Patents

Literature

810results about "Roll speed control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

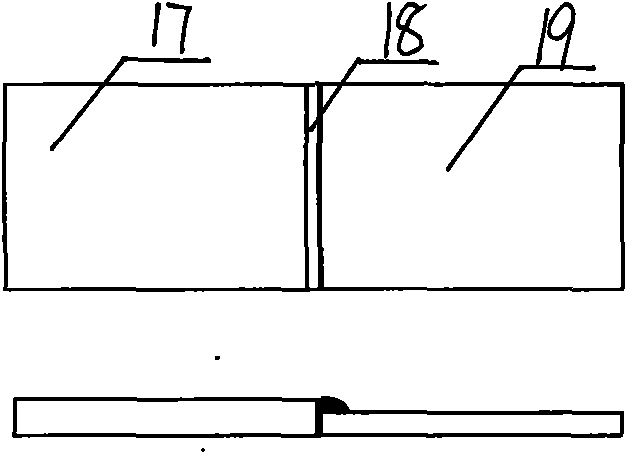

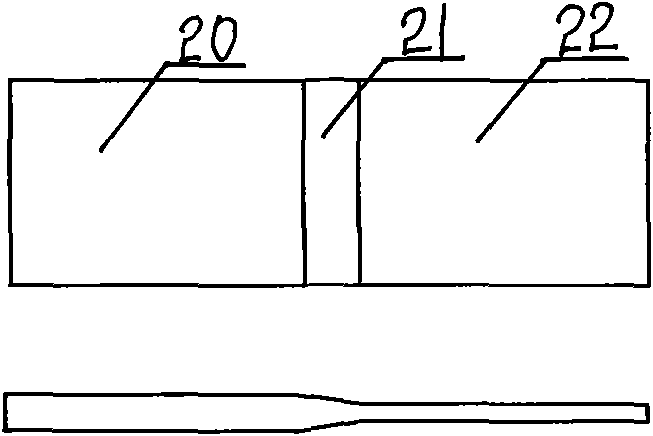

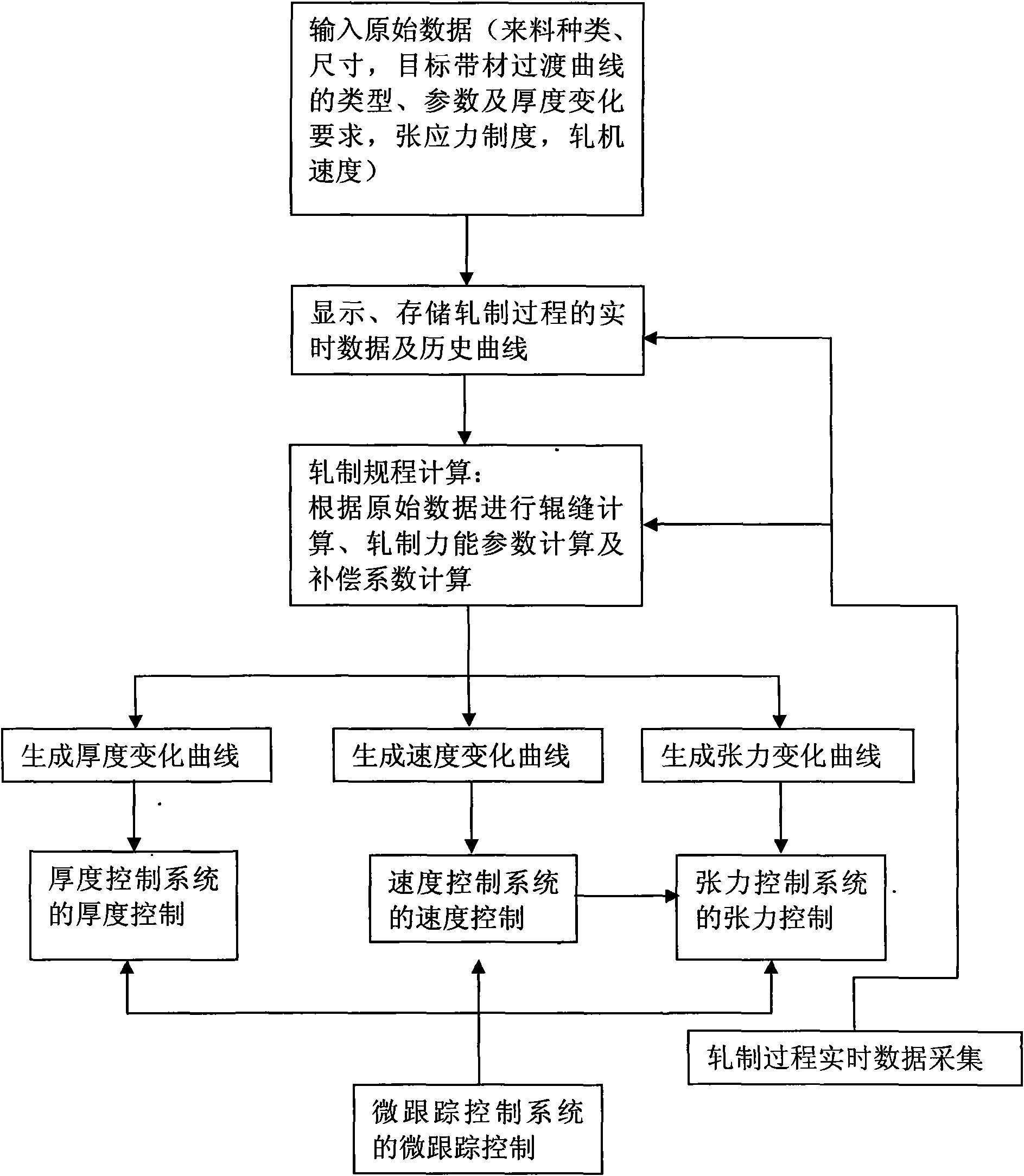

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

Production process of precise stainless steel band for vehicle sealing pad

InactiveCN101716594AImprove quality requirementsThickness tolerance fluctuations are smallBell type furnacesTension/compression control deviceSolution treatmentStress relieving

The invention relates to a production process of a precise stainless steel band for a vehicle sealing pad. The production process comprises the following working procedures of: first cold rolling, solid solution, second cold rolling, spraying and degreasing, hot water spraying, hot wind drying, pre-bending straightening, stress relieving annealing, final bending straightening, finished product cutting, and the like. The production process adopts a 20-roller sendzimir mill and a unique rolling process to carry out cold rolling. Through the processes of degreasing, solid solution treatment, bending straightening, stress relieving annealing, and the like, the thickness tolerance undulation of a product is small, mechanical properties are stable, the plate flatness is good, the product is not easy to generate cracks and secondary deformation during stamping, and the quality of the product is obviously improved, thus the production process is suitable for industrial production and can meet the requirement for high quality of the vehicle part industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

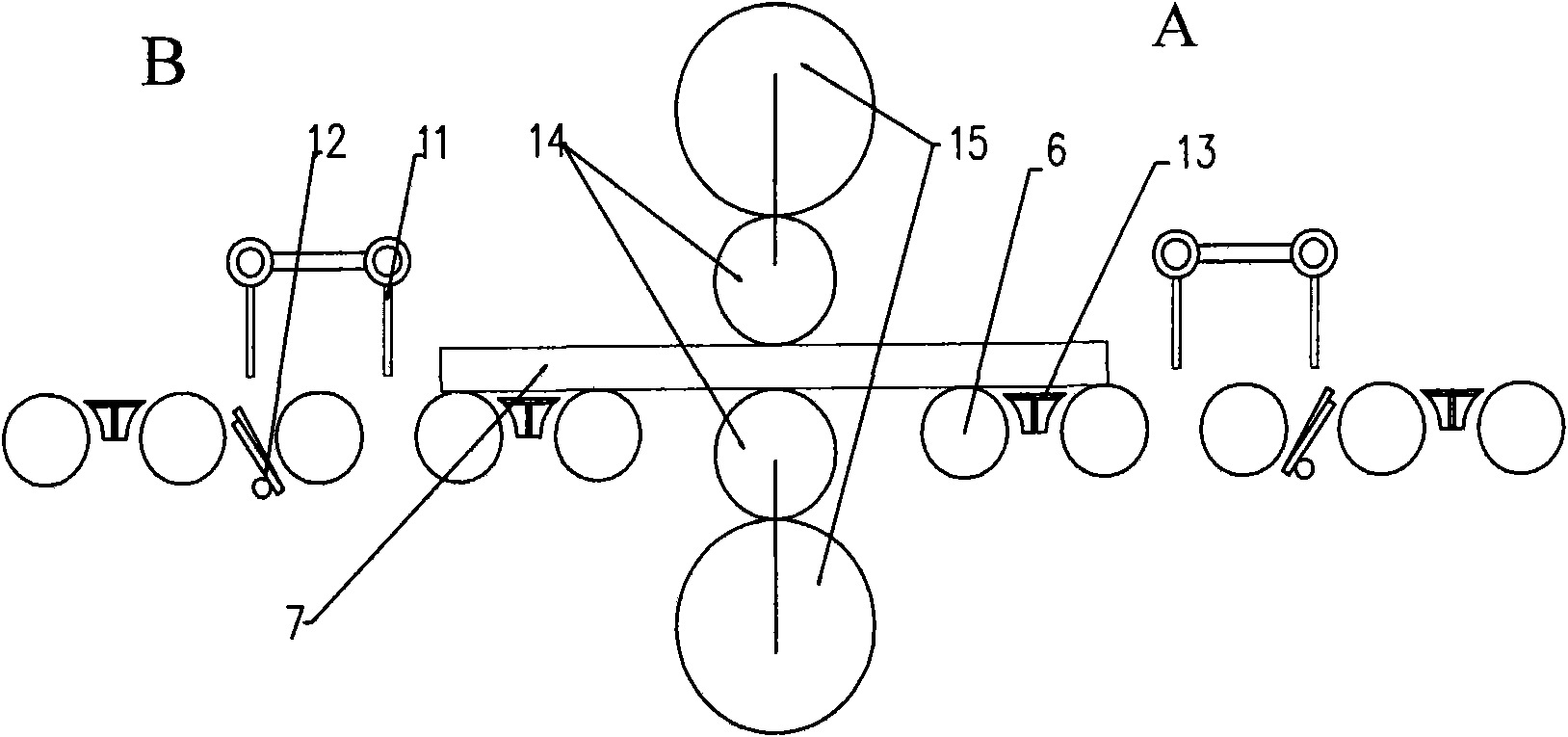

Device and method for detecting and controlling tilting buckle head of band steel in rough rolling process

ActiveCN101920270AImprove rolling qualityImprove operational safetyMeasuring devicesMetal rolling arrangementsSheet steelHead tilting

The invention discloses a device and a method for detecting and controlling the tilting buckle head of band steel in the rough rolling process. The actual head tilting or buckle head condition of the rolled band steel can be detected by using head tilting and buckling detectors arranged above roller beds and between the roller beds and then the rolling speeds of an upper roller and a lower roller for biting the band steel can be automatically adjusted when the next band steel is rolled, so that upper surface band steel and the lower surface band steel consistently extend and the aim of controlling the tilting buckle head of the band steel can be achieved, wherein the control belongs to the feedback control. According to the invention, the rolling speeds of the upper roller and the lower roller can be adjusted by detecting the actual head tilting or buckle head condition of the band steel, and the detection process is not influenced by logged water, fog, the roughness of the rollers, the elevation of a rolling line, the amplitude of rolling reduction, the thickness of the band steel, the rolling speed and other factors, so that the invention has high accuracy of controlling the tilting buckle head, effectively improves the rolling quality of steel plates and the operation safety of operators and reduces the labor intensity.

