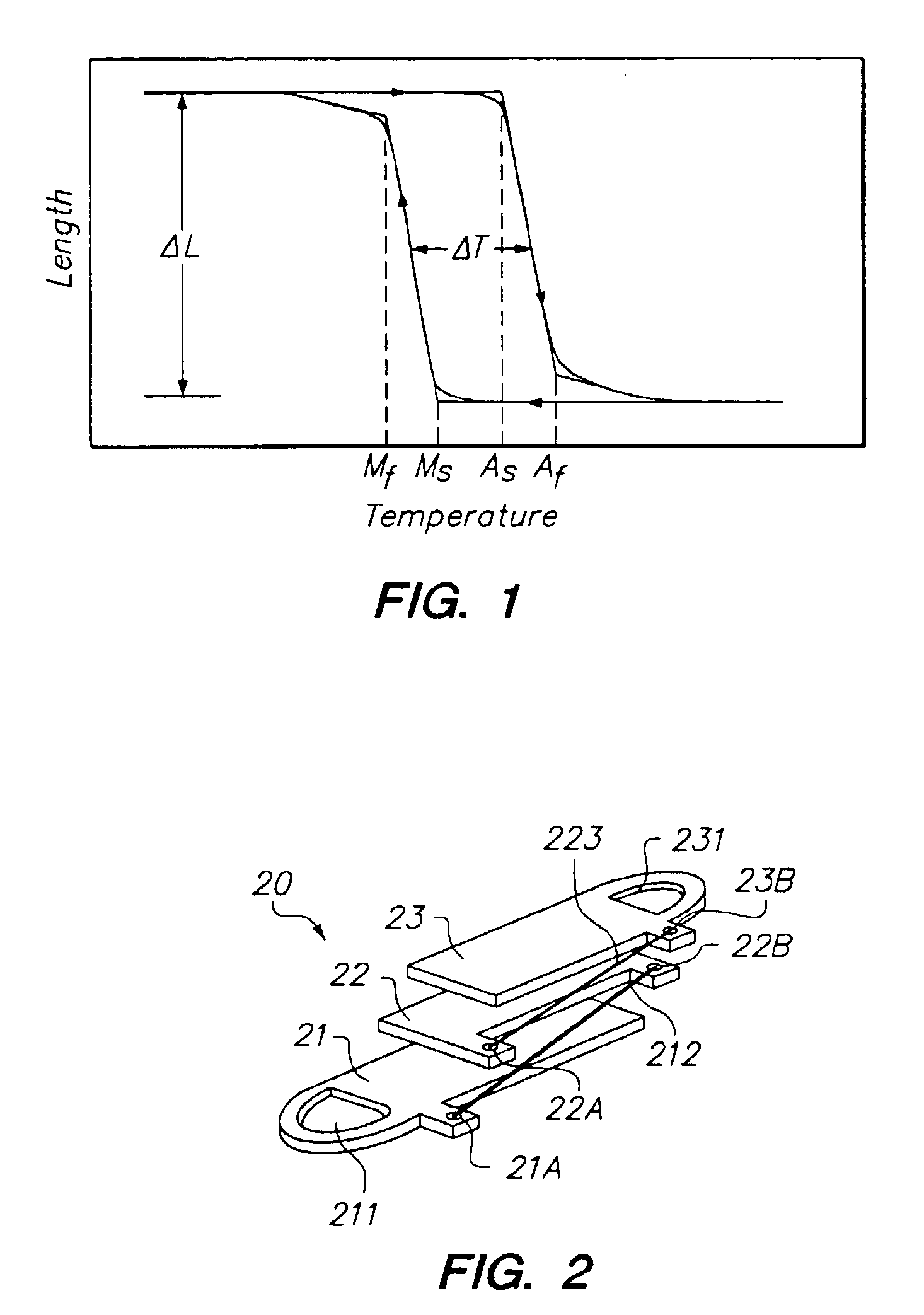

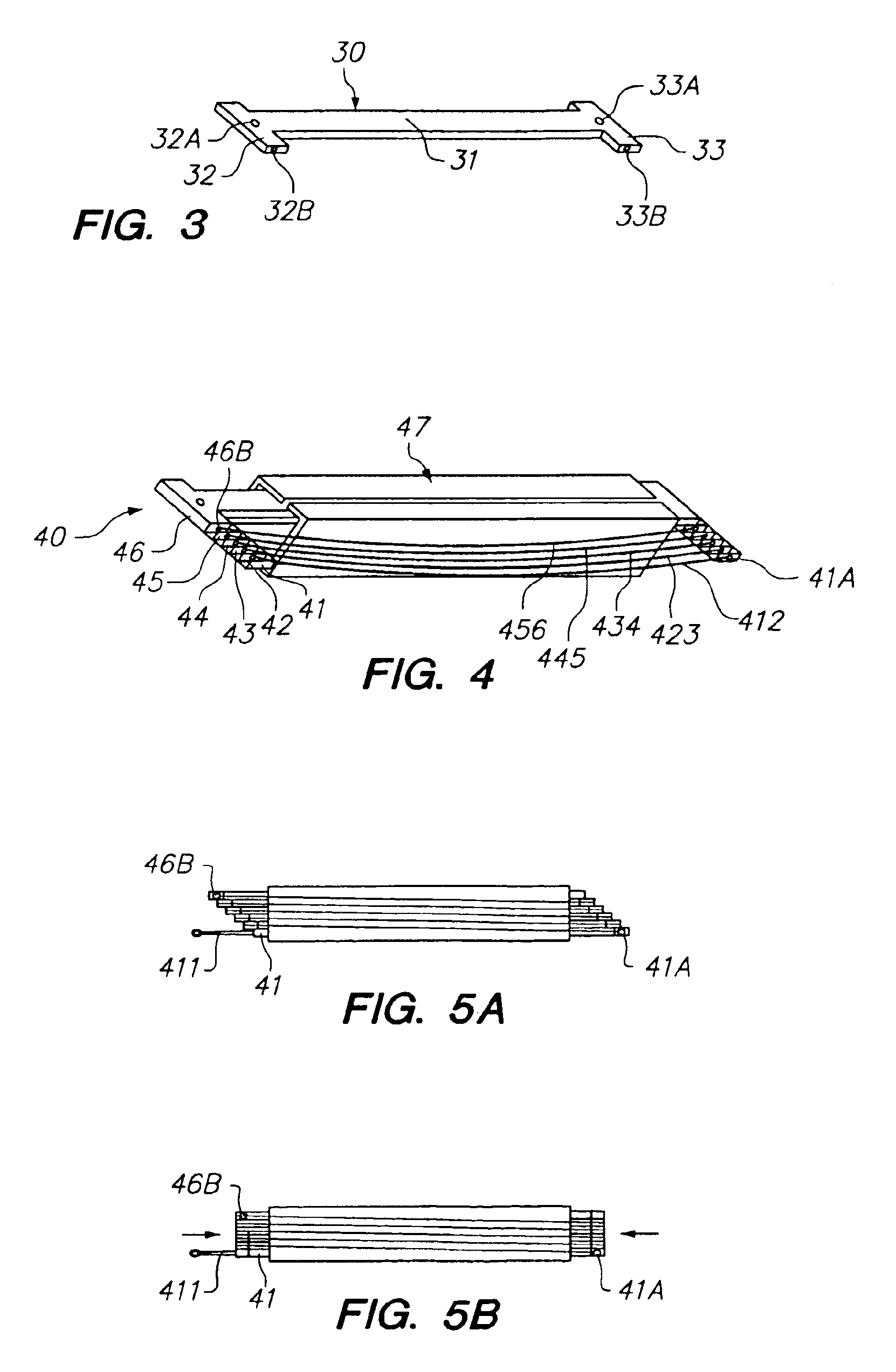

InactiveUS6981374B2Improve cooling effectRapid responseEngine componentsMechanical power devicesTemperature controlActive cooling

A SMA actuator having rigid members and SMA wires, in which improved temperature control of the SMA wires of the actuator is provided by a heat sink, which may be the rigid members themselves, in close proximity to at least a central portion of the wires. Optionally, the heat sink is sized and placed such that the end portions of the wires where they are attached to the rigid members are not in close proximity to the heat sink. Where the heat sink is external, it optionally has a cooling element that acts passively as a heat sink during the heating cycle of the actuator and that acts as an active cooling element during the cooling cycle of the actuator. An SMA actuator having a desired contraction limit and a power supply circuit has a switch in the power supply circuit that is normally closed when the actuator is contracted to less than the desired contraction limit and is opened by the actuator reaching the desired contraction limit. This improved temperature control provides greater cooling of the SMA wires for a faster response and an extended working life of the actuator.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

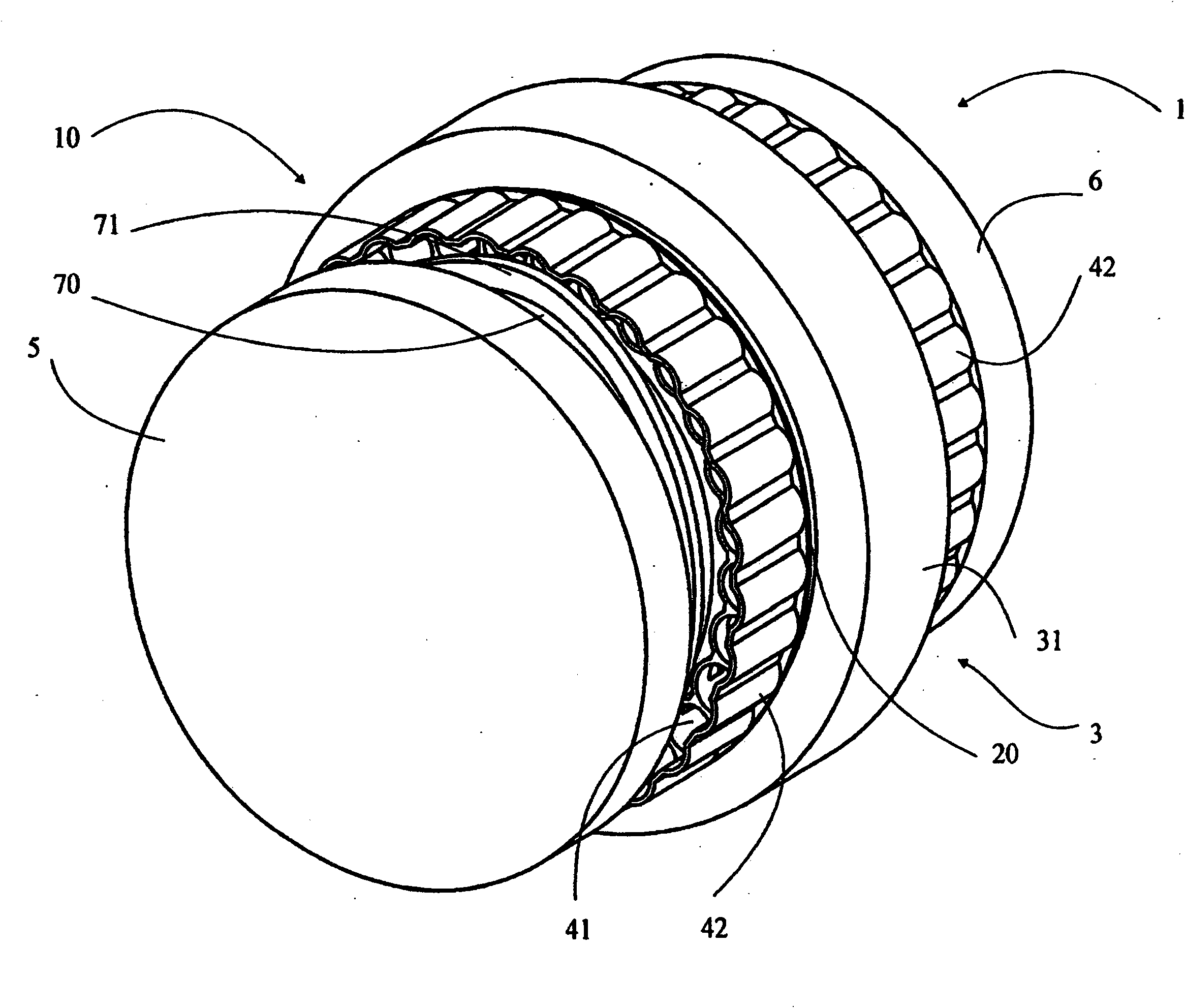

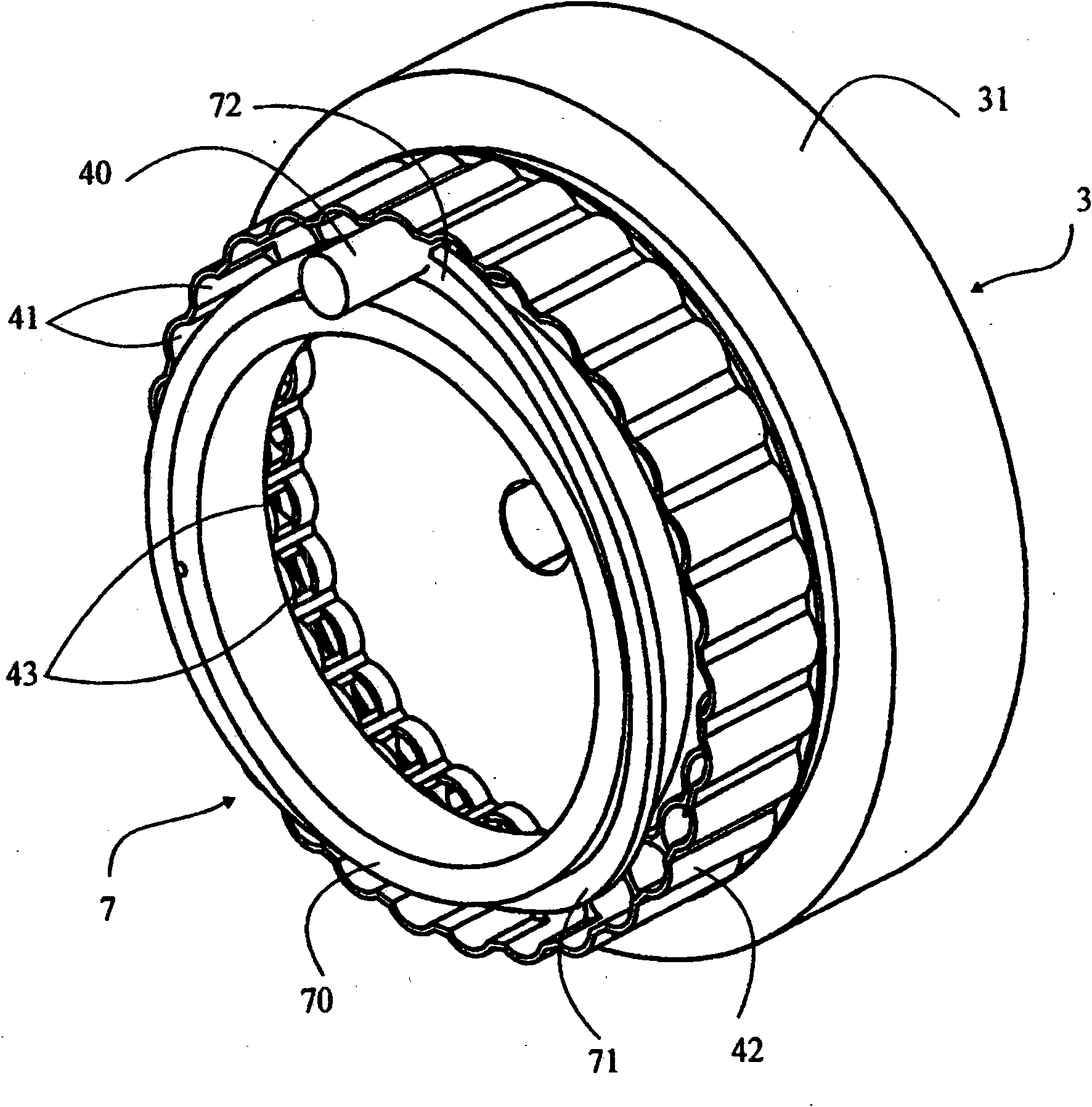

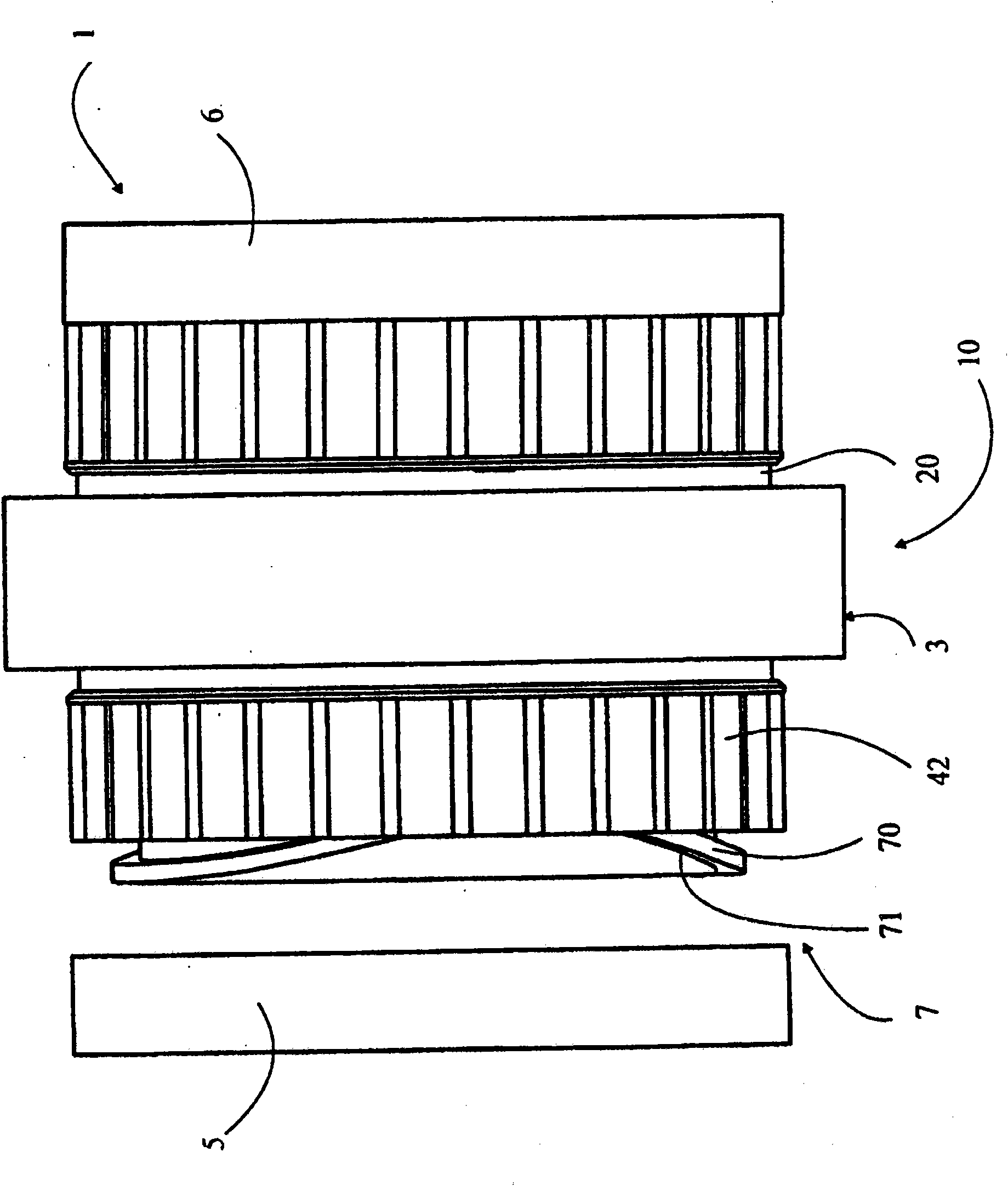

Thermal generator with magneto-caloric material

ActiveCN101842647AEnergy efficient heating/coolingMachines using electric/magnetic effectsHeat carrierReciprocating motion

The invention relates to a thermal generator (1) characterised in that it comprises at least one thermal module (10) including N adjacent magneto-caloric members (2) arranged in a circle about a central axis (A) and submitted to a magnetic field variation generated by a magnetic means (3) in order to vary their temperature. The magneto-caloric members (2) are associated with N pistons (40) driven according to a reciprocating translation movement by a control cam (70) in order to move the heat-carrier fluid contained in the thermal module (10) simultaneously in two opposite directions, so that a first fraction of the heat-carrier fluid flows towards a hot exchange chamber (5) through the magneto-caloric members (2) submitted to a heating cycle, and so that a second fraction of the heat-carrier fluid flows towards a cold exchange chamber (6) through the magneto-caloric members (2) submitted to a cooling cycle, and vice versa. The exchange chambers (5, 6) are coupled to outer calorie- and frigorie-consuming circuits, such as heating circuits, air conditioning circuits, tempering circuits, etc.

