Patents

Literature

398results about "Elongation control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

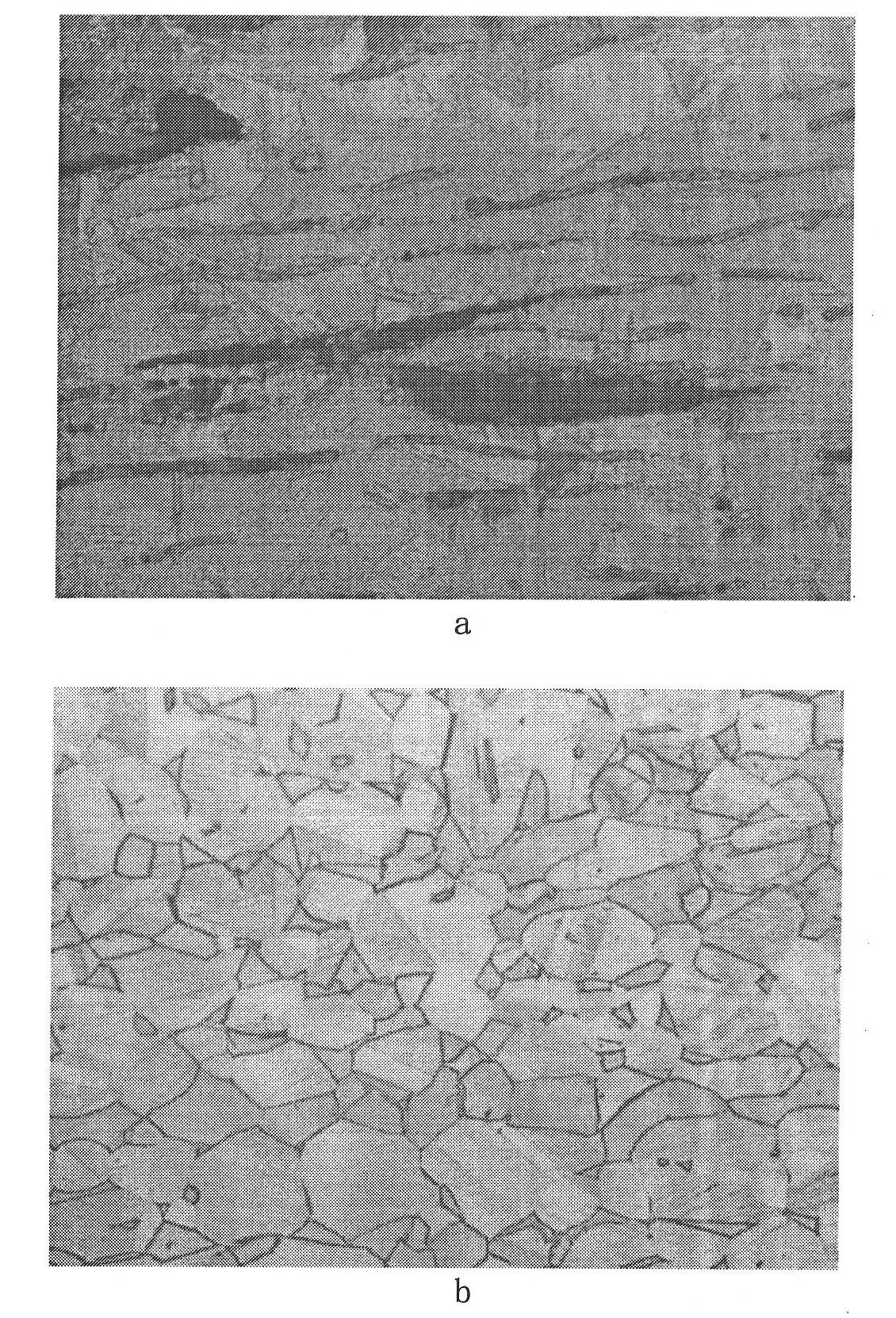

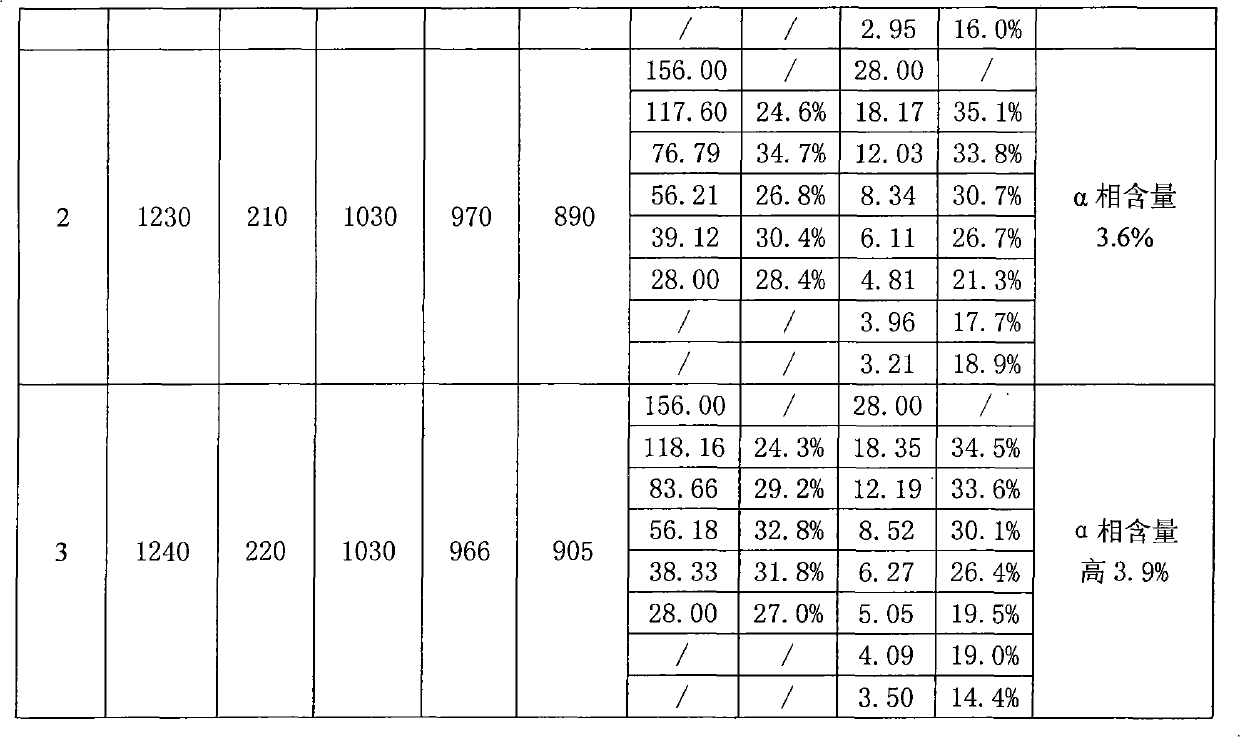

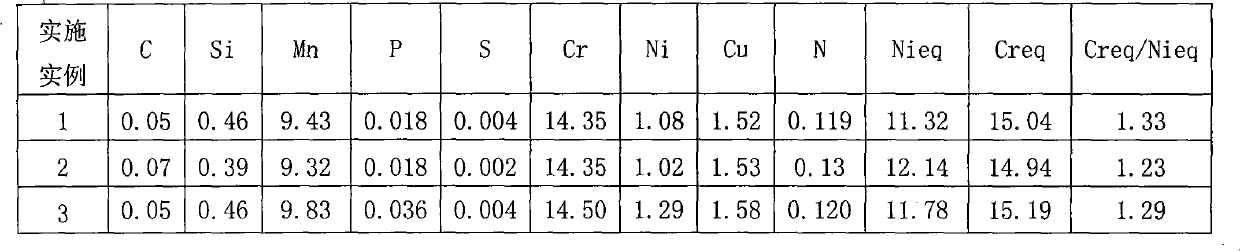

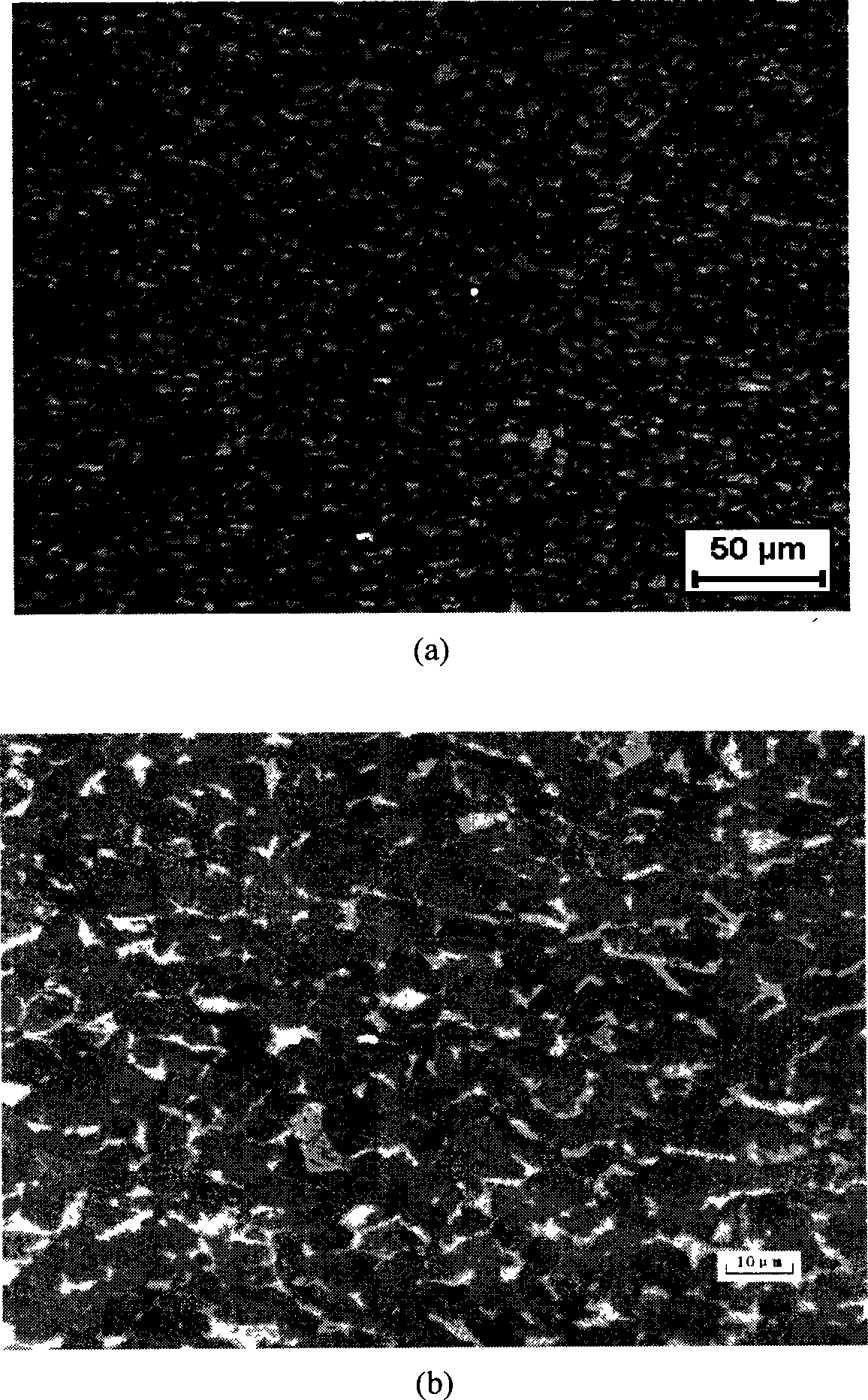

Production technology for inhibiting nickel-saving austenitic stainless steel hot-rolled plate edge crack

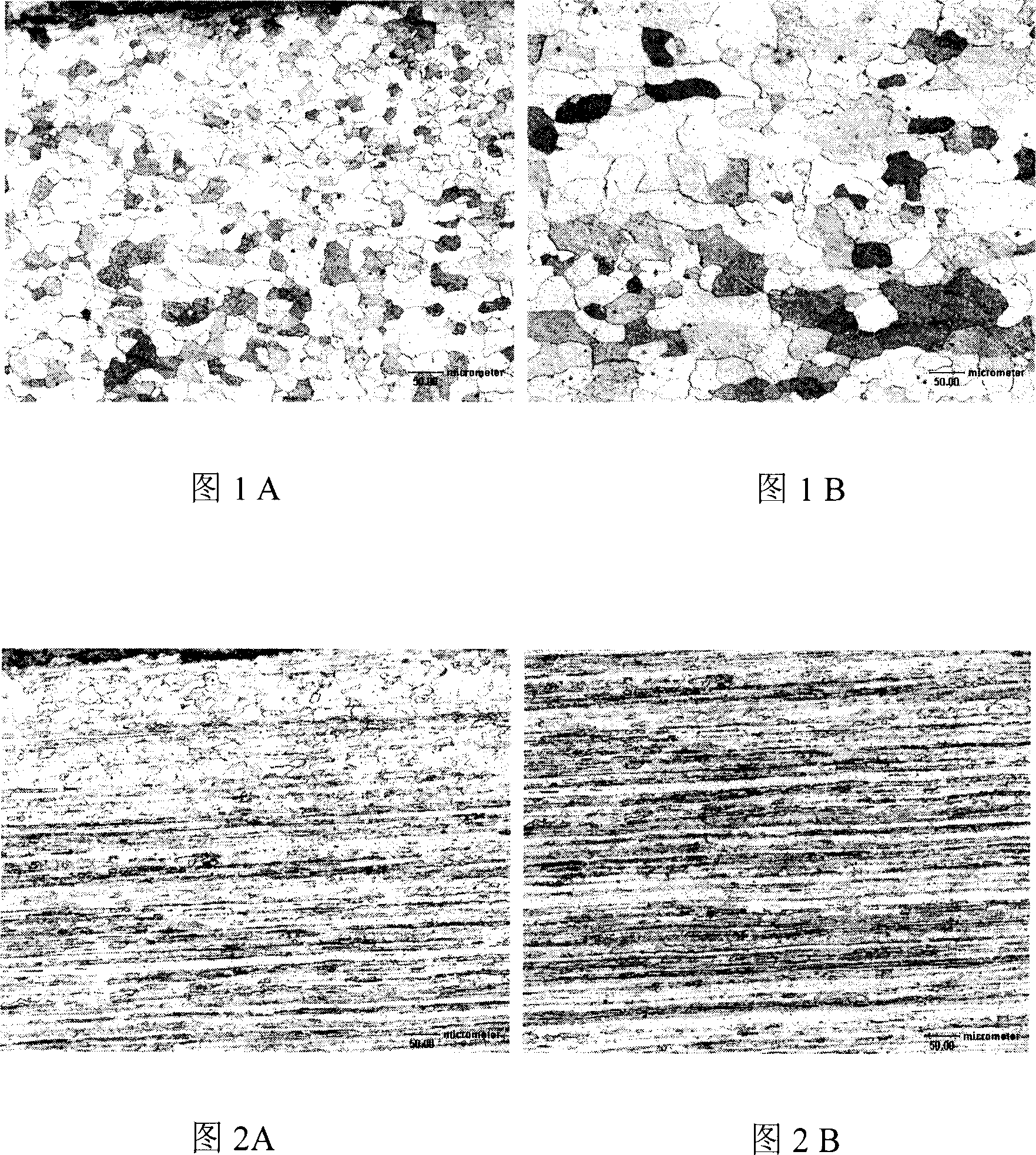

InactiveCN101947549AImprove plasticityEliminate edge cracksTemperature control deviceHeat treatment process controlSS - Stainless steelHeating temperature

The invention relates to production technology for inhibiting nickel-saving austenitic stainless steel hot-rolled plate edge crack, which comprises the following steps of: smelting and continuous casting, grinding plate blanks, heating blanks, rolling and the like. By controlling N content in steel below 0.13 percent, controlling Creq / Nieq within 1.35, controlling alpha-phase content in a casting blank texture within 4 percent, setting the reasonable heating temperature of plate blanks by combining on-site reality, and adopting the plate blank one-pass descaling box and frame final-pass descaling descaling technology, in particular the rolling technology of tightly combining hot-rolled rolling pass deformation and blank temperature, the production technology has the advantages of avoiding the edge crack of the produced stainless steel hot-rolled plates, obviously improving the yield, solving the problem of edge crack quality for steel coils in the rolling process through a steckel mill, guaranteeing the edge quality of the hot-rolled steel coils and improving the width yield of finished rolled plates.