Owner:BAOSHAN IRON & STEEL CO LTD

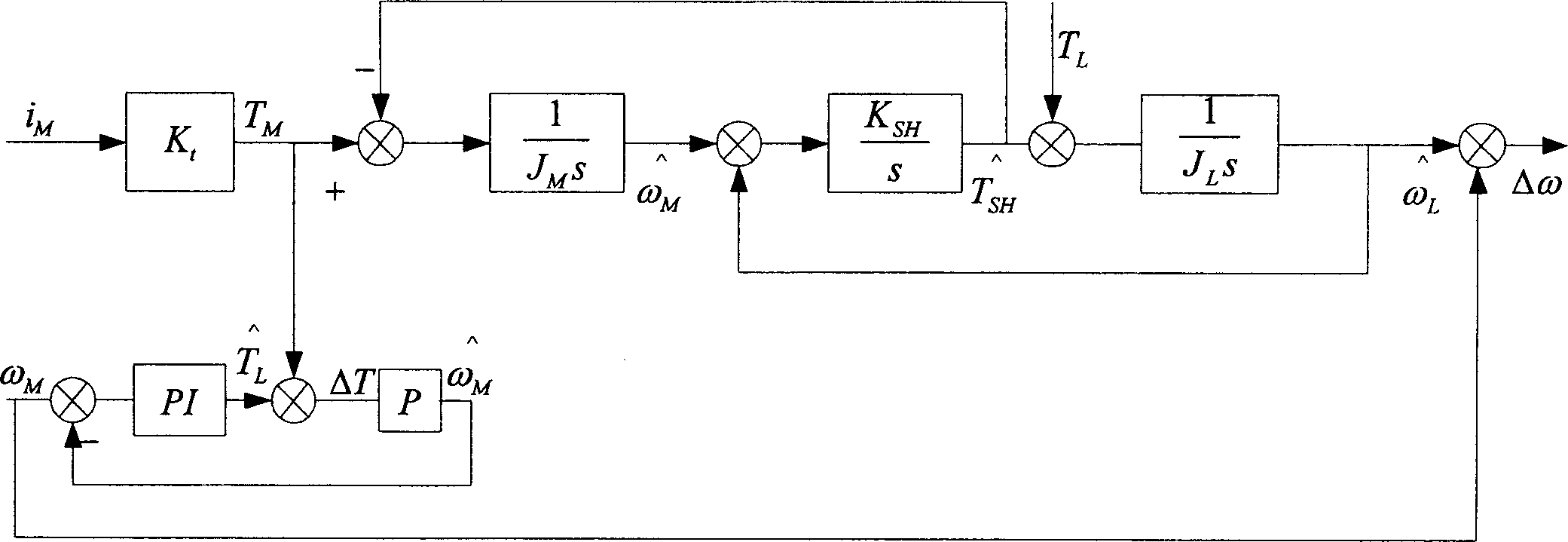

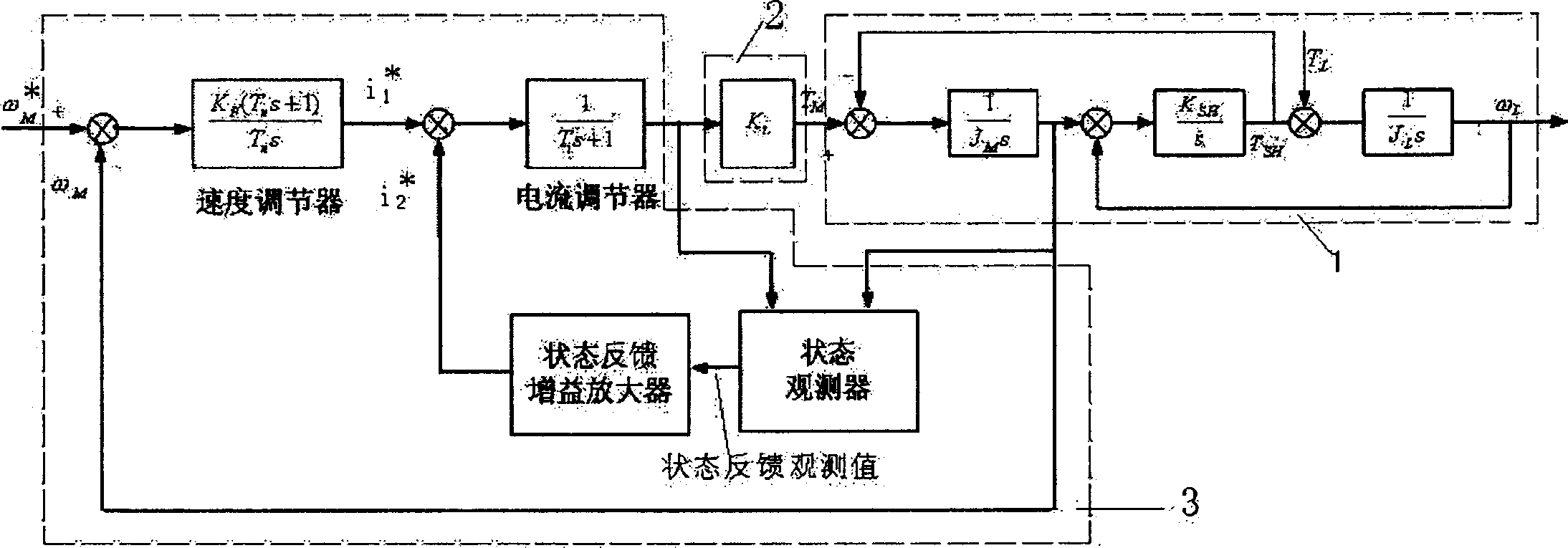

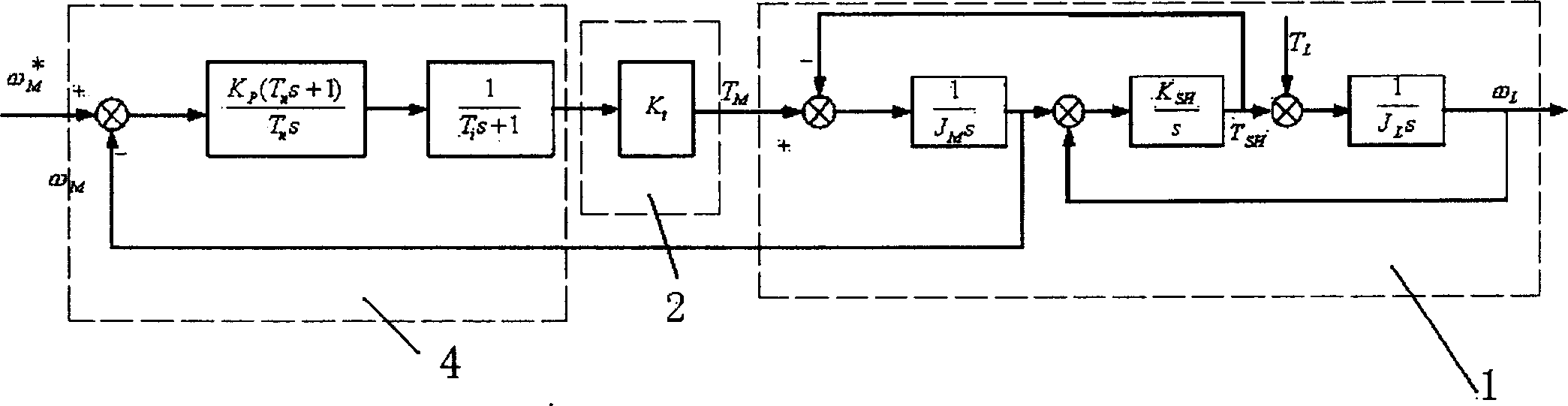

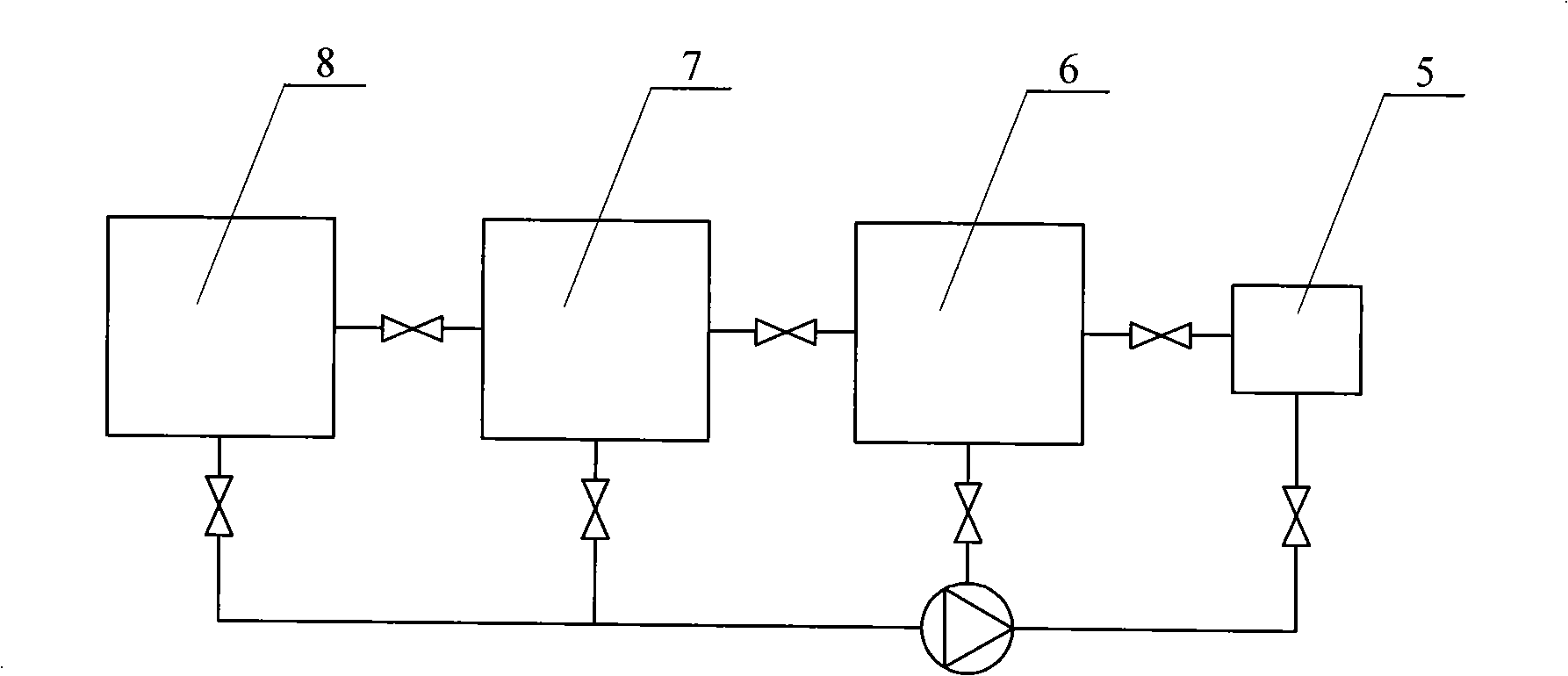

Control system for suppressing impact speed drop and torsional oscillation of rolling mill transmission system

InactiveCN1803326AEasy to implementSimple structureMetal rolling arrangementsRoll speed control deviceMotor speedTorsional oscillations

The invention discloses a control system of dynamic deceleration and torsional to inhibit the driving system of rolling mill in the rolling mill driving control domain, which comprises the following parts: two-quality elastic driving system of rolling mill, control system and power variable-flow system, wherein two-quality elastic driving system of rolling mill contains rolling mill and roller to connect by connection axle; the control system contains load observer, state feedback gain amplifier and motor speed-adjusting system; the power variable-flow system is electric power electronic transformer, which transforms the electrical network voltage and current into fitful motor voltage and current to drive the motor speed-adjusting operation according to the control pressure.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND +1

Production process of continuous-casting tandem-rolling coiled sheet of medium thick plate

InactiveCN1840252ASave shipping timeImprove work rateMetal rolling stand detailsWork cooling devicesComputer control systemThree level

The invention discloses a cut deal blank joint continuous casting and rolling coil manufacturing technique, which is characterized by the following: the conticaster is fillet-bevel crystallizer; the conticaster adopts double-machine four-flow, four-flow in one technique, straight-rolling heat-feed heat-transfer technique and straight-rolling technique; the big mill adopts fore-and-aft edger roll device; the form is adhesion-upper drive-roller; the finishing mill group adopts work roller trending-running and bend bar device; the fine rolling uses raising speed rolling, which has maximum speed at 22.8m / s and roller way speed at 5.89m / s; the front of finishing mill group installs edge-part calorifier, multistage coarse, fine adjusting-valve group, which adopts cool three-stage laminar flow chilling control technique, adds heat cover on delivery roll table, reduces the temperature dropping of intermediate area blank and head-to-tail temperature difference; the automatic system is three-level computer-controlled system. The invention improves the device, manufacturing technique, which improves the product quality.

Owner:ANGANG STEEL CO LTD

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

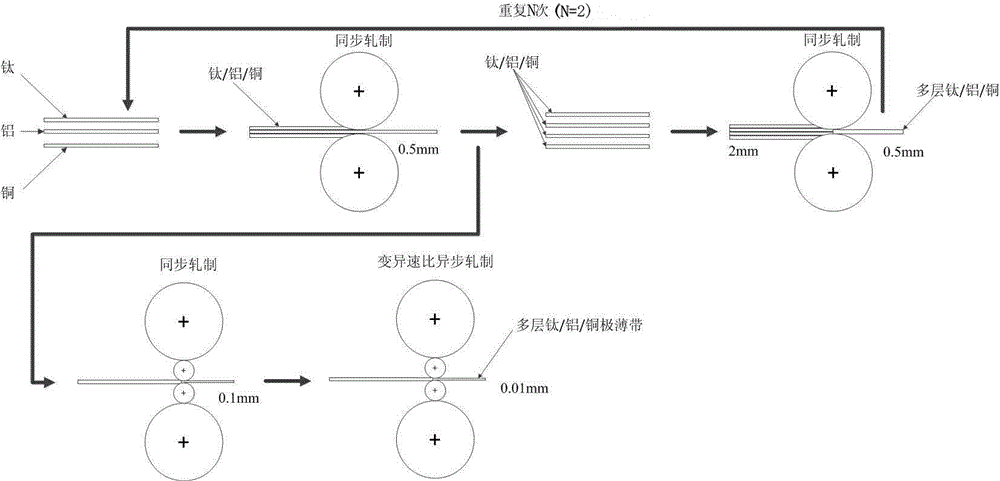

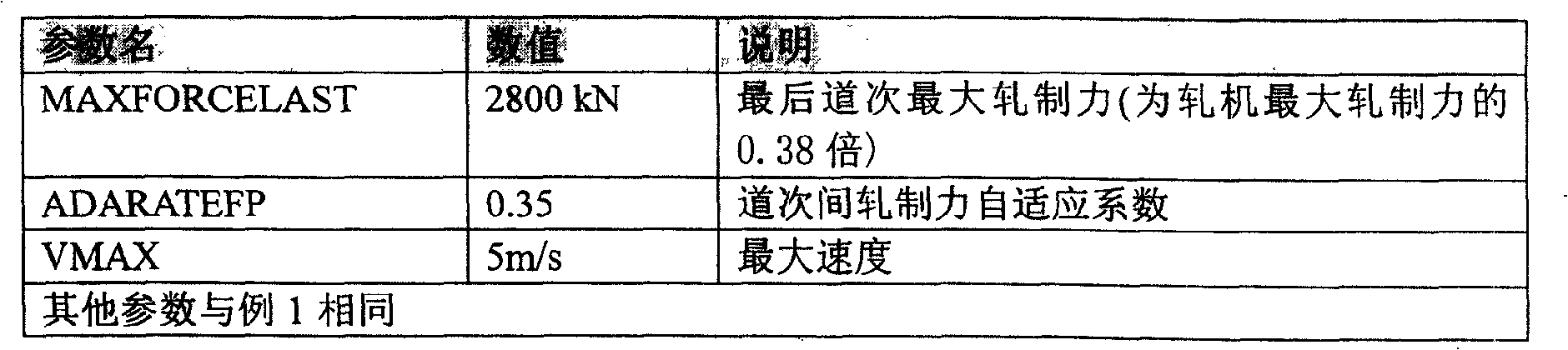

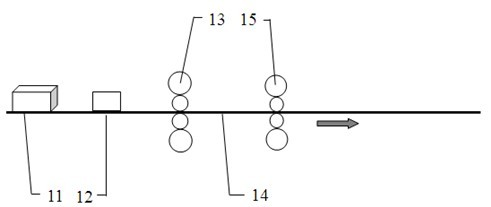

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

6mm steel plate rolling technique

InactiveCN101259482APrevent lateral movementStable rolling processRoll force/gap control deviceTemperature control deviceSheet steelEngineering

The invention provides a rolling technique for rolling a steel plate of 6mm by using a middle-thickness rolling mill which carries out corresponding settlements on the furnace discharge temperature of a stock, the stock thickness, rolling gates, an automatic gauge control, a rolling force, the self-adaptation coefficients of the rolling force between the gates, an opposite convexity and the matching between the linear speed of a transmission roller gate and the linear speed of the working roller of a rolling mill. The technique solves the problems of waves, bending, camber, frame scraping and waste rolling appearing in the plank stuffs during the testing rolling of 6mm plates of the existing middle-thickness rolling mill, leads the rolling to be stable and can manufacture qualified products in batch.