Owner:马格诺里克公司

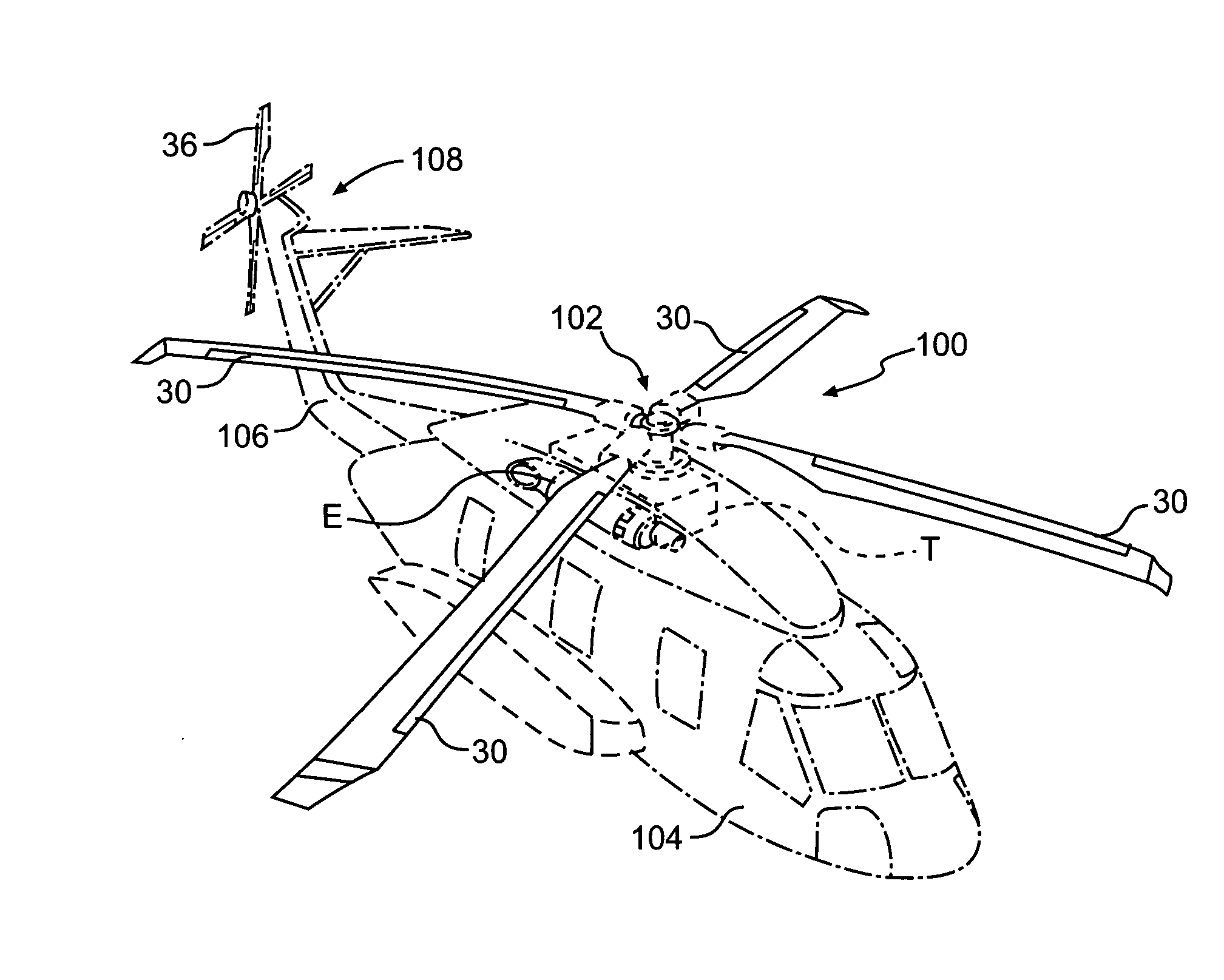

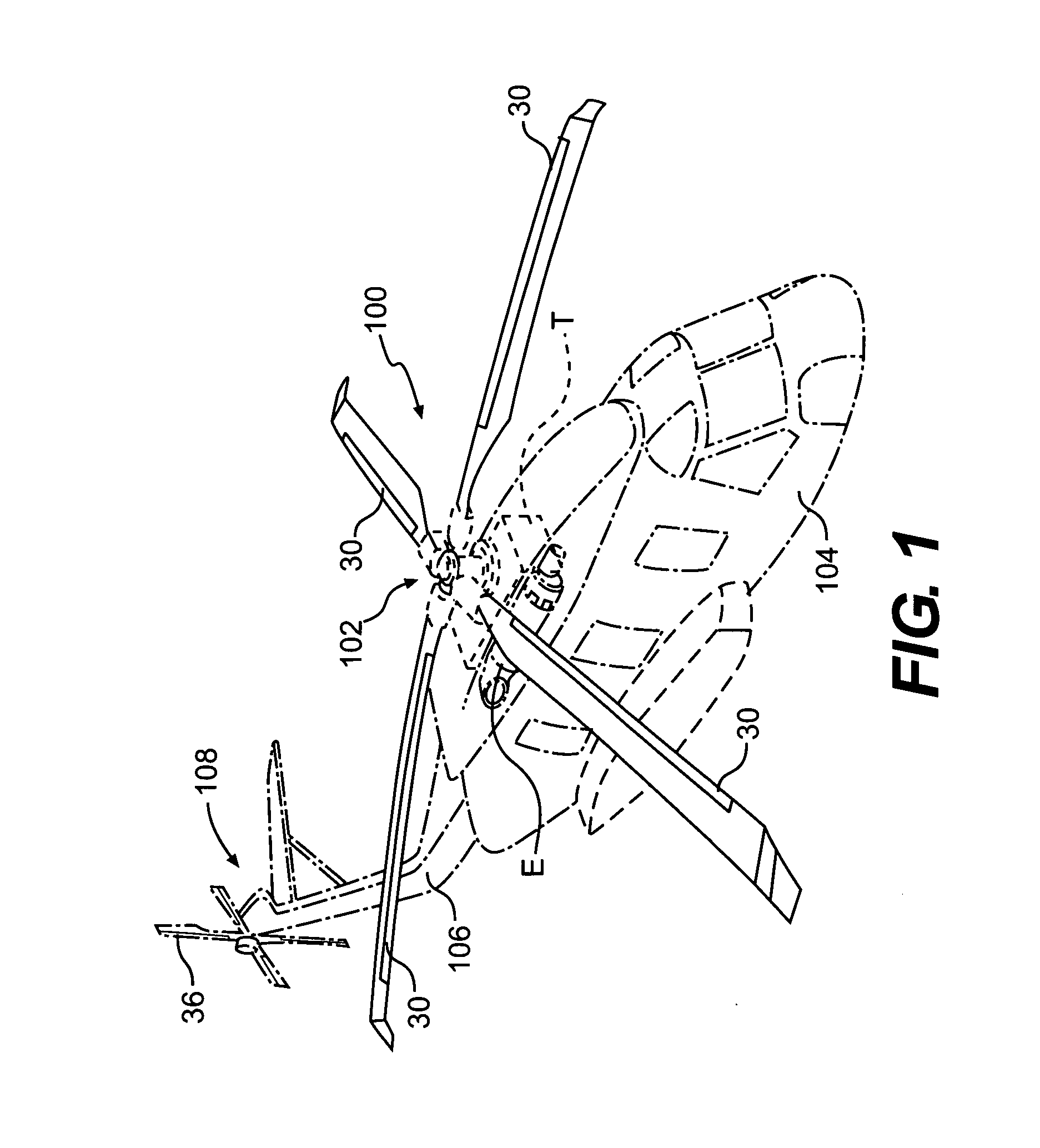

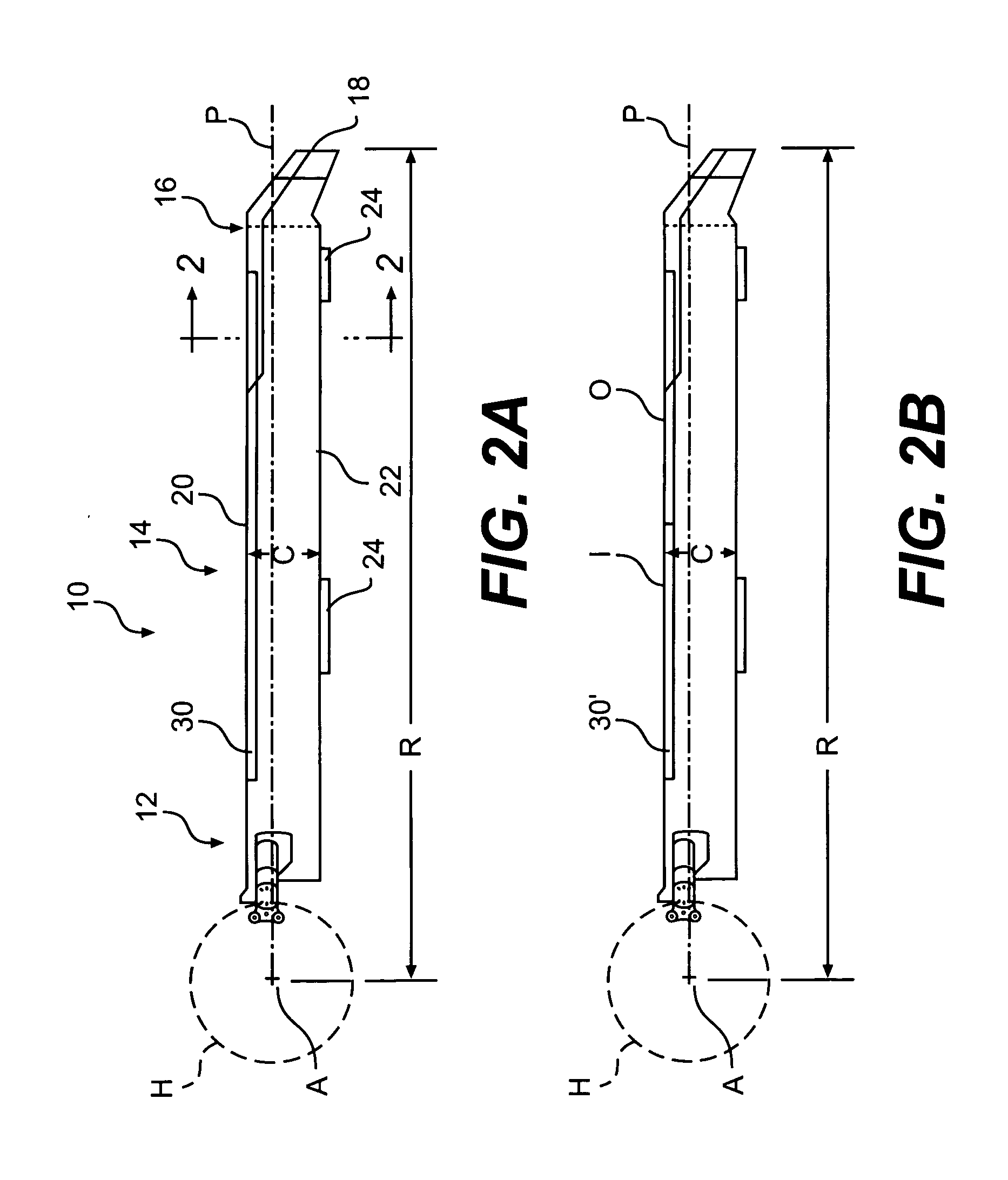

Dual-channel deicing system for a rotary wing aircraft

ActiveUS20060226292A1Minimize the possibilityReserved functionElectric heatingDe-icing equipmentsEngineeringTail rotor

A deicing system includes dual deice system components to provide a redundant deice system. Each redundant portion of the system generally includes a controller, an air data computer, an ice rate controller, and an ice rate probe. The controller communicating a heating cycle which defines a multiple of electric pulse trains to sequentially provides power to a multiple of heating elements in a designated blade set. Each electric pulse train is defined by an element on-time, a null time between the element on-time for this element and the next element, and an off-time between repetition of the heating cycle for the first heater element. The element on-time is a function of outside air temperature (OAT). The off-time is a function of liquid water content. The tail rotor heating cycle is a more straightforward version of the main rotor heating cycle as each of the tail rotor blade are activated simultaneously and there is only a single heating element on each tail rotor blade.

Owner:SIKORSKY AIRCRAFT CORP

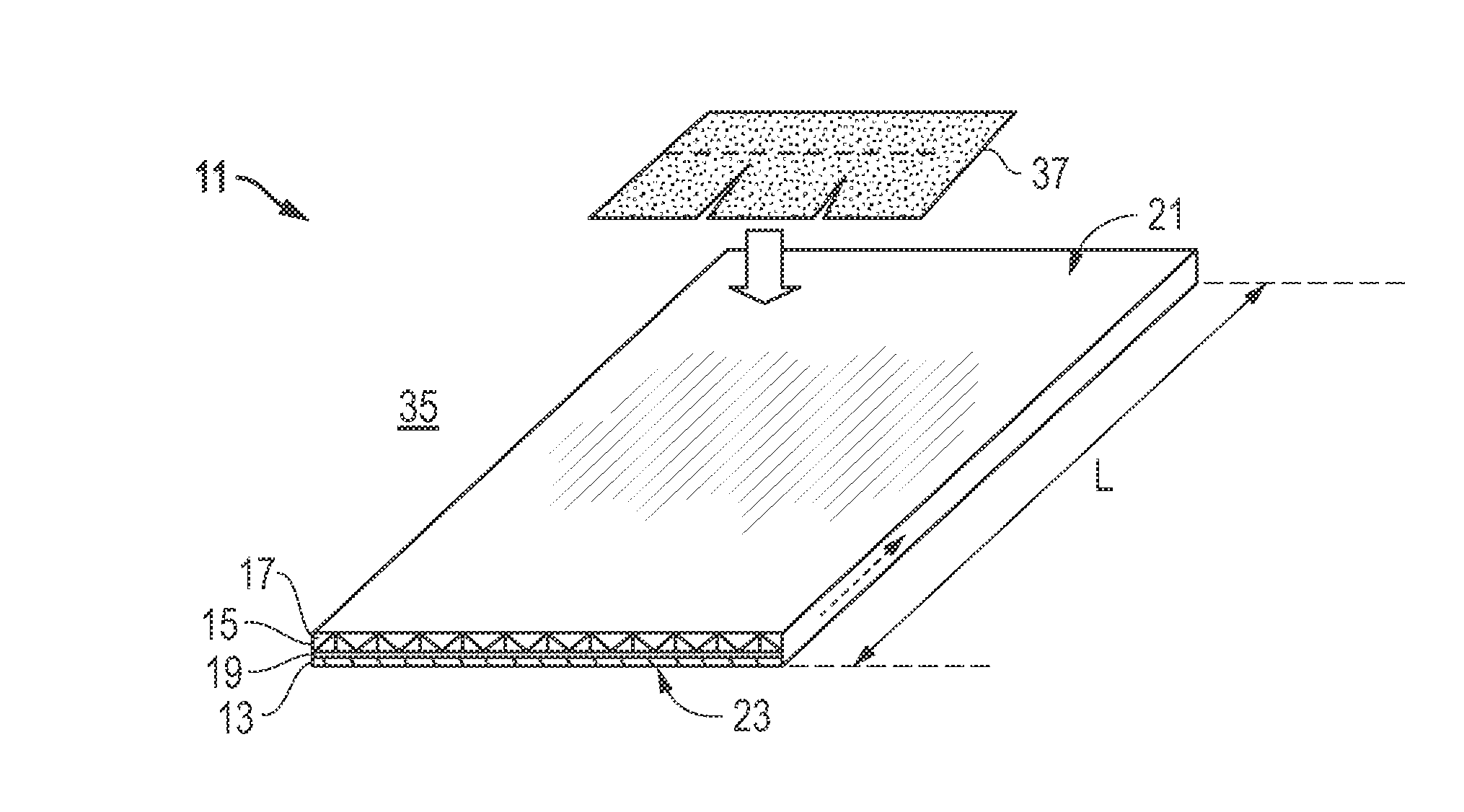

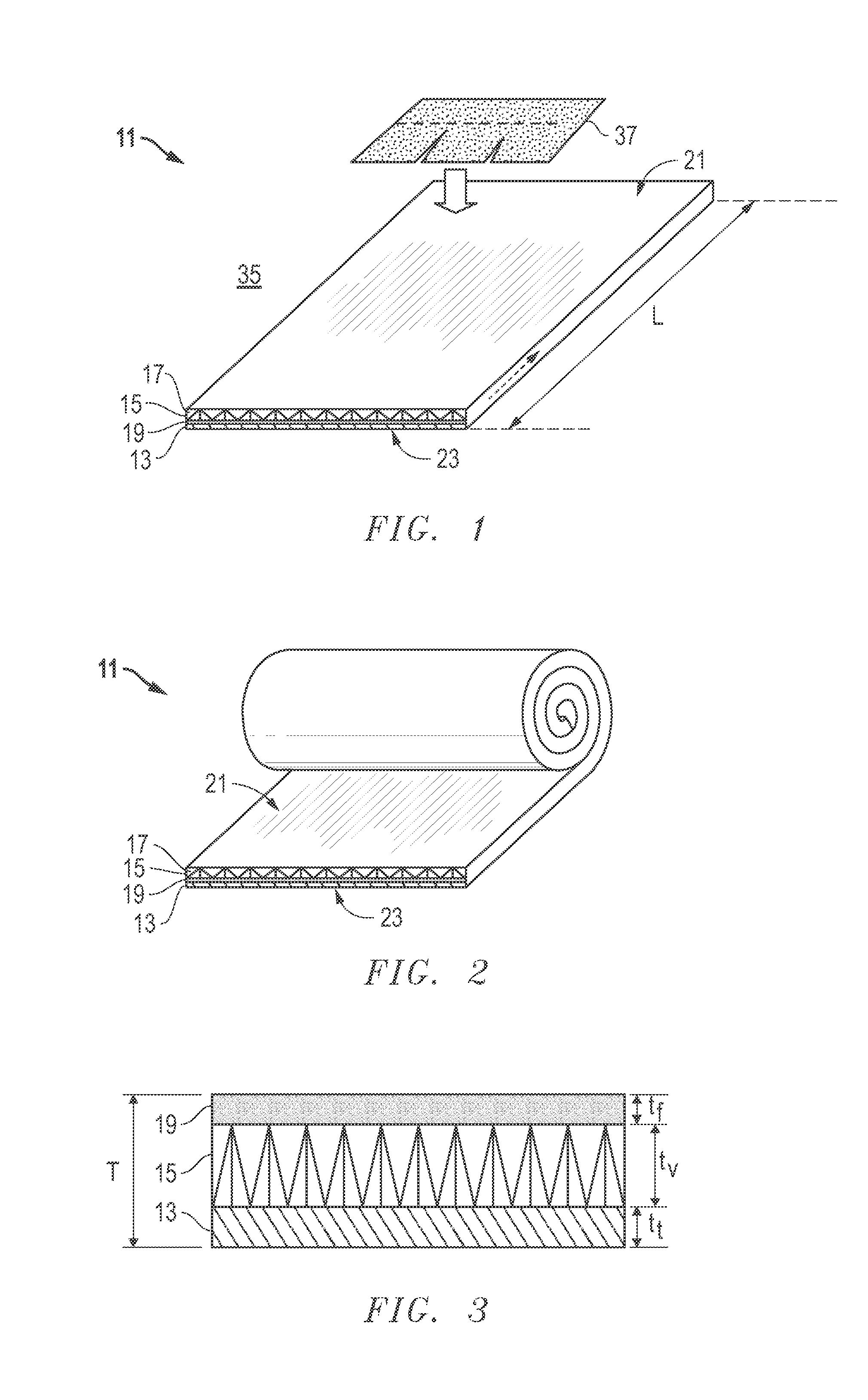

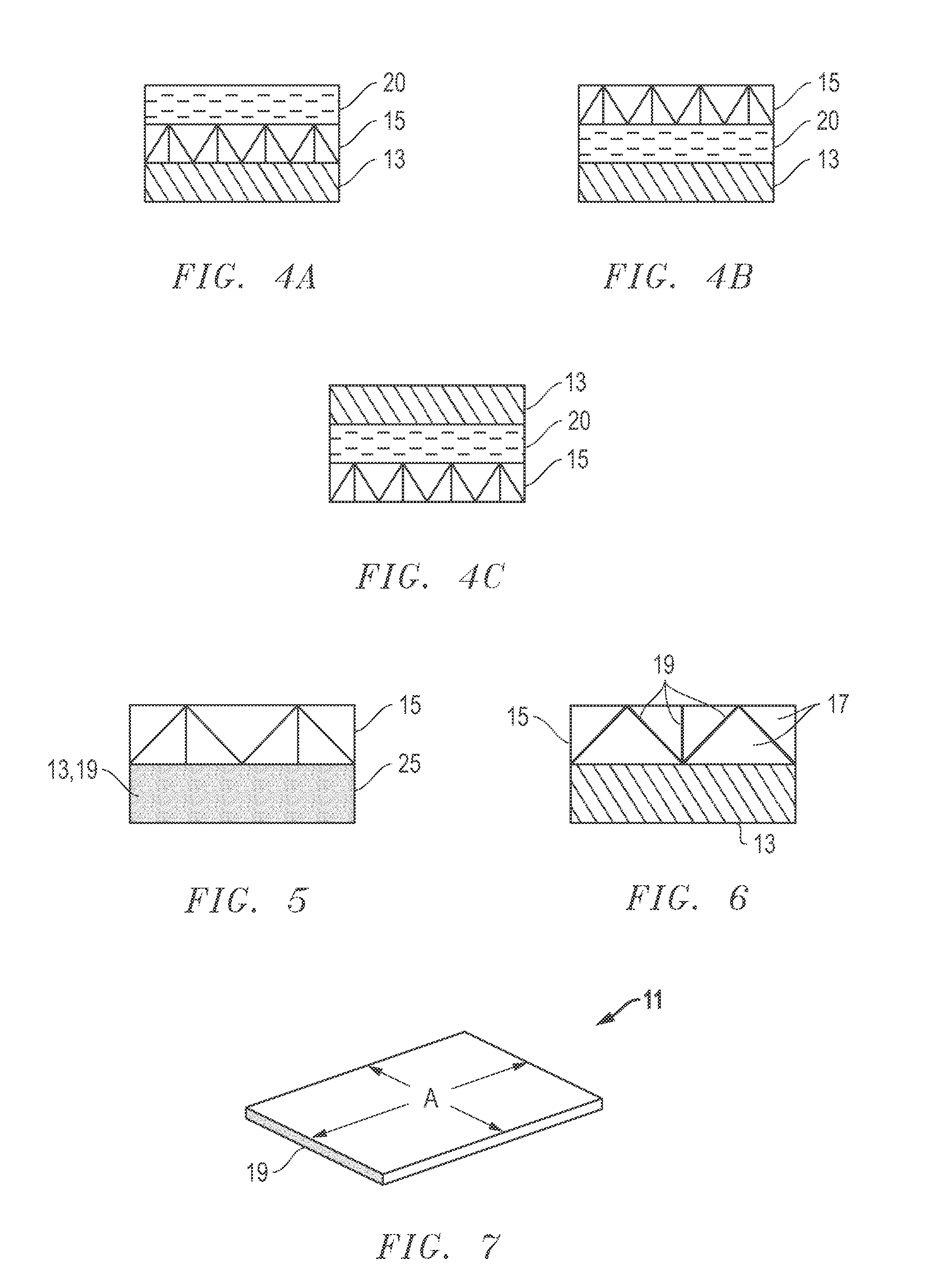

System, method and apparatus for thermal energy management in a roof

A roof product has a thermal heat storage layer, a vent layer with channels for transferring excess heat through a length of the roof product, and a flame retardant to suppress fire through the vent layer. These three materials form a unitary structure. The roof product may have a radiant layer, the thermal heat storage layer and the vent layer to form the unitary structure. The roof products are assembled in an abutting configuration on the roof of a building. The vent layer vents excess heat from an eave of the roof up to a ridge of the roof and out to atmosphere. The roof products manage thermal energy in the roof by storing thermal heat with the unitary roof product during a heating cycle; venting excess heat through the unitary product; and releasing the stored thermal heat from the unitary product into or out of the building during a cooling cycle.