Owner:SHANDONG TAISHAN STEEL GROUP

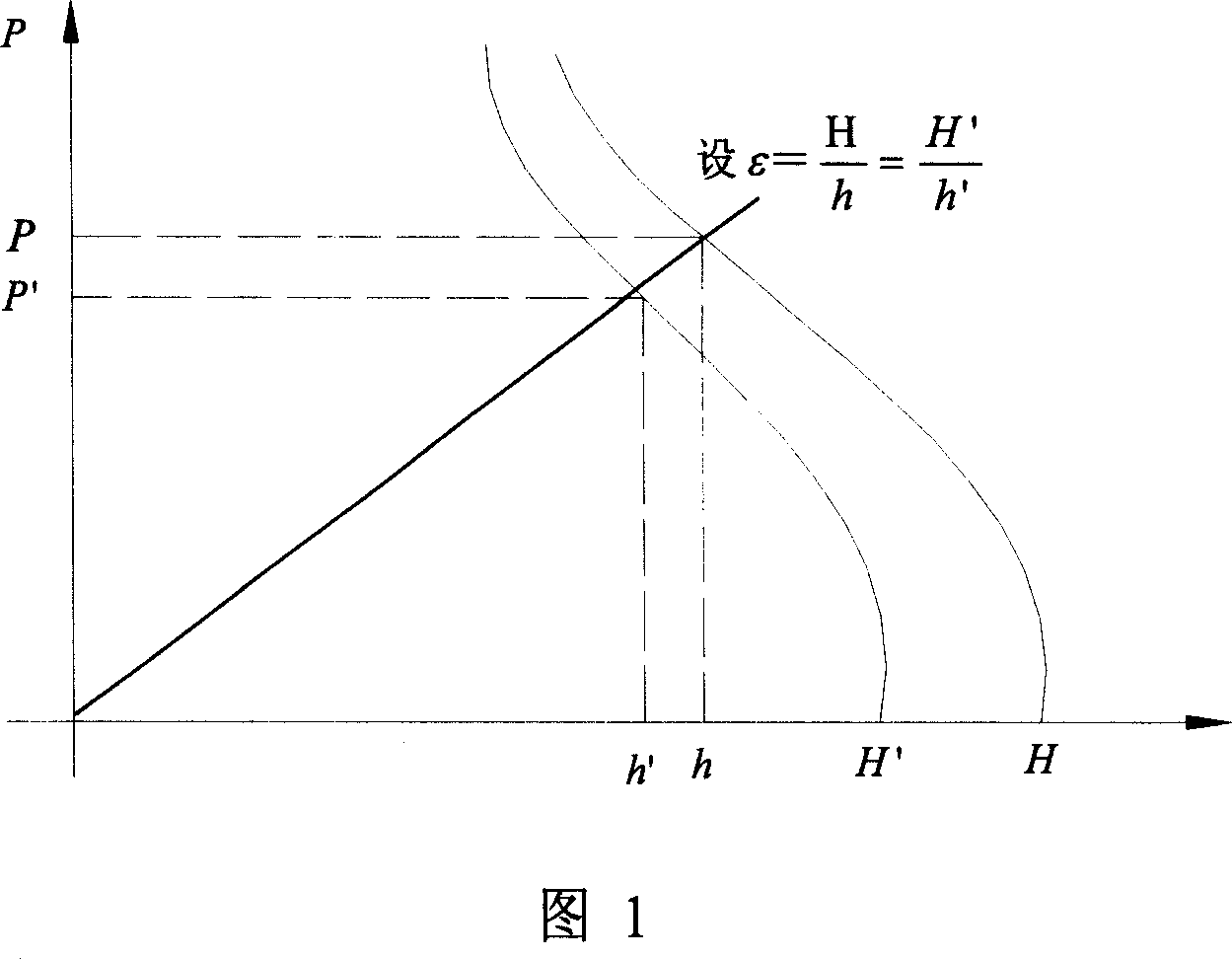

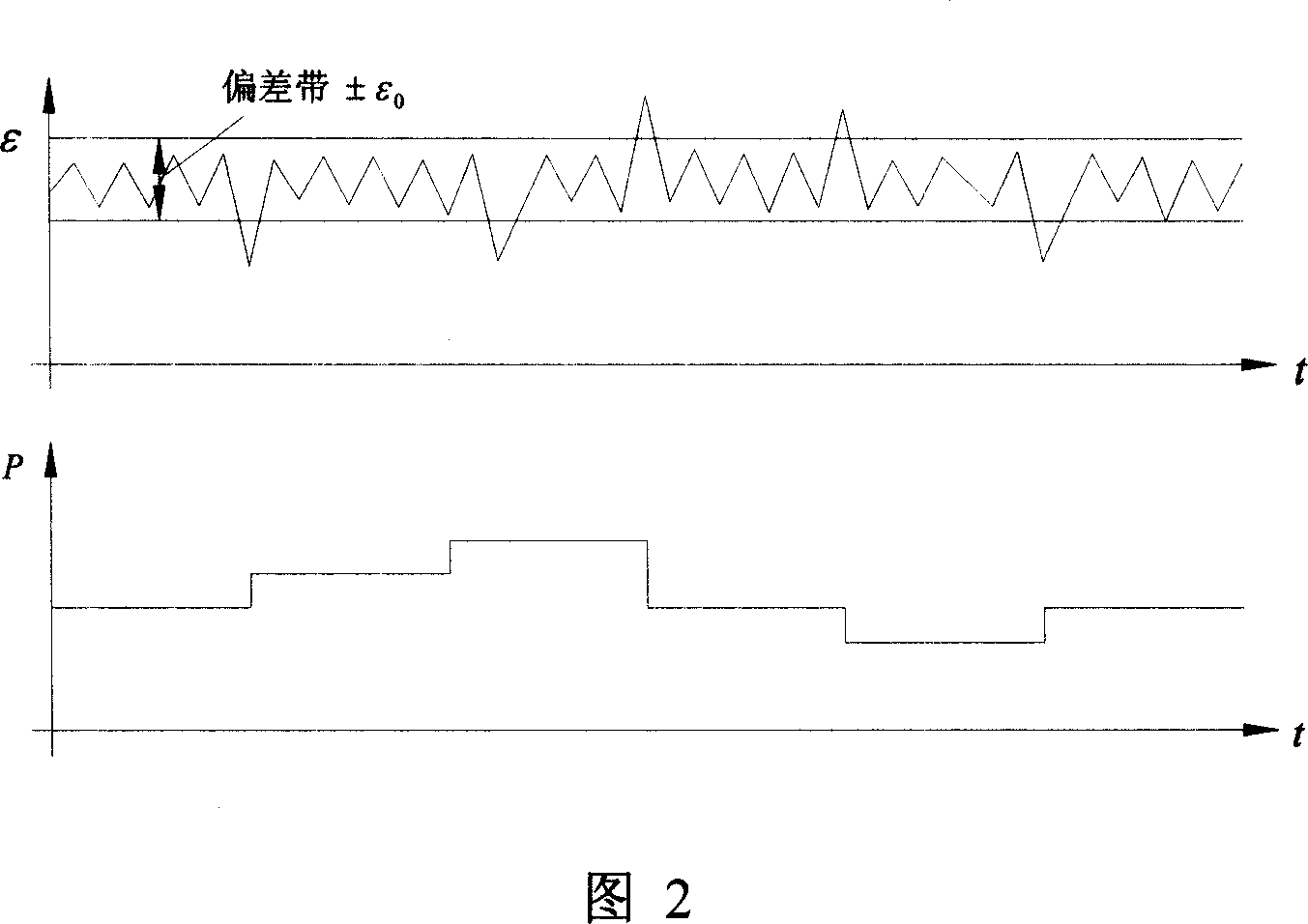

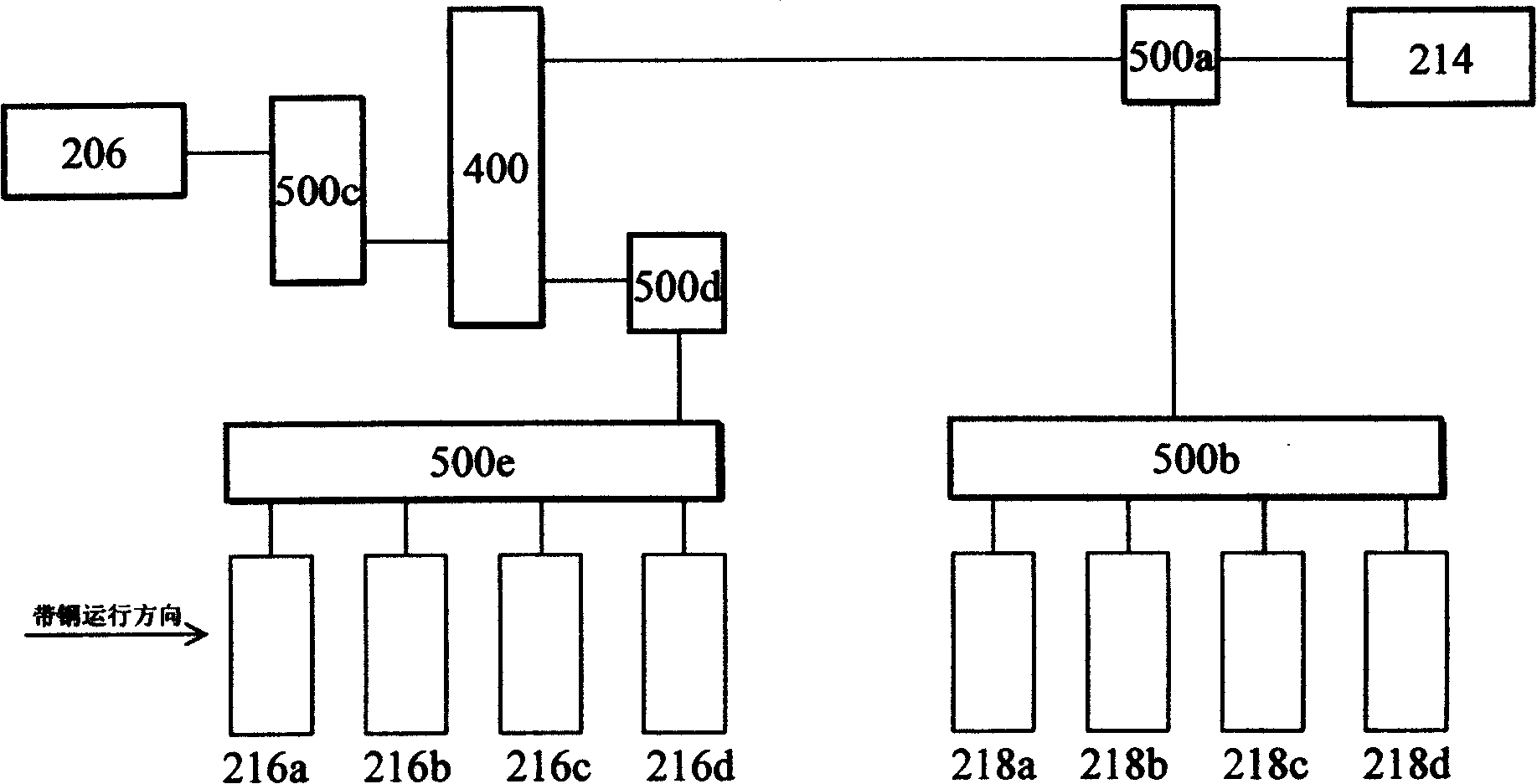

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

ActiveCN1923391AGuaranteed accuracyGuarantee the shape qualityRoll force/gap control deviceTension/compression control deviceControl systemClosed loop