Owner:XINYU IRON & STEEL CO LTD

Quenched and tempered steel sheet and manufacturing method thereof

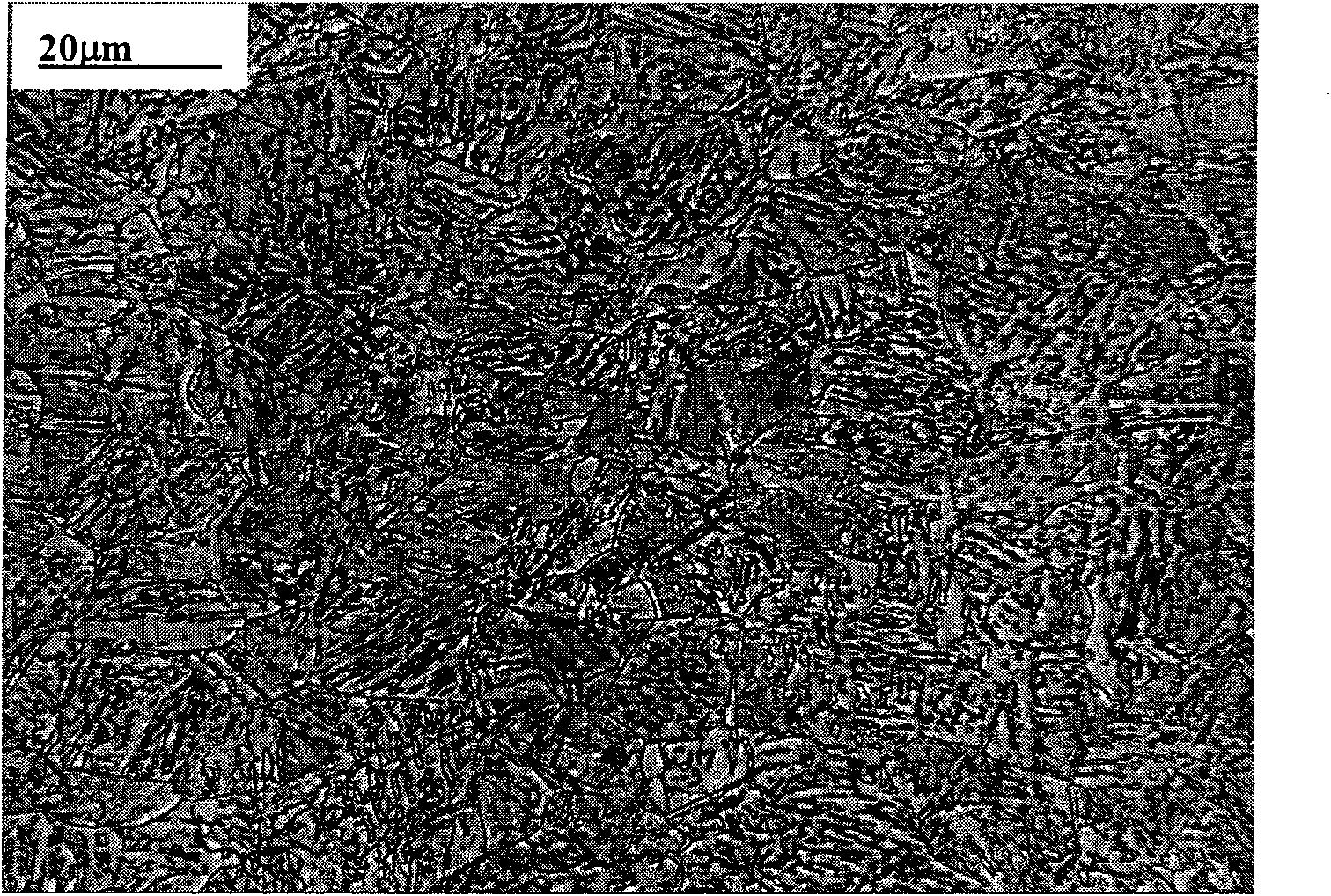

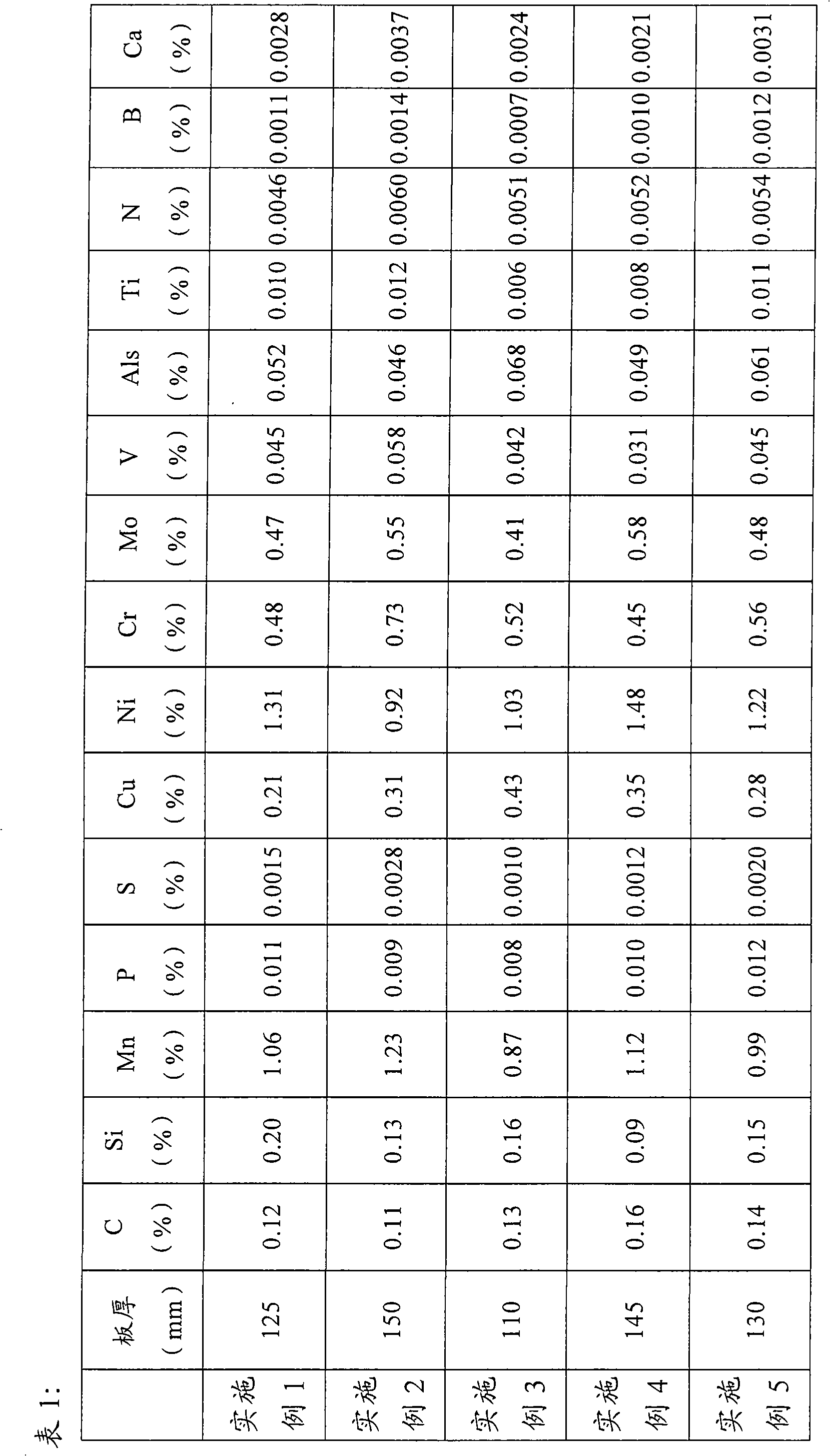

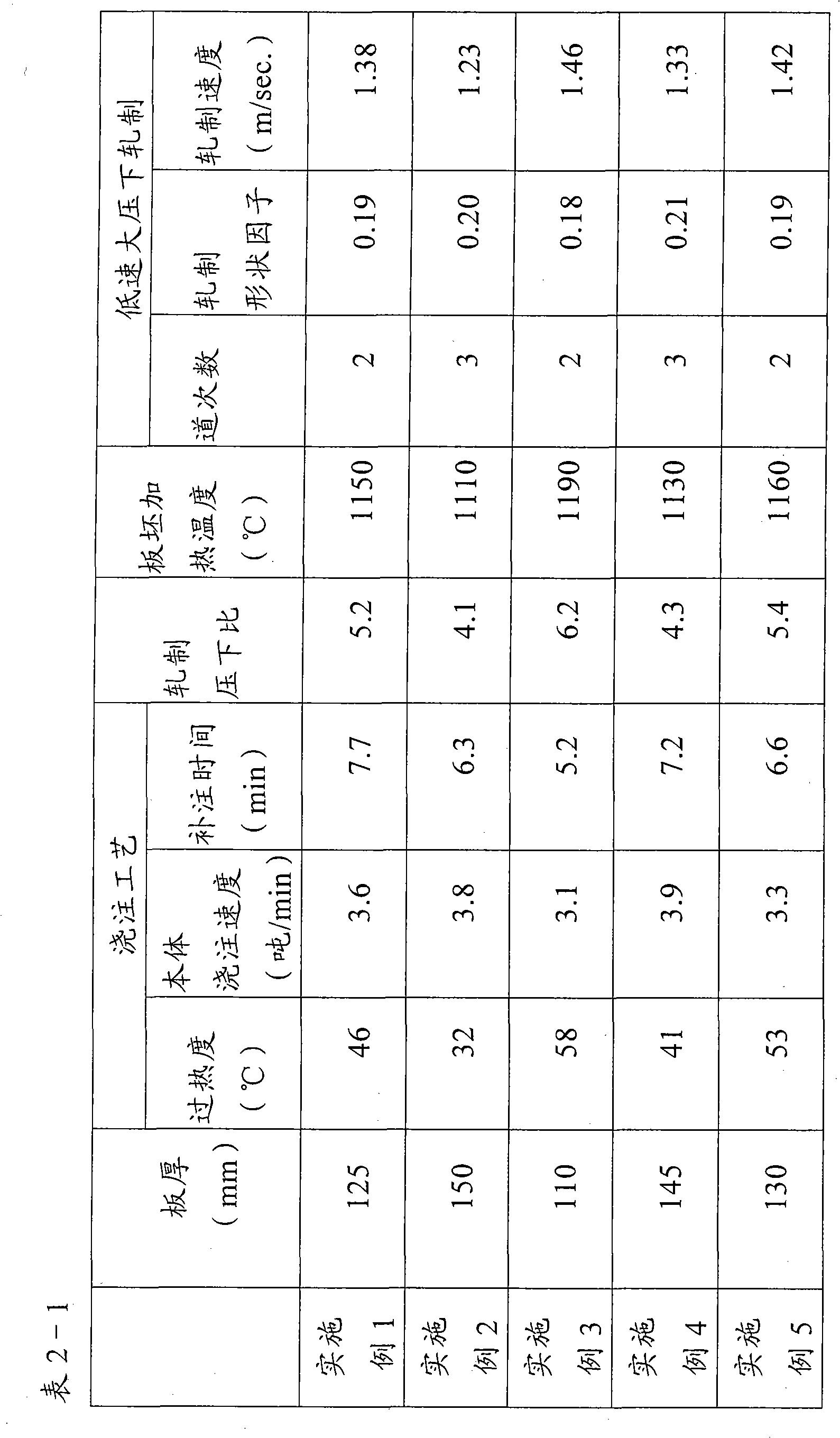

ActiveCN101962741AStrong plastic matchingSimple welding processRoll force/gap control deviceMolten metal pouring equipmentsSheet steelChemical composition

The invention provides a 80kg extra-thick quenched and tempered steel sheet. The steel sheet comprises the following chemical compositions: 0.10 to 0.16 percent of C, less than or equal to 0.20 percent of Si, 0.85 to 1.25 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0030 percent of S, 0.20 to 0.45 percent of Cu, 0.90 to 1.50 percent of Ni, 0.45 to 0.75 percent of Cr, 0.40 to 0.65 percent of Mo, 0.030 to 0.060 percent of V, 0.045 to 0.070 percent of Als, 0.006 to 0.012 percent of Ti, less than or equal to 0.0060 percent of N, 0.0006 to 0.0014 percent of B, 0.001 to 0.005 percent of Ca, and the balance of iron and inevitable impurities, wherein the chemical compositions meet the following conditions that: the Mn equivalent / C is more than or equal to 10 and less than or equal to 20; the Als is more than or equal to (Mn equivalent / c)*(N-0.292Ti); the Ni equivalent is more than or equal to 1.15 percent; the Mo equivalent is more than or equal to 0.25 percent; Ca / S is more than or equal to 0.80 and less than or equal to 3.00, and (Ca)(S)0.18 is more than or equal to 5*10<-4> and less than or equal to 2.5*10<-3>; and F*DI equals to the effective hardenability index Deff and is more than or equal to 1.00*t. The invention also relates to a method for manufacturing the quenched and tempered steel sheet. The technology of optimal recrystallization controlled rolling+offline quenching and tempering is adopted to ensure that the microstructure of the finished product steel sheet is a fine tempered bainite and tempered martensite, the average colony size is less than 25mu m, and excellent obdurability / plasticity matching and uniform mechanical performance along the direction of the sheet thickness can be acquired.

Owner:BAOSHAN IRON & STEEL CO LTD

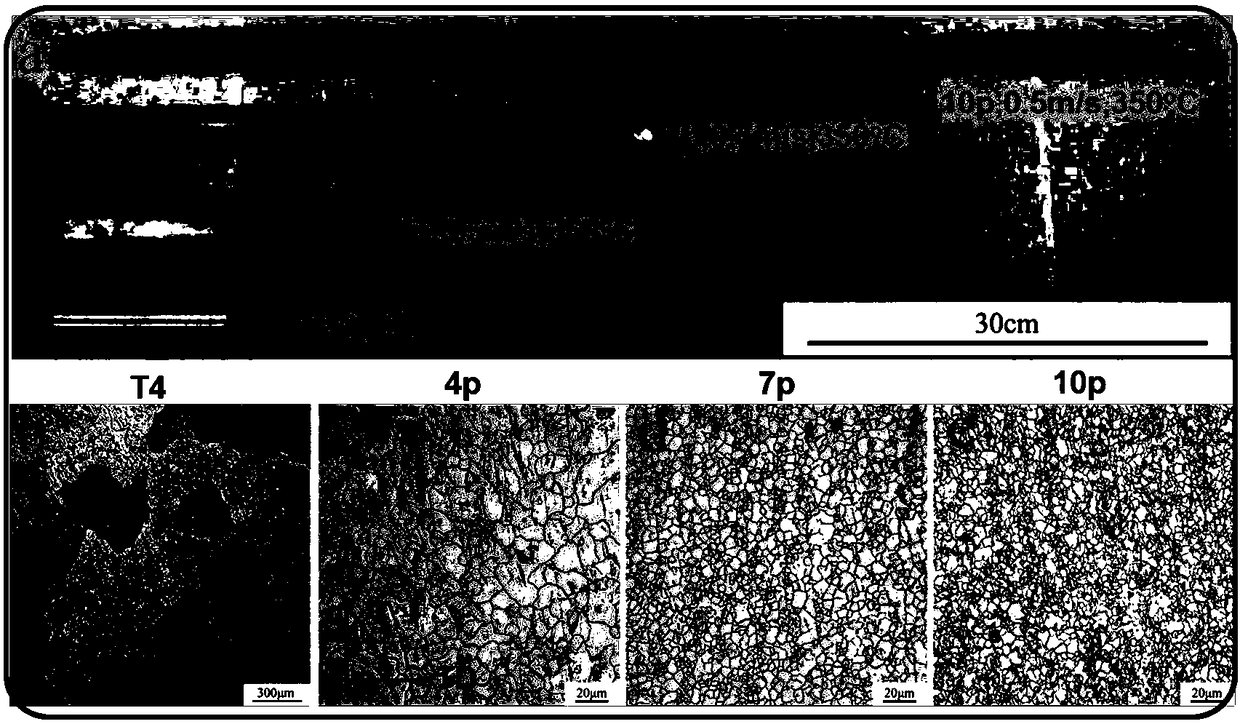

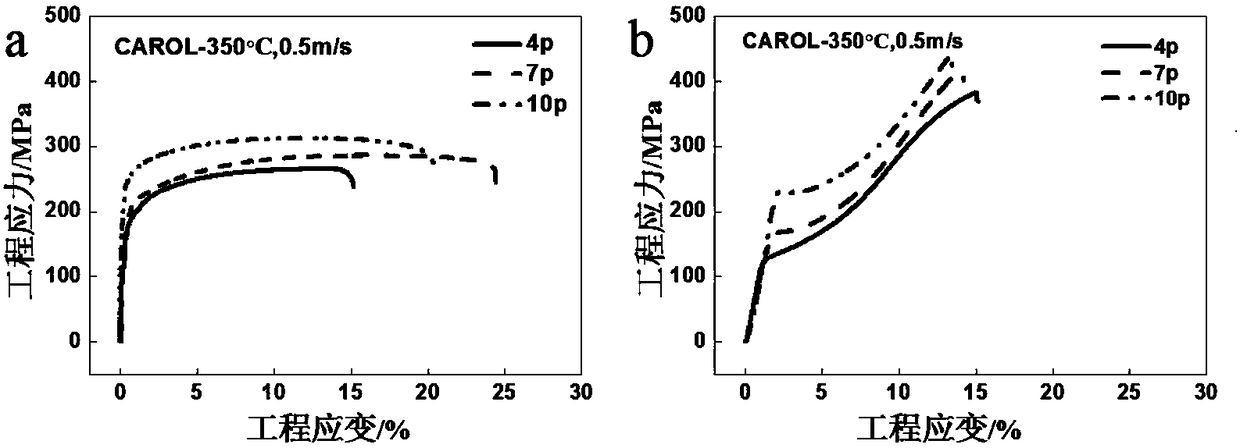

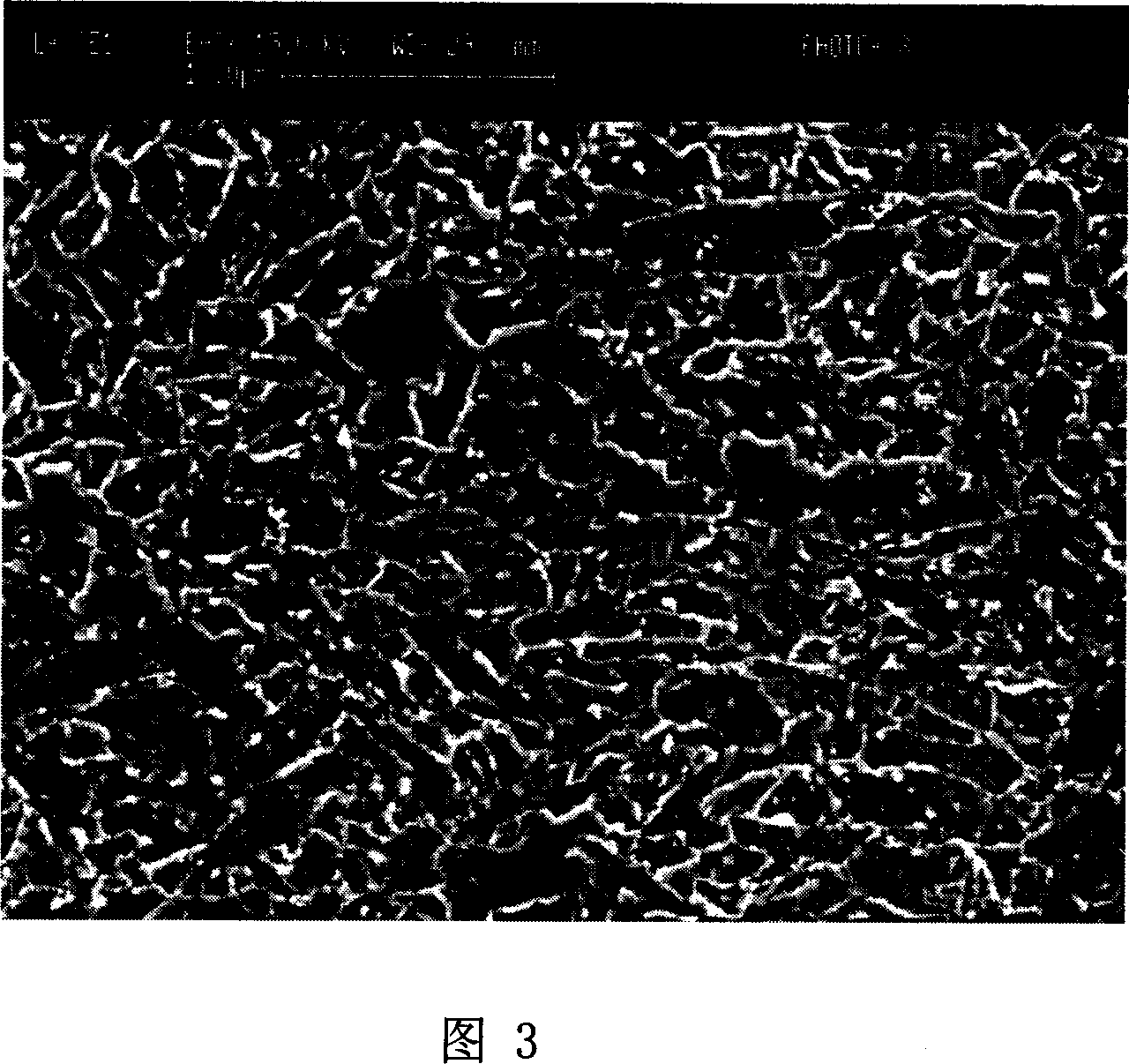

Preparing method for high-performance magnesium alloy bar

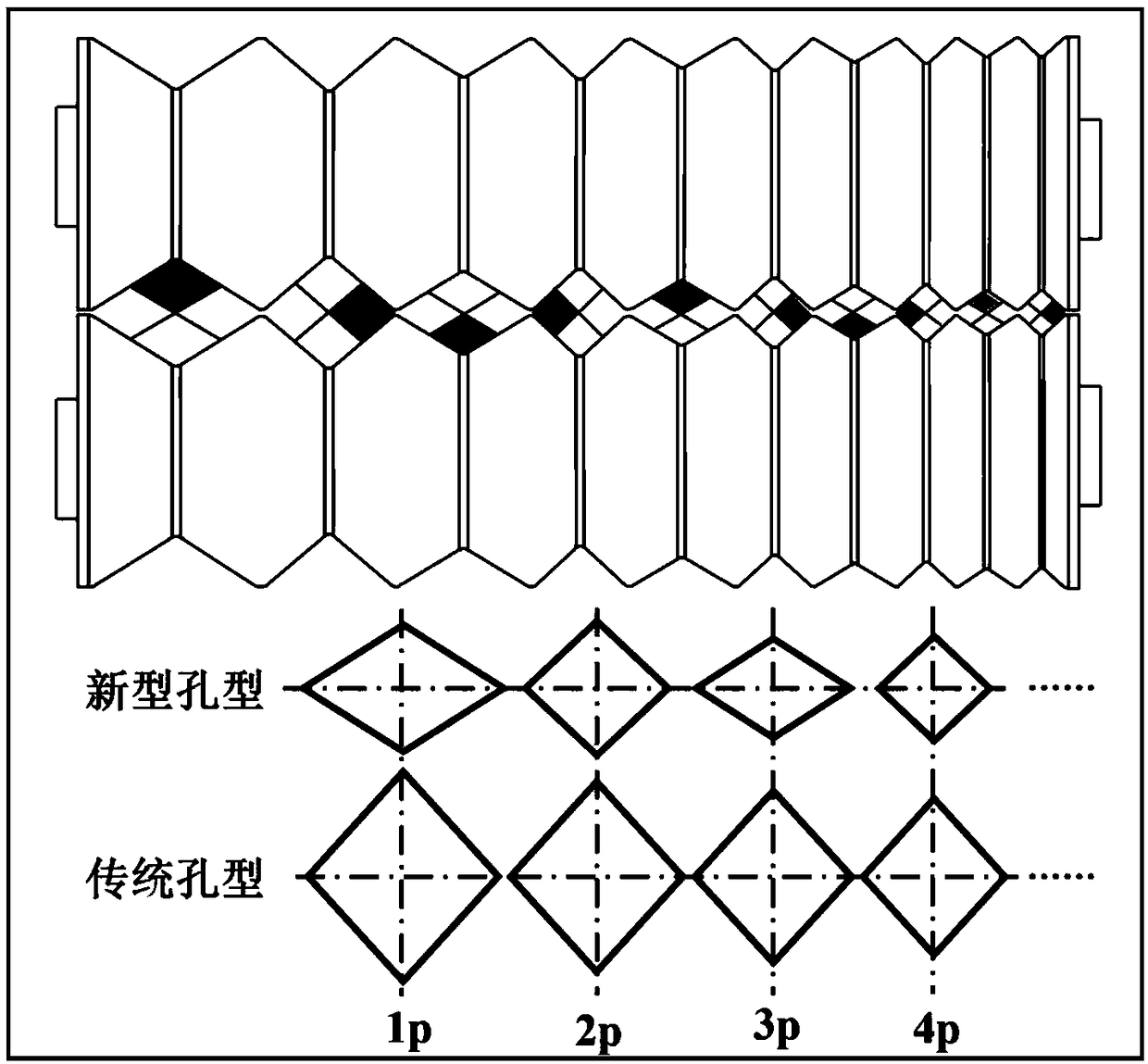

ActiveCN108220725AImprove toughnessOvercome the disadvantage of low strainRollsMetal rolling arrangementsDeformation effectRoom temperature