Owner:CERTAINTEED CORP

Method and apparatus for supplying refrigerant fluid

InactiveUS20050081541A1Reduce riskRapid responseCompression machinesSurgical instruments for coolingControl signalEngineering

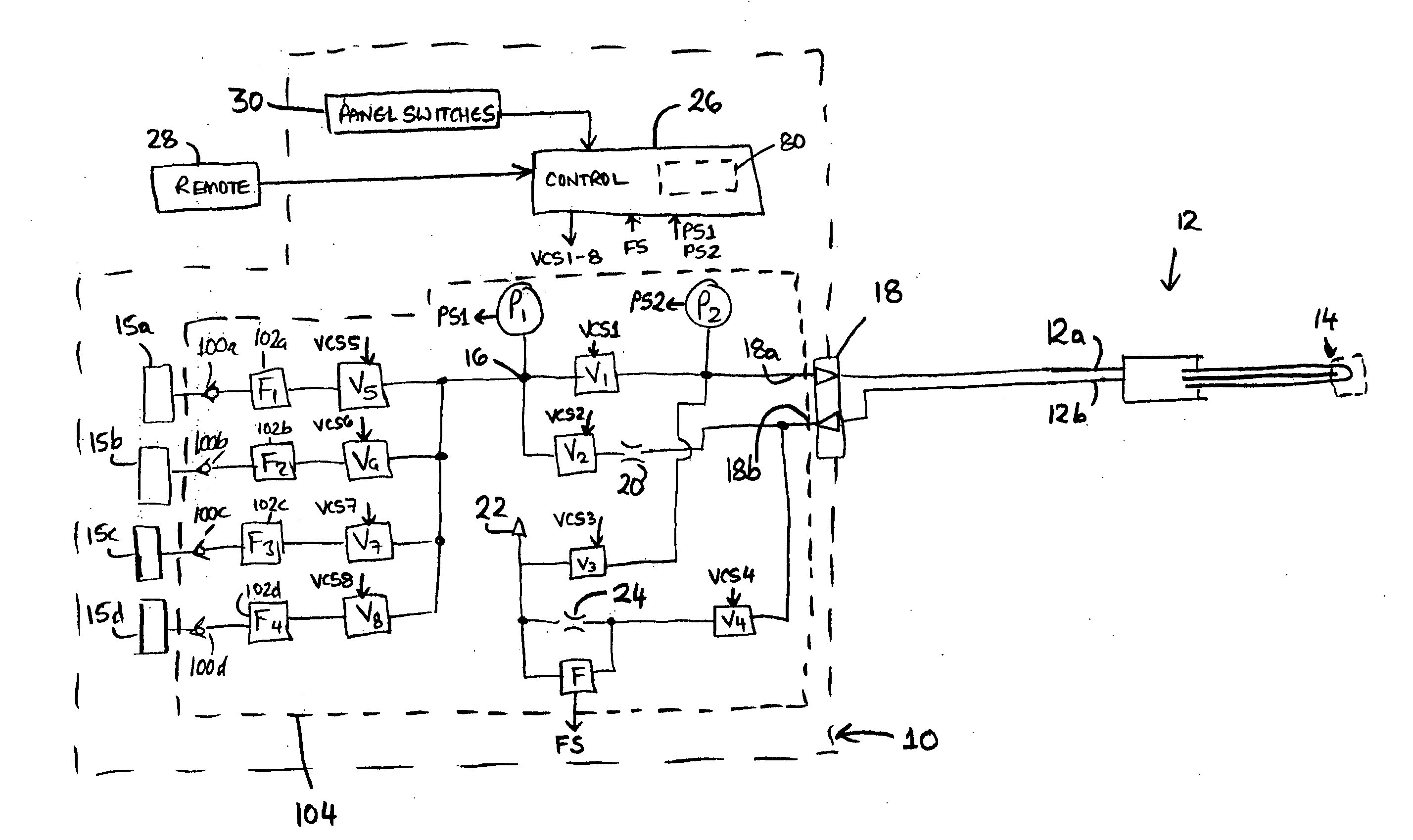

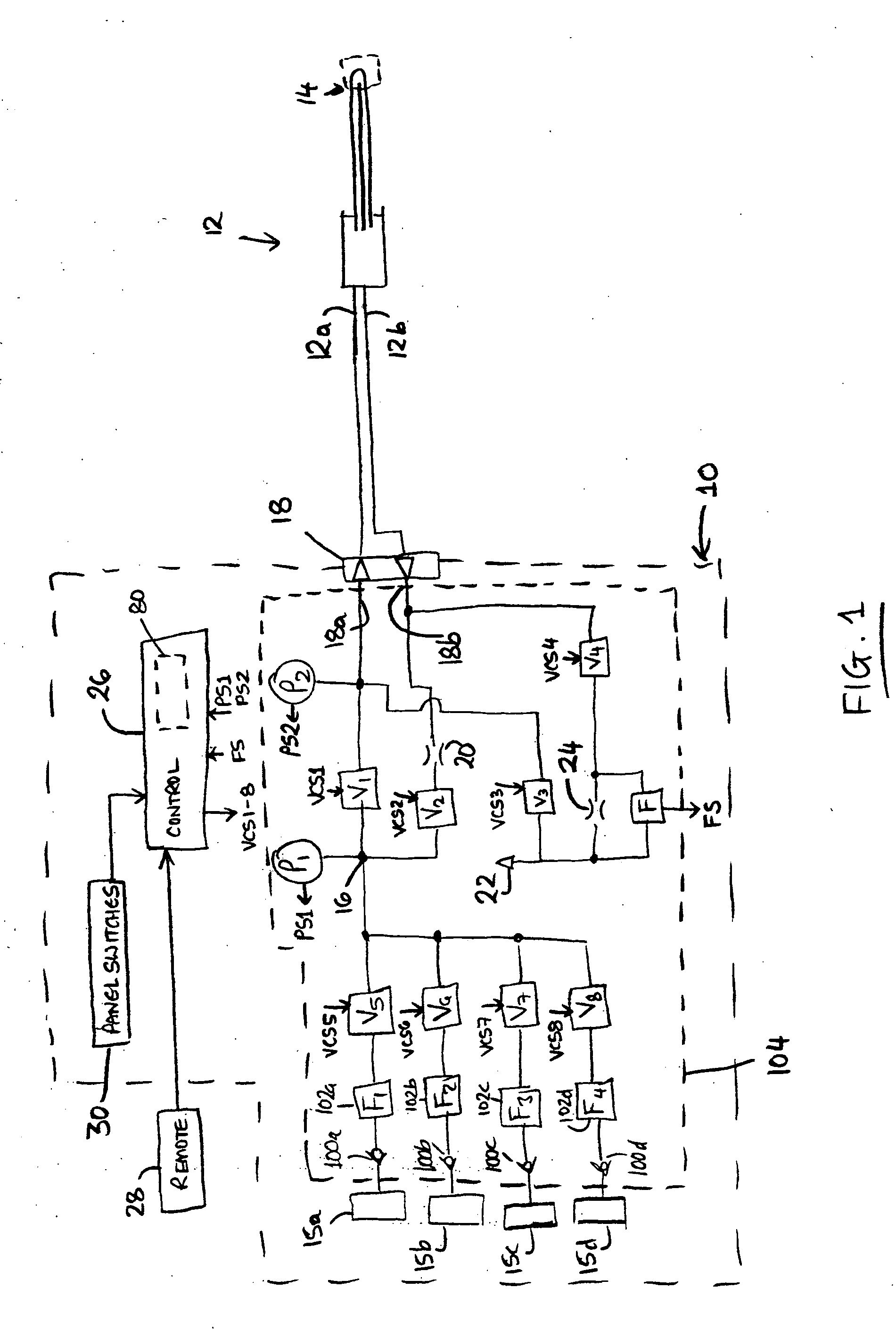

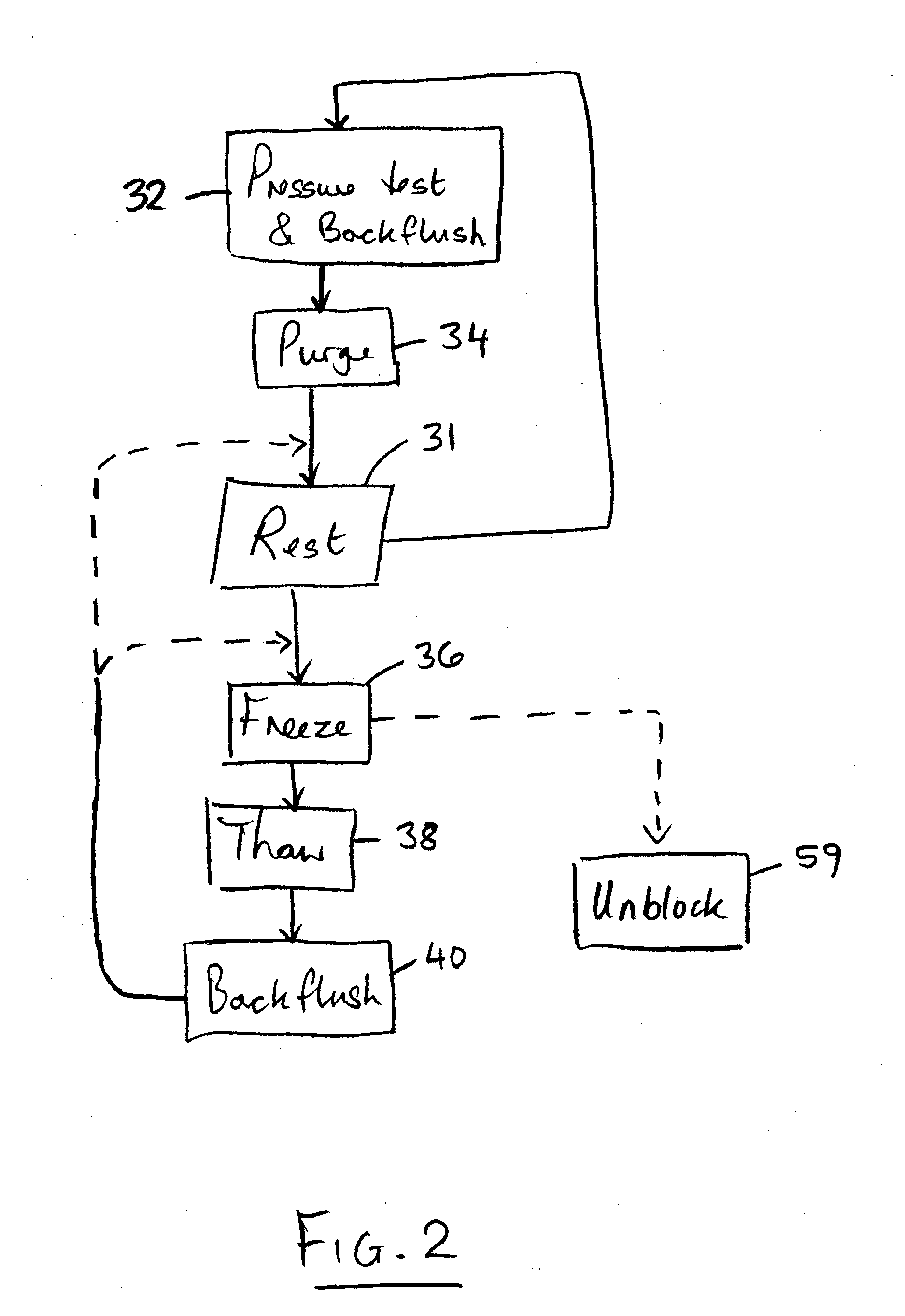

An apparatus is disclosed for supplying a refrigerant fluid to a cooling device, such as a cryosurgical probe. An arrangement of valves may control the supply of fluid to and from the cooling device. Fluid may flow in a forward direction through the cooling device for generating cooling by expansion of the fluid in the cooling device. The apparatus may execute a programmed sequence of cooling and heating cycles automatically. Backflushing of the fluid may be used for clearing contaminants from the inlet side of the cooling device. A pulse width modulated control signal may be used to control one of the valves to have a variable effective aperture. A flow rate sensor may detect the flow rate through the cooling device. The detected flow rate may be used to detect an occurrence of a blockage and / or for controlling the fluid supplied to the cooling device. A blockage may be cleared by automatic backflushing.

Owner:COPPING GARETH

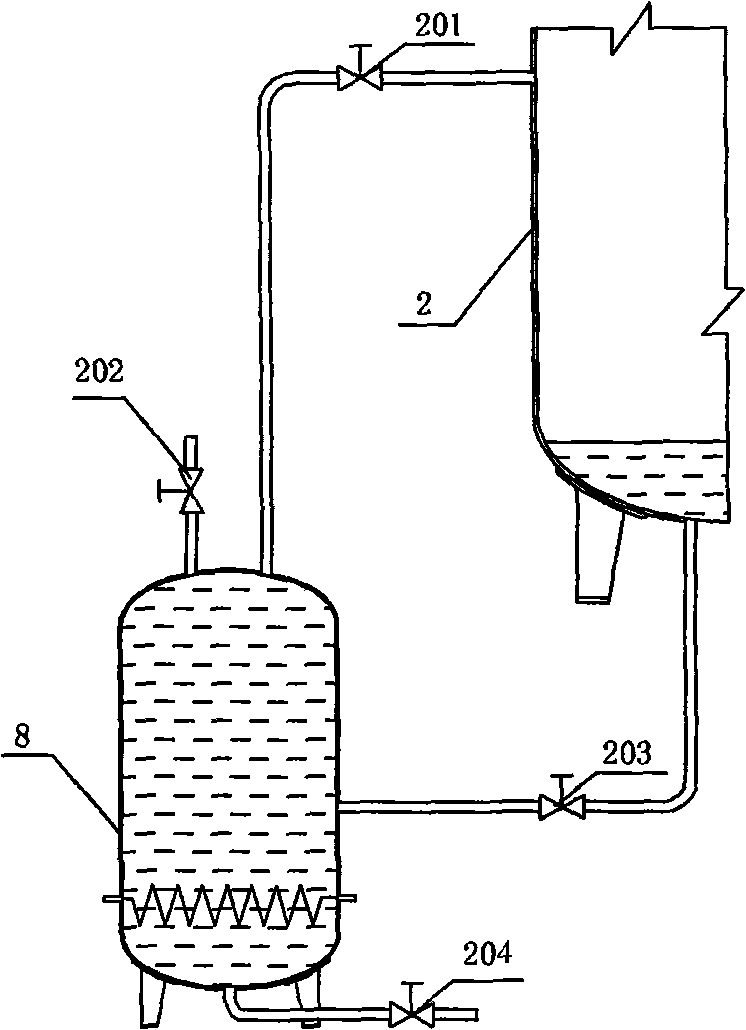

Solar seawater desalination device

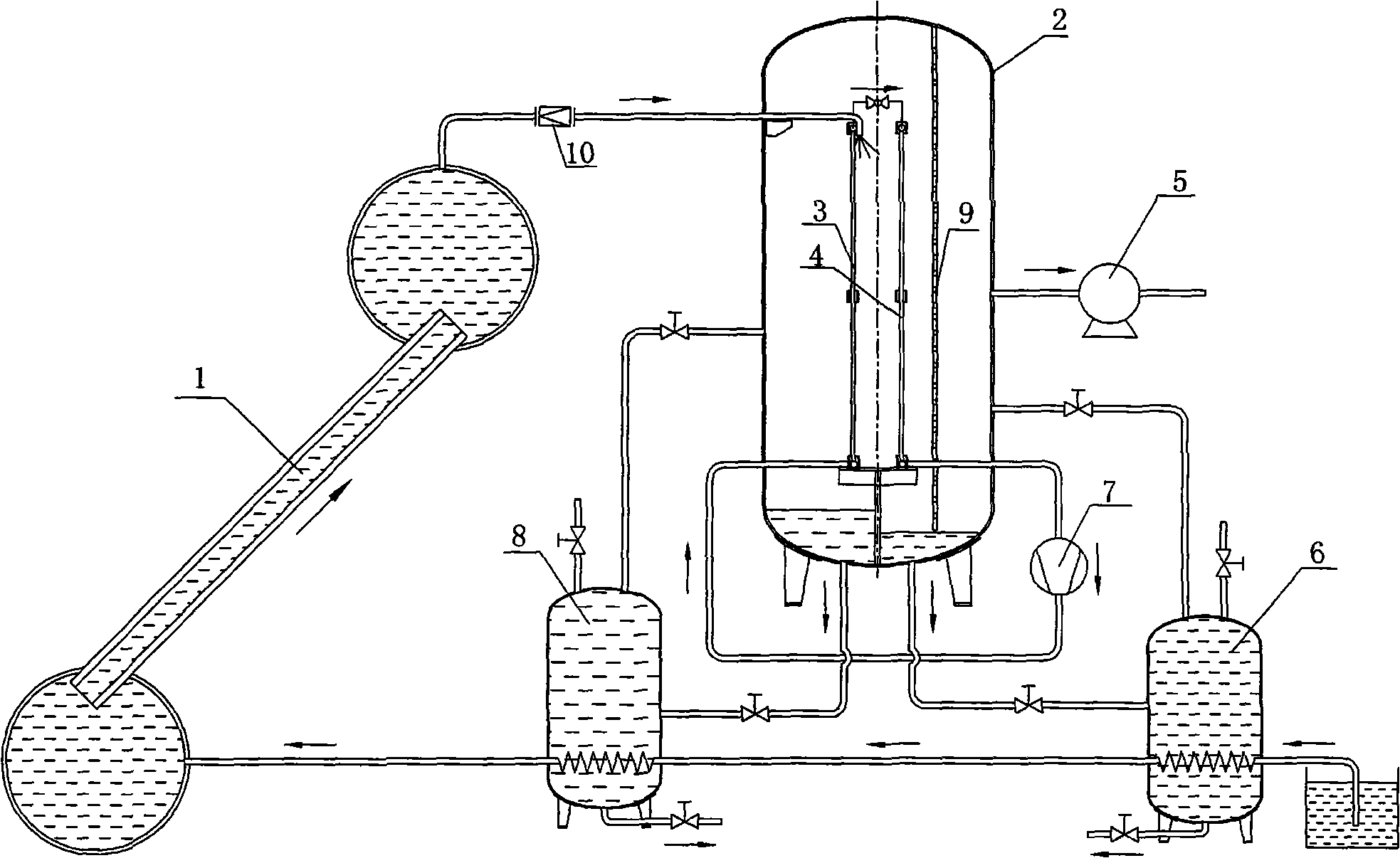

InactiveCN101591042AReduce loadReduce energy consumptionHeat recovery systemsGeneral water supply conservationWater vaporSystem pressure

The invention discloses a solar seawater desalination device, which comprises a vacuum tube type solar heat collector with cold and hot water tanks, a combined evaporative condenser, a seawater evaporator, a vapor condenser, a scroll vacuum pump, a heat pump circulation system, a fresh water tank, a strong brine tank, a sieve plate, a pressure reducing valve and the like. The device adopts the scroll vacuum pump to obtain higher negative system pressure to reduce the evaporation temperature of seawater; between the seawater evaporator and the vapor condenser, the heating cycle of a heat pump is utilized to supply the latent heat released by vapor condensation to the seawater evaporator and provide the heat for the evaporation of the seawater, and the device fully and effectively recovers the latent heat of condensation of water vapor; and the combined evaporative condenser is adopted to ensure that the seawater can be immediately condensed after the evaporation of the seawater and reduce the load of the vacuum pump. The device has the advantages of high efficiency, low energy consumption, compact structure, high fresh water yield and the like, and is suitable to solve the water drinking problem in water-deficient areas and the water drinking problem of operating personnel on ships and offshore platforms all year round.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