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

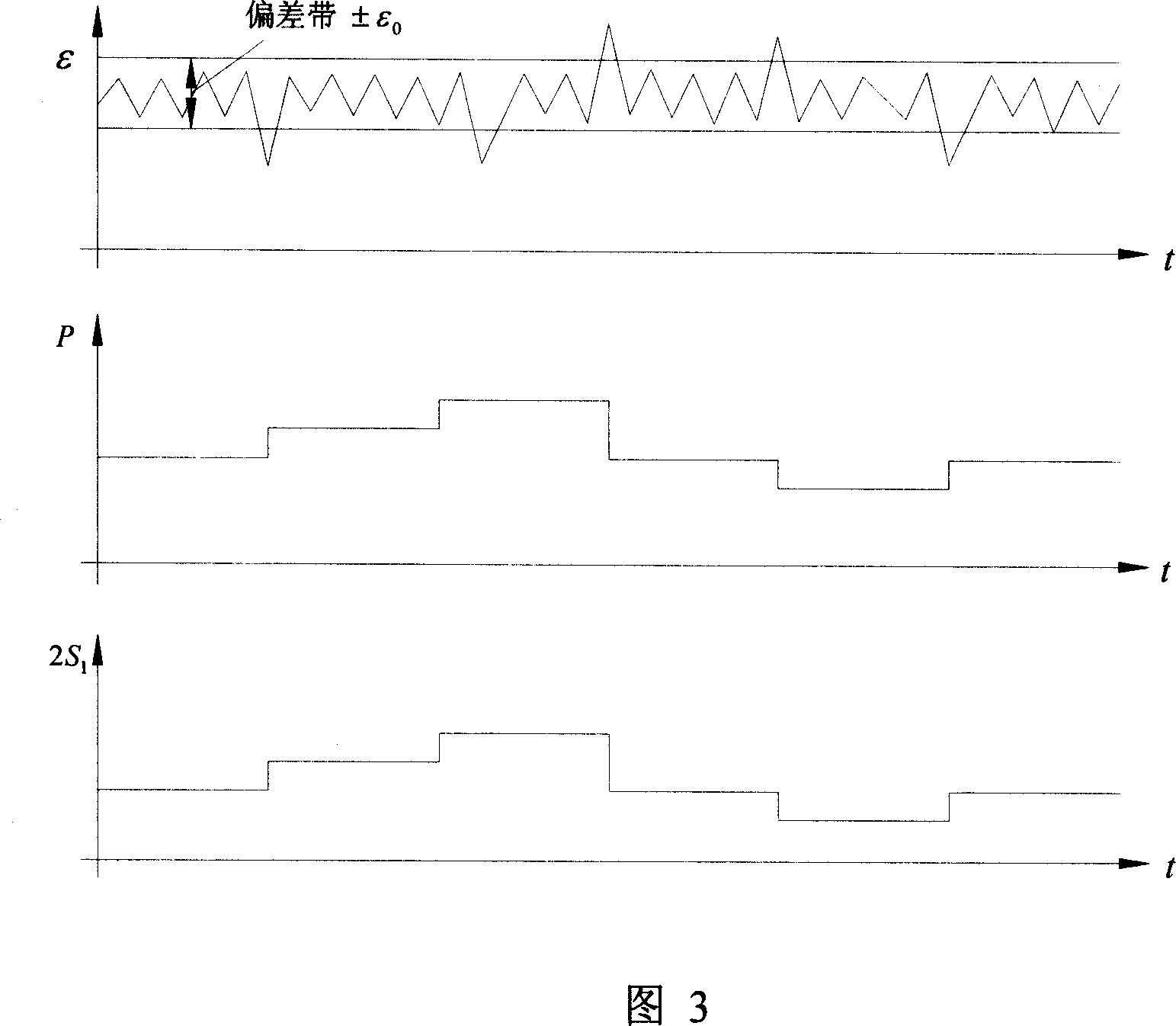

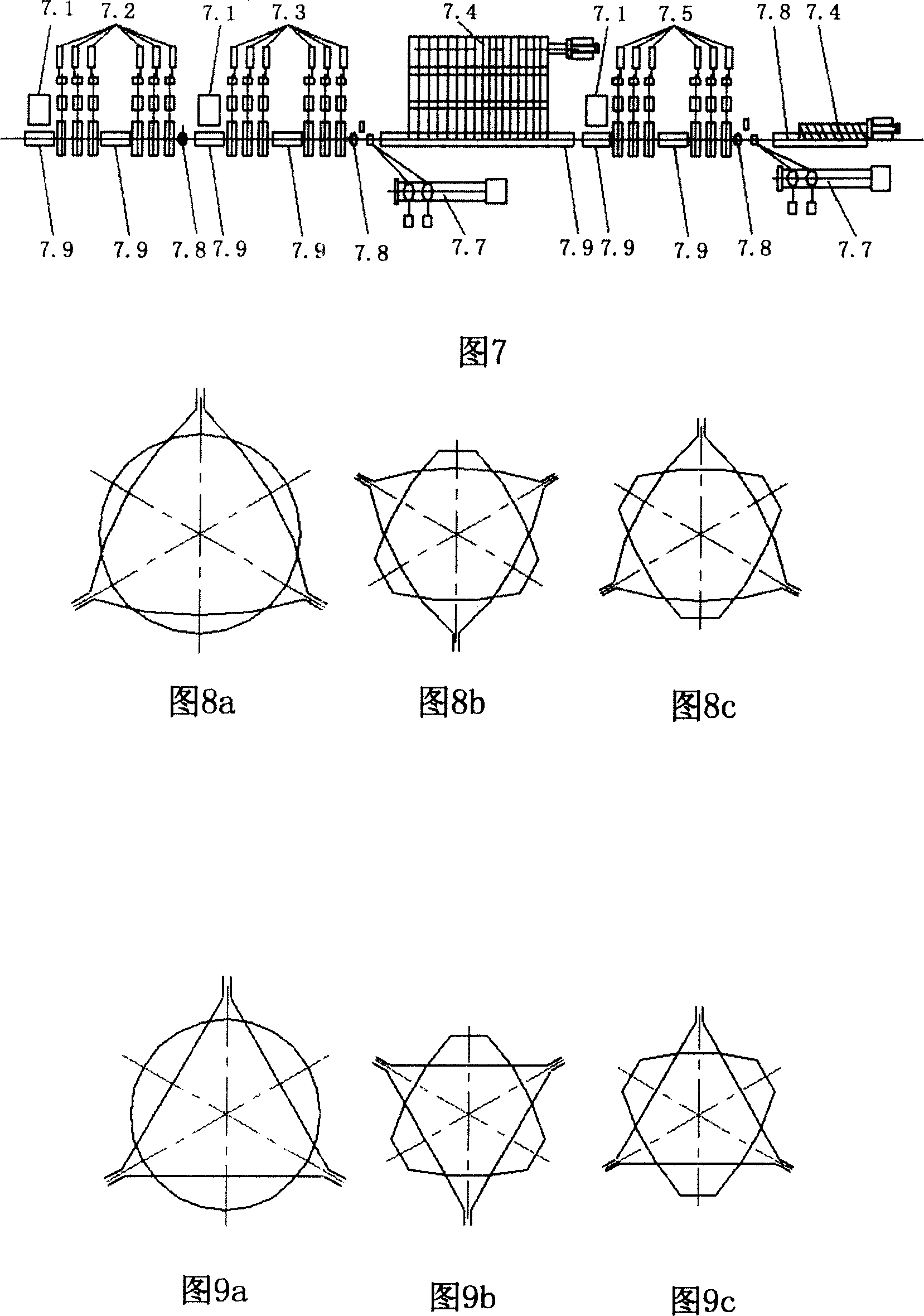

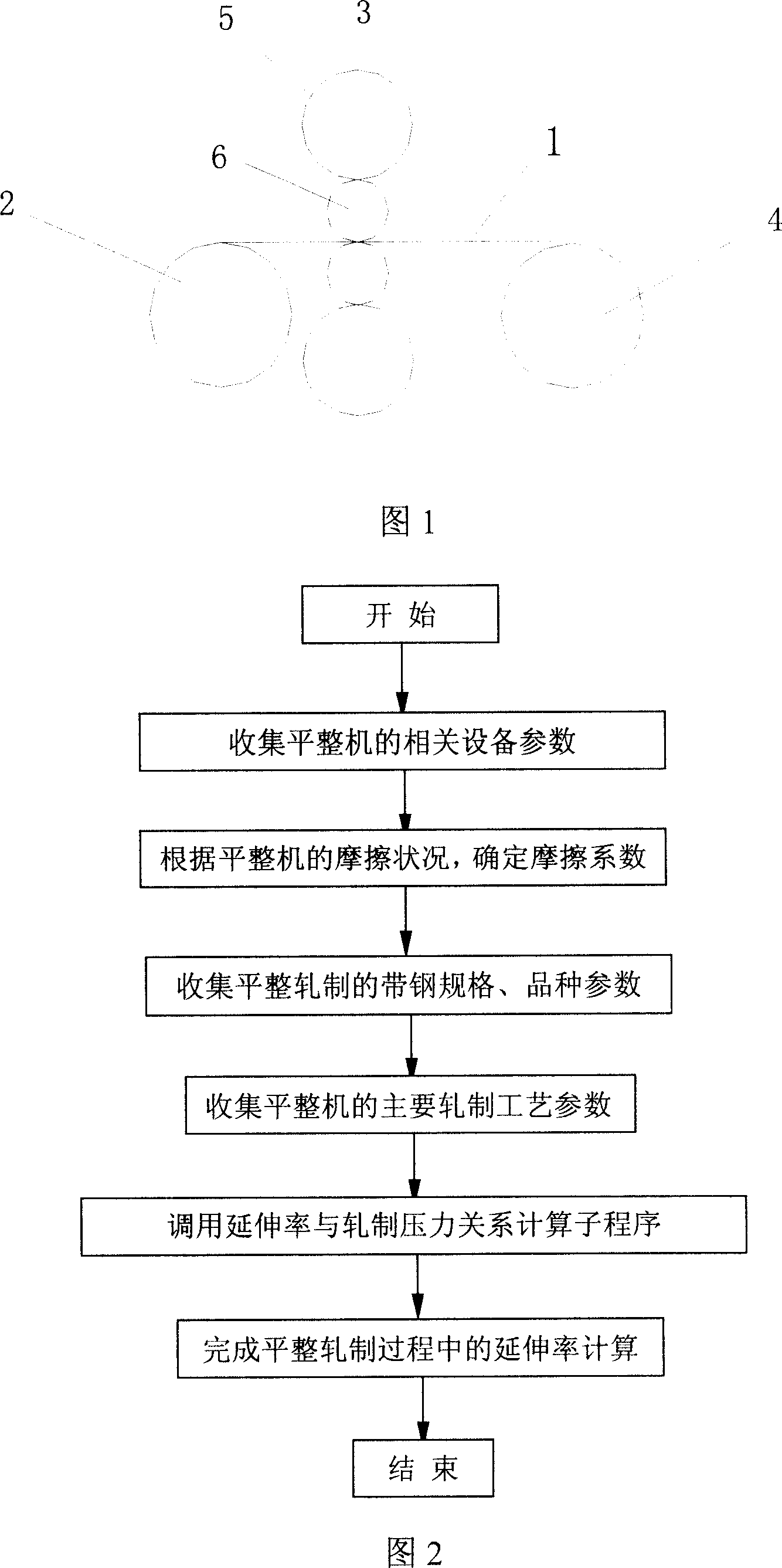

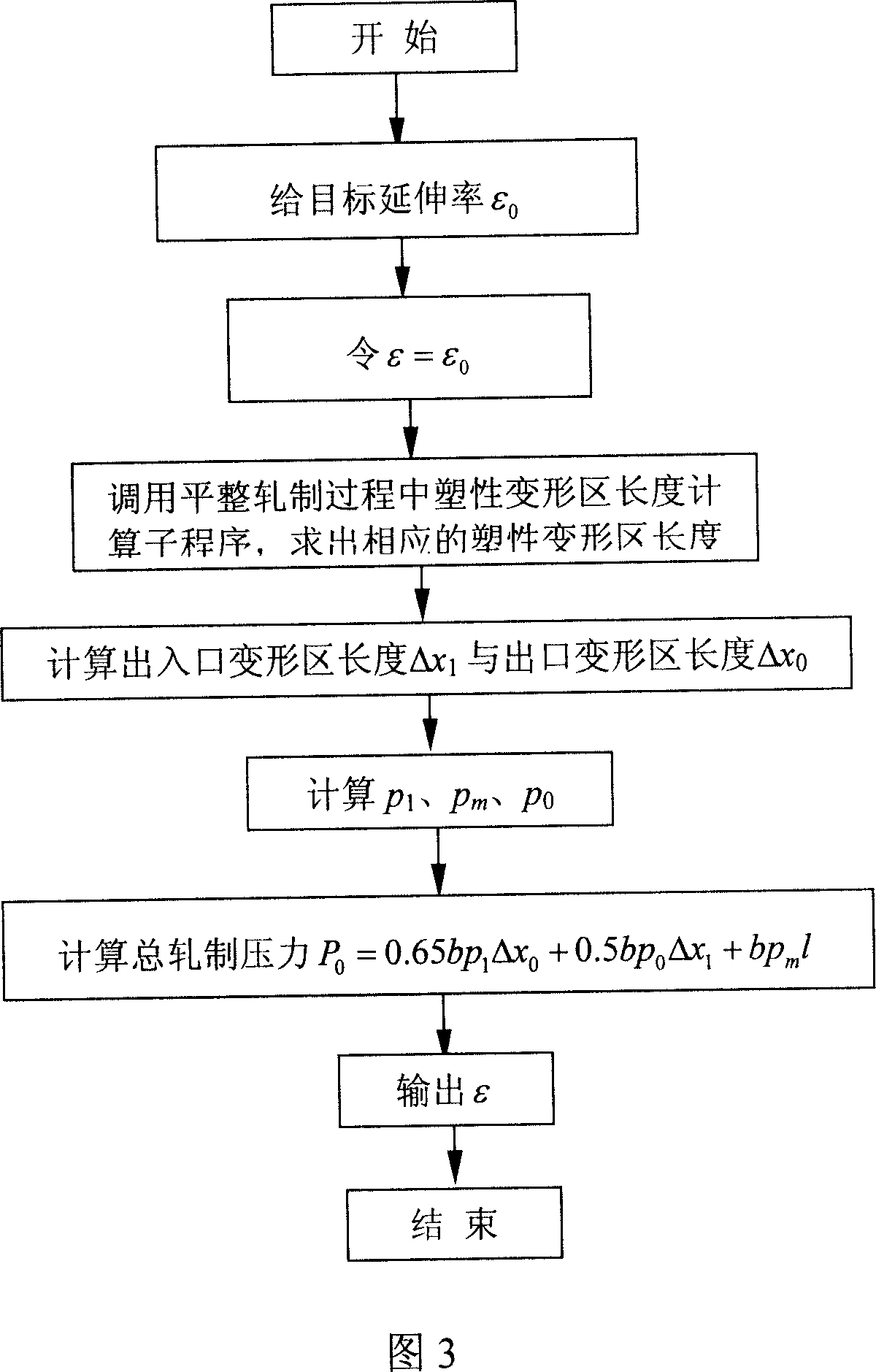

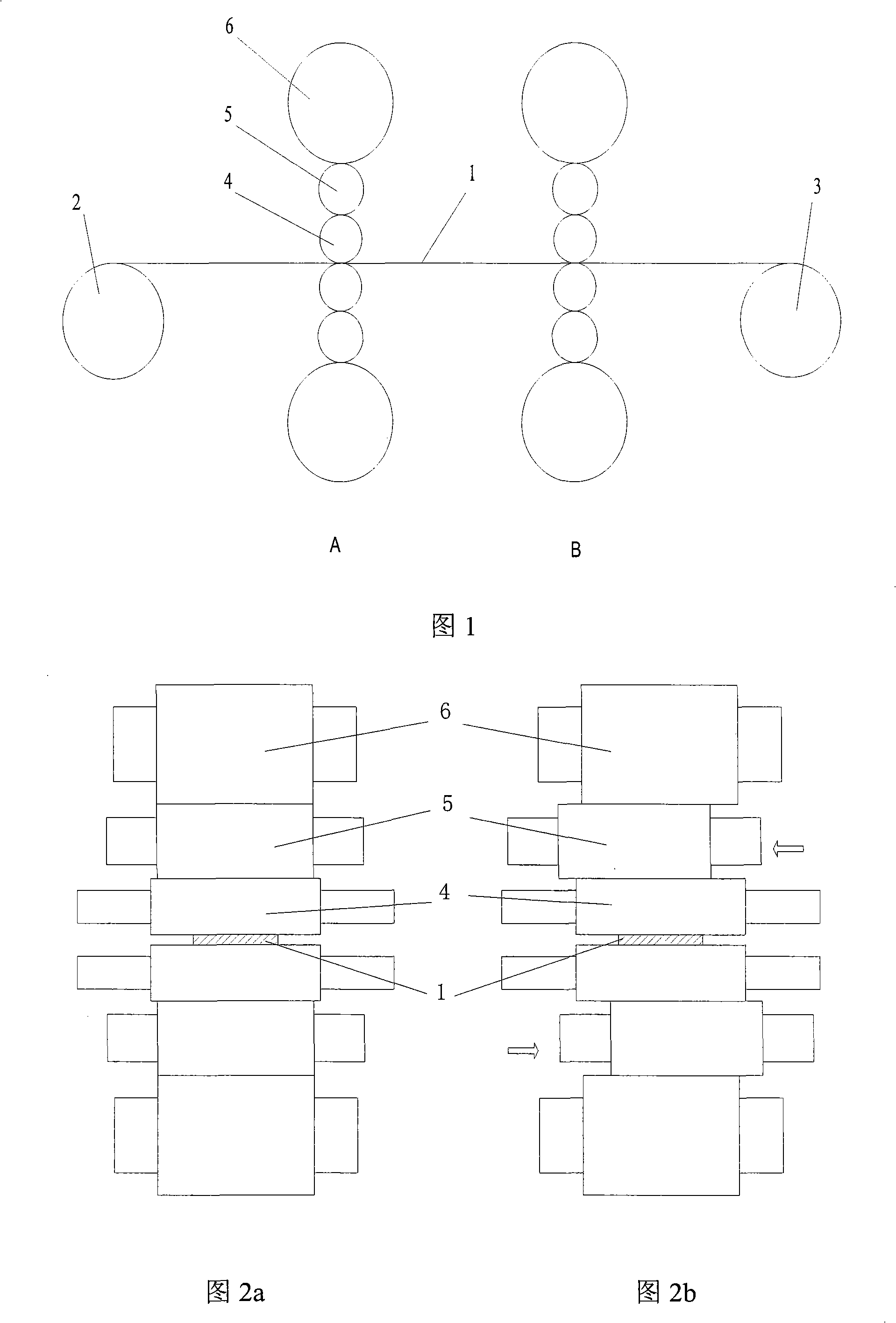

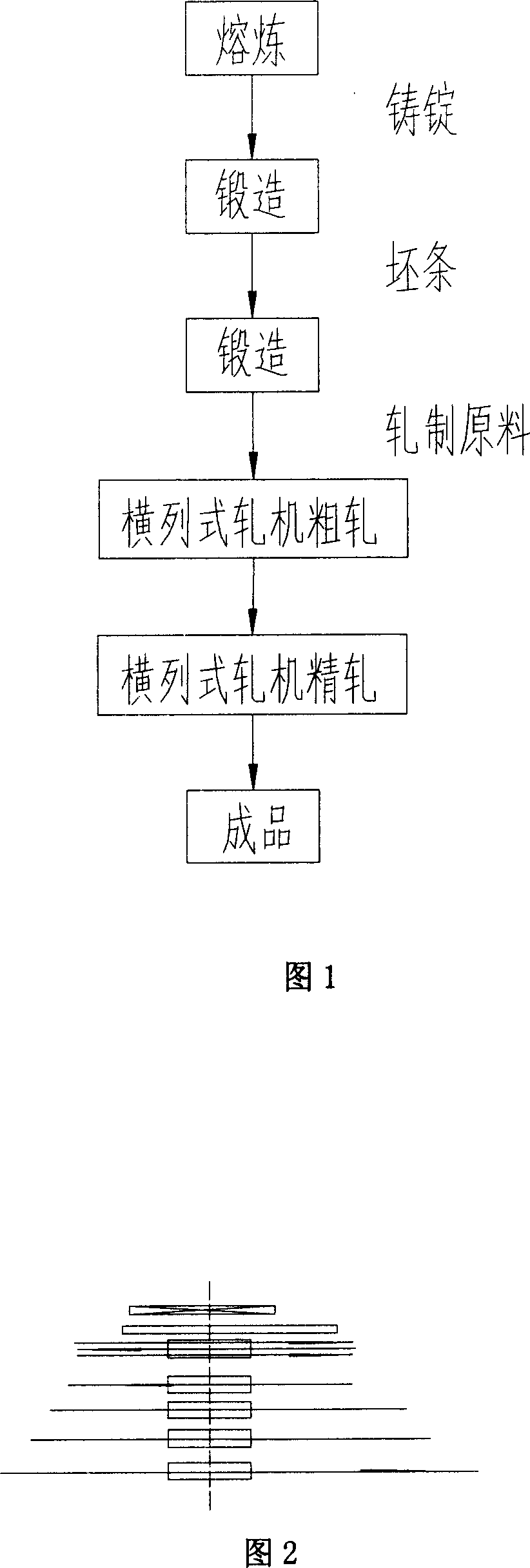

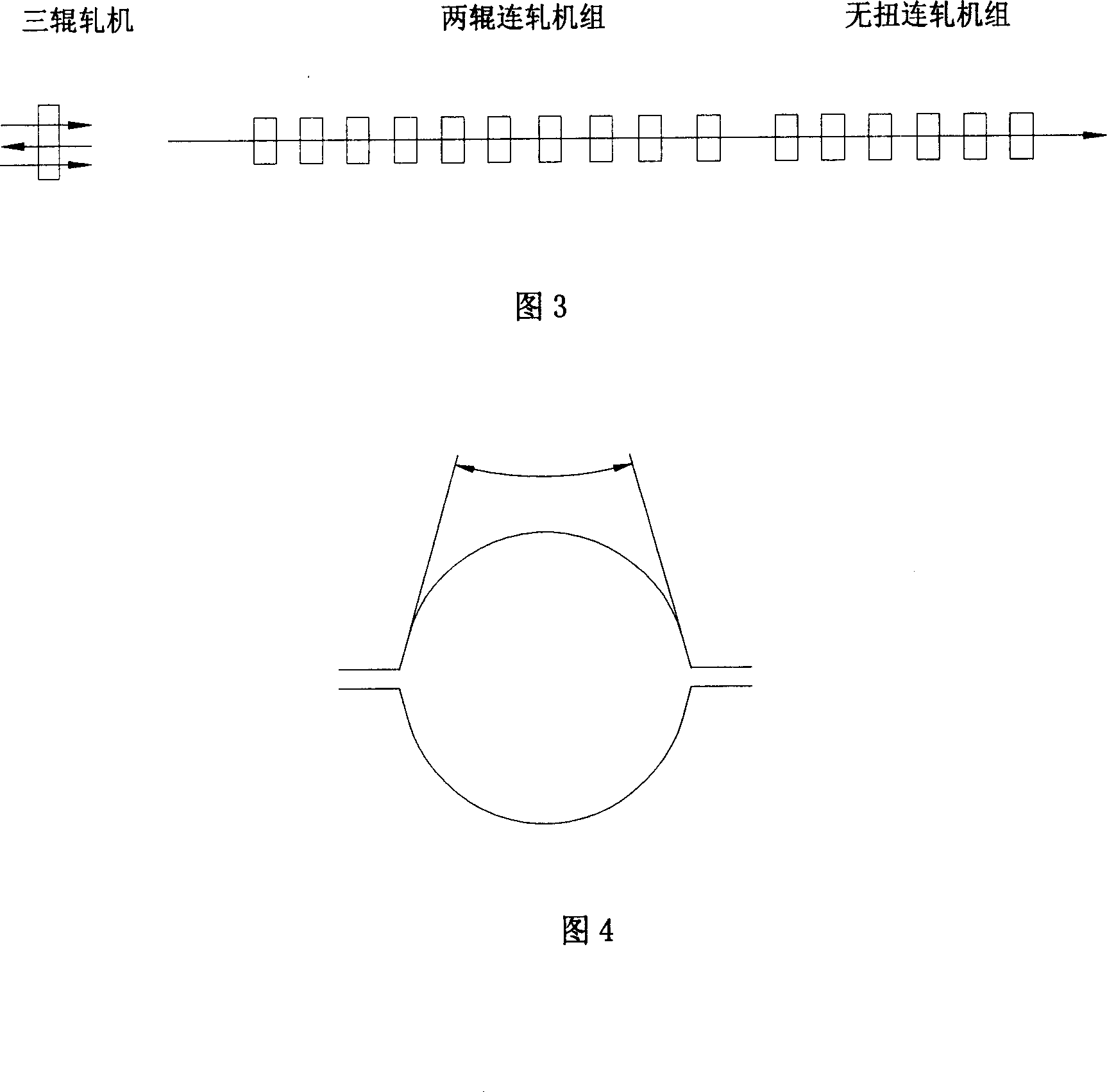

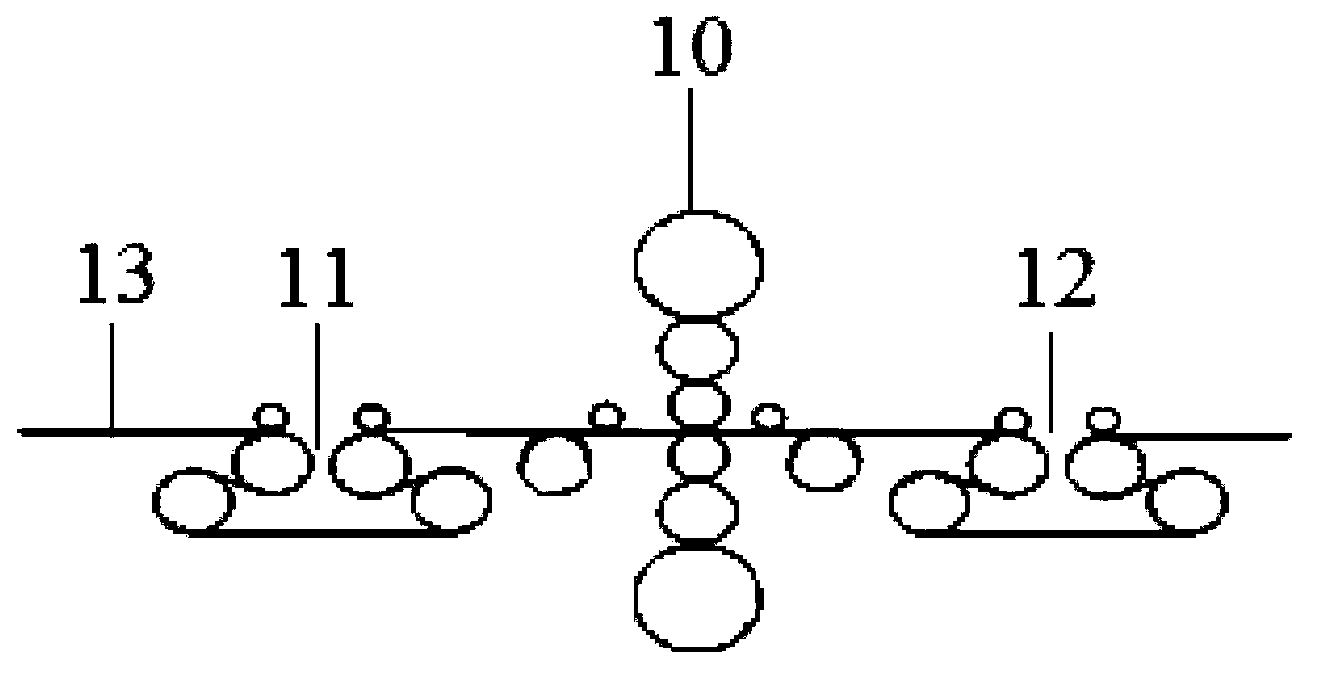

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

InactiveCN101152653AImprove surface qualityFew beginningsTemperature control deviceMetal rolling stand detailsLow noiseWire rod

The invention provides a method for rolling of titanium and titanium alloy bar and wire rod with three-roller Y continuous rolling mill. The technical proposal of the invention is as follows that the three-roller Y continuous rolling mill group is used for 6 to 18 pass continuous rolling of heated titanium and titanium alloy bar billet of phi50mm to form bar billet of 30 to 8mm (or hexagonal and triangular structure of 24 to 8mm) or rolling wire billet of phi20 to 8mm. by adopting the method, bar billet of phi50mm can be rolled into bar billet of phi30 to 8mm (or triangular and hexagonal structure) or rolling wire billet of phi20 to 8mm after heated for one time. Compared with the prior methods of multiple fire time casting, swaging, two-roller transverse-arrangement non-continuous rolling and two-roller longitudinal-arrangement continuous rolling, all of which are used for production of titanium and titanium alloy bar or rolling wire billet, the invention not only has the advantages of high efficiency, energy saving, low noise, small occupying and high precision of the size as well as good organization perforation of titanium and titanium alloy bar and wire rod, but also can produce triangular or hexagonal section and other allotype section.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

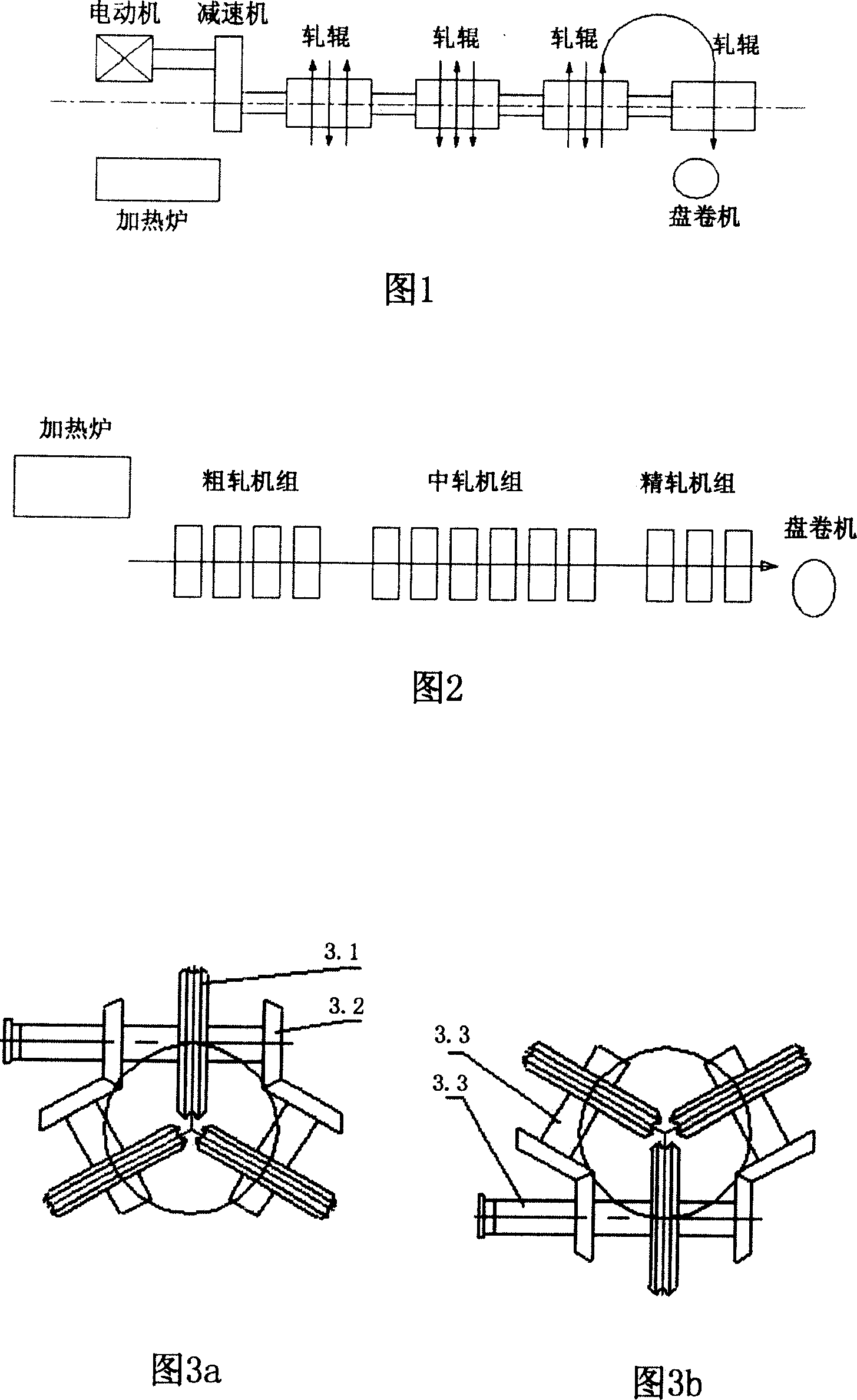

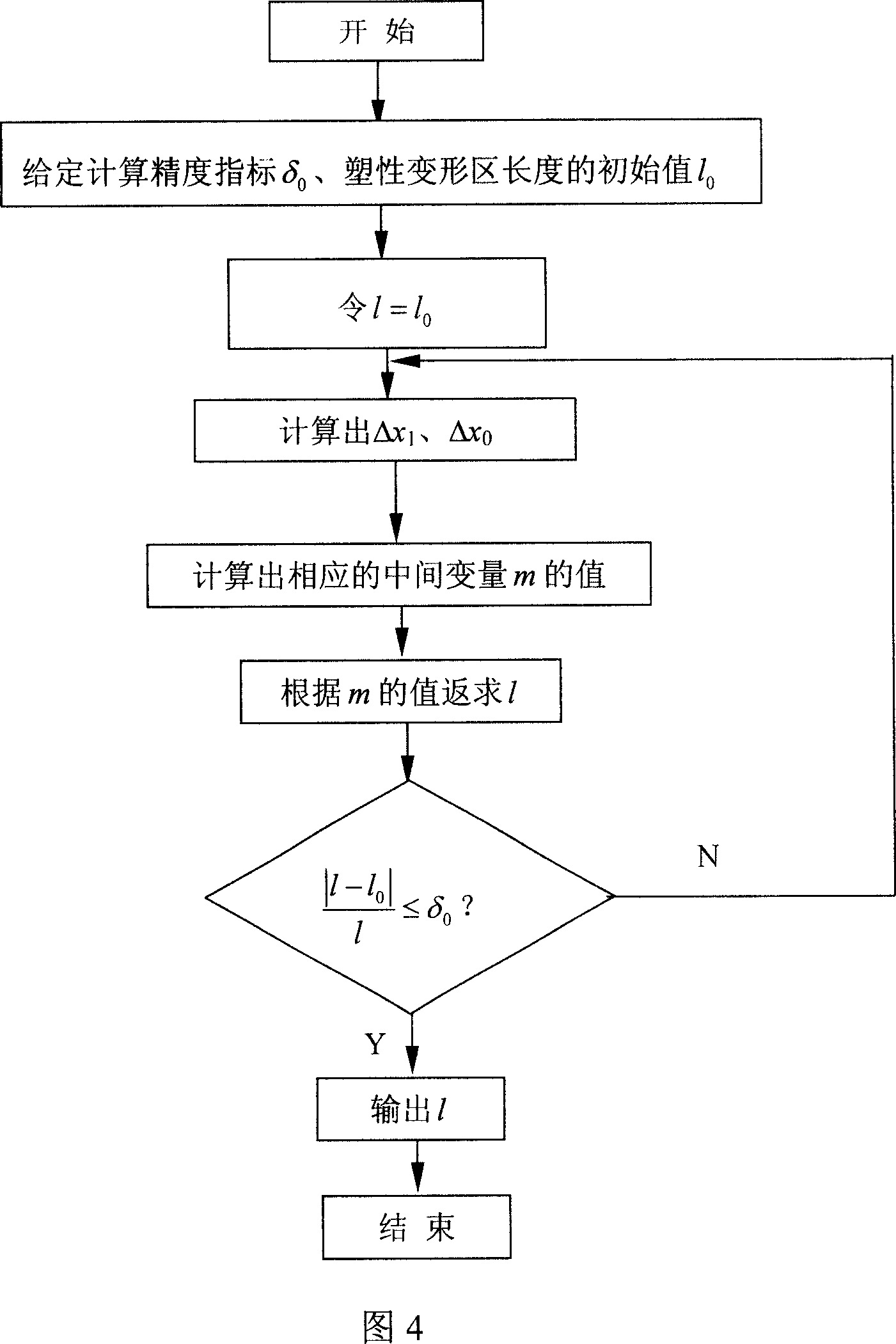

Method for comprehensive control of elongation coefficient and plate shape of steel band during even rolling process

InactiveCN101003063AImprove mechanical propertiesQuality improvementProfile control deviceMetal rolling arrangementsControl objectiveStrip steel

A method for controlling the elongation percentage, plate shape, etc in the skin rolling procedure of band steel features that an elongation percentage control unit, a plate shape control unit and an integrated control unit for both elongation percentage and plate shape are used, which use respectively three different optimizing algorithms to be used in a single iterative calculation procedure consisting of multiple optimizing calculation sub-procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

A kind of steel for high-hardness tin-plated original plate and its manufacturing method

InactiveCN102286688AHigh strengthReduce hot surface crispnessTemperature control deviceElongation control deviceChemical compositionSheet steel

The invention relates to a high-hardness tin-plated original steel produced by secondary cold rolling. S≤0.015%, Al: 0.01-0.05%, N: 0.0080-0.0160%, and the rest are iron and unavoidable impurities. The manufacturing method of the steel for high-strength tin-plated raw plate includes: smelting the above-mentioned components and continuously casting them into billets; heating the billets to 1150-1250°C for hot rolling, and the final rolling temperature is above Ar3; coiling, coiling The temperature is ≤580°C; the first cold rolling, the deformation is controlled at 80-90%; the annealing is performed after the first cold rolling, the annealing temperature is 580-650°C, and the annealing time is 40-120 seconds; the second cold rolling, the deformation is controlled Between 15% and 28%. The steel plate for high-strength tin-plated original plate of the present invention has a hardness of HR30T 70-80, and has excellent weldability and processability. Suitable for use such as making three-piece cans.