The invention discloses a preparing method for a high-performance magnesium alloy bar. The method comprises the following steps that a magnesium alloy raw blank is ground, subjected to homogenizationtreatment, pretreated and preheated, groove rolling machining is conducted, the roller speed ranges from 0.1 m / s to 0.5 m / s, 6-10 rolling passes are adopted, the area of each pass is reduced by 19.8%-24.6%, and the accumulated reduction amount is 71.9%-88.0%. In the groove rolling process, the rhombic hole pass and the square hole pass are alternately conducted, and square hole rolling is adoptedas final rolling; and after rolling of each pass is finished, rolling of the next pass is immediately conducted after the bar is rotated by 90 degrees. After groove rolling is finished, room-temperature cooling is conducted. According to the preparing method, the toughness of the alloy can be obviously improved, and the anisotropy of the alloy is improved. Meanwhile, the multi-direction deformation effect is improved through the adopted novel hole pattern, large strain can be more effectively guided in, the production efficiency is improved, and the preparing method is suitable for producing the high-performance magnesium alloy material in the industrial short process.

Owner:HEBEI UNIV OF TECH

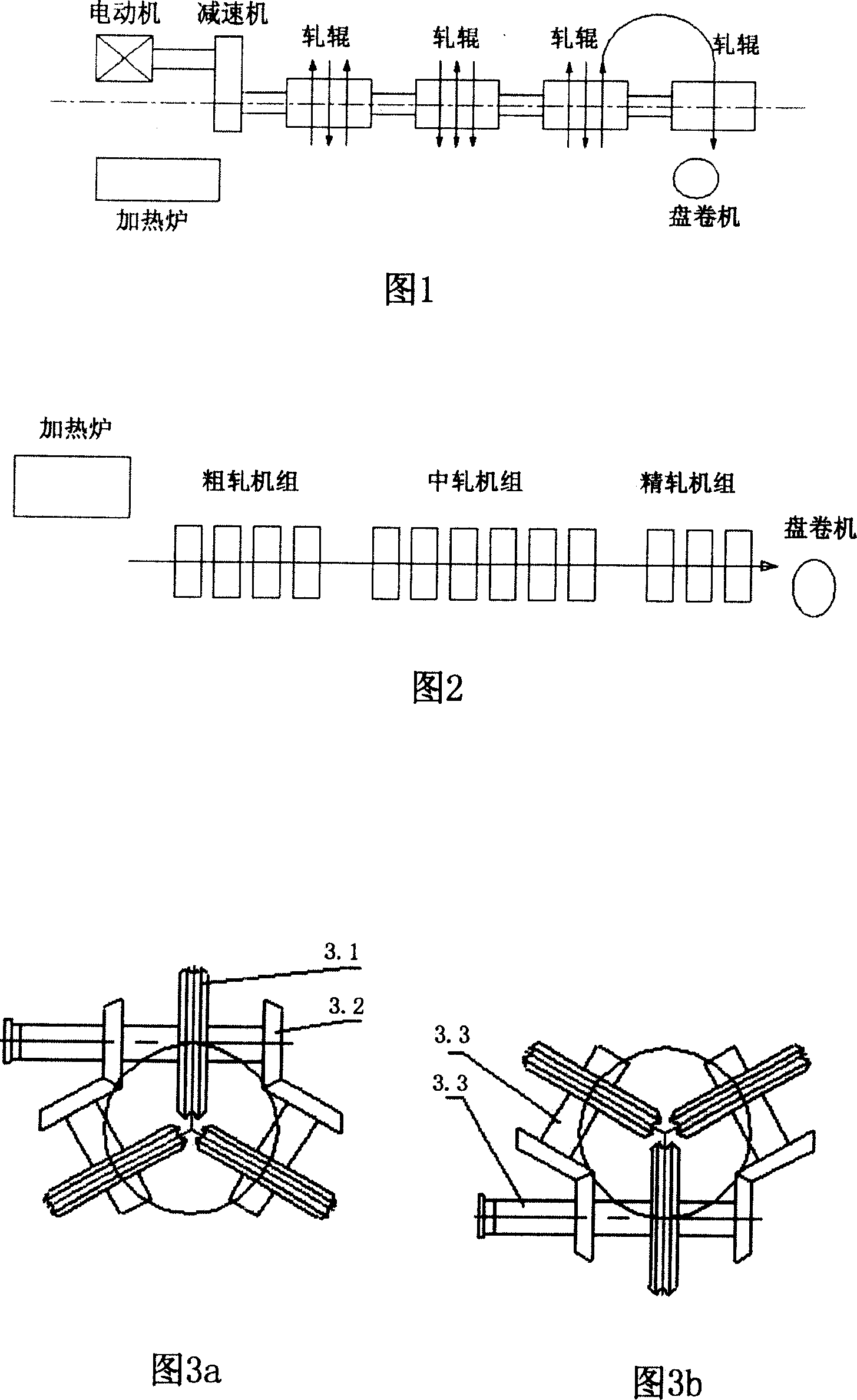

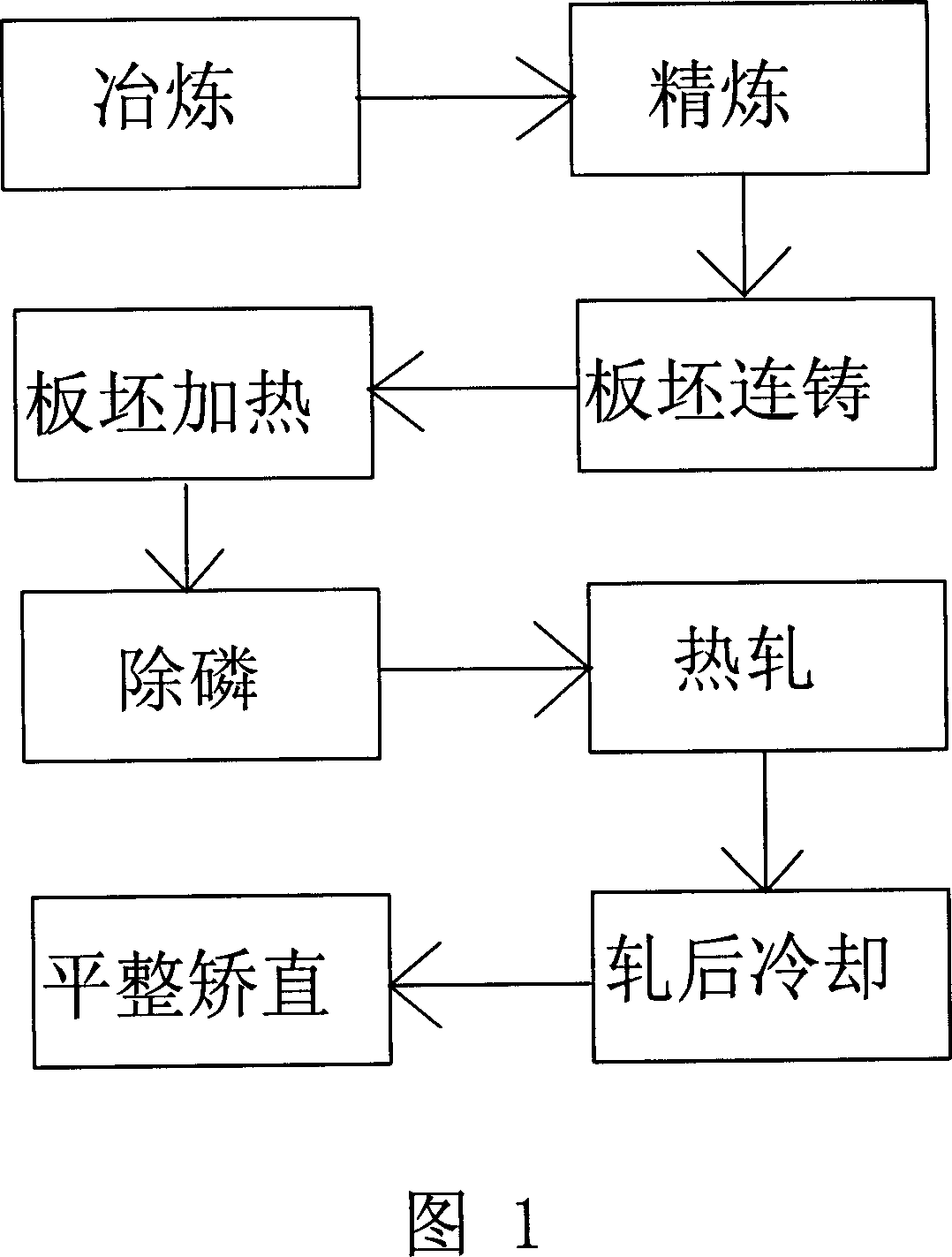

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

InactiveCN101152653AImprove surface qualityFew beginningsTemperature control deviceMetal rolling stand detailsLow noiseWire rod

The invention provides a method for rolling of titanium and titanium alloy bar and wire rod with three-roller Y continuous rolling mill. The technical proposal of the invention is as follows that the three-roller Y continuous rolling mill group is used for 6 to 18 pass continuous rolling of heated titanium and titanium alloy bar billet of phi50mm to form bar billet of 30 to 8mm (or hexagonal and triangular structure of 24 to 8mm) or rolling wire billet of phi20 to 8mm. by adopting the method, bar billet of phi50mm can be rolled into bar billet of phi30 to 8mm (or triangular and hexagonal structure) or rolling wire billet of phi20 to 8mm after heated for one time. Compared with the prior methods of multiple fire time casting, swaging, two-roller transverse-arrangement non-continuous rolling and two-roller longitudinal-arrangement continuous rolling, all of which are used for production of titanium and titanium alloy bar or rolling wire billet, the invention not only has the advantages of high efficiency, energy saving, low noise, small occupying and high precision of the size as well as good organization perforation of titanium and titanium alloy bar and wire rod, but also can produce triangular or hexagonal section and other allotype section.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

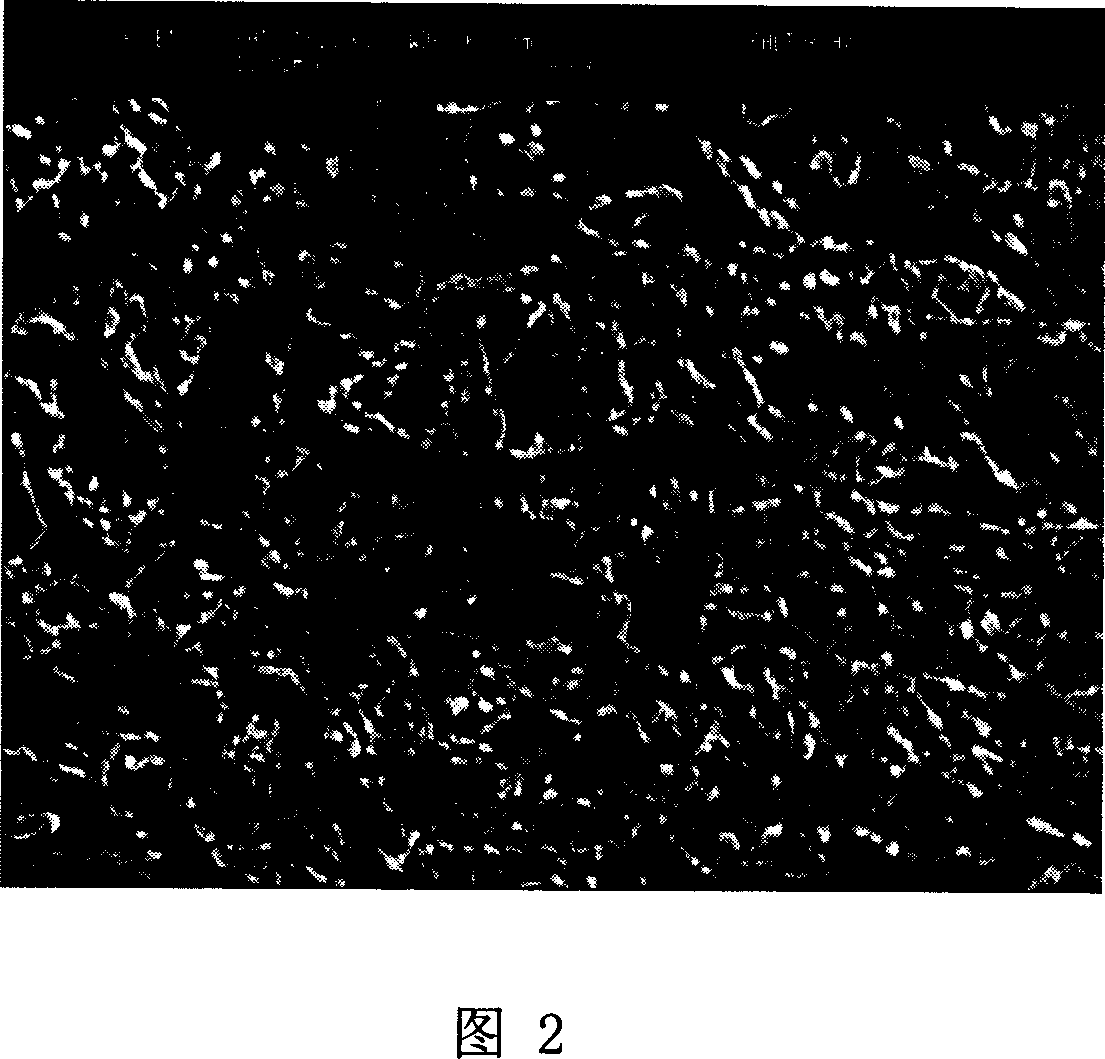

Manufacturing technique of low compression ratio high grade pipe line steel

InactiveCN1927486AImprove performanceRoll force/gap control deviceTemperature control deviceNiobiumHeating temperature

The invention relates to a method for producing high-strength low-alloy steel. Wherein, it comprises smelting, refining, casting sheet blank, heating blank, removing phosphor, cooling and flattening; the smelting step uses pure steel, low phosphor, and low sulfur; in the casting step, the loose of blank and the aliquation are lower than B0.5level; in the heating step, vanadium+niobium+ titanium0.15%, nickel+chromium+copper<=0.50%, and the heating temperature is 1180-1220Deg. C; in the thermal rolling step, in the crystallize process, the deformation temperature is 1070-1000Deg. C, the deformation amount is 40-60%, and the rolling speed is 1.5-2.5m / s, and in the second step that rolling the non-crystallized area, the pressure is 200-400MPa, the rolling speed is 5-1.5m / s, and the deformation amount is 60-75%; and the interlayer cooling speed in the cooling step is 15Deg. C / s-25Deg. C / s.

