Tension control system and method for planetary gear structure tension roller type evener

A planetary gear and tension control technology, applied in tension/pressure control, control/regulation system, mechanical pressure/force control, etc., can solve problems such as loss of tension, middle waves, and strip relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

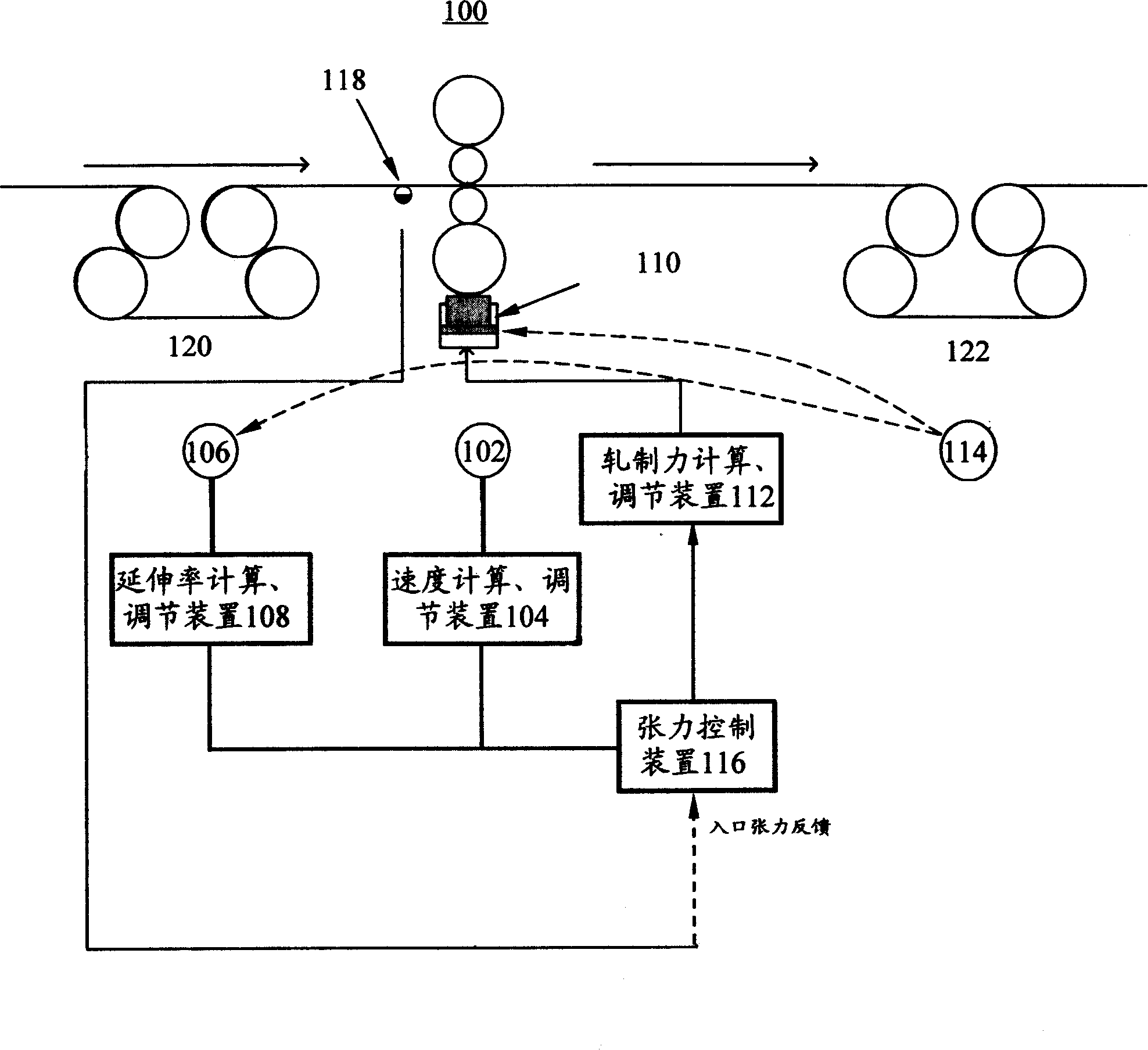

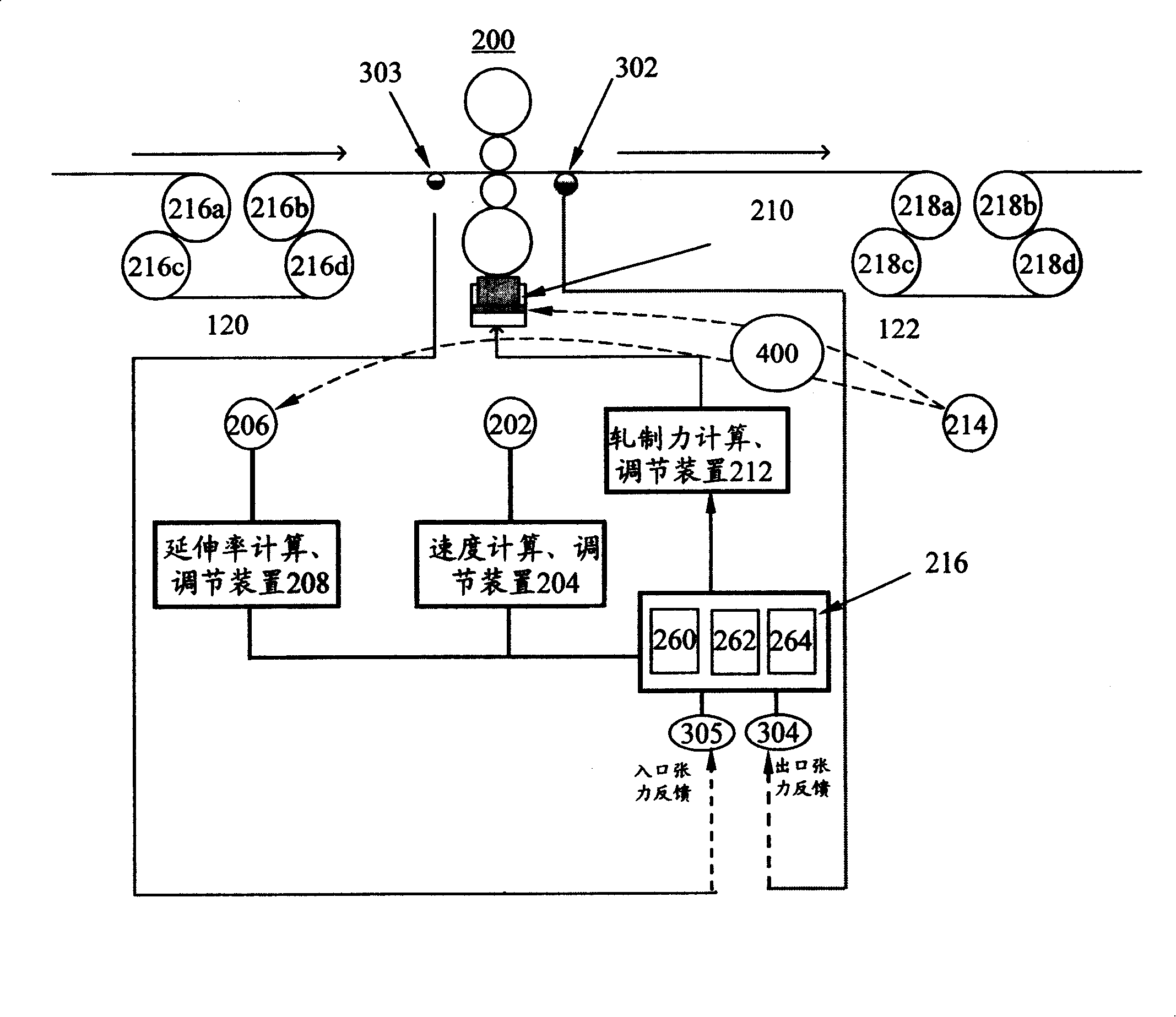

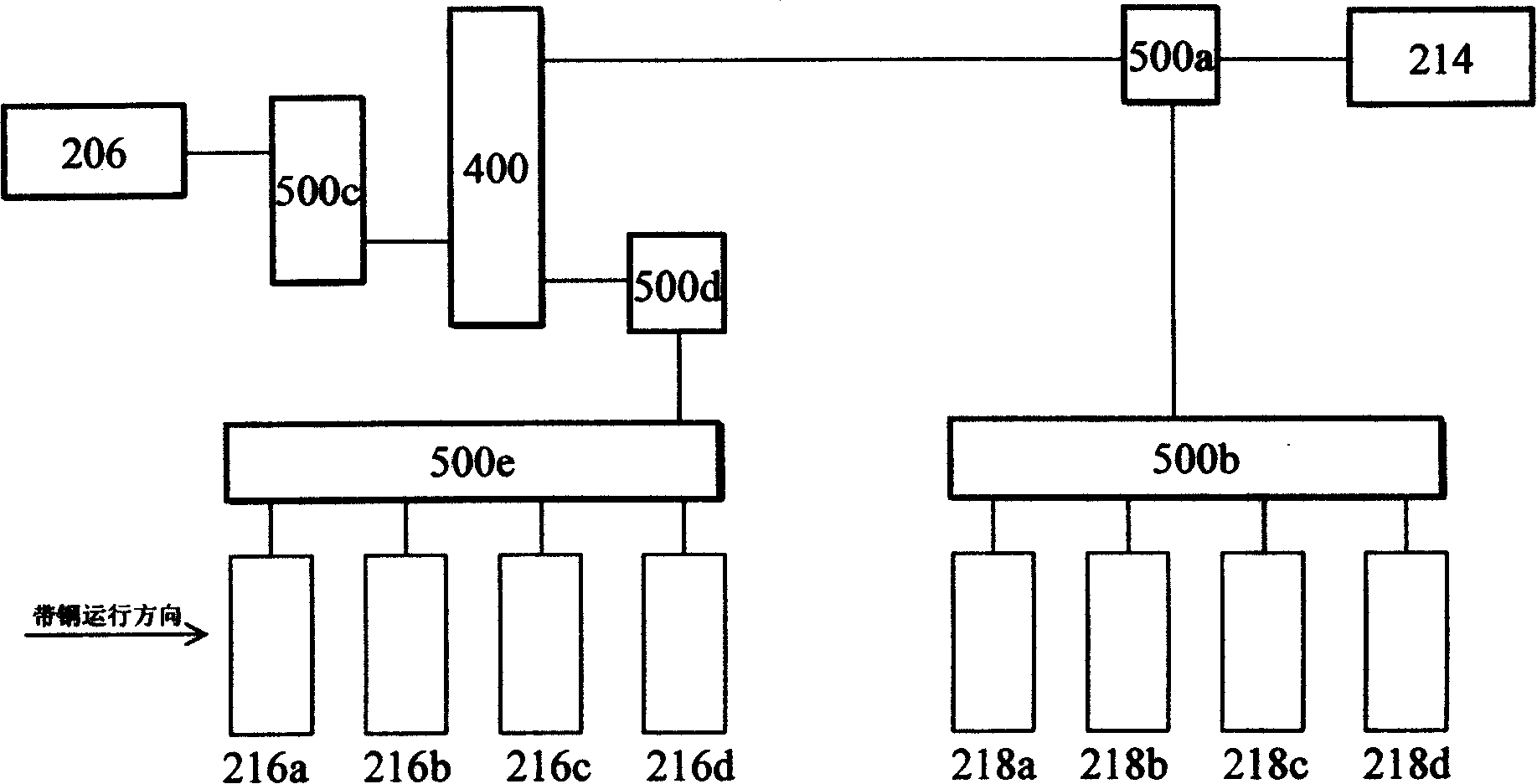

[0074] The technical solution of the utility model is further described below in conjunction with the accompanying drawings and embodiments.

[0075] First of all, the present invention mainly provides a tension control system of a planetary gear structure tension roller type skin passer, the system includes:

[0076] Exit tension gauge, placed at the exit of the temper mill, to measure the tension of the strip at the exit;

[0077] The exit tension feedback device feeds back the tension of the strip steel at the exit measured by the exit tension meter to the control circuit of the tempering machine;

[0078] The tension control device receives the exit tension feedback device, and the fed back strip tension at the exit is combined with the strip tension at the entrance to determine the rolling force, elongation, and temper speed of the temper mill.

[0079] Through the above-mentioned tension control system, the measurement and control of the outlet tension of the planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com