Owner:BAOSHAN IRON & STEEL CO LTD

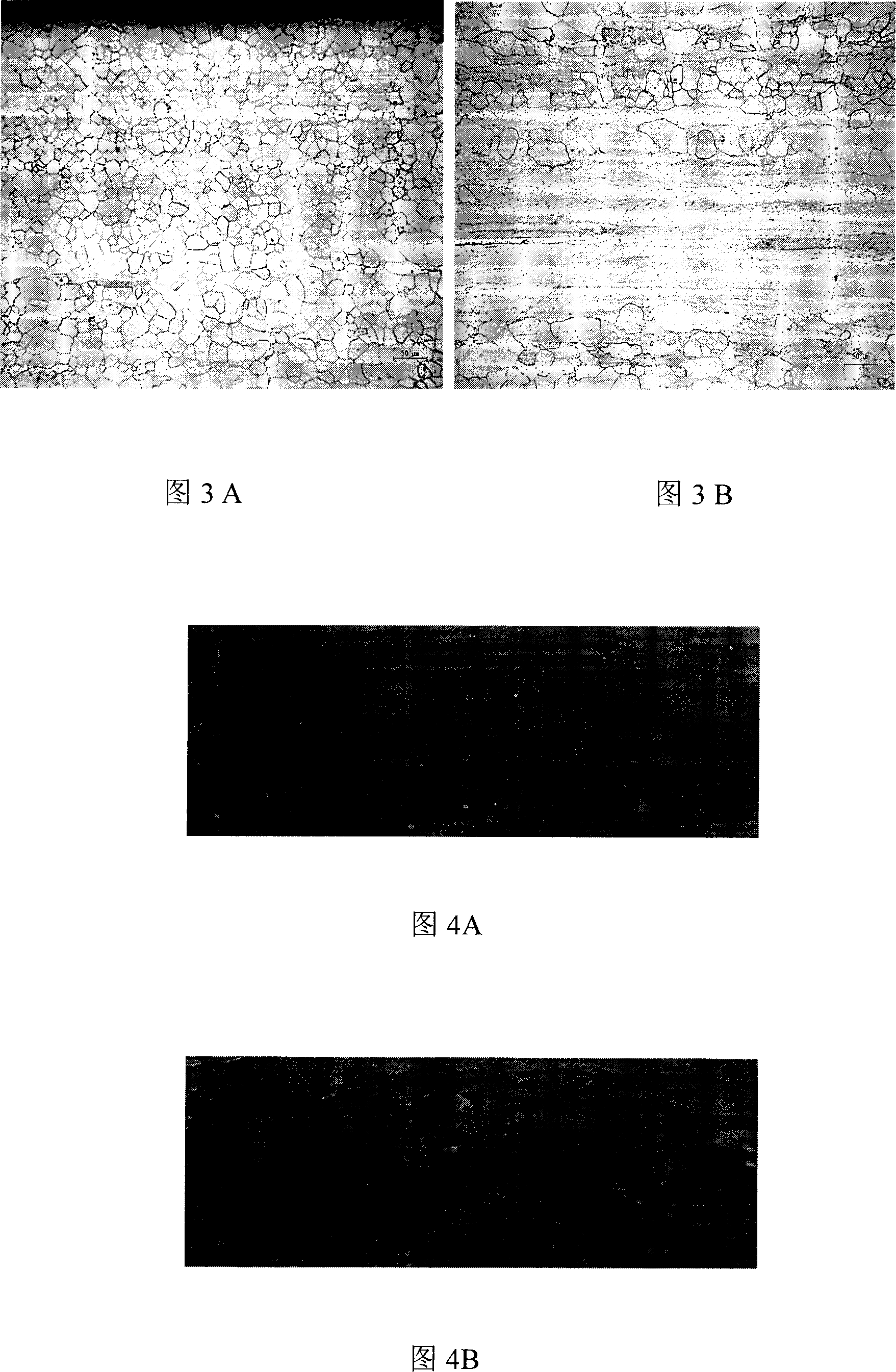

Process for producing ferritic stainless steel

ActiveCN101008043APromote recrystallizationGood recrystallized structureRoll force/gap control deviceTemperature control deviceAcid washingStrip steel

The invention relates to a modified method for preparing ferrite non-corrodible steel, comprising heating casting blank, phosphorus removing, roughing down, phosphorus removing, fine rolling, cooling, spiraling, acid washing and cold reducing. The heating temperature is controlled between 1000- 1200 Deg. C; the outlet for roughing down is controlled between 900- 1100 Deg. C, and the relative pressing rate for roughing down is distributed backwards to increase break deformation energy restoration and promote break recrystallization; increase swing steel of middle roller way of 10- 100s between roughing down and fine rolling to ensure the time and condition for middle blank recrystallization; the temperature for fine rolling inlet is controlled between 850- 1050 Deg. C, for outlet the temperature is controlled between 750- 950 Deg. C, the relative pressing rate for fine rolling is distributed backwards to increase break deformation energy restoration and promote break recrystallization; the break after rolling is cooled to 600- 800 Deg. C for batching.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

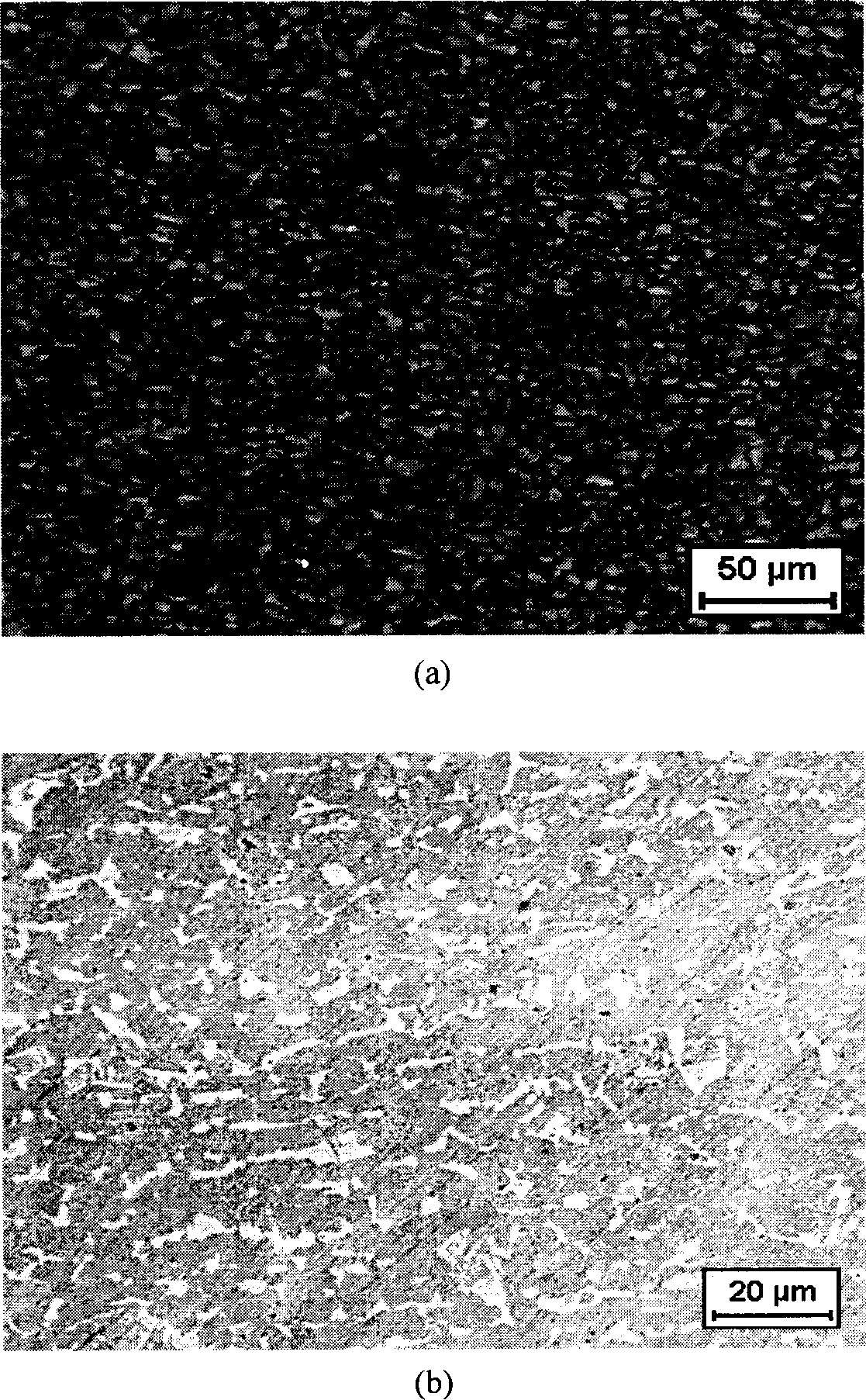

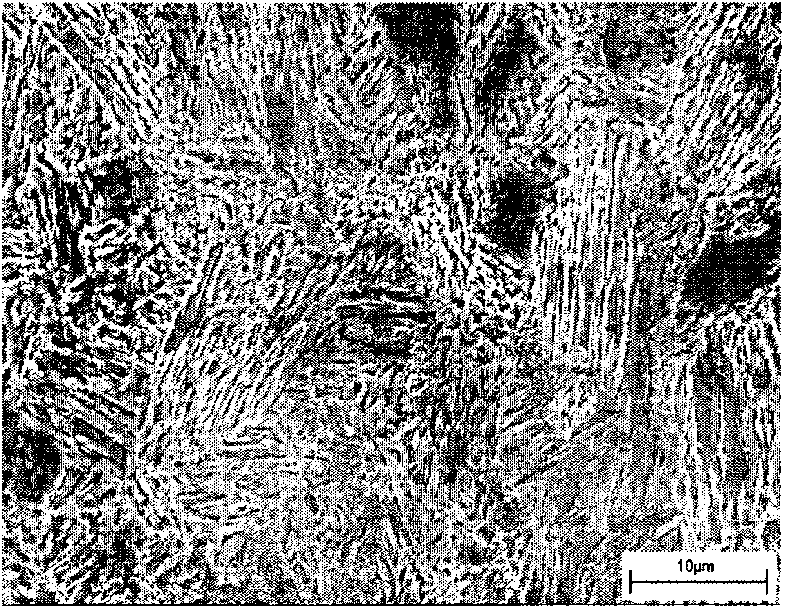

Medium carbon steel on-line balling rolling tech.

ActiveCN100999775AExcellent cold workabilityQuality improvementTemperature control deviceHeat treatment process controlMechanical componentsRoom temperature

The present invention discloses on-line medium carbon steel nodularizing and rolling process. The process includes low temperature finish rolling at 680-850 deg.c and accumulated cross section deformation of 50 %-80 %, controlled cooling after rolling at 3-15 deg.c / s to 660-720 deg.c, isothermal course, and naturally cooling to room temperature. The said technological scheme results in metallographic structure of the rolled piece with high ferrite component, less pearlite component, small and dispersed pearlite and granular cementite, lowered strength and hardness, raised plasticity and excellent cold machining performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Control process for continuous skin pass operation for metal strip

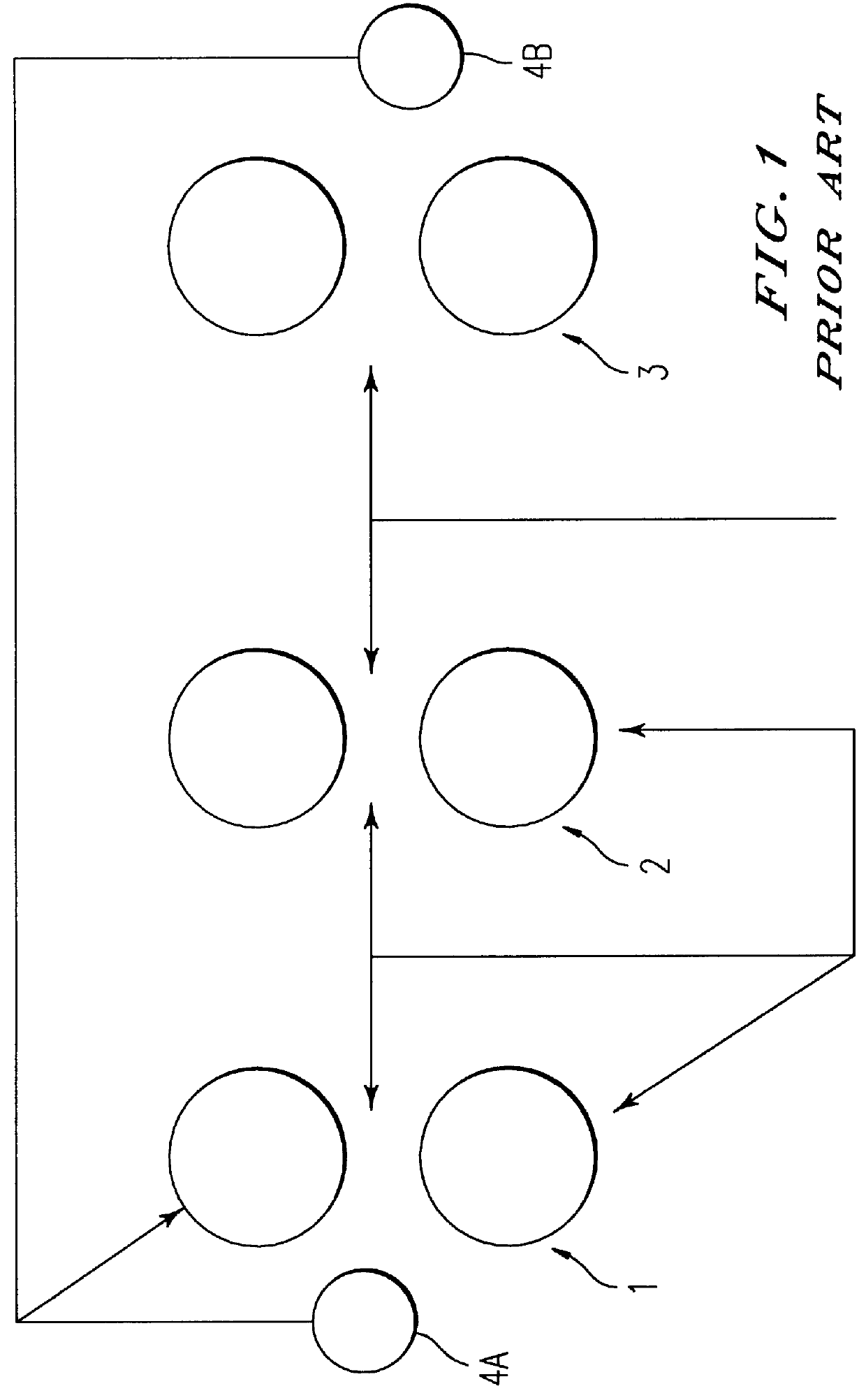

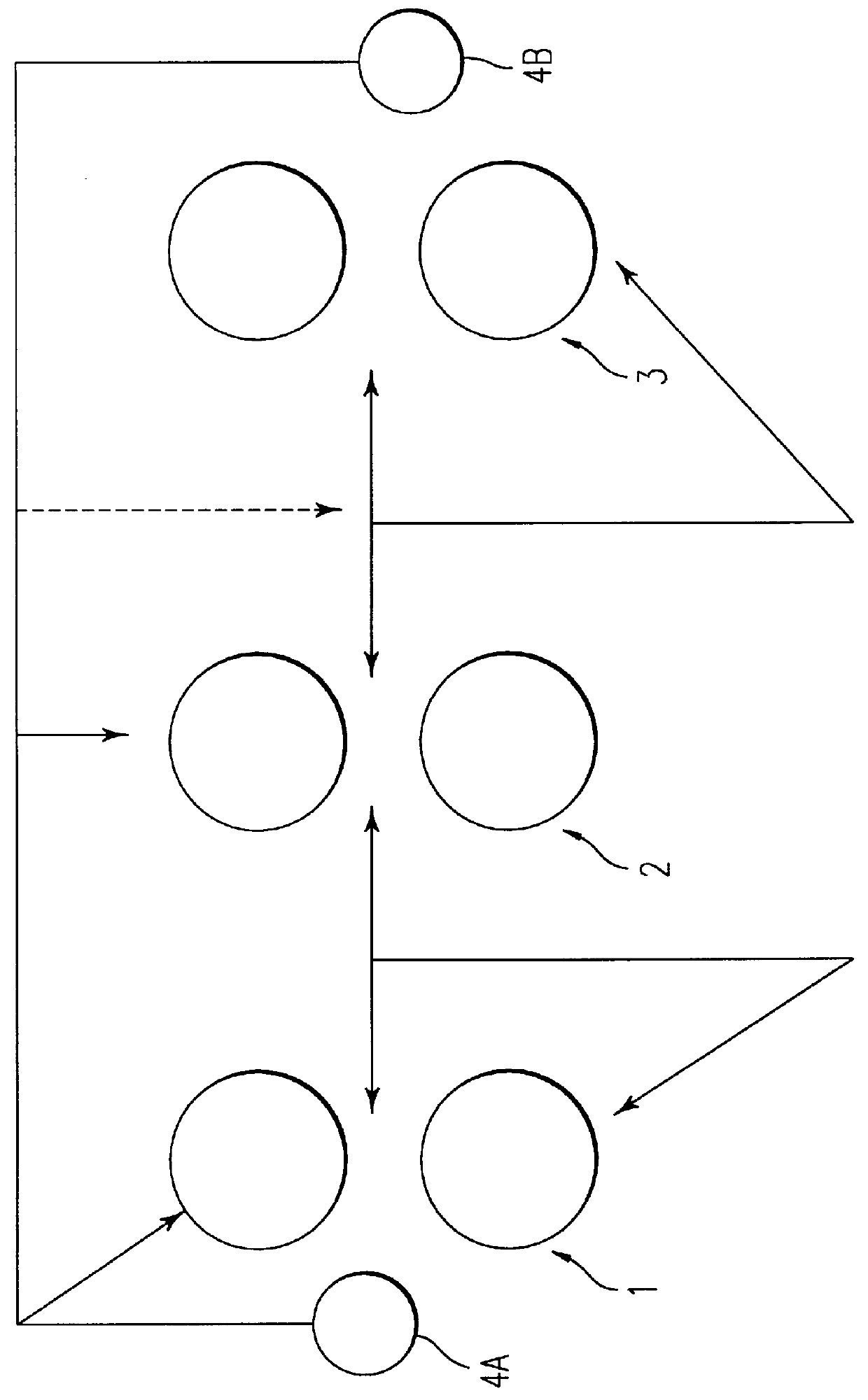

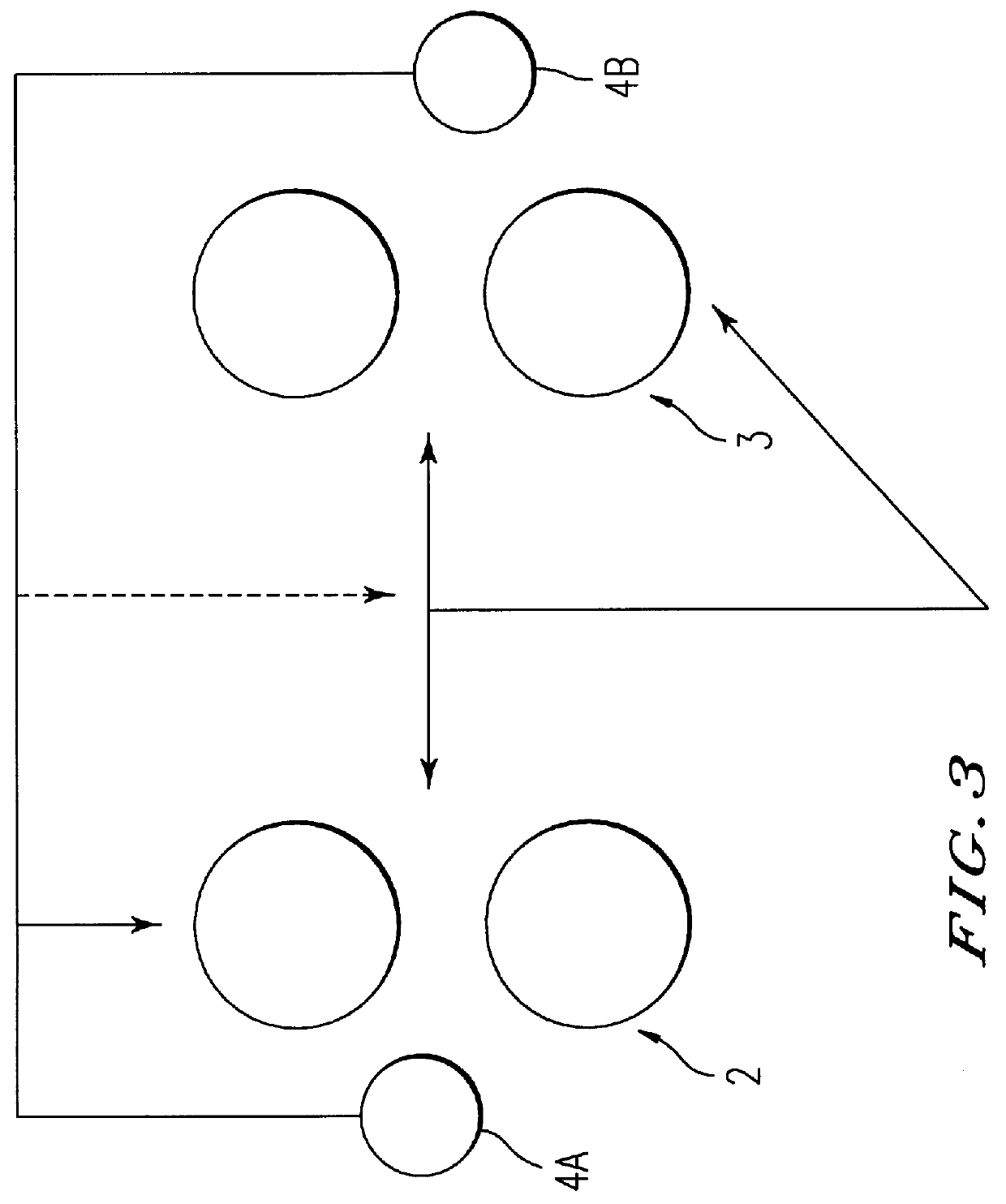

InactiveUS6079242AEliminate disadvantagesRoll force/gap control deviceTensioning/braking arrangementsMechanical engineeringEngineering

A method of controlling a continuous skin-pass and reduction operation for a metal strip includes the steps of passing a strip through a gap between working rollers of at least two successive rolling stands, only an upstream one of the stands providing substantial thickness reduction of the strip; determining an extension rate of the strip provided by the upstream stand; determining a tension of the strip downstream of the upstream stand; adjusting the speed of the working rollers of the upstream stand compared to the speed of the working rollers of a downstream one of said stands according to the determination of the extension rate; and adjusting the squeezing force of the upstream stand according to the downstream tension determination. A response time to the step of adjustment of the squeezing force is longer than a response time to the step of adjusting the speed of the working rollers.