Owner:NANJING IRON & STEEL CO LTD +1

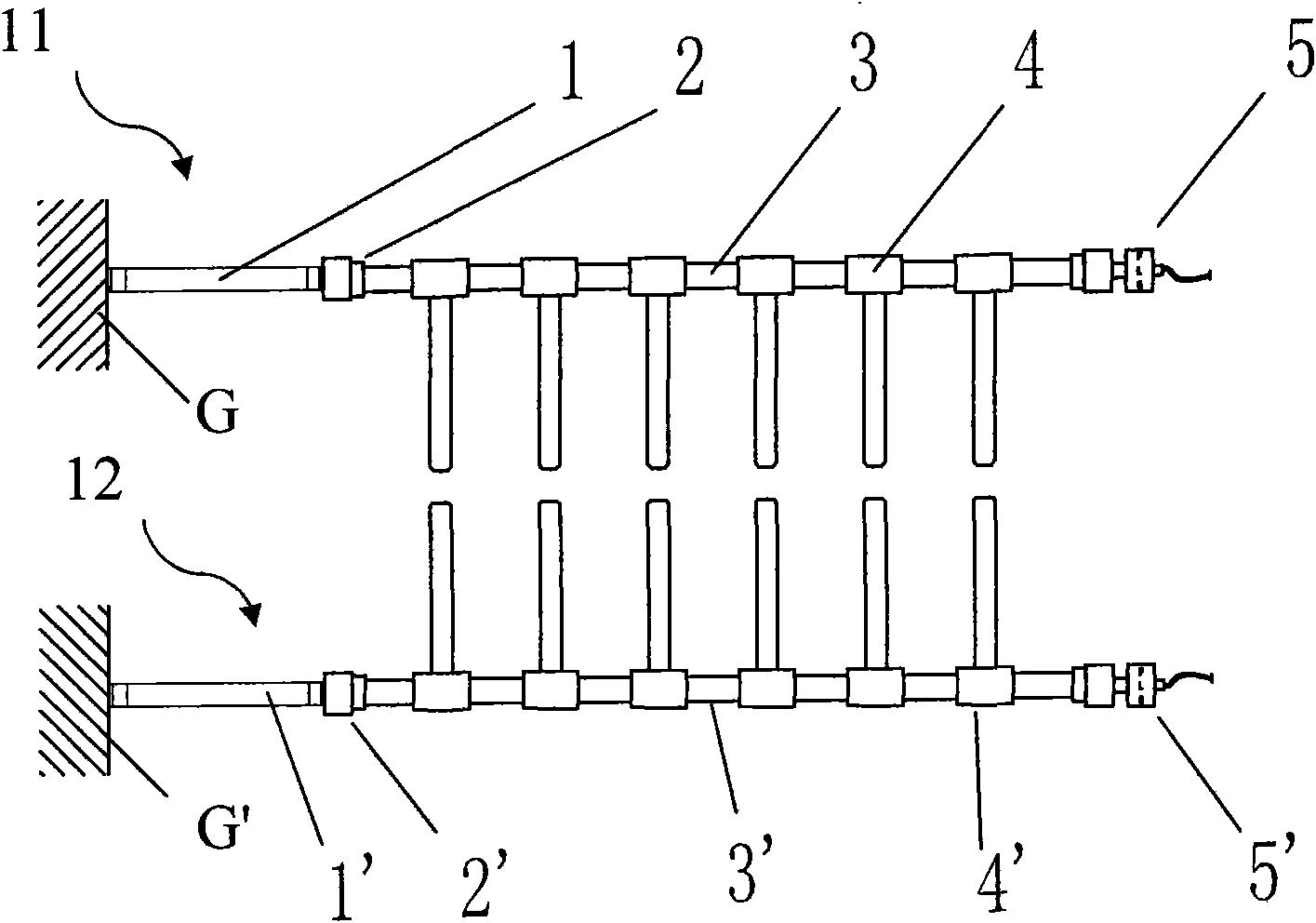

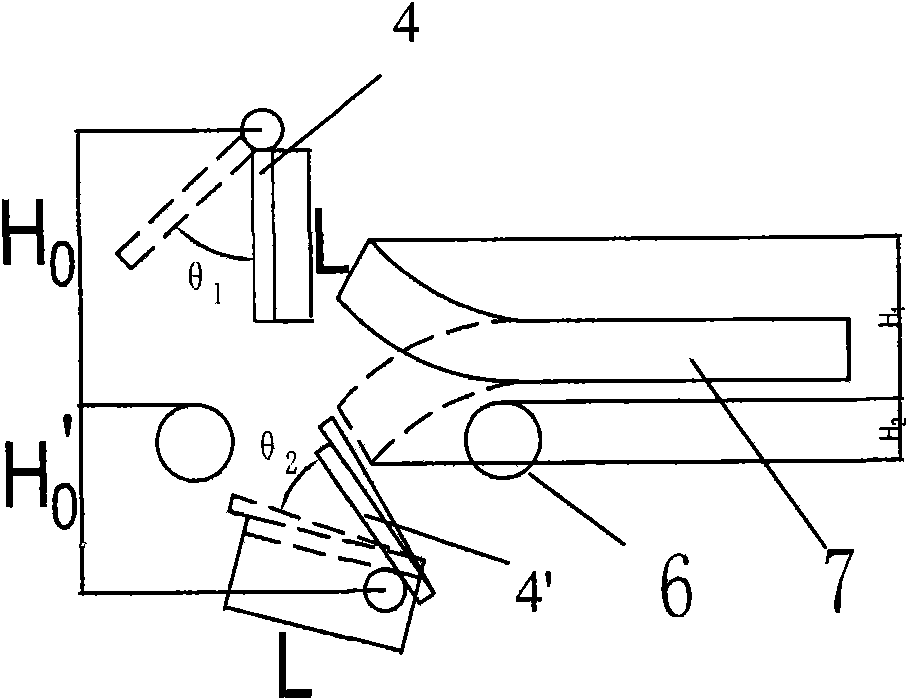

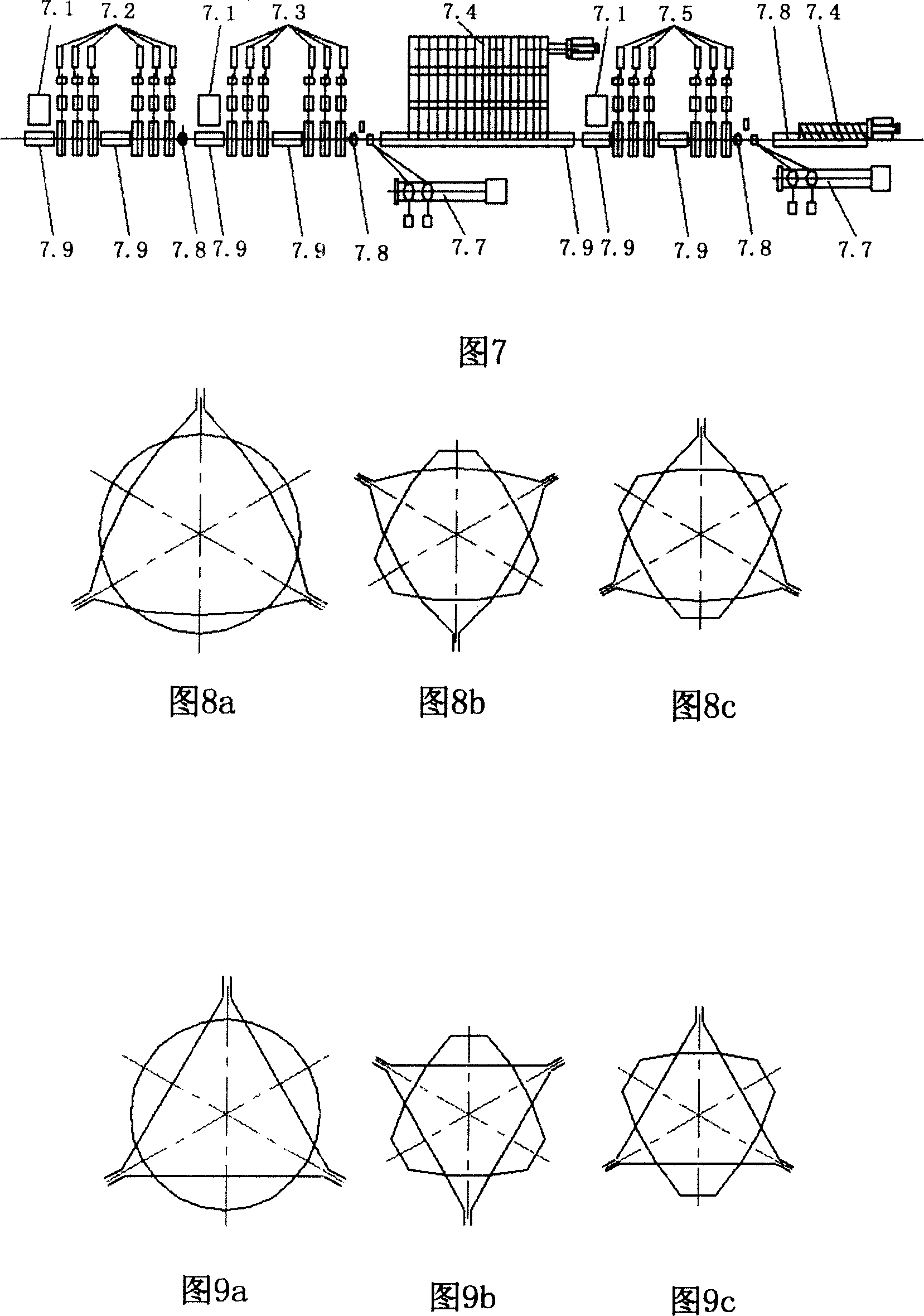

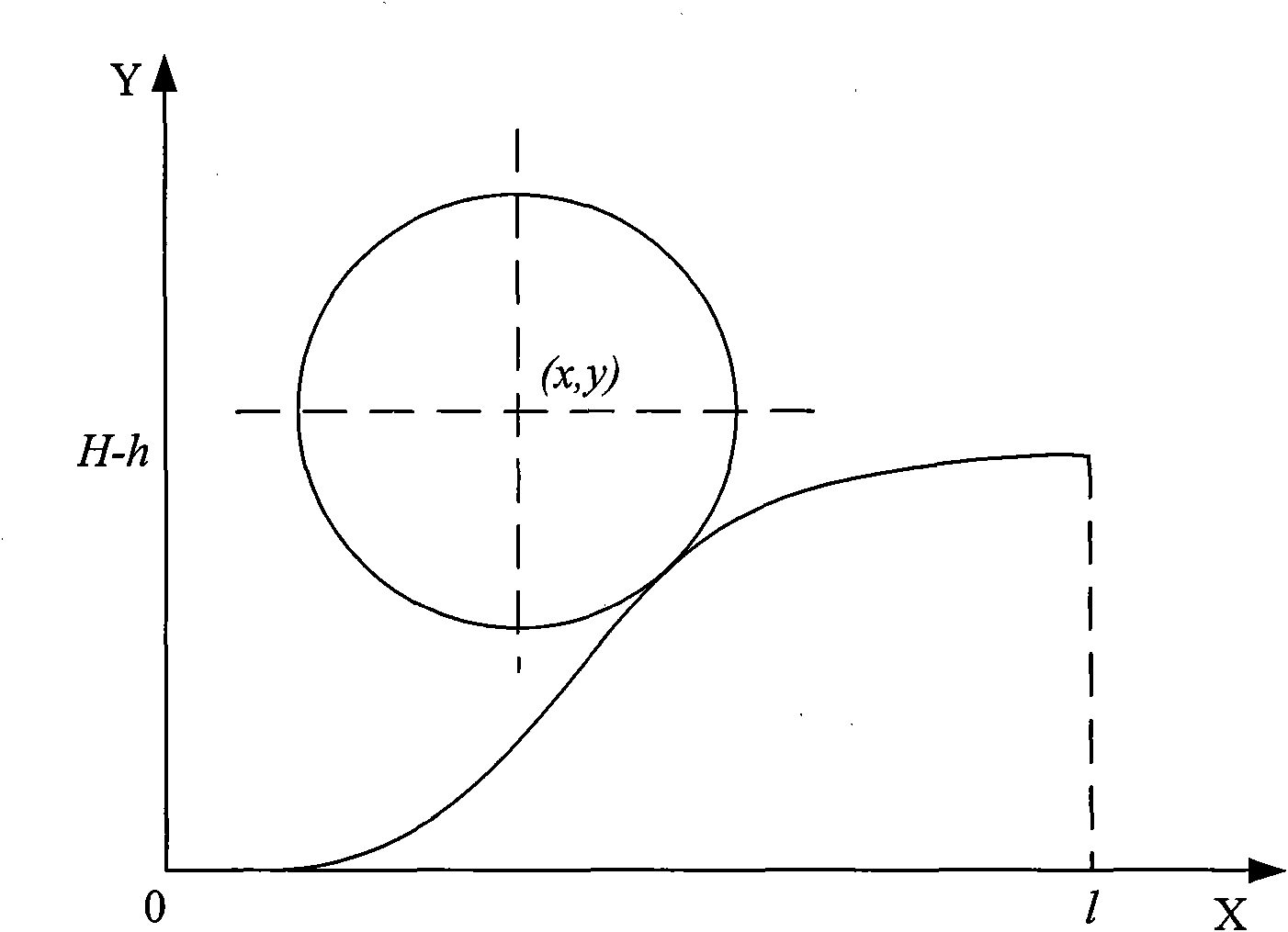

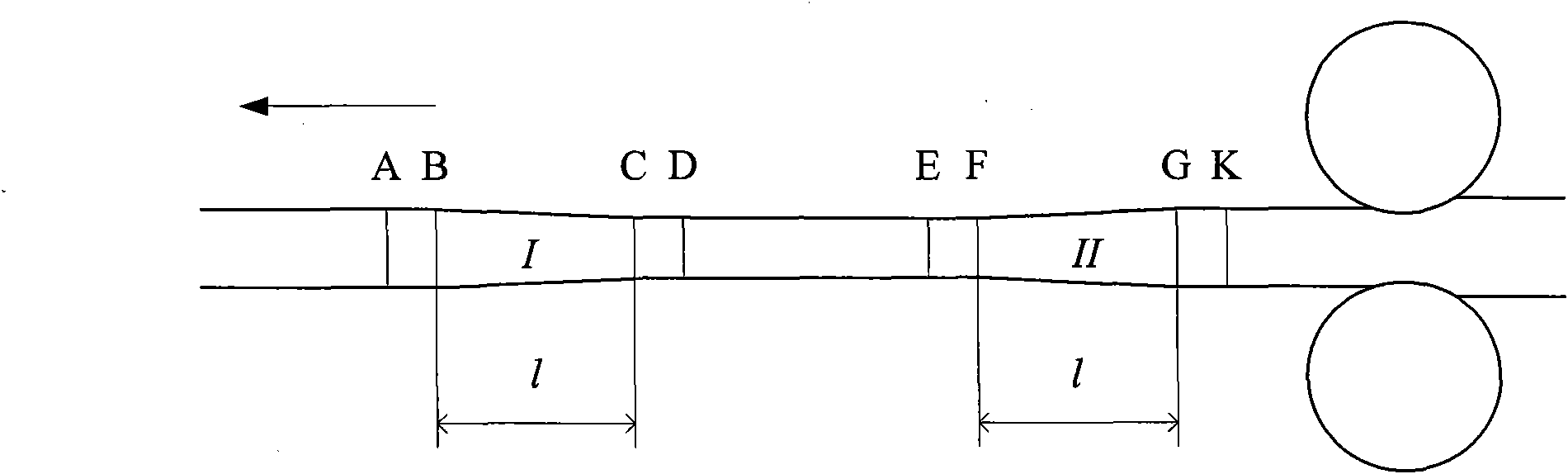

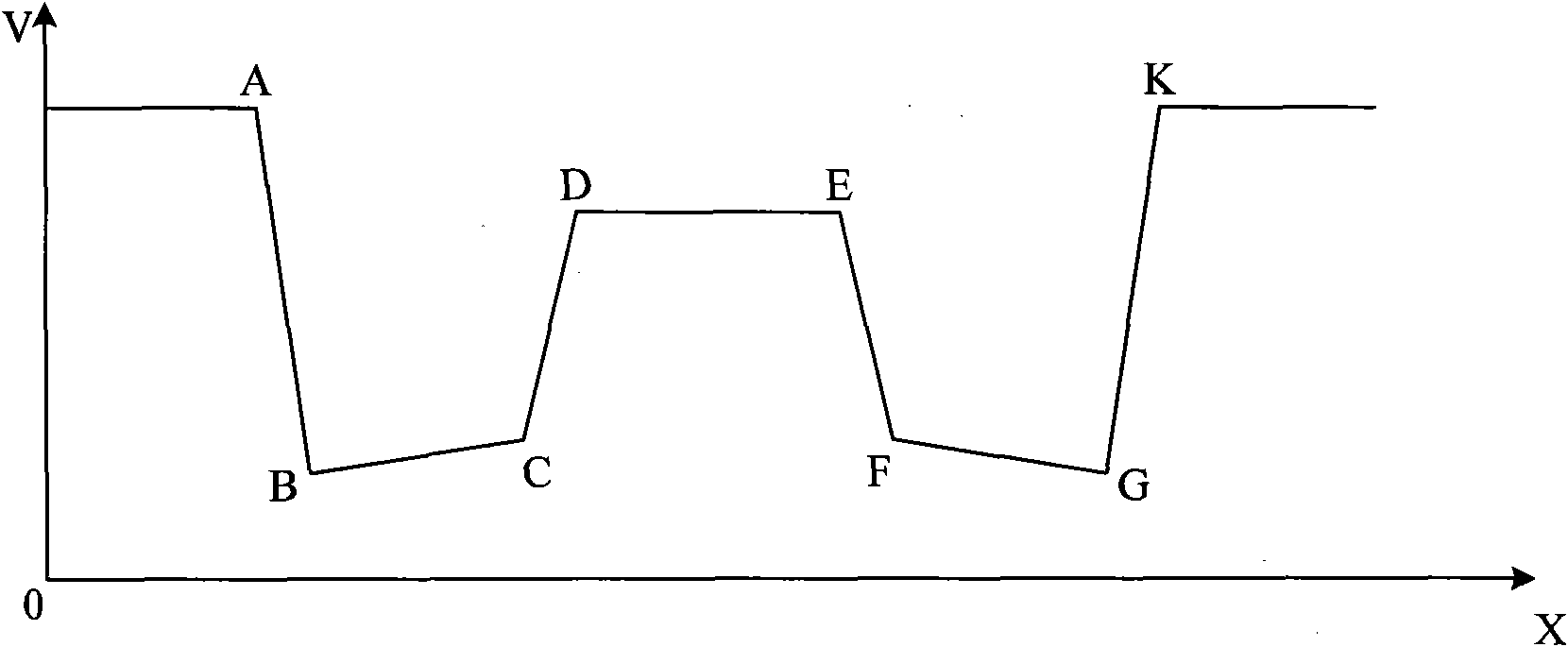

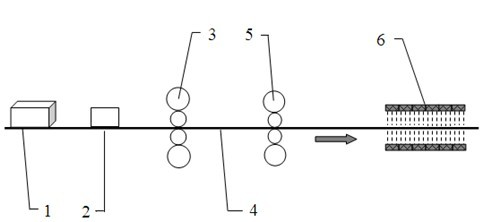

Control method for periodic variable-thickness strip rolling speed

ActiveCN101890434AGuaranteed shapeGuaranteed sizeMetal rolling arrangementsRoll speed control deviceVariable thicknessControl theory