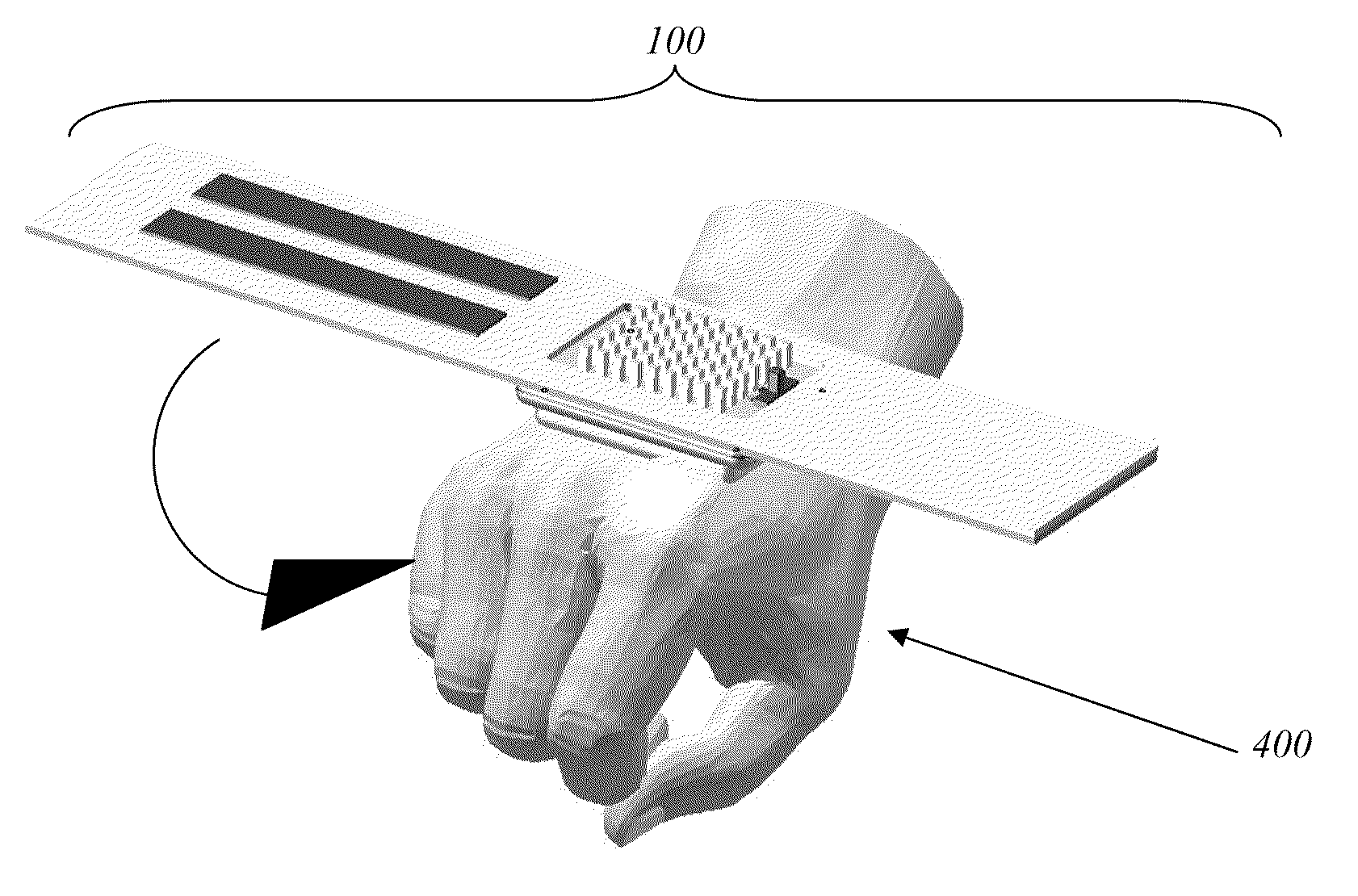

Cyclic Heat Therapy Device

The therapy device enables the automatic application of customized and well controlled contrast therapy to localized areas of human and animal bodies. An electronic control circuit is used in conjunction with heat dissipating and heat absorbing surfaces to control the operation of a thermoelectric cooling module (TEC) to enable the administering of localized contrast therapy on human and animal bodies. The use of temperature sensors, timing circuits, and microprocessors in connection with the TEC and heat absorbing and dissipating surfaces allows precise control of the applied temperature and the time duration for cooling and heating cycles. The device is programmable and is capable of automatic cycling between desired heating and cooling temperatures for variable lengths of time.

Owner:MOORE JOSHUA JOHN EDWARD

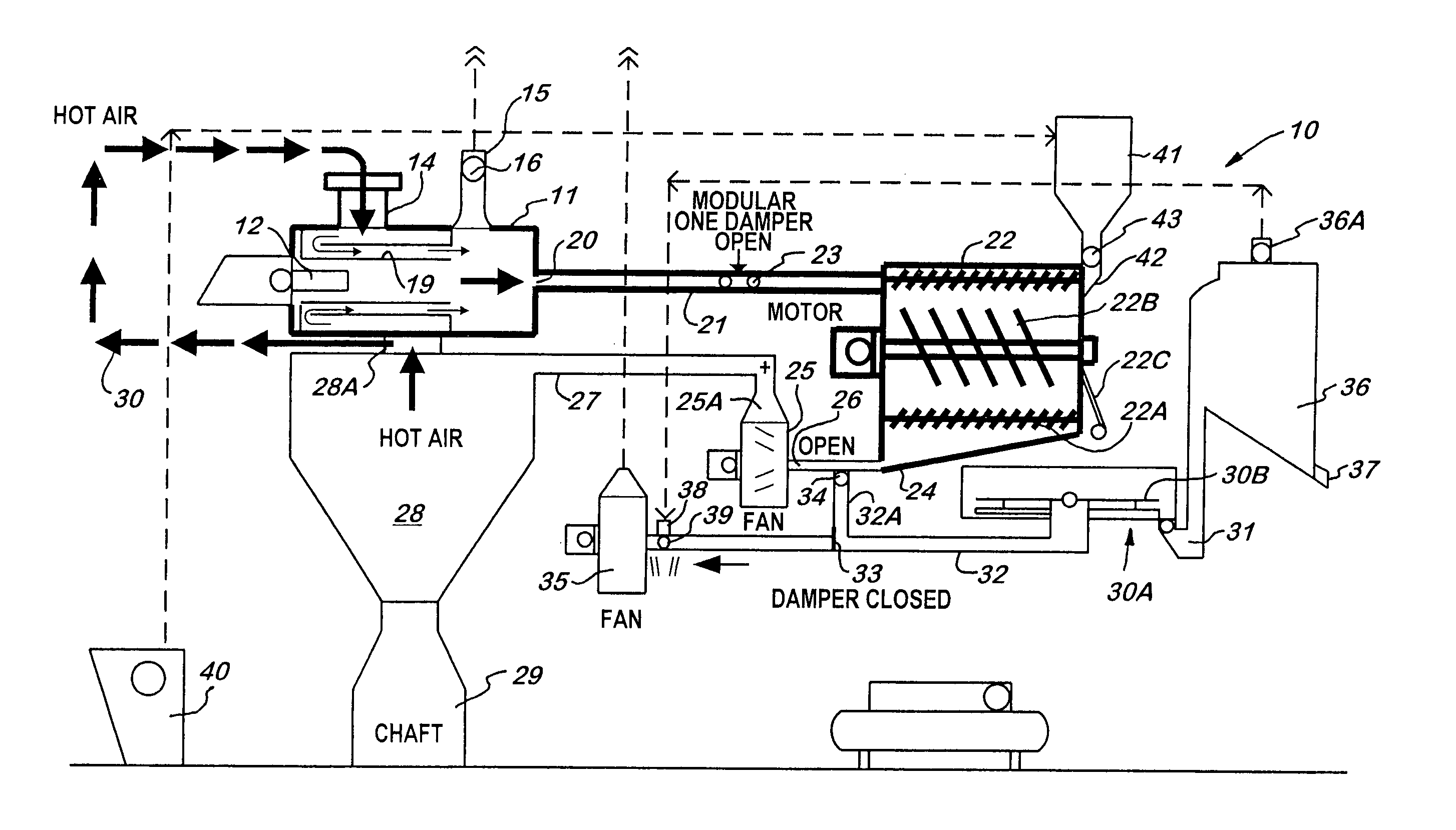

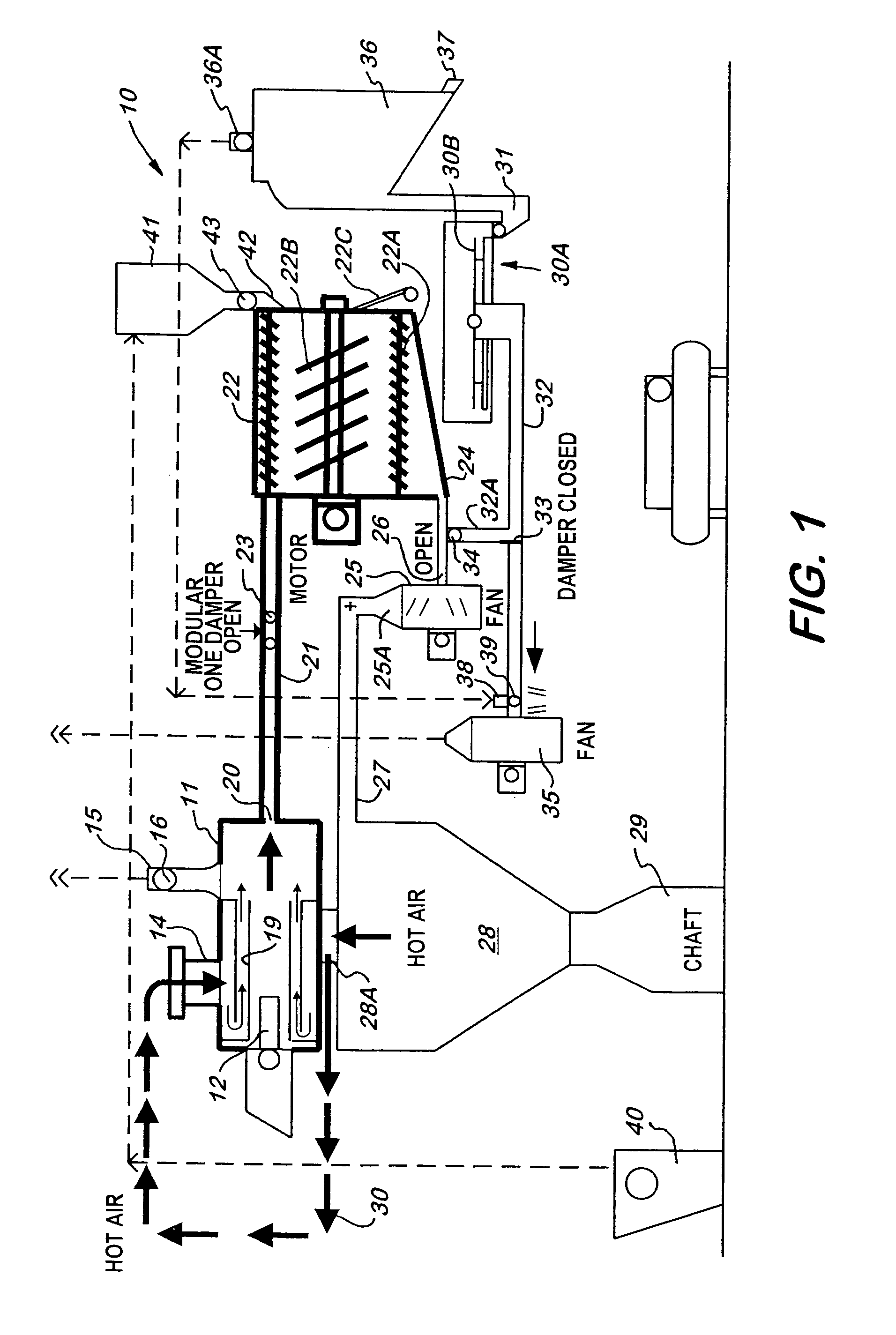

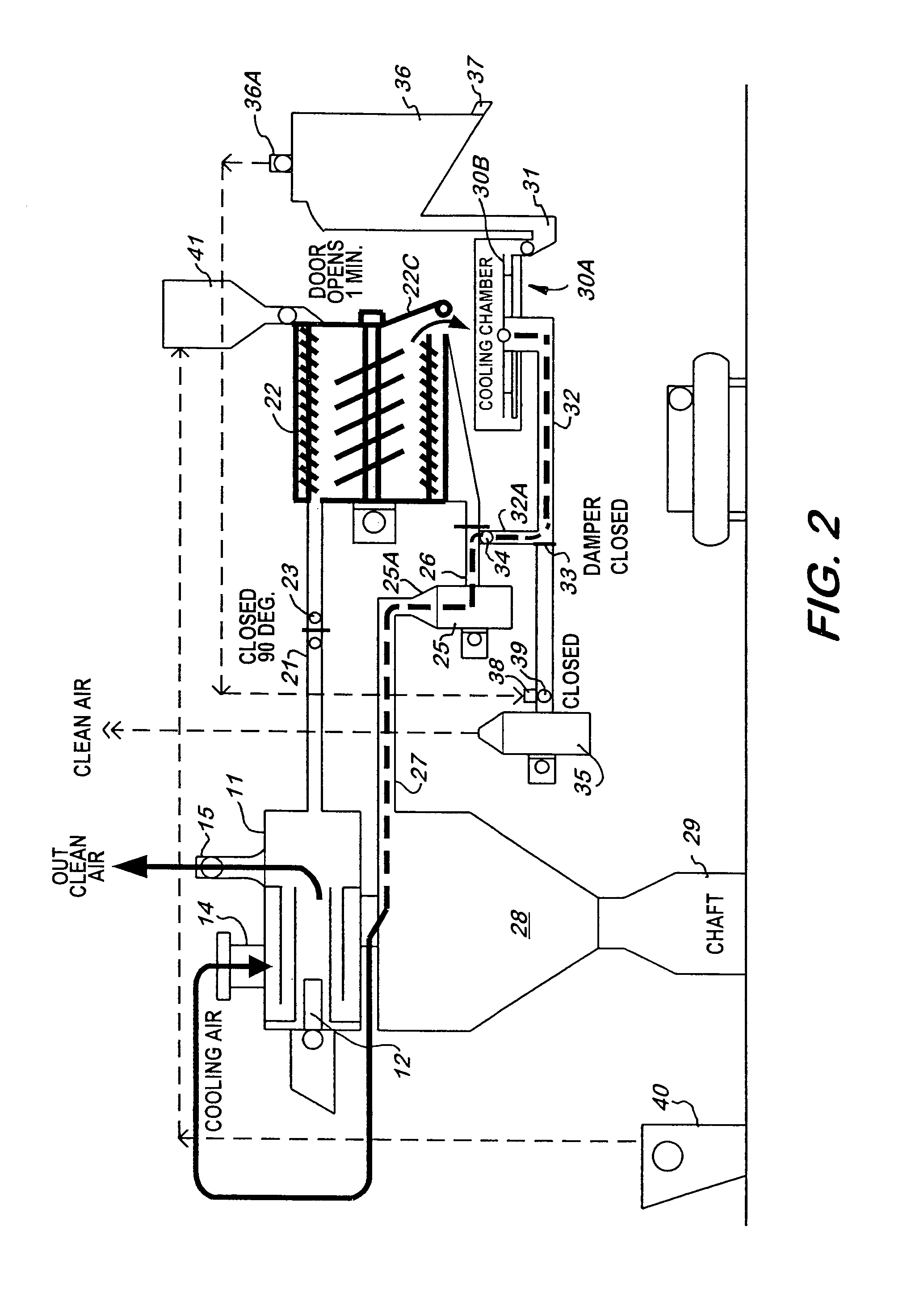

Coffee roasting apparatus and method

InactiveUS7143686B1Reduce the temperatureAir-treating devicesMilk preservationCombustion chamberCooling chamber

A coffee roaster that includes a combustion chamber and a connected roasting oven in which the heating gases for roasting the coffee beans are recirculated to the combustion chamber wherein the coffee bean chaff is separated from the recirculating heating gases prior to venting to atmosphere, and an associated cooling chamber wherein the roasted coffee beans are cooled in a two-stage-heating cycle wherein the cooling air is recirculated to the combustion chamber to be reheated to roasting temperatures and vented to atmosphere during the second stage of cooling. The coffee beans being de-stoned as the cooled coffee beans are conveyed from the cooling chamber to the discharge hopper.