Owner:SOLLAC (SA)

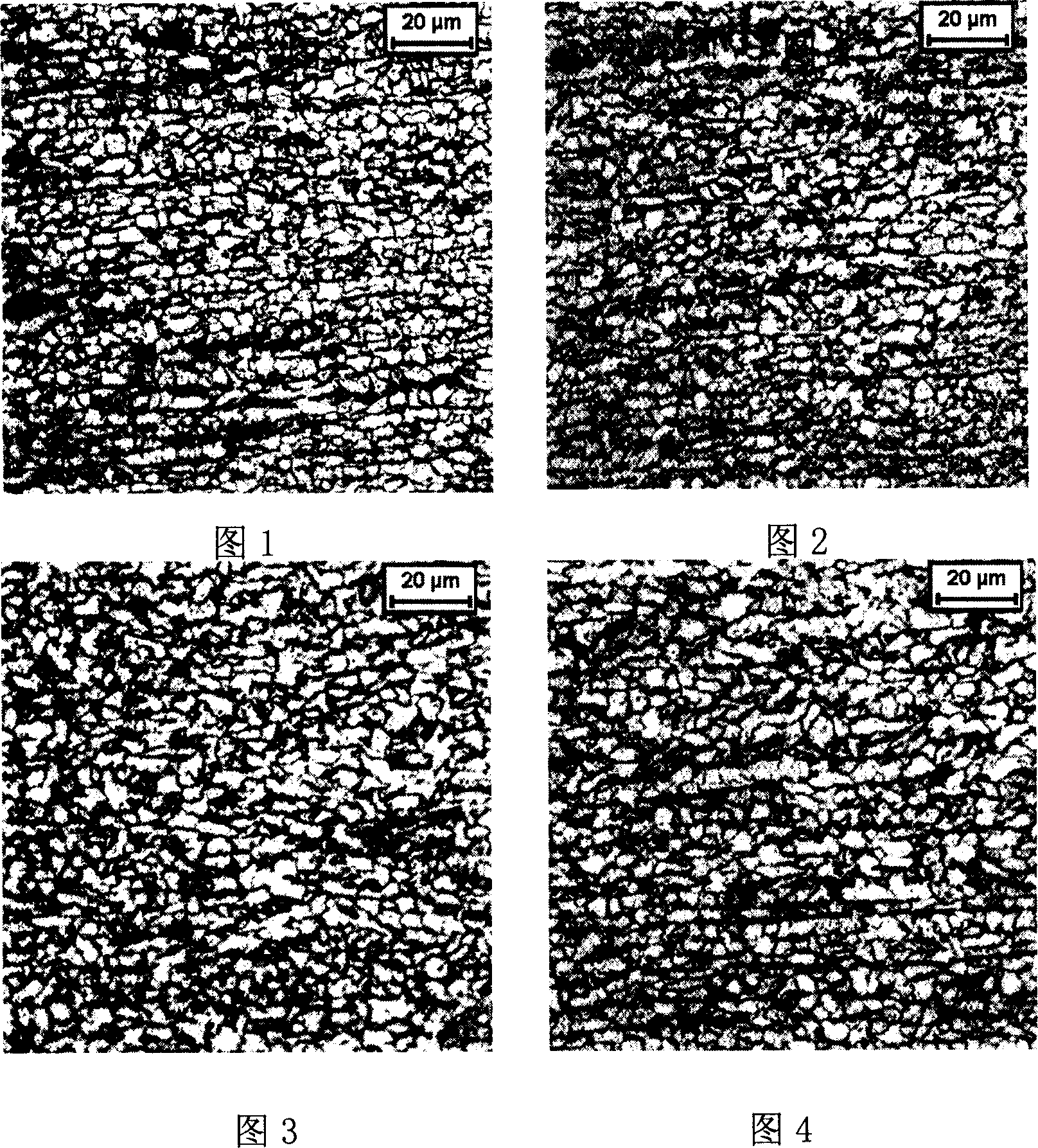

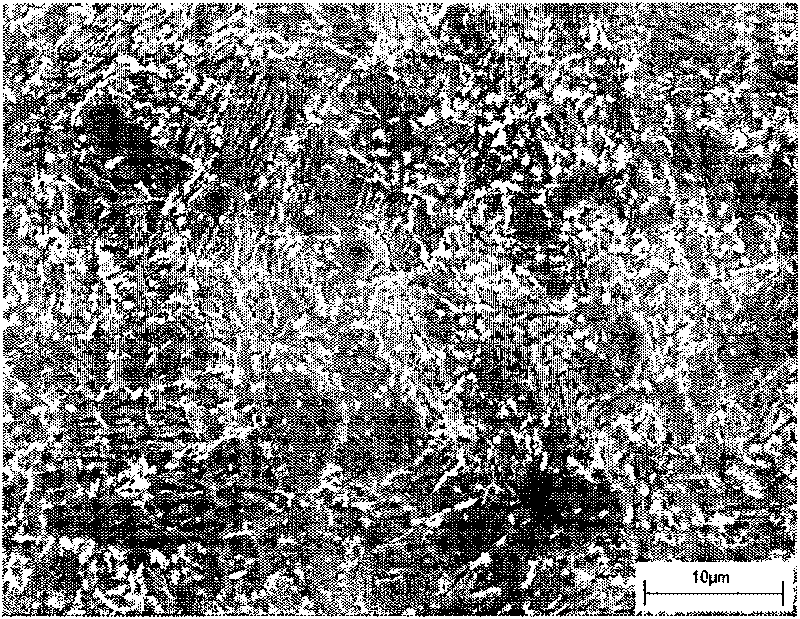

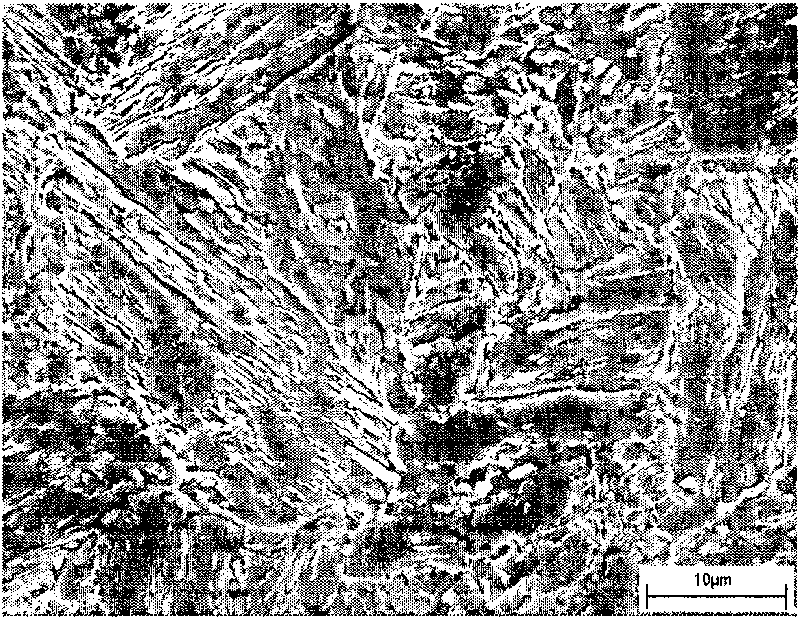

Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

InactiveCN1995431ASimple chemical compositionImprove plastic toughnessTemperature control deviceFurnace typesSheet steelChemical composition

The invention discloses a manufacturing method of hyperfine crystal steel board through continuous rolling thin board, which comprises the following steps: allocating raw material with 0.12-0.18% C, 0.15- 0.35% Si, 0.65-1. 20% Mn, not more than 0.02% P, not more than 0.015% S and Fe; casting in the 100-200mm*1000-2000mm blank; setting the loading temperature over 800 deg. c; heating to 1100-1280 deg. c; reducing rough rolling of blank to 30-60 mm; setting refining rolling temperature between 920 and 1050 deg. c; exerting multi-channel and large-deforming strain accumulation with even deforming velocity at 1-10 / s; setting the refining rolling outlet temperature at 750-900 deg. c; setting cooling speed of laminar flow at 10-45 deg. c / s; coiling at 400-620 deg. c; setting the norm of continuous heat rolling steel at 2-18mm with even crystal size at 3-7um and yielding strength over 400Mpa; making the extending proof strength between 510 and 580 Mpa and extending rate over 26%.

Owner:ANGANG STEEL CO LTD

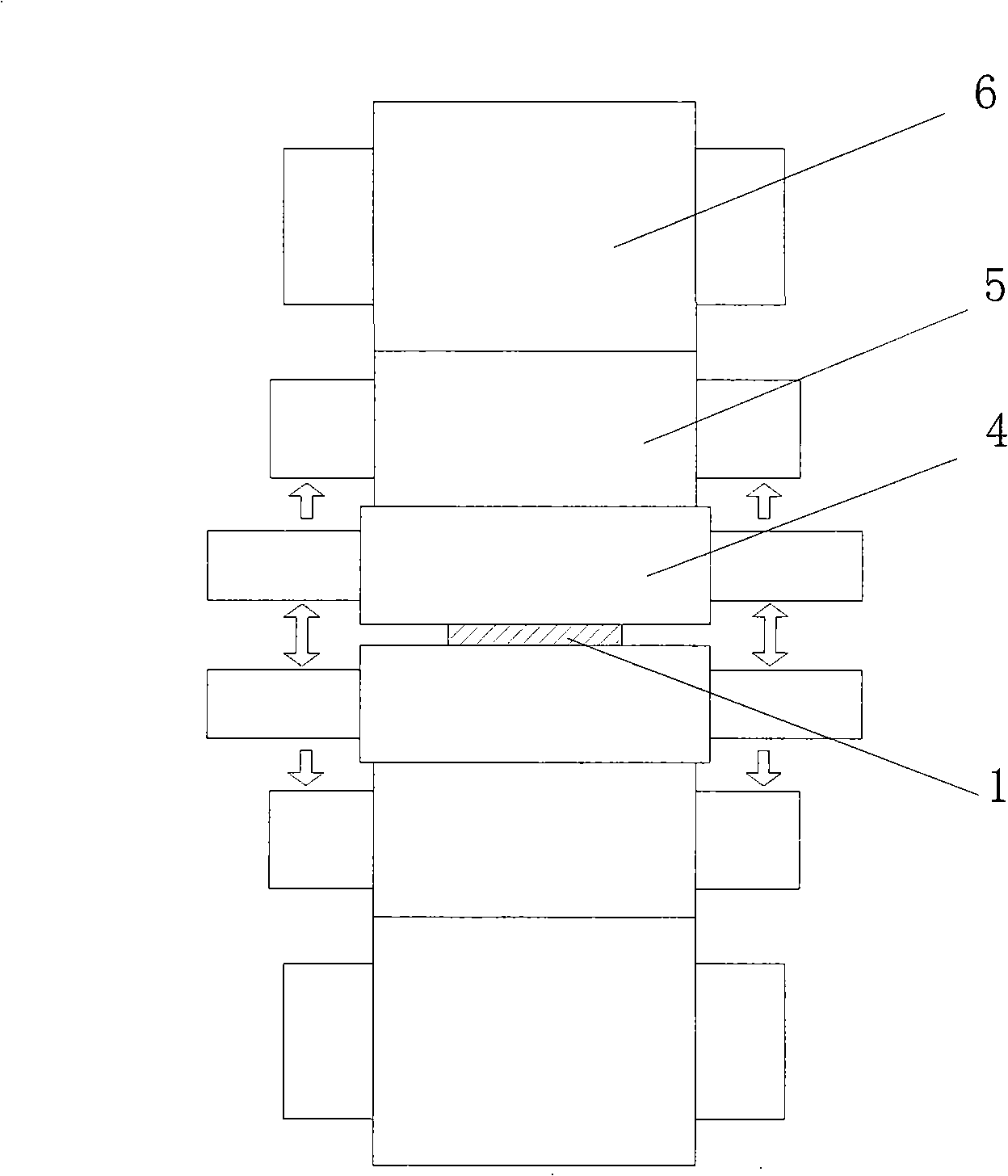

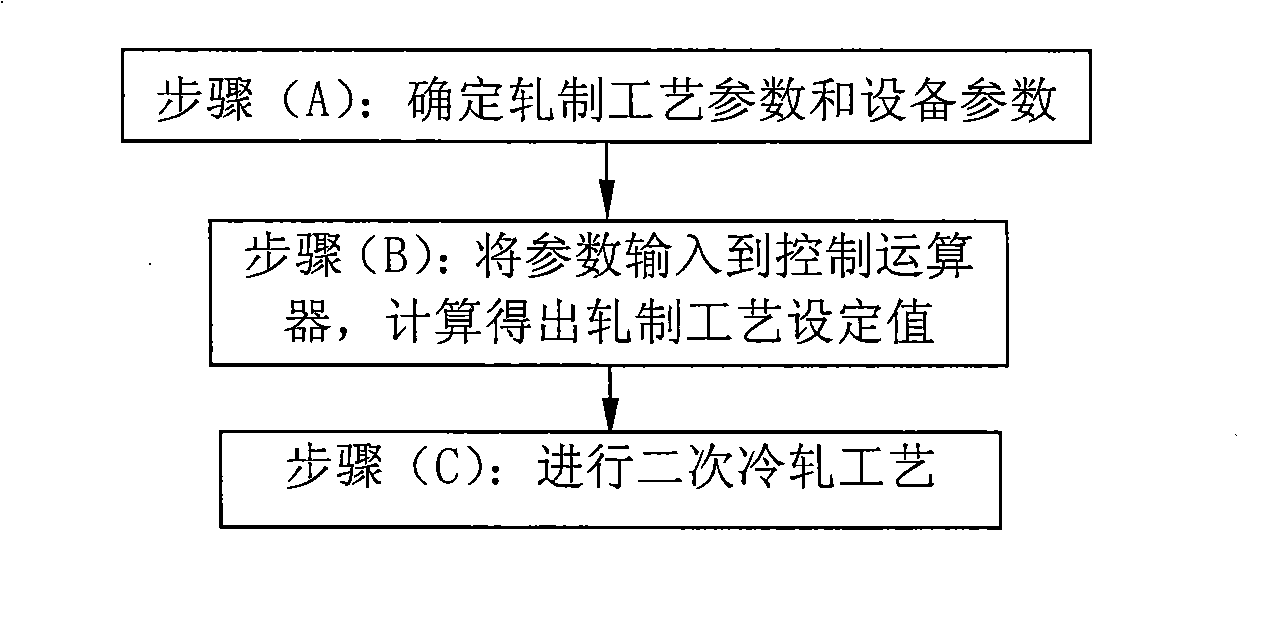

Method for leveling strip produced by secondary cold rolling unit

ActiveCN101513647AEasy to shapeQuality improvementTension/compression control deviceProfile control deviceHorizontal distributionWork roll

The invention provides a method for leveling a strip produced by a secondary cold rolling unit, which controls the surface roughness of the strip by reasonably setting the partition coefficients of the roughness and elongation of the working rolls of first and second machine frames and controls the shapes of finished strips other possible surface defects by reasonably setting a bending-roller force, a roll shifting rate and the tension of the front, middle and rear sections of the machine frames to achieve uniform front tension of finished strips and uniform horizontal distribution of a rolling force, thereby establishing effectively improved technology for leveling high-brightness micro plates produced by a secondary cold rolling unit. The principle of the method is clear, a secondary cold rolling process is carried out smoothly according to obtained rolling process set values, the quality of the shape and surface of leveled strips is high, the calculation is quick, and the method issuitable for online use.

Owner:BAOSHAN IRON & STEEL CO LTD

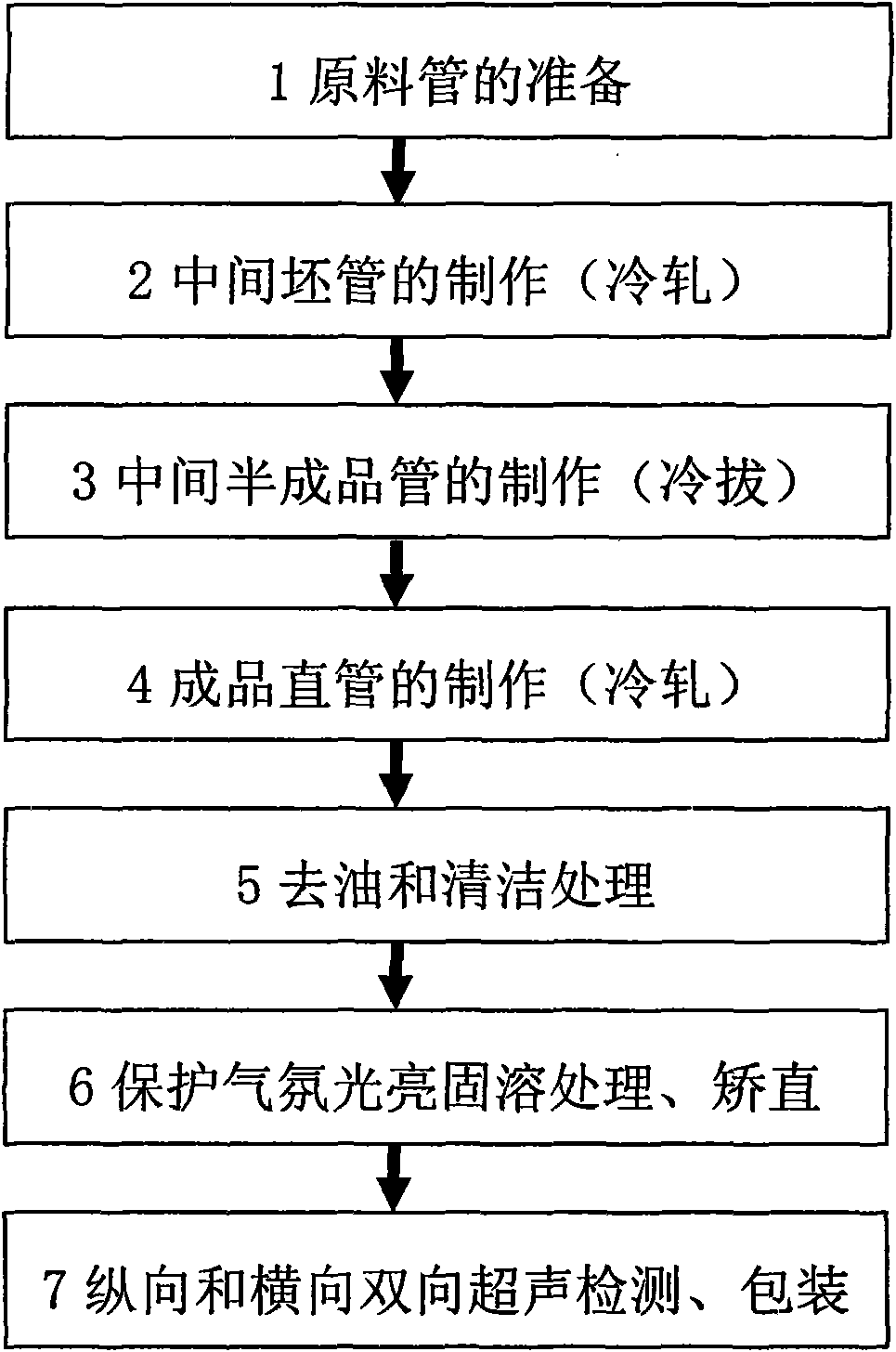

Method for manufacturing stainless steel heat transfer pipe of nuclear heat exchanger

ActiveCN101623719ASmall caliberThin wallAnalysing solids using sonic/ultrasonic/infrasonic wavesFurnace typesPlate heat exchangerHigh pressure

The invention relates to a method for manufacturing a stainless steel heat transfer pipe, in particular to a method for manufacturing a stainless steel heat transfer pipe of a nuclear heat exchanger, comprising the following steps: cold rolling a material pipe to a middle parison pipe having the required pipe outside diameter and wall thickness through a cold rolling device; cold drawing the middle parison pipe to a middle semi-finished product pipe having the required pipe outside diameter and wall thickness through a cold-drawing pipe, and applying a low-frequency alternating magnetic field with a magnetic field frequency of 10-30Hz and a power range of 20-40kW; cold rolling the middle semi-finished product pipe to a finished product straight pipe having the required pipe outside diameter and wall thickness, and applying high-frequency alternating magnetic field with a magnetic field frequency of 30-50Hz and a power range of 70-90kW; performing multiple wiping inside the finished-product straight pipe, deoiling and cleaning; and performing brightness thermal processing and straightening processing. The stainless steel heat transfer pipe of the nuclear heat exchanger produced with a production technique has the characteristics of small caliber, thin wall, high precision, and the like and accords with the using requirement of high-pressure resistance and corrosion resistance of the nuclear heat exchanger in performance.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Method for leveling titanium board coil

InactiveCN101486051AStress reliefEliminate its influenceTension/compression control deviceRoll speed control deviceNational standardTitanium

The invention provides a method for levelling a titanium plate coil, which comprises the following steps: delivering the titanium plate coil subjected to annealing treatment to a levelling machine, and directly carrying out levelling extension on the titanium plate coil by a levelling roll on the levelling machine or carrying out wet levelling on the titanium plate coil by the levelling roll under the conditions that the rolling speed is 50 to 200 meters per minute, the uncoiling tension is 0.5 and 4 tons, the curling tension is between 3.0 and 5.0 tons, and the extension rate is between 0.80 and 2.0 percent. After the cold-rolled and annealed titanium plate coil is subjected to leveling extension by the levelling roll on the levelling machine, the levelling method can eliminate stress and influence of the stress, level plate surfaces, and obtain better surface quality; and all the plate shape, dimension, surface quality, mechanical property, and the like of the leveled titanium plate coil achieve national standard requirements, and completely meet market demand.