The invention discloses a control method for a periodic variable-thickness strip rolling speed, and belongs to the technical field of rolling. The control method comprises horizontal rolling speed control and the vertical rolling speed control of a roller, wherein the horizontal rolling speed control is performed in a way that: a thick region of a strip is rolled at a thick region rolling speed; the rolling speed starts to decrease at a near point A of a transition region and decreases to VB at a starting point B of the transition region; at the transition region, the horizontal rolling speed at the transition region is calculated according to a transition region curvilinear equation and a second flow equivalence principle; and the rolling speed starts to increase after an end point C of the transition region and increases to a thin region rolling speed at a far point D of the transition point to start to roll a thin region; the vertical rolling speed control of the roller is performed in the way that: the vertical rolling speed of the roller is 0 when the thick region of the strip is rolled; after the thick region is rolled and a rolled piece reaches the starting point B of the transition region, the roller starts downward pressing, and the vertical rolling speed of the transition region is Vdy(x); the Vdy(x) starts to decrease after reaching a maximum point Q1 and decreases to 0 at the end point C of the transition region; and the steps are repeated periodically.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

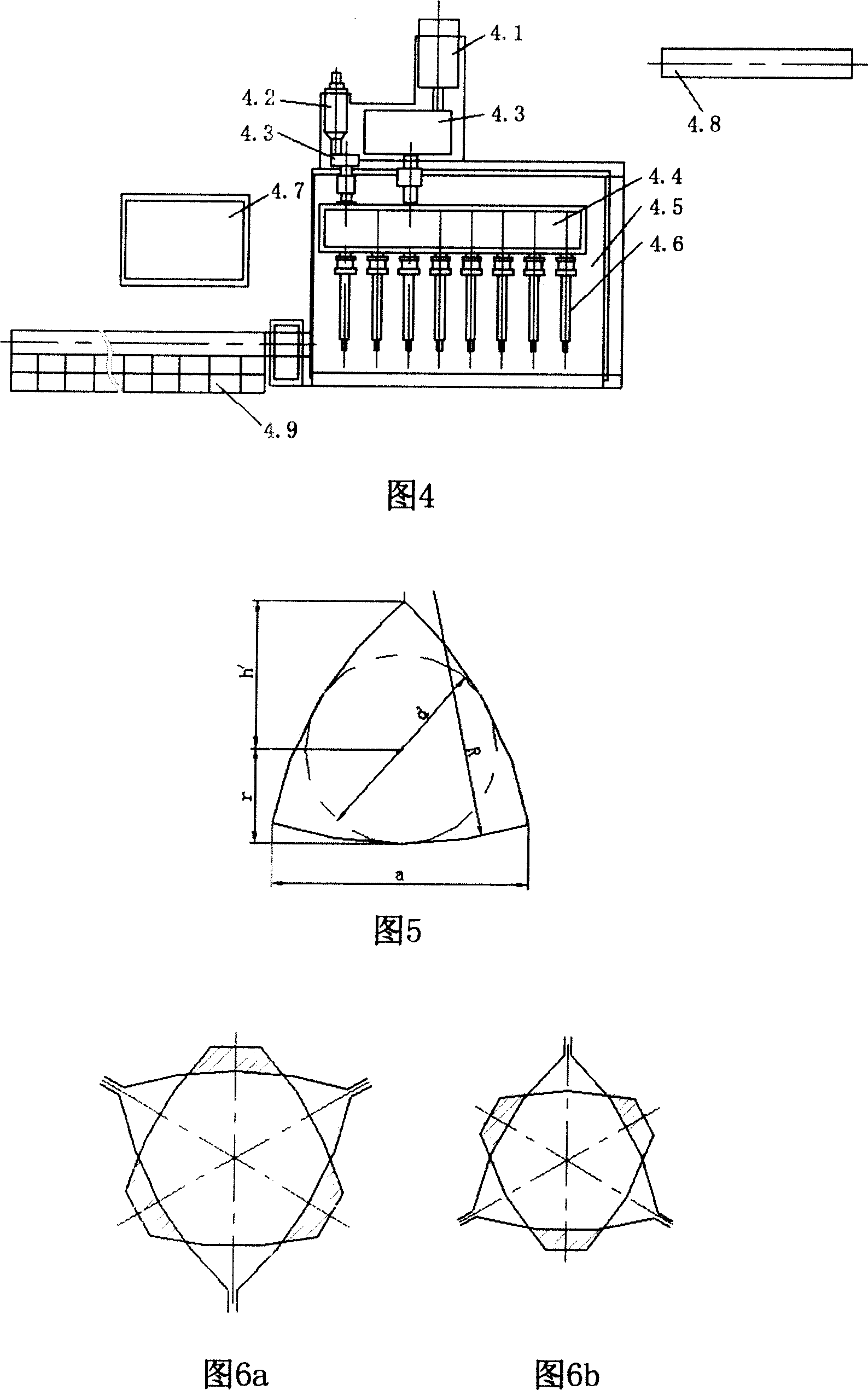

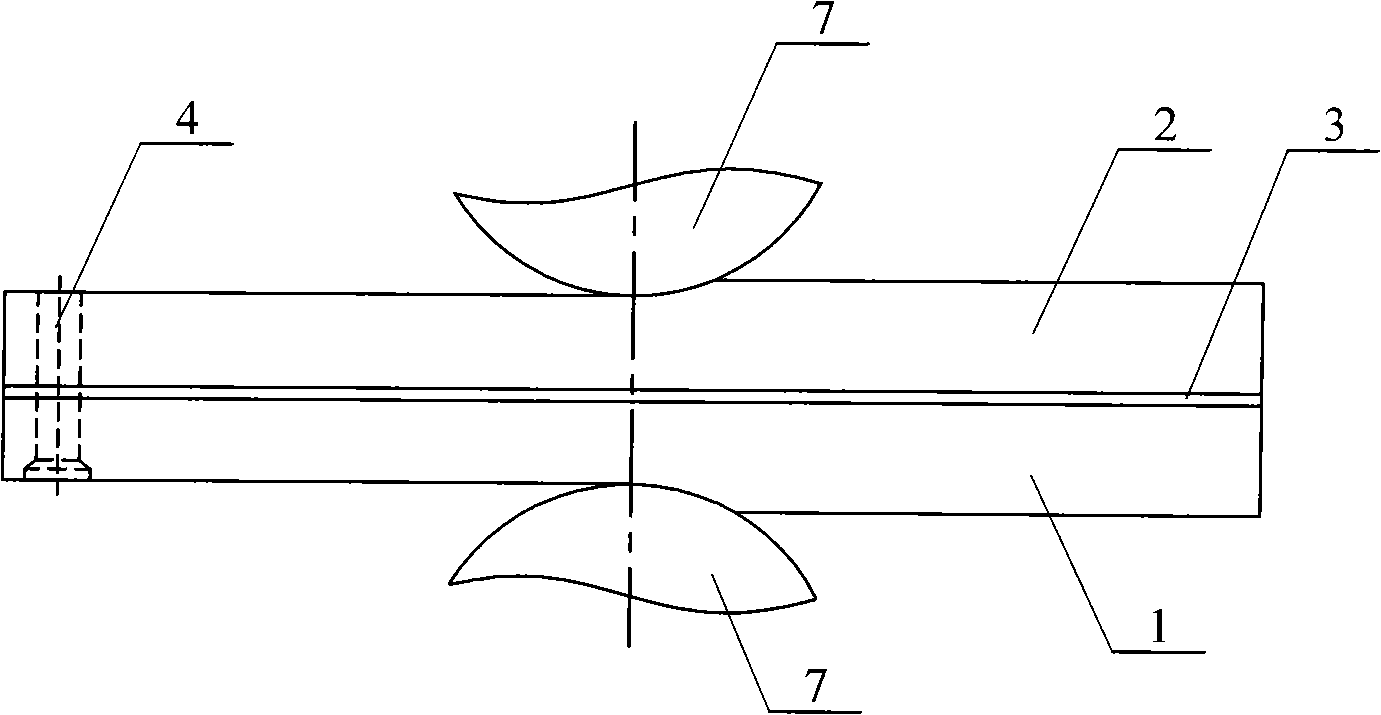

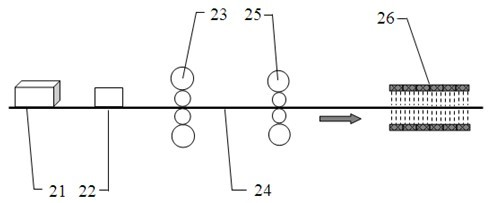

Vacuum hot rolling compounding method of titanium alloy plate and stainless steel plate

InactiveCN101288877AAvoid the problem of severe embrittlementReduce the degree of diffusionTemperature control deviceWork treatment devicesLiquid metalCopper foil

The invention provides a vacuum hot-rolled composite method of a titanium alloy plate and a stainless steel plate, which relates to a composite method for the titanium alloy plate and the stainless steel plate. Aiming at the problems that intense mixing of liquid metal and high welding stress are generated during the melt welding of the titanium alloy plate and the stainless steel plate, the contradiction between the diffusion and the controlling of volume fraction of compounds in connection interface metals is boosted to ensure the connection during the vacuum diffusion welding and the explosion weld joint is difficult to be applied to high-temperature and corrosive temperature, the method is characterized in that the stainless steel plate (1) and the titanium alloy plate (2) are used; furthermore, a copper foil or aluminium foil (3) is used; the surfaces of the two plates are milled flatly and the copper foil or the aluminium foil (3) is laminated and fix between the two plates, so as form a specimen; the specimen is arranged in a vacuum loading chamber (5); when the vacuum degree in a vacuum heating furnace (6) is (1-3)*10<-3> Pa and the temperature is 600-1100 DEG C, the specimen is delivered into the vacuum heating furnace for heating and heat preservation, and then welded by a roller (7) and cooled. The method of the invention has small welding stress, can control the volume fraction of compounds in the metals with high hardness and large brittleness; furthermore, the weld joint can be applied to the high-temperature and corrosive environment.

Owner:HARBIN INST OF TECH

Process for producing accurate stainless steel band applied in electronic industry

InactiveCN101716595AImprove quality requirementsThickness tolerance fluctuations are smallFurnace typesTension/compression control deviceSolution treatmentThermal water

The invention relates to a process for producing an accurate stainless steel band applied in an electronic industry. The process comprises the following steps of: the first cold rolling process; the first spray degreasing process; the first hot-water spraying process; the first hot-wind drying and solid dissolving process; the second cold rolling process; the second spray degreasing process; the second hot-water spraying process; and the second hot-wind drying process, bending stretching and straightening process and the process of cutting into finished products. According to the production process, a twenty-Hi sendzimir rolling mill and an unique rolling process are adopted for cold rolling; and the processes such as degreasing, solid dissolving treatment, bending stretching, straightening, and the like are performed, so that the product has little tolerance fluctuation of the thickness, stable performance, uniform surface color and roughness and no color difference, good plate flatness, improved quality and capacity of meeting the requirements of the electronic industry on top quality.

Owner:YONGXIN PRECISION MATERIAL WUXI

Rolling process of limit-specification steel plate of 2800mm double-stand heavy and medium plate mill

ActiveCN102688884ATo overcome the rapid temperature dropOvercome head and tailTemperature control deviceWork treatment devicesSheet steelThick plate

The invention discloses a rolling process of a limit-specification steel plate of a 2800mm double-stand heavy and medium plate mill, realizing the production of a 1200mm limit thick plate, a 6mm limit thin plate, a 2585mm limit wide plate and a 1585mm limit narrow plate. The limit-specification steel plate with good shape and qualified performance is obtained by controlling the temperature of a heating furnace in different phases, the soaking time, the furnace-on time, the tapping temperature, the high-pressure water descaling system, the pass reduction of the roughing roll, the finishing temperature of the roughing roll, the rolling cycle, the pass reduction in the finish rolling phase, the finishing temperature of the finish rolling and the re-reddening temperature. The invention broadens the specification range of the steel plate of the 2800mm double-stand heavy and medium plate mill, ensures normal operation of the rolling mill, meets the performance and shape requirement of the limit-specification steel plate, improves the rolling rate at one time, enhances the output of the limit-specification steel plate and has high economic benefits.

Owner:NANJING IRON & STEEL CO LTD

Medium carbon steel on-line balling rolling tech.

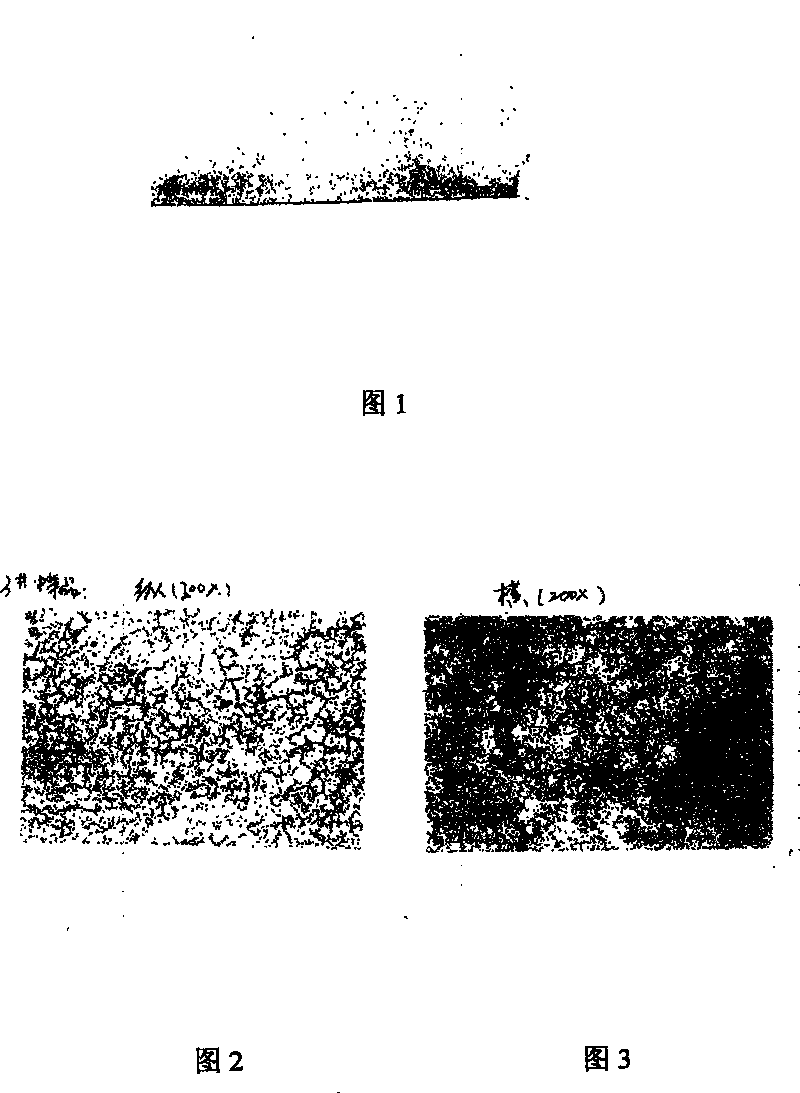

ActiveCN100999775AExcellent cold workabilityQuality improvementTemperature control deviceHeat treatment process controlMechanical componentsRoom temperature

The present invention discloses on-line medium carbon steel nodularizing and rolling process. The process includes low temperature finish rolling at 680-850 deg.c and accumulated cross section deformation of 50 %-80 %, controlled cooling after rolling at 3-15 deg.c / s to 660-720 deg.c, isothermal course, and naturally cooling to room temperature. The said technological scheme results in metallographic structure of the rolled piece with high ferrite component, less pearlite component, small and dispersed pearlite and granular cementite, lowered strength and hardness, raised plasticity and excellent cold machining performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Technique for continuously and flatly rolling welding seams of cold-rolled sheets

InactiveCN101658869APrevent the phenomenon of pinchingAvoid Printing DefectsRoll force/gap control deviceMetal rolling arrangementsHydraulic cylinderSheet steel

The invention relates to a technique for continuously and flatly rolling welding seams of cold-rolled sheets. A computer controls a hydraulic cylinder of a flat roll and front and back tension rolls of a leveler, adjusts rolling force and strip steel running speed, and adopts a control method for firstly slowing down the speed and then reducing the rolling force, and firstly recovering the rollingforce and then recovering the speed to realize the continuous and flat rolling of the welding seams of the cold-rolled sheets. The technique does not influence the production of previous and subsequent procedures, and eliminates punch marks of the welding seams on the flat roll, so the punch mark defects of the steel sheets are avoided, the surface quality of the steel sheets is improved, and a value of 2.6 million Yuan can be saved each year. The rolling force is reduced, so power consumption is reduced and energy is saved; and the technique dose not need increasing any equipment and investment, is simple and feasible, and has quick response.

