Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

A production process, spring steel technology, applied in the field of metallurgy, can solve the problems that affect the processing performance of products, serious decarburization on the surface of finished products, uneven performance of cleaning rods, etc., to ensure production stability, eliminate surface decarburization, and reduce oxidation The effect of the amount of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the production process of the 65Mn spring steel wire rod and the 65Mn spring steel wire rod of the present invention will be described in detail in combination with exemplary embodiments.

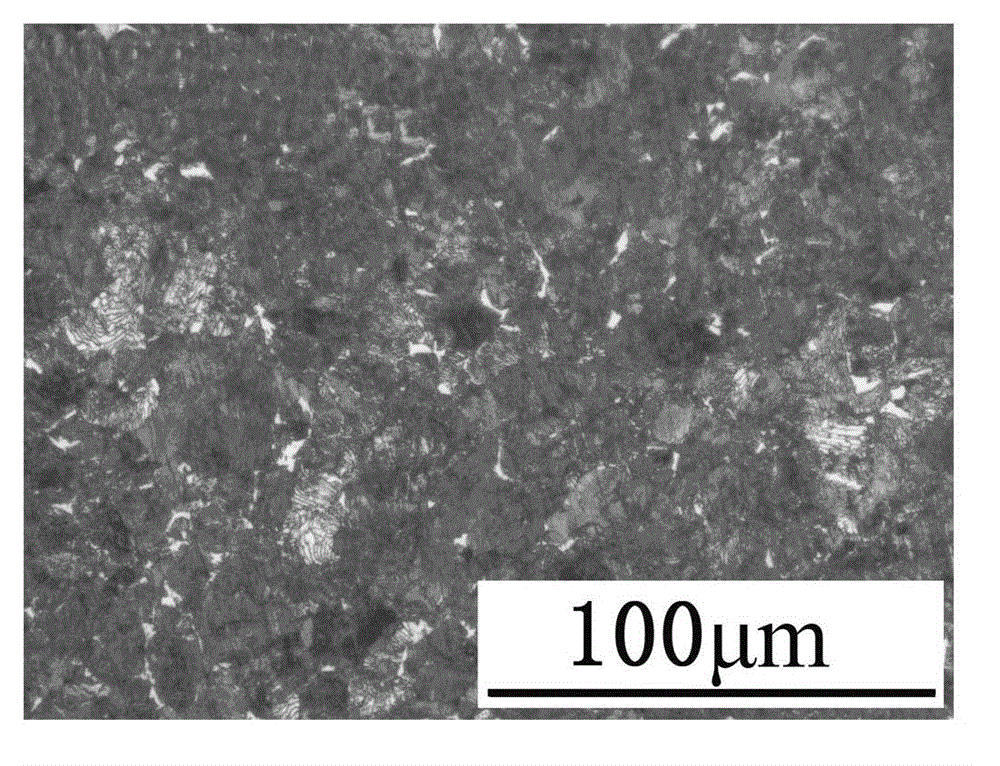

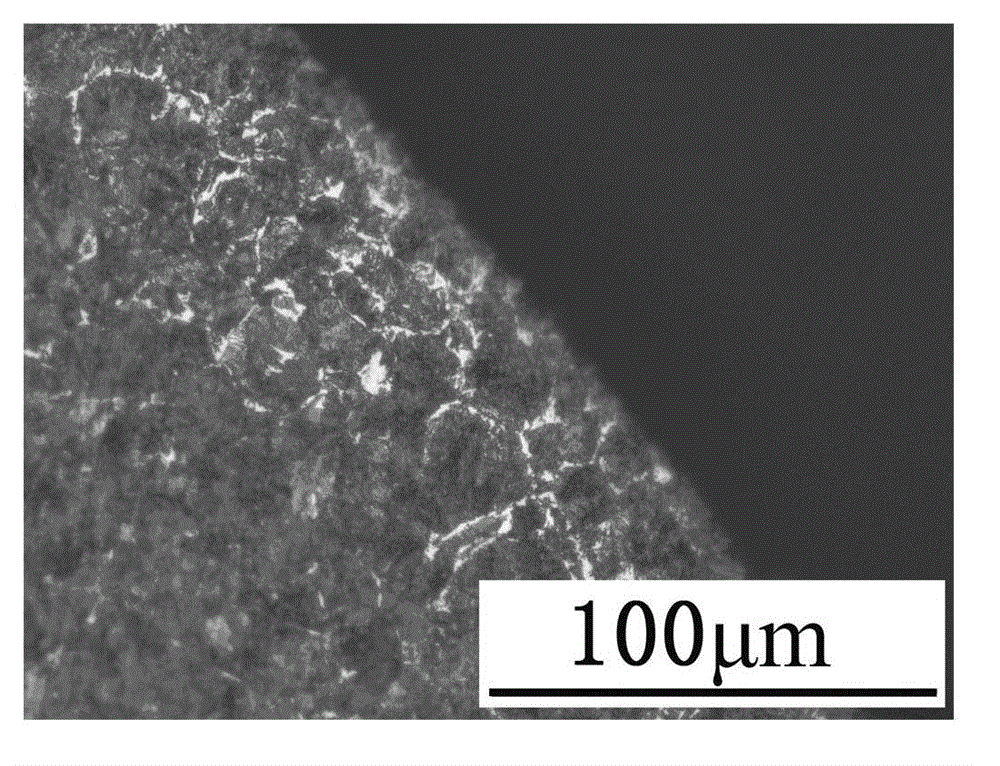

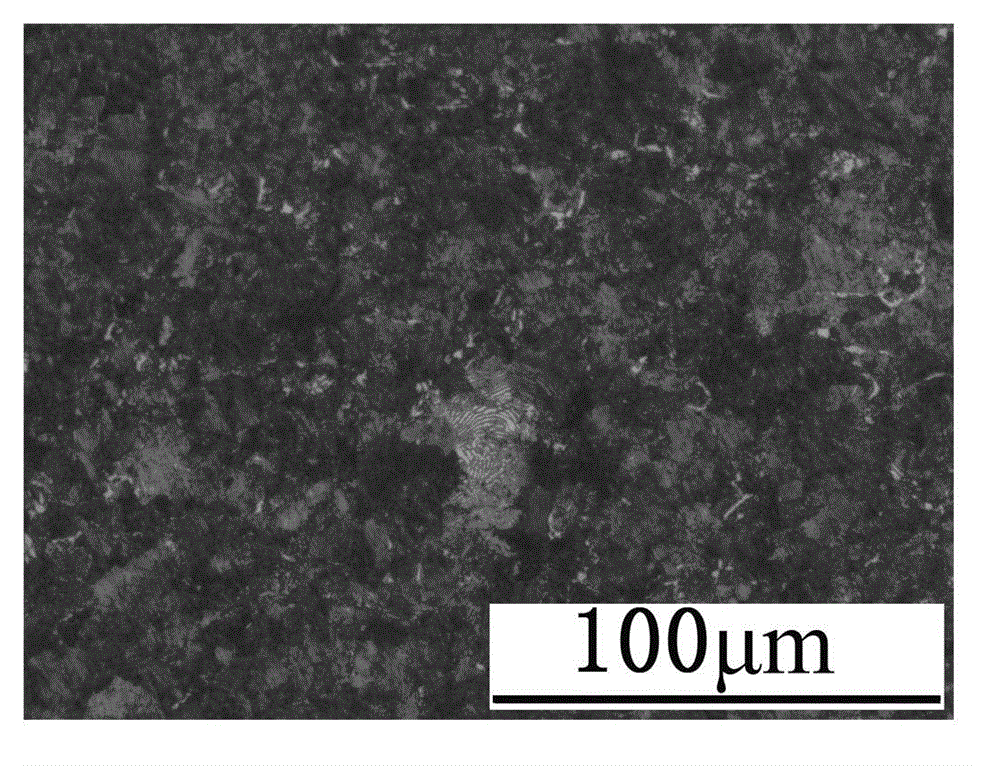

[0021] According to an exemplary embodiment of the production process of the 65Mn spring steel wire rod of the present invention, the production process includes the following steps: raw material preparation, molten steel smelting, continuous casting into slabs, heating of continuous casting slabs, high temperature rolling into wire rods, spit out Controlled cooling after rolling and post-treatment to obtain the finished wire rod after wire, wherein, in weight percentage, the finished wire rod includes the following chemical components: C: 0.63-0.68%, Si: 0.15-0.30%, Mn: 0.95- 1.15%, P≤0.018%, S≤0.016%, Cr≤0.15%, Ni≤0.15%, Cu≤0.10%, Mo≤0.02%, Ti≤0.01%, Al s≤0.015%, and the balance of Fe and Avoided impurities; in the step of heating the continuous casting slab, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com