Owner:SANDOLO RAFFAEL

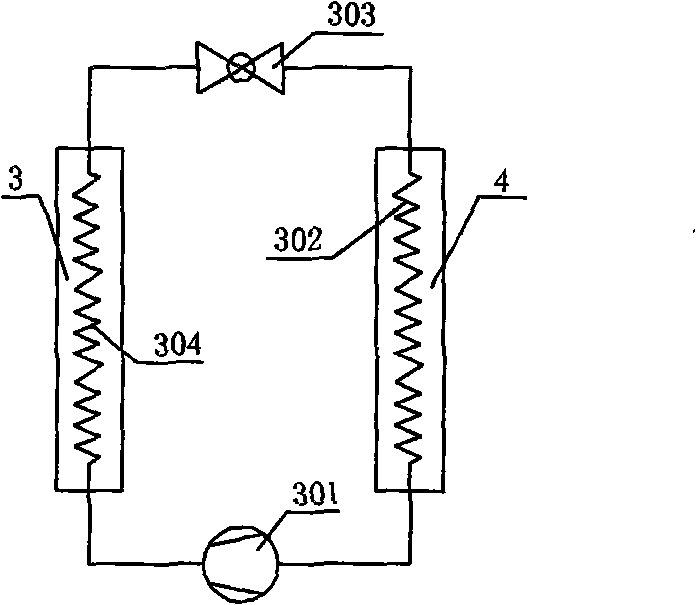

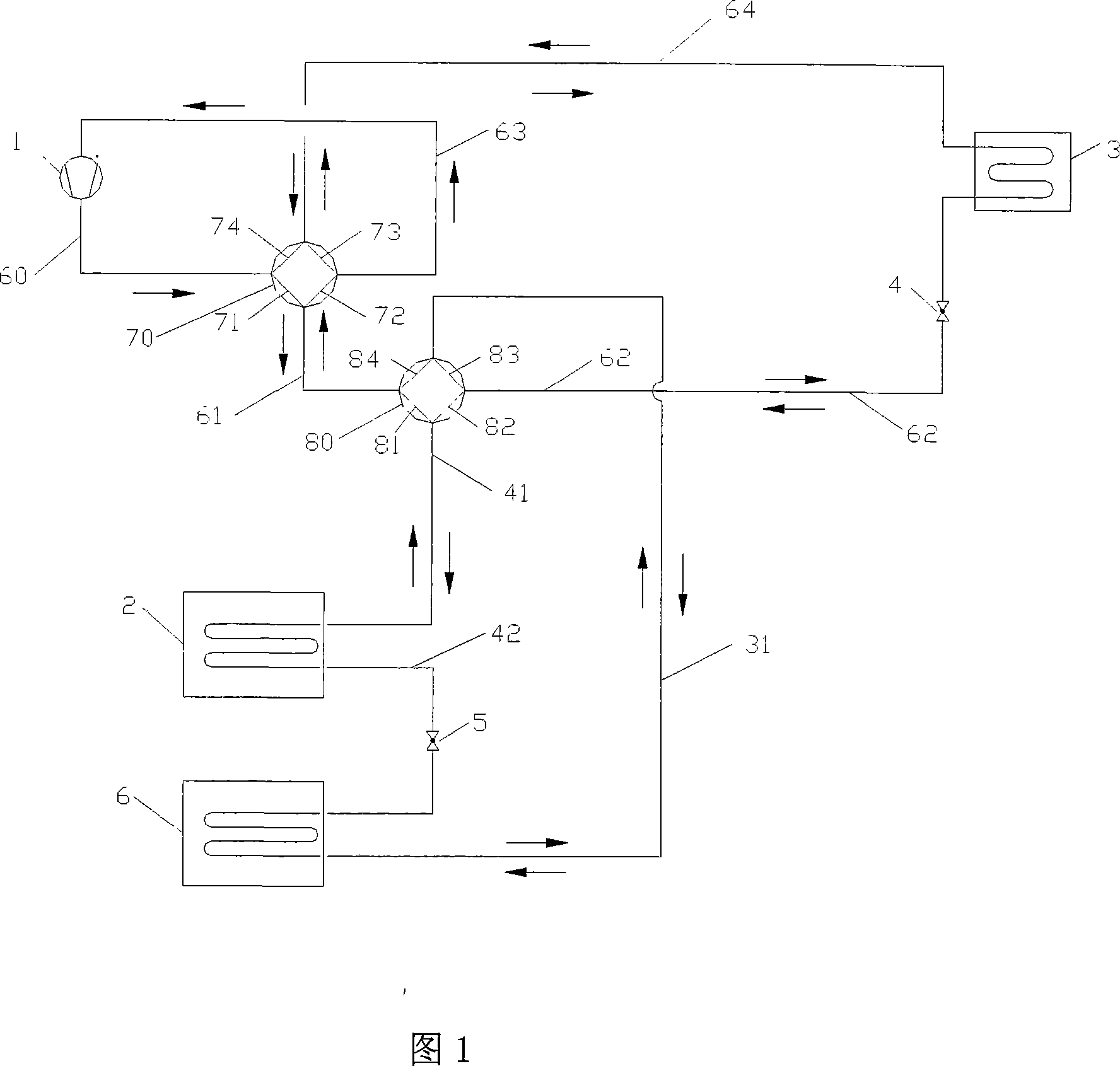

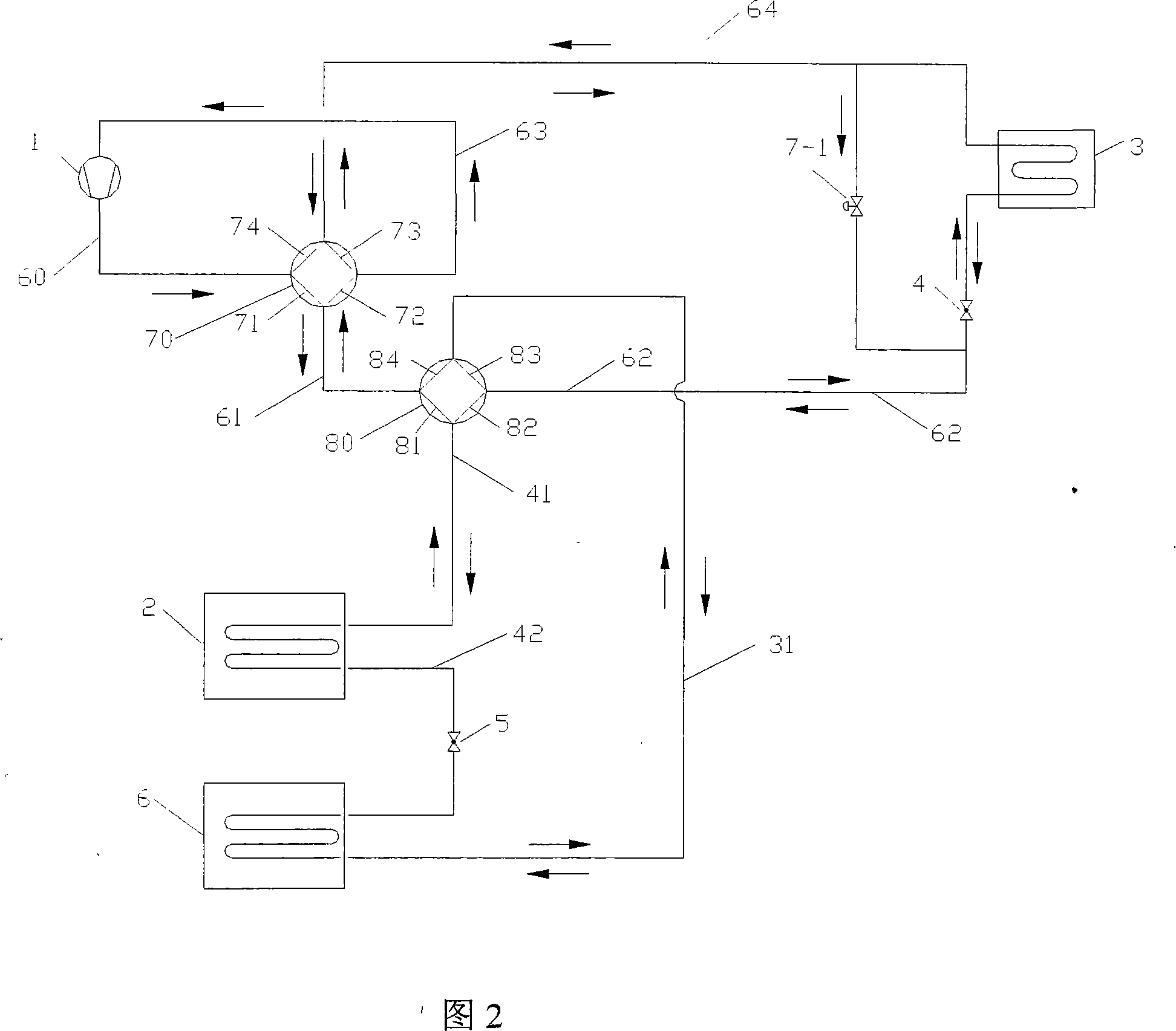

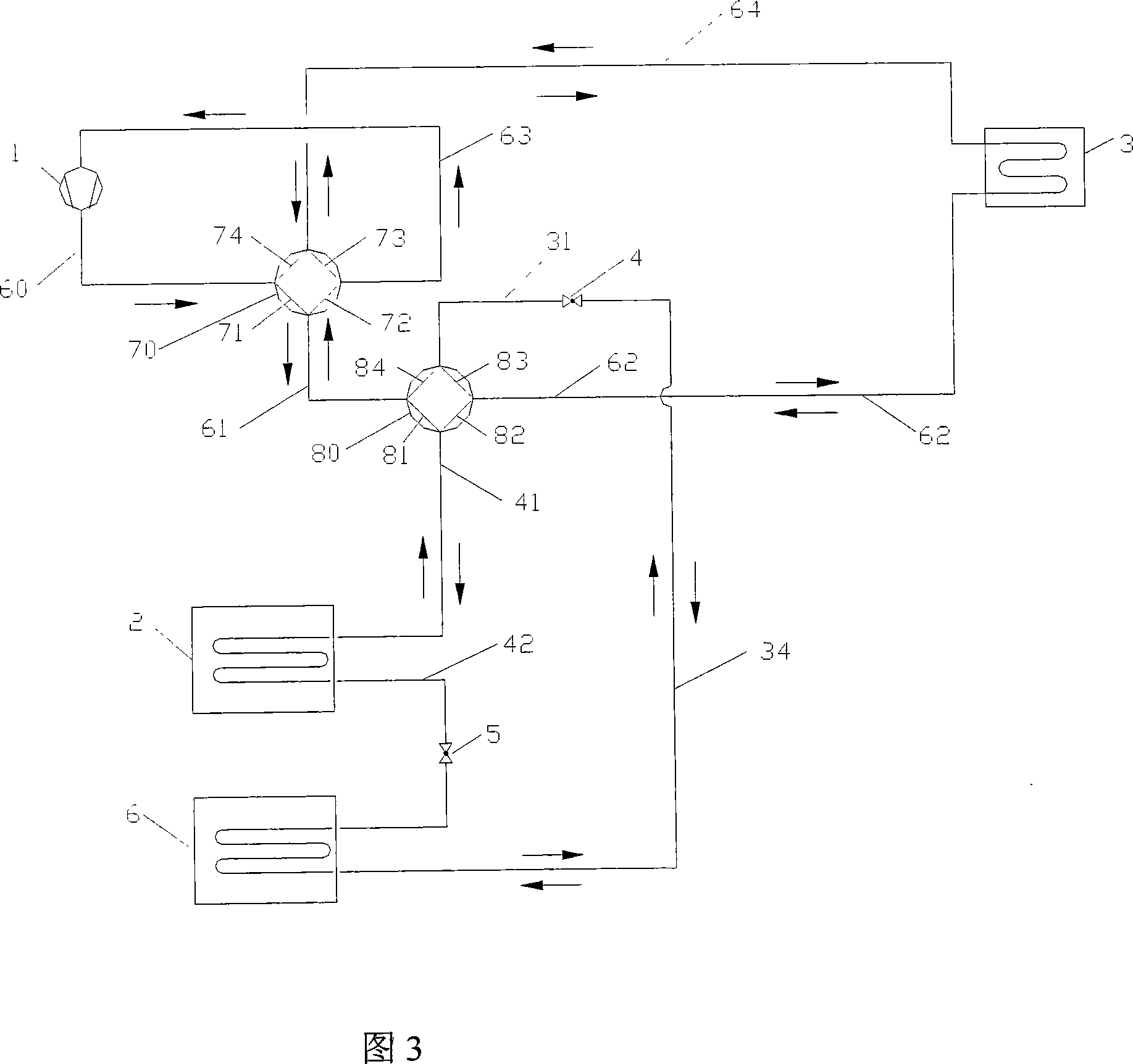

Dual-purpose heat pump device for winter and summer

InactiveCN101144662AImprove performanceAvoid canceling each other outHeat pumpsCorrosion preventionSuper coolingFour-way valve

The invention discloses a heat pump device which can be used both in summer and winter. The heat pump device comprises a compressor, a heat source side heat exchanger, a user side heat interchanger, a throttling mechanism and a four-way valve; and the heat pump device also comprises a second heat interchanger, a second throttling mechanism and a second four-way valve. The four-way valve is provided with four nodes, a four-way valve node is connected with the output end of the compressor through a pipeline, the four-way valve node is connected with the input end of the compressor through the pipeline, the four-way valve node is connected with one end of the user side heat interchanger through the pipeline, the four-way valve node is connected to the node of the four-way valve through the pipeline, the other node of the four-way valve is connected with the other ends of the user side heat interchanger in sequence through the pipeline and the throttling mechanism, the four-way valve node is connected with one end of the heat source side heat exchanger, and the other end of the heat source side heat exchanger is connected with the four-way valve node through the throttling mechanism and the second heat interchanger. The heat pump device produces the hot water to refrigerate or heat in the operation process. The recycling produces the low temperature afterheat. In the process of refrigeration cycle in summer and heating cycle in winter, the super cooling of a refrigeration agent can be realized. The invention is suitable for the industrial and civil use.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

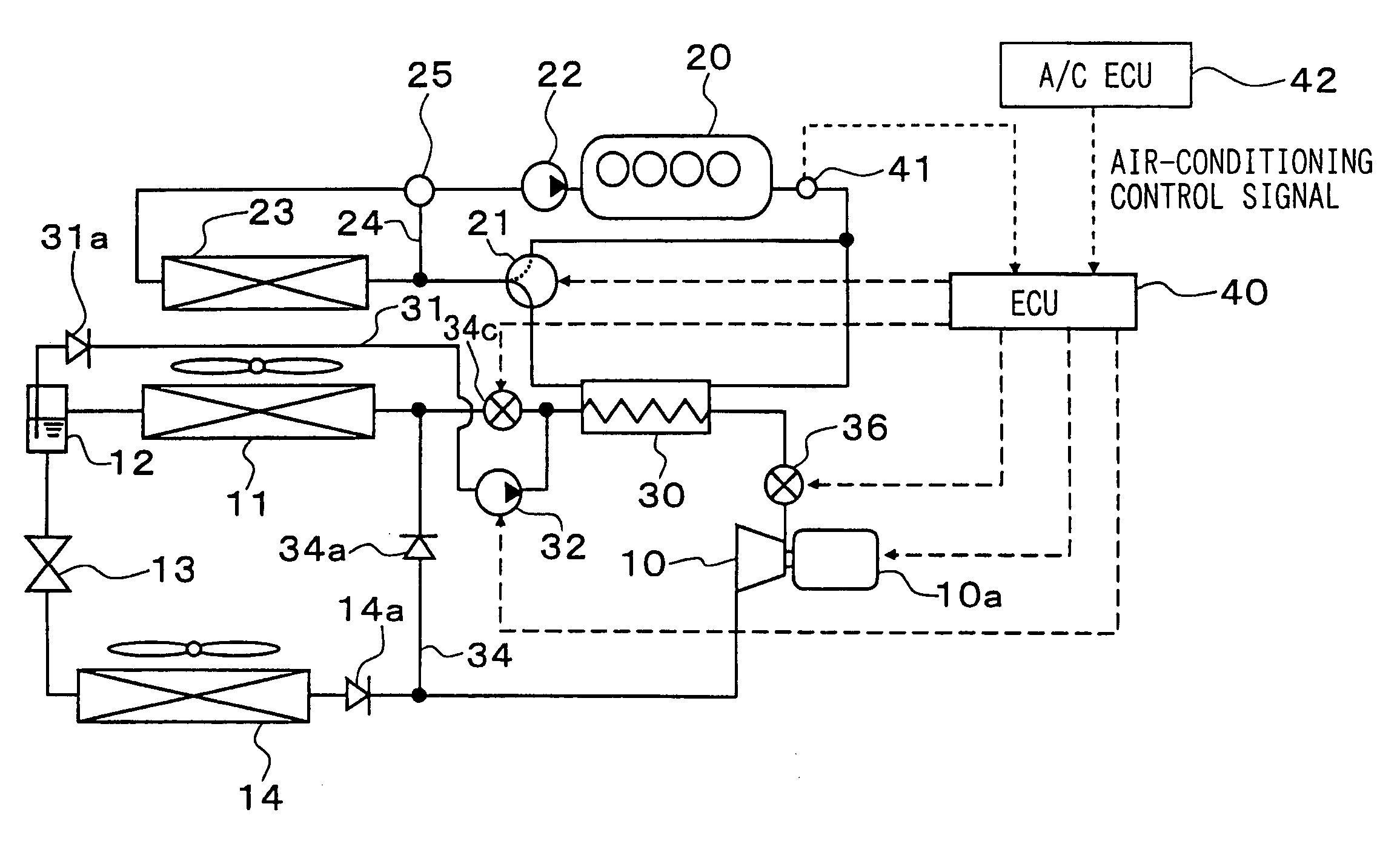

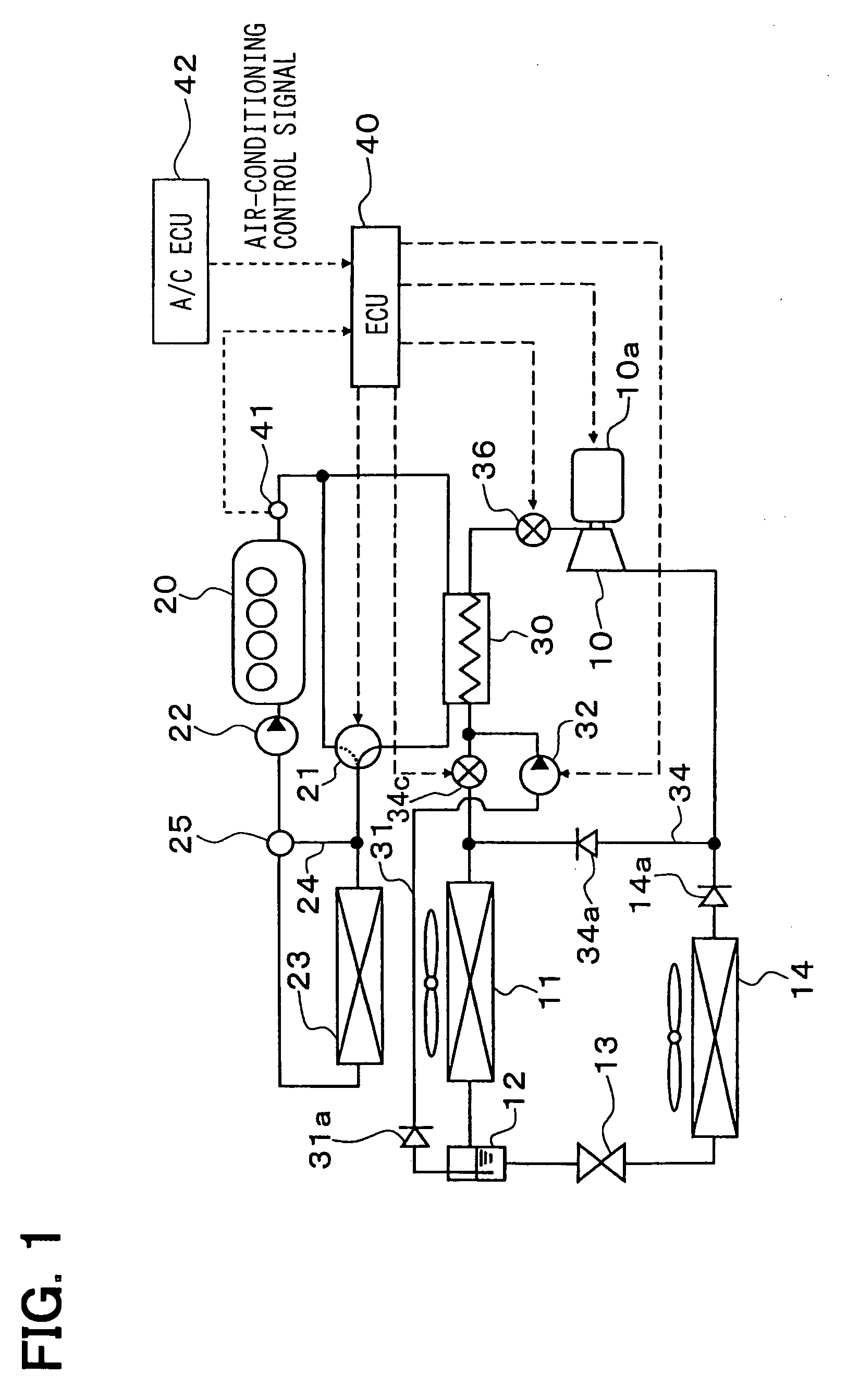

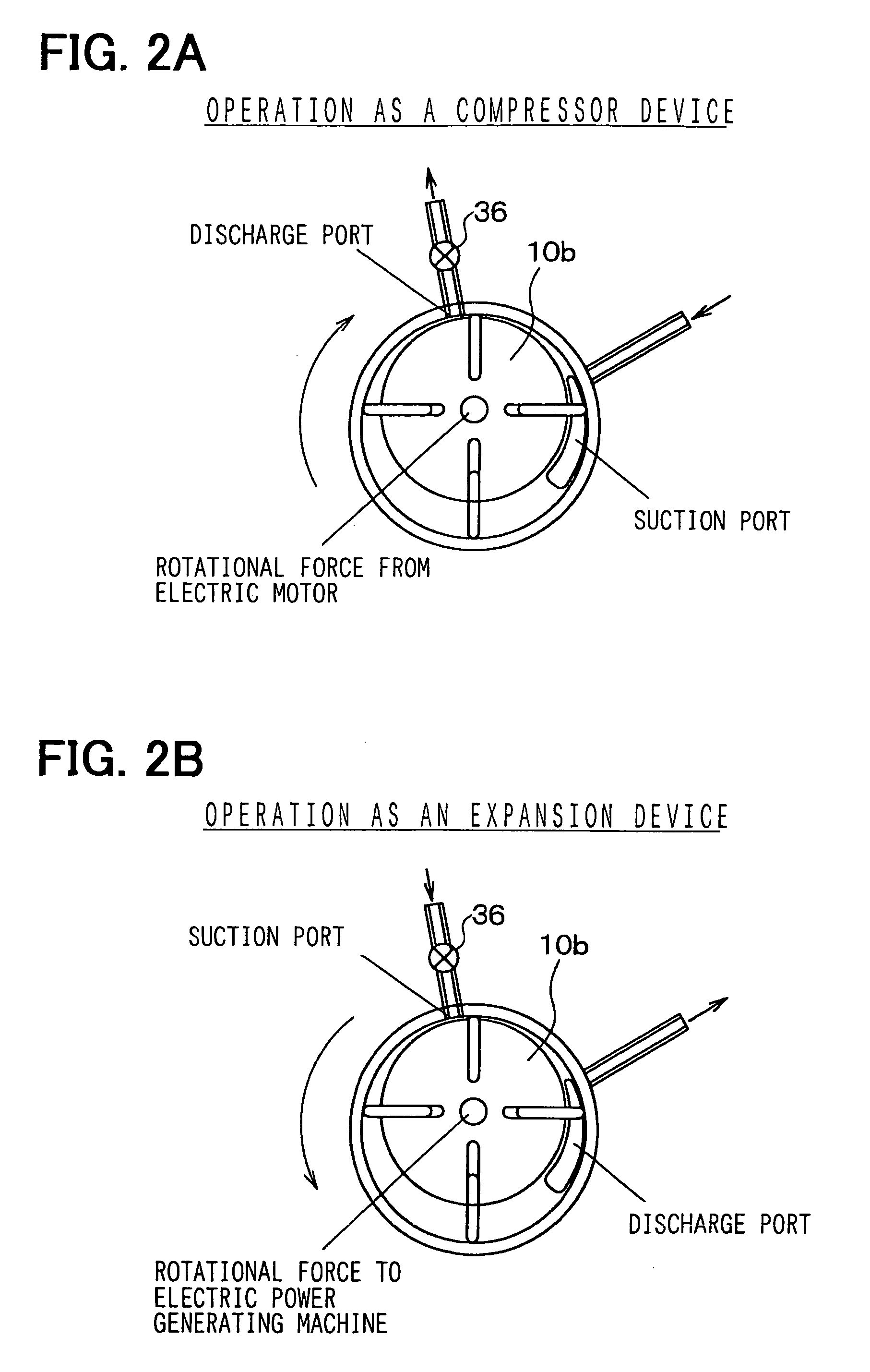

Waste heat collecting system having rankine cycle and heating cycle

InactiveUS6928820B2Increase frictional resistanceReduce the temperatureAir-treating devicesInternal combustion piston enginesMobile vehicleAir conditioning

An object of the invention is to provide a rankine cycle suitable for a use for a motor vehicle. In a waste heat collecting system having the rankine cycle and a refrigerating cycle, when ECU receives an air-conditioning signal from A / C ECU, the refrigerating cycle is operated, by preceding the operation of the rankine cycle. In the case that there is no air-conditioning signal and a temperature of an engine cooling water is higher than a predetermined value, the rankine cycle is operated.