Owner:YUNNAN TITANIUM IND

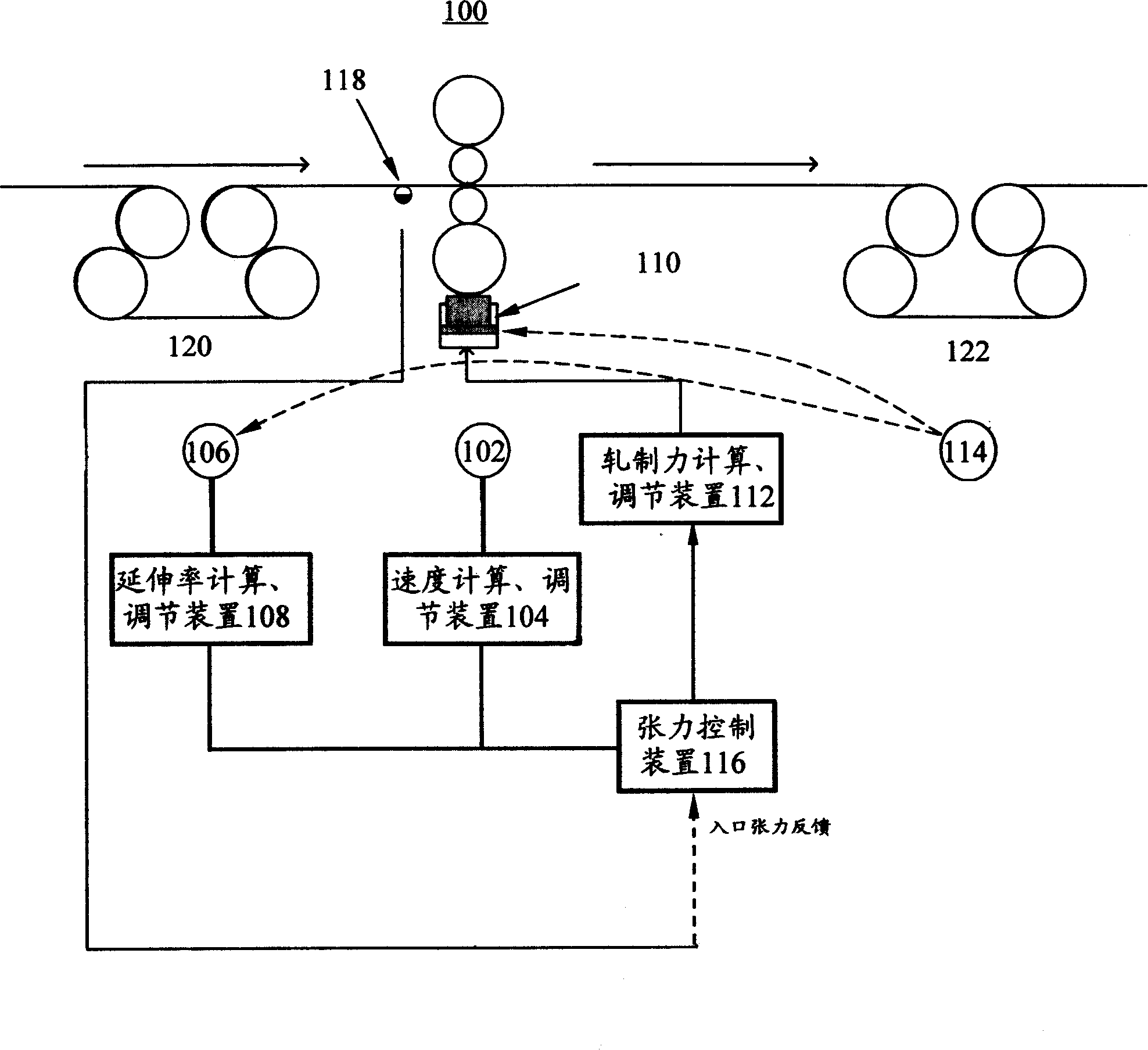

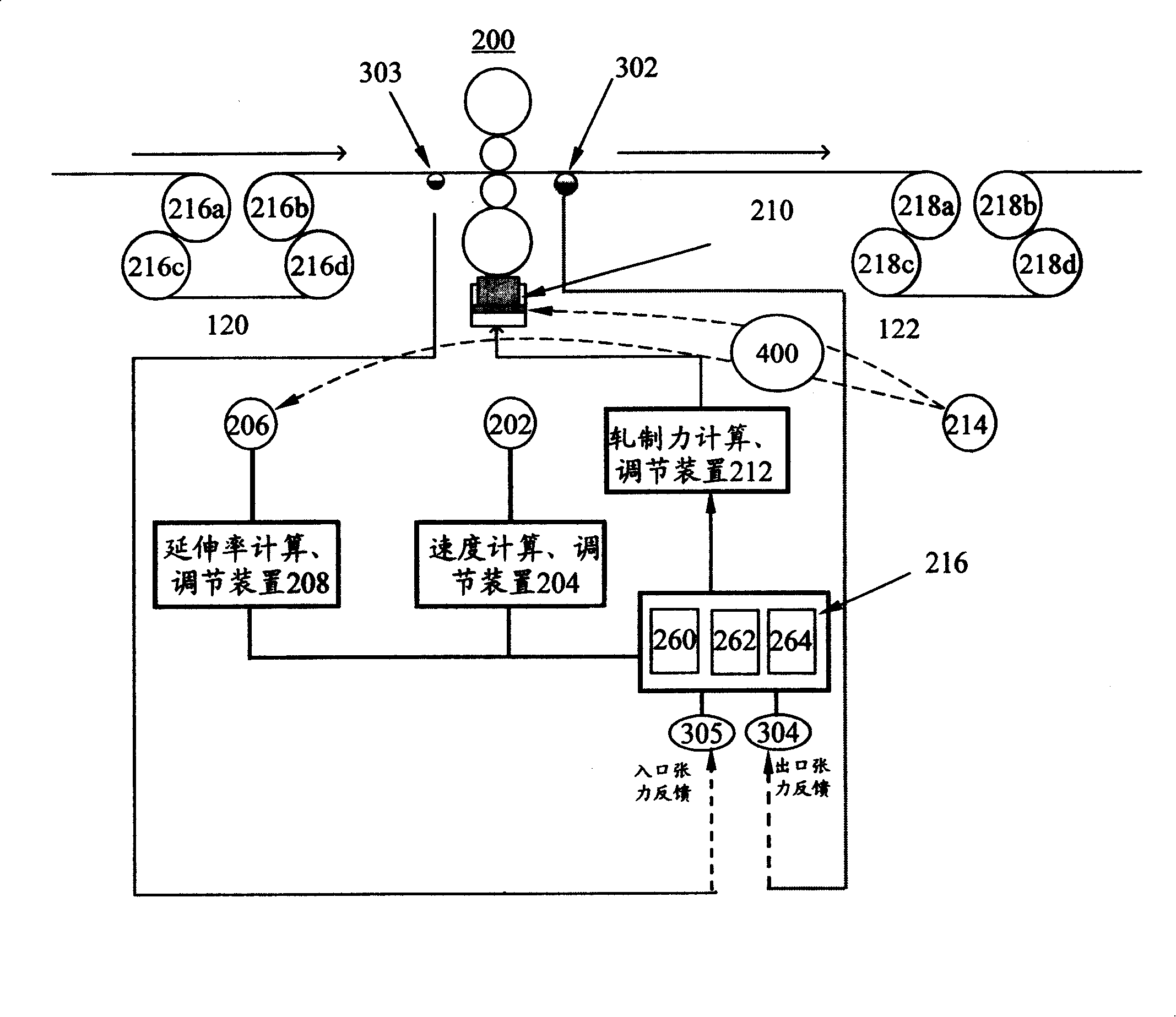

Tension control system and method for planetary gear structure tension roller type evener

ActiveCN101168172AElongation stabilityRoll force/gap control deviceTension/compression control deviceControl systemEngineering

The invention discloses a tension control system of an epicyclic gear tension roll leveler, which comprises an inlet pull tension gage and an inlet tension feedback device, an outlet pull tension gage which is provided in the outlet of the leveler for measuring the strip tension in the outlet, an outlet tension feedback device for feedback the strip tension in the outlet which measuring by the outlet pull tension gage, a tension control device for receive the strip tension in the outlet which is feedback from the outlet tension feedback device. The roll-force, the elongation and the speed of the leveler can be definite by the association of strip tension in the inlet and outlet. The three key parameters comprises the roll-force, the elongation and the speed of epicyclic gear tension roll leveler, the coordinate cooperated controlled can be constructed among the three key parameters. According to the addition of tension in outlet with the outlet pull tension gage by the technical scheme of the invention, meanwhile the stable elongation, roll-force and tension control can be realized, and the order of stable strip steel property and shape can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Tensile strength 600Mpa grade dual phase steel plate and its production method

InactiveCN1807669AGood mechanical propertiesTemperature control deviceHeat treatment process controlChemical compositionSheet steel

Disclosed is a steel sheet with a tensile strength of 600 MPa grade wherein its constituents by mass percentage comprise C 0.05-0.08%, Si 0.20-0.40%, Mn 1.30-1.60%, and balancing Fe. Its tissue is a diphase of ferrite and martensite, wherein the volume fraction of the ferrite is 85-90%, the volume fraction of the martensite is 10-15%, and the manufacturing process consists of sheet bar continuous casting and rolling, fast cooling, soaking continuous casting sheet bar through tunnel furnace, controlling the tapping temperature to be 1100-1150 deg. C, controlling the initial rolling temperature between 1100-1150 deg. C, and end rolling temperature at 780-850 deg. C, fast cooling after rolling, and drawing-up after cooling.

Owner:NORTHEASTERN UNIV

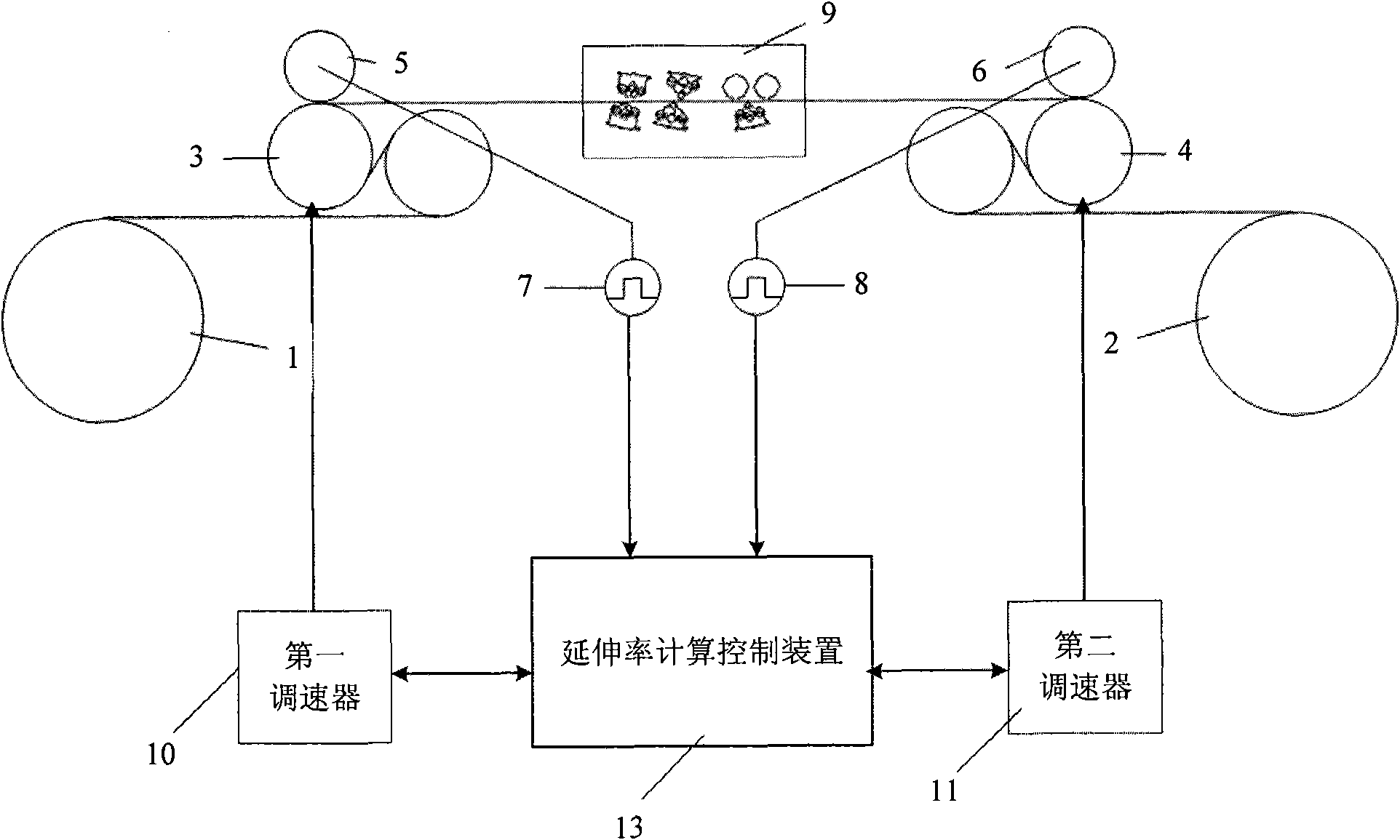

Band steel stretch-bending straightening system capable of controlling elongation rate and control method thereof

InactiveCN101585058AQuality improvementRealize closed-loop controlElongation control deviceMeasurement deviceAutomatic control

The invention provides a band steel stretch-bending straightening system with capable of controlling the elongation rate and a control method thereof, wherein the band steel stretch-bending straightening system comprises an unreeling inlet roller, a stretch-bending straightener, a reeling outlet roller, a first motor and a second motor, wherein the first motor and the second motor respectively drive the inlet roller and the outlet roller. The band steel stretch-bending straightening system is characterized by also comprising a band steel inlet, an outlet speed measuring device, a first speed regulator, a second speed regulator and an elongation rate computing control device. The band steel stretch-bending straightening system capable of controlling the elongation rate and the automatic control method of the elongation rate of the band steel can realize the closed-loop control to the elongation rate of the band steel in the stretch-bending, straightening and producing processes of the band steel, have the advantages of high automation degree, simple, convenient and rapid operation, high stability and high precision and greatly improve the leveling production of the band steel and the quality of a processing product of the band steel.

Owner:上海精祥企业发展有限公司

Method for controlling finishing elongation rate of strip steel by utilizing second flow

ActiveCN102407240AHigh yieldStable productionElongation control deviceHuman–machine interfaceLoop control

The invention provides a method for controlling a finishing elongation rate of strip steel by utilizing second flow, comprising the following steps of: respectively measuring an actual speed value and an actual tension value by using an encoder and a tension meter for measuring the speeds of an inlet and an outlet of a finishing machine; additionally arranging a second flow closed loop control system module in a programmable controller of the finishing machine, i.e., a PLC (Programmable Logic Controller); additionally arranging a second flow function option button in a human-computer interface; adopting a speed control mode for a main motor as well as a front tension roller and a back tension roller of the finishing machine; introducing an outlet tension deviation matching coefficient to a rolling force controller; and carrying out gain processing on a system function according to an input time interval. By using the method, the set value of the rolling force as well as parameters such as speed, tension and the like before and after finishing are not needed to be changed according to the material of the strip steel, the speed and the tension before and after the finishing are in astable state, the elongation rate is controlled more precisely, the steel plate pattern and the elongation rate index before and after the specification changes are effectively improved, a favorable surface quality of a product is obtained, and the yield of the strip steel is increased.

Owner:ANGANG STEEL CO LTD

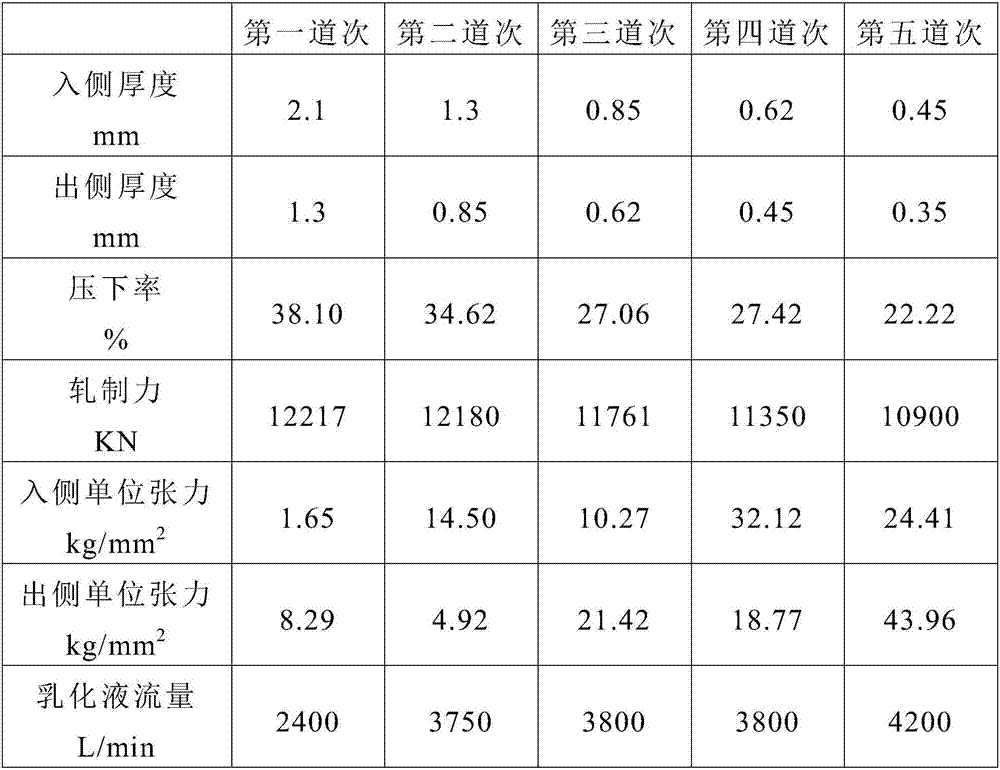

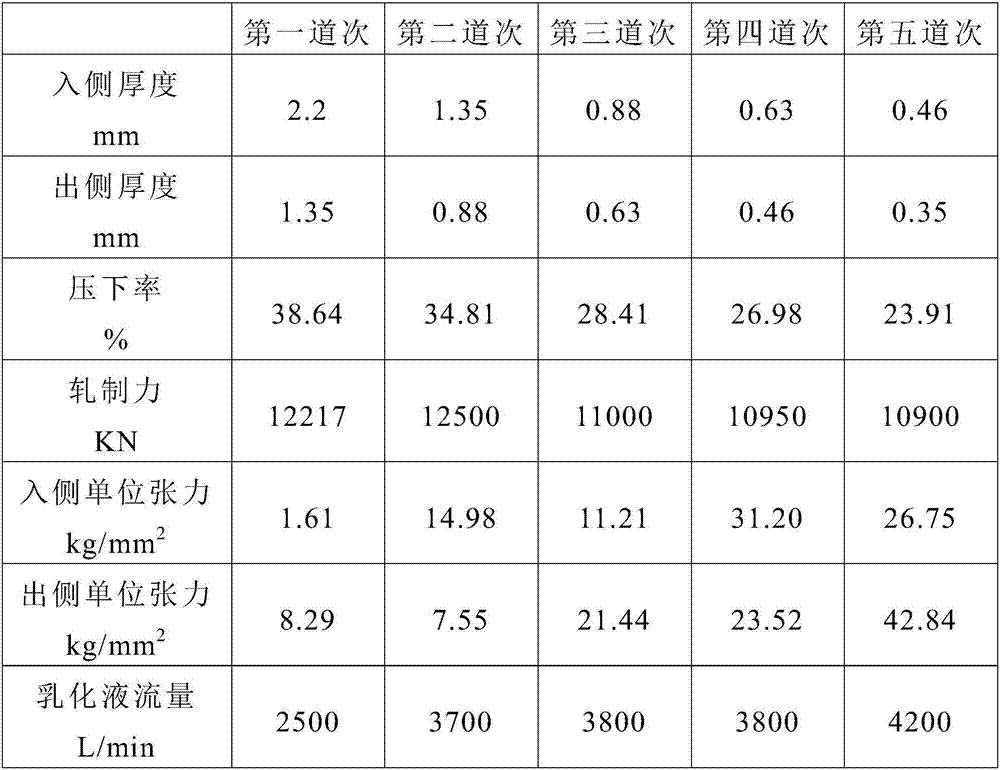

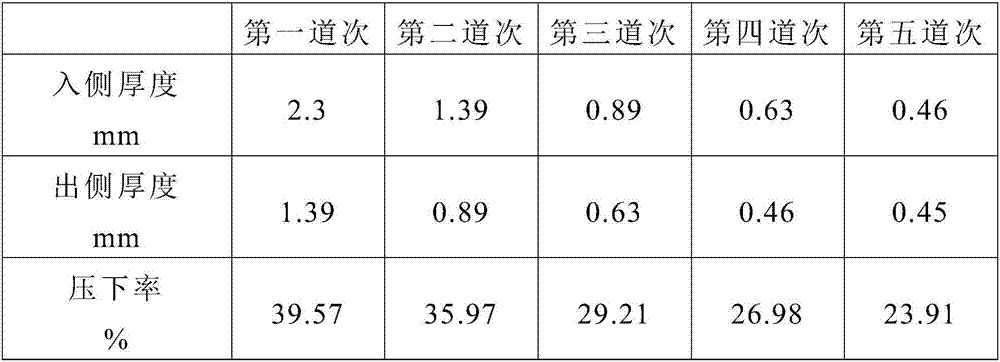

Cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting

ActiveCN107962075ALow costReduce resistanceRoll force/gap control deviceTemperature control deviceReduction rateThermal expansion

The invention relates to the field of silicon steel cold rolling, and discloses a cold rolling method for high grade non-oriented silicon steel through hot rolling, acid pickling and non-edge-cutting.The cold rolling method comprises the following steps that a steel coil is obtained, non-edge-cutting normalizing acid pickling is carried out, then a one-time cold rolling method is adopted for continuous reversible type five-pass cold rolling, the reduction rate, rolling force, entry side unit tension and exit side unit tension of each pass are controlled, emulsified liquid spraying is adoptedin rolling for process lubricating and cooling, thermal expansion adjustment steel coil plate shape of a working roll is controlled in a partitioned cooling mode, a rolled product is obtained, and then subsequent procedures are conducted conventionally. The cold rolling method for high grade non-oriented silicon steel through hot rolling solves the problems of poor rolling efficiency and poor finished product rate of high silicon content varieties.

Owner:武汉钢铁有限公司

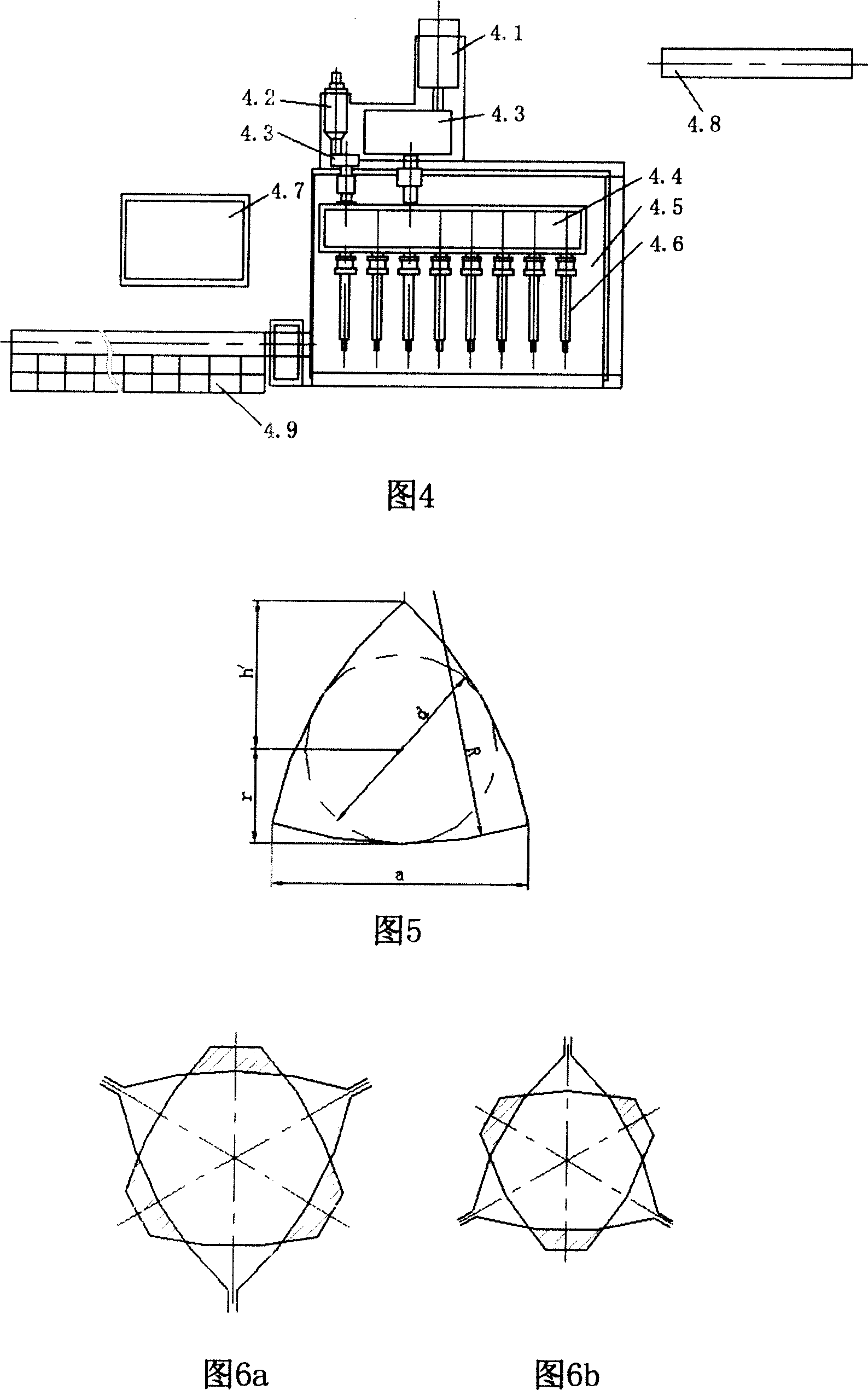

Rolling controlling method and device for double-roller continuous casting magnesium alloy sheet

InactiveCN101190491AImprove performanceGood molding effectRoll force/gap control deviceTemperature control deviceThin slabContinuous annealing

The invention discloses a dual-roll continuous casting magnesium alloy thin plate rolling control method and a device. The method comprises that magnesium alloy solution is formed in an integrated casting and rolling machine; the temperature of a casting plate out of a casting roll is 300 DEG C to 500 DEG C and casting and rolling speed is 10m / min to 90m / min; the casting and rolling plate is cooled in oil with control temperature of 200 DEG C to 400 DEG C and plate-out thickness is 1mm to 4mm; uniform annealing disposal is carried out before the hot rolling of the casting and rolling plate; the front and the rear of a rolling machine are provided with heat preservation rolls for heat supplementation; finished magnesium alloy plate of 0.2mm to 1mm can be rolled in an annealing period. The device comprises an integrated casting and rolling machine, a continuous annealing furnace behind the casting and rolling machine, three four-roll hot rolling machines arranged in 90 DEG and heat preservation rolls at the front and the rear, a flying shear and an edge-cutting shear. By adopting casting rolling and rolling methods to produce the magnesium alloy plate, the invention has the advantages of short flow, low production cost, uniform composition of products, good surface quality and uniform mechanical performance in all directions. The method and the device can be applied to the production of the magnesium alloy and aluminium alloy thin plates in all series.

