Rotary austenite toughening-based low-temperature steel and method for preparing same

A low-temperature steel and austenite technology, applied in the field of low-temperature steel rolling and heat treatment process, can solve the problems of low product qualification rate and unstable heat treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

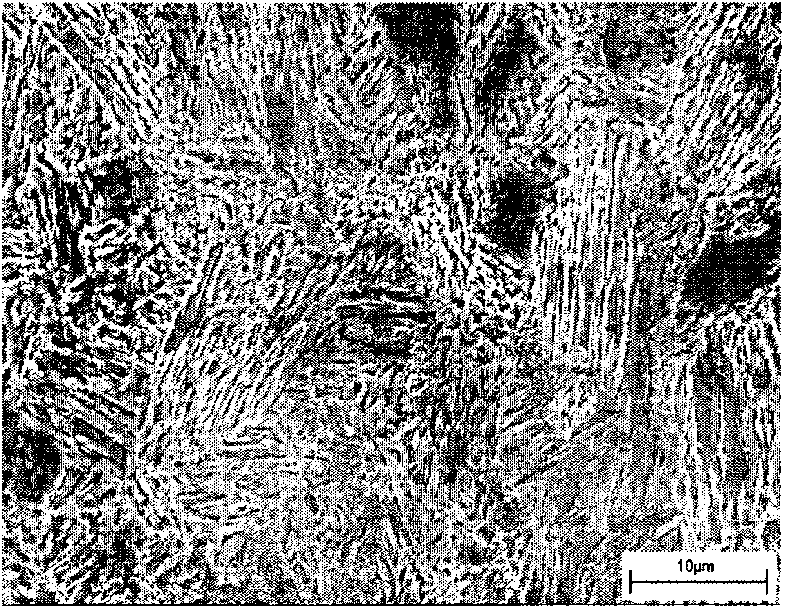

[0035] The invention relates to a method for preparing a low-temperature steel based on rotary austenite toughening, the process comprising:

[0036] The mass percentage of the chemical composition of steel is selected as C: 0.02% ~ 0.04%, Si: 0.05% ~ 0.15%, Mn: 0.5% ~ 0.8%, Mo: 0.07 ~ 0.1%, Ni: 8.5 ~ 9.5%, P: ≤0.01%, S: ≤0.005%, the balance is Fe and unavoidable impurities; steelmaking is carried out by smelting in a vacuum induction furnace, slowly cooled to room temperature after pouring, and sent to a heating furnace. The heating temperature is 1200 ~ 1220 ℃, after 1 hour of heat preservation, it is taken out for rolling. The rolling adopts two-stage controlled rolling, and a total of 9 passes, the first 4 passes are rough rolling, and the last 5 passes are finish rolling. Rough rolling is rolled in the austenite complete recrystallization zone, the starting rolling temperature is 1150°C, and the finishing rolling temperature is controlled at 980°C; the finish rolling is r...