Owner:DENSO CORP +1

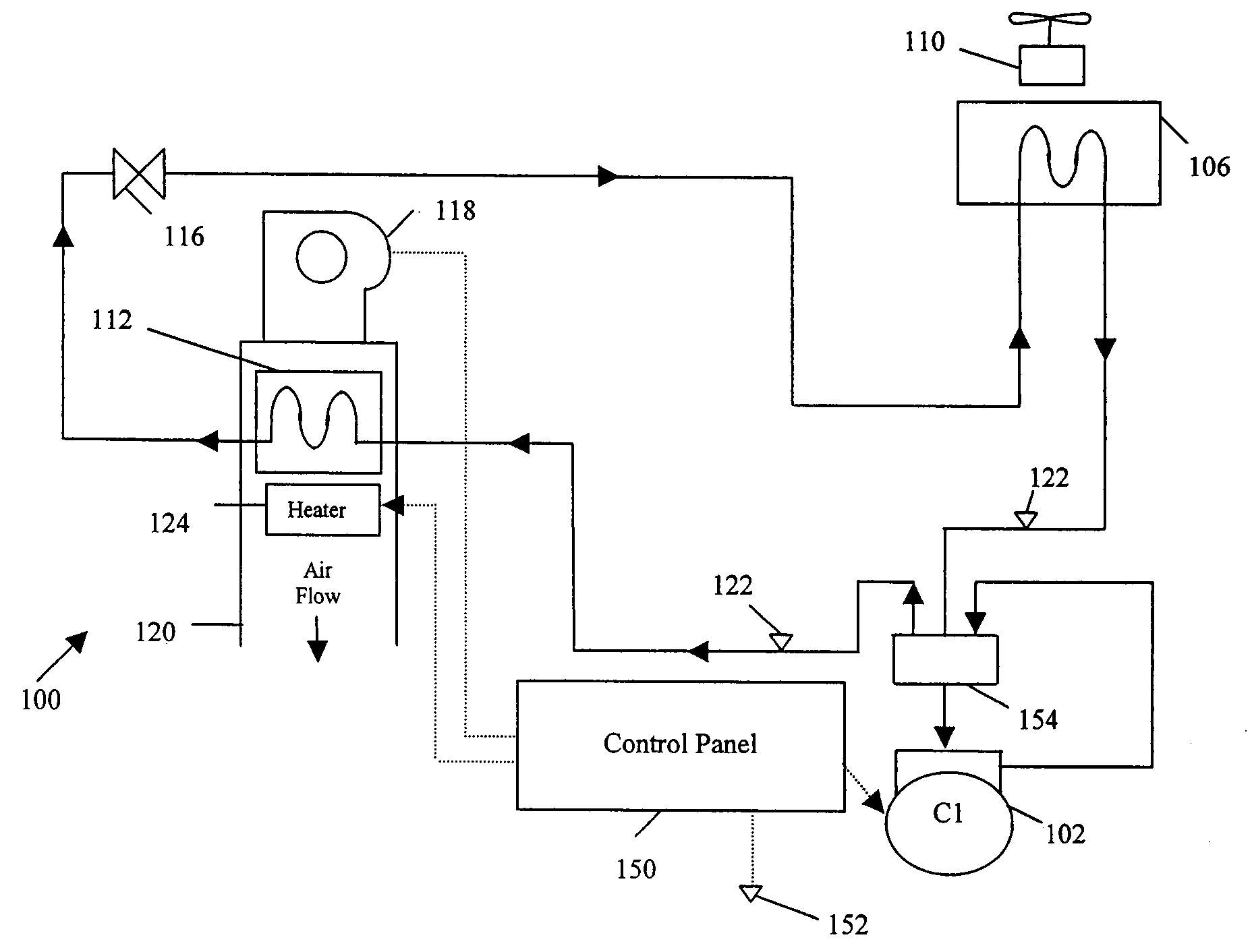

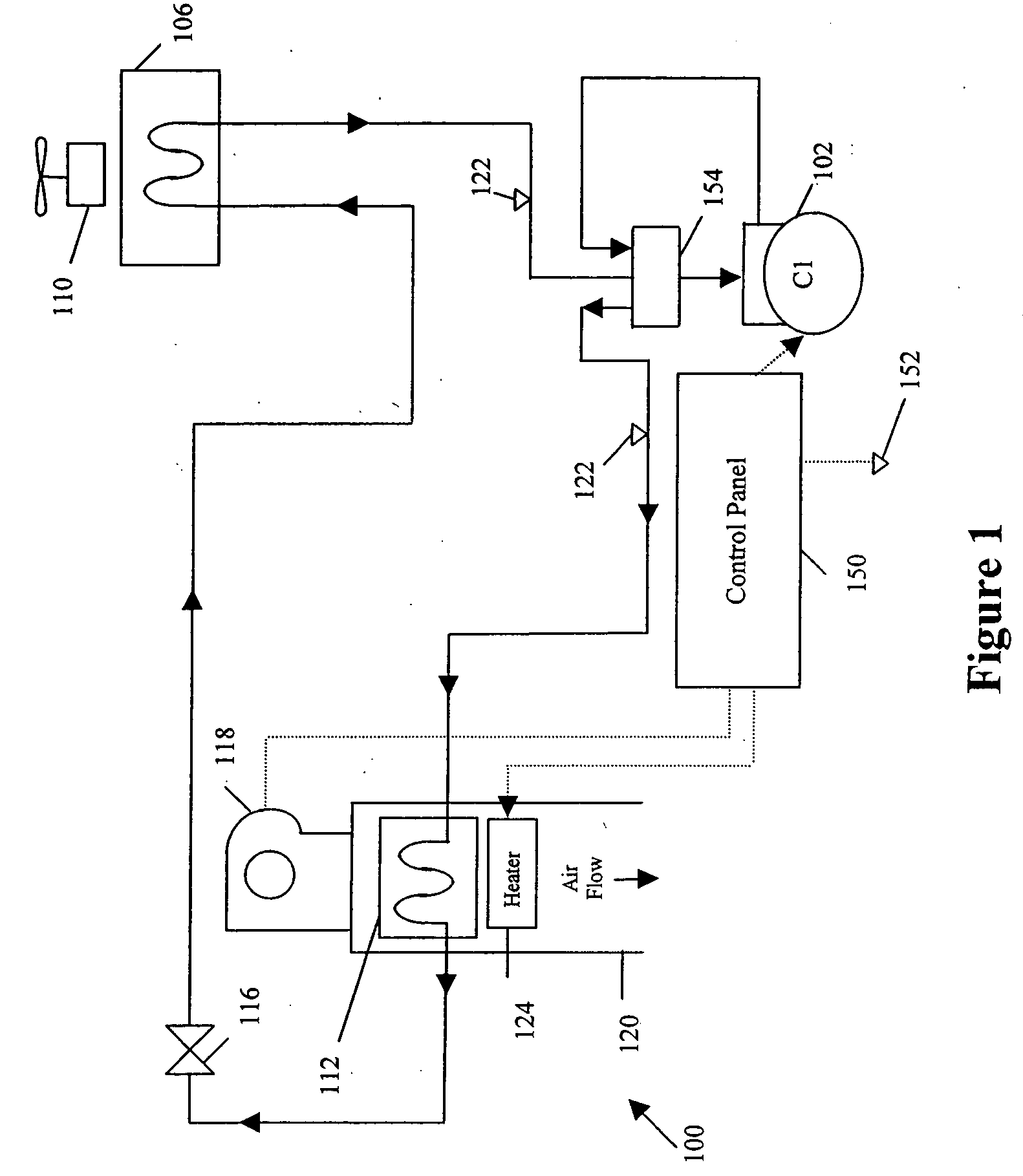

Method and apparatus to prevent low temperature damage using an HVAC control

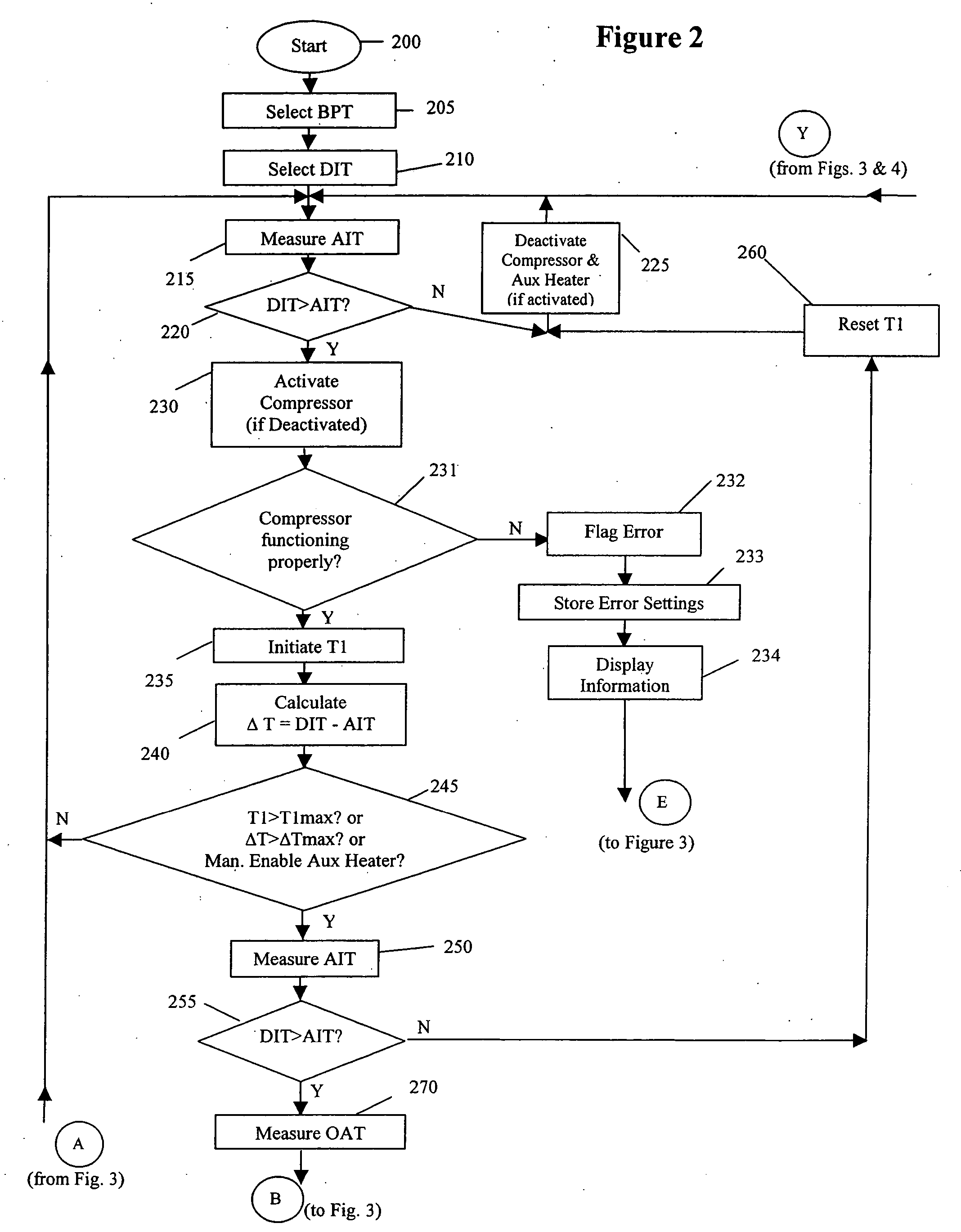

ActiveUS20050234597A1Reduce harmSampled-variable control systemsMechanical apparatusEngineeringHeating cycle

A heating control method is provided for a multi-stage heating system including a heating circuit having a compressor, a condenser and an evaporator. An auxiliary heater is provided that is selectively controlled independently of the heating circuit. During a heating cycle in which the ambient outside temperature is greater than the balance point temperature associated with the operation of the heating circuit, the auxiliary heating circuit is normally prevented from operating. However, if the heating requirements are not satisfied after a predetermined time or the compressor is non-functional or operating improperly, the auxiliary heater is enabled.

Owner:YORK INT

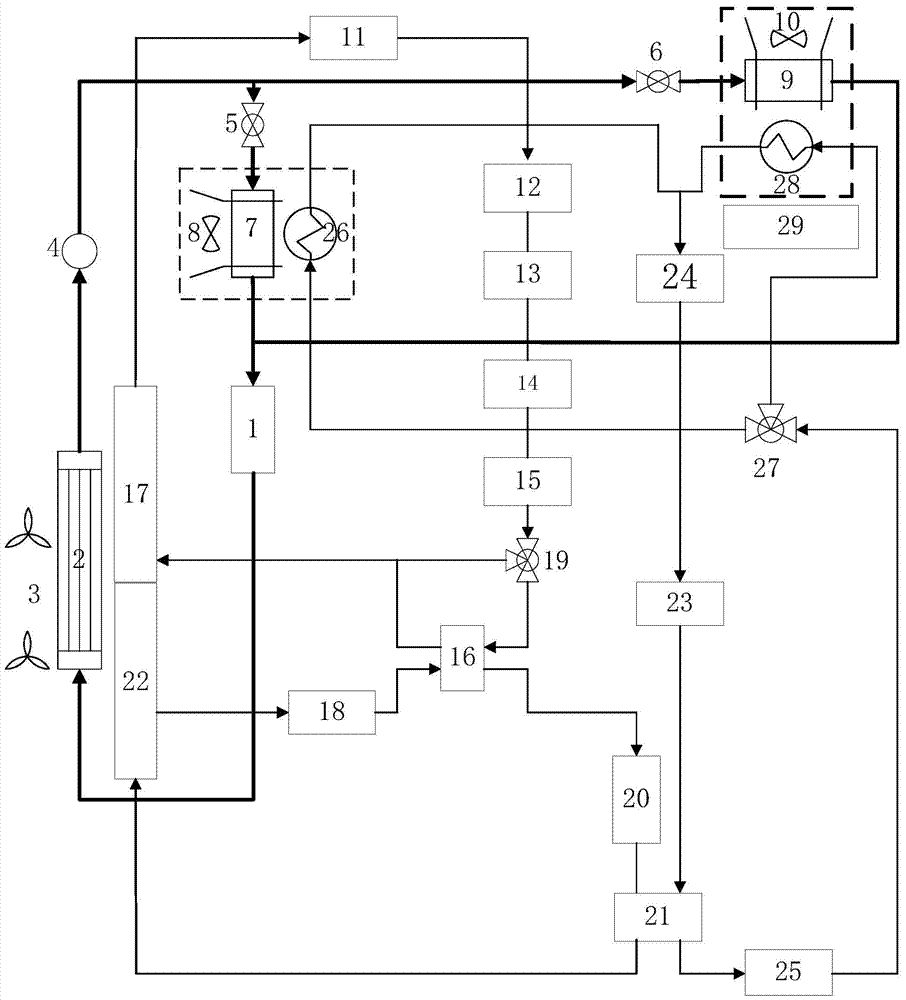

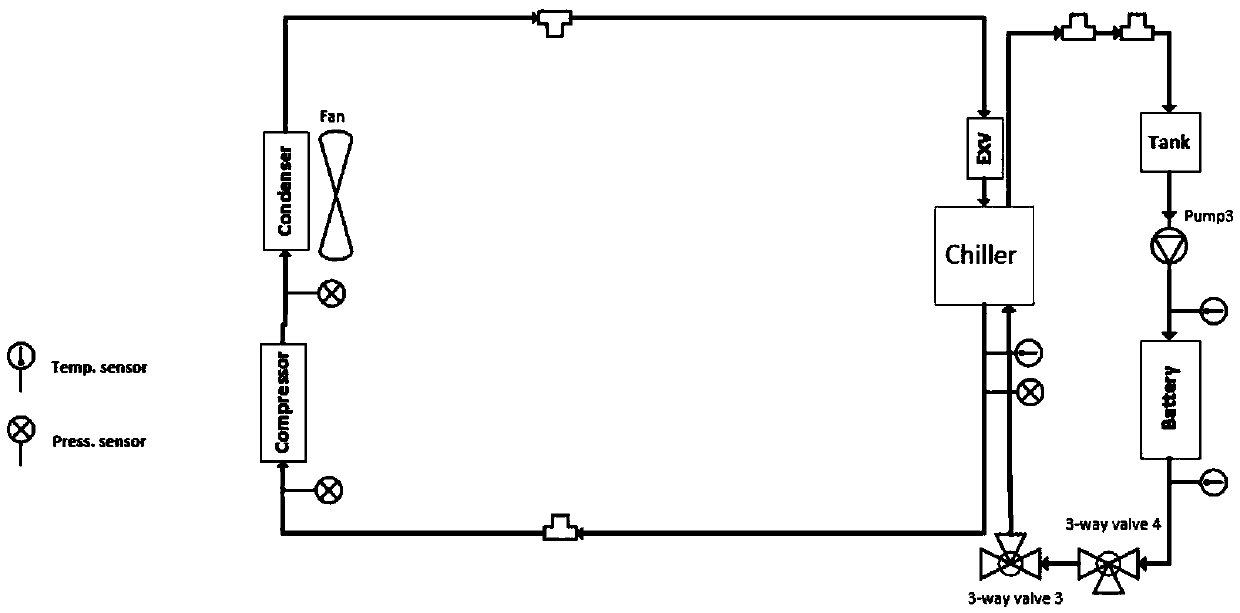

Heat control system for hybrid power or range-extending type electric automobile

InactiveCN103660916AImprove heating efficiencyImprove fuel efficiencyAir-treating devicesVehicle heating/cooling devicesDrive motorThermal control system

The invention discloses a heat control system for a hybrid power or range-extending type electric automobile. A power battery system supplies power to a refrigeration cycle system and a heating cycle system, and a whole automobile controller controls the refrigeration cycle system or the heating cycle system in the mode that the battery temperature and voltage information transmitted by the power battery system is collected through a CAN bus. An electric driving refrigeration cycle system preheats an engine for starting through heat generated by an electric appliance part, and an engine refrigeration cycle system enables the temperature of refrigeration liquid of the heating cycle system to be raised through heat generated after the engine is started. According to the heat control system, effective heat control over each component of the electric automobile is achieved, waste heat of electrical apparatus elements and waste heat of the engine are adopted for improving the heating efficiency of the electric automobile, heat waste is reduced, the energy utilization rate is improved, waste heat of a driving motor or an electric heater system can be used for preheating the engine, the engine burning efficiency is improved, and good control over heating or refrigerating of a power battery package can be achieved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