Owner:ANGANG STEEL CO LTD

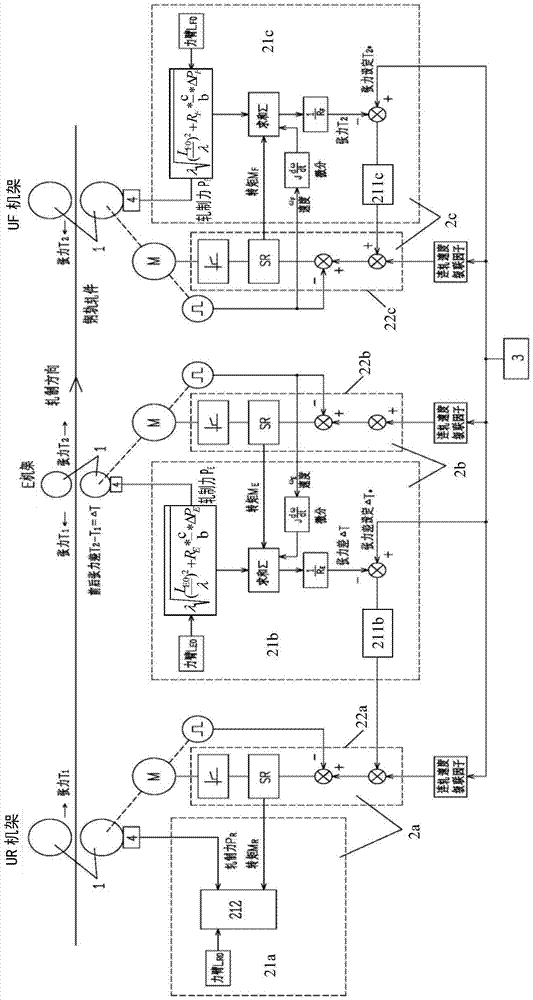

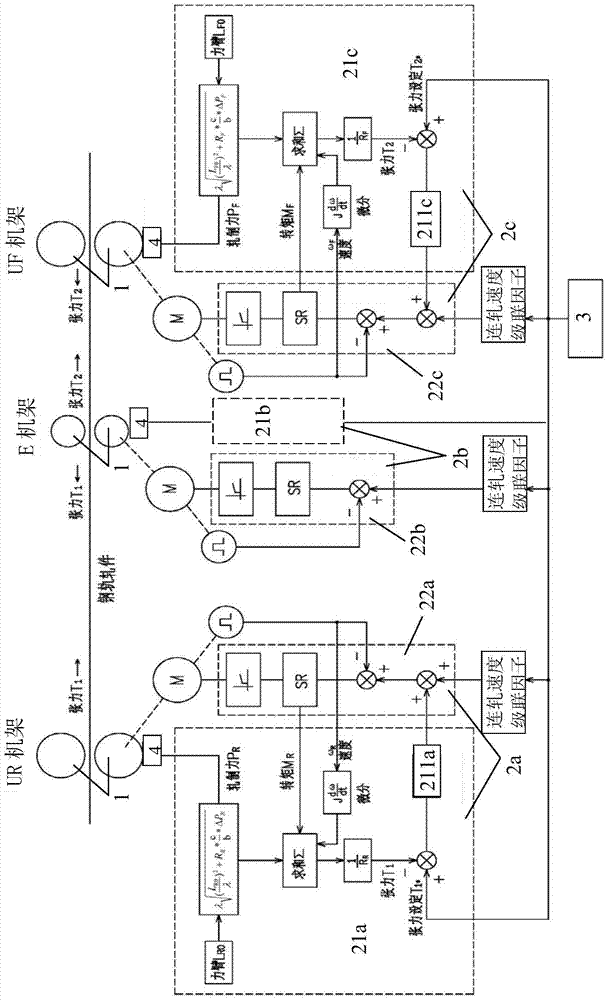

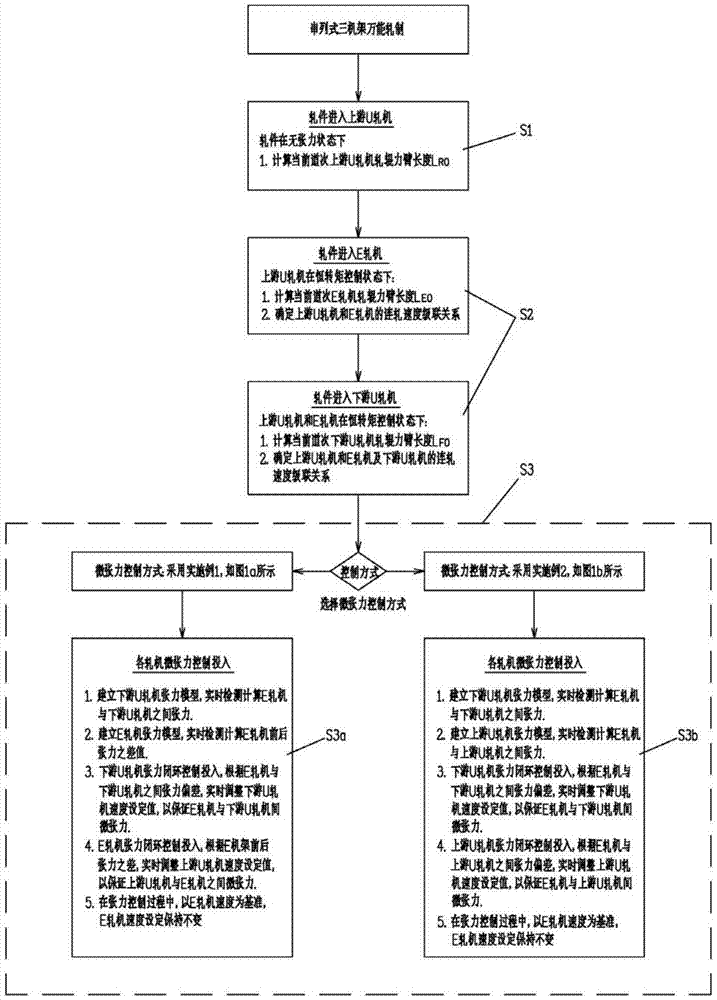

Micro-tension control system and method

ActiveCN103567230AGuaranteed tension control accuracyGeometry out-of-tolerance reductionMeasuring devicesTension/compression control deviceLoop controlClosed loop

The invention discloses a micro-tension control system and method. In the hot continuous rolling process, when a rolled piece enters a current machine frame and is stably bitten, the current machine frame is kept under speed control, speed control of main motors of machine frames on the upstream of the current machine frame is switched to constant torque control, on the basis, the torque and the rolling force of a main motor of the current machine frame are sampled to calculate the initial length of a rolling force arm, and the tension measurement calculating accuracy is improved. Each machine frame is provided with a pressure measuring head device to directly detect the rolling force, and consideration is given to the situation that the length of the rolling force arm is changed along with changes of the rolling force. Tension between the machine frames is obtained in real time through tension calculating models to form micro-tension closed-loop control to adjust the speeds of the machine frames so as to correct the tension deviations between the machine frames. As for a serial type universal rolling mill, the speed of the E machine frame serves as a standard, the rolling speed of the E machine frame is kept unchanged while speed set values of the other machine frames are adjusted, and real-time control is carried out on dynamic instantaneous values of the tension difference of the E machine frame before and after the adjustment process to guarantee micro-tension rolling of series universal rolling.

Owner:BERIS ENG & RES CORP

High-tensile quenched and tempered steel plate for large-thickness structures and production method thereof

InactiveCN102080185AGood lamellar tear resistanceImprove low temperature toughnessRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

The invention discloses a high-tensile quenched and tempered steel plate for large-thickness structures and a production method thereof, wherein the high-tensile quenched and tempered steel plate comprises the following chemical compositions in percentage by weight: less than or equal to 0.19% of C, less than or equal to 0.50% of Si, 1.00-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.20% of microalloying elements (Nb+V+Ti+Ni), less than or equal to 0.050% of Als, and the balance of Fe and residual elements. By reasonably taking a chemical composition design on composite multicomponent microalloying elements and adopting an LF+VD (ladle refining + vacuum degassing)process, the purity of the steel plate is ensured, and the sum of levels of various inclusions is not more than 3.0; and by utilizing a thermo mechanical control process and adopting normalizing treatment, the grain fineness number of the steel plate reaches level 9.0-10.0; by means of the effective implementation of the measures, the extra-thick steel plates (thickness: greater than or equal to 100mm) for high-rise buildings with guaranteed flaw detection and mechanical properties are produced successfully.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

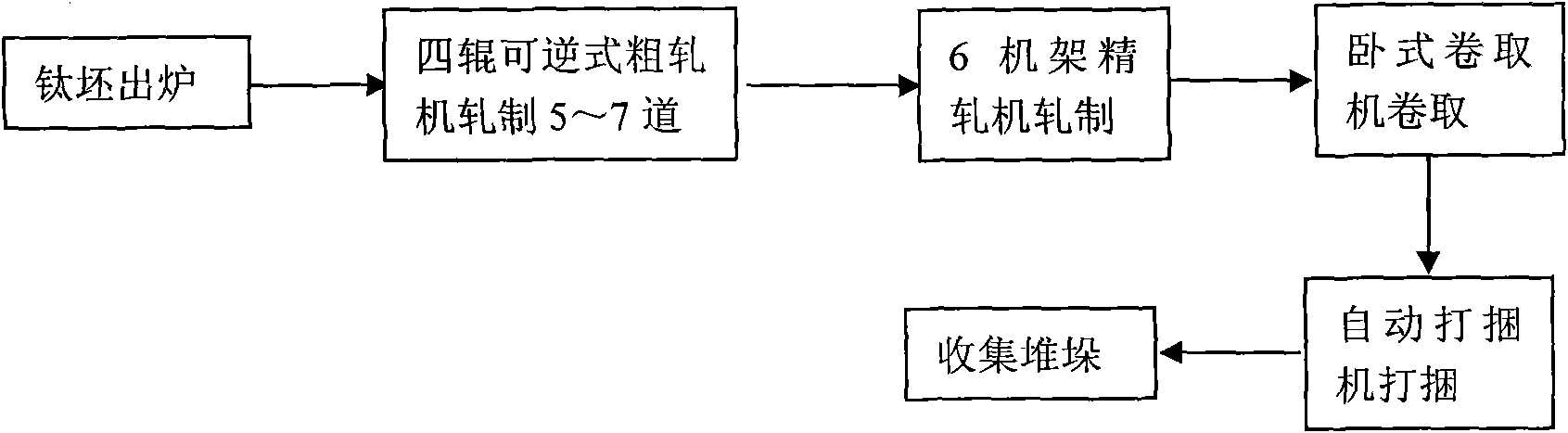

Method for producing metallic titanium plate using medium-wide strip hot rolling machine set

ActiveCN101412038ALow investment costRoll force/gap control deviceTemperature control deviceSocial benefitsProduction line

The invention discloses a method for producing a metallic titanium plate by adopting a medium-wide band heat rolling set. The method comprises the following steps: heating a titanium plate blank with a thickness of between 50 and 90 millimeters in a roller-hearth type soaking furnace to between 800 and 1,000 DEG C, controlling inlet temperature of the titanium plate blank entering the medium-wide band heat rolling set at a temperature of between 800 and 950 DEG C, controlling process temperature to between 700 and 950 DEG C, and keeping final rolling temperature at a temperature of between 700 and 800 DEG C after fine rolling for seven times; and well controlling roll gap width, depressing rate, roll force and roll (rolling) speed of each stander of the heat rolling set, controlling the rolling speed of the titanium plate rolled by the tail stander of the heat rolling set at between 4.0 and 8.0 meters per second, and coiling the titanium plate by a coiling machine after cooling the titanium plate by water, wherein the coiling temperature is between 550 and 680 DEG C. The method uses a CSP production line to produce the non-ferrous metallic titanium plate (coil) for domestic initiation, and has extremely great economic and social benefits.

Owner:湖南湘投金天钛金属股份有限公司 +1

Method for producing patterned plate with thickness of 1.4mm through CSP process

ActiveCN107716552AEnsure the use of mechanics and aestheticsQuality improvementTemperature control deviceMetal rolling arrangementsEngineeringEnergy conservation

The invention provides a method for producing a patterned plate with the thickness of 1.4mm through the CSP process. The method comprises the steps of (1) conducting conventional smelting, conductingcasting to form a blank and heating the casting blank; (2) conducting finish rolling through a finishing mill rack except a tail rack; pressing patterns on the tail rack; (3) conducting cooling; and (4) conducting winding. By means of the method, on the premise of guaranteeing the application dynamics and attractive appearance of the patterned steel plate, the weight-loss ratio can be made not tobe lower than 10%; the purposes of energy conservation and emission reduction can be achieved; the high market requirements can be met; moreover. The pattern incomplete rate is reduced from original 11% to at most 2%. The plate flattening rework rate is reduced from original 53% to at most 7%. The plate quality is excellent.

Owner:武汉钢铁有限公司

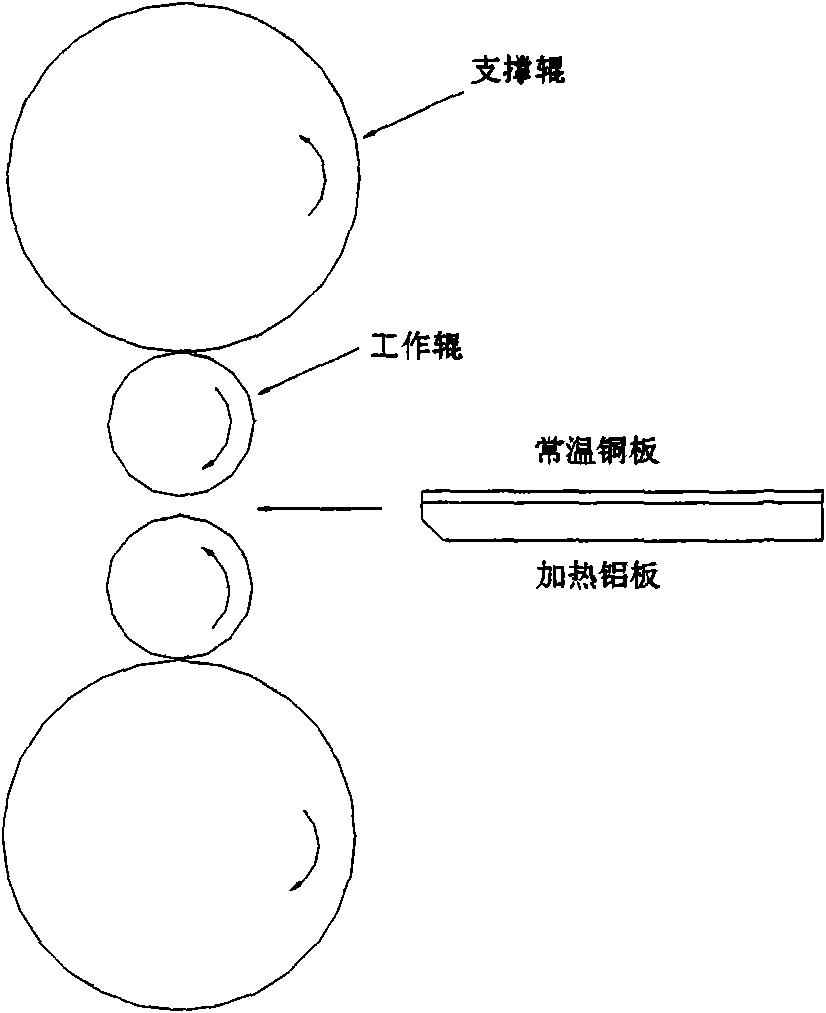

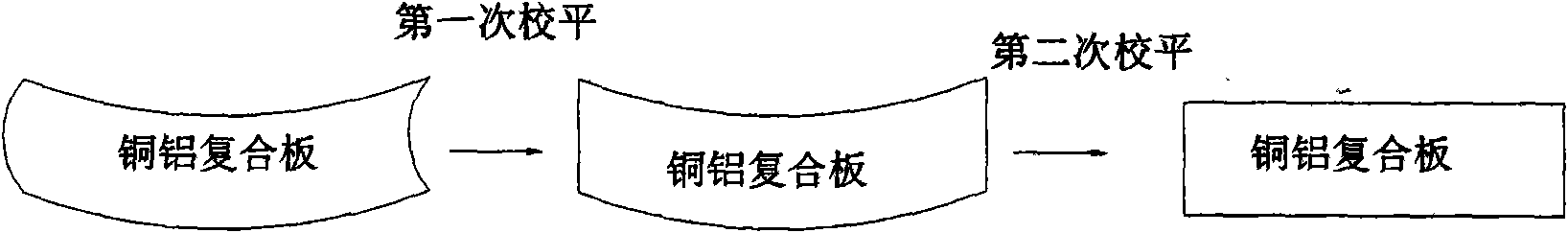

Manufacturing method of copper-aluminum composite board

InactiveCN101559557APrevent oxidationImprove bindingTemperature control deviceTension/compression control deviceCopperAluminum composites

The invention discloses a manufacturing method of a copper-aluminum composite board, comprising the following steps: 1. removing oil for preliminary treatment; 2. grinding a junction surface; 3. heating an aluminum board, not heating a copper board and performing inreversible and isodromic rolling in one pass; 4. adopting a common leveler with fifteen rollers to carry out twice leveling; and 5. cutting to form into finished products. The invention solves the problem that the bonding strength of copper and aluminum is lower and achieves the beneficial effects of producing the high-quality copper-aluminum composite boards in batch with low cost.