Owner:UNIV OF SCI & TECH LIAONING +1

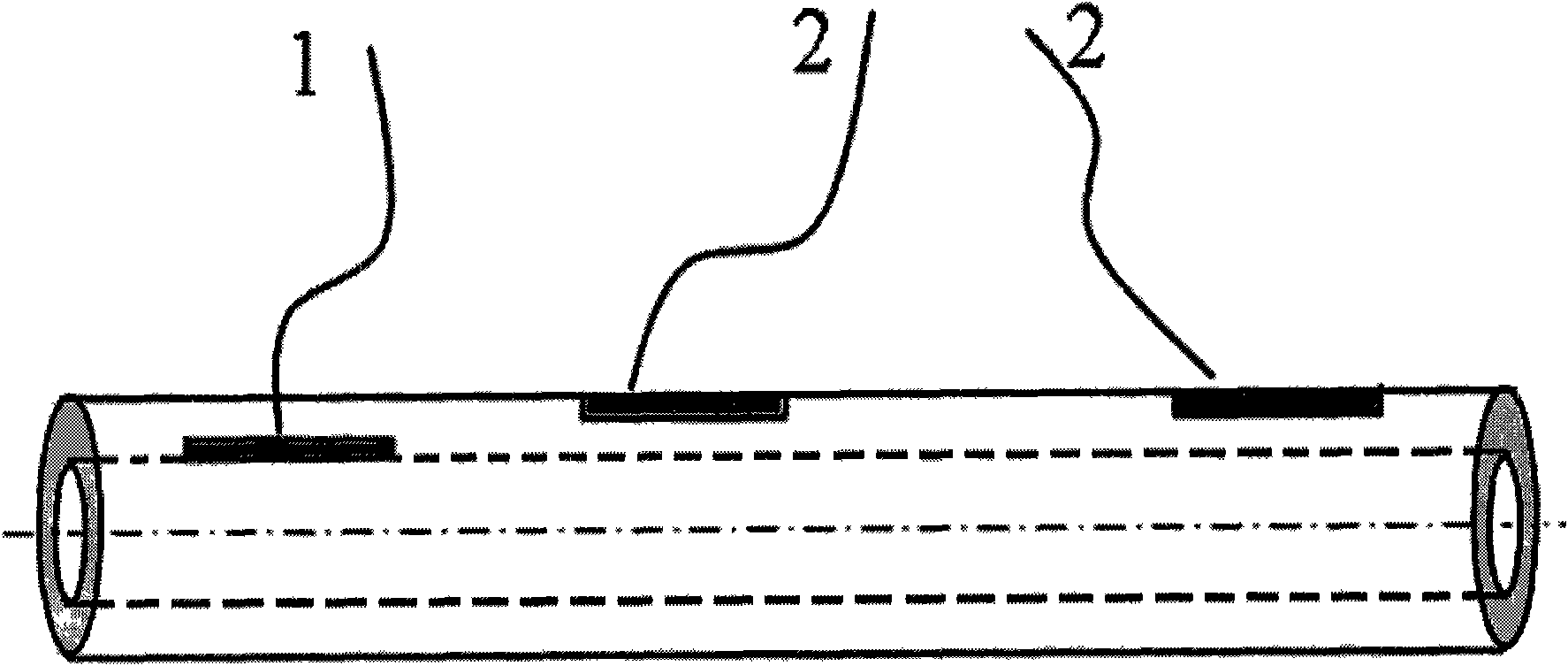

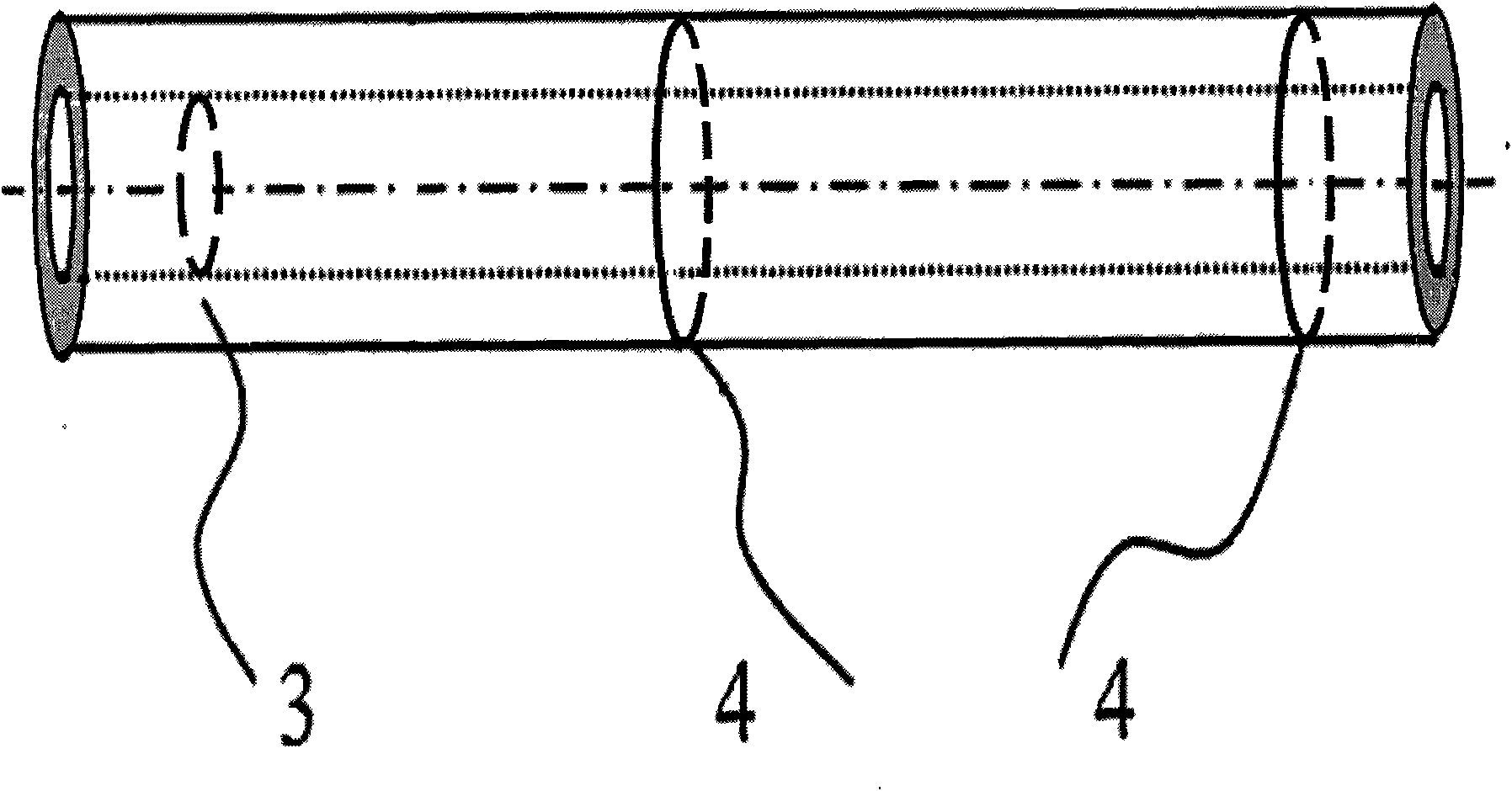

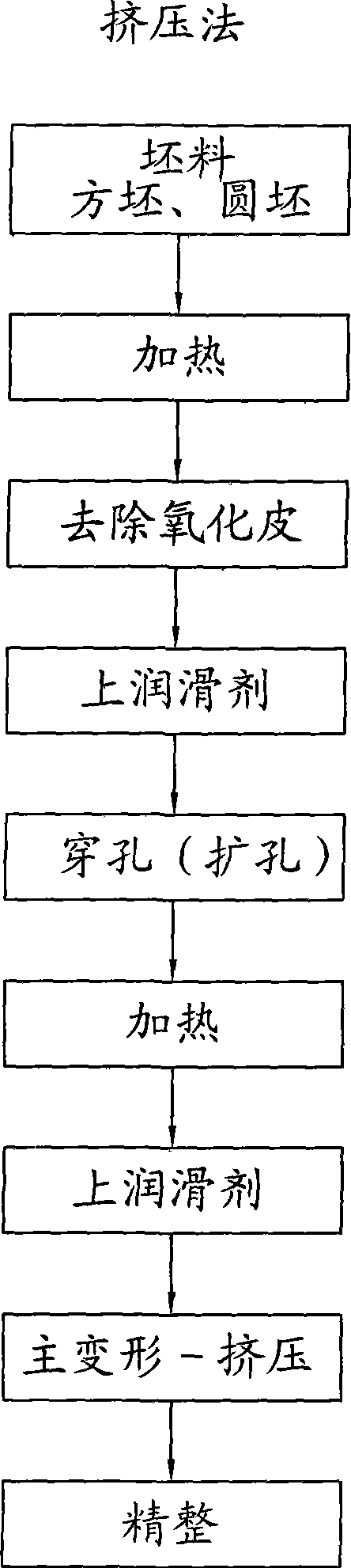

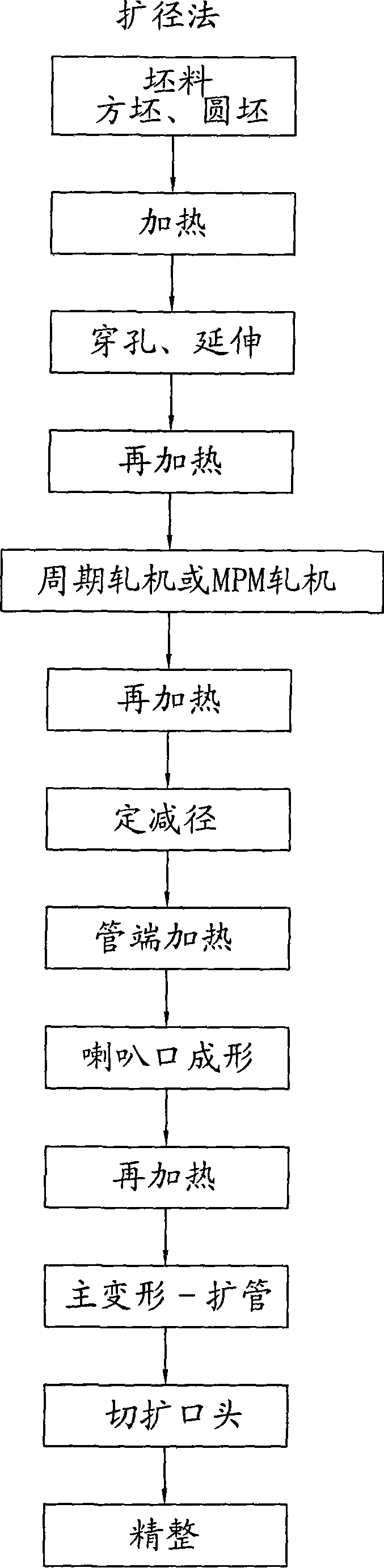

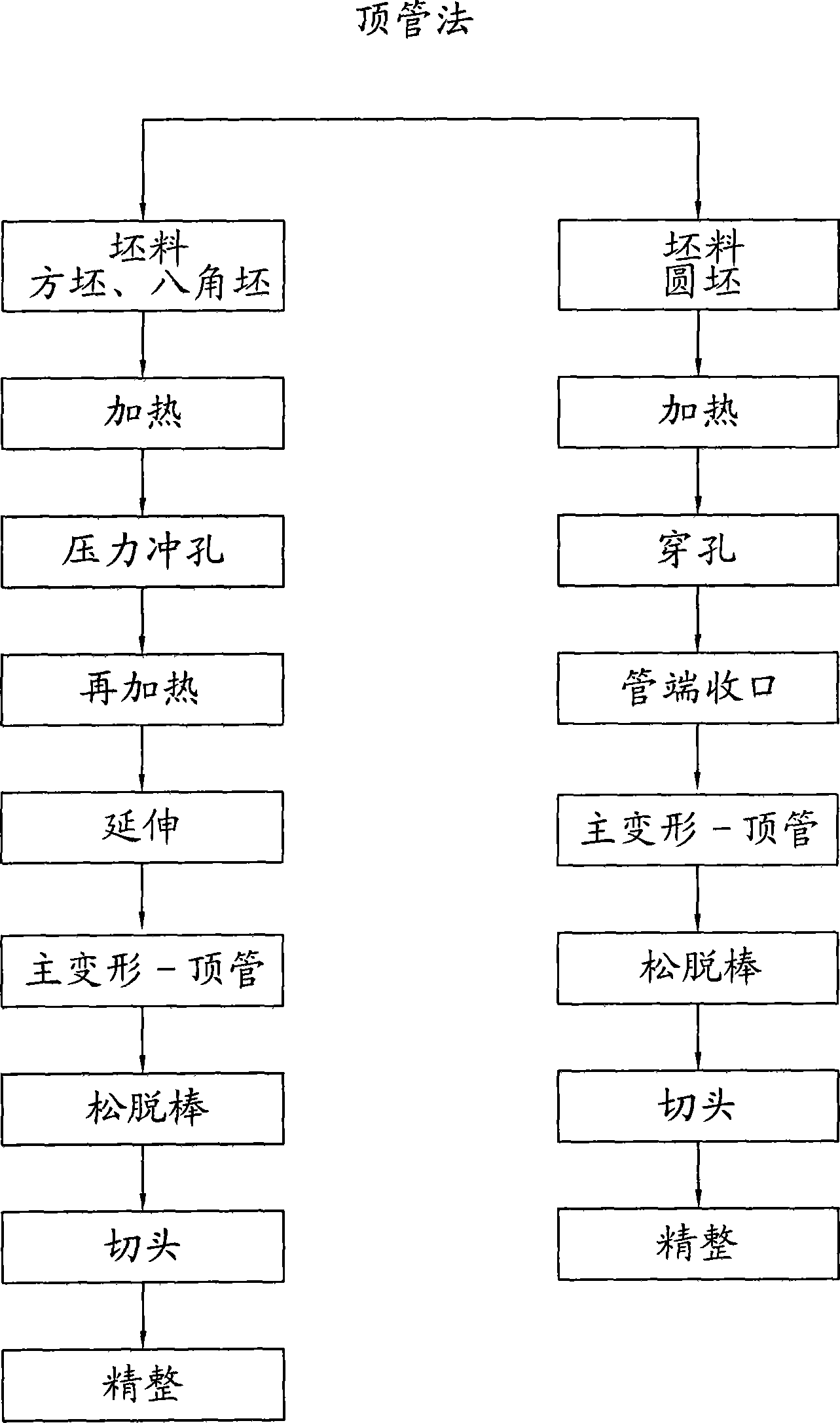

Novel technique for producing seamless steel pipe

InactiveCN101376204AQuality improvementLess centrifugal castingMetal rolling arrangementsElongation control deviceNovel techniquePipe fitting

A new process for producing a seamless steel pipe comprises the following processing steps: firstly, producing a hollow pipe blank, at one end of which an annular cup bottom is arranged, through centrifugal casting; secondly, mechanically processing the inner surface and the outer surface of the hollow pipe blank; thirdly, heating the processed hollow pipe blank; fourthly, performing pipe jacking mill processing to the heated hollow pipe blank, and obtaining pipe fittings meeting the requirements of the wall thickness, the diameter and the length; and fifthly, after bar loosening and bar releasing, performing end cropping and finishing operation to the pipe fittings after the pipe jacking mill processing, and obtaining qualified finished product pipe materials. The invention can produce a high-quality stainless steel and special steel pipe difficult to process, and overcomes the defects in the prior art, so as to form an energy-saving, high-quality and economic new process with the short procedure for producing the seamless steel pipe compared with the traditional method.

Owner:北京蓝海科融新技术有限公司

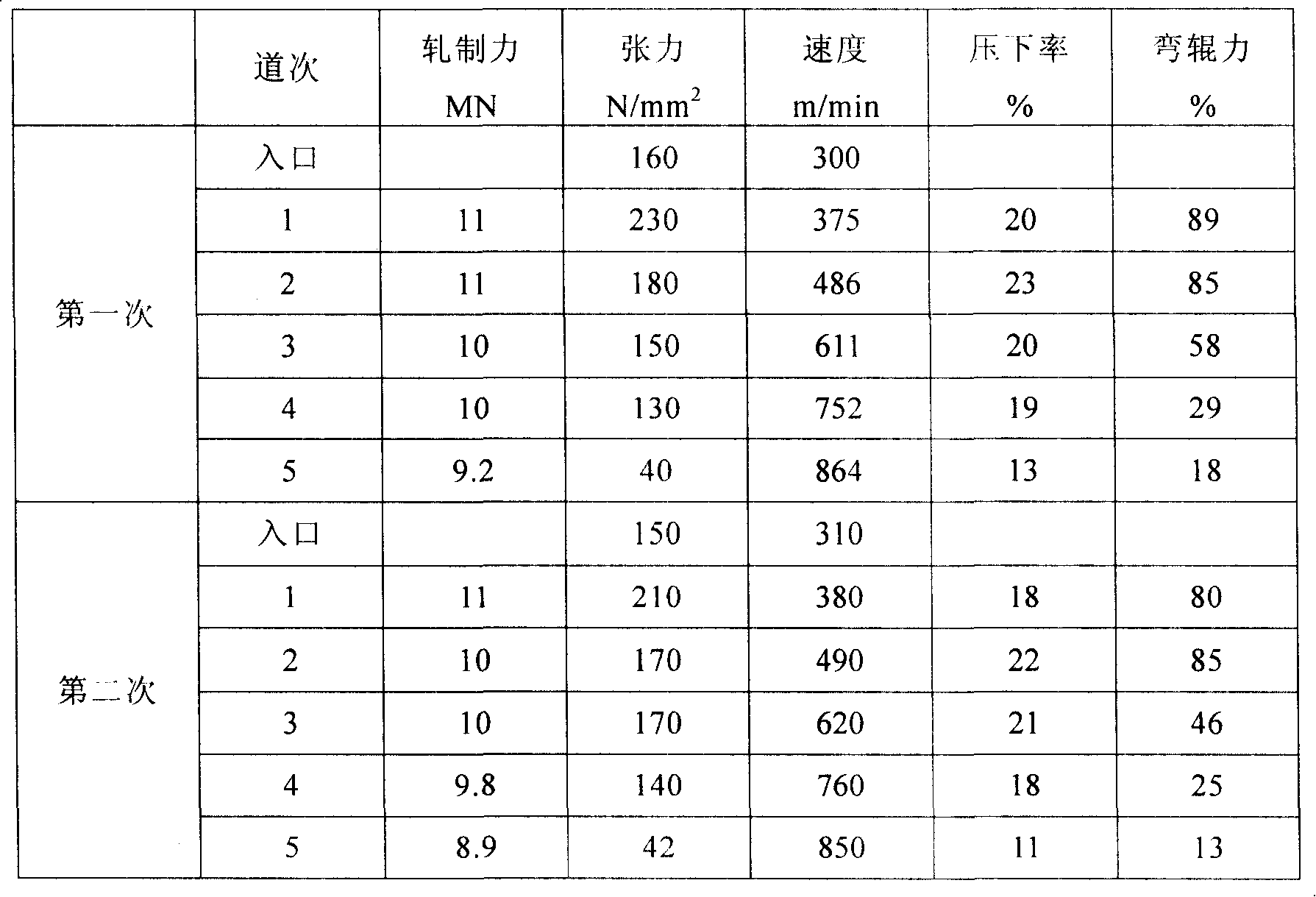

Method for producing stainless steel band

InactiveCN101239357AIncrease costGood shape with steel plateWork treatment devicesFurnace typesShielding gasWork in process

The invention relates to a producing method for a stainless steel band, specifically used in war industry, automotive vehicle industry, electron industry or household electrical appliance industry, pertaining to cold rolling base plate technique field. The method is characterized in: selecting stainless steel band blank, performing a first rolling process to obtain semi-finished stainless steel bands; feeding the semi-finished stainless steel bands into an annealing oven, charging protective gas at the same time, and dividing the temperature in the annealing oven into six sections and a preheating section; performing a second rolling process after annealing to roll the semi-finished stainless steel bands into finished stainless steel bands with thickness of 0.2-0.5mm; straightening and flattening the rolled stainless steel bands, cutting and packing to be termination products. The invention is provided with a good cooling effect and reduced rolling pass which can decline the production cost and improve the product quality and yield, at the same time the surface finishment and straightness are improved, and operating requirement of users for hardness degree is satisfied.

Owner:WUXI JIALIAN STAINLESS STEEL

Method for rolling pure titanium rod and wire

InactiveCN101085451AReduce energy consumptionIncrease productivityTemperature control deviceMetal rolling arrangementsWire rodTitanium

The invention relates to pure titanium products rolling method. It rolls the Phi100mm pure titanium bar blank heated to 600- 850deg.C for 6-8 times, using two rolling machine connected set vertically rolling to Phi20-10mm bars or wire blanks for 8-12 times, using torque free linking roll set rolling the wire blank to Phi8-6mm for 2-6 times by rolling the Phi10mm wires. It only needs to heat once if it is using blank smaller than the size of Phi100mm. It is highly efficient, energy saving, high in precision, and fine in structure compared with existing ones.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Nickel-free micro-alloy low-temperature pressure vessel steel and manufacturing method thereof

ActiveCN101082104AHigh strengthImprove low temperature toughnessTemperature control deviceElongation control deviceSheet steelNickel free

The microalloy steel without Ni for low temperature pressure container consists of C 0.04-0.08 wt%, Si less than 0.6 wt%, Mn 1.0-1.6 wt%, Nb 0.010-0.030 wt%, Ti 0.005-0.030 wt%, V less than 0.070 wt%, Al 0.004-0.060 wt%, N less than 0.008 wt%, P less than 0.015 wt%, S less than 0.010 wt%, and Fe and inevitable impurity for the rest. By means of reasonable alloy component design and technological process including TMCP rolling, the steel plate has yield strength up to 360 MPa, tensile strength over 490 MPa, high low temperature impact toughness, excellent plasticity and welding performance, low production cost and short production period.

Owner:BAOSHAN IRON & STEEL CO LTD

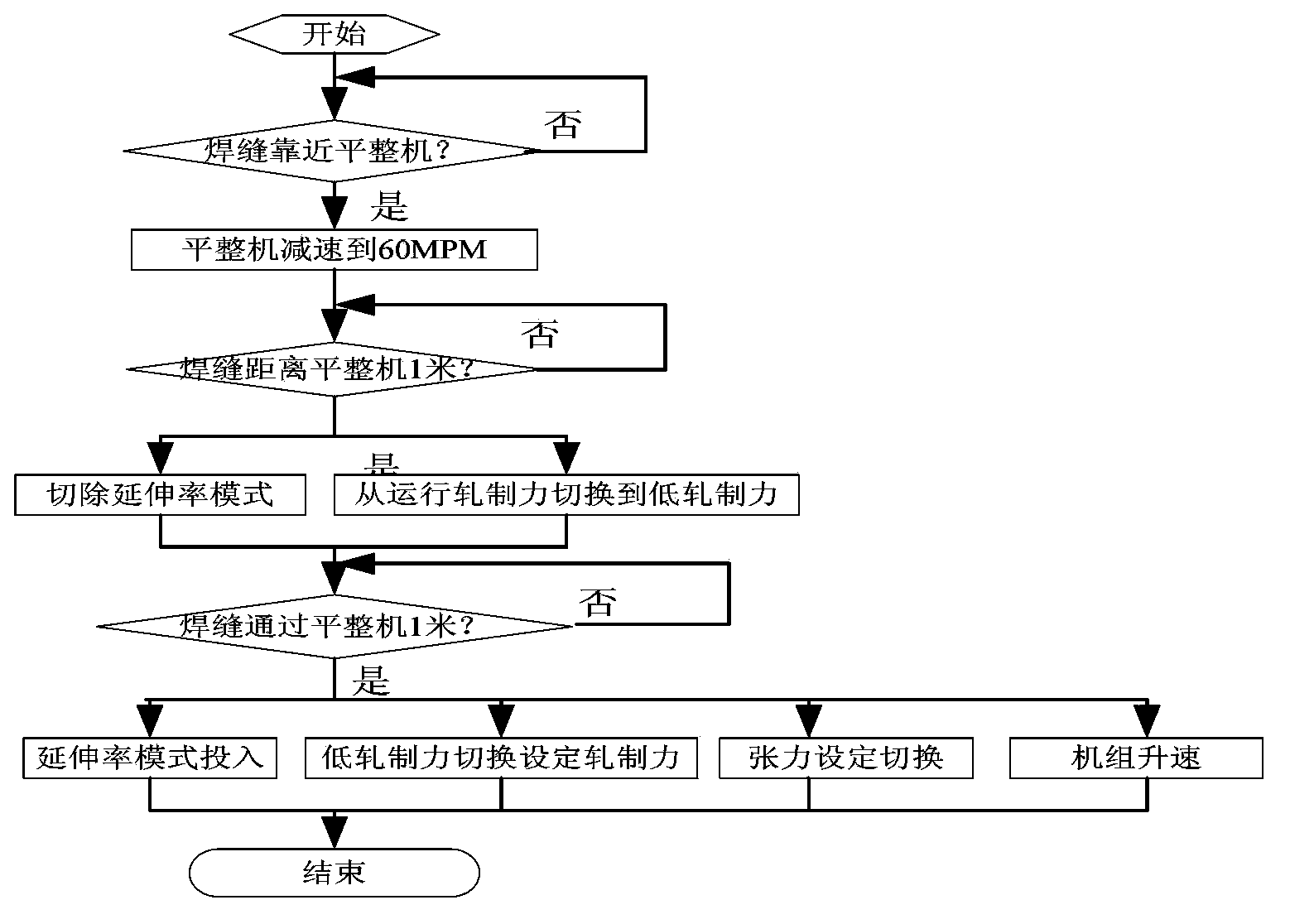

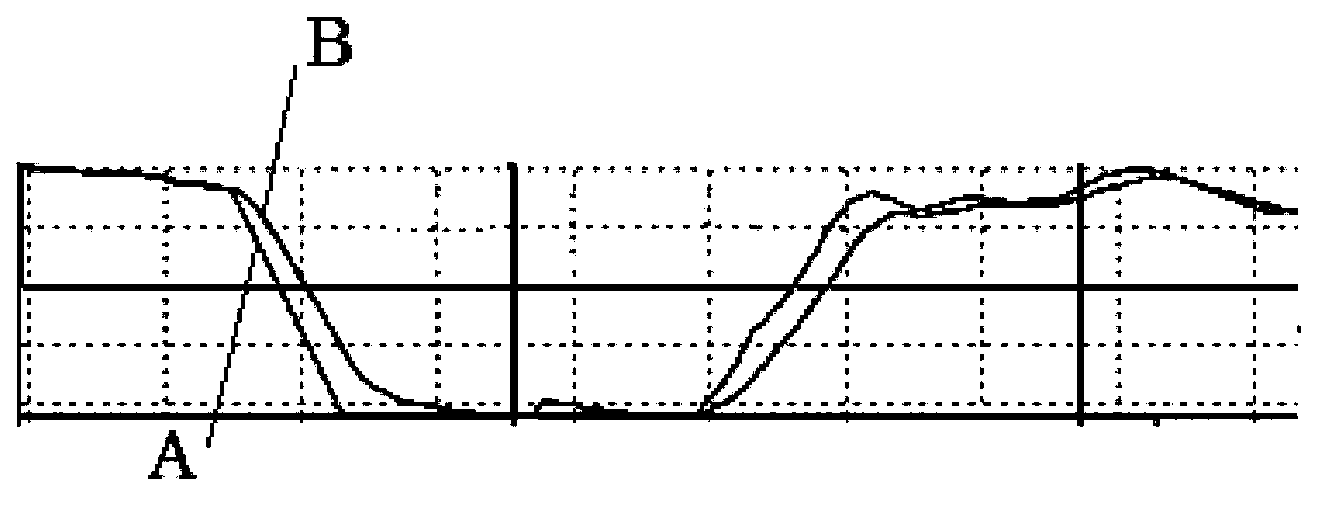

Method for accurately controlling band-steel ductility when welding joints pass leveling machine

ActiveCN104107837AControl strip elongationShorten the lengthElongation control deviceEngineeringStrip steel

The invention discloses a method for accurately controlling band-steel ductility when welding joints pass a leveling machine. The method includes steps that firstly, when band steel moves to the welding joints and is close to the leveling machine, the moving speed of the band steel is reduced to 30-70m / min, and the welding joints needs to be more 1m away from the leveling machine after speed reduction; when the band steel moves to the welding joints and passes the leveling machine, rolling force is reduced to 80-150 tons; when the band steel moves to the welding joints and goes through the leveling machine, a current practical ductility value and a ductility target value are compared, if the former is larger than the latter, rolling force is 300-800 tons; if the former is smaller than the latter, rolling force is 90-150 tons, and if the former is equal to the latter, all steps are finished; the band steel keeps moving, whether the current practical ductility value is approximate to the ductility target value or not is judged, if yes, the next step is performed, and if not, rolling force rises at the speed of 500-1500 tons; the steps are finished.

Owner:BAOSHAN IRON & STEEL CO LTD

Tensile strength 540Mpa grade dual phase steel plate and its production method

InactiveCN1807670AGood mechanical propertiesTemperature control deviceHeat treatment process controlChemical compositionSheet steel

Disclosed is a steel sheet with a tensile strength of 540 MPa grade wherein its constituents by mass percentage comprise C 0.05-0.08%, Si 0.20-0.40%, Mn 1.00-1.30%, and balancing Fe. Its tissue is a diphase of ferrite and martensite, wherein the volume fraction of the ferrite is 85-90%, the volume fraction of the martensite is 10-15%, and the manufacturing process consists of sheet bar continuous casting and rolling, fast cooling, soaking continuous casting sheet bar through tunnel furnace, fast cooling after rolling, and drawing-up after cooling.

Owner:NORTHEASTERN UNIV

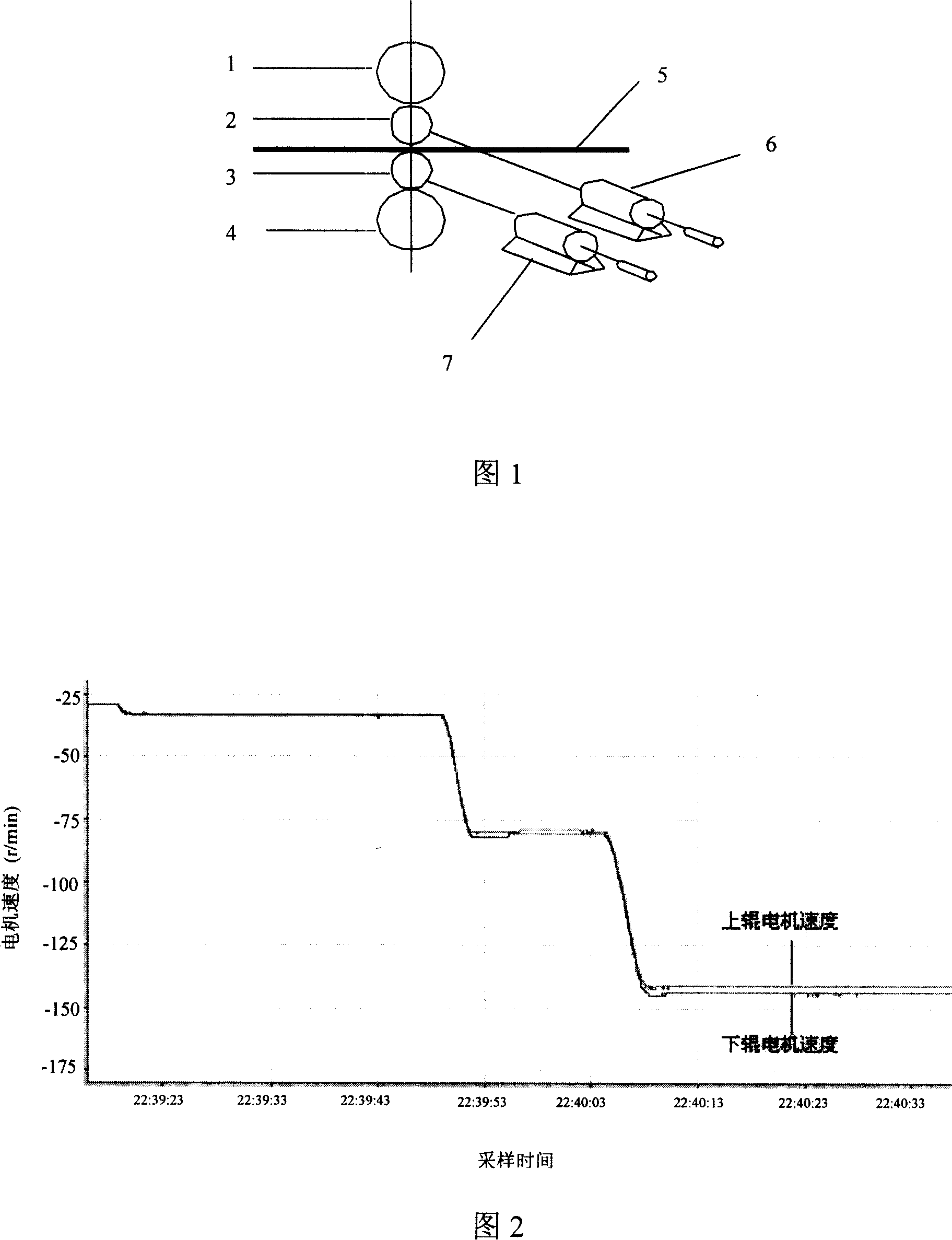

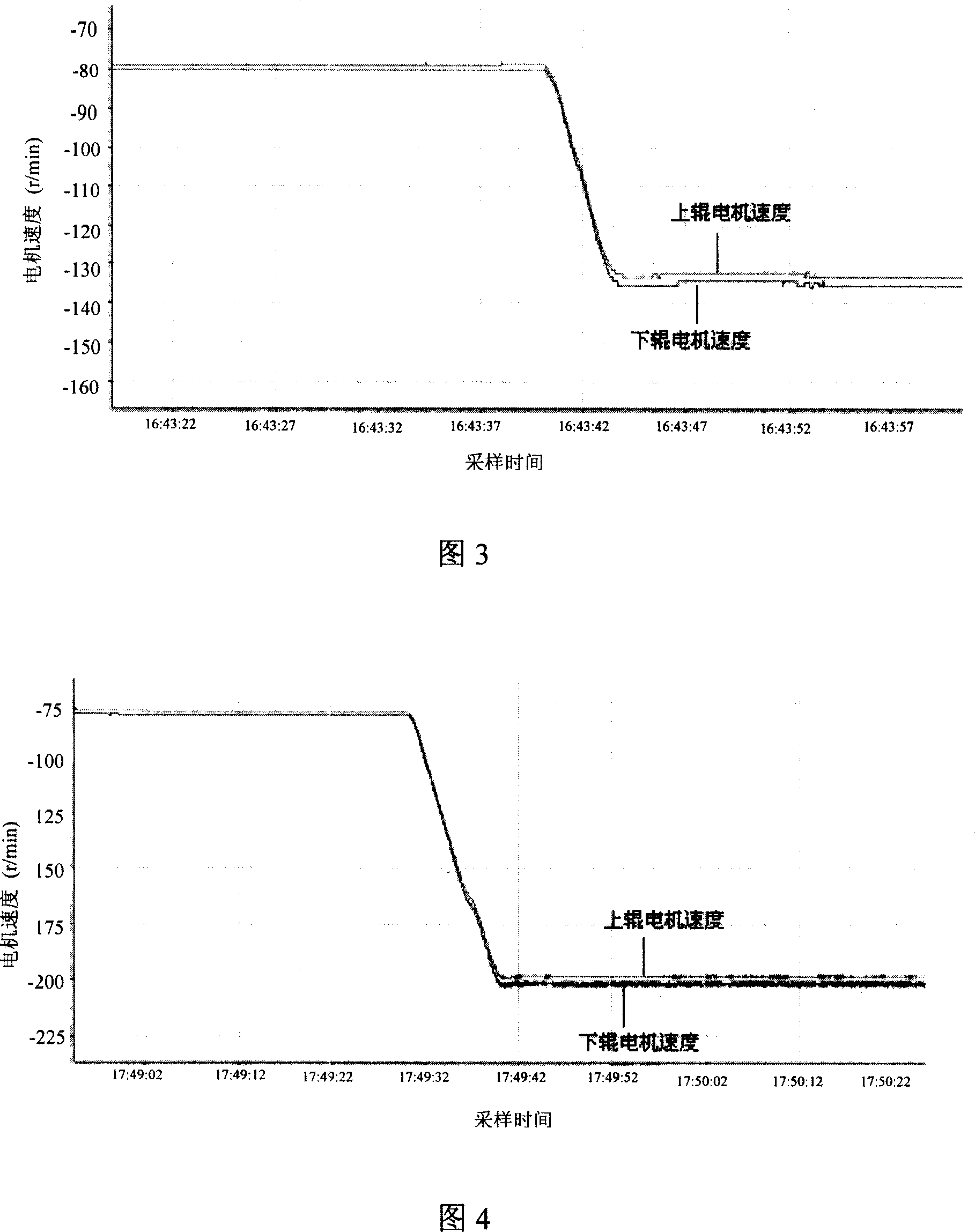

Method for controlling load balance of rolling mill for cold rolled steel strip driven by dual electrical motors

InactiveCN101091965AReduce rolling loadReduce the speed difference between the upper and lower work rollsTension/compression control deviceMetal rolling arrangementsMotor speedMotor drive

The invention discloses a control method for load balance of cold-strip steel rolling mill of double motor drive. The feature is that it is realized by control the technical parameter of roller, technical parameter of emulsion, dynamically adjusting rolling unit tension, percent of reduction and acceleration of raising speed of driving motor. The invention could compensate the work roller friction by the control parameters of percent of reduction, unit tension and acceleration of driving motor according to the actual parameter of rolling strip steel. The method could improve the stability during rolling process and control the motor speed difference caused by load difference by 3%.

Owner:ANGANG STEEL CO LTD

Rotary austenite toughening-based low-temperature steel and method for preparing same

The invention discloses rotary austenite toughening-based low-temperature steel and a method for preparing the same. The low-temperature steel is refined from C, Si, Mn, Mo and Ni which are taken as main chemical components. The method for preparing the low-temperature steel of the invention comprises the following steps: firstly, selecting raw materials, smelting the raw materials with a vacuum induction furnace, pouring a smelting product, slowly cooling the product until temperature reaches the room temperature, transferring the product to a heating furnace for heating and heat preservation for 1 hour, and taking the product out for rolling, wherein the rolling is controlled through two stages of a recrystallization type and a non-recrystallization type for 9 times; and after the rolling, controlling a cooling speed and a final cooling temperature, finally rolling the product into a 15 mm thick steel plate and then performing quenching and tempering heat treatment or dual-quenching heat treatment. The low-temperature steel prepared by the method comprises rotary austenite with different contents and different distributions, so the products with different strengths and low-temperature toughness can be obtained; and the low-temperature steel is 550-710 MPa and 680-750 MPa in yield strength and tensile strength respectively, is 150-220 J in transverse impact energy under the experiment condition of -196 DEG C, and can meet the performance requirements required by LNG building.

Owner:UNIV OF SCI & TECH BEIJING

Method for cold rolling high silicon electric steel

InactiveCN101209459ASolve the problem of welding broken stripsGuaranteed surface qualityRoll force/gap control deviceOther manufacturing equipments/toolsMechanical energyAcid washing

The invention provides a cold rolling method for high-silicon electrical steel. The method comprises conventional processes of a first cold rolling for a hot rolled plate after being treated with acid washing or a second cold rolling with annealing during operation, decarbonization annealing and recrystallization annealing, etc., and is characterized in that the hot rolled plate before being treated with acid washing is done with welding end to end and then continuous endless rolling is done by a mill with multi-stands; a warm rolling is realized by that mechanical energy is transformed into heat energy during the rolling and the temperature of the steel plate raises; the tension among each mill stand is 100-300 N / mm <2> and 30-80 N / mm<2> for the last mill stand; the draft is 15-30 percent and 5-15 percent for the last mill stand and the outlet speed of the rolling mill is no less than 500m / min and the thickness of the finished product is 0.2-0.8mm. By adopting a plurality of mill stands to realize the warm rolling, the invention effectively solves the breakage occurred in edges; the last mill stand is served as the pass mill stand of finished products so as to guarantee the quality of the surface of the steel strip; large tension is adopted during the rolling so as to ensure that a forward slipping area can be reduced and deformation bands are increased. Compared with the method by a single mill stand, the method of the invention prolongs the cycle of roll changing, reduces the labor intensity, shortens the production cycle and improves productivity and quality of steel plates. In addition, the method of welding from head to tail for transition with low-silicon steel can effectively solve the problem of breakage during the welding of the high-silicon electrical steel.

Owner:ANGANG STEEL CO LTD

CSP production process of steel for automobile crossbeam

ActiveCN1974823ALow costEasy stability controlTemperature control deviceWork treatment devicesProduct inspectionChemical composition

The production process of SCP for automobile crossbeam includes the steps of converter smelting, LF refining, continuous casting and rolling, coiling and product inspection. The steel of SCP for automobile crossbeam consists of C 0.16-0.20 wt%, Si 0.3-0.5 wt%, Mn 1.3-1.5 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Ti 0.01-0.03 wt%, Als 0.020-0.035 wt%, N not more than 65 PPm. Compared with available technology, the present invention has the advantages of relatively low alloy content in the steel, easy control of the chemical comprise, short production process and low production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

8B cold-rolling precision steel belt and manufacturing method thereof

ActiveCN105195510AReduce lossImprove post-spot welding workabilityFurnace typesWork cleaning devicesAcid washingManganese

The invention belongs to the technical field of manufacturing of strip steel and discloses a manufacturing method of an 8B cold-rolling precision steel belt. The manufacturing method comprises the following steps: carrying out sizing vertical shearing on a raw material steel coil; carrying out cold rolling on the vertically-sheared steel coil; degreasing the coldly-rolled steel coil, and carrying out bright whole-soft-cover type annealing; carrying out small-ductility flattening on the annealed steel coil and carrying out large-ductility oil flattening and tempering; splitting the flattened steel coil to obtain the cold-rolling precision steel belt, wherein the raw material steel coil is a hot-rolling acid washing coil, and is prepared from the following components in mass percent: 0.02 to 0.055 percent of carbon, 0.002 to 0.30 percent of silicon, 0.0120 to 0.20 percent of manganese, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.09 percent of aluminum and the balance of iron and unavoidable impurities, and the equivalent weight of the carbon of the acid washing coil is not more than 0.30 percent, the thickness range is 2.5mm to 3.5mm, and the width range is 1250mm to 1280mm. According to the manufacturing method provided by the invention, a technical process from material selection to cold rolling is optimized, the quality is improved and the performance requirements of products are adapted.

Owner:宝武轻材(武汉)有限公司

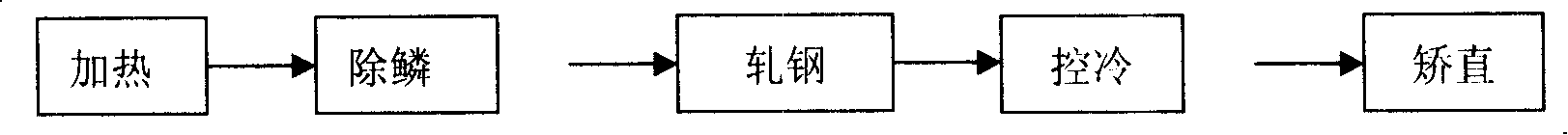

High-strength medium plate production process

InactiveCN101209456ASolve the problems caused by no pre-levelerMeet the use requirementsRoll force/gap control deviceTemperature control deviceSheet steelHigh intensity

The invention discloses a production method of a high-intensity and medium-thickness steel plate and the technique process comprises heating-descaling-rolling-straightening-controlled cooling, while the specific technique is that: the temperature is heated to 1150-1200 DEG C; the temperature range of rough rolling is set at 1000-1100 DEG C; the rough rolling is done no less than three passes and the initial draft is no less than 10 percent; large rolling reduction is adopted in a finish rolling stage and the cumulative amount of deformation of the finish rolling is no less than 60 percent and the temperature of the finish rolling is 840-930 DEG C while the temperature of final finish rolling is 800-880 DEG C; the steel plate out from a finishing mill is conveyed to a straightening machine directly with the straightening temperature of 800-880 DEG C and then is controlled cooling with the cooling speed of 6-15 DEG C per second and the final cooling temperature of 400-500 DEG C. Due to adjustment of technique of heating, rolling, straightening and cooling, etc., the medium-thickness steel plate with straightness below 10 IU can account for 95 percent, thereby solving the problem that the straightness of the medium-thickness steel plate fails to meet the standard so as to meet the application demand from users, reducing damages of production equipment in the low-temperature rolling process as well as the problems caused by that the steel plate has not been pre-treated by the straightening machine before the controlled cooling.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com