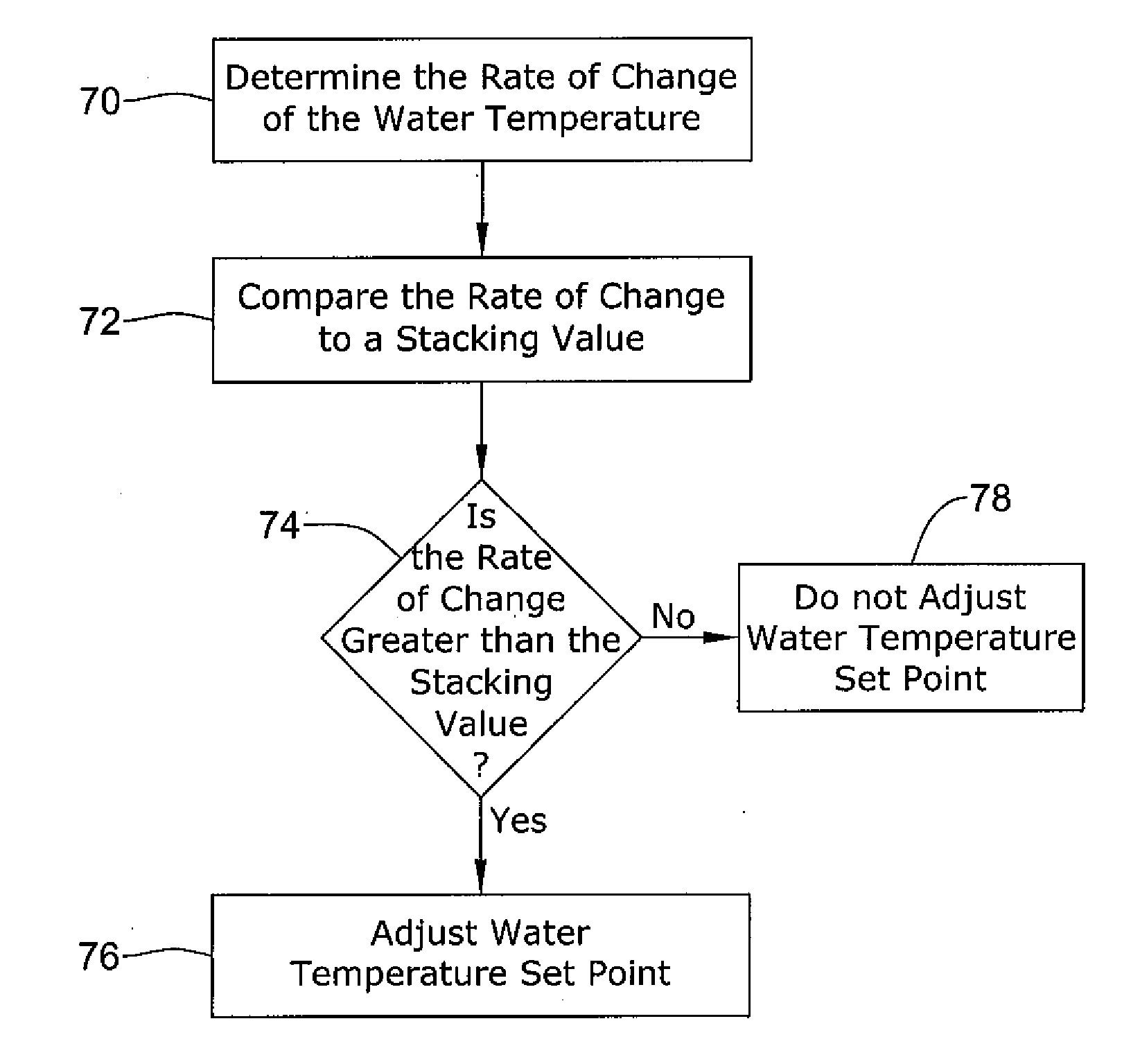

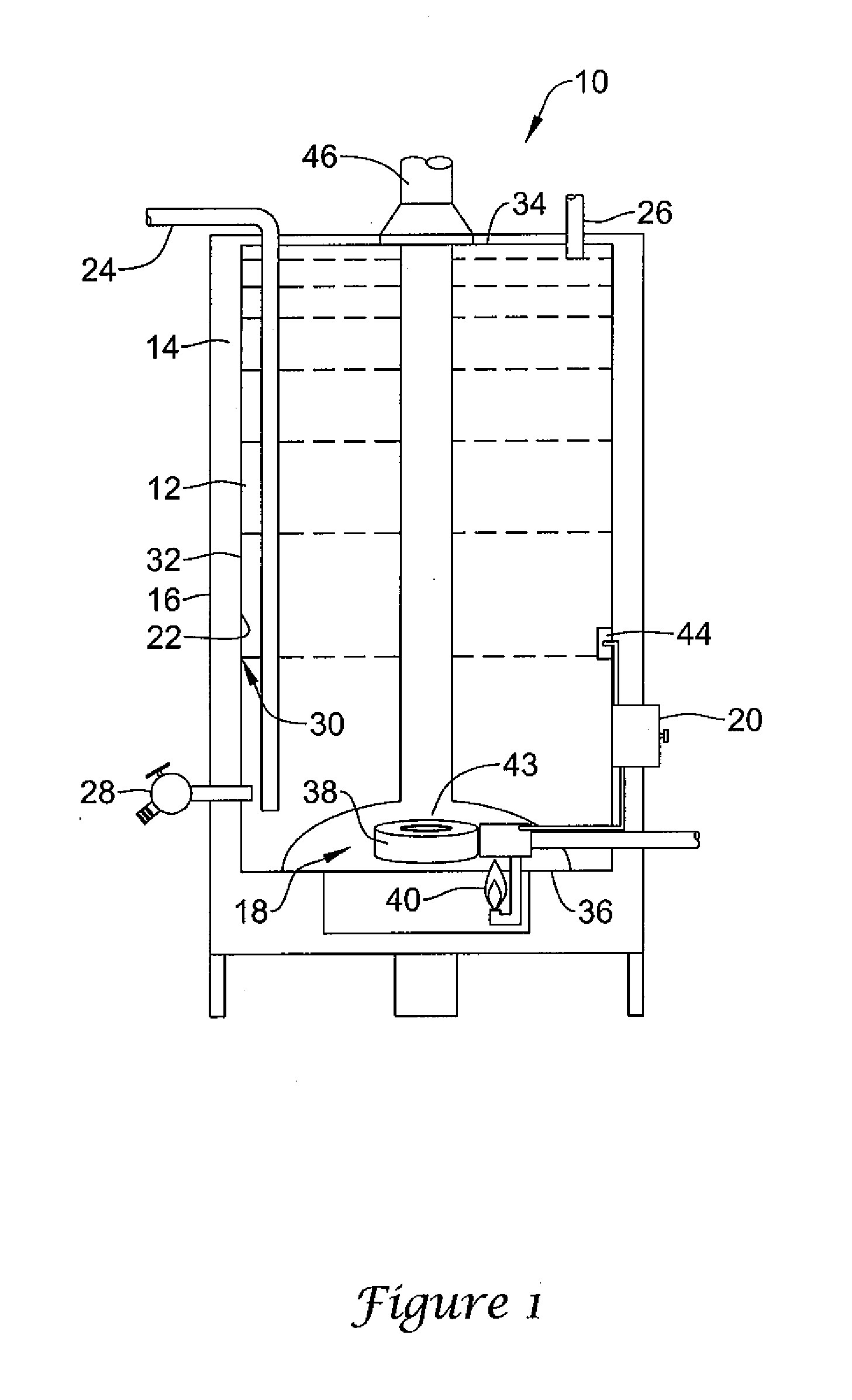

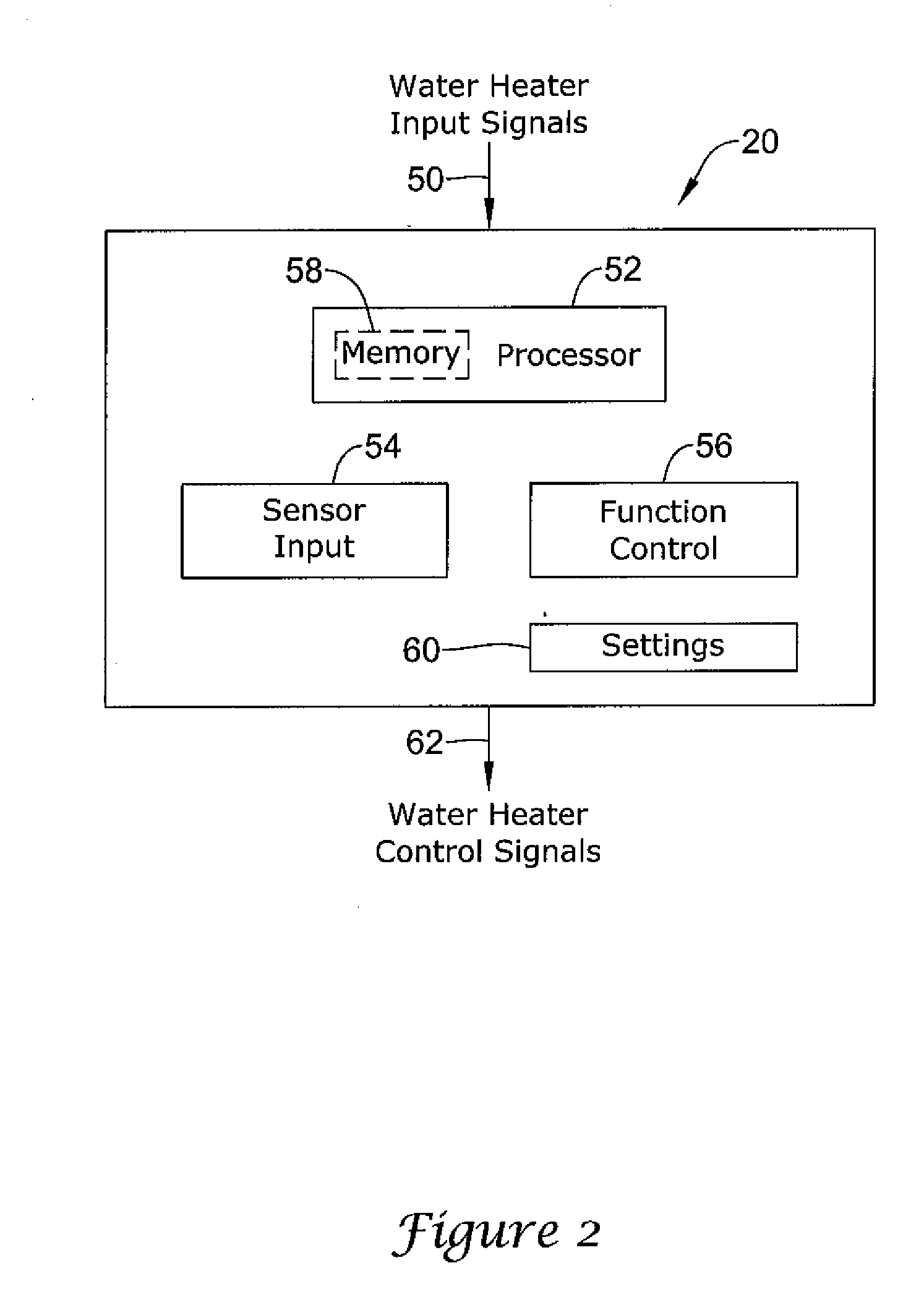

Water heater stacking detection and control

ActiveUS20080314999A1Weaken stacking effectReduce pointsTemperature control without auxillary powerFuel supply regulationEngineeringHeating cycle

Methods and systems for operating a water heater to limit the effects of stacking in a water heater tank are disclosed. In some cases, the water heater controller may determine a rate of change of the water temperature in the water heater tank. If the rate of change exceeds a threshold value, the controller may adjust the water heater temperature set point downward to help reduce stacking in the water heater. In some cases, the water heater temperature set point may be returned to the original water heater temperature set point when stacking is no longer likely to be of a concern. In one illustrative embodiment, the controller may track the time that the heater of the water heater is in the “on” state, or the time that the heater is in the “off” state, during subsequent heating cycles. The controller may then compare the “on” time or the “off” time to respective recovery threshold times. If the “on” time or the “off” time exceeds its respective recovery threshold time, then the controller may adjust the set point toward the original water heater temperature set point, sometimes in an incremental manner.

Owner:ADEMCO INC

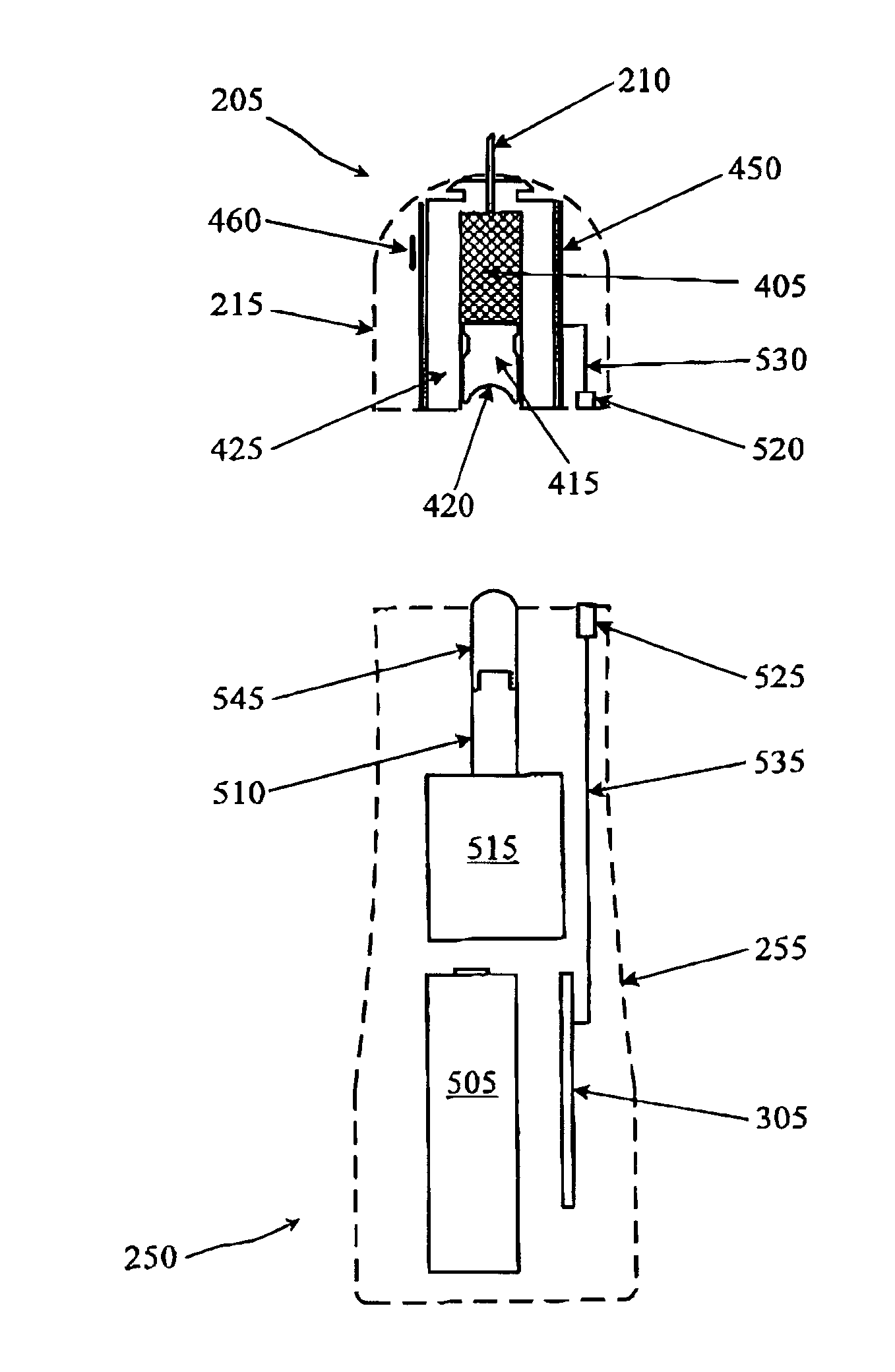

Drug Heating Cycle Limiter For Injection Device

An injection assembly includes a dispensing chamber housing, a temperature control device, a thermal sensor, a switch, and a controller. The dispensing chamber housing has an inner surface and an outer surface. The inner surface partially defines a dispensing chamber for receiving a quantity of a substance. The temperature control device at least partially surrounds the dispensing chamber housing and alters a temperature of a substance in the dispensing chamber. The thermal sensor is located near the temperature control device and reads a temperature near the temperature control device. The switch is coupled to the temperature control device. The controller controls the temperature control device and the switch such that a first voltage is applied to the temperature control device until the temperature control device reaches a desired temperature, and a second voltage is applied to the temperature control device thereafter to maintain the temperature control device at the desired temperature.

Owner:ALCON RES LTD

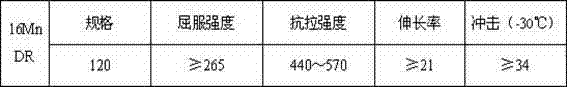

120mm low temperature pressure vessel 16mndr steel thick plate and production method thereof

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

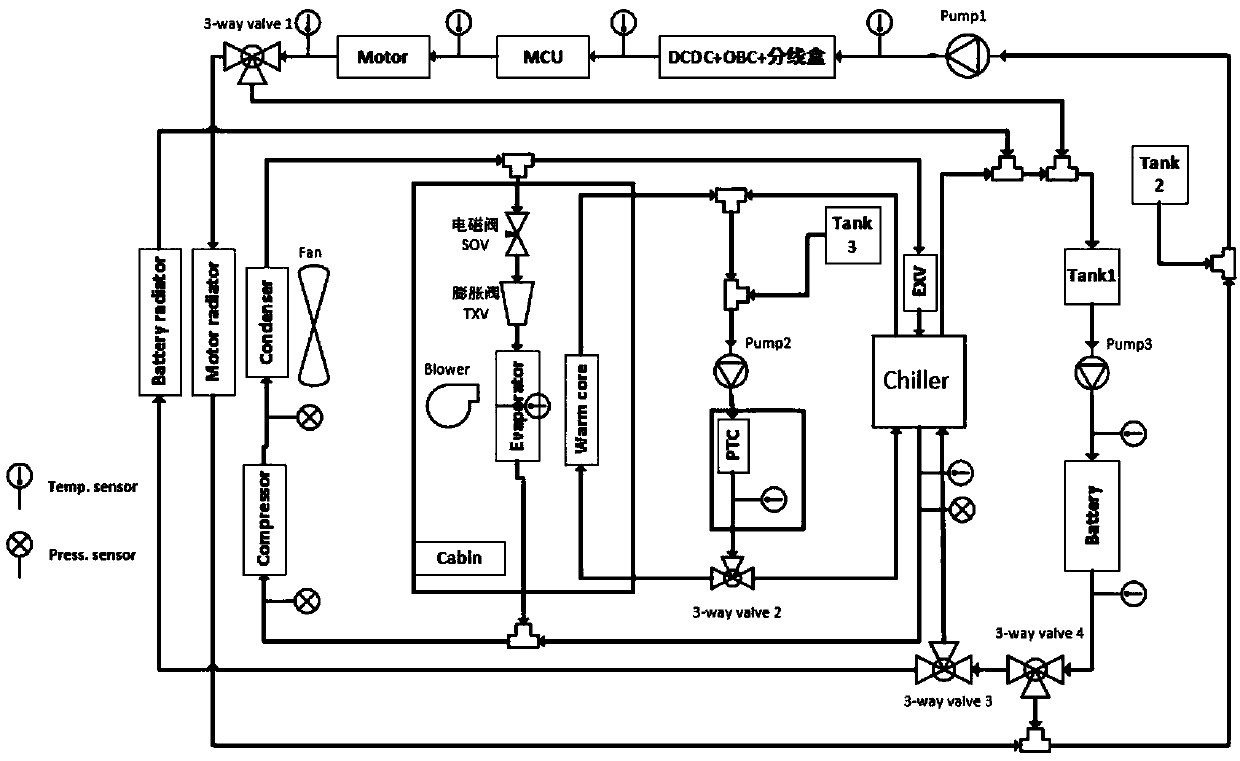

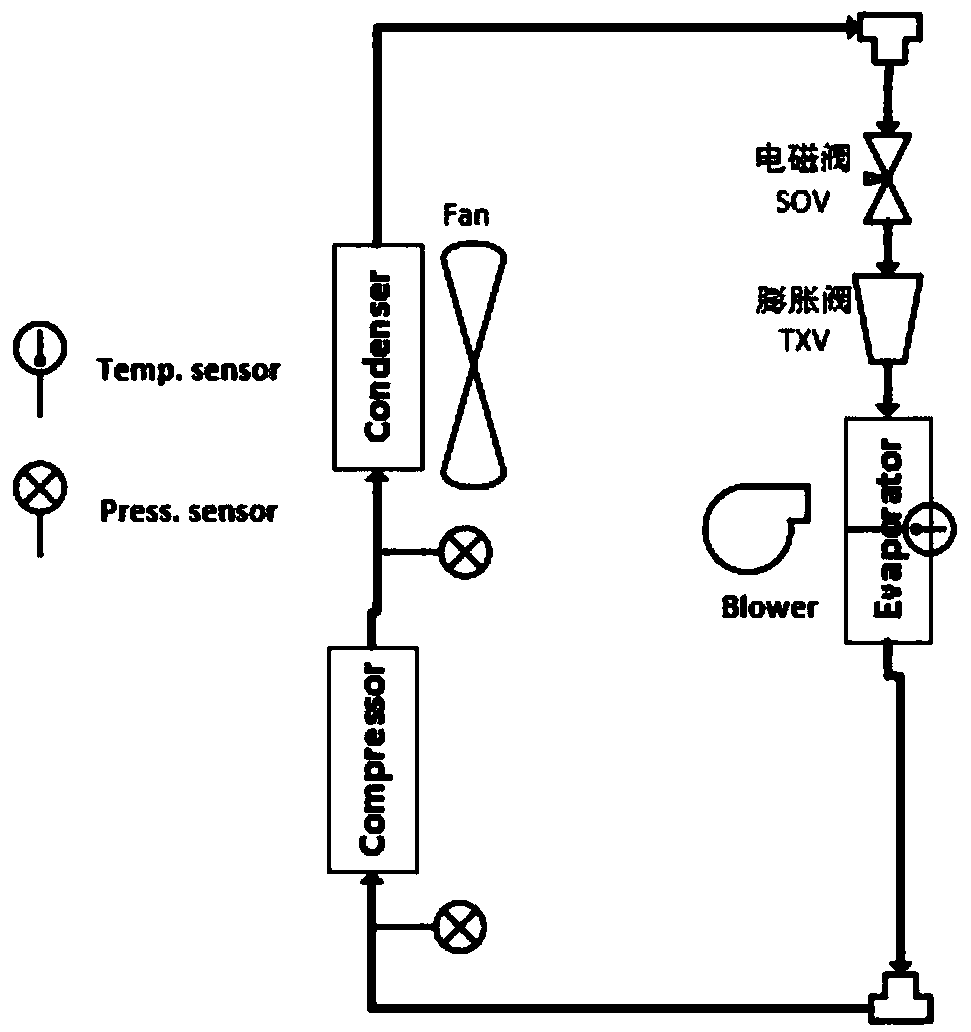

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

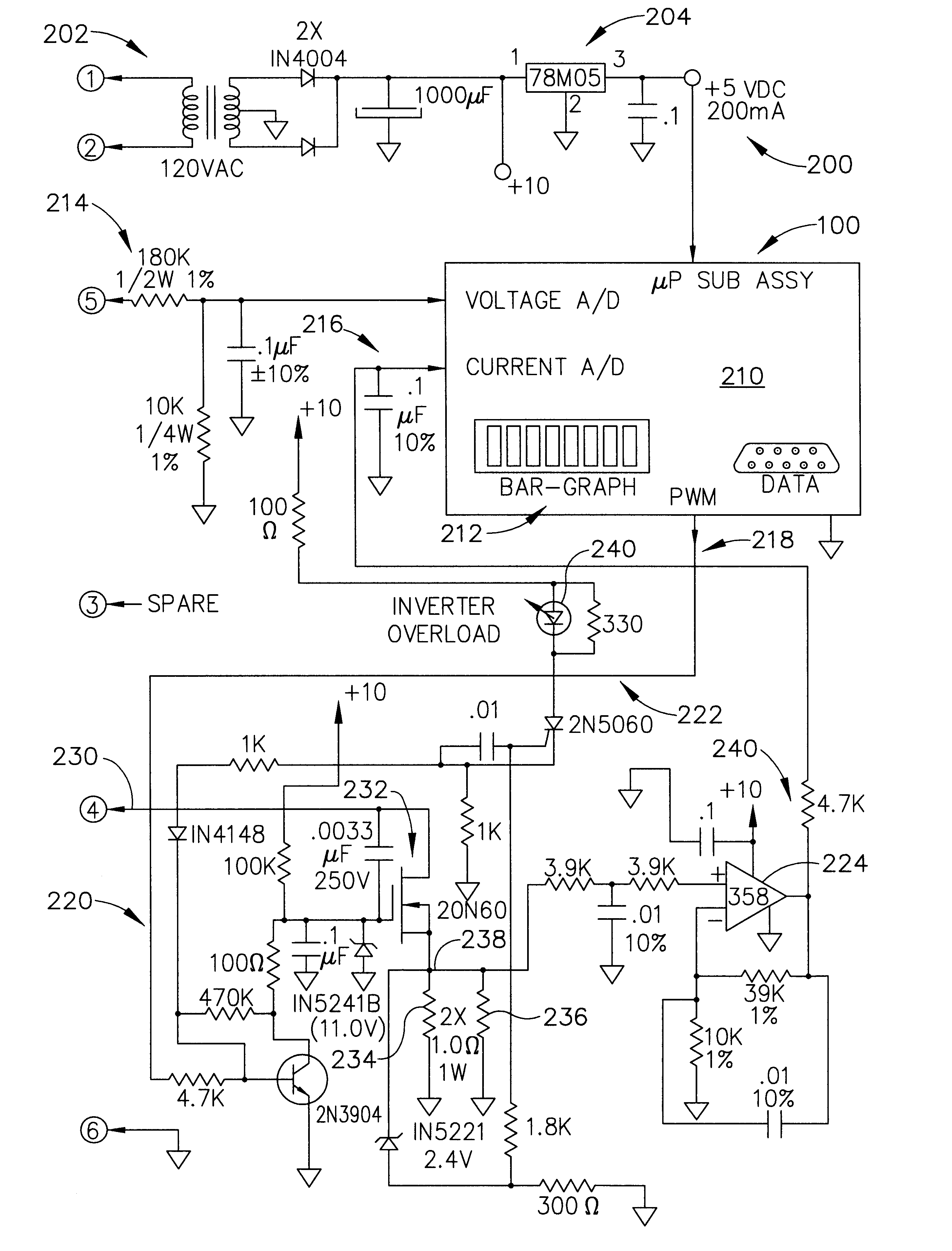

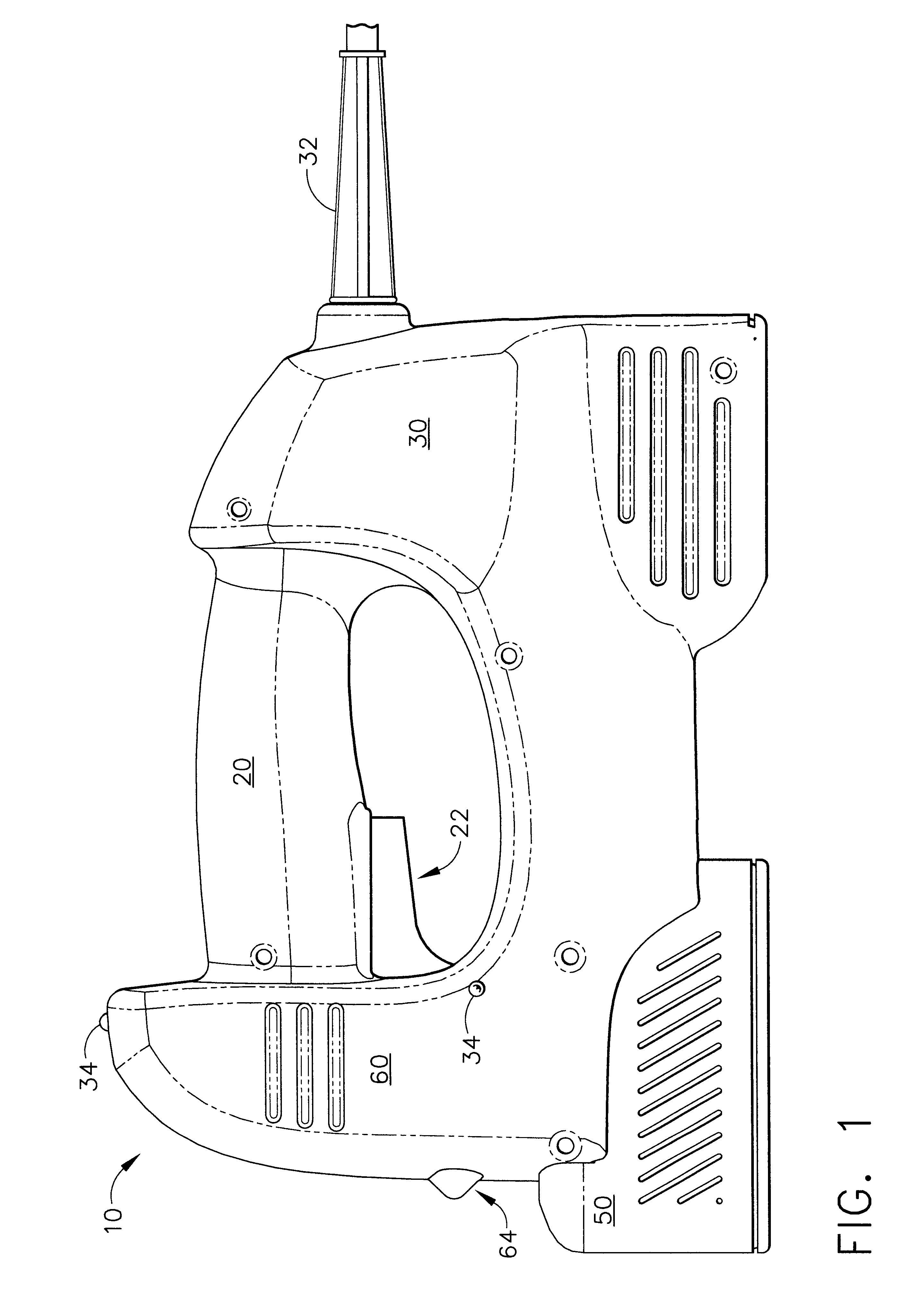

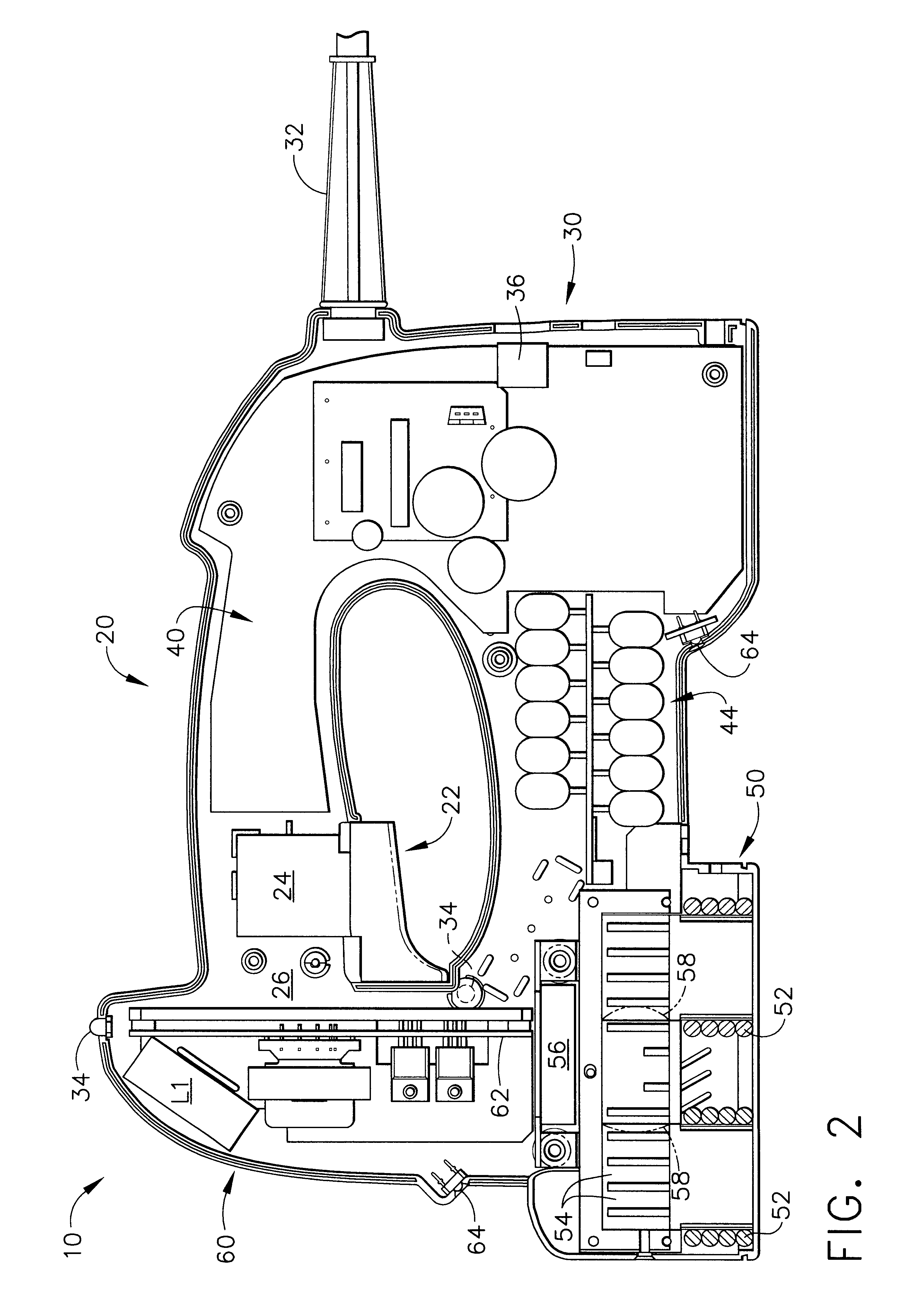

Hand held induction tool with energy delivery scheme

An apparatus and system for using magnetic fields to heat magnetically susceptible materials within and / or adjacent to adhesives, resins, or composites so as to reversibly or irreversibly bond, bind, or fasten opaque or non-opaque solid materials to one another. The system makes use of the effect that alternating magnetic fields induce eddy currents and generate heat within susceptors, and the effect that alternating magnetic fields additionally induce magnetic hysteresis that occurs in magnetic materials and thereby generate heat. An induction heating tool is used to emit the magnetic field at its work coil, and an electronic controller measures the energy being used by a power converter that generates the alternating current driving the work coil which creates the magnetic field. The distance between the susceptor and work coil is repeatedly analyzed based upon the power converter's input energy, and the work coil is driven at a repeatedly corrected power level during the heating cycle. Once a sufficient accumulated energy has been delivered to the susceptor, the magnetic field is turned off automatically by the tool, thus preventing overheating of the susceptor.

Owner:OMG INC

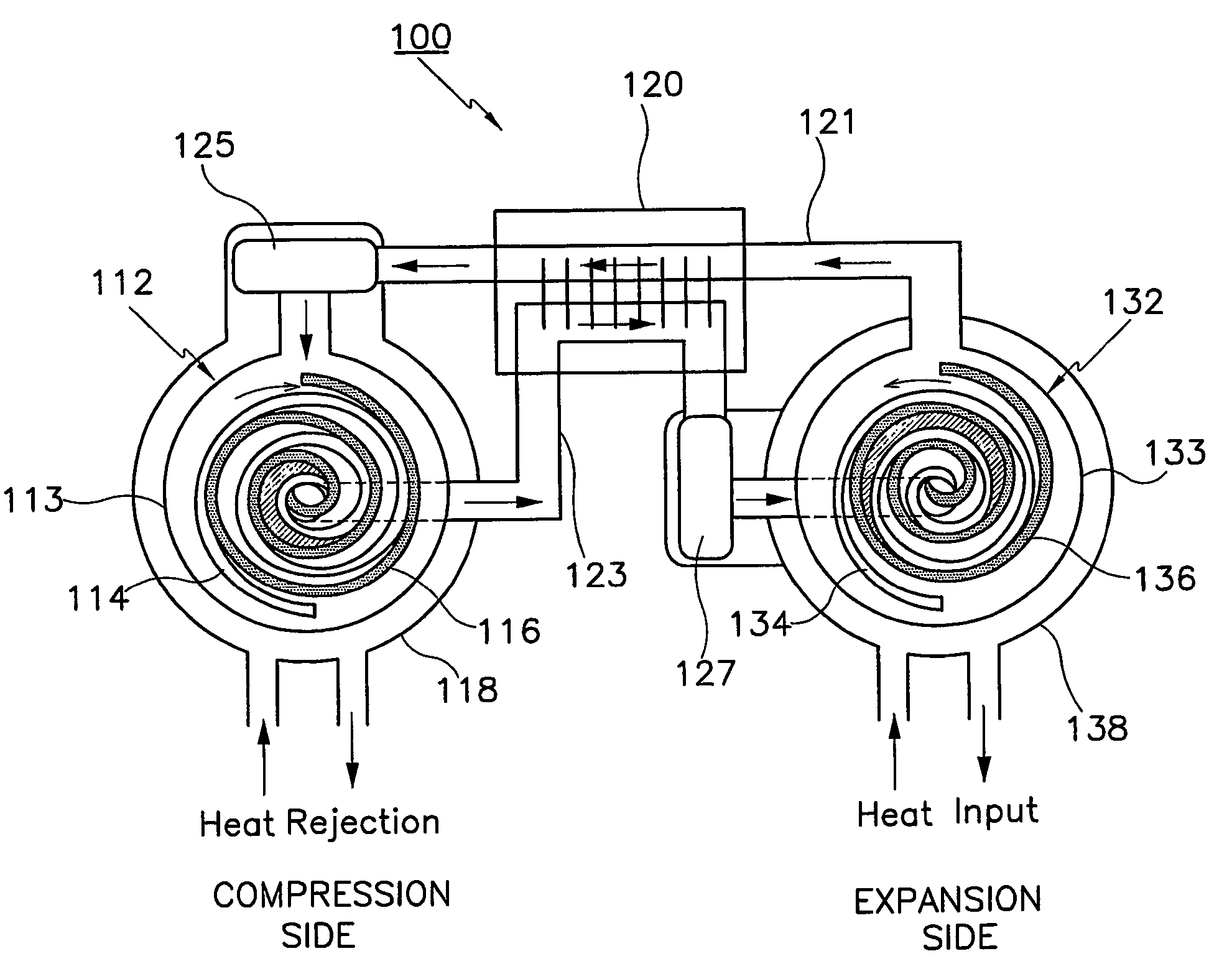

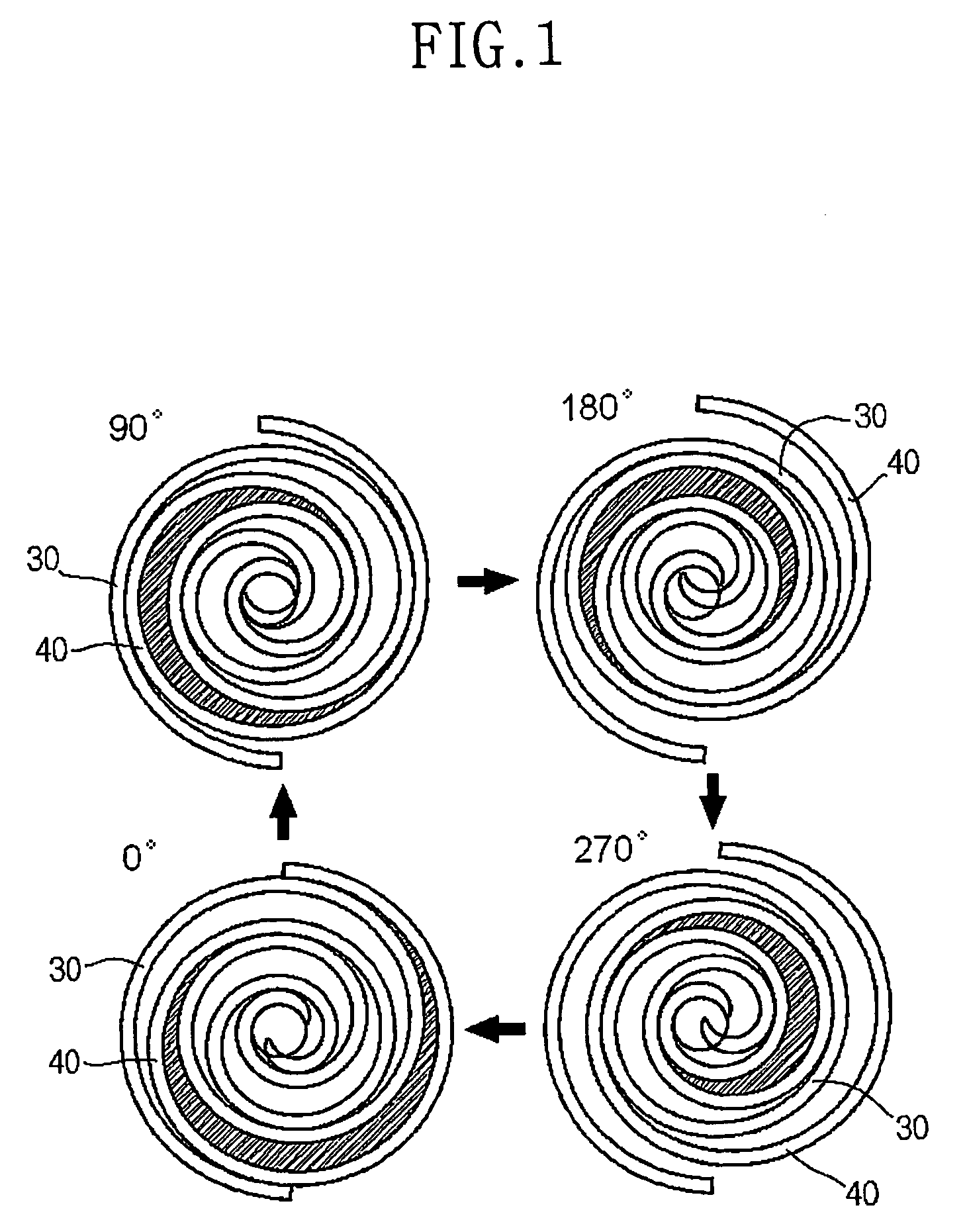

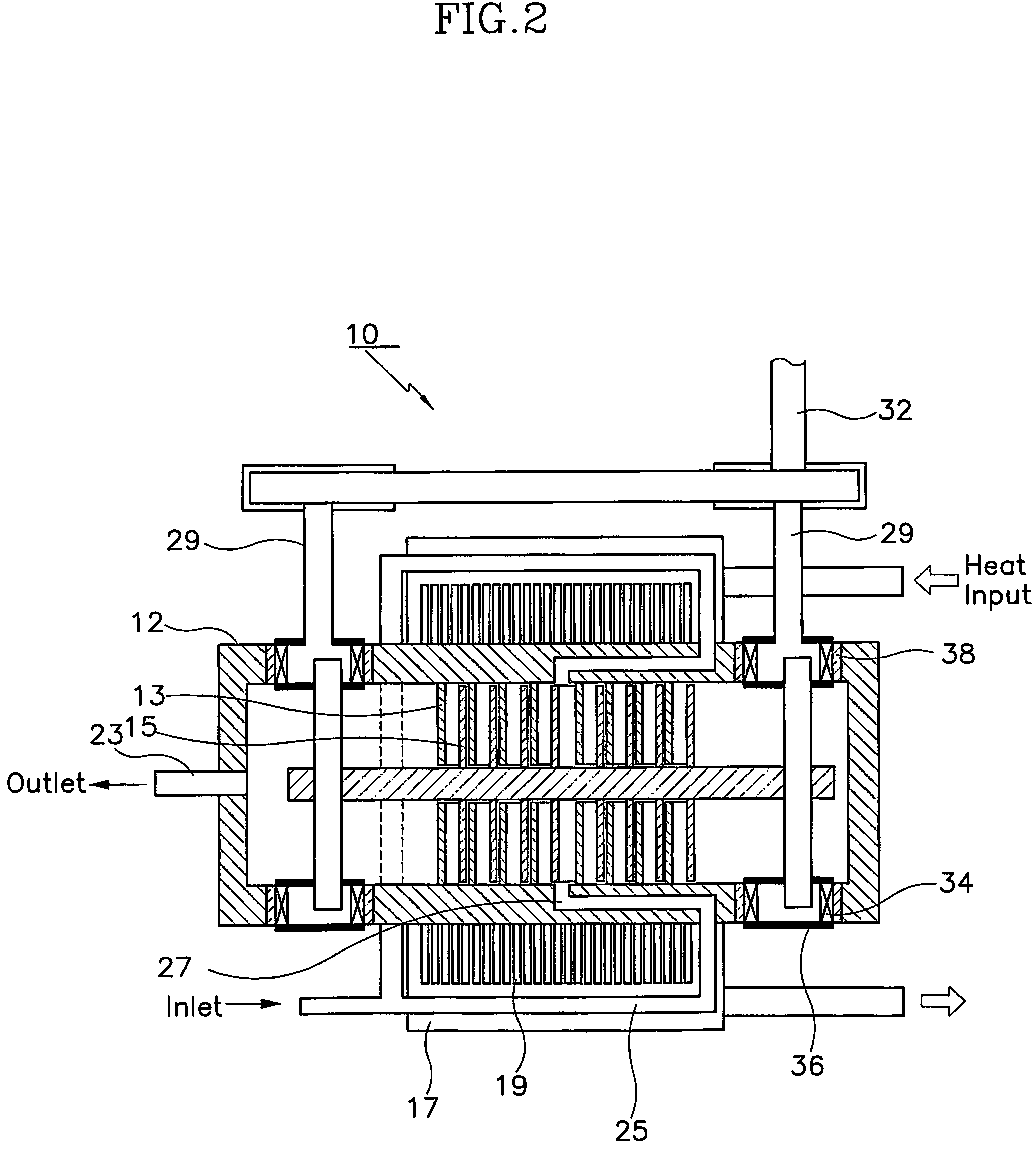

Scroll-type expander having heating structure and scroll-type heat exchange system employing the expander

InactiveUS7124585B2No reduction in efficiencyMinimizes difference in temperatureRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesWorking fluidEngineering

The present invention provides a scroll-type expander that simultaneously performs expansion and re-heating such that efficient expansion is realized and there is no reduction in efficiency caused by pressure loss occurring during the supply of an working fluid to the scroll-type expander, and that minimizes a difference in temperature between a stationary scroll member and a rotating scroll member, as well as a temperature distribution of a scroll wrap. The present invention also relates to a heat exchange system that uses a scroll-type expander to replace pistons in a conventional reciprocating Stirling engine or refrigerator with a pair of scroll-type compressor and expander such that the heat exchange system may be used as a Stirling engine or refrigerator. The present invention also provides a steam engine, in which a steam turbine in the conventional steam engine (Rankine system) is replaced with a scroll-type expander such that the steam cycle has both a re-heating cycle and a regeneration cycle.

Owner:KOREA INST OF MACHINERY & MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com