Owner:上海新东蒸发器有限公司

Stainless steel band production method for mobile telephone

InactiveCN101386024AImprove surface roughnessEliminate the need for frostingFurnace typesTension/compression control deviceMaterials preparationSolution treatment

The invention discloses a method for producing a stainless steel band for a mobile phone, in particular relates to a method for producing the stainless steel band for processing the mobile phone shell. The method is characterized by comprising the steps of material preparation, primary rolling, solution treatment, primary cleaning, secondary rolling, secondary cleaning and straightening and withdrawal, etc. The stainless steel band produced by the method is further processed into the mobile phone shell which produces no fingerprint after being touched by hands and is beautiful. The method can meet the demand of the mobile phone shell while the production cost is reduced.

Owner:无锡华生精密材料股份有限公司

Method for producing titanium strip by adopting conventional hot continuous rolling machine set

InactiveCN101811135AAbundant resourcesReduce manufacturing costTemperature control deviceTension/compression control deviceSocial benefitsTitanium

The invention discloses a method for producing a titanium strip by adopting a conventional hot continuous rolling machine set, wherein the method comprises the following steps: heating a titanium plate blank with the thickness of 150 to 250mm to the temperature of 800 to 900 DEG C in a walking beam type heating furnace, manufacturing the titanium strip with the thickness of 2.5 to 20mm through five passes of rough rolling and continuous rolling of six stands, and coiling into a strip coil through a coiler, wherein the finishing temperature is larger than 650 DEG C, the coiling temperature is larger than 550 DEG C, and the coil weight is 5 to 15 tons. Producing the titanium strip through the conventional hot continuous rolling machine set belongs to domestic initiation and has great economic and social benefits.

Owner:SHANDONG IRON & STEEL CO LTD

Method for leveling titanium board coil

InactiveCN101486051AStress reliefEliminate its influenceTension/compression control deviceRoll speed control deviceNational standardTitanium

The invention provides a method for levelling a titanium plate coil, which comprises the following steps: delivering the titanium plate coil subjected to annealing treatment to a levelling machine, and directly carrying out levelling extension on the titanium plate coil by a levelling roll on the levelling machine or carrying out wet levelling on the titanium plate coil by the levelling roll under the conditions that the rolling speed is 50 to 200 meters per minute, the uncoiling tension is 0.5 and 4 tons, the curling tension is between 3.0 and 5.0 tons, and the extension rate is between 0.80 and 2.0 percent. After the cold-rolled and annealed titanium plate coil is subjected to leveling extension by the levelling roll on the levelling machine, the levelling method can eliminate stress and influence of the stress, level plate surfaces, and obtain better surface quality; and all the plate shape, dimension, surface quality, mechanical property, and the like of the leveled titanium plate coil achieve national standard requirements, and completely meet market demand.

Owner:YUNNAN TITANIUM IND

Production method of stainless steel band for electric thin shrapnel

InactiveCN101386126AHigh hardnessHigh yield strengthRoll force/gap control deviceFurnace typesComposite material

Owner:无锡华生精密材料股份有限公司

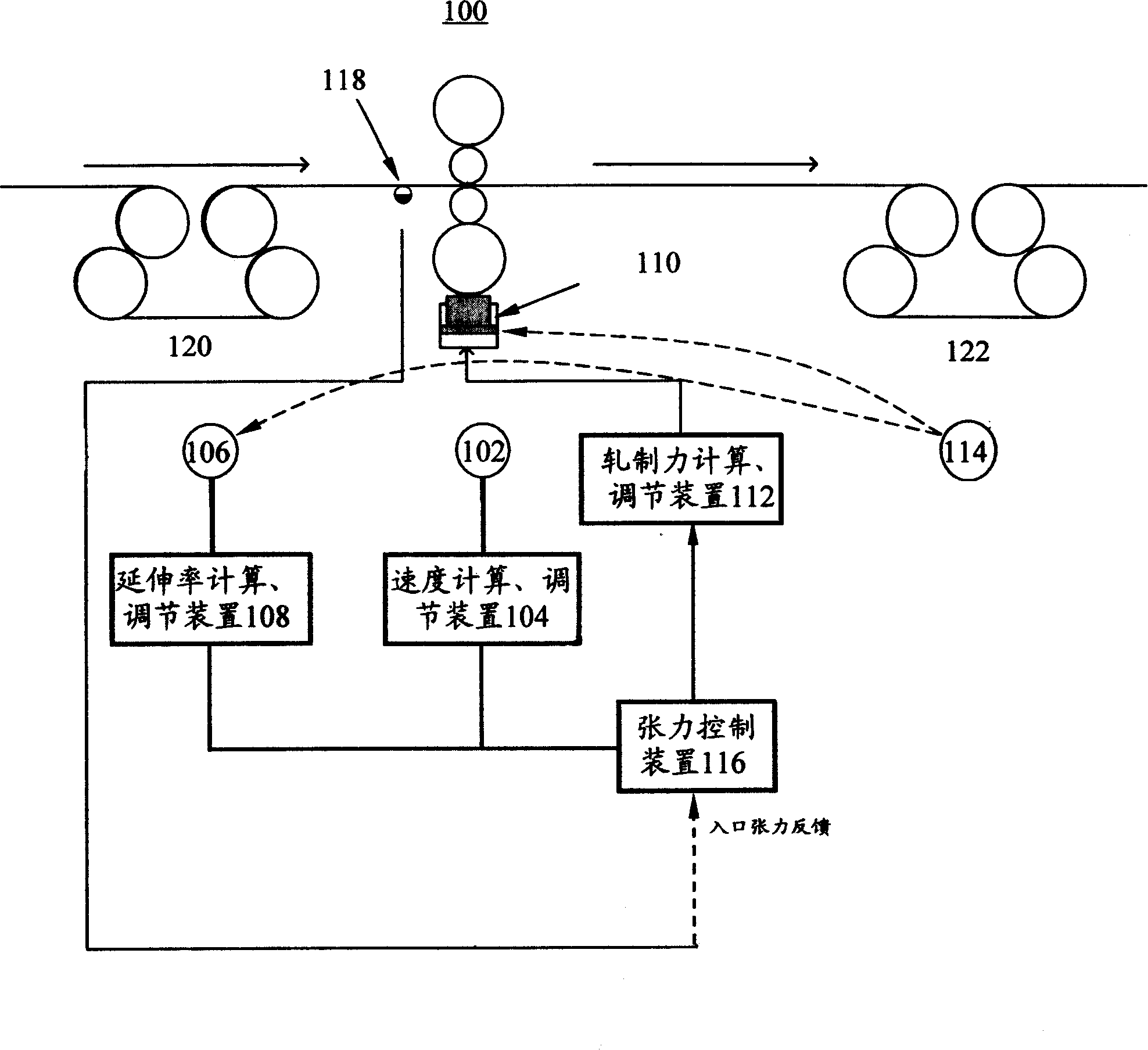

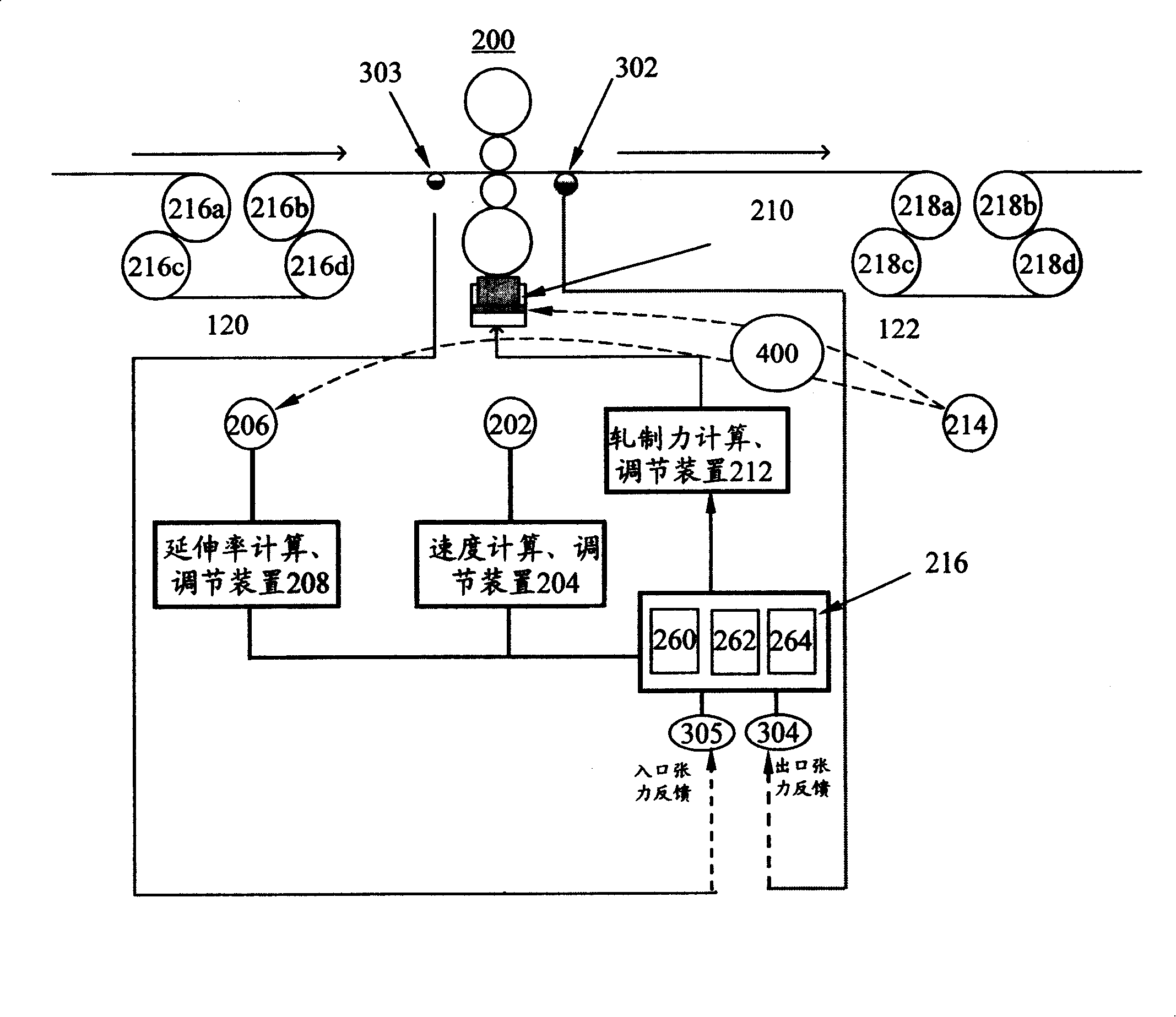

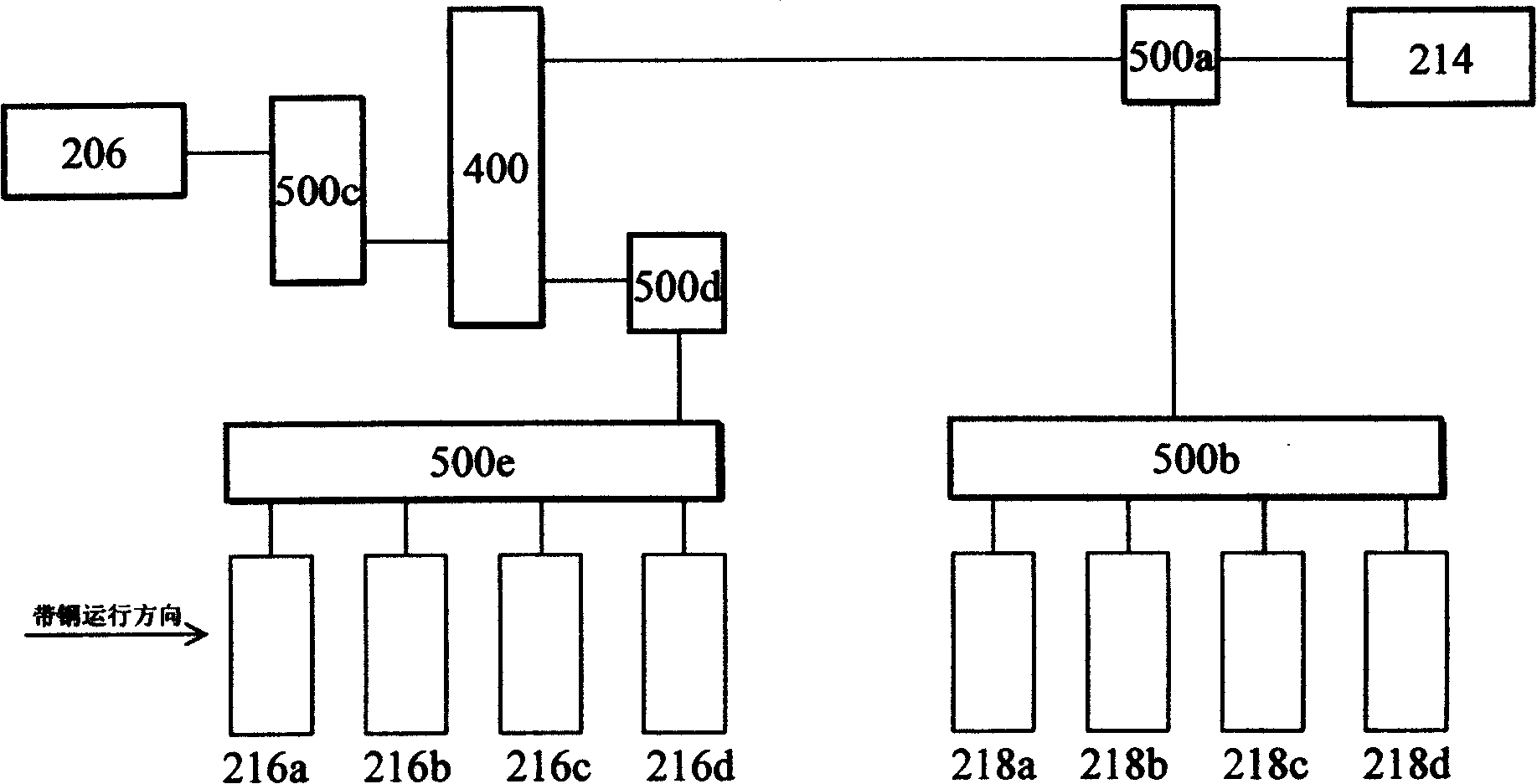

Tension control system and method for planetary gear structure tension roller type evener

ActiveCN101168172AElongation stabilityRoll force/gap control deviceTension/compression control deviceControl systemEngineering

The invention discloses a tension control system of an epicyclic gear tension roll leveler, which comprises an inlet pull tension gage and an inlet tension feedback device, an outlet pull tension gage which is provided in the outlet of the leveler for measuring the strip tension in the outlet, an outlet tension feedback device for feedback the strip tension in the outlet which measuring by the outlet pull tension gage, a tension control device for receive the strip tension in the outlet which is feedback from the outlet tension feedback device. The roll-force, the elongation and the speed of the leveler can be definite by the association of strip tension in the inlet and outlet. The three key parameters comprises the roll-force, the elongation and the speed of epicyclic gear tension roll leveler, the coordinate cooperated controlled can be constructed among the three key parameters. According to the addition of tension in outlet with the outlet pull tension gage by the technical scheme of the invention, meanwhile the stable elongation, roll-force and tension control can be realized, and the order of stable strip steel property and shape can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

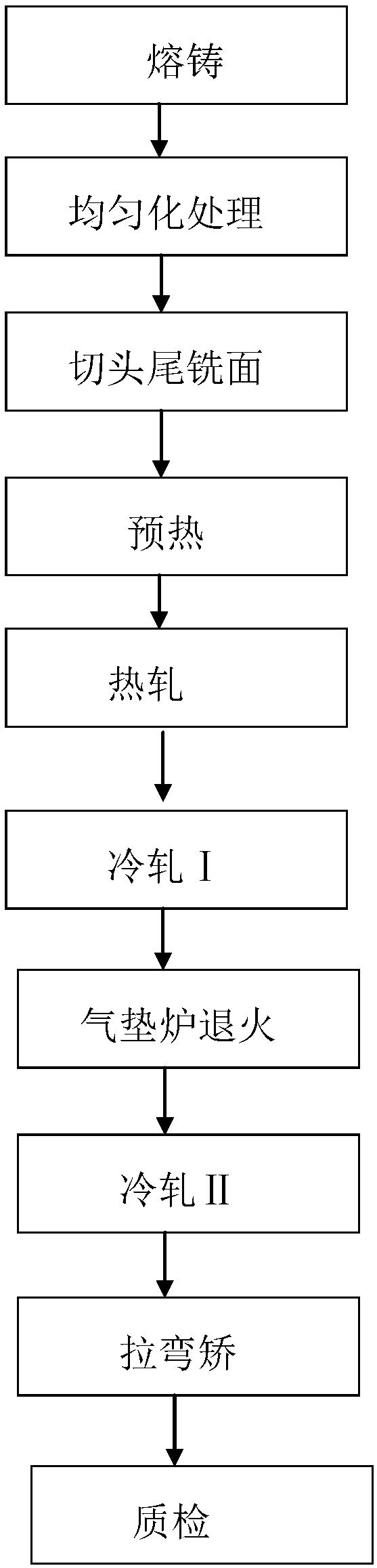

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com