Embodiment 1

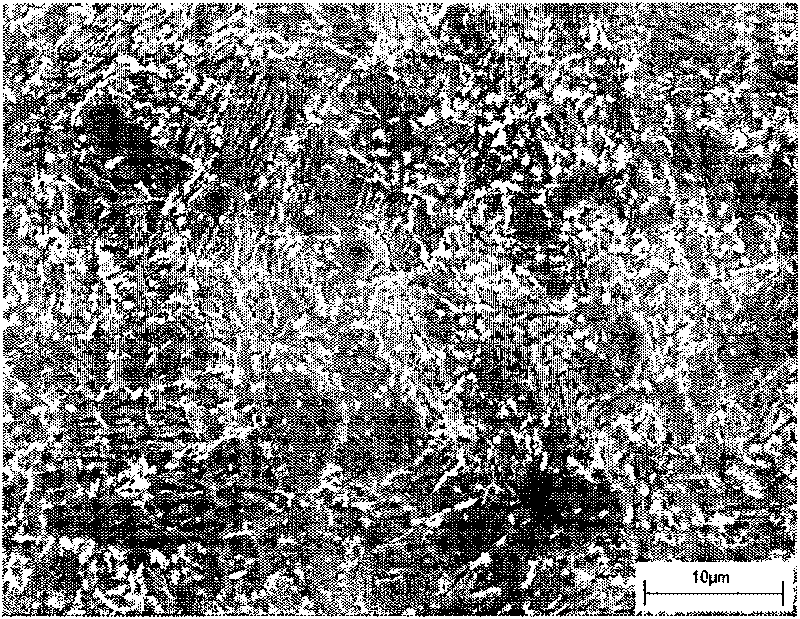

[0038] The chemical composition of the selected steel is: C 0.036%, Si 0.10%, Mn0.70%, Ni 9.02%, Mo 0.096%, P 0.0068%, S 0.005%, and the balance is Fe and unavoidable impurities. The steel is smelted in a vacuum induction furnace. After pouring, it is slowly cooled to room temperature and sent to the heating furnace. The heating temperature is 1200 ~ 1220 ℃, after 1 hour of heat preservation, it is taken out for rolling. The rolling adopts two-stage controlled rolling, and a total of 9 passes, the first 4 passes are rough rolling, and the last 5 passes are finish rolling. Rough rolling is rolled in the austenite complete recrystallization zone, the starting rolling temperature is 1150°C, and the finishing rolling temperature is controlled at 980°C; the finish rolling is rolling in the austenite non-recrystallizing zone, the starting rolling temperature is 900°C, and the finishing rolling temperature is 900°C. Control at 800°C, control the cooling rate and final cooling tempera...

Embodiment 2

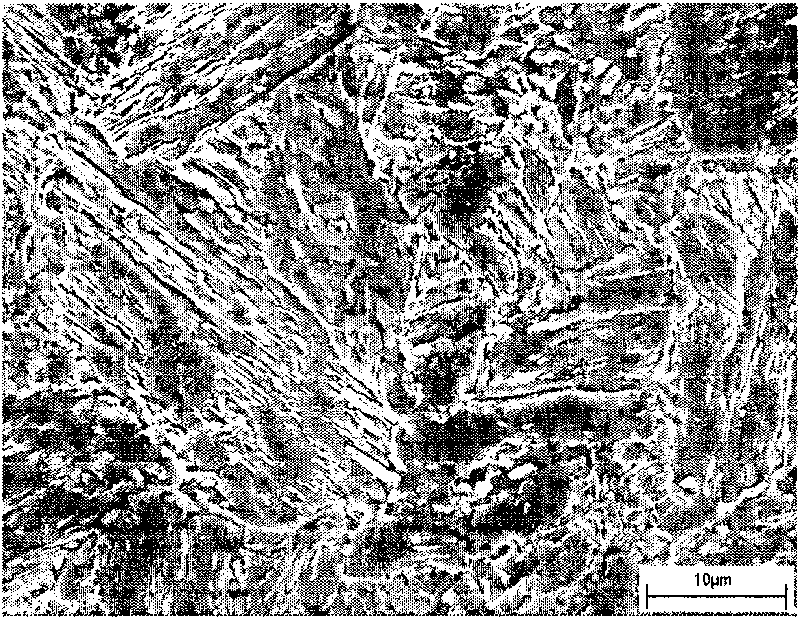

[0041] The selection of raw materials, steelmaking, rolling and testing steps are the same as those in Example 1. The difference from Example 1 is that the heat treatment process adopts a double quenching process, and the solution quenching process is 800 ° C for 1 hour, water cooling; two-phase zone quenching The process is 650°C for 1h, water cooling, and the tempering process is 570°C for 1h, water cooling.

[0042] Such as figure 2 , Figure 8 Shown: After testing, when the above double quenching process is adopted: the yield strength is 645MPa, the tensile strength is 700MPa, the elongation after fracture is 25%, the impact energy at -196°C is 177J, and the structure is lath martensite and ferrite. body and 10.15% swivel